Patents

Literature

4254 results about "Superalloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

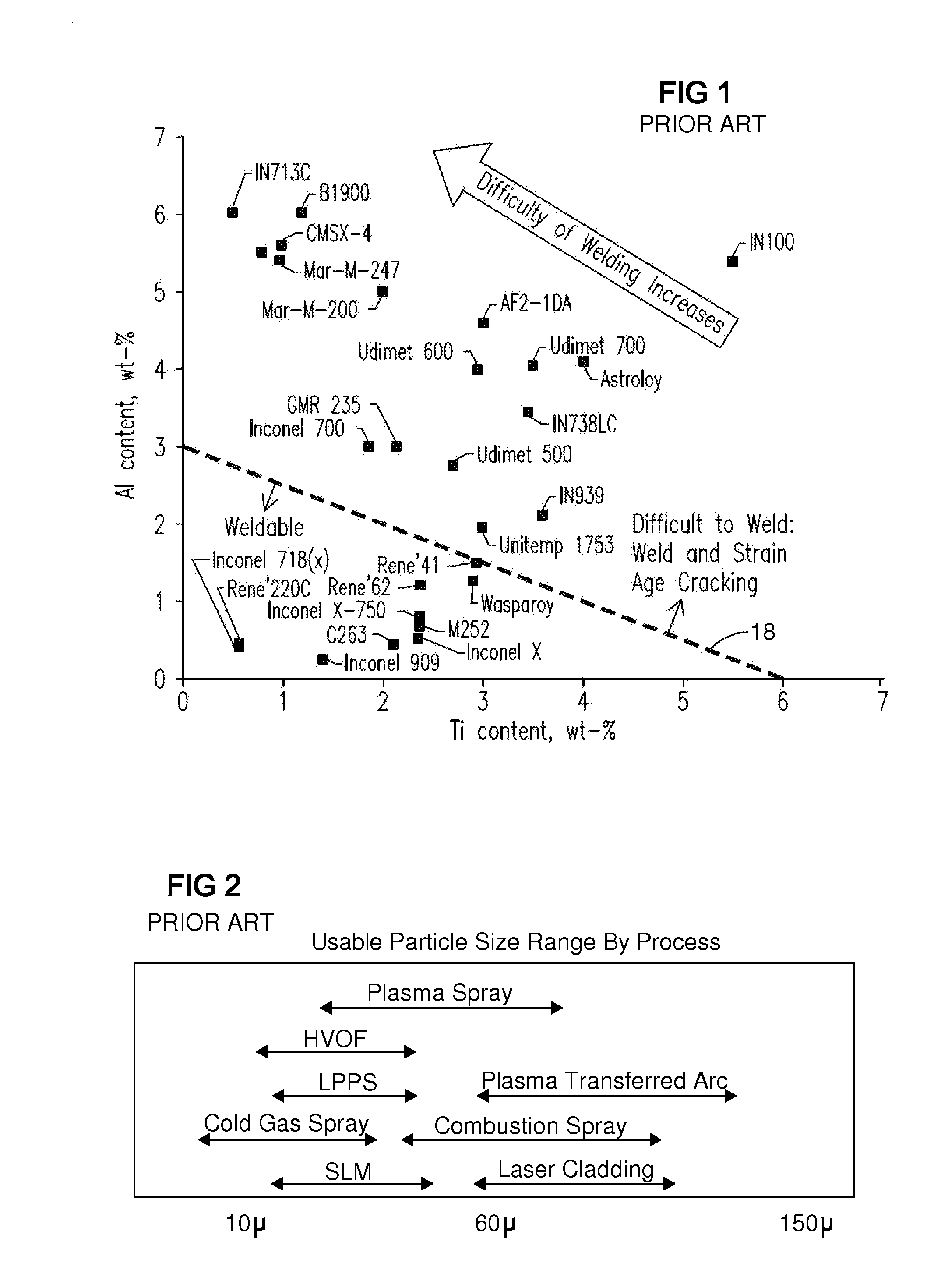

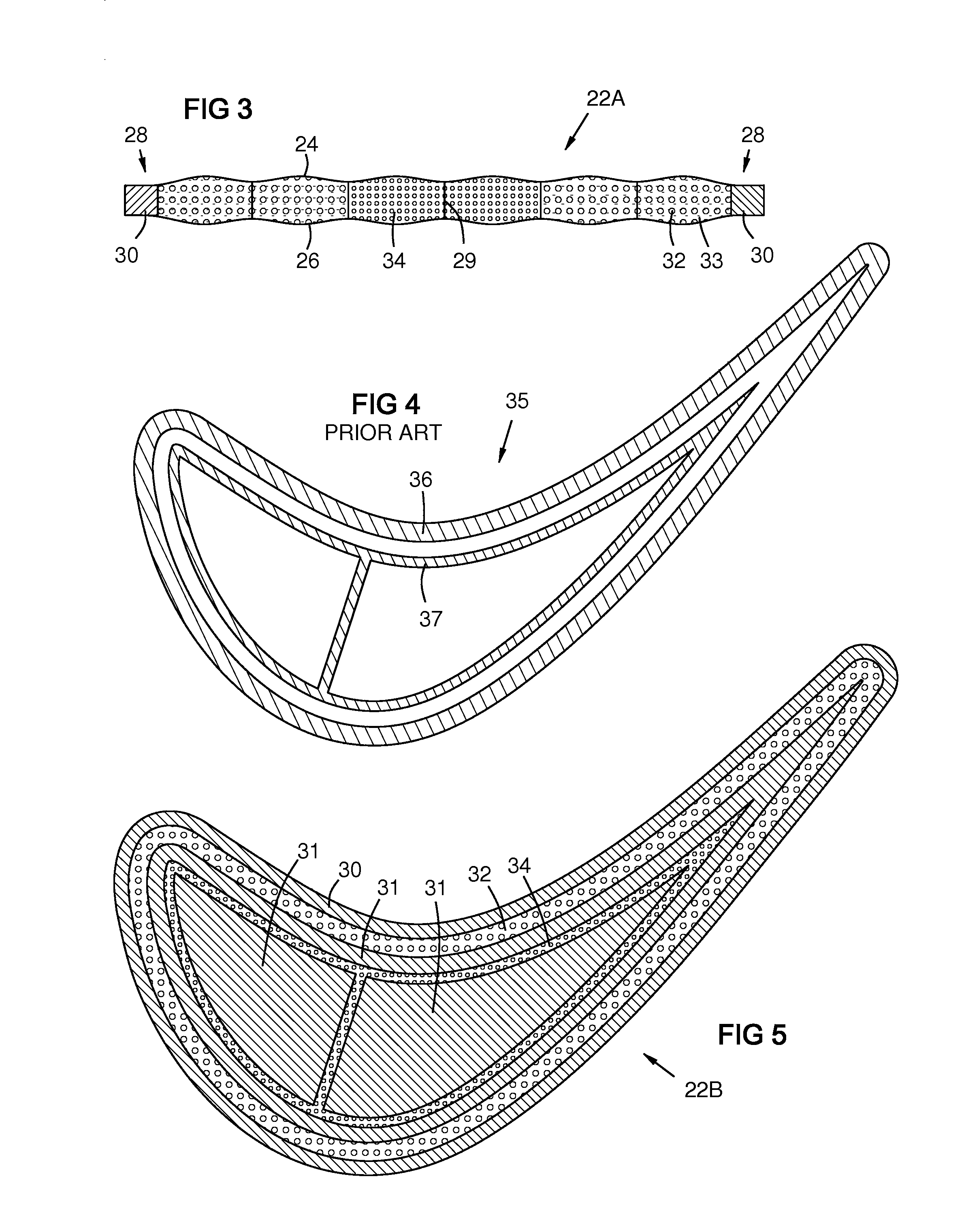

A superalloy, or high-performance alloy, is an alloy that exhibits several key characteristics: excellent mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation. The crystal structure is typically face-centered cubic austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys.

Selective laser melting / sintering using powdered flux

InactiveUS20130136868A1TurbinesRadiation applicationsSelective laser meltingSelective laser sintering

An additive manufacturing process (110) wherein a powder (116) including a superalloy material and flux is selectively melted in layers with a laser beam (124) to form a superalloy component (126). The flux performs a cleaning function to react with contaminants to float them to the surface of the melt to form a slag. The flux also provides a shielding function, thereby eliminating the need for an inert cover gas. The powder may be a mixture of alloy and flux particles, or it may be formed of composite alloy / flux particles.

Owner:SIEMENS ENERGY INC

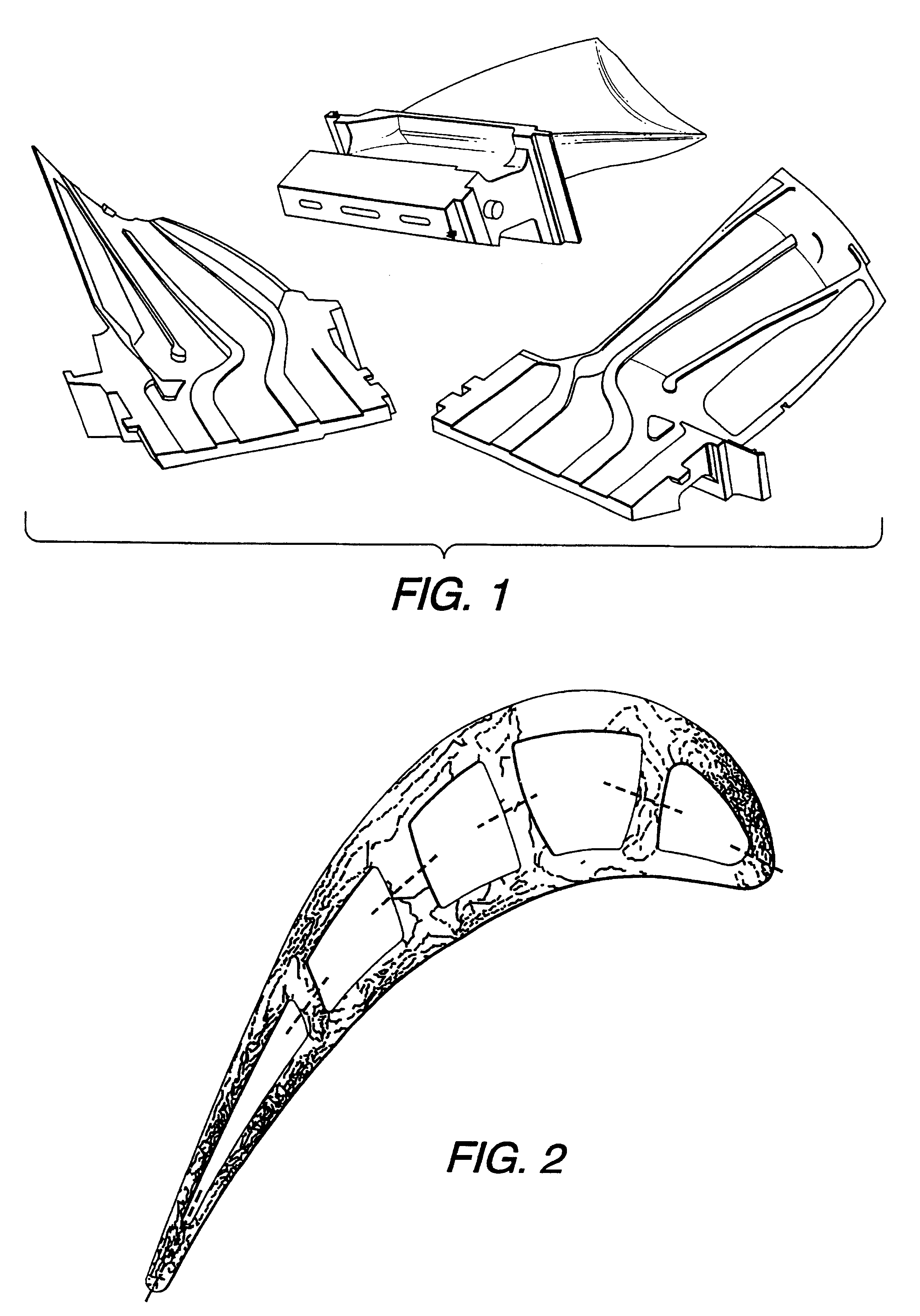

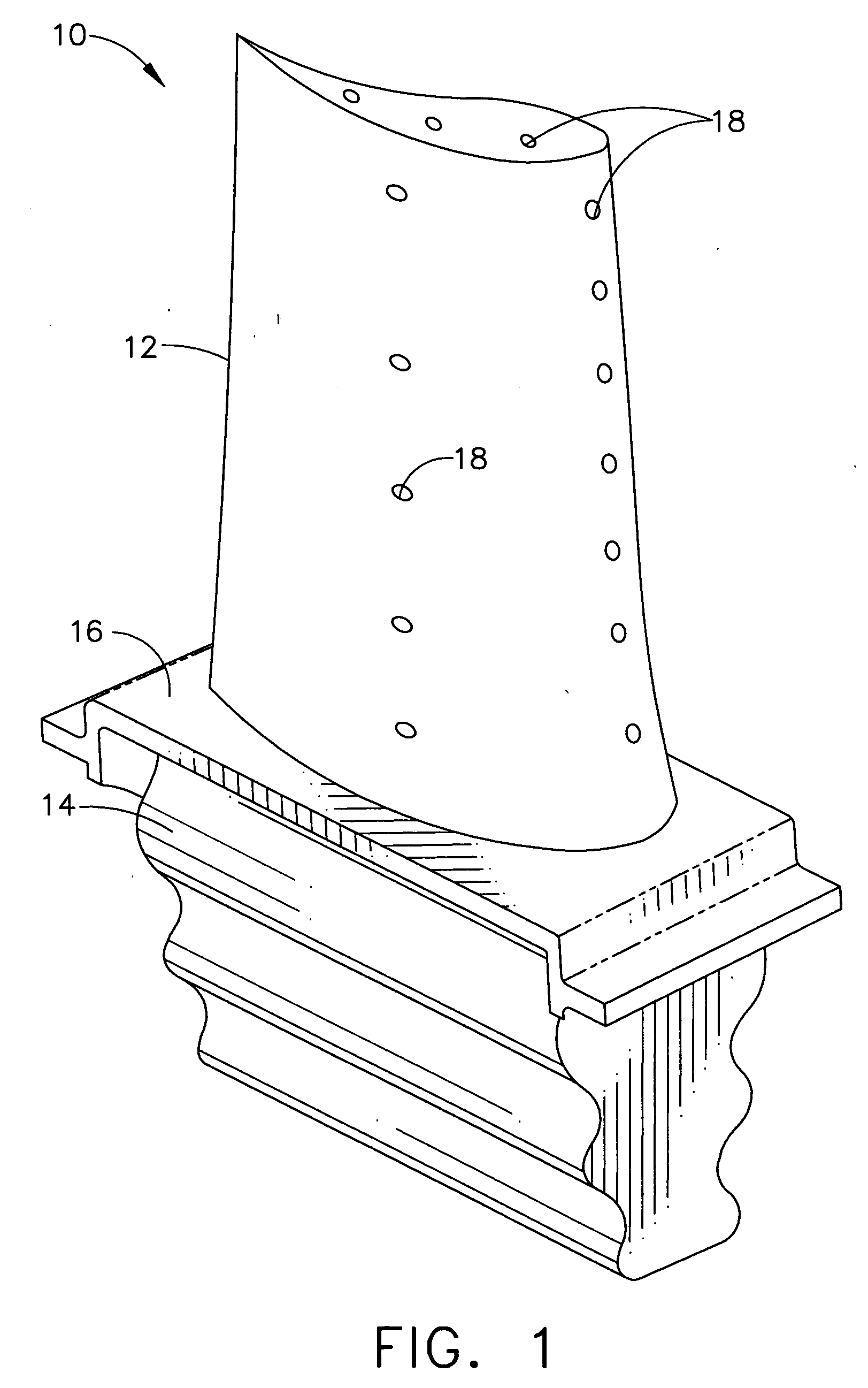

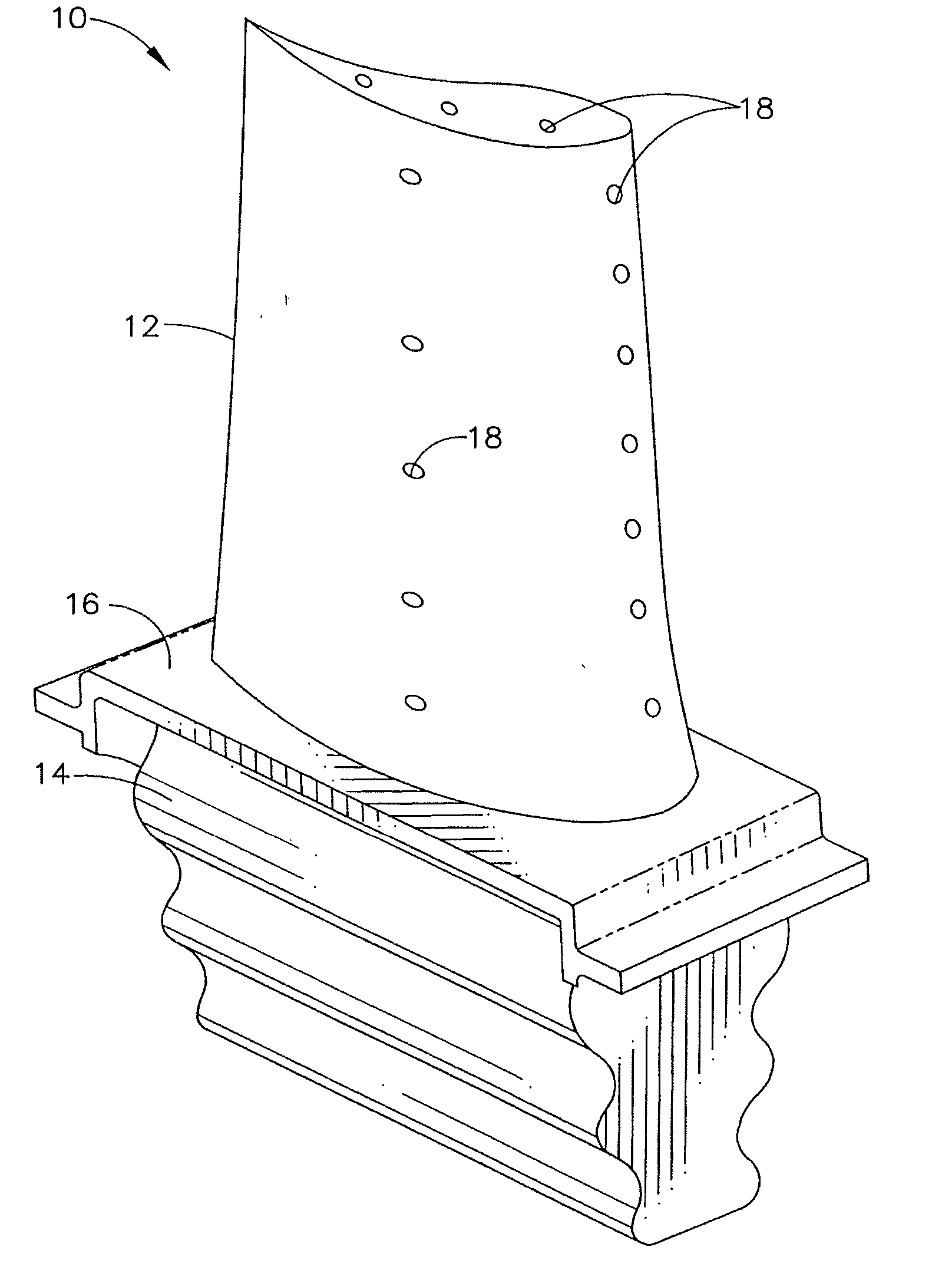

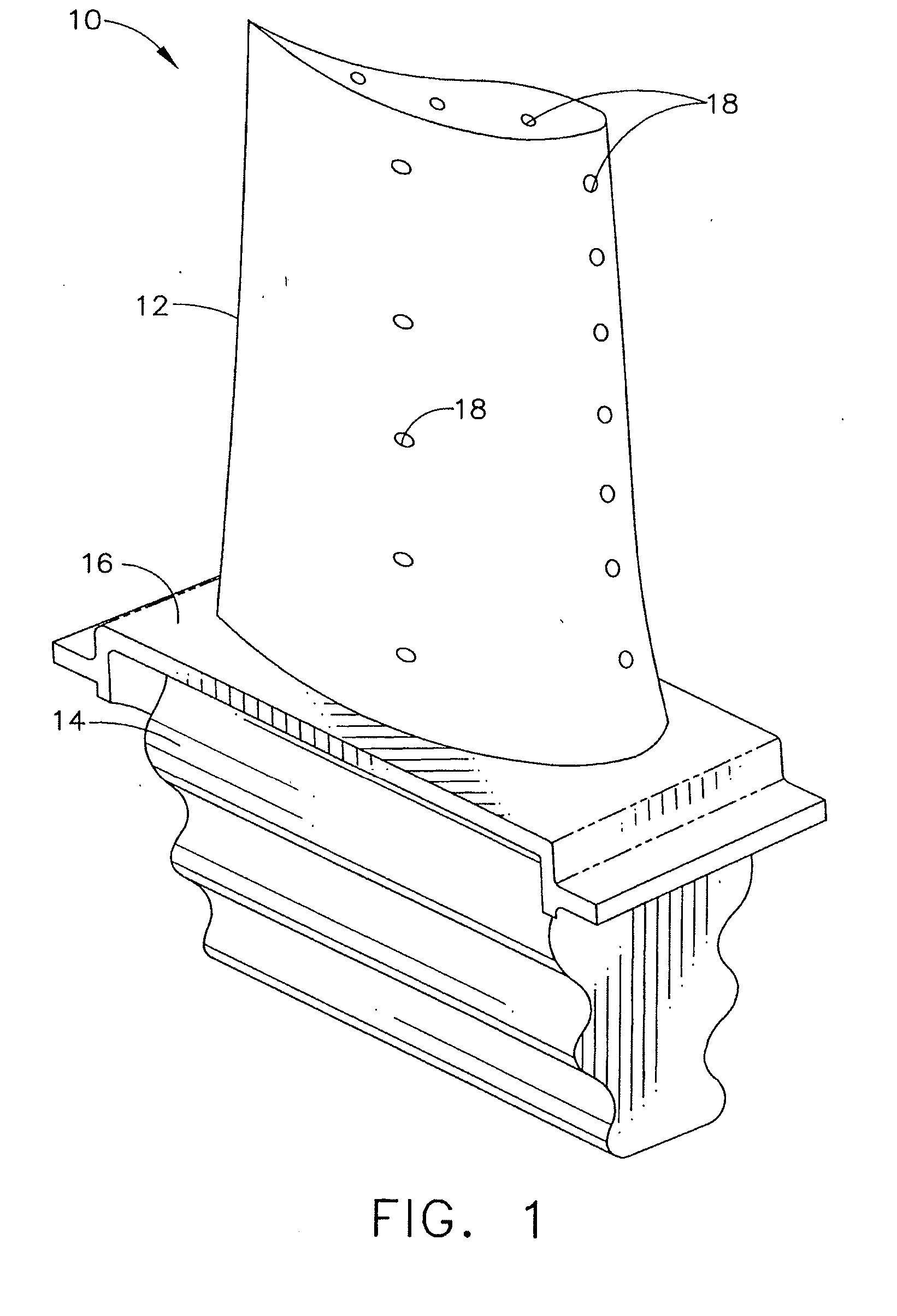

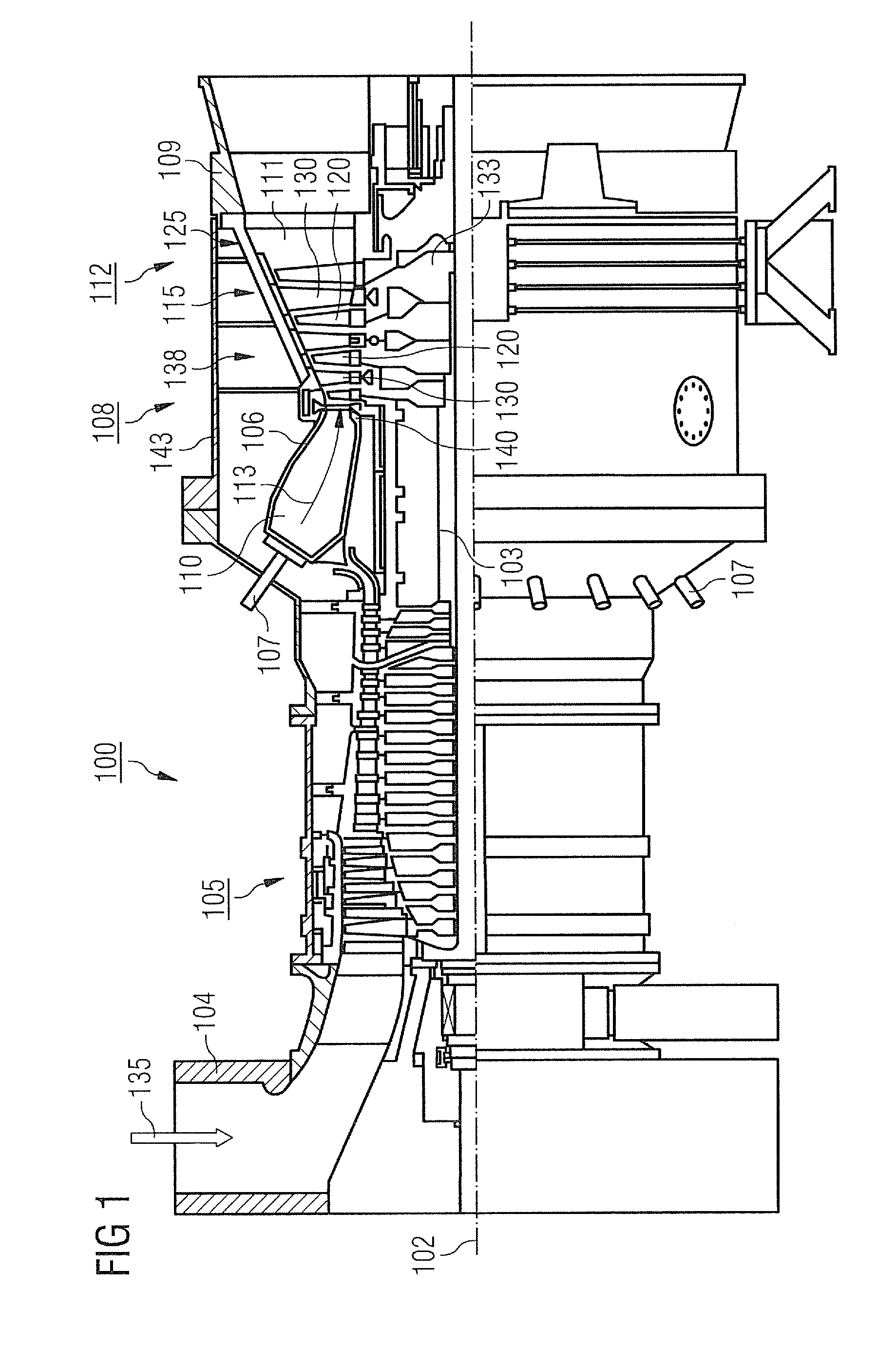

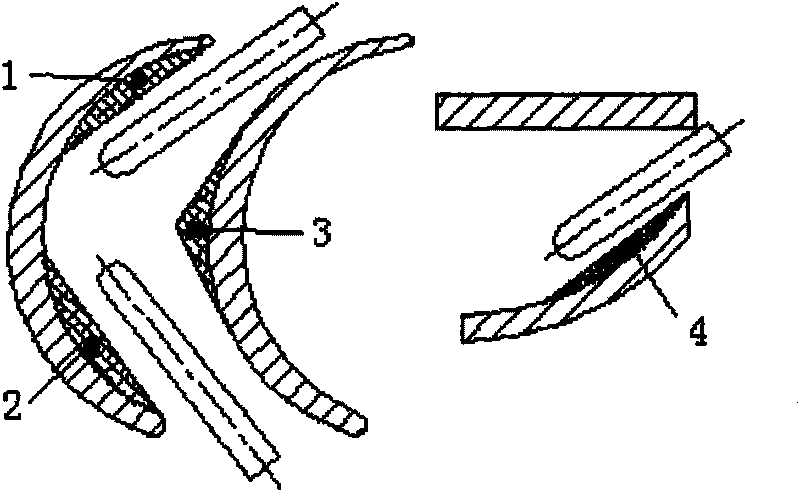

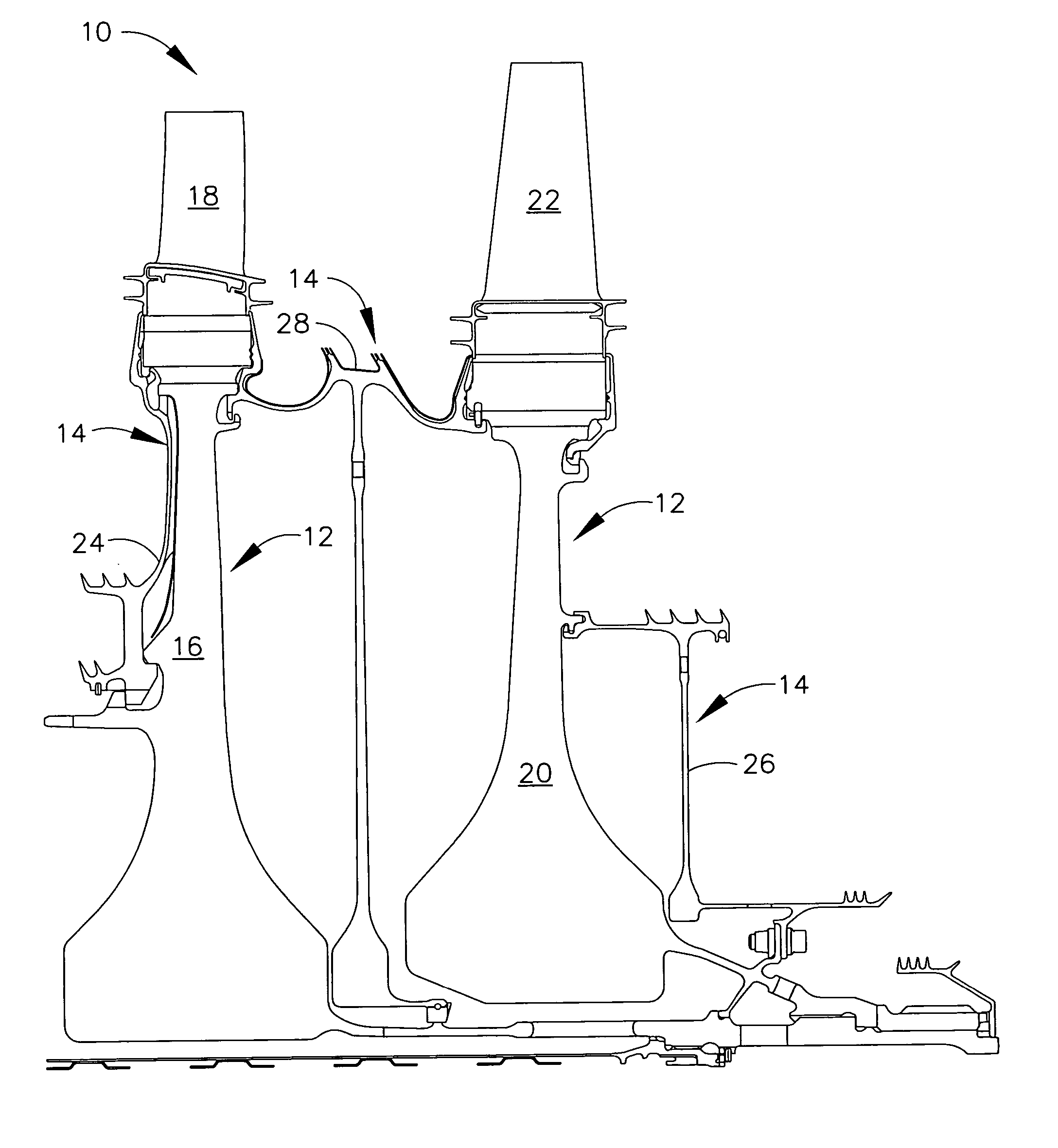

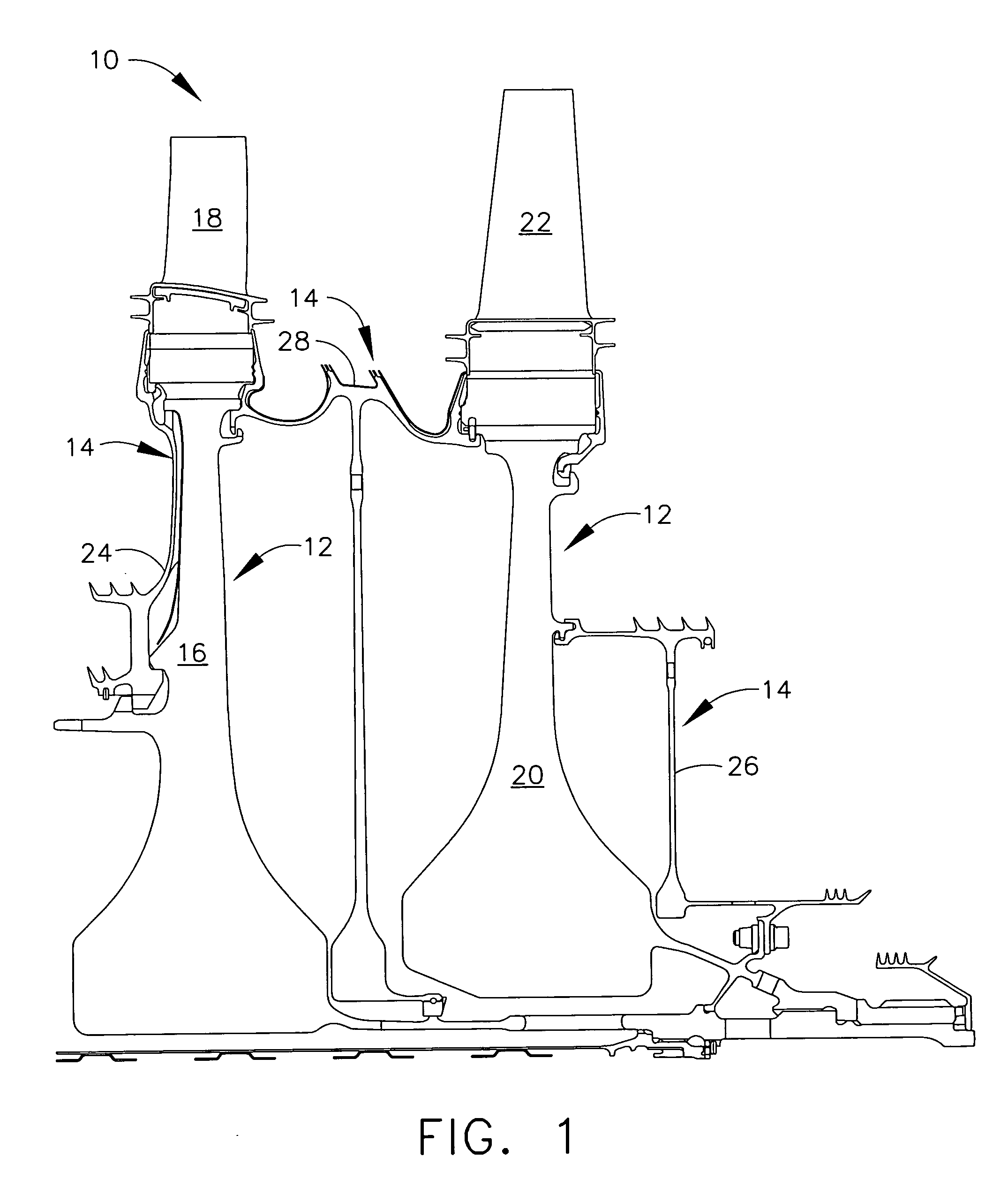

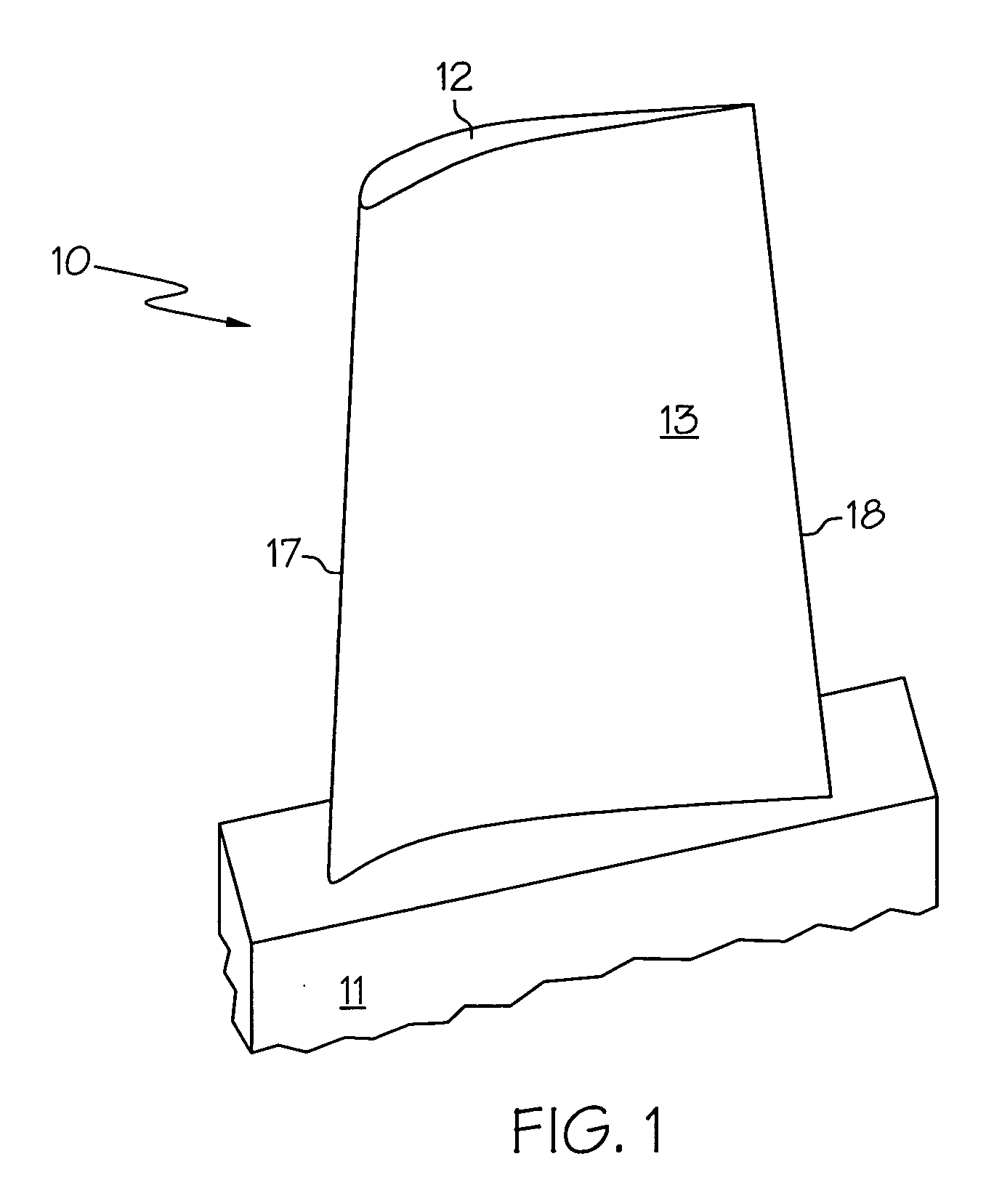

Turbine blades made from multiple single crystal cast superalloy segments

InactiveUS6331217B1Improve bindingQuality improvementPropellersFrom frozen solutionsTurbine bladeSingle crystal

Large gas turbine blades made from separate cast segments of superalloys are disclosed. The turbine blade is designed such that bond lines between adjacent segments are placed in low stress regions of the blade. The cast superalloy segments of the blades are aligned and fitted together with specified tolerances. The turbine blade segments are then joined by transient liquid phase bonding, followed by a controlled heat treatment which produces the desired microstructure in the bond region. The method allows for the production of large, high quality turbine blades by joining small, high quality cast superalloy sections, in comparison with prior attempts to cast large turbine blades as single pieces which have produced very low yields and high individual component costs.

Owner:SIEMENS ENERGY INC

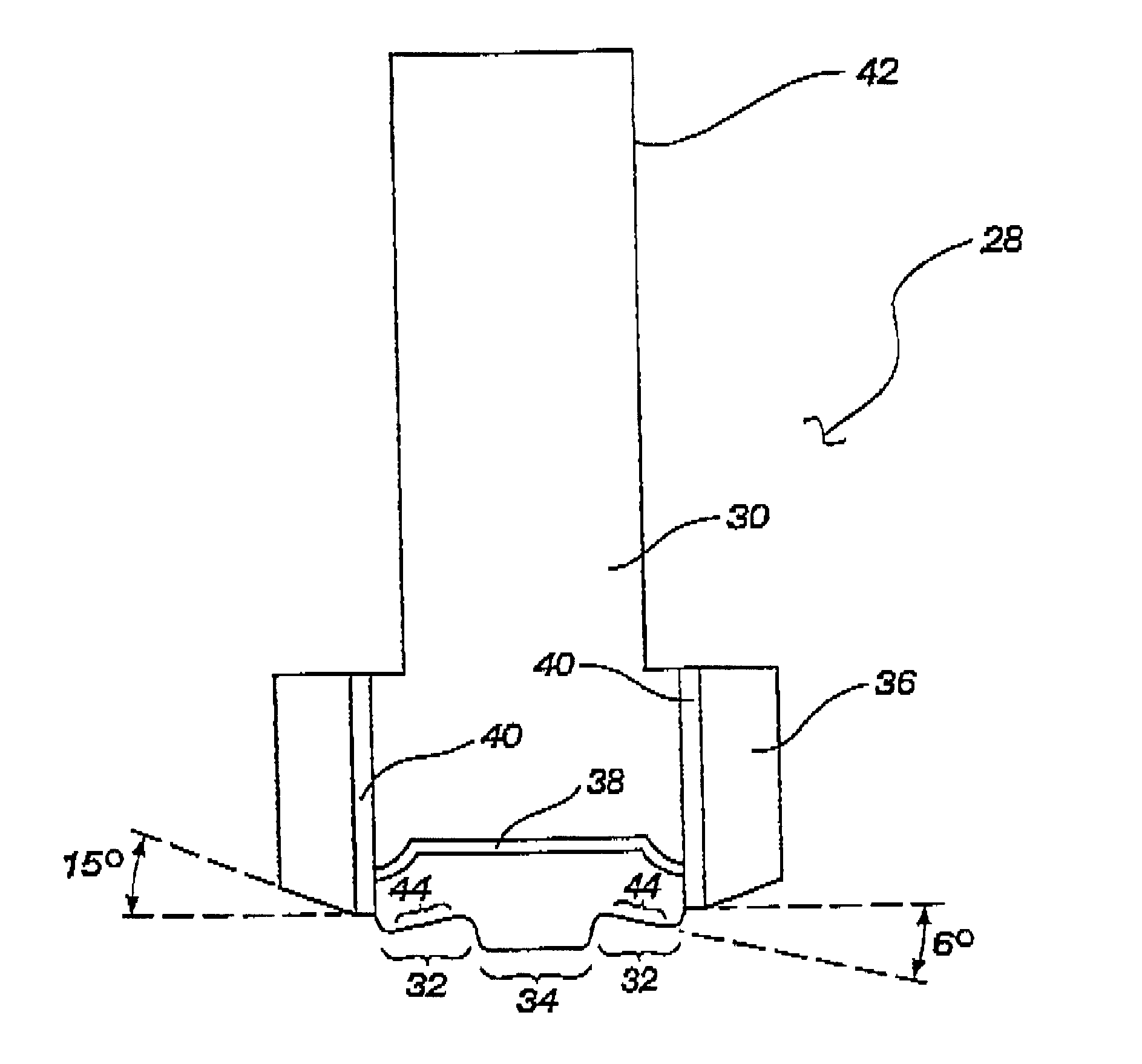

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

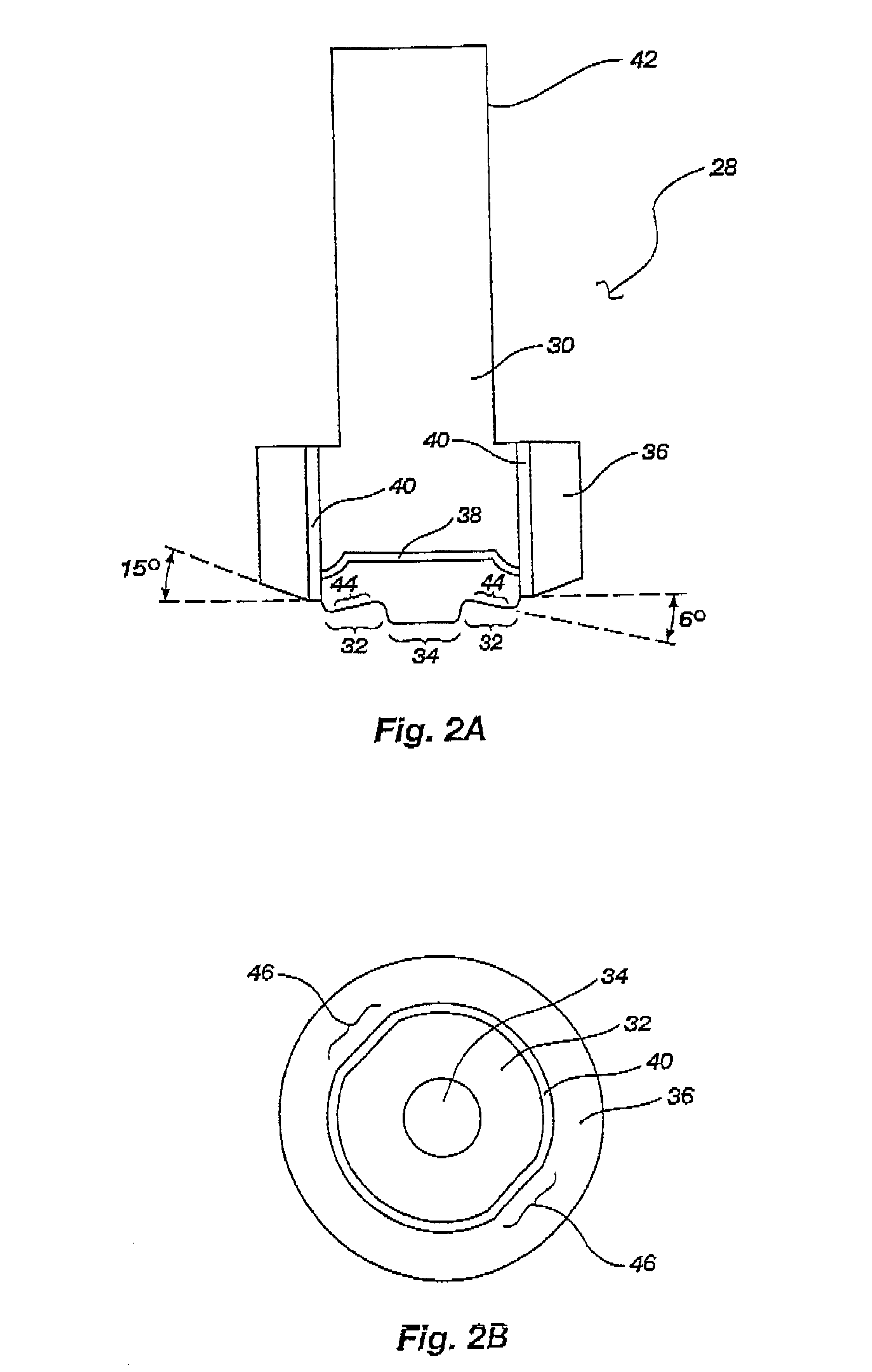

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

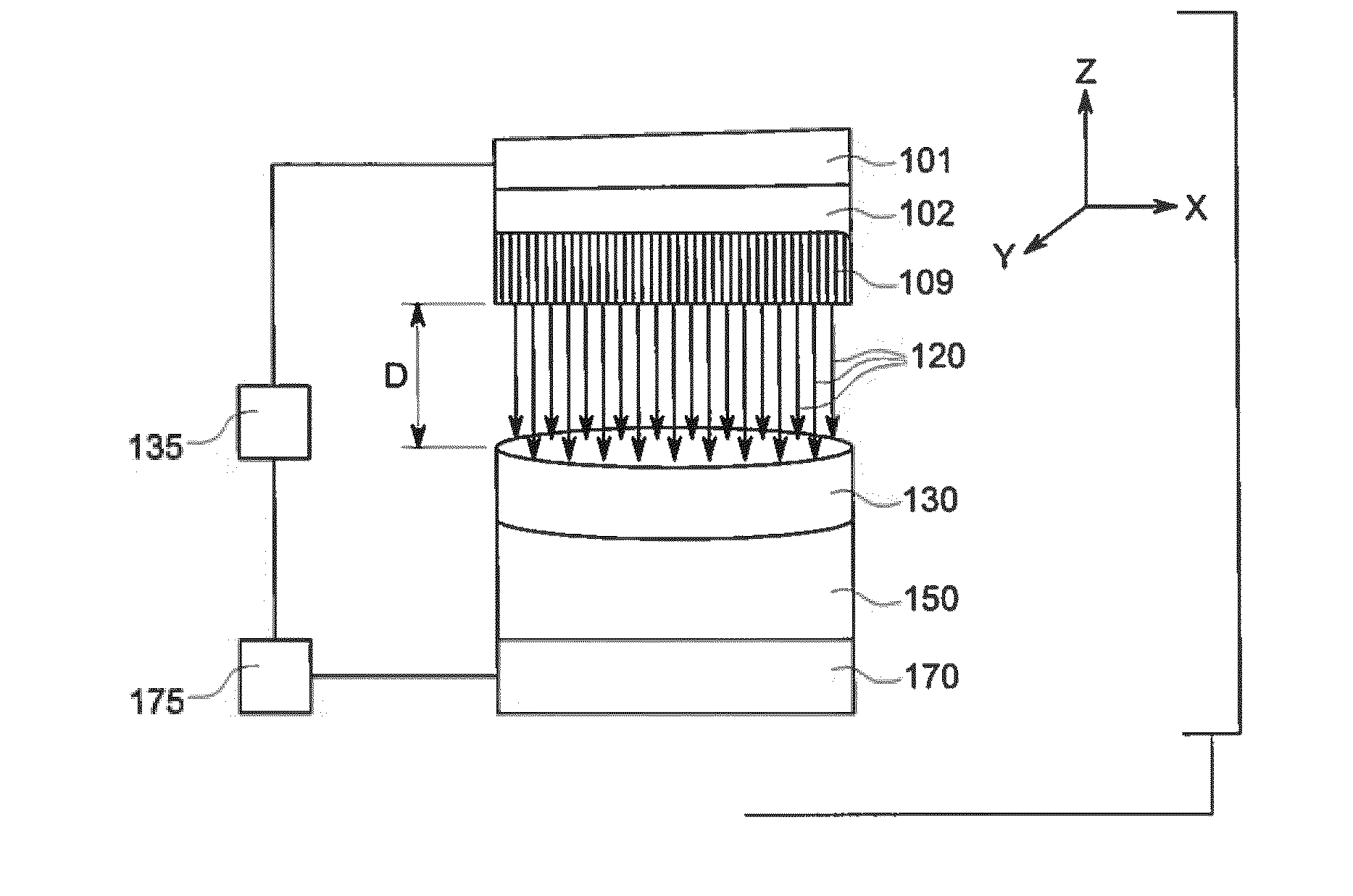

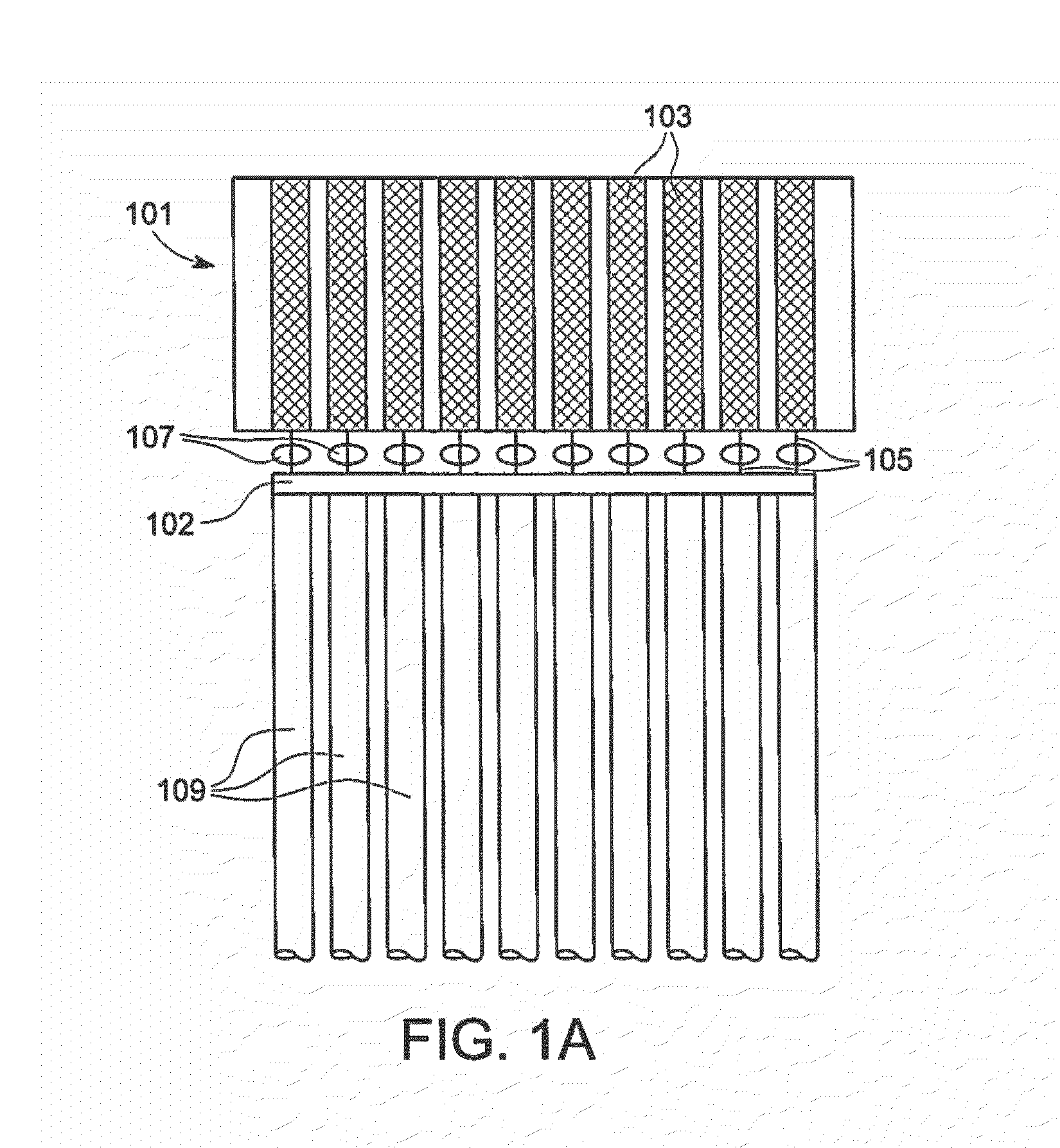

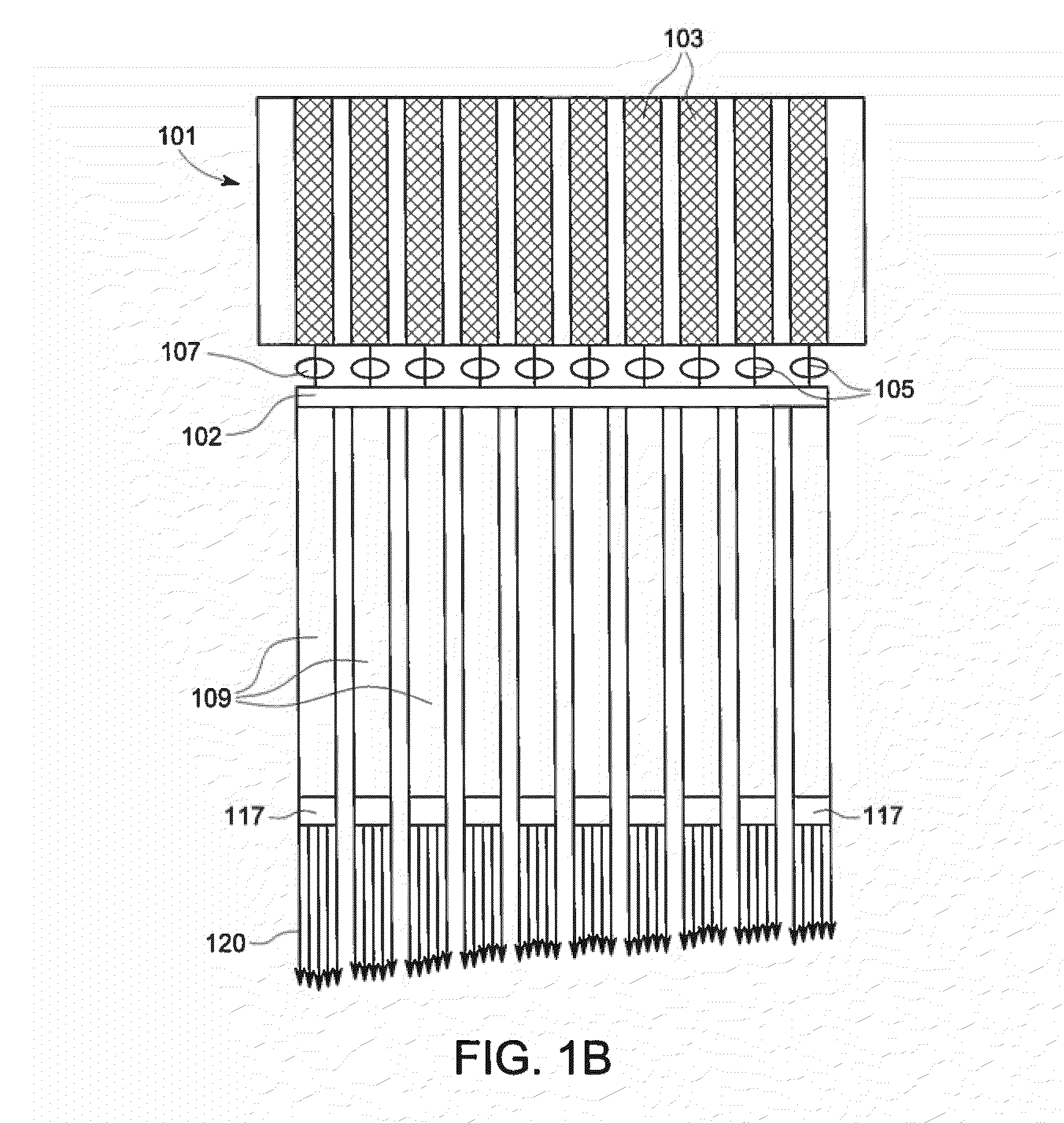

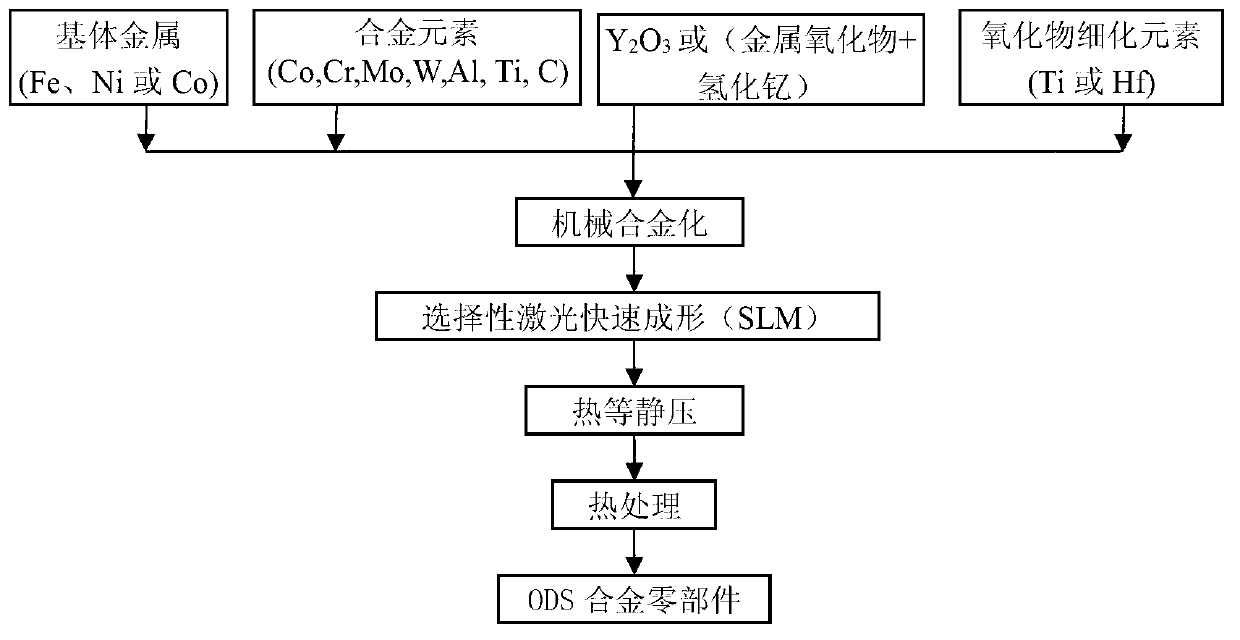

Control of solidification in laser powder bed fusion additive manufacturing using a diode laser fiber array

A method of method of forming or repairing a superalloy article having a columnar or equiaxed or directionally solidified or amorphous or single crystal microstructure includes emitting a plurality of laser beams from selected fibers of a diode laser fiber array corresponding to a pattern of a layer of the article onto a powder bed of the superalloy to form a melt pool; and controlling a temperature gradient and a solidification velocity of the melt pool to form the columnar or single crystal microstructure.

Owner:GENERAL ELECTRIC CO

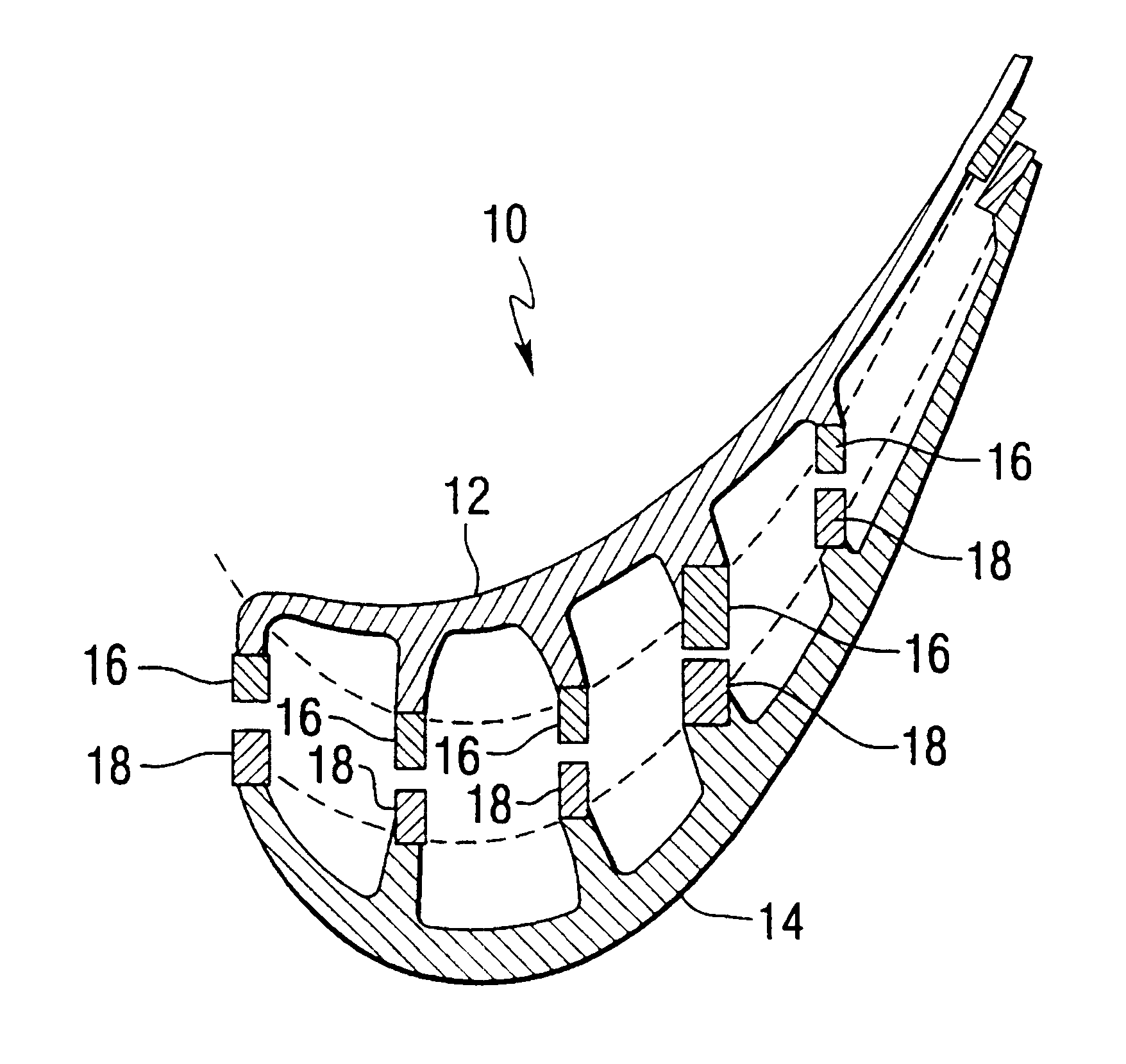

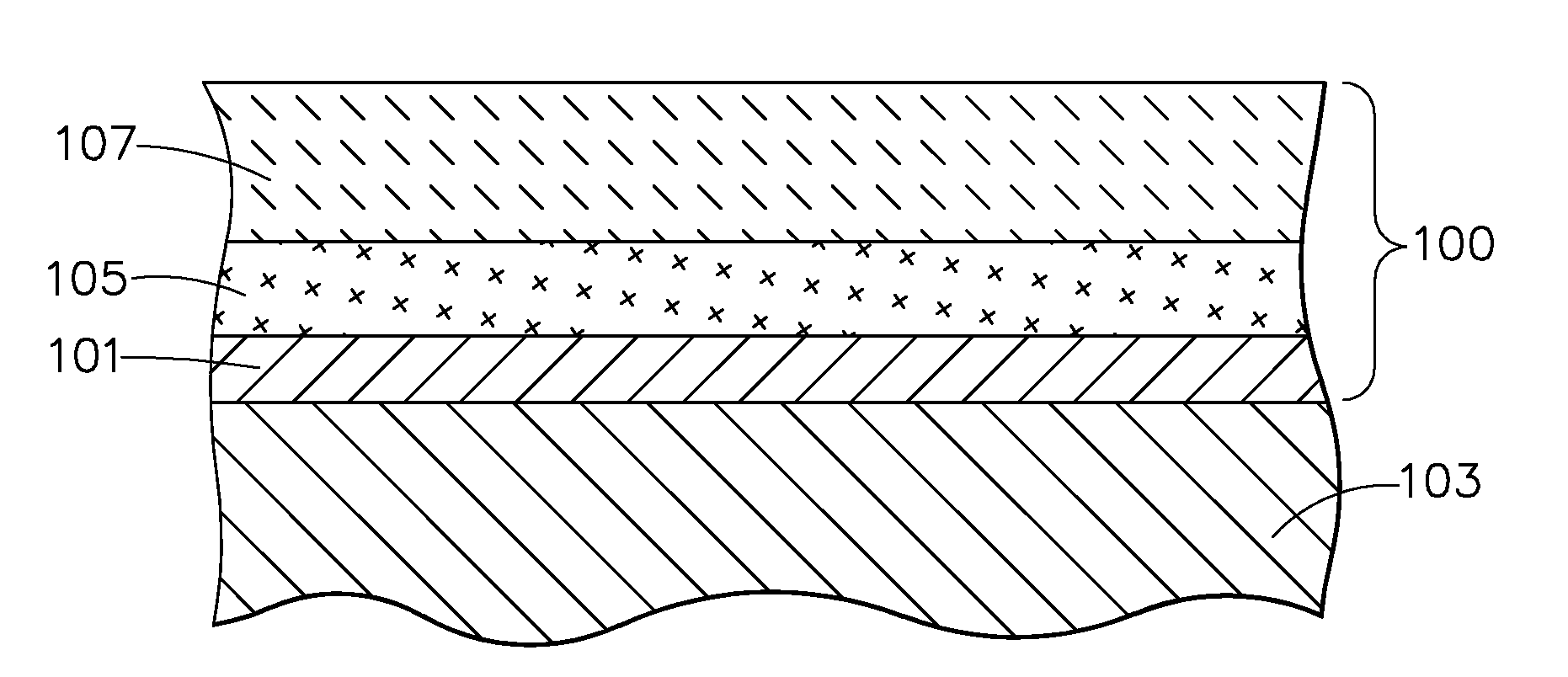

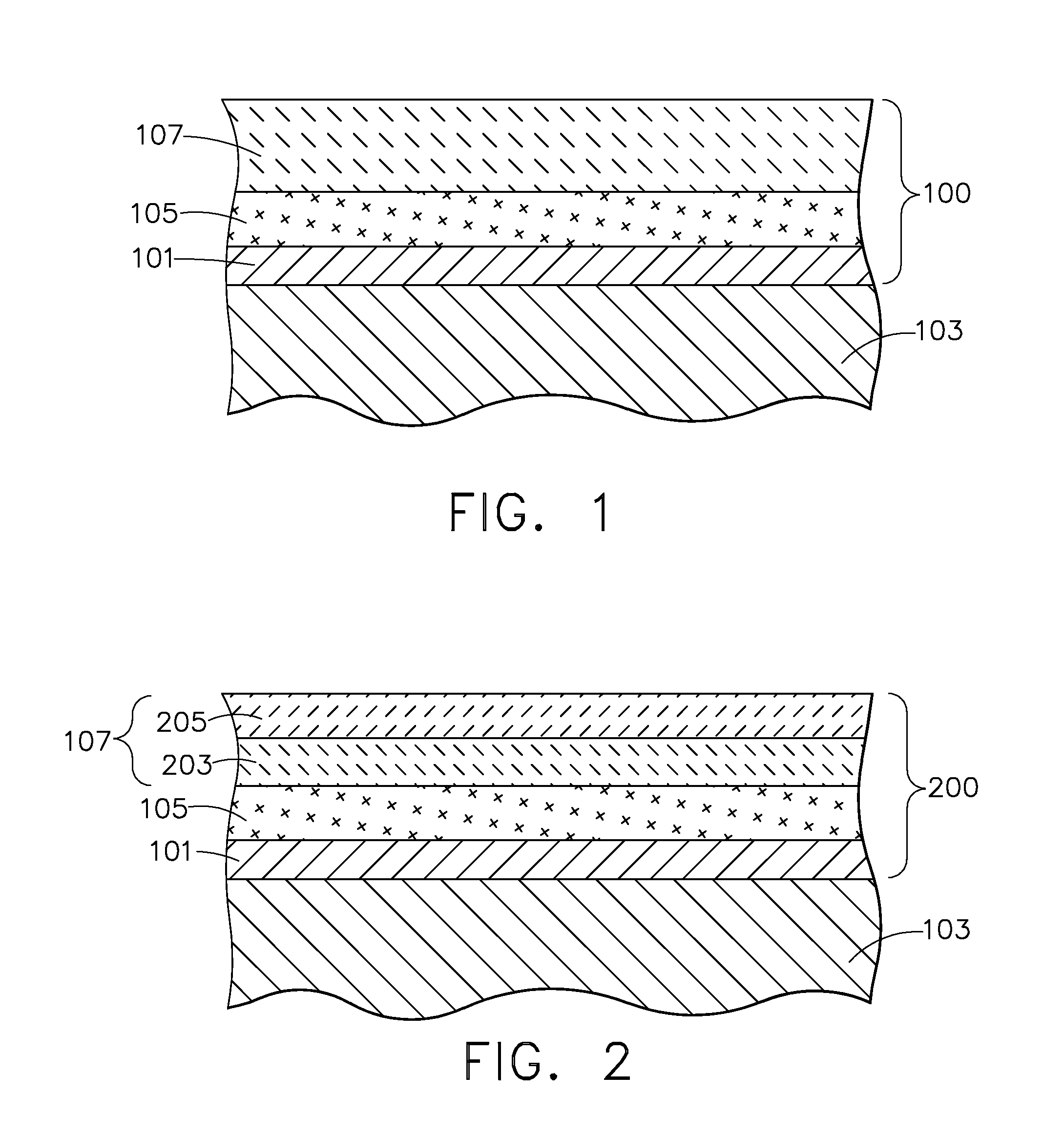

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

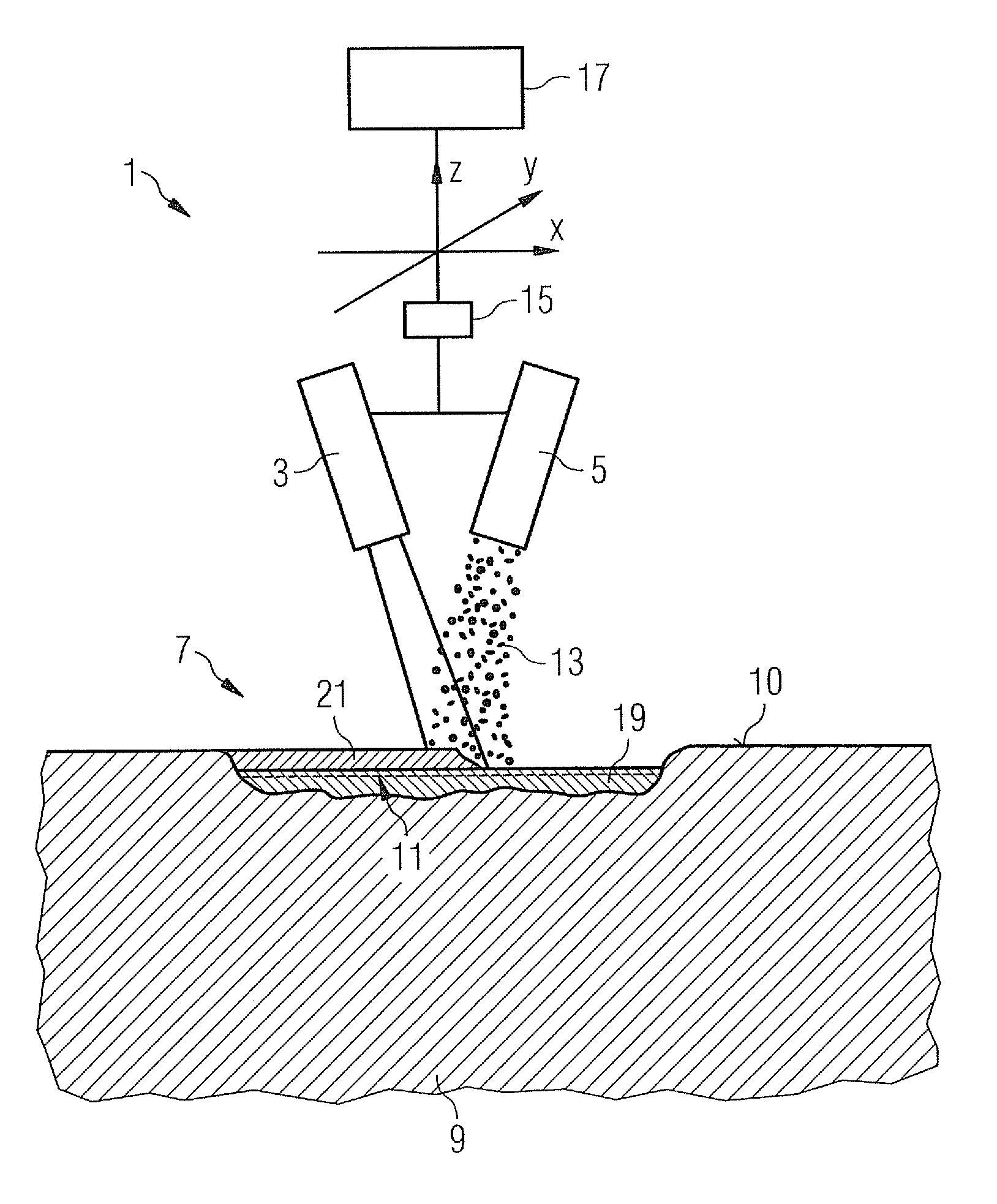

Method for welding workpieces made of highly heat-resistant superalloys, including a particular mass feed rate of the welding filler material

InactiveUS20120267347A1Improve cooling effectIncrease chanceTurbinesEngine manufactureHeat resistanceRelative motion

A welding method for welding workpieces made of highly heat-resistant superalloys is provided. The method includes generating a heat input zone on the workpiece surface by means of a heat source, feeding welding filler material into the heat input zone by means of a feeding device, and generating a relative motion between the heat source and the feeding device on one hand and the workpiece surface on the other hand by means of a conveying device. Furthermore, according to the welding method, the mass feed rate is ≦350 mg / min.

Owner:SIEMENS AG +1

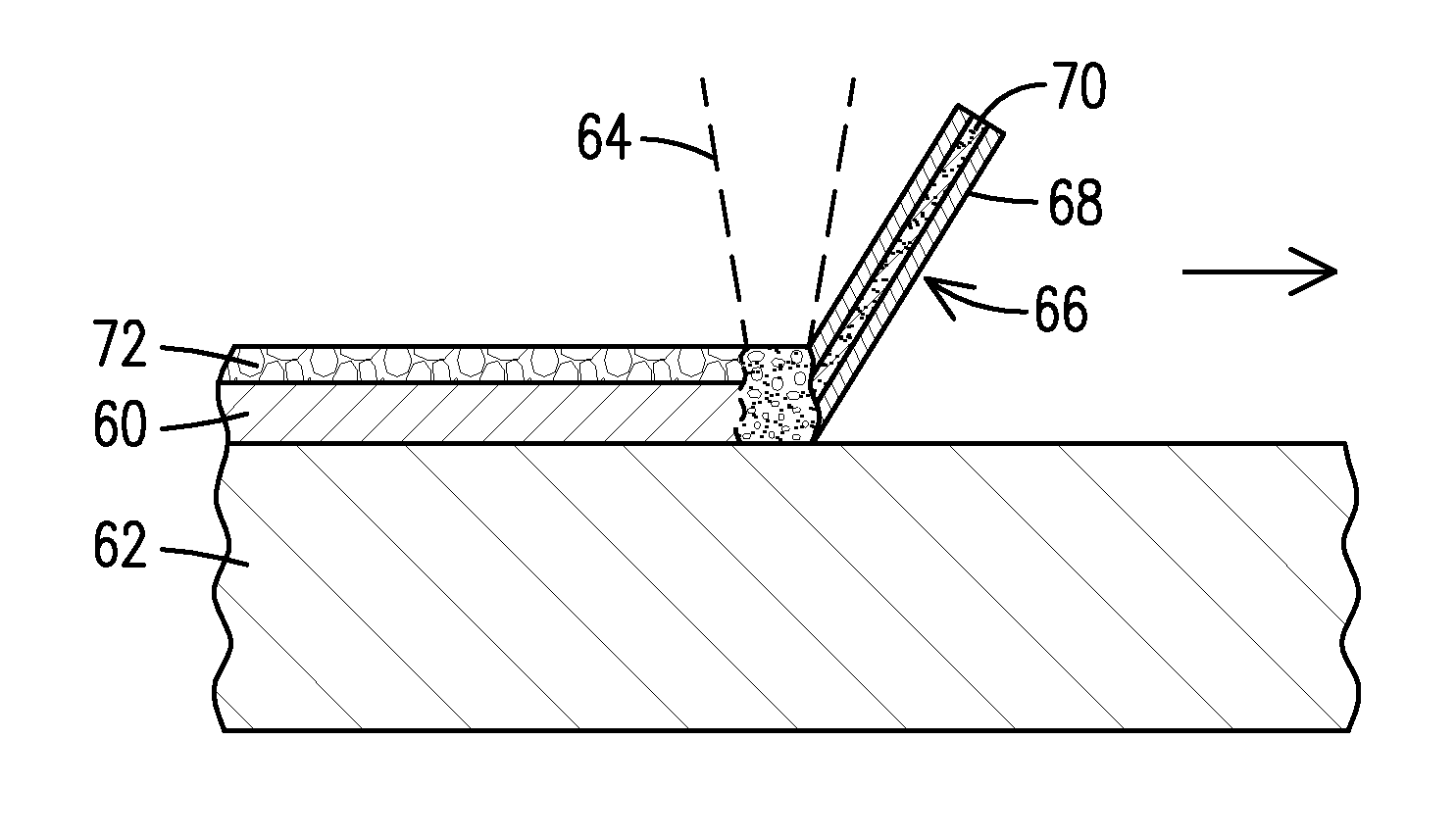

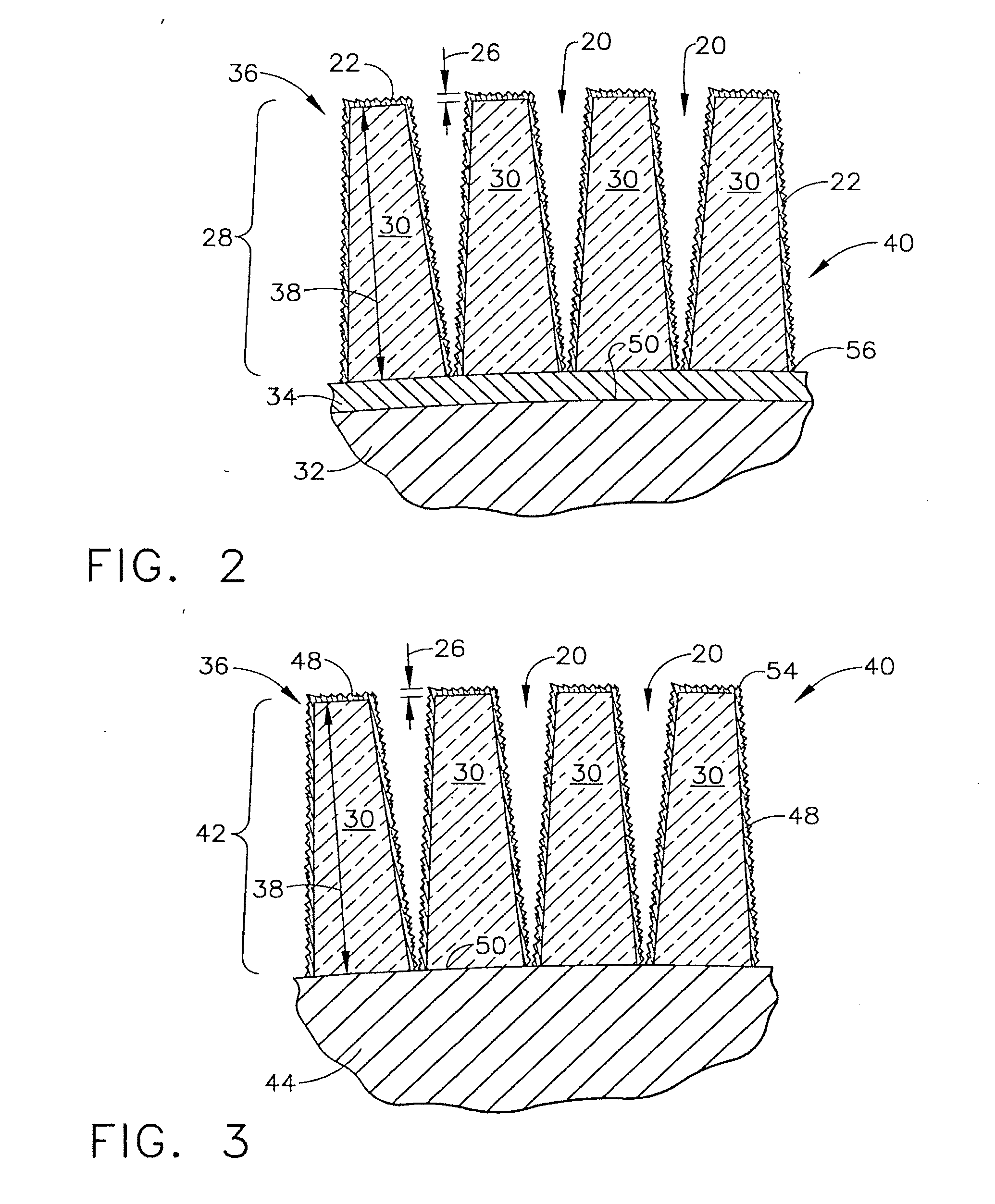

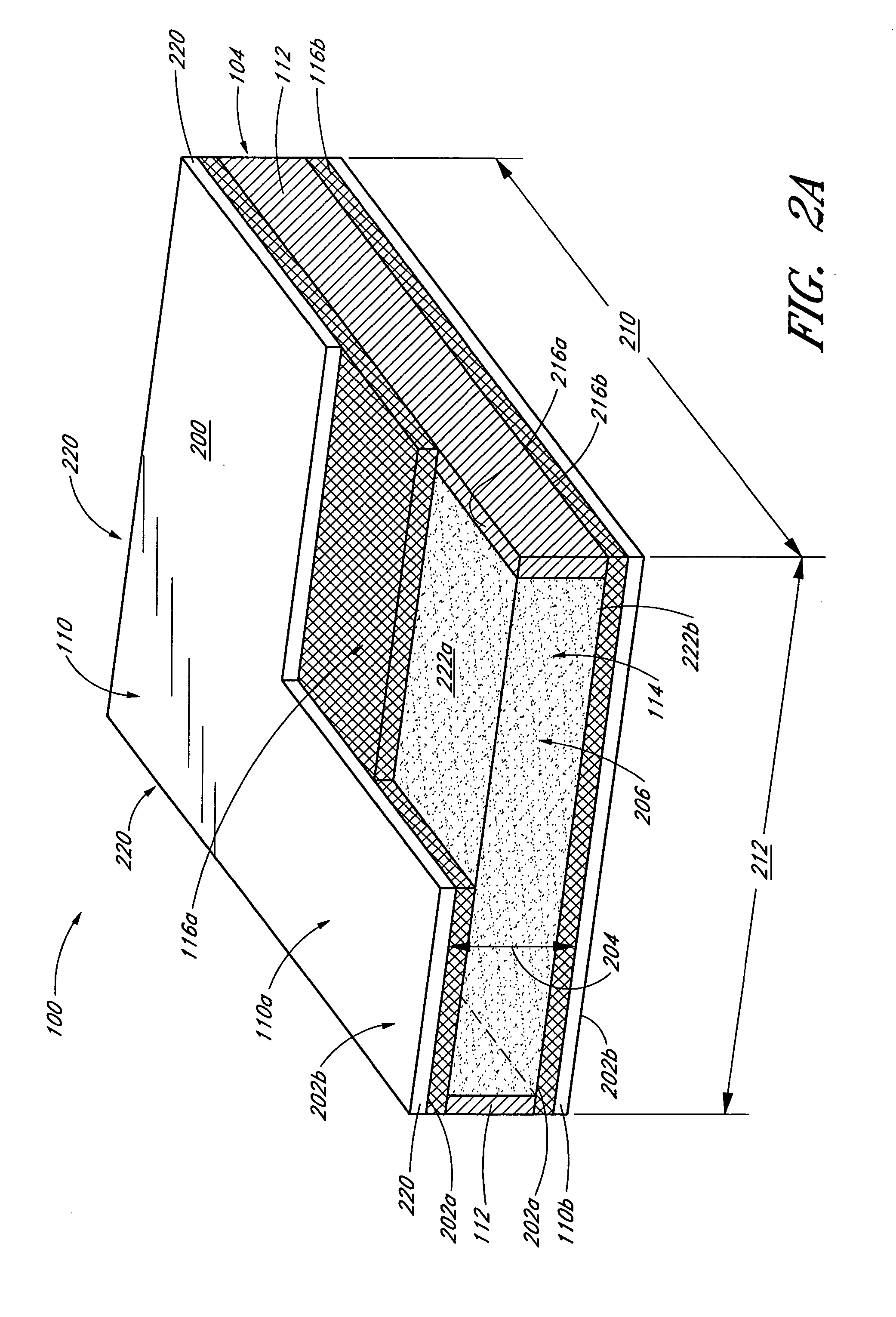

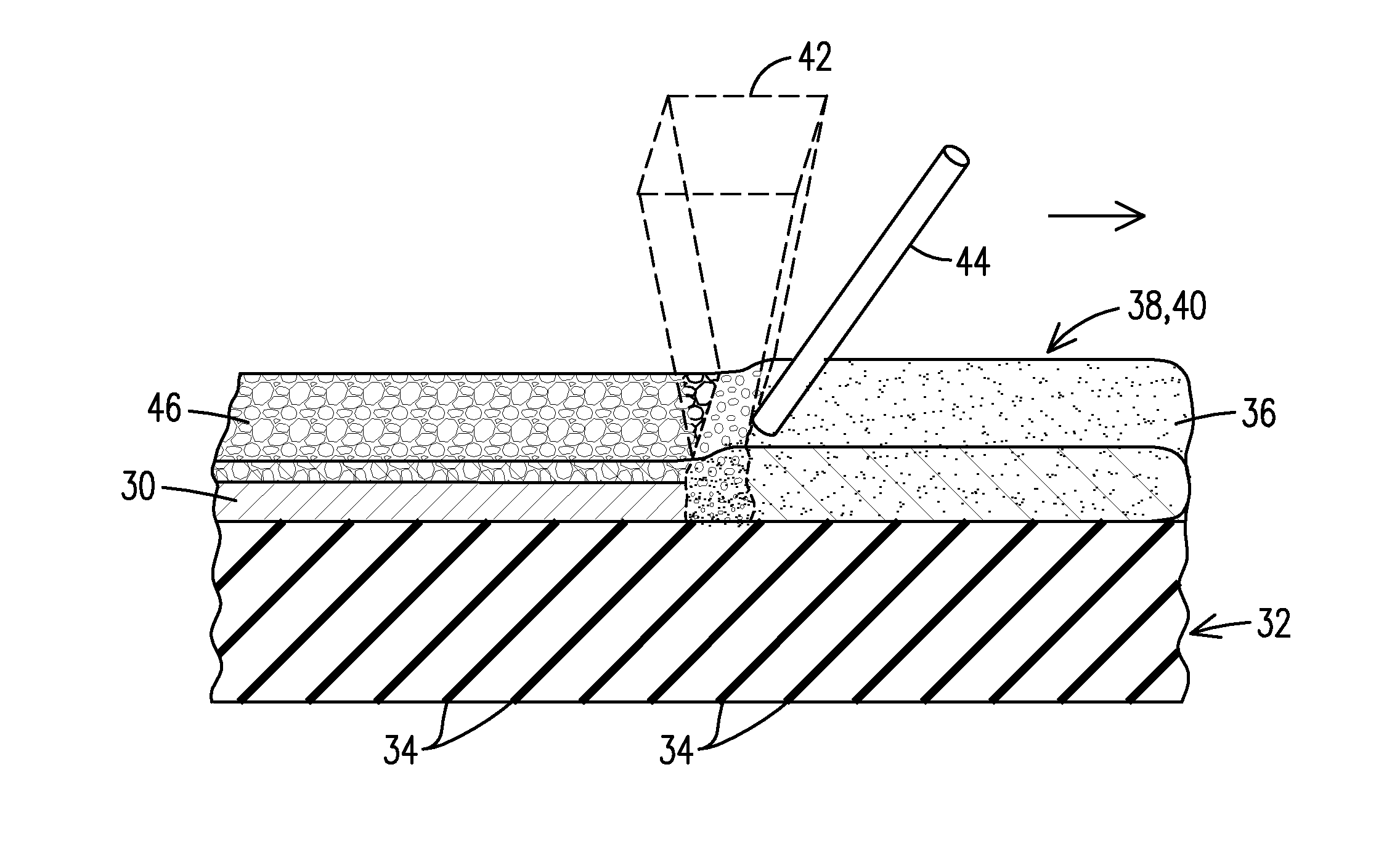

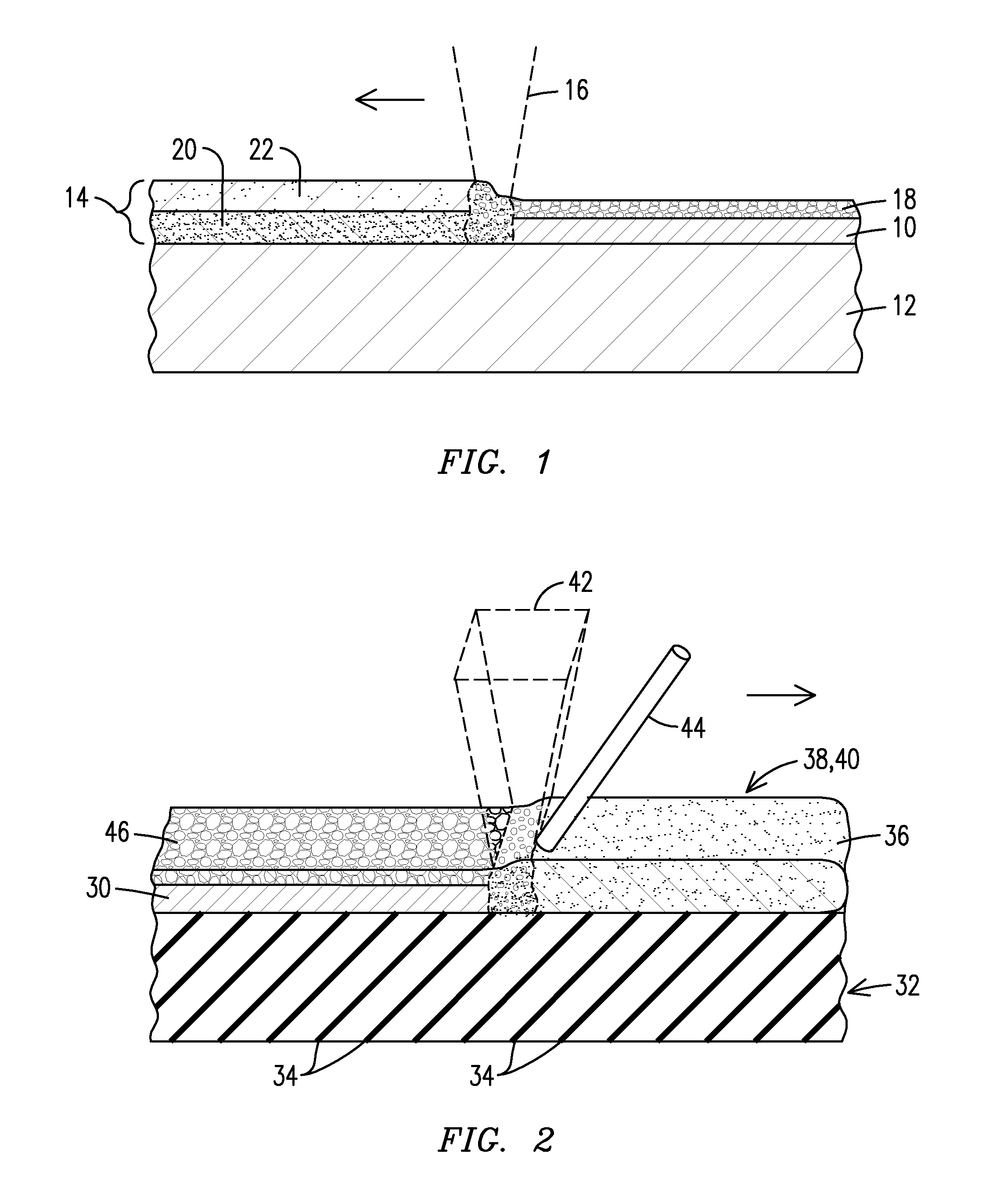

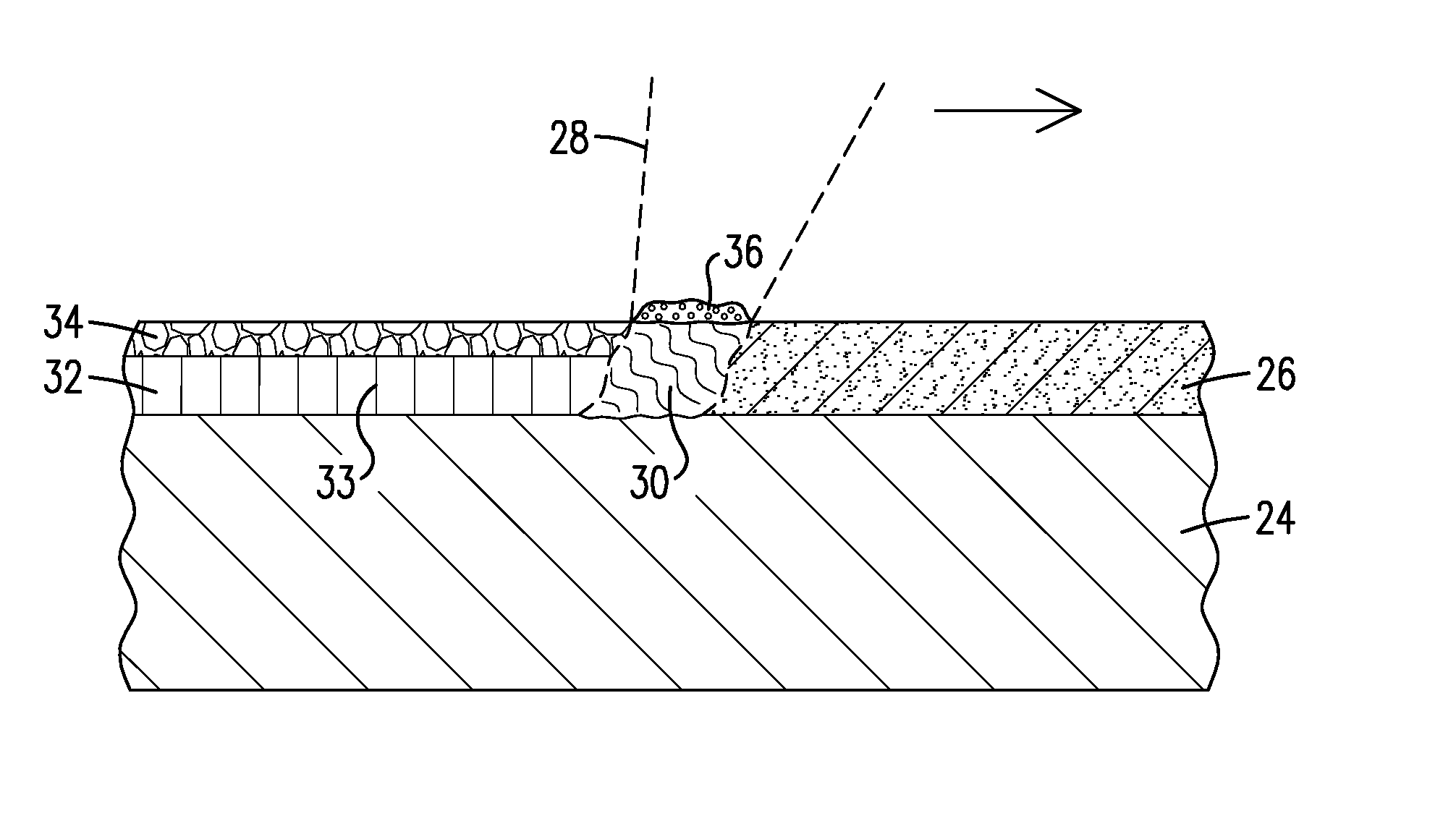

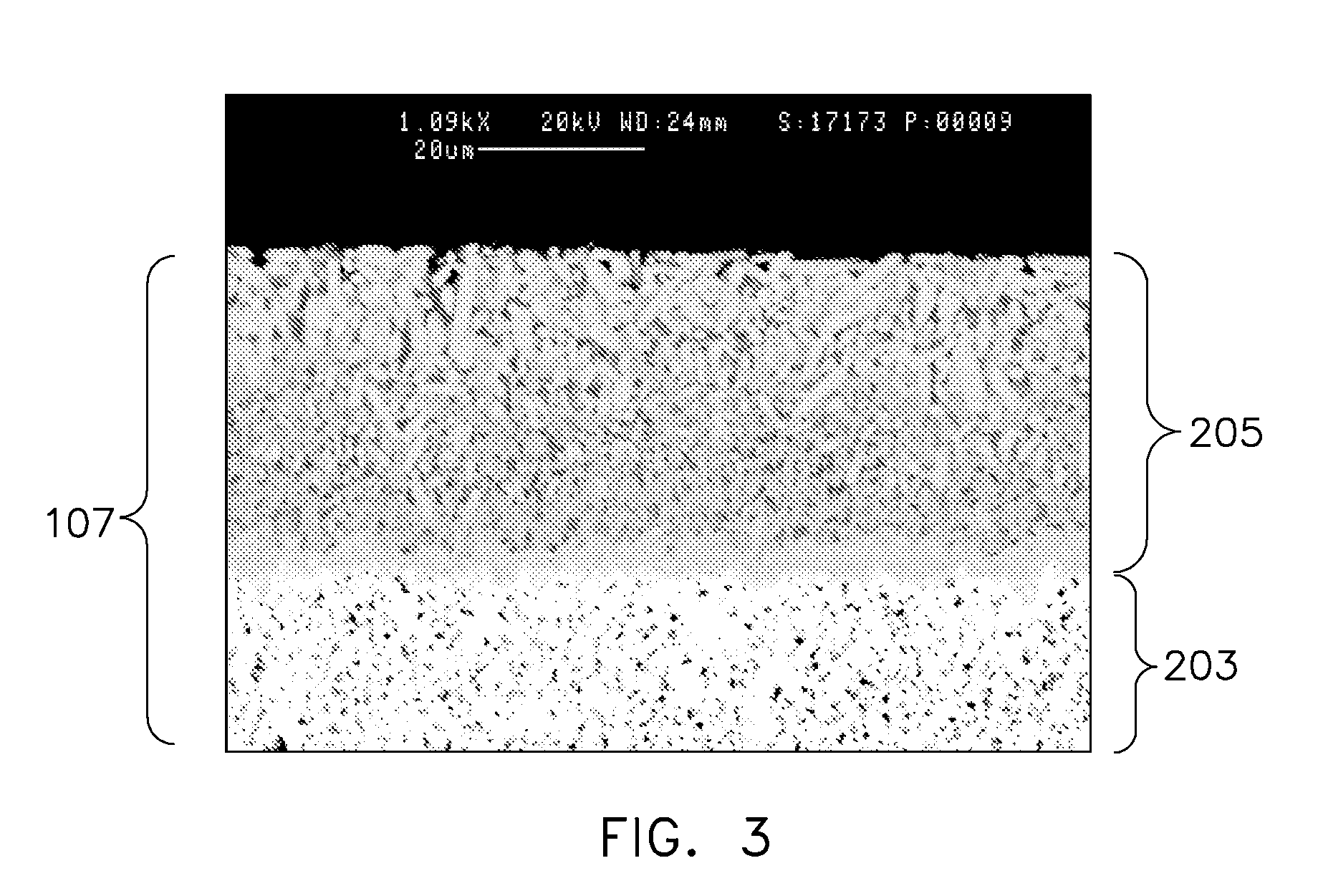

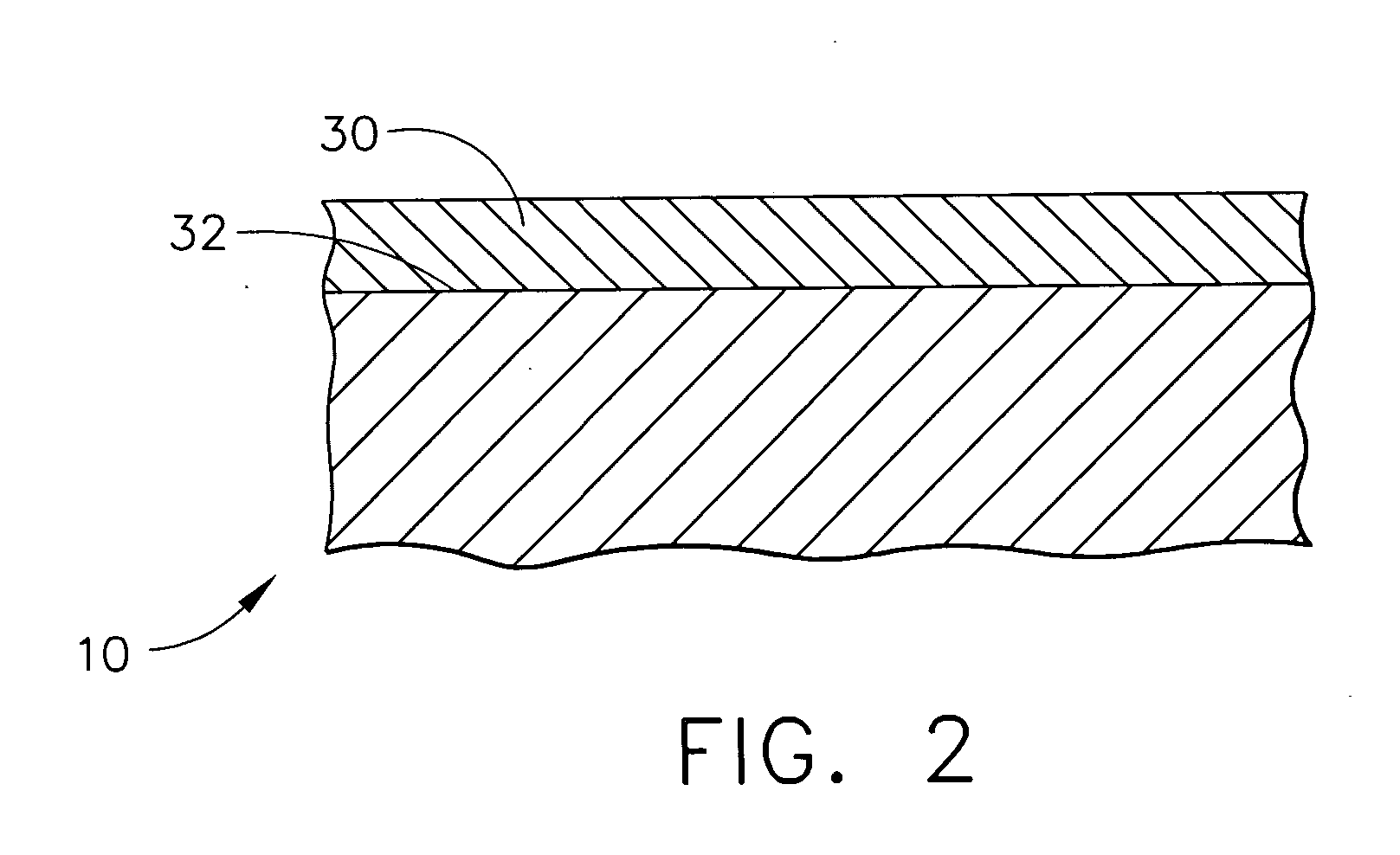

Deposition of superalloys using powdered flux and metal

A method for depositing superalloy materials. A layer of powder (14) disposed over a superalloy substrate (12) is heated with an energy beam (16) to form a layer of superalloy cladding (10) and a layer of slag (18). The layer of powder includes flux material and alloy material, formed either as separate powders or as a hybrid particle powder. A layer of powdered flux material (22) may be placed over a layer of powdered metal (20), or the flux and metal powders may be mixed together (36). An extrudable filler material (44) such as nickel, nickel-chromium or nickel-chromium-cobalt wire or strip may be added to the melt pool to combine with the melted powder to give the superalloy cladding the composition of a desired superalloy material.

Owner:SIEMENS ENERGY INC

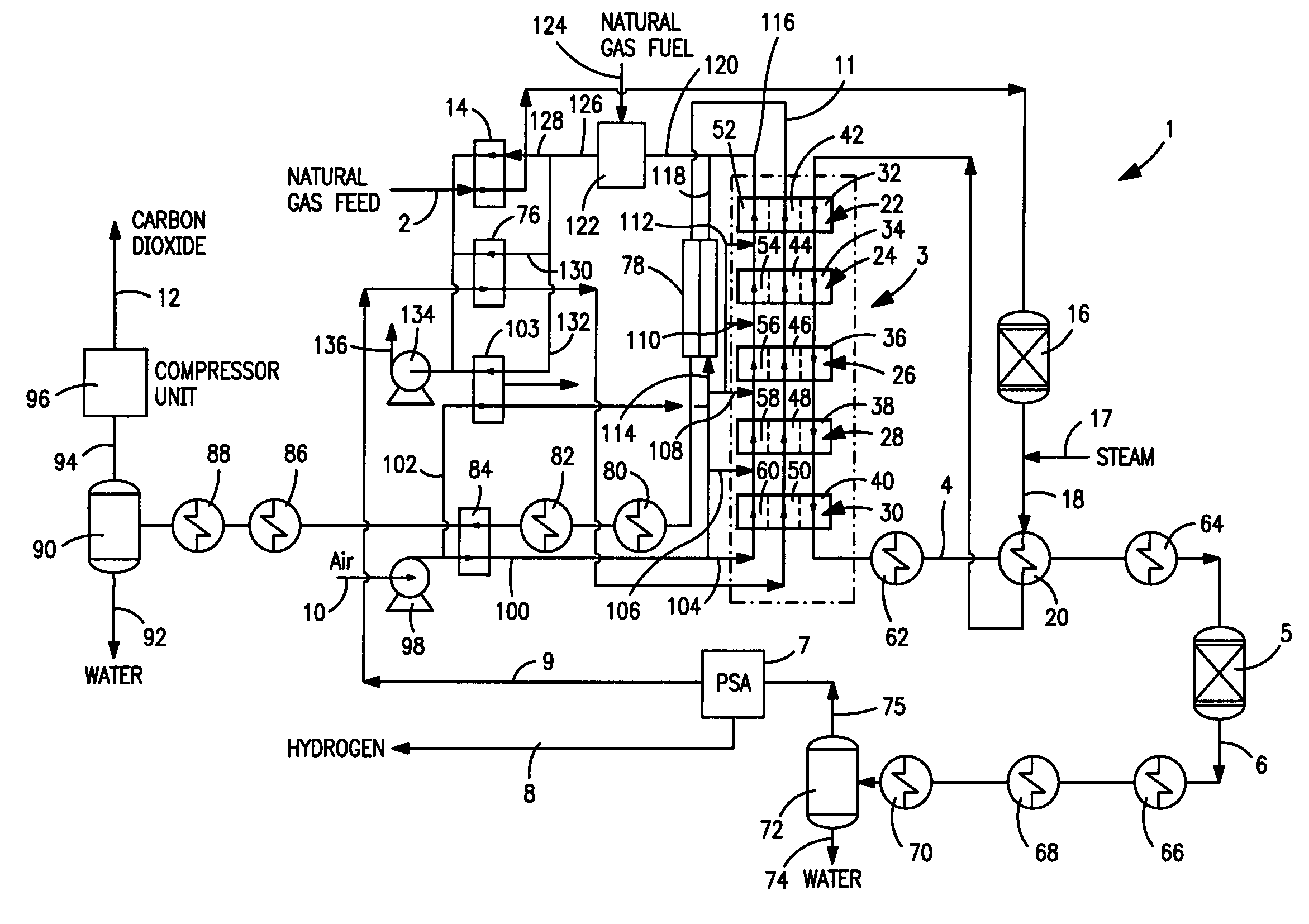

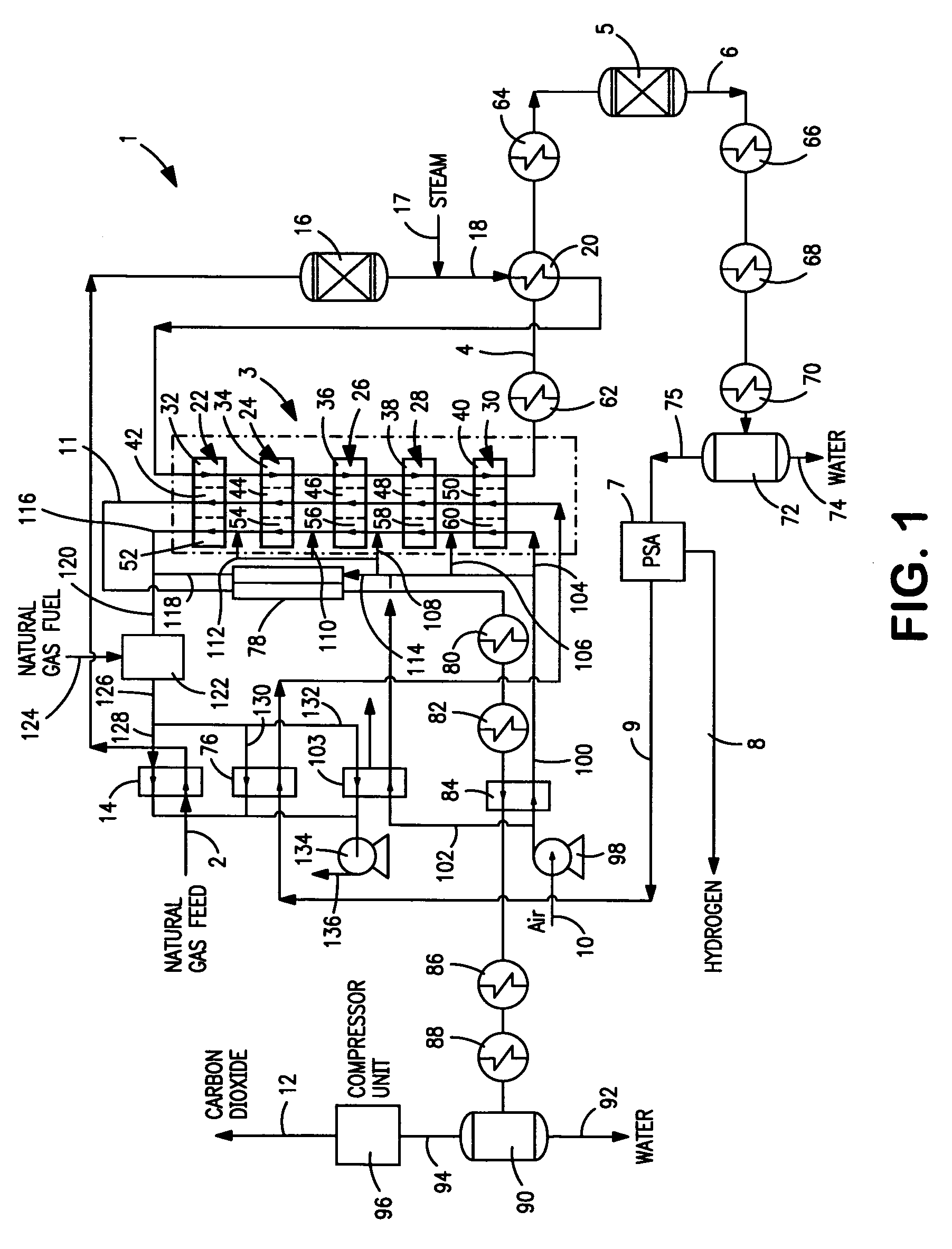

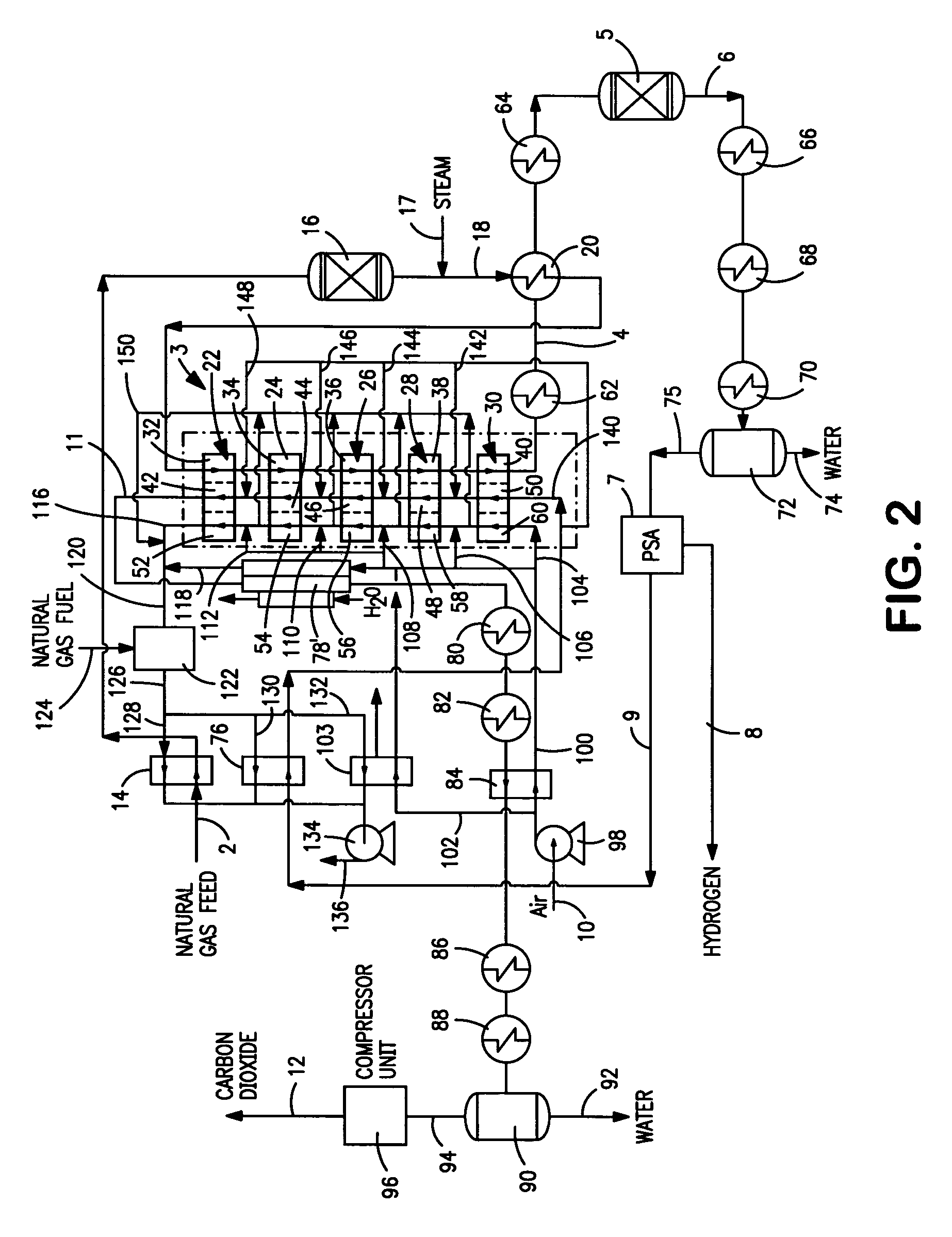

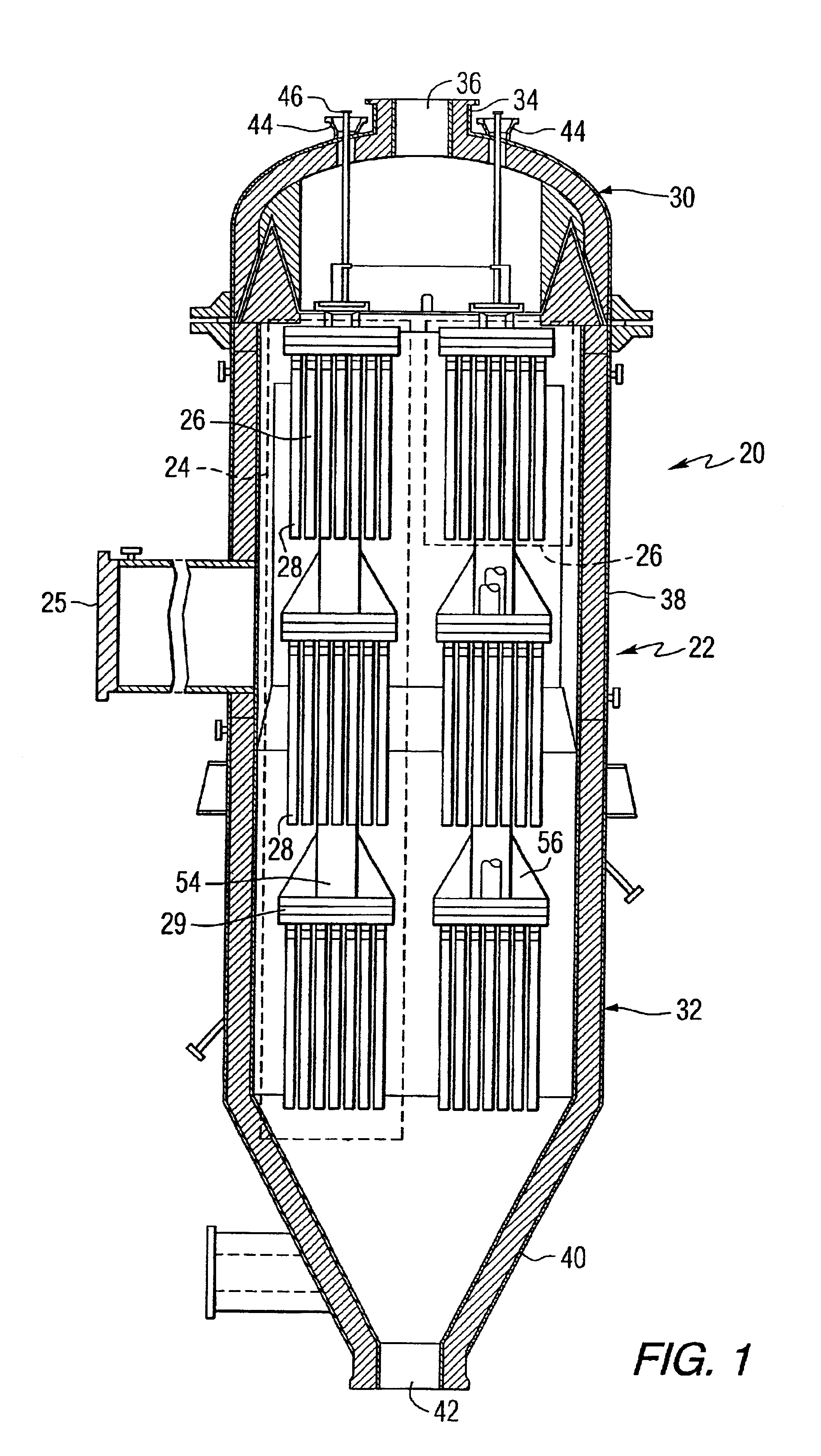

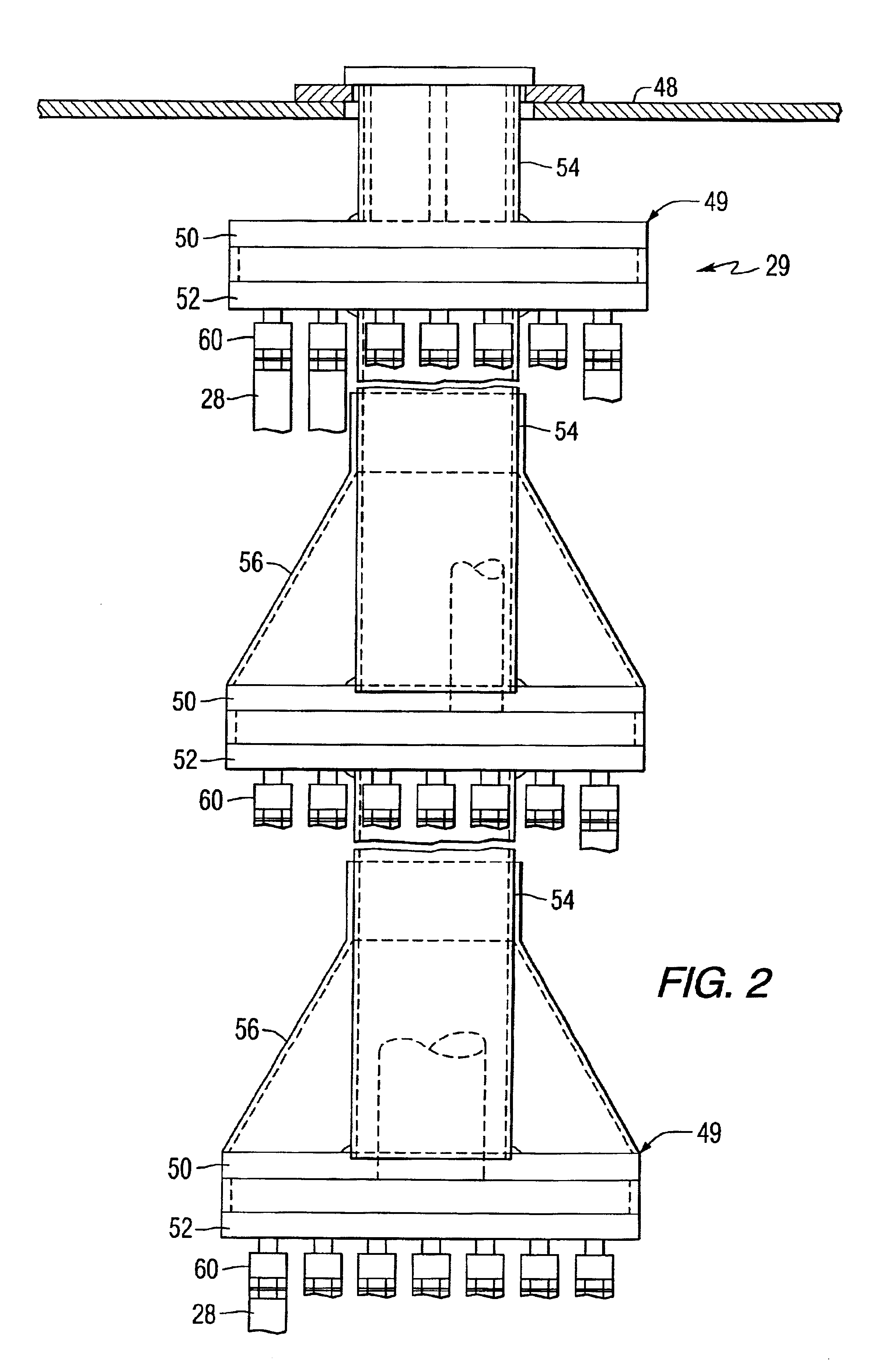

Method and apparatus for producing synthesis gas

InactiveUS20070289215A1Increase the number ofCatalytic gas-gas reactionOxygen/ozone/oxide/hydroxideSyngasCombustion

A method and apparatus for reacting a hydrocarbon containing feed stream by steam methane reforming reactions to form a synthesis gas. The hydrocarbon containing feed is reacted within a reactor having stages in which the final stage from which a synthesis gas is discharged incorporates expensive high temperature materials such as oxide dispersed strengthened metals while upstream stages operate at a lower temperature allowing the use of more conventional high temperature alloys. Each of the reactor stages incorporate reactor elements having one or more separation zones to separate oxygen from an oxygen containing feed to support combustion of a fuel within adjacent combustion zones, thereby to generate heat to support the endothermic steam methane reforming reactions.

Owner:PRAXAIR TECH INC +1

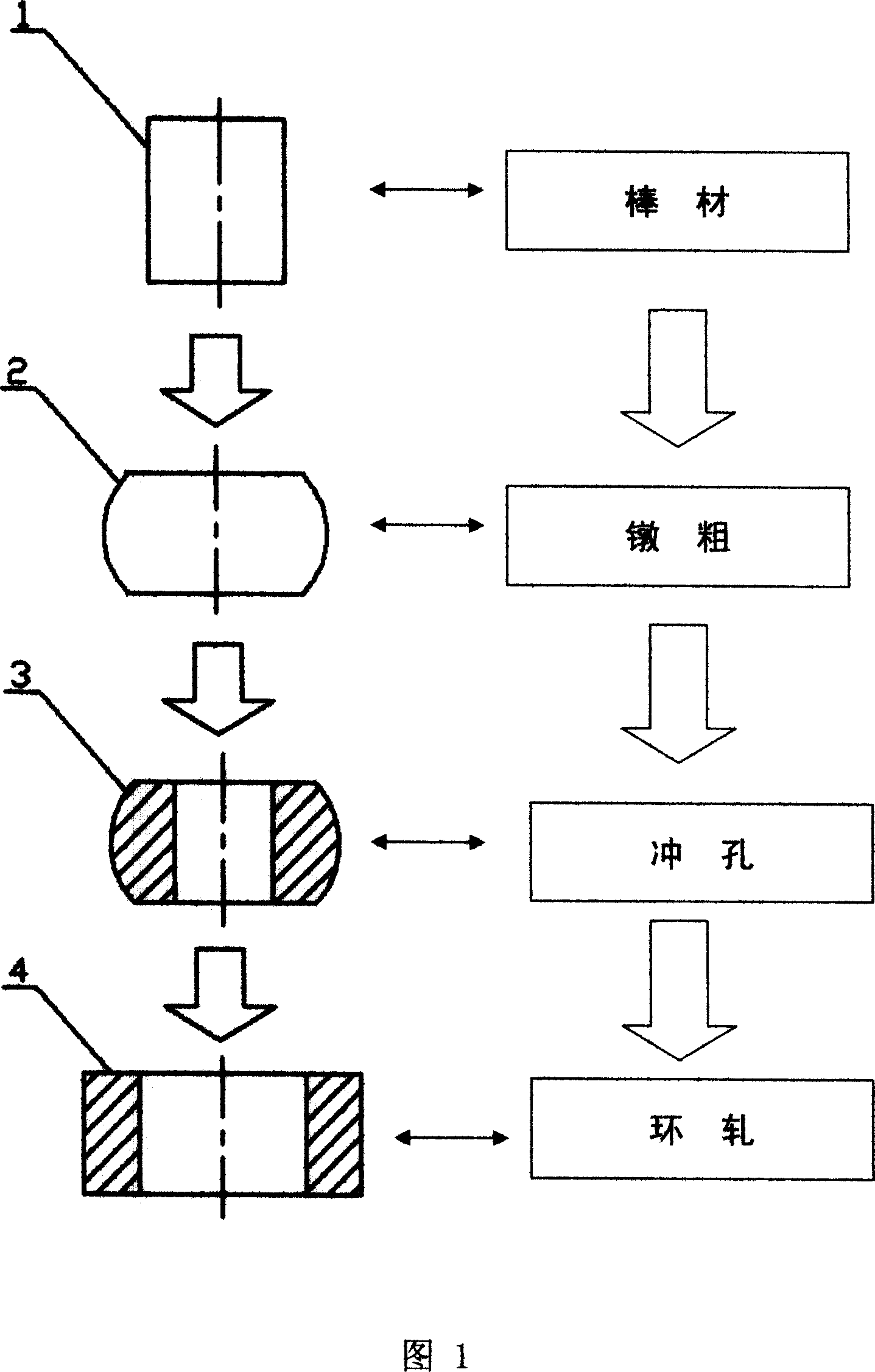

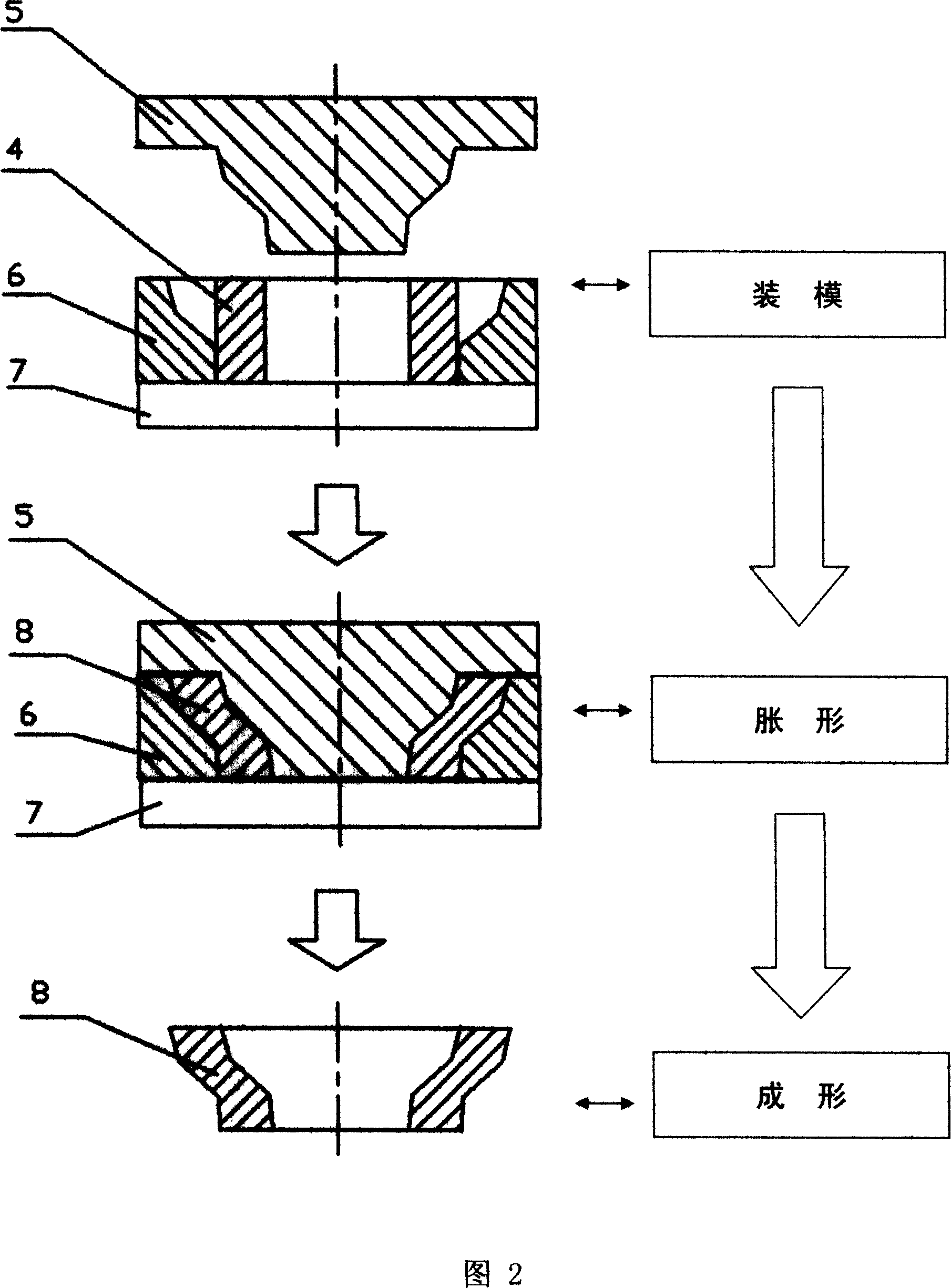

Making process of large irregular ring blank of high temperature alloy

InactiveCN101020284AEasy to achieve billet formingEasy to manufactureForging/hammering/pressing machinesSuperalloy

Owner:GUIZHOU ANDA AVIATION FORGING

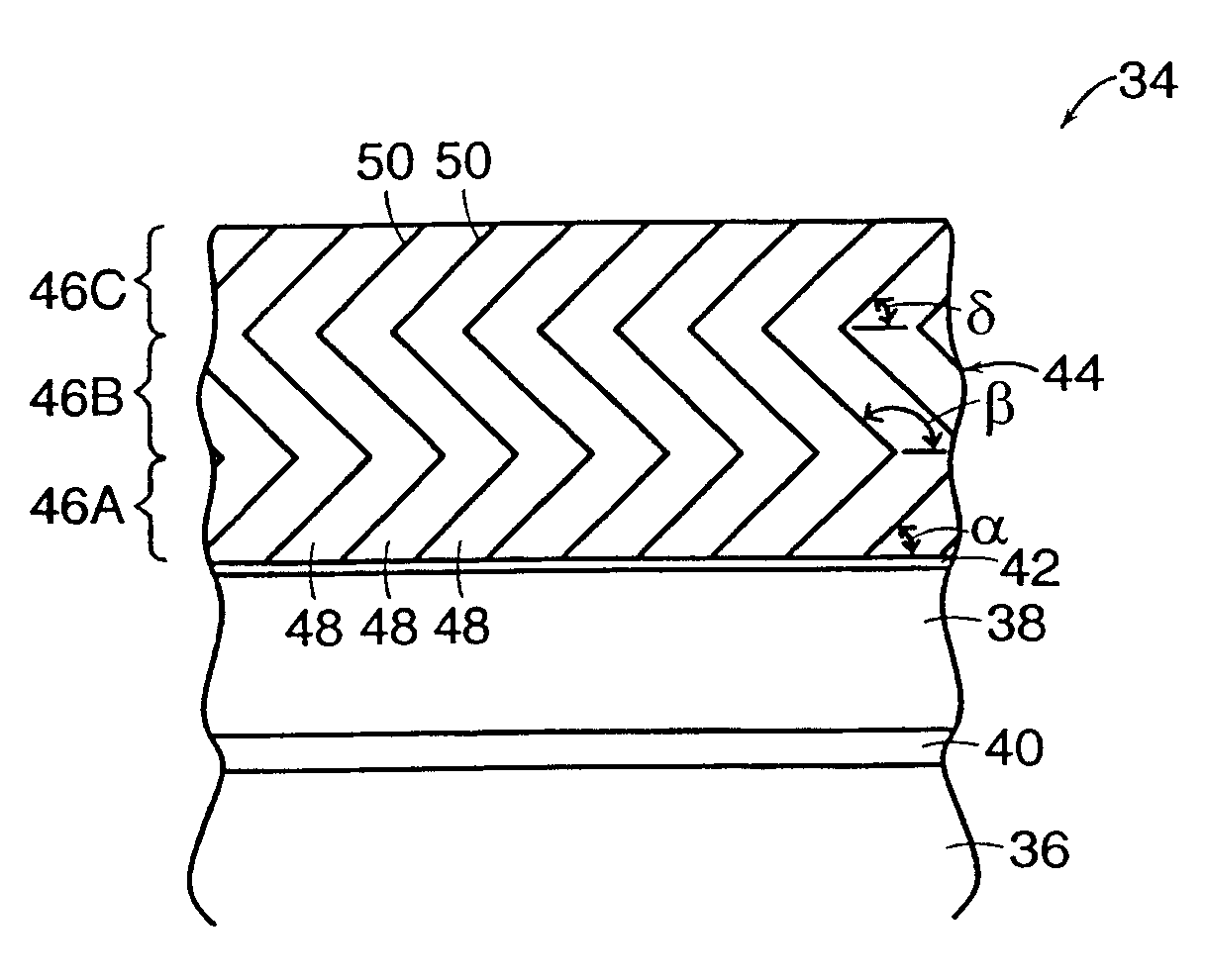

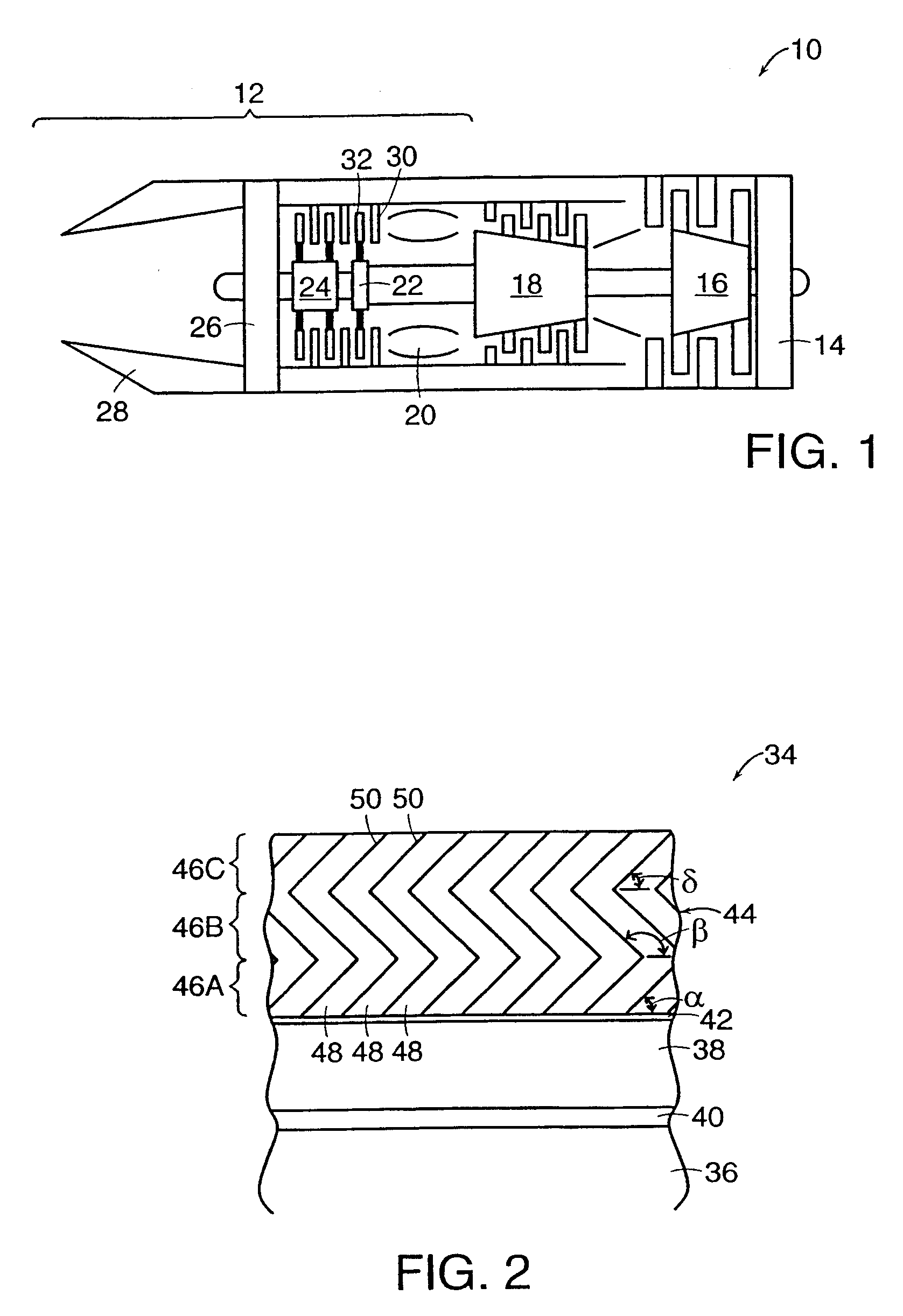

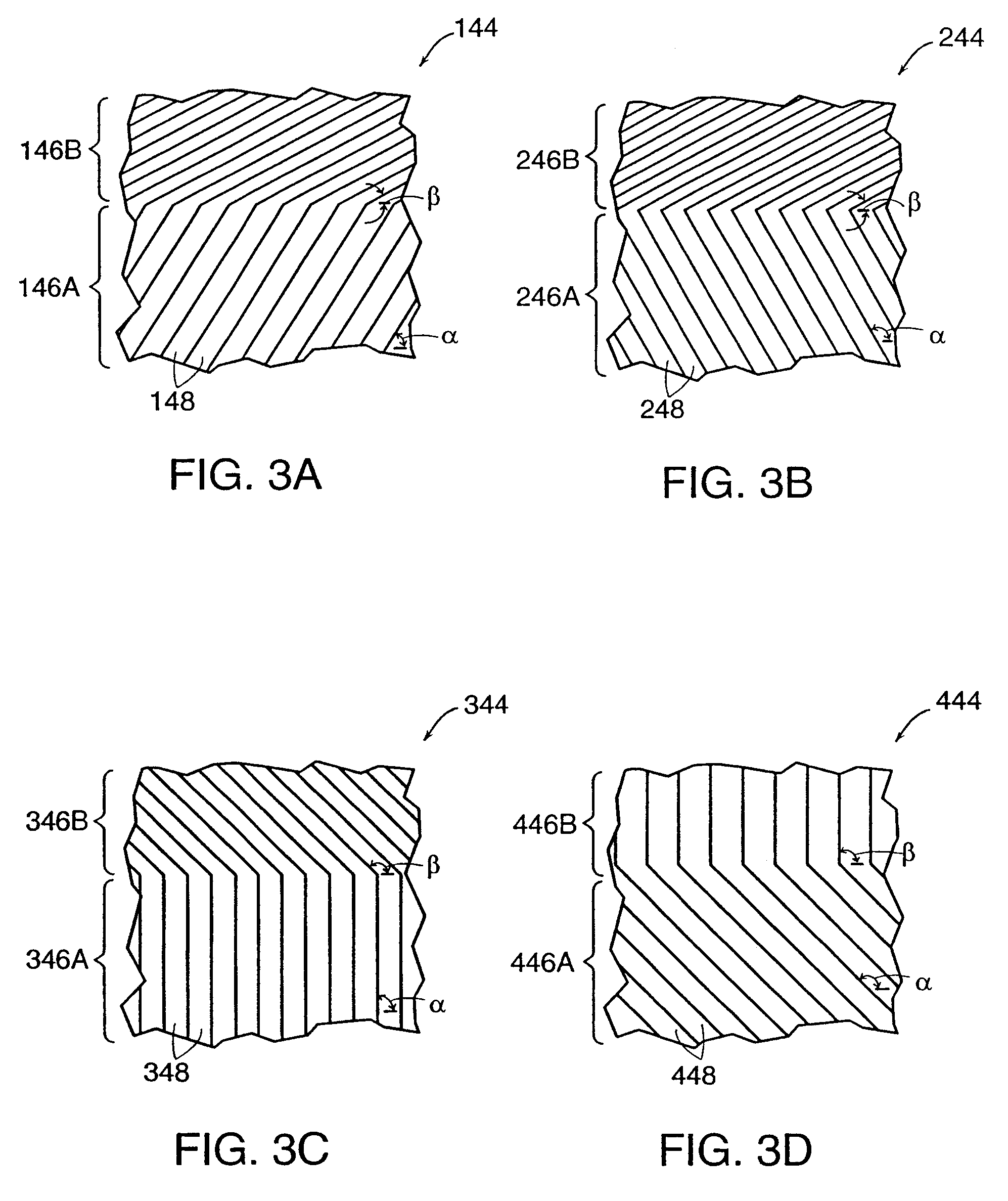

Thermal barrier coating ceramic structure

InactiveUS6455173B1PropellersSurface reaction electrolytic coatingElectron beam physical vapor depositionVapor cloud

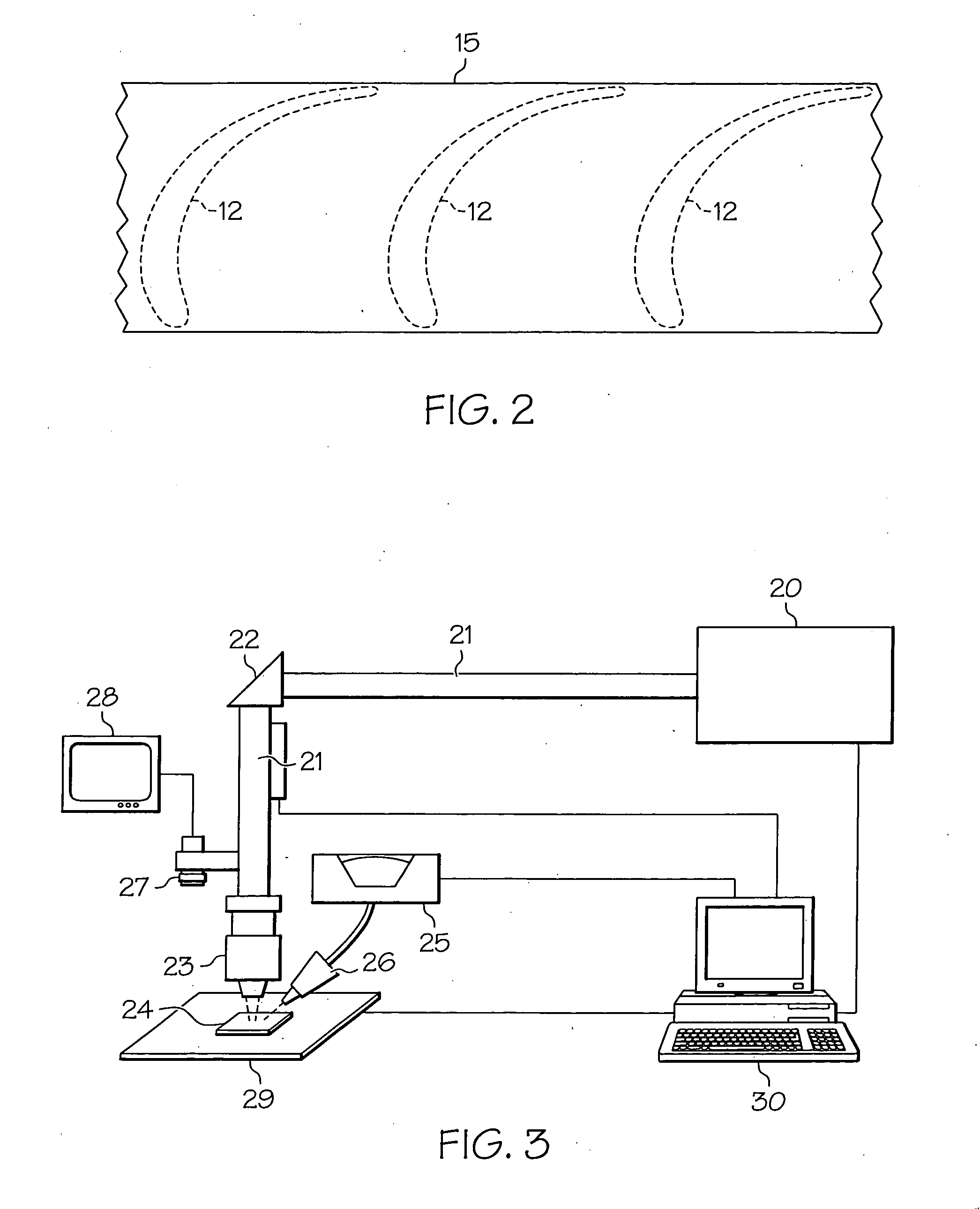

A multilayered ceramic topcoat of a thermal barrier coating system is useful for high temperature corrosive applications such as hot section components in gas turbine engines. The ceramic topcoat includes at least two layers, each having generally columnar grain microstructures with different grain orientation directions. A preferred method of producing the multilayered ceramic topcoat includes positioning a superalloy substrate at a first angled orientation relative to a ceramic vapor cloud in an electron beam physical vapor deposition apparatus for a time sufficient to grow a first ceramic layer. The substrate is then reoriented to a second, different angled orientation for a time sufficient to grow a second ceramic layer. The ceramic layers exhibit columnar microstructures having respective grain orientation directions which are related to the first and second substrate orientations. For uniformly coating a complex contoured surface such as a turbine blade airfoil, the blade can be rotated during coating deposition at each angled orientation. Alternatively, the article may be continuously reoriented according to a predetermined speed cycle to produce generally arcuate, sinusoidal, helical, or other columnar grain microstructures.

Owner:MARIJNISSEN GILLION HERMAN +4

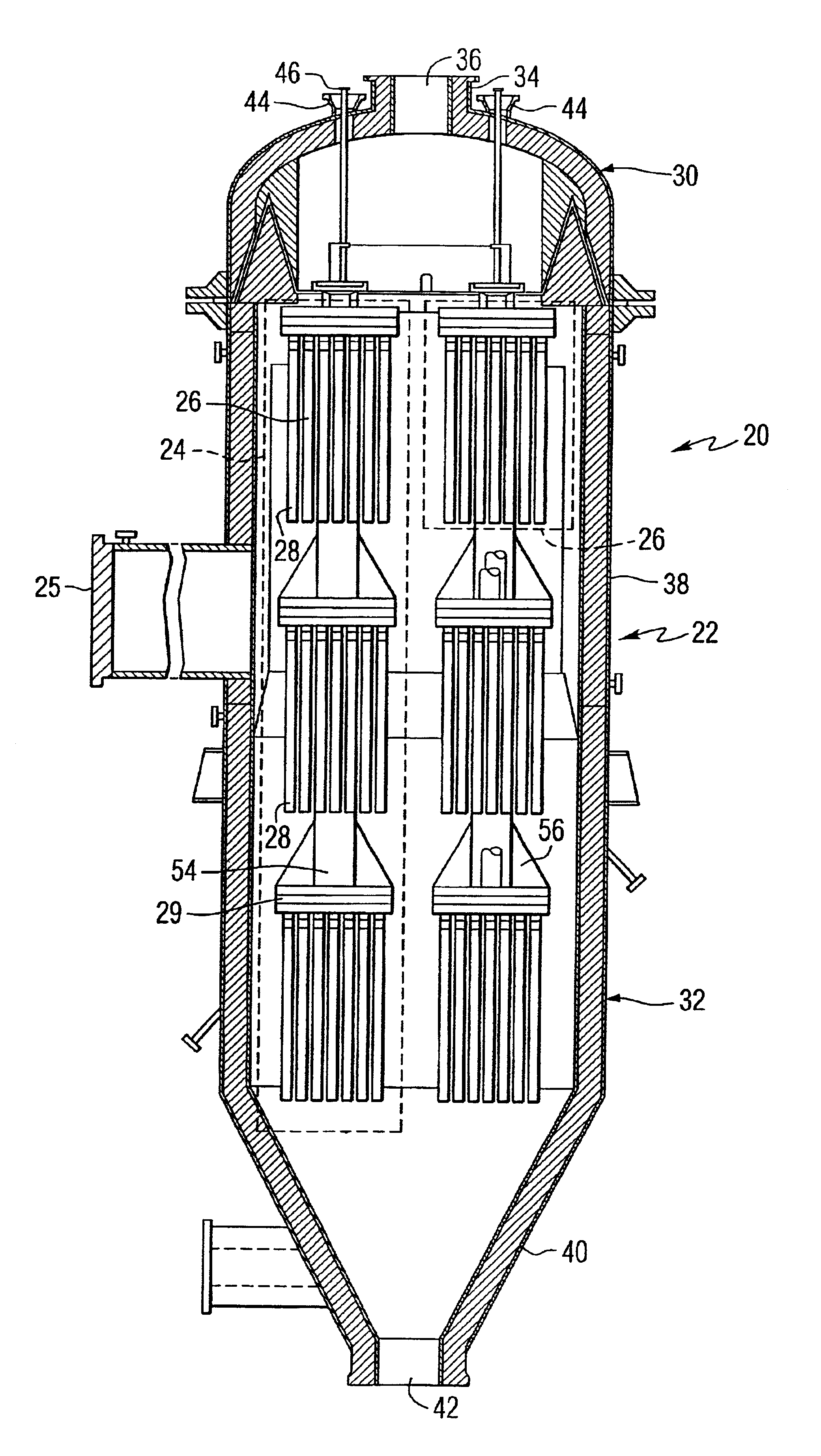

Catalytically enhanced filtration apparatus

A hot gas filtration apparatus includes a vessel, a plurality of filter elements mounted within the vessel and positioned such that hot gas flows through said filter elements, with each of said filter elements having a porous body, and a catalytic layer on surfaces of the porous body. The porous body of the filter element may include one of: a porous ceramic monolithic matrix, a continuous fiber reinforced ceramic composite (CFCC) matrix, a metallic matrix, an intermetallic matrix, a superalloy, and a metal-ceramic composite matrix. When the porous body is a nonoxide ceramic, a metallic matrix, an intermetallic matrix, a superalloy, or a metal-ceramic composite matrix, the invention further includes an oxidative resistant layer coating surfaces within the porous body, and the catalytic layer is on the oxidative resistant layer. A porous particulate removal membrane can be positioned on one or more surfaces of the filter element. The porous membrane can also provide a surface for one or more catalysts. The catalysts on the porous surface of the membrane(s) can be the same as or different from the catalysts on surfaces within the porous body.

Owner:SIEMENS ENERGY INC

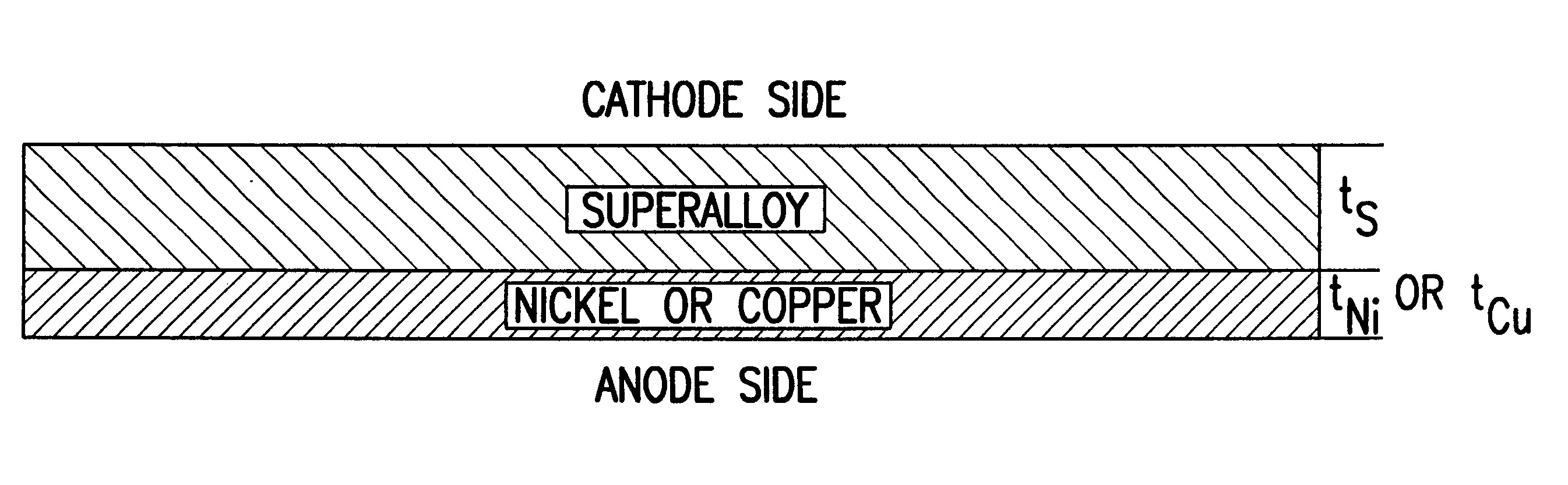

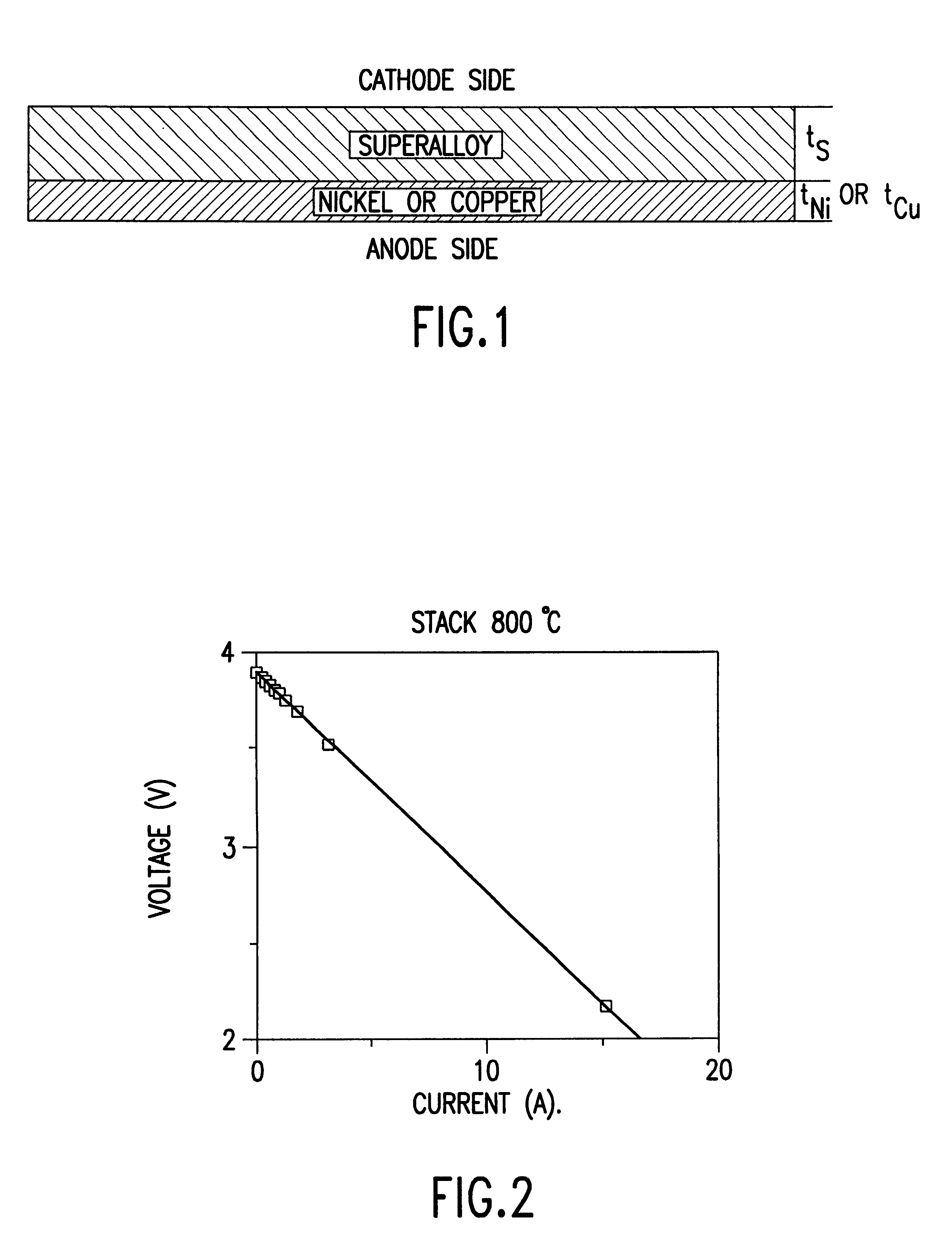

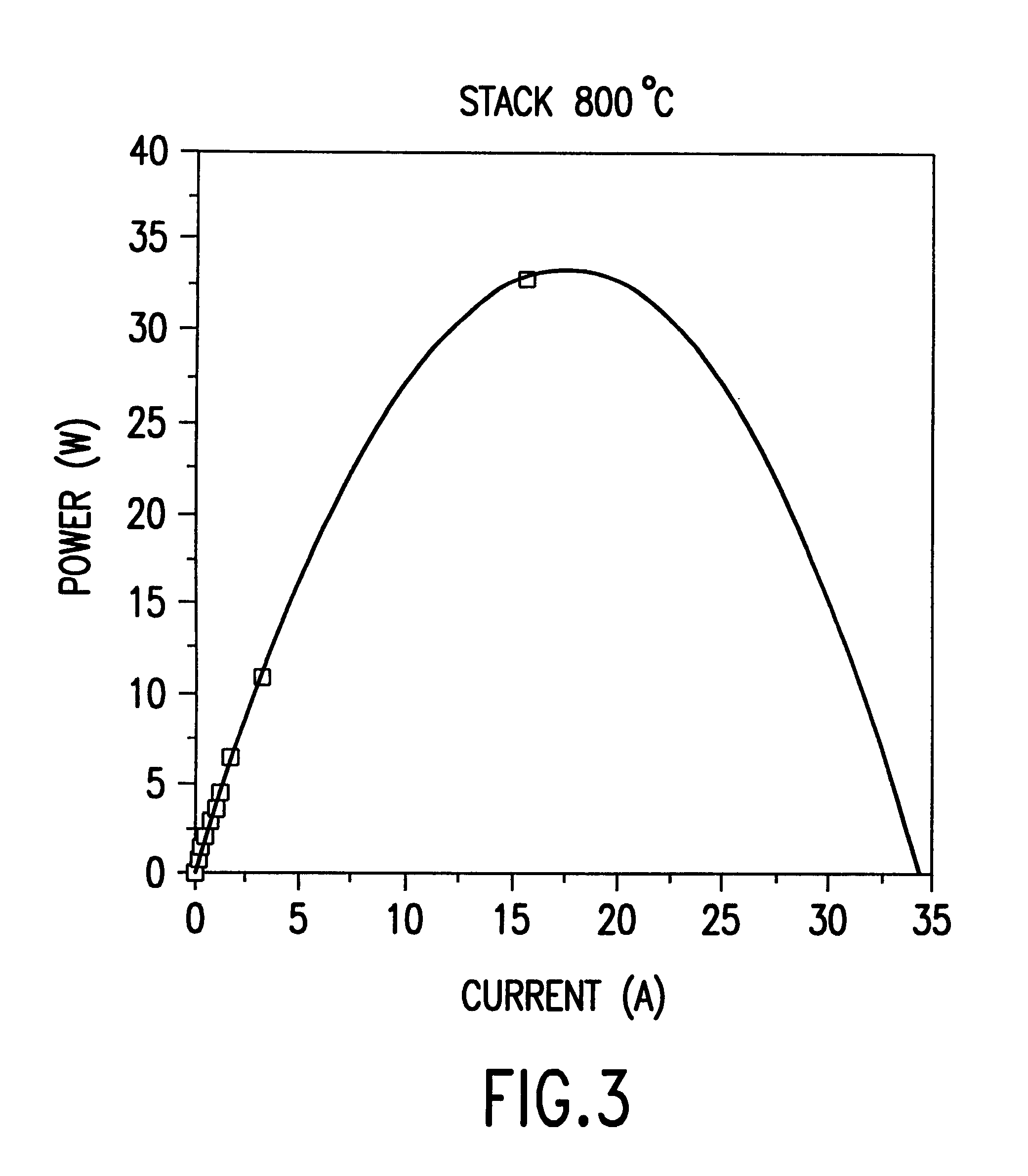

Solid oxide fuel cell interconnector

A solid oxide fuel cell interconnector having a superalloy metallic layer with an anode-facing face and a cathode-facing face and metal layer on the anode-facing face of the superalloy metallic layer. The metal layer is a metal which does not oxidize in a fuel atmosphere, preferably nickel or copper.

Owner:VERSA POWER SYST

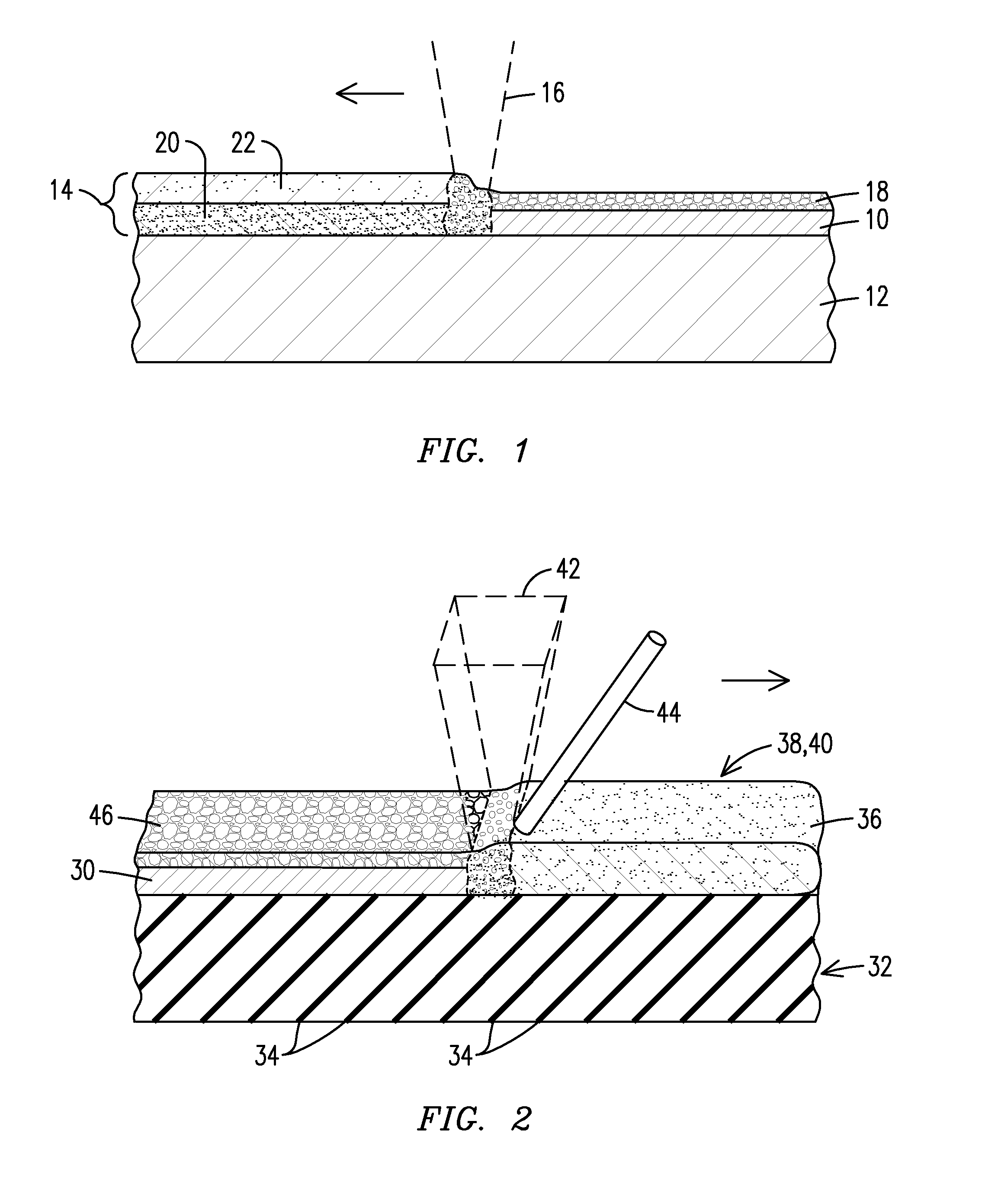

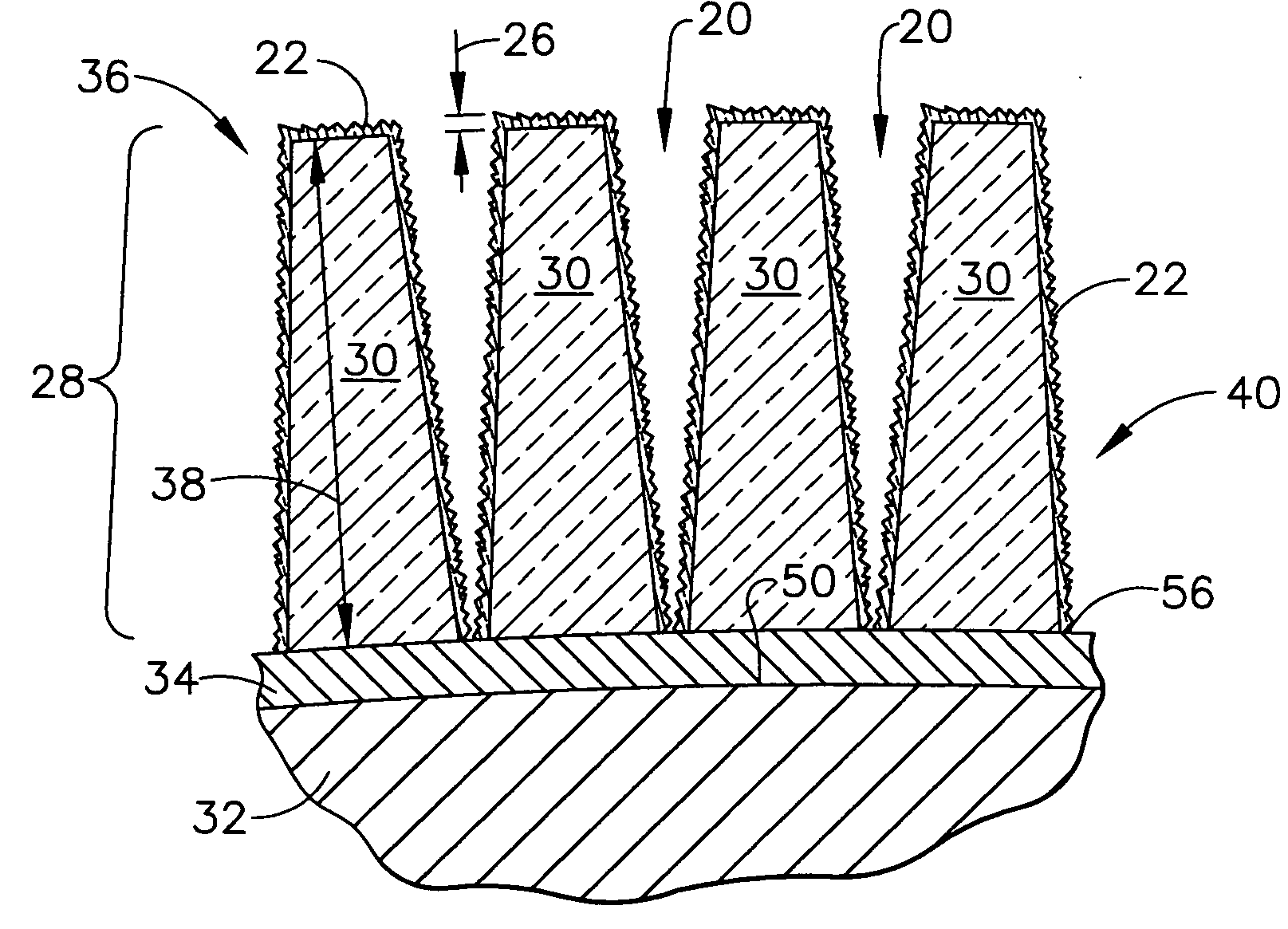

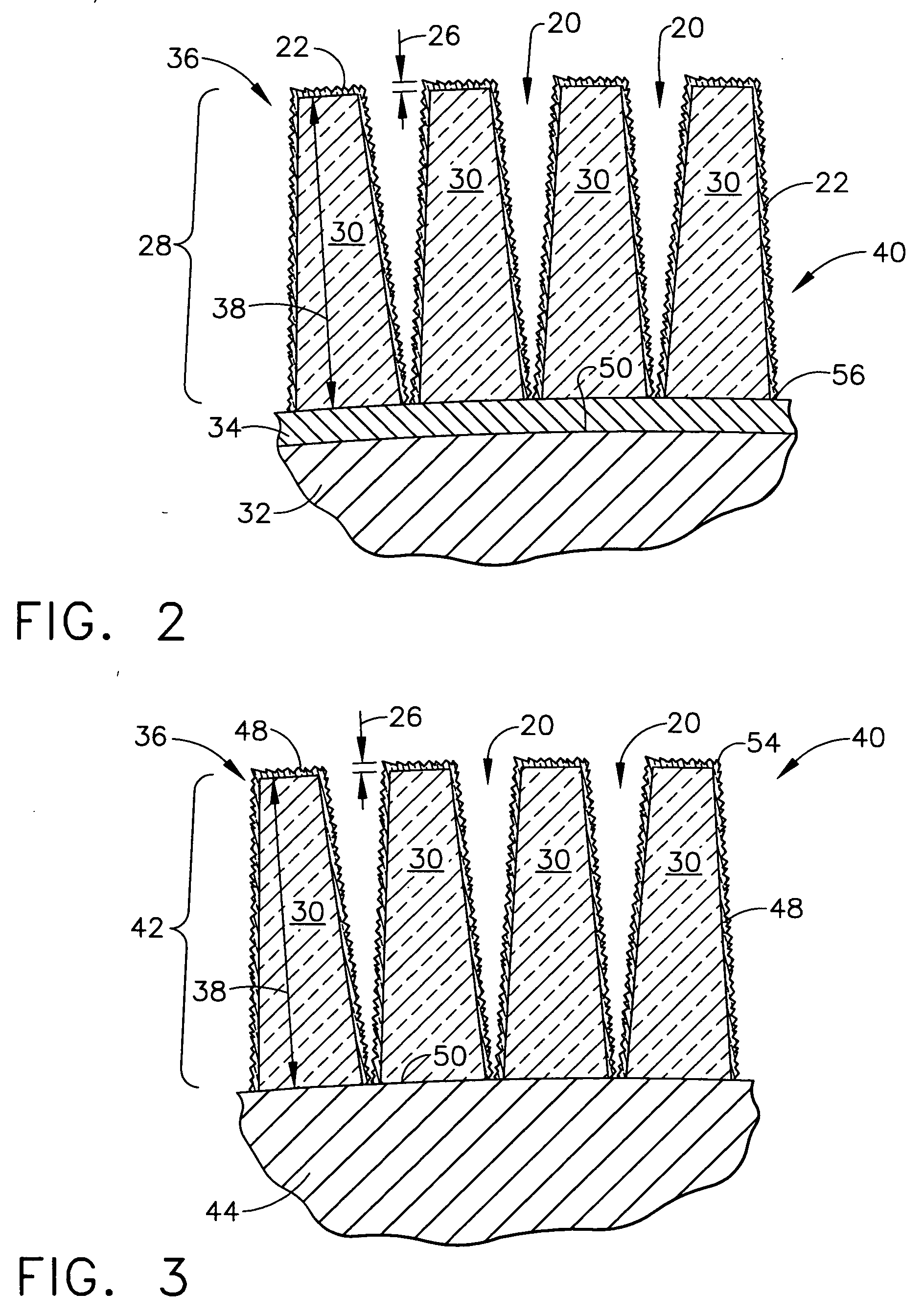

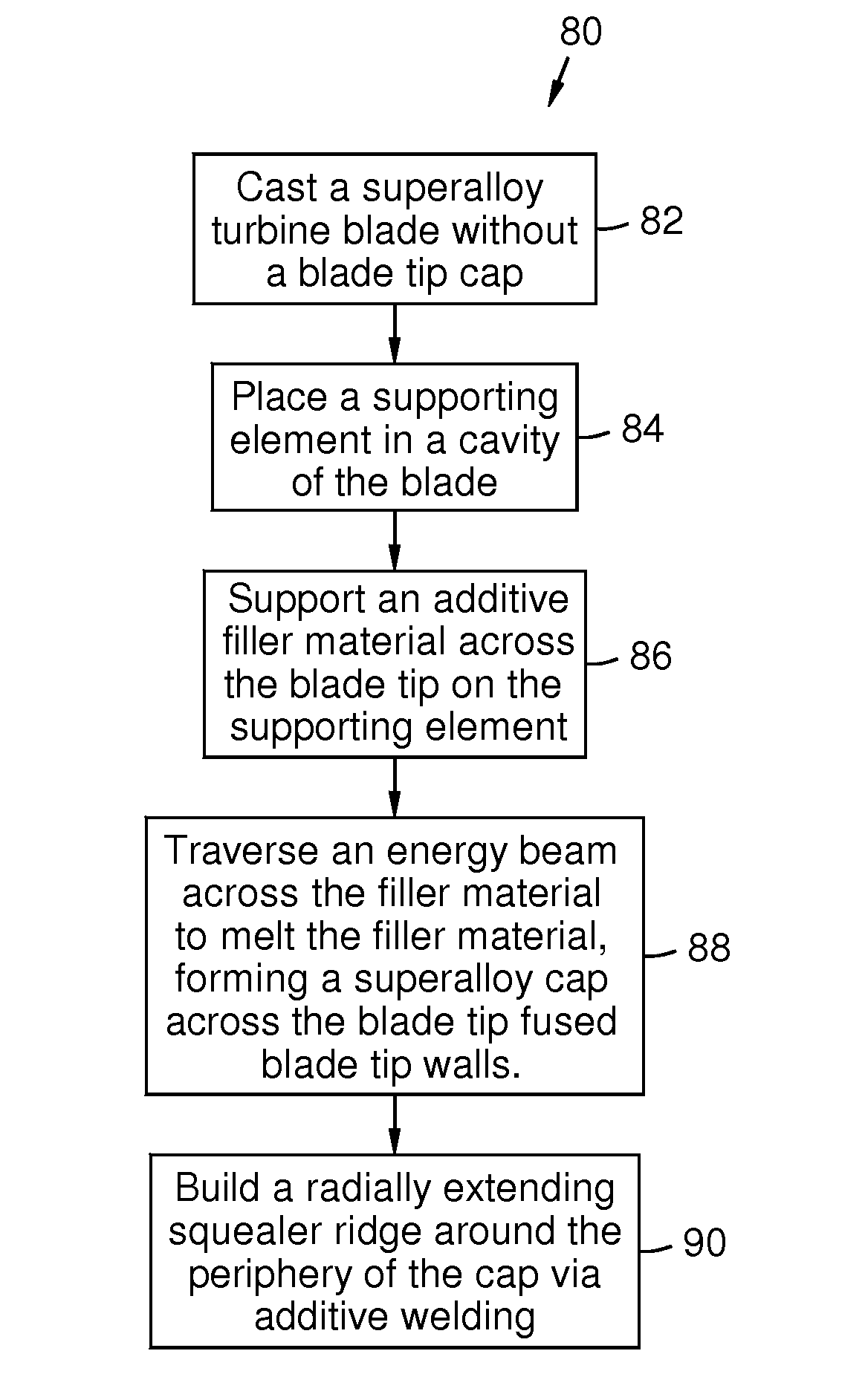

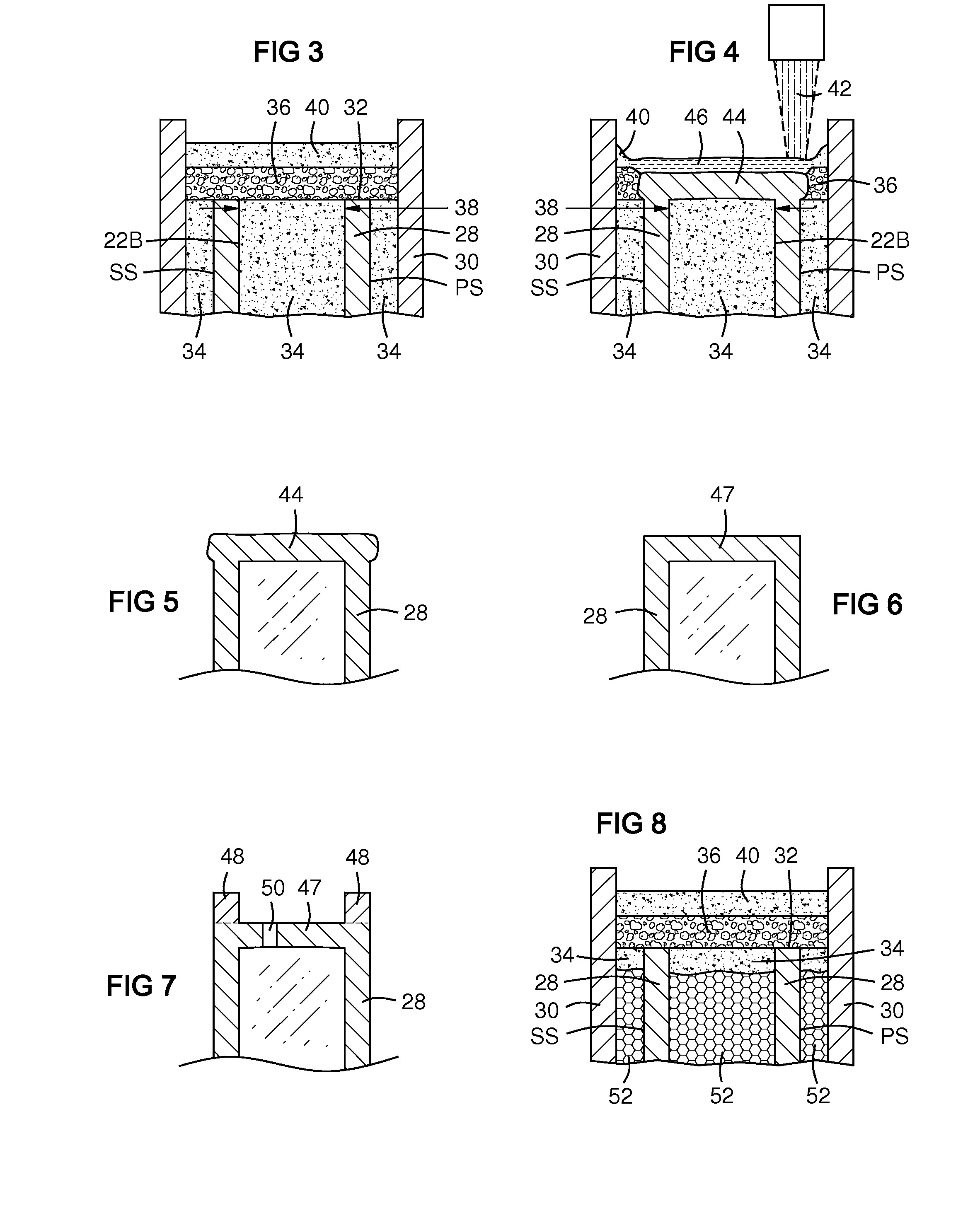

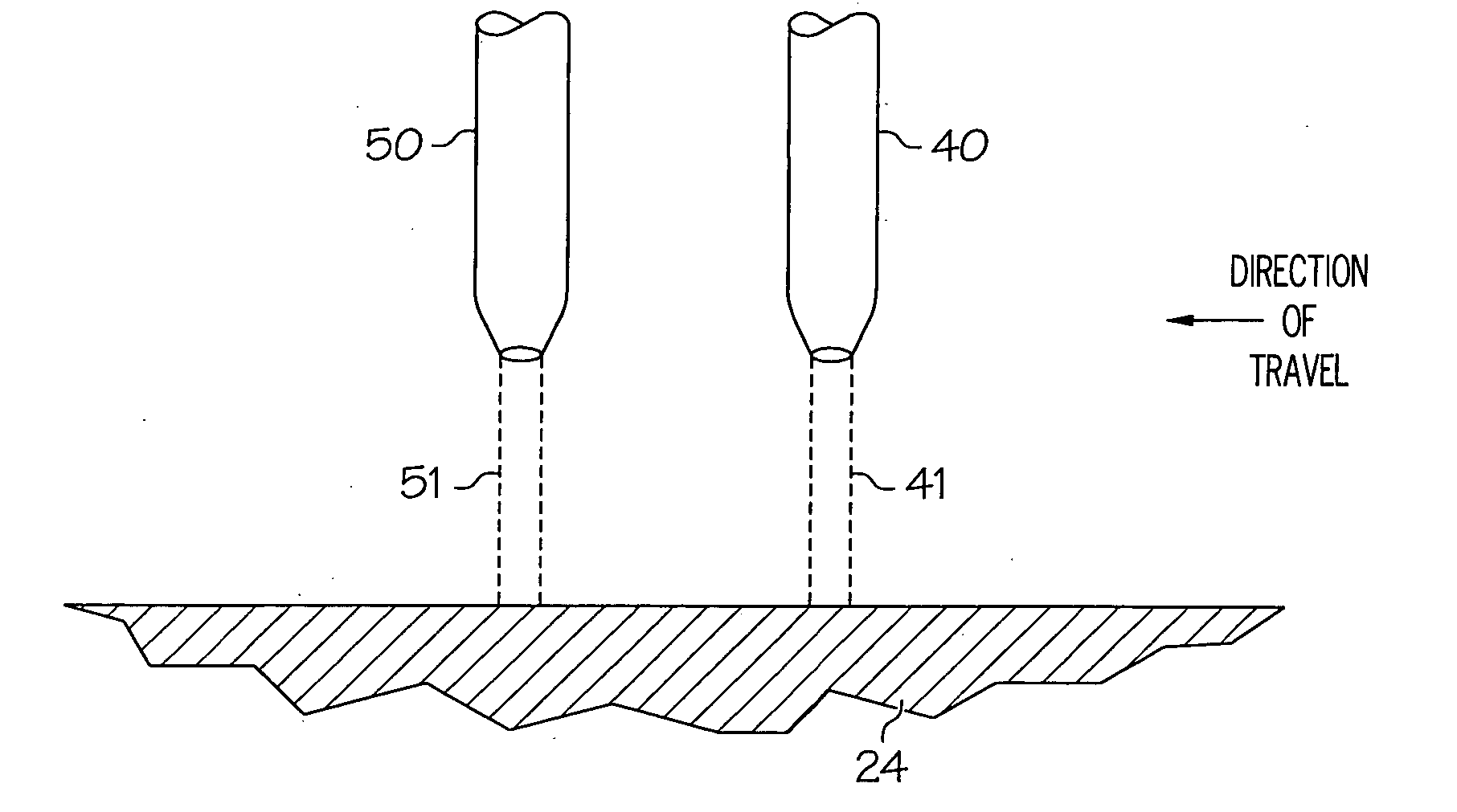

Building and repair of hollow components

A method of building or repair of a hollow superalloy component (20, 61) by forming an opening (38, 62) in a wall (28) of the component; filling a cavity (22B, 64) behind the opening with a fugitive support material (34, 52, 54, 68) to support a filler powder (36) across the opening; traversing an energy beam (42) across the filler powder to form a deposit (44) that spans and closes the opening; in which the deposit is fused to the edges (32, 62) of the opening. The filler powder includes at least metal, and may further include flux. The support material may include filler powder, a solid (54), a foam (52) insert, a flux powder (34) and / or other ceramic powder (68). Supporting powder may have a mesh size smaller than that of the filler powder.

Owner:SIEMENS ENERGY INC

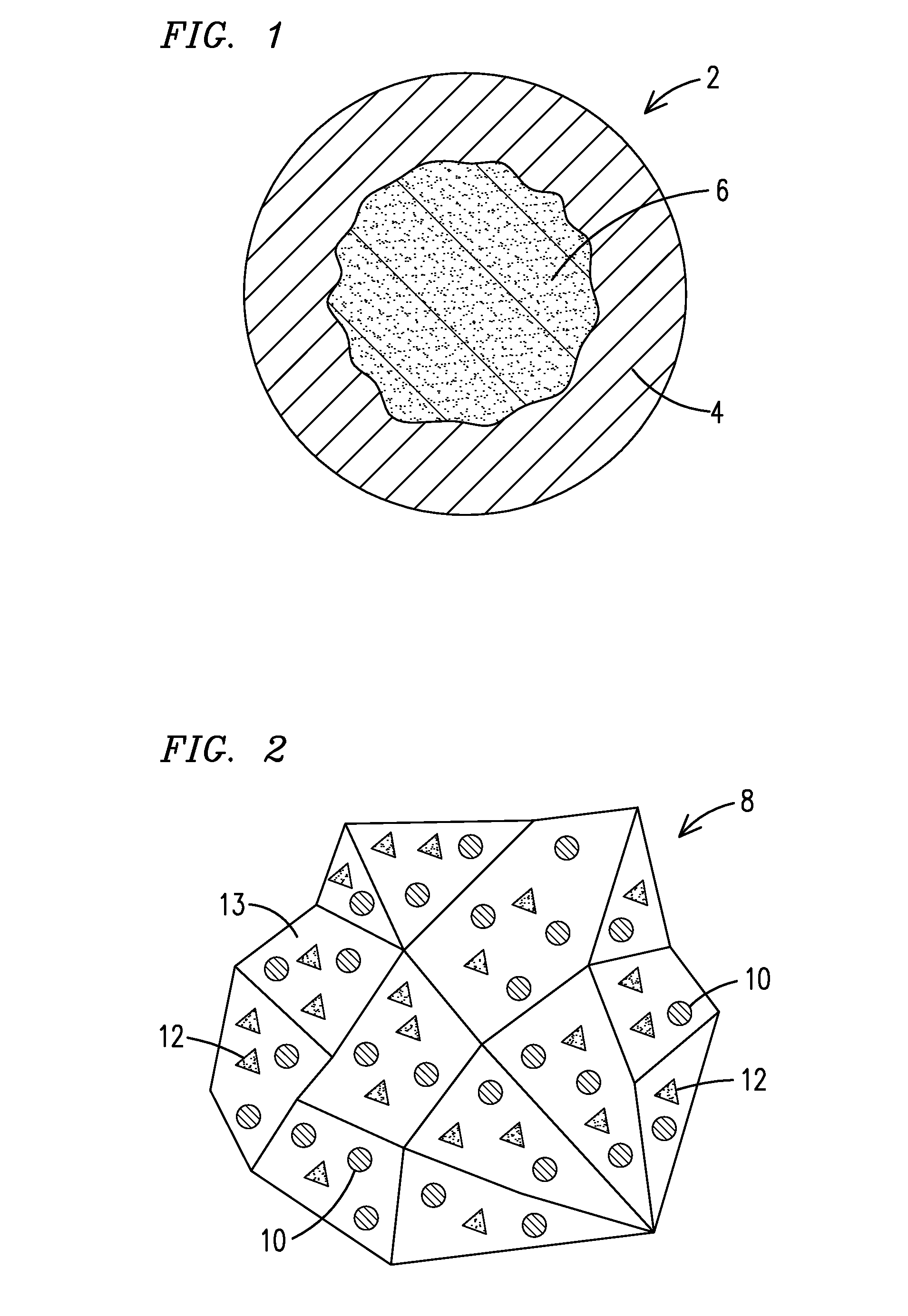

Composite materials and methods for laser manufacturing and repair of metals

Composite materials (2, 8) disclosed herein include a metal alloy (4, 10) and a flux composition (6, 12). The metal alloy may be a superalloy, and a volume ratio of the flux composition to the metal alloy may range from about 30:70 to about 70:30. The composite materials may be in the form of particles (2) containing a core (6) surrounded by a metallic layer (4), in which the core contains the flux composition and the metallic layer contains the metal alloy. The composite materials may also be in the form of fused materials (8) in which the metal alloy (10) and the flux composition (12) are randomly distributed and randomly oriented. Also disclosed are processes involving melting of composite materials to form metal deposits (32).

Owner:SIEMENS ENERGY INC

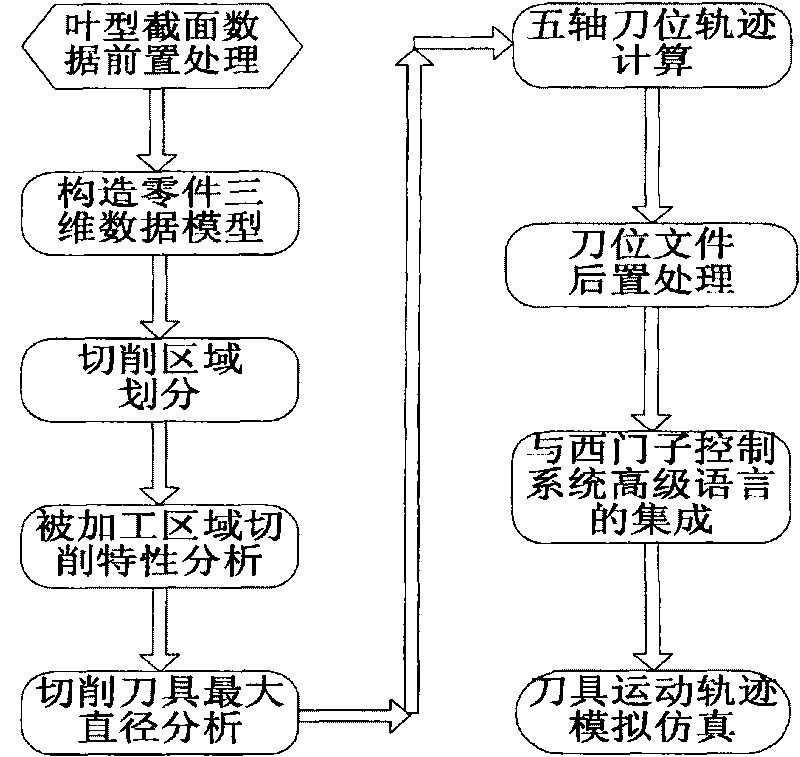

Numerically controlled drilling and milling processing method for runner of blisk of engine

InactiveCN101733618AImprove processing efficiencyShorten the manufacturing cyclePositioning apparatusNumerical controlAngular degreesEngineering

The invention provides a numerically controlled drilling and milling processing method for a runner of a blisk of an engine. The main technical flow before drilling and milling the runner comprises the following steps: lathing each surface of a blank, performing nondestructive testing, lathing inner and outer cavities of the blisk, finely milling a needed periphery and an axial benchmark, drilling and boring an angular datum hole, drilling and milling the runner and inspecting. A part and a fixture are in peripheral seam allowance fit to limit a radial degree of freedom of the part; an end face gland and a central pull bar axially limit an axial degree of freedom of the part; and a precise positioning pin angularly limits an angular degree of freedom of the part. The method has the advantages that: by applying the drilling and milling processing method to a part machining process of the blisk of the engine having the material removing rate of over 90 percent, the method improves the processing efficiency, shortens the manufacturing period of the product, and provides a new technical means for removing a large amount of remainder materials of the blisk; and the processing of a high-temperature alloy, a titanium alloy and other difficult-to-process materials shows that the material is more difficult to process, the removing rate is bigger and the effect is more obvious.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

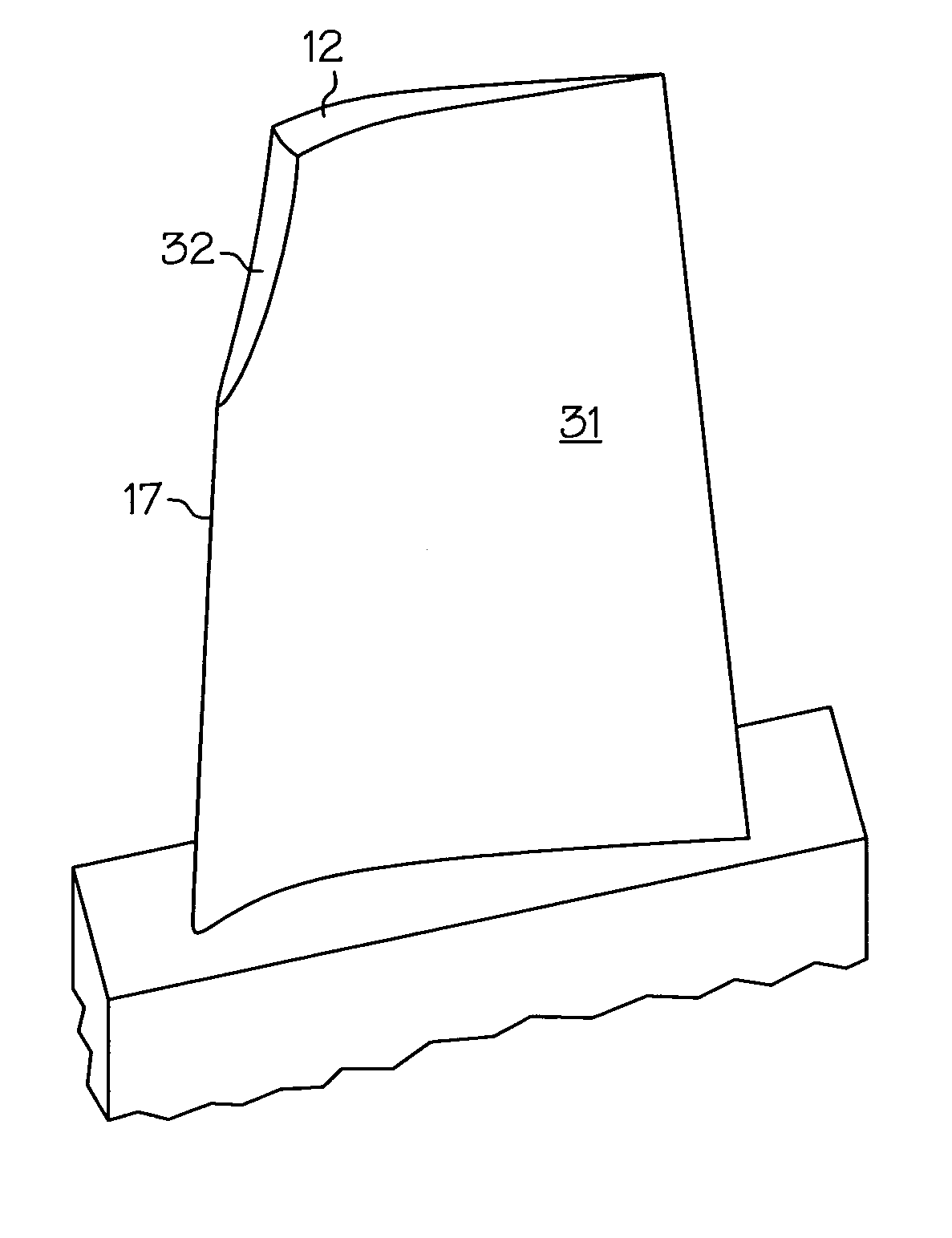

Method of bonding cast superalloys

A method of bonding cast superalloys is disclosed. The method includes the steps of casting separate superalloy component parts, machining the mating surfaces of the separate parts in a controlled manner to avoid recrystallization of the material and to ensure a tight fit between the parts, bonding the parts together, and thermally treating the bonded component. In a preferred embodiment, the component is a turbine blade for a land-based gas turbine.

Owner:SIEMENS ENERGY INC

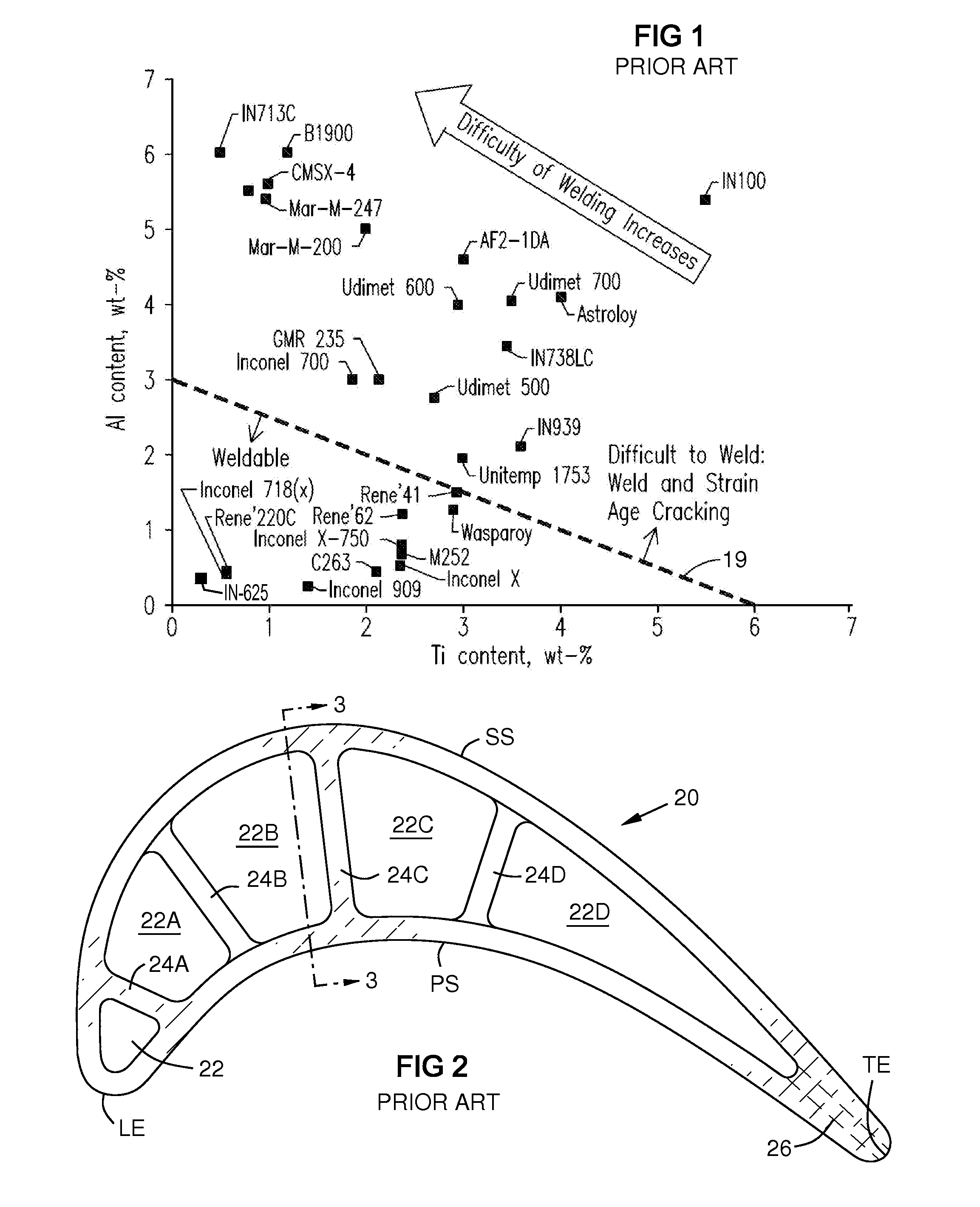

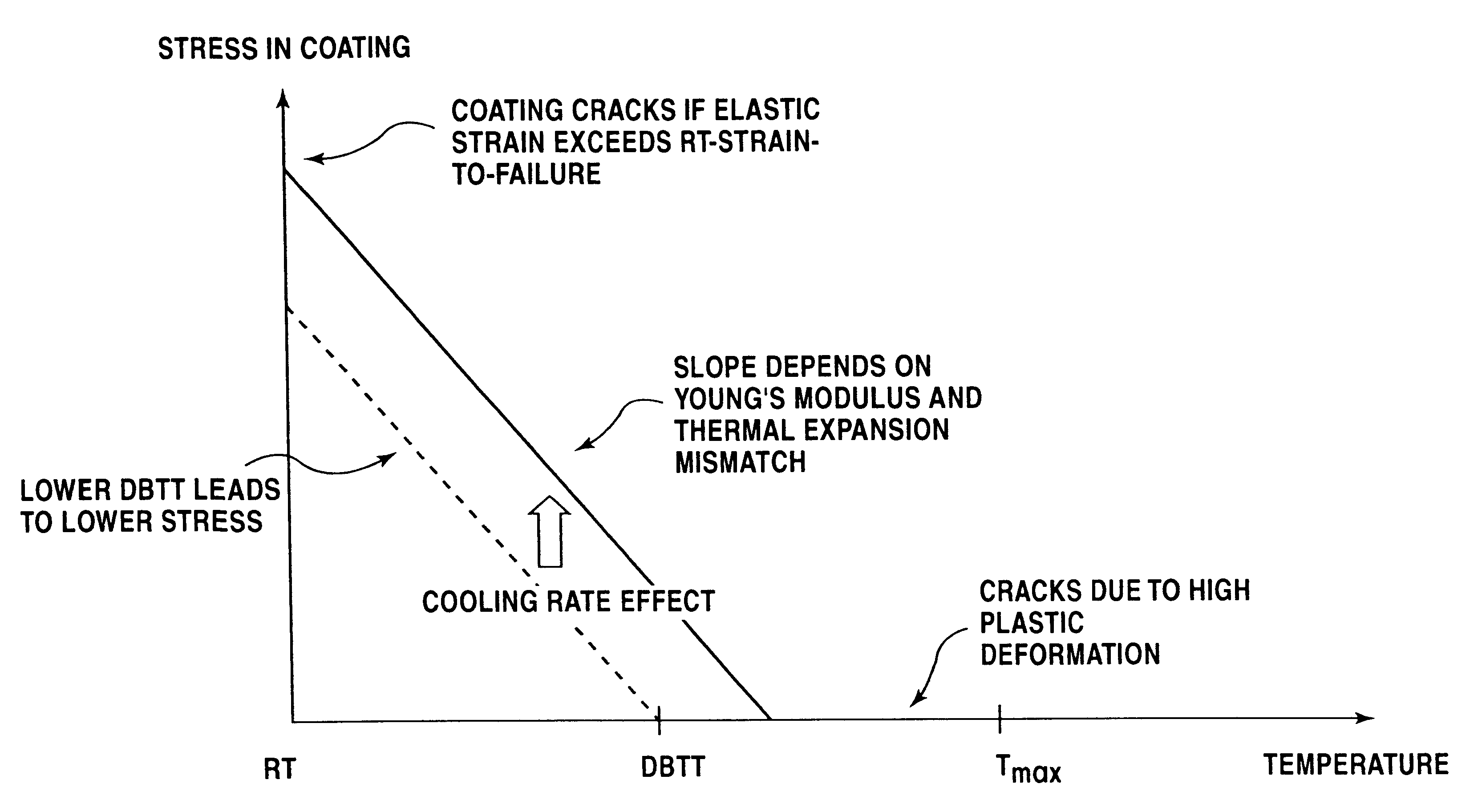

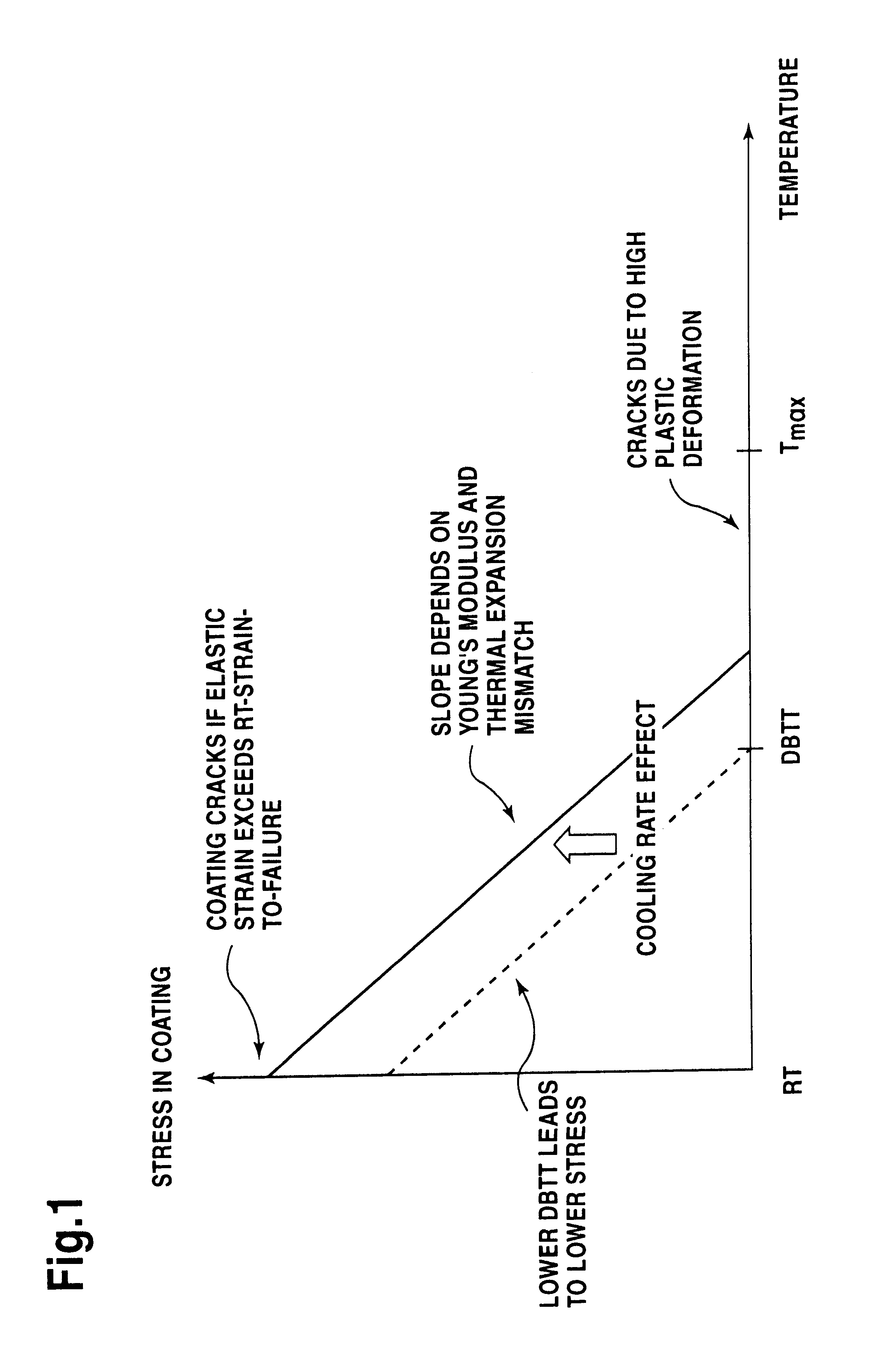

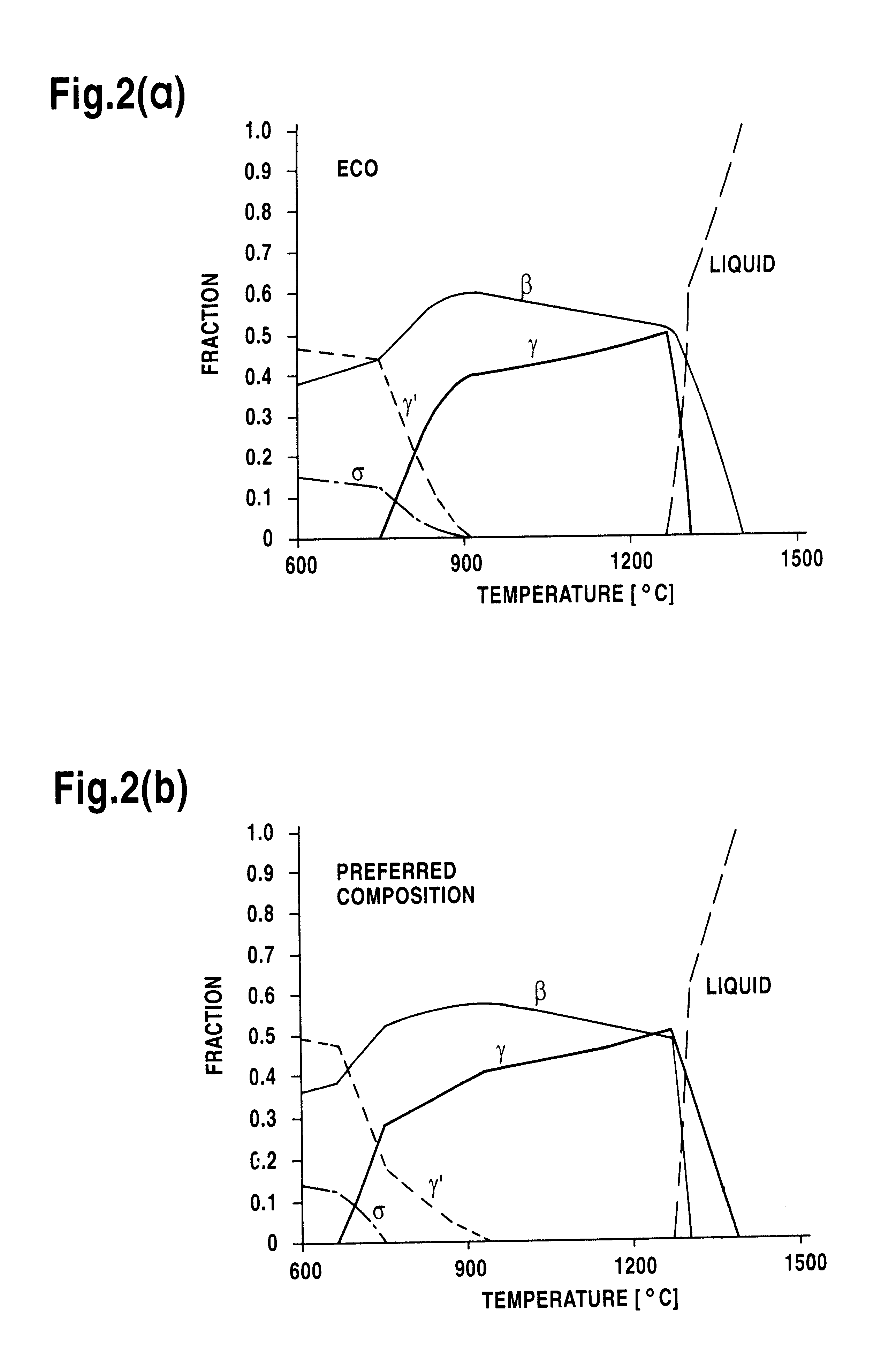

Coating composition for high temperature protection

InactiveUS6221181B1Improve mechanical propertiesLower resistanceSuperimposed coating processThin material handlingEnvironmental resistanceSuperalloy

The invention relates to a coating composition for superalloy structural parts, especially for gas turbine vanes and blades, which provides simultaneously excellent environmental resistance and highly improved thermomechanical behavior. The coating consists essentially of, by weight, 28-35% Co, 11-15% Cr, 10-13% Al, 0-1% Re, 1-2% Si, 0.2-1% Ta, 0.005-0.5% Y, 0-5% Ru, 0-1% Ca, 0-1% Mg, 0-0.5% La (or elements from the La series), 0-0.1% B, balance Ni and incidental impurities.

Owner:ANSALDO ENERGIA IP UK LTD

Yttria containing thermal barrier coating topcoat layer and method for applying the coating layer

ActiveUS20080145674A1Reduced and eliminated infiltrationIncrease gas turbine engine component lifePropellersReaction enginesCoating systemBond coating

A gas turbine engine component and coating system including a superalloy substrate having a coating system disposed thereon. A bond coating may be applied to the substrate. An adherent layer of ceramic material forming a thermal barrier coating is present on the bond coat layer. A topcoat layer overlies the thermal barrier coating. The topcoat layer includes greater than about 20 wt % yttria.

Owner:GENERAL ELECTRIC CO

MEMS bubble generator

ActiveUS20060250453A1High material strengthHigh densityInking apparatusOther printing apparatusVapor bubbleSuperalloy

A MEMS vapor bubble generator with a chamber for holding liquid and a heater positioned in the chamber for heating the liquid above its bubble nucleation point to form a vapour bubble; wherein, the heater is formed from a superalloy.

Owner:SILVERBROOK RES PTY LTD

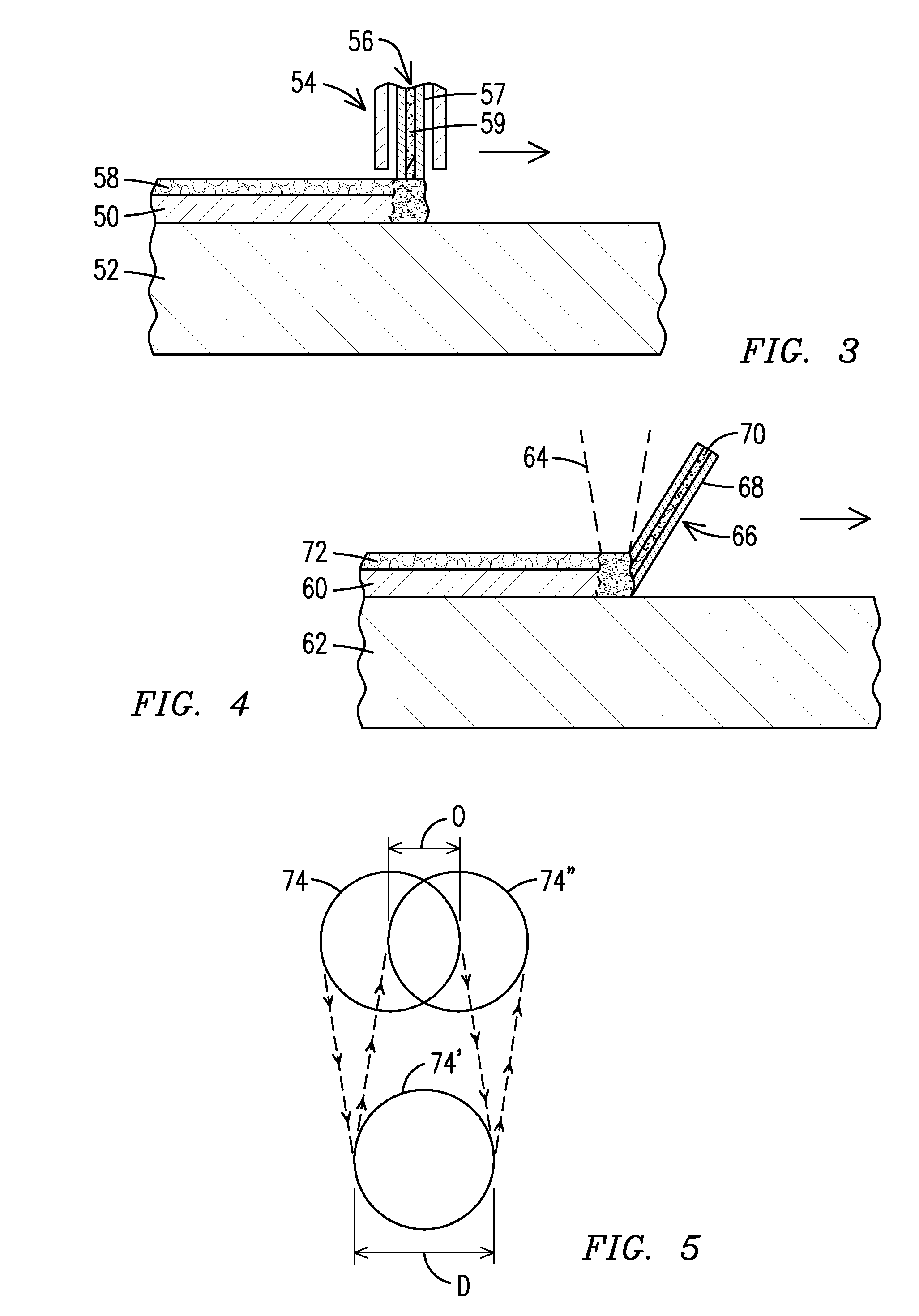

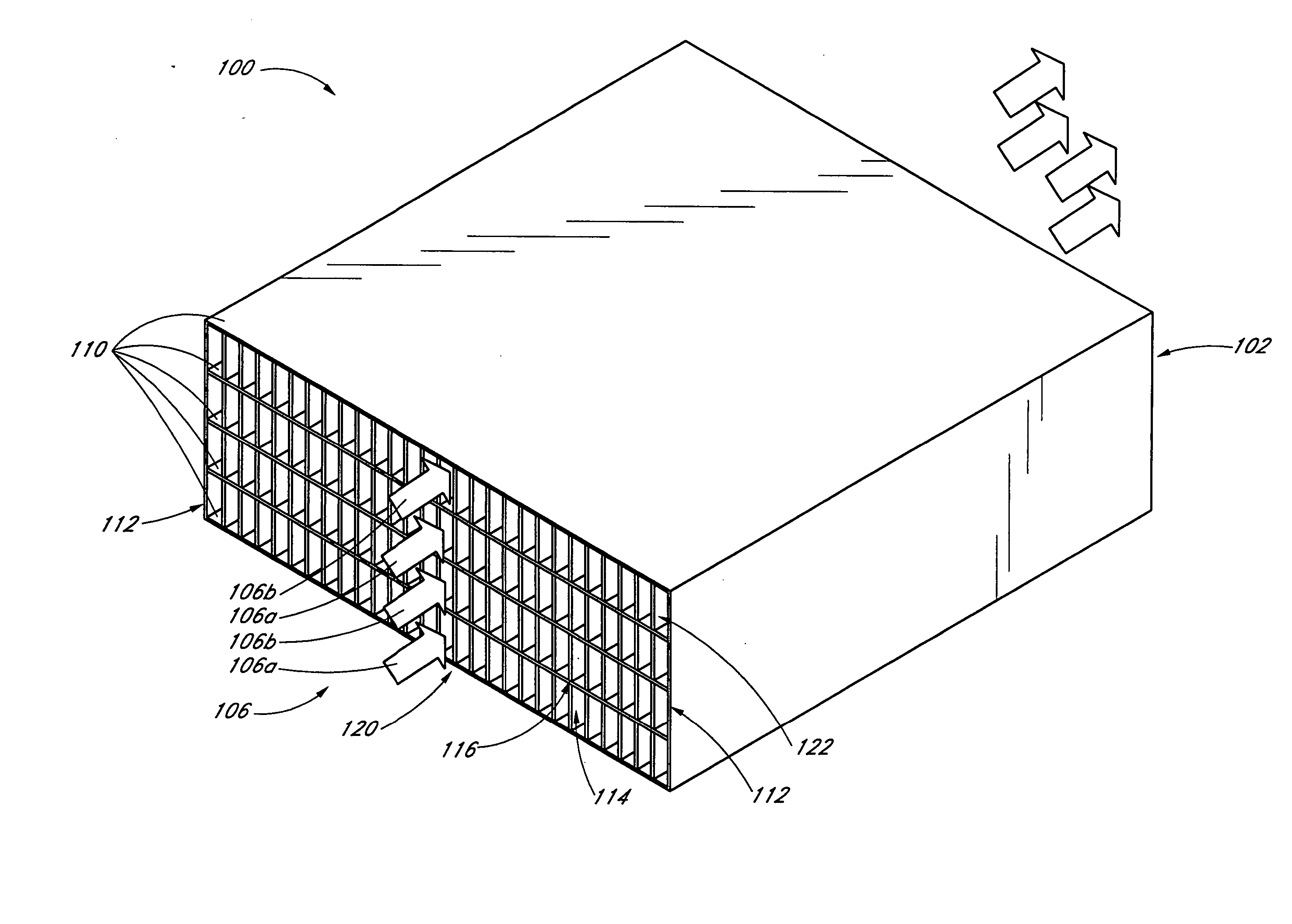

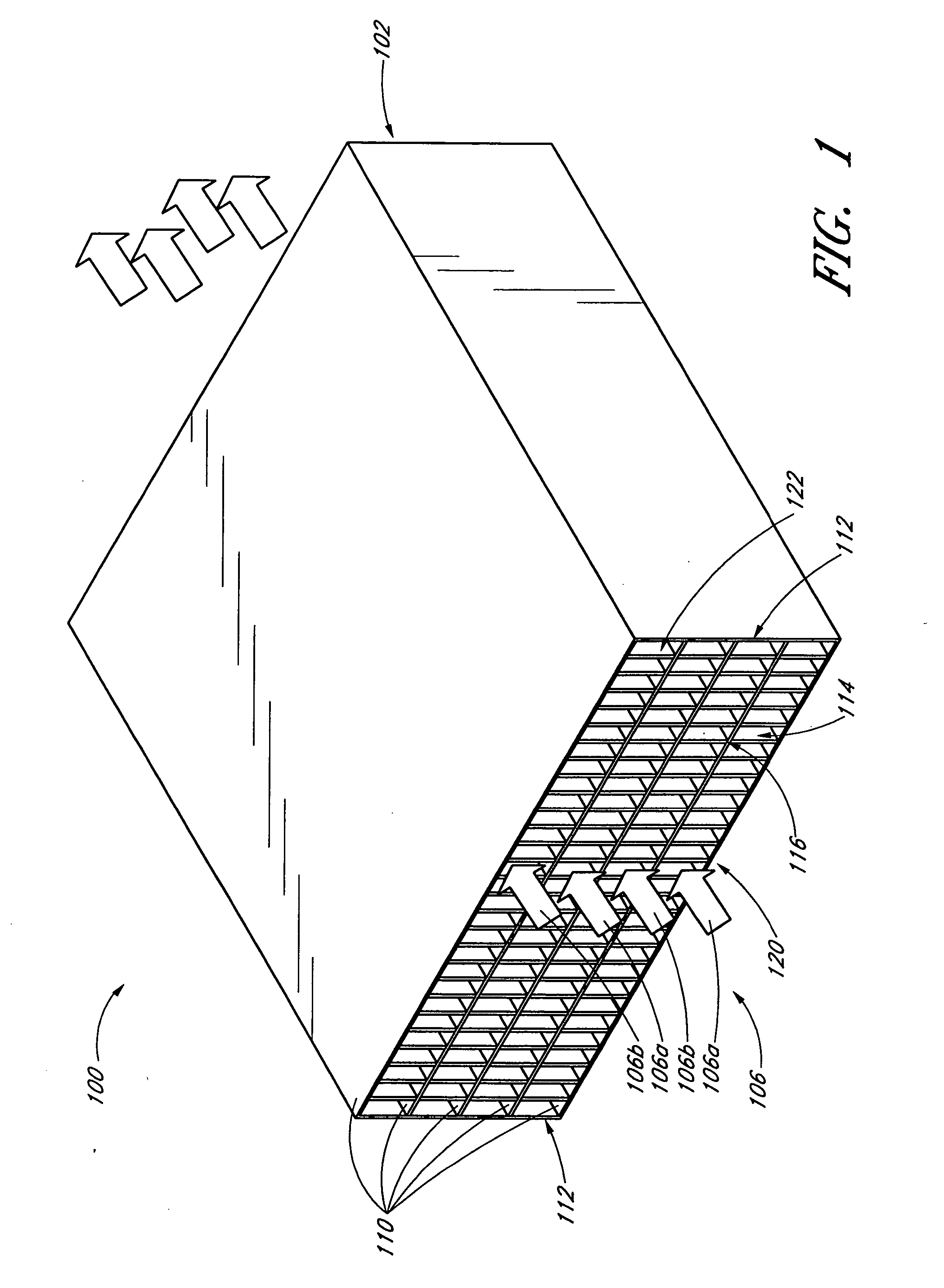

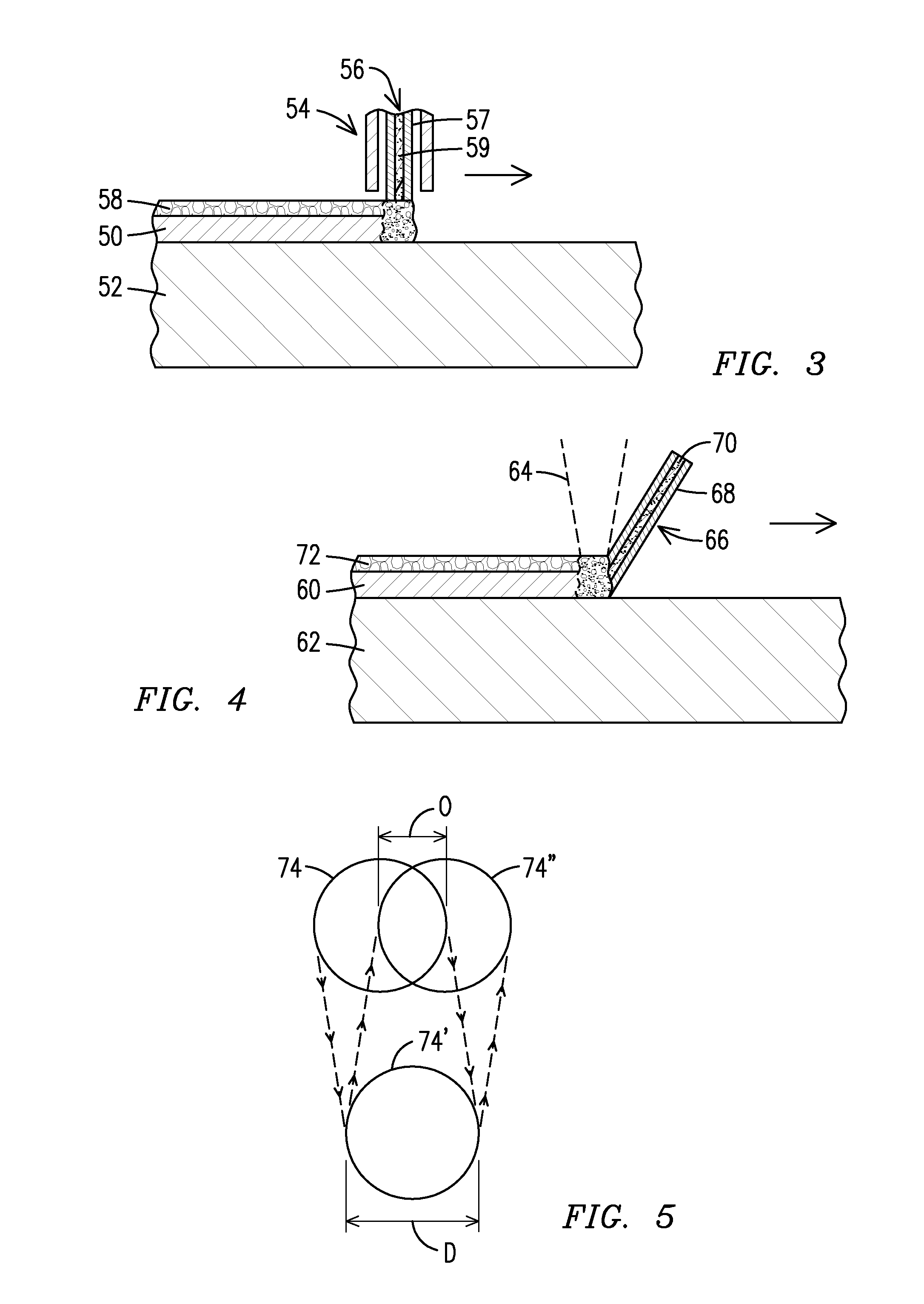

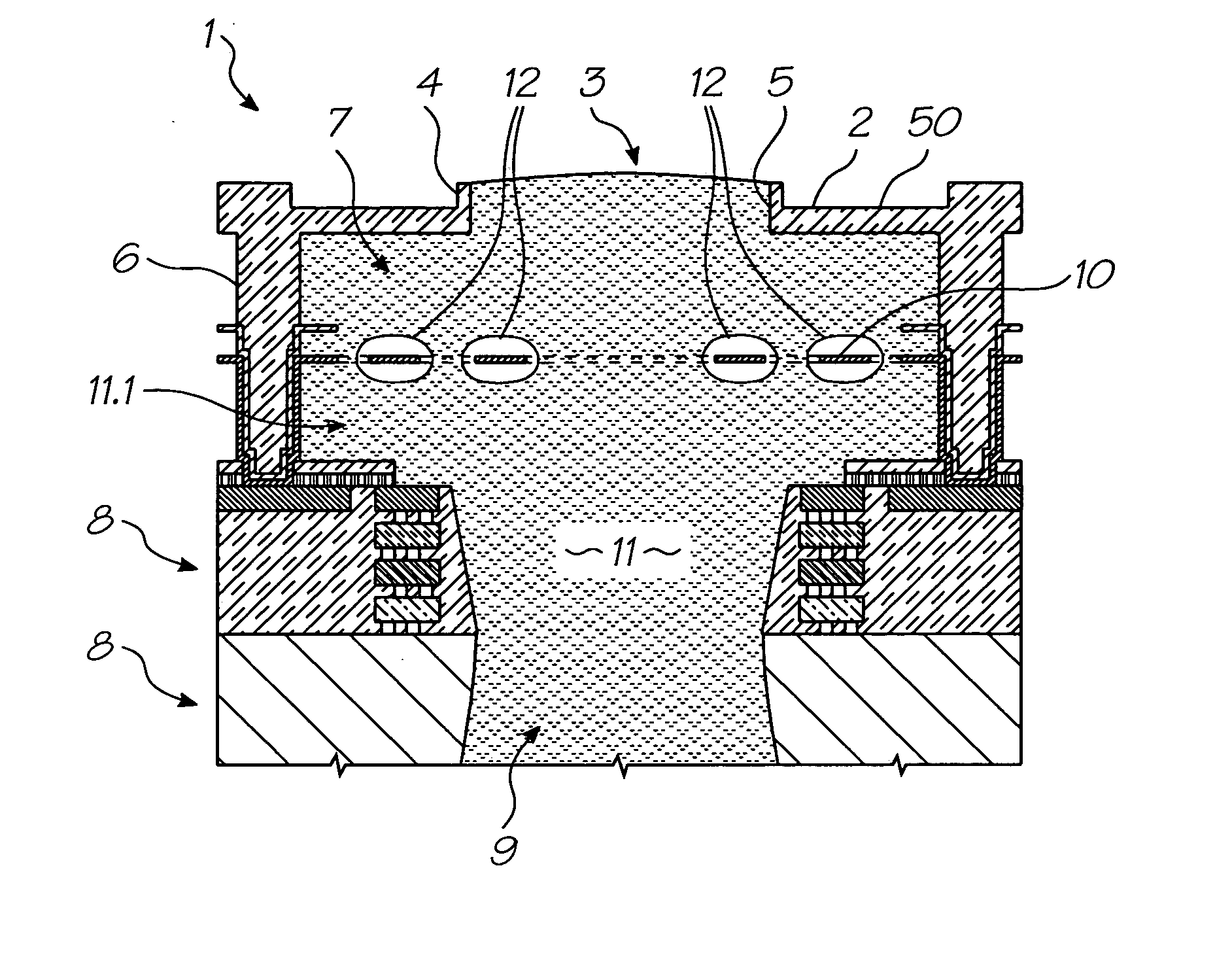

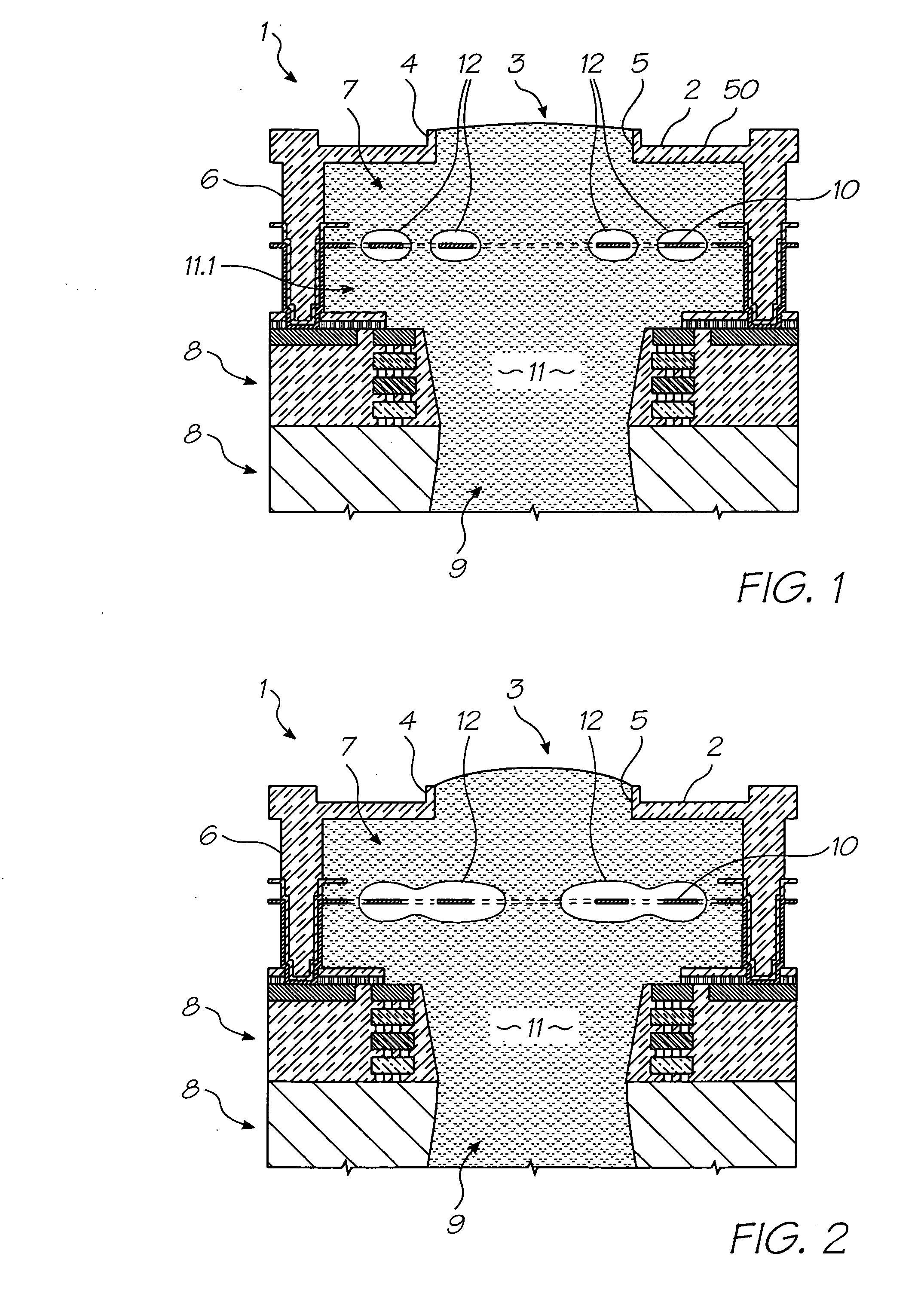

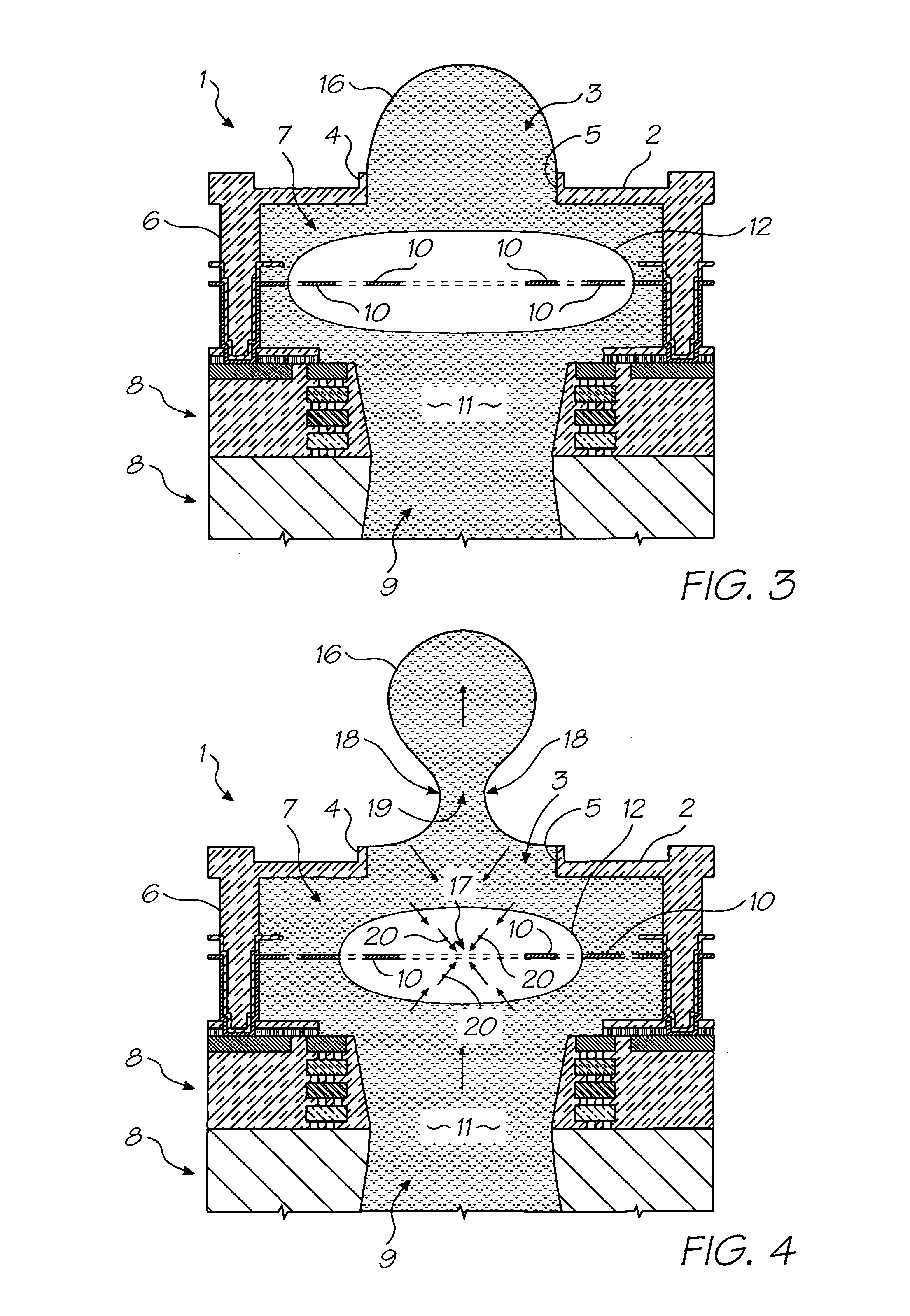

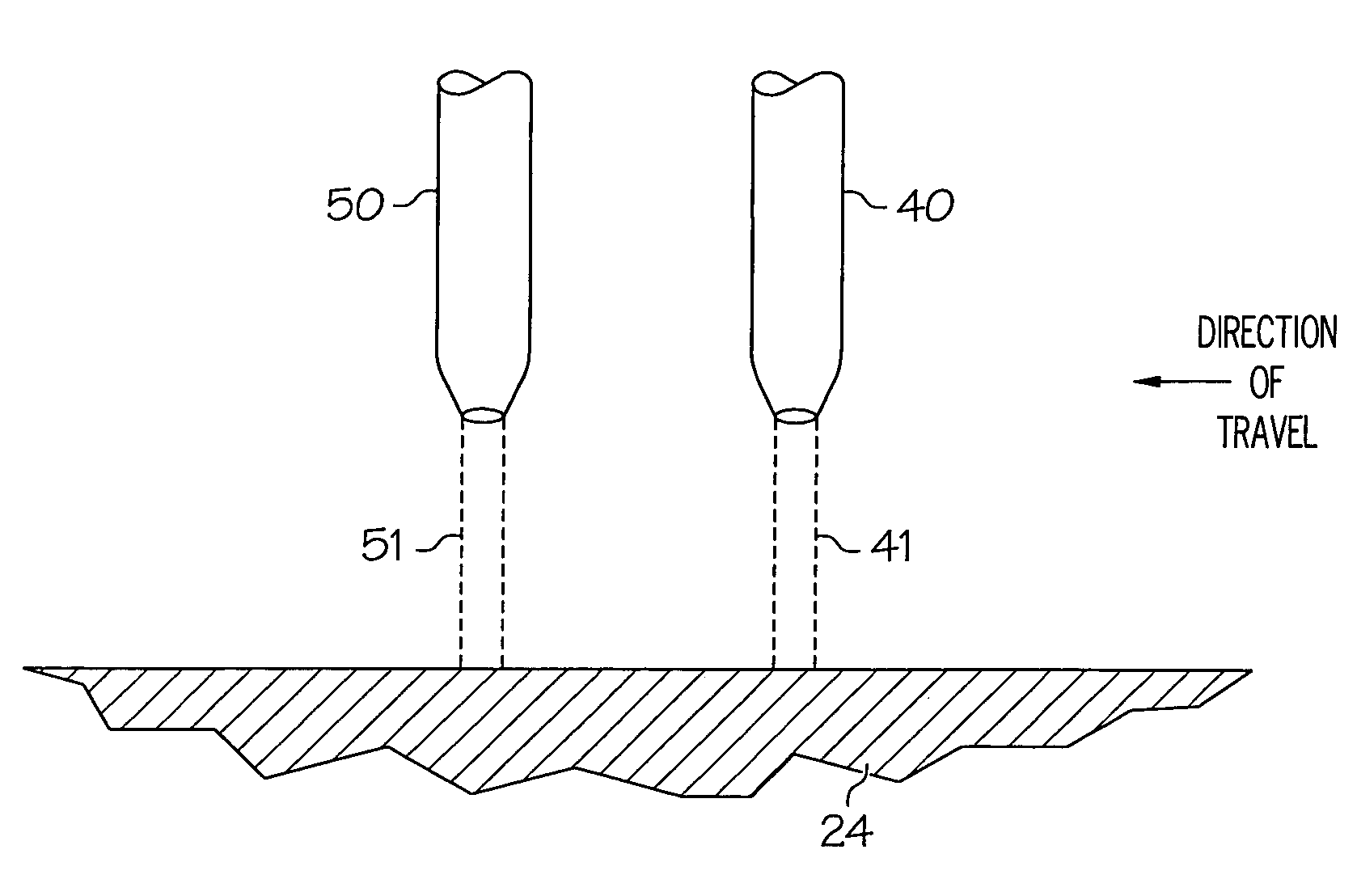

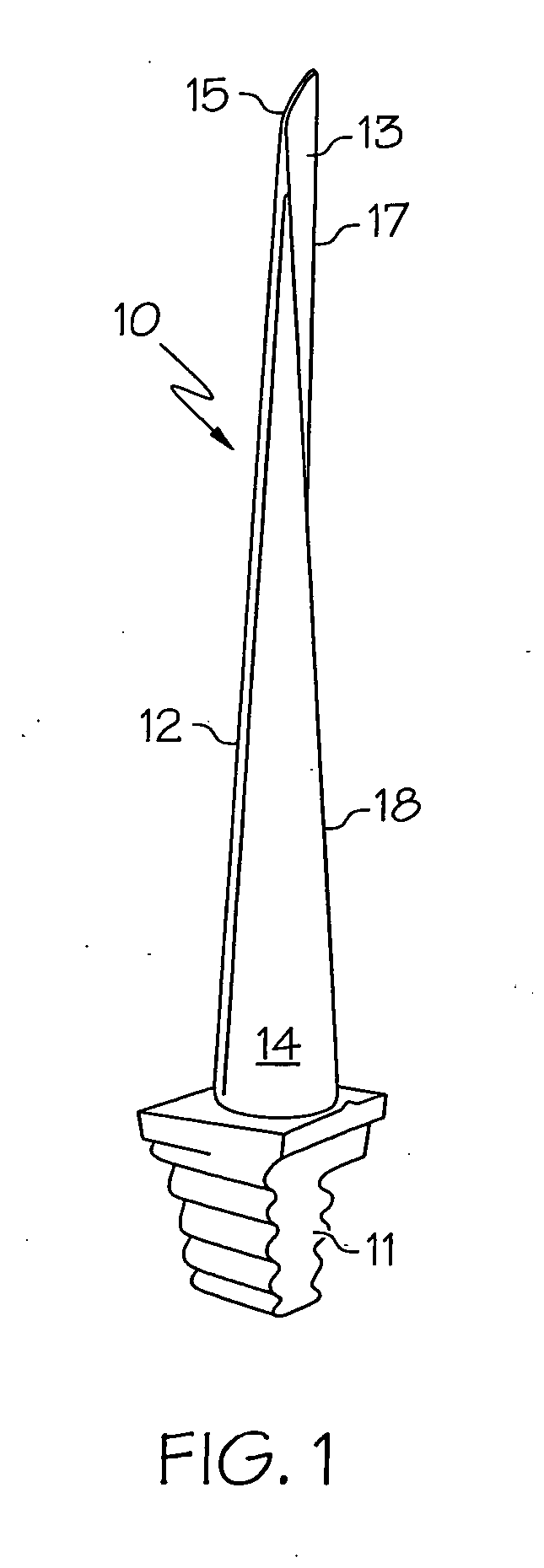

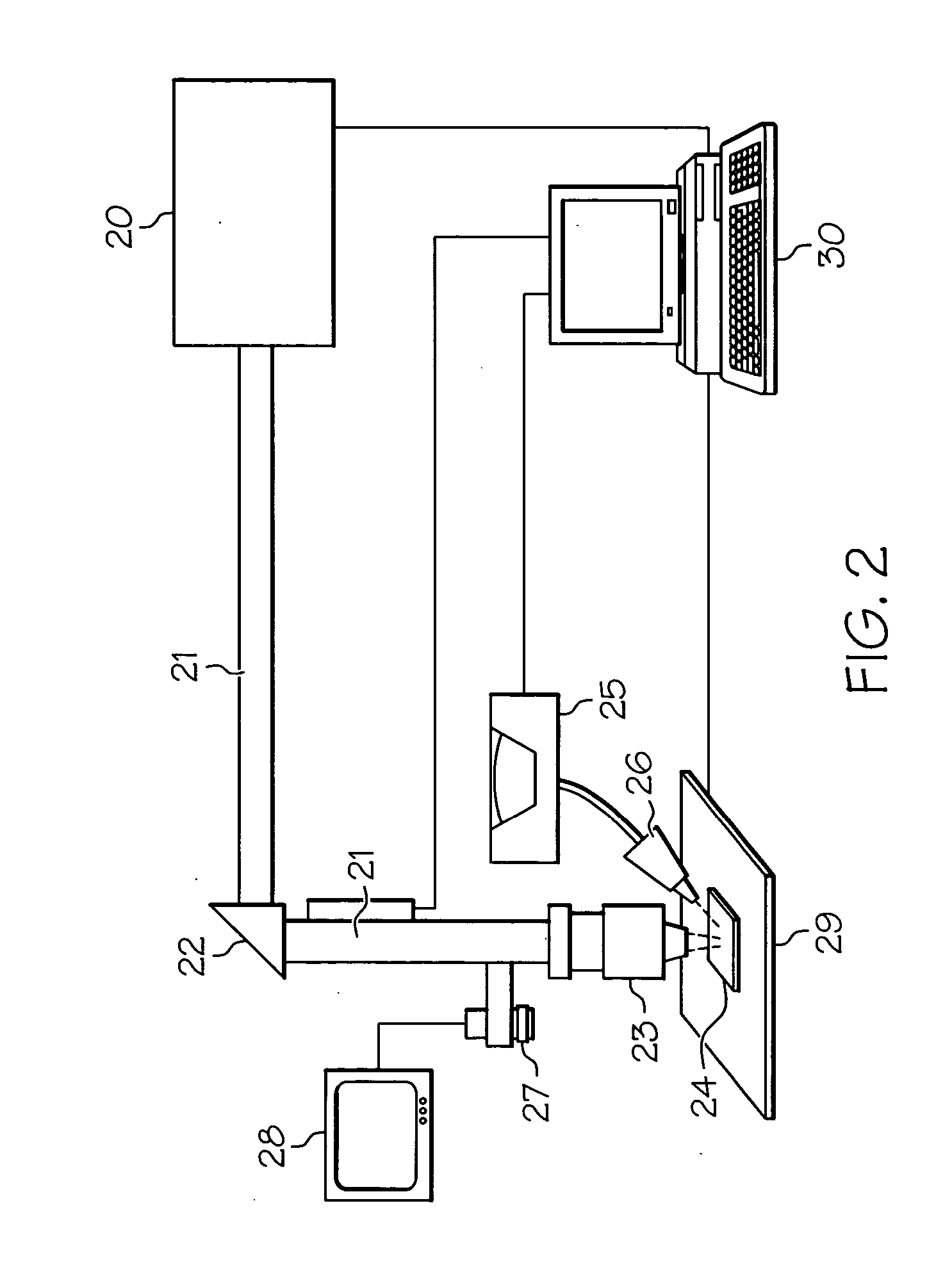

Multi-laser beam welding high strength superalloys

InactiveUS6972390B2Reducing and eliminating damageLow costTurbinesBlade accessoriesTurbine bladeHigh intensity

A method is provided for repairing degraded and / or eroded areas on gas turbine blades and vanes. The method is directed to turbine blades and vanes made of advanced superalloy materials with high elevated-temperature properties. The method uses multiple laser beams to perform steps of preheating the repair area, welding the repair area, and post-welding heating of the repaired area. The method uses an array of two or more lasers to perform the steps of heating, welding, and post-weld heat treatment in nearly simultaneous operation thereby dramatically reducing or eliminating the hot cracking associated with other welding methods used with superalloy materials. The method is further directed to cladding or material buildup of degraded turbine blades where the weld material is the same as the matrix or better superalloy materials.

Owner:HONEYWELL INT INC

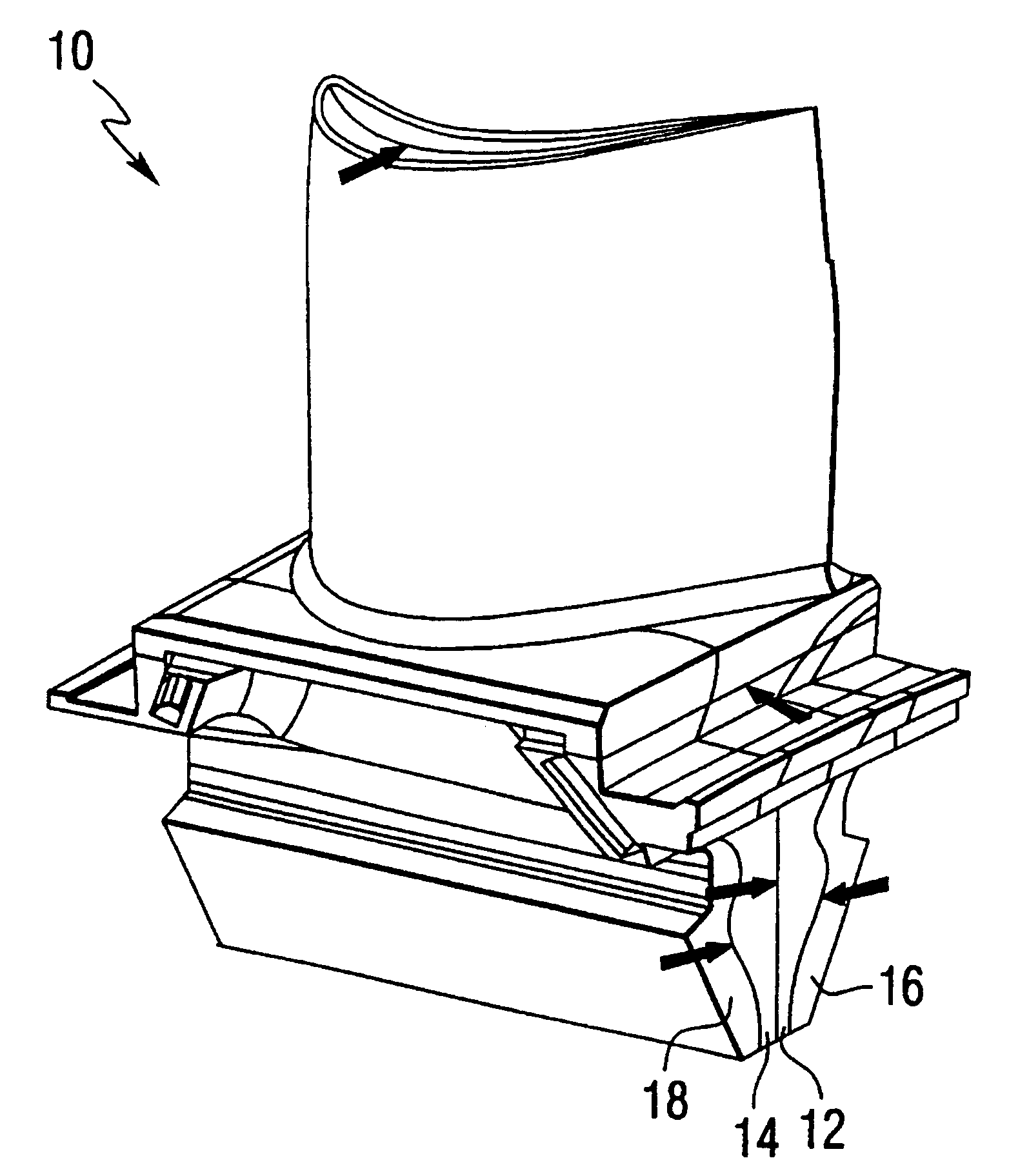

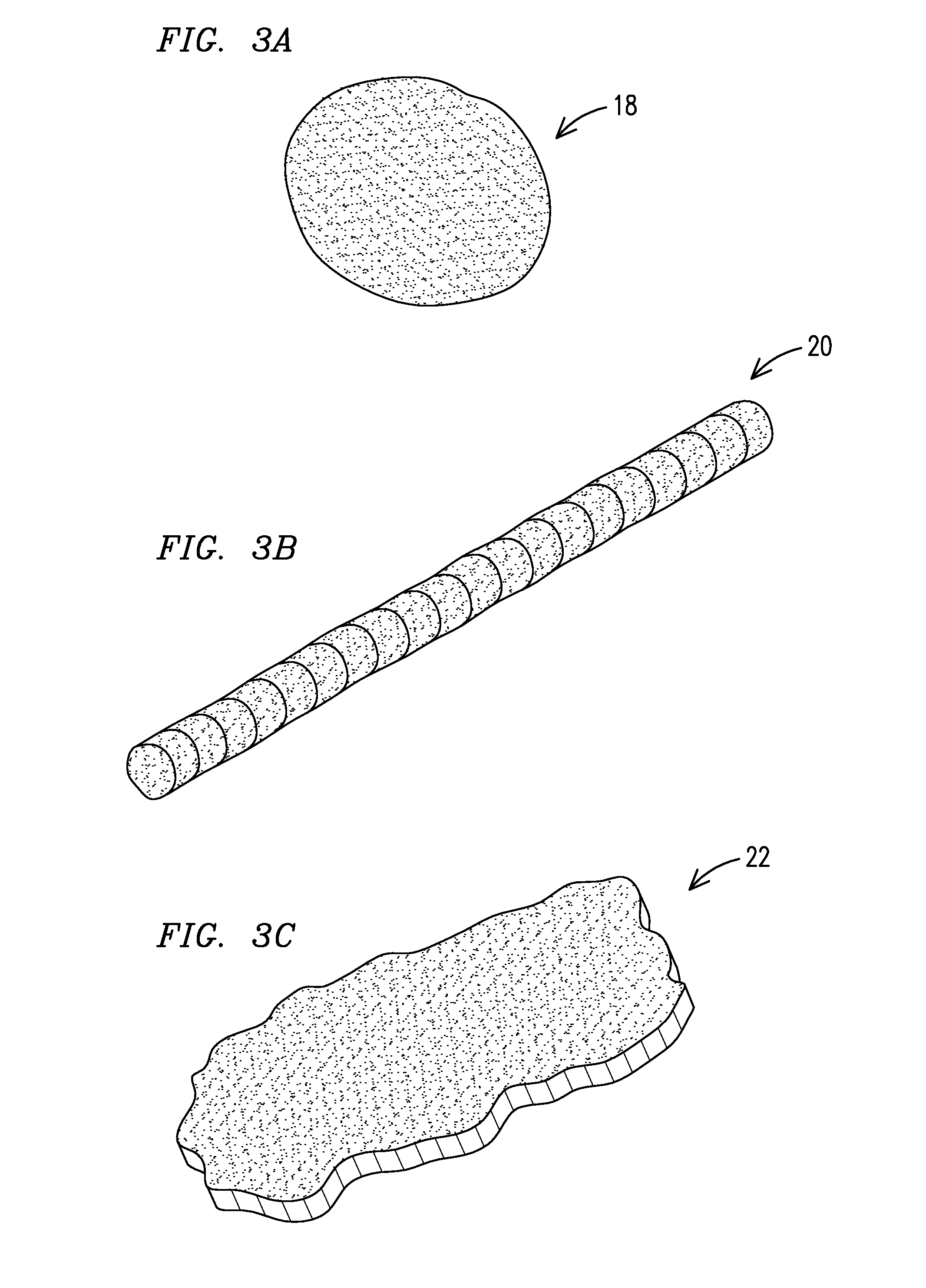

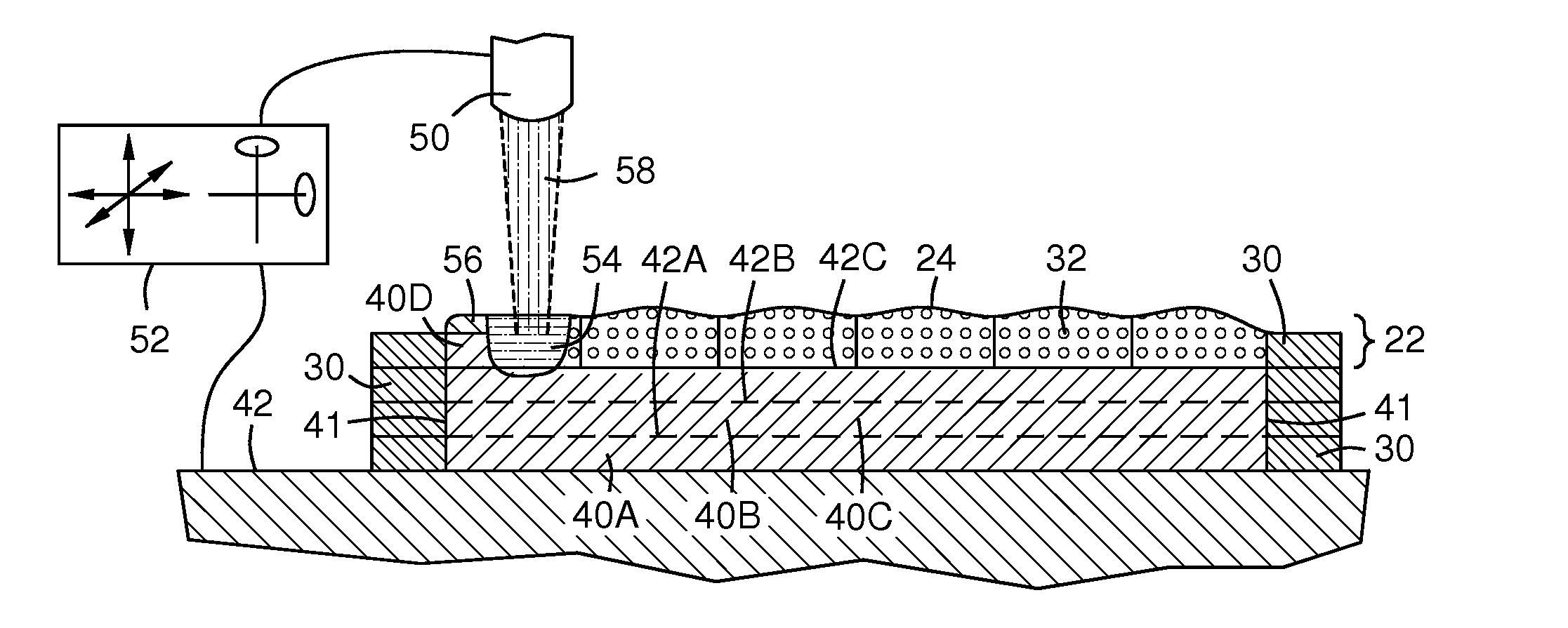

Superalloy solid freeform fabrication and repair with preforms of metal and flux

A preform (22, 22A-U) containing metal (32, 34) and flux (33) for forming a metal layer to be added to a component being repaired or additively manufactured. The metal may be constrained in the preform in a distribution that forms a shape of a sectional layer or a surface repair of a component in response to an energy beam (58) that melts the preform. The preform is placed on a working surface (42), which may be a previously formed layer (42A-C) in additive manufacturing, or may be an existing component surface (122) for repair The preform is then melted by the energy beam (58) to form a new integrated layer (40A-F) on the component with an over-layer of slag (56) that shields and insulates the melt pool (54) and the solidifying layer The slag is removed, and a subsequent layer may be added.

Owner:SIEMENS ENERGY INC

Multi-laser beam welding high strength superalloys

InactiveUS20050194363A1Reduces and eliminates weld-induced damageLow costTurbinesBlade accessoriesTurbine bladeHigh intensity

A method is provided for repairing degraded and / or eroded areas on gas turbine blades and vanes. The method is directed to turbine blades and vanes made of advanced superalloy materials with high elevated-temperature properties. The method uses multiple laser beams to perform steps of preheating the repair area, welding the repair area, and post-welding heating of the repaired area. The method uses an array of two or more lasers to perform the steps of heating, welding, and post-weld heat treatment in nearly simultaneous operation thereby dramatically reducing or eliminating the hot cracking associated with other welding methods used with superalloy materials. The method is further directed to cladding or material buildup of degraded turbine blades where the weld material is the same as the matrix or better superalloy materials.

Owner:HONEYWELL INT INC

Method for processing high-temperature alloy furnace tube

ActiveCN101565808AReduce the degree of carburizationExtended cycleSolid state diffusion coatingMetallurgySuperalloy

The invention relates to a method for processing a high-temperature alloy furnace tube, which comprises the following steps: controlling the pressure of low-oxygen partial pressure gas to 0-3 atmospheric pressure; introducing the low-oxygen partial pressure gas into an atmosphere furnace provided with the high-temperature alloy furnace tube after passing through ammonia water; raising the temperature to between 600 and 1,100 DEG C; keeping the temperature for 5 to 80 hours; and forming an oxidized protective layer on the surface of the high-temperature alloy furnace tube to obtain the processed high-temperature alloy furnace tube. The method for processing the high-temperature alloy furnace tube is adopted to process a furnace tube of a hydrocarbon cracking furnace and the like, so that the compact and stable oxidized protective layer on the surface of the furnace tube, and the requirement for long-term use can be met; and the method can inhibit or retard the phenomena of catalysis and coking, reduces the carburization degree of the furnace tube, and prolongs the decoking cycle and the service life of the furnace tube.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation process of high-temperature alloy multigang hollow turbine blade

InactiveCN101992268AIncrease success rateAvoid eccentricityFoundry mouldsFoundry coresTurbine bladeSuperalloy

The invention relates to a preparation process of a high-temperature alloy multigang hollow turbine blade. The process comprises the following steps of: (1) partitioning the multigang blade into a plurality of blade units and manufacturing a blade body wax mold for each unit blade, wherein a blade body is provided with a ceramic mold core, the unit blade body wax mold with the ceramic mold core is molded in an injection molding way, injection temperature is between 63 and 68 DEG C, the pressure is between 0.3 and 0.5 MPa, the injection time is between 10 and 30 seconds and the pressure is preserved for 10 to 30 seconds; (2) putting each unit blade body wax mold with the ceramic mold core into a multigang mold and injecting wax for primary molding so as to obtain a multigang hollow blade wax mold; and (3) coating, dewaxing, sintering, pouring, clearing and stripping the multigang hollow blade wax mold so as to obtain a high-temperature alloy multigang hollow turbine blade casting.

Owner:SHENYANG POLYTECHNIC UNIV

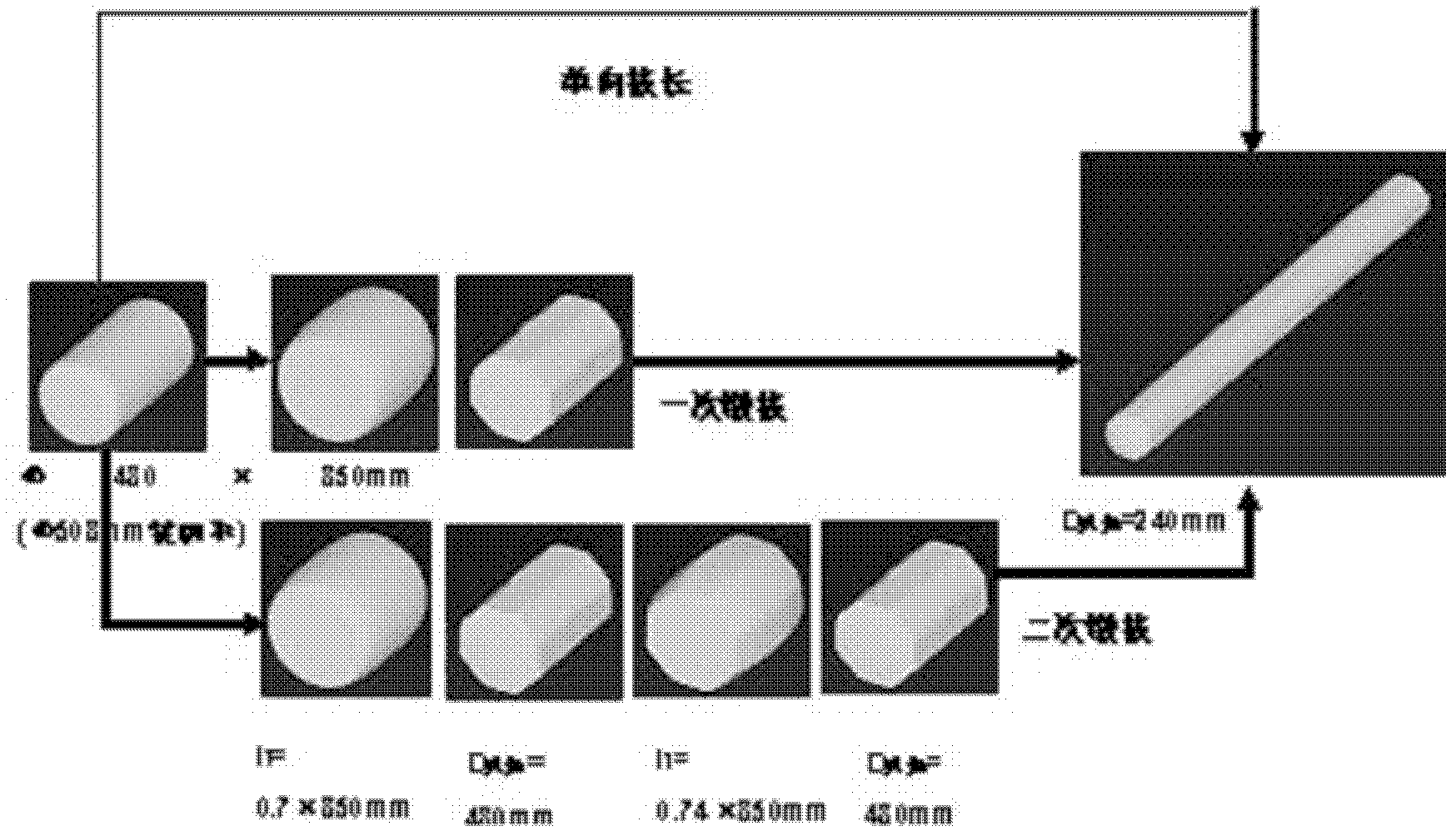

Method for preparing oxide dispersion strengthened alloy by rapid forming

InactiveCN103008657AHigh densitySmall particle sizeAdditive manufacturingIncreasing energy efficiencyOxide dispersion-strengthened alloySoftware design

The invention belongs to the technical field of high-temperature alloy near net shape forming and discloses a method for preparing oxide dispersion strengthened alloy by rapid forming. The method includes: using the mechanical alloying process to obtain oxide dispersion strengthened alloy powder, using CAD (computer-aided design) software to design a three-dimensional solid model of an ODS (oxide dispersion strengthened) alloy part, subjecting the three-dimensional model to layering and slicing to disperse the three-dimensional model into a series of two-dimensional layers, smelting the ODS alloy powder layer by layer according to slicing information to obtain a laser rapidly formed blank in a needed shape, eliminating residue pores in the laser rapidly formed blank by means of hot isostatic pressing, and optimizing structure property by means of subsequent annealing or solid solution and aging heat treatment to obtain an ODS alloy part in a complex shape. Wrap packaging or fixture moulds are not needed, the complexity of shapes of parts is unlimited, and alloy components and structures are easy to control. The prepared ODS alloy is small in oxide dispersed phase, and products are high in compactness and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

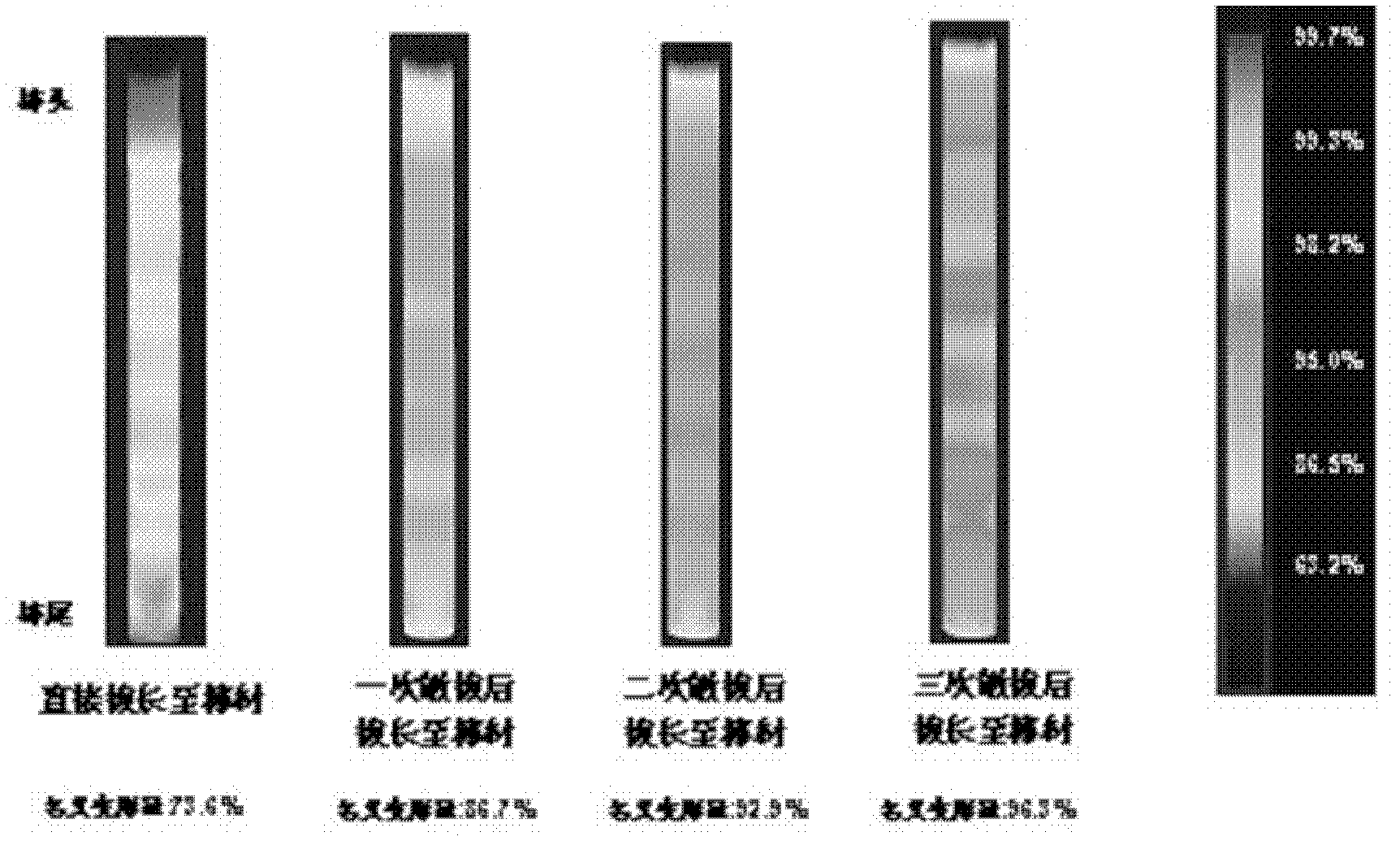

Forging method of high-temperature alloy fine-grained bars

The invention belongs to the technical field of forging, and relates to a forging method of high-temperature alloy fine-grained bars. According to the invention, a combined breakdown production method of upsetting and stretching, and radial forging is adopted. A deflection is large, deflection directions are changed alternately, carbide is sufficiently crushed, and carbide is distributed in a dispersed state, such that the fatigue property of the alloy is improved. The bar is finally subject to one-heating molding through radial forging, such that grain growing caused by the direct fired bar which is delivered back to a furance is avoided. Also, the method is beneficial for excircle deflection of the bar. Therefore, fine-grained bars with a grain grade difference smaller than 2 grades areobtained. The method is a novel method with a good prospect. The method is suitable for high-temperature alloy fine-grained bar productions. If the method is popularized, good social and economical benefits can be brought in.

Owner:CENT IRON & STEEL RES INST

Superalloy article having corrosion resistant coating thereon

InactiveUS20050255329A1Improve adhesionMinimal diffusionPropellersMolten spray coatingCarbideSuperalloy

Owner:GENERAL ELECTRIC CO

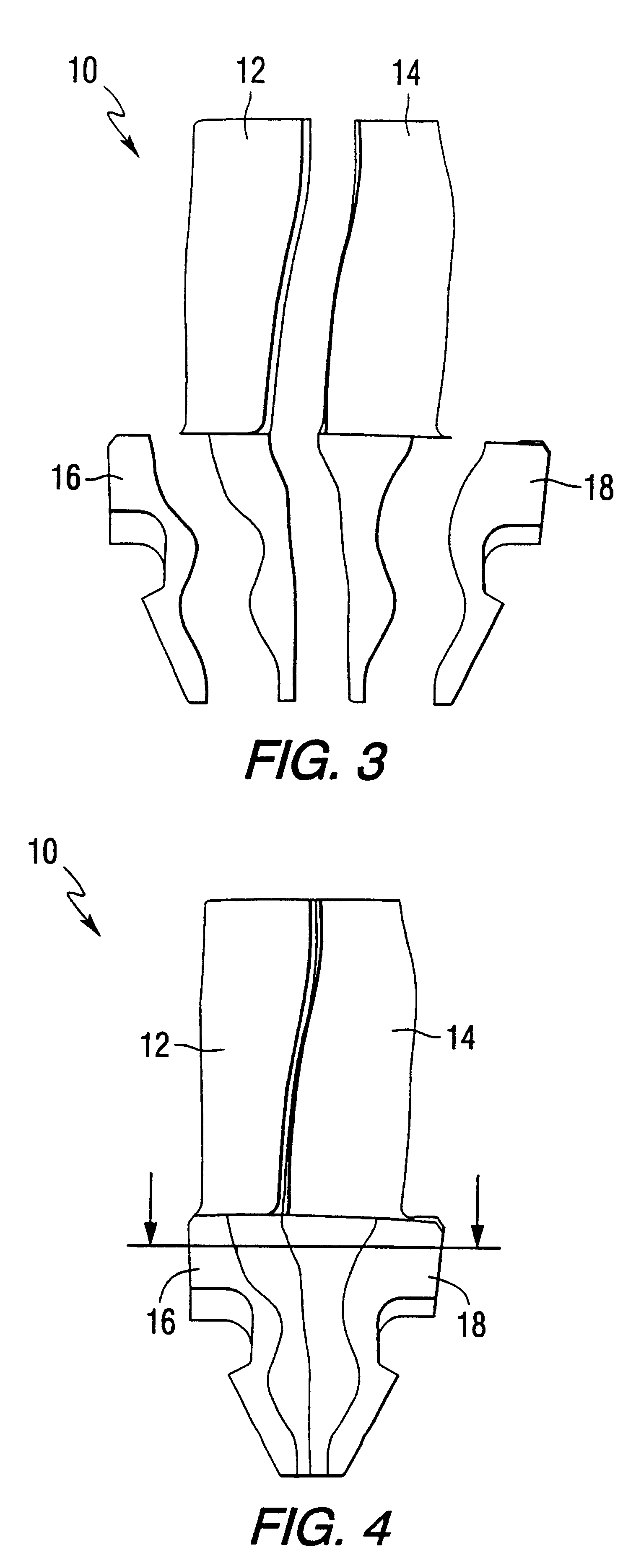

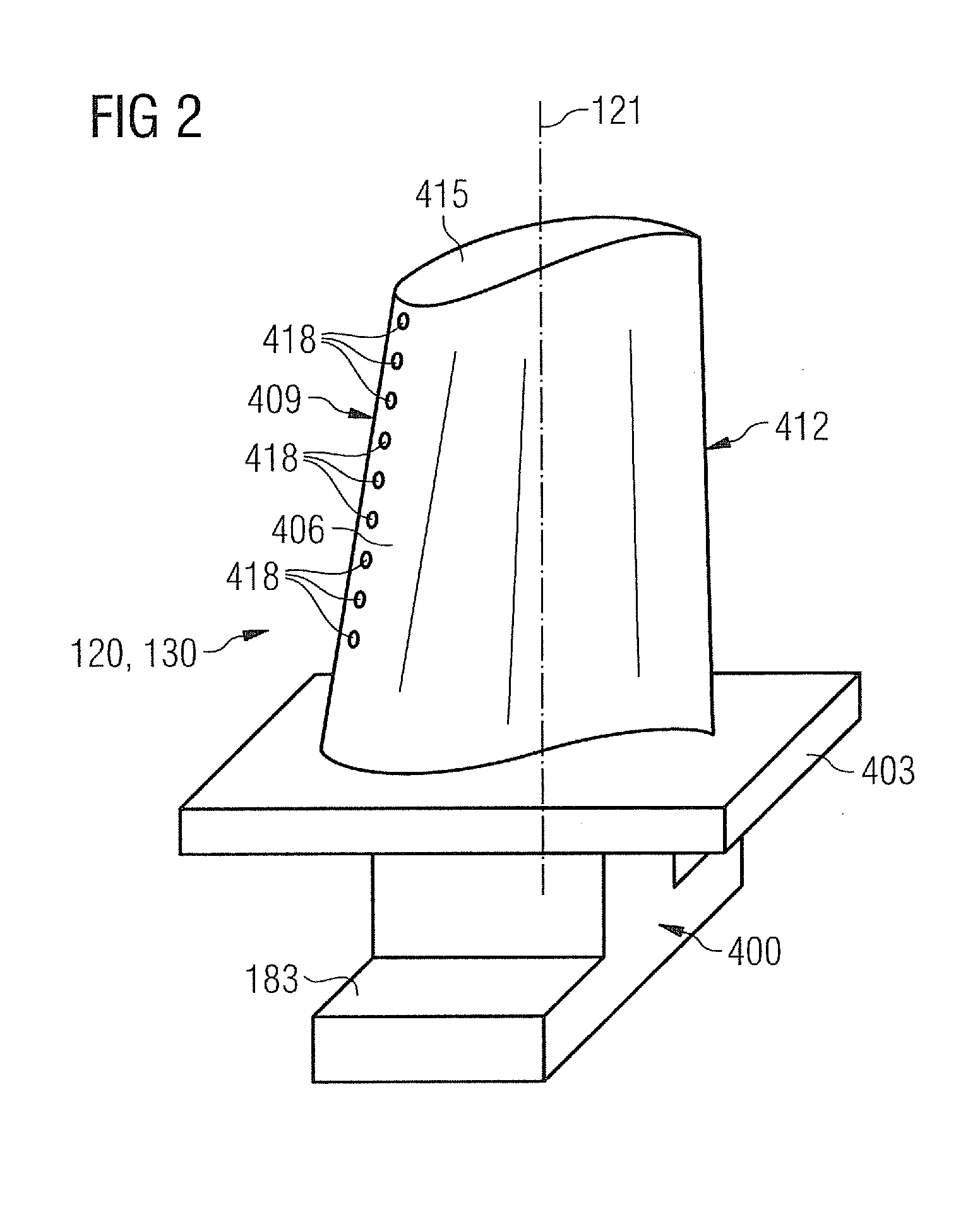

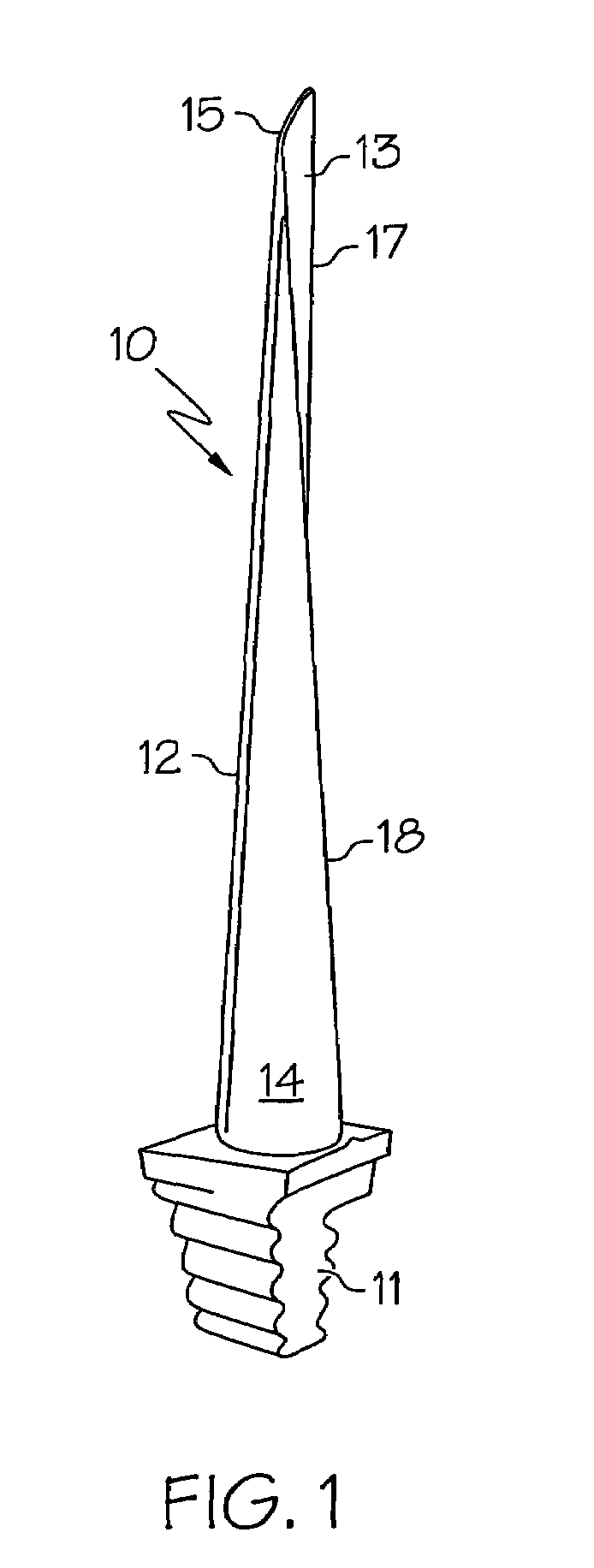

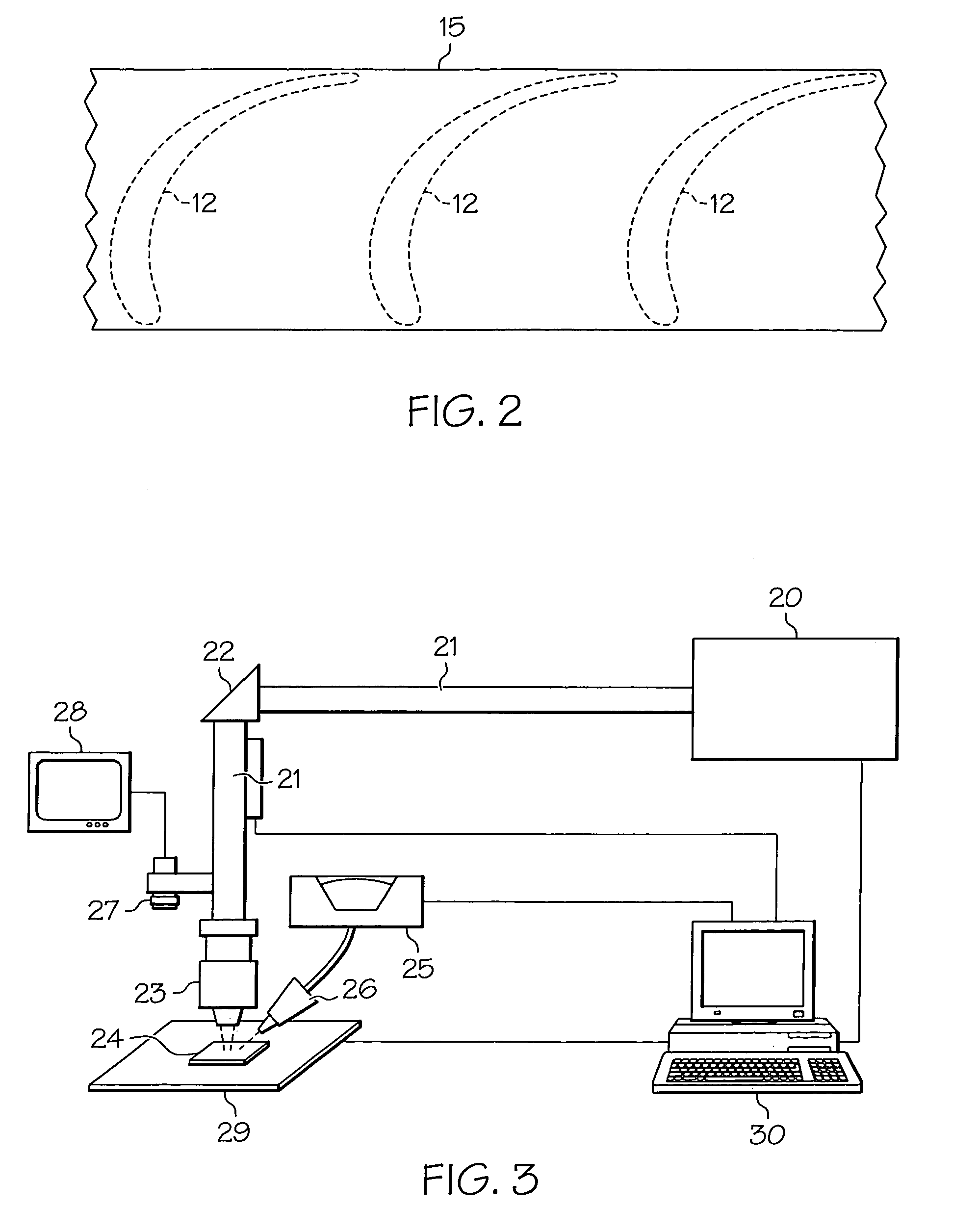

Method to restore an airfoil leading edge

The present invention provides methods and apparatus to restore a blade leading edge on a gas turbine engine component such as an airfoil of a turbine blisk. The method utilizes welding image technology and power control systems in order to provide effective welding with superalloy materials such as Inconel 713 and Inconel 625. The method includes machining away a damaged leading edge and providing a repaired region through successive depositions of superalloy powder filler through laser fusion welding. Deposition material is added until the repaired region exceeds the original dimensions of the airfoil. The airfoil is then machined and finished to return it to original airfoil dimensions.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com