Numerically controlled drilling and milling processing method for runner of blisk of engine

A technology of an integral blisk and a processing method, which can be used in digital control, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as difficulty in meeting product requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

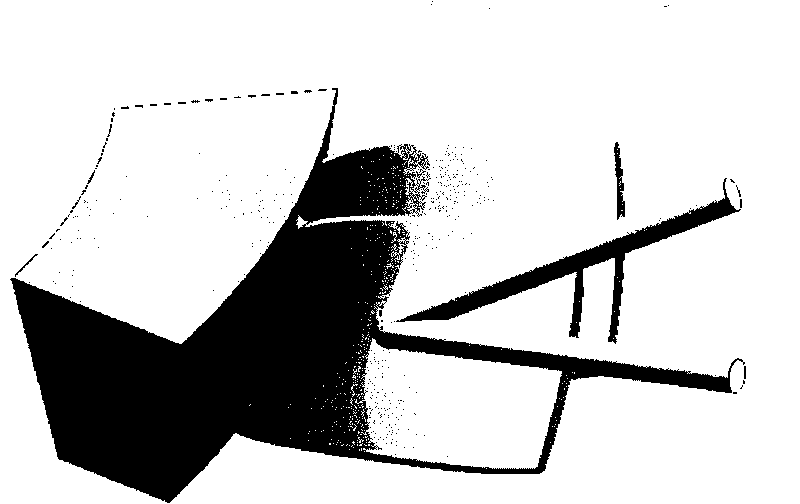

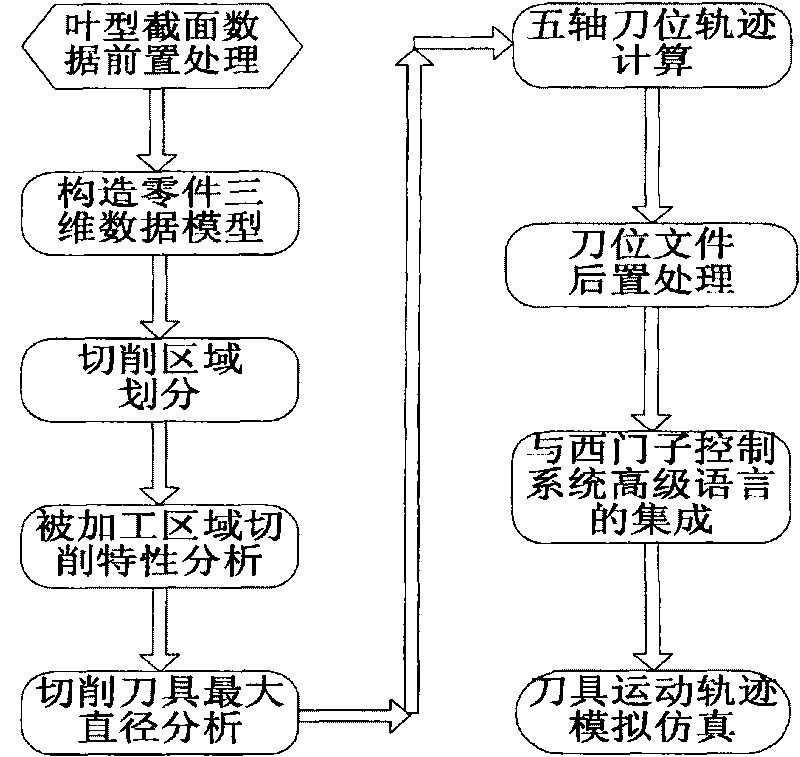

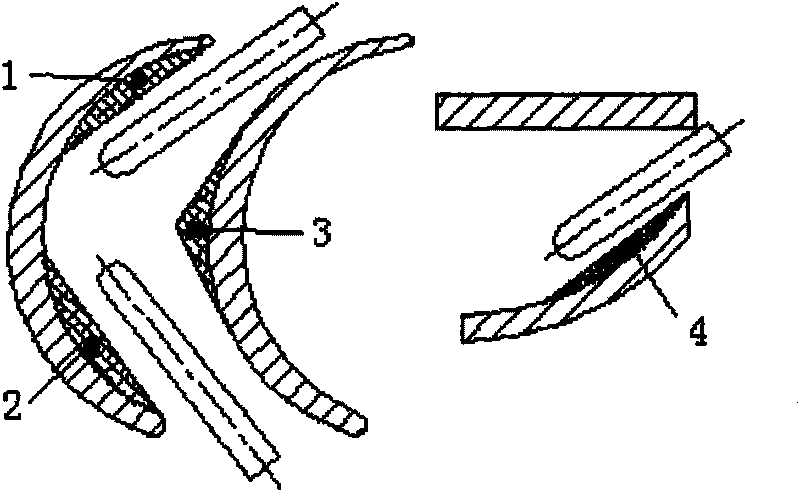

[0092] This embodiment provides a numerical control drilling and milling machining method for the integral blisk flow passage of an engine, characterized in that: the numerical control drilling and milling machining method for the integral blisk flow passage of the engine is the main process flow before drilling and milling the flow passage. Each surface of the blank → non-destructive inspection → turning the inner and outer cavity of the blisk → finishing and milling the required circumferential and axial datum → drilling and boring the angular datum hole → drilling and milling the runner → inspection;

[0093] Clamping method of parts: The positioning base surface of the fixture is required to be as close as possible to the contour of the blisk in the processing area. The part and the peripheral stop of the fixture are matched to limit the radial freedom of the part. The axial freedom is restricted by the central tie rod and the end face gland. Degrees and angles adopt precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com