Patents

Literature

779 results about "Advanced manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Advanced manufacturing is the use of innovative technology to improve products or processes, with the relevant technology being described as "advanced," "innovative," or "cutting edge." Advanced manufacturing industries "increasingly integrate new innovative technologies in both products and processes. The rate of technology adoption and the ability to use that technology to remain competitive and add value to define the advanced manufacturing sector."

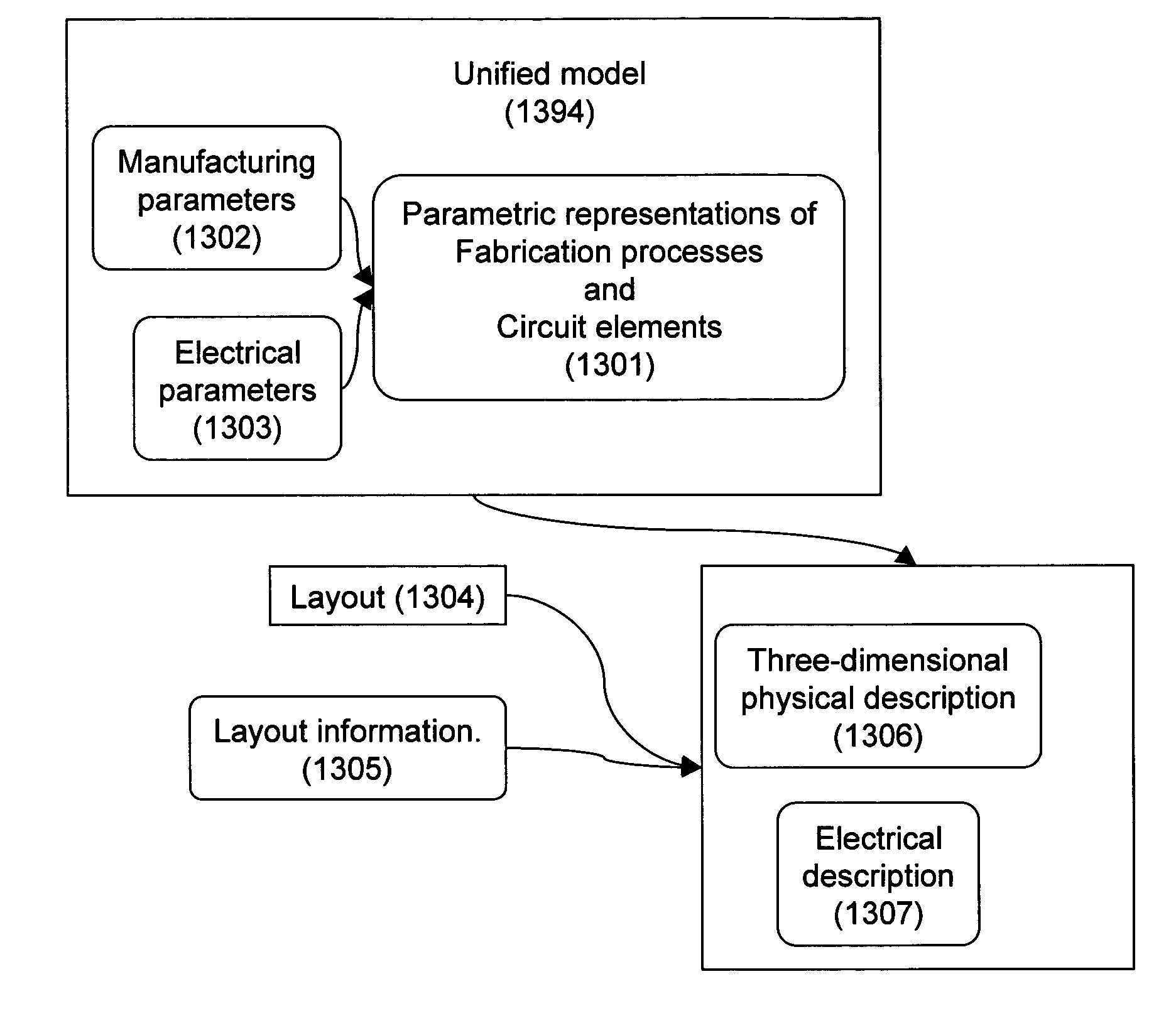

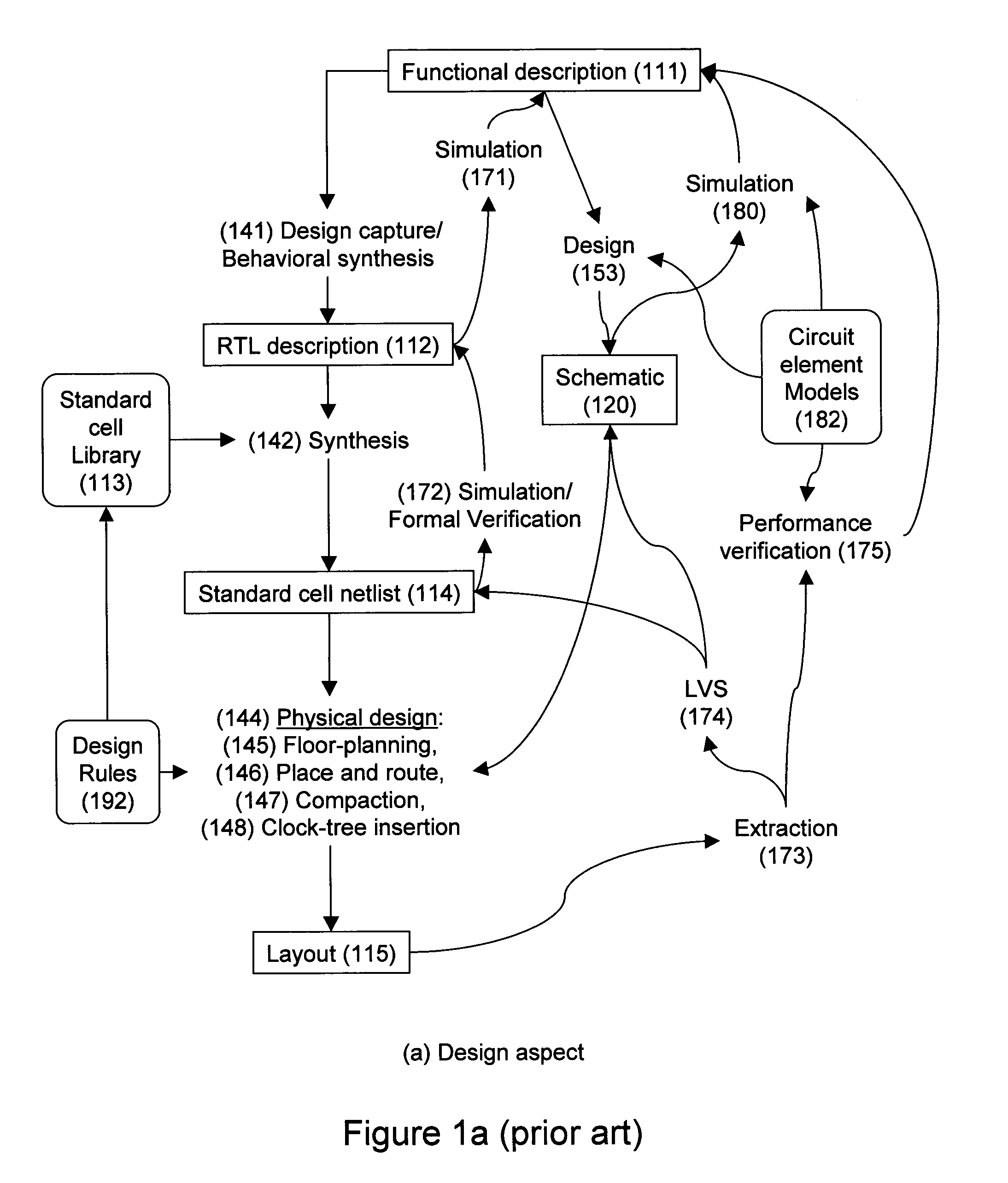

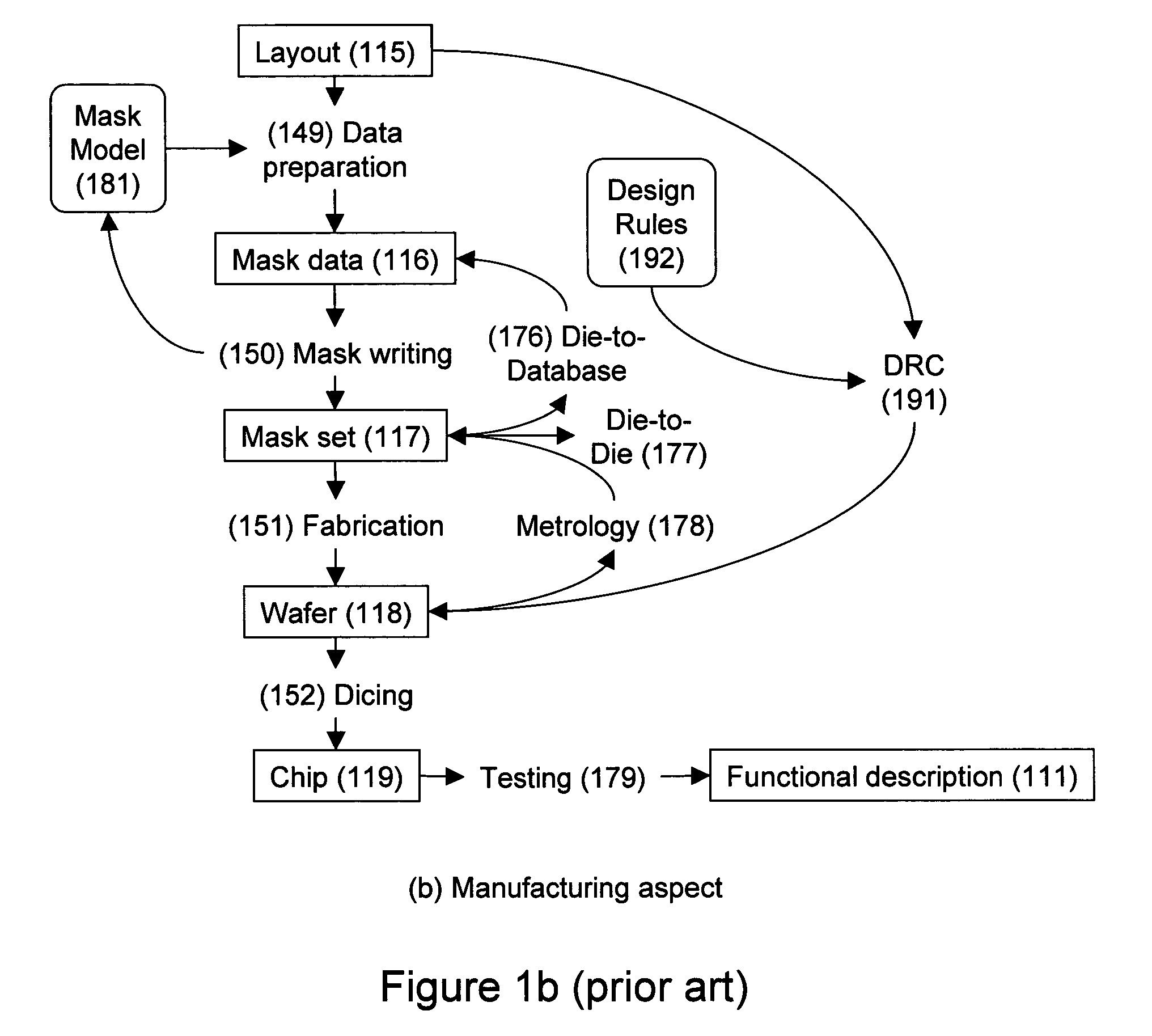

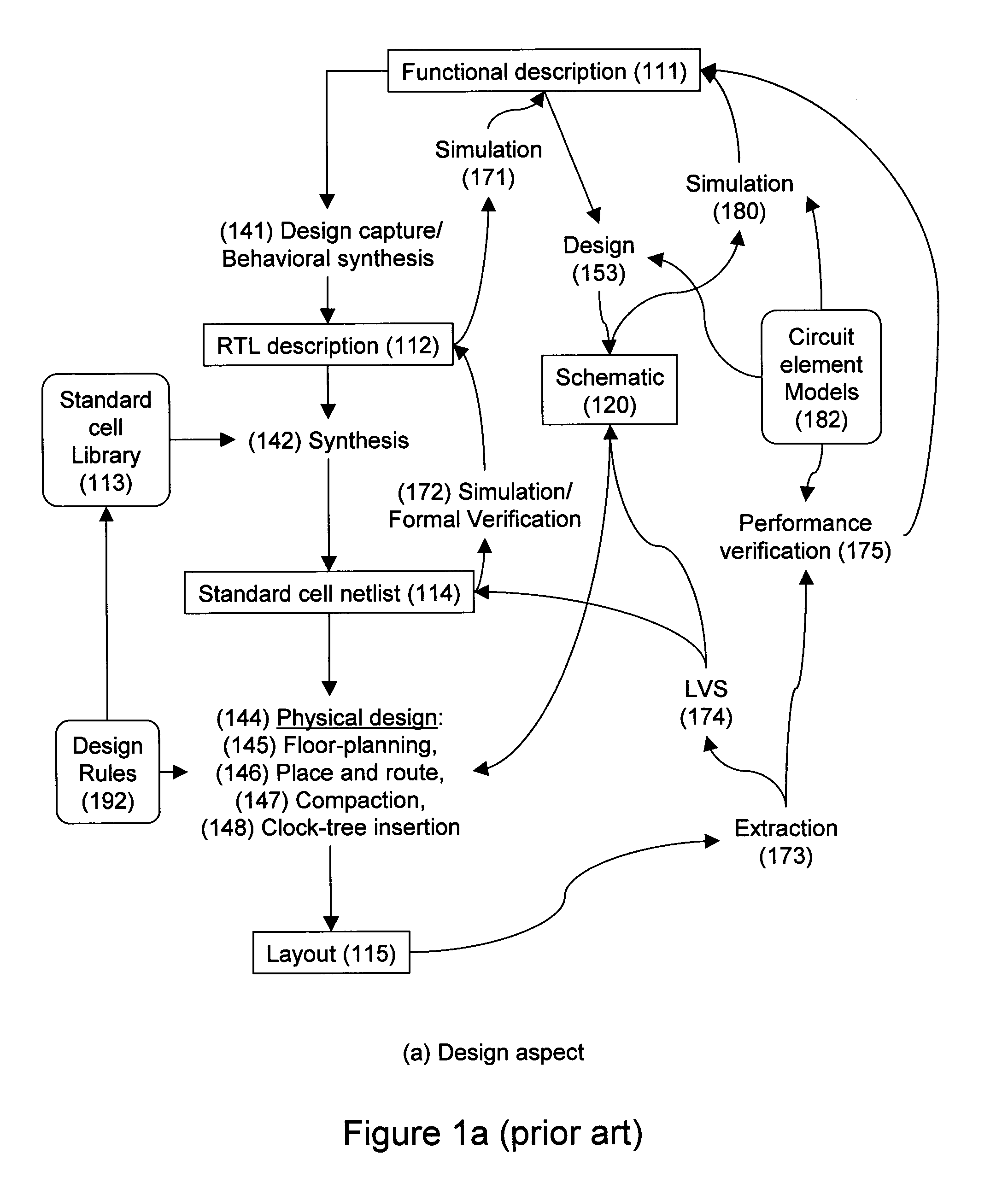

Design-manufacturing interface via a unified model

ActiveUS7155689B2Create additionalImprove accuracyCAD circuit designSpecial data processing applicationsMiniaturizationEngineering

Owner:SYNOPSYS INC

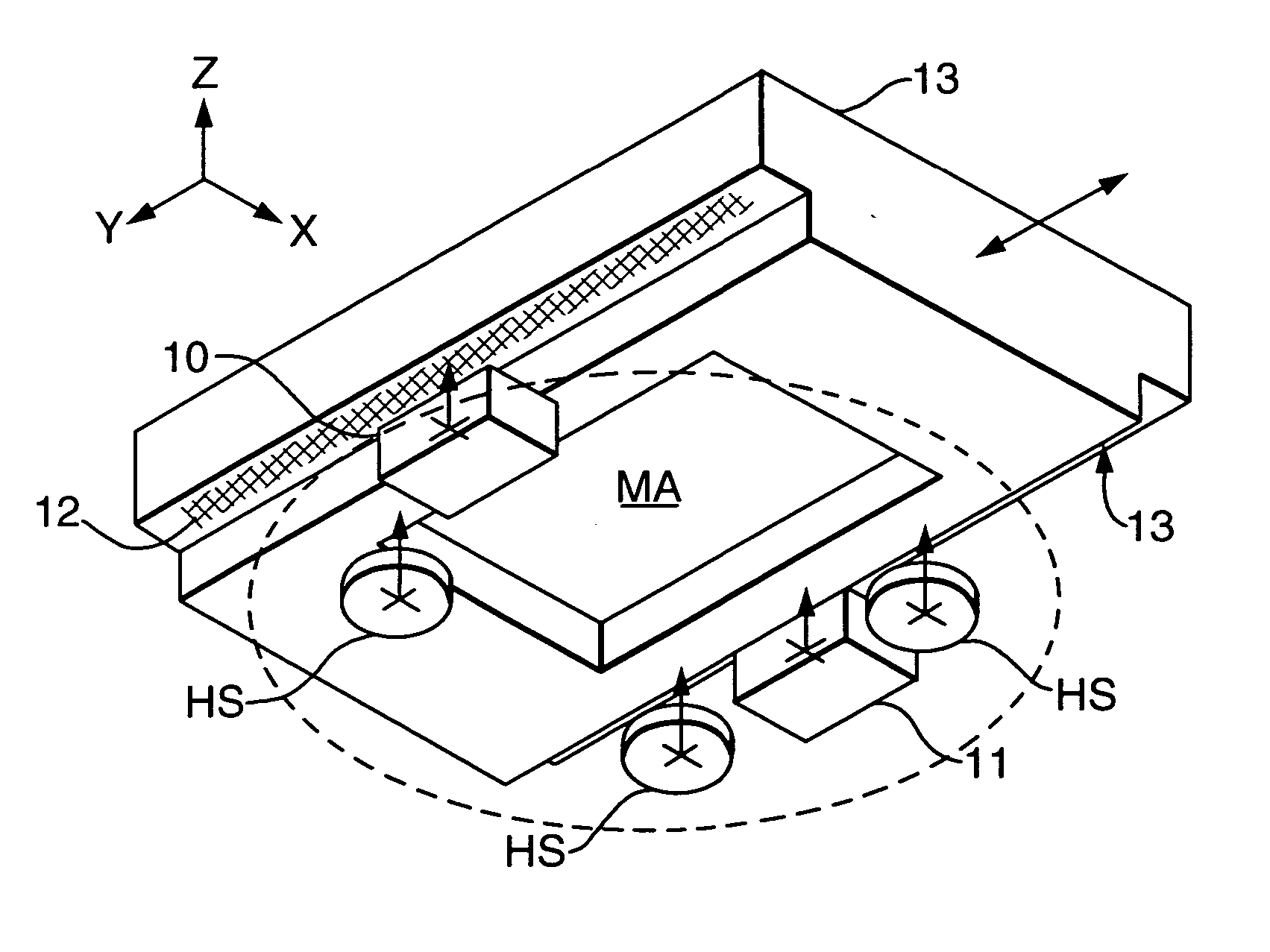

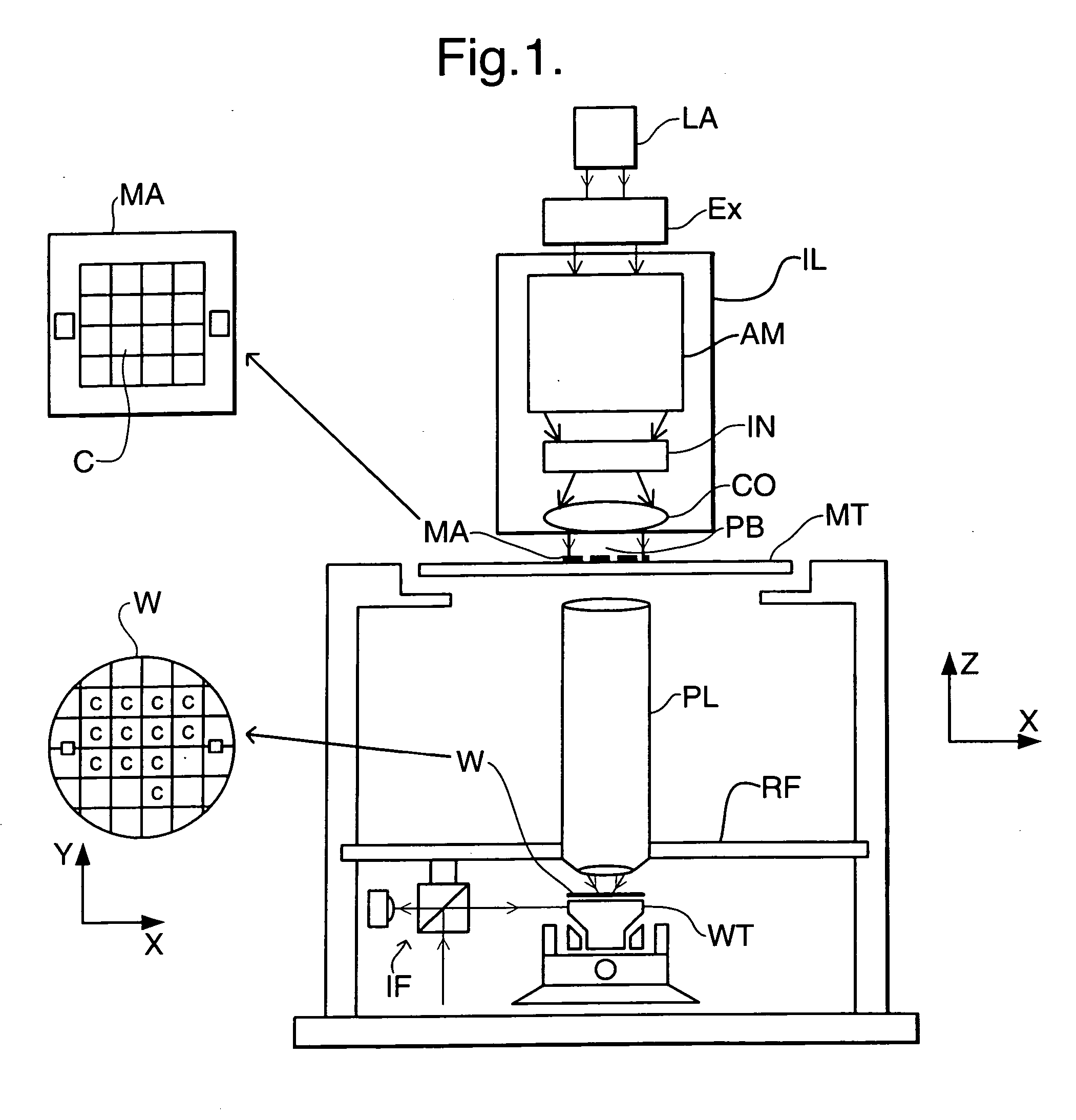

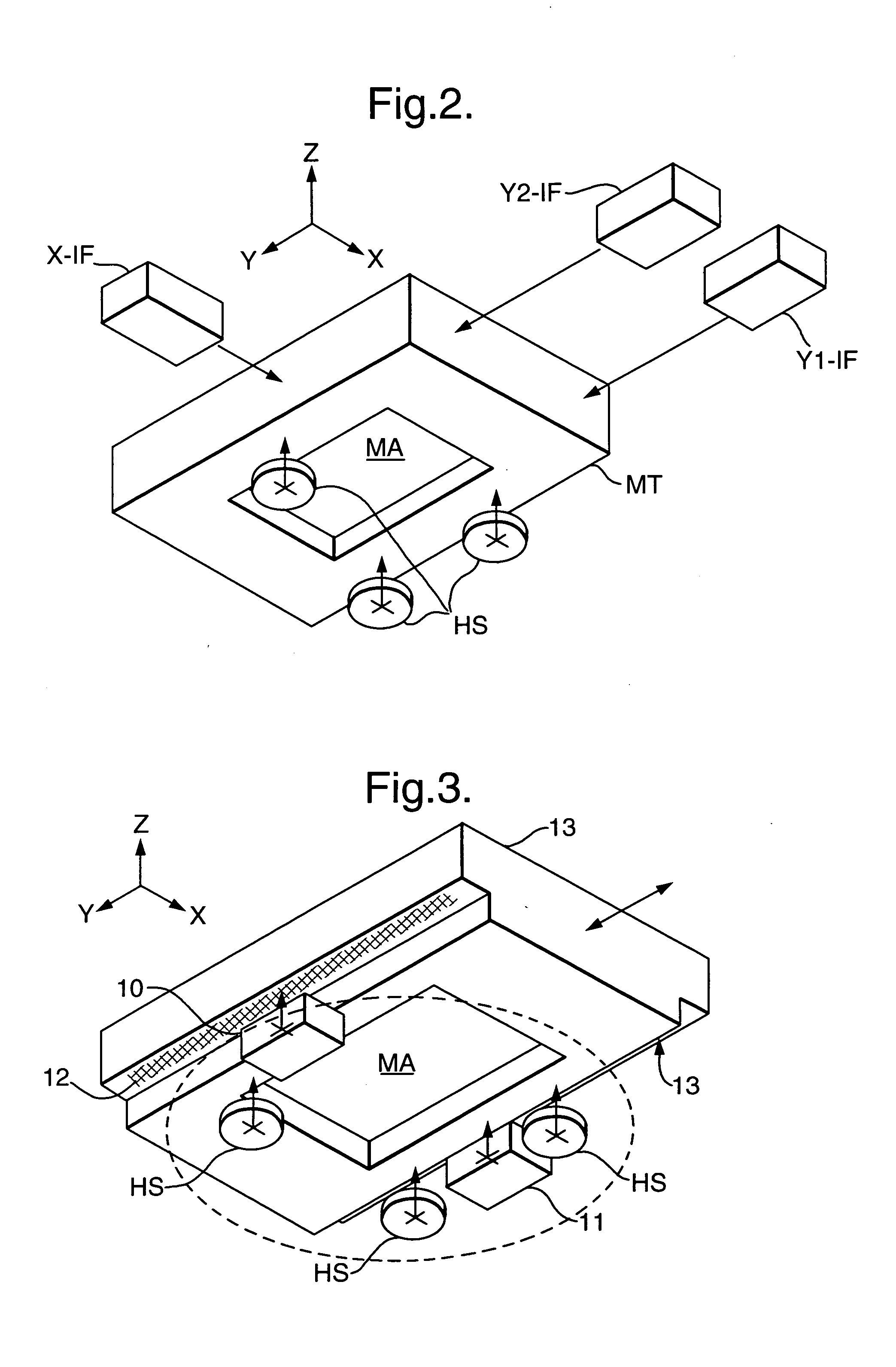

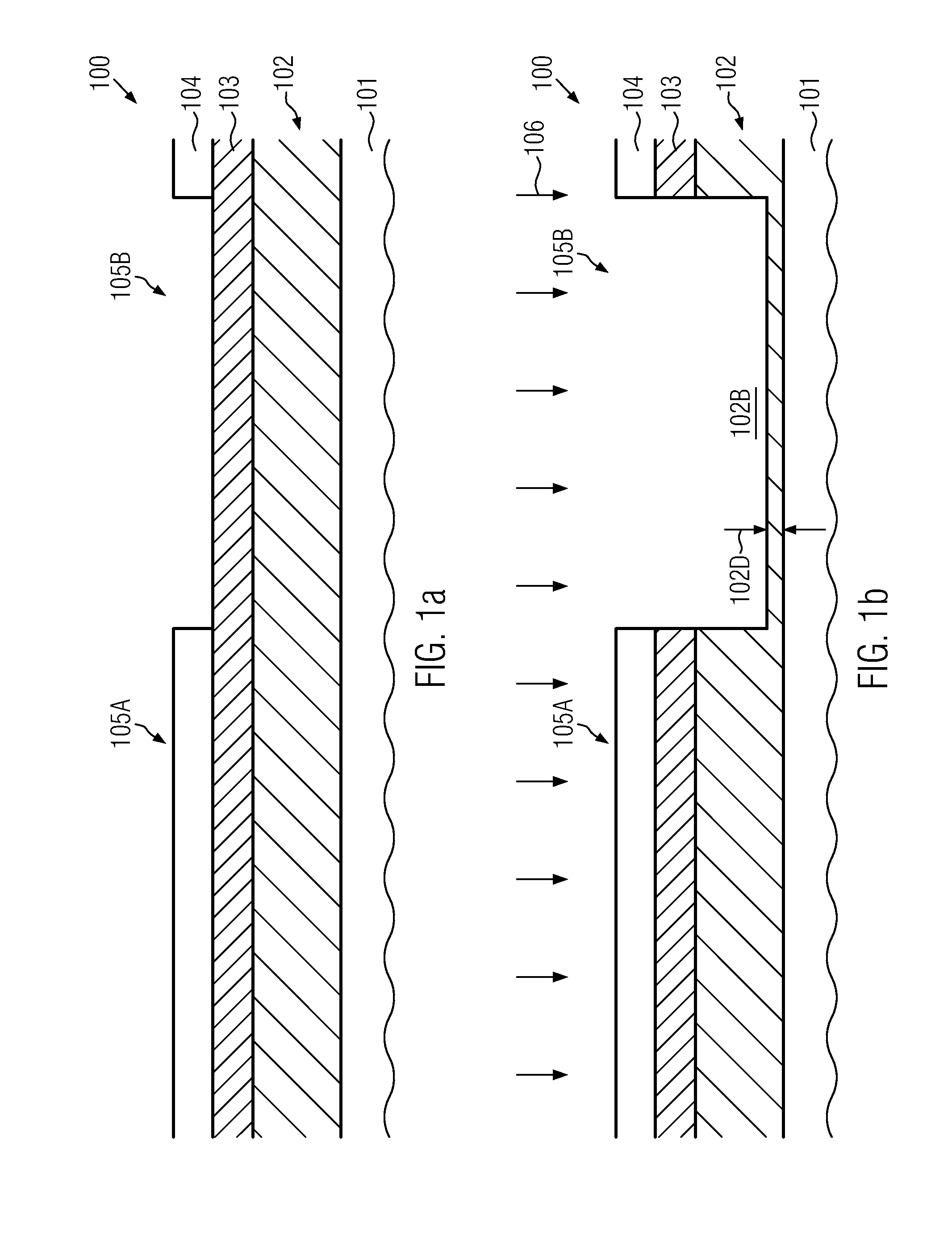

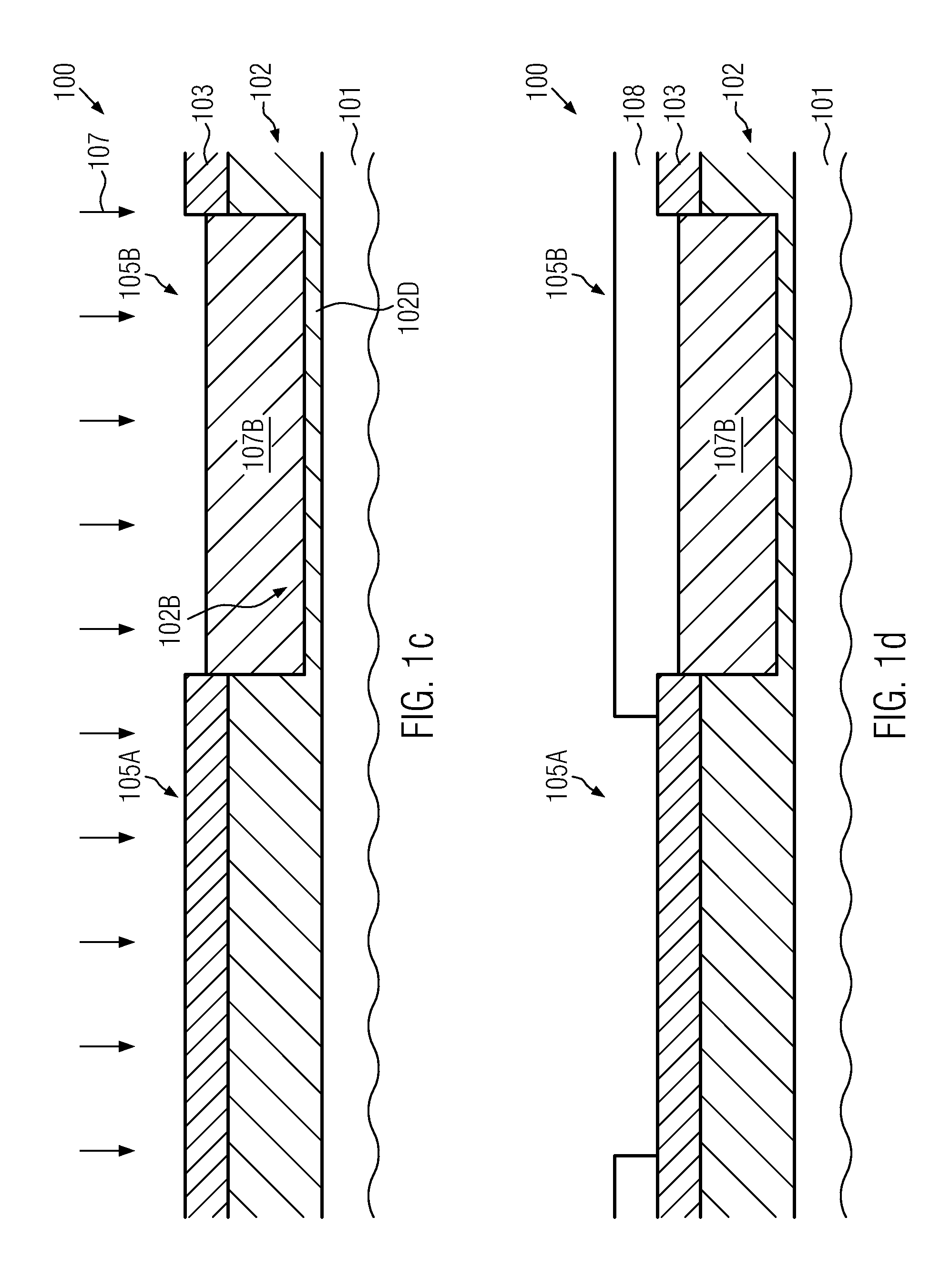

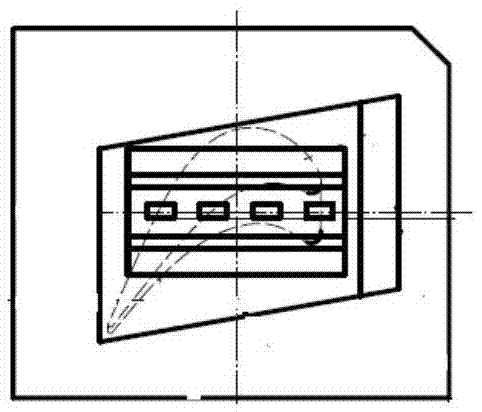

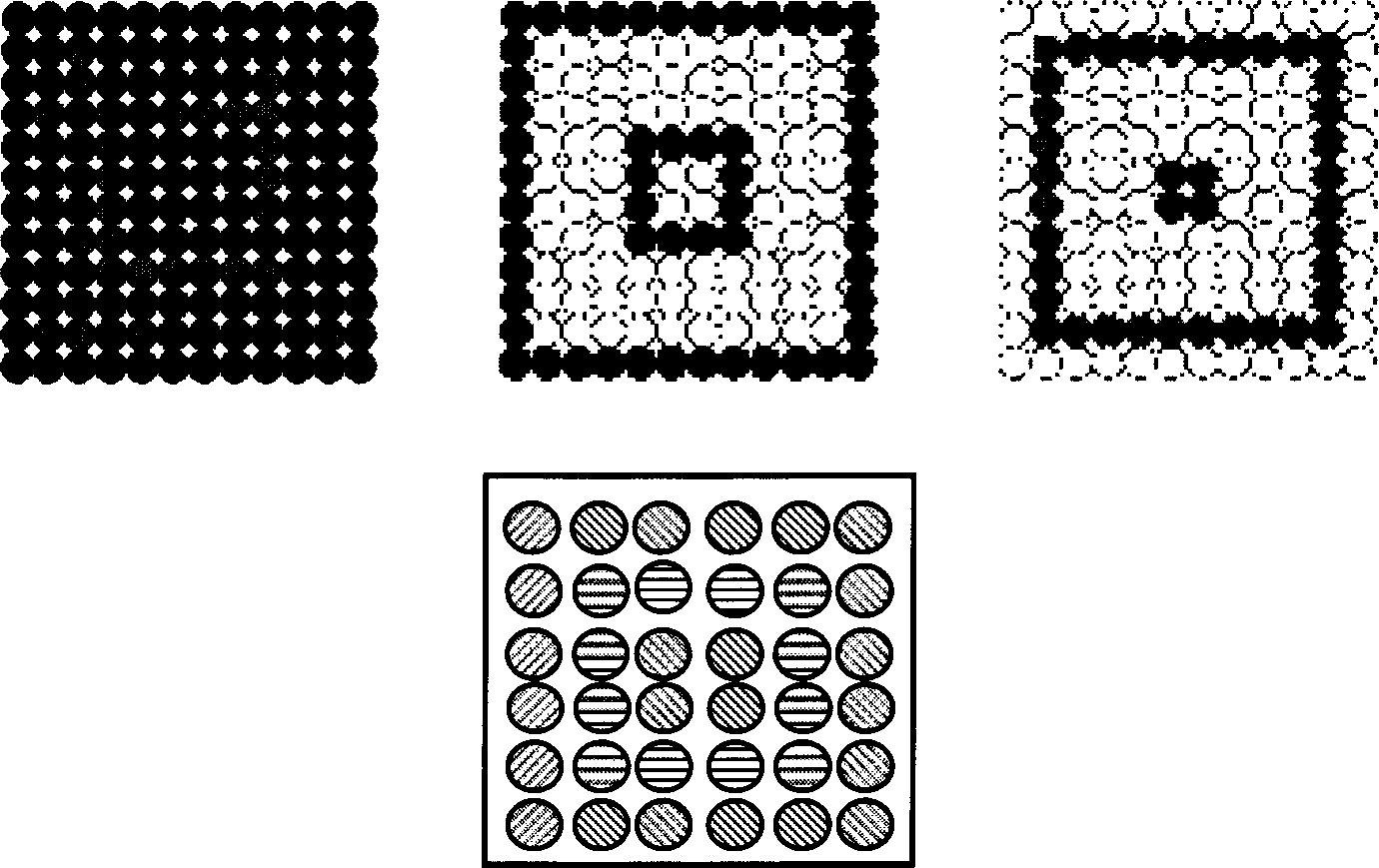

Lithographic apparatus, device manufacturing method and device manufacturing thereby

InactiveUS20040263846A1Improve stabilityReduce impactUsing optical meansPhotomechanical exposure apparatusCapacitanceGrating

The X, Y and Rx positions of a mask stage are measured using two optical encoder-reading heads measuring displacements of respective grid gratings mounted on the mask stage. The grid gratings are preferably provided on cut-away portions of the mask table so as to be coplanar with the pattern on the mask itself. Measurements of the table position in the other degrees of freedom can be measured with capacitative or optical height sensors.

Owner:ASML NETHERLANDS BV

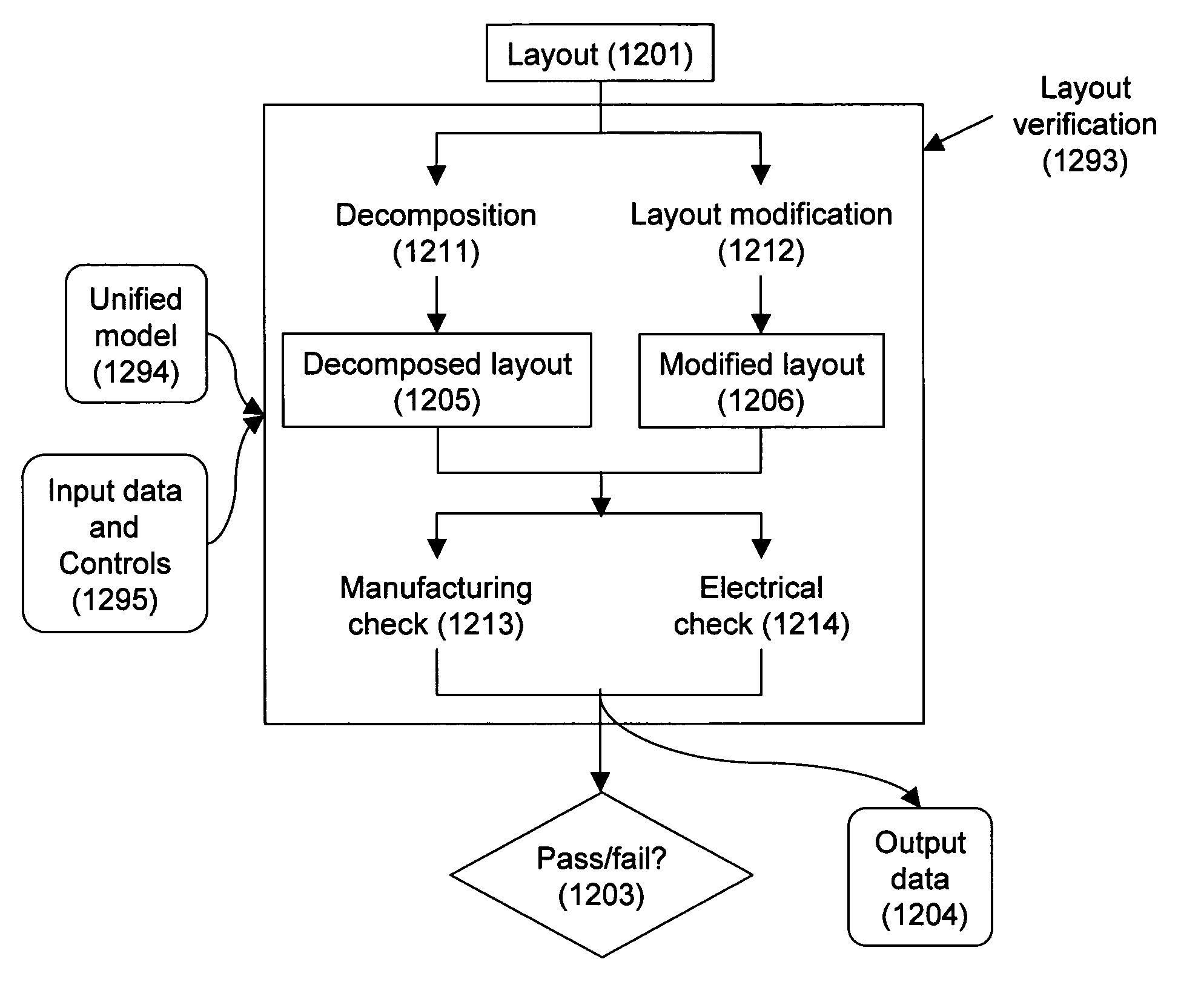

Design-manufacturing interface via a unified model

ActiveUS20050076316A1Create additionalImprove accuracyCAD circuit designSoftware simulation/interpretation/emulationManufacturing technologyMiniaturization

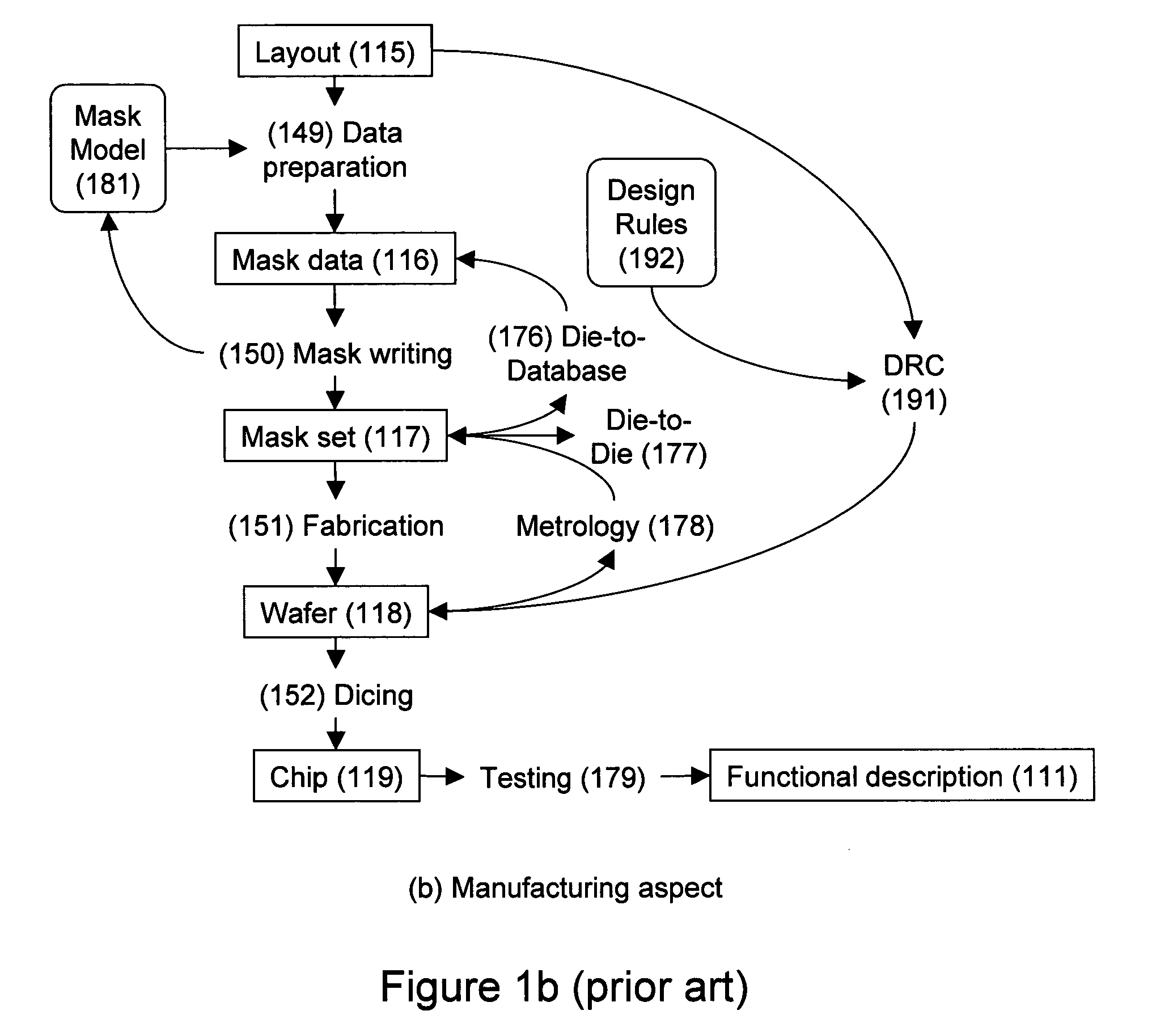

Subtleties of advanced fabrication processes and nano-scale phenomena associated with integrated circuit miniaturization have exposed the insufficiencies of design rules. Such inadequacies have adverse impact on all parts of the integrated circuit creation flow where design rules are used. In addition, segregation of the various layout data modification steps required for deep sub-micrometer manufacturing are resulting in slack and inefficiencies. This invention describes methods to improve integrated circuit creation via the use of a unified model of fabrication processes and circuit elements that can complement or replace design rules. By capturing the interdependence among fabrication processes and circuit elements, the unified model enables efficient layout generation, resulting in better integrated circuits.

Owner:SYNOPSYS INC

Personalized Fit and Functional Designed Medical Prostheses and Surgical Instruments and Methods for Making

ActiveUS20130245801A1Simple designFast learningMedical simulationAdditive manufacturing apparatusPersonalizationManufacturing technology

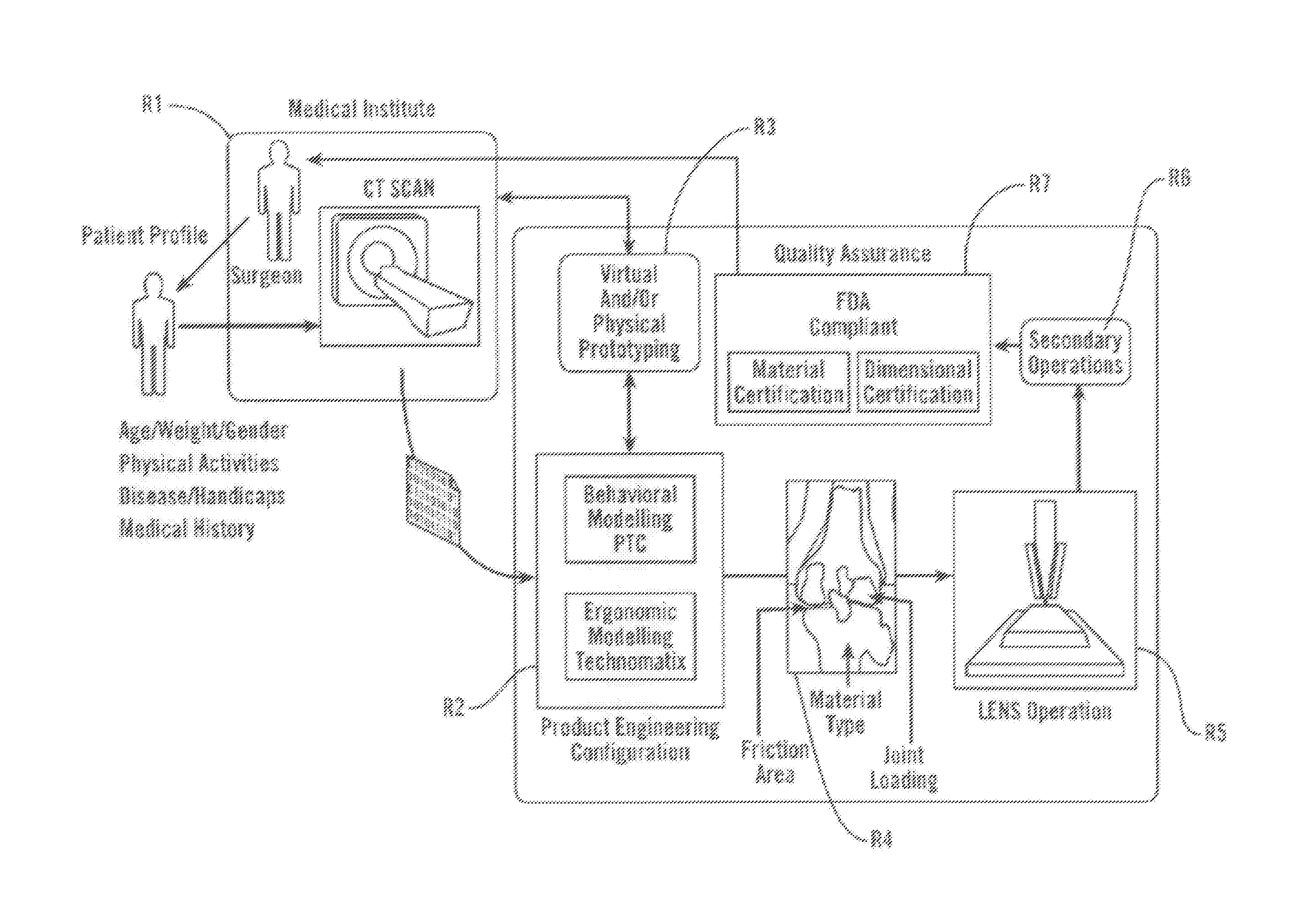

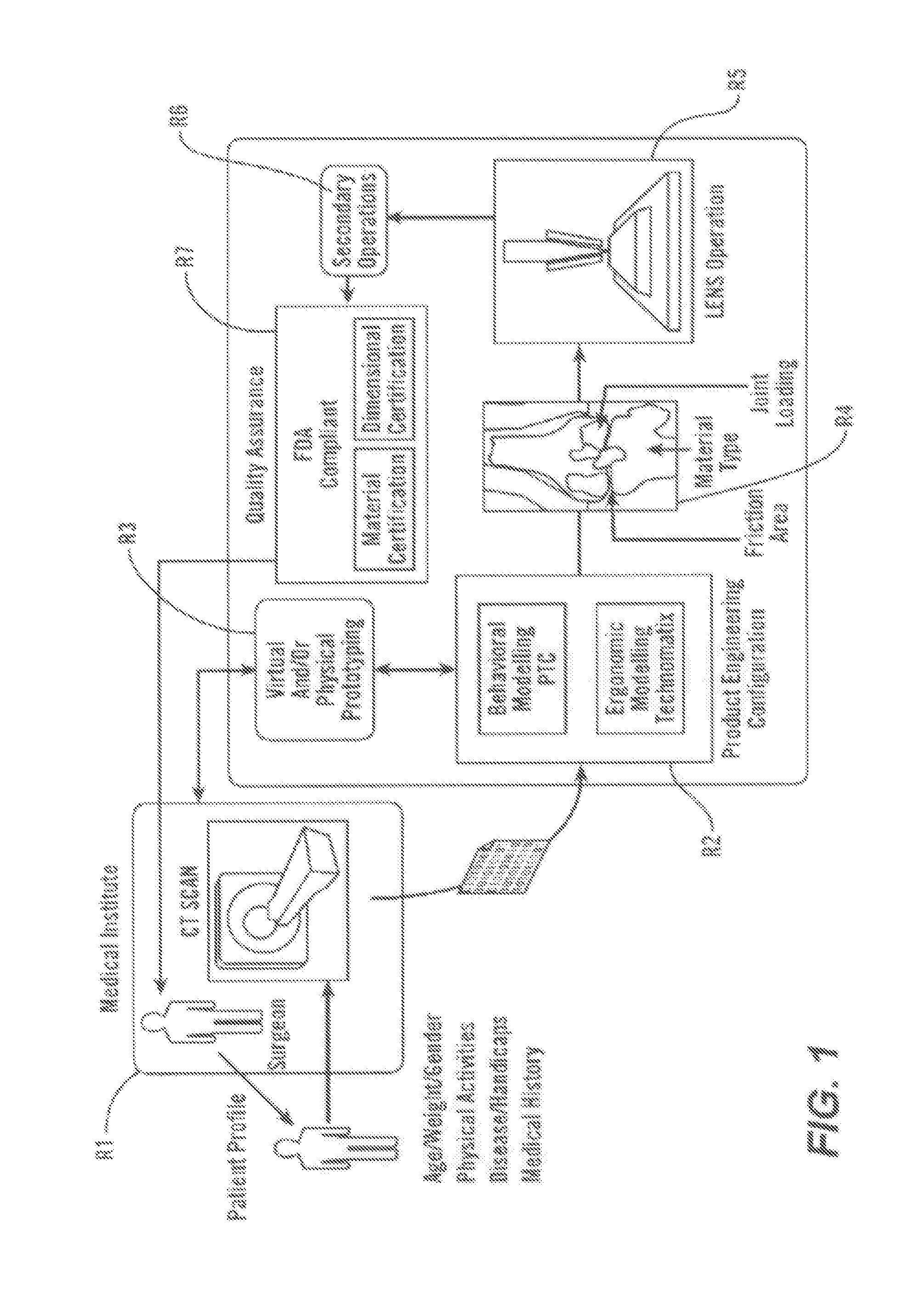

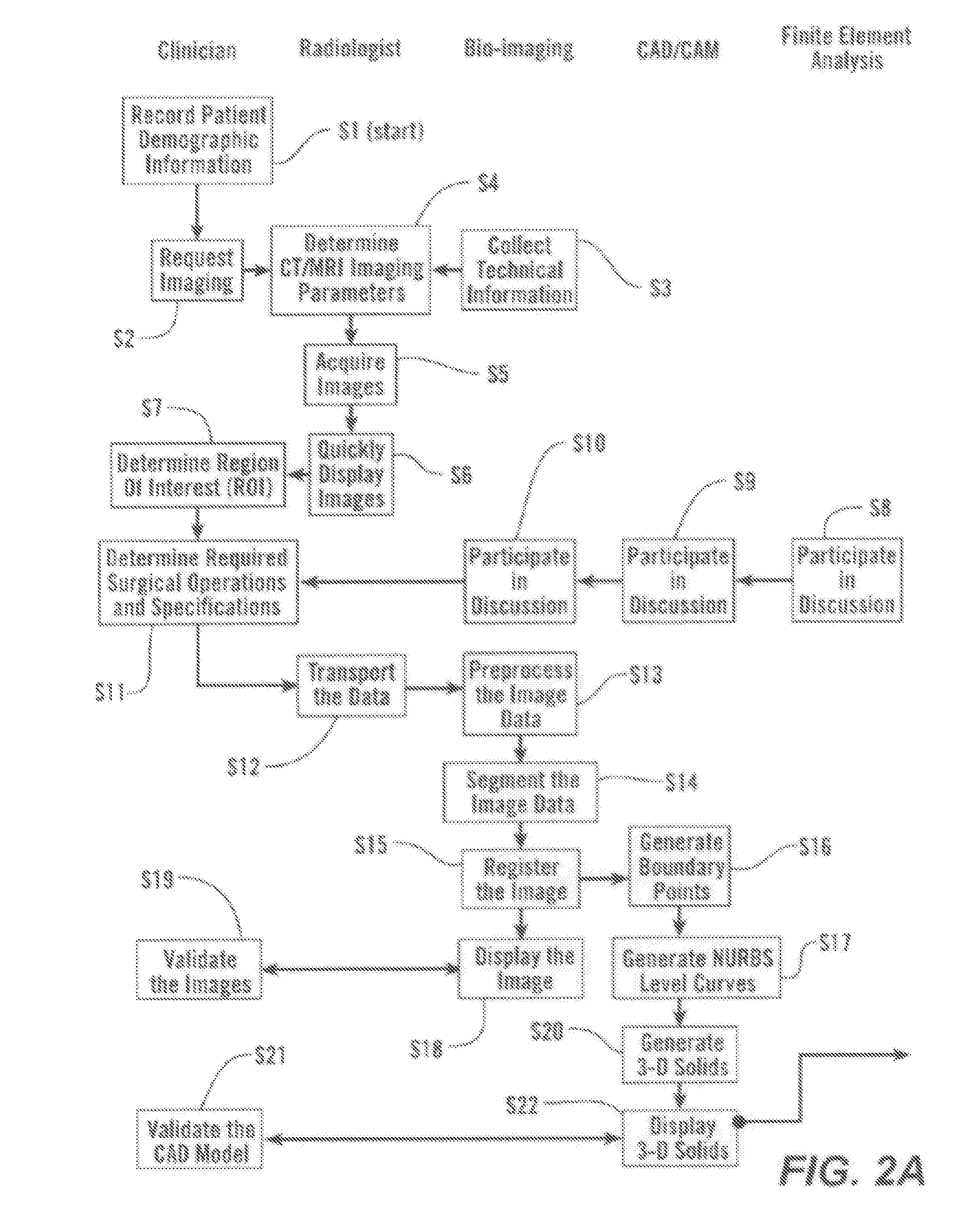

Methods, devices and systems for virtual, remote and real-time collaboration between surgeons and engineers using system learning and intelligent and timely disbursement of design and performance information to engineering teams embarking on the preliminary design event of a personalized orthopedic implant or personalize surgical instrument utilizing a case-based reasoning expert system. Additive manufacturing technology and statistically controlled advanced manufacturing processes quickly produce personalized medical devices worldwide.

Owner:SCHROEDER JAMES

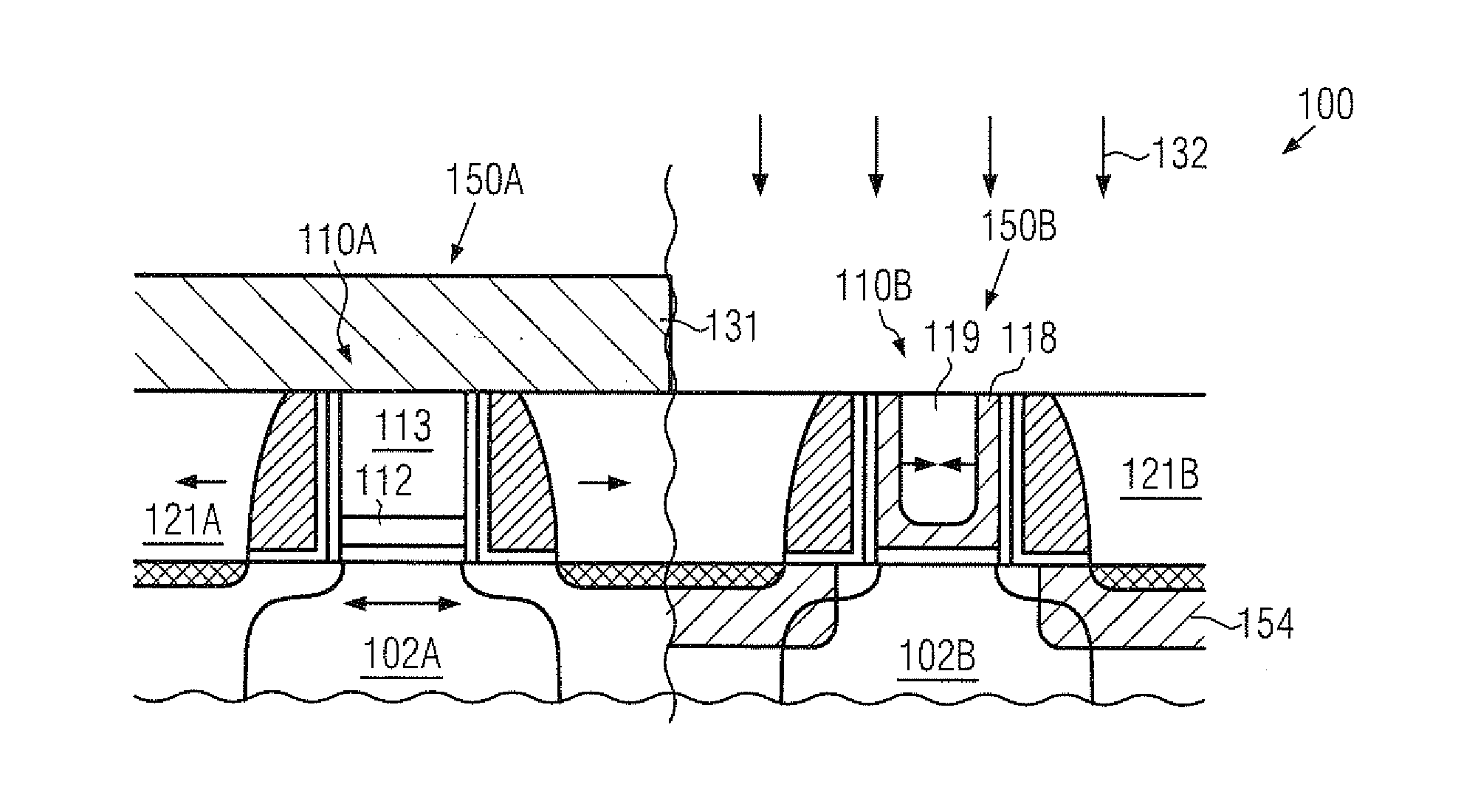

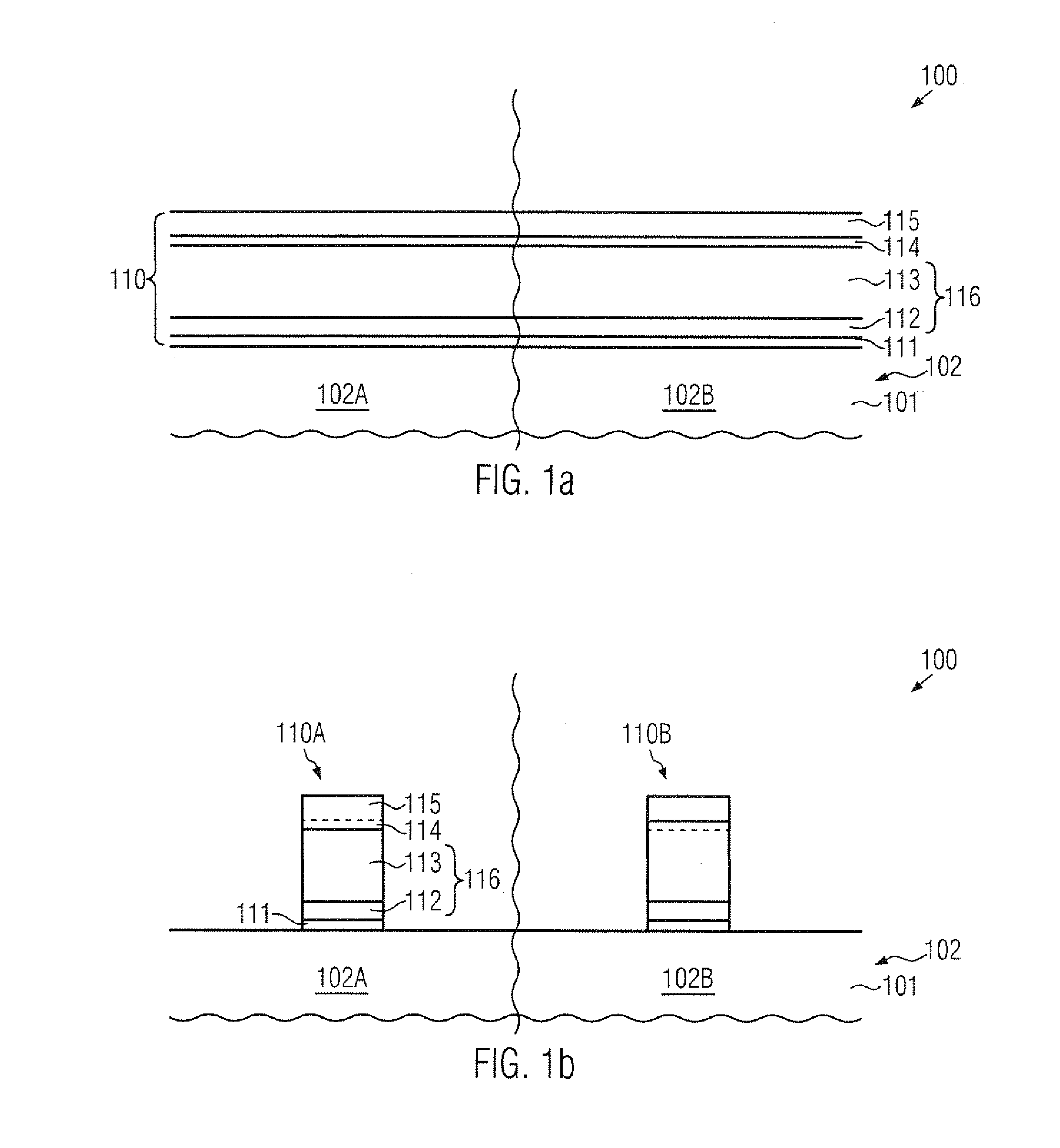

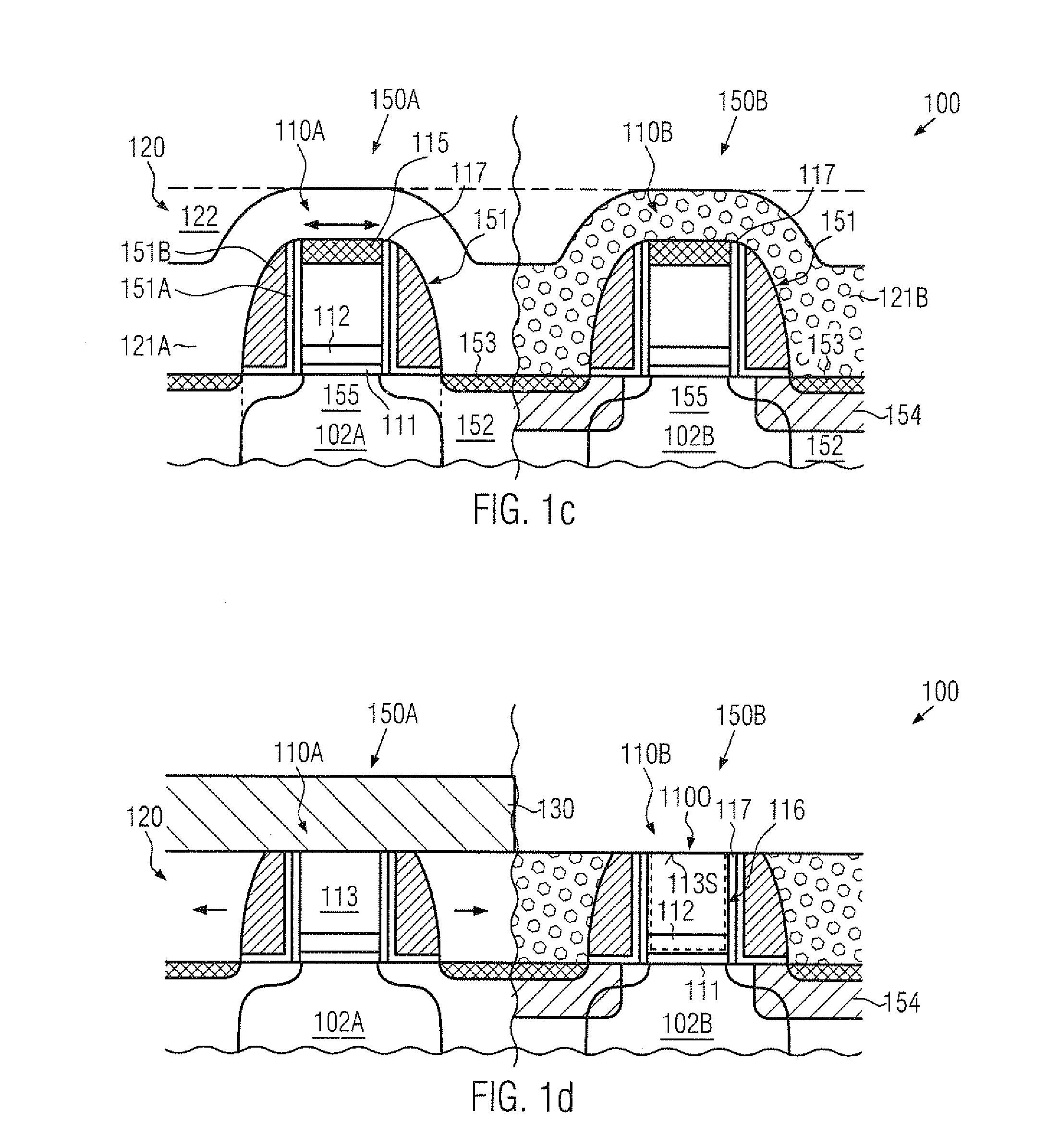

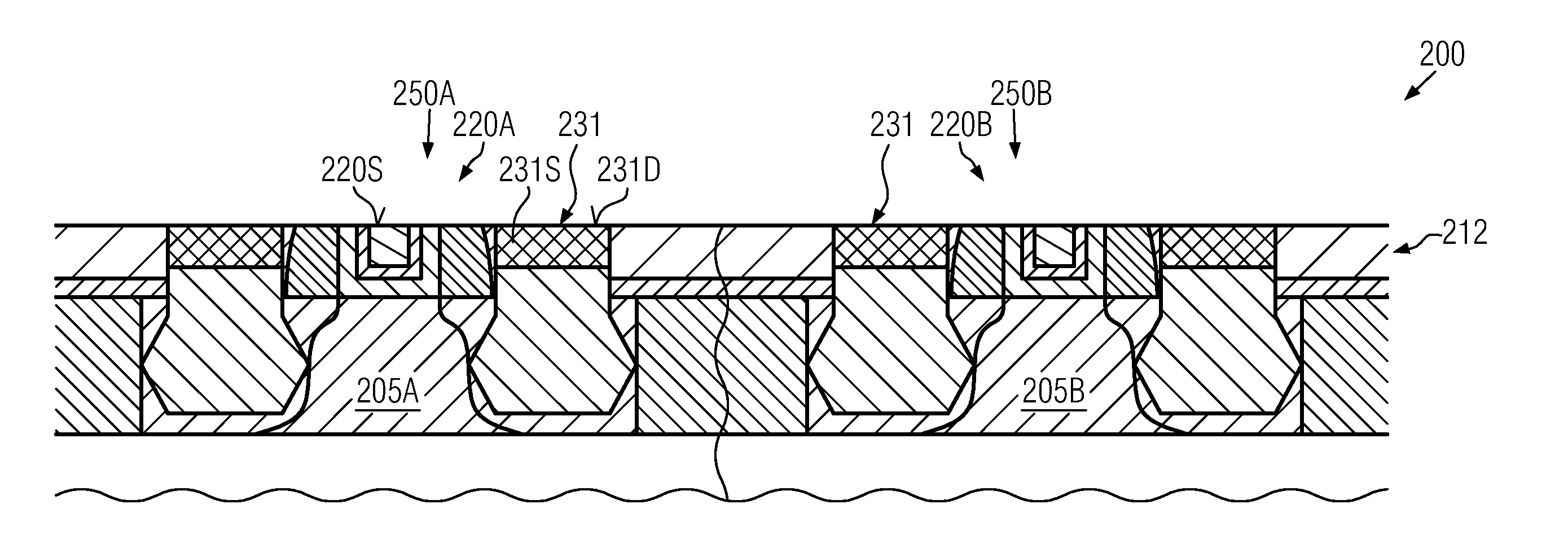

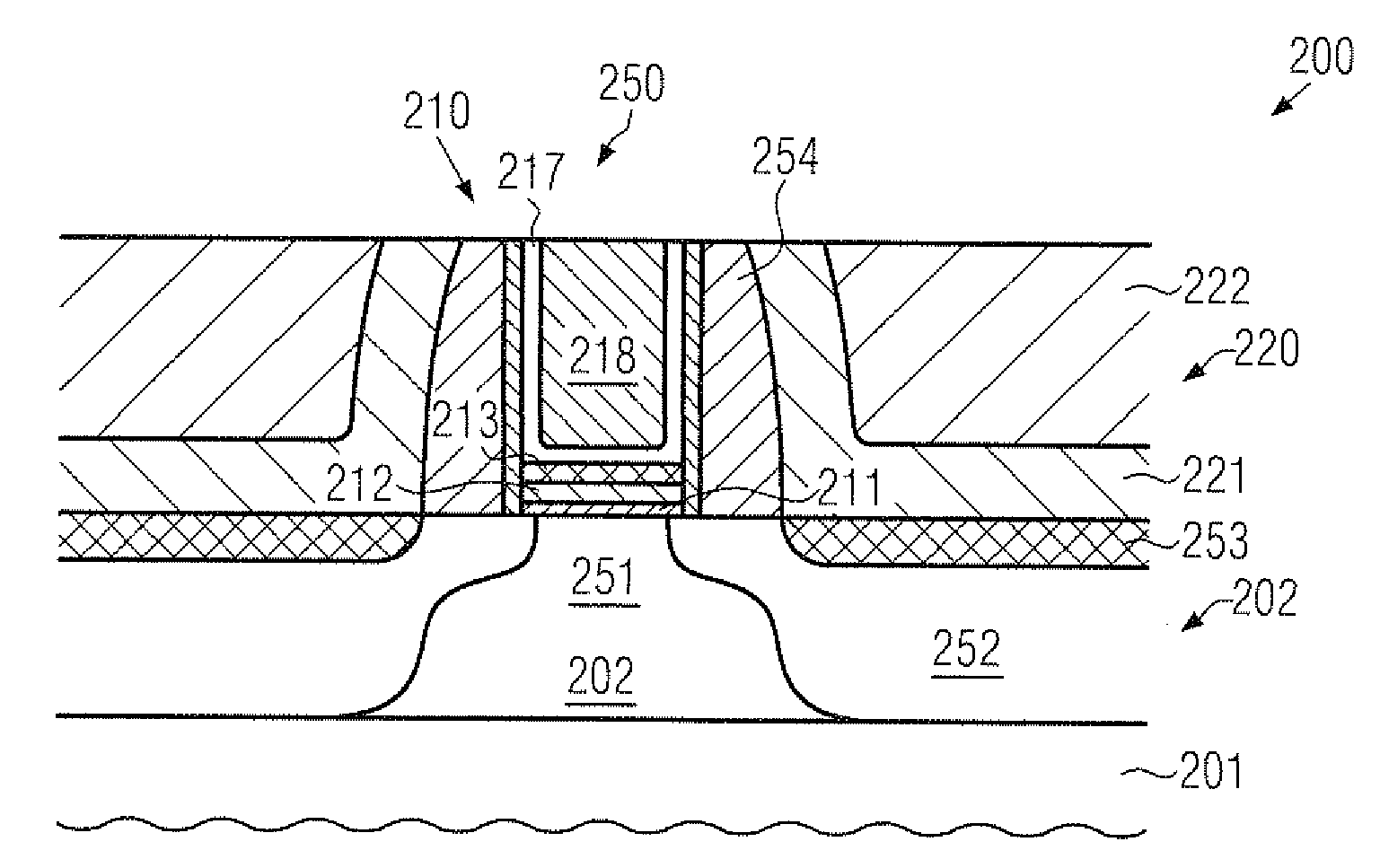

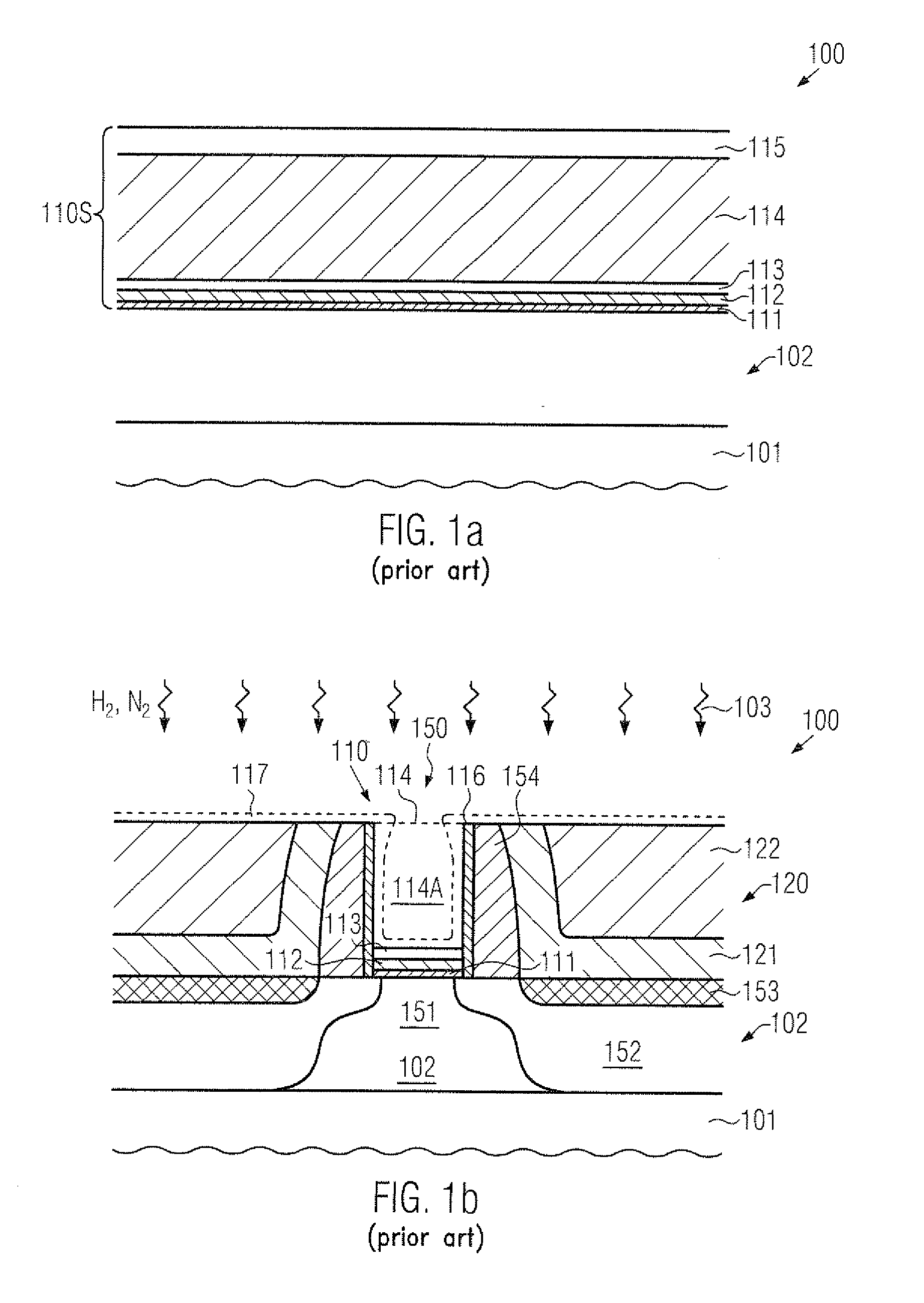

High-k metal gate electrode structures formed at different process stages of a semiconductor device

ActiveUS20110156154A1Improve device performanceEffective regulationTransistorSemiconductor/solid-state device manufacturingWork functionGate stack

Sophisticated high-k metal gate electrode structures are provided on the basis of a hybrid process strategy in which the work function of certain gate electrode structures is adjusted in an early manufacturing stage, while, in other gate electrode structures, the initial gate stack is used as a dummy material and is replaced in a very advanced manufacturing stage. In this manner, superior overall process robustness in combination with enhanced device performance may be achieved.

Owner:GLOBALFOUNDRIES US INC

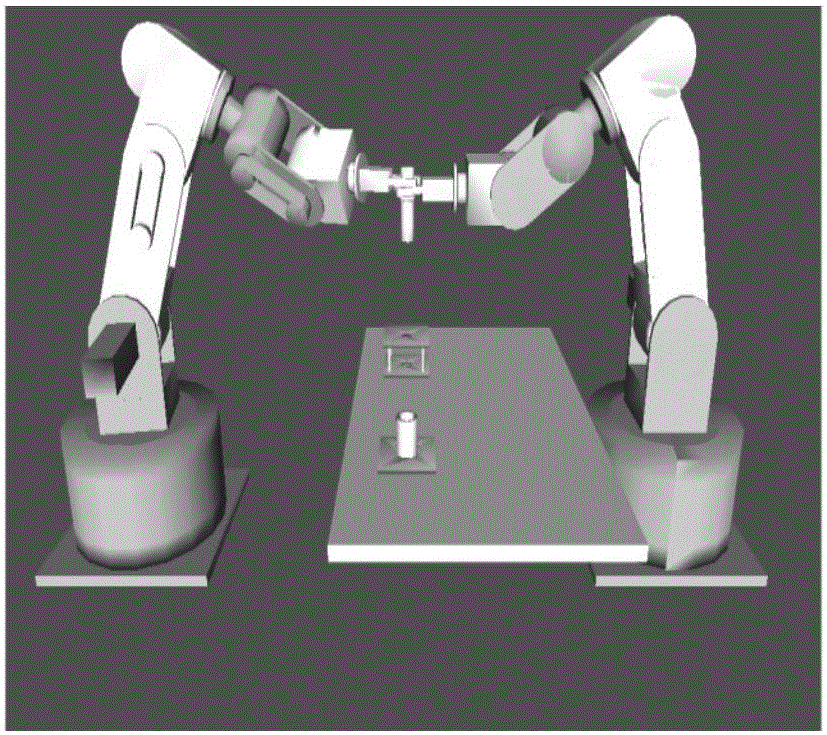

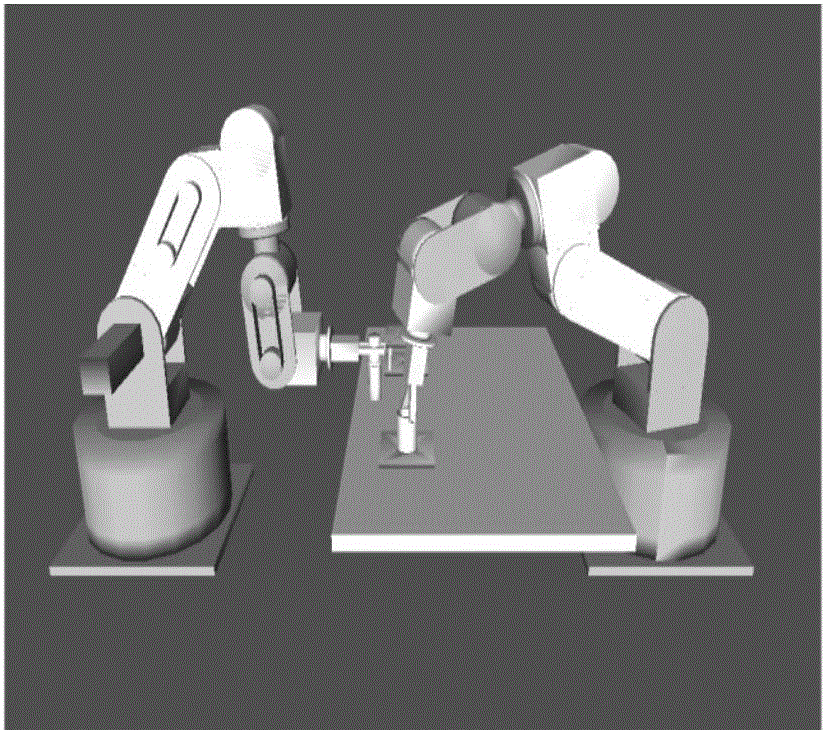

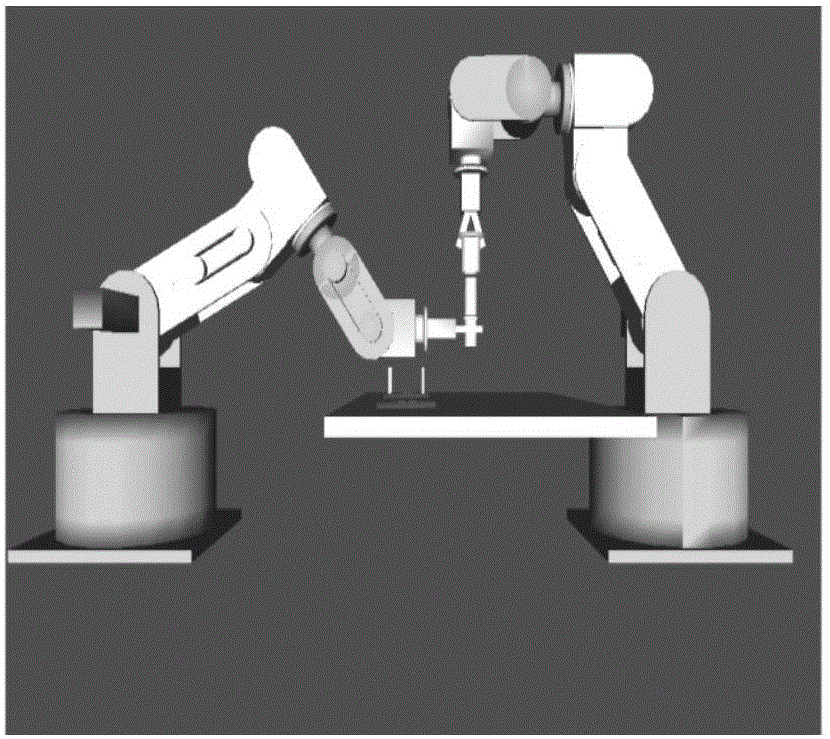

Operating method on basis of master-slave industrial robot collaboration

InactiveCN105751196AIncrease autonomyImprove robustnessProgramme controlProgramme-controlled manipulatorAdvanced manufacturingPlanning method

The invention discloses an operating method on basis of master-slave industrial robot collaboration. The operating method comprises three parts of collaboration control, track planning and operation implementation, and aims to overcome the limitation of single industrial robot operation, to enable master-slave industrial robots to collaboratively complete a more complicated operation, and to enable the master-slave industrial robots to have higher autonomy, higher robustness and higher adaptability. The operating method is characterized in that a motion track of each of the master-slave industrial robots can be controlled by adoption of a collaboration control method, a track planning method and an operation implementation method according to position and gesture restriction relationships between the master-slave industrial robots, so that the master-slave industrial robots mutually collaboratively complete the monotonous, repeated and heavy operations of grabbing, carrying and assembling. The operating method on the basis of the master-slave industrial robot collaboration can be applied to an advanced manufacturing industry and a flow production line of the advanced manufacturing industry.

Owner:SOUTH CHINA UNIV OF TECH

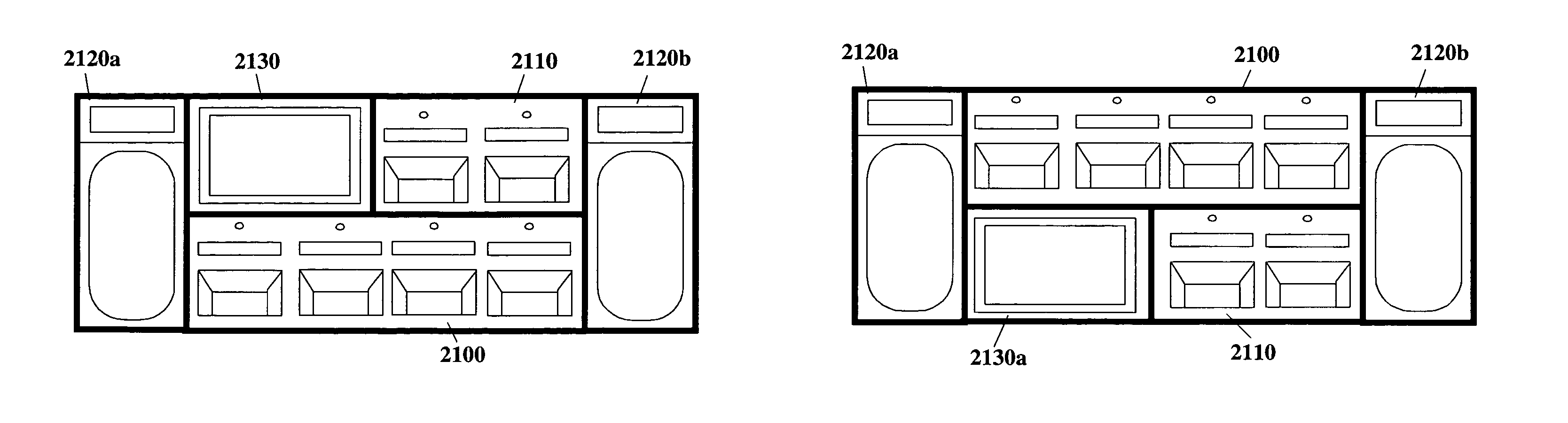

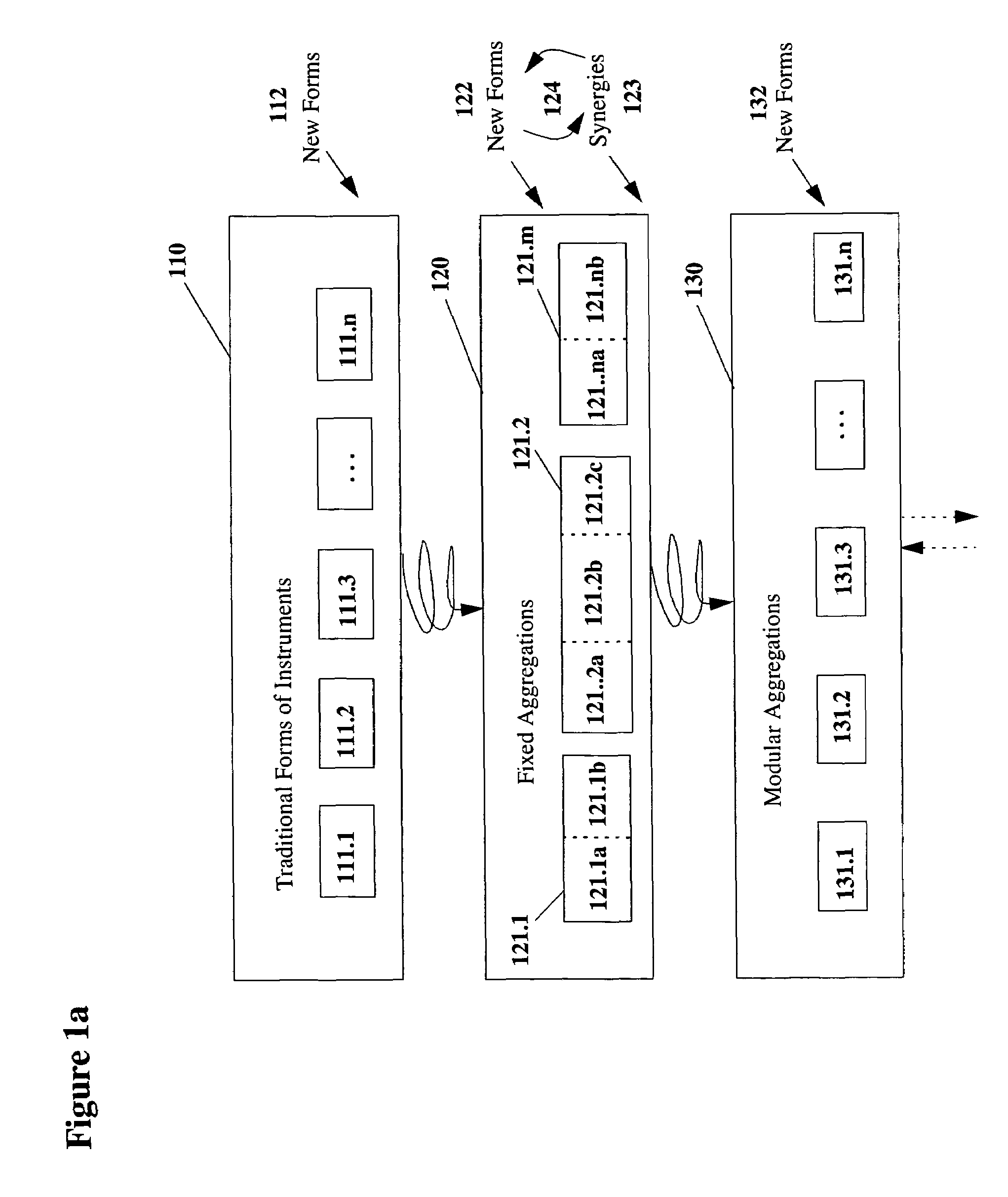

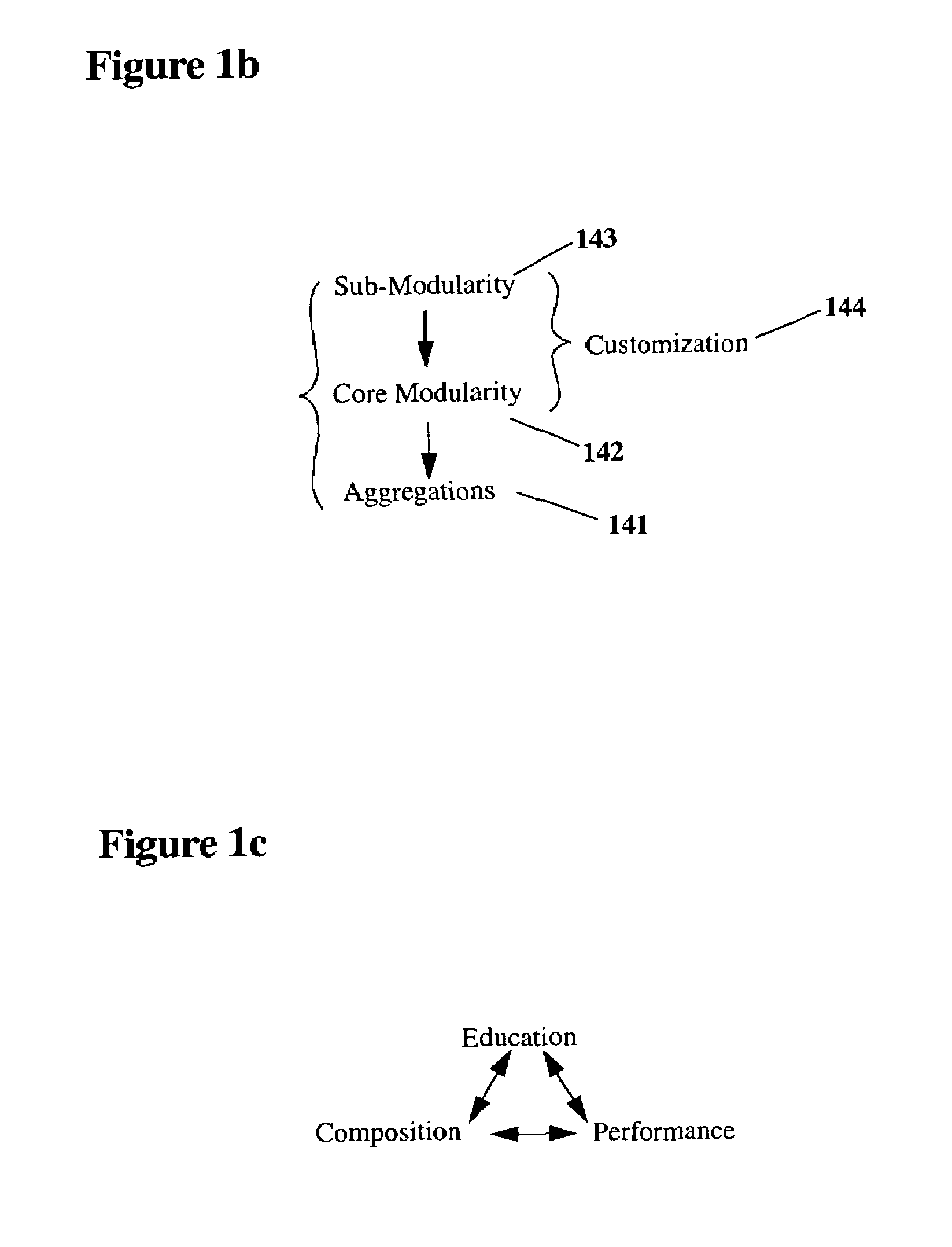

Modular structures facilitating field-customized floor controllers

InactiveUS7608776B2Easy and robust creationMaximum functionElectrophonic musical instrumentsModularityModular structure

The invention allows for easy field-customization of floor controllers using techniques that are similar to those applicable to the easy creation of aggregated instruments. The invention further facilitates entirely new manufacturing, marketing, and sales paradigms permitting a broad range of open industry development and commerce, thus making an individual musician's creation of new floor controller arrangements an economically viable sector for both mass manufacturing and the niche cottage industry. New opportunities are provided for the creation of multiple-vendor standardizations, multiple-vendor manufacturing, multiple-vendor competitive features, etc. while offering the music equipment user and music industry as a whole, access to an extensive range of customization and diversification. The principles of the invention thus create a rich environment for floor controllers, their users, their features, their application, and the floor controller market.

Owner:NRI R&D PATENT LICENSING LLC

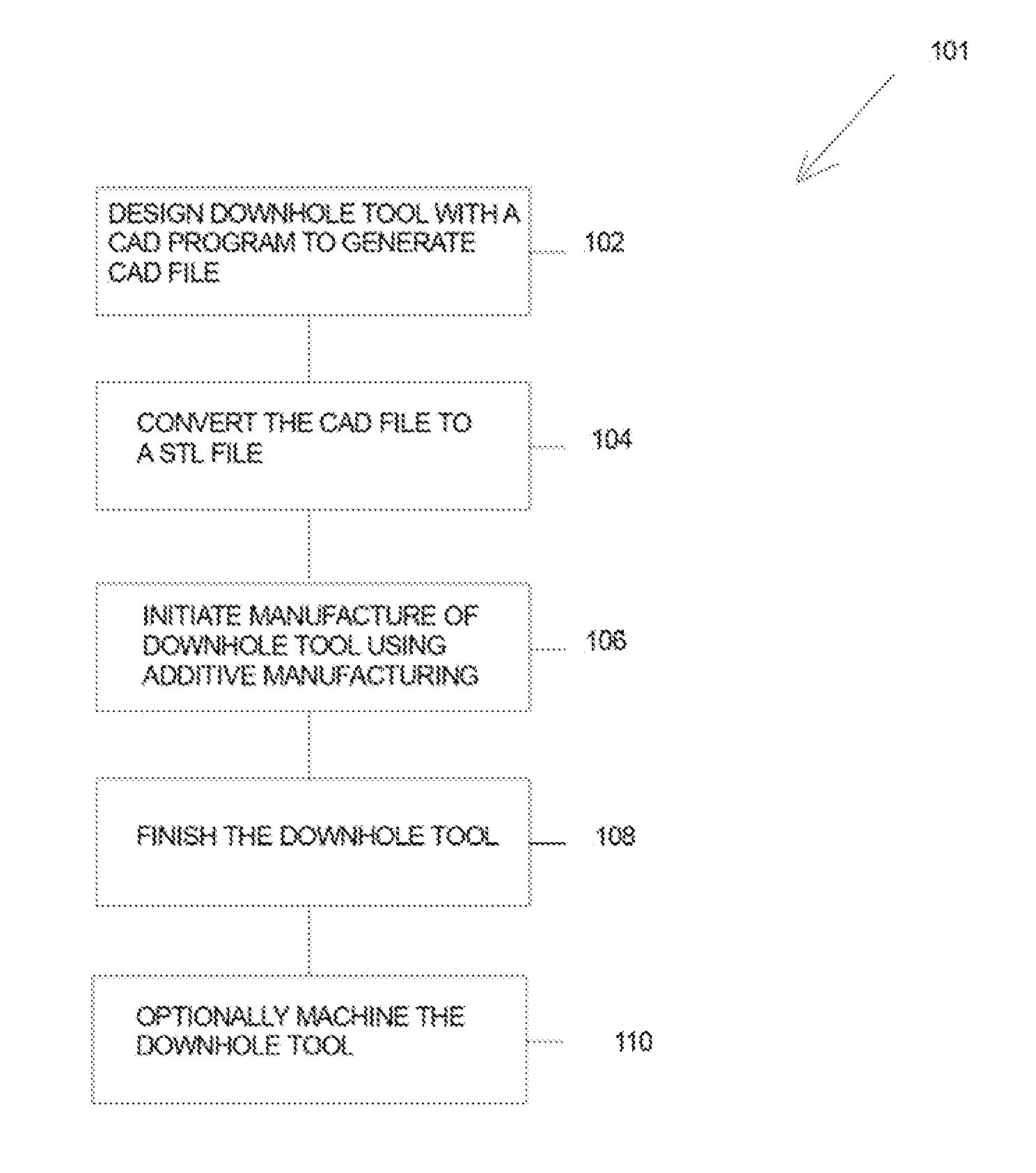

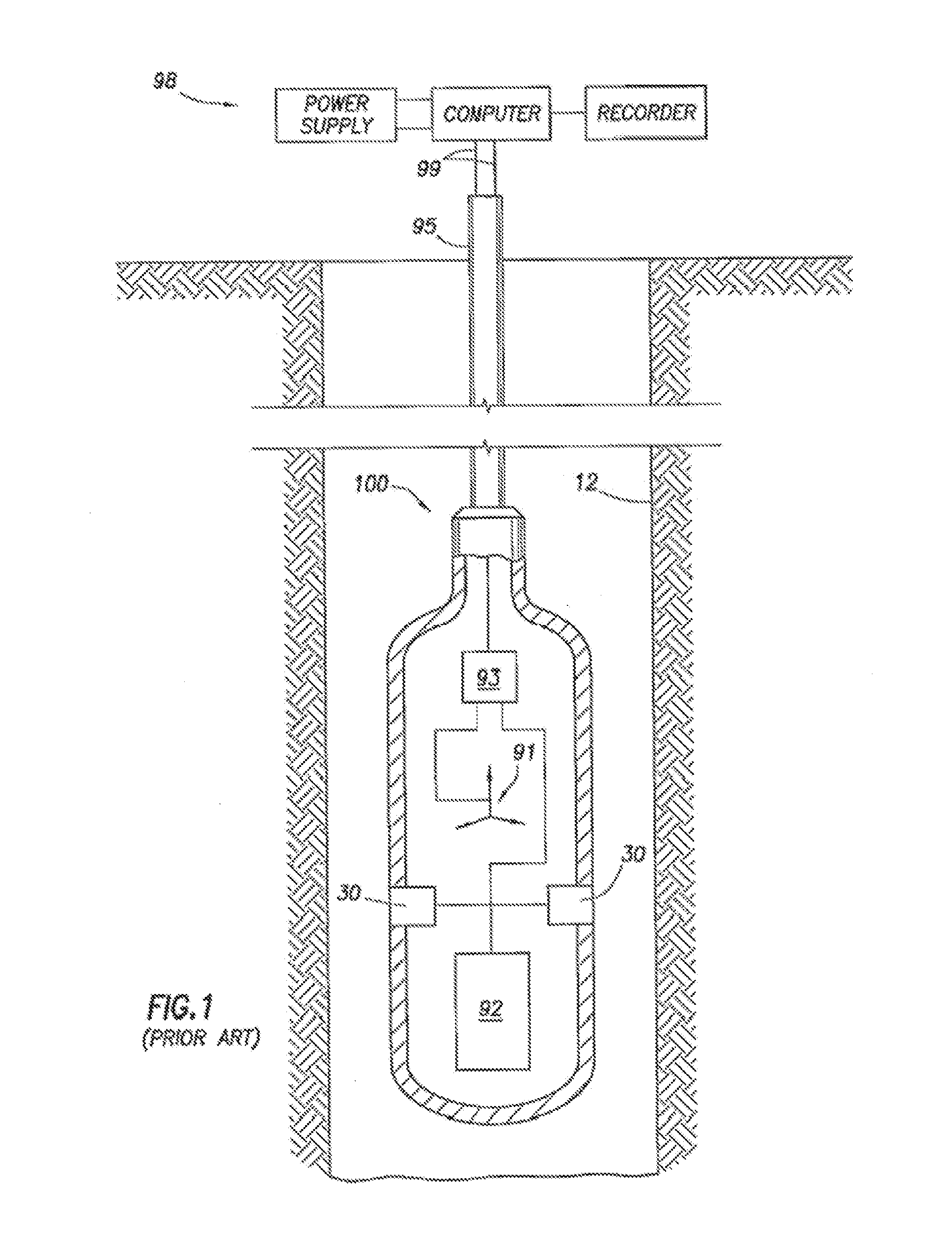

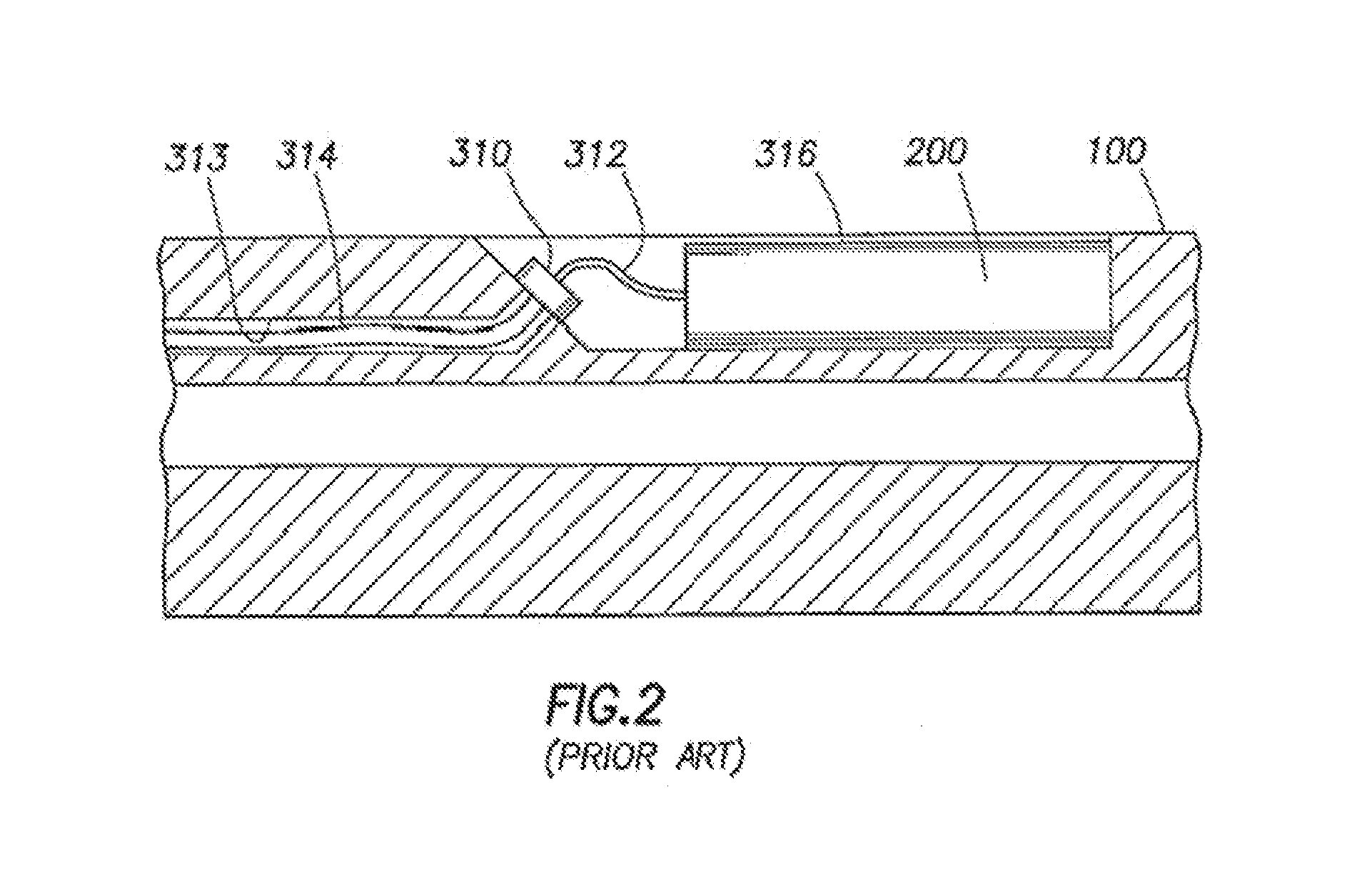

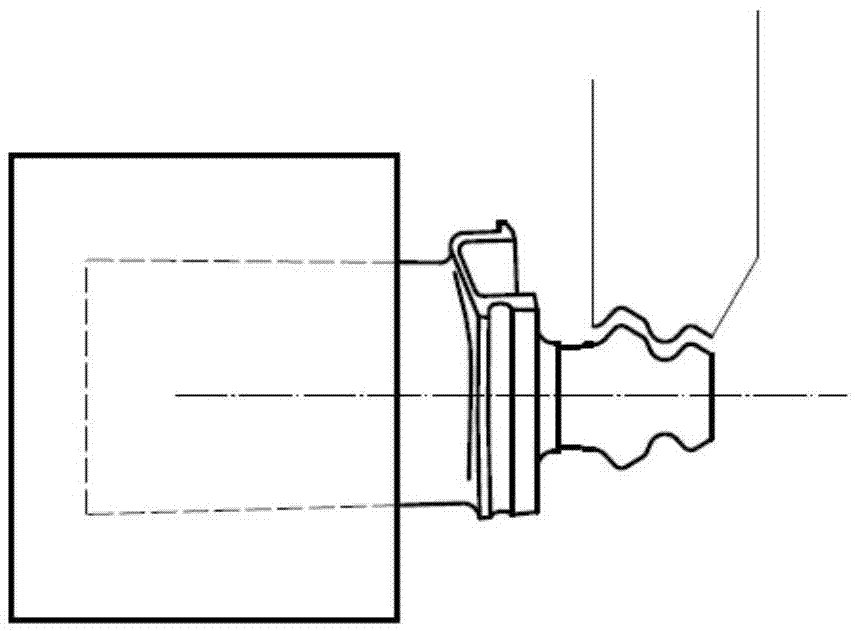

Addititve manufacturing of components for downhole wireline, tubing and drill pipe conveyed tools

InactiveUS20130310961A1Additive manufacturing apparatusIncreasing energy efficiencyDirect metal laser sinteringSelective laser sintering

Additive manufacturing may be used to manufacture components of downhole tools conveyed by downhole wireline, tubing, drill pipe and / or the like. A method in accordance with one or more aspects of the disclosure uses starting materials to incorporate one or more feedthroughs, passages, channels, chambers and the like in a downhole tool structure during the formation of the structure. A CAD may be made and then converted to a STL file, and then stereo lithography, selective laser sintering, fused deposition modeling, direct metal laser sintering and / or electron beam melting may be used to form the downhole tool. Subtractive manufacturing may be performed on the downhole tool after the downhole tool is formed by additive manufacturing.

Owner:SCHLUMBERGER TECH CORP

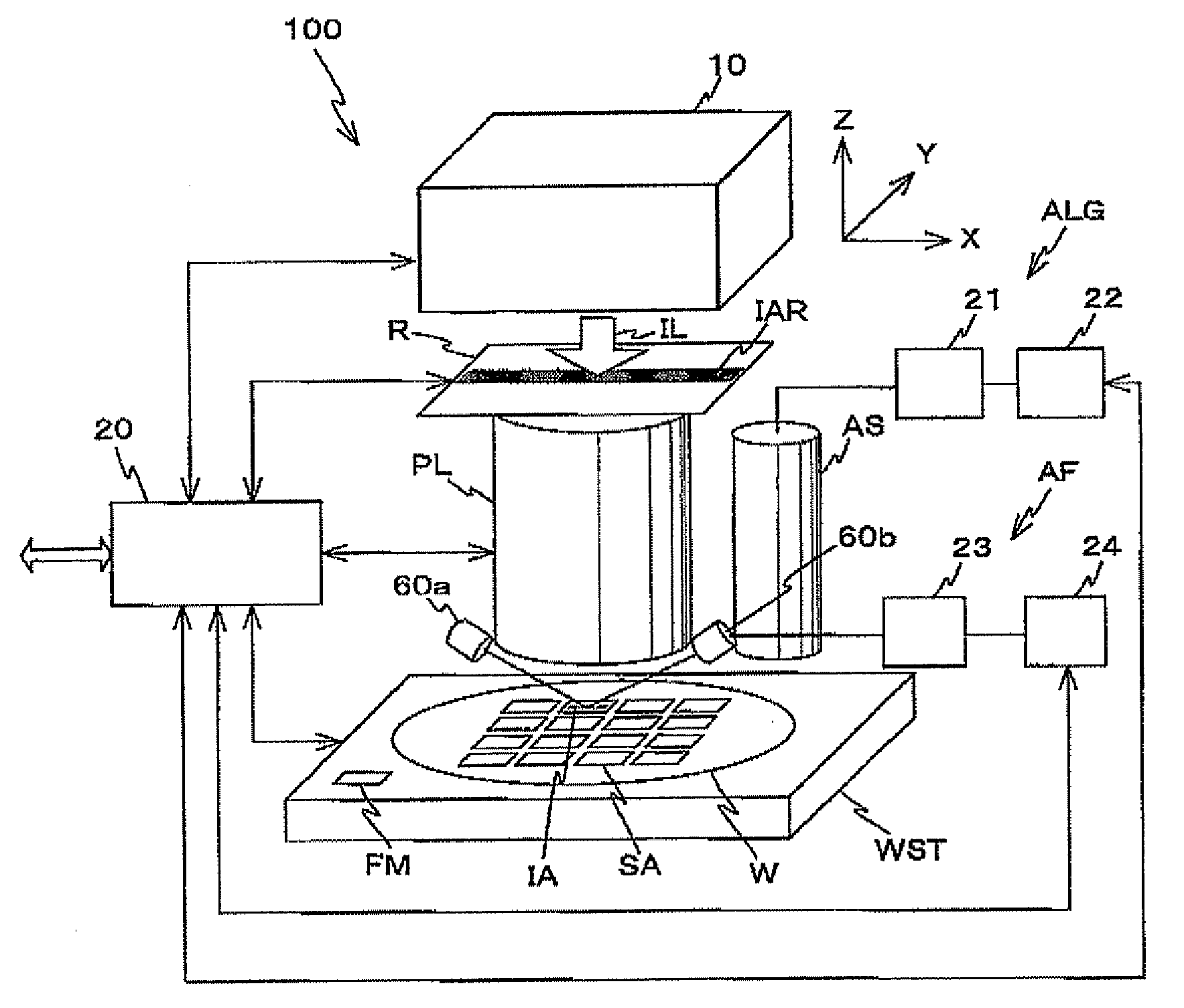

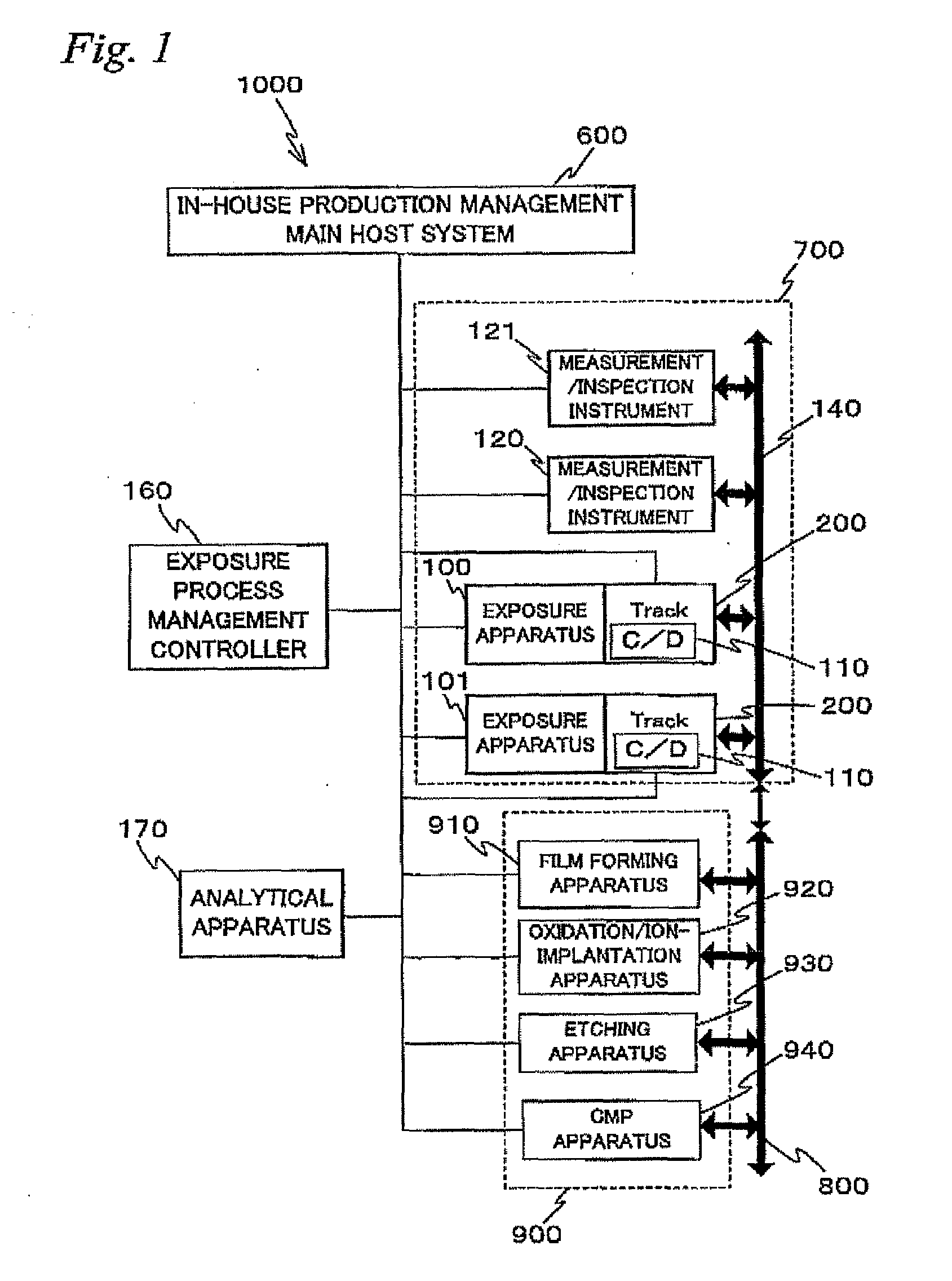

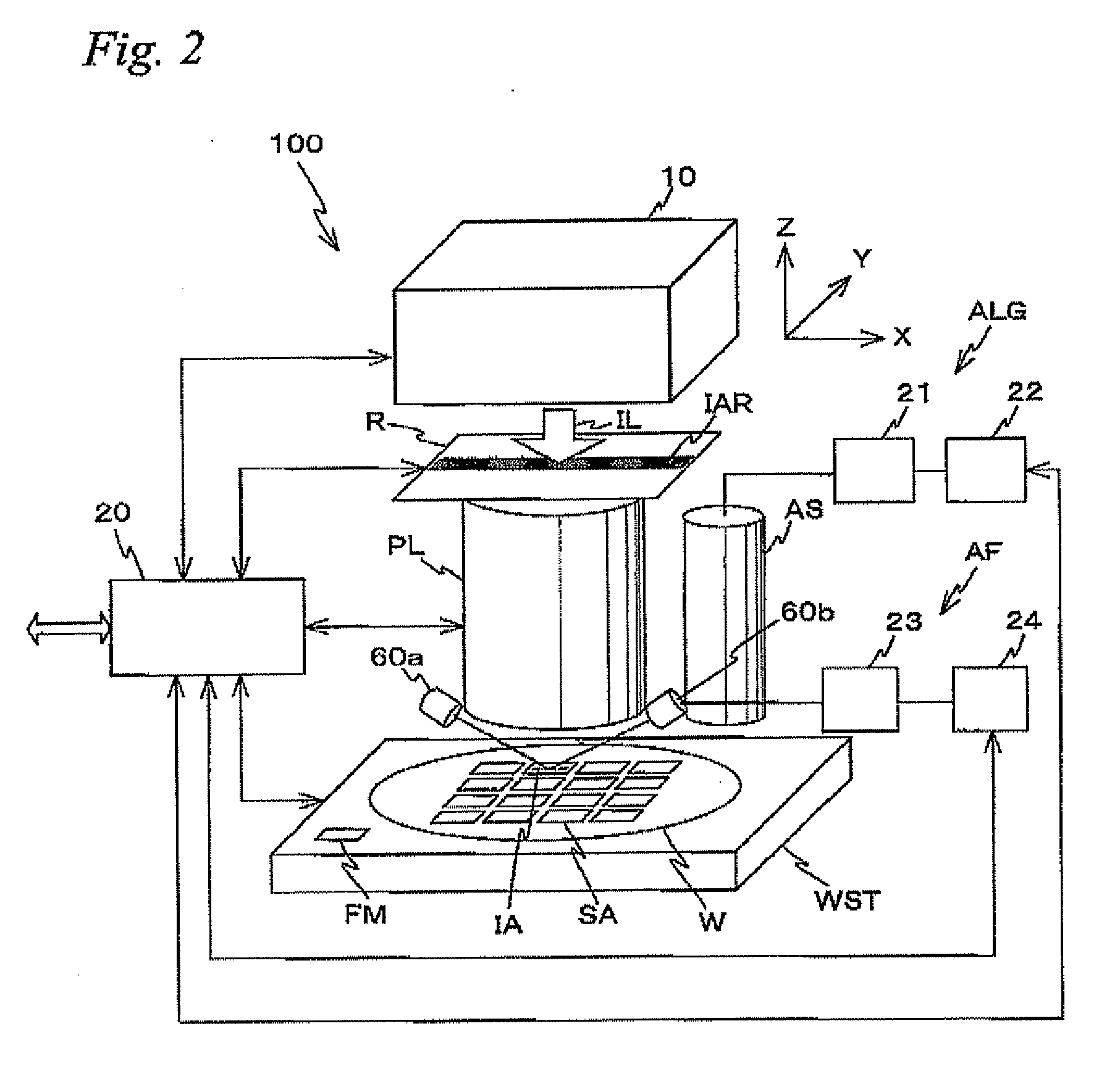

Device manufacturing method, device manufacturing system, and measurement/inspection apparatus

ActiveUS20090009741A1Semiconductor/solid-state device testing/measurementSolid-state devicesMeasurement deviceEngineering

In the case where measurement / inspection of a wafer is performed in a measurement / inspection instrument before and after exposure is performed in an exposure apparatus, various kinds of conditions of the exposure apparatus and the measurement / inspection instrument such as environment in the apparatus / instrument, a measurement condition of an alignment system a measurement condition of an AF measurement device, a wafer grid, and image distortion are made to be matched. In particular, in accordance with a processing state of the exposure apparatus and a coater developer, a measurement result of a film, and the like, exclusion of a mark for overlay error measurement, adjustment of the measurement condition and correction of the measurement result, adjustment of the environment, correction of the measurement result according to the environment, and adjustment of pattern defect inspection are performed. Further, in calibration processing, aberration of a projection optical system of an exposure apparatus that transfers a pattern on a wafer for calibration, and the like are also taken into consideration. Accordingly, the yield of device production can be improved.

Owner:NIKON CORP

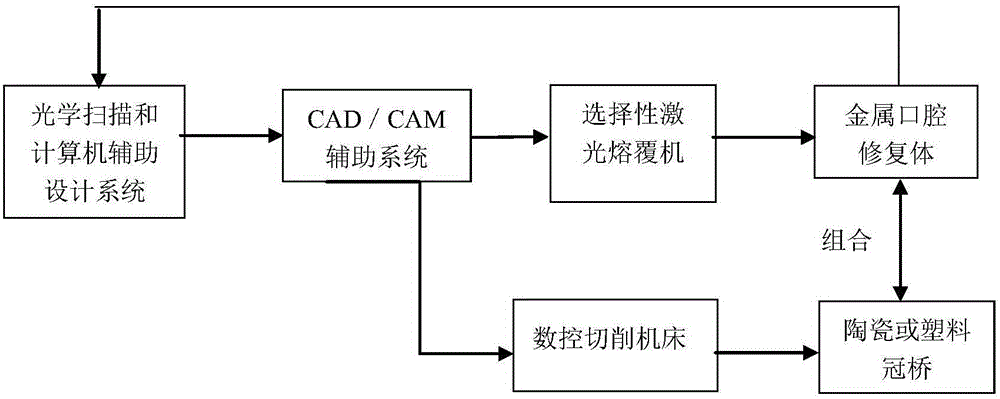

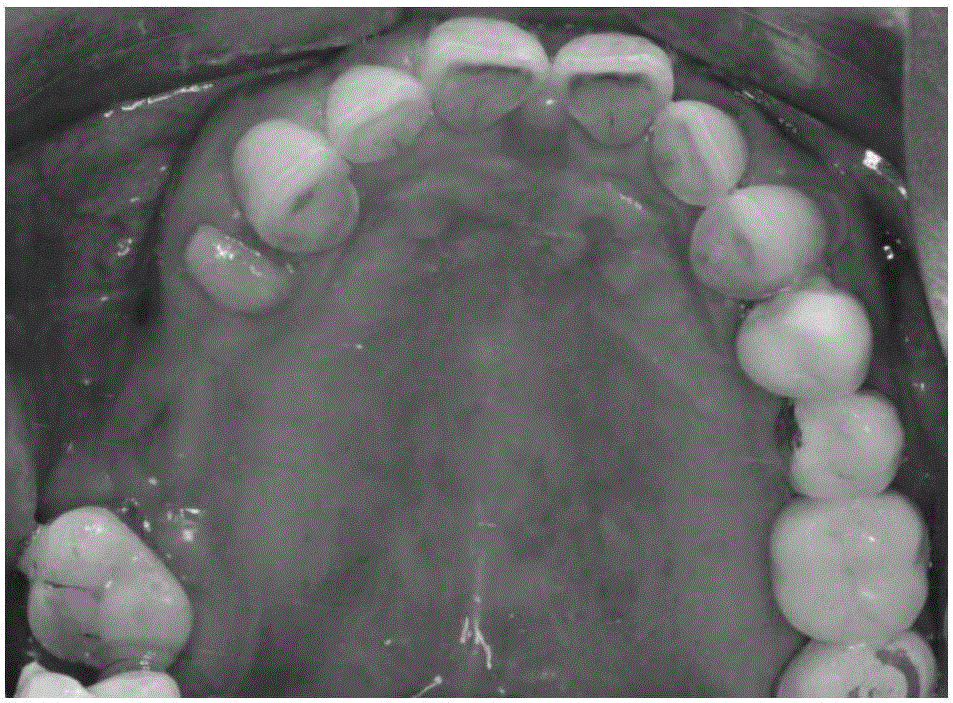

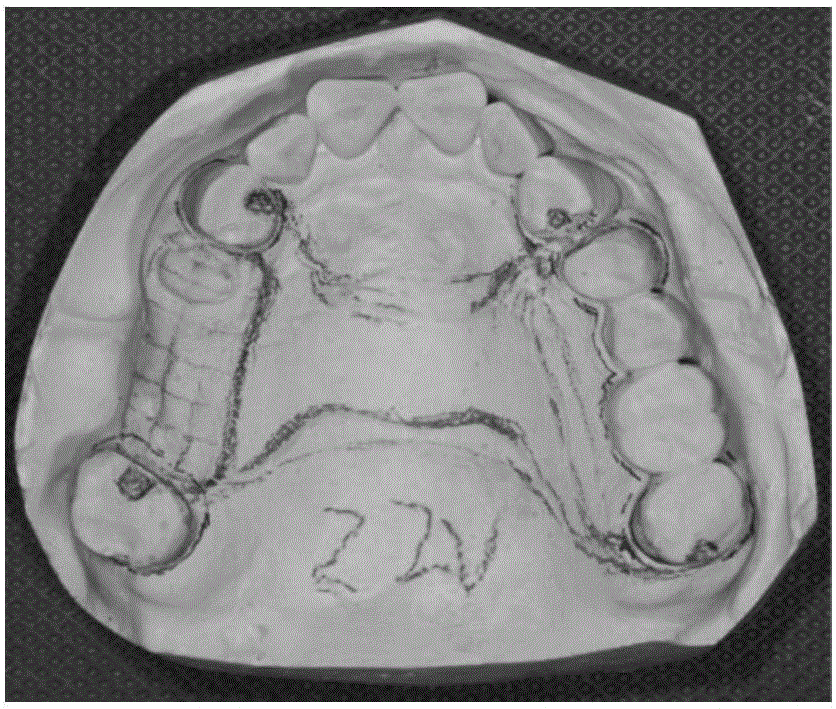

Automatic CAD/CAM/3D processing method of dental prostheses

The invention relates to an automatic CAD / CAM / 3D processing method of dental prostheses. The method comprises the step of processing dental prostheses by employing a composite system composed of an optical scanner and a computer aided design system, a CAD / CAM aided system, a selective laser cladding machine and a numerical control cutting machine tool, wherein prostheses such as removable partial dentures, fixed dentures, complete dentures and implant dentures can be rapidly manufactured. The method is characterized in that numerical control cutting (subtractive manufacturing called as subtraction) and the 3D printing technology (additive manufacturing called as addition) are organically combined and highly unified. Two aspects of the unity and opposites are merged into one uniform aspect; the automatic production efficiency of the dental prostheses, especially complex prostheses, can be greatly improved, complicated procedures of a conventional handmade dental prosthesis are eliminated, the manufacturing quality and stability of the prostheses are improved, the purposes of quickness, accuracy and individualized manufacturing are achieved, and the dental prostheses meet the urgent demands of most agomphosis patients.

Owner:维视医疗信息科技山东有限公司

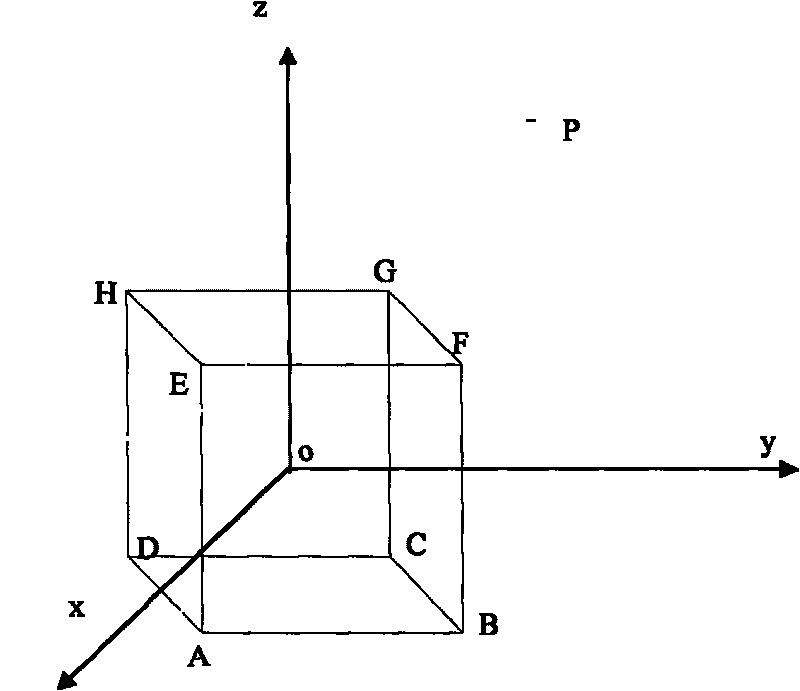

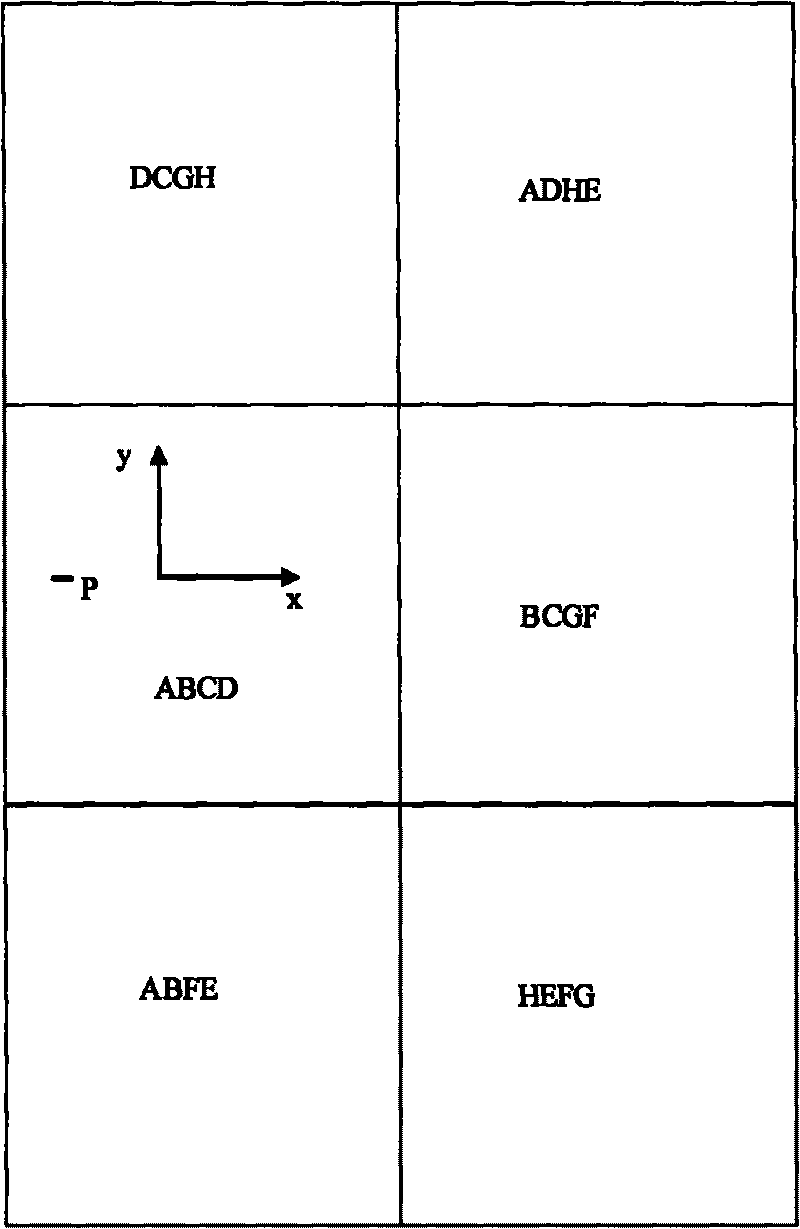

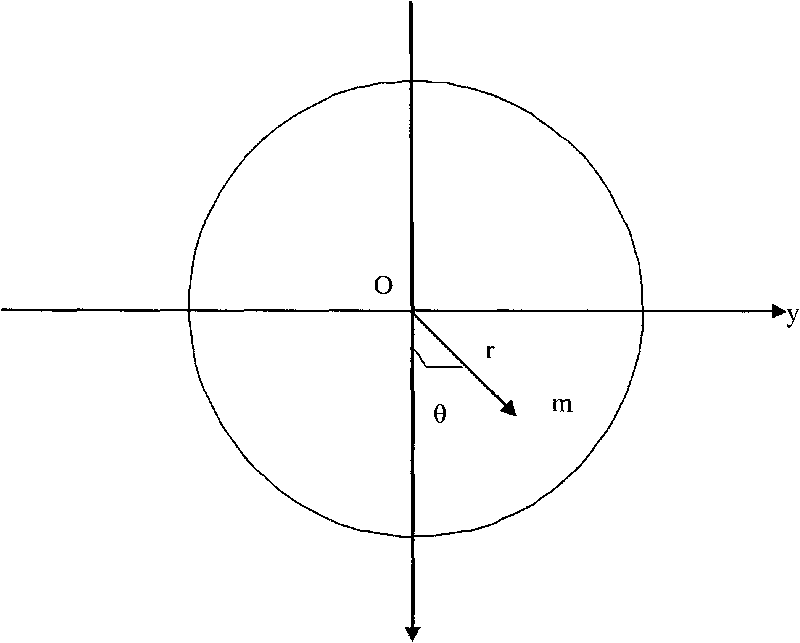

Correction method of fisheye image distortion on basis of cubic projection

InactiveCN101726855AOvercome geometric deformationIn line with intuitive feelingOptical elementsViewpointsFisheye lens

The invention belongs to the field of advanced manufacturing technology, relating to a correction method of fisheye image distortion on the basis of cubic projection. The correction method comprises the following steps: 1. using a fisheye lens to obtain an imaging model, and calibrating the fisheye lens according to the imaging model to obtain a calibration parameter; 2. according to the collected fisheye image, determining a viewpoint, taking the viewpoint as the original point of a coordinate system, and building a cubic perspective projection model to obtain the cubic perspective projection of a spatial point; 3. building a mapping relation between the cubic perspective projection of the spatial point and the fisheye image; and 4. using bilinearity interpolation to realize the distortion correction of the fisheye image. The invention utilizes a cubic projection model to correct distorted fisheye images and can effectively overcome the geometric distortion existing in the original fisheye images, and the corrected image conforms to the intuitional feeling of people and has strong sense of reality.

Owner:HEBEI UNIV OF TECH

Transistors Comprising High-K Metal Gate Electrode Structures and Embedded Strain-Inducing Semiconductor Alloys Formed in a Late Stage

ActiveUS20120025266A1Improve performance efficiencyImprove production efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsSemiconductor alloys

In sophisticated semiconductor devices, replacement gate approaches may be applied in combination with a process strategy for implementing a strain-inducing semiconductor material, wherein superior proximity of the strain-inducing semiconductor material and / or superior robustness of the replacement gate approach may be achieved by forming the initial gate electrode structures with superior uniformity and providing at least one cavity for implementing the strained channel regions in a very advanced manufacturing stage, i.e., after completing the basic transistor configuration.

Owner:GLOBALFOUNDRIES US INC

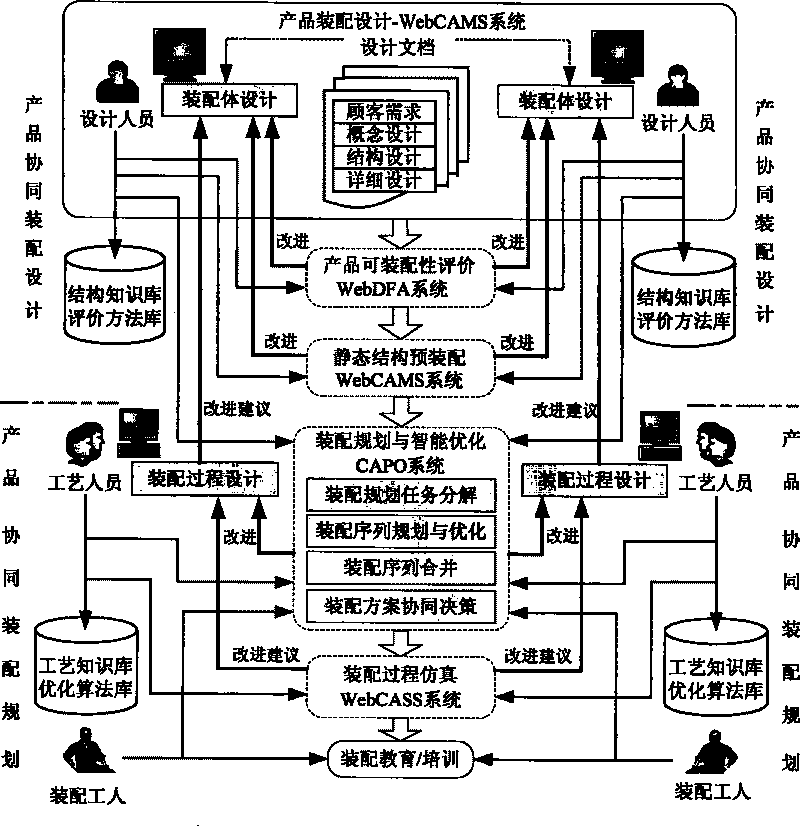

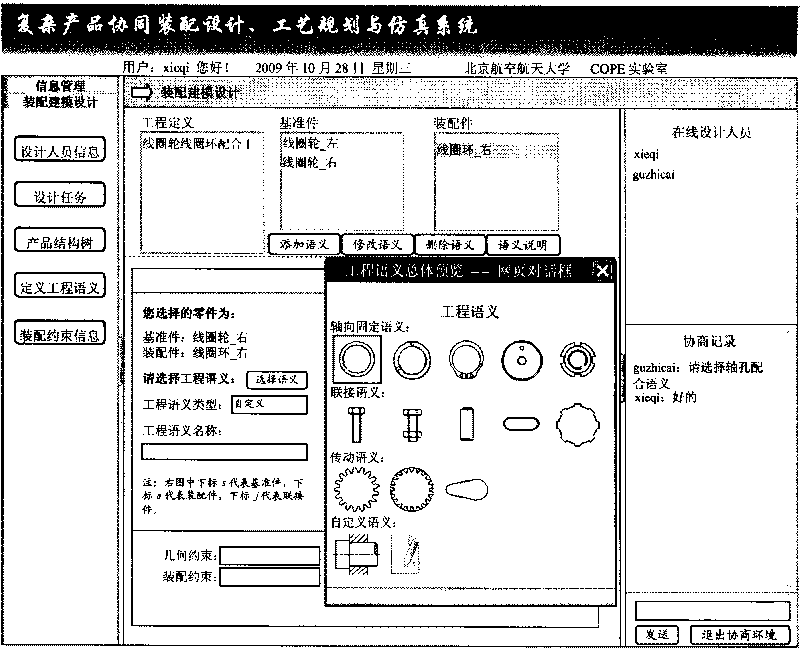

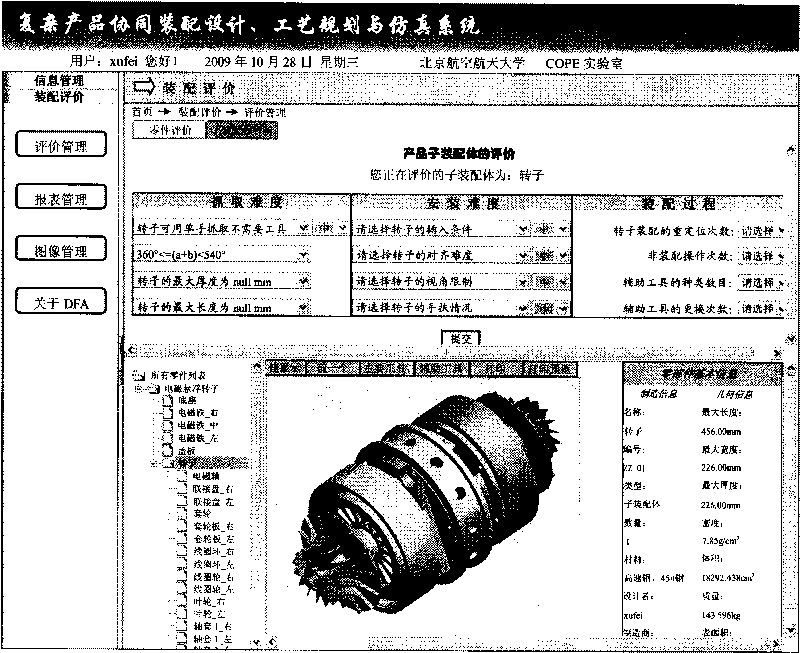

Integration method of collaborating assembly design, process planning and simulation verification of complicated product

The invention relates to an integration method of collaborating the assembly design, the process planning and the simulation verification of a complicated product, belonging to the research contents of a modern manufacture integration technology in the technical field of advanced manufacture. The invention provides technical methods and decision supports for remotely collaborating the assembly design, the analysis estimation, the planning optimization and the assembly process simulation of the complicated product, stimulates the organic integration of the assembly design and the assembly process, comprehensively utilizes a digital design and manufacture technology, a network technology and an artificial intelligence technology and provides the method for collaborating a human-computer collaboration working mode and a human-human collaboration working mode and collaborating the assembly design, the analysis estimation, the planning optimization the assembly simulation of the complicated product and finally realizes the multi-subject collaborative optimization design of the product-developing process. To a certain degree, the invention solves the problem of difficulty for collaborating and integrating the assembly design, the process planning and the simulation verification of the complicated product and provides an effective path for closely integrating the assembly design and the assembly process.

Owner:BEIHANG UNIV

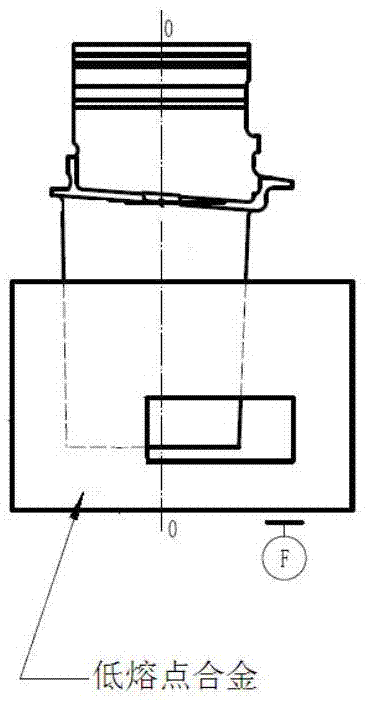

Machining method for turbine work blade

The invention discloses a machining method for a turbine work blade. The machining method for the turbine work blade aims to improve the production quality and production efficiency of the turbine blade and meet the machining and use requirements for the turbine work blade of an aero-engine. According to the technical scheme, the machining process comprises the steps of oil removing, precision positioning of the blade, wax filling, grinding of tenon teeth and the tooth exhaust side, wax removing, melting of low-melting-point alloy, pollutant removing, grinding of the bottoms of the tenon teeth, grinding of a marginal plate and the tooth air inlet lateral face, fluorescent inspection, comprehensive detection, machining of film holes, cleaning and storage. A five-axis numerical control creep feed grinder is adopted, the turbine work blade machining process with the advanced manufacturing technology is achieved, novelty, creativity and practicability are high, the process route is arranged reasonably, the production efficiency is high, the blade machining quality is high, the requirement for production of a large batch of turbine blades can be met, and the machining method can be widely used for machining turbine work blades of aero-engines.

Owner:AECC AVIATION POWER CO LTD

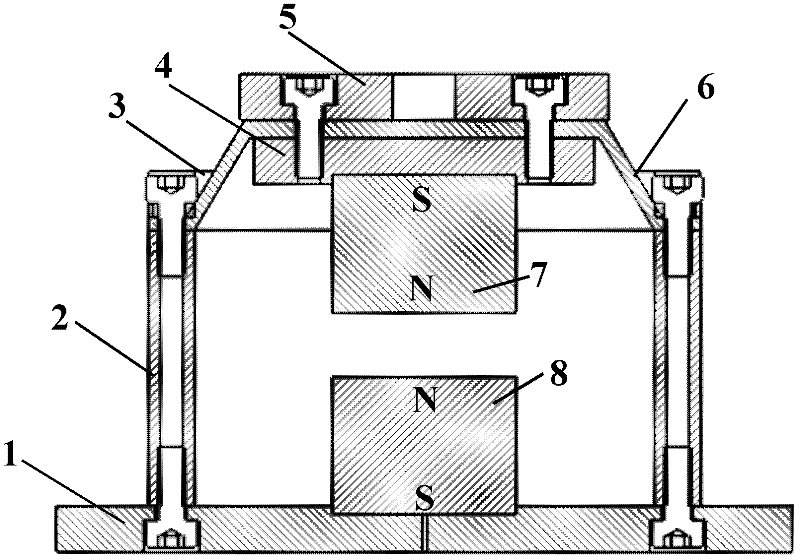

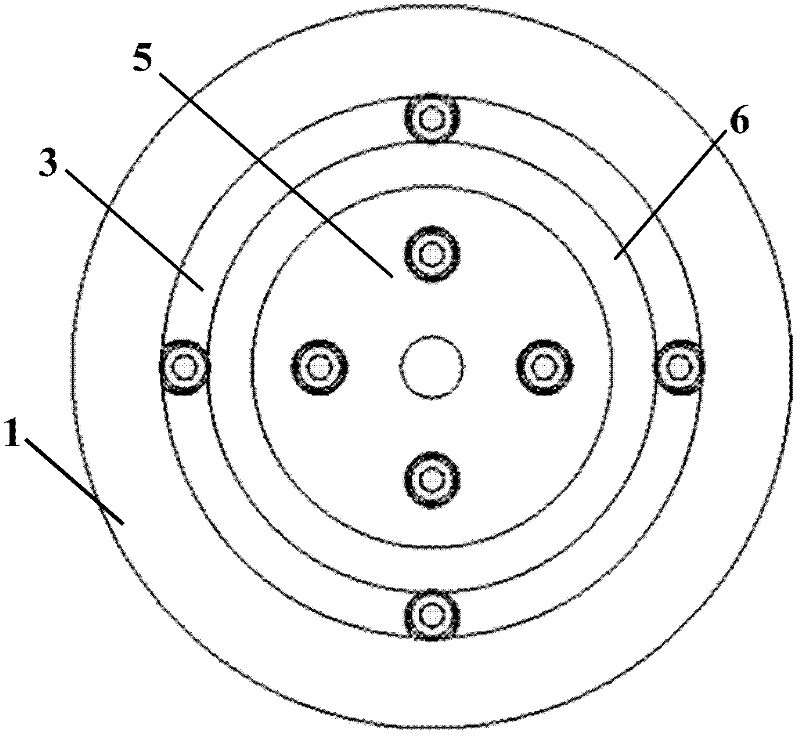

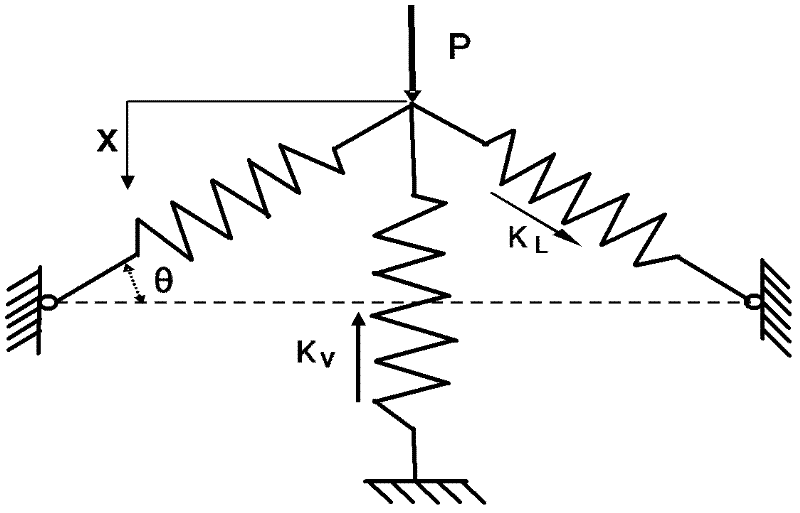

Permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on negative stiffness principle

InactiveCN102410337ASimple structureLow costNon-rotating vibration suppressionMagnetic springsExternal energyThree degrees of freedom

A permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on the negative stiffness principle comprises a lower permanent magnet, an upper permanent magnet, a rubber sheet, a lower permanent magnet fixing plate, a rubber fixing seat, an upper permanent magnet fixing plate, a rubber pressure block and a rubber sheet edge fixing pressure ring, wherein the permanent magnets are magnetized in the vertical direction and opposite for same poles. A positive stiffness system is formed by the permanent magnets under the action of repulsive force, the rubber sheet is stretched to a negative stiffness system under the action of repulsive force of the permanent magnets, two systems are combined to form a low-frequency vibration isolation mechanism, the single vibration isolation mechanism can realize three degrees of freedom low-frequency vibration isolation, and three or four systems are combined in parallel to realize the six degrees of freedom low-frequency vibration isolation. The vibration isolation mechanism can be used in vacuum without the input of external energy. The vibration isolation mechanism has the characteristics of simple structure, low cost and easy processing, and can be used in the fields like optics, acoustics, biology, advanced manufacturing equipment, semiconductor manufacturing and precision measurement, etc.

Owner:TSINGHUA UNIV

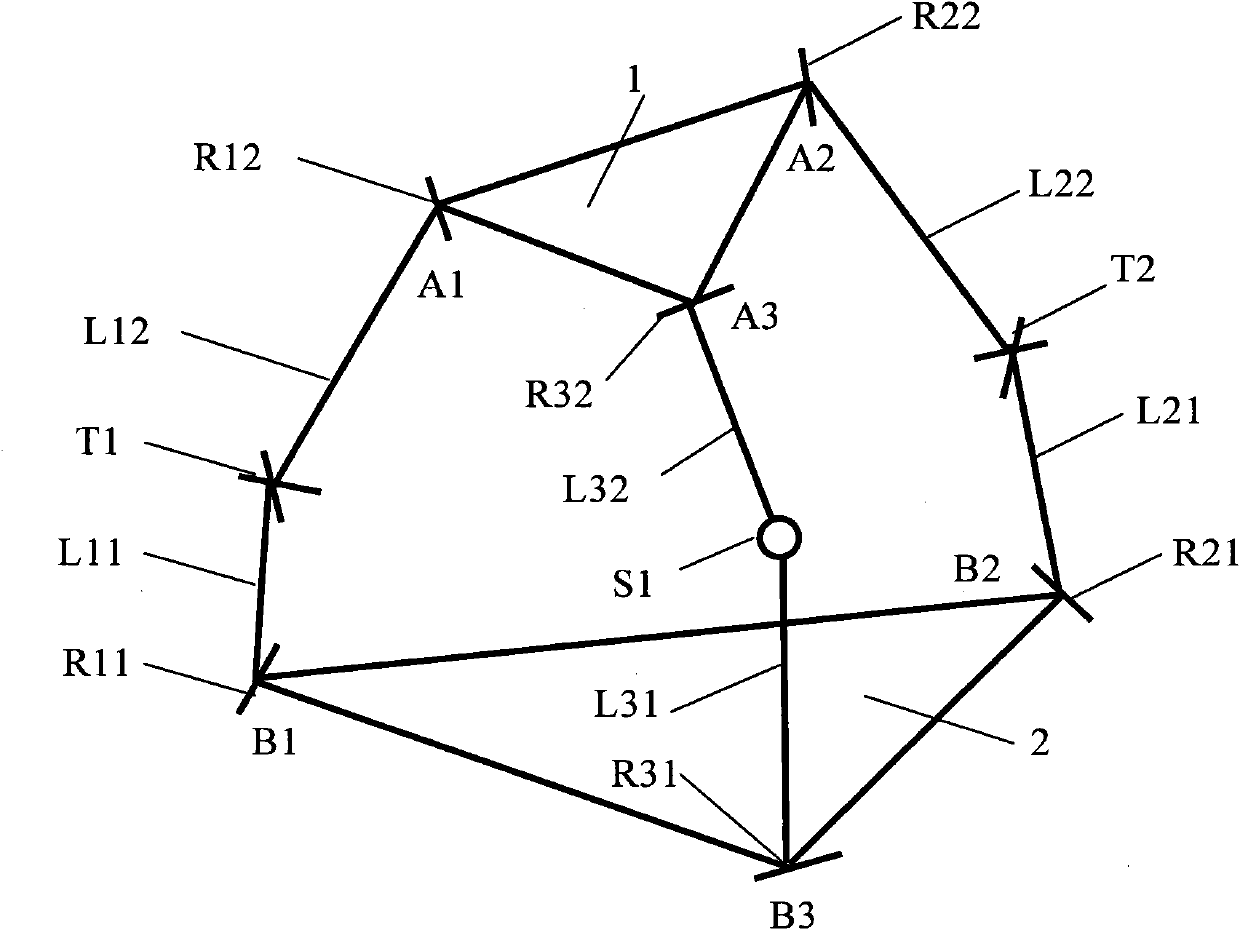

Three-translation spatial parallel robotic mechanism

InactiveCN101905458AFew jointsSmall inertiaProgramme-controlled manipulatorThree degrees of freedomKinematic pair

The invention discloses a three-translation spatial parallel robotic mechanism, and relates to the technical fields of robots and advanced manufacturing, in particular to a spatial three-degrees-of-freedom parallel robotic mechanism capable of realizing spatial three-translation. The mechanism consists of a moving platform, a fixed platform and three branched chains for coupling the two platforms, wherein two branched chains are respectively composed of a revolute joint, a hooke joint and a revolute joint from the moving platform to the fixed platform, and connecting rods among the joints; and the other branched joint is composed of a revolute joint, a ball joint and a revolute joint from top to bottom, and connecting rods among the joints. The working platform of the mechanism can realize three-dimensional translational motion output under Cartesian coordinates; and the mechanism has a few joints, and the total number of the degrees of freedom of kinematic pairs is only 13, so that the mechanism can effectively solve the problems of easy deflection and torsional deflection of the parallel mechanism due to excessive degrees of freedom of the kinematic pairs. The three driving pairs (revolute joints) of the mechanism are directly connected with the fixed platform, so the motion inertia of the mechanism is greatly reduced, and the high-speed motion of the mechanism can be realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

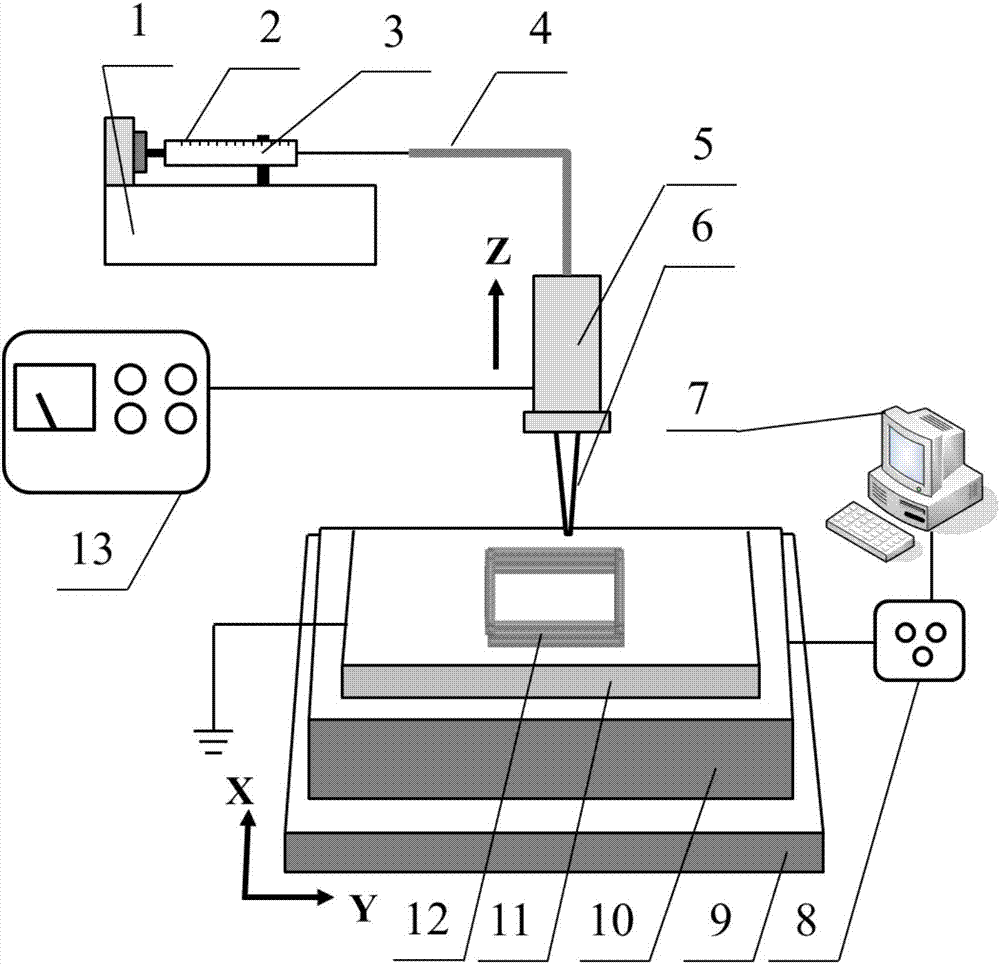

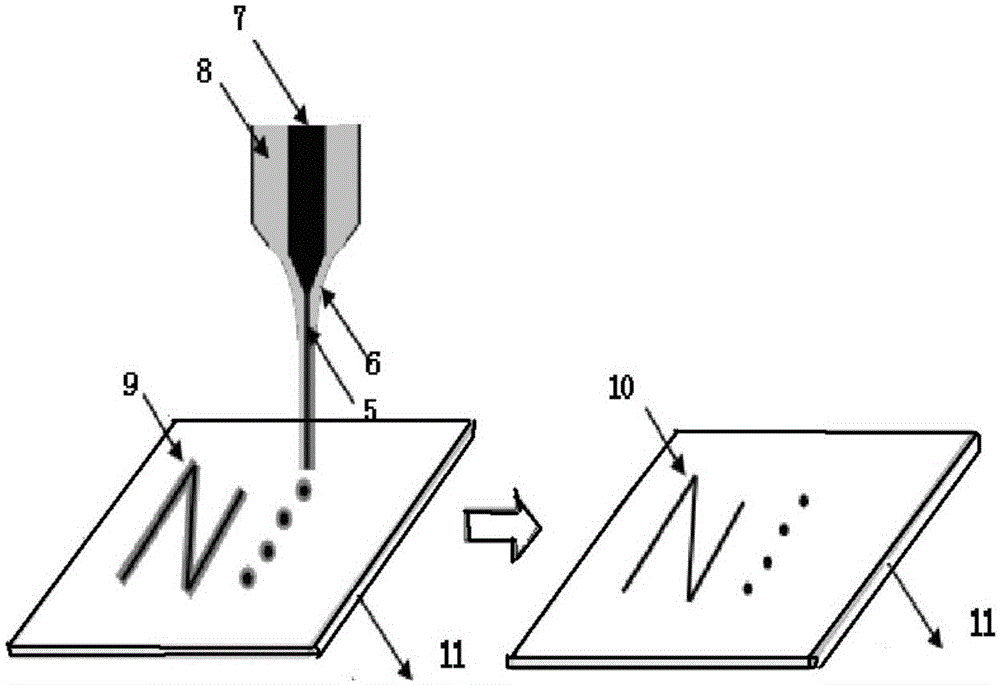

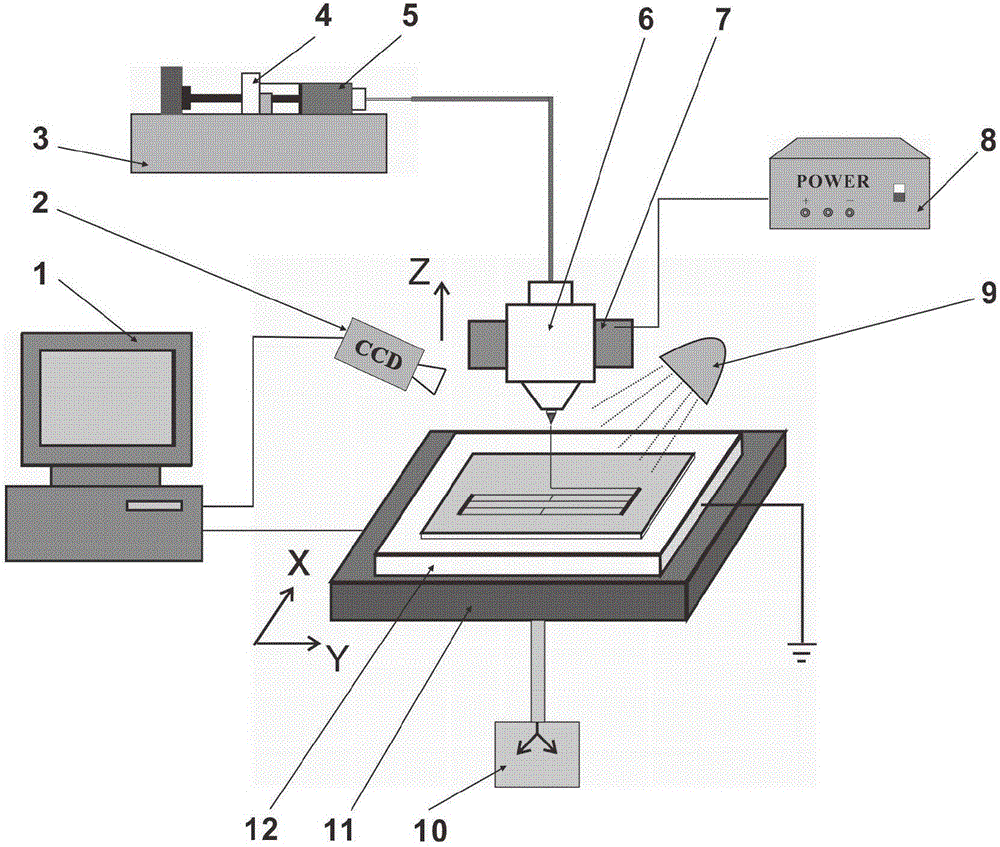

Electrojet 3D printing device and method based on combination of electric field and heat field

ActiveCN107053653AAdaptableManufacturing driving meansManufacturing heating elementsMicro nanoEngineering

The invention belongs to the technical field of advanced manufacturing, and relates to an electrojet 3D printing device and method based on the combination of an electric field and a heat field. According to the method, in the process of electrojet 3D micro-nano printing under the combined action of the electric field and the heat field, ink reaches an opening of a spray needle at the constant flow speed under the combined action of the fluid field and the gravity field, then the ink is drawn through electric field shear force between the spray needle and a substrate so as to form stable micro-nano flow with the size far smaller than the size of a spray hole, a solvent in the ink is promoted to evaporate in an accelerated mode through the heat radiation effect of the heat field on the ink, and finally jet flow is stacked on the substrate layer by layer, so that a 3D structure with the micro-nano dimension is formed. Compared with a drop-jet type printing technique, the electrojet 3D printing method based on the combination of the electric field and the heat field has the advantages that the material adaptability is high, and complex micro-nano 3D structures can be manufactured.

Owner:DALIAN UNIV OF TECH

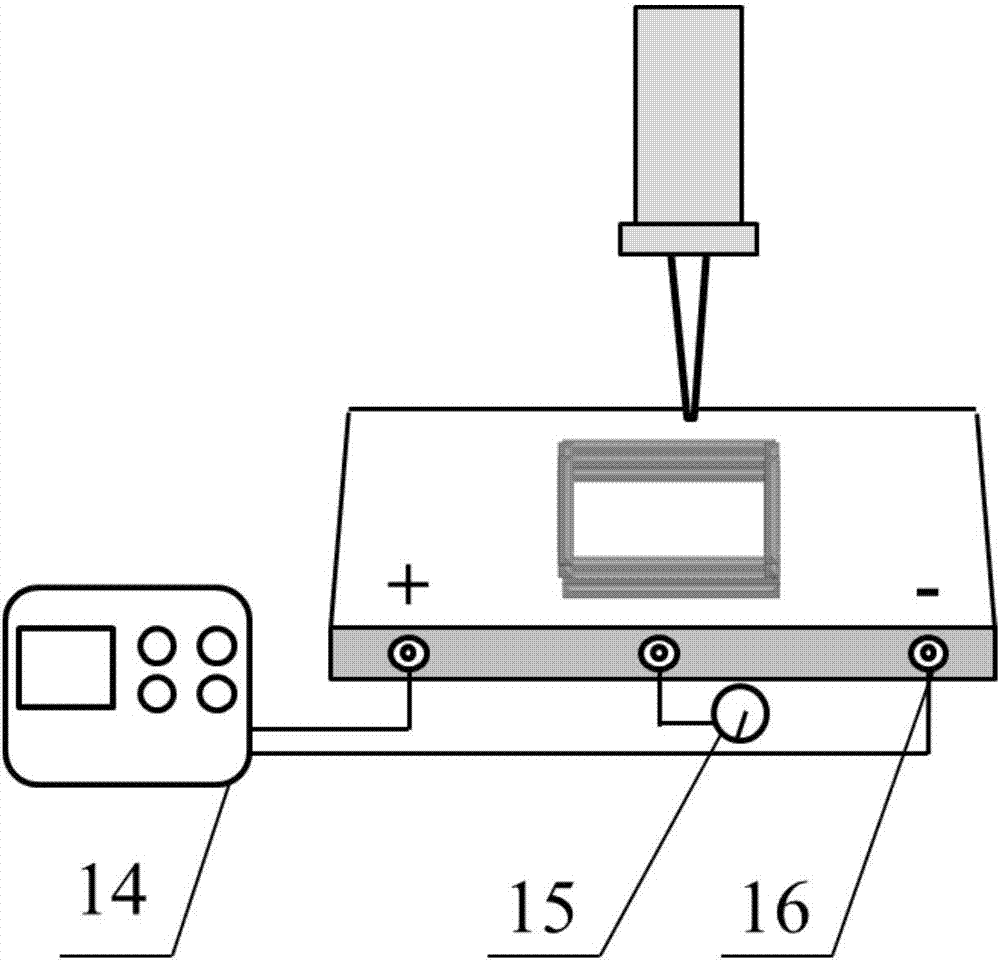

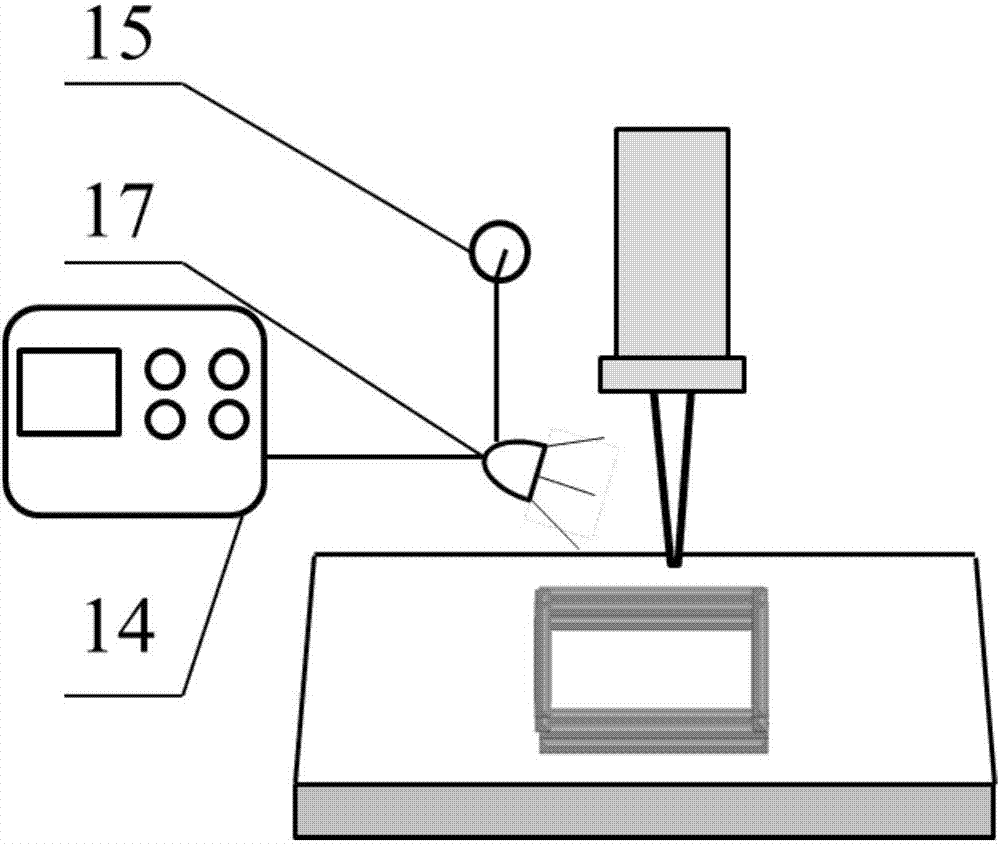

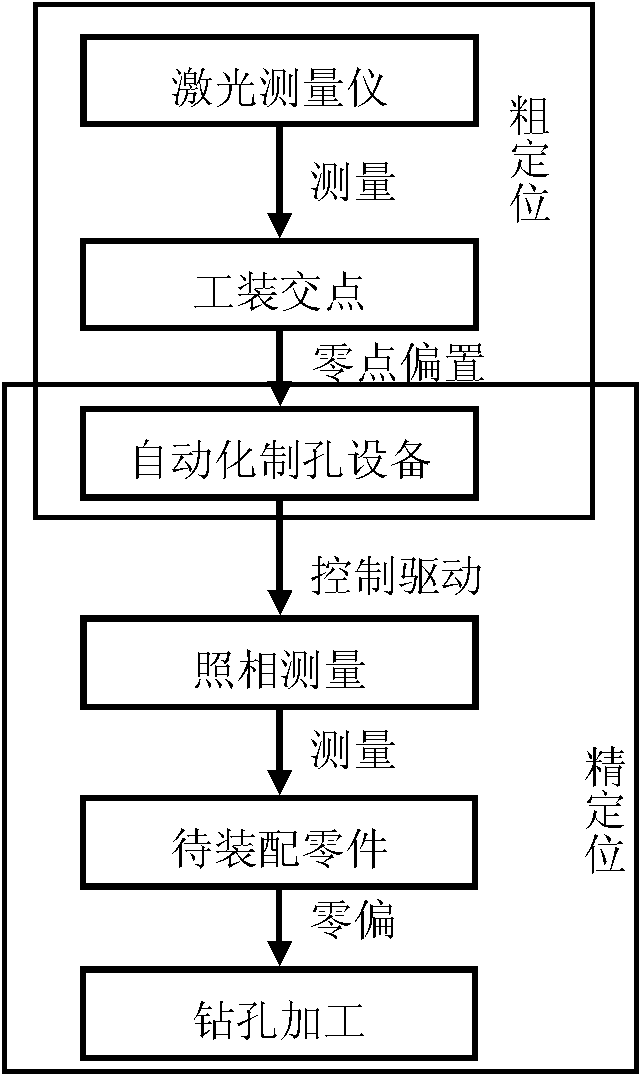

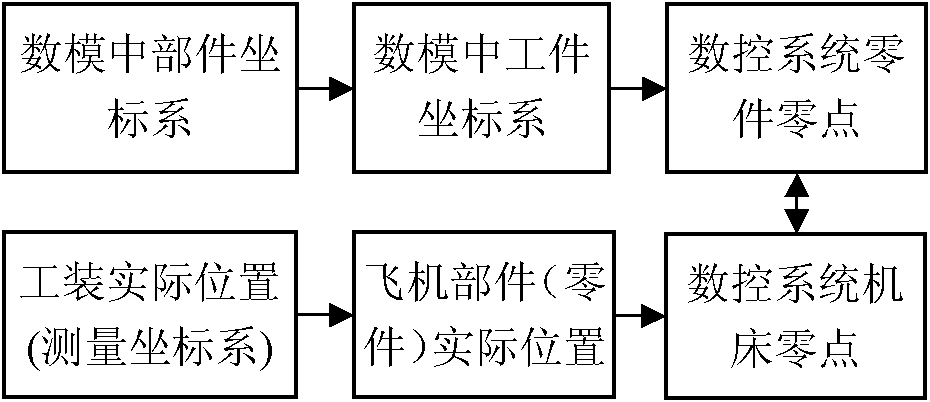

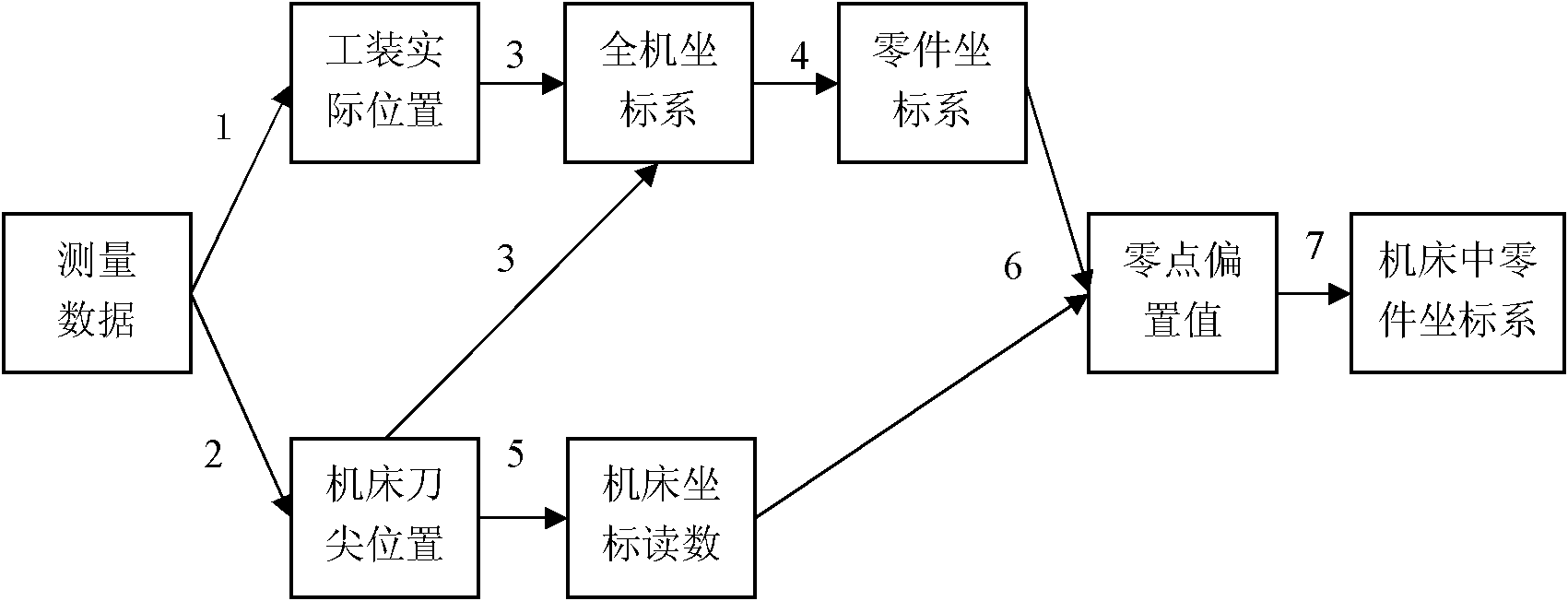

Hybrid measurement positioning method of part to be assembled in flexible assembly of airplane components

InactiveCN102416581AGive full play to the advantagesPrecise positioning methodMeasurement/indication equipmentsAutomatic test equipmentManufacturing technology

The invention discloses a hybrid measurement method for positioning a part to be assembled in the flexible assembly process of airplane components, belonging to the research contents of modern manufacturing technology in the field of advanced manufacturing technology. The method is a measurement positioning method for establishing a relative positional relationship between automatic hole making equipment and the part to be assembled in the flexible assembly process of the airplane components. The method adopts a laser measurement apparatus as a rough positioning means of the hole making equipment and adopts photographing measurement equipment as a means of accurately positioning the part to be assembled, and realizes accurate positioning of the part to be assembled by two steps. Through the method, the problem of incoordination between the automatic hole making equipment and a workpiece to be assembled resulting from excessive error accumulation of the assembly process in the flexible assembly process of the airplane components is solved to a certain degree, and an effective means of using automatic equipment in the flexible assembly of the airplane components is provided.

Owner:BEIHANG UNIV

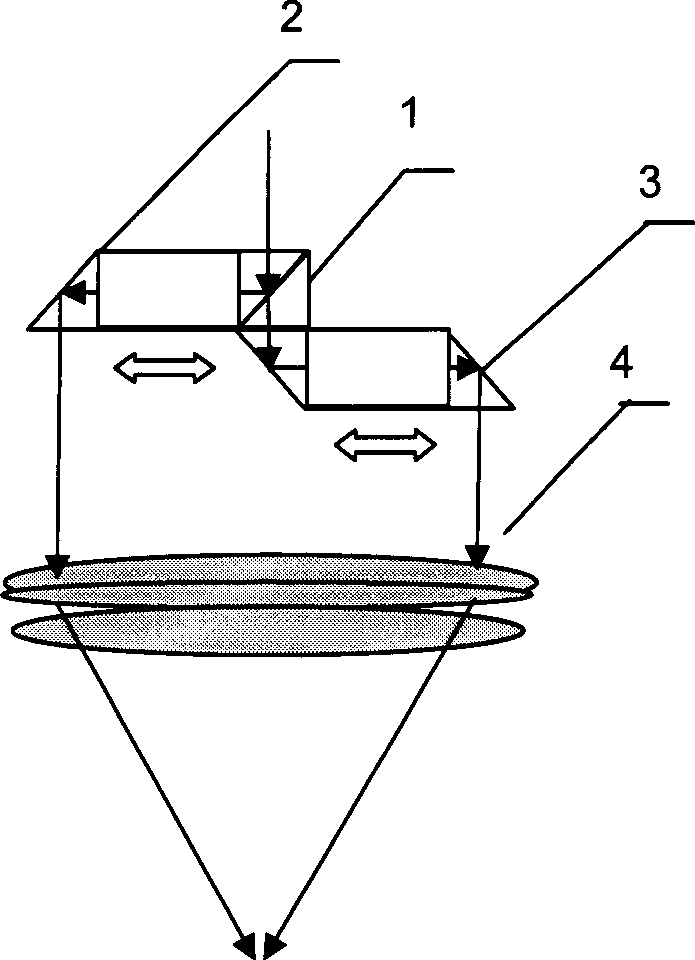

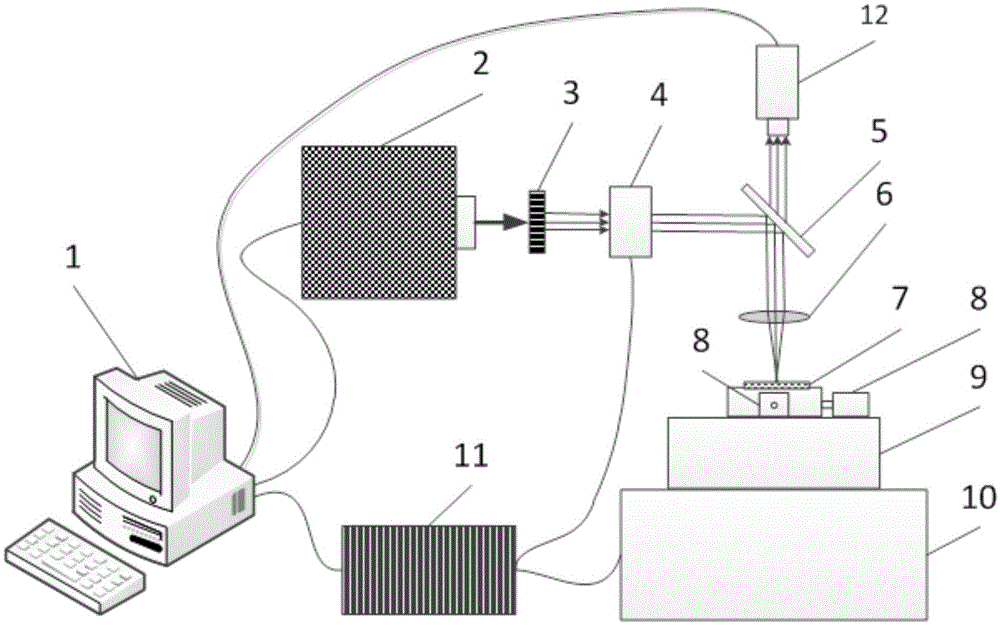

Method and system for high speed laser directly writing of diffraction light change image

ActiveCN1786748ADistance controlEasy to adjustDiffraction gratingsNon-linear opticsGratingBeam splitting

The invention relates to diffracted light image changing high speed laser write through method. It includes the following steps: do electrostatic image for incidence parallel light reaches beam-splitting element though diaphragm; gathering the beam-slitting light to produce interference fringe optical field; orderly photoengraving interference fringe with different trend to form micro light grating image. Its features are that it is adopted solid state ultraviolet laser to produce laser beam; and it is used TTL signal control to realize laser beam pulse output; the two sets of the laser beam have zero optical path difference; optical system and photoresist dry plate are moved on two one dimension directions which are vertical with each other; photolithography is adopted continual motion, continual pulse exposing type. Thus the invention realizes high speed laser write through photolithography system to make diffracted light changing image original edition manufacturing shorten between many hours to seventeen hours. It really enters industrialization application period, and is the important breakthrough of digitalization advanced manufacturing technique in laser holographic technique field.

Owner:SUZHOU UNIV +1

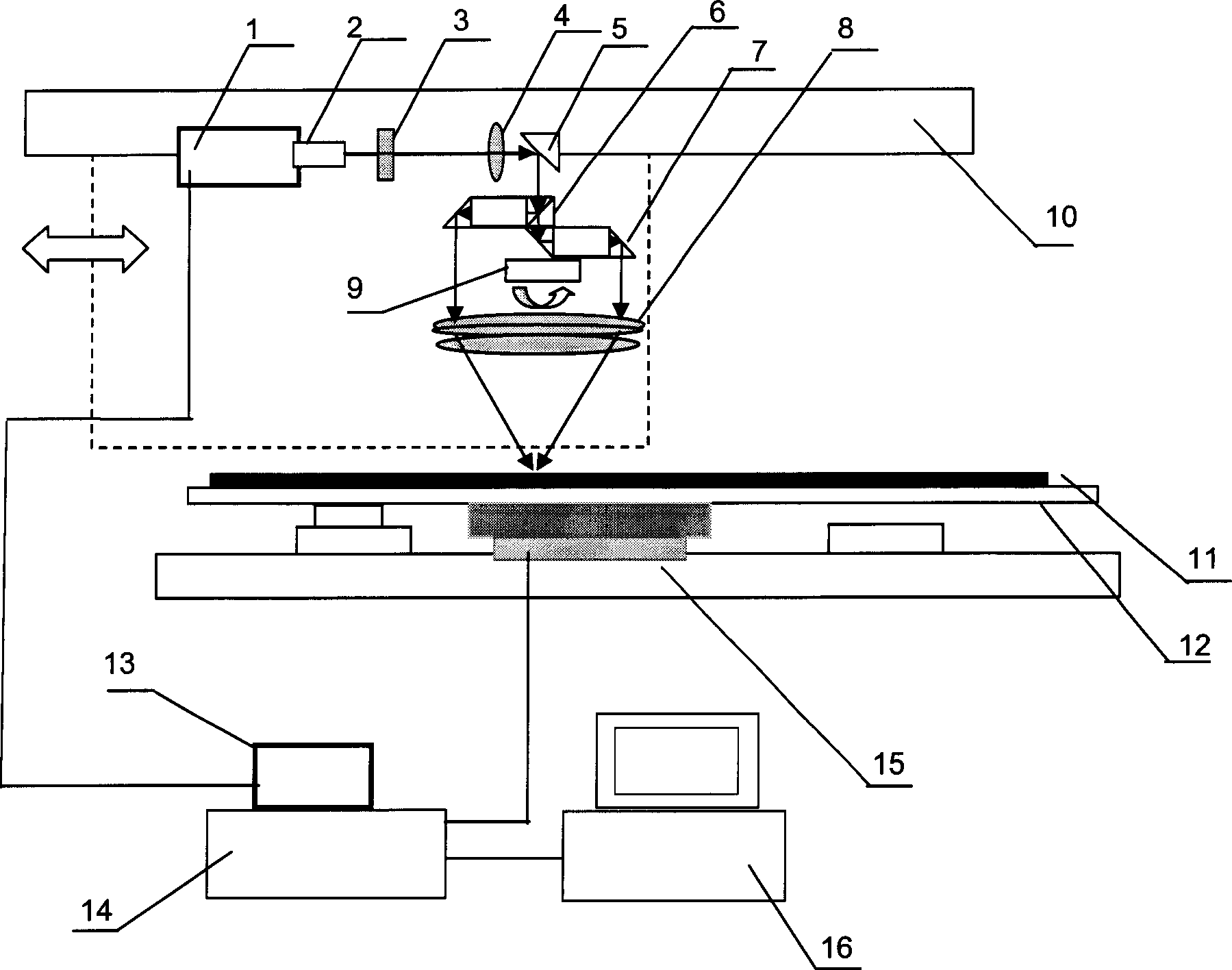

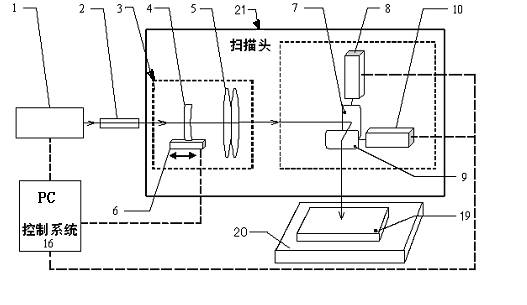

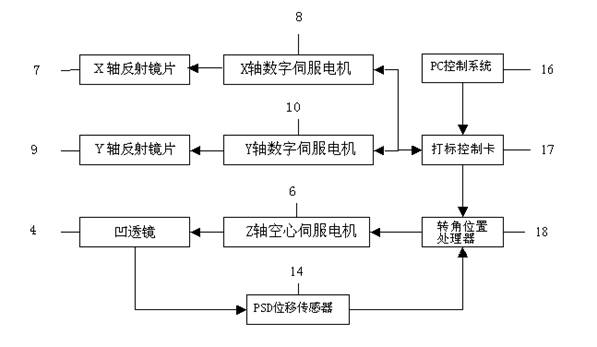

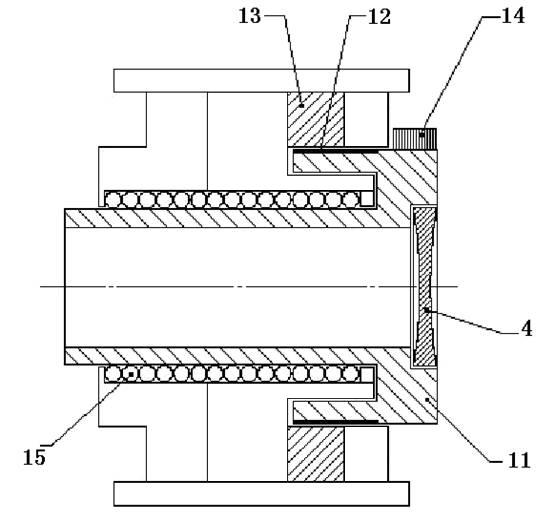

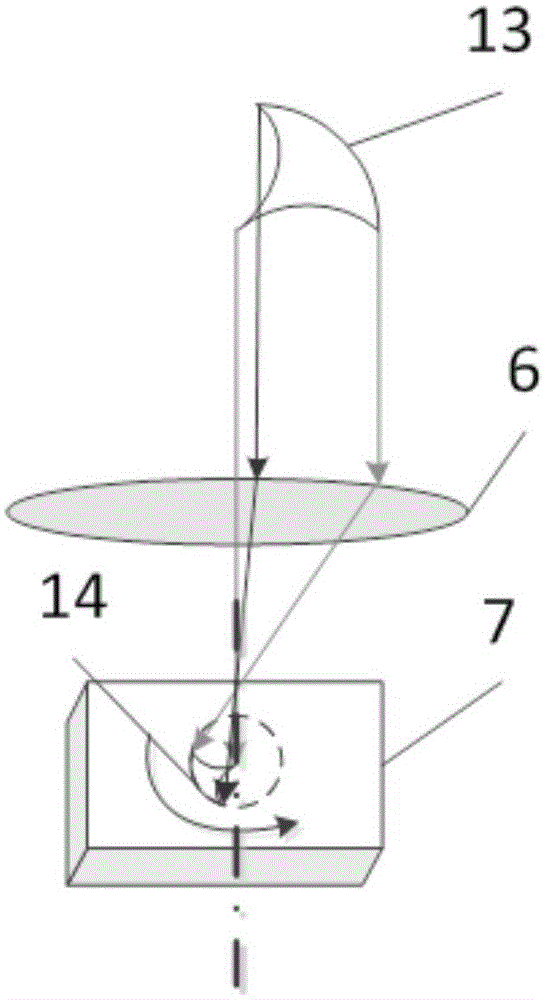

System and method for processing dynamic focusing scanning spot track of optical fiber laser or disk laser

InactiveCN101913024AQuality improvementImprove efficiencyLaser beam welding apparatusElectric machineLaser scanning

The invention discloses a system and a method for processing dynamic focusing scanning spot track of optical fiber laser or disk laser. Aiming at the defects in scanning technology of the current laser scanning welding system, an optical fiber laser or a disk laser, a PSD displacement sensor, and a dynamic focusing fast scanning head driven by a high-accuracy hollow-shaft linear motor are adopted for implementing loop closing and real-time control of a dynamic focusing module, in order to perform spot scanning processing of fast spot track on workpiece. The system and the method have the advantages of large processing scope, high quality, fast welding or spotting speed and high efficiency, in addition, accuracy and welding quality of the system are enhanced effectively, 3D welding can be realized, and extensive application value in the field of advanced manufacture is achieved.

Owner:SHANGHAI INST OF LASER TECH

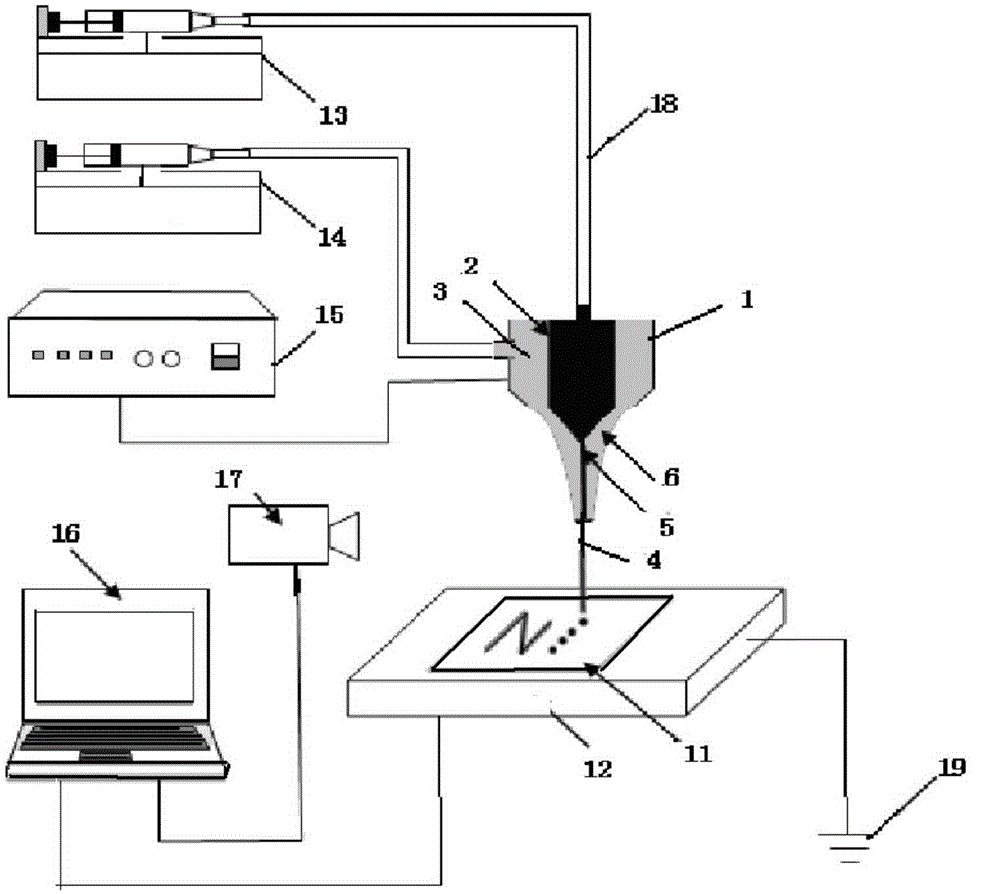

Coaxial focusing electro stream printing method

ActiveCN105058786AAdaptableStrong interferenceAdditive manufacturing apparatusJet flowMicrometer scale

The invention relates to a coaxial focusing electro stream printing method, belongs to the technical field of advanced manufacture and relates to a coaxial focusing electro stream printing method. According to the method, in the coaxial focusing electro stream printing process, two kinds of liquid are contained in a coaxial focusing electro stream printing nozzle, one kind of the liquid is a required forming material called inner function liquid, and the other kind of the liquid is an auxiliary material called outer liquid; the outer liquid and the inner function liquid are not dissolved mutually, and the viscosity of the outer liquid is larger than that of the inner function liquid. The coaxial focusing electro stream printing nozzle forms coaxial focusing jet flow with the two layers of liquid during printing and prints a bi-layer structure on a substrate; and finally, an outer printing material is removed to obtain an inner function structure. The method has the characteristics of being high in printing resolution, material adaptability and microenvironment disturbance resistance and is capable of achieving high-resolution patterned printing through a spray needle of micrometer scales at normal temperatures and pressures.

Owner:DALIAN UNIV OF TECH

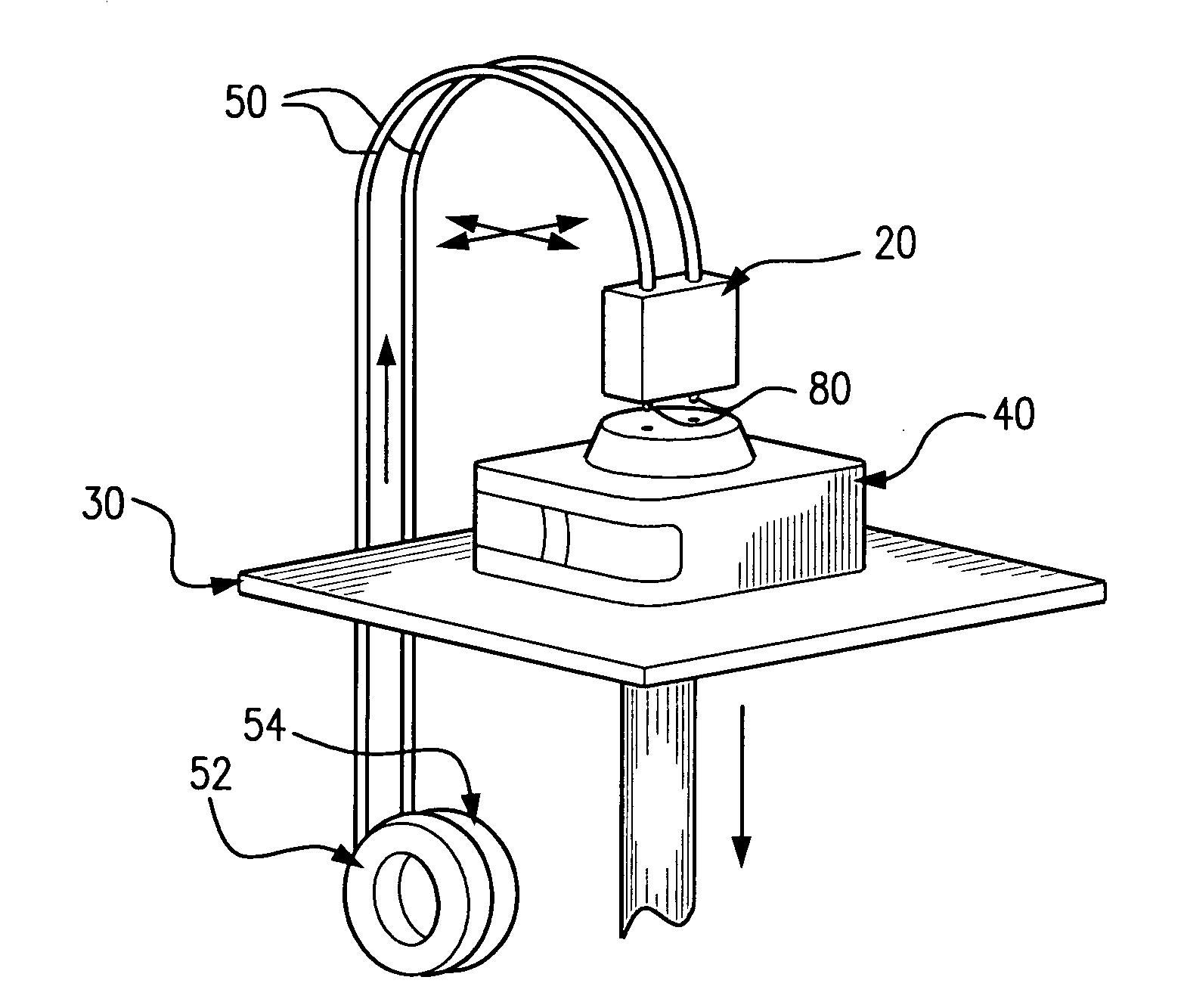

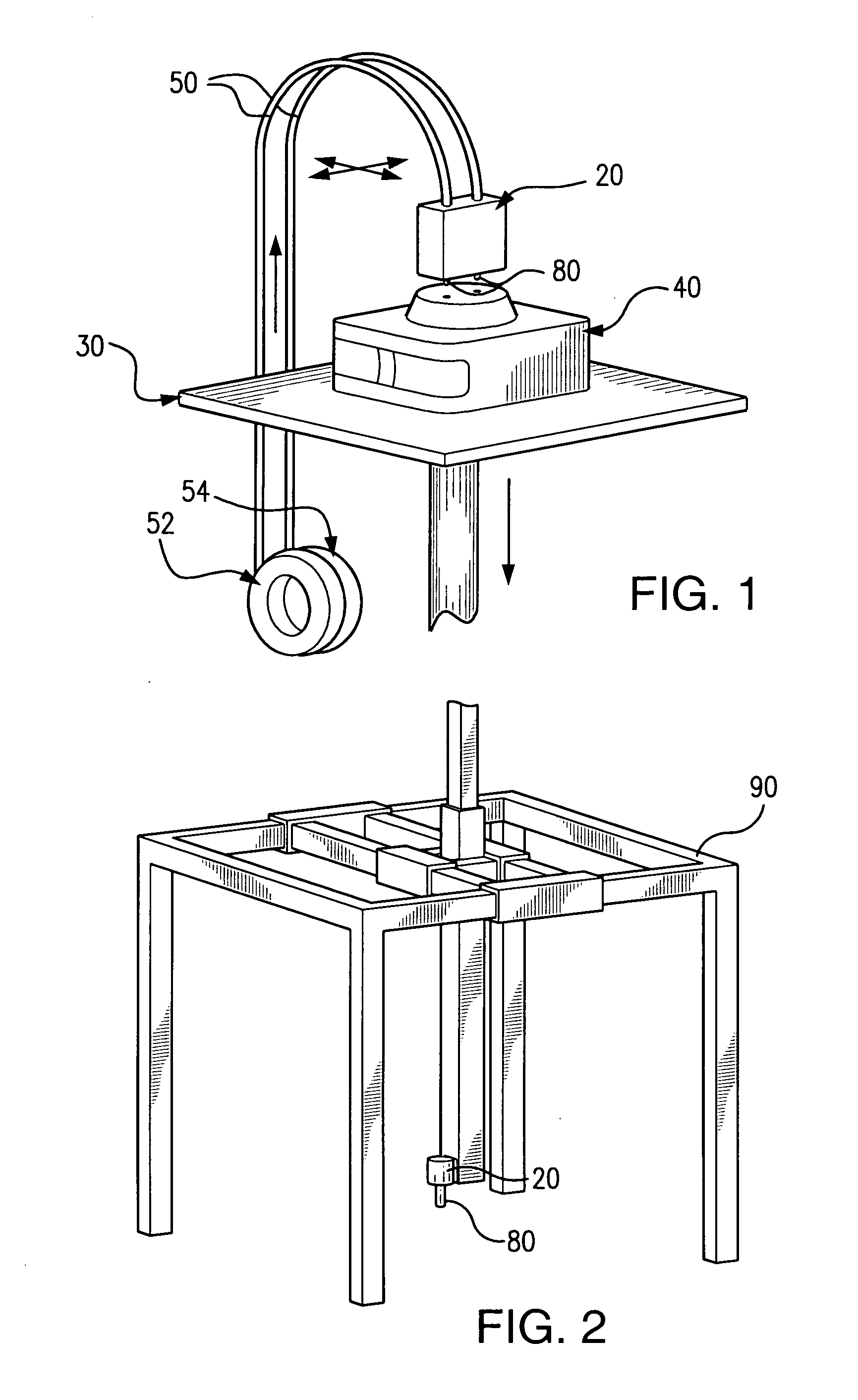

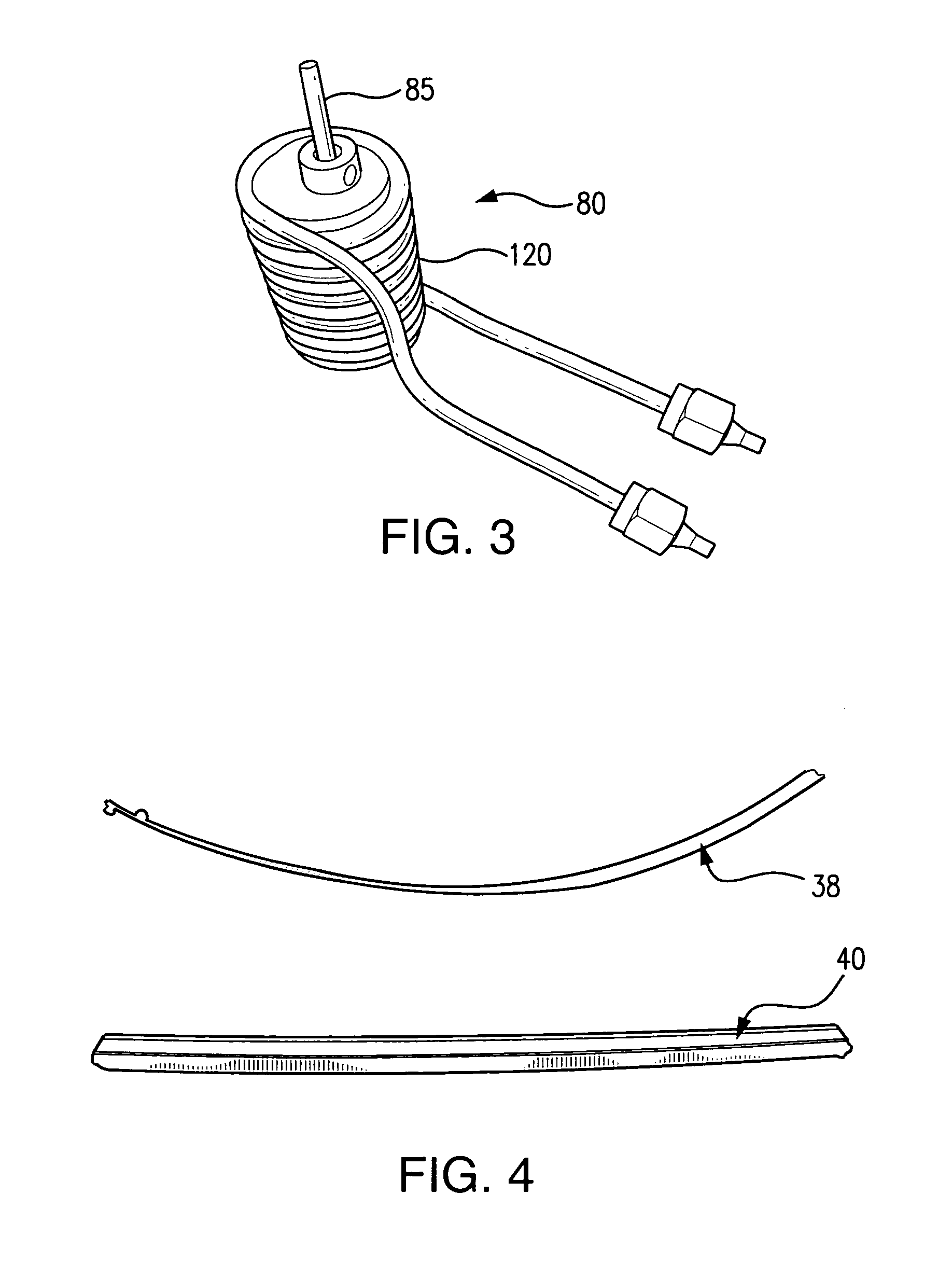

Large scale room temperature polymer advanced manufacturing

InactiveUS20150183159A1Aid in structural stabilityHigh strengthAdditive manufacturing apparatusMouldsAtmospheric temperatureRoom temperature

A manufactured component, method and apparatus for advanced manufacturing that includes a nozzle for extruding a working material, wherein the polymeric working material includes a carbon fiber reinforced polymer. The build of the component takes place on a work surface at atmospheric temperatures.

Owner:UT BATTELLE LLC

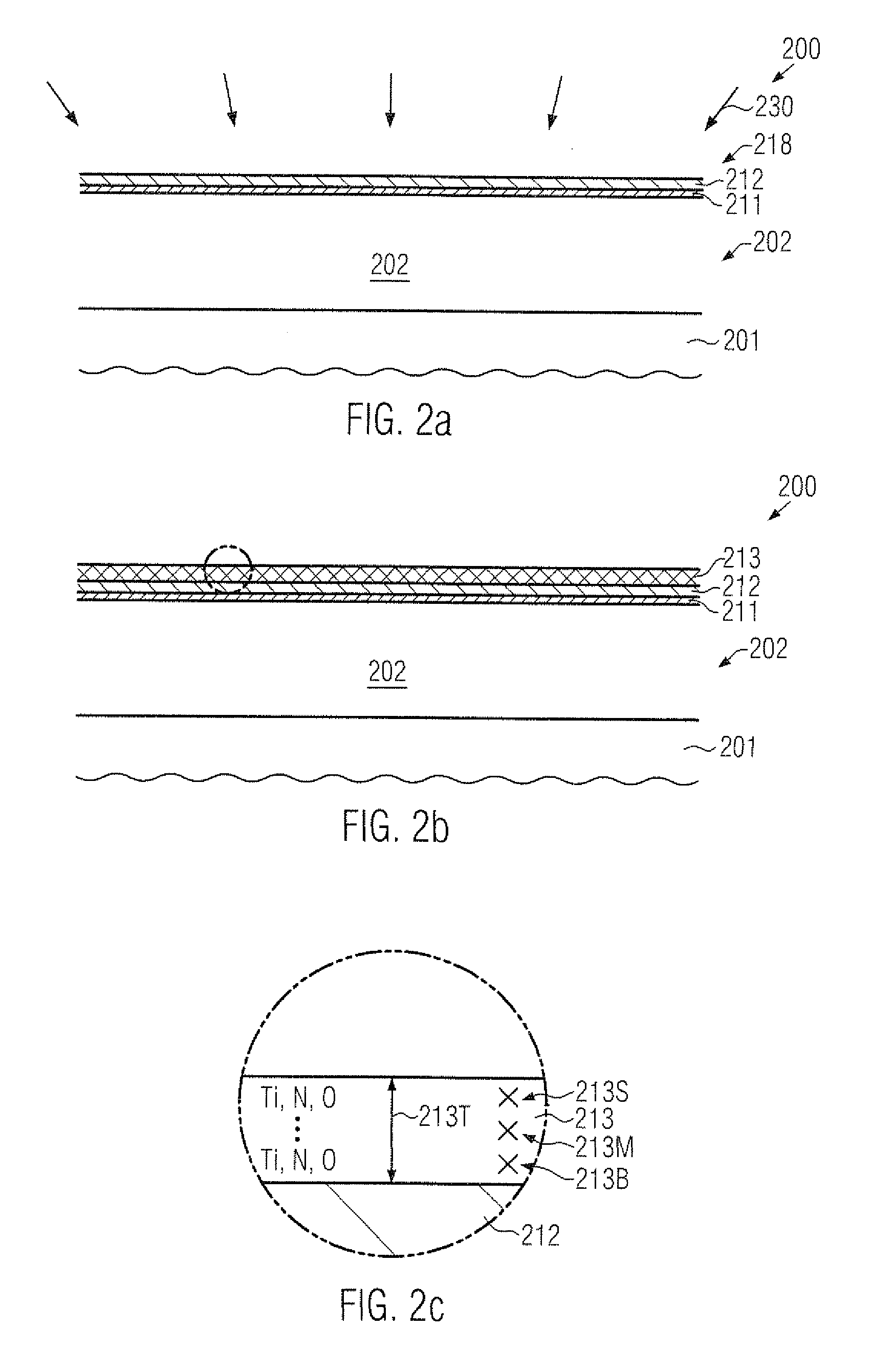

Increasing stability of a high-k gate dielectric of a high-k gate stack by an oxygen rich titanium nitride cap layer

InactiveUS20110127590A1Improve stabilityReduce amountSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

In a replacement gate approach, the oxygen contents of a cap material may be increased, thereby providing more stable characteristics of the cap material itself and of the high-k dielectric material. Consequently, upon providing a work function adjusting metal species at a very advanced manufacturing stage, corresponding additional treatments may be reduced in number or may even be completely avoided, while at the same time threshold voltage variations may be reduced.

Owner:GLOBALFOUNDRIES INC

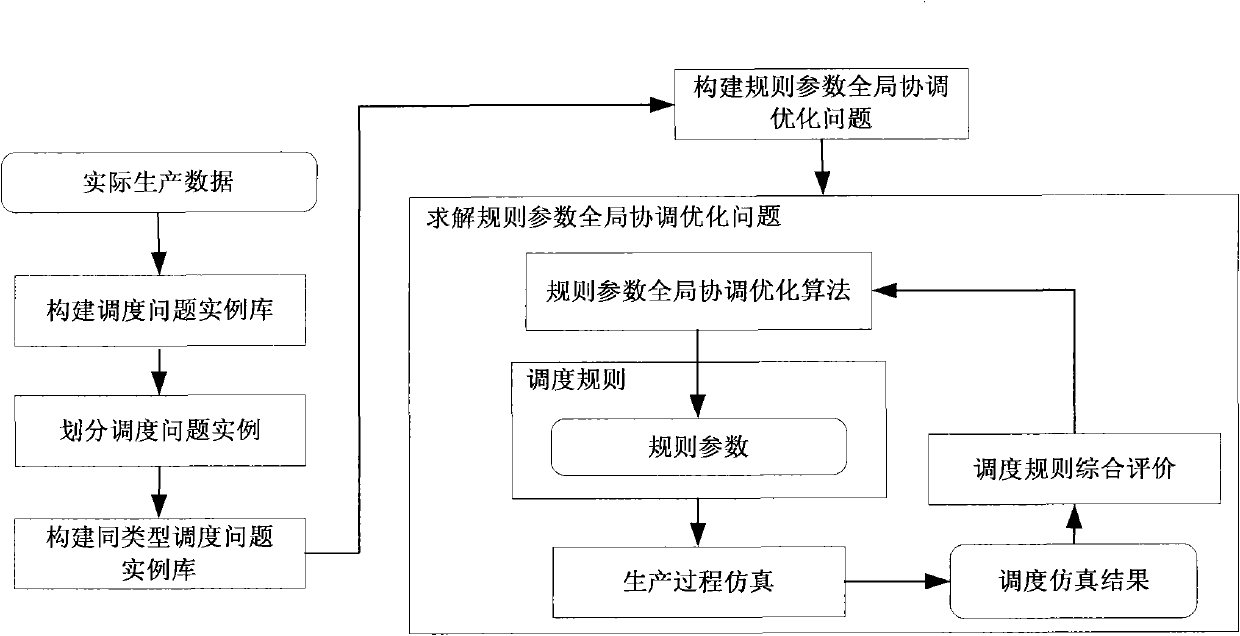

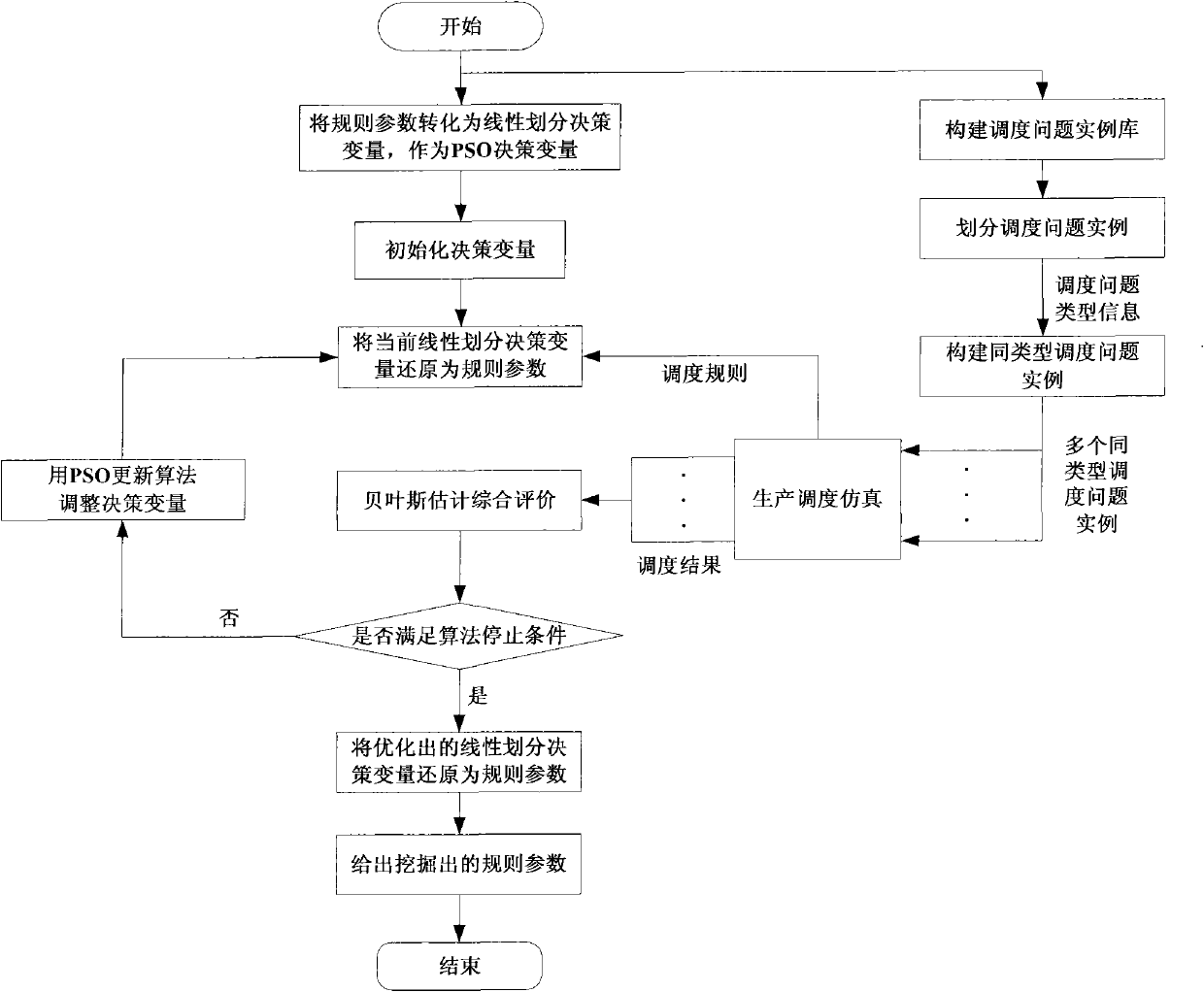

Scheduling rule intelligent excavating method based on rule parameter global coordination optimization

The invention relates to a scheduling rule intelligent excavating method based on rule parameter global coordination optimization, belonging to the automatic control, information technology and advanced manufacturing field, in particular relates to a complex production process oriented scheduling rule intelligent excavating method for scheduling environment in real time. The invention is characterized in that the method includes the following steps: a complex production process oriented scheduling rule intelligent excavating frame for scheduling environment in real time is built, a scheduling problem instance classification model is build, and scheduling rule parameter global coordination optimization problem is constructed and solved. The invention is based on the scheduling rule intelligent excavating frame provided by the invention and adopts double-layer fuzzy C-means clustering method to classify scheduling problem instances. Rule parameter global coordination optimization problem is constructed directing at scheduling problem instance in each class and linear partition based particle swarm optimization is adopted to solve and optimize the problem, wherein Bayes estimation method is adopted to carry out comprehensive evaluation on scheduling rule performance. The obtained scheduling rule has better scheduling effect on different problem instances in similar scheduling environment.

Owner:TSINGHUA UNIV

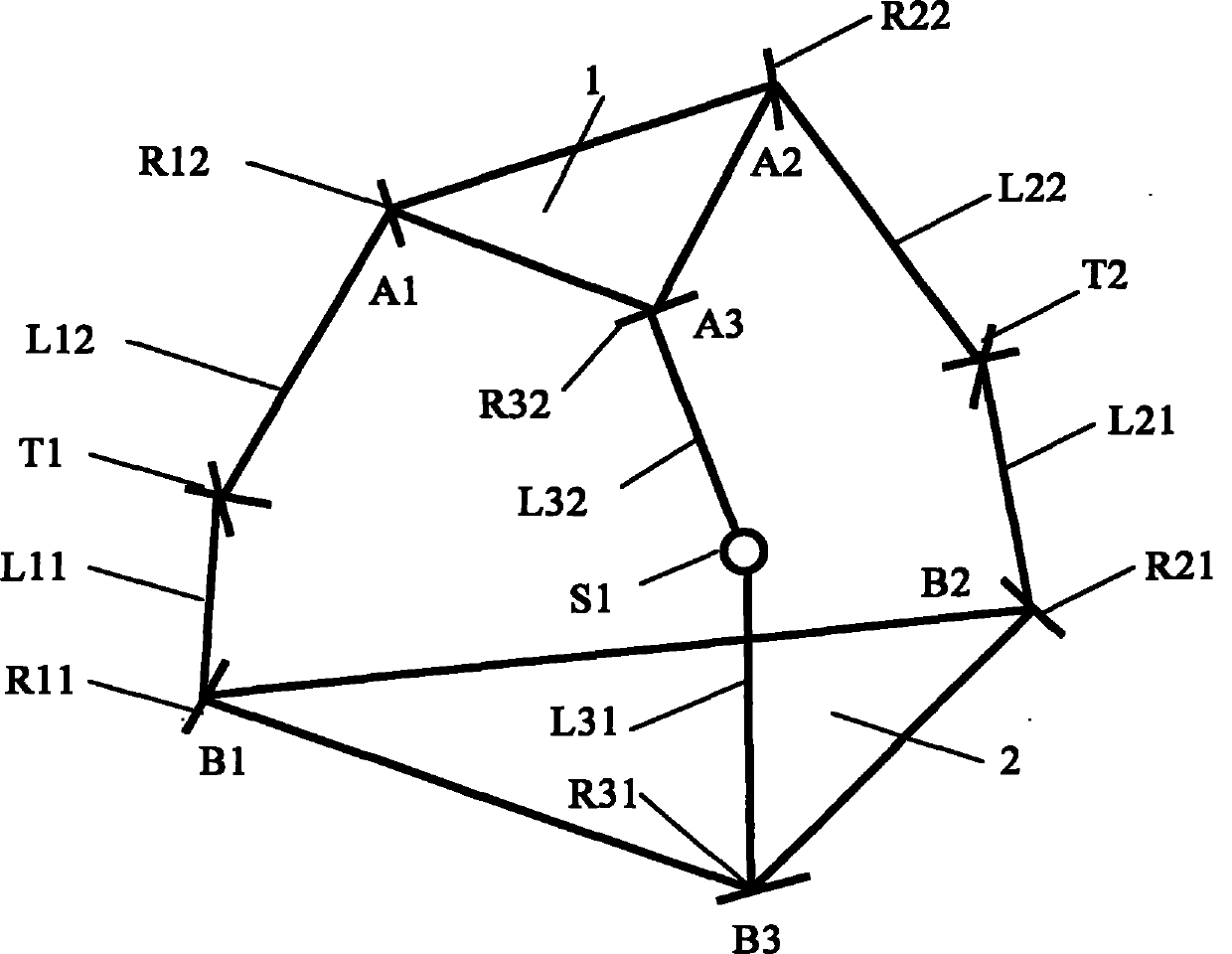

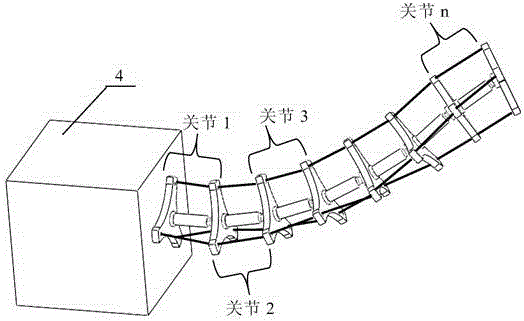

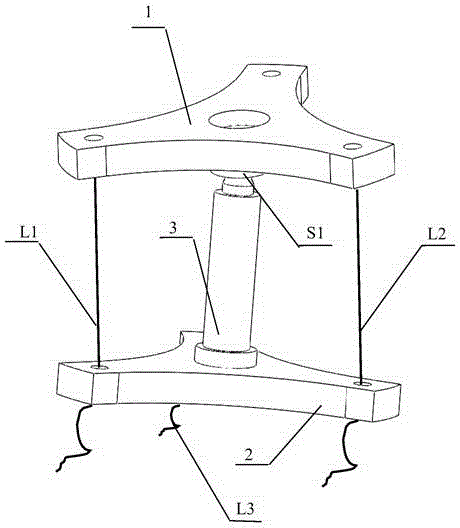

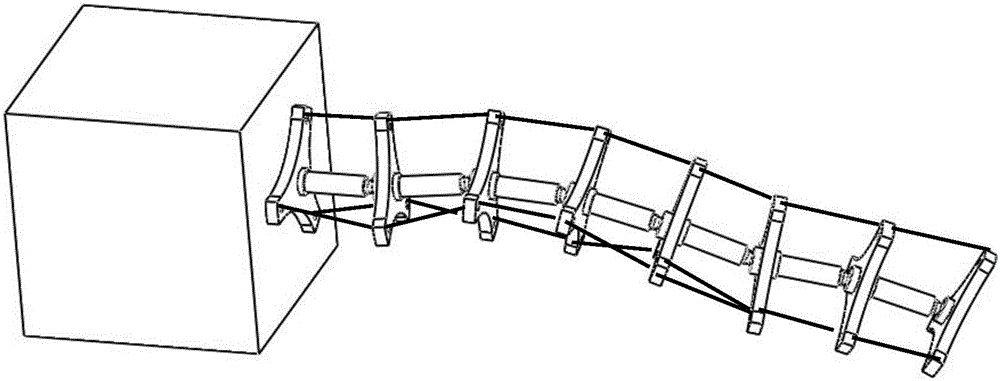

Rigid-flexible coupled trunk-shaped continuous robot

InactiveCN105729458AAchieve continuous motion outputSmall inertiaProgramme-controlled manipulatorReducerEngineering

The invention discloses a rigid-flexible coupled trunk-shaped continuous robot, and relates to the technical fields of robots and advanced manufacturing. The robot comprises a control box and a group of joints which are mounted on one side of the control box, have completely the same structure and are connected end to end, wherein each joint comprises a movable platform, a fixed platform, and a supporting rod and three driving ropes which connect the movable platform and the fixed platform; one end of the supporting rod is fixedly connected with the fixed platform vertically, and the other end of the supporting rod is connected with the movable platform through a ball pair; one ends of the three driving ropes are fixedly connected with three endpoints of the movable platform respectively, and the other ends of the three driving ropes penetrate through three endpoints of the fixed platform to be connected with the ropes in the control box; and the ropes are connected with a motor through a speed reducer. According to the rigid-flexible coupled trunk-shaped continuous robot, working platforms of each joint can achieve motion output of three-dimensional rotation under a cartesian coordinate system; and the motion output of each movable platform is achieved through transmission of the rigid supporting rod and the three driving ropes, so that the rigid-flexible coupled motion characteristic is achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

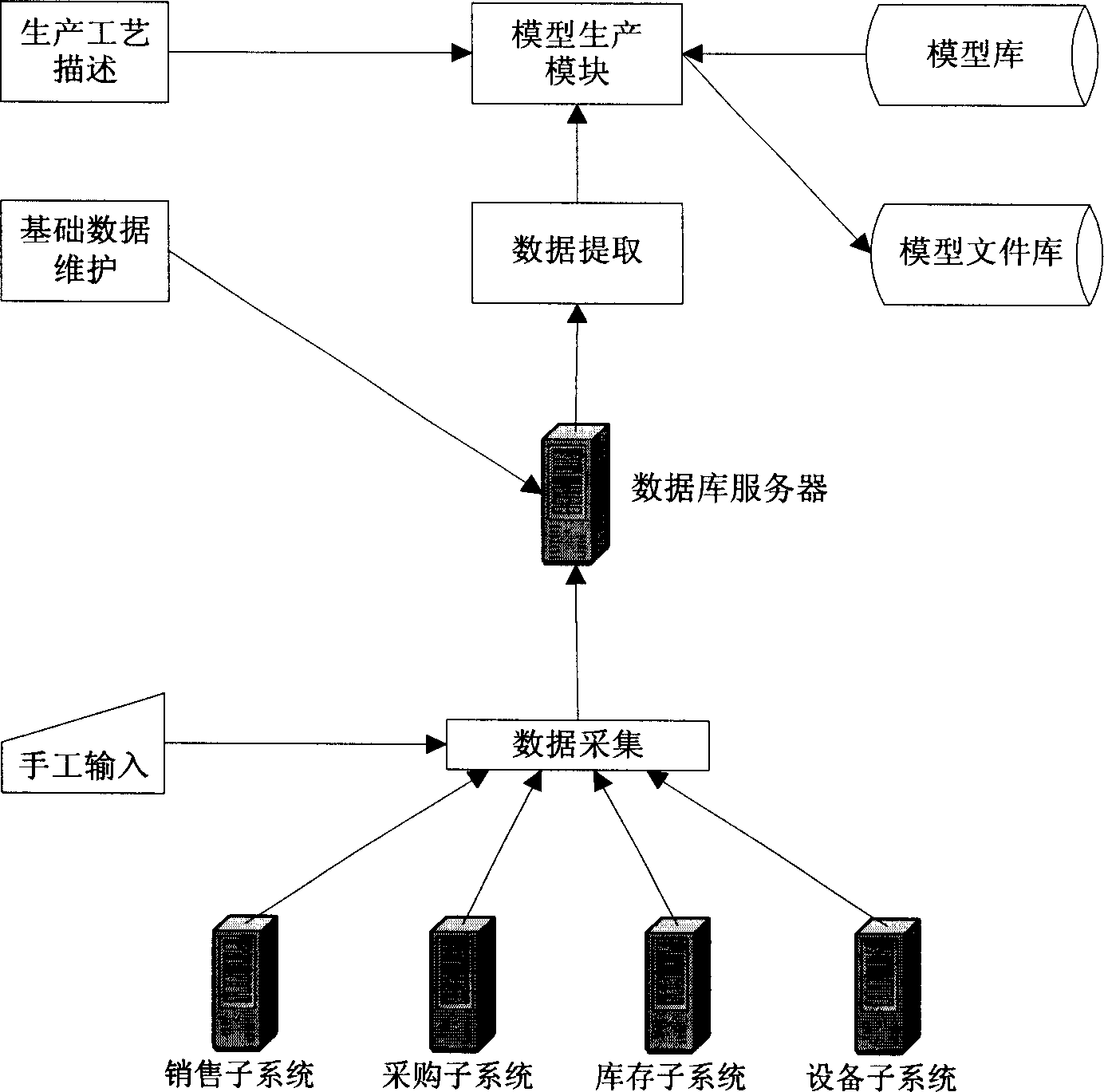

Modeling method for visible production process description of process industry

The invention discloses effective description based on visible production system in the advanced manufacture and automatic technique domain, which is characterized by the following: basic data maintenance establishes and maintains basic information of production device or equipment to provide basic data for production system modeling; data collection collects the needed data for modeling according to the dispatching time scale; production technique description provides production technique flow visible description for production system; model generation forms production system resource data text file of model base requirement according to the input optimum dispatching parameter of user. The invention can dispose wide dispatching problem in the production course.

Owner:HANGZHOU DIANZI UNIV

High-melting metal arc spraying rapid die-manufacturing method

InactiveCN101434026ALow costShort preparation cycleMolten spray coatingFoundry mouldsAfter treatmentHigh intensity

The invention belongs to the field of the advanced manufacturing technology in the manufacturing industry, relates to a quick die manufacturing method, in particular to a quick die manufacturing method through arc spraying of high-melting metals. The method adopts a non-roasting ceramic master die as a composite mold base, arranges fused drop on the surface of the master die through arc spraying of the high-melting metals, adds a die frame on the rear of a shell after spraying of a certain thickness, fills resin and high-strength cement back lining, and performs after-treatment such as edge cutting and polishing on the surface of the shell after demoulding. The invention provides the quick and low-cost die manufacturing integrated technology.

Owner:XI AN JIAOTONG UNIV +1

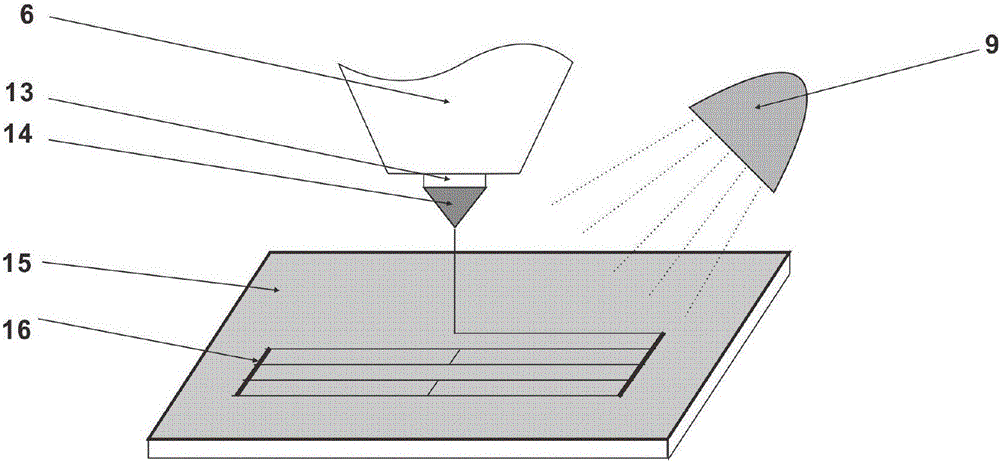

E-jet printing method for solar photovoltaic cell electrode

ActiveCN106653877AImprove photoelectric conversion efficiencyReduce manufacturing costPrintingPhotovoltaic energy generationEngineeringWidth ratio

The invention belongs to the technical field of advanced manufacturing and provides an e-jet printing method for a solar photovoltaic cell electrode. Firstly, fluid pressure is applied to conductive ink, and the conductive ink flows out of a nozzle hole at a certain flow speed; then, a certain electric field is applied to the conductive ink, fine jet far smaller than the inner diameter of the hole is thus formed; the jet is then heated, and the partial solvent of the conductive ink is evaporated; and finally, jet printing of an electrode structure on a heated photovoltaic cell semiconductor sheet is carried out, the conductive ink is quickly cured, and a photovoltaic cell electrode structure is formed. The comprehensive effects on the conductive ink by the electric field-thermal field are used and control on the moving track of the solar photovoltaic cell semiconductor sheet by a moving platform is matched, and thus, the solar photovoltaic cell electrode is made. The electrode structure jet printing technology provided by the invention has the advantages of simple process, easy control, high precision and strong material adaptability, and making of a large-height-width ratio electrode structure in high temperature can be realized.

Owner:DALIAN UNIV OF TECH

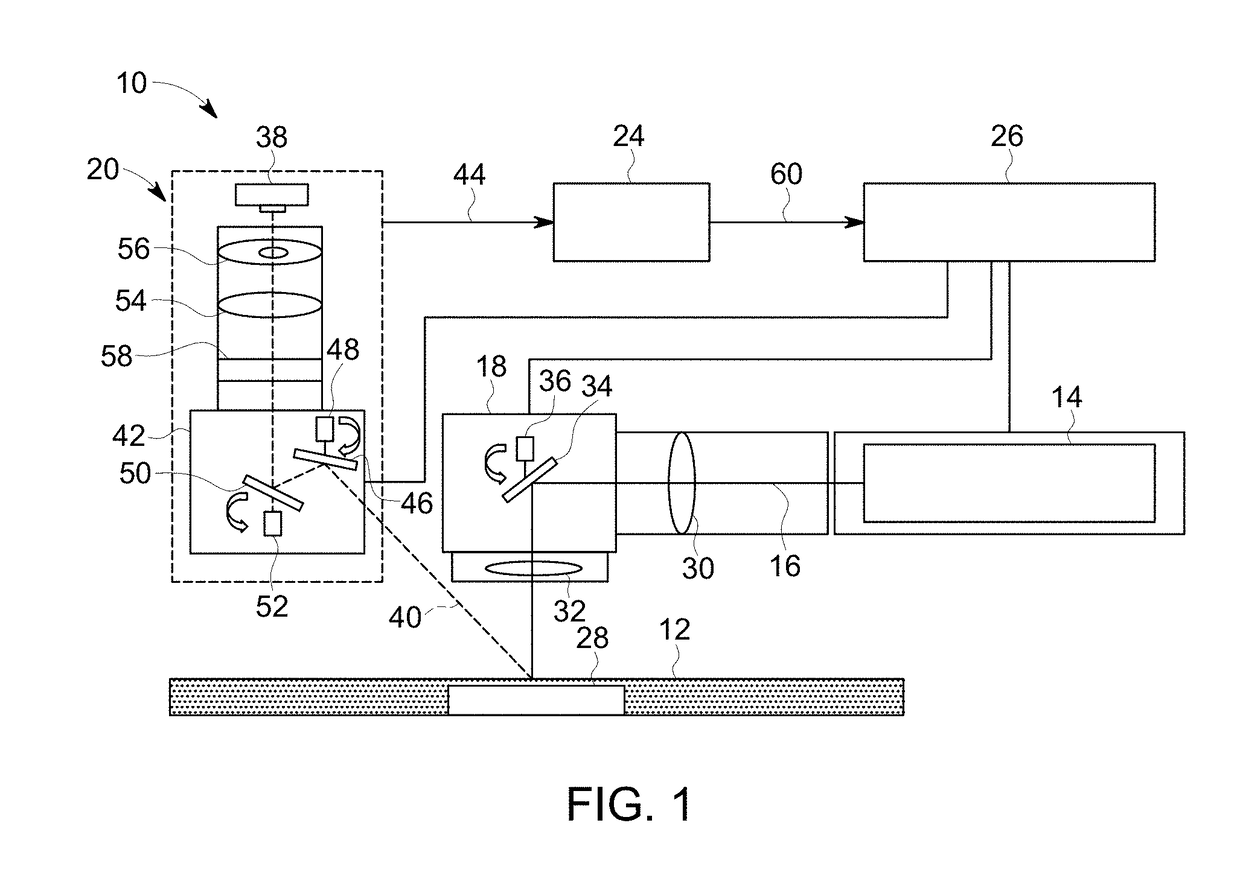

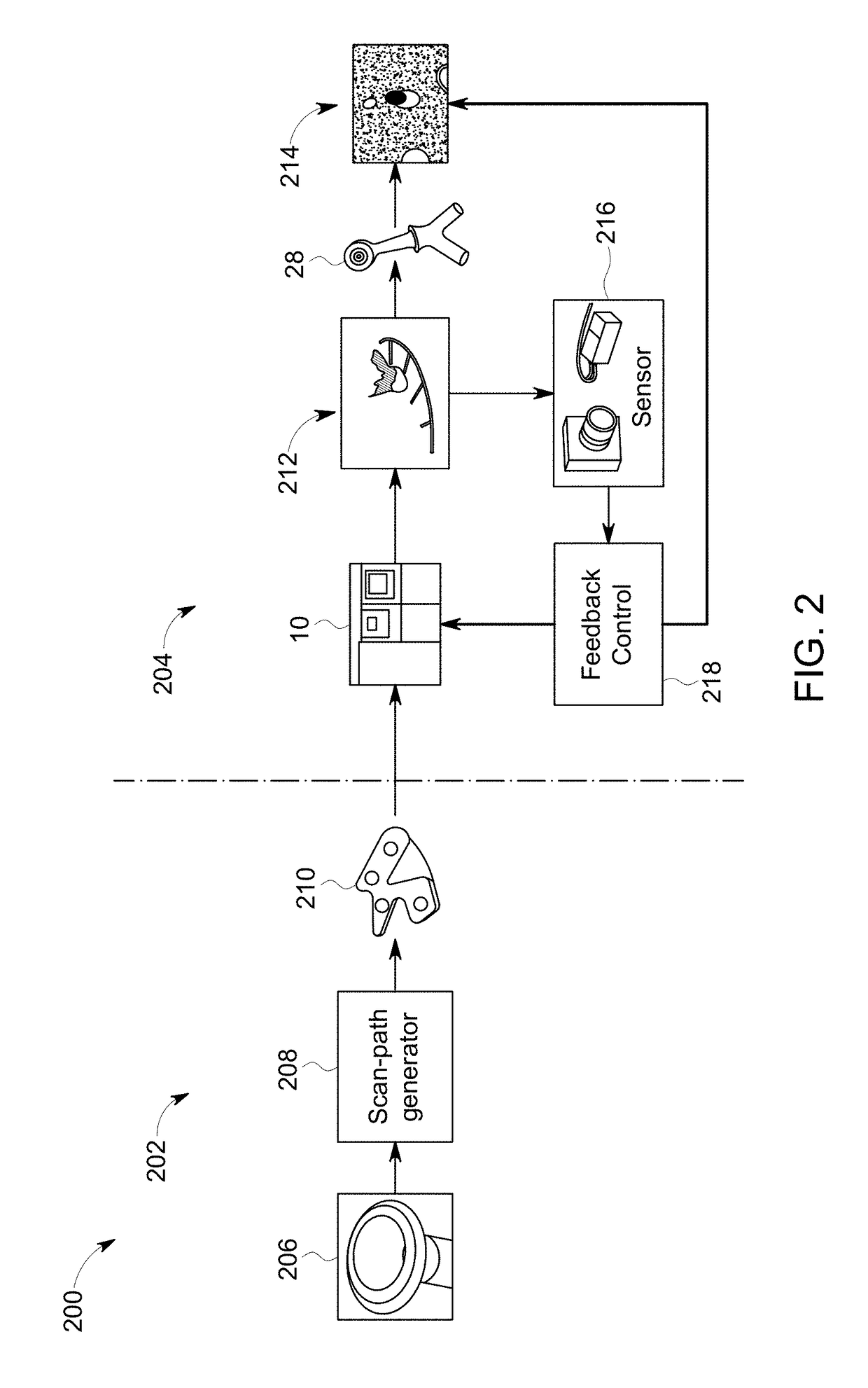

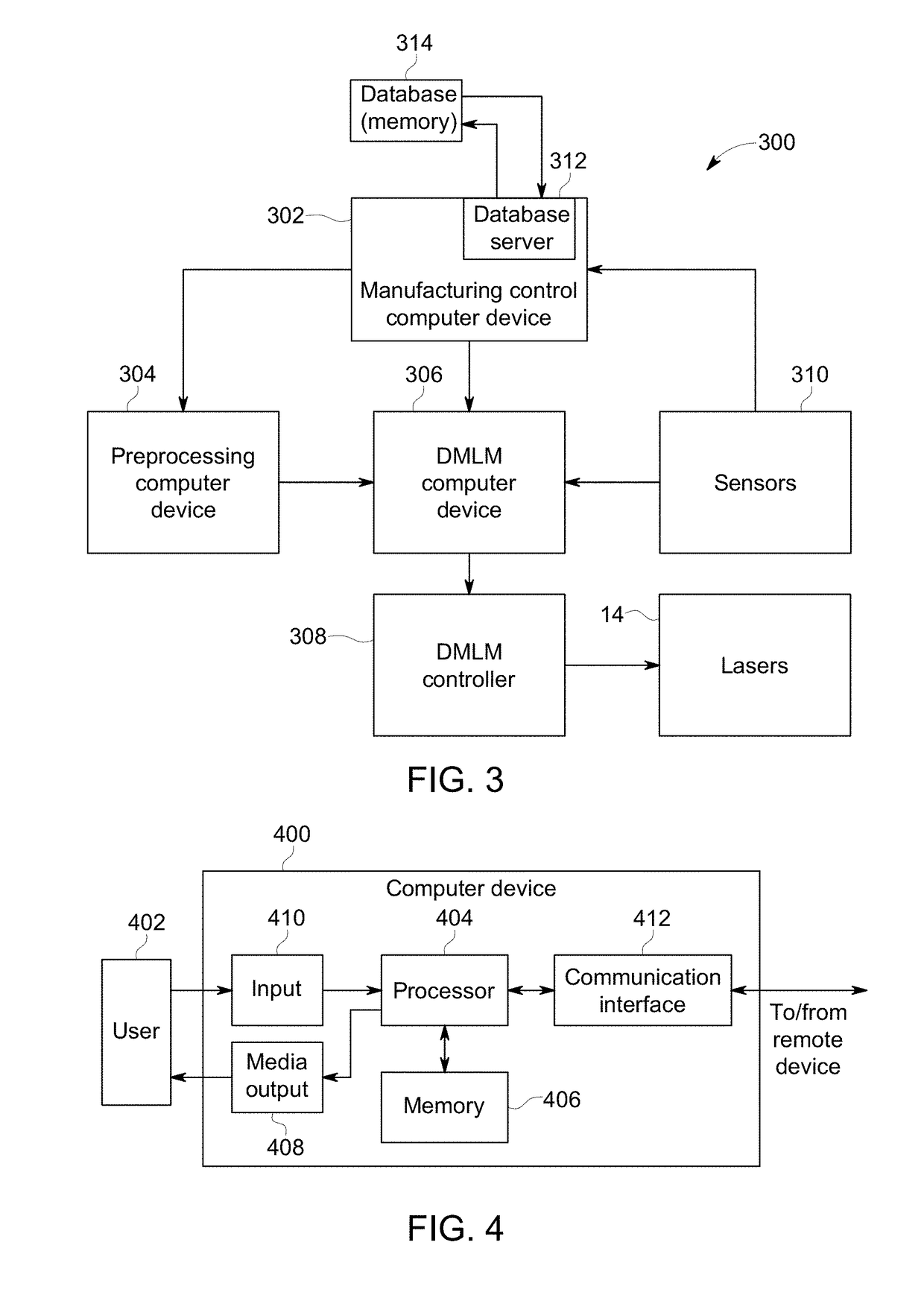

Systems and method for advanced additive manufacturing

ActiveUS20190004079A1Programme controlAdditive manufacturing apparatusComputer scienceAdditive layer manufacturing

A manufacturing computer device for dynamically adapting additive manufacturing of a part is provided. The manufacturing computer device includes at least one processor in communication with at least one memory device. The at least one memory device stores a build file for building the part including a plurality of geometries that each include one or more values of a first build parameter. The processor is programmed to receive sensor information of a build of the part by a machine, compare the sensor information for each geometry of the plurality of geometries to the corresponding one or more values of the first build parameter, determine one or more values for a second build parameter for each of the geometries based on the one or more differences, and generate an updated build file for the part including the one or more values for the second build parameter.

Owner:GENERAL ELECTRIC CO

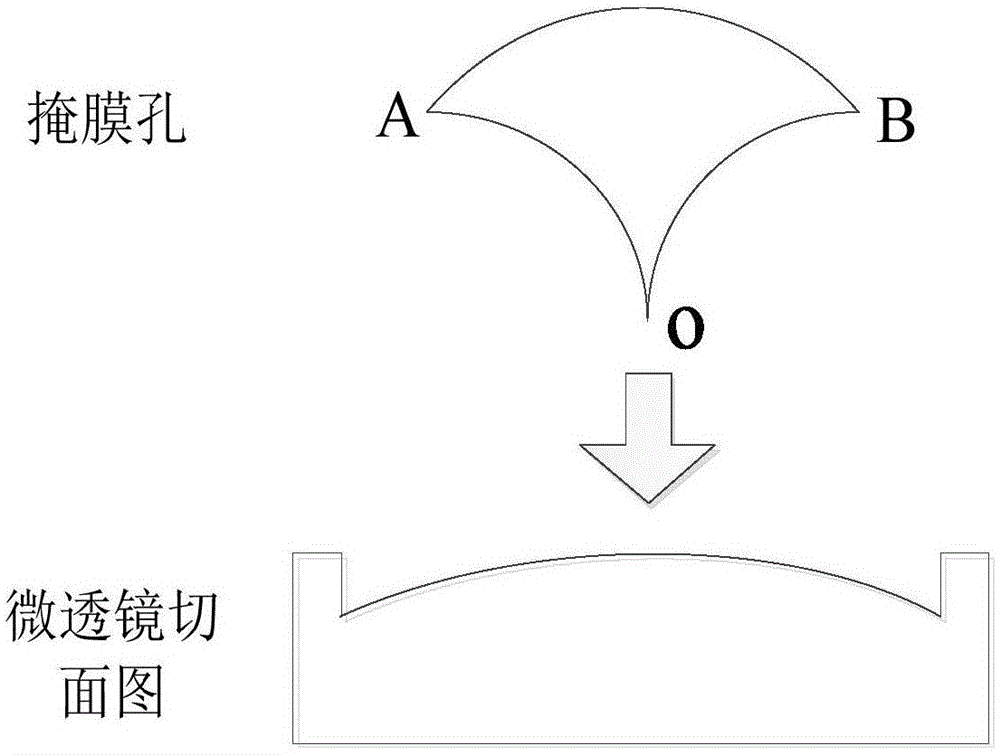

Method for quickly preparing synthetic glass microlens having adjustable curvature through excimer laser rotary etching

InactiveCN105108347AImprove absorption rateReduce thermal effectsLaser beam welding apparatusEtchingManufacturing technology

The invention relates to a method for quickly preparing a synthetic glass microlens having adjustable curvature through excimer laser rotary etching, and belongs to the field of micro-optical devices and laser advanced manufacturing technology. A machining system is mainly composed of a computer, a laser, a laser homogenizer, a mask layer, a mask layer, a mask layer exchanging platform, a focusing object lens, a coaxial observation system, a rotating platform and a micromotion workbench. A synthetic glass PMMA is machined through a mask layer projection rotary etching method to make a microlens having good circularity, after mask layer design, preparation of optical paths a machining system and calibration of an axle center of the rotating platform, the shape and the size of a hole in mask layer is determined according to parameters of a microlens to be machined. The method can be used for making a microlens or a microlens array, and the method is low in heat effect influence and cost, high in efficiency and precision, good in repeatability without contact and having adjustable curvature.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com