Coaxial focusing electro stream printing method

An electric jet, coaxial technology, applied in the direction of additive processing, etc., can solve the problems of limited tangential force of the jet electric field, unstable jet flow, limited jet size, etc., to improve resolution and controllability, and resist micro-environmental interference. The effect of strong strength and material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

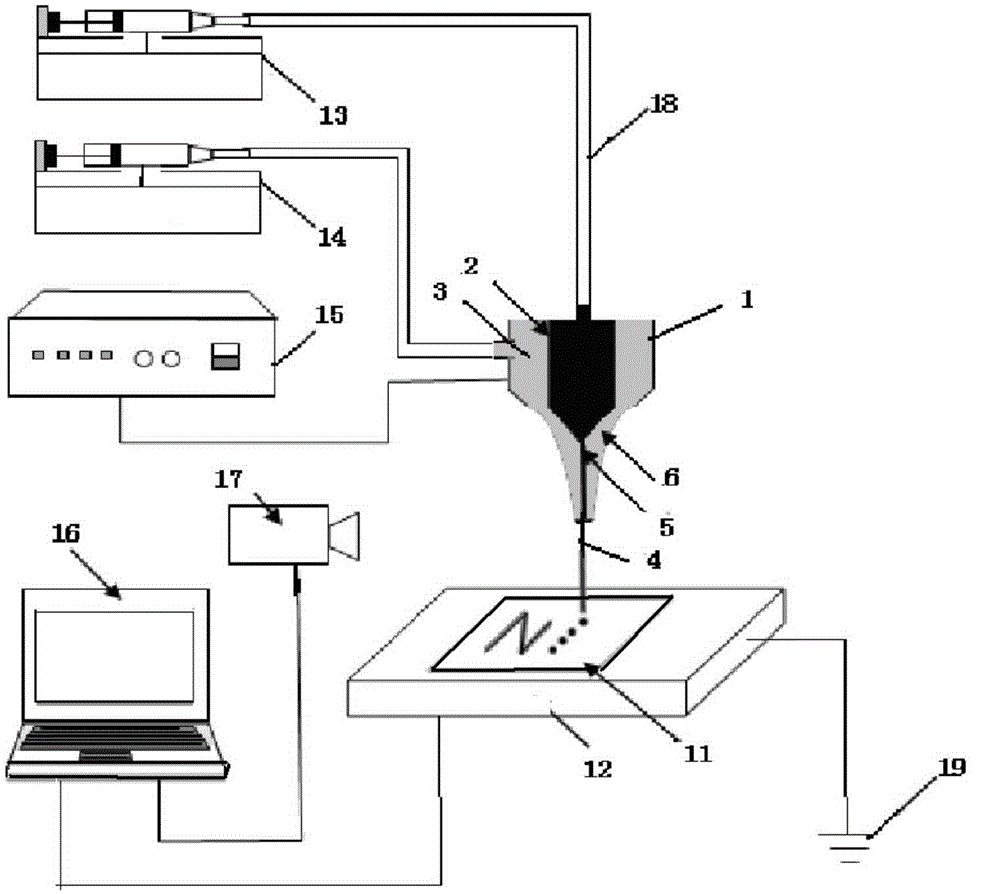

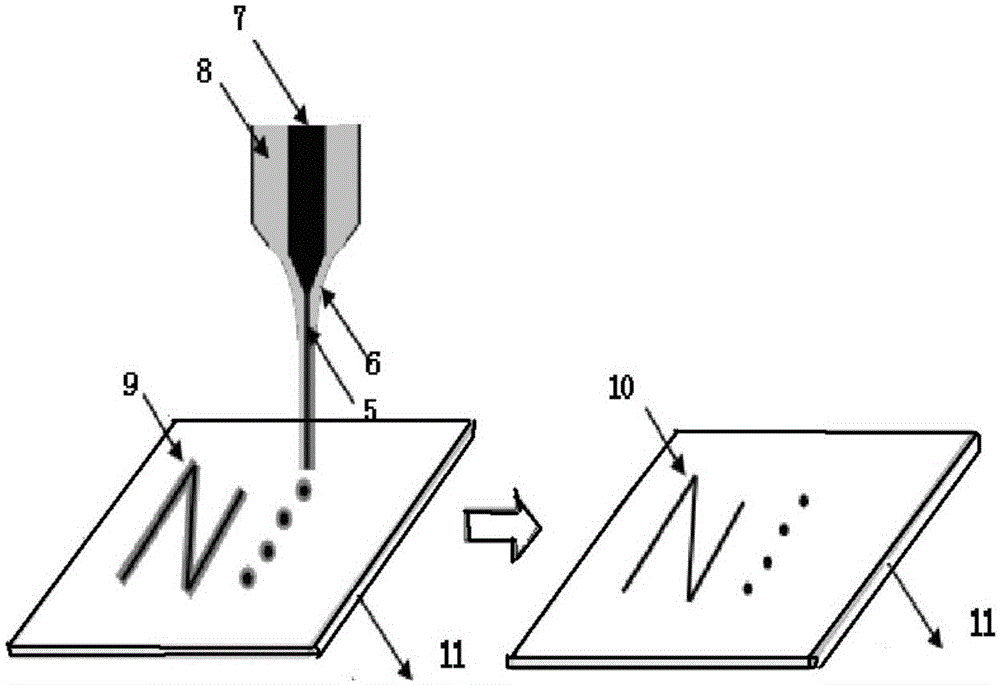

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. Coaxial focusing electro-jet printing is to pass the inner layer liquid and outer layer liquid into the inner and outer nozzles of the coaxial focusing electro-jet printing head respectively. The function of the outer liquid is to provide greater shear force to the inner liquid jet and protect the inner liquid. When a certain voltage is applied at an appropriate flow rate, a coaxial focused electric jet will be formed at the outlet of the coaxial focused electric jet printing needle. The tangential force of the deformation of the inner liquid jet is improved, the size of the jet is reduced, and it is free from the interference of the external micro-environment. The coaxial focused electric jet is used to print the double-layer structure first, and then remove the outer wrapping material. High-resolution pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com