Patents

Literature

233 results about "Nozzle clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing ultra-low-carbon steel

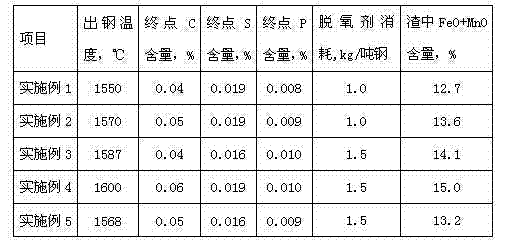

A method for producing ultra-low-carbon steel belongs to steel-making technology field. The process route is: molten iron desulfuration preprocess -converter smelting -RH vacuum process -slab continuous casting. The iron desulfuration preprocess applies blowing magnesium granules for desulfuration; the converter smelting terminal carbon content and oxygen activity of molten steel; applying slag dam operation when tapping without deoxidation; the ladle furnace proceeds operation of top slag modification and temperature controlling; RH vacuum processing to control the maximum vacuum; applying Al for deoxidation when the decarburization is finished, and alloying if the deoxidation is finished and assuring the deep vacuum processing time after the deoxidation; calming the molten steel when the vacuum is finished; applying non-carbon covering agent and non-carbon protection slag in the slab casting process; the continuous casting process uses full protection casting, and the casting process controls a reasonable pulling speed according to slab section. The advantages are: the invention resolves problem of nozzle clogging and improves castability of the ultra-low-carbon steel and implements multi-furnace continuous casting, and the components of carbon, phosphorus, sulphur and nitrogen of the completed product conforms smelting request of the ultra-low-carbon steel.

Owner:SHOUGANG CORPORATION

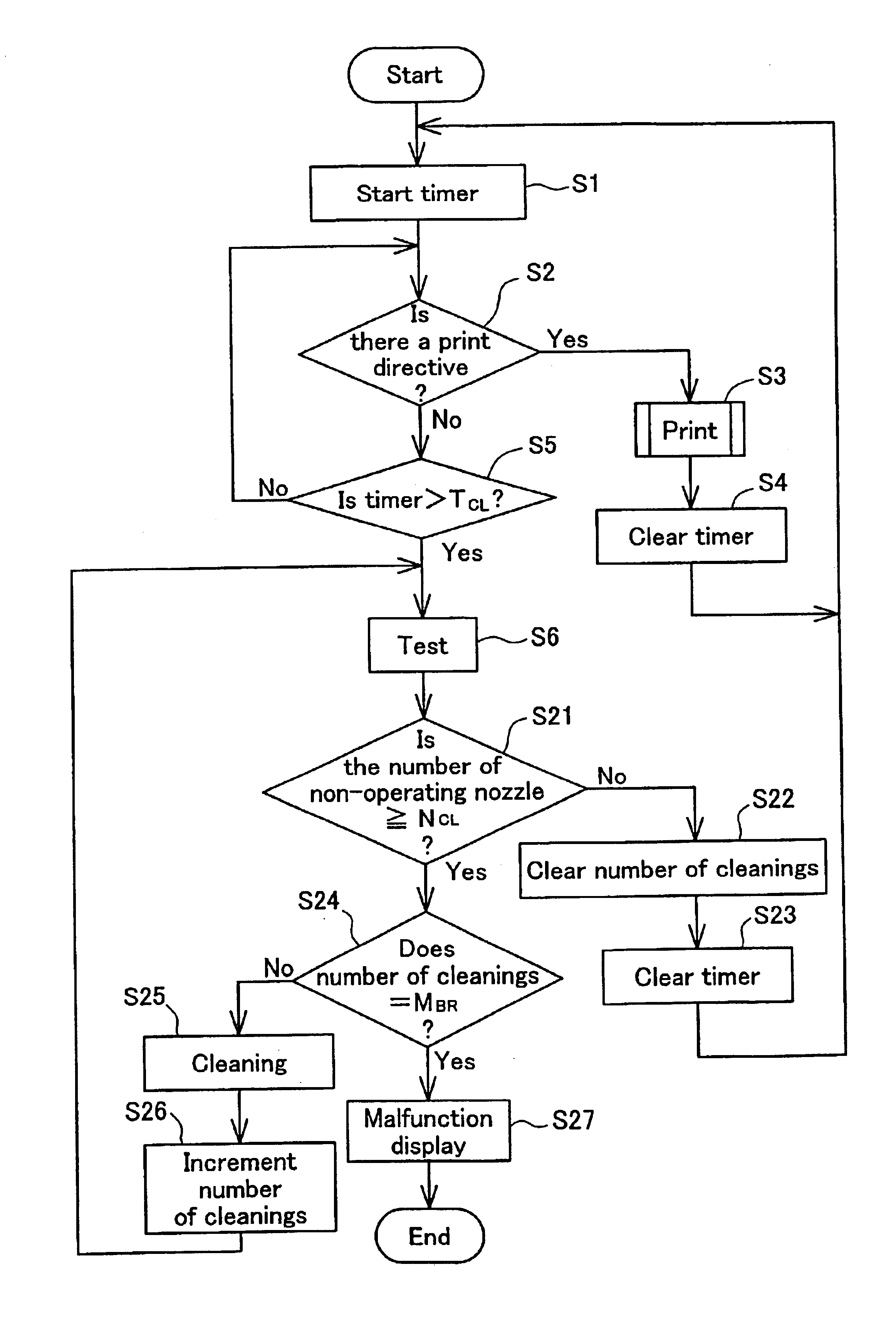

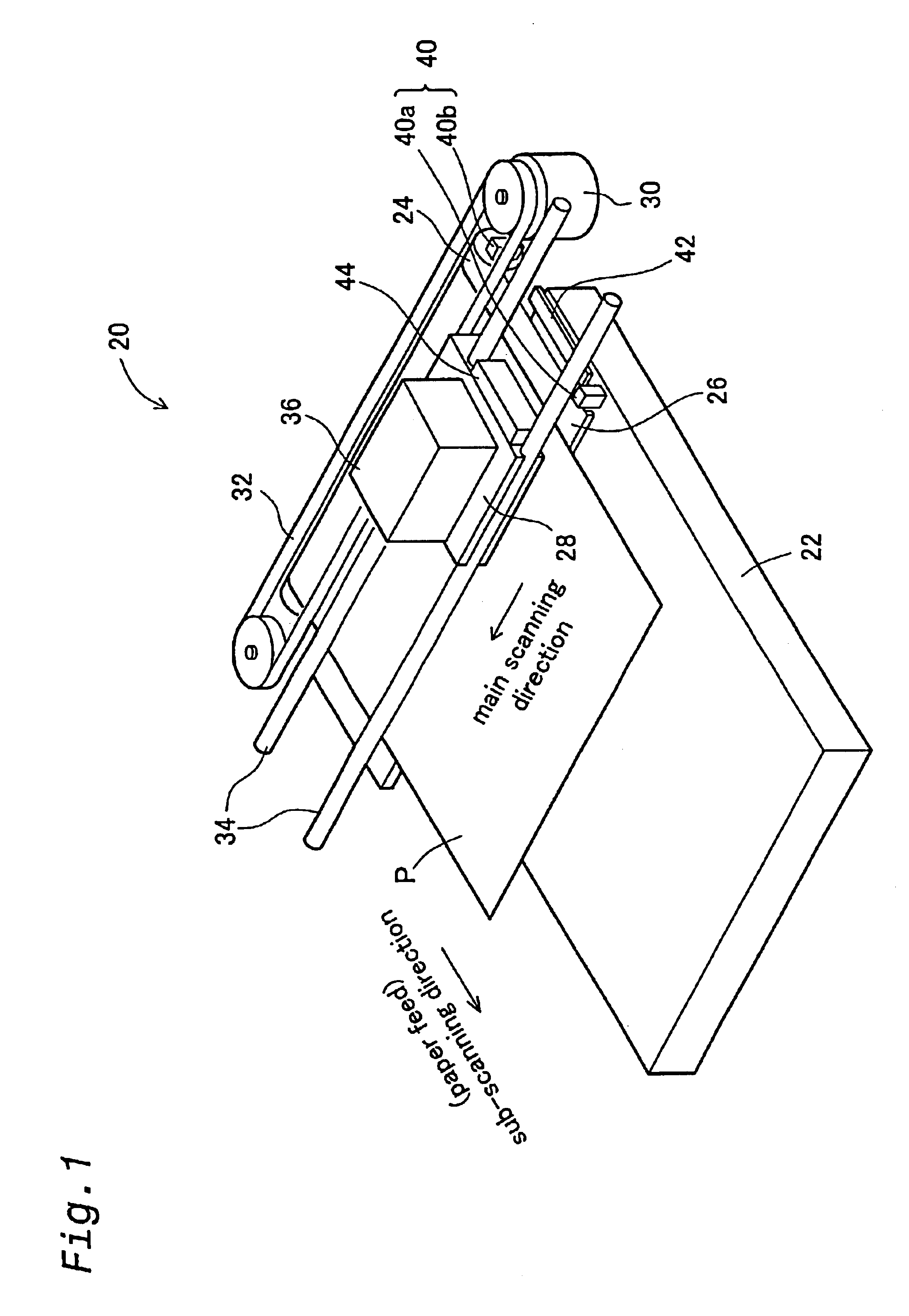

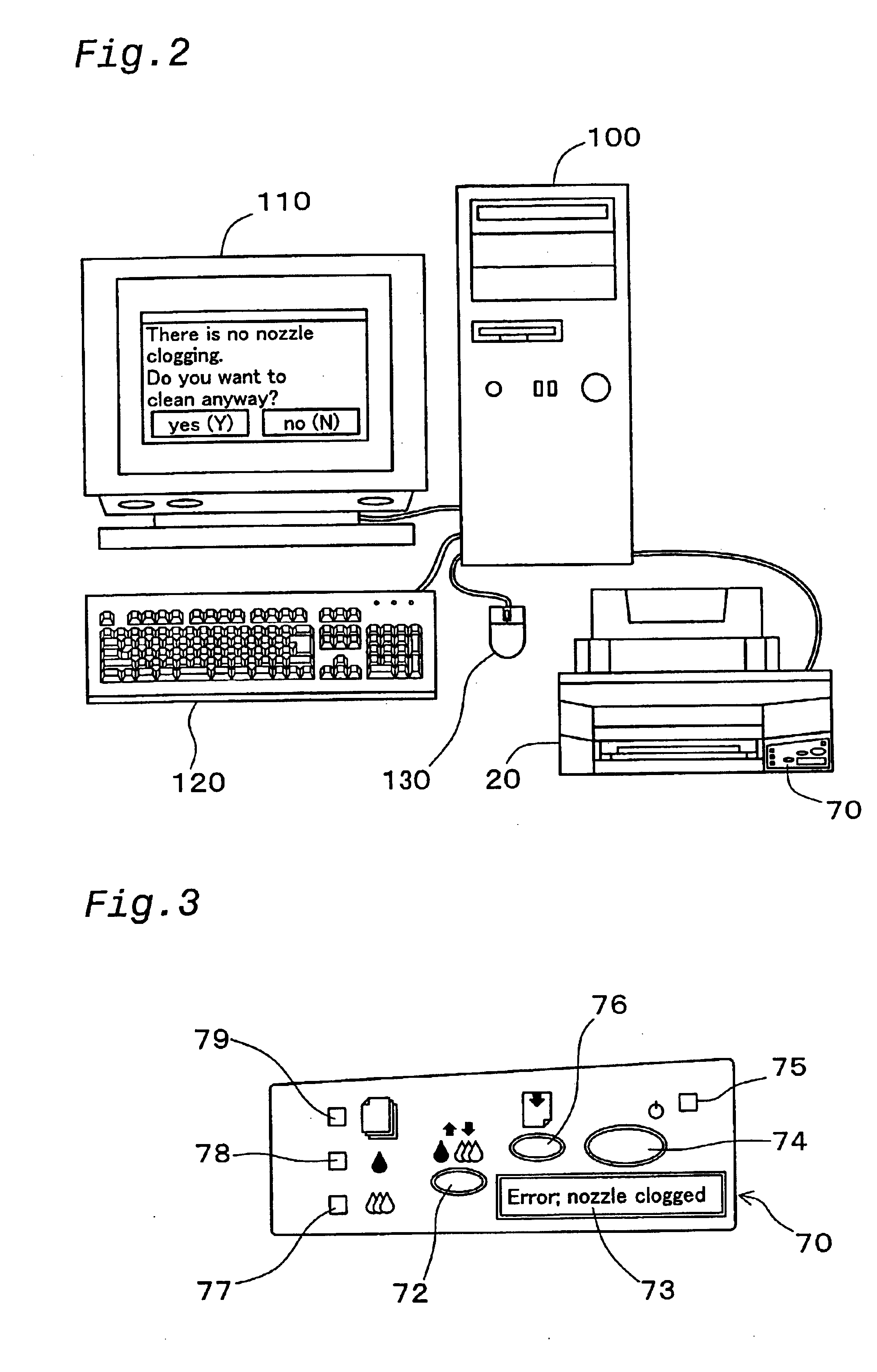

Nozzle testing before and after nozzle cleaning

InactiveUS6565185B1Degradation of image qualityLow ability to clearOther printing apparatusNozzle cloggingNozzle

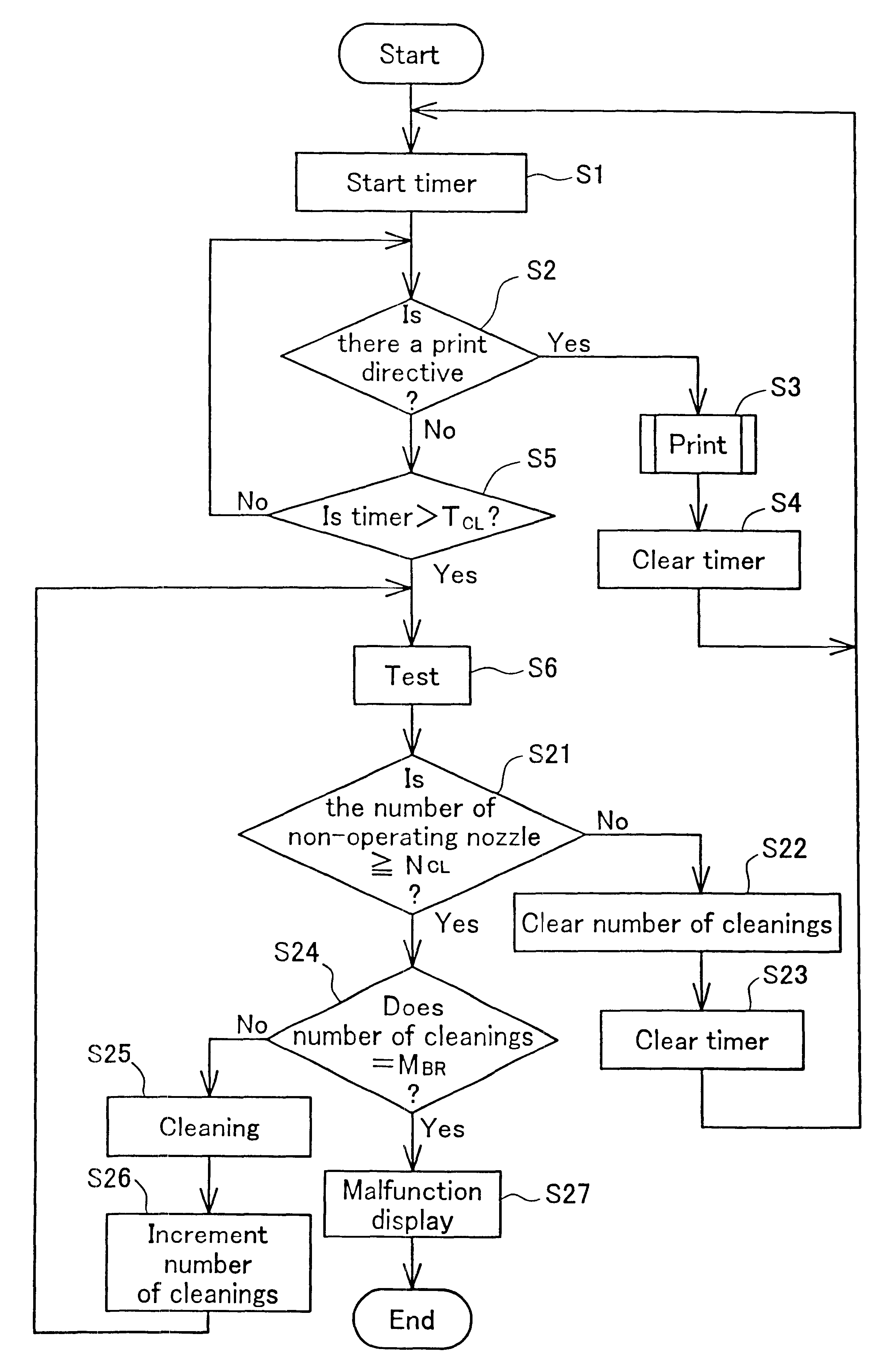

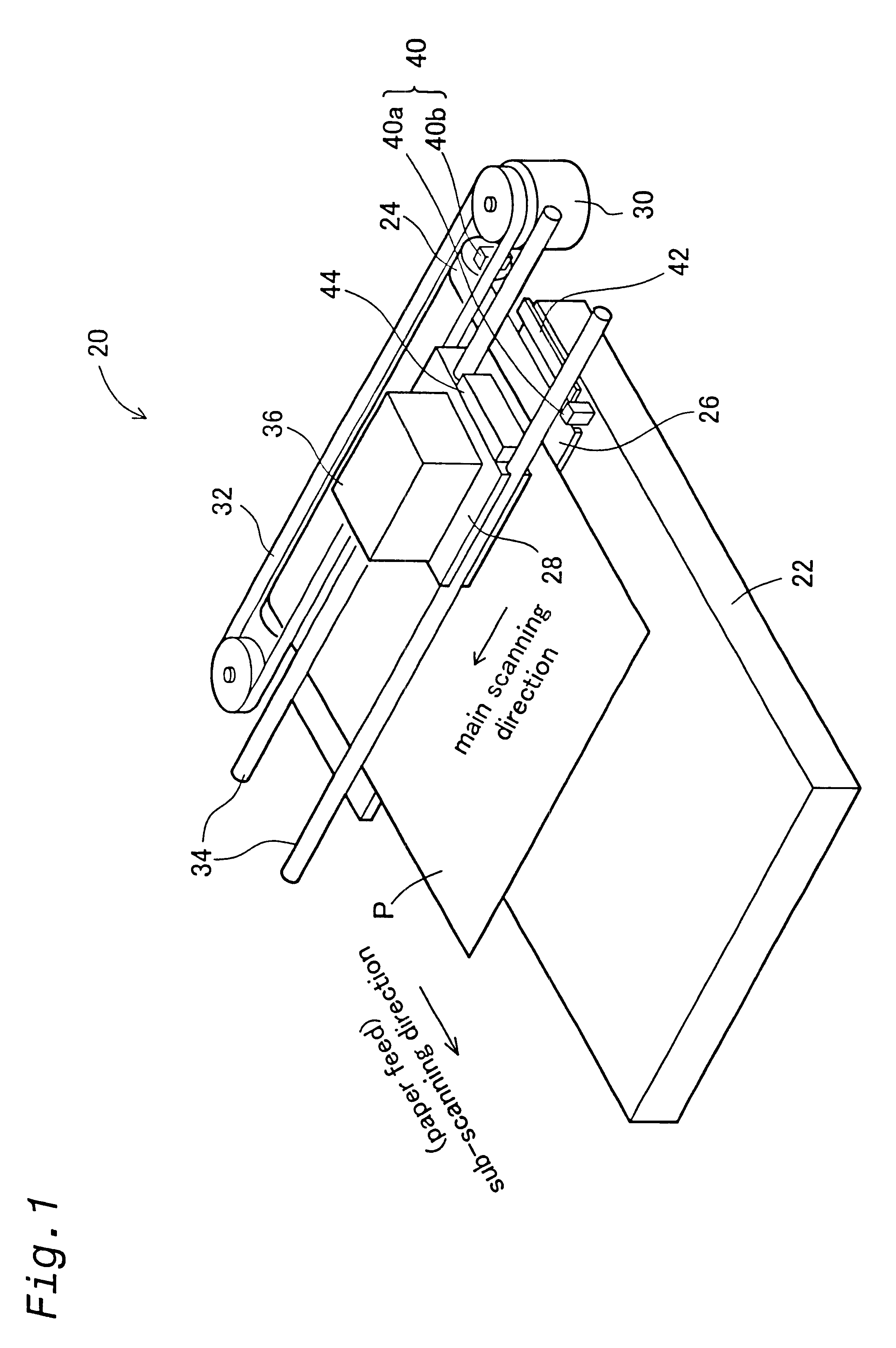

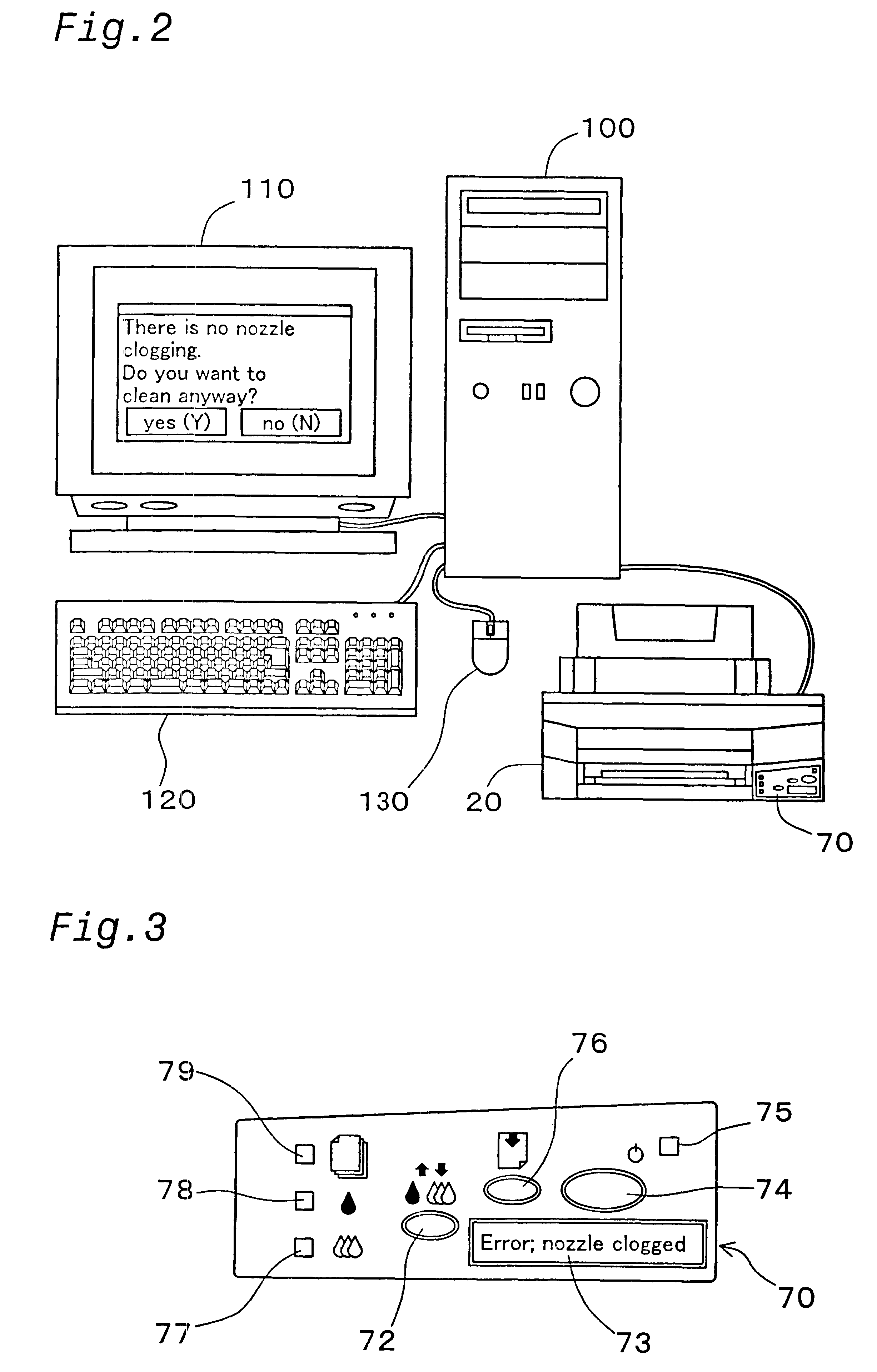

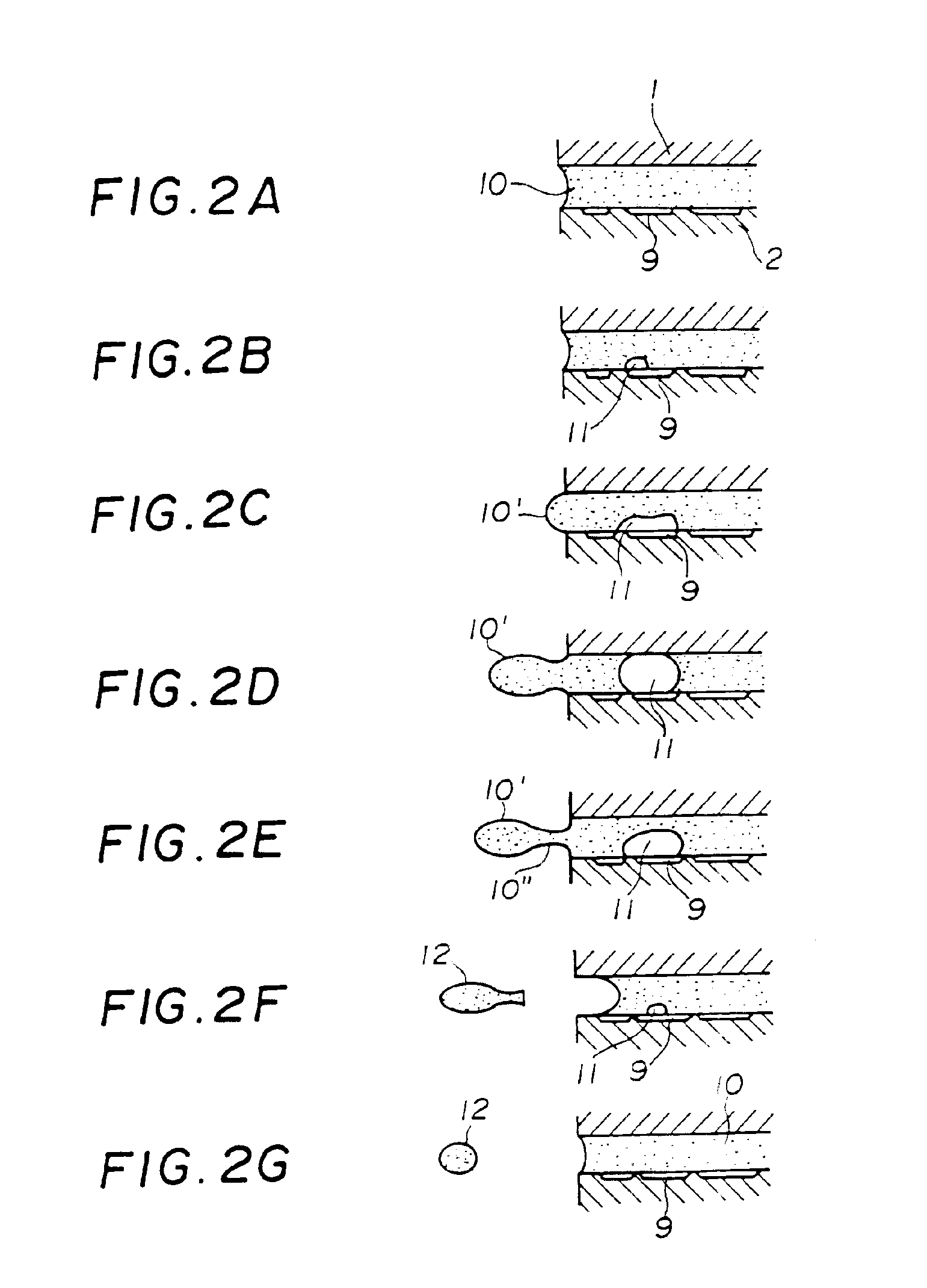

It is an object of the invention to provide a technique for reducing the likelihood that cleaning will cause nozzle clogging. In periodic automatic cleaning of a printer that is not being used, the ejecting of ink droplets from each nozzle is tested prior to the cleaning to determine whether each nozzle is an operating nozzle capable of ejecting ink droplets or a non-operating nozzle incapable of ejecting ink droplets. The nozzles are only cleaned if non-operating nozzles are detected. The testing of the nozzles is also automatically carried out after cleaning.

Owner:SEIKO EPSON CORP

Ink-jet printing system with reduced nozzle clogging

A fluid dispensing system for ink-jet printing can comprise an ink-jet ink including anionic dye colorant and from 0.05 wt % to 1.0 wt % of an anionic dispersant polymer, and a fixer composition including a cationic crashing agent that is with a component of the ink-jet ink. The fixer composition can be stored separately from the ink-jet ink, and the fluid dispensing system can be configured for overprinting or underprinting the fixer composition with respect to the ink-jet ink.

Owner:HEWLETT PACKARD DEV CO LP

Ultra-low-carbon steel slag modifier and addition method thereof

InactiveCN102108430AReduce turbulenceReduce oxidationManufacturing convertersChemical compositionSlag

The invention relates to an ultra-low-carbon steel slag modifier and an addition method thereof. The ultra-low-carbon steel slag modifier is formed by carrying out dry mixing on passivated aluminum powder, alumina and active lime. The ultra-low-carbon steel slag modifier comprises the following chemical components in percentage by weight: 10-20% of Al, 15-25% of Al2O3, 40-50% of CaO, at most 8% of SiO2, at most 1% of C, at most 0.05% of S and at most 0.05% of P. After an RH (Ruhrstahl Heraeus, vacuum circulation degassing) furnace finishes treating molten steel, the steel slag modifier is added to 2-4 times of the amount of slag on the ladle top, and the molten steel is stirred in weak argon for 5-10 minutes. The invention can obviously lower the degree of turbulence in the pouring process of IF (interstitial-free) steel, degrade the oxidizability of the IF steel slag, reduce the reoxidation generated in the pouring process of the molten steel, avoid nozzle clogging, enhance the pourability of the molten steel, and ensure the quality of the molten steel.

Owner:ANGANG STEEL CO LTD

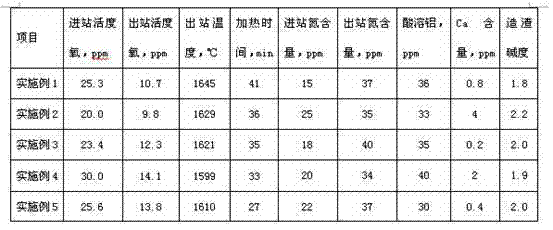

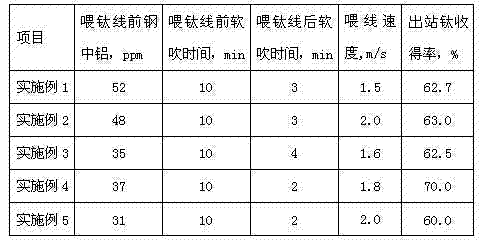

Titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging

InactiveCN104259414AReduce nodulationIncrease the number of continuous pouring furnacesManufacturing convertersProcess efficiency improvementSteelmakingTitanium

The invention discloses a titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging and belongs to the technical field of steel making. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging includes processing steps that (1) smelting in a top-bottom combined blowing converter, to be specific, using low-sulfur molten iron and high-quality waste steel to blow; (2) refining in an LF furnace; (3) performing titanium alloying in an LF furnace, to be specific, softly blowing molten steel for 10 minutes, and feeding low-aluminum low-nitrogen 70Ti iron-packaged core to the molten steel to perform the titanium alloying after finishing soft blowing; (4) protecting casting in the whole process. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging is aimed to solve the continuous casting water feed nozzle and submerged nozzle clogging problem for the titanium-containing solder wire steel production; the titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging alleviates the nozzle clogging degree through optimizing the steel making, refining and continuous casting techniques, improves the continuous casting furnace number and cast blank yield and effectively lowers the production cost.

Owner:HEBEI IRON AND STEEL

Method for producing medium and low carbon aluminum killed steel

The invention provides a method for producing medium and low carbon aluminum killed steel, which comprises the following steps of: controlling the content of sulfur in molten iron to be not more than 0.015 percent; primarily smelting the molten iron to form molten steel, and tapping; adding an aluminum deoxidizer into the molten steel when 20 to 30 weight percent of molten steel is tapped; adding4.0 to 6.0kg of active lime and fluorite in an amount which is 0.2 times that of the active lime into each ton of molten steel when 31 to 50 weight percent of molten steel is tapped; performing argonblowing refining for the first time; adding aluminum in two or three batches and 1.5 to 4kg of refining slag into each ton of steel in a steel ladle, heating, and refining; performing calcium treatment on the molten steel; performing argon blowing refining for the second time; and performing continuous casting. By the method, the castability of the molten steel can be improved, the phenomenon of water nozzle clogging is avoided, and the continuous casting heats of a single tundish in the continuous casting process of the medium and low carbon aluminum killed steel are not less than 8 heats.

Owner:PANZHIHUA IRON AND STEEL +2

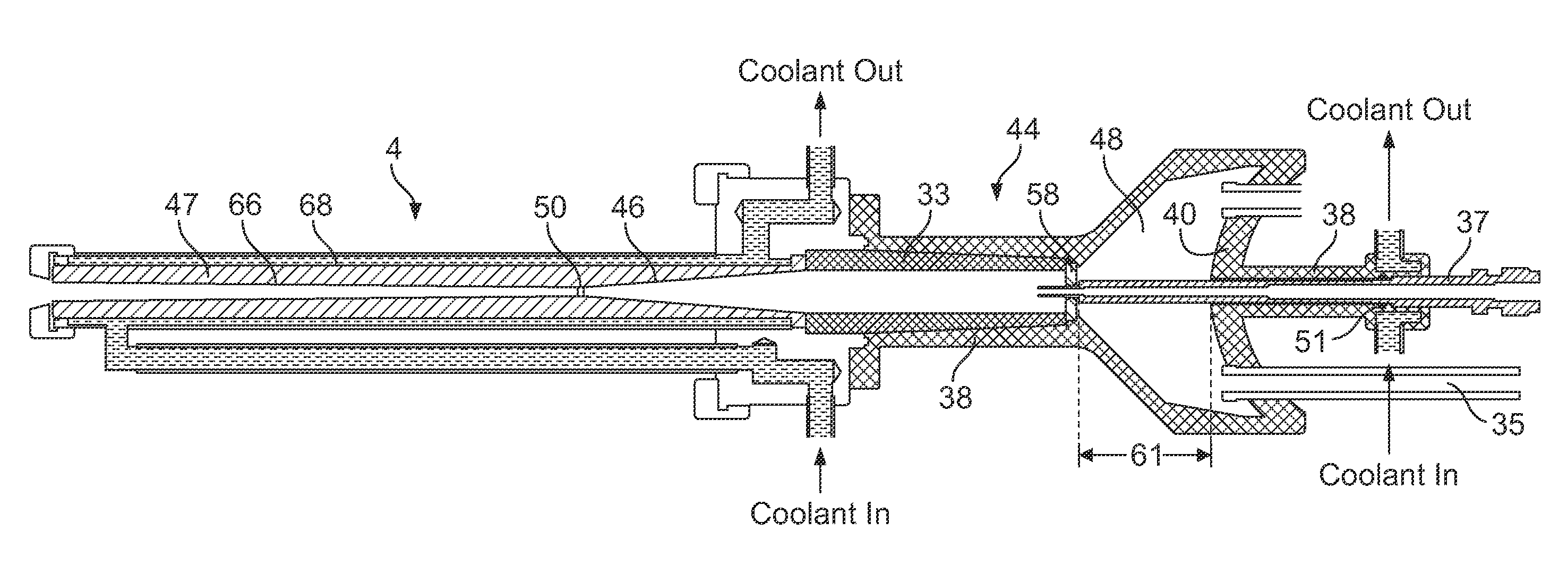

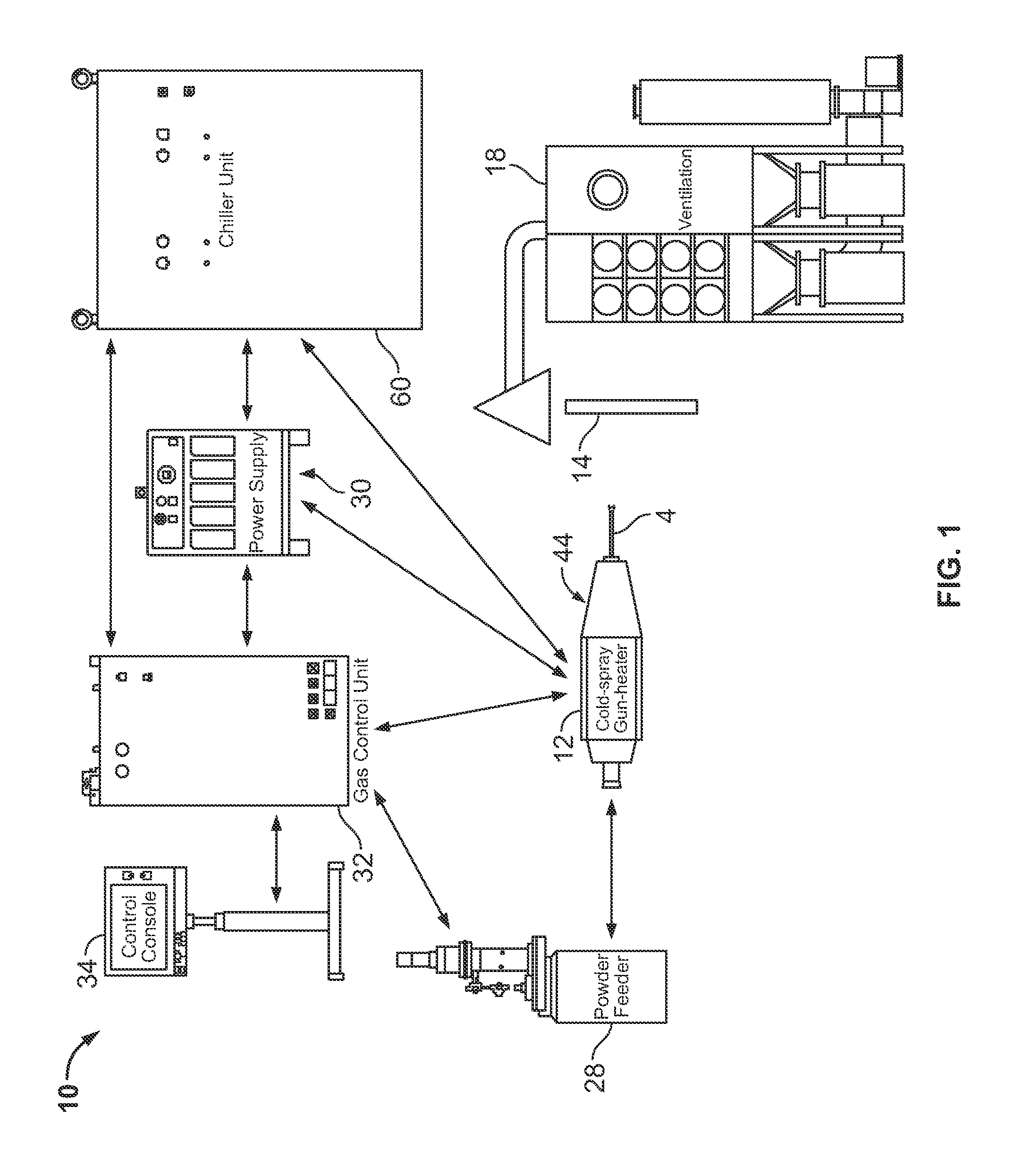

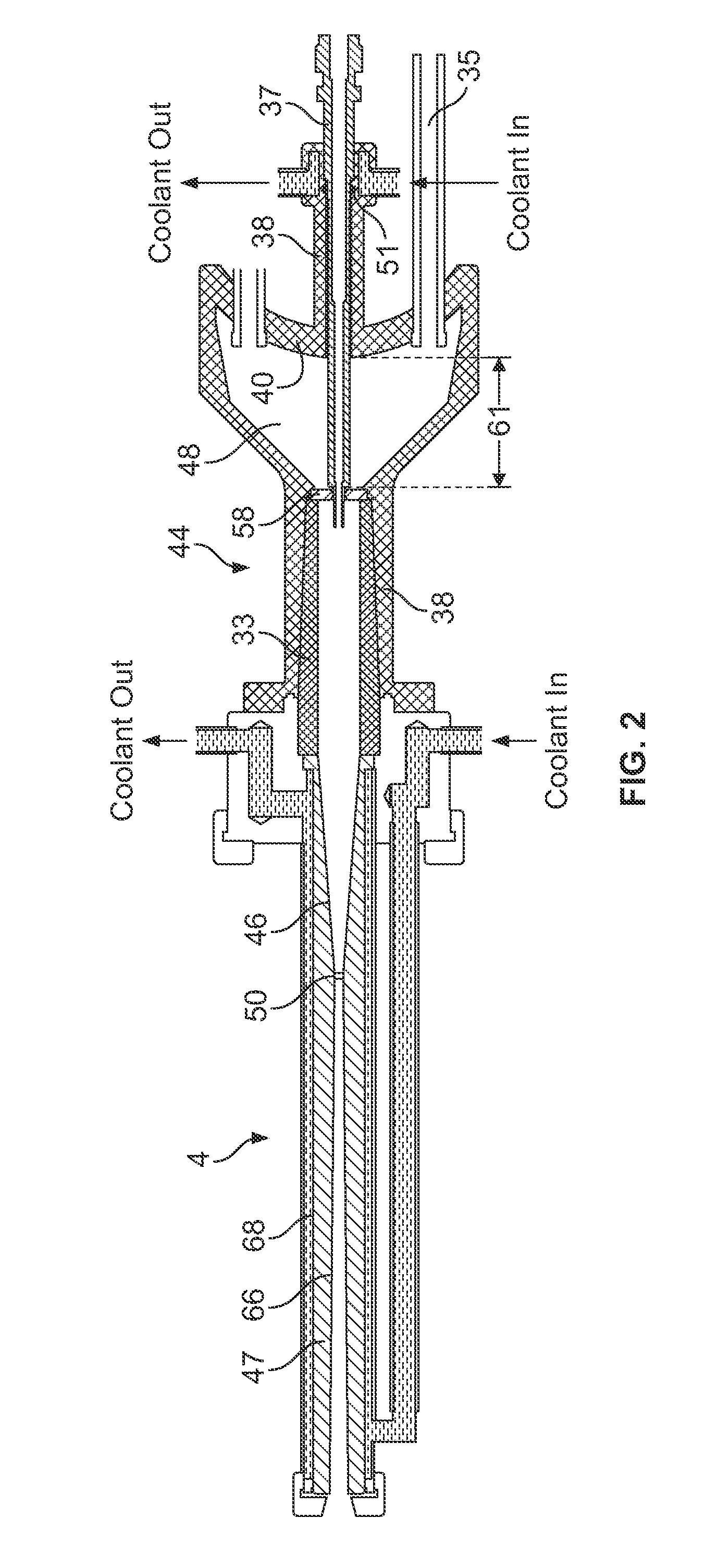

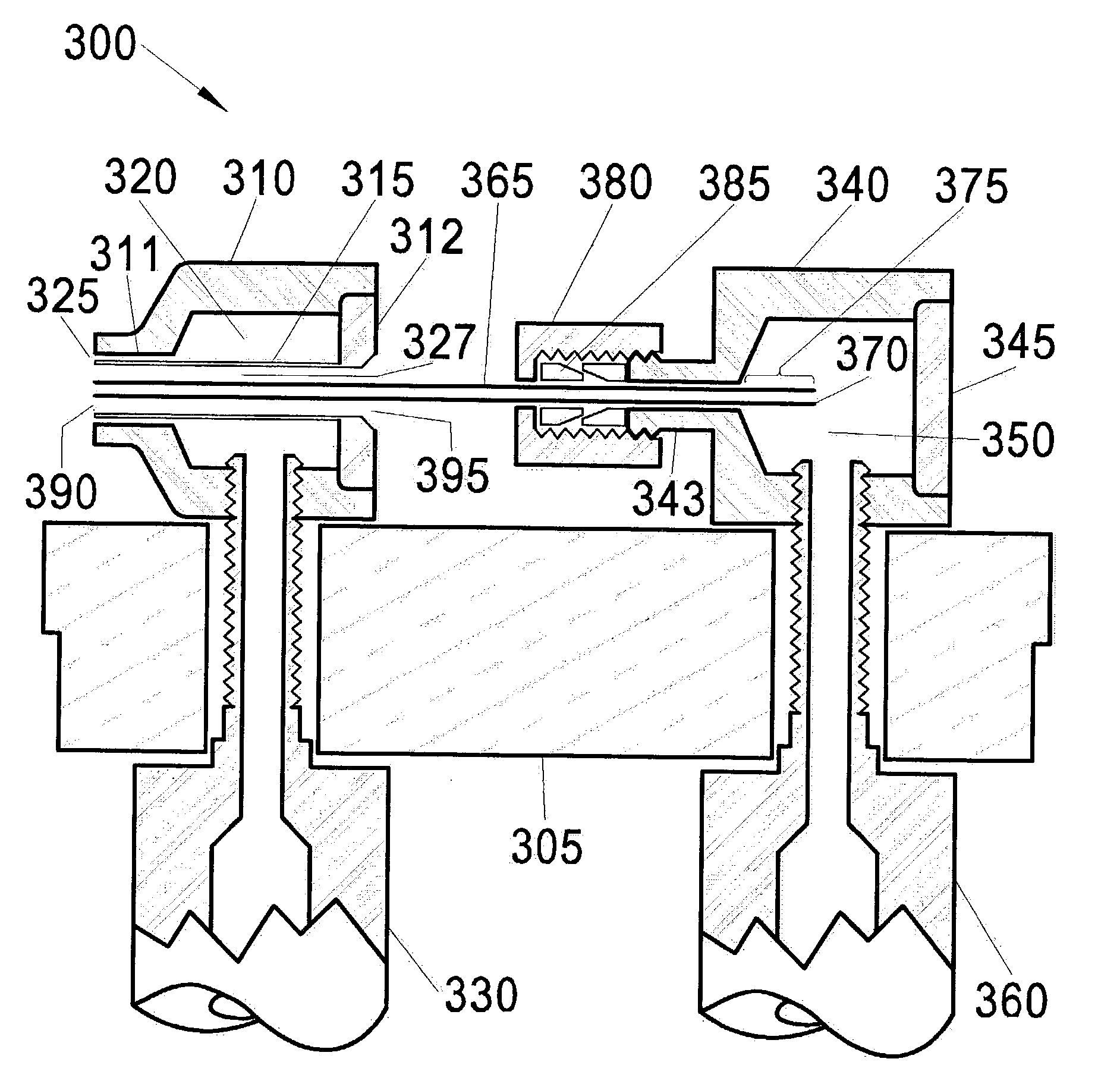

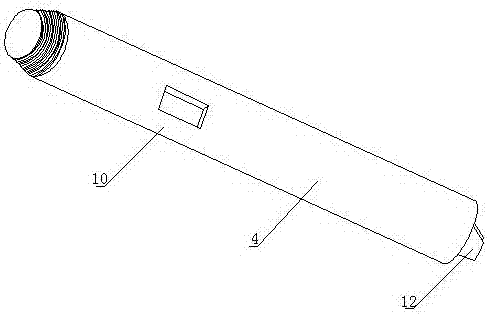

Cold spray gun

InactiveUS20130087633A1Improved cooling systemLiquid surface applicatorsSpray nozzlesEngineeringVolumetric Mass Density

An improved cold spray gun apparatus and system, which prevents nozzle clogging and erosion of the nozzle material. The nozzle can be configured as a non-monolithic assembly that includes a passageway for spraying powder material. The passageway can include a converging section and a diverging section. Such an arrangement is, in part, a result of a selection of specific nozzle material for the diverging section and a cooling system. The improved cold spray gun enables applying coatings at high spray parameters (e.g., pressure up to 5 MPa, temperature up to and in excess of 1000° C.), and can achieve high quality coatings, deposition efficiency, density, adhesion and cohesion, and other advantages. Additionally, the disclosed apparatus makes it possible to spray a wide range of powder materials in commercial applications without nozzle clogging or nozzle erosion during continuous operation.

Owner:PLASMA GIKEN +1

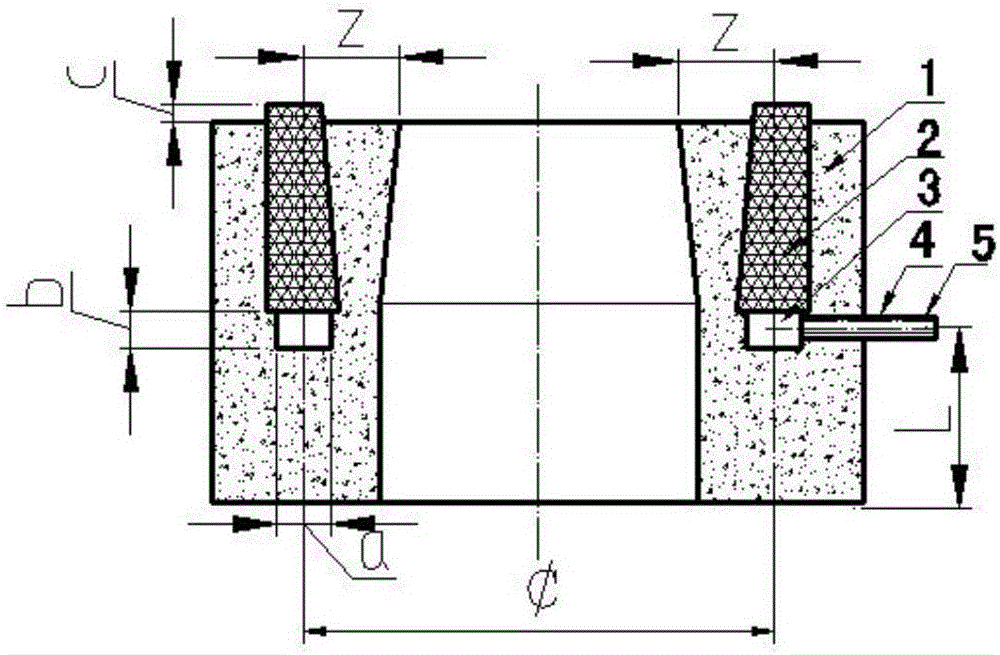

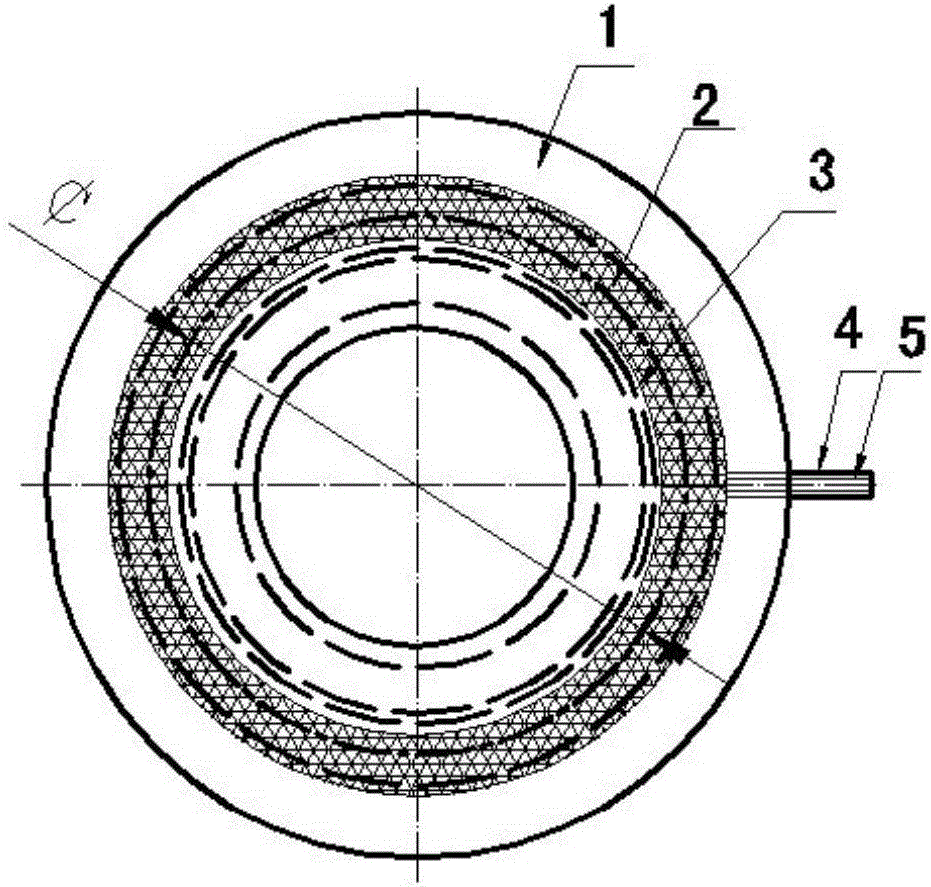

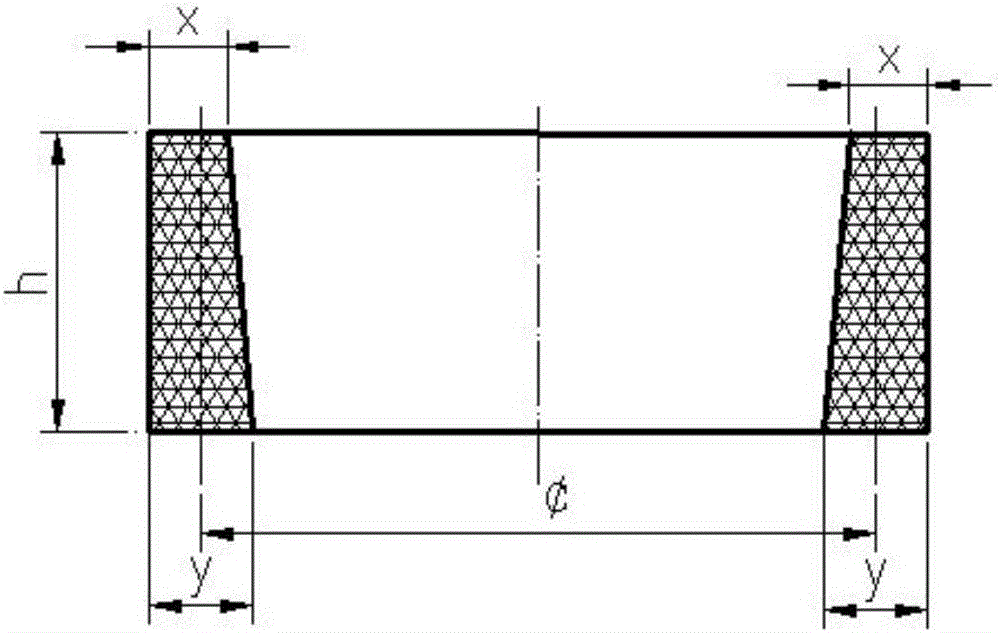

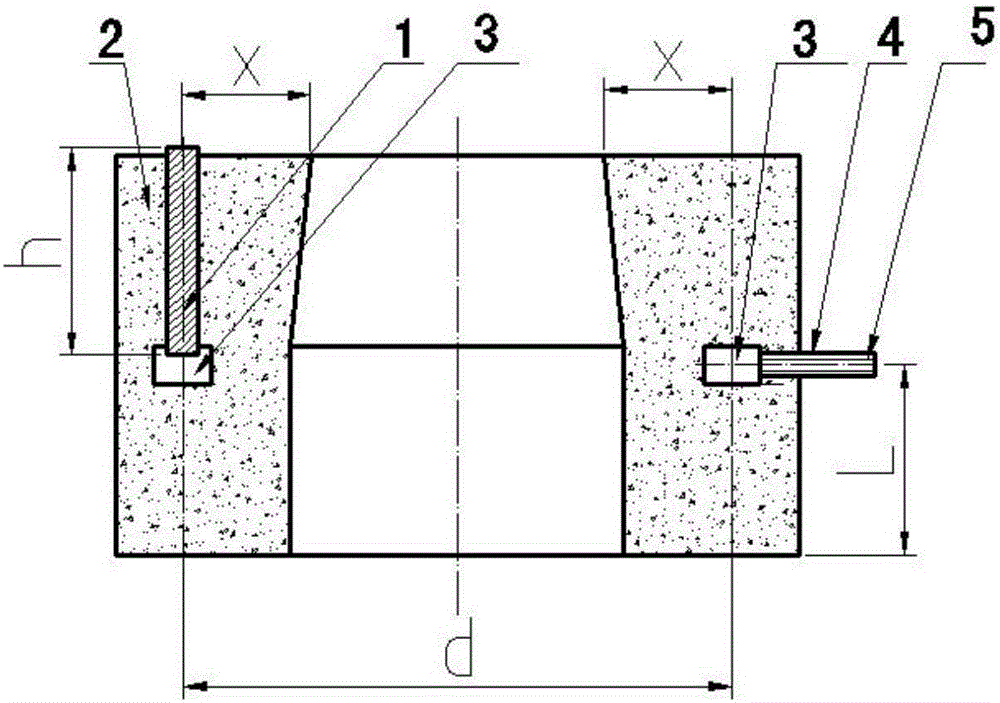

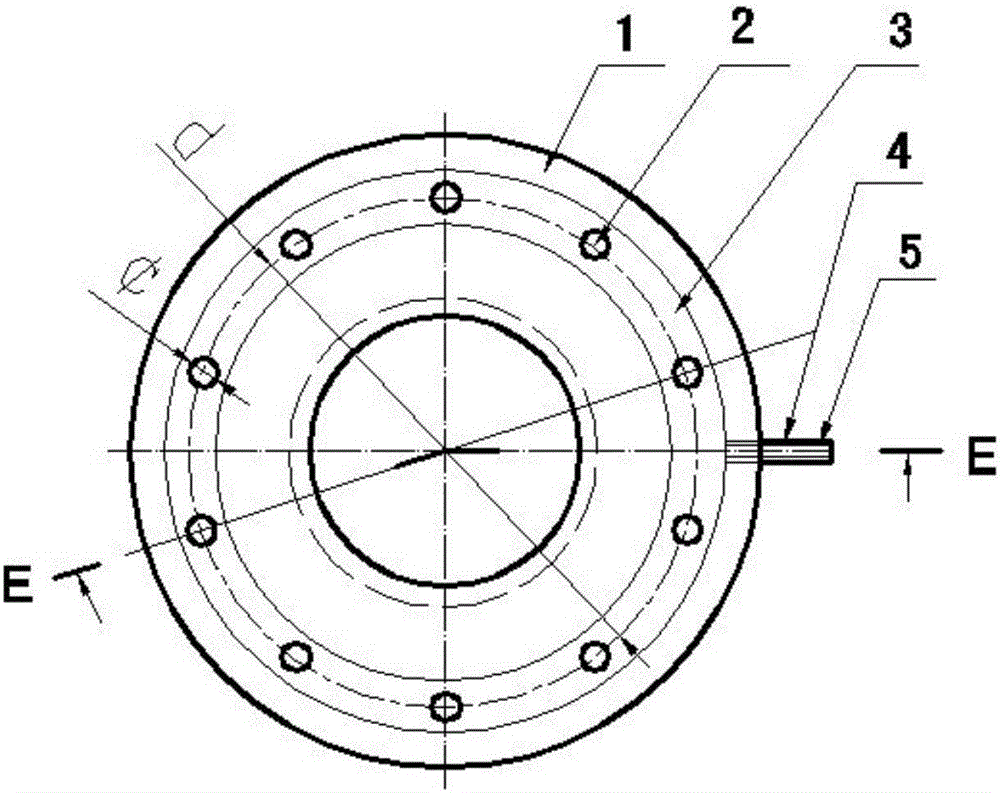

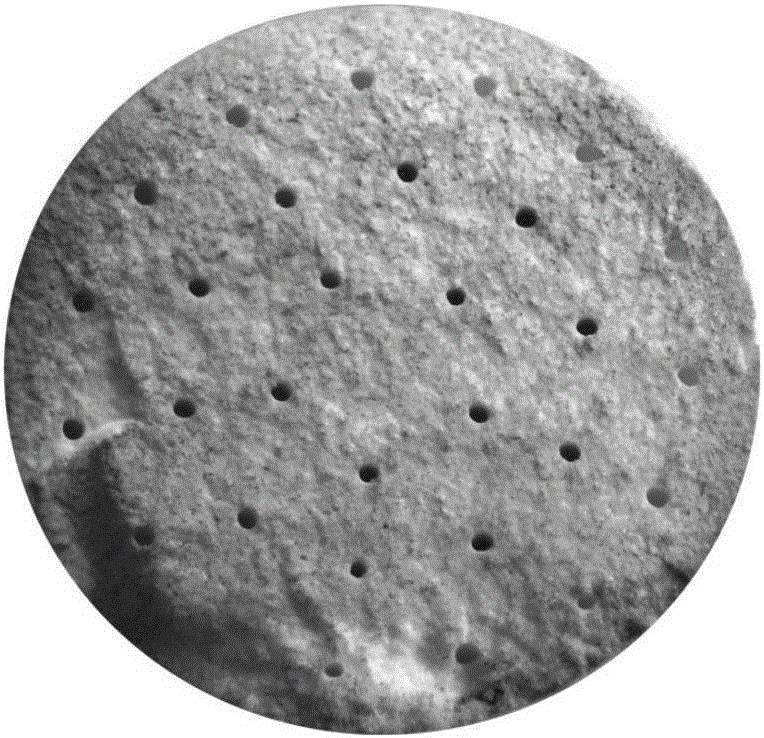

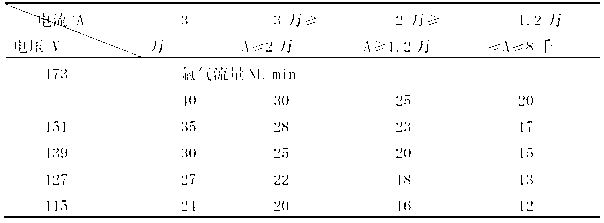

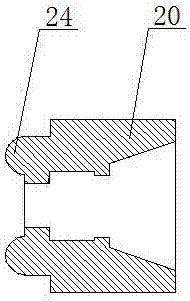

Continuous casting tundish diffuse-type gas-permeable ring upper nozzle brick cup and argon blowing refining method thereof

The invention relates to a continuous casting tundish diffuse-type gas-permeable ring upper nozzle brick cup and an argon blowing refining method thereof. The upper nozzle brick cup comprises an upper nozzle brick cup body, diffuse-type gas-permeable rings, a gas chamber and a gas inlet pipe, wherein the gas-permeable rings are uniformly arranged in a circle; the gas-permeable rings and the circular gas chamber are arranged in the upper nozzle brick cup body; the air chamber is arranged at the bottoms of the diffuse-type gas-permeable rings and communicate with the diffuse-type gas-permeable rings; the upper parts of the gas-permeable rings extend out of the upper surface of the upper nozzle brick cup body by 5 to 10 mm; the gas inlet pipe is connected to one side part of the gas chamber; one end of the gas inlet pipe communicates with the air chamber; the other end of the gas inlet pipe extends out of one side part of the upper nozzle brick cup body, is connected with a metal pipe fitting and communicates with an external argon gas source; an upward circular air curtain barrier is formed after argon gas is blown into the gas inlet pipe, so that gas washing of molten steel entering an upper nozzle is realized, and floating and removing of inclusions are promoted; and a certain quantity of argon bubbles enter the upper nozzle along with a steel flow, so that a stable and continuous circular gas flow is formed, which not only solves the problem of nozzle clogging, but also solves the technical problem that protective argon bubbles enter steel to cause sub-surface bubbles of a casting blank.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Electrode container box, printing device and nozzle inspection method

InactiveUS20070134969A1Coupling device detailsOther printing apparatusBiomedical engineeringHead parts

A cap 41 is used for nozzle inspections for clogging on the basis of a waveform of an output signal at a print head 24 when, in a state in which a potential difference has been generated among the print head 24, a regulating member 143 that is the opposing electrode opposite to the print head 24, or an ink-absorbing member 142, an operation is performed of ejecting ink from the nozzles 23 of the print head 24 to an opposing electrode. The cap 41 comprises a box member 141 in which the regulating member 143 and the ink-absorbing member 142 are contained and an electrode pin 145 that penetrates the box member 141 in a liquid-tight manner, and that is electrically connected with the regulating member 143. Thus, even when ink accumulates in the box member 141 after a nozzle inspection for clogging has taken place, no ink will leak from the part that the electrode pin 145 penetrates.

Owner:SEIKO EPSON CORP

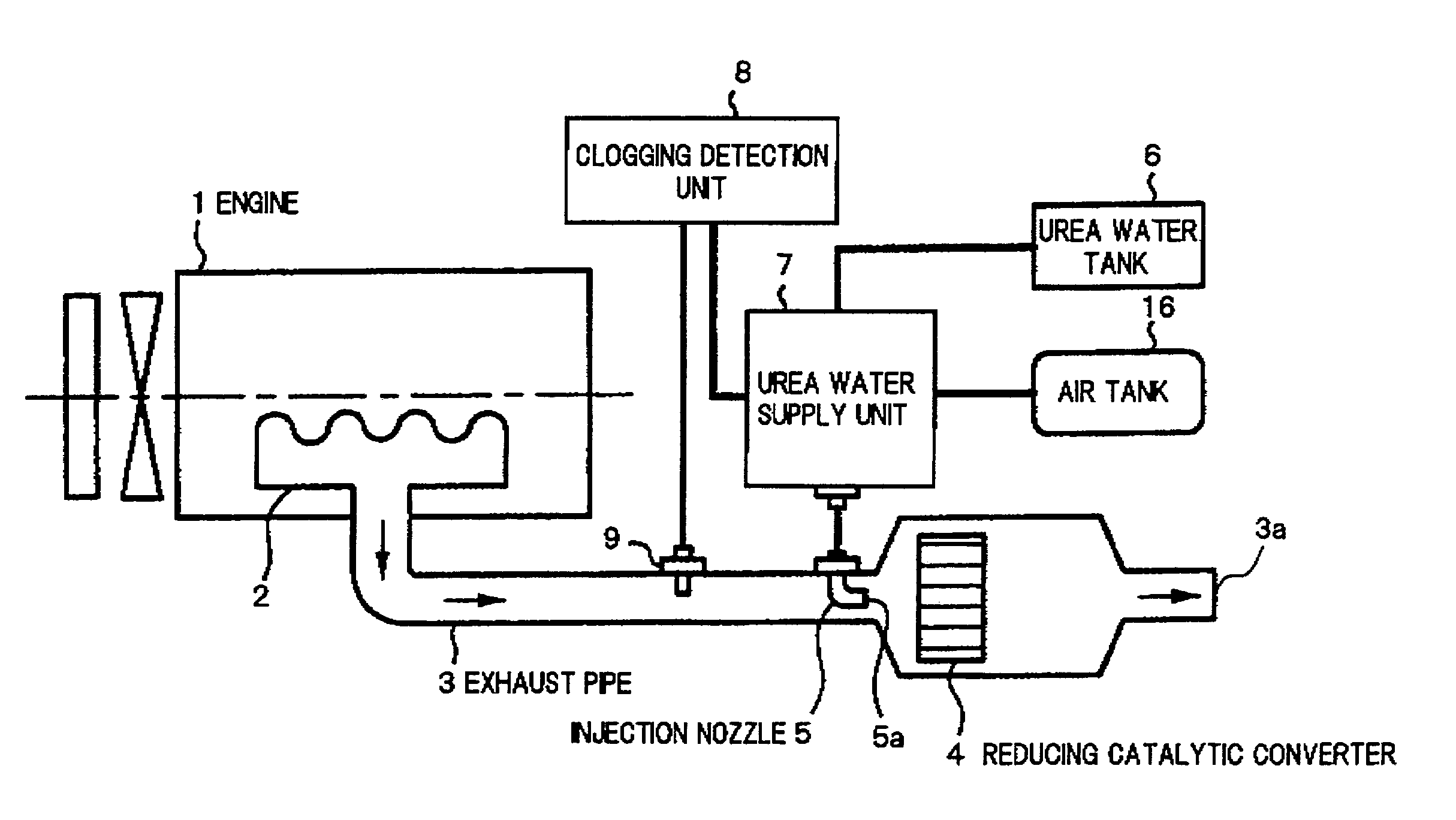

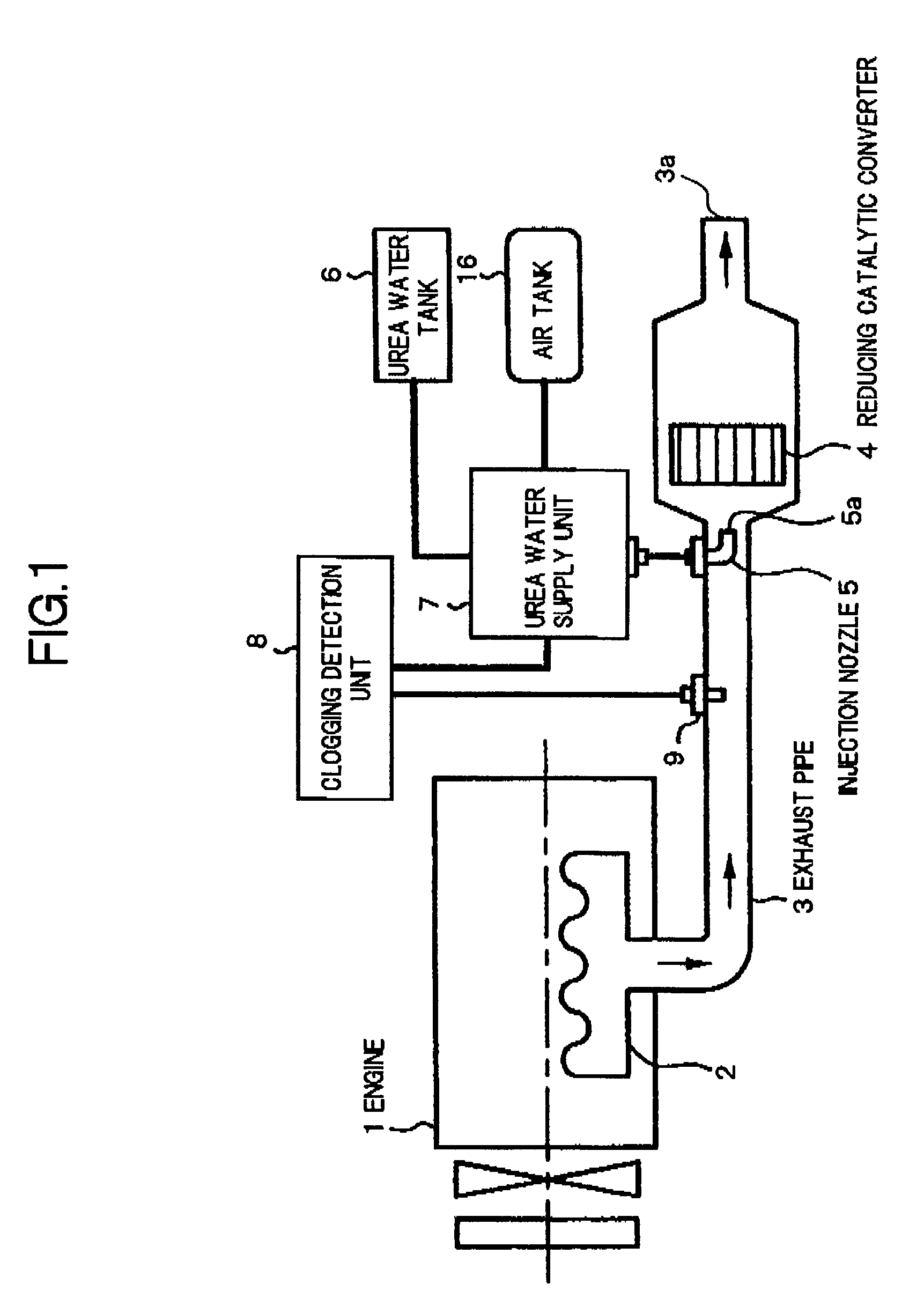

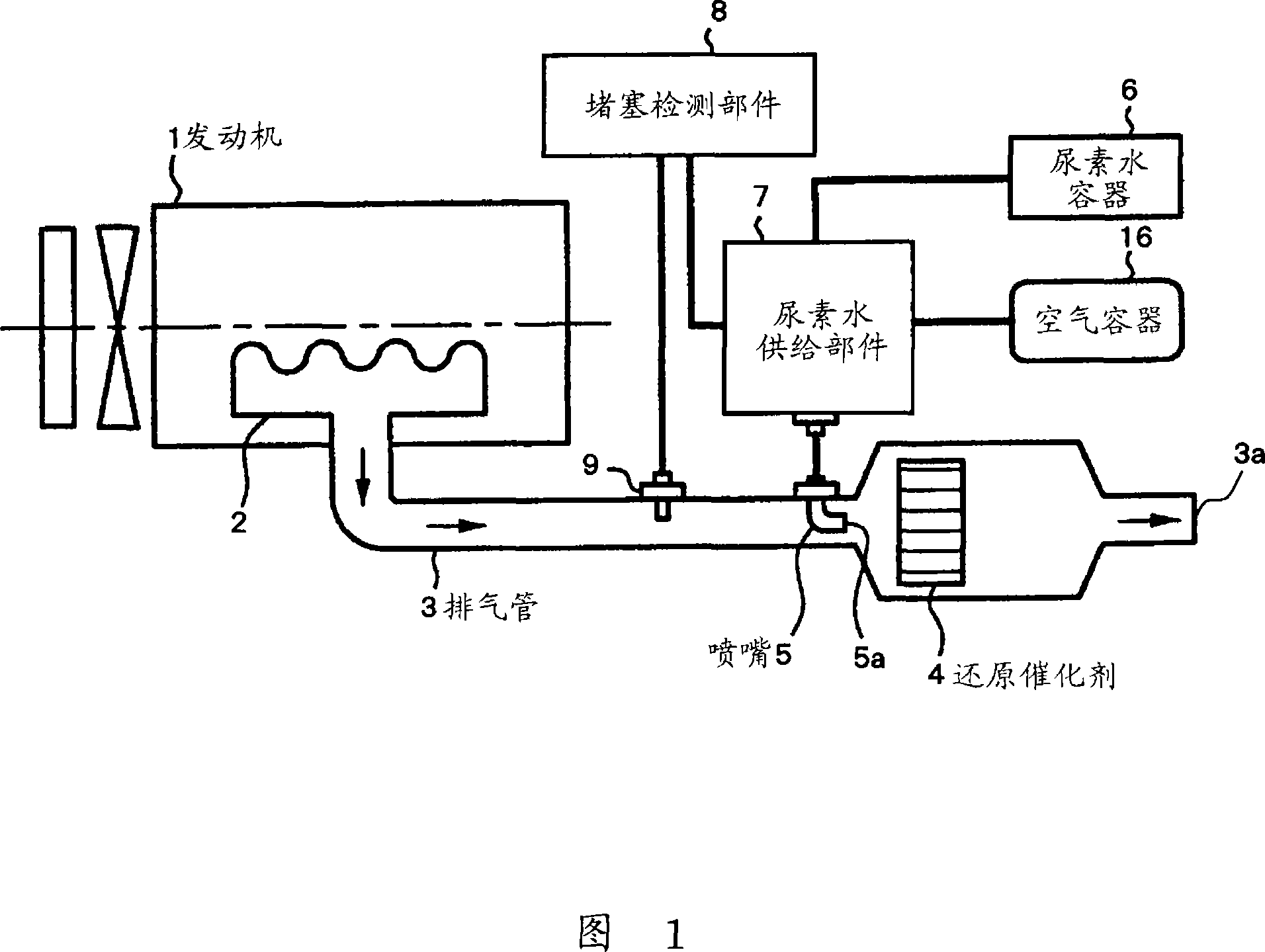

Exhaust gas purification apparatus

ActiveUS7743603B2Prevent false detectionAvoid mistakesGas treatmentElectrical controlNitrogen oxidesExhaust fumes

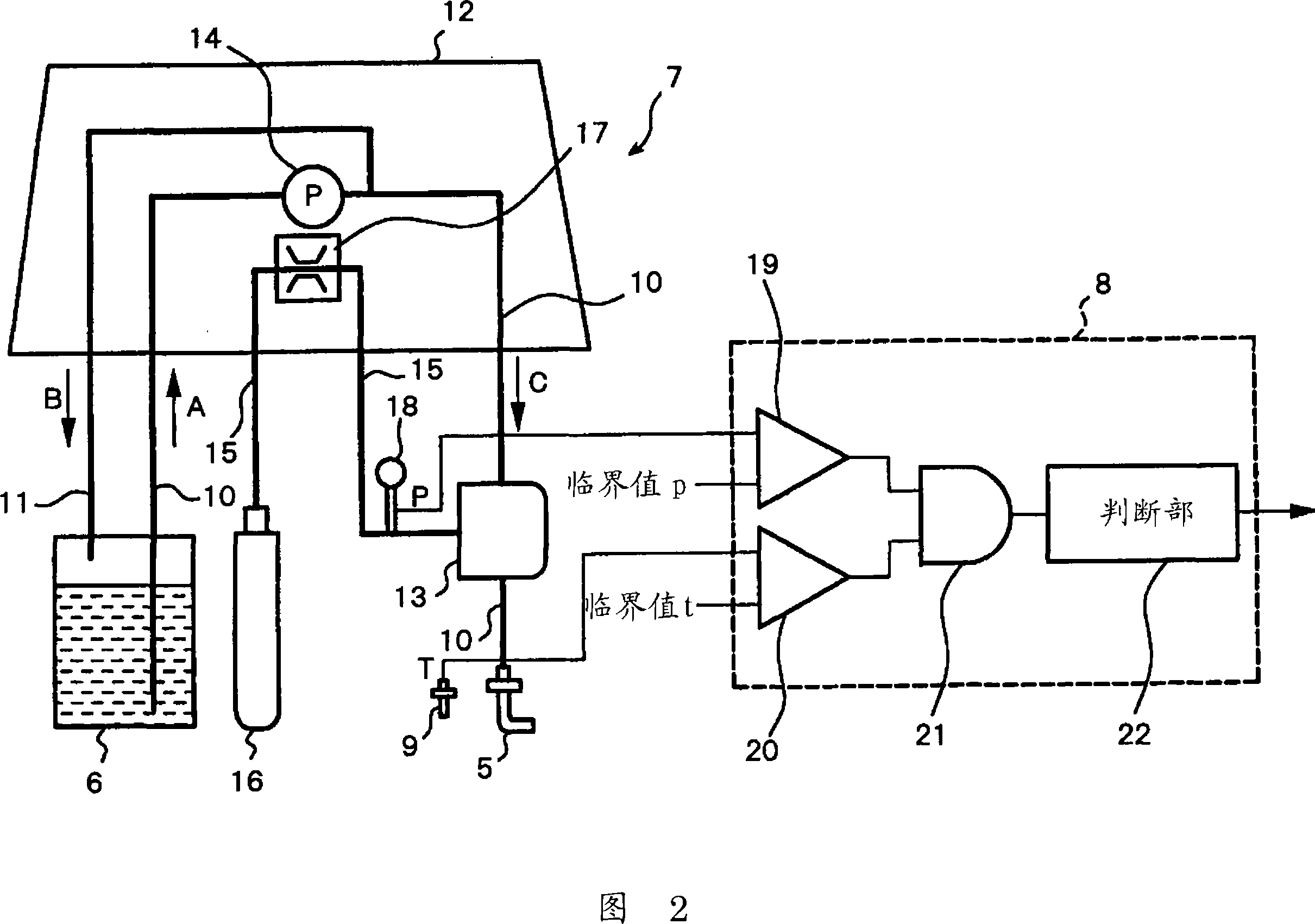

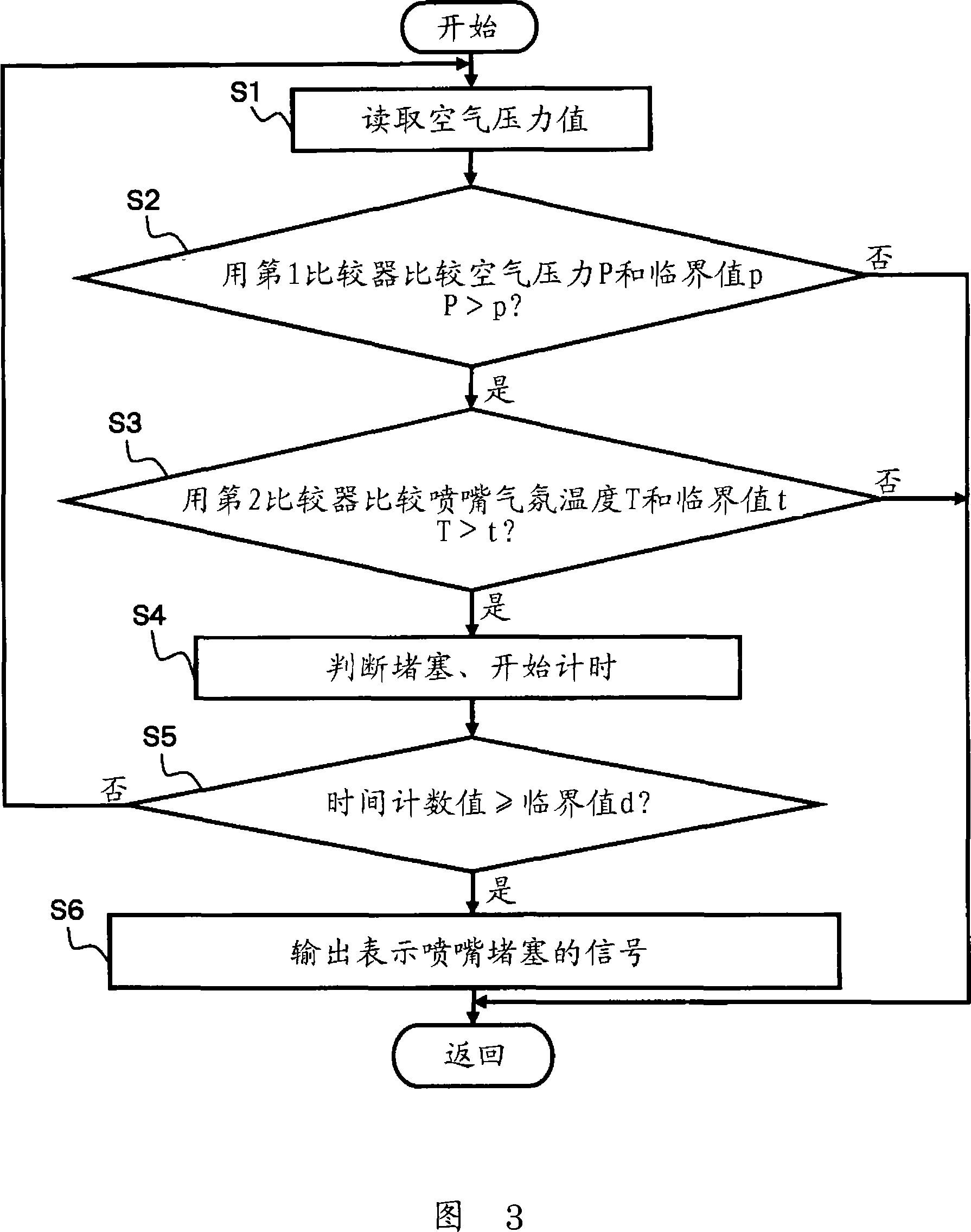

An exhaust gas purification apparatus of an engine, capable of preventing erroneous detection of an injection nozzle clogging, and having a reducing catalytic converter disposed in an exhaust system, for reducing and purifying nitrogen oxide in the exhaust gas using urea water; a urea water tank storing the urea water; a urea water supply unit sucking up the urea water from the urea water tank and mixes it with high-pressure air for delivery; and an injection nozzle injecting the urea water mixed with the high-pressure air, into an exhaust gas moving upstream side of the reducing catalytic converter in an exhaust gas passage, and further having a clogging detection unit capable of detecting clogging of the injection nozzle based on each detection output of a pressure of the air introduced into the urea water supply unit, and a temperature of the injection nozzle.

Owner:VOLVO LASTVAGNAR AB

Nozzle testing before and after nozzle cleaning

InactiveUS6764159B2Degradation of image qualityLow ability to clearOther printing apparatusNozzle cloggingNozzle

It is an object of the invention to provide a technique for reducing the likelihood that cleaning will cause nozzle clogging. In periodic automatic cleaning of a printer that is not being used, the ejecting of ink droplets from each nozzle is tested prior to the cleaning to determine whether each nozzle is an operating nozzle capable of ejecting ink droplets or a non-operating nozzle incapable of ejecting ink droplets. The nozzles are only cleaned if non-operating nozzles are detected. The testing of the nozzles is also automatically carried out after cleaning.

Owner:SEIKO EPSON CORP

Production method of billet continuous casting bearing steel

The invention discloses a production method of billet continuous casting bearing steel. The method comprises the following steps: (1) injecting molten steel after refinement into a tundish and controlling the superheat degree of the molten steel in the tundish to be 25-45 DEG C; (2) injecting the molten steel in the tundish into a crystallizer for crystallization under the electromagnetic stirring effect of the crystallizer, and adding crystallizer protection slag into the crystallizer; (3) pulling out crystals from the crystallizer to obtain a continuous casting billet, and cooling the continuous casting billet by enabling the continuous casting billet to pass through a secondary cooling zone and an air cooling zone in sequence. According to the production method provided by the invention, the occurrence rate of nozzle clogging of the tundish can be reduced and the quality defects of slag pits in the surface of the continuous casting billet, cracks on the surface and under the skin of the casting billet, segregation and looseness of the casting billet and the like in a billet continuous casting production process are overcome.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

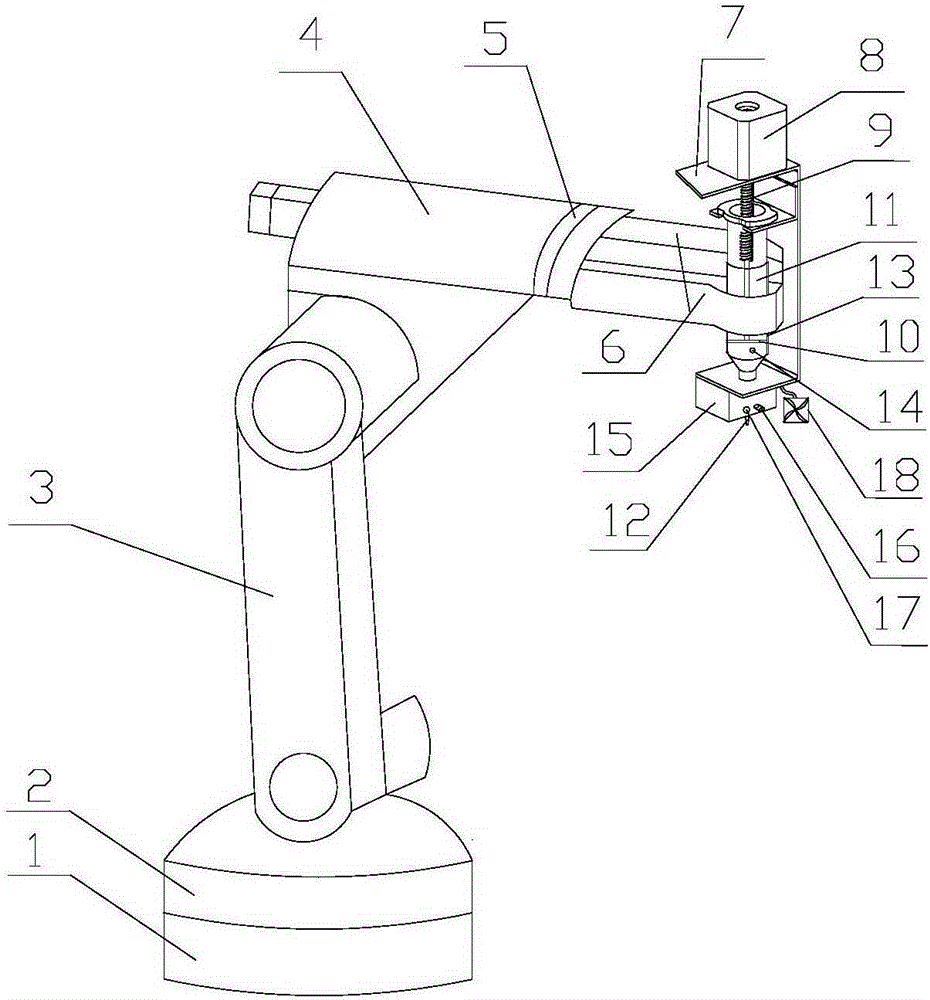

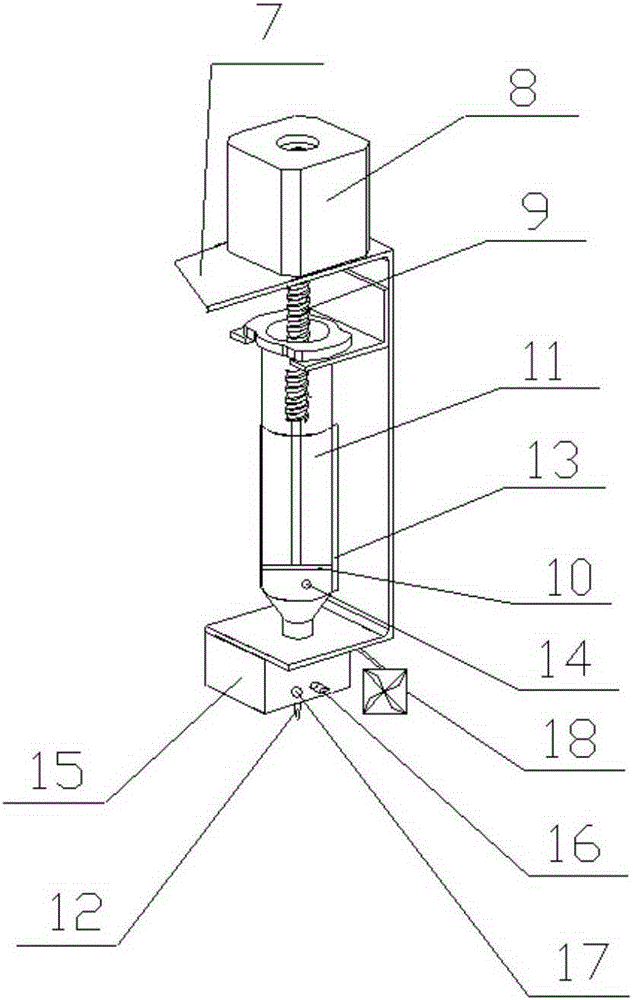

Mechanical arm-based 3D food printer

InactiveCN105341280APrint space openEasy to integrateAdditive manufacturing apparatusCocoaNozzle cloggingRaw material

The present invention provides a mechanical arm-based 3D food printer which includes a mechanical arm, a feeding device, a heating device and a cooling device The feeding device is arranged on the mechanical arm. The mechanical arm-based 3D food printer realizes a 360 degree all-round print around the mechanical arm by controlling the mechanical arm movement, is large print range and open in print space, and can print multiple food once and print food pattern anywhere. The heating device installed on the feeding device avoids food raw material condensation and nozzle clogging caused by food cooling and improves the printing accuracy. The cooling device is used to conduct temperature lowering for just print food.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

Exhaust gas purification apparatus

ActiveCN101076657ASuppress false detectionEasy to judgeGas treatmentElectrical controlNitrogen oxidesHigh pressure

An exhaust gas purification device where occurrence of detection failure of injection nozzle clogging is suppressed. An exhaust gas purification device for an engine, having a reduction catalyst (4) provided in the exhaust system of the engine (1) and reducing and purifying a nitrogen oxide in exhaust gas by a urea water, a urea water tank (6) storing the urea water, a urea water supply means (7) for sucking up the urea water and sending it out after mixing it with high-pressure air, and an injection nozzle (5) for injecting the urea water, mixed with the high-pressure air, inside an exhaust pipe (3) of the exhaust gas system, to the exhaust gas upstream side of the reduction catalyst (4). The exhaust gas purification device further has a clogging detection means (8) for detecting clogging of the injection nozzle based on a detection output on the pressure of air introduced into the urea water supply means (7) and a detection output on the temperature of the injection nozzle (5).

Owner:VOLVO TRUCK CORP

Liquid jet recording apparatus using a fine particle dispersion recording composition

InactiveUS6871940B2Clogging problemImprove light resistanceInking apparatusDuplicating/marking methodsLiquid jetEngineering

In an apparatus producing a high-quality and high-resolution image having high water and light resistances with an orifice having a diameter less than φ25 μm (less than 500 μm2 in terms of cross-sectional area of the orifice) by use of a fine particle dispersion recording composition, nozzle clogging can be prevented. A recording is accomplished by a liquid jet recording apparatus for ejecting a recording composition including dispersed fine particles from a small orifice toward a receiving medium, wherein a size Dp of the fine particles and a diameter Do of the small orifice are determined by a relationship 0.001≦Dp / Do≦0.01.

Owner:RICOH KK

Method for production of non-oriented electrical steel strip

InactiveUS20050000596A1Excellent physicalExcellent magnetic characteristicInorganic material magnetismElectrical steelTransformer

The present invention relates to a method for producing a non-oriented electrical steel with improved magnetic properties and improved resistance to ridging, brittleness, nozzle clogging and magnetic aging.. The chromium bearing steel is produced from a steel melt which is cast as a thin slab or conventional slab, cooled, hot rolled and / or cold rolled into a finished strip. The finished strip is further subjected to at least one annealing treatment wherein the magnetic properties are developed, making the steel sheet of the present invention suitable for use in electrical machinery such as motors or transformers.

Owner:AK STEEL PROPERTIES +1

Inkjet recording ink for sublimation transfer and method of dyeing

InactiveUS7234805B2Reduce environmental pollutionMaintain performanceMeasurement apparatus componentsDuplicating/marking methodsDispersion stabilityCarbon number

An ink for sublimation transfer ink jet recording includes water, at least one sugar alcohol containing not less than four OH groups, a sublimation dye, a dispersant, and a compound expressed by the following chemical formula (I):R—O—(CH2CH2O)n—H (I)where R is an alkyl group having a carbon number of 25 to 150 and n is from 2 to 100. The ink is printed on a sheet medium by ink jet printing, and then the sheet medium is heated to sublimate and transfer the sublimation dye onto an object to be dyed. The ink for ink jet recording and the sublimation transfer dyeing method using the ink not only can maintain performances such as storage stability and high-quality recording images, but also can reduce environmental pollution, effectively prevent nozzle clogging, exhibit good dispersion stability, and achieve a high redispersion property that ensures stable ejection both during long continuous operation and after stopping the operation for a long time.

Owner:KIWA CHEM IND CO LTD

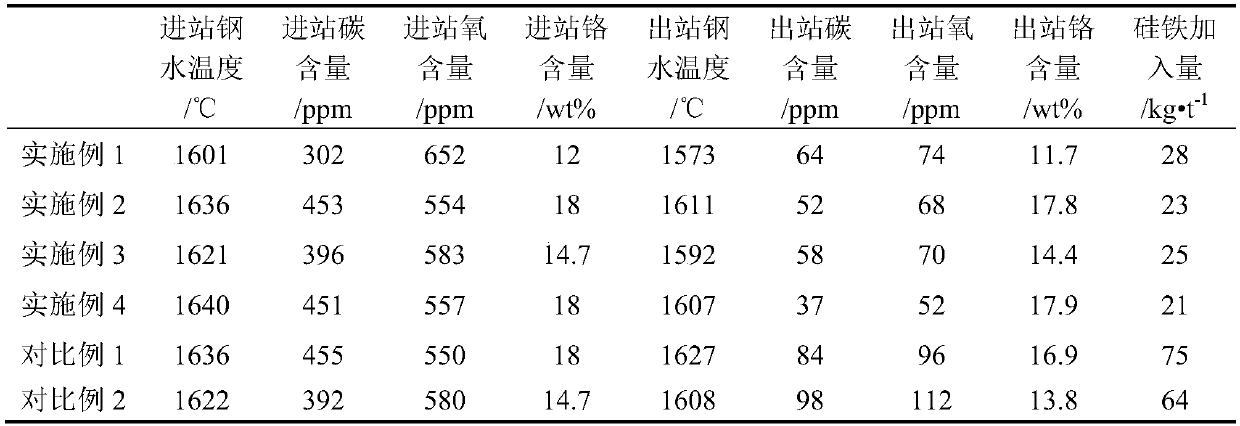

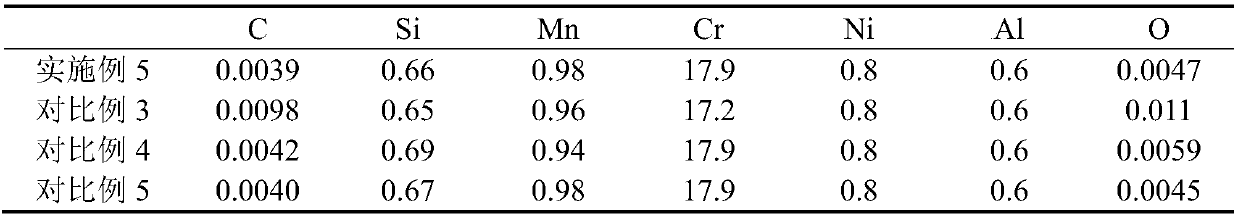

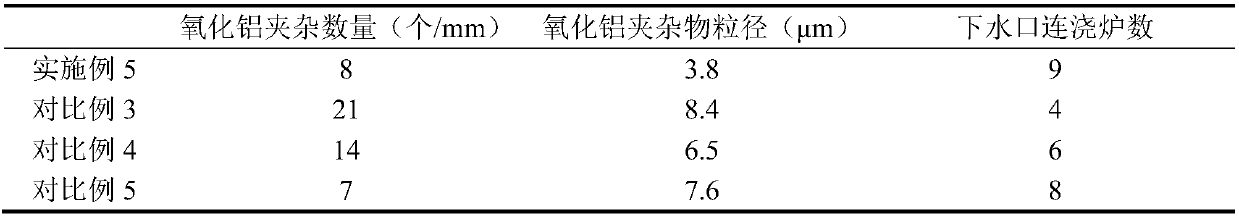

RH refining method of low-carbon stainless steel

The invention provides an RH refining method of low-carbon stainless steel. Under the condition that the incoming carbon and oxygen contents are high, the carbon, oxygen and hydrogen contents of molten steel can be fast reduced to the ultralow level through high-temperature preliminary decarburization, oxygen blowing forced decarburization, hydrogen blowing deoxygenation and vacuum degassing, meanwhile, chromium keeps the high yield, the slag amount can be reduced, aluminum is not used for deoxygenation, and aluminum oxide occluded foreign substances are reduced. The RH refining method can befurther used for smelting low-carbon high-aluminum stainless steel, the aluminum adding process and the hydrogen blowing process cooperate, aluminum is added after hydrogen blowing is circulated for aperiod of time, hydrogen blowing continues, the content of acid soluble aluminum in the steel can be increased, aluminum consumption can be reduced, and the number and particle size of the aluminum oxide occluded foreign substances are reduced. By means of the RH refining method of the low-carbon stainless steel, the cleanliness degree of the molten steel can be improved, nozzle clogging in the continuous casting process is avoided, the production efficiency is improved, the production cost is reduced, and the product quality is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Continuous casting tundish breathable ceramic tube upper nozzle brick cup and argon blowing refining method thereof

The invention relates to a continuous casting tundish breathable ceramic tube upper nozzle brick cup and an argon blowing refining method thereof. The upper nozzle brick cup comprises an upper nozzle brick cup body, a plurality of ceramic tubes, a gas chamber and a gas inlet pipe, wherein the ceramic tubes are uniformly arranged in a circle; the ceramic tubes and the circular gas chamber are arranged in the upper nozzle brick cup body; a plurality of sockets are uniformly arranged on the gas chamber in a circle; the top ends of the ceramic tubes extend out of the upper surface of the upper nozzle brick cup body by 5 to 10 mm; the lower ends of the ceramic tubes are fixed in the sockets on the gas chamber, and communicate with the gas chamber; the gas inlet pipe is connected to one side part of the gas chamber, and communicates with an external argon gas source by being connected with a metal pipe fitting; an upward circular air curtain barrier is formed after argon gas is blown into the gas inlet pipe, so that gas washing of molten steel entering an upper nozzle is realized; and a certain quantity of argon bubbles enter the upper nozzle along with a steel flow, so that a stable and continuous circular gas flow is formed, which not only solves the problem of nozzle clogging, but also solves the technical problem that protective argon bubbles enter steel to cause sub-surface bubbles of a casting blank.

Owner:SHANDONG IRON & STEEL CO LTD

Inkjet recording ink for sublimation transfer and method of dyeing

InactiveUS20050036019A1Reduce environmental pollutionMaintain performanceMeasurement apparatus componentsDuplicating/marking methodsDispersion stabilityCarbon number

An ink for sublimation transfer ink jet recording includes water, at least one sugar alcohol containing not less than four OH groups, a sublimation dye, a dispersant, and a compound expressed by the following chemical formula (I):R—O—(CH2CH2O)n—H (I)where R is an alkyl group having a carbon number of 25 to 150 and n is from 2 to 100. The ink is printed on a sheet medium by ink jet printing, and then the sheet medium is heated to sublimate and transfer the sublimation dye onto an object to be dyed. The ink for ink jet recording and the sublimation transfer dyeing method using the ink not only can maintain performances such as storage stability and high-quality recording images, but also can reduce environmental pollution, effectively prevent nozzle clogging, exhibit good dispersion stability, and achieve a high redispersion property that ensures stable ejection both during long continuous operation and after stopping the operation for a long time.

Owner:KIWA CHEM IND CO LTD

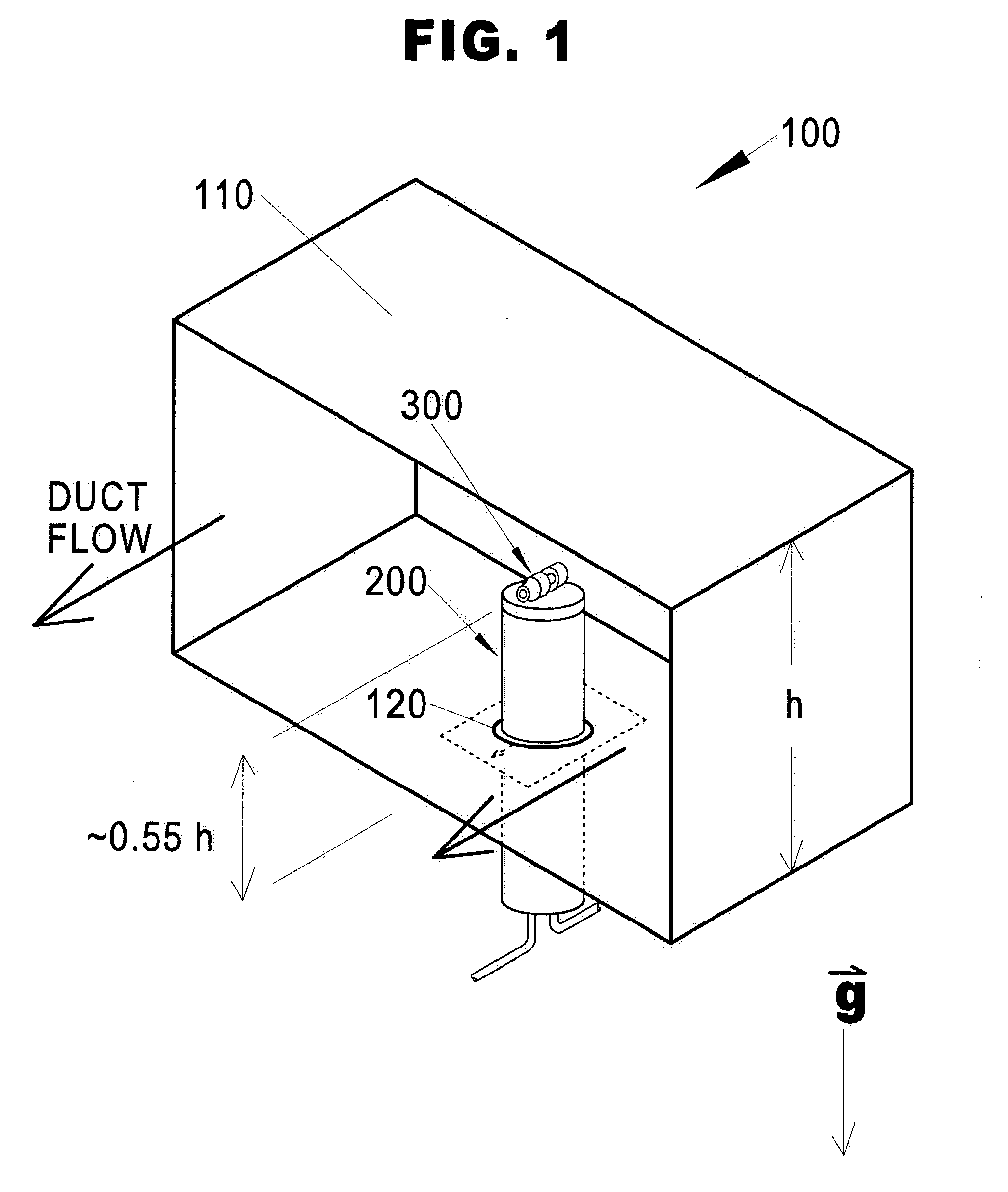

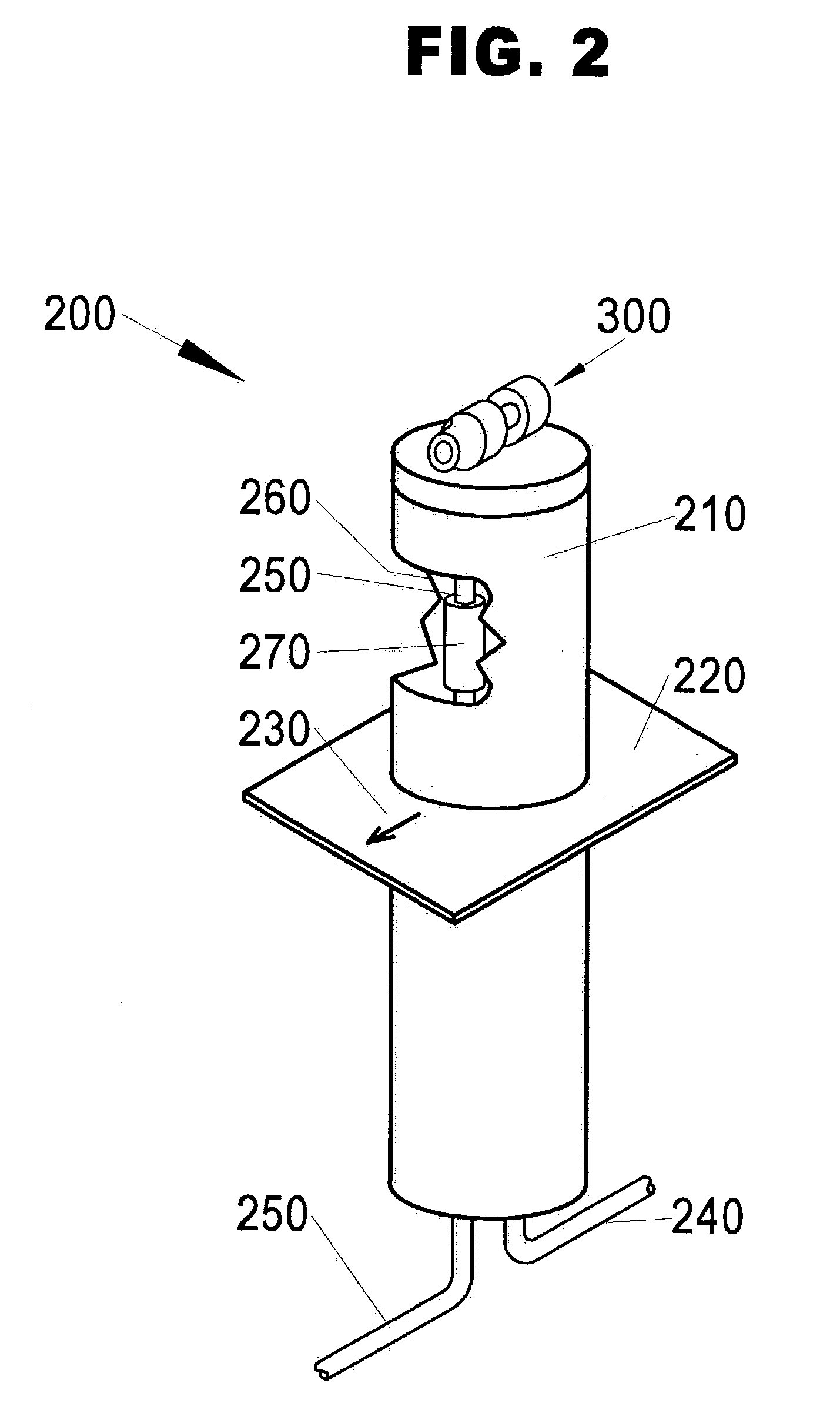

Method and apparatus for duct sealing using a clog-resistant insertable injector

A clog-resistant injector spray nozzle allows relatively unobtrusive insertion through a small access aperture into existing ductwork in occupied buildings for atomized particulate sealing of a ductwork. The spray nozzle comprises an easily cleaned and easily replaced straight liquid tube whose liquid contents are principally propelled by a heated propellant gas, such as heated air. Heat transfer is minimized from the heated propellant gas to the liquid tube until they both exit the injector, thereby greatly reducing the likelihood of nozzle clogging. A method of duct sealing using particles driven by heated propellant gas is described, whereby duct-sealing operations become both faster, and commercially practicable in inhabited commercial and residential buildings.

Owner:RGT UNIV OF CALIFORNIA

Nanometer pigment ink for computer to plate inkjet print and preparing method thereof

InactiveCN101747683AInksPhotosensitive materials for photomechanical apparatusOrganic solventImage resolution

The present invention relates to an environment-friendly nanometer pigment ink for computer to plate inkjet print and a preparing method thereof, belonging to the field of jet ink. The ink has long print life and good resolution ratio. Based on mass percentages, 5 to 40% of lipophilic crosslinkable resin, 2 to 10% of nanometer pigment, 2 to 10% of humectant and 40 to 91% of organic solvent are mixed. A stable system is formed after the ingredients are physically dispersed. The ink having the ingredients is printed on the surface of an aluminium plate treated with anodic oxidation by inkjet printing plate equipment to produce an image. The image can be directly printed on a machine, or baked at a certain temperature and then printed on the machine. Print life can be improved. The jet ink has the advantages of simple formula, fluent print, little possibility of nozzle clogging, excellent adaptability, high resolution rate of plates made and strong durability. The present invention provides an efficient and environment-friendly plate making ink for computer to plate inkjet print.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for smelting phosphorus-containing ultra-low carbon steel

The invention provides a method for smelting phosphorus-containing ultra-low carbon steel. The method comprises the first step of pretreating molten iron, specifically, blowing desulphurizing powder into the molten iron to enable the S content to be less than or equal to 0.003wt%, the second step of conducting deoxygenation and decarburization in a converter, blowing oxygen for 15-18 min, adding slag making materials, conducting slag-stopping and steel tapping when the content of C in the molten steel is less than or equal to 0.06%, the content of O reaches 0.05-0.09%, and the temperature of the molten steel in the converter reaches 1680-1720 DEG C, and adding 2-5 kg / t lime through an argon station, the third step of carrying out ladle furnace (LF) refining, specifically, adding slag former into a steel ladle, carrying out bottom argon blowing and stirring, transferring the molten steel to carry out RH vacuum refining, decarburization and denitrification when the temperature of the molten steel reaches 1630-1650 DEG C, carrying out alloying in batches when the content of C in the steel is less than or equal to 0.0050wt%, carrying out still standing for 15-25 min and then continuous casting when the content of compositions and temperature reach the target content and temperature, blowing argon into spaces between plates at a long nozzle, a stopper rod, an upper nozzle and a submerged nozzle when pouring is conducted on a tundish, and adding carbon-free covering agents to protect pouring. By means of the method, the purity degree of the molten steel and the castability of the steel can be improved, nozzle clogging is effectively controlled, the smelting production efficiency and the steel quality are improved, consumption of spare parts is reduced, and the cost of per ton of steel is lowered.

Owner:ANGANG STEEL CO LTD

Technological method for improving equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets

The invention provides a technological method for improving the equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets. The technological method comprises the steps of aprimary melting furnace, AOD, VOD, LF and continuous casting. According to the technological method provided by the invention, the equiaxed crystal ratio of the bistable ferrite stainless steel continuous casting billets is improved largely, and the cold machining and molding performances of ferrite stainless steel as well as the surface quality of products are improved; and the problems of nozzle clogging and blockage caused by TiN and TiOx generated by adding excessive Ti in the continuous casting technological process are solved effectively.

Owner:UNIV OF SCI & TECH BEIJING

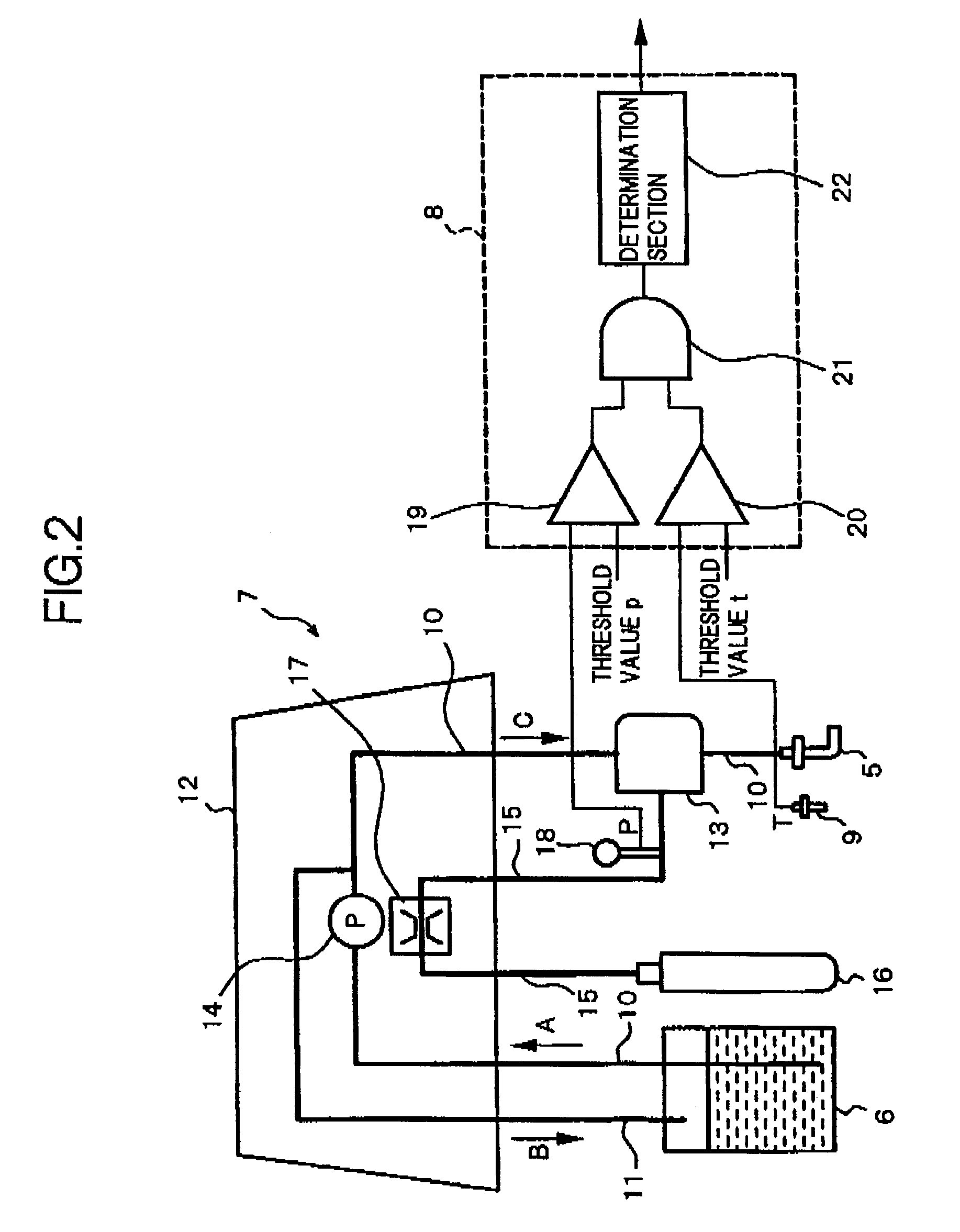

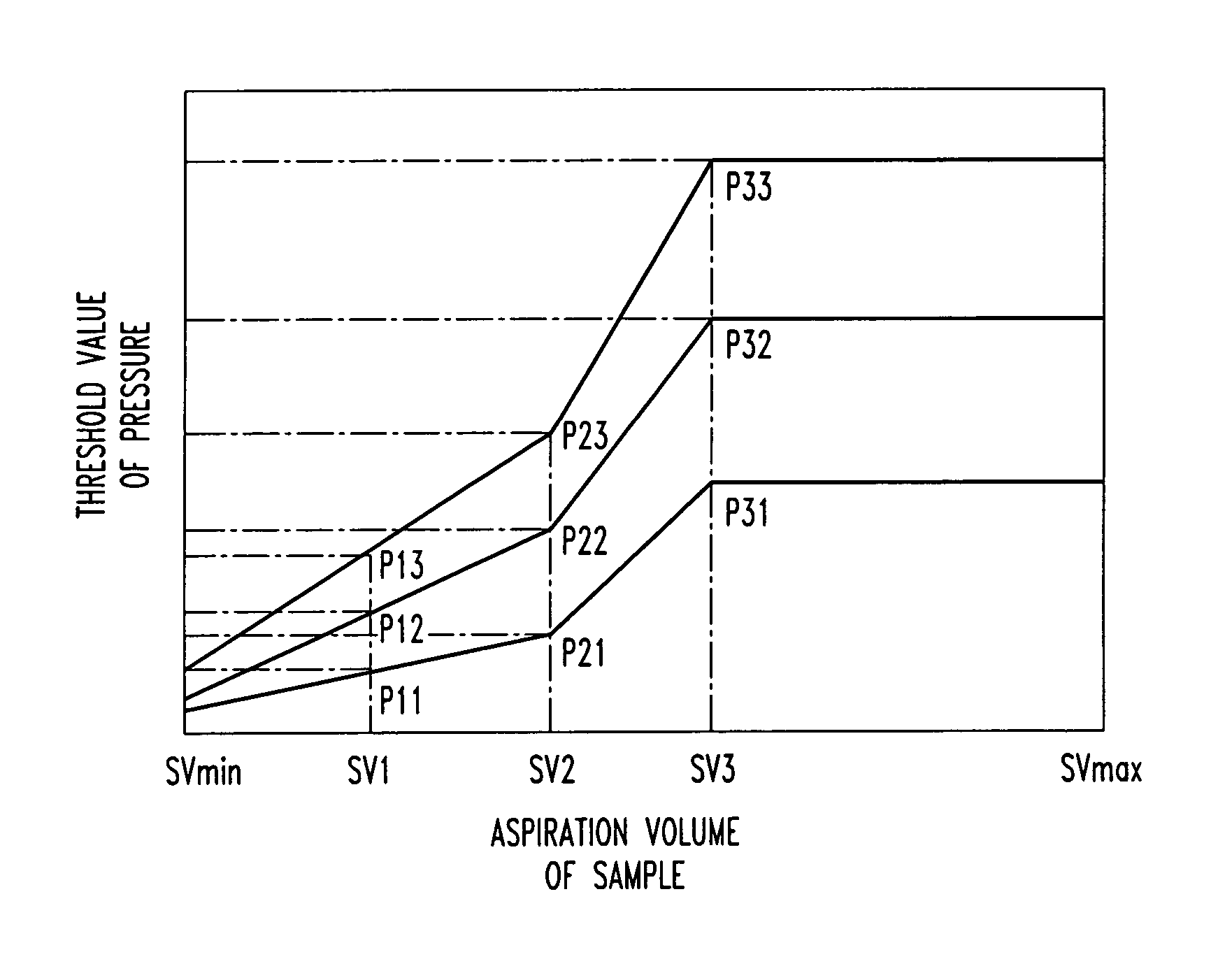

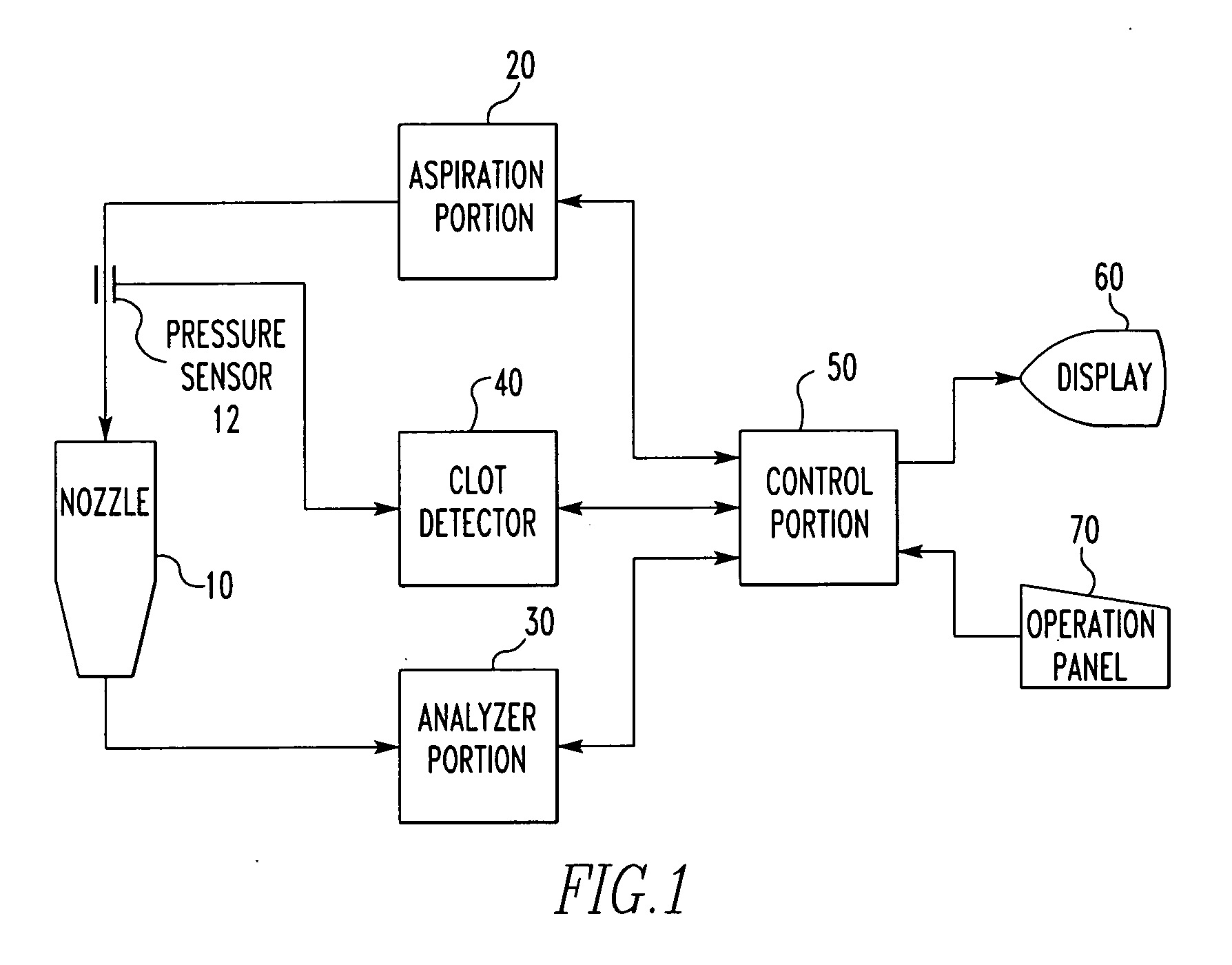

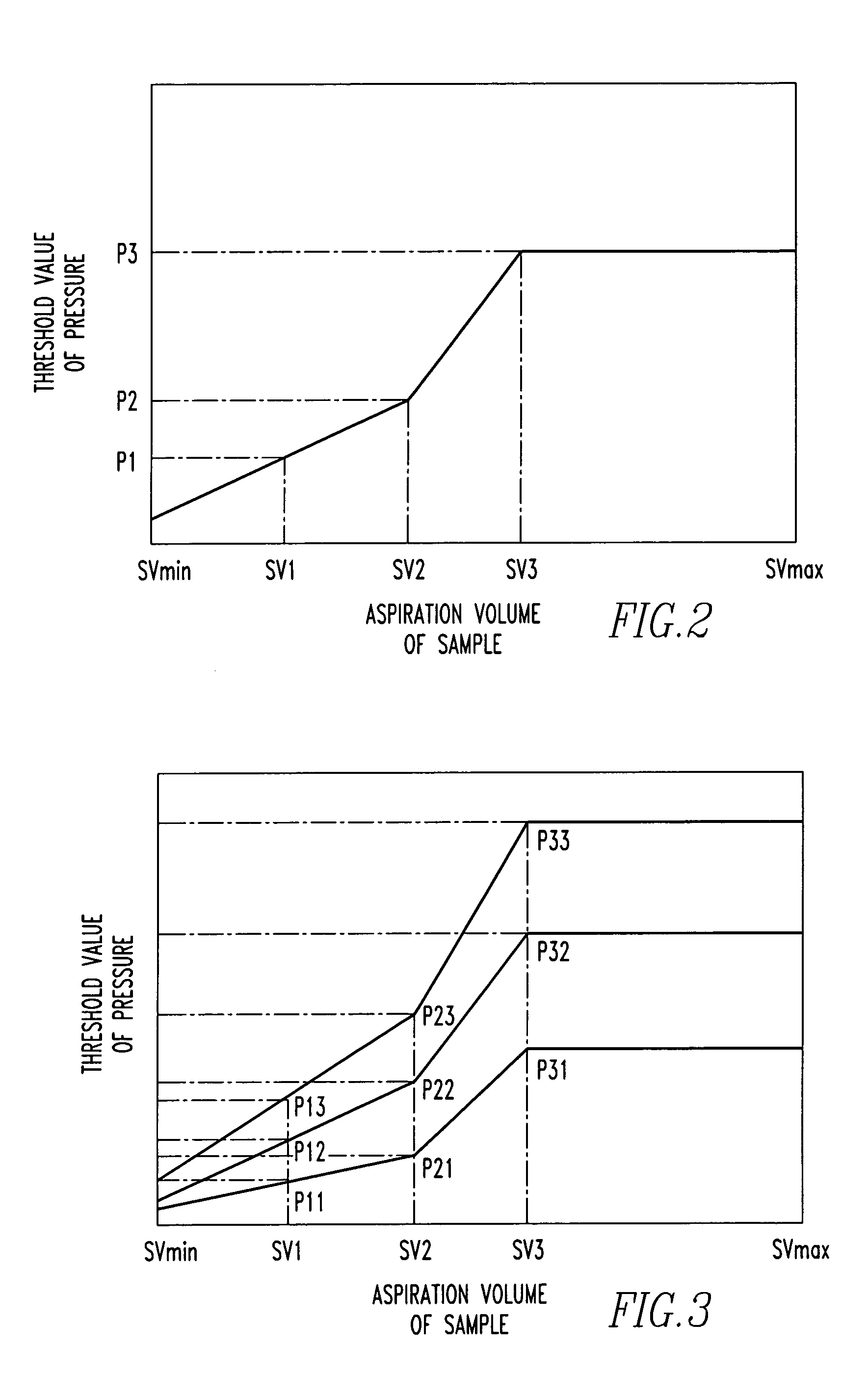

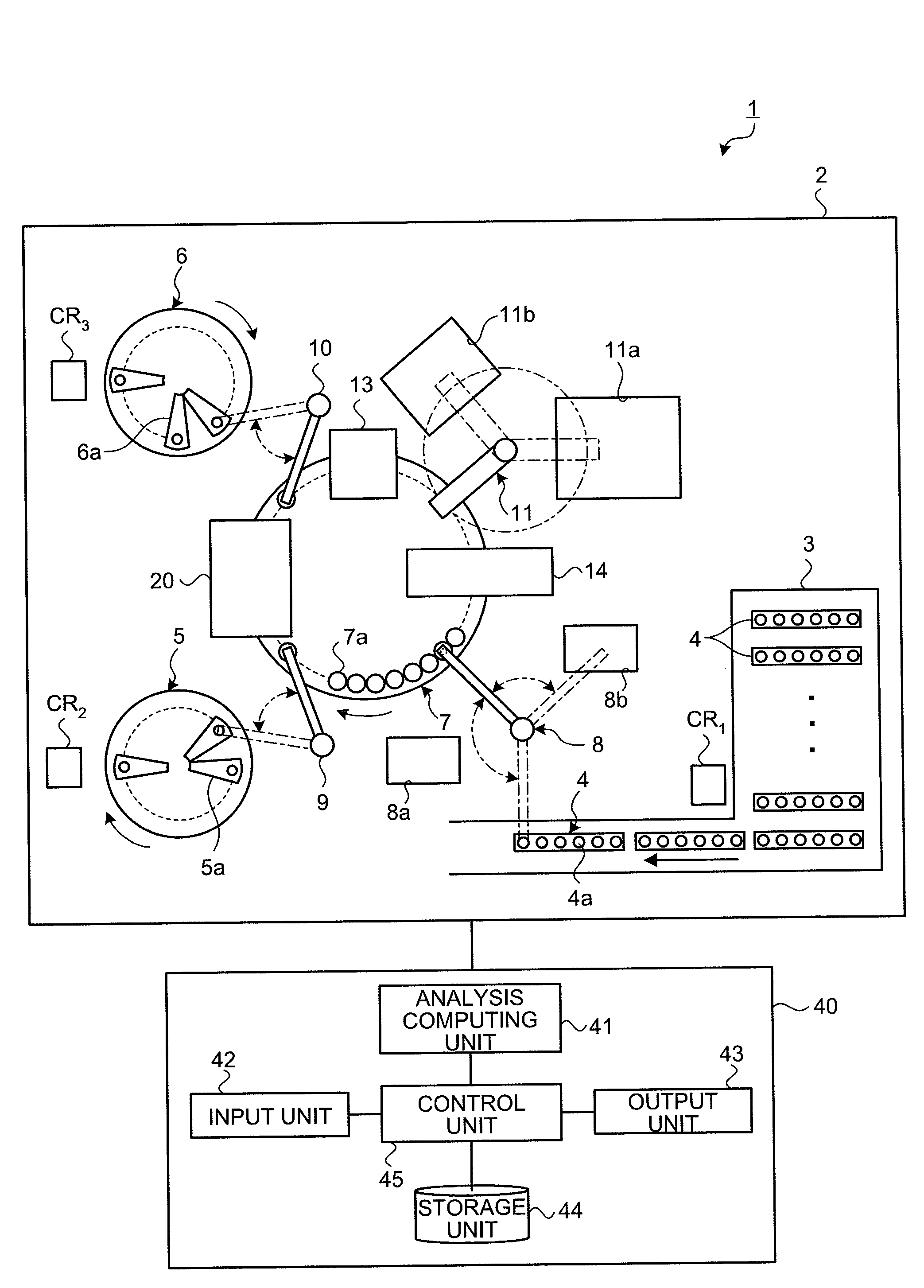

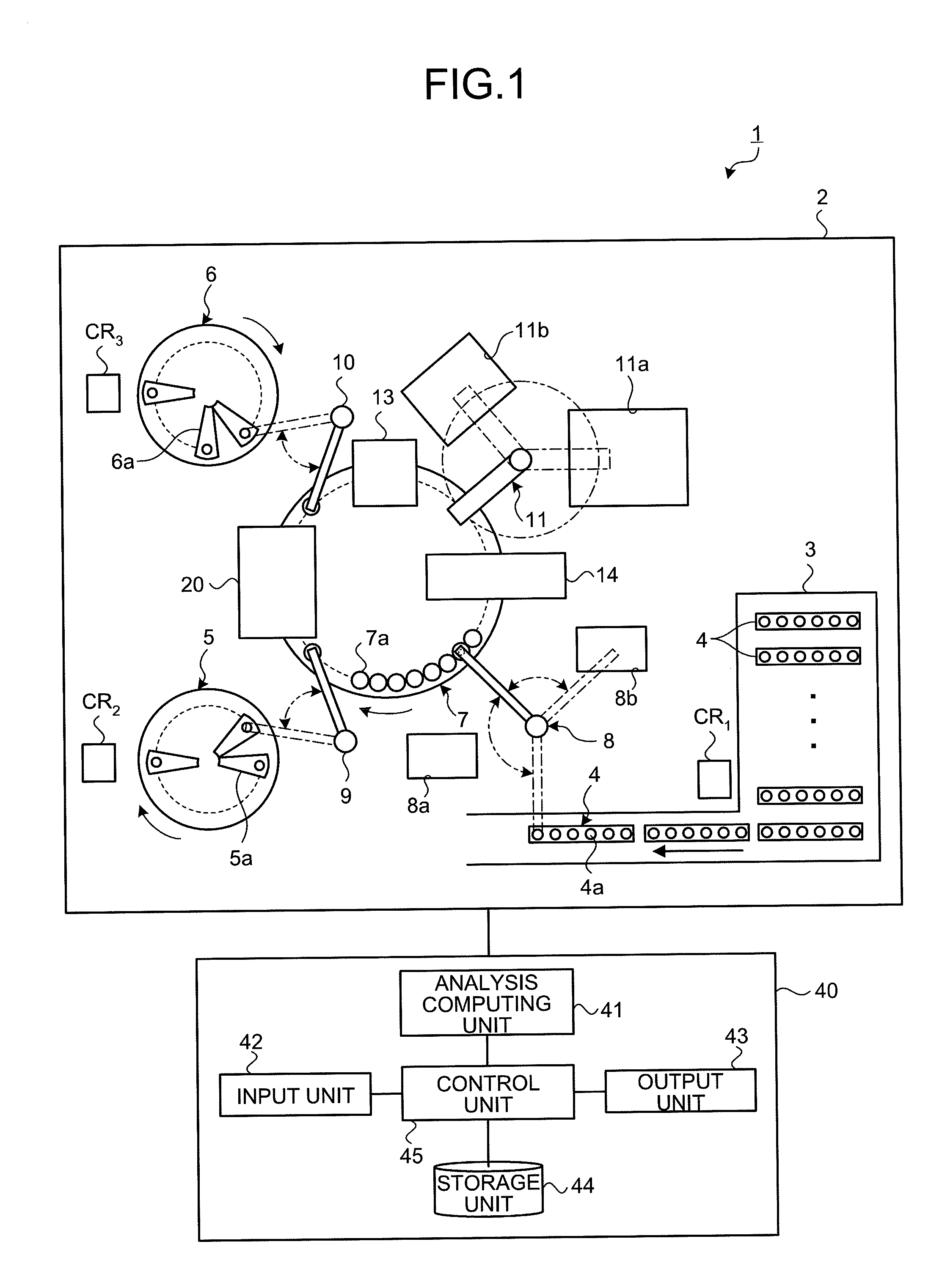

Method of detecting nozzle clogging and analytical instrument

A method of detecting nozzle clogging by the use of threshold values that can be set easily is accomplished. Also, an analytical instrument equipped with a nozzle clogging detection means using threshold values that can be set easily is accomplished. Threshold values corresponding to aspiration volumes of sample are calculated from plural threshold values (P1, P2, and P3) that have been set for discrete aspiration volumes (SV1, SV2, and SV3), respectively. The threshold values are found for each of plural aspiration programs corresponding to plural sets of conditions under which a sample is diluted, and for each of plural aspiration programs corresponding to plural kinds of samples. Threshold values are found for each of plural detection sensitivities.

Owner:JEOL LTD

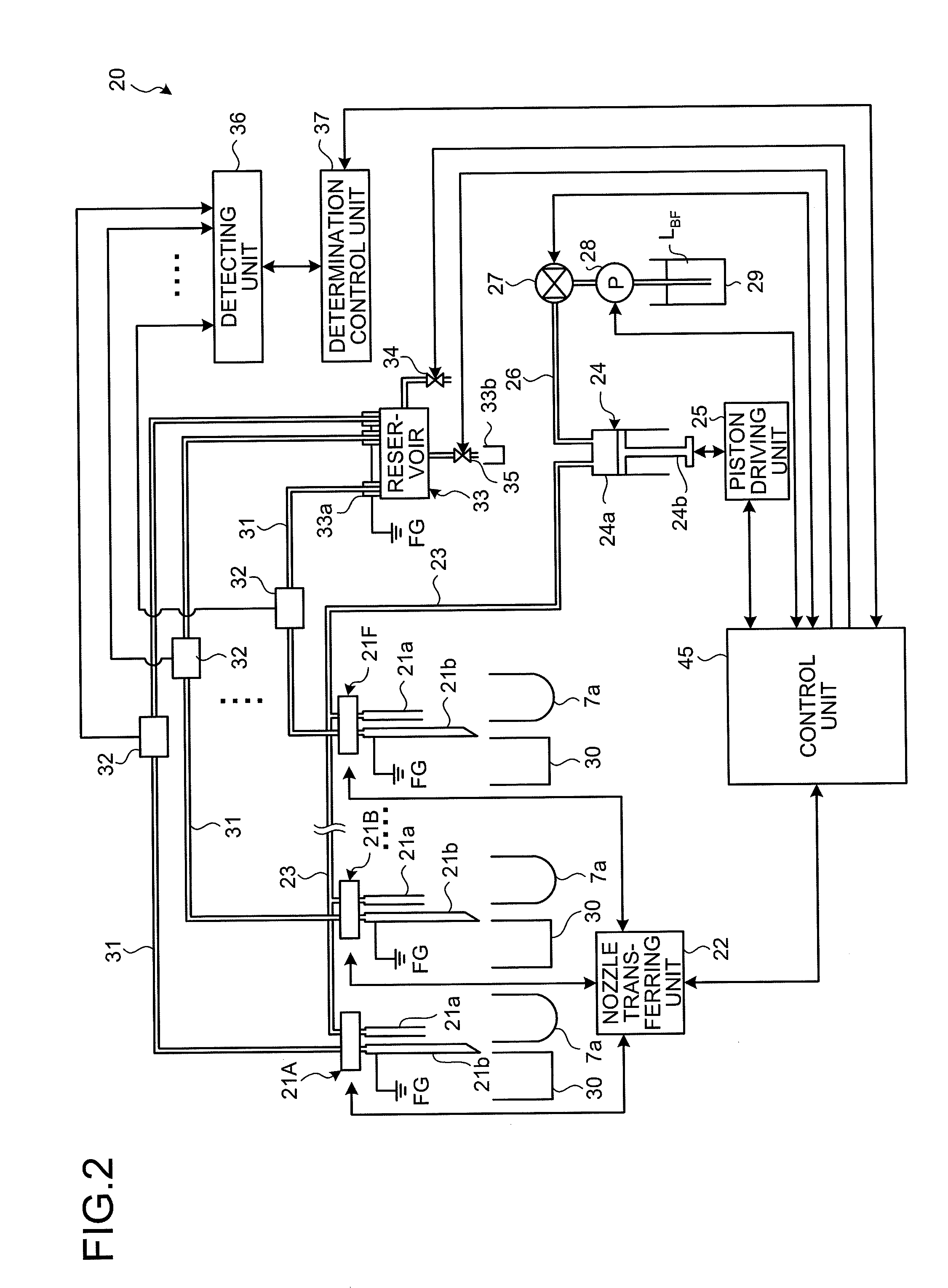

Cleaning device, method for detecting suction nozzle clogging, and automatic analyzer

A cleaning device includes a discharge nozzle that discharges cleaning liquid; a suction nozzle that sucks the cleaning liquid or reaction liquid in the cleaning tank or the reaction vessel; a discard vessel connected to the suction nozzle via a pipe to discard the cleaning liquid or the reaction liquid; a detecting unit that detects whether an electrostatic capacity at least between the suction nozzle and an electrode provided in the pipe exceeds a threshold value; a determination unit that determines that the suction nozzle is clogged when a totalizing time, for which the electrostatic capacity exceeds the threshold value during a preset clogging determination time, is longer than a totalizing time, for which the electrostatic capacity exceeds the threshold value during a preset normal determination time; and a control unit that stops the discharge nozzle from discharging the cleaning liquid to the reaction vessel when the suction nozzle is clogged.

Owner:BECKMAN COULTER INC

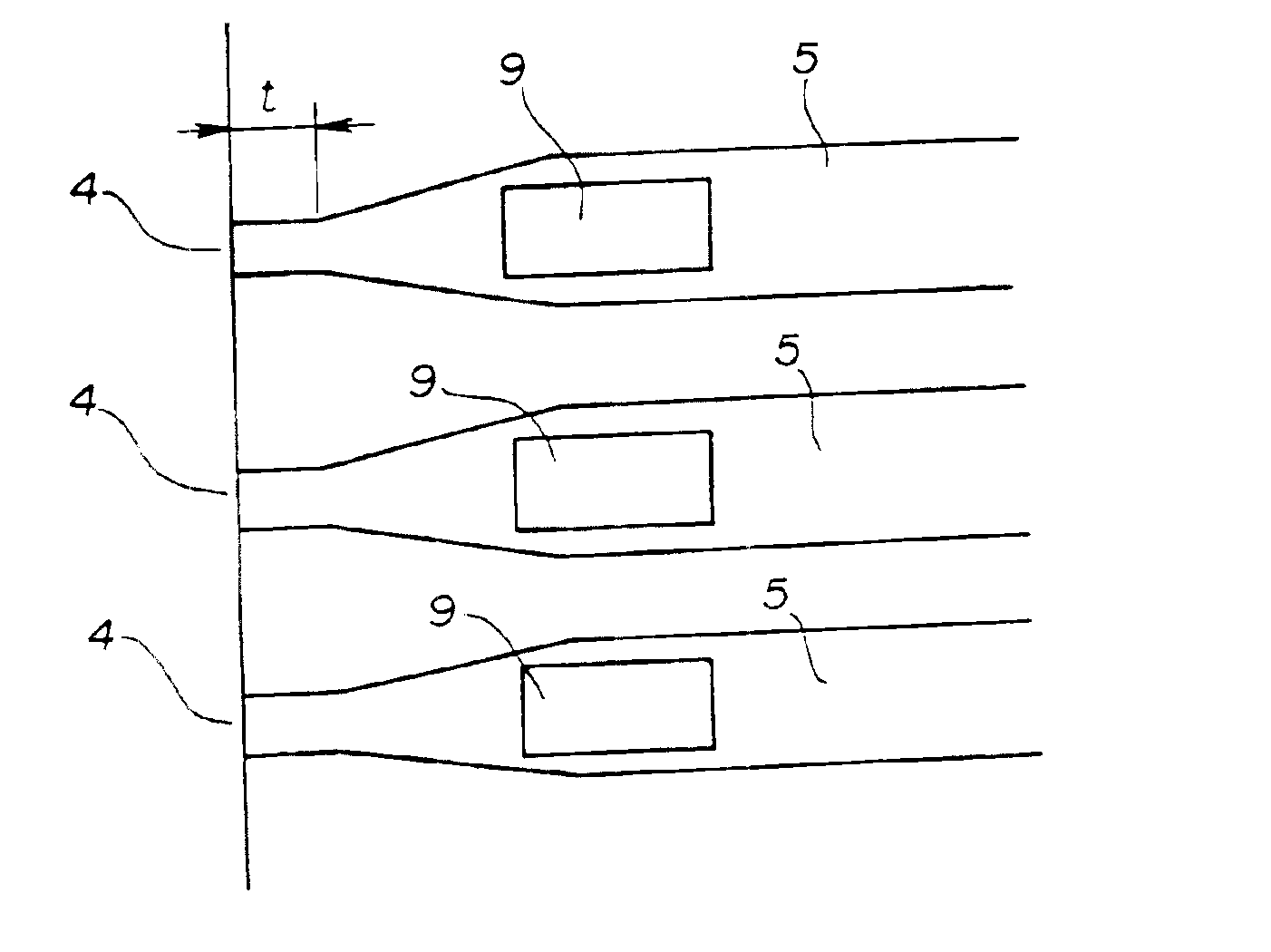

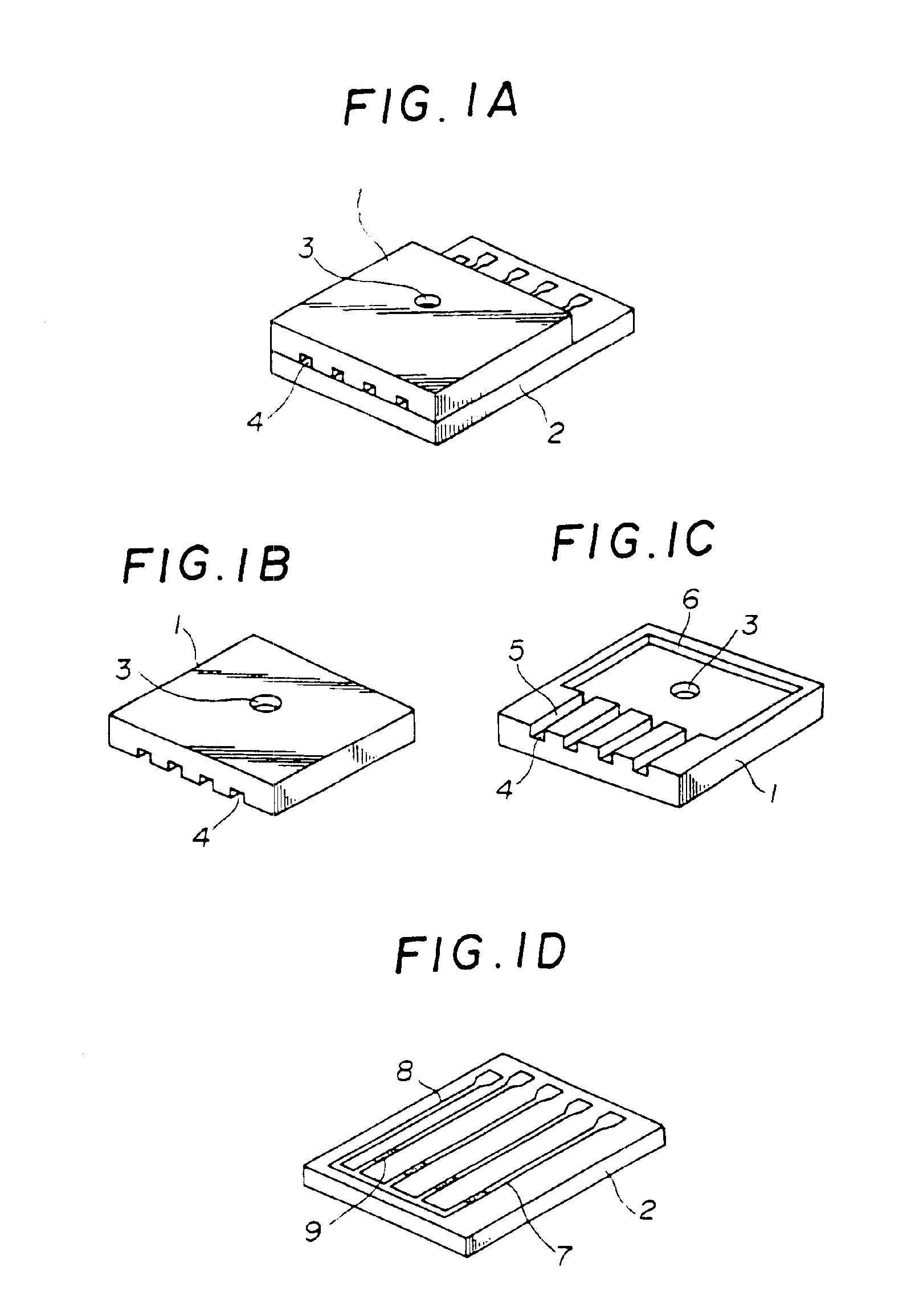

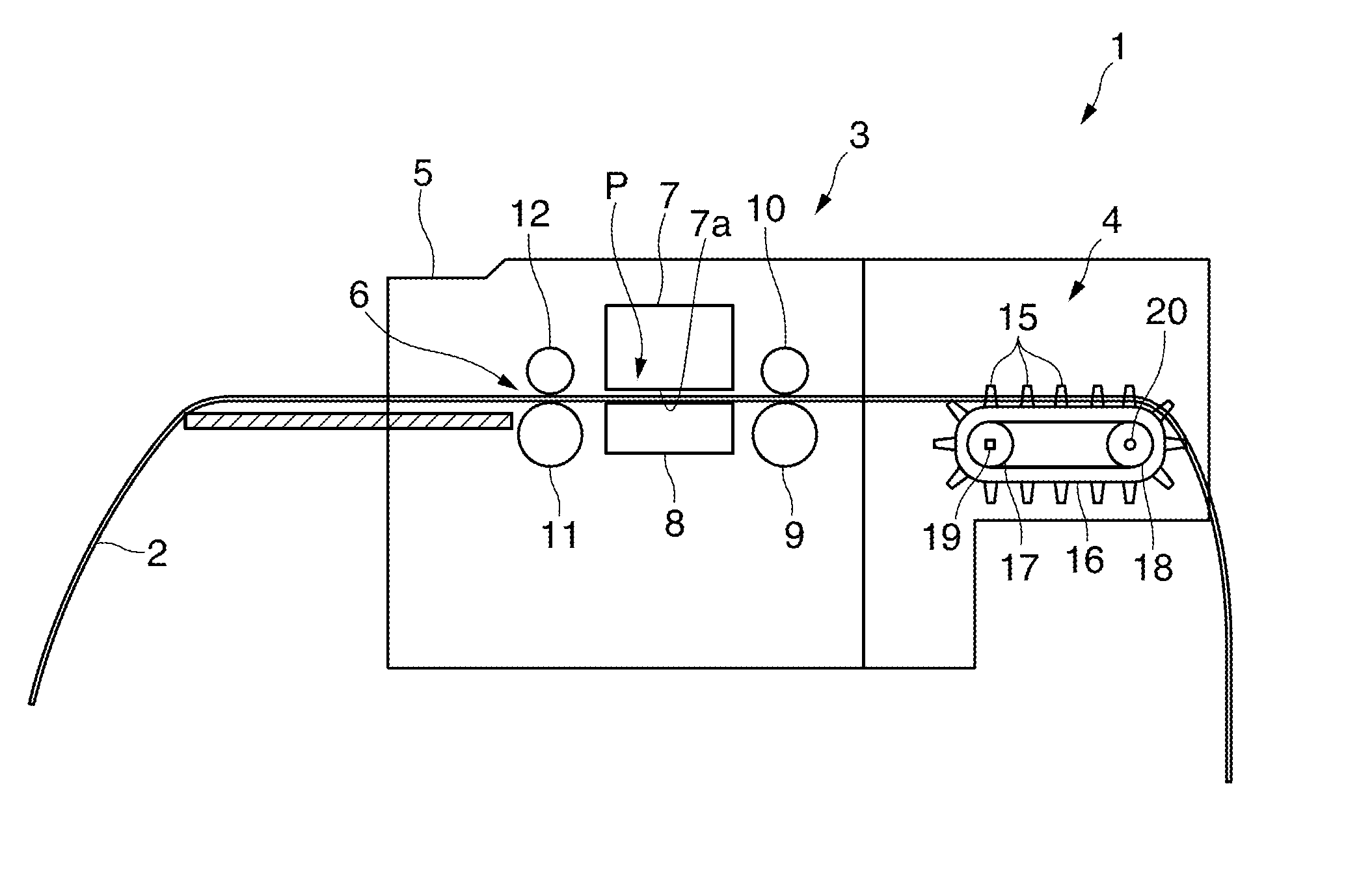

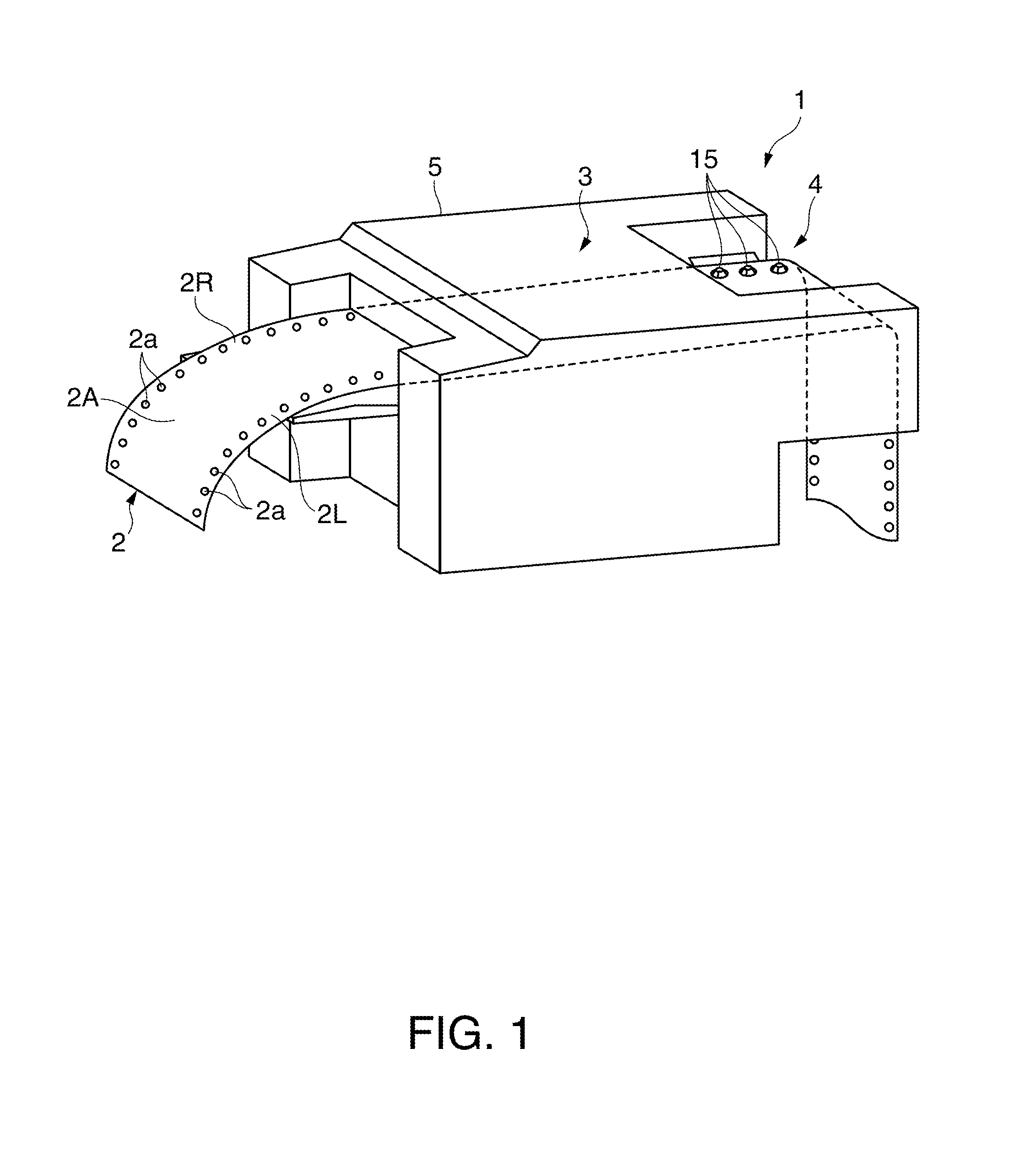

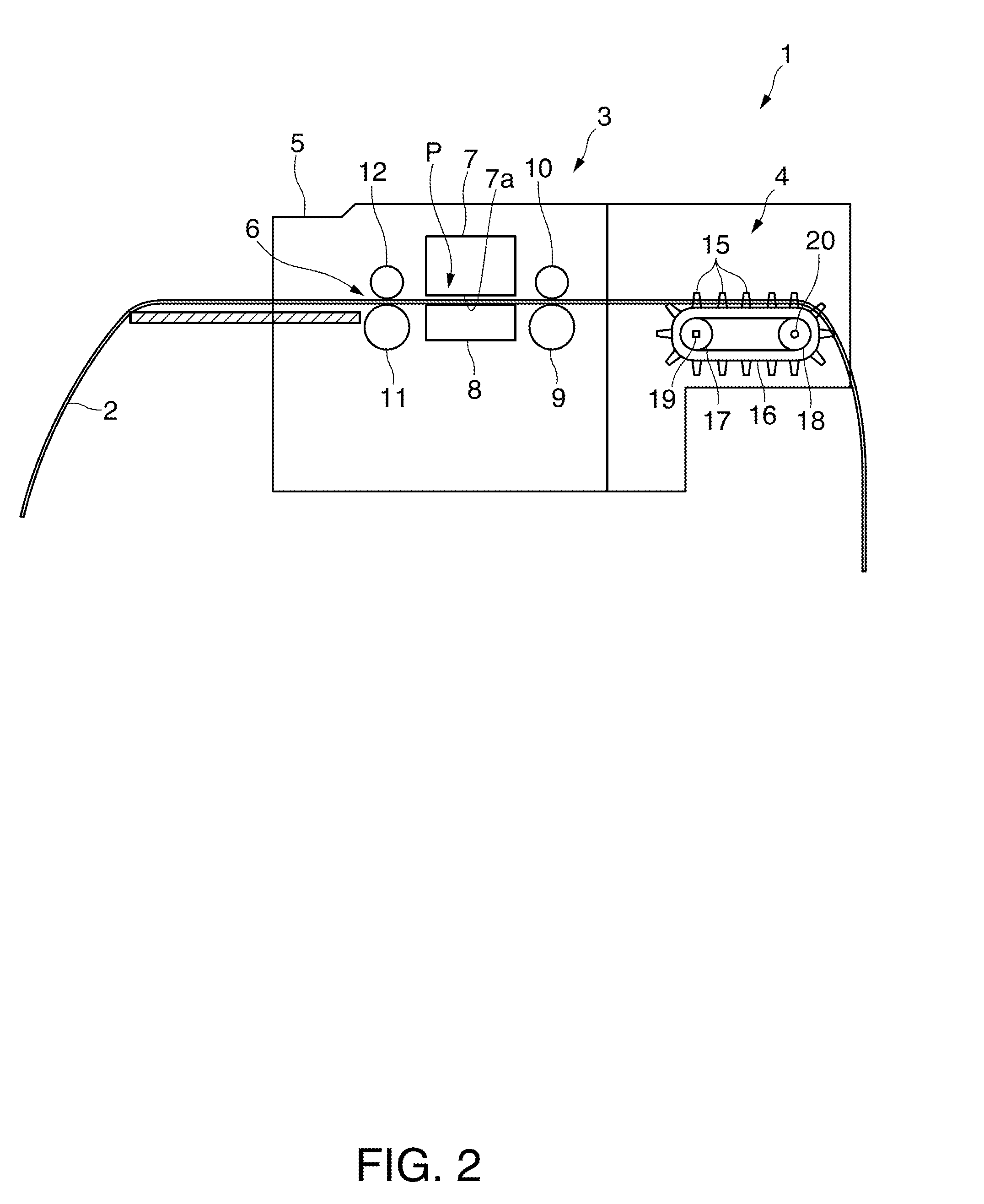

Inkjet printer having a paper edge cover

An inkjet printer (1) has an inkjet head (7), a paper conveyance path (6) that conveys tractor feed paper (2) passed the printing position P of the inkjet head (7), and a pair of paper edge covers (21L, 21R) disposed on the opposite sides of the conveyance path portion passing the printing position P of the paper conveyance path (6). The paper edge covers (21L, 21R) are covers that cover and hide the edge portions (2L, 2R) where the sprocket holes (2a) of the tractor feed paper (2) conveyed passed the printing position P are formed from the inkjet head (7). The paper edge covers (21L, 21R) can reliably prevent problems such as nozzle clogging caused by paper dust from the sprocket holes (2a) at the edges of the tractor feed paper (2) clinging to the nozzle face (7a) of the inkjet head (7).

Owner:SEIKO EPSON CORP

Long continuous casting control method for titanium-containing austenitic stainless steel

The invention relates to a long continuous casting control method for titanium-containing austenitic stainless steel, and belongs to the technical field of stainless steel smelting. The control method comprises the steps of (1), after smelting of molten steel is completed in an electric-arc furnace, adding the molten steel into an AOD refining furnace for whole-process argon gas blowing type smelting; (2), after input of silicon iron and fluorite is completed during the reduction period, adding Al for deep deoxidization, carrying out reduction after stirring is completed and guaranteeing the tapping temperature; (3), after the molten steel subjected to AOD refining enters a ladle furnace, beginning to add titanium wires when the temperature is within the range from 1580 DEG C to 1590 DEG C and carrying out micro-stirring, wherein the addition amount of the titanium wires guarantees that the molten steel meets the requirement that titanium is greater than or equal to 6C; (4), carrying out tapping when the tapping compositions of the molten steel meet the standard requirements and guaranteeing the content of Ti*N and Ca / Al. According to the control method, the number of continuous casting furnaces is greatly increased by controlling O and N in the molten steel from AOD to the ladle furnace and restraining nozzle clogging material from the source, and the continuous casting length of production of stainless steel slabs with the section being 200mm*1530mm can be greater than 900 meters according to practical operation. The control method greatly lowers the smelting cost, lowers the rejection rate of casting blanks and the rejection rate after rolling and is suitable for large-scale production.

Owner:GUANGDONG GUANGQING METAL TECH

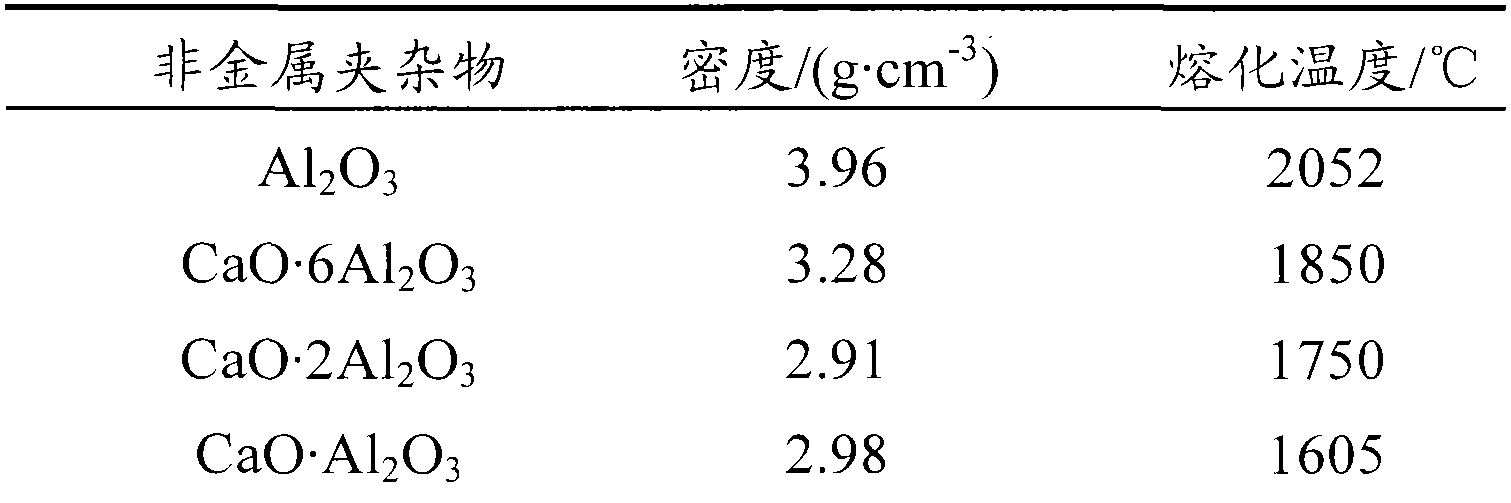

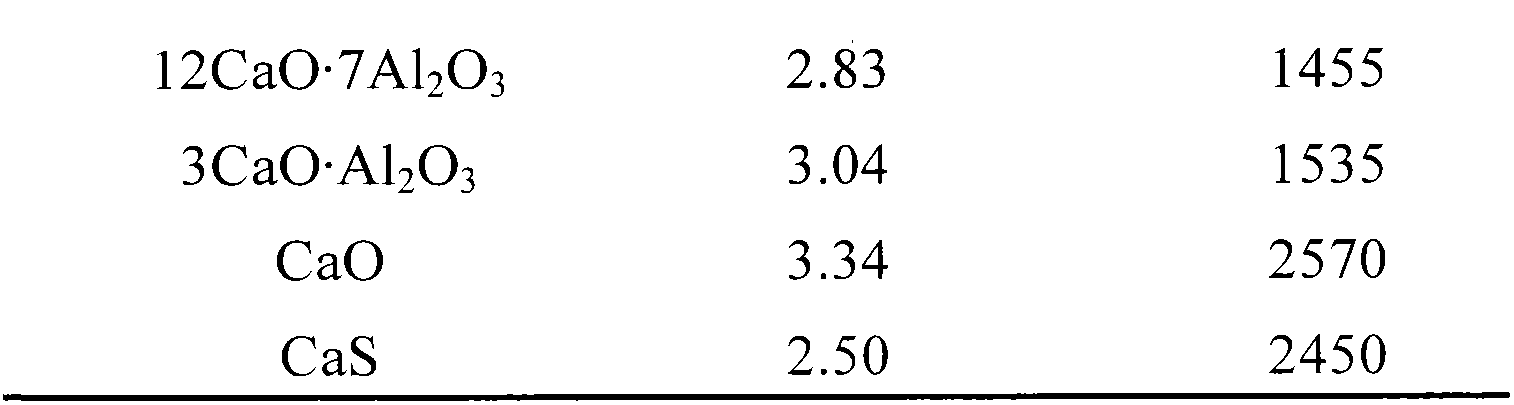

Method of controlling molten steel pourability under condition of calcium-free treatment

ActiveCN103255259AIncrease productivityManufacturing convertersProcess efficiency improvementSlagManganese

The invention provides a method of controlling molten steel pourability under the condition of calcium-free treatment. The method comprises the steps of: (1) carrying out pre-deoxidation before entering an LF (Ladle) furnace, ensuring end point carbon of a converter to be no more than 0.30 percent by virtue of a converter catching carbon technology, adding 2.5Kg of ferro-manganese-aluminum in the process from steel tapping to a steel ladle, and removing at least 95 percent of free oxygen in the molten steel; (2) rapidly producing white slags by virtue of the LF furnace, and ensuring the keeping time of the white slags to be no less than 12minutes; (3) carrying out LF furnace argon blowing-electrifying intelligent control, and intelligently controlling an LF furnace bottom blowing rate by phases and heating powers; and (4) carrying out argon blowing control by phases by virtue of a VD (Vacuum Ladle) furnace. With the adoption of the control method, the amount of molten steel continuous casting furnaces capable of treating without calcium reaches 45, and non-planned nozzle change due to poor molten steel mobility which is caused by reasons of steel breakout, nozzle clogging and the like does not exist.

Owner:LAIWU IRON & STEEL GRP

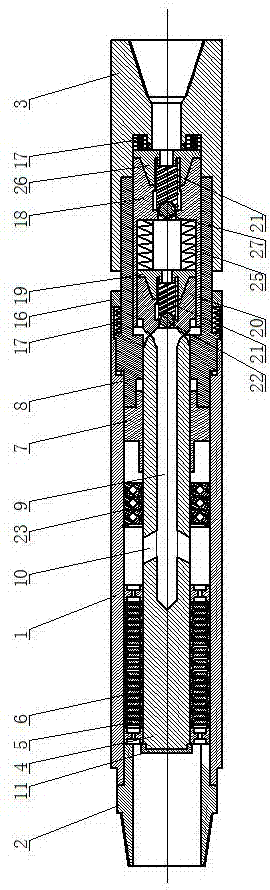

Coupling impactor used for petroleum drilling

PendingCN107542397AImprove rock breaking efficiencyAvoid mud baggingBorehole drivesHydro energy generationCompressed fluidPetroleum

The invention relates to a coupling impactor used for petroleum drilling, and belongs to the technical field of petroleum drilling and production equipment. The impactor comprises a shell, an upper connector, a lower connector, a central shaft, a turbine fixed valve, a turbine moving valve, an upper hammer block and a lower hammer block, the upper connector is in threaded connection with one end of the shell, and the central shaft is installed in the shell at the inner side of the upper connector through the turbine fixed valve and the turbine moving valve; the upper hammer block is fixedly installed on the central shaft, and the lower hammer block is installed on the central shaft at one side of the upper hammer block in a sleeving mode, and the lower hammer block is in key connection with the shell. According to the coupling impactor used for petroleum drilling, under the action of drilling fluid, the upper hammer block is driven by the central shaft to produce periodical axial impact and periodic torsional impact on the lower hammer block, at the same time, the lower end of the central shaft makes an upper piston body periodically compress the fluid in a cavity, so that the drilling fluid periodically produces a certain pressing effect before entering in a drill bit, and pulse fluctuation is formed; under the coupling action, the contact stress between the drill bit and rocks and the rock crushing effect can be effectively improved, rock crushing efficiency, the drilling speed are improved, the drilling cost is reduced, and meanwhile, the phenomena of drill bit nozzle plugging and drill bit balling are avoided.

Owner:YANGTZE UNIVERSITY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com