Patents

Literature

220 results about "Computer to plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer-to-plate (CTP) is an imaging technology used in modern printing processes. In this technology, an image created in a Desktop Publishing (DTP) application is output directly to a printing plate.

Development enhancement of radiation-sensitive elements

InactiveUS20050003296A1High sensitivityEasy to operateDuplicating/marking methodsPhotomechanical apparatusDirect imagingComputer to plate

A positive-working radiation-sensitive composition for use with a radiation source comprises one or more polivinyl acetal polymers capable of being dissolved in an alkaline aqueous solution and a development-enhancing compound. The sensitivity of a radiation-sensitive coating based on the composition of this invention is increased without compromising the handling characteristics. Radiation-sensitive elements based on the composition of the invention have good development latitude. A positive-working lithographic printing precursor is based on the radiation-sensitive composition coated on a hydrophilic surface. The precursor is developable using an alkaline aqueous solution, and may be used with a radiation source in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging applications. The precursor is stable in its state before exposure and has an excellent handling property.

Owner:KODAK GRAPHIC COMM CANADA CO

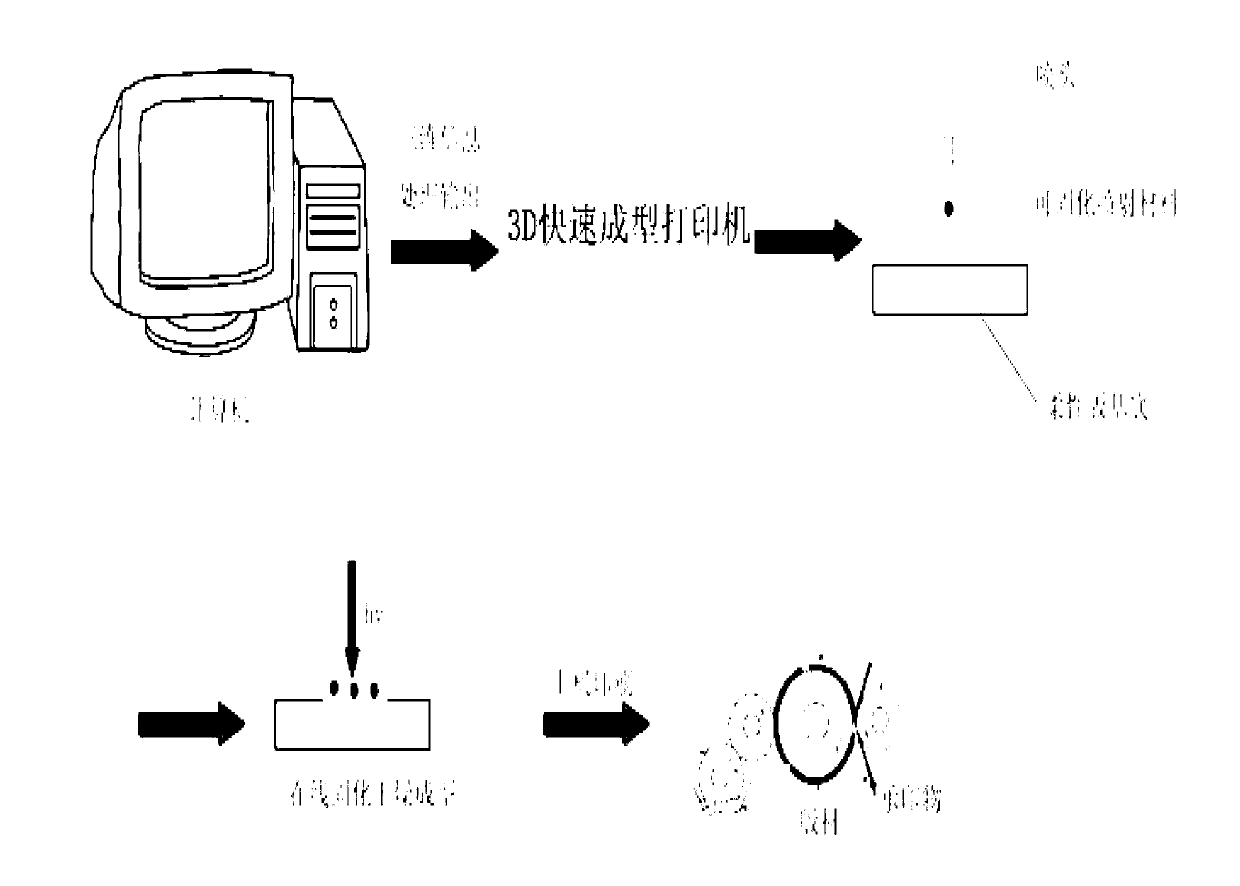

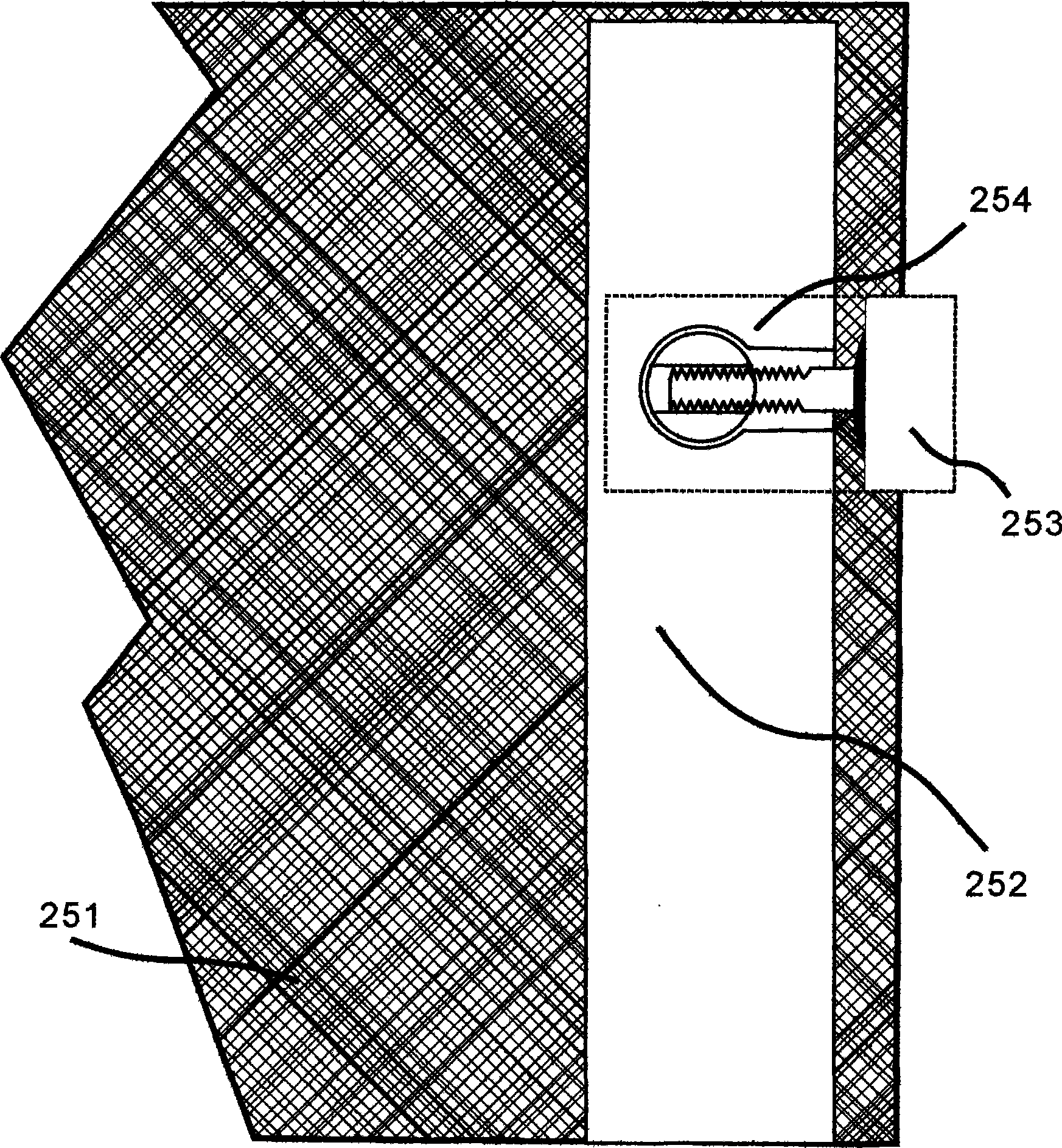

Flexographic plate CTP (computer to plate) direct printing method and equipment based on 3D rapid forming printing principle

ActiveCN103121323AEliminate complicated operation linksLow costPlate printingFoil printingComputer to plateEngineering

The invention discloses a flexographic plate CTP (computer to plate) direct printing method and equipment based on a 3D rapid forming printing principle and belongs to the technical field of printing flexographic plate manufacture. The equipment comprises a computer, a 3D rapid forming printer and one of photocuring equipment and heat drying equipment. The 3D rapid forming printer is utilized to spray a solidifiable forming material on the base surface of a flexographic plate so as to form a relieve image, the relieve image is subjected to light curing or thermocuring on-line drying so that the printing information is stabilized on the base surface of the flexographic plate, and then the printer can be used for printing; and the base of the flexographic plate is an organic polymer plate or an organic polymer-organic polymer compound plate. The method omits the middle process such as exposure and development, the plate manufacturing speed is greatly accelerated, the printing quality is improved, the printing cost is reduced, the flow is greatly shortened, the flexography environment friendliness is realized, and the application area is further expanded.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Computer-to-plate by ink jet

InactiveUS6526886B2Simple and inexpensive methodProduce littlePlaten pressesDuplicating/marking methodsComputer to plateEngineering

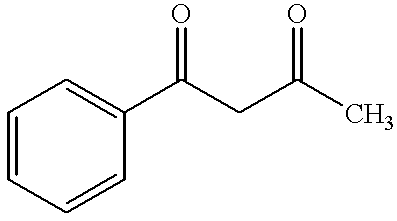

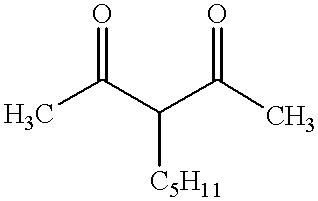

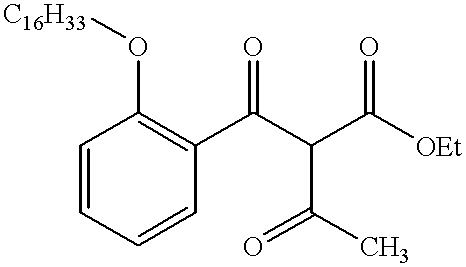

A method for preparing a lithographic printing plate by means of ink jet is disclosed. In the ink jet fluid an oleophilizing compound is incorporated containing a 1,3-dicarbonyl group in its chemical formula.

Owner:AGFA NV

Method of pre-exposing relief image printing plate

InactiveUS20050266358A1Quench oxygenDeleterious effectSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusComputer to plateOxygen

The present invention is directed to a method of selectively pre-exposing a photosensitive printing element prior to imagewise exposure in order to remove oxygen from the photosensitive layer prior to imagewise exposure. The invention is usable in a computer-to-plate process to produce flexographic relief image printing elements.

Owner:MACDERMID PRINTING SOLUTIONS

Dual-wavelength positive-working radiation-sensitive elements

InactiveUS7279263B2High sensitivityEasy to operateSemiconductor/solid-state device manufacturingDiazo compound compositionsRadiation sensitivityUltraviolet

A positive-working radiation-sensitive composition for use with a radiation source comprises one or more polymers capable of being eluted in an alkaline aqueous solution and a development-enhancing compound. The invention provides a positive-working photosensitive composition of good sensitivity for use with one or both of ultra-violet radiation and an infrared laser radiation source. The composition is stable in its state before exposure and has an excellent handling property. The sensitivity of a radiation-sensitive coating based on the composition of this invention is increased without compromising the handling characteristics. Radiation-sensitive elements based on the composition of the invention have good development latitude. A positive-working lithographic printing precursor is based on the radiation-sensitive composition coated on a hydrophilic surface. The precursor is developable using an alkaline aqueous solution, and may be used with a radiation source in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging applications. The precursor is stable in its state before exposure and has an excellent handling property.

Owner:KODAK GRAPHIC COMM CANADA CO

Method of pre-exposing relief image printing plate

InactiveUS20090042138A1Widen meansSemiconductor/solid-state device manufacturingPlate printingComputer to plateOxygen

The present invention is directed to a method of selectively pre-exposing a photosensitive printing element prior to imagewise exposure in order to remove oxygen from the photosensitive layer prior to imagewise exposure. The invention is usable in a computer-to-plate process to produce flexographic relief image printing elements.

Owner:MACDERMID PRINTING SOLUTIONS

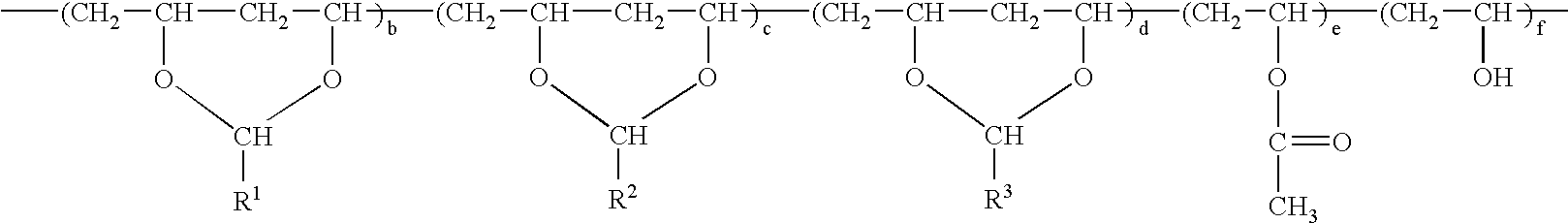

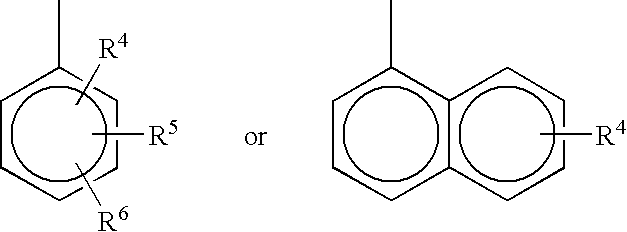

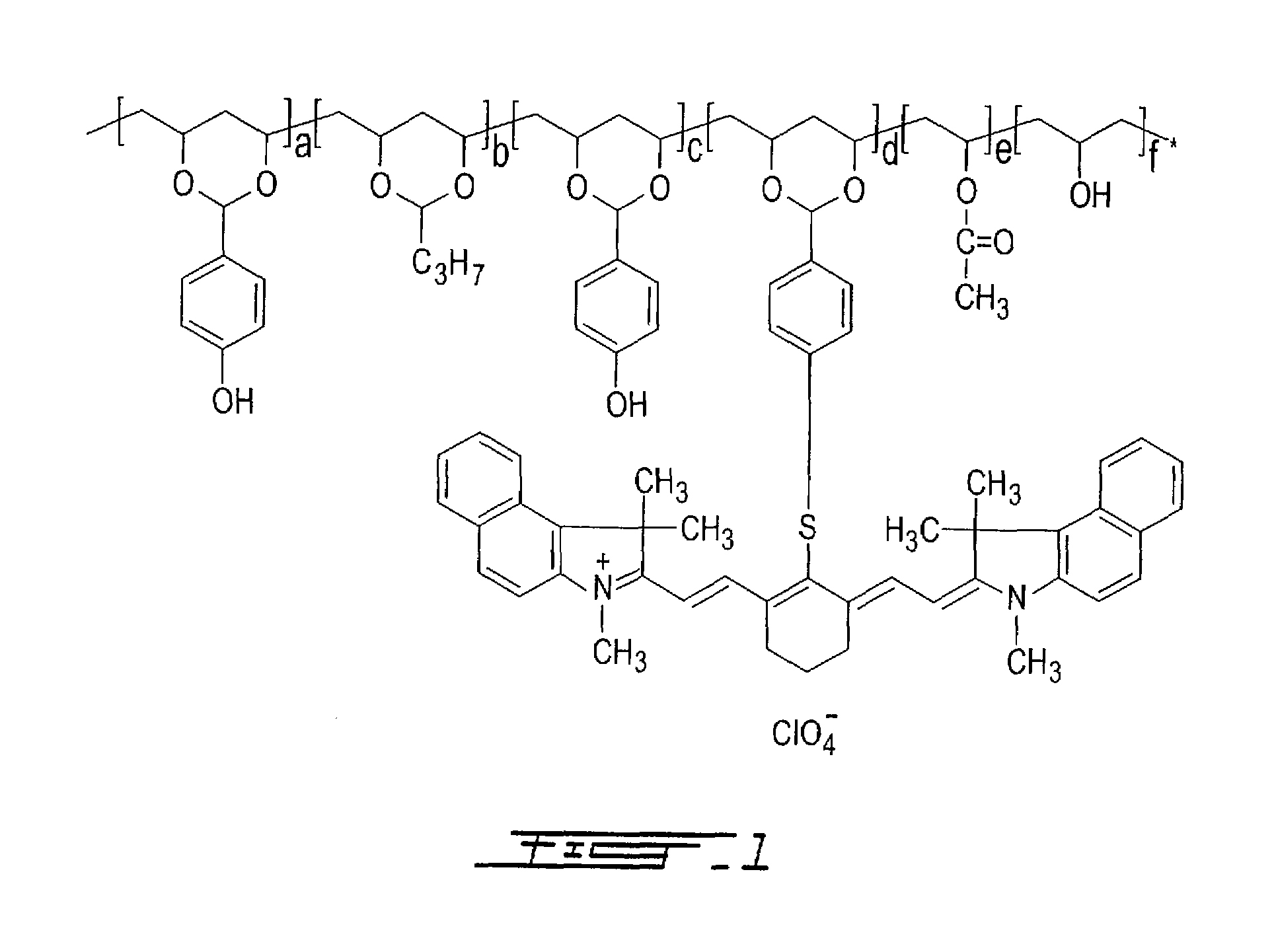

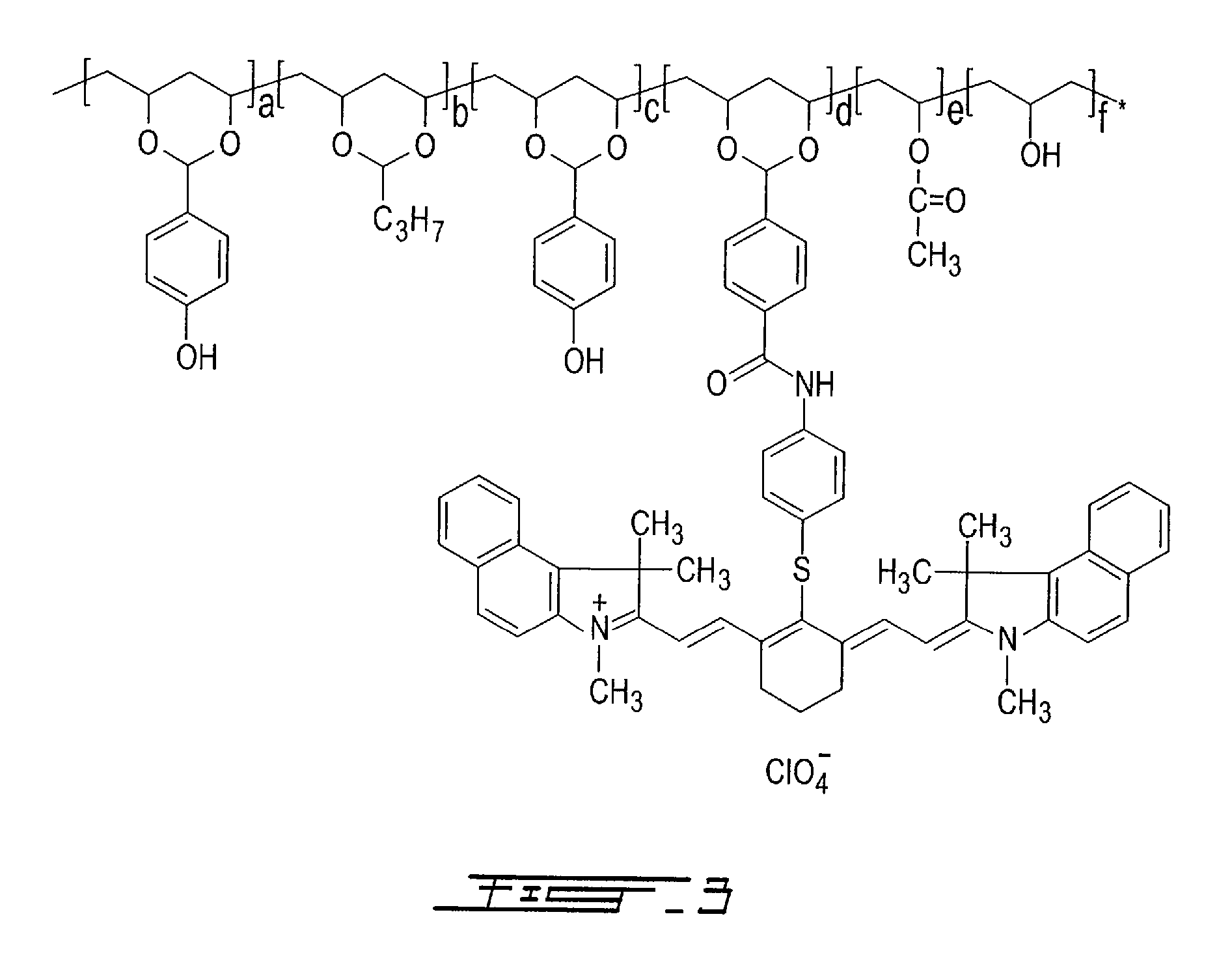

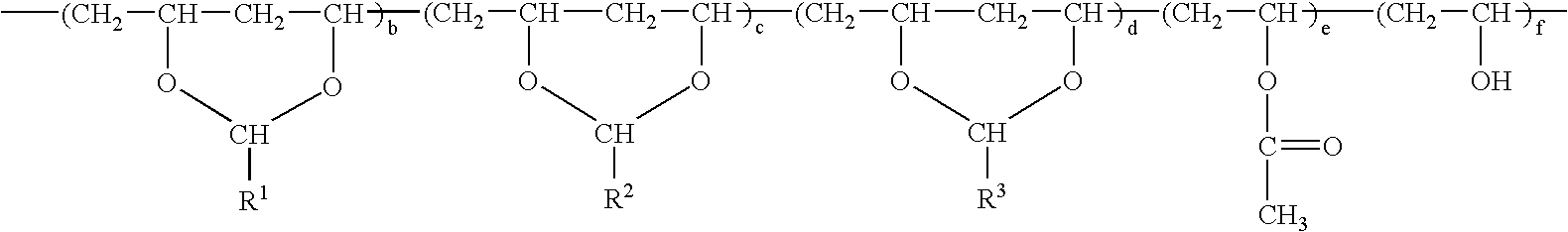

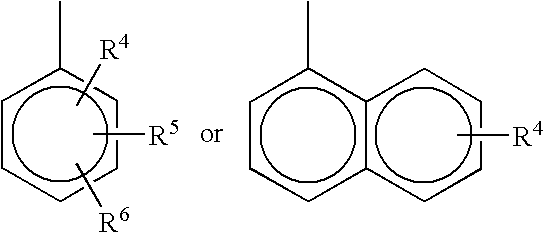

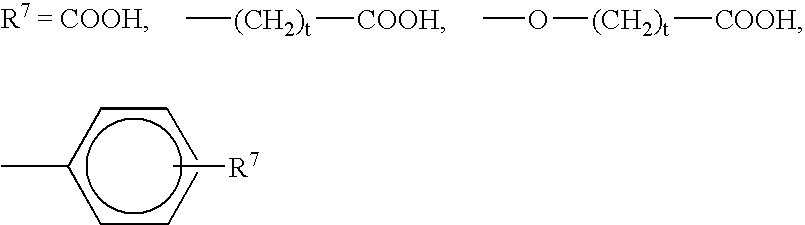

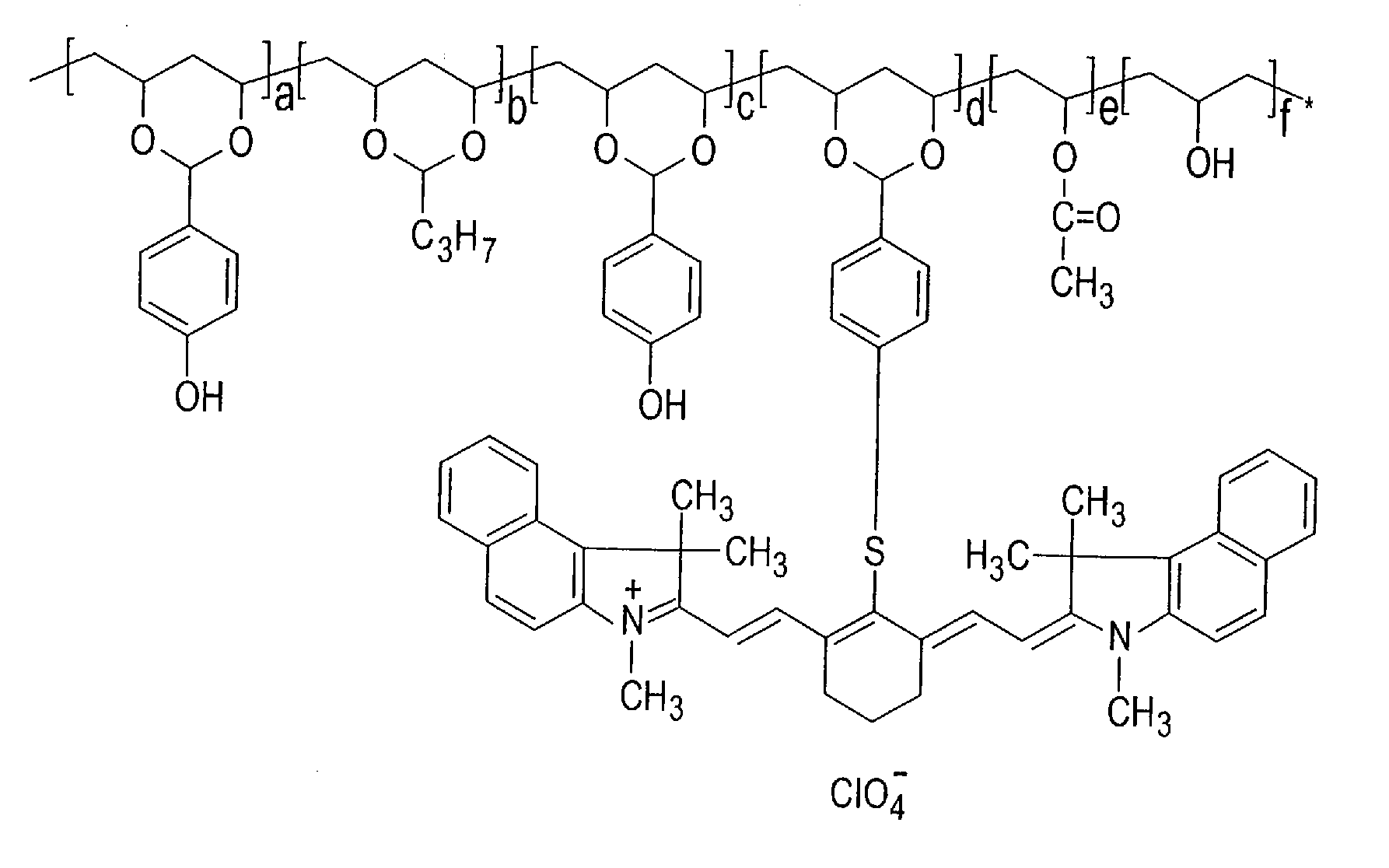

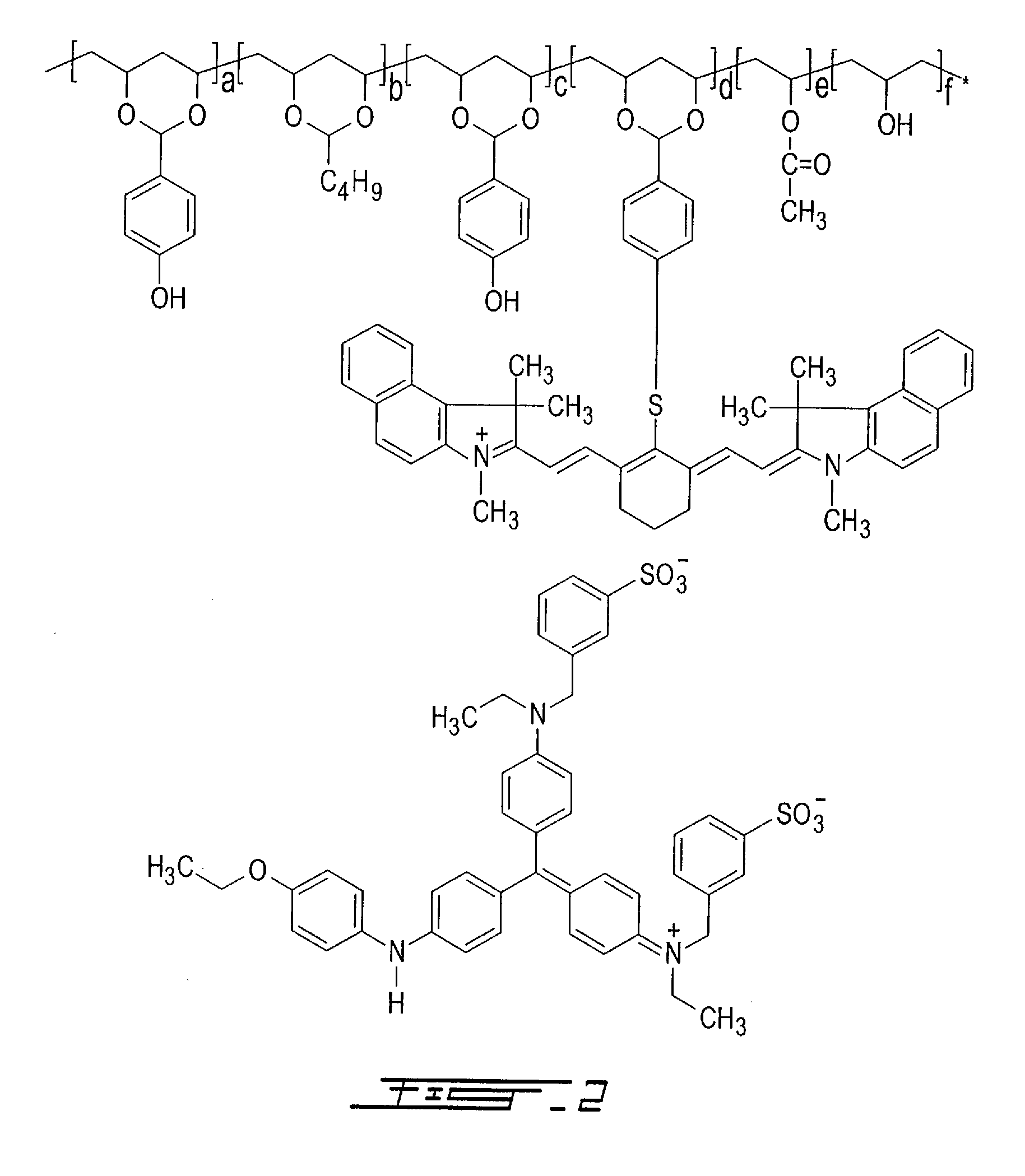

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

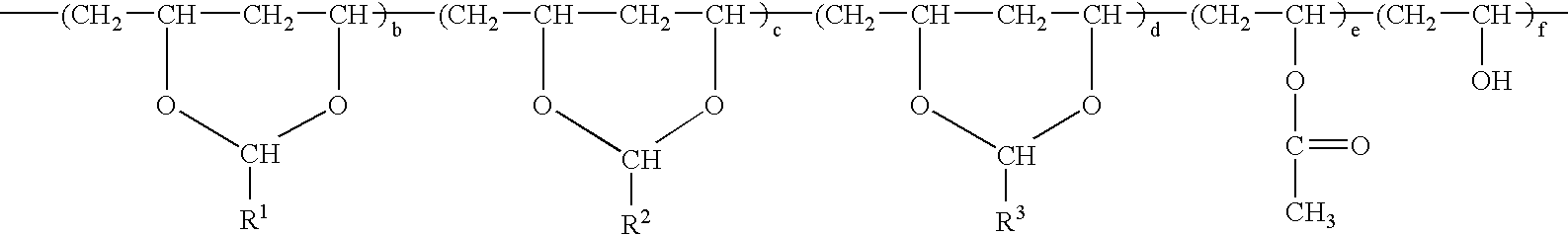

InactiveUS7473515B2Photosensitive materialsSemiconductor/solid-state device manufacturingGum printingAcetal copolymer

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

1050 alloy CTO (computer-to-plate) substrate and preparation method thereof

The invention provides a 1050 alloy CTO (computer-to-plate) substrate which comprises the following components in percentage by mass: 0.28-0.32% of Fe, 0.08-0.12% of Si, at most 0.03% of Ti, at most 0.02% of Cu, at most 0.02% of Mn, at most 0.02% of Mg, at most 0.02% of Zn, at most 0.02% of V and the balance of Al. The invention also provides a preparation method of the 1050 alloy CTP substrate. A piezoelectric template control technique, a normal-temperature high-speed multichannel cast-rolling technique, a furnace-out Al-5Ti-B wire matching supersonic grain refinement technique and a continuous rolling technique are utilized to prepare the original cast-rolling structure with abundant uniform and fine crystal grains and dispersedly distributed diphase compounds at the grain boundary, and a processing structure with flat template quality and uniform deformation.

Owner:浙江中金铝业有限公司

Development of radiation-sensitive elements

InactiveUS20060154187A1Easily rinse awayModerates aggressivenessPhotomechanical apparatusOriginals for photomechanical treatmentSodium metasilicatePolyvinyl alcohol

An aqueous alkaline developer for use with an imaged lithographic printing precursor comprises an aqueous alkaline medium, sodium metasilicate, a steric or electrosteric stabilizer, and a rinse aid or a phase stabilizer. It is suited for developing a lithographic printing precursor comprising, on a substrate, a coated and dried layer of a radiation-sensitive composition comprising one or more acetal resins. The developer may further contain a moderator, a dispersing agent capable of solvating a hydrophobic image colorant, and a wetting agent. The acetal resin of the precursor may be derived from polyvinyl alcohol by condensation with aldehydes. The imageable element is imageable by radiation, preferably infrared radiation, and provides good sensitivity for use in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging elements and applications when treated with the developer. The invention also provides a positive-working lithographic printing master comprising a precursor as aforesaid, imaged and developed with the developer. The invention further provides a method for cleaning the processor equipment in which the imaged lithographic printing precursor has been developed, comprising treating the deposit with an acid to yield liberated image colorant and treating the liberated image colorant with a cleaning composition.

Owner:KODAK GRAPHIC COMM CANADA CO

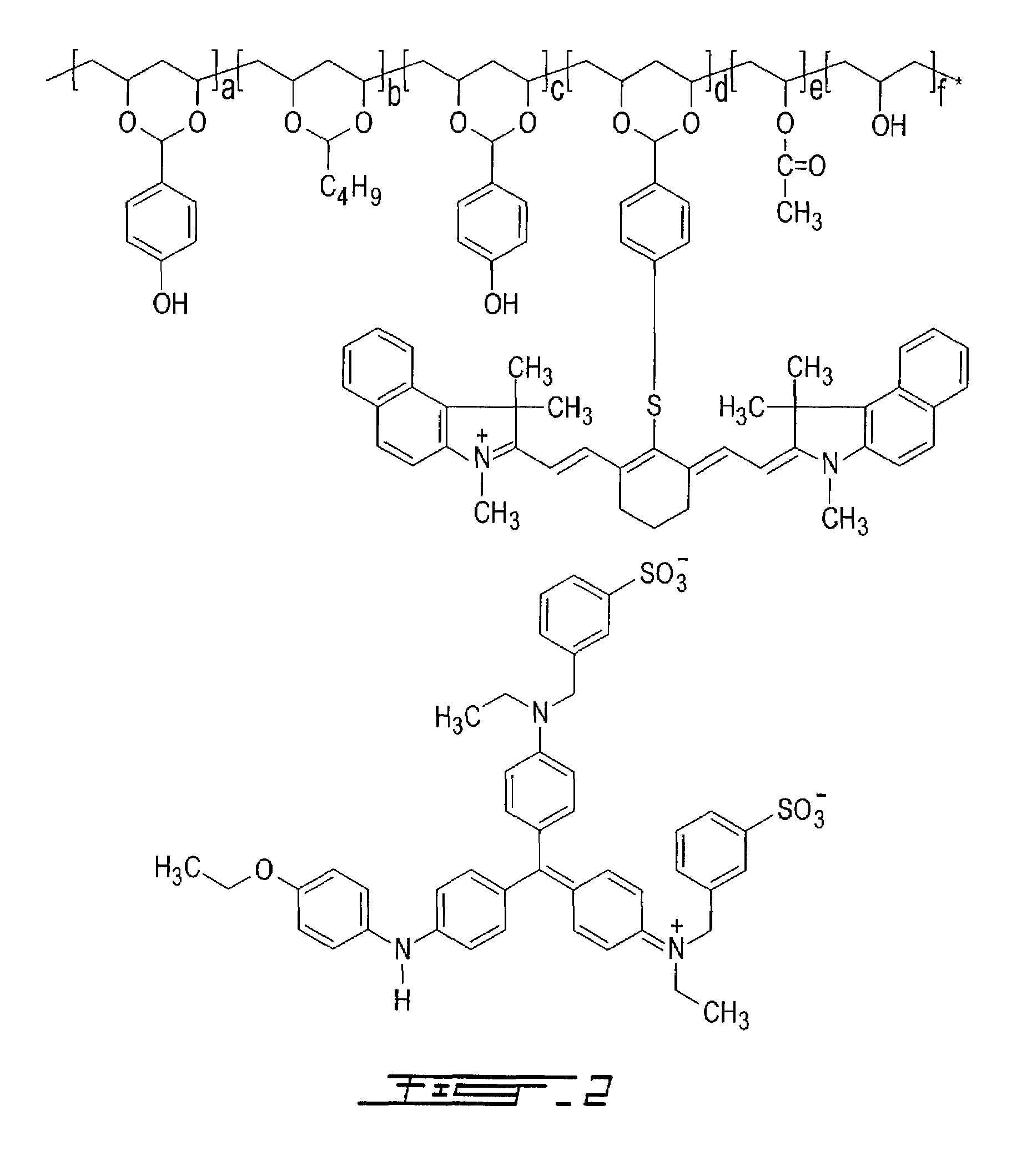

Thermally reactive near-infrared absorbing acetal copolymers, methods of preparation and methods of use

InactiveUS20060275698A1Photosensitive materialsSemiconductor/solid-state device manufacturingAcetal copolymerNear infrared radiation

Described herein are novel thermally reactive near-infrared absorbing acetal copolymers that undergo chemical and physical changes upon exposure to near-infrared radiation. Also described are the methods of preparation of the novel acetal copolymers starting either with vinyl-alcohol polymers or with acetal copolymers. Also described are the methods of use of the new near-infrared absorbing acetal copolymers in coatings used in lithographic offset printing plates that can be directly imaged with near-infrared laser imaging devices in computer-to-plate and digital offset printing technologies. The novel acetal copolymers are also useful in photoresist applications, rapid prototyping of printed circuit boards and chemical sensor development.

Owner:AMERICAN DYE SOURCE

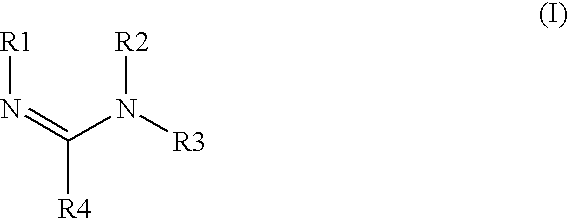

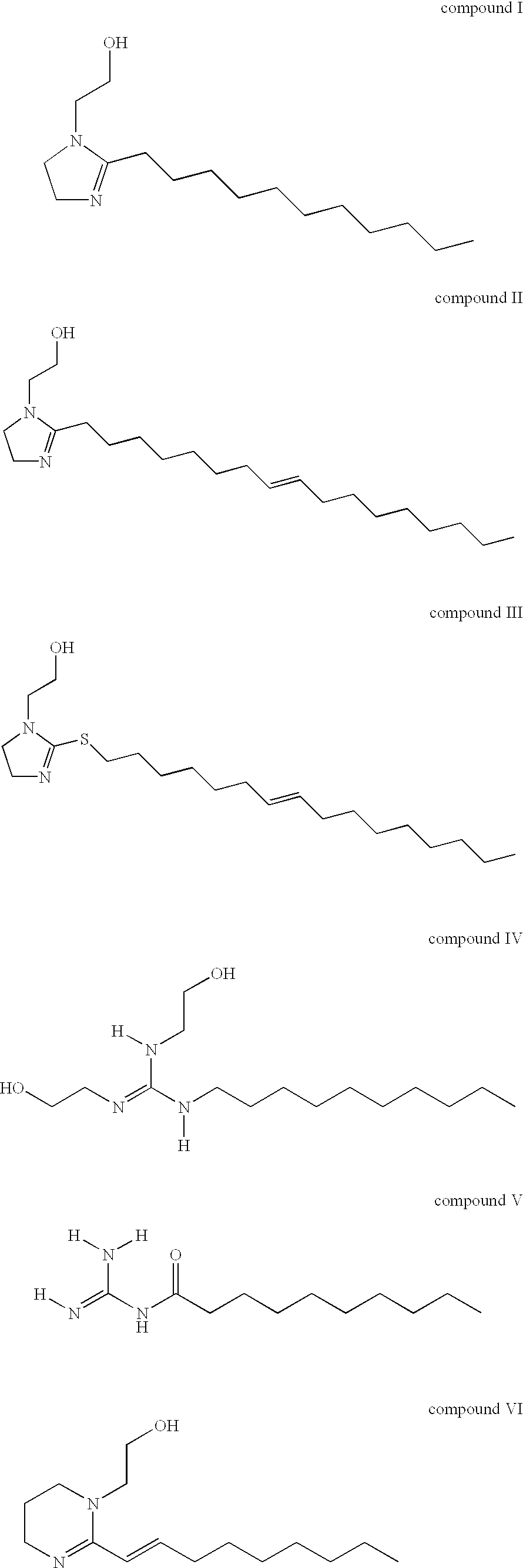

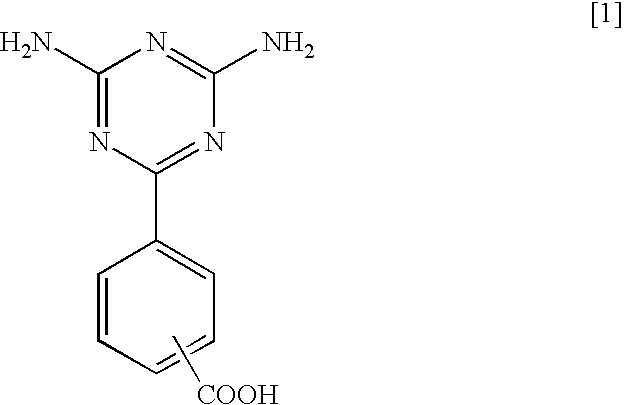

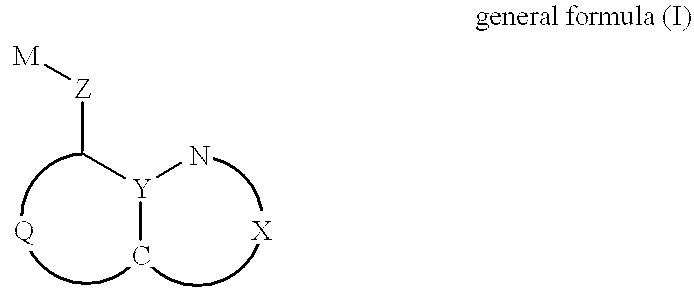

Preparation of lithographic printing plate by computer-to-plate by ink jet method utilizing amidine-containing oleophilizing compound

InactiveUS6852363B2Simple and inexpensive methodProduce littleOther chemical processesCoatingsChemical structureCompound a

Owner:AGFA NV

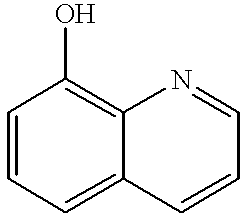

Computer-to-plate by ink jet

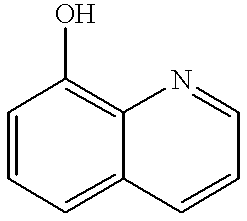

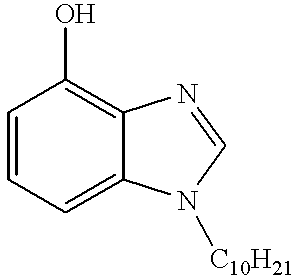

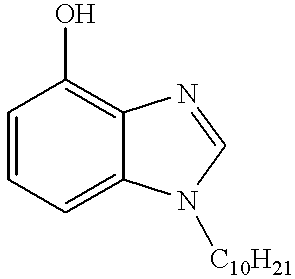

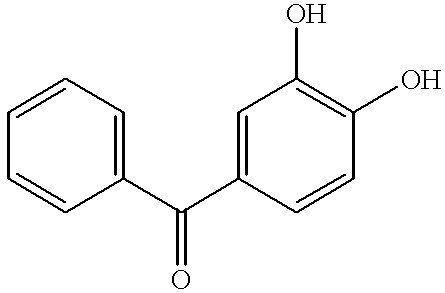

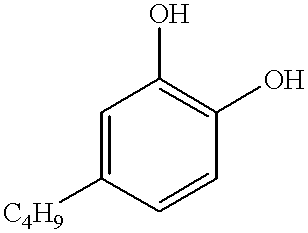

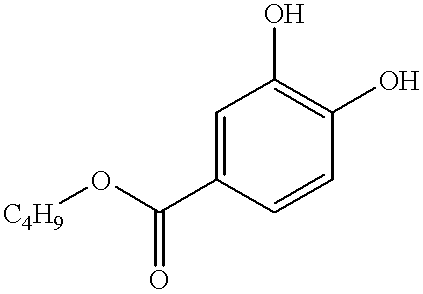

InactiveUS20020043171A1Simple and inexpensive methodProduce littleDuplicating/marking methodsHand compositionComputer to plateHydroxybenzotriazole

A method for preparing a lithographic printing plate by means of ink jet is disclosed. The ink jet fluid contains an oleophilizing compound as defined in the description. Preferred compounds are 8-hydroxyquinolines, 7-hydroxybenzimidazoles, and 7-hydroxybenztriazoles.

Owner:AGFA NV

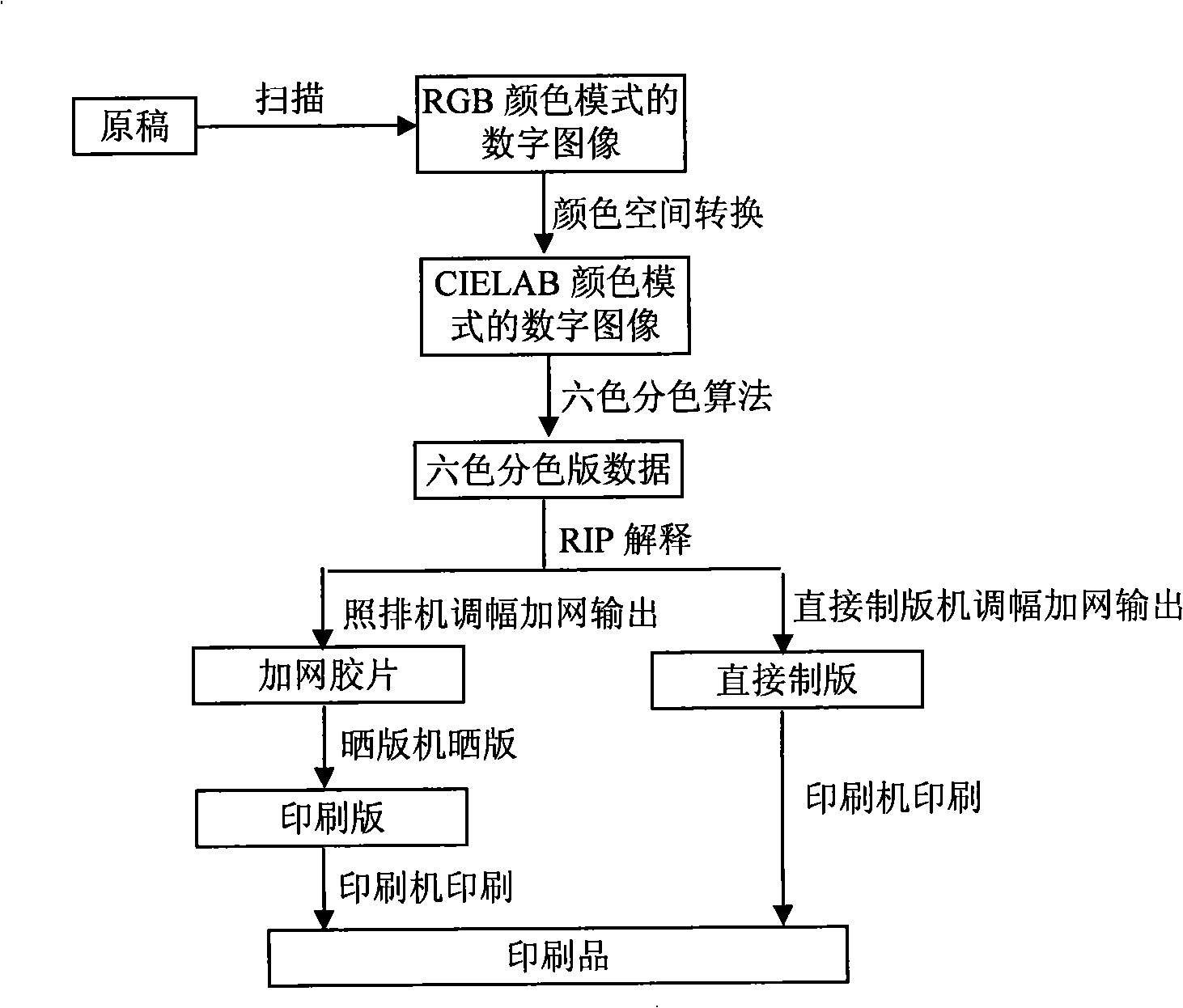

Colorful picture six color separation printing method

InactiveCN101276142AThe phenomenon of collision does not occurQuality improvementColour-separation/tonal-correctionGratingCell separation

The present invention provides a six-color separation printing method of a color chart, effectively resolving the problems that the color of the prints is not bright and full, and each color version is easy to generate bumping net phenomenon under the prior equipment and technical condition, the technical solution includes following steps: the manuscript is scanned to a digital image of red, green and blue mode, changed to a digital image of CIELAB color mode after the color space conversion, divided into a six-color separation version data of yellow, magenta, cyan, black, orange and green by an algorithm of six-color separation, the data is outputted to a screening film by amplitude modulation and screening of a camera after explained of a raster image processor, burnt to a printing plate by a copyboard, printing by a printer, or outputted by amplitude modulation and screening of a direct platemaker, the prints is printed by the printer, the invention greatly improves the quality of the prints, the prints have bright and full color, each color version does not produce bumping net phenomenon, especially for printing high exquisite articles.

Owner:THE PLA INFORMATION ENG UNIV

Computer-to-plate by ink jet

InactiveUS6523472B1Simple and inexpensive methodProduce littleDuplicating/marking methodsPlate printingChemical structureComputer to plate

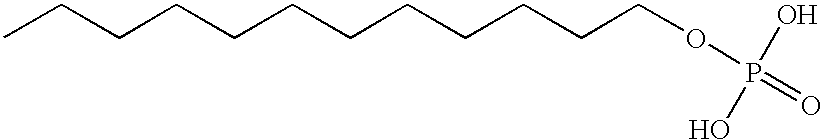

A method for preparing a lithographic printing plate by means of ink jet printing is disclosed. The ink jet fluid contains an oleophilizing compound having in its chemical structure a phosphorous containing group capable of reacting with the surface of a lithographic receiver.

Owner:AGFA NV

Method for producing computer-to-plate lining paper

ActiveCN101787662ASolve acidityStrong acidNatural cellulose pulp/paperWater-repelling agents additionAluminium sulfateComputer to plate

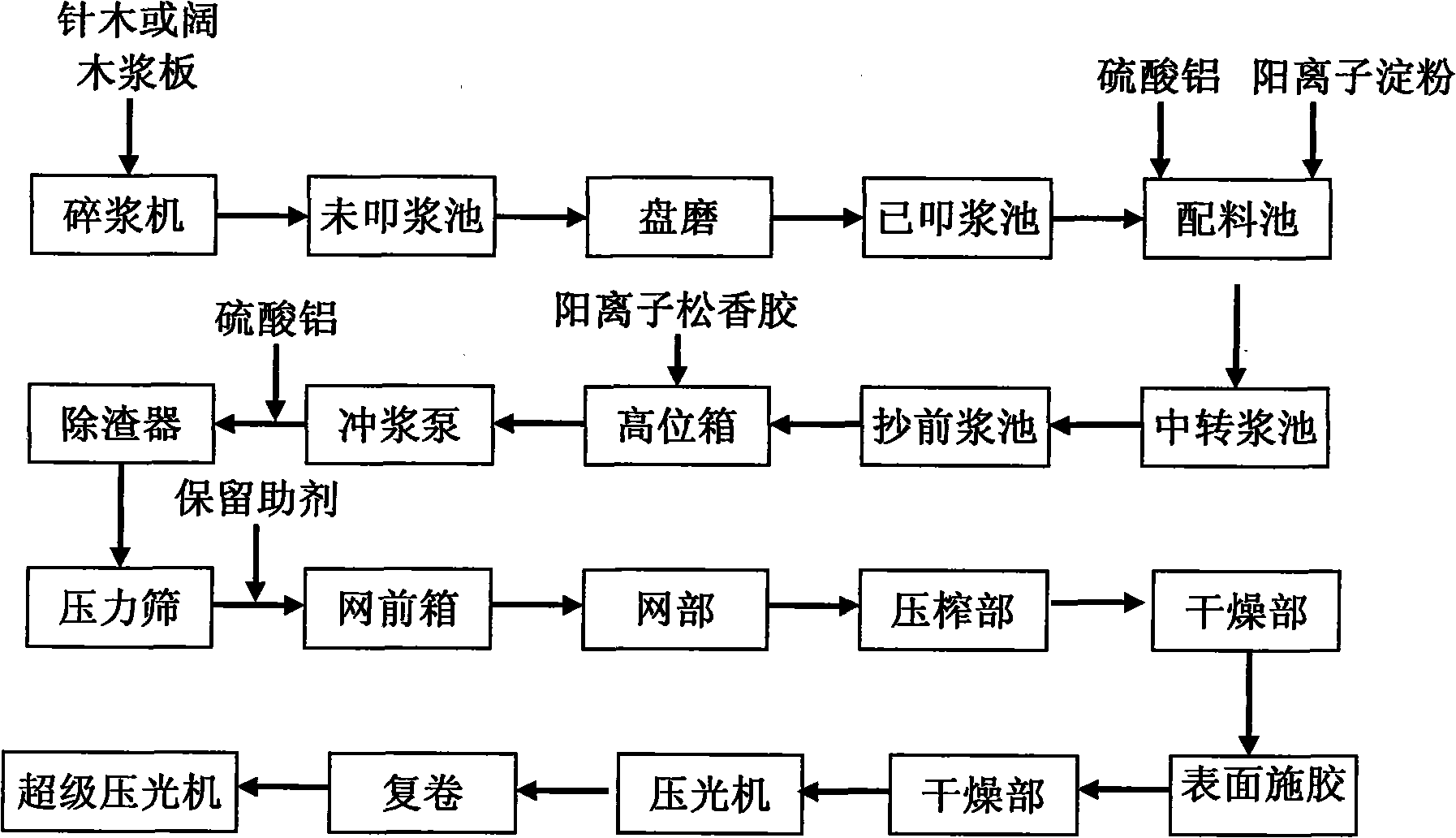

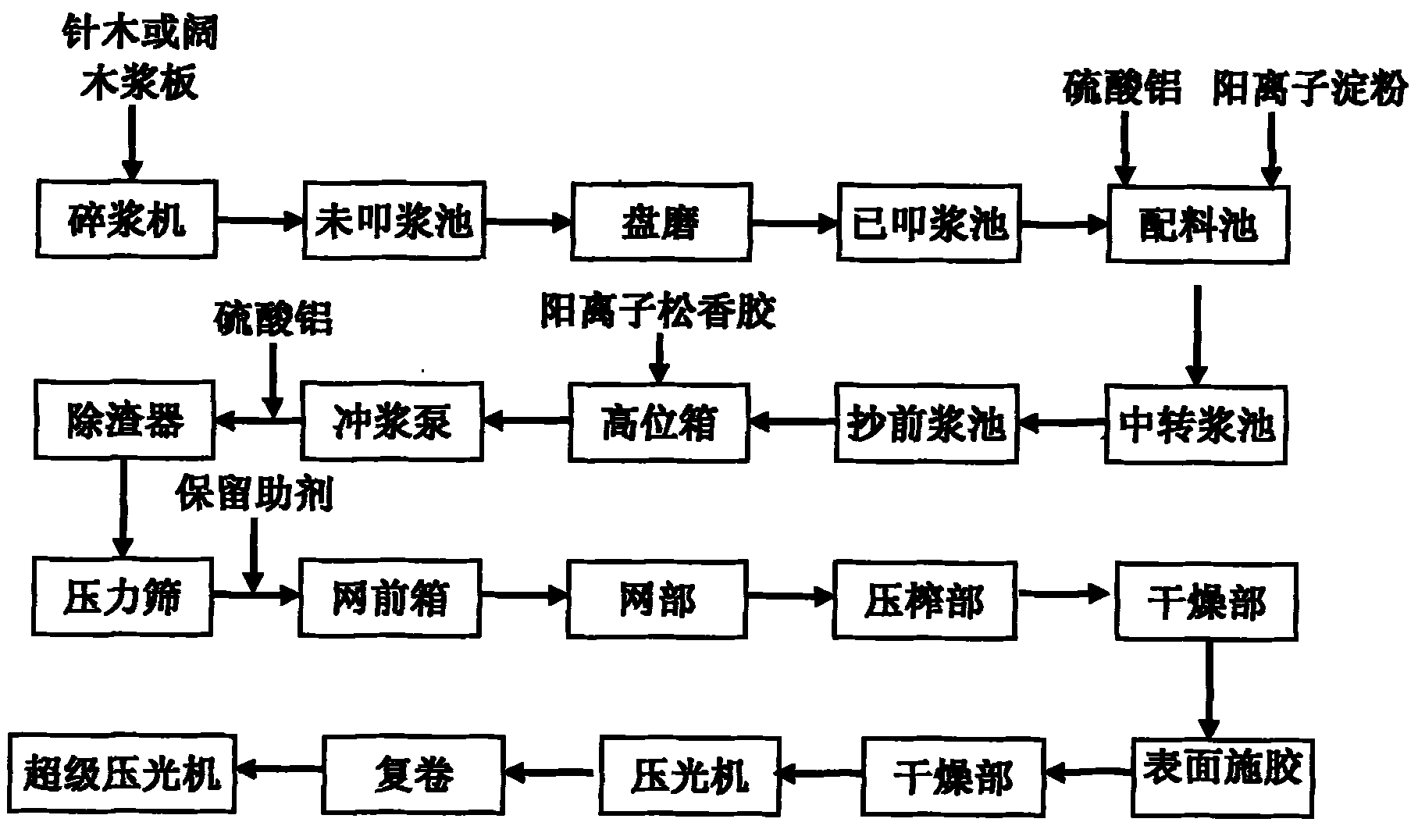

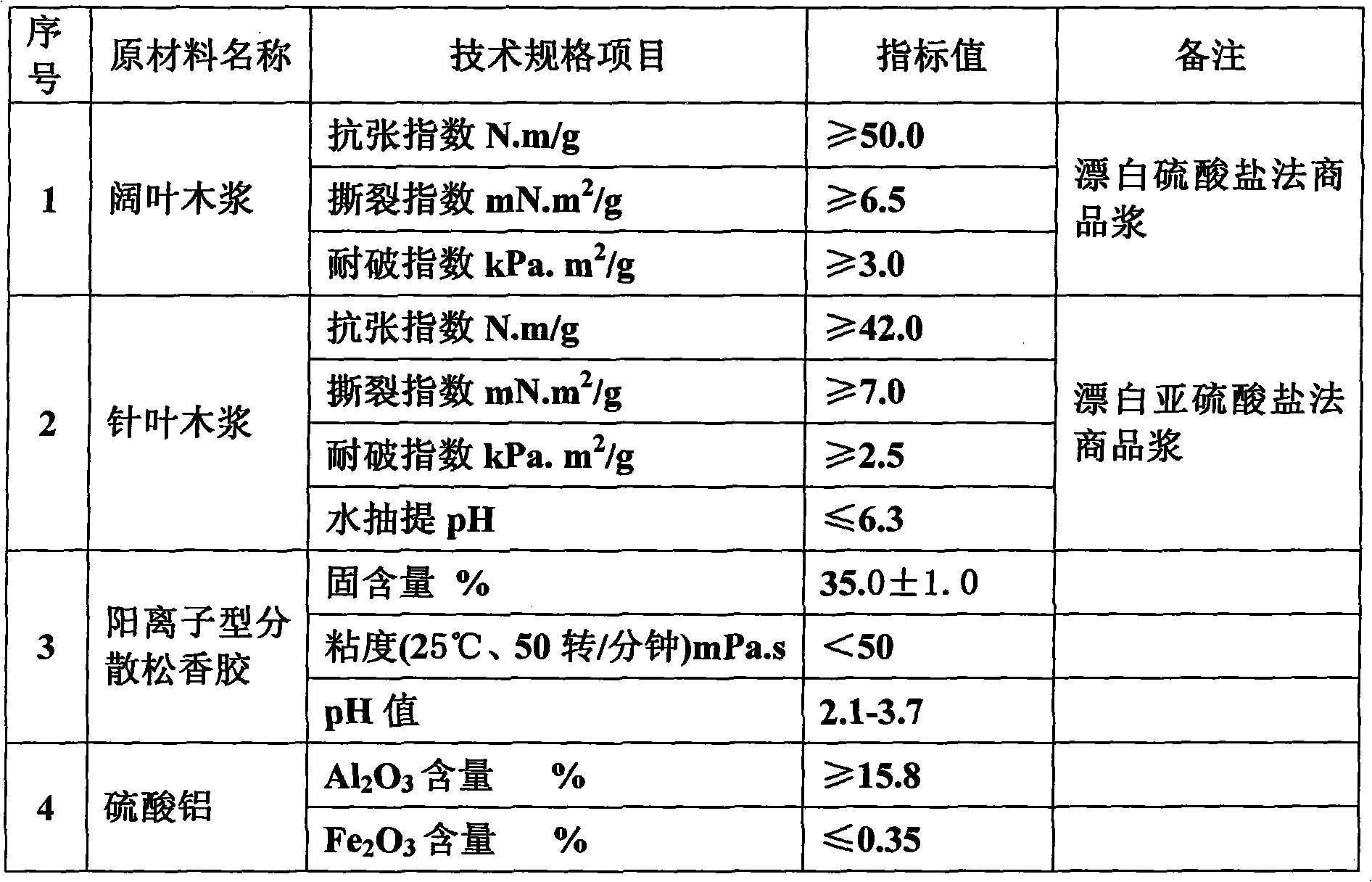

The invention provides a method for producing computer-to-plate (CTP) lining paper, which is characterized in that: the lining paper is produced by using a common multi-cylinder long mesh paper machine, and the production process comprises the following steps: pulp beating, pulp proportioning, paper manufacturing with pulps, surface sizing, press polish and rewinding to produce base paper, then carrying out subsequent press polish treatment on the base paper to produce finished paper; the CTP lining paper is produced from paper pulps which are made of hardwood pulps and softwood pulps, chemical additive cationic starch, cationic dispersed rosin size and auxiliary sizing agent aluminum sulfate serving as raw materials. In the method, the cationic dispersed rosin size is used and the auxiliary sizing agent aluminum sulfate is added for two times on a proportioning pool and at an outlet of a fan pump, so that the problem of producing the CTP lining paper by using cationic dispersed rosin acid sizing technology is successfully solved. The pH value of the water extract of the produced base paper is kept within a range of 5.2 to 5.8, so that the key indicator of the paper, namely, the pH value of the water extract of the paper, meets the quality requirement on the CTP lining paper.

Owner:ZHENJIANG DADONG PULP & PAPER

Oily ink for inkjet computer to plate, preparation method and application thereof

The invention relates to an oily ink for inkjet computer to plate, a preparation method and application thereof. Thermoplastic resin 1-40 wt% of a total weight of the oily ink, oil 0.01-25 wt% of a total weight of the oily ink, nano dye and / or micron dye 0.01-5 wt% of a total weight of the oily ink and the balance of organic solvent are mixed; the mixed solution is stirred at room temperature and filtered to remove particle impurities therein, so as to obtain the oily ink. The oily ink is sprayed on a nude base by an ink jet printer to form images; then the base sprayed with the oily ink is heated to 60-300 DEG C; thermoplastic resin crosslinked and solidified under effect of non-saturated groups in the oily ink, so as to increase resistance of the images on the printing plate to cleaning paste containing alcohol. The obtained printing plate has good printability and high pressrun during printing on a machine, and a presswork has an image resolution reaching 1751pi.

Owner:INST OF CHEM CHINESE ACAD OF SCI

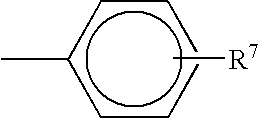

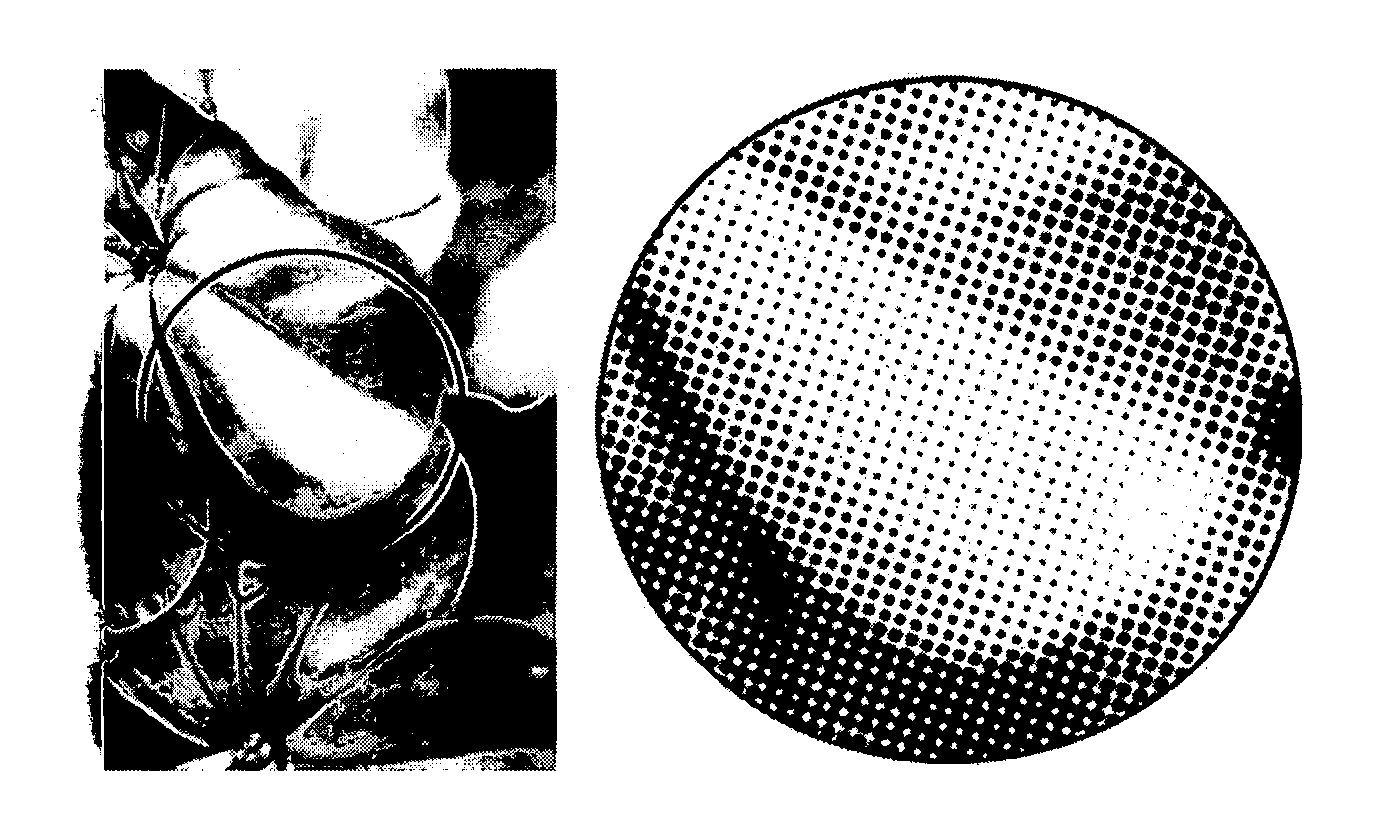

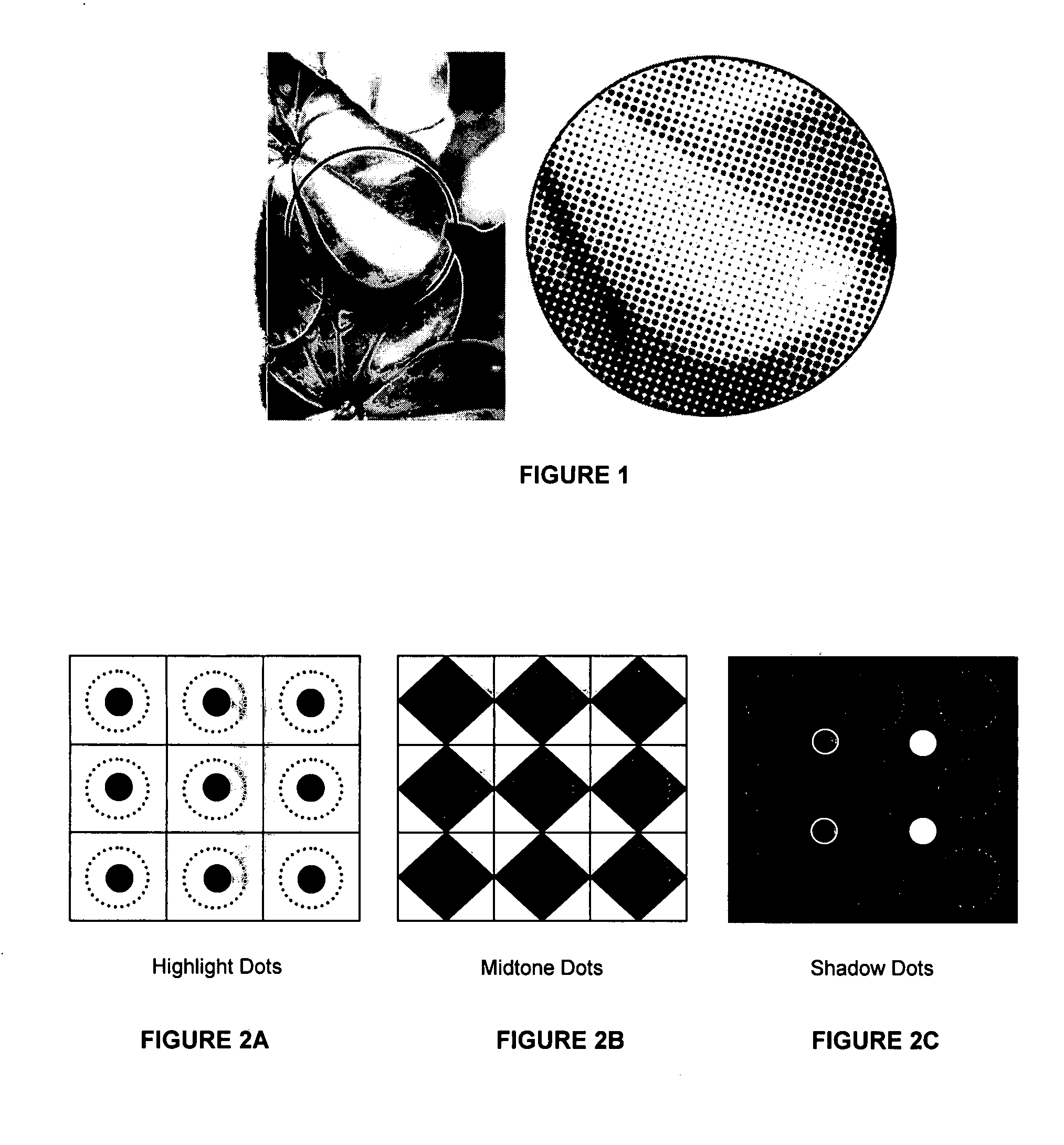

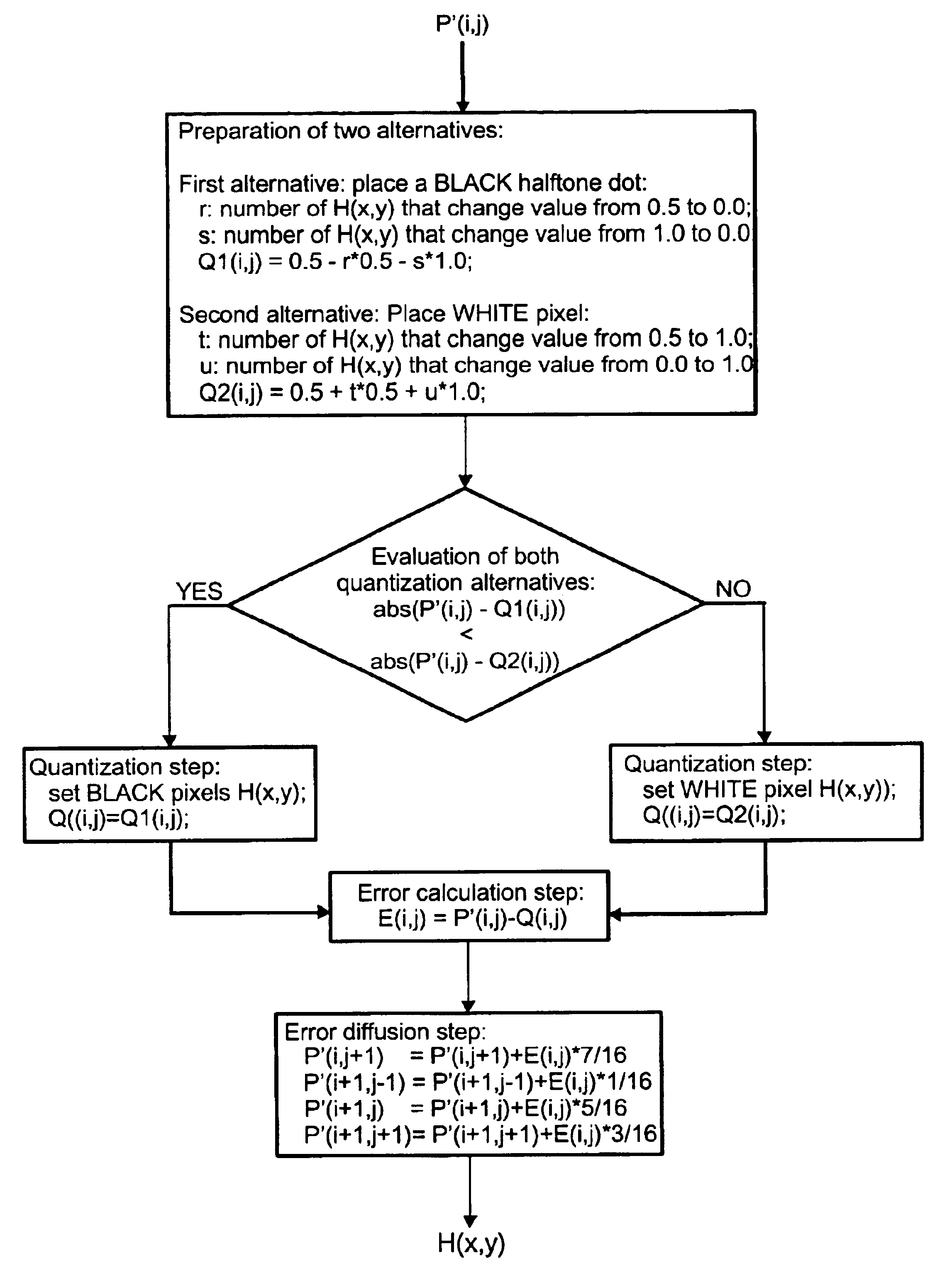

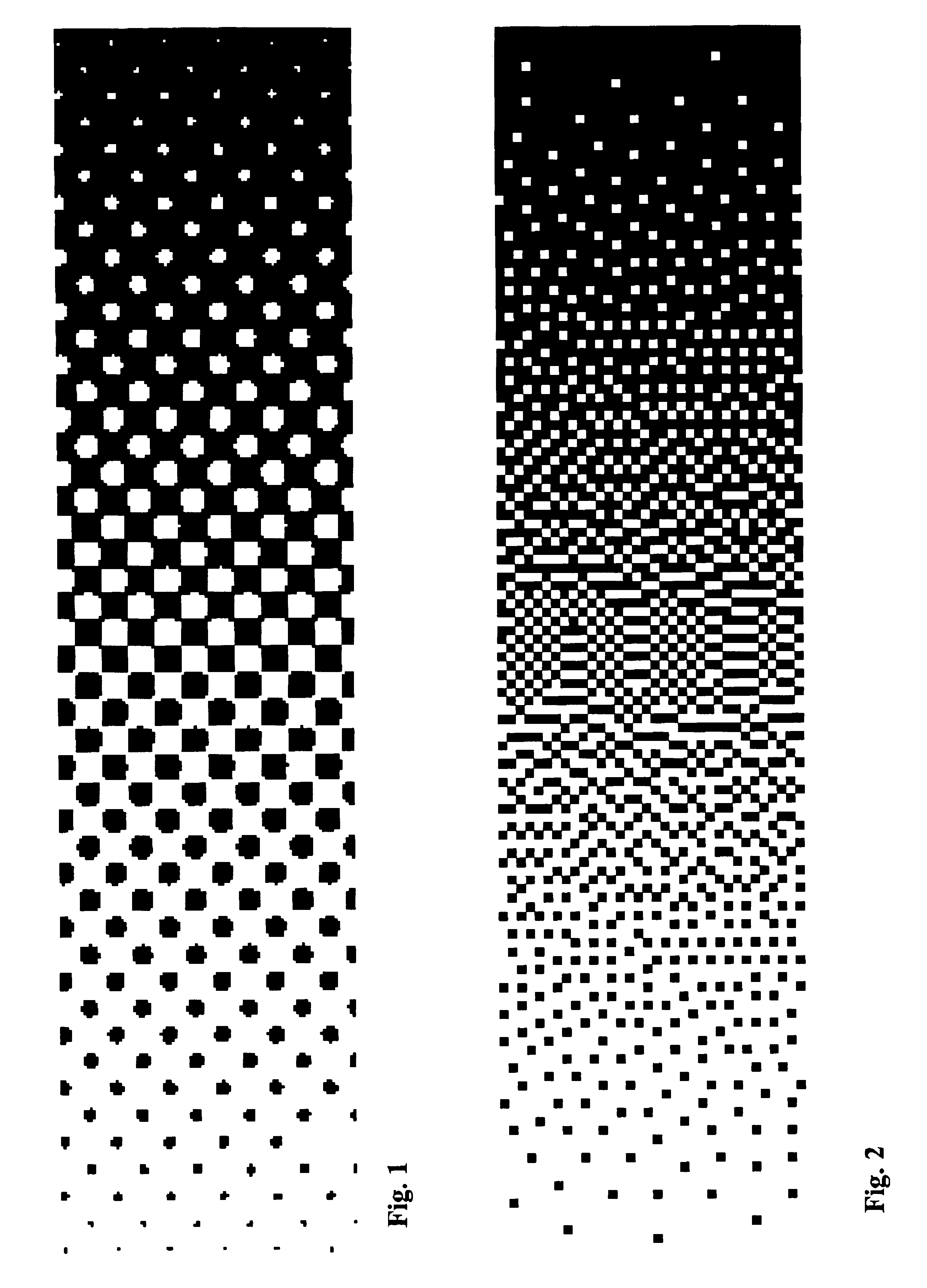

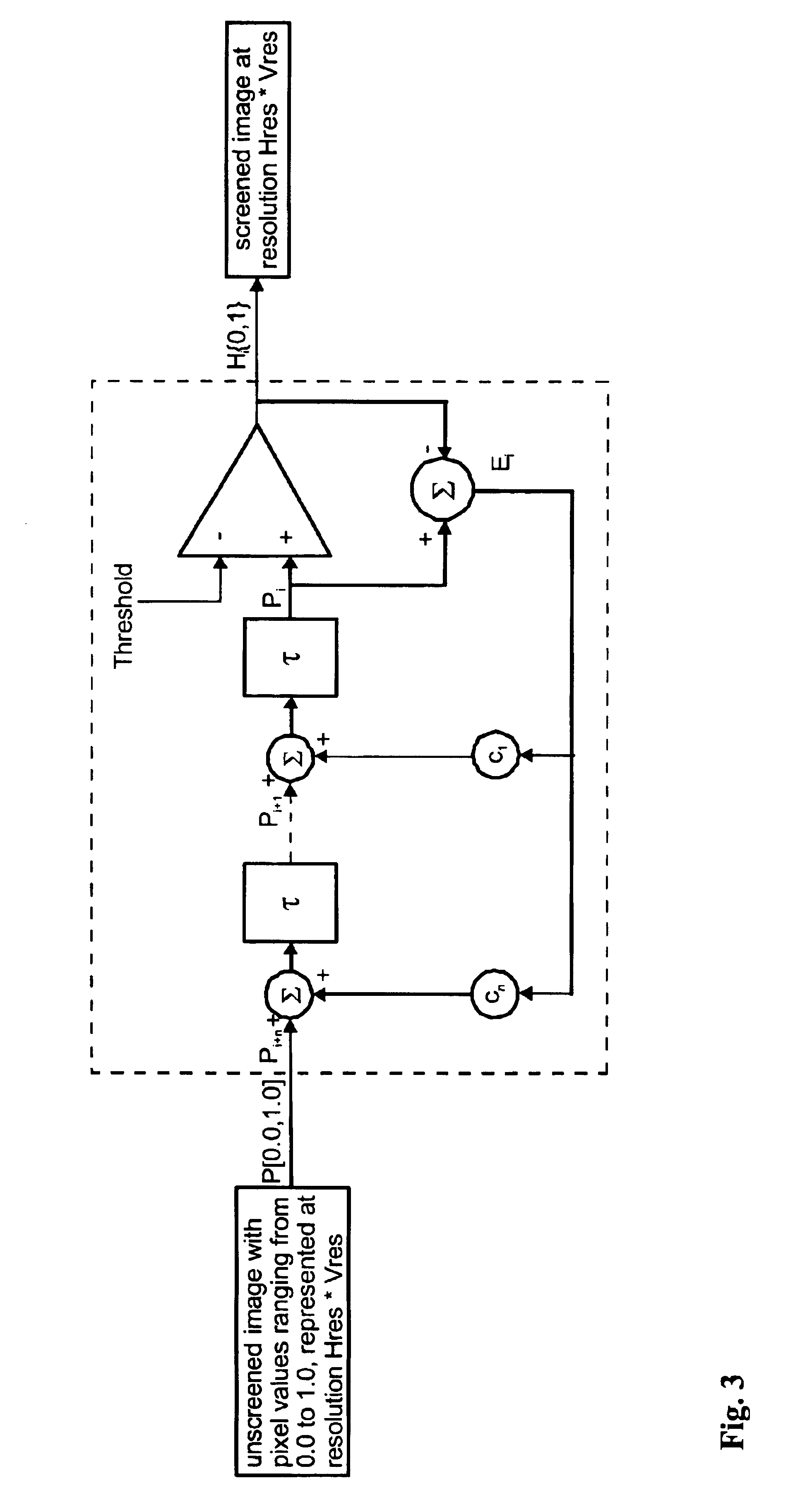

Sub-dot phase modulation for computer to plate inkjet system

ActiveUS6962400B2Apparent advantagePlate printingVisual presentationComputer to plateError diffusion

Printing masters are produced by use of an inkjet printing system.The smallest halftone dot size which can be printed by the inkjet printing system is larger than the size of a pixel of the recording grid defined by the addressability of the printing device.The error diffusion algorithm is especially adapted to make use of the high addressability of the recording system.Using a sub-dot phase modulated error diffusion halftoning algorithm allows for the distance between the halftone dots to be modulated in much smaller increments than the size of the halftone dots themselves.Results can be further improved by dynamically influencing the threshold value in the error diffusion algorithm in accordance with previous output quantisation determinations.Variable coverage percentage of the pixels can be taken into account.The method can be extended to multilevel systems.

Owner:AGFA OFFSET BV

Lithographic printing plate and image forming method

InactiveUS6509133B1Excellent printing resistanceShow resistanceX-ray/infra-red processesPhotosensitive materialsWater dispersibleComputer to plate

In order to provide a computer-to-plate (CTP) plate in which an image can be inscribed by a laser beam having Ithe maximum strength in a near infrared or infrared region, and heat processing is not necessary prior to developing a latent image, and which allows the use of a conventional printing apparatus as it is upon printing, (I) a lithographic printing plate is provided which has on a substrate, a photosensitive layer comprising a photosensitive composition containing a crosslinking agent, an aqueous dispersion of resin fine particles made of a resin which is self water-dispersible having a carboxylic group and a functional group capable of performing cross-linking reactions with the crosslinking agent, and an infrared absorption agent; and (II) an image forming method is provided which is characterized in that after an image has been formed on a photosensitive layer of the lithographic printing plate set forth in the above (I) by using a laser beam, the image is subjected to wet development.

Owner:DAINIPPON INK & CHEM INC

Method of producing an image on a printing screen

InactiveUS20060098235A1Trend downRapidly and economically produceDuplicating/marking methodsPlate printingCross-linkComputer to plate

Methods of producing an image on a printing screen are described. The method uses inkjet printing technology to form an image on the screen using a computer to screen or computer to plate imaging technique. According to particular embodiments a specially formulated emulsion is used in which the emulsion is mixed with a cross-linking agent to create a self curing image.

Owner:NAT RES COUNCIL OF CANADA +2

Computer-to-plate by ink jet

InactiveUS6457413B1Simple and inexpensive methodProduce littleDuplicating/marking methodsPrinting pre-treatmentComputer to plateEngineering

A method for preparing a lithographic printing plate by means of ink jet is disclosed. The ink jet fluid contains an oleophilizing compound as defined in the description. Preferred compounds are 8-hydroxyquinolines, 7-hydroxybenzimidazoles, and 7-hydroxybenztriazoles.

Owner:AGFA NV

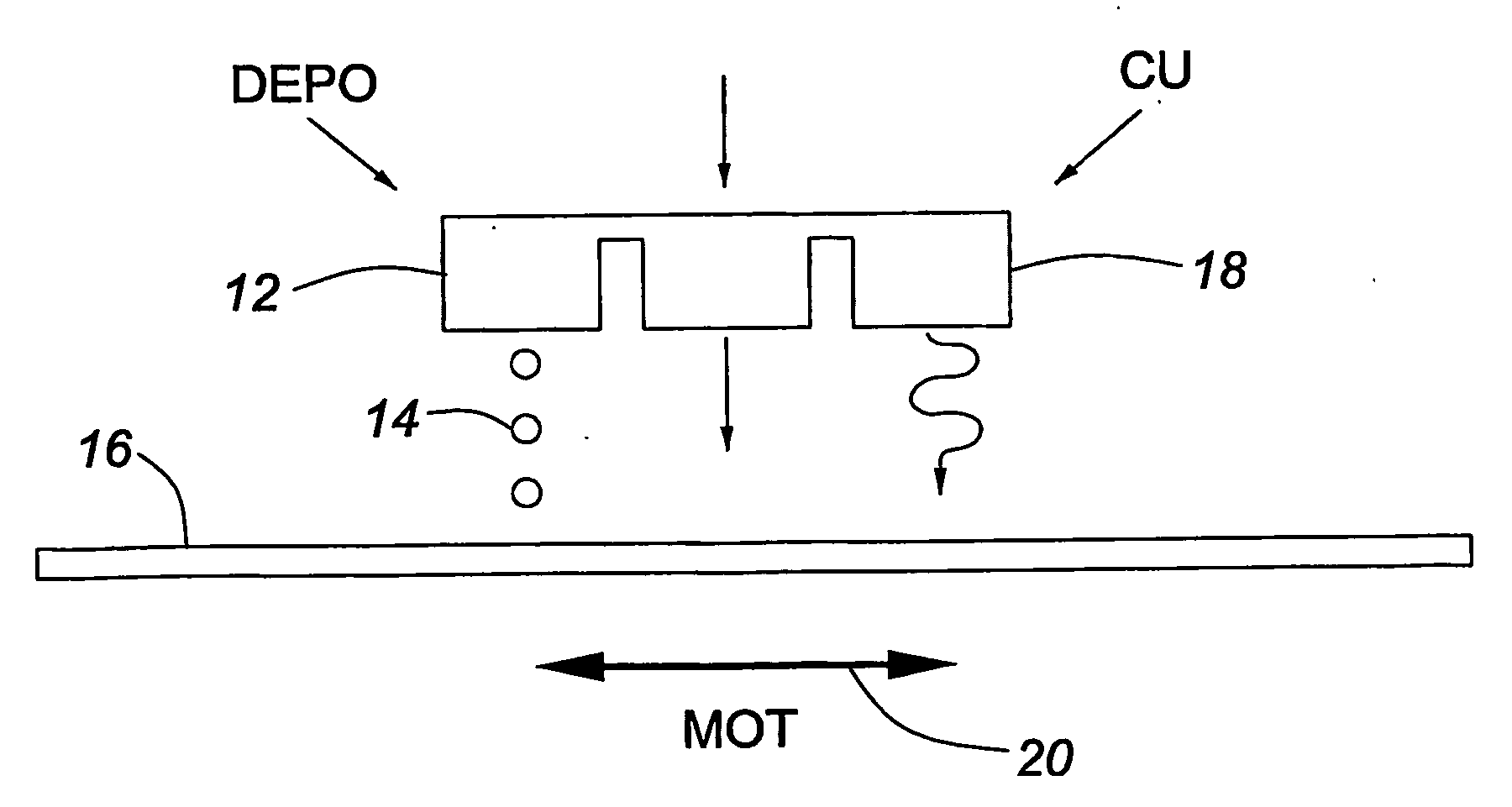

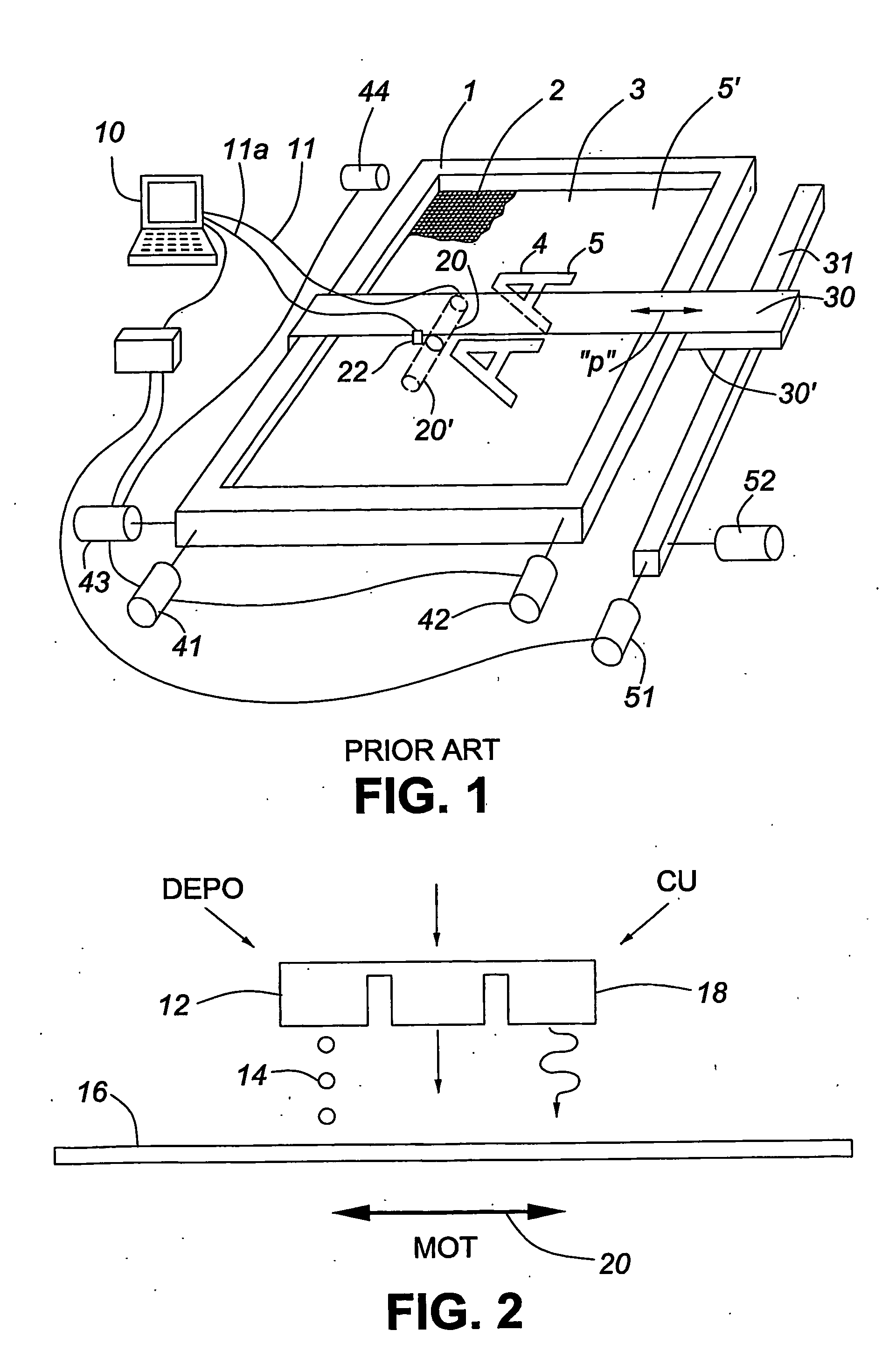

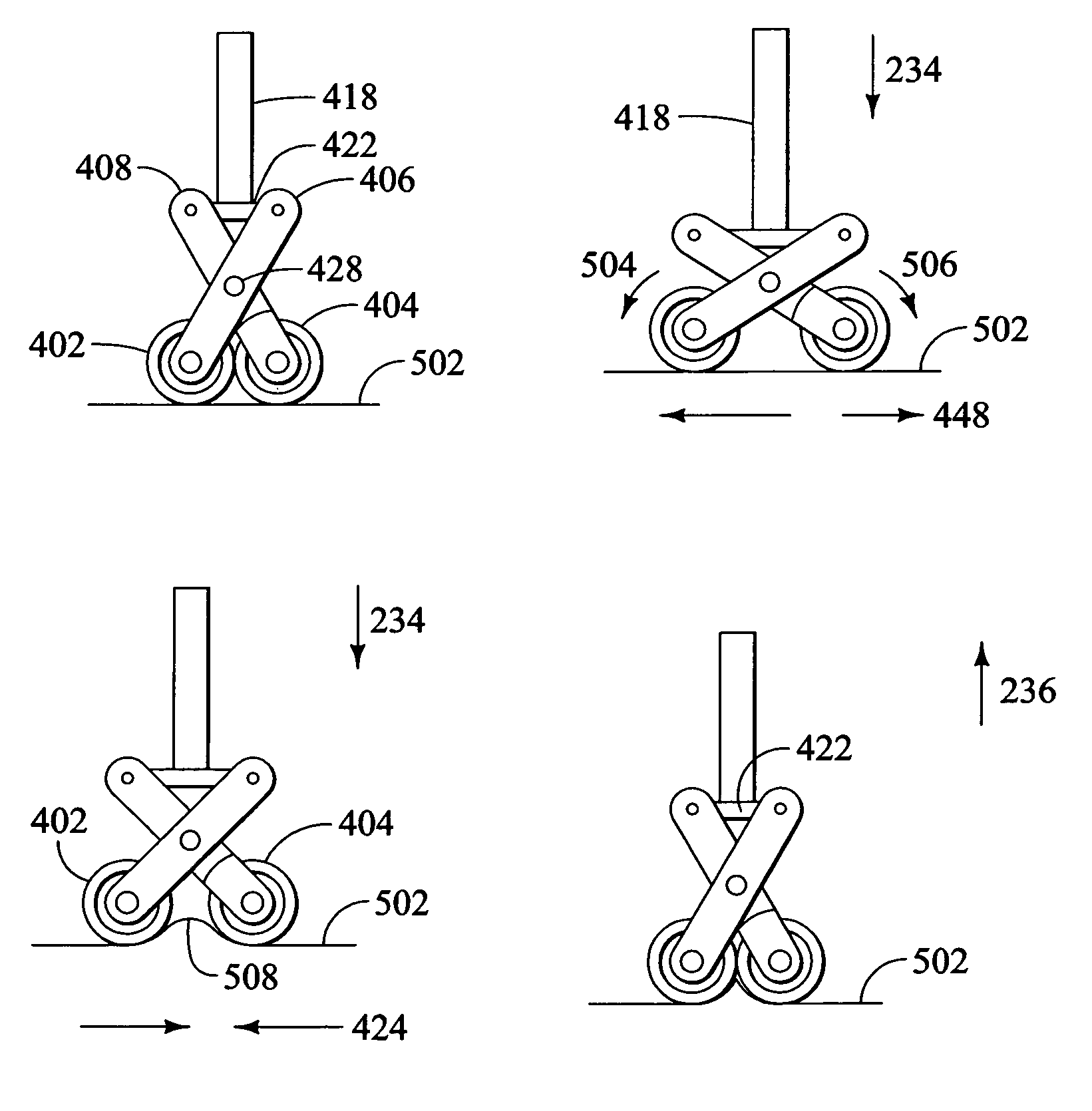

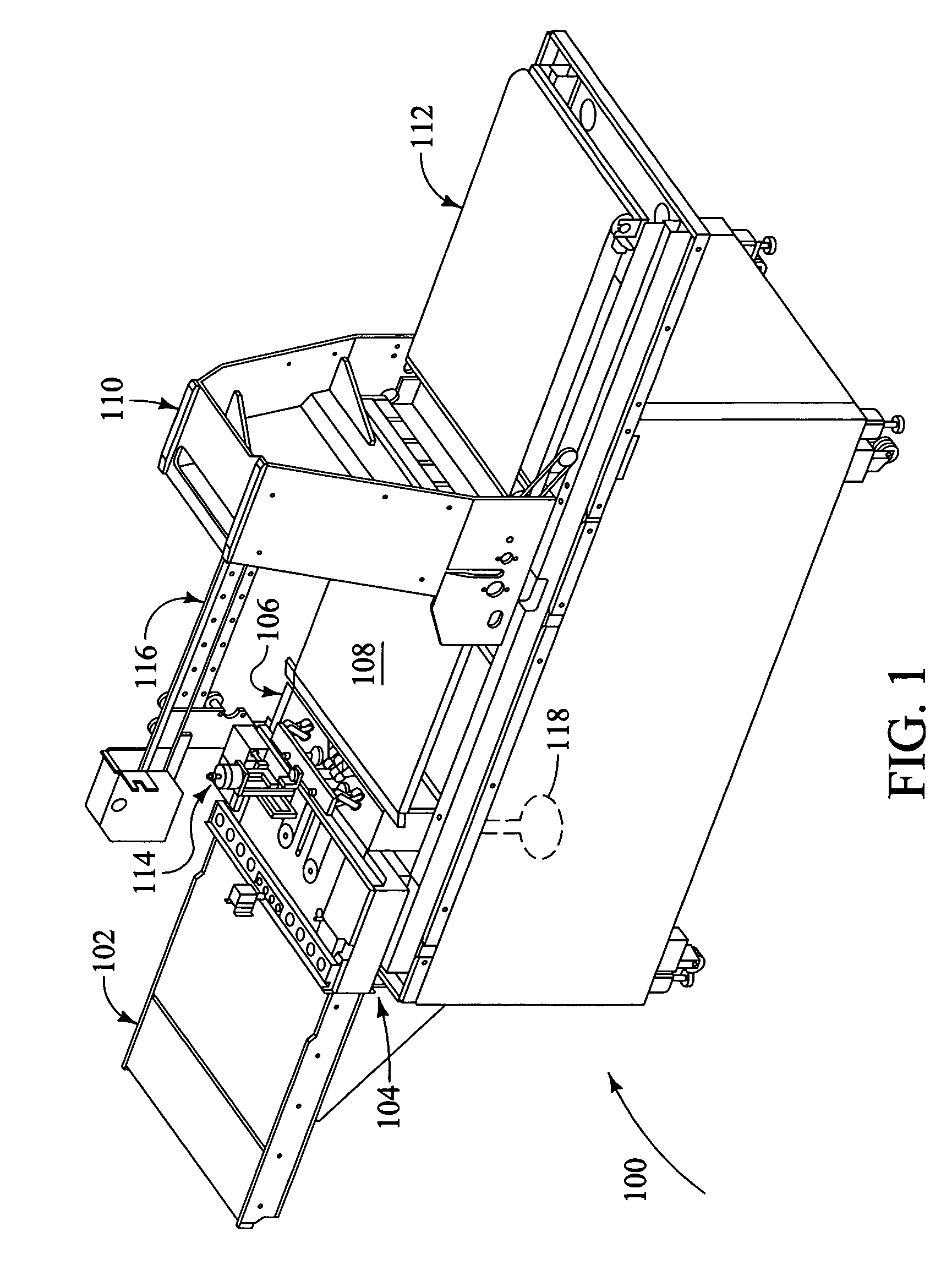

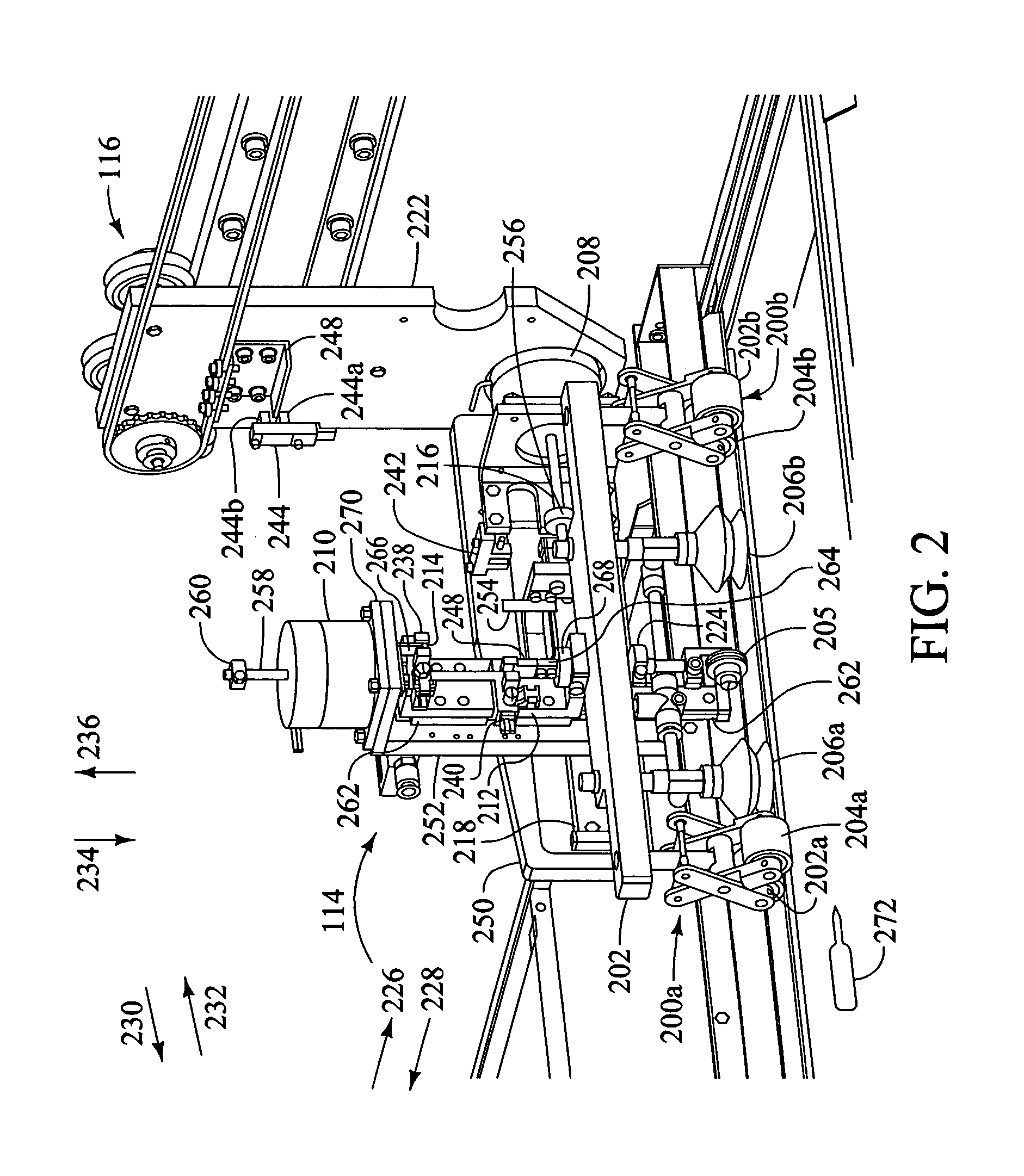

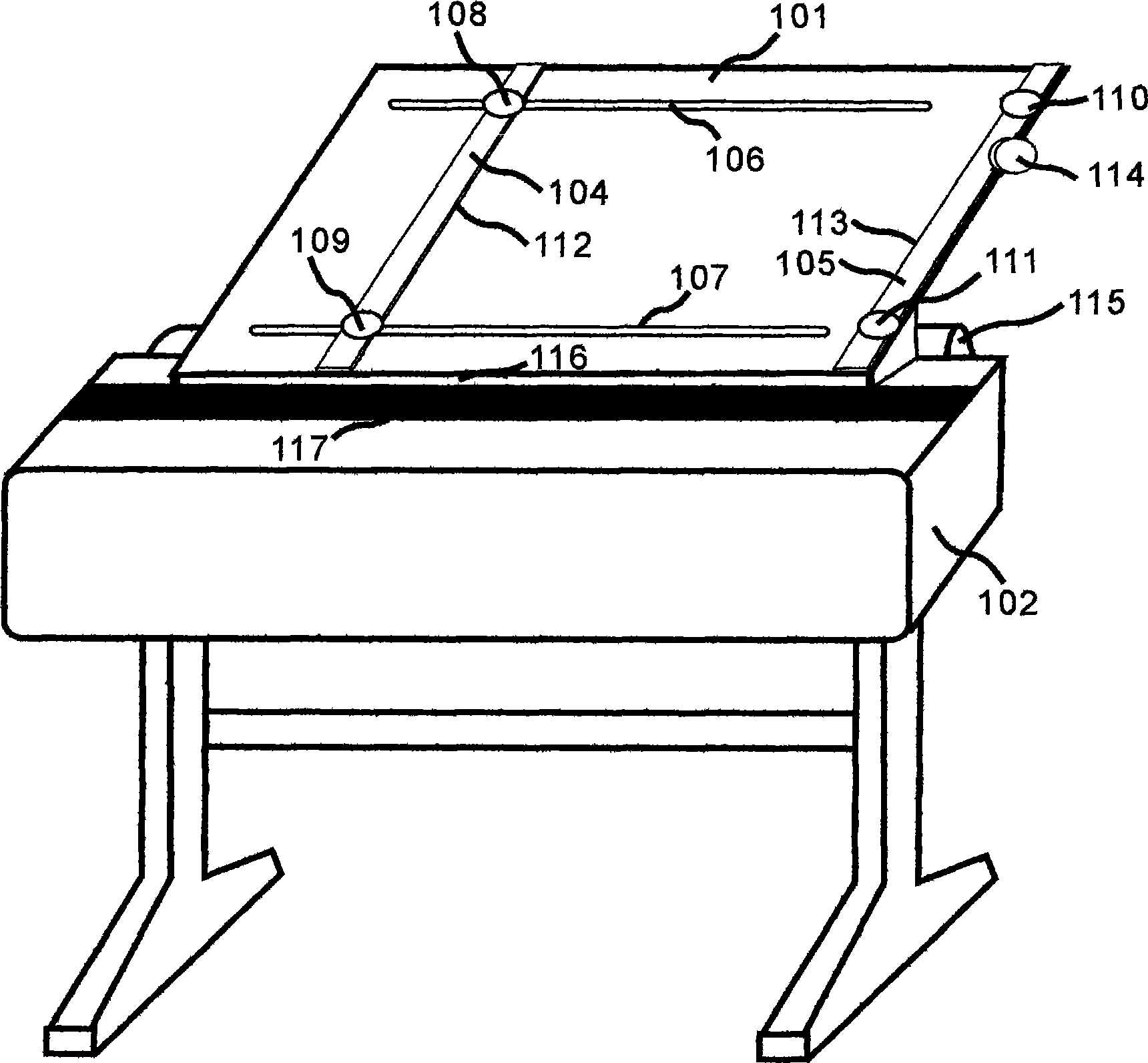

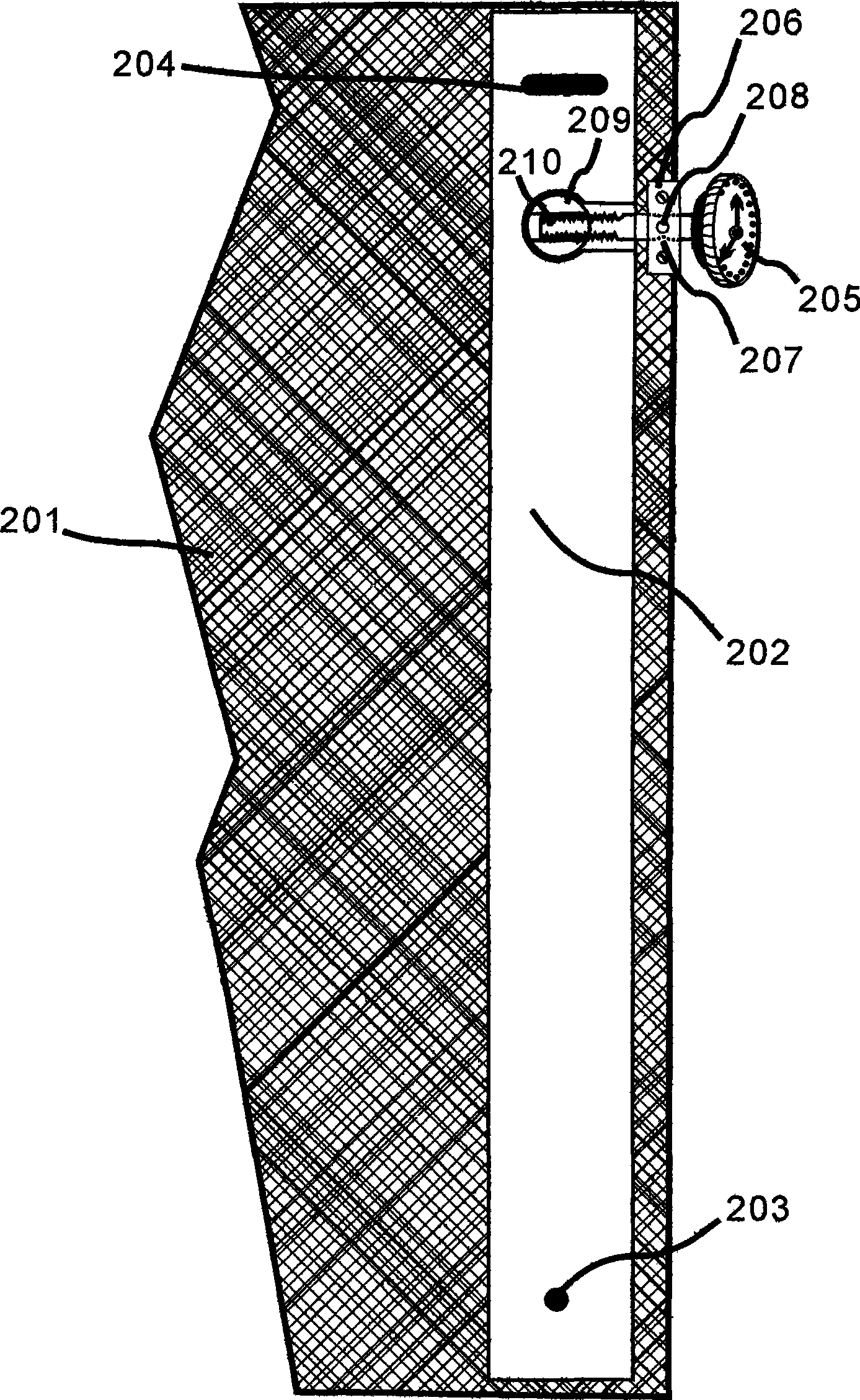

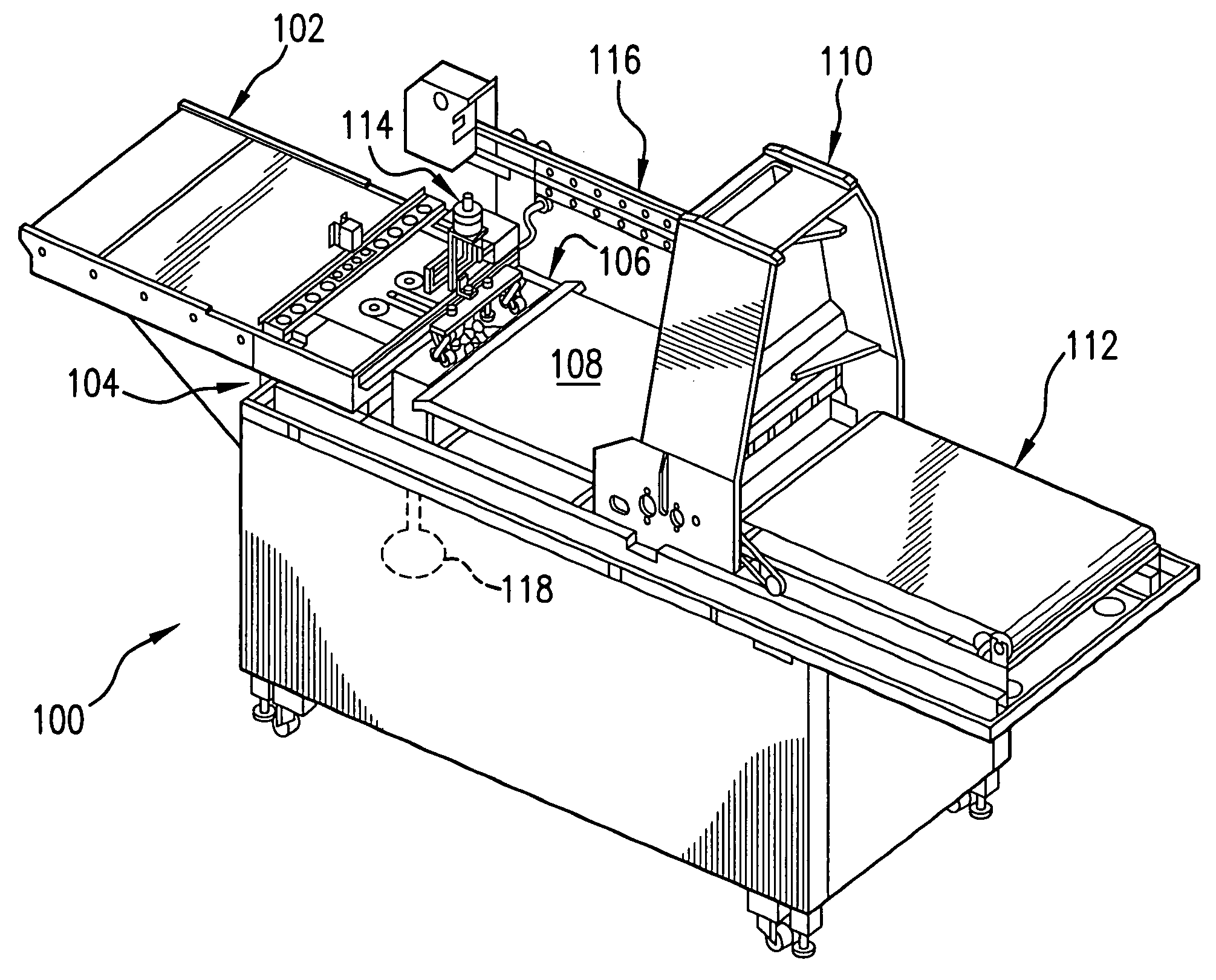

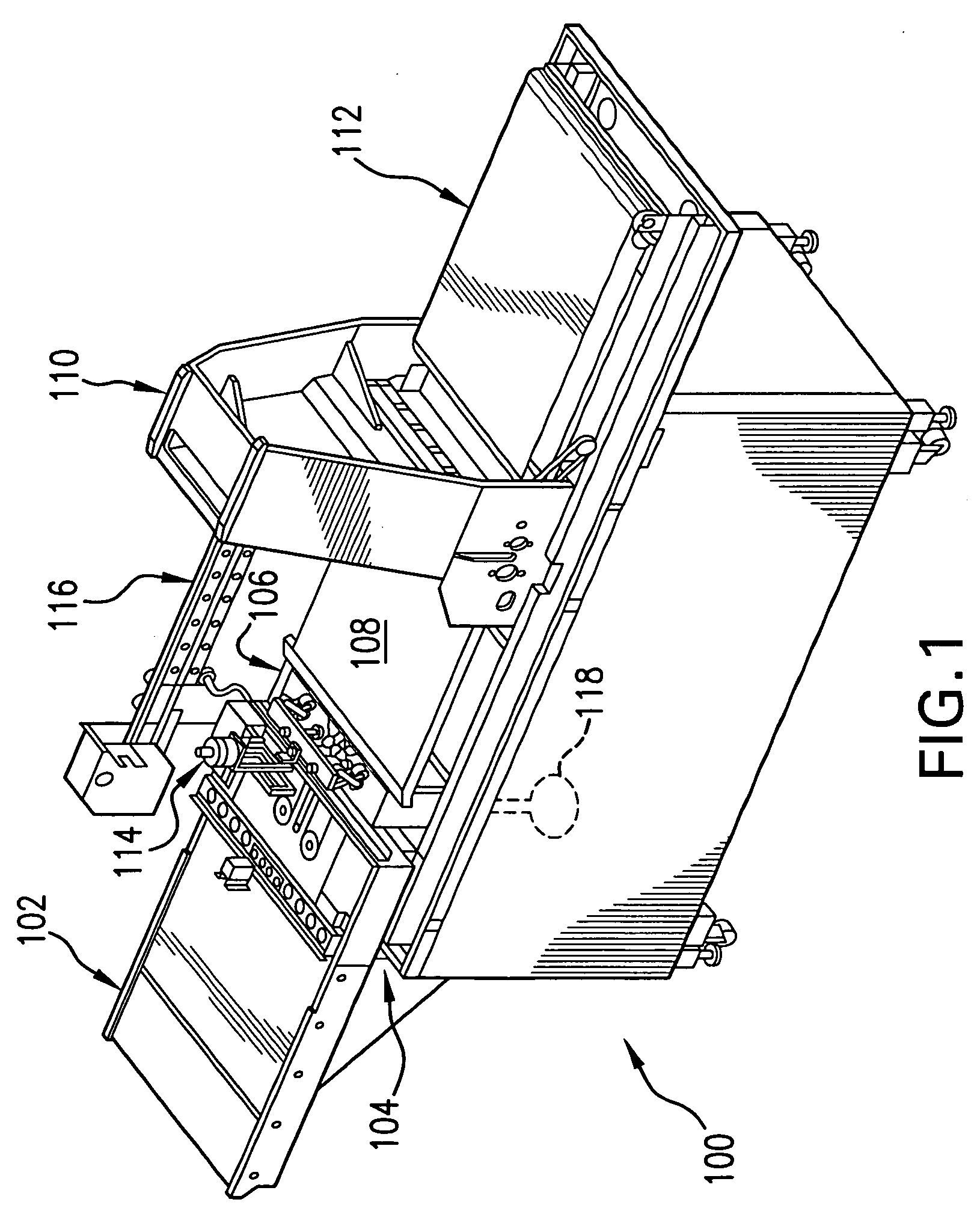

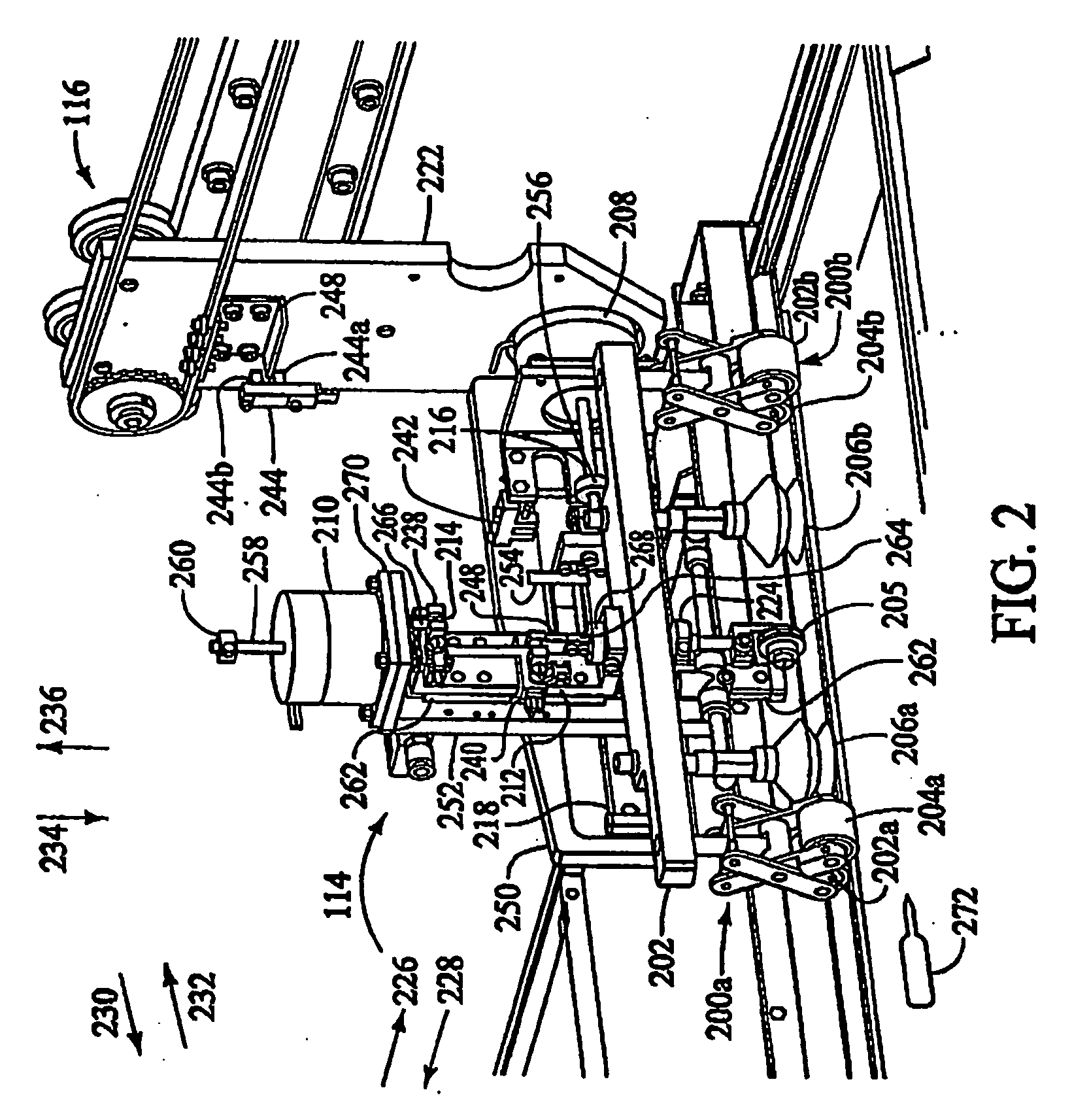

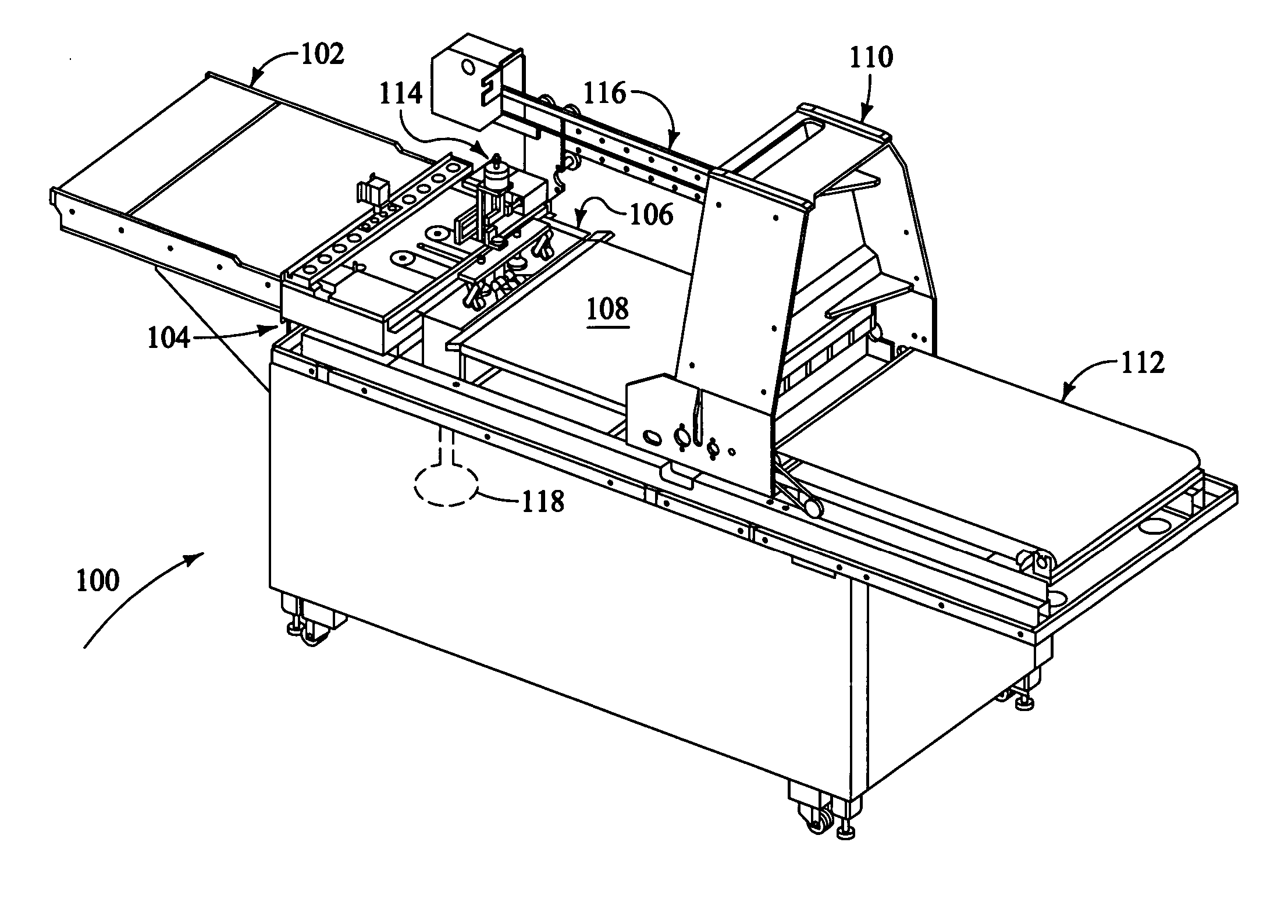

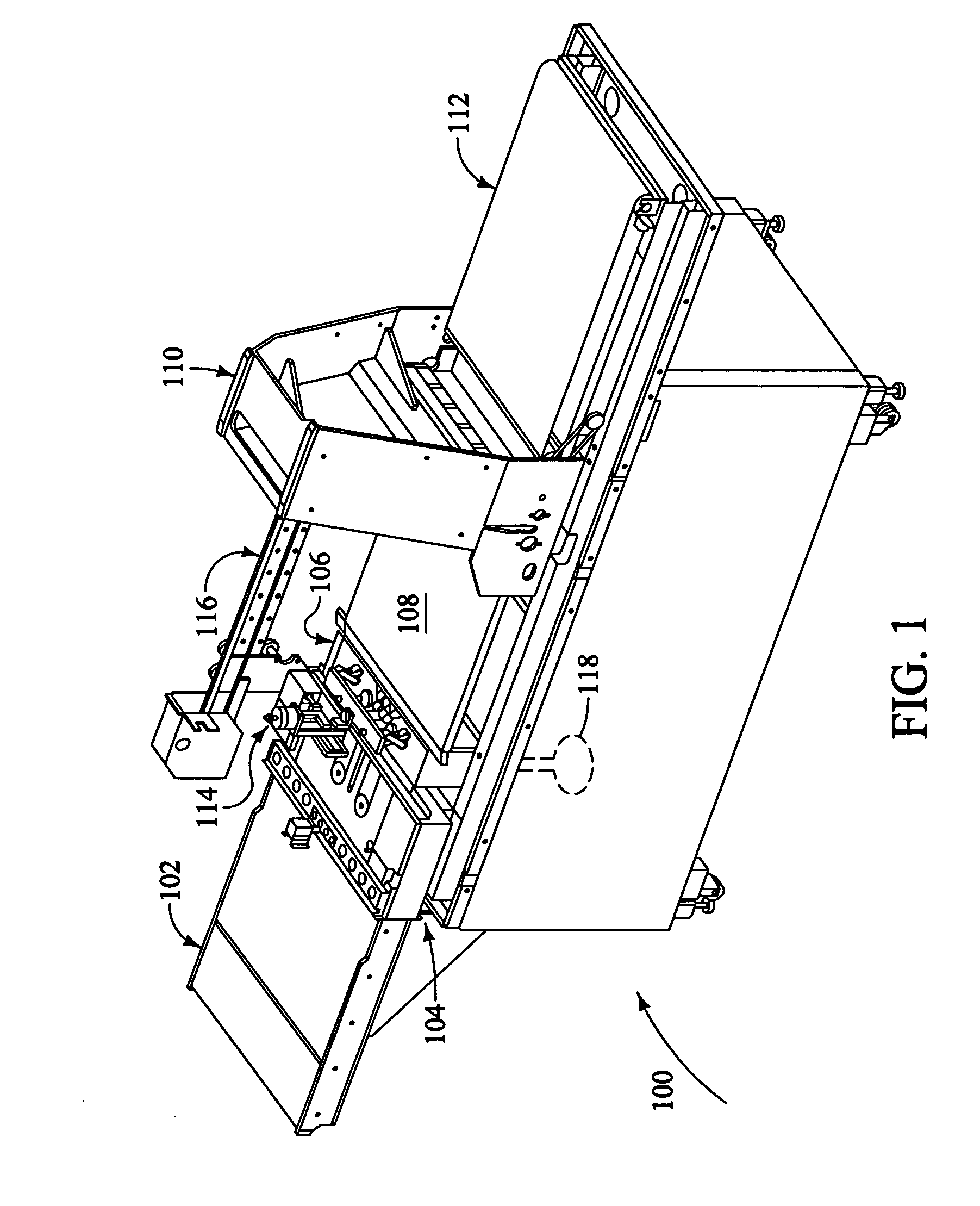

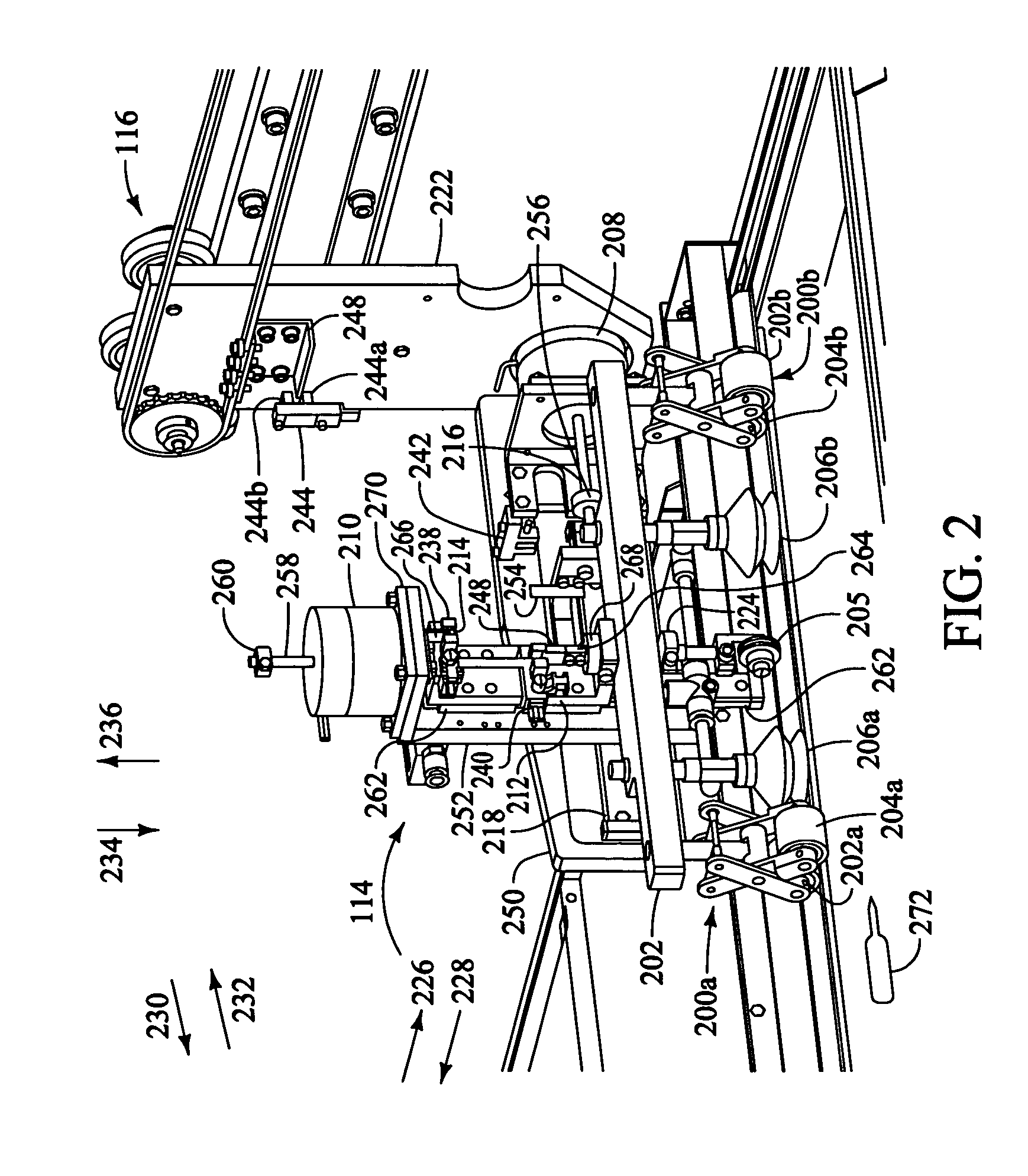

System and method for interleaf sheet and/or plate sheet removal and/or transport for use with a printing apparatus

InactiveUS7000541B2Minimize the numberSimple and low solutionAddressographsLetterpress printingComputer to plateImage system

The present invention relates generally to systems and methods that remove an interleaf sheet interposed between plate sheets from a material stack used, for example, in a computer-to-plate imaging system and / or environment. Embodiments of the system and method can also remove plate sheets from an interleaf sheet, and transport the plate sheet for subsequent imaging.

Owner:ECRM

Computer-to-plate by ink jet

InactiveUS6523473B2Simple and inexpensive methodProduce littleDuplicating/marking methodsPlate printingComputer to plateSalicylic acid

A method for preparing a lithographic printing plate by means of ink jet is disclosed. The ink jet fluid contains an oleophilizing compound chosen from the group consisting of a catechol, a pyrogallol, and a salicylic acid.

Owner:AGFA NV

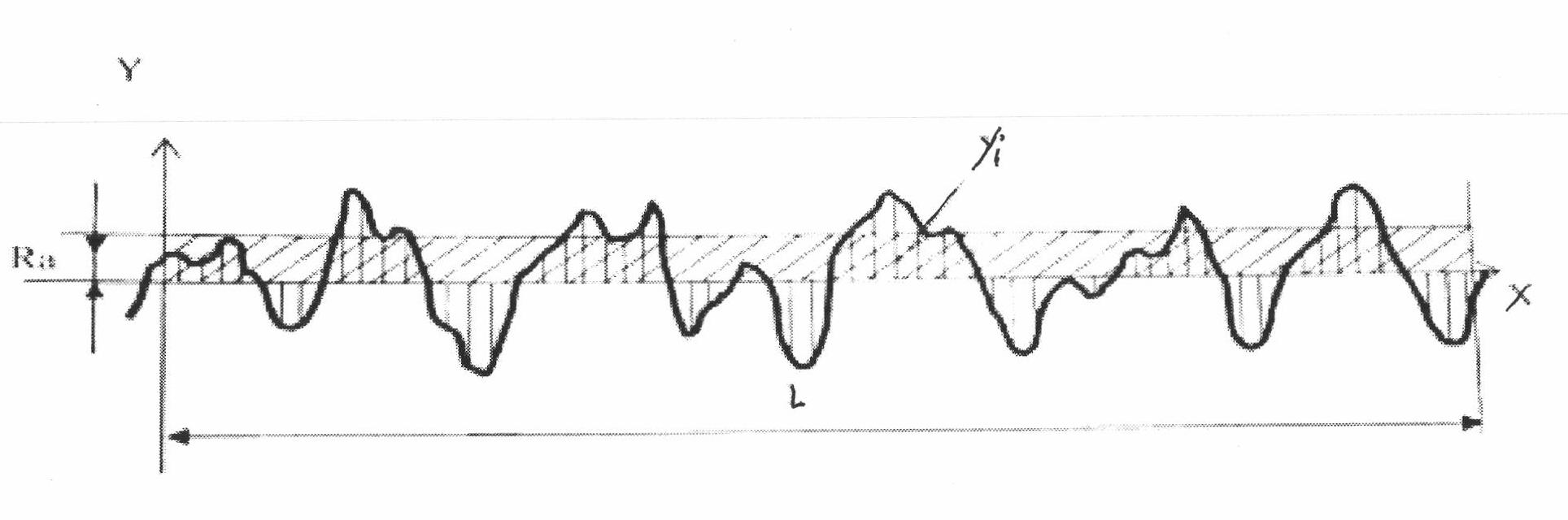

Method for preparing aluminum plate base for inkjet computer to plate and hydrophilic coating

ActiveCN102102214AAbsorbentImprove wear resistanceAnodisationPrinting pre-treatmentHydrophilic coatingComputer to plate

The invention belongs to a method for preparing an aluminum plate base for printing, and relates to a method for preparing an aluminum plate base for inkjet computer to plate and a hydrophilic coating for coating the surface of the aluminum plate base. The method for preparing the aluminum plate base comprises the steps of deoiling the aluminum plate base, performing electrolysis, dedusting, performing anodic oxidation and the like, and coating the hydrophilic coating on the treated aluminum plate base. The electrolysis and anodic oxidation processes in the prior art are improved, so that a nanometer and micrometer structure can be constructed on the surface after the aluminum plate base is subjected to the anodic oxidation; the diffusion behavior of ink droplets is controlled, and the hydrophilic coating is coated on the surface of the aluminum plate base, so that the aluminum plate base has certain roughness, ink absorption property and high wear resistance simultaneously; printing ink is sprayed on the aluminum plate base coated with the hydrophilic coating by an inkjet computer to plate technology so as to form a text area; and by adjusting the preparation process of the plate base and coating the hydrophilic coating, contrast between the text area and a non-text area during printing is increased, and text resolution is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Digital print making Filin direct printing and digital proofing output system

InactiveCN101380851AHigh edge resolutionAvoid lostTypewritersOther printing apparatusImage resolutionComputer to plate

The invention discloses a comprehensive multitask output system which realizes trinity of CTP(Computer To Plate), CTF(Computer To Film) and CTD(Computer To Digital Proofing) by a high precision control platform, a high resolution inkjet printer, a computer image processing software, etc. No darkroom operation is needed in the invention. A traditional low-cost PS photographic plate is used in digital printing and plate making, thus simplifying the structure of a selenium plate and improving the output quality. Plate making can be carried out directly in a computer digital film output part without a chemical developing machine. By adopting a high resolution inkjet image color management system and a screening technology in printing, the image output by the CTD is exquisite and natural, and the invention is a comprehensive prepress technology of digitalization of a traditional printing device.

Owner:谷京陆

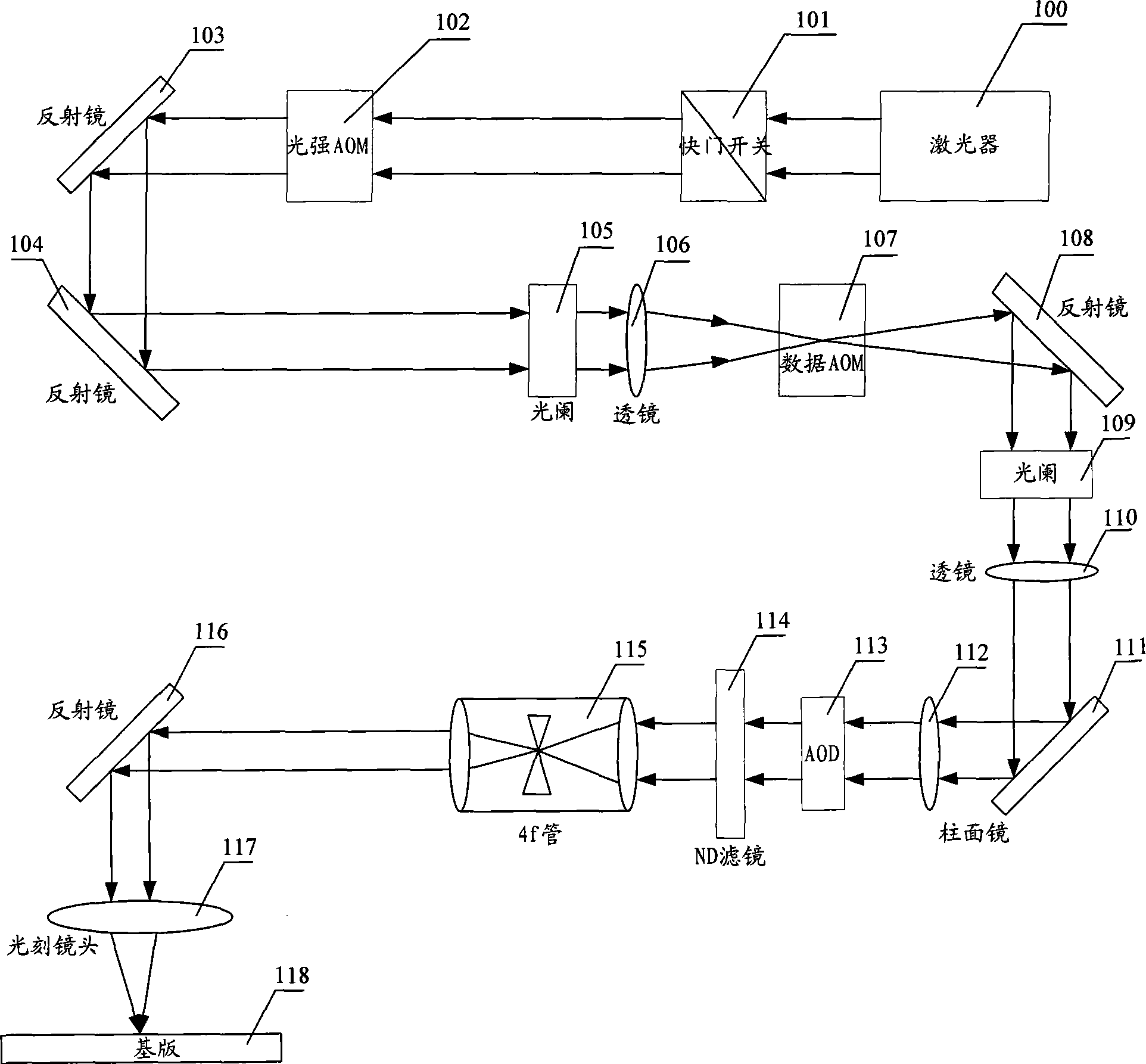

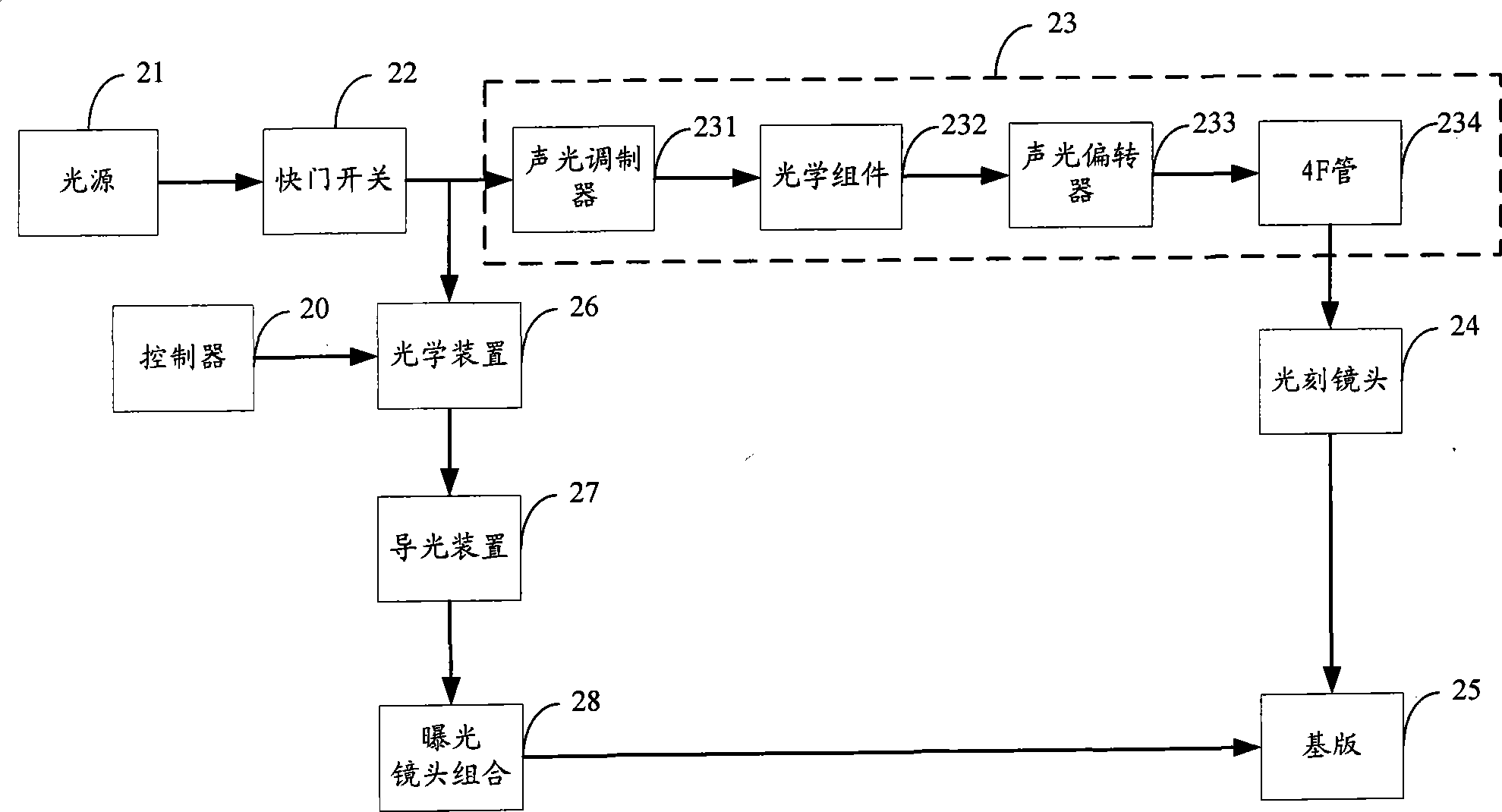

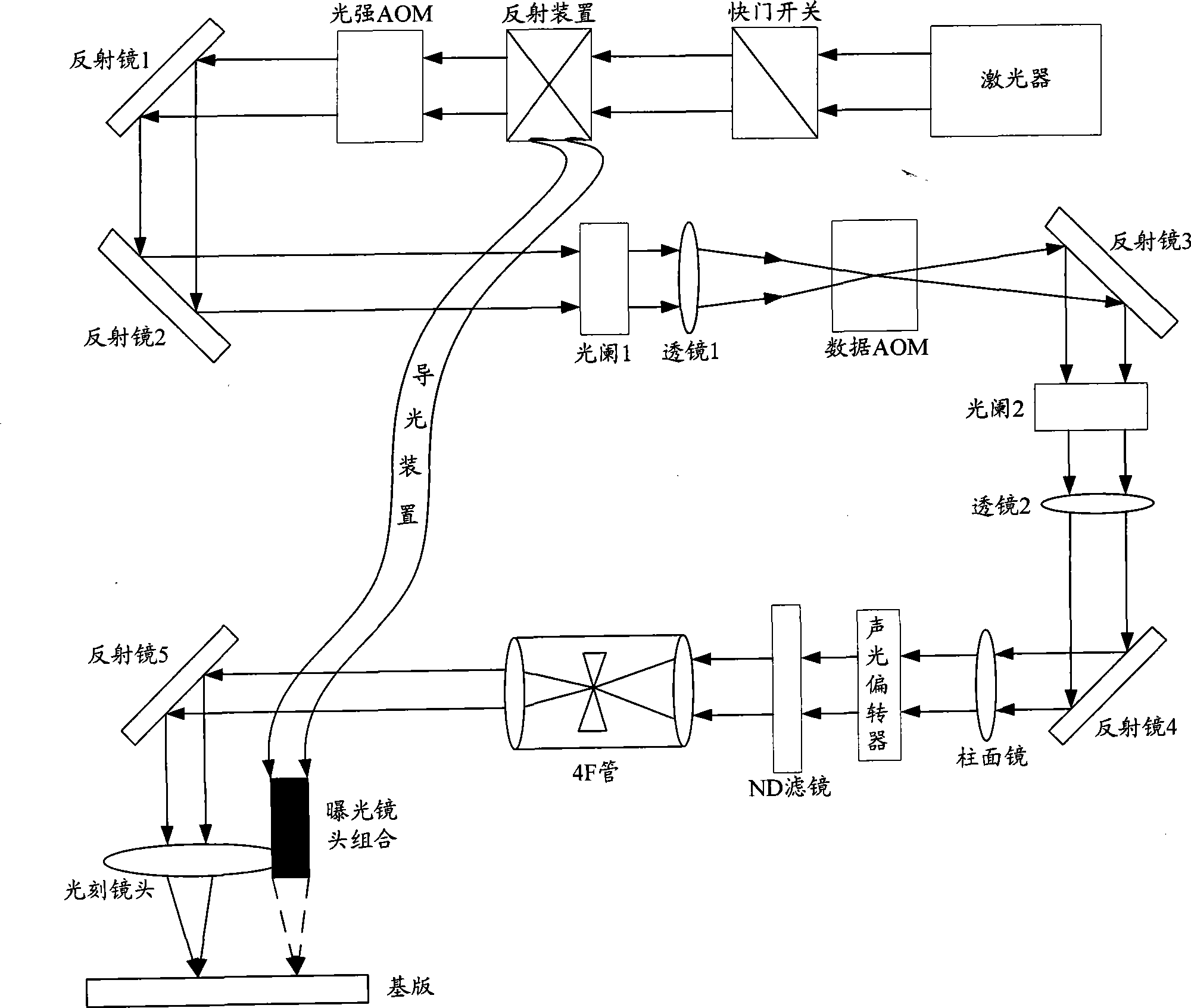

Exposure system of photo-etching machine and control method thereof

ActiveCN101364053AImprove work efficiencyExposure does not affectPhotomechanical exposure apparatusMicrolithography exposure apparatusCamera lensComputer to plate

The invention relates to the field of photolithography based on computer-to-plate techniques and provides a photolithographic machine exposure system and a control method thereof. The photolithographic machine exposure system comprises a light source, a light path assembly, a photolithographic lens and a substrate, which are connected in sequence. The light path assembly modulates the optical signal emitted by the light source and then outputs the optical signal. The photolithographic lens focuses the optical signal output from the light path assembly onto the substrate to form a first light spot. The photolithographic machine exposure system further comprises an optical device, a controller and an exposure lens assembly, wherein the controller controls the optical device to emit the optical signal from the light source, and the exposure lens assembly focuses the optical signal emergent from the optical device onto the substrate to form a second light spot. The diameter of the second light spot is larger than that of the first light spot. The photolithographic machine exposure system adopts the optical device to change the travel direction of the optical signal, adopts the exposure lens assembly to focus the optical signal on the substrate to form the large light spot, achieves the effect of rapid exposure of the large clear area without affecting the exposure of the fine pattern, and increase the work efficiency of the photolithographic machine.

Owner:深圳清溢光电股份有限公司

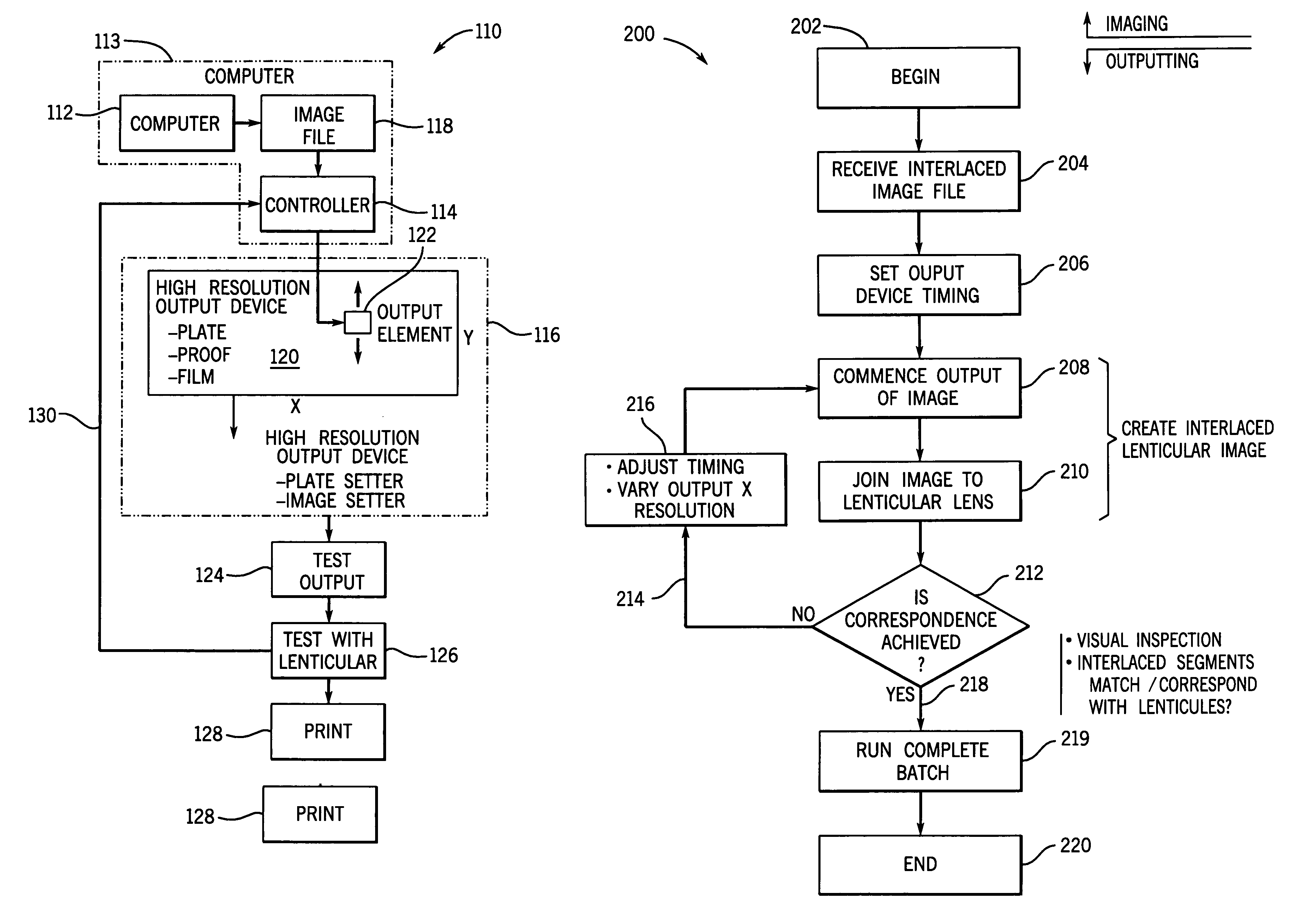

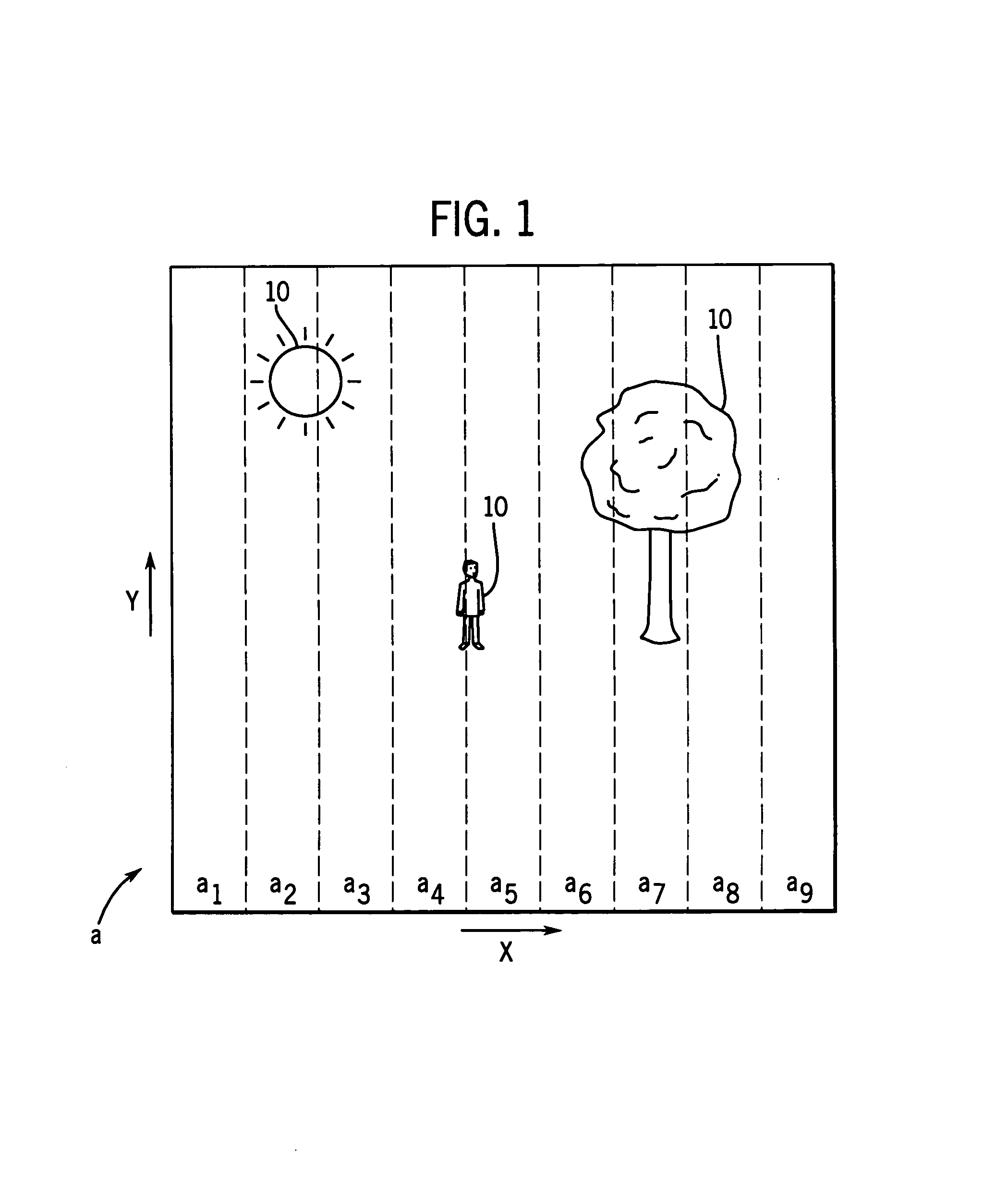

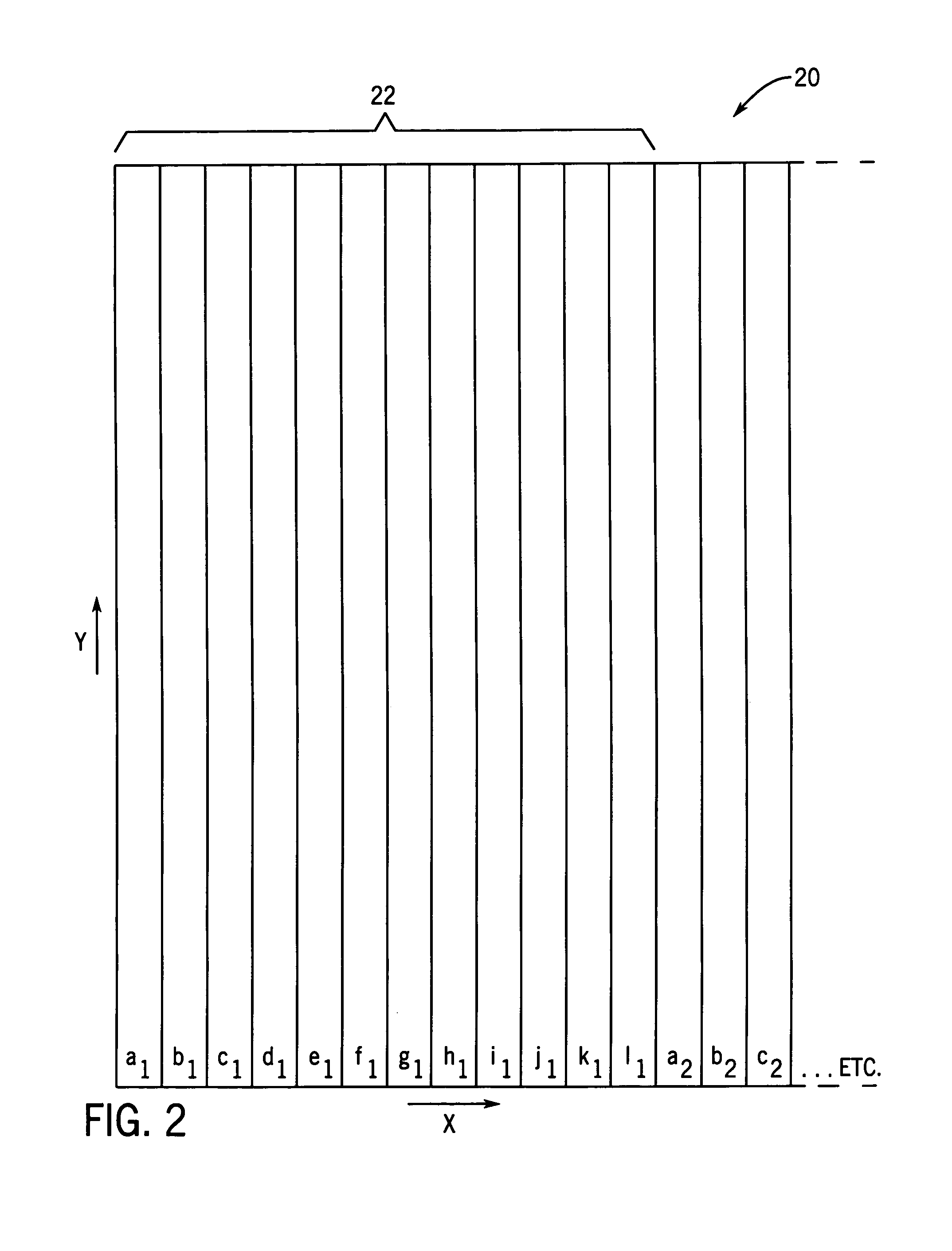

Corresponding lenticular imaging

ActiveUS7136185B2Reduce blurImprove clarityDigitally marking record carriersDigital computer detailsImage resolutionComputer to plate

Disclosed herein is a method of making a corresponding lenticular image comprising: providing an output device in communication with a computer having a memory; receiving into the computer memory an interlaced image file; converting the interlaced image file into an output having an output resolution; varying the resolution of the output to define a varied output resolution; and creating a corresponding lenticular image using the output at the varied output resolution. In a preferred embodiment, the output device is a plate setter and the output is a plate. As such, in at least one embodiment, the method is suitable for use with a Computer-to-Plate (“CTP”) system.

Owner:PACUR LLC

System and method for interleaf sheet and/or plate sheet removal and/or transport for use with a printing apparatus

InactiveUS20060174790A1Easy to separateSimple actionAddressographsLetterpress printingComputer to plateEngineering

One or more embodiments of the present invention relate generally to systems and methods that remove an interleaf sheet interposed between plate sheets from a material stack used, for example, in a computer-to-plate imaging system and / or environment.

Owner:ECRM

System and method for interleaf sheet and/or plate sheet removal and/or transport for use with a printing apparatus

InactiveUS20060117975A1Minimize the numberSimple and low solutionPlaten pressesFunction indicatorsComputer to plateImage system

The present invention relates generally to systems and methods that remove an interleaf sheet interposed between plate sheets from a material stack used, for example, in a computer-to-plate imaging system and / or environment. Embodiments of the system and method can also remove plate sheets from an interleaf sheet, and transport the plate sheet for subsequent imaging.

Owner:ECRM

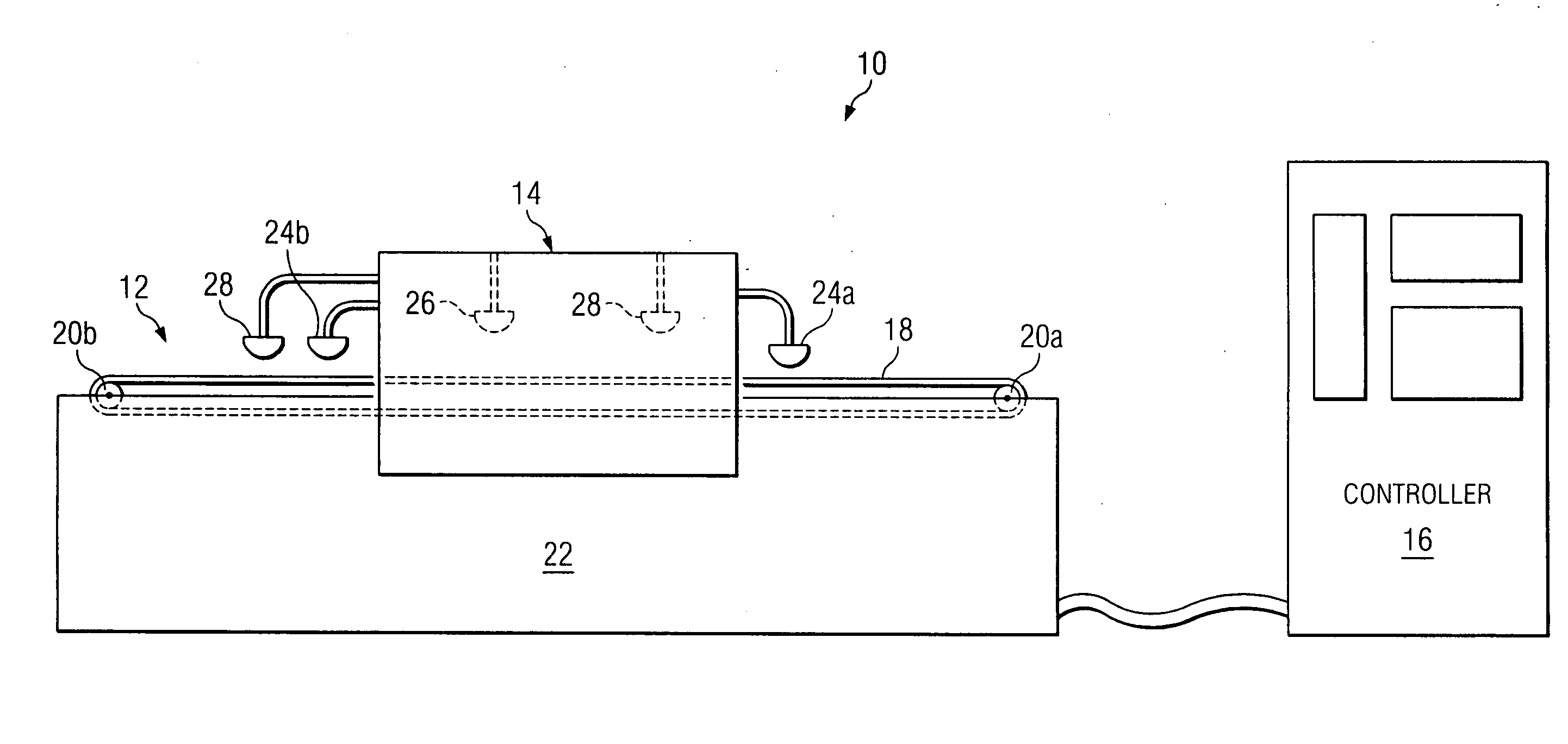

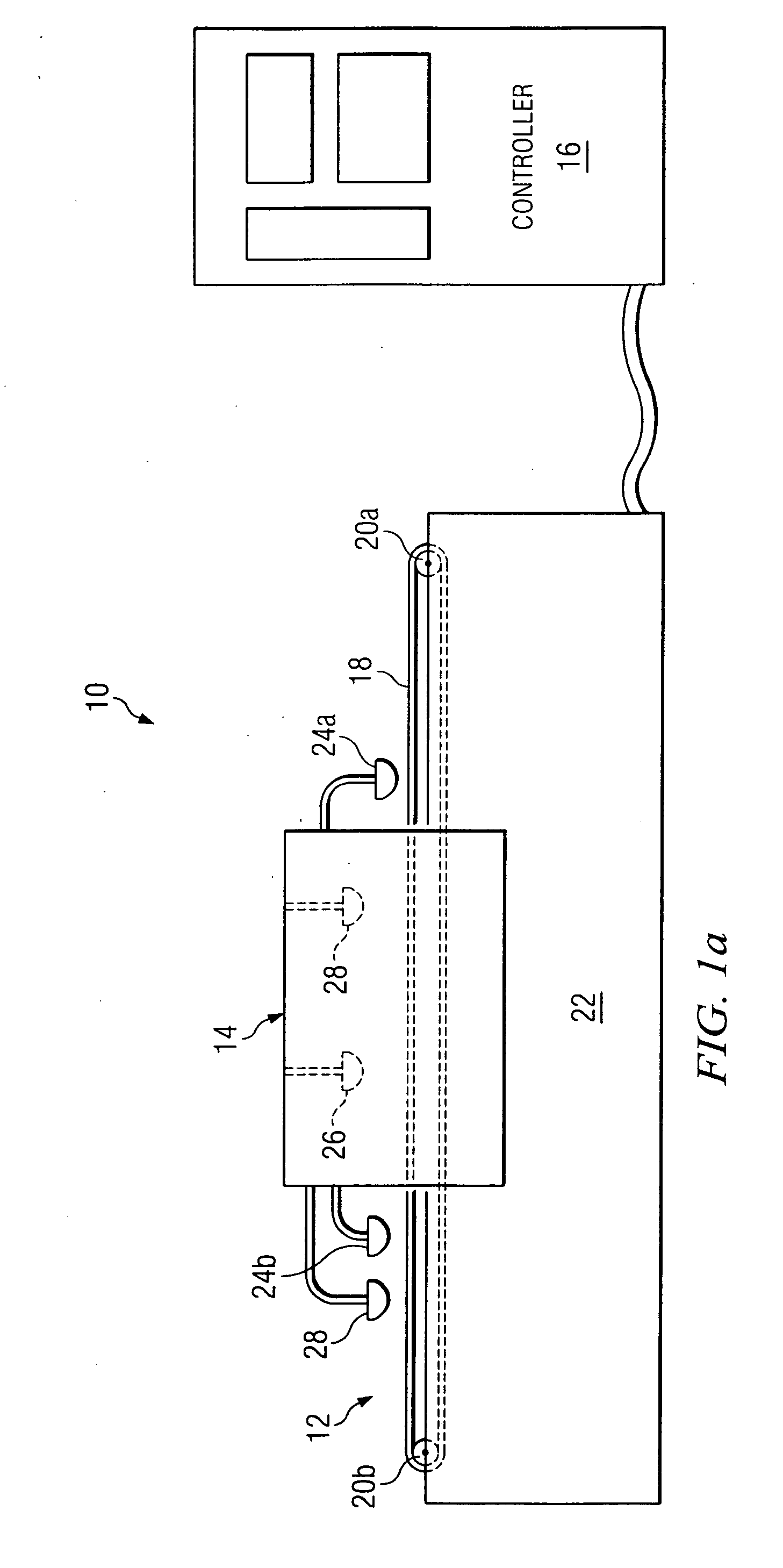

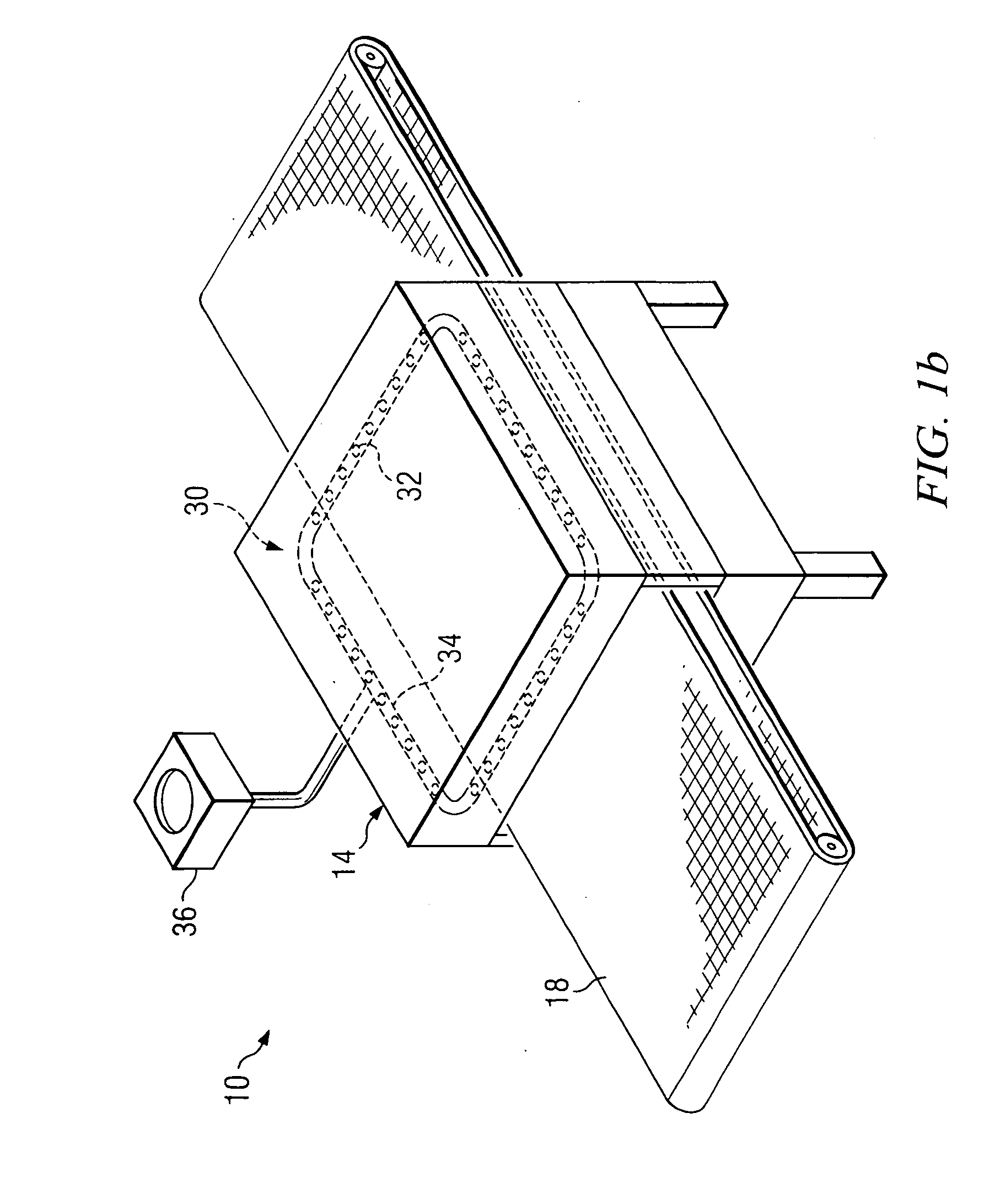

Computer to plate curing system

InactiveUS20060174508A1Drying solid materials with heatHearth type furnacesControl powerComputer to plate

A system for curing printing plates with controlled radiant energy sources. A conveyor moves a printing plate through a chamber having energy radiators above and below the conveyor. Power to the radiators is controlled for each radiator or to groups of radiators defining radiation zones. Curing time may be controlled by adjusting power to the radiators and adjusting the conveyor speed. Sensors detect a plate as it enters and exits the chamber. Heat sensors may detect chamber or plate temperatures. A color sensor may detect plate color as an indicator of degree of curing. A computer system stores curing scenarios and uses the sensor signals and operator inputs to control power to the radiators and conveyor speed to provide uniform curing of the plate.

Owner:PRINTING RES

Positive image thermosensitive lithographic printing plate

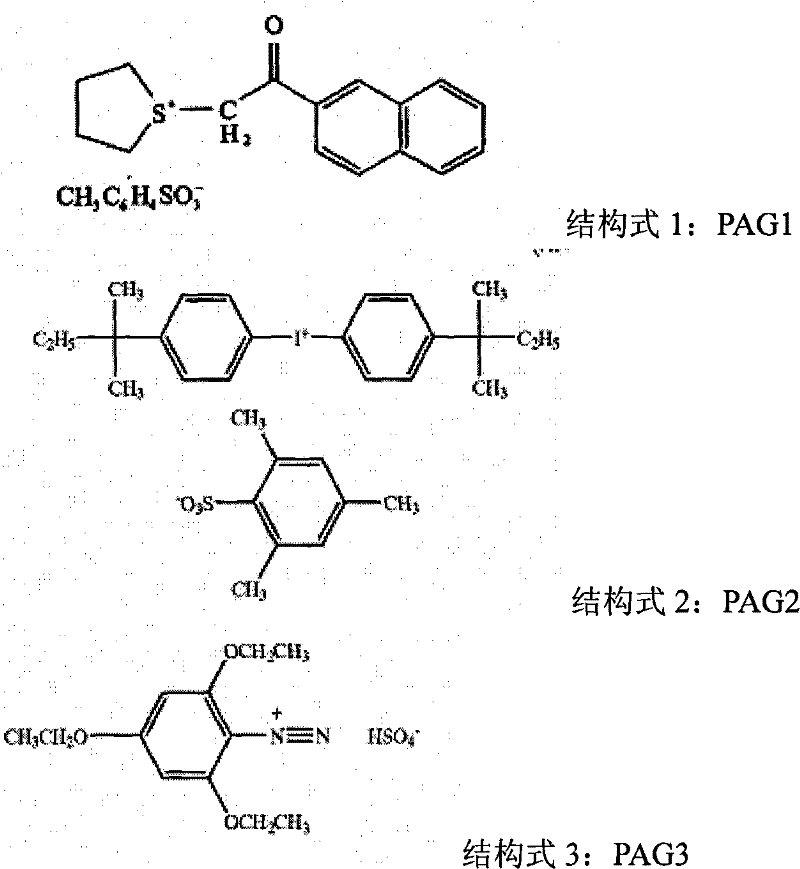

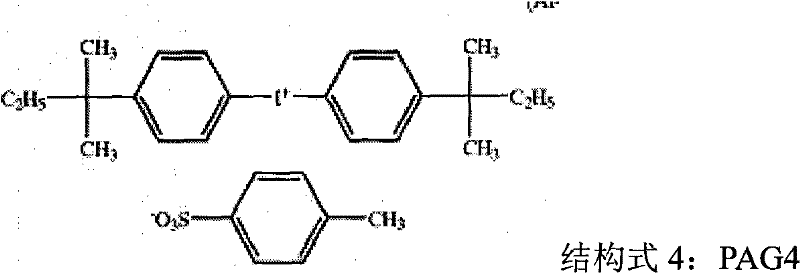

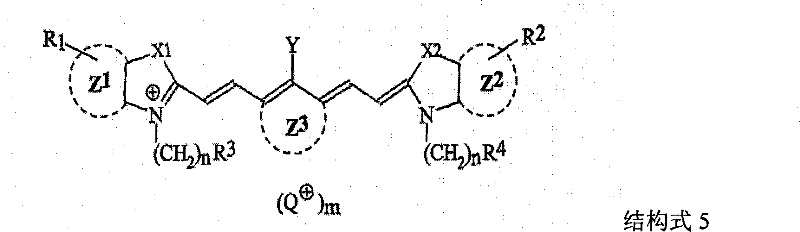

InactiveCN102540728AImprove developmentIncreased sensitivityPhotosensitive materials for photomechanical apparatusForme preparationComputer to plateDouble coating

The invention relates to a positive image thermosensitive lithographic printing plate. A resin layer and a thermosensitive layer are successively coated onto a support with hydrophilic surface, wherein the resin layer comprises alkali-soluble resin, and the thermosensitive layer comprises alkali-soluble resin and infrared absorbent. The resin layer of the positive image thermosensitive lithographic printing plate contains an acid generator and an infrared absorbent. In the invention, the acid generator and the infrared absorbent are added into the resin layer of the double-coating positive image CTP (Computer-to-Plate) plate into heat, so that the acid generator generates acid, and the exposed portion is easily dissolved or dispersed in a developing liquid and removed by the developing liquid. As long as the upper layer is removed, the lower layer is very easy to remove. Unexposed portion does not generate acid and is not easy to remove by the developing liquid, the sensitivity of the plate is increased, the development of the plate is accelerated, and the sensitive and the development latitude of the plate are also improved.

Owner:LUCKY HUAGUANG GRAPHICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com