Patents

Literature

94 results about "Addressability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Addressability is the ability of a digital device to individually respond to a message sent to many similar devices. Examples include pagers, mobile phones and set-top boxes for pay TV. Computer networks are also addressable, such as via the MAC address on Ethernet network cards, and similar networking protocols like Bluetooth. This allows data to be sent in cases where it is impractical (or impossible, such as with wireless devices) to control exactly where or to which devices the message is physically sent.

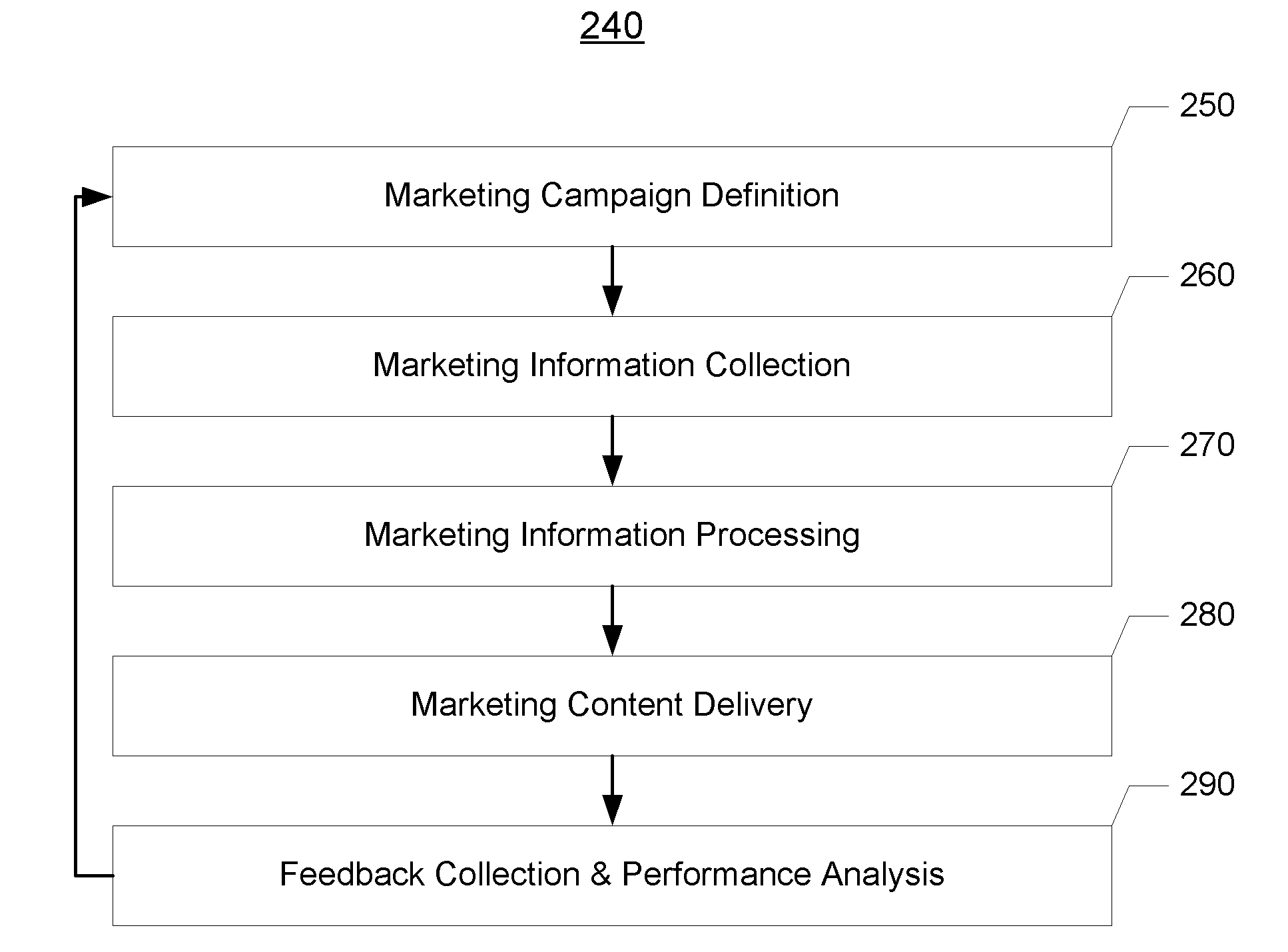

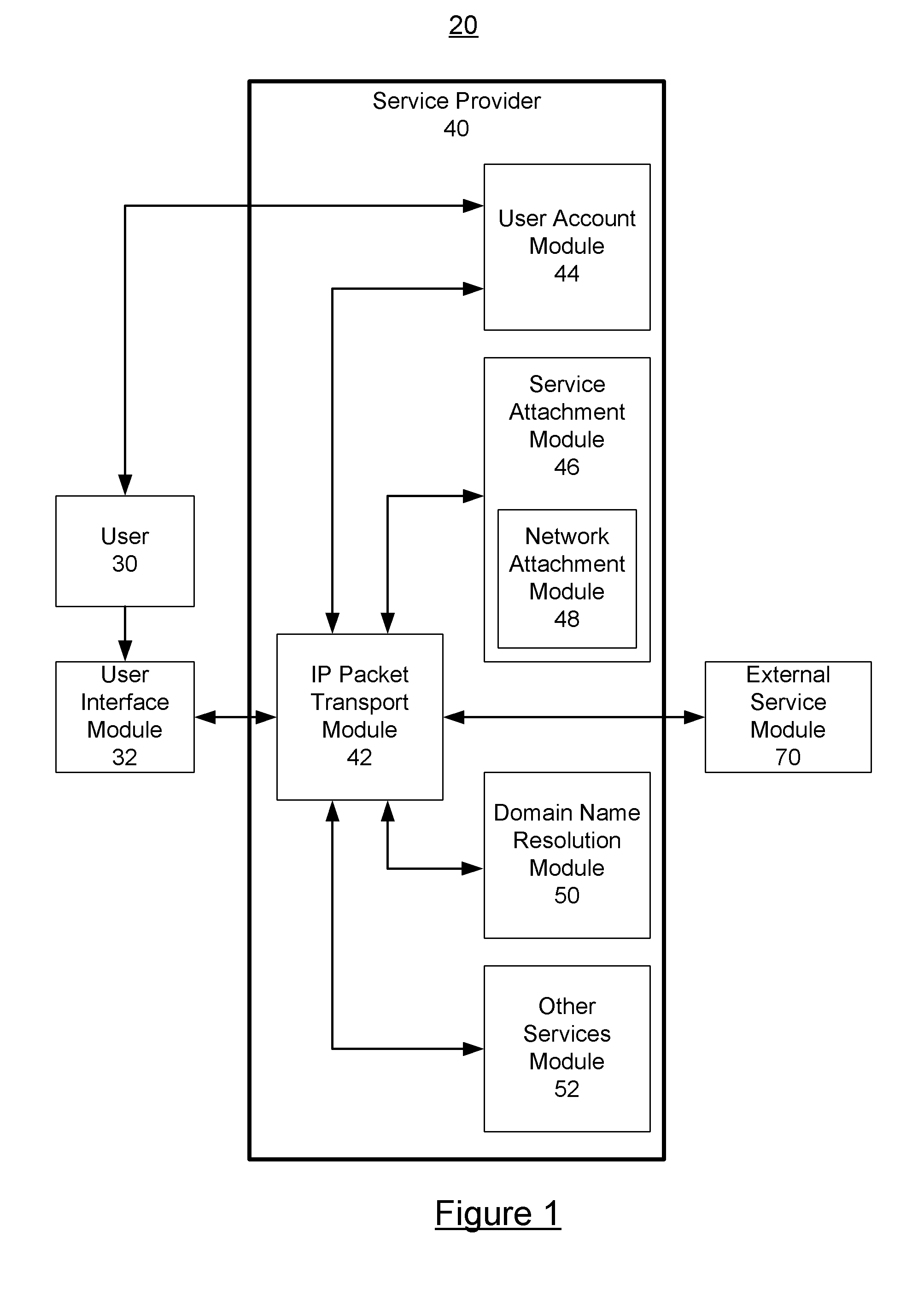

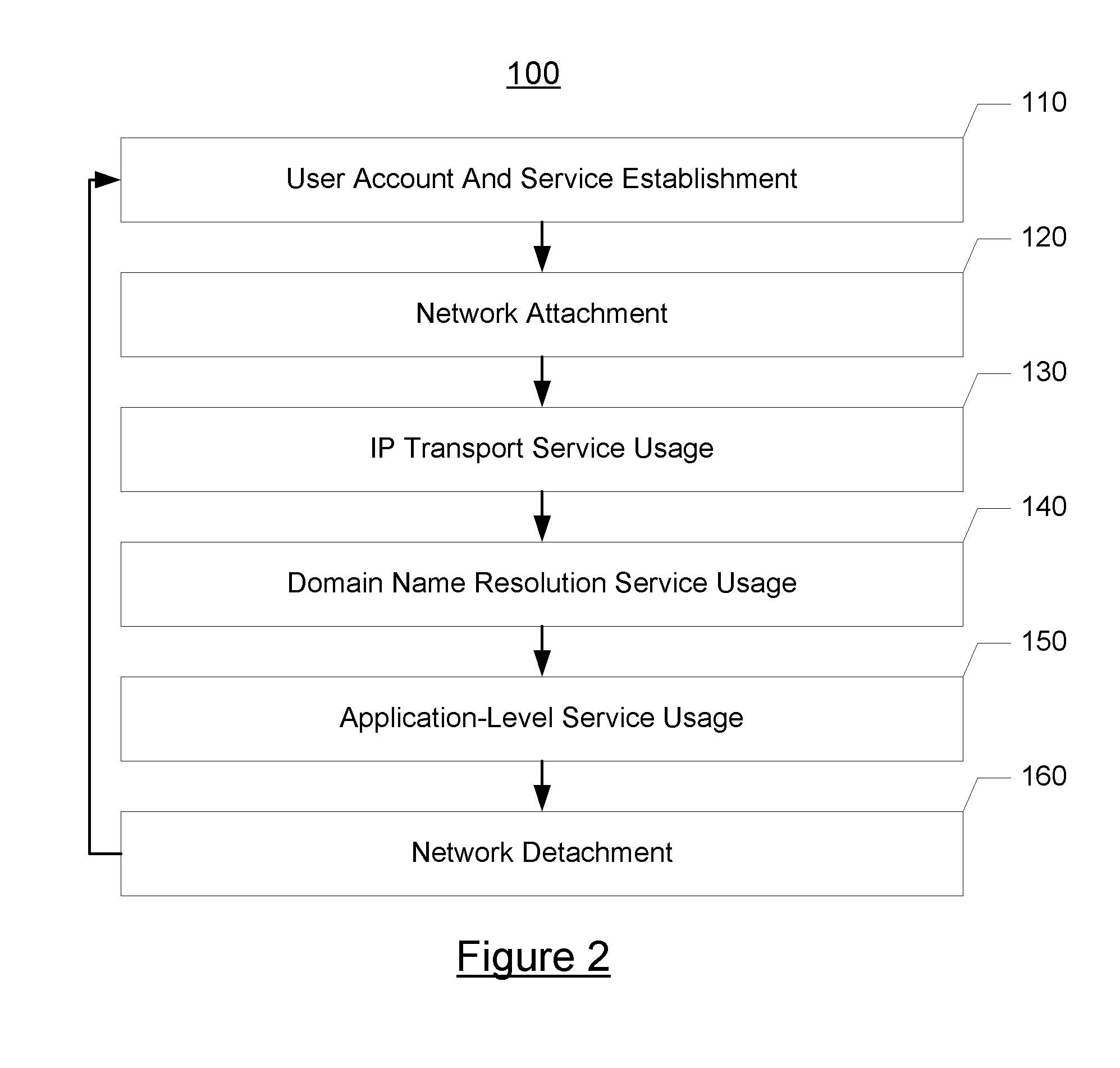

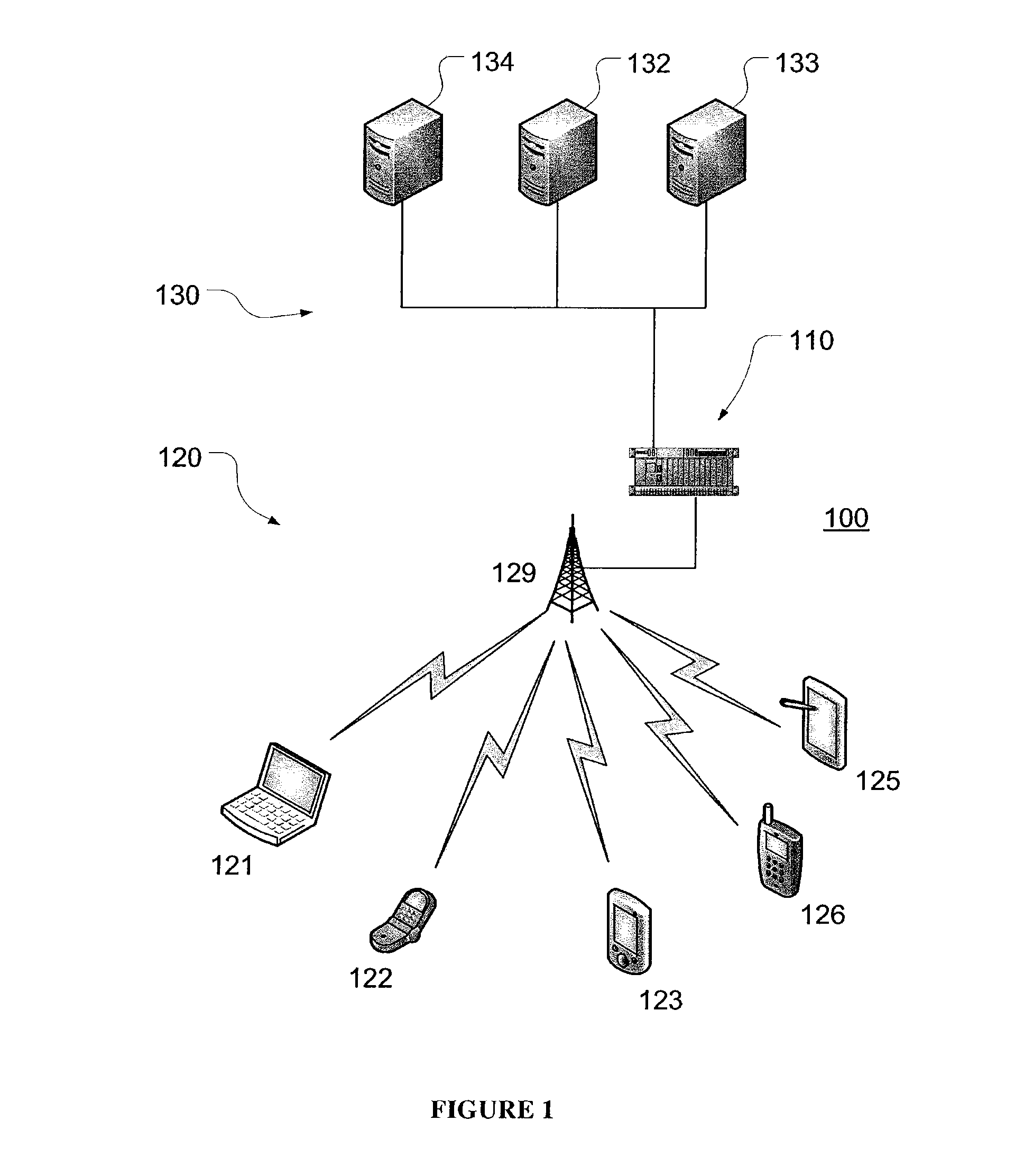

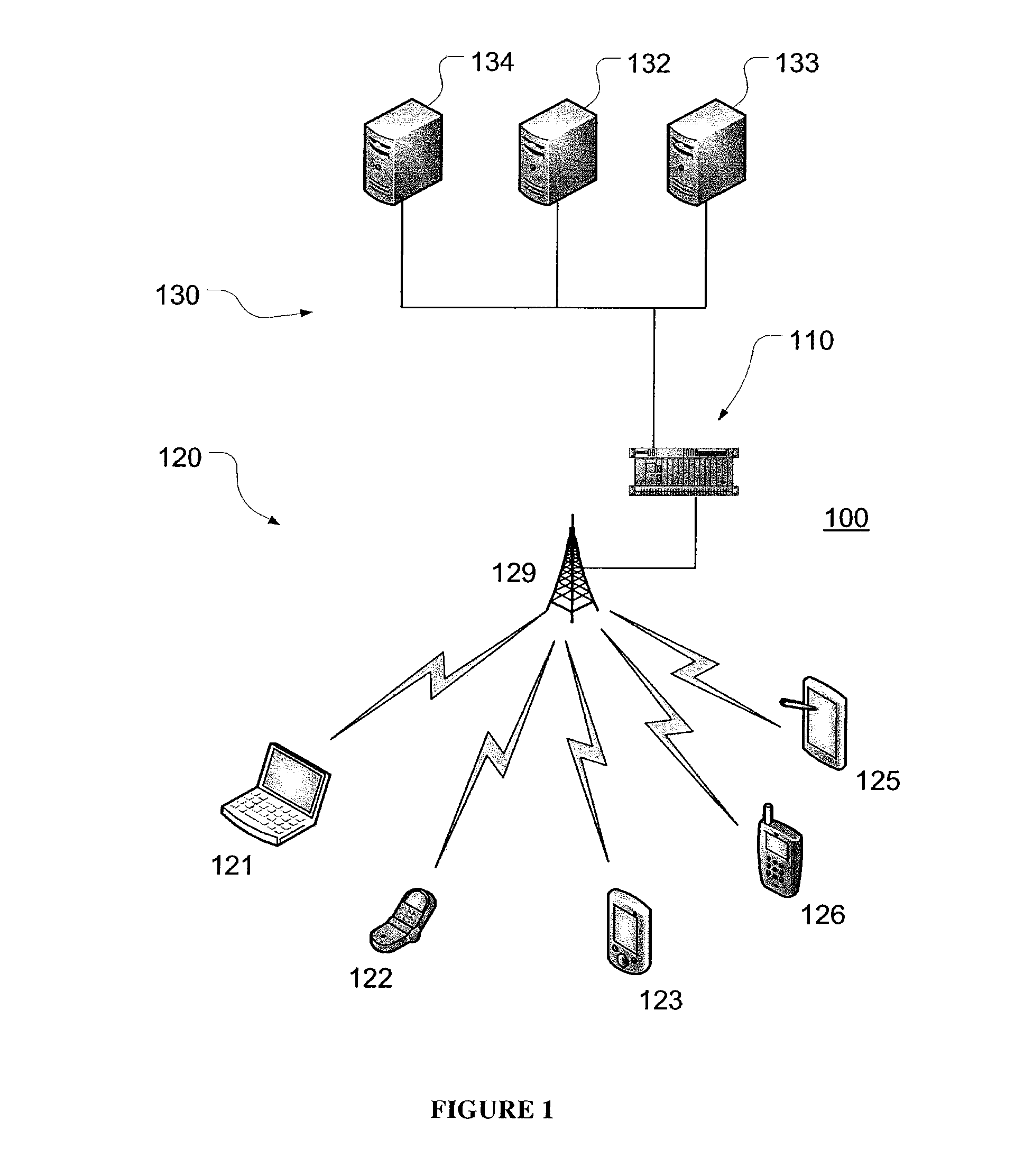

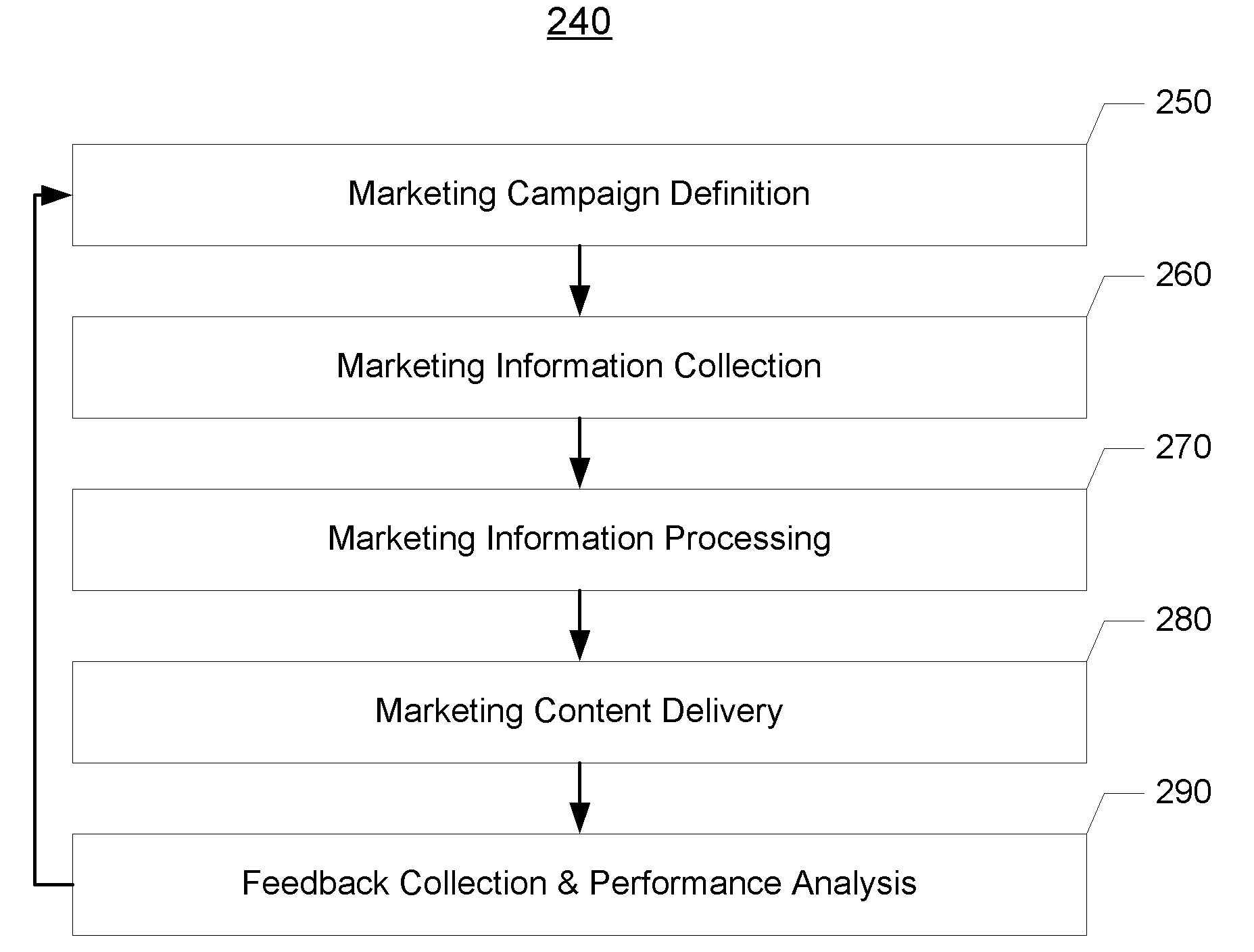

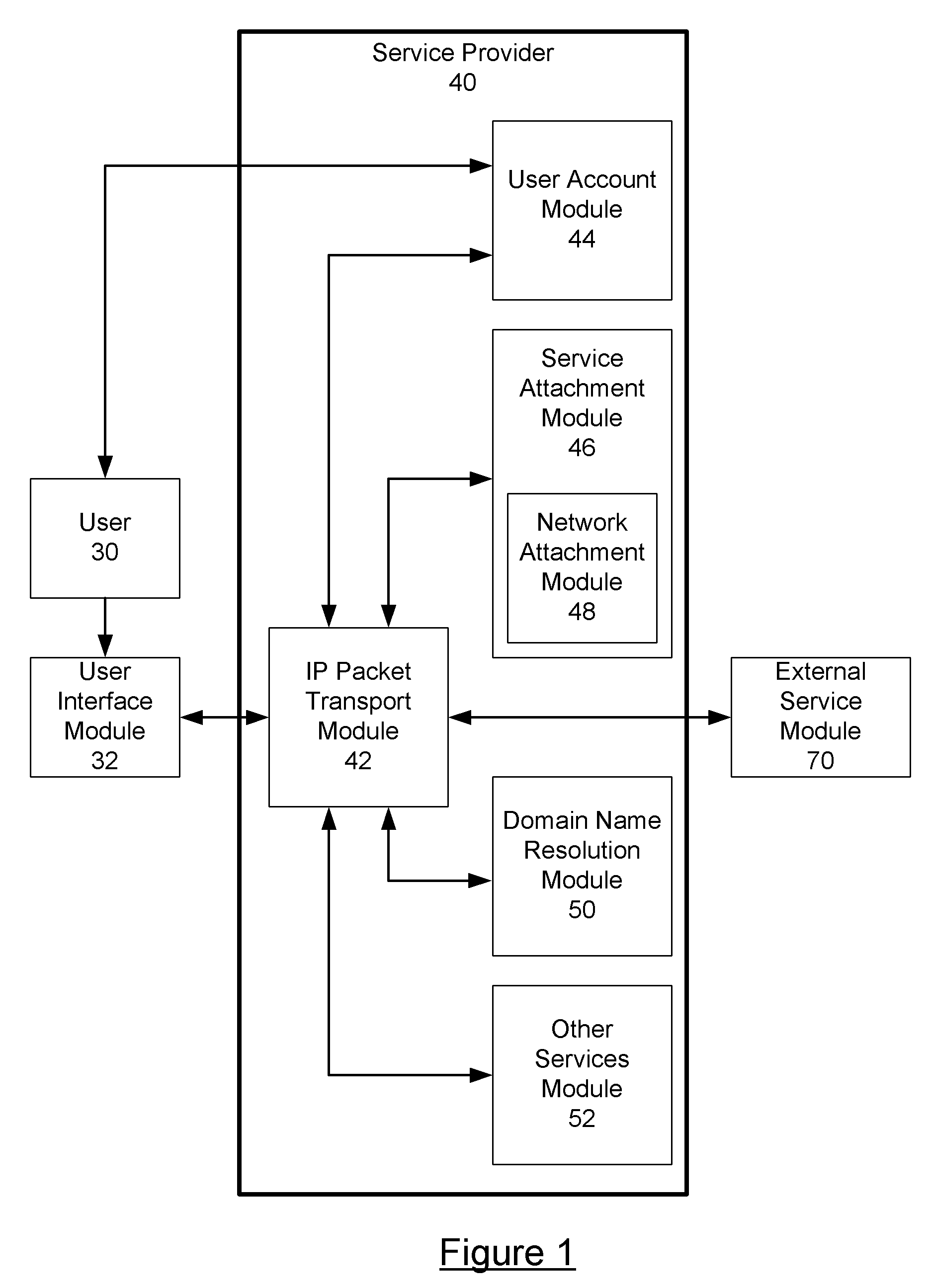

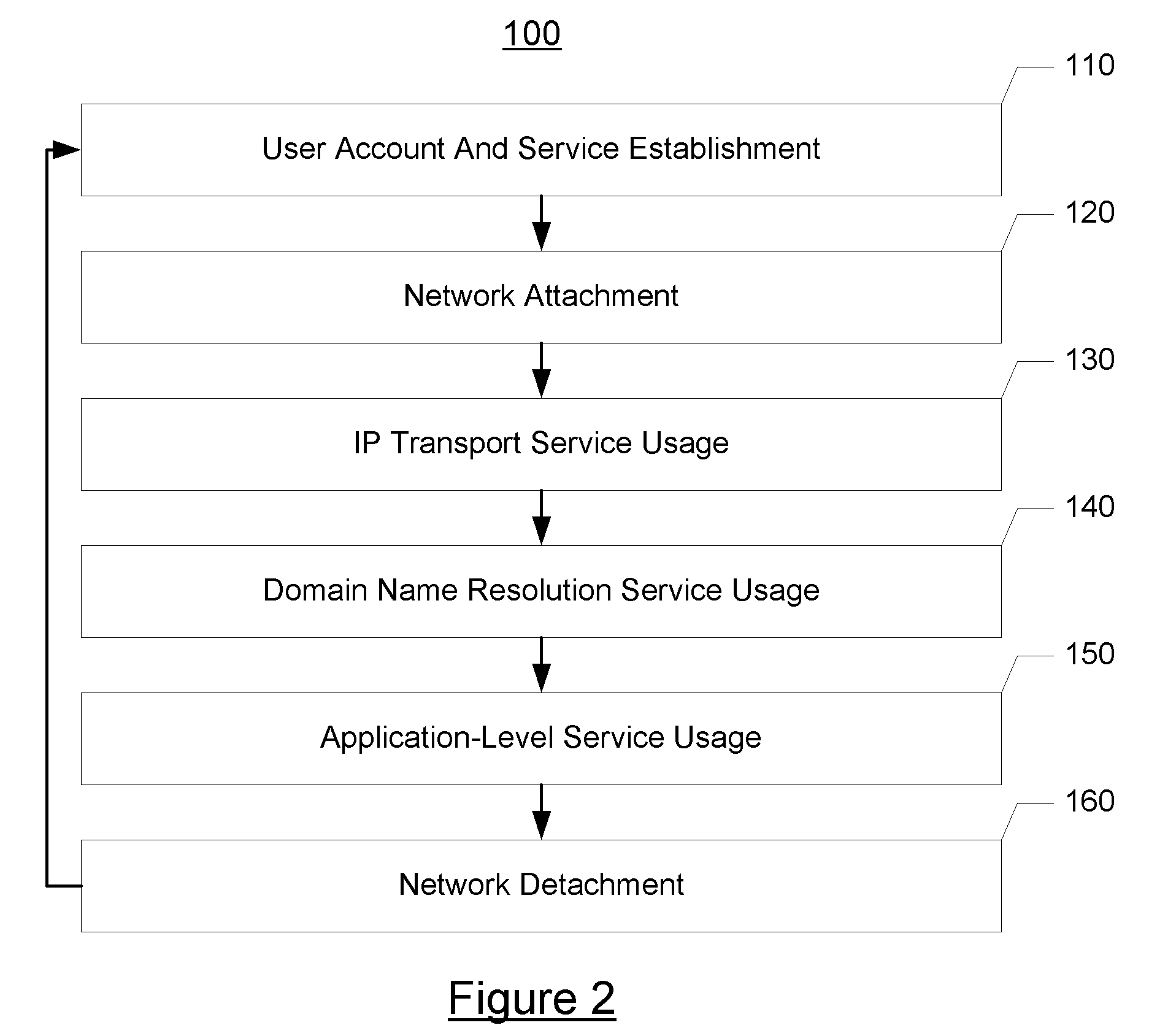

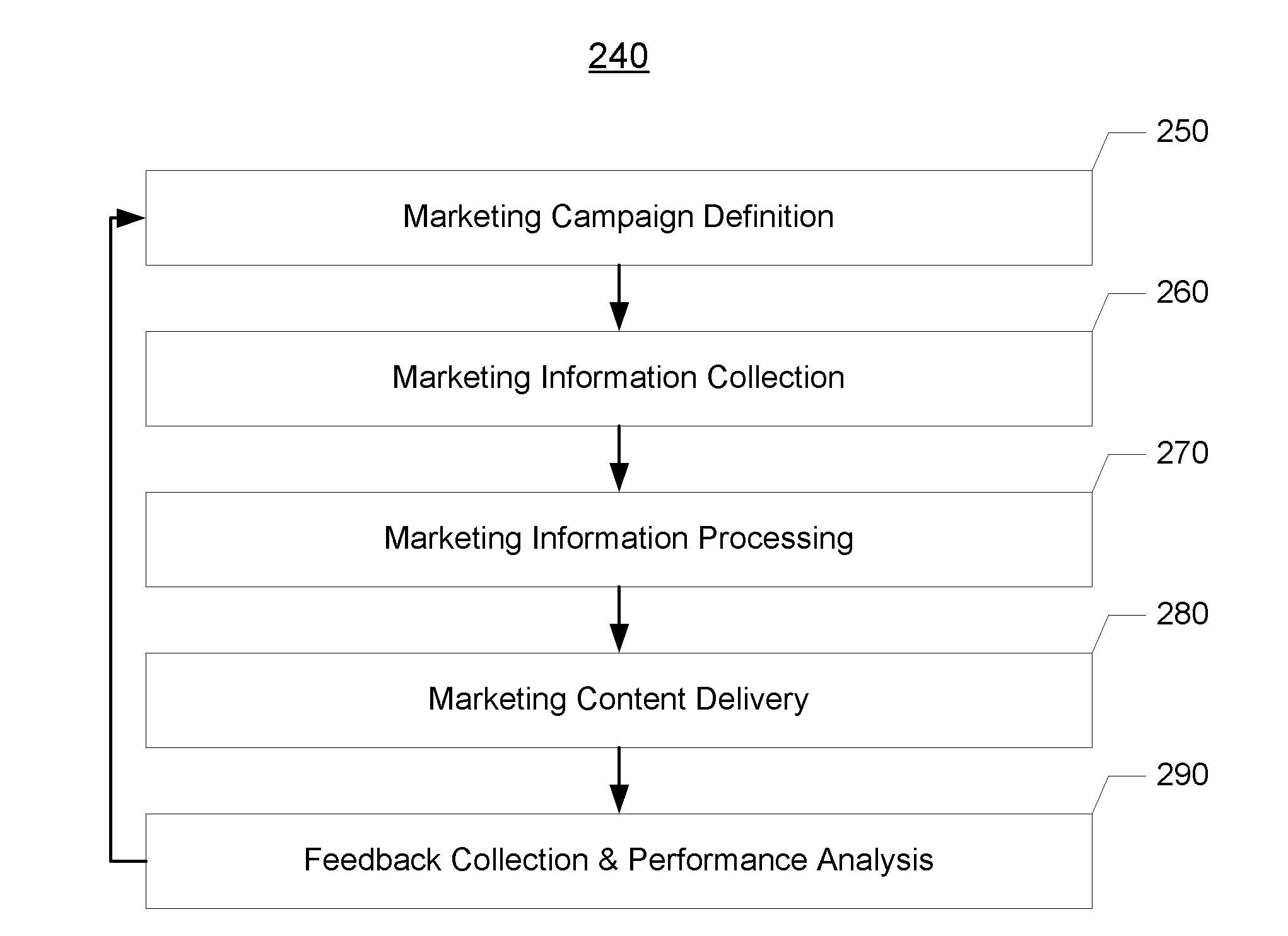

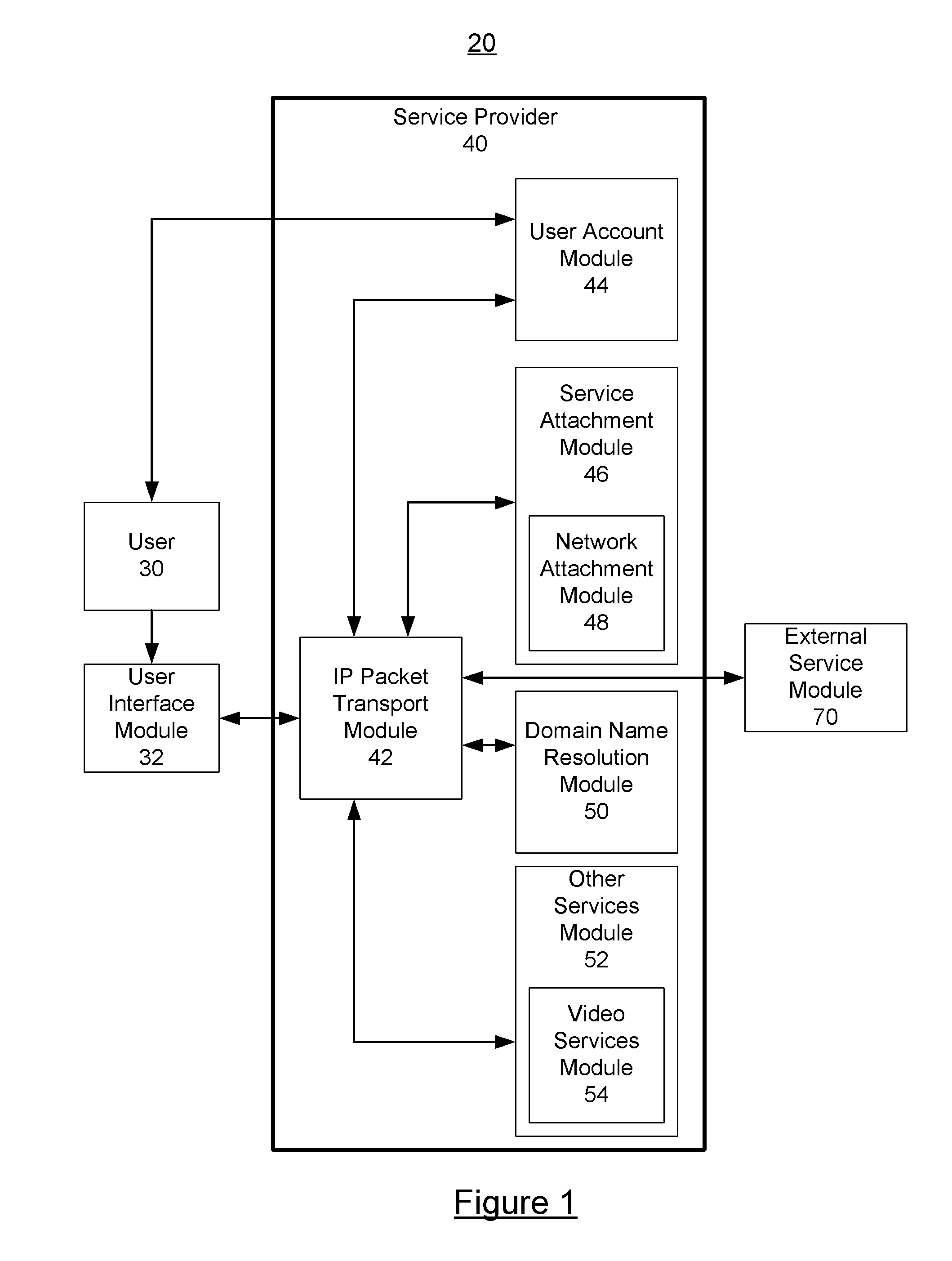

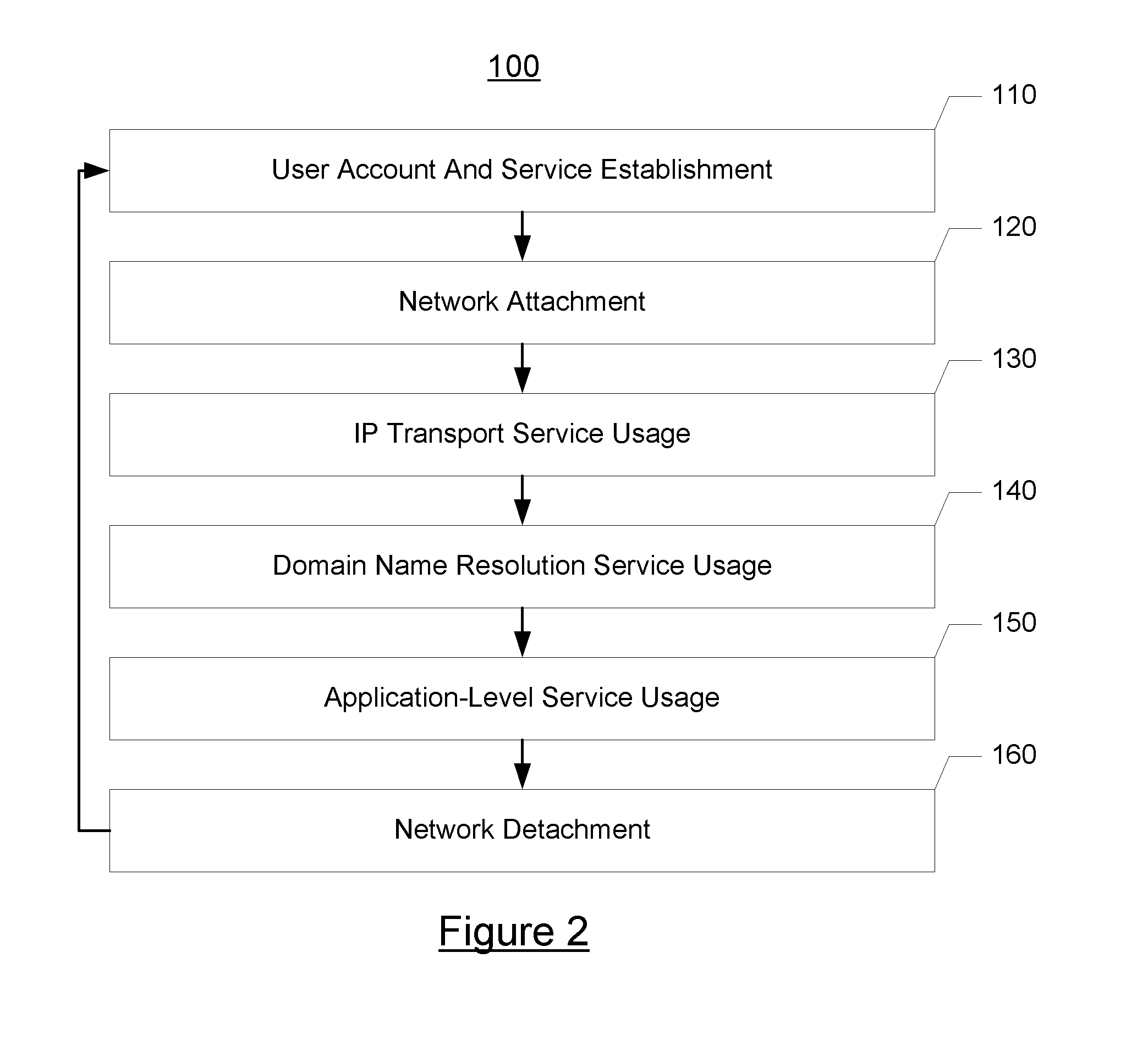

Systems and methods for using IP transport records to provide targeted marketing services

InactiveUS20080281699A1AdvertisementsSelective content distributionService provisionNetwork communication

Systems and methods can include collecting addressability information about users accessing a service provider's IP-based network communication services, collecting information sufficient to identify when the user is accessing the service provider's IP-based network communication services, collecting data from the IP packets sent or received by the user and using the collected data to associate the user with certain marketing content. The systems and methods can further include sending the marketing content to the user through various distribution channels by using the addressability information. The systems and methods can further include recording the collected information over time to refine the ability to predict the user's receptiveness to certain marketing content so as to improve the effectiveness of TMS.

Owner:VERIZON PATENT & LICENSING INC

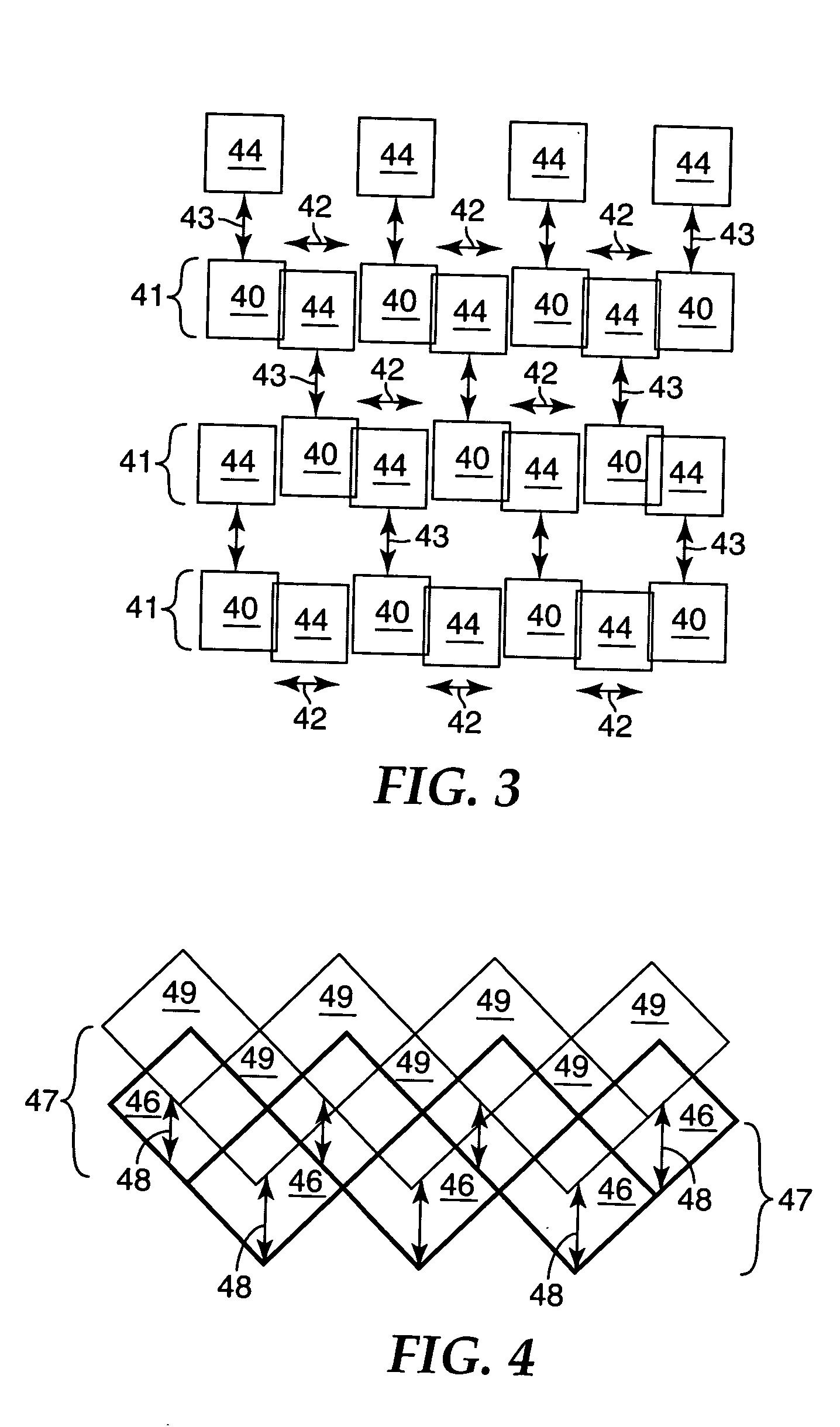

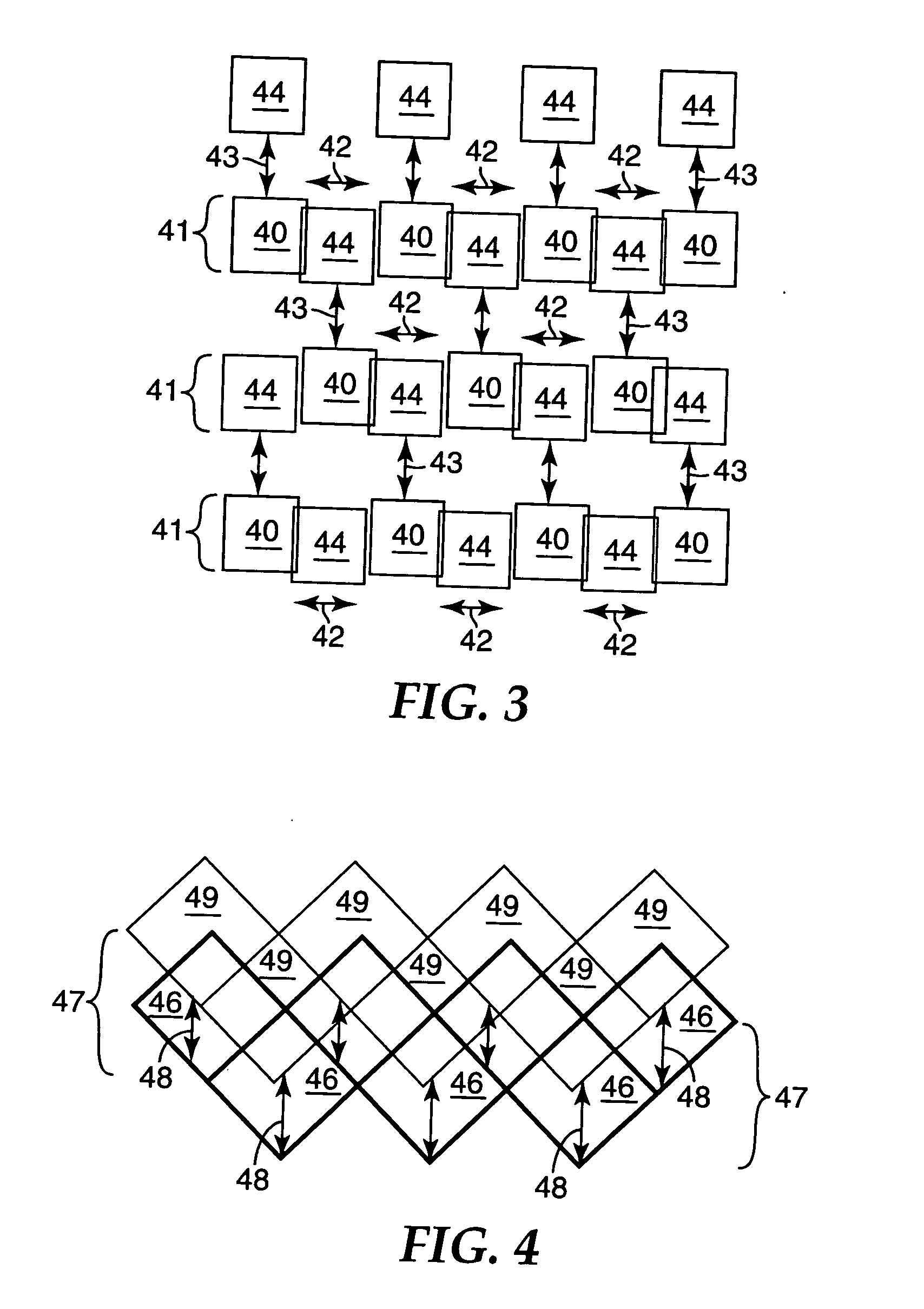

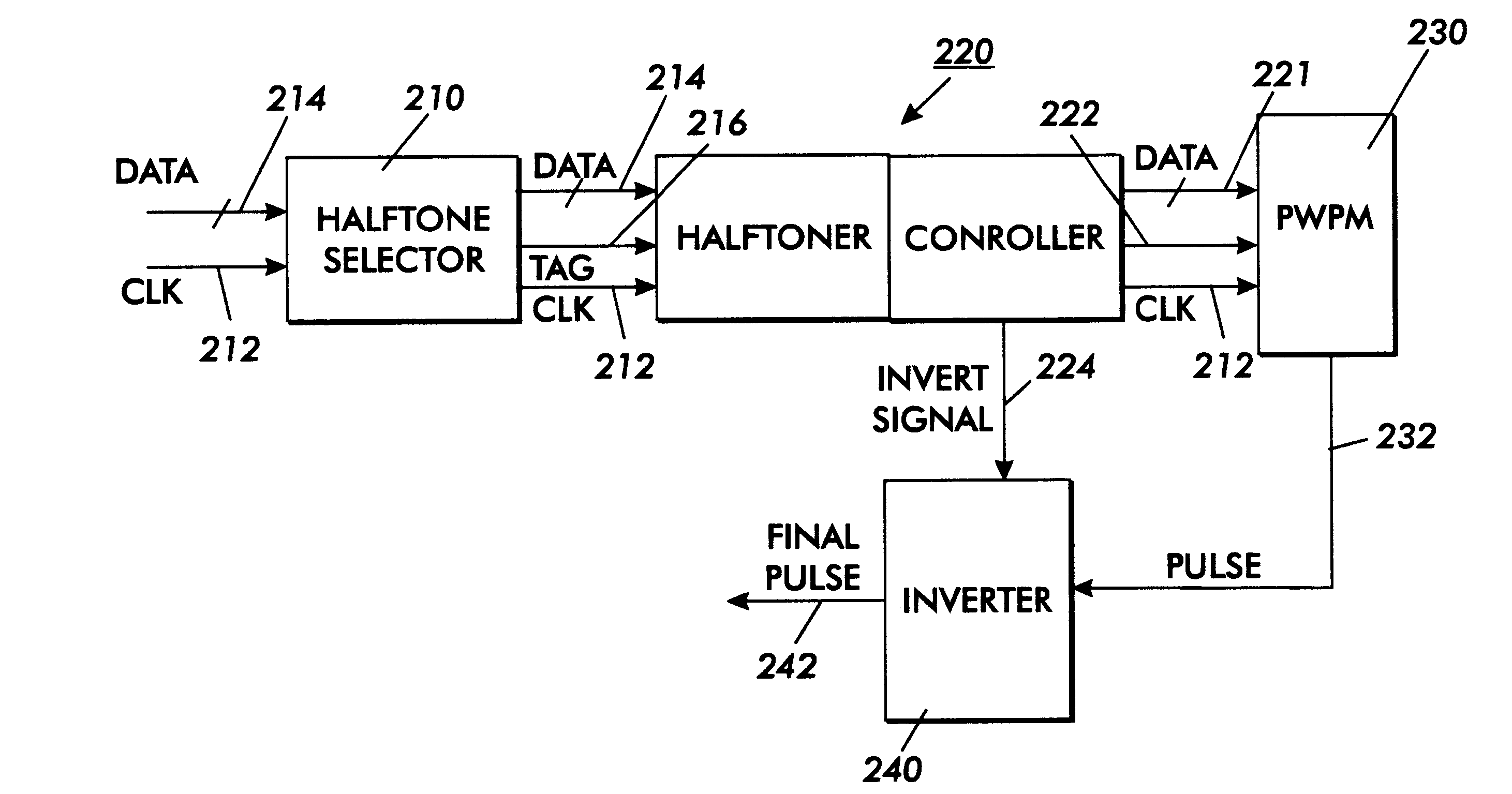

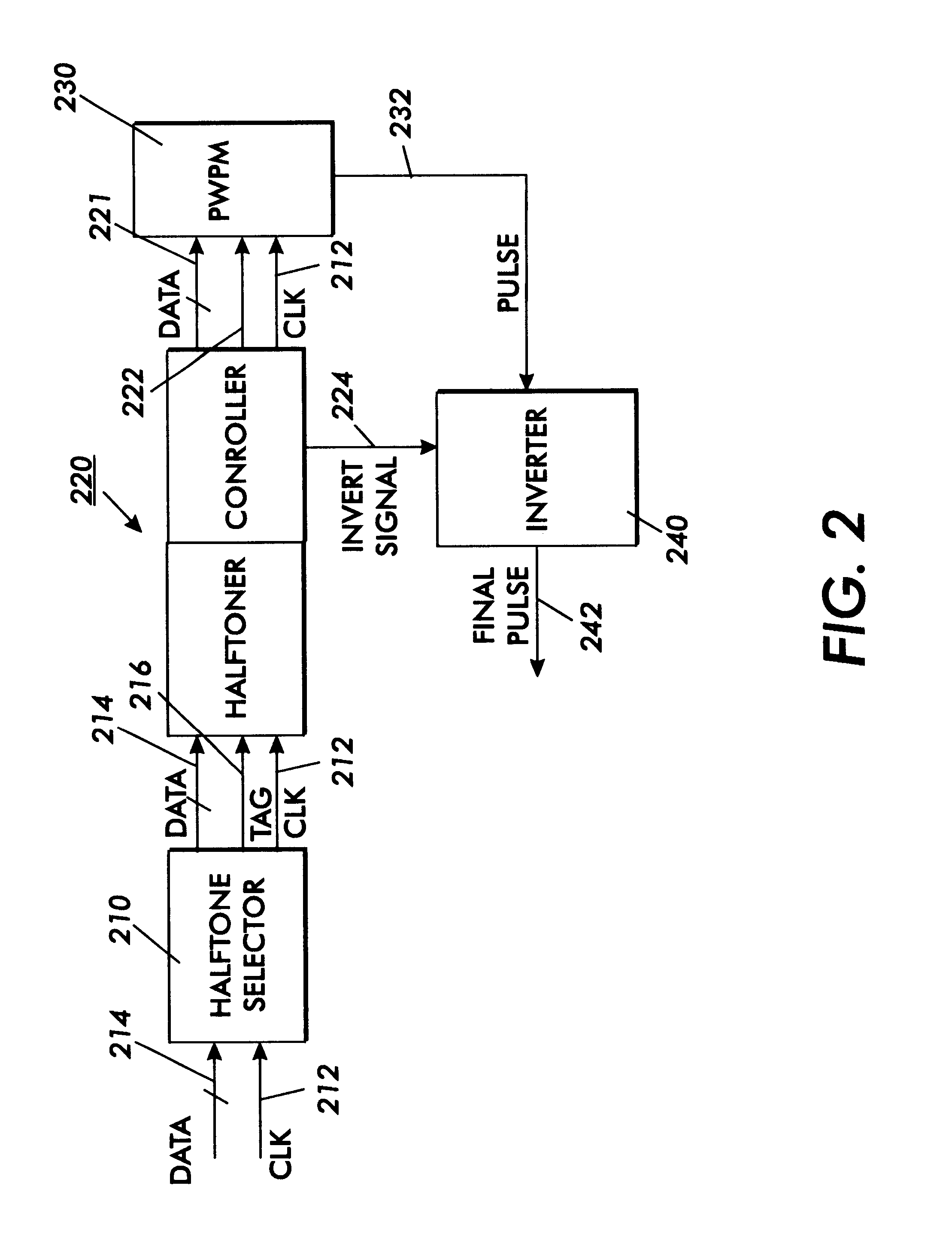

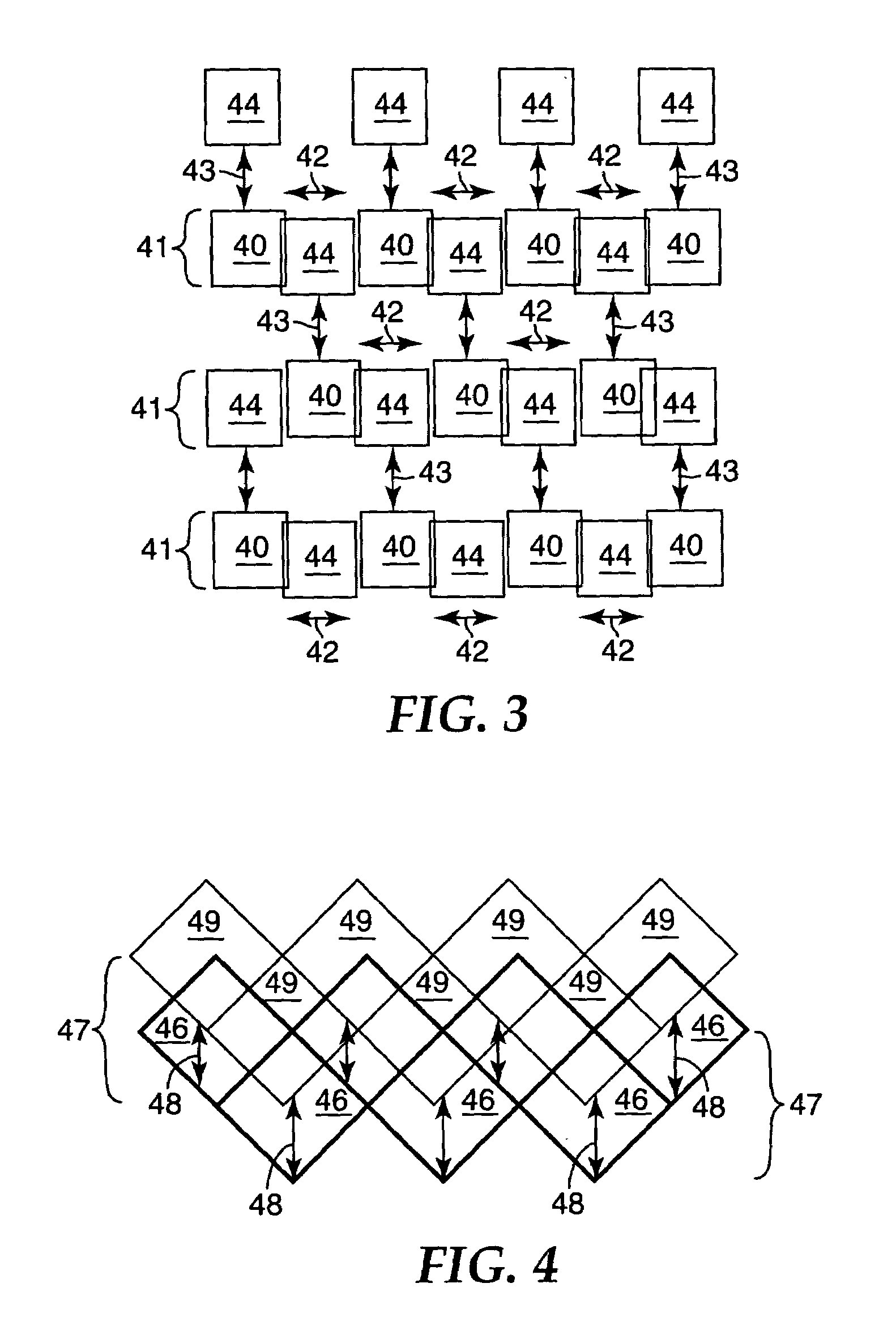

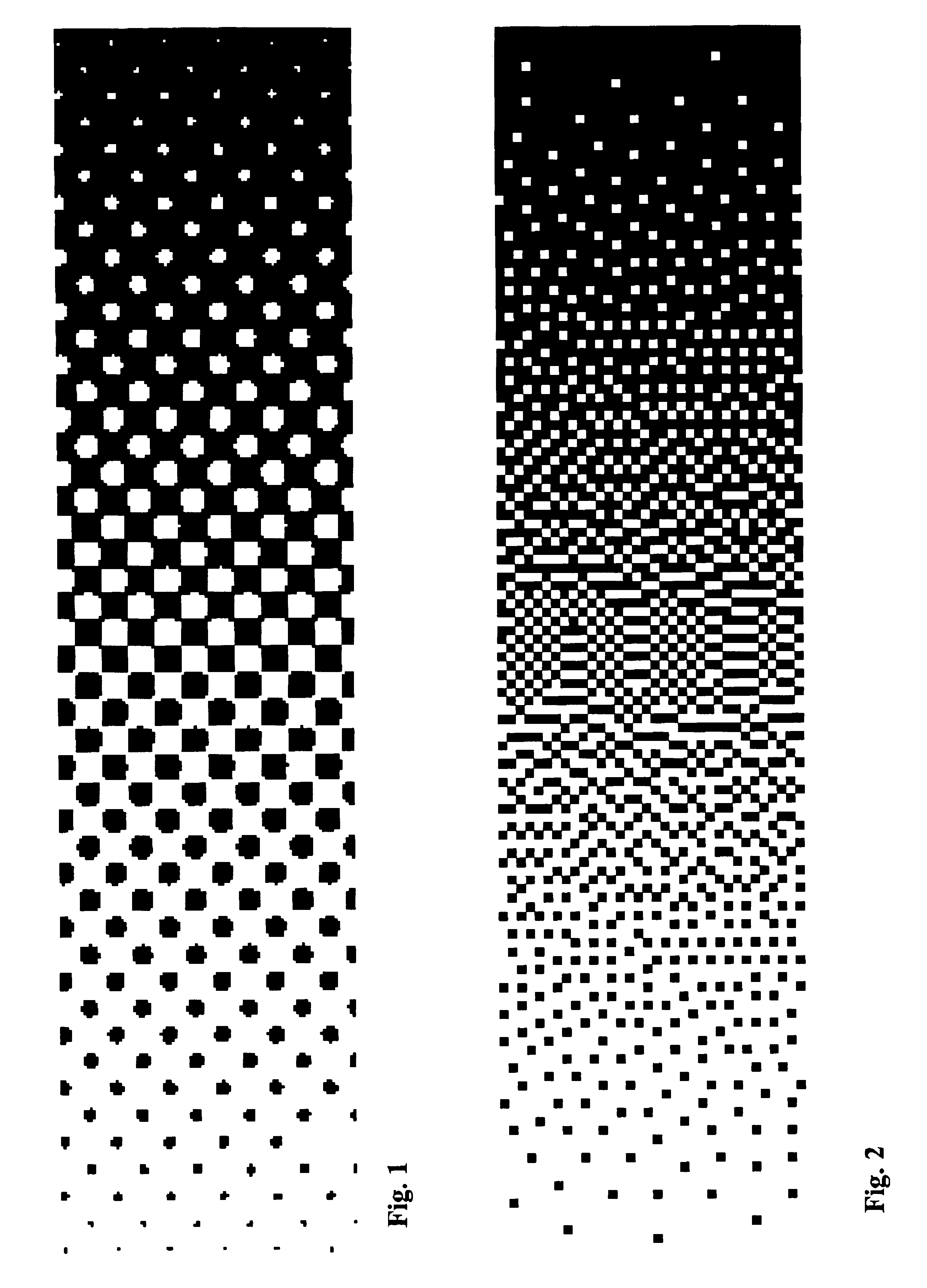

Apparatus and method for halftone hybrid screen generation

InactiveUS20010030769A1Promote reproductionGood freedomVisual presentationPrintingDigital dataSingle image

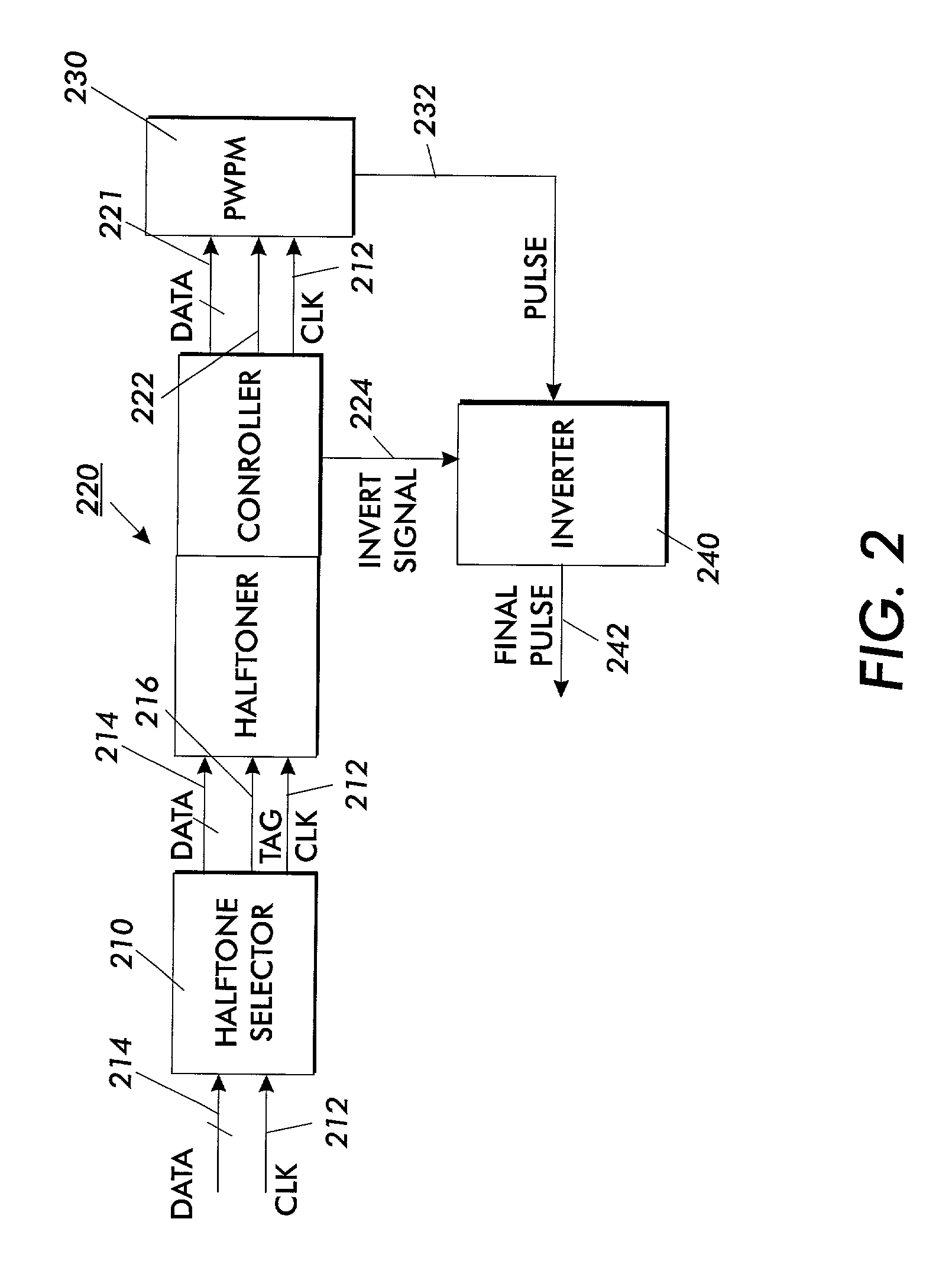

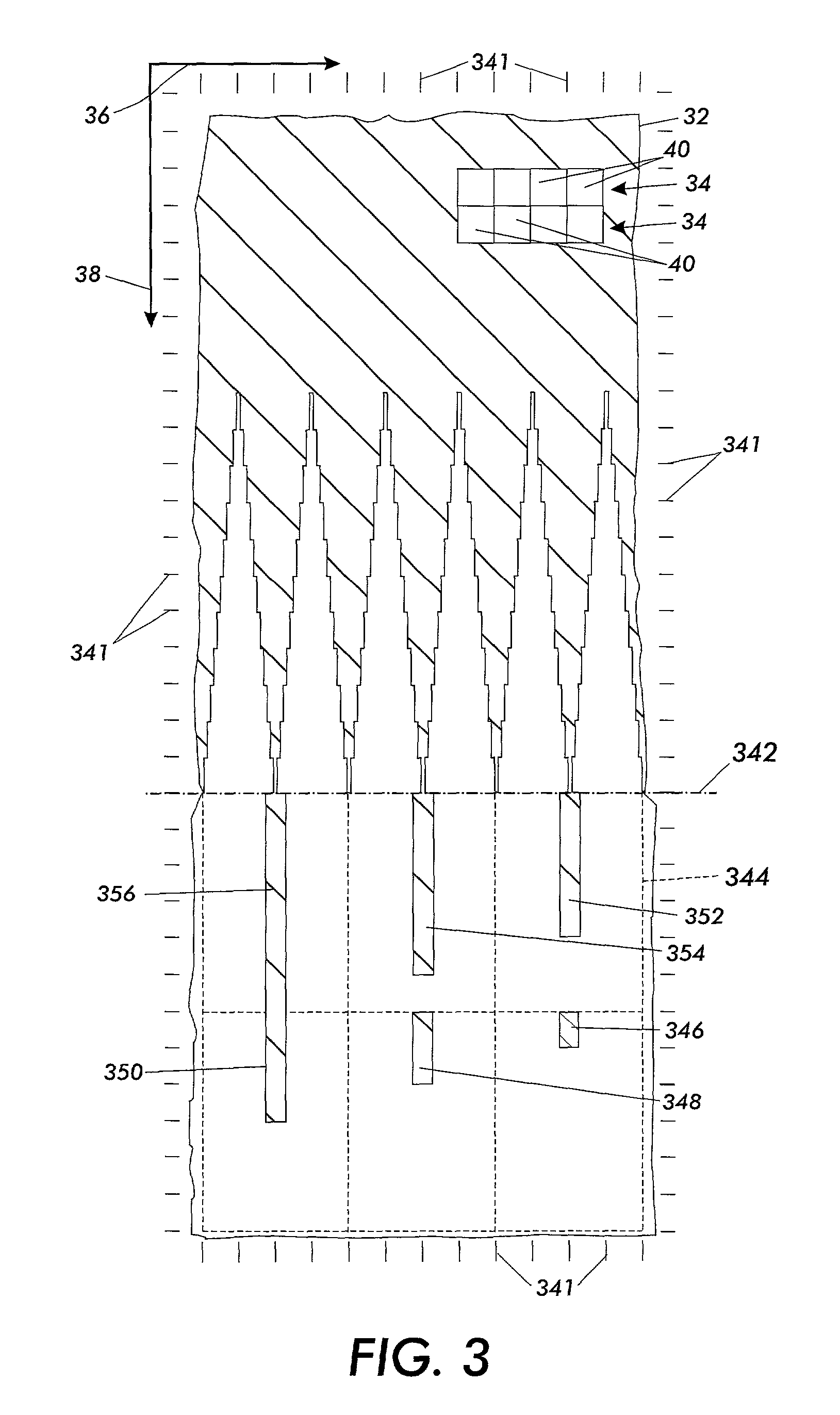

The present invention is a method and apparatus allowing the application of two or more distinct halftone types in the rendering of a single image. The invention employs a halftone selector of a threshold type, or as an alternative a segmenter type. The halftone selector determines which areas of an image will receive which type of grayscale halftone treatment on a pixel by pixel basis. Examples of various halftone types include stochastic, clustered dot, line screen, and other high addressability types. Each pixel of data is treated by the appropriate halftoner circuit which in response outputs digital data. A controller circuit remaps the digital data into the appropriate width and position signals for a pulse width position modulator, including any other signals as needed for any additional inverter circuitry. The pulse width position modulator generates a video signal which may be inverted by the inverter circuit as responsive to the controller circuit remapping determination. This final video signal is provided to an image output terminal.

Owner:XEROX CORP

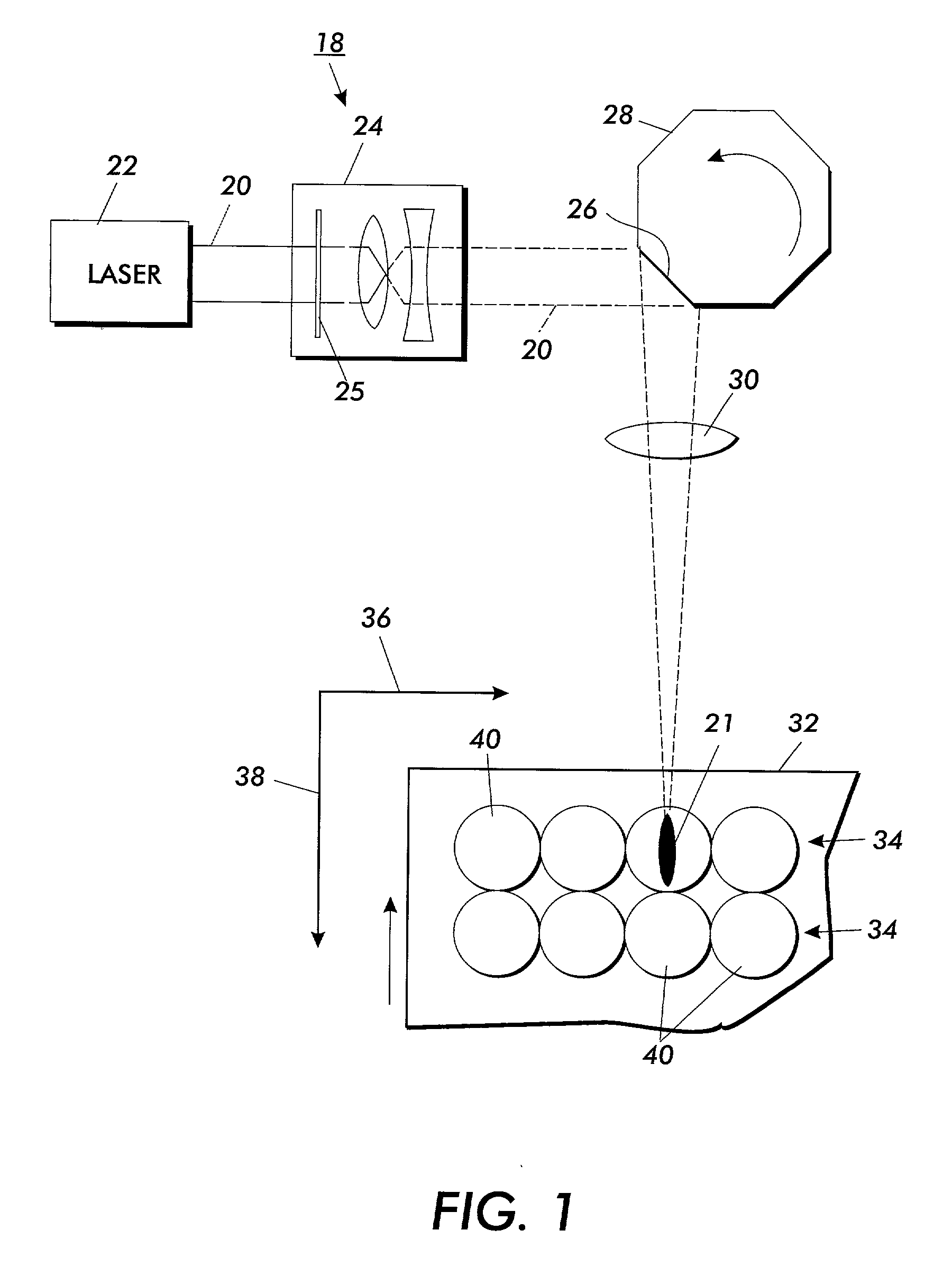

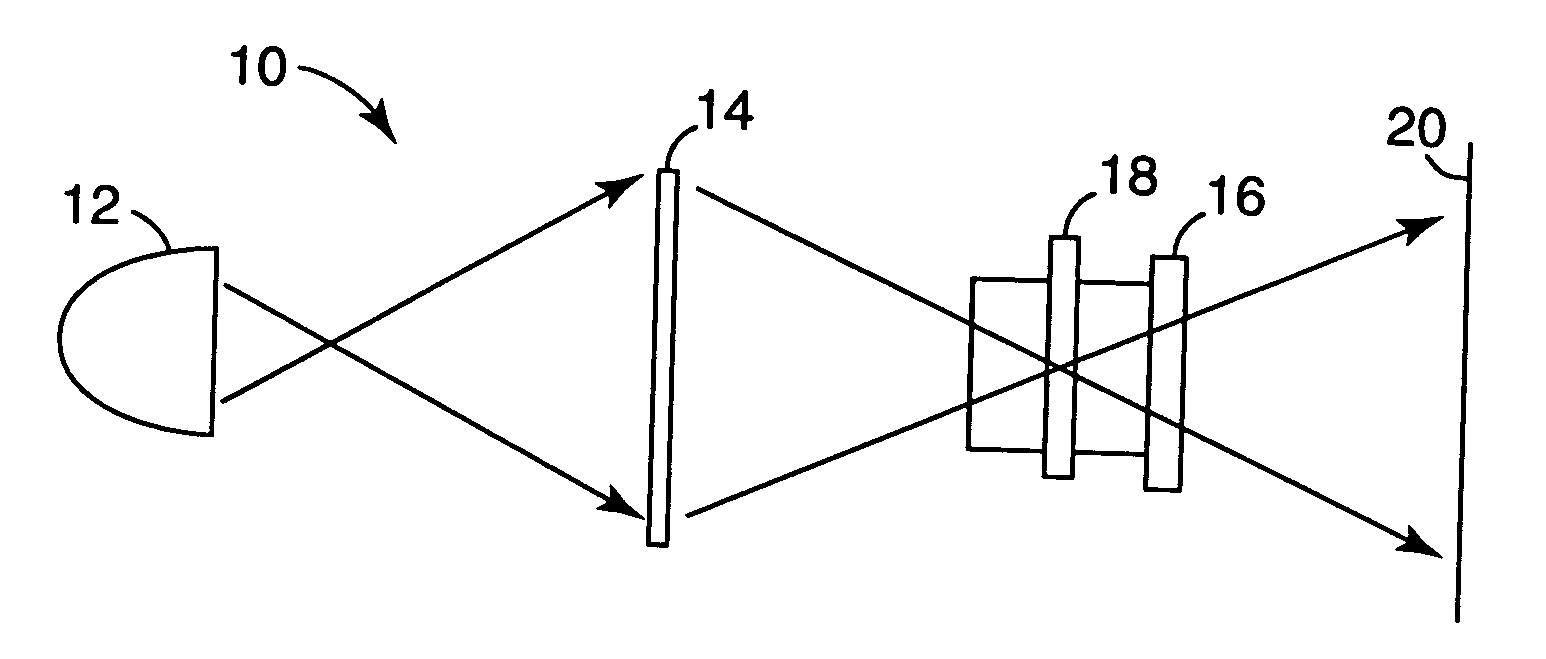

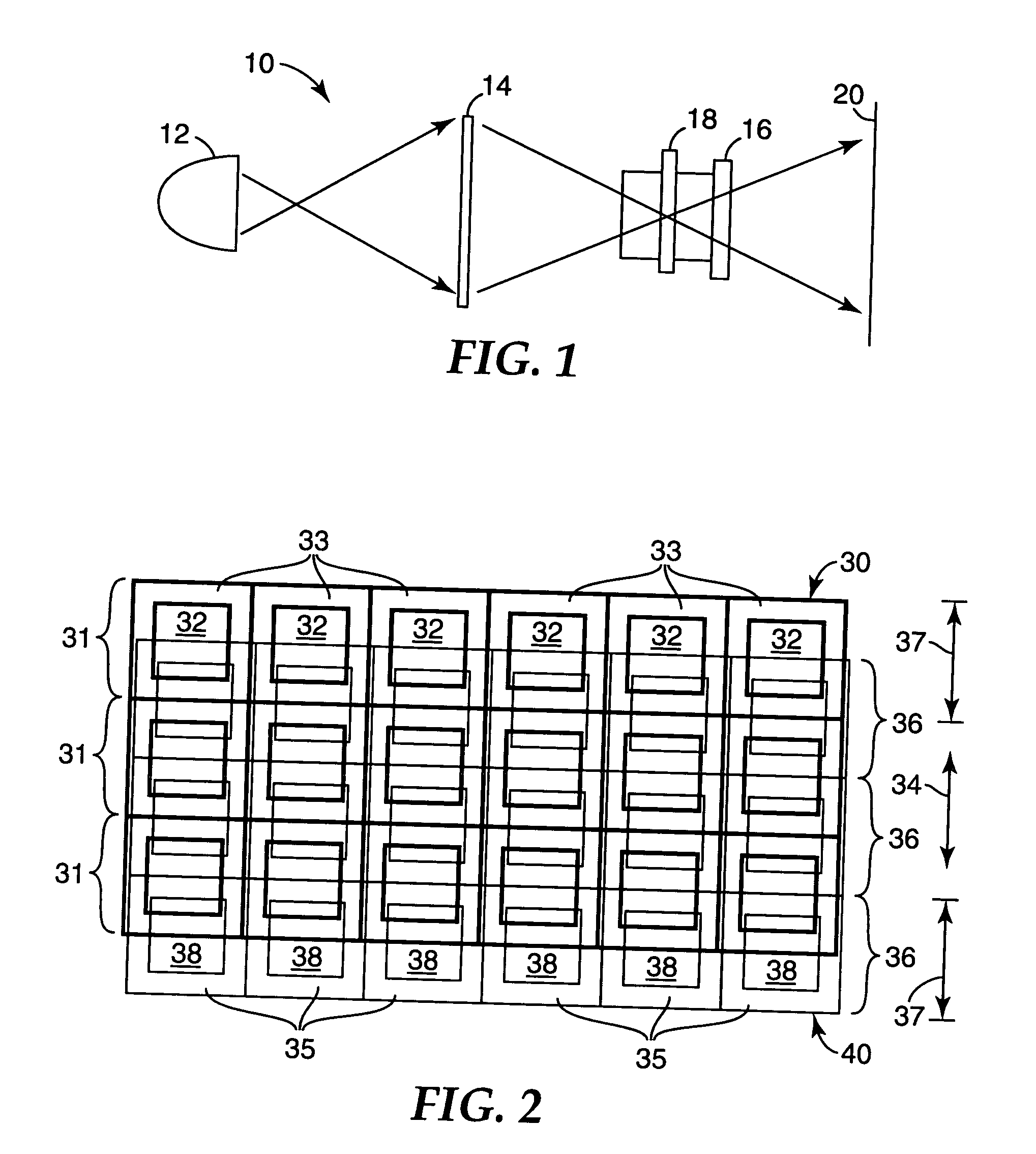

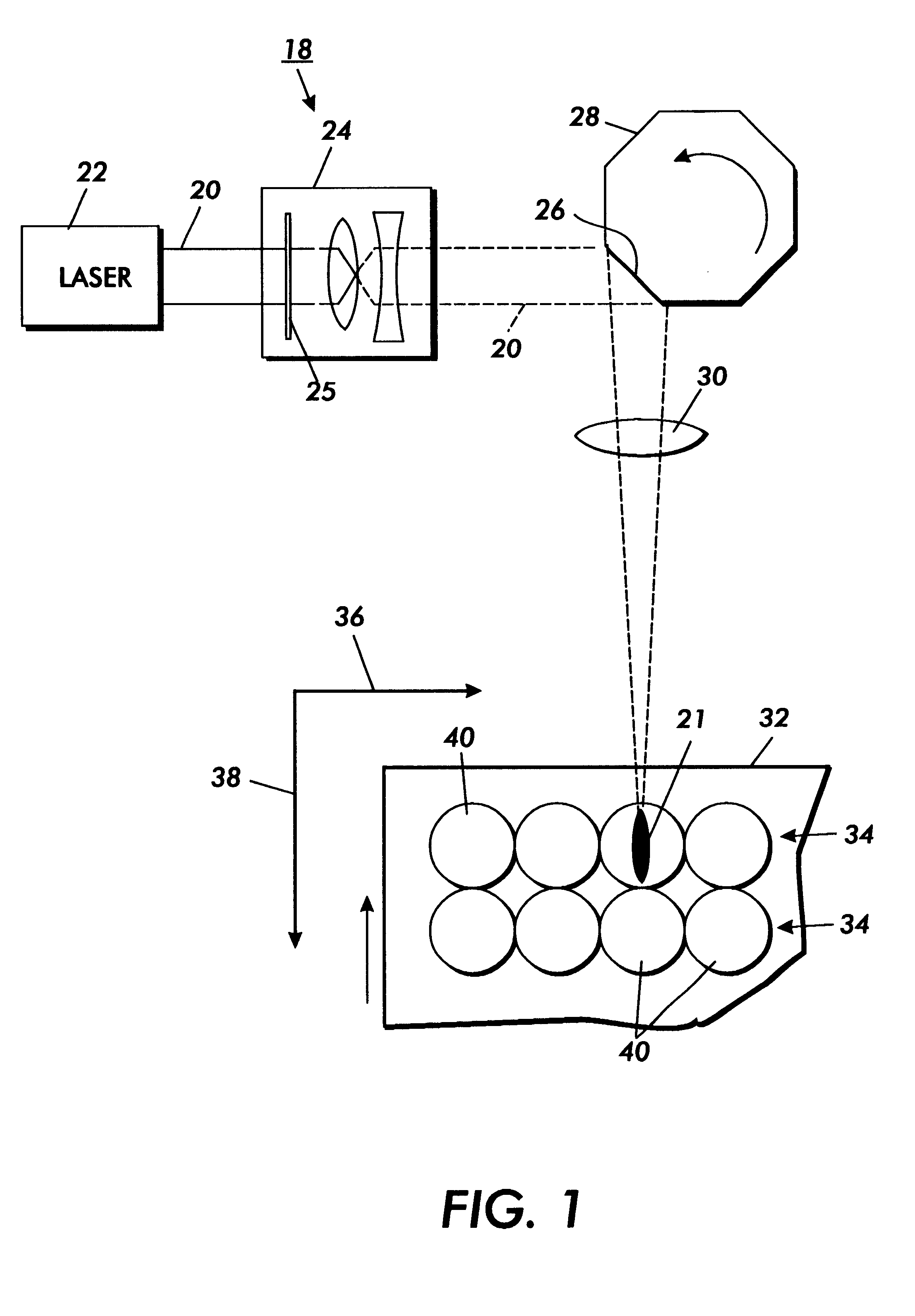

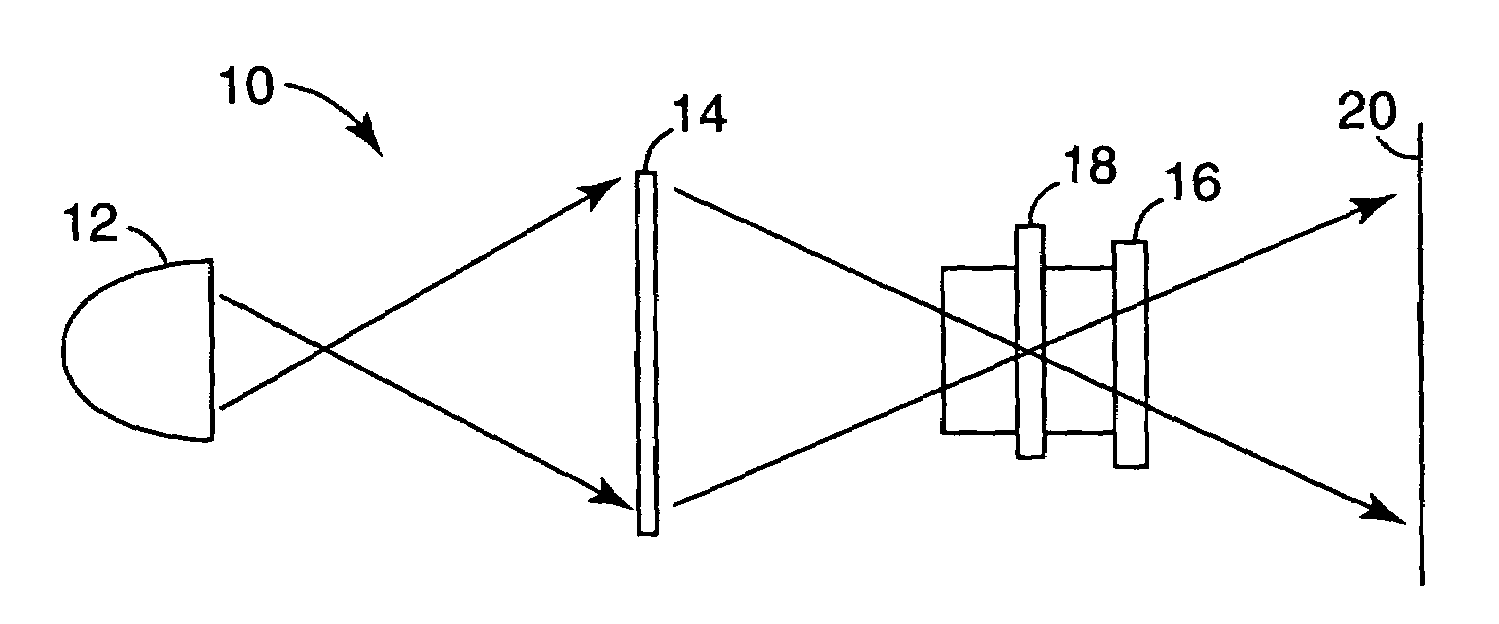

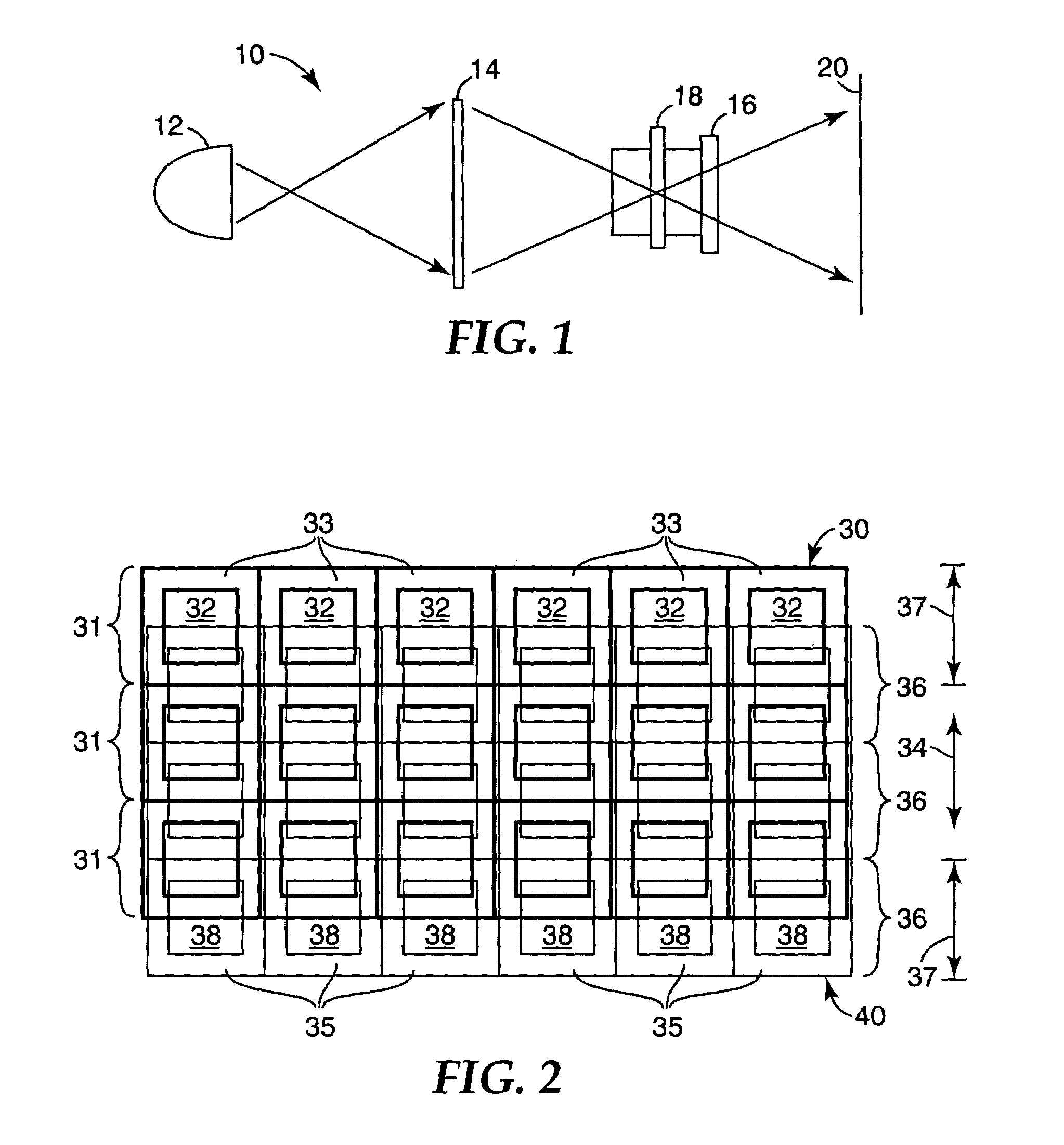

Pixel-shifting projection lens assembly to provide optical interlacing for increased addressability

InactiveUS20050134805A1Reduce difficultySmall sizeTelevision system detailsProjectorsDisplay deviceProjection lens

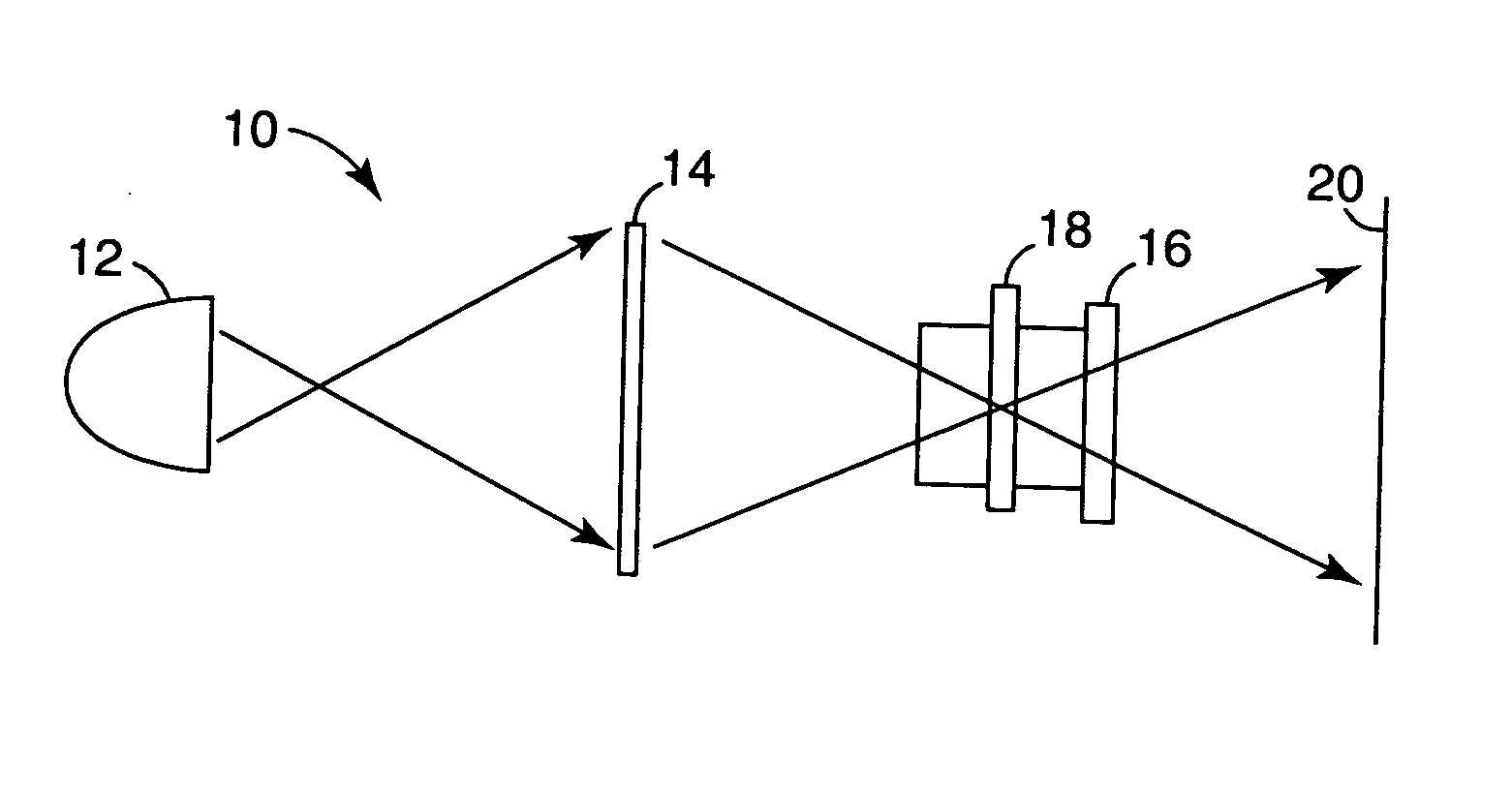

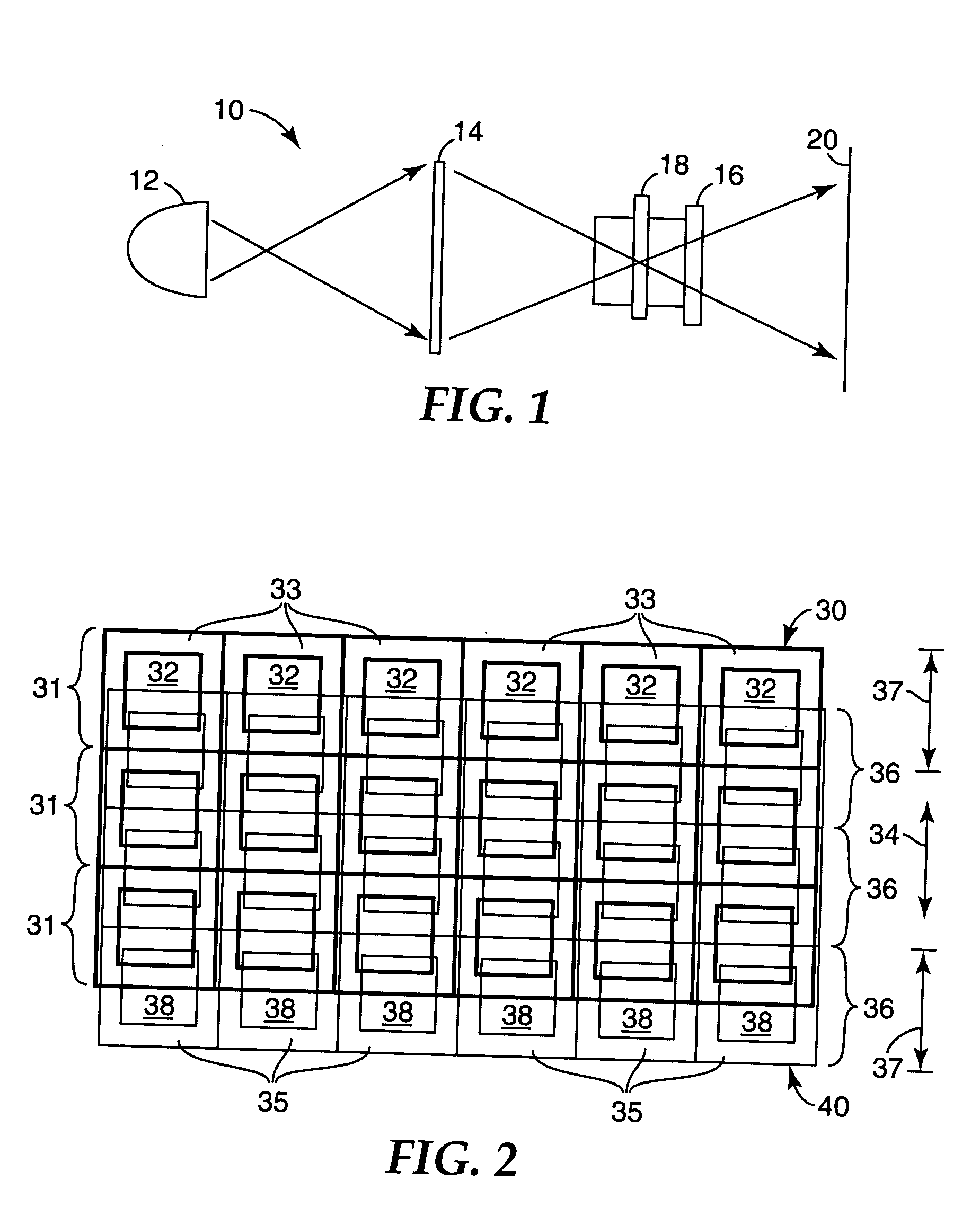

A projection display system includes a projection lens assembly that has multiple projection lens elements that are configured to receive light imparted with display information by a pixelated display device. The projection lens elements project the light toward a display screen. A pixel-shifting element is included within the projection lens assembly to cyclically shift between at least two positions within the projection lens assembly to form at a display screen at least two interlaced arrays of pixels. An electromechanical transducer is coupled to the pixel-shifting element to impart on it the cyclic shifting between positions.

Owner:3M INNOVATIVE PROPERTIES CO

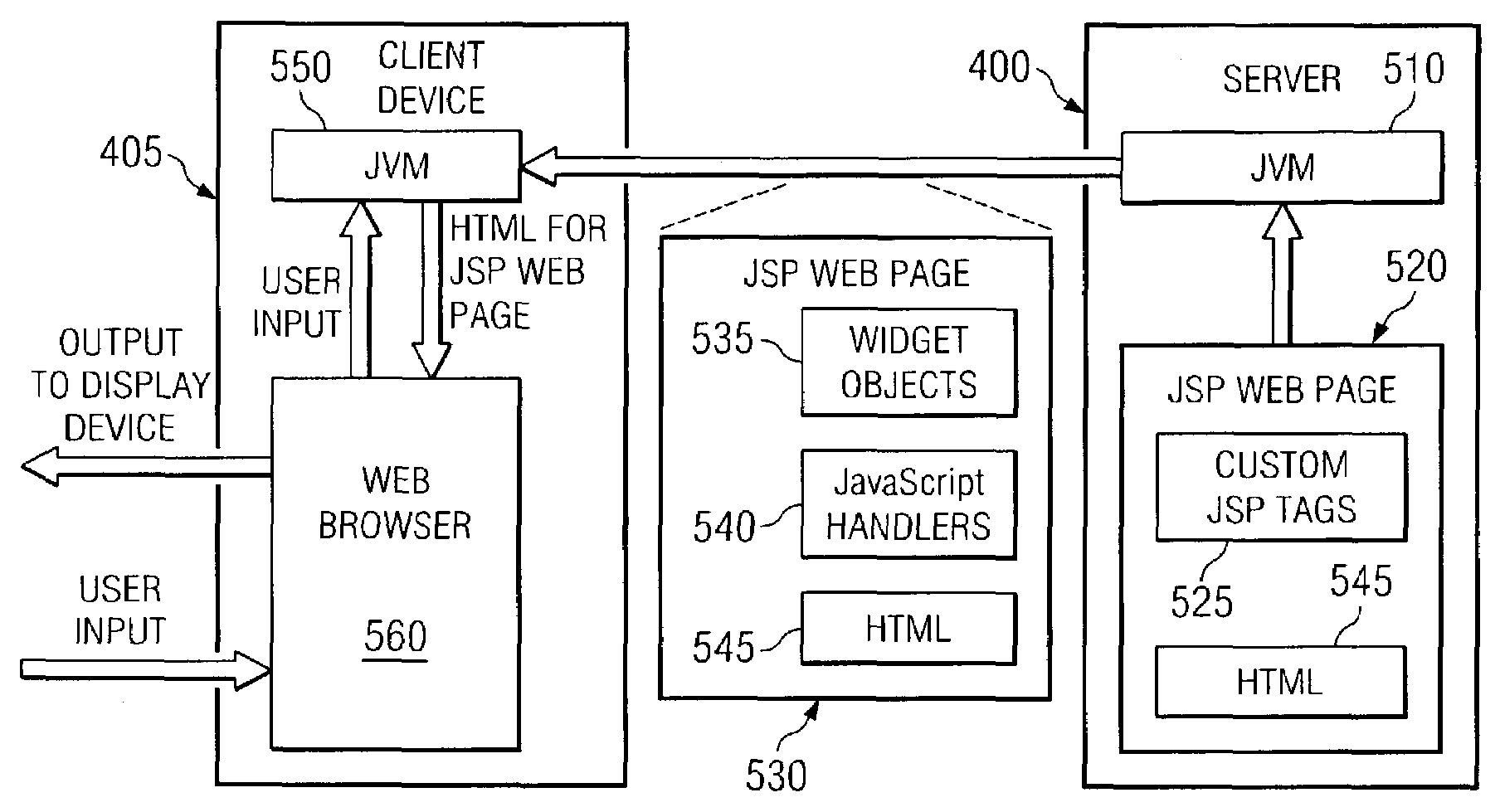

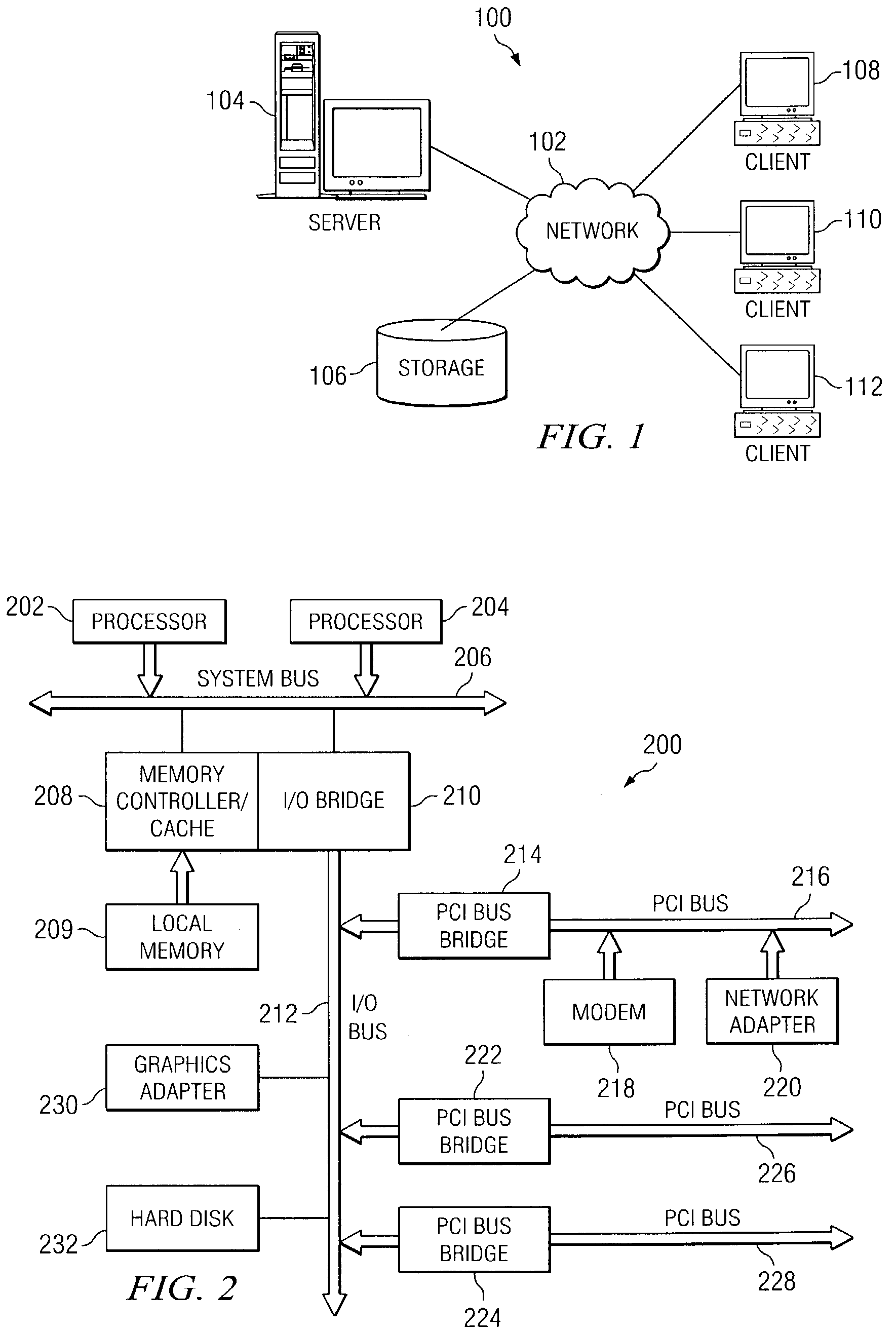

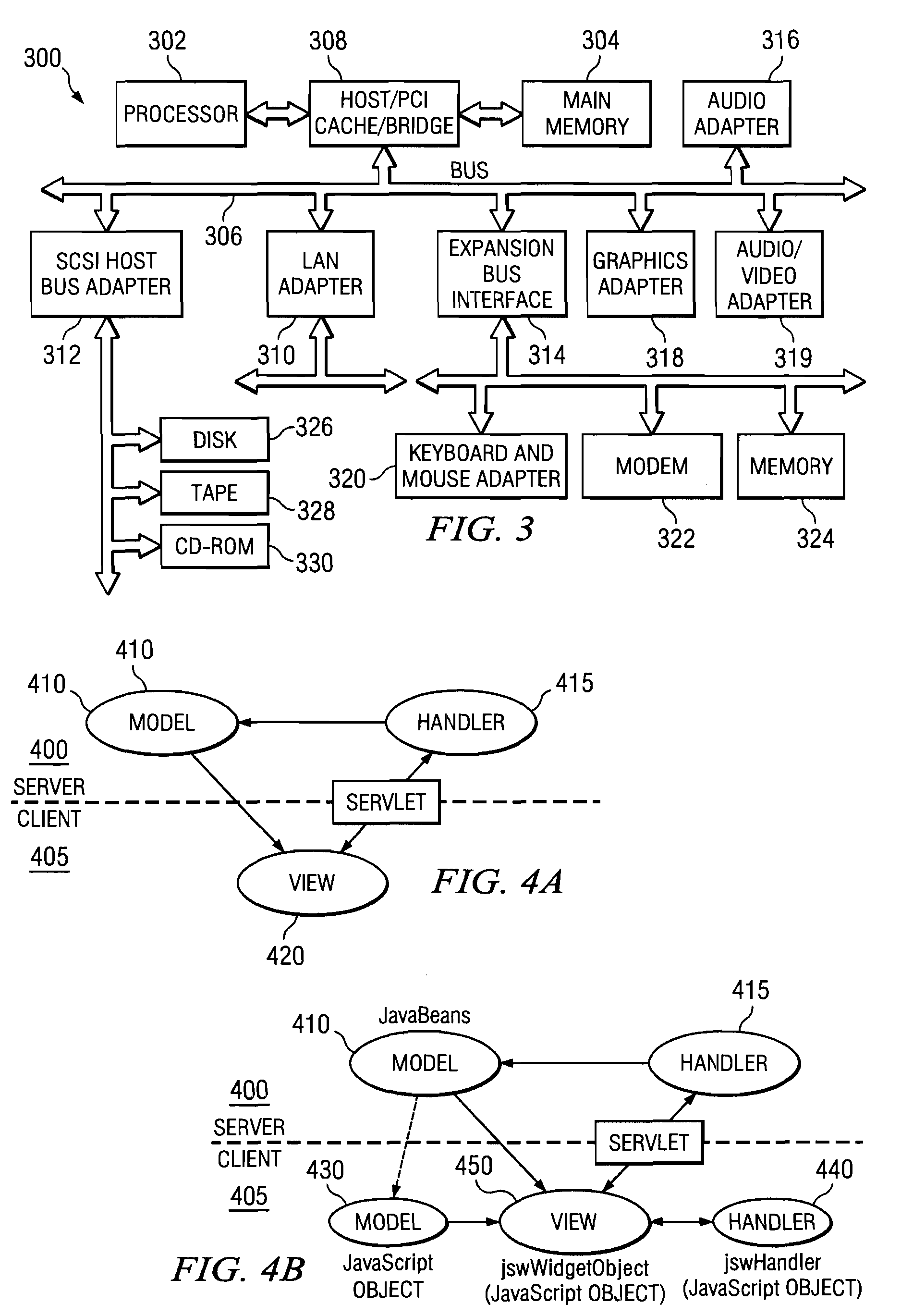

System and method for generating high-function browser widgets with full addressability

ActiveUS7269792B2Firmly connectedImprove protectionDigital computer detailsMultiprogramming arrangementsWeb browserClient-side

A system and method for generating high-function browser widgets with full addressability are provided. With the system and method, custom JSP tags are utilized that generate JavaScript objects to provide the high-function browser widgets. The JavaScript objects, in turn, output HTML for use by a client side Web browser. These JavaScript objects have instance-level functions or actions that are encapsulated in the widget as well as a complete client-side model representation of the data also encapsulated in the widget object. These objects and actions are fully addressable by the developer via a getWidgetByID method on a global utility object. As a result, higher-level features and full inter-widget communication are achievable using the custom JSP tags of the present invention.

Owner:GOOGLE LLC

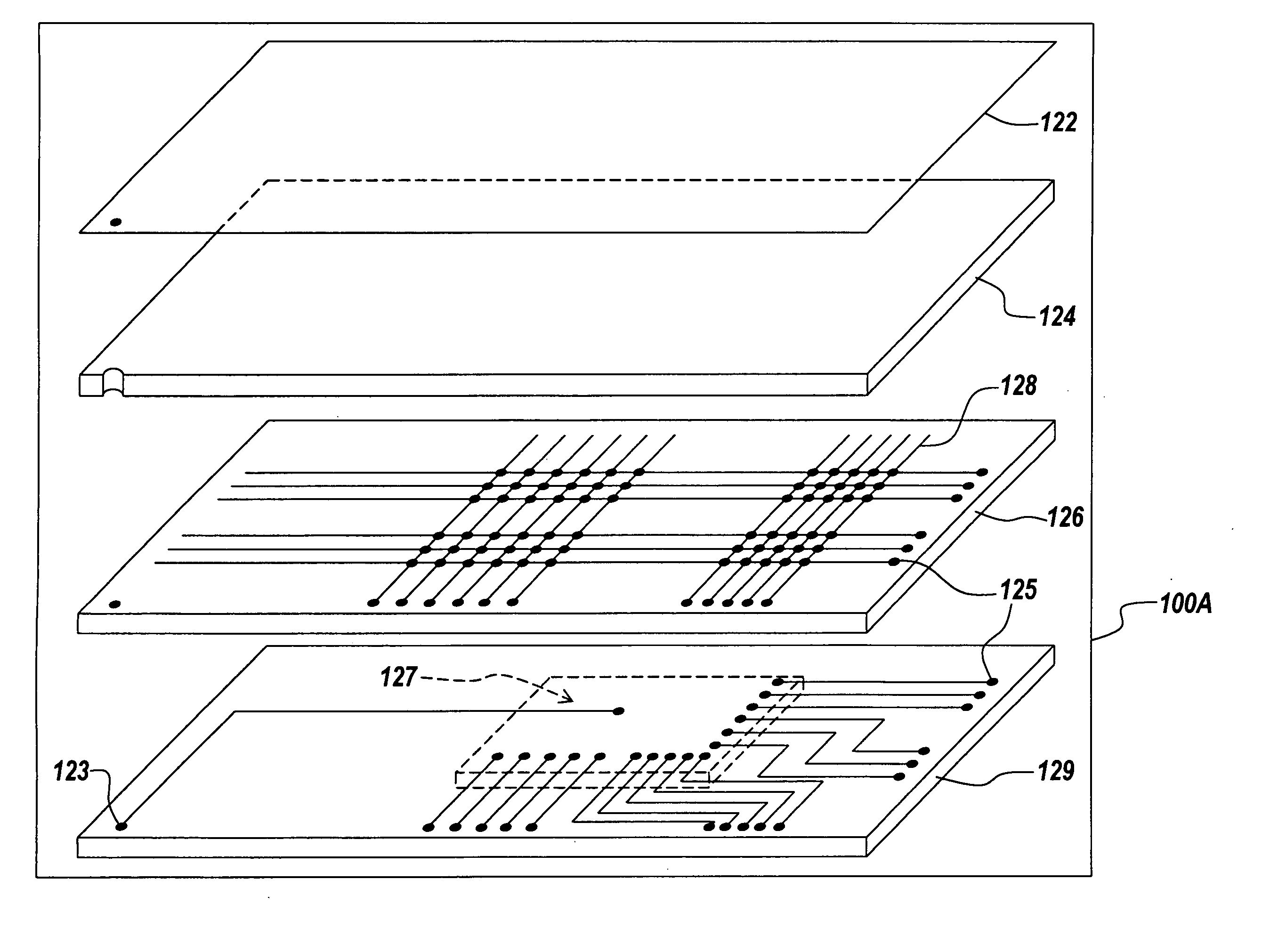

Electronic sign

InactiveUS20080198098A1Static indicating devicesData switching by path configurationComputer graphics (images)Display device

An electronic sign employs a bi-stable, non-volatile display material activatable by electrodes to convey information. A sensor detects when the electronic sign is inserted in or in the vicinity of an insertion area, and controls the operation of the sign based on the detected location. A backplane in the electronic sign includes different patterns of addressable elements to provide a display that pixel, font region, or icon addressable or have a combination of one or more of the pixel, font region, or icon addressability. A remote device communicates with the electronic sign, and multiple electronic signs may communicate with each other via a communication protocol, such as mesh networking.

Owner:METROLOGIC INSTR

Pixel-shifting projection lens assembly to provide optical interlacing for increased addressability

InactiveUS20050225732A1Reduce difficultySmall sizeTelevision system detailsProjectorsDisplay deviceProjection lens

A projection display system includes a projection lens assembly that has multiple projection lens elements that are configured to receive light imparted with display information by a pixelated display device. The projection lens elements project the light toward a display screen. A pixel-shifting element is included within the projection lens assembly to cyclically shift between at least two positions within the projection lens assembly to form at a display screen at least two interlaced arrays of pixels. An electromechanical transducer is coupled to the pixel-shifting element to impart on it the cyclic shifting between positions.

Owner:3M INNOVATIVE PROPERTIES CO

Apparatus and method for halftone hybrid screen generation

InactiveUS6252675B1Promote reproductionGood freedomDigitally marking record carriersDigital computer detailsDigital dataSingle image

The present invention is a method and apparatus allowing the application of two or more distinct halftone types in the rendering of a single image. The invention employs a halftone selector of a threshold type, or as an alternative a segmenter type. The halftone selector determines which areas of an image will receive which type of grayscale halftone treatment on a pixel by pixel basis. Examples of various halftone types include stochastic, clustered dot, line screen, and other high addressability types. Each pixel of data is treated by the appropriate halftoner circuit which in response outputs digital data. A controller circuit remaps the digital data into the appropriate width and position signals for a pulse width position modulator, including any other signals as needed for any additional inverter circuitry. The pulse width position modulator generates a video signal which may be inverted by the inverter circuit as responsive to the controller circuit remapping determination. This final video signal is provided to an image output terminal.

Owner:XEROX CORP

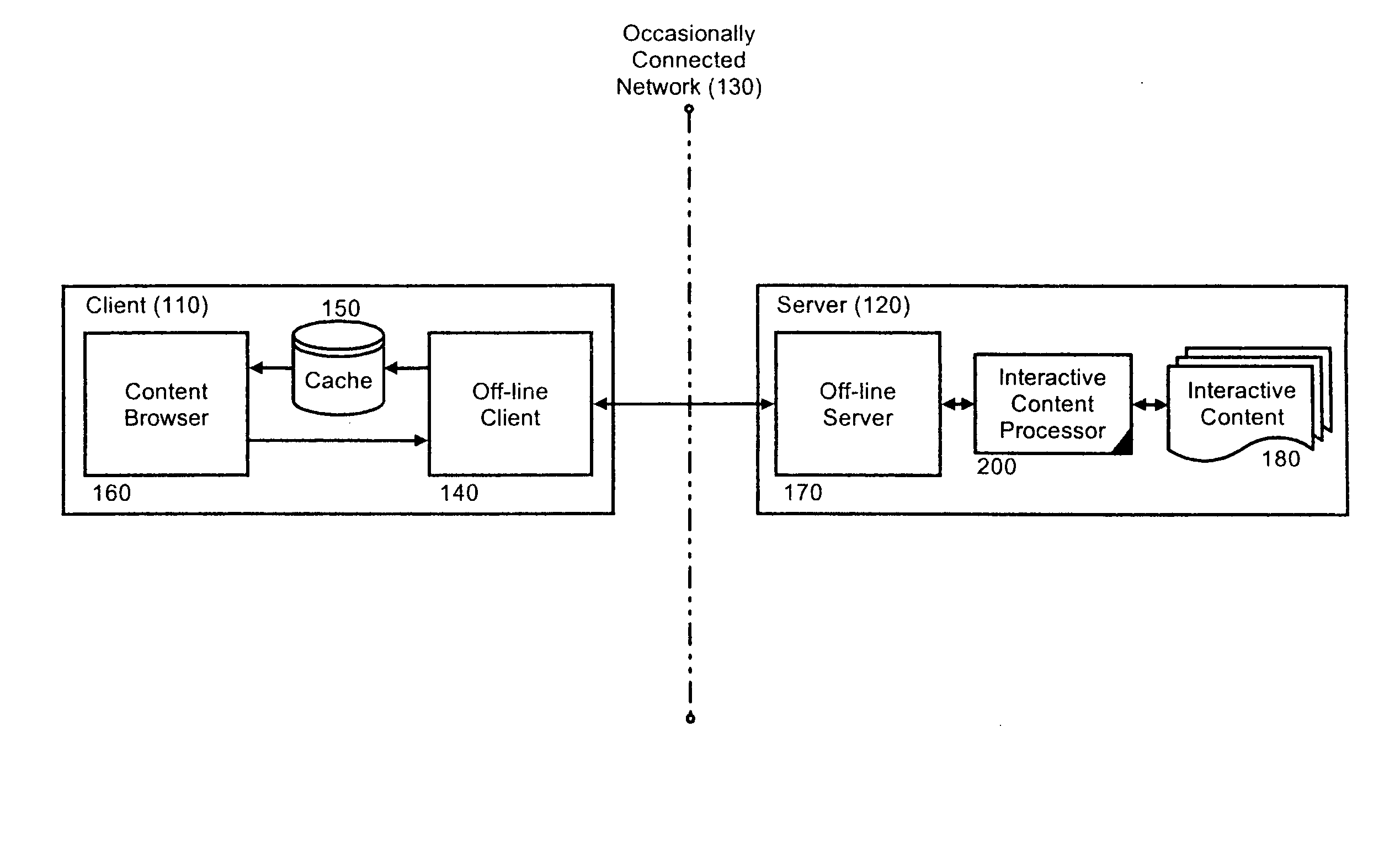

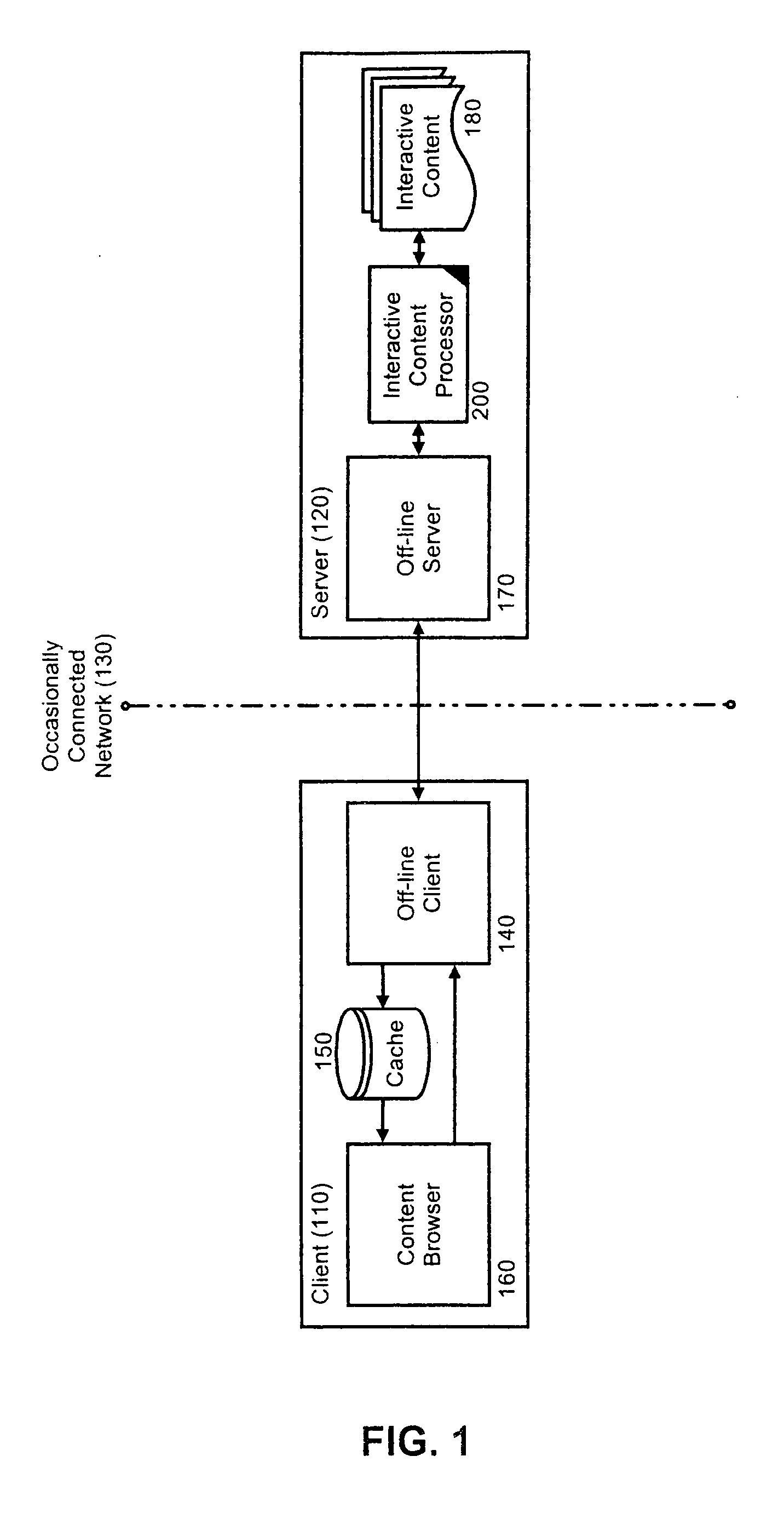

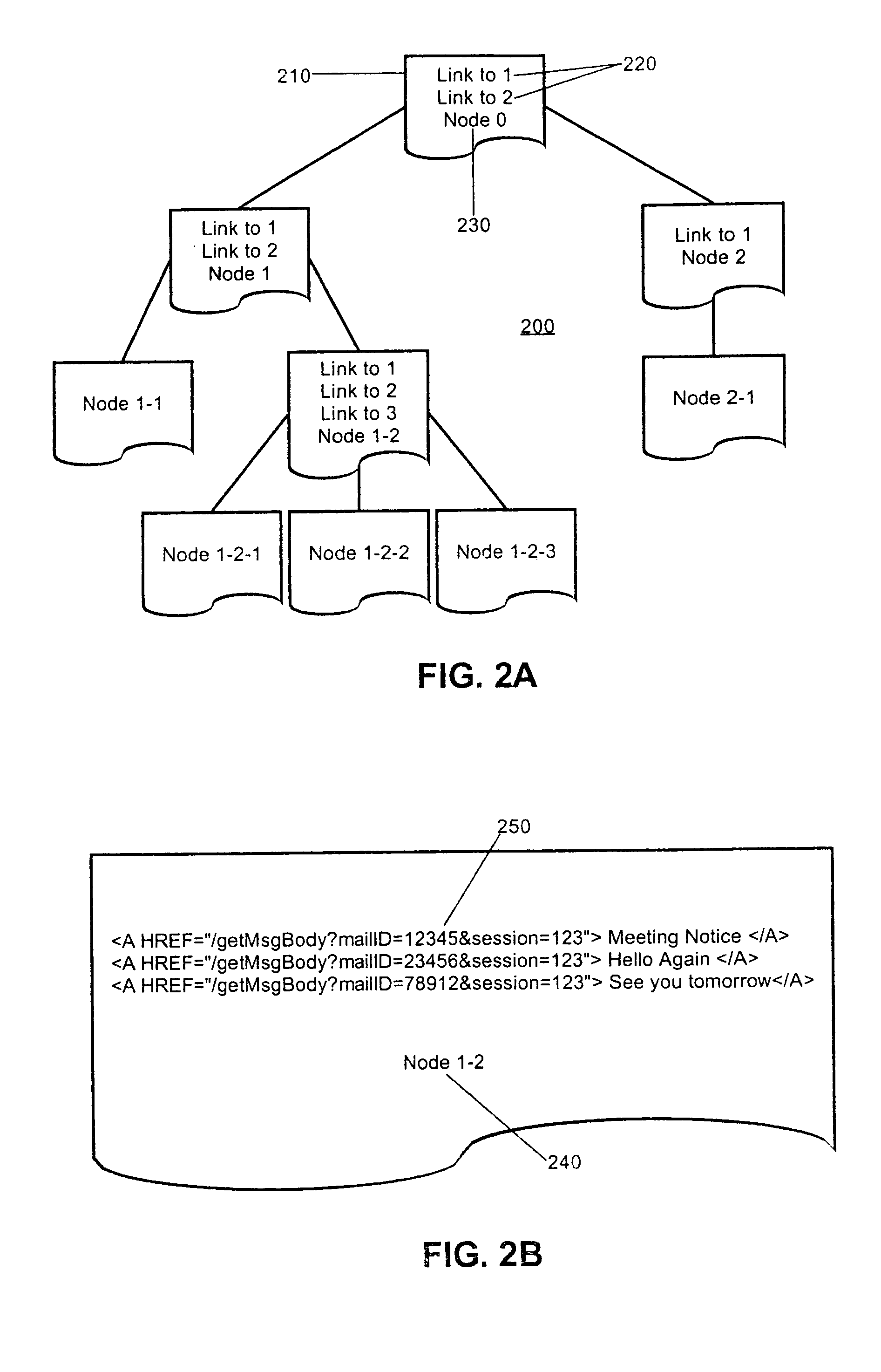

Processing interactive content offline

InactiveUS20050091340A1Digital data information retrievalMultiple digital computer combinationsHyperlinkInteractive content

A method, system and apparatus for processing interactive content off-line in a dynamic system having transient addressability. A method for processing off-line interactive content in a dynamic system with variable addressability can include serving content for caching in a client device; generating a pathway navigation map (PNM) for the served content; and, annotating the served content with endpoint directives for modifying hyperlink behavior referenced by the directives in the cached content. In a preferred aspect of the invention, the generating step can include forming a document tree having a plurality of nodes; assigning each node of the tree to a document in the content accessible through a hyperlink referenced by a parent node; and, disposing within each node a set of hyperlink references to child pages in the content and a reference to a pathway to a root node of the document tree.

Owner:IBM CORP

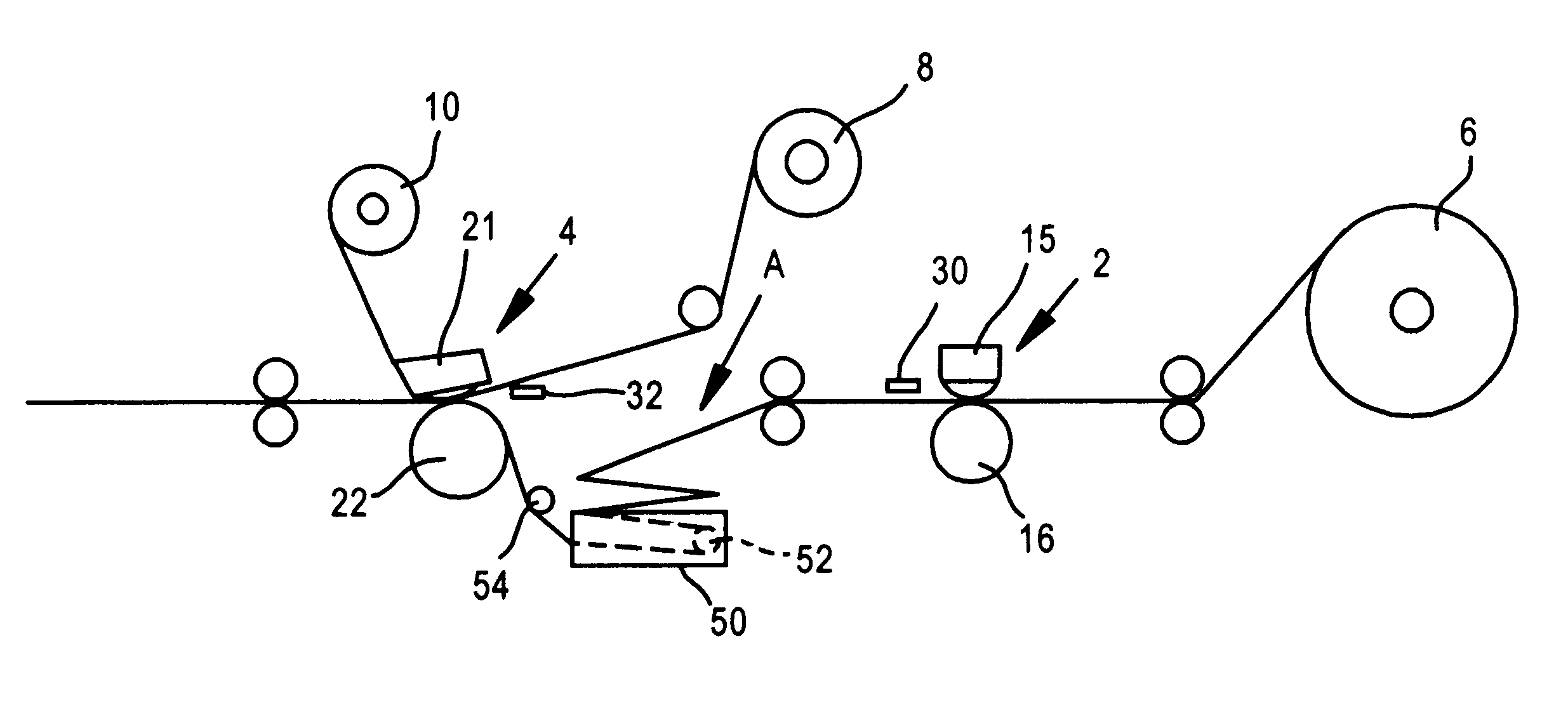

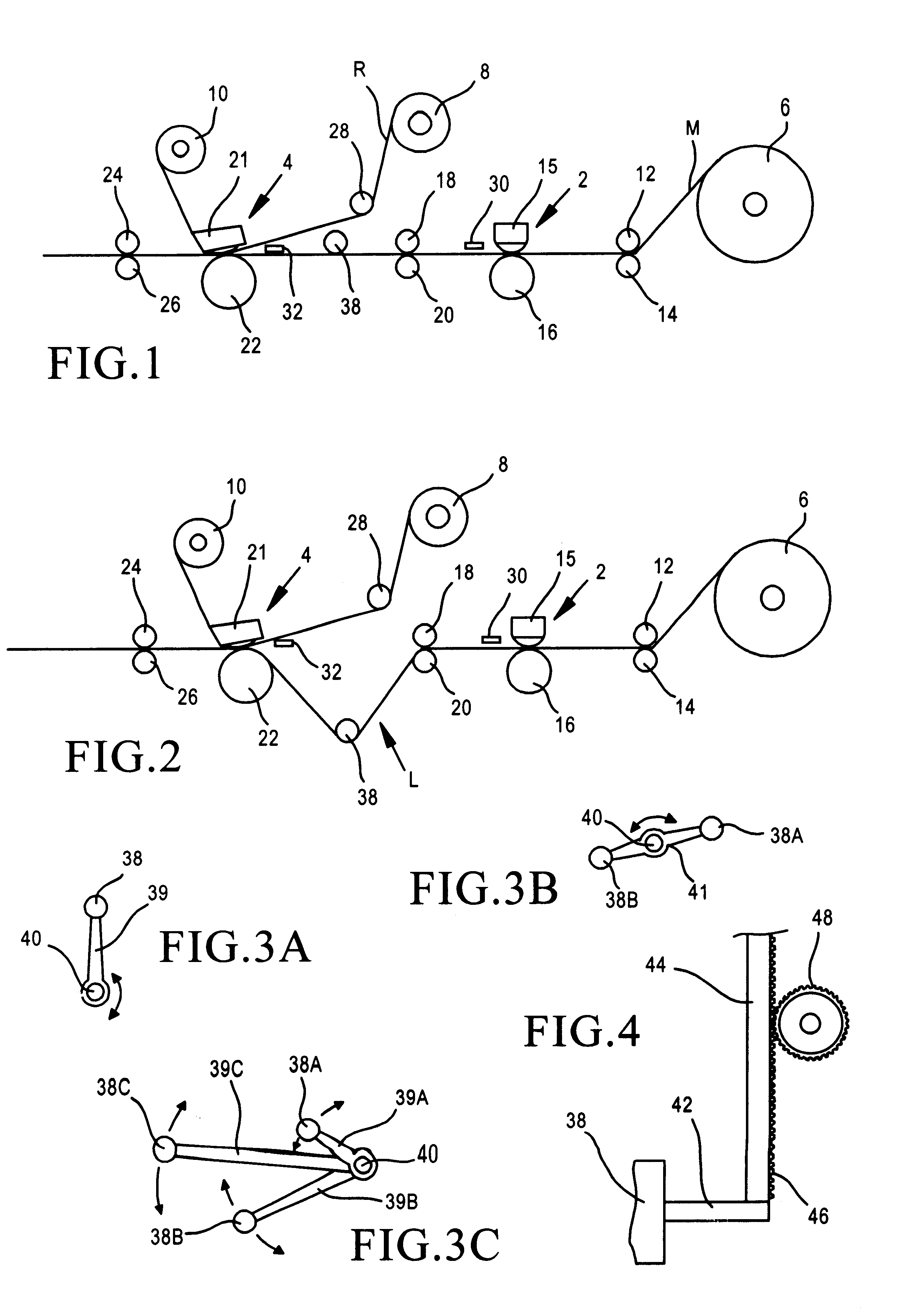

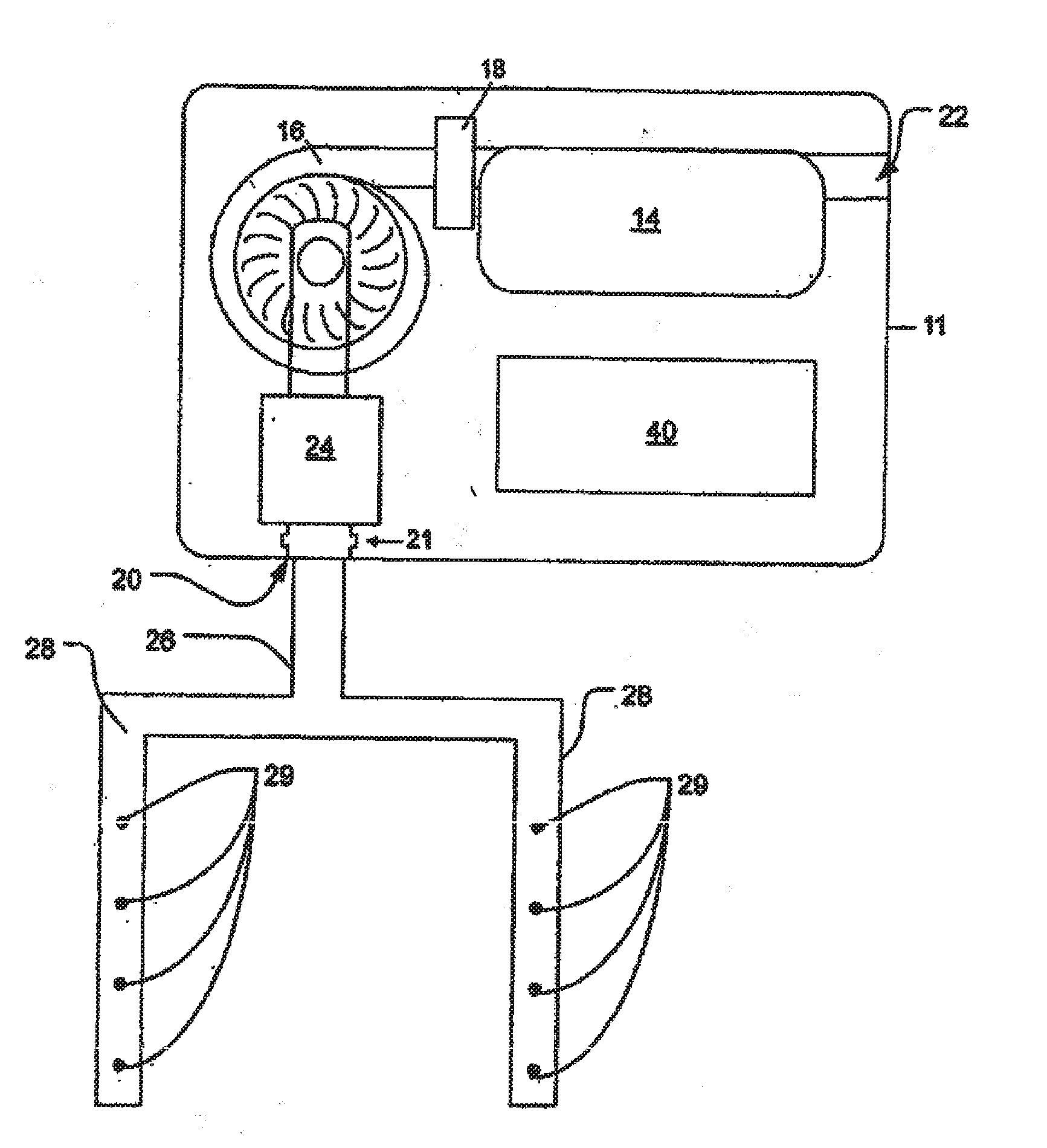

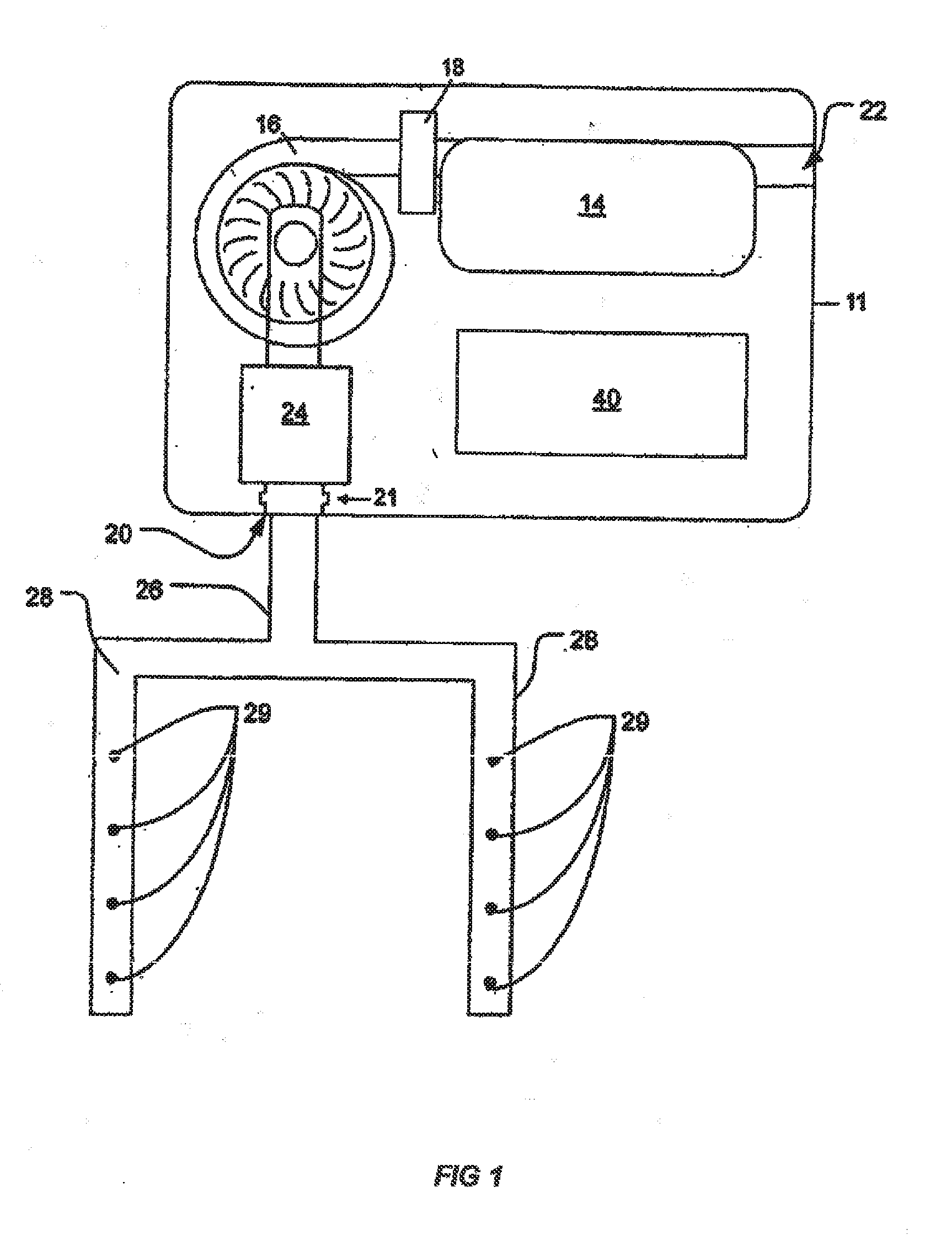

Dual technology printer

InactiveUS6203131B1Efficient and reliable printingQuick and efficient printingRecording apparatusTypewritersColor imageImage resolution

A dual technology printer includes first and second print stations having a polychromatic print engine and a monochromatic print engine, respectively. The print engines are preferably an ink jet print engine and a thermal print engine. A variable length media queue is formed between the two print stations. The queue may be formed by a guide roller that defines a loop of media between the stations and that is movable to adjust the length of the loop and thereby the length of the queue. Preferably, the second print station has a predetermined pixel addressability and a resolution substantially equal to the addressability to produce sharp borders for machine readable symbologies. In a printing operation, the printing of color images at the first print station may be carried out ahead of demand for a particular batch printing operation during which monochromatic images are printed at the second print station.

Owner:INTERMEC IP

Pixel-shifting projection lens assembly to provide optical interlacing for increased addressability

InactiveUS7182463B2Reduce difficultySmall sizeTelevision system detailsProjectorsInterlaced videoDisplay device

A projection display system includes a projection lens assembly that has multiple projection lens elements that are configured to receive light imparted with display information by a pixelated display device. The projection lens elements project the light toward a display screen. A pixel-shifting element is included within the projection lens assembly to cyclically shift between at least two positions within the projection lens assembly to form at a display screen at least two interlaced arrays of pixels. An electro-mechanical transducer is coupled to the pixel-shifting element to impart on it the cyclic shifting between positions.

Owner:3M INNOVATIVE PROPERTIES CO

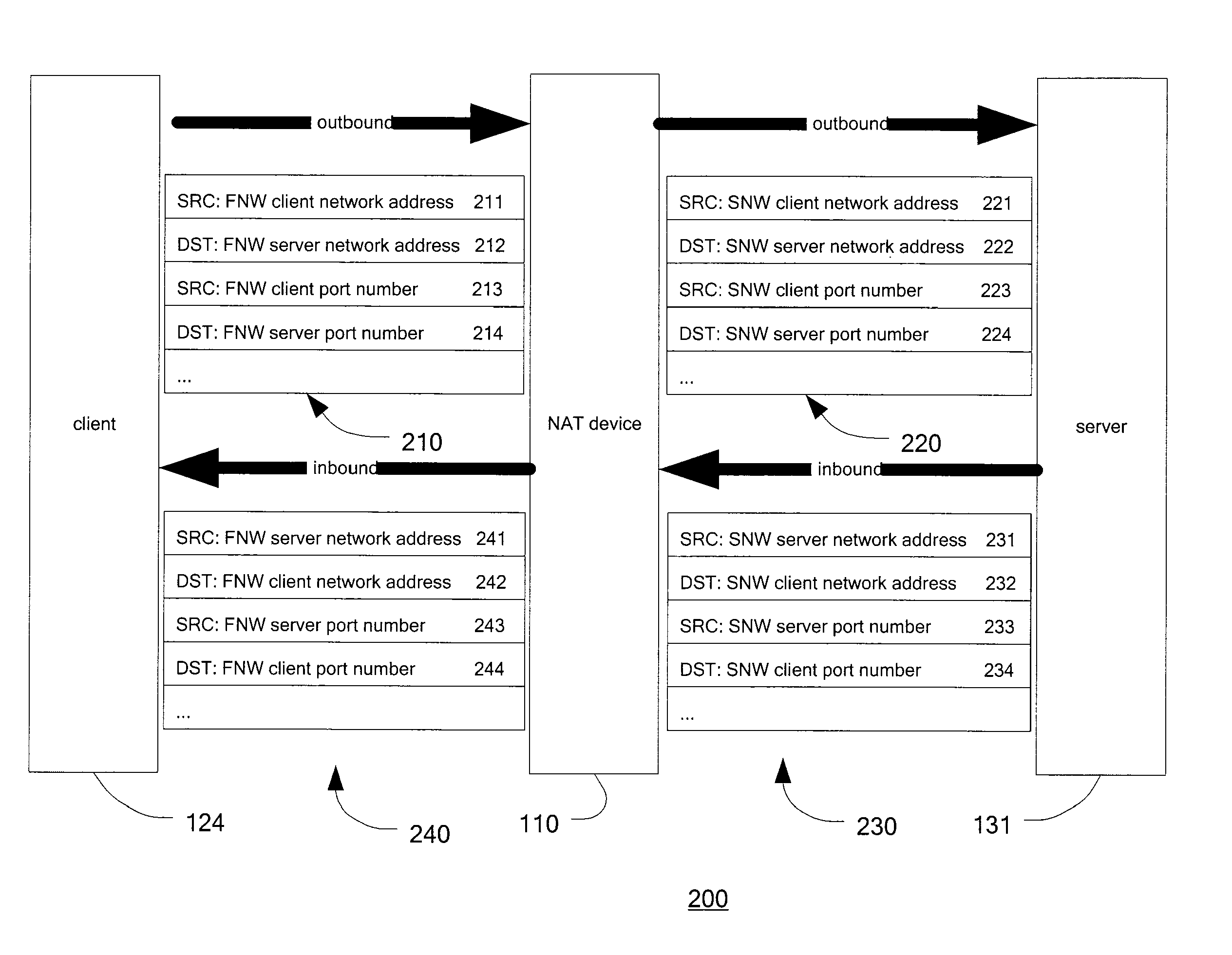

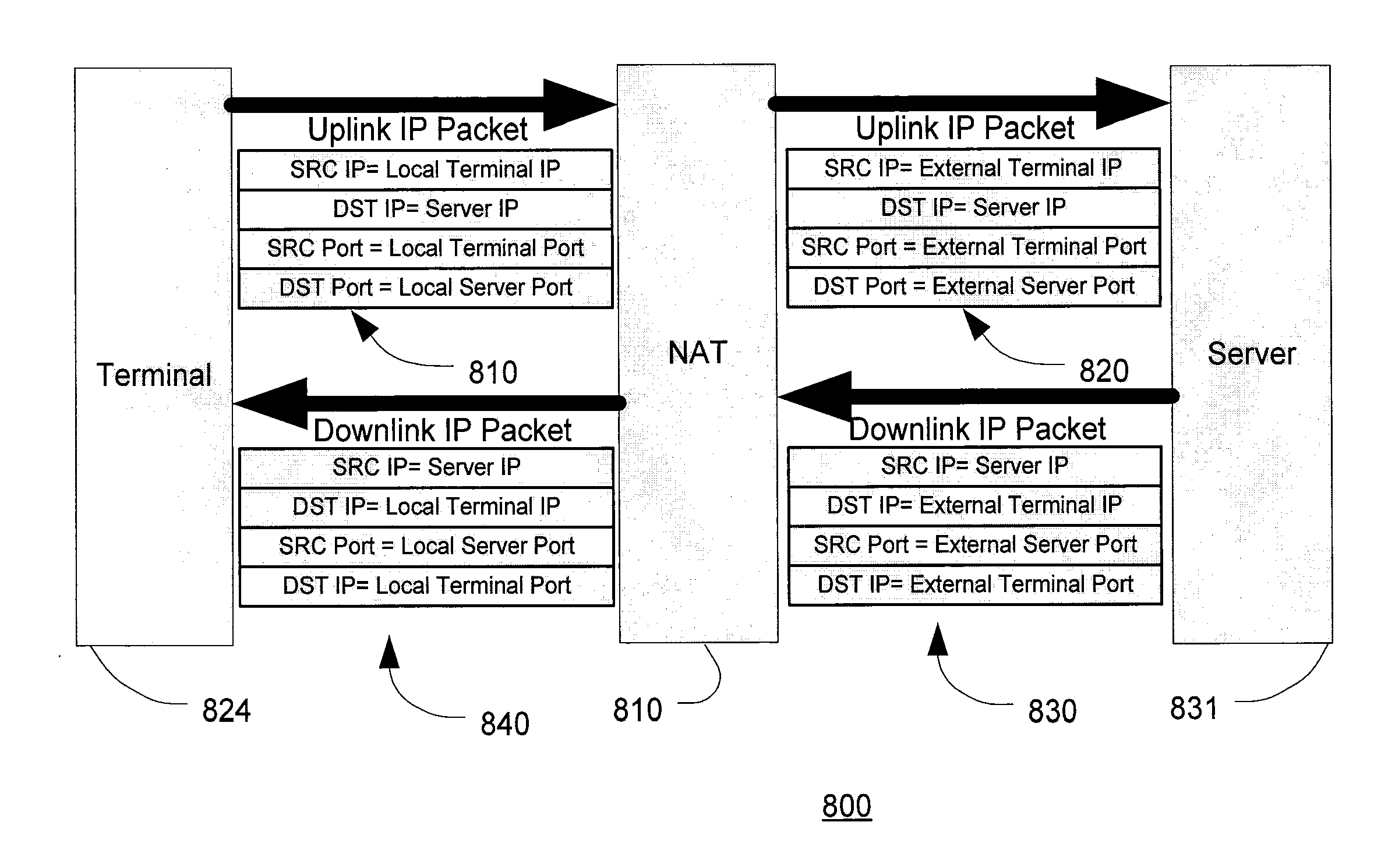

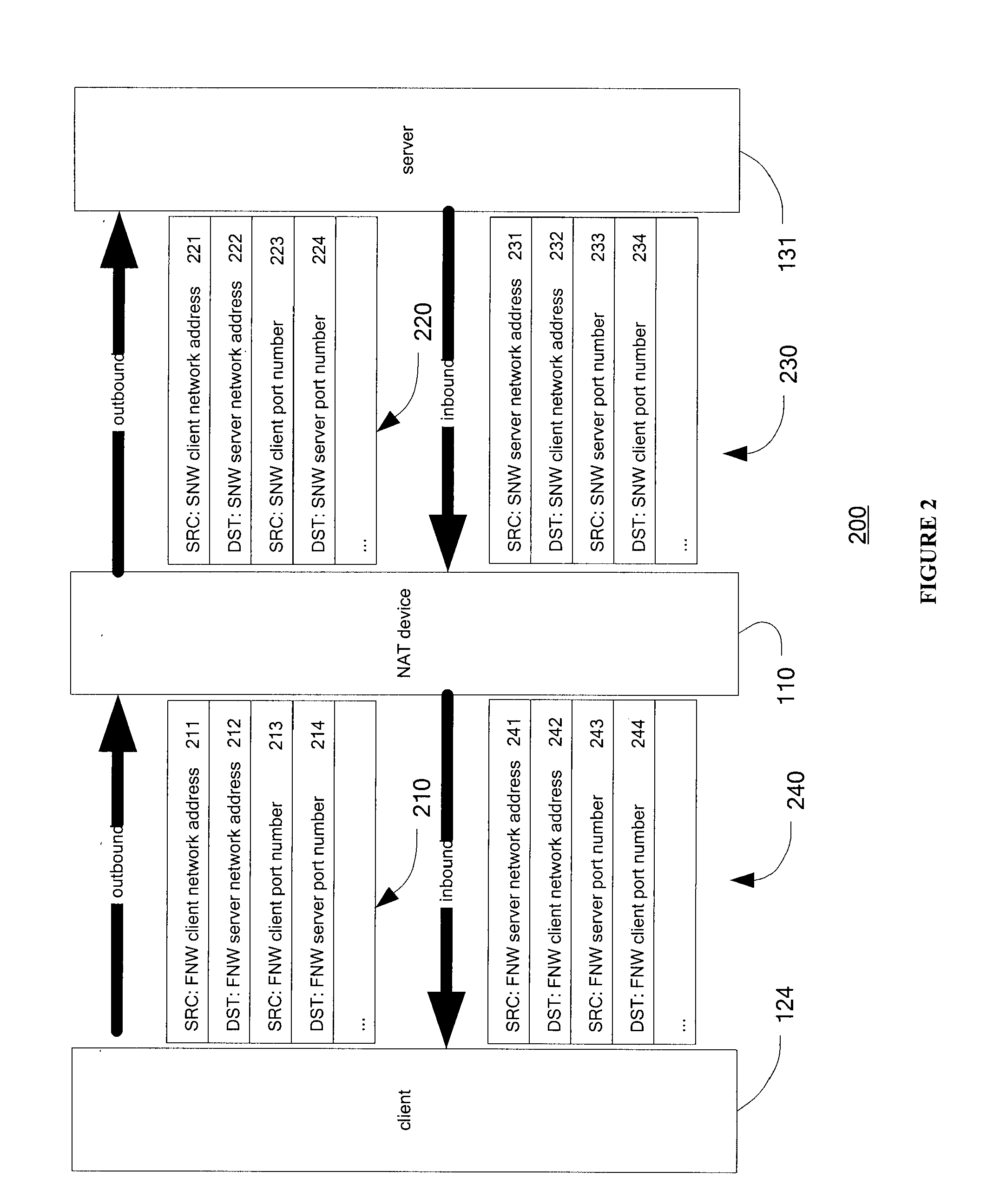

Method and apparatus for network port and network address translation

ActiveUS8812730B2Multiple digital computer combinationsStore-and-forward switching systemsComputer networkNetwork address translation

Owner:SEMTECH CORP

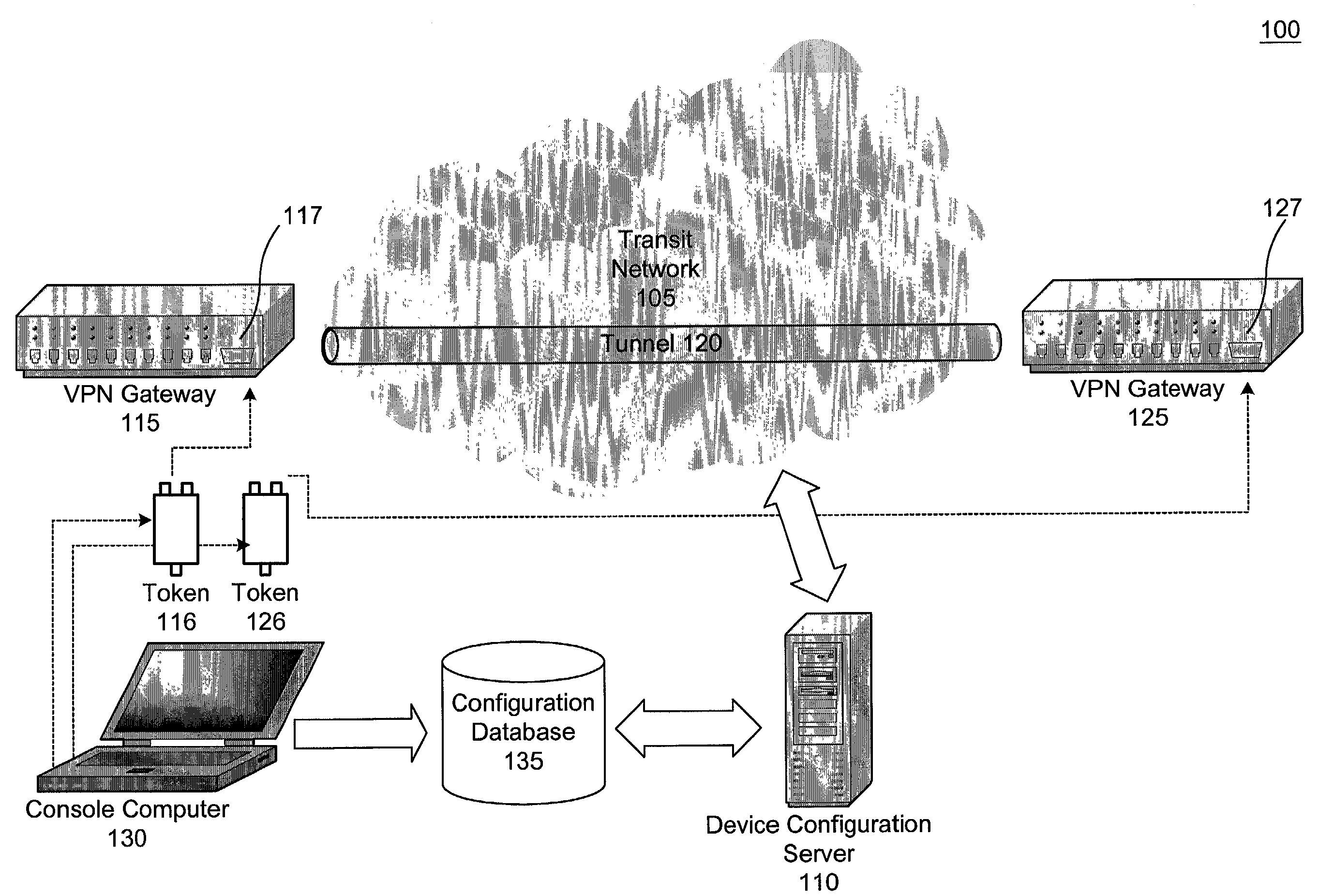

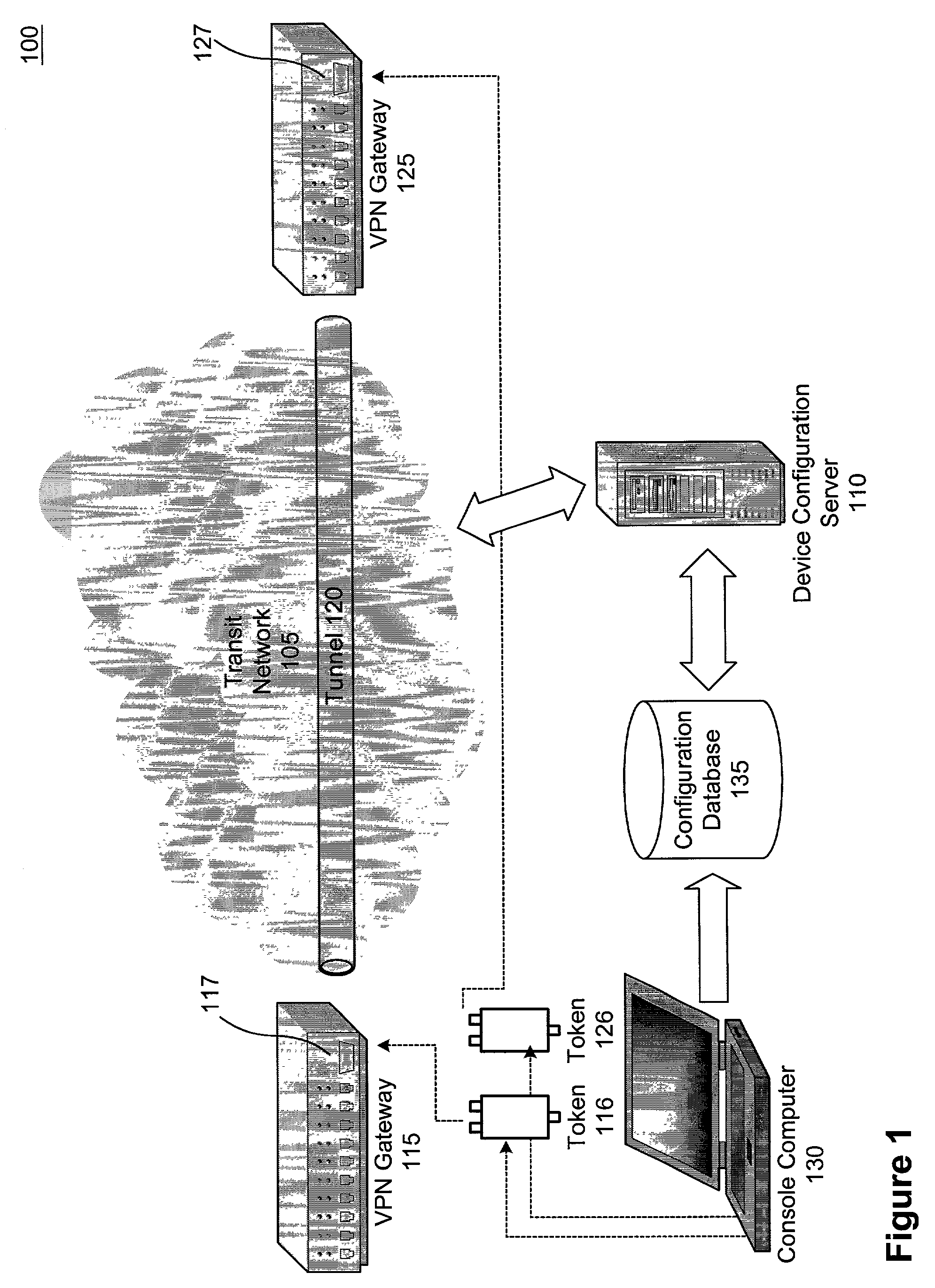

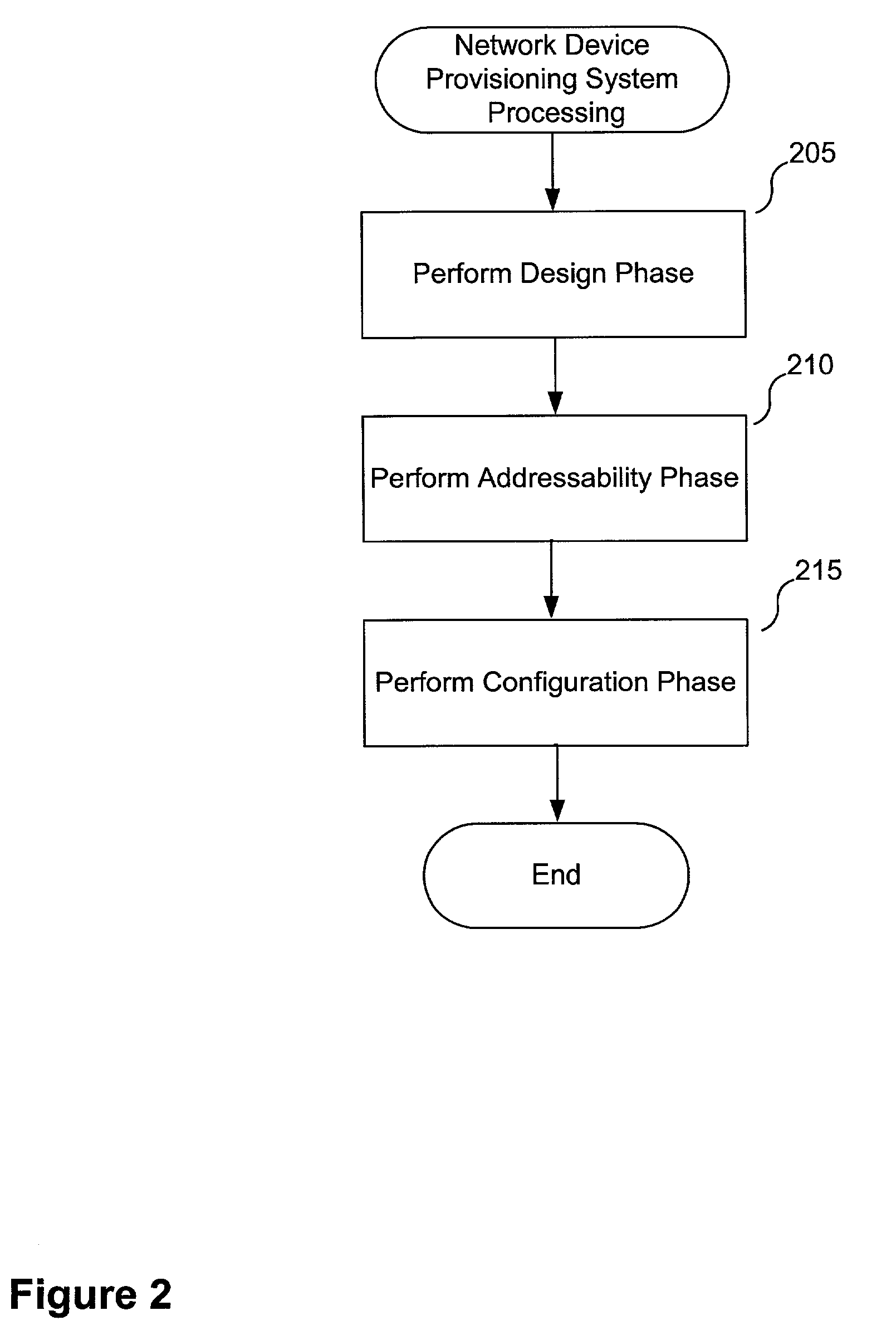

Automated establishment of addressability of a network device for a target network environment

InactiveUS7313819B2Multiple digital computer combinationsProgram controlComputer networkNetwork Communication Protocols

Apparatus and methods are provided for remote, automated, and secure network device provisioning over a pre-existing communications network. According to one embodiment, automated establishment of addressability of a network device is supported for a target network environment. A boot time process of a network device in a factory default configuration detects the presence of a storage device containing therein addressability data that allows the network device to communicate and be addressable within the target network environment. After detecting the presence of the storage device, the network device receives the addressability data from the storage device by using a communication protocol associated with the storage device. Finally, addressability of the network device is established to enable it to communicate with and be addressed by other nodes in the target network environment by configuring one or more address parameters of the network device based upon the addressability data.

Owner:INTEL CORP

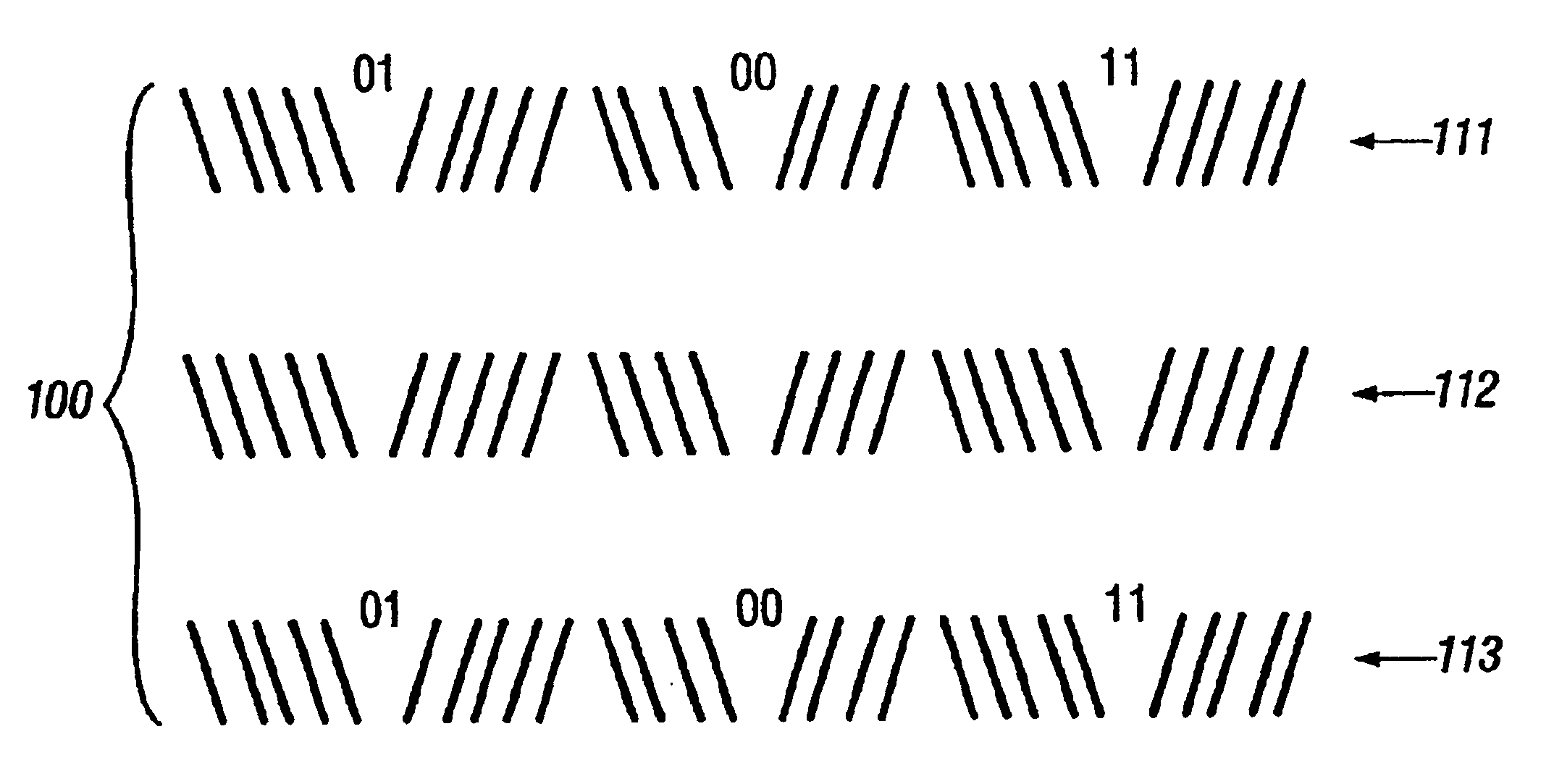

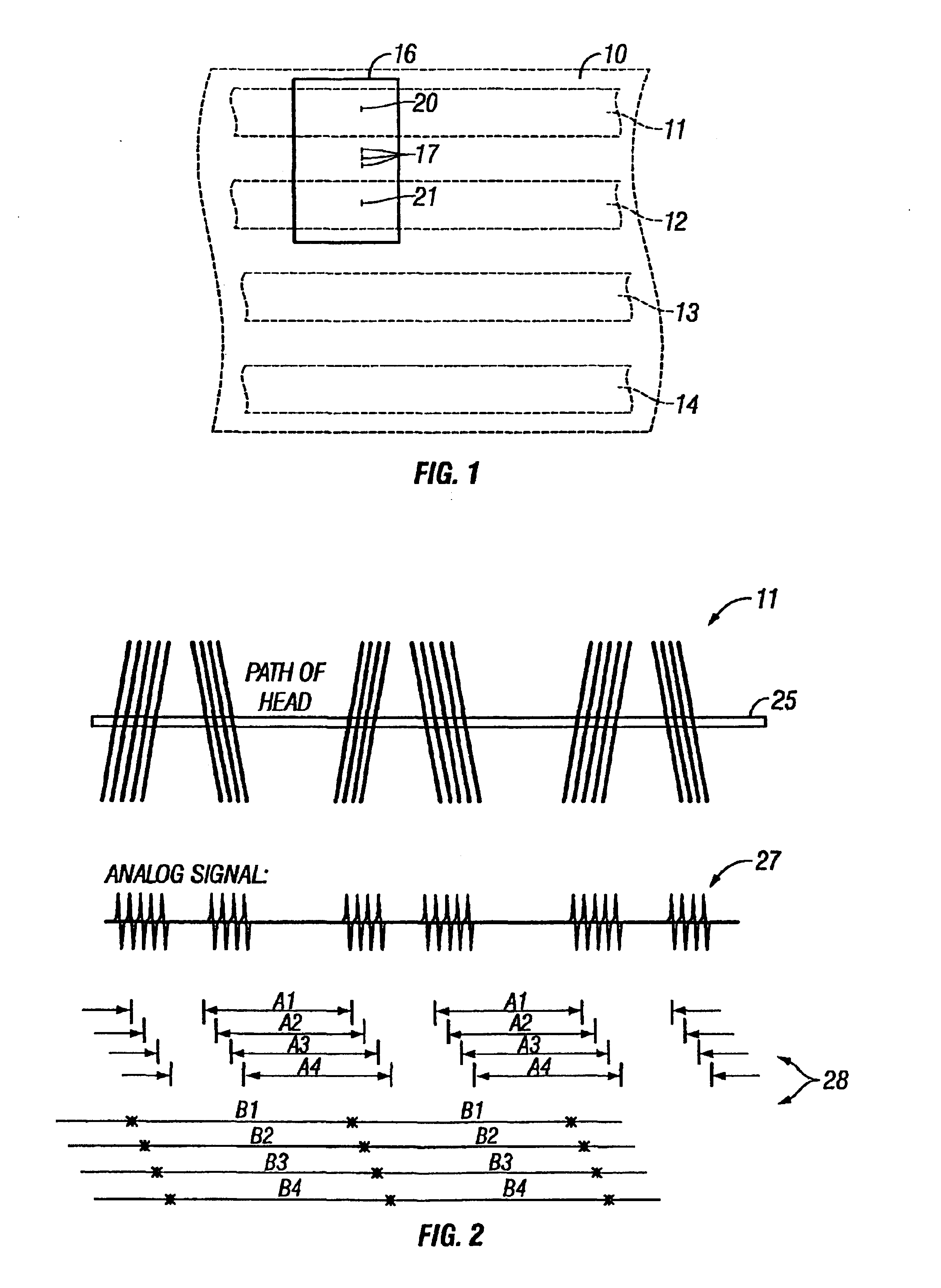

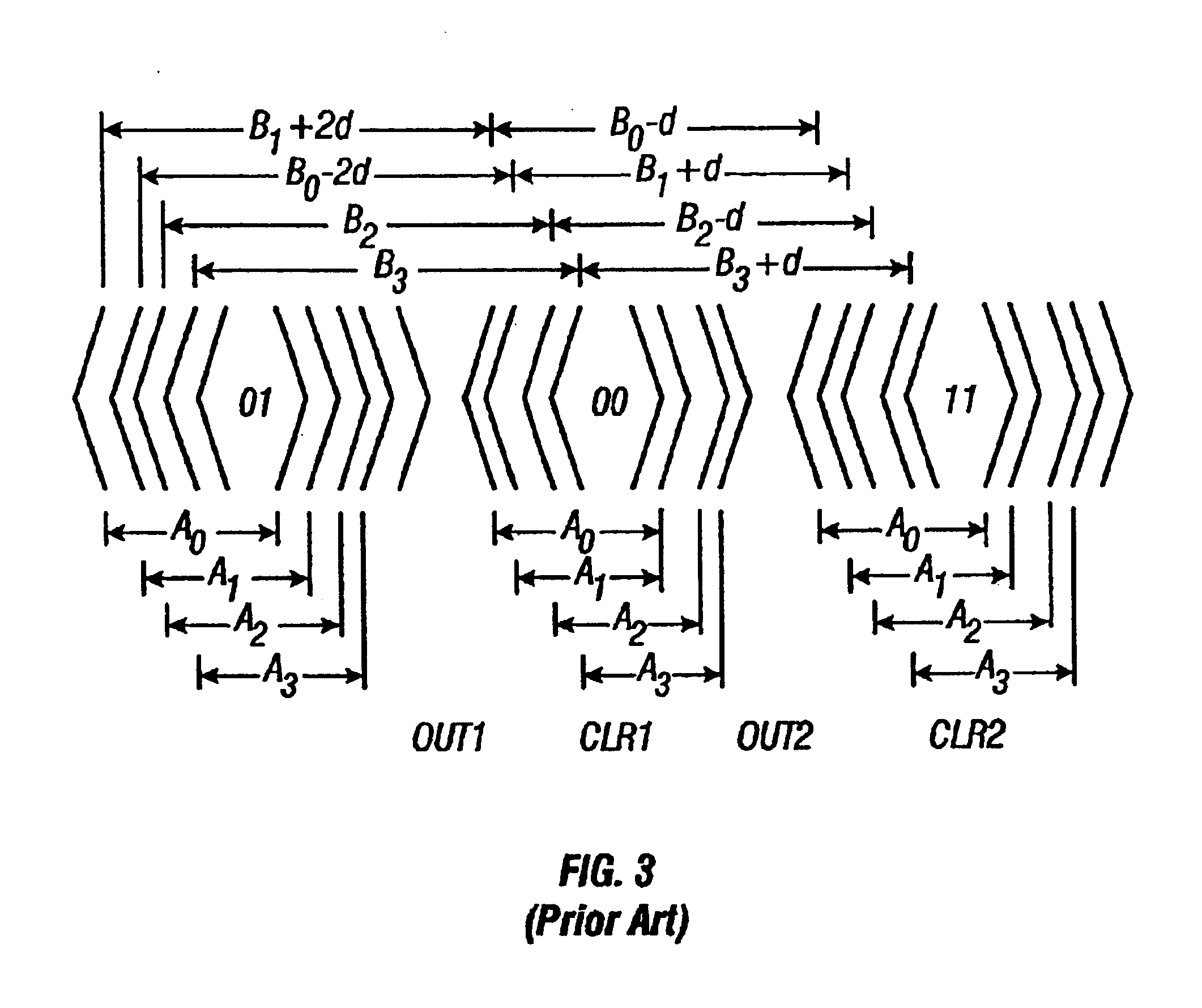

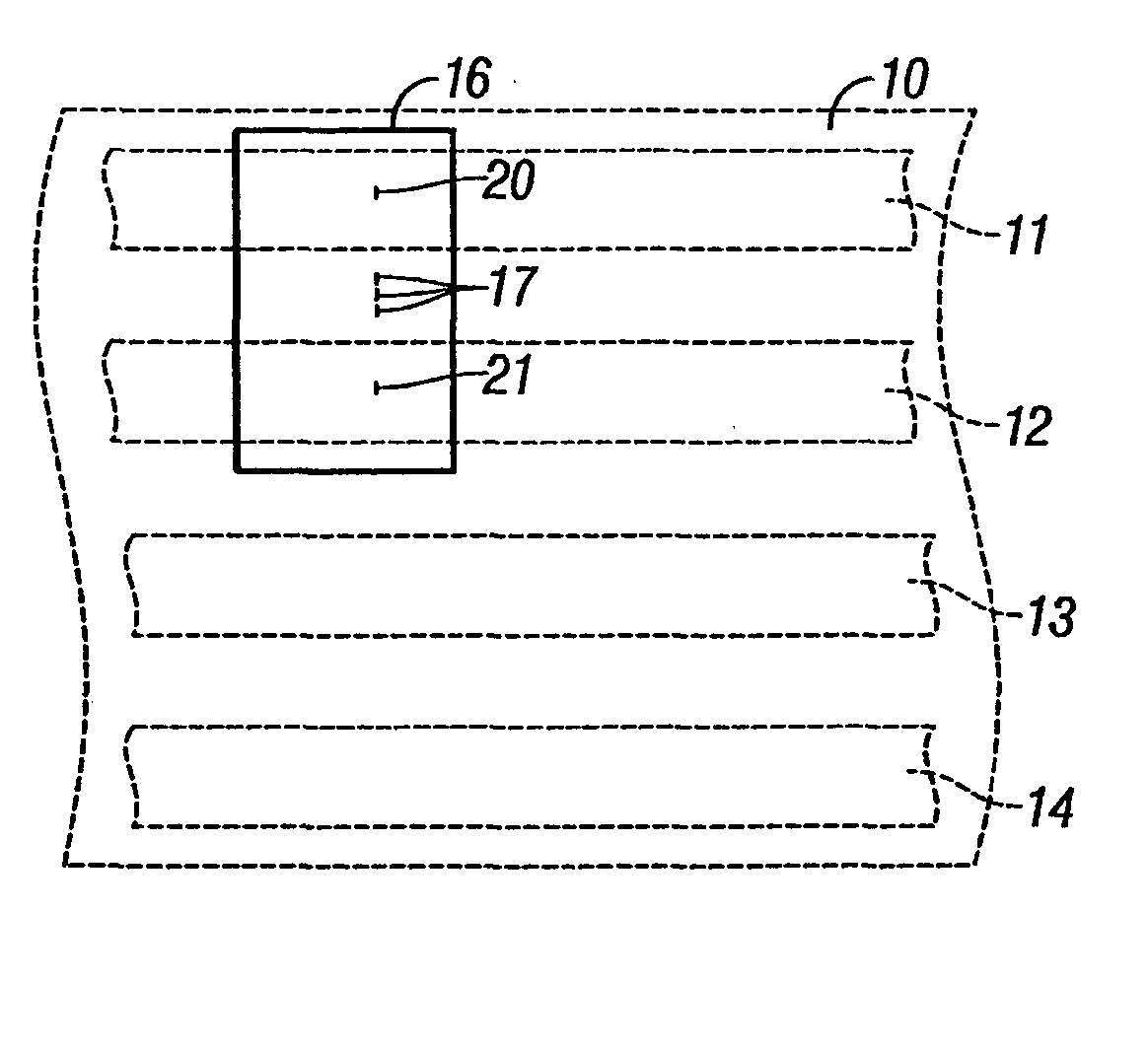

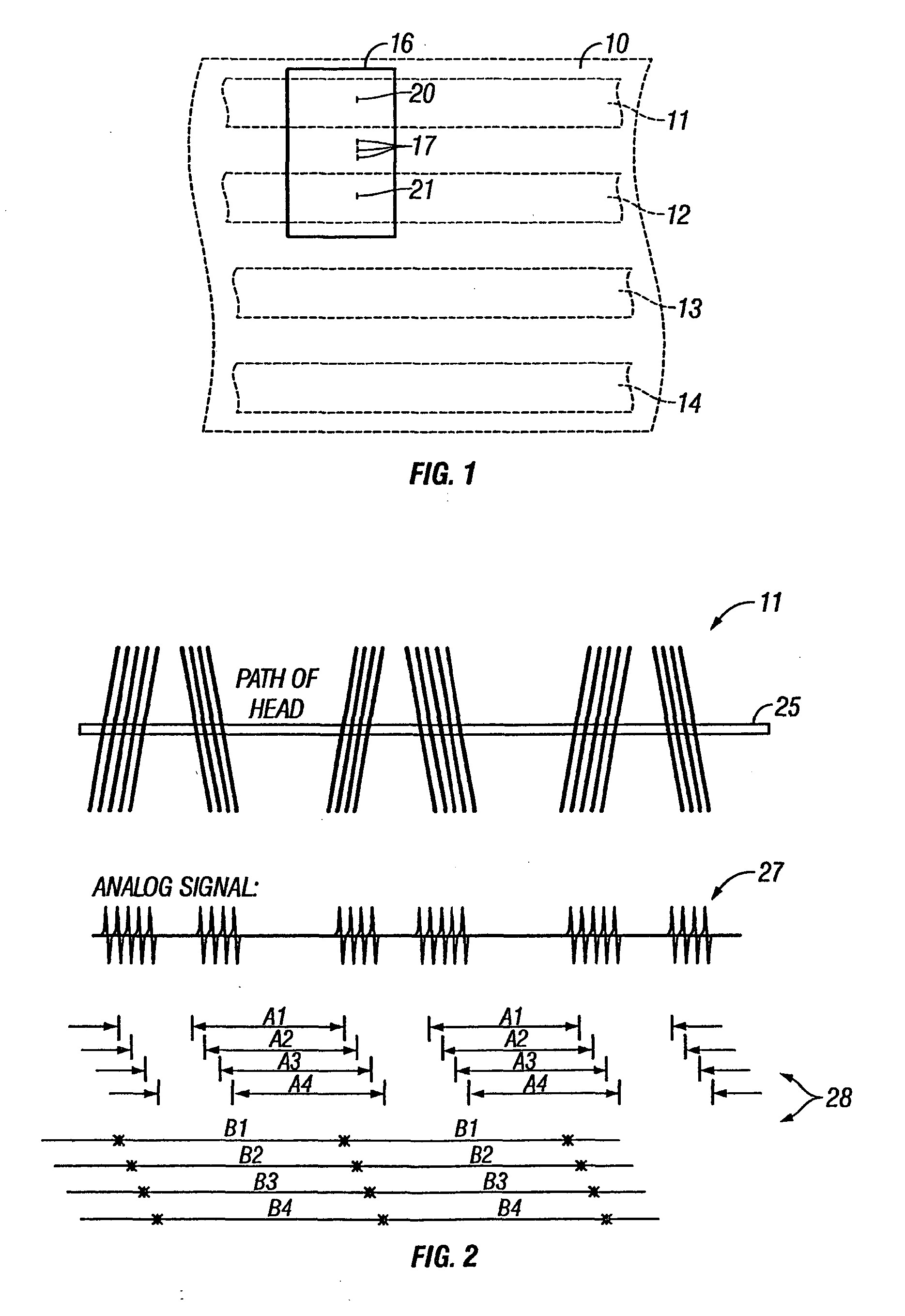

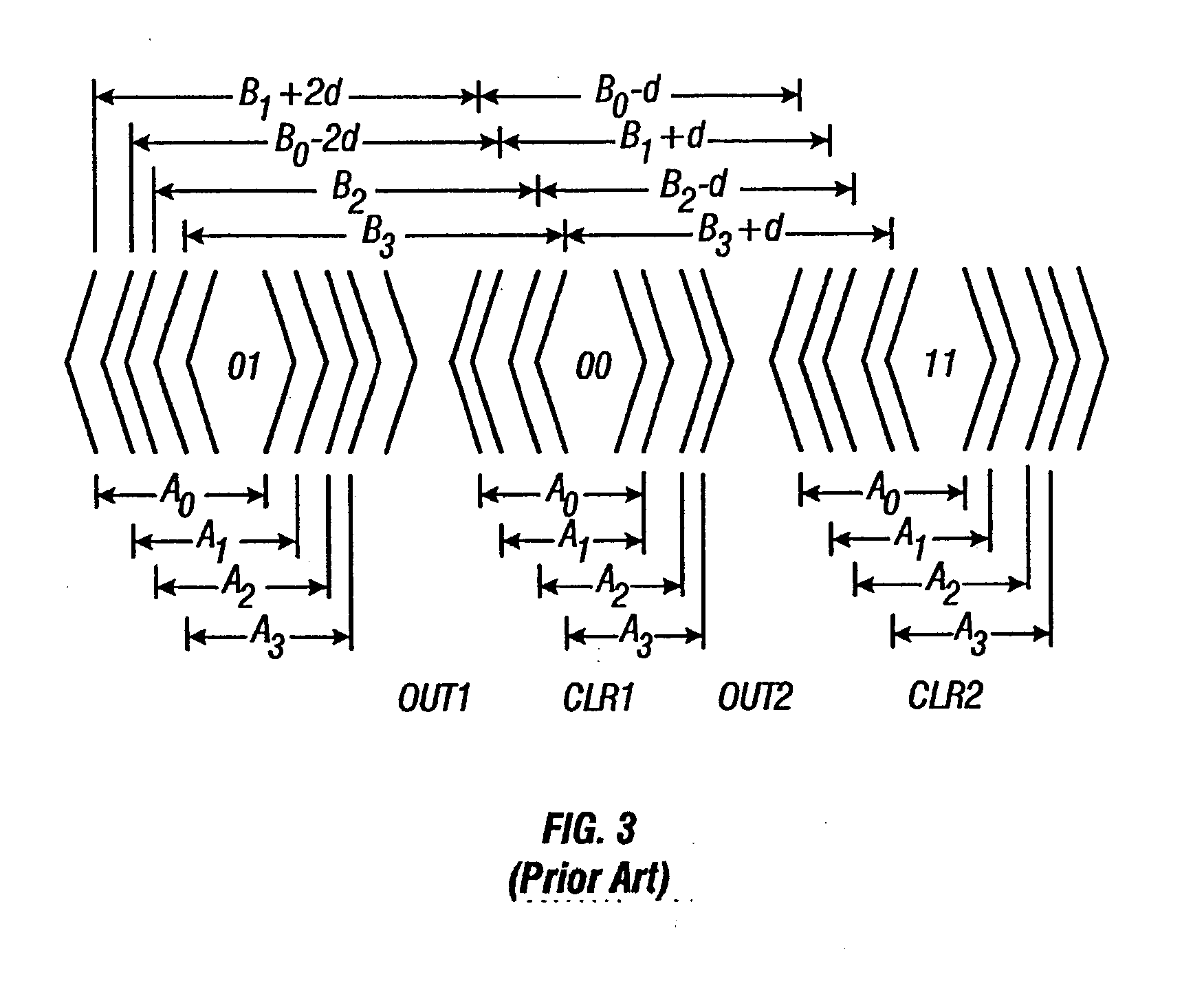

Tape servo information with superimposed data information providing servo band identification

InactiveUS6937413B2Driving/moving recording headsFilamentary/web record carriersData informationMagnetic tape

In magnetic tape having separate longitudinal servo bands of servo information with superimposed data information, the separate servo bands have selected different superimposed data information, to identify the separate servo bands for independent addressability. The servo information comprises non-parallel laterally extending transitions to indicate lateral positioning, and the selected different superimposed data information may comprise a lack thereof in portion(s) of the servo bands. Where the superimposed data information is longitudinal position information of the tape, the selected different superimposed data information may comprise different longitudinal position information of one or more servo band(s). The selected different superimposed data information may comprise a band identifier in the superimposed data information of one or more of the servo bands.

Owner:INT BUSINESS MASCH CORP

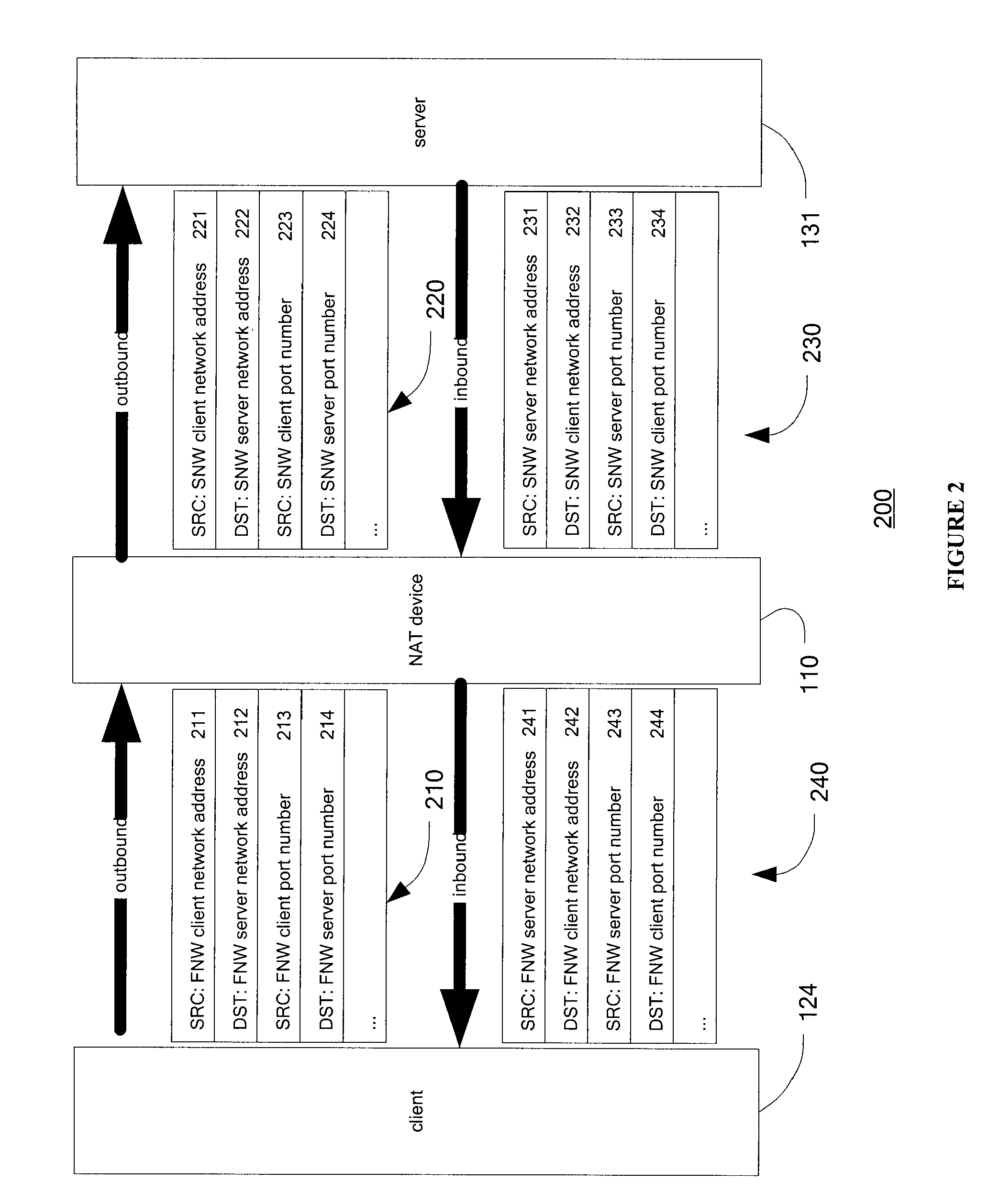

Method and apparatus for network port and network address translation

ActiveUS20120023257A1Multiple digital computer combinationsStore-and-forward switching systemsComputer networkNetwork address port translation

The present invention provides a method and apparatus for network port and network address translation. Several problems with limited addressability may occur when transmitting data packets between a terminal in a first network and a terminal in a second network that is outside the first network. Data forwarding rules are used to define if and how identifiers of data packets to be forwarded between the two networks correlate with each other. According to embodiments, a data forwarding rule includes a first identifier associated with the first network and a second identifier associated with the second network, wherein each identifier has two parts: a source address and source port number corresponding to a source network node, and a destination address and destination port number corresponding to a destination network node.

Owner:SEMTECH CORP

Tape servo information with superimposed data information providing servo band identification

ActiveUS20050030662A1Driving/moving recording headsFilamentary/web record carriersData informationMagnetic tape

In magnetic tape having separate longitudinal servo bands of servo information with superimposed data information, the separate servo bands have selected different superimposed data information, to identify the separate servo bands for independent addressability. The servo information comprises non-parallel laterally extending transitions to indicate lateral positioning, and the selected different superimposed data information may comprise a lack thereof in portion(s) of the servo bands. Where the superimposed data information is longitudinal position information of the tape, the selected different superimposed data information may comprise different longitudinal position information of one or more servo band(s). The selected different superimposed data information may comprise a band identifier in the superimposed data information of one or more of the servo bands.

Owner:IBM CORP

Method for decimation of images

InactiveUS20110087718A1Geometric image transformationPrinted circuit manufactureEngineeringCell size

In the case of printing at high addressability, where the cell size is smaller than the spot size, an image can be decimated in a manner that will limit the large accumulation of printed material. The proper decimation of the image will depend on the spot size, the physics of drop coalescence and the addressability during printing. A simple method of using concentric decimation is disclosed herein to enable this process.

Owner:PALO ALTO RES CENT INC

Systems and methods for using DNS records to provide targeted marketing services

Systems and methods can include collecting addressability information about users accessing a service provider's IP-based network communication services, collecting information sufficient to identify when the user is accessing the service provider's IP-based network communication services, collecting the domain names accessed by the user and using the collected information to associate the user with certain marketing content. The systems and methods can further include sending the marketing content to the user through various distribution channels by using the addressability information. The systems and methods can further include recording the collected information over time to refine the ability or predict the user's receptiveness to certain marketing content so as to improve the effectiveness of TMS.

Owner:VERIZON PATENT & LICENSING INC

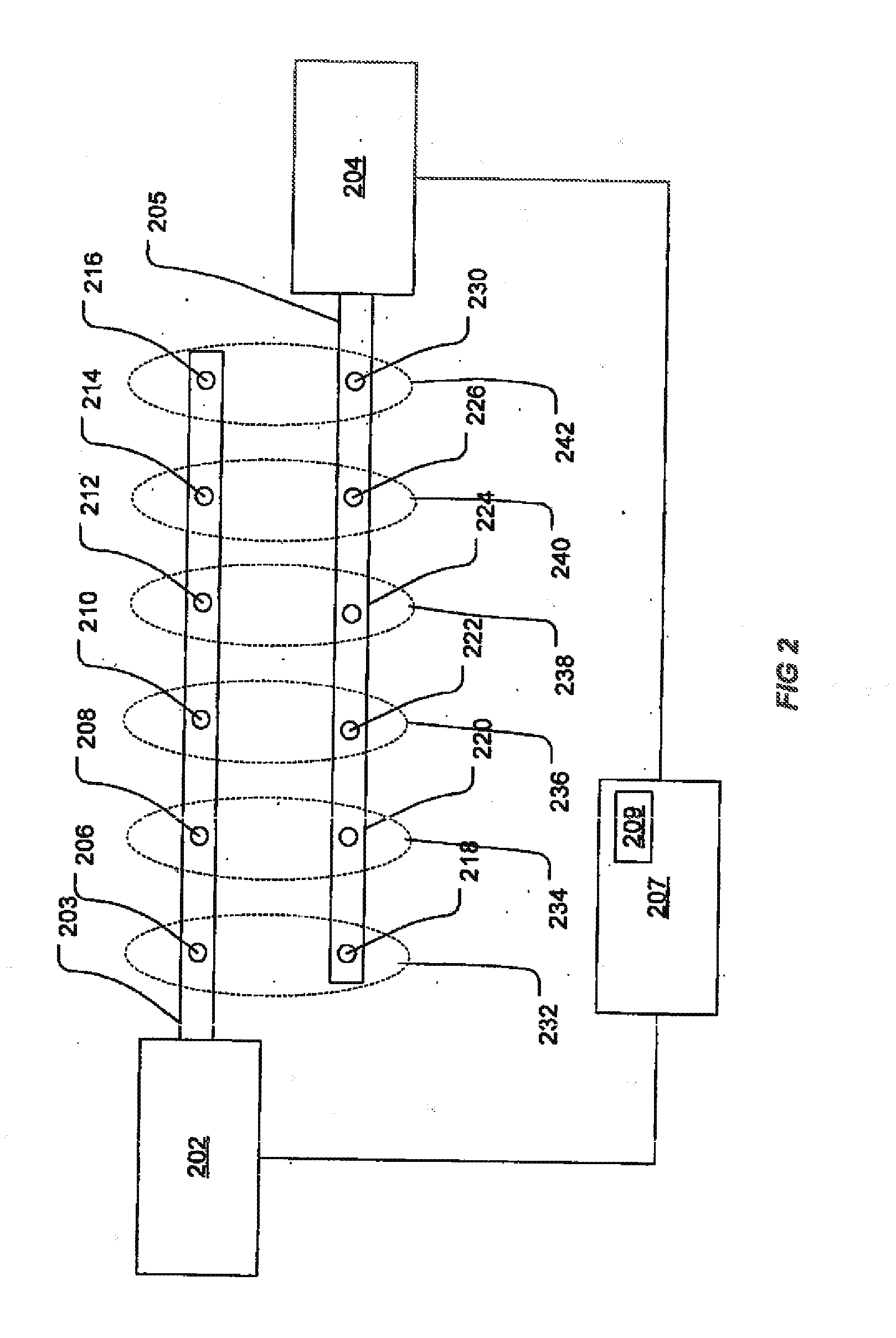

Addressability in particle detection

ActiveUS20150253165A1Minimize complexityReduce ambiguityAnalysing fluids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesAir sampleEngineering

A method of determining at least one point of entry of smoke into a smoke detection system, the system having a sampling pipe network including at least one sampling pipe and a plurality of sampling inlets through which an air sample can enter the at least one sampling pipe of the smoke detection system for analysis by a particle detector, said method including: determining a volume of sample air that has passed through at least part of the smoke detection system since a predetermined event or a value corresponding to said volume; and determining through which sampling inlet of the plurality of sampling inlets the smoke entered the smoke detection system based, at least in part, on the determined volume or value. Systems for implementing such a method and related methods are also described.

Owner:GARRETT THERMAL SYST LTD

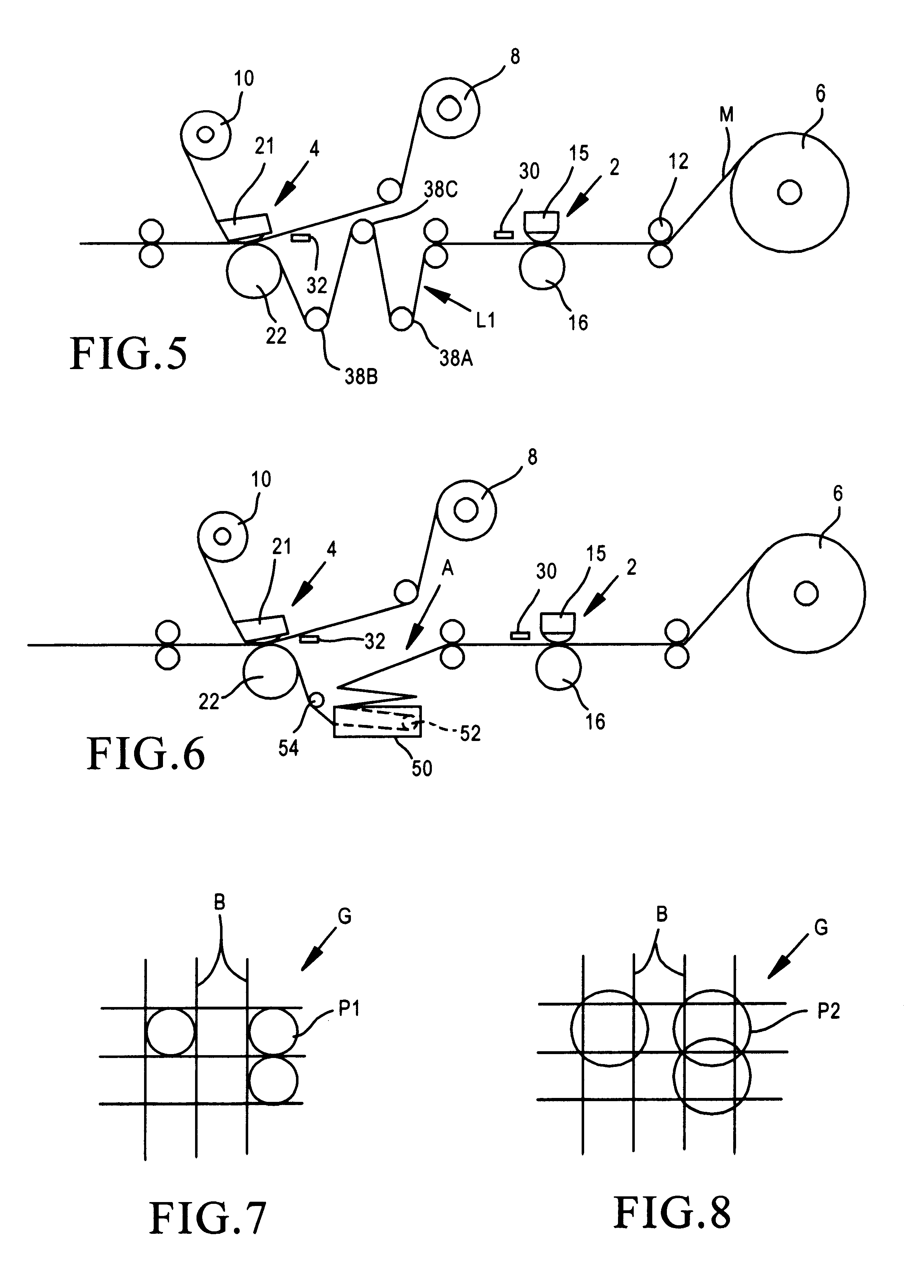

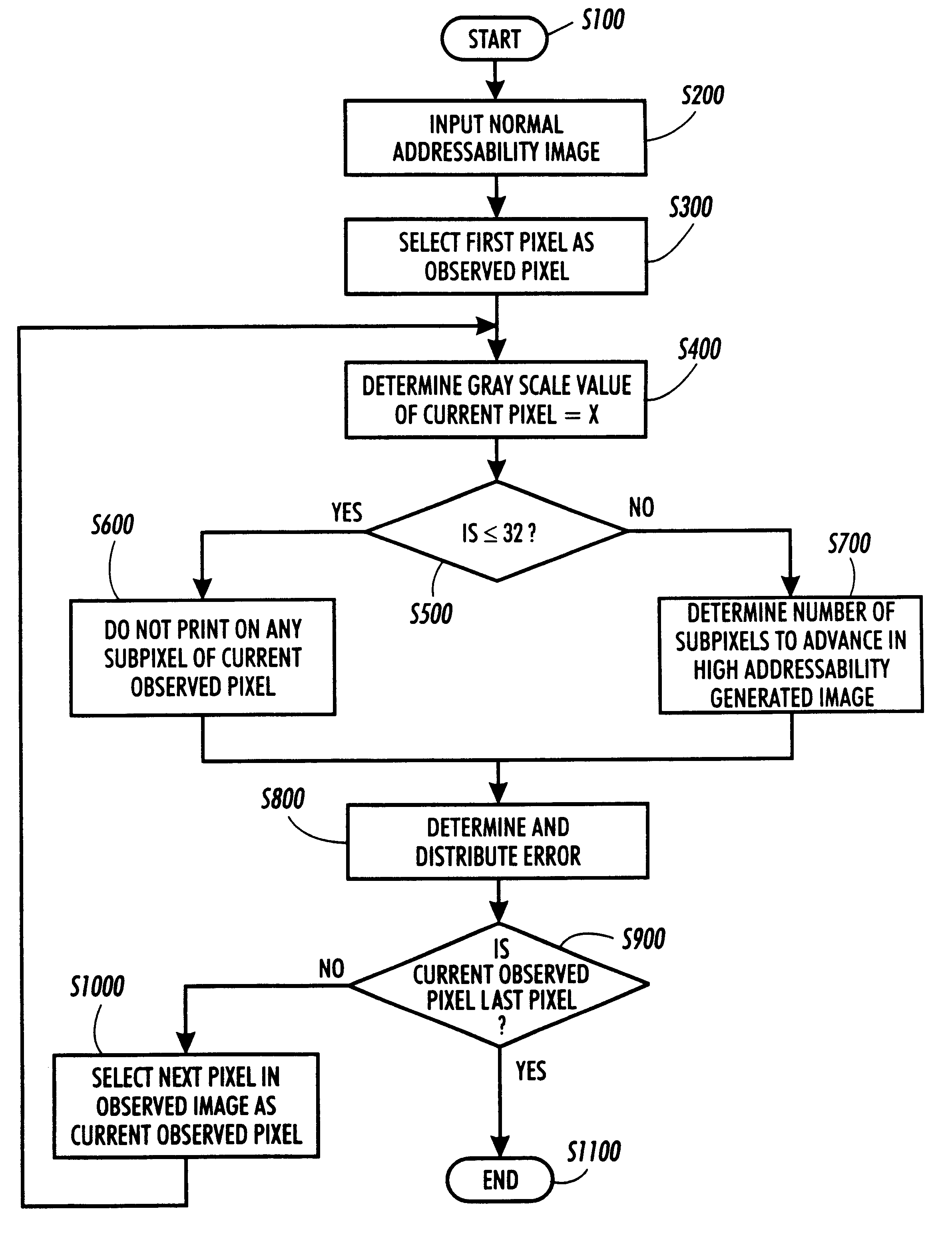

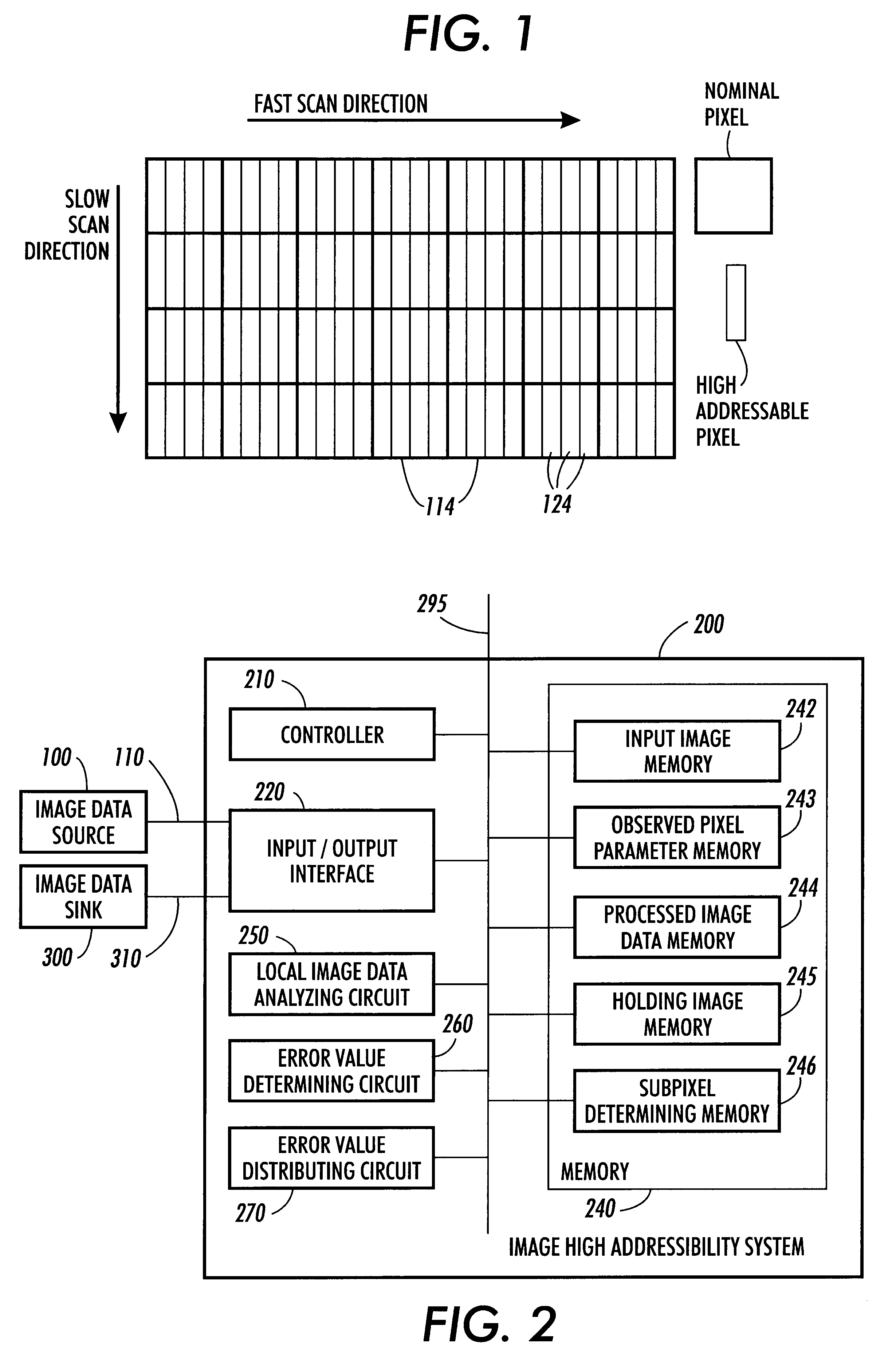

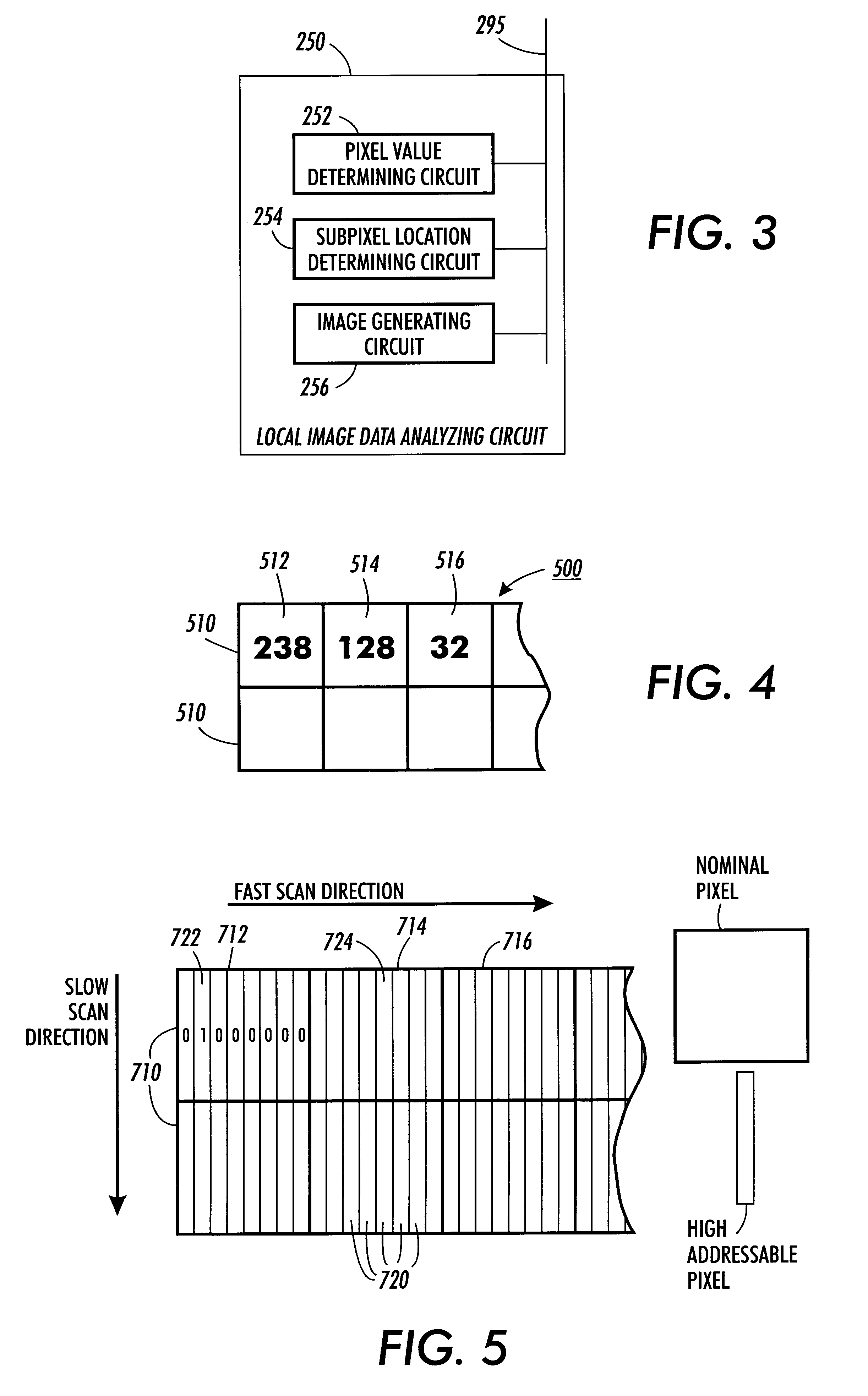

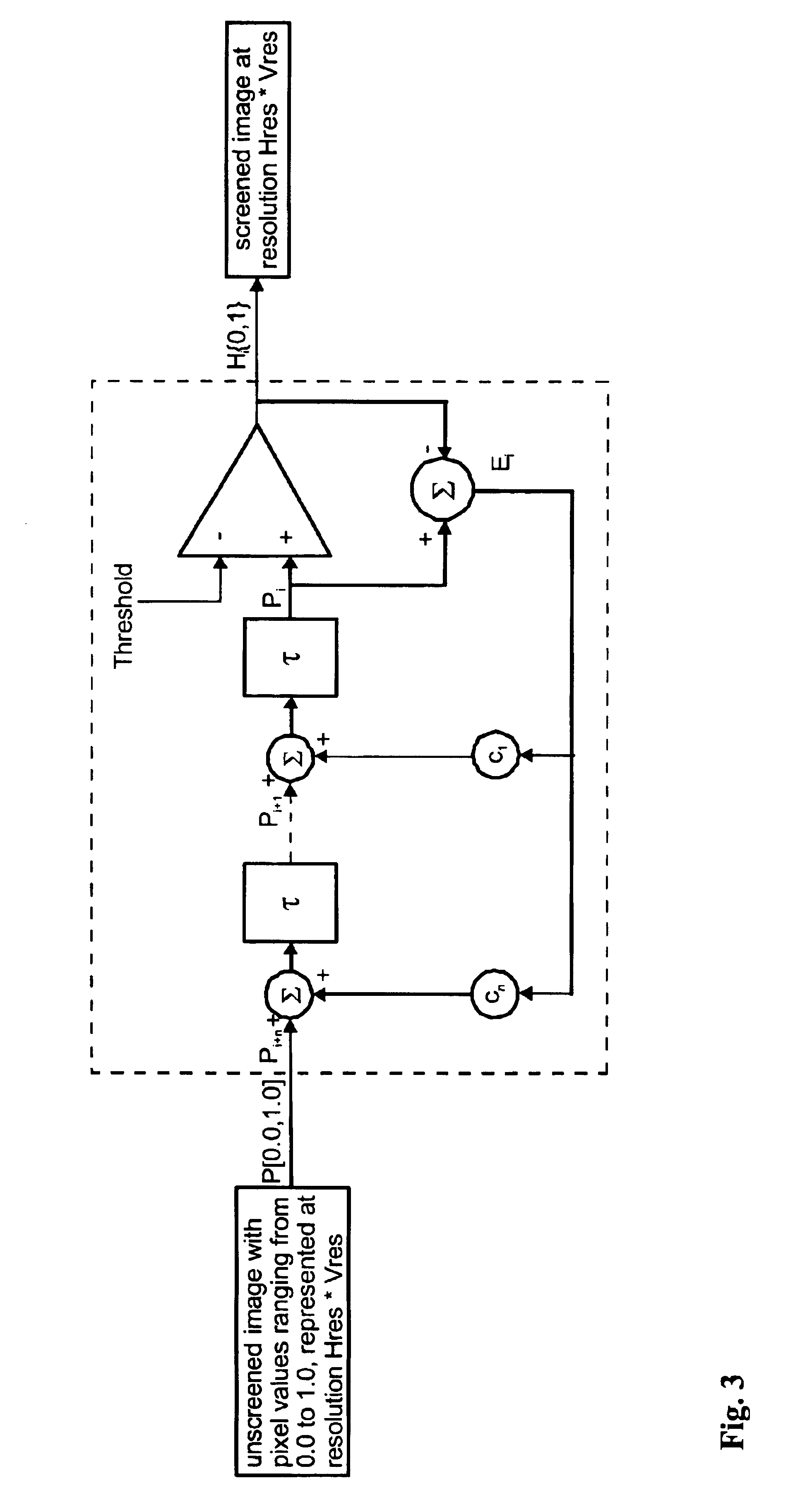

Systems and methods for generating high addressability images

InactiveUS6325487B1Image enhancementDigitally marking record carriersPattern recognitionComputer graphics (images)

Image systems and methods generate improved high addressability images. The generated image may be input into a printer for printing. An image is processed so that the location of an ink drop in a high addressability image is determined. The location of a printed subpixel, within a pixel, is determined by the magnitude of the grayscale value of an observed pixel, the magnitude of the error that has been previously accumulated, and a predetermined threshold value. The grayscale value of the observed pixel, accumulated error, and threshold value are used to determine a subpixel value. This subpixel value determines how soon another subpixel is fired after a previously fired subpixel. If the subpixel value is low, then another subpixel will be fired relatively soon after the previously fired subpixel. If the subpixel value is high, then the printer will wait a longer time before firing another subpixel. In other words the lower the subpixel value the sooner another subpixel prints. The image generating process may effectively weight the error on neighboring pixels to effectively generate images having both shadow and highlight regions.

Owner:XEROX CORP

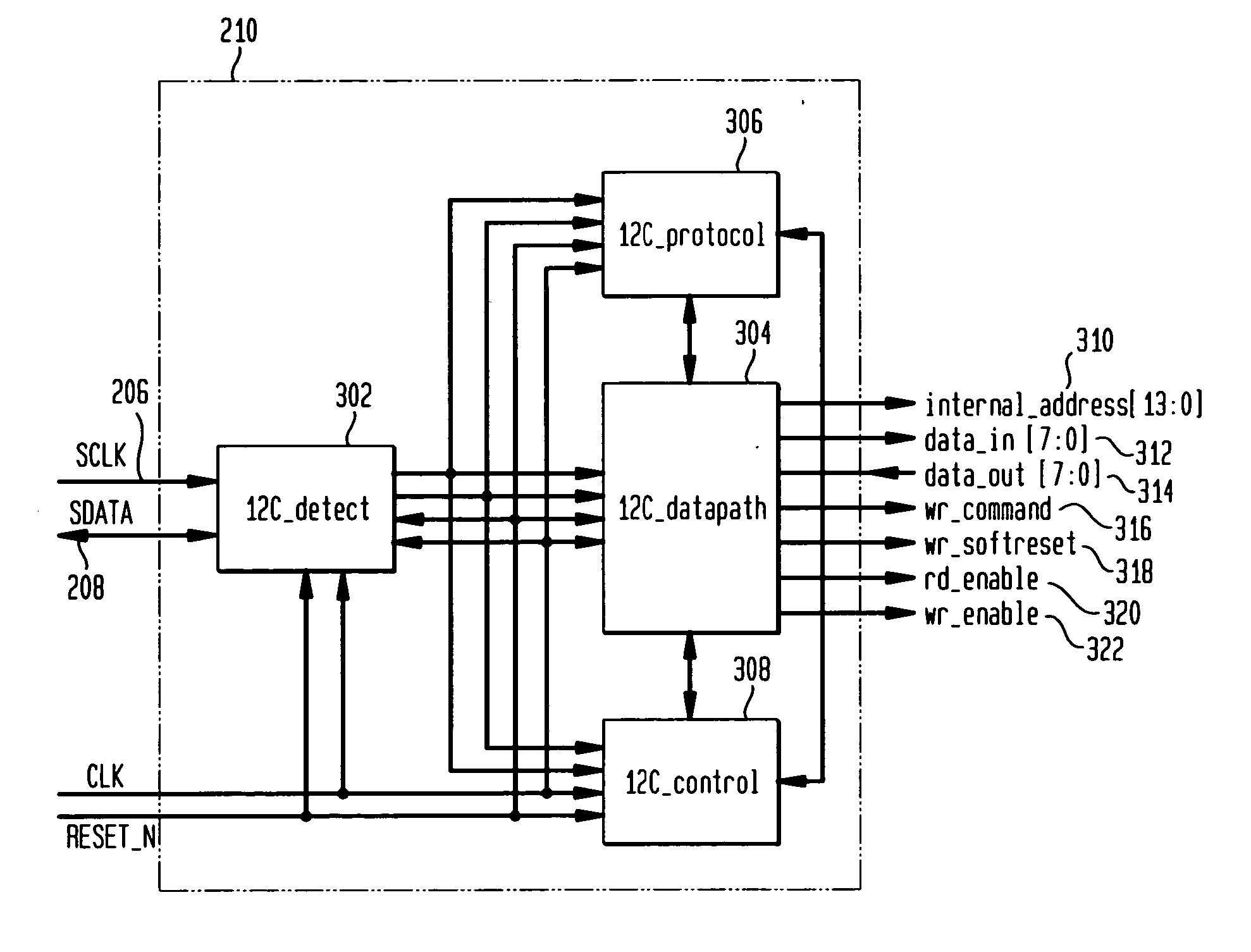

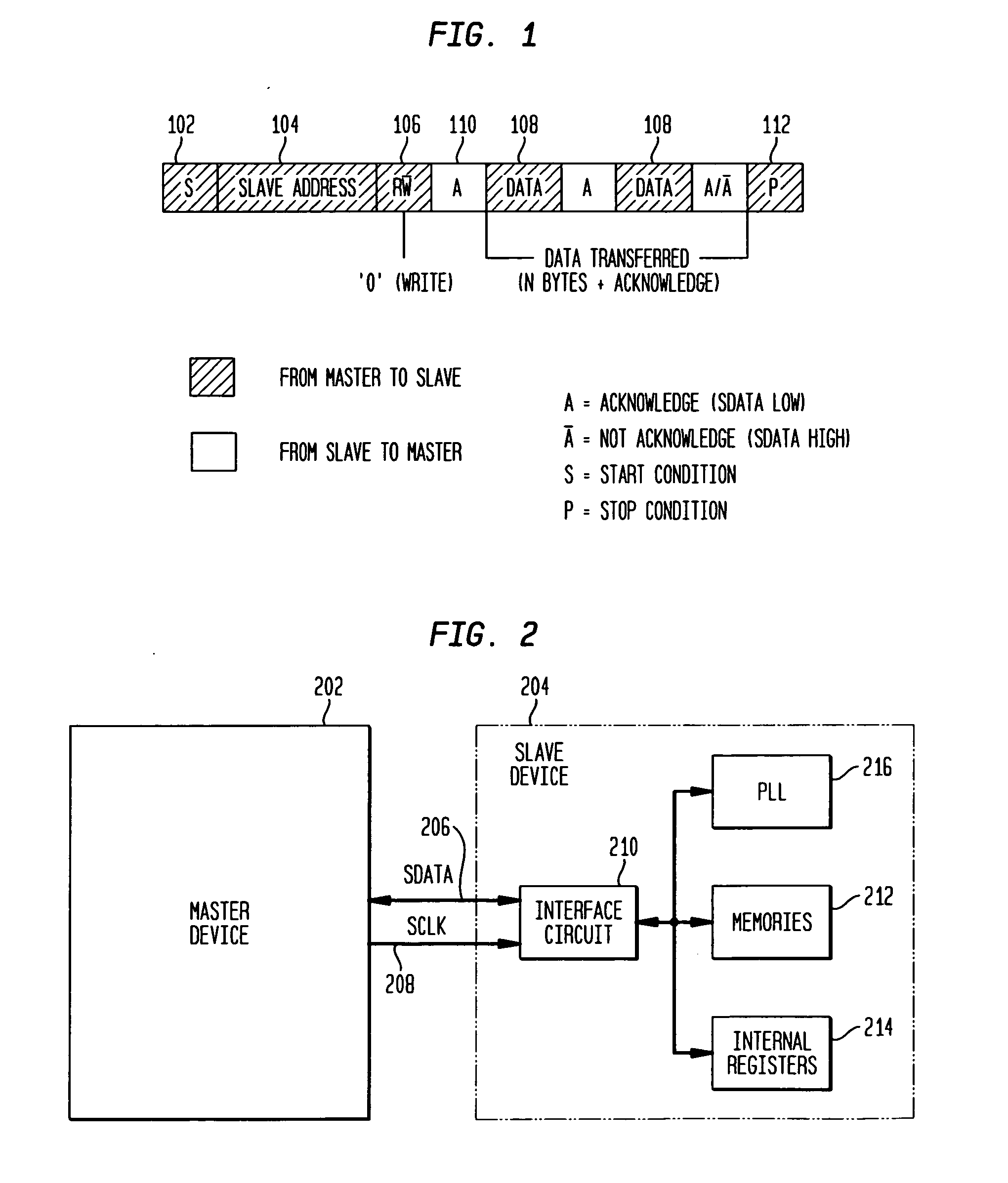

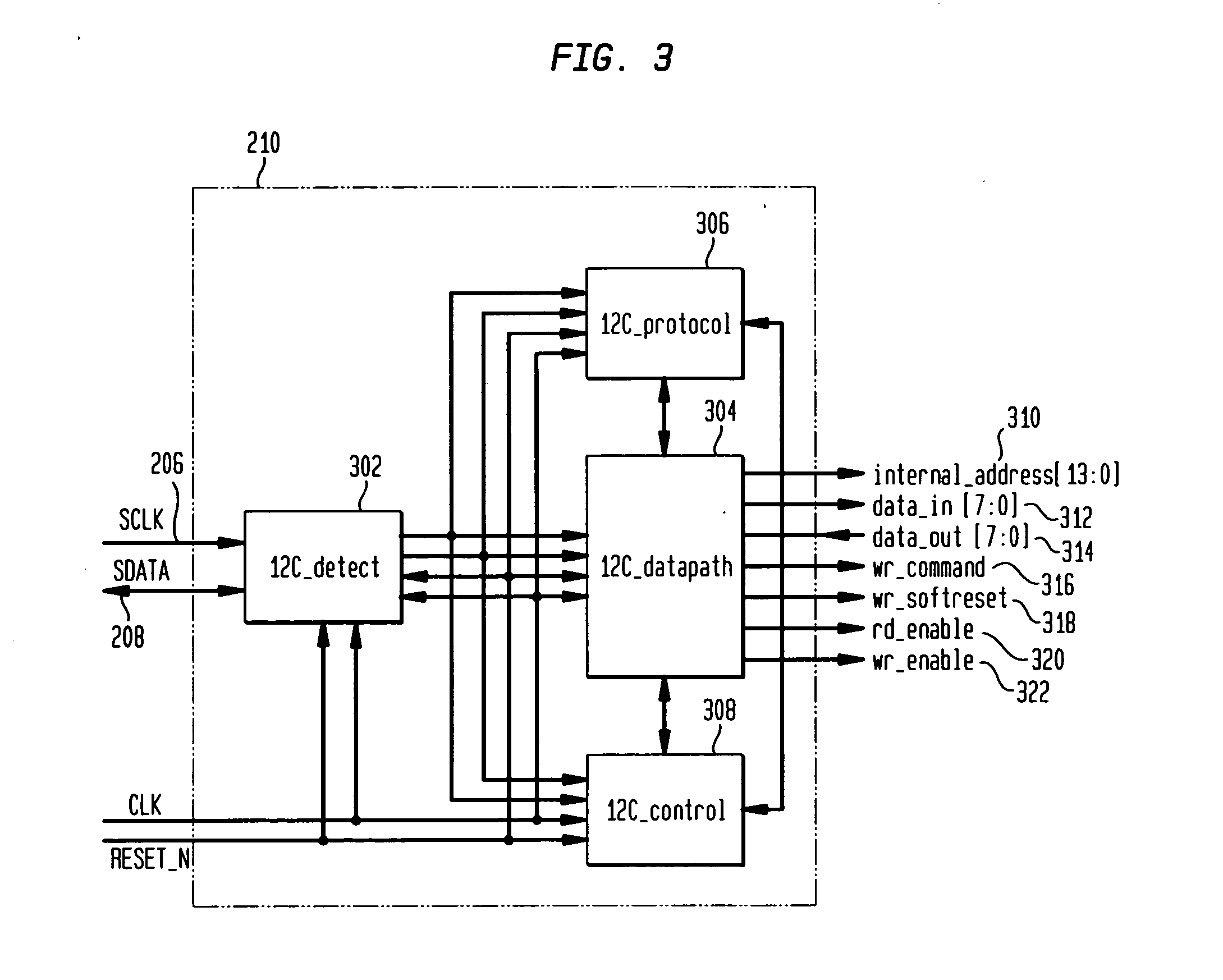

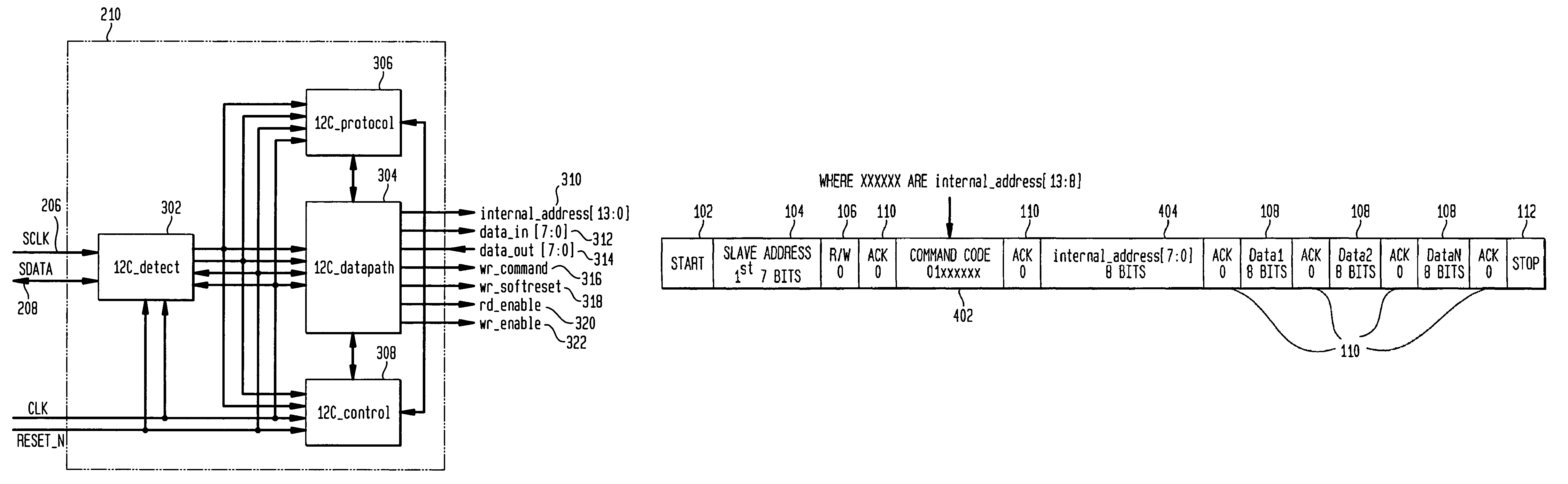

Method and apparatus for providing an inter integrated circuit interface with an expanded address range and efficient priority-based data throughput

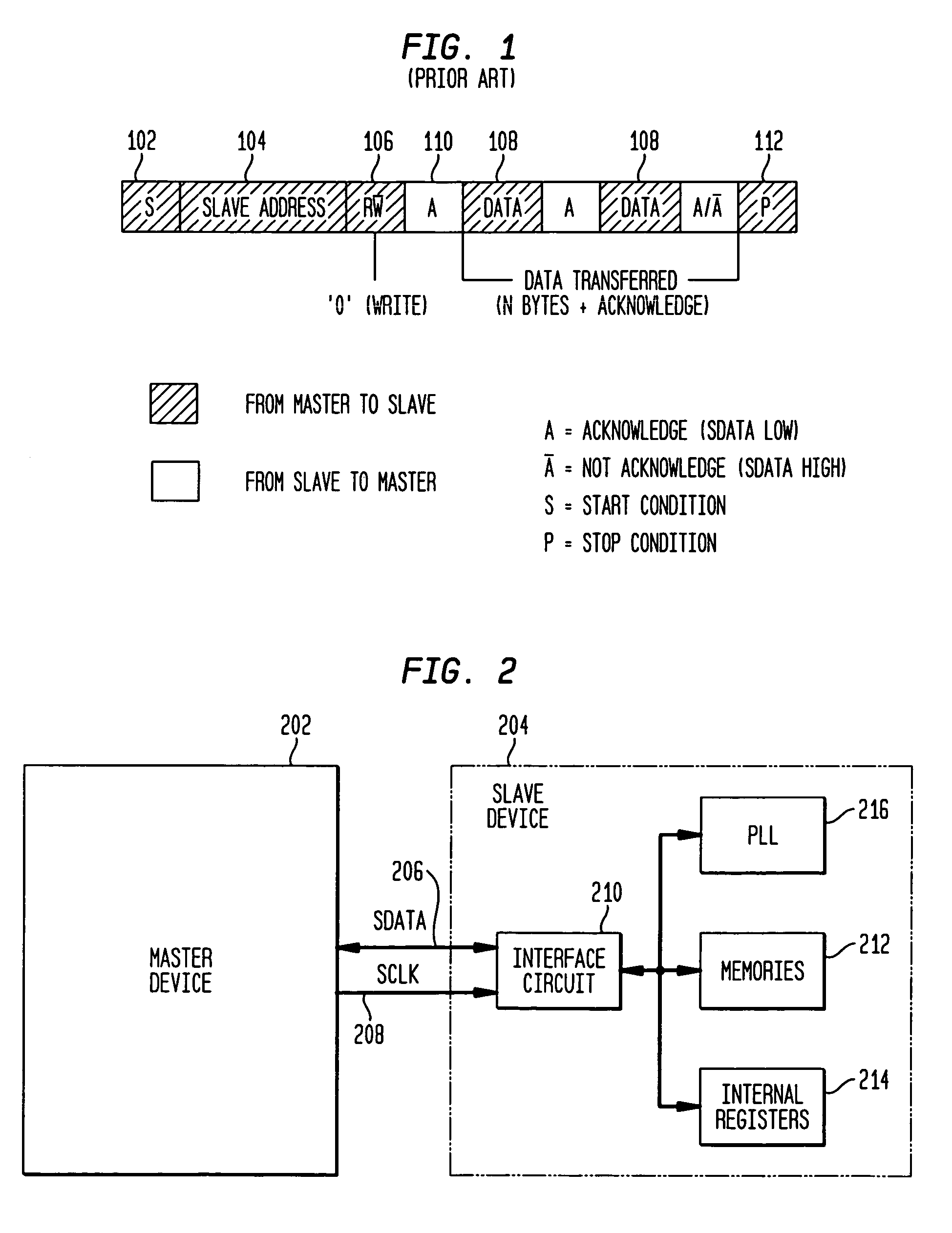

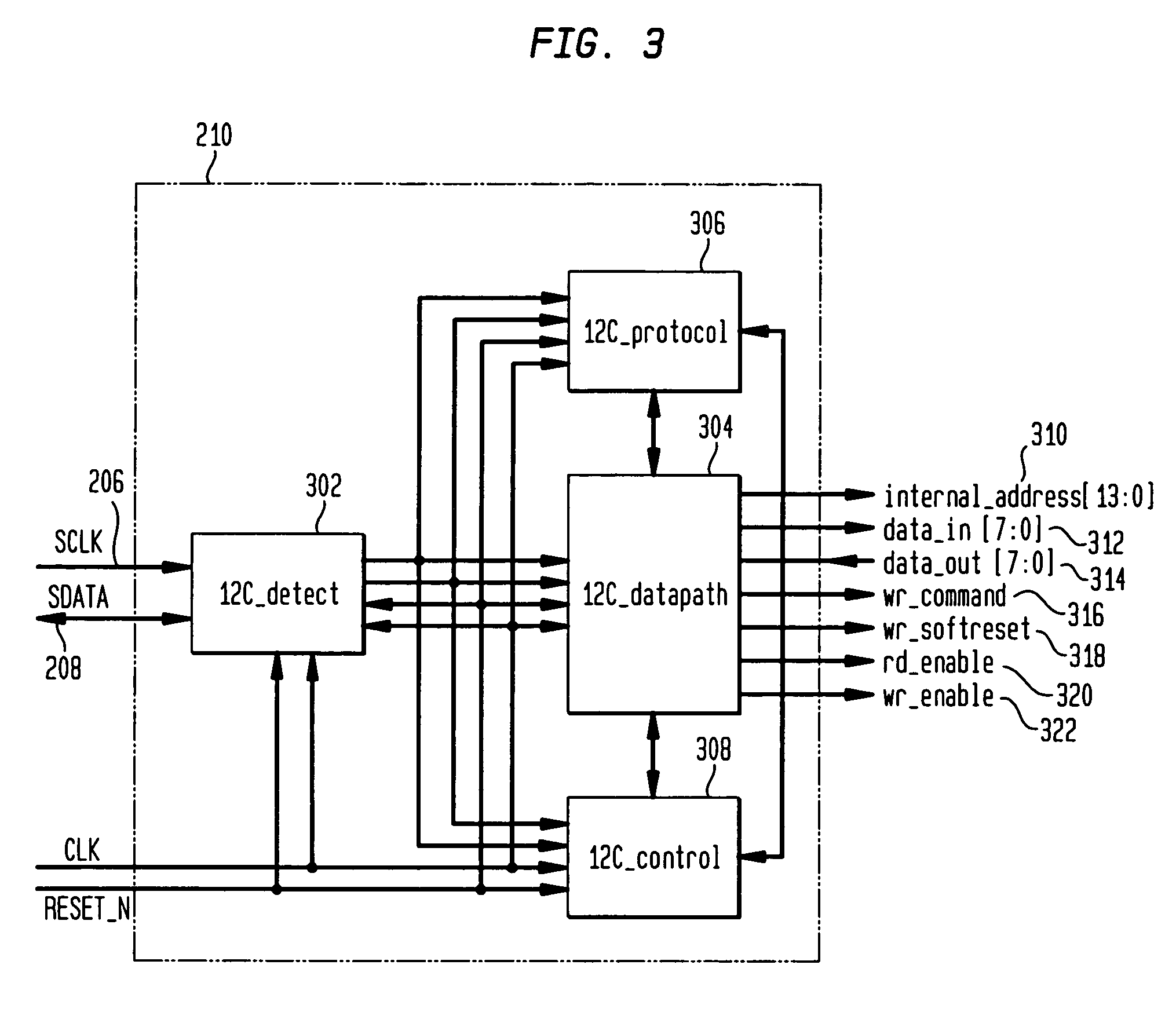

A method and apparatus implementing an enhanced protocol between an I2C master and an I2C slave. In various embodiments the invention permits greater addressability space and high priority access to the slave device. The enhanced protocol is implemented by the addition of command code data being transmitted which is recognized through an interface circuit inside the slave device. The invention provides an I2C solution for accessing high priority address space with one command byte, medium priority space with two command bytes and low priority space with three command bytes.

Owner:AVAGO TECH INT SALES PTE LTD

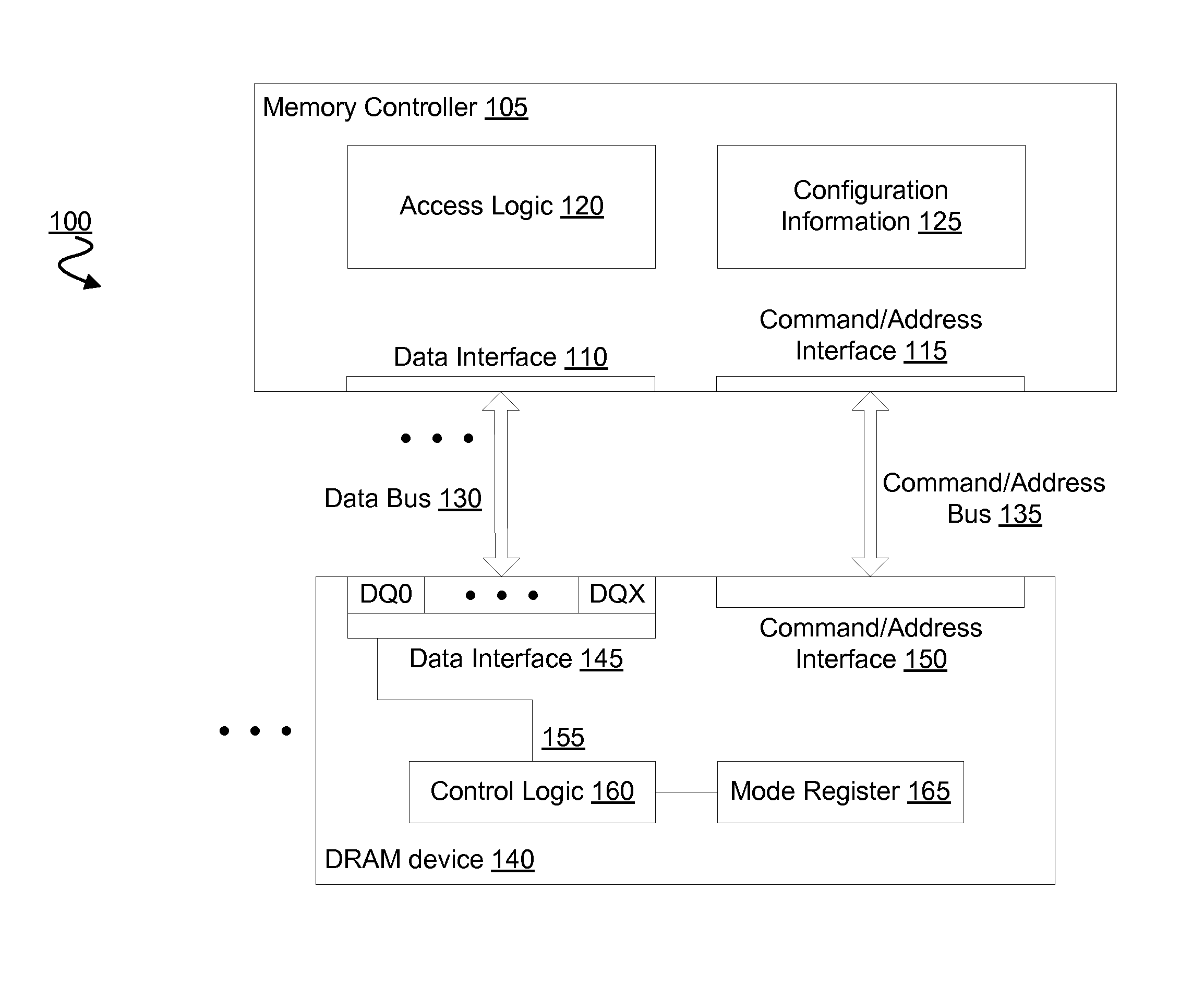

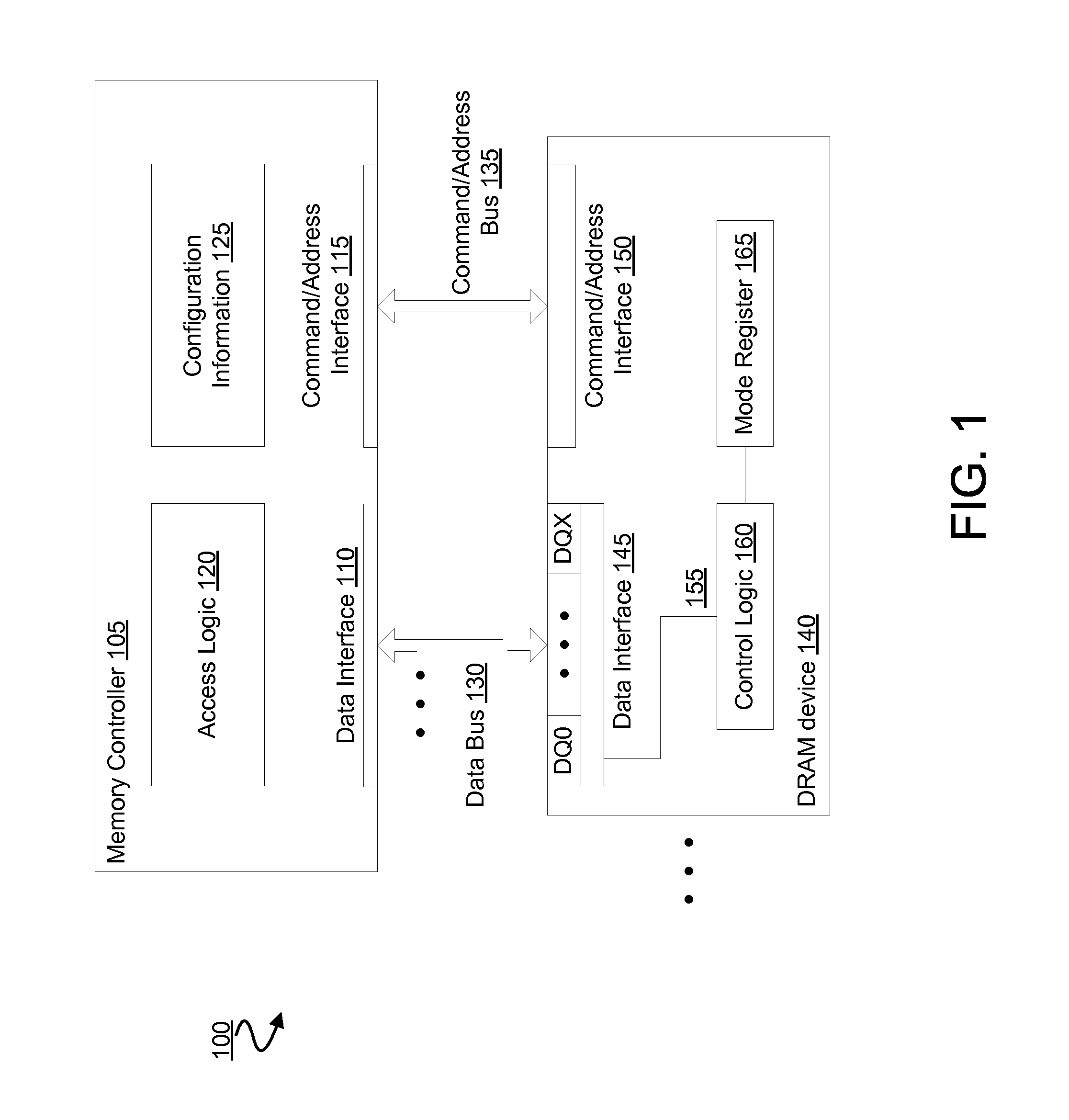

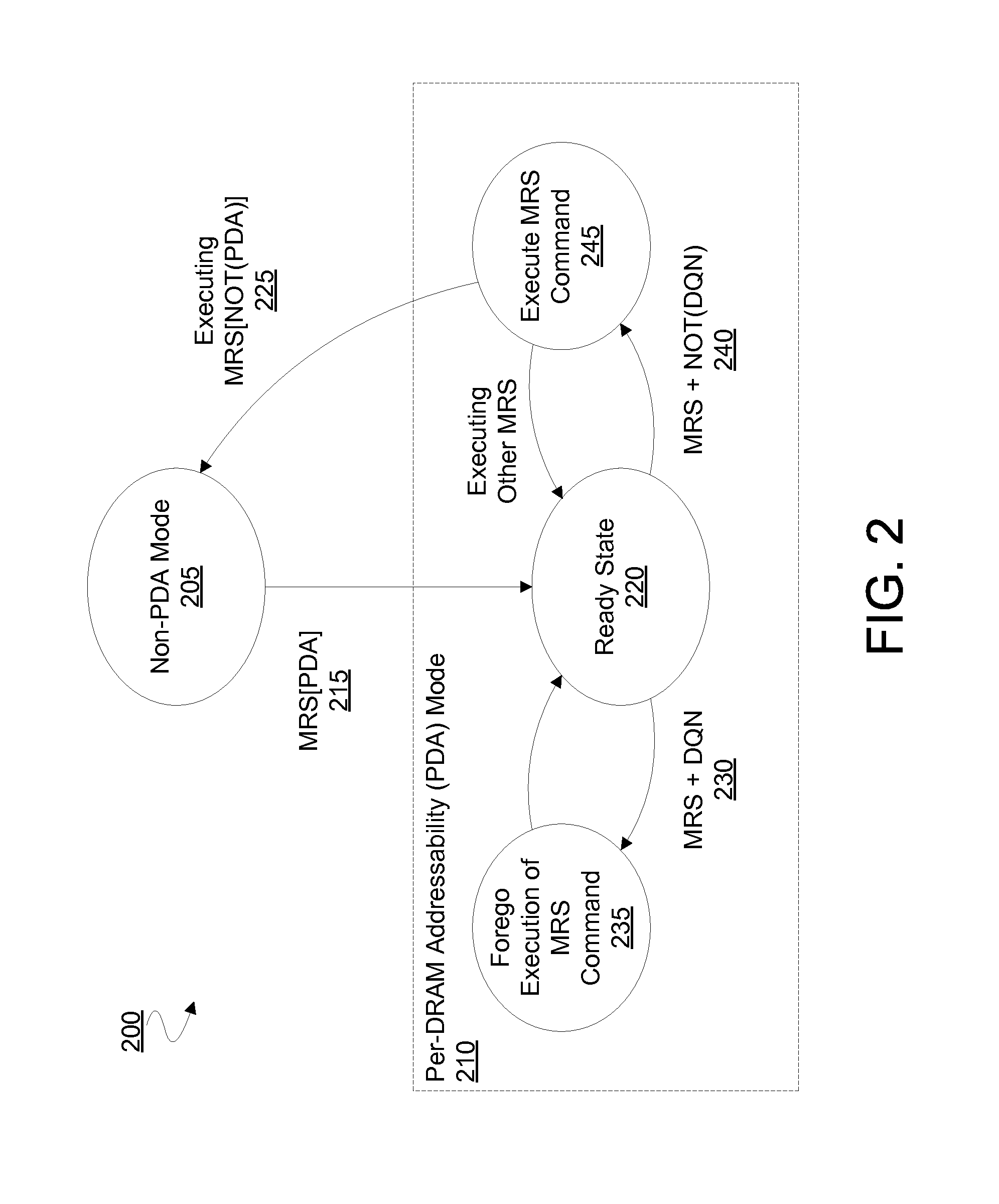

Method, apparatus and system for a per-dram addressability mode

Techniques and mechanisms for programming an operation mode of a dynamic random access memory (DRAM) device. In an embodiment, a memory controller stores a value in a mode register of a DRAM device, the value specifying whether a per-DRAM addressability (PDA) mode of the DRAM device is enabled. An external contact of the DRAM device is coupled to the memory controller device via a signal line of a data bus. In another embodiment, the memory controller sends a signal to the external contact while the PDA mode of the DRAM device is enabled, the signal to specify whether one or more features of the DRAM device are programmable.

Owner:INTEL CORP

Systems and methods for using video services records to provide targeted marketing services

InactiveUS20080281697A1AdvertisementsSelective content distributionService provisionNetwork communication

Systems and methods can include collecting addressability information about users accessing a service provider's IP-based network communication services, collecting information sufficient to identify when the user is accessing the service provider's IP-based network communication services, collecting data from video services usage by the user and using the collected data to associate the user with certain marketing content. The systems and methods can further include sending the marketing content to the user through various distribution channels by using the addressability information. The systems and methods can further include recording the collected information over time to refine the ability o predict the user's receptiveness to certain marketing content so as to improve the effectiveness of TMS.

Owner:VERIZON PATENT & LICENSING INC

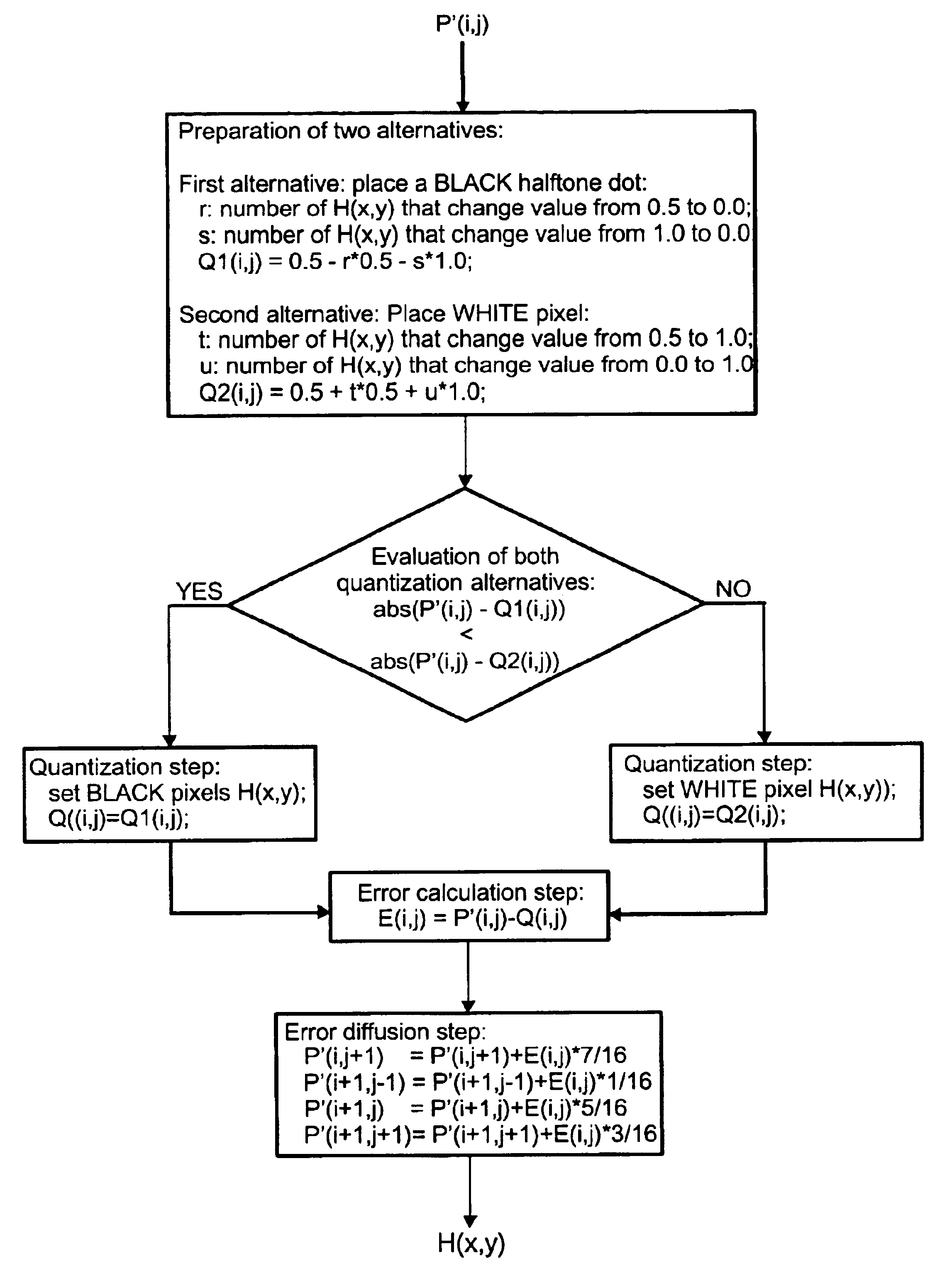

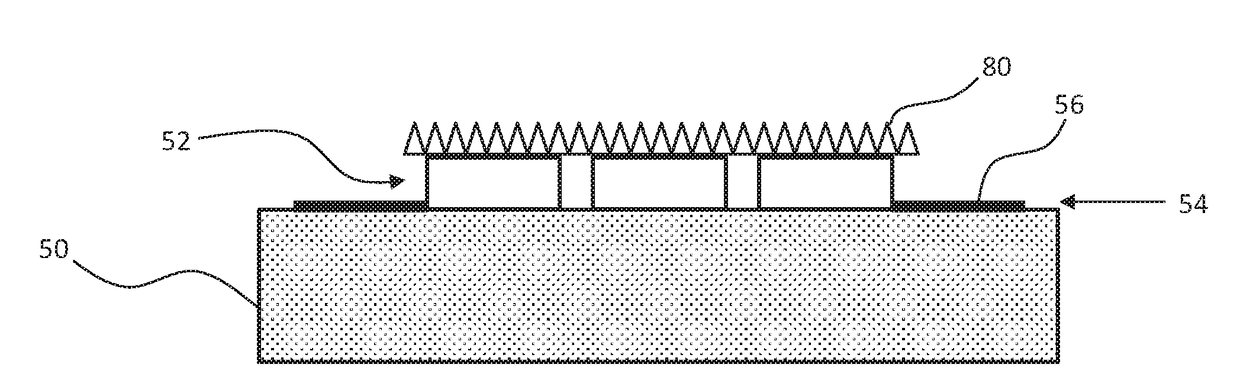

Sub-dot phase modulation for computer to plate inkjet system

ActiveUS6962400B2Apparent advantagePlate printingVisual presentationComputer to plateError diffusion

Printing masters are produced by use of an inkjet printing system.The smallest halftone dot size which can be printed by the inkjet printing system is larger than the size of a pixel of the recording grid defined by the addressability of the printing device.The error diffusion algorithm is especially adapted to make use of the high addressability of the recording system.Using a sub-dot phase modulated error diffusion halftoning algorithm allows for the distance between the halftone dots to be modulated in much smaller increments than the size of the halftone dots themselves.Results can be further improved by dynamically influencing the threshold value in the error diffusion algorithm in accordance with previous output quantisation determinations.Variable coverage percentage of the pixels can be taken into account.The method can be extended to multilevel systems.

Owner:AGFA OFFSET BV

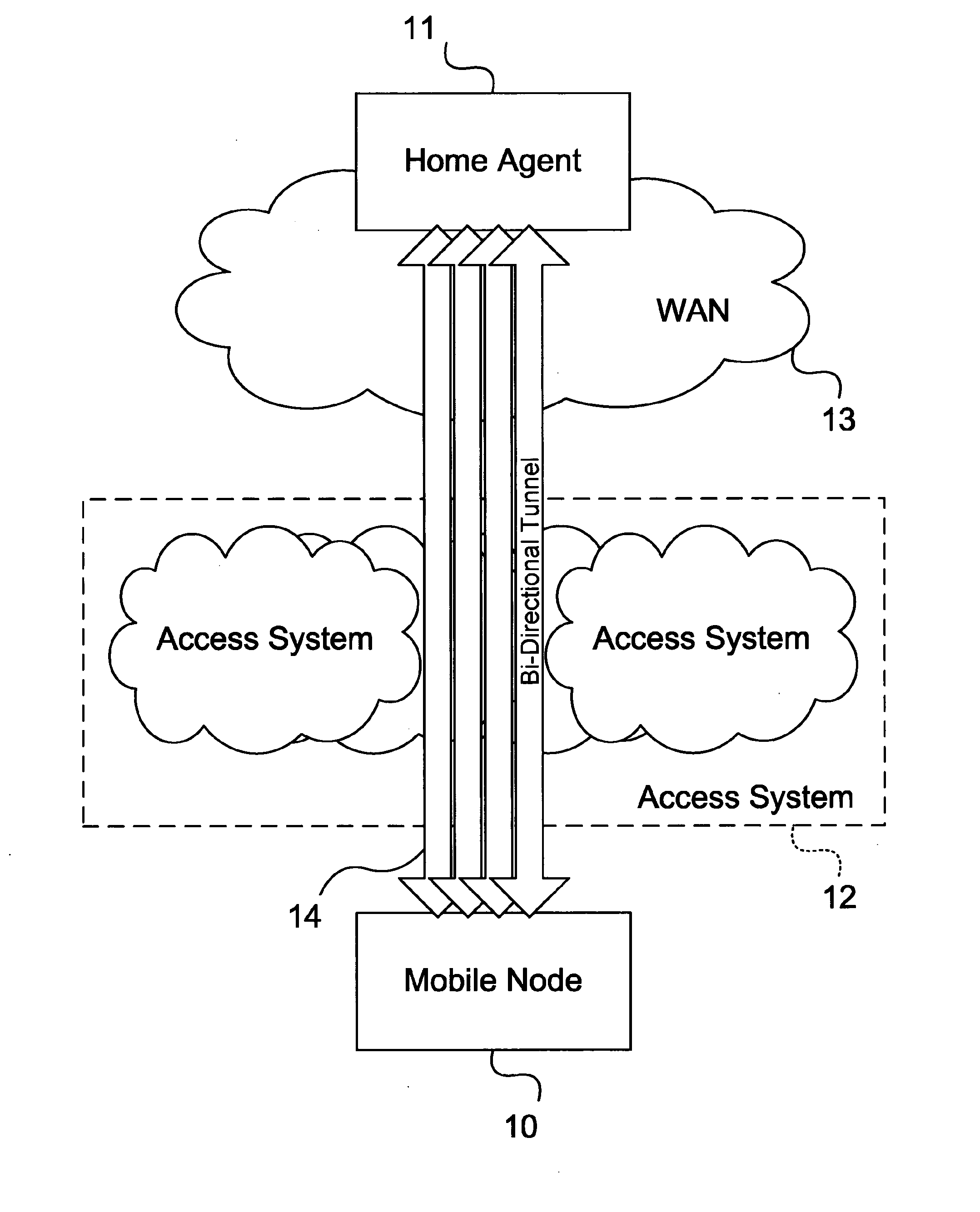

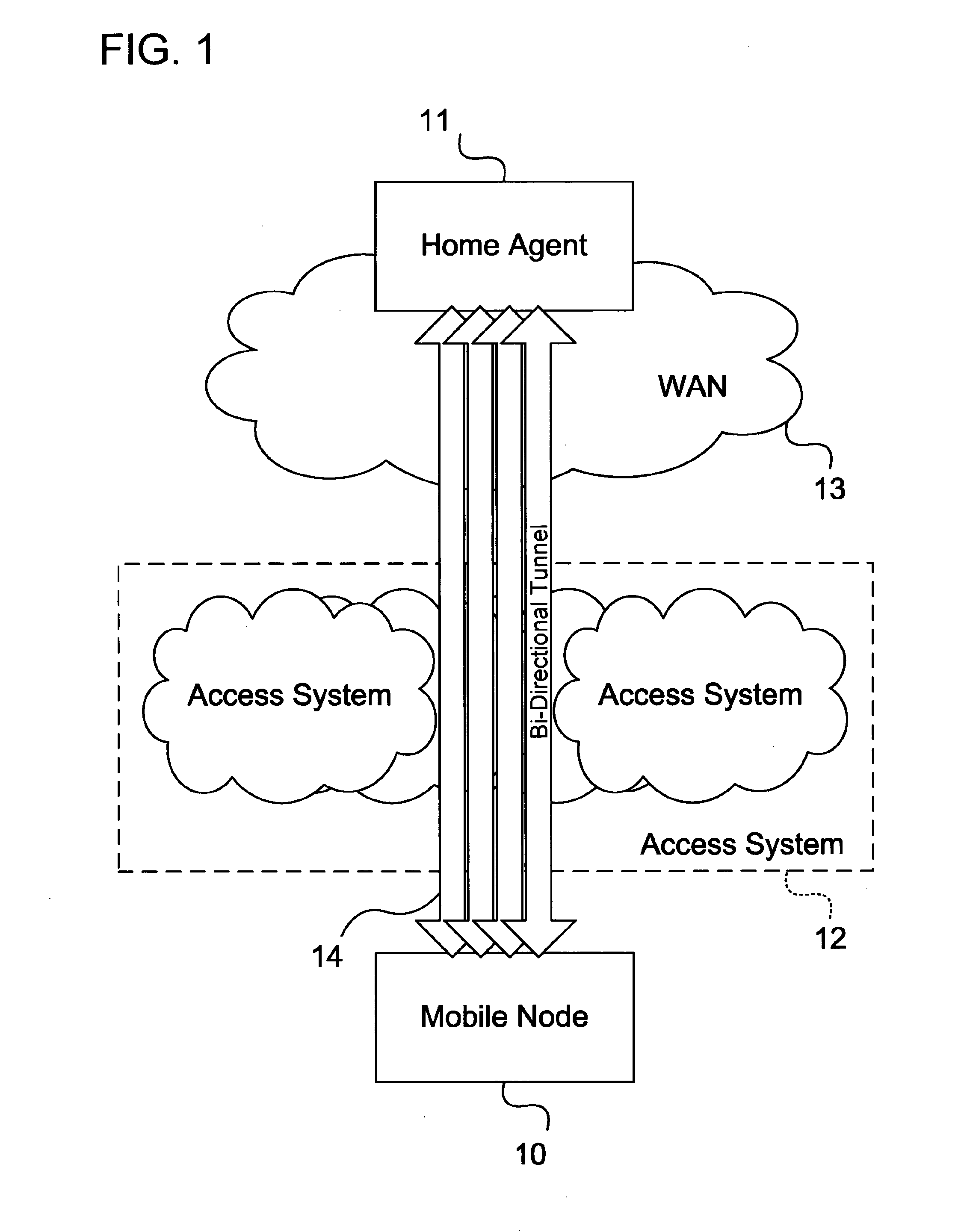

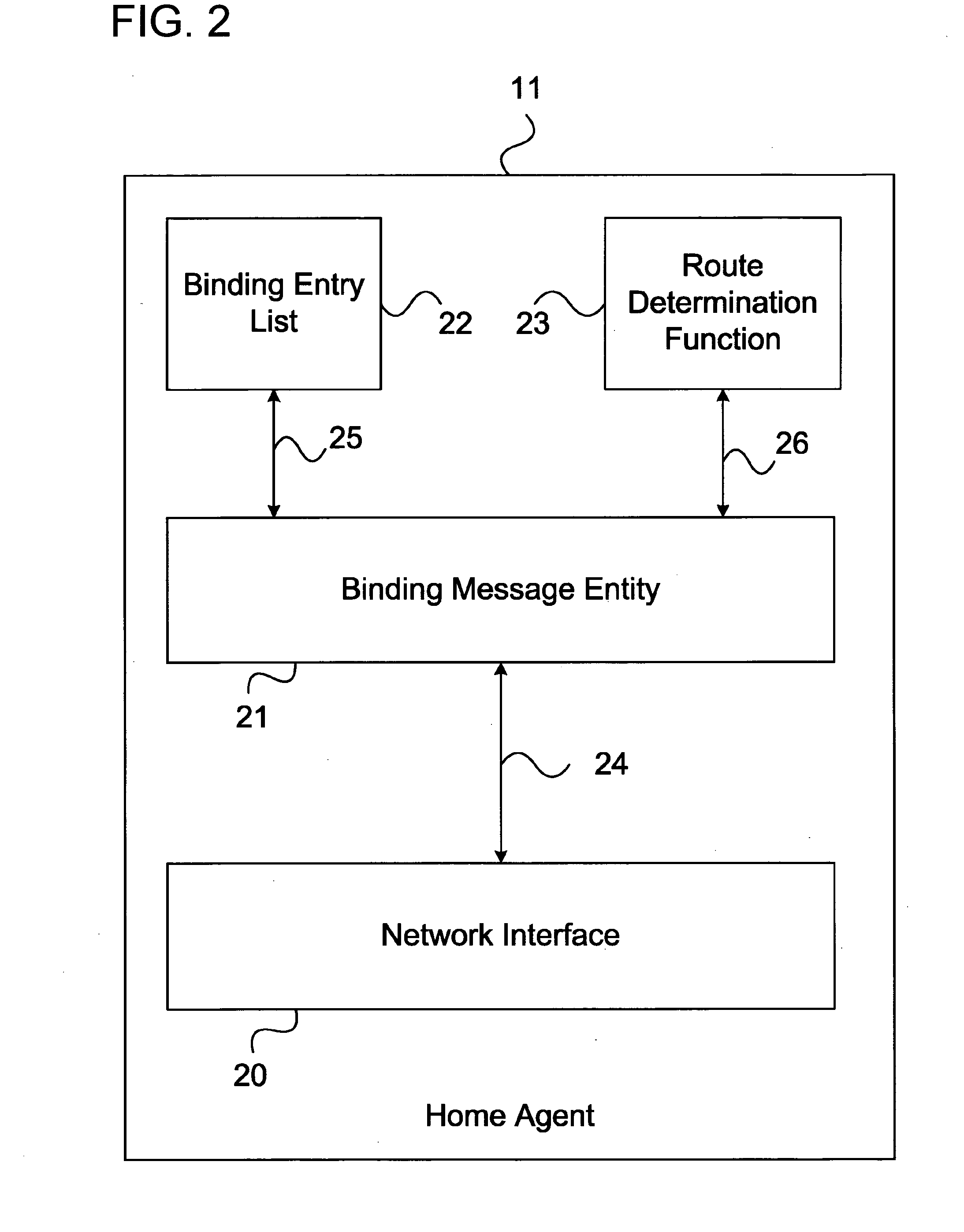

Method and apparatus for address verification during multiple addresses registration

InactiveUS20100241737A1Digital computer detailsWireless network protocolsValidation methodsAddressability

In this present invention, when the HA is performing Bulk Registration for a Multimode Node, the HA will tagged those CoAs specified within the single BU as unverified. A verification mechanism implemented at the HA will be triggered to test the addressability of the unverified CoA before using the said unverified CoA. The method of verification involves the HA to send an acknowledgment message to an unverified CoA of the Multimode Node to test the said unverified CoA for its addressability. When the Multimode Node receives the acknowledgment message from the HA, the Multimode Node replies the HA with another single BU. Upon the receipt of the second single BU from the Multimode Node, the HA can then verify that the said unverified CoA of the Multimode Node.

Owner:PANASONIC CORP

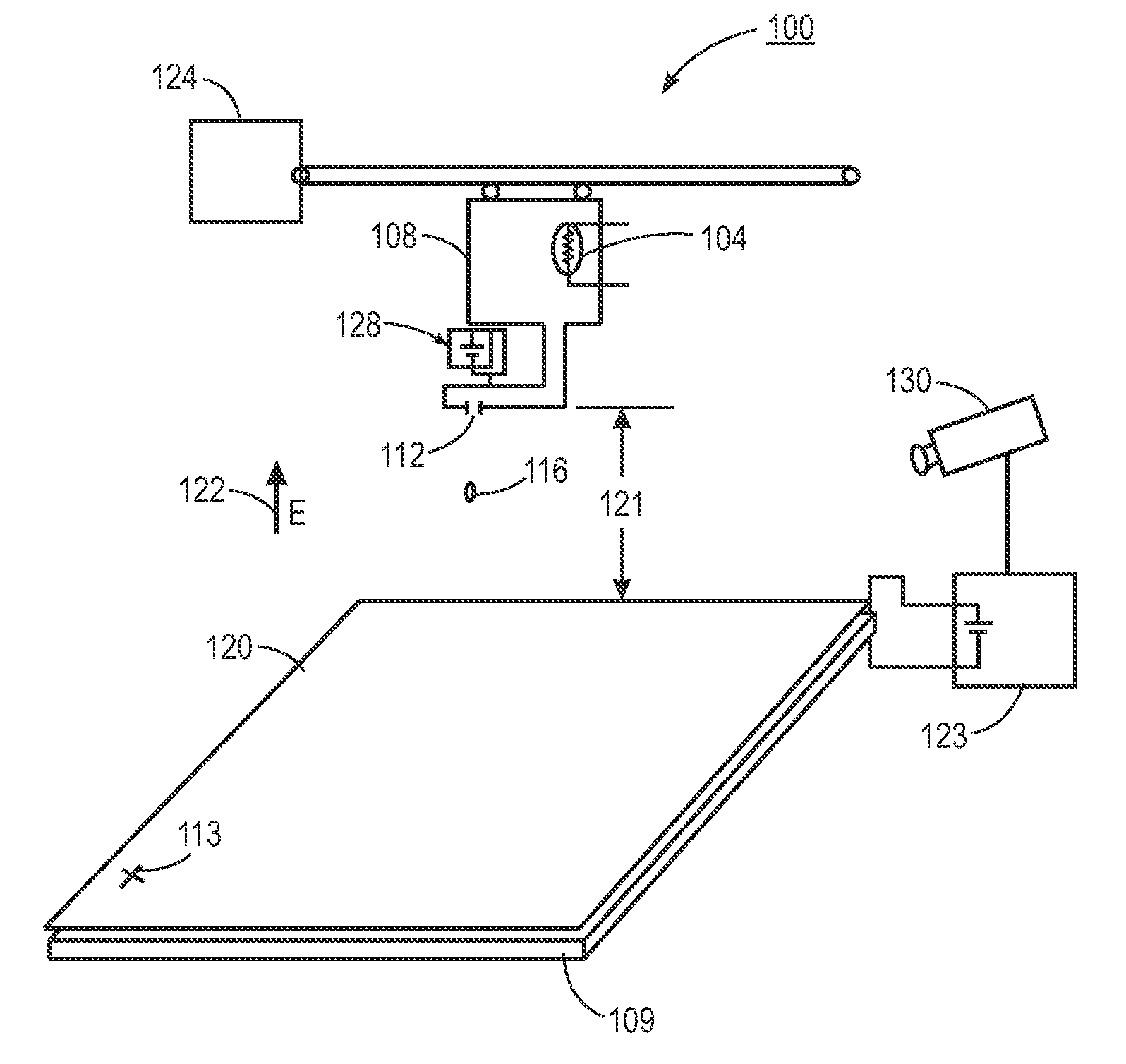

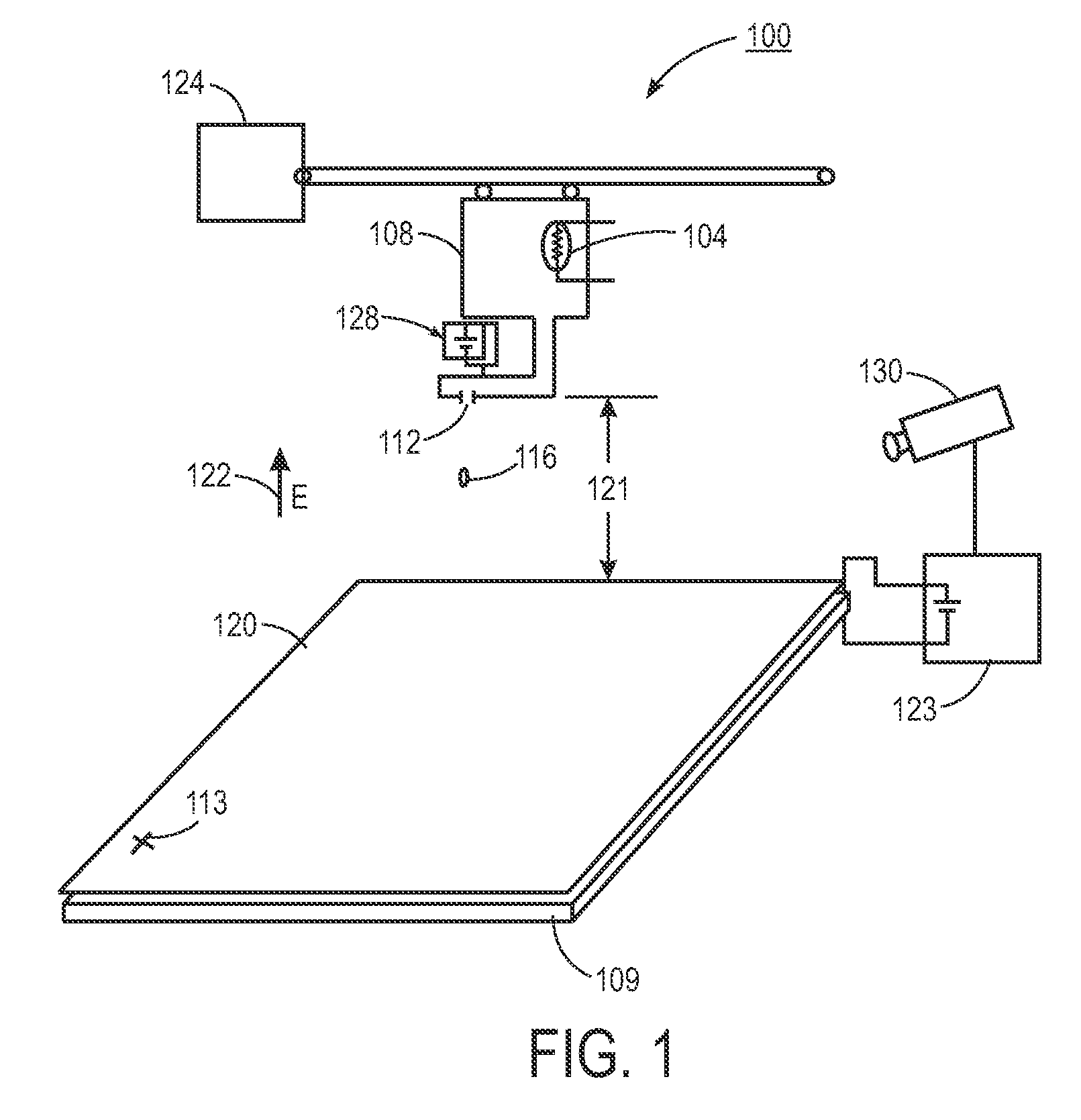

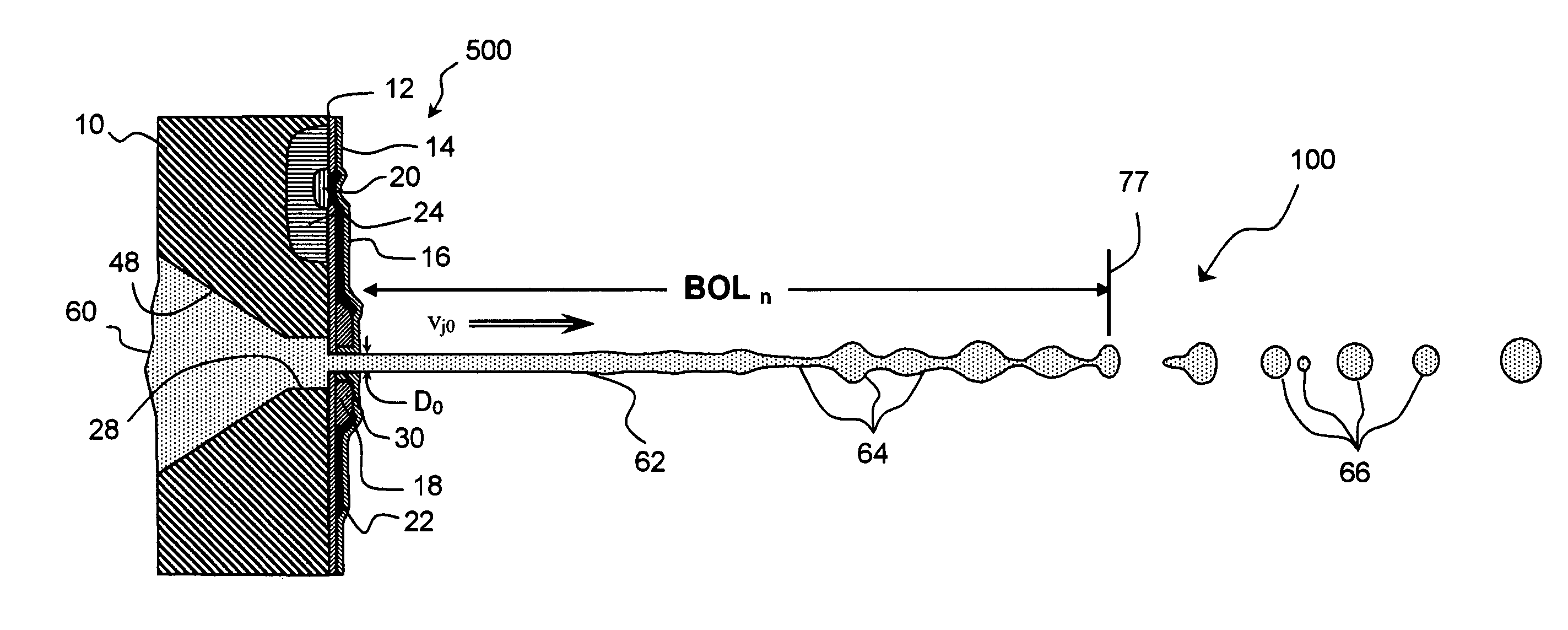

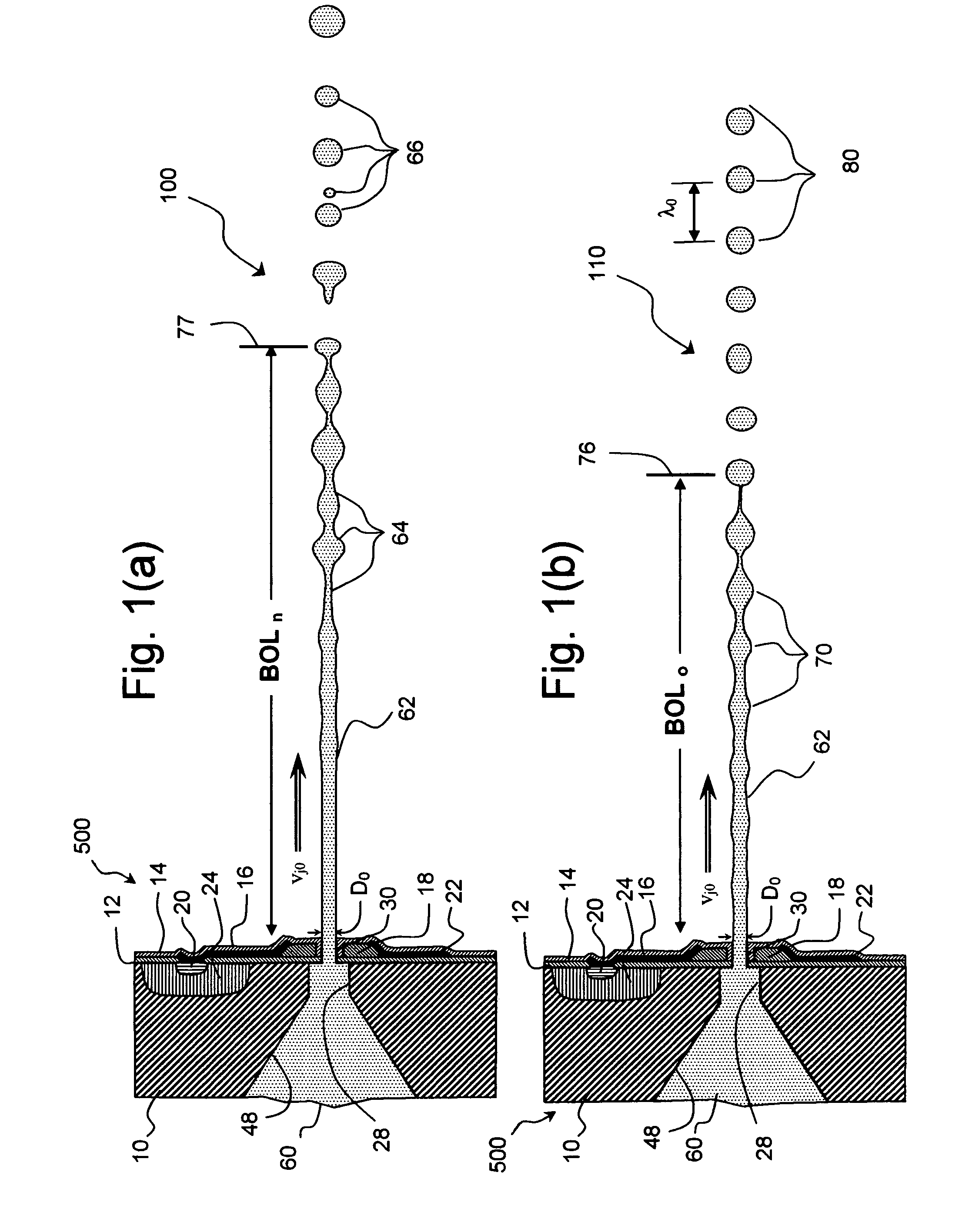

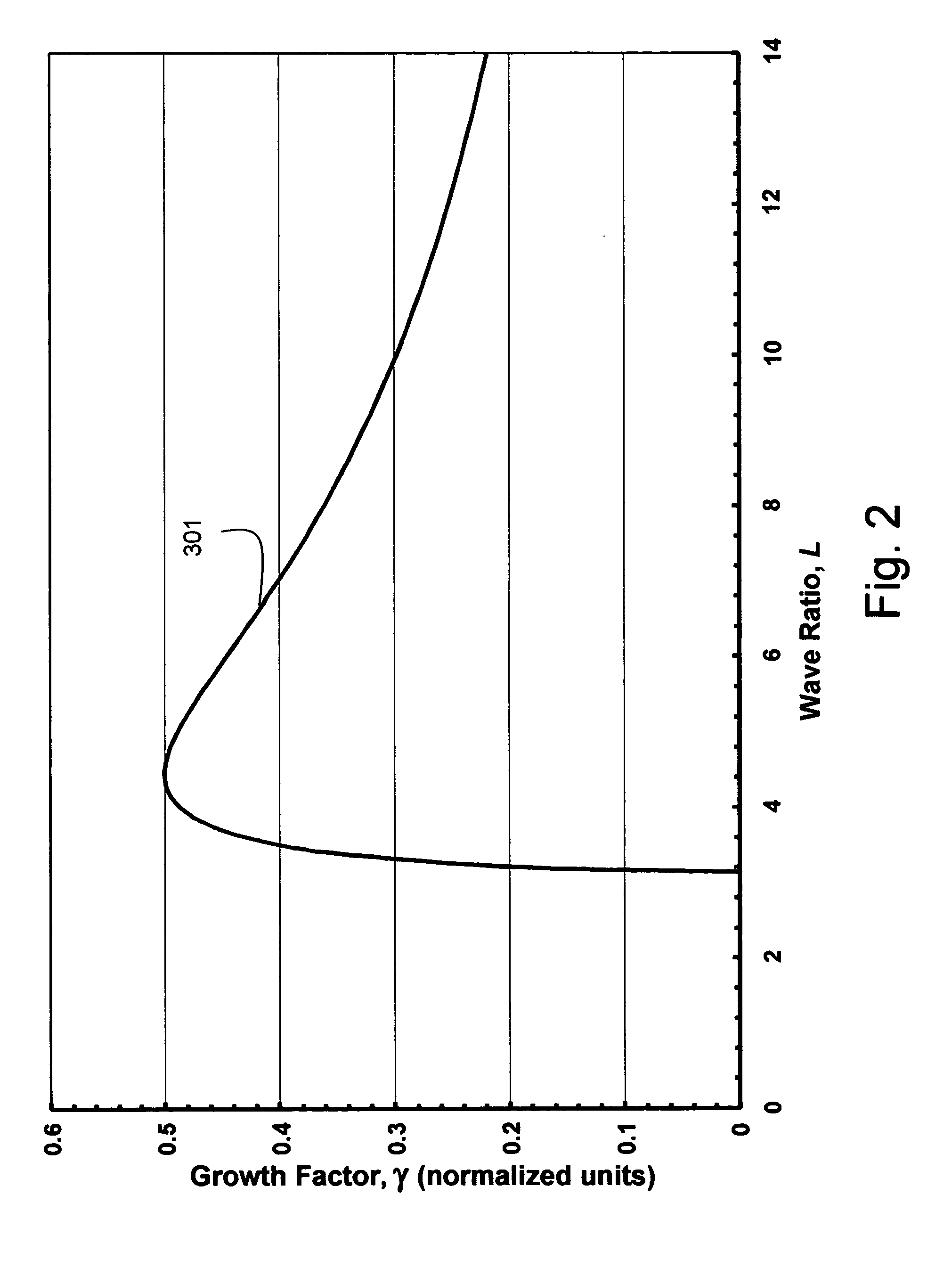

High speed, high quality liquid pattern deposition apparatus

InactiveUS7249829B2Fast processingMaintaining drop volume uniformityInking apparatusElectrical resistance and conductanceLiquid layer

A drop deposition apparatus for laying down a patterned liquid layer on a receiver substrate, for example, a continuous ink jet printer, is disclosed. The liquid deposition apparatus comprises a drop emitter containing a positively pressurized liquid in flow communication with a linear array of nozzles for emitting a plurality of continuous streams of liquid having nominal stream velocity vj0, wherein the plurality of nozzles have effective nozzle diameters D0 and extend in an array direction with an effective nozzle spacing Ly. Resistive heater apparatus is adapted to transfer thermal energy pulses of period τ0 to the liquid in flow communication with the plurality of nozzles sufficient to cause the break-off of the plurality of continuous streams of liquid into a plurality of streams of drops of predetermined nominal drop volume V0. Relative motion apparatus is adapted to move the drop emitter and receiver substrate relative to each other in a process direction at a process velocity S so that individual drops are addressable to the receiver substrate with a process direction addressability, Ap=τ0S. The effective nozzle spacing is less than 85 microns, the process speed S is at least 1 meter / sec and the addressability, Ap, of individual drops at the receiver substrate in the process direction is less than 6 microns. Drop deposition apparatus is disclosed wherein the predetermined volumes of drops include drops of a unit volume, V0, and drops having volumes that are integer multiples of the unit volume, mV0. Further apparatus is adapted to inductively charge at least one drop and to cause electric field deflection of charged drops.

Owner:EASTMAN KODAK CO

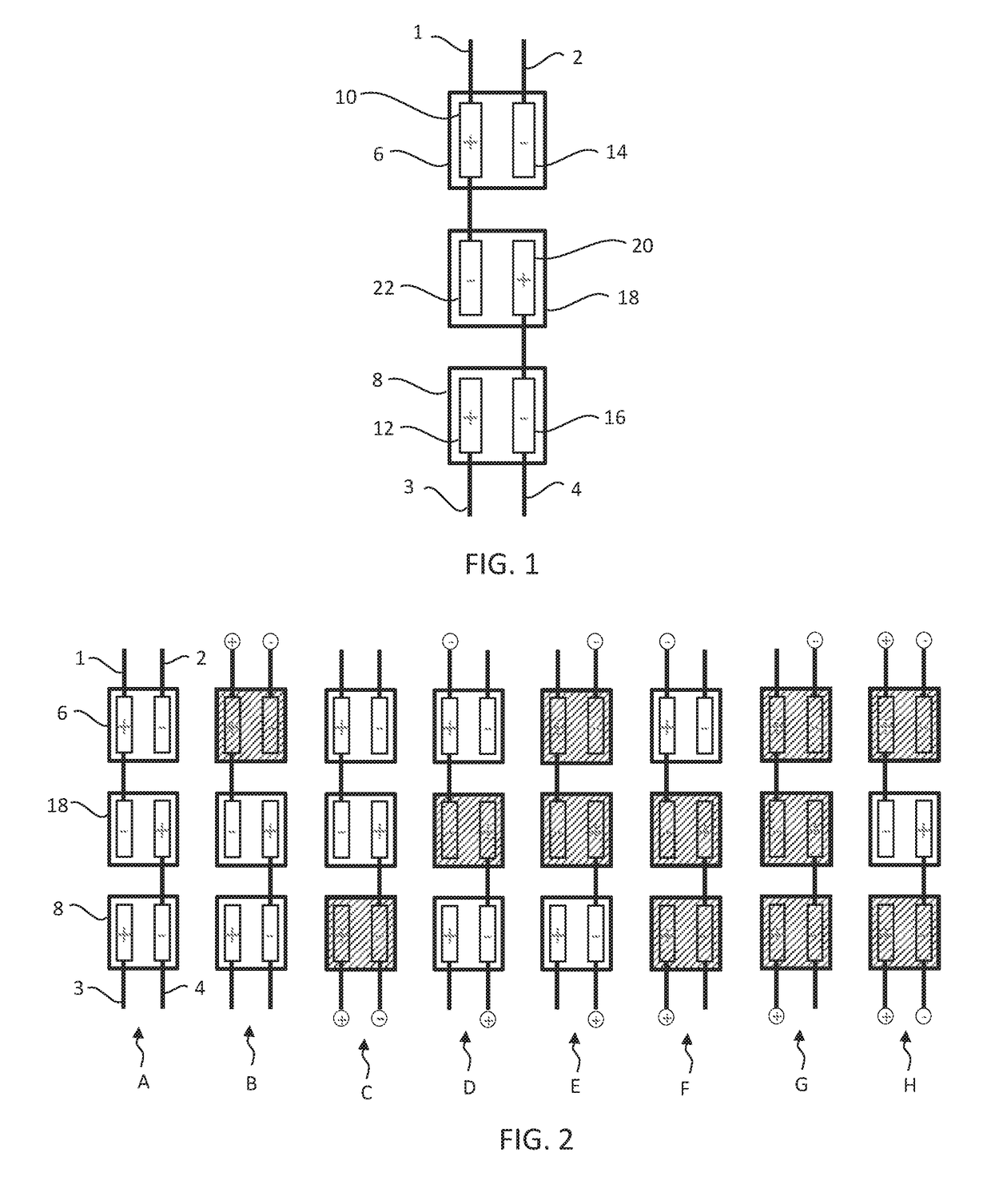

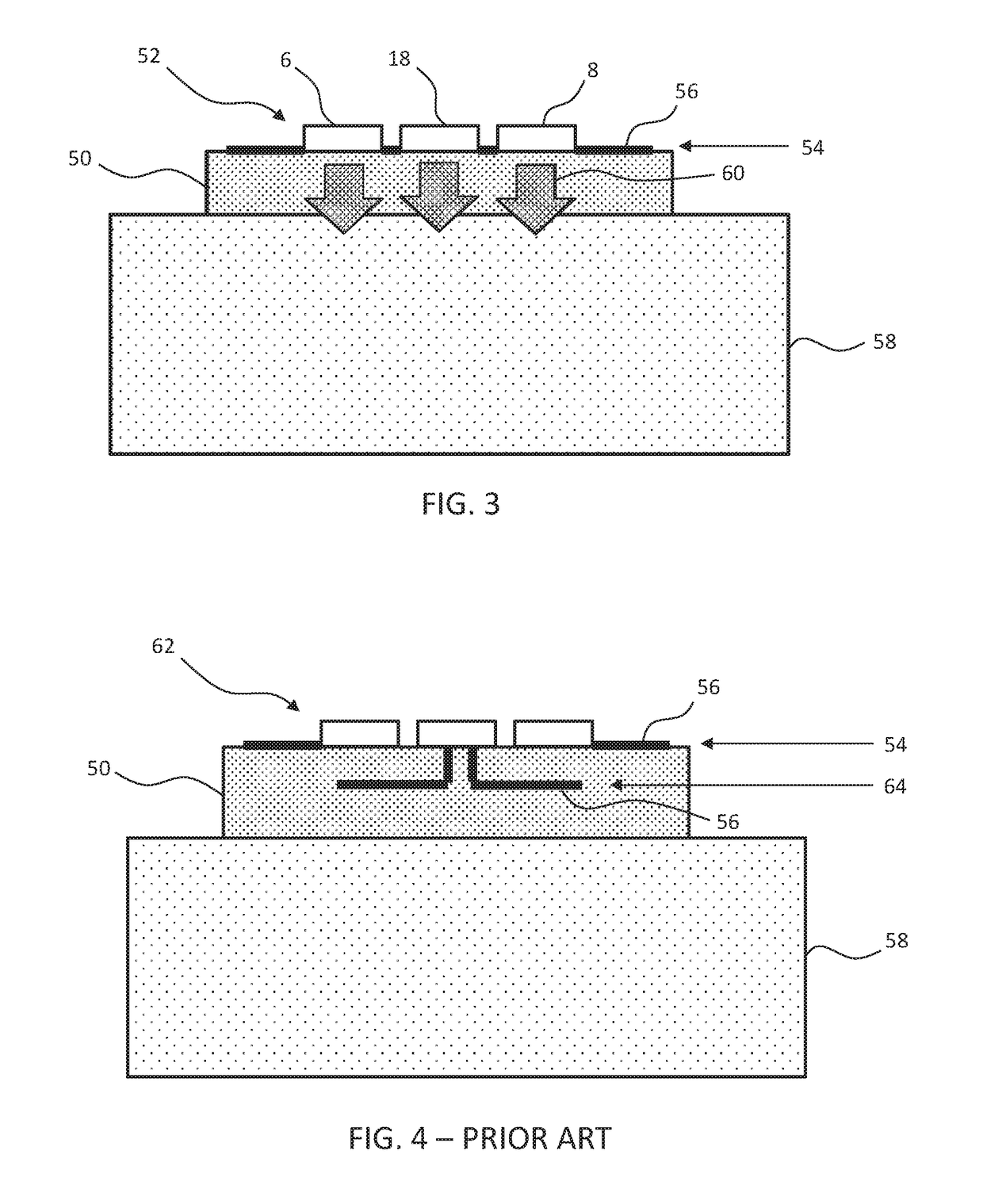

LED device having individually addressable LED modules

ActiveUS20170318636A1Minimising overall light-emitting area—andImprove thermal conductivityVehicle headlampsElectric circuit arrangementsLed arrayLight beam

The invention provides an interconnected string of three LED modules, having internal and external connections such that each LED in the string is fully individually addressable. LED biases and interconnects are oriented and configured such that individual addressability is achieved without the need for direct external signal connections to each LED in the string. Consequently embodiments are provided comprising pluralities of strings, arranged so as to form an array of LED modules, wherein wiring tracks running beneath, or along the intermediary spaces between, rows of LEDs are not required. Hence are provided LED devices comprising an array of individually addressable LED modules, having reduced spacing between rows and columns, and having optimal thermal path perpendicularly across the substrate layer. Provided devices have improved heat dissipation and greater achievable LED array density. Also provided are embodiments comprising one or more lens arrangements, suitable, for example, for adaptive beam-shaping applications.

Owner:KONINKLJIJKE PHILIPS NV

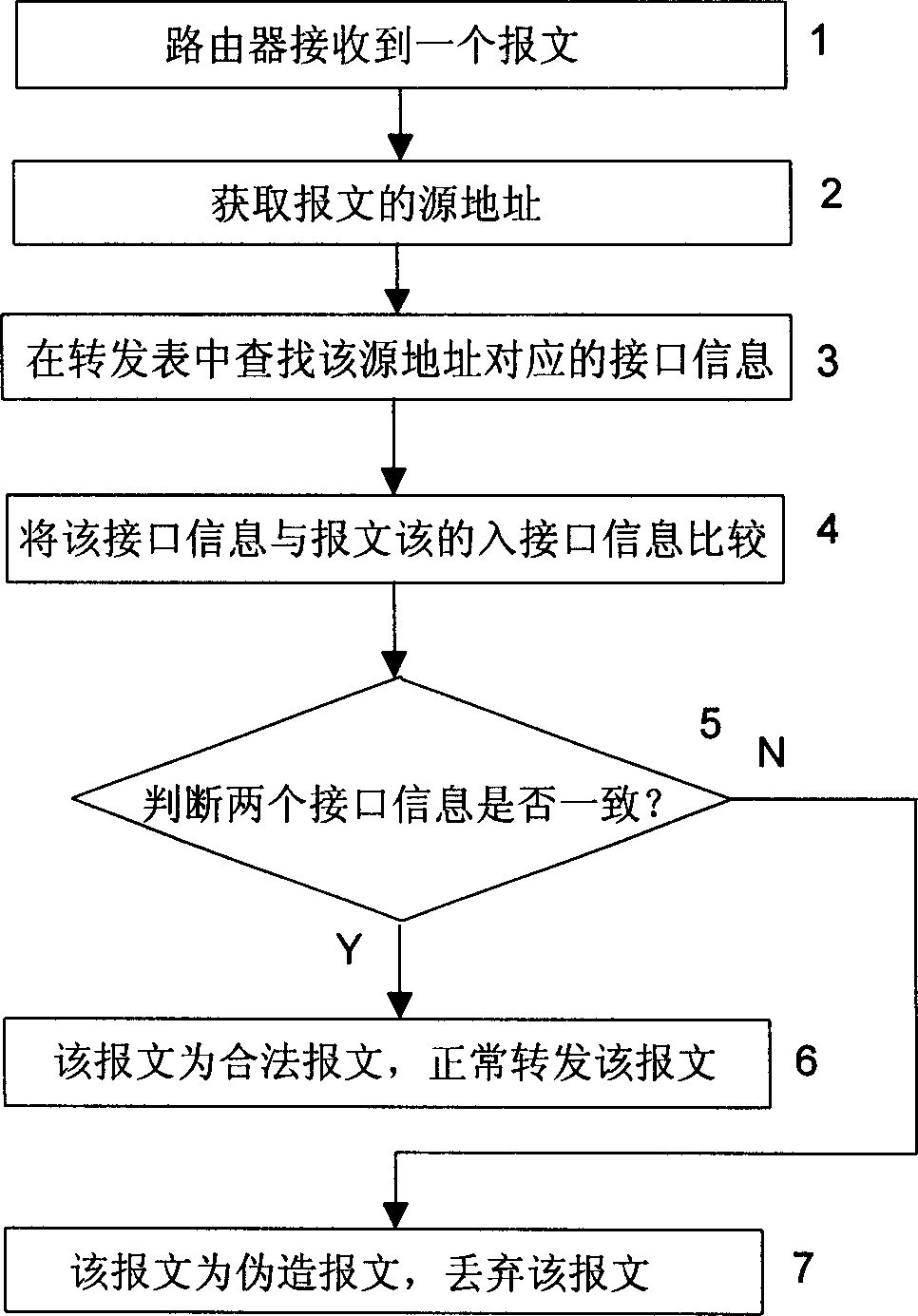

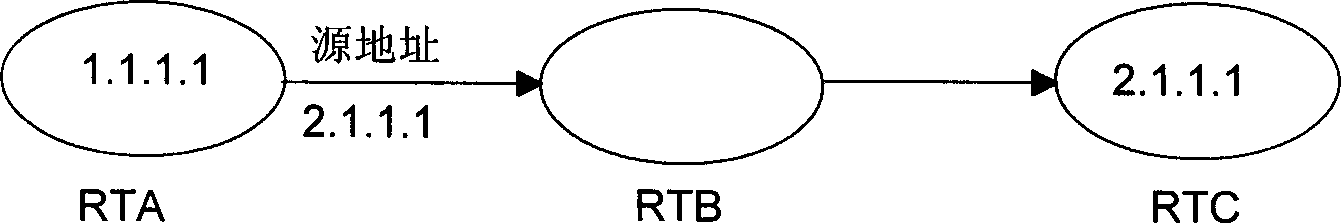

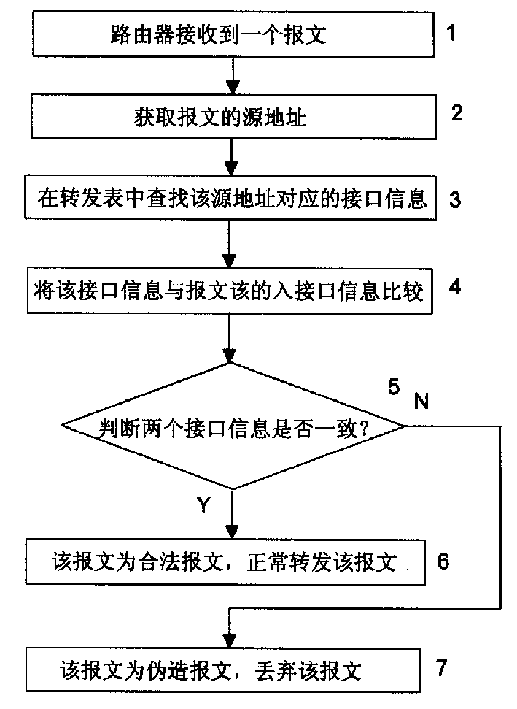

Method of guarding network attack

InactiveCN1411208AEnsure safetyPrevent cyber attacksData switching networksSecuring communicationNetwork addressingNetwork address

This invention relates to a method for preventing network from attack includes firstly, setting network address and interface information correspondent relationship list in network equipment, namely,network addresses of other network equipment connected with the said network equipment interface and applied interface information correspondent relation list of other network equipment connected on the said network; the route transferred list can be used in a router then the network equipment looks for the said correspondent relationship list according to the original address of the received message and makes judgment in terms of the result it is fake to determine the addressability of the message.

Owner:HUAWEI TECH CO LTD

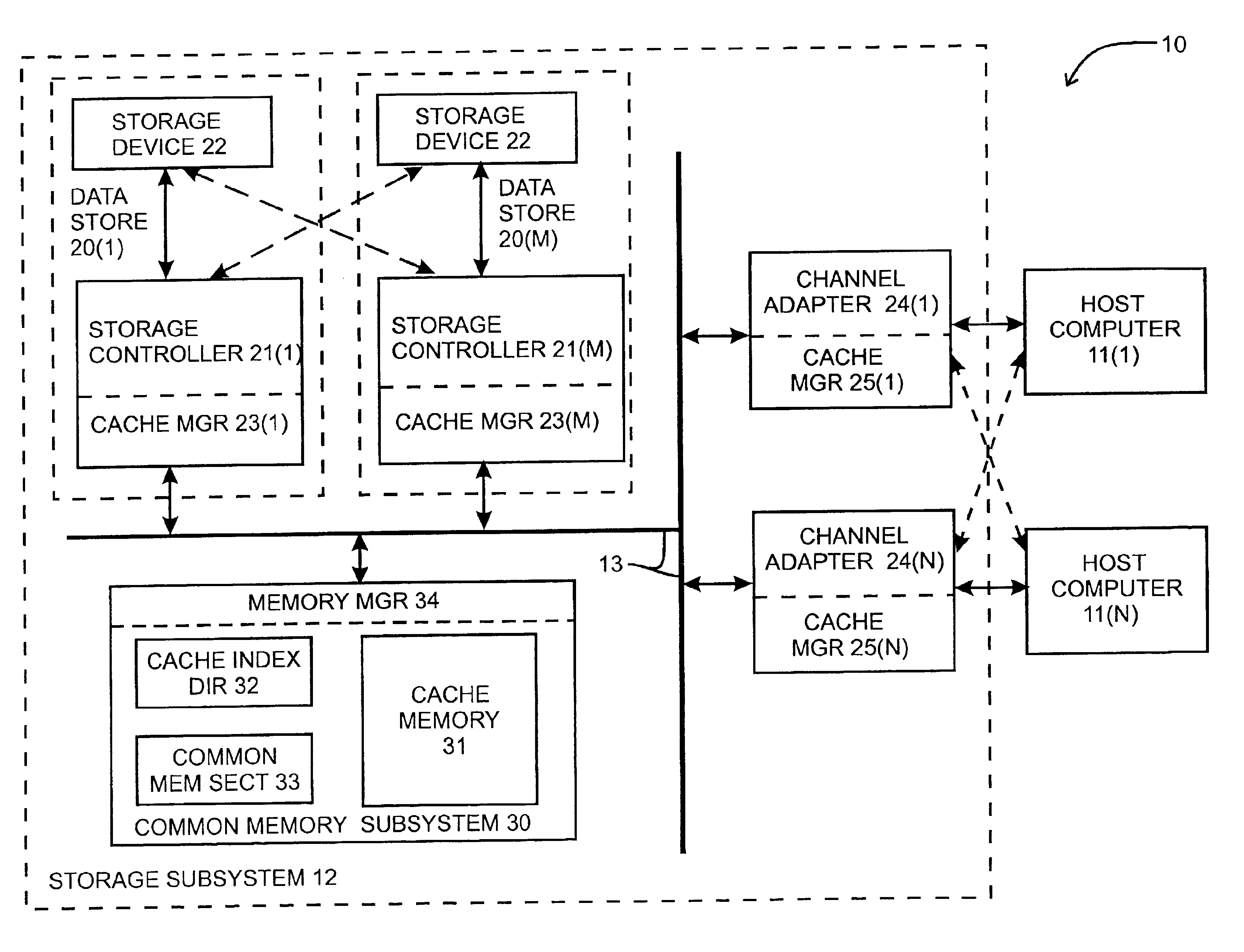

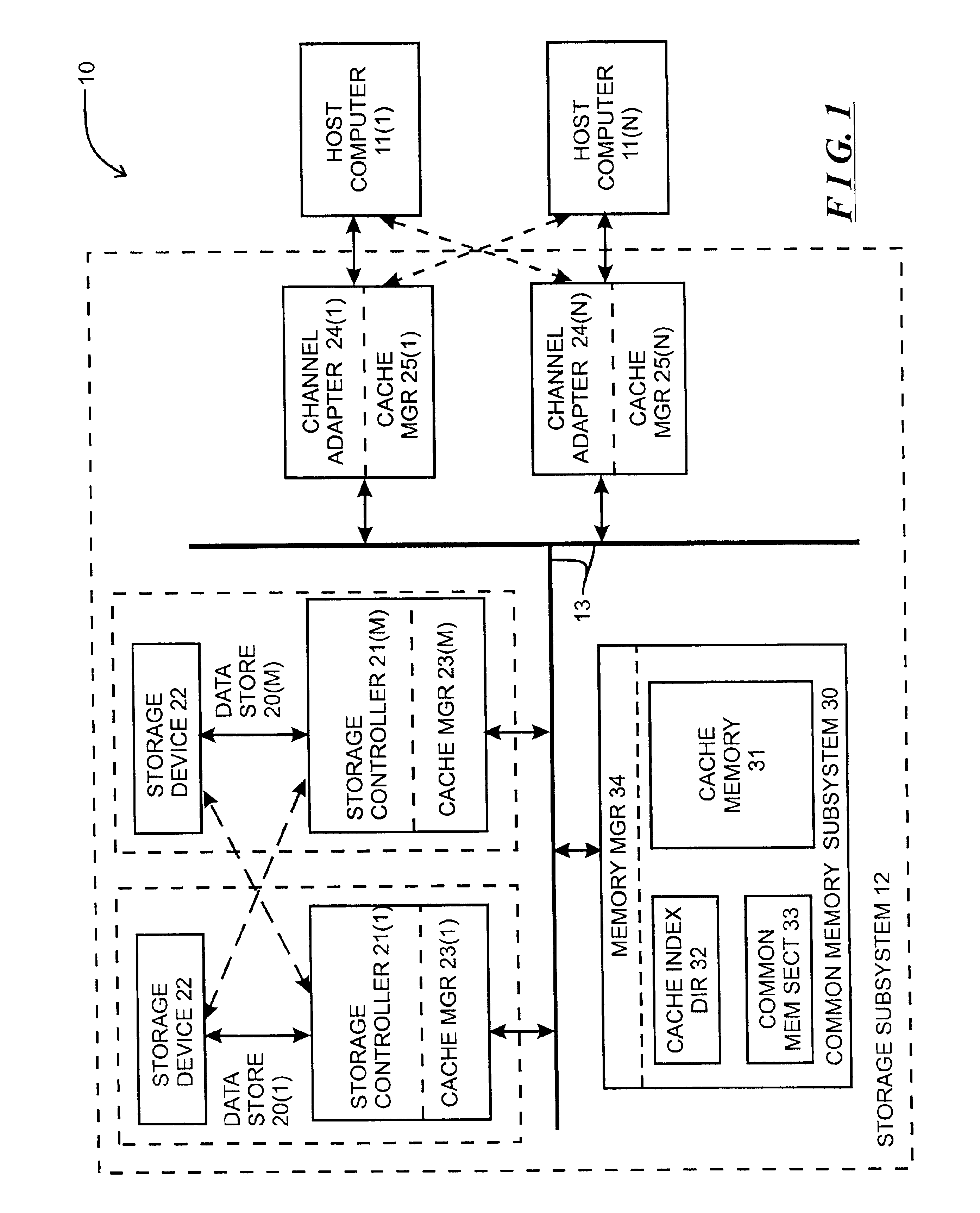

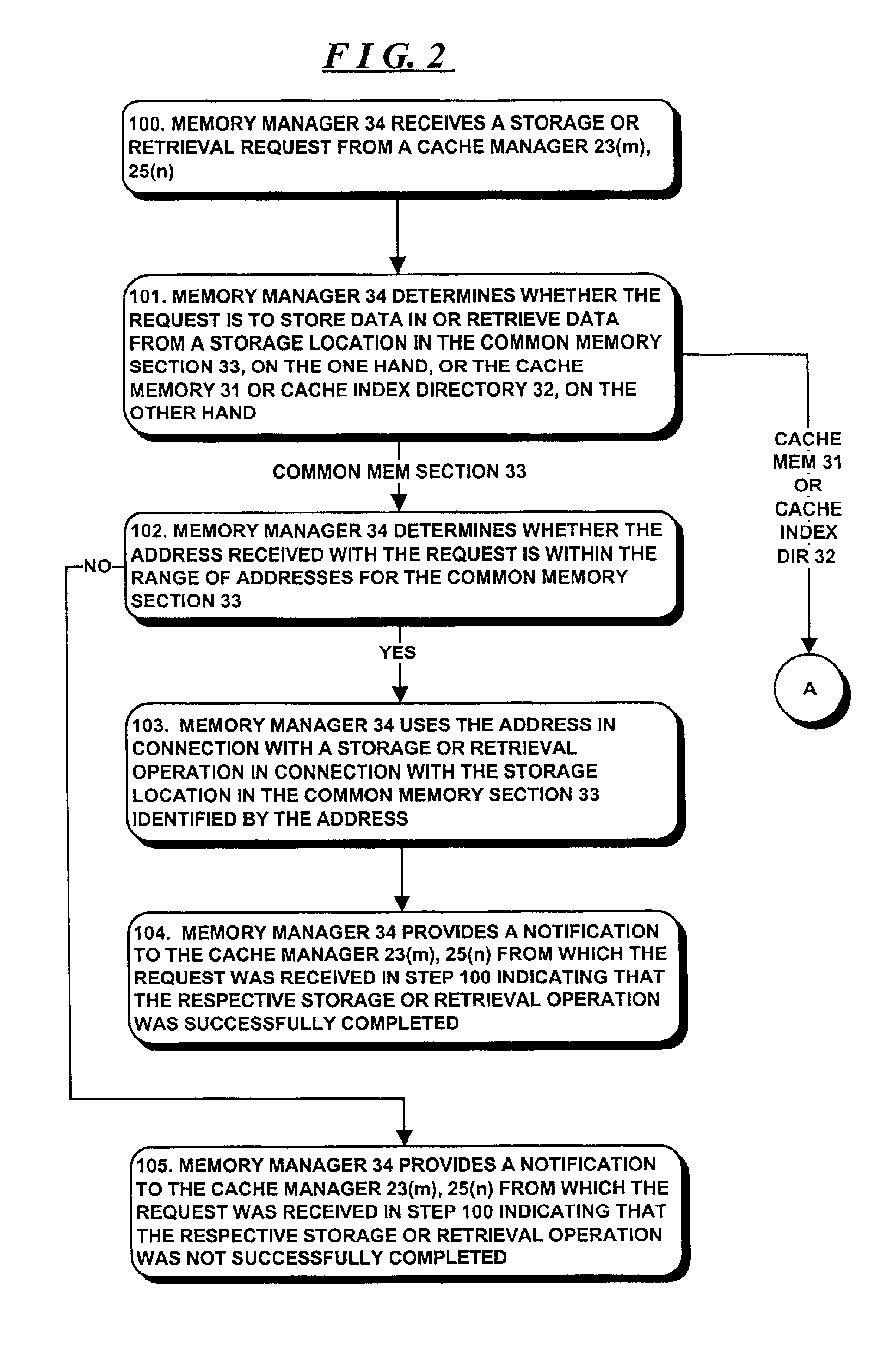

Digital data storage subsystem including arrangement for increasing cache memory addressability

InactiveUS6842843B1Increasing cache memory addressabilityMemory architecture accessing/allocationMemory adressing/allocation/relocationCombined useAddressability

A memory manager for use in connection with a memory comprises a memory access request receiver module, an address translation module and a memory access operation control module. The memory access request receiver module is configured to receive an access request requesting an access operation in connection with the memory, the access request including an address. The address translation module is configured to, (i) if the access request requests an access operation in connection with one of a plurality of sections of the memory, provide the address in the access request as an absolute address identifying at least one storage location in the one section; and (ii) if the access request requests an access operation in connection with another of said sections, generate an absolute address from the address provided in the access request, the address in the access request including a segment identifier and an offset, the address translation module being configured to process the segment identifier and offset to generate an absolute address identifying at least one storage location in the other of said sections. The memory access operation control module is configured to perform an access operation in connection with the memory using the absolute address generated by the address translation module.

Owner:EMC CORP

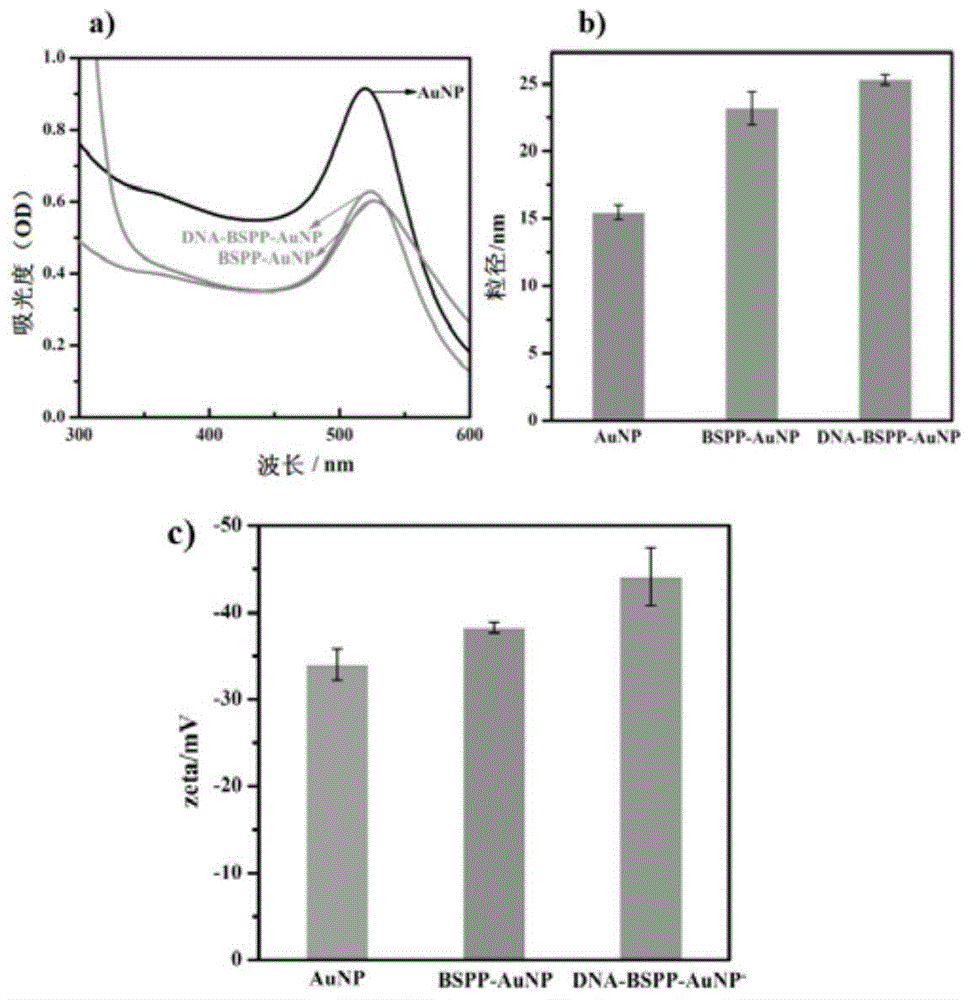

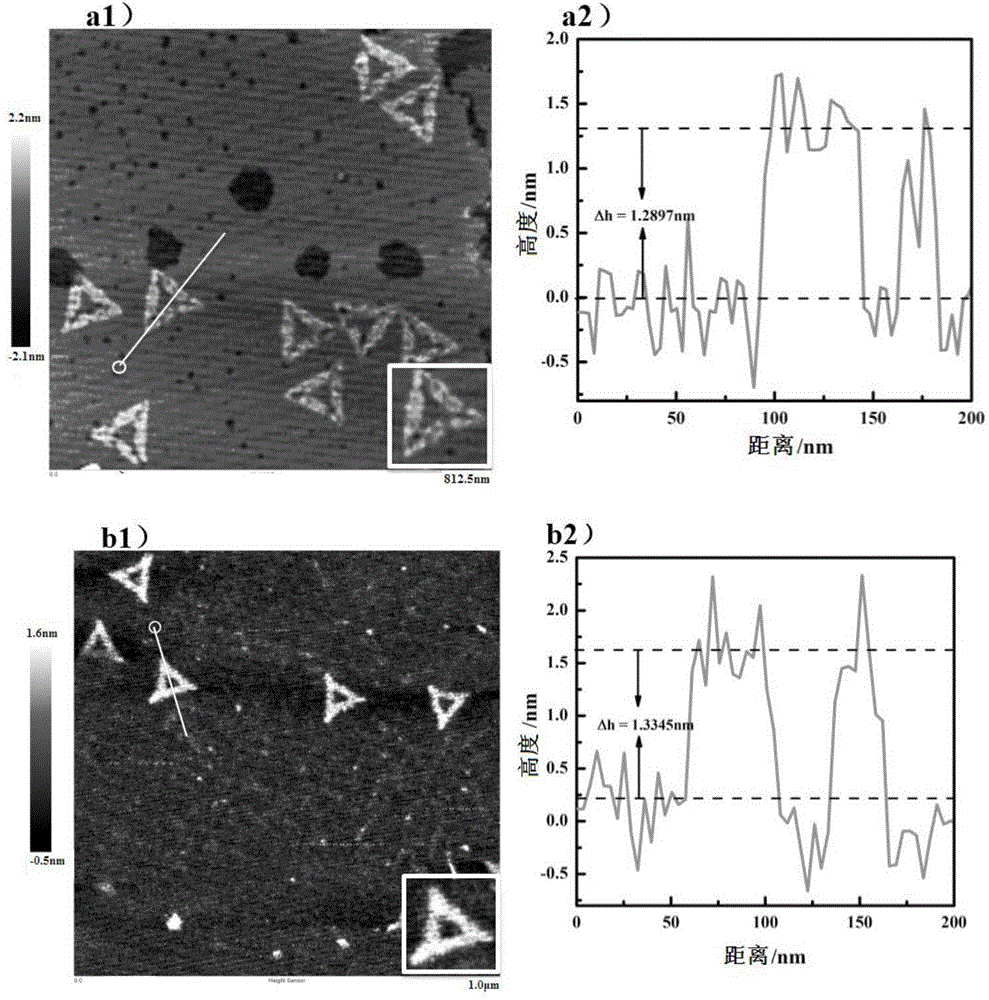

DNA flexagon nano structure-nanogold biosensor based on adapter modification and preparing method and application of DNA flexagon nano structure-nanogold biosensor

ActiveCN104962615AExact Space AddressabilityOvercoming the disadvantages of poor autoimmunityMicrobiological testing/measurementNano structuringAutoimmunity

The invention discloses a DNA flexagon nano structure-nanogold biosensor based on adapter modification and a preparing method and application of the DNA flexagon nano structure-nanogold biosensor. The biosensor comprises DNA flexagon and nanogold, the DNA flexagon comprises an adapter nucleotide sequence of a detected object, and the nanogold is nanogold modified by a DNA fragment complementary with the adapter nucleotide sequence. The method includes the following beneficial effects that the DNA flexagon has the accurate space addressability, and the complicated marking step is avoided after the nanogold is added; an adapter can be synthesized in batch with a chemical method, so that the cost is greatly reduced; the shortcoming that the autoimmunity of micromolecule matter is poor is overcome; the DNA flexagon nano structure-nanogold biosensor has the lower detection limit, and LOD reaches the nanogram stage; an atomic force microscope and electrophoresis are adopted for conducting representation, qualitative and quantitative analysis is carried out by using the characteristic that the nanogold is high in light in an atomic force microscope height map; and compared with a traditional survey method, the advantages of being easy and convenient, reliable, lower in requirement for experiment conditions and the like are achieved.

Owner:SOUTHWEST UNIVERSITY

Method and apparatus for providing an inter integrated circuit interface with an expanded address range and efficient priority-based data throughput

A method and apparatus implementing an enhanced protocol between an I2C master and an I2C slave. In various embodiments the invention permits greater addressability space and high priority access to the slave device. The enhanced protocol is implemented by the addition of command code data being transmitted which is recognized through an interface circuit inside the slave device. The invention provides an I2C solution for accessing high priority address space with one command byte, medium priority space with two command bytes and low priority space with three command bytes.

Owner:AVAGO TECH INT SALES PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com