Patents

Literature

684 results about "Lateral positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lateral position Sims' position. lithotomy position the patient lies on the back with the legs well separated, thighs acutely flexed on the abdomen, and legs on thighs; stirrups may be used to support the feet and legs. See illustration.

Cervical interspinous process distraction implant and method of implantation

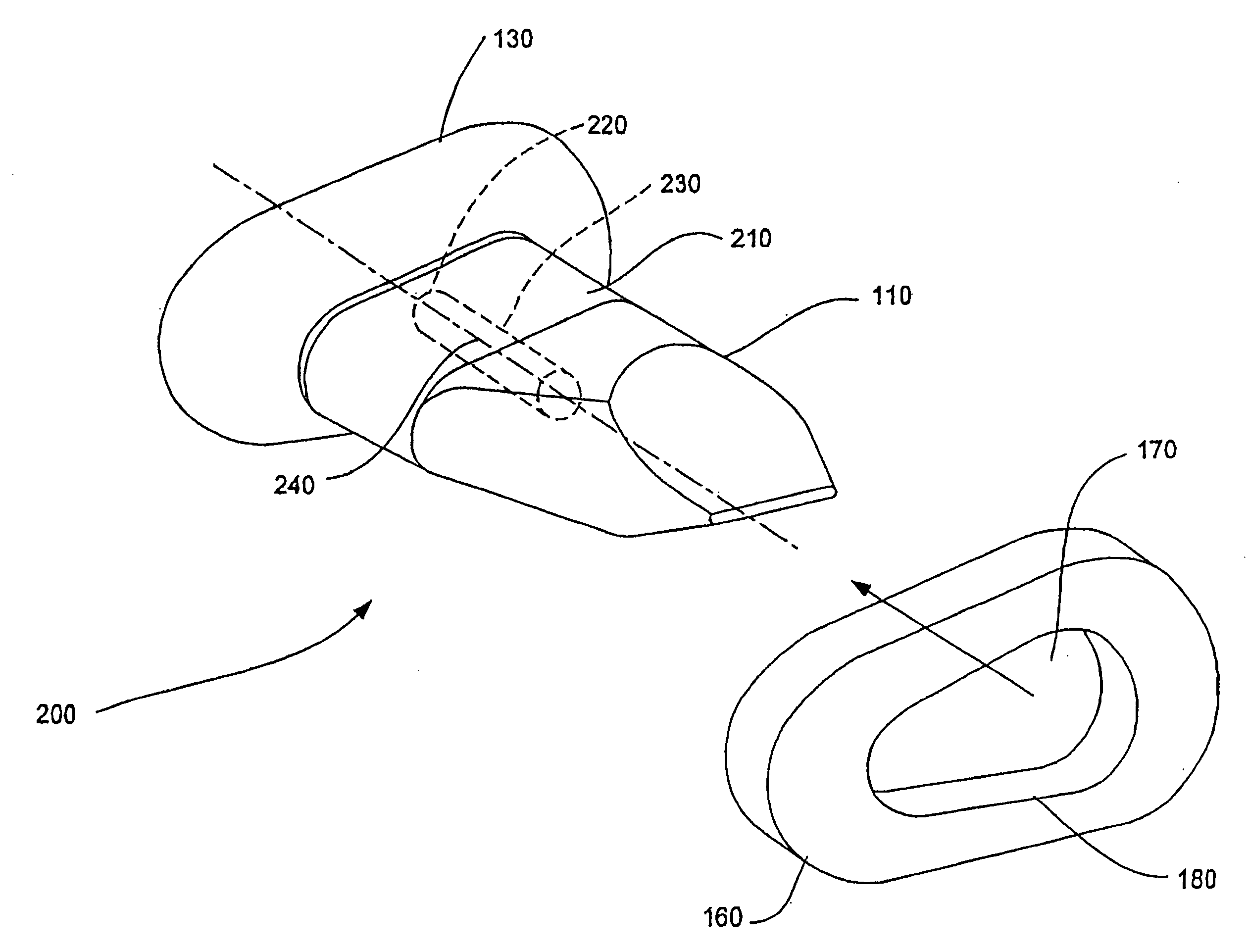

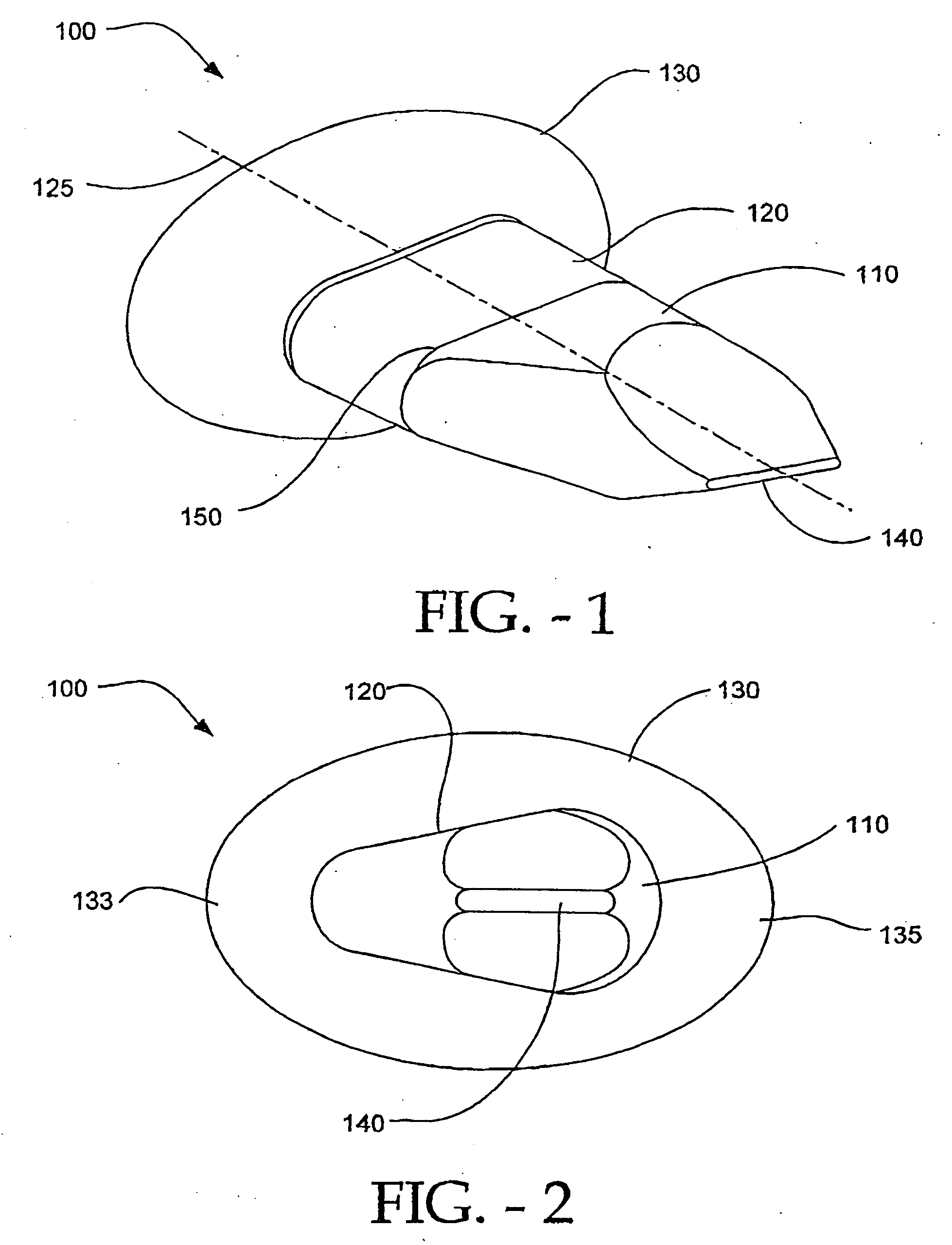

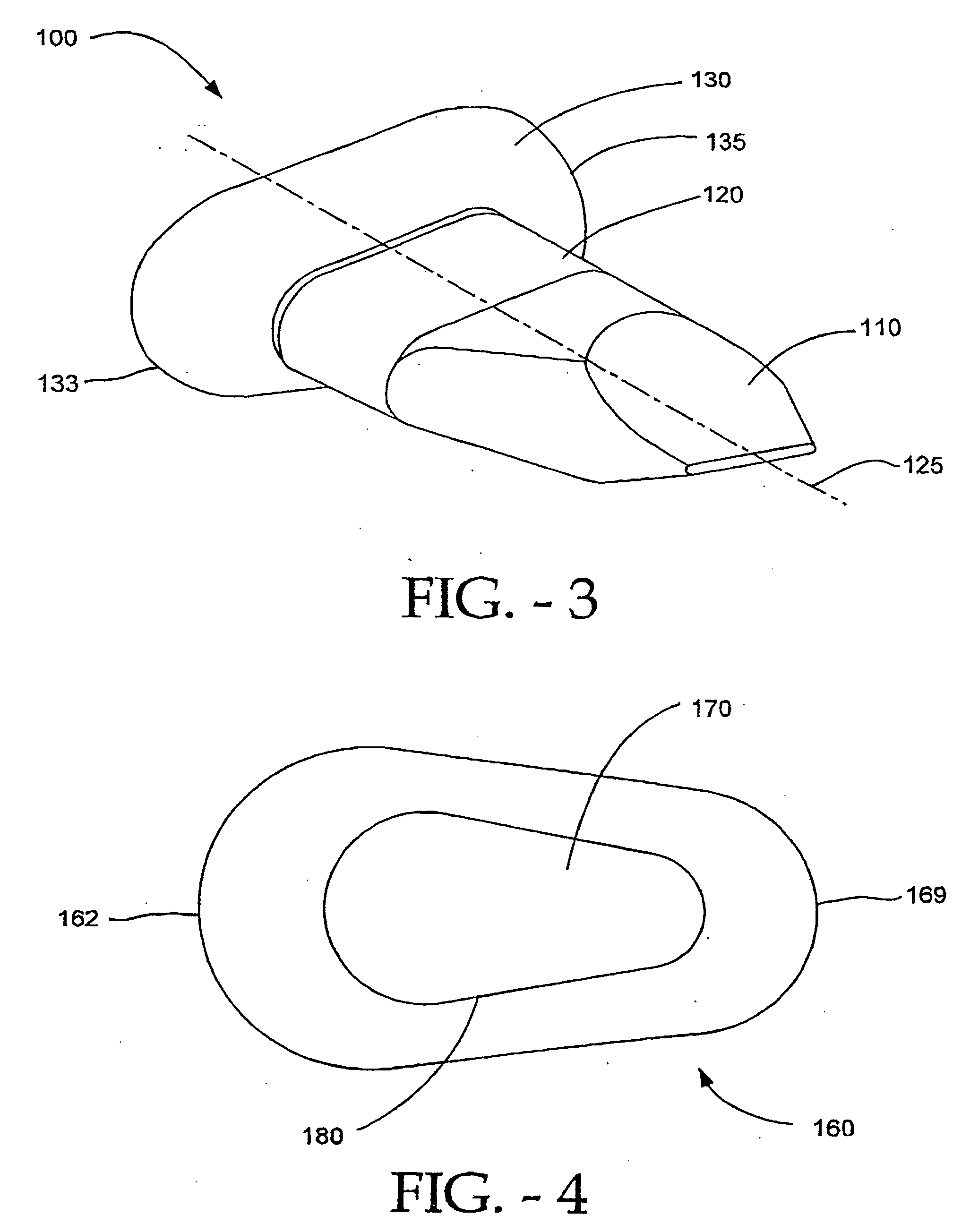

An implant for positioning between the spinous processes of cervical vertebrae include first and second wings for lateral positioning and a spacer located between the adjacent spinous processes. The implant can be positioned using minimally invasive procedures without modifying the bone or severing ligaments. The implant is shaped in accordance with the anatomy of the spine.

Owner:MEDTRONIC EURO SARL

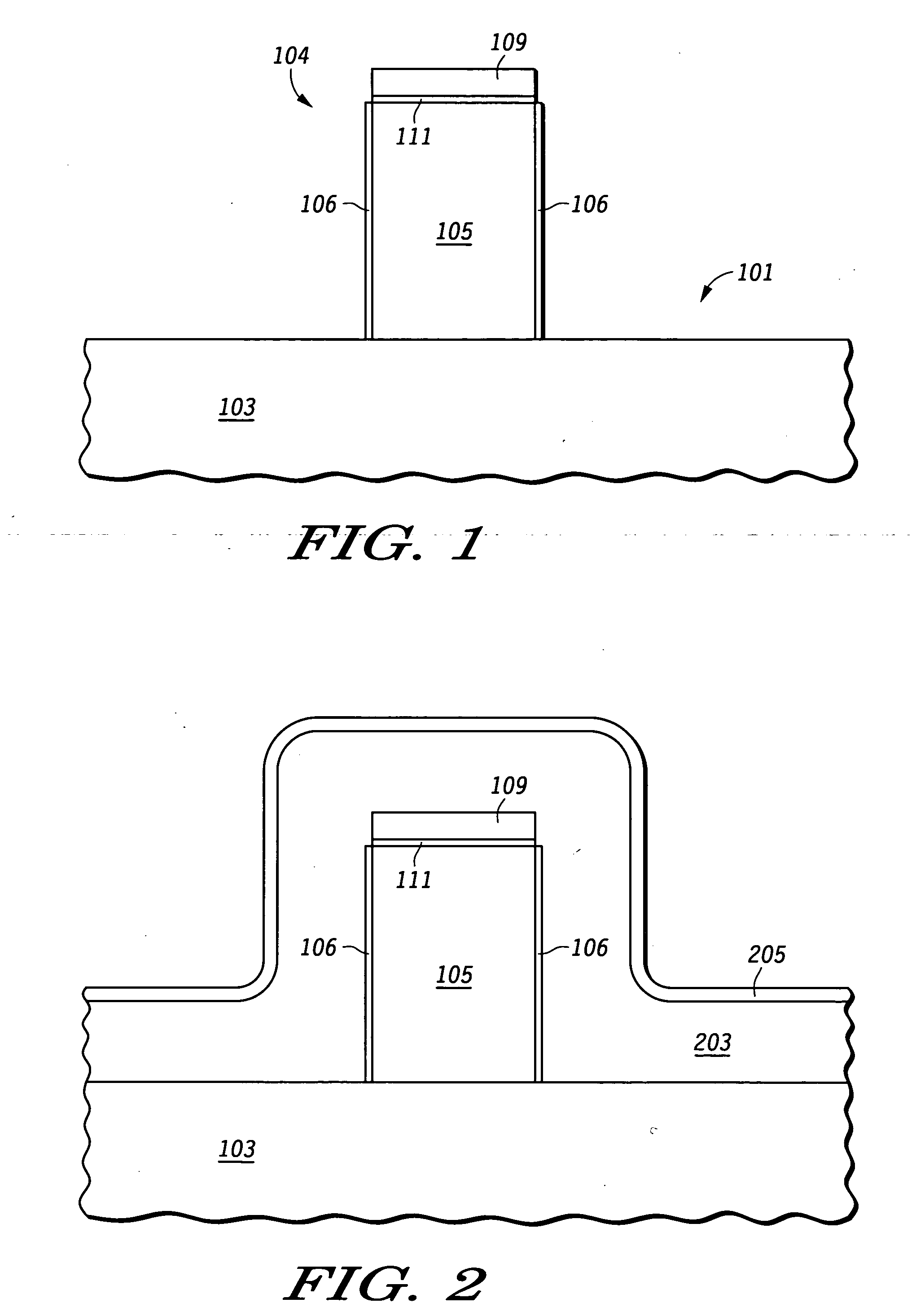

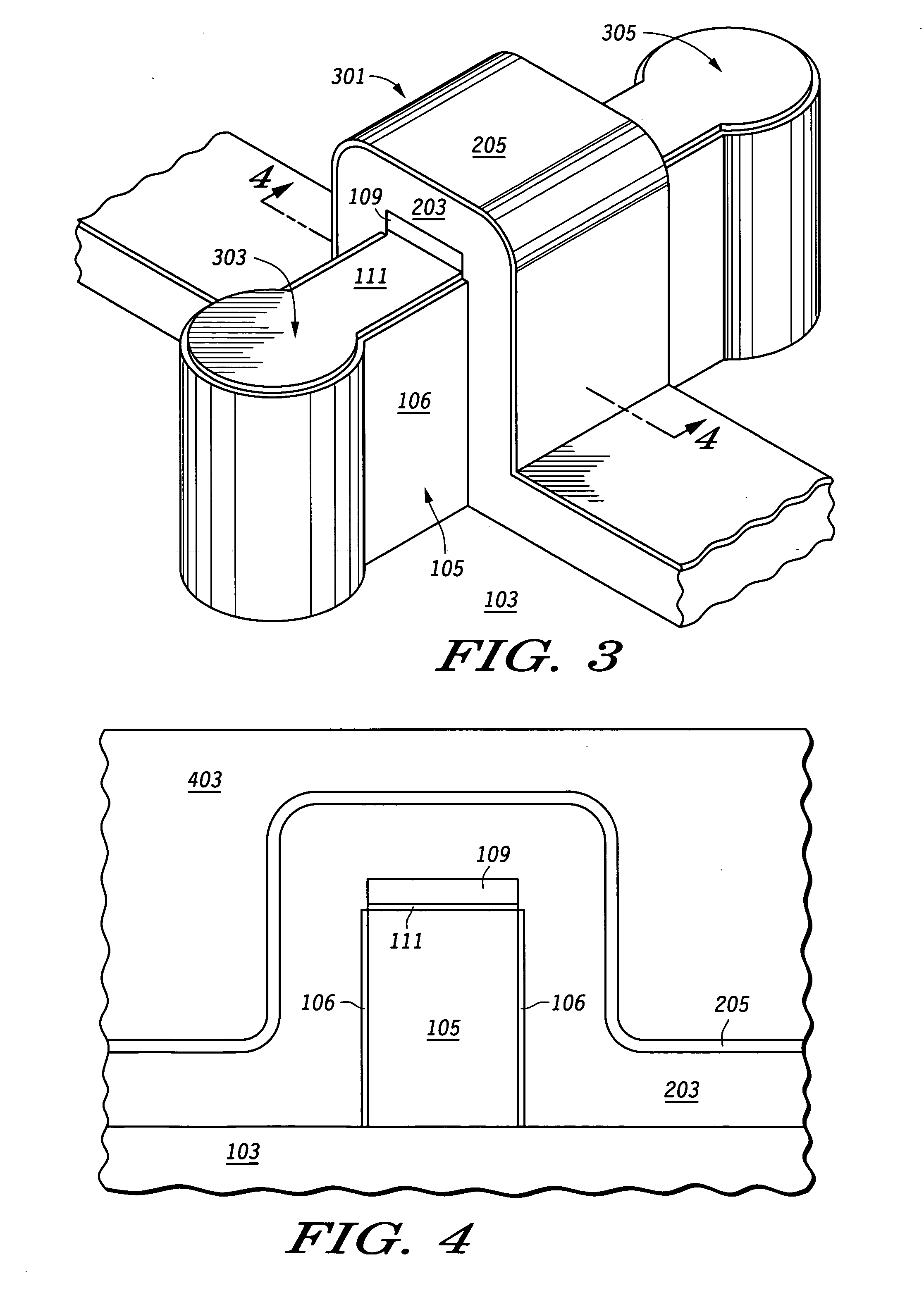

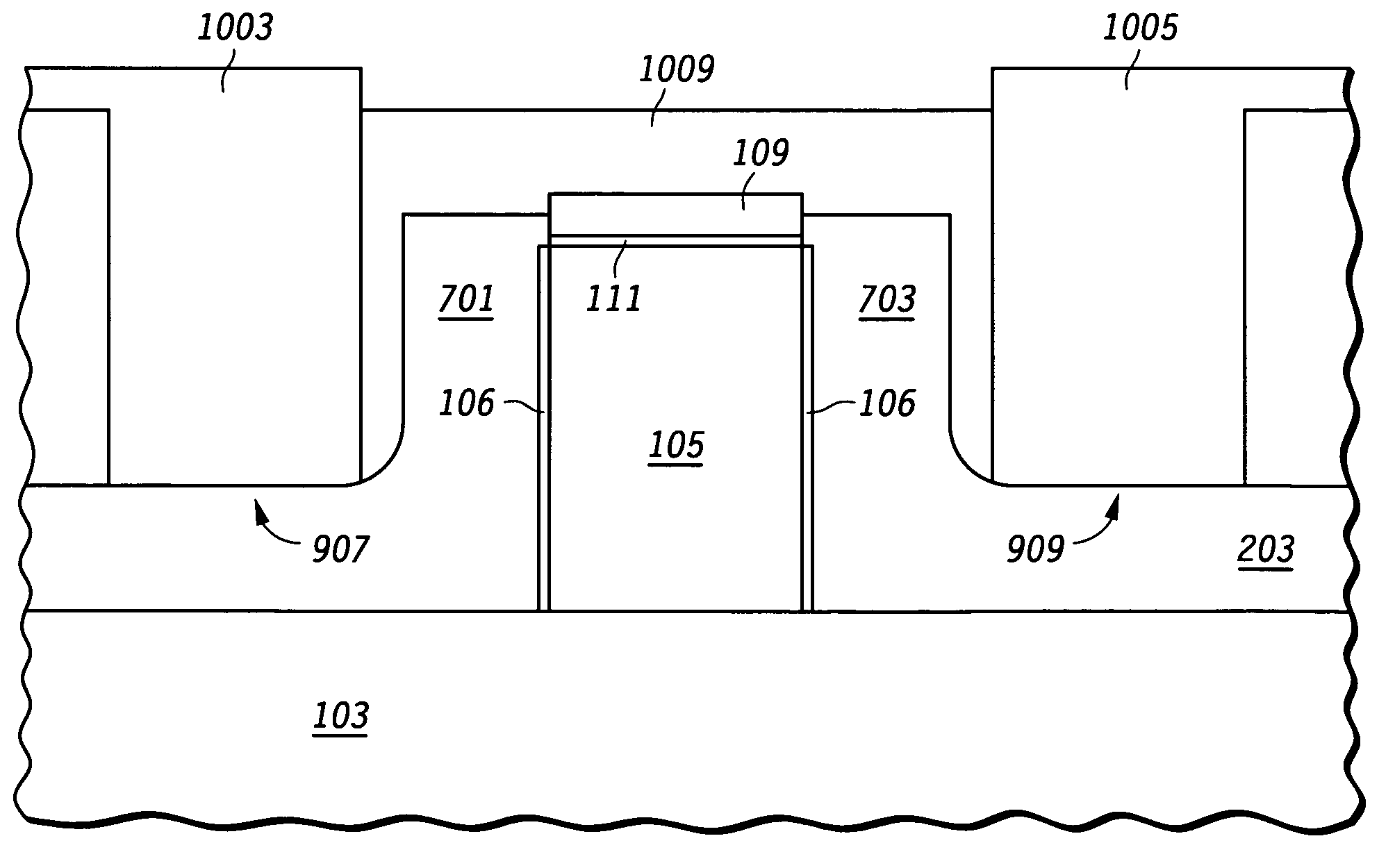

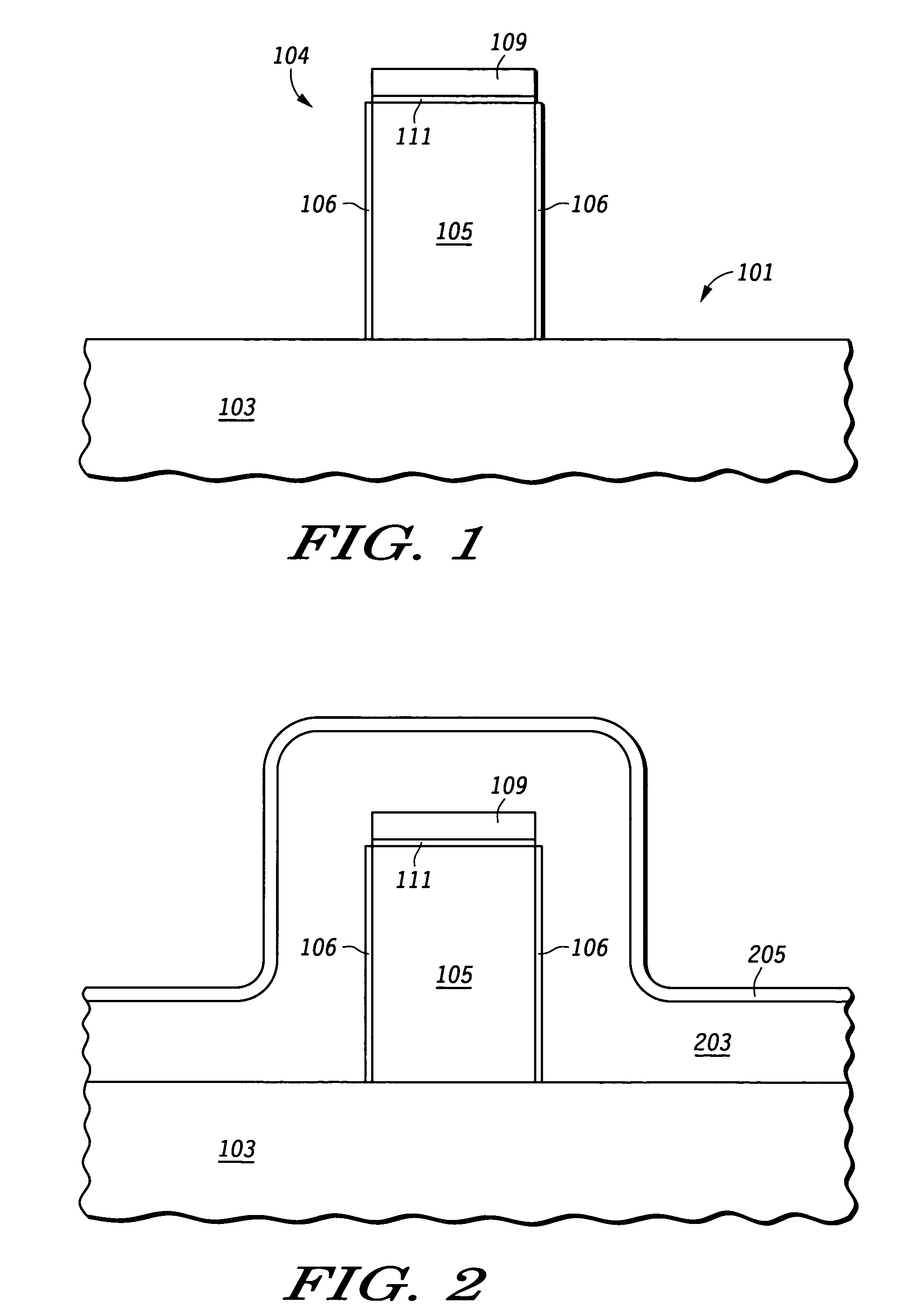

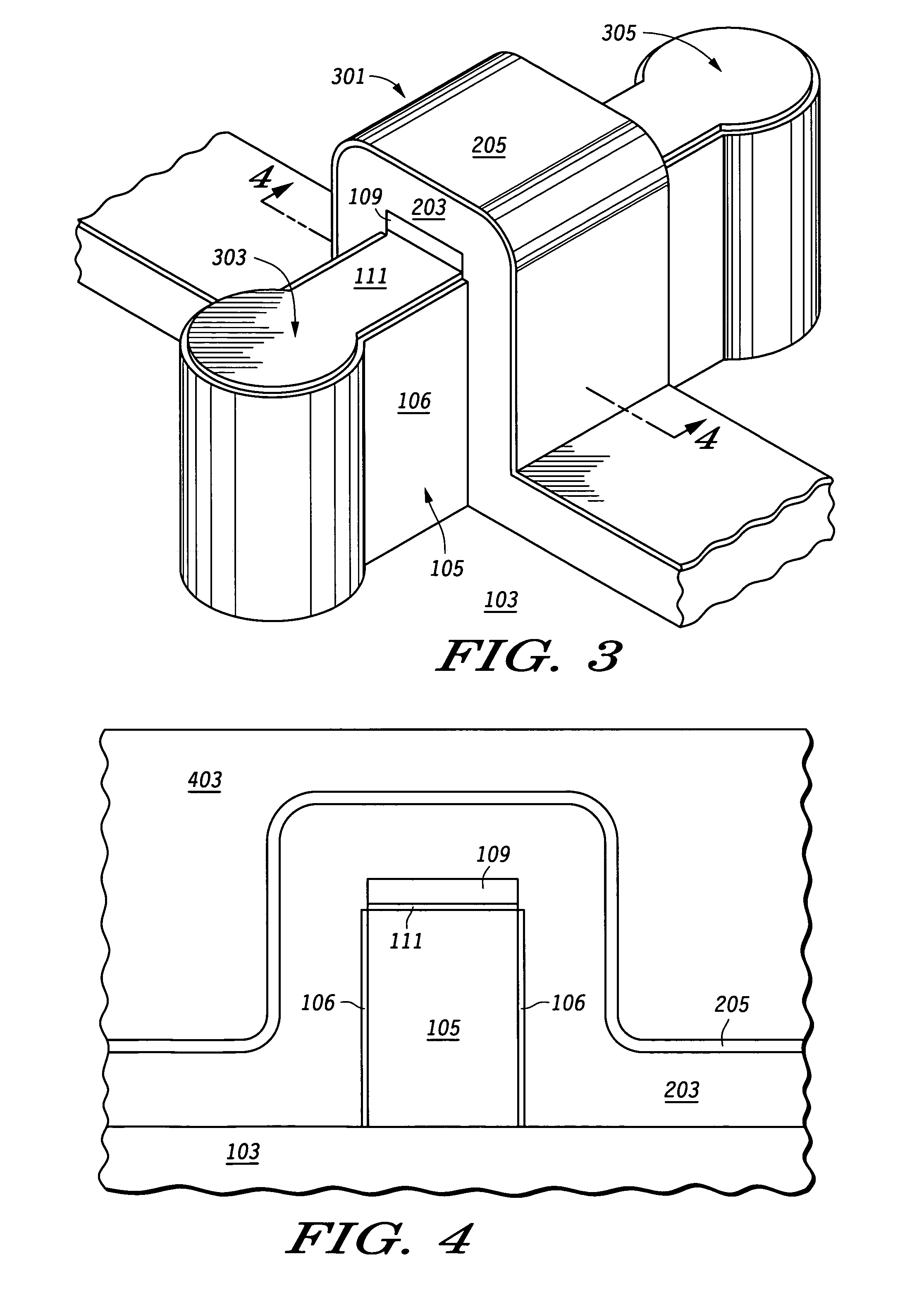

Method and circuit for multiplying signals with a transistor having more than one independent gate structure

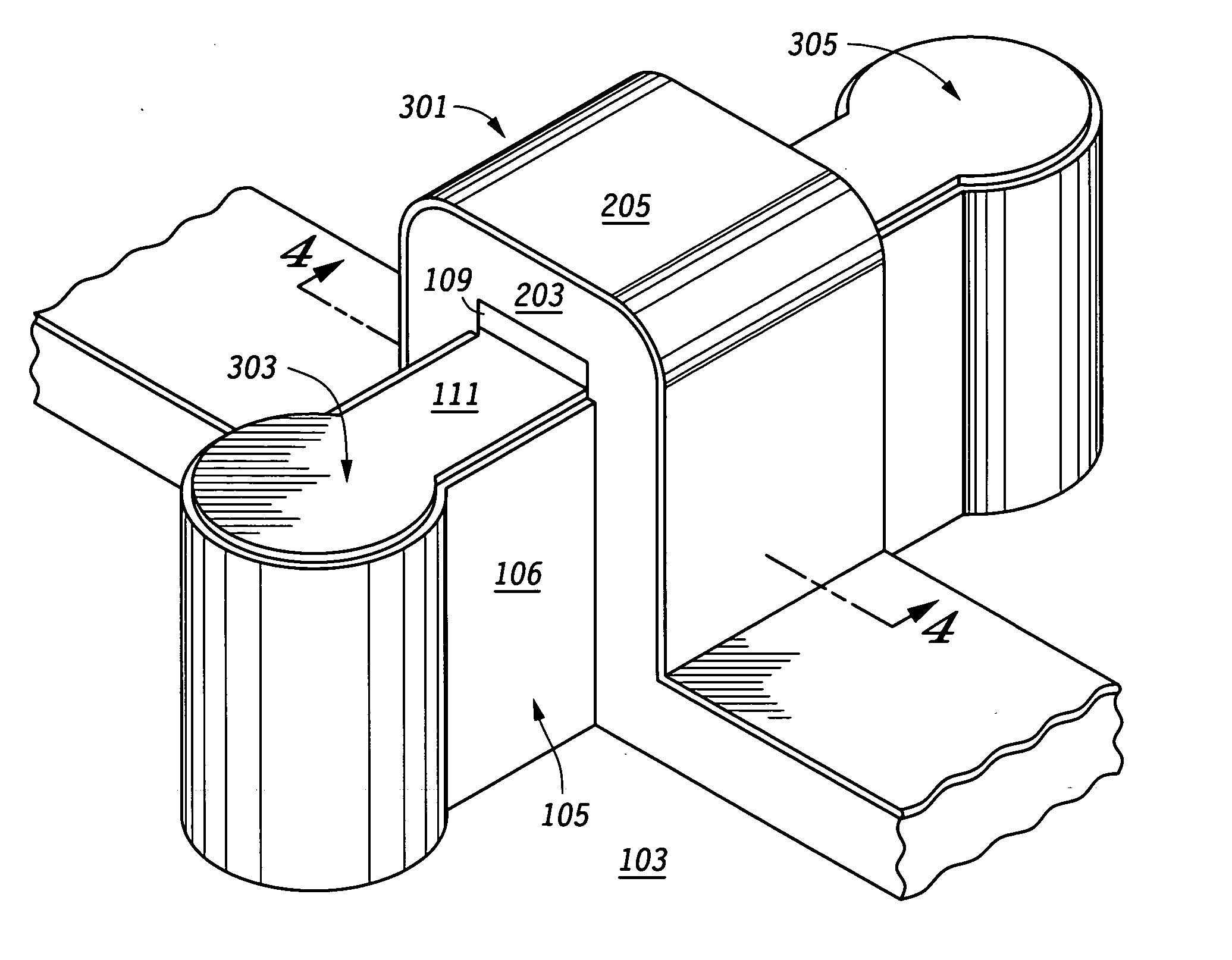

A double gate semiconductor device (2006) is used beneficially as a multiplier (2000). The double gate semiconductor device (2006) has a lateral fin (105) as the channel region with the gates formed opposite each other on both sides of the fin. The lateral positioning of the fin provides symmetry between the two gates. To increase drive current, multiple transistors are easily connected in parallel by having a continuous fin structure (2106) with alternating source / drain terminals (2120, 2122, 2124, 2126) in which the sources are connected together and the drains are connected together. Gates (2116, 2110) are positioned between each pair of adjacent source / drain terminals and electrically connected together. The multiplier (2000) may also be used as a mixer and further as a phase detector.

Owner:NORTH STAR INNOVATIONS

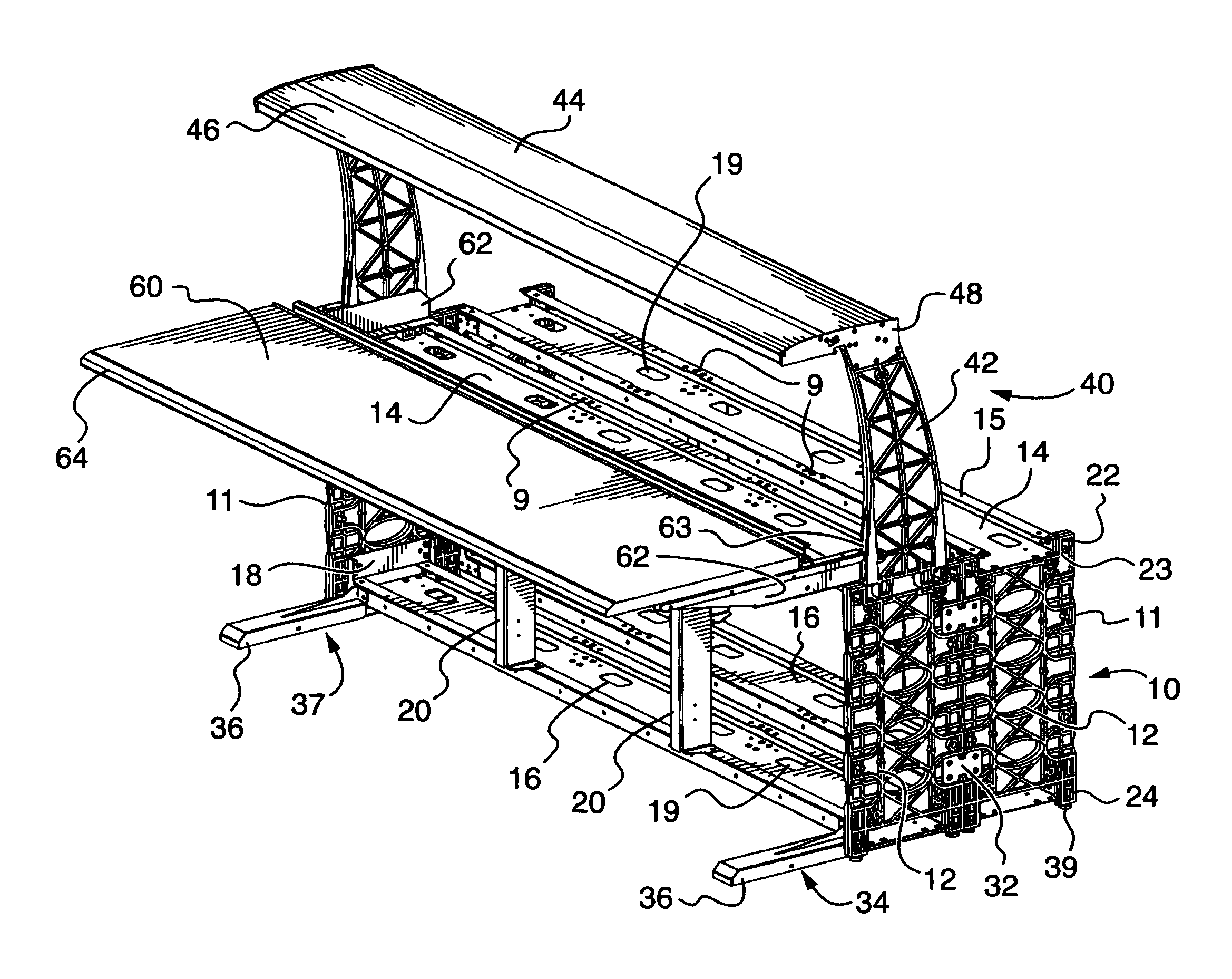

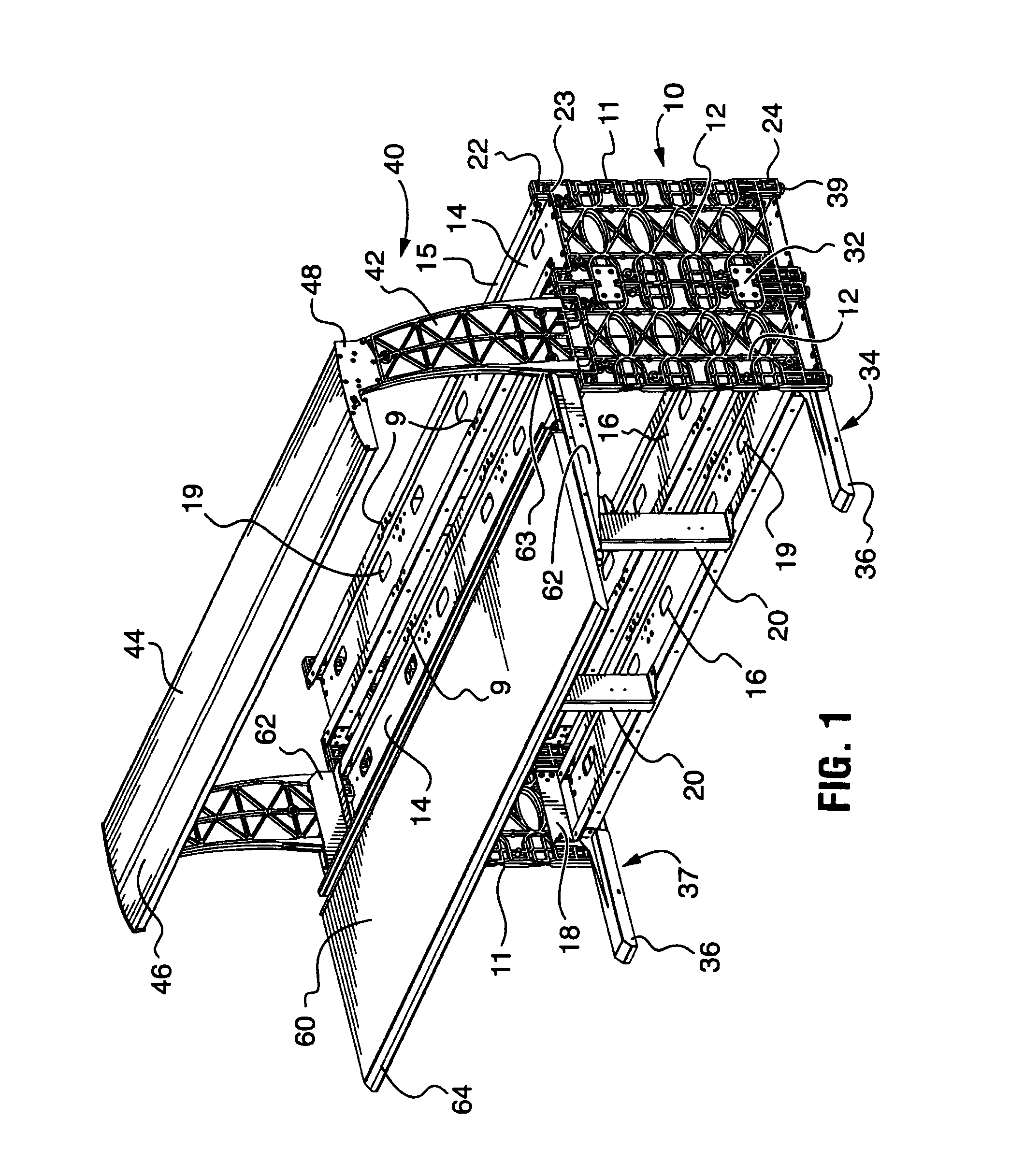

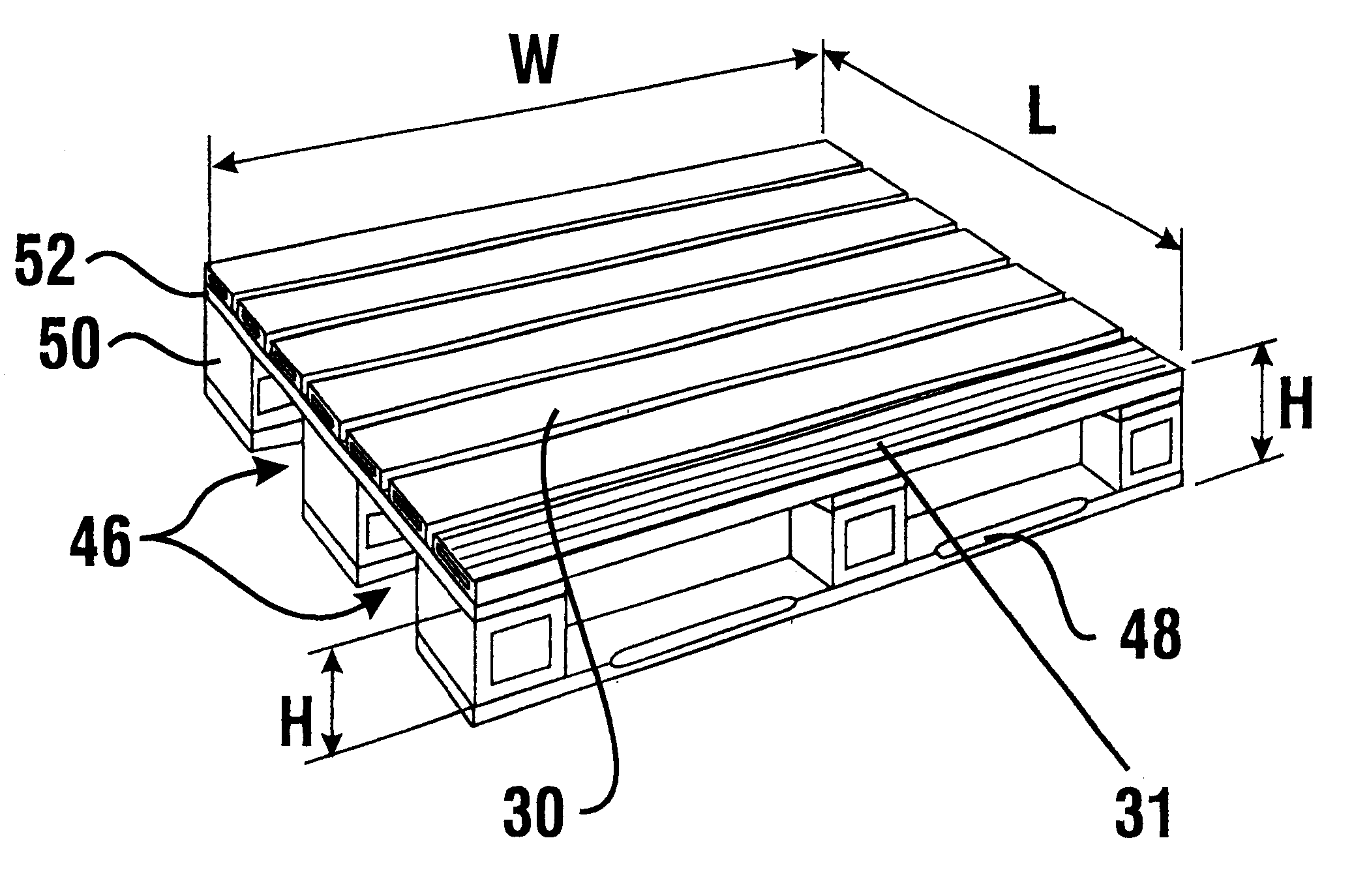

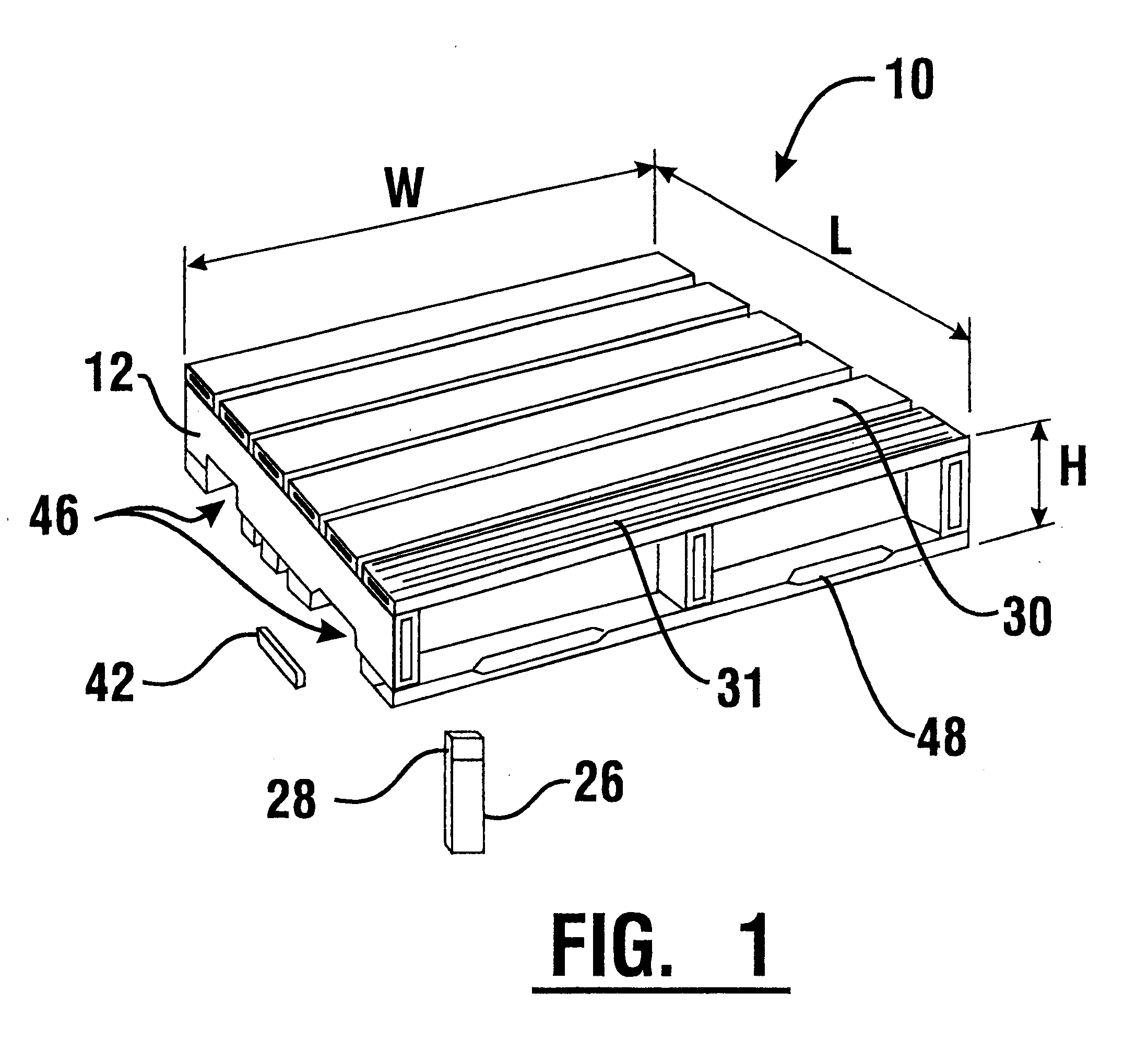

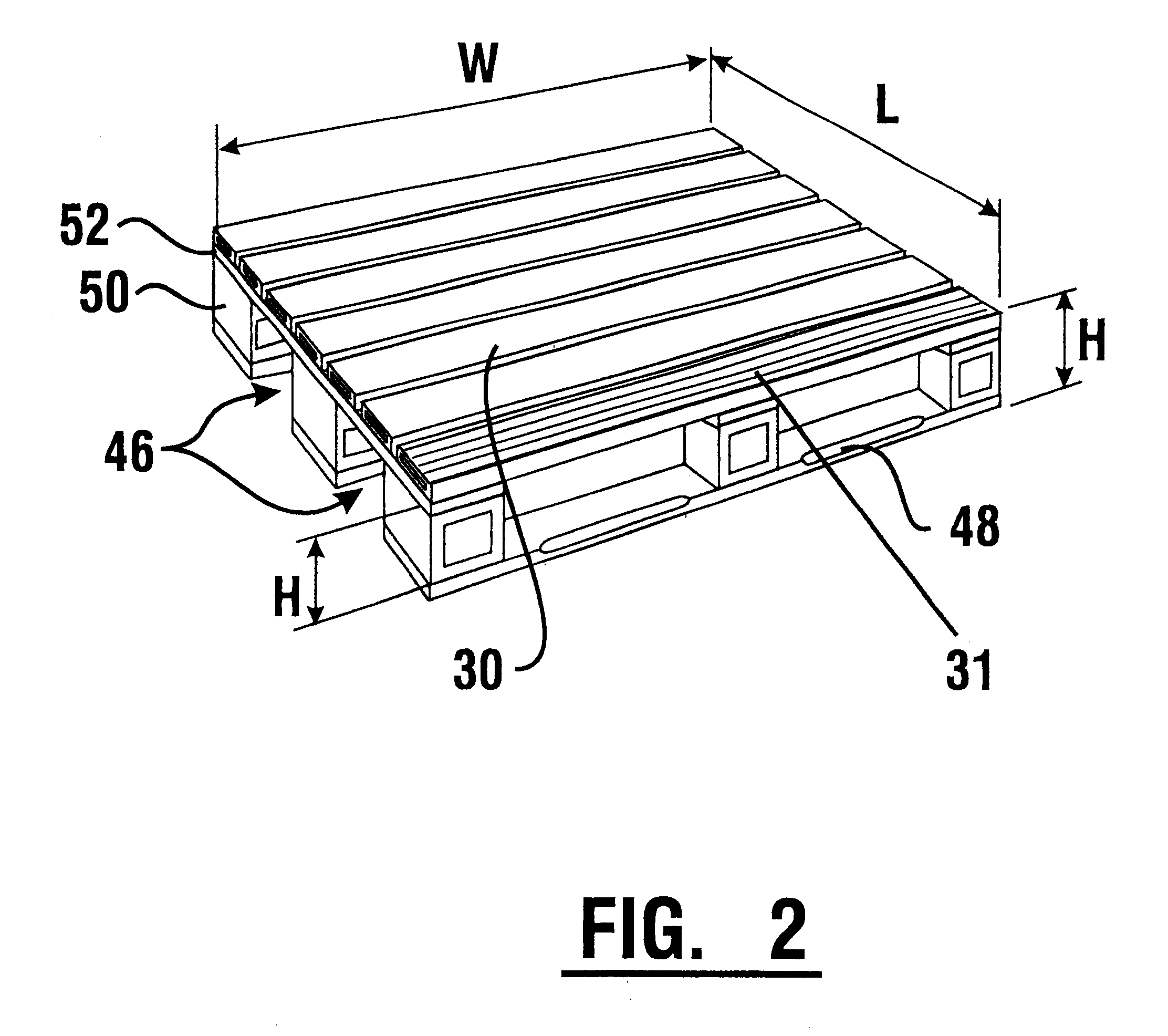

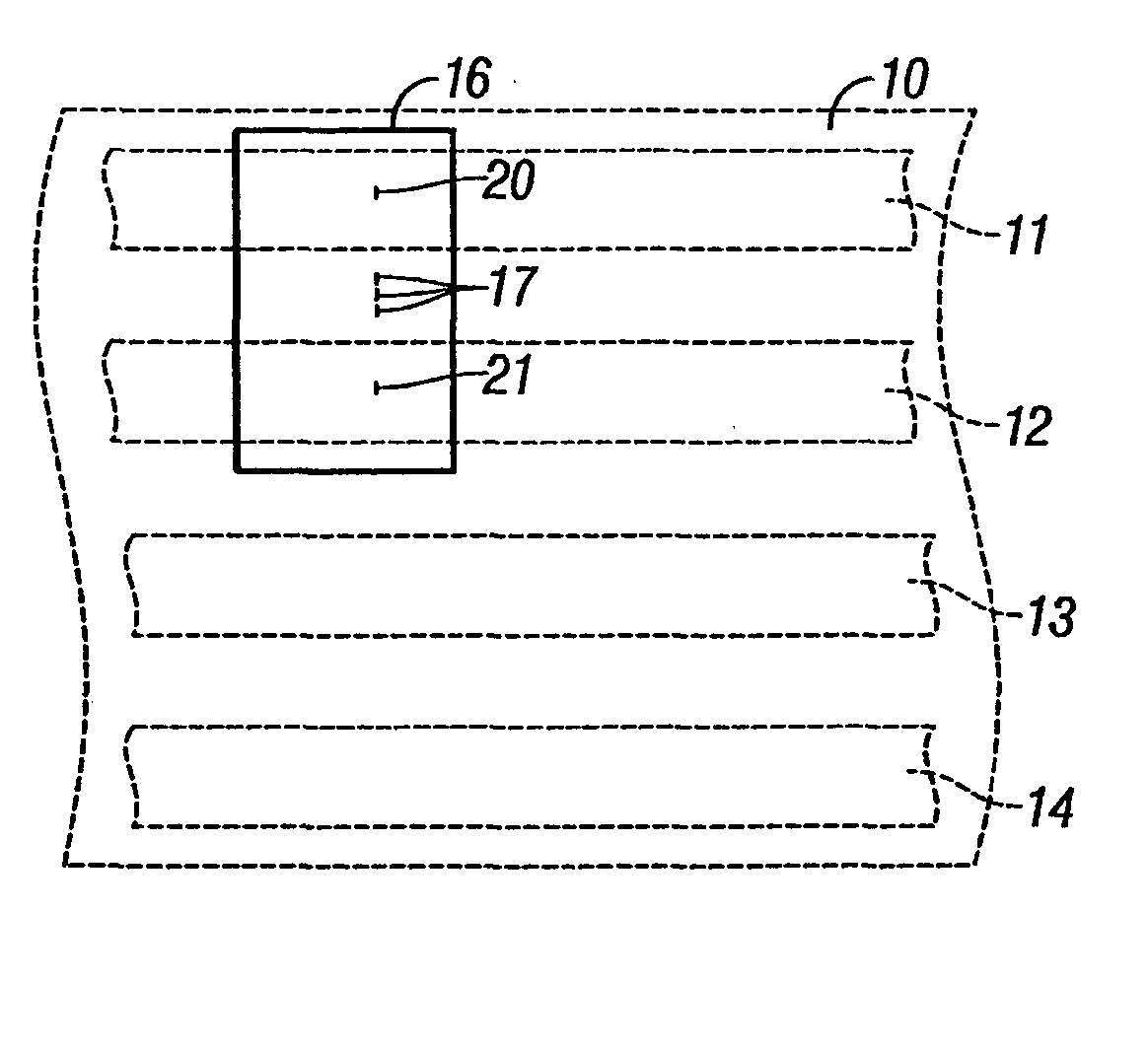

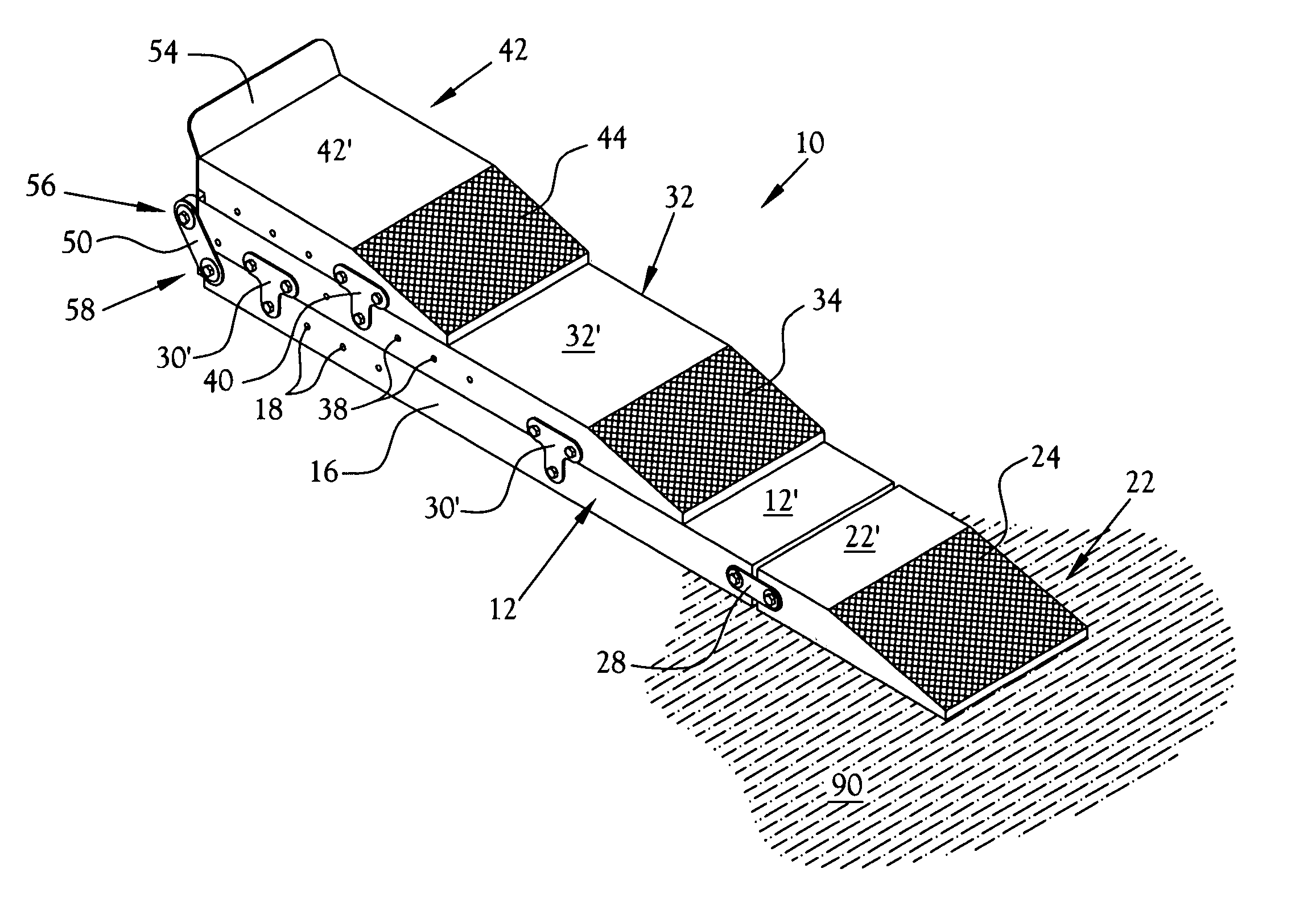

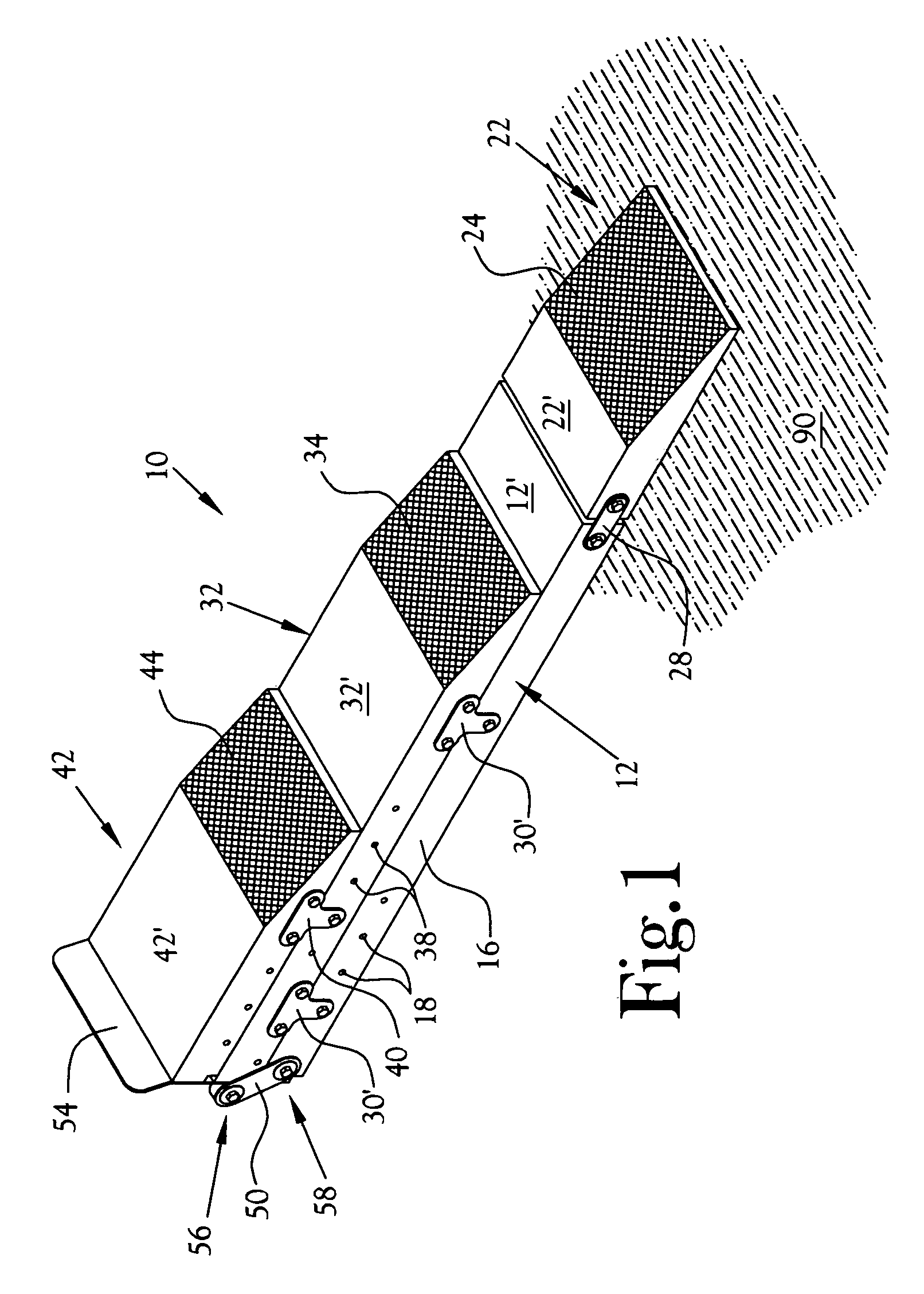

Plastic pallet

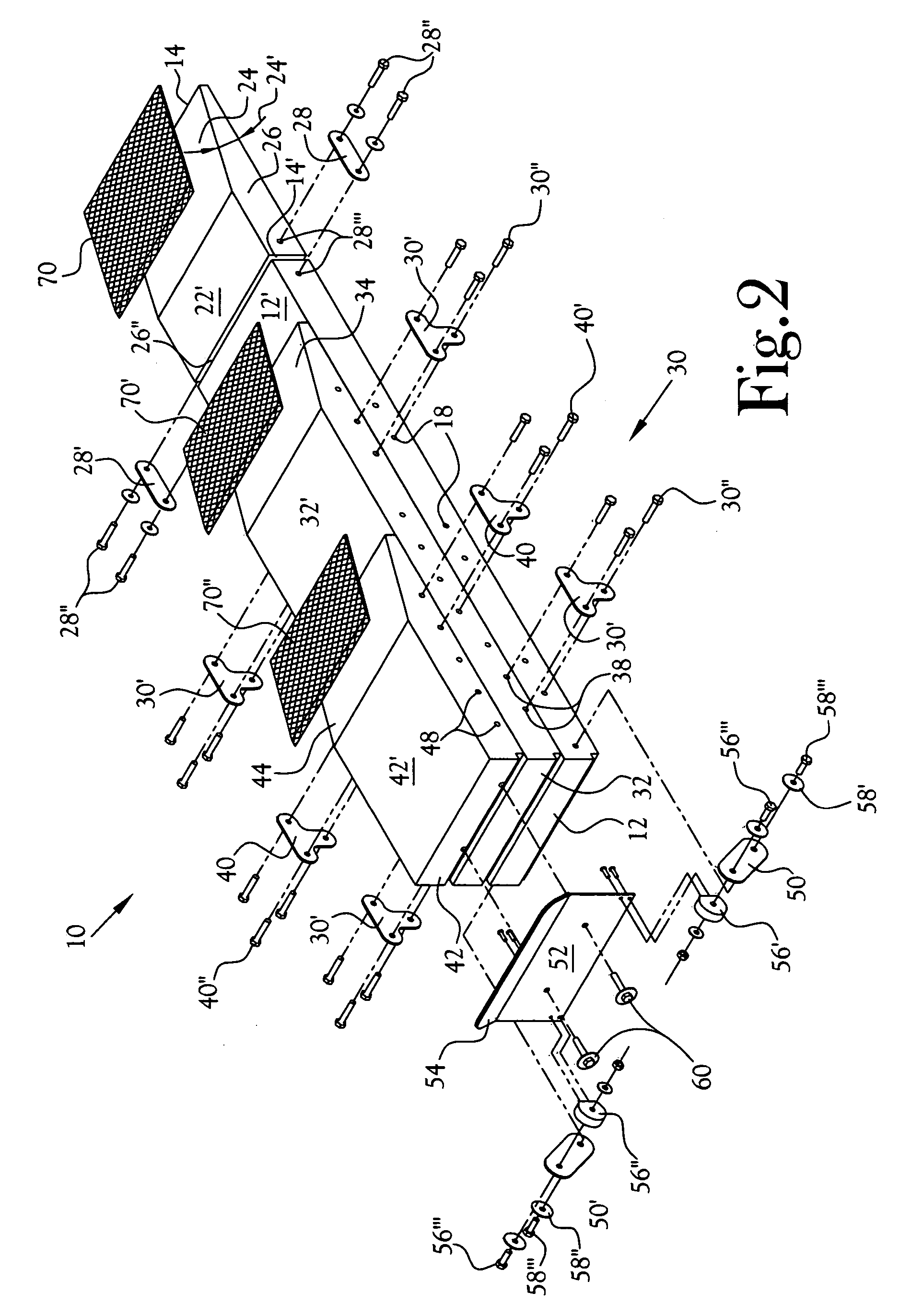

A plastic pallet (10) having good load bearing construction and held together without mechanical fasteners, includes deck boards (30). The deck boards include ridges (24) on an upper side (32) and a lower side (34) thereof. Deck boards are positioned transversely on stringers (12) and joined thereto by either an adhesive or thermoplastic welding processes. The stringers and deck boards may be provided with end caps (26, 42) which seal interior areas of the stringers and deck boards and prevent tearing thereof. The stringers and deck boards have interior reinforcement ribs (22,40). The cross sectional profiles of the stringers, deck boards, and end caps provide a cost effective and light weight pallet. Openings which extend between the stringers allow for either two way fork entry and / or four way fork entry. The stringers and deck boards provide flexibility in constructing pallets of various designs. The plastic pallet preferably is highly durable and fully recyclable.

Owner:THE GEON CO

Interspinous process distraction implant and method of implantation

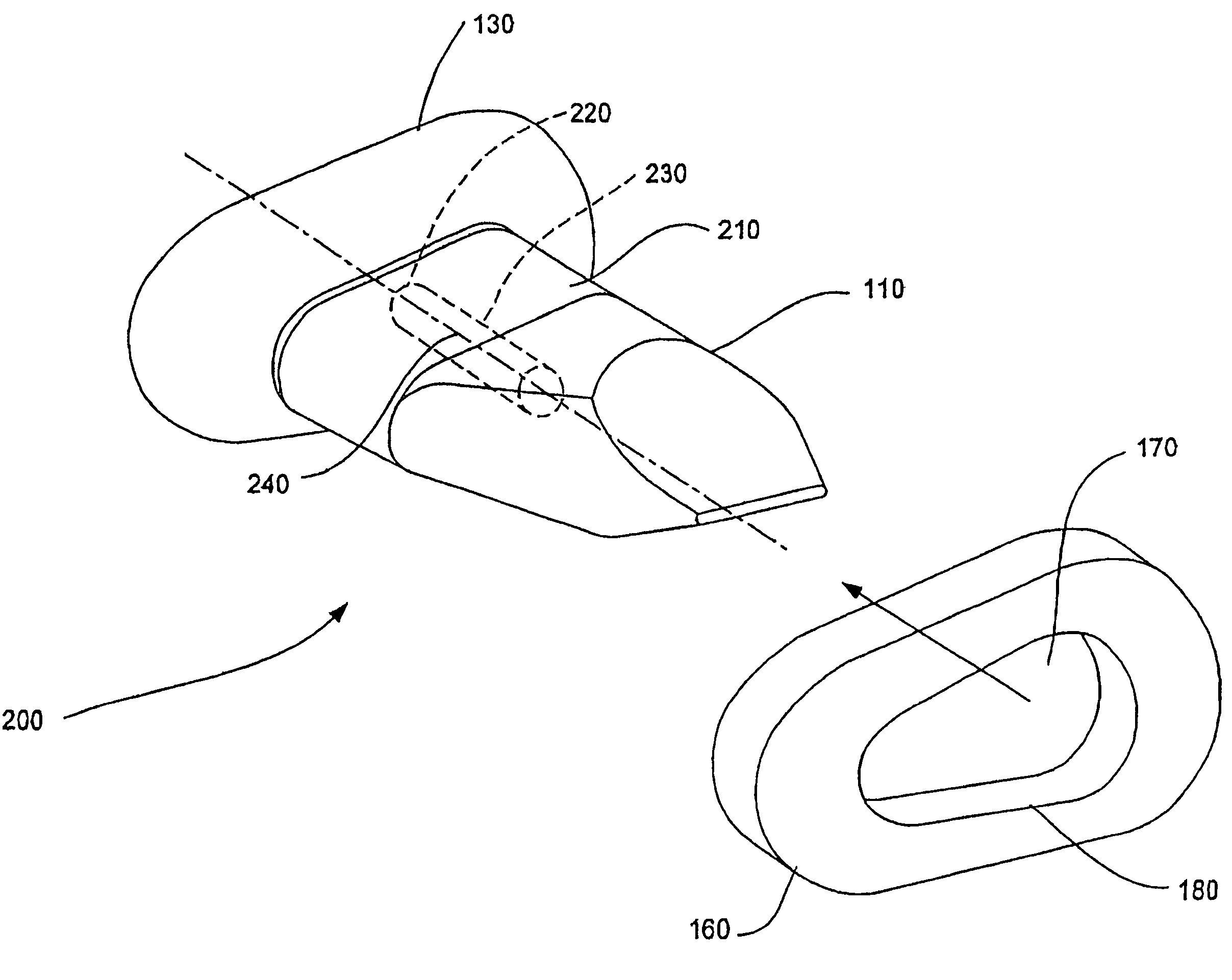

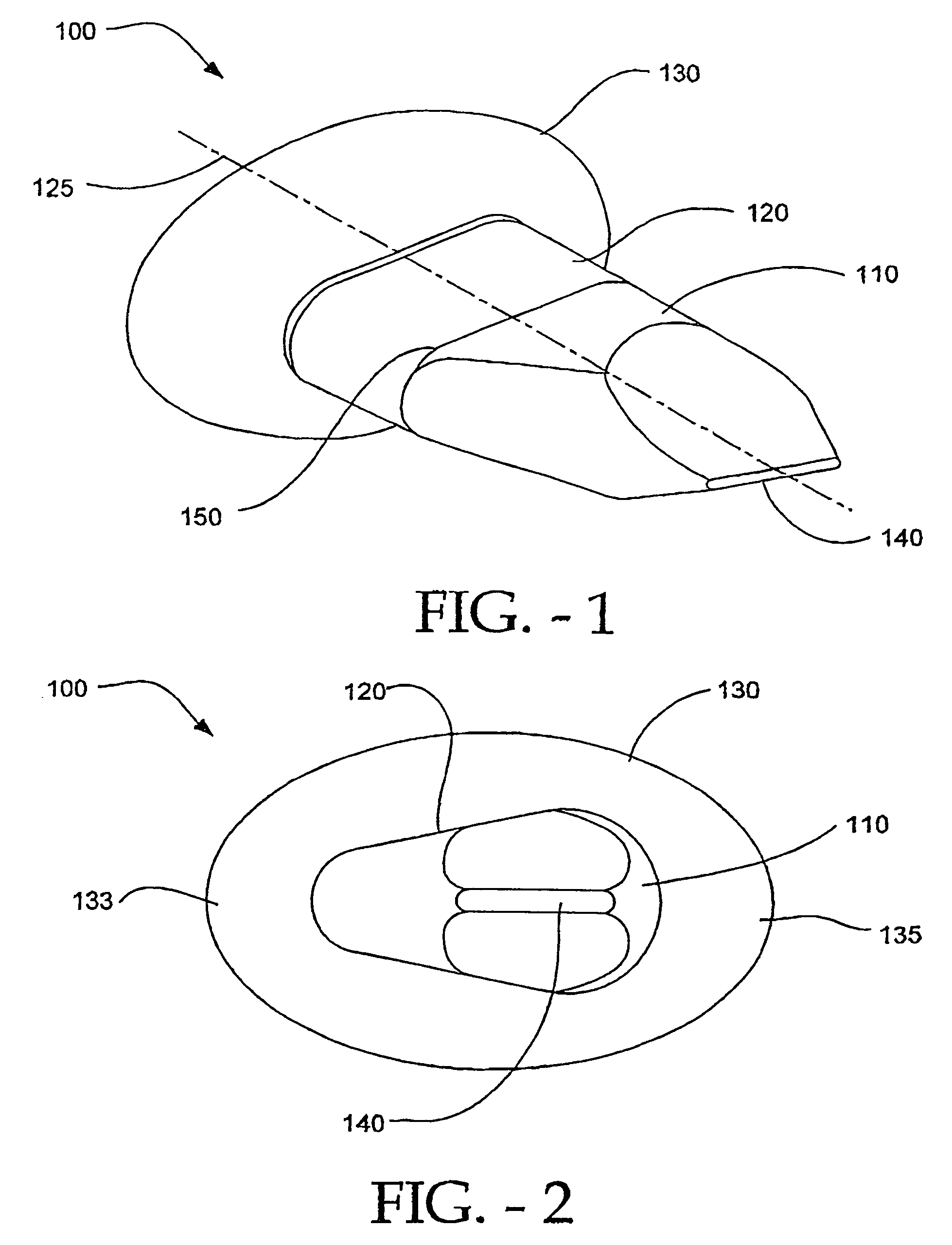

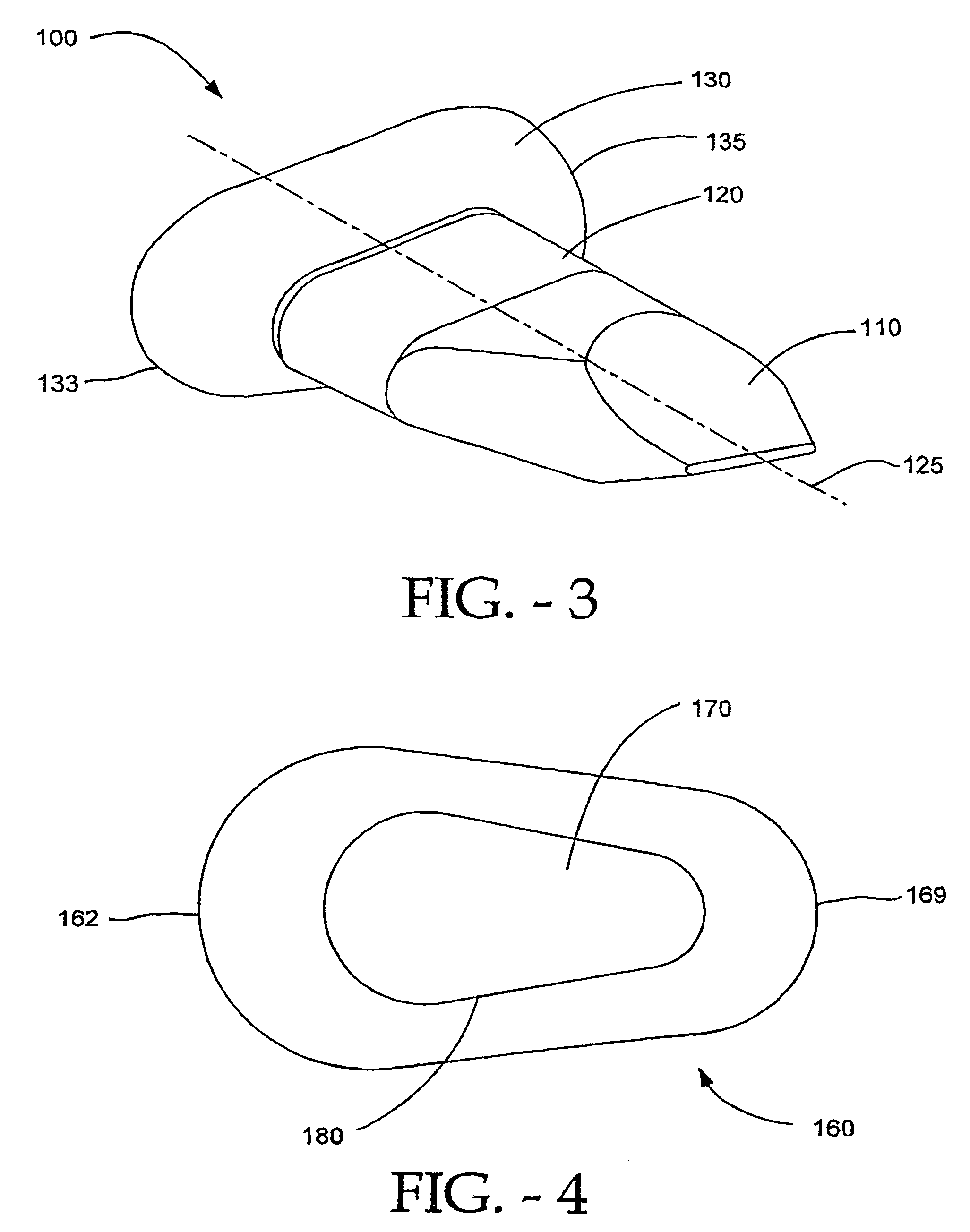

An implant for positioning between the spinous processes, such as the spinous processes of cervical vertebrae, include first and second wings foe lateral positioning and a spacer located between the adjacent spinous processes. The implant can be positioned using minimally invasive procedures without modifying the bone or severing ligaments. The implant is shaped in accordance with the anatomy of the spine.

Owner:MEDTRONIC EURO SARL

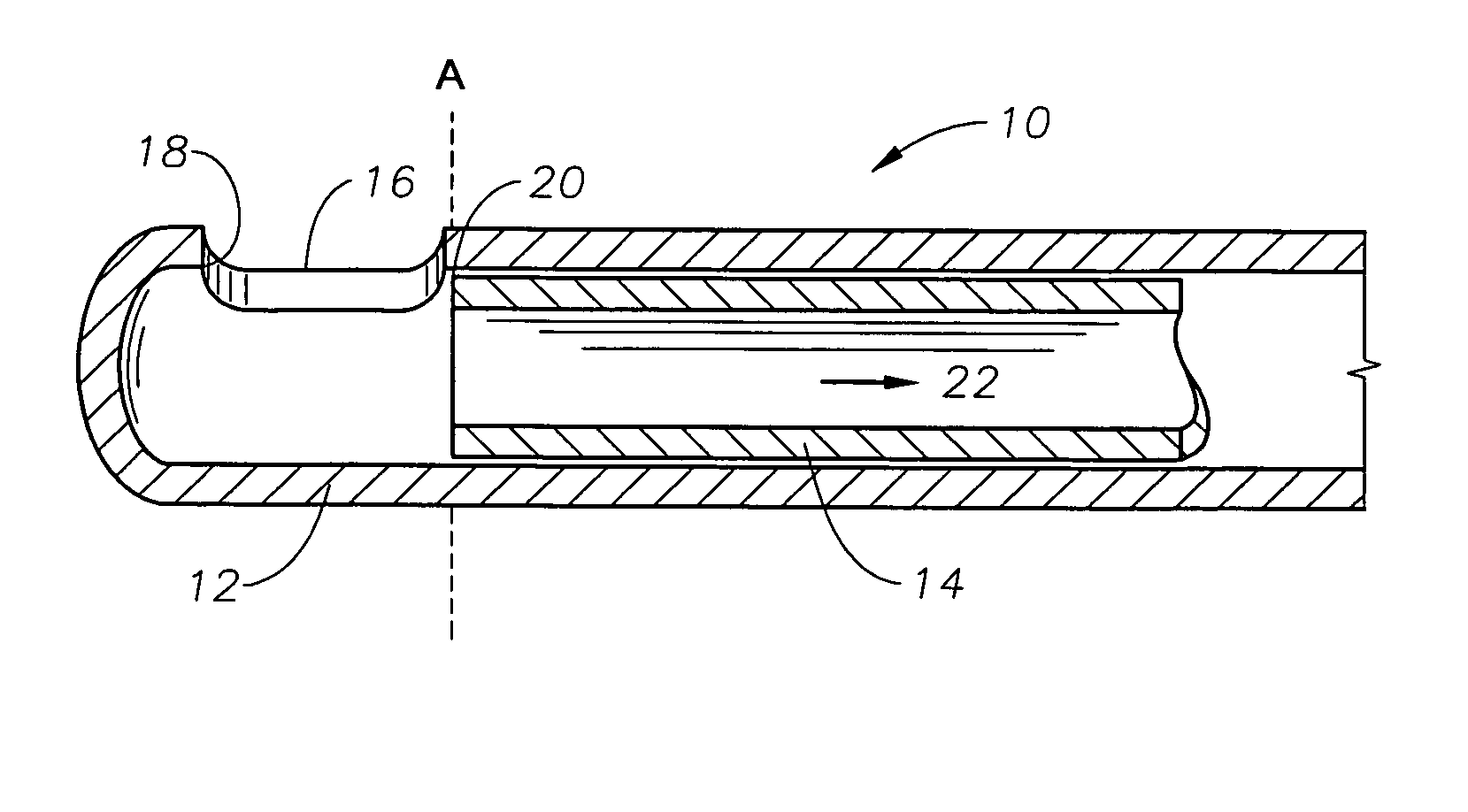

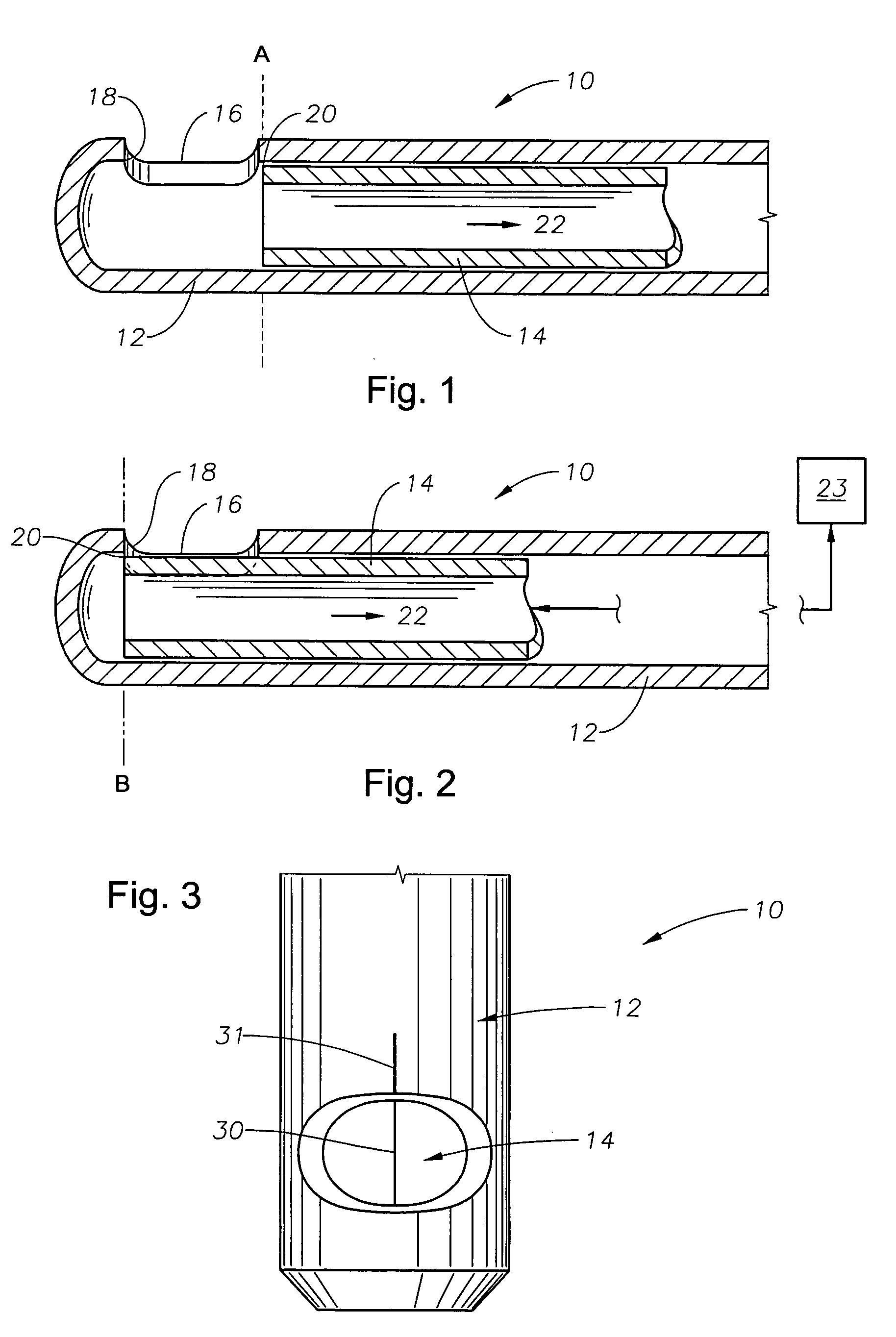

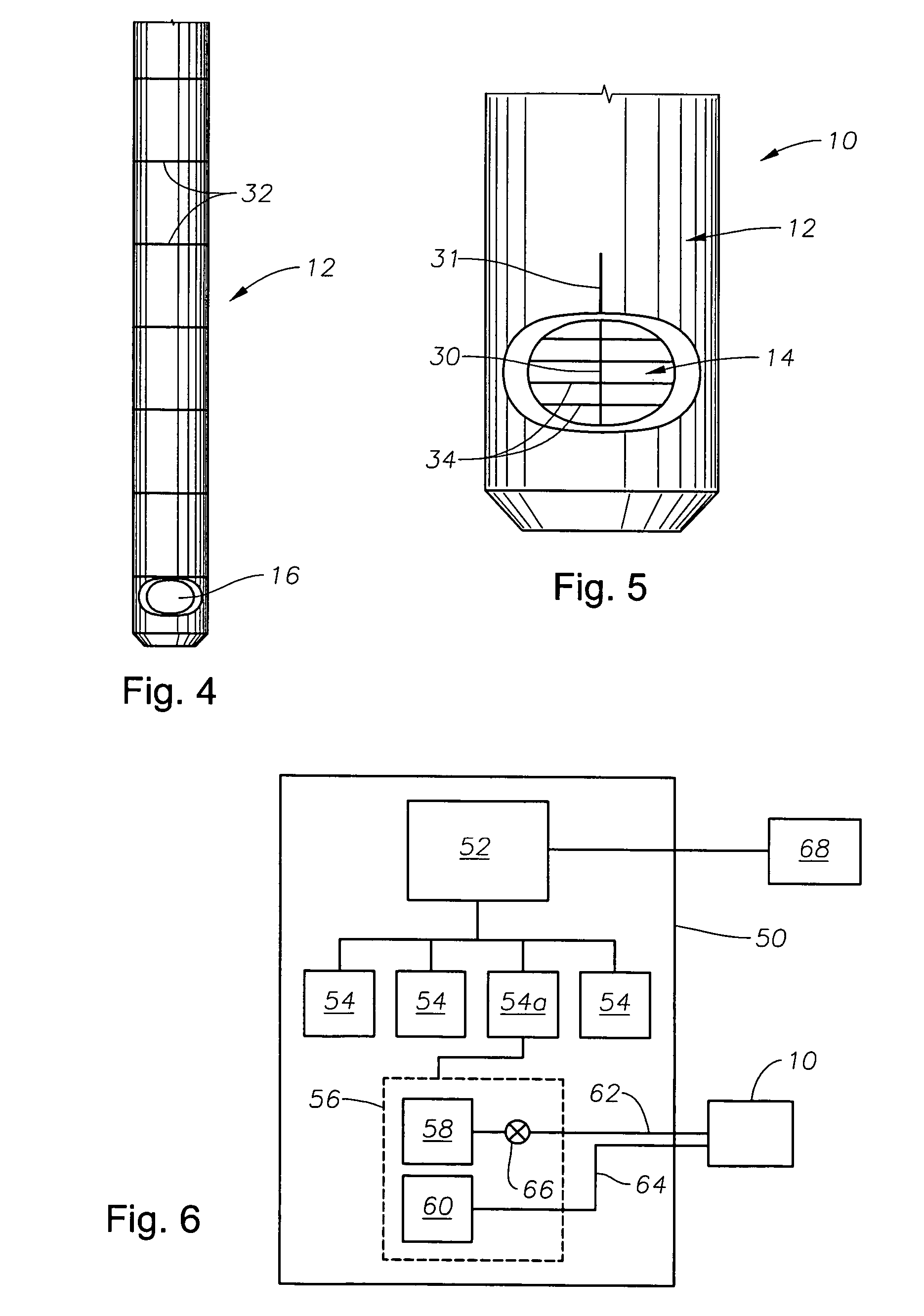

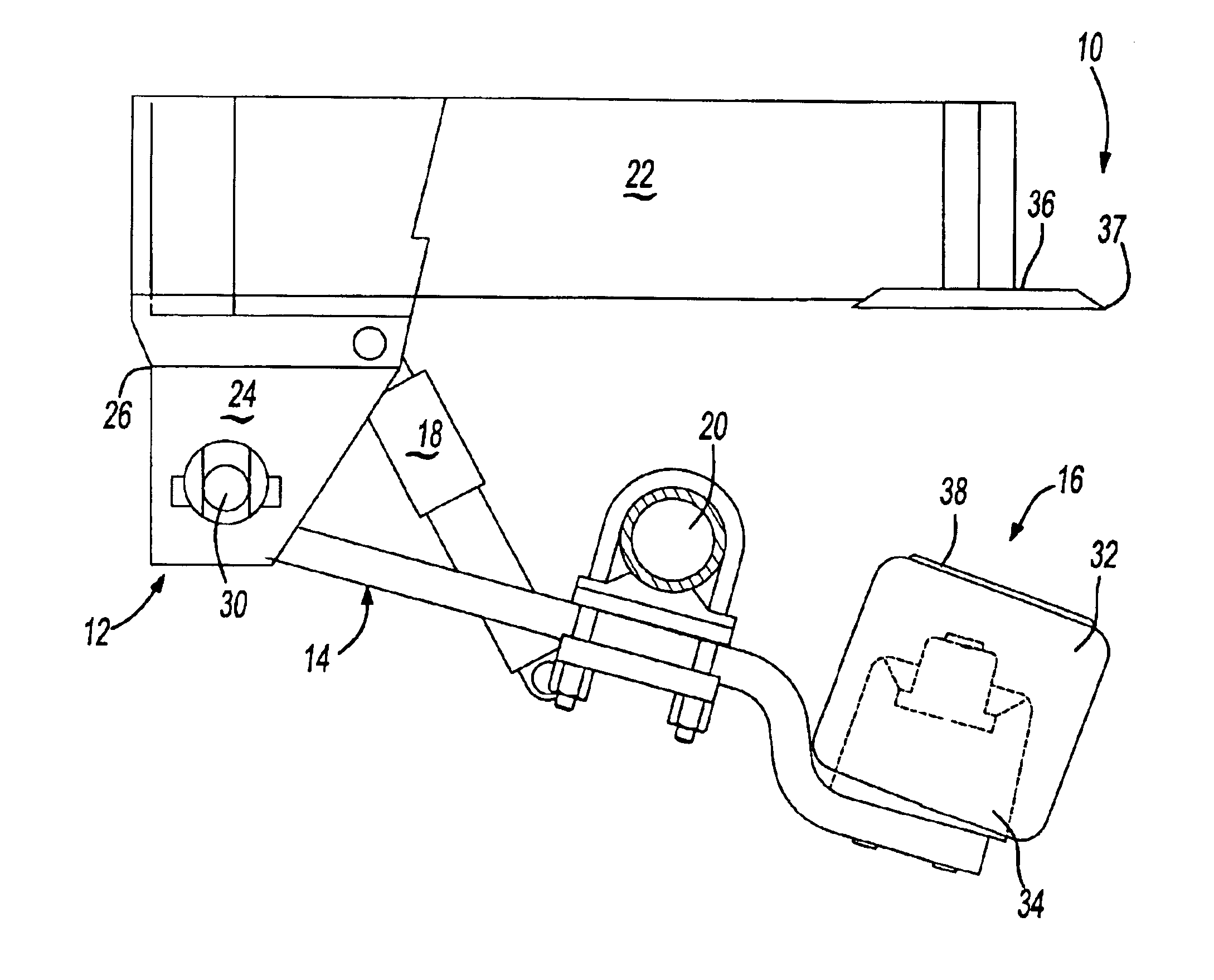

Calibrated surgical probe

A microsurgical probe tip and method of using same are disclosed. One embodiment of the microsurgical probe tip comprises: an outer cutting member, comprising a first tube having a wall, a closed end and a port formed in the wall near the closed end; an inner cutting member, comprising a second tube coaxial with and operable to move in a reciprocating motion within the first tube and having a first end operable to be coupled to a driving mechanism and a second end with a cutting edge for cutting tissue; a first alignment mark on the outer cutting member at a first predetermined position adjacent to the port; and a second alignment mark on the inner cutting member at a second predetermined position adjacent to the cutting edge of the inner cutting member, wherein the second alignment mark is visible through the port and operable to be aligned with the first alignment mark such that when the first and second alignment marks are aligned, a preferred relative positioning between the inner and outer cutting members is achieved. The microsurgical probe tip can further comprise one or more radial alignment marks on the inner cutting member, wherein the radial alignment marks are parallel to one another at fixed intervals from one another and positioned so that one or more of the radial alignment marks are visible through the port so as to indicate the relative lateral positioning between the inner cutting member and the outer cutting member. The radial alignment marks can be made by a method, or combination of methods, such as laser cutting, inkjet printing, and mechanical scribing. The driving mechanism can be a pneumatic driving mechanism, an electro-mechanical driving mechanism, and / or a magnetic driving mechanism. The microsurgical probe tip can further comprising a plurality of gauge marks on an outer surface of the outer cutting member, wherein the gauge marks are parallel to one another at a fixed interval (e.g., 1 millimeter) from one another and positioned so that the gauge marks can be used as a measuring tool in a surgical environment

Owner:ALCON INC

Method and circuit for multiplying signals with a transistor having more than one independent gate structure

A double gate semiconductor device (2006) is used beneficially as a multiplier (2000). The double gate semiconductor device (2006) has a lateral fin (105) as the channel region with the gates formed opposite each other on both sides of the fin. The lateral positioning of the fin provides symmetry between the two gates. To increase drive current, multiple transistors are easily connected in parallel by having a continuous fin structure (2106) with alternating source / drain terminals (2120, 2122, 2124, 2126) in which the sources are connected together and the drains are connected together. Gates (2116, 2110) are positioned between each pair of adjacent source / drain terminals and electrically connected together. The multiplier (2000) may also be used as a mixer and further as a phase detector.

Owner:NORTH STAR INNOVATIONS

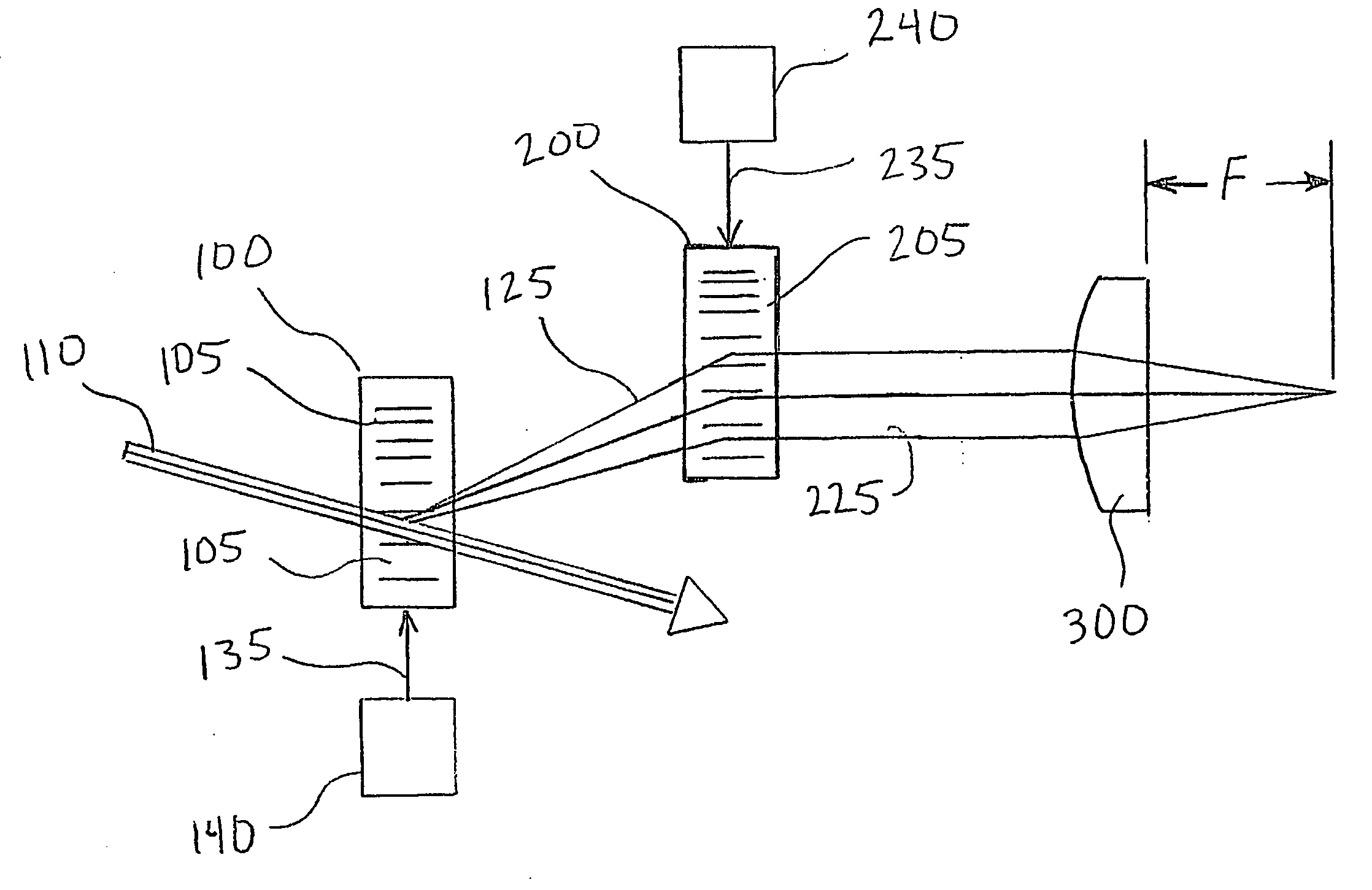

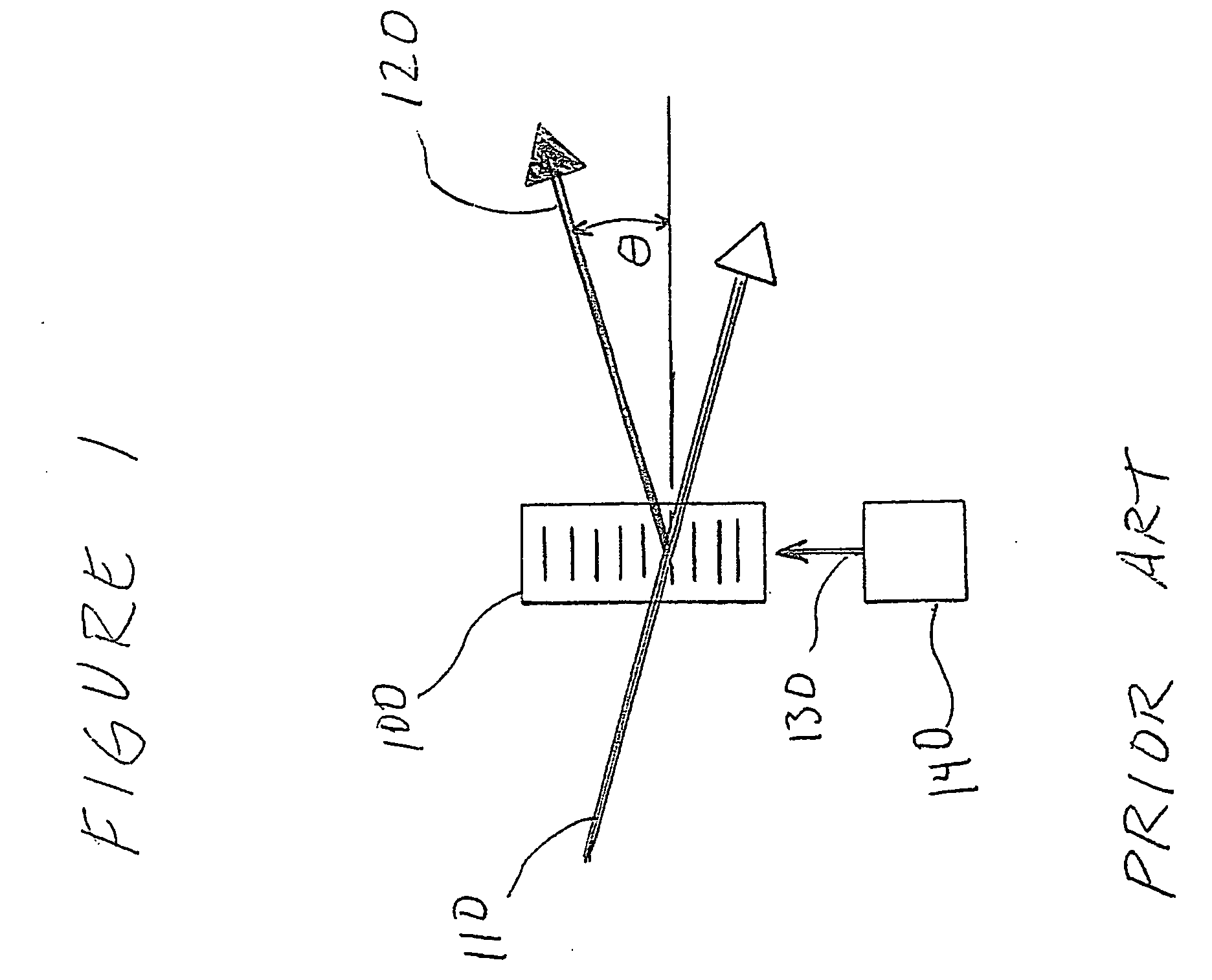

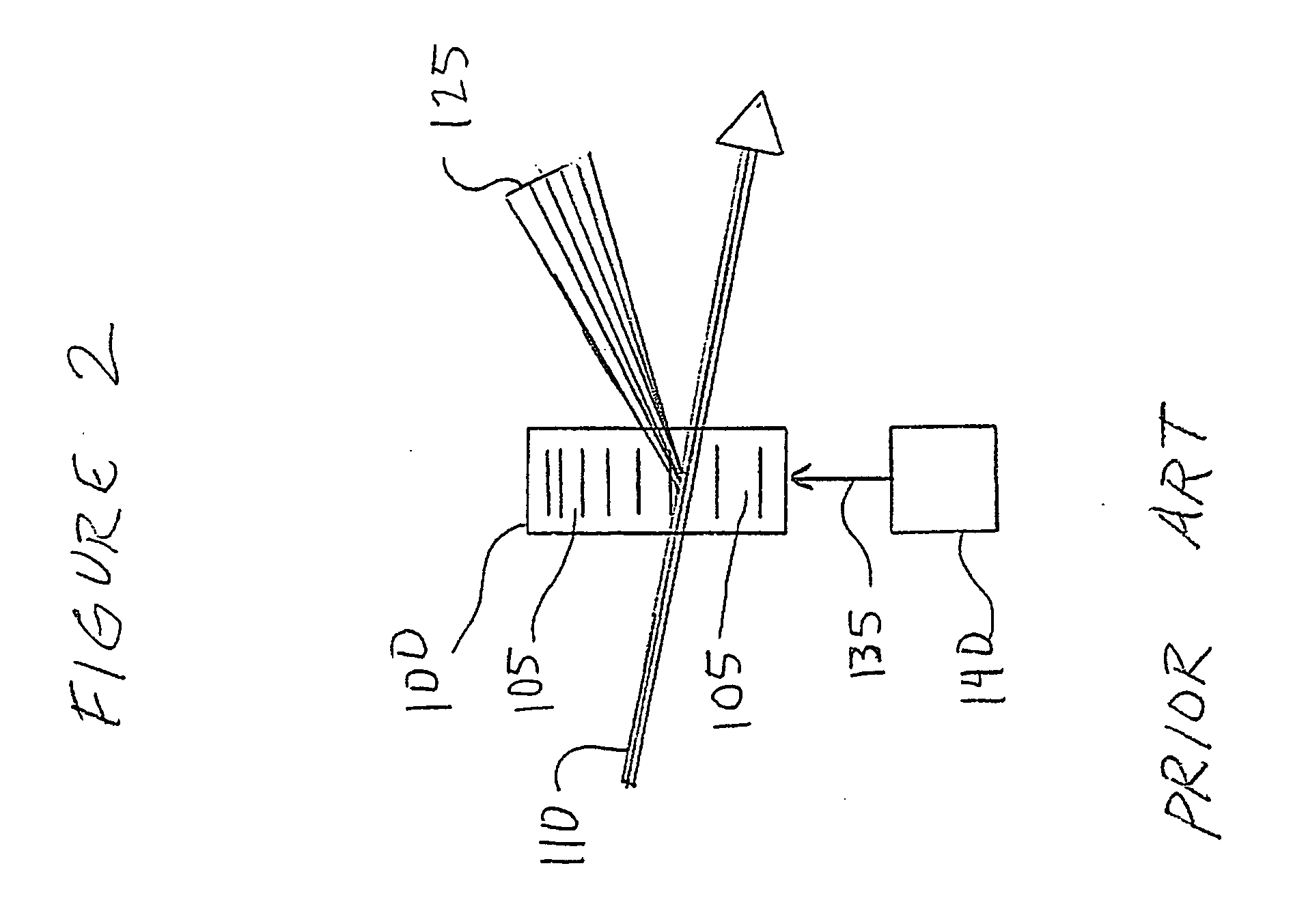

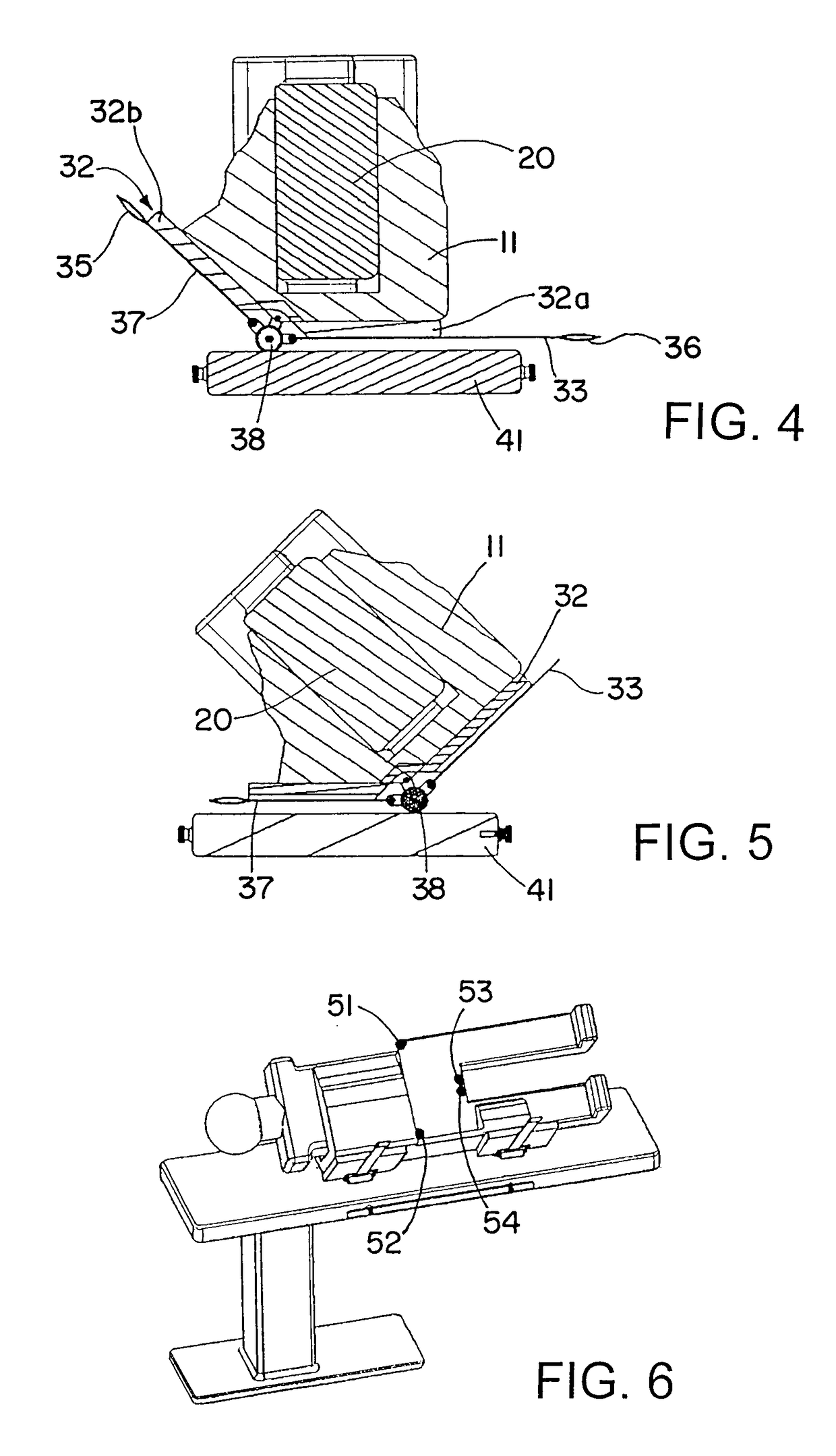

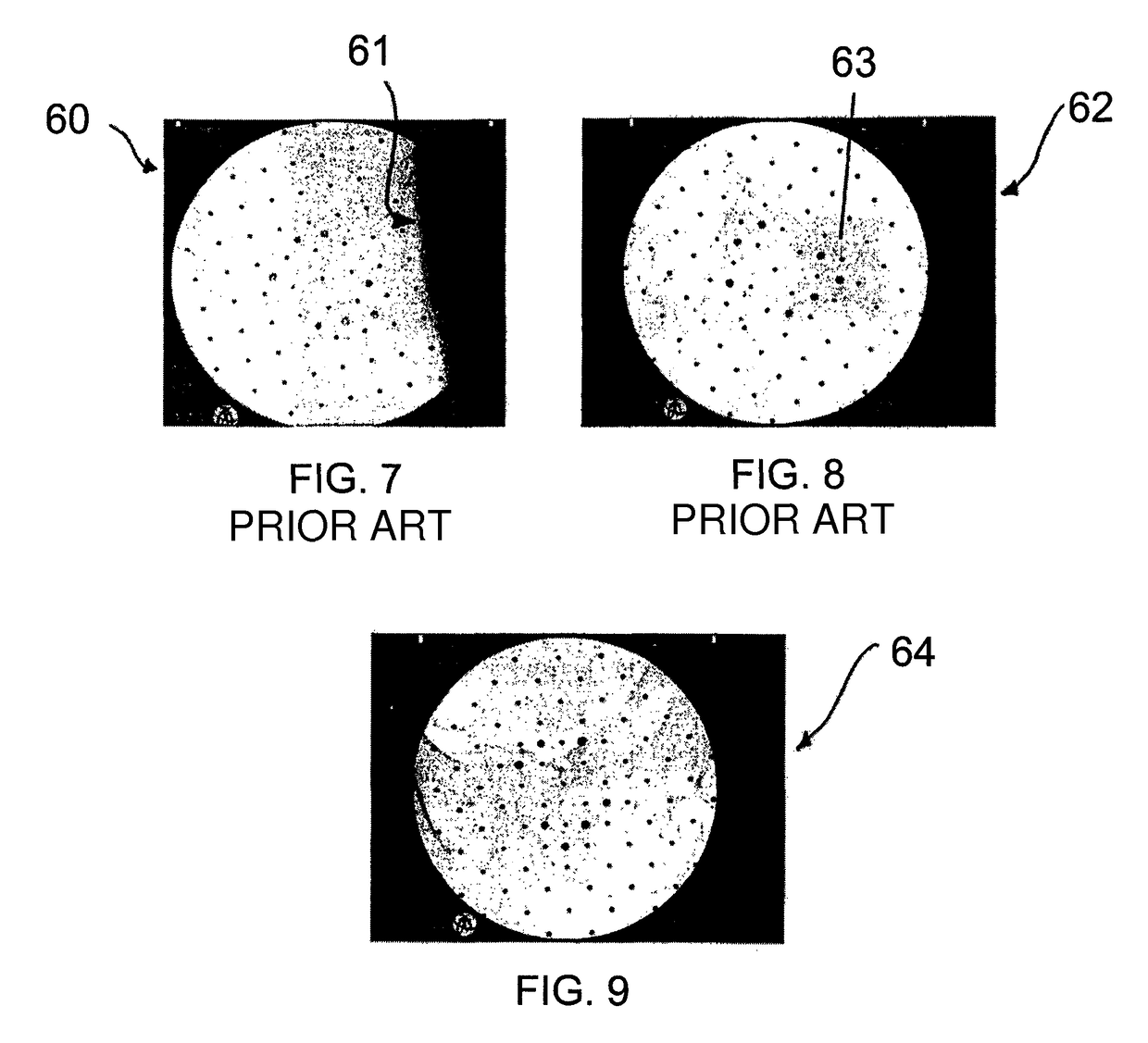

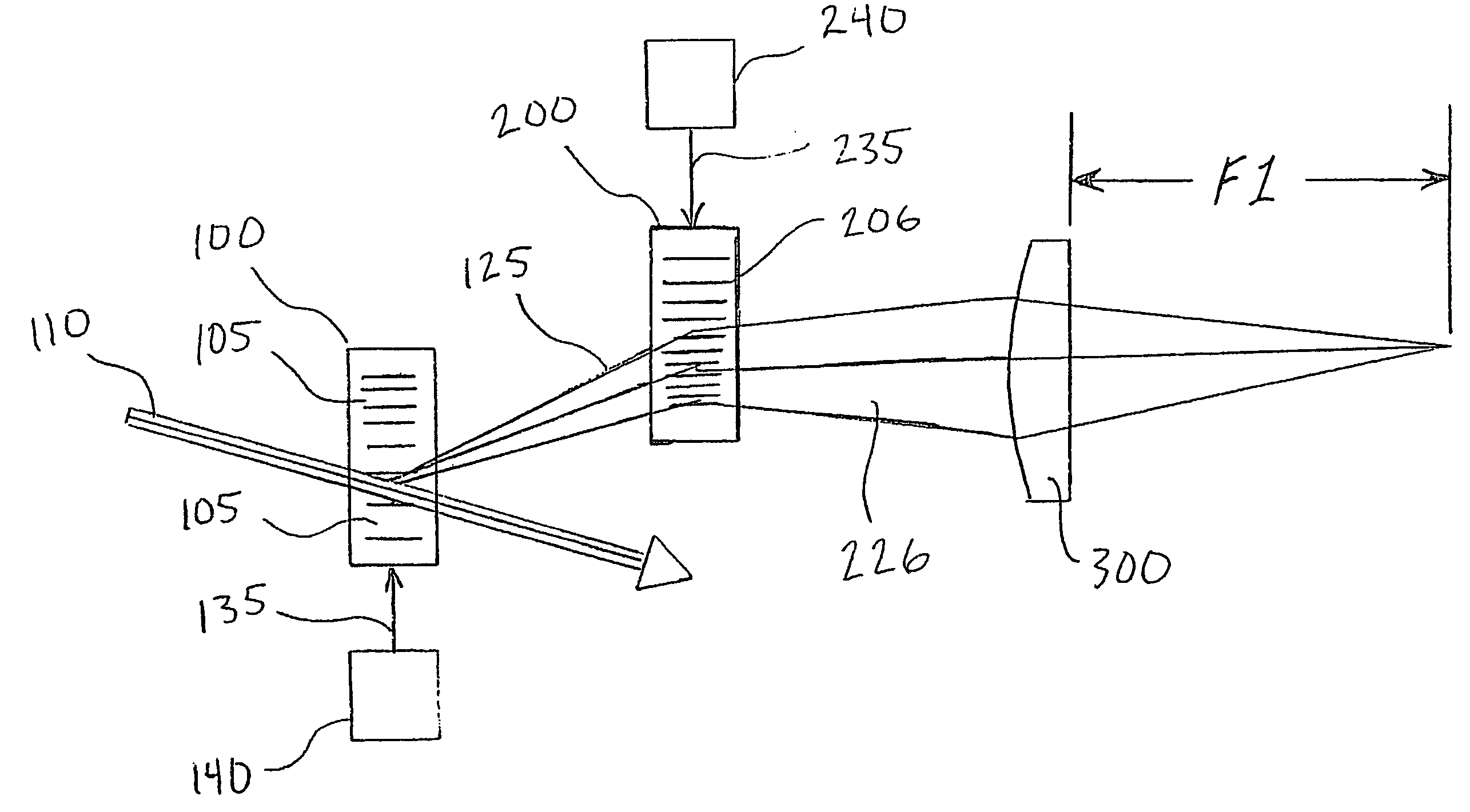

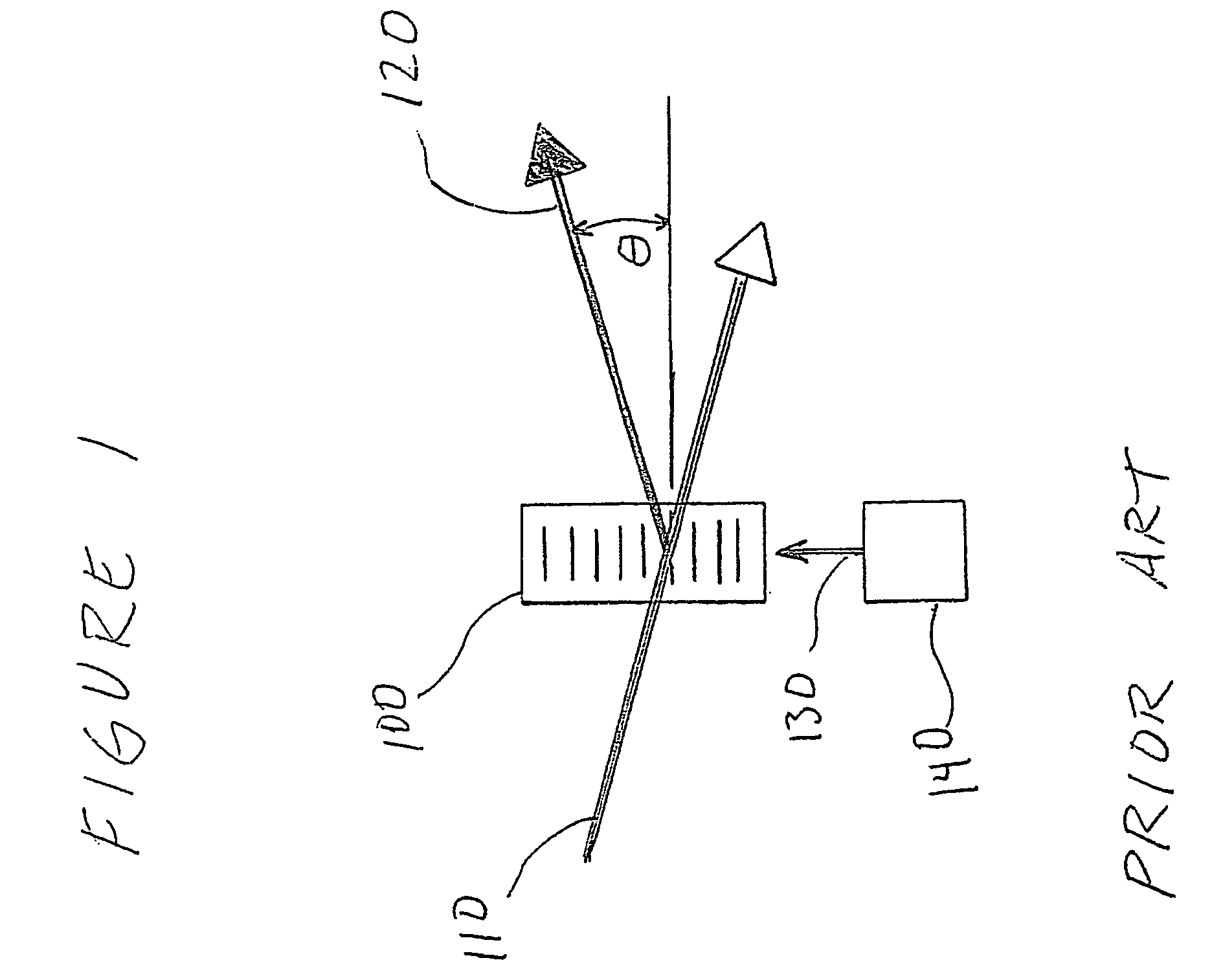

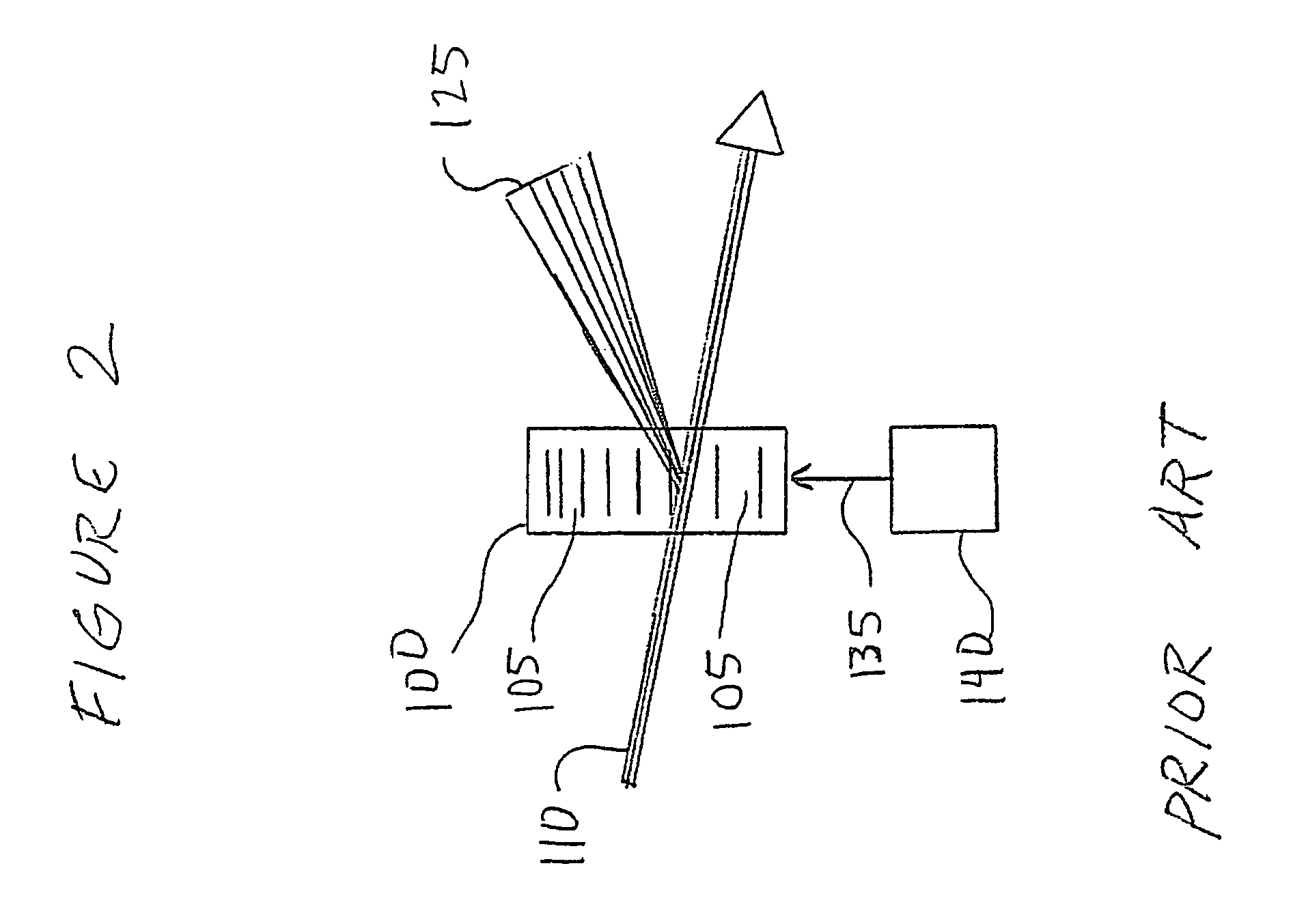

High speed microscope with three-dimensional laser beam scanning

InactiveUS20060071143A1Removes time dependenceFast scanningBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansAcousto optic deflectorLight beam

A system and method for independently controlling the collimation and lateral positioning of a light beam comprises at least one acousto-optic deflector and a pair of counter propagating acoustic waves with offset frequencies. While the frequency offset controls the lateral positioning of the light beam, a frequency gradient across the acousto-optic deflectors controls the collimation of the light beam.

Owner:BAYLOR COLLEGE OF MEDICINE

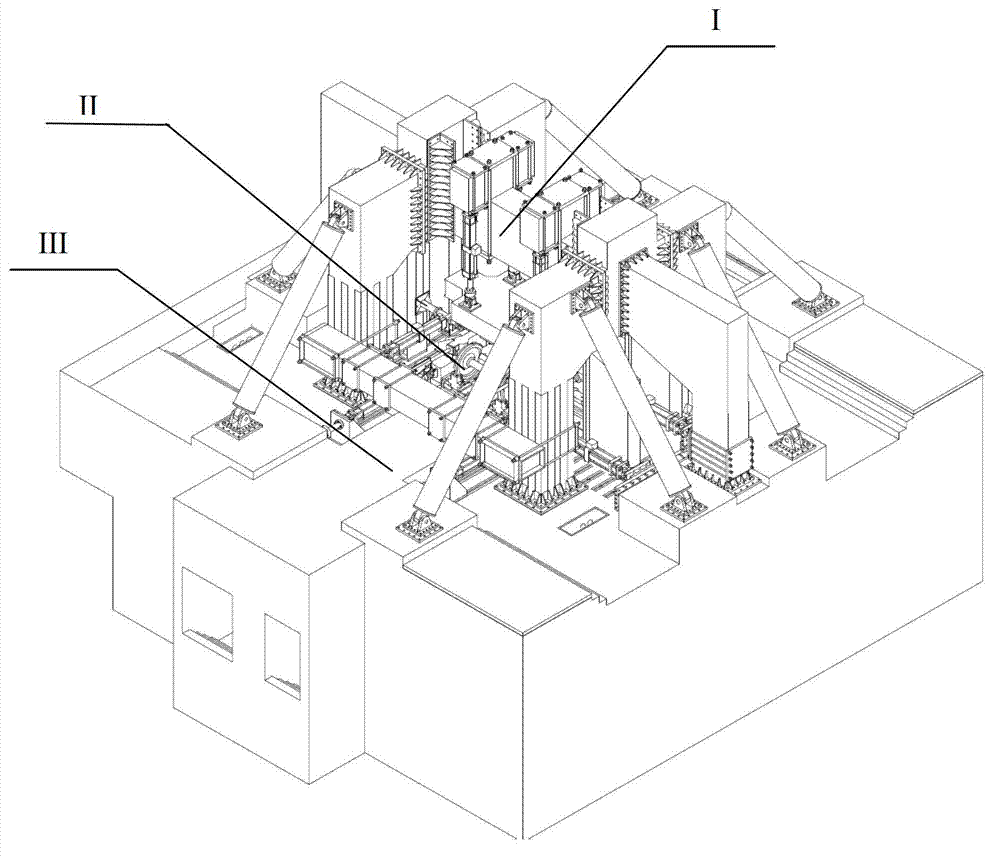

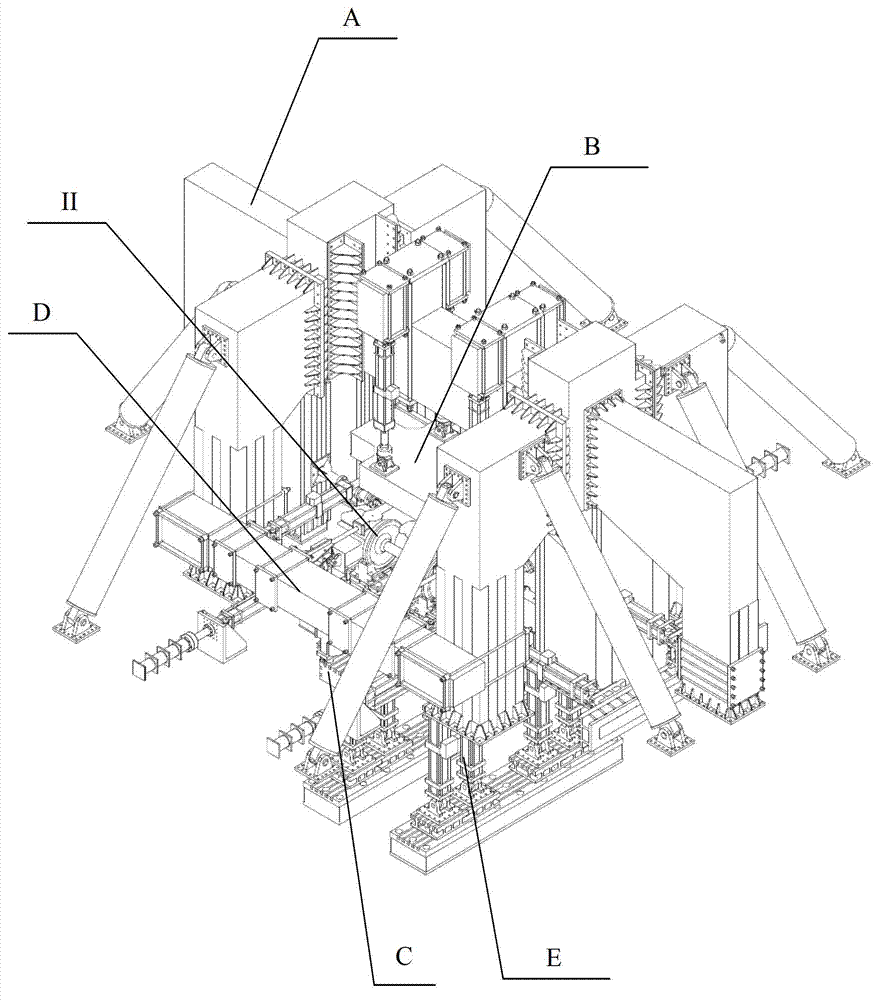

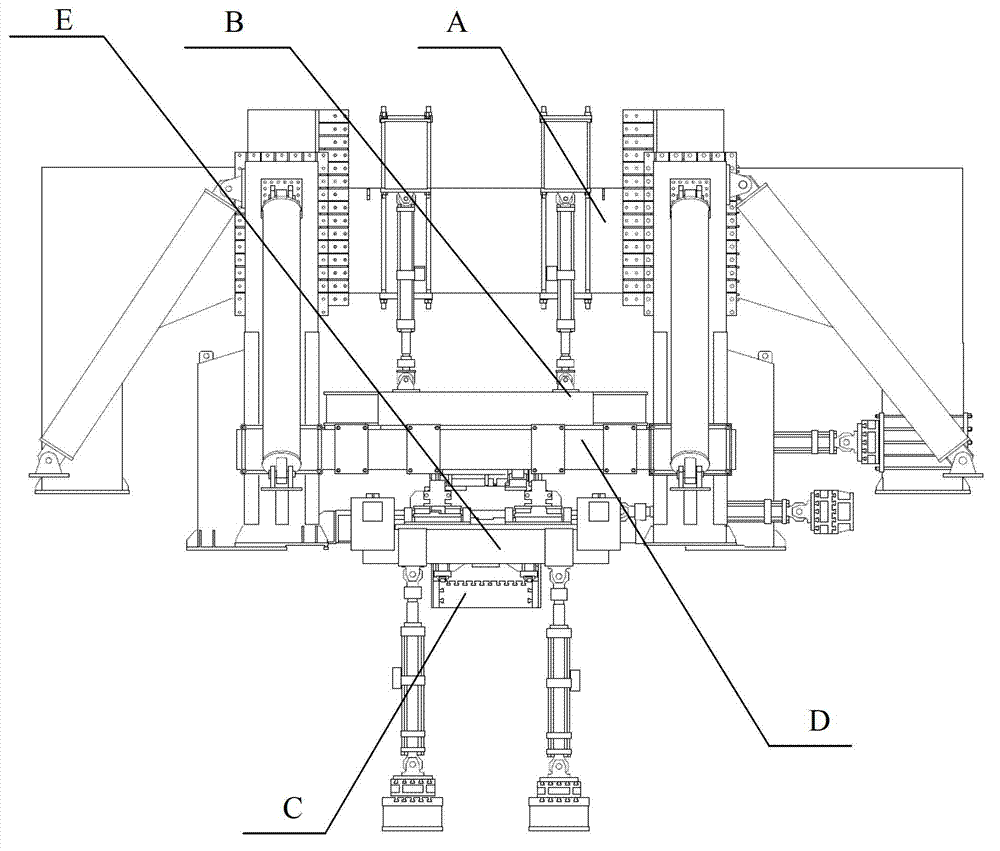

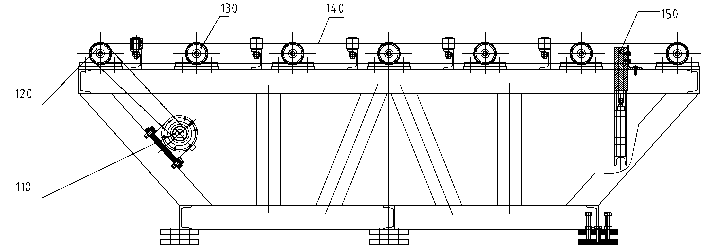

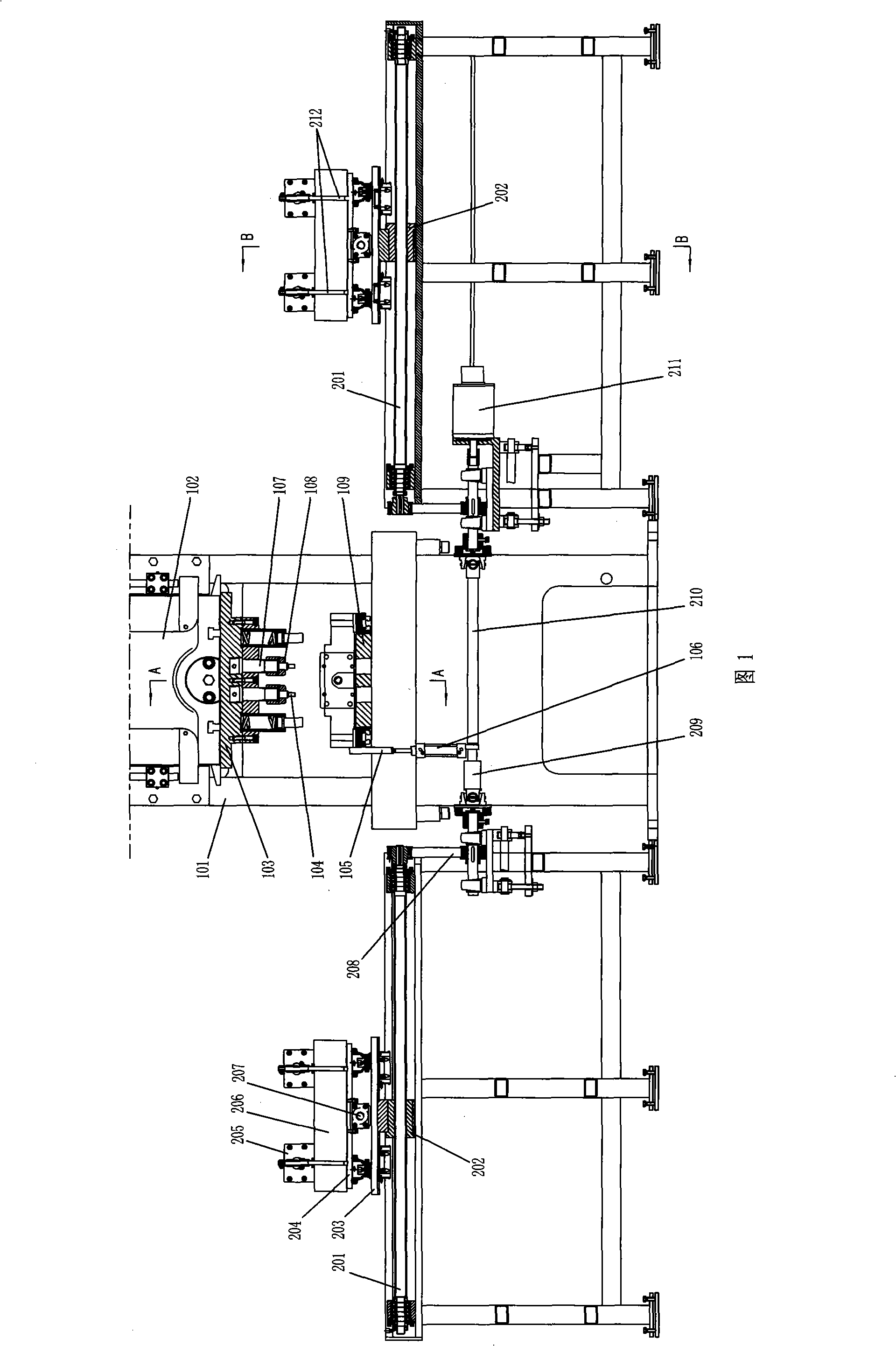

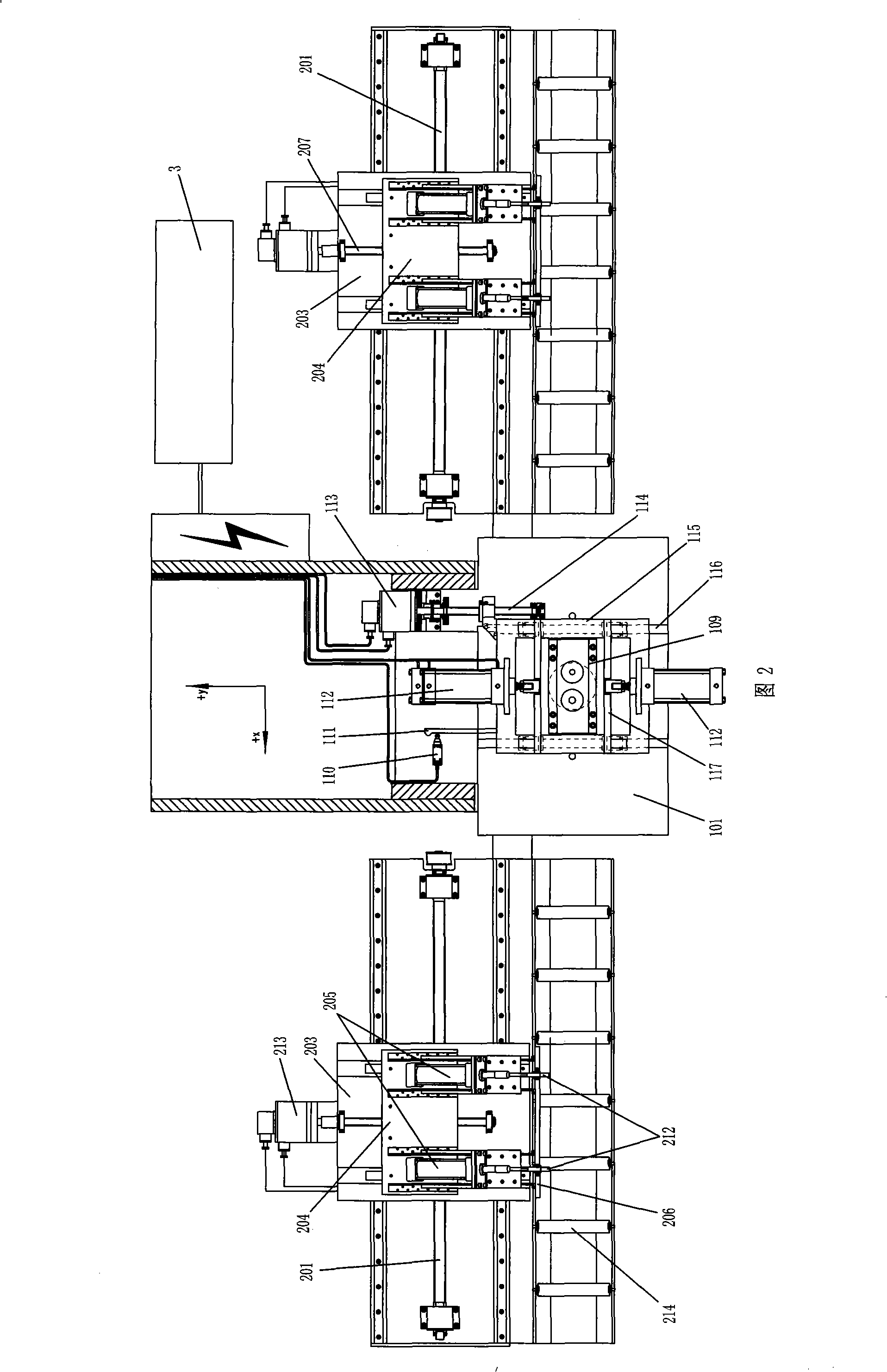

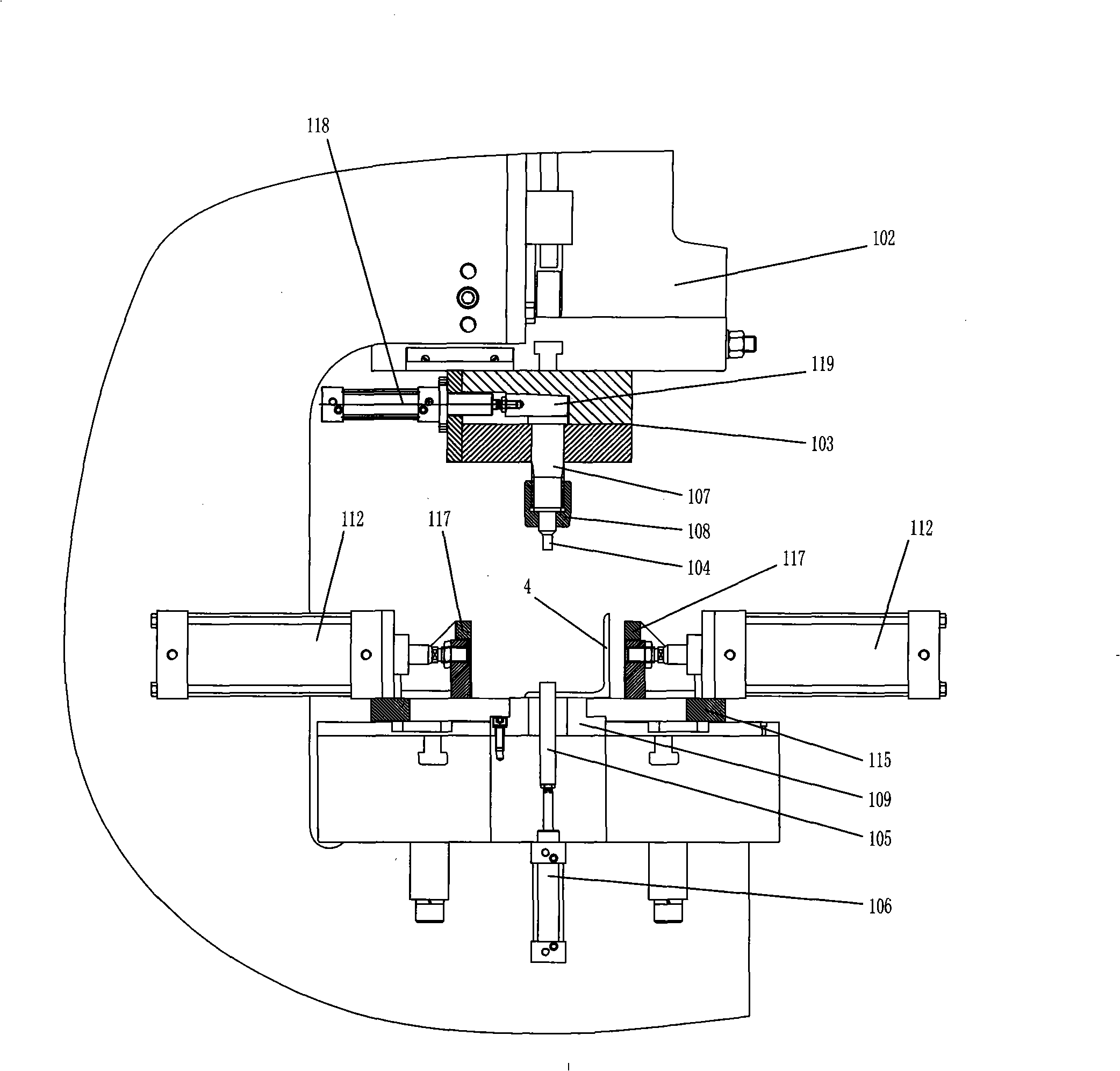

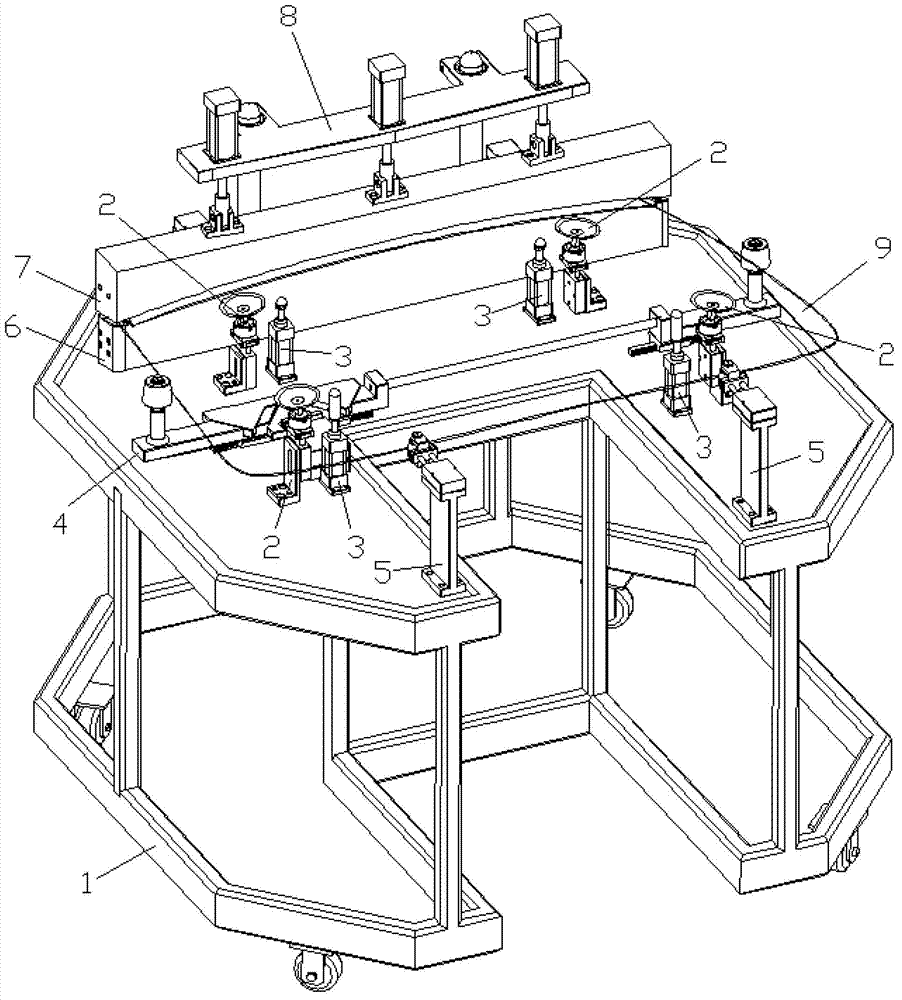

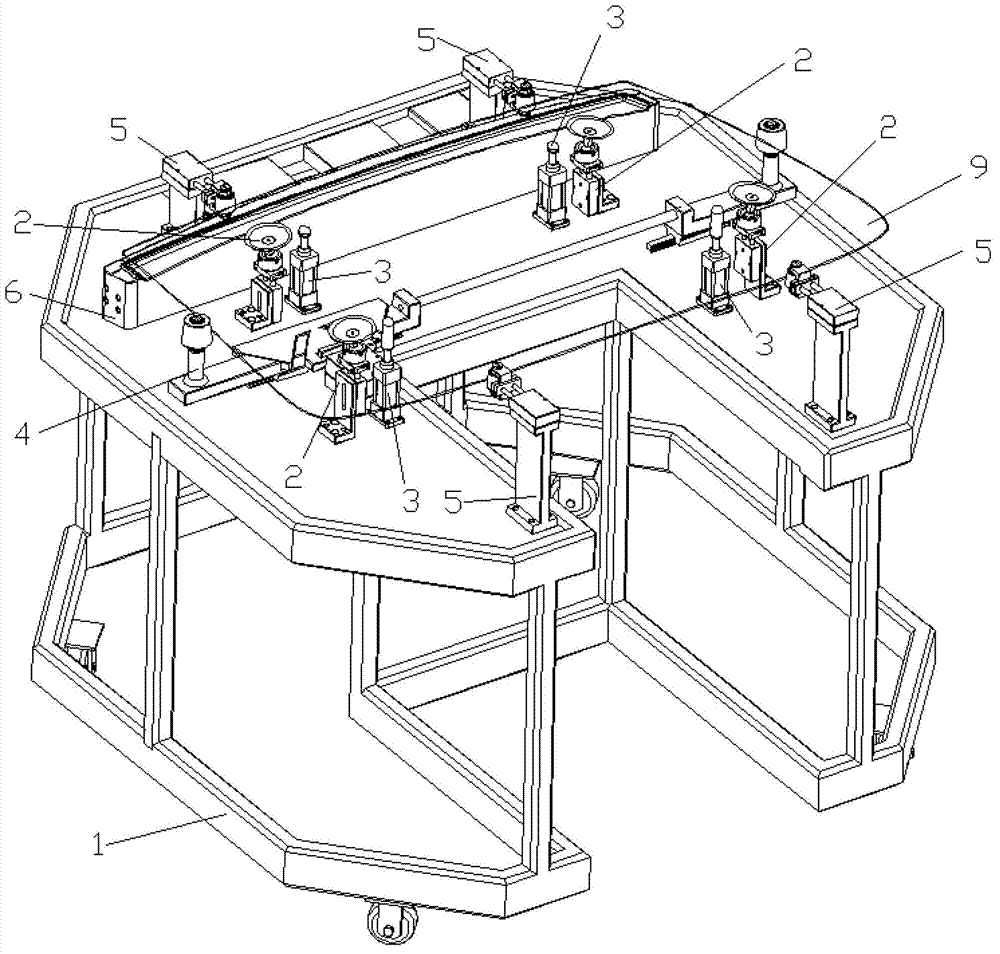

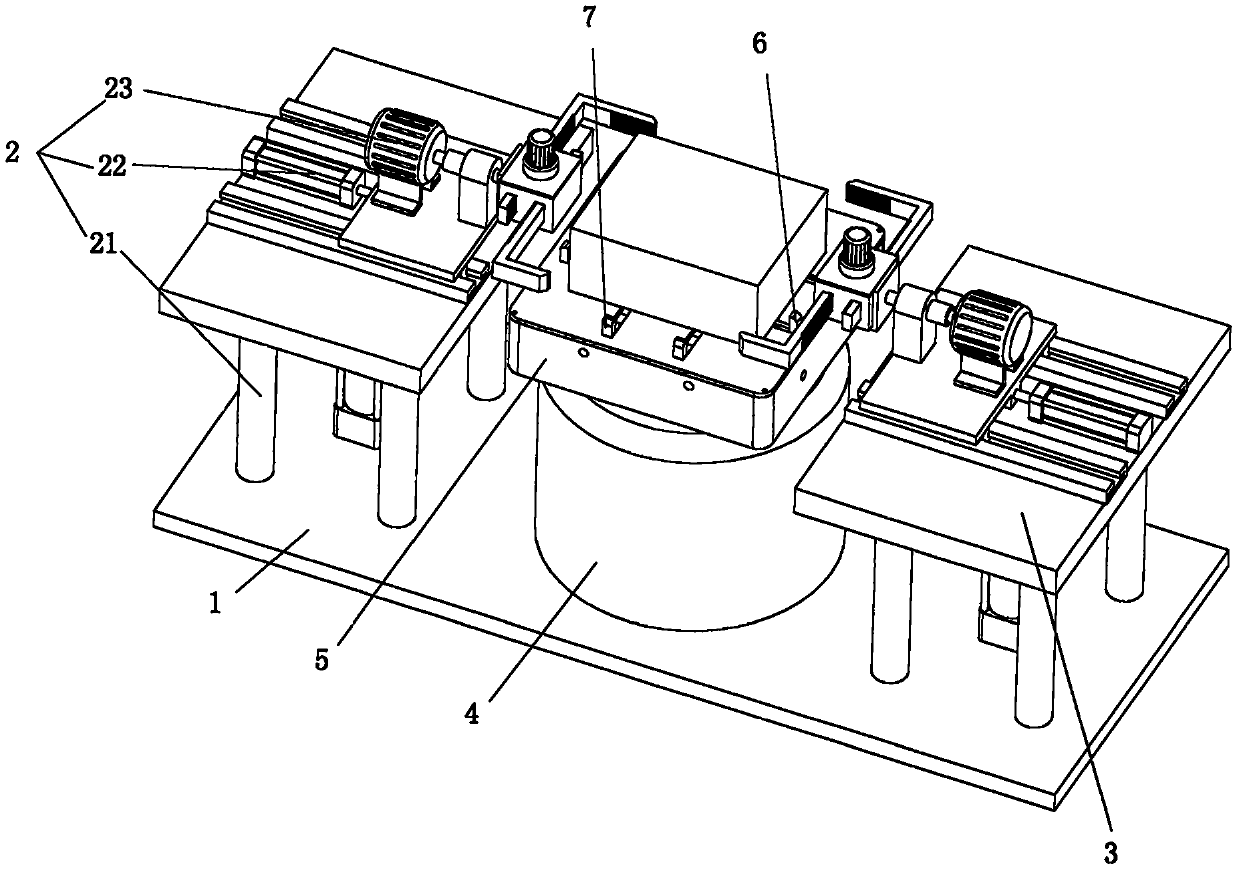

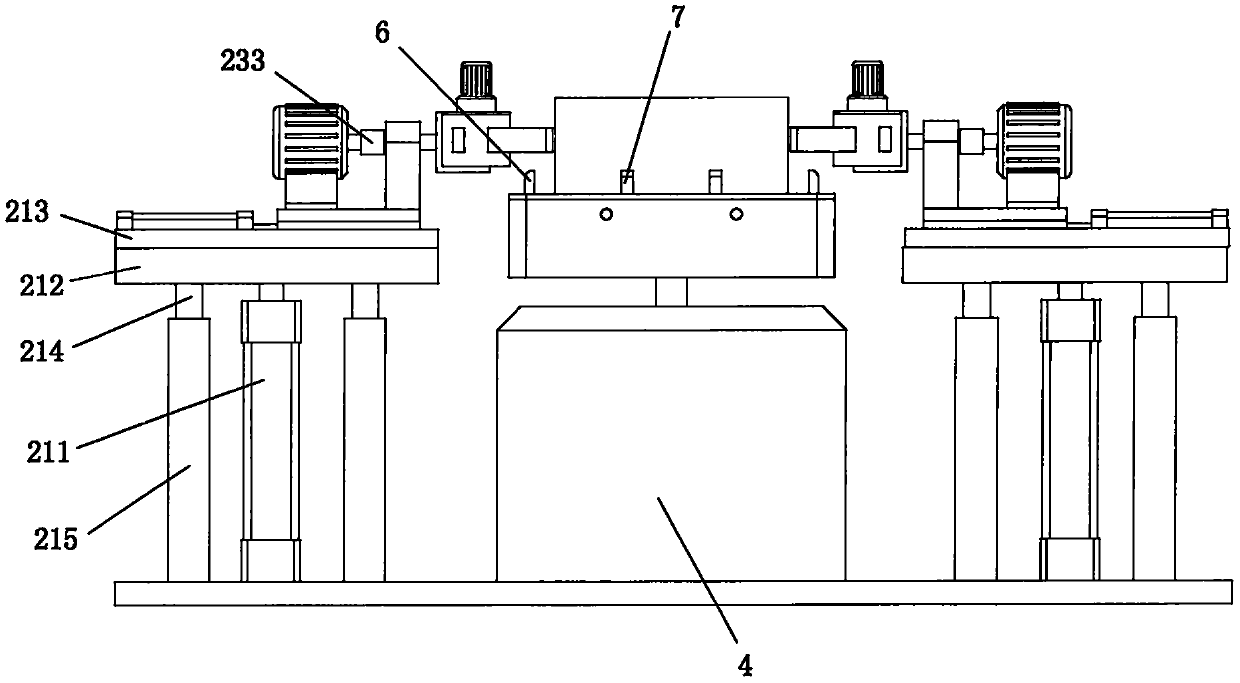

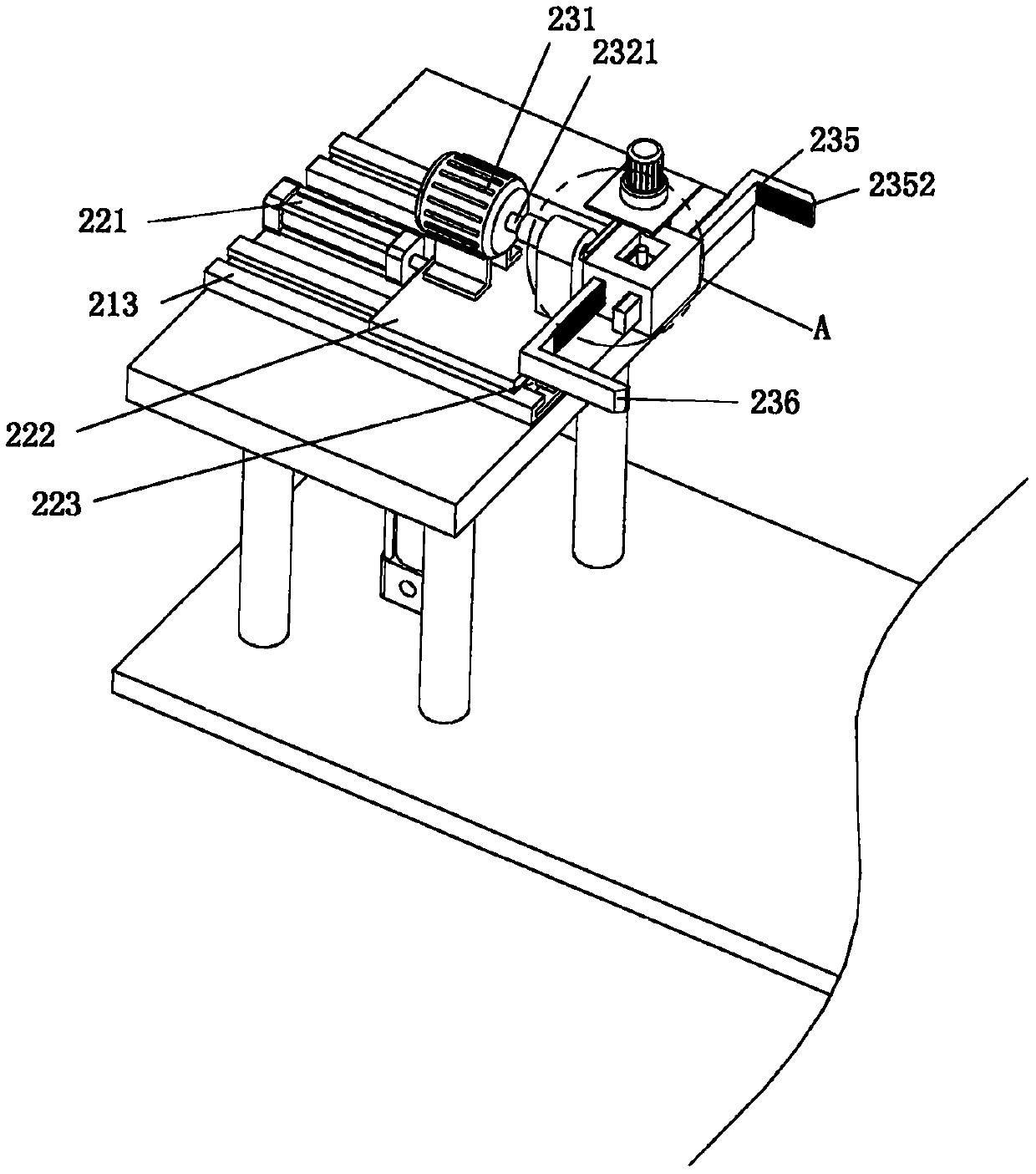

Parameter determining test bed for gantry framework type rail vehicle bogie

The invention relates to a parameter determining test bed for a gantry framework type rail vehicle bogie. The test bed mainly consists of a counter-force type gantry mechanical framework, a six-degree-of-freedom loading mechanism assembly, a bogie transfer bridge device and a bogie positioning and clamping mechanism assembly, wherein the counter-force type gantry mechanical framework provides counter-force support to a test bed loading mechanism and a positioning and clamping mechanism; the six-degree-of-freedom loading mechanism assembly is used for the vertical, lateral and longitudinal loading of the tested bogie; the bogie transfer bridge device is used for smoothly and flexibly transferring the tested bogie to a test bed loading platform; and the bogie positioning and clamping mechanism assembly is used for the vertical, longitudinal and lateral positioning and fixing of a second tested bogie frame. According to the test bed, the tests of parameters, such as the vertical, longitudinal and lateral rigidity of the first bogie and the second bogie, and the bogie torsion rigidity, can be realized, the rigidity coefficient and the flexibility coefficient of each part of the bogie can be automatically calculated by software, and the automation and the efficiency when the bogie parameter is measured are improved.

Owner:JILIN UNIV +1

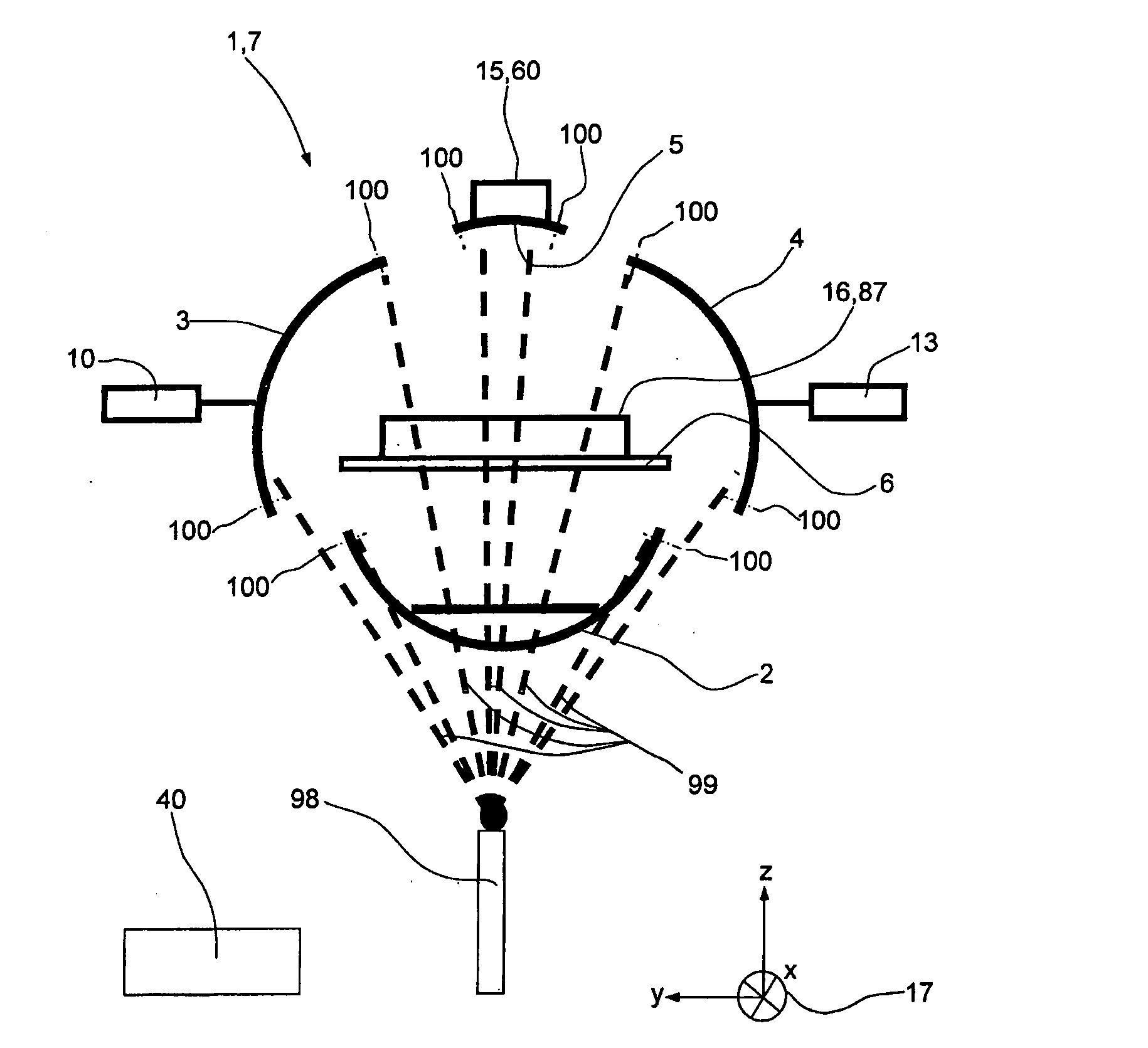

Patient lateral positioning device for pelvic treatments comprising a vacuum mattress

ActiveUS8118029B2Easy to provideImprove performanceStuffed mattressesOperating chairsPelvisLower body

A patient lateral positioning device for pelvic treatments suitable to support a patient in a defined lateral position includes a vacuum mattress. The vacuum mattress includes an upper body support attachable to an upper body portion of the patient, and a lower body support attachable to a lower body portion of the patient. A region between said upper and lower body support is formed such that when the vacuum mattress is attached to the patient, both a front pelvic side and an upper pelvic side of the patient are exposed.

Owner:SMITH & NEPHEW ASIA PACIFIC PTE LTD +2

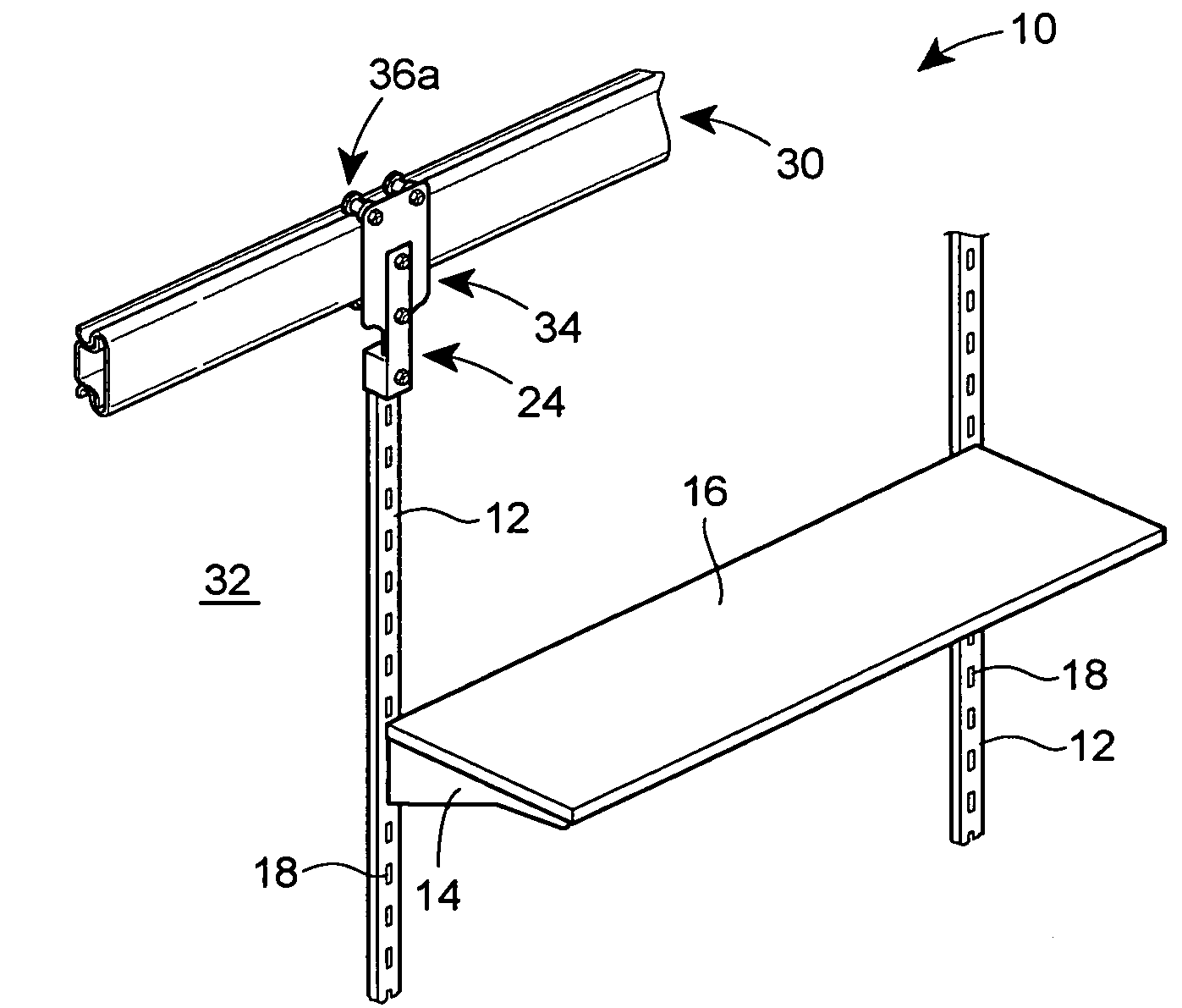

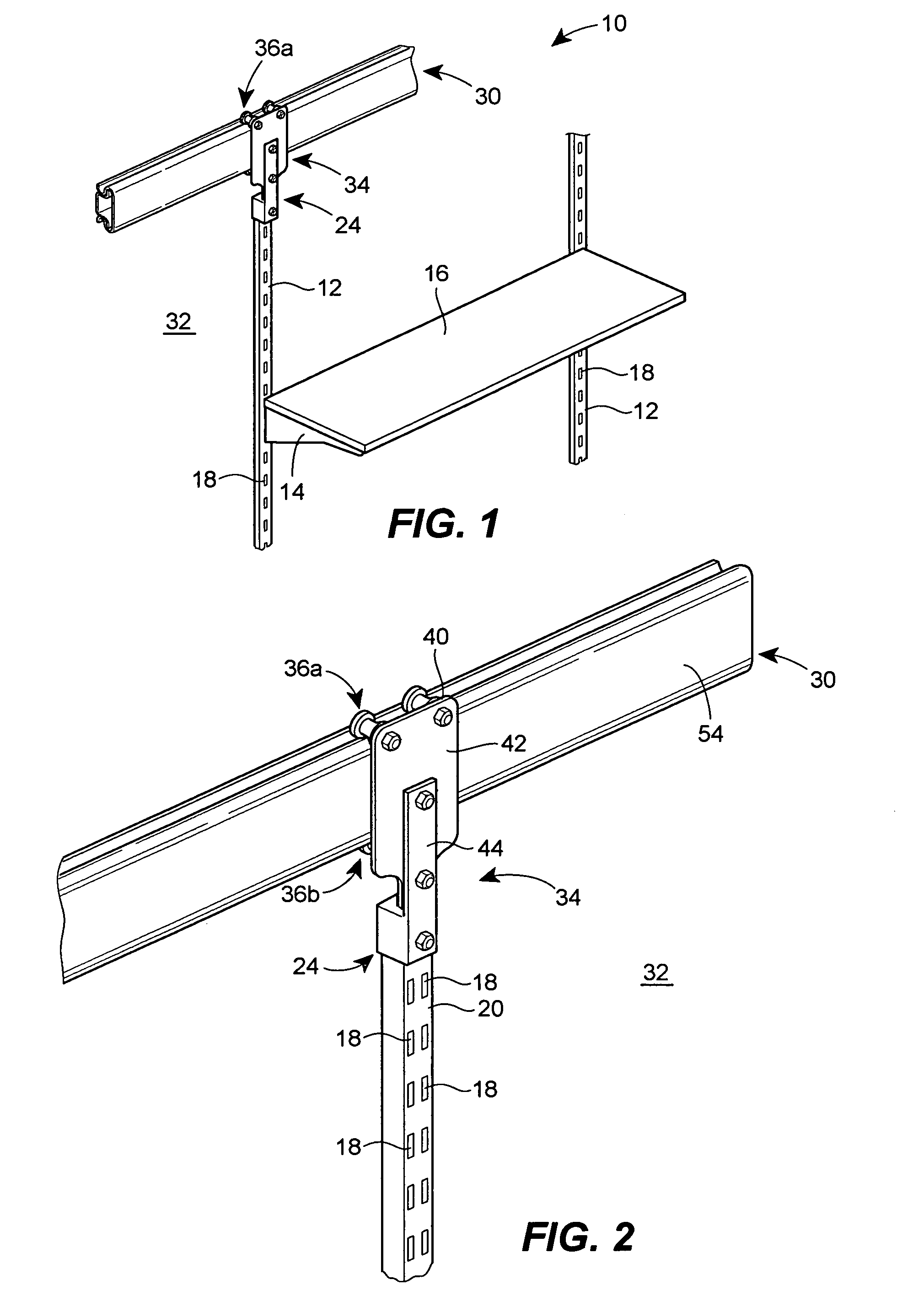

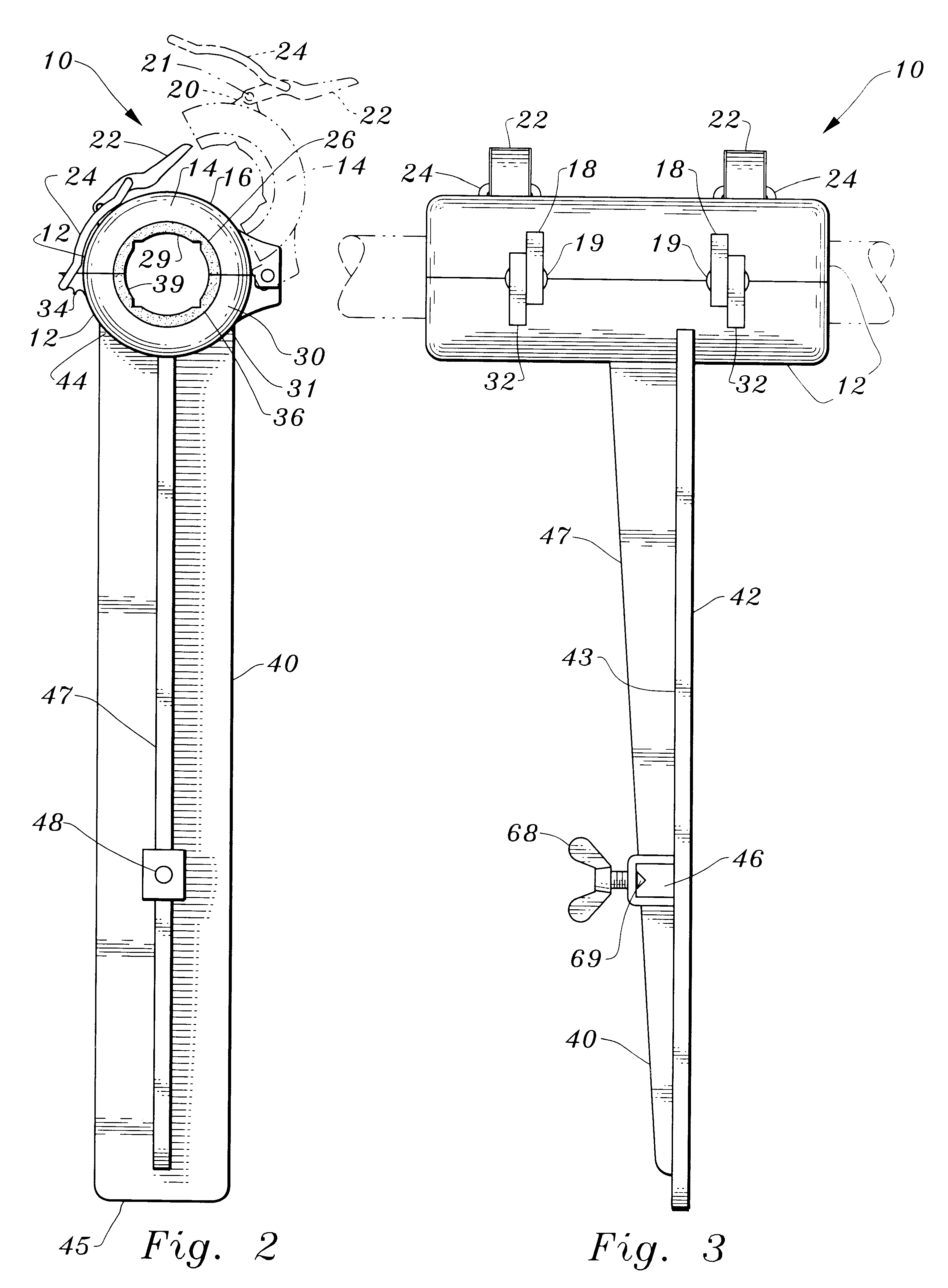

Organizer system and vertical upright with rollers

An adjustable organizer system has a horizontal top rail with an upward facing top side. At least one vertical upright support has one or more contact surfaces carried on an upper end of the upright support. Each of the contact surfaces has at least a downward facing portion engaged with the top side of the top rail. The upright support is suspended from the top rail such that the one or more contact surfaces can move along the top rail while remaining in contact with the top side to selectively position the at least one vertical upright support laterally along the top rail.

Owner:RUBBERMAID

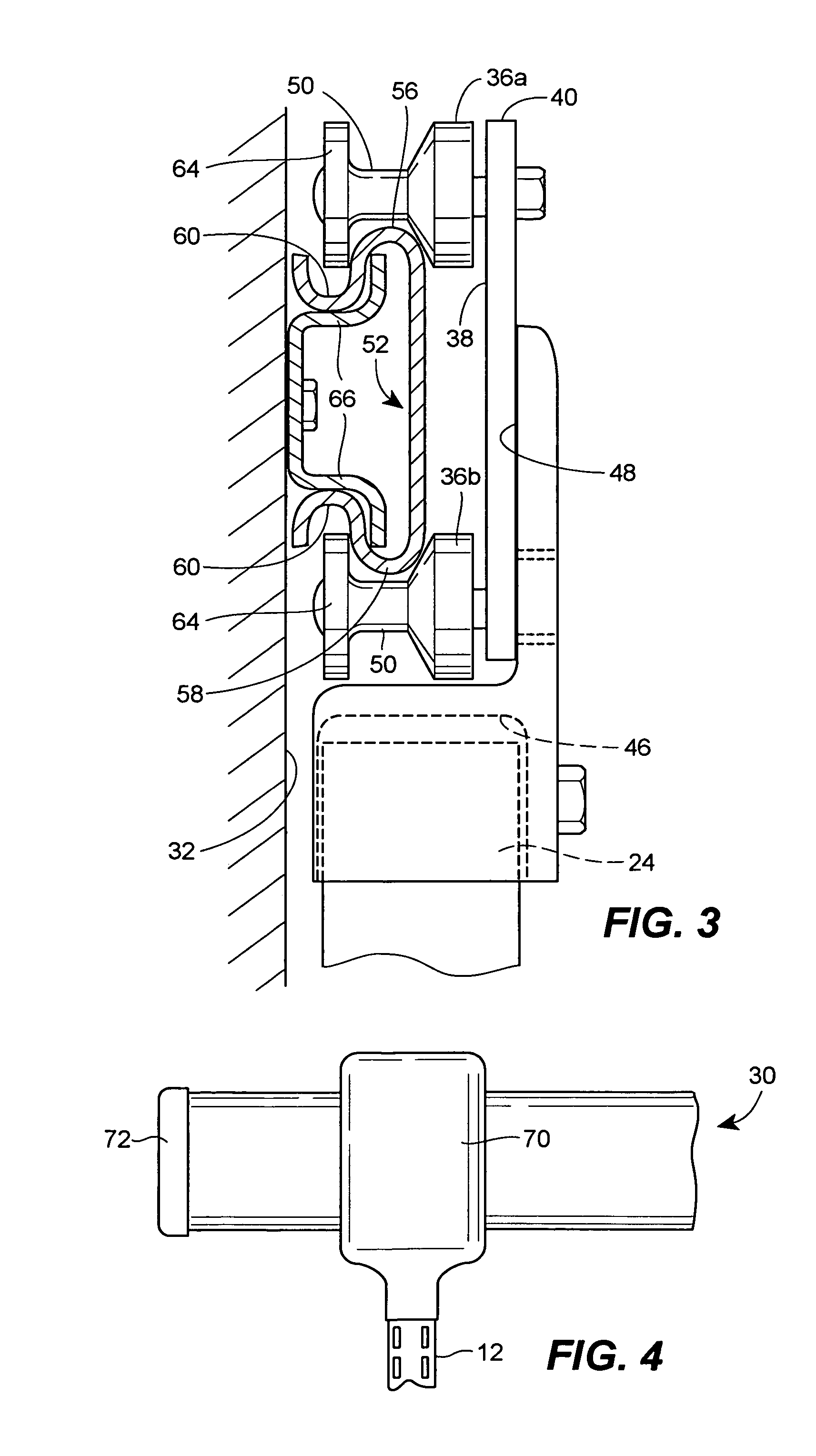

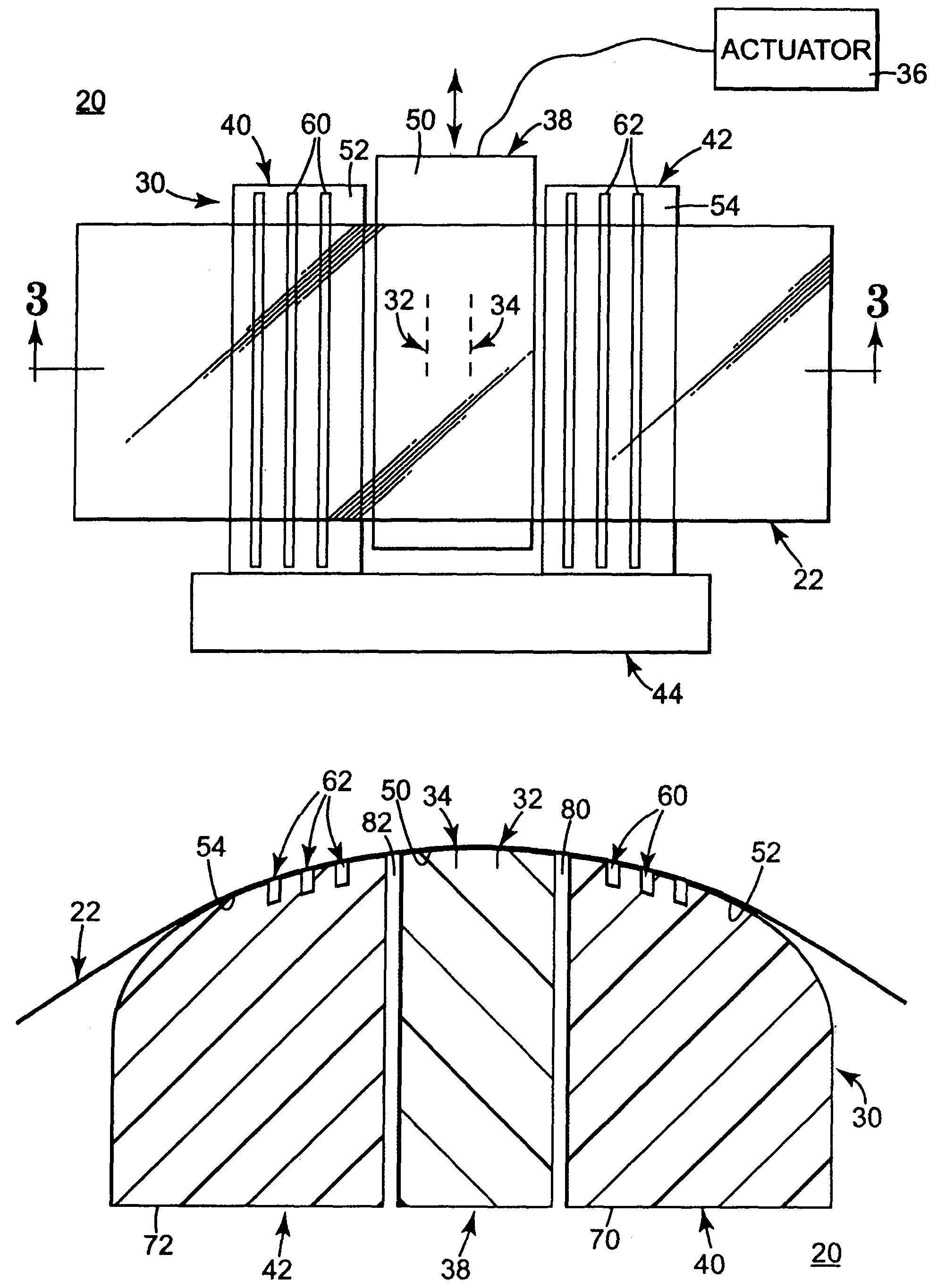

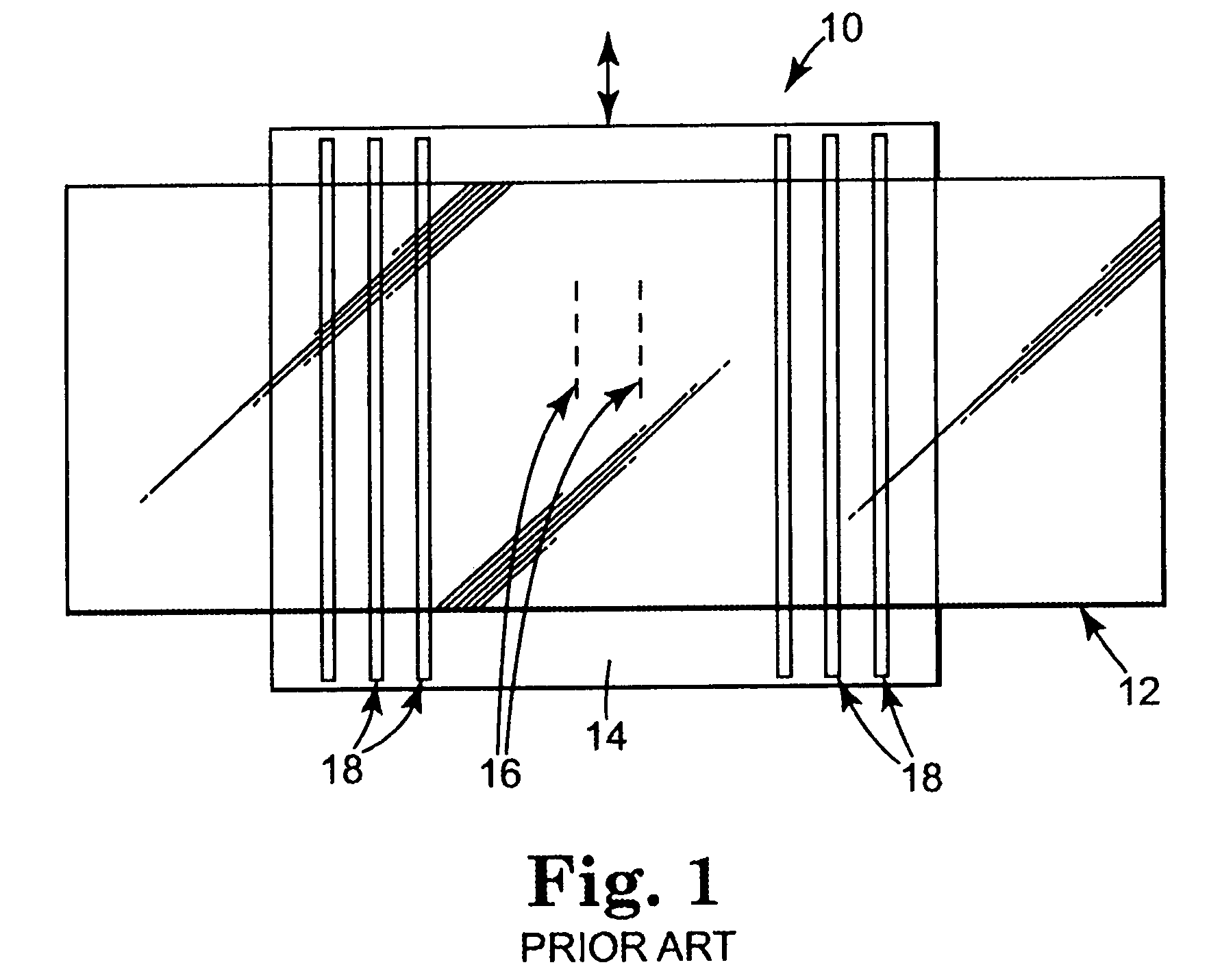

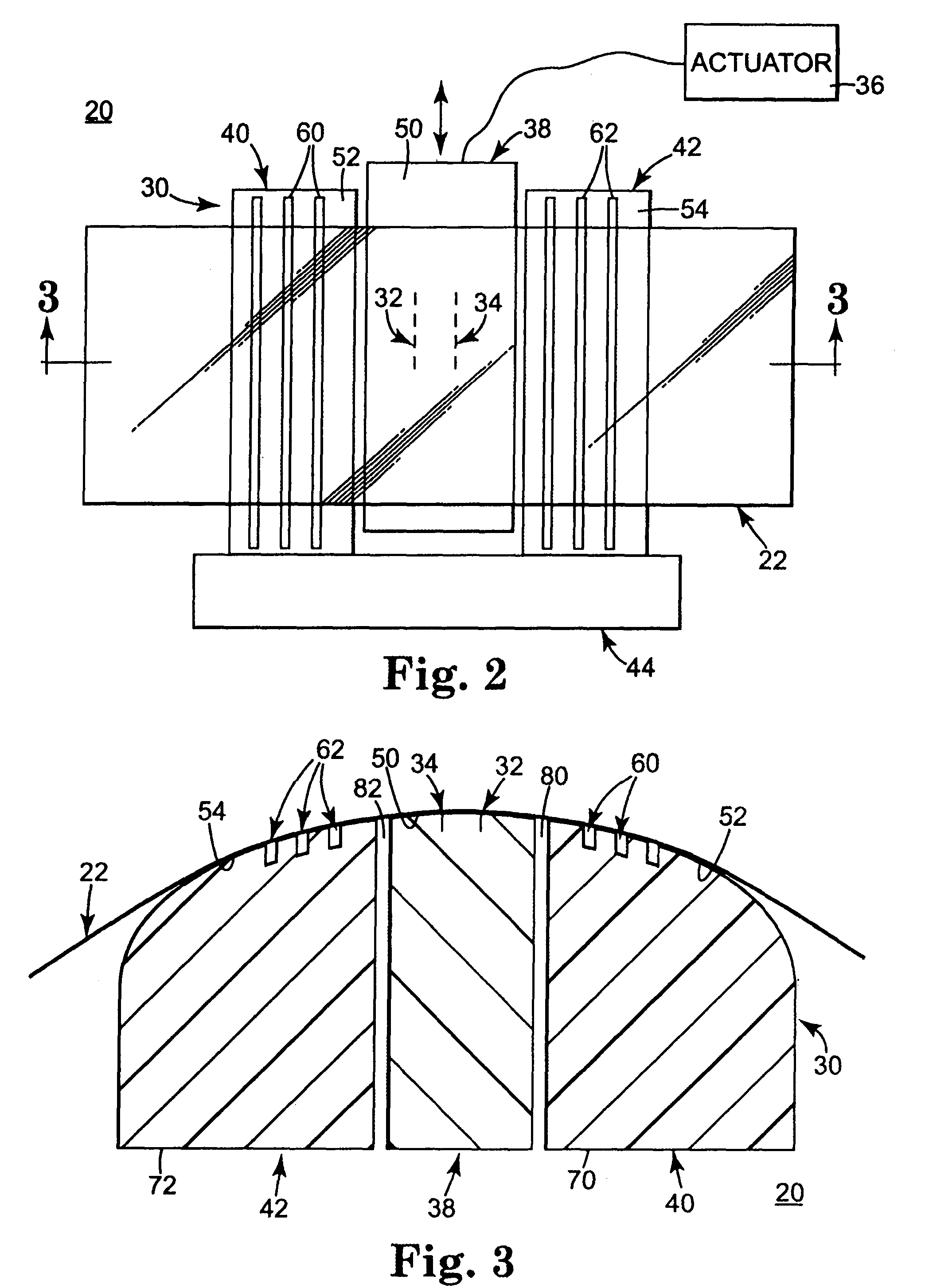

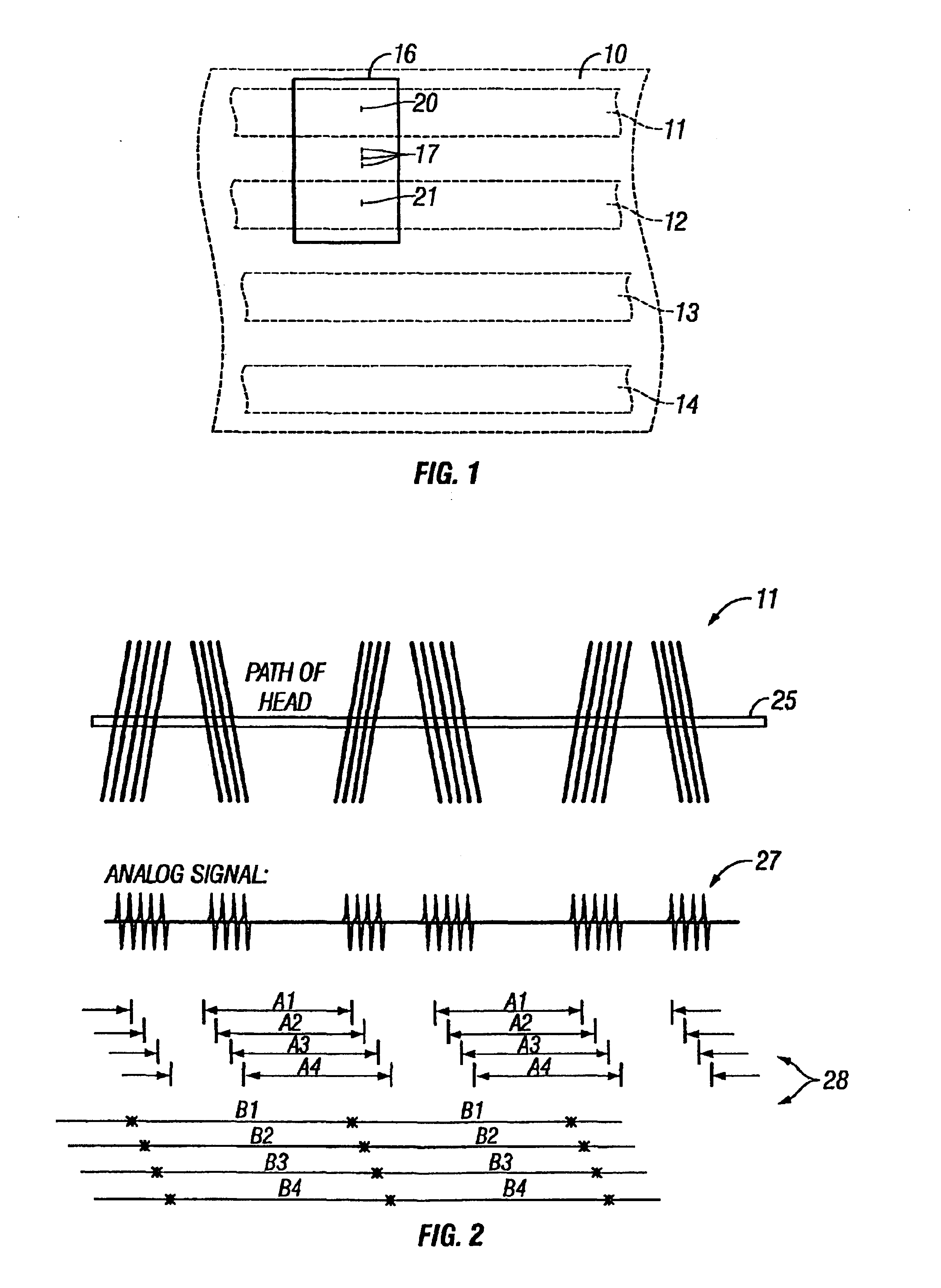

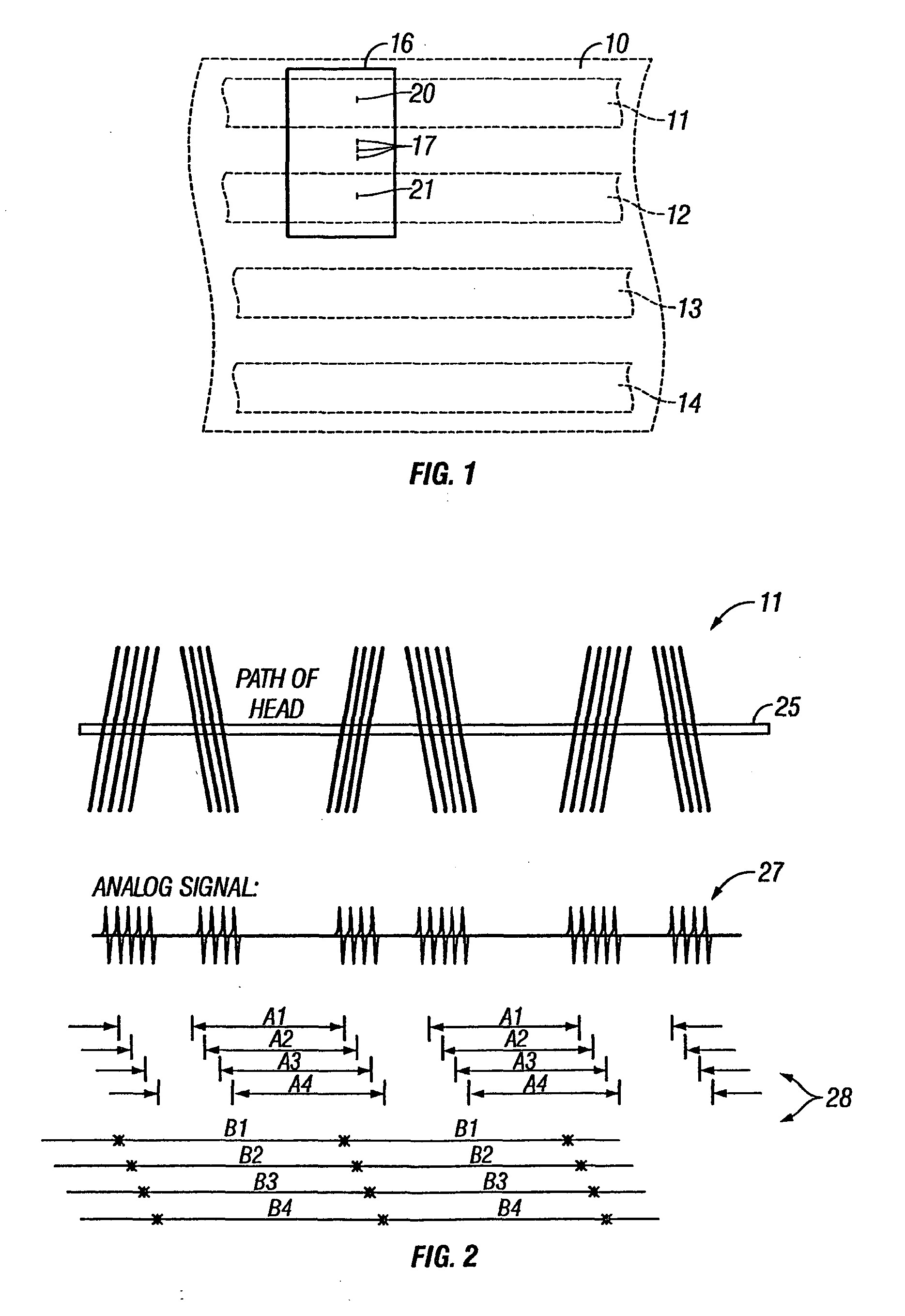

Magnetic tape head assembly with laterally moveable central section

InactiveUS7006329B2Manufacture head surfaceManufacturing heads with multiple gapsCantilevered beamMagnetic tape

A magnetic head assembly in a linear tape system. The magnetic head assembly includes a magnetic head having a central section, a first outrigger, and a second outrigger. The central section maintains at least one read / write element. The first outrigger is positioned adjacent the central section and forms at least one air bleed slot. The second outrigger is positioned adjacent the central section opposite the first outrigger and also forms at least one air bleed slot. Finally, the central section is laterally moveable relative to the outriggers. With this configuration, the moveable, central section, otherwise used for lateral positioning of the read / write element relative to a magnetic tape, is separated from the outriggers that otherwise minimize a fly height between the magnetic tape and the outriggers.

Owner:IMATION

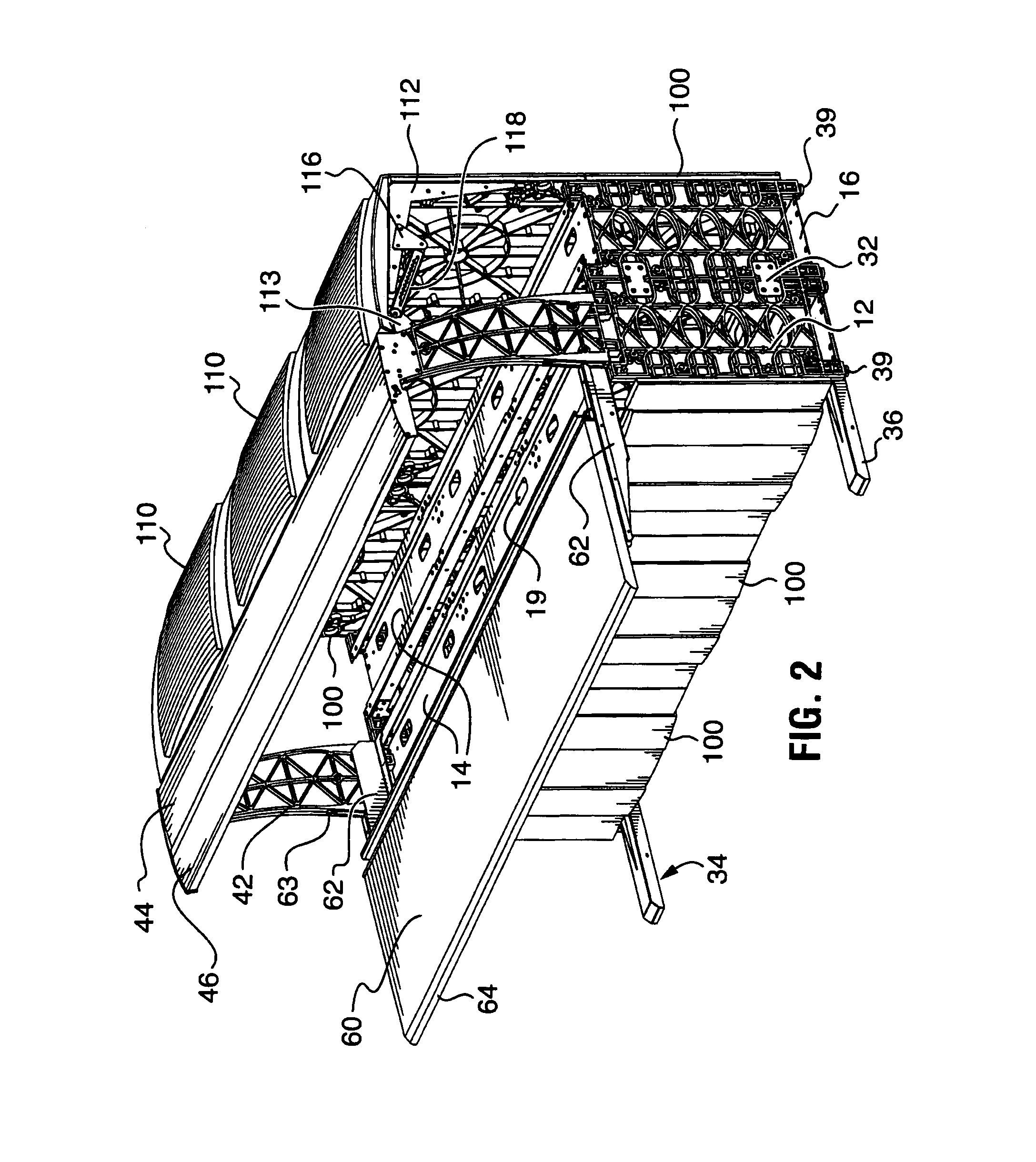

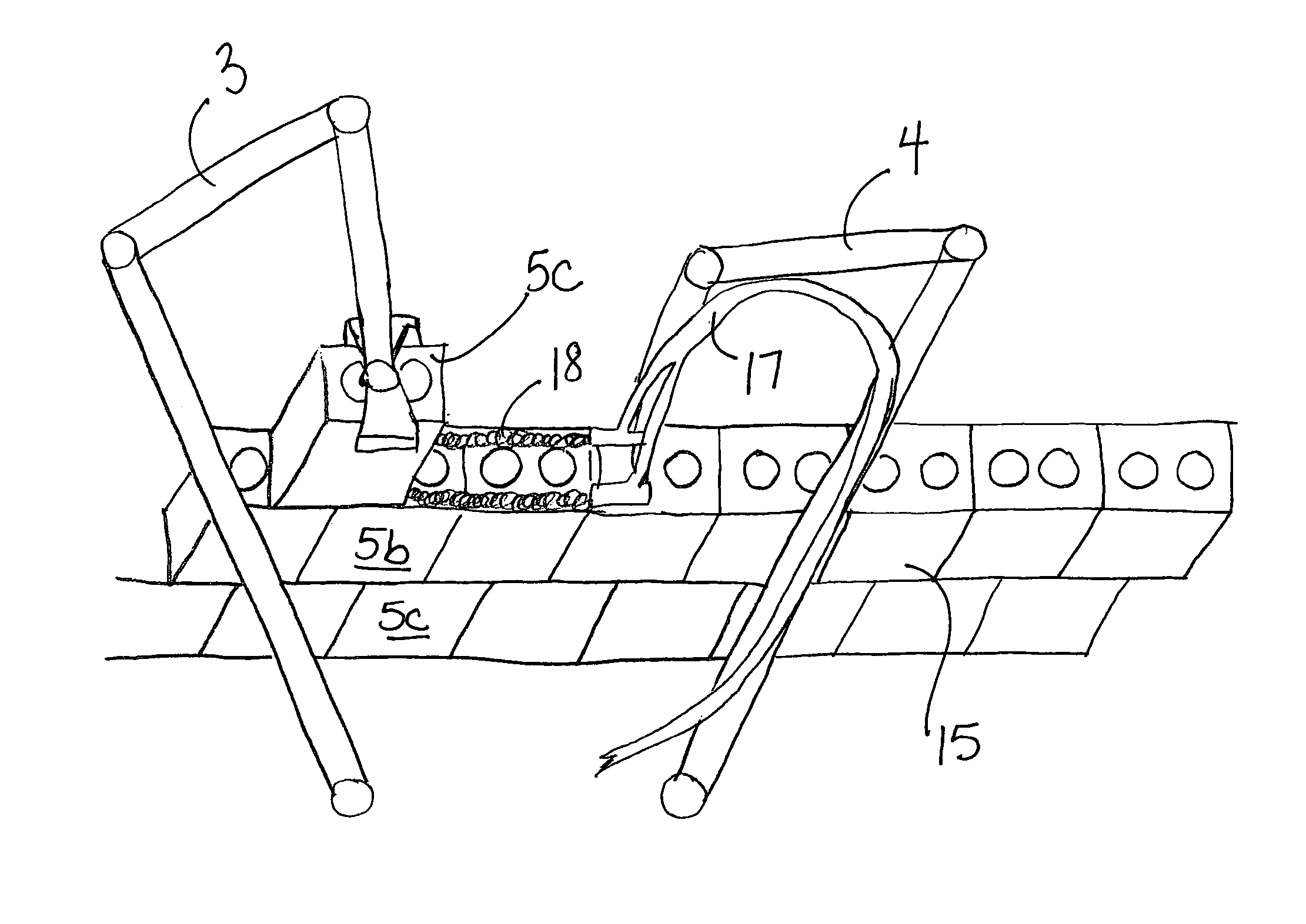

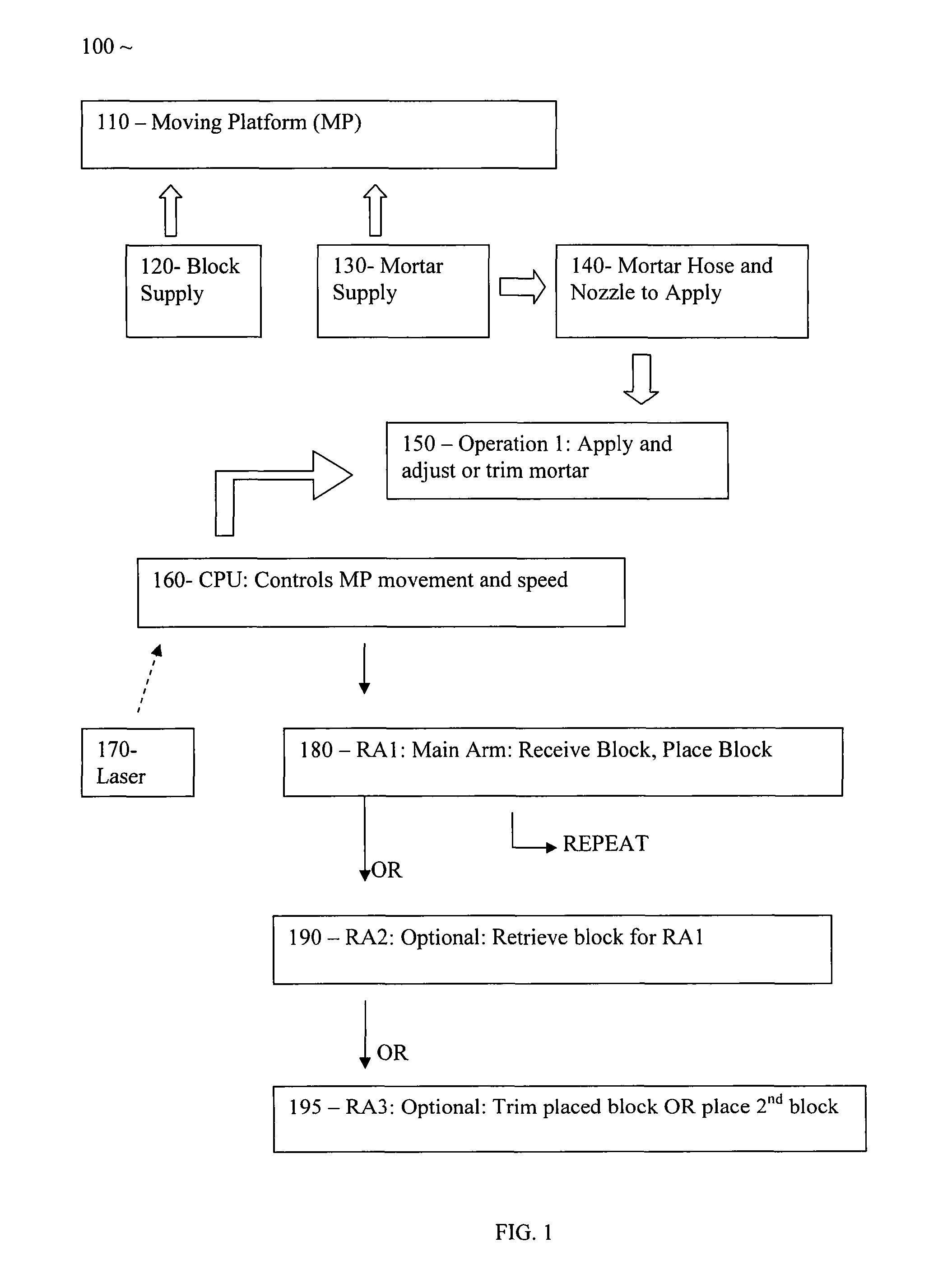

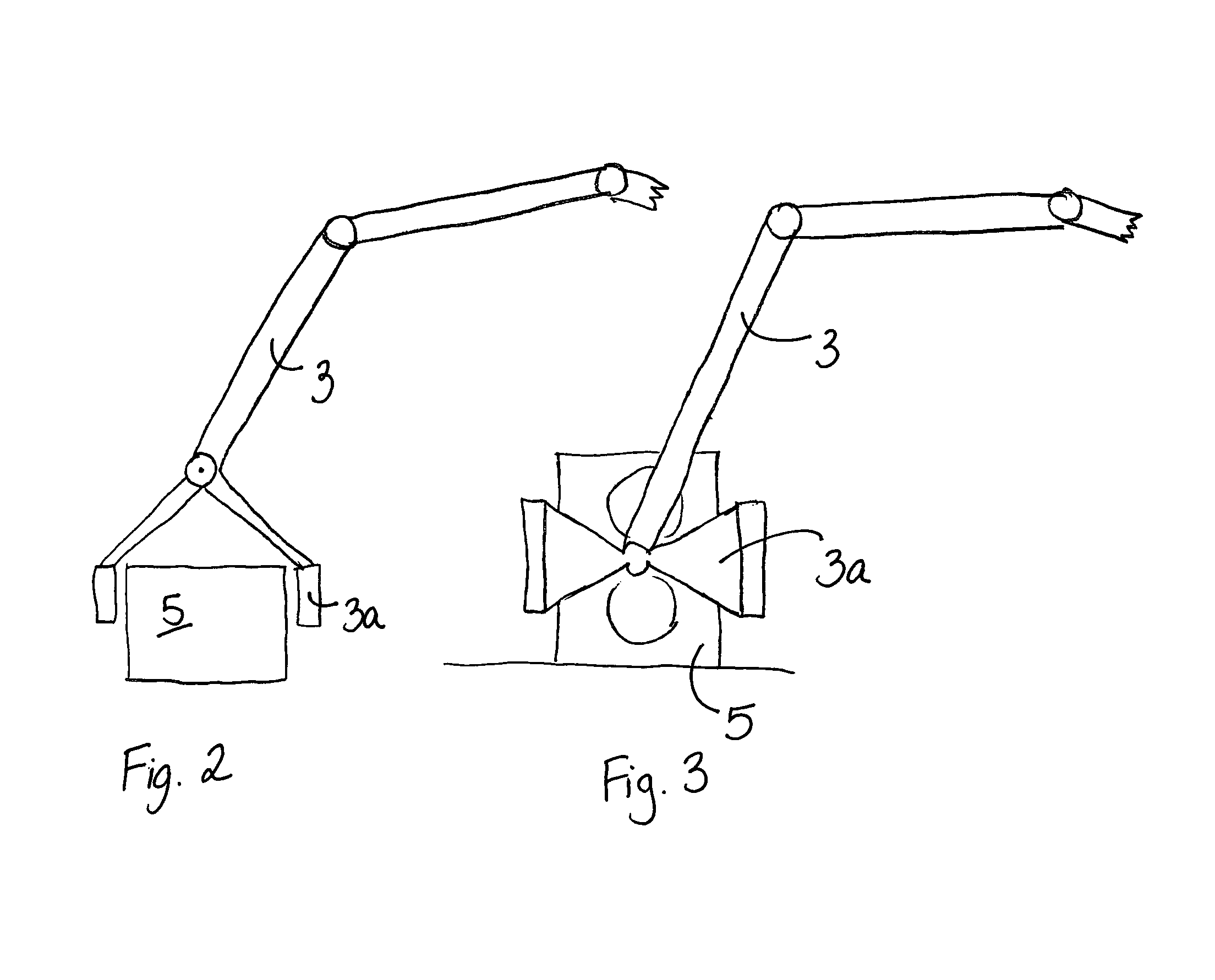

Automated construction machinery and method

InactiveUS8825208B1Faster and accurate installationReduce labor costsWallsComputer controlGuidance systemBrick

An automated block or brick construction apparatus is provided by adapting a base transport assembly with a specialized working platform for brick, block and mortar. The working platform houses at least one robotic arm to accurately position mortar and block or brick in place on a wall construction. The working platform is controlled by a 3-D stringless guidance system for positioning vertically, horizontally, and laterally. The robotic arms place and position a block or brick and stage the subsequent blocks or bricks for installation. A first robotic arm can apply mortar onto a wall while a second robotic arm places a concrete masonry unit accurately onto the mortar and also place blocks in position. Application and movement of mortar and blocks are controlled by a programmable central processing unit.

Owner:BENSON RICHARD MARK

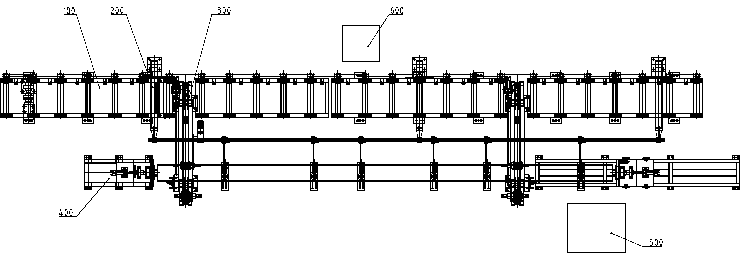

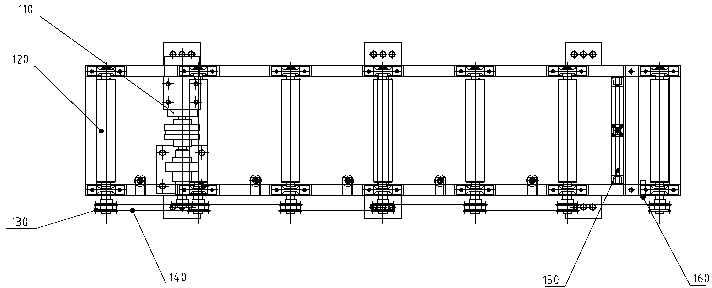

Turnover welding and molding production line of H profile steel

ActiveCN102837140AEasy to operateImprove securityWelding/cutting auxillary devicesAuxillary welding devicesLateral positioningElectrical control

The invention discloses a turnover welding and molding production line of H profile steel. The turnover welding and molding production line comprises a longitudinal material duct and a transverse conveying material duct which are used for guiding the H profile steel, wherein the longitudinal material duct and the transverse conveying material duct are respectively connected with a hydraulic power device and an electric control device. The production line also comprises a connection plate positioning device and turnover welding molding devices, wherein the turnover welding molding devices are connected with the hydraulic power device and the electric control device; a longitudinal positioning device is arranged on the longitudinal material duct; a lifting device and the transverse positioning device are arranged on the transverse conveying material duct; and the turnover welding molding devices can turn over randomly in an angle of 360 DEG. In the work, the length and the position of a positioning swing arm of the connection plate positioning device and a distance between the two turnover welding molding devices are adjusted according to the model number of the H profile steel and the position of the connection plate to be welded; the H profile steel is held and clamped tightly; the position of the connection plate is adjusted and fixed so as to carry out spot welding; the H profile steel turns over the angle of 180 DEG; and the welding work is carried out repeatedly. At the time, the overall welding procedure is finished, and the next procedure begins.

Owner:济南天辰智能装备股份有限公司

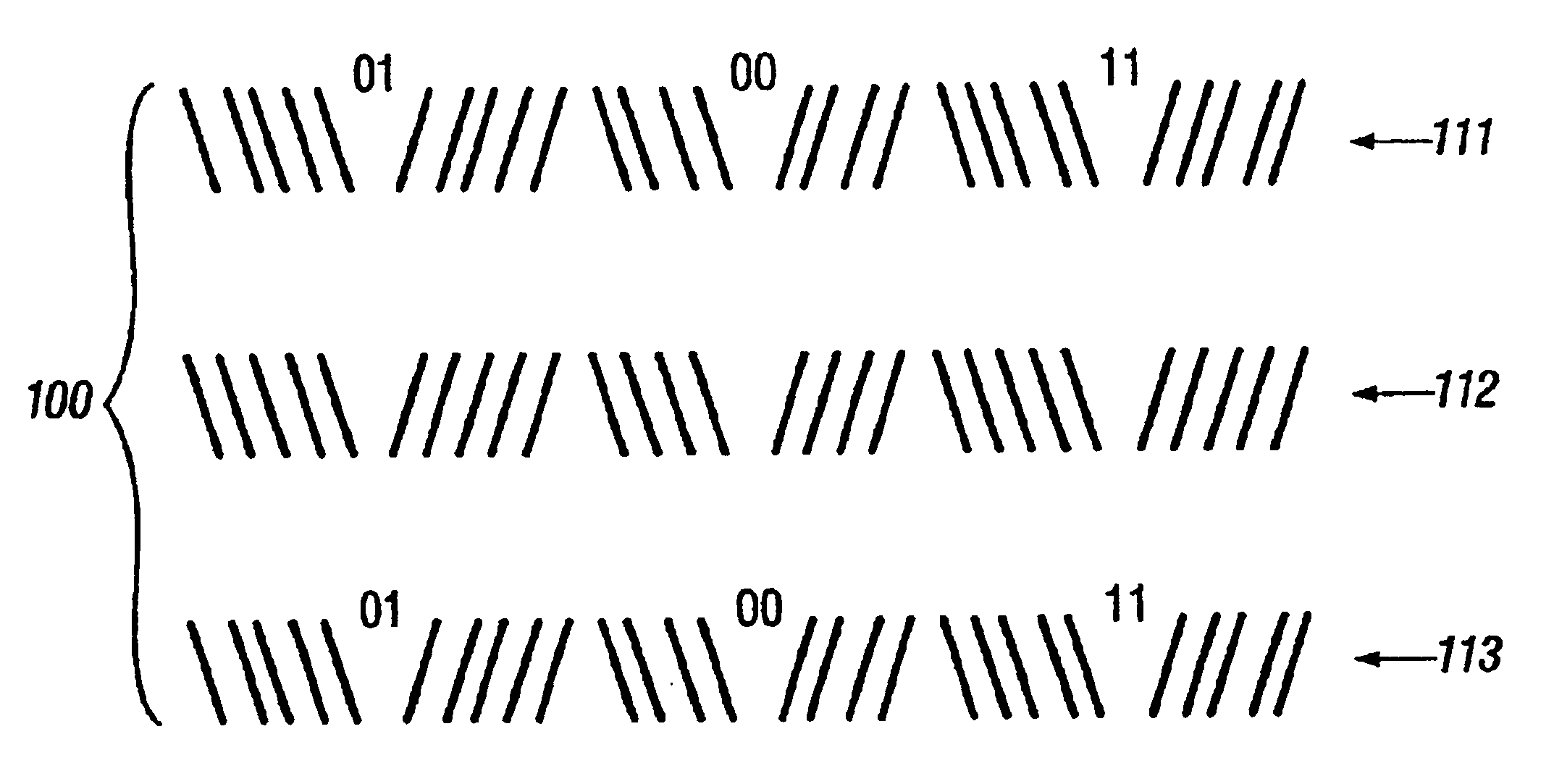

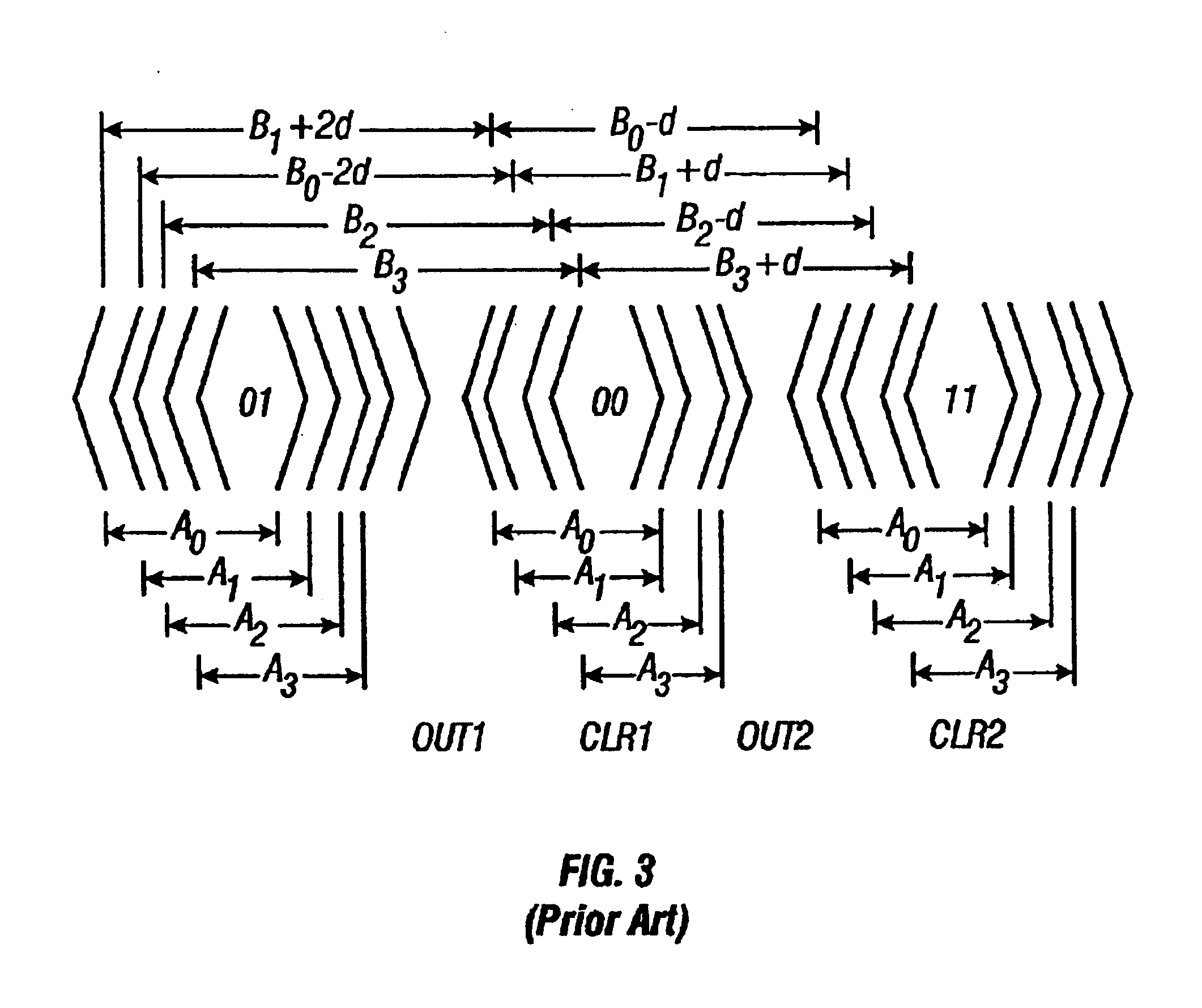

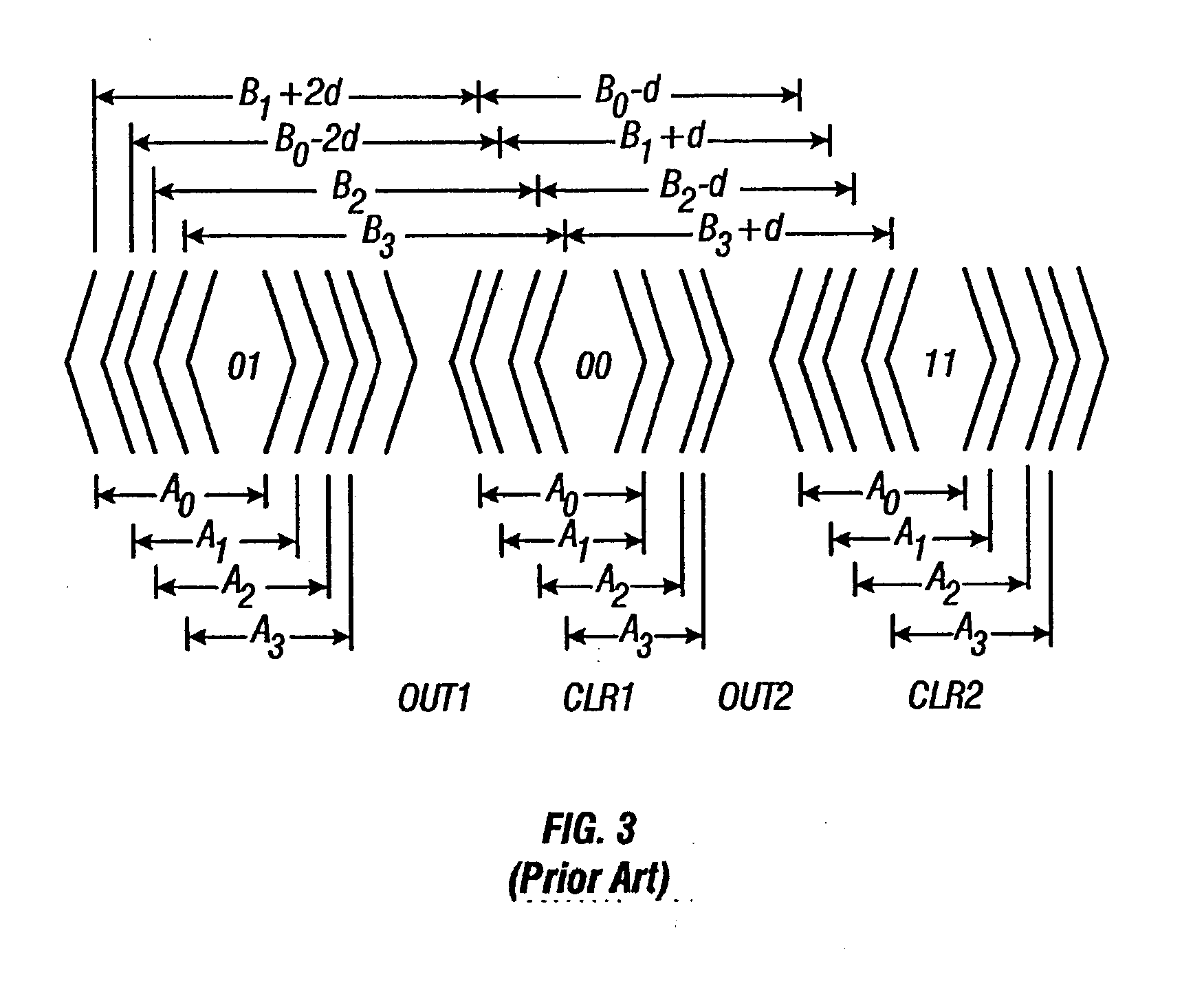

Tape servo information with superimposed data information providing servo band identification

InactiveUS6937413B2Driving/moving recording headsFilamentary/web record carriersData informationMagnetic tape

In magnetic tape having separate longitudinal servo bands of servo information with superimposed data information, the separate servo bands have selected different superimposed data information, to identify the separate servo bands for independent addressability. The servo information comprises non-parallel laterally extending transitions to indicate lateral positioning, and the selected different superimposed data information may comprise a lack thereof in portion(s) of the servo bands. Where the superimposed data information is longitudinal position information of the tape, the selected different superimposed data information may comprise different longitudinal position information of one or more servo band(s). The selected different superimposed data information may comprise a band identifier in the superimposed data information of one or more of the servo bands.

Owner:INT BUSINESS MASCH CORP

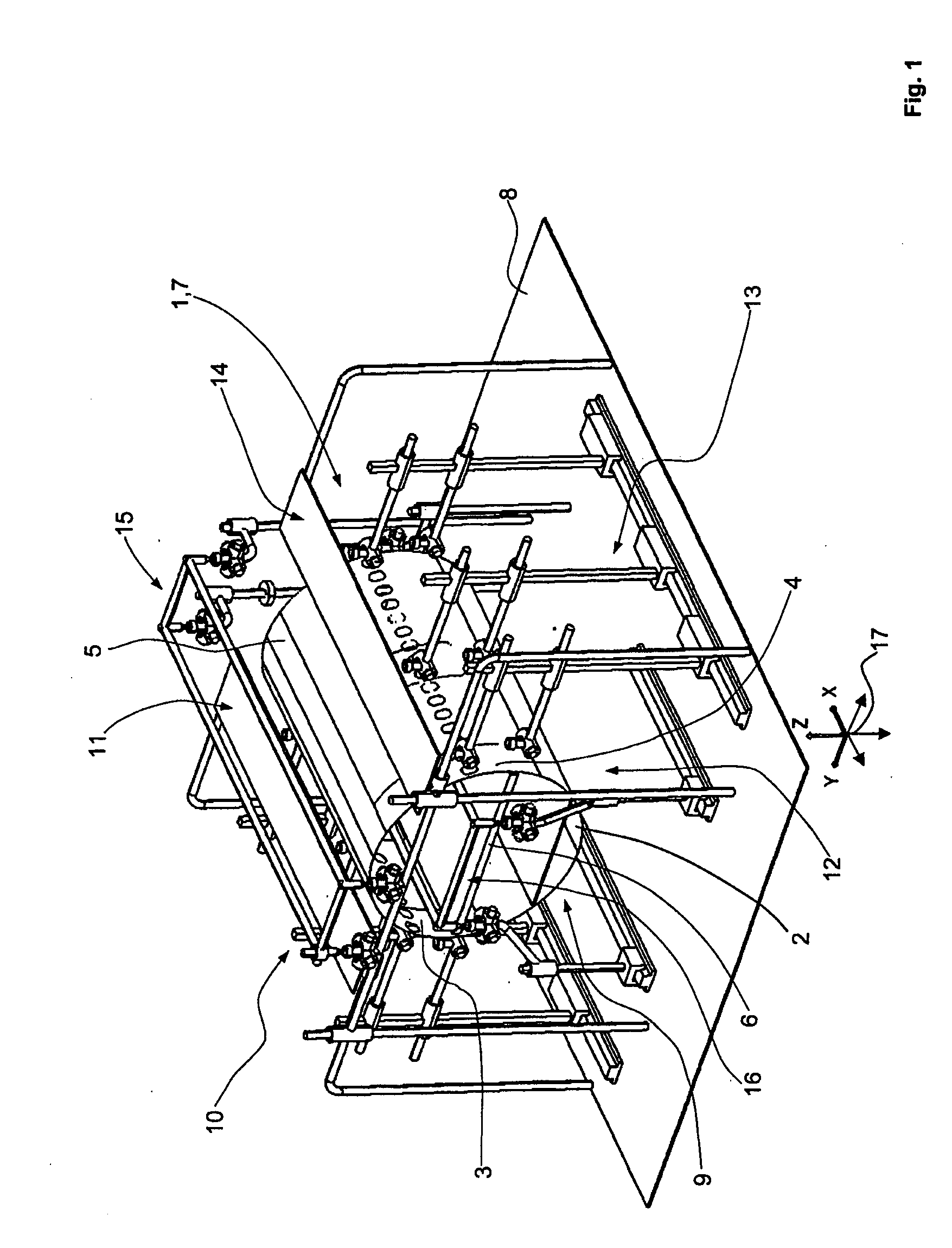

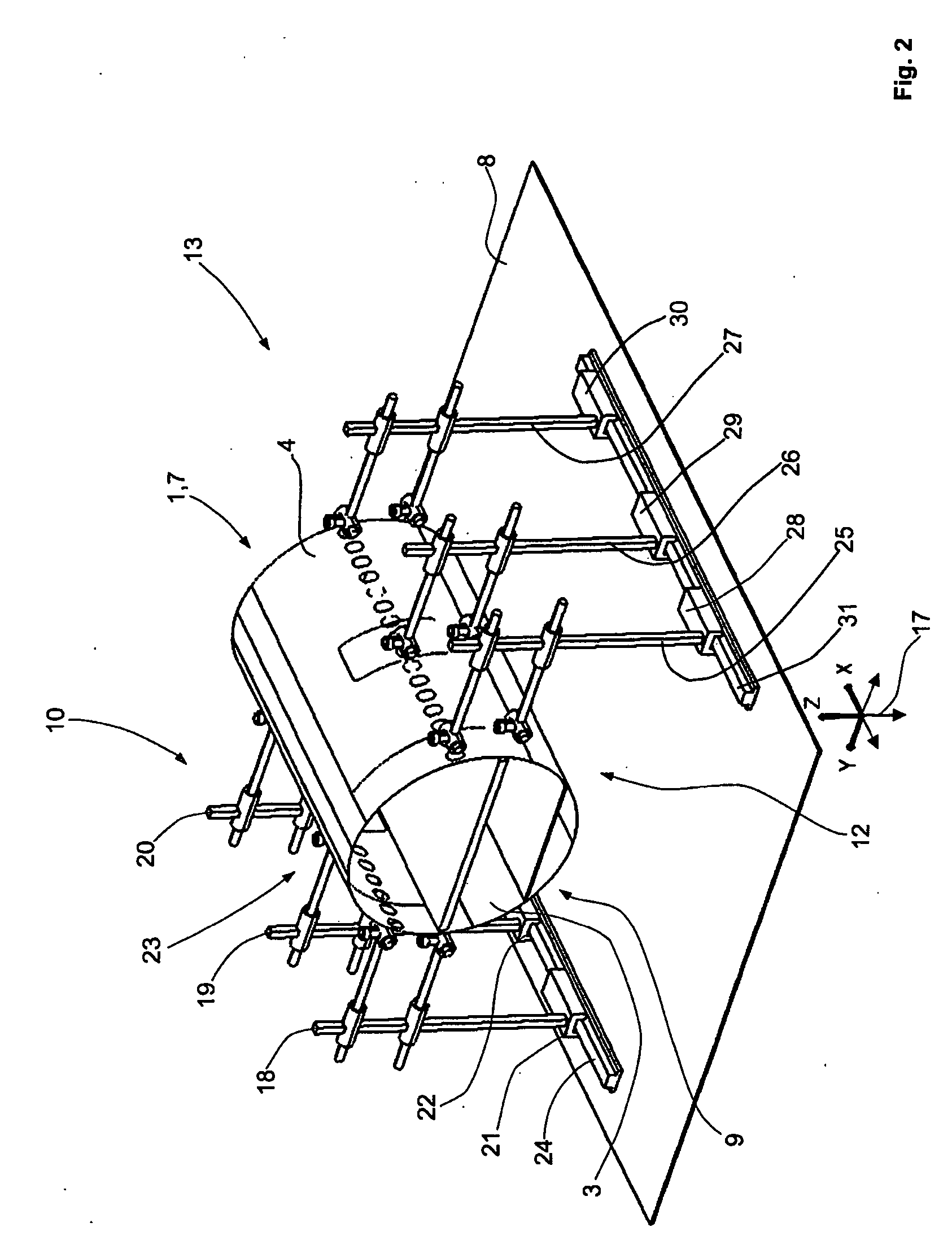

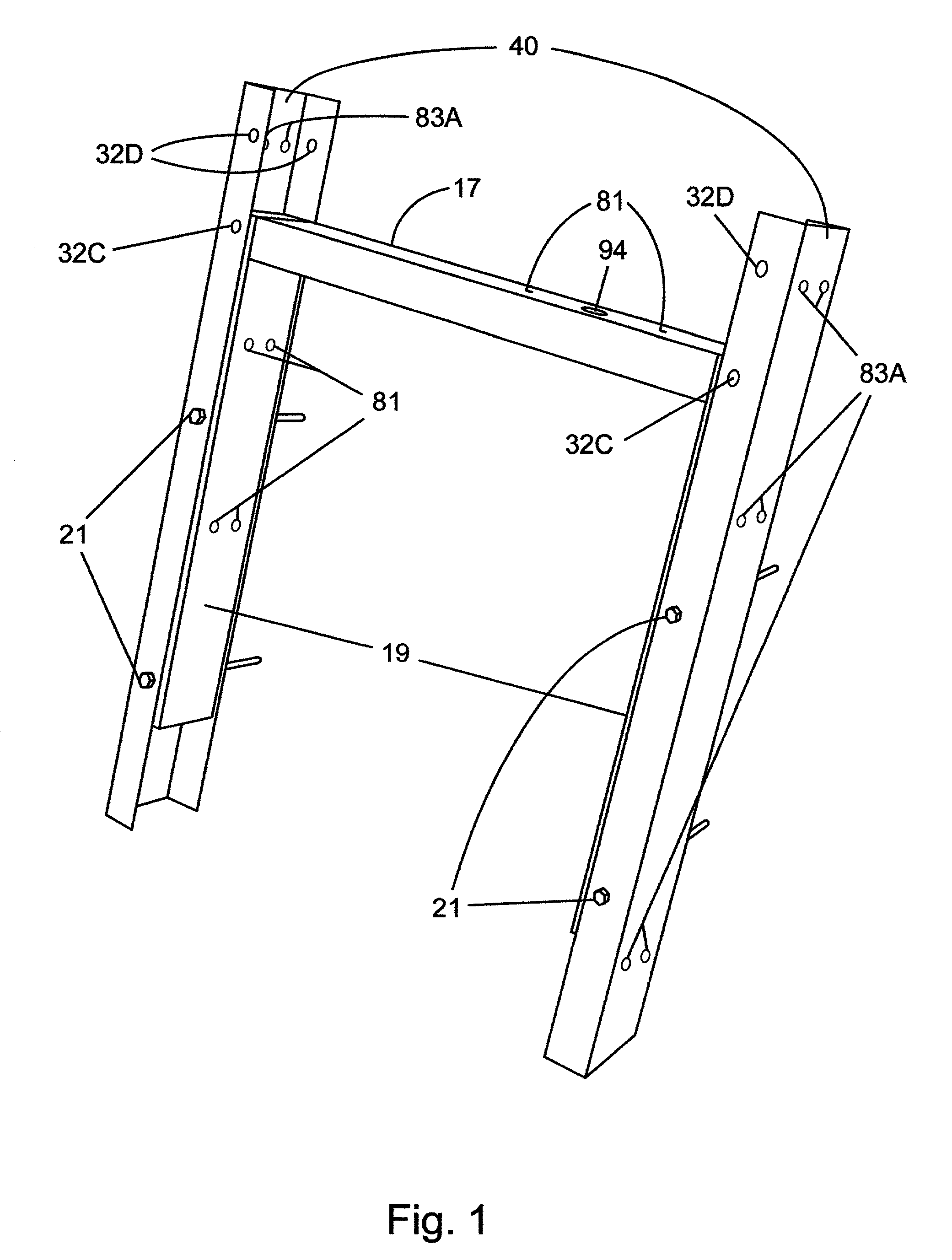

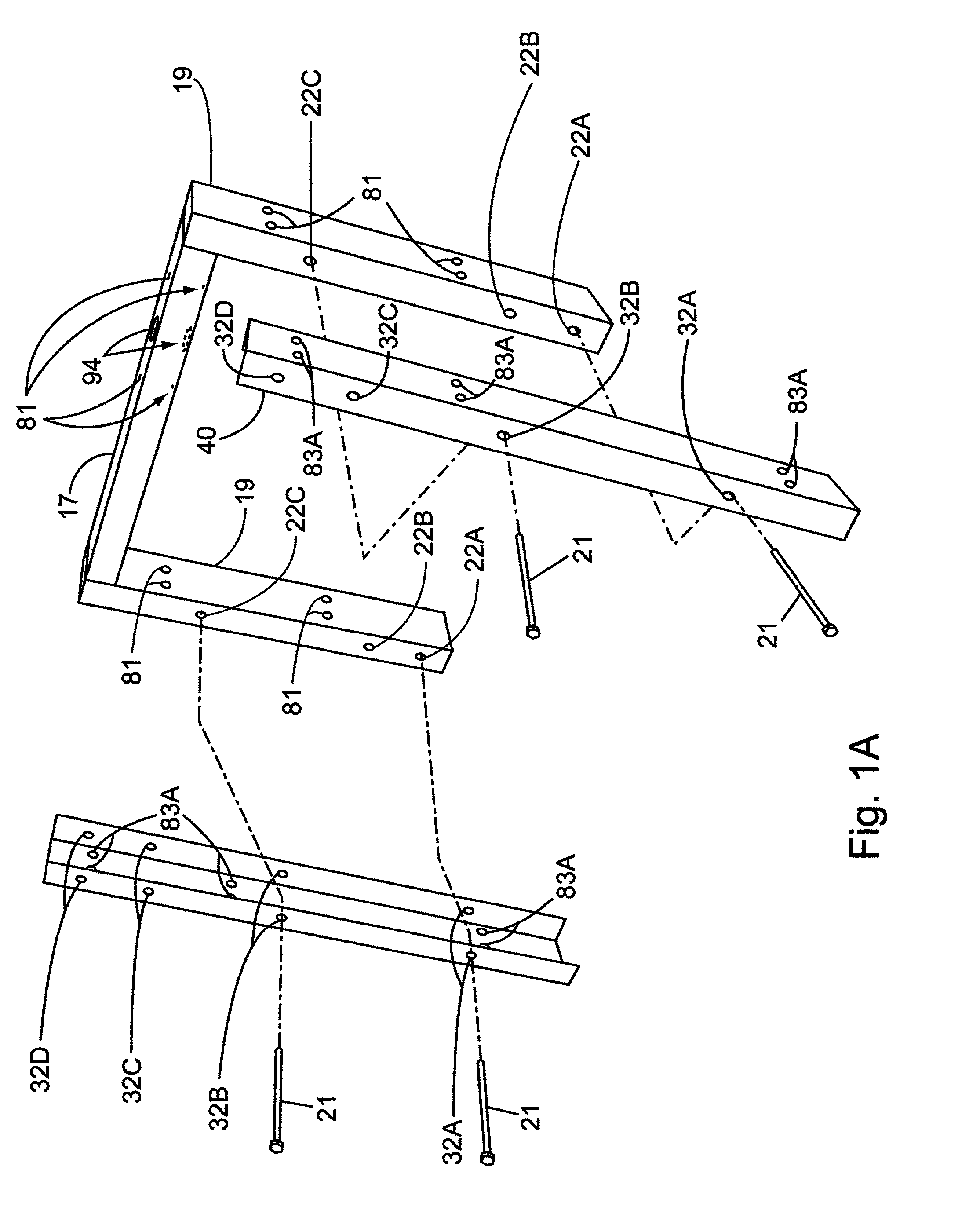

Device and method for joining and tacking sections for transportation vehicles

ActiveUS20060162140A1Accurate spatial positioningWelding/cutting auxillary devicesMeasurement/indication equipmentsEngineeringLaser

A device and method for joining and tacking several individual components independently of shape and / or size to form inherently rigid, transportable sections for transportation vehicles, such as an aircraft is disclosed. According to one embodiment of the invention, the individual components may be spatially positioned relative to each other independently of shape and / or size. The spatial positions of the individual components may be determined by a measuring device, such as a laser measuring device, and varied via several positioning devices until a preset spatial position of the individual components has been reached in which the individual component are tacked together to form a section. In another embodiment, the positioning devices may be designed as base positioners, a first lateral positioner, a second lateral positioner, an upper positioner as well as an inner positioner. Joining and tacking of several individual components 1 may form varying sections such as sections with varying cross sectional geometries and / or cross sectional dimensions and / or linear dimensions for different types of aircraft or for derivatives of the same aircraft types. In addition, the sections may have two working platforms on either side of the section.

Owner:AIRBUS OPERATIONS GMBH

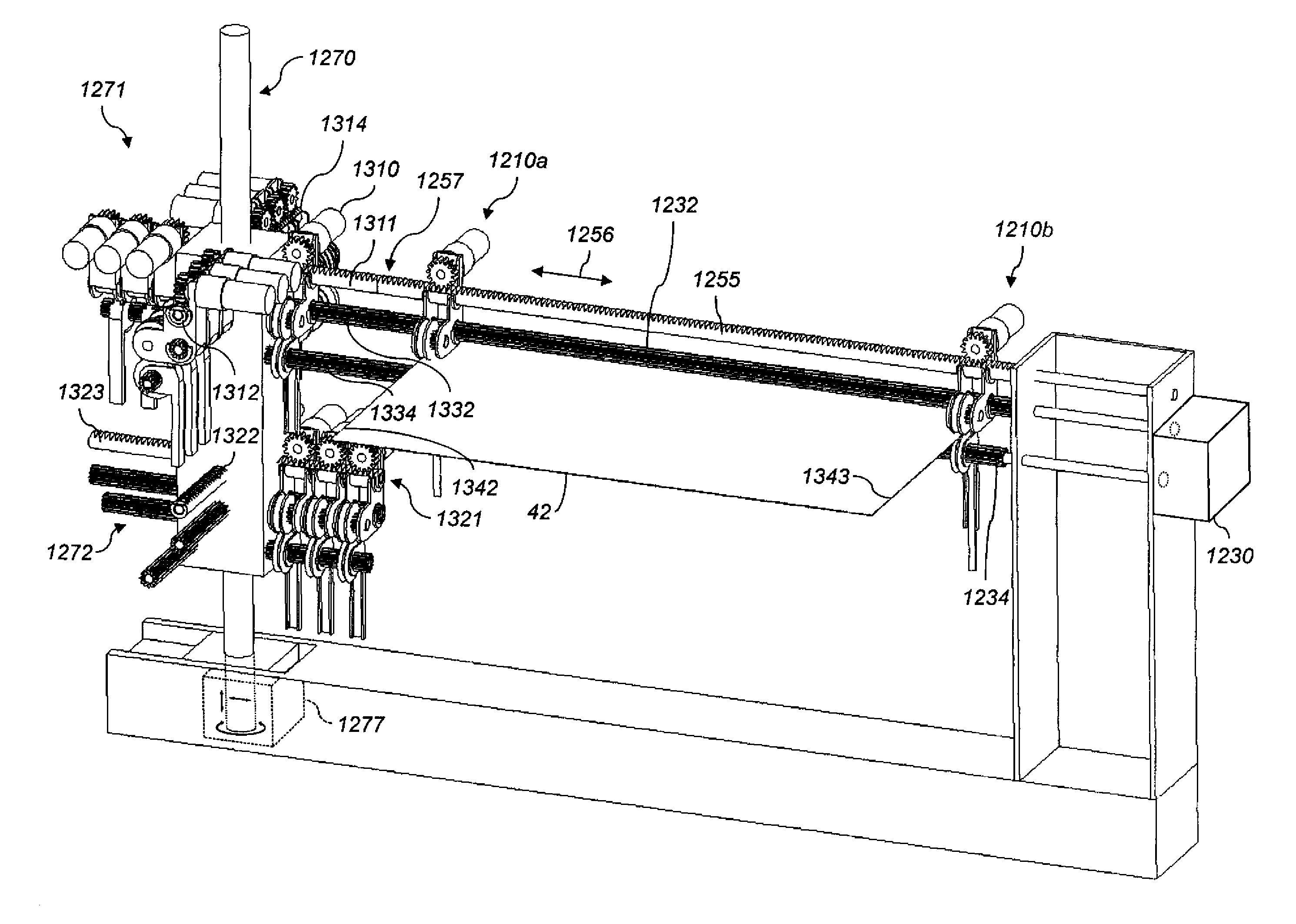

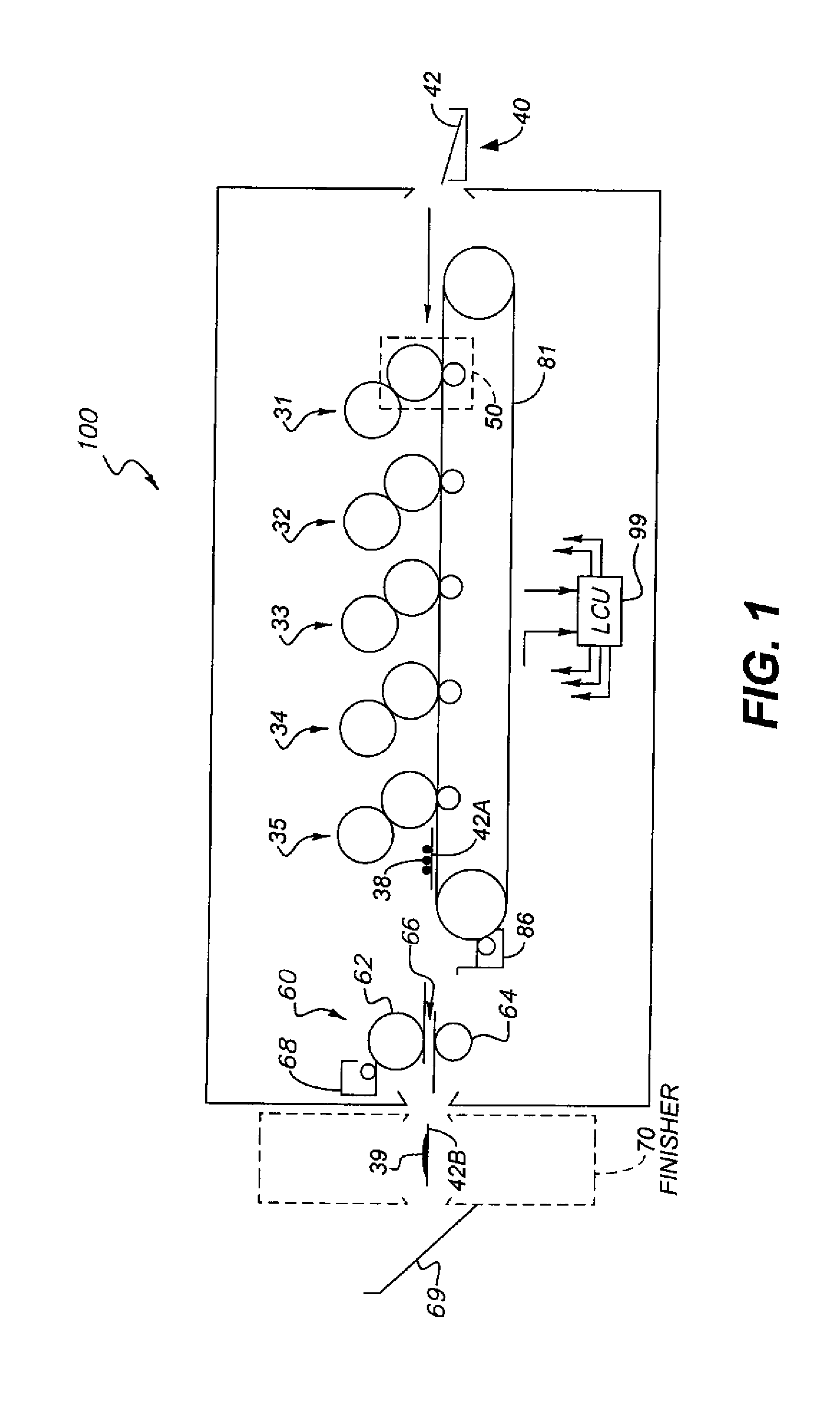

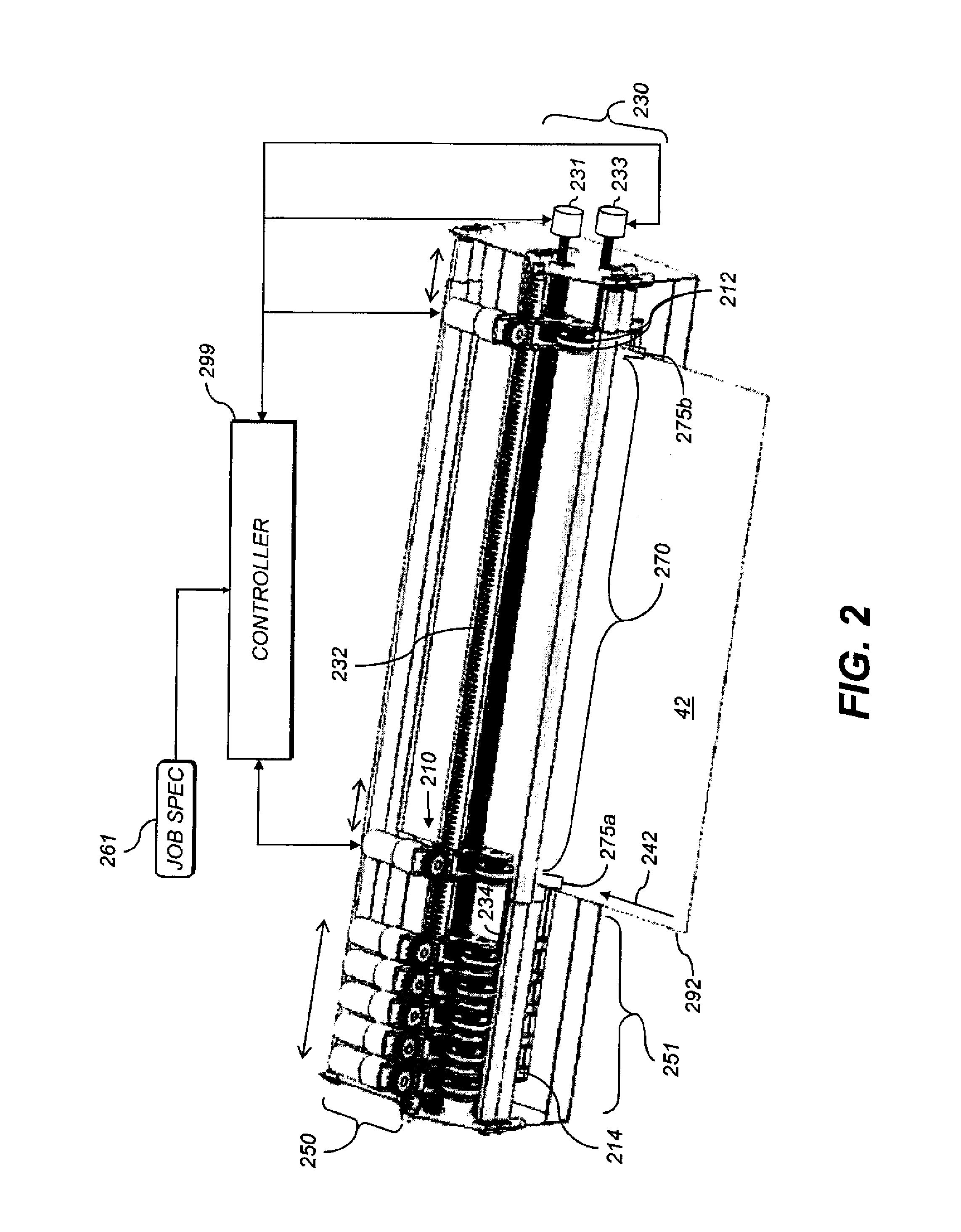

Receiver-puncturing device with translating puncturing devices

InactiveUS20140121085A1Less audible noiseReduce power consumptionAutomatic control devicesTool changing apparatusEngineeringPuncturing

Apparatus for selectively puncturing a moving receiver includes puncturing devices, each with two parallel puncturing wheels and a pressure wheel. A drive mechanism rotates the puncturing wheels or pressure wheel of two or more puncturing devices so that the rotating puncturing wheels engage the moving receiver to puncture the moving receiver parallel to its feed direction in the puncturing areas. A transport mechanism selectively moves the plurality of puncturing devices perpendicular to the feed direction of the receiver. A controller receives a job specification including two or more specified puncture locations and causes the transport mechanism to laterally position two or more of the plurality of puncturing devices to puncture the moving receiver in the specified puncture locations. A rotatable turret with various shaft segments can be arranged so that perforating devices can be moved on and off the shaft segments.

Owner:EASTMAN KODAK CO

Air spring and pedestal

InactiveUS6840525B1Avoid trappingPrecise positioningSpringsResilient suspensionsAir springEngineering

A suspension system includes a longitudinal member, an air spring, a damper and an axle assembly. The air spring is not directly attached to the chassis but is mounted to contact a locating plate attached to the chassis. The locating plate includes a lip such that the locating plate is of a frustum configuration that laterally locates and self aligns the air spring upon pivotal movement and re-alignment of the air spring with the chassis. Preferably, the suspension system includes a protective skirt which aids in bringing the air cell into a correct position with the locating plate. In addition the axle assembly extends away from the chassis at a speed restricted by the damper such that the anti-vacuum system can equalize the pressure within the air cell.

Owner:MERITOR HEAVY VEHICLE SYST

Angle steel eyelet work product line

InactiveCN101402118ARealize automatic clampingAchieve positioningPerforating toolsMetal-working feeding devicesProduction linePunching

The invention discloses a production line for punching angle iron. A transverse feed device and a transverse positioning device are used to realize the feed displacement and the positioning of an angle iron work piece along the transverse direction(the X axis); a vertical feed device, a vertical displacement device and a vertical positioning device which are matched with each other are used to realize the displacement and the positioning of the angle iron work piece along the vertical direction(the Y axis); and in the whole process of punching, after the angle iron work piece is put on the production line for punching, the clipping, feed, displacement, accurate positioning and punching are automatically realized, thereby not only realizing the automatic accurate positioning and continuous punching on any position of a punching face of the angle iron along the X and the Y axes, but also greatly improving the punching accuracy, production efficiency and processing stability and reliability.

Owner:浙江博雷重型机床制造有限公司

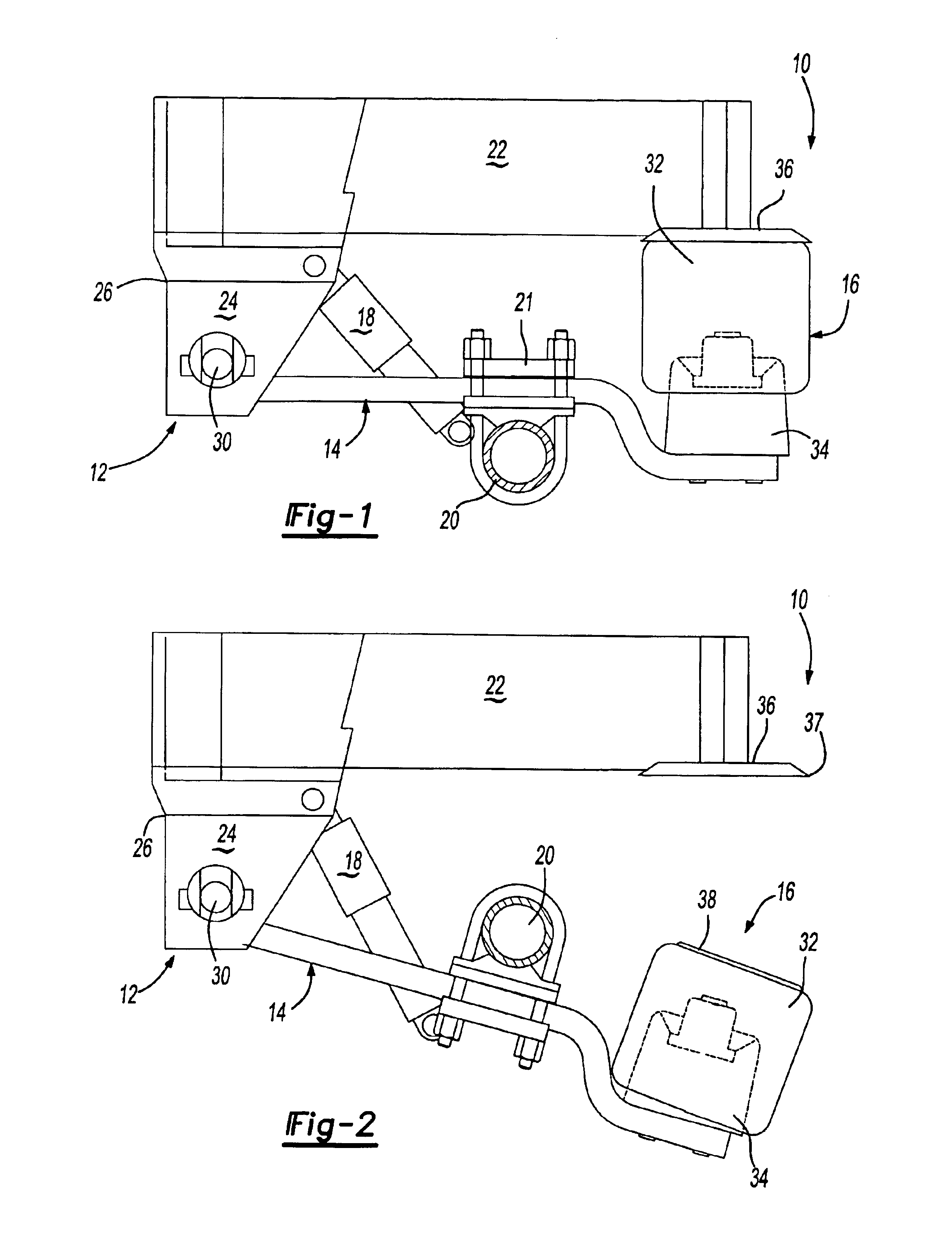

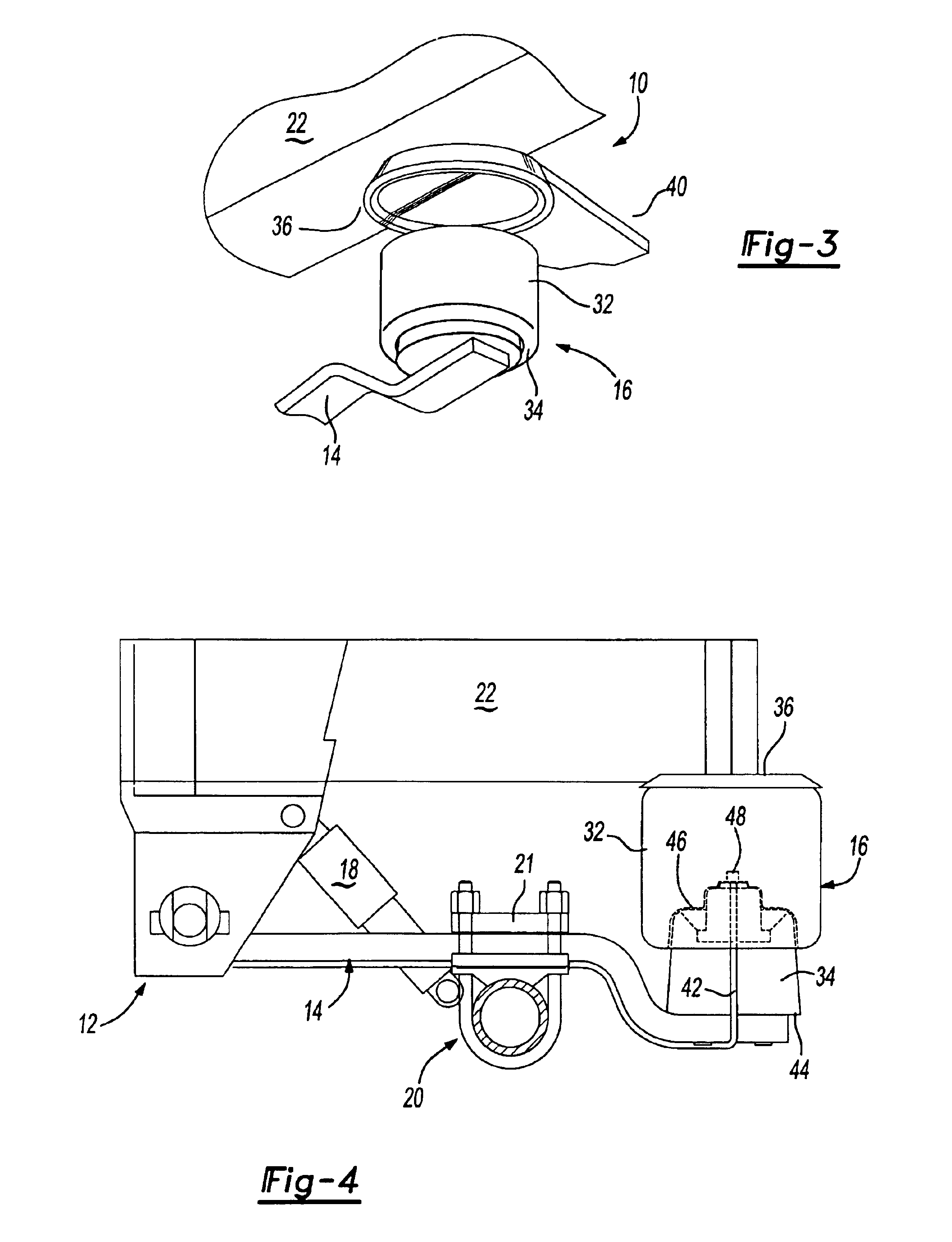

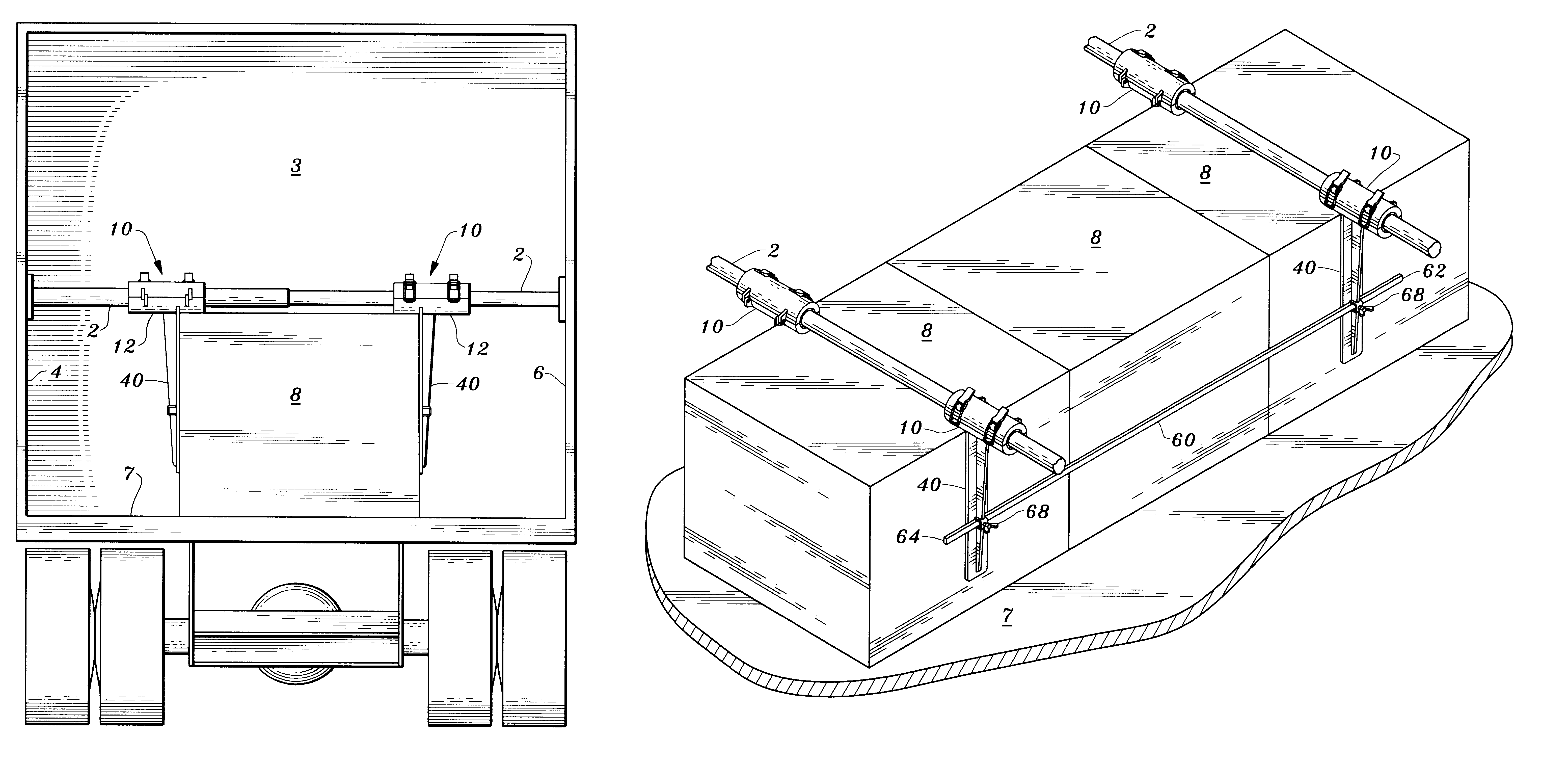

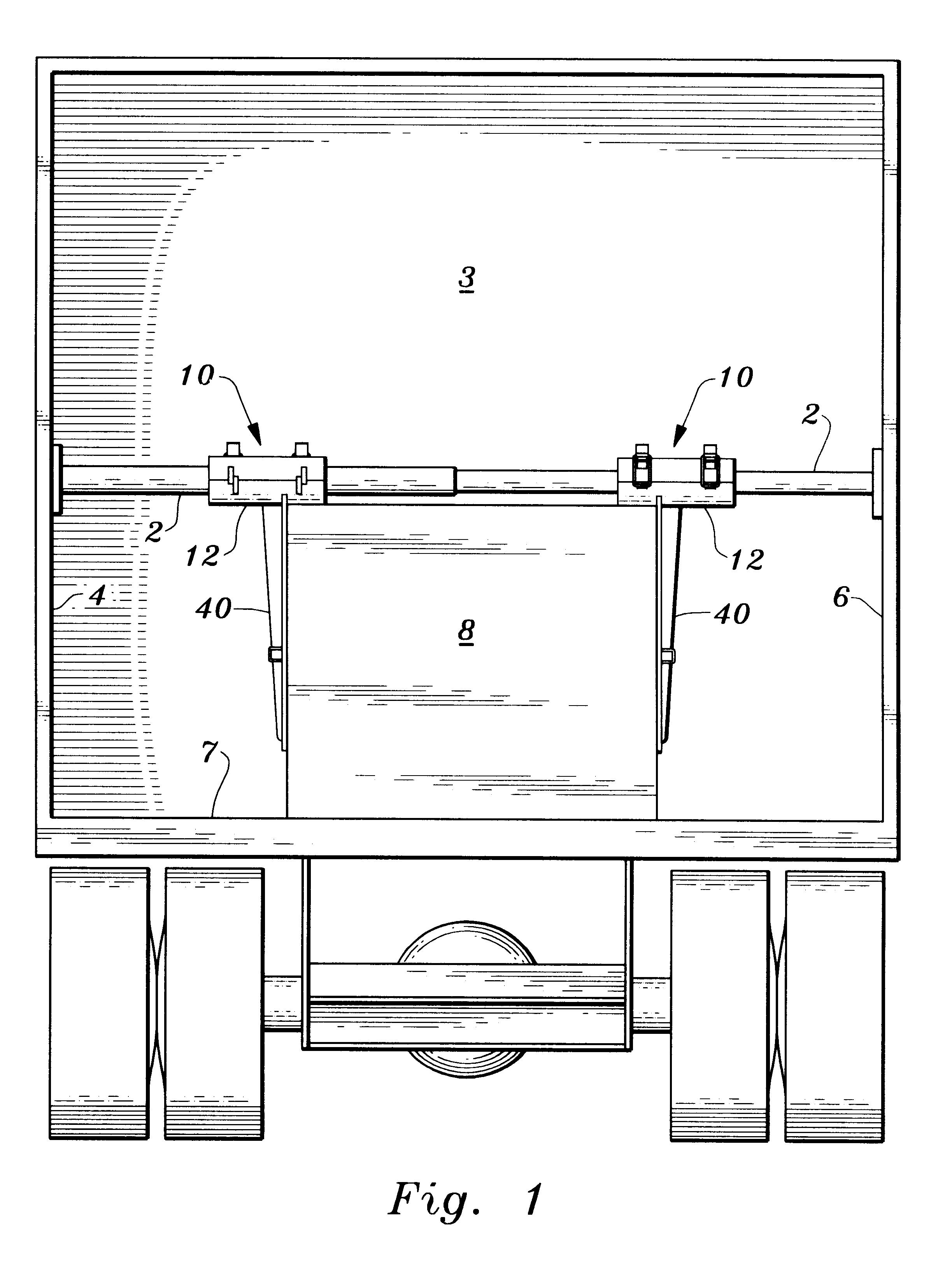

Lateral vehicle cargo restraint tool

InactiveUS6238154B1Simple processEliminate needPreventing unwanted cargo movementLoad securingFastenerLateral positioning

Owner:DAPRATO JAMES A

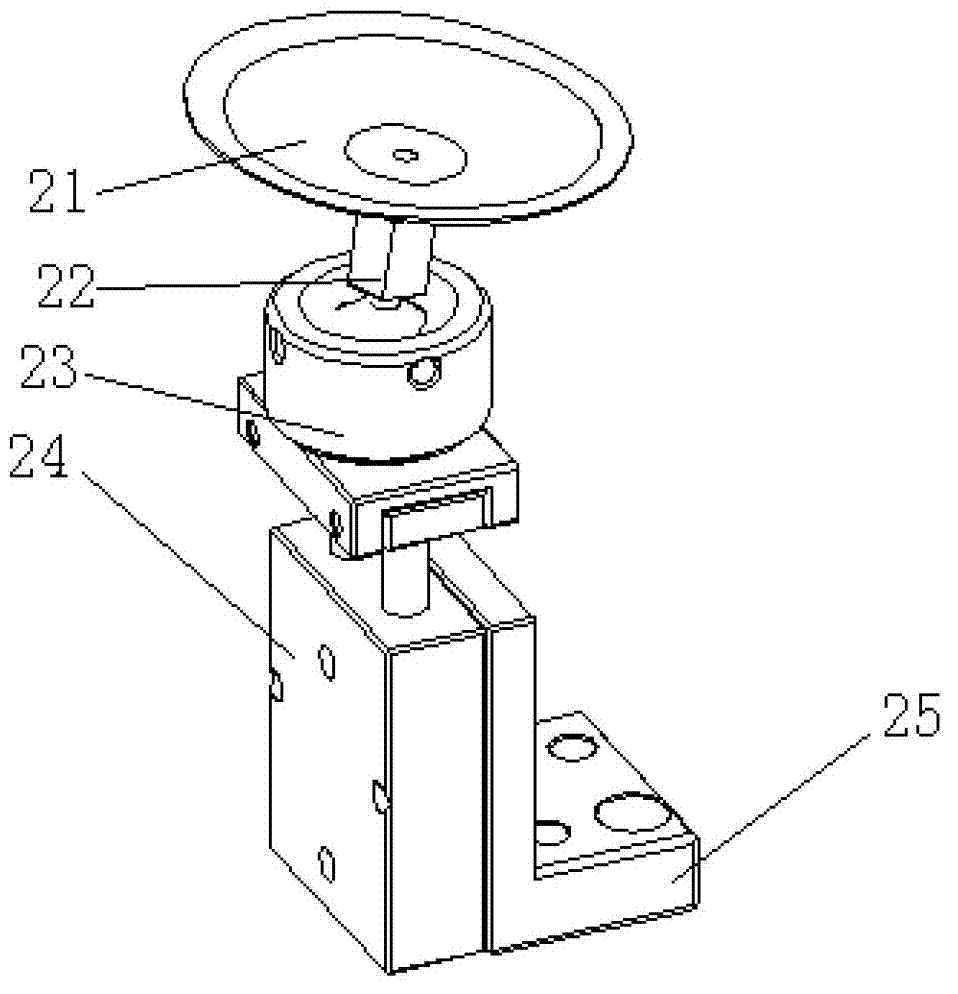

Frock device used for mounting glazing tapes and method thereof

InactiveCN102774447AHigh bonding strengthSimple processVehiclesBonding processTemperature and pressure

The invention relates to the technical field of glass accessories mounting, and particularly relates to a frock device used for mounting glazing tapes and a method of the frock device. The device comprises a sucker device, a mandril device, a lateral positioning device, a longitudinal positioning device, a glazing tape fixing block, a glazing tape pressing block and a pressing block lifting device, wherein the glazing tape fixing block is provided with a locating groove corresponding to the glazing tape in shape; a vacuum hole which is communicated with a gas-type fitting at the side surface of the glazing tape fixing block is formed in the locating groove; and the device is characterized in that the glazing tape fixing block is internally provided with a heating device. The surfaces to be bonded of the glass and the glazing tape are coated with the same first coat, according to the frock device, the glazing tape and the glass are firmly bonded through the first coats under certain temperature and pressure control. The frock device has the advantages of being simple in structure, low in cost, simple in bonding process and good in bond performance, and having low requirements on glass dimensional precision and high yield.

Owner:FUYAO GLASS IND GROUP CO LTD

Tape servo information with superimposed data information providing servo band identification

ActiveUS20050030662A1Driving/moving recording headsFilamentary/web record carriersData informationMagnetic tape

In magnetic tape having separate longitudinal servo bands of servo information with superimposed data information, the separate servo bands have selected different superimposed data information, to identify the separate servo bands for independent addressability. The servo information comprises non-parallel laterally extending transitions to indicate lateral positioning, and the selected different superimposed data information may comprise a lack thereof in portion(s) of the servo bands. Where the superimposed data information is longitudinal position information of the tape, the selected different superimposed data information may comprise different longitudinal position information of one or more servo band(s). The selected different superimposed data information may comprise a band identifier in the superimposed data information of one or more of the servo bands.

Owner:IBM CORP

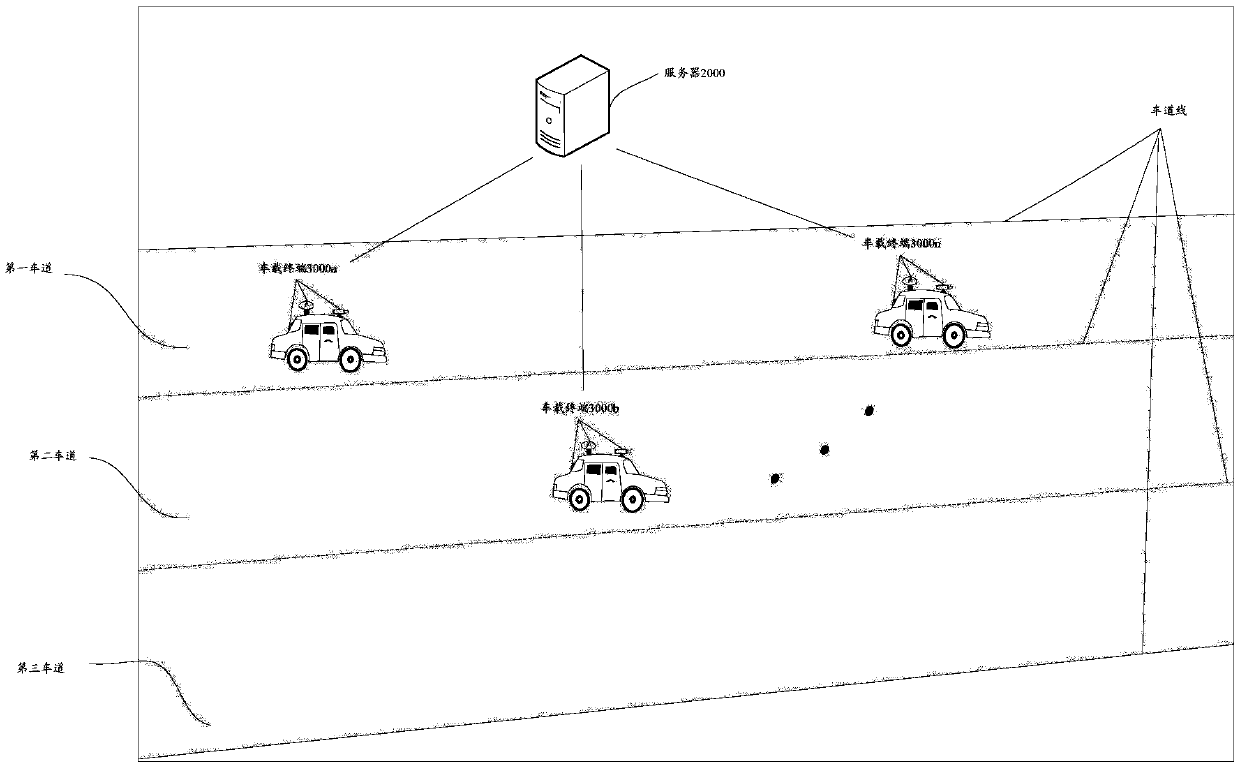

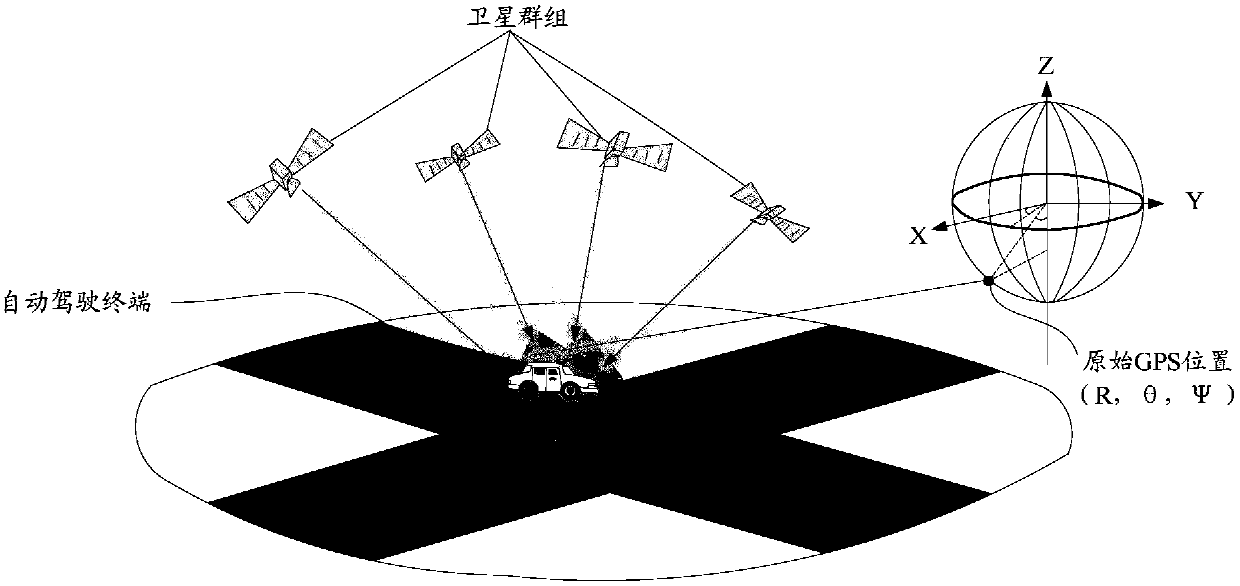

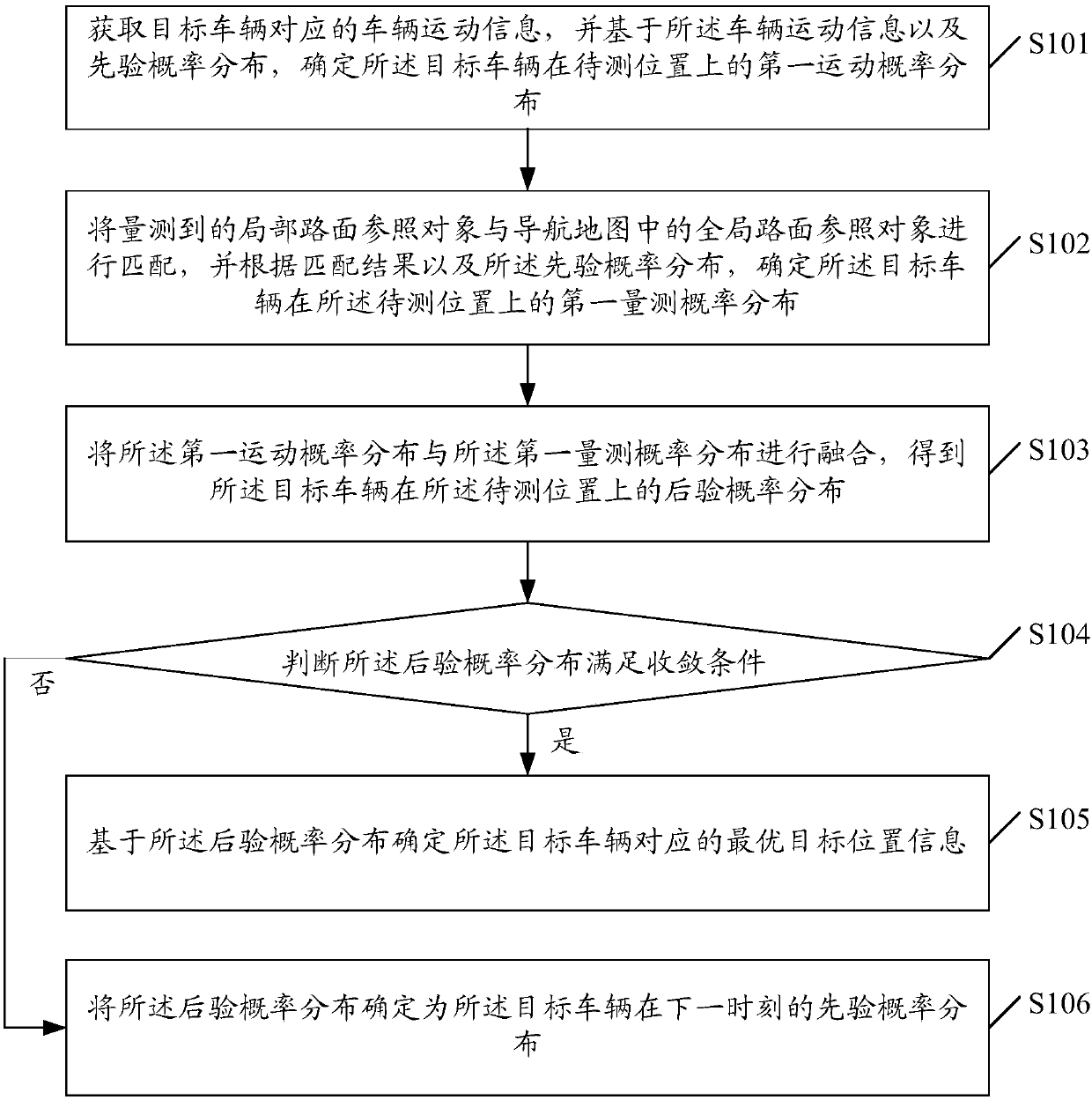

Positioning data processing method

ActiveCN110146909AImprove accuracyImprove lateral positioning accuracySatellite radio beaconingPattern recognitionRoad surface

Embodiments of the invention disclose a positioning data processing method. The method comprises the steps of obtaining vehicle movement information corresponding to a target vehicle and determining afirst movement probability distribution, on a to-be-measured position, of the target vehicle on the basis of the vehicle movement information and a prior probability distribution; matching a measuredlocal pavement reference object with a global pavement reference object in a navigation map and determining a first measurement probability distribution, on the to-be-measured position, of the targetvehicle according to the matching result and the prior probability distribution; fusing the first movement probability distribution with the first measurement probability distribution to obtain a posterior probability distribution, on the to-be-measured position, of the target vehicle; and determining optimum target position information corresponding to the target vehicle on the basis of the posterior probability distribution. By adoption of the positioning data processing method, the lateral positioning precision for the vehicles can be enhanced and the correctness of the positioning data can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

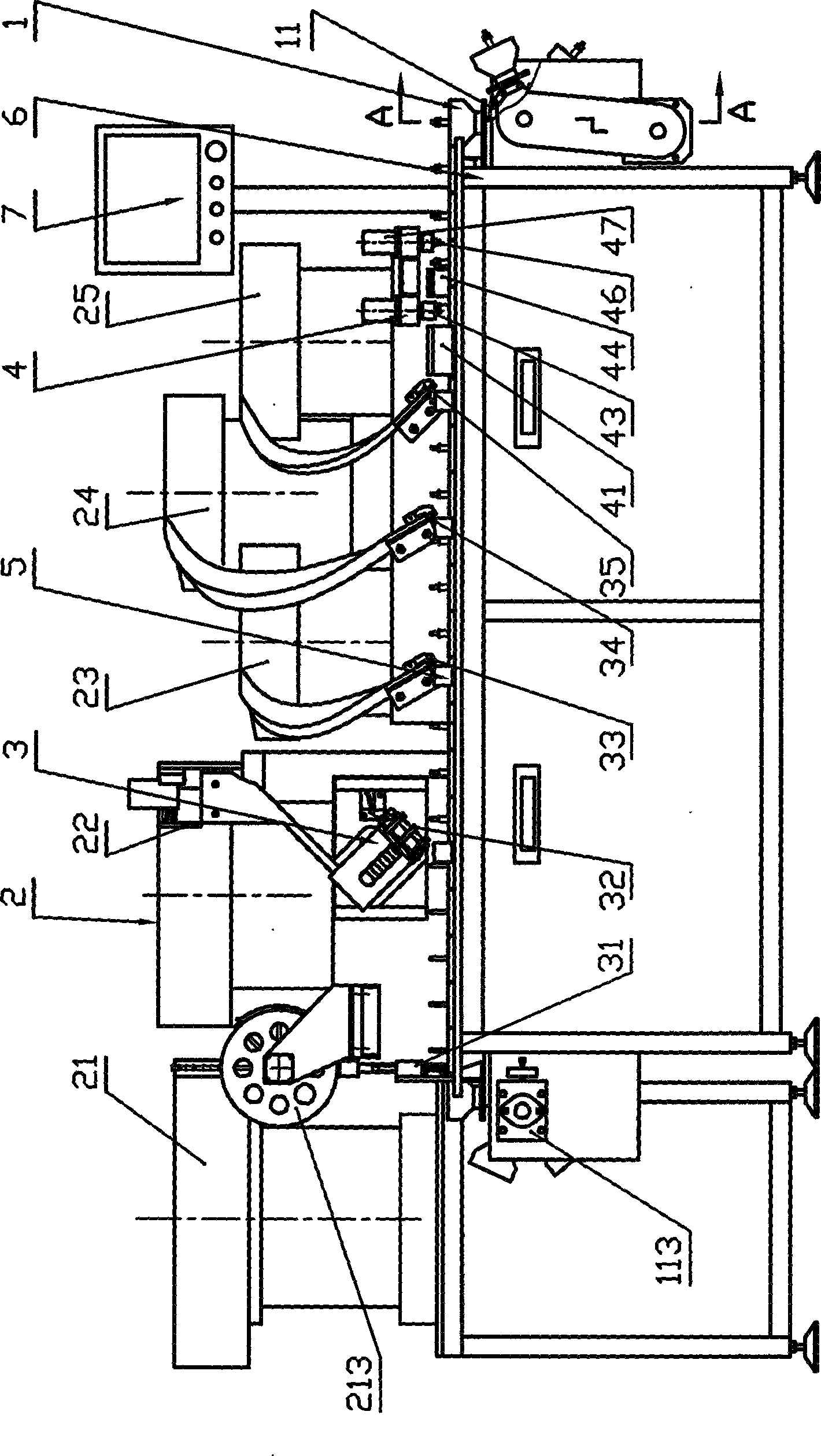

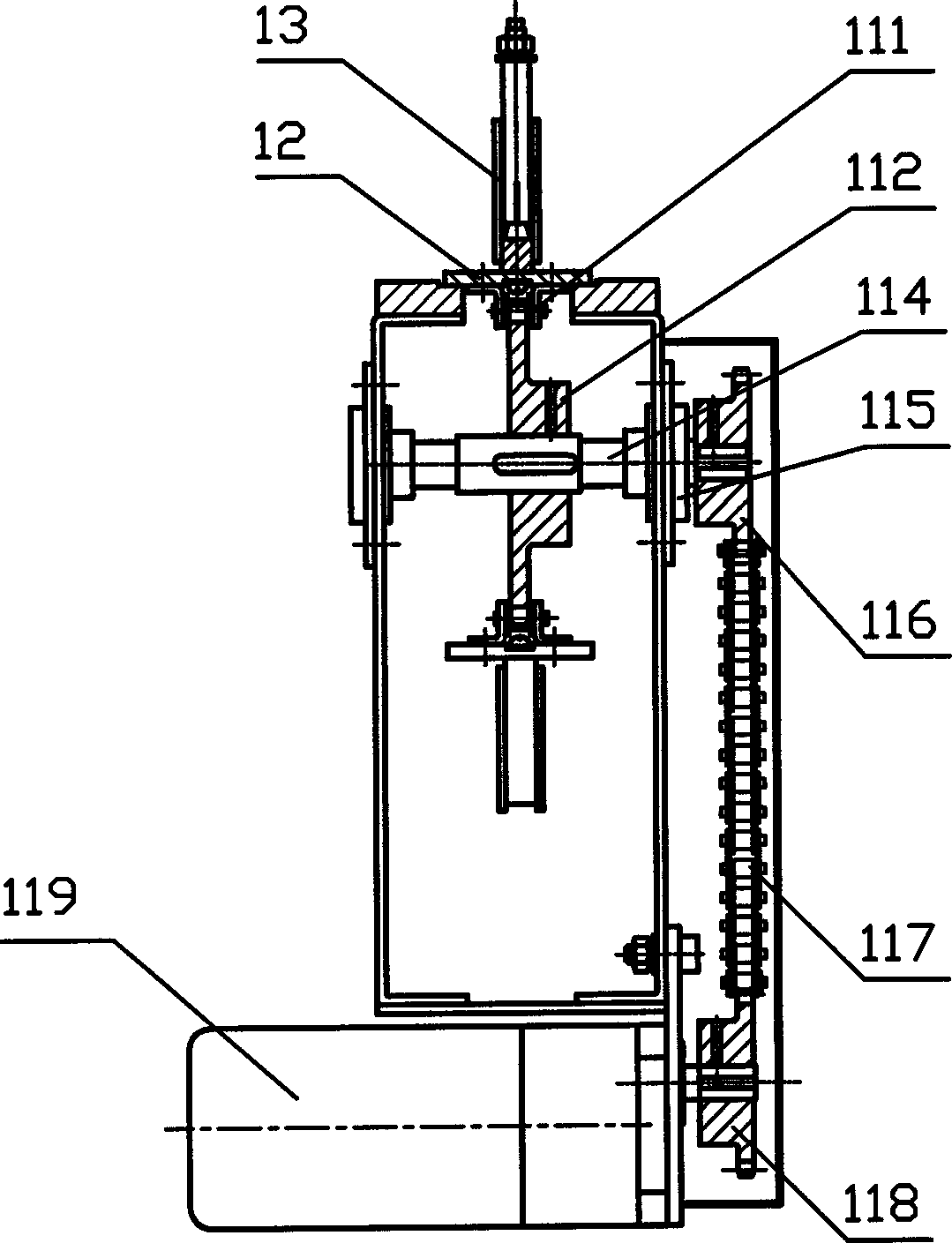

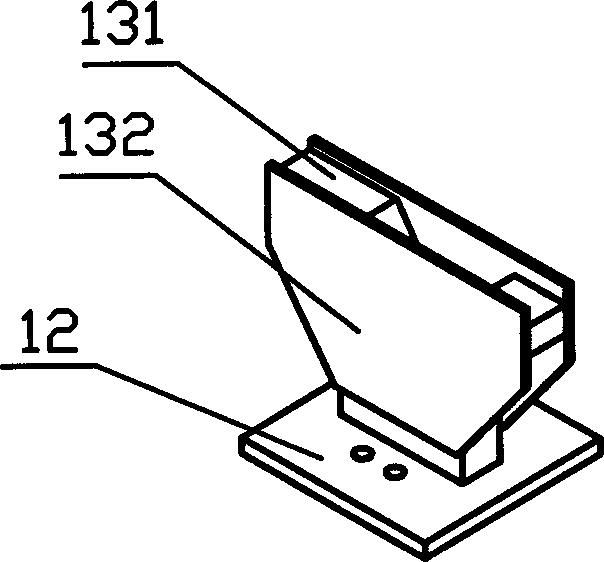

Automatic assembling machine of expansion screw bolts

The invention relates to an automatic assembling machine of expansion screw bolts and belongs to the field of hardware machinery. The assembling machine consists of a chain plate type conveying device, a part feeding device, a part escapement device, a screw nut screwing device, a screw rod small head lateral positioning device, a machine frame and a control system, wherein the part feeding device and the part escapement device are used for the ranging, the storage for package and the one-by-one release of parts, the chain plate type conveying device is arranged on the machine frame, semi-finished products and finished products with different stations are transferred through expansion screw bolt seat combination elements arranged on a chain plate, the screw rod small head lateral positioning device is arranged at the front end of the part escapement device for realizing the lateral positioning of each station screw rod, the screw nut screwing device comprises a screw nut pre-screwing friction plate, a first screw nut screwing wheel, a clamping stagnation release friction plate, a second screw nut screwing wheel, a small motor and the like. The assembling machine can realize the automatic assembly of each part of the expansion screw bolts and has the characteristics that the assembly efficiency is high, and the cost is low; and screw nuts are subjected to two links of pre-screwing and screwing, and the assembly quality is ensured.

Owner:ZHENGZHOU UNIV

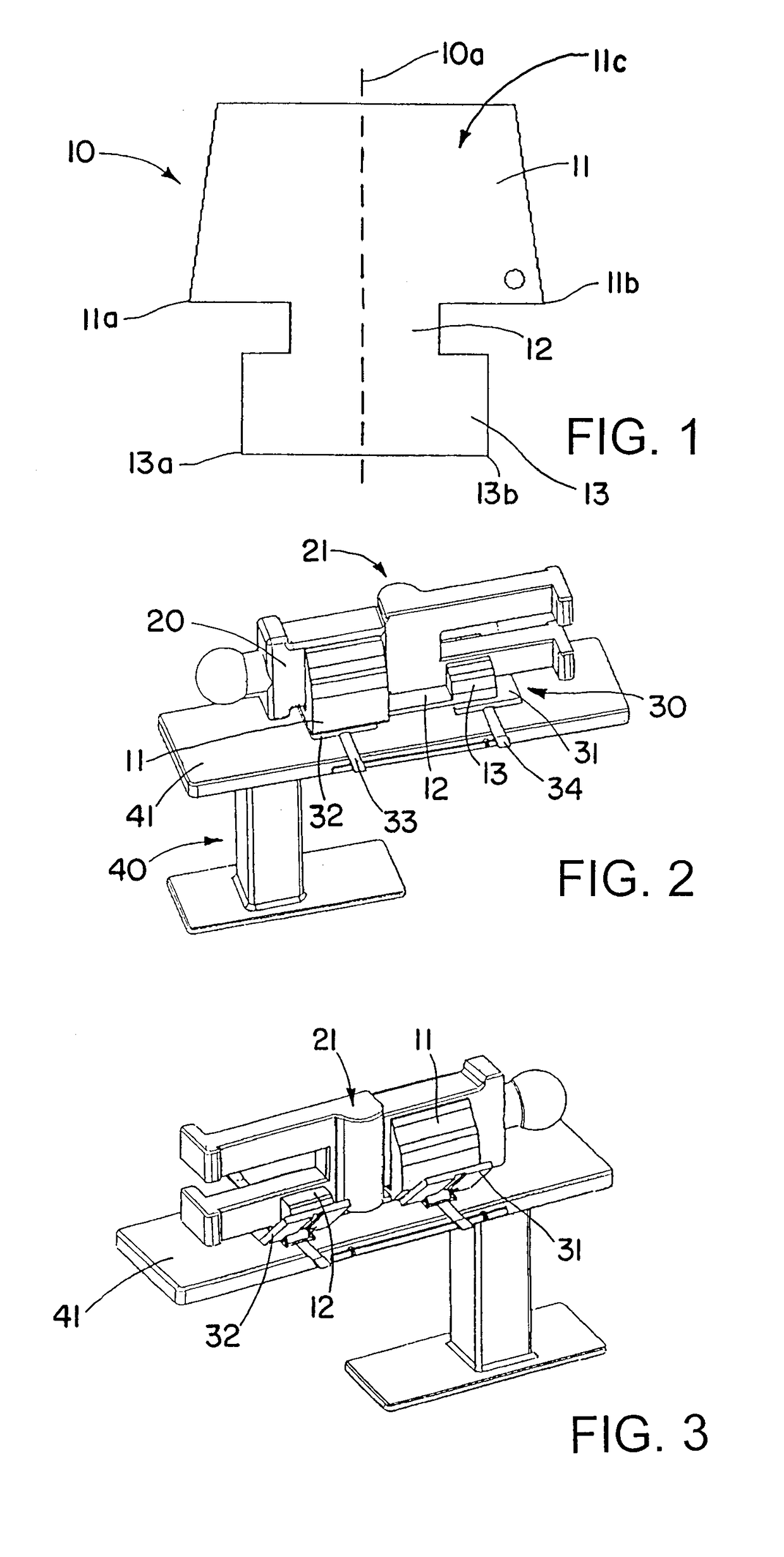

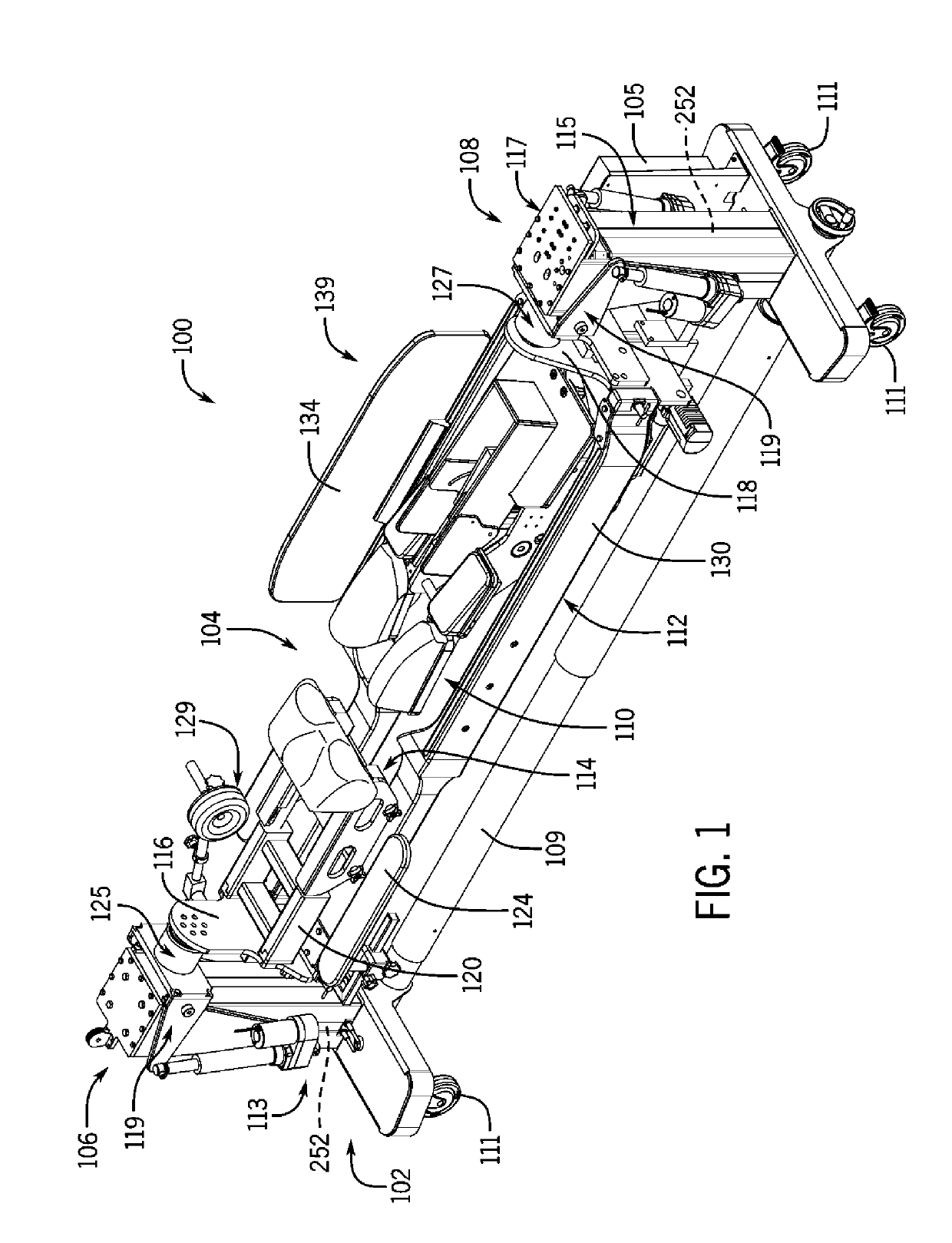

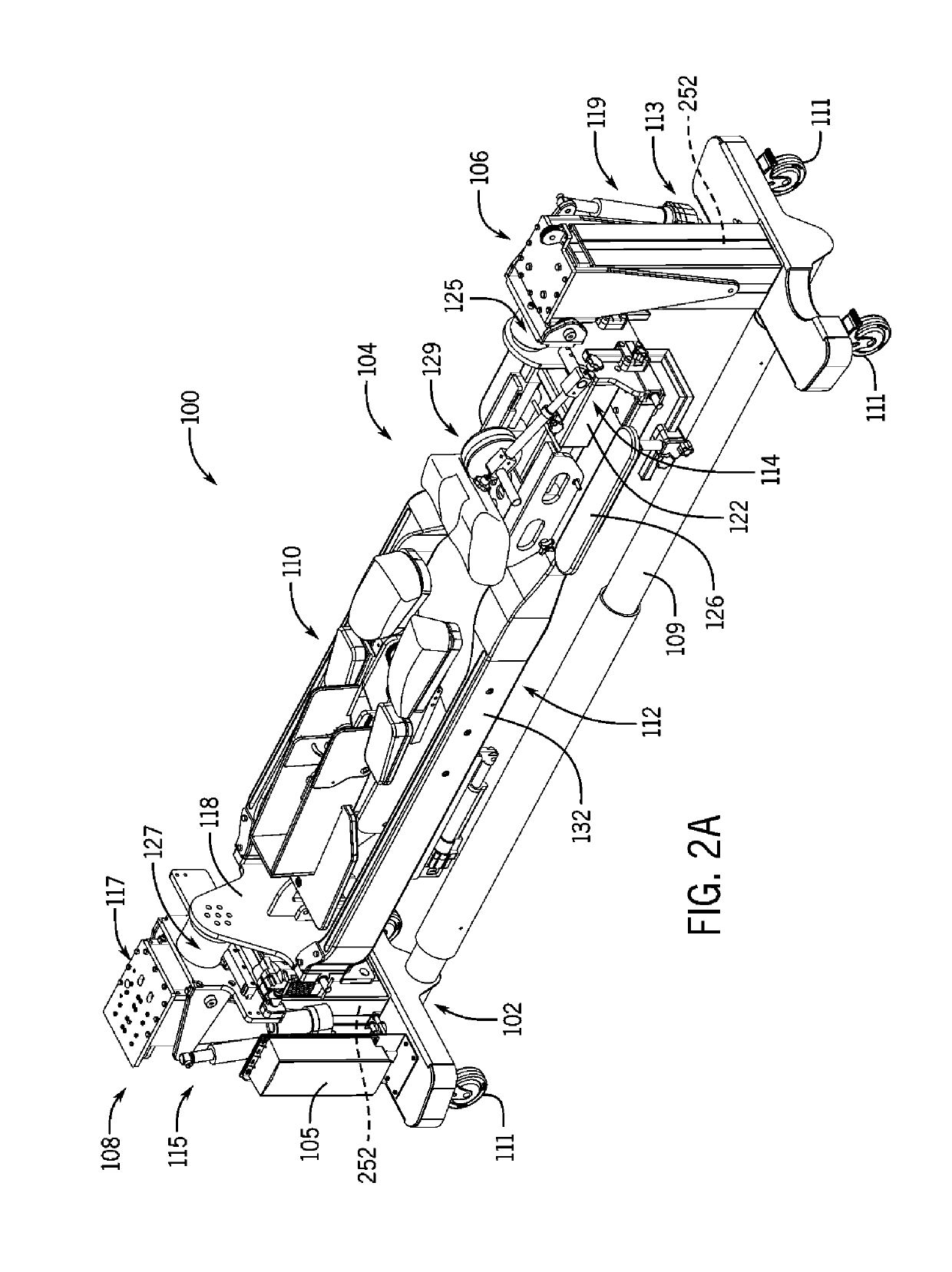

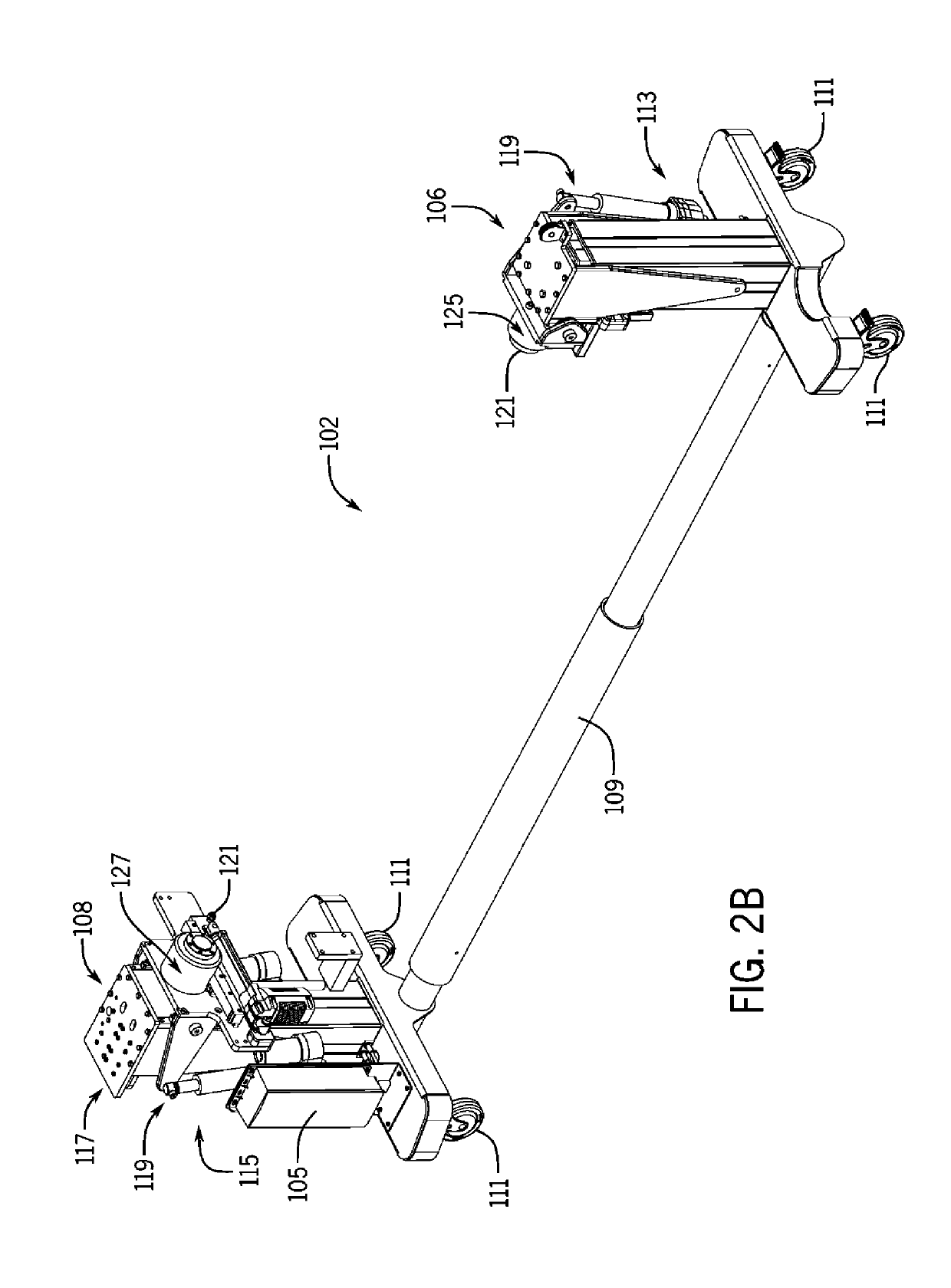

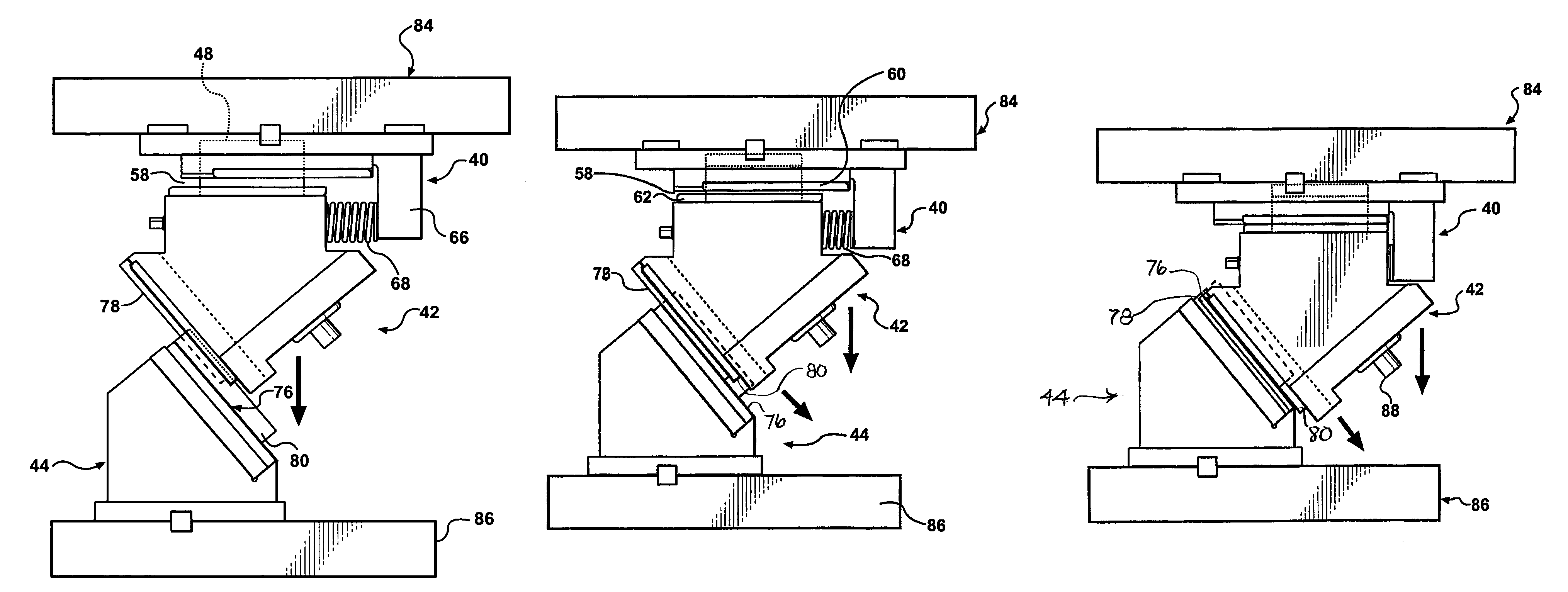

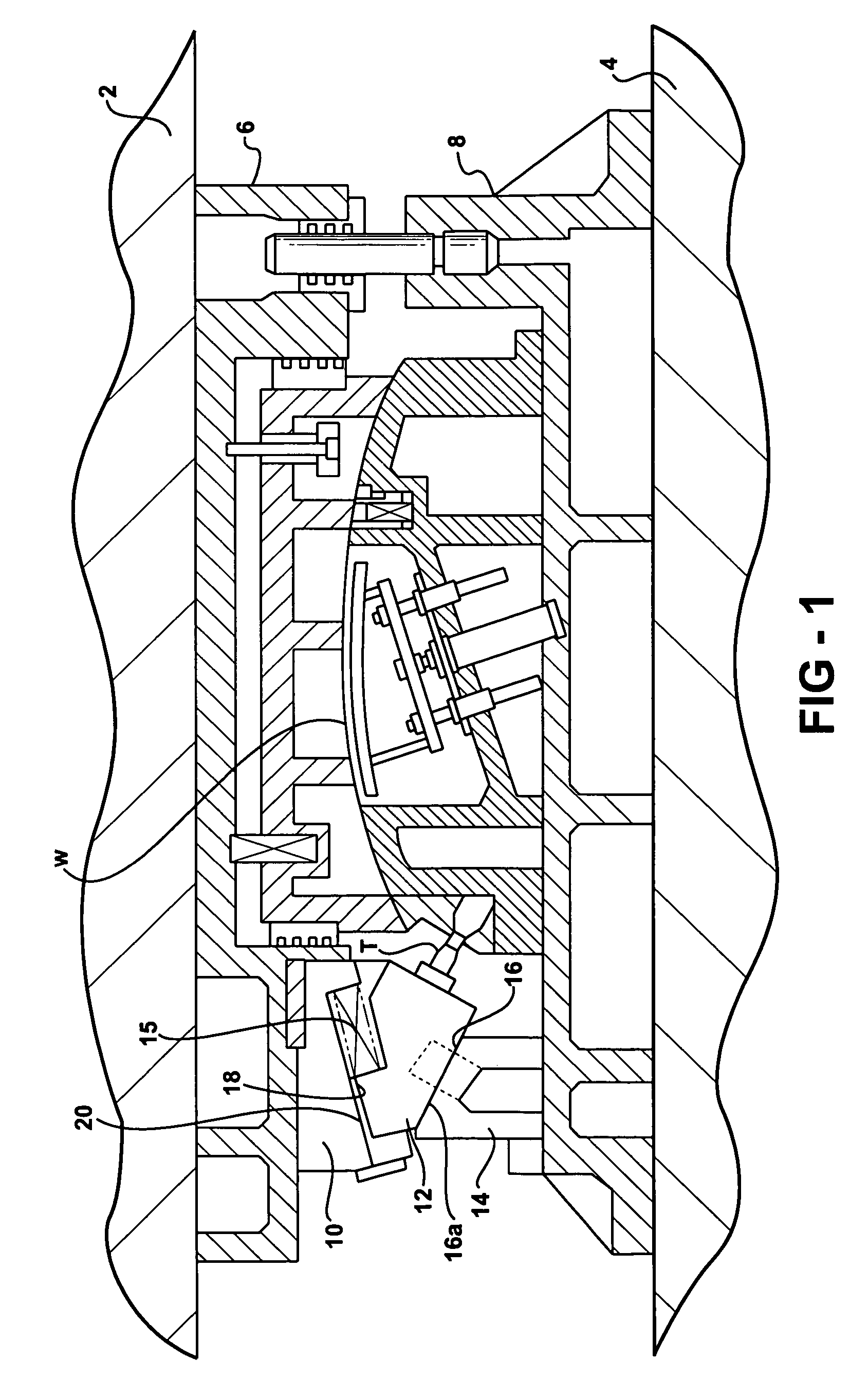

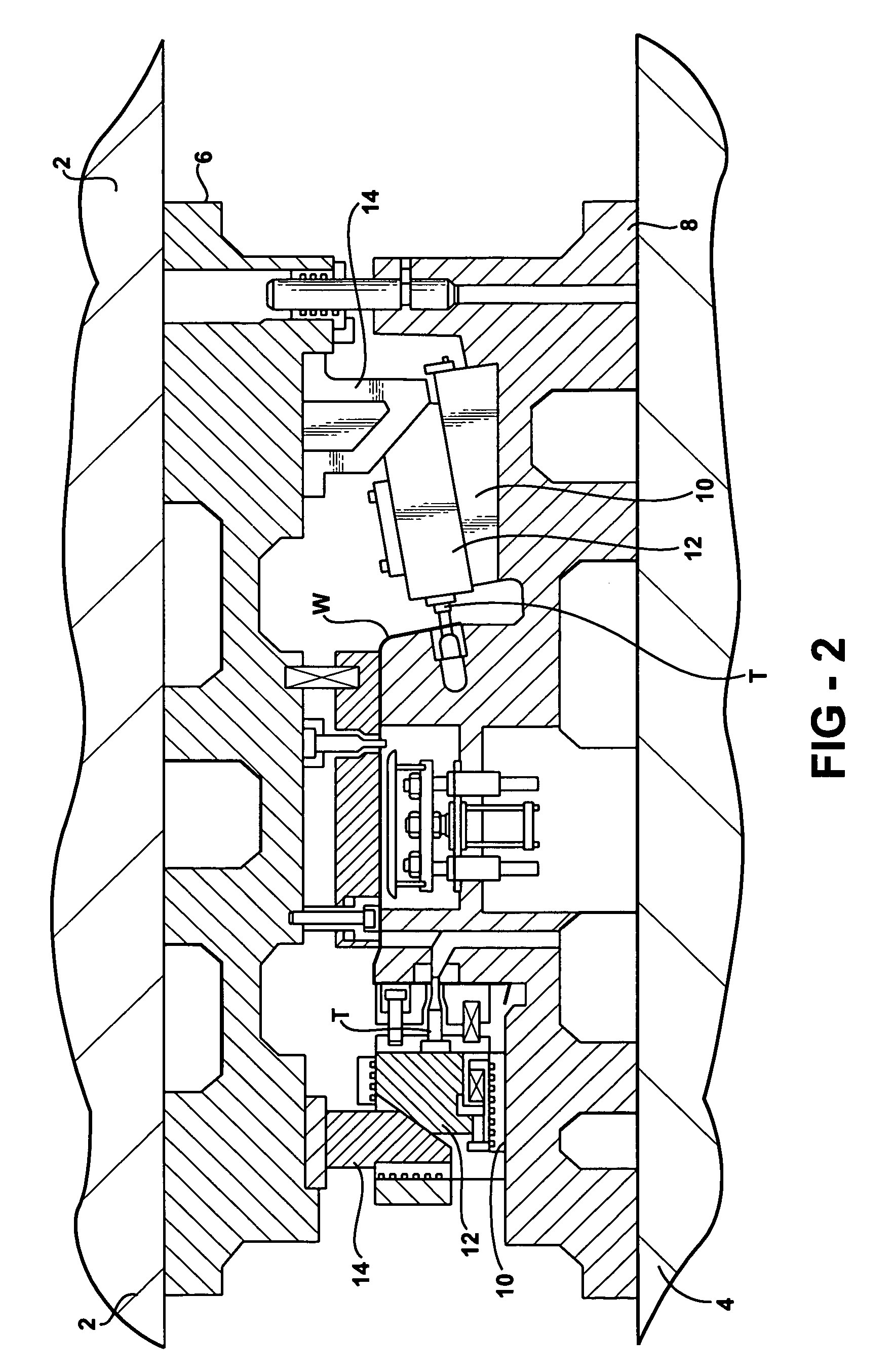

Prone and lateral surgical table

A surgical table for prone and lateral positioning of a patient, where the table includes a base and a patient support structure. The base may include a head and a foot end support structure. The patient support structure may include an upper body support structure cantilevered off of the head end support structure at a first end and a lower body support structure cantilevered off of the foot end support structure at a second end. The upper body support structure may include a chest pad. The lower body support structure may include a lower body translation and rotation structure and at least one pelvic pad supported thereon.

Owner:WARSAW ORTHOPEDIC INC

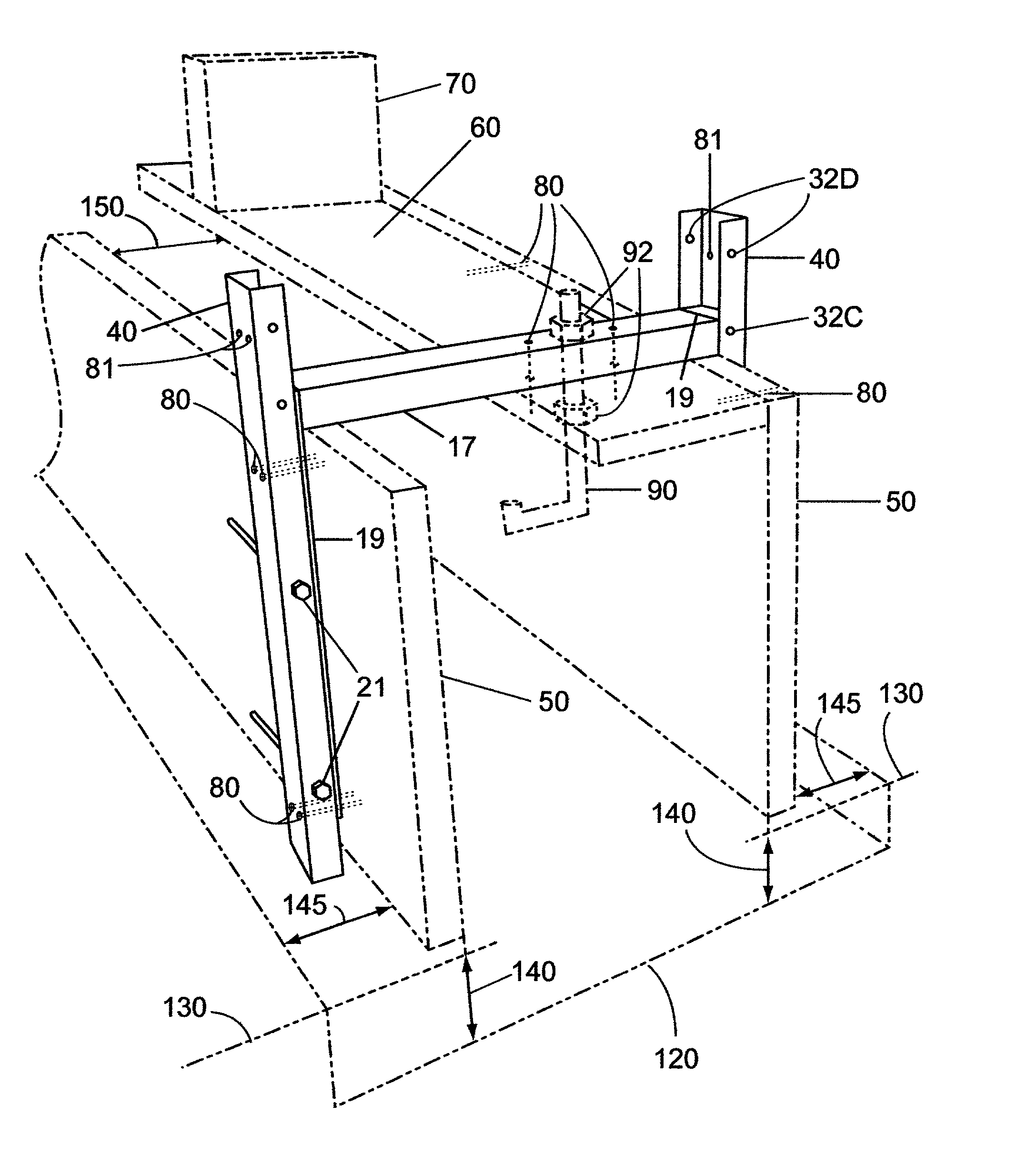

Foundation from bracket and method

InactiveUS20030101670A1Shorten the timeEliminate needFiling appliancesFoundation engineeringEngineeringStructural engineering

A pre-fabricated building foundation form assembly is installed beneath a pre-existing temporarily supported structure in its final position, and a footing dug below the line of the lowest building timber. A rigid sheet form element is positioned along the upper and outside perimeter side portion of the lowest building timber. The brackets are positioned over the lowest timber and against the sheeting at specified intervals and held in place with connectors. Adjustable supports are attached to the brackets and connectors attach brackets to sheeting. J-bolts along with structural steel are installed. A rigid sheet form element is laterally positioned along the inside perimeter of the inner side of the brackets and held with connectors, which completes the suspended enclosure. A flowable and settable foundation material fills the space within the enclosure and extends essentially continuously upwardly from the footing below the site surface to meet the lower surface of the lowest floor timber to support the building thereon once the foundation material has cured. The footing below the rigid sheet form element has a lateral width greater than the space between the portions of the enclosure to form a foundation footing of suitable width.

Owner:GUSTIN MORRIS HOUSTON

Portable modular wheel lift

InactiveUS7073777B2Easy to stackLess lengthInclined ship-liftingLifting framesEngineeringShort length

A modular wheel lift provides elevation of a vehicle wheel enclosed by body portions of a low height above the ground. A base lift unit includes a lift surface height selected to be less than the body portions height. A ramp unit is aligned and hingedly attached to one end of the base lift unit, to allow rotational movement of a wheel to the base lift surface. Additional lift units having ramp ends and progressively decreasing lengths are laterally positioned and stacked on the base lift surface. Side brackets are releasably positioned along either side surface to secure the stacked additional lift units to allow rotational movement of the vehicle wheel to an uppermost lift surface. A method of assembly and elevating includes laterally positioning and stacking a plurality of lift units having progressively shorter lengths to provide lifting of a vehicle wheel without disruption of the vehicle body portions.

Owner:BRANSTETTER ANN

Special turnover facility for installation of electromechanical equipment

InactiveCN110193810AImprove securityRealize automatic flipWork holdersWork benchesElectric machineryEngineering

The invention relates to the technical field of electromechanical equipment, in particular to a special turnover facility for installation of the electromechanical equipment. The special turnover facility for installation of the electromechanical equipment comprises a base plate, a left clamping mechanism, a right clamping mechanism, a rotating workbench and a locating jig. The left clamping mechanism and the right clamping mechanism are symmetrically arranged on the base plate. The rotating workbench is located between the left clamping mechanism and the right clamping mechanism. A driving motor is arranged in the rotating workbench, and the output end of the driving motor penetrates through the top of the rotating workbench. The locating jig is installed at the output end of the drivingmotor. A transverse locating assembly and a longitudinal locating assembly are arranged in the locating jig and distributed in a crossed mode, and the transverse locating assembly is located over thelongitudinal locating assembly. By the adoption of the special turnover facility for installation of the electromechanical equipment, the purpose of conducting automatic turnover on the electromechanical equipment is achieved, the safety of workers is improved, and the electromechanical equipment with different sizes can be automatically located and fixed through the transverse locating assembly and the longitudinal locating assembly.

Owner:YANGTZE NORMAL UNIVERSITY

High speed microscope with three-dimensional laser beam scanning including acousto-optic deflector for controlling the lateral position and collimation of the light beam

InactiveUS7227127B2Eliminate dependenceIncrease in sizeBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansAcousto optic deflectorLight beam

A system and method for independently controlling the collimation and lateral positioning of a light beam comprises at least one acousto-optic deflector and a pair of counter propagating acoustic waves with offset frequencies. While the frequency offset controls the lateral positioning of the light beam, a frequency gradient across the acousto-optic deflectors controls the collimation of the light beam.

Owner:BAYLOR COLLEGE OF MEDICINE

Press mounted cam

ActiveUS7191635B2Reduce noiseEliminate precision issuesForging/hammering/pressing machinesForging press detailsDriver/operatorDetent

A press mounted cam has a slide guided on an adapter by structural features including as one or more T blocks fixed to the slide and received in a respective channel formed in the adapter. In an aerial cam embodiment, a vertical clearance space is provided between the T block and adapter channel such that positive driving engagement between cam surfaces on the slide and the adapter is momentarily delayed after the initial engagement of the slide and driver surfaces to let the momentum of the slide be absorbed prior to the beginning of positive driving by the press motion, reducing shock and noise. The slide is laterally located with respect to the driver by an upwardly projecting locator-guide key on the driver received in a central channel in the slide. A positive return is provided by engagement of a driver key having T features received in a T-shaped slide channel and captured therein when the slide is driven laterally. This engagement creates a positive return of the slide when the press upper platen is raised.

Owner:ANCHOR LAMINA AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com