Parameter determining test bed for gantry framework type rail vehicle bogie

A gantry frame and rail vehicle technology, applied in the field of rail vehicles, can solve problems such as complex operation, single test function, and large test error, and achieve the effects of shortening the cycle, ensuring production quality, and improving automation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific content of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the scope of the present invention cannot be limited thereto. Even the equivalent changes and modifications made according to the patent scope of the present invention still belong to the scope covered by the present invention.

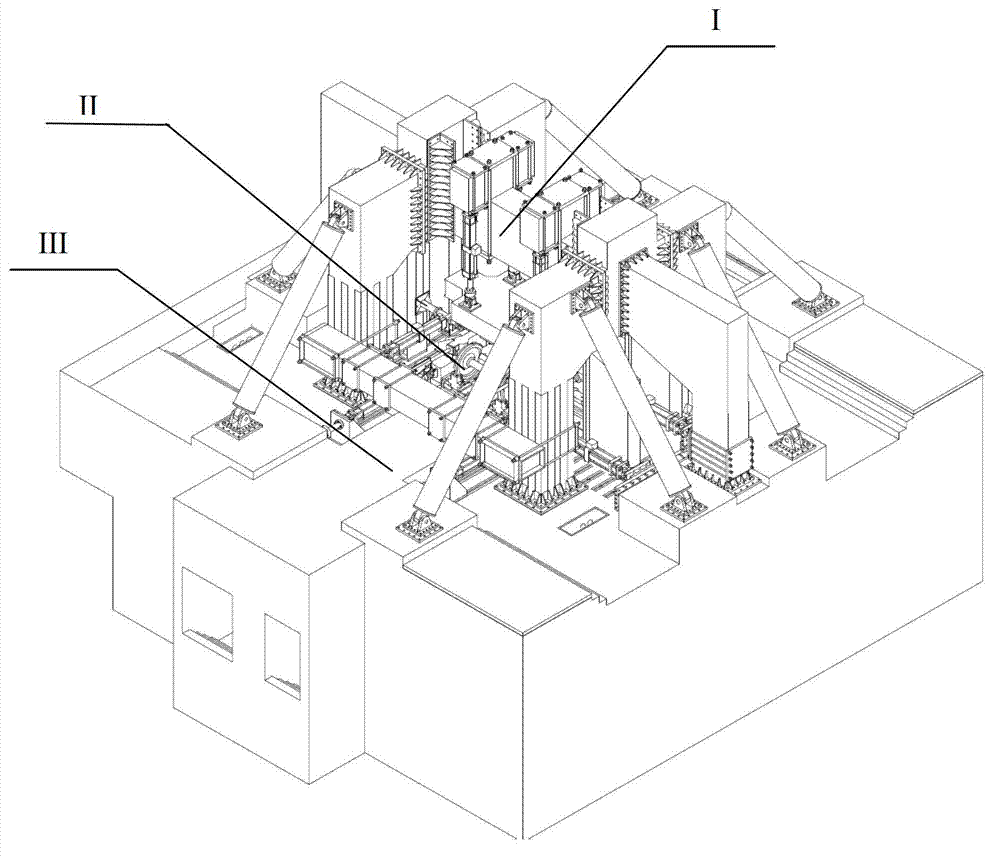

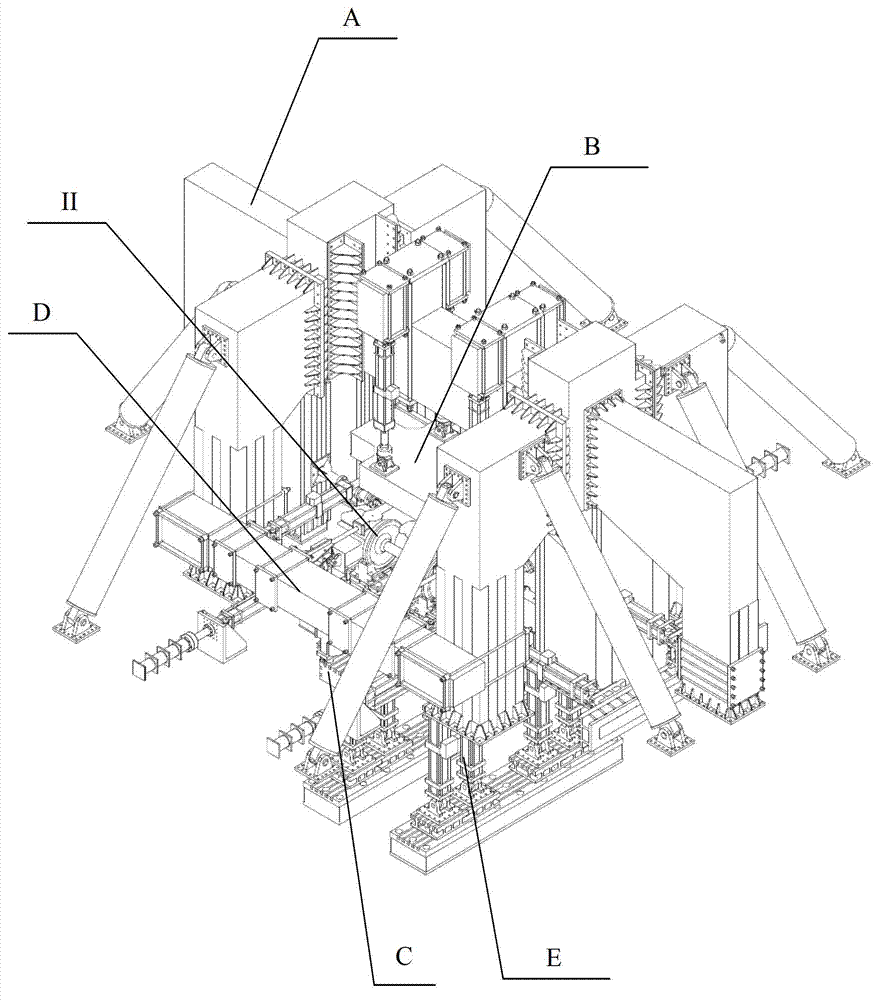

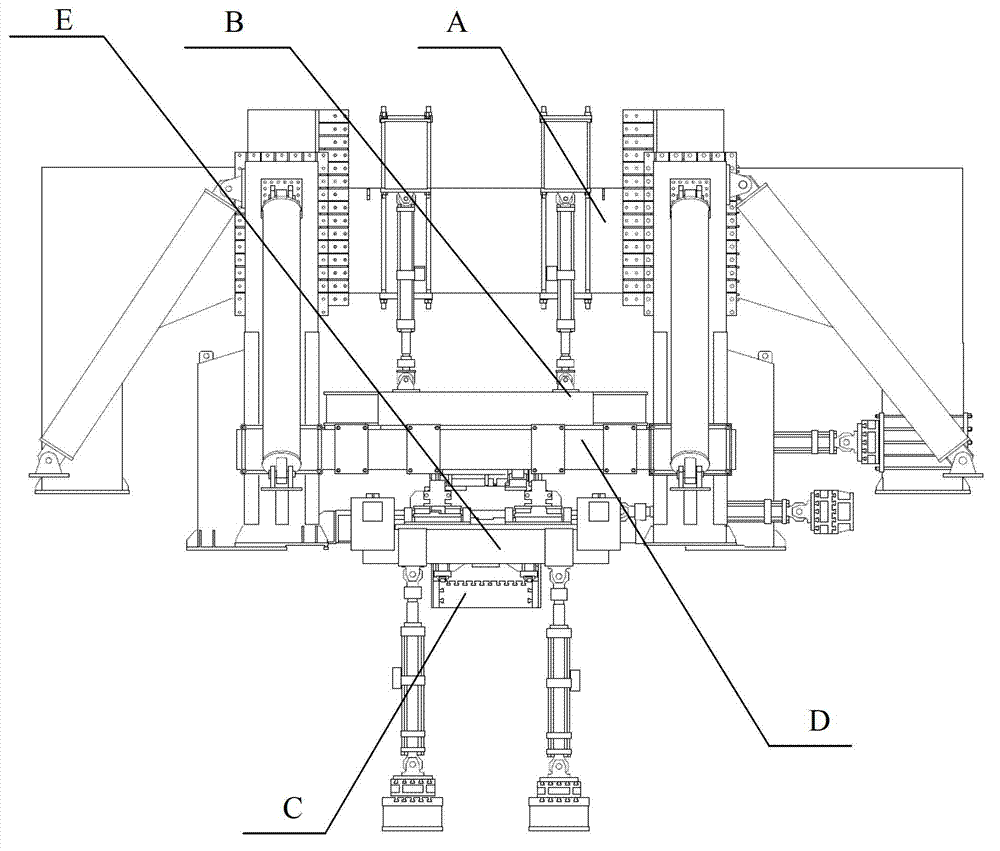

[0048] refer to figure 1 , 2 3. The gantry frame rail vehicle bogie parameter measurement test bench of the present invention mainly consists of a reaction force gantry mechanical frame A, an upper six-degree-of-freedom excitation platform assembly B, a bogie bridge device C, and a steering frame It is composed of frame positioning and clamping mechanism assembly D and lower double six-degree-of-freedom excitation platform assembly E. It is characterized in that the reaction force gantry mechanical frame A is fixed on the foundation III of the test bench by bolts, and is the loading mechanism and positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com