Patents

Literature

10955results about How to "Short cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

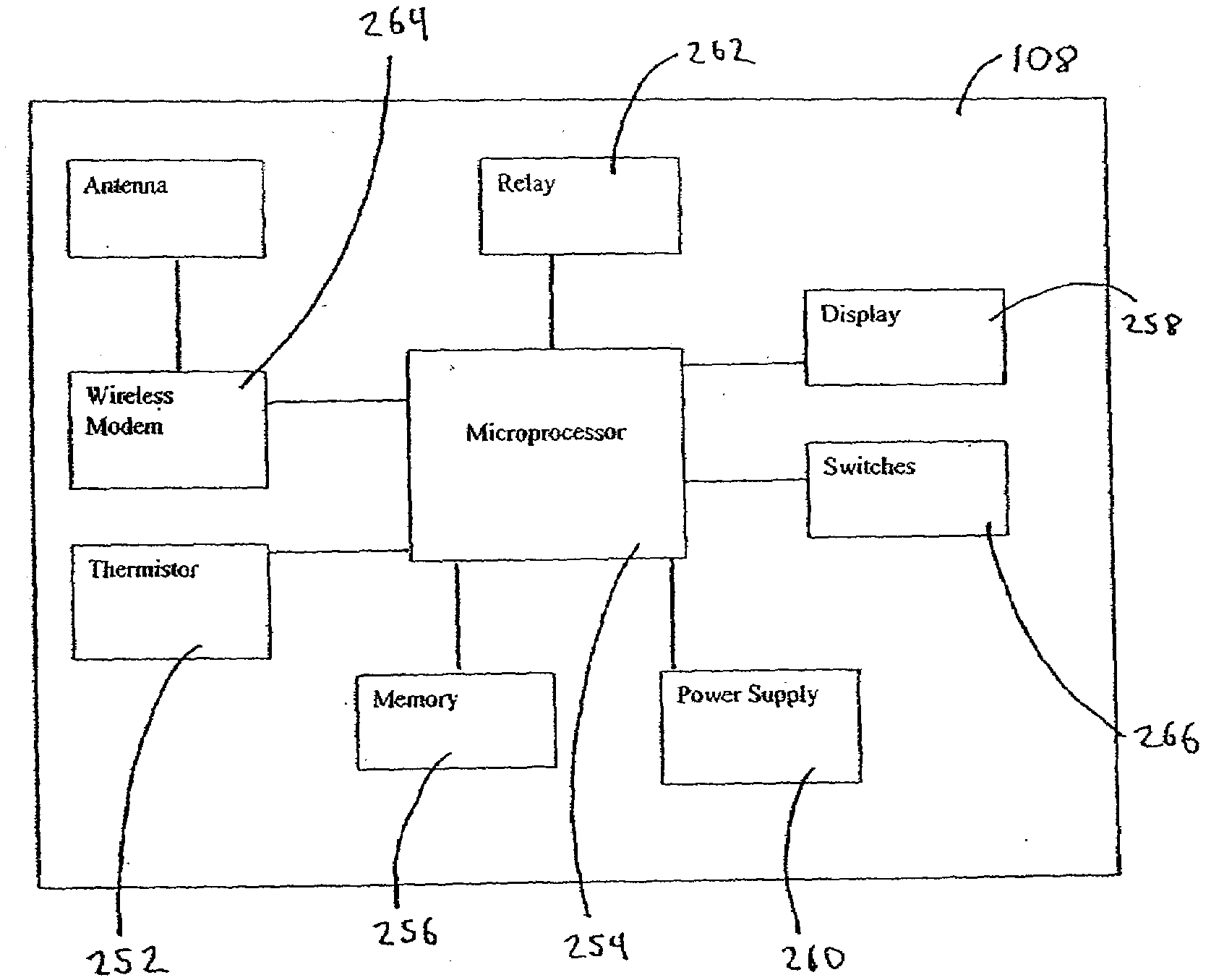

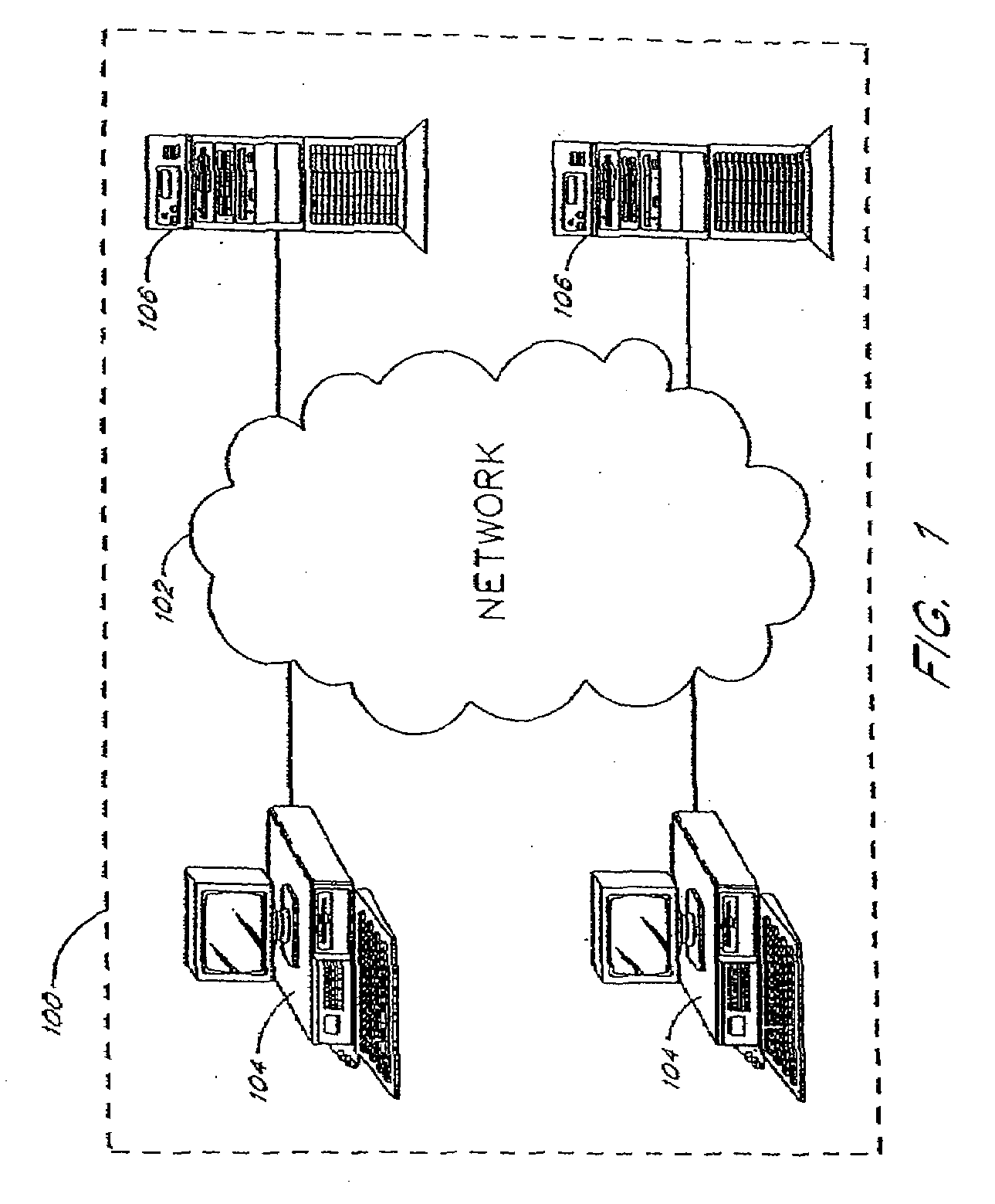

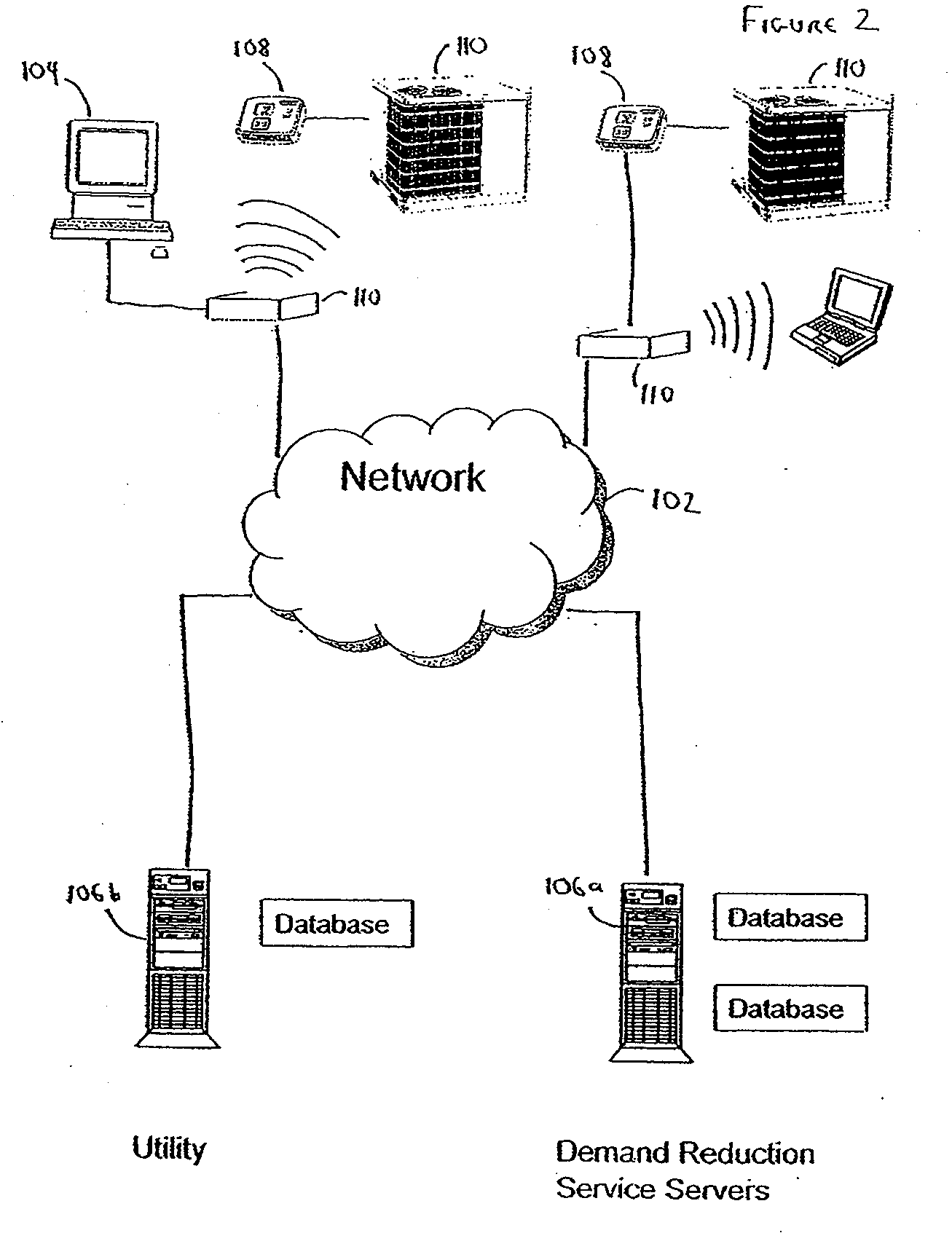

System and method for evaluating changes in the efficiency of an HVAC system

ActiveUS8019567B2Improve comfortReduce energy useTime indicationSpace heating and ventilationControl systemEngineering

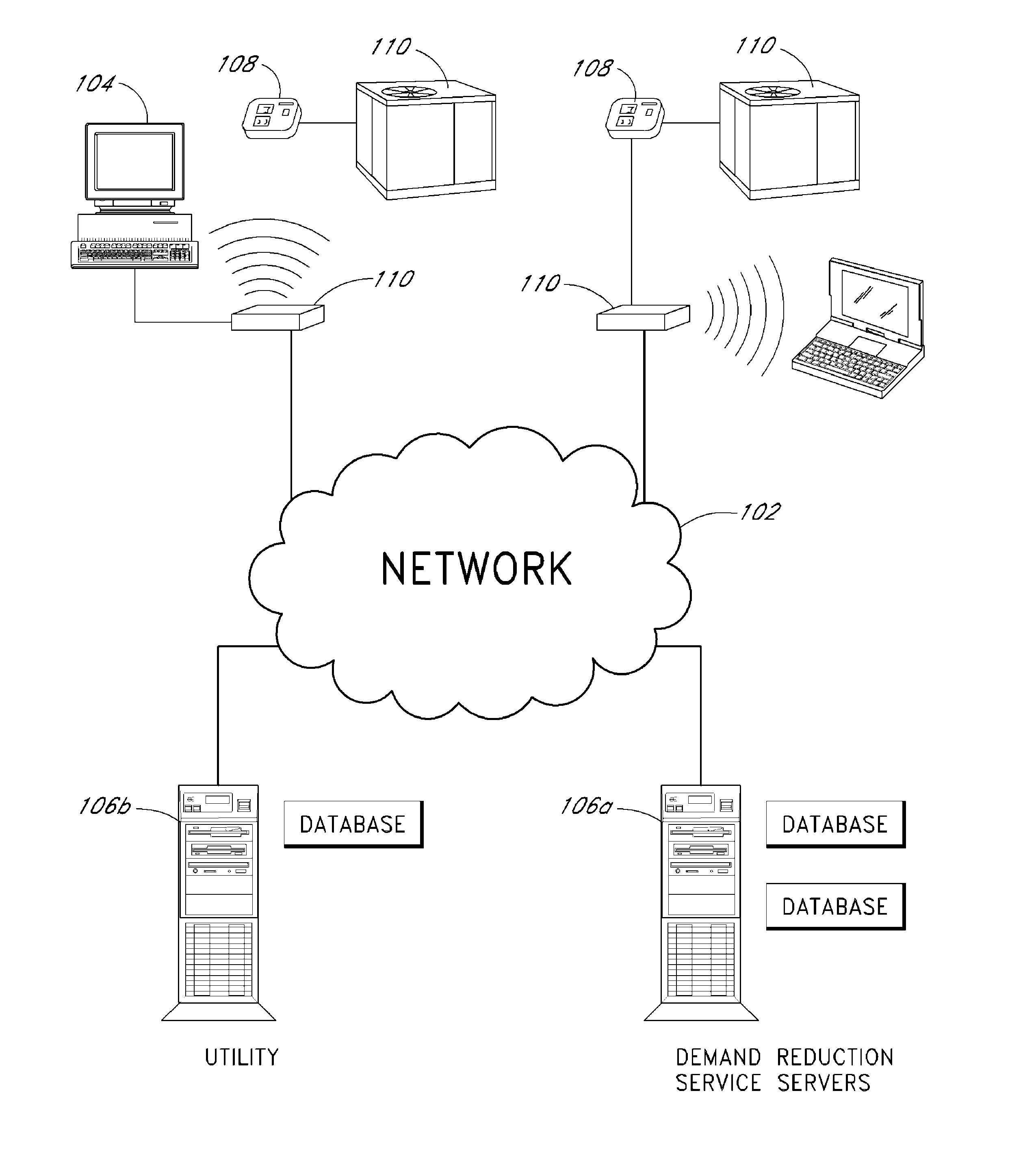

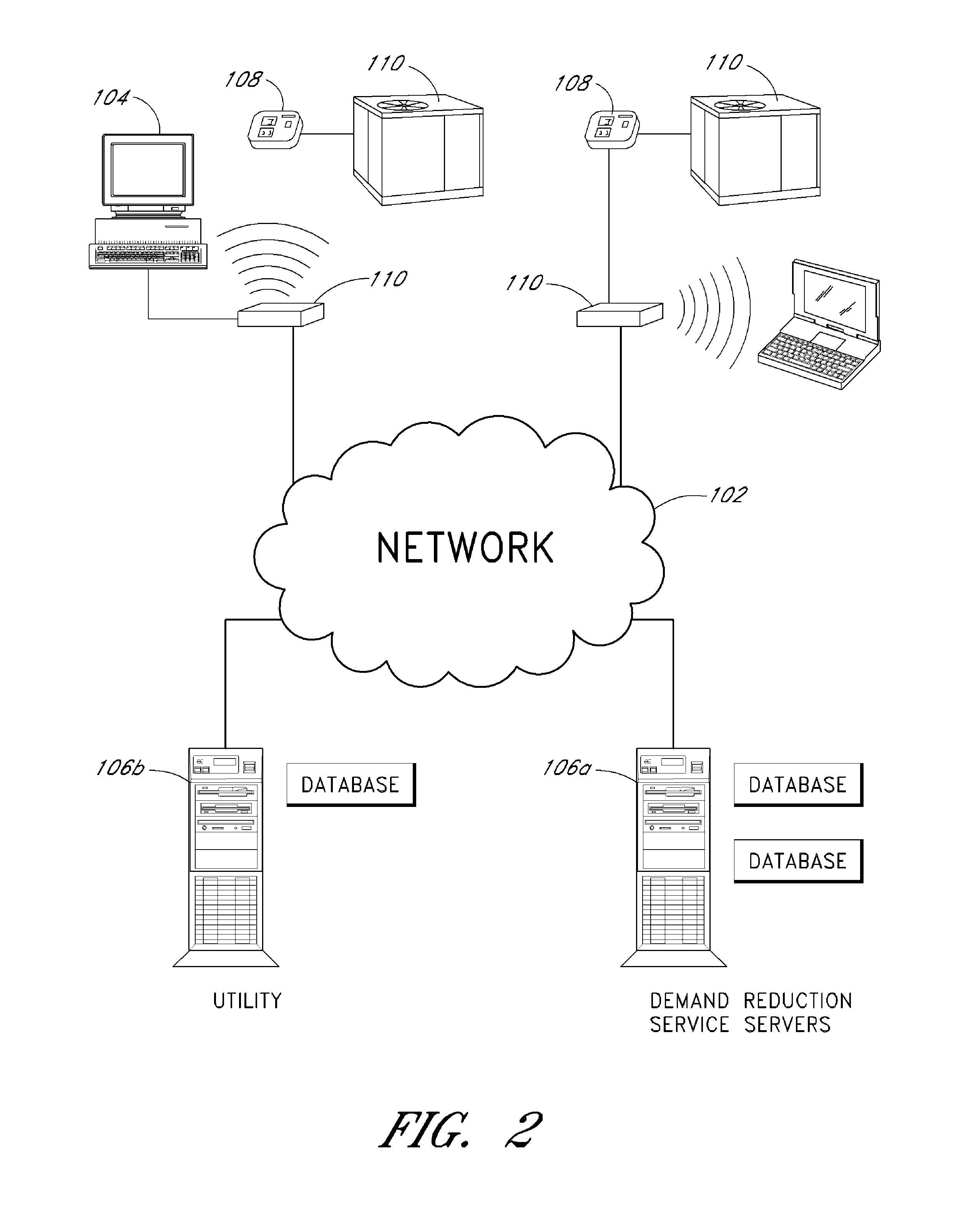

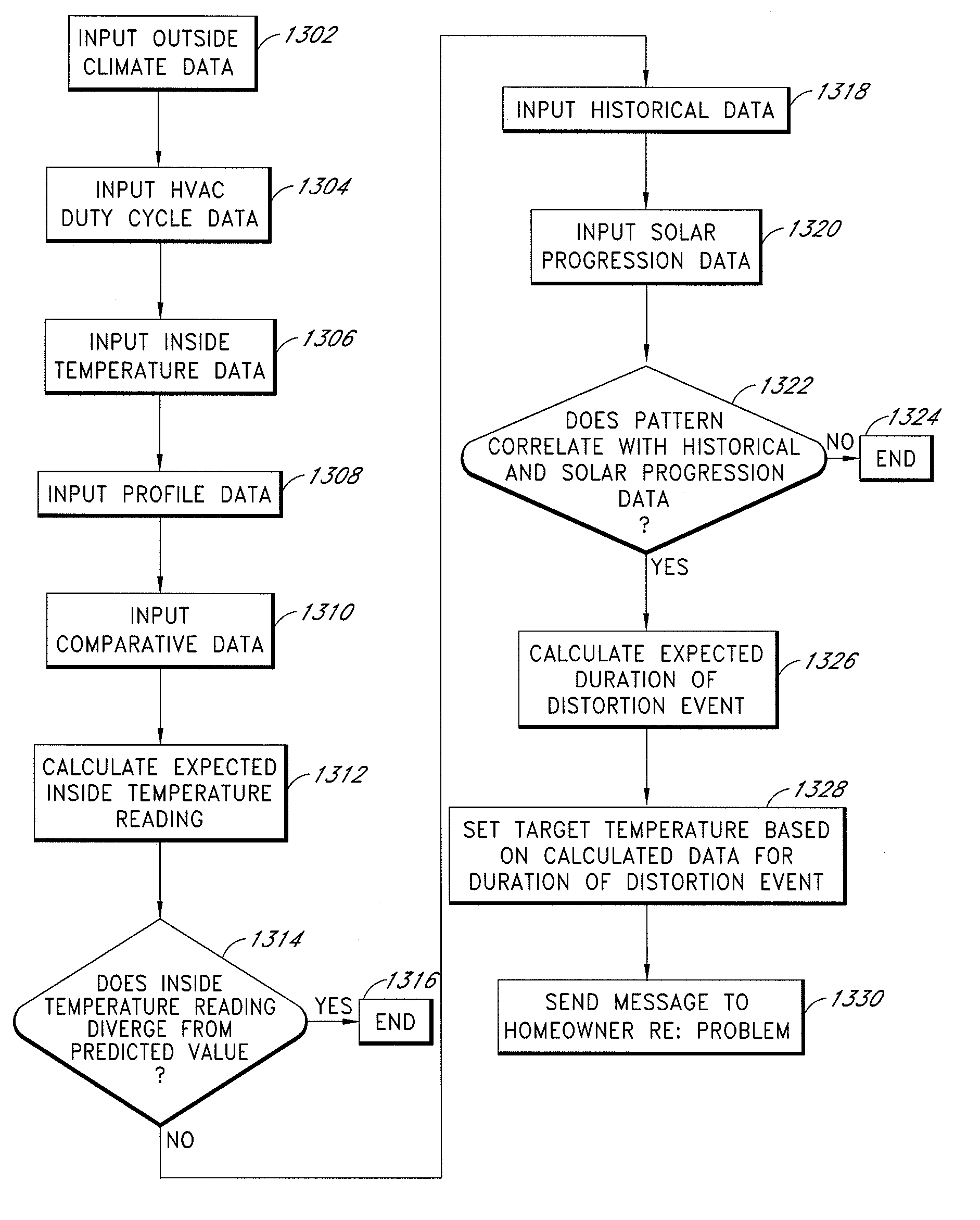

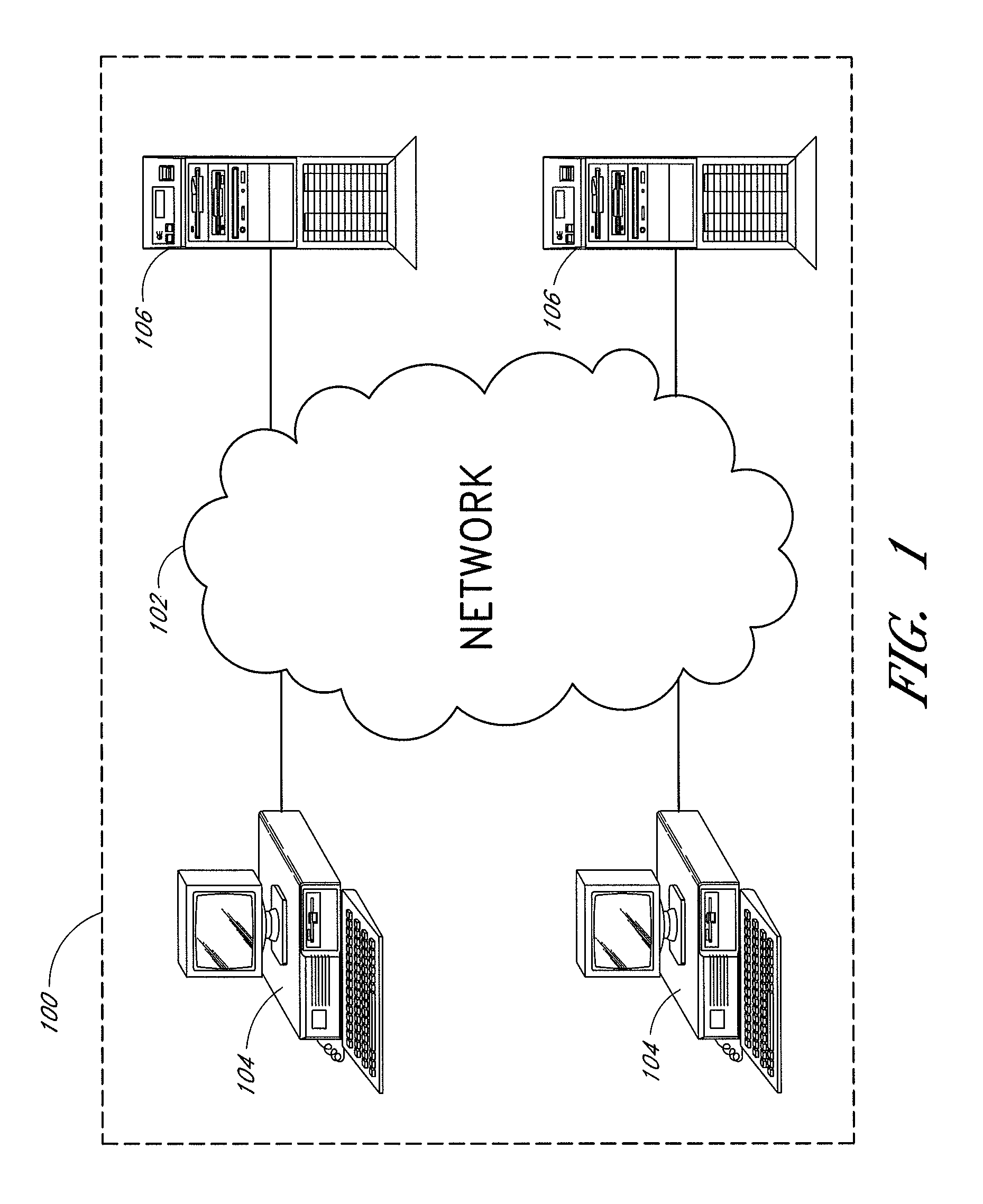

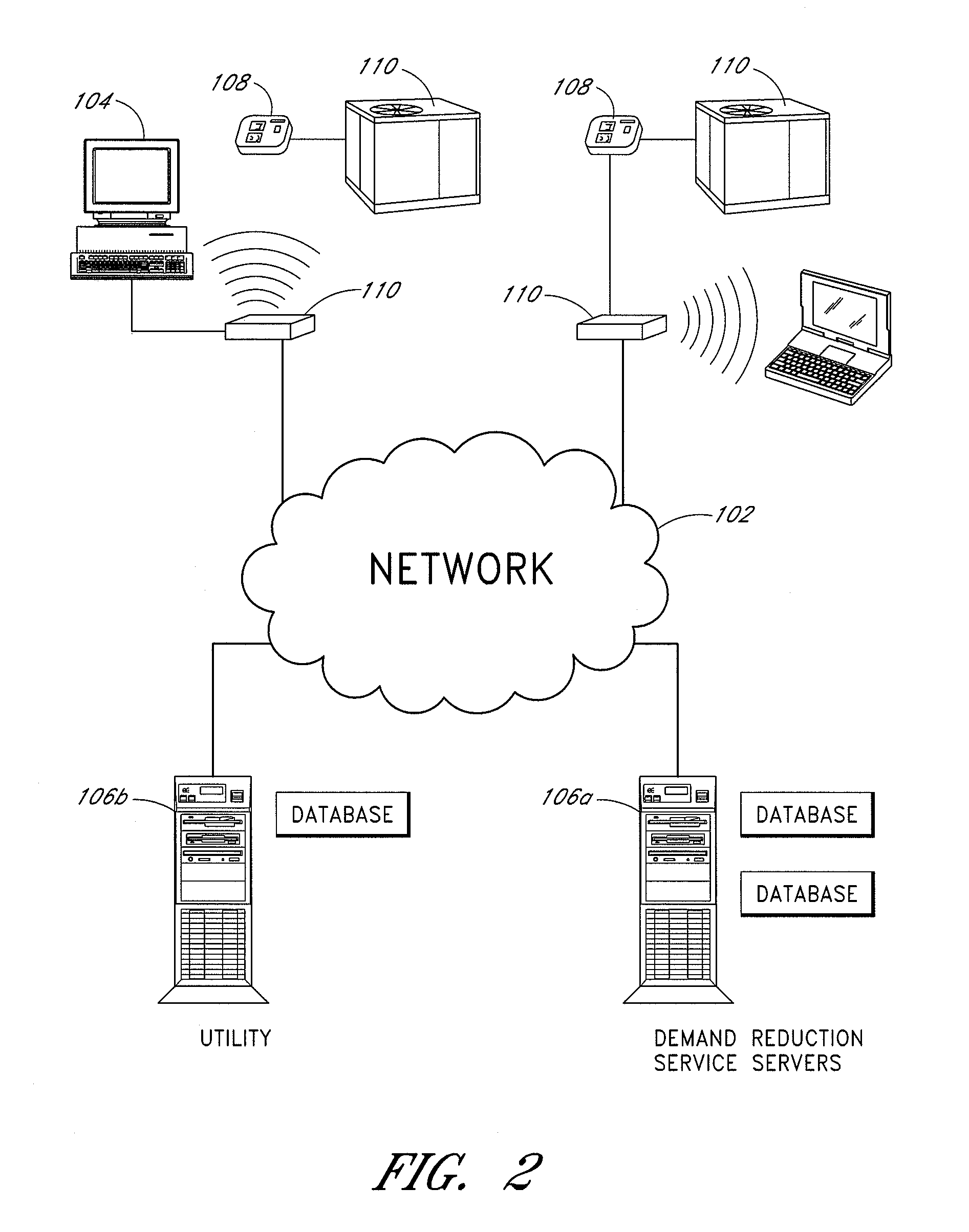

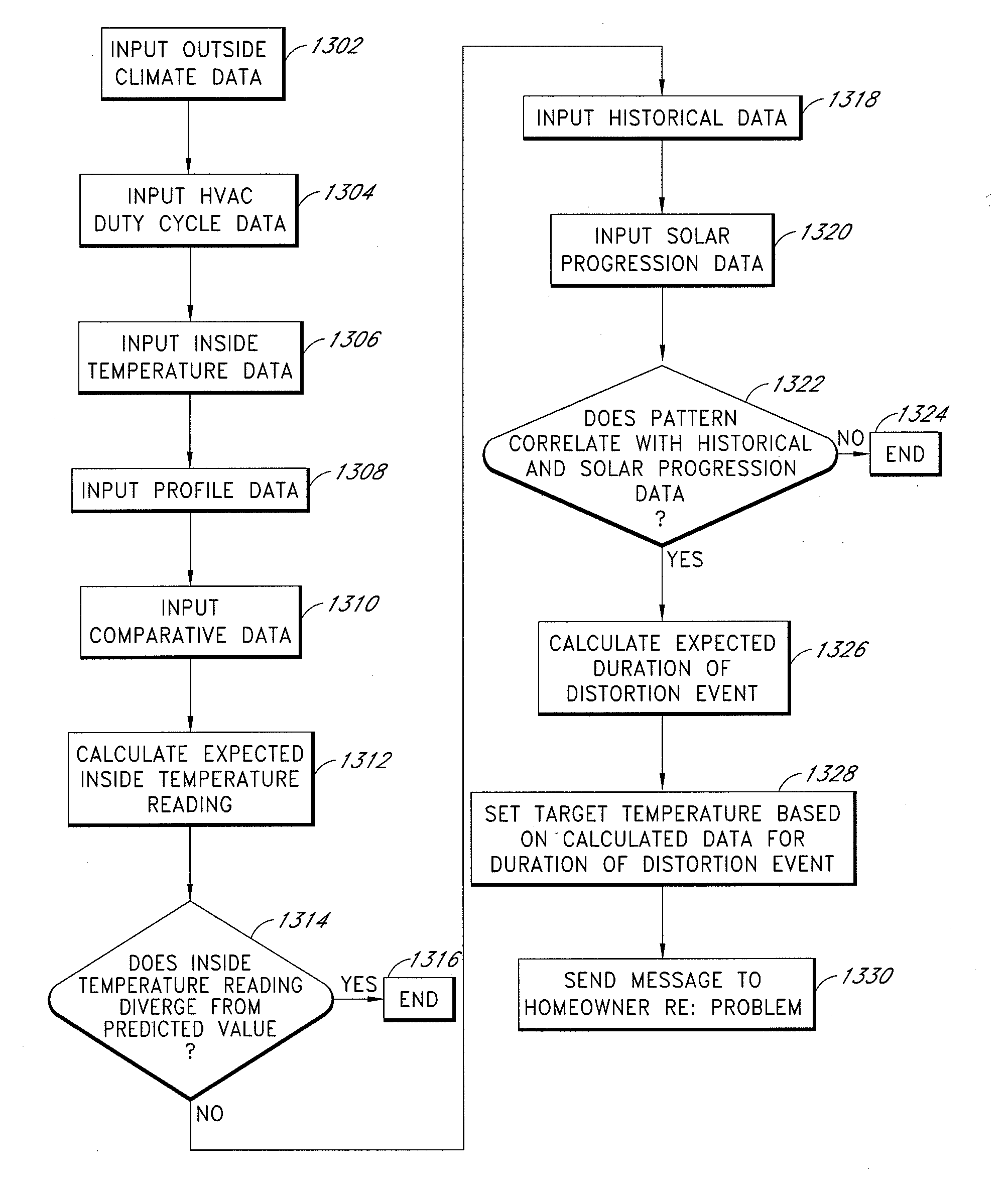

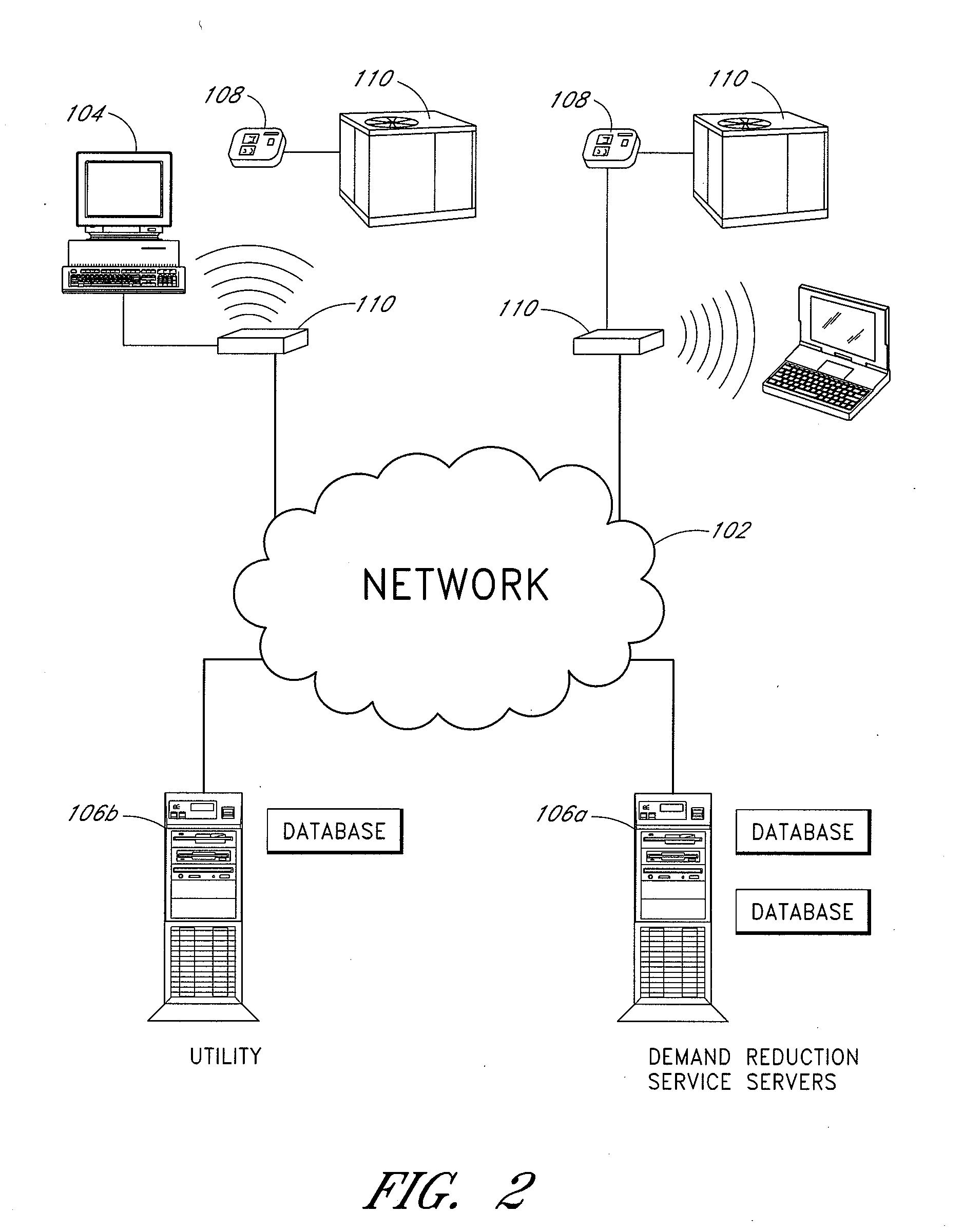

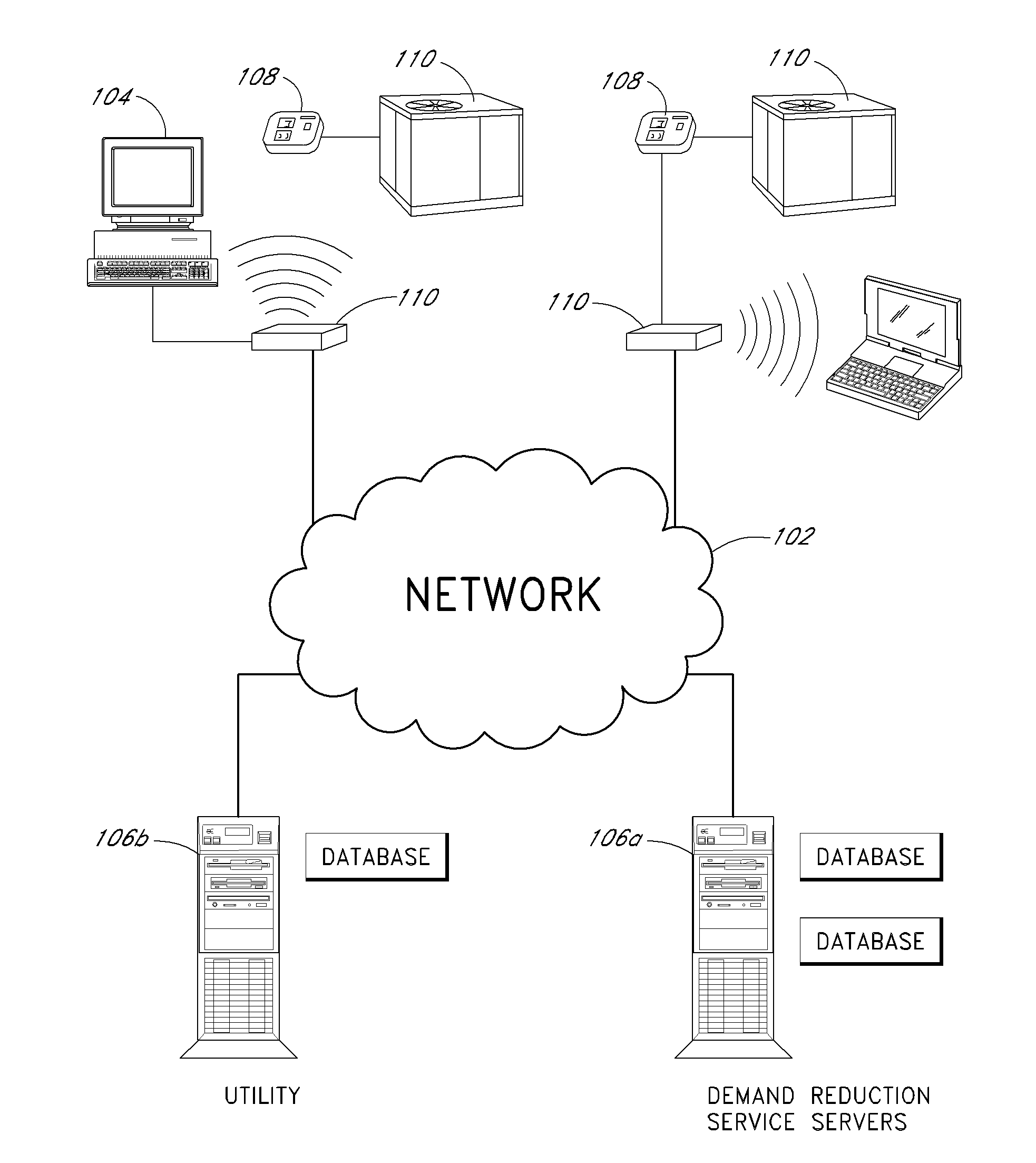

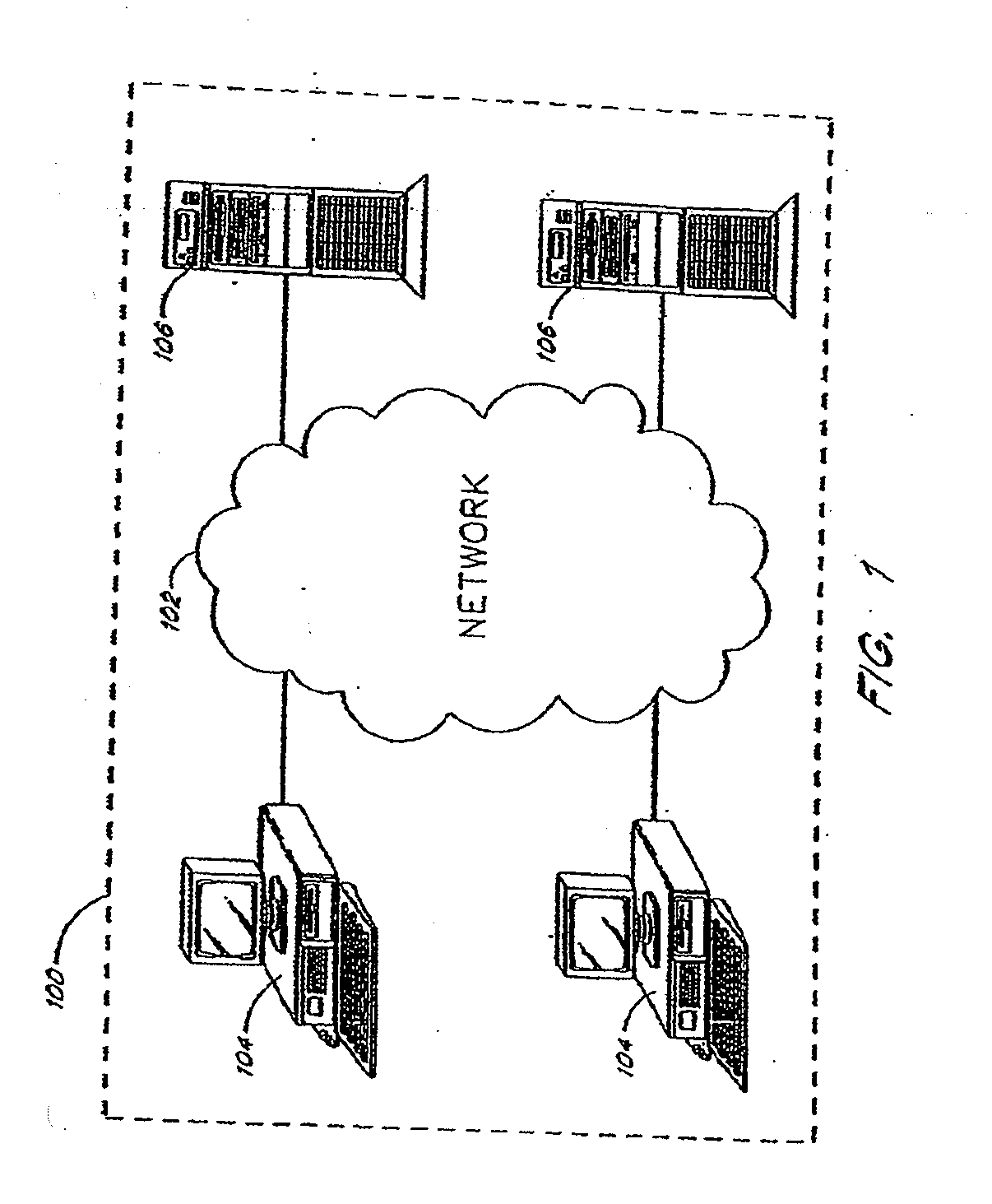

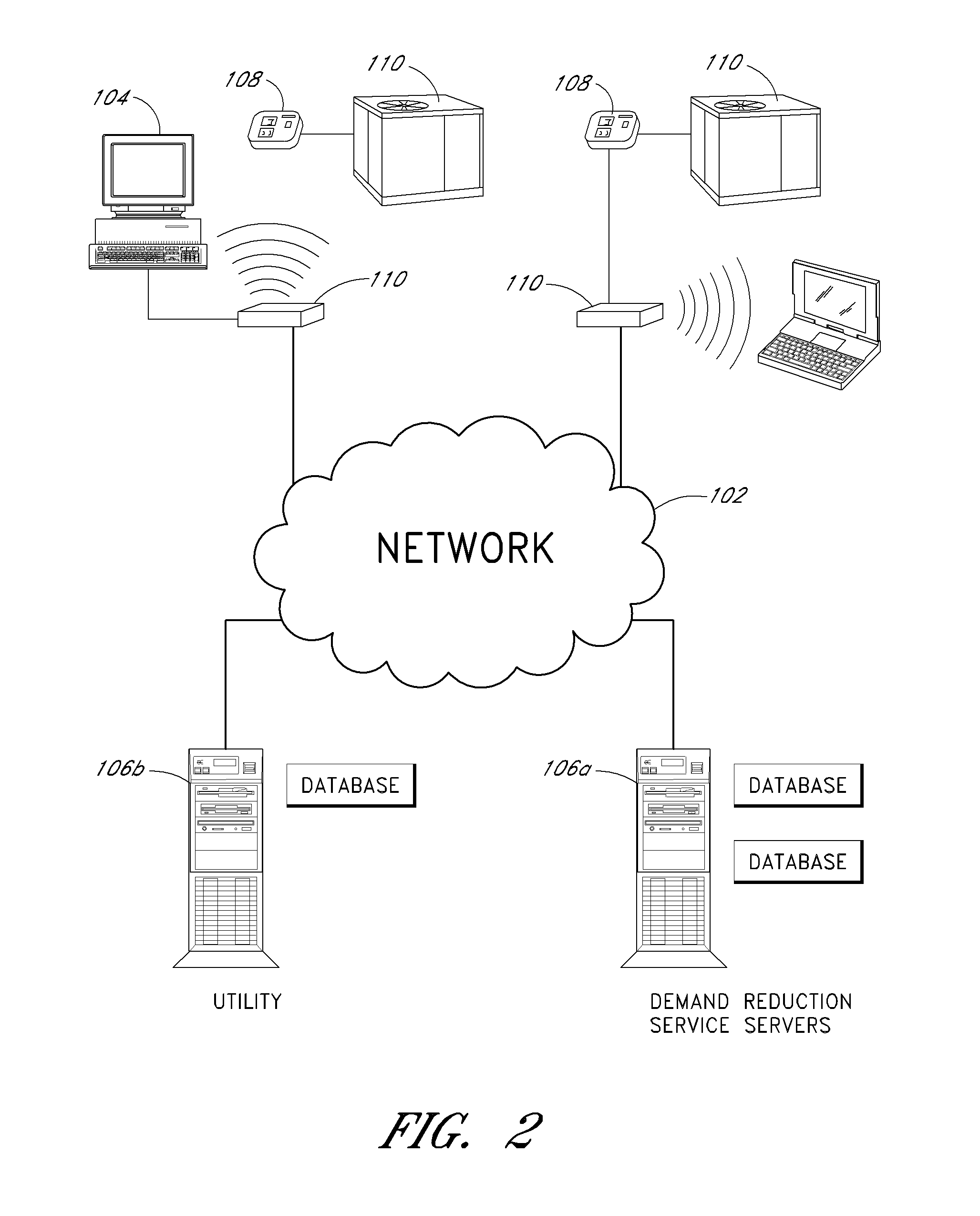

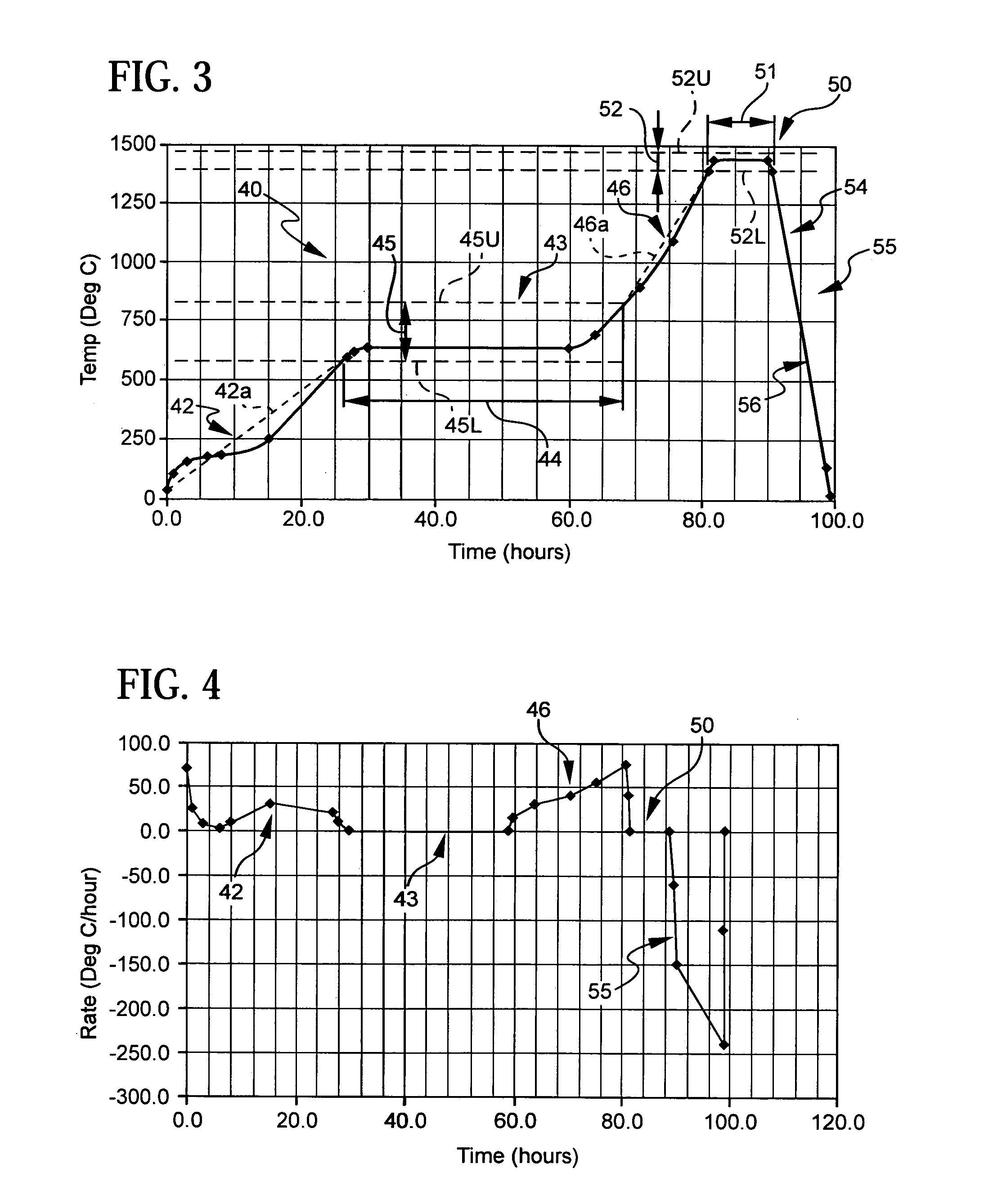

The invention comprises systems and methods for evaluating changes in the operational efficiency of an HVAC system over time. The climate control system obtains temperature measurements from at least a first location conditioned by the climate system, and status of said HVAC system. One or more processors receives measurements of outside temperatures from at least one source other than said HVAC system and compares said temperature measurements from said first location with expected temperature measurements. The expected temperature measurements are based at least in part upon past temperature measurements.

Owner:ECOFACTOR

System and method for calculating the thermal mass of a building

ActiveUS7848900B2Improve comfortReduce energy useSpace heating and ventilationTemperatue controlControl systemHVAC control system

Owner:ECOFACTOR

System and method for evaluating changes in the efficiency of an HVAC system

ActiveUS20120065935A1Improve comfortReduce energy useMechanical apparatusSpace heating and ventilation safety systemsControl systemControl engineering

The invention comprises systems and methods for evaluating changes in the operational efficiency of an HVAC system over time. The climate control system obtains temperature measurements from at least a first location conditioned by the climate system, and status of said HVAC system. One or more processors receives measurements of outside temperatures from at least one source other than said HVAC system and compares said temperature measurements from said first location with expected temperature measurements. The expected temperature measurements are based at least in part upon past temperature measurements.

Owner:ECOFACTOR

System and method for evaluating changes in the efficiency of an HVAC system

ActiveUS20100070234A1Decrease energy useIncrease comfortTime indicationSpace heating and ventilationHVACTemperature measurement

The invention comprises systems and methods for evaluating changes in the operational efficiency of an HVAC system over time. The climate control system obtains temperature measurements from at least a first location conditioned by the climate system, and status of said HVAC system. One or more processors receives measurements of outside temperatures from at least one source other than said HVAC system and compares said temperature measurements from said first location with expected temperature measurements. The expected temperature measurements are based at least in part upon past temperature measurements.

Owner:ECOFACTOR

System and method for calculating the thermal mass of a building

ActiveUS20100070084A1Improve comfortReduce energy useSpace heating and ventilationTemperatue controlControl systemEngineering

The invention comprises a system for calculating a value for the effective thermal mass of a building. The climate control system obtains temperature measurements from at least a first location conditioned by the climate system. One or more processors receive measurements of outside temperatures from at least one source other than the control system and compare the temperature measurements from the first location with expected temperature measurements. The expected temperature measurements are based at least in part upon past temperature measurements obtained by said HVAC control system and said outside temperature measurements. The processors then calculate one or more rates of change in temperature at said first location.

Owner:ECOFACTOR

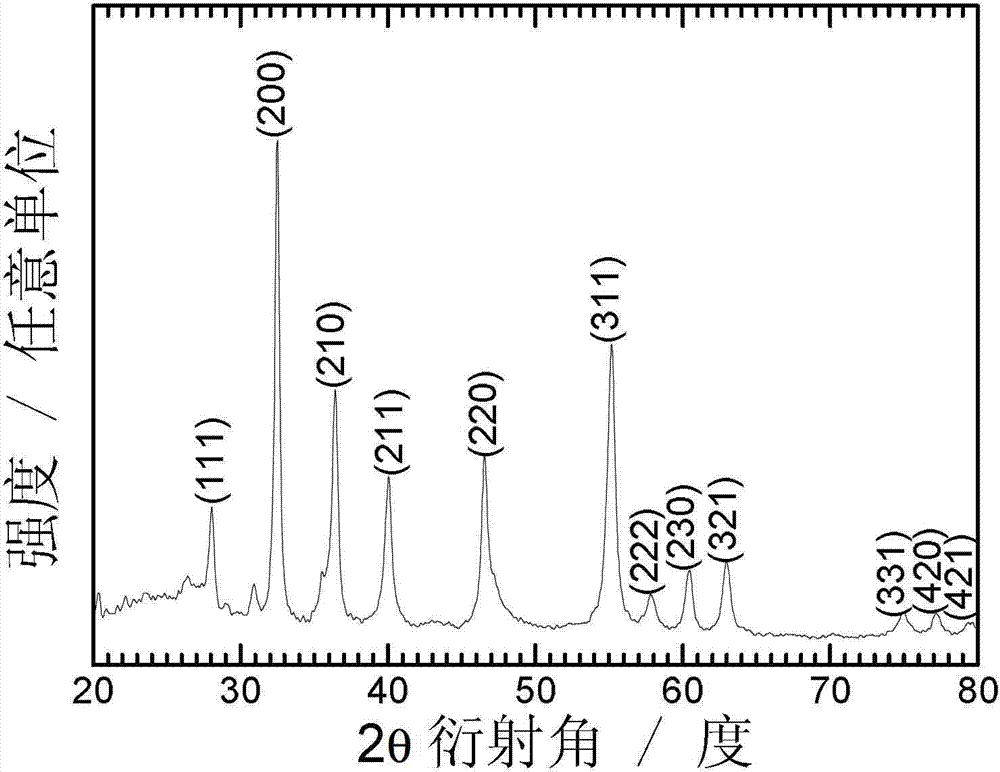

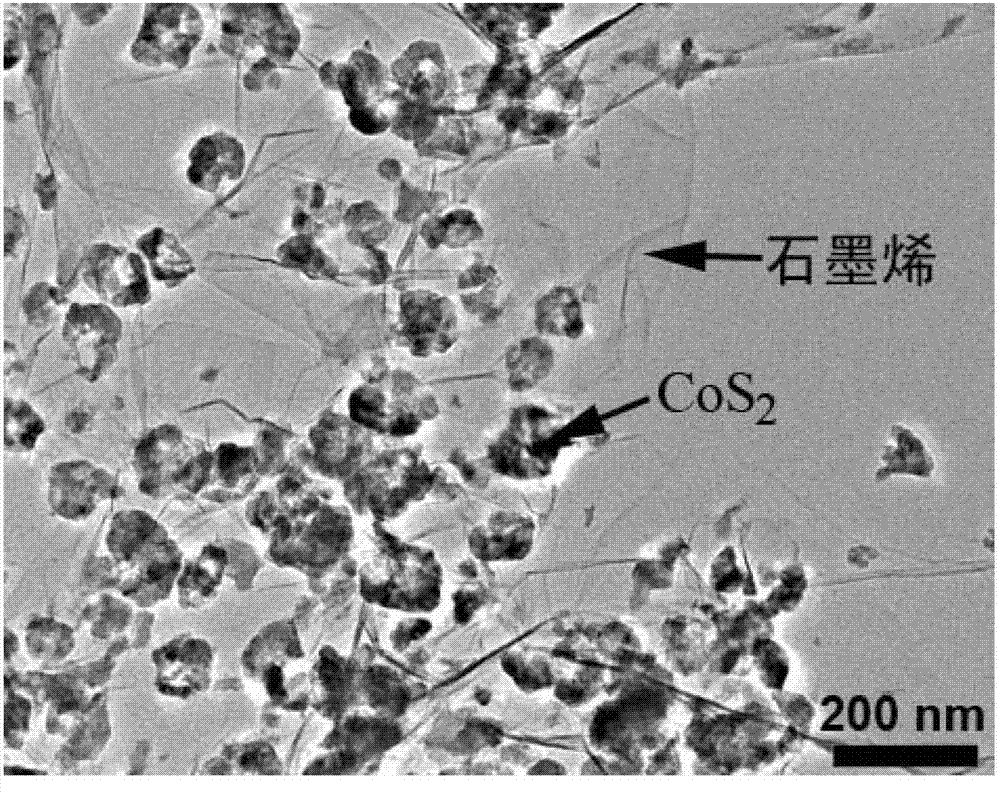

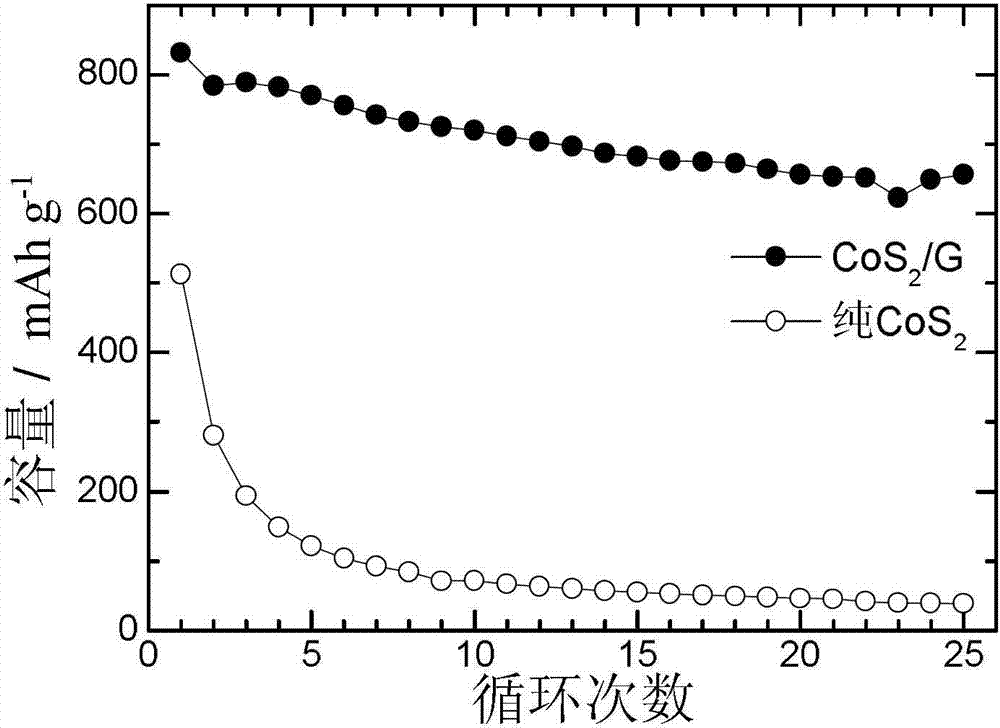

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

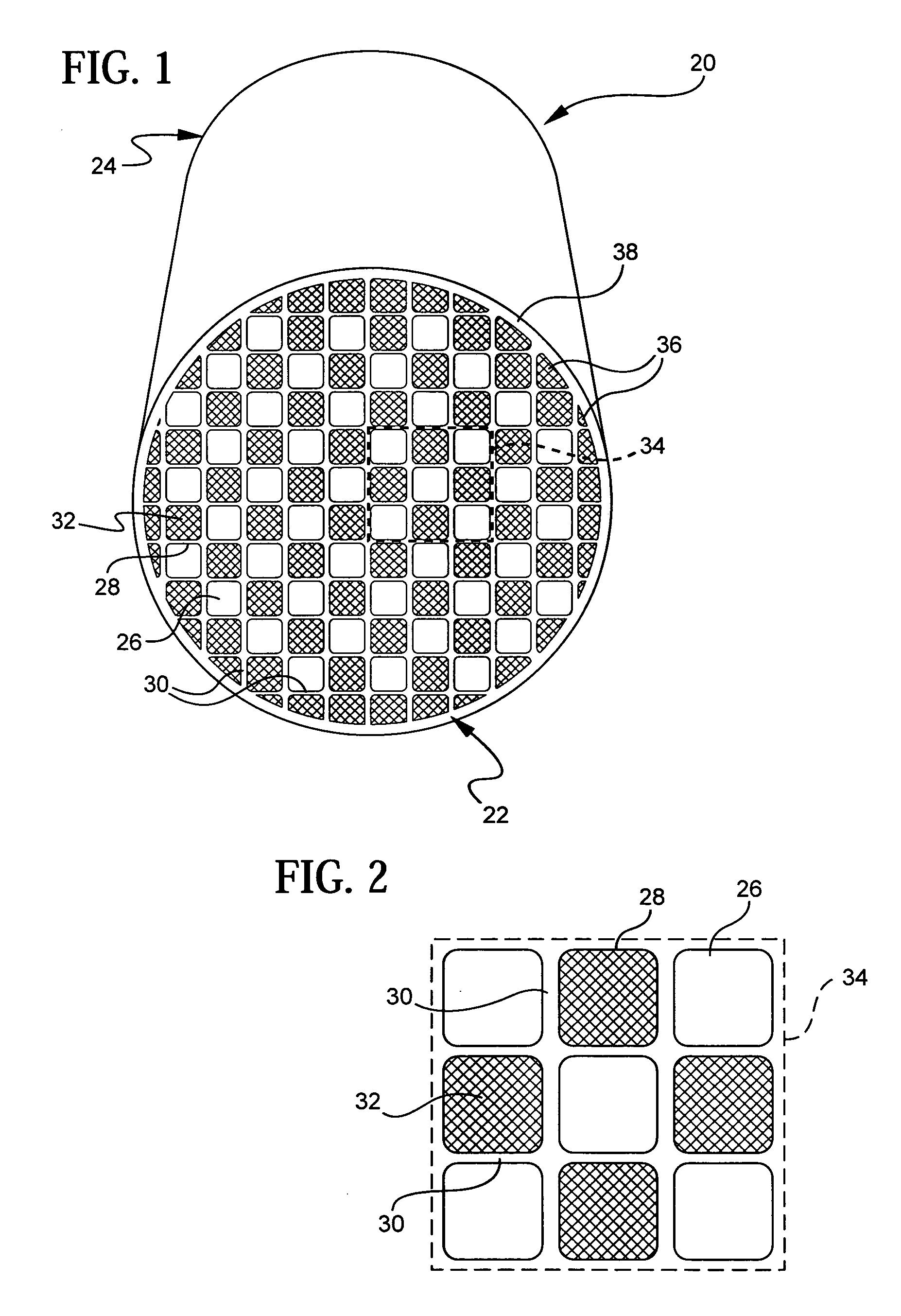

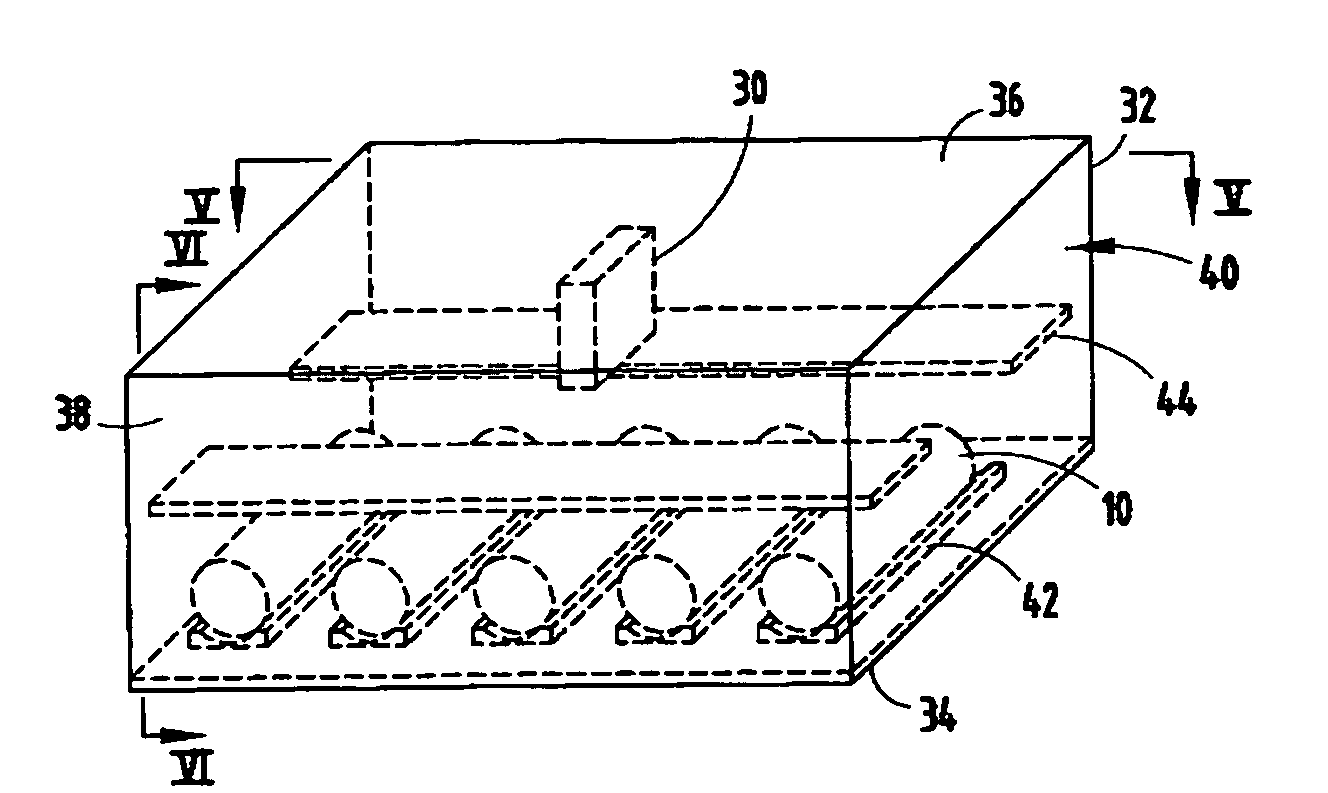

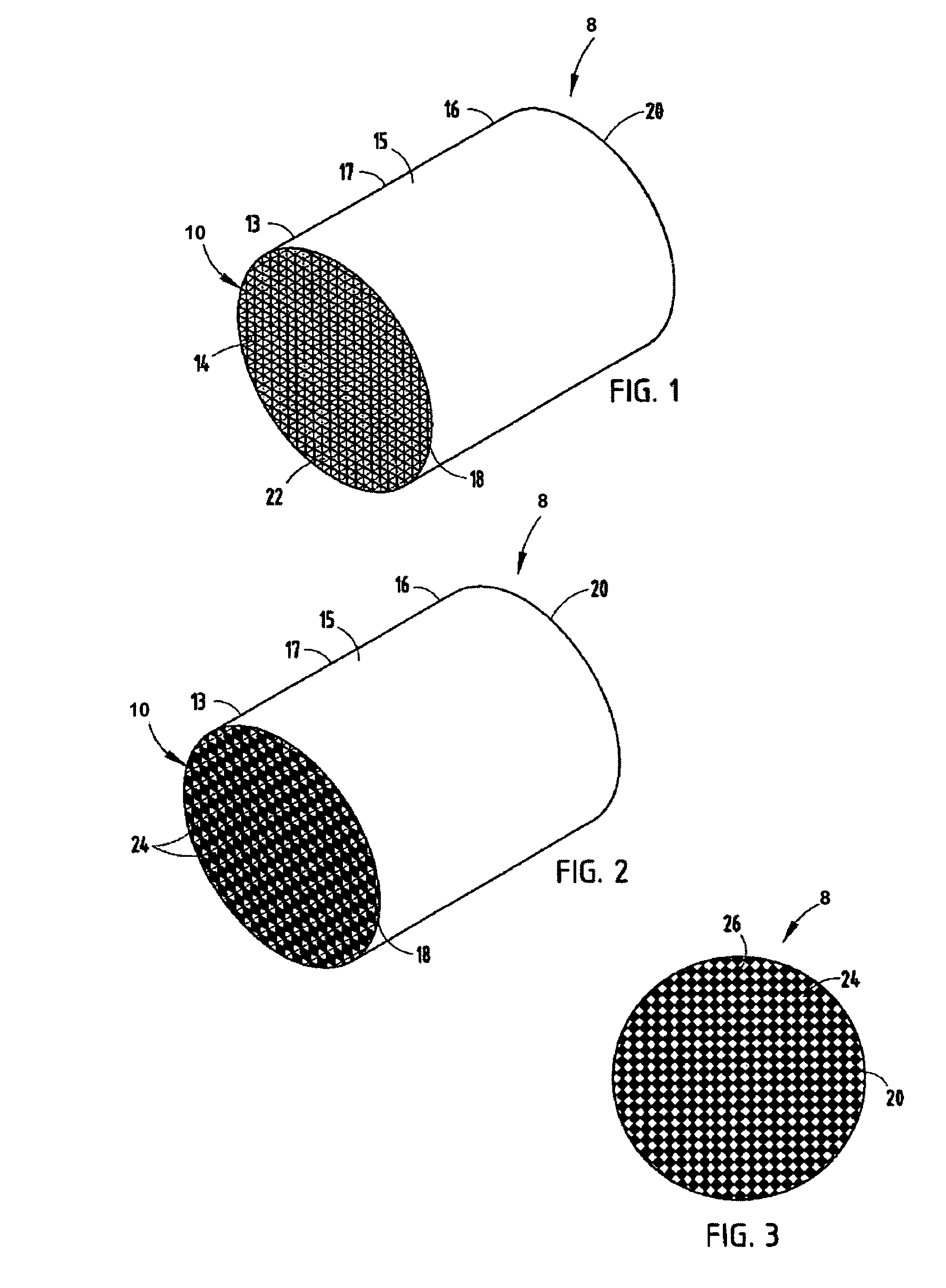

Aluminum titanate ceramic forming batch mixtures and green bodies including pore former combinations and methods of manufacturing and firing same

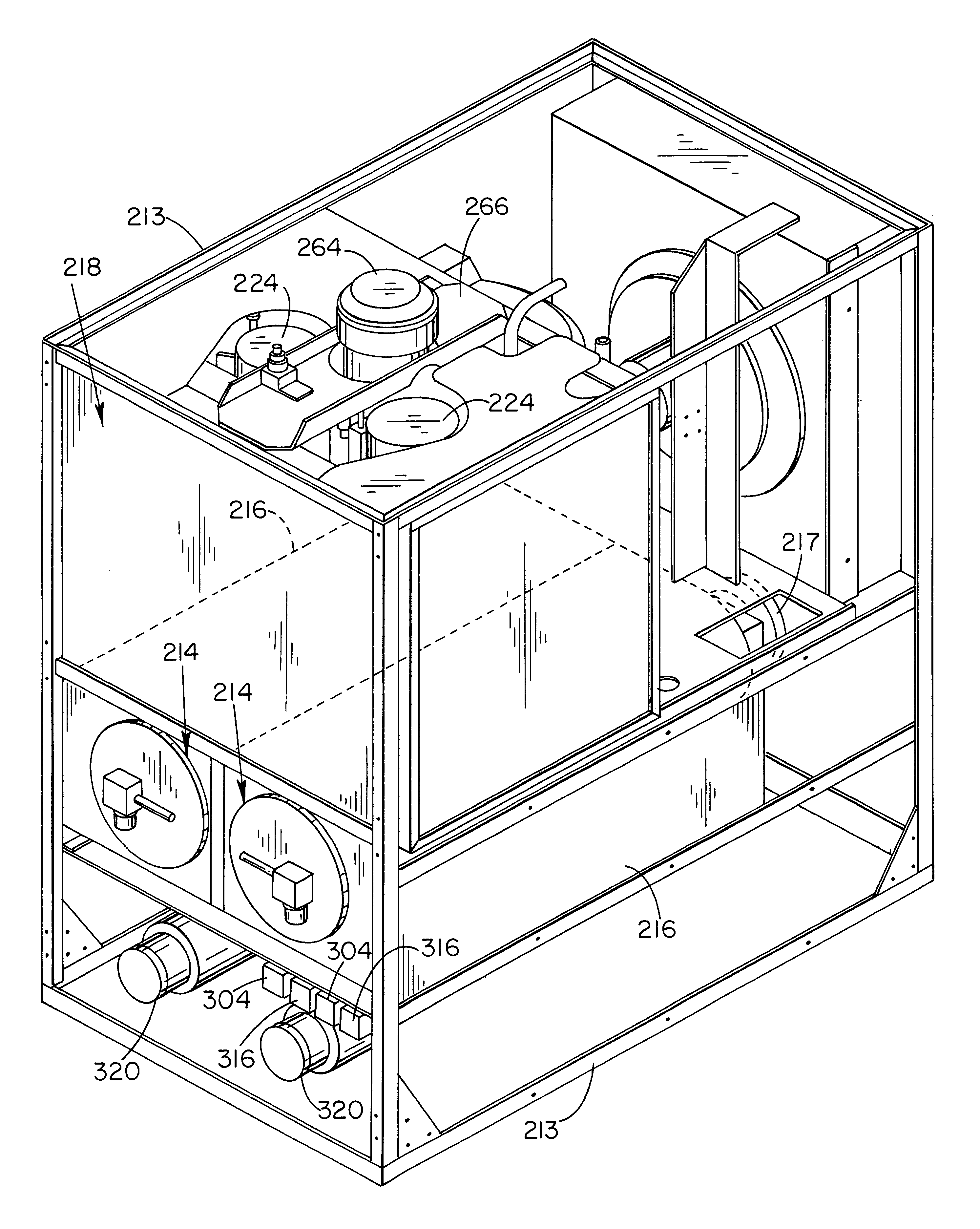

InactiveUS20070006561A1Low exothermic reaction and exothermic reactionReduction tendencyDispersed particle filtrationTransportation and packagingCeramic moldingSolvent

A ceramic forming batch mixture including inorganic batch materials, such as sources of alumina, titania, and silica, a pore former combination including first and second pore formers with different compositions; an organic binder; and a solvent. Also disclosed is a method for producing a ceramic article involving mixing the inorganic batch materials with the pore former combination having first and second pore formers of different composition, adding an organic binder and a solvent, forming a green body; and firing the green body. A green body having a combination of first and second pore formers with different compositions is disclosed, as are several methods for firing to produce ceramic articles such as aluminum titanate.

Owner:CORNING INC

Semi-frozen food product producing machine

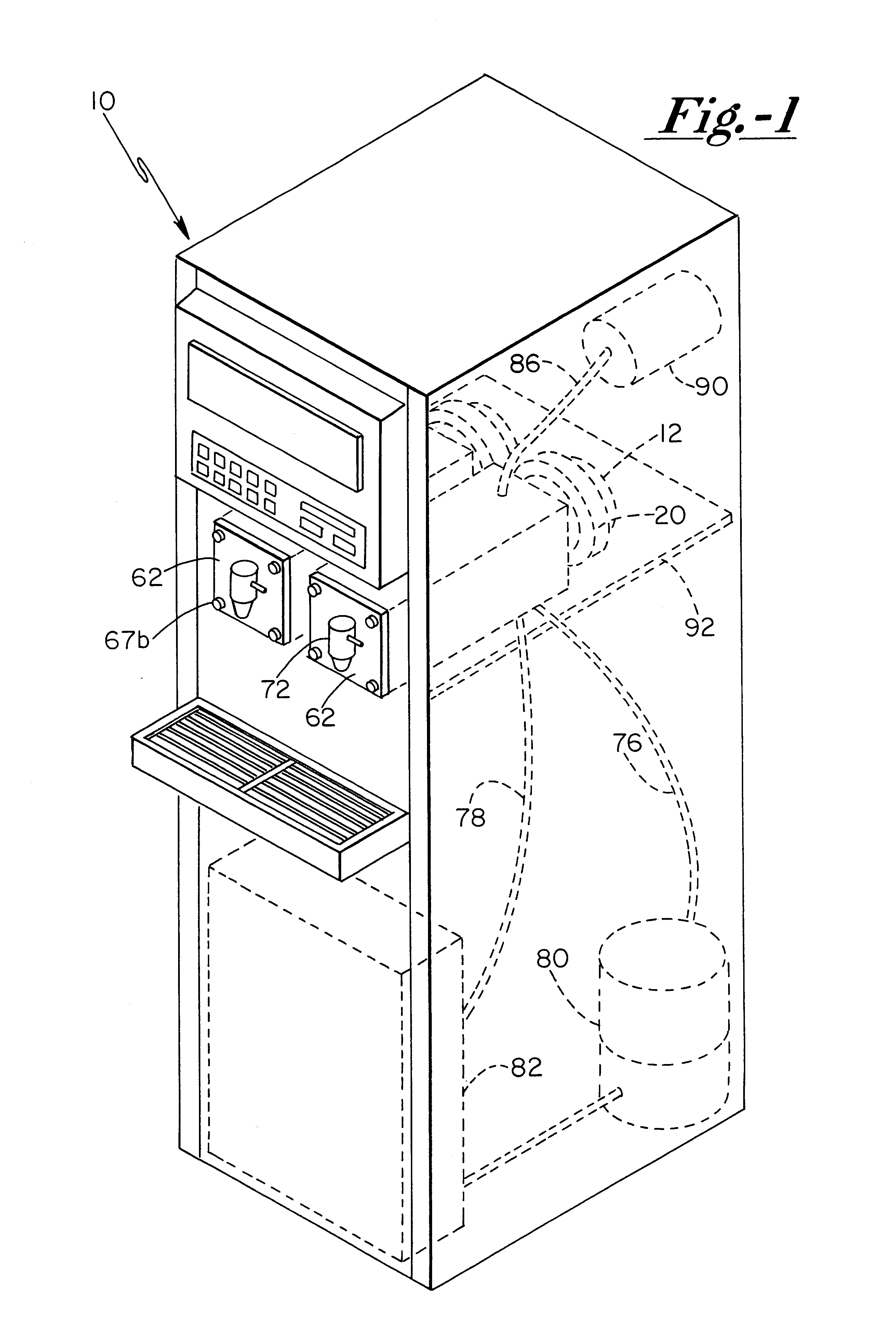

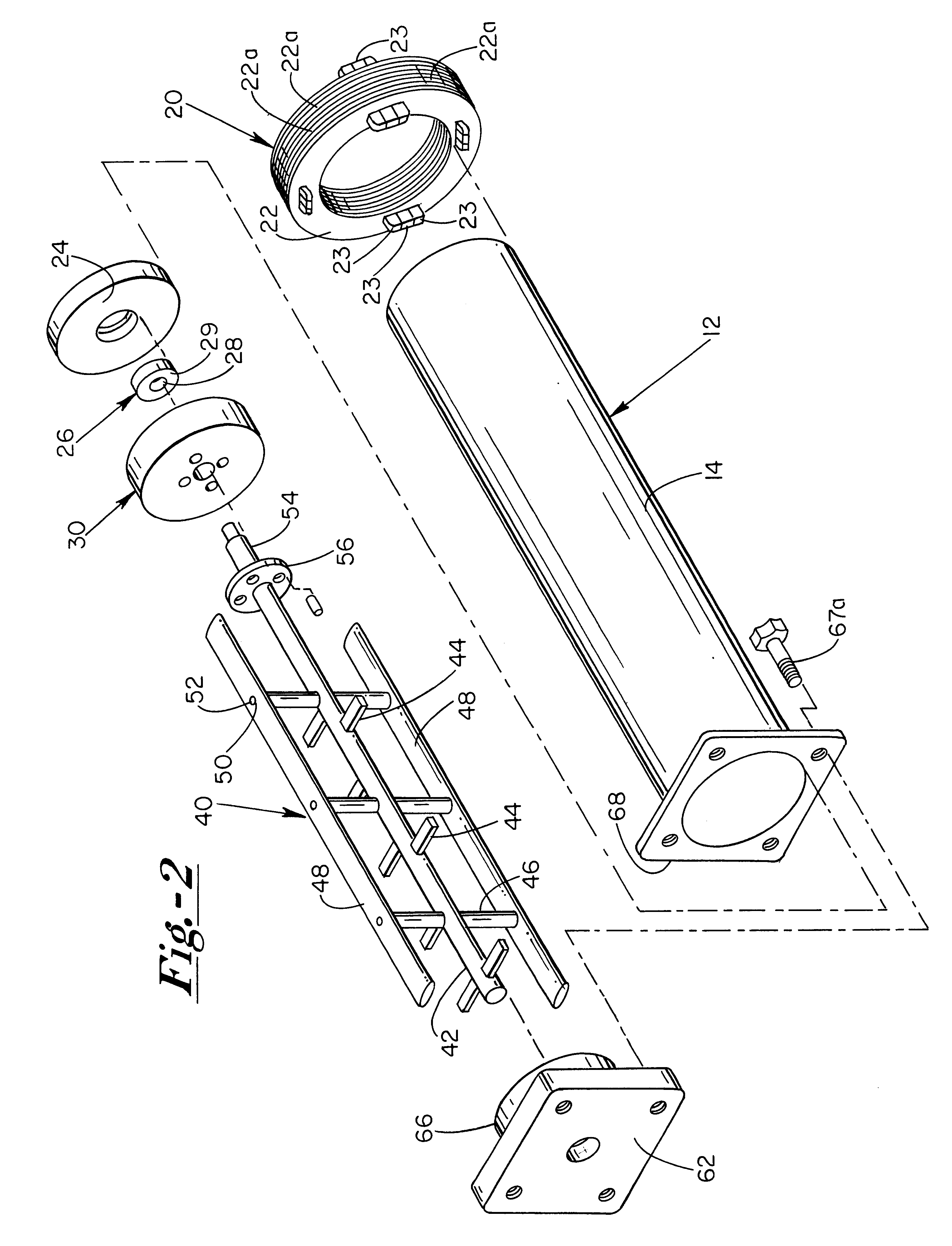

InactiveUS6220047B1Low viscosityShort cycleMagnetic circuit rotating partsDomestic cooling apparatusCarbon dioxideCooling power

The present invention includes a dual purpose carbonator / blending bottle connected to a source of beverage syrup, a source of potable water and to a source of pressurized carbon dioxide gas. The dual purpose bottle is retained within an ice bank water bath tank. A pair of ratio valves provide for metering the water and syrup at a desired ratio. The mixed beverage first flows through a serpentine coil, also located in water bath, and then flow into the dual purpose bottle. A refrigeration system provides for cooling an evaporator located in the water tank for forming the ice bank thereon. The carbonated beverage then flows from the bottle into a freeze cylinder. The freeze cylinder also includes a further evaporator coiled around an exterior perimeter thereof. The freeze cylinder evaporator is connected to and cooled by the same refrigeration system that cools the evaporator in the water bath tank. A scraping mechanism within the cylinder provides for scraping frozen beverage from the inner surface of the cylinder. A control mechanism provides for controlling the refrigeration system and the cooling of both evaporators. The beverage is therefore pre-cooled to a temperature just above its freezing point before delivery to the freeze cylinder. Thus, less cooling power is needed to reduce the beverage to a frozen state. The present invention utilizes a method of controlling the operation of the refrigeration system and the cooling of both evaporators thereof. The control system provides for directing refrigerant to one or the other of the evaporators as is most efficient so as to avoid short cycling or pressure build up. The present invention uses a control strategy that can more accurately maintain a pre-selected temperature differential between the inlet and outlet temperatures of the evaporators. The control algorithm utilizes a proportional integral differential control approach that safely permits a much narrower temperature difference so that a greater length of each freeze cylinder evaporator can be utilized for efficient heat transfer cooling.

Owner:CORNELIUS INC

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

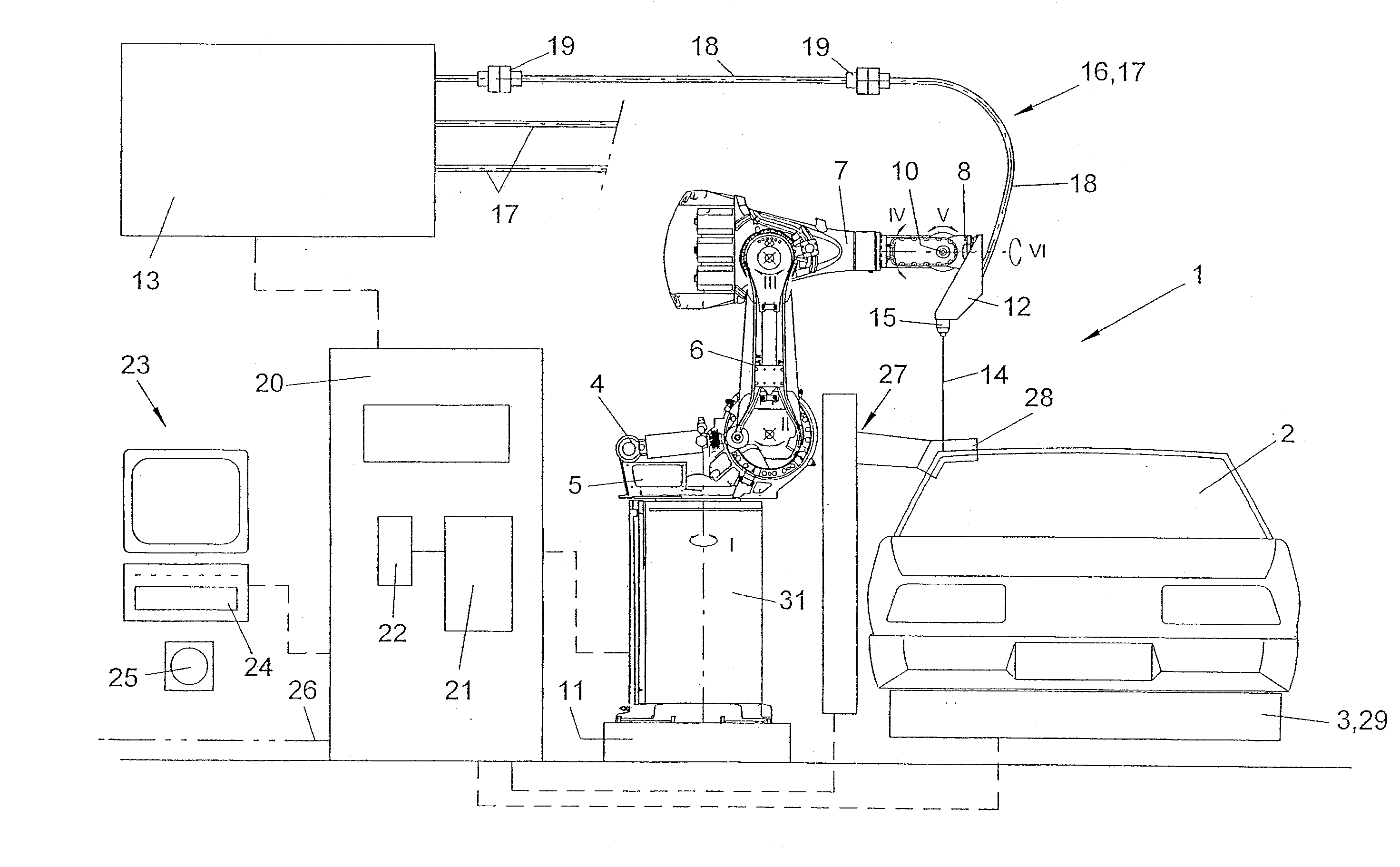

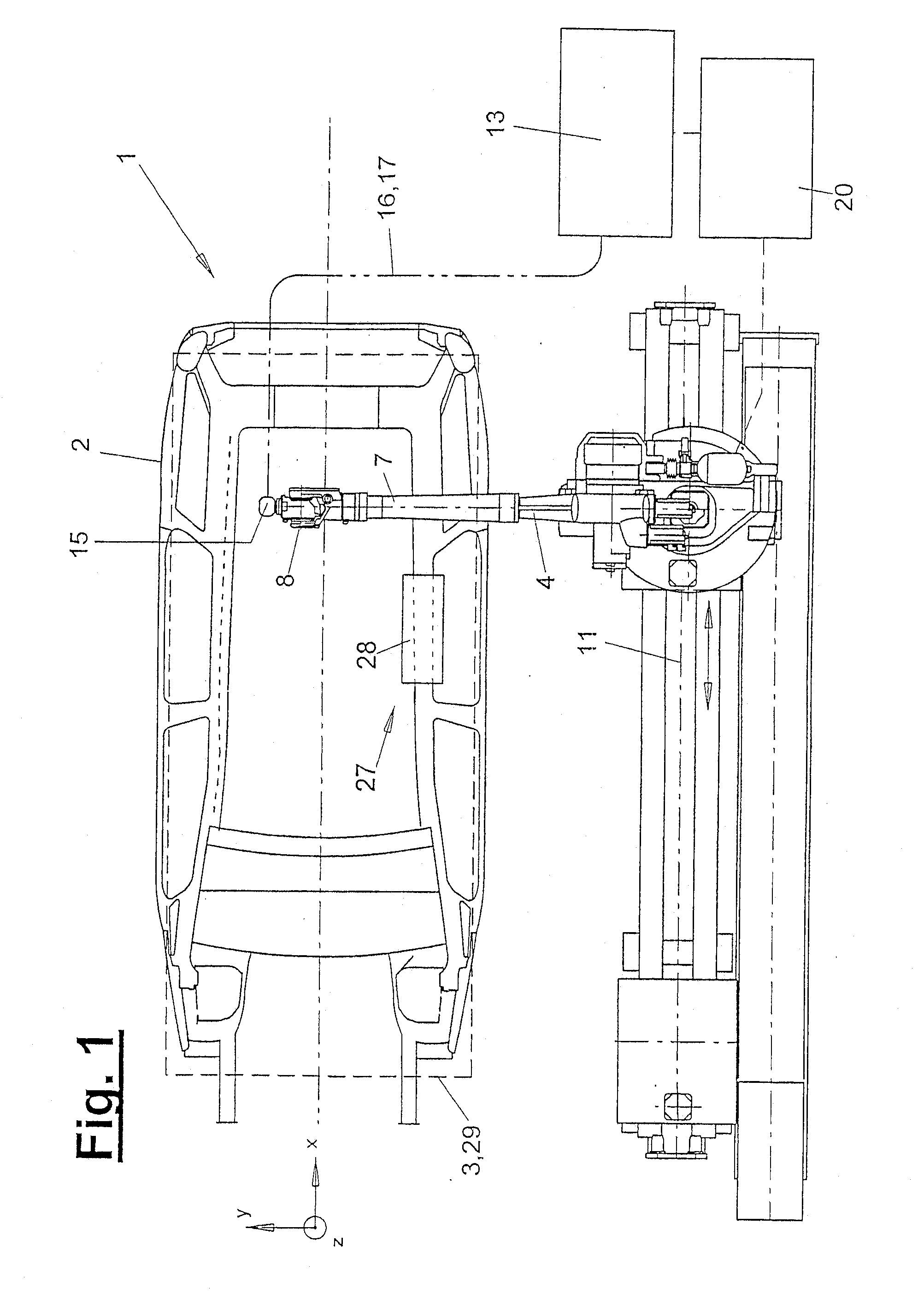

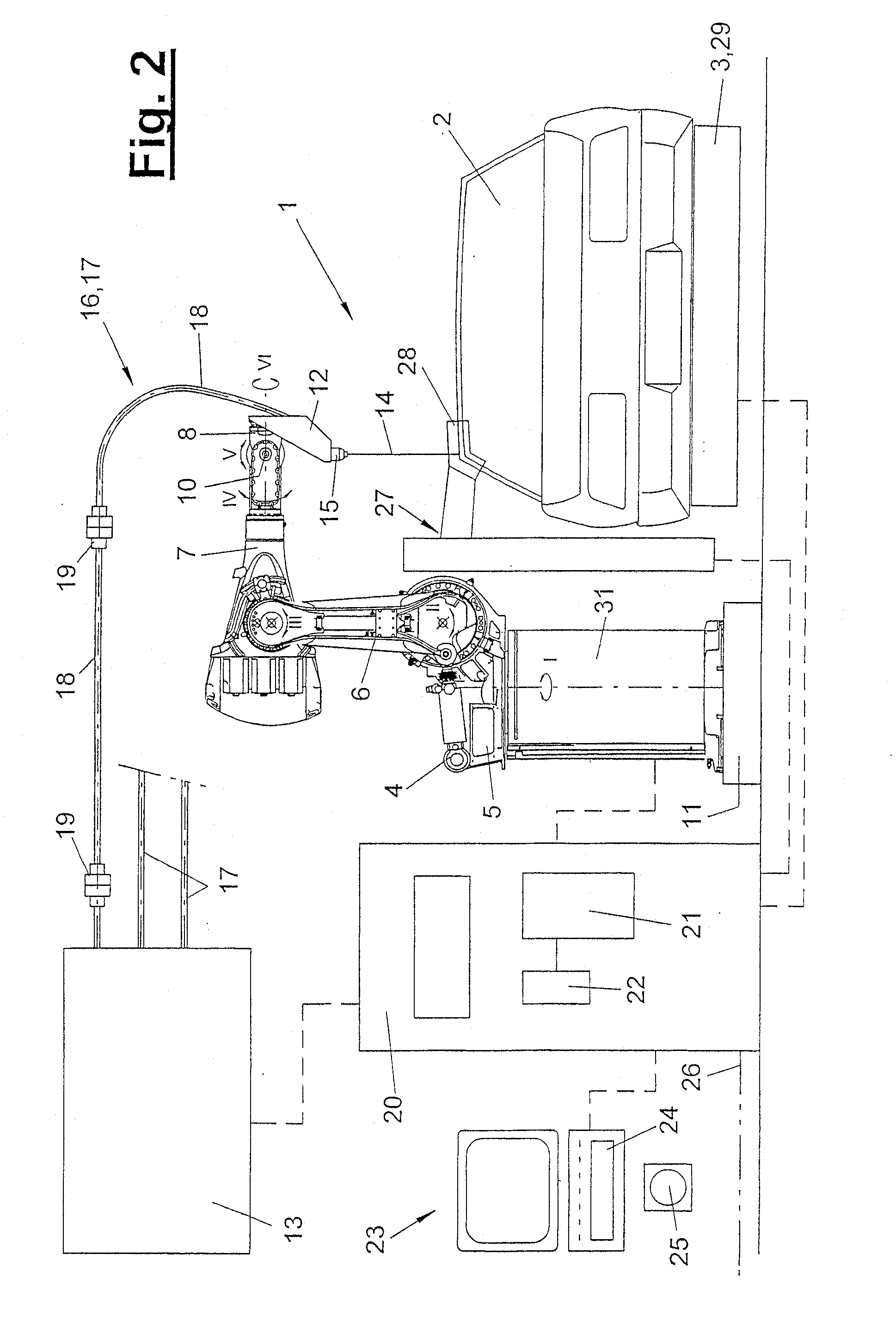

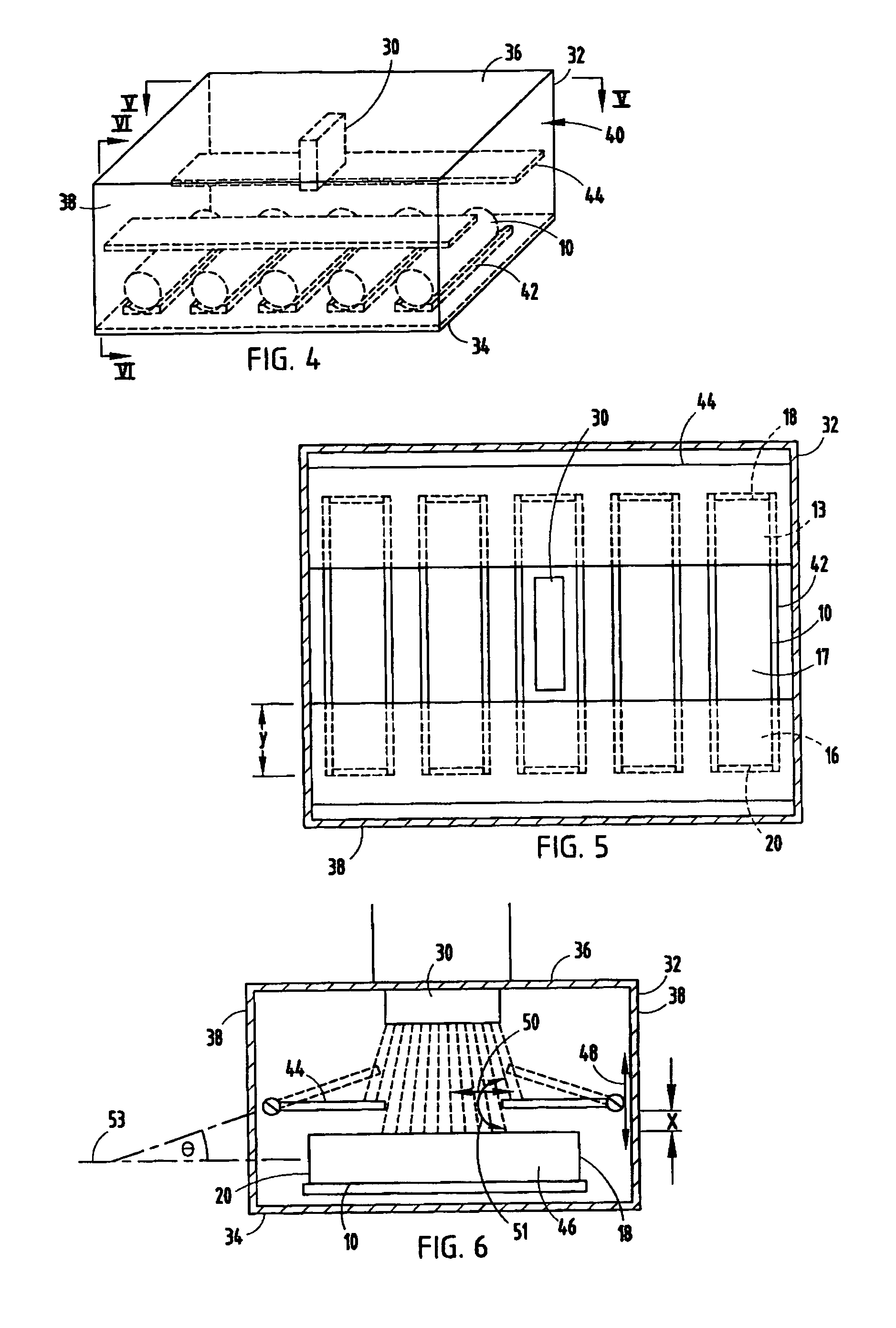

Method For Laser Machining And Laser Device With Laser Power Controlled As a Function Of The Laser Motion

InactiveUS20070199929A1Laser welding techniqueGood techniqueVehicle componentsMetal working apparatusContact freeRobot hand

A method and device (1) for laser machining vehicle bodies or body parts (2) uses a laser beam (14) that is guided from a laser source (13) to a remote laser tool (15) on a robot hand by a guiding device (16). The robot (4) maintains the laser tool (15) in a suspended manner over the tool (2), at a focal length (F) and at a contact free distance and guides it along a machining path (30). The laser beam (14) is deviated, by movement of the hand axis (IV, V, VI), about a variable deviation angle (α), and the laser source (13), whose power is variable, is controlled according to the movement of the laser beam. The beam deviation of the hand axis (IV, V, VI) can be superimposed on an offset movement of the robot (4).

Owner:KUKA SYSTEMS

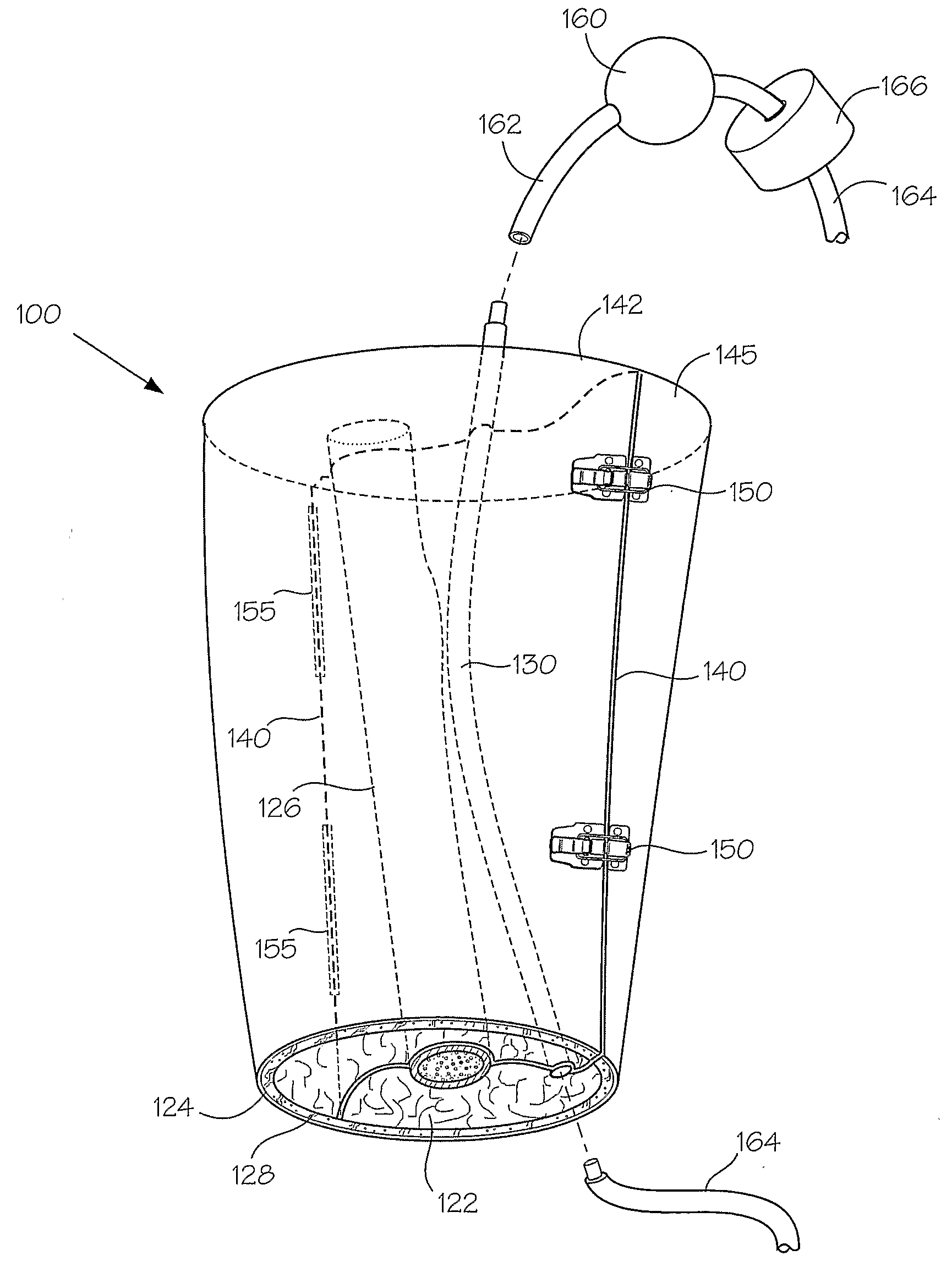

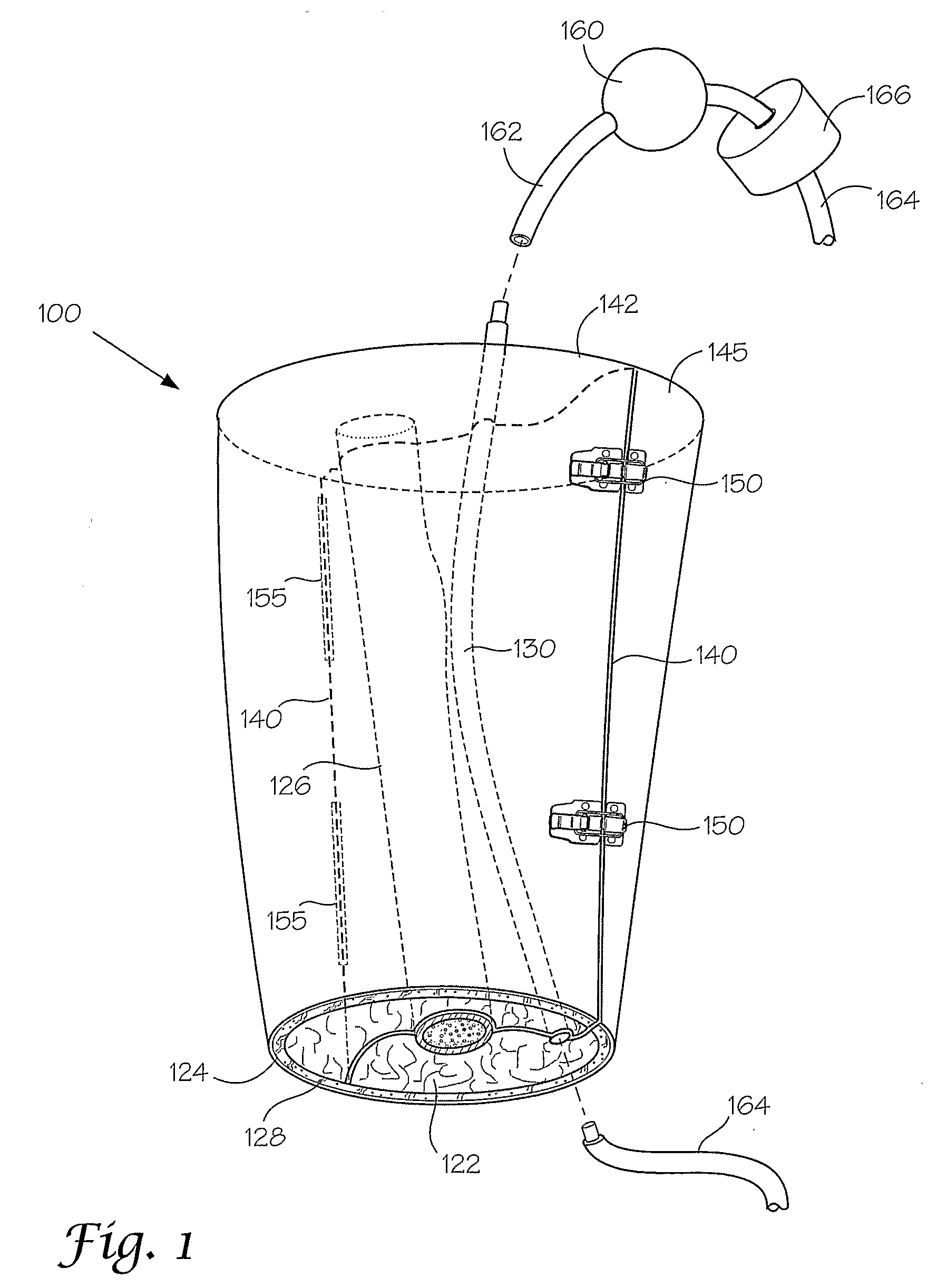

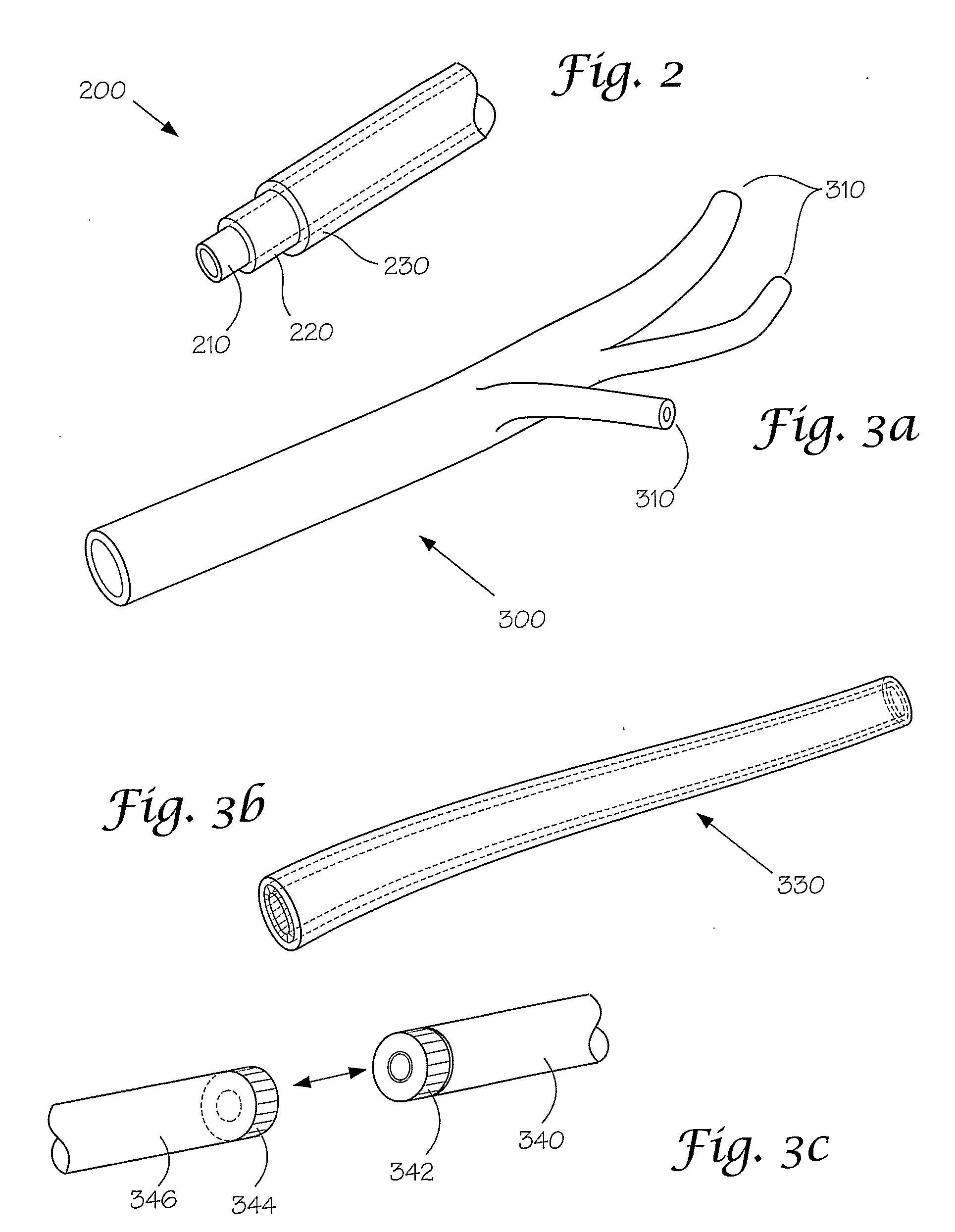

Models And Methods Of Using Same For Testing Medical Devices

ActiveUS20080187895A1Avoid product qualityIncreased development costAdditive manufacturing apparatusEducational modelsHuman bodyAnatomical structures

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device compam'es, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

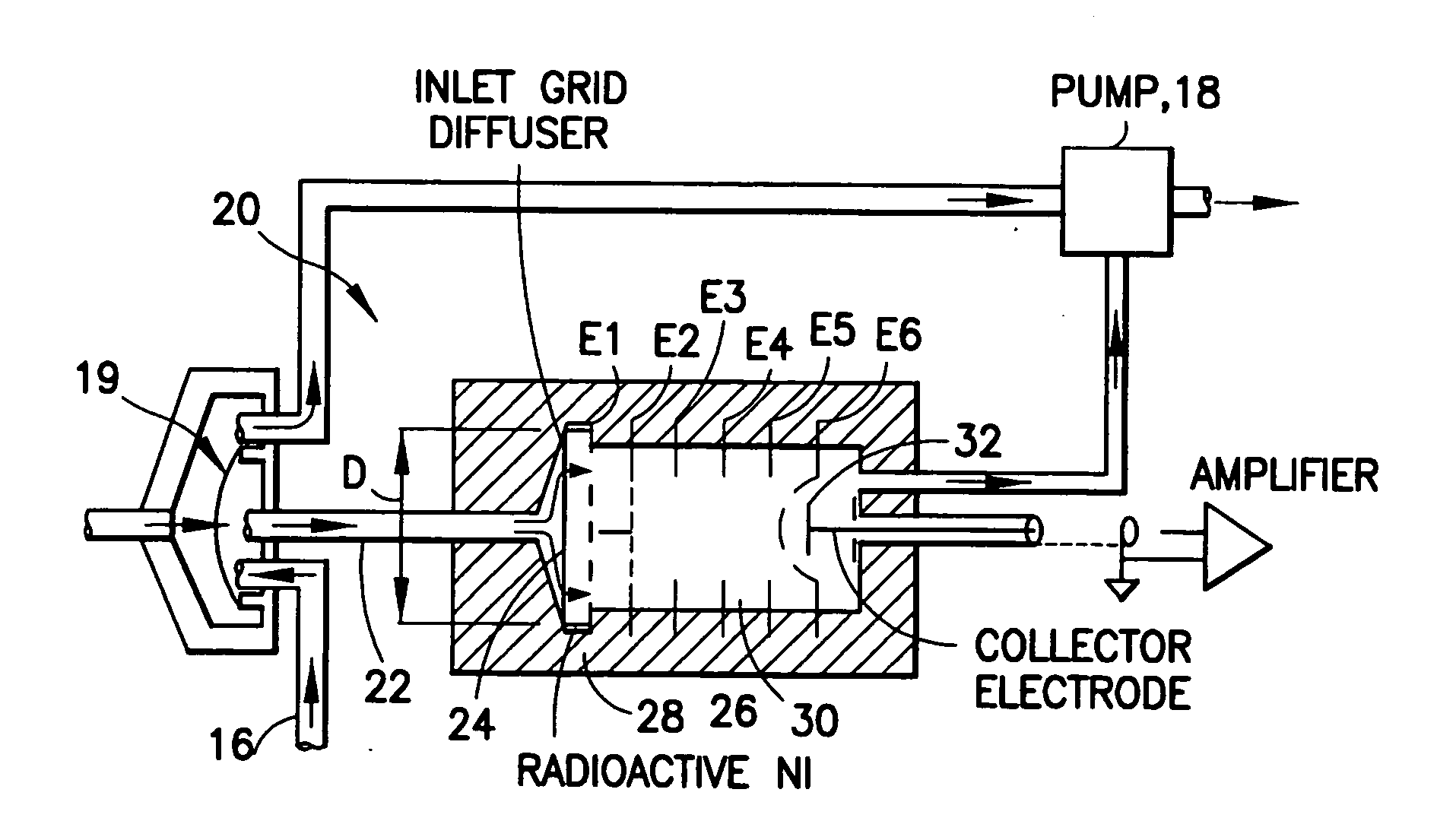

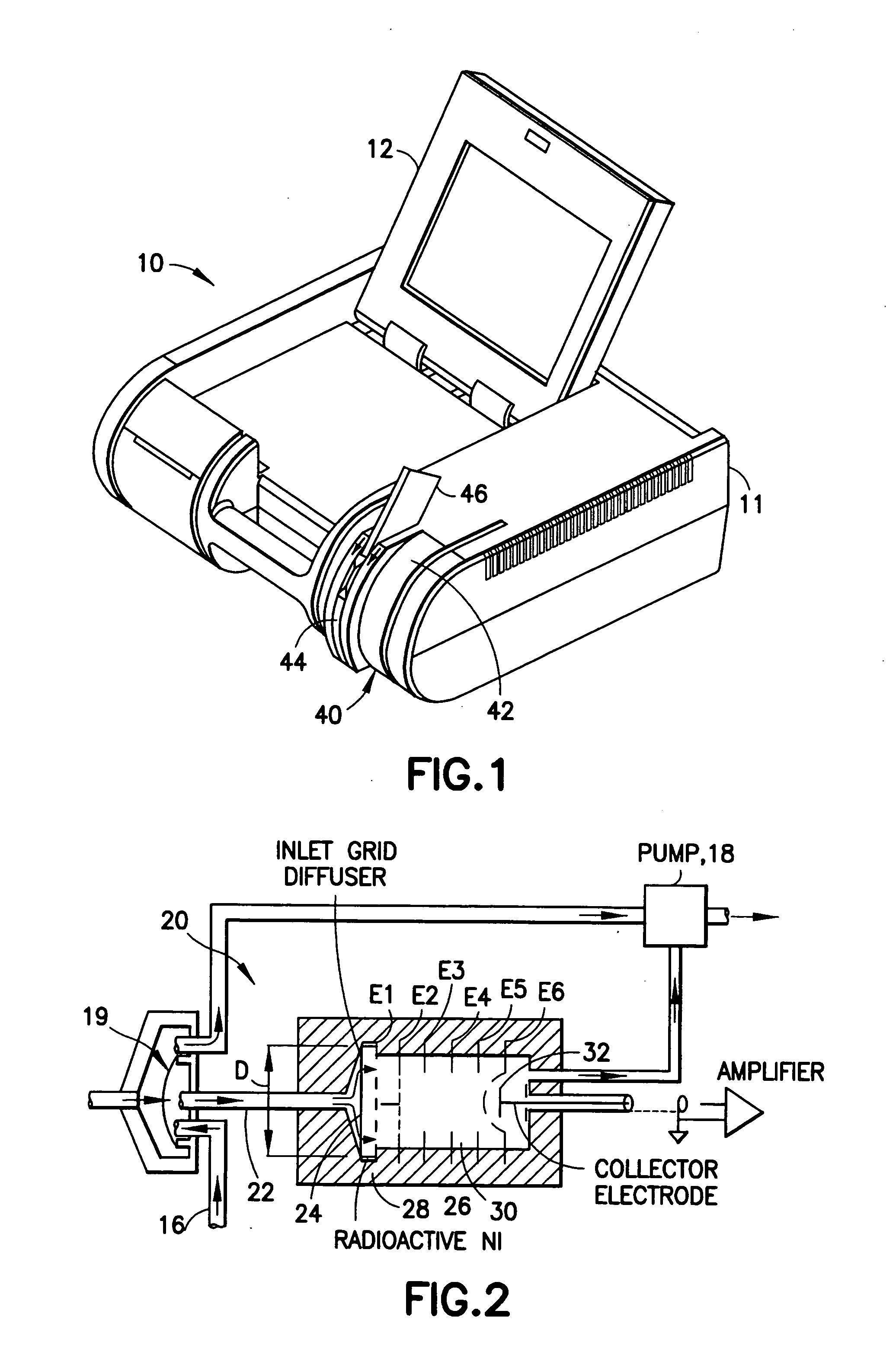

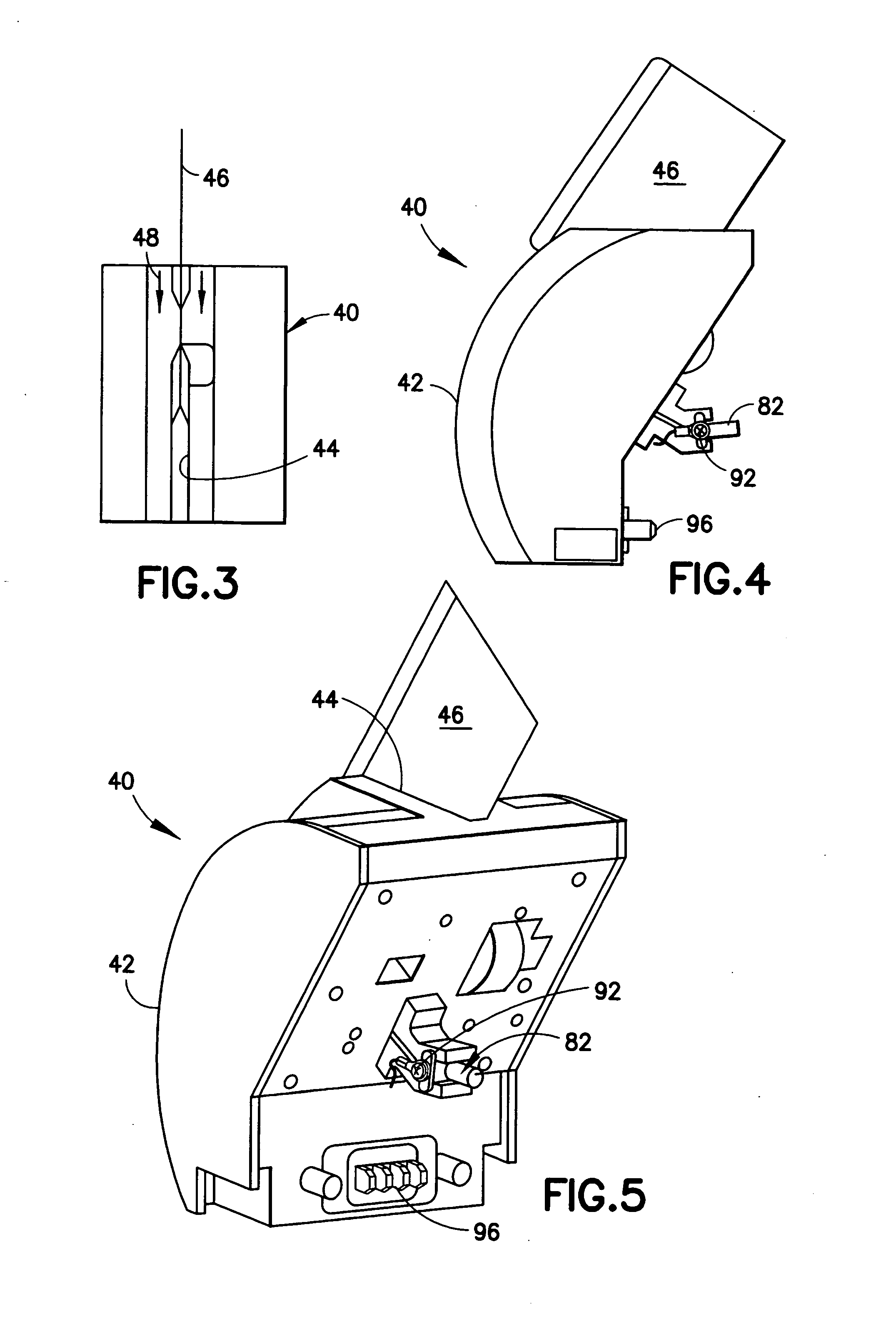

Device for testing surfaces of articles for traces of explosives and/or drugs

InactiveUS20050019220A1Laborious and time-consumingHeating fastMaterial analysis using wave/particle radiationTime-of-flight spectrometersExplosive materialMetal

A device is provided for testing surfaces of a card for the presence of explosives, drugs or other substances of interest. The device includes a slot for receiving the card. Thin metallic wiper blades are dispose in alignment with the slot and wipe over surfaces of the card as the card is passed through the slot. Thus, substances on the surface of the card are transferred to the wiper blade. The wiper blade then is enclosed and rapidly heated to desorb the material retrieved from the card. The enclosure then is placed in communication with a detector to test for the presence of substances of interest.

Owner:RAPISCAN SYST INC (US)

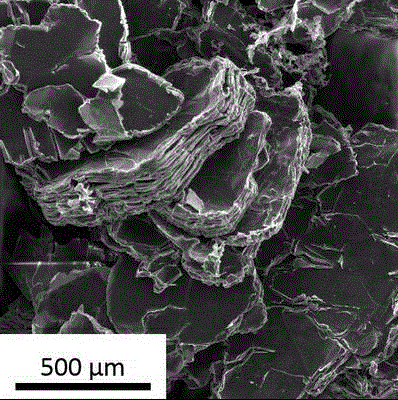

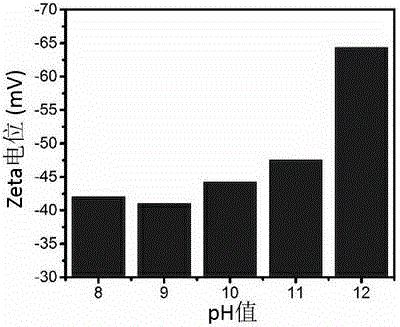

Method for preparing graphene through large-scale aqueous phase

The invention provides a method for preparing graphene through a large-scale aqueous phase. According to the method, graphite serves as a raw material. The method comprises the following steps: intercalating the graphite by adopting an intercalator, so that interlayer spacing between graphene sheet layers is enlarged, and the interaction force between the layers is weakened; and directly treating the intercalated graphite through ultrasonic waves, stripping and uniformly dispersing the graphite in an alkaline aqueous solution with the pH value of 10-14, wherein the content of graphene in the dispersion can be over 100mg / mL (about 10 weight percent of graphene), the content of single-layer graphene in the aqueous phase dispersion is more than 90 percent, the equivalent diameter of the graphene sheet layers can be over 1-10 microns, and a graphene film formed by filtering has a complete lattice structure and high electric conductivity. The prepared high-concentration aqueous phase graphene paste can be stored for a long time and is convenient to transport and use. The method is simple in process flow, high in production efficiency, low in energy consumption and low in cost, a commercially available low-cost reagent is adopted, the reagent is easy to recover, and the production process is environment-friendly and pollution-free.

Owner:安徽百特新材料科技有限公司

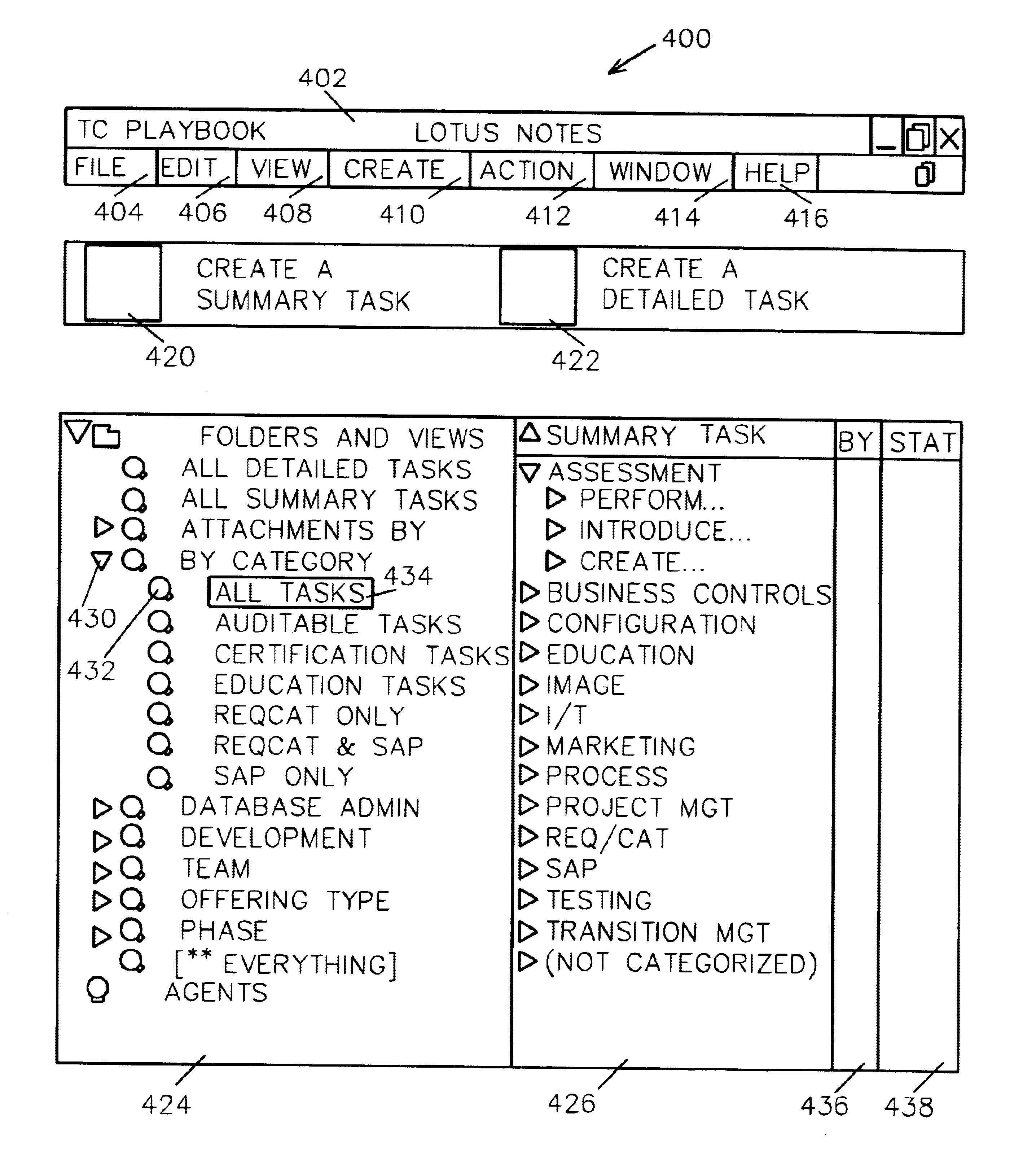

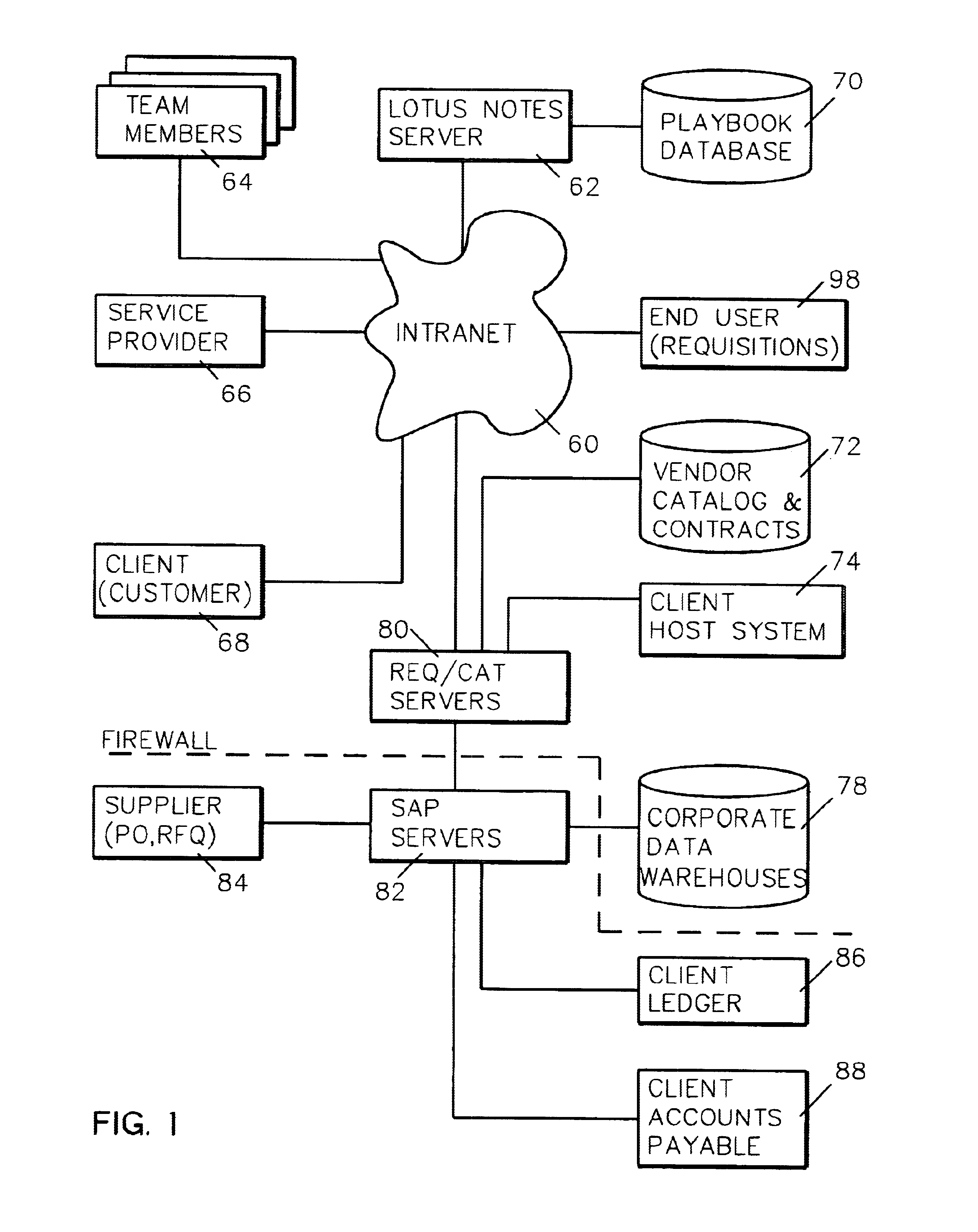

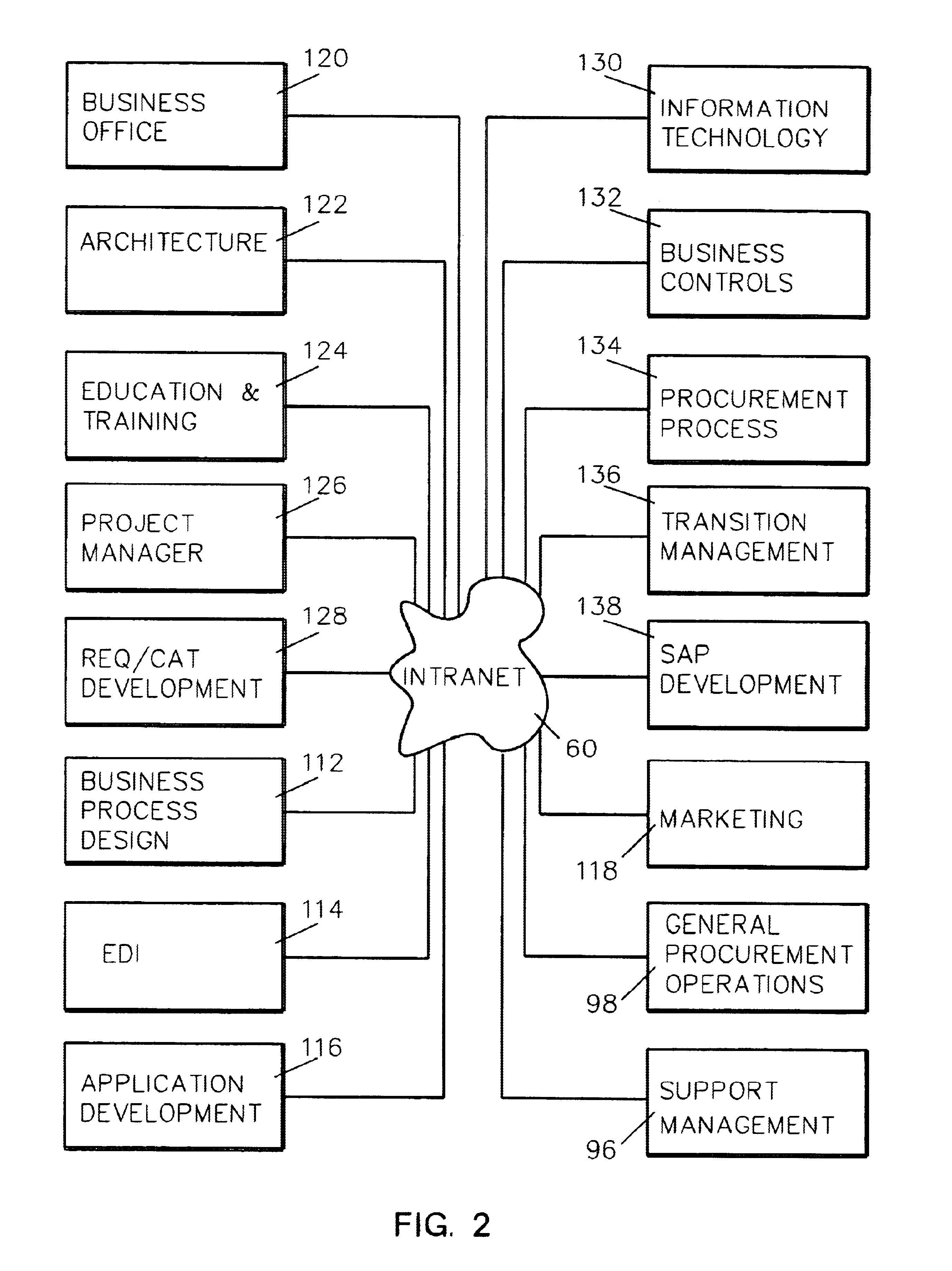

System and method for assessing a procurement and accounts payable system

A system for deploying to a client accounting installation a general procurement and accounts payable application specifically configured for the client by an enterprise includes a database server for (1) maintaining on a storage device a database of templates describing procedures for assessing, preparing, developing, deploying and supporting the application, and for (2) serving these templates to team members operating web-enabled terminals for coordinating, recording and tracking team activities with respect to the application while generating a description for adapting a front end server and an accounting system server to the requirements of the client.

Owner:PAYPAL INC

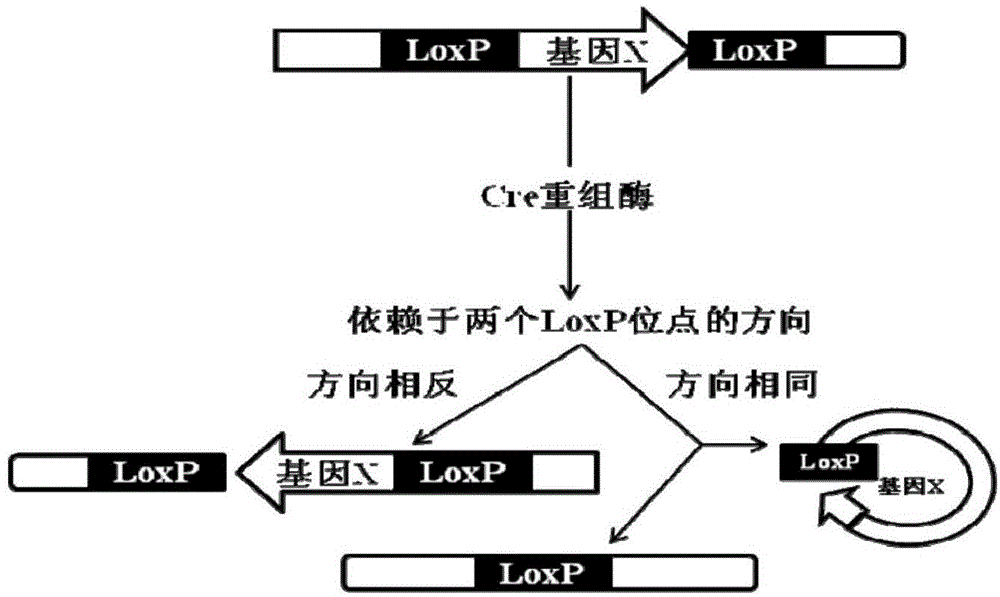

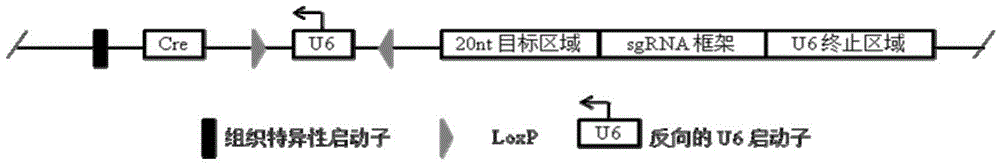

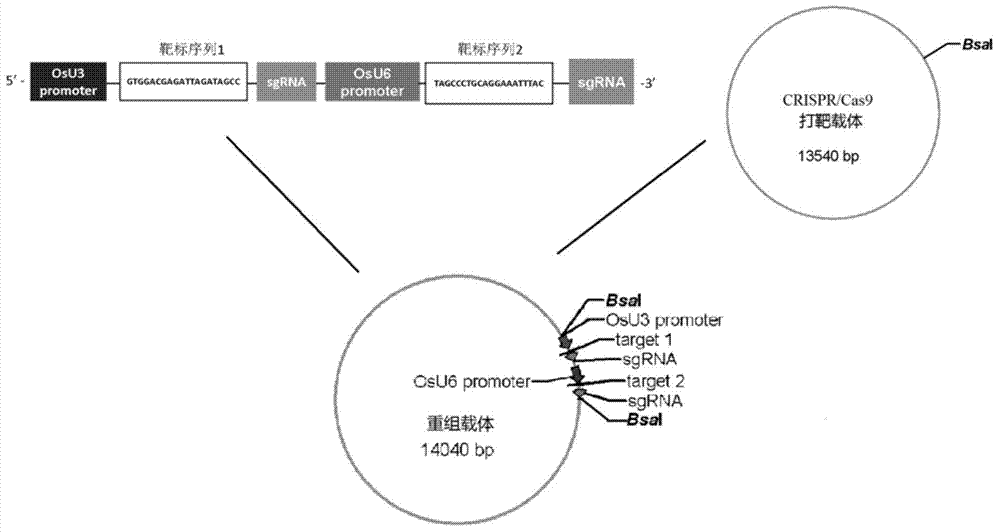

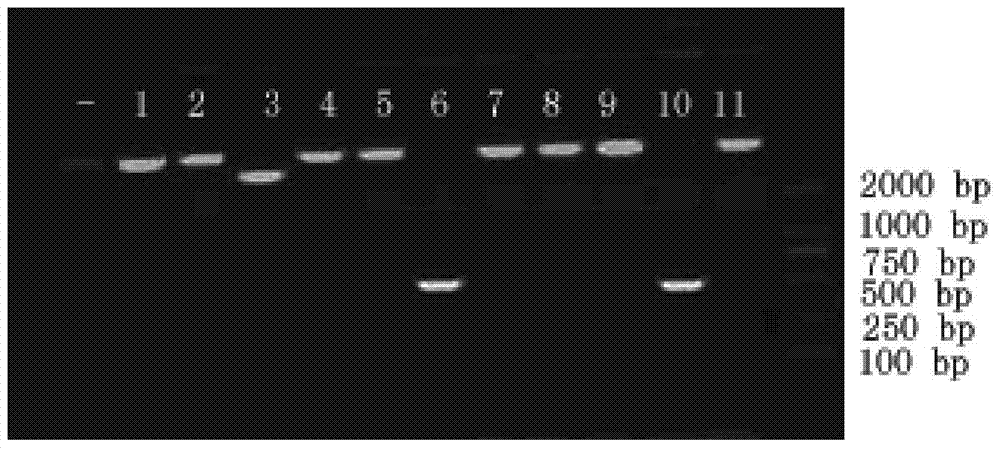

Conditional gene knockout method based on CRISPR/Cas9 technology

ActiveCN104404036AShort cycleImprove efficiencyVector-based foreign material introductionDNA/RNA fragmentationTool MouseGene Modification

The invention discloses a primer used for gene knockout, which comprises five groups of primer, and can be respectively shown in a SEQ NO:1, a SEQ NO:2, a SEQ NO:3, a SEQ NO:4, a SEQ NO:5, a SEQ NO:6, a SEQ NO:7, a SEQ NO:8, SEQ NO:9 and a SEQ NO:10. The invention also discloses an application of the primer in gene knockout aspect. The invention also discloses a conditional gene knockout method based on a CRISPR / Cas9 technology. The method can performing condition specificity, space-time specificity, and medicine-induced type gene modification; harm due to other cells can be reduced, function of constitutive expression gene in a specific tissue can be researched; tissue and space specificity gene knockout or induction type gene knockout can be realized by only using Cas9 tool mice; test period is short, and time and cost are saved.

Owner:CYAGEN BIOSCI INC

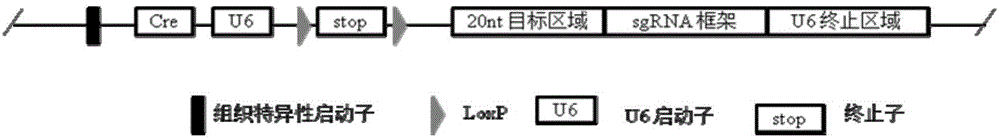

Automatic vehicle-mounted mobile power charging and exchanging station for electric vehicle and method for quickly exchanging battery

ActiveCN102180200ACompact structureLess investmentElectric propulsion mountingTractor-trailer combinationsElectricityAutomatic control

The invention discloses an automatic vehicle-mounted mobile power charging and exchanging station for an electric vehicle and a method for quickly exchanging a battery. The automatic vehicle-mounted mobile power charging and exchanging station comprises a tractor, a semitrailer and a battery box storage rack, a battery box, an automatic power exchanging device, a charging system, an electric quantity counting system, an automatic control unit and the like which are arranged on the semitrailer, wherein the storage rack can store a plurality of battery boxes three-dimensionally; the battery boxes are standard exchanging modules connected with a battery house on the lower part of a vehicle body by using a plurality of quick-opening locking bolts; the automatic power exchanging device comprises a lifting table, a transmigration machine, a shifting machine and a plurality of unlocking / locking bushings; the automatic power exchanging device can automatically transport and store the battery boxes, and lock or unlock the battery boxes and the battery house due to mutual matching of the lifting table, the unlocking / locking bushings and the quick-opening locking bolts, so automatic dismantling and exchange of the battery boxes can be realized; and the charging system is used for automatically charging the battery boxes. The station is complete in system, compact in structure, flexible in maneuvering, low in investment and short in construction period, so the automatic power charging / exchanging requirement of the battery of the electric vehicle can be met.

Owner:柳崇禧 +1

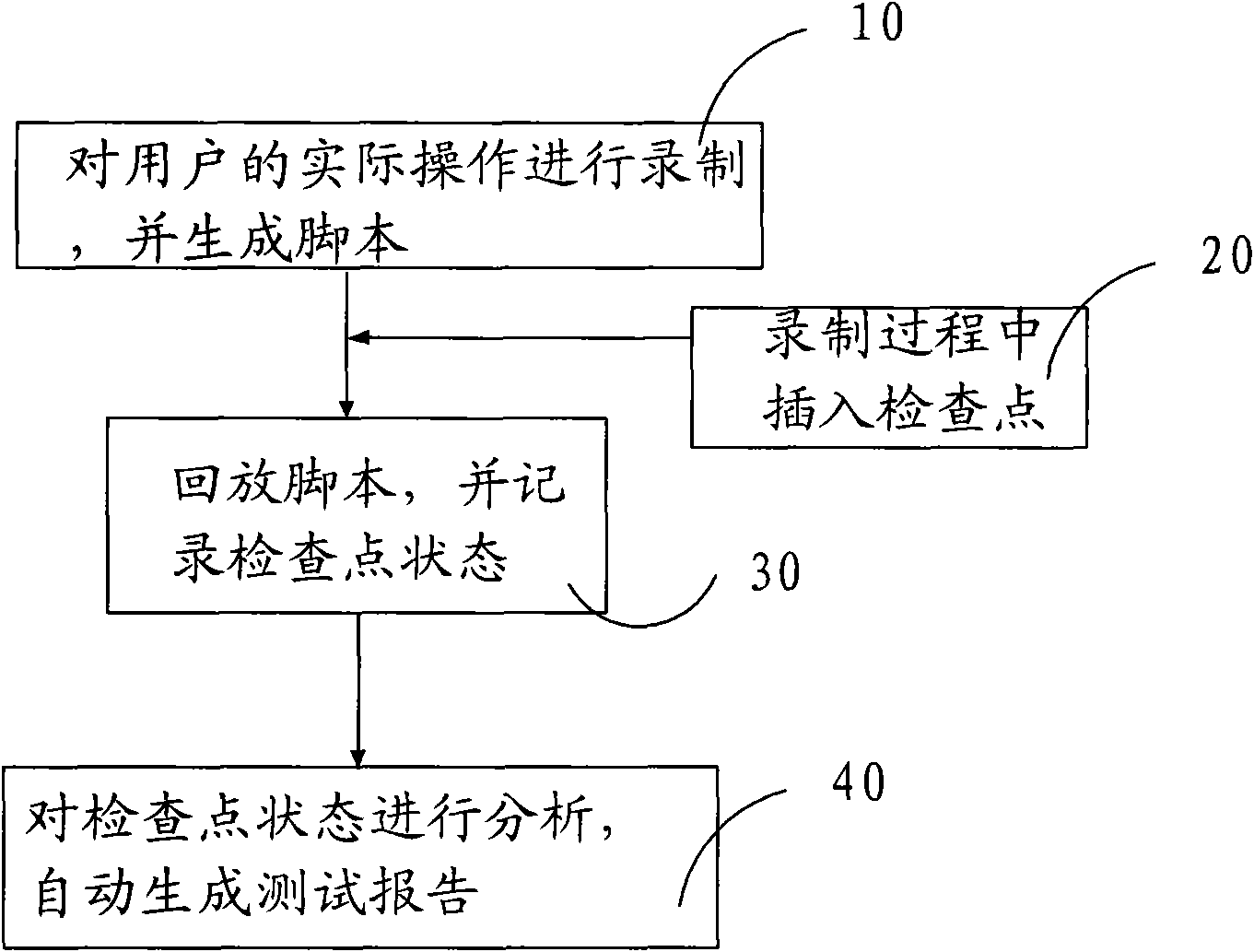

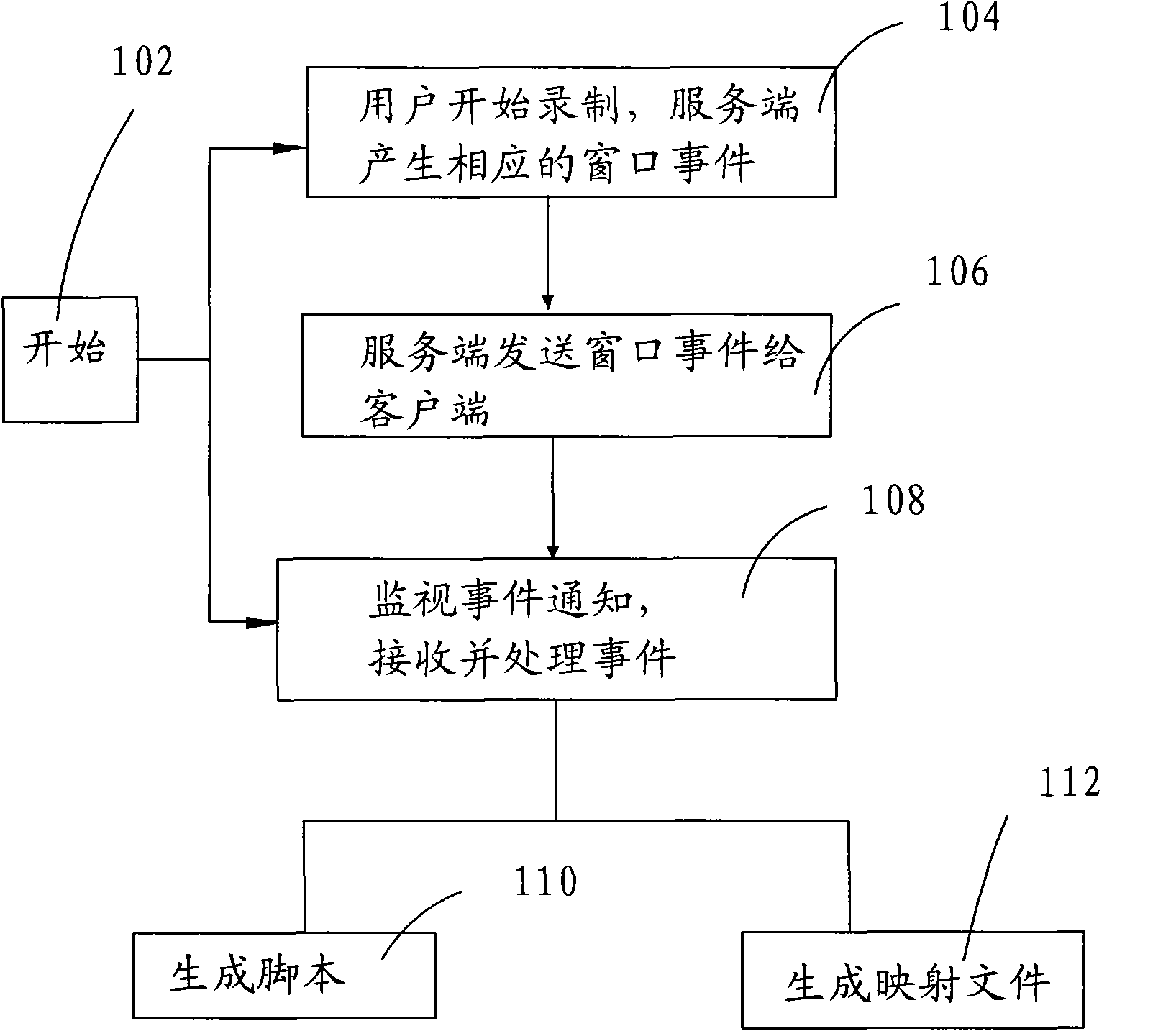

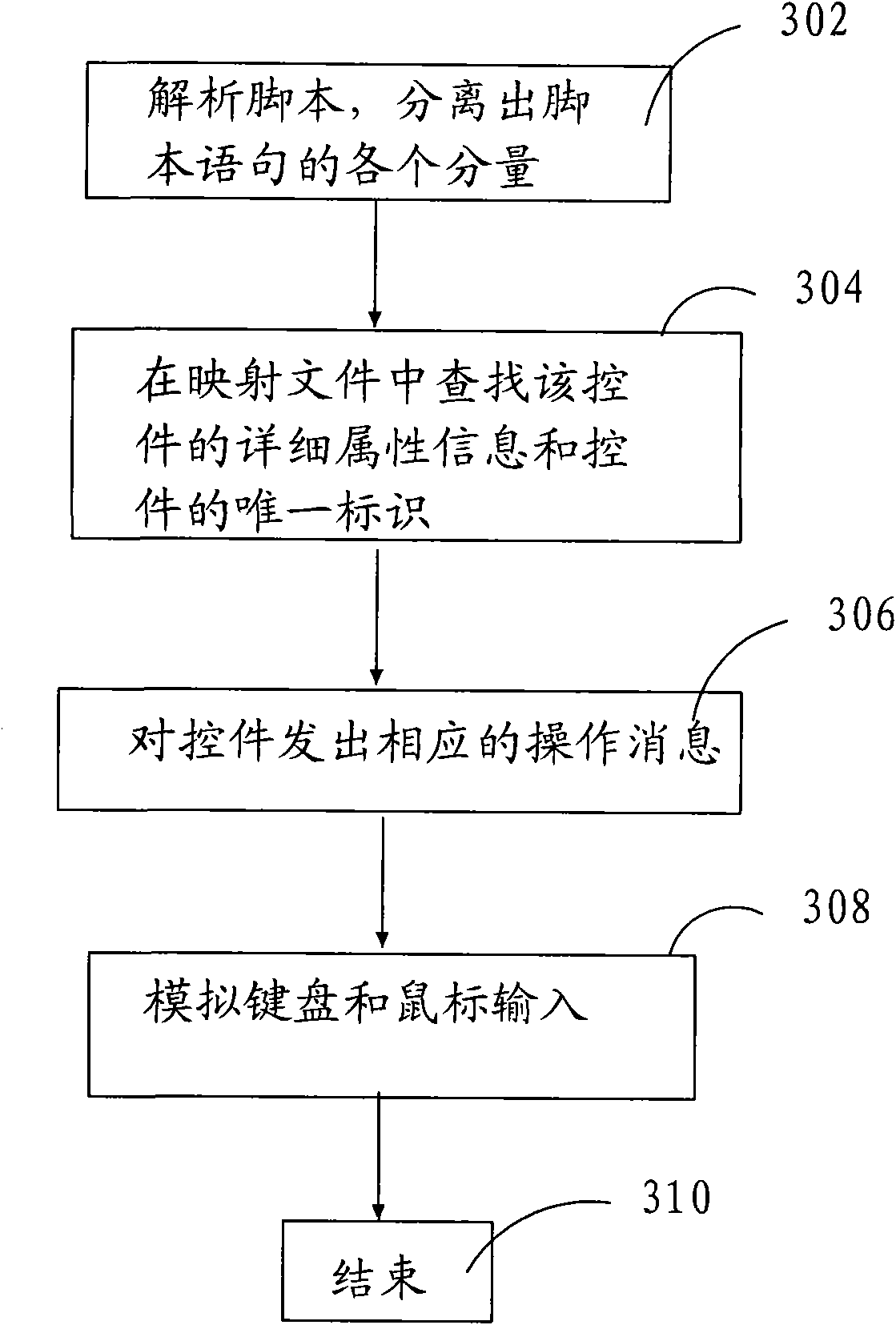

Method for automatically testing recording playback mode of terminal system

InactiveCN101620564ACheckpoints are reliableShorten test timeSoftware testing/debuggingCheck pointTerminal system

The invention relates to a method for automatically testing a recording playback mode of a terminal system, which comprises the following steps: 10, recording actual operation of a user, which comprises mouse operation and keyboard operation, and automatically generating a script which is easily understood by the user and can be edited manually; 20, in the recording process in the step 10, inserting a check point of which the state is required to be checked in an automatic test; 30, playing the script generated in the step 10 back, automatically executing the test, and recording the state of the check point; and 40, finishing the playback of the script, analyzing the recorded state of the check point, summarizing test results, and automatically generating a test report. The method has the advantages of being suitable for automatic functional tests of terminal embedded systems and non-embedded systems, supporting tests for functions of protocols such as ICA, RDP and the like, providing reliable check points for testing GUI functions, and saving testing time.

Owner:FUJIAN CENTM INFORMATION

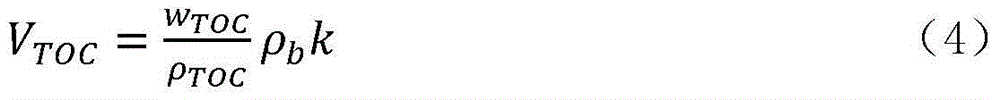

Method for acquiring gas content of shale reservoir through well logging data

ActiveCN104573344AConforms to gas-containing characteristicsShort cycleSpecial data processing applicationsMaterial analysisShale gasPhase state

The invention relates to a method for acquiring the gas content of a shale reservoir through well logging data. The method comprises the following steps: I, selecting a shale gas well in a research region for coring, and measuring the porosity phicore, organic carbon content TOCcore, water saturation Sw-core, cementation index m, saturation index n, Langmuir volume VL, Langmuir pressure PL, formation grain density rhom and formation fluid density rhofl of an identical shale sample respectively; II, calculating the key parameter of the gas content of the shale reservoir through the well logging data; III, calculating the adsorption gas content and the free gas content respectively by using the key parameter, and representing the total gas content of the shale reservoir by using the sum of adsorption gas and free gas. The gas content of the shale reservoir is calculated through the well logging data, so that the well drilling coring cost is reduced, and the gassiness evaluation period of the reservoir is shortened. Meanwhile, the total amount of natural gas in the shale reservoir of the reservoir is calculated from the two phase states of adsorption gas and free gas respectively, so that the gassiness characteristic of the shale reservoir is met, and the calculation accuracy is higher.

Owner:CHINA NAT OFFSHORE OIL CORP +1

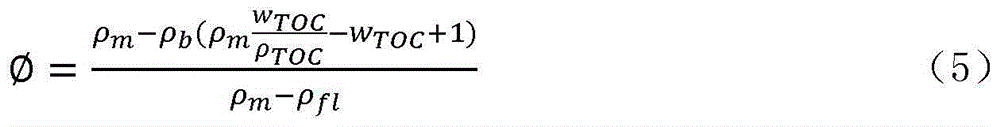

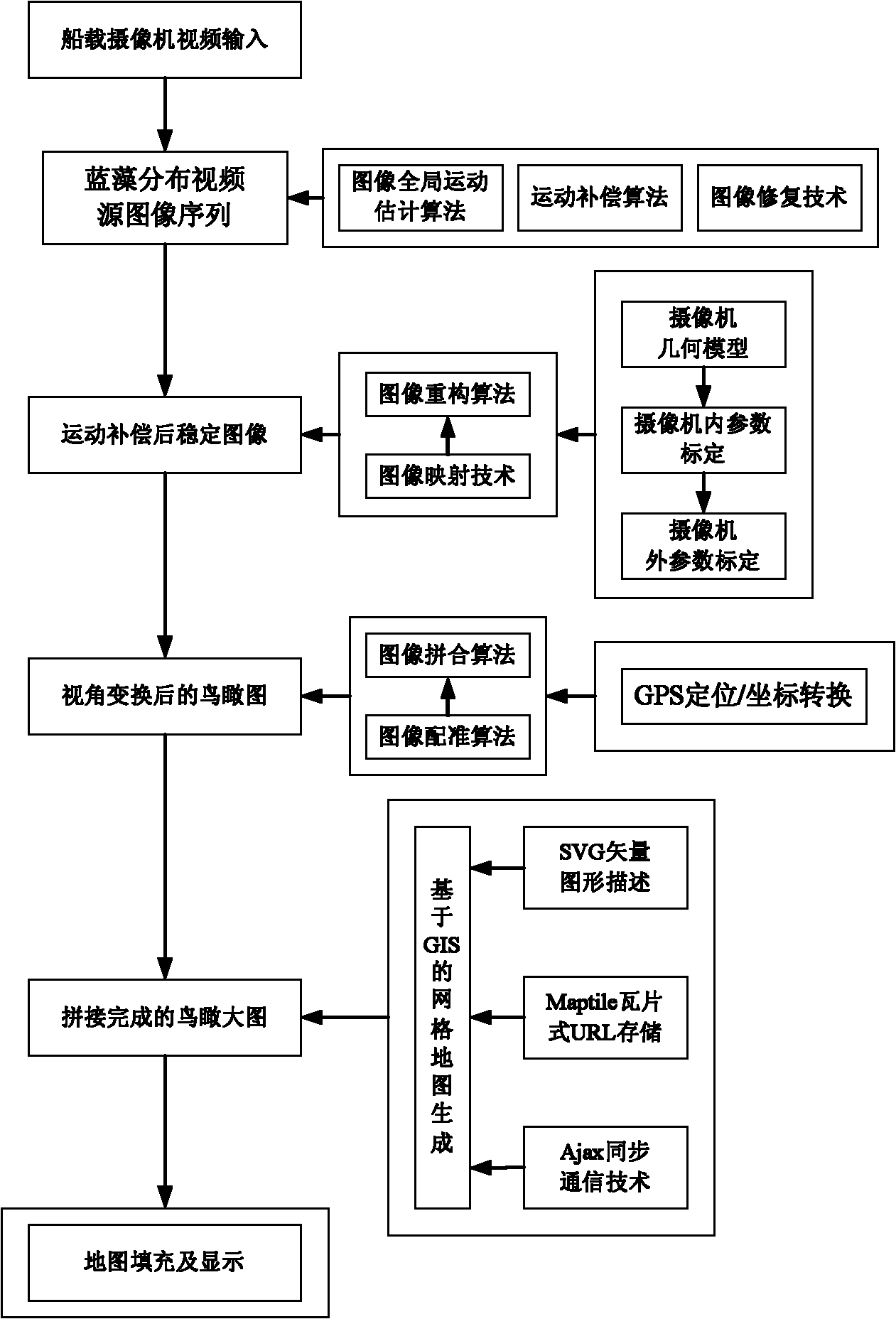

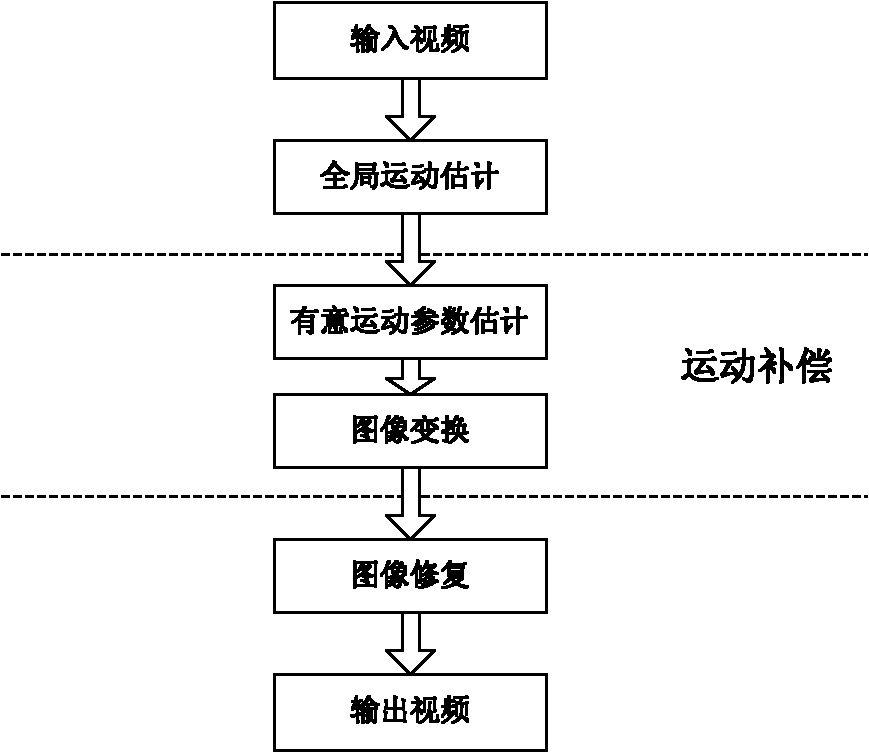

Cruise image based imaging method of water-surface aerial view

InactiveCN101976429ASmall distortionReduce noise interferenceImage enhancementImage analysisImaging processingDistortion

The invention relates to a cruise image based imaging method of a water-surface aerial view, which comprises the steps of: firstly, establishing an imaging system which comprises a server image processing system, a client interface display and interactive system, and a video collecting system of a cruise boat; installing a video camera and a GPS (Global Position System) device on the boat; collecting water-surface video data; processing the video data by the server image processing system to obtain a water aerial view; and inputting the water-surface aerial view into the client interface display and interactive system. A water-surface video is collected by the cruise boat, and is converted into the water aerial view. The method has the advantages of small distortion, short period, high aging performance, low investment and good compatibility, and is disturbed by less noise.

Owner:NANJING UNIV

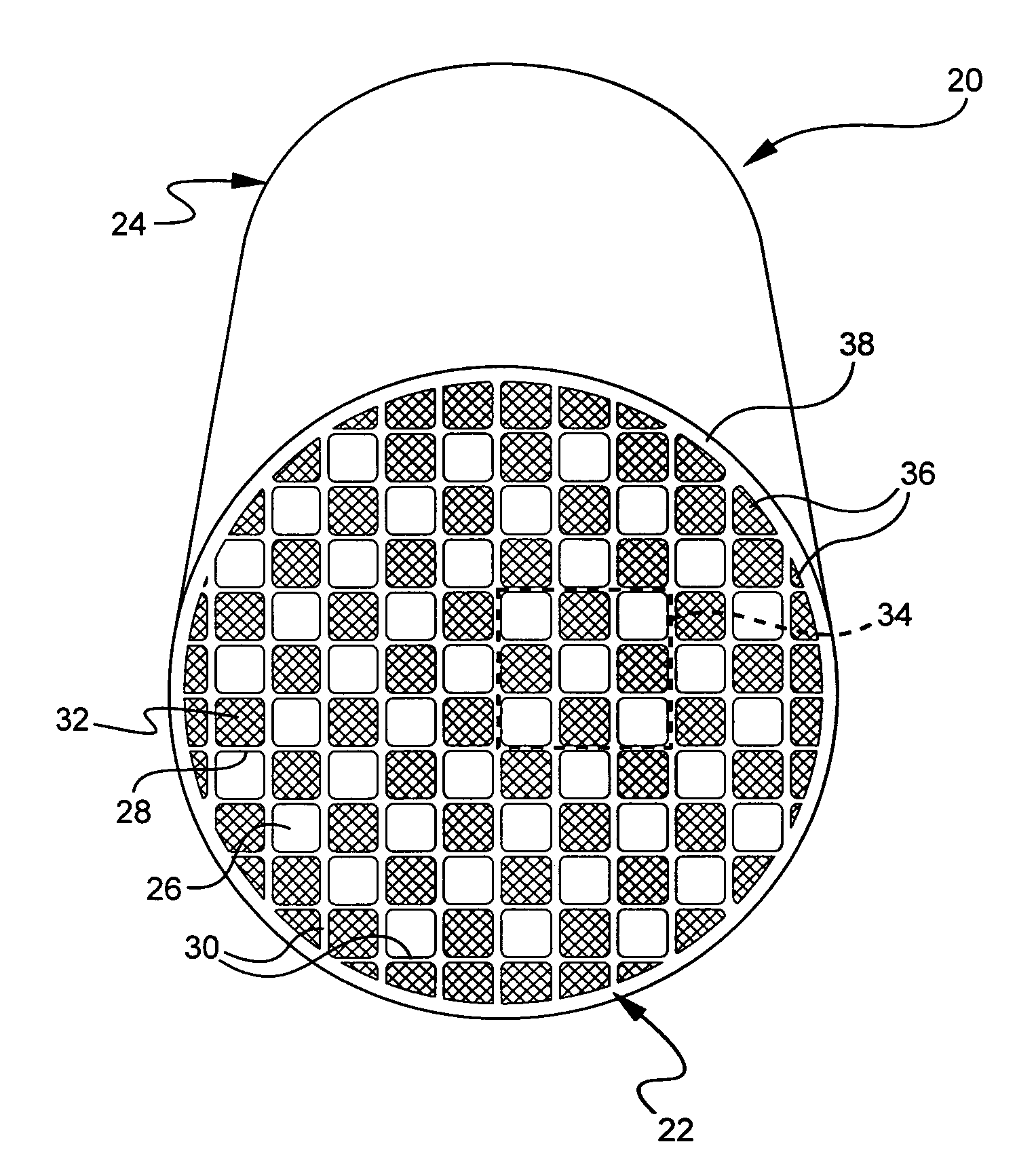

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

Preparation method of hollow-structure metal or ceramic part

InactiveCN102351542AShort cycleShorten the production cycleCeramic shaping apparatusAdhesiveCo injection

The invention relates to a preparation method of a hollow-structure metal or ceramic part, which comprises the following steps: selecting metal or ceramic powder as the raw material, mixing, and granulating to obtain a feed material; selecting a core material; injecting the core material into a die by co-injection molding to obtain a core in hollow shape, and injecting the metal or ceramic feed material to be completely coated on the core, thereby obtaining a green body; and carrying out solvent extraction and heating on the green body to remove the adhesive and core, and sintering to obtain the hollow-structure product. The invention implements one-step molding of the hollow metal or ceramic part; from the raw material to the product, the production cycle is short, and the automation degree of equipment is high, thereby greatly enhancing the efficiency and forming a randomly complex and completely hollow die cavity; and thus, the invention can be used for preparing a completely hollow part with no joint, greatly lowers the cost of the product, and is especially suitable for preparing hollow metal and ceramic parts.

Owner:CENT SOUTH UNIV

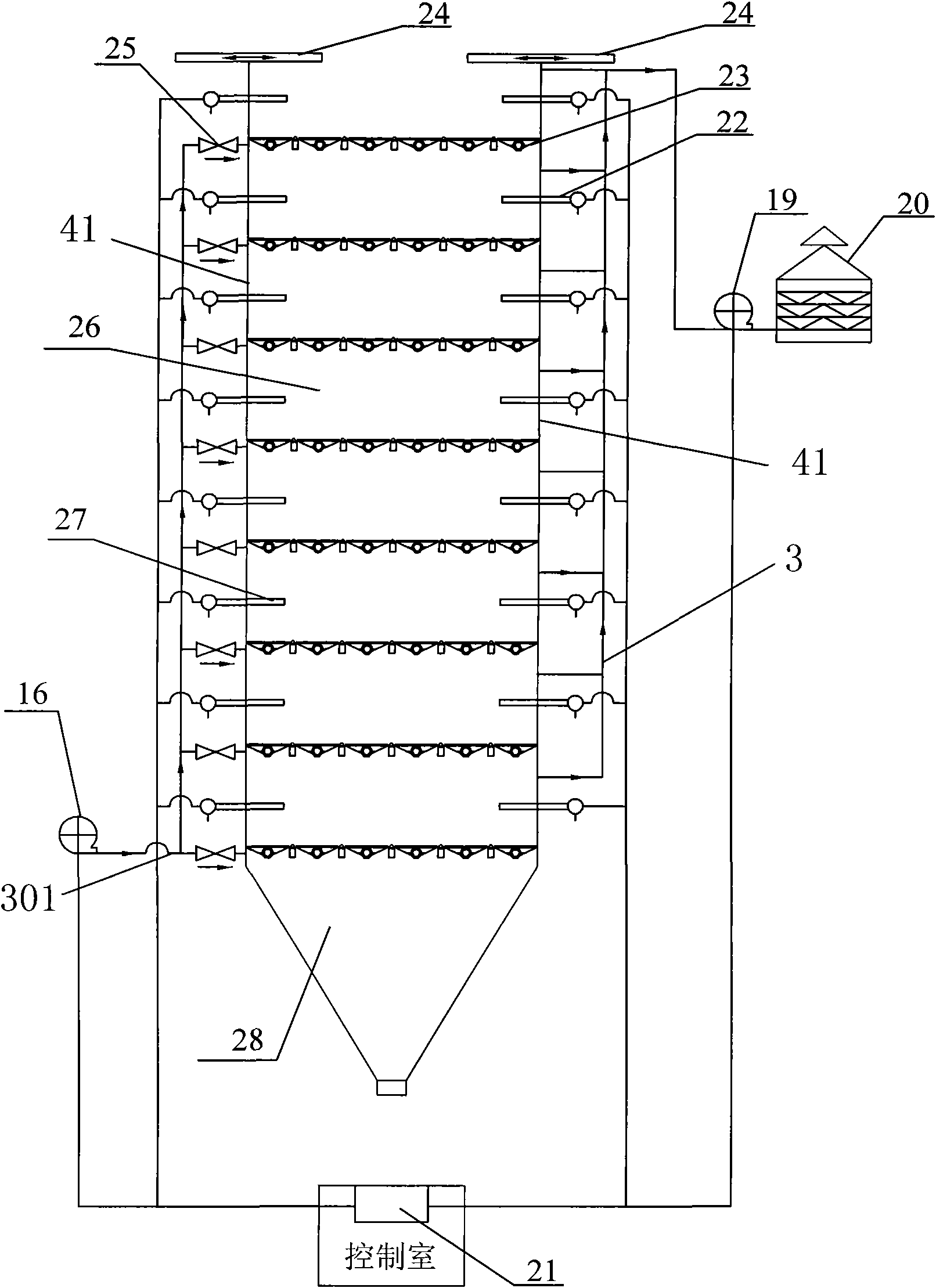

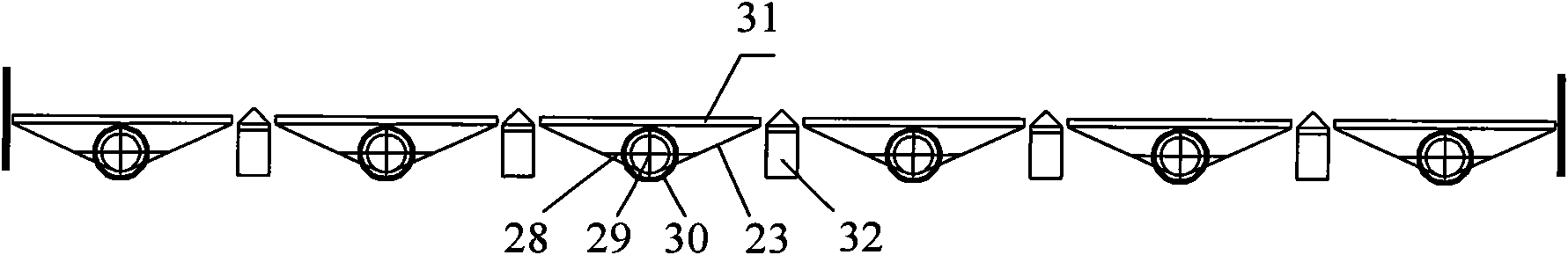

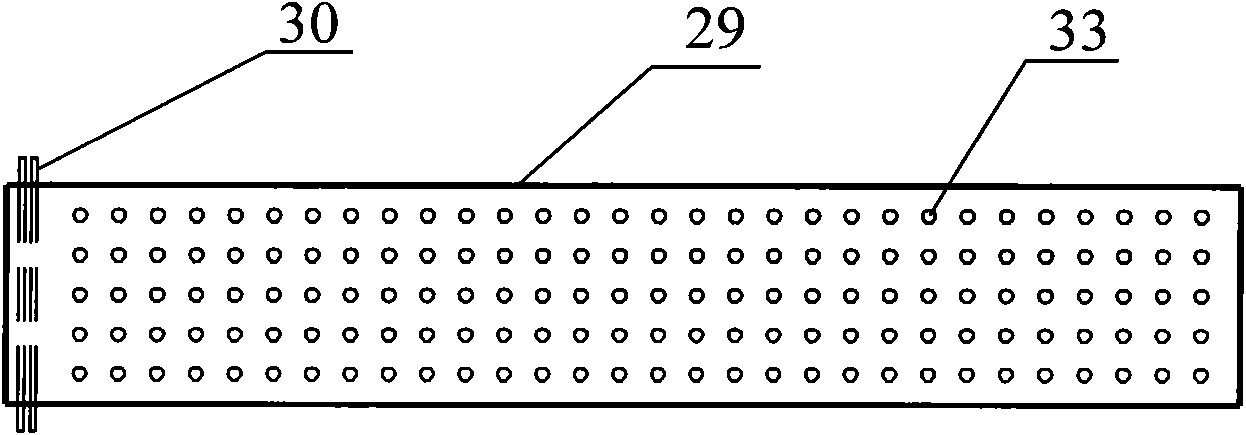

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

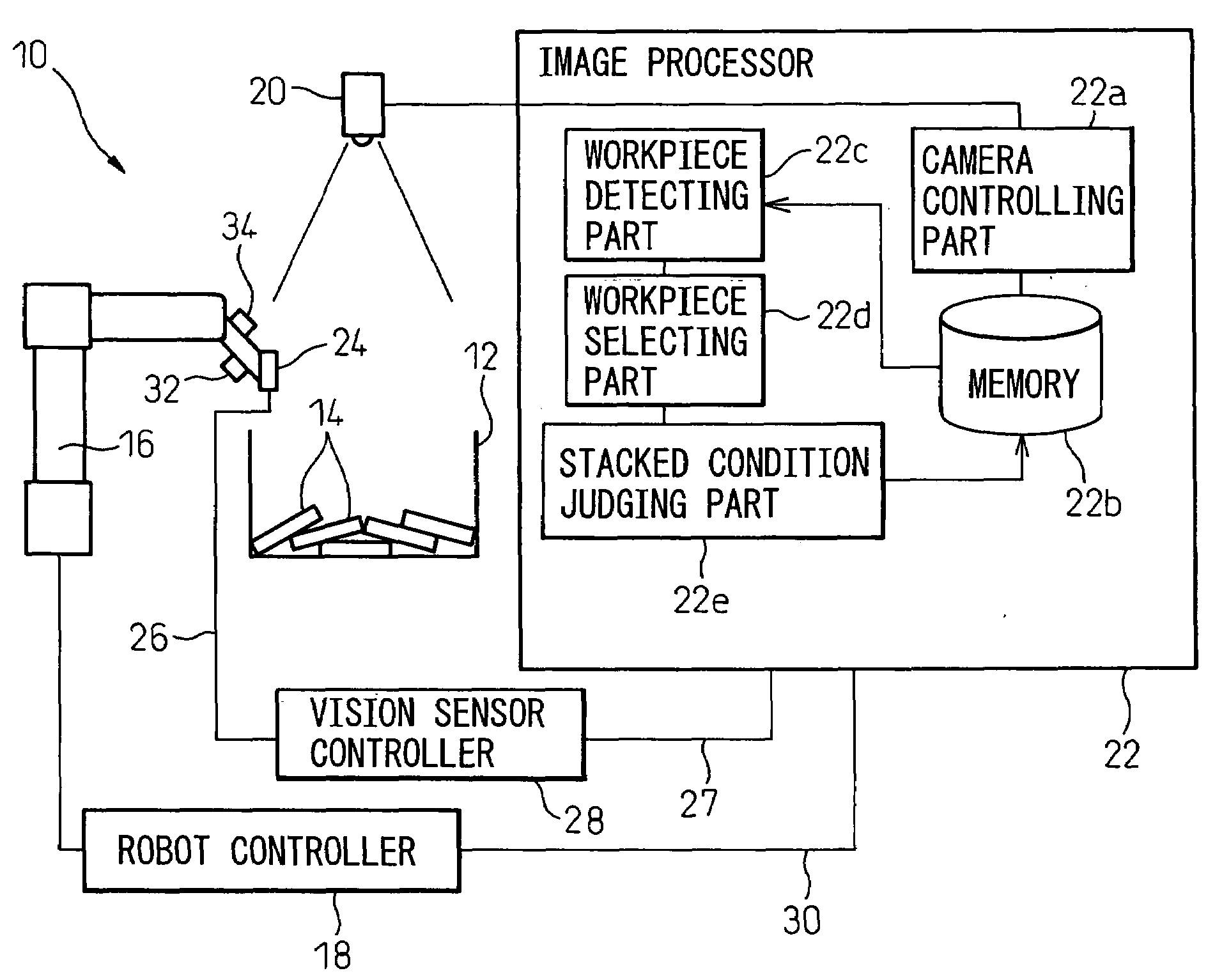

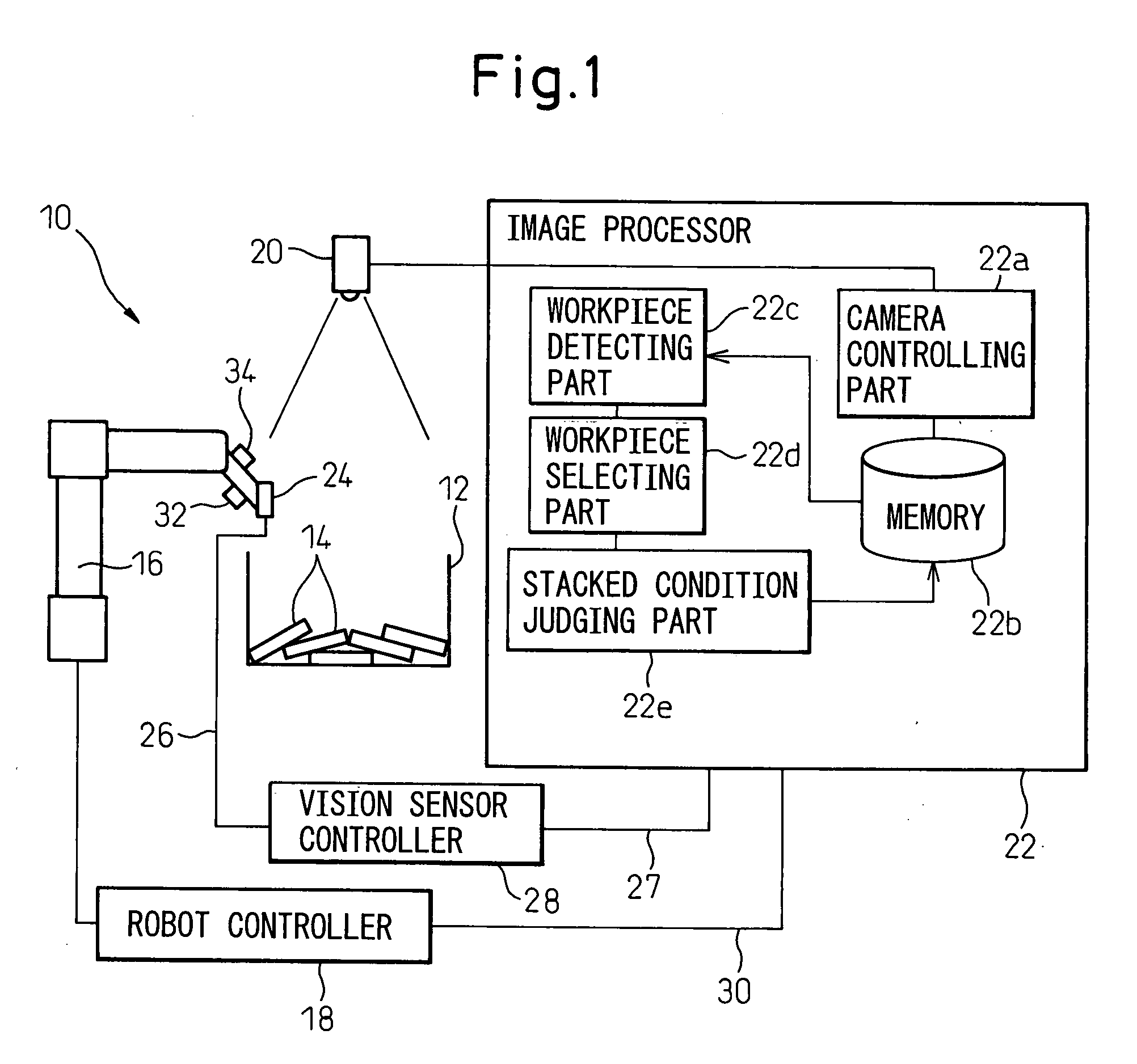

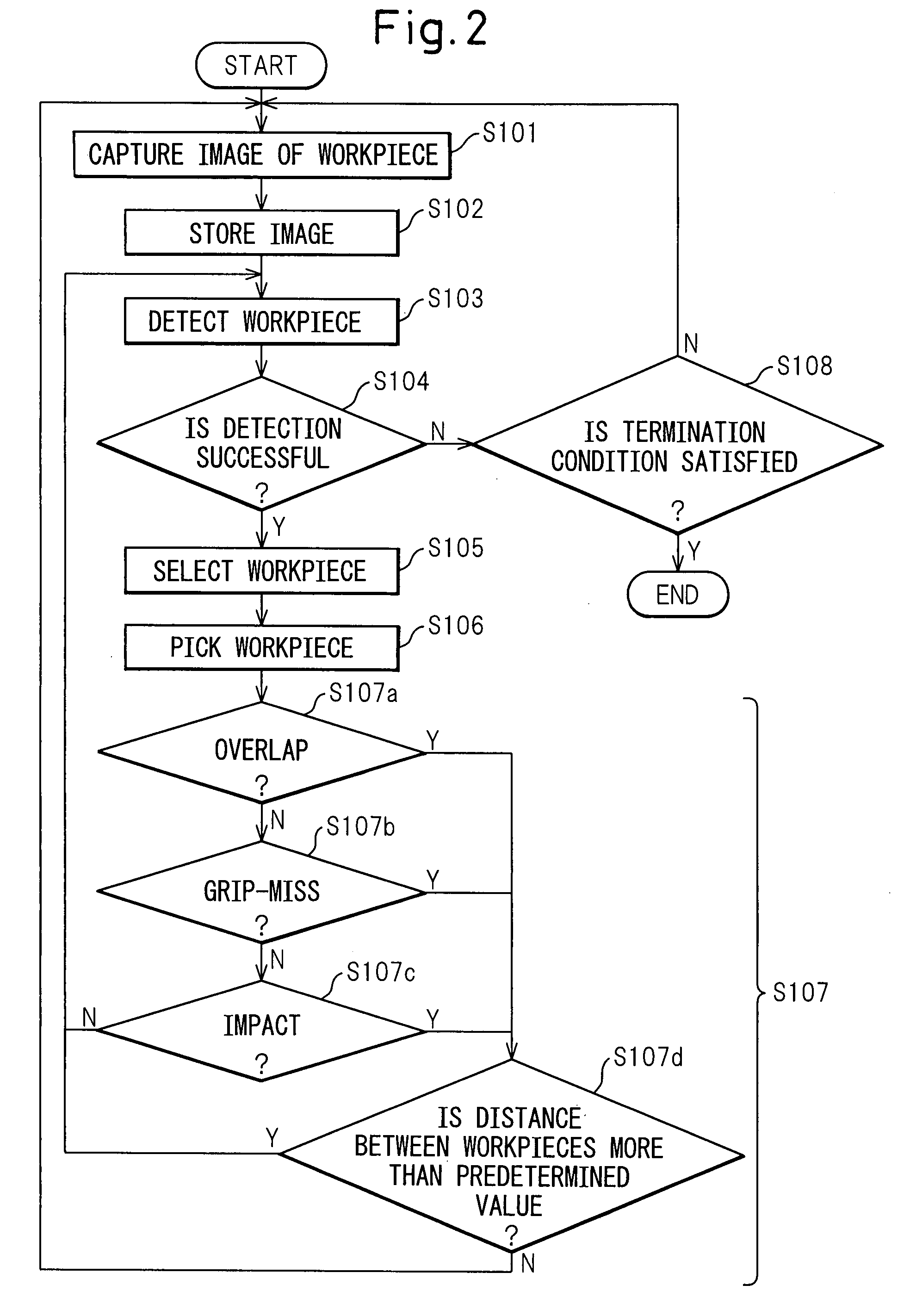

Workpiece picking device and method

InactiveUS20070274812A1Short cycleProgramme controlProgramme-controlled manipulatorCamera controlCycle time

A workpiece picking device and method for reducing the cycle time of a picking operation of workpieces, by omitting or reducing the movement of a robot manipulator when an image of the workpieces is captured. An image processor of the picking device includes a camera controlling part for reading image data from a camera, a memory for storing the image data, a workpiece detecting part for extracting one or more images from the memory and detecting one or more workpieces in the image, and a workpiece selecting part for selecting a workpiece to be picked among the workpieces detected by the workpiece detecting part. The image processor further includes a stacked condition judging part for determining whether the condition of the stacked workpieces in a container is changed.

Owner:FANUC LTD

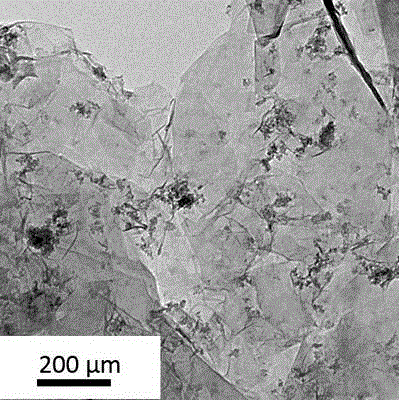

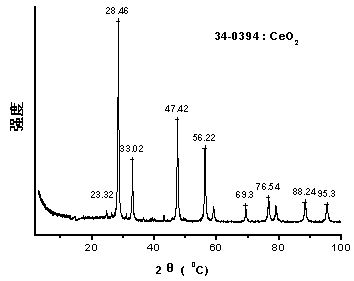

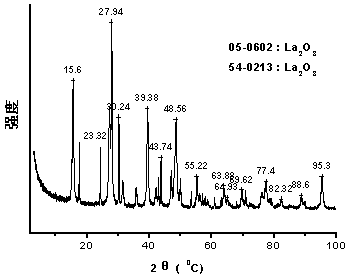

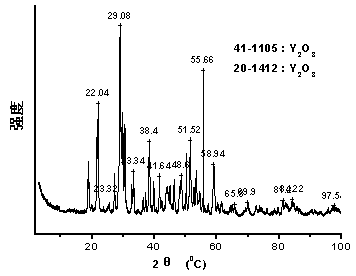

Grapheme/rare earth oxide nanometer composite material and preparation method and application thereof

InactiveCN103066292ANot easy to reuniteHigh specific surface areaMaterial nanotechnologyCell electrodesLithium-ion batteryNanocomposite

The invention relates to a graphene / rare earth oxide nanometer composite material and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing oxidized graphene dispersion liquid and a soluble rare earth compound at the weight ratio of (1:1)-(1:10), regulating a pH value to alkalescence, and carrying out hydrothermal reaction to obtain the graphene-rare earth oxide nanometer composite material; and uniformly mixing the oxidized graphene dispersion liquid and the soluble rare earth compound at the weight ratio of (1:1)-(1:10), adding a reducer, and carrying out reflux reaction at certain temperature to obtain the graphene-rare earth oxide nanometer composite material. According to the invention, rare earth oxides are successfully loaded to the surface of graphene, the rare earth oxides can be connected in a physical loading or chemical bonding way because of the electrostatic action of the surface of the oxidized graphene and uniformly dispersed to the surface of a nanometer graphene sheet by being formed into nanometer level particles, the particle size is 5-50 nanometers, and the sheet thickness is 1-5 layers, so that the agglomeration phenomena of the graphene is obviously improved, and the electrochemical property of the graphene nanometer composite material as a cathode material and the circulation stability of the graphene nanometer composite material in the charge-discharge process are effectively enhanced and superior to those the cathode of the traditional commercial lithium ion battery. The preparation method disclosed by the invention has the advantages of simple process, low cost, short period, and the like.

Owner:TONGJI UNIV

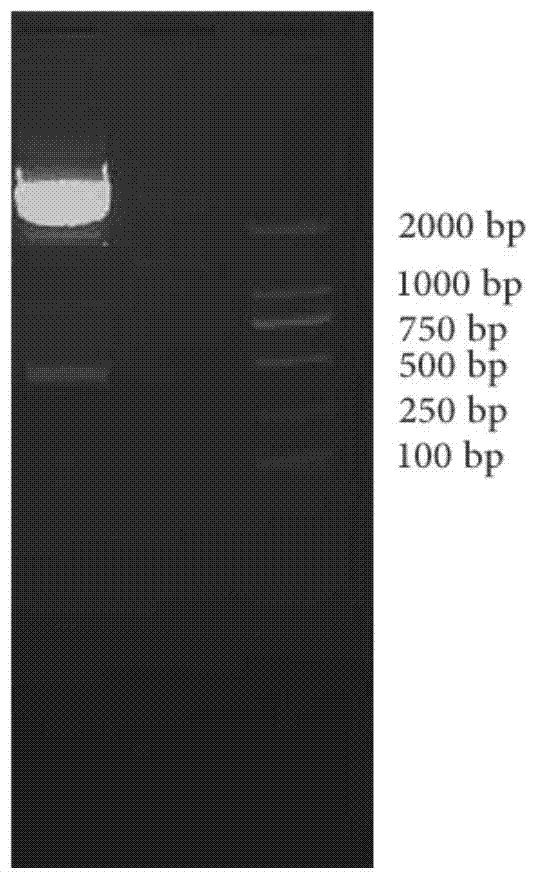

Method for deleting selection marker gene of transgenic rice

ActiveCN104846010AHigh distribution frequencyEasy to operateVector-based foreign material introductionAngiosperms/flowering plantsGenetically modified ricePlant genetic engineering

The invention provides a method for deleting a selection marker gene of transgenic rice and belongs to the field of plant gene engineering. The method for efficiently deleting the marker gene of the transgenic rice in a plant level is established by utilizing a genome fixed-point editing technology mediated by a CRISPR / Cas9 system. The whole segment of the marker gene can be effectively deleted by utilizing the method, and only an expression frame of the marker gene is deleted pointedly without change of the expression of other components in the transgenic rice. Thus, the transgenic rice without the selection marker gene can be efficiently bred by utilizing the method, so that the safety doubt of people about the selection marker gene can be completely removed.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

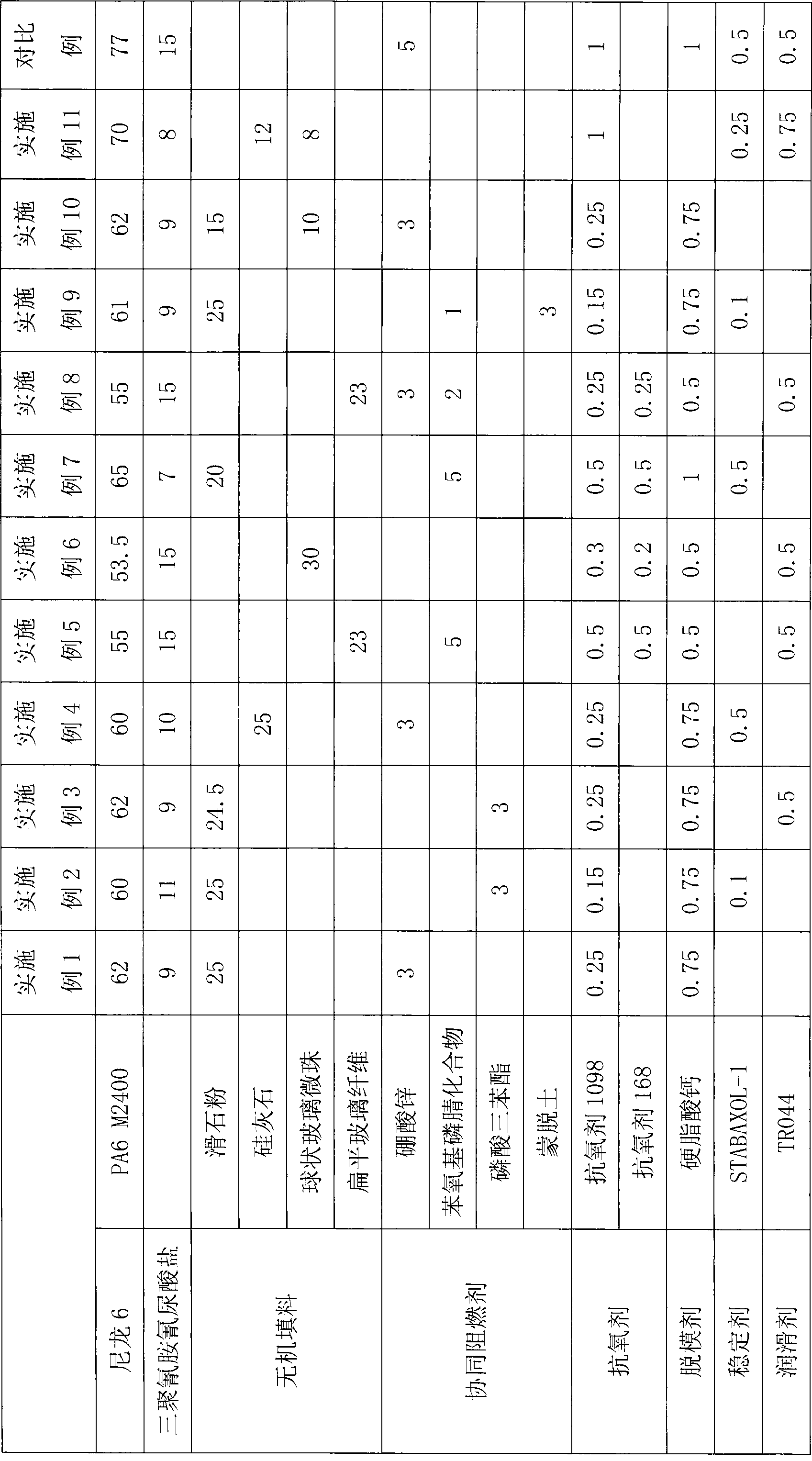

Halogen-free filling flame-retardant nylon 6 composite material and preparation method thereof

The invention provides a halogen-free filling flame-retardant nylon 6 composite material and a preparation method thereof. The halogen-free filling flame-retardant nylon 6 composite material provided by the invention is characterized by being prepared from the following raw materials: 53-70 parts by weight of nylon 6 resin, 7-15 parts by weight of melamine cyanurate, 20-30 parts by weight of inorganic filling material, 0-5 parts by weight of synergistic flame retardant, and 1-5 parts by weight of processing agent. Compared with the prior art, the halogen-free filling flame-retardant nylon 6 composite material provided by the invention has the beneficial effects the halogen-free filling flame-retardant nylon 6 composite material is capable of passing the GWFI (Glow Wire Flammability Index) test at 960 DEG C, also has the characteristics of being low in cost, high in modulus and strength, excellent size stability, environment-friendly, flame-retardant and the like, and has good application prospect.

Owner:SHANGHAI KINGFA SCI & TECH +1

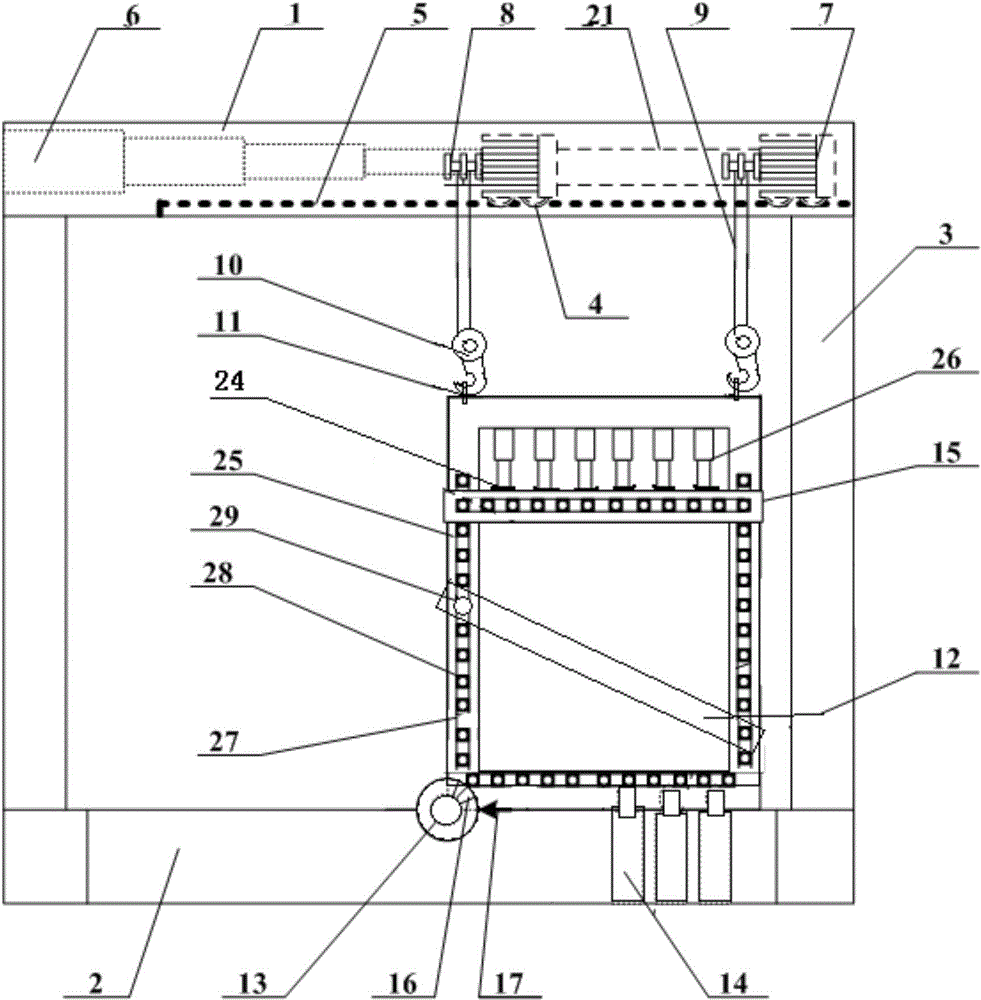

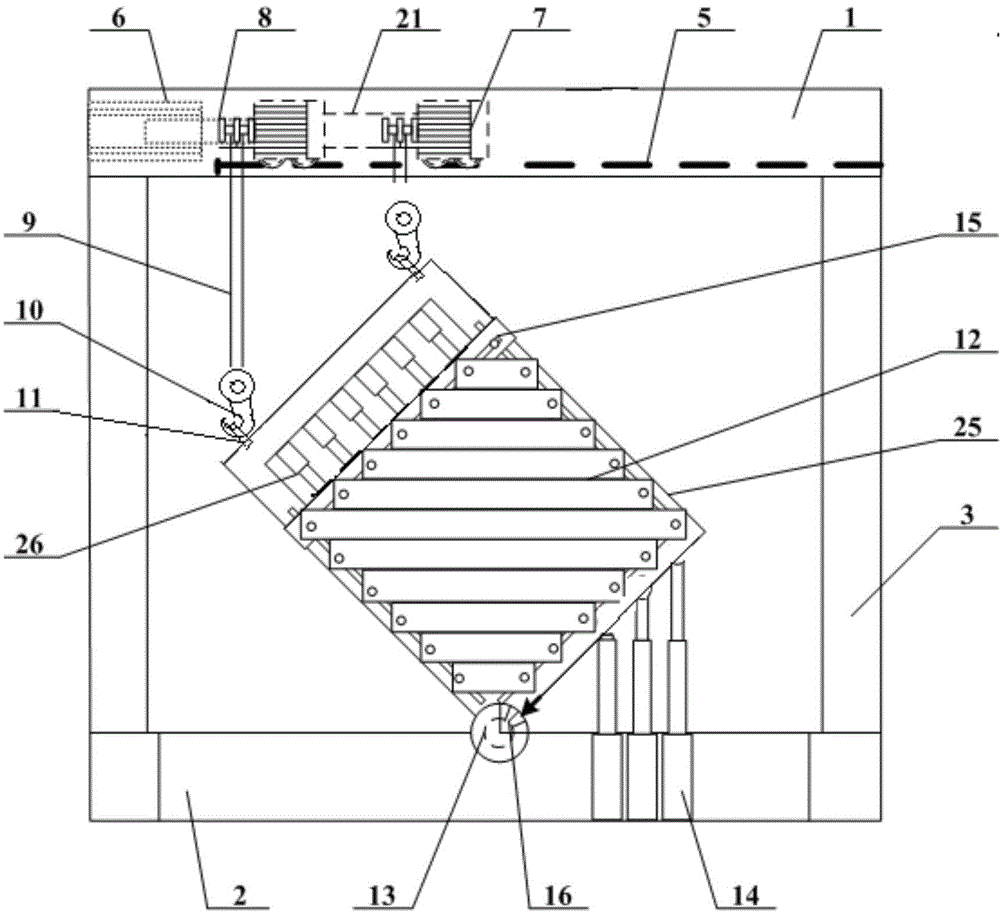

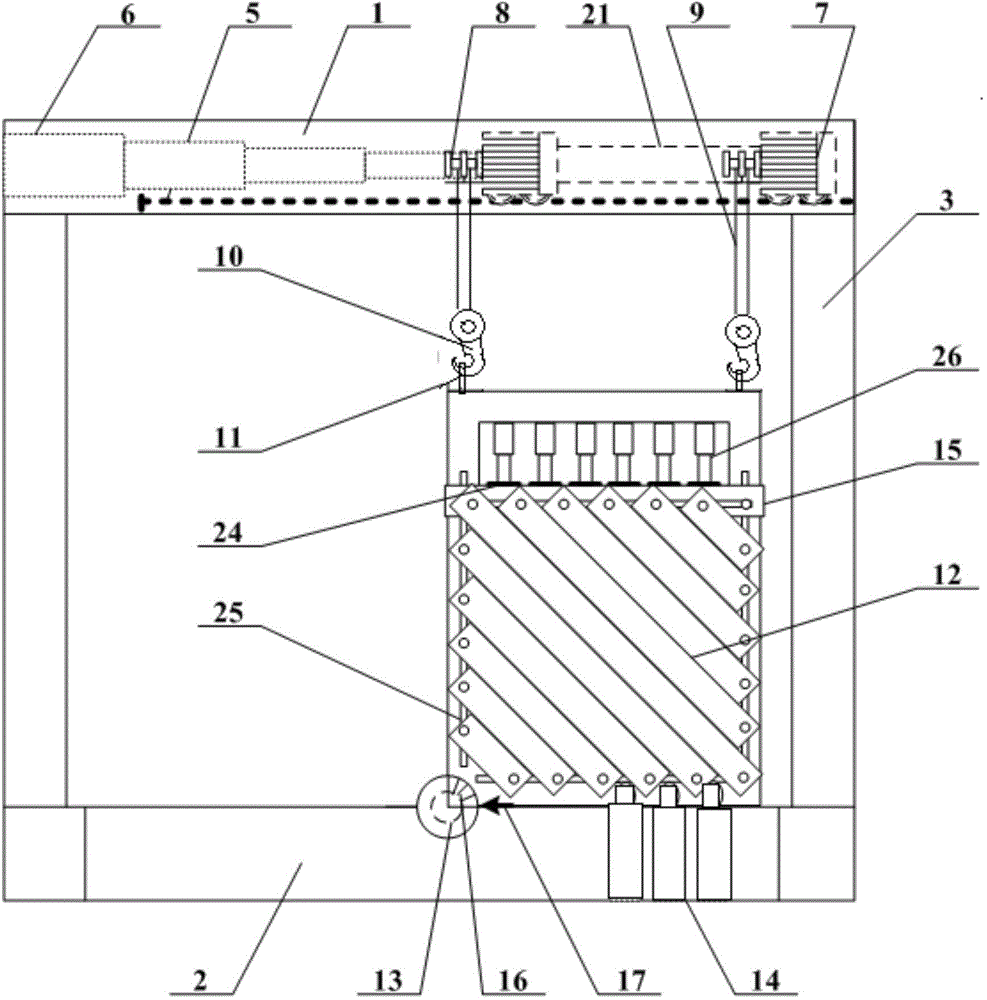

Physical similar simulation test device and physical similar simulation test method for tilted stratums

ActiveCN104596855AGuaranteed balance and stabilityEliminate potential safety hazardsMaterial strength using tensile/compressive forcesUsing optical meansStress distributionComputer science

The invention discloses a physical similar simulation test device and a physical similar simulation test method for tilted stratums. The physical similar simulation test device comprises an external framework, a tiltable rack, a front baffle, a rear baffle, a hydraulic supporting device and a hanging hoisting device, a similar simulation test is performed on stratums with different tilt angles by adopting the device and the method, physical mechanical performances of stress distribution, displacement change and the like inside the stratums under the action of external disturbance, ground stress, external force application and the like can be measured to obtain related technical indexes and parameters so as to research the rule of the true stratums in the process, and the effective struts can be facilitated during the construction of the stratums, thus providing a guarantee for the safety construction of the stratums.

Owner:SHANDONG UNIV OF SCI & TECH

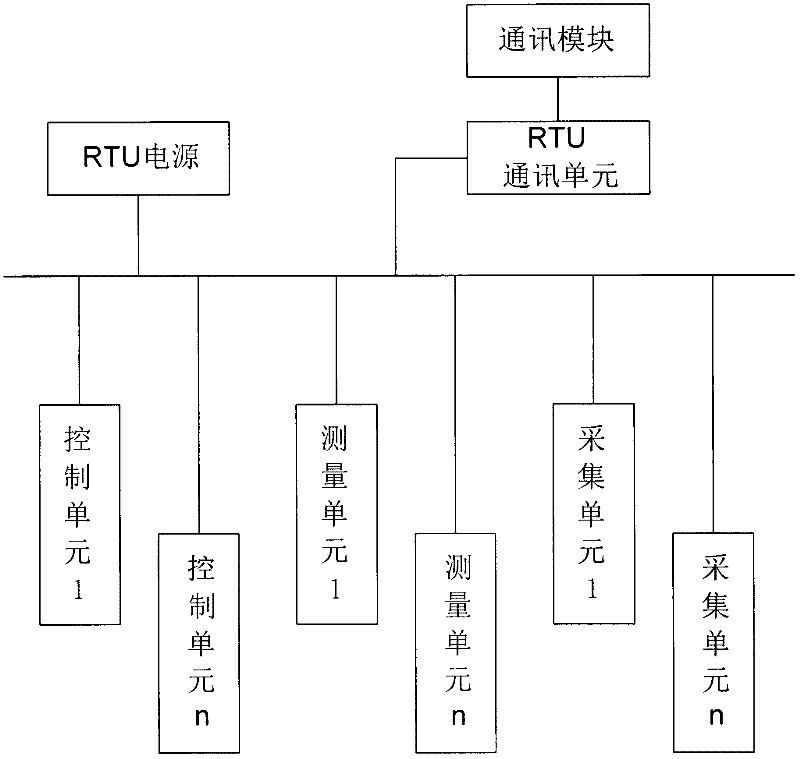

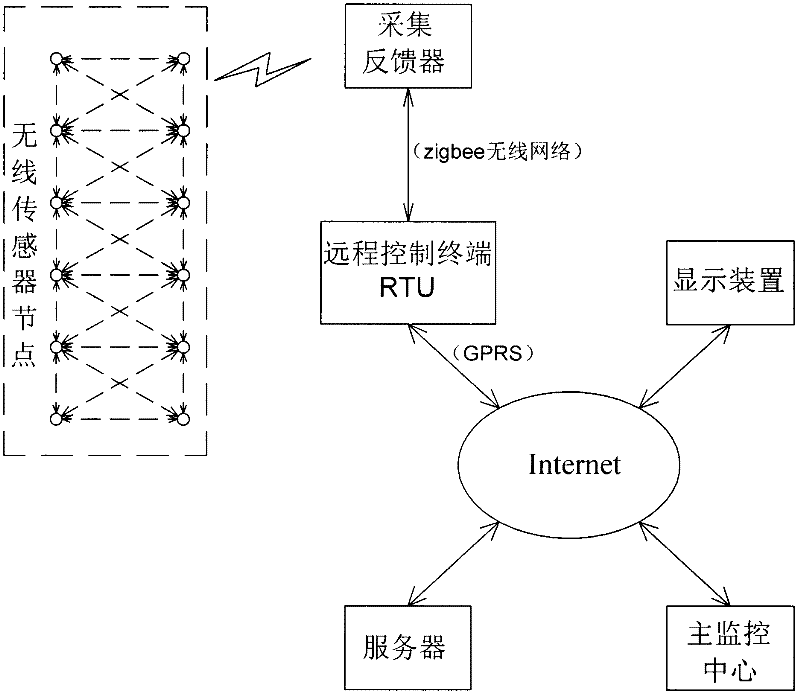

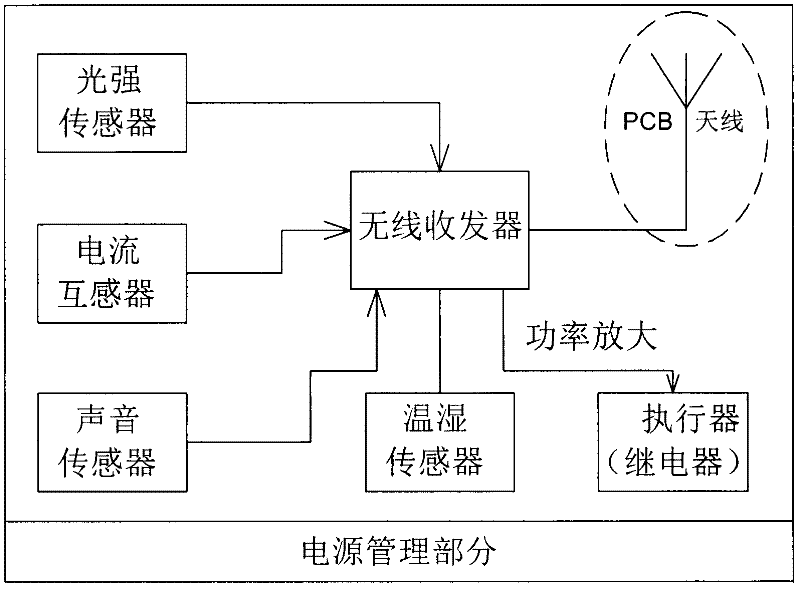

Street lamp energy-saving and managing system based on internet of things

InactiveCN102413611ALow construction costShort cycleEnergy efficient ICTNetwork topologiesGeneral Packet Radio ServiceTransformer

The invention belongs to the technical field of street lamp illumination, and in particular mainly relates to a street lamp energy-saving and managing system based on internet of things. The system mainly consists of a main monitoring center, a remote terminal unit (RTU) and wireless sensor nodes, wherein the wireless sensor node which is responsible for detecting and controlling single lamp street to operate and executing a lamping switching-on and switching-off operation by receiving an instruction sent by the RTU is arranged on each street lamp, the wireless sensor nodes are connected with the RTU through a GPRS (General Packet Radio Service) module, and the RTU arranged at a transformer workstation is respectively connected with the main monitoring center, a server and a display device through Internet. The street lamp energy-saving and managing system disclosed by the invention can realize illumination as required, high efficiency and energy saving and fine management, solves the problems generally existing in the current street lamp monitoring management system and has the advantages of wide application range and suitability for popularization.

Owner:成都智汇科技有限公司

Highly effective straw decomposition composite flora

The invention relates to a biotechnology dealing agricultural discard stem with an highly effective stem decomposing composite bacterial, which dissolves the problem of single species of applying microbiological bacterial, weak breaking up, low total degradability rate of cellulose, long developmental cycle. The composite bacterial comprises the following parts: yellow archespore wool bacterium leather bacterial, mushroom bacterial, haci trichoderma, green trichoderma, coninic trichoderma, aspergillus niger, bacillus subtilis, feed bacillus, bacillus megaterium, candida, distillery yeast, food-yeast, brown sphere azotobacter, thermoactinomyces, and so on. The composite bacterial can overall degrade lignin, cellulose, hemicellulose and other organic material in the stem, has a more than 80% degrading rate, a 10-15 days short cycle, keeps a long time for providing a solid bacteria.

Owner:韩农

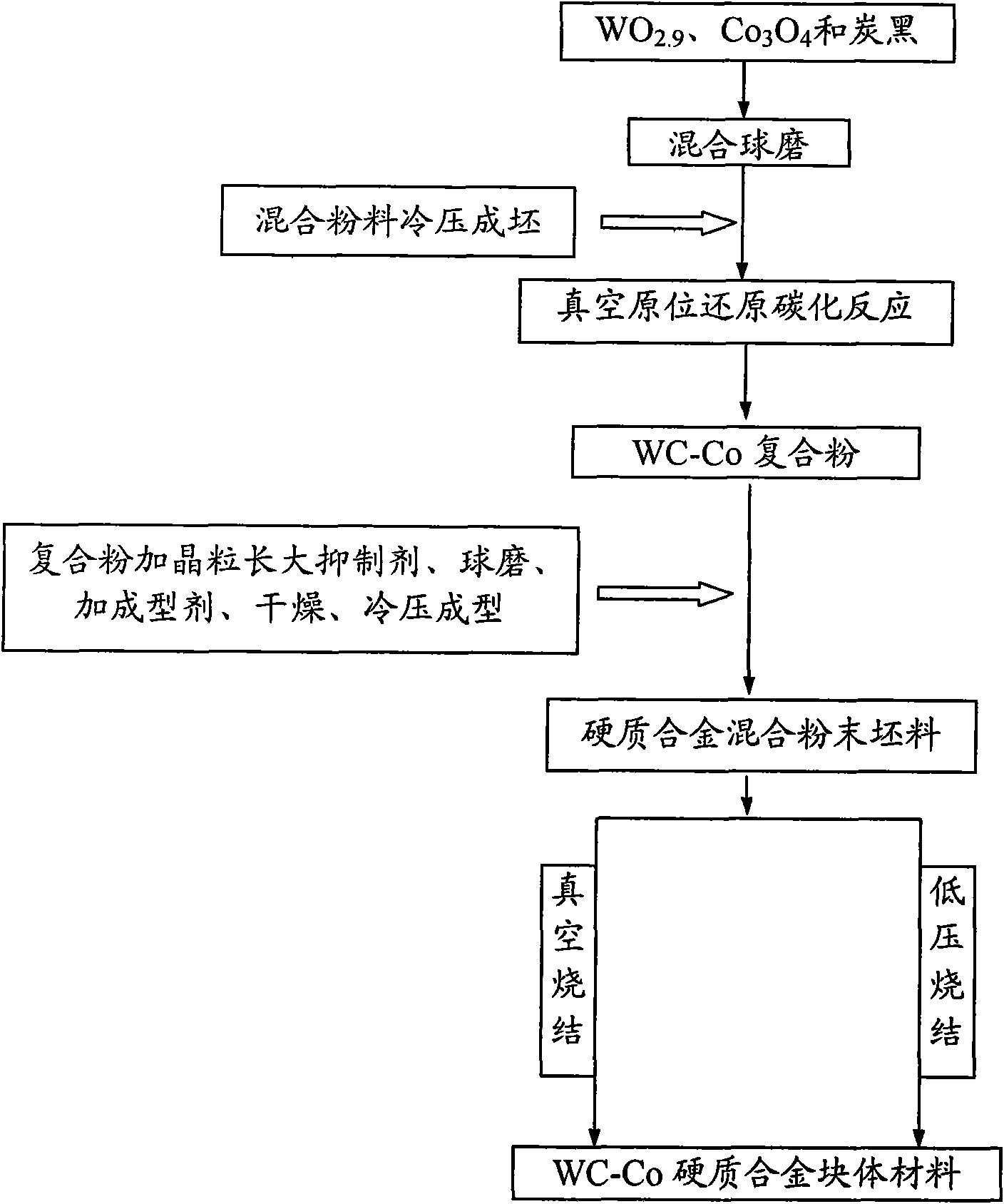

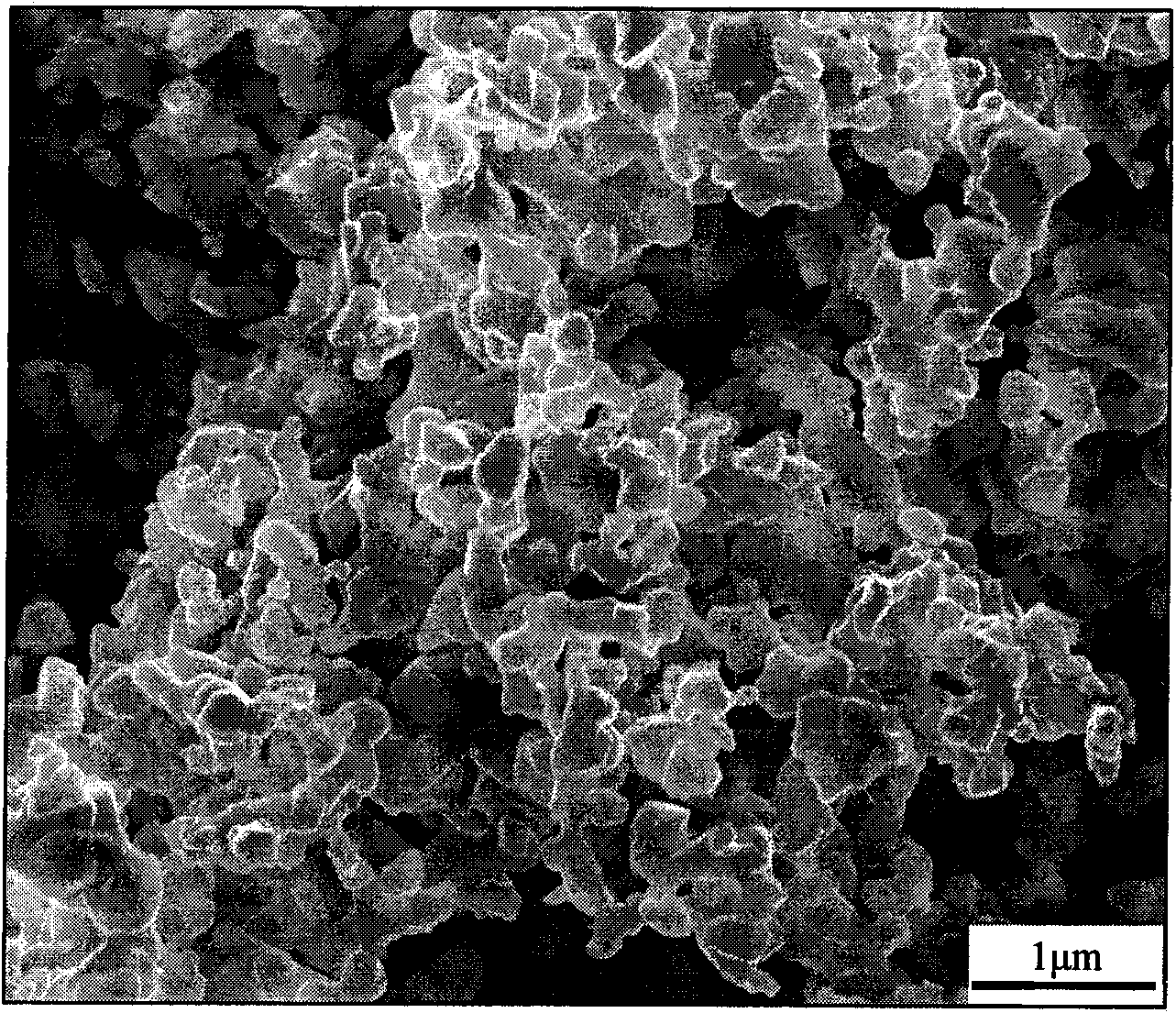

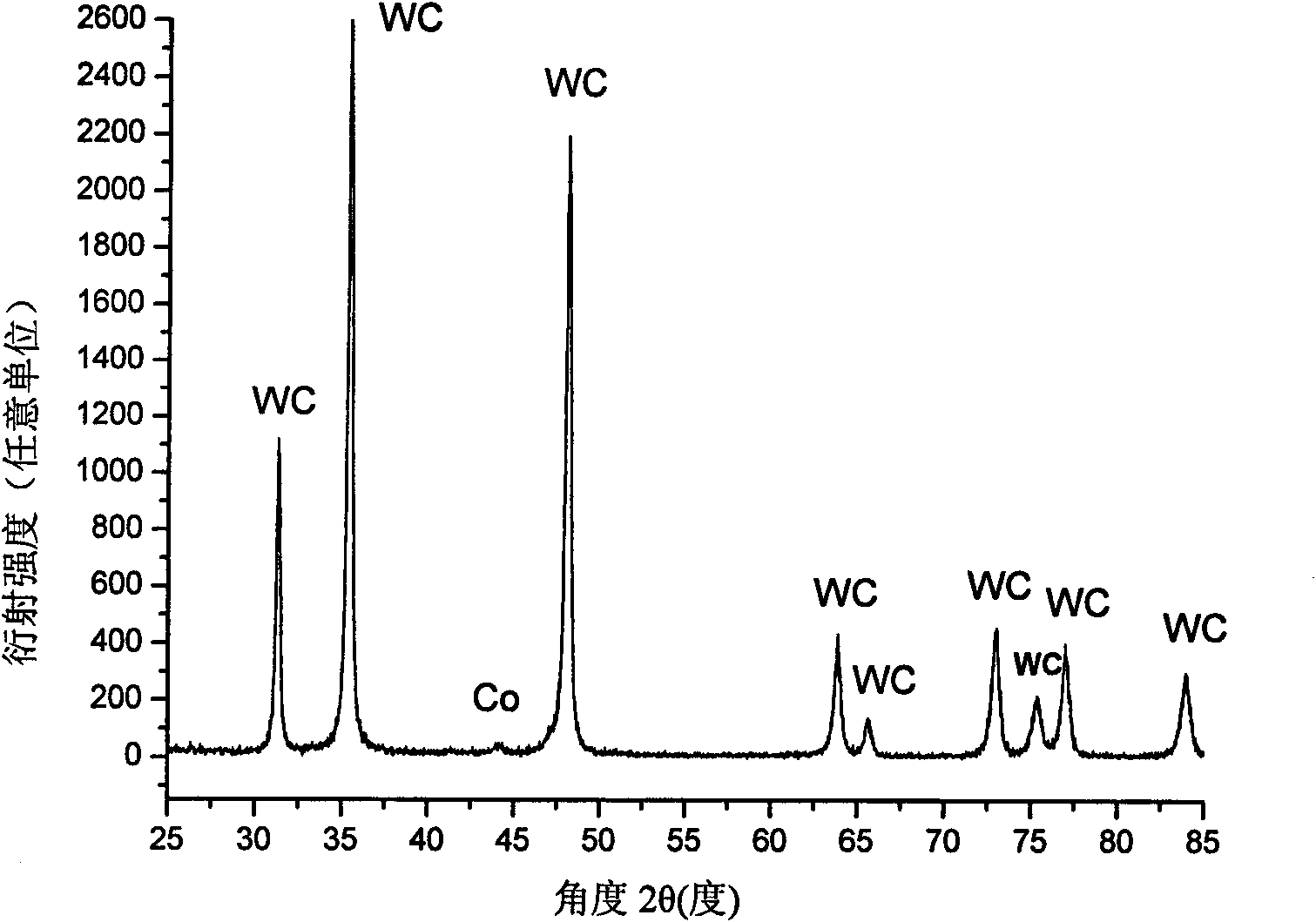

Industrialized preparation method of WC-Co hard alloy with low cost and high performance

ActiveCN101624673ASolve the problem that it is difficult to mix evenlyReduce energy consumptionPolyethylene glycolPrice ratio

The invention relates to an industrialized preparation method of a WC-Co hard alloy with low cost and high performance, which belongs to the technical field of hard alloys and powder metallurgy. The method comprises the following steps: taking WO2.9, Co3O4 and carbon soot as raw materials, and computing the usage ratio of the three materials according to the requirement of the Co content in a final hard alloy block material; adding 0-1.0 percent by weight of grain growth inhibitor into the prepared WC-Co composite powder, and adding polyethylene glycol as a forming agent into a ball milling tank 4-8 hours before ball milling is finished, wherein 30-80ml of polyethylene glycol is added into the powder material per kilogram; acquiring WC-Co mixed powder with a nanocrystal structure after ball milling, and putting the mixed powder into a mould for press forming after vacuum drying; and sintering the mixed powder stock after press forming in a mode of vacuum sintering or low-pressure sintering. The industrialized preparation method markedly shortens a production period, the provided integrated preparation course markedly reduces the production cost while ensuring the high performance of the hard alloy and has a high performance-price ratio, and the preparation method is suitable for industrialized scale production.

Owner:北硬科技香河有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com