Patents

Literature

260 results about "Proportional integral differential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

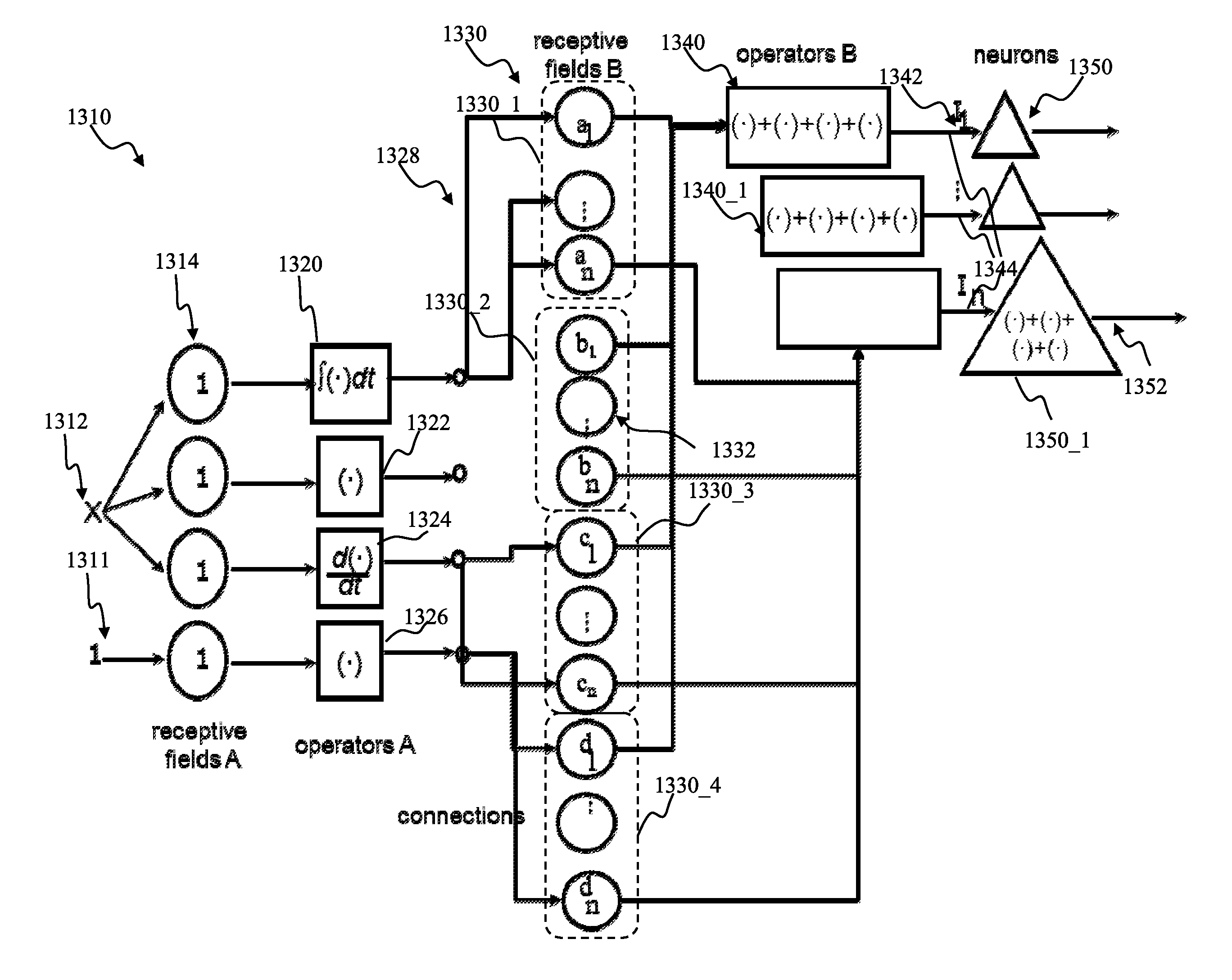

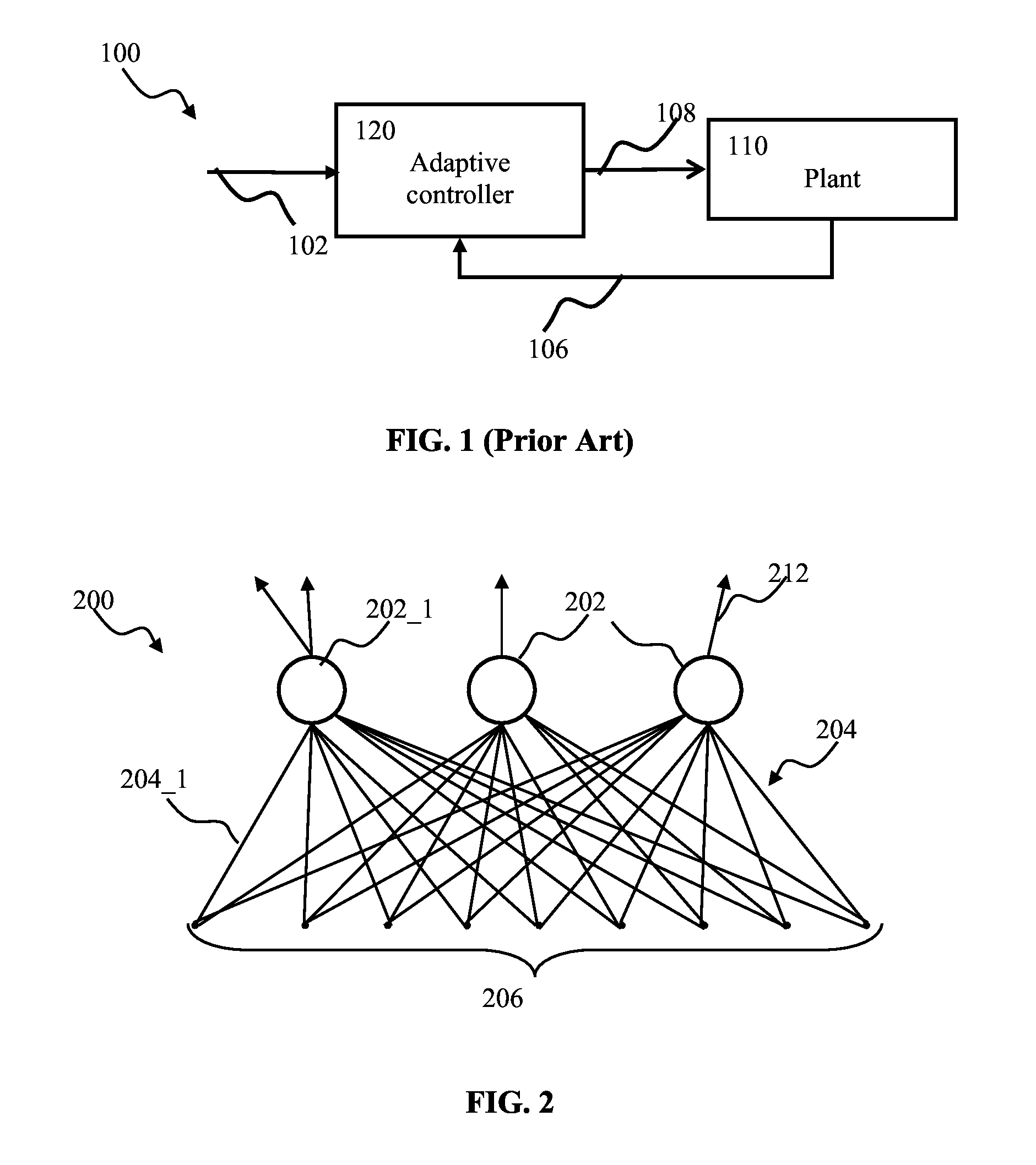

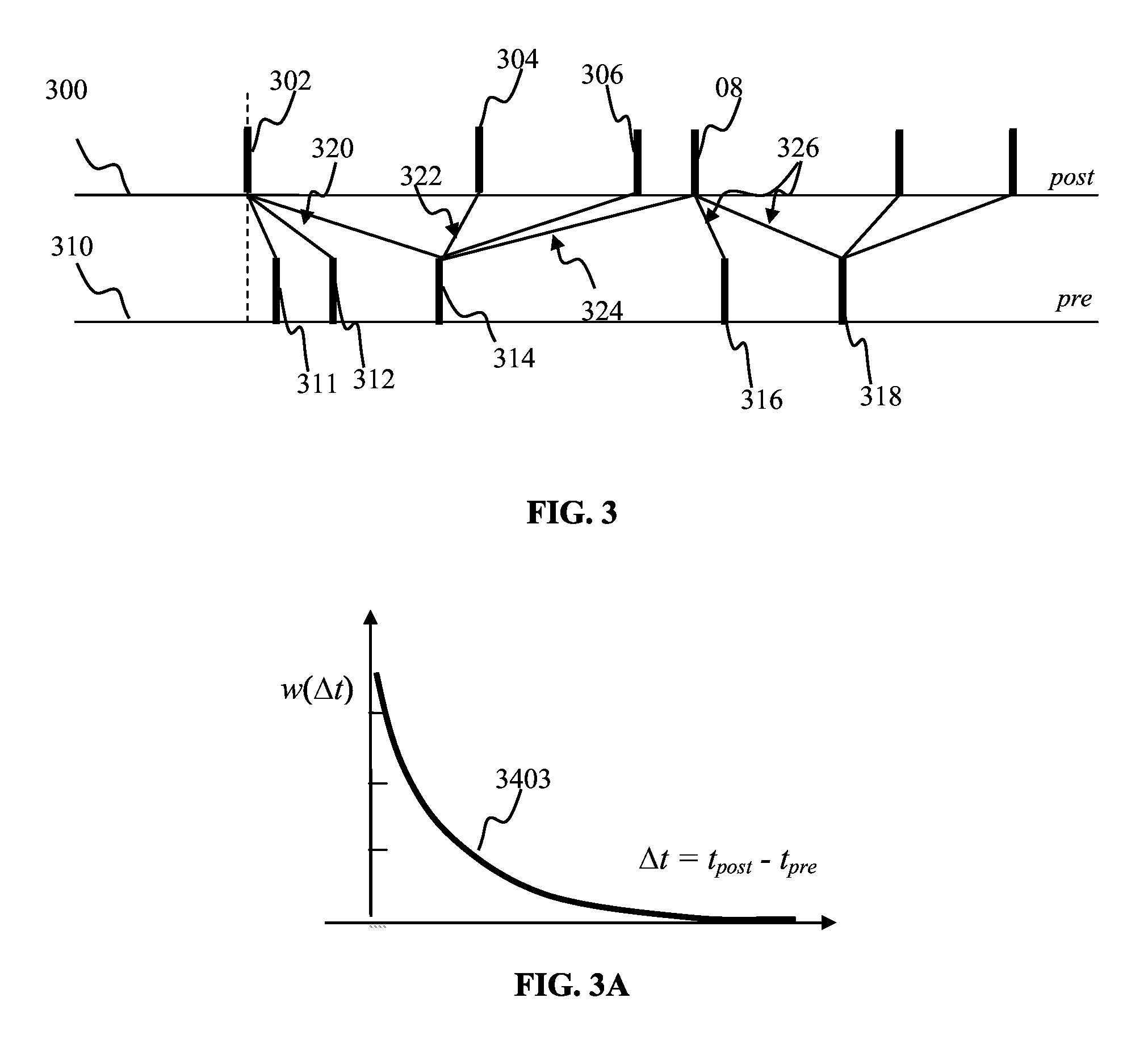

Proportional-integral-derivative controller effecting expansion kernels comprising a plurality of spiking neurons associated with a plurality of receptive fields

ActiveUS9082079B1Improve connection efficiencyEasy to measureDigital computer detailsNeural architecturesNeuron networkControl engineering

Adaptive proportional-integral-derivative controller apparatus of a plant may be implemented. The controller may comprise an encoder block utilizing basis function kernel expansion technique to encode an arbitrary combination of inputs into spike output. The basis function kernel may comprise one or more operators configured to manipulate basis components. The controller may comprise spiking neuron network operable according to reinforcement learning process. The network may receive the encoder output via a plurality of plastic connections. The process may be configured to adaptively modify connection weights in order to maximize process performance, associated with a target outcome. Features of the input may be identified and used for enabling the controlled plant to achieve the target outcome.

Owner:BRAIN CORP

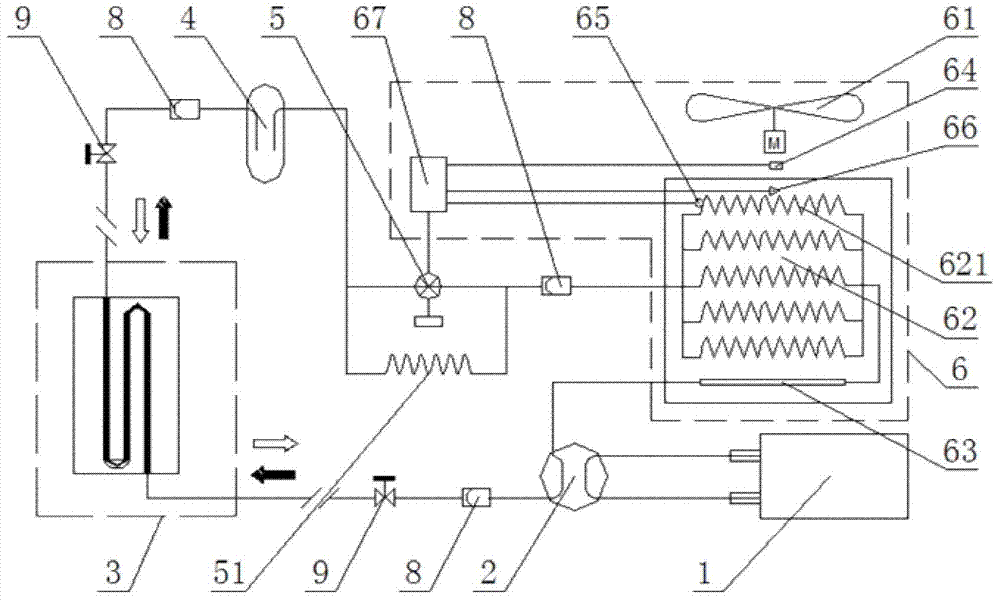

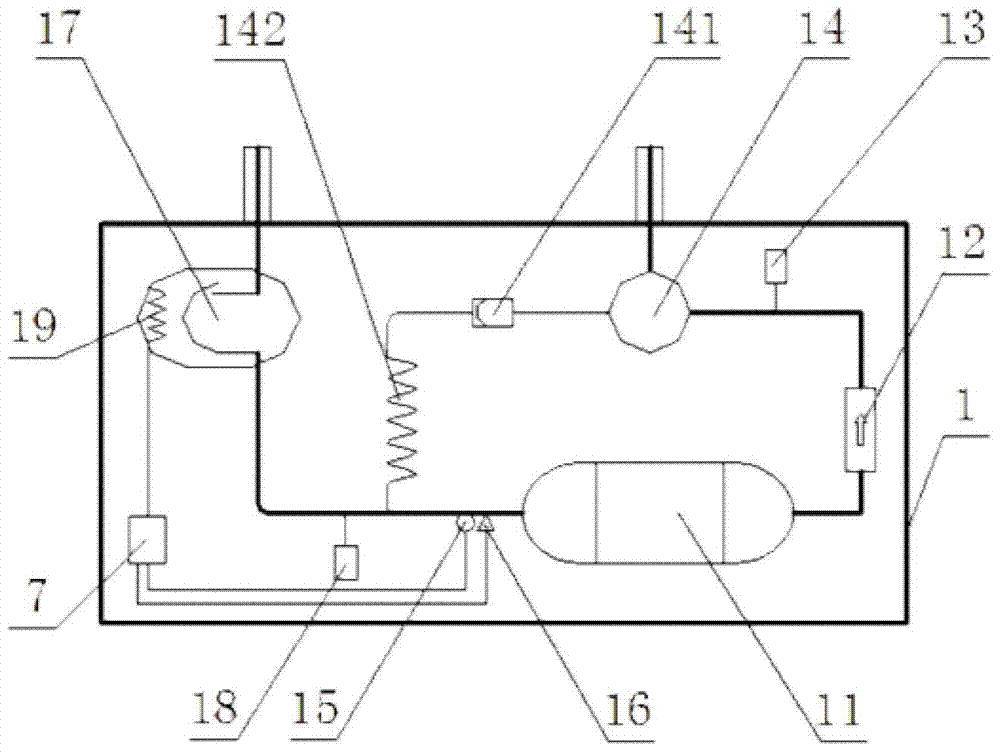

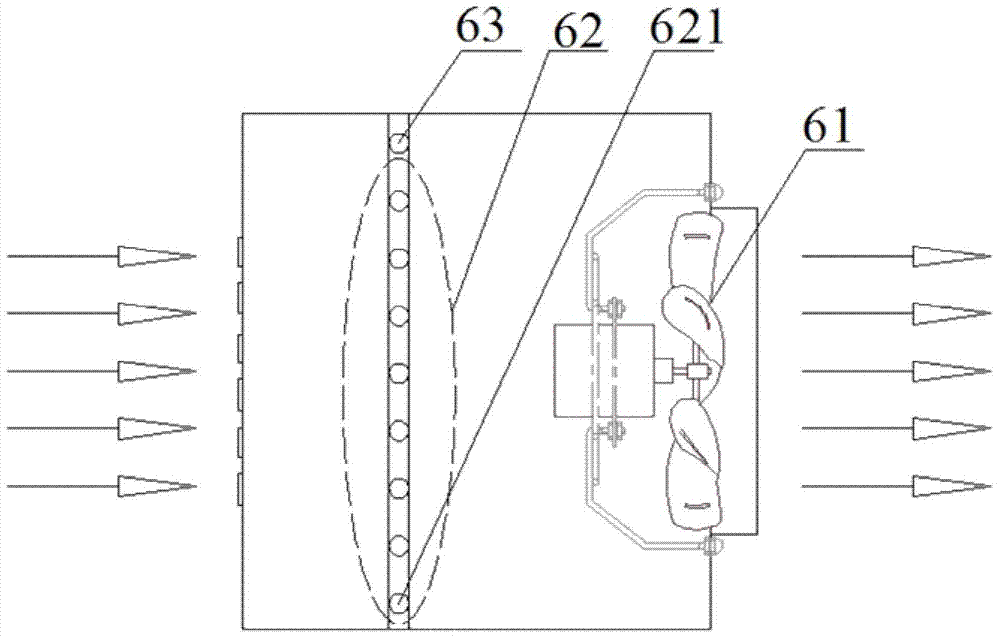

Frost-less air-source heat pump hot water unit and proportional-integral-differential control method for same

InactiveCN103245151AWell mixedImprove performanceFluid heatersCorrosion preventionProportional integral differentialEngineering

The invention discloses a frost-less air-source heat pump hot water unit and a proportional-integral-differential control method for the same. The proportional-integral-differential control method includes performing computation according to received air temperature and humidity parameters, received air pressure parameters and received surface temperature parameters of an evaporator when outdoor temperature parameters which are transmitted by a temperature and humidity sensor and are received by a computation controller are lower than 0 DEG C, controlling the opening of an electronic expansion valve according to a computation result and regulating the surface temperature of the evaporator by means of increasing or reducing the opening of the electronic expansion valve so that the surface temperature of the evaporator is constantly higher than a frost formation point; and enabling a silicon-controlled power regulator to judge a suction superheat degree of a compressor according to received suction temperature and suction pressure of the compressor, increasing or reducing the power of an electric heater and maintaining that the suction superheat degree of the compressor only varies within a set value range. The frost-less air-source heat pump hot water unit and the proportional-integral-differential control method have the advantage that adjustment for the opening of the electronic expansion valve is matched with adjustment for the power of the electronic heater, so that the purpose of maintaining safe and efficient running of a system is achieved.

Owner:NANJING NORMAL UNIVERSITY +1

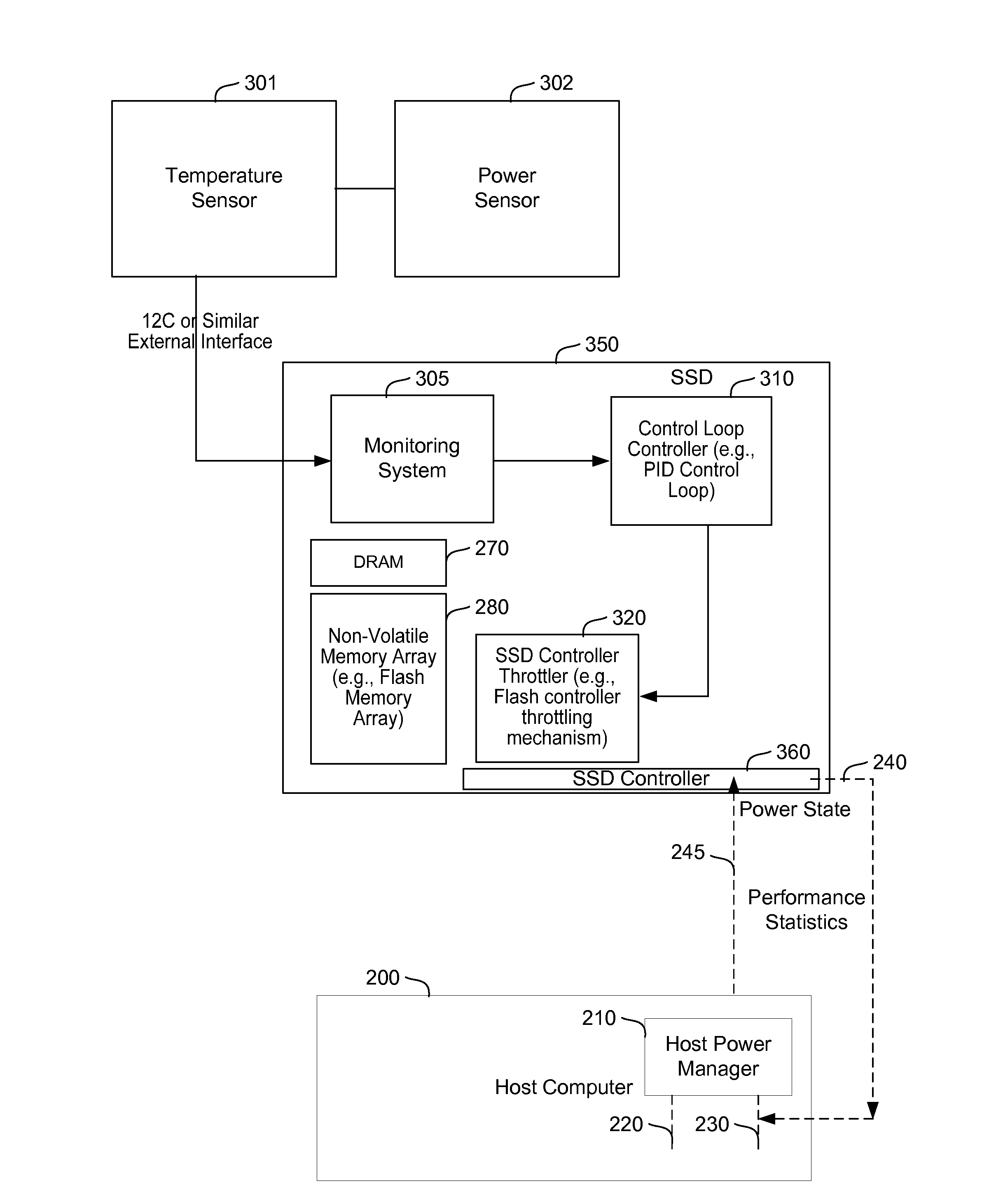

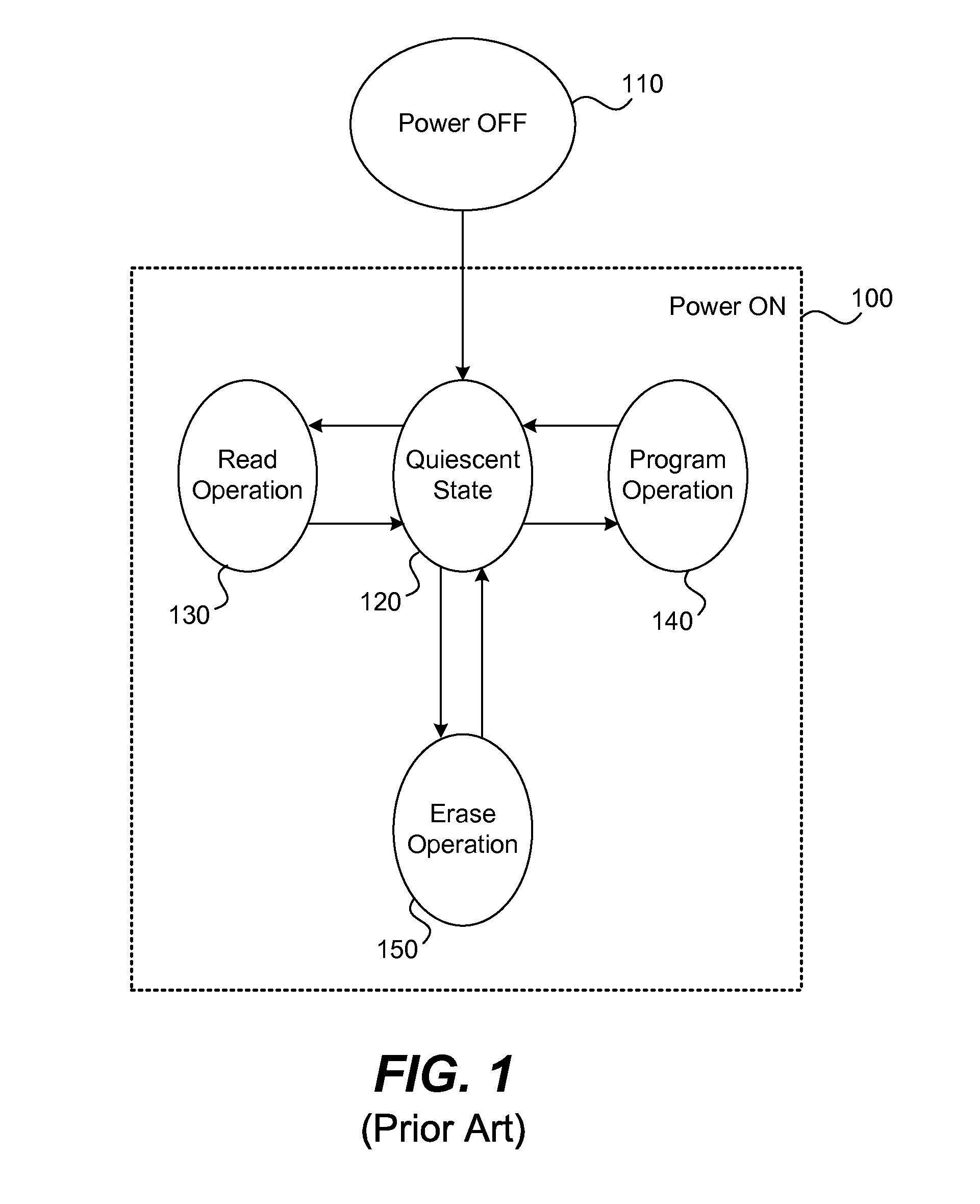

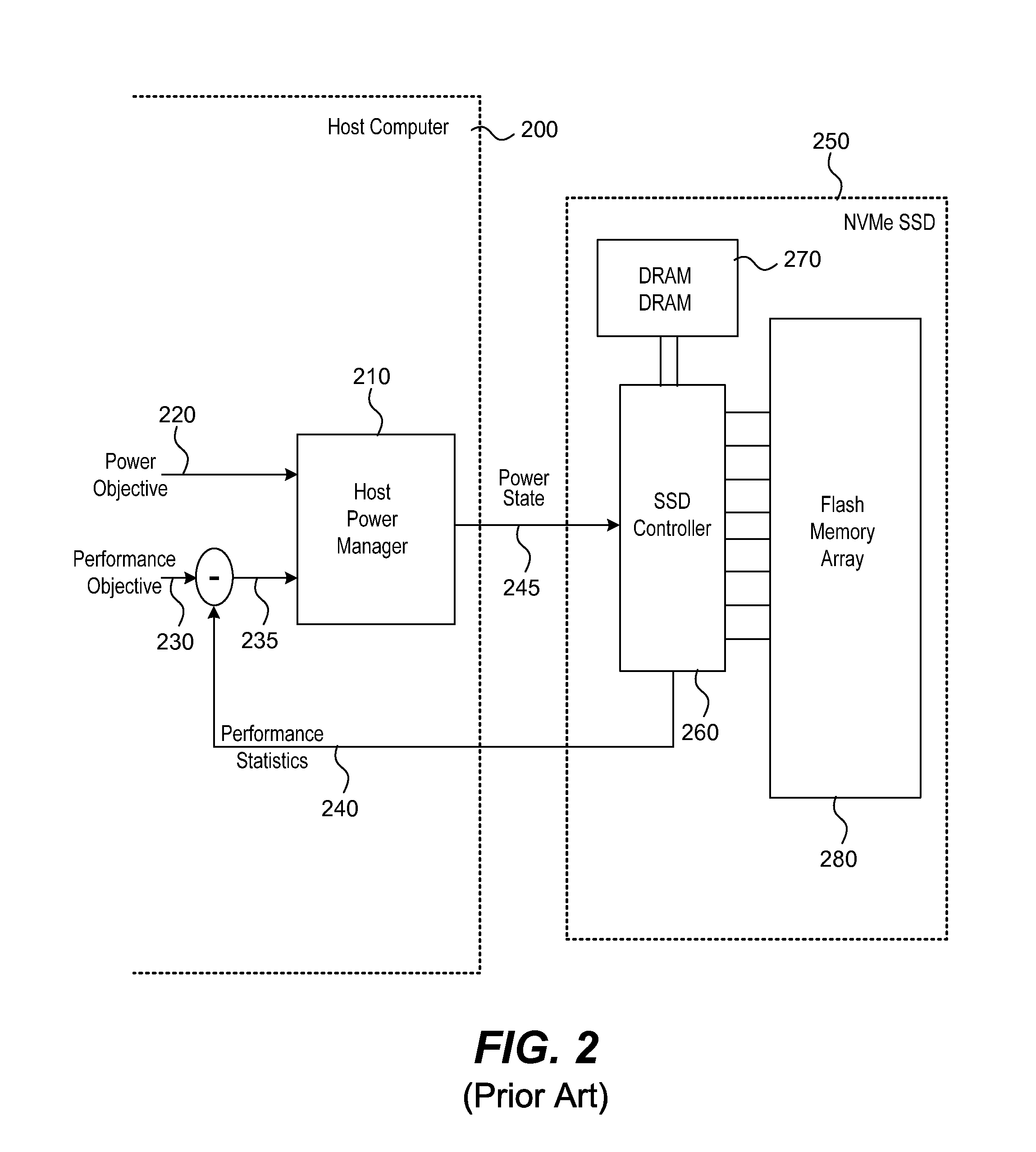

Dynamic power throttling in solid state drives

ActiveUS20160320995A1Input/output to record carriersDigital data processing detailsProportional integral differentialMonitoring system

An apparatus, system, and method is provided to dynamically throttle a solid state drive based on measured local temperature and power measurements. The solid state drive includes a monitoring system to monitor temperature and power. A controller in the solid state drive determines a throttle setting. The controller may be implemented as proportional integral differential (PID) control loop. The throttling may include adjusting the rate of concurrent non-volatile memory operations between a minimum value and a maximum value.

Owner:KIOXIA CORP

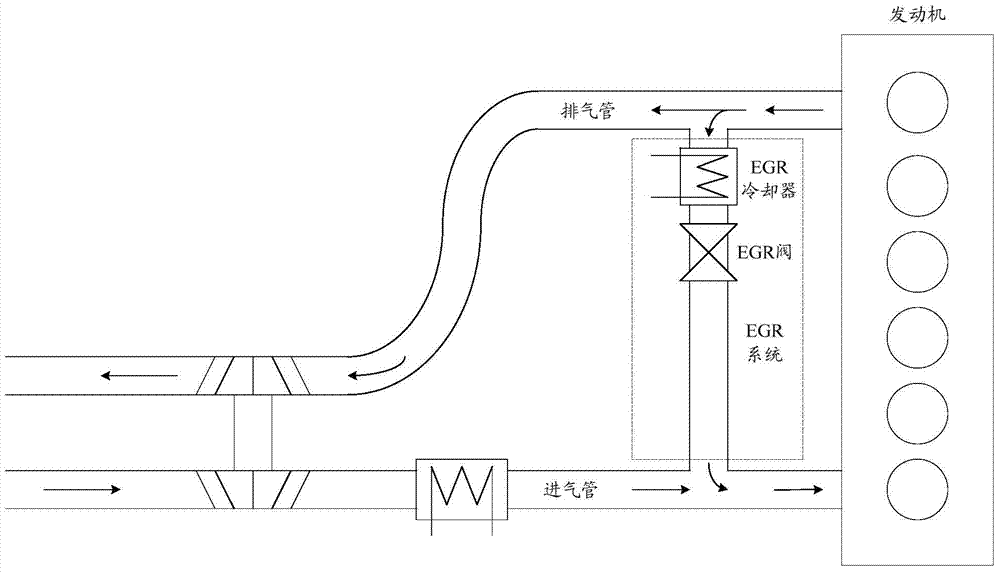

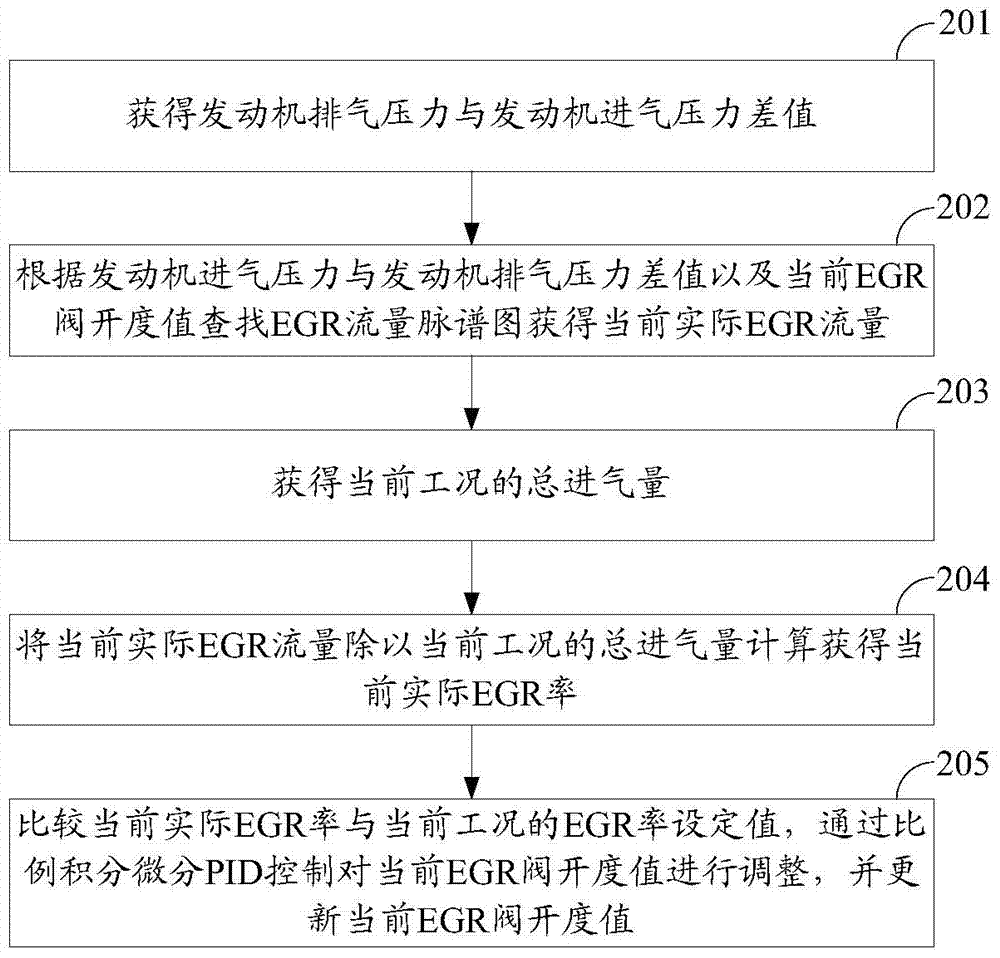

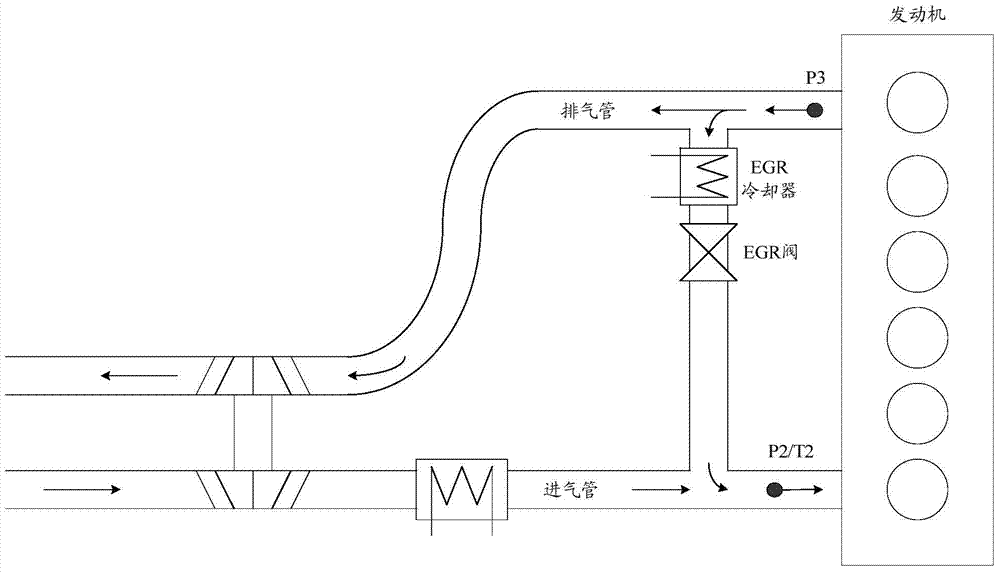

Method for realizing opening control of EGR (Exhaust Gas Recirculation) valve, device and system

ActiveCN103696862AImprove powerImprove economyEngine controllersMachines/enginesProportional integral differentialExhaust gas recirculation

The invention discloses a method for realizing opening control of an EGR (Exhaust Gas Recirculation) valve, a device and a system, which are used for lowering the cost and increasing the accuracy in the opening control of the EGR valve. The method comprises the following steps: acquiring the difference value between the discharge pressure of an engine and the intake pressure of the engine; searching for an EGR flow pulse spectrogram according to the difference value between the discharge pressure of the engine and the intake pressure of the engine and the current opening value of the EGR valve to obtain the current practical EGR flow; acquiring the total air inflow under a current working condition; dividing the current practical EGR flow by the total air inflow under the current working condition to obtain the current practical EGR rate; comparing the current practical EGR rate with an EGR rate set value under the current working condition, adjusting the opening value of the EGR valve through proportional-integral-differential (PID) control, and updating current opening value of the EGR valve.

Owner:WEICHAI POWER CO LTD

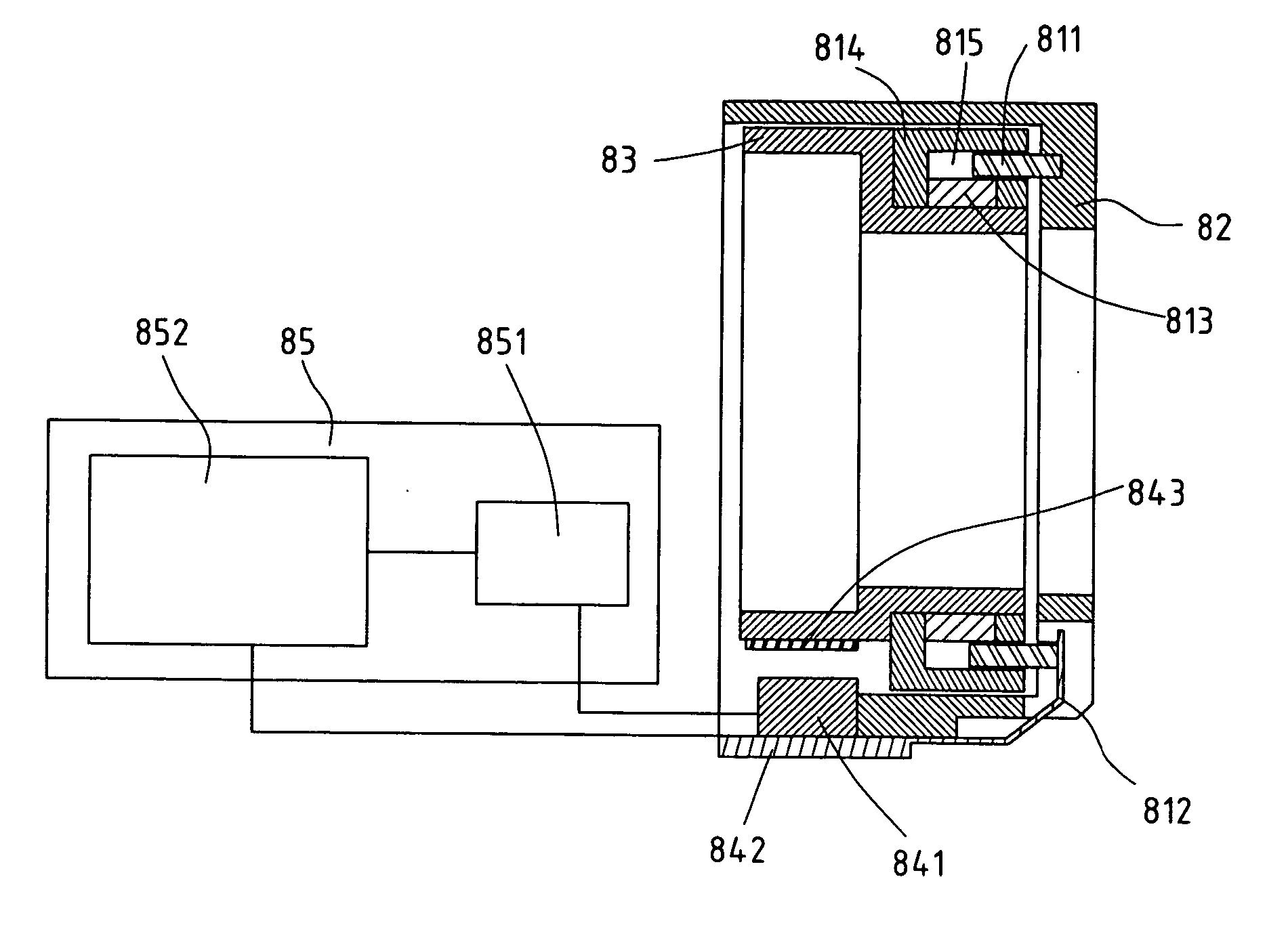

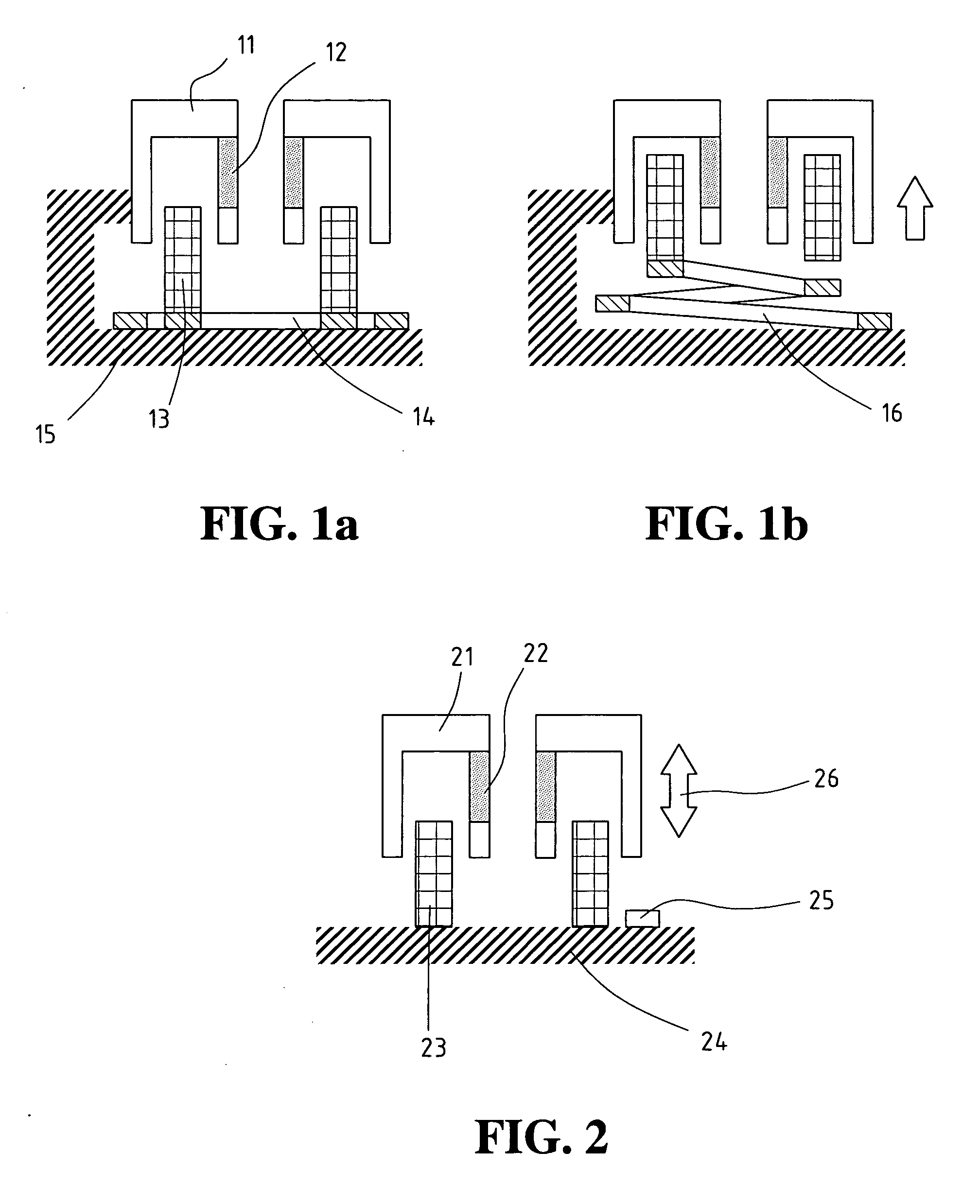

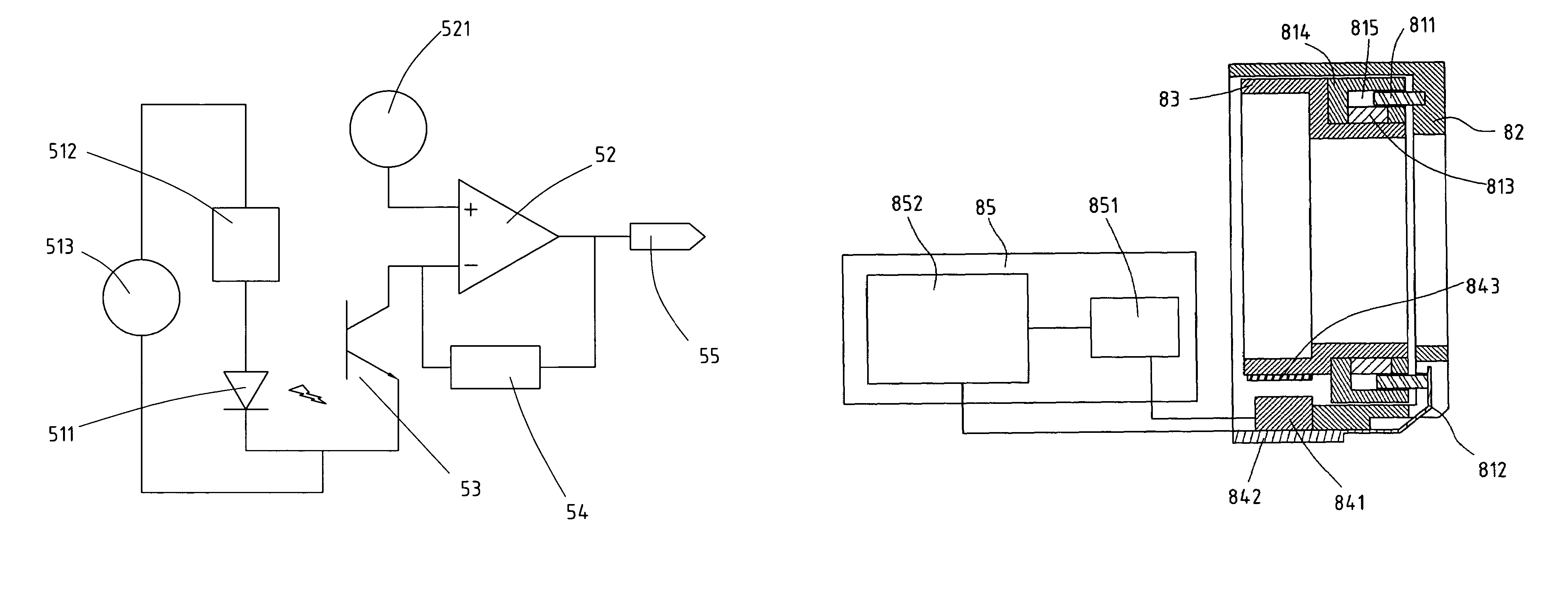

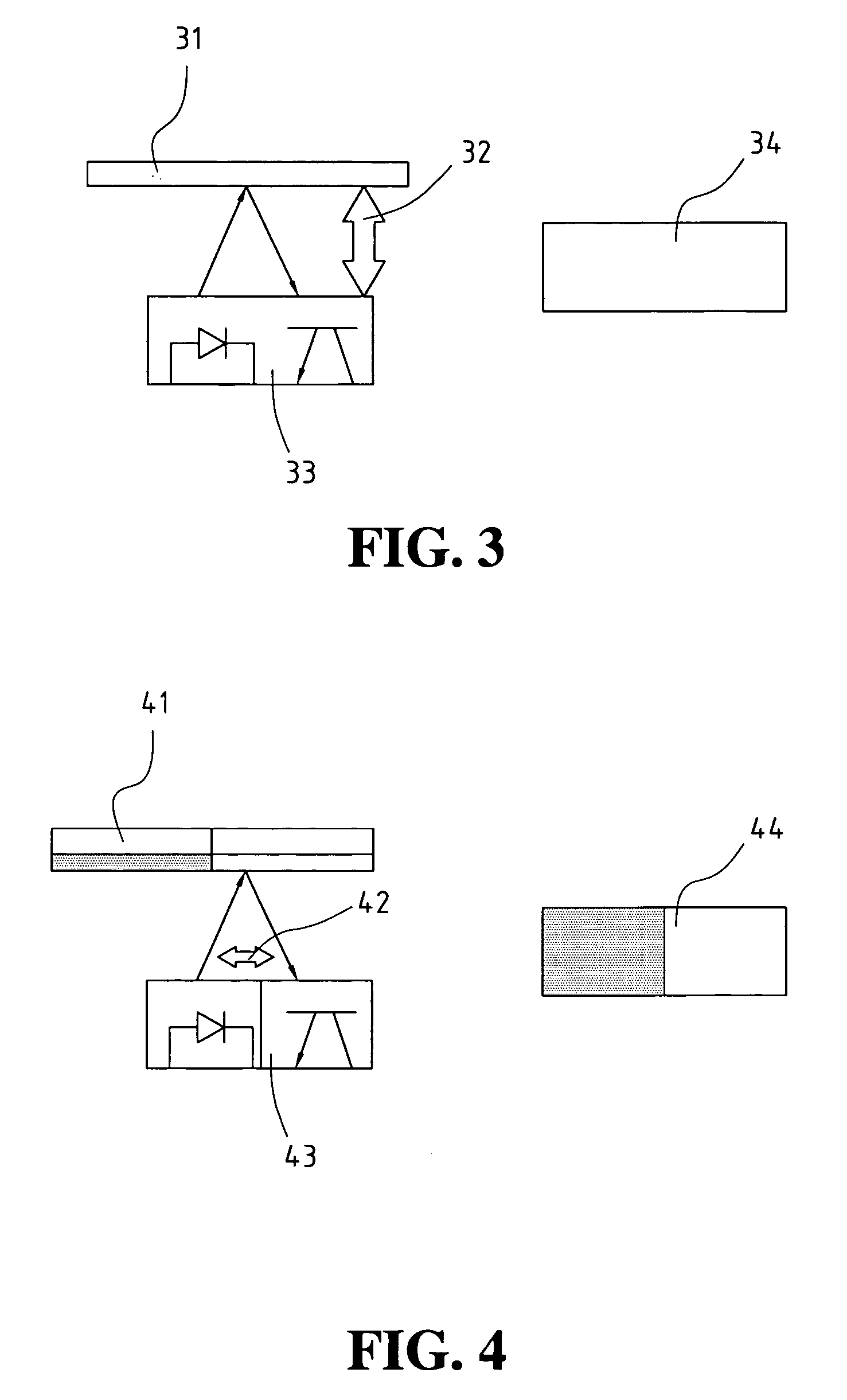

Voice coil motor apparatus for positioning

InactiveUS20060055252A1Precise positioningSpace minimizationAC motor controlDC motor speed/torque controlProportional integral differentialPower cable

A voice coil motor apparatus for positioning is disclosed. The voice coil motor is used by the auto-focus lens control module of a miniature camera. The apparatus contains a voice coil motor, a position feedback sensor, and a positioning controller. The voice coil of the voice coil motor can be either movable or stationary, where in the former case the attached power cable is a flexible circuit board, and in the latter case the power cable is fixed. The position feedback sensor includes a photo interrupter, a light reflector, and a bias circuit used for tracking any displacement of the movable part of the motor. The positioning controller uses the voltage signals to be processed through a proportional-integral-differential computation unit to manipulate an output current for accurate positioning of the movable part of the motor within a prescribed range.

Owner:VASSTEK INT

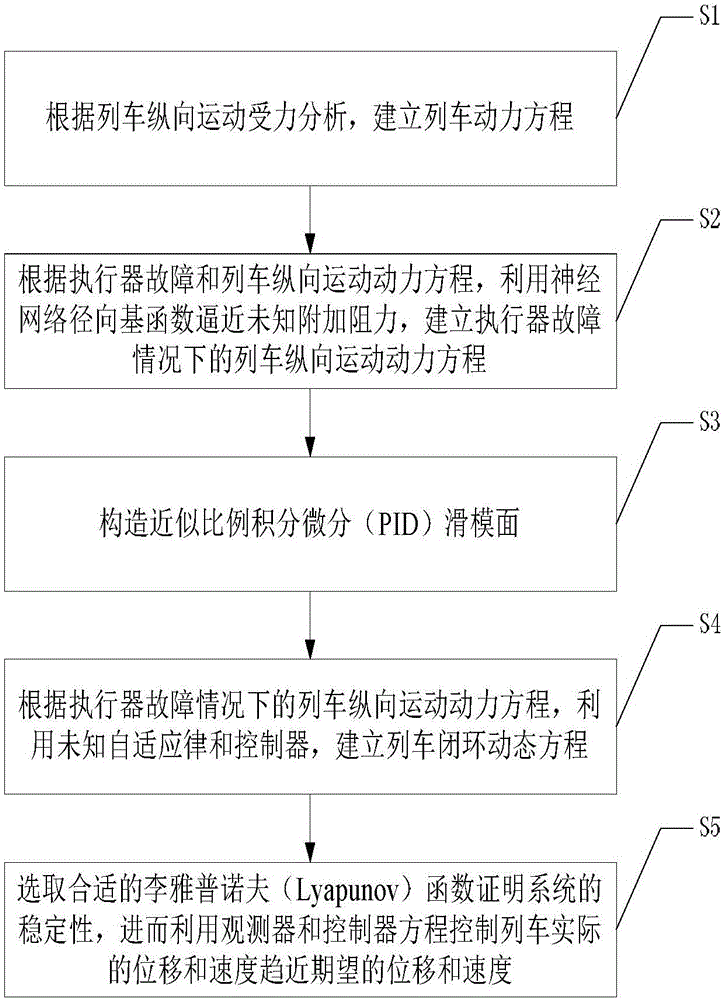

Nerve self-adaption fault-tolerant control method for train unknown perturbation

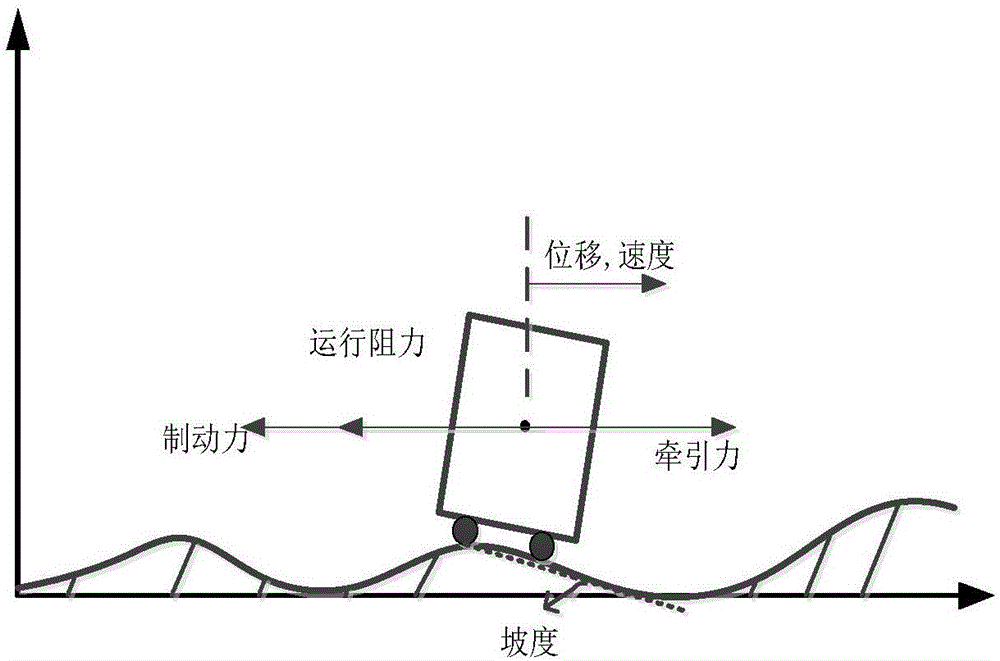

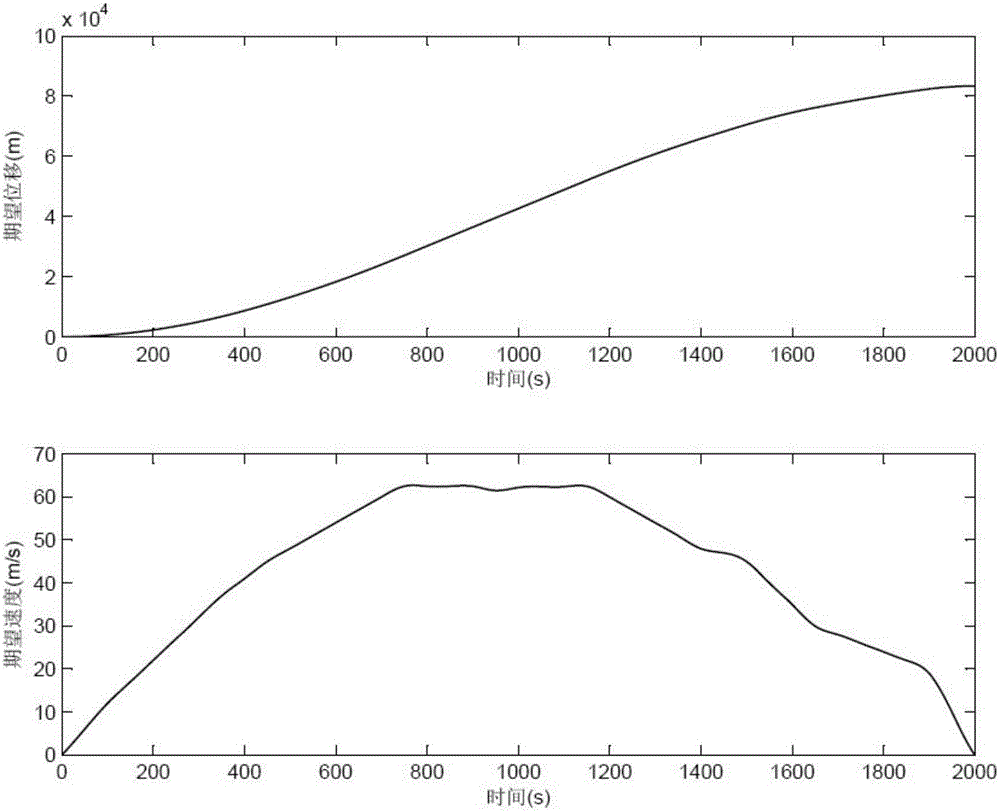

ActiveCN106249591ACompensation effectAttenuate or remove influenceAdaptive controlProportional integral differentialMotion dynamics

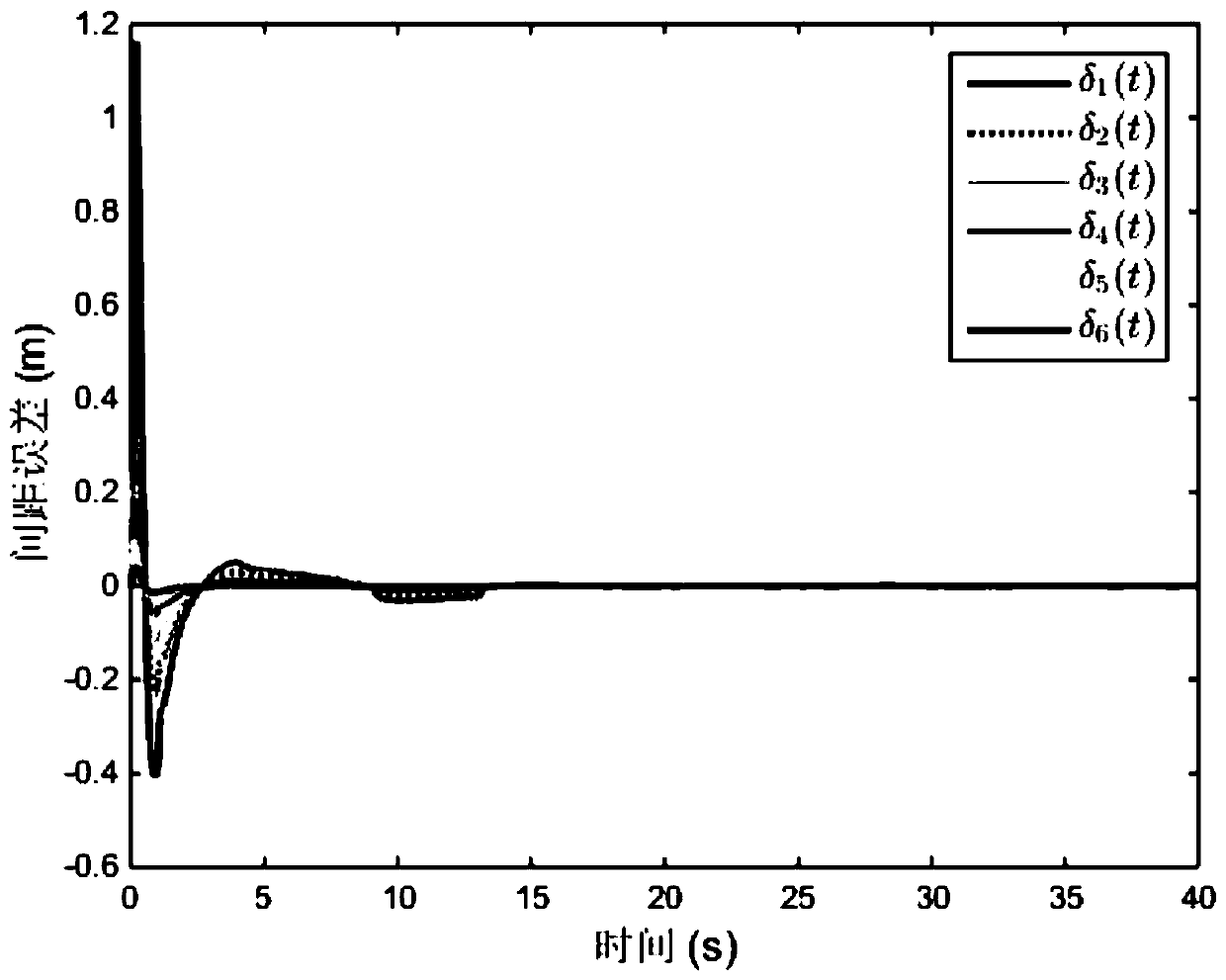

The invention relates to a nerve self-adaption fault-tolerant control method for train unknown perturbation. Based on the stress analysis of the longitudinal motion of a train, the longitudinal motion dynamic equation of the train is established. According to an actuator fault and the longitudinal motion dynamic equation of the train, a neural network radial basis function is used to approximate unknown additional resistance. The longitudinal motion dynamic equation of the train in the case of the actuator fault is established, and then a proportional-integral-differential sliding-mode surface is constructed. According to the longitudinal motion dynamic equation of the train in the case of the actuator fault, the closed-loop dynamic equation of train is established through an unknown self-adaption law and a controller. The stability of the system is proved, and then an observer and a controller equation are used to control the actual displacement and velocity of the train to approach expected displacement and velocity. According to the invention, the influence of the actuator fault on the train system can be compensated; the influence of additional resistance on the train system is attenuated or removed; and the train system has a good position and velocity tracking performance.

Owner:BEIJING JIAOTONG UNIV

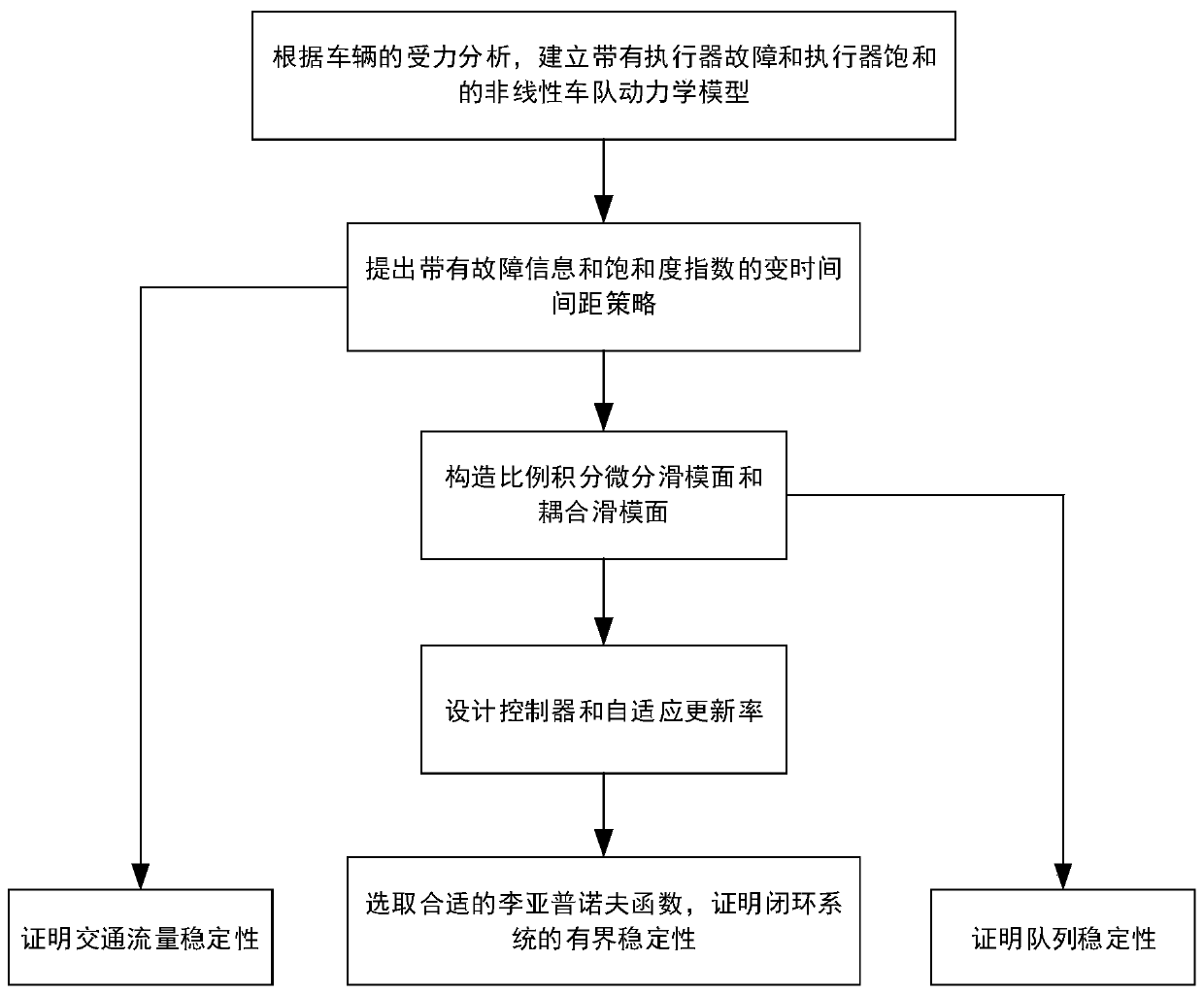

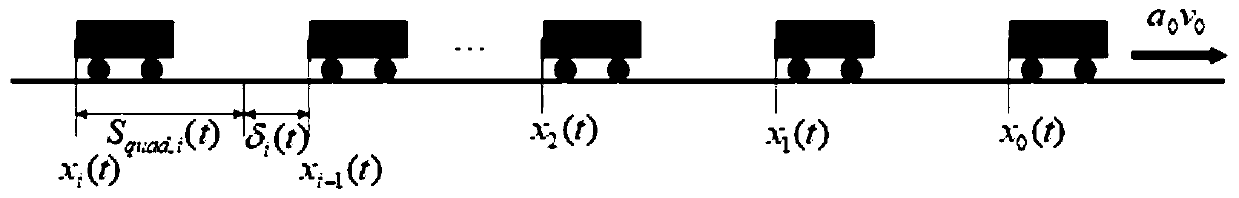

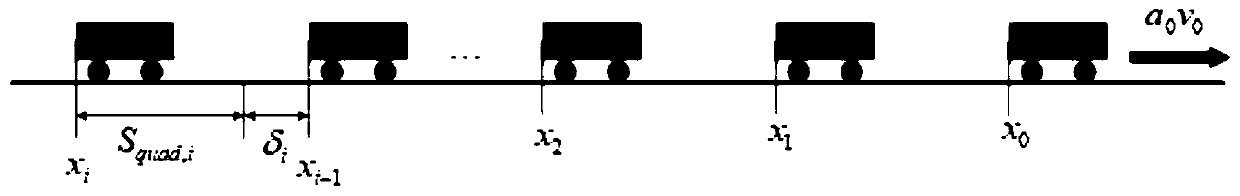

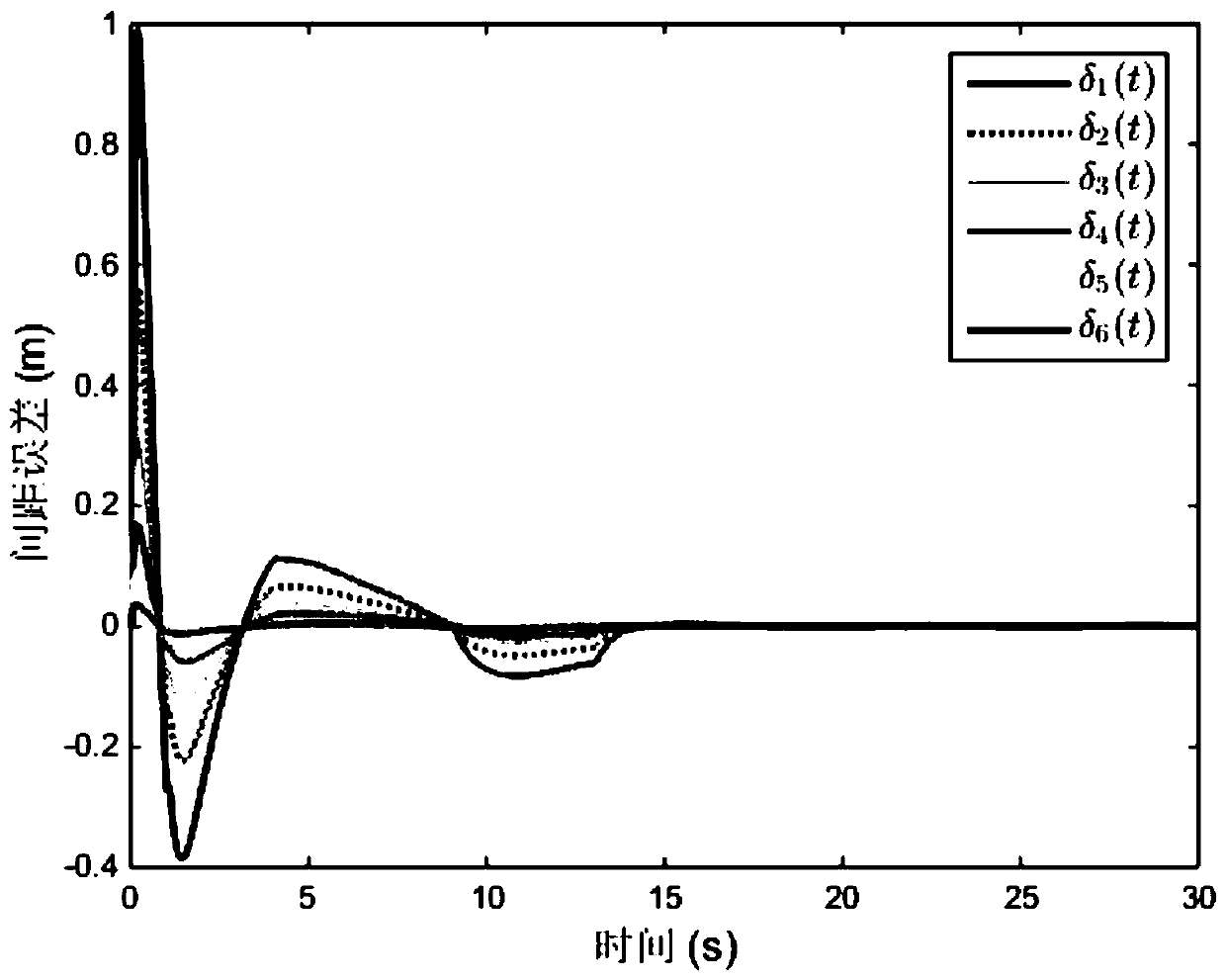

Heterogeneous vehicle team fault-tolerant control method based on actuator faults and saturation

ActiveCN110244747AGuaranteed stabilityGuaranteed uptimeAdaptive controlPosition/course control in two dimensionsProportional integral differentialTraffic capacity

The invention provides a heterogeneous vehicle team fault-tolerant control method based on actuator fault and saturation. The method comprises the following steps: carrying out stress analysis on longitudinal movement of vehicles, and by combining actuator fault and saturation models, building a vehicle longitudinal dynamics model under the actuator fault and saturation; according to information of the vehicles, constructing a variable time interval strategy with fault information and a saturation index; and based on the constructed variable time interval strategy, establishing a proportional integral differential sliding mode surface and a coupling sliding mode surface; and selecting a proper Lyapunov function, designing a fault-tolerant controller and an adaptive updating rate, and proving the limited time stability of a system. Compared with a traditional variable time interval strategy, the variable time interval strategy with the fault information and the saturation index not only can solve the problem of non-zero initial interval error but also can expand critical traffic capacity.

Owner:DALIAN MARITIME UNIVERSITY

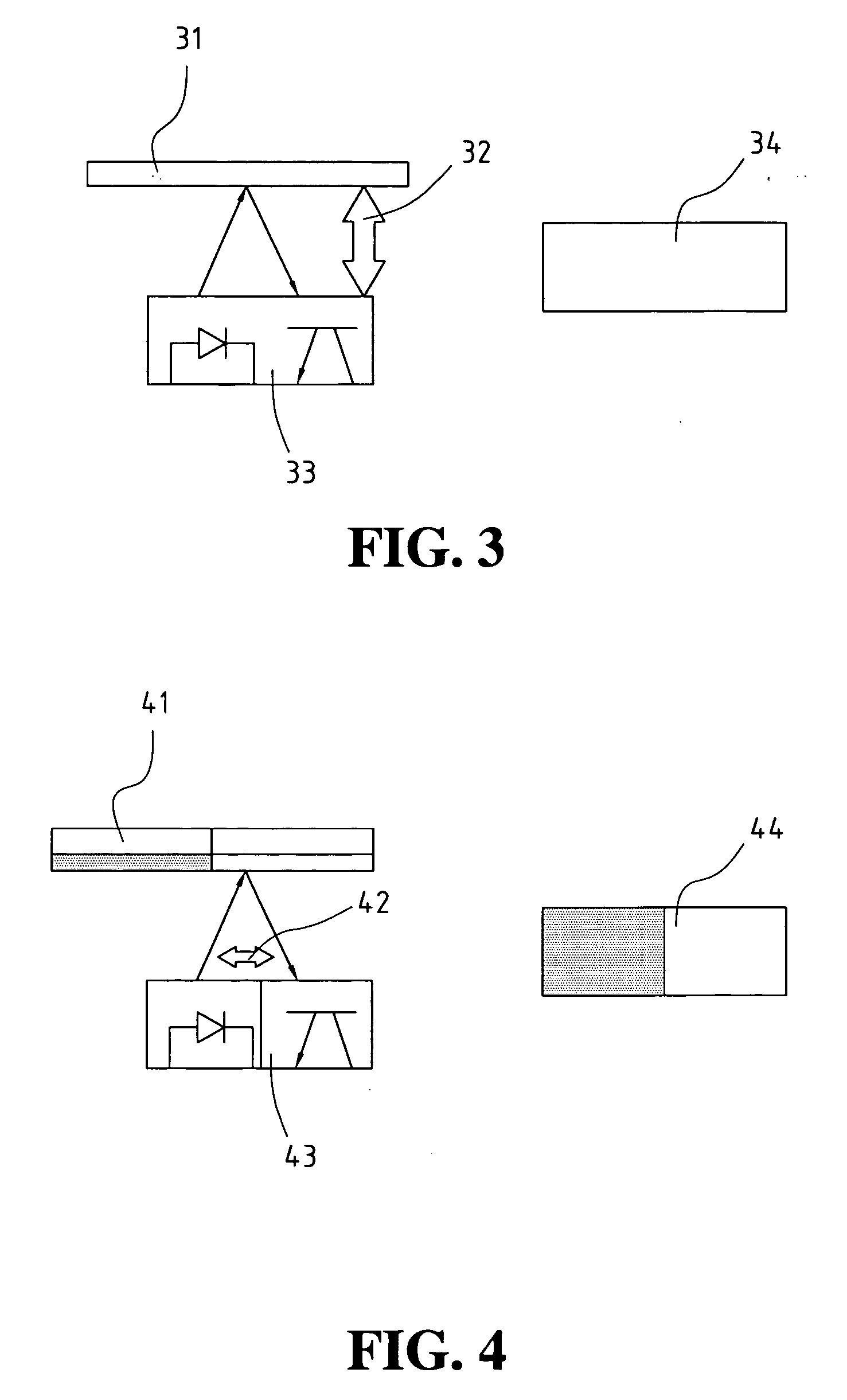

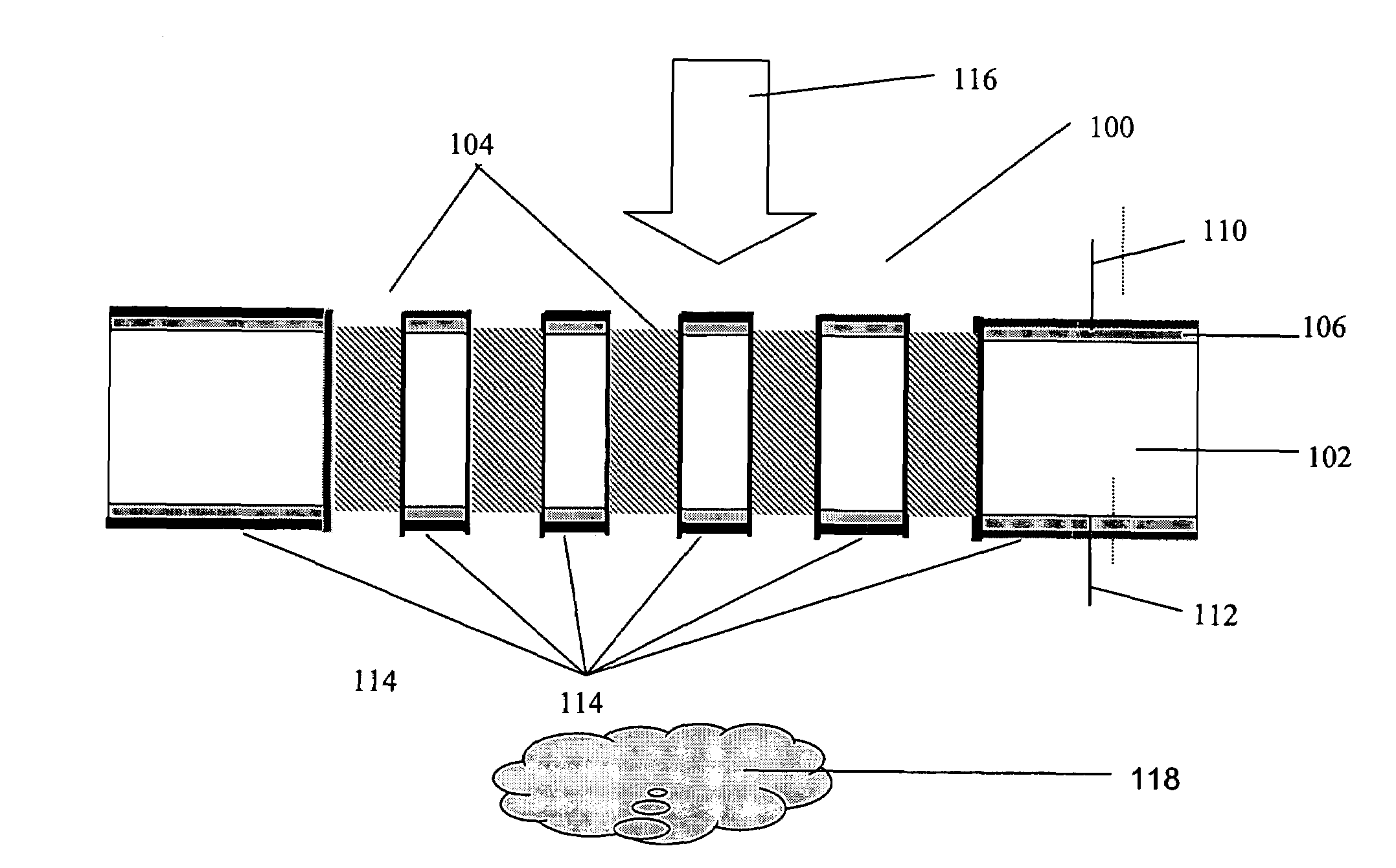

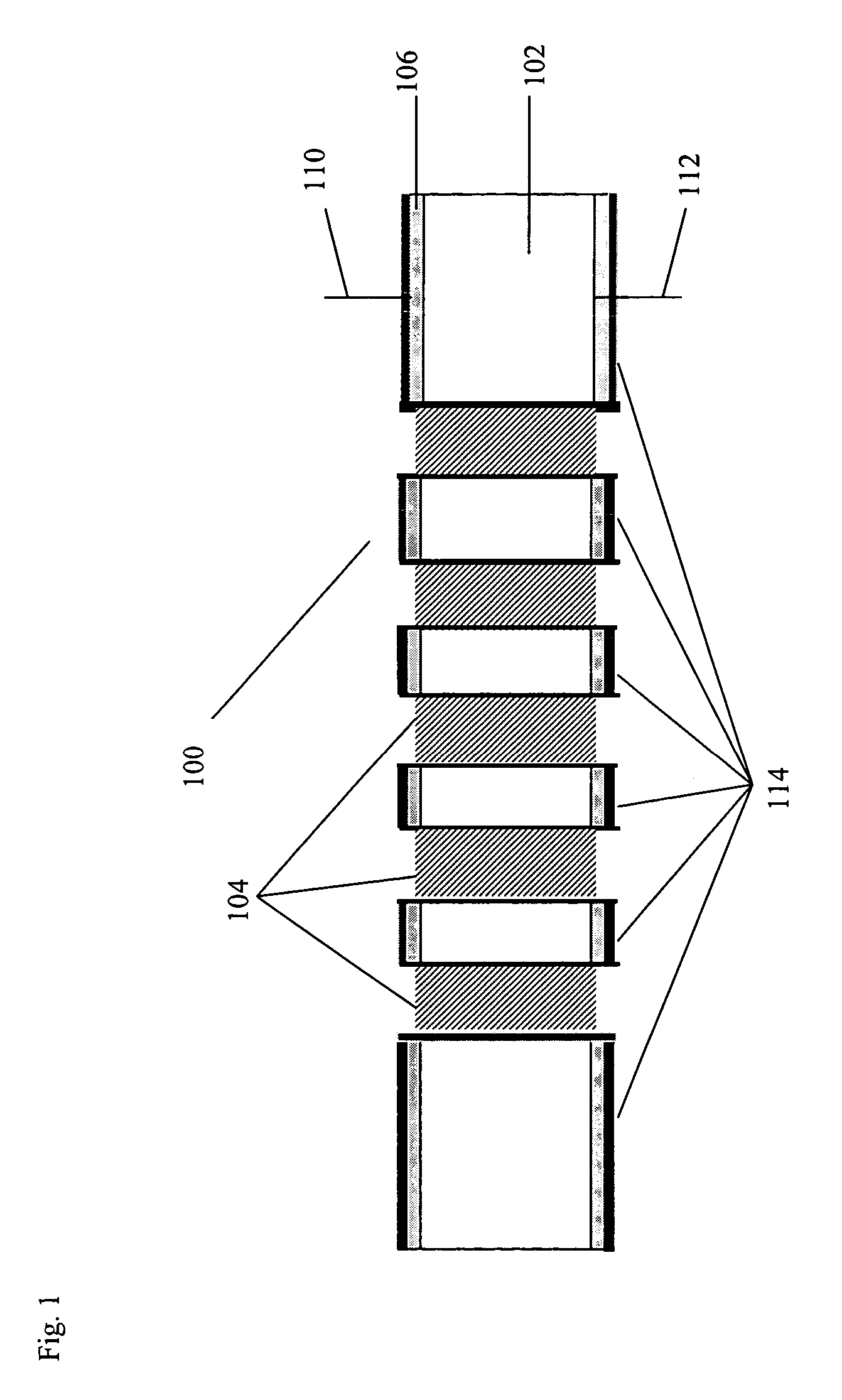

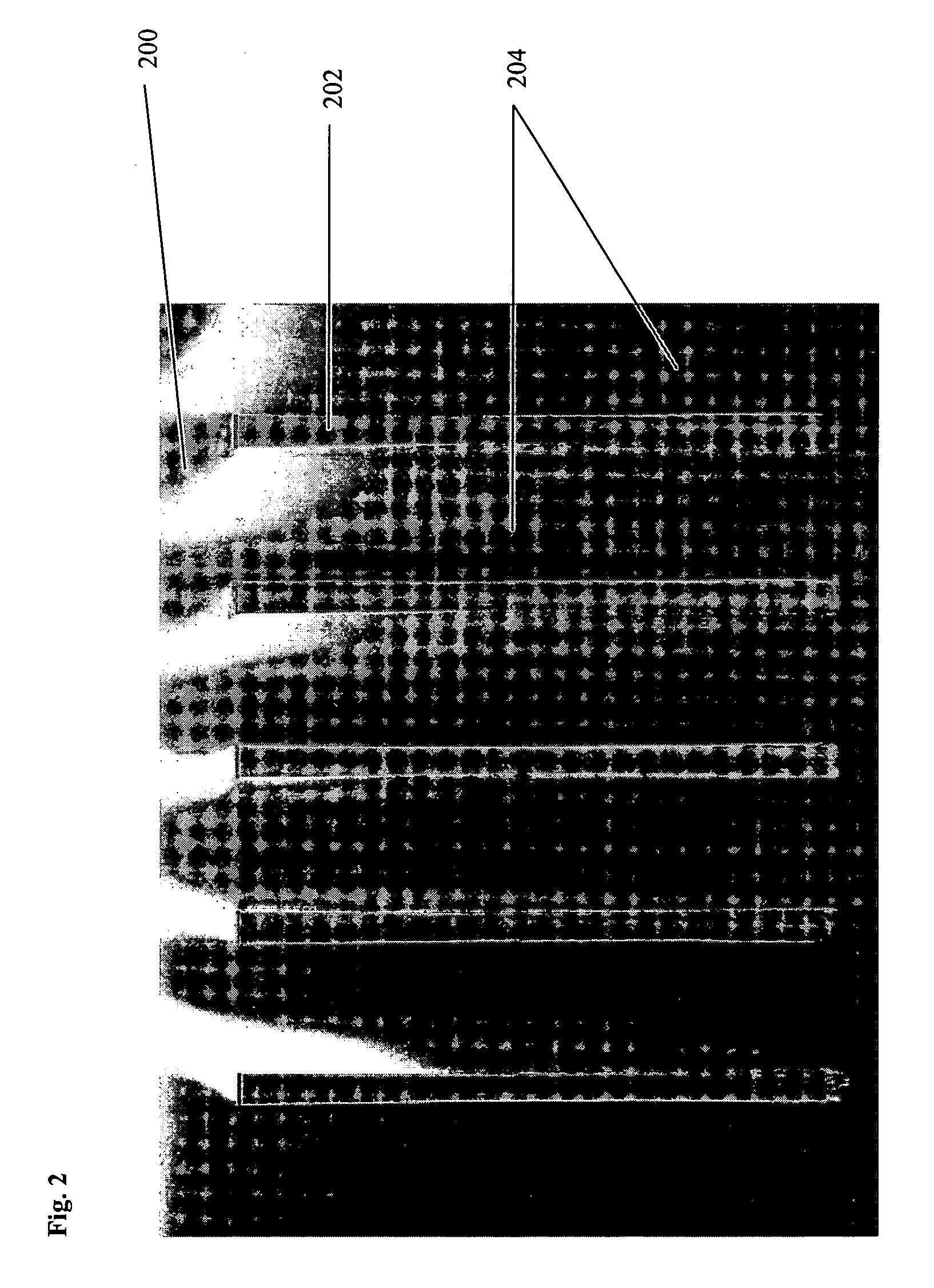

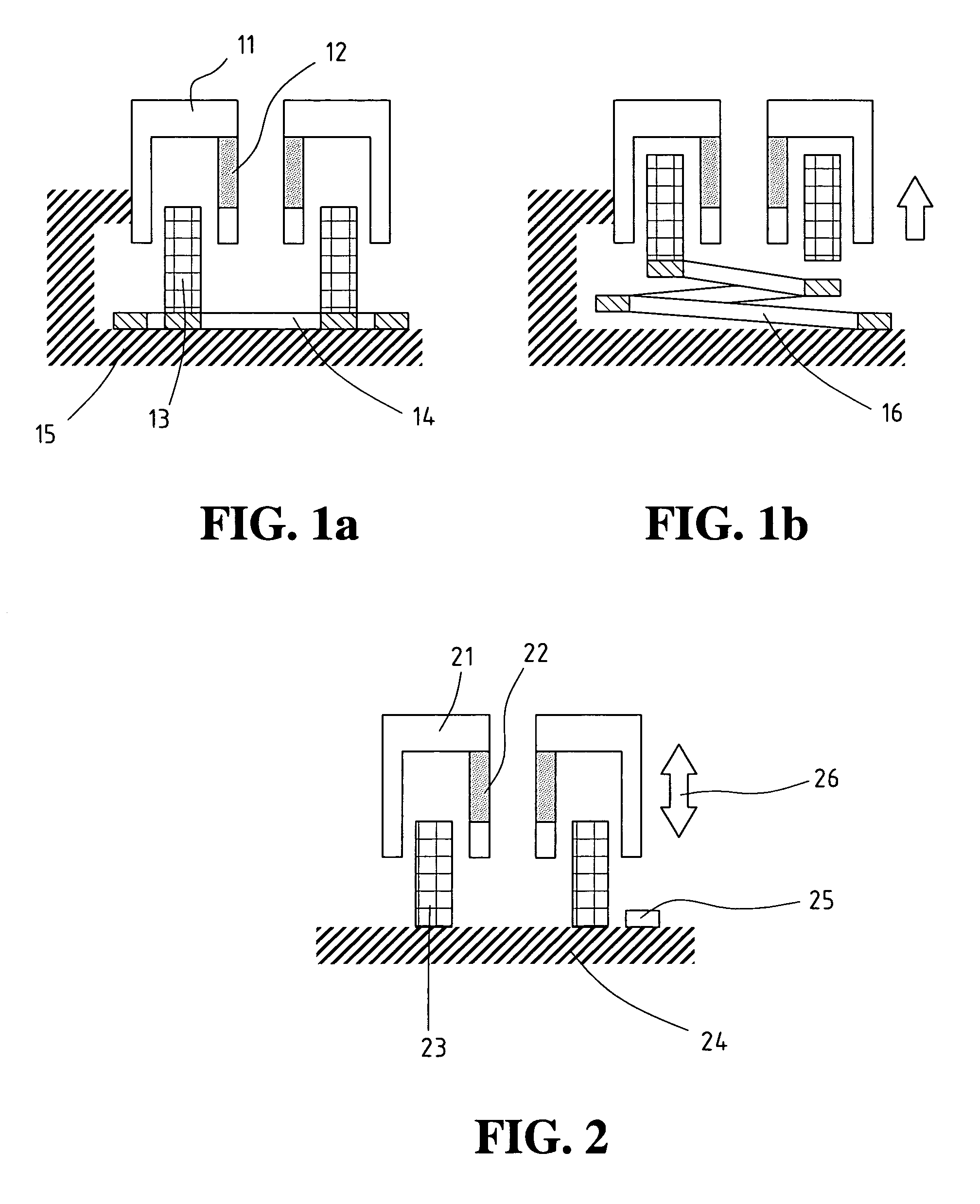

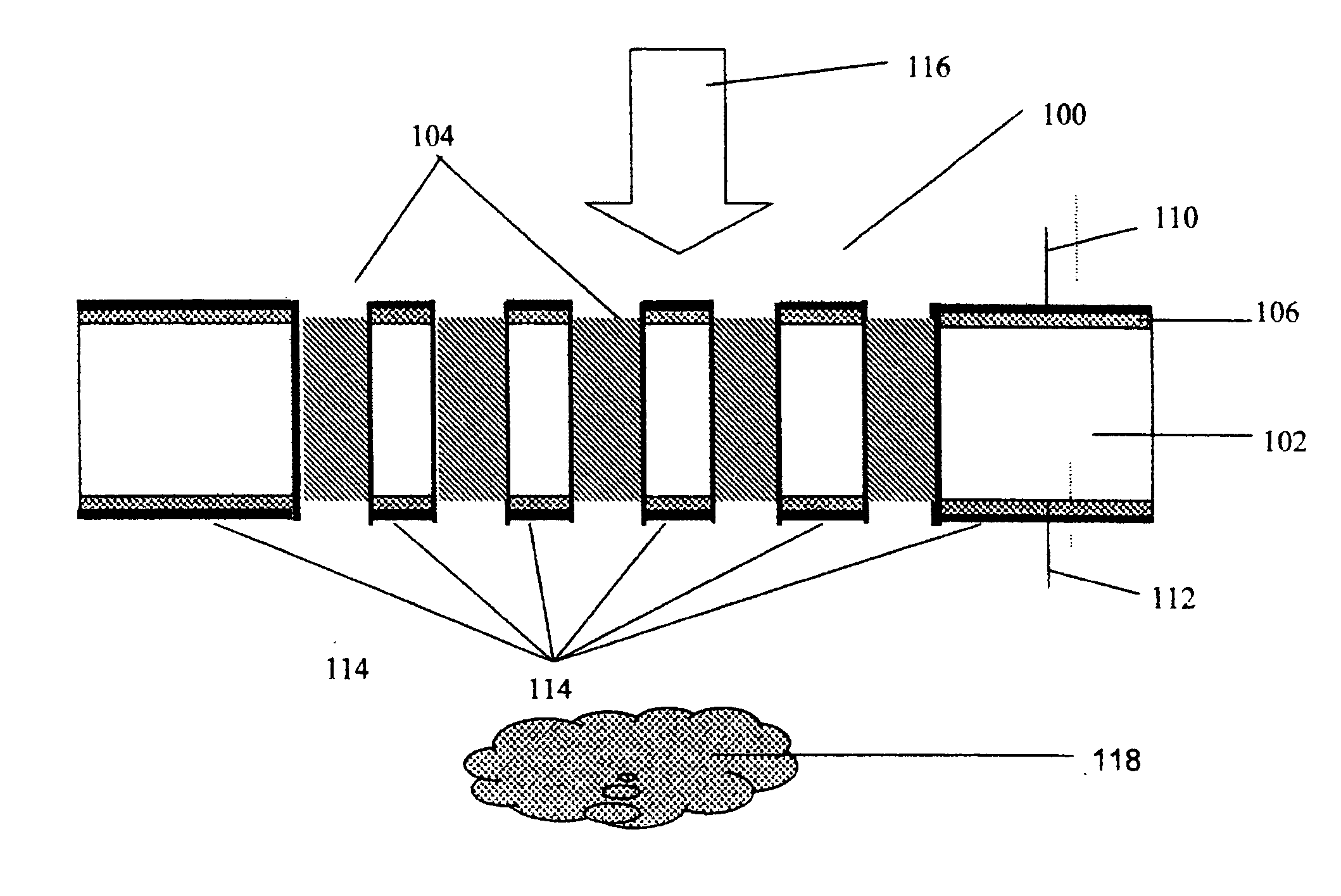

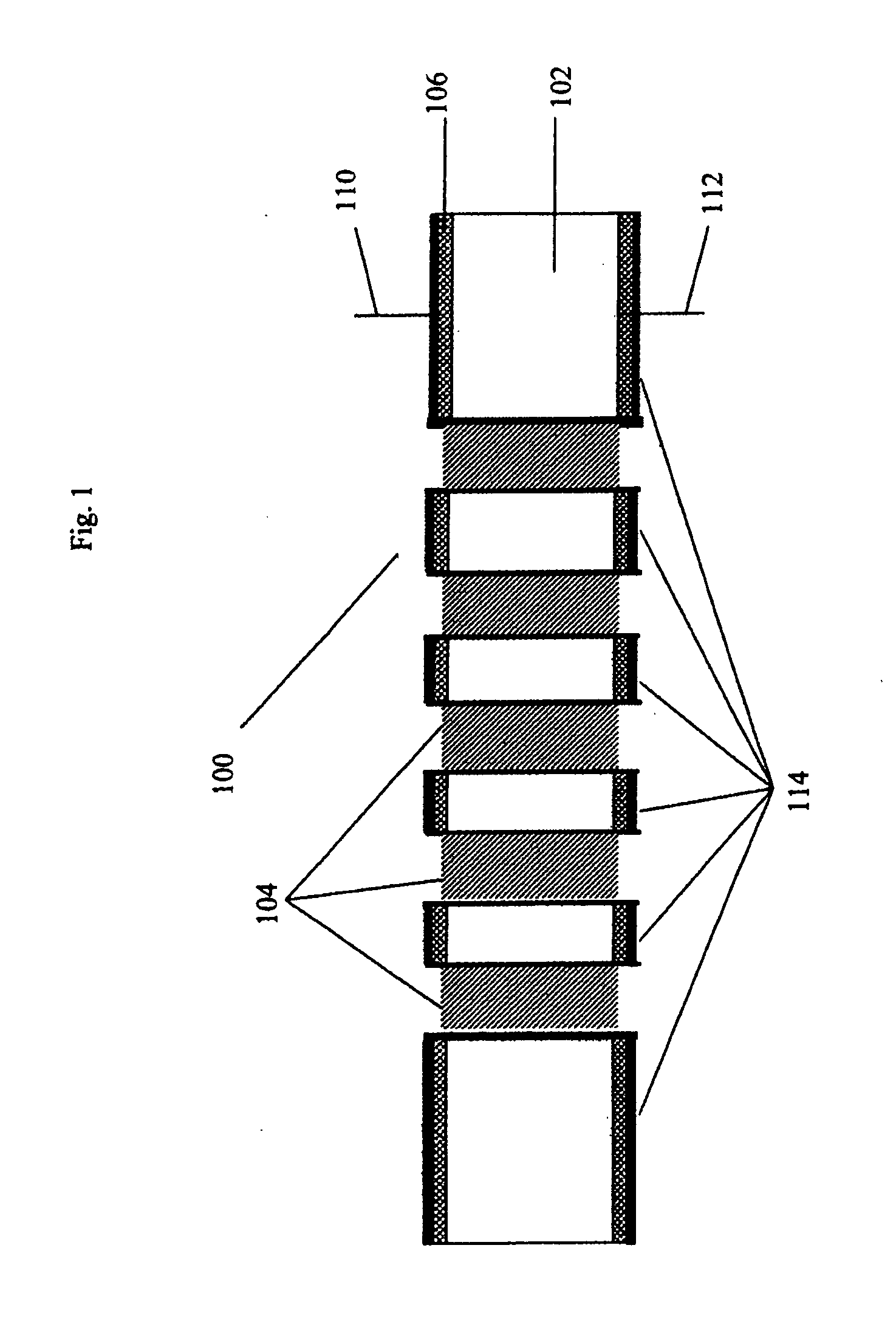

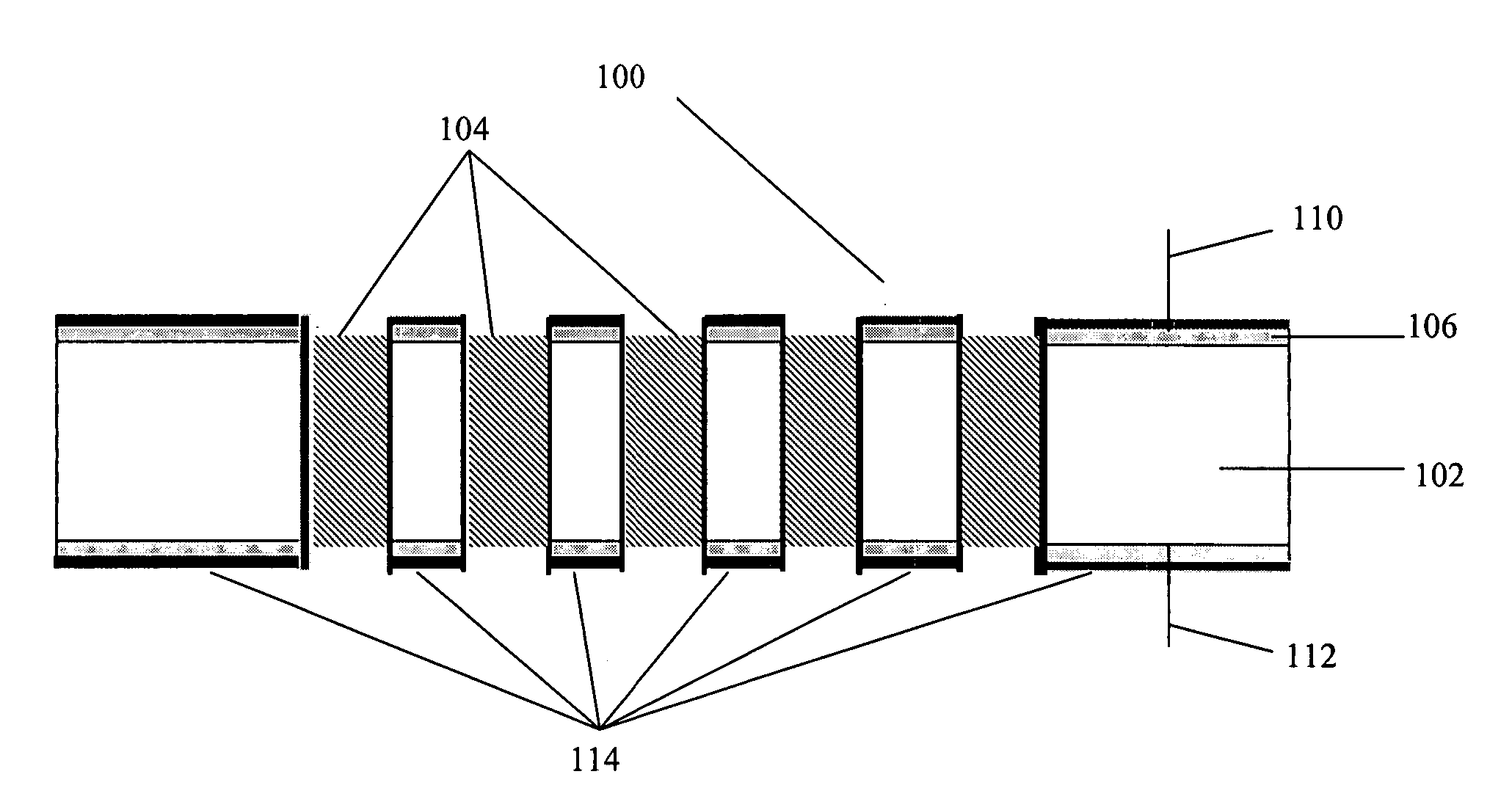

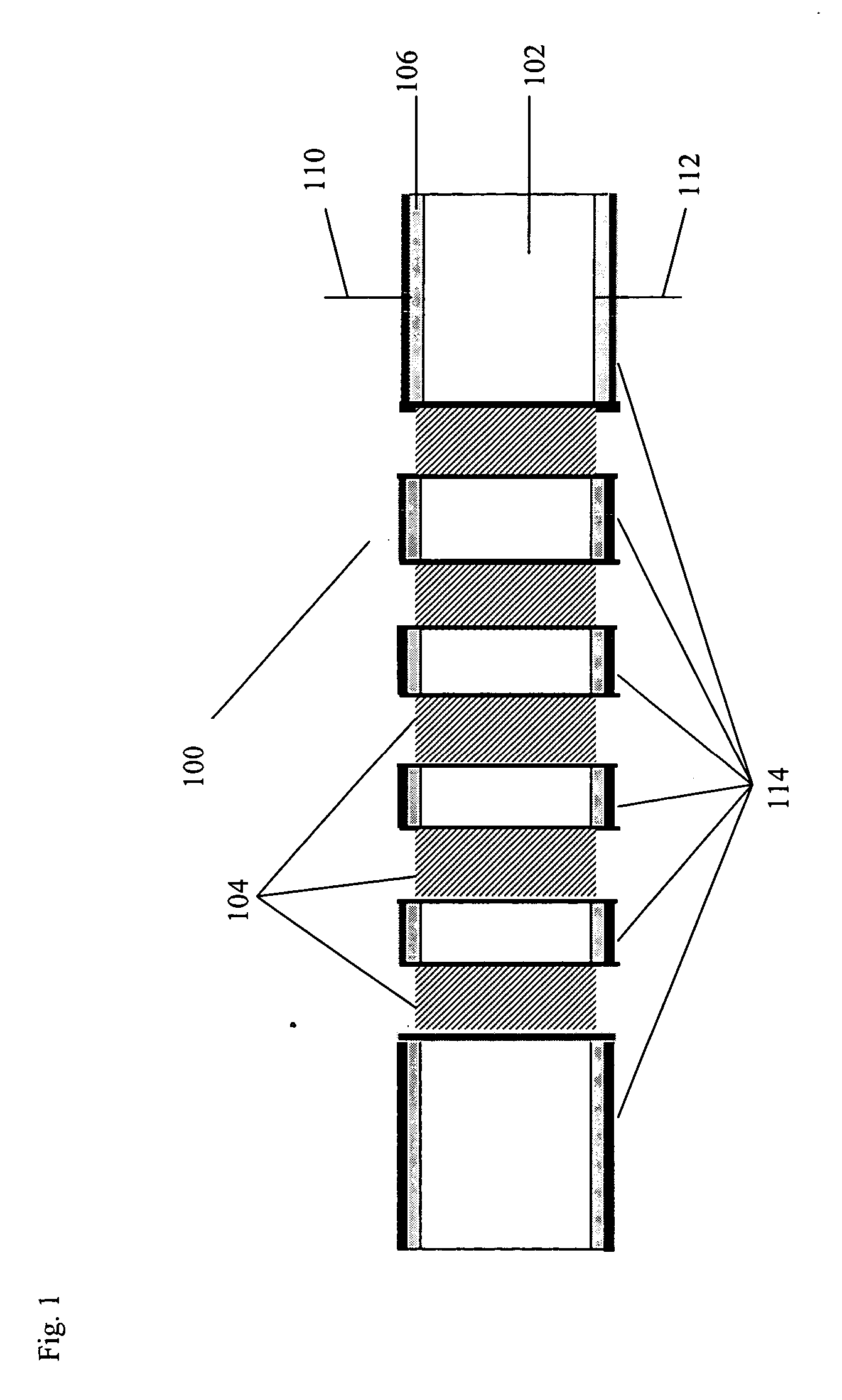

3D miniature preconcentrator and inlet sample heater

ActiveUS7306649B2Low thermal massIncrease surface areaComponent separationWithdrawing sample devicesProportional integral differentialAnalyte

The present invention relates to a three dimensional preconcentrator and inlet heater. The preconcentrator consists of a substrate with passageways, a conductive material coated to the top and the bottom of the substrate and an adsorbent coating covering the entire substrate. This substrate is suspended in a holding frame by a connecting bridge. The preconcentrator may also include a resistor and a proportional-integral-differential controller. The device may be used inline with a detector and can be retrofitted to existing devices. An array of preconcentrators may also be formed. The invention also relates to methods of use of the preconcentrator and methods of manufacture. A method of use includes contacting an analyte and a preconcentrator, allowing the analyte to adsorb to the preconcentrator and then desorbing the analyte. A method of manufacture involves applying the adsorbent coating by misted chemical deposition.

Owner:OWLSTONE MEDICAL LTD

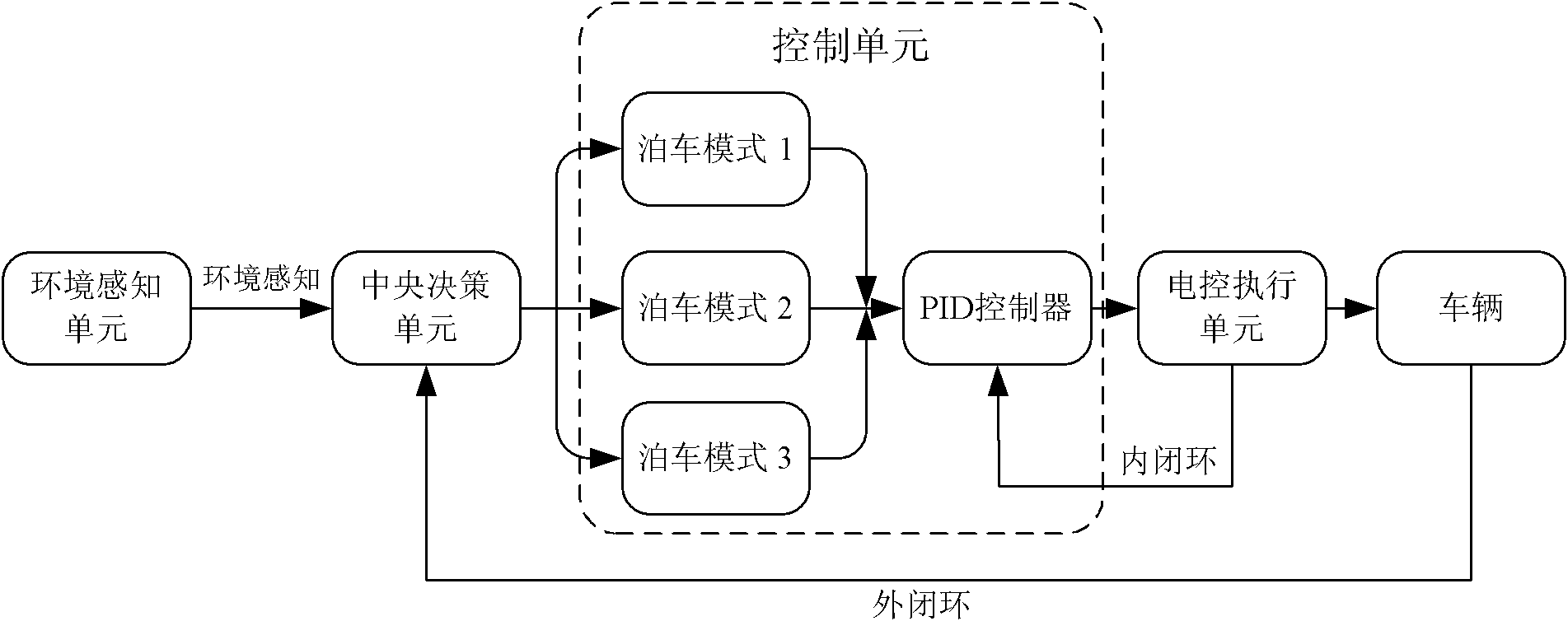

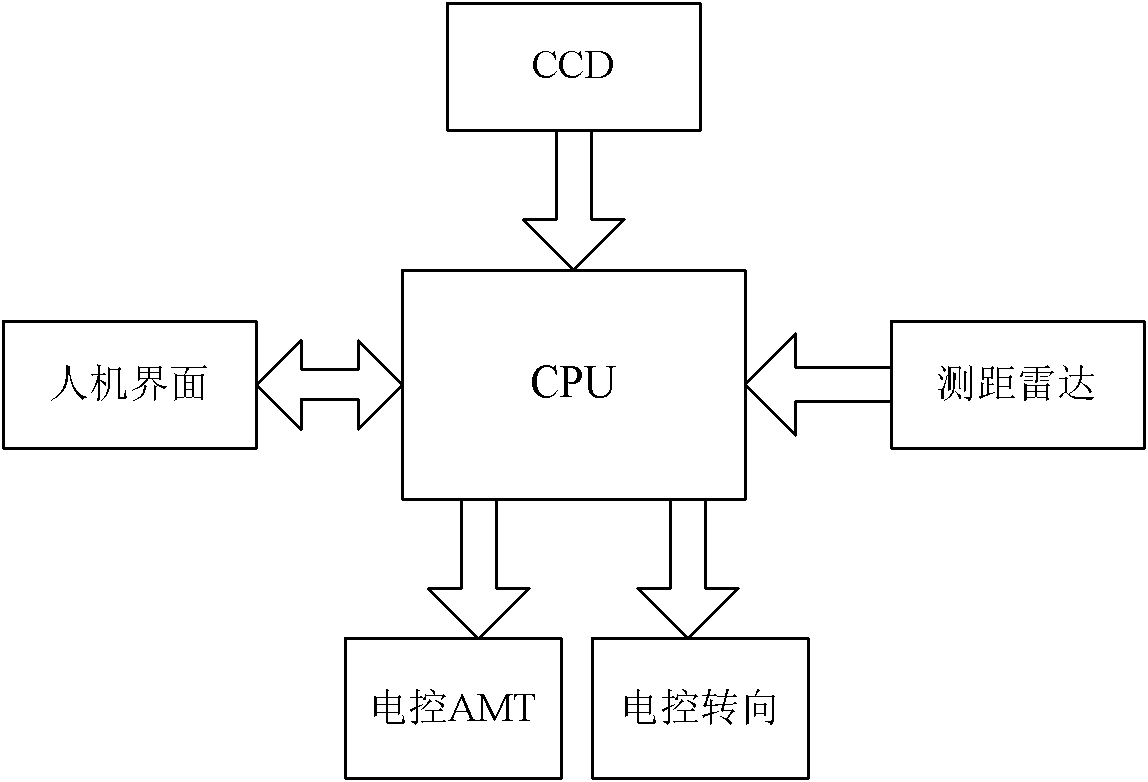

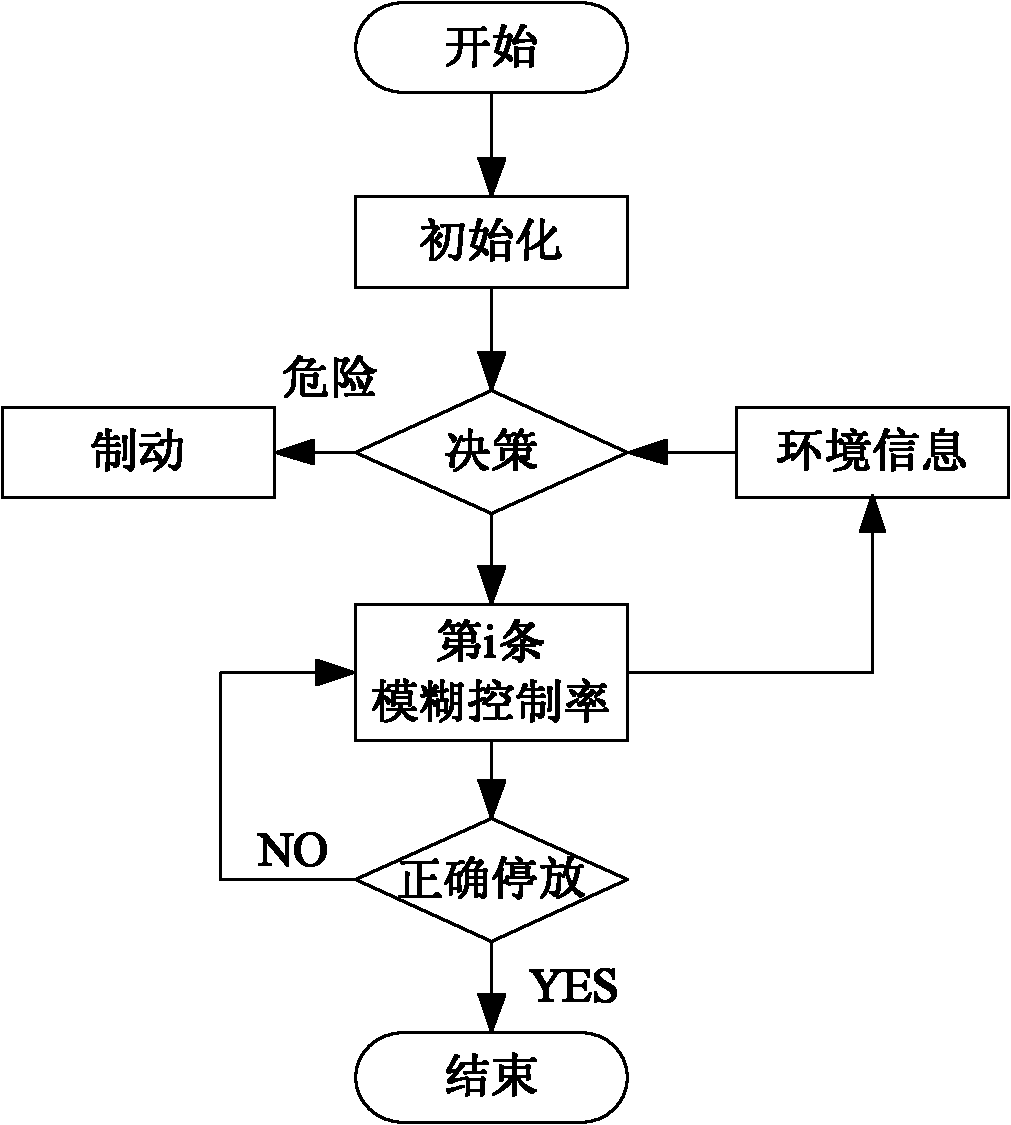

Intelligent parking system

InactiveCN102069799AReduce the burden onImprove portabilityMicrocontrollerProportional integral differential

The invention discloses an intelligent parking system, which belongs to the field of control of automatic parking. The parking system consists of an environment perception unit, a central decision unit, a control unit and an electrical control execution unit which are sequentially connected, wherein the electrical control execution unit acts on vehicles. The environment perception unit is used for acquiring position information of a vehicle body and distance information of obstacles in the environment; the central decision unit is used for matching according to environmental information to select an appropriate parking controller; the control unit is formed by connecting a group of fuzzy parking controllers and a proportional-integral-differential (PID) controller, each fuzzy parking controller is obtained by learning the parking experience of excellent drivers and is implemented by adopting a singlechip NLX230; and the electrical control execution unit is used for executing an output result of the control unit and controlling a steering wheel. The intelligent parking system improves the safety and accuracy of the parking, and has strong control adaptive capability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

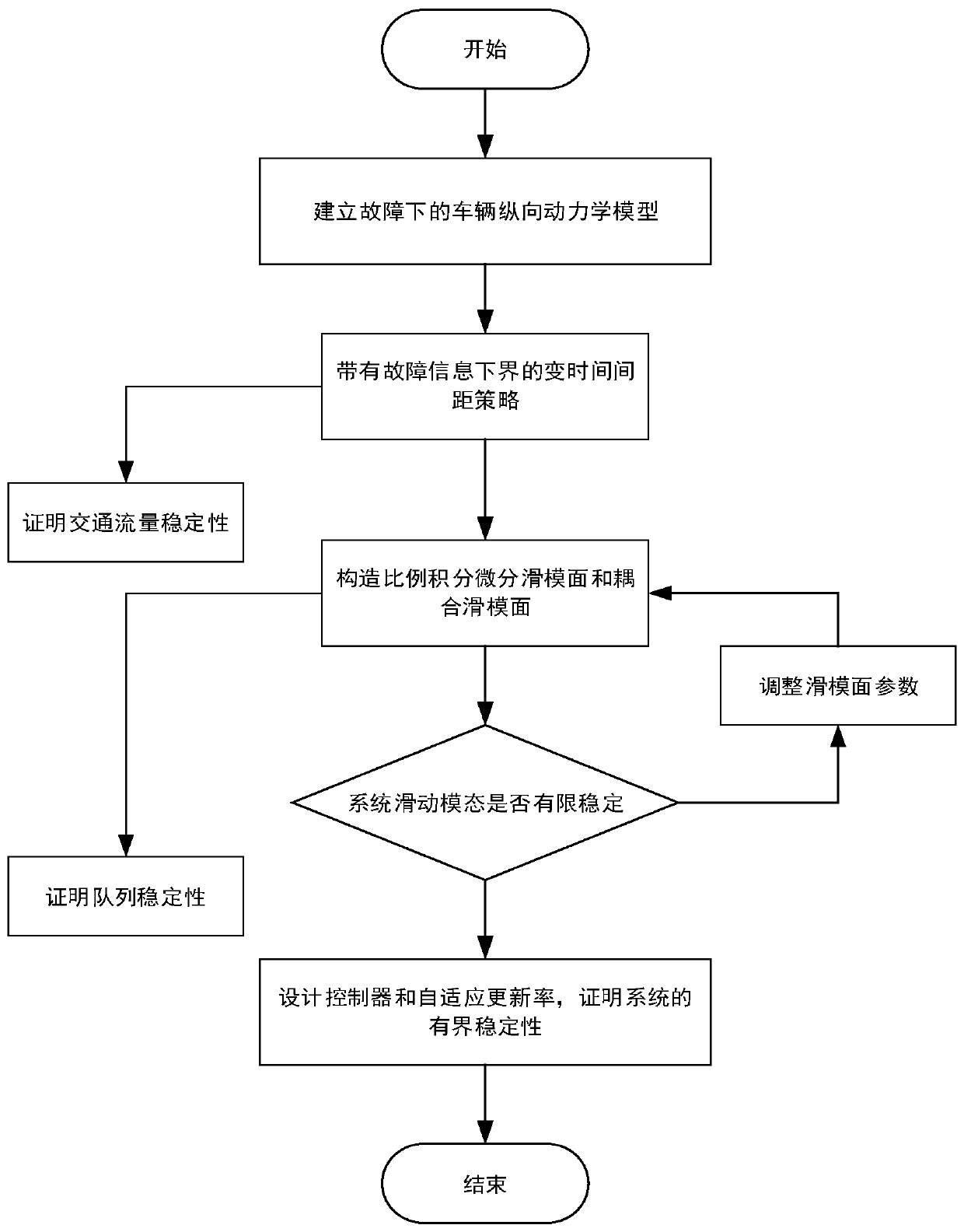

Heterogeneous fleet fault tolerance control method based on variable time interval strategy

ActiveCN110333728AGuaranteed stabilityIncrease critical traffic capacityPosition/course control in two dimensionsVehiclesProportional integral differentialTraffic capacity

The invention provides a heterogeneous fleet fault tolerance control method based on a variable time interval strategy. The method comprises the following steps of carrying out force analysis on longitudinal motion of vehicles and combining an actuator fault model to establish a vehicle longitudinal dynamics model under an actuator fault; constructing the variable time interval strategy with a lower boundary of fault information according to information of the vehicles; based on the constructed variable time interval strategy, establishing a proportional integral differential sliding mode surface and a coupled sliding mode surface; and selecting an appropriate Lyapunov function to design a fault-tolerant controller and an adaptive update rate, and proving finite time stability of a system.Traffic flow stability is proved based on the variable time interval strategy with the lower boundary of the fault information. Queue stability is proved based on the proportional integral differential sliding mode surface and the coupled sliding mode surface. Compared with a traditional variable time interval strategy, by using the technical scheme of the invention, a problem of a non-zero initial spacing error can be solved, and a critical traffic capacity can be increased.

Owner:DALIAN MARITIME UNIVERSITY

Voice coil motor apparatus for positioning

InactiveUS7309932B2Precise positioningSpace minimizationDC motor speed/torque controlAC motor controlProportional integral differentialPower cable

A voice coil motor apparatus for positioning is disclosed. The voice coil motor is used by the auto-focus lens control module of a miniature camera. The apparatus contains a voice coil motor, a position feedback sensor, and a positioning controller. The voice coil of the voice coil motor can be either movable or stationary, where in the former case the attached power cable is a flexible circuit board, and in the latter case the power cable is fixed. The position feedback sensor includes a photo interrupter, a light reflector, and a bias circuit used for tracking any displacement of the movable part of the motor. The positioning controller uses the voltage signals to be processed through a proportional-integral-differential computation unit to manipulate an output current for accurate positioning of the movable part of the motor within a prescribed range.

Owner:VASSTEK INT

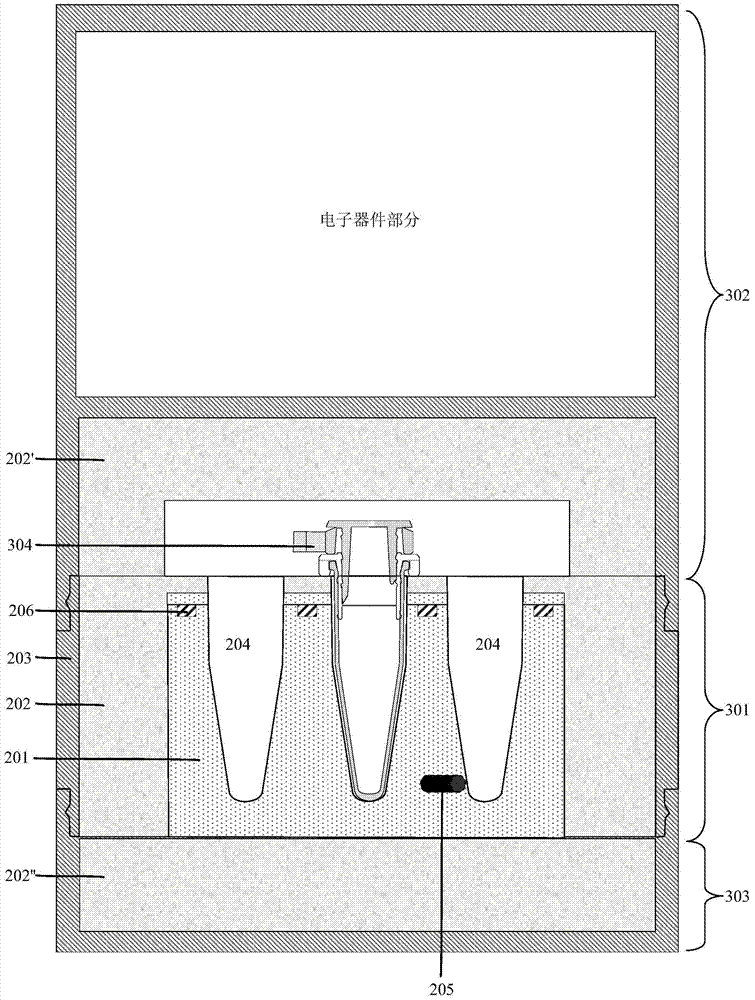

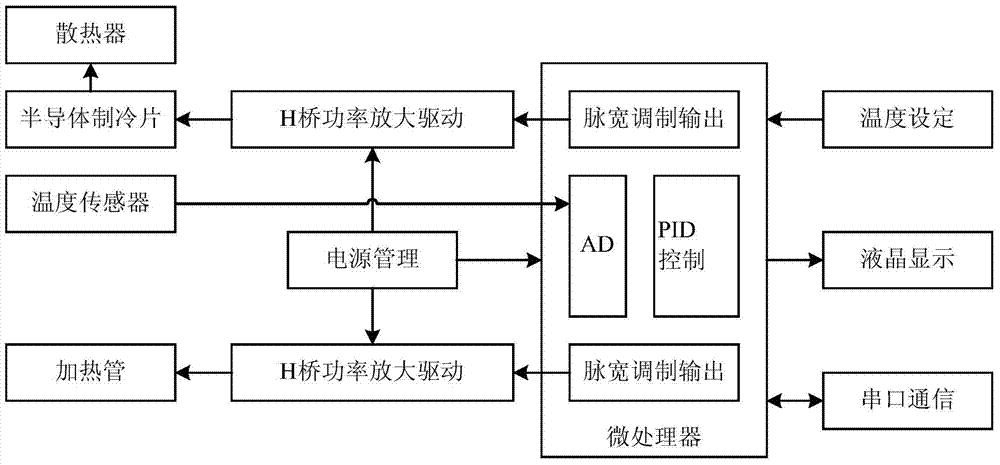

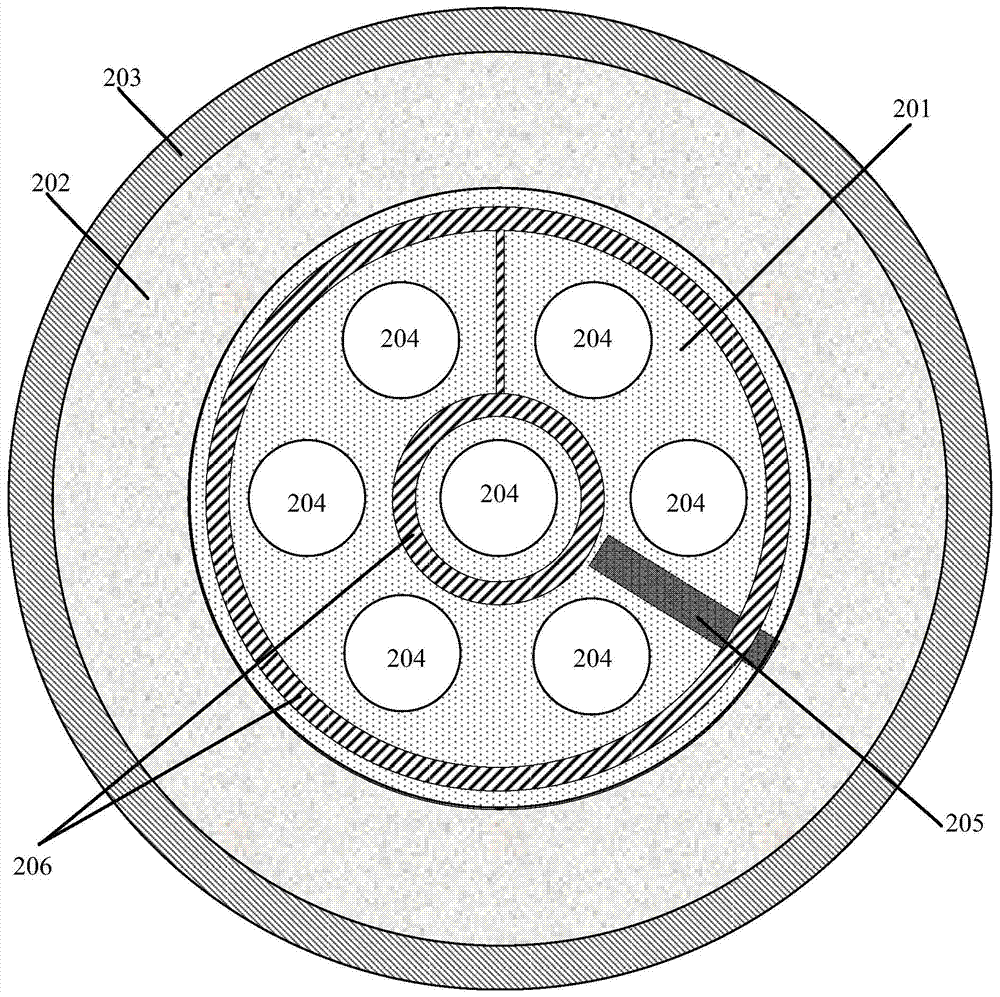

Temperature control system and method for miniature constant-temperature box

ActiveCN103941778ANot limited by ambient temperatureGood heat preservation with low energy consumptionAuxillary controllers with auxillary heating devicesProportional integral differentialTemperature control

The invention relates to a constant-temperature storage device in examination and chemical analysis of biology and clinical medicine, and discloses a temperature control system and method for a miniature constant-temperature box. According to the temperature control system and method for the miniature constant-temperature box, the proportional-integral-differential algorithm is adopted for calculating the detected temperature in a constant-temperature box body, the detected environment temperature and a preset target temperature to determine heating or refrigerating and obtain the heating time or the refrigerating time. The portion, storing biological samples, in the constant-temperature box body is heated or refrigerated, so that the temperature in the constant-temperature box body is equal to the target temperature constantly. According to the temperature control system and method for the miniature constant-temperature box, the temperature in the constant-temperature box body can be automatically adjusted to reach the set target temperature, and the limitation of the environment temperature is avoided.

Owner:上海企诺电子科技有限公司

3D miniature preconcentrator and inlet sample heater

InactiveUS20080121103A1Low thermal massIncrease surface areaSamplingComponent separationProportional integral differentialAnalyte

The present invention relates to a three dimensional preconcentrator and inlet heater. The preconcentrator consists of a substrate with passageways, a conductive material coated to the top and the bottom of the substrate and an adsorbent coating covering the entire substrate. This substrate is suspended in a holding frame by a connecting bridge. The preconcentrator may also include a resistor and a proportional-integral-differential controller. The device may be used inline with a detector and can be retrofitted to existing devices. An array of preconcentrators may also be formed. The invention also relates to methods of use of the preconcentrator and methods of manufacture. A method of use includes contacting an analyte and a preconcentrator, allowing the analyte to adsorb to the preconcentrator and then desorbing the analyte. A method of manufacture involves applying the adsorbent coating by misted chemical deposition.

Owner:OWLSTONE NANOTECH

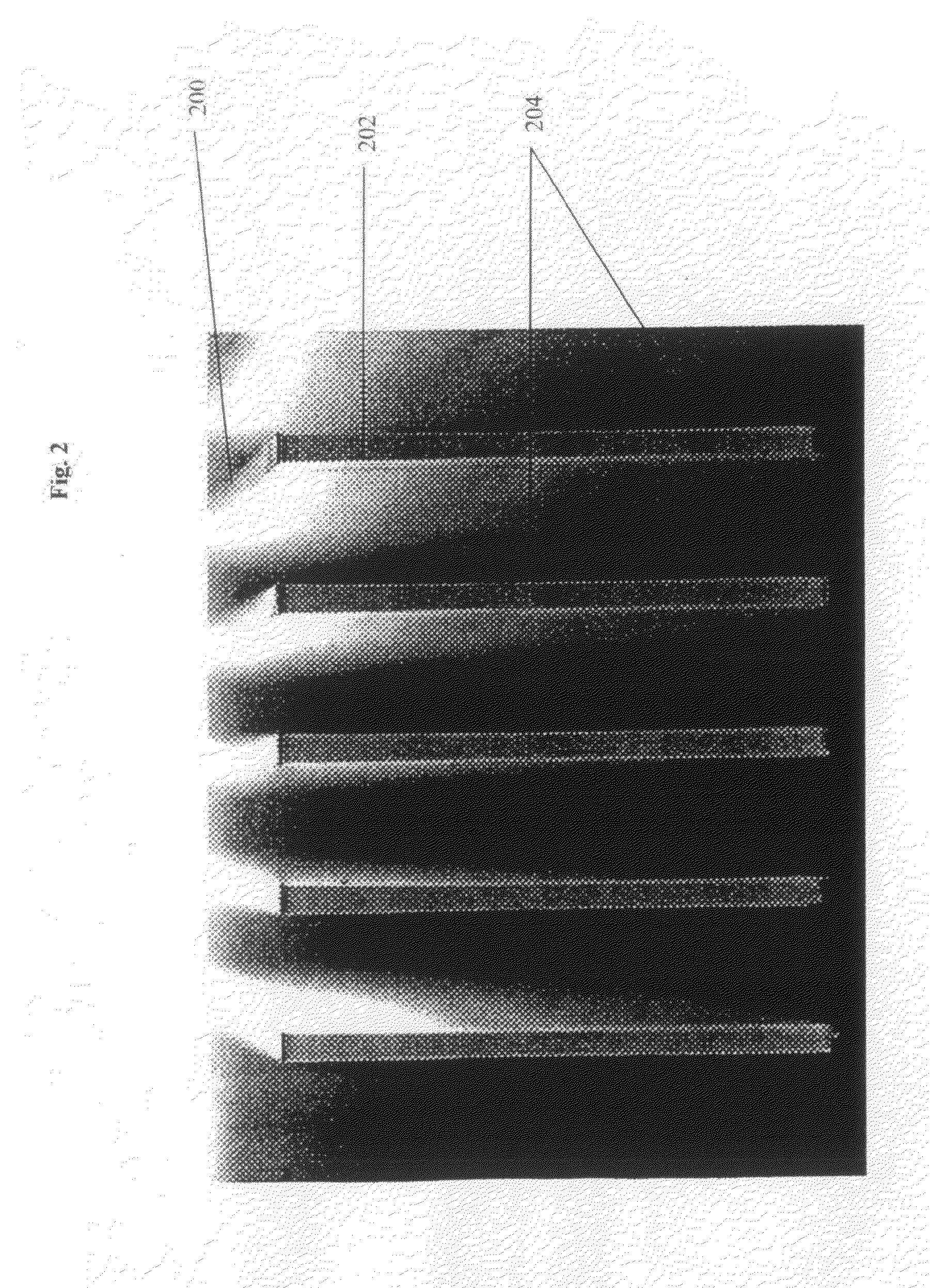

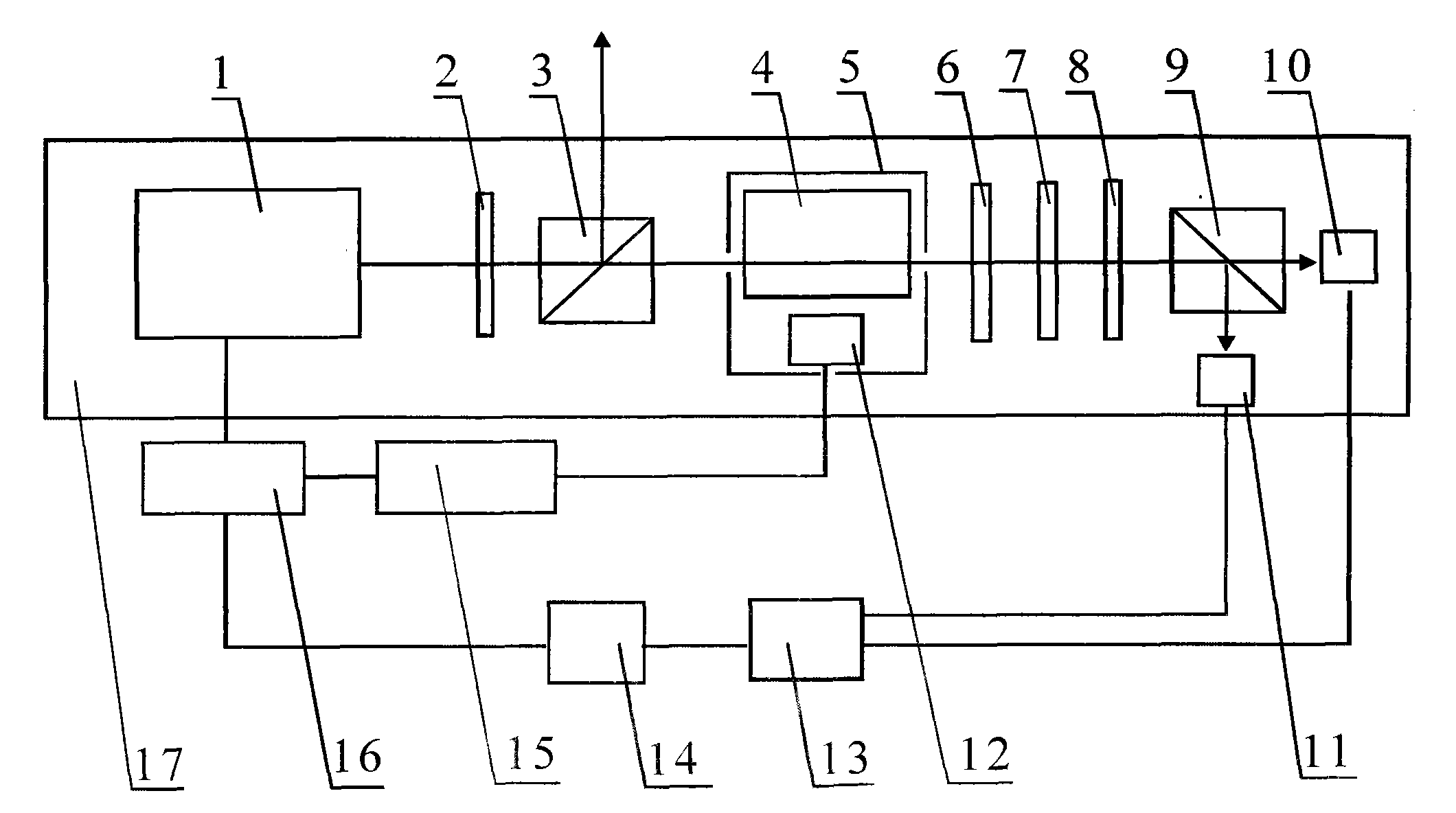

Laser frequency stabilizing device for atomic clock

InactiveCN102111154AImprove frequency stabilityResolve disturbancePulse automatic controlProportional integral differentialPhotovoltaic detectors

The invention relates to a laser frequency stabilizing device for an atomic clock, wherein a laser, a 1 / 2 wave plate, a first polarization splitting prism, a magnetic shielding box which is internally provided with a reference atom source and a third photoelectric probe, a first 1 / 8 wave plate, a partial reflection mirror, a second 1 / 8 wave plate and a second polarization splitting prism are orderly arranged on a bottom plate from the left to right in the horizontal optical axis direction; connecting holes are formed on the magnetic shielding box, and light guide holes are formed on two sidewalls in the same horizontal optical axis direction; a first photoelectric probe is arranged in the outgoing direction of the second polarization splitting prism on the bottom plate, and a second photoelectric probe is arranged in the reflecting direction; a subtracter connected with the first photoelectric probe and second photoelectric probe via the leads, a proportional-integral differential controller connected with the subtracter via the leads, and a microprocessor connected with the third photoelectric probe via the leads are arranged on the bottom plate; and a controllable switch which is connected with the laser, the microprocessor and the proportional-integral differential controller via the leads is arranged on the bottom plate.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

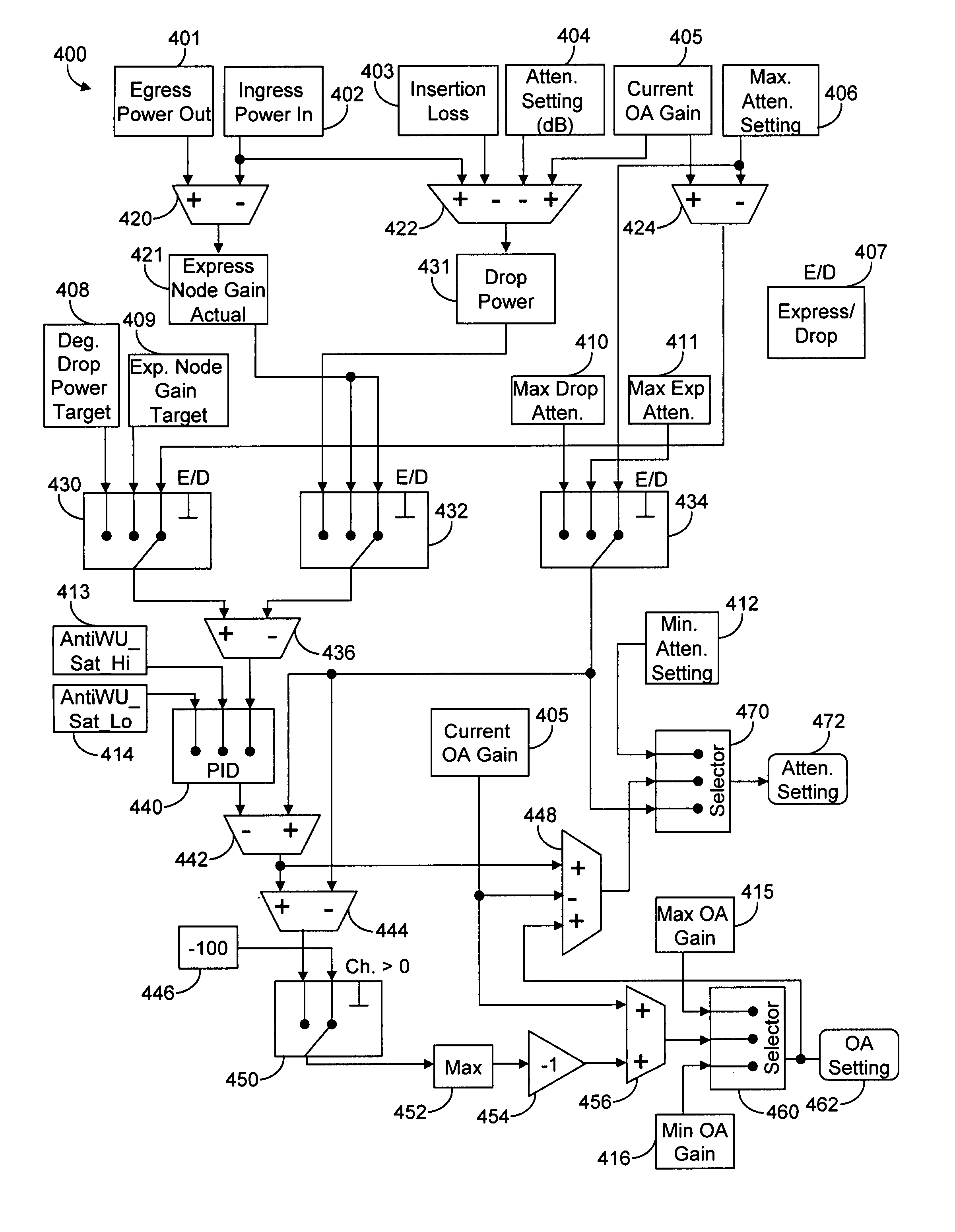

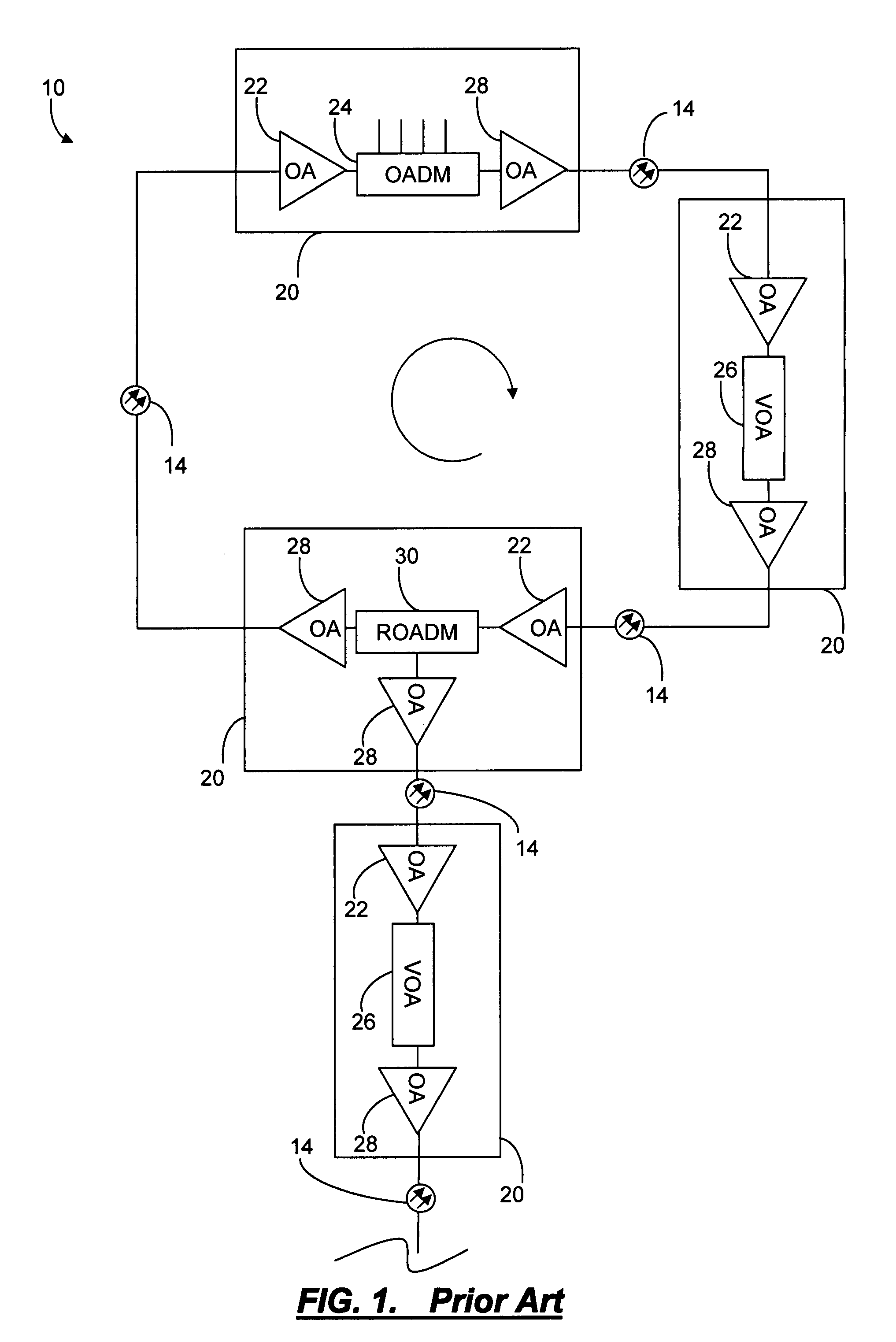

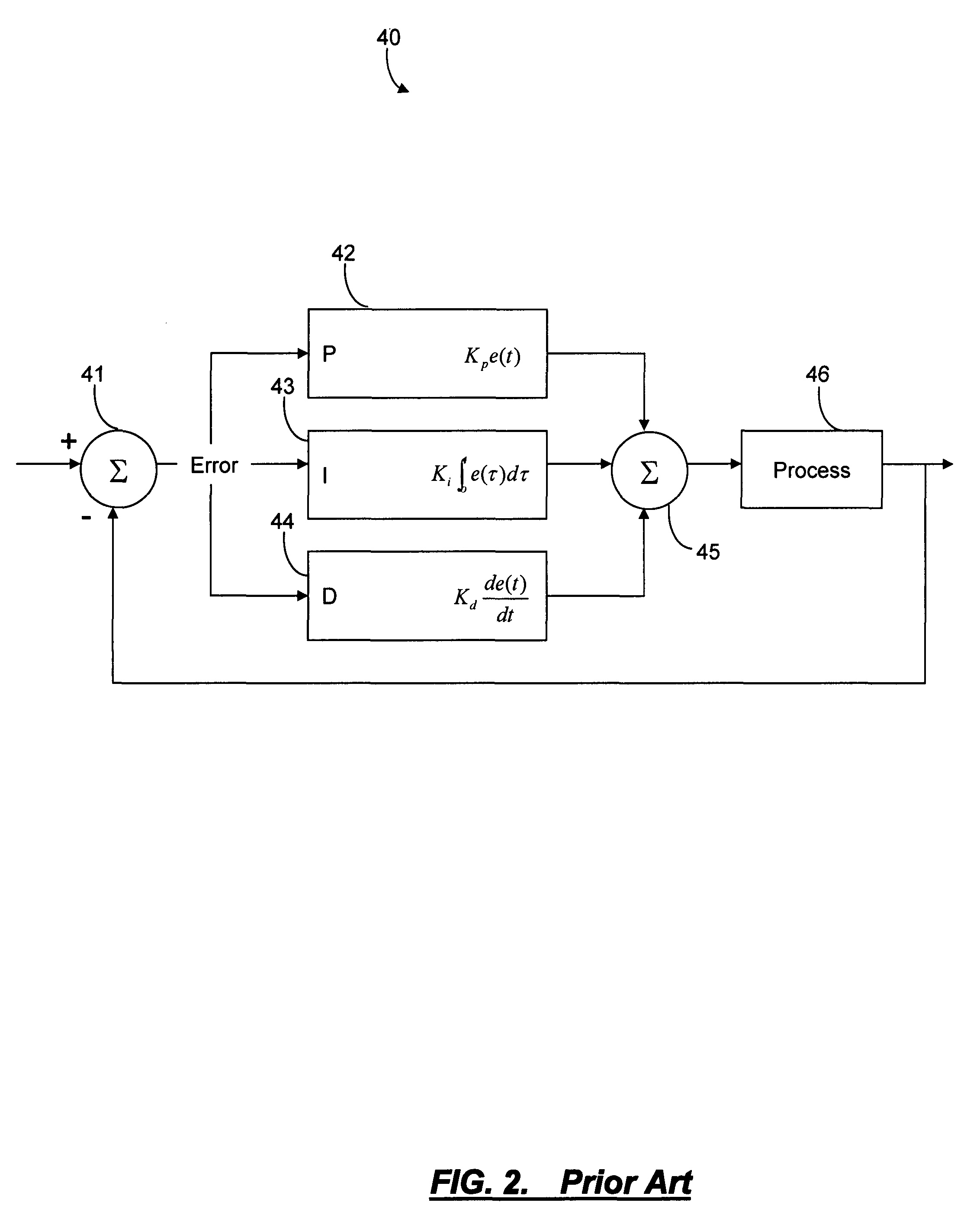

Systems and methods for a multiple-input, multiple-output controller in a reconfigurable optical network

ActiveUS8095008B2Rapid optimized settingAmplifier gain is increasedMultiplex system selection arrangementsWavelength-division multiplex systemsUltrasound attenuationProportional integral differential

The present invention provides systems and methods to convert a reconfigurable optical node multiple-input multiple-output (MIMO) system to a single-input single-output (SISO) system suitable for a proportional-integral-differential (PID) control process. Advantageously, the present invention allows PID control to apply to a MIMO optical node by modeling the node as two SISO systems. The present invention optimizes the division of gain and loss between components in the reconfigurable optical node. This provides means to control the net gain and loss of a series of components when the component chain being controlled includes those components that have a single action affecting multiple channels and components that affect only one channel. The present invention utilizes control of a single quantity of amplifier gain minus attenuation for each channel, and the coupling together of all channels in the amplifier which makes the channels inter-dependent.

Owner:CIENA

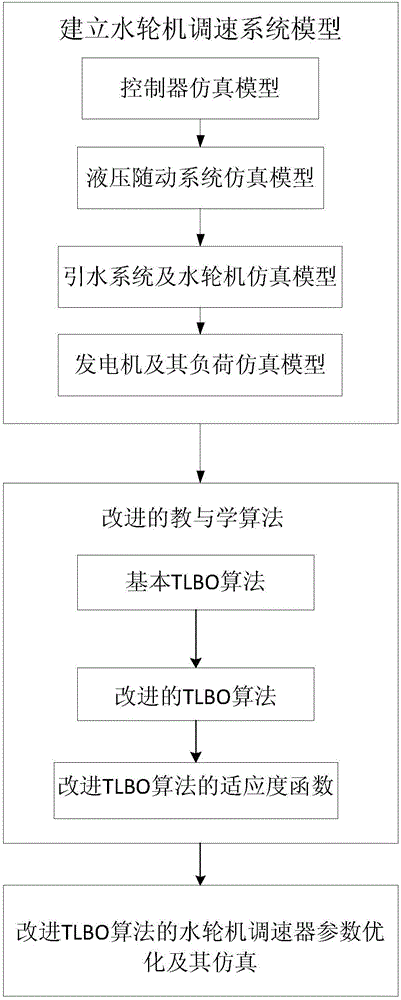

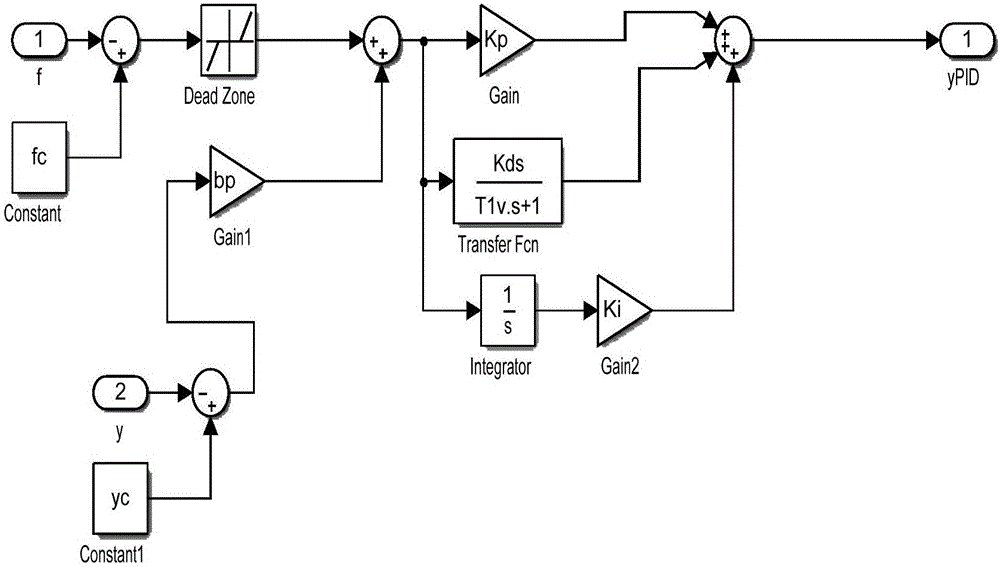

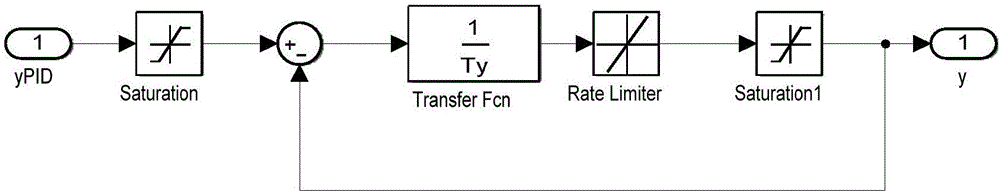

Improved TLBO (teaching-learning-based optimization) algorithm-based hydroelectric generating set PID (proportional-integral-differential) speed regulator parameter optimization

ActiveCN106837678AAvoid premature convergenceEngine fuctionsHydro energy generationProportional integral differentialLocal optimum

The invention belongs to the technical field of hydroelectric generation, and particularly relates to improved TLBO (teaching-learning-based optimization) algorithm-based hydroelectric generating set PID (proportion-integration-differentiation) speed regulator parameter optimization. The optimization comprises the following steps of (1) building a hydroturbine speed regulating system simulation model; (2) improving a basic TLBO algorithm; (3) applying the improved TLBO algorithm to optimizing parameters of the speed regulator of a hydroturbine speed regulating system, and obtaining a simulation result. Self-adaptive teaching factors, i.e., absorption weight of students and the after-school tutoring of teachers are added into the basic TLBO algorithm, while the convergence speed and the convergence precision are guaranteed, the phenomena of early-maturing and early convergence of the algorithm are avoided. An ITAE index of rotation rate deviation of a hydroturbine set serves as a standard fitness function, and the improved TLBO algorithm is used to optimize the parameters of the speed regulator, so that the convergence speed optimization efficiency is obviously improved, and the phenomenon of local optimum is avoided.

Owner:DALIAN UNIV

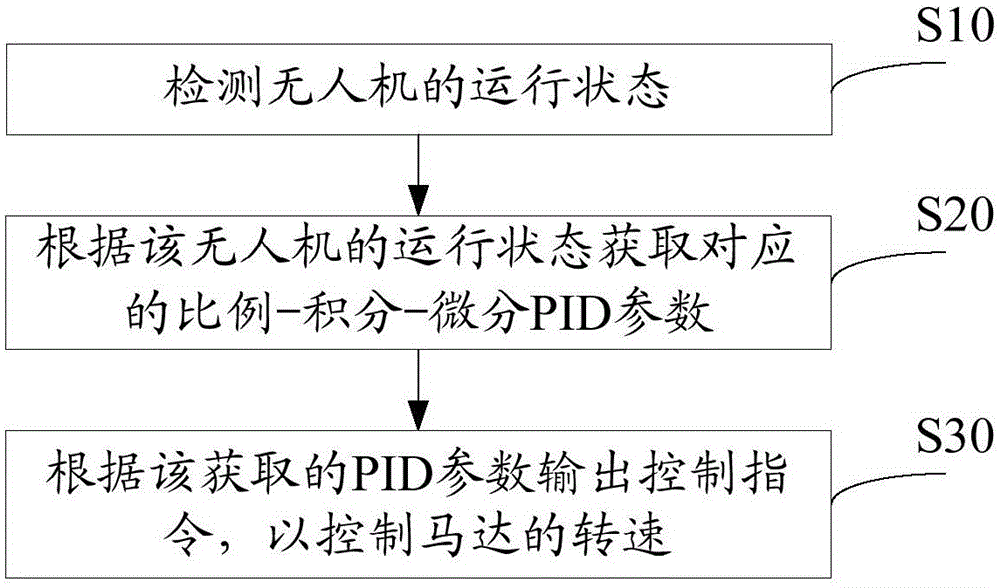

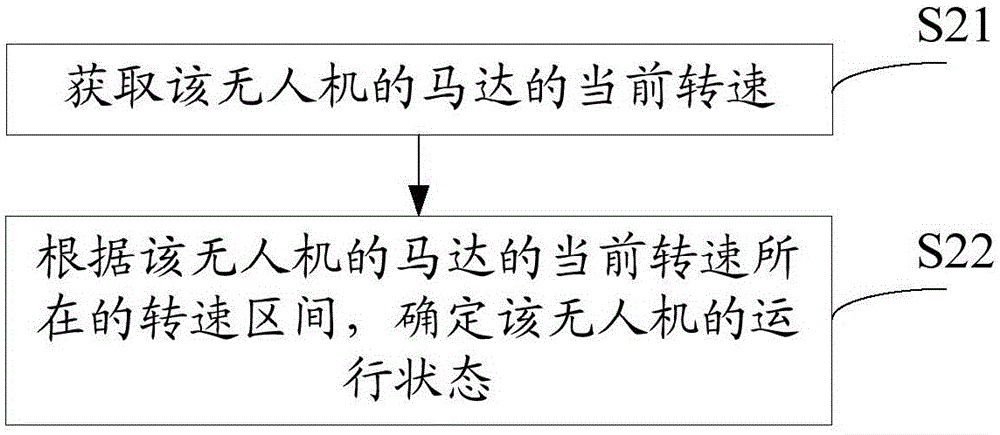

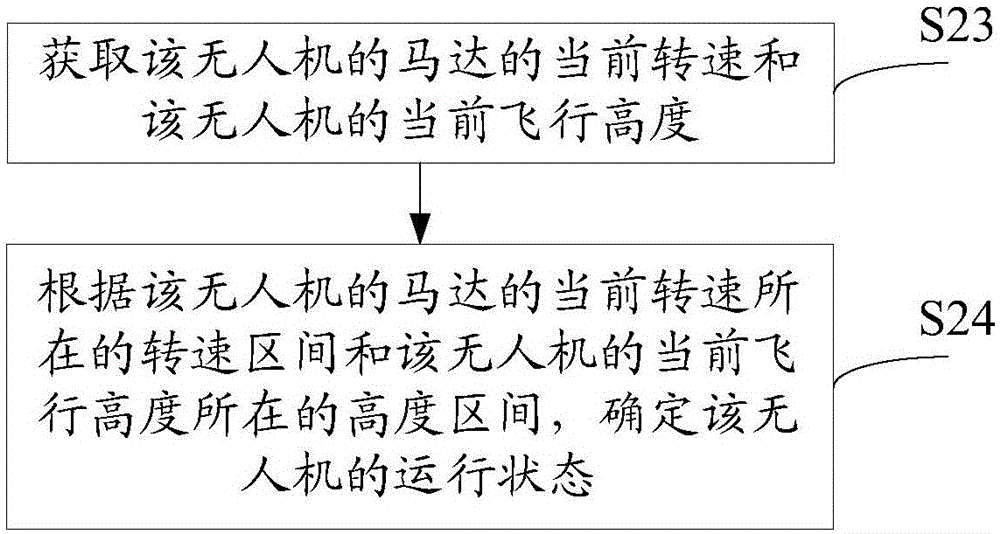

Unmanned aerial vehicle flight control method and device

InactiveCN105083567AImprove stabilityControl speedAircraft power plantsProportional integral differentialUncrewed vehicle

The invention discloses an unmanned aerial vehicle flight control method. The unmanned aerial vehicle flight control method comprises the steps of detecting a running state of an unmanned aerial vehicle, obtaining corresponding proportional integral differential (PID) parameters according to the running state of the unmanned aerial vehicle, outputting a control instruction according to the obtained PID parameters so as to control the rotation speed of a motor. The invention further discloses an unmanned aerial vehicle flight control device. By means of the unmanned aerial vehicle flight control method and device, the flight stability of the unmanned aerial vehicle can be improved.

Owner:SHENZHEN AEE AVIATION TECH

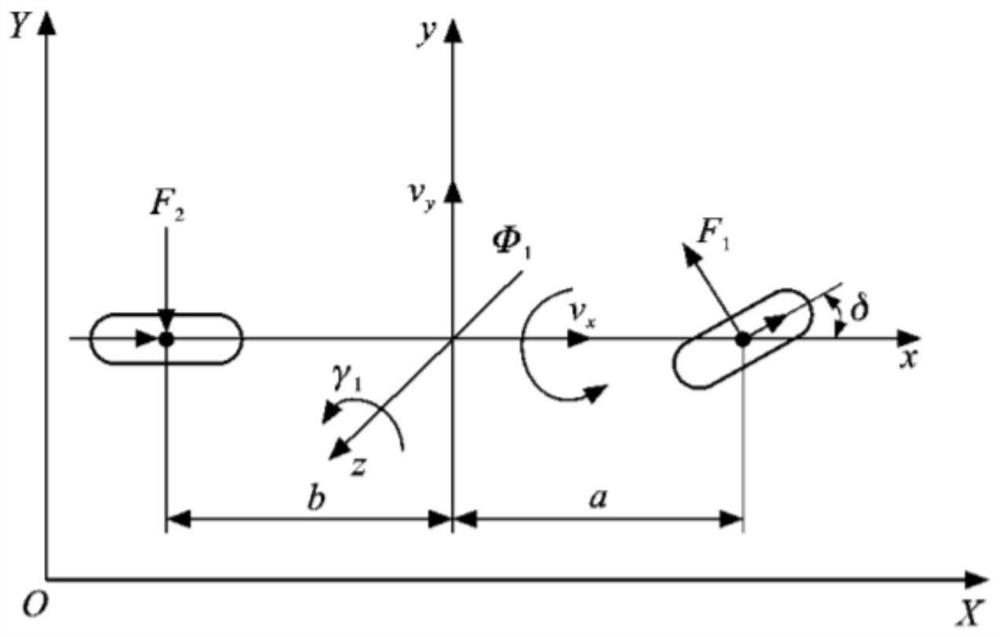

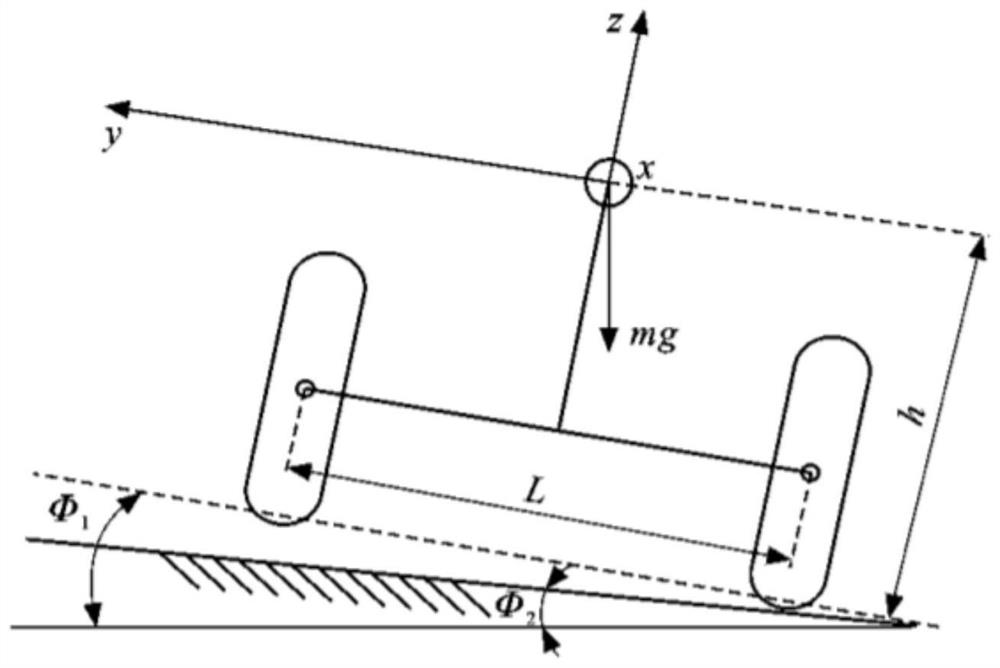

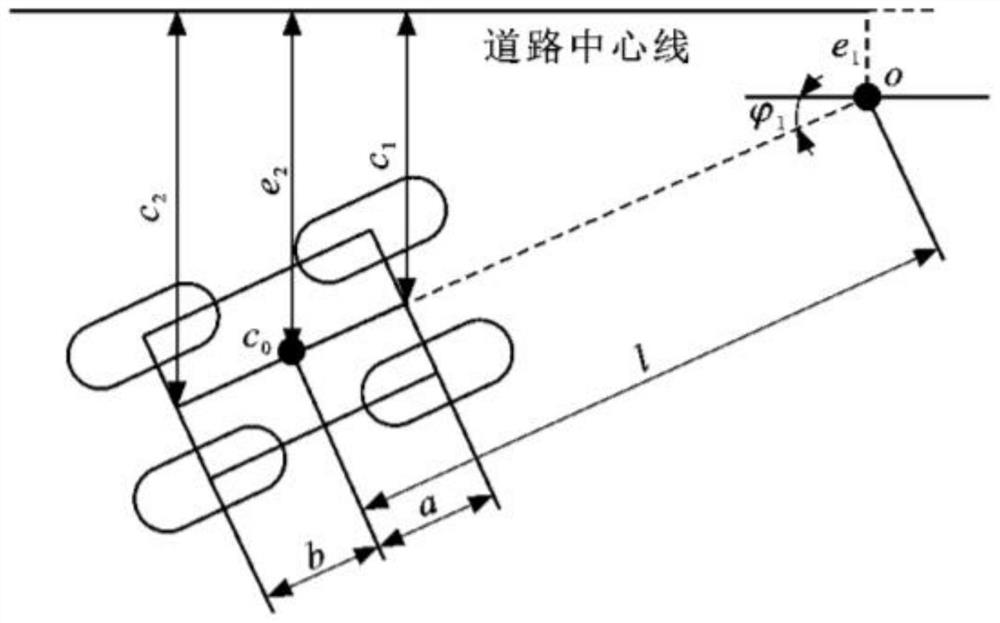

Stability-fused intelligent automobile path tracking control method

PendingCN111923908ASolve the problem of fixed preview distanceImprove stabilityControl devicesProportional integral differentialTime domain

The invention provides a stability-fused intelligent automobile path tracking control method, and aims to improve the path tracking precision and improve the automobile stability. The method comprisesthe steps of establishing a high-speed vehicle equivalent dynamic model and a vehicle preview error model considering pavement topography, designing a preview distance generator, and establishing a function relationship between a prediction time domain and road curvature. A path tracking controller is designed based on a model prediction control algorithm; an index model is used for representingthe expected speed of the vehicle, and a proportional-integral-differential longitudinal controller is designed; meanwhile, a mass center slip angle phase plane graph is used for representing vehiclestability characteristics, and a proportional-integral-differential vehicle stability controller is designed. According to the control method provided by the invention, the vehicle tracking performance can be optimized on pavements with different adhesion coefficients, and the problem of low tracking precision on a large-curvature road is solved. The path tracking precision under the high-speed working condition is improved, and the driving stability is improved.

Owner:HARBIN UNIV OF SCI & TECH

3D miniature preconcentrator and inlet sample heater

ActiveUS20070084347A1Increase surface areaLow thermal massComponent separationWithdrawing sample devicesProportional integral differentialAnalyte

The present invention relates to a three dimensional preconcentrator and inlet heater. The preconcentrator consists of a substrate with passageways, a conductive material coated to the top and the bottom of the substrate and an adsorbent coating covering the entire substrate. This substrate is suspended in a holding frame by a connecting bridge. The preconcentrator may also include a resistor and a proportional-integral-differential controller. The device may be used inline with a detector and can be retrofitted to existing devices. An array of preconcentrators may also be formed. The invention also relates to methods of use of the preconcentrator and methods of manufacture. A method of use includes contacting an analyte and a preconcentrator, allowing the analyte to adsorb to the preconcentrator and then desorbing the analyte. A method of manufacture involves applying the adsorbent coating by misted chemical deposition.

Owner:OWLSTONE MEDICAL LTD

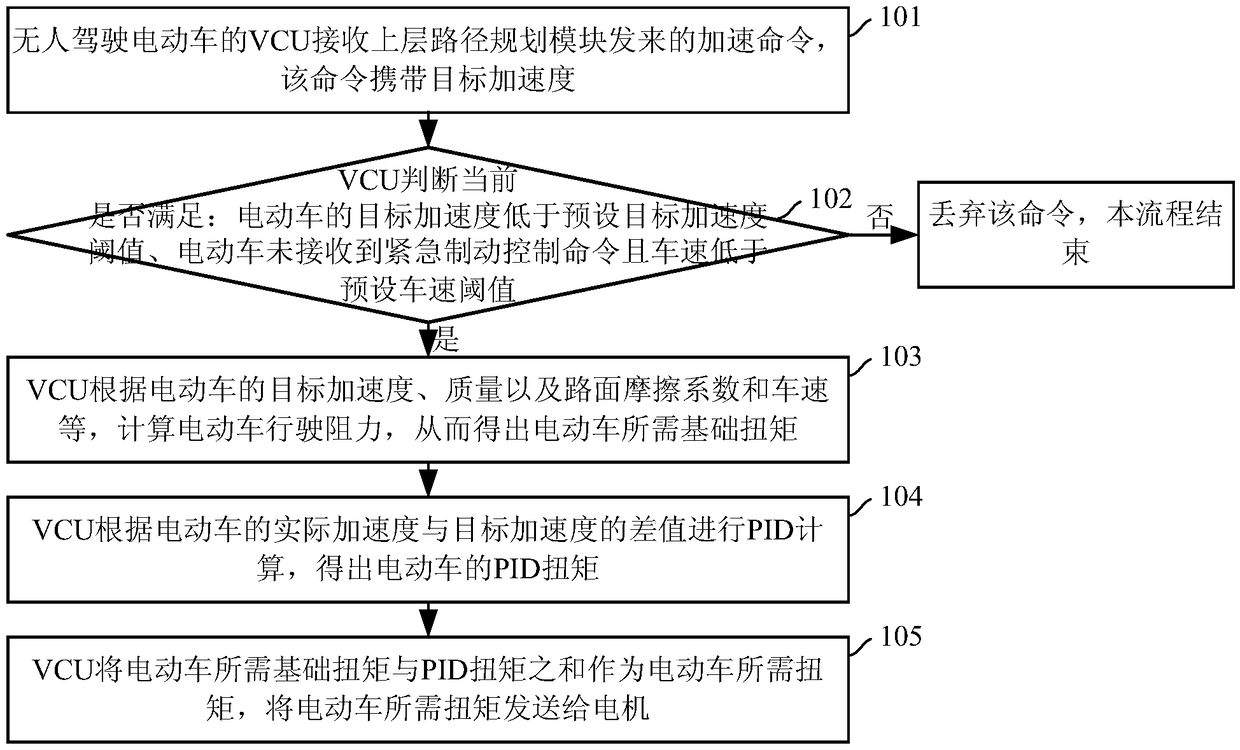

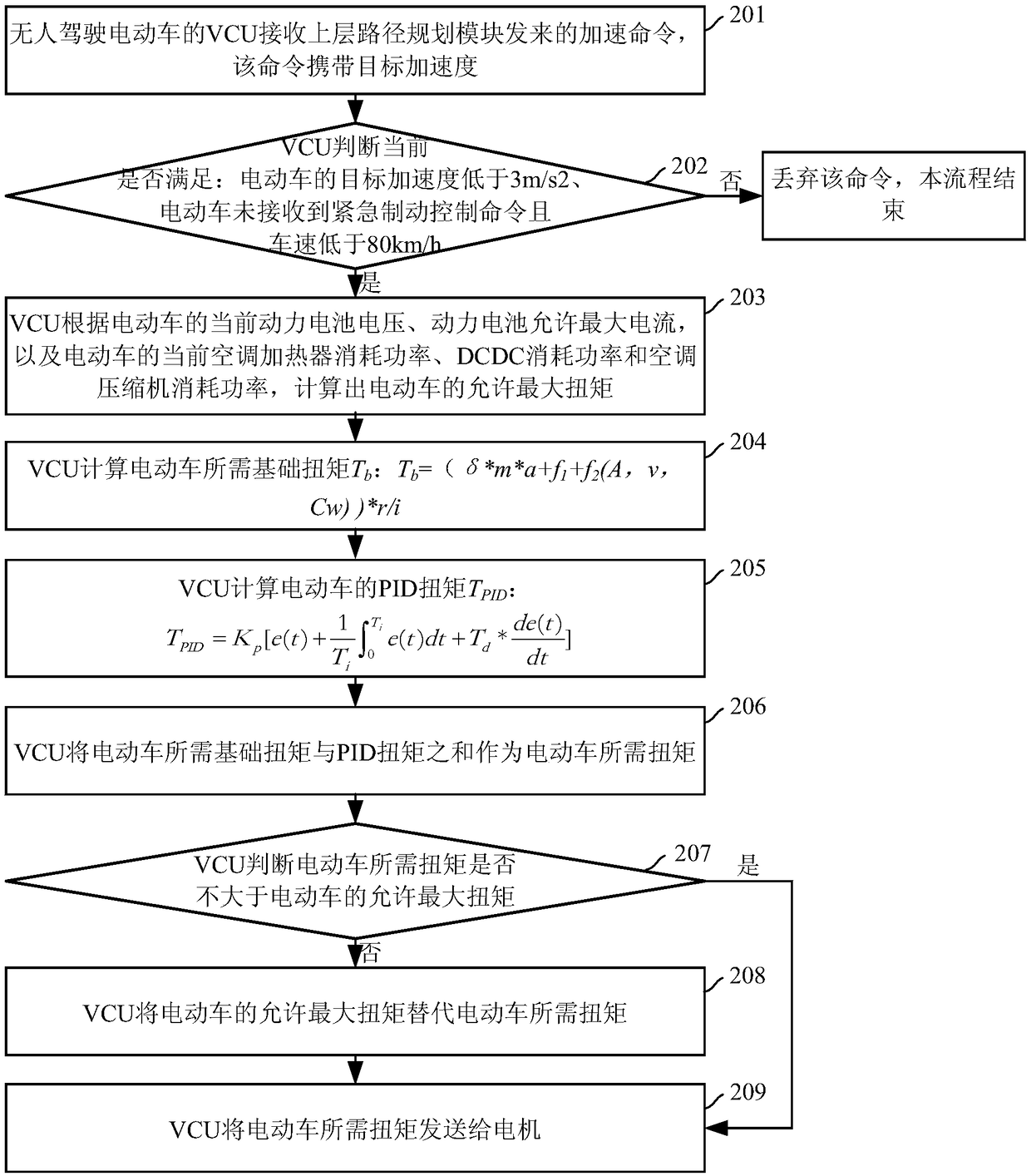

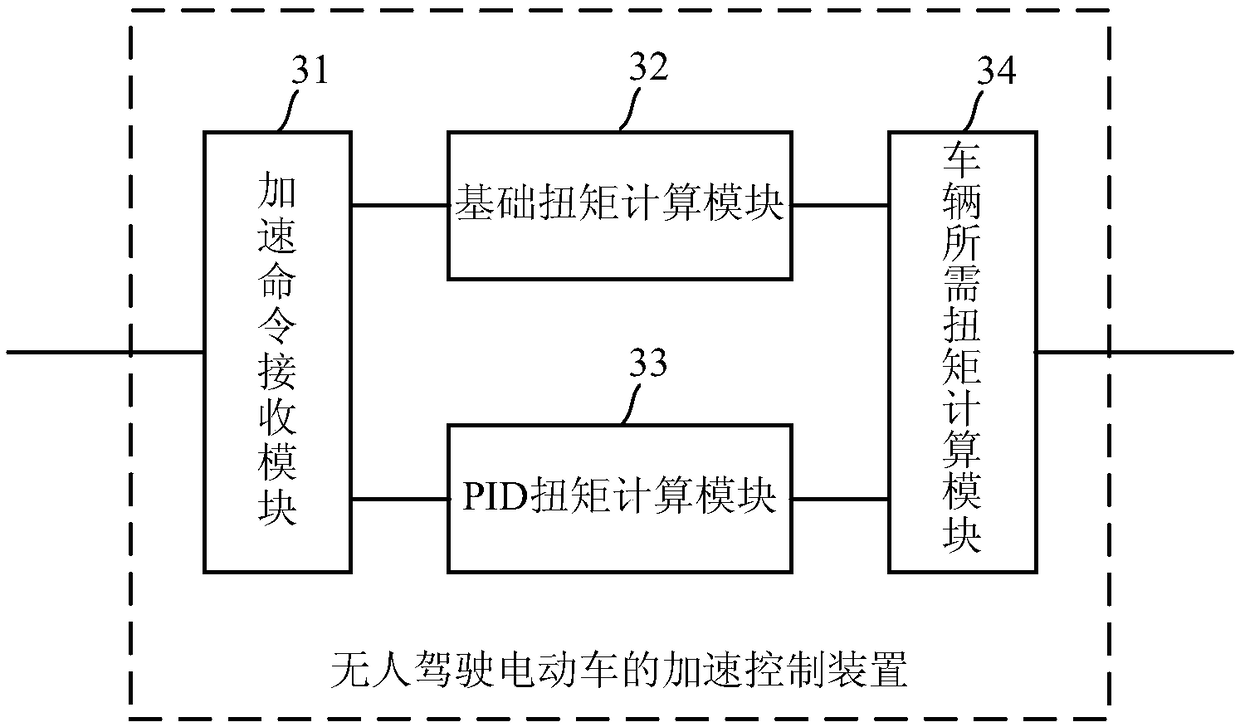

Acceleration control method and device for unmanned electric vehicle

ActiveCN108891304AImprove accuracySpeed controllerElectric energy managementProportional integral differentialElectric vehicle

The invention provides an acceleration control method and device for an unmanned electric vehicle. The method includes the steps of receiving an acceleration command sent by an upper path planning module of the unmanned electric vehicle, wherein the command contains target acceleration; calculating base torque required by the electric vehicle according to the target acceleration; according to a difference value between the actual acceleration of the electric vehicle and the target acceleration, calculating proportional integral differential PID torque of the electric vehicle; using the sum ofthe base torque required by the electric vehicle and the PID torque as torque required by the electric vehicle, and transmitting the torque required by the electric vehicle to a motor of the electricvehicle. The method and device improve the accuracy of control over the acceleration of the unmanned electric vehicle.

Owner:CH AUTO TECH CORP CO LTD

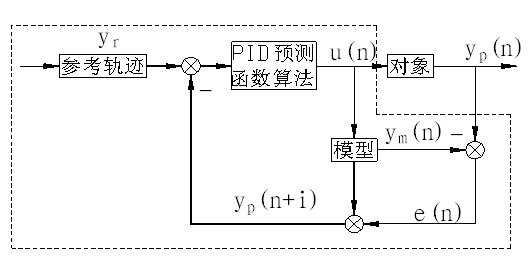

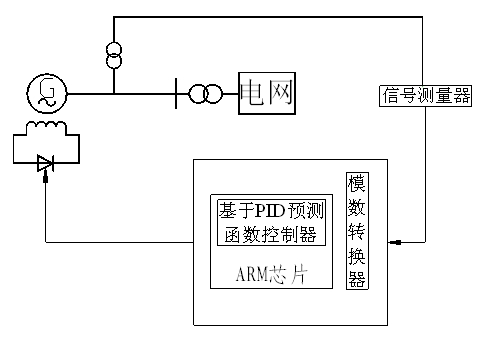

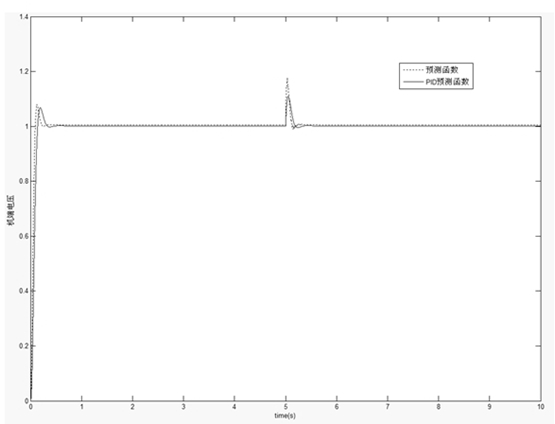

PID prediction function-based excitation control method

InactiveCN101997471AOvercome the disadvantage of limited adjustment rangeEffective control strategyGenerator control by field variationProportional integral differentialControl objective

The invention discloses a proportional-integral-differential (PID) prediction function-based excitation control method, which is used for an excitation control system for a synchronous generator. By combining characteristics of PID and prediction function control, a PID form-based prediction function controlled target function is provided, and the optimized controlled quantity is obtained by optimized calculation, and is taken as a control end input signal of a silicon controlled (or a full-control device) in the excitation control system so as to control the excitation current of the synchronous generator and further influence the terminal voltage thereof. An excitation controller acquired by the method has structural characteristics of proportion, integral and differential in a broad sense, has respective advantages of the PID and the prediction function control, and is convenient to implement. The method overcomes the defects that the conventional prediction control method has high on-line calculated amount and the PID control method has a limited regulating range, and is a novel and effective control strategy for stabilizing a power system.

Owner:淮安市富脉科技有限公司

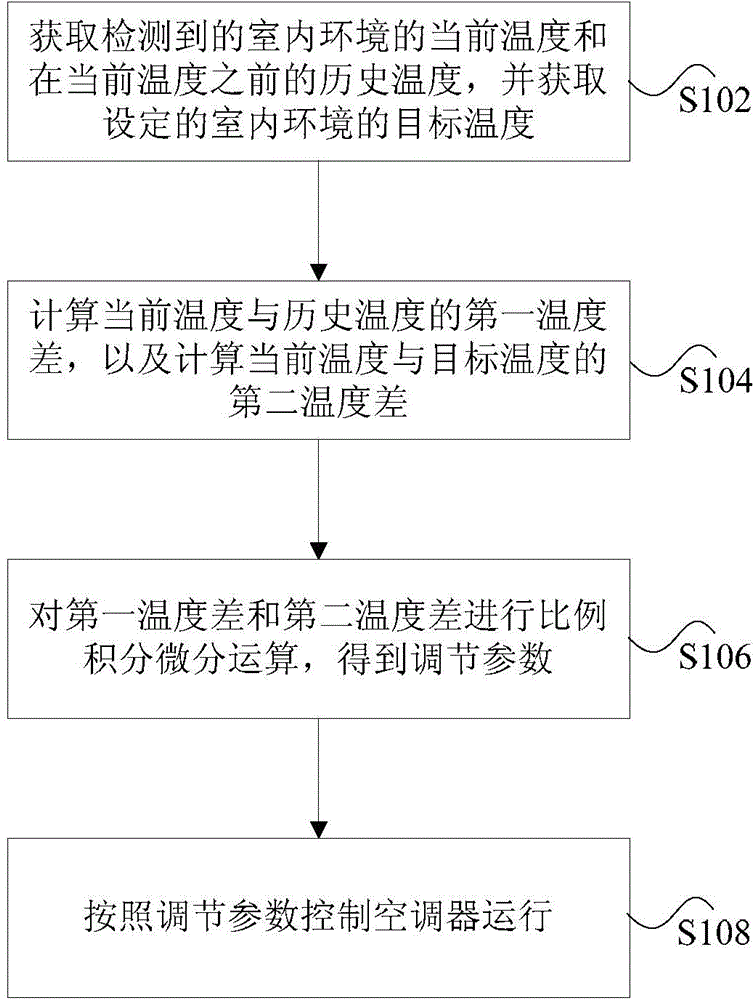

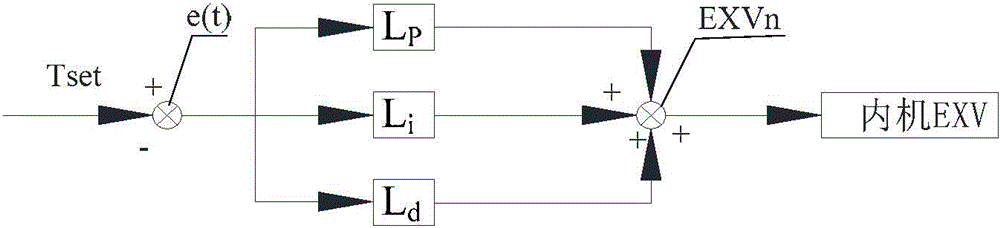

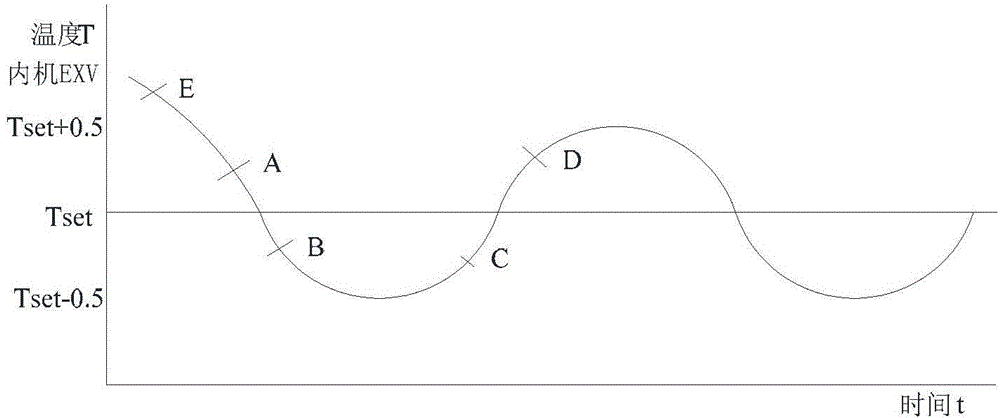

Air conditioner as well as control method and device thereof

ActiveCN105783182ATroubleshooting prone to failure issuesExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusProportional integral differentialTemperature difference

The invention discloses an air conditioner as well as a control method and device thereof. The control method of the air conditioner comprises the steps of acquiring the detected current temperature of an indoor environment and the historical temperature before the current temperature, and acquiring the set target temperature of the indoor environment; calculating a first temperature difference of the current temperature and the historical temperature and a second temperature difference of the current temperature and the target temperature; carrying out proportional-integral-differential operation on the first temperature difference and the second temperature difference to obtain an adjusting parameter; and controlling the operation of the air conditioner according to the adjusting parameter. Through the air conditioner as well as the control method and device thereof, the problem that a compressor easily has a fault in the prior art is solved, and the effects of prolonging the service life of the compressor and improving the operation stability of the air conditioner are taken.

Owner:GREE ELECTRIC APPLIANCES INC

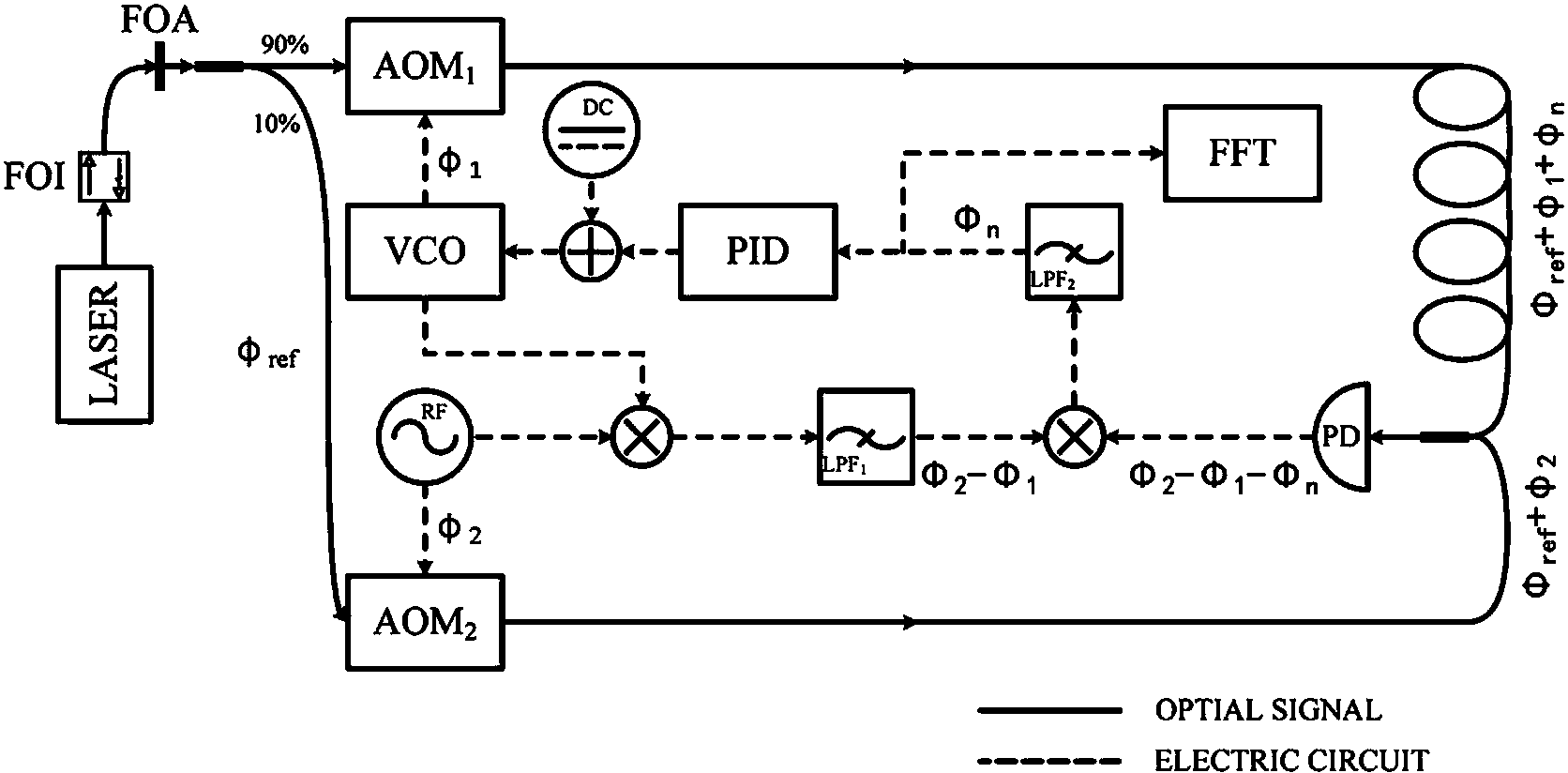

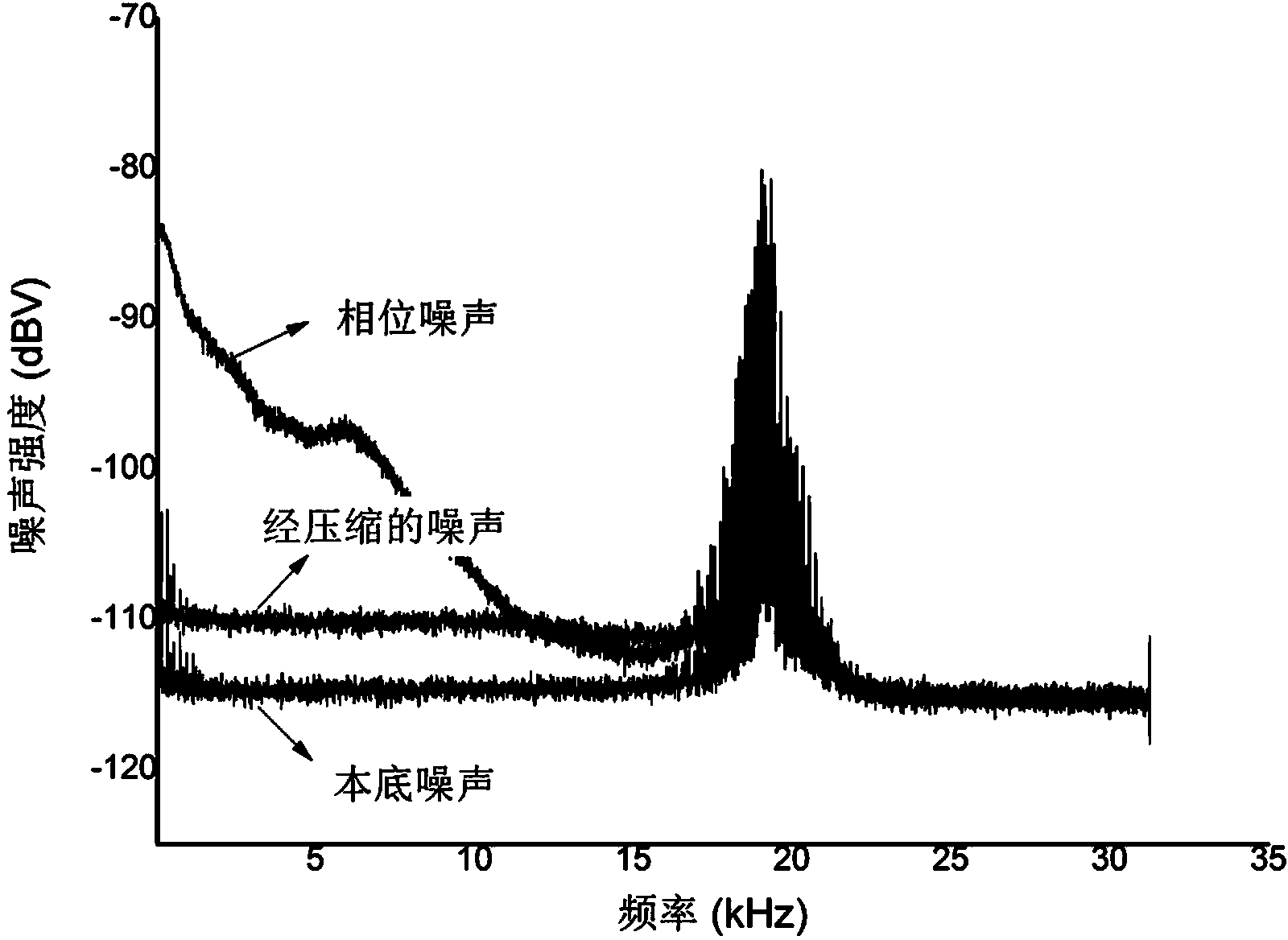

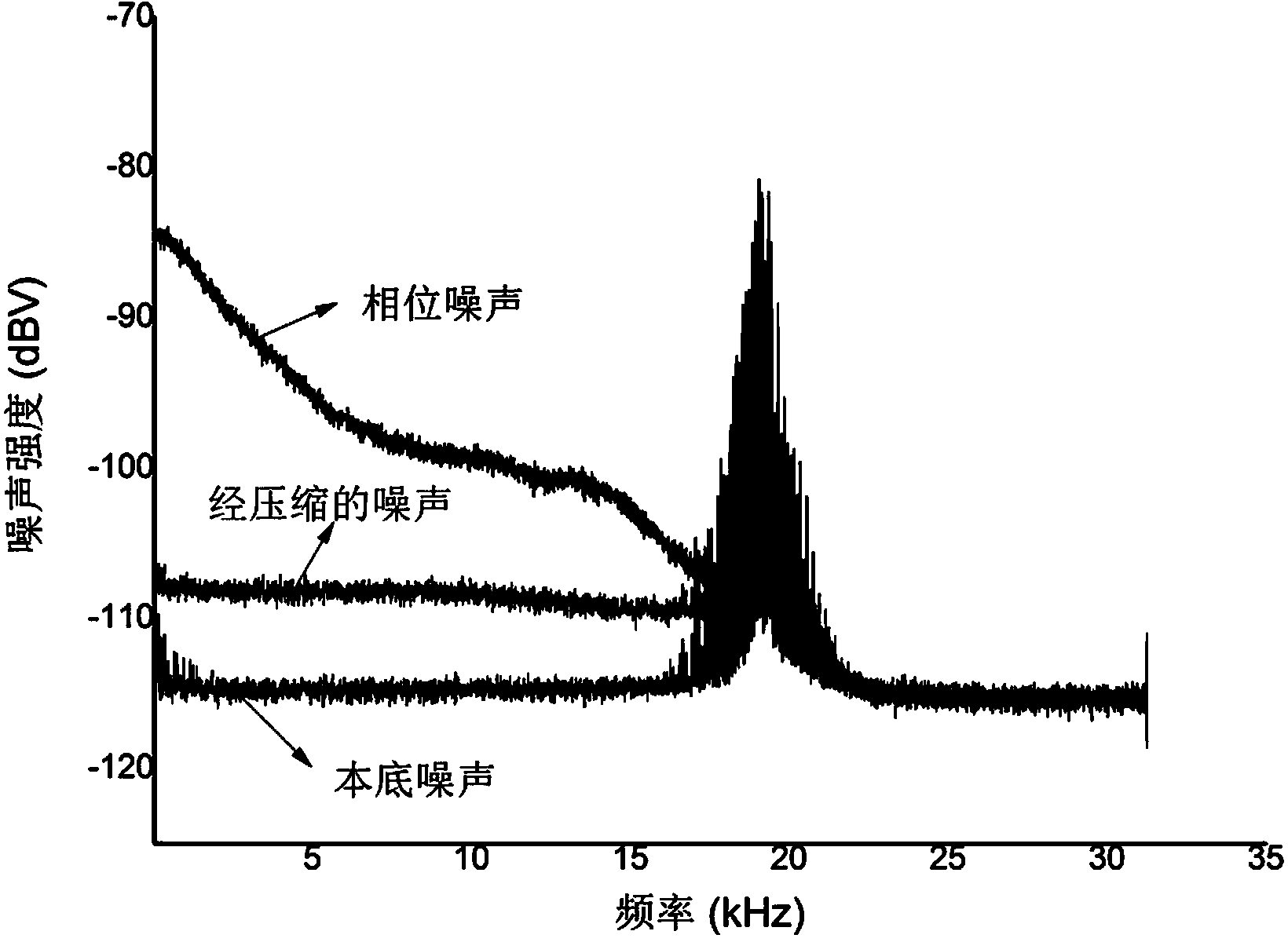

Method for compressing low-frequency phase noise in optical fiber transmission process

InactiveCN103916189AAvoid interferenceCompression of Low Frequency Phase NoiseDistortion/dispersion eliminationProportional integral differentialPhase noise

The invention relates to a phase noise compression technology, in particular to a method for accurately eliminating low-frequency phase noise in the optical fiber transmission process. According to the method, the problem that due to the fact that in the prior art, noise in different frequency bands is different in contribution to a feedback loop, the phase noise cannot be accurately eliminated is solved, a low-frequency portion in the phase noise is extracted through a low-pass filter and is fed back, and the low-frequency phase noise is effectively compressed; proportional integral differential processing is carried out on noise signals, then the processed noise signals are fed back to an acousto-optic modulator, frequency shifting is carried out on light beams through the acousto-optic modulator to adjust the phase, and finally accurate compression of the low-frequency phase noise is achieved. According to the method for accurately eliminating the low-frequency phase noise in the optical fiber transmission process, the problem that the low-frequency phase noise cannot be effectively eliminated through an existing compensation method is effectively solved, and the method is suitable for phase noise processing of an optical fiber transmission system for quantum secret key distribution, coherence measurement and the like.

Owner:SHANXI UNIV

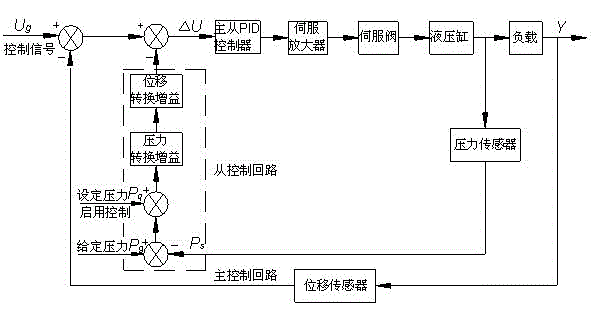

Position and pressure master-slave control method of hydraulic servo system of valve-controlled cylinder

InactiveCN103148063APrecise master-slave controlHigh control precisionFluid-pressure actuator componentsProportional integral differentialHydraulic cylinder

The invention relates to a position and pressure master-slave control method of a hydraulic servo system of a valve-controlled cylinder, and belongs to the technical field of control of a high-flow quantity and high-speed hydraulic servo system. The method comprises the following steps of using a position signal in the hydraulic servo system of the valve-controlled cylinder as a master feedback signal of the whole system, and using the position control as the master closed loop control of the whole system; using a pressure signal as a slave control signal, and using the pressure feedback control as the slave closed loop control; and introducing the pressure conversion gain into the slave closed loop control, when the load of an executing mechanism reaches the setting range of the master control pressure, starting the position and pressure master-salve control of the hydraulic servo system of the valve-controlled cylinder, comparing the actual pressure signal with the given pressure signal to obtain a result, converting the result into a position deviation signal, compensating the deviation signal into a position closed loop of the whole system, and enabling the system to adjust a servo valve by a master-salve PID (proportional integral differential) controller according to the general position deviation signals, so as to precisely adjust the position of a hydraulic cylinder. The method has the advantages and beneficial effects that the position and pressure master-salve control of the hydraulic servo system is realized, the control precision of the system is improved, and the control performance of the system is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

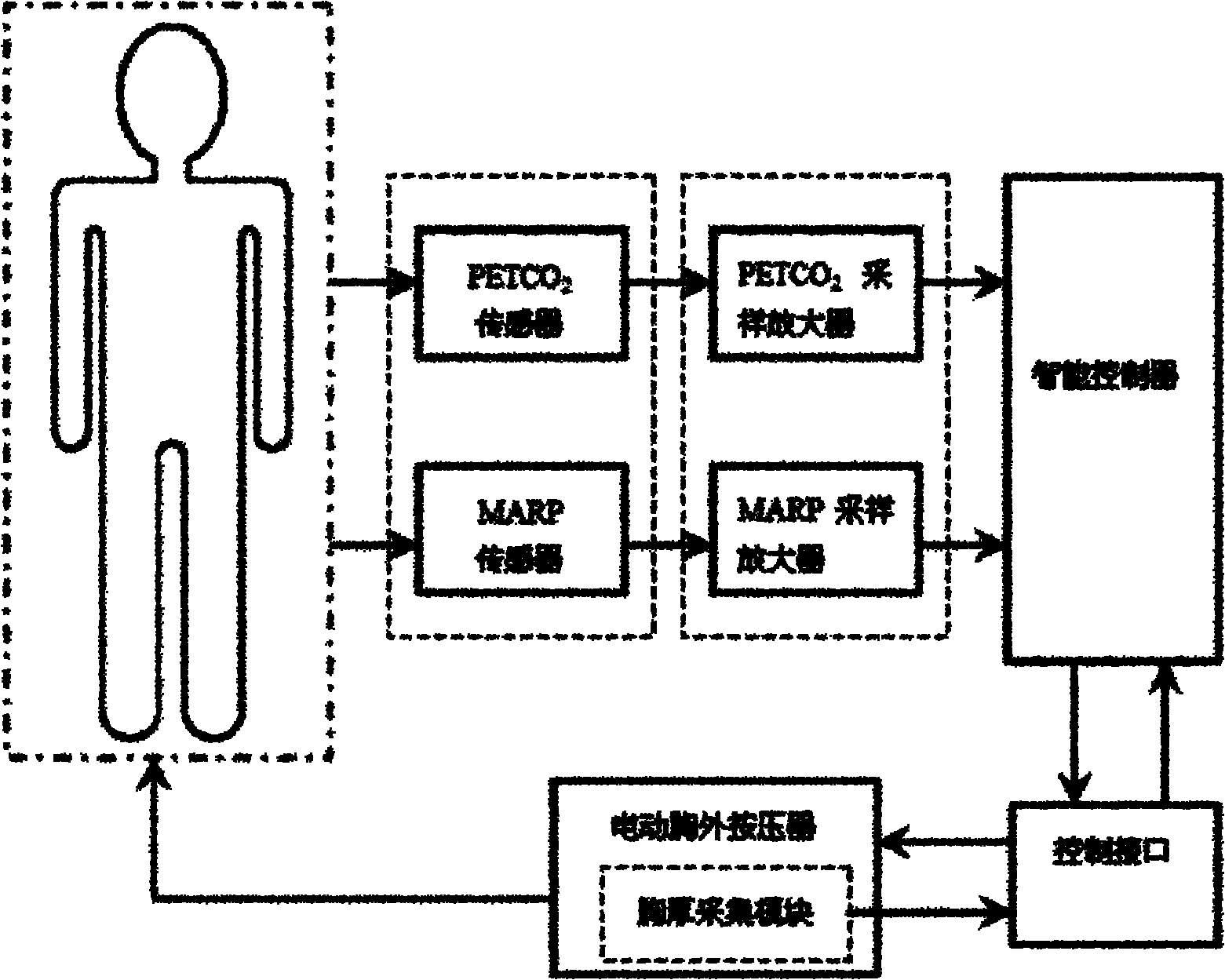

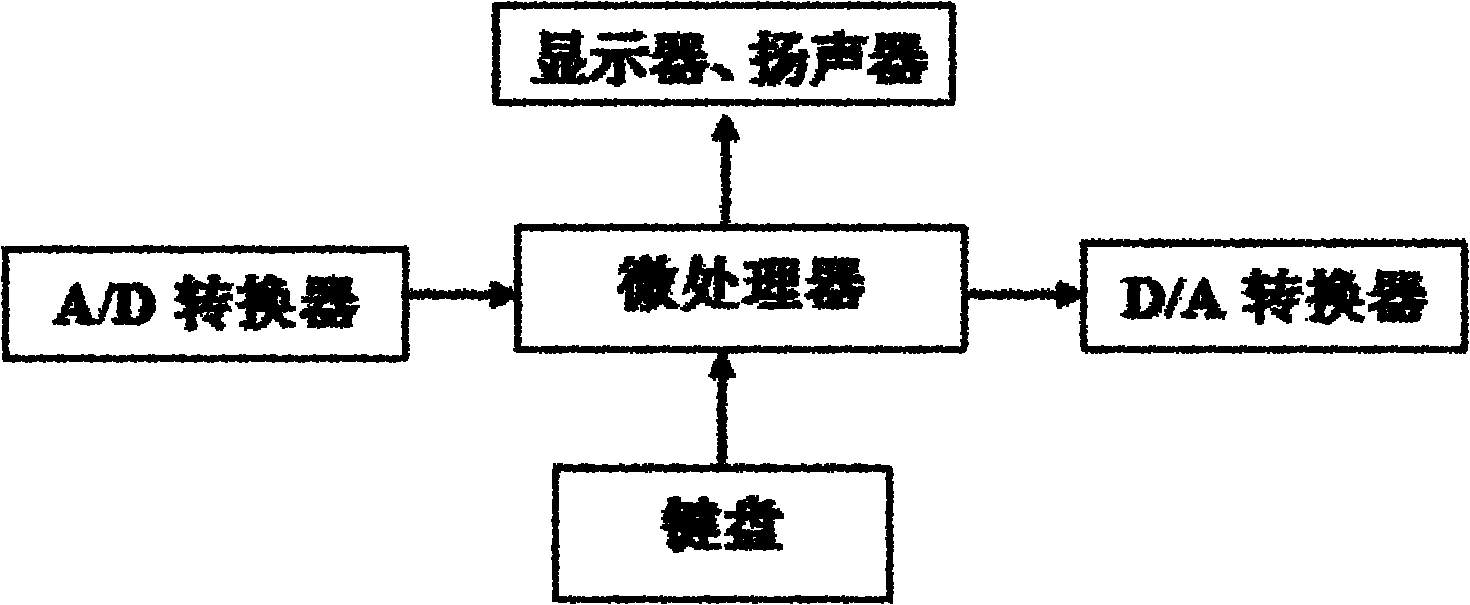

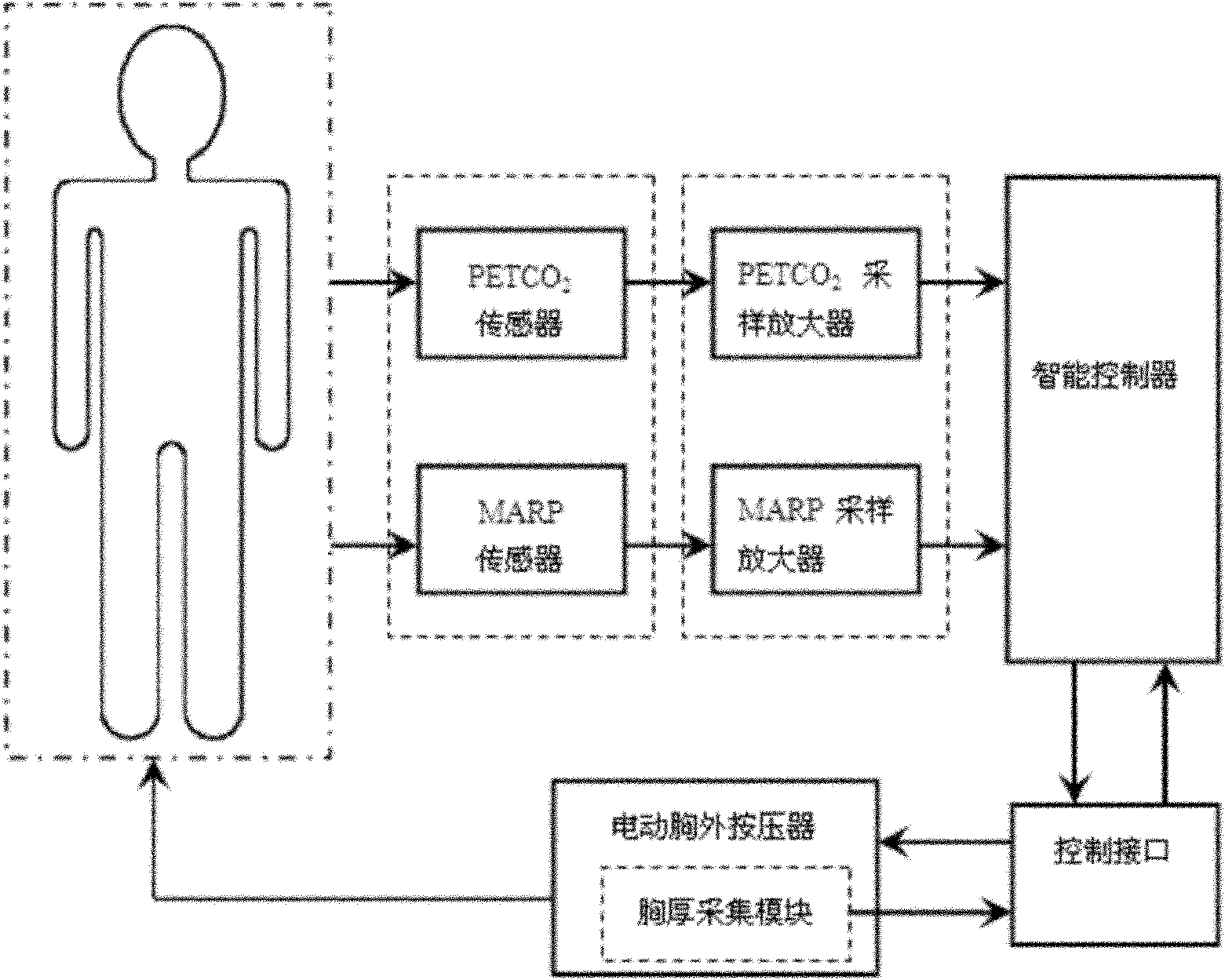

Closed-loop external chest compression system

InactiveCN102119908AImproved quality of chest compressionsElectrotherapyArtificial respirationProportional integral differentialControl signal

The invention discloses a closed-loop external chest compression system. The system comprises a feedback physiological signal acquiring module, a postprocessing and amplifying module, an intelligent controller, a control interface, an electrical external chest compressor and a chest thickness signal acquiring module, wherein the intelligent controller samples an analogue signal which comes from the postprocessing and amplifying module and a patient chest thickness signal which is sampled by the chest thickness signal acquiring module, compares the analogue signal which reflects actual feedback physiological information with a target physiological signal, and generates the depth and frequency control signal of the external chest compression to be implemented, which can accord with the target physiological signal, by combining a fuzzy control algorithm or a fuzzy proportional integral differential (PID) control algorithm. By continuously monitoring partial pressure of end-tidal carbon dioxide (PETCO2) and mean arterial pressure (MARP) in real time and using the feedback physiological signal, the closed-loop control over the depth and the frequency of the external chest compression is performed on the basis of the fuzzy control algorithm or the fuzzy PID control algorithm. The closed-loop external chest compression system is suitable for pre-hospital emergency treatment and continuous treatment of patients with sudden cardiac arrest.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

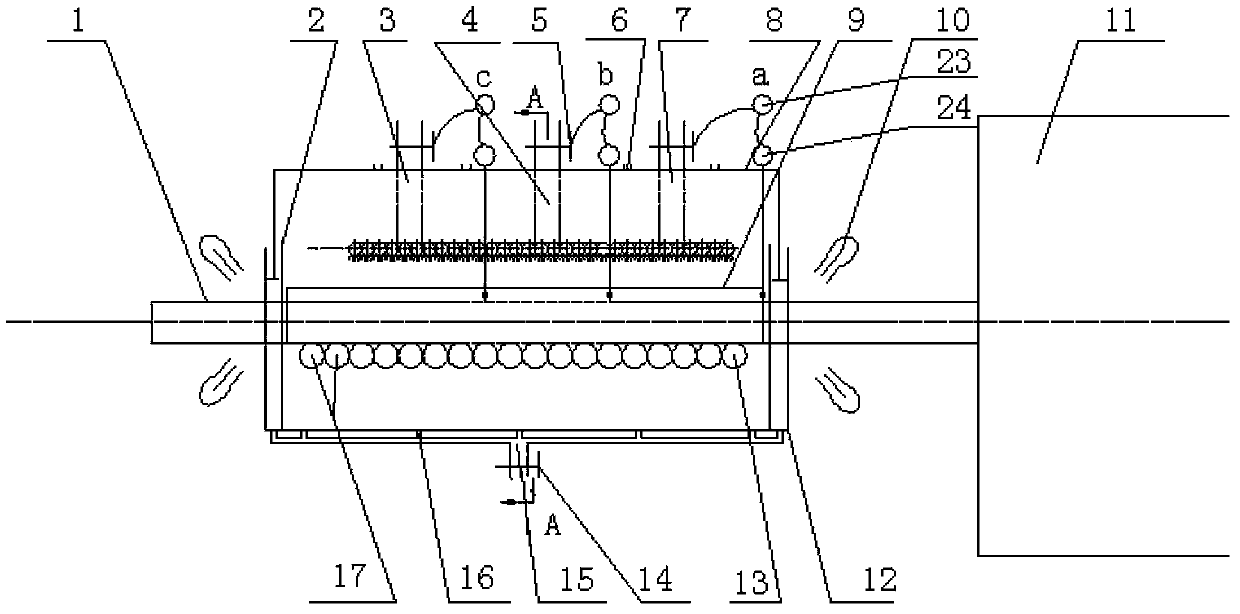

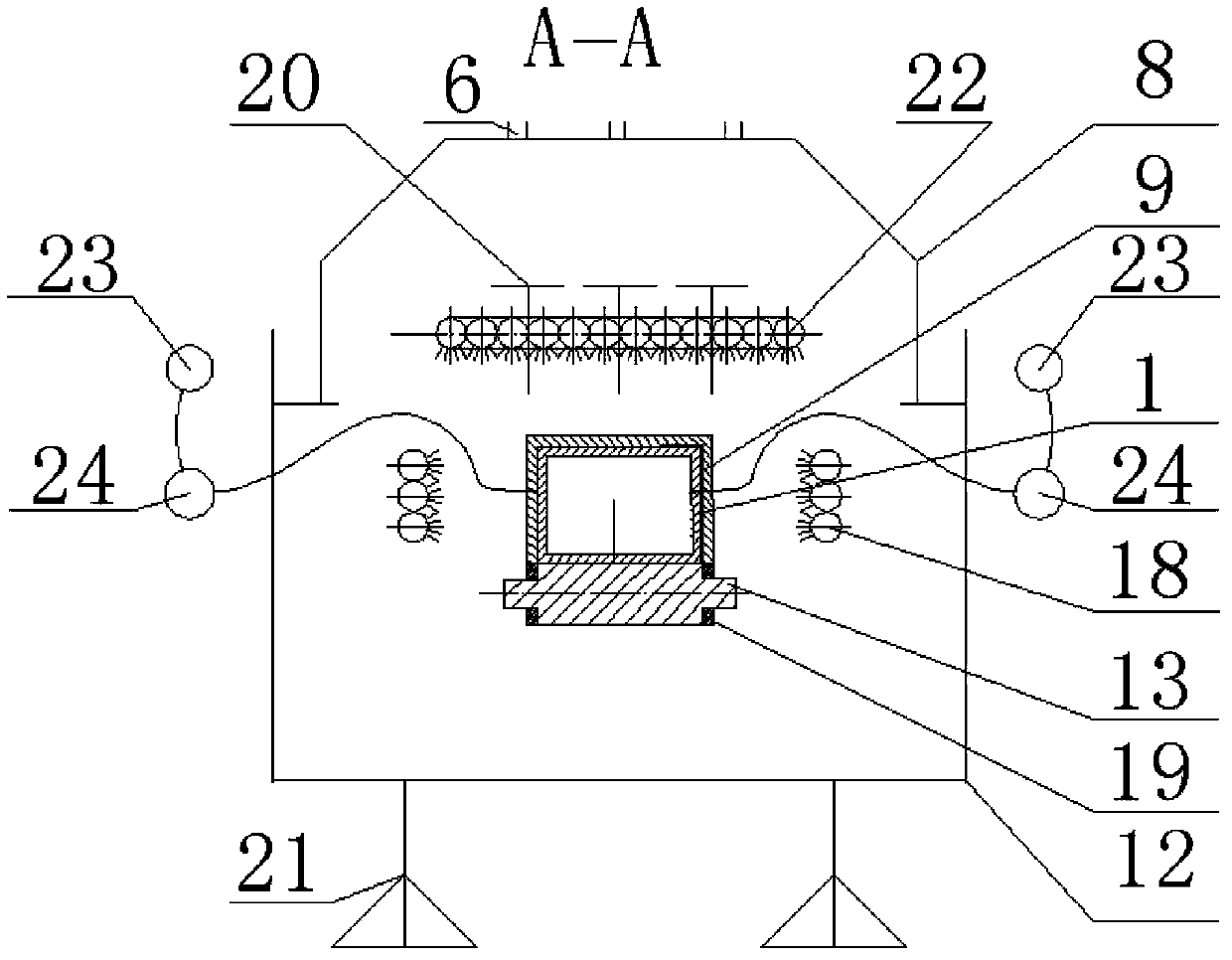

Aluminum profile quenching device

ActiveCN103397285AReduce temperature distribution non-uniformityReduce deformation defectsQuenching devicesProportional integral differentialStructure property

The invention discloses an aluminum profile quenching device, comprising a water tank, a felt roller, a stock mould, a temperature sensor and a PID (Proportional Integral Differential) controller, wherein the water tank is provided with a water inlet pipe and a water outlet pipe, each of the water inlet pipe and the water outlet pipe is provided with a control valve, the felt roller is arranged in the water tank and used for receiving aluminum profiles to be quenched, the stock mould is arranged at the upper part of the felt roller and comprises an inner cavity, a nozzle connected with the water inlet pipe is arranged between the stock mould and the water tank, the temperature sensor is connected with the stock mould, and the PID controller is connected with the temperature sensor and the control valve arranged on the water inlet pipe and is used for receiving a temperature signal sent by the temperature sensor and regulating the opening of the control valve on the water inlet pipe. The aluminum profile quenching device is capable of adjusting cooling rates and cooling stages of different positions according to the section sizes and materials of different profiles, so that the nonuniformity of temperature distribution is reduced and further the uniform structure properties of the profiles are ensured. Due to existence of the stock mould, the degree of freedom of displacement on a cross section is limited and further the deformation defects are reduced.

Owner:NORTHEASTERN UNIV

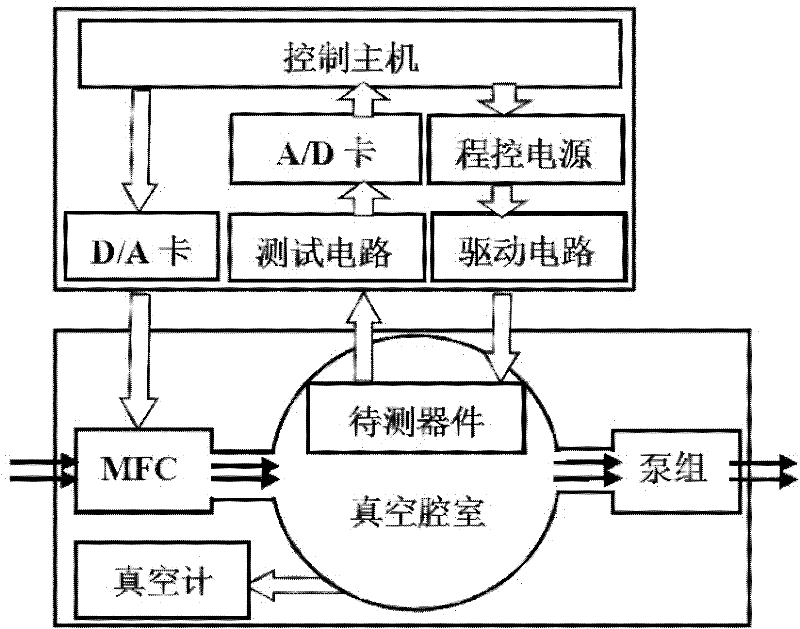

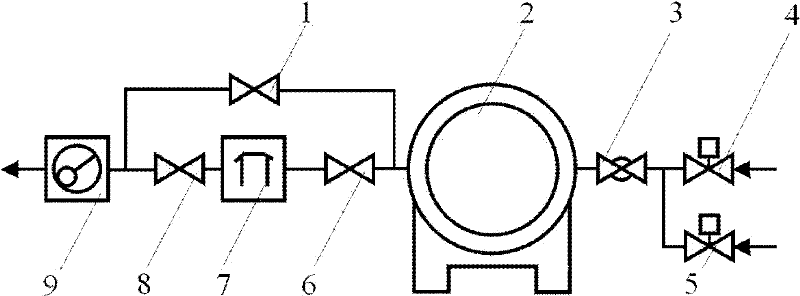

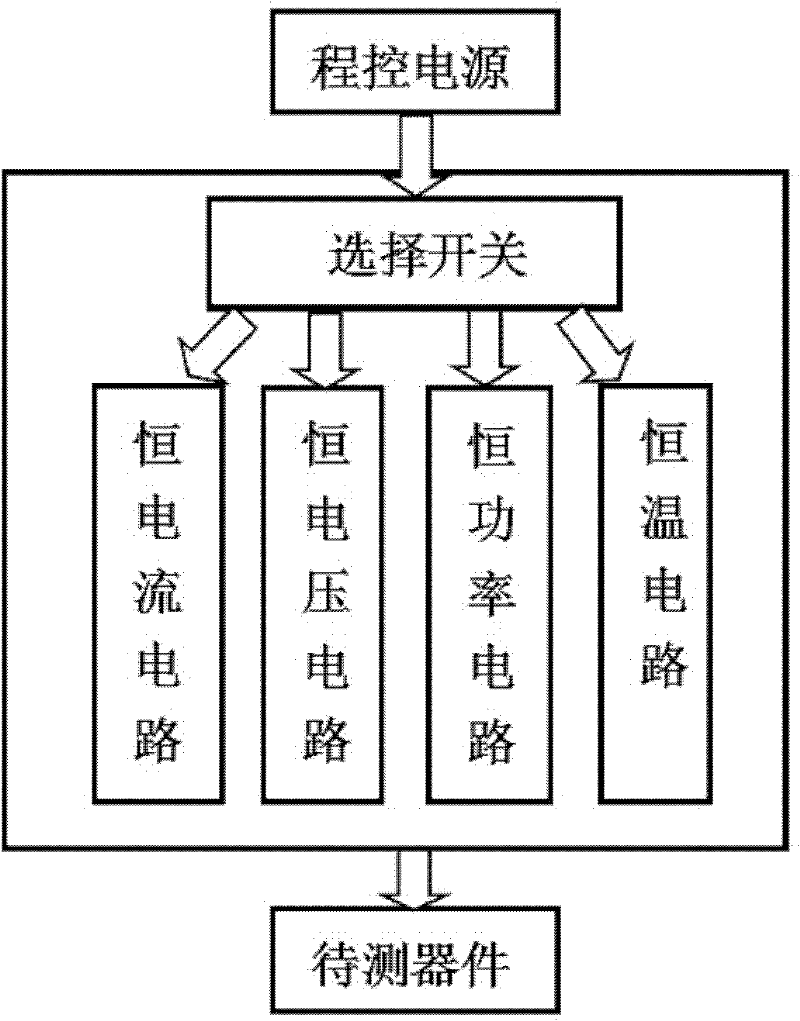

Semiconductor micro air pressure sensor test system

InactiveCN102564695AMeet the test requirementsSolve balance problemsFluid pressure measurementProportional integral differentialEngineering

The invention relate to a semiconductor micro air pressure sensor test system which comprises a microcomputer controlling part and a vacuum acquiring part. The microcomputer controlling part comprises a control host, a programmable power supply, a drive circuit, a test circuit, A / D card and a D / A card; the control host is used for controlling the programmable power supply; the response signal of a device under test is transmitted to the control host through the test circuit and the A / D card; the vacuum acquiring part comprises a vacuum chamber, a pump group, a mass flow controller and a vacuum gauge; the vacuum chamber is connected with the mass flow controller and the pump group; the air flows in from the mass flow controller and flows out from the pump group; the mass flow controller is connected with the D / A card and used for keeping the air pressure in the vacuum chamber balanced through the fuzzy PID (proportional-integral-differential) control algorithm; the vacuum gauge serves as the calibration reference of a sensor under test. The semiconductor micro air pressure sensor test system can generate the dynamically-balanced vacuum environment of the pure gas, improve the stability and the interference resistance of the testing process and provide four working circuits for the device under test and is convenient for the calibration and the test of a semiconductor micro air pressure sensor.

Owner:DALIAN UNIV OF TECH

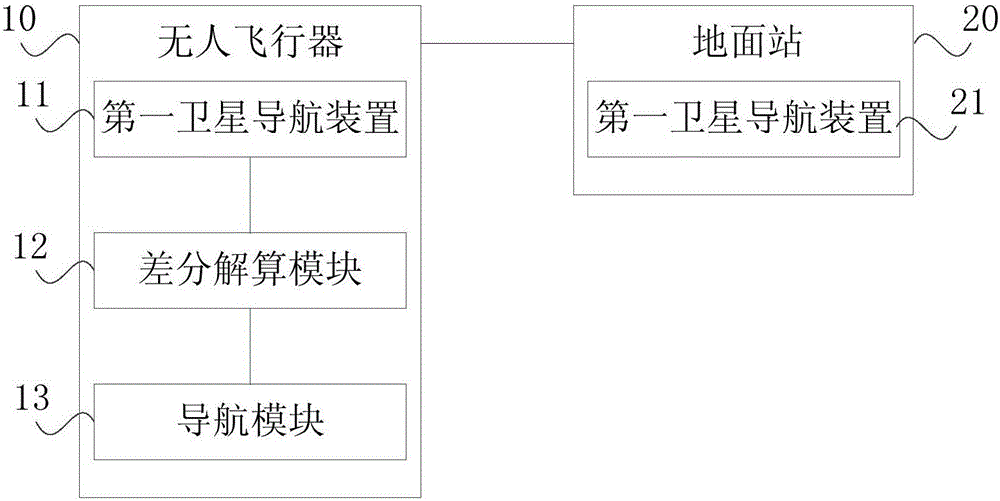

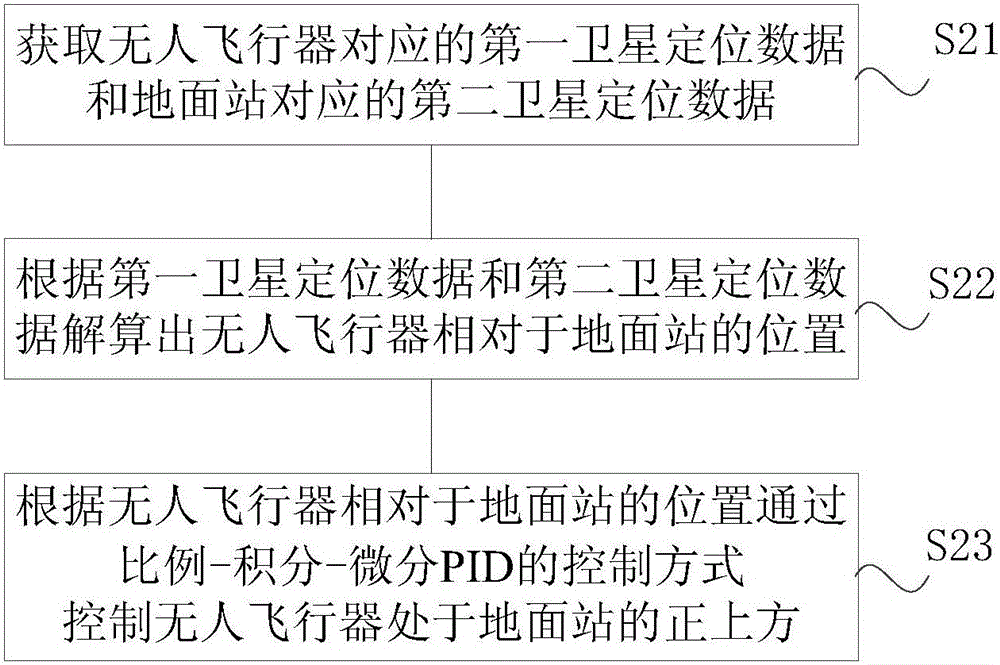

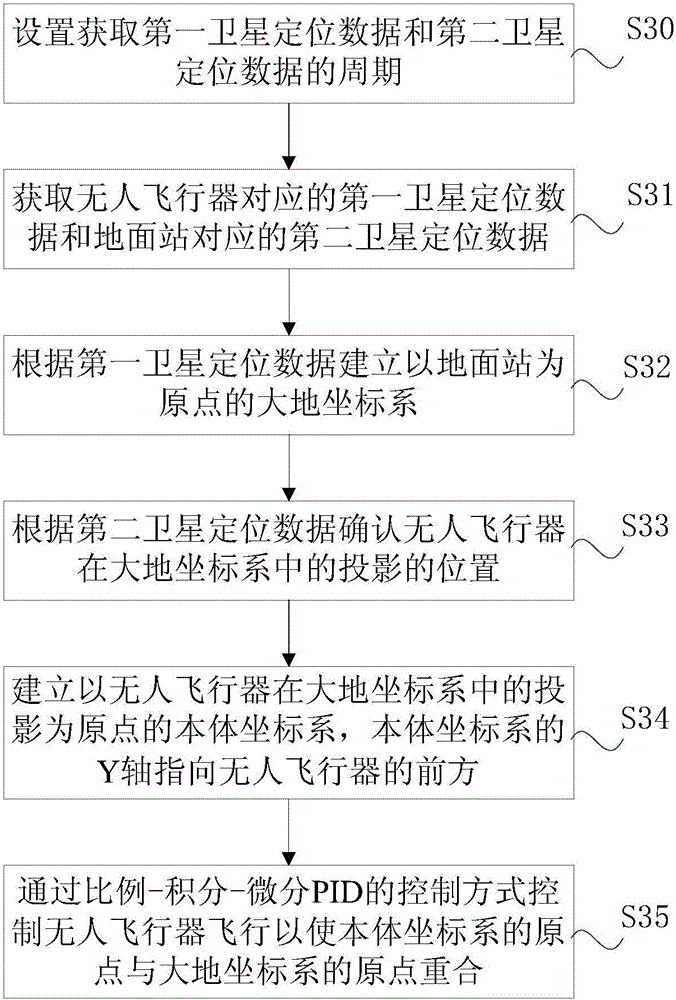

Unmanned aerial vehicle tracking system and method based on differential satellite navigation

ActiveCN106200656AHigh precisionAccurate distanceSatellite radio beaconingAttitude controlProportional integral differentialControl manner

The invention discloses an unmanned aerial vehicle tracking system and method based on differential satellite navigation. The system comprises a first satellite navigation device, a second satellite navigation device, a differential resolving module and a navigation module. The first satellite navigation device is arranged on the ground station of an unmanned aerial vehicle and receives first satellite positioning data. The second satellite navigation device is arranged on the unmanned aerial vehicle and receives second satellite positioning data. The differential resolving module resolves the position of the unmanned aerial vehicle relative to the ground station according to the first satellite positioning data and the second satellite positioning data. The navigation module controls the unmanned aerial vehicle to be directly above the ground station according to the position of the unmanned aerial vehicle relative to the ground station in a proportional-integral-differential PID control manner. According to the invention, the accuracy of mooring tracking of the unmanned aerial vehicle is improved, and accurate relative distance and azimuth of centimeter level are acquired.

Owner:BEIJING DAGONG TECH CO LTD

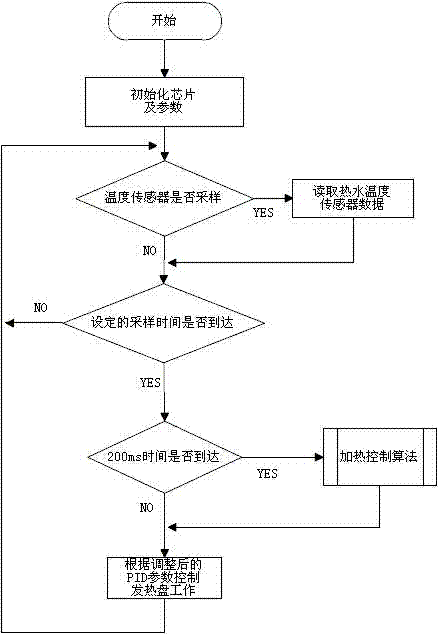

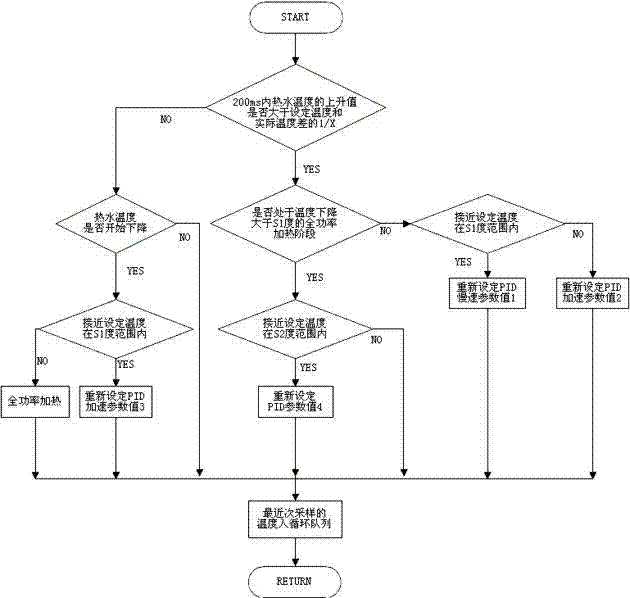

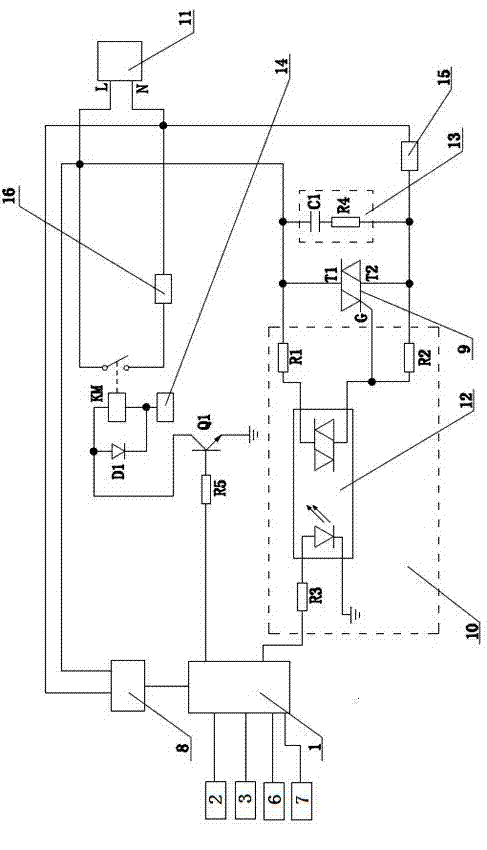

Water dispenser energy-saving control method and water dispenser control circuit

ActiveCN103202663AReduce lossReduce consumptionBeverage vesselsProportional integral differentialPulse control

The invention discloses a water dispenser energy-saving control method and a water dispenser control circuit. A first temperature sensor is used for detecting a temperature value of water in a water dispenser inner container and sending the temperature value to a central processing unit. The central processing unit calculates the temperature value to obtain a pulse control quantity required by an input end of a heating control execution module and drives an output end of the heating control execution module to obtain corresponding heating power. The control method comprises the steps of controlling hot water in the water dispenser inner container to be constant at a set temperature T0 and enabling heating power of a water dispenser to vary according to changes of T0. An extremely small temperature difference occurs between starting and shutdown of a heater, and almost no temperature difference occurs. Output power of the heater is controlled through a variable pulse fuzzy control heating algorithm based on a proportional integral differential (PID) controller, a fuzzy pulse control quantity is output, and energy is hardly consumed or an extremely small amount of energy is consumed within extremely short time. The water dispenser energy-saving control method and the water dispenser control circuit are suitable for all water dispensers.

Owner:ELECTROTEMP TECHNOLOGIES CHINA INC

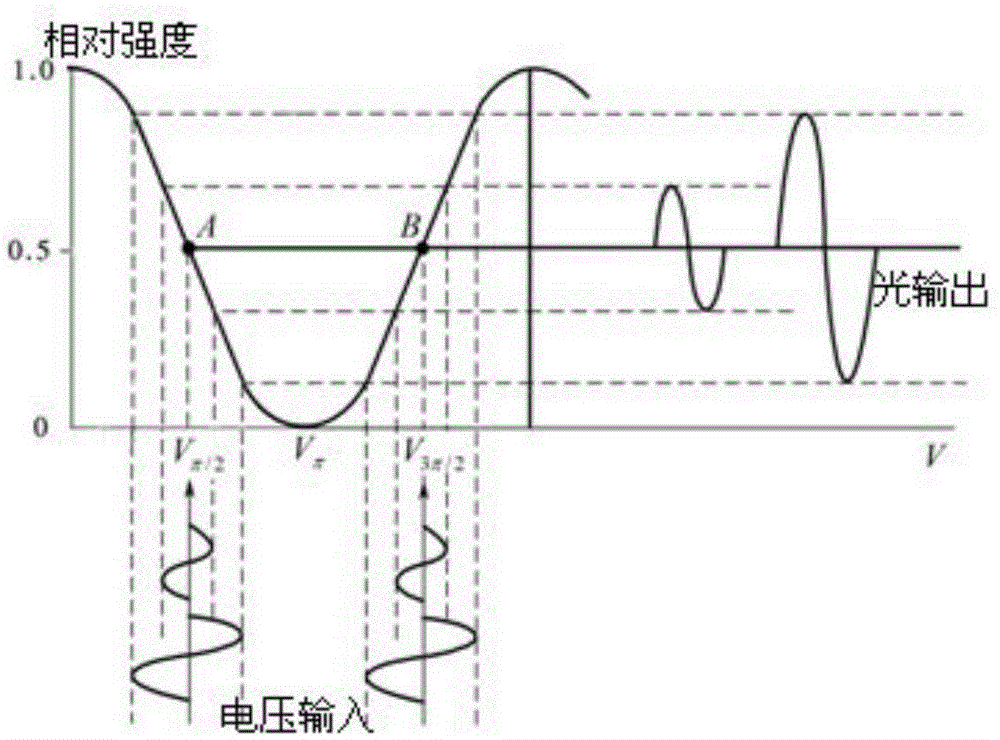

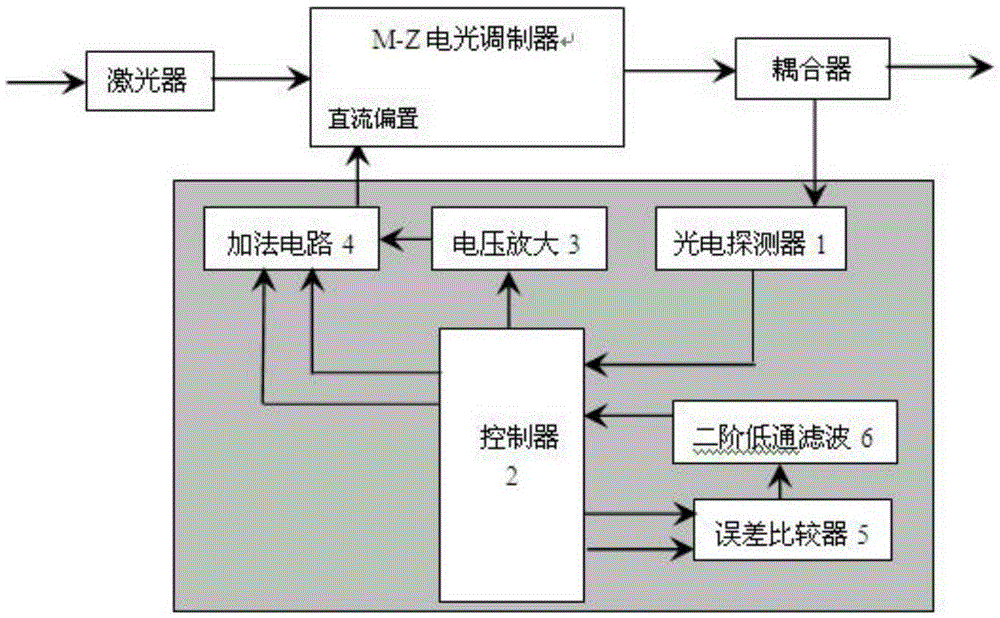

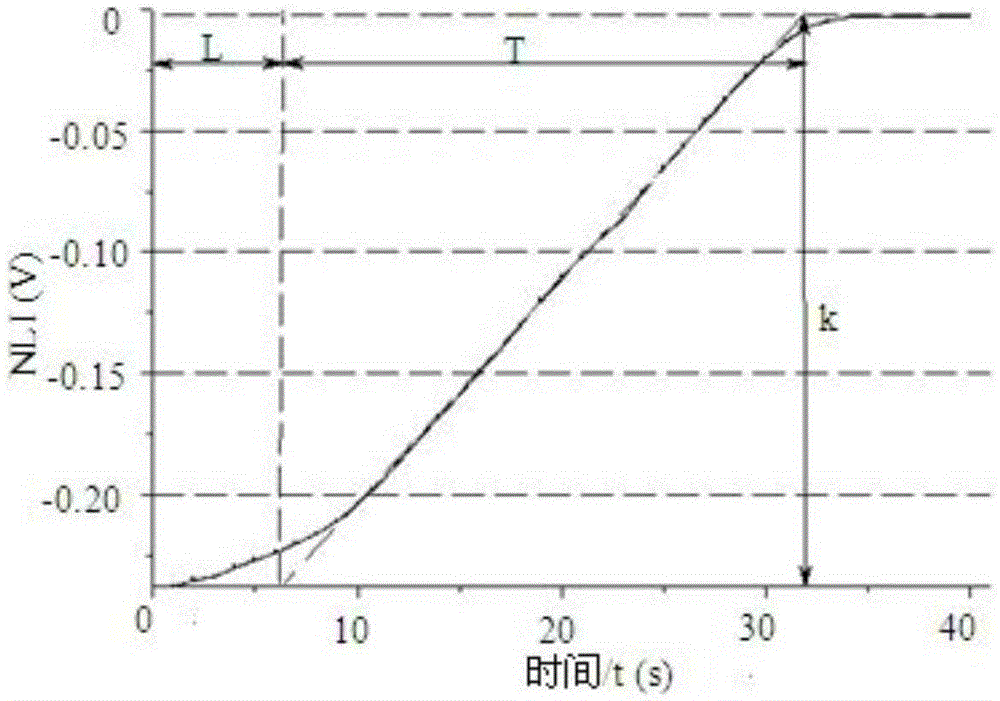

Device and method for controlling offset working point of electro-optic modulator

InactiveCN105302019AProgramme controlComputer controlProportional integral differentialLow-pass filter

The invention relates to the field of optical transmission networks, and discloses a device and a method for controlling an offset working point of an electro-optic modulator. Especially in allusion to characteristics of high frequency and high speed of an organic polymer Mach-Zehnder electro-optic modulator, a purpose that the electro-optic modulator works at an optimal working point is achieved through adopting a programmable system on chip (PsoC) and a proportional-integral-differential (PID) control algorithm. The device is composed of a photoelectric detector (1), a controller (2), a voltage amplification circuit (3), an adding circuit (4), an error comparator (5) and a second-order low-pass filter circuit (6). According to the invention, a programmable computation ability of the PsoC is utilized, and the accurate PID control algorithm is adopted, thereby enabling the device to have the characteristics of simple structure, small size, easy implementation, high precision and ability of not relying on other external equipment. The device and the method disclosed by the invention solve problems that the control precision is low and that circuit are complex in the prior art, and realize high-precision control for the offset working point.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com