Patents

Literature

320 results about "Out stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress absorbing flexible heart valve frame

ActiveUS7473275B2Facilitate such flexionFacilitates a supra-annular implant techniqueHeart valvesMedicineProsthetic heart

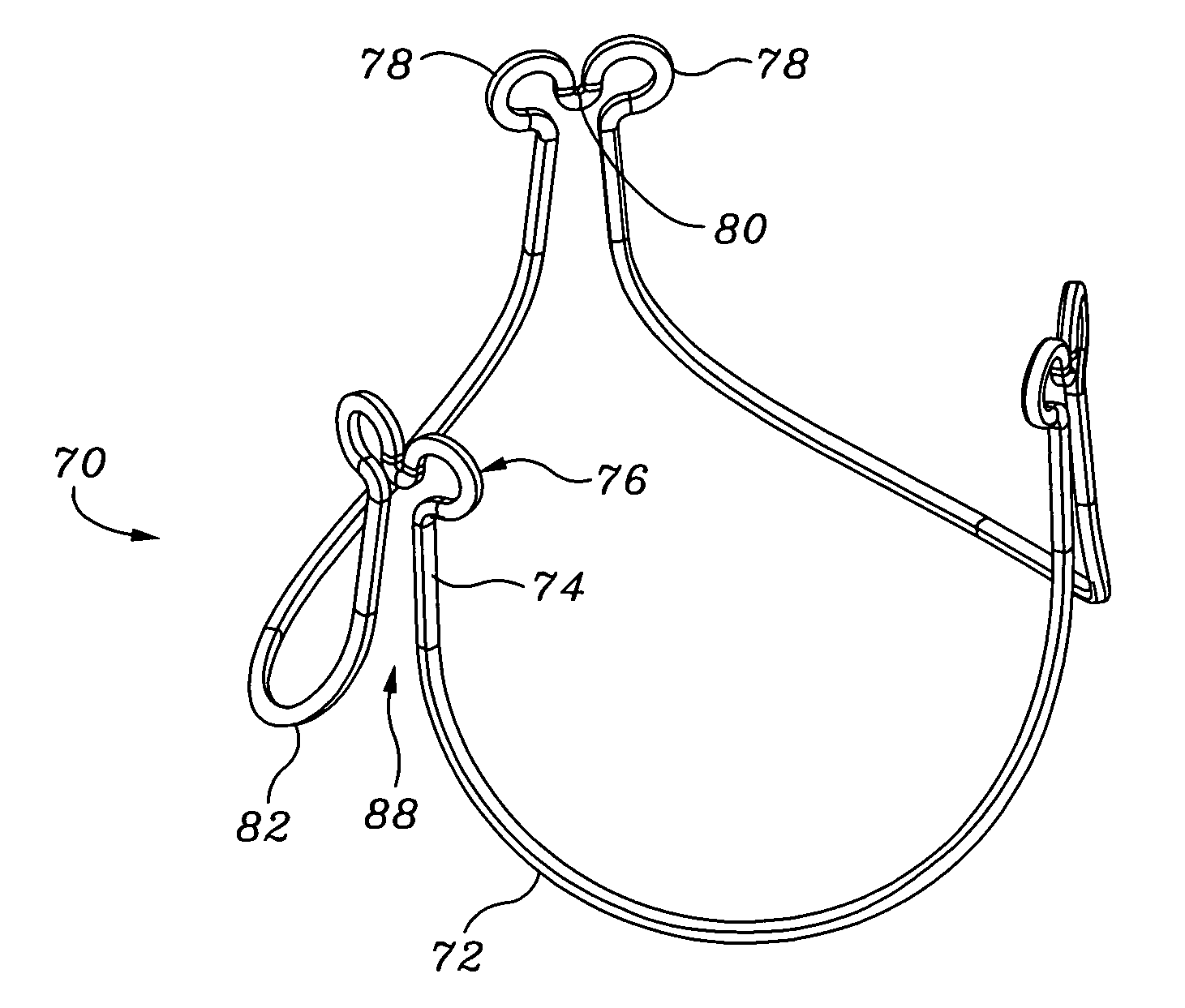

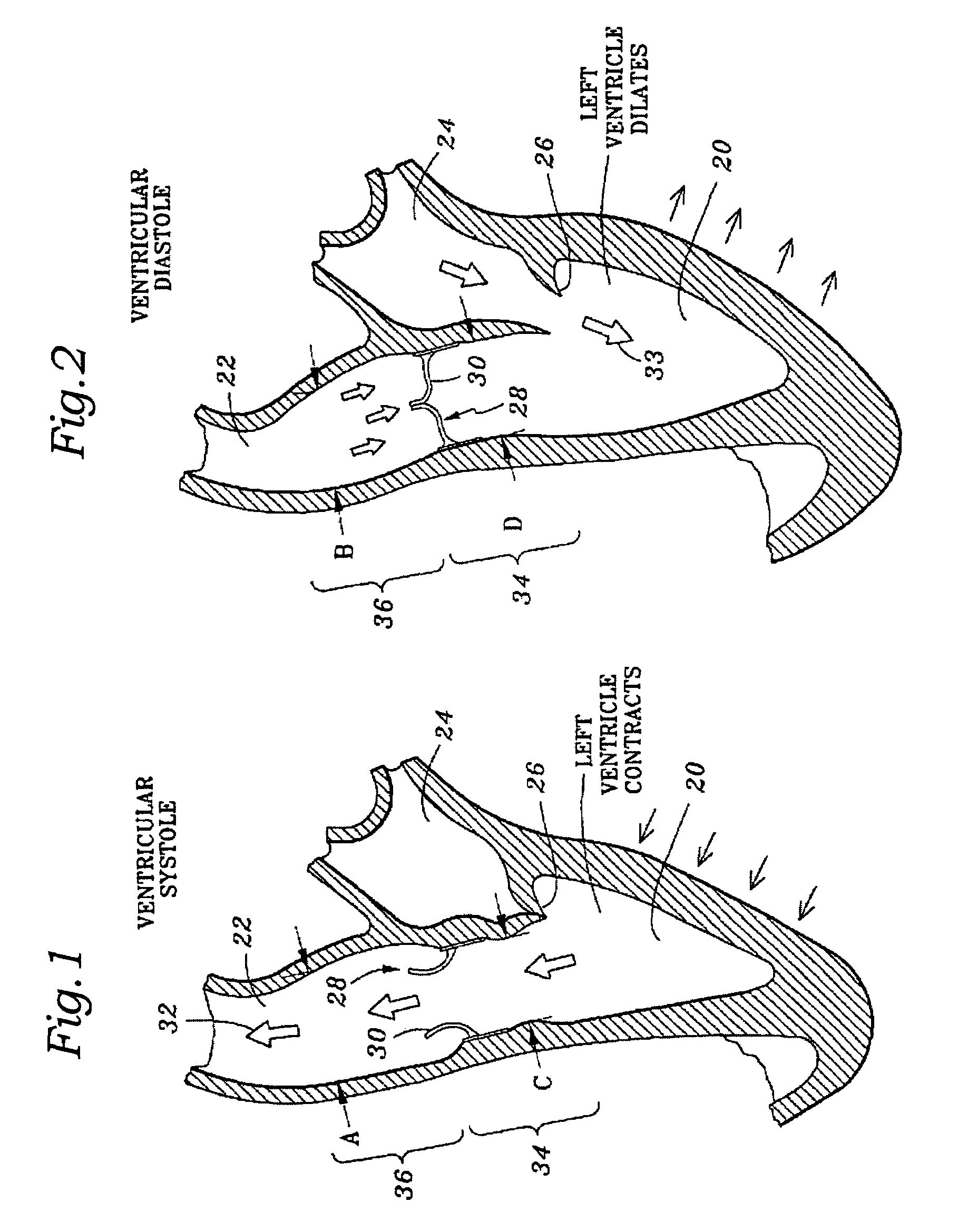

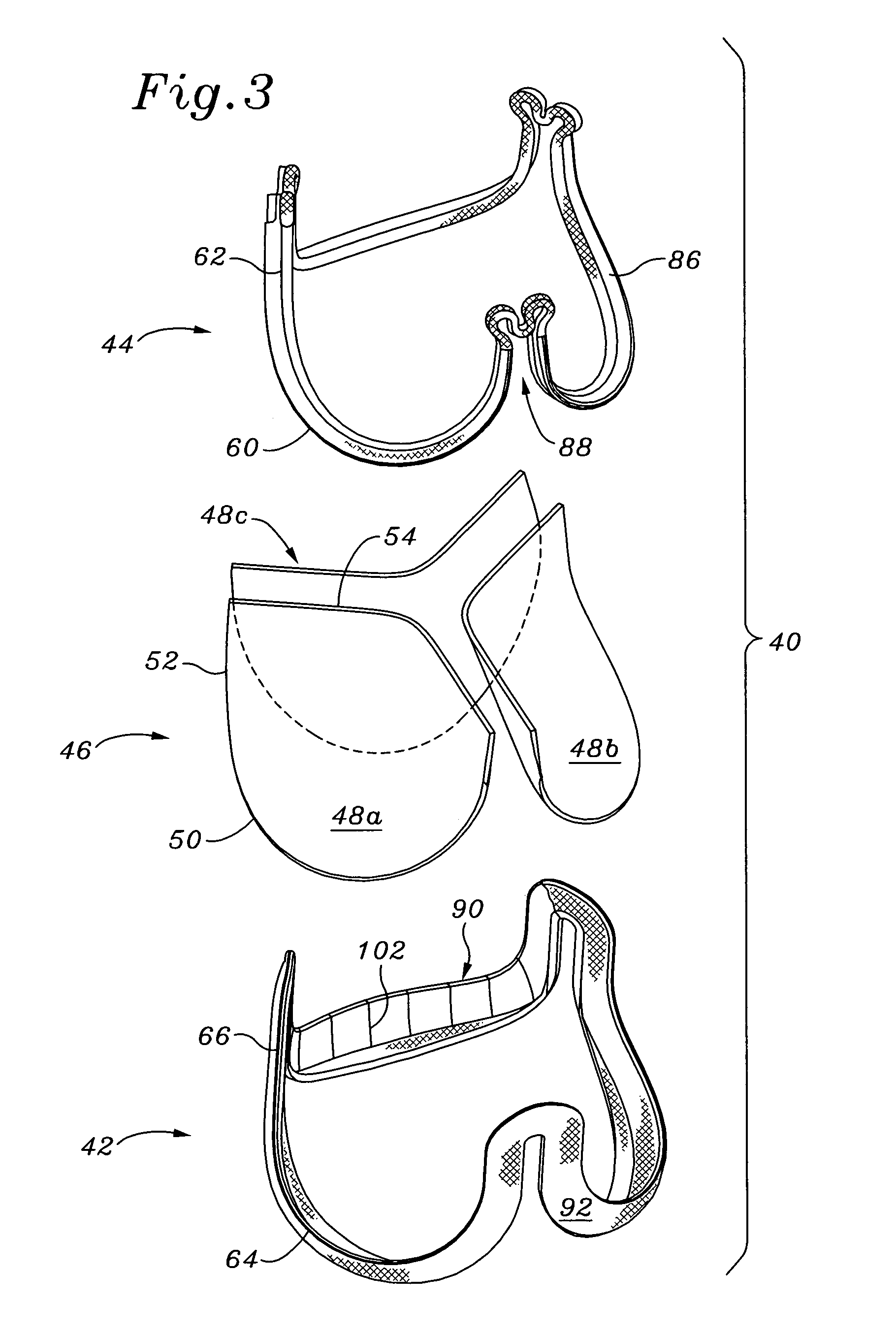

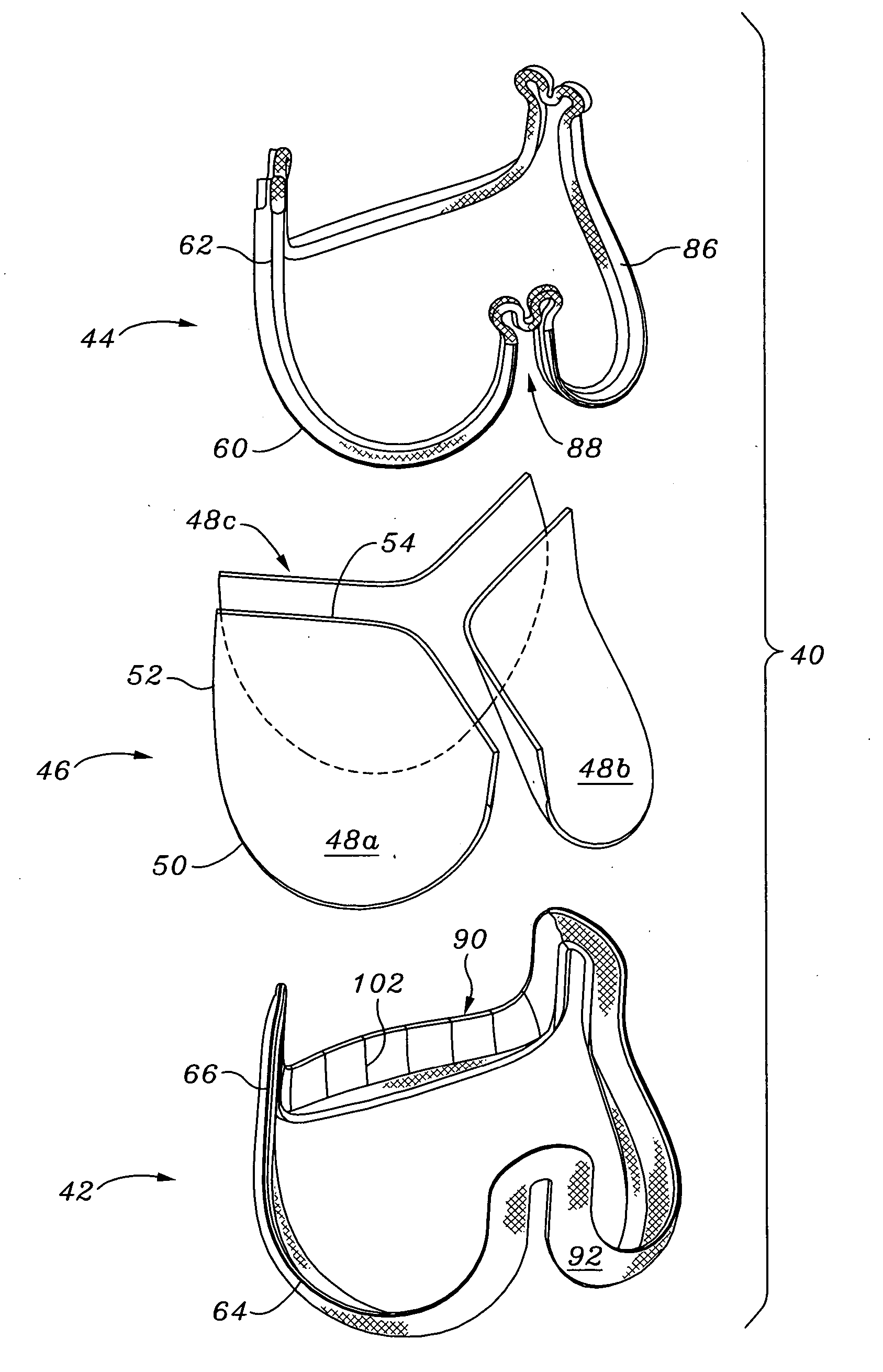

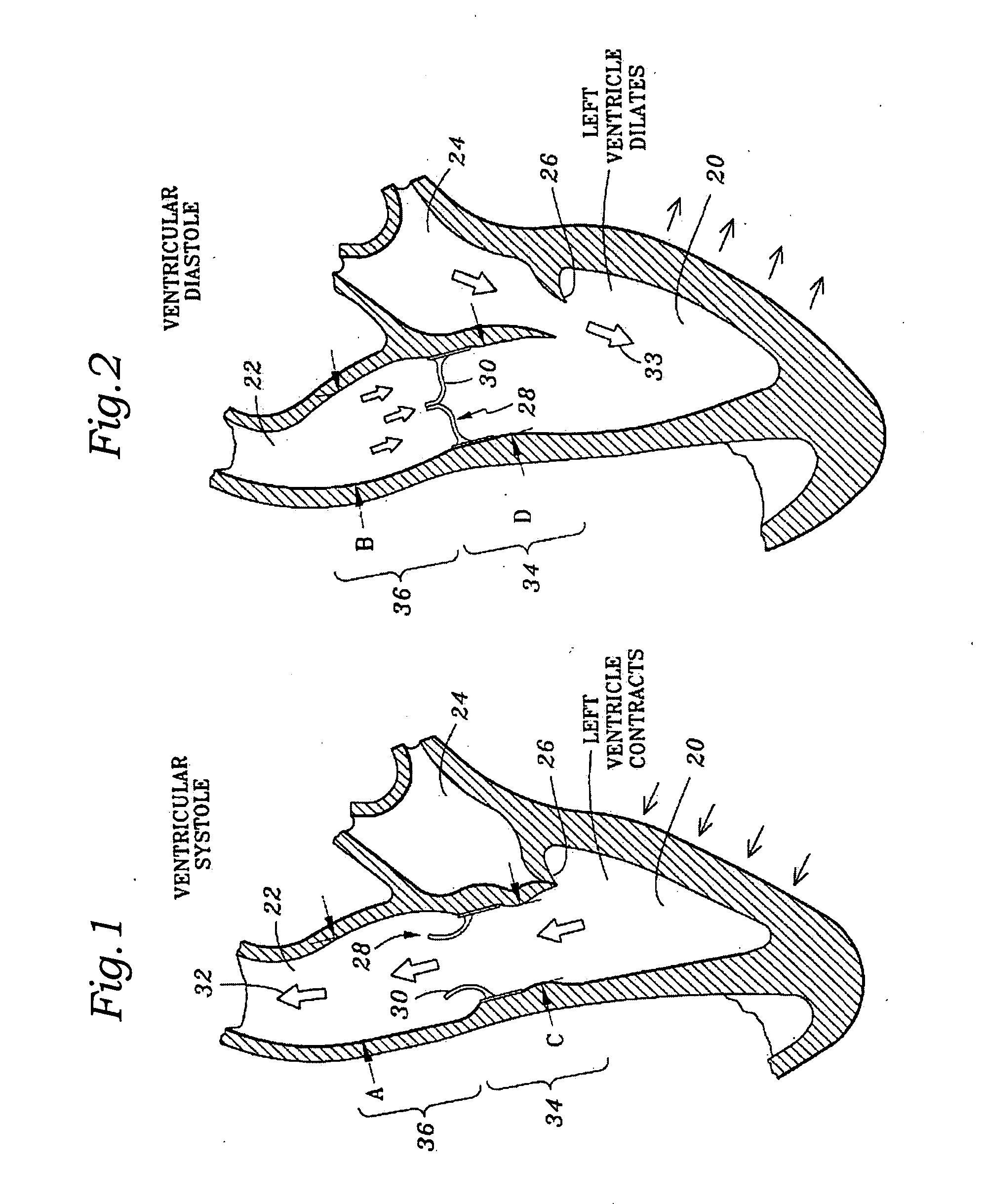

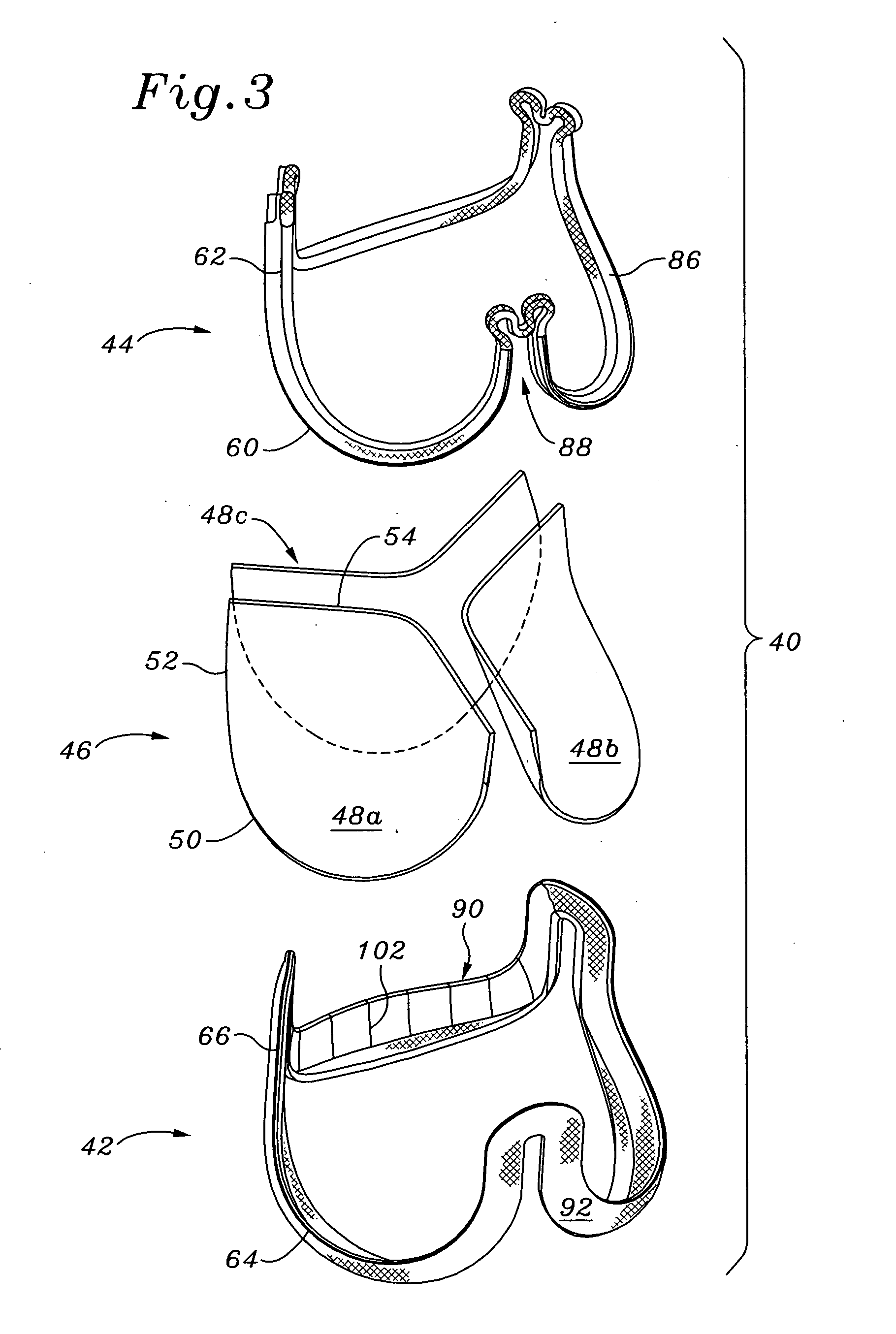

A flexible support frame for a prosthetic heart valve having commissure tips that are shaped to even out stresses imposed during use. The support frame is an elongated wire-like element formed by a plurality, typically three, of arcuate cusp regions on an inflow end alternating with the same number of commissures terminating in tips on an outflow end. The commissure tips are elongated relative to more simple shapes. The commissure tips may be shaped with a complex curve having two enlarged convex flexure portions separated by a concave bridge portion at the midpoint of the commissure tip. The support frame may be fabricated by separating a two-dimensional blank from a sheet and then converting the blank into a three-dimensional support frame shape. The cross-sectional thickness of the support frame may be variable, such as by adjusting the thickness of the pattern of the two-dimensional blank in the sheet. Desirably, the radial thickness remains constant while the circumferential dimension varies with a maximum located at the commissure tips.

Owner:EDWARDS LIFESCIENCES CORP

Stress absorbing flexible heart valve frame

ActiveUS20060229718A1Facilitates supra-annular attachmentIncrease flexibilityHeart valvesMedicineProsthetic heart

A flexible support frame for a prosthetic heart valve having commissure tips that are shaped to even out stresses imposed during use. The support frame is an elongated wire-like element formed by a plurality, typically three, of arcuate cusp regions on an inflow end alternating with the same number of commissures terminating in tips on an outflow end. The commissure tips are elongated relative to more simple shapes. The commissure tips may be shaped with a complex curve having two enlarged convex flexure portions separated by a concave bridge portion at the midpoint of the commissure tip. The support frame may be fabricated by separating a two-dimensional blank from a sheet and then converting the blank into a three-dimensional support frame shape. The cross-sectional thickness of the support frame may be variable, such as by adjusting the thickness of the pattern of the two-dimensional blank in the sheet. Desirably, the radial thickness remains constant while the circumferential dimension varies with a maximum located at the commissure tips.

Owner:EDWARDS LIFESCIENCES CORP

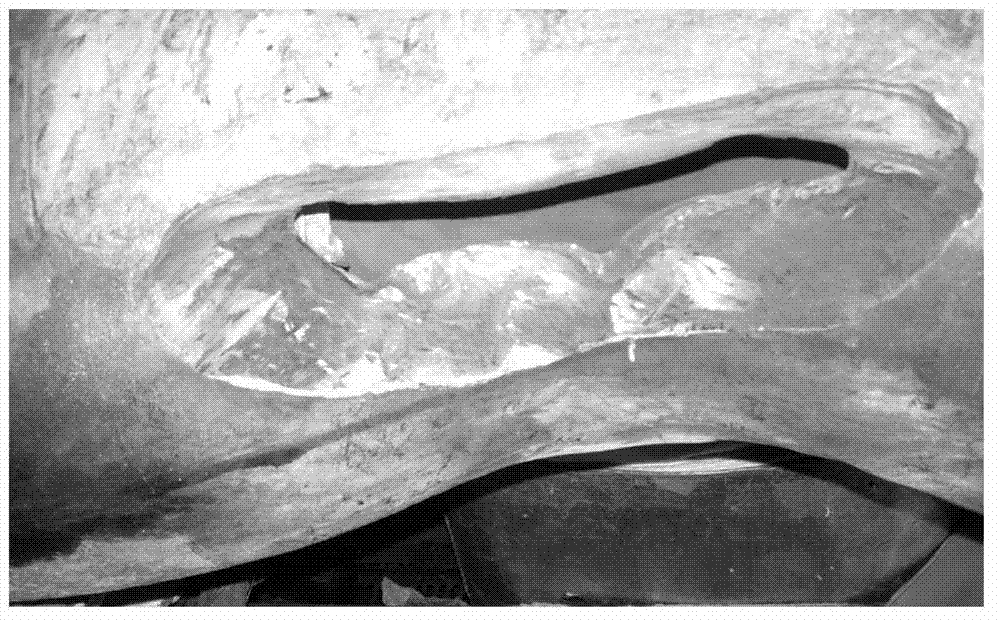

Field welding repair method especially for larger and penetrating defects in steel casting with heavy wall thickness

The invention relates to a field welding repair method especially for larger and penetrating defects in a steel casting with heavy wall thickness. The method comprises a pre-welding preparation process, a welding repair process and a post-welding quality inspection process, wherein the welding repair process comprises the steps of (1) preheating; (2) carrying out 1 to 2 layers of backing weld for all positions of a groove by adopting TIG weld, and filling the whole bottom of the groove with solid wire materials; (3) warming up to 220 to 330 DEG C, carrying out constant thermal insulation for 3 to 8 hours, adopting manual arc welding to implement the filler welding for the groove, hammering the welded bead immediately with an air hammer, and ensuring the dense and uniform traces of the hammer; (4) carrying out dehydrogenation heat treatment; (5) carrying out post-welding treatment: carrying out stress annealing at the temperature of 500 to 550 DEG C, then carrying out high tempering at the temperature of 700 to 750 DEG C, and finally, cooling at the speed of 65 to 150 DEG C / h to the room temperature. After welding repair, a welding seam is tested to be good in quality, and have low possibility of cracking again.

Owner:SUZHOU NUCLEAR POWER RES INST +4

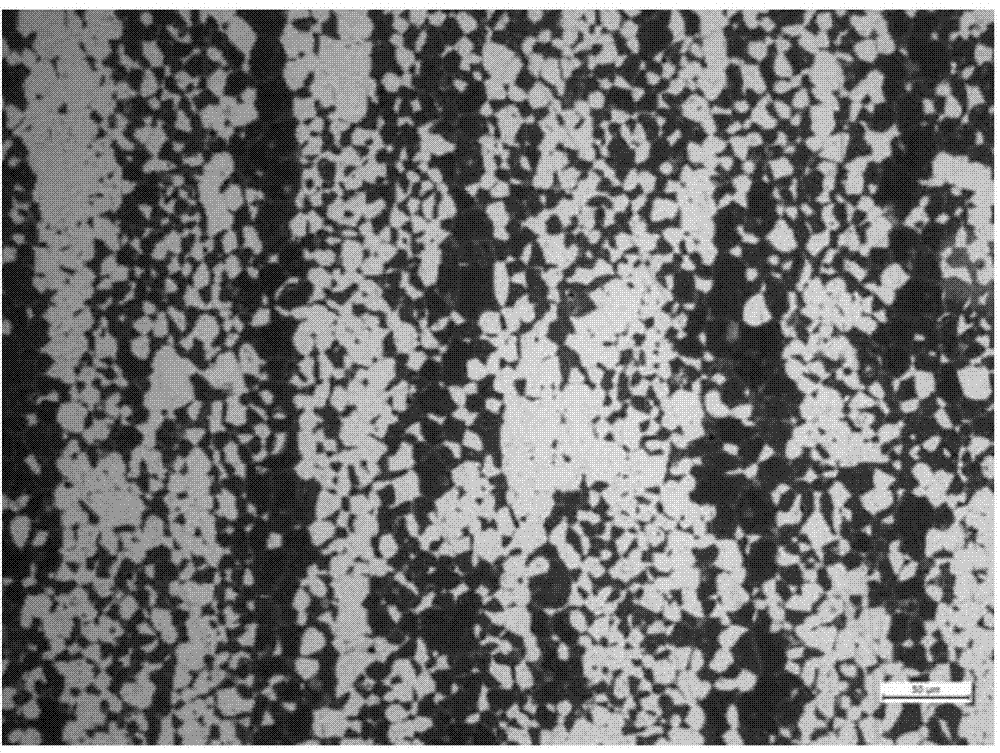

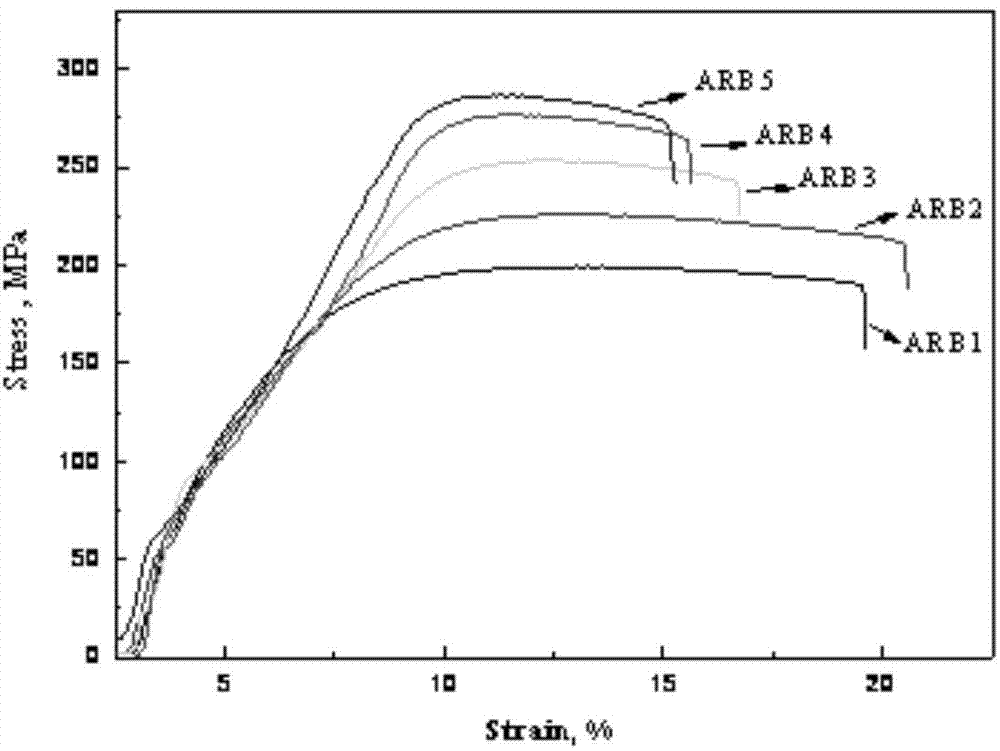

High-strength/toughness magnesium lithium alloy and preparation method thereof by accumulative roll bonding process

InactiveCN104498793AHigh fatigue limitImprove plasticityMetal rolling arrangementsLithiumThermal deformation

The invention provides a high-strength / toughness magnesium lithium alloy and a preparation method thereof by an accumulative roll bonding process. The method comprises the following steps: a) carrying out homogenizing treatment on a smelted magnesium lithium alloy cast ingot; b) carrying out thermal deformation processing to obtain a magnesium lithium alloy plate; c) carrying out stress-relief annealing; d) cutting the plate for accumulative roll bonding into two pieces with equal size, and carrying out surface treatment; e) fixing the two Mg-Li alloy plates; f) rolling; g) repeating the roll bonding according to the steps d)-f) 4-6 times; and h) carrying out annealing treatment. The obtained alloy comprises the following components in percentage by mass: 7.5-9.5% of Li, 2.5-3.5% of Al, 0.5-1.5% of Zn, less than 0.03% of inevitable impurities (Fe, Cu, Ni, Mn and Si), and the balance of Mg. The magnesium lithium alloy is reinforced according to the specific alloying elements and proportioning thereof, and subjected to multipass accumulative roll bonding at proper temperature to refine the magnesium lithium alloy crystal grains, so that the alloy has higher strength on the premise of keeping favorable plasticity.

Owner:HARBIN ENG UNIV

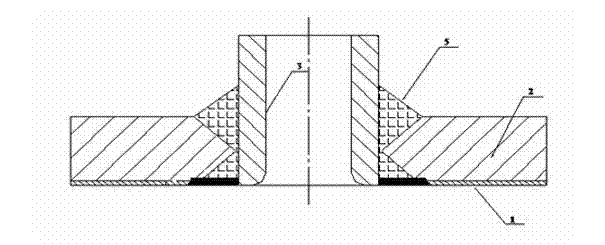

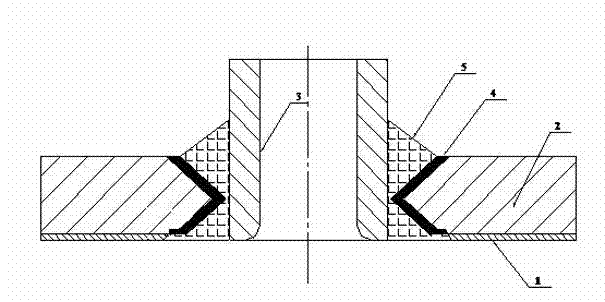

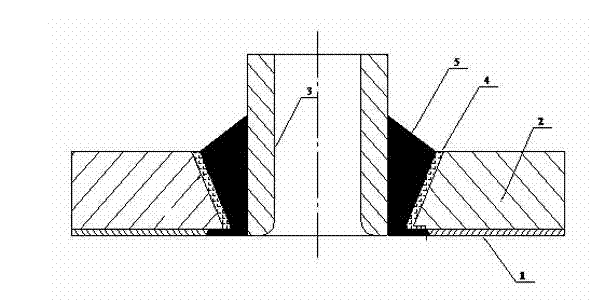

Welding method for stainless steel composite board pressure vessel shell and insert-type stainless steel connecting pipe

InactiveCN102513713AAvoid crackingEasy to useFurnace typesWorkpiece edge portionsChromium nickelStainless steel electrode

The invention discloses a welding method for a stainless steel composite board pressure vessel shell and an insert-type stainless steel connecting pipe. The method comprises the steps of a) arranging a pipe hole of the stainless steel connecting pipe in a stainless steel composite board pressure vessel shell, and manufacturing a pipe hole wall to be a primary bevel with a K shape or a single V shape; b) performing bead-welding on a primary bevel surface by using high chromium nickel stainless steel welding rods to form a transition isolating layer with certain thickness, so as to form a secondary bevel; c) carrying out stress-relief heat treatment on the stainless steel composite board pressure vessel shell after the bead welding; and d) welding corner connecting joints between the stainless steel connecting pipe and the stainless steel composite board bead-welding layer by using stainless steel welding rods with different materials according to a stainless steel composite layer on a composite board. As the transition isolating layer with the certain thickness is firstly bead-welded on the primary bevel of the basic layer side of the stainless steel composite board by using the high chromium nickel stainless steel welding rods, and then the corner connecting joints are welded by the stainless steel welding rods, so that carbon steel and low alloy steel components are transited into stainless steel components, the welding line plasticity can be transited from low to high, cracks are avoided, and the using performance is reliable.

Owner:CSSC SHENGHUI EQUIP

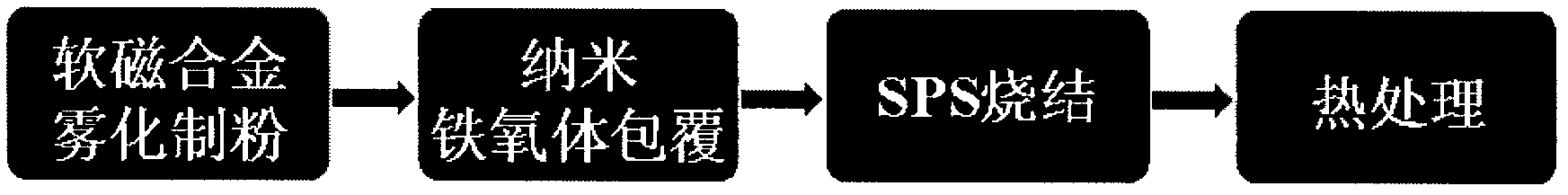

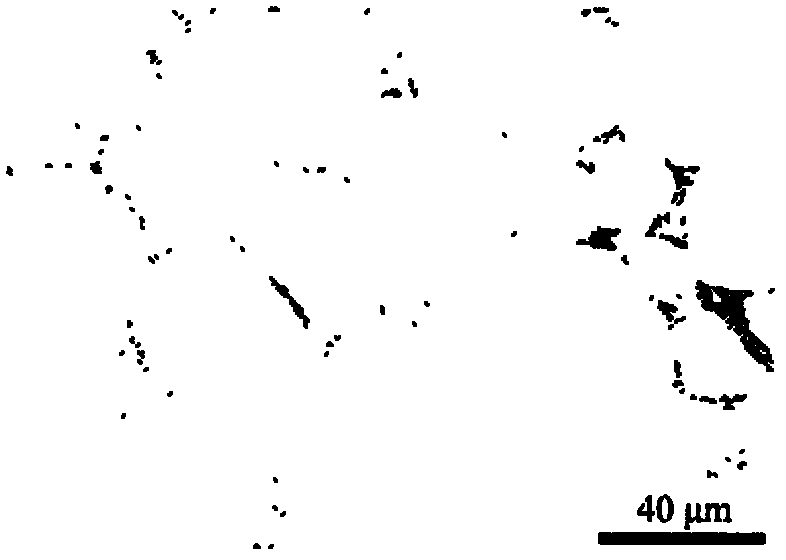

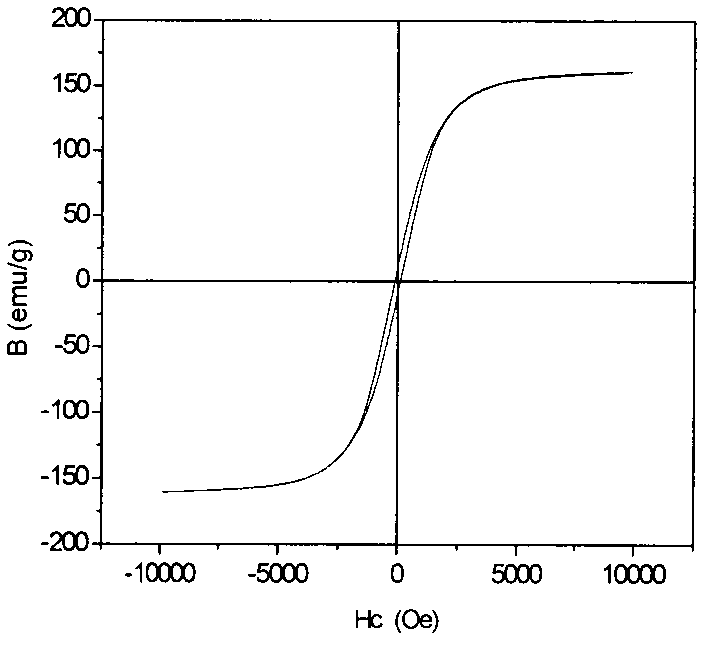

High-efficiency soft magnetic composite material and preparation method thereof

ActiveCN102136331AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseAlloy

The invention discloses a high-efficiency soft magnetic composite material and a preparation method thereof. The material is in a nest wall structure composed of soft ferrite of high electrical resistivity; the ferrite in the nest wall structure completely isolates the soft magnetic metal in the nest or an alloy particle soft magnetic phase to cause the soft magnetic metal in the nest or the alloy particle soft magnetic phase to mutually isolate; the content of the soft magnetic metal or the alloy particle is 50-99wt%; and the balance is the soft ferrite. The preparation method comprises the following steps: mixing the soft magnetic metal or alloy particles and the soft ferrite powder at a ratio; causing the soft ferrite powder to completely and evenly coat the surface of the soft magnetic metal or the alloy particles; complexly sintering and shaping by spark plasma sintering densification; and finally, carrying out stress removal annealing heat treatment. The high-efficiency soft magnetic composite material has the characteristics of high-saturation induction density, high resistivity, high magnetic conductivity, low coercive force, low magnetic core loss and excellent comprehensive mechanical property. The high-efficiency soft magnetic composite material can be applied to occasions with higher working efficiency, high magnetic field and high stress. The preparation method issimple and the technological operation is convenient.

Owner:CHANGCHUN UNIV OF TECH

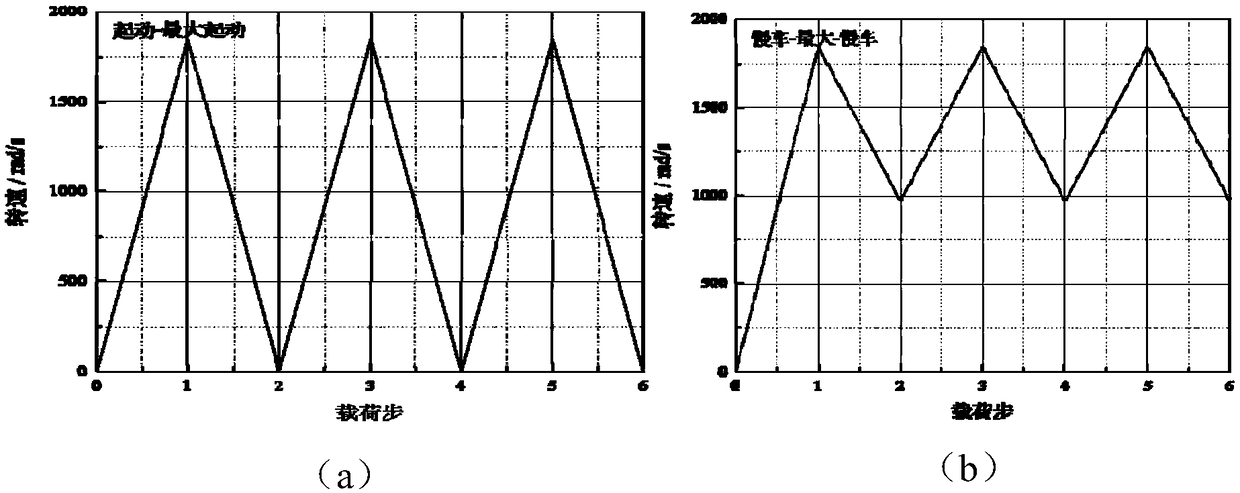

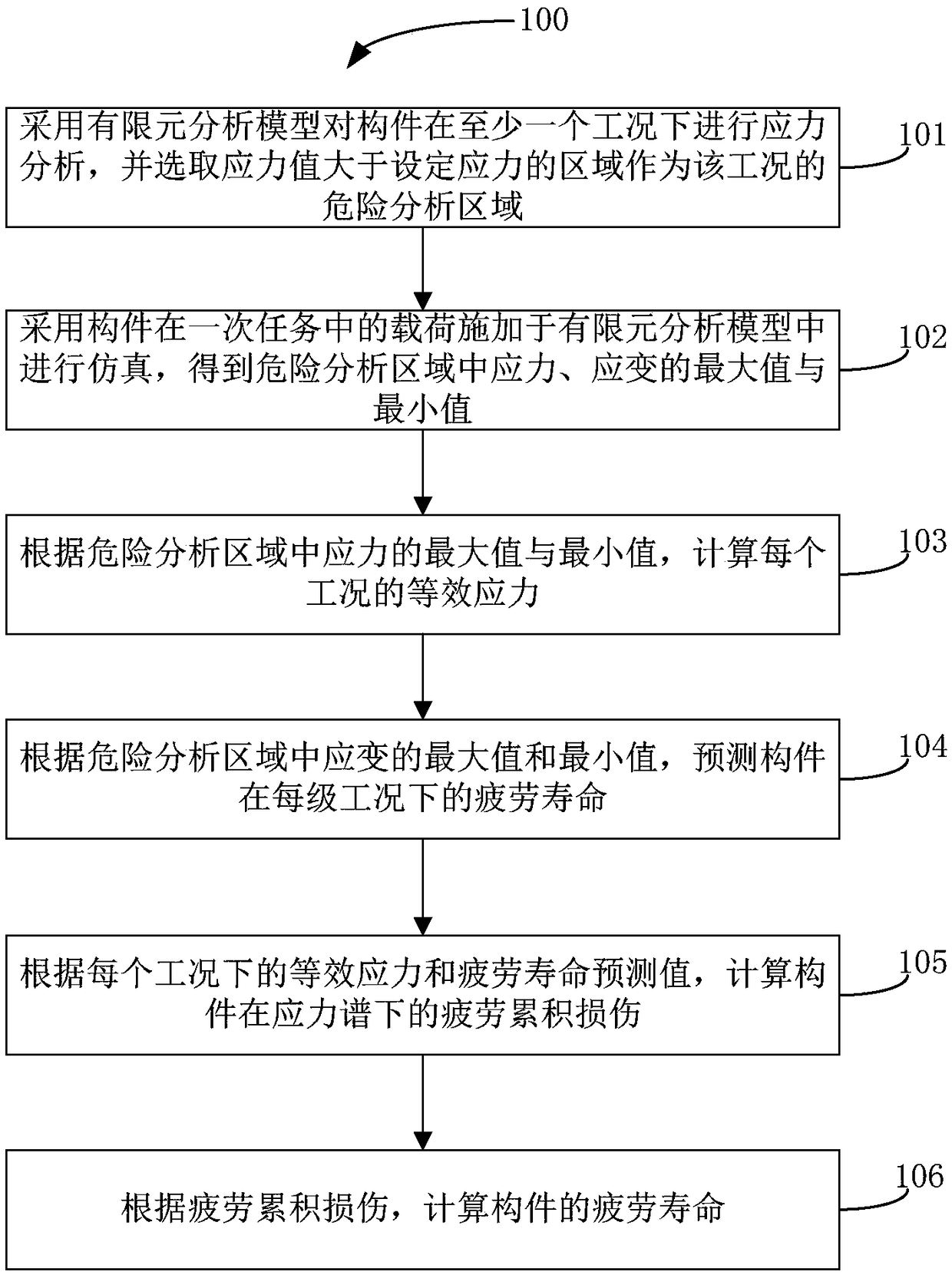

Fatigue life assessment method of components based on nonlinear fatigue damage accumulation theory

InactiveCN109033709AAccurate calculationHigh accuracy of fatigue life predictionDesign optimisation/simulationSpecial data processing applicationsFatigue damageElement analysis

The invention discloses a fatigue life evaluation method of a component based on a nonlinear fatigue damage accumulation theory, which comprises the following steps of: adopting a finite element analysis model to carry out stress analysis on the component under at least one working condition, and selecting a region with a stress value greater than a set stress as a hazard analysis region under theworking condition; obtaining the maximum and minimum of stress and strain in the hazard analysis area by simulating the load on the finite element analysis model of the component in one mission. According to the maximum and minimum value of stress in the hazard analysis area, the equivalent stress of each working condition is calculated. According to the maximum and minimum value of strain in thehazard analysis area, the fatigue life prediction value of the component under each working condition is predicted. According to the equivalent stress and fatigue life predicted under each working condition, the fatigue cumulative damage of the member under stress spectrum is calculated. According to the accumulated fatigue damage, the fatigue life of the component is calculated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

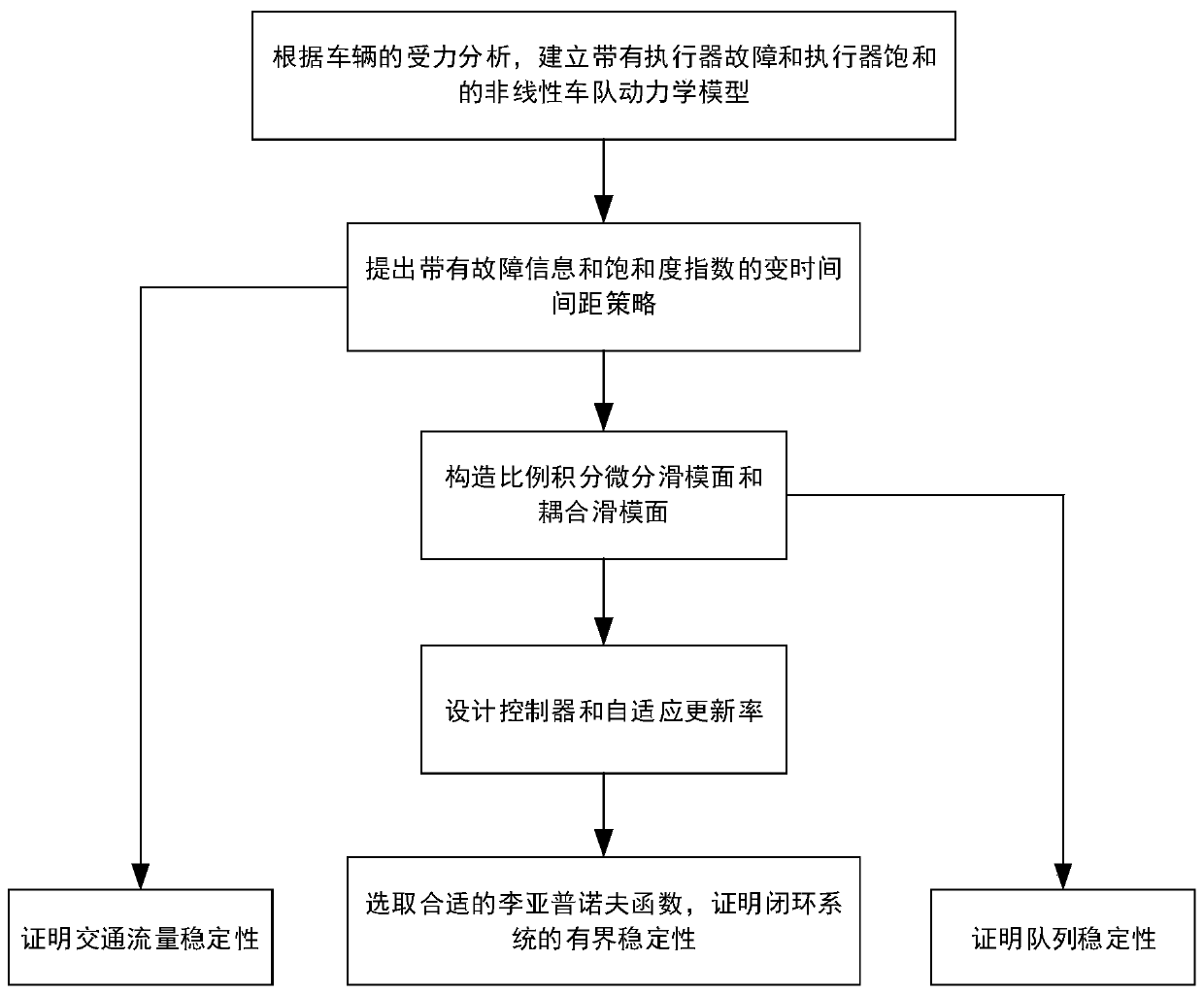

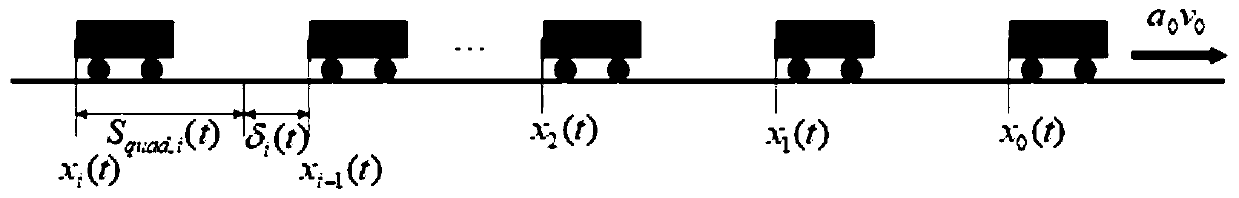

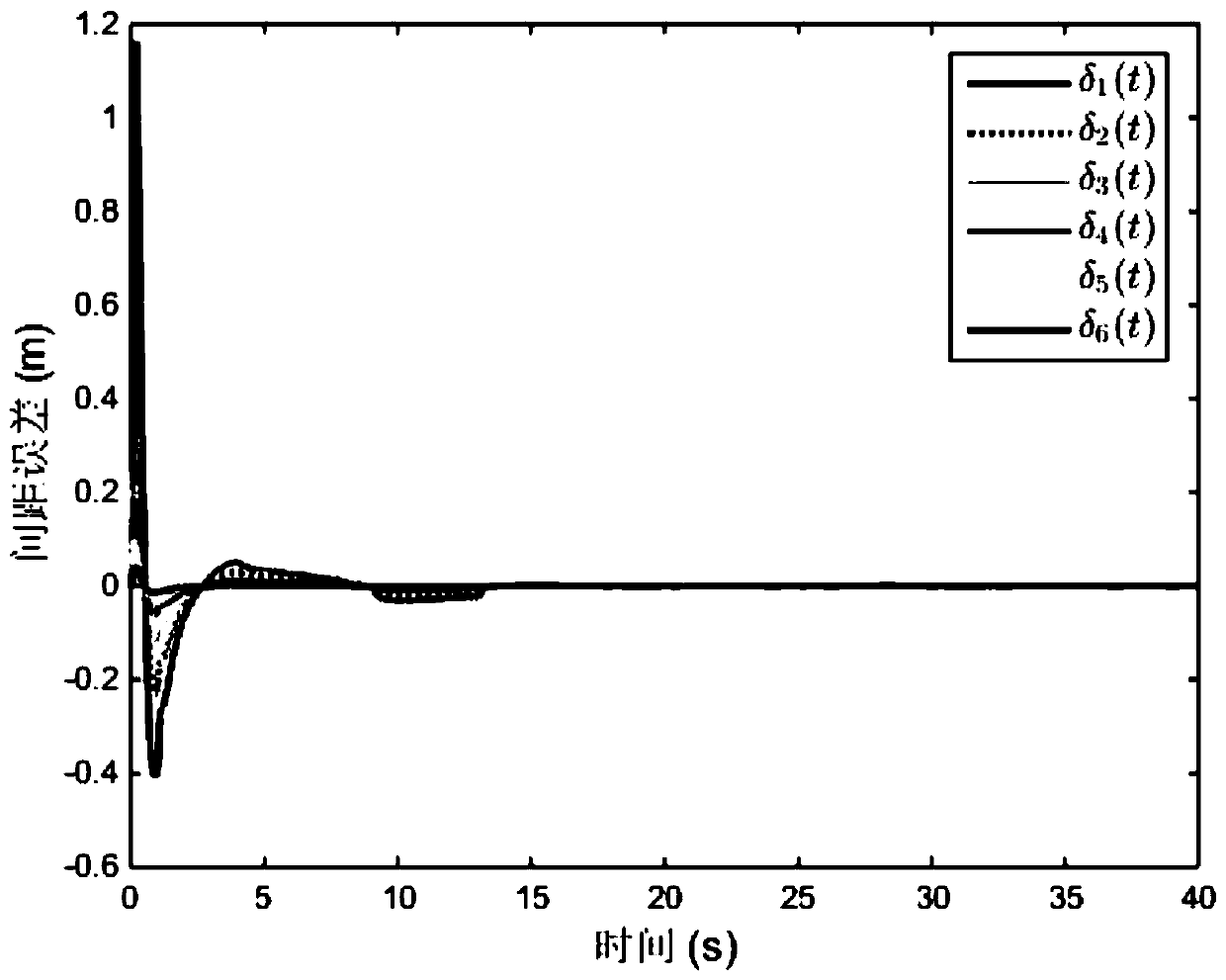

Heterogeneous vehicle team fault-tolerant control method based on actuator faults and saturation

ActiveCN110244747AGuaranteed stabilityGuaranteed uptimeAdaptive controlPosition/course control in two dimensionsProportional integral differentialTraffic capacity

The invention provides a heterogeneous vehicle team fault-tolerant control method based on actuator fault and saturation. The method comprises the following steps: carrying out stress analysis on longitudinal movement of vehicles, and by combining actuator fault and saturation models, building a vehicle longitudinal dynamics model under the actuator fault and saturation; according to information of the vehicles, constructing a variable time interval strategy with fault information and a saturation index; and based on the constructed variable time interval strategy, establishing a proportional integral differential sliding mode surface and a coupling sliding mode surface; and selecting a proper Lyapunov function, designing a fault-tolerant controller and an adaptive updating rate, and proving the limited time stability of a system. Compared with a traditional variable time interval strategy, the variable time interval strategy with the fault information and the saturation index not only can solve the problem of non-zero initial interval error but also can expand critical traffic capacity.

Owner:DALIAN MARITIME UNIVERSITY

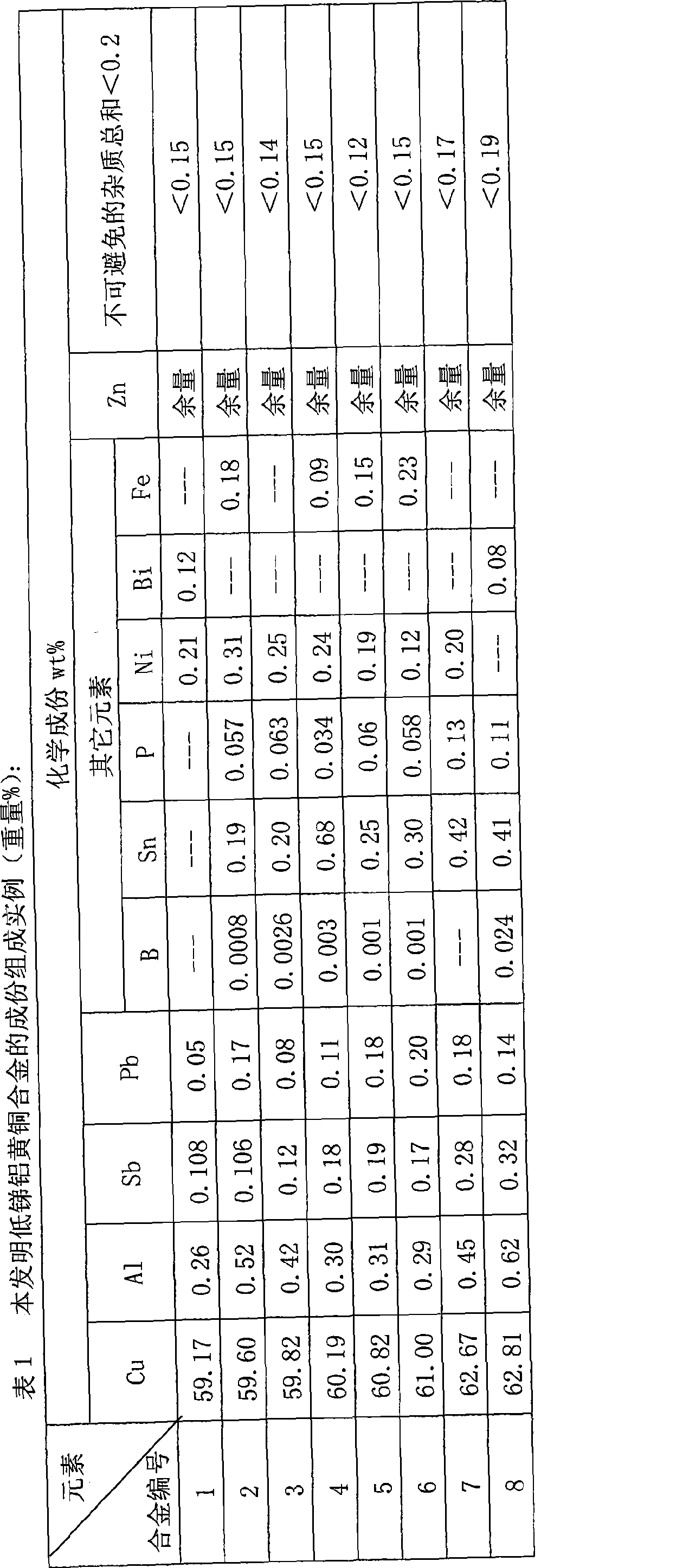

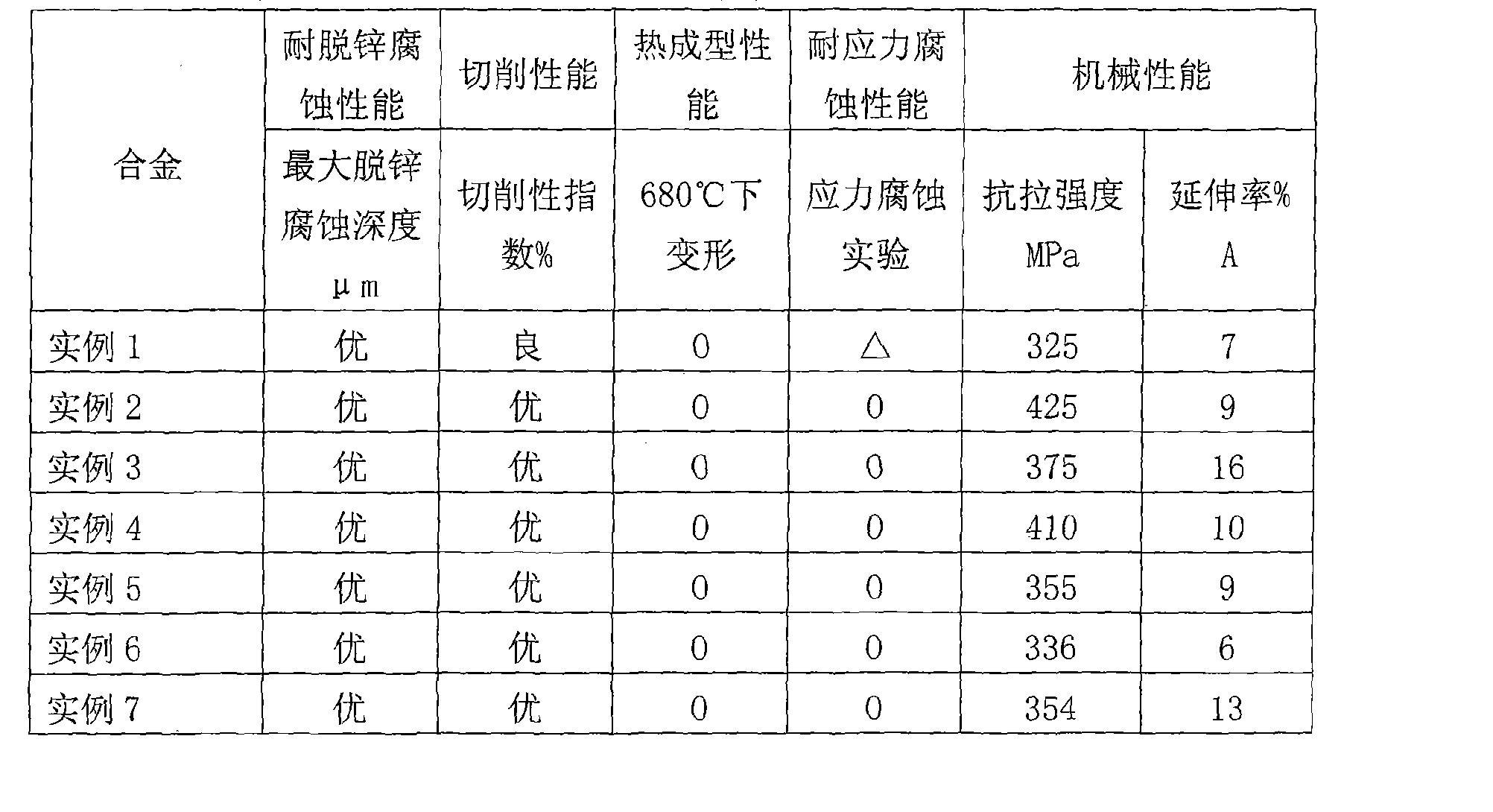

Dezincification corrosion resistant low-stibium aluminum yellow brass alloy and manufacturing method thereof

InactiveCN101440443AExcellent resistance to dezincificationImprove mechanical propertiesMechanical propertyImpurity

The invention discloses a low-stibium aluminum-brass alloy with dezincification corrosion resistance and a preparation method thereof. The alloy comprises the following chemical components: 58.8 to 63 weight percent of copper, 0.25 to 0.65 weight percent of aluminum, 0.105 to 0.35 weight percent of stibium, 0.03 to 0.25 weight percent of lead, 0.04 to 1.5 weight percent of other element, and the balance being zinc and inevitable impurities, wherein the weight percentage of the copper, the zinc, the aluminum, the stibium and the lead is more than 98.2 weight percent, and the other element is at least one element selected from boron, tin, phosphorus, nickel, bismuth and iron. The preparation method comprises: adopting methods of alloying treatment, covering, protecting, dreg removing, purifying and refining, casting the low-stibium aluminum-brass alloy by fusion, thermally processing the alloy at a temperature of between 680 and 740 DEG C; and then carrying out cold processing and intermediate thermal treatment on the alloy, and carrying out stress relieving annealing at a temperature of lower than 380 DEG C after a finished product is subjected to cold processing. The alloy product has the advantages of excellent dezincification corrosion resistance, thermal forming property, mechanical property and easy polishing and plating properties, good cutting property, remarkably excellent hygienic safety, simple manufacturing technique, low cost and easy recycling.

Owner:NINGBO POWERWAY ALLOY MATERIAL

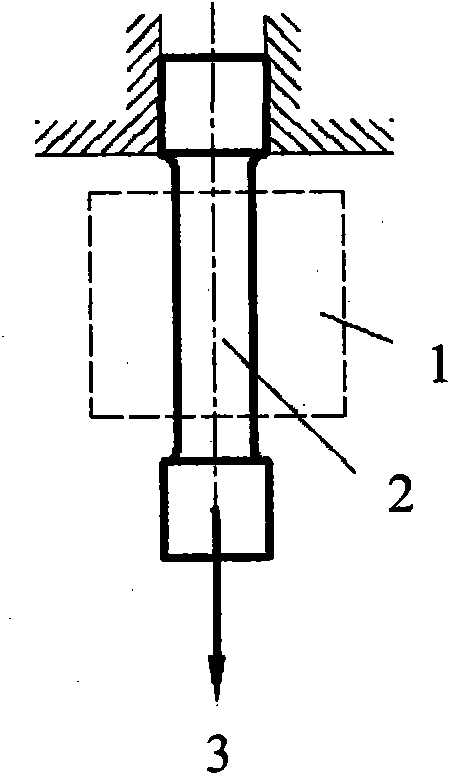

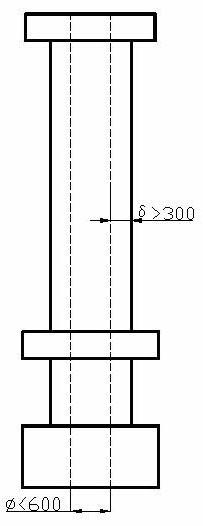

Novel stress corrosion test specimen and experiment method

InactiveCN101881709AEasy to processConvenient preloadWeather/light/corrosion resistancePreparing sample for investigationStatistical analysisStress corrosion cracking

The invention discloses a novel stress corrosion test specimen and an experiment method thereof. The test specimen is in a rectangular flat plate shape, and the plate-shaped test specimen is cut and formed in one step by a line cutting method. The method comprises the following steps: step 1. preparing the test specimen for getting ready to do the displacement deformation stretching stress corrosion experiment of the stress corrosion crack test; step 2. preparing 42 percent of MgCl2 solution and NaCl / NaOH mixed solution; step 3. building an experiment device, and placing the prepared test specimen into the experiment environment for carrying out stress corrosion experiment until the test specimen has corrosion cracks; and step 4. taking the test specimen for carrying out gold phase observation, finding the crack initialization position, and carrying out statistical analysis on the two-phase stainless steel stress corrosion mechanism. The processing of the test specimen of the invention is very convenient, and can be completed through one-step processing by line cutting in existence of plate-shaped test blocks.

Owner:EAST CHINA UNIV OF SCI & TECH

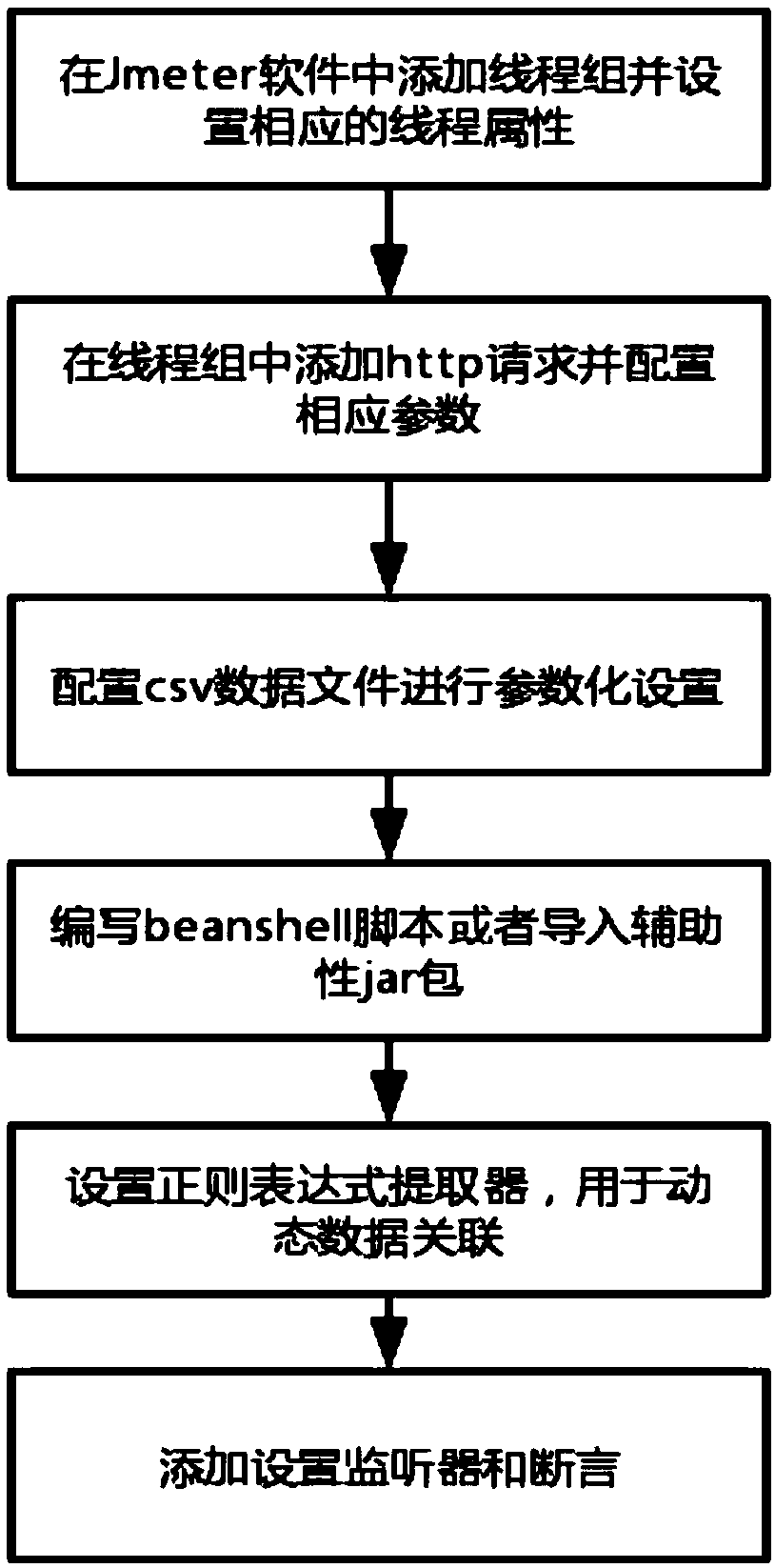

An automatic interface testing method based on Jmeter

InactiveCN109597761AThe test is accurateWide range of testsSoftware testing/debuggingComputer hardwareData file

The invention discloses an automatic interface testing method based on Jmeter. a Jmeter test software tool is used; a thread group to configure its number of concurrent, number of loops, thread starttime parameters, etc. are added to simulate the normal user to send a request to carry out stress test on the server interface,; secondly, c a csv data file is configured to carry out parameterizationsetting so that an interface is accurately tested;, a beanshell script is written or an auxiliary jar packet is imported, and finally a monitor and assertion are added to judge whether a result corresponding to a request is an expected result or not, so as to complete the automatic test of the interface. The method provided by the invention can solve the problems that errors are easy to fill whenrequest data are configured manually during testing at present, the workload of finding and modifying the errors is large, test requests cannot be concurrent, and test data cannot be changed.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

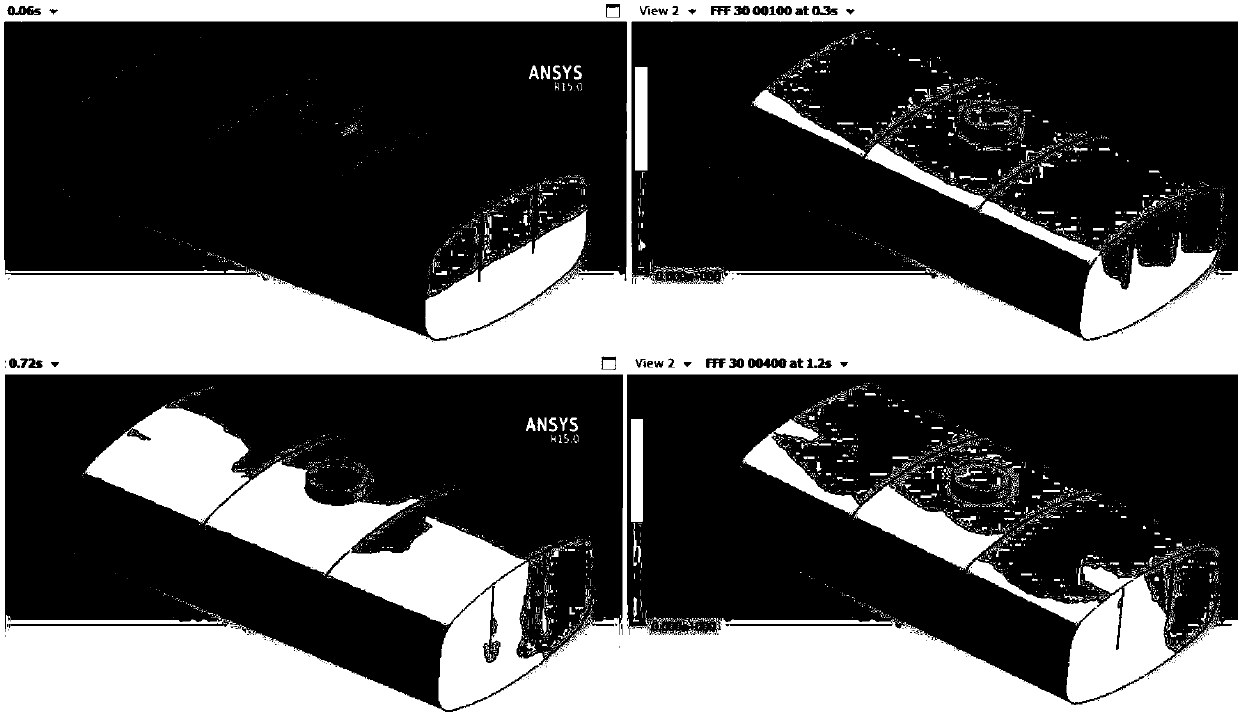

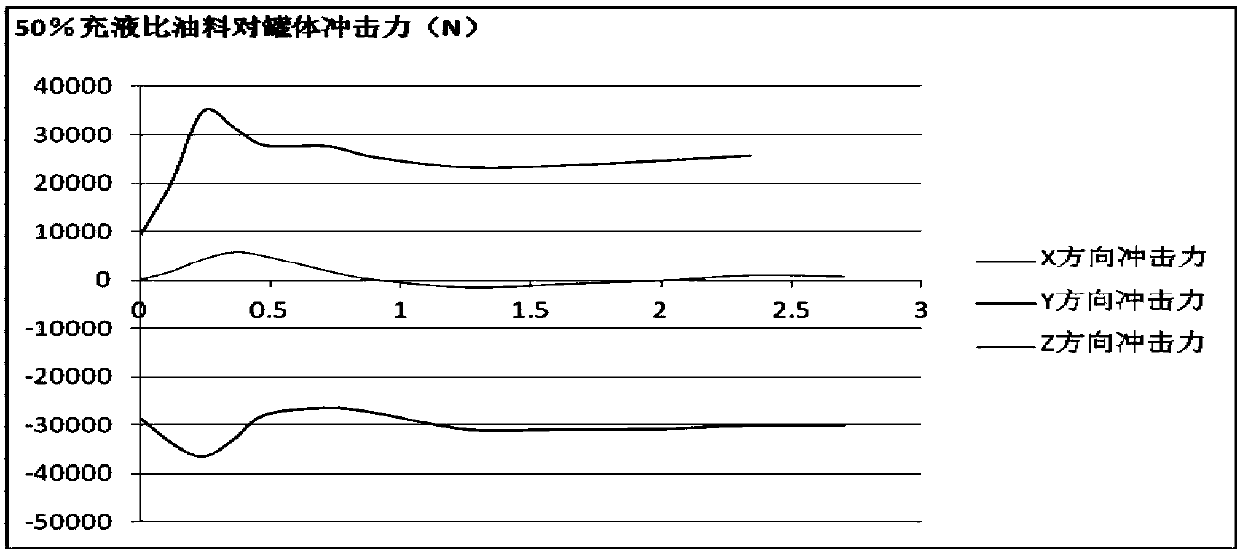

Method for establishing sloshing numerical model of oil in vehicle-mounted metal oil tank

InactiveCN107436981AImprove structural strengthImproved rollover stabilityGeometric CADDesign optimisation/simulationThree dimensional simulationTank truck

The invention discloses a method for establishing a sloshing numerical model of oil in a vehicle-mounted metal oil tank. The method comprises the steps of building an oil sloshing basic equation, determining boundary conditions of oil sloshing, carrying out stress analysis on a solid structure region and the like. A VOF method and a dynamic coordinate system are used for establishing a three-dimensional simulation model for sloshing of the oil in the vehicle-mounted metal oil tank, wherein the three-dimensional model is established according to actual sizes of a tank body, an internal medium and a swash plate, and coupling analysis of stress and deformation of a solid tank wall region can be achieved. An inertia force function corresponding to the change of braking deceleration in the braking process of a tank truck is loaded into a momentum equation to be solved, the calculation time is saved, and the higher precision is guaranteed. The method can be mainly used for researching the side turning stability during emergency turning of the off-road metal oil tank truck and the structural strength of the tank body during emergency braking.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

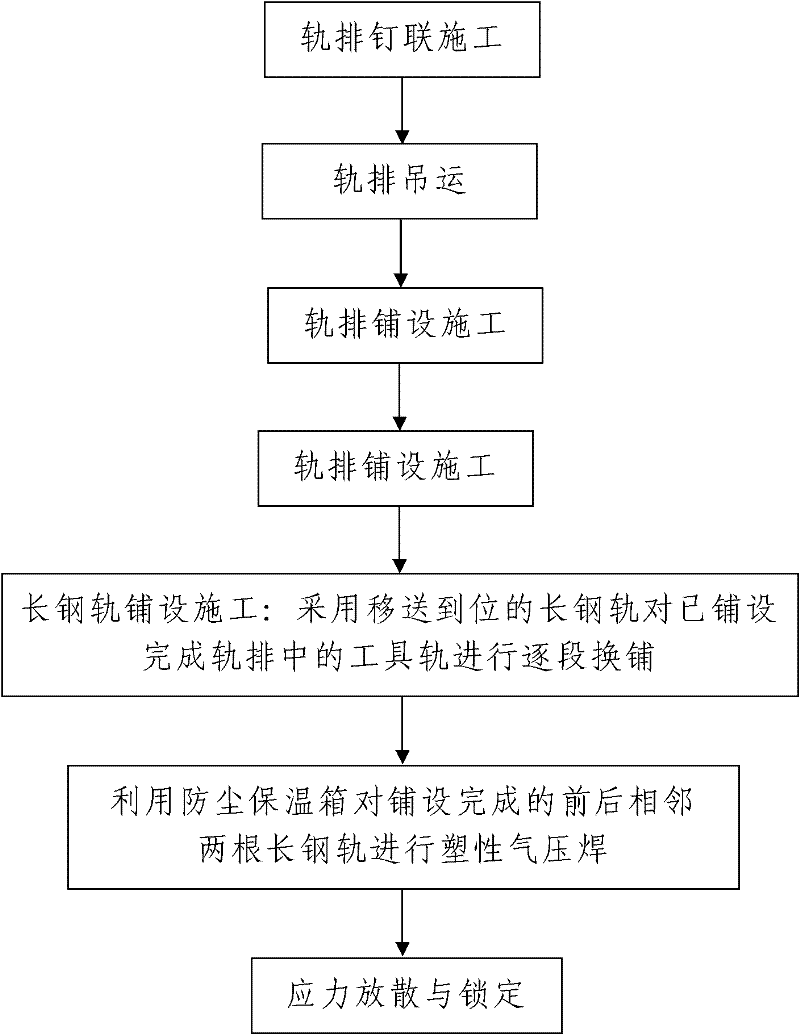

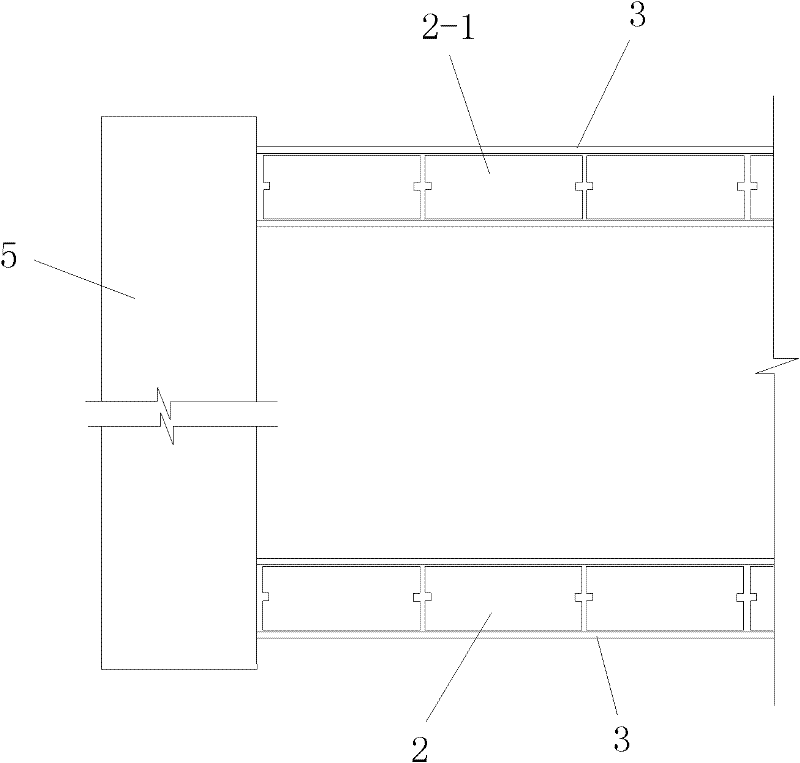

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

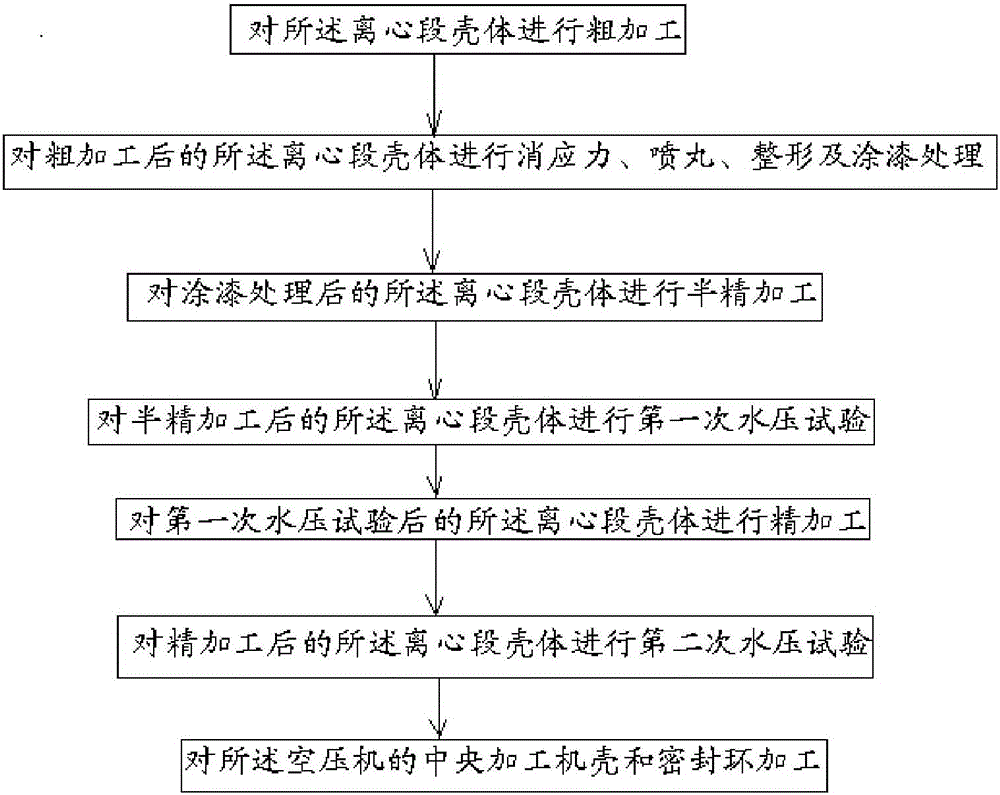

Machining method of machine case of ultra-heavy and ultra-large-size type compressor

The invention discloses a machining method of a machine case of an ultra-heavy and ultra-large-size type compressor and belongs to the technical field of air compressors. The machining method of the machine case of the ultra-heavy and ultra-large-size type compressor comprises the following steps: machining a centrifugal section shell of the air compressor, wherein the machining of the centrifugal section shell of the air compressor comprises the following steps: carrying out rough machining on the centrifugal section shell, and carrying out stress relieving, shot blasting, reshaping and paint spraying treatment on the roughly machined centrifugal section shell; carrying out semi-finishing machining on the machined centrifugal section shell subjected to the paint spraying treatment; carrying out first time of water pressure test on the centrifugal section shell subjected to the semi-finishing machining; carrying out fine machining and second time of water pressure test on the centrifugal section shell subjected to the first time of water pressure test; machining a central machining machine case and a sealing ring of the air compressor. With the adoption of the machining method of the machine case of the ultra-heavy and ultra-large-size type compressor, the machining size of each part of the centrifugal section shell is guaranteed; the precision of the central machining machine case can be guaranteed, and the precision can also be guaranteed after the sealing ring and the central machining machine case are assembled; the machine case is not deformed by selecting a reasonable water pressure test scheme and a detection scheme.

Owner:SHENYANG TURBO MASCH CORP

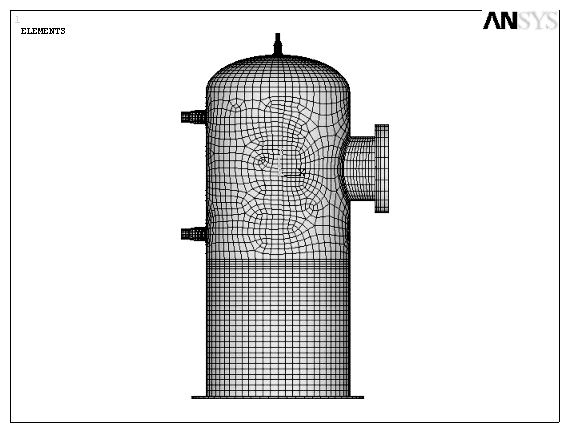

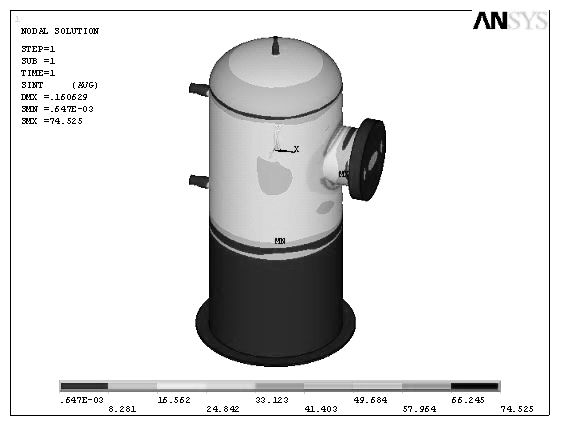

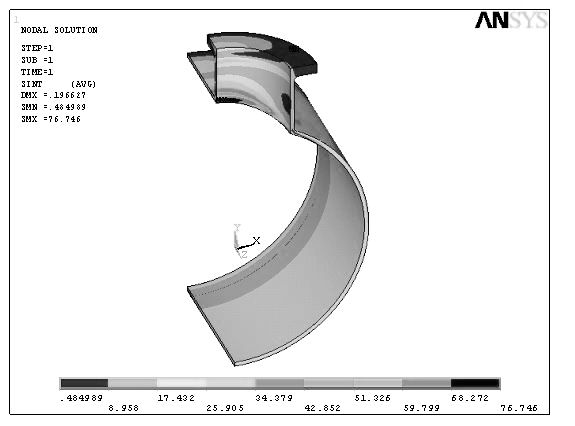

Method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software

ActiveCN102184289AShorten design timeSave design costSpecial data processing applicationsElement modelDesign specification

The invention discloses a method for carrying out stress analysis on first-class nuclear reactors through using ANSYS software, belonging to the technical field of analysis and design methods for first-class nuclear reactors. The method comprises the following steps: firstly, after carrying out routine design according to a design specification, thus obtaining a design drawing; establishing a geometric model and a finite element model by using a simulation device in an ANSYS; carrying out analysis and calculation on all nuclear parts; extracting a stress analysis result; and carrying out strength assessment according to the specifications stipulated in subsections NB and NF of section III of ASME (American society of mechanical engineers), then obtaining a detailed design report. Compared with the prior art, the method disclosed by the invention summarizes and improves a method for carrying out analysis and design on first-class nuclear reactors through using ANSYS software; compared with an analytical method and a test method, by using the method disclosed by the invention, the design time is greatly shortened, the design expense is reduced, the analysis efficiency is greatly improved, and the analysis cost is reduced; and in the process of analysis, an entity is adopted for modeling a hexahedron unit, thereby improving the calculation accuracy.

Owner:大连船舶重工集团装备制造有限公司

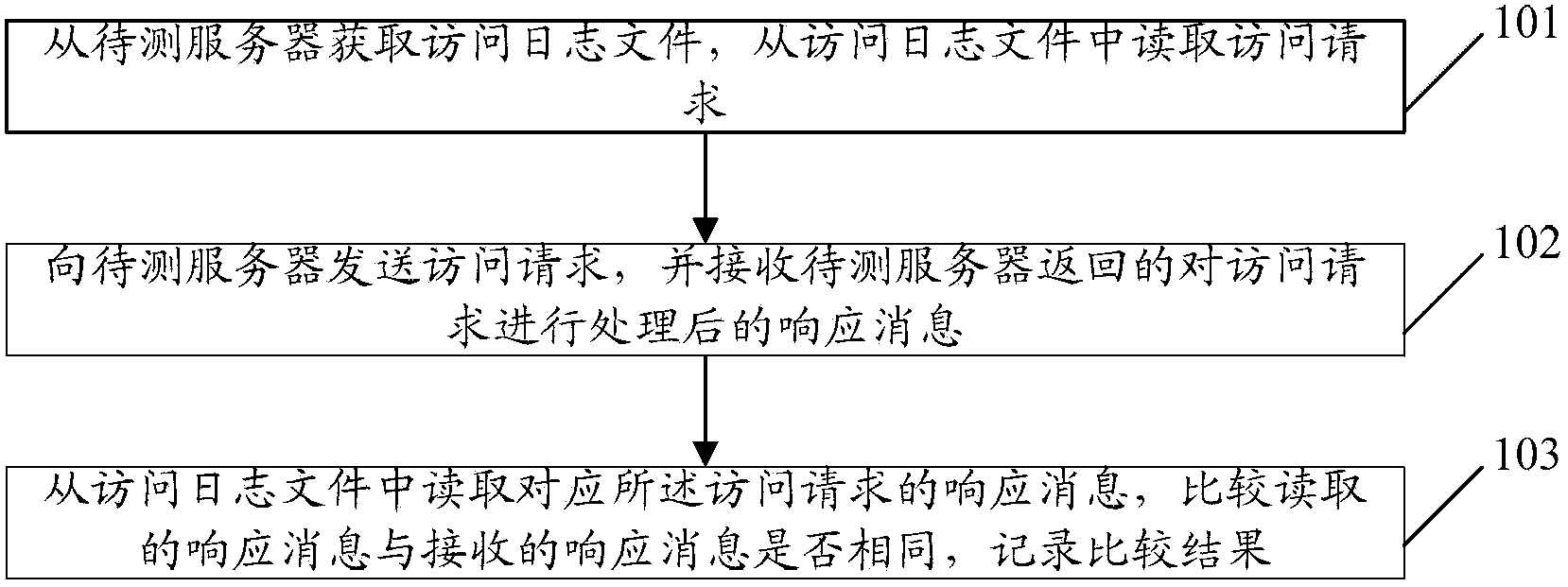

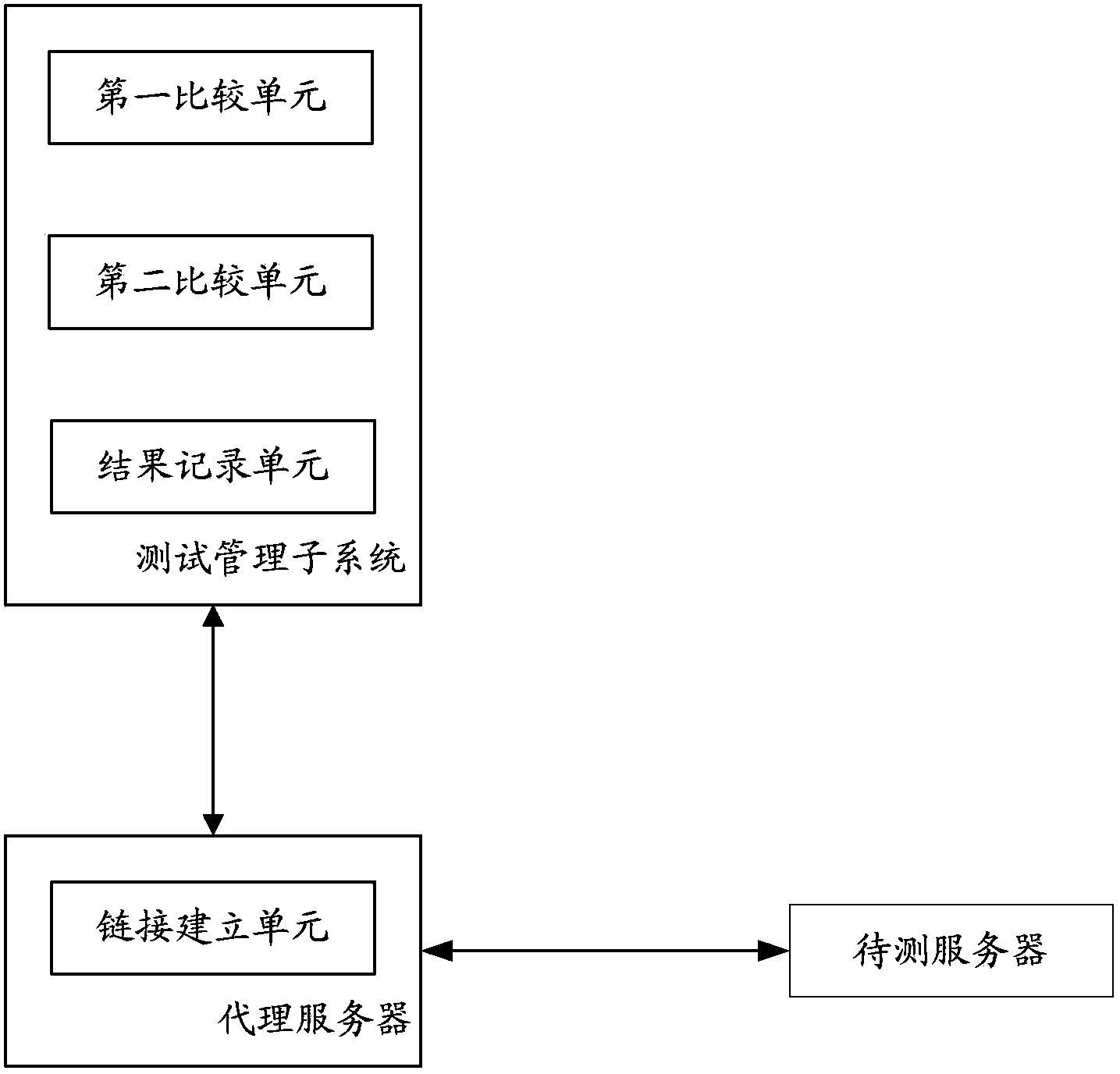

Method and system for carrying out stress test on server

The invention provides a method and system for carrying out a stress test on a server. The method comprises the steps of obtaining an access log file from the server to be tested, reading an access request from the access log file, sending an access request to the server to be tested, receiving a response message returned from the server to be tested after the access request is processed, reading a response message corresponding to the access request from the access log file, comparing whether the read response message and the received response message are the same, and recording the comparison result. According to the scheme, the workload of the stress test can be reduced, and the test result about consistency of the response message can be obtained.

Owner:LINKTECH NAVI TECH

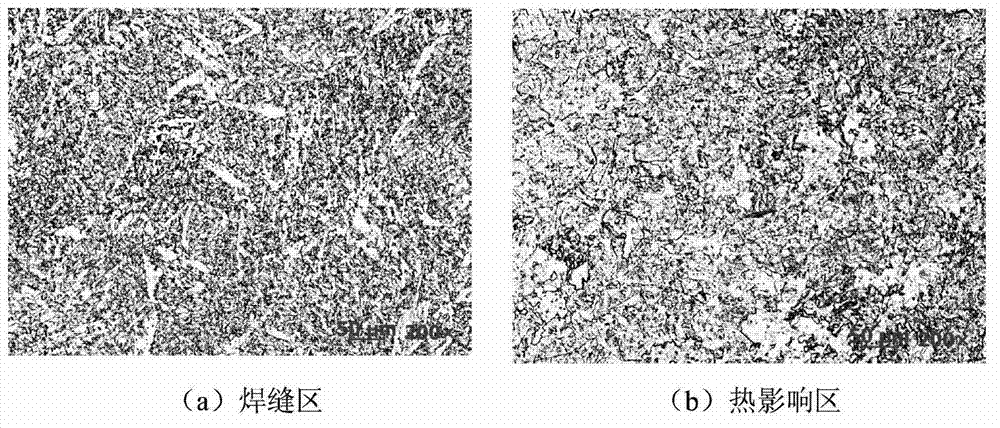

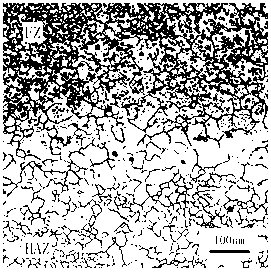

Method for improving weld structure and performance of magnesium alloy

The invention provides a method for improving a weld structure and performance of a magnesium alloy, which comprises the following steps: firstly, placing an magnesium alloy welding plate in a heat treatment furnace to carry out stress relief annealing for a certain time at a temperature of 250 DEG C to 350 DEG C; then, polishing and flattening a weld joint by adopting abrasive paper for metallograph to enable the magnesium alloy welding plate to be at the same height with a base material; and heating the magnesium alloy to a certain temperature higher than a recrystallization temperature and carrying out hot rolling after carrying out heat preservation for a certain time. The method is generally suitable for weld penetration magnesium alloy plates such as an AZ31 magnesium alloy plate, an AZ61 magnesium alloy plate, an AZ80 magnesium alloy plate and the like. Intensity of the weld joint and a heat affected zone of the welded magnesium alloy plate is obviously lower than that of the base material. By a means of carrying out hot rolling after carrying out heat preservation at a certain temperature, the method can effectively improve intensity of a magnesium alloy welding part and enables tissues and performance of the weld joint, the heat affected zone and a base metal to be consistent.

Owner:CHONGQING UNIV

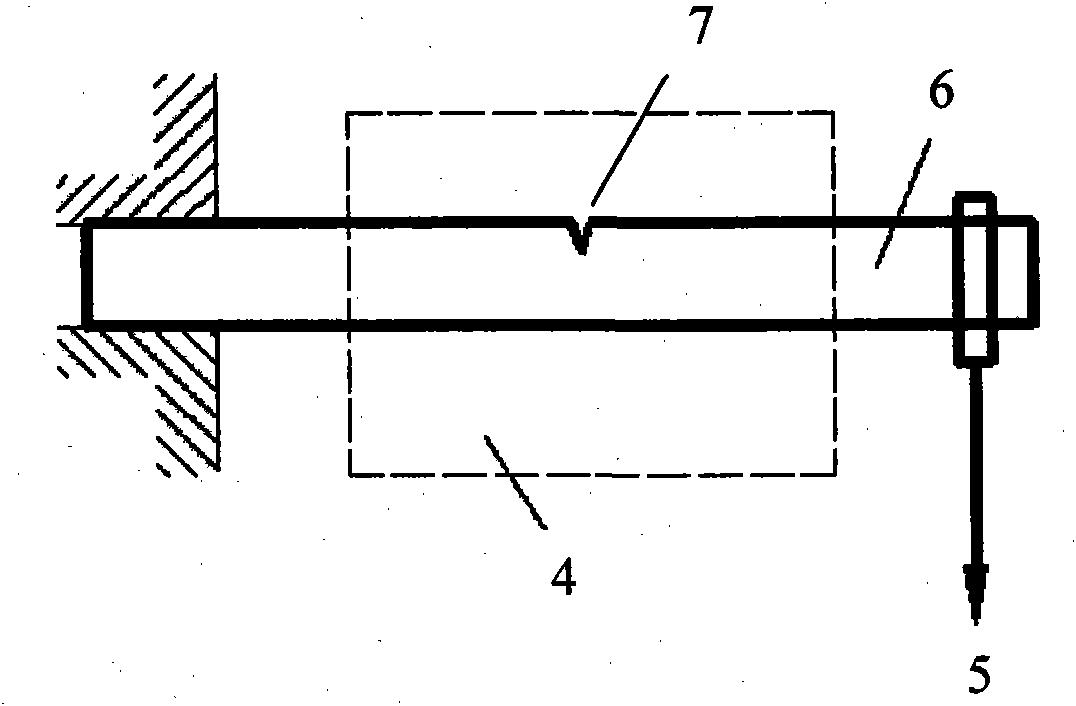

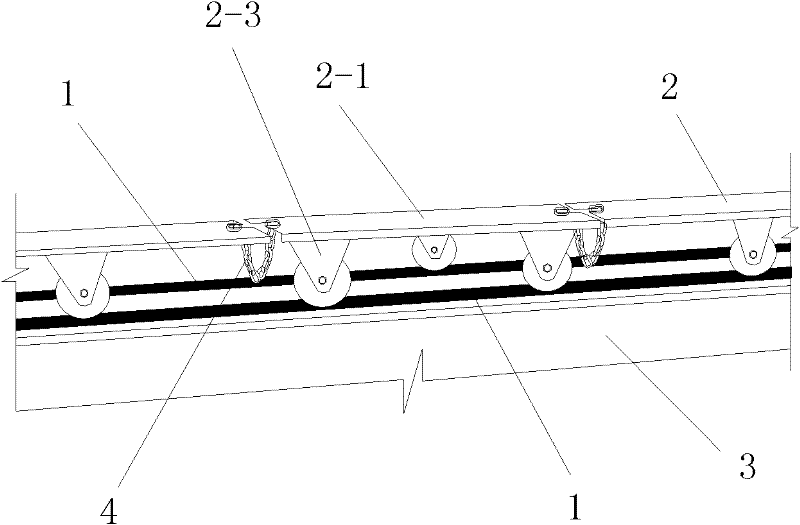

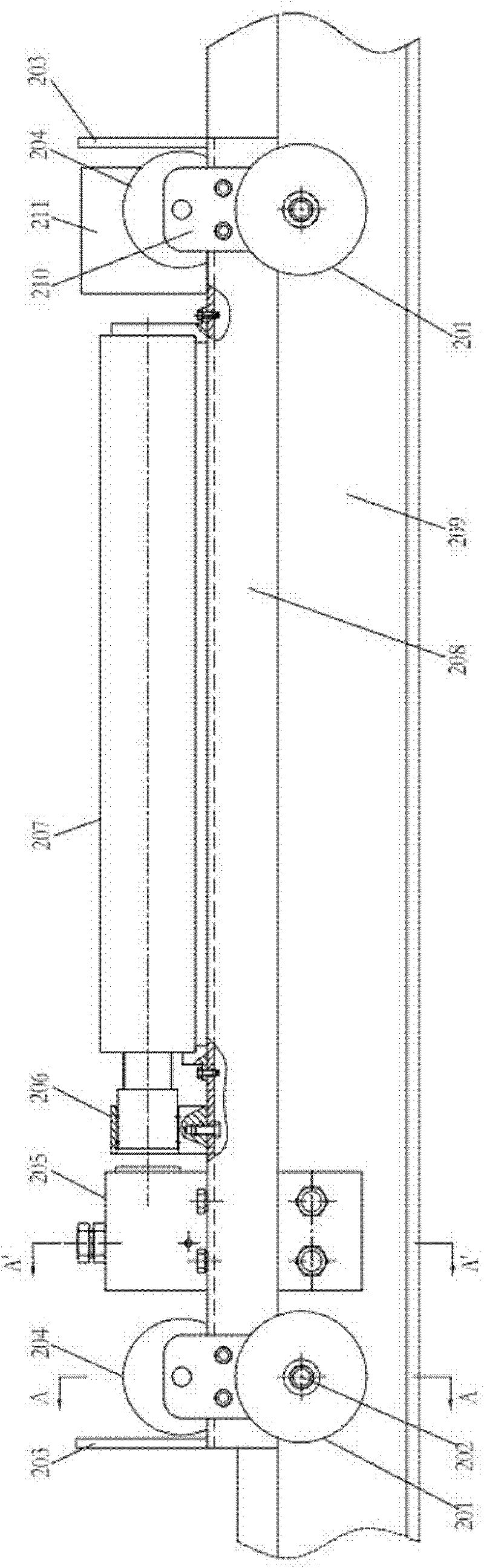

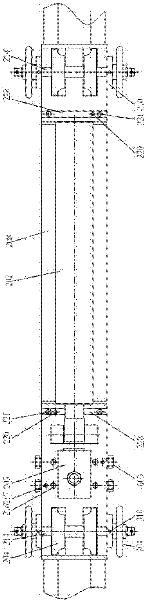

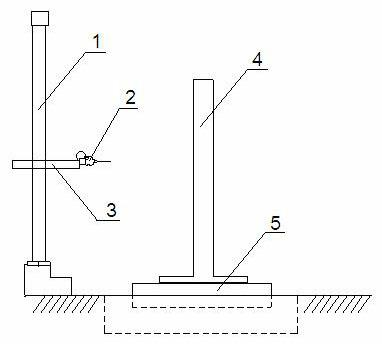

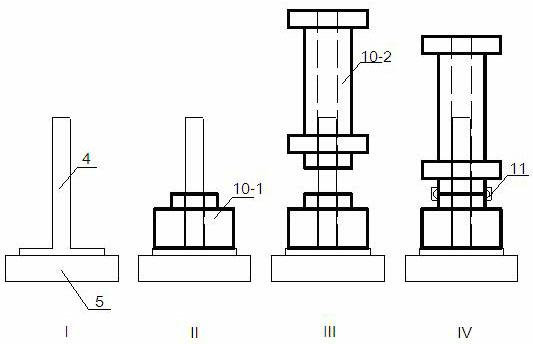

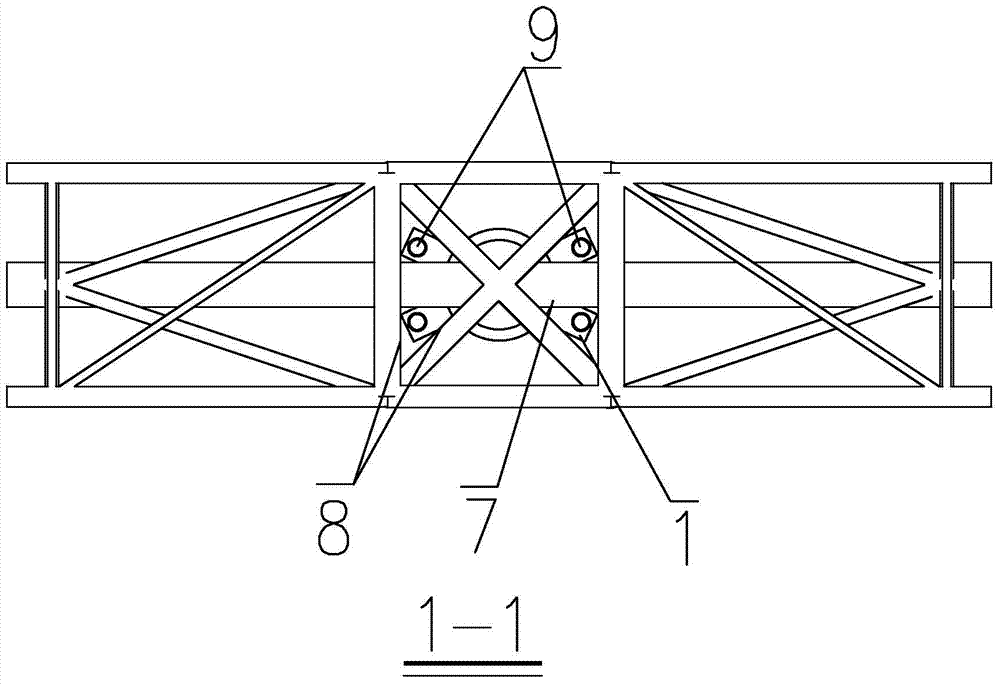

Stress-relieving device for seamless rails by using vibration method

InactiveCN102226326AEasy to carryBalance overturning momentRailway track constructionElectricityStress relieving

The invention discloses a stress-relieving device for seamless rails by using a vibration method, and is implemented by carrying out field detection on the stress-relieving effect of rails mainly by using a device for realizing the stress homogenization of rails in a periodic-vibration gas-liquid pressurized mode and supplementarily by using a stress sensor, and then carrying out stress-relieving operation in a machine-liquid-electricity integrated automatic mode. The whole stress-relieving device disclosed by the invention is light in weight, and provided with an anti-overturn device for ensuring a trolley is not overturned to the side during the operation of the trolley, thereby reducing the labor intensity and improving the operating efficiency and quality.

Owner:HUBEI UNIV OF TECH

Production technology for smelting and cladding alloy reinforced wear-resisting sliding plate

InactiveCN102703896ASave materialLow priceMetallic material coating processesLaser beam welding apparatusSlide plateTorch

The invention relates to a smelting and cladding alloy reinforced wear-resisting sliding plate, sliding block and lining plate in the industries, such as metallurgical equipment, mining equipment, mine equipment, petroleum drilling machine equipment and the like. The production technology for the smelting and cladding alloy reinforced wear-resisting sliding plate, sliding block and lining plate comprises the following steps of: 1) carrying out torch cutting and baiting to the matrix steel plate of the sliding plate, and cleaning torch cutting residues; 2) tempering and processing the matrix; 3) roughly processing the matrix; 4) carrying out stress relief annealing; 5) roughly grinding a matrix working plane, and cleaning surface greasy dirt; 6) smelting and cladding the working plane; 7) carrying out high-temperature tempering; 8) correcting; 9) carrying out machining; 10) carrying out stress relief annealing; and 11) roughly and finely grinding a smelting and cladding layer to obtain the smelting and cladding alloy reinforced wear-resisting sliding plate. The smelting and cladding alloy reinforced wear-resisting sliding plate disclosed by the invention has the advantages of good wear resistance, no delamination, good toughness and small possibility of deforming, the hardness can be above 55HRC, a hardness layer is eternally combined with the matrix, the product can be repaired and used, and the material cost can be greatly lowered.

Owner:河南宝贵实业有限公司

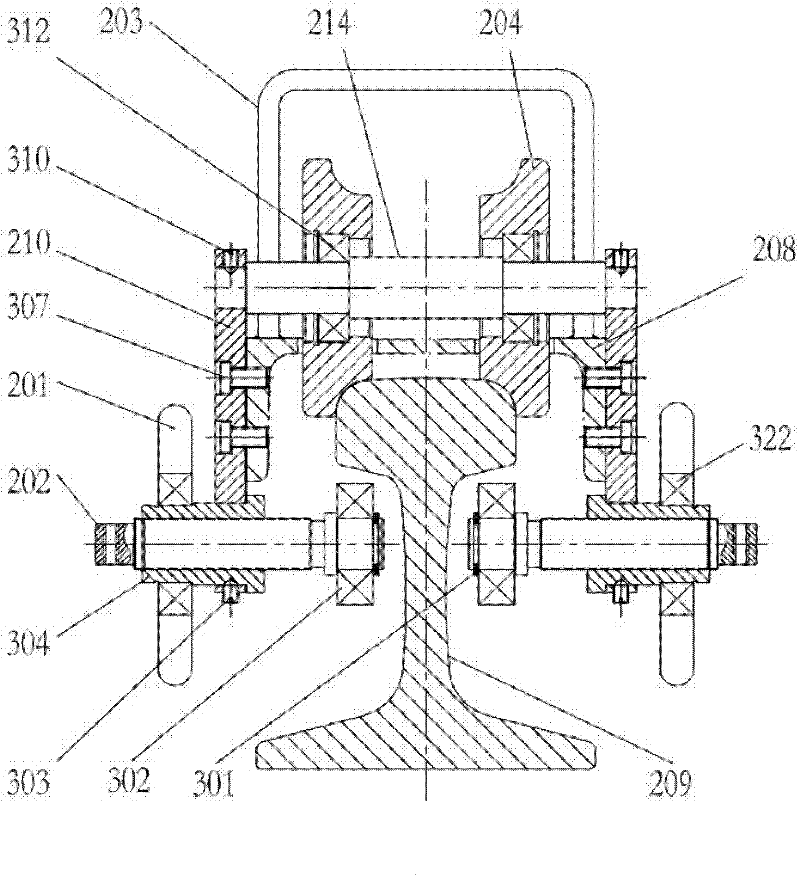

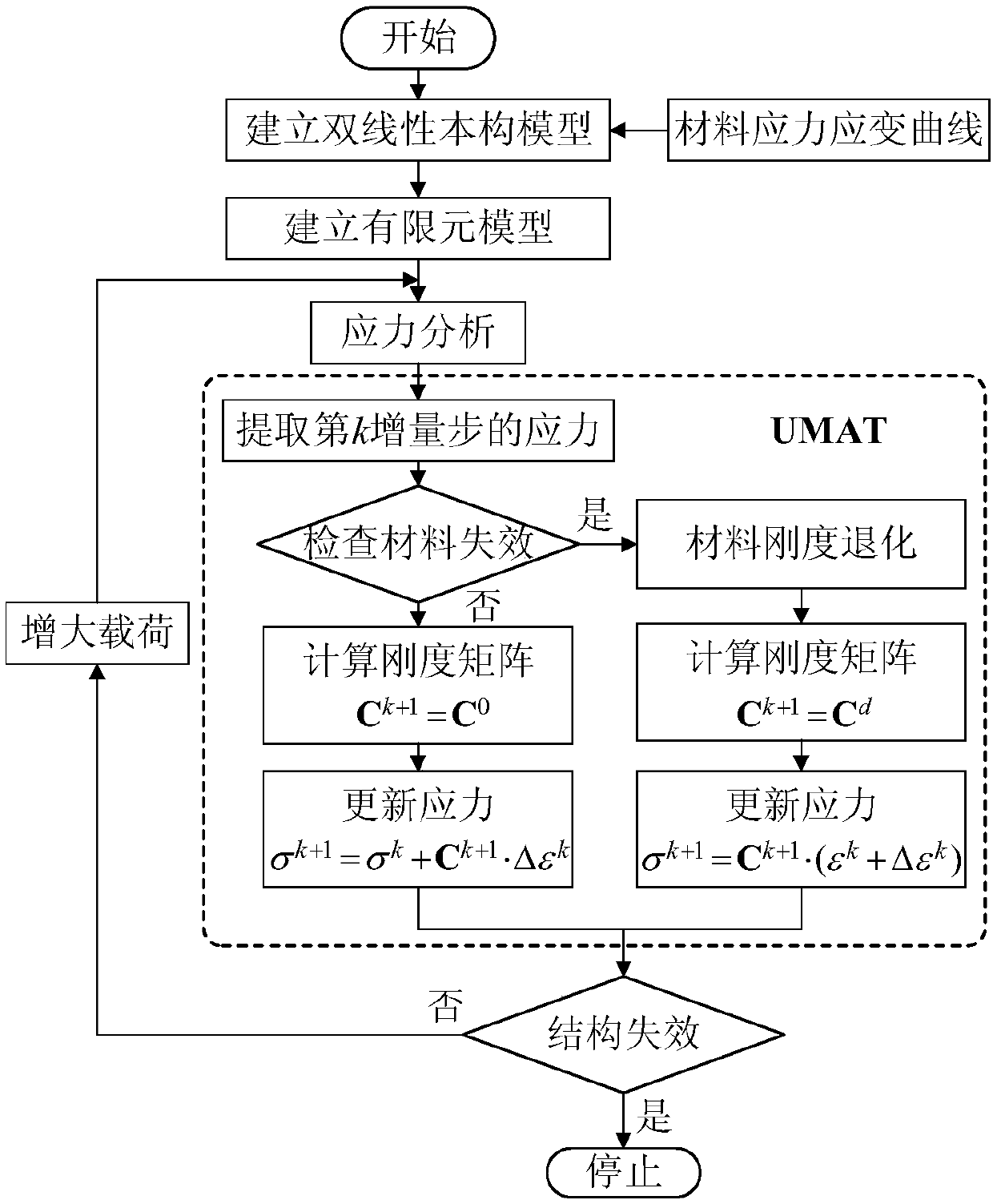

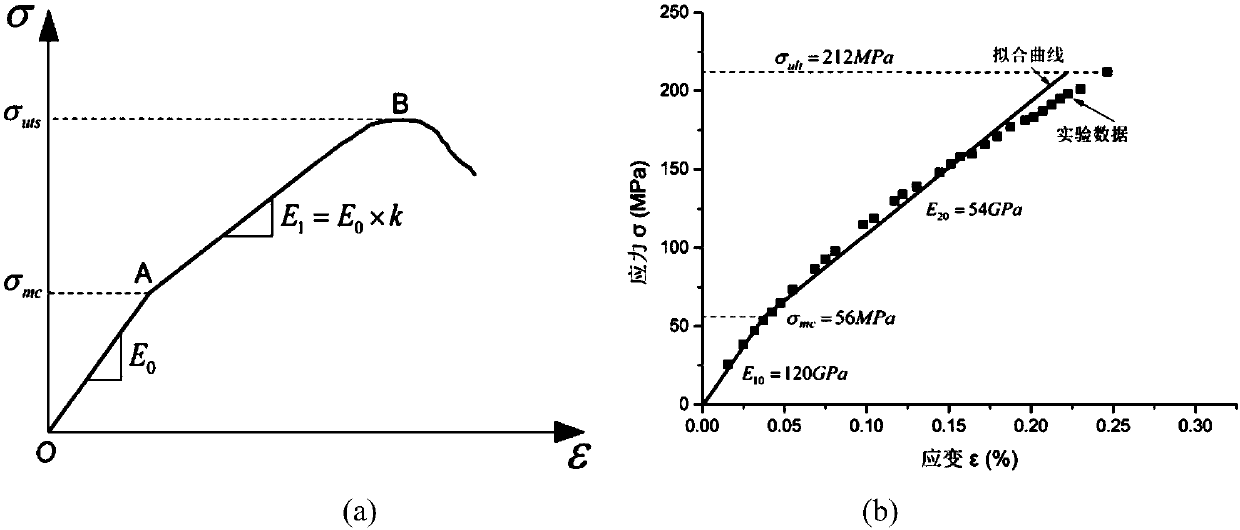

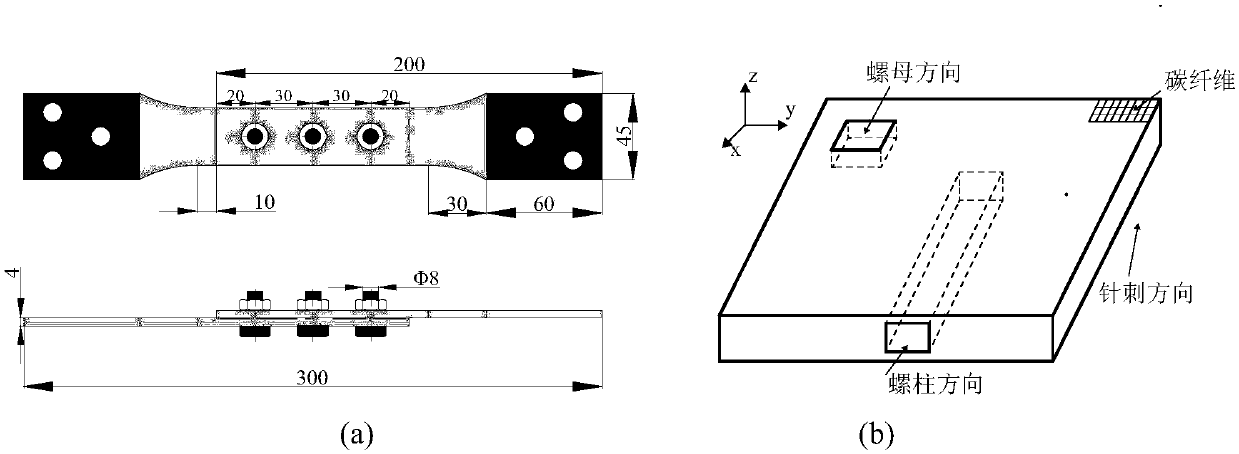

Progressive damage model-based full-SiC composite material multi-nail connection structure failure analysis method

ActiveCN107832560AAccurately describe nonlinear propertiesWell formedDesign optimisation/simulationSpecial data processing applicationsElement modelStrength of materials

The invention relates to a progressive damage model-based full-SiC composite multi-nail connection structure failure analysis method. The method comprises the following steps of: (1) establishing a bilinear constitutive model of materials on the basis of C / SiC composite material mechanical property test; (2) establishing a composite material structure three-dimensional finite element model according to a C / SiC composite material multi-nail connection structure geometric parameter; (3) carrying out stress analysis on the basis of the composite material structure three-dimensional finite elementmodel; (4) predicting failure states of the composite materials by applying a failure criterion suitable for C / SiC composite materials; (5) carrying out material rigidity degeneration on the failurematerials according to a degeneration model; and (6) judging whether damages in the composite materials cause structure damage or not, and if the judging result is negative, continuously carrying outloading until the materials fail. The method is suitable for engineering application, and is capable of effectively analyzing and predicting the failure of C / SiC composite material multi-nail connection structures, remarkably reducing the test cost and providing references for engineering practices.

Owner:BEIHANG UNIV

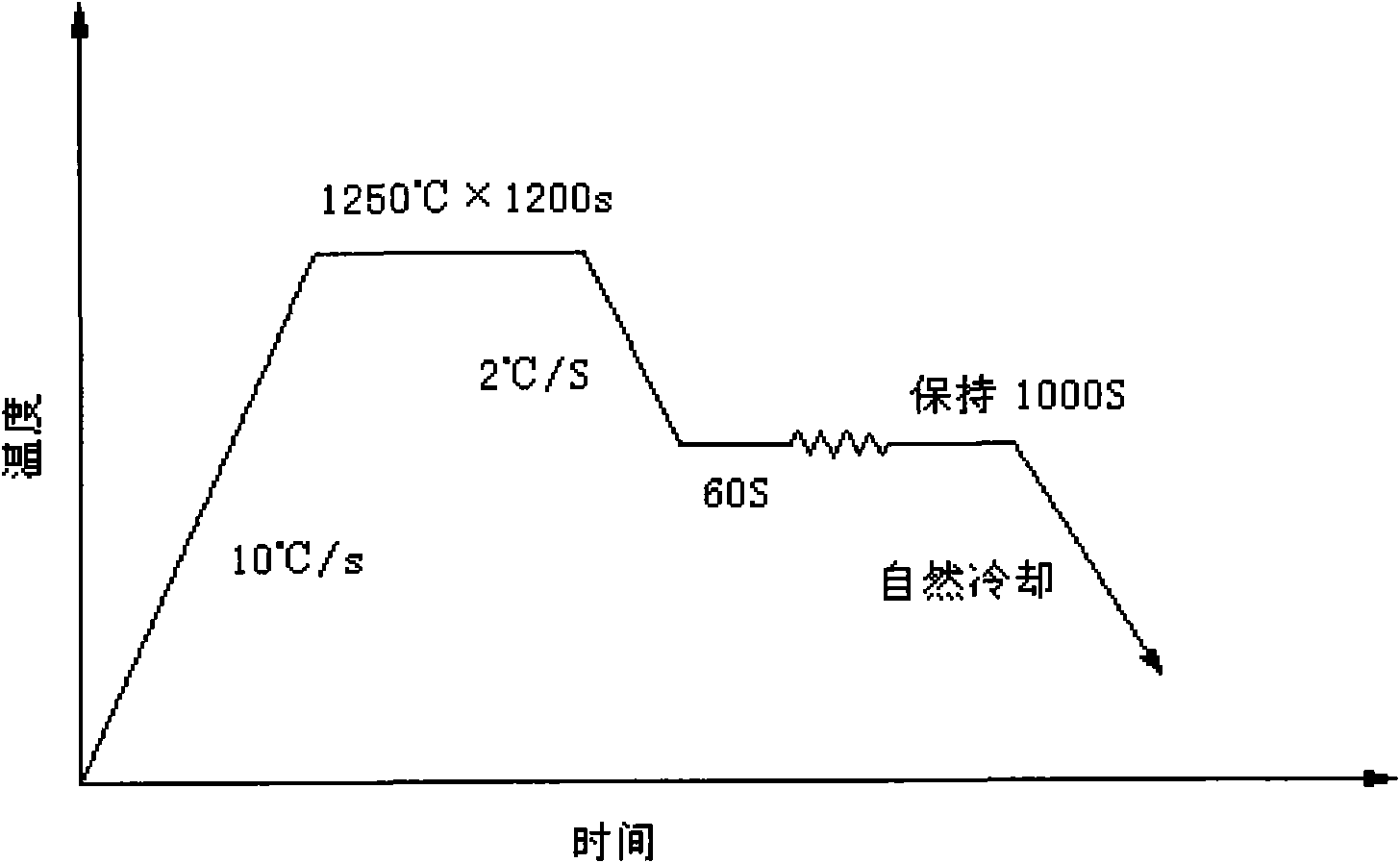

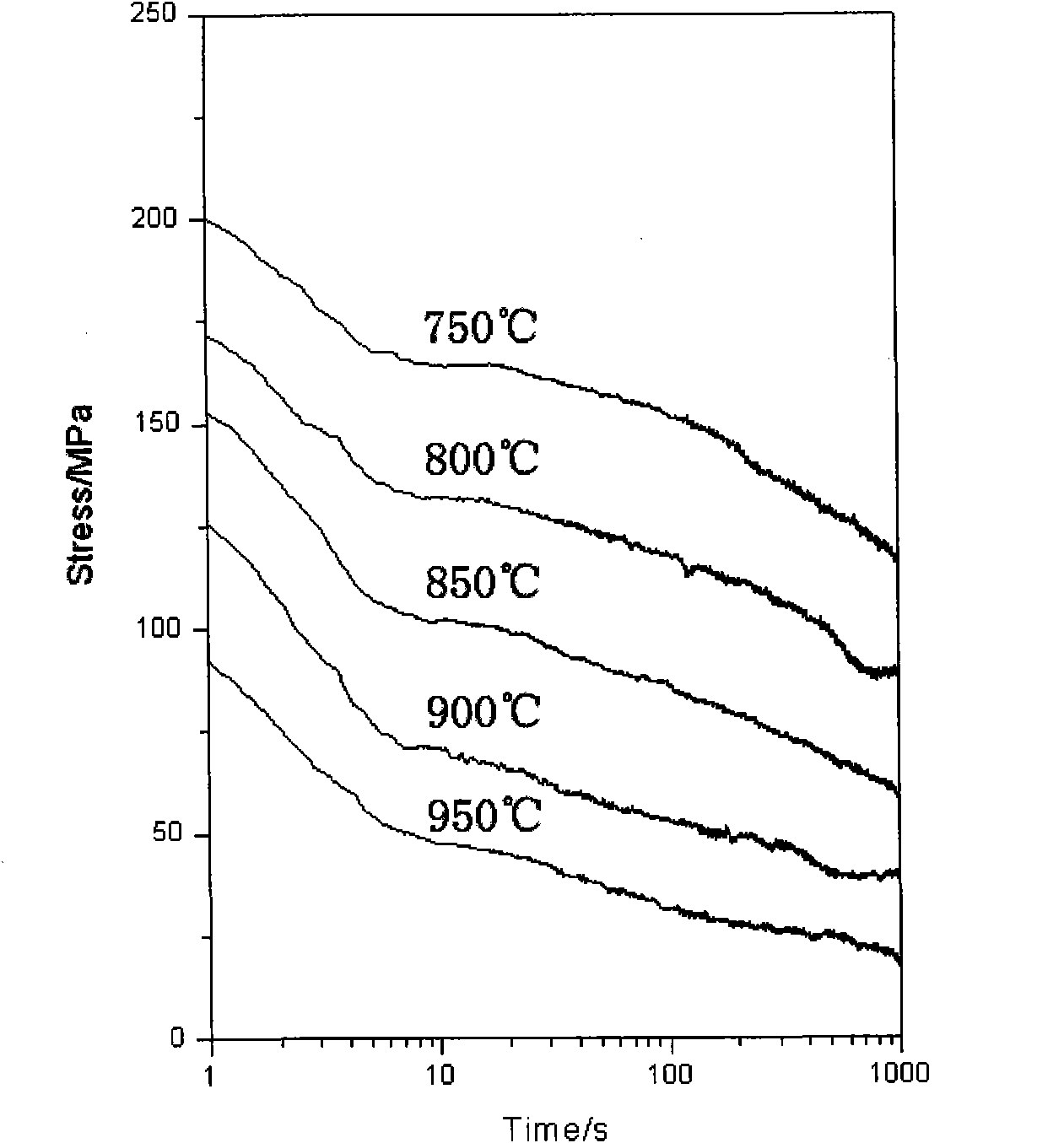

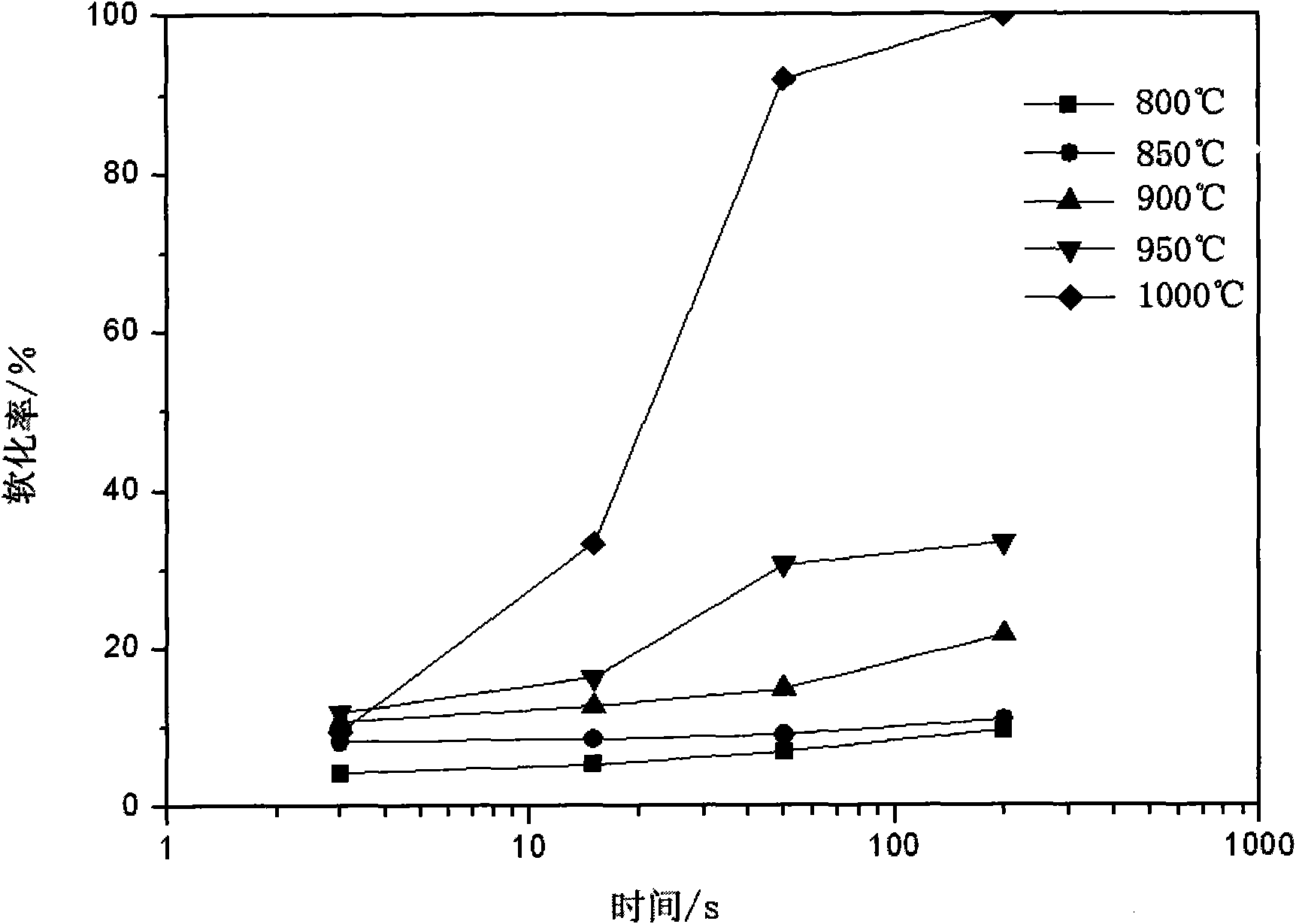

Method for carrying out stress relaxation test on Gleeble3800 hydraulic wedge unit in Jaw control mode

InactiveCN101793644ALow costHigh precisionMaterial strength using tensile/compressive forcesEngineeringFriction force

The invention discloses a method for carrying out a stress relaxation test on a Gleeble3800 hydraulic wedge unit in a Jaw control mode, which comprises the following steps: welding a thermocouple onto a sample, adopting a K-shaped thermocouple when the heating temperature of the sample is below 1200 DEG C, and adopting an S-shaped thermocouple when the heating temperature of the sample is above 1250 DEG C; respectively spreading a lubricant on a pressure head and the sample to reduce the friction force in compression, and isolating the pressure head and the sample through a tantalum sheet to prevent the pressure head and the sample to react in a high temperature state; opening an air hammer, compacting the sample, controlling the pressure to be about 100Kg, then opening a Gleeble3800 thermal simulation tester and leftwards moving the pressure head to a proper position; carrying out vacuum pumping, and charging Ar gas for protection when the vacuum degree is up to 2.4*10 to 1tau; carrying out compression by adopting the Jaw control mode; and after equipment operation is finished, reserving a high temperature organization state by adopting a direct quenching method, verifying precipitation and recrystallization conditions, and finishing the stress relaxation test. The invention has low cost and high precision and can be used for researching the precipitation behavior of various strain induced precipitates.

Owner:NANJING IRON & STEEL CO LTD

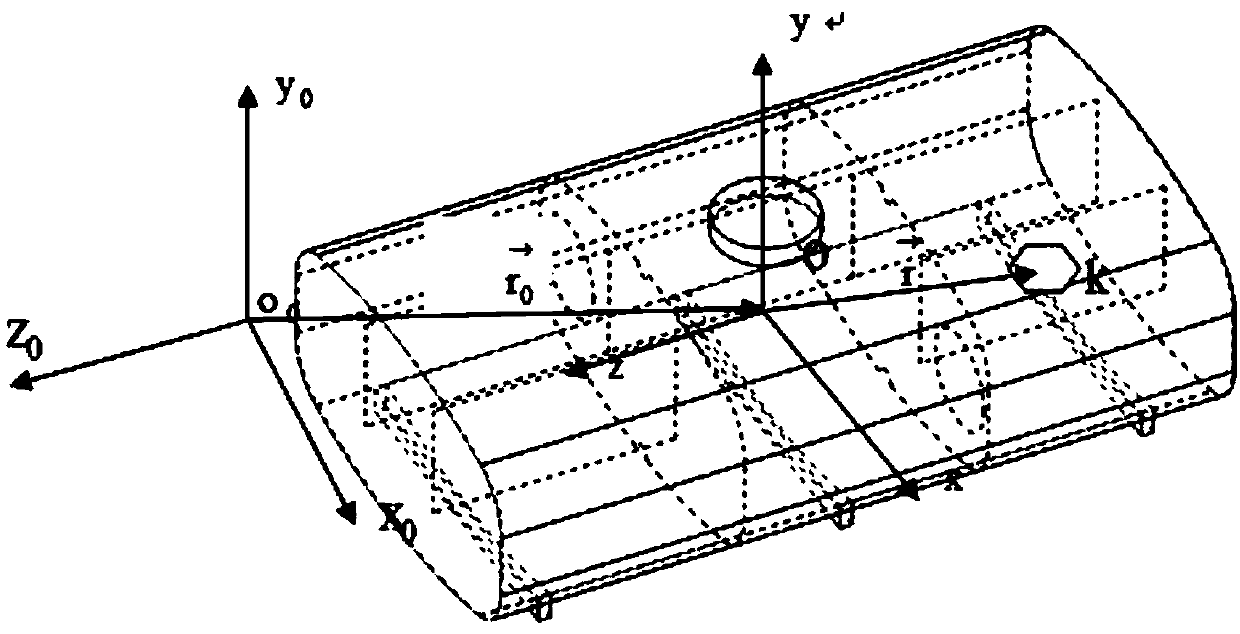

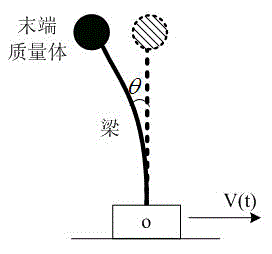

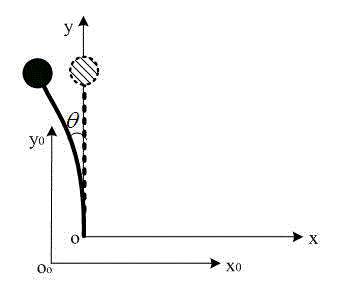

Flexible beam system dynamics modeling method with terminal quality body and control method thereof

The invention provides a flexible beam system dynamics modeling method with a terminal quality body and a control method thereof. The flexible beam system dynamics modeling method comprises the following steps of (1) establishing a system dynamics physical model, (2) carrying out deformation description on a system, (3) establishing a double-coordinate system which facilitates system analysis, (4) carrying out stress analyzing, (5) establishing the dynamic equation of the system, (6) selecting a boundary condition, and (7) determining a control objective. According to the flexible beam system dynamics modeling method with the terminal quality body, in the condition that a beam terminal has no state feedback detection, the terminal quality body of the flexible beam system with rapid action and frequent point-to-point motion can be rapidly positioned at an object point, and a basis is provided for the realization of a subsequent controller. The flexible beam system dynamics control method with the terminal quality body is convenient and practical.

Owner:GUANGDONG UNIV OF TECH

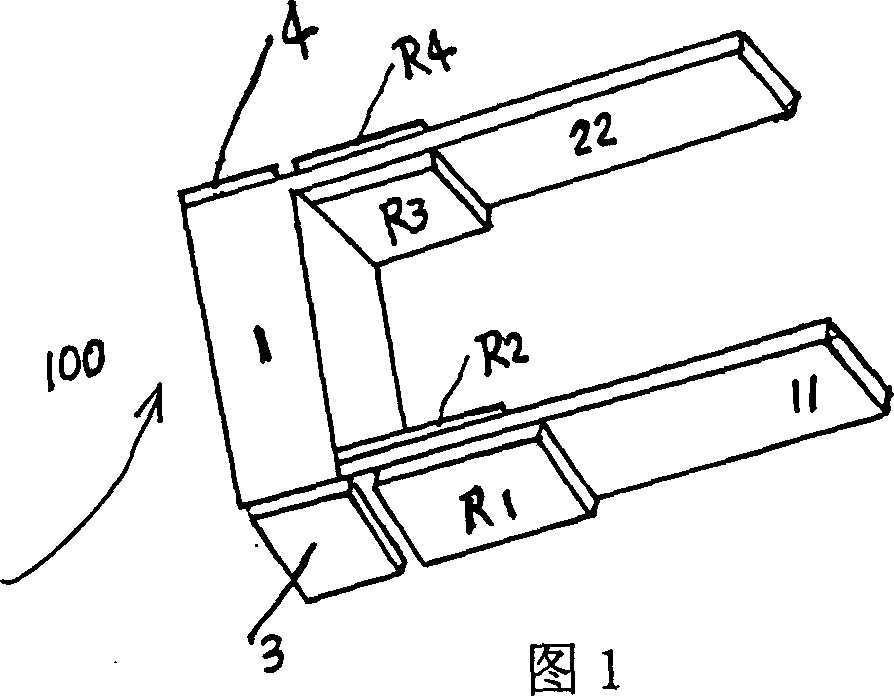

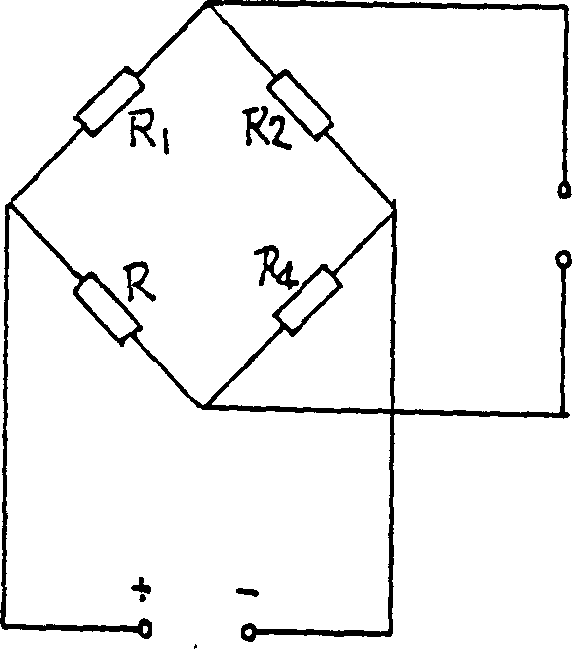

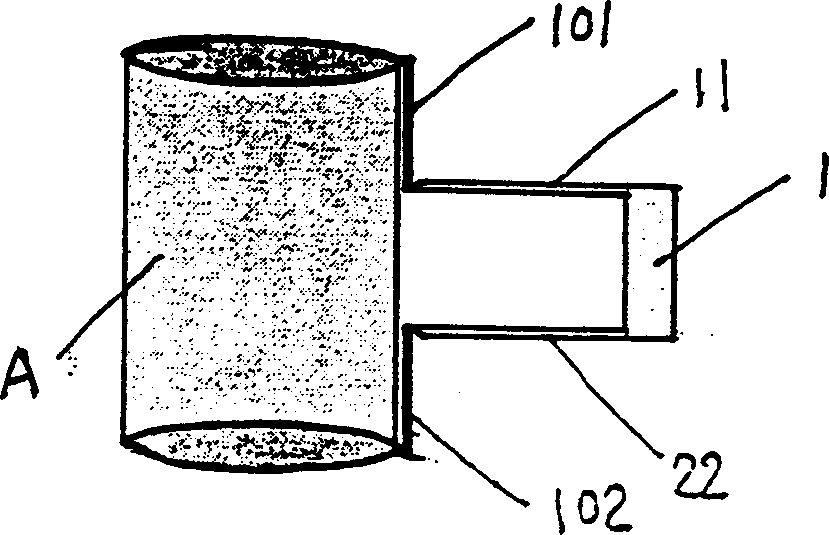

Method for measuring polymer-base foam material elastic modulus by displacement sensor

InactiveCN1779432AImprove accuracyHigh sensitivityMaterial strength using tensile/compressive forcesUsing mechanical meansElectrical resistance and conductanceTransducer

A method for measuring elastic modulus of polymer based foam material by utilizing displacement transducer includes fixing measurement zone of said material to be measured on ends of said transducer two pincer arms then placing them into universal material tester, connecting leading wire of said transducer resistance foil gauge connected to be wheatstone bridge to strain gauge separately and connecting strain gauge to computer, exerting compression or tensile force on said material for obtaining stress ¿C strain data then sending it to computer for plotting out stress ¿C strain curve then obtaining said material property modulus as per the curve.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Manufacturing method of small-inner-diameter hollow spindle

InactiveCN102430893AClear depthClear widthWorkpiece edge portionsWelding accessoriesManufacturing cost reductionWeld seam

The invention provides a manufacturing method of a small-inner-diameter hollow spindle, which comprises the following steps: dividing a small-inner-diameter spindle into a plurality of spindle sections, respectively carrying out sectional forging, welding into an integral body, and carrying out stress-relief annealing on the small-inner-diameter spindle to finish the outer circle and the inner circle, thereby obtaining the finished product. The inner side of the welding joint of every two adjacent spindle sections is an assembly seam / spigot, and the outer side is a welding seam bevel. The welding process comprises the following two steps: carrying out bottoming and root welding in an argon arc welding mode, and filling and capping in a submerged arc welding mode. The invention implements sectional processing of the small-inner-diameter hollow spindle of a hydroelectric generating set, thereby greatly lowering the manufacturing cost, shortening the production cycle of the small-inner-diameter spindle, ensuring the welding quality of the small-inner-diameter spindle and relieving the manufacturing bottleneck of the small-inner-diameter spindle.

Owner:DONGFANG ELECTRIC MACHINERY

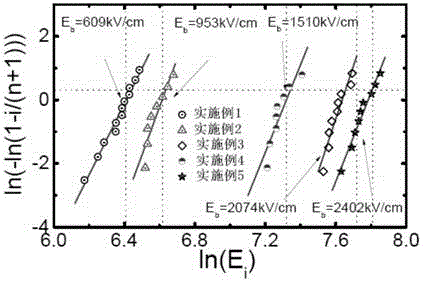

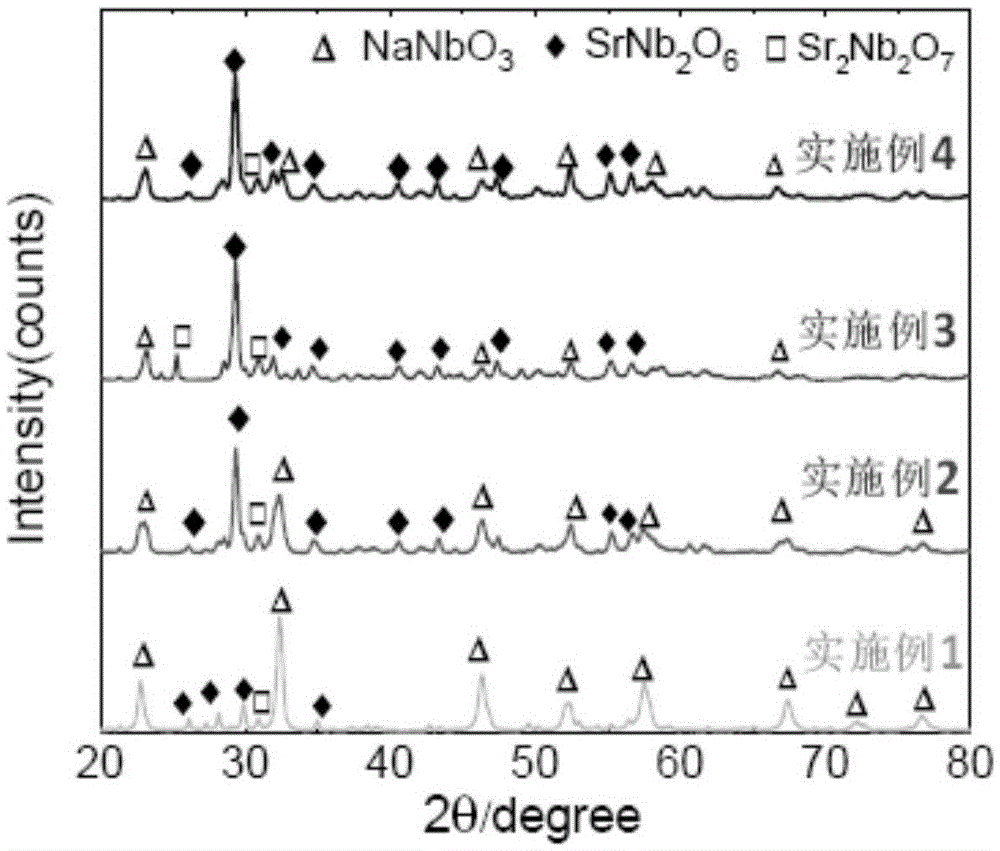

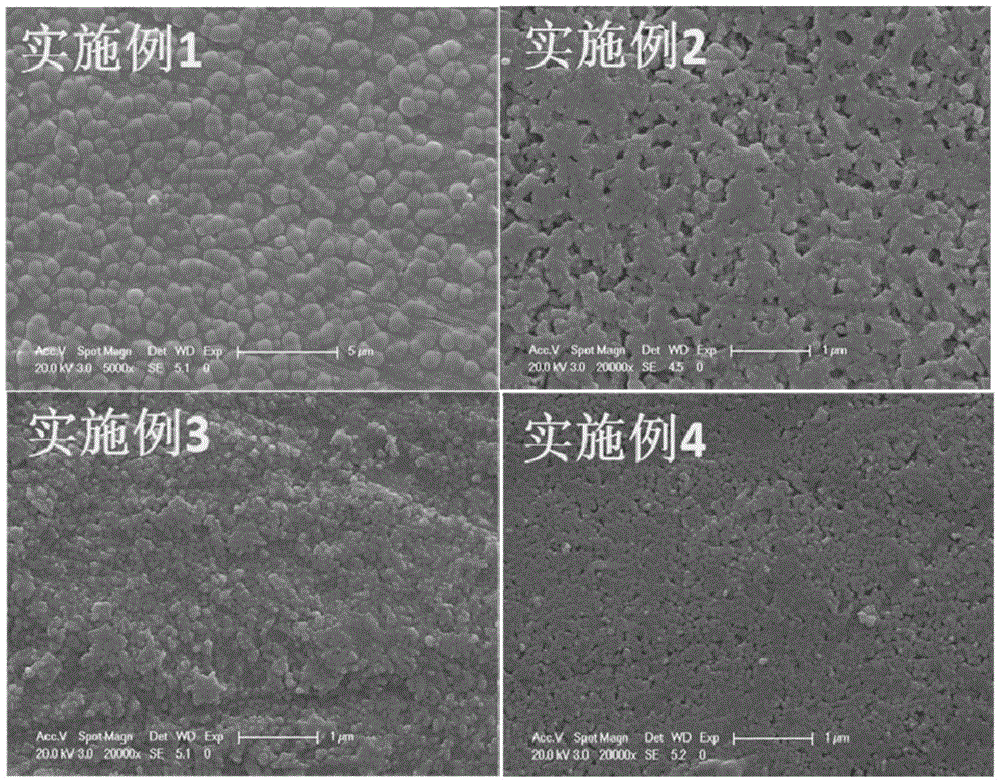

High-energy-storage-density strontium-sodium-niobate-base glass ceramic energy storage material, and preparation and application thereof

InactiveCN105645772ASimple structureImproved breakdown fieldFixed capacitor dielectricHigh energyGlass sheet

The invention relates to a high-energy-storage-density strontium-sodium-niobate-base glass ceramic energy storage material, and preparation and application thereof. The strontium-sodium-niobate-base glass ceramic energy storage material comprises SrO, Na2O, Nb2O5 and SiO2 in a mole ratio of 42x:42(1-x):28:30. The preparation method comprises the following steps: weighing the raw materials, mixing by ball milling, drying, and carrying out high-temperature melting to obtain a high-temperature melt; and casting the high-temperature melt into a preheated metal mold, carrying out stress-relief annealing to obtain transparent glass, cutting the transparent glass into glass sheets with the thickness of 0.9-1.2mm, and carrying out controlled crystallization to obtain the product. The product is applicable to an energy storage capacitor material. Compared with the prior art, the preparation method provided by the invention is simple, does not need complicated after-treatment steps, and is economical and practical. The prepared glass ceramic energy storage material has higher breakdown field strength resistance (2402kV / cm), and the energy storage density of the material is obviously enhanced to 16.86J / cm<3>. The strontium-sodium-niobate-base glass ceramic energy storage material is applicable to an energy storage capacitor material.

Owner:TONGJI UNIV

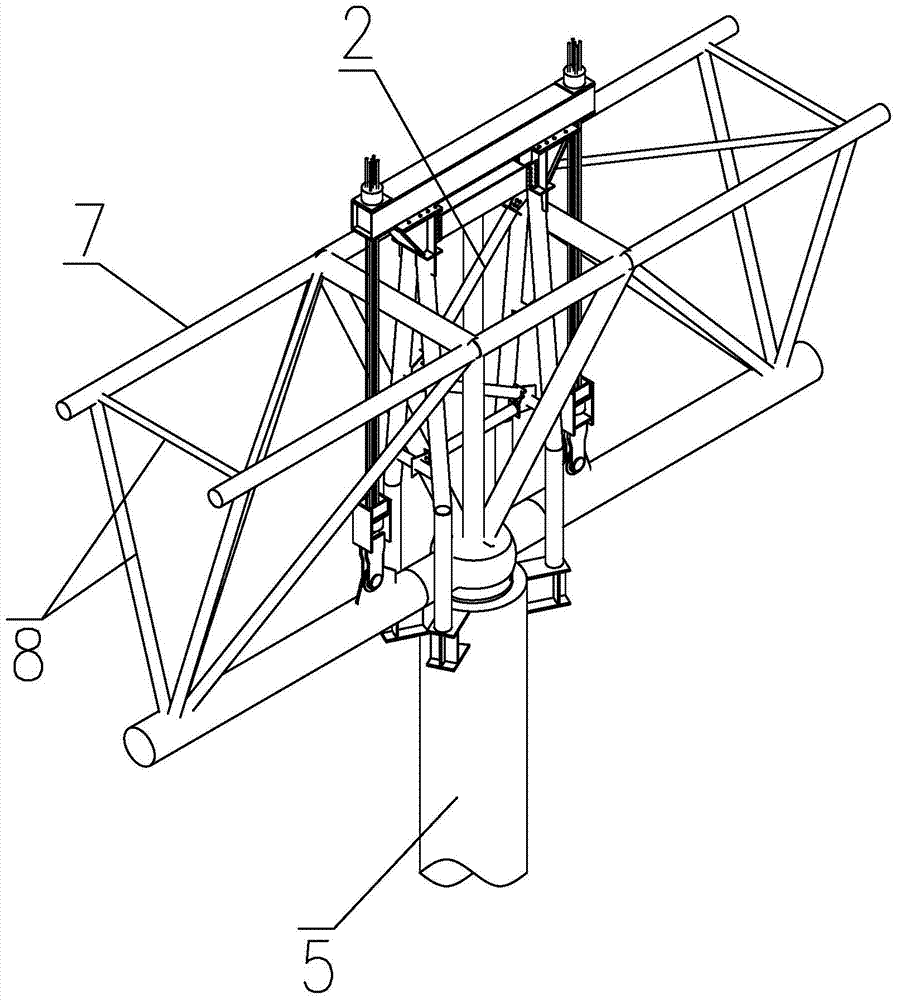

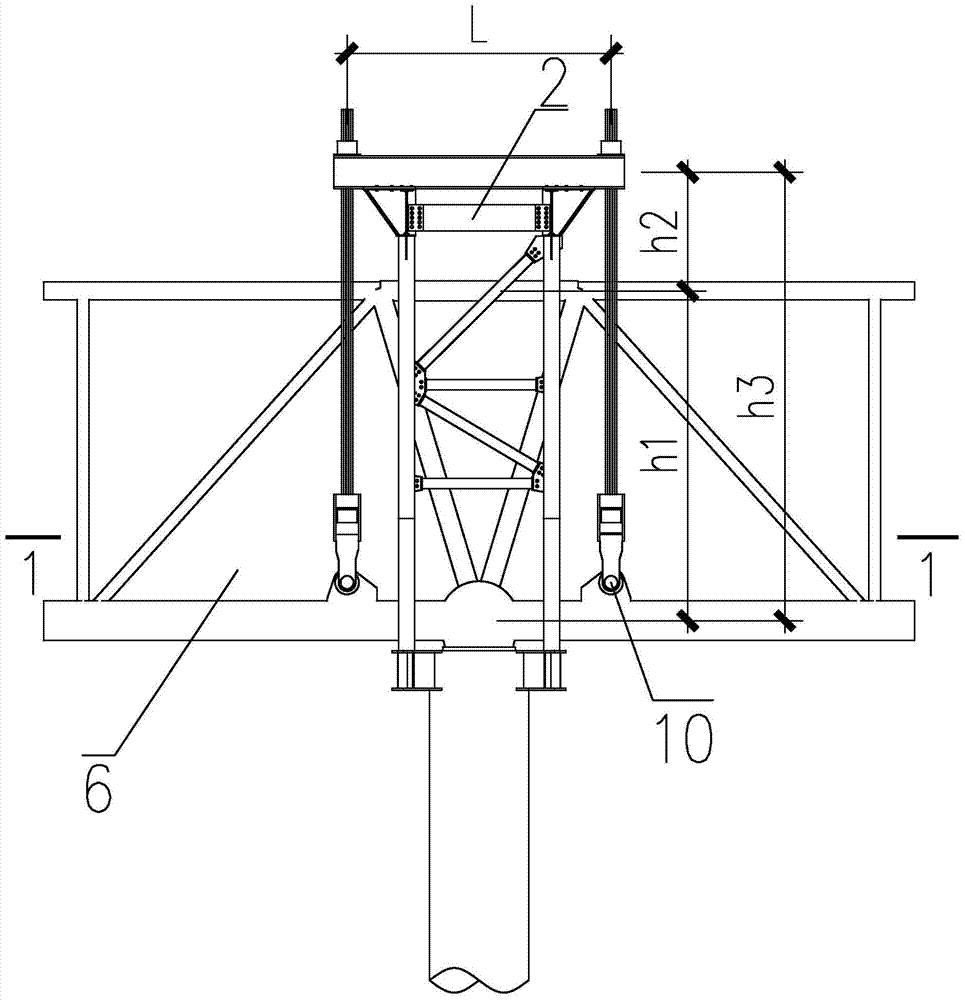

Hoisting frame design application method of continuous truss column top hinging structure

ActiveCN104265002AIntegrity guaranteedAvoid fragmentationBuilding material handlingControl theoryComputational analysis

The invention belongs to the field of steel structure buildings, and particularly relates to a hoisting frame design application method of a continuous truss column top hinging structure. The method comprises the following steps of: 1, a hoisting frame system arrangement stage; 2, a computational analysis stage; 3, a hoisting system design and manufacturing stage; 4, an installation stage; 5, a hoisting and monitoring stage: installing a hydraulic hoisting device and a temporary reinforcement device, hoisting a continuous truss to a target elevation, and carrying out stress strain monitoring; and 6, an unloading and dismounting stage: hoisting the structure to a target elevation position, then, unloading the hydraulic hoisting device, dismounting a hoisting frame and a conversion cross beam, cutting brackets, and finishing the construction. The hoisting frame design application method has the advantages that the completeness of the original truss structure is ensured; the influence on an existing structure is avoided; the form is simple and compact; the stress is reasonable; the construction is convenient; and the economical performance is good, and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

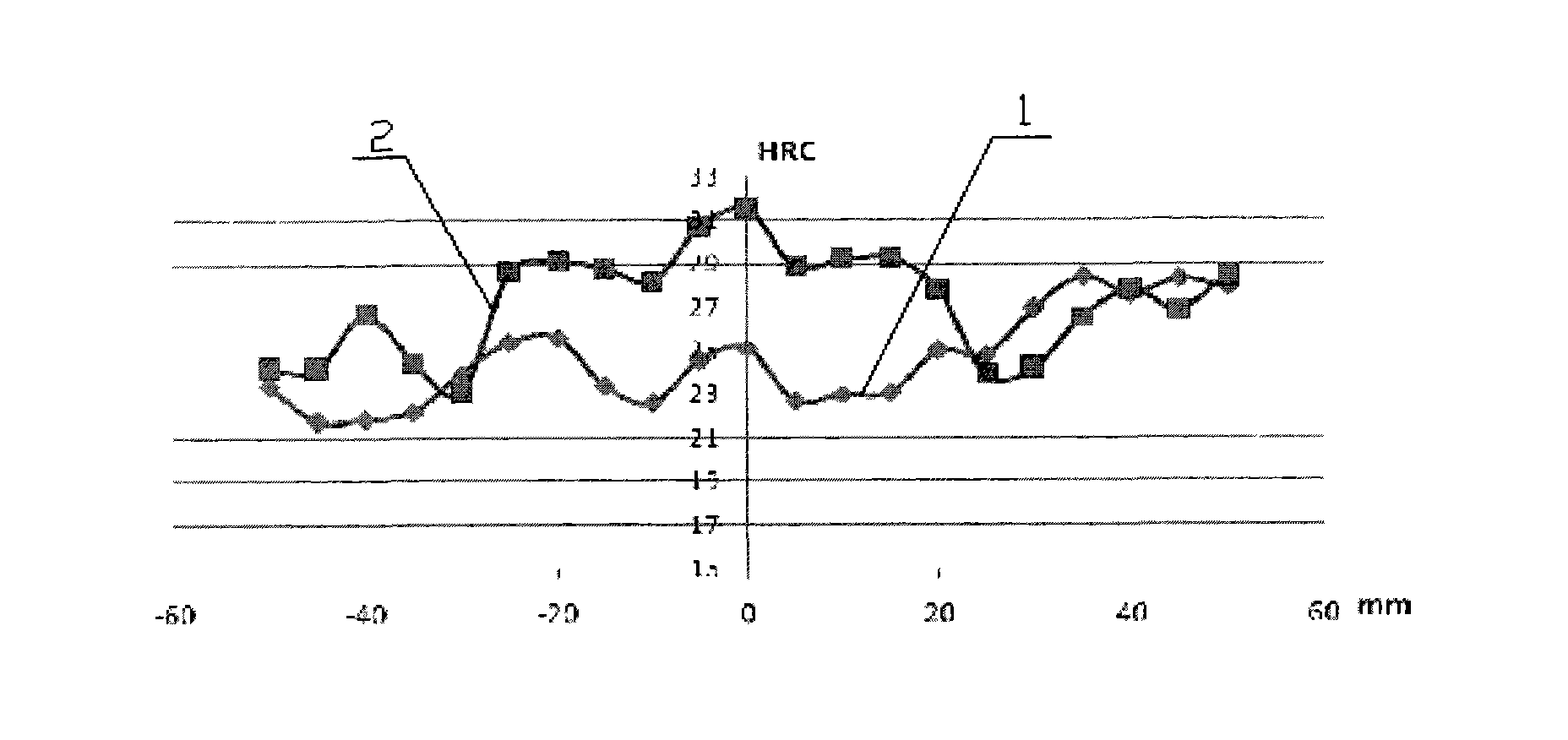

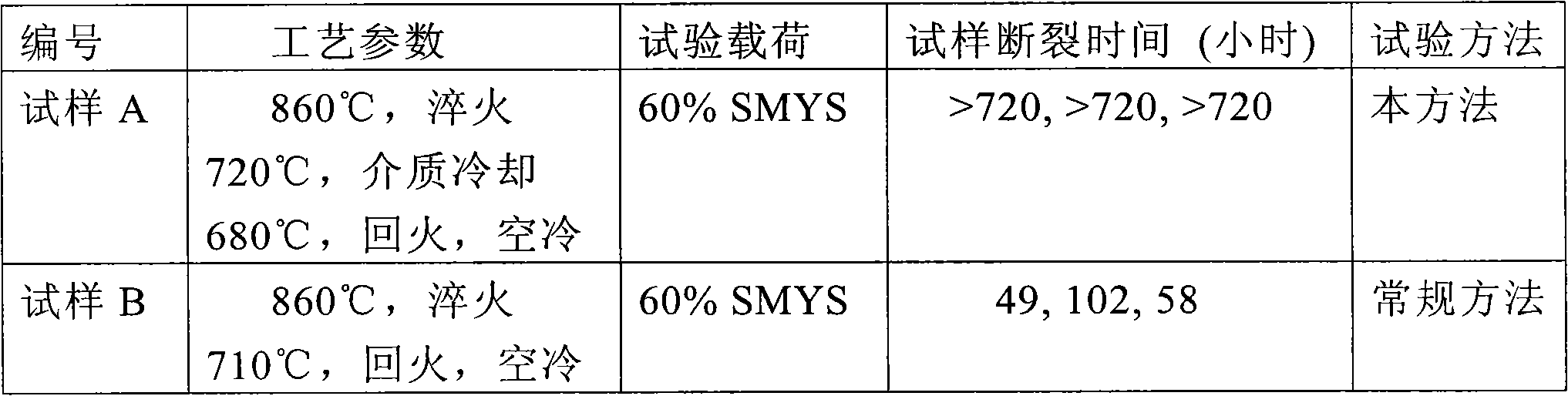

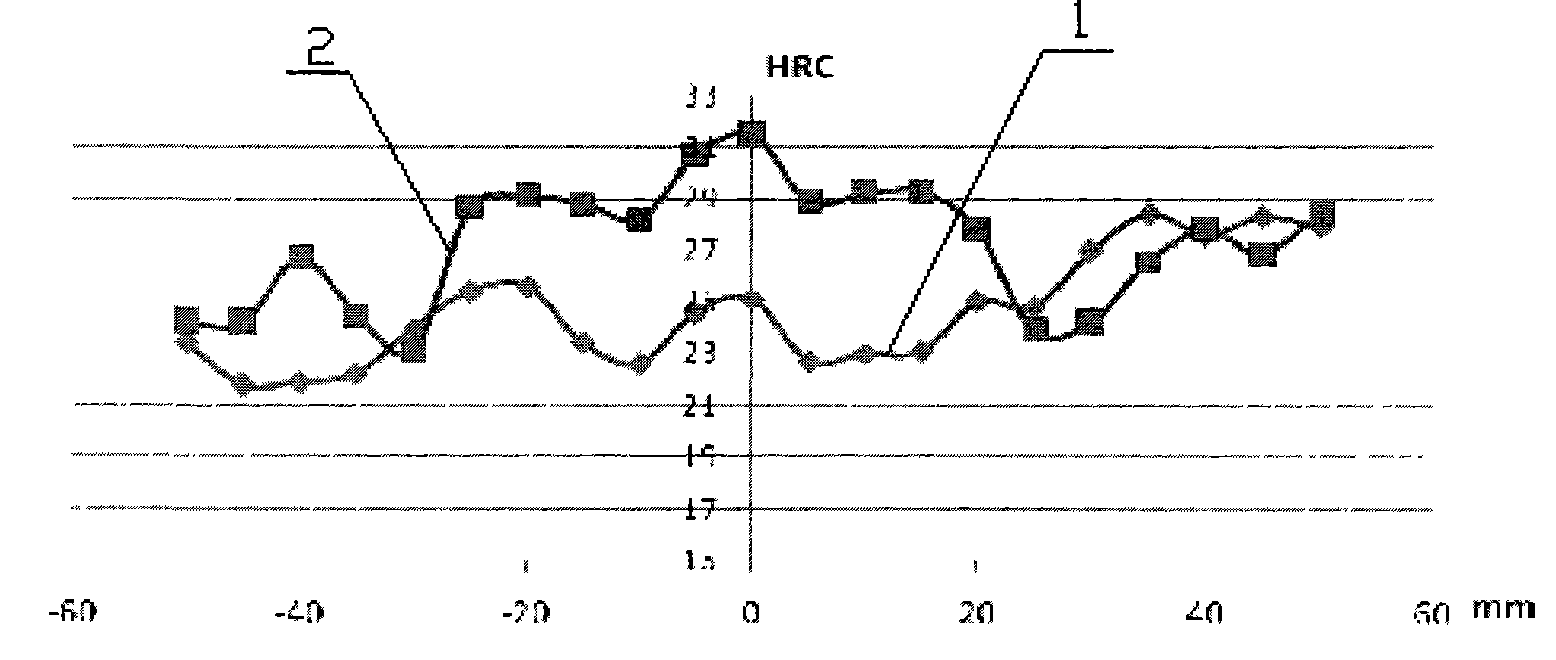

Treatment method for welding zone of high-performance sulfur-resisting drill pipe body and joint

InactiveCN101988147AAvoid lostImproved resistance to sulfide stress corrosion crackingIncreasing energy efficiencyFurnace typesStress corrosion crackingQuenching

The invention discloses a treatment method for a welding zone of a high-performance sulfur-resisting drill pipe body and a joint, which comprises the following steps: respectively carrying out overall quenched-tempered heat treatment on the pipe body and the joint with the same components, and then connecting the pipe body and the joint into a whole by friction welding; carrying out medium-frequency induction heating on the welding zone to 300 DEG C-600 DEG C, then carrying out stress-relief annealing, turning flashing and burrs, and carrying out post-welding heat treatment; carrying out medium-frequency induction heating on the welding zone to 780 DEG C-900 DEG C, preserving the temperature for 3-30 minutes, and then carrying out spray quenching by using a quenching medium of 20 DEG C-40 DEG C; carrying out medium-frequency induction heating on the welding zone to 690 DEG C-750 DEG C, preserving the temperature for 5-30 minutes, and then carrying out spray cooling by using a quenching medium of 20 DEG C-40 DEG C; and carrying out medium-frequency induction heating on the welding zone to 600 DEG C-700 DEG C, preserving the temperature for 5-30 minutes, and then air cooling to room temperature. After the drill pipe is treated by the method, the cracking-resisting capacity of the welding zone is improved, and the welding zone has appropriate strength, toughness, lower hardness and even distribution, thereby avoiding loss caused by sulfide stress corrosion cracking of the drill pipe.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +1

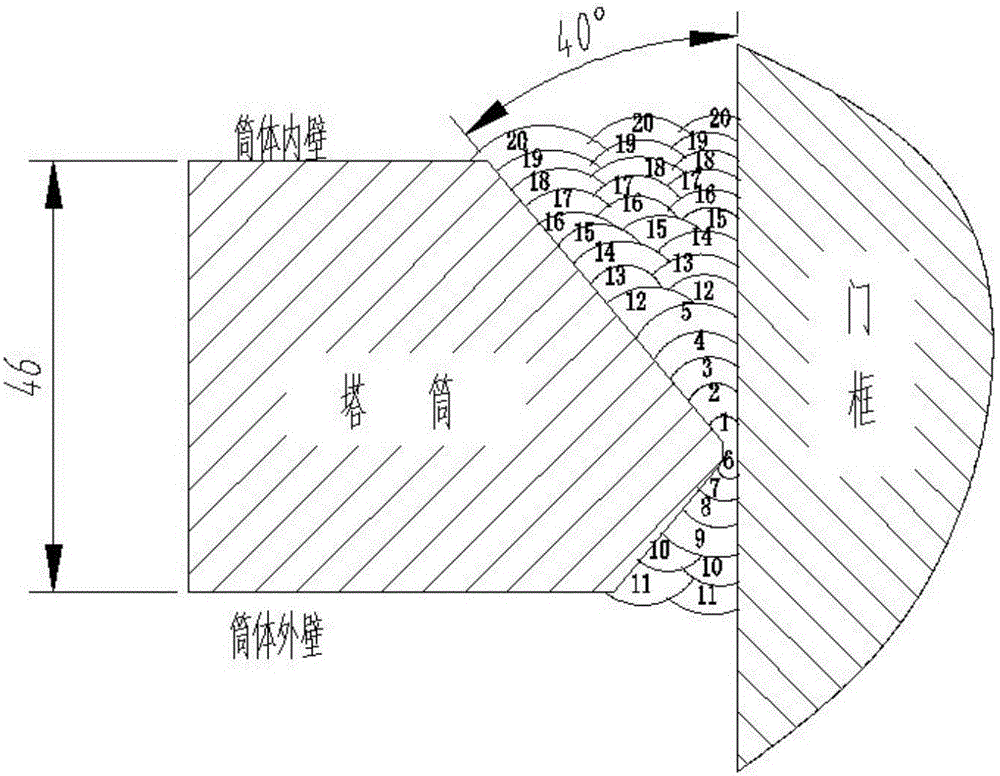

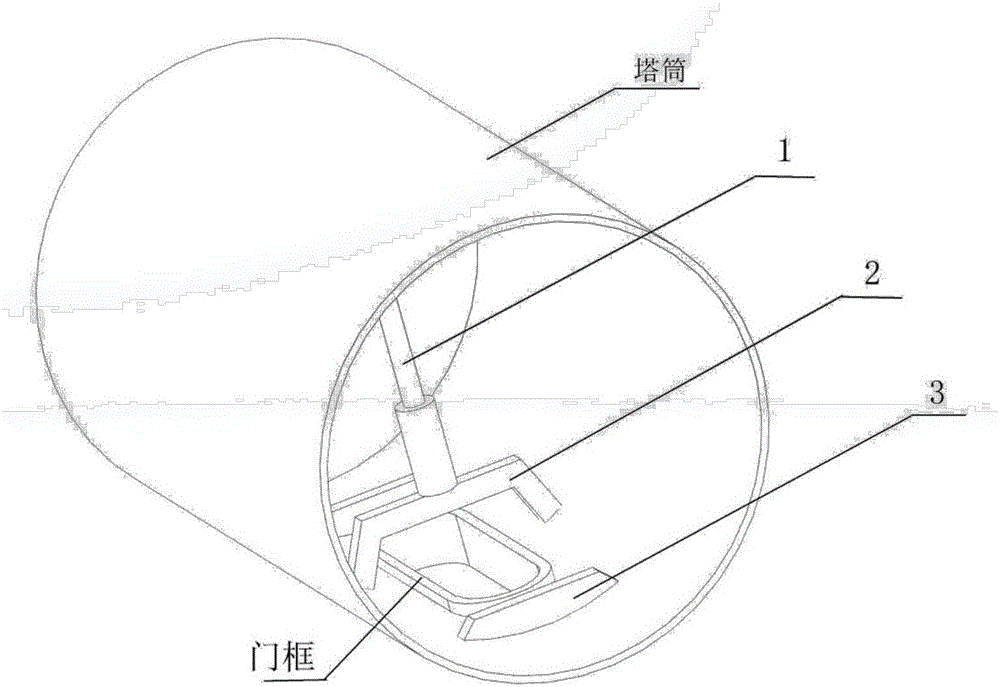

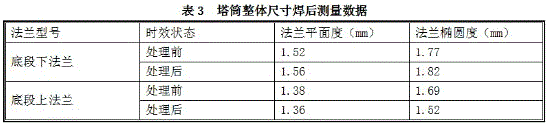

Method for welding door frame of ultra-low-temperature high-power wind turbine tower

ActiveCN106002008AReduce mistakesIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesElectricityStress concentration

The invention discloses a method for welding a door frame of an ultra-low-temperature high-power wind turbine tower. The method comprises the following five main steps: preparing materials of the door frame; cutting a door hole; mounting an anti-deformation tool; welding corner weld of the door frame and the tower; and carrying out stress relief treatment after welding. Stress concentration of a welding region of the door frame and the tower under the working condition of ultra-low temperature and the condition of high-power generation requirements can be eliminated, defects of welding cracks and lamellar tearing are avoided, and requirements of impact energy at the low temperature of minus 40 DEG C are met; influences of stress concentration to yield of flatness and ovality of a flange of the tower is avoided; and first-pass yield of inspection and acceptance of the tower is improved.

Owner:SINOHYDRO BUREAU 4 JIUQUAN NEW ENERGY EQUIPCO

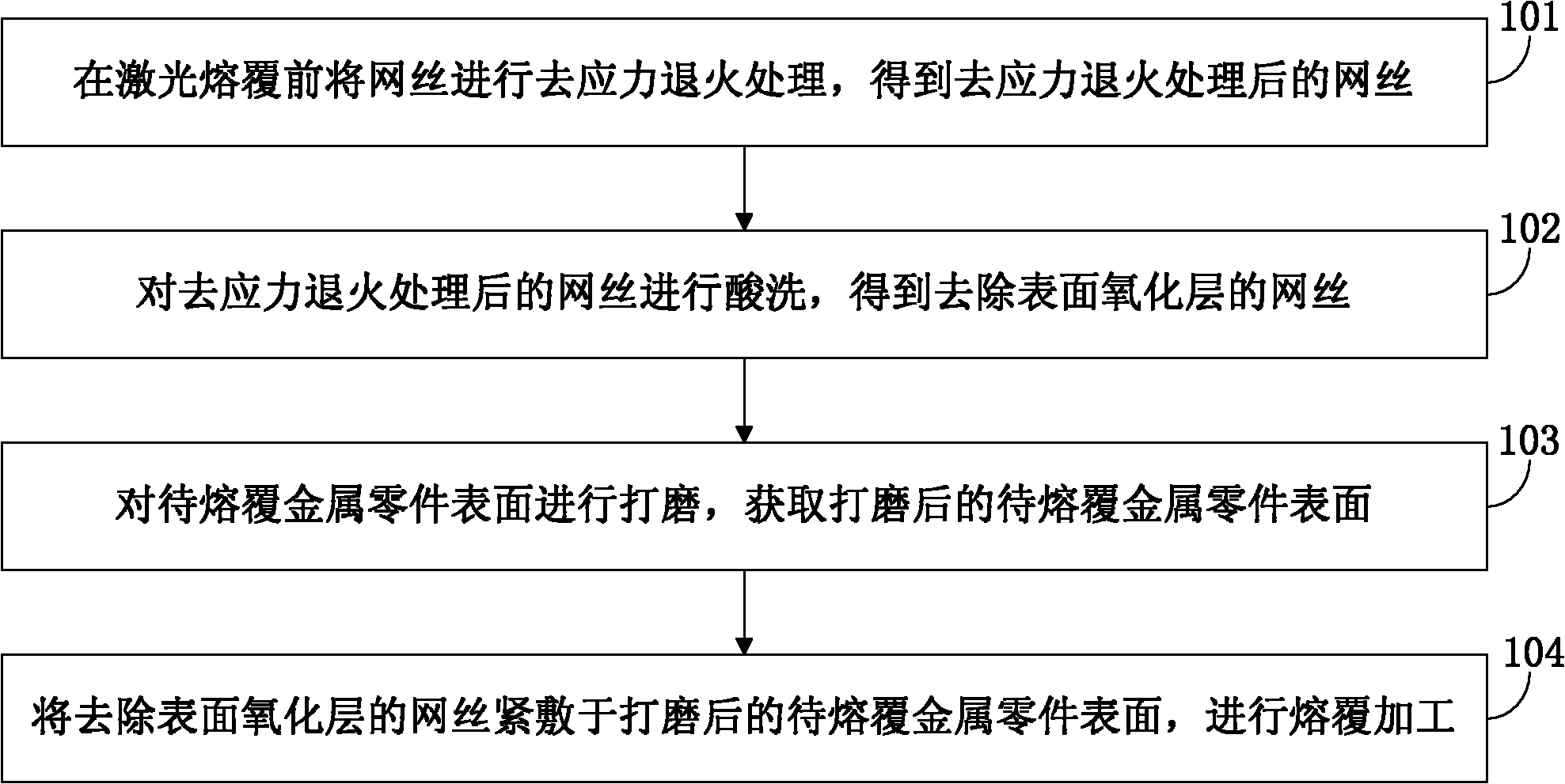

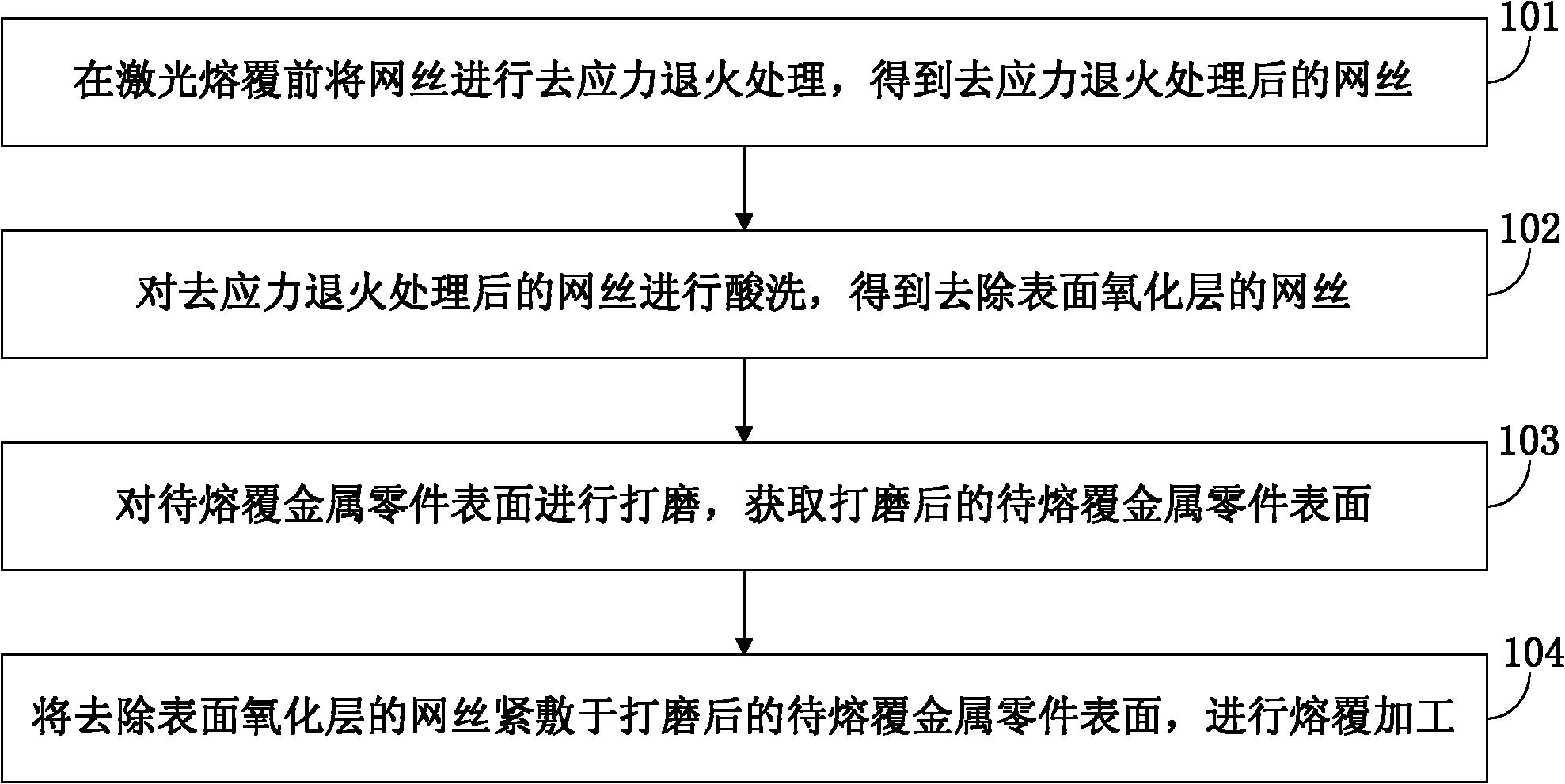

Cladding layer crack control method of laser surface cladding process

The invention discloses a cladding layer crack control method of a laser surface cladding process, belonging to the field of laser surface processing and manufacture. The cladding layer crack control method comprises the following steps of: carrying out stress relief annealing processing on netting wires before the lasers are clad to obtain the netting wires subjected to the stress relief annealing processing; scouring the netting wires subjected to the stress relief annealing processing to obtain the netting wires with surface oxidation layers removed; polishing the surface of a metal part to be cladded, and acquiring the surface of the polished metal part to be clad; tightly applying the netting wires with the surface oxidation layers removed on the surface of the polished metal part to be clad, and carrying out cladding processing. The invention limits the range of crack extension, thereby realizing the purpose of crack control; in addition, the cladding layer crack control method of the laser surface cladding process is applicable to laser cladding forming and repair of metal parts, laser surface strengthening, and other related technical fields.

Owner:LIANGYI LASER TECH TIANJIN

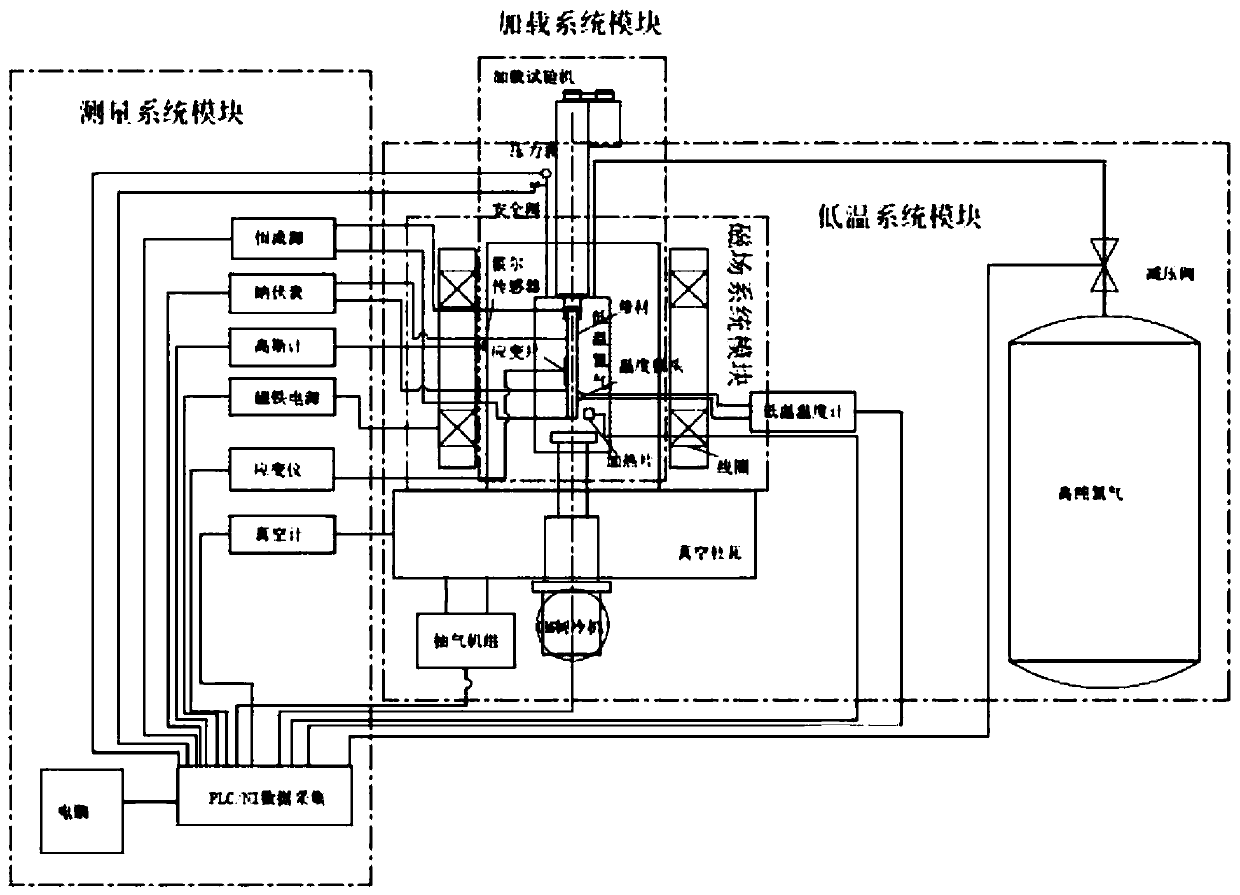

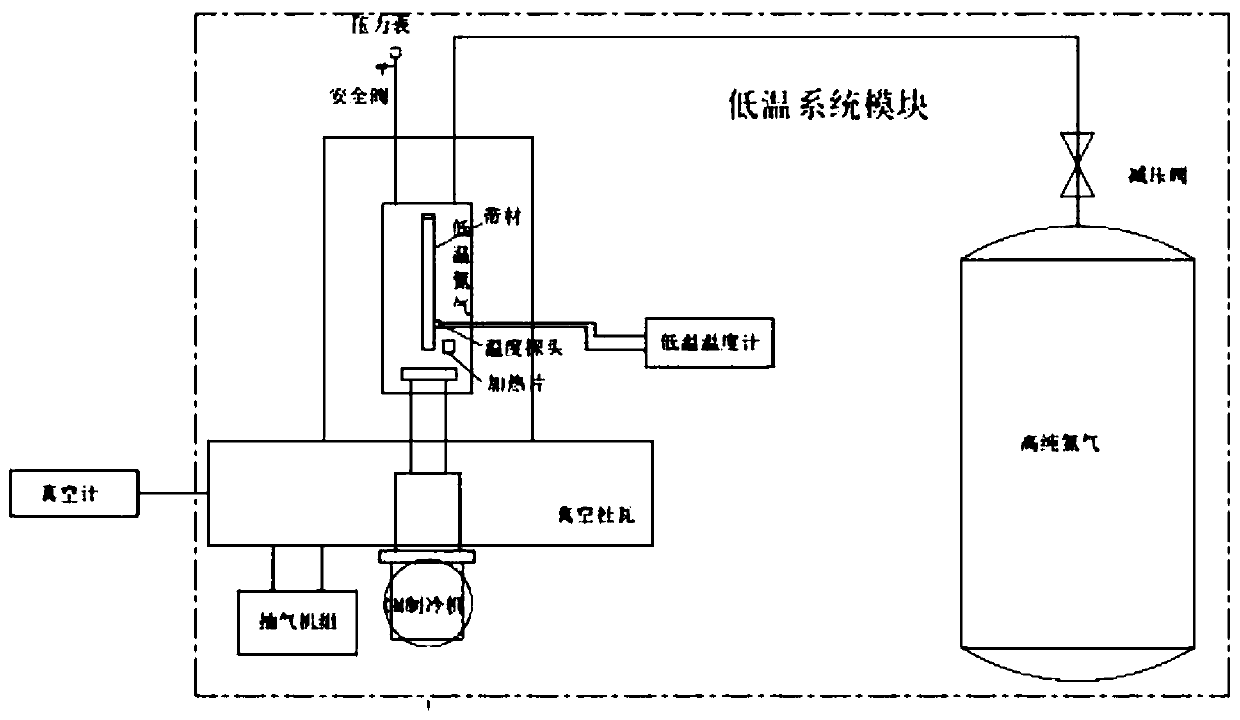

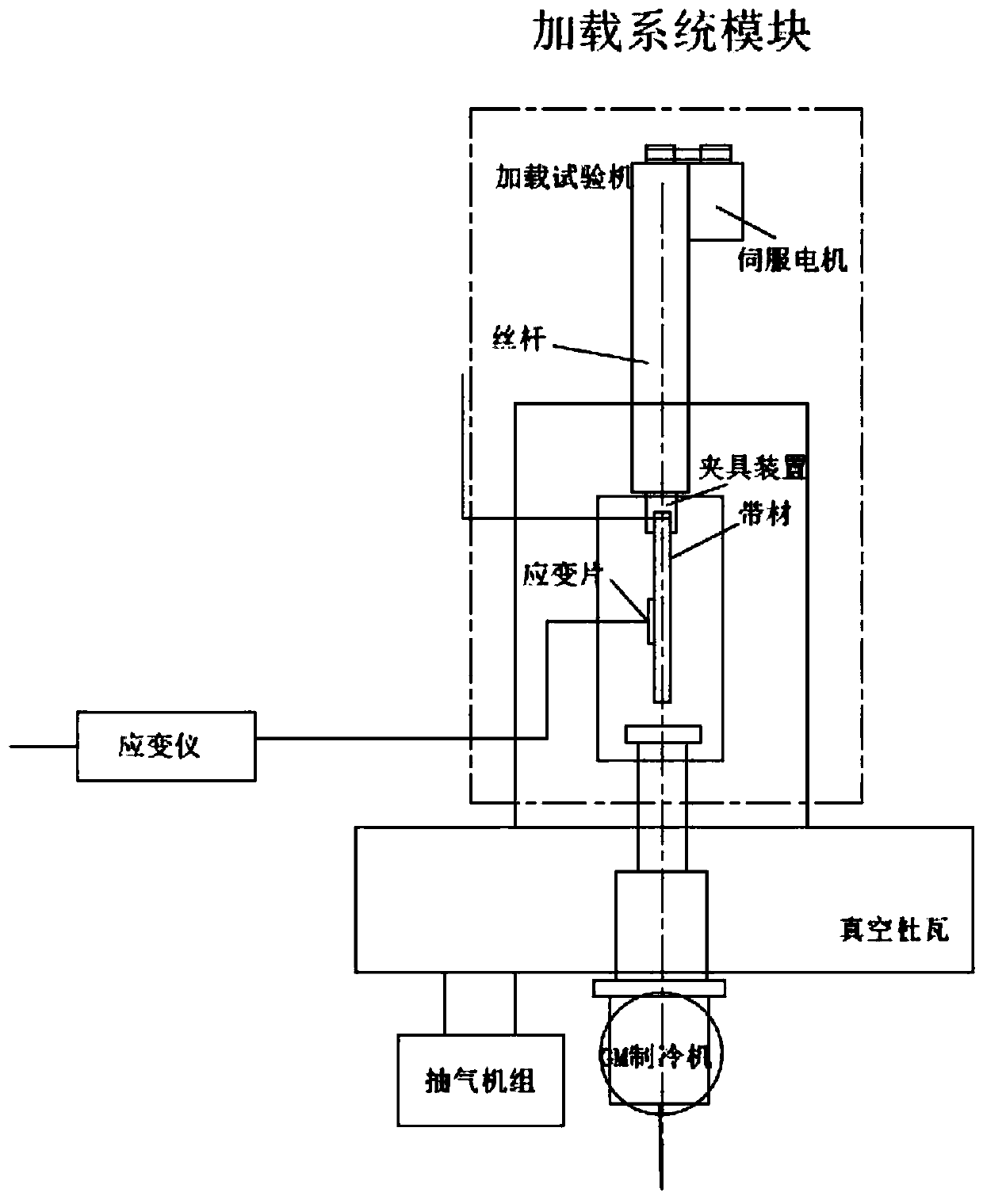

Device and method for testing current-carrying capacity of high-temperature superconducting tape or coil under multi-field coupling

ActiveCN110632425AImplement bridging relationshipsTroubleshoot coupled testing issuesMeasuring interference from external sourcesEnvironmental/reliability testsMulti fieldEngineering

The invention discloses an experimental device for testing the current-carrying capacity of a high-temperature superconducting tape or coil under multi-field coupling. The device comprises a loading system module, a low-temperature system module, a magnetic field system module and a measurement system module. The loading system module, the low-temperature system module and the magnetic field system module are used for comprehensively simulating the actual application environment of a superconducting wire. The measurement system module is used for measuring characteristic parameters of a superconducting wire or coil in states of temperature zone disturbance, magnetic field disturbance, and stress strain on the superconducting wire or coil. In addition, the invention also discloses a methodcomprising the following steps: acquiring a high-vacuum environment and a low-temperature environment and controlling a loading system to carry out stress loading on the high-temperature superconducting tape or the coil or controlling a magnetic field system to carry out magnetic field loading on the high-temperature superconducting tape or the coil; and controlling a constant current source to carry out current loading on the superconducting tape or the coil and recording the change of a nanovoltmeter. Therefore, a multi-field coupling test problem of the high-temperature superconducting tapetest is solved; and the domestic blank is filled.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com