Patents

Literature

542 results about "Life evaluation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cycle creep and fatigue life evaluation method under conditions of high temperature and multiaxial spectrum load

ActiveCN103926152AEasy accessReduce testing costsMaterial strength using tensile/compressive forcesFatigue damageCreep stress

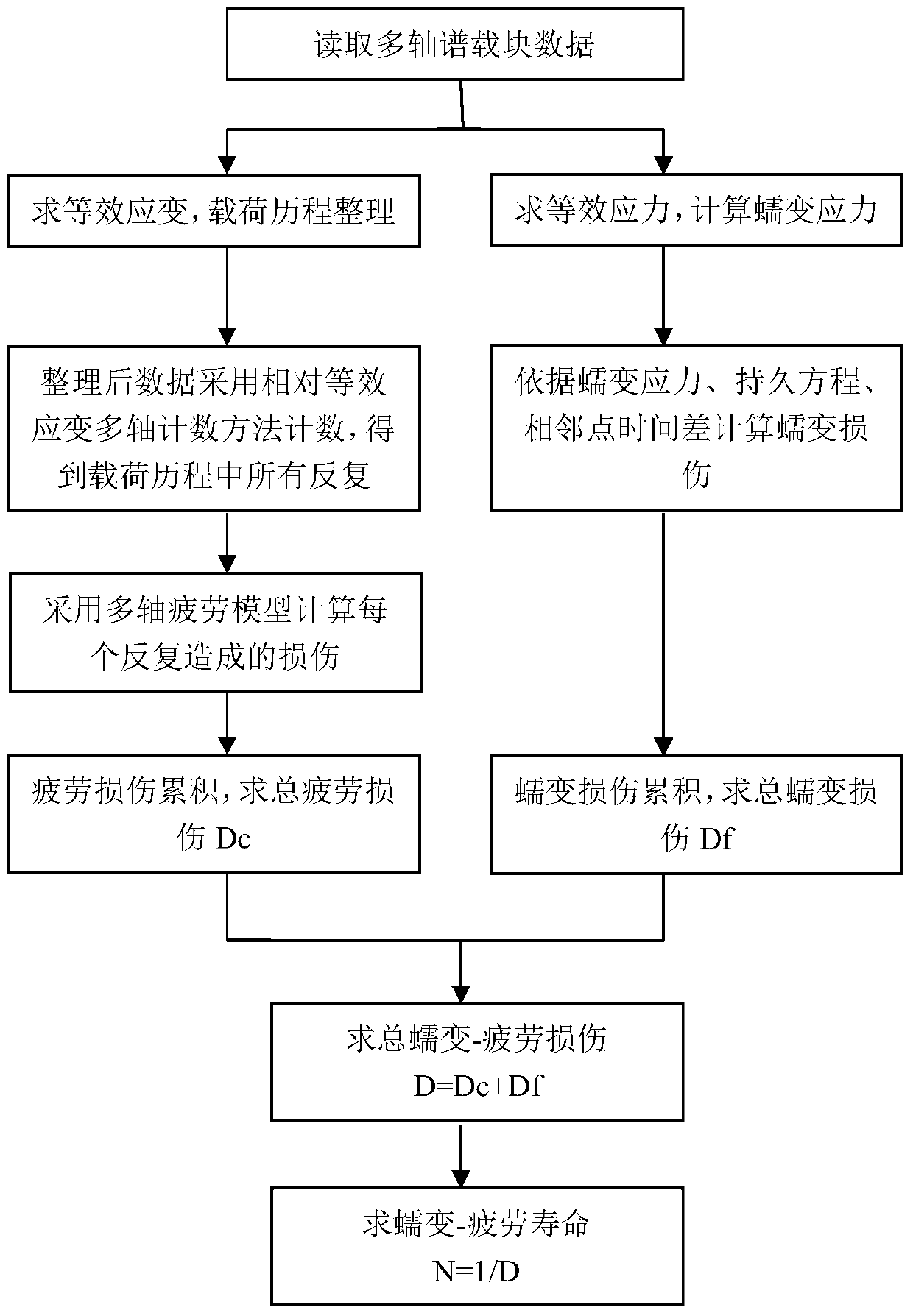

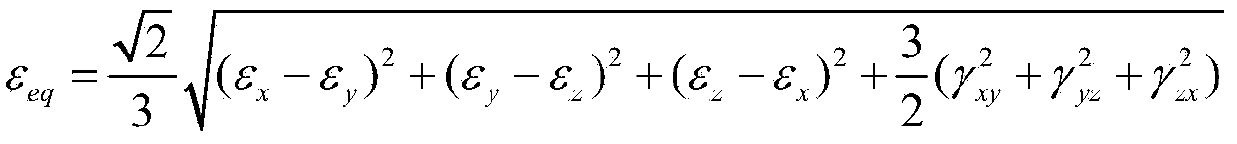

The invention relates to a low-cycle creep and fatigue life evaluation method under the conditions of high temperature and multiaxial spectrum load. The method comprises the following steps of reading a stress strain history in a multiaxial loading spectrum data block, working out equivalent strain, and finishing a loading history; repeatedly extracting by adopting a relative equivalent strain multi-axis counting method; working out all repeated fatigue damage by adopting a unified multiaxial fatigue damage life prediction model; accumulating the fatigue damage to work out the total fatigue damage; working out equivalent creep stress by utilizing the original loading history; working out creep damage Dc according to the equivalent creep stress and the stress history by combining a creep lasting equation; working out the total damage D caused by a multiaxial load spectrum block at the high temperature; and estimating the multiaxial creep and fatigue life. According to the method, the fatigue damage under the multiaxial stress and the creep damage under the multiaxial stress can be respectively calculated in the whole loading spectrum data block, the fatigue material constant at the room temperature is adopted in the calculation of the fatigue damage, and lasting equation material constant recommended by specification is adopted in the calculation of the creep damage; through experimental verification, the method has a good prediction effect.

Owner:BEIJING UNIV OF TECH

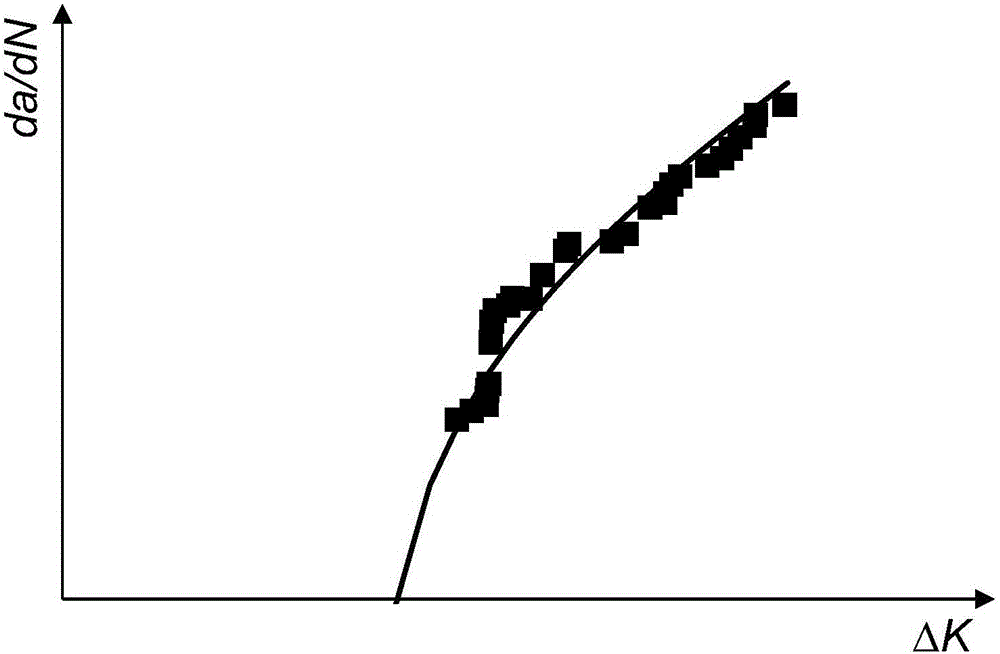

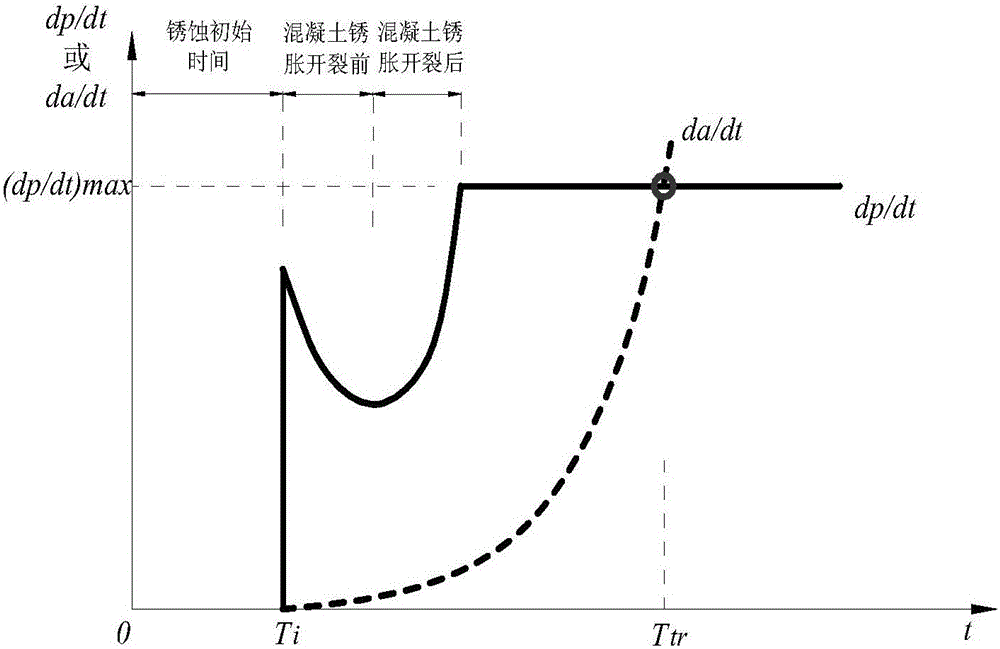

Method for evaluating fatigue life of aged reinforced concrete bridge

ActiveCN105825030AThe prediction method is reasonableGeometric CADForecastingStress concentrationCrazing

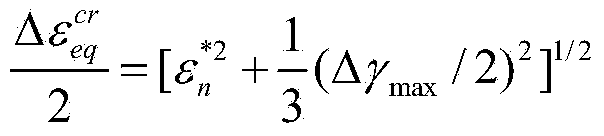

The invention discloses a method for evaluating the fatigue life of an aged reinforced concrete bridge. The method comprises the following steps of obtaining initial corrosion time of reinforcement in concrete based on the second diffusion law of Fick, and considering the influence of concrete cracking due to corrosion expansion in a corrosion rate model; adopting a small crack growth and near threshold growth analysis and determining relevant parameters of fatigue crack propagation rate of materials by developing a fatigue crack propagation test of reinforced concrete materials; performing a corrosion fatigue test or finite element analysis on corroded reinforcement to obtain stress concentration factors at different corrosion levels, and integrating into a stress intensity factor model to obtain the fatigue crack propagation rate of the reinforcement under the influence of corrosion; comparing the magnitude of a corrosion pit growth rate and the fatigue crack propagation rate and gradually converting into a single growth analysis on fatigue cracks of the reinforcement; meanwhile, combining with vehicle load observing information to realize life evaluation of a bridge at different service stages. The prediction method disclosed by the invention is reasonable and high in popularization, and can provide technical support for evaluating the life of the concrete bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

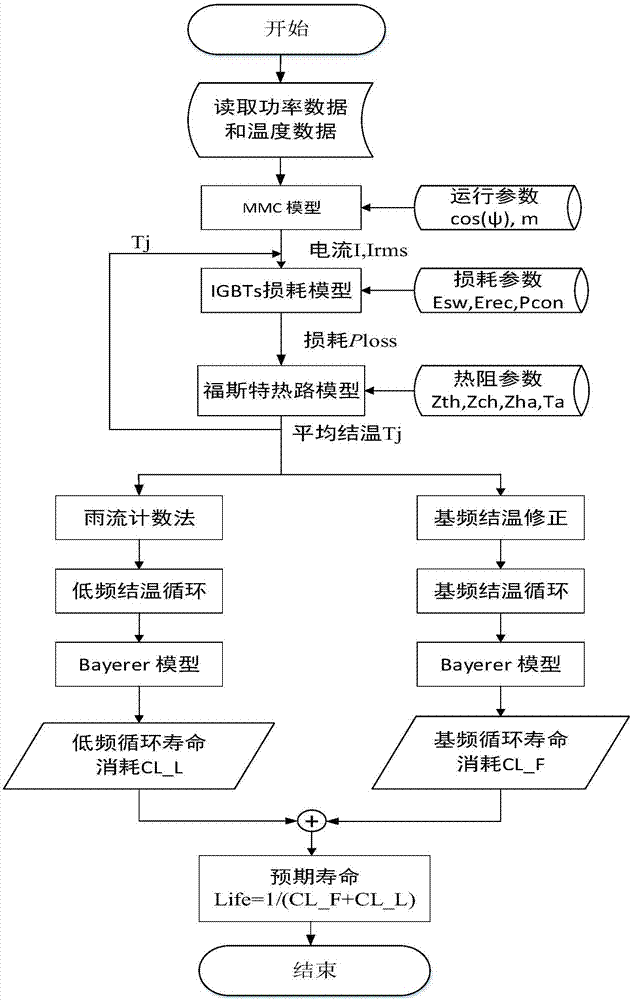

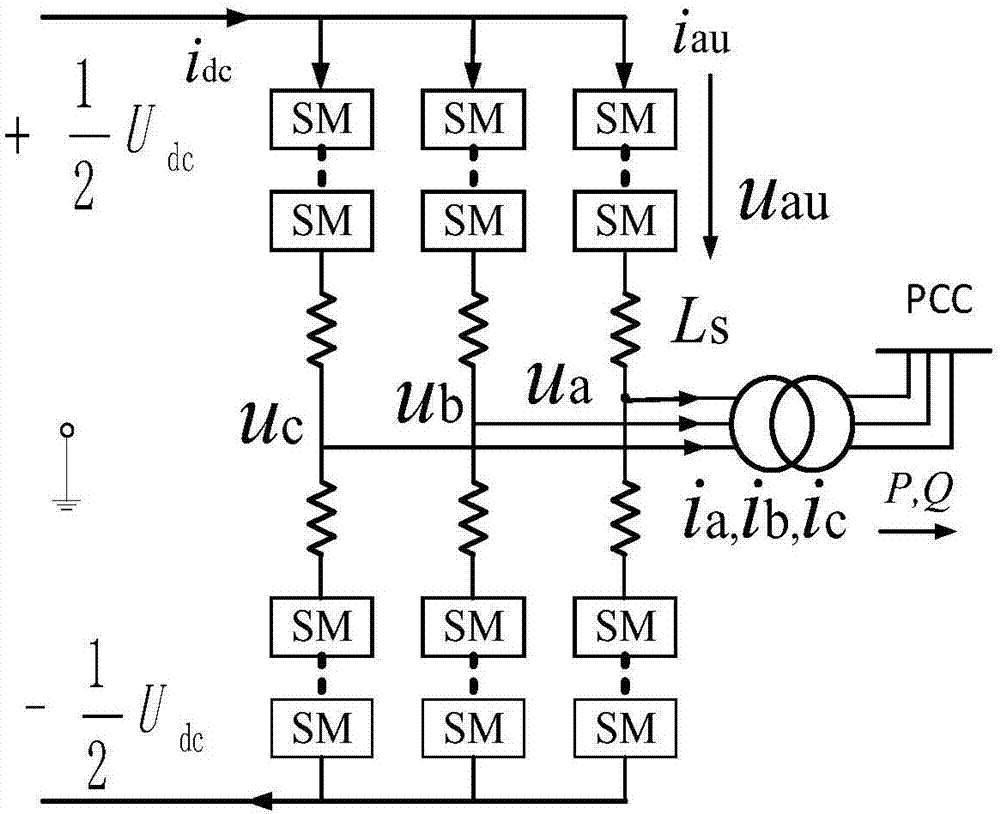

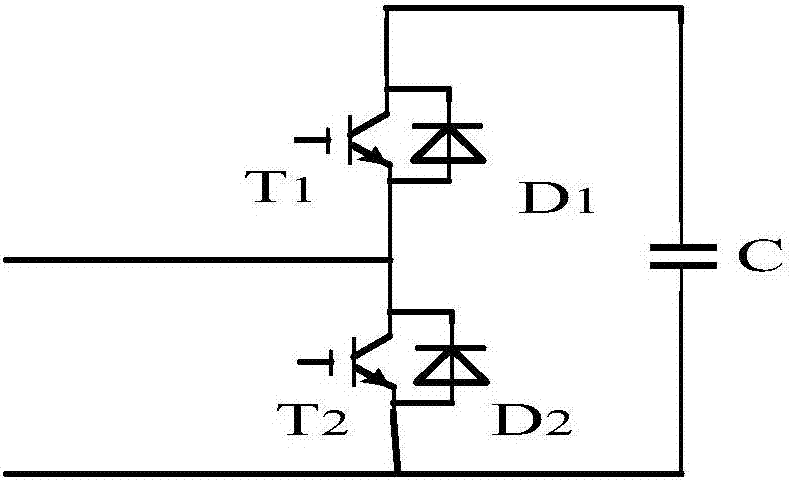

Life evaluation method for modular multilevel converter

ActiveCN107341326AFast operationImprove accuracyAc-dc conversionDesign optimisation/simulationJunction temperatureEngineering

The invention discloses a life evaluation method for a modular multilevel converter (MMC). The life evaluation method comprises the following steps: reading year-round temperature data of a running natural environment of the MMC and power data input into the MMC; performing analytic calculation on the average value and the effective value of the current of sub-modules IGBT and Diode of the MMC; calculating the average loss power Ploss,T and Ploss,D of the sub-modules IGBT and Diode of the MMC within the fundamental frequency period; calculating the average temperature rise Tja of a semiconductor device within the working frequency period by use of a Forster network model to obtain the average junction temperature value Tj of IGBT modules (IGBT modules, IGBTs, including IGBT and Diode); modifying fitting calculation of loss of the IGBTs according to the average junction temperature of the IGBTs; calculating the extreme values of the function temperature within the working frequency and counting the year-round fundamental frequency junction temperature cycle; counting fluctuation information of the year-round low-frequency junction temperature; and calculating the failure number Nf of the fundamental frequency and the low frequency of the semi-conductor device by use of a Bayerer life model, and obtaining the life of the MMC in combination with operation conditions. The life evaluation method can reliably forecast the life of the MMC, can effectively improve the forecasting calculation speed through obtaining an analytical expression of both current and the junction temperature, and has the characteristics of project operational capability and the like.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

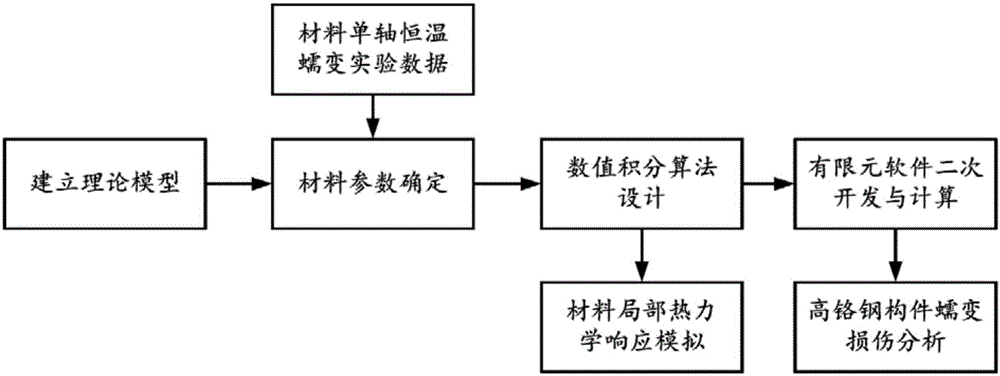

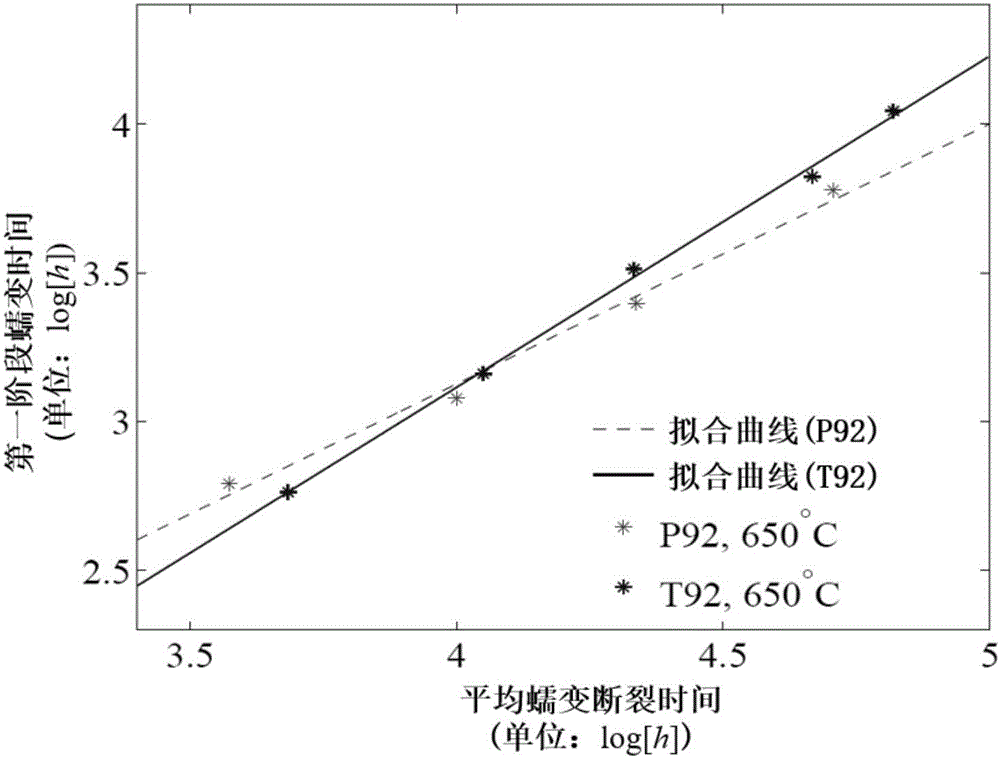

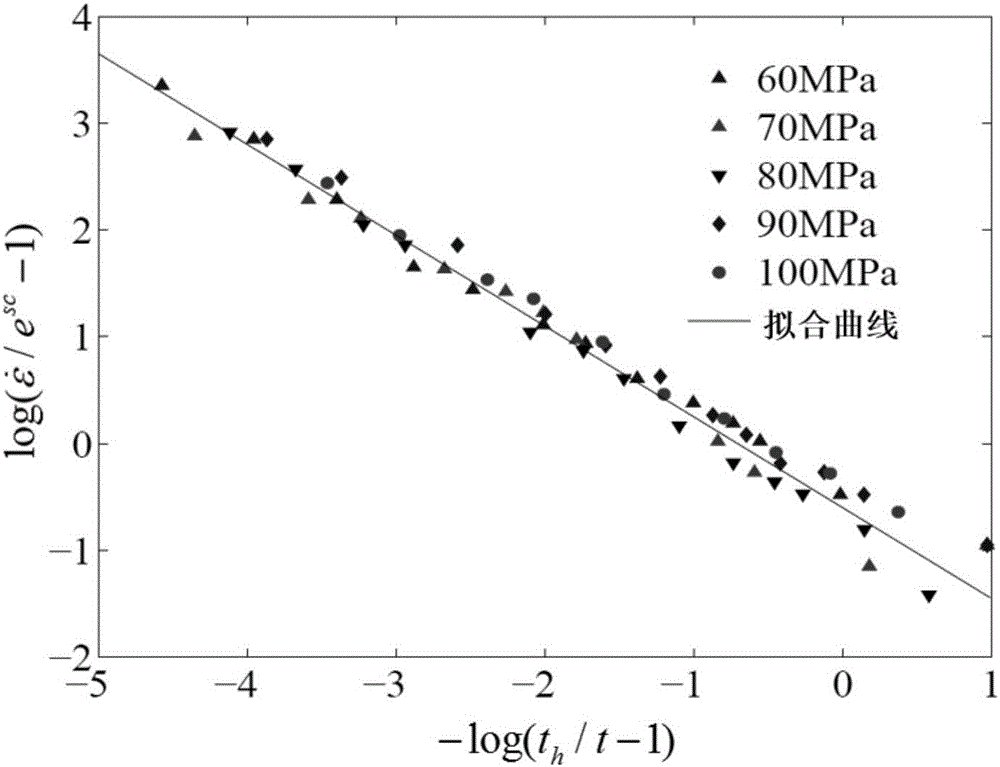

High-temperature creep deformation prediction and creep damage analysis method for high-chrome steel component

InactiveCN106529017AAccurate predictionAchieving Precise ForecastingGeometric CADDesign optimisation/simulationSecurity designEngineering

The invention discloses a high-temperature creep deformation prediction and creep damage analysis method for a high-chrome steel component. The method comprises the following steps of: establishing a theoretical model, determining material parameters, designing a numerical integration algorithm, carrying out the secondary development of finite element software, carrying out the creep damage analysis of the component and the like. Compared with an existing technical scheme, the method disclosed by the invention is characterized in that a great improvement is carried out, the accurate prediction of the creep behavior and the creep damage of the high-chrome steel component can be realized, and therefore, the method has an important application value in the fields of the security design and the residual life evaluation of high-temperature high-pressure components in a supercritical generator set.

Owner:SOUTH CHINA UNIV OF TECH

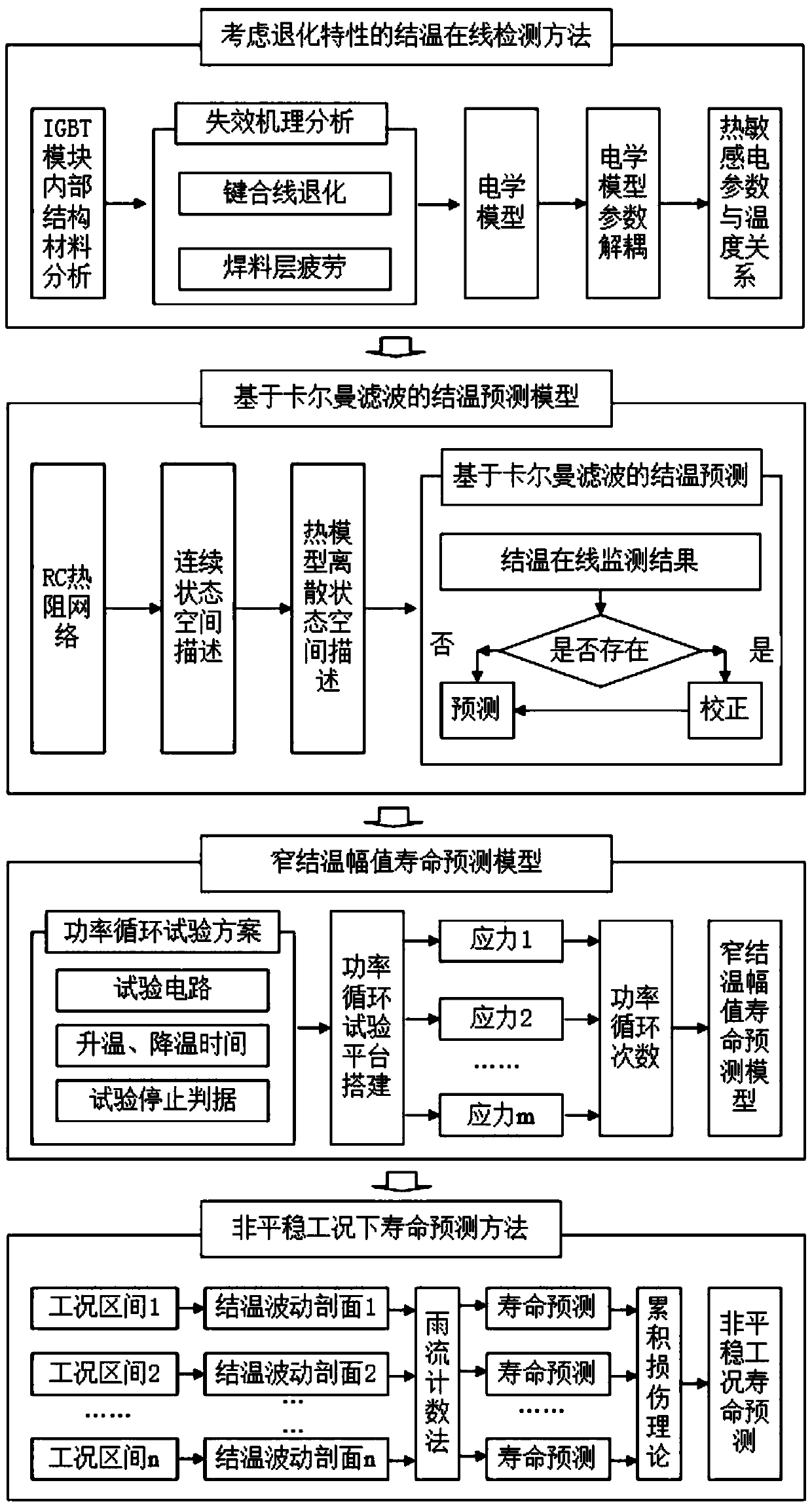

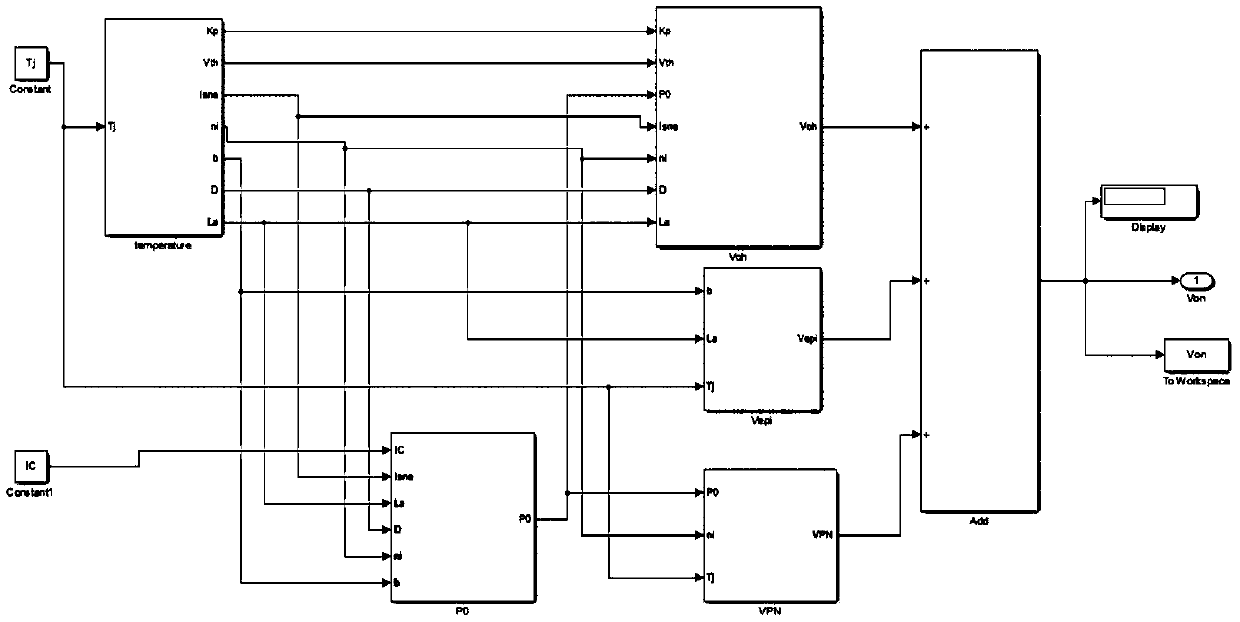

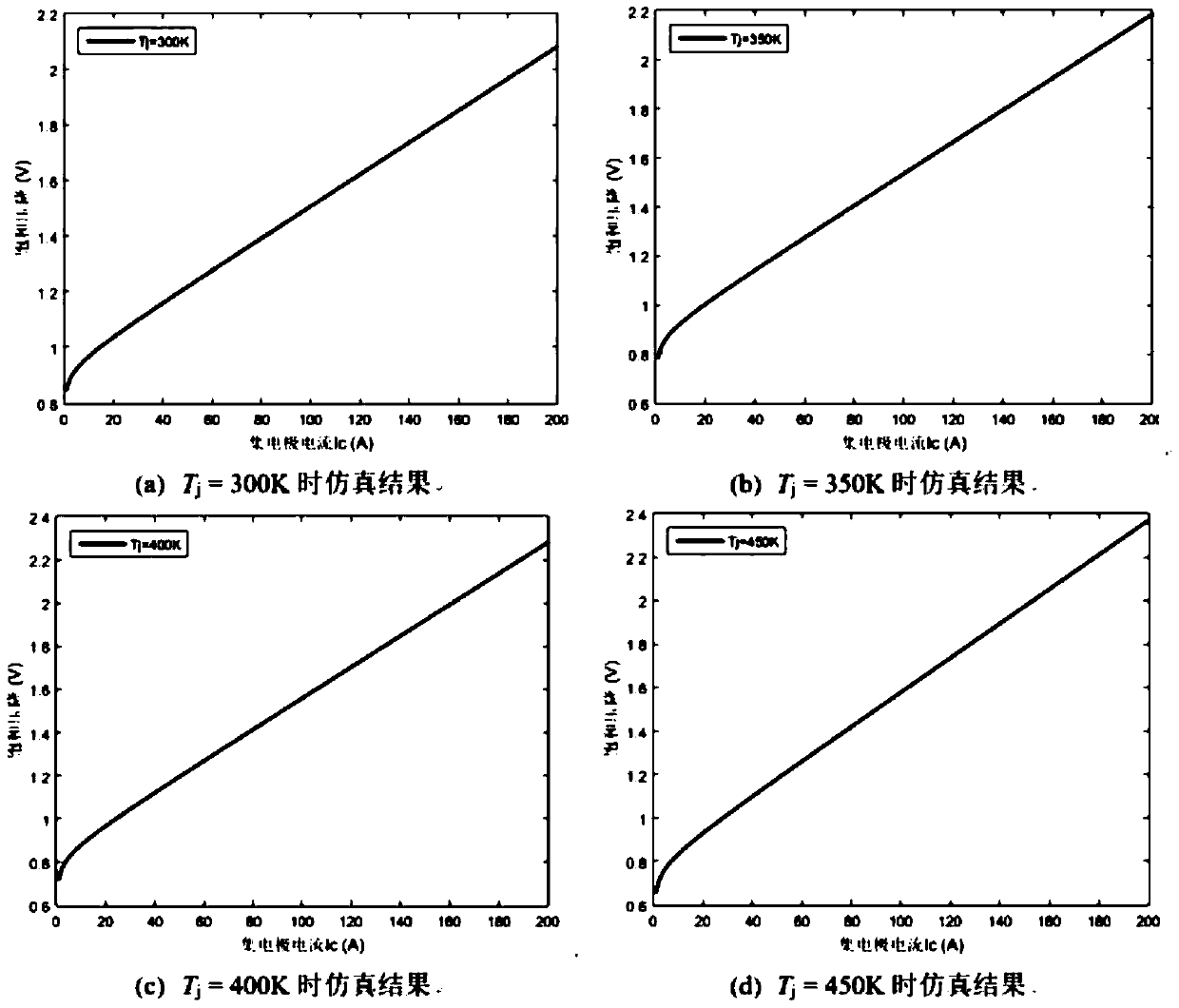

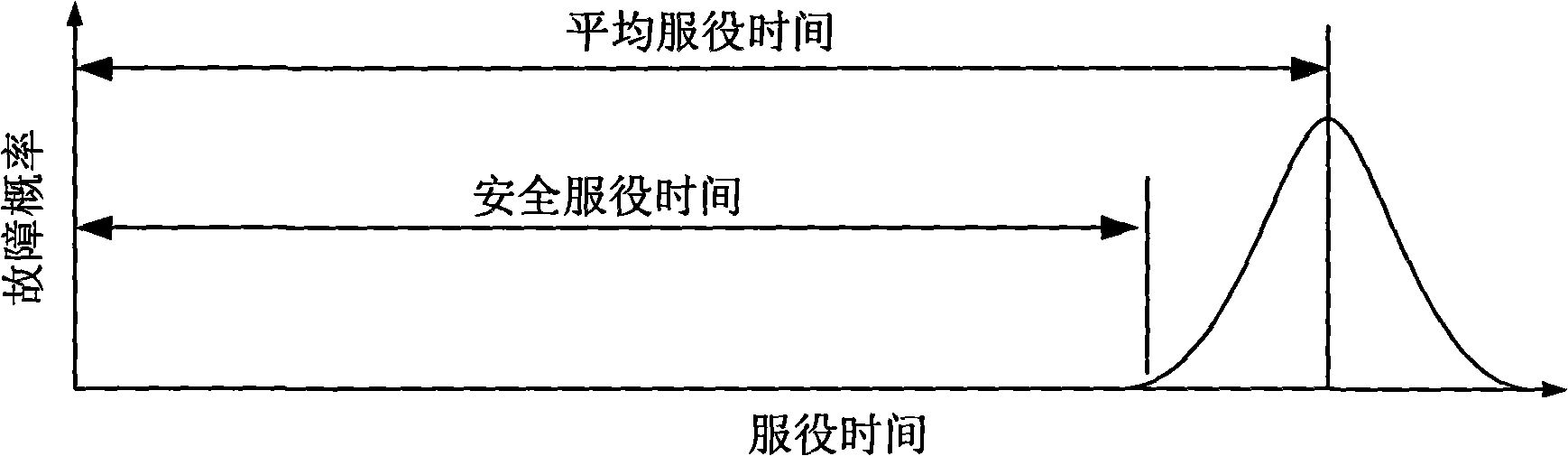

IGBT module life prediction method under non-stationary working condition

ActiveCN109738773AImprove accuracySpecial data processing applicationsIndividual semiconductor device testingWork taskPower cycle

The invention relates to an IGBT module life prediction method under a non-stationary working condition. The method comprises the following steps: 1) investigation on degradation mechanisms of an IGBTmodule; 2) establishment of an electrical model of the IGBT module; 3) parameter decoupling of the IGBT electrical model based on Simulink; 4) junction temperature on-line monitoring with degradationcharacteristics being considered; 5) establishment of a narrow junction temperature amplitude life prediction model; 6) construction of a power cycle test platform; 7) establishment of a narrow junction temperature amplitude life prediction model; and 8) establishment of an IGBT module life prediction model under the non-stationary working condition. The method is characterized by, to begin with,calculating a junction temperature-time curve of a power module under actual working conditions based on a device electro-thermal model and a work mission profile, and extracting corresponding junction temperature fluctuation information; then, calculating cumulative damage to the device caused by different junction temperature fluctuations based on the life prediction model of the power module;and finally, evaluating MTTF of the IGBT module under actual working conditions by combining the cycle times of each junction temperature stress. The method belongs to the technical field of life evaluation of the IGBT module.

Owner:BEIHANG UNIV

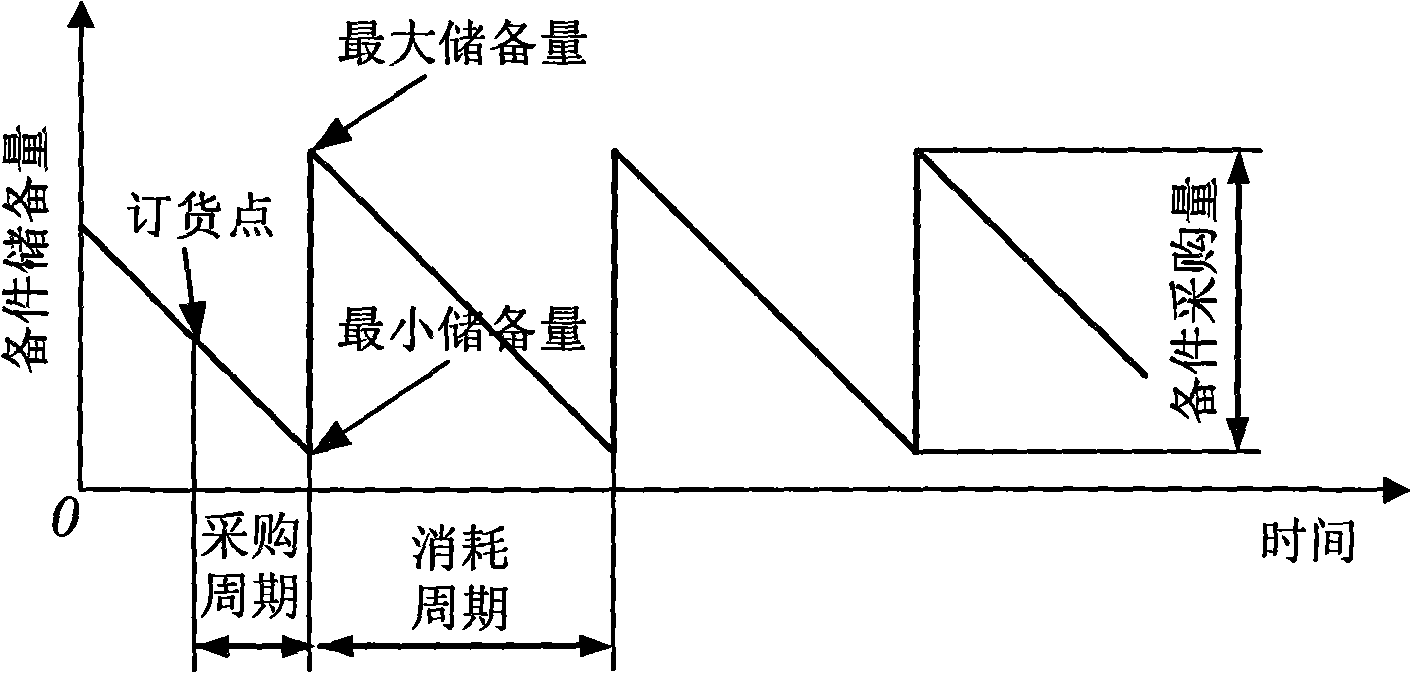

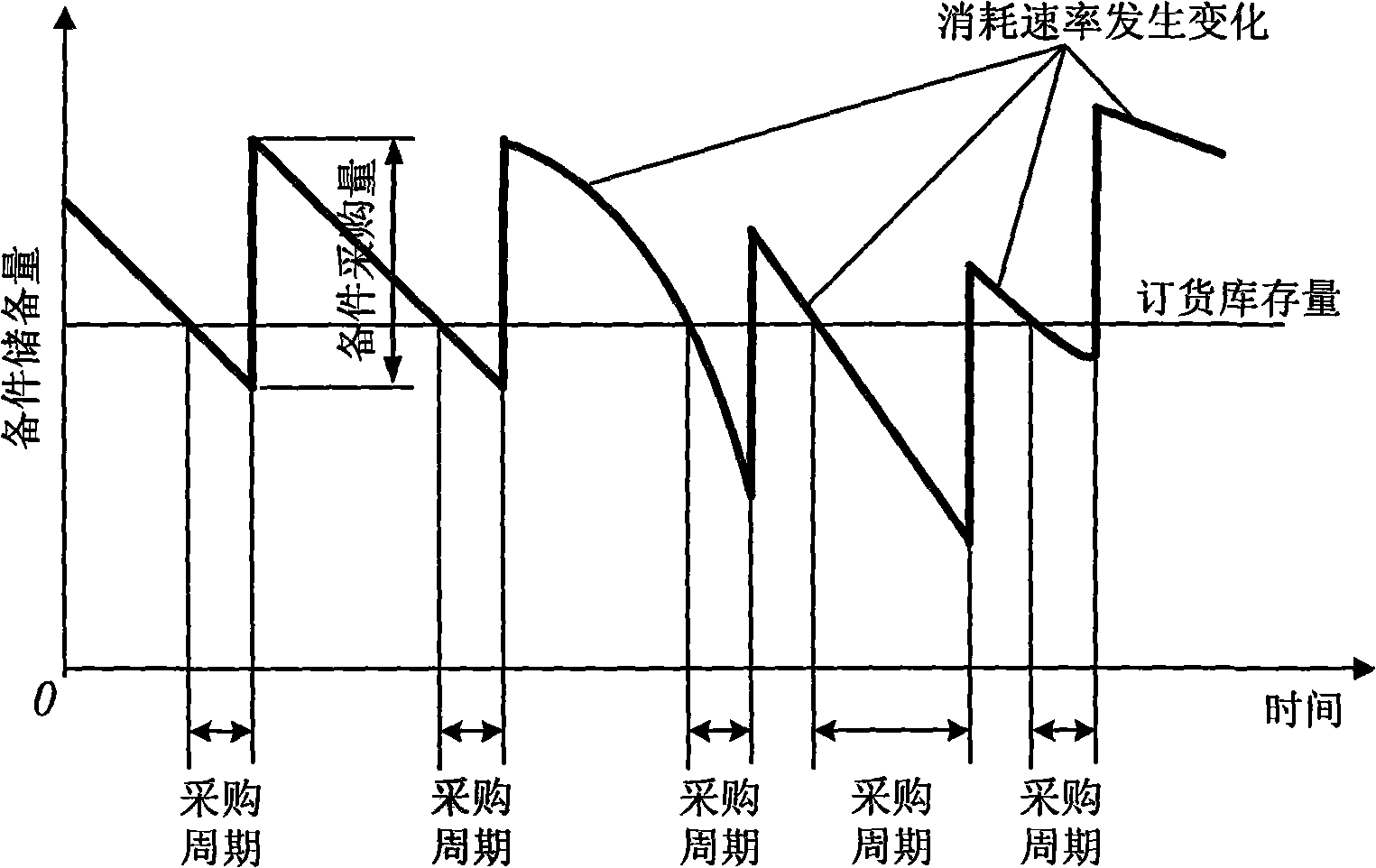

Spare part demand forecast method based on in-service lift estimation

InactiveCN101320455AMeet the statistical reliabilityReasonable Personalized EstimatesSpecial data processing applicationsPredictive methodsOne step prediction

The present invention discloses an in-service life evaluation based spare part demand forecasting method. The present invention uses the historical record of changing parts and components during equipment running process to establish a statistic model and evaluate the life of a spare part under the current in-service condition; spare part demand function is defined according to the evaluation value of in-service life and practical service life, and the spare parts demand total quantity of a plurality of sets of equipment within certain rang of time is forecasted further. The method combines the spare part life evaluation with practical service condition closely, improves the accuracy for forecasting the spare part demand, is applicable to the maintenance instruction of frequently changed parts and components at the equipment and has important meaning for the enterprise to ensure the supply of the spare part and reduce the spare part stock.

Owner:XI AN JIAOTONG UNIV

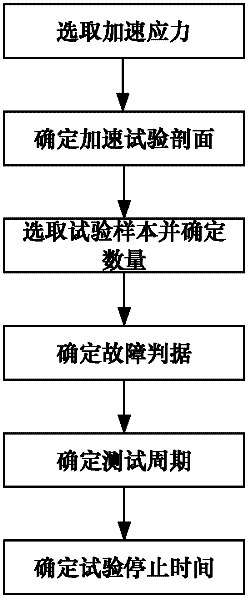

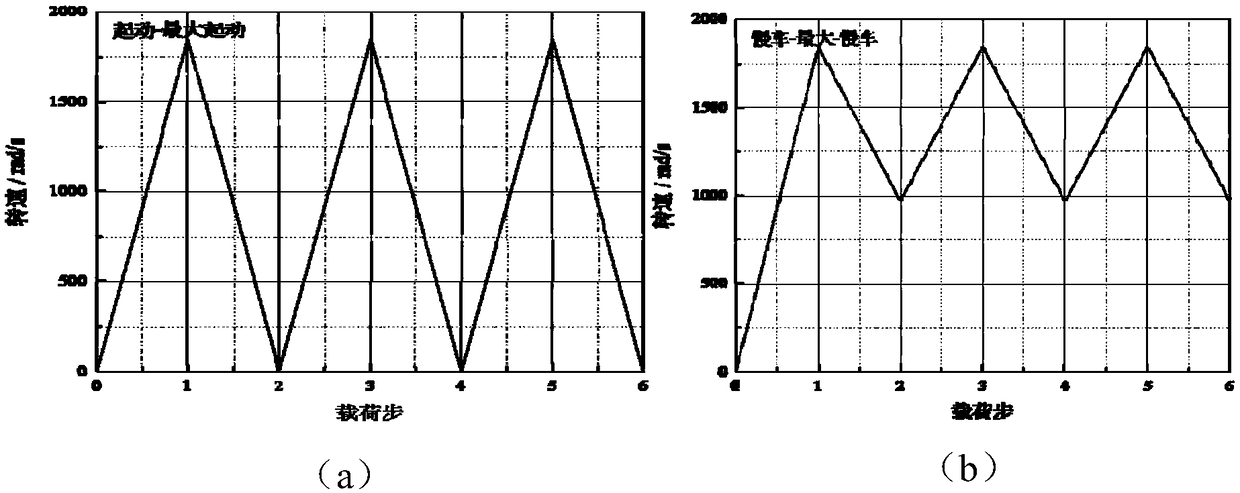

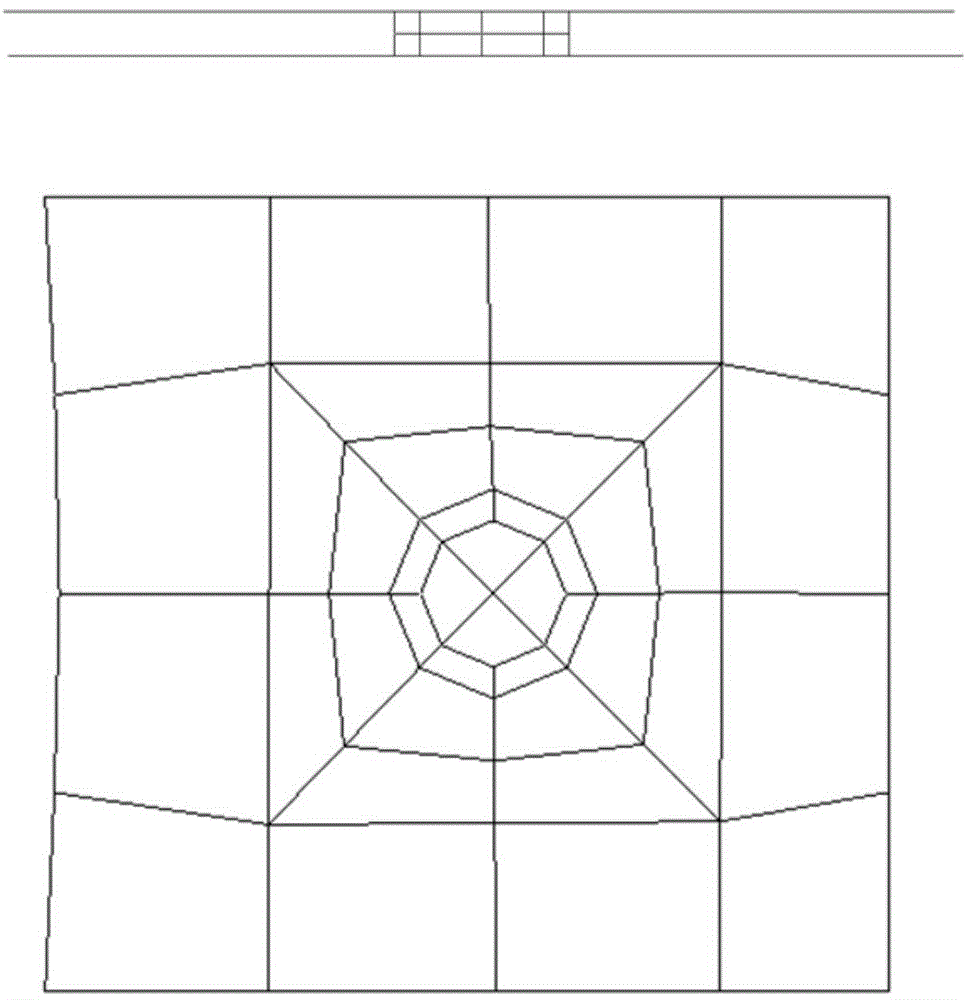

Combined stress acceleration life test method of spaceflight drive assembly

The invention, which belongs to the spaceflight drive assembly reliability and life evaluation field, relates to a combined stress acceleration life test method of a spaceflight drive assembly. According to the method, an acceleration stress is selected; an acceleration testing profile is determined and as a result, a combined stress acceleration life testing profile is employed; testing samples are selected and the number of samples is determined; fault determination and a testing period are determined; testing stop time is determined; and according to data obtained by the above-mentioned testing process, a life characteristic value of the spaceflight drive assembly is evaluated. According to the method, a combined stress is employed to carry out acceleration life testing and an acceleration effect is obvious; therefore, rapid evaluation on reliability and life of the spaceflight drive assembly is realized.

Owner:BEIHANG UNIV

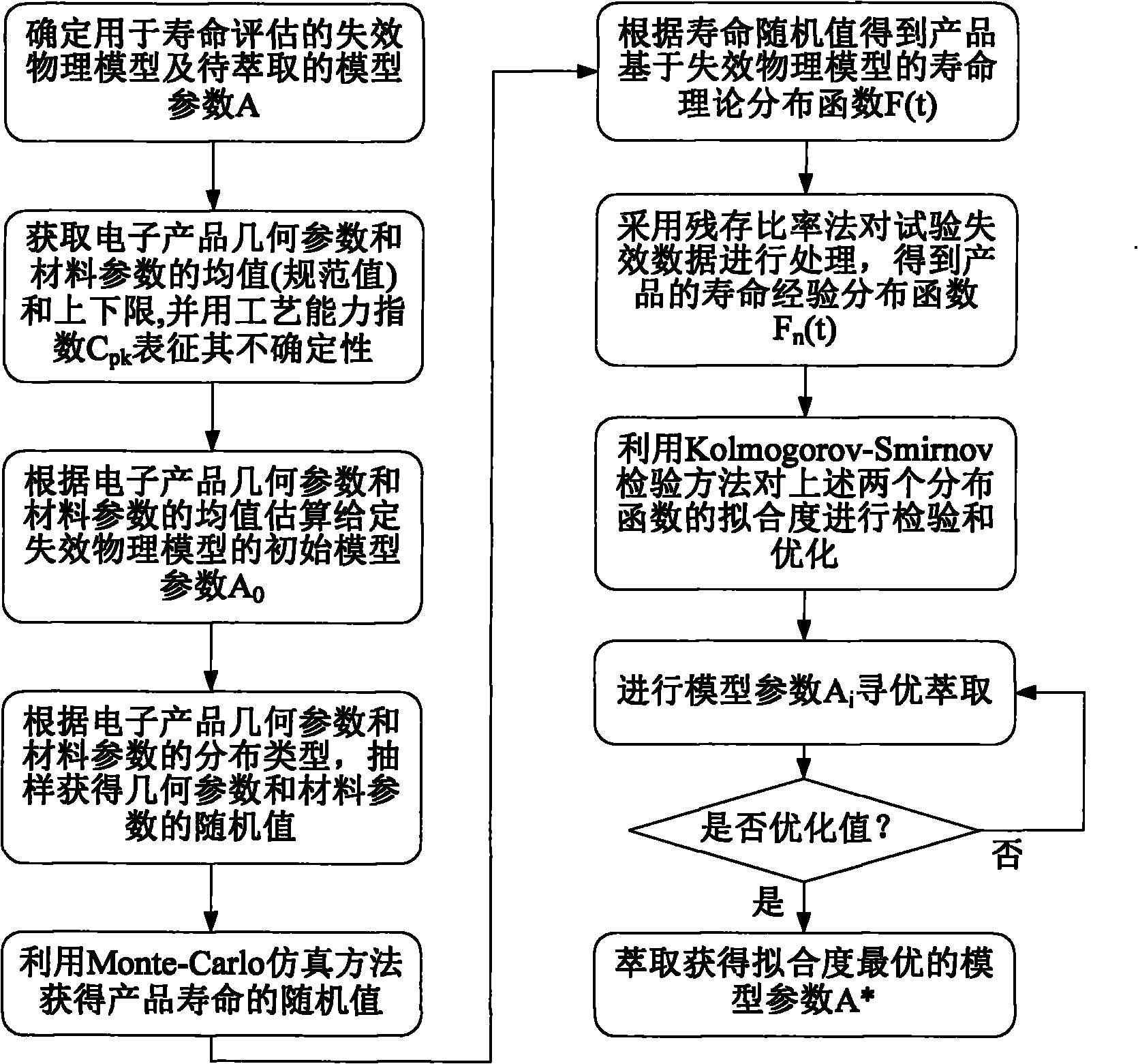

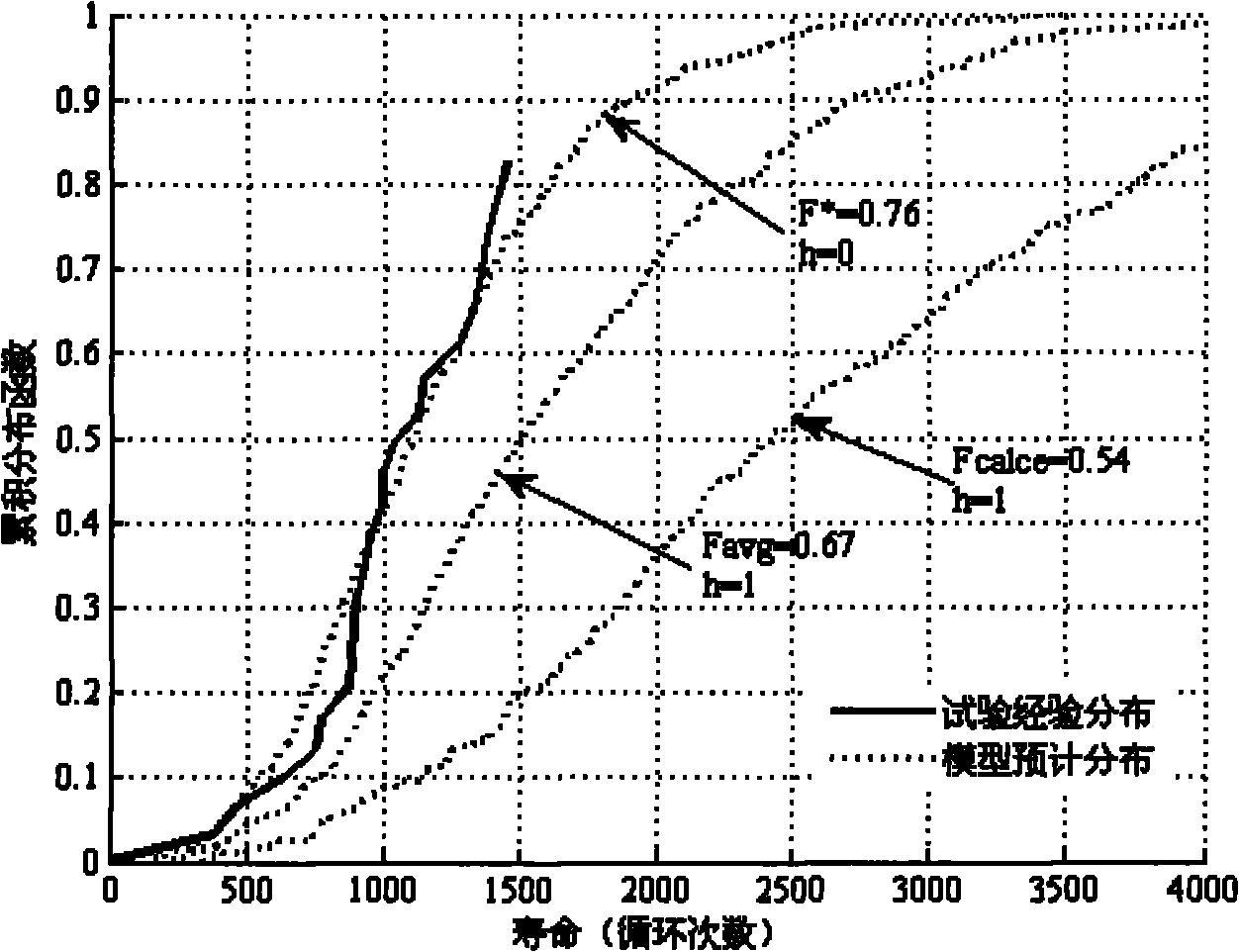

Practical electronic product service life evaluation model parameter high-accuracy extraction method

ActiveCN102103658AGuaranteed accuracyAddress usability bottlenecksSpecial data processing applicationsPhysical modelData mining

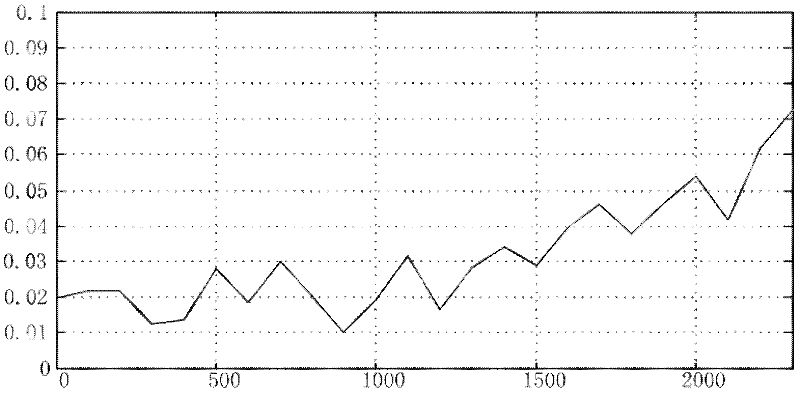

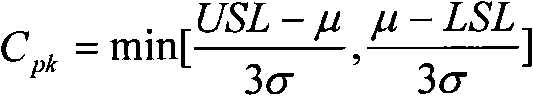

The invention discloses a practical electronic product service life evaluation model parameter high-accuracy extraction method, which comprises the following steps of: (1) determining a failure physical model and model parameters to be extracted; (2) acquiring mean values, upper limits and lower limits of geometric and material parameters of a product, and representing the uncertainty of the parameters by adopting process capability indexes; (3) evaluating initial model parameters of the failure physical model according to the mean values of the geometric and material parameters of the product; (4) performing sampling according to distribution types of the geometric and material parameters to obtain random values of the geometric and material parameters; (5) obtaining the random value of the service life of the product by combining a Monte-Carlo simulation method; (6) obtaining a theoretical distribution function of the service life of the product according to the random value of the service life; (7) processing experimental failure data by adopting a remaining ratio method to obtain an empirical distribution function of the service life of the product; (8) checking a degree of fitting of the two service life distribution function by utilizing a K-S checking method; and (9) performing optimal extraction on the model parameters until the model parameters with an optimal degree of fitting are obtained.

Owner:北京可维创业科技有限公司

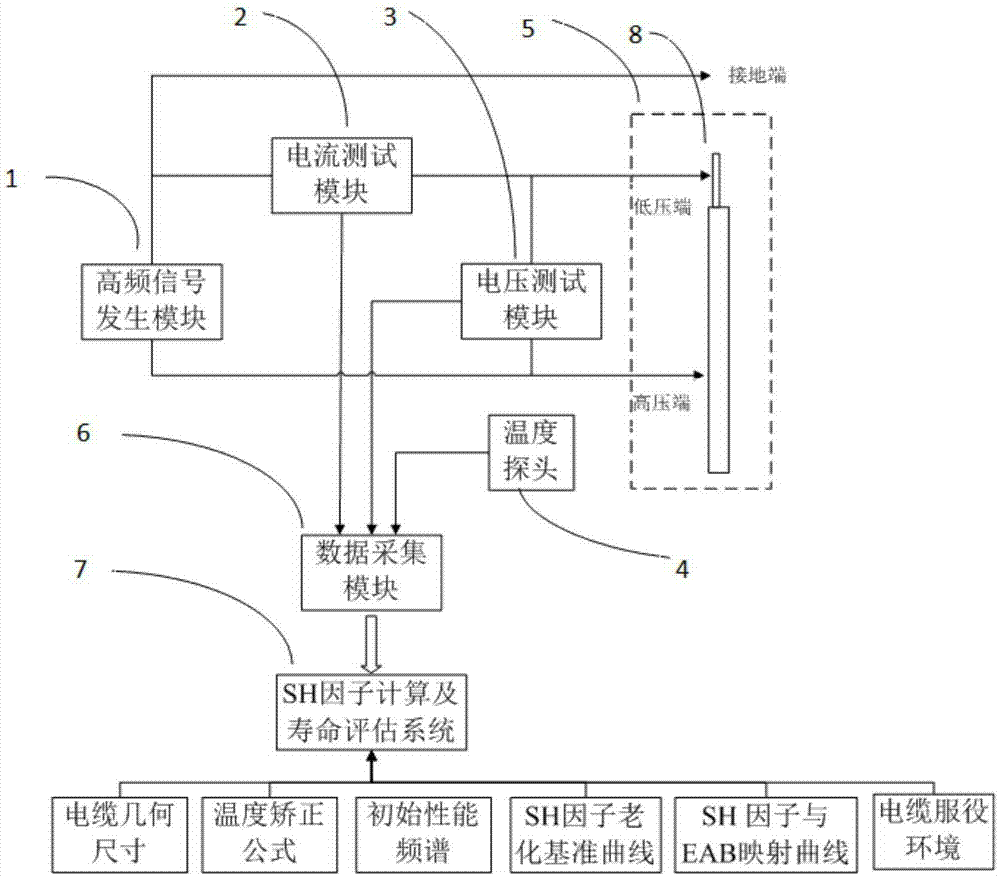

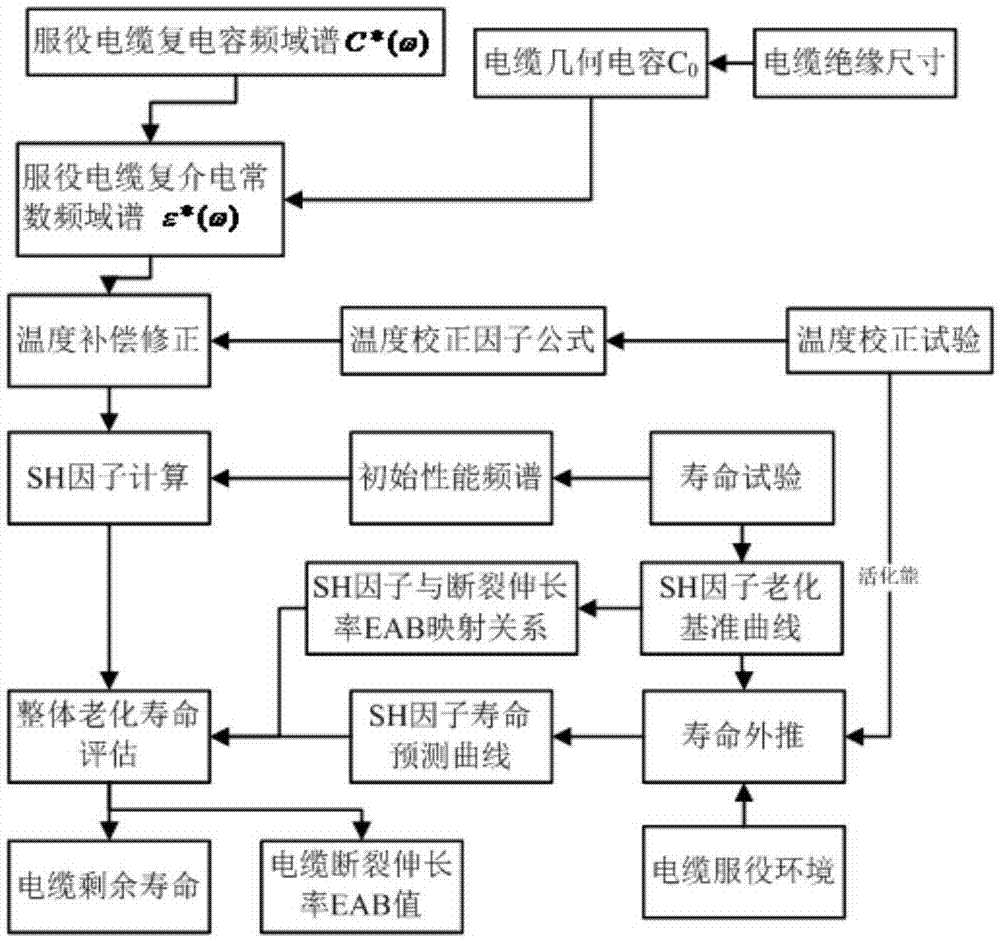

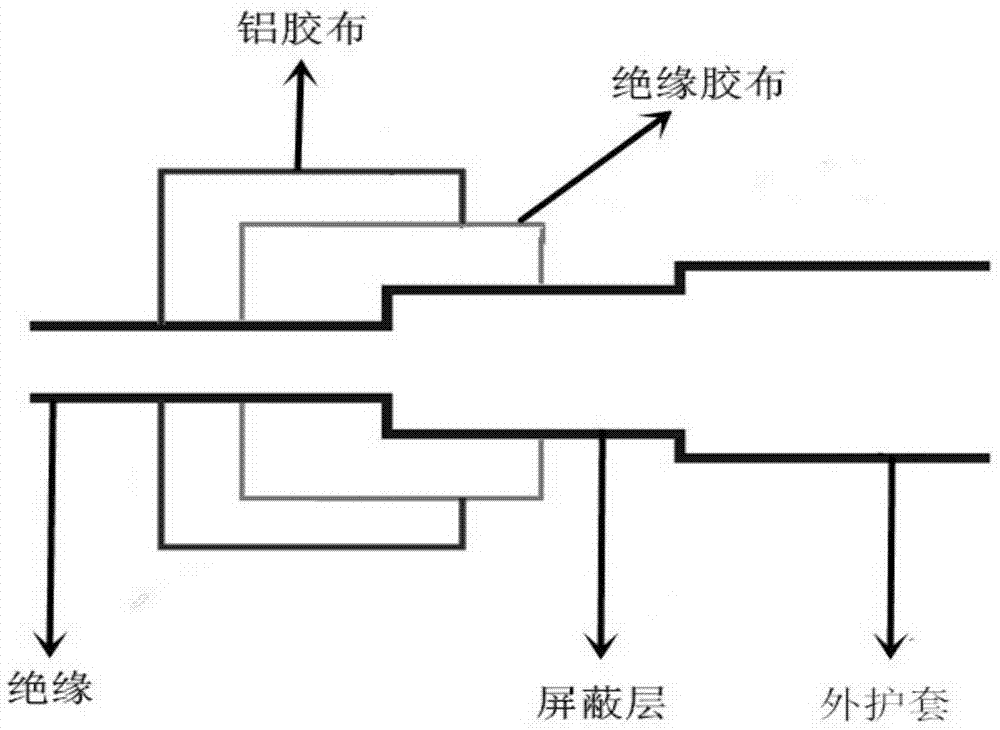

Frequency domain test and analysis system and method for cable overall ageing life evaluation

ActiveCN106855605AAccurate aging stateSolve the problem of longevityTesting dielectric strengthResistance/reactance/impedenceCapacitanceFrequency spectrum

The invention belongs to the technical field of cable nondestructive test and life evaluation and specifically relates to frequency domain test and analysis system and method for cable overall ageing life evaluation. A data acquisition module collects voltage and current response of a cable under actions of AC signals in different frequencies, and calculates cable complex capacitance spectrum and dielectric spectrum; according to temperature signals measured by a temperature probe, the dielectric spectrum calculated based on the test data is subjected to temperature correction treatment by calling temperature compensation factor of the cable in such material stored in the system to obtain a corrected frequency domain curve under a reference temperature; and an SH factor calculation and life evaluation system calculates an SH factor value for reflecting a current state of the cable according to the corrected dielectric spectrum curve, and extrapolates residual life of the cable under the current service condition and a current EAB (elongation at break ) value according to curve information recorded in the system. The system can realize in-service inspection and life evaluation of the on-site in-service cable.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

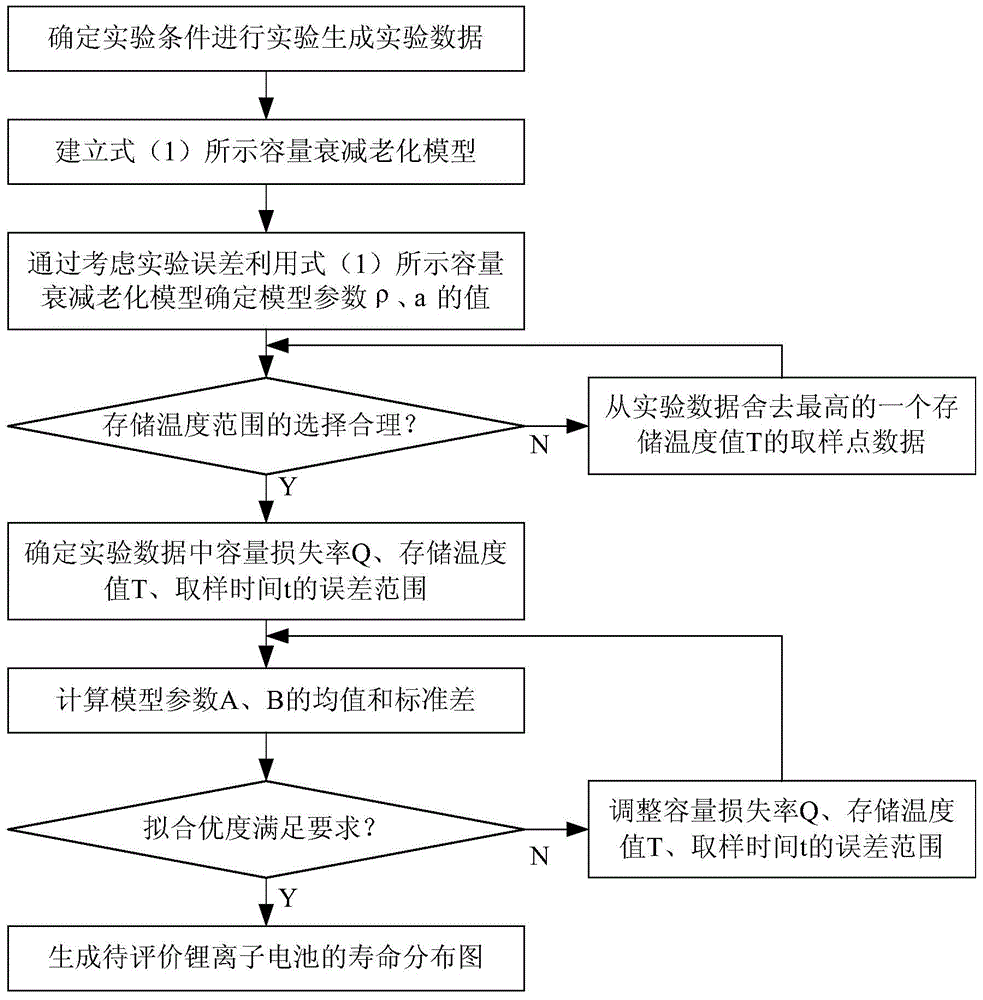

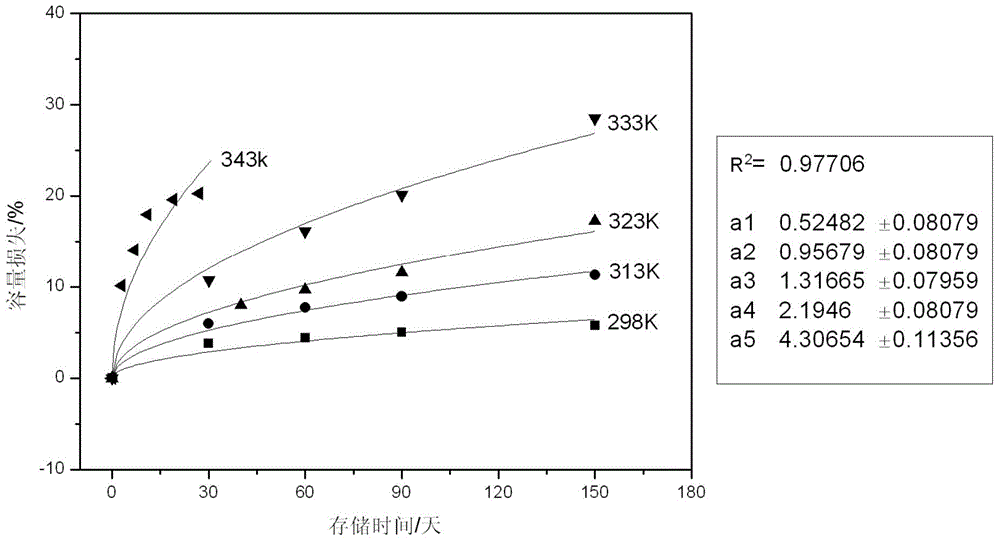

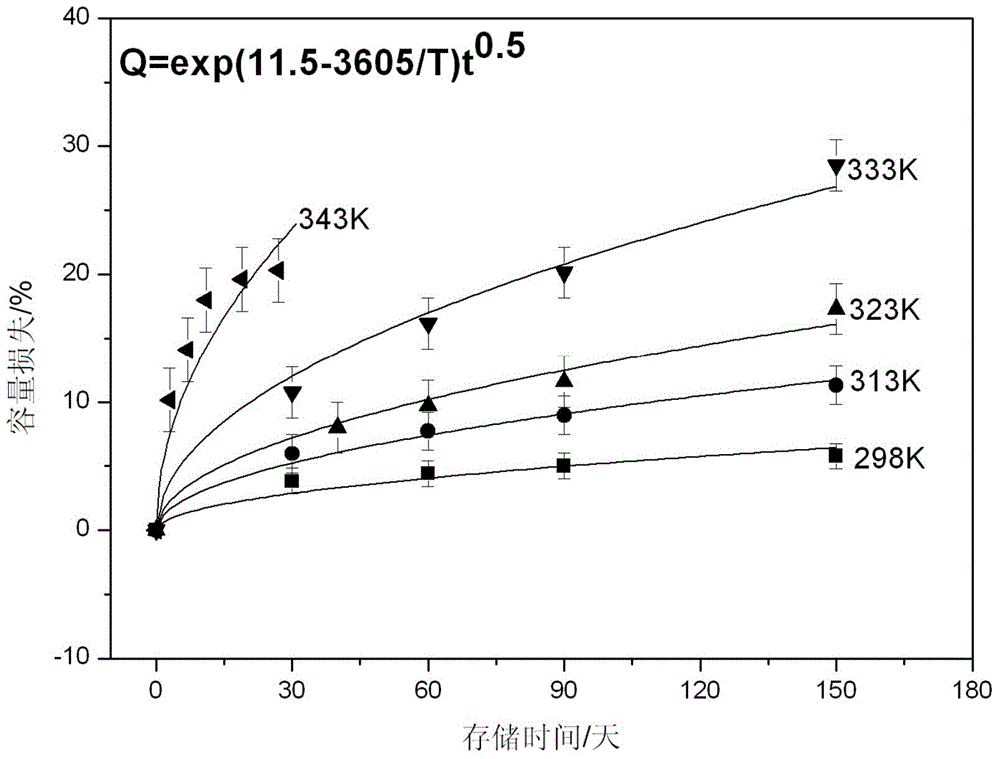

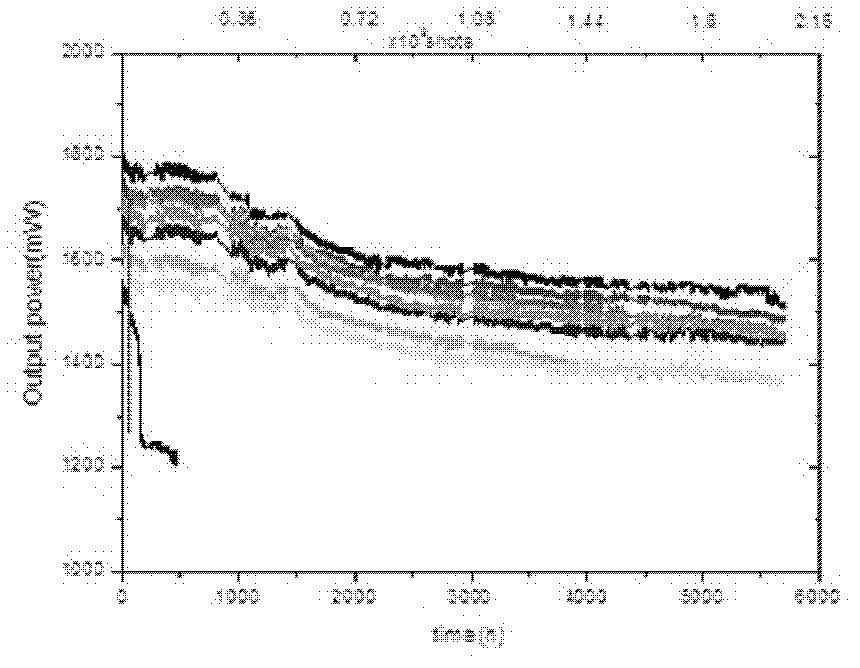

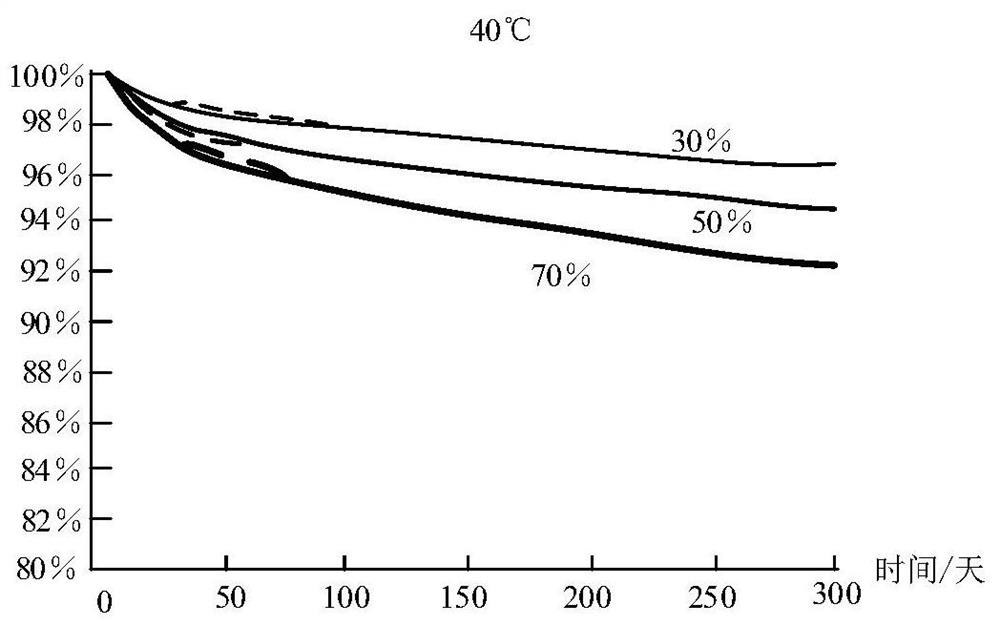

Lithium ion battery full charge storage service life evaluation method

ActiveCN105116337AThe principle of life evaluation is sufficientHigh data reliabilityElectrical testingCapacity lossUltrasound attenuation

The invention discloses a lithium ion battery full charge storage service life evaluation method. The method comprises steps: a battery sample for evaluation of lithium ion battery full charge states is stored at a plurality of storage temperature values T for appointed sampling time t, a capacity loss rate Q is obtained, and experiment data are generated; a capacity attenuation aged model is established, and values of a model parameter rho and a model parameter a are determined; the selection rationality of the storage temperature scope is determined based on the situation whether the model parameter a meets the Arrhenius formula at each storage temperature value T; a mean value and a standard deviation standard deviation of a model A and a model B are obtained through statistics; the value of the model parameter rho and the mean value of the models A and B are substituted into the model and fitting goodness determination is carried out; after fitting goodness is met, the service life of the lithium ion battery to be evaluated is predicted at a normal temperature and a service life distribution diagram is obtained. The evaluation method has advantages of sufficient service life evaluation principle, high data reliability, high precision, short evaluation time, wide application scope, is simple and practicable, and is easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

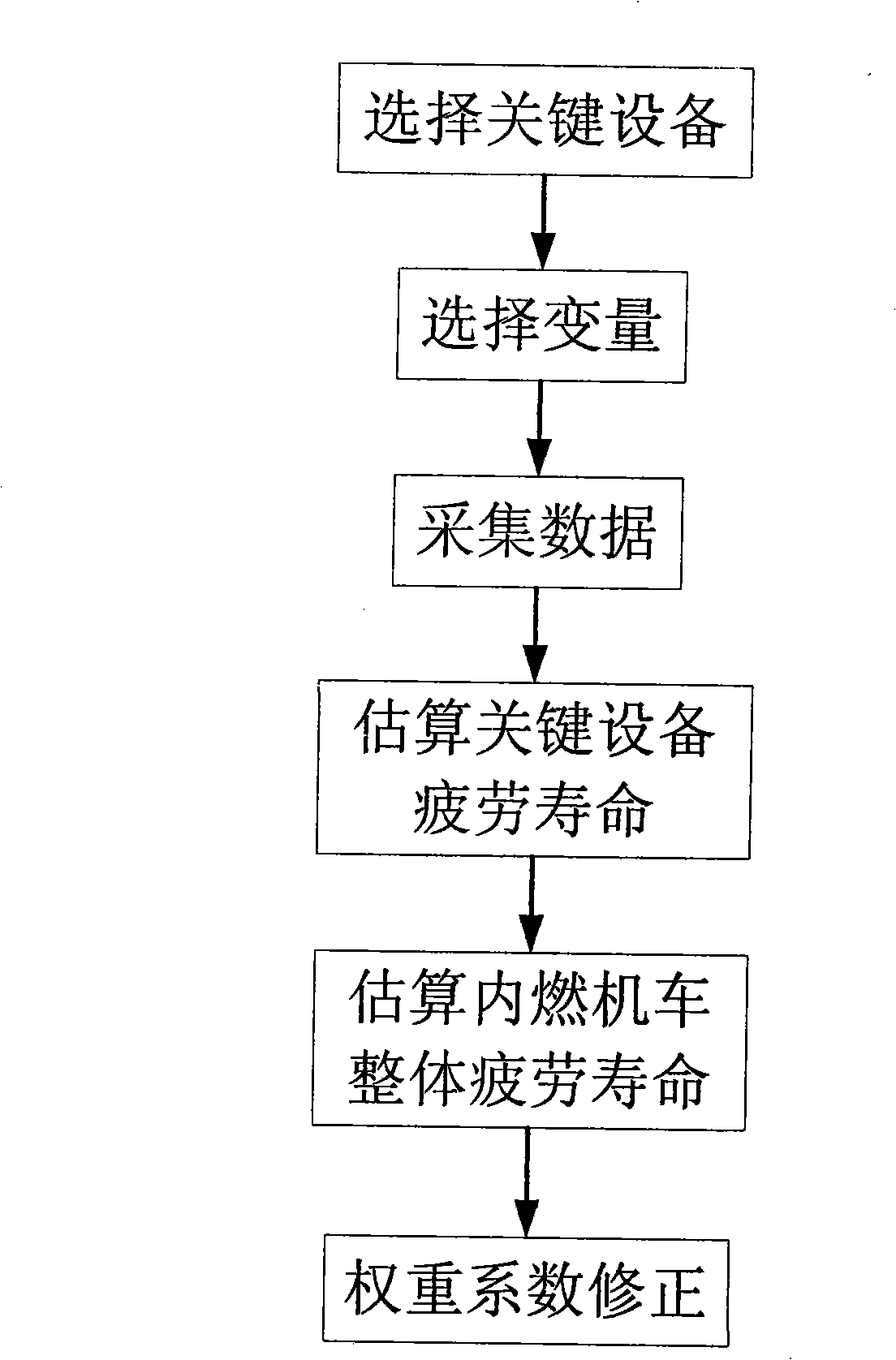

Fatigue life evaluation method of diesel locomotive

InactiveCN101319966AReflect damageIncrease credibilityRailway vehicle testingFatigue damageWeight coefficient

The invention relates to a fatigue service life estimation method for a gas engine which includes the follows: firstly selecting the key devices for estimating the fatigue service life of the gas engine; then selecting a variable which affects the fatigue service life of each key device; obtaining the needed variable value by collecting relevant data; working out the injury tolerance of each key device by utilizing a Miner rule in a fatigue accumulation injury theory; when the value is equal to 1, considering the devices to reach the fatigue service life and need to be overhauled. The integral fatigue injury tolerance for the gas engine is equal to the fatigue injury tolerance of each key device multiplied by the sum of the corresponding weight coefficients; when the value is larger than 1, then the engine is considered to reach the fatigue service life and need to be heavily repaired. Finally an estimation result is led to approach the actual injury situation of the engine by correcting the weight coefficients, thus being used as a basic for confirming the heavy repair period of the engine. The invention is different from the traditional method which uses the running kilometrages and the equivalent kilometrages to confirm the period for the heavy repair of the engine and essentially reflects the injury situation of the gas engine; so the reliability of the estimation result is higher.

Owner:BEIJING JIAOTONG UNIV +1

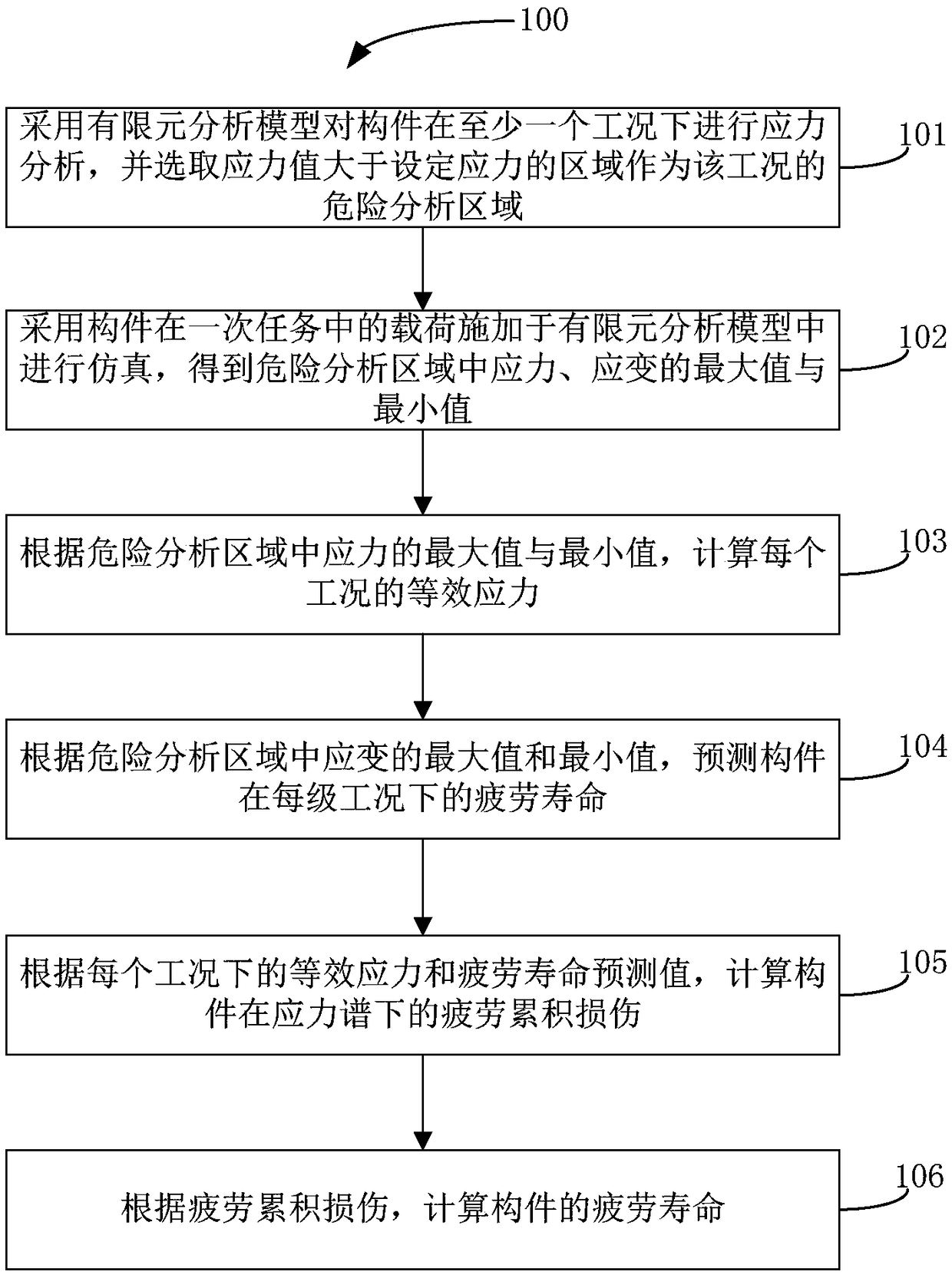

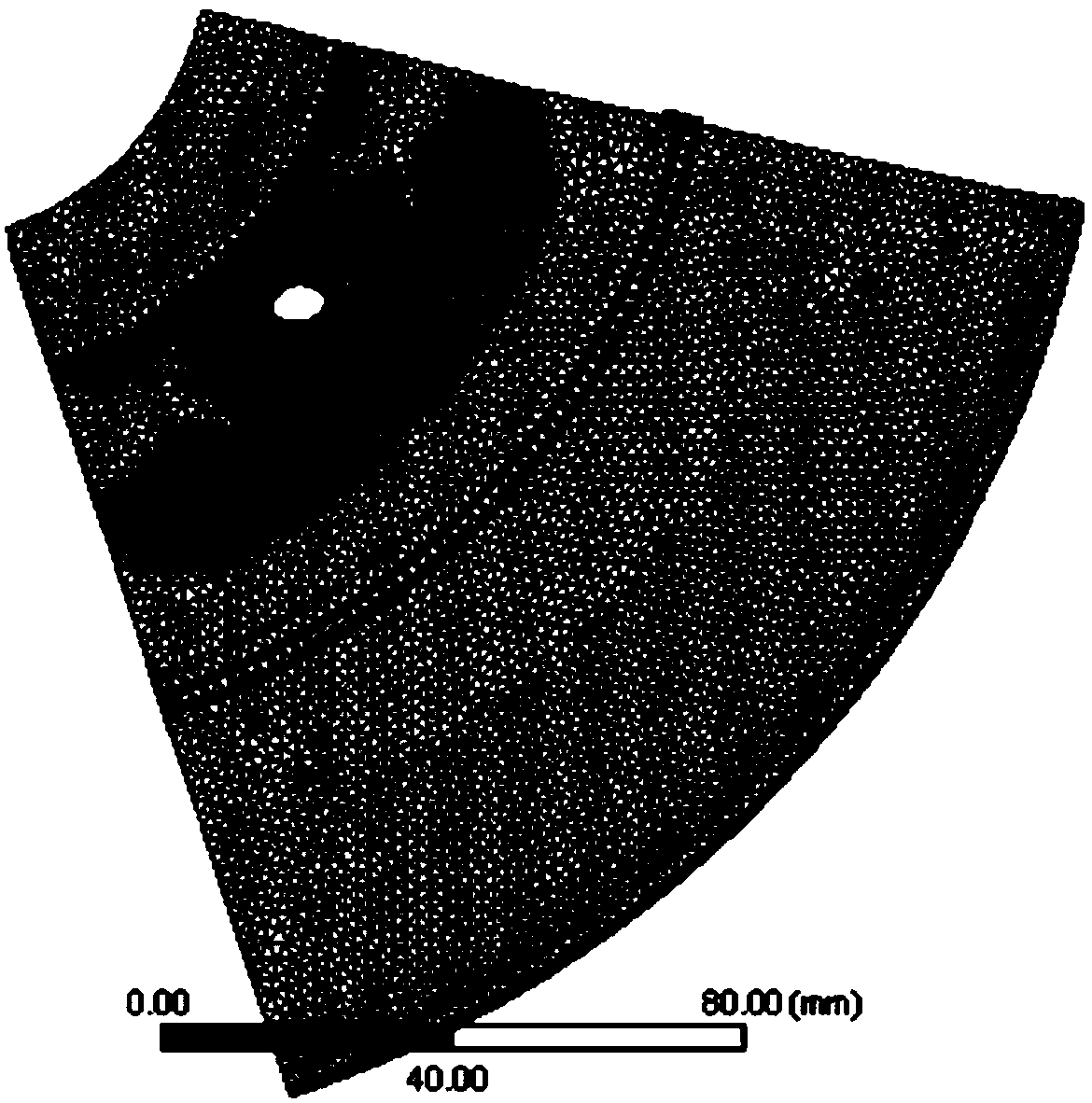

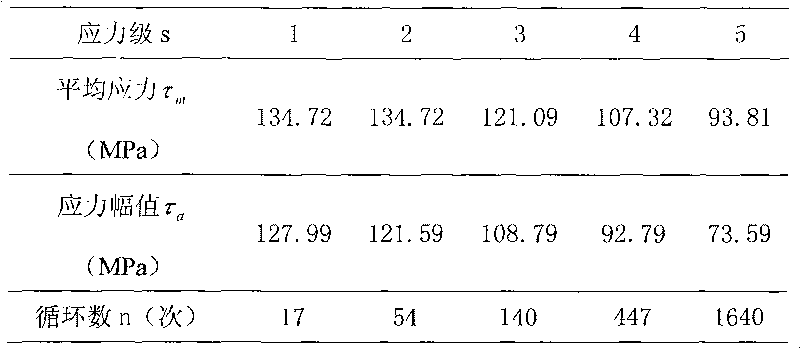

Fatigue life assessment method of components based on nonlinear fatigue damage accumulation theory

InactiveCN109033709AAccurate calculationHigh accuracy of fatigue life predictionDesign optimisation/simulationSpecial data processing applicationsFatigue damageElement analysis

The invention discloses a fatigue life evaluation method of a component based on a nonlinear fatigue damage accumulation theory, which comprises the following steps of: adopting a finite element analysis model to carry out stress analysis on the component under at least one working condition, and selecting a region with a stress value greater than a set stress as a hazard analysis region under theworking condition; obtaining the maximum and minimum of stress and strain in the hazard analysis area by simulating the load on the finite element analysis model of the component in one mission. According to the maximum and minimum value of stress in the hazard analysis area, the equivalent stress of each working condition is calculated. According to the maximum and minimum value of strain in thehazard analysis area, the fatigue life prediction value of the component under each working condition is predicted. According to the equivalent stress and fatigue life predicted under each working condition, the fatigue cumulative damage of the member under stress spectrum is calculated. According to the accumulated fatigue damage, the fatigue life of the component is calculated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

CFB furnace tube longevity assessment method based on gray prediction theory

InactiveCN101493392ALess raw dataEasy to calculateSpecial data processing applicationsInvestigating abrasion/wear resistanceLife timeLongevity

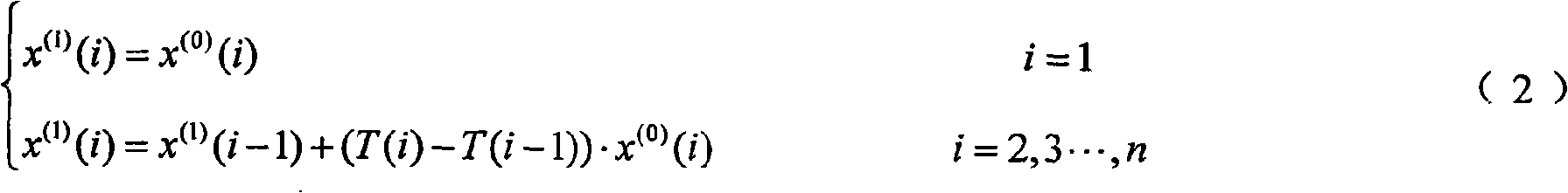

The invention discloses a life evaluation method of a CFB furnace tube based on grey prediction theory. The life evaluation method helps solve the problems of hard life evaluation and the like of the current furnace tube and does not need to consider factors which thins wall thickness, such as complex wear, even corrosion and the like; and the life evaluation method has the advantages of requiring fewer raw data, convenient computation and high precision, and can be used in actual engineering practice and the like. The life evaluation method comprises the following steps: (1) measuring a set of wear data; (2) adopting the measured data and a method for weighting processing on time interval in the process of accumulating and reducing the raw data to establish an unequal time interval GM (1,1) prediction model based on the CFB furnace tube wear of the measured wearing capacity data; (3) computing the wearing capacity, that is, wall thickness reduction amount by the established prediction model; (4) comparing a computation result with a measurement result, and optimizing the model; (5) obtaining a specific prediction model of the furnace tube wall thickness reduction amount of a boiler; and (6) predicting the subsequent wear capacity according to the specific prediction model, thus computing the residual life of the furnace tube.

Owner:SHANDONG ELECTRIC POWER RES INST

Multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method

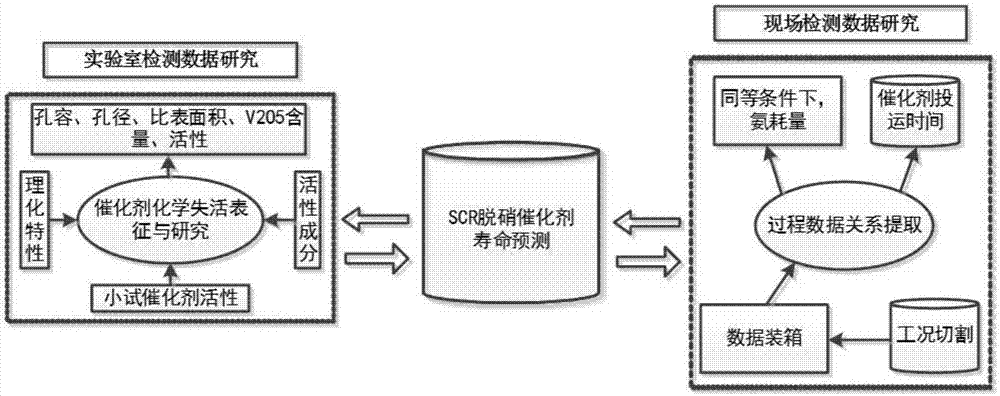

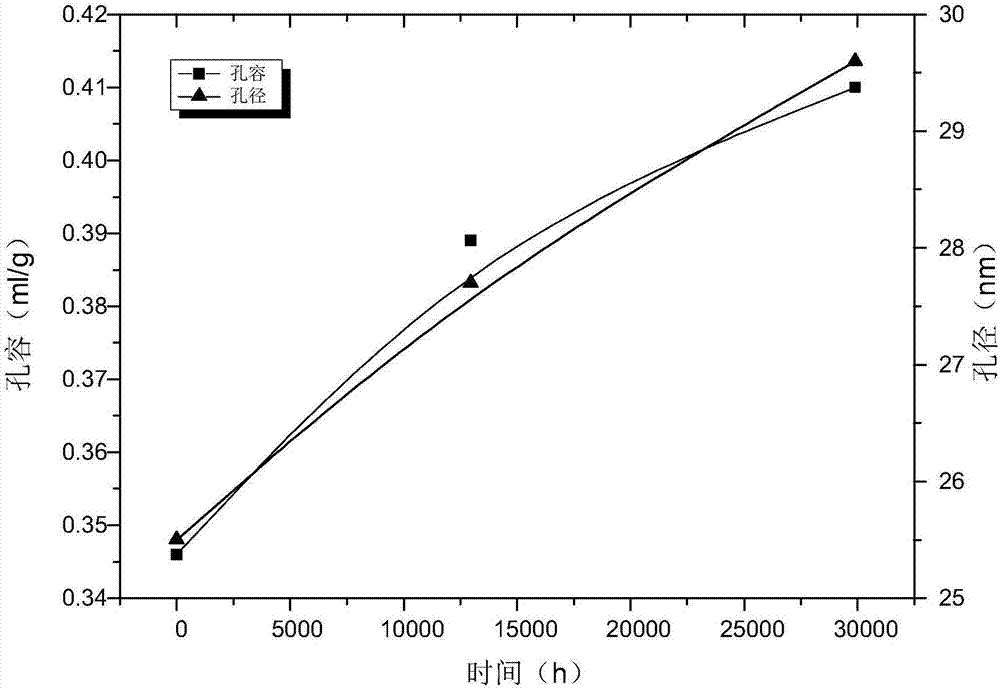

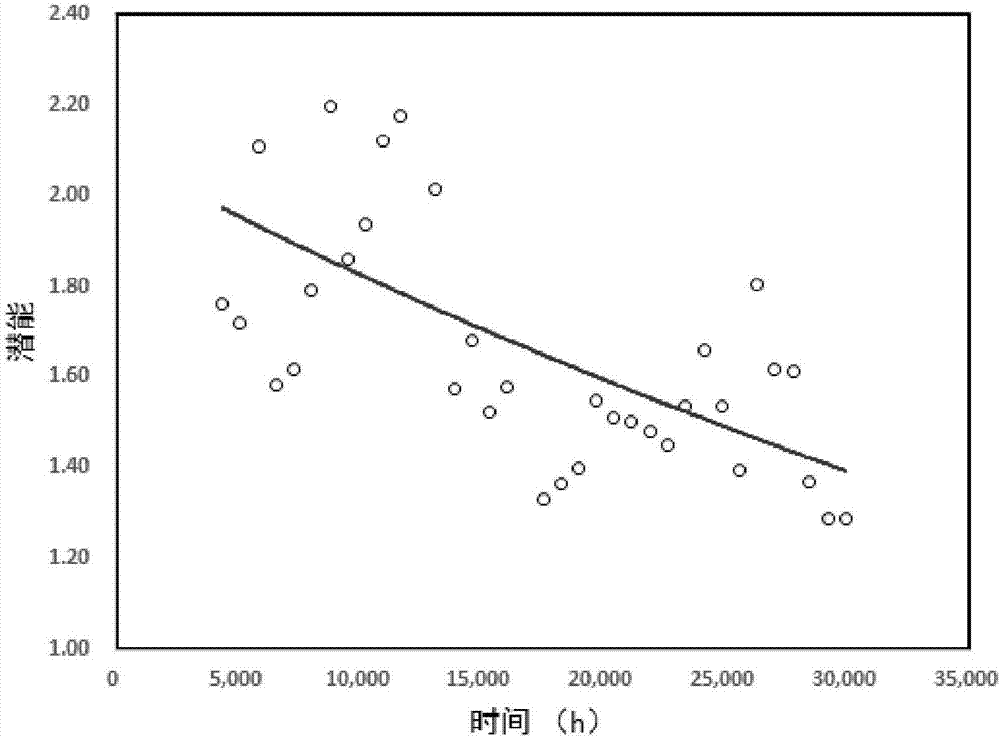

ActiveCN107103176AImprove accuracyImprove stabilityChemical analysis using catalysisChemical processes analysis/designPower stationProcess engineering

The invention provides a multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method. The multi-source information fusion technique based coal-fired boiler SCR catalyst life evaluation method includes the following steps: performing multiple sampling on a catalyst used in a power station boiler, performing laboratory detection on a sample, and acquiring a microscopic feature index capable of representing the activity of the catalyst; acquiring a macro-performance index of the catalyst sample through a micro reactor test; counting and mining power station historical operation data to acquire a macro index capable of reflecting the power station SCR reactor performance; and fusing the indexes associated with the catalyst life, and completing comprehensive evaluation of the catalyst life. The evaluation method can acquire a catalyst life prediction model according to historical laboratory detection data and an actual operation parameter of the catalyst through a fuzzy mathematical method, and can improve the accuracy and stability of catalyst performance evaluation.

Owner:SOUTHEAST UNIV +1

Probabilistic life evaluation method based on crack detection probability model

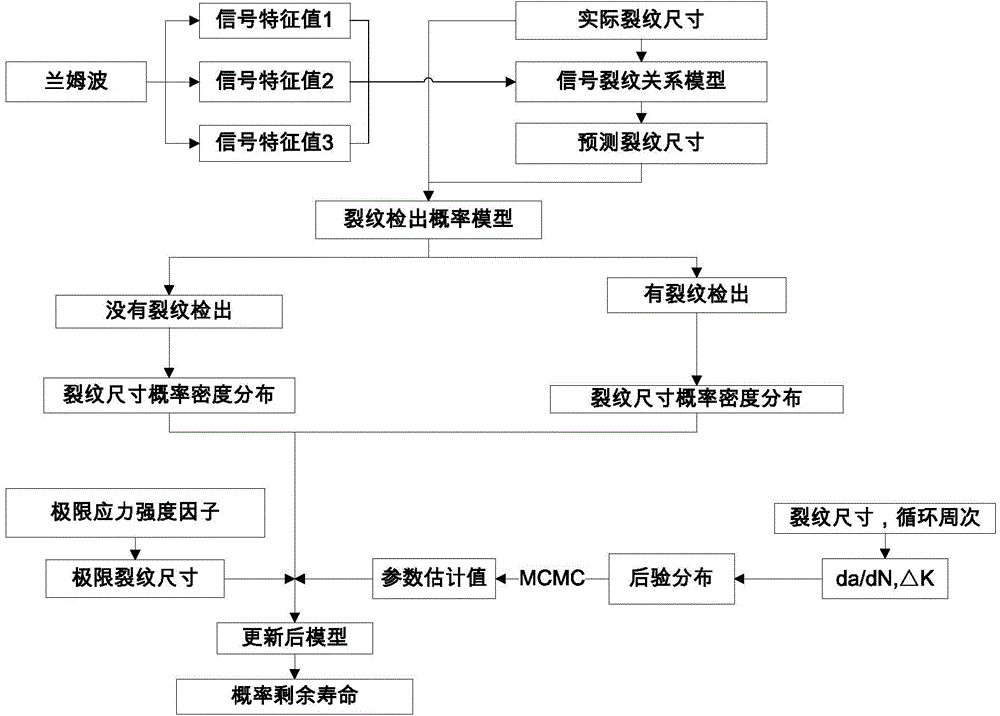

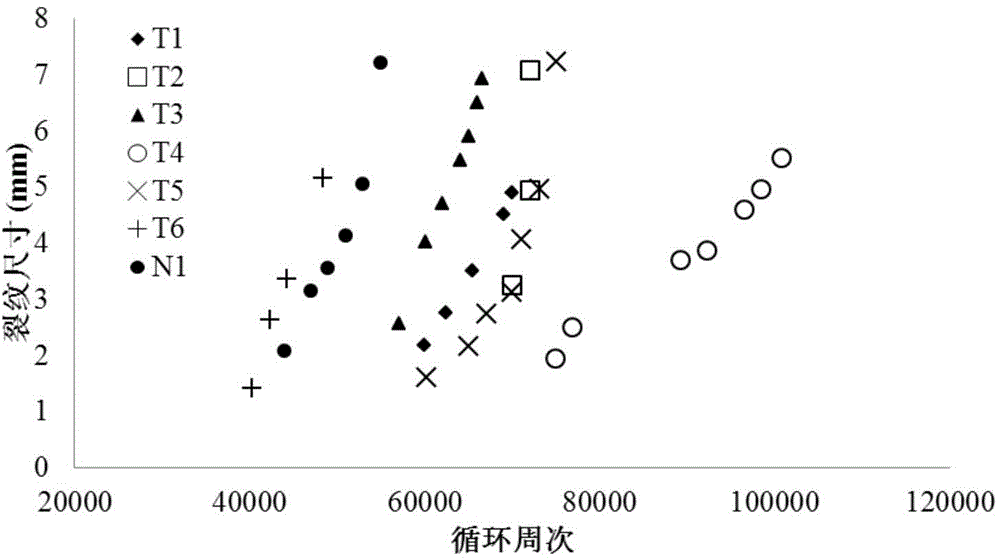

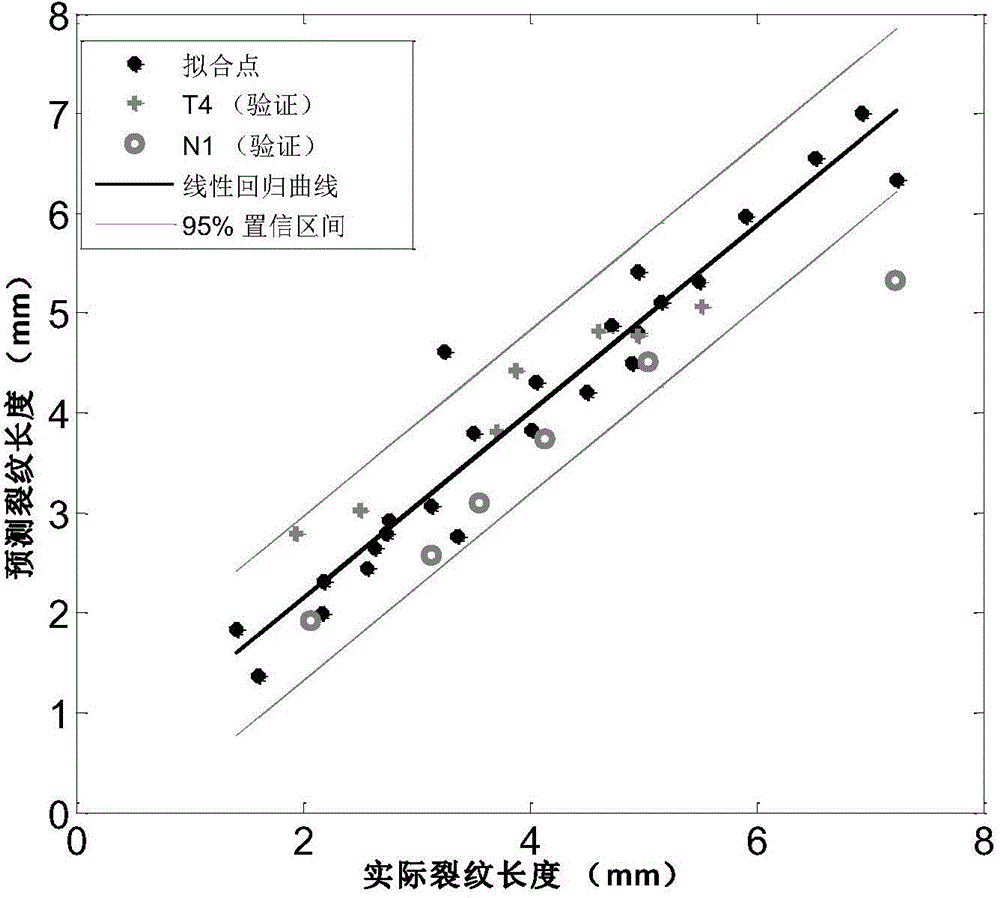

InactiveCN104392122AImprove applicabilityImprove accuracySpecial data processing applicationsProbit modelDecision maker

The invention discloses a probabilistic life evaluation method based on a crack detection probability model and belongs to the field of structure health monitoring technology. According to the probabilistic life evaluation method, experiment data is used as a basis; corresponding models are chosen by theoretical analysis for simulating; the correctness and effectiveness of the method are verified by original experiment data, so that a more sufficient basis is provided for a decision maker. Real-time Bayesian updating and estimation are carried out on parameters of a crack propagation model, so that the model is high in applicability and has the characteristics of high accuracy and high analysis speed.

Owner:BEIHANG UNIV

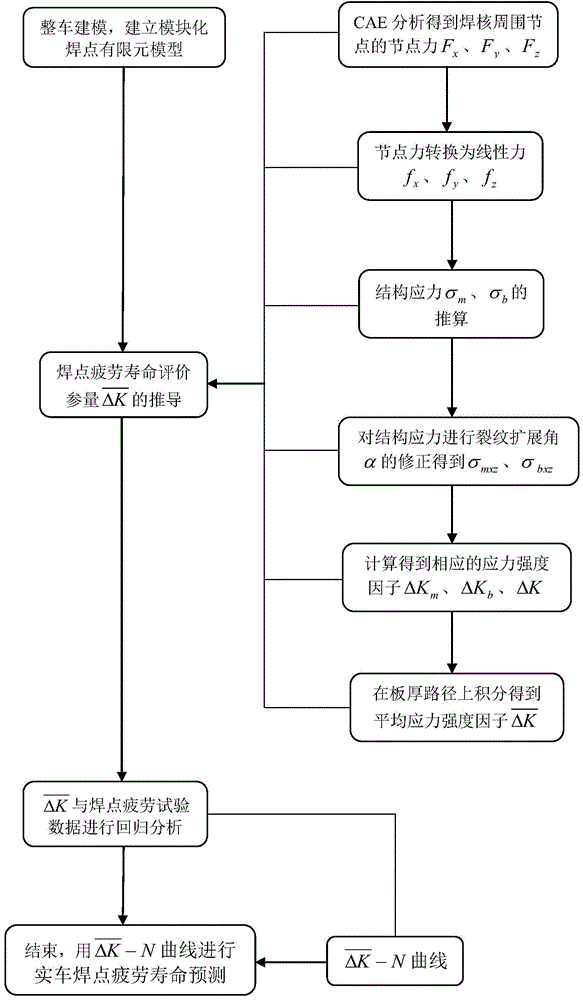

Spot-weld fatigue life predicting method

InactiveCN104573392AImprove efficiencyConform to the physical geometrySpecial data processing applicationsElement modelRegression analysis

The invention relates to a spot-weld fatigue life predicting method. The spot-weld fatigue life predicting method includes steps of 1, modeling a full vehicle and establishing a modularized spot-weld finite element model; 2, deducing spot-weld fatigue life evaluation parameter, mean stress strength factor; 3, subjecting spot-welded joints of different materials to systematic fatigue test, and subjecting the mean stress strength factor and fatigue test data of the spot-welded joints of different materials to regression analysis to obtain a curve of the spot-welded joints of different materials. The spot-weld fatigue life predicting method adopts the modularized spot-weld model to predict the spot-weld fatigue life, in actual application, only nodes of a border unit of the modularized spot-weld model are superposed with nodes of a welding structure unit, and spot-weld modeling efficiency in the full-vehicle modeling is improved.

Owner:HUNAN UNIV

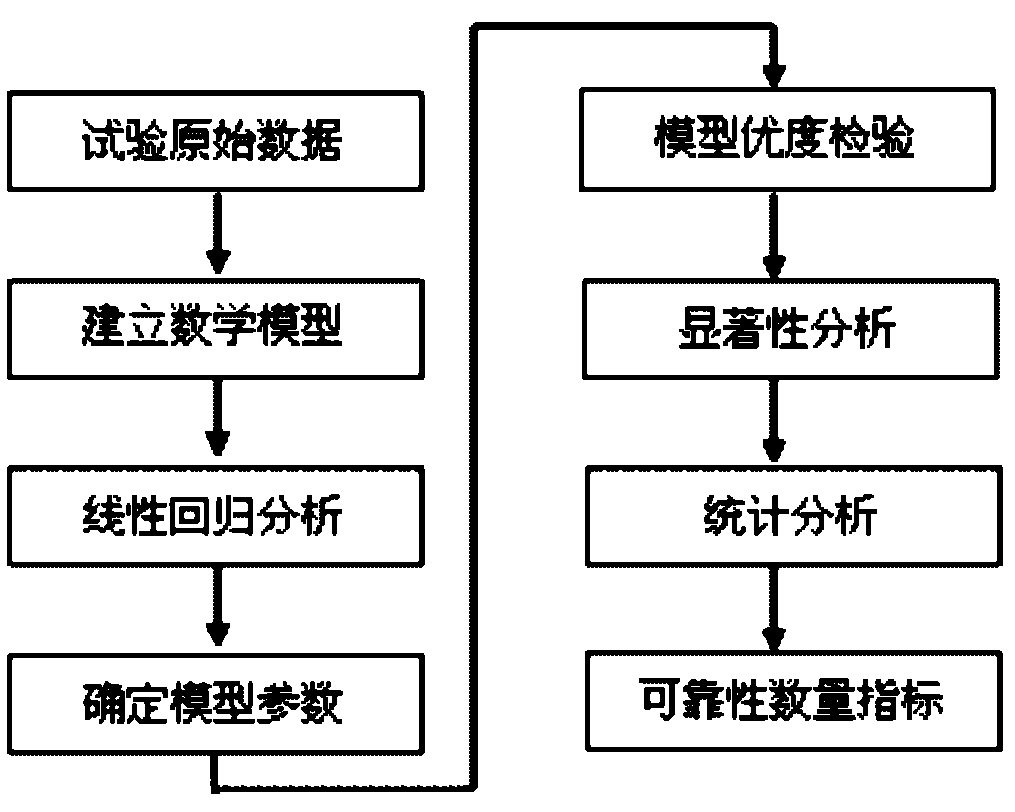

Short-term life test data-based quick life evaluation method

ActiveCN102426307AShorten the timeCost savingsIndividual semiconductor device testingStatistical analysisMathematical model

The invention discloses a short-term life test data-based quick life evaluation method, which comprises the following steps of: (1) selecting proper stress to perform life test on a device to obtain original data; (2) establishing a mathematical model based on data obtained by the life test; (3) performing linear regression analysis on the life test data; (4) determining model parameters by using a least square method principle; (5) performing calculation of test of goodness of fit to judge validity of the model; (6) calculating significance test statistic, and determining whether a regression equation has significance under a given significance level condition; and (7) statistically analyzing a reliability quantitative index of the test device by using a weibull distribution function and the established mathematical model to obtain a life index and life distribution of the device.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

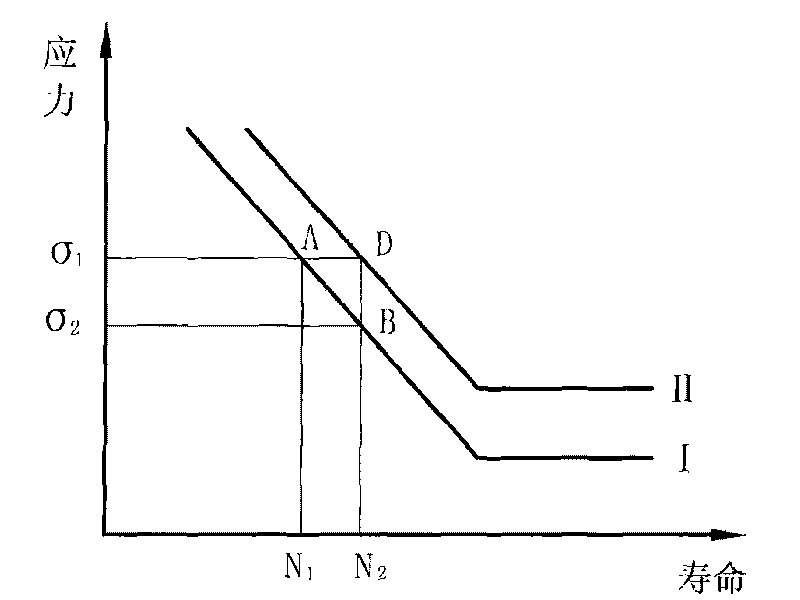

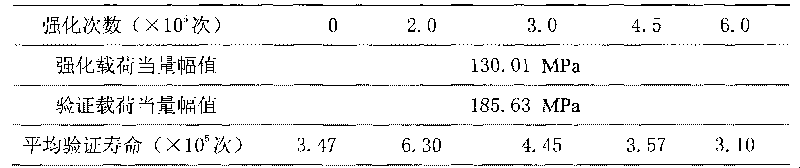

Evaluation method of residual strength and service life under strengthening and damaging combined action

InactiveCN101718651AAccurately assess durabilitySolve the disadvantages of strength attenuationStrength propertiesFatigue IntensityResidual strength

The invention relates to an evaluation method of residual strength and service life under strengthening and damaging combined action, which is characterized in that: (A) virtual stress-life curve of a material or a part is obtained by test or technical resources, and the fatigue strength and low amplitude loading range are determined; (B) the low-load strengthening general rule of the material or the part with different strength grades are built according to low-load strengthening performance data of low-strength and high-strength materials or parts by virtue of a numerical method of spline interpolation; (C) the fatigue strength changing rule is built according to the stress-life curve of the material or the part under the strengthening and damaging combined action; in addition, according to the loading grade and frequency of a loading spectrum, the instantaneous fatigue strength value, that is, the residual fatigue strength of the part with given using mileage is calculated; (D) according to the instantaneous stress-life curve, the life evaluation of the material or the part is carried out according to Miner linear damage theory. The invention provides a specific method for the service life of the part and the light-weight design.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

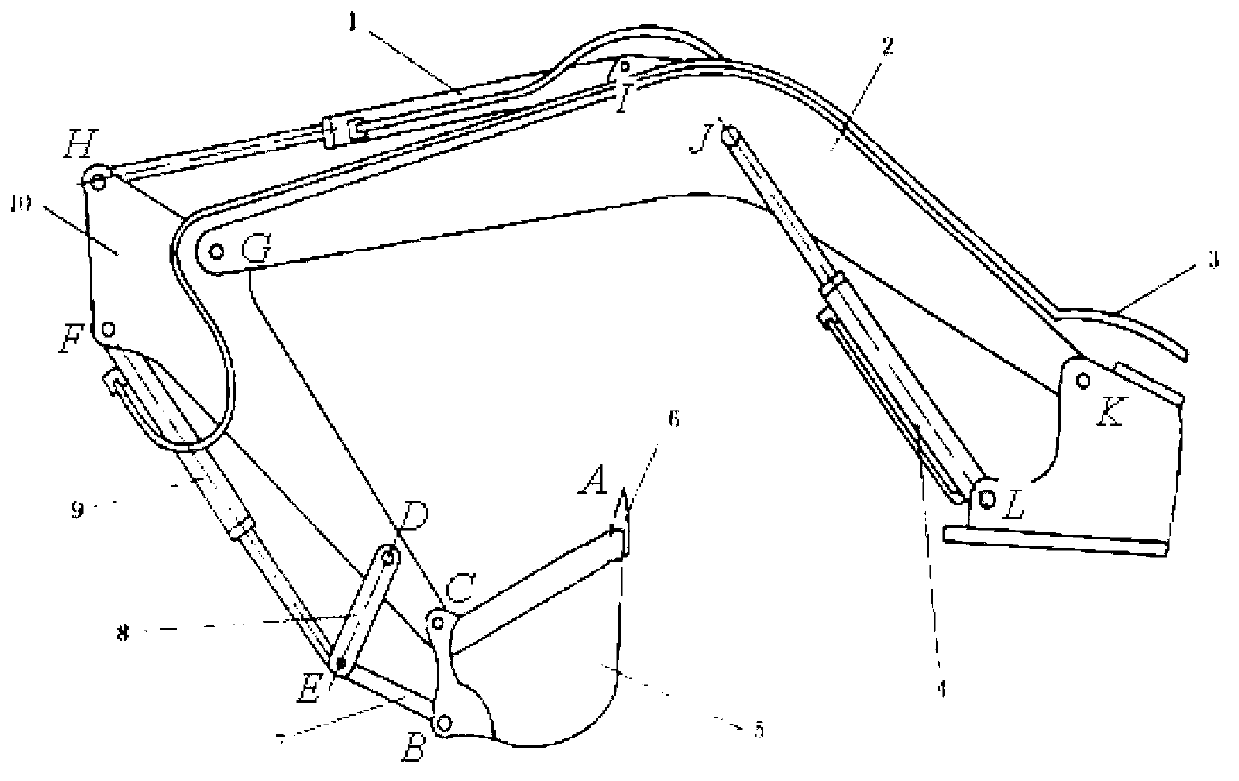

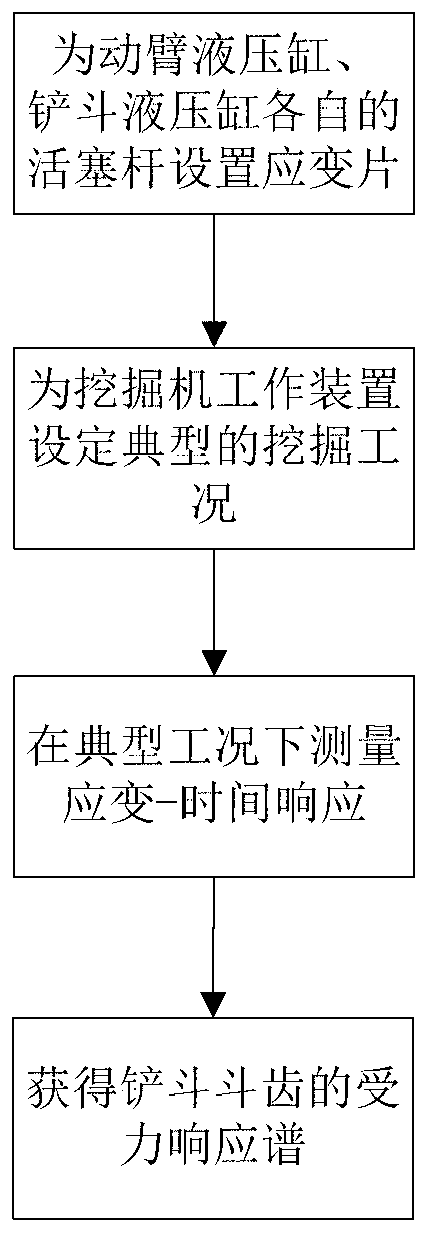

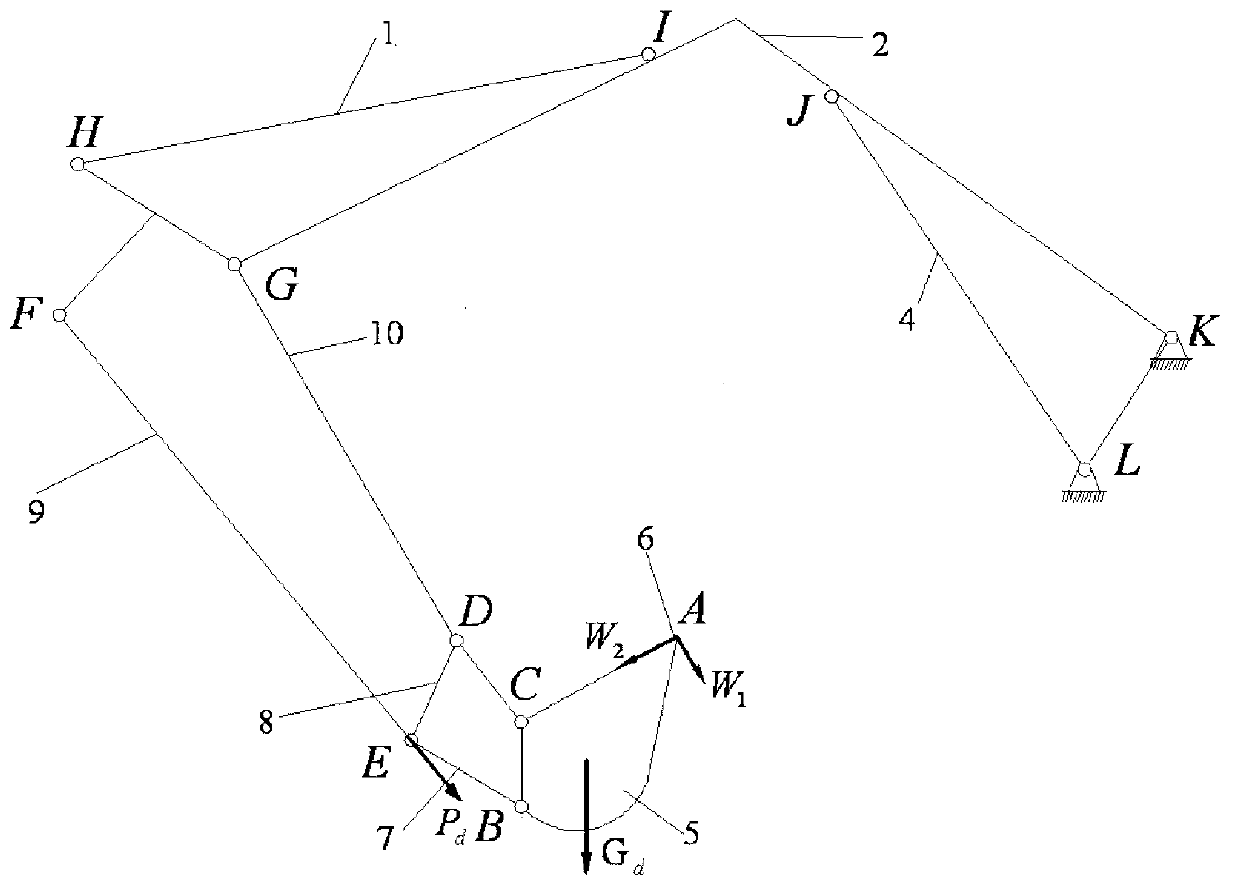

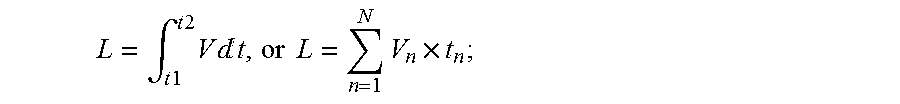

Load spectrum testing method for hydraulic excavator working device

InactiveCN103217307ASimple test operationSimple calculationStructural/machines measurementHydraulic cylinderTime response

The invention discloses a load spectrum testing method for a hydraulic excavator working device. The load spectrum testing method comprises the following steps of (a) respectively arranging strain foils on piston rods of a movable arm hydraulic cylinder and a scraper pan hydraulic cylinder; (b) locking the movable arm hydraulic cylinder and a scraper pan rod hydraulic cylinder, only enabling the piston rod of the scraper pan hydraulic cylinder to flex so as to push a scraper pan to execute an excavation operation, and respectively testing strain-time response data of the piston rods of the movable arm hydraulic cylinder and the scraper pan hydraulic cylinder in the respective rod length directions under the conditions; and (c) obtaining a stress response spectrum of excavator scraper pan teeth and taking the stress response spectrum as the load spectrum of the working device by utilizing the tested strain-time response data. The invention further discloses a stress response spectrum simplification operation formula constructed based on stress analysis; according to the load spectrum testing method for the hydraulic excavator working device, which is disclosed by the invention, the load spectrum test process of the excavator working device can be realized by a simple, quick and easy-to-operate manner, the tested load spectrum can be applied to the life evaluation, and the effective evidence can be provided for the structure optimization design of hydraulic excavator working device.

Owner:WUHAN UNIV OF SCI & TECH

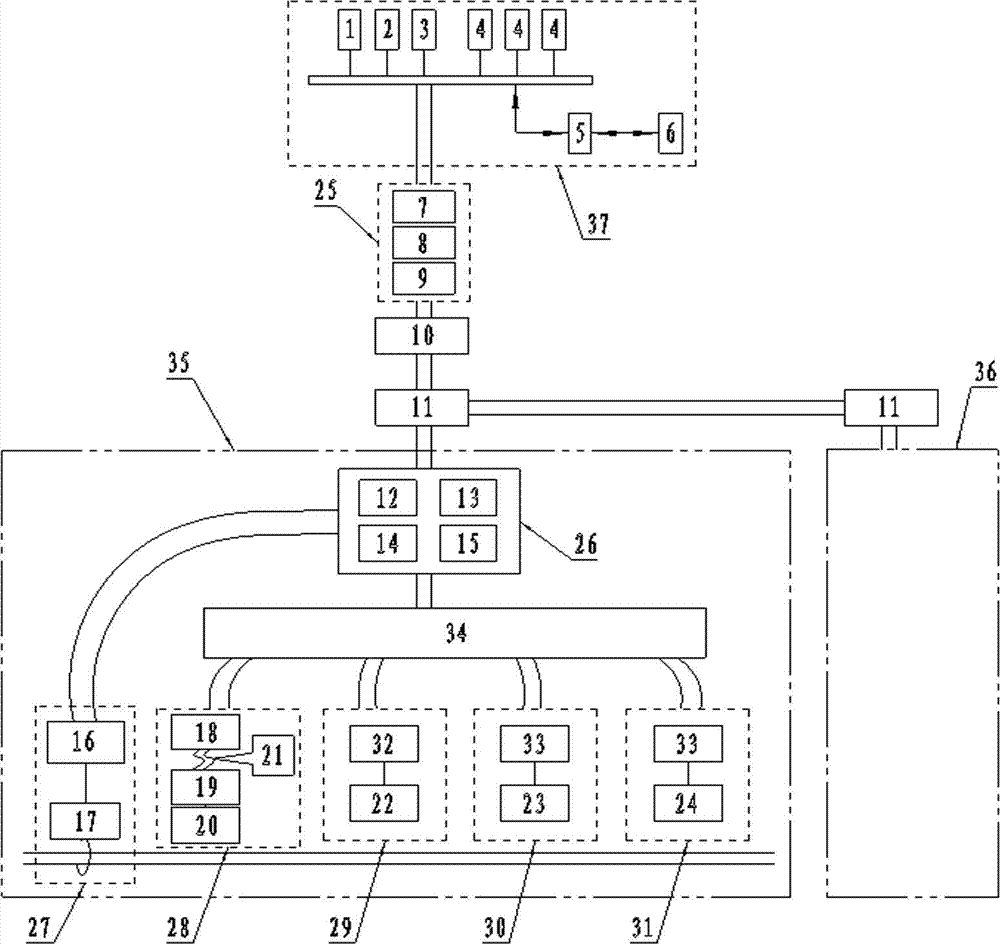

Cable running state intelligent monitoring system

InactiveCN103791947AReach cycle managementSolve management problemsCircuit arrangementsFault locationEngineeringHigh pressure

A cable running state intelligent monitoring system comprises a field monitoring system and a data intelligent monitoring and managing platform. A monitoring data transmission system is arranged between the field monitoring system and the data intelligent monitoring and managing platform. The field monitoring system comprises a first-level grounding net communication device. The monitoring data transmission system is provided with a second-level grounding net communication device. Compared with the prior art, the cable running state intelligent monitoring system has the advantages that the problem of online monitoring and managing of key positions of urban power grid cables is solved, the decision basis for route optimization design, running state evaluation, maximum dynamic current-carrying capacity control and defect overhaul is provided for the design department, the scheduling department and the running detection department, a cable running defect diagnosis and analysis model is set up, the health condition of high voltage cables is judged through the model, the life cycle of the cables is periodically managed, and the aims of intelligent cable running management such as intelligent analysis, safety precaution, residual life evaluation and the like are achieved. The cable running state intelligent monitoring system has the advantages of being reliable in performance, convenient to install, high in compatibility and the like.

Owner:ZHEJIANG TUWEI ELECTRICITY TECH

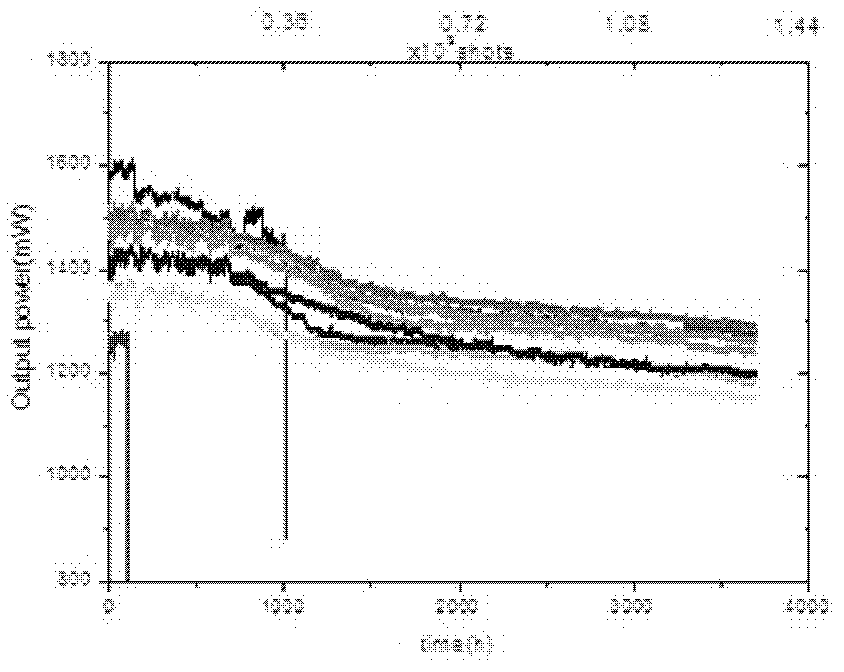

Prediction method for storage life of plastic packaged photoelectric coupler

ActiveCN108388694AShorten test timeReduce testing costsDesign optimisation/simulationSpecial data processing applicationsTemperature stressPhysical model

The invention provides a prediction method for storage life of a plastic packaged photoelectric coupler. The method comprises the following seven steps of 1, determining sensitive parameters; 2, defining a physical acceleration model; 3, determining a temperature stress for keeping a failure mechanism unchanged; 4, carrying out an acceleration life test; 5, preprocessing test data; 6, estimating parameter values in the physical model; and 7, calculating the service life of the plastic packaged photoelectric coupler under a storage stress. The method is novel in conception and simple in program, can calculate the service life of the plastic packaged photoelectric coupler in a storage state, reflects the failure mechanism, can reduce the cost, solves the problem that conventional service life prediction cannot ensure failure mechanism consistency, and has wide application prospects in the field of component storage life evaluation.

Owner:BEIHANG UNIV

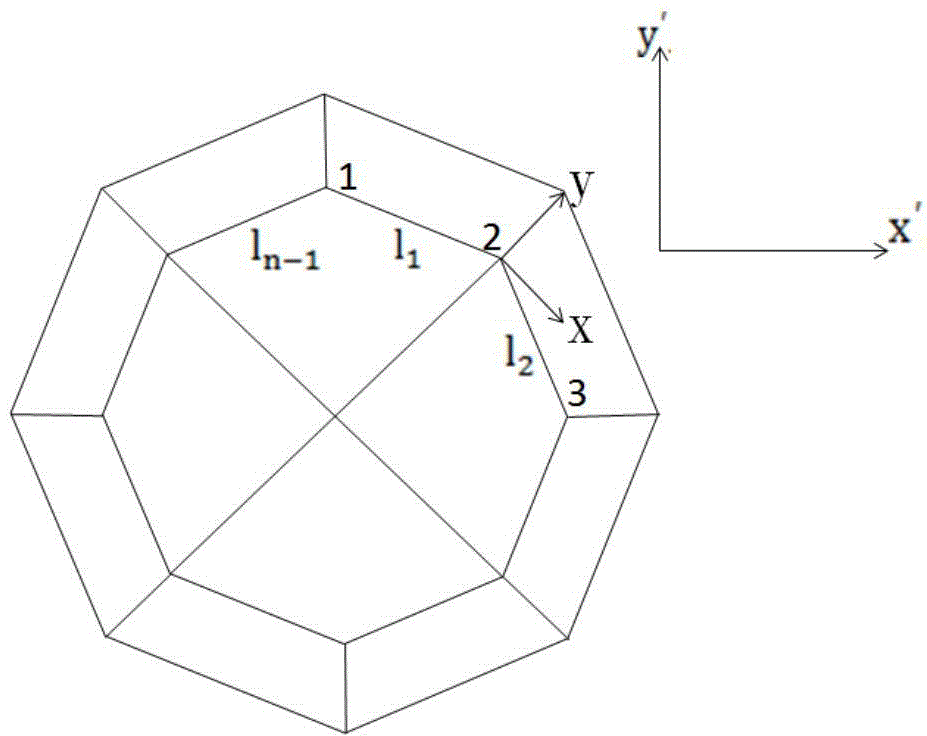

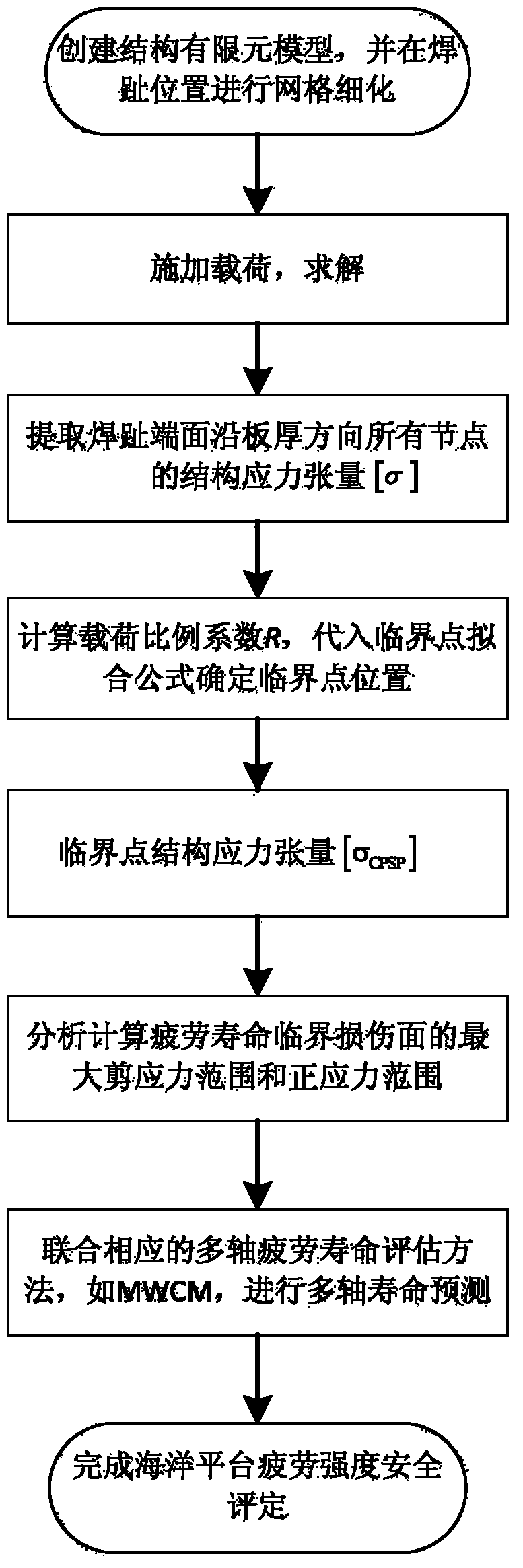

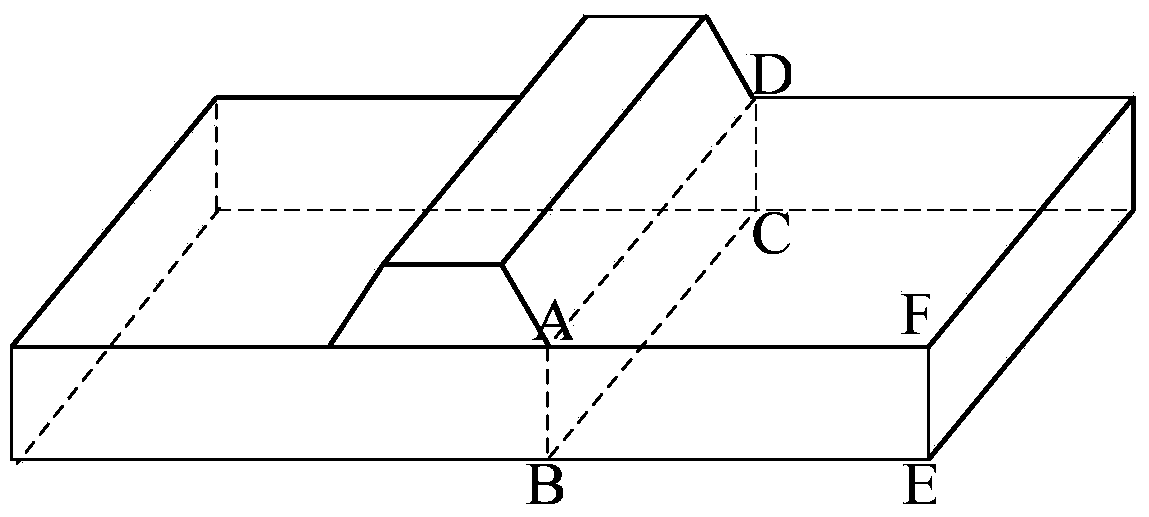

Welding structure multi-axial fatigue life evaluation method

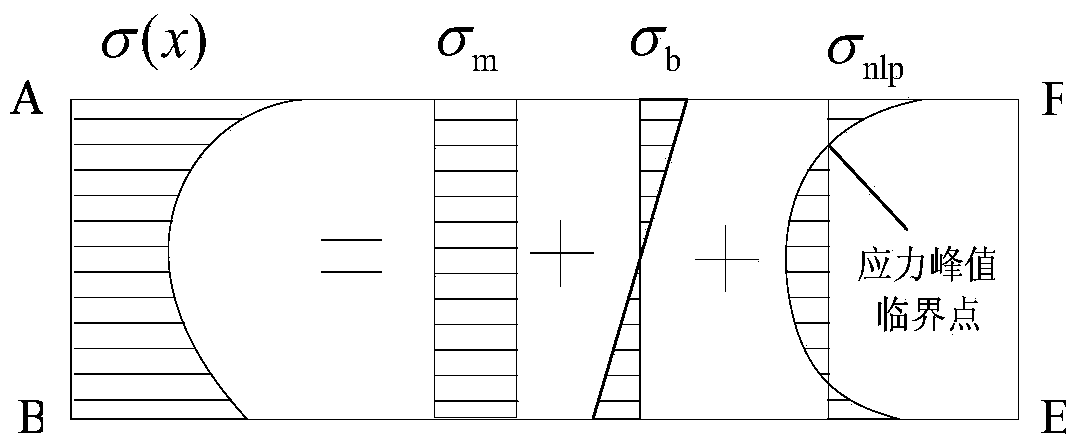

The invention discloses a welding structure multi-axial fatigue life evaluation method. The method includes the following steps that a finite element model of a welding structure to be measured is established; multiple test loads are applied to the welding structure, and structural stress tensors [sigma] of all joints of the end face of a weld toe in the board thickness direction are obtained through solving; corresponding load proportionality coefficients R of the joints are worked out according to the structural stress tensors [sigma] of the joints, and then the position of a stress peak critical point is determined; the structural stress tensor [sigma CPSP] of the stress peak critical point is obtained through the interpolation method; the maximum shear stress and normal stress range of a fatigue life critical damage plane are worked out according to the structural stress tensor [sigma CPSP] of the stress peak critical point, and multi-axial fatigue life evaluation is carried out through the union multi-axial fatigue life evaluation method MWCM.

Owner:DALIAN UNIV OF TECH

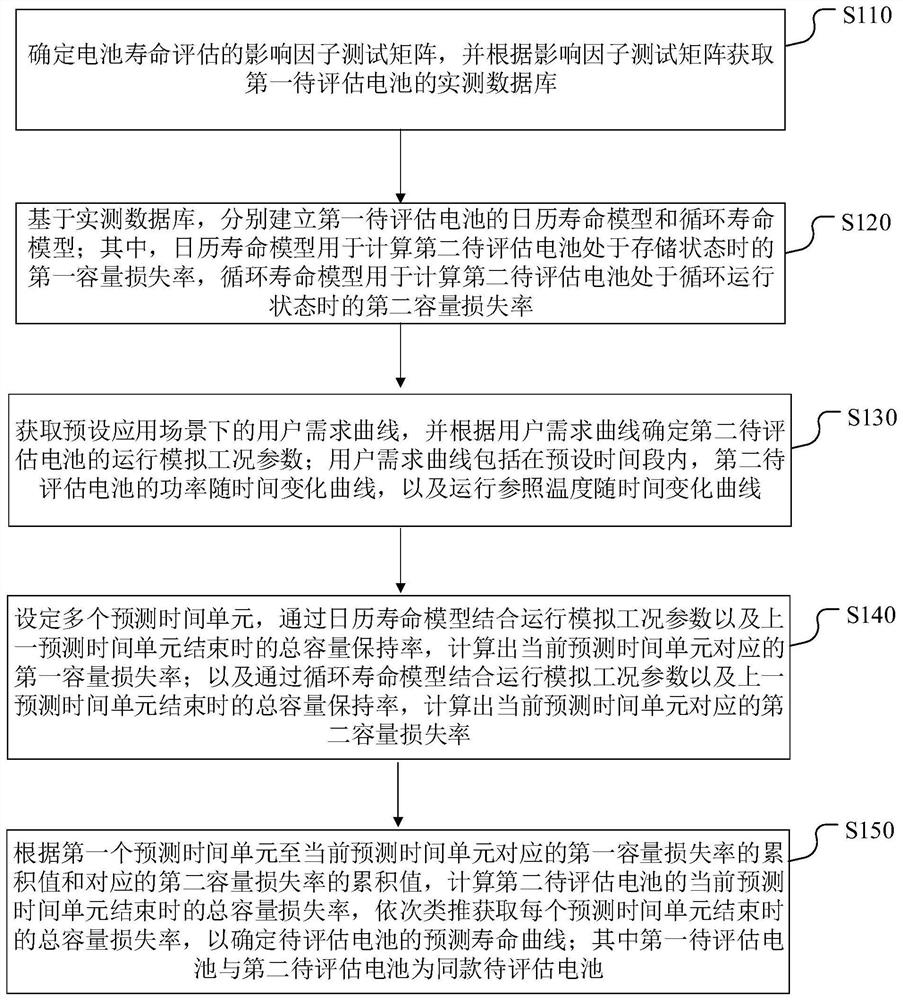

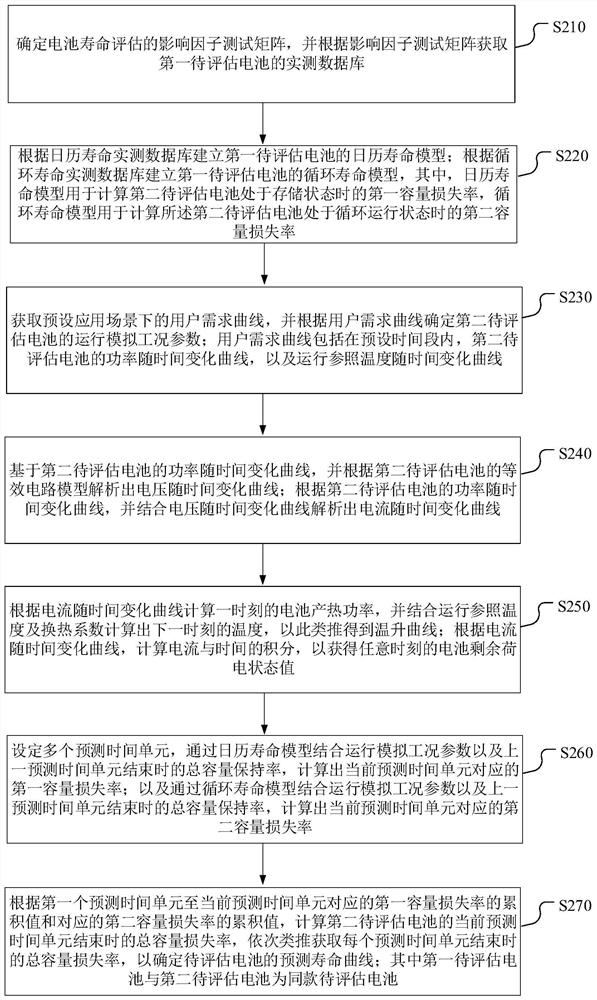

Battery life evaluation method

PendingCN112731164AImproving the Efficiency of Lifespan AssessmentAvoid forecast biasElectrical testingCapacity lossSimulation

The embodiment of the invention discloses a battery life evaluation method, and the method comprises the following steps: respectively establishing a calendar life model and a cycle life model, and determining operation simulation working condition parameters according to a user demand curve, respectively calculating a total capacity loss rate when each prediction time unit in a plurality of set prediction time units ends through a calendar life model and a cycle life model in combination with operation simulation working condition parameters, and when the total capacity loss rate of each prediction time unit is calculated, correcting the current total capacity loss rate through the total capacity retention rate of the previous prediction time unit. The service life condition of the battery is comprehensively predicted and evaluated by adopting a calendar service life and cycle life mutual coupling calculation method, so that the prediction result deviation caused by the fact that a traditional empirical model can only predict a single working condition and interaction influence is not considered when calendar attenuation and cycle attenuation are mutually superposed is avoided; and the prediction accuracy and the battery life evaluation efficiency are improved, and the method is suitable for actual application scenes.

Owner:EVE ENERGY CO LTD

Submerged-arc welding repair method after alkali production squeezing roller is worn

ActiveCN104084750AIncrease binding rateImprove wear resistanceArc welding apparatusWelding/cutting media/materialsEngineeringHardness

The invention provides a submerged-arc welding repair method after an alkali production squeezing roller is worn, and belongs to the field of squeezing roller repair and remanufacturing. The method includes the steps that a workpiece is cleaned, a fatigue layer on the roller surface is removed, the size of the repaired part is detected, and the damage part and the abrasion loss are determined; material analysis and hardness detection are conducted on the parent metal of the squeezing roller, and failure analysis and life evaluation are conducted on the workpiece through metallographic detection; relevant parameters of a welding wire and a submerged-arc welding machine are selected according to the detection result and then welding is conducted on the roller surface of the alkali production squeezing roller; mechanical machining is conducted according to requirements; surface colouration flaw detection and overall ultrasonic flaw detection are conducted on the machined workpiece, and roughness of the roller surface is detected. The method has the advantages of being good in wear resistance, high in hardness and strength, and the phenomena of chip off-falling and falling off cannot occur when the method is used.

Owner:河北瑞兆激光再制造技术股份有限公司

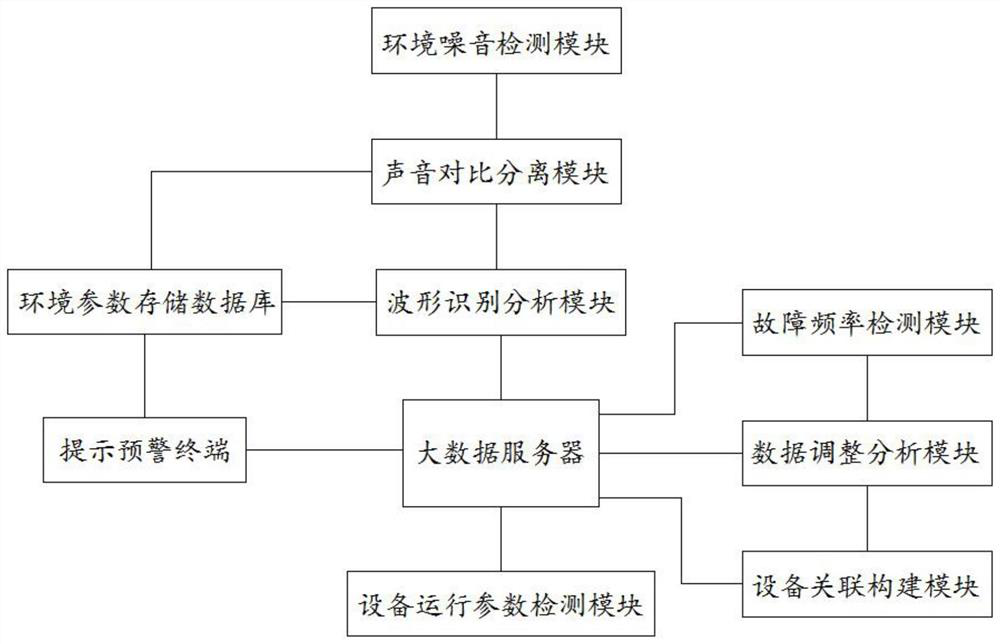

Communication machine room protection monitoring management system based on big data

ActiveCN111609883AFast and accurate identificationRepair in timeMeasurement devicesCharacter and pattern recognitionEnvironmental noiseMixed noise

The invention discloses a communication machine room protection monitoring management system based on big data. The system comprises an environmental noise detection module, a sound comparison and separation module, a waveform recognition and analysis module, an environmental parameter storage database, a fault frequency detection module, an equipment association construction module, an equipmentoperation parameter detection module, a data adjustment and analysis module, a big data server and a prompt early warning terminal. According to the invention, the mixed noise in a machine room is analyzed; whether each device has a fault and the type of the fault are determined; the failure frequency of the device, the repair waiting time and the temperature change condition of the device are analyzed; the operation life evaluation coefficient corresponding to each device under the influence of the device and other devices is comprehensively analyzed by combining association tightness coefficients, fault repair time and the like of other devices and a device to be detected; the characteristic of high detection accuracy is achieved, protection early warning reminding is achieved, and protection monitoring management can be conveniently carried out on the devices in the machine room.

Owner:山东联信数字科技有限公司

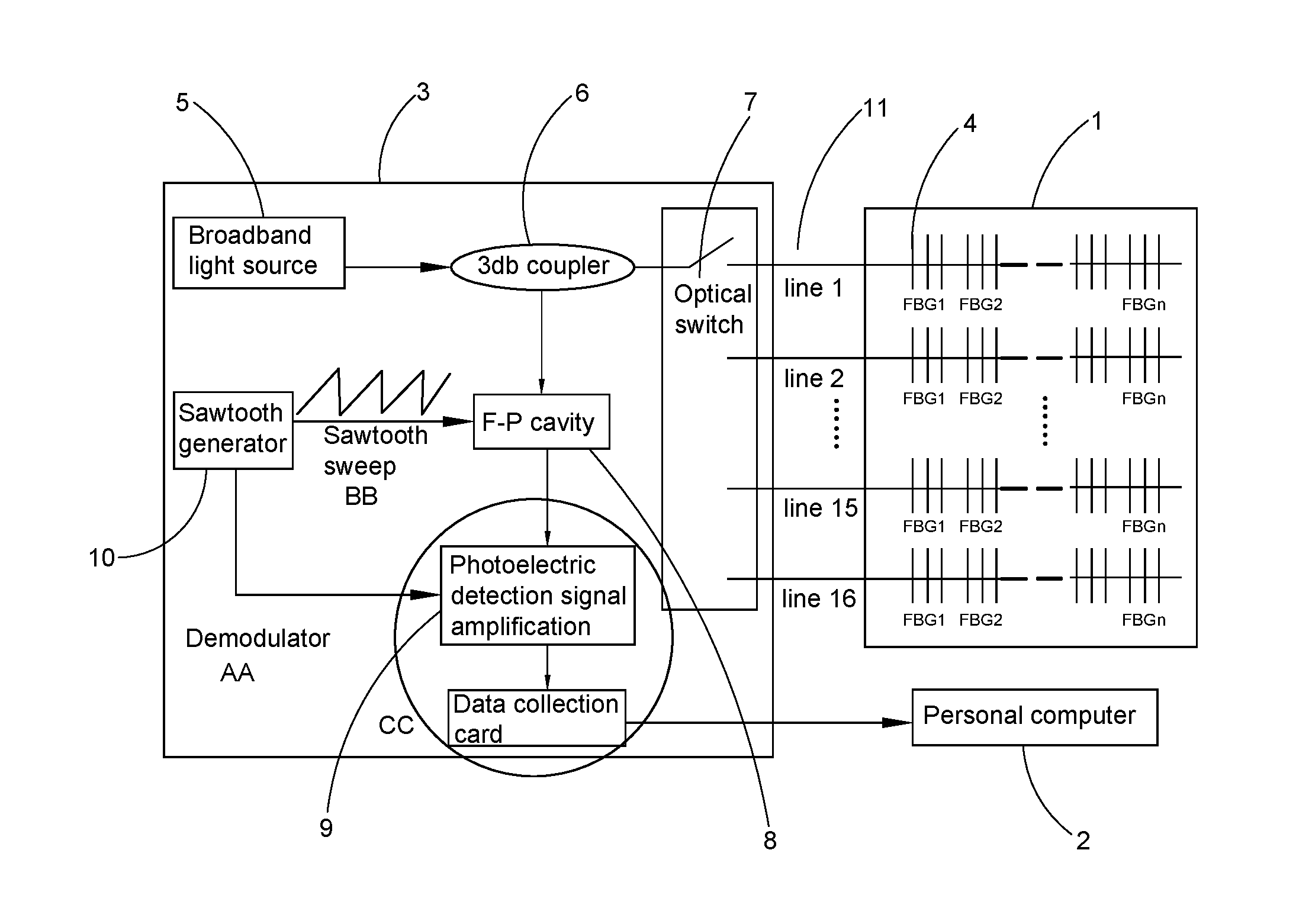

Method for Predicting the Life of Transformer based on Fiber Grating Temperature Measurement System

InactiveUS20160320324A1Improve operationTesting dielectric strengthThermometers using value differencesFiberGrating

A method for predicting the life of a transformer includes: conducting a quasi-distributed description on an internal temperature of a transformer by using a fiber grating temperature measurement system; determining the position of an internal hottest spot of the transformer and conducting a life evaluation on an internal local region of the transformer; and according to the life loss of each position of the transformer, by combining the insulation characteristic of the transformer with the influence of the life of the position on the entire life of the transformer, predicting the life of the transformer scientifically and reasonably. The method can use the fiber grating temperature measurement system to calculate and evaluate the life loss of the internal insulation of the transformer and the rate of change thereof

Owner:TAIYUAN POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +2

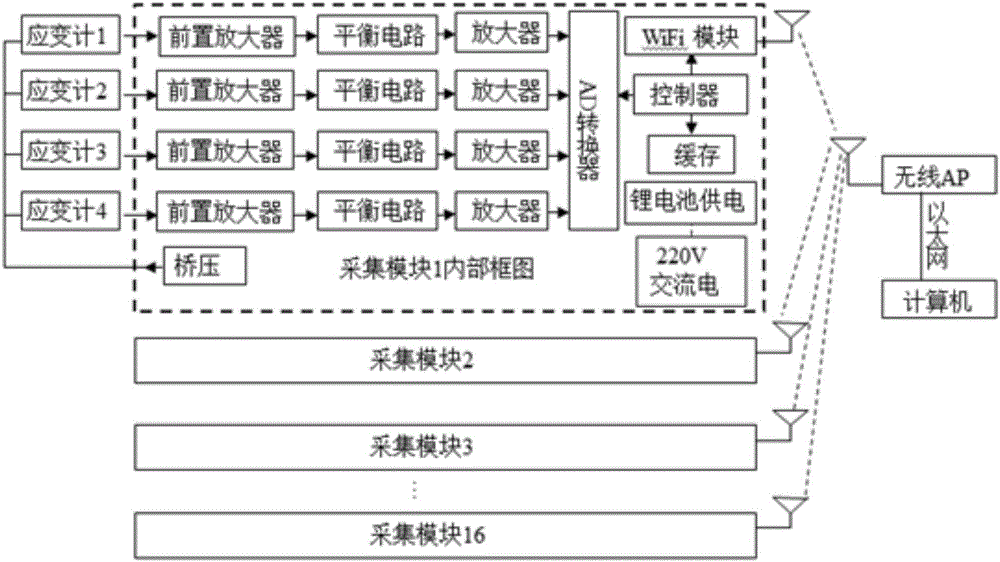

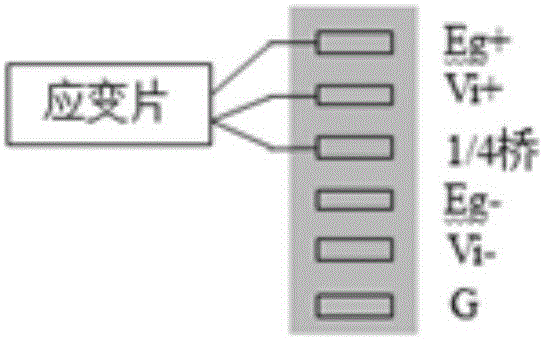

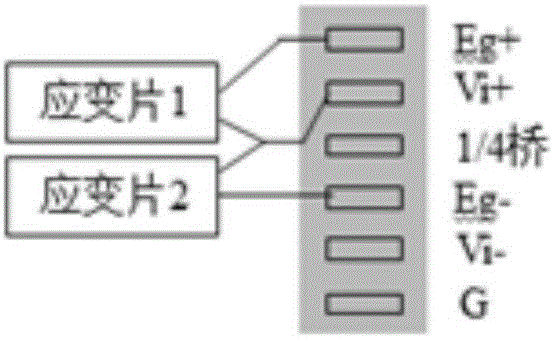

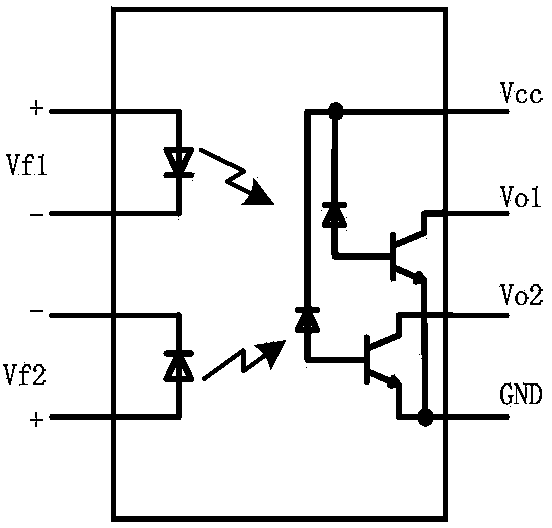

Method for evaluating service life of metallic structure of offshore platform crane

InactiveCN106556522AEasy to useReduce lossesStructural/machines measurementTime courseFatigue damage

The invention relates to a method for evaluating a service life of a metallic structure of an offshore platform crane. The method comprises: a computer uses a wireless dynamic strain acquisition module to obtain strain time course data collected by a strain gauge arranged at a weak part of a metallic structure of a crane within fixed time; and the computer processes the strain time course data according to a rain-flow counting method, calculates a cumulative fatigue damage D of a component, and calculates a fatigue service life T of the component based on the cumulative fatigue damage D. Using the method provided by the invention, wireless strain monitoring and residual life evaluation on the metallic structure of the offshore platform crane can be realized remotely and wirelessly. On the basis of the service life evaluation result of the component, a corresponding service life prolong plan can be formulated before the fatigue damage of the component, so that the offshore platform crane can work normally and unnecessary losses can be reduced.

Owner:TIANJIN JINAN HEAVY IND +1

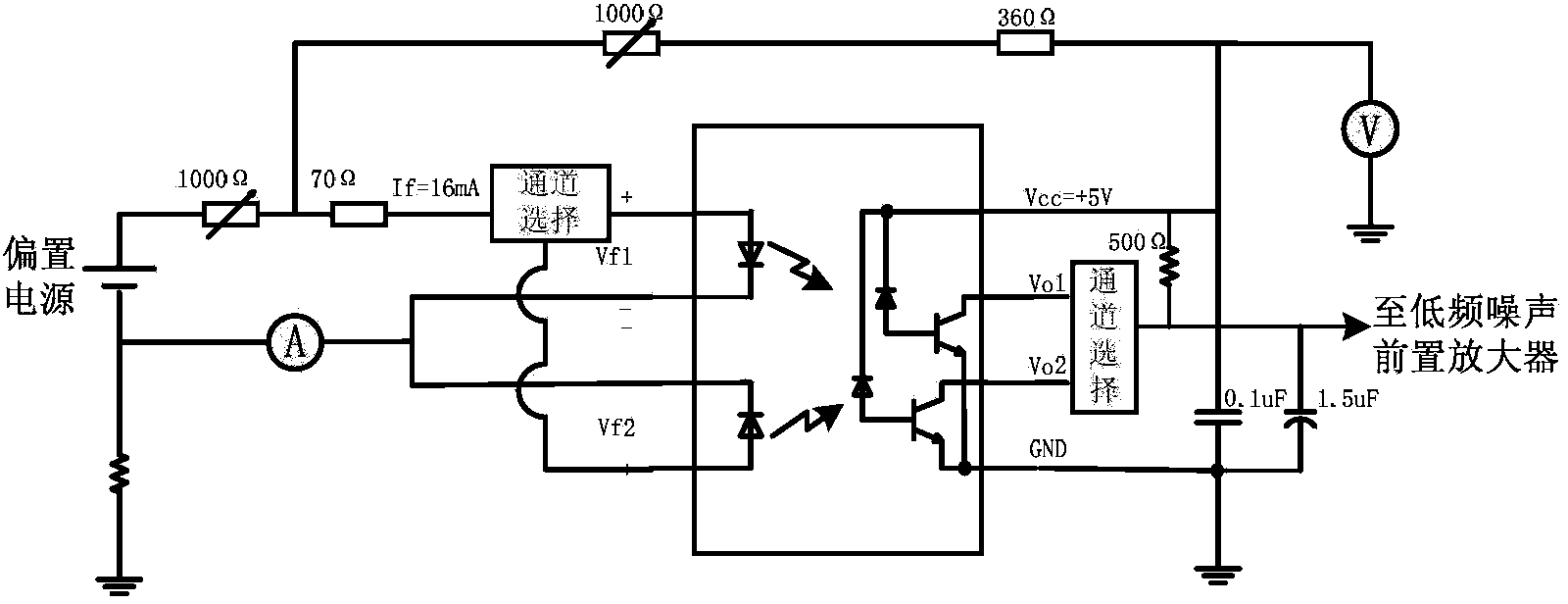

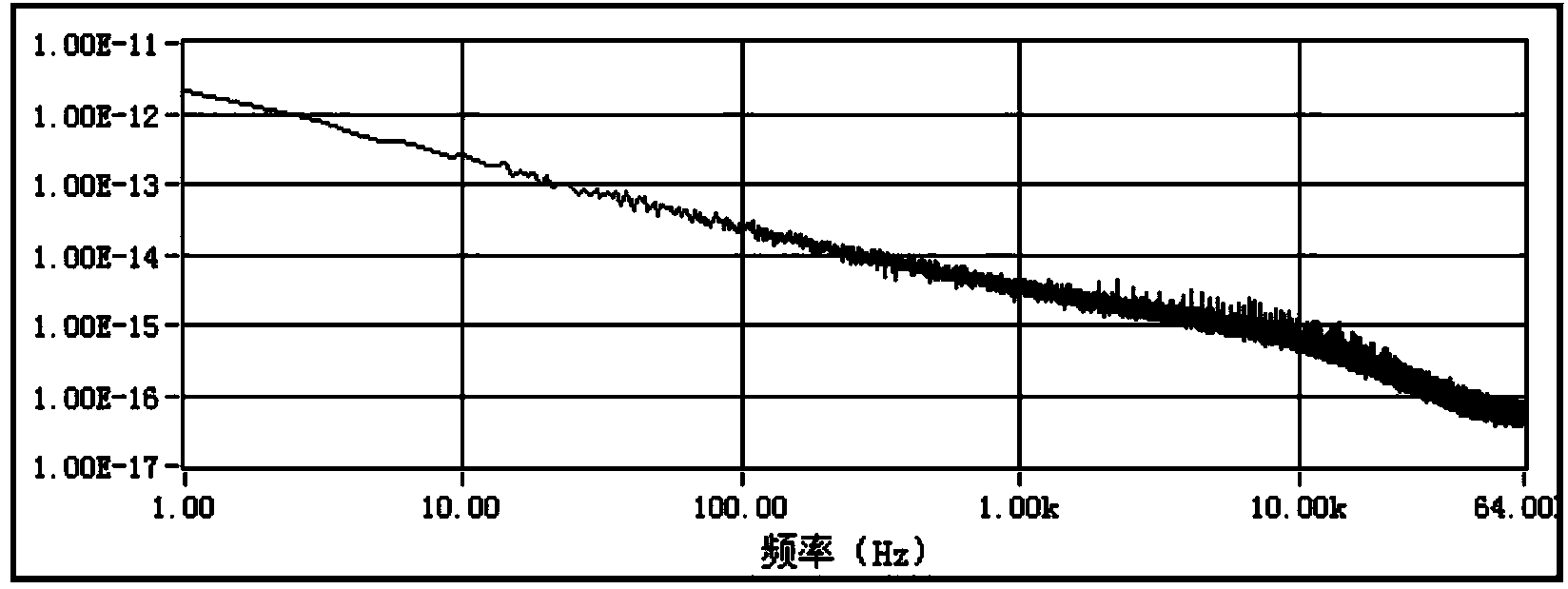

Method for evaluating opto-coupler storage life based on low-frequency noise classification

ActiveCN103777098AHigh precisionNoise figure or signal-to-noise ratio measurementElectrical testingHigh temperature storageNoise classification

A method for evaluating the opto-coupler storage life based on low-frequency noise classification comprises the following steps that firstly, a low-frequency noise adapter is arranged according to the inner structure of each opto-coupler; secondly, original low-frequency noise of each opto-coupler is measured; thirdly, samples are classified according to the low-frequency noise; fourthly, the temperature of a accelerated life test is determined and the accelerated life test is conducted on the samples in a classified mode; fifthly, a function of a degeneration trend is determined; sixth, the opto-coupler storage life at the normal temperature is extrapolated through a high-temperature storage result. According to the method for evaluating the opto-coupler storage life based on low-frequency noise classification, the opto-couplers of the same batch are classified, service life evaluation is respectively conducted on the opto-couplers, a thought allowing the service lives of the opto-couplers to be ranked and classified before the accelerated life test is conducted is provided, an effective way is offered for the current research in the aspect of storage life evaluation of a semiconductor circuit, the opto-couplers with the similar service life are in the same classification, and therefore the accuracy of opto-coupler service life evaluation is improved.

Owner:天航长鹰(江苏)科技有限公司

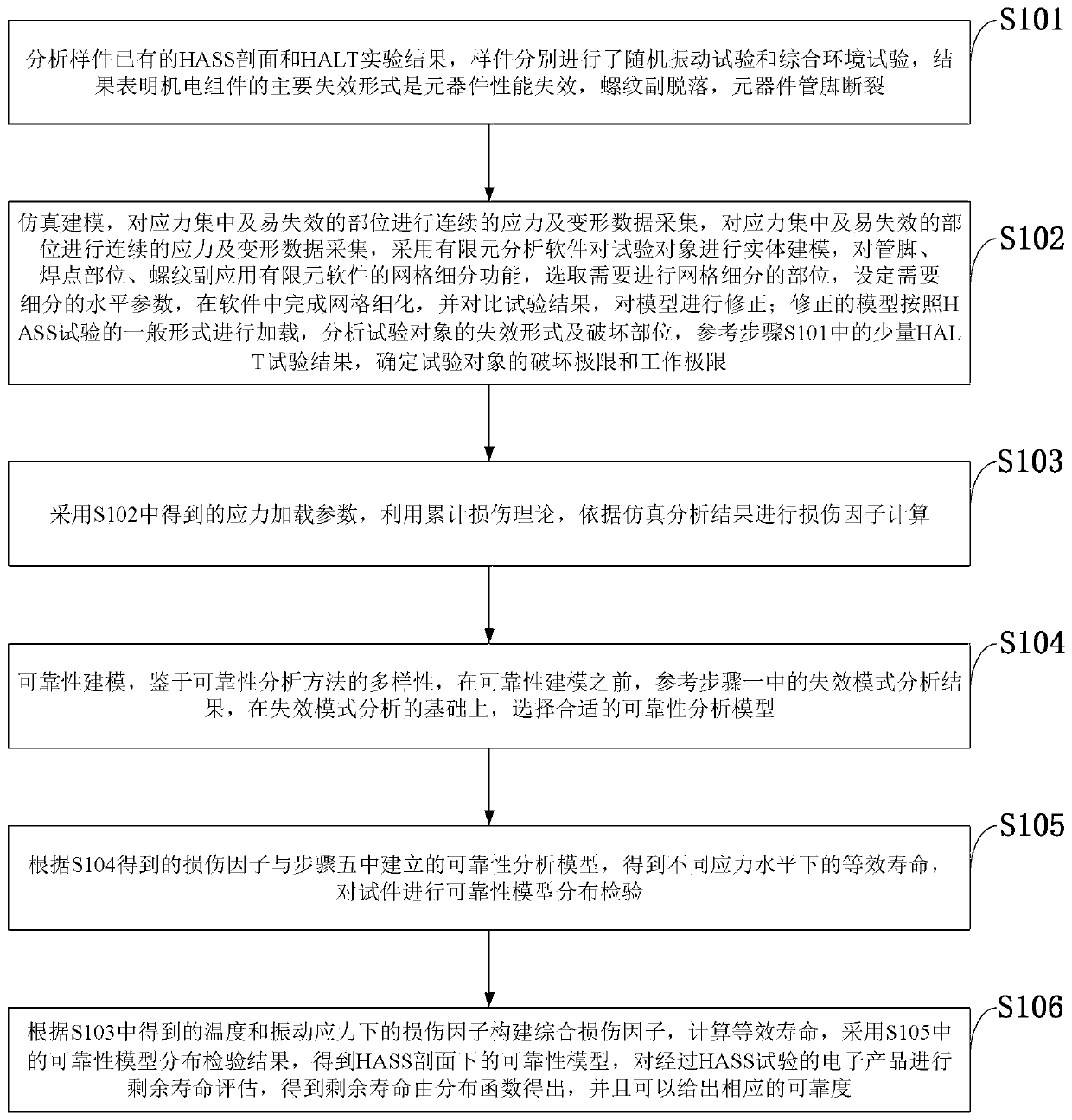

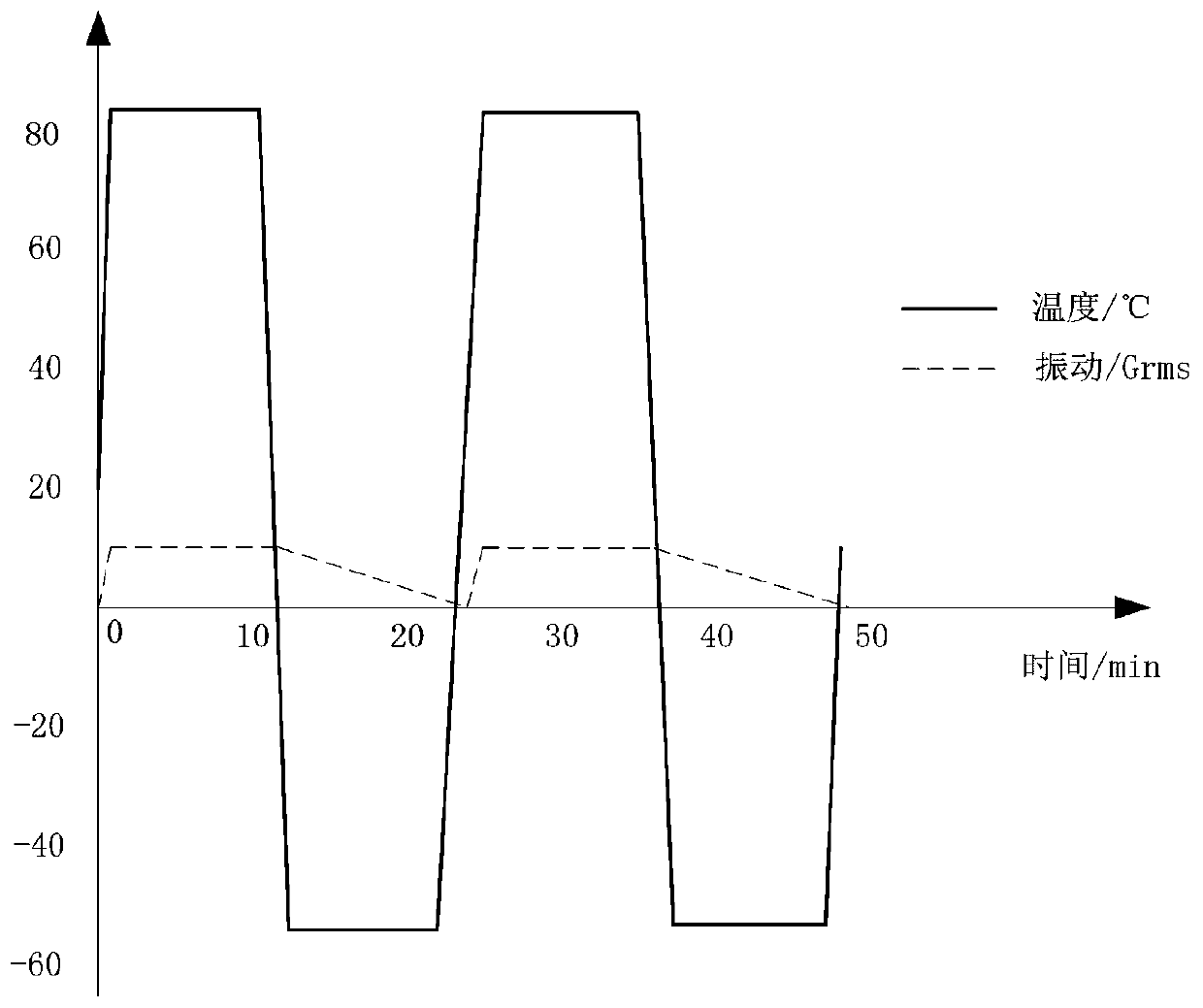

A residual life evaluation and reliability analysis method for a high-acceleration stress screening test

ActiveCN109783850AReduced physical consumptionAccurate quantitative indicatorsSpecial data processing applicationsEngineeringScreening test

The invention belongs to the technical field of high-acceleration stress screening tests, and discloses a residual life evaluation and reliability analysis method for a high-acceleration stress screening test. The method includes: Performing entity modeling by adopting finite element analysis software; Loading the screening object model according to a damage limit and a working limit in a high acceleration service life (HASS) test; Performing finite element simulation analysis under temperature and vibration stress according to the determined damage limit and working limit to obtain damage factors and equivalent life under different stress levels; carrying out Sorting statistics and analysis on the failure mode and the failure time of the screening object, and selecting a reliability analysis model; Constructing a comprehensive cumulative damage factor under temperature and vibration stress, calculating an equivalent life, obtaining a reliability model under an HASS profile, and carrying out residual life assessment and reliability analysis on the object subjected to the HASS test.

Owner:XIDIAN UNIV

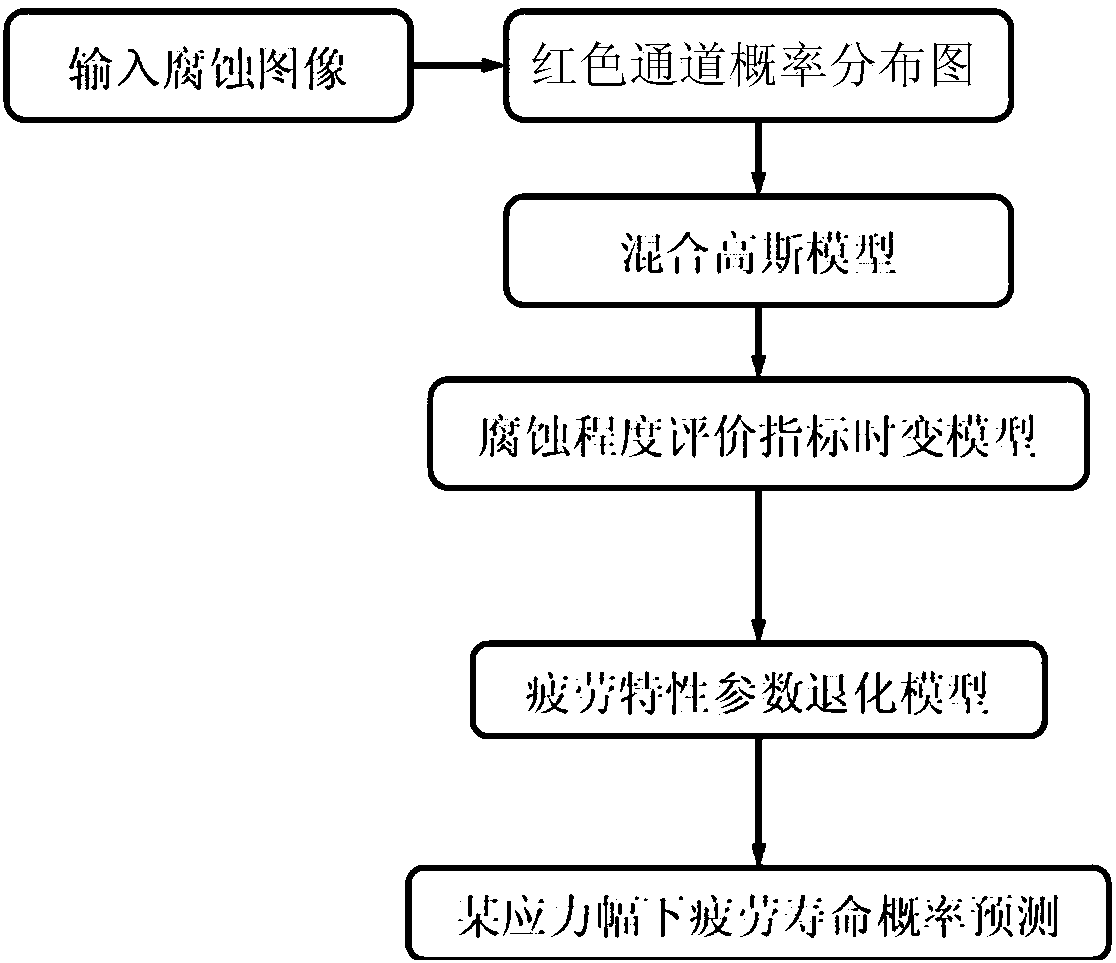

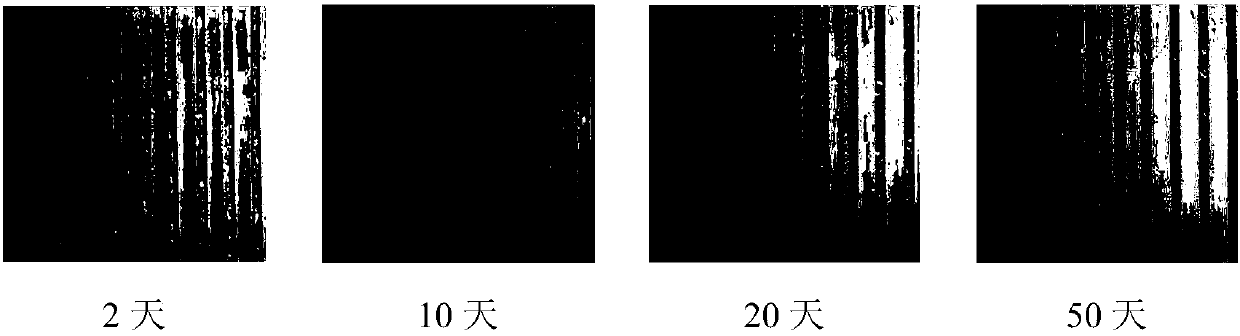

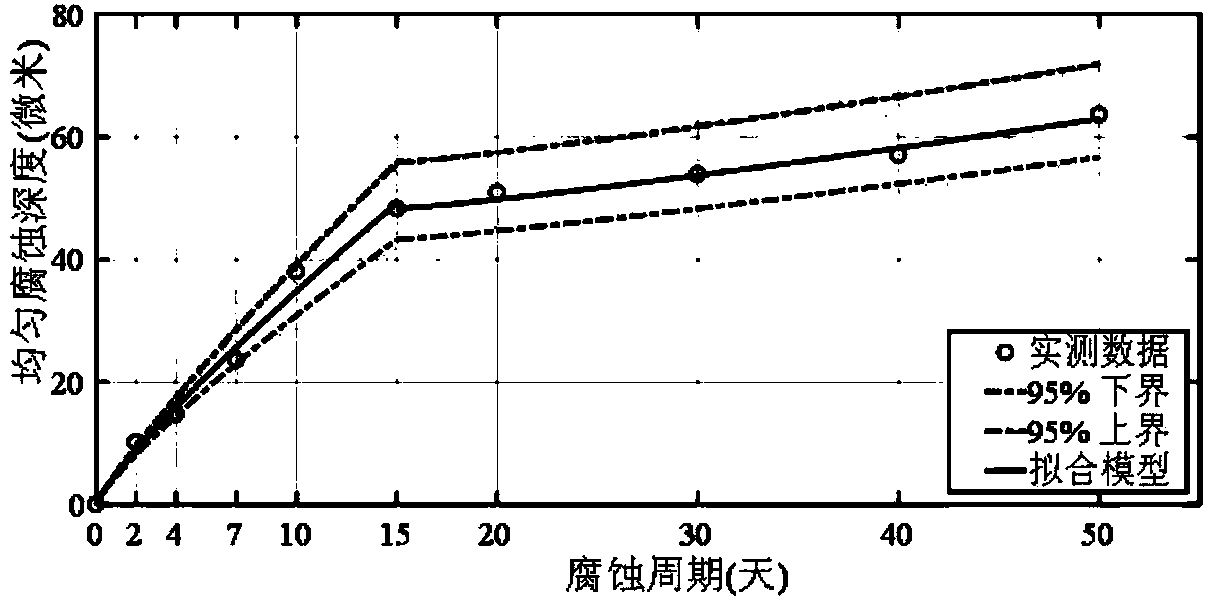

Method for monitoring and recognizing pulling rope corrosion and evaluating fatigue life on basis of computer vision

ActiveCN108225906AImprove accuracyImprove stabilityWeather/light/corrosion resistanceStrength propertiesPattern recognitionData set

The invention provides a method for monitoring and recognizing pulling rope corrosion and evaluating a fatigue life on the basis of computer vision. The method comprises the following steps: shootingan image of a corroded high-strength steel wire by a perspective inspection window at an anchoring end of a pulling rope, extracting image characteristics from the image, then building a corrosion-degree evaluation model, then building a fatigue-life characteristic energy number evaluation model, matching with a performance degrading state of the corrosion and the fatigue of the steel wire under an artificially accelerated corrosion test, and finally finishing the corrosion-state recognition and the fatigue-life evaluation of the in-service pulling rope. The method provided by the invention has the beneficial effects that the recognition accuracy is high, the speed is fast and the cost is low; the requirement for real-time data processing of online monitoring and early warning of corrosionand fatigue of the pulling rope also can be met, i.e., the image acquired by a consumer-grade ordinary camera is directly recognized without data-set updating; the automation, intelligentization, accuracy and robustness of corrosion monitoring and recognition and fatigue-life evaluation of the pulling rope are improved, and a solution is provided for automatic monitoring and recognition of the corrosion and the fatigue of the pulling rope of a bridge structure.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com