Patents

Literature

15450 results about "Power station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

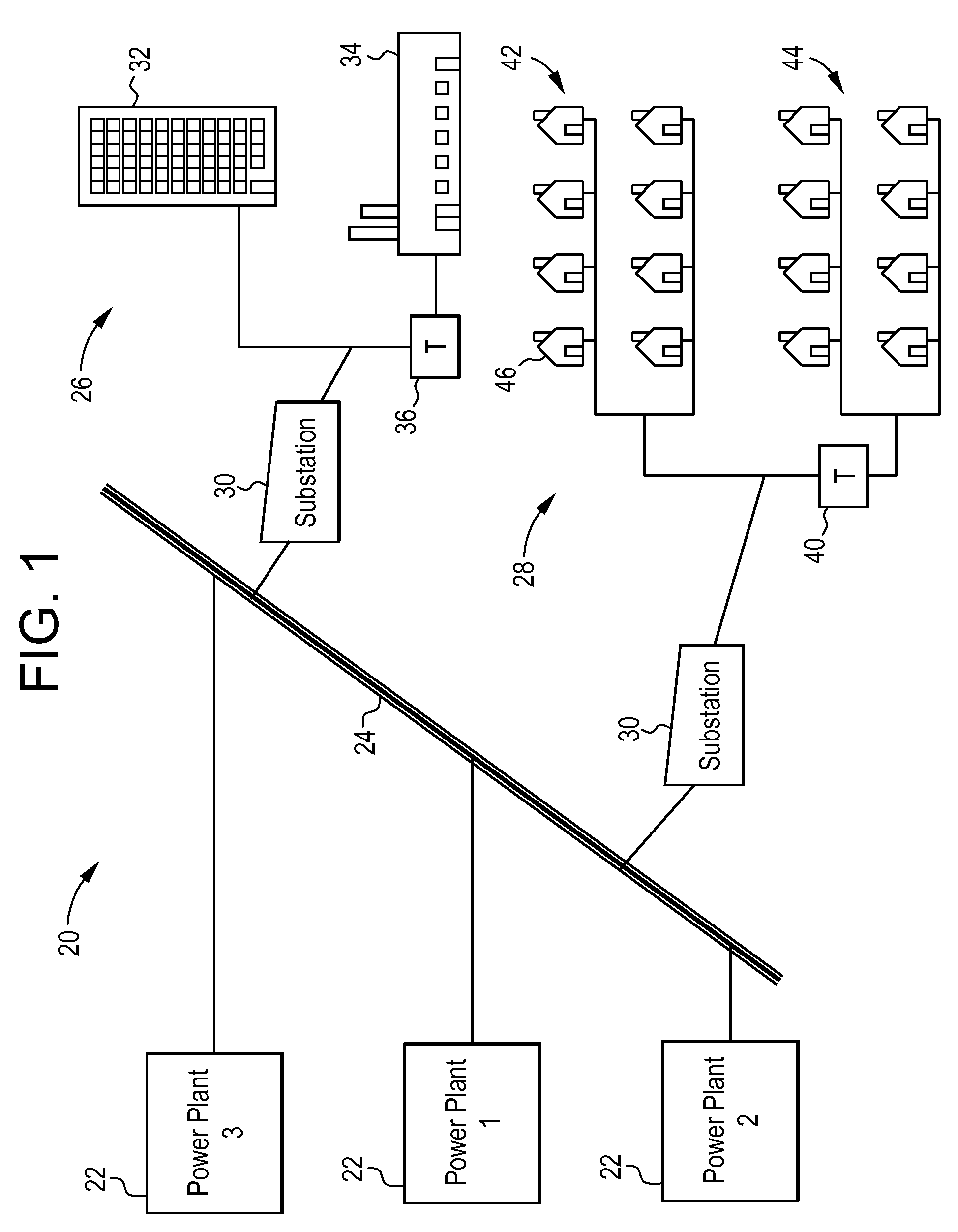

A power station, also referred to as a power plant or powerhouse and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Most power stations contain one or more generators, a rotating machine that converts mechanical power into three-phase electric power. The relative motion between a magnetic field and a conductor creates an electric current. The energy source harnessed to turn the generator varies widely. Most power stations in the world burn fossil fuels such as coal, oil, and natural gas to generate electricity. Cleaner sources include nuclear power, biogas and an increasing use of renewables such as solar, wind, wave and hydroelectric.

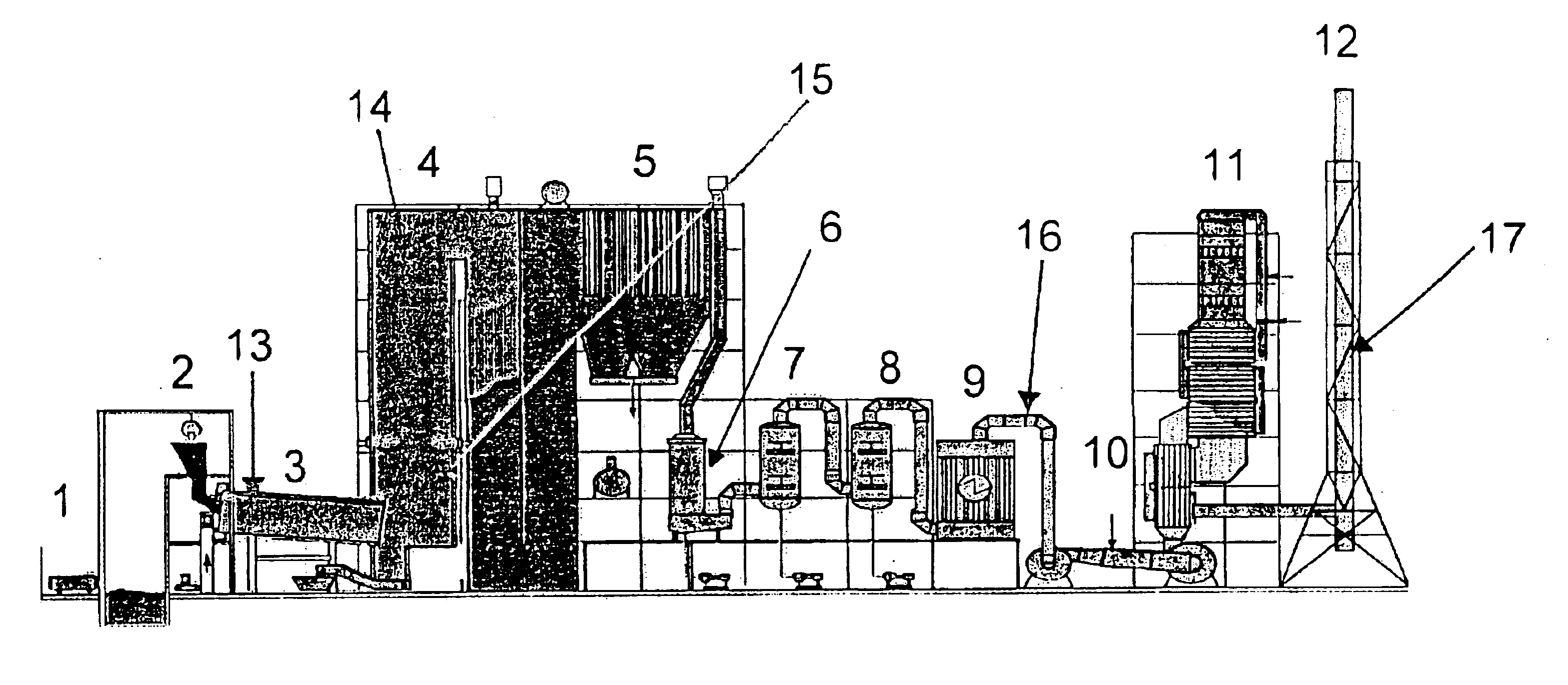

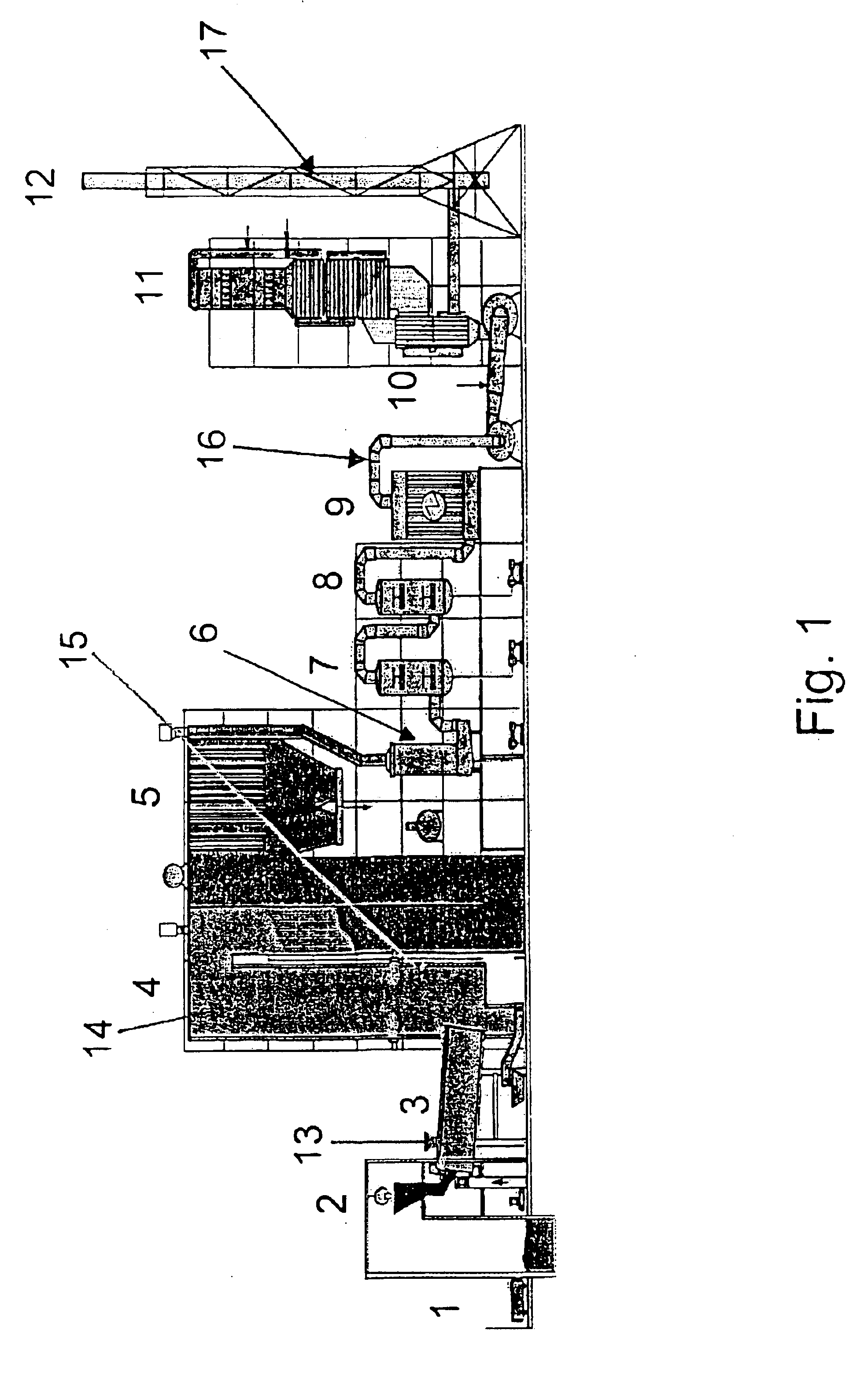

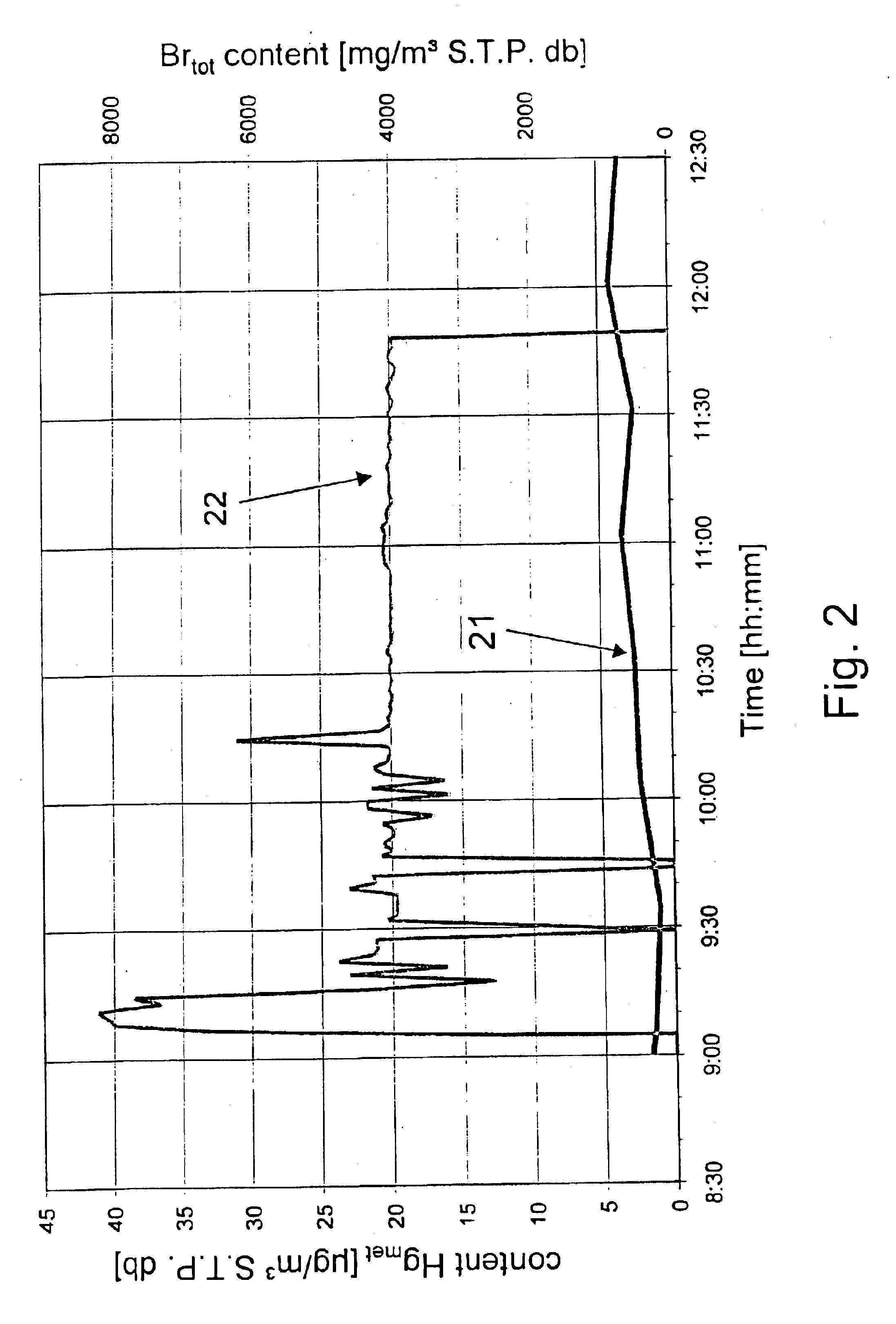

Process for removing mercury from flue gases

InactiveUS6878358B2Reduce operating costsSmall amountUsing liquid separation agentChemical/physical processesPower stationCombustion

Process for removing mercury from flue gases of high-temperature plants, in particular power stations and waste incineration plants in which a bromine compound is fed to the multistage furnace and / or the flue gas in a plant section downstream of the furnace, the temperature during contact of the bromine compound with the flue gas being at least 500° C., preferably at least 800° C. The combustion is carried out in the presence of a sulphur compound, in particular sulphur dioxide. Subsequently to the furnace, the flue gas is subjected to an optional multistage cleanup for removing mercury from the flue gas, which cleanup comprises a wet scrubber and / or a dry cleanup.

Owner:BROMERC

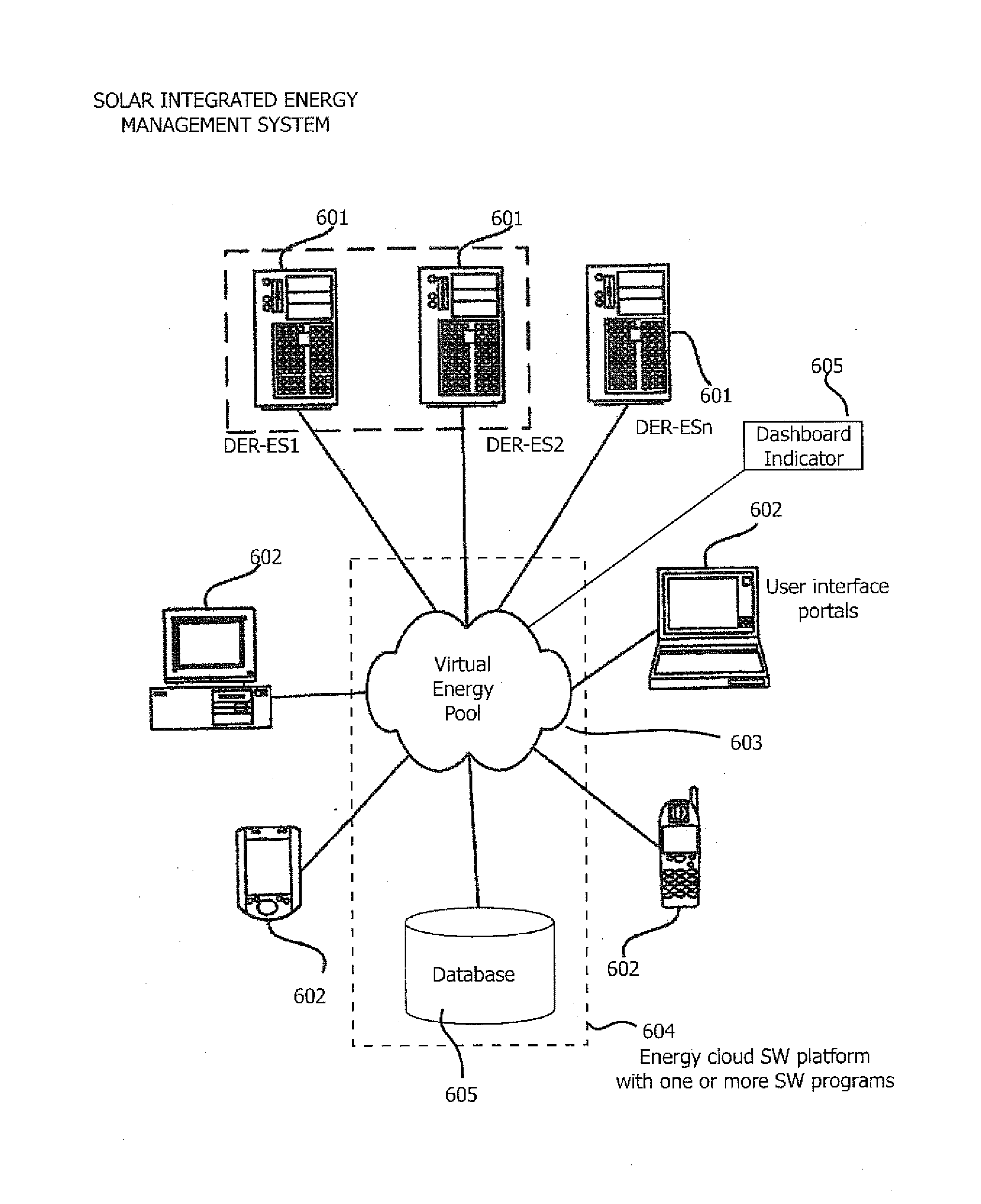

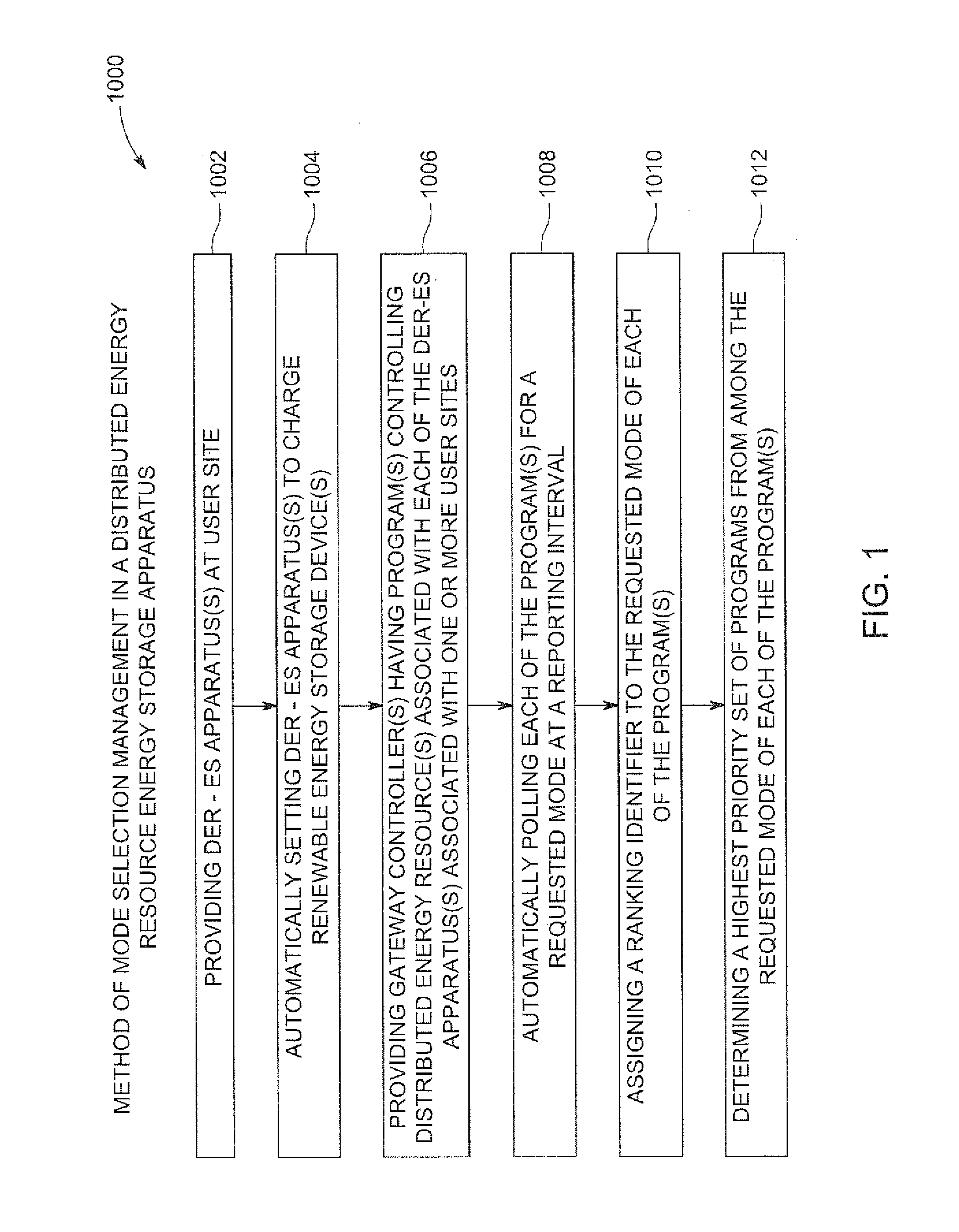

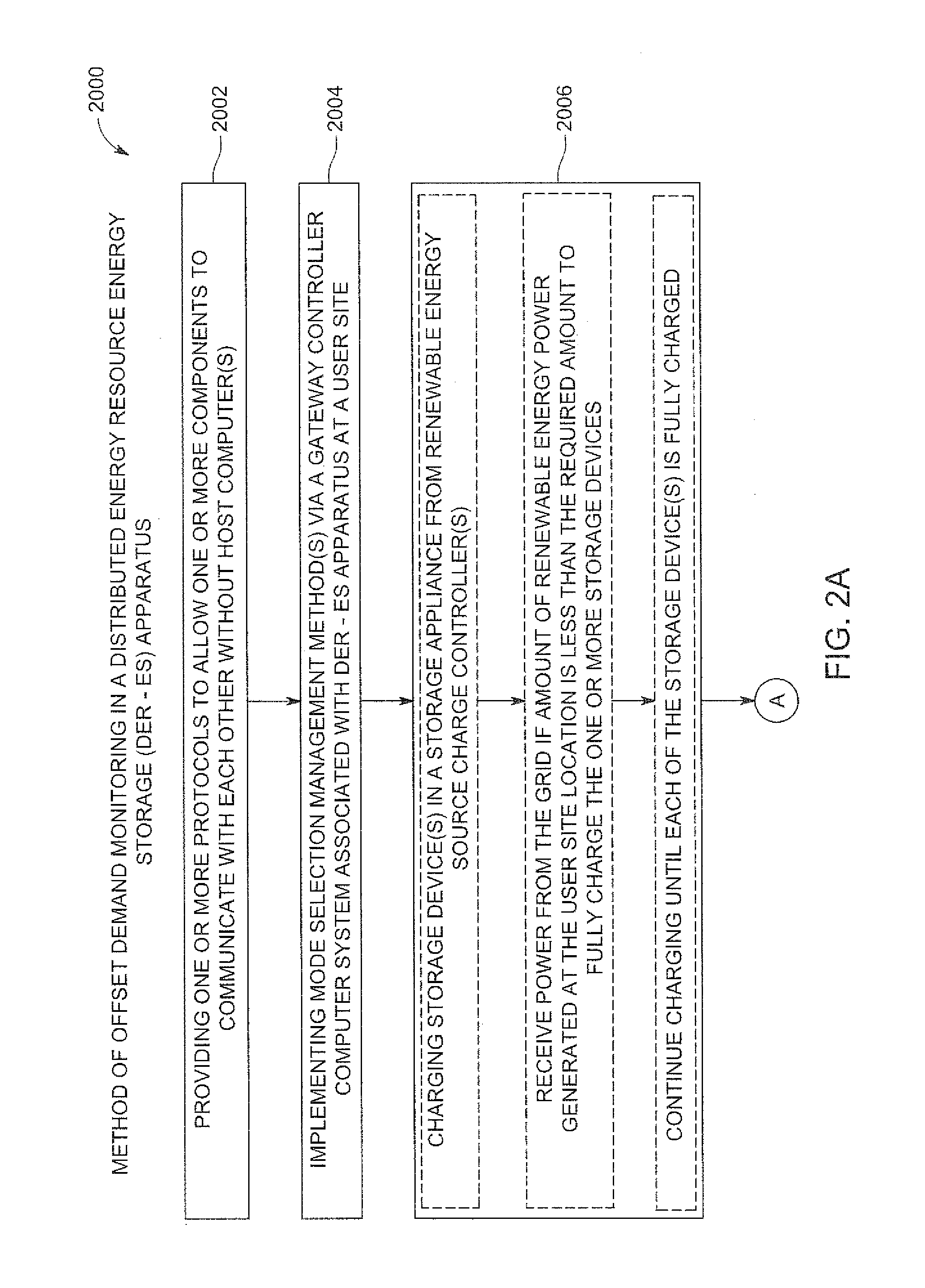

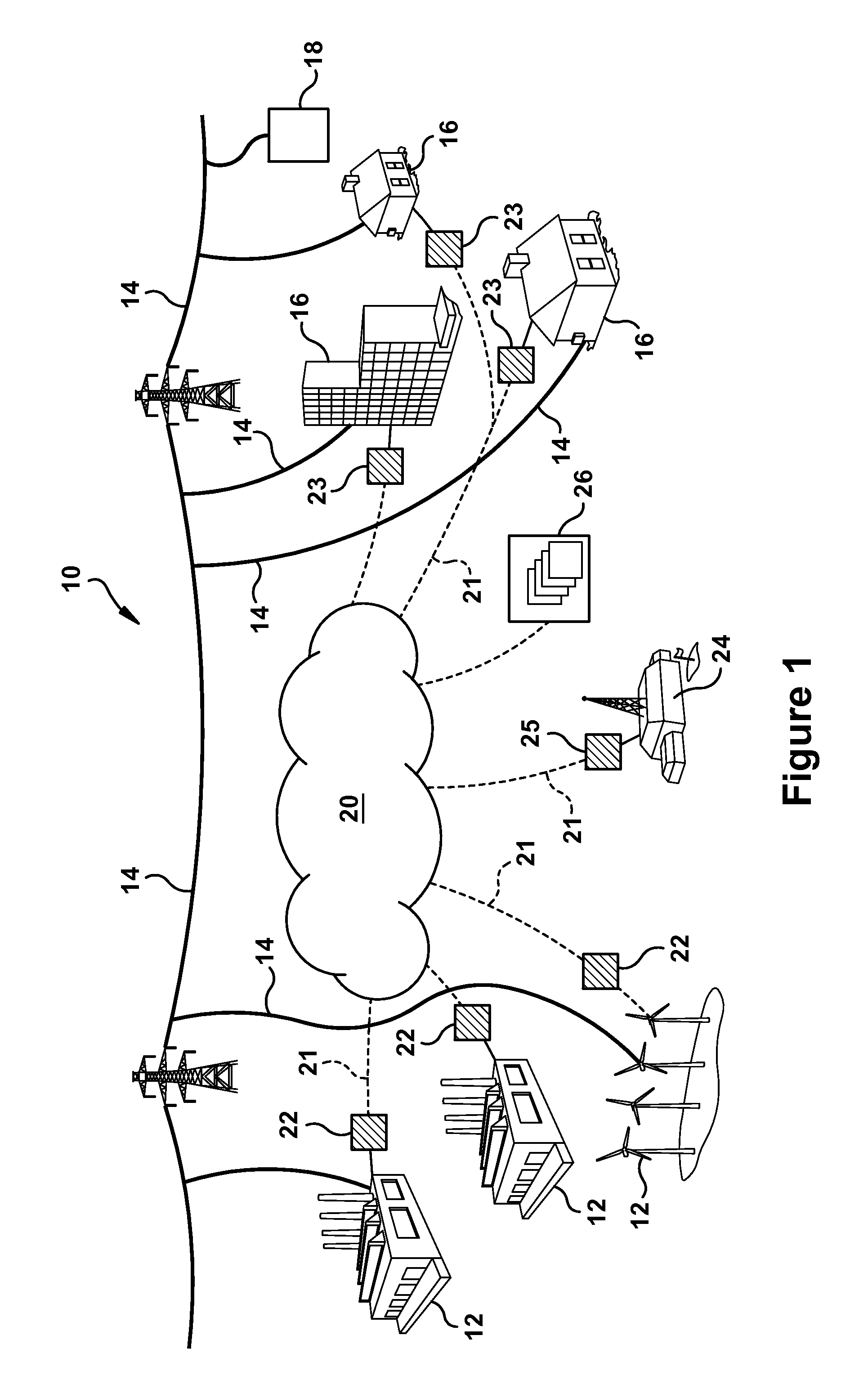

Renewable energy integrated storage and generation systems, apparatus, and methods with cloud distributed energy management services

ActiveUS20170005515A1Guaranteed uptimeImprove performanceElectrical storage systemBatteries circuit arrangementsPrediction algorithmsEnergy management software

A software platform in communication with networked distributed energy resource energy storage apparatus, configured to deliver various specific applications related to offset demand monitoring, methods of virtual power plant and orchestration, load shaping services, methods of reducing demand at aggregated level, prioritizing computer programs related to virtual energy pool, energy cloud controllers methods, charge discharge orchestration plans of electric vehicles, distributed energy resources, machine learning predictive algorithms, value optimizing algorithms, autonomous sensing event awareness, mode selection methods, capacity reservation monitoring, virtual power plant methods, advanced DER-ES apparatus features, energy management system for governing resources and methods, aggregated energy cloud methods, load shaping methods, marginal cost cycle-life degradation, load shaping API, forward event schedule, on demand request, and load service state request methods. Various rules, constraints of predictive algorithms for signal inputs to determine incremental storage cycles, cycle life degradation marginal cost, iterative and forward event schedule development, and load control.

Owner:SUNVERGE ENERGY

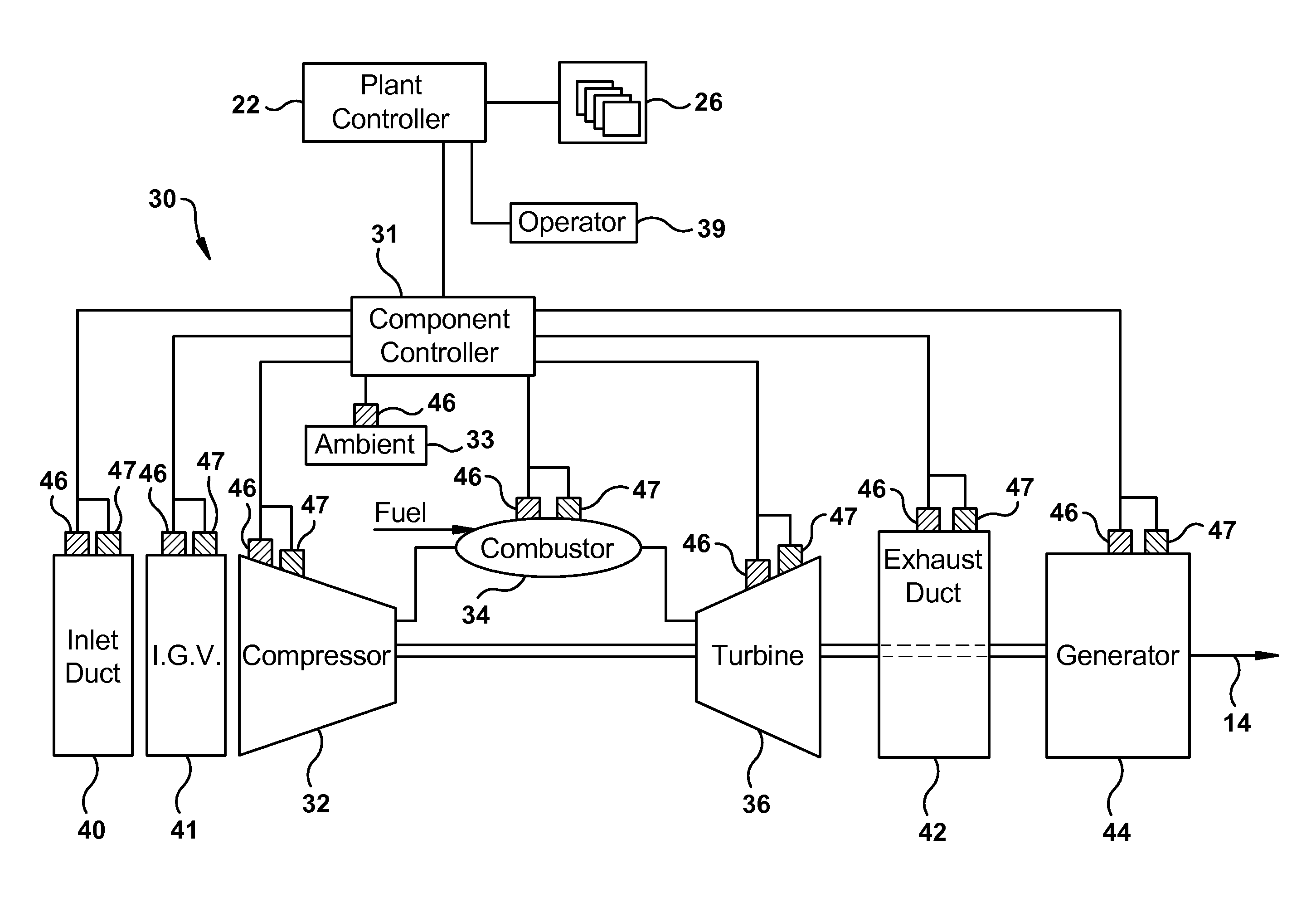

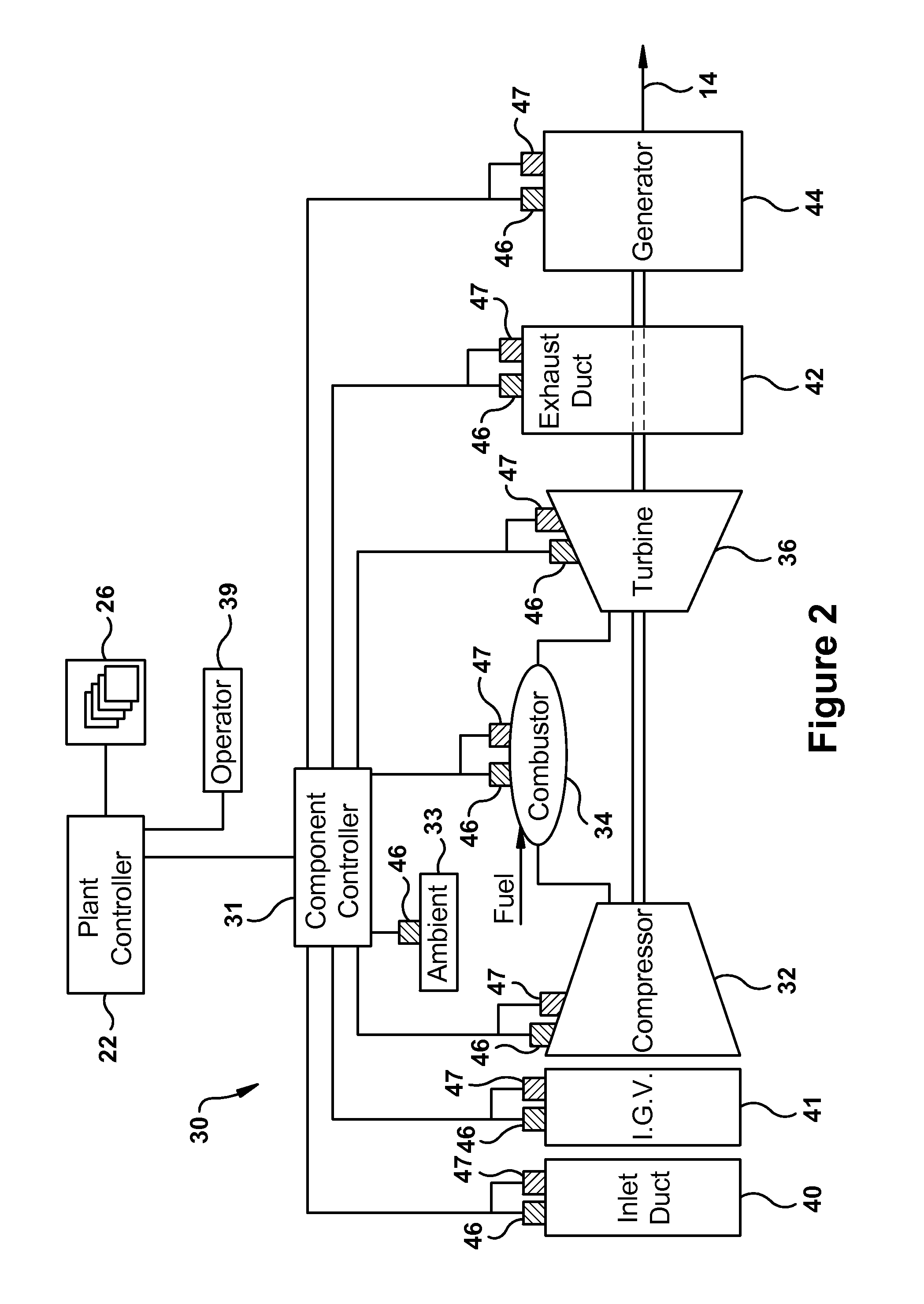

Methods and systems for enhancing control of power plant generating units

A control method for optimizing or enhancing an operation of a power plant that includes thermal generating units for generating electricity. The power plant may include multiple possible operating modes differentiated by characteristics of operating parameters. The method may include tuning a power plant model so to configure a tuned power plant model. The method may further include simulating proposed operating modes of the power plant with the tuned power plant model. The simulating may include a simulation procedure that includes: defining a second operating period; selecting the proposed operating modes from the possible operating modes; with the tuned power plant model, performing a simulation run for each of the proposed operating modes whereby the operation of the power plant during the second operating period is simulated; and obtaining simulation results from each of the simulation runs.

Owner:GENERAL ELECTRIC CO

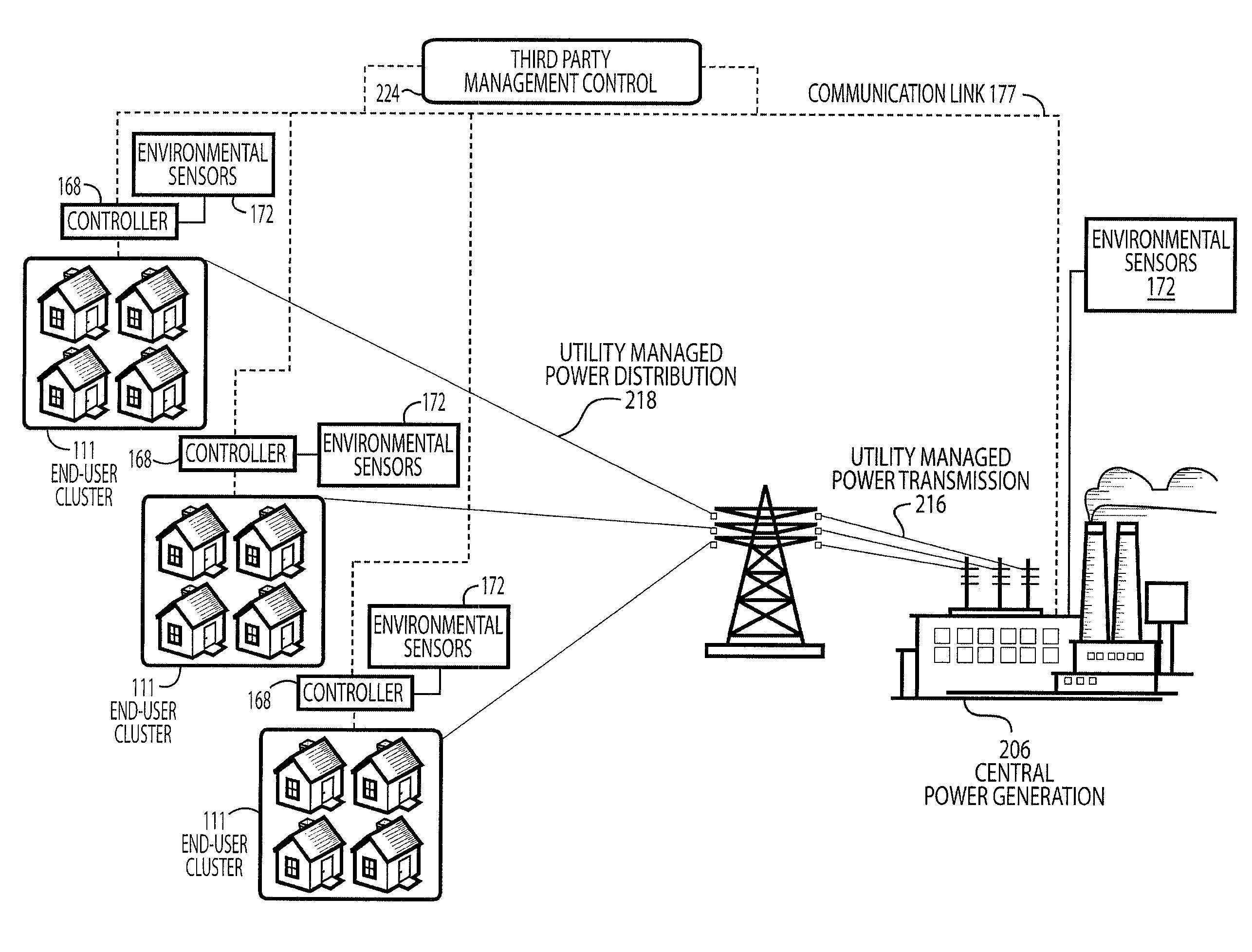

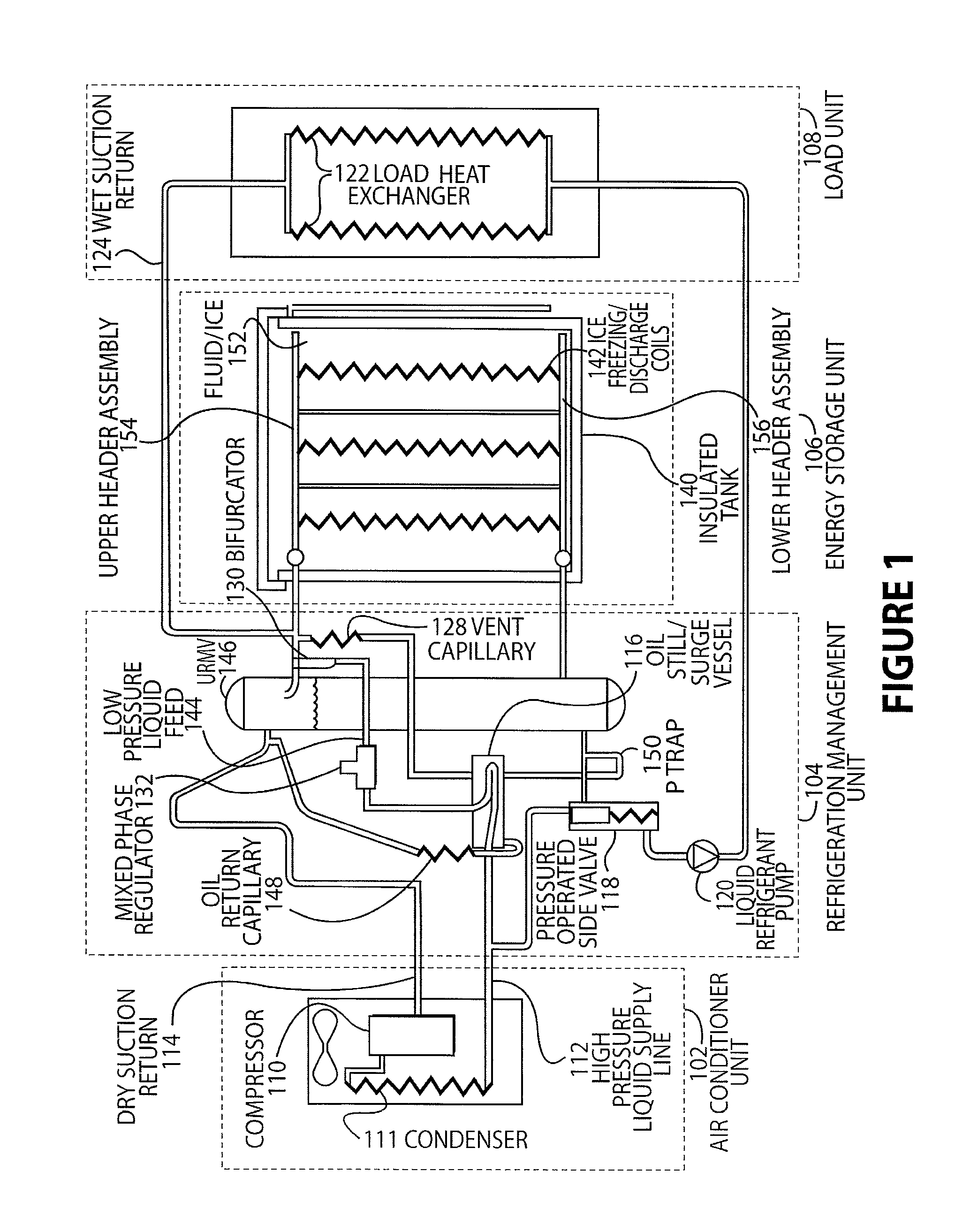

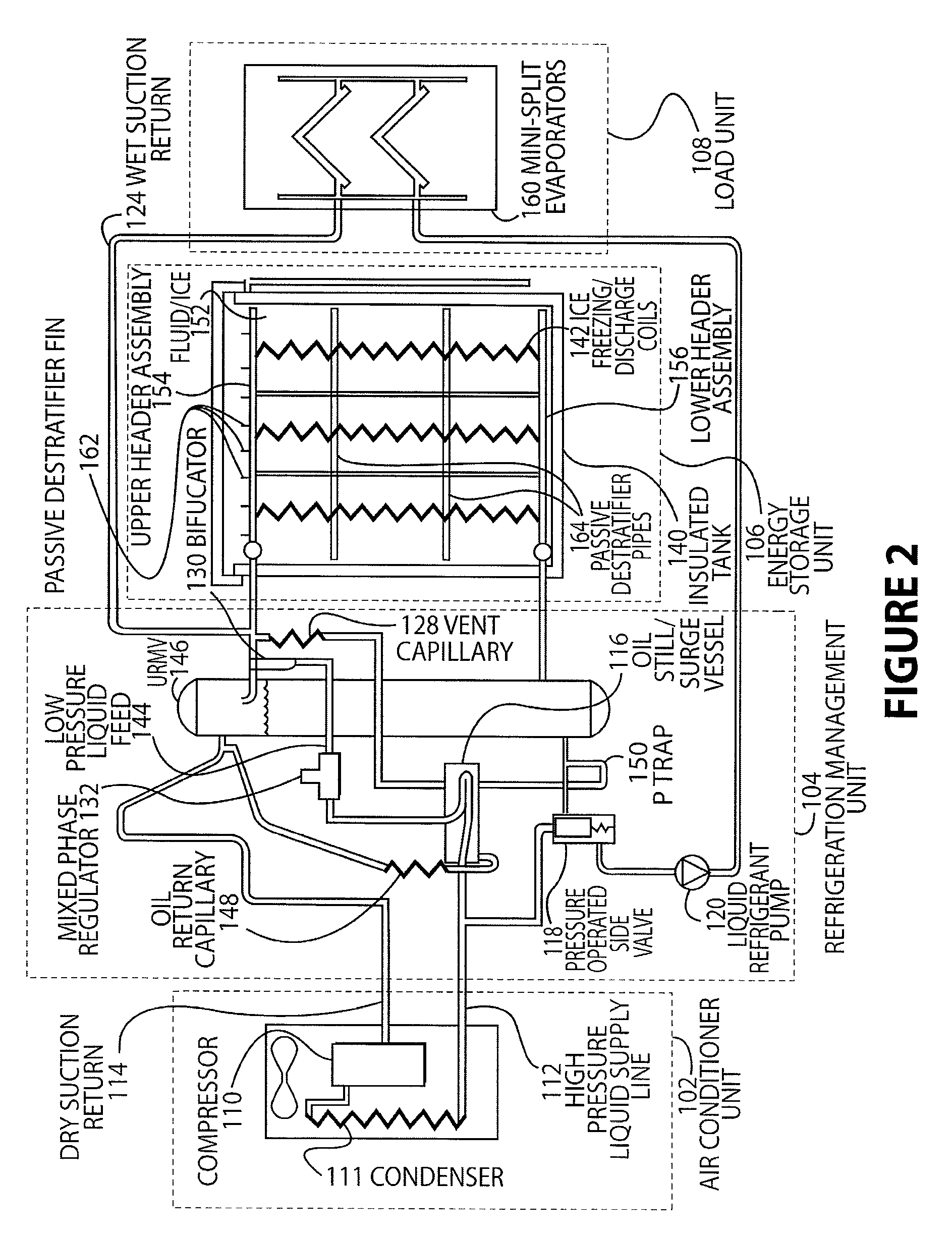

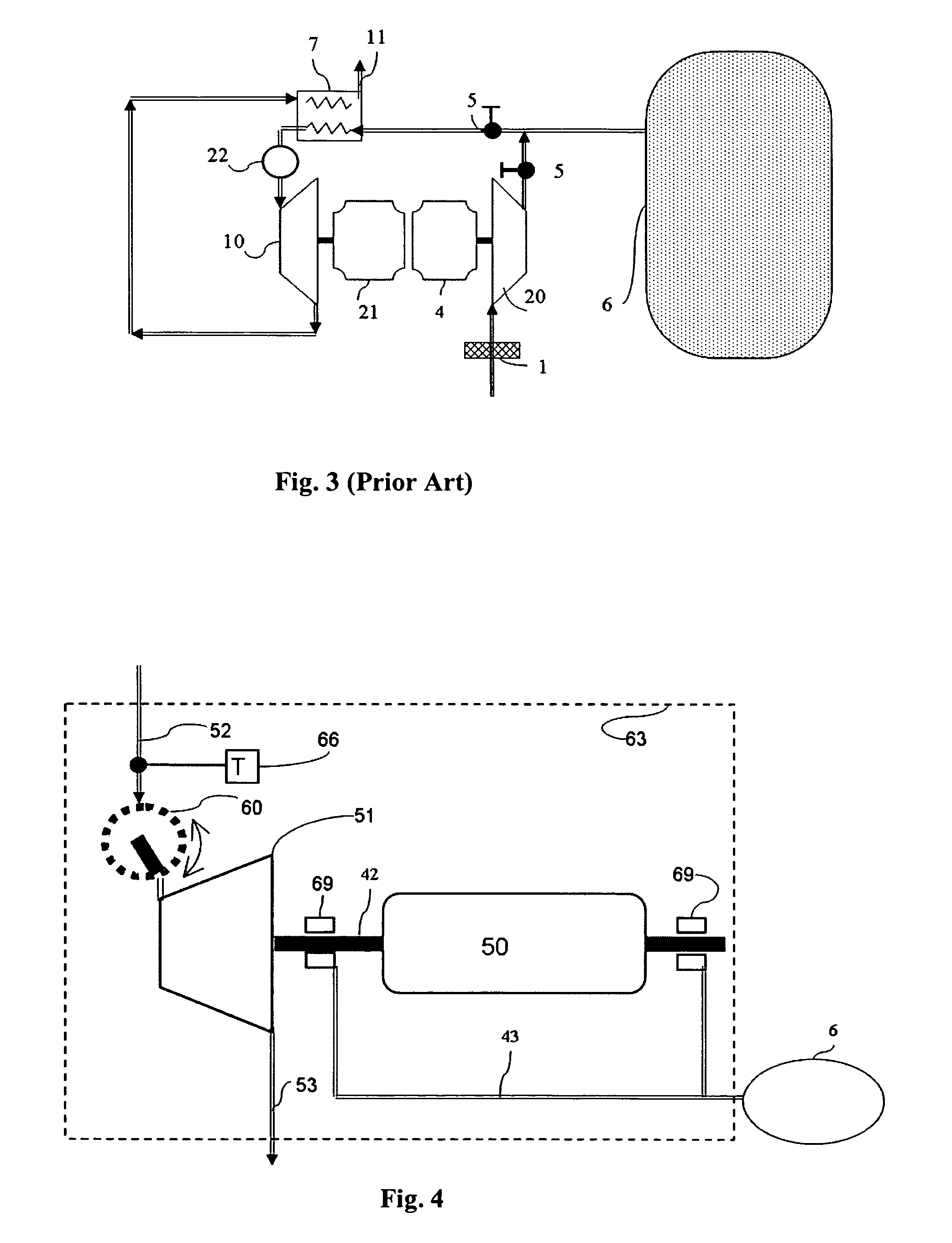

Utility managed virtual power plant utilizing aggregated thermal energy storage

Disclosed is a system and method for providing power generation and distribution with on-site energy storage and power input controlled by a utility or a third party manager. The system allows a utility manager to decide and direct how energy is delivered to a customer on both sides of the power meter, while the customer directs and controls when and how much energy is needed. In the disclosed embodiments, the utility controls the supply (either transmitted or stored) and makes power decisions on a system that acts as a virtual power plant, while the end-user retains control of the on-site aggregated power consumption assets. The disclosed systems act to broker the needs of the utility and end-user by creating, managing and controlling the interface between these two entities.

Owner:BLUE FRONTIER LLC

Renewable energy system monitor

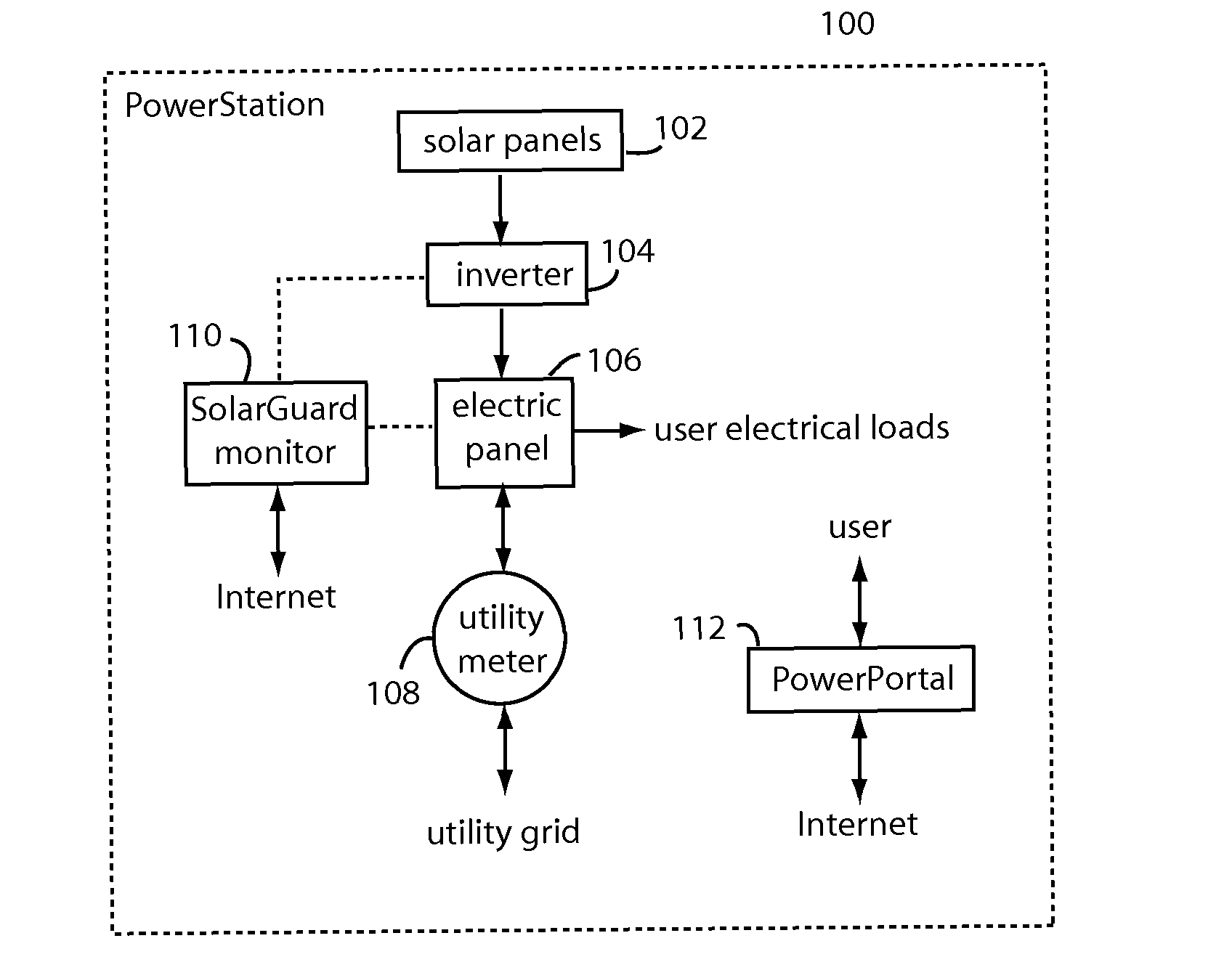

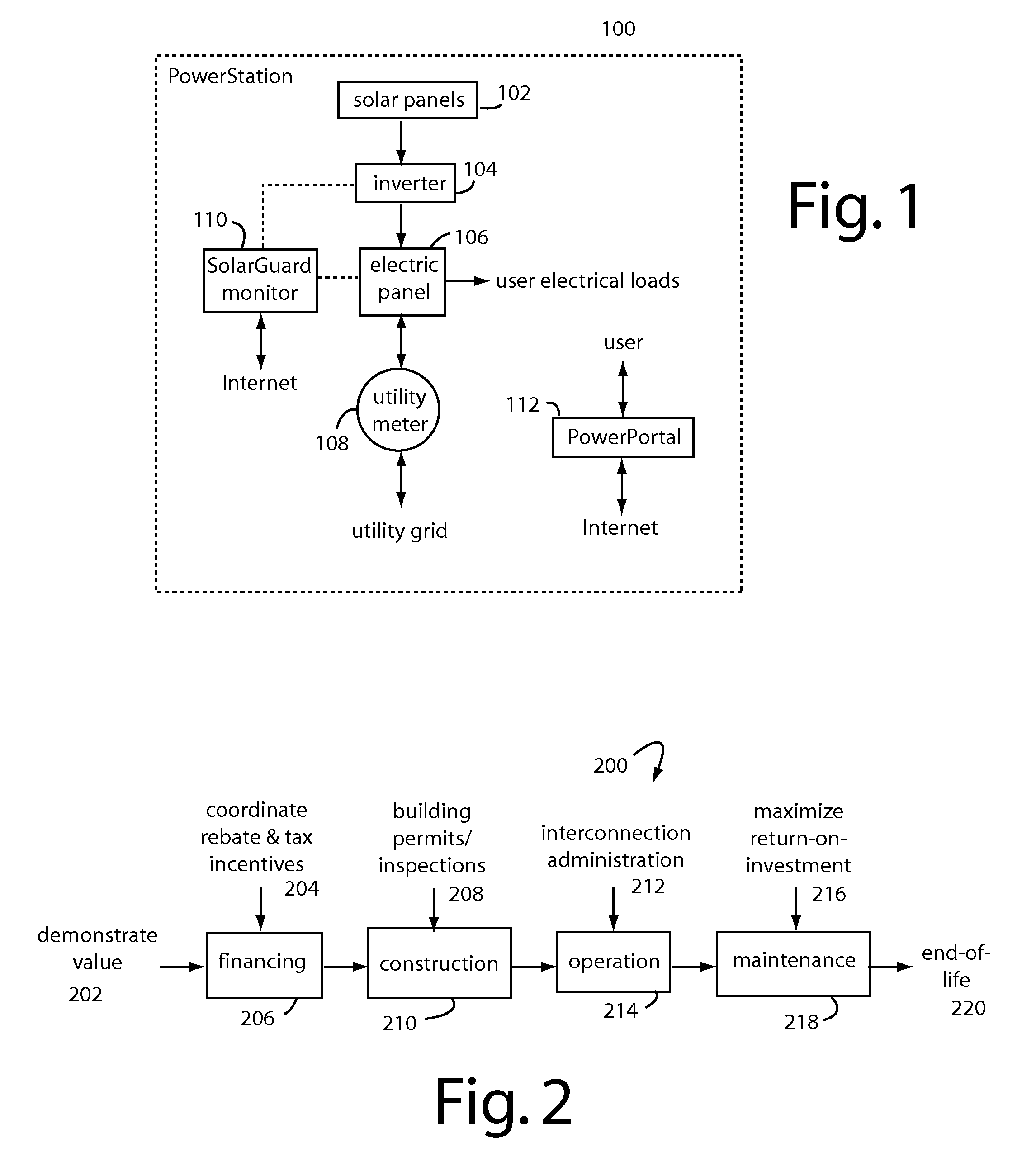

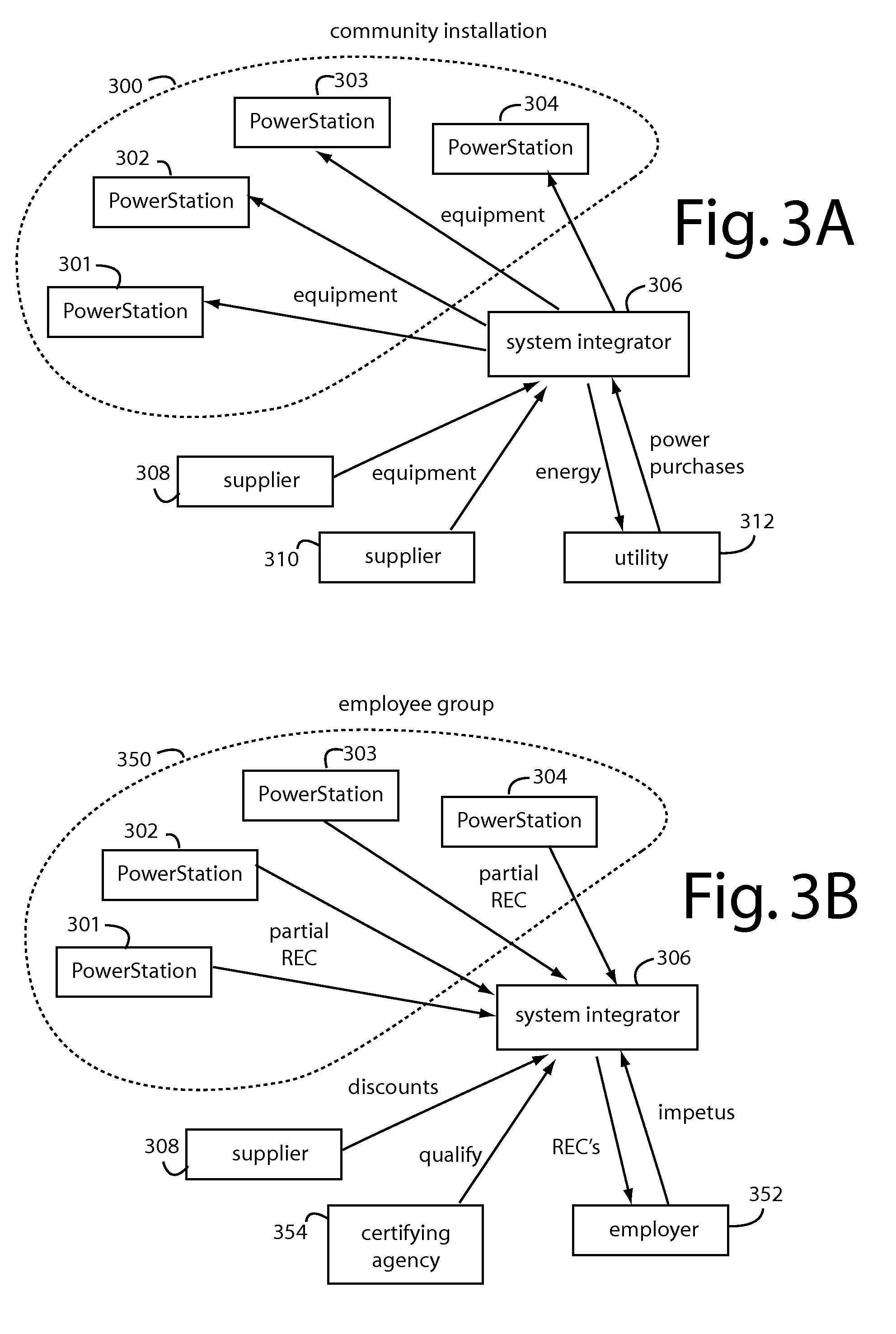

ActiveUS7925552B2Complete banking machinesElectric signal transmission systemsPower stationEngineering

Embodiments of the present invention include a renewable energy system monitor. In one embodiment, information is received in a server from solar power stations across a network. The information includes operational data for each solar power station identified by a particular power station identification (ID). The information is stored in a database and grouped data groups corresponding different solar power stations. Data groups are processed using different models associated with different power stations to control the different power stations. Software or parameters may be sent to different devices in the different power stations to control the power stations.

Owner:SOLARCITY

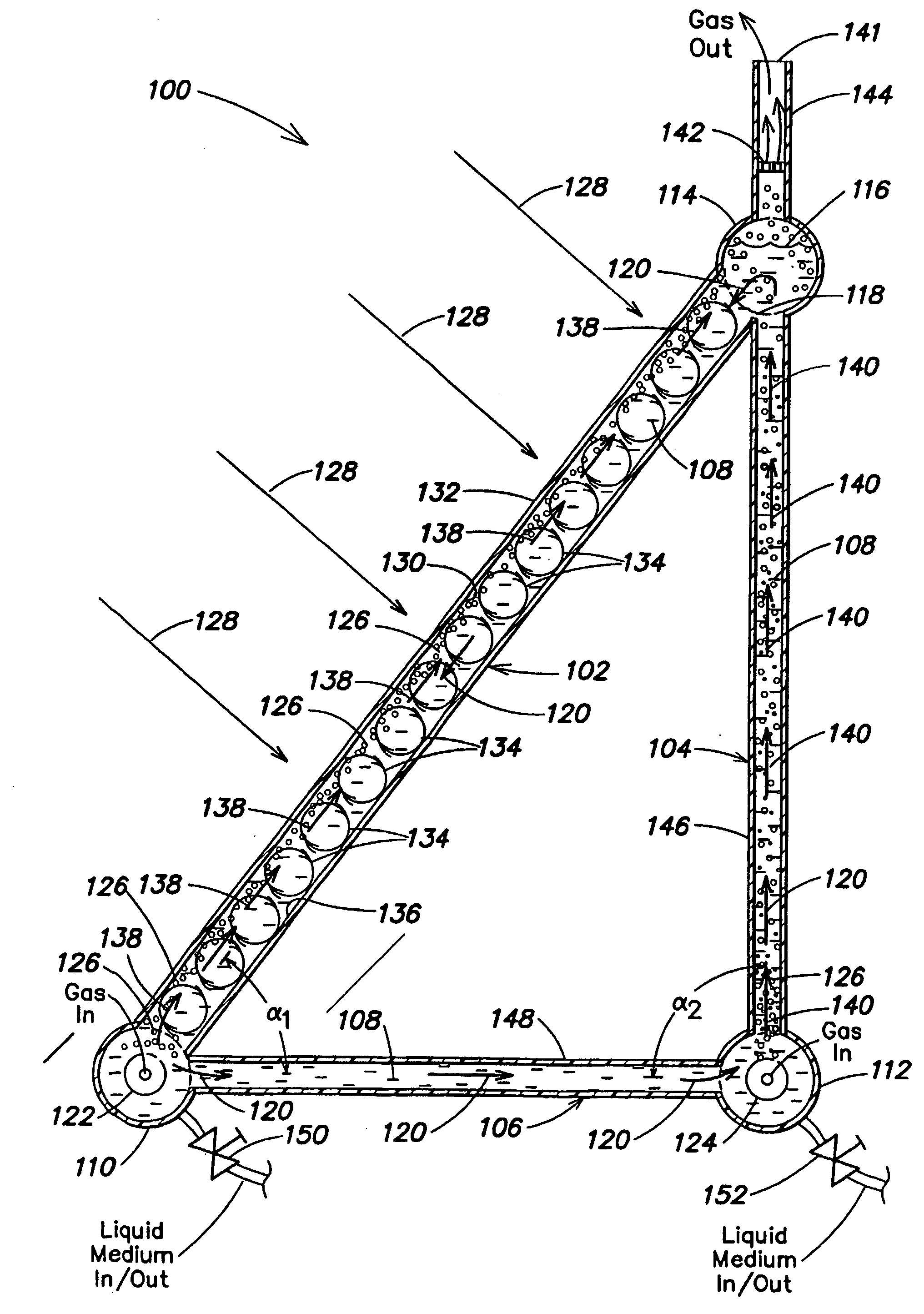

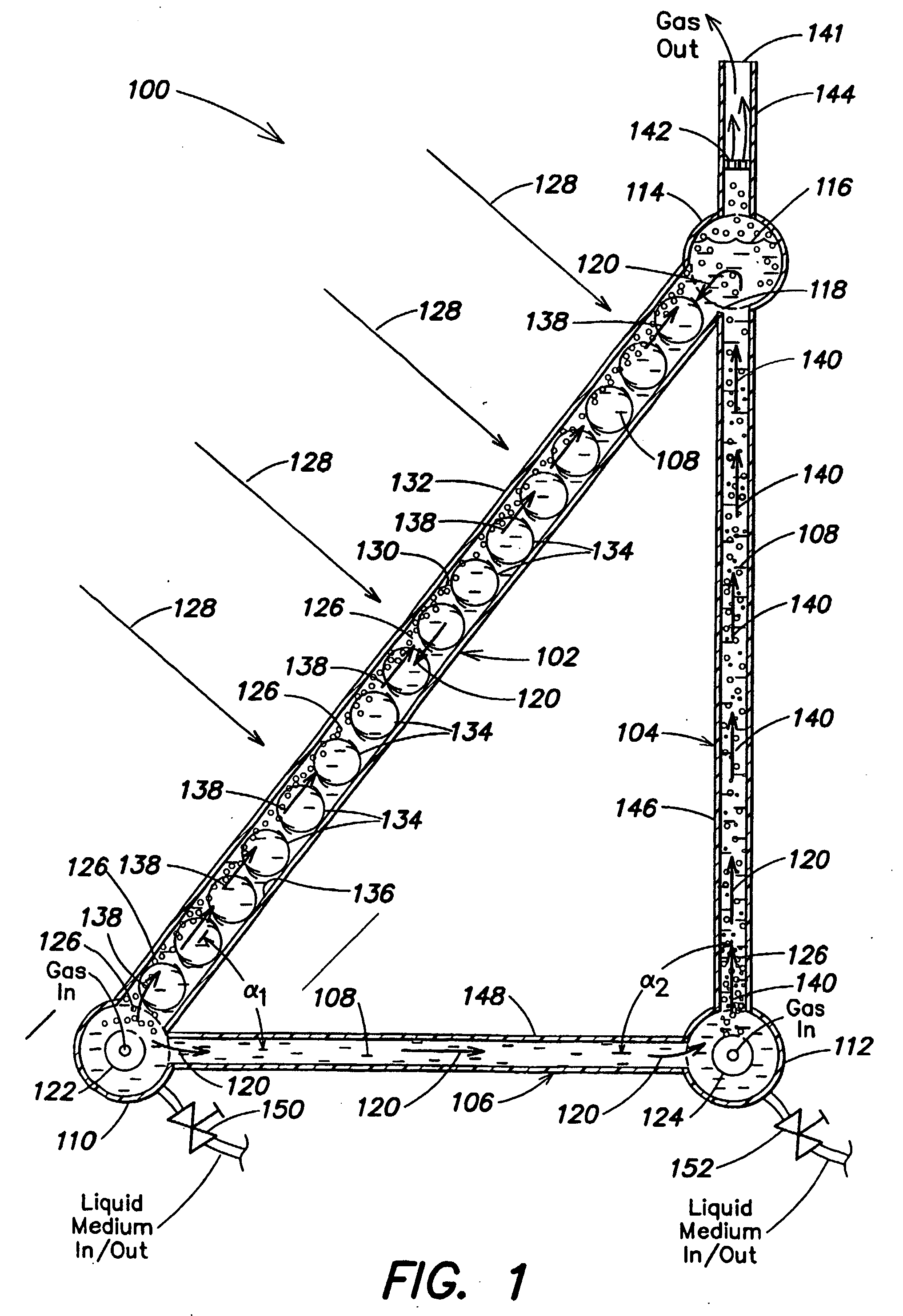

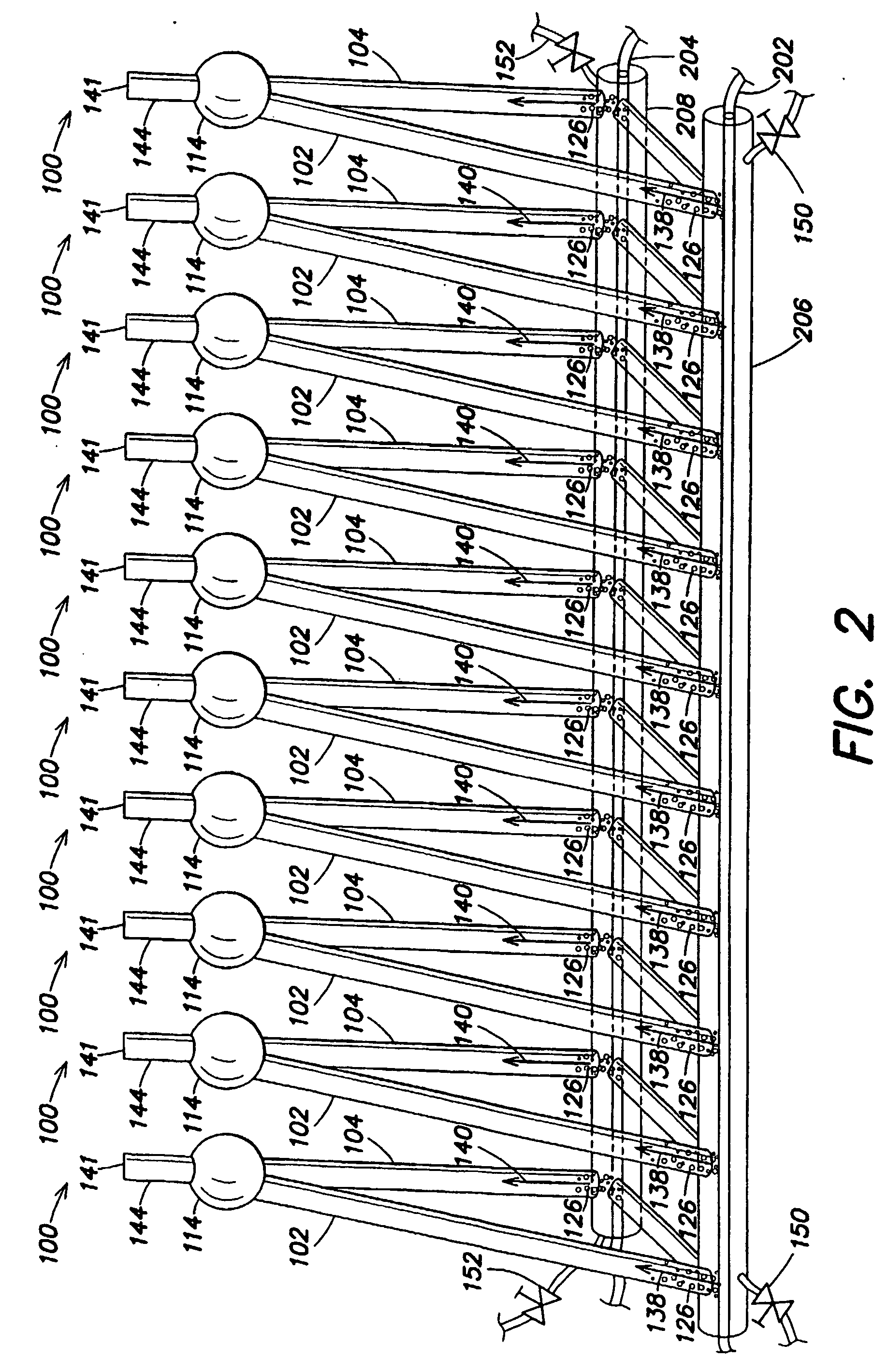

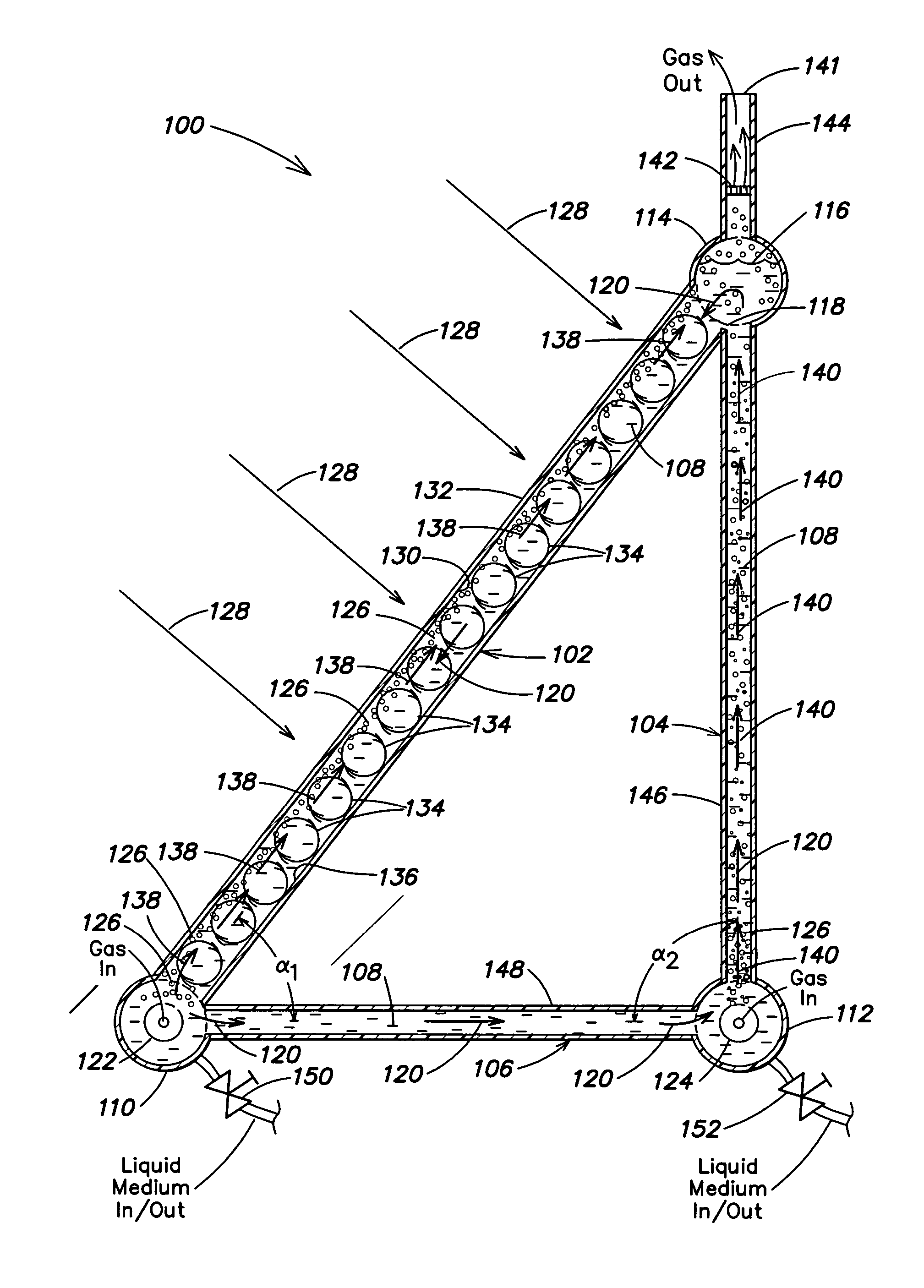

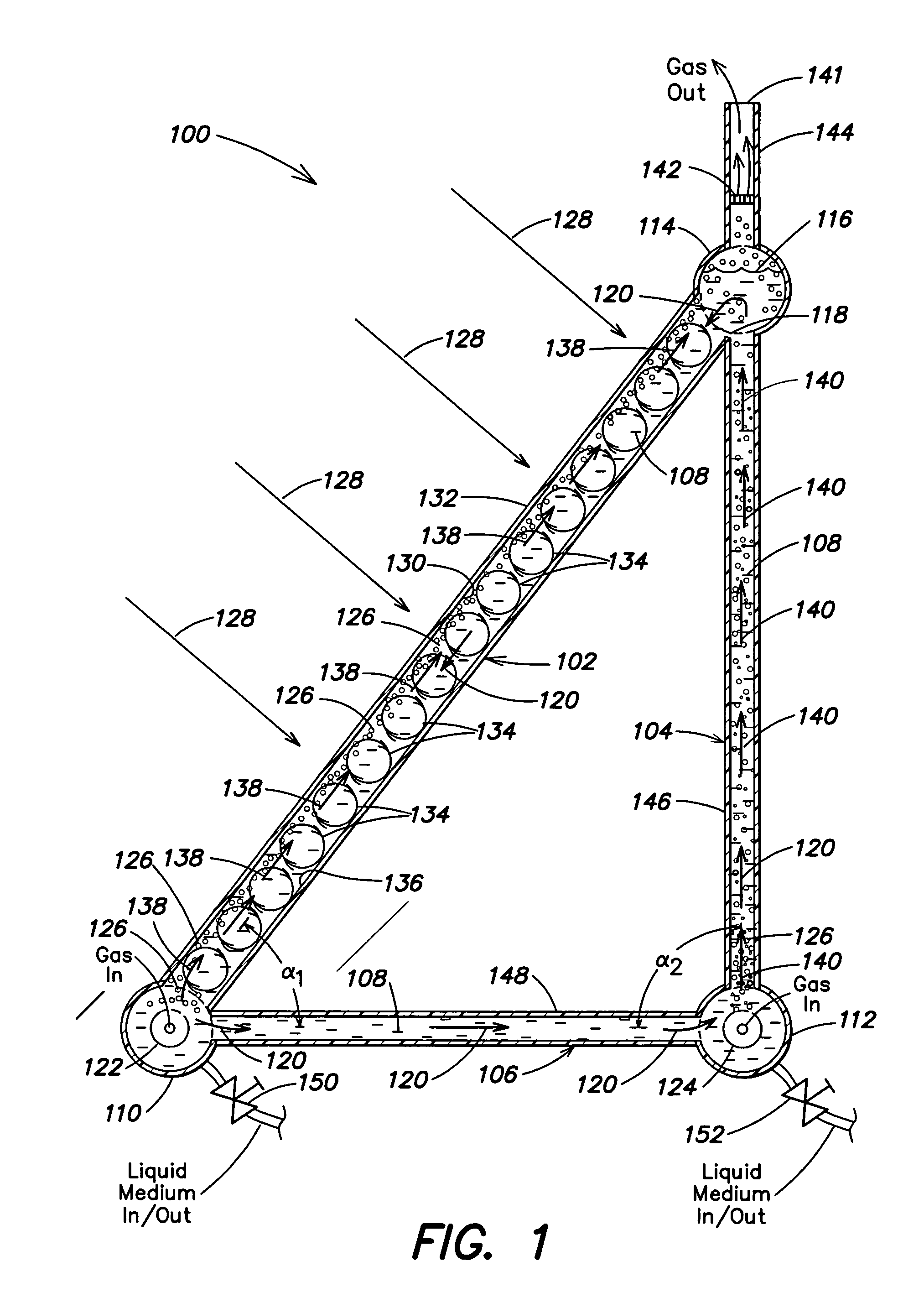

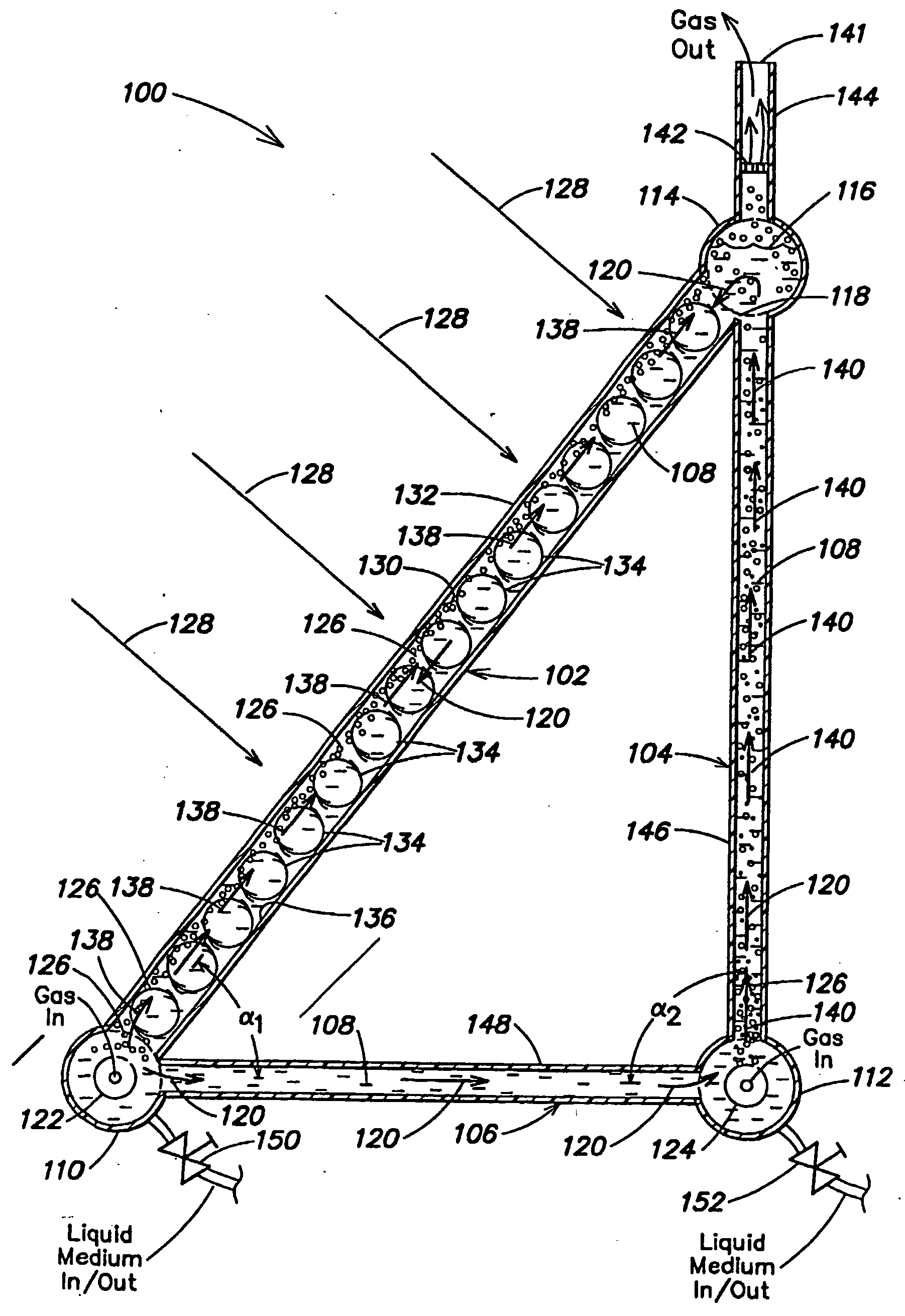

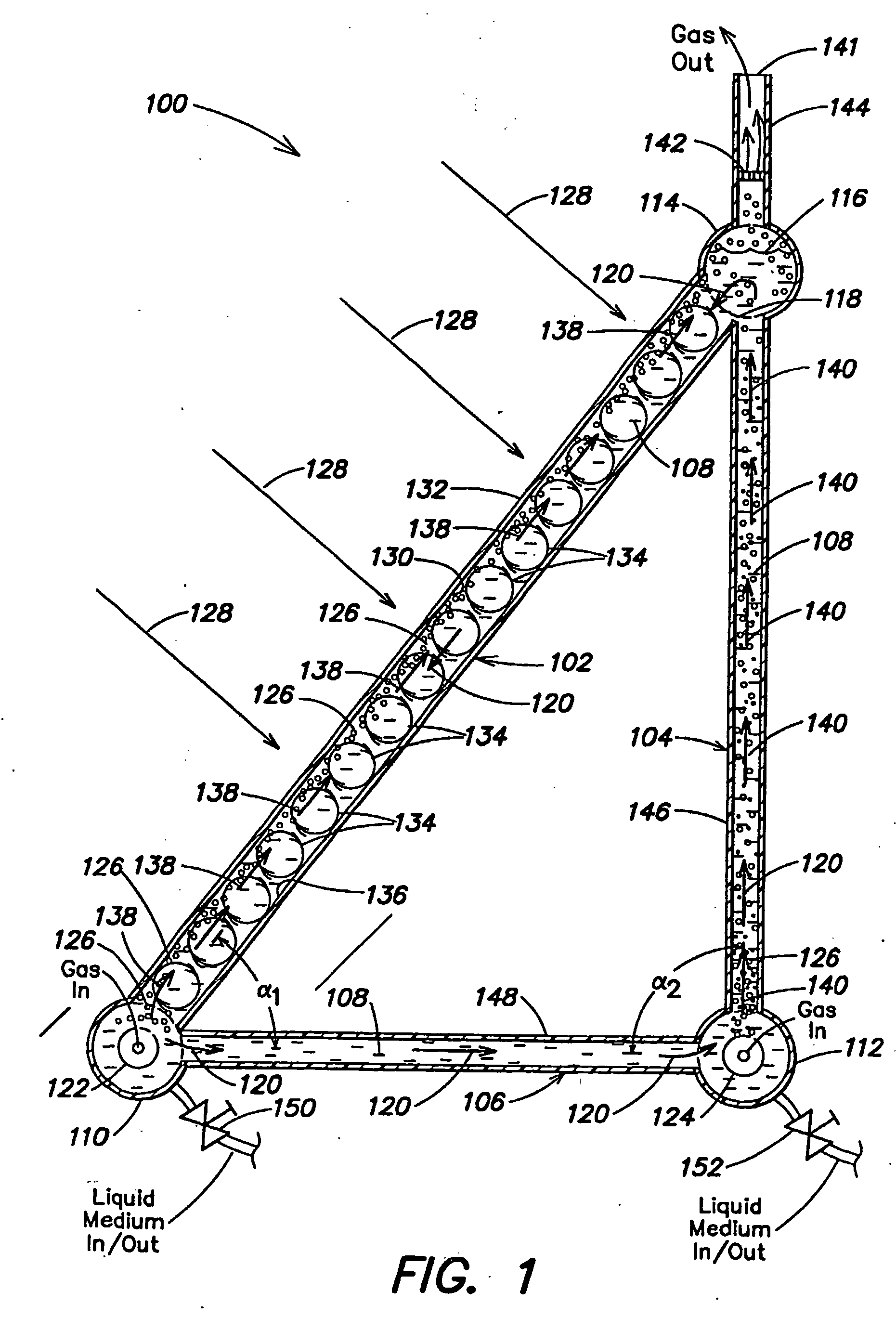

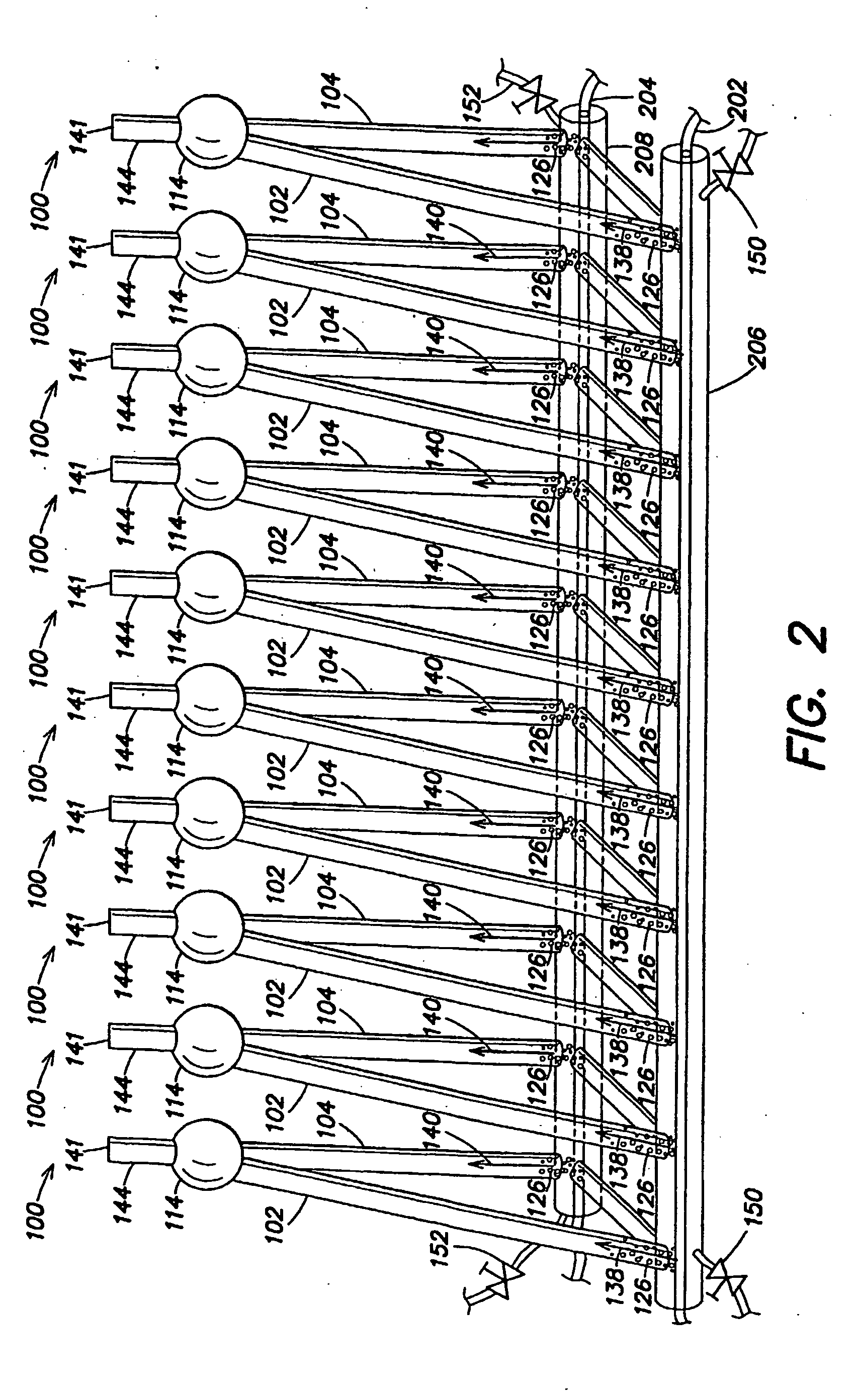

Photobioreactor and process for biomass production and mitigation of pollutants in flue gases

InactiveUS20050260553A1Easy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumEngineering

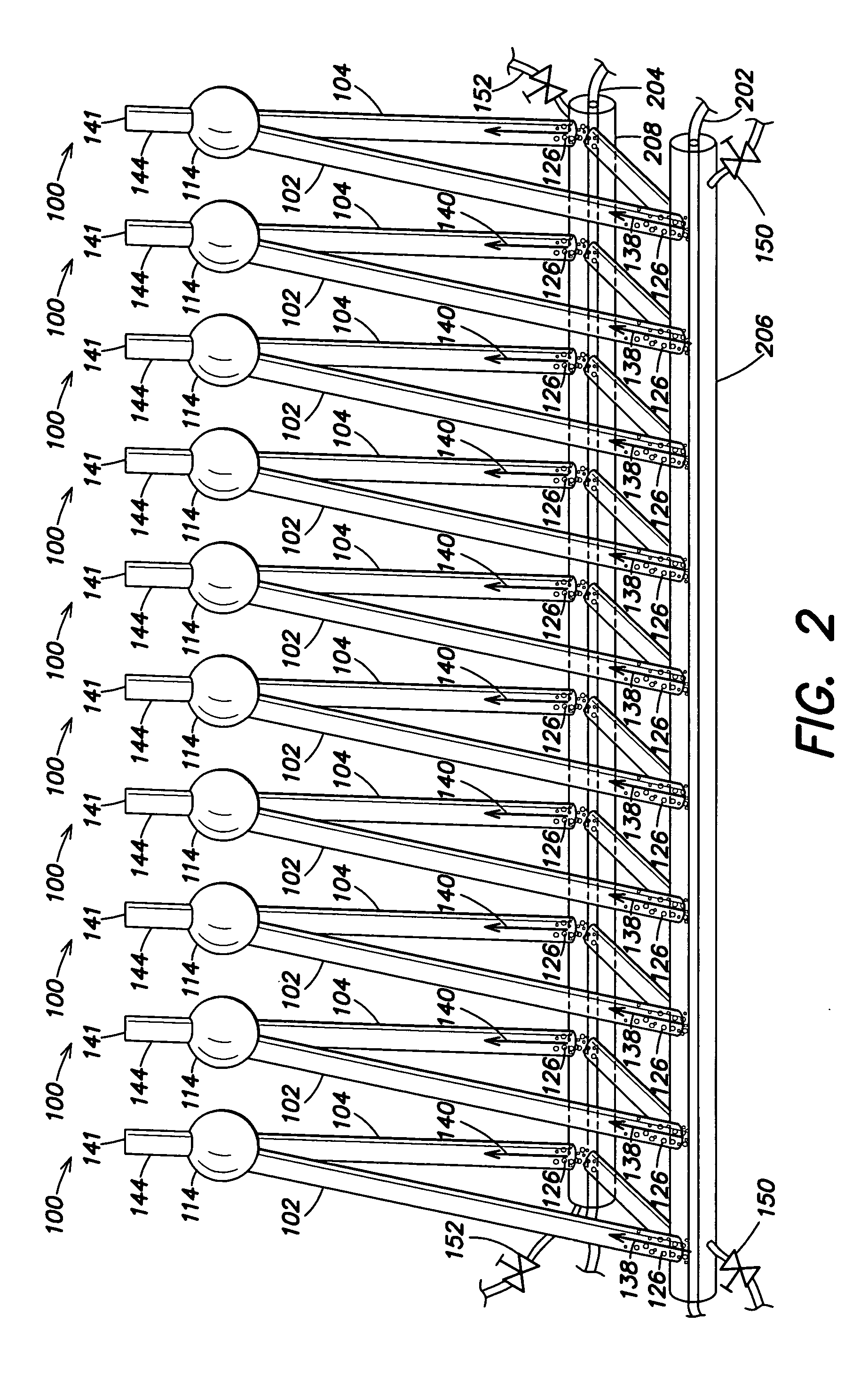

Certain embodiments and aspects of the present invention relate to photobioreactor apparatus (100) designed to contain a liquid medium (108) comprising at least one species of photosynthetic organism therein, and to methods of using the photobioreactor apparatus (100) as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a gas stream (608). In certain embodiments, the disclosed photobioreactor apparatus (100 can be utilized as part of an integrated combustion method and system, wherein photosynthetic organisms utilized within the photobioreactor (100) at least partially remove certain pollutant compounds contained within combustion gases, e.g. CO2 and / or NOX, and are subsequently harvested from the photobioreactor (100), processed, and utilized as a fuel source for a combustion device (e.g. an electric power plant generator and / or incinerator).

Owner:GREENFUEL TECHNOLOGIES CORPORATION

Synthetic and biologically-derived products produced using biomass produced by photobioreactors configured for mitigation of pollutants in flue gases

InactiveUS20050239182A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Certain embodiments and aspects of the present invention relate to photobioreactor apparatus designed to contain a liquid medium comprising at least one species of photosynthetic organisms therein, and to methods of using the photobioreactor apparatus as part of a production process for forming an organic molecule-containing product, such as a polymeric material and / or fuel-grade oil (e.g. biodiesel), from biomass produced in the photobioreactor apparatus. In certain embodiments, the disclosed organic molecule / polymer production systems and methods, photobioreactor apparatus, methods of using such apparatus, and / or gas treatment systems and methods provided herein can be utilized as part of an integrated combustion and polymer and / or fuel-grade oil (e.g. biodiesel) production method and system, wherein photosynthetic organisms utilized within the photobioreactor are used to at least partially remove certain pollutant compounds contained within combustion gases, e.g. CO2 and / or NOx, and are subsequently harvested from the photobioreactor, processed, and utilized as a source for generating polymers and / or organic molecule-containing products (e.g. fuel-grade oil (e.g. biodiesel)) and / or as a fuel source for a combustion device (e.g. an electric power plant generator and / or incinerator).

Owner:GREENFUEL TECHNOLOGIES CORPORATION

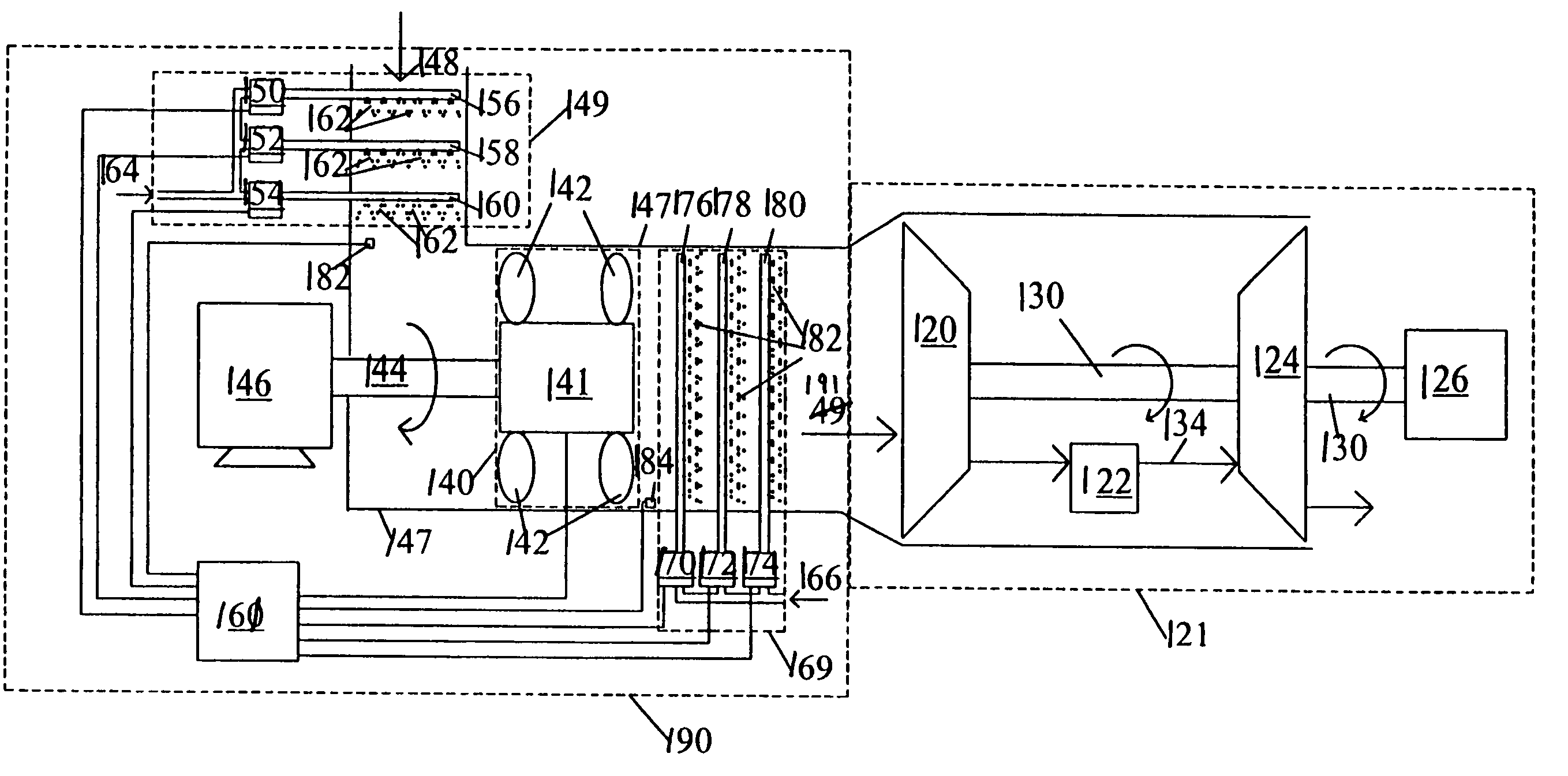

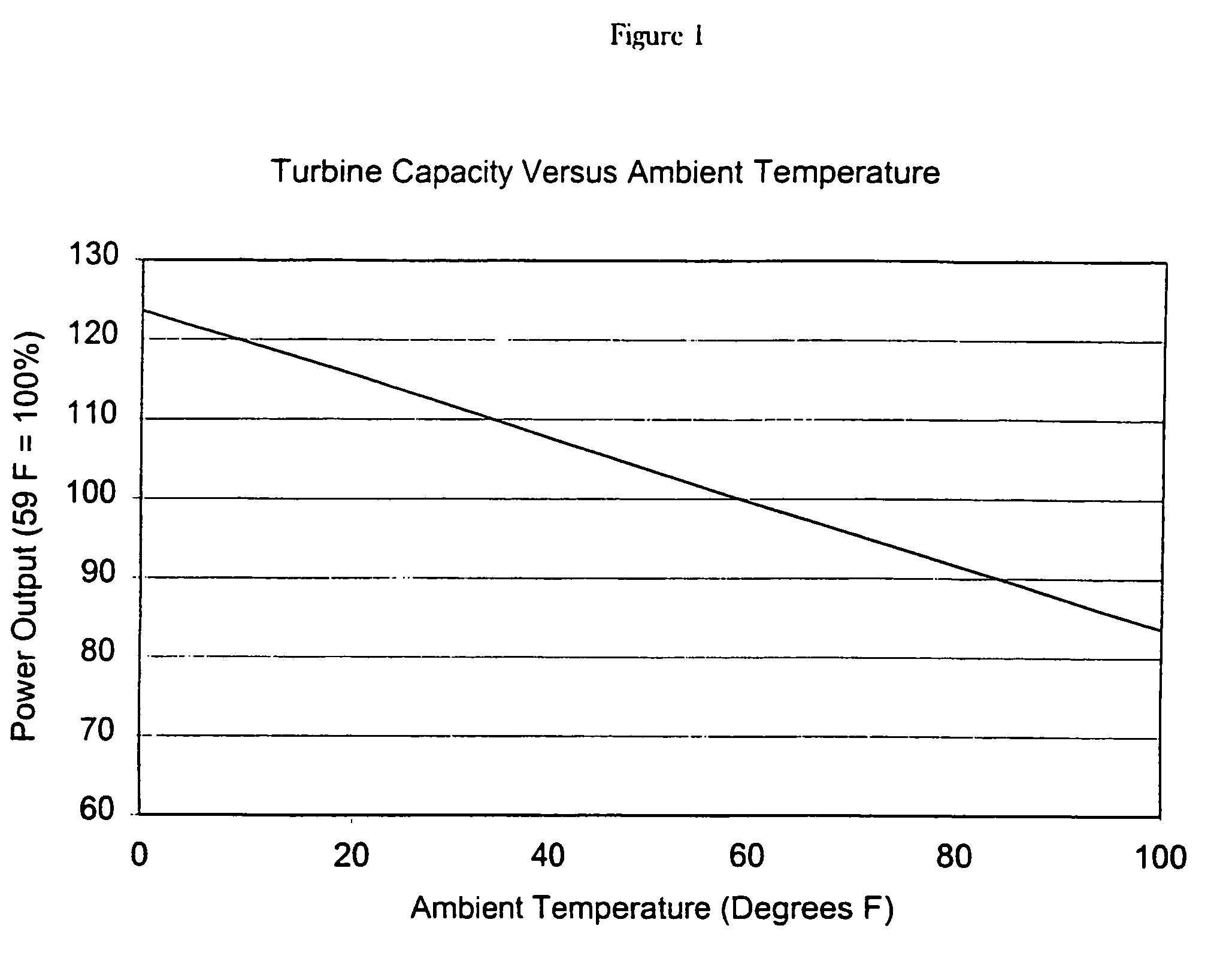

Supercharging system for gas turbines

InactiveUS7065953B1Increase turbine capacityReduce installation costsEfficient propulsion technologiesGas turbine plantsCombustorPower station

A supercharging system for gas turbine power plants (11). The system includes a supercharging fan (30, 32) and controller (50) for limiting turbine power output to prevent overload of the generator (28) at lower ambient temperatures. The controller can limit power output by burner control, inlet temperature control, control of supercharging fan pressure and other options. The system can be retrofit on an existing turbine without replacing the generator and associated parts.

Owner:ENHANCED TURBINE OUTPUT HLDG

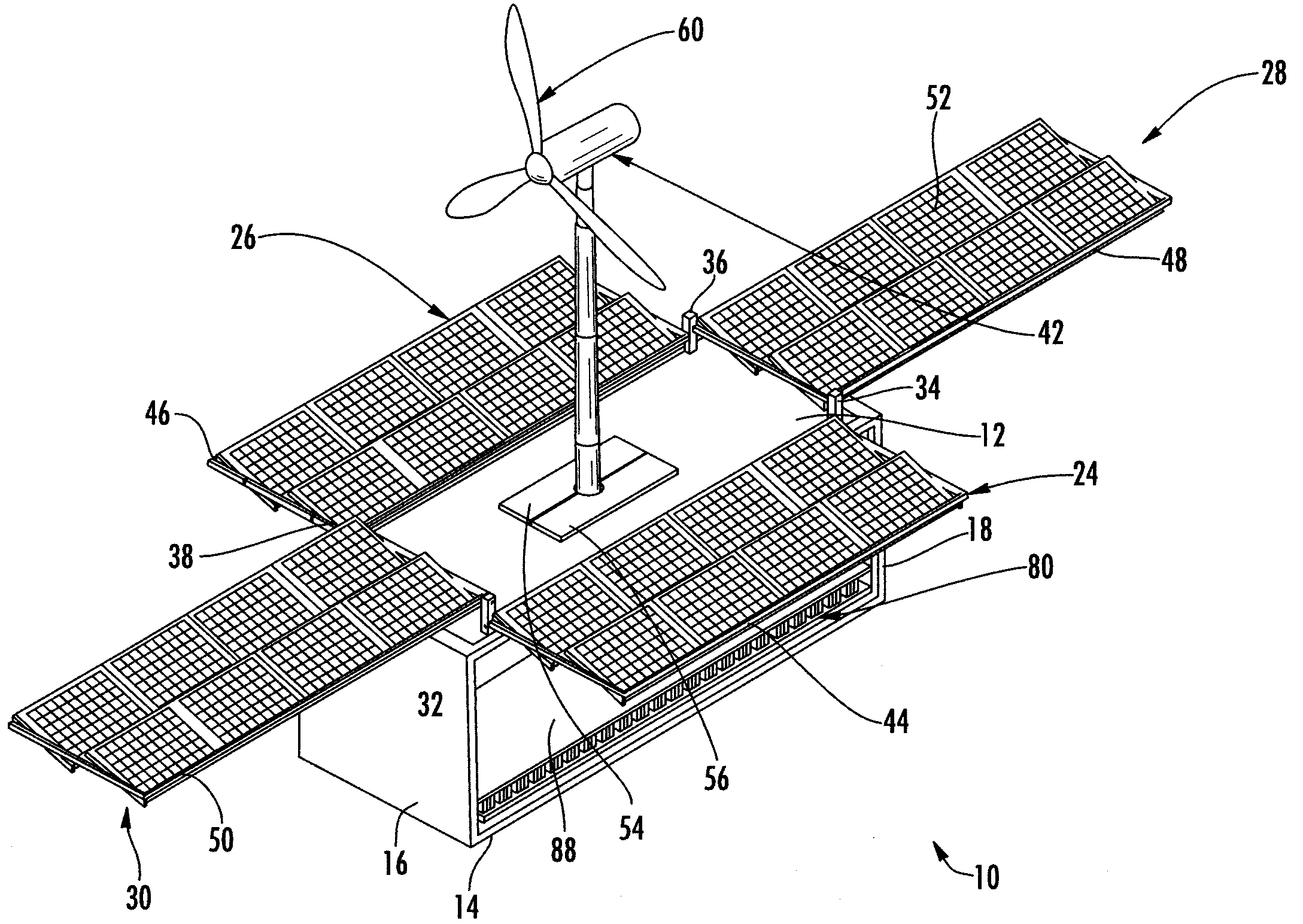

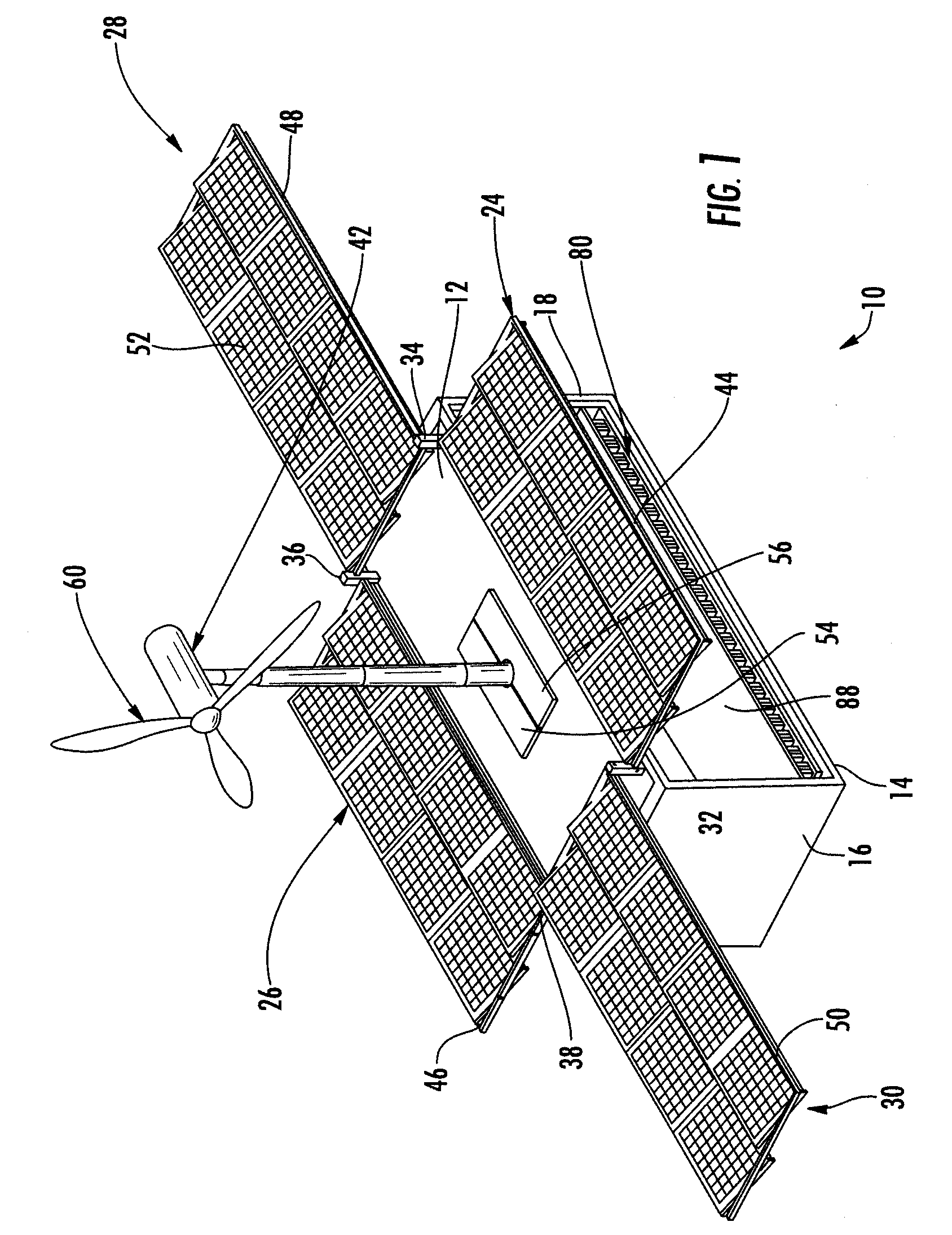

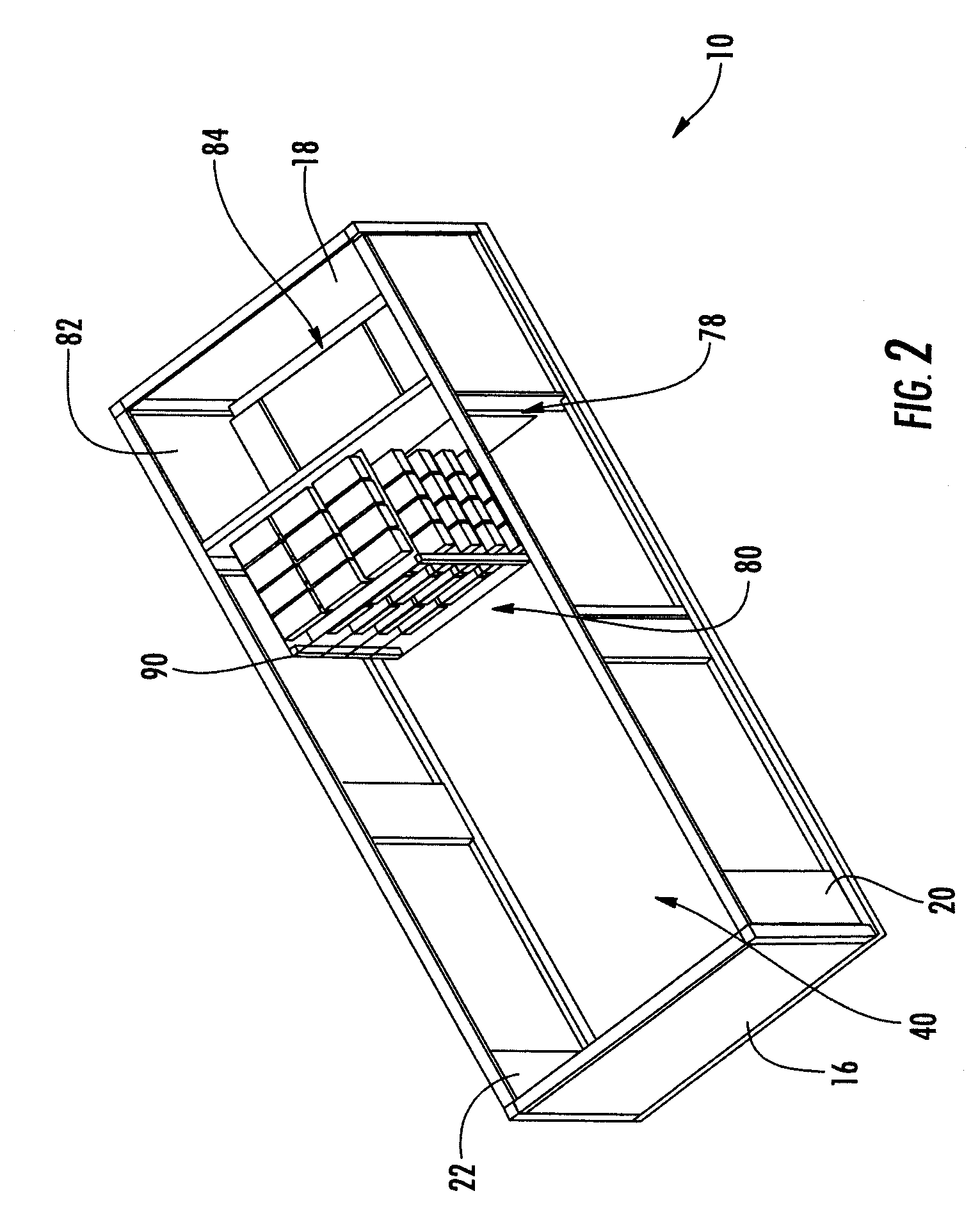

Portable, self-sustaining power station

InactiveUS20080196758A1Improve stabilityQuickly and easily deployed by a single personPhotovoltaic supportsPropellersElectricityPower station

A self-sustaining, portable, power station that may be moved by land, air, or sea to an area that has no utilities. The station is provided with at least one wind turbine and / or solar panel arrays in communication with at least one electrical distribution and storage means. The derived electricity is used to power various systems including, albeit not limited to, a communications system, a water filtration system, a water distribution system to allow the public to draw potable water and provide basic hygiene. The electricity derived may also be used to run outside systems, such as schools, hospitals, or the like.

Owner:ECOSPHERE TECH

Hydrogen production with photosynthetic organisms and from biomass derived therefrom

InactiveUS20050064577A1Bioreactor/fermenter combinationsDispersed particle separationLiquid mediumCombustion

Certain embodiments and aspects of the present invention relate to photobioreactor apparatus designed to contain a liquid medium comprising at least one species of photosynthetic organism therein, and to methods of using the photobioreactor apparatus as part of a hydrogen production process and system configured to generate hydrogen with and / or from biomass produced in the photobioreactor apparatus. In certain embodiments, the disclosed hydrogen production systems and methods, photobioreactor apparatus, methods of using such apparatus, and / or gas treatment systems and methods provided herein can be utilized as part of an integrated combustion and hydrogen production method and system, wherein photosynthetic organisms utilized within the photobioreactor are used to at least partially remove certain pollutant compounds contained within combustion gases, e.g. CO2 and / or NOx, and are subsequently harvested from the photobioreactor, processed, and utilized as a fuel source for generating hydrogen and / or as a fuel source for a combustion device (e.g. an electric power plant generator and / or incinerator).

Owner:GREENFUEL TECHNOLOGIES CORPORATION

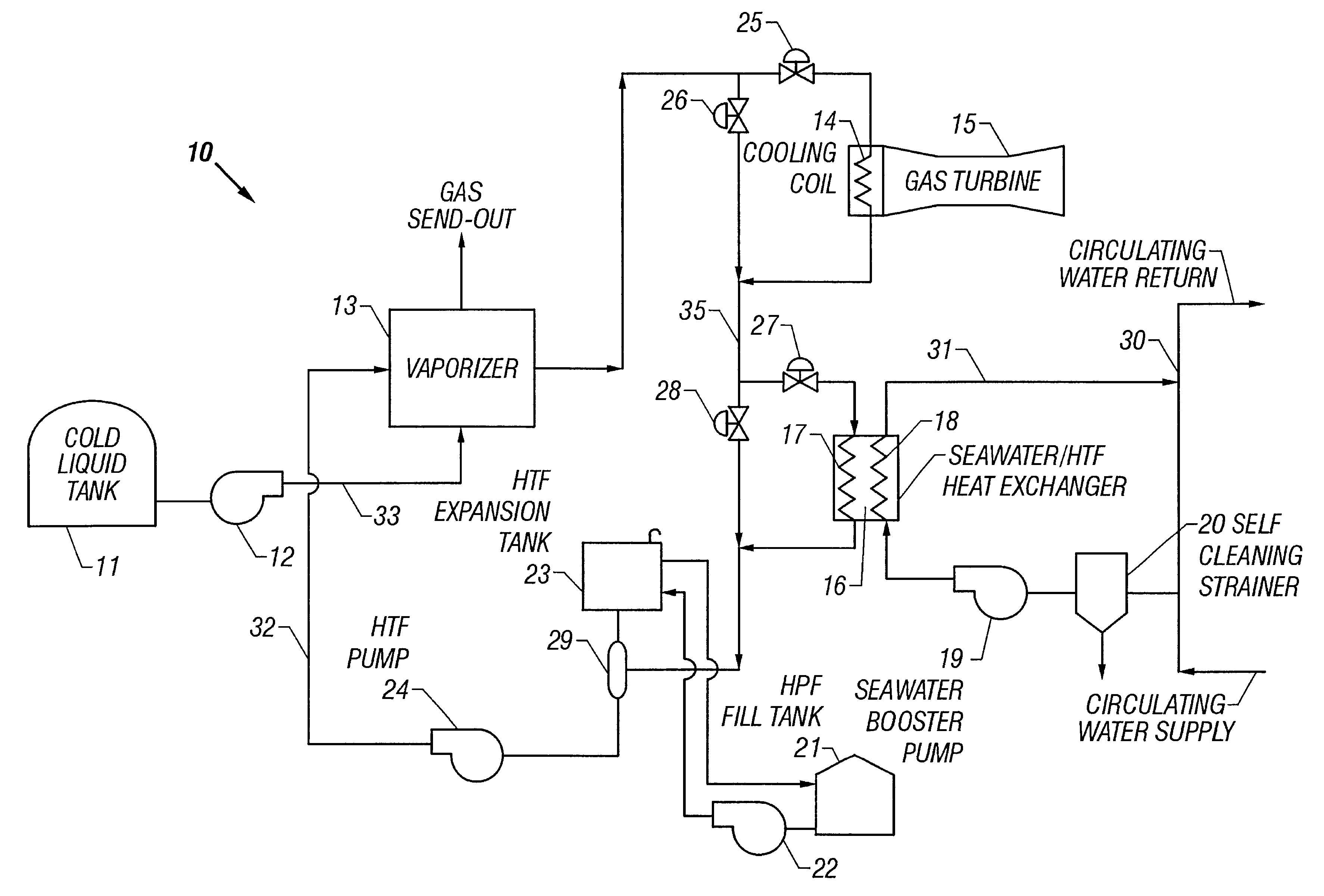

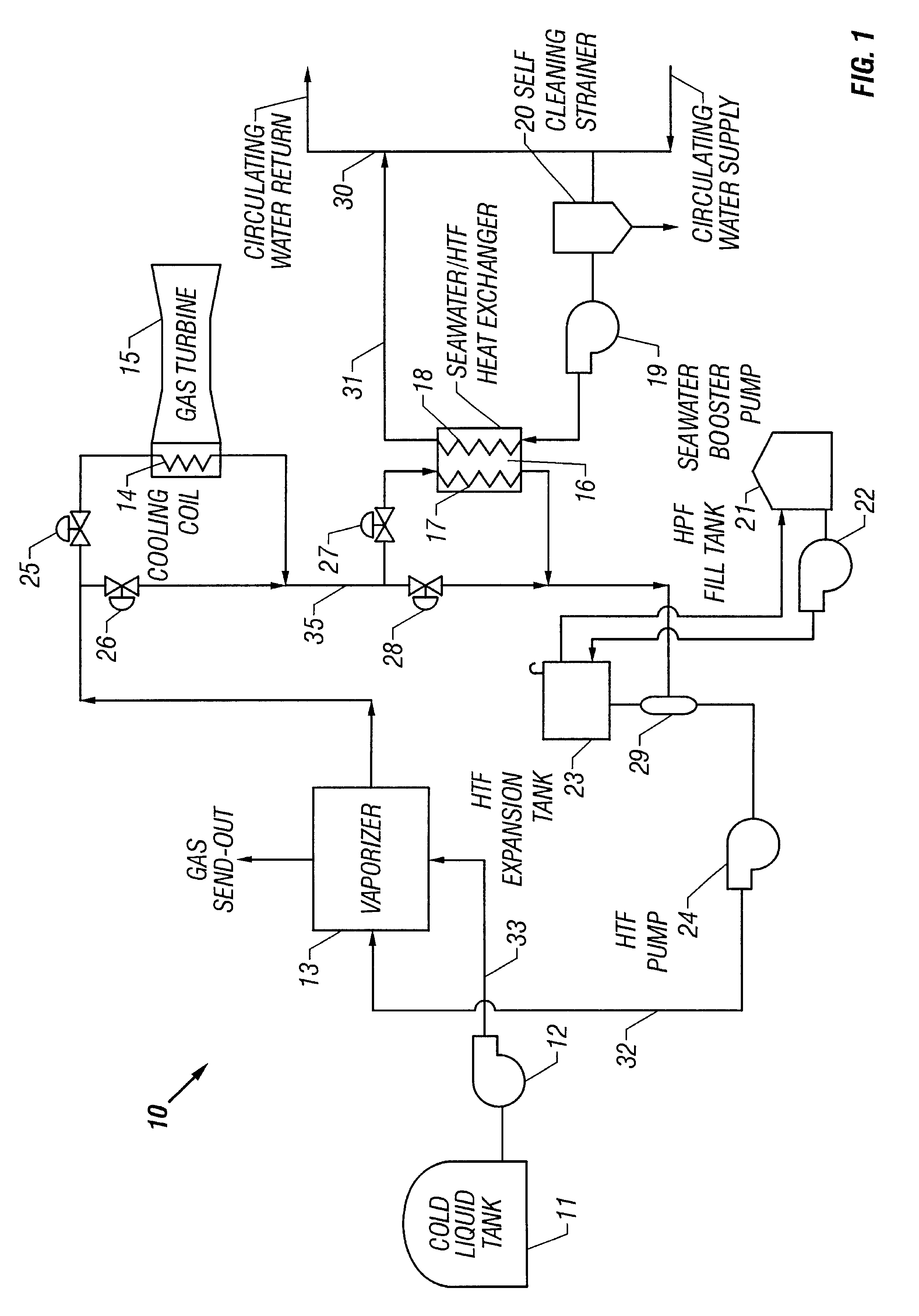

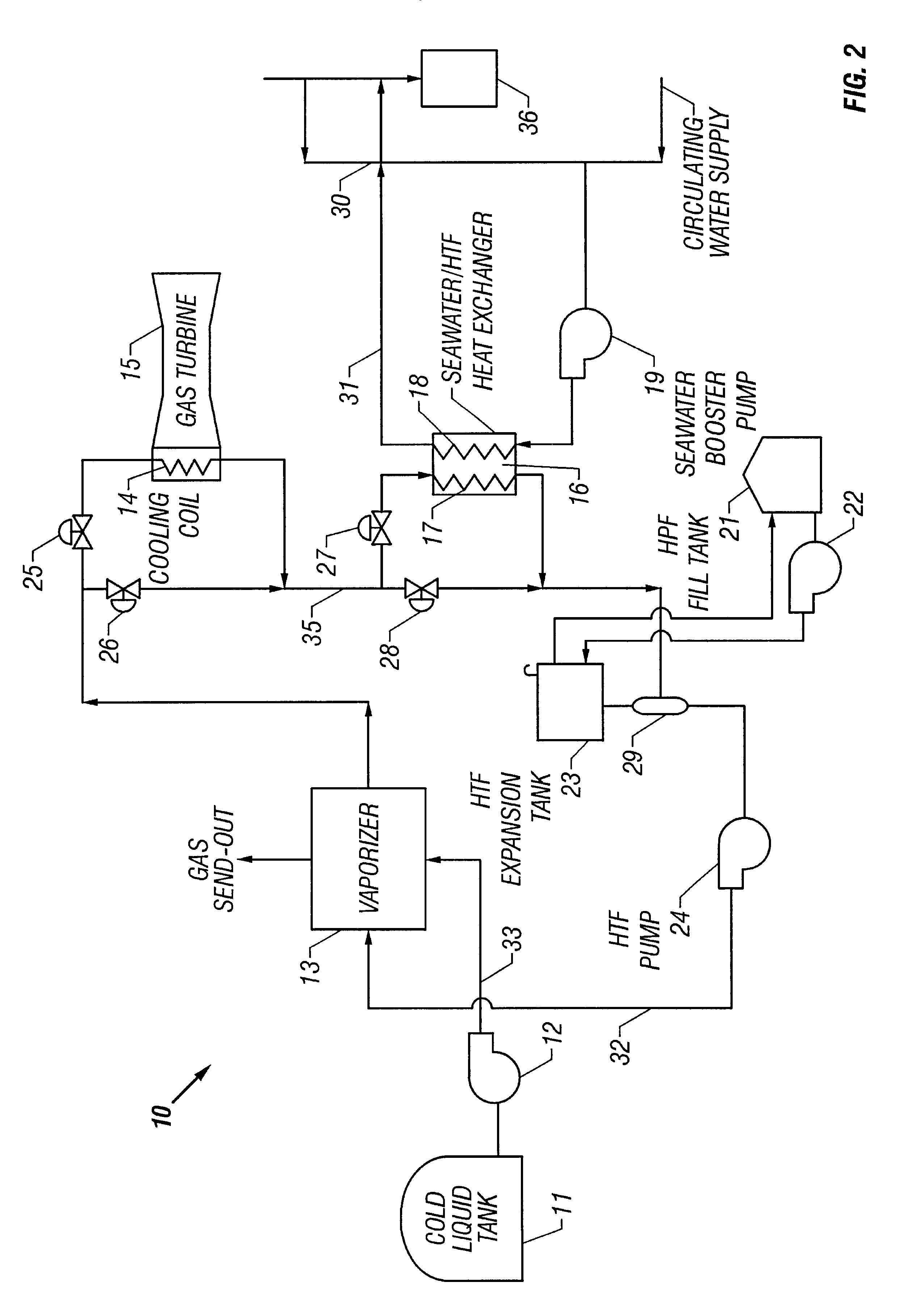

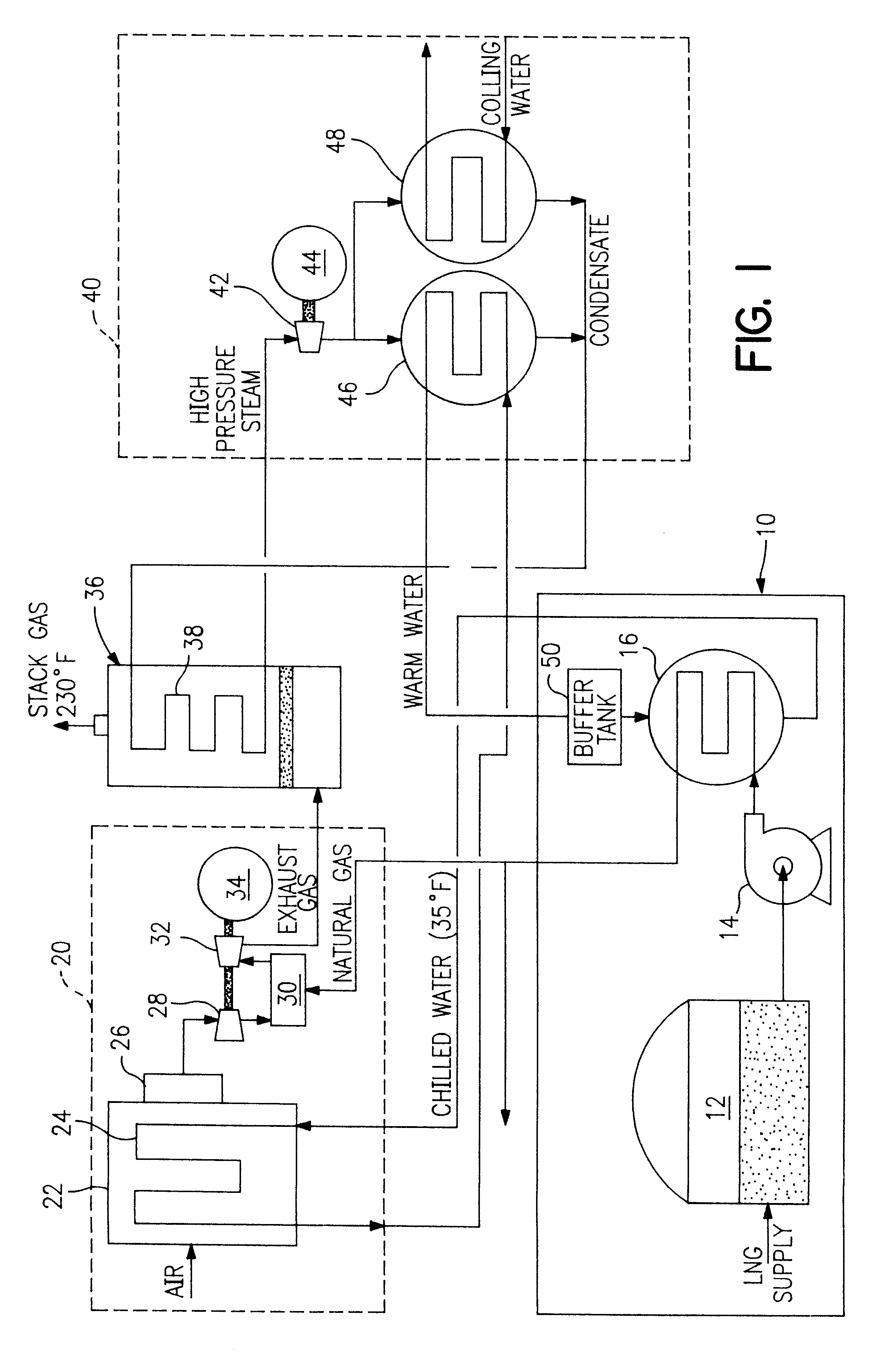

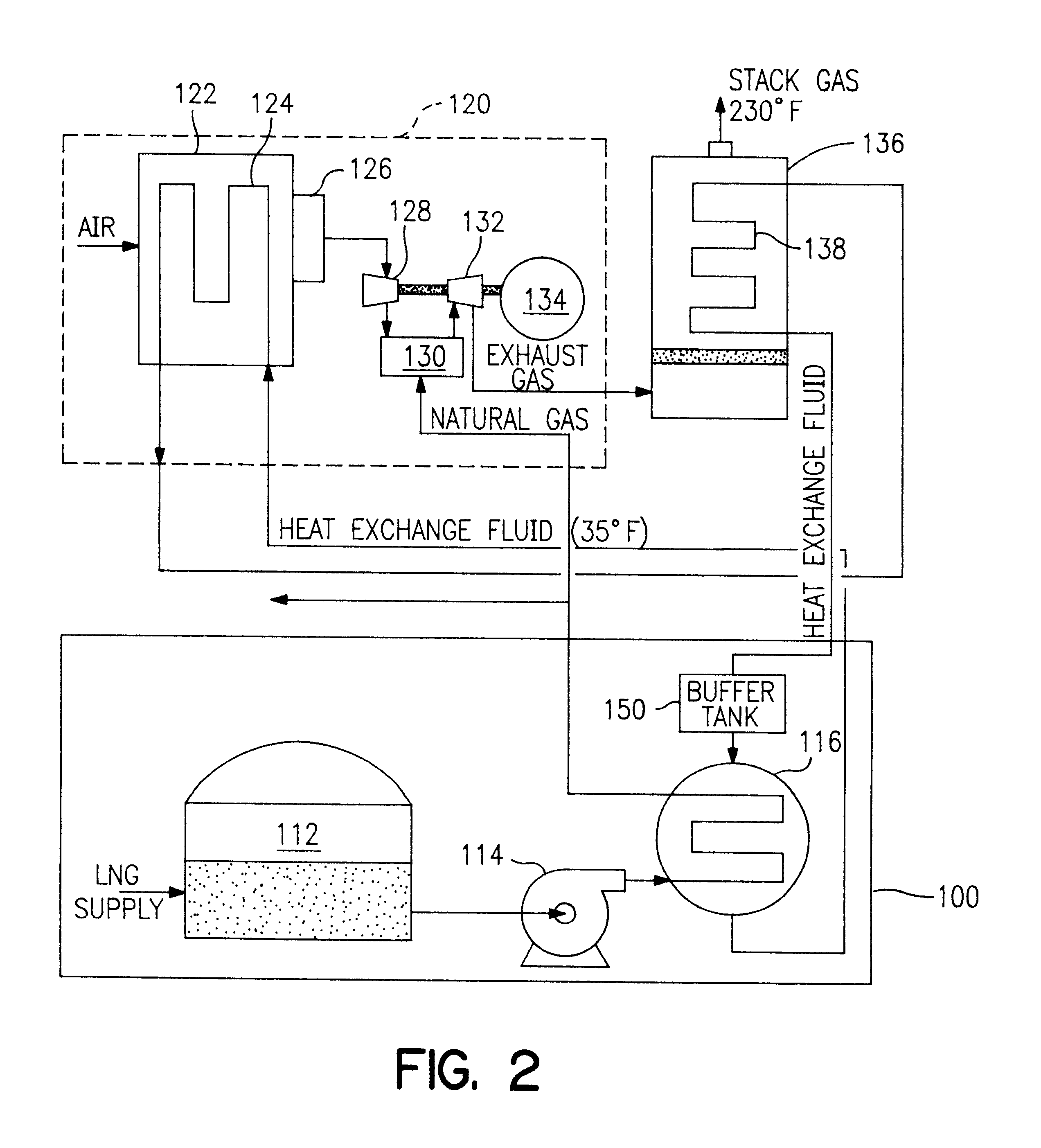

Method and apparatus for vaporizing liquid natural gas in a combined cycle power plant

InactiveUS6367258B1Turbine/propulsion engine coolingTurbine/propulsion fuel heatingPower stationProcess engineering

A method and apparatus for increasing the efficiency of a combined cycle generation plant by assisting the vaporization of cold liquid including liquefied natural gas ("LNG") or liquefied petroleum gas (LPG) in a combined cycle power plant. Cold liquid vaporization is assisted by circulating a warm heat transfer fluid to transfer heat to a LNG / LPG vaporizer. The heat transfer fluid is chilled by LNG / LPG cold liquid vaporization and warmed by heat from a gas turbine. The heat transfer fluid absorbs heat from the air intake of a gas turbine and from a secondary heat transfer fluid circulating in a combined cycle power plant. Chilling the gas turbine air intake densifies the air and increases the gas turbine output. Chilling the steam condenser cooling water increases steam turbine output. The effects of chill recovery is higher output and better efficiency of the combined cycle plant.

Owner:BECHTEL CORP

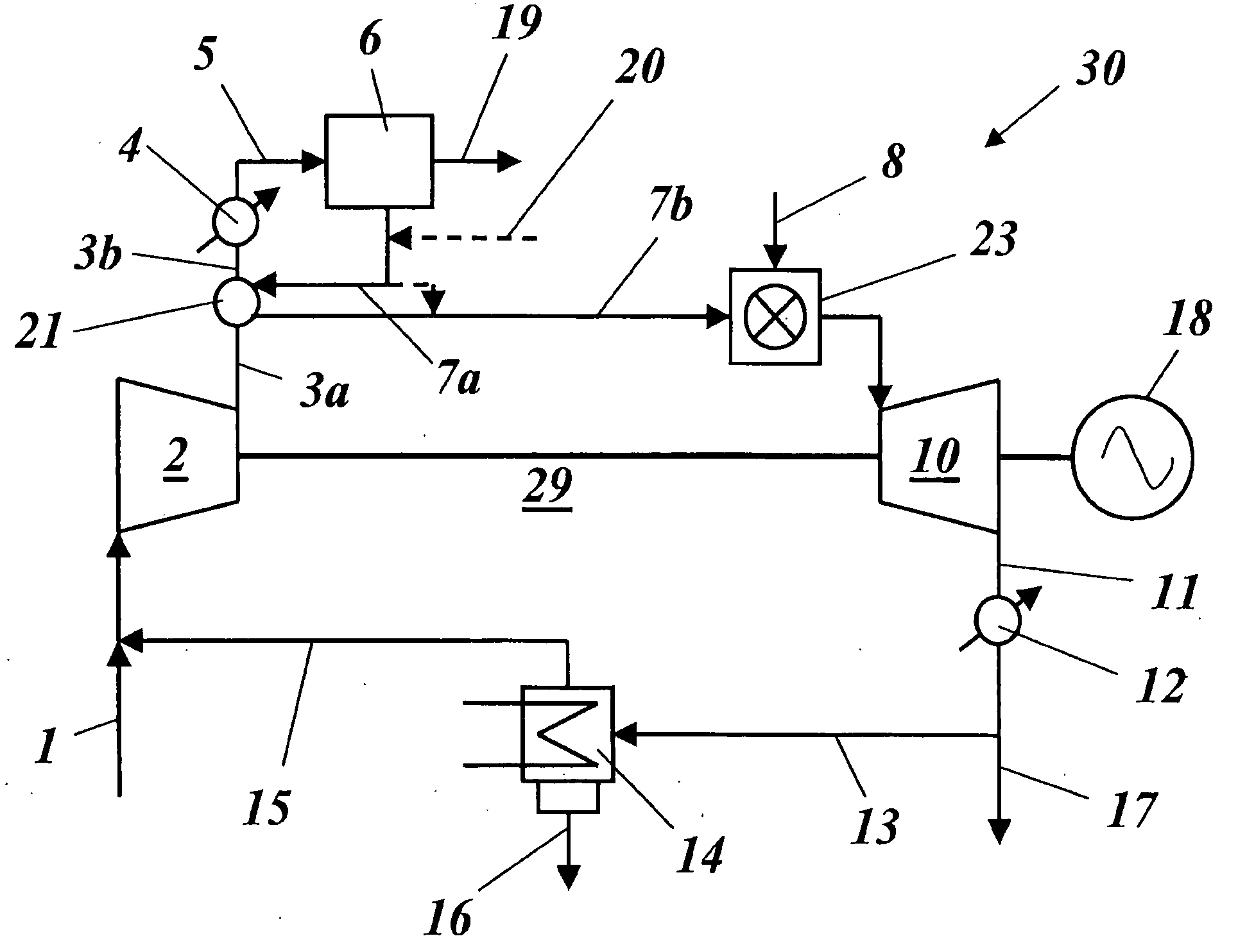

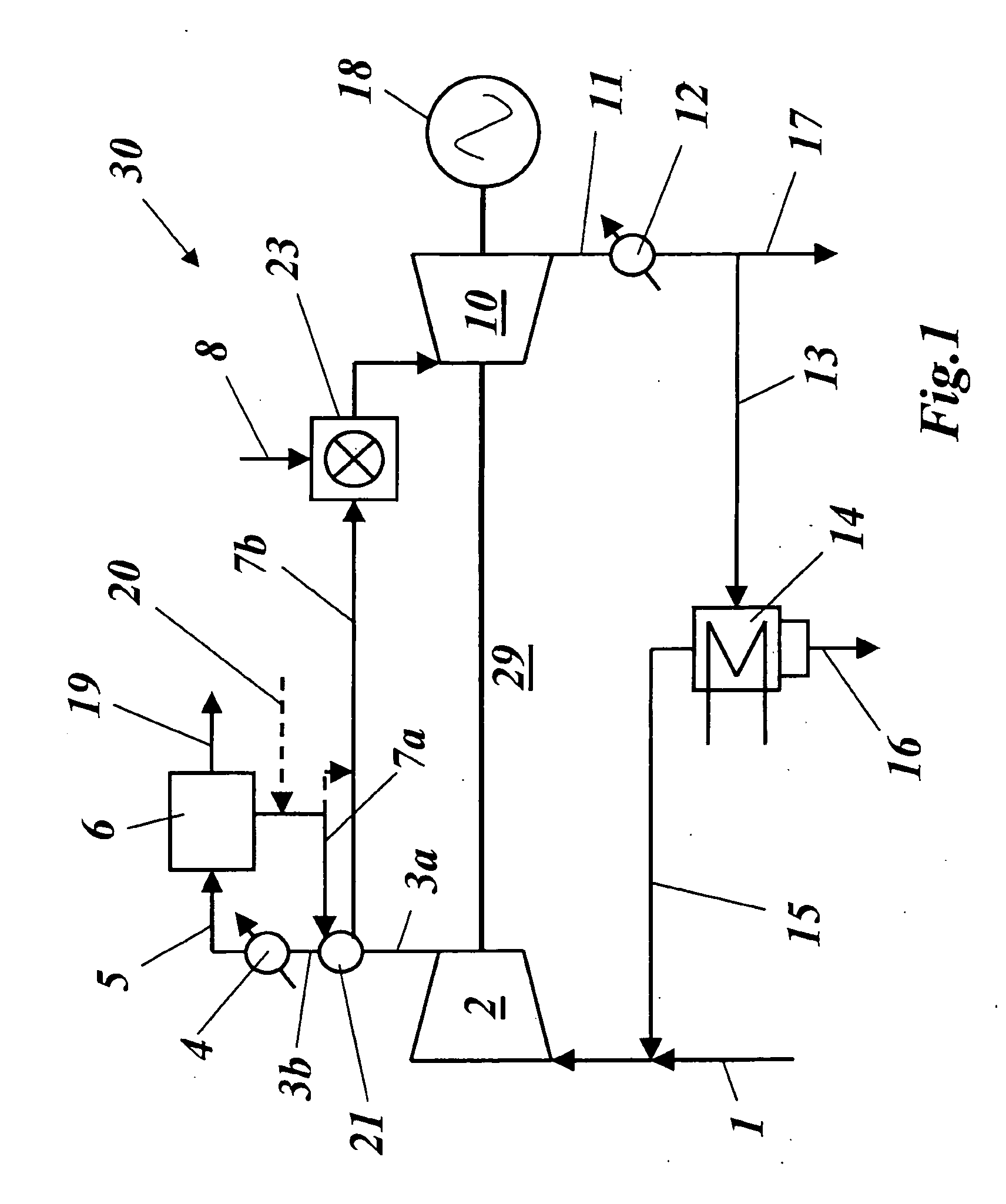

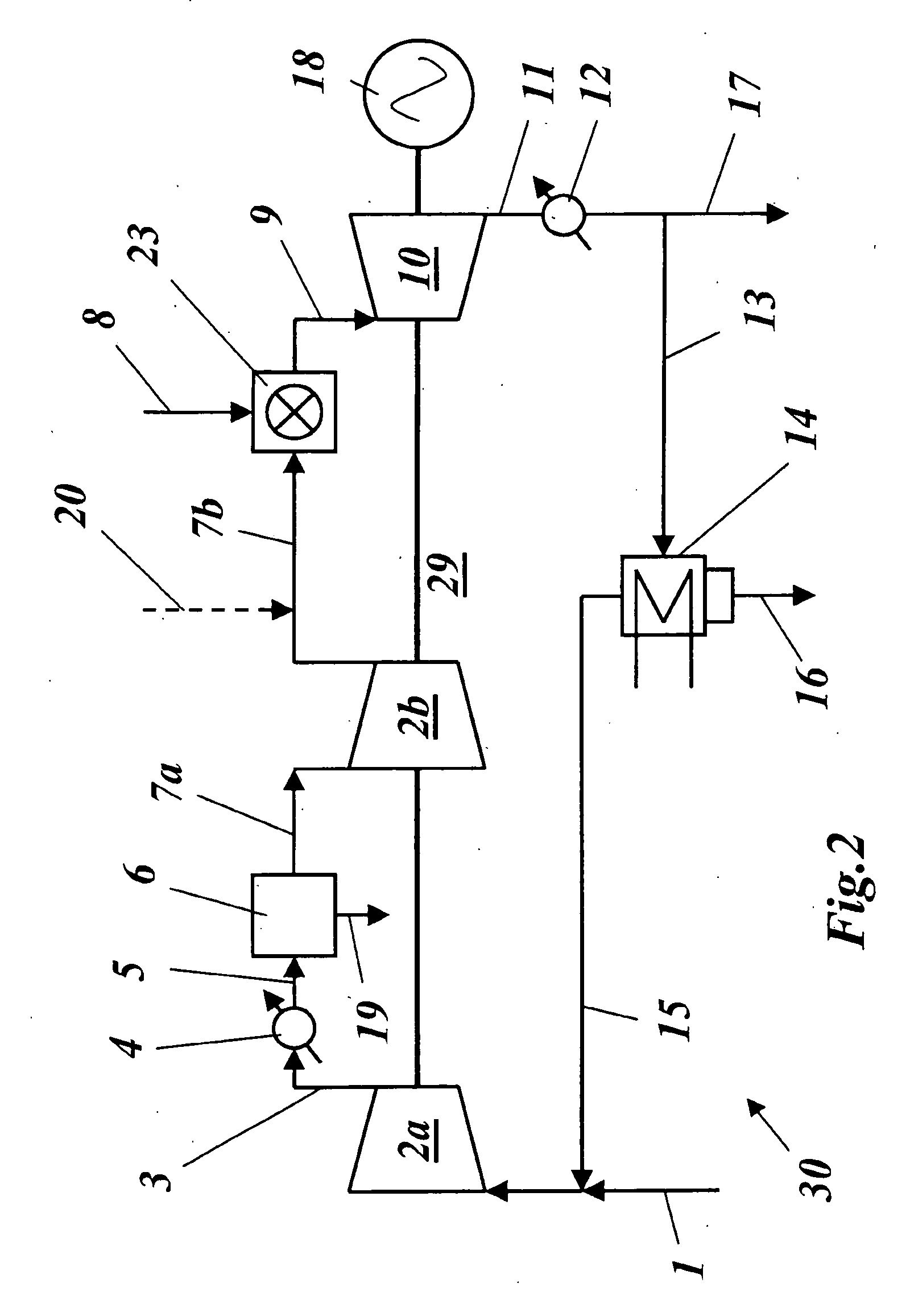

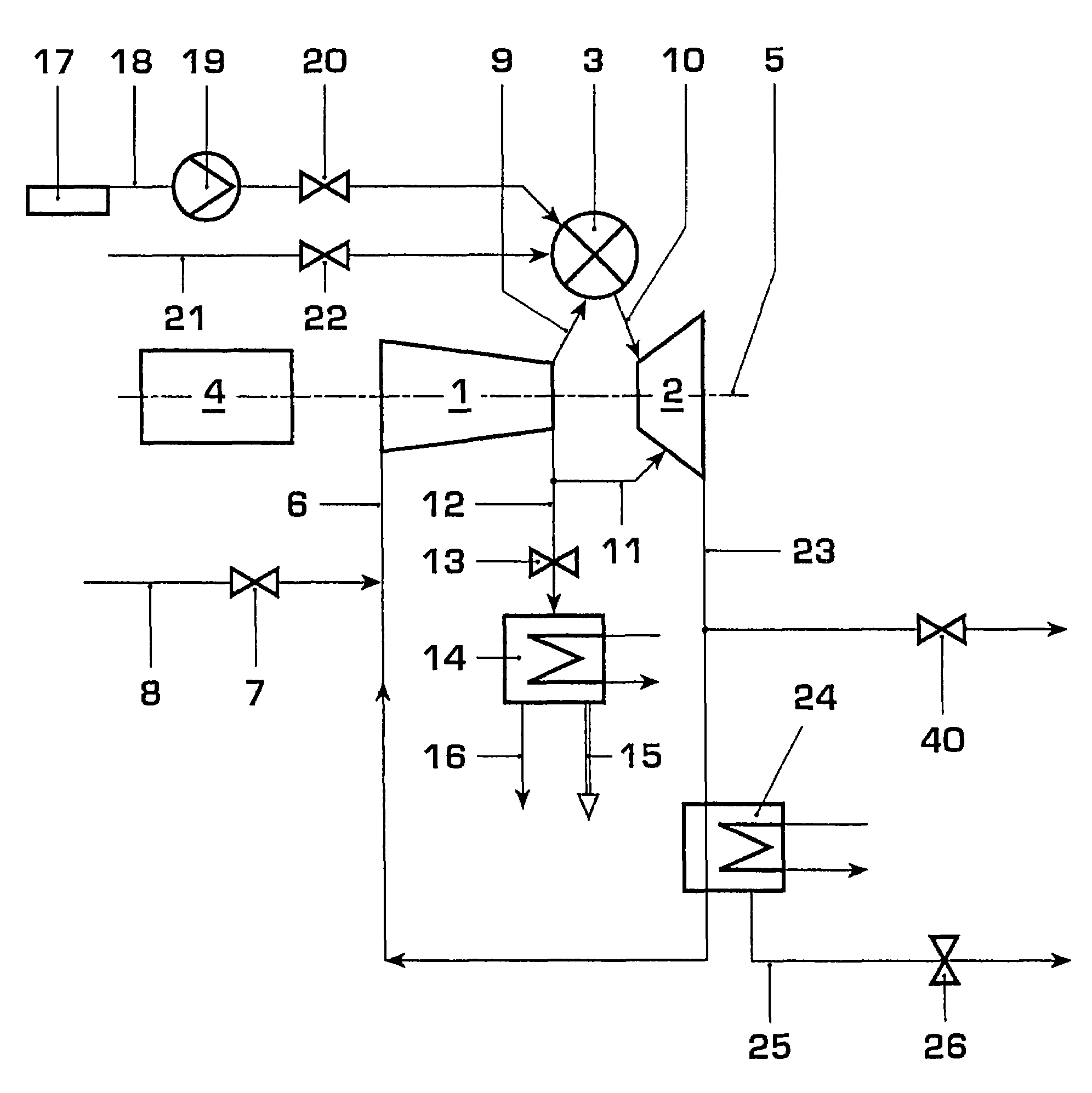

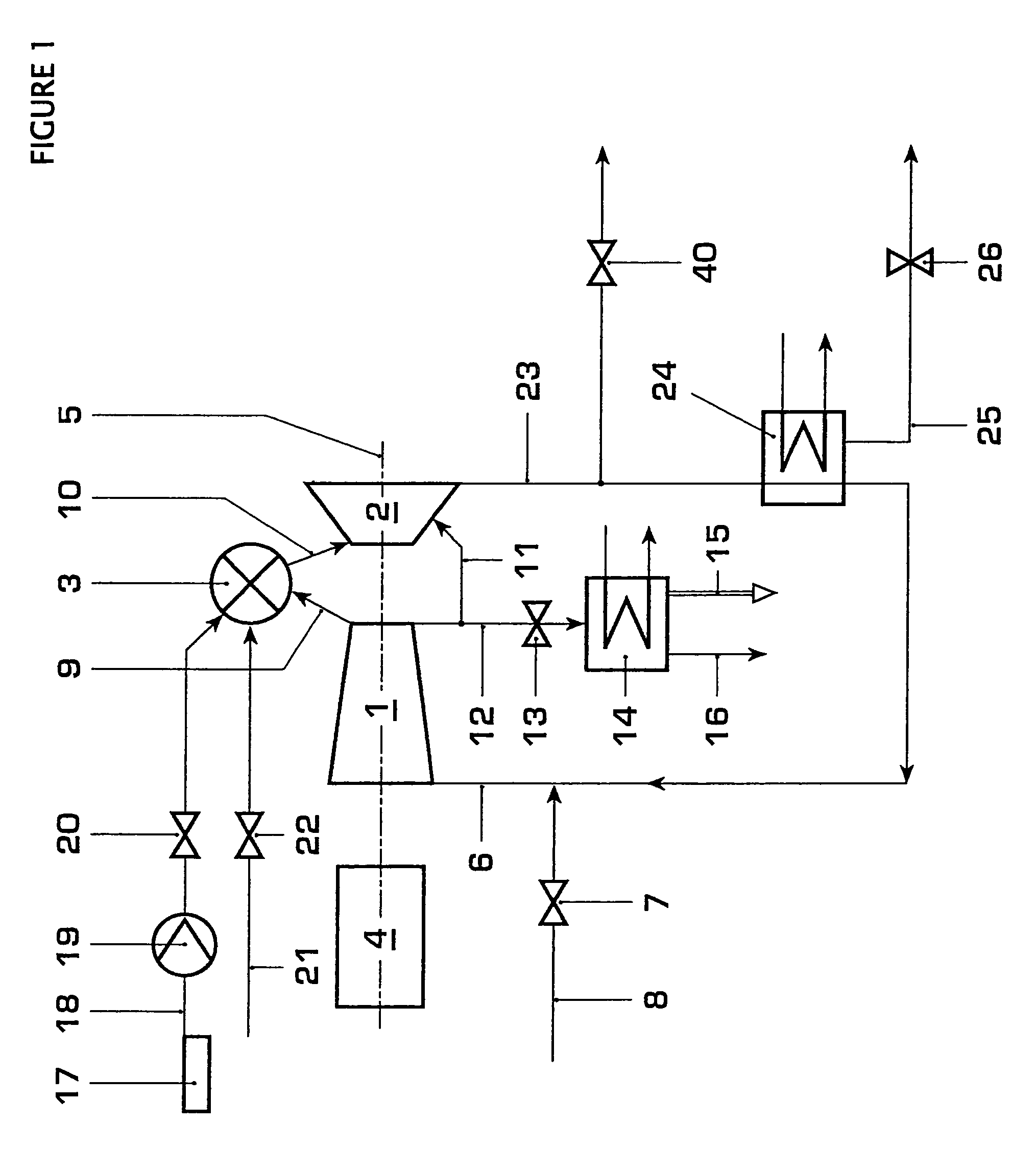

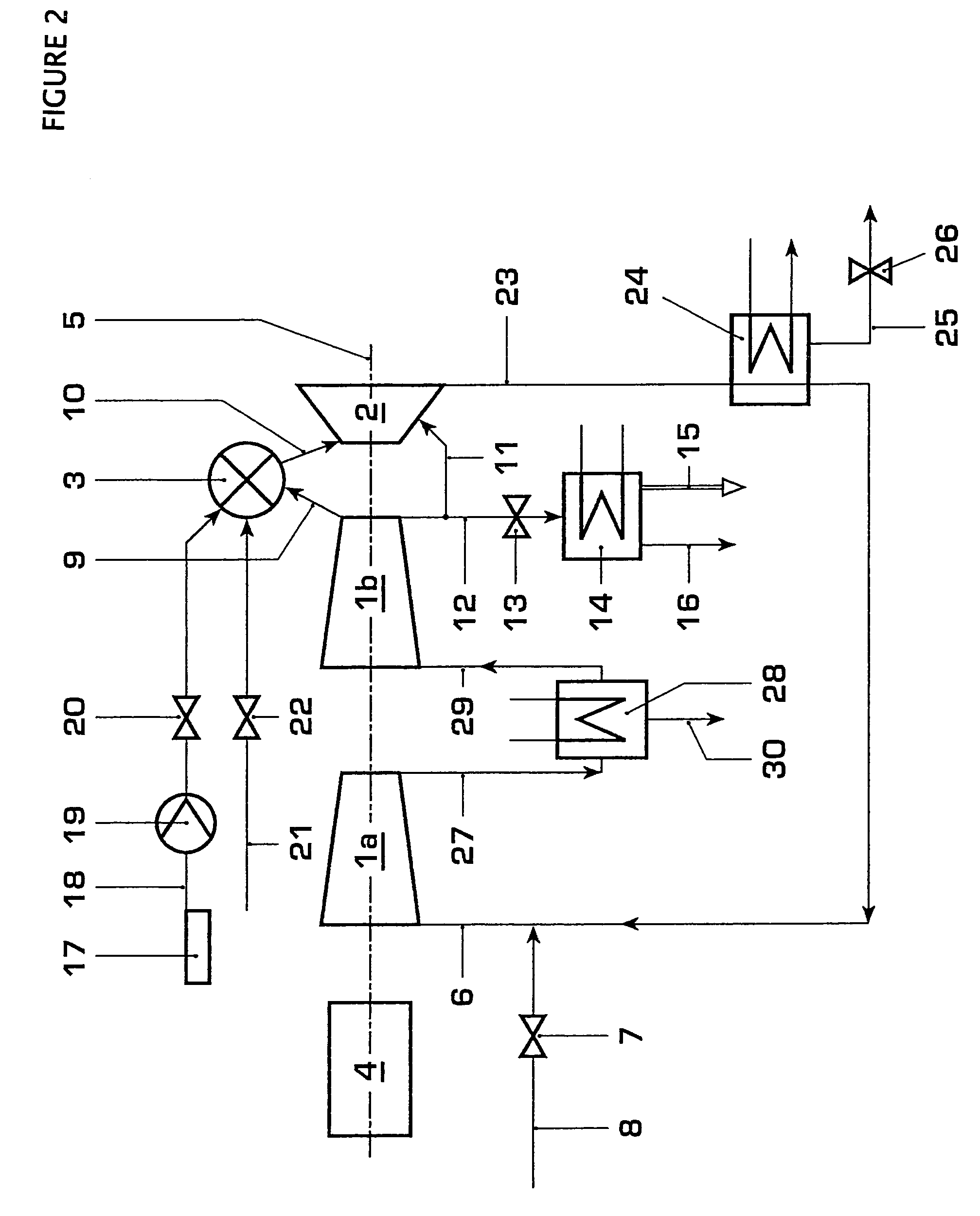

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

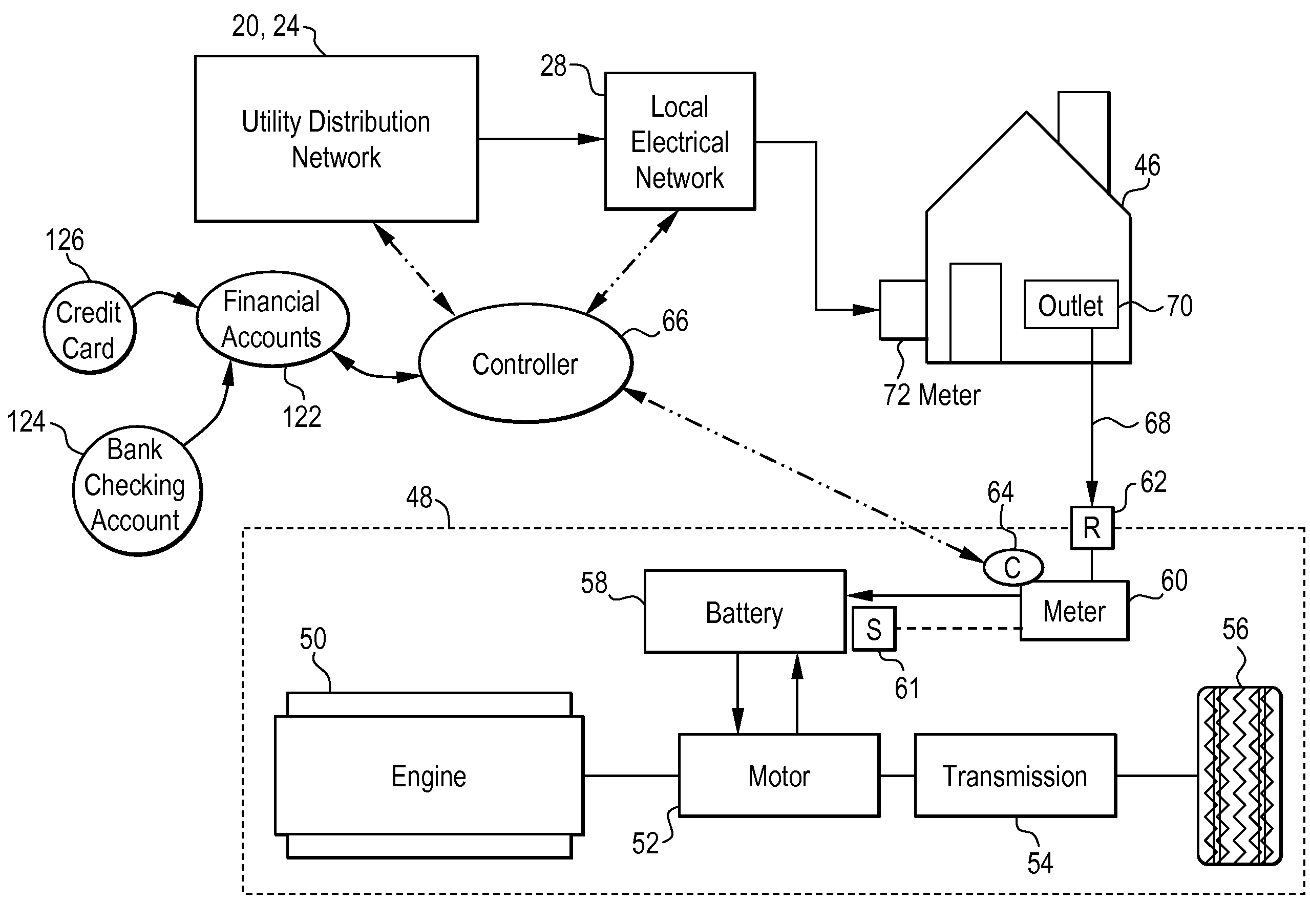

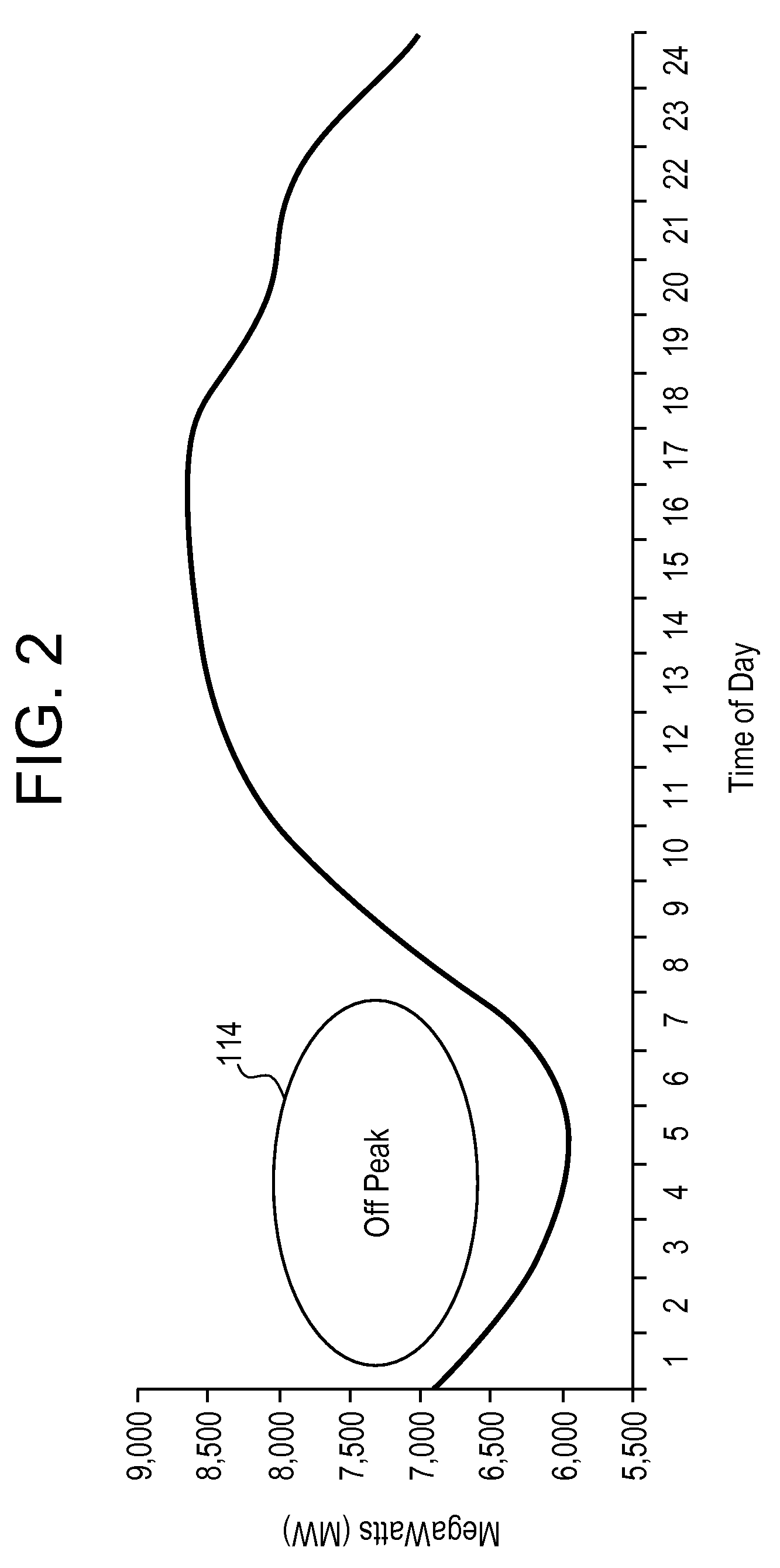

Hybrid vehicle recharging system and method of operation

A system and method for recharging a plug-in hybrid vehicle. The system includes a controller that schedules the recharging of the vehicles on local electrical distribution networks. The system arranges the schedule to minimize the demand loading on the local distribution network to more efficiently operate power plants providing electrical power to the distribution networks. A system for collecting charges associated with the recharging of plug-in hybrid vehicles is also disclosed providing for prepaid utility accounts.

Owner:CONSOL EDISON OF NEW YORK

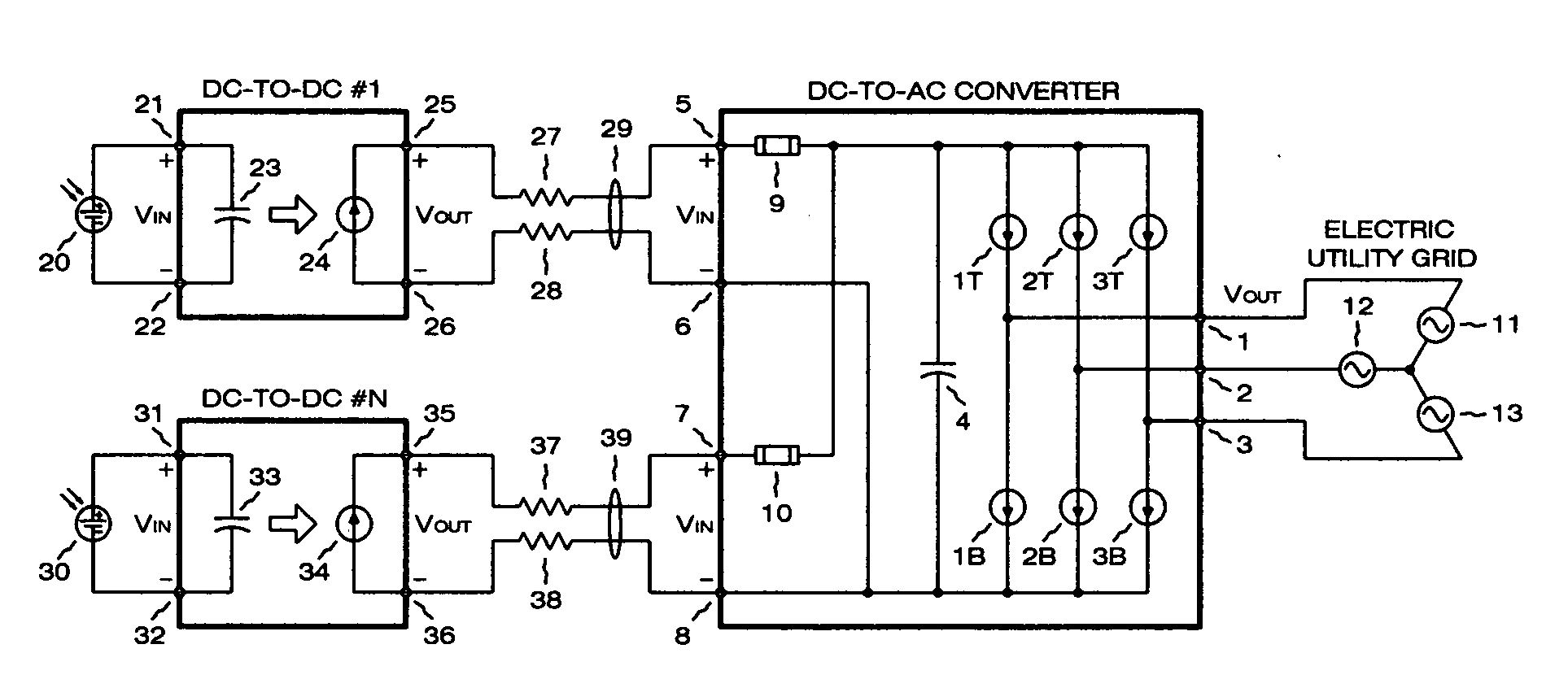

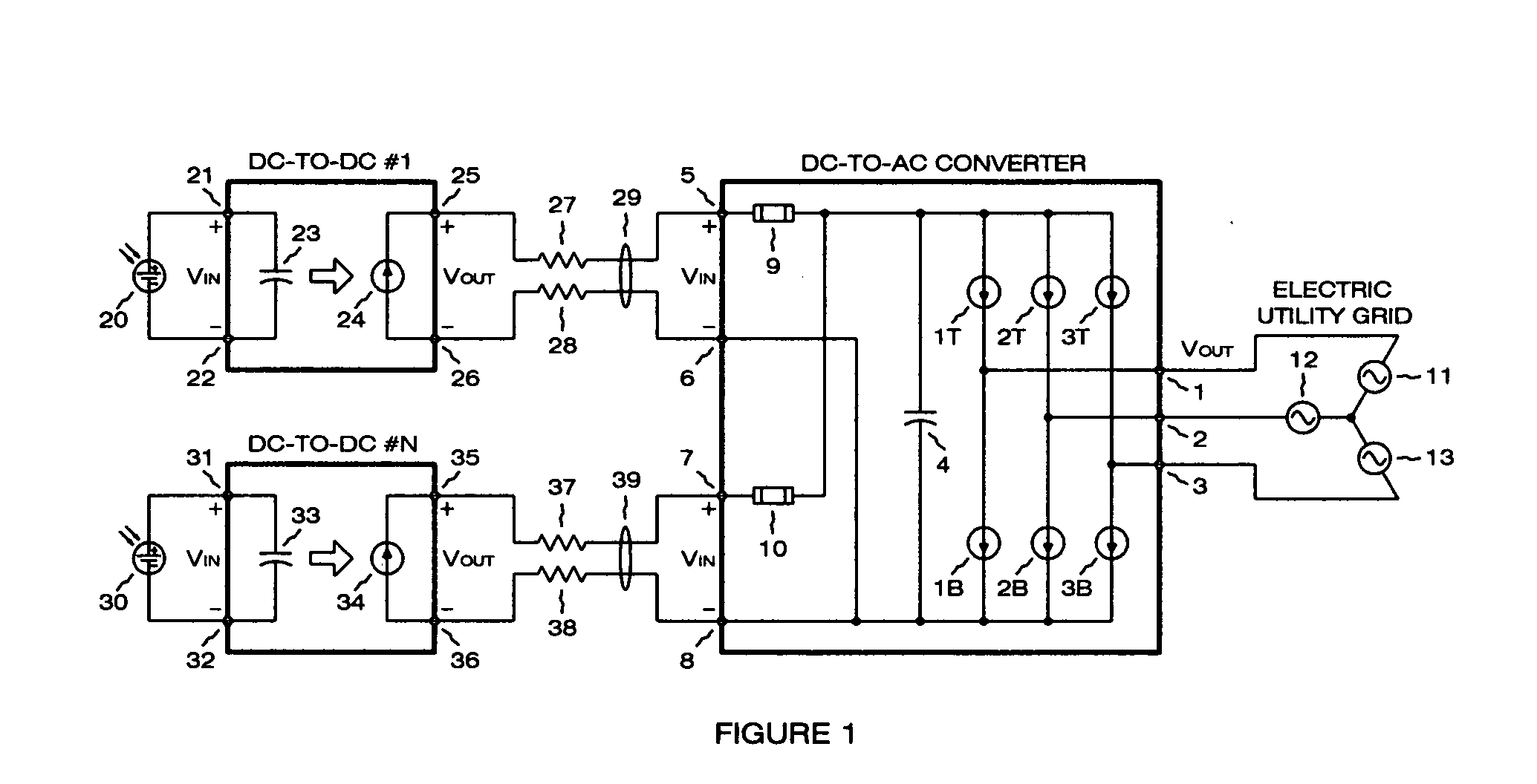

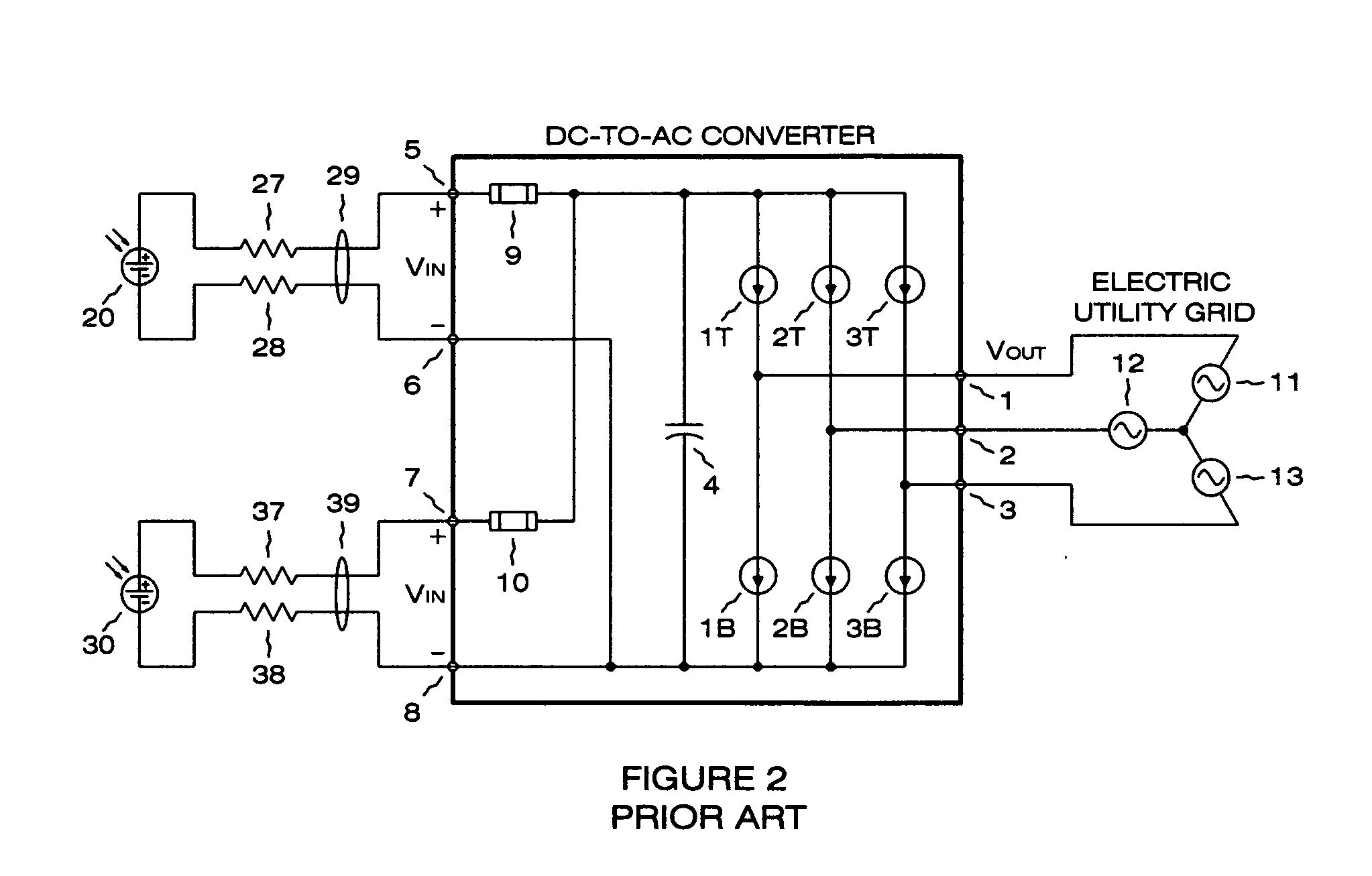

Photovoltaic power plant with distributed DC-to-DC power converters

A solar photovoltaic plant is disclosed where a number of distributed DC-to-DC converters are used in conjunction with a central DC-to-AC converter. Each DC-to-DC converter is dedicated to a portion of the photovoltaic array and tracks the maximum power point voltage thereof. The DC-to-DC converters also boost the photovoltaic voltage and regulate a DC output current for transmission to the central DC-to-AC converter. Five distinct advantages are had over the prior art. First, efficiencies in intra-field power collection are greatly improved by transferring power at higher DC voltages. Second, the number of independent photovoltaic maximum power point trackers in the power plant can be increased, in a cost effective manner, to optimize the overall photovoltaic array energy harvest. Third, each DC-to-DC converter output “looks” like a current source at the input of the DC-to-AC converter and therefore can be easily paralleled. Fourth, the current source nature of the DC-to-DC converter outputs enables the DC-to-AC converter to operate with a minimum, fixed DC bus voltage to provide maximum DC-to-AC power conversion efficiencies. And fifth, each distributed DC-to-DC converter can isolate a faulted portion of the photovoltaic array while the remainder of the array continues producing power.

Owner:PARKER INTANGIBLES LLC

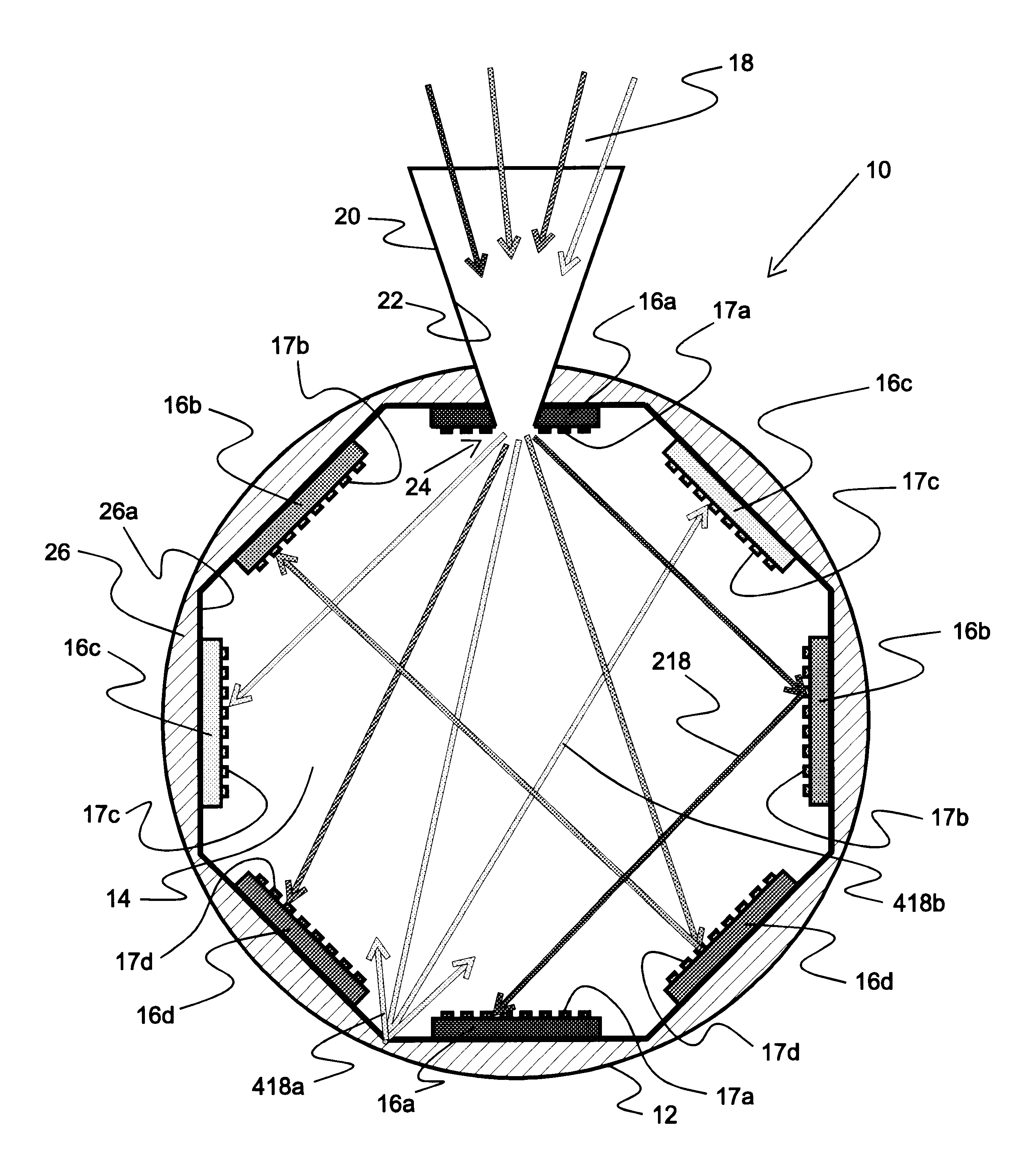

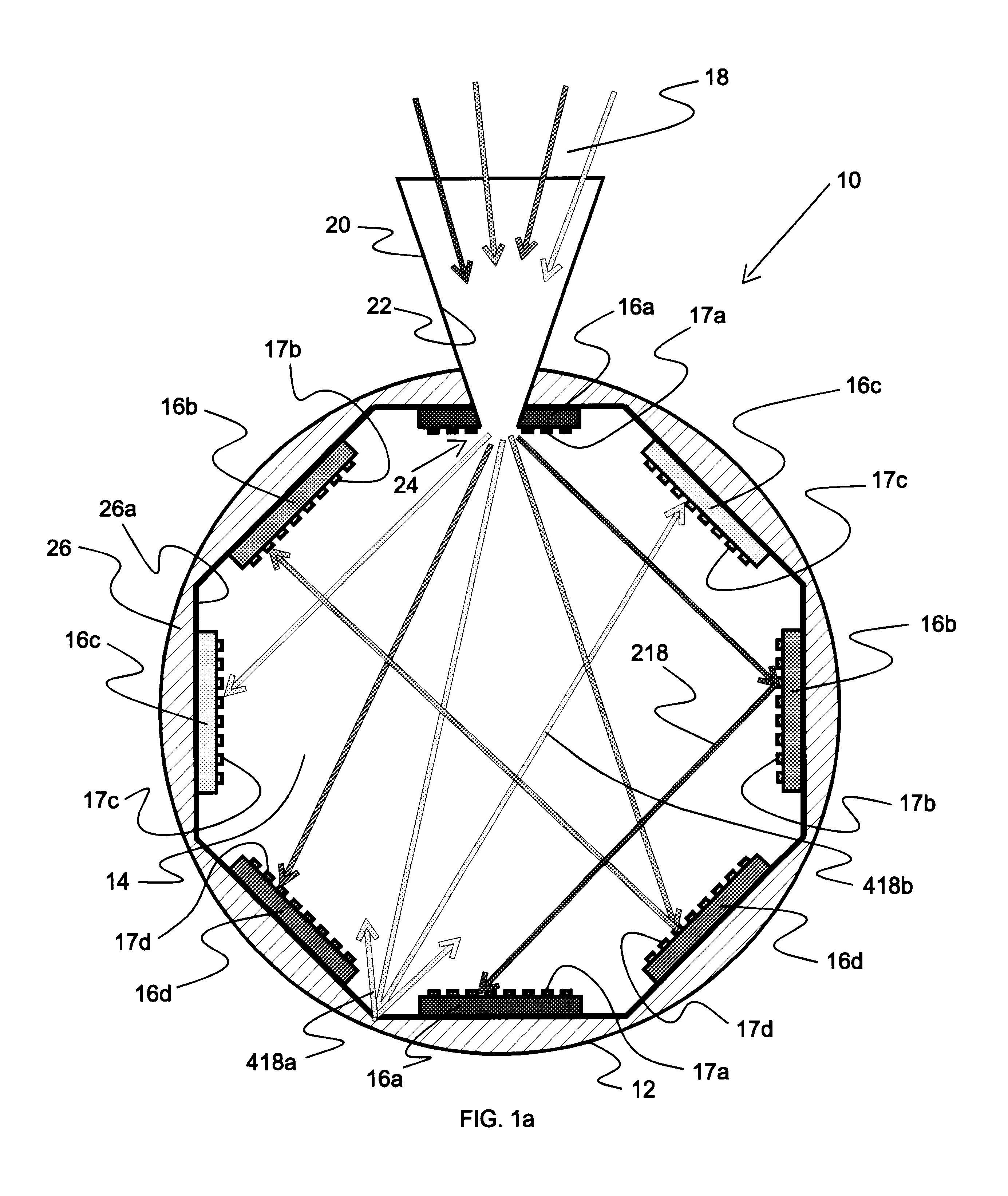

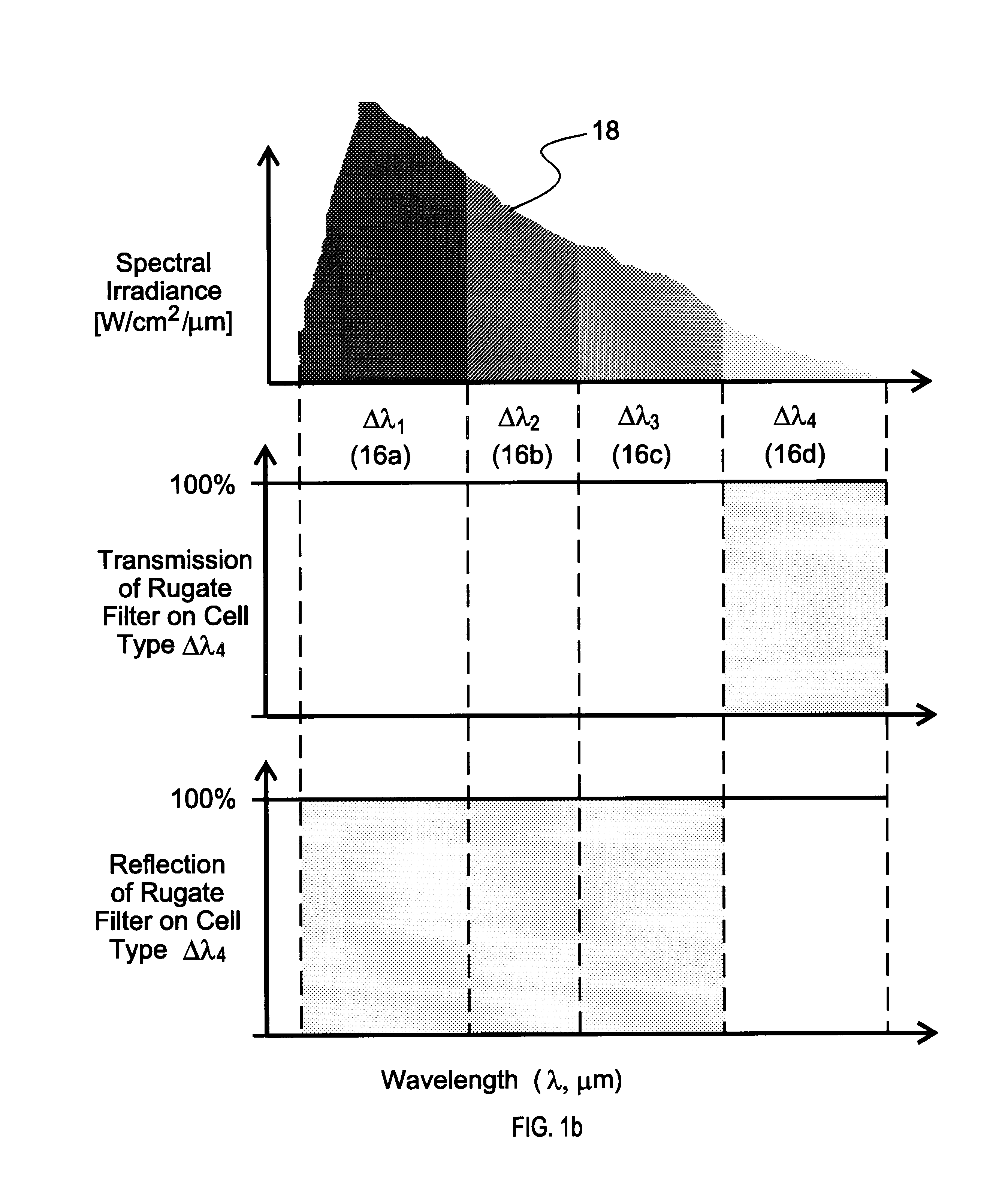

Concentrating photovoltaic cavity converters for extreme solar-to-electric conversion efficiencies

InactiveUS6689949B2Maximize utilizationAuxillary drivesFrom solar energyEngineeringEnergy conversion efficiency

A concentrating photovoltaic module is provided which provides a concentration in the range of about 500 to over 1,000 suns and a power range of a few kW to 50 kW. A plurality of such modules may be combined to form a power plant capable of generating over several hundred megaWatts. The concentrating photovoltaic module is based on a Photovoltaic Cavity Converter (PVCC) as an enabling technology for very high solar-to-electricity conversions. The use of a cavity containing a plurality of single junction solar cells of different energy bandgaps and simultaneous spectral splitting of the solar spectrum employs a lateral geometry in the spherical cavity (where the cell strings made of the single junction cells operate next to each other without mutual interference). The purpose of the cavity with a small aperture for the pre-focused solar radiation is to confine (trap) the photons so that they can be recycled effectively and used by the proper cells. Passive or active cooling mechanisms may be employed to cool the solar cells.

Owner:UNITED INNOVATIONS

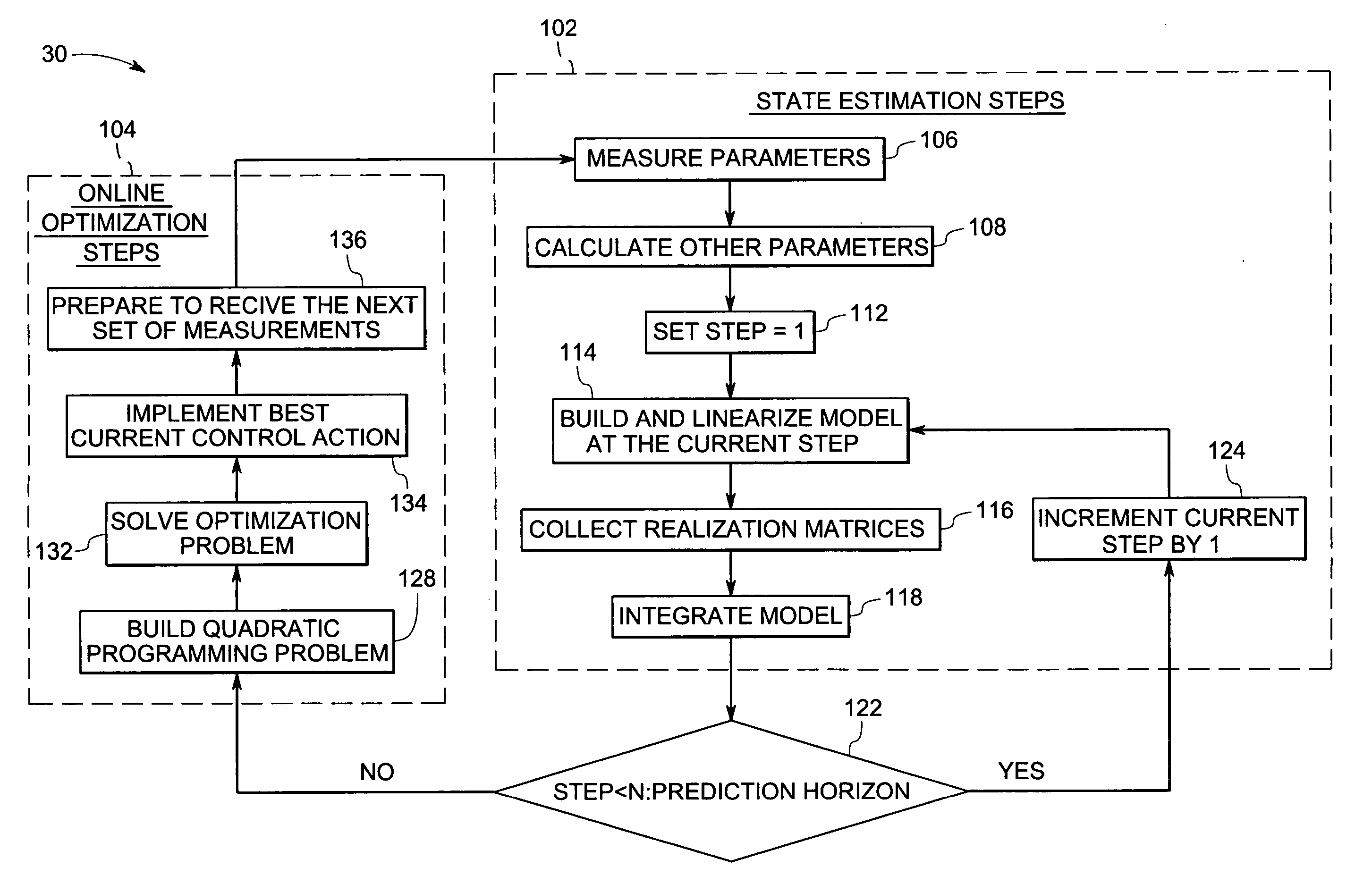

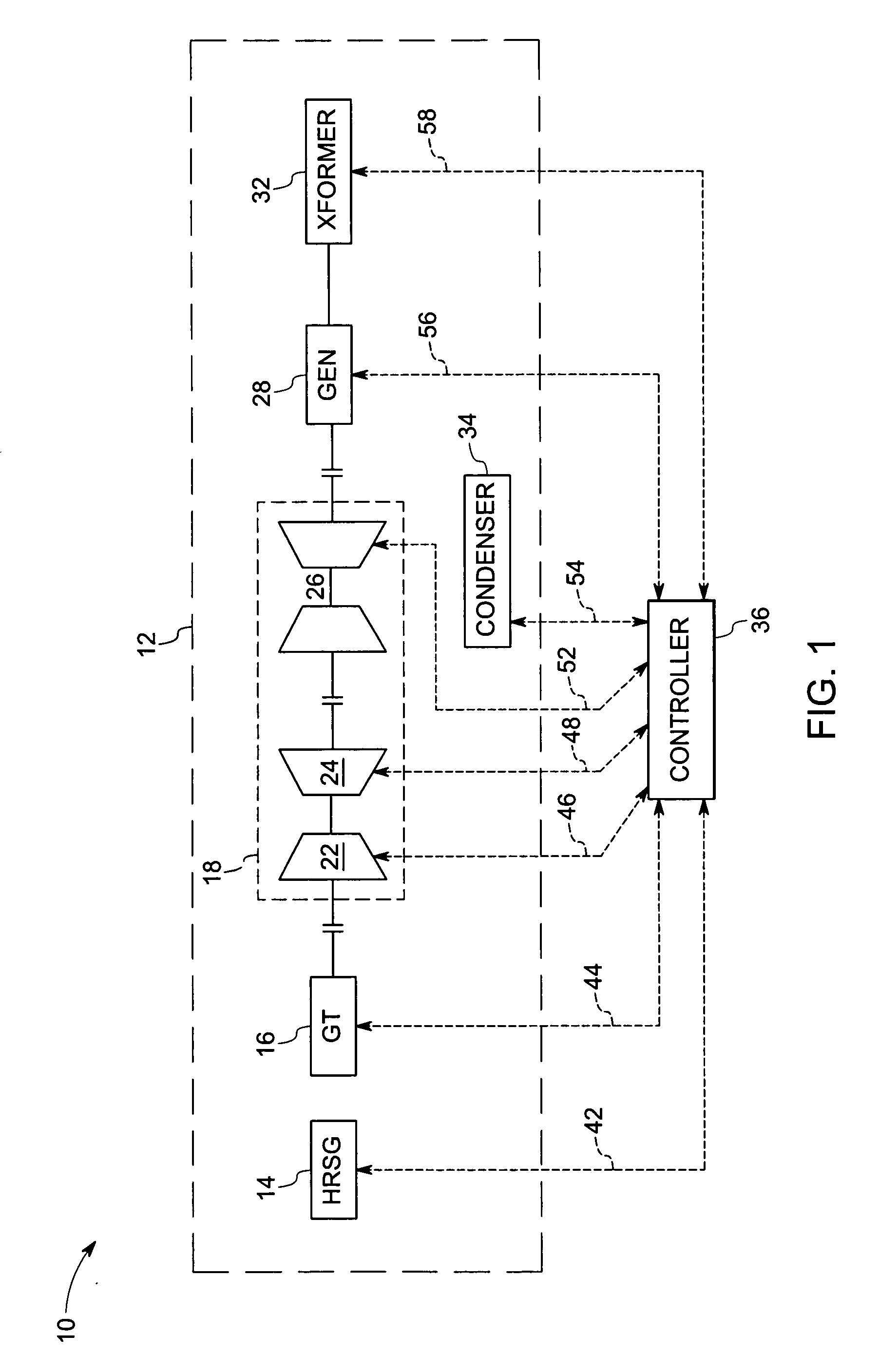

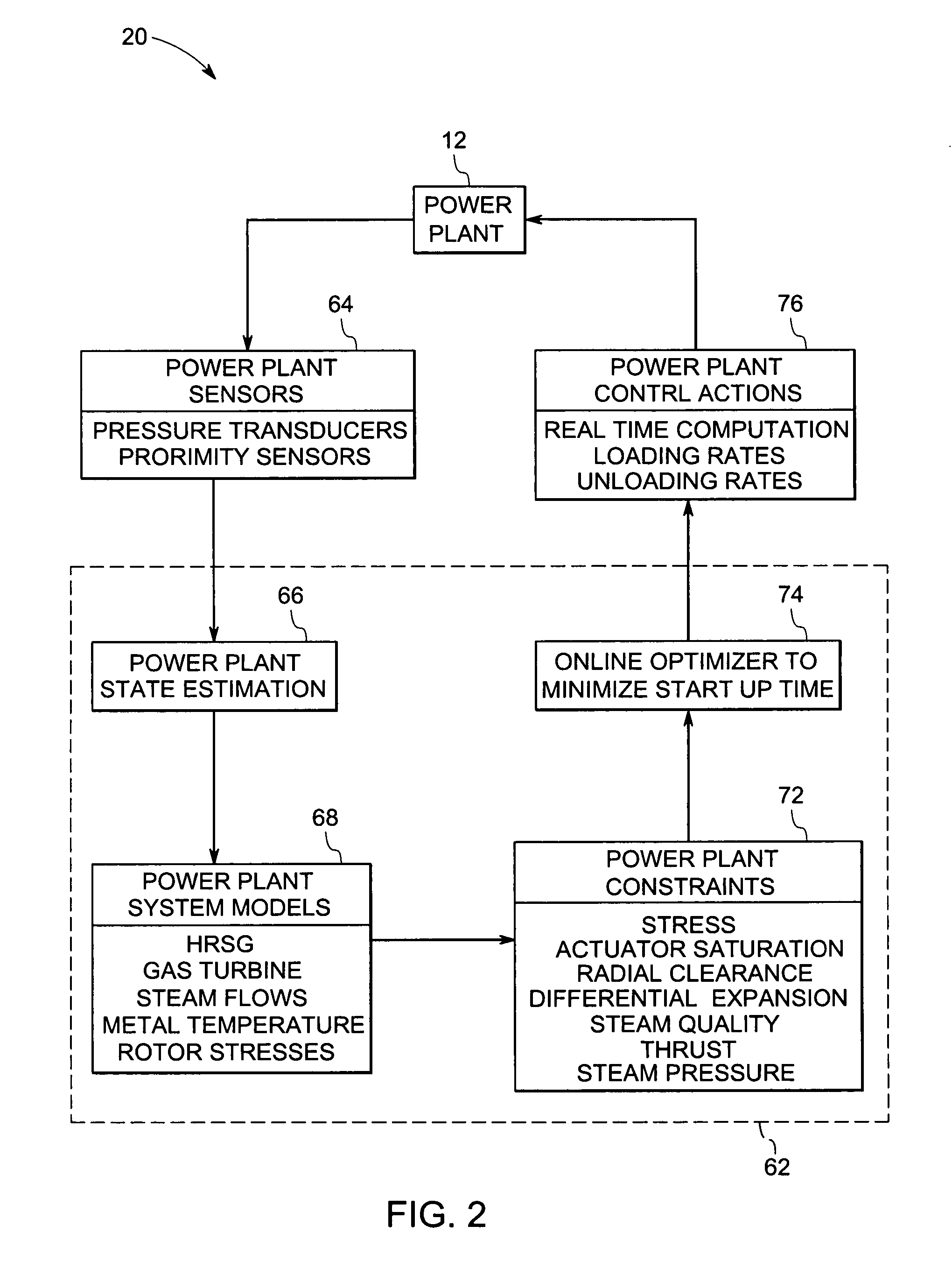

Method and system for model predictive control of a power plant

InactiveUS20070055392A1Improves performance criterionImproving performance criterionCombined combustion mitigationAdaptive controlPower stationModel predictive control

System and method for model predictive control of a power plant. The system includes a model for a number of power plant components and the model is adapted to predict behavior of the number of power plant components. The system also includes a controller that receives inputs corresponding to operational parameters of the power plant components and improves performance criteria of the power plant according to the model. There is also provided a method for controlling a power plant.

Owner:GENERAL ELECTRIC CO

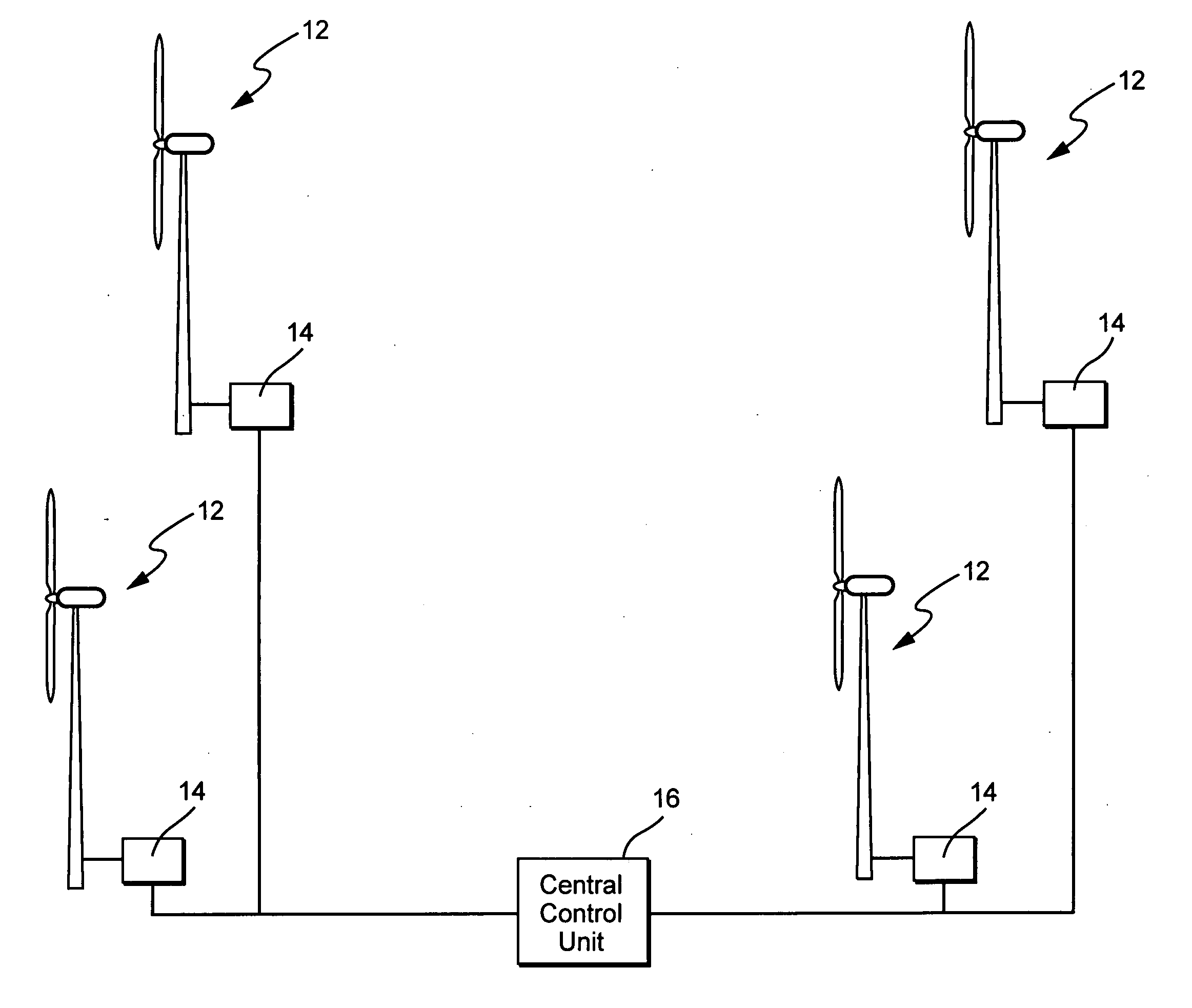

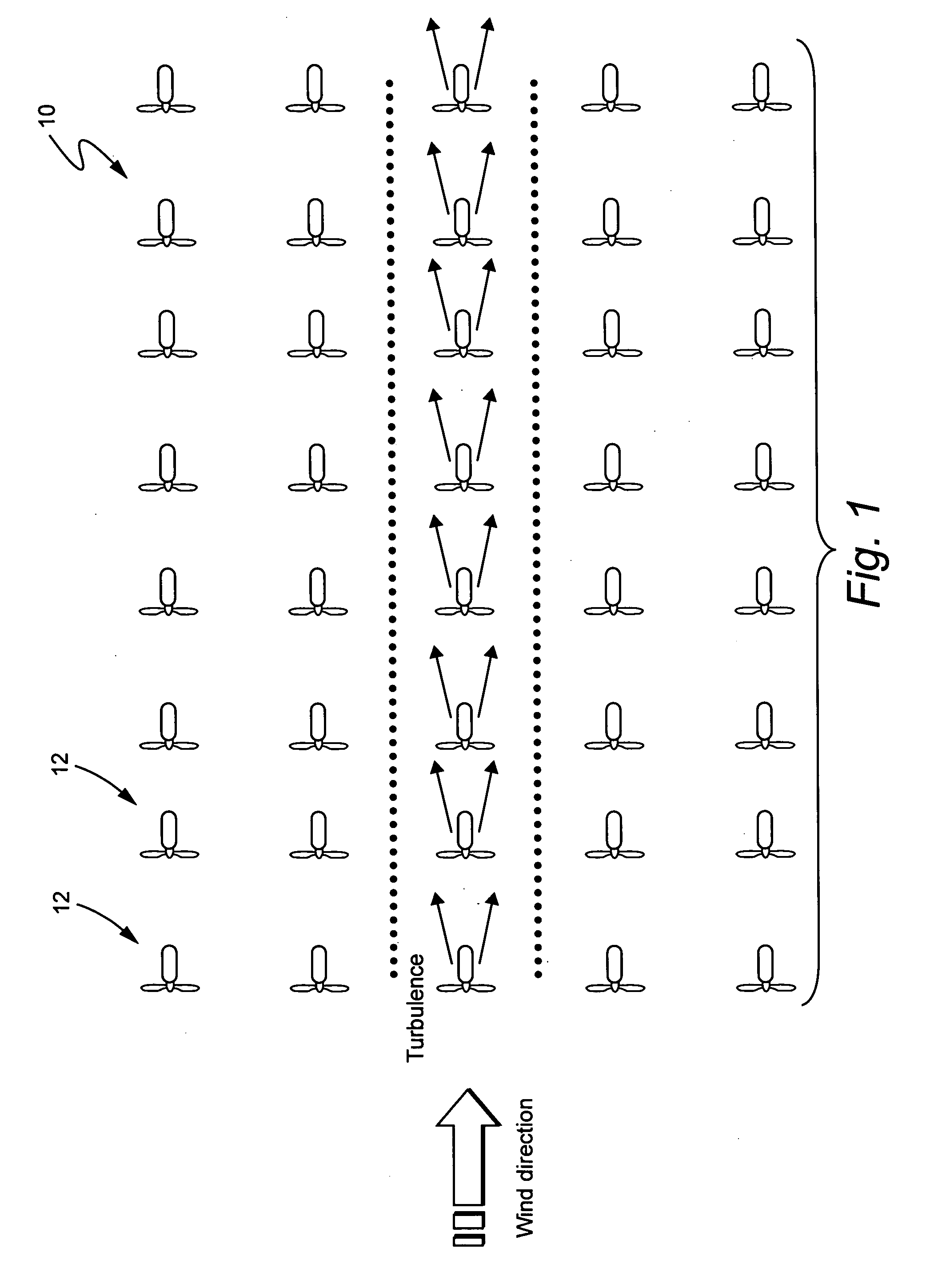

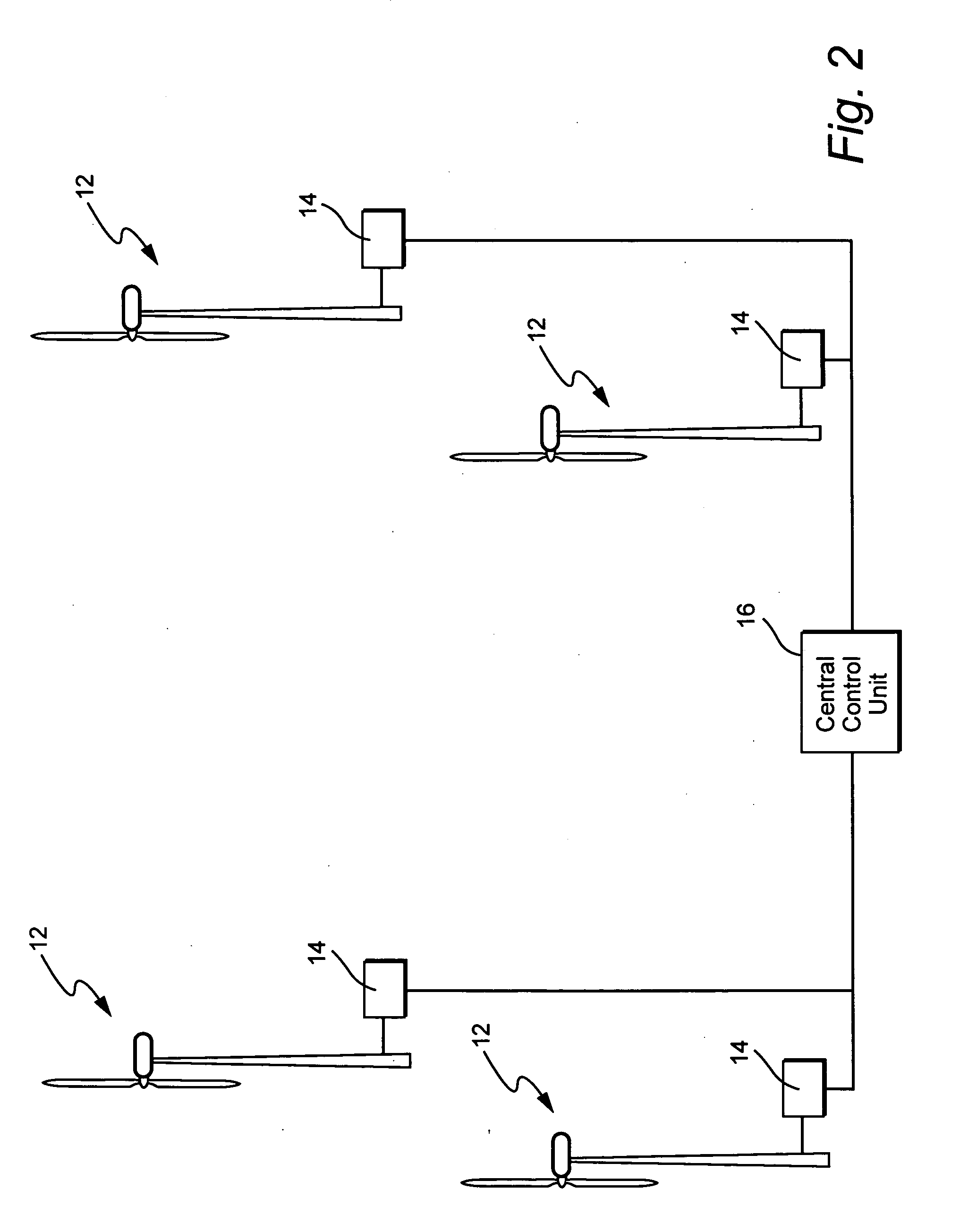

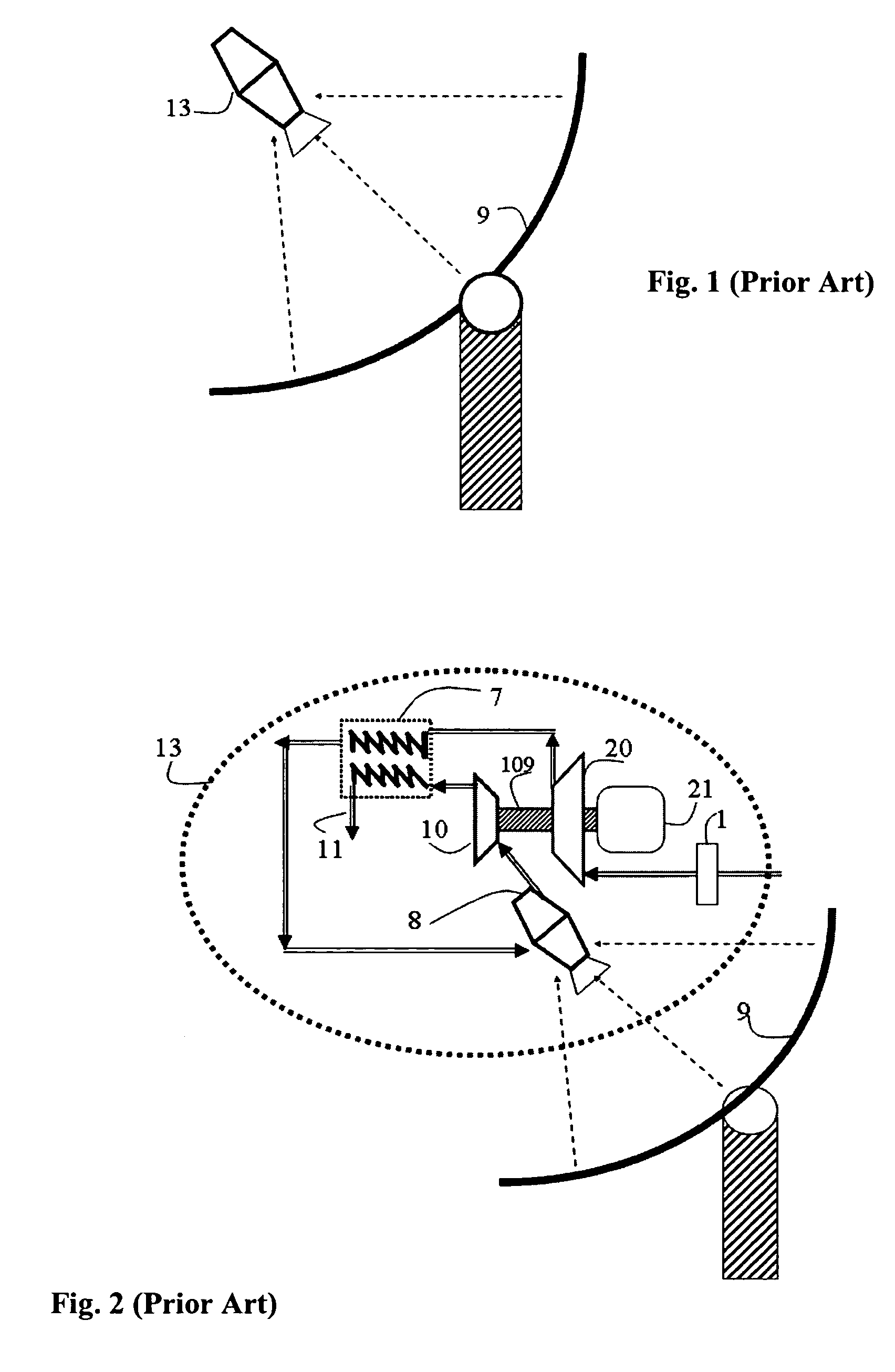

Windpark turbine control system and method for wind condition estimation and performance optimization

InactiveUS20070124025A1Minimize loading impactShorten speedLevel controlWind motor controlPower stationControl system

A method and system for controlling a windpark power plant includes a central processing and control unit operatively coupled to wind turbines in the windpark to receive data from and selectively transmit at least one of data and control signals to each wind turbine, to reduce fatigue loads and comply with power limits.

Owner:GENERAL ELECTRIC CO

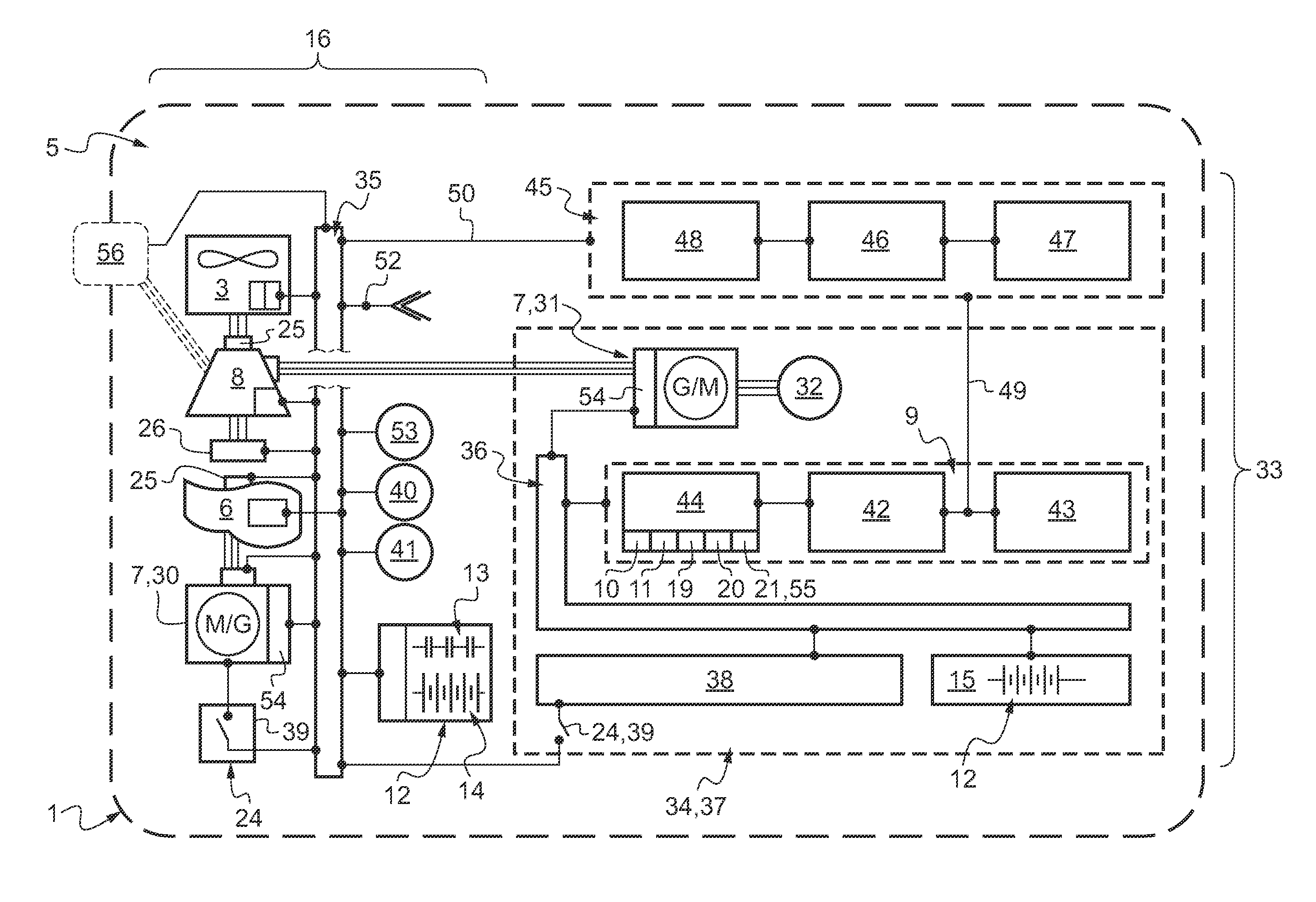

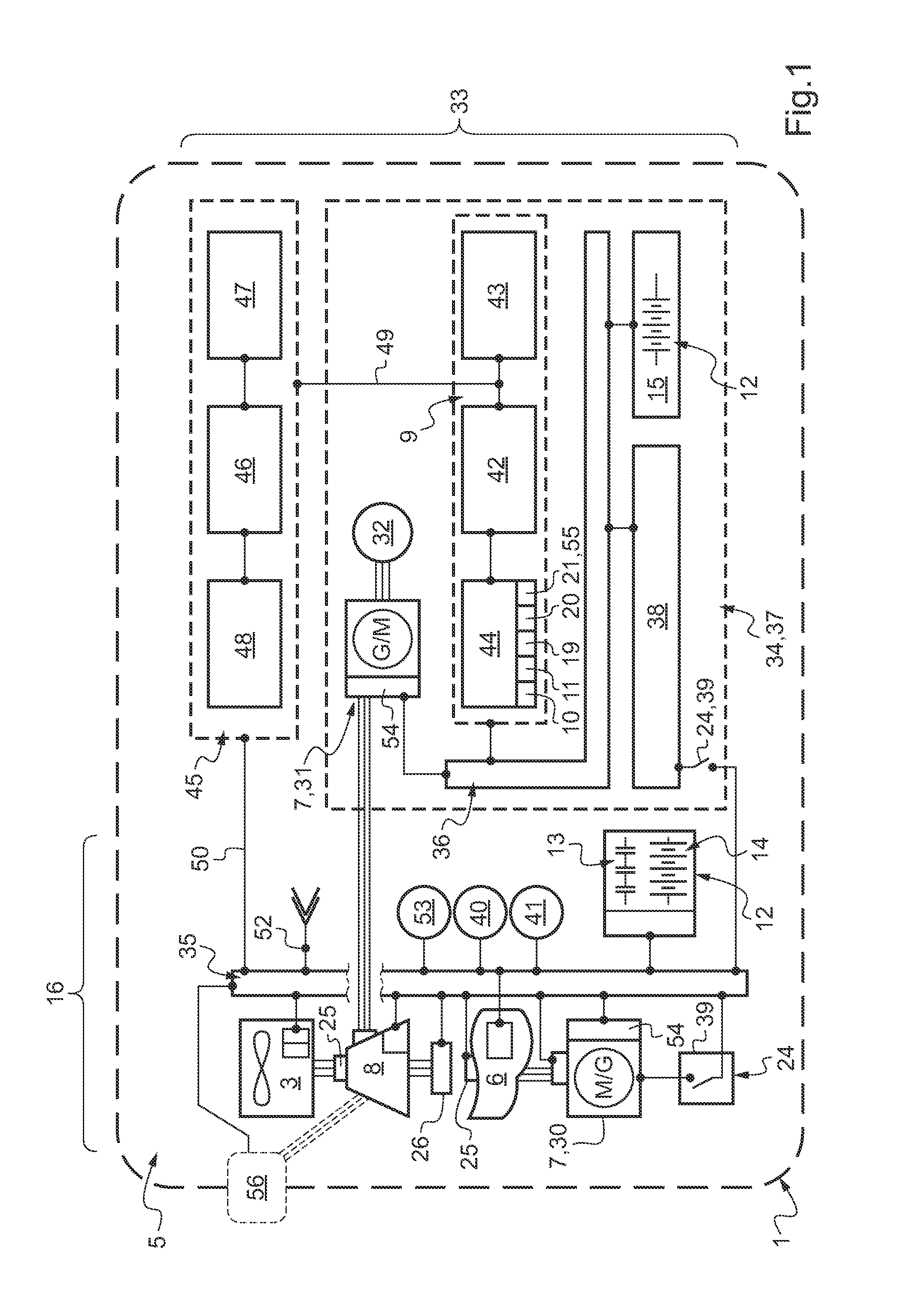

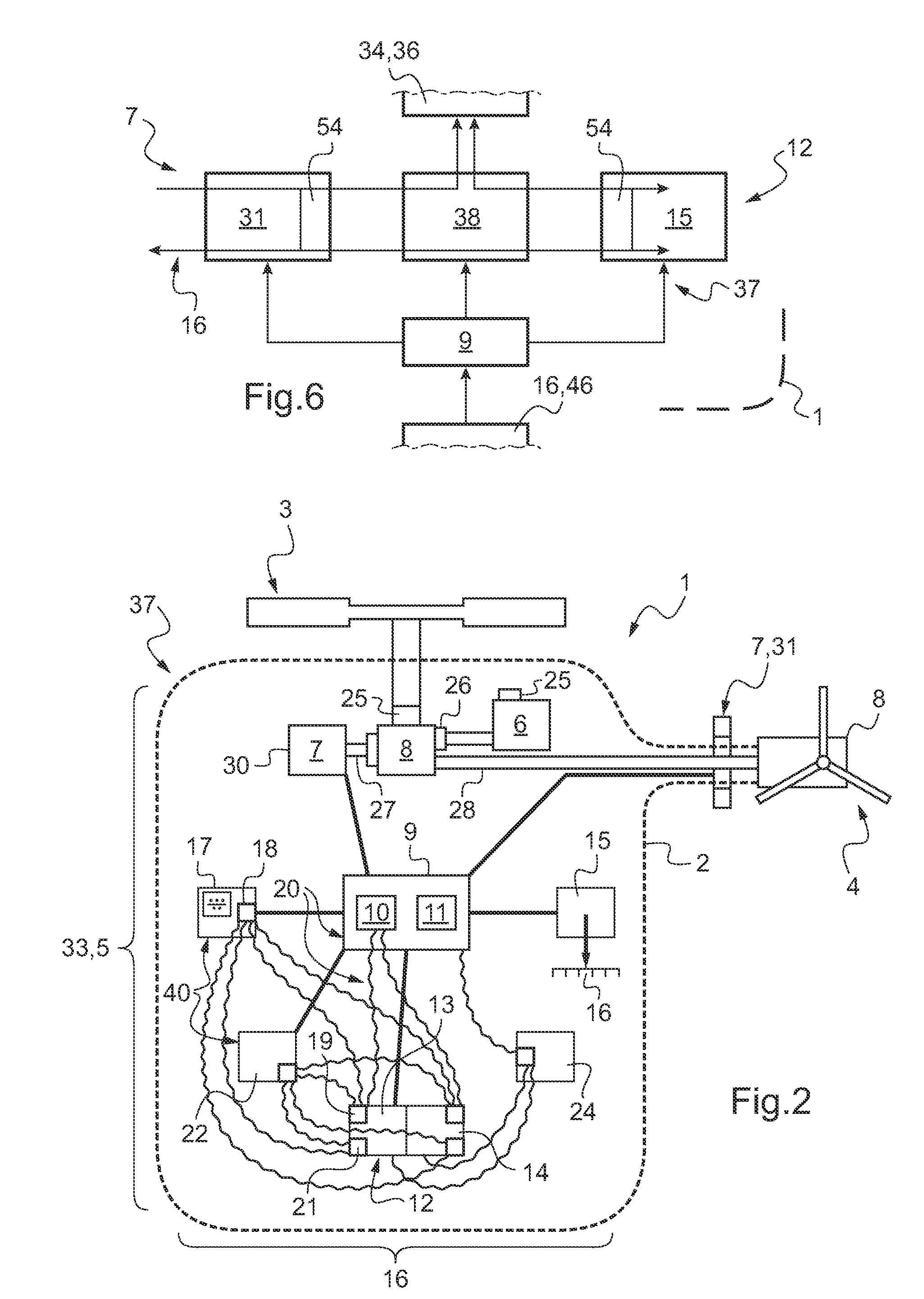

Electrical architecture for a rotary wing aircraft with a hybrid power plant

ActiveUS20120025032A1Reduce loadSave energy consumptionAircraft power plant componentsPropulsion by batteries/cellsOn boardEngineering

A hybrid power plant (5) for an aircraft (1) comprises at least: a hybrid drive system (37) having a main on-board electricity network (16) and an auxiliary electricity network (34); and a selective adaptation interface (38) arranged to enable electrical energy to be exchanged selectively between the main and auxiliary electricity networks (16; 34). At least one engine and a hybrid drive auxiliary electrical machine (7, 31) are mechanically connected to a transmission (8); said machine (7) being electrically connected to at least one auxiliary electrical bus (36) in parallel with at least one auxiliary device for delivering electric charge.

Owner:EUROCOPTER

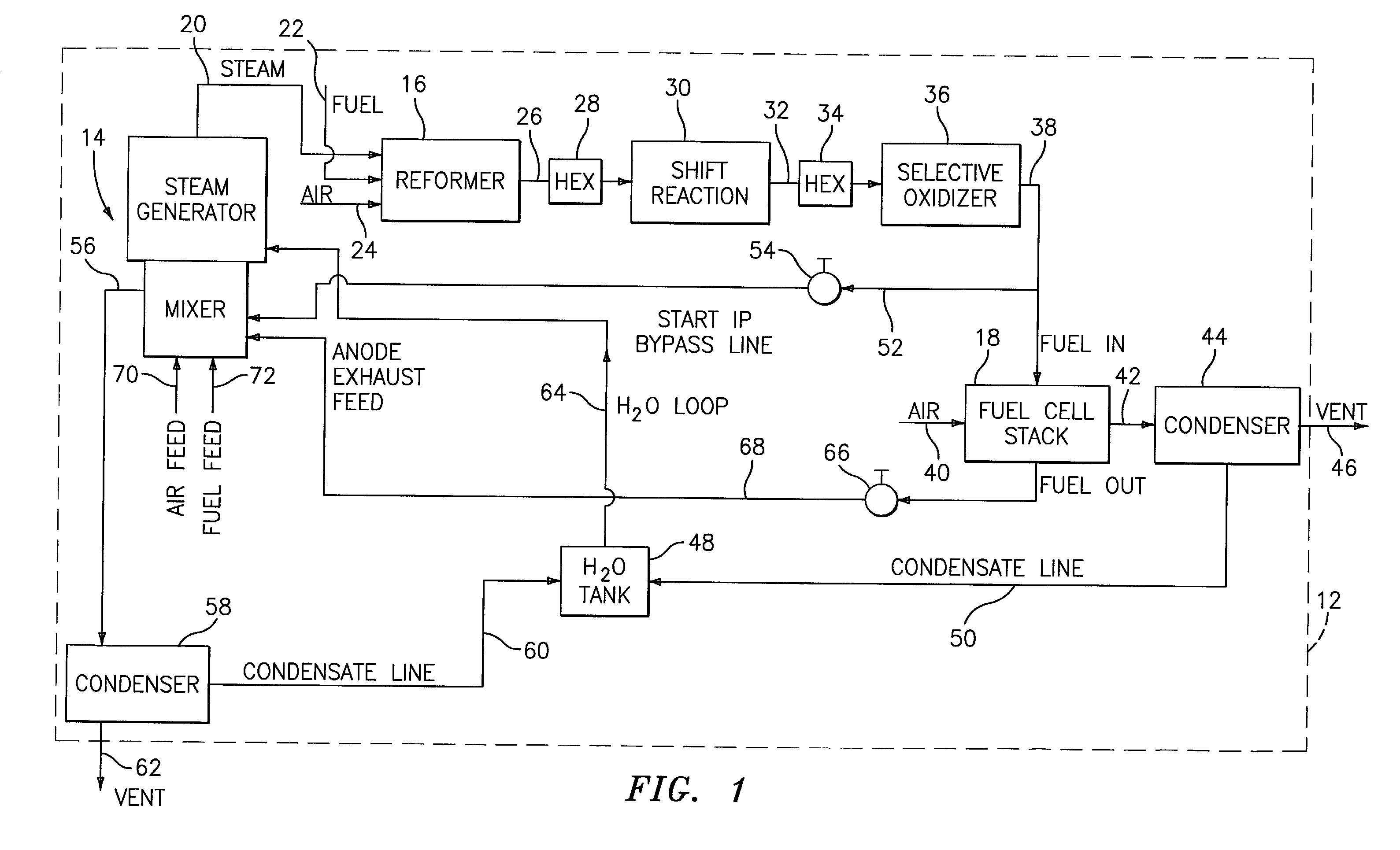

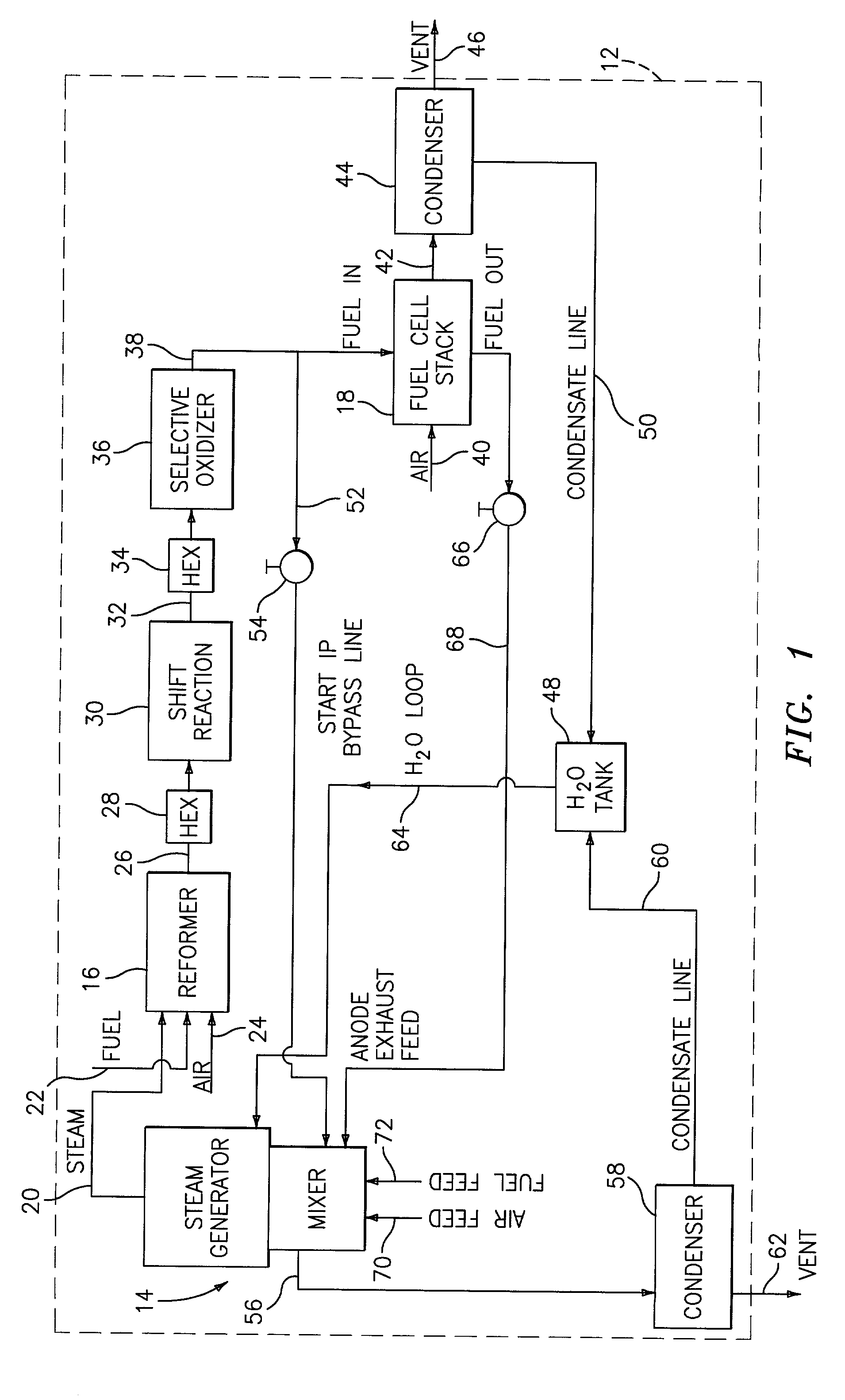

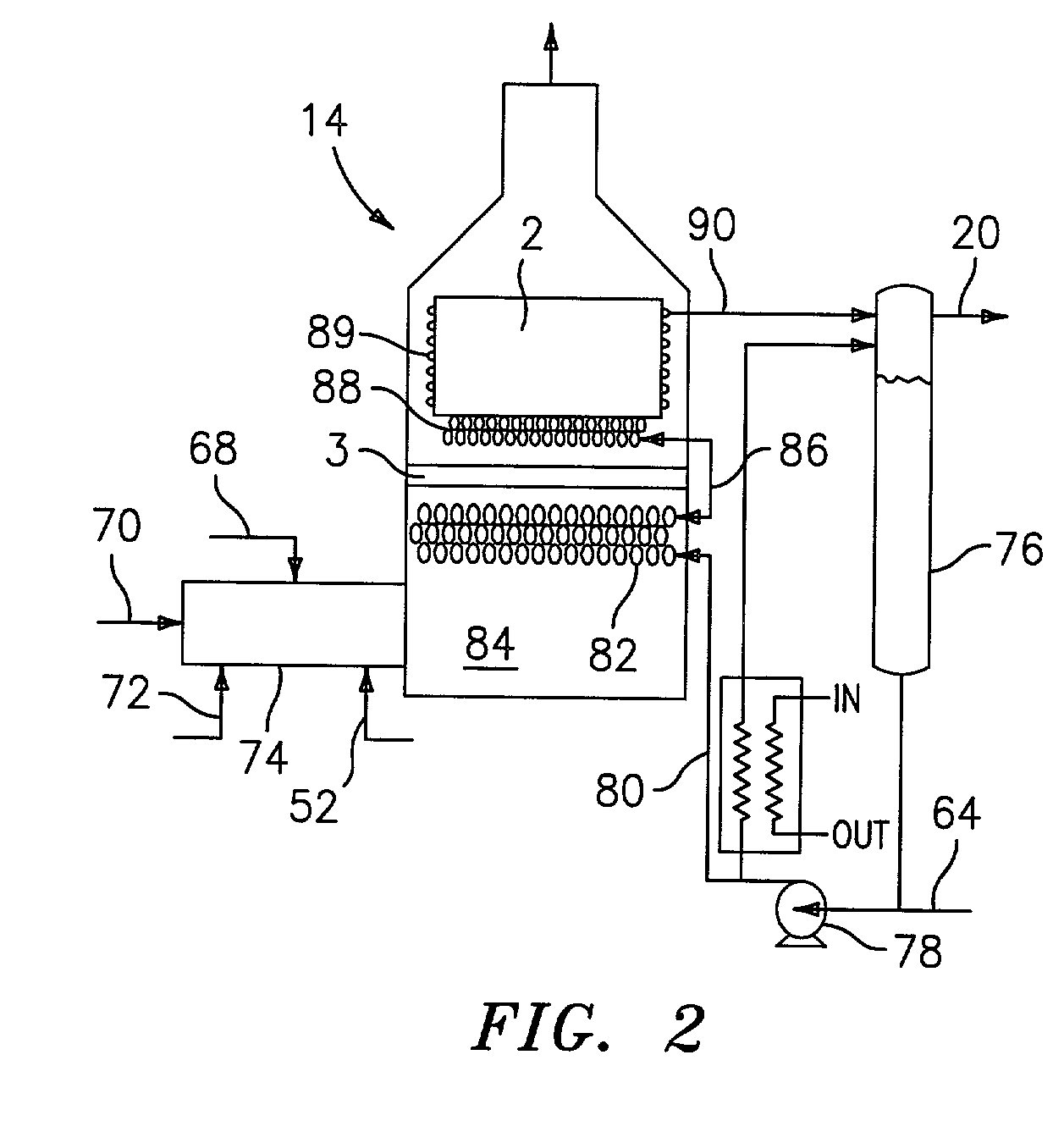

Steam generator for a PEM fuel cell power plant

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

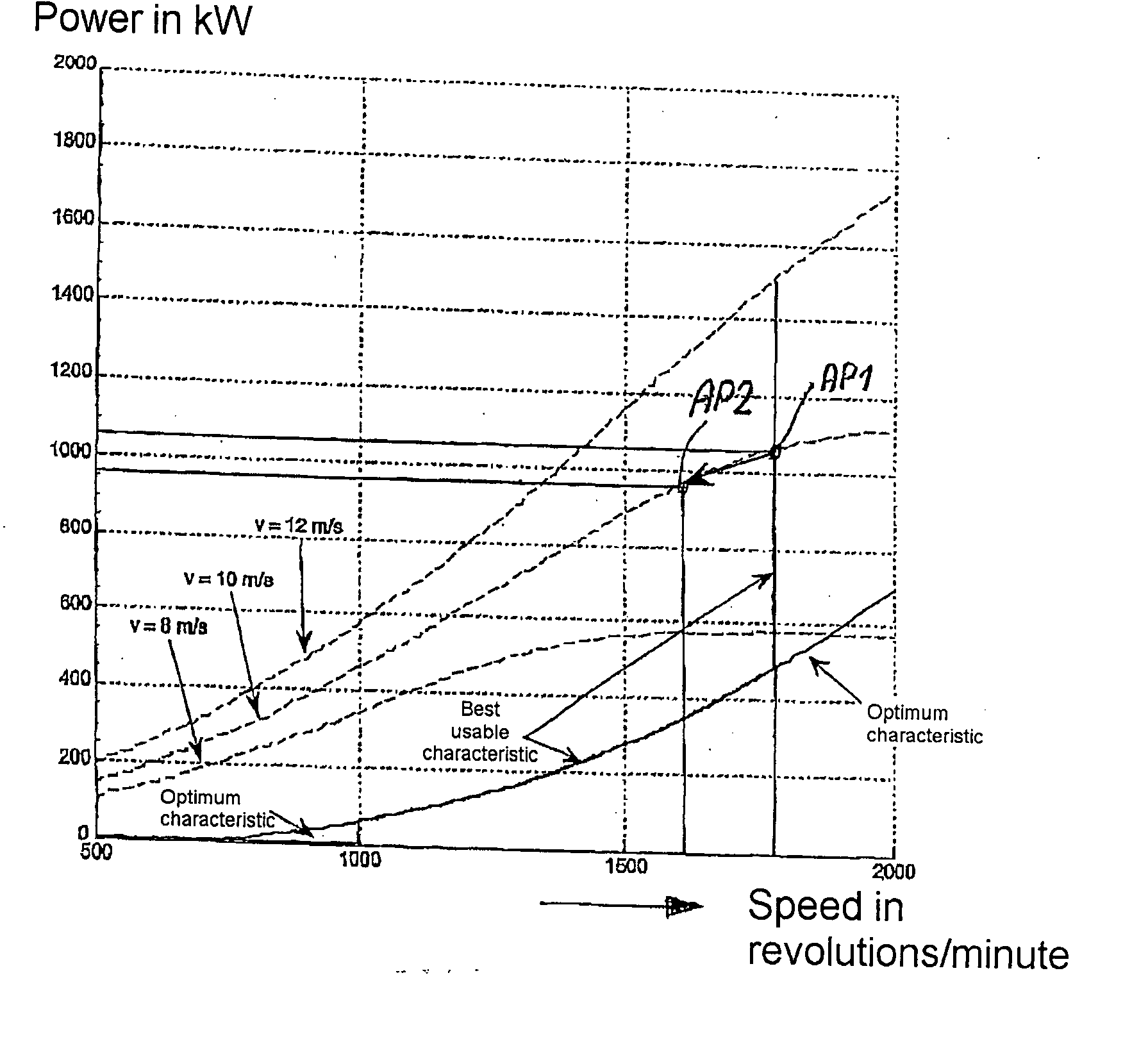

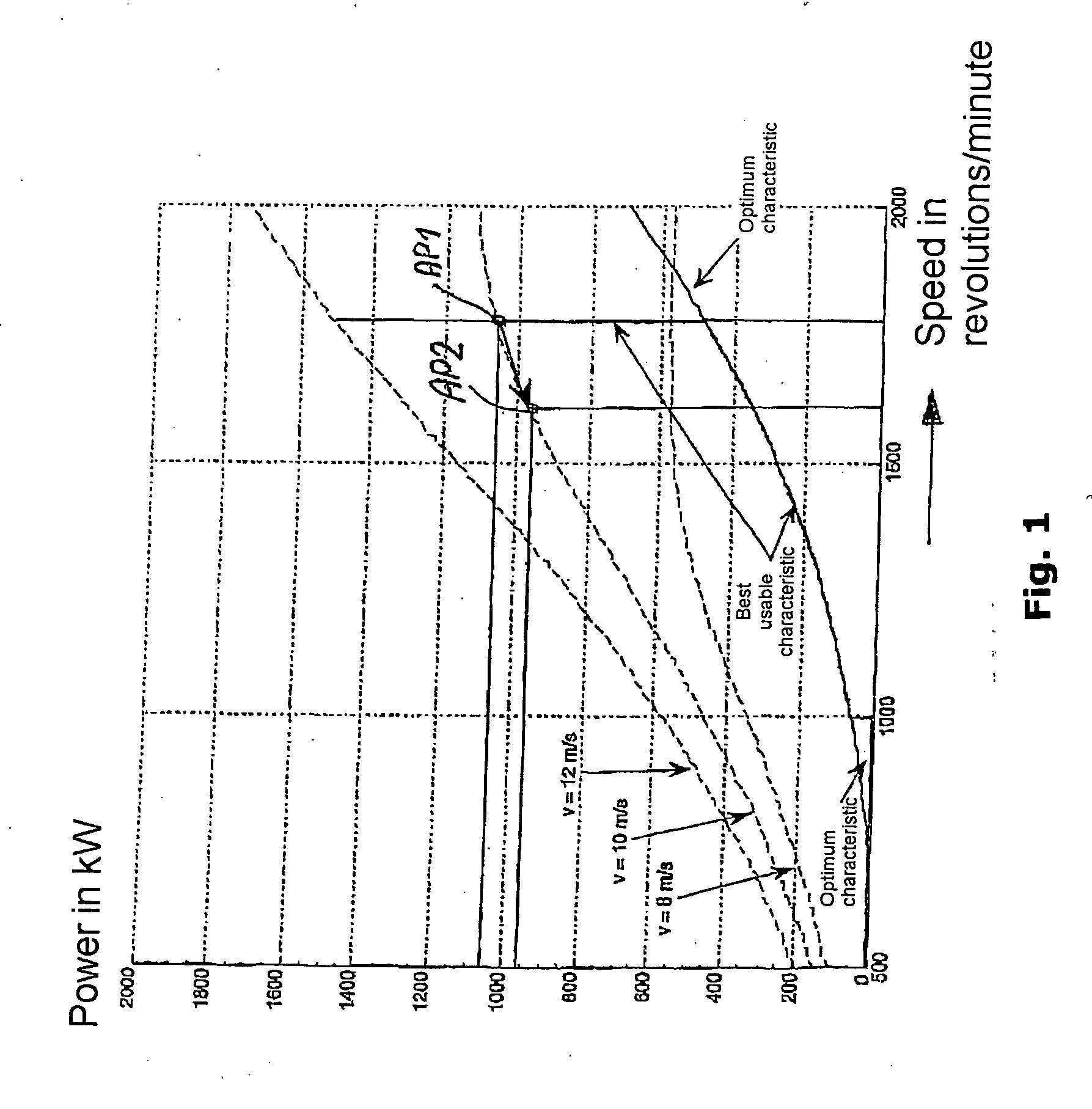

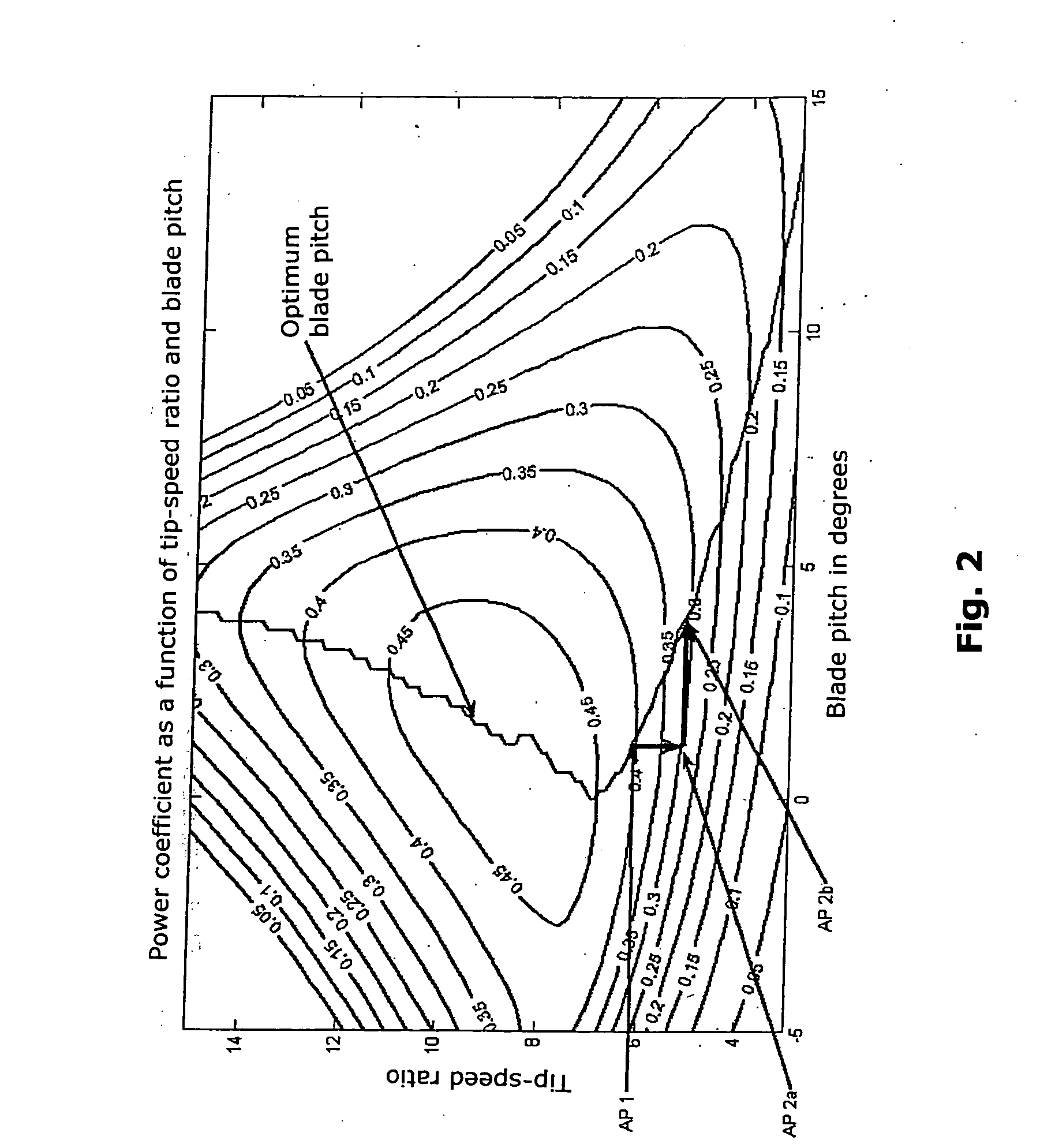

Method for operating or controlling a wind turbine and method for providing primary control power by means of wind turbines

ActiveUS20070085343A1Reduce yield lossImprove power transmissionWind motor controlSingle network parallel feeding arrangementsElectric forcePower station

A method for operating at least one wind turbine with a rotor and an electric generator coupled to the rotor for delivering electrical power into an energy distribution system with the aid of a control device ensures that the wind turbine operates within its operating range. The wind turbine is controlled in response to the change of a system operating parameter and for a period of time, in such a manner that a higher power is fed into the system than belongs to the operating range of the steady-state operation. The same conditions also apply to a method for providing control power or primary control power for an electric energy generator and distributor system to which a multiplicity of power stations including wind turbines is connected, and to a wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

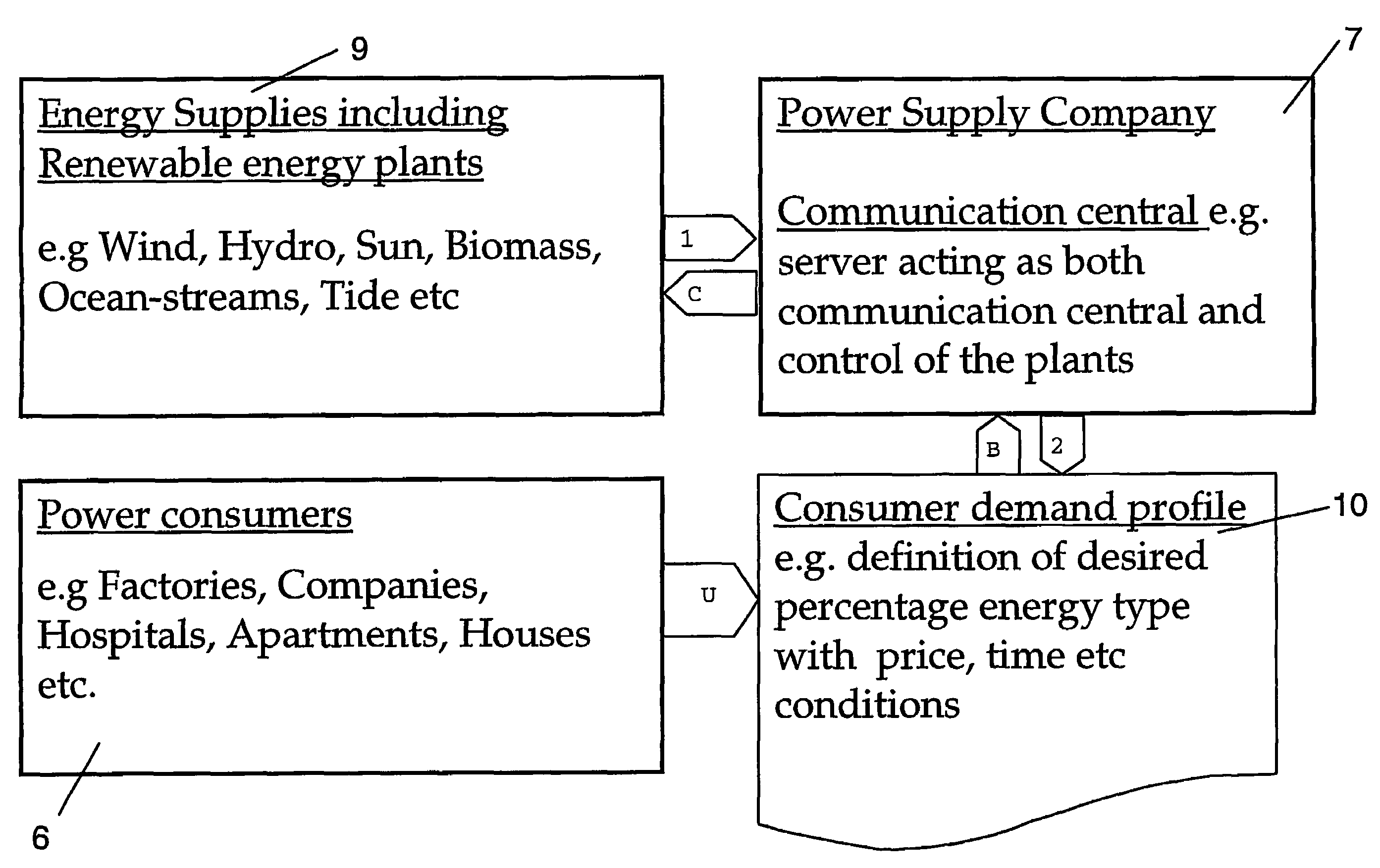

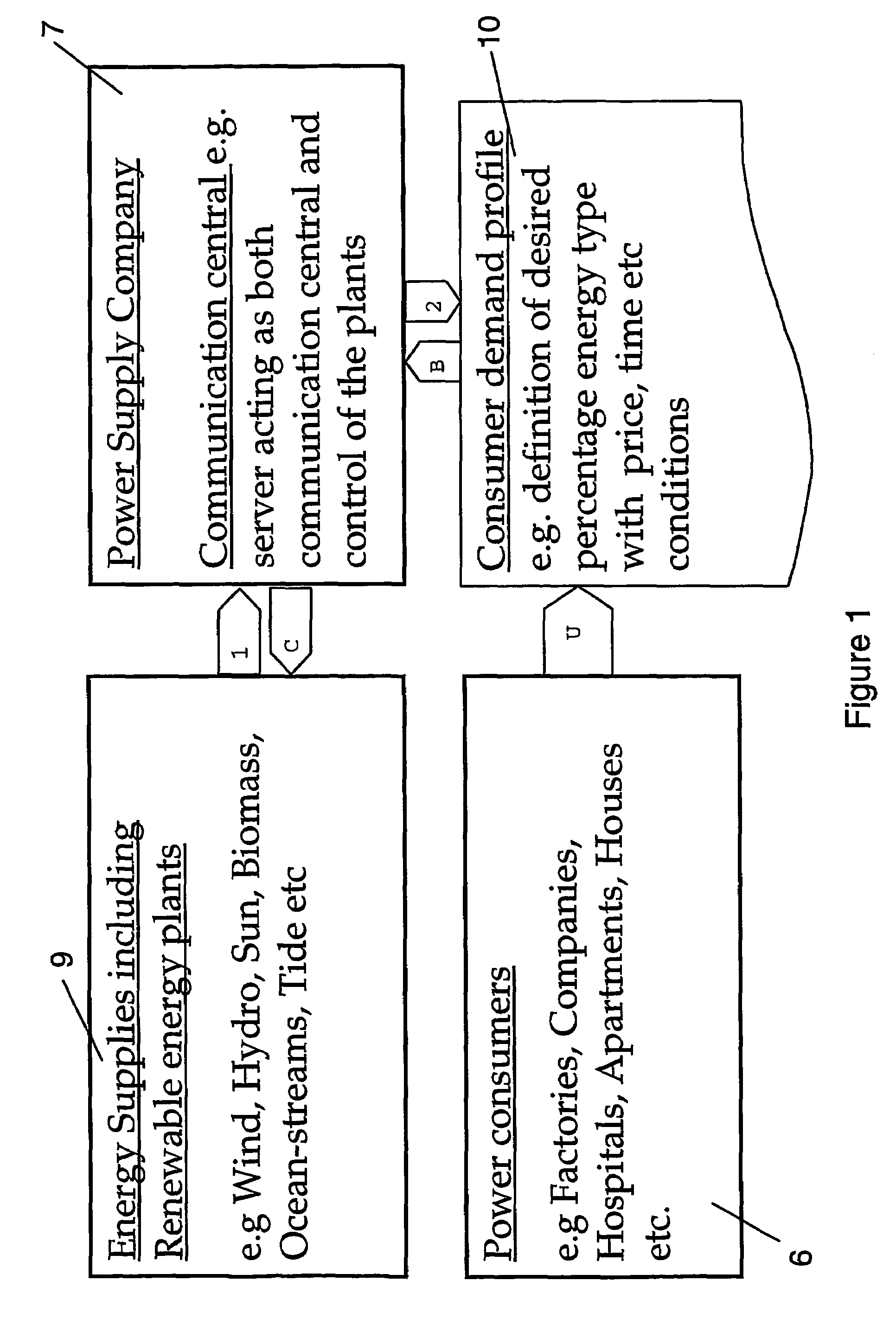

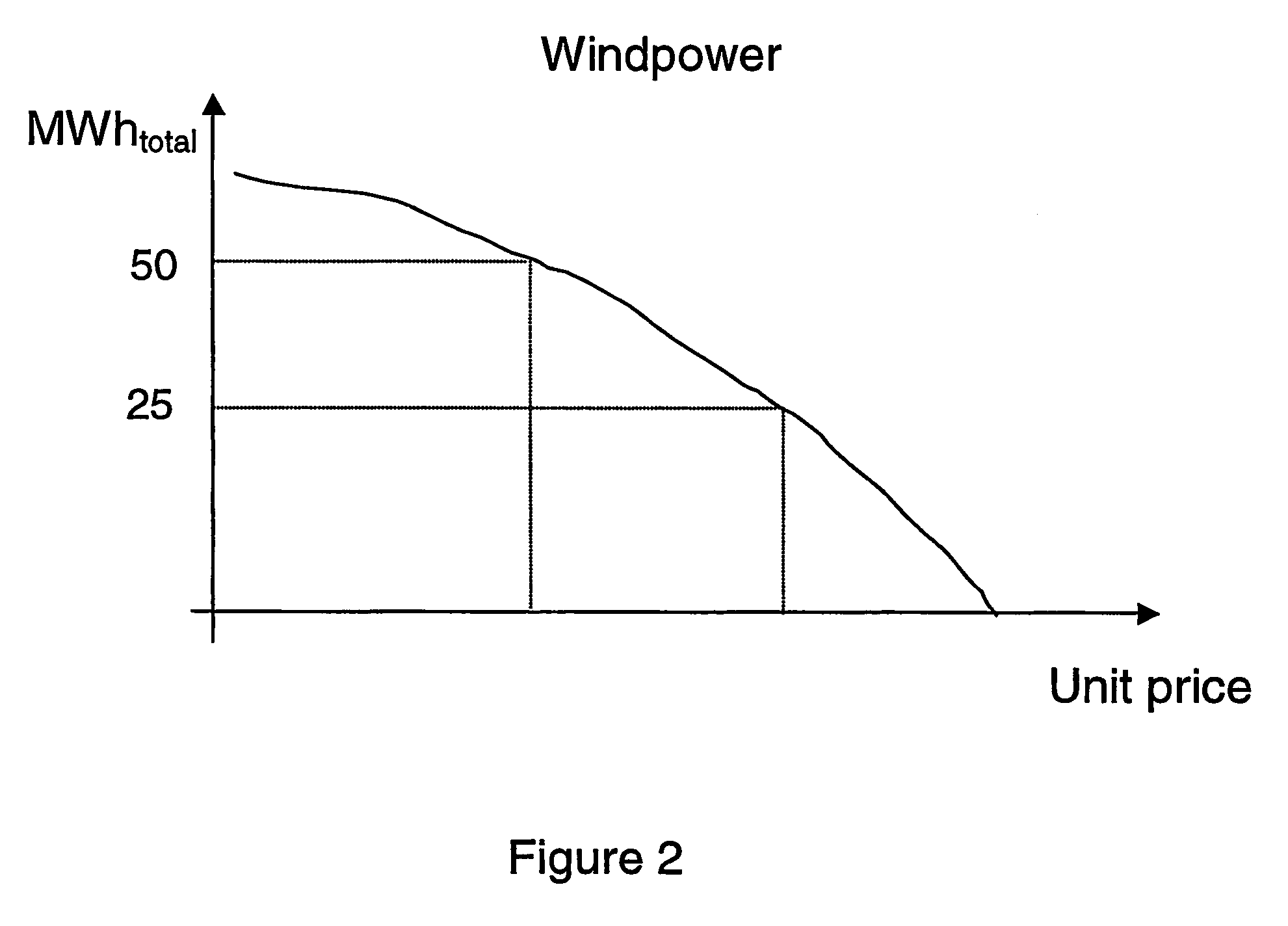

Method and system to calculate a demand for energy

A method to calculate energy demand in an energy generation, transmission and distribution network including one or more power plants based on different energy source types including renewable energy, a communications system and one or more local consumption metering units. A customer demand profile for one or more customers is provided. A customer-specified proportion of power demand to be supplied from a given energy source type is registered. A total predicted energy demand dependent is calculated in part on an accumulated demand for the given energy source type.

Owner:HITACHI ENERGY SWITZERLAND AG

Power conversion systems

Power generation systems and methods are provided with features directed to various innovations including ones relating to the conversion of concentrated solar and biomass energy to electricity, load-shifting of electrical power supply systems, gas turbine devices and cycles, and power plant control systems.

Owner:BRAYTON ENERGY

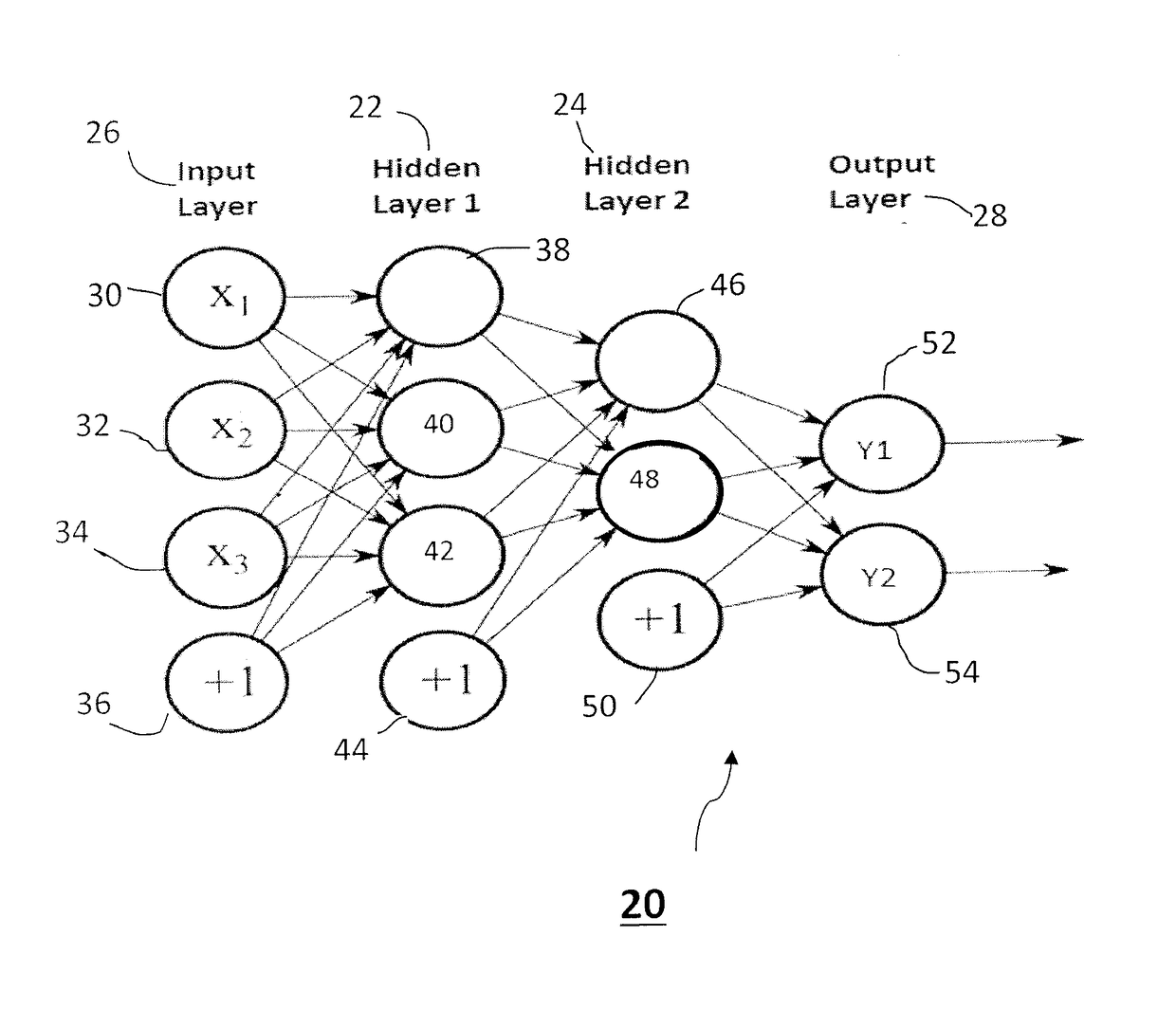

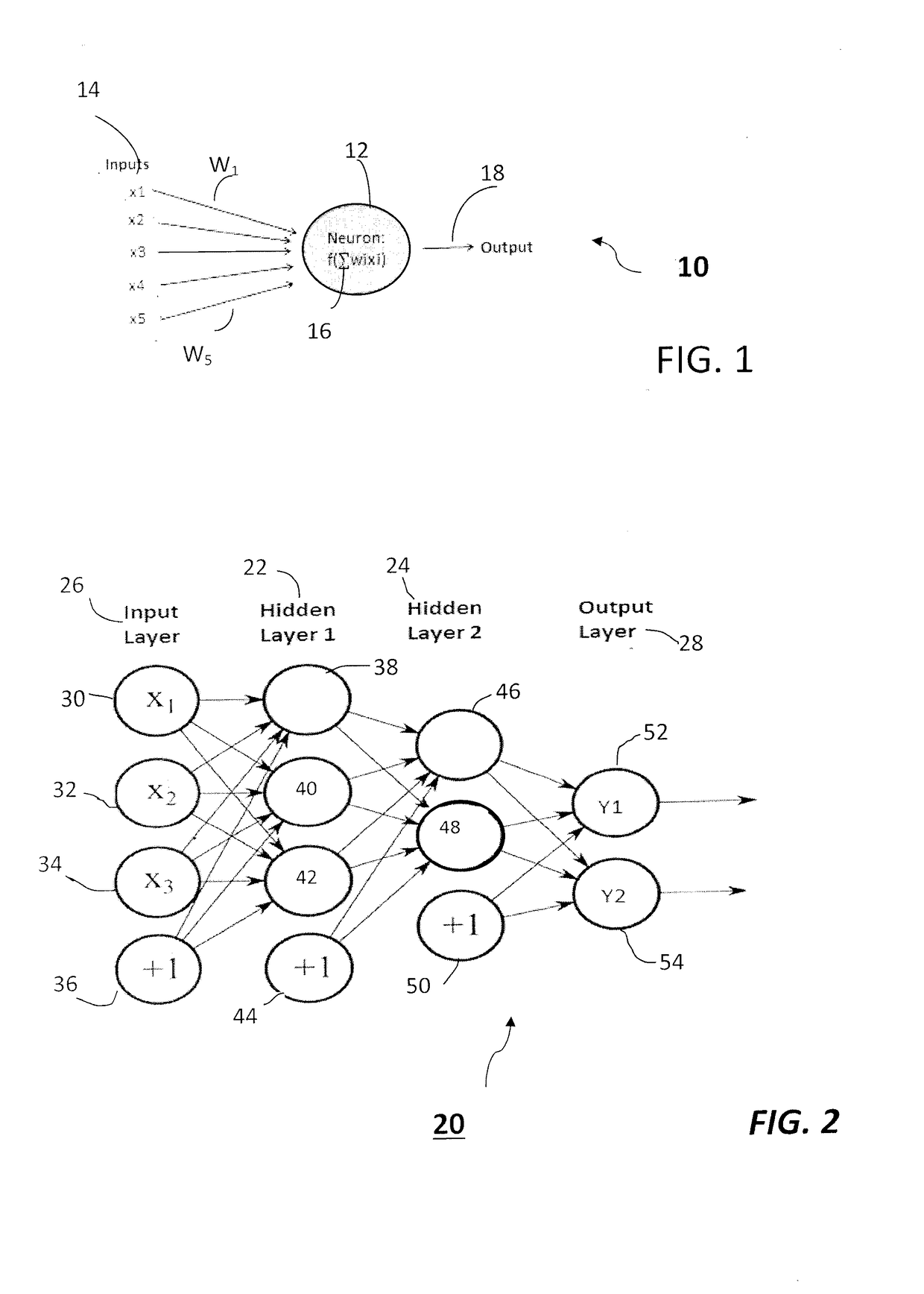

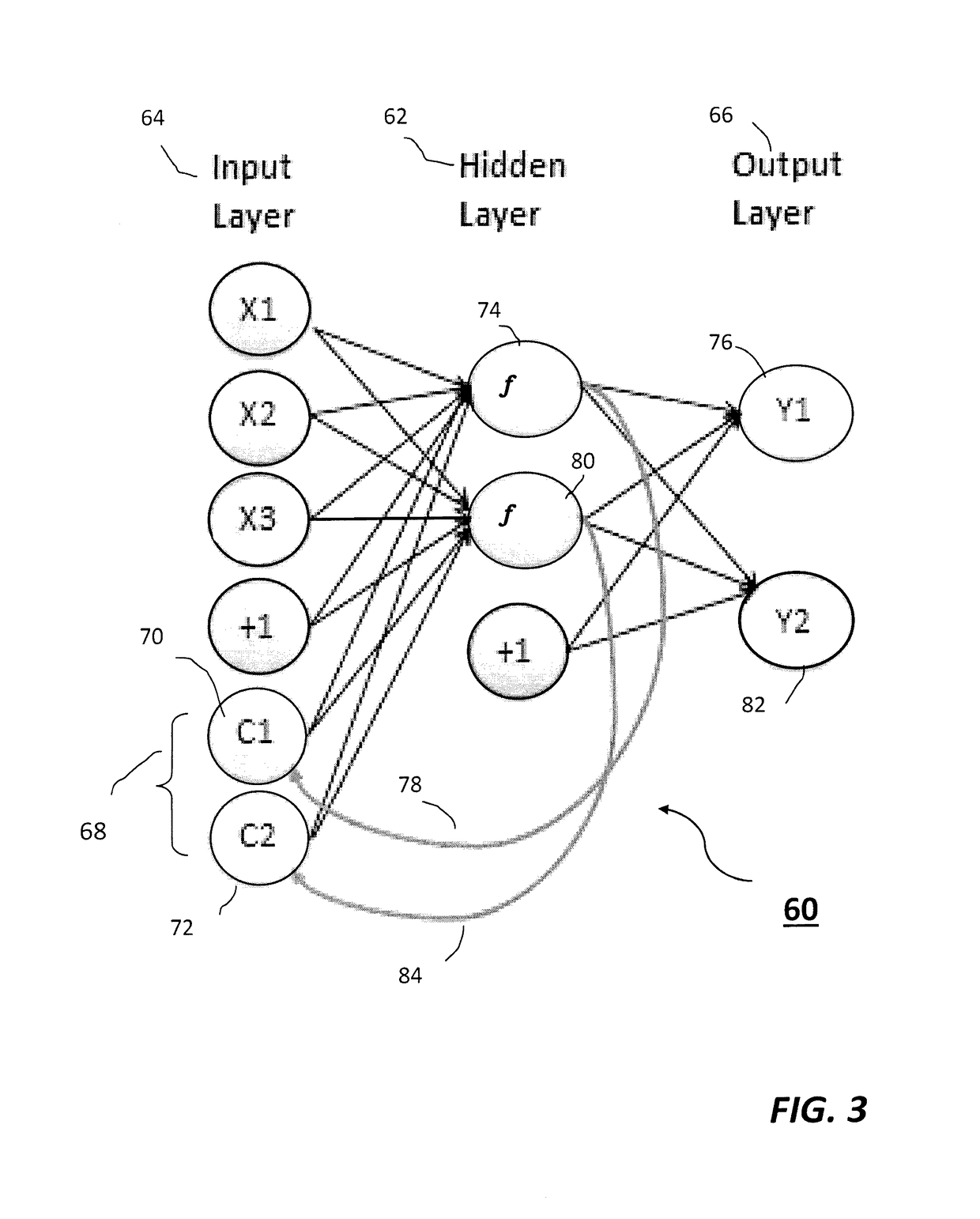

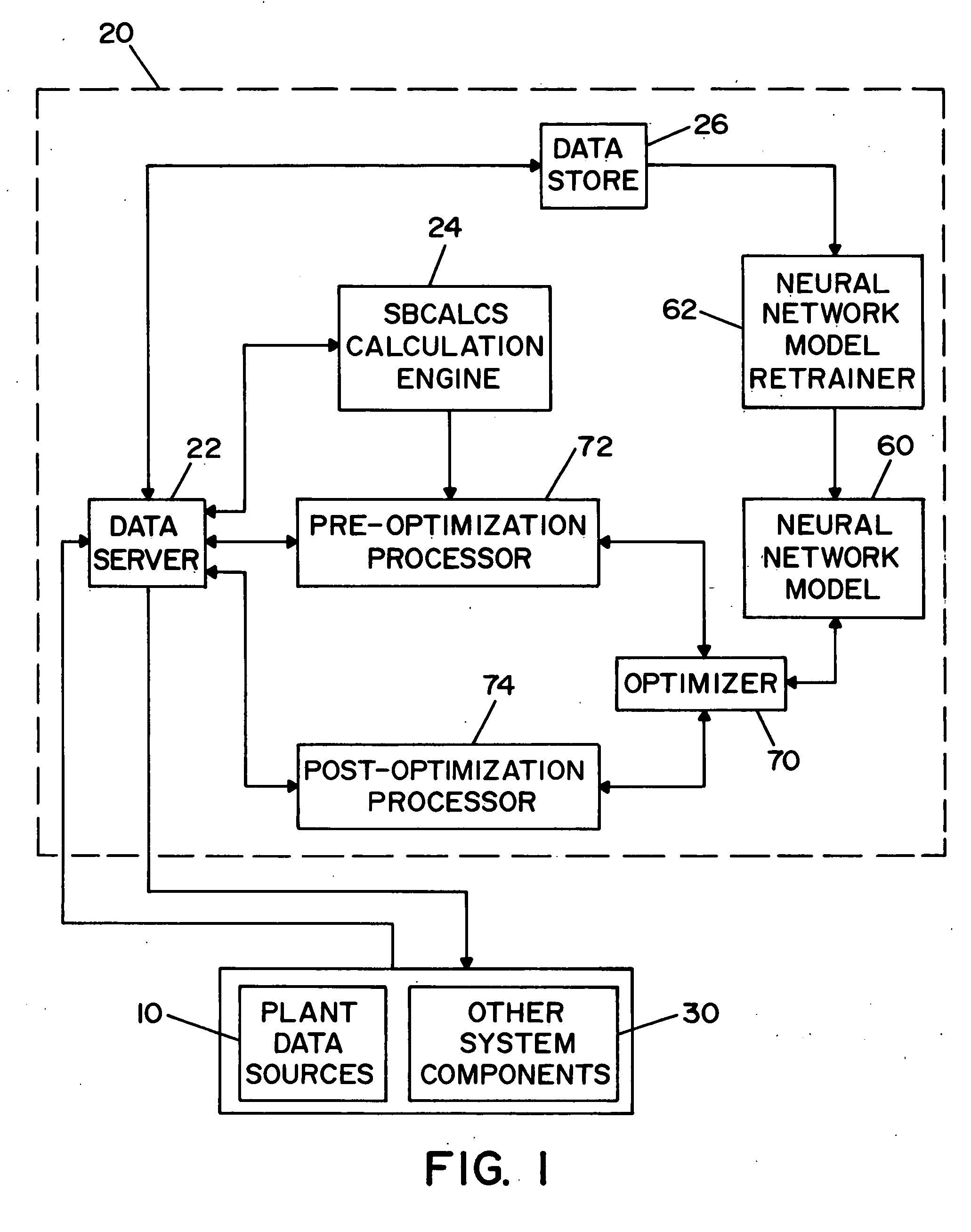

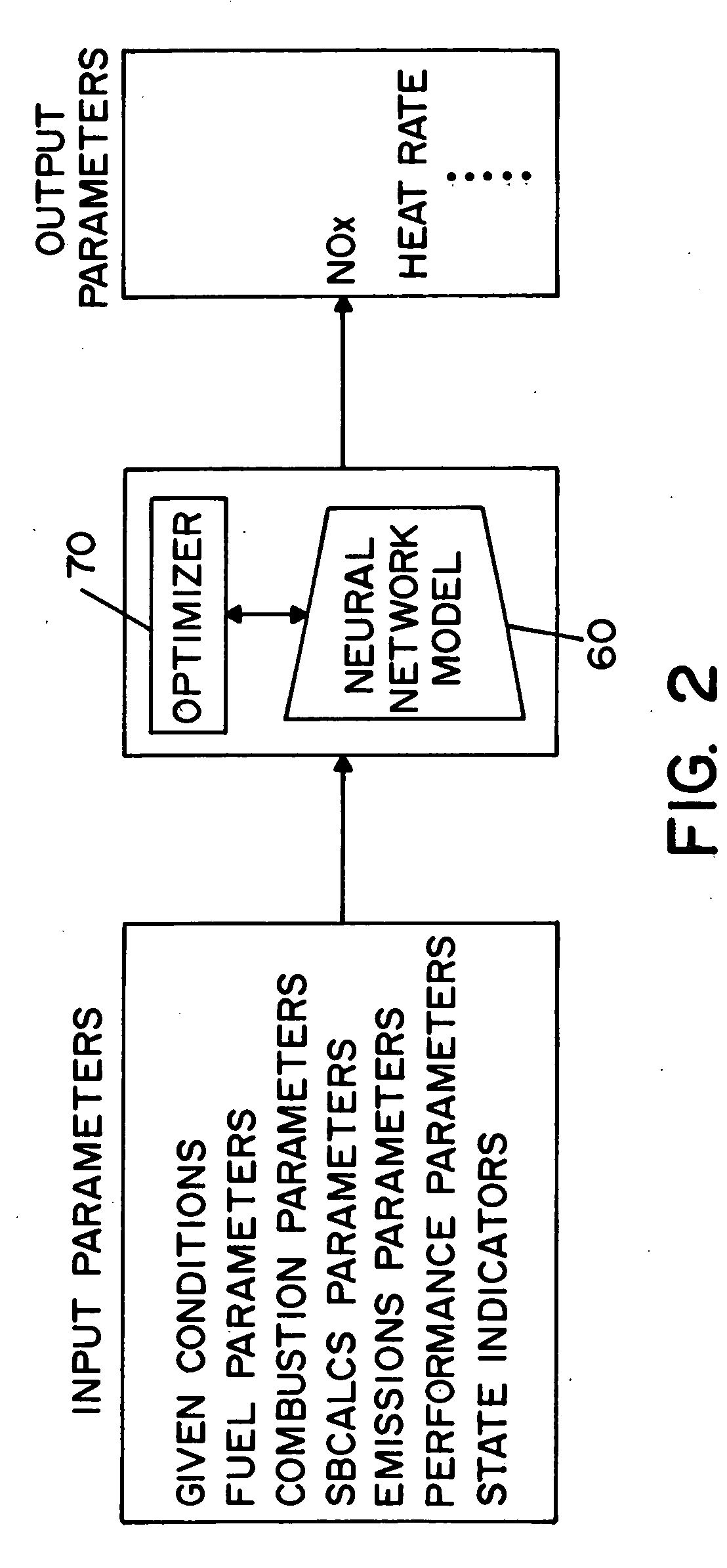

System and method for predicting power plant operational parameters utilizing artificial neural network deep learning methodologies

A system and method of predicting future power plant operations is based upon an artificial neural network model including one or more hidden layers. The artificial neural network is developed (and trained) to build a model that is able to predict future time series values of a specific power plant operation parameter based on prior values. By accurately predicting the future values of the time series, power plant personnel are able to schedule future events in a cost-efficient, timely manner. The scheduled events may include providing an inventory of replacement parts, determining a proper number of turbines required to meet a predicted demand, determining the best time to perform maintenance on a turbine, etc. The inclusion of one or more hidden layers in the neural network model creates a prediction that is able to follow trends in the time series data, without overfitting.

Owner:SIEMENS AG

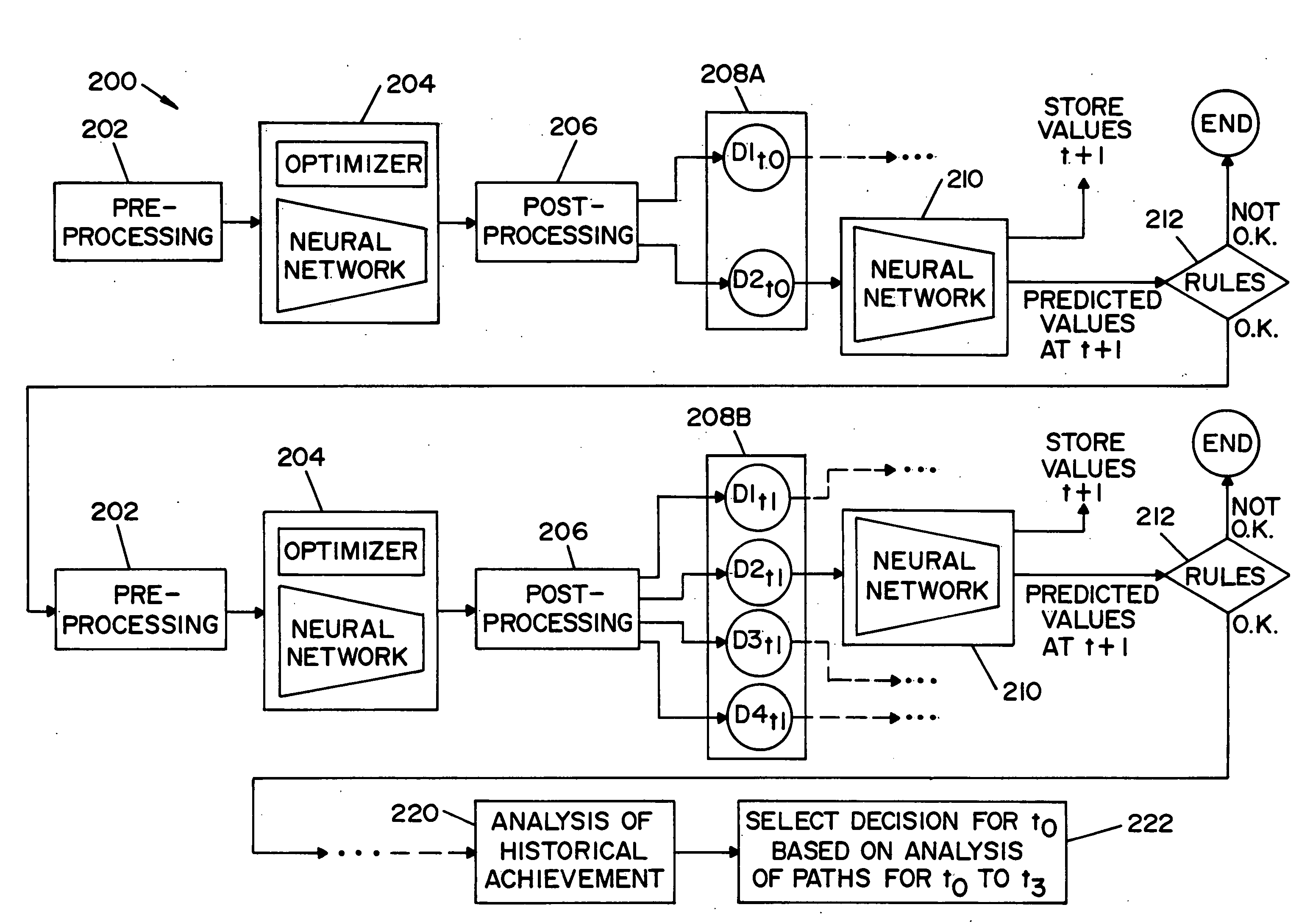

Method and apparatus for optimizing operation of a power generating plant using artificial intelligence techniques

ActiveUS20060178762A1Easy to cleanAccelerate buildingTemperatue controlAdaptive controlPower stationProcess engineering

A method and apparatus for optimizing the operation of a power generating plant using artificial intelligence techniques. One or more decisions D are determined for at least one consecutive time increment, where at least one of the decisions D is associated with a discrete variable for the operation of a power plant device in the power generating plant. In an illustrated embodiment, the power plant device is a soot cleaning device associated with a boiler.

Owner:GENERAL ELECTRIC CO

Method for operating a power plant by means of a CO2 process

InactiveUS7089743B2Retreatment is simpler and less expensiveInternal combustion piston enginesGas turbine plantsCombustionPower station

Owner:ALSTOM SA

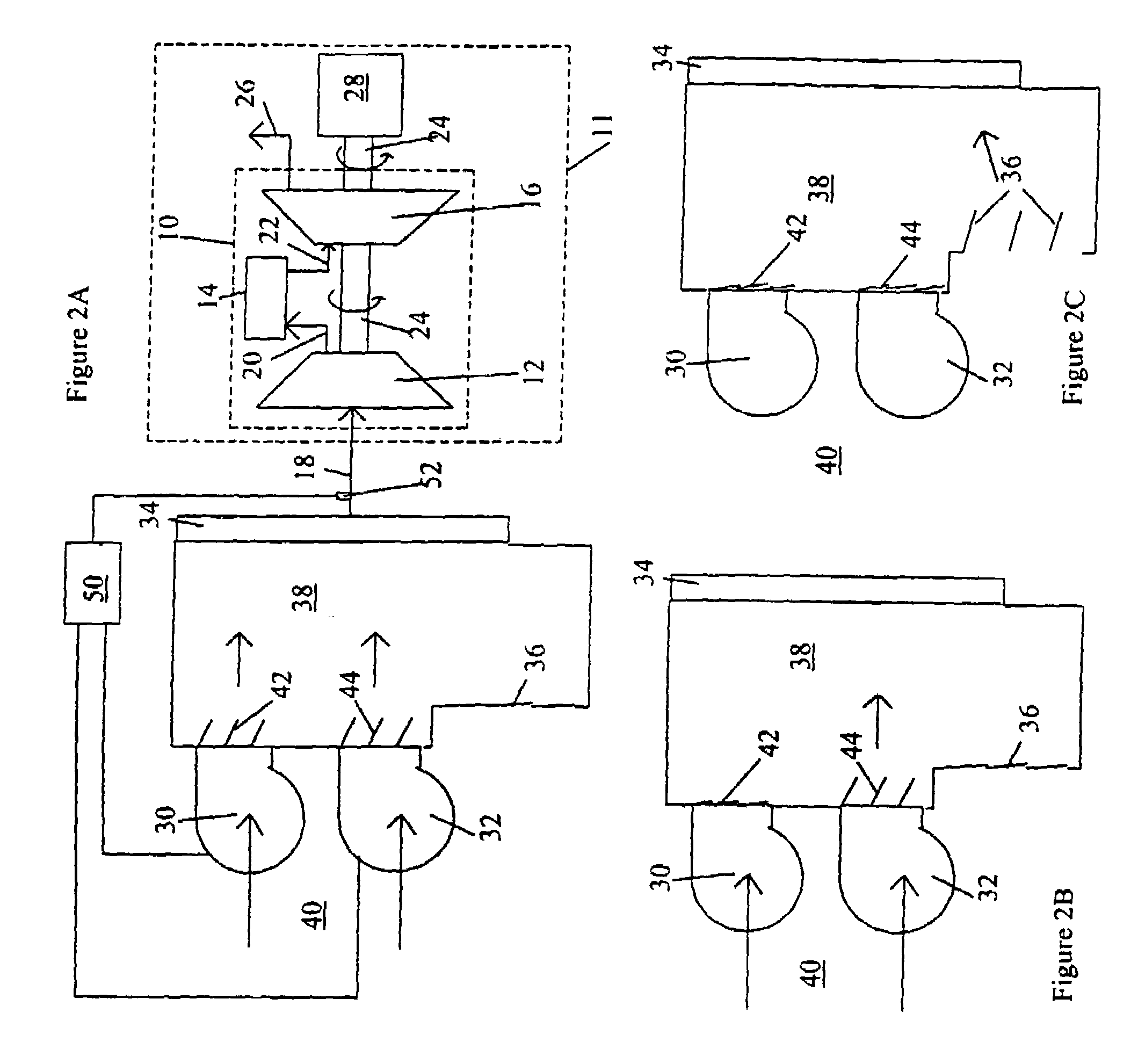

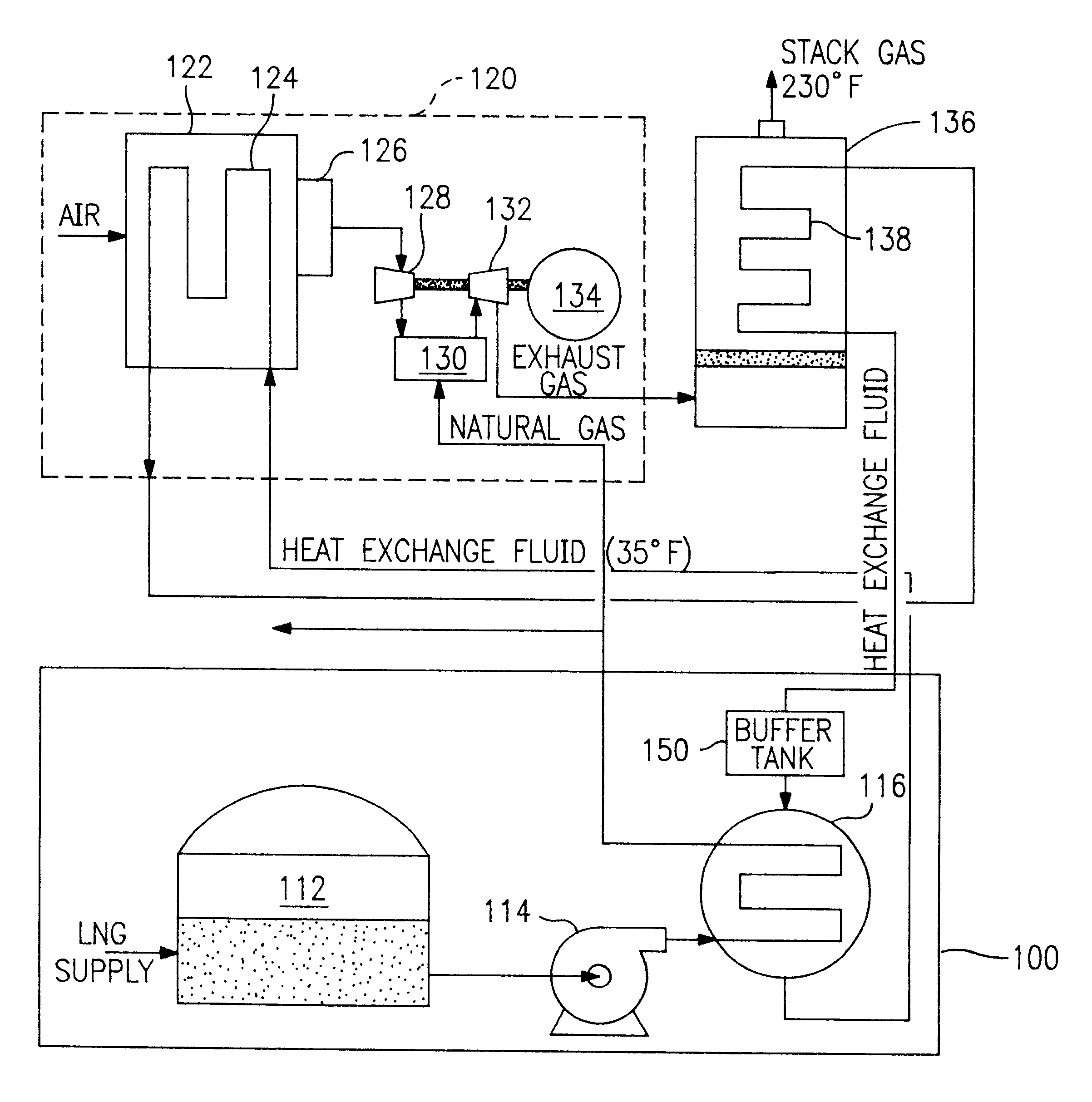

Liquified natural gas (LNG) fueled combined cycle power plant and a (LNG) fueled gas turbine plant

InactiveUS6374591B1Improve efficiencyParts are smallGas handling applicationsGas turbine plantsCombustion chamberPower station

A process and system which improves the capacity and efficiency of a power plant. A LNG supply system fuels the plant. Gasified LNG in a combustor mixes with the air from an air compressor to provide the hot combustion gas for a gas turbine. The expanding LNG is used to chill a heat exchange fluid, e.g. water, which heat exchange fluid cools and densifies the intake air for the air compressor. Subsequently, the heat exchange fluid is used in another heat exchange step and is then re-chilled and recycled to cool and densify the intake air.

Owner:SUEZ LNG NA

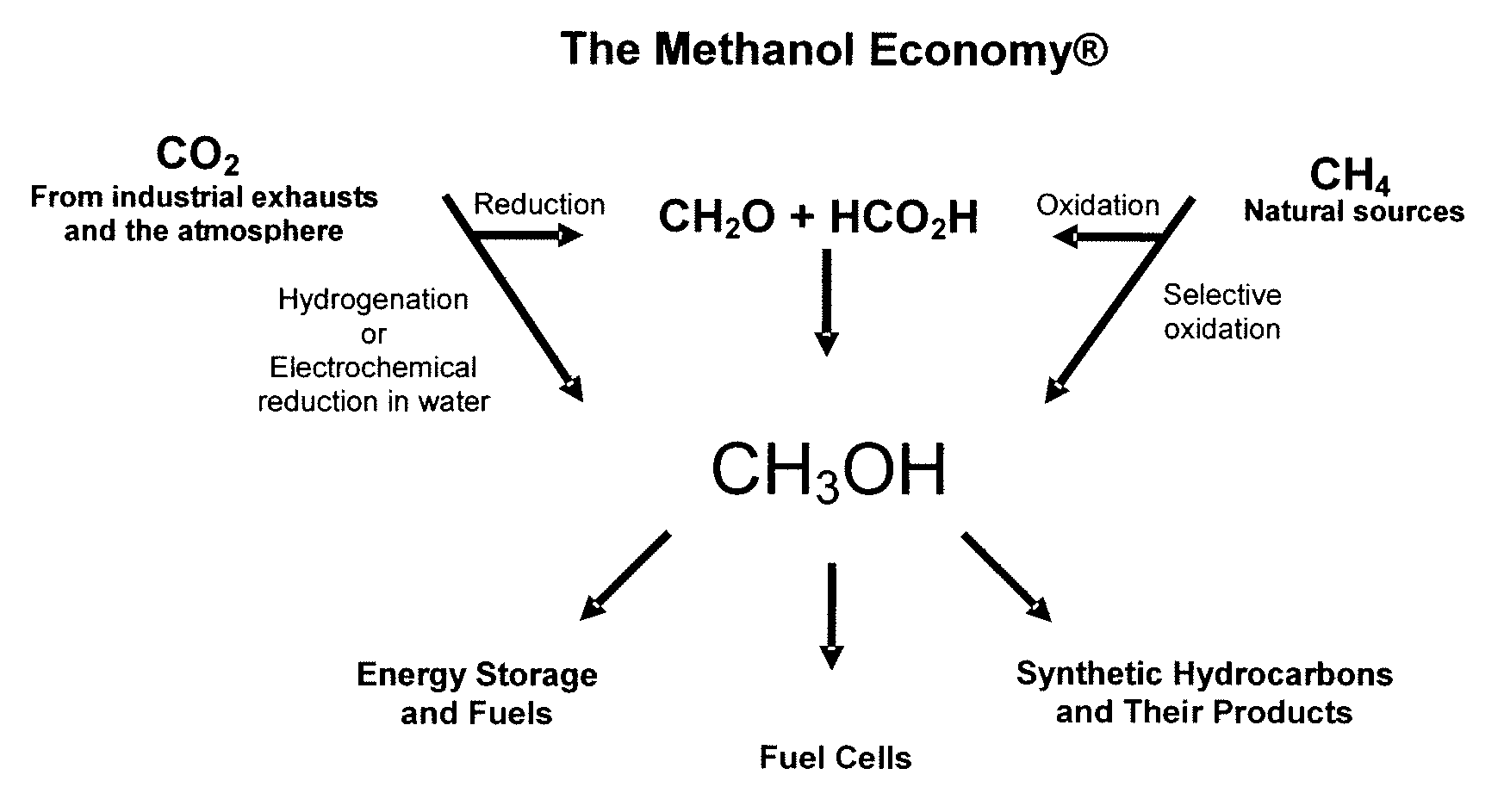

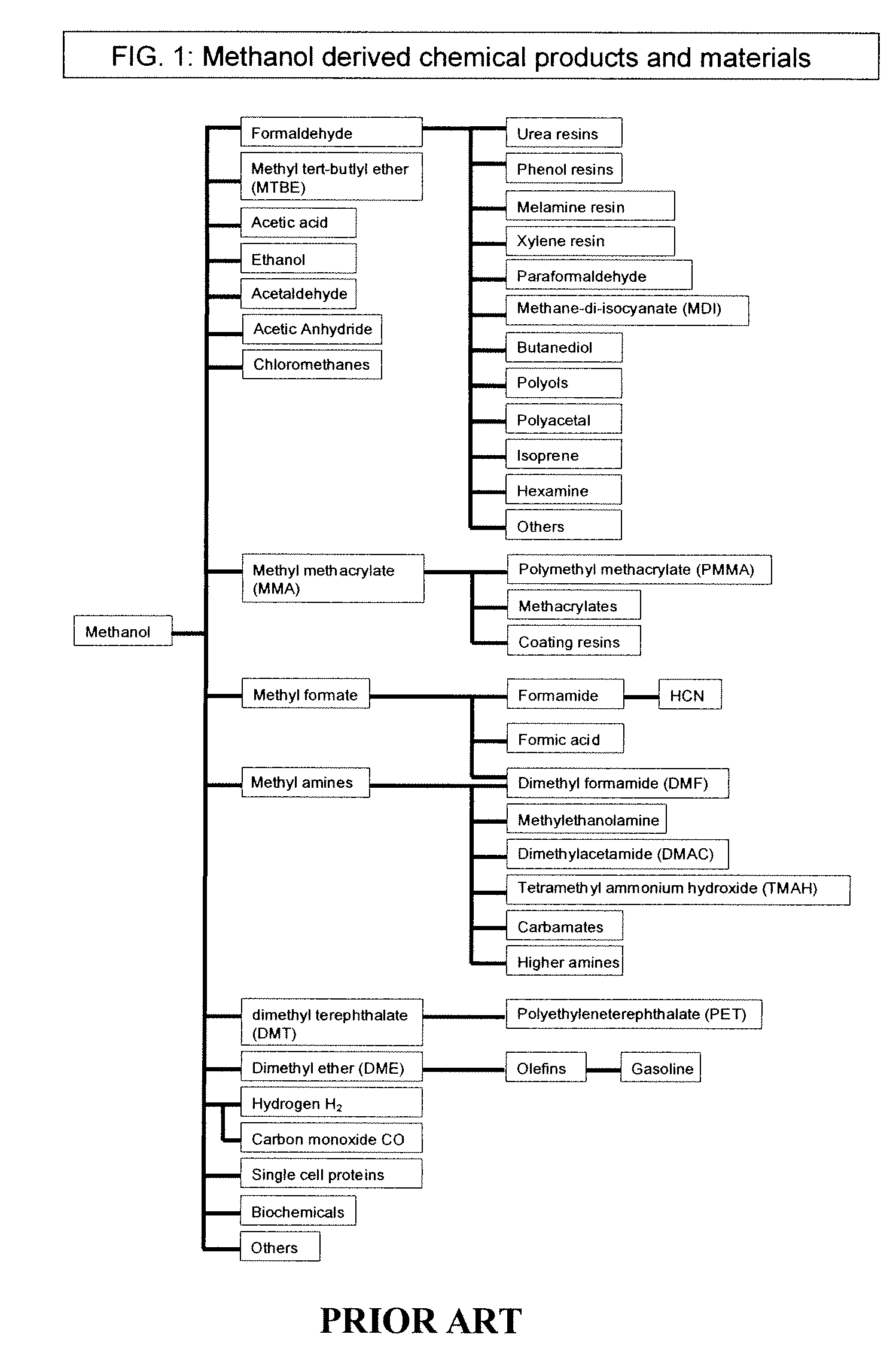

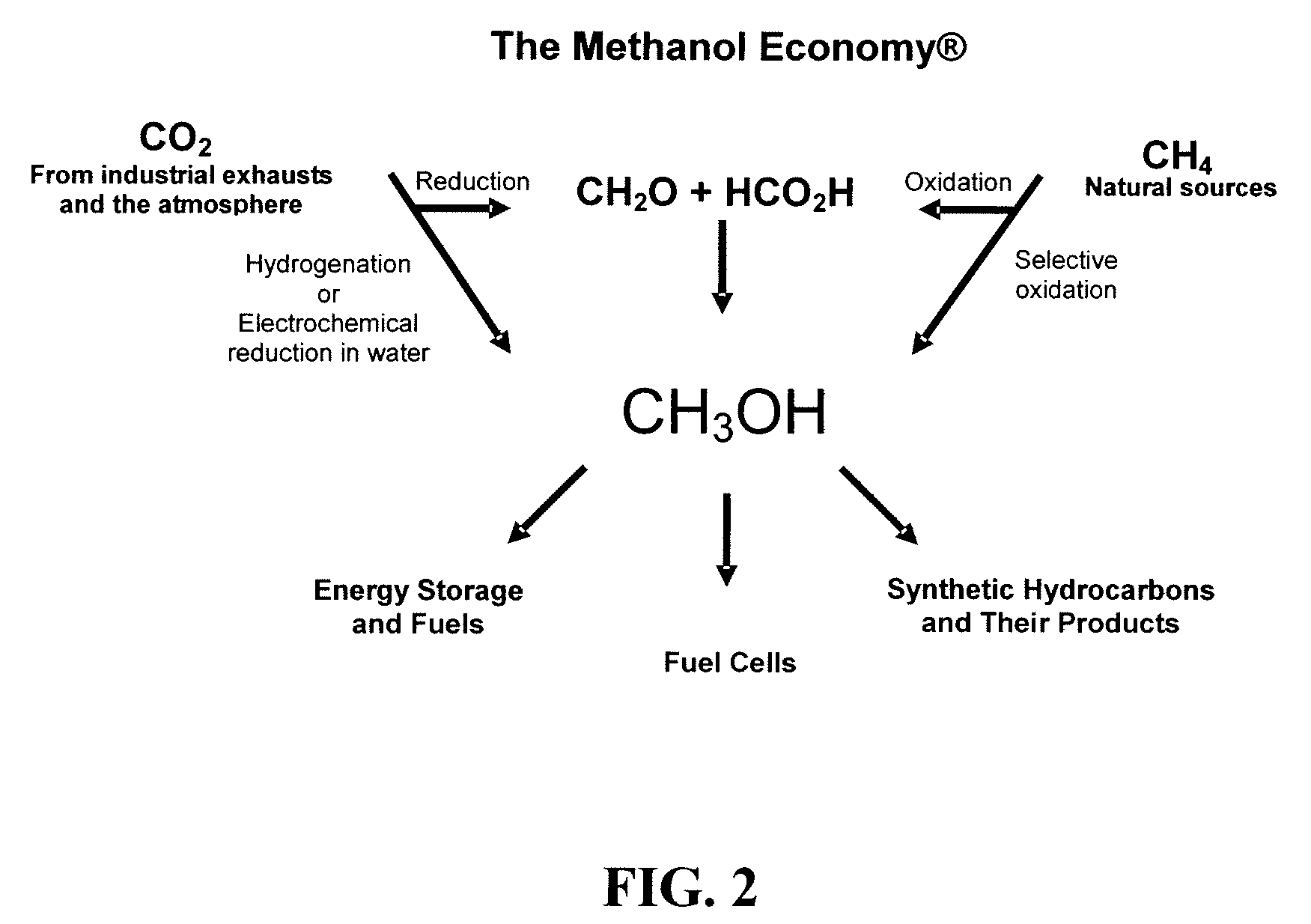

Electrolysis of carbon dioxide in aqueous media to carbon monoxide and hydrogen for production of methanol

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning power plants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by an electrochemical reduction of carbon dioxide in a divided electrochemical cell that includes an anode in one cell compartment and a metal cathode electrode in another cell compartment that also contains an aqueous solution comprising methanol and an electrolyte of one or more alkyl ammonium halides, alkali carbonates or combinations thereof to produce therein a reaction mixture containing carbon monoxide and hydrogen which can be subsequently used to produce methanol while also producing oxygen in the cell at the anode.

Owner:UNIV OF SOUTHERN CALIFORNIA

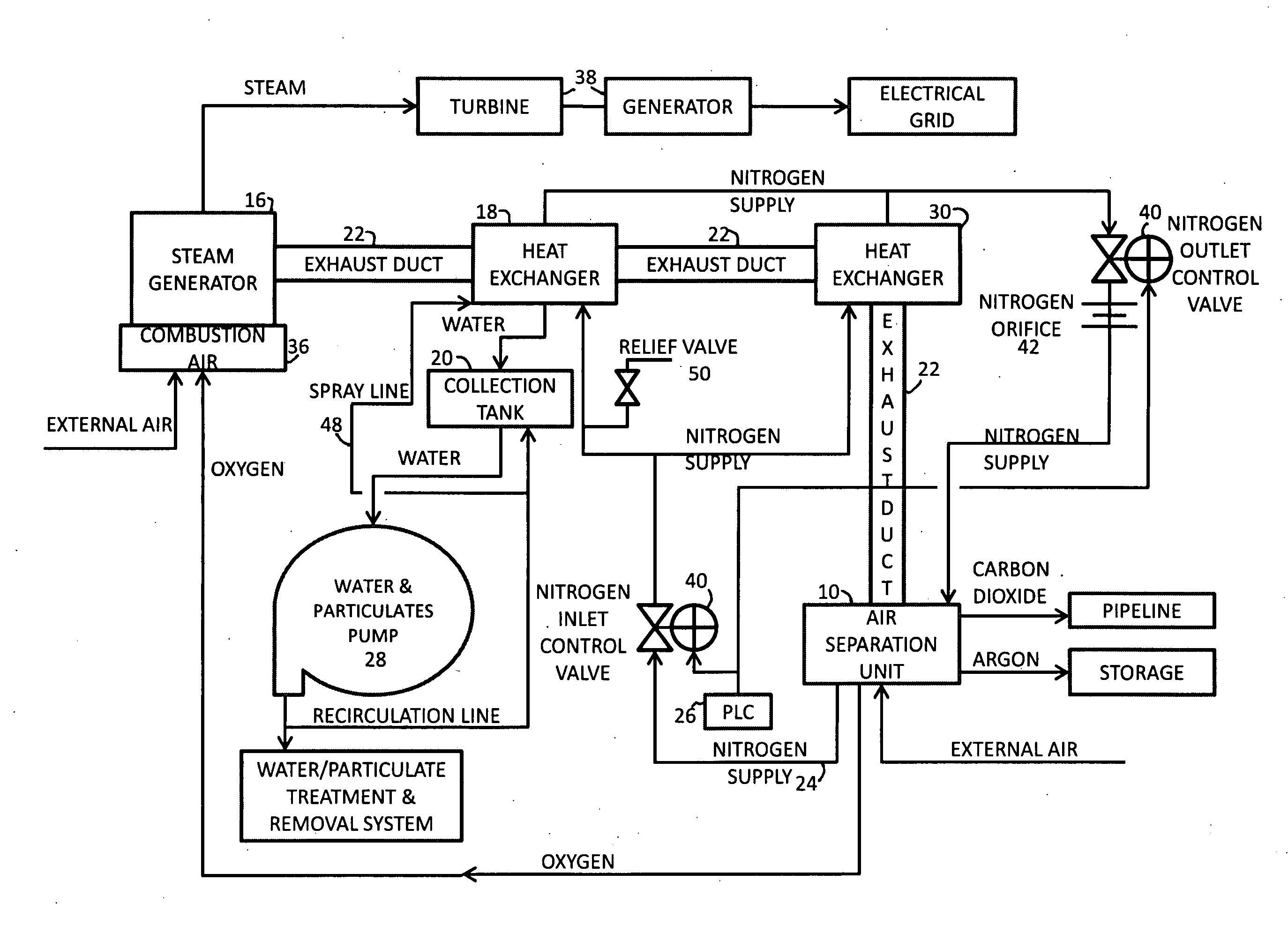

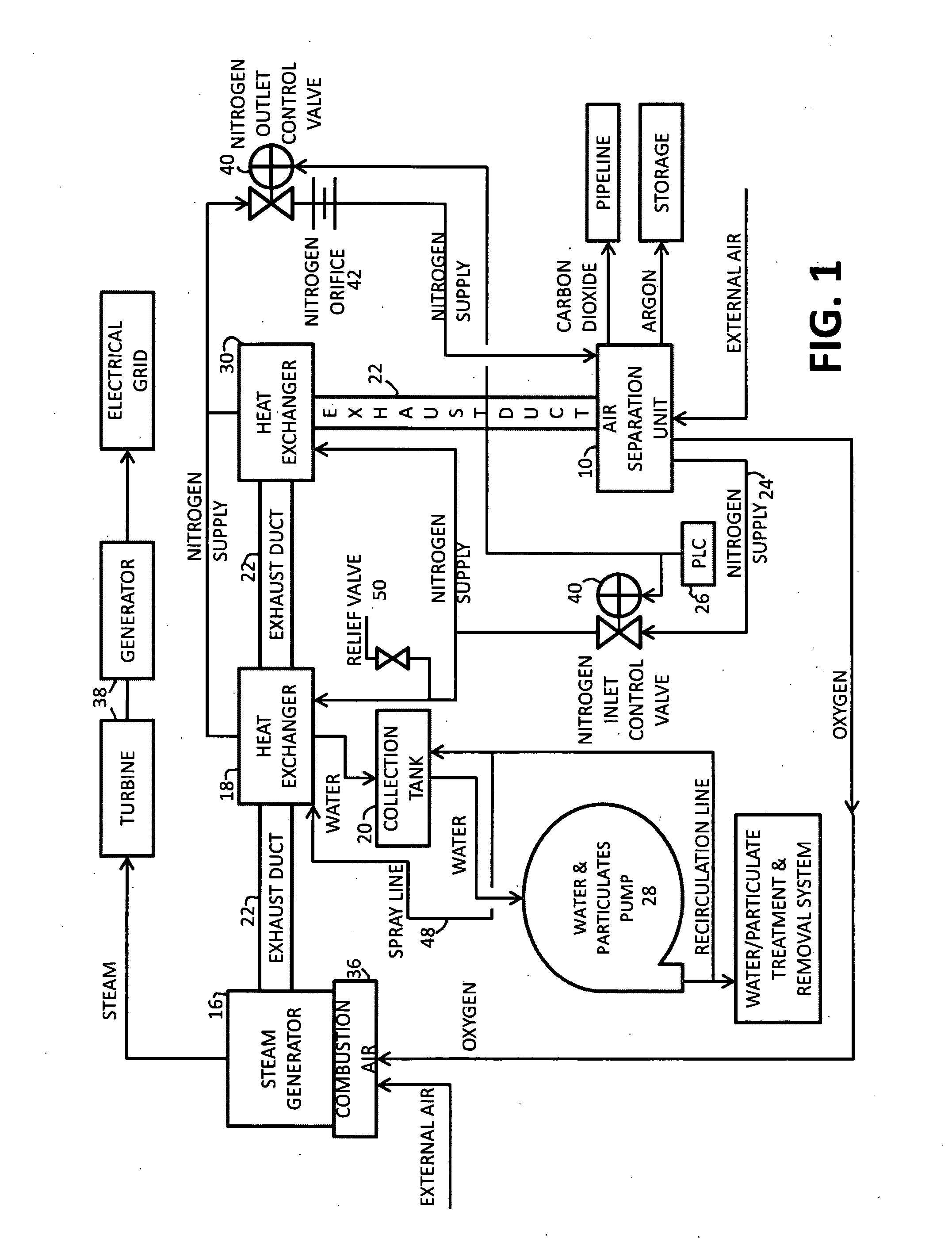

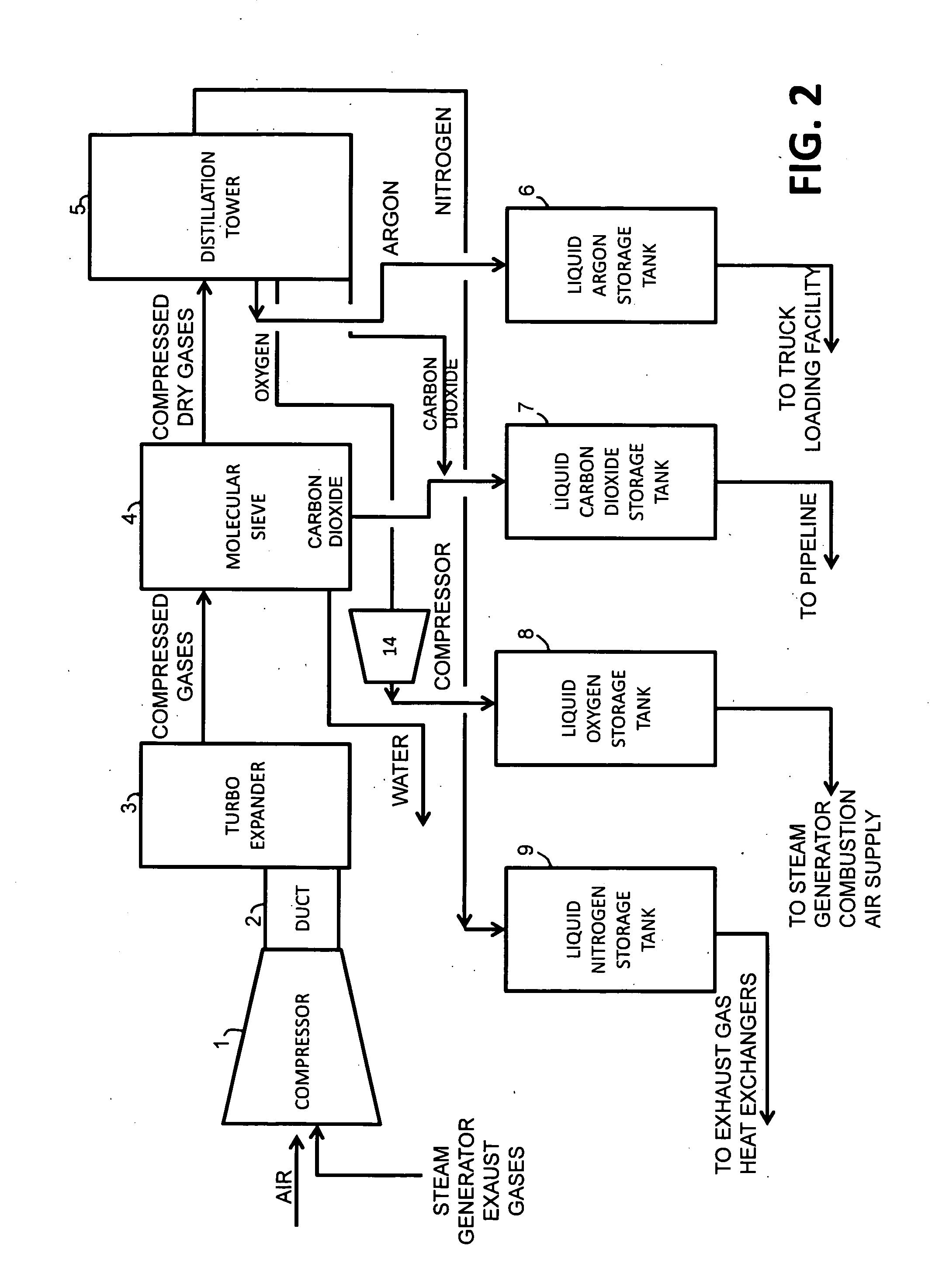

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

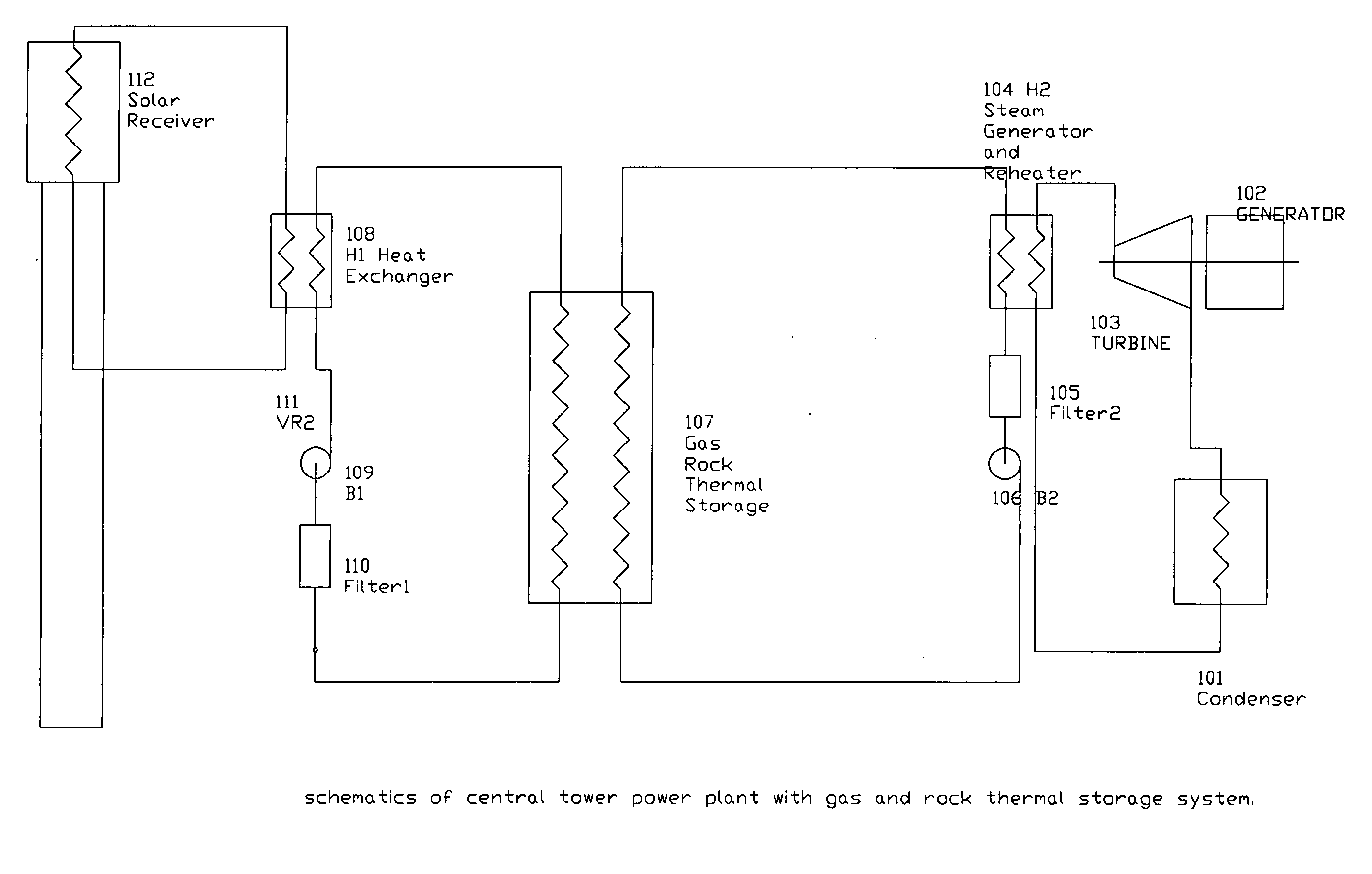

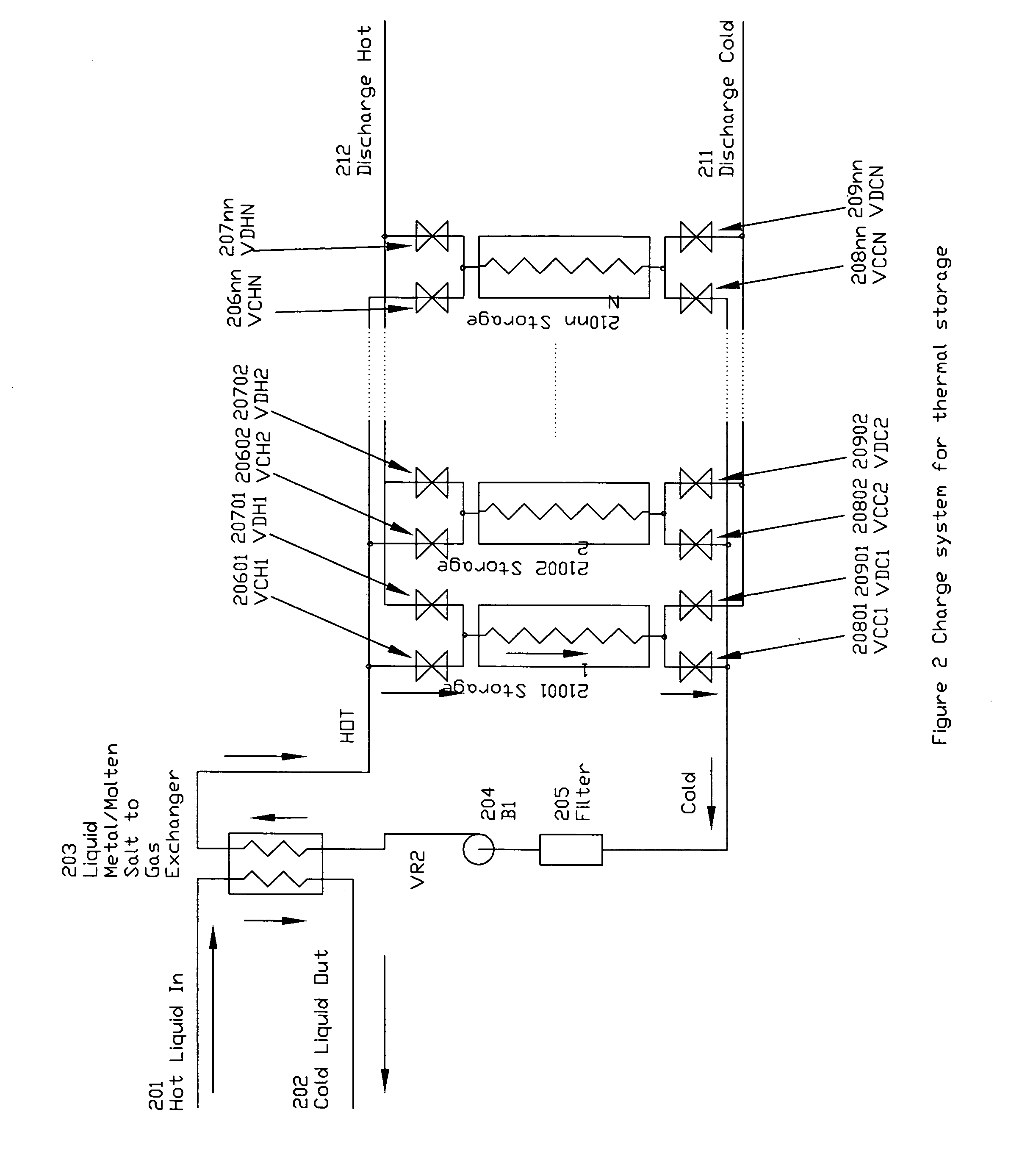

Method and apparatus for solar energy storage system using gas and rock

InactiveUS20080066736A1Quality improvementLow costSolar heating energyFrom solar energyThermal energyEngineering

A method and Apparatus for solar energy storage system uses gas for thermal transport for central tower solar thermal electric power plant to provide high quality, low cost, and continuously electric power generation. The storage contains a number of storage modules that each module can store energy for a given period of time. The thermal energy from central tower charges the modules one by one during the sunny time, while the thermal electric power plant discharge the modules one by one as long as it works. A control and a connection valve system control and connect the charge and discharge modules with the central tower and the power plant according to pre-arranged sequences. Fans at the cool side of the storage system push the circulation gas into the central tower or the thermal storage modules. In the discharge system, the hot gas from storage system is send to the heat exchange system, and to generate steam and to super heat steam for the power plant. In the charge system, the cold gas is pushed into the central receiver thermal exchange unit and to be heated, and the hot gas is then circulated back to storage system to charge up the storage system.

Owner:ZHU YANONG

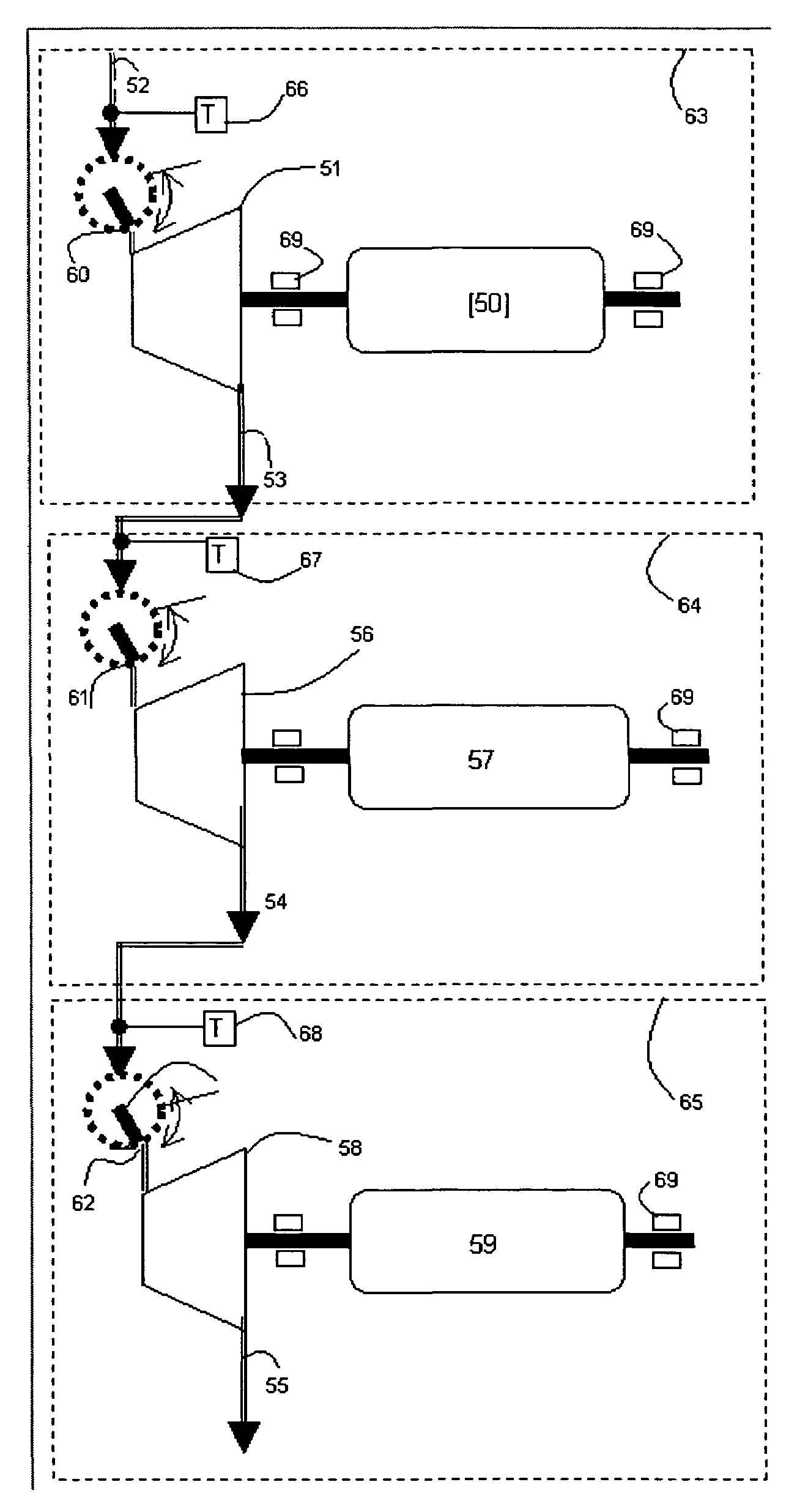

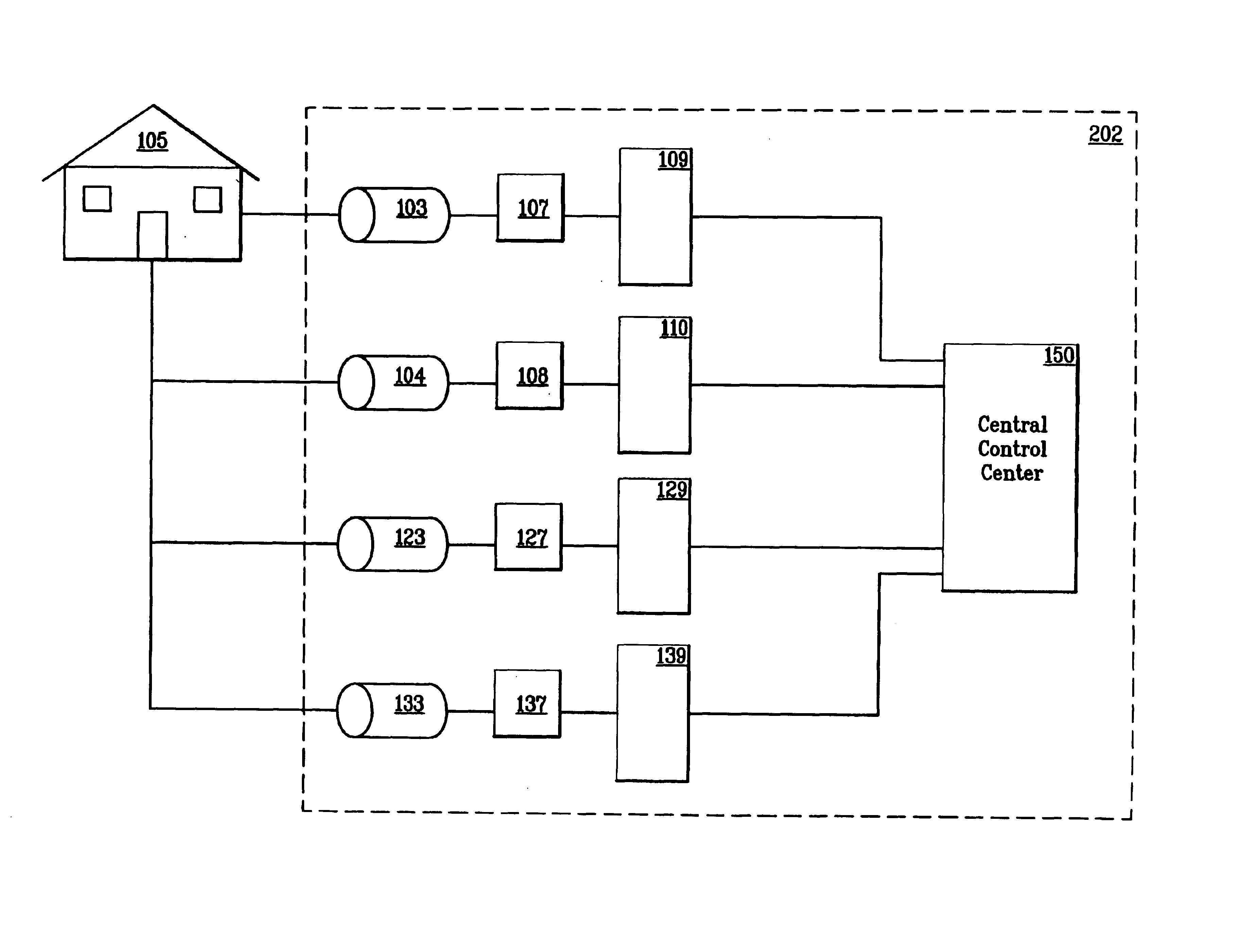

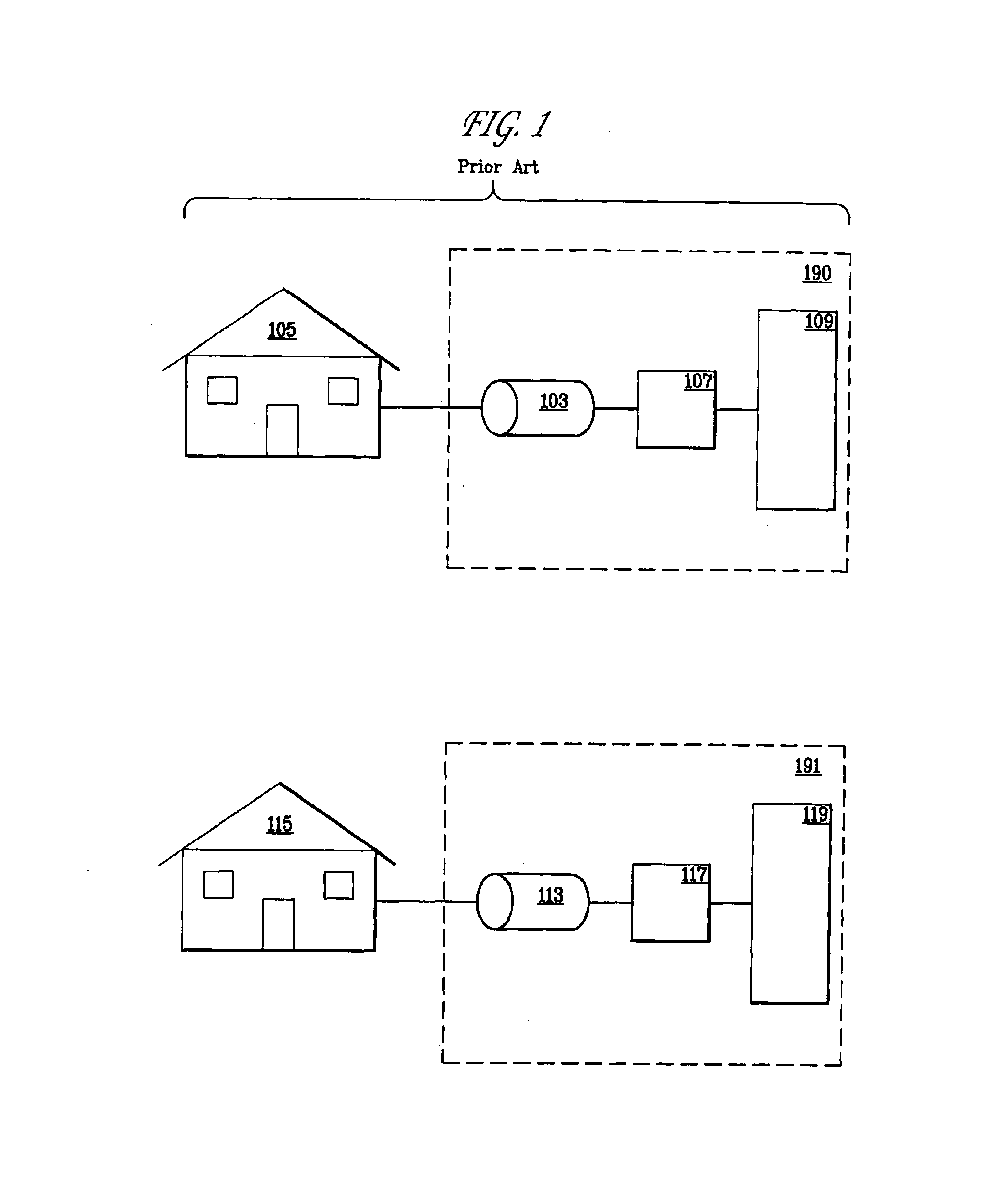

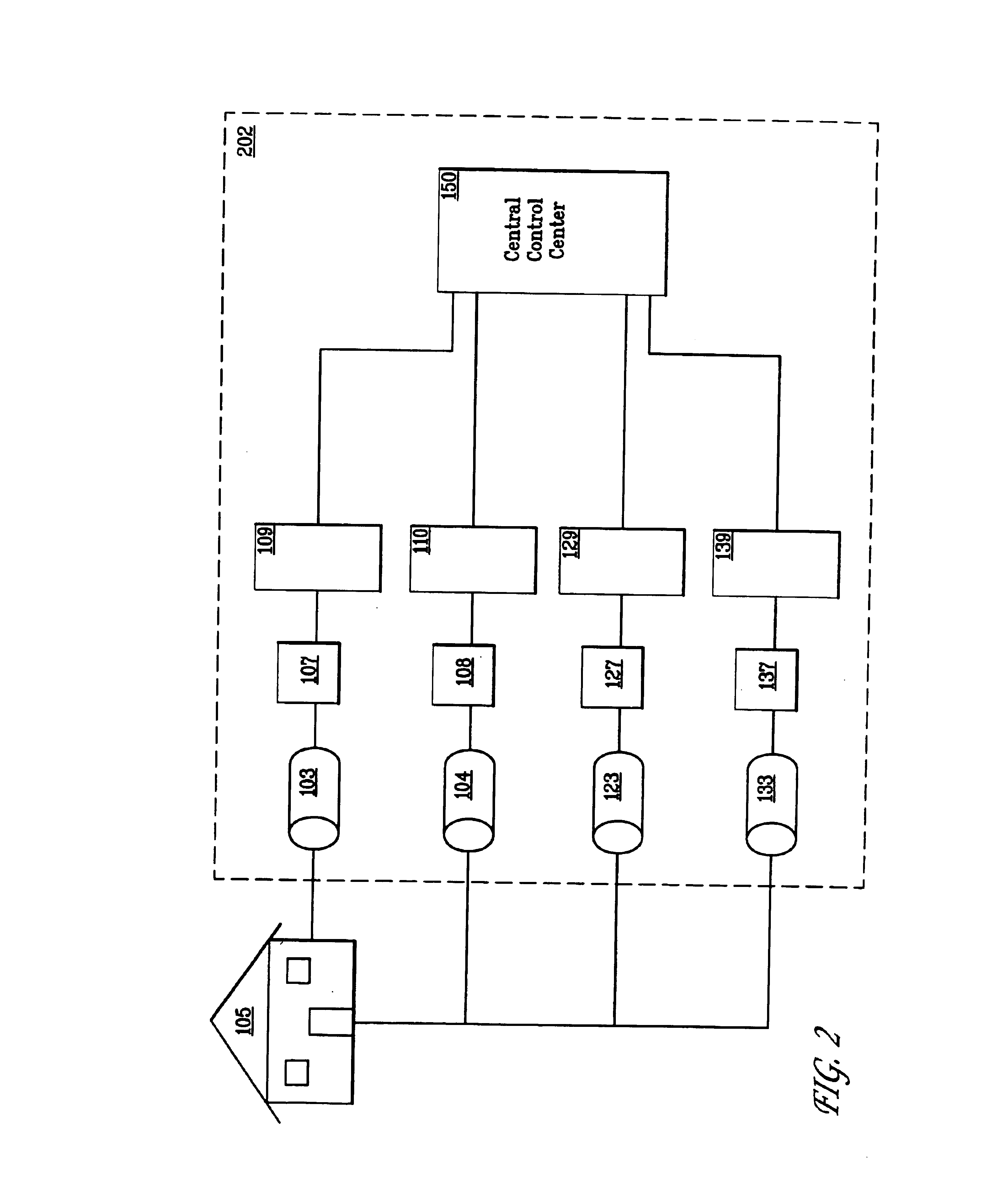

Communication and control network for distributed power resource units

InactiveUS6882904B1Easy to operateMechanical power/torque controlLevel controlPower stationEngineering

Methods and systems are disclosed for managing a plurality of power resource assets from a central control center, operating the plurality of power resource assets in an automated fashion as a single power plant.

Owner:ABB POWER GRIDS SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com