Patents

Literature

278results about How to "Improve power transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

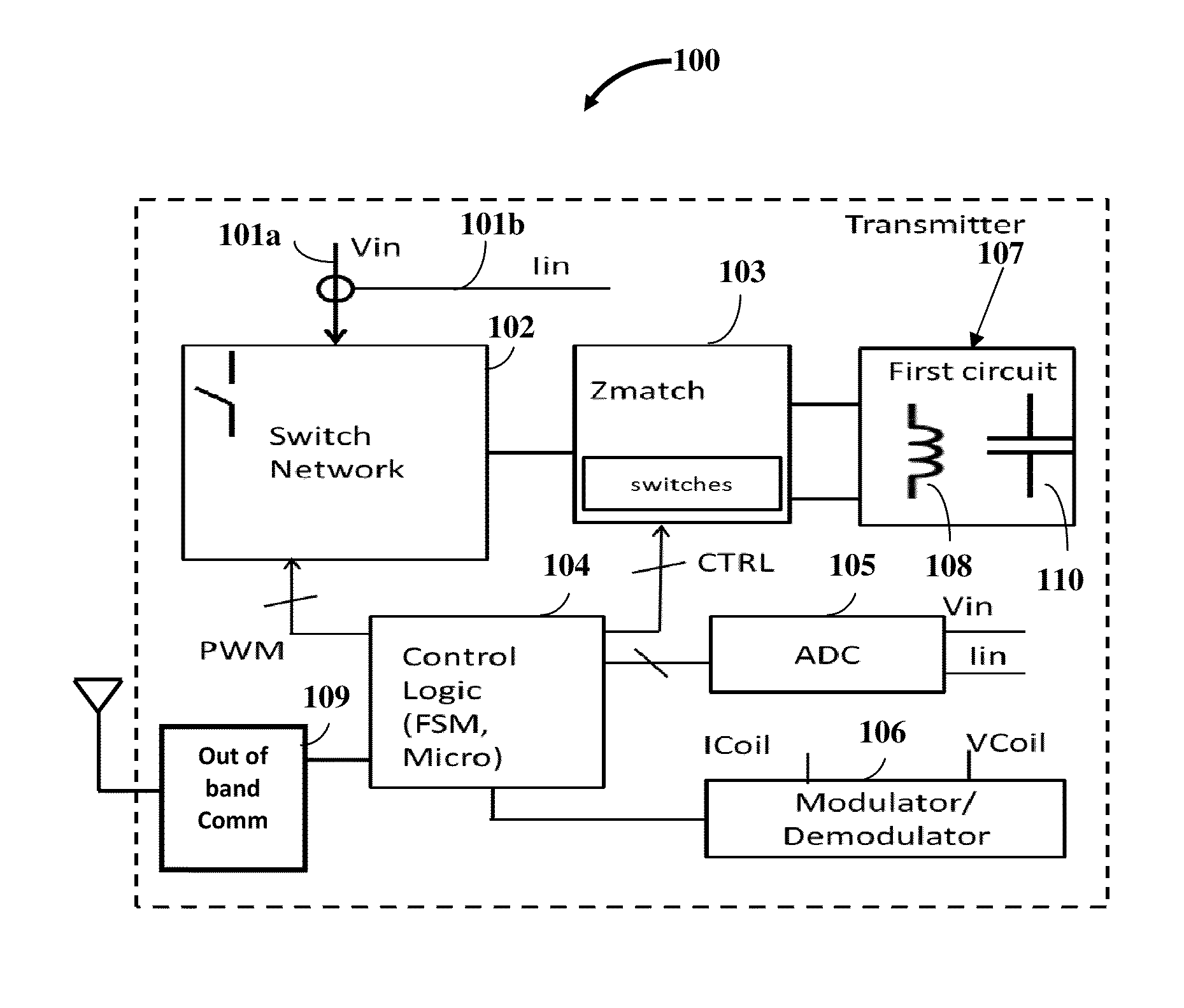

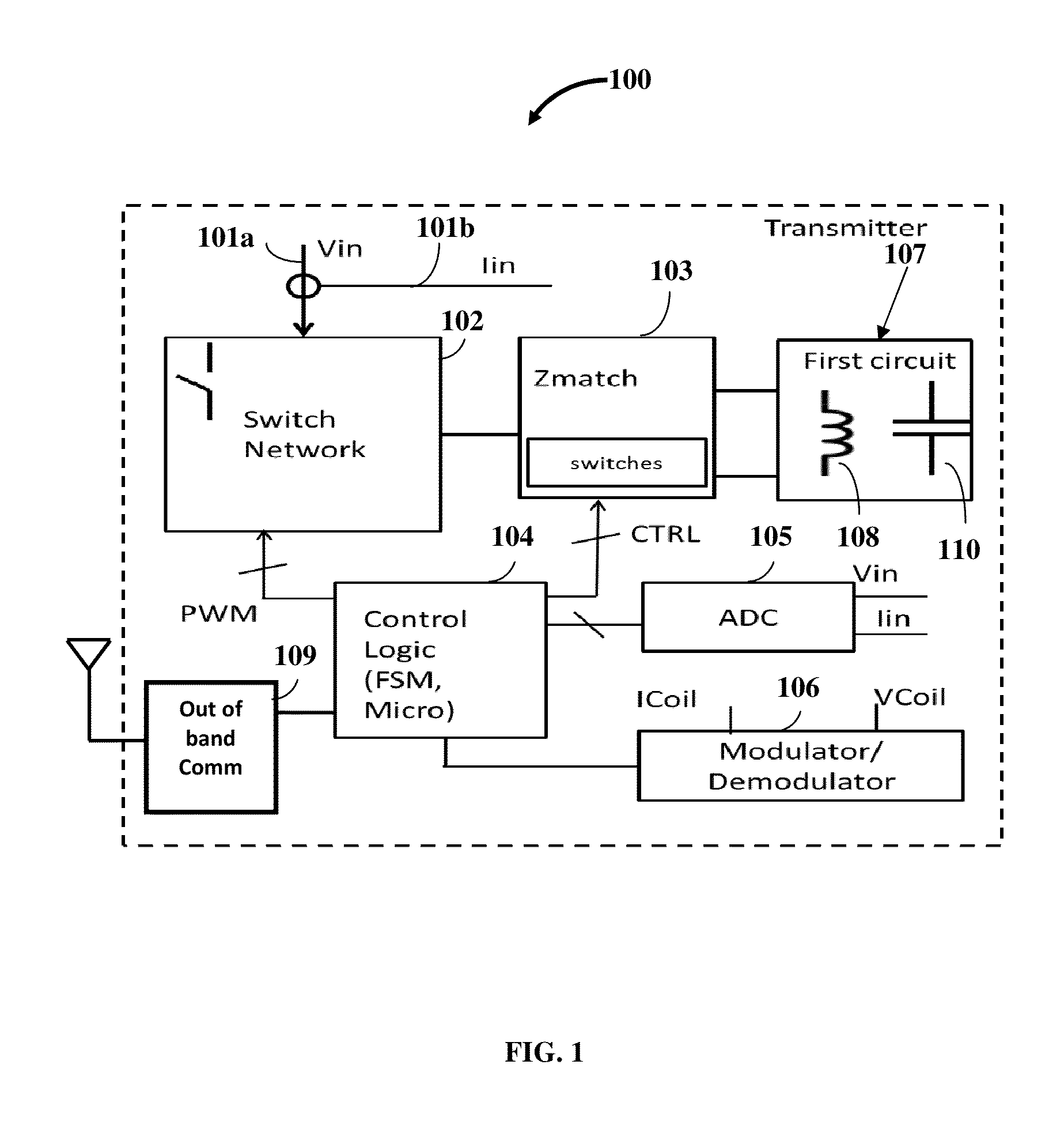

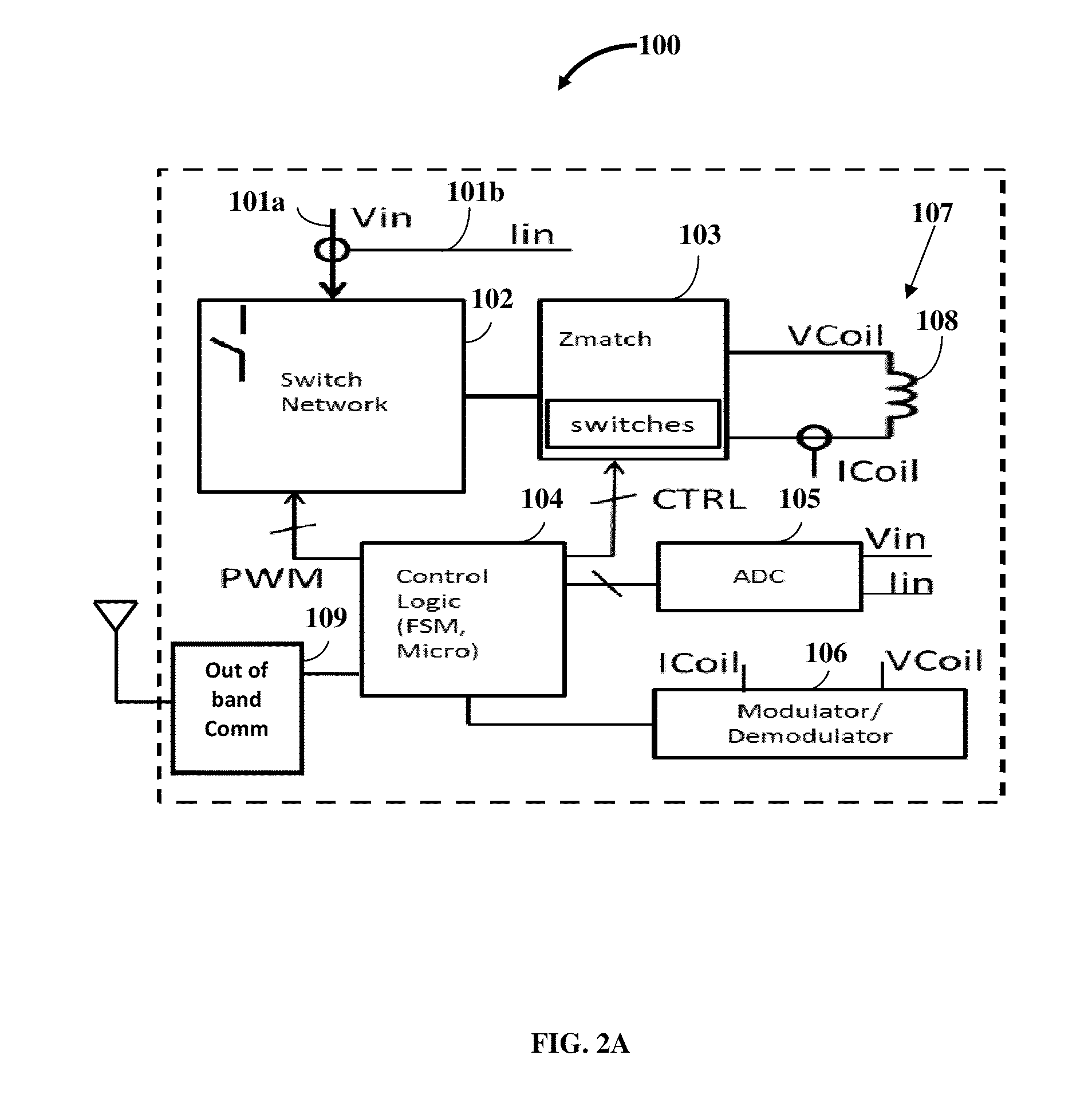

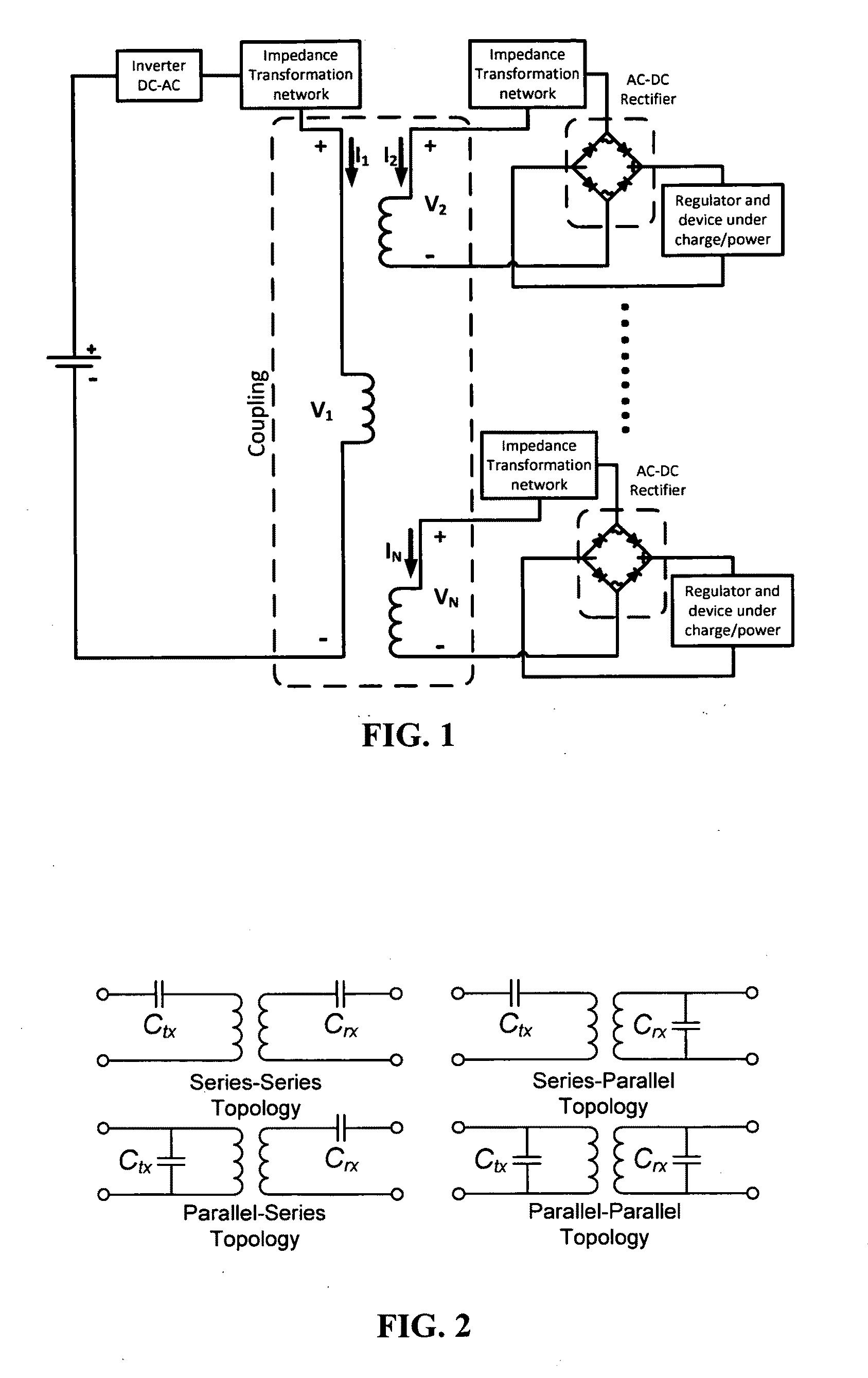

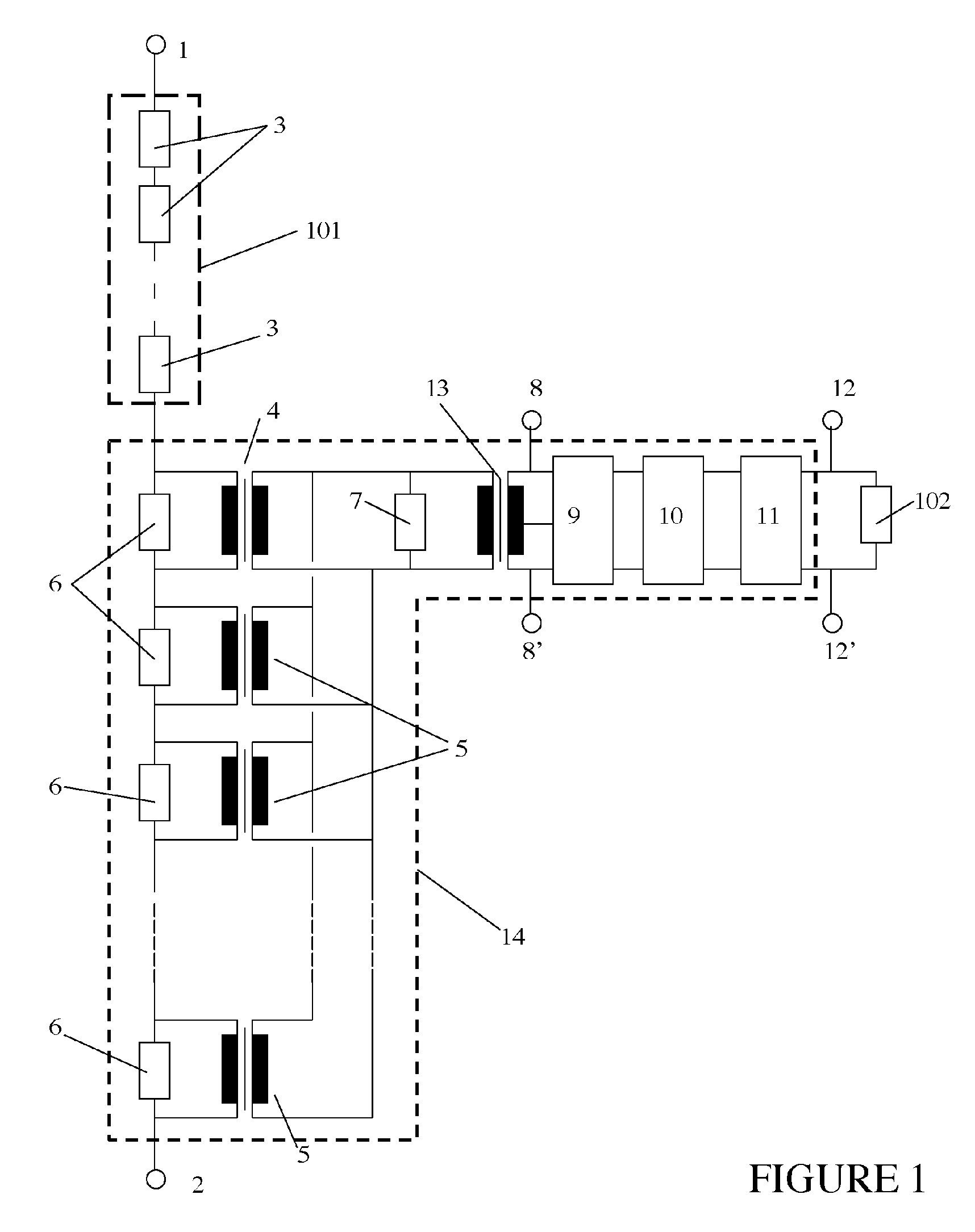

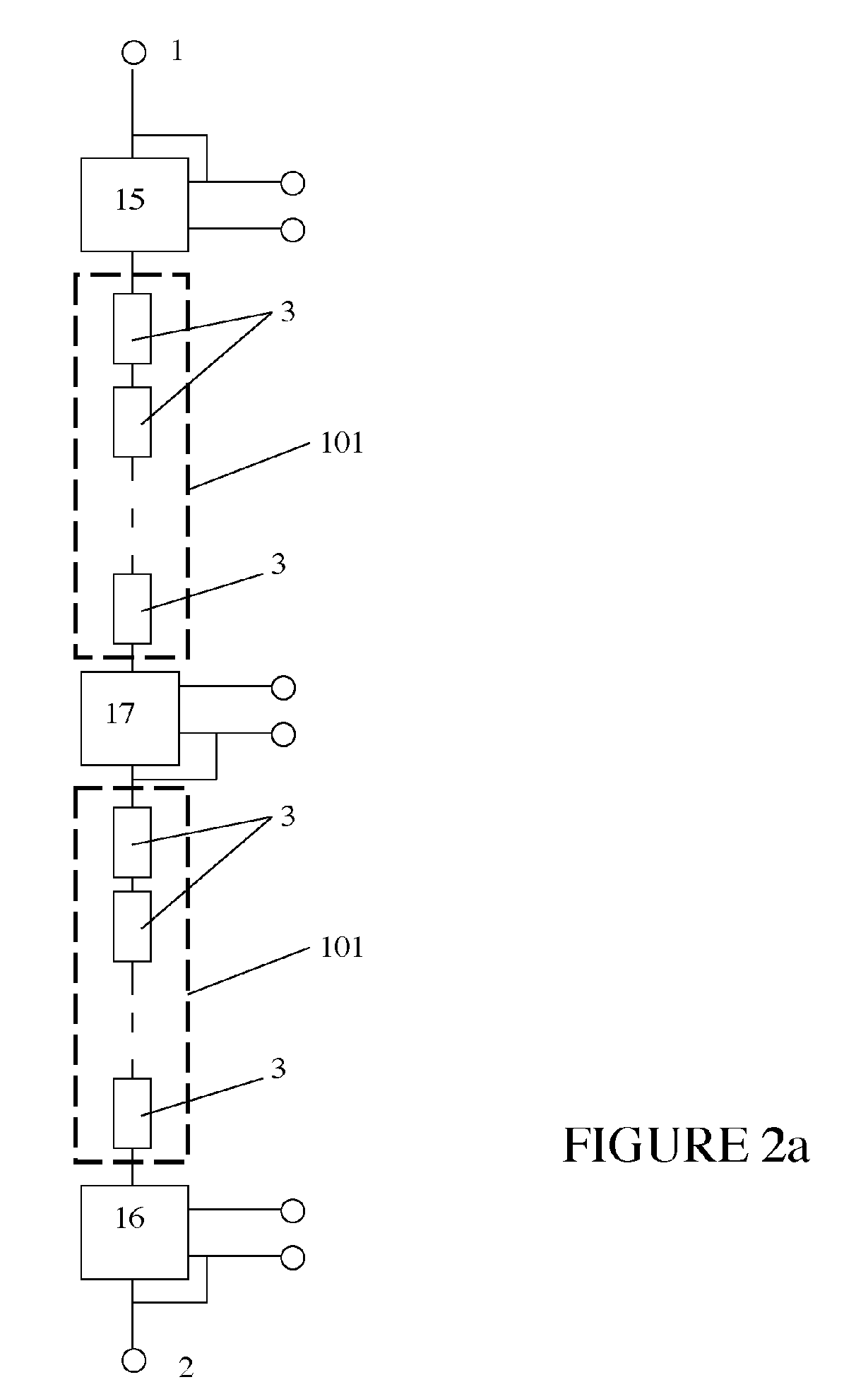

Multi-mode Multi-coupling Multi-protocol Ubiquitous Wireless Power Transmitter

InactiveUS20140139034A1Transmit power can be effectivelyGuaranteed normal transmissionBatteries circuit arrangementsElectromagnetic wave systemExchange networkTransmitted power

A multi-mode multi-coupling multi-protocol wireless power transmitter (WPT) and its embodiments transmit power to a wireless power receiver (WPR) in a power transfer mode (PTM) and a wireless power protocol (WPP) of the WPR. A first circuit of the WPT includes inductors or capacitors emanating power via a magnetic field or electric field PTM respectively. The WPT sequentially parses a test condition to identify a PTM, a power coupling linkage (PCL) between the WPT and the WPR, and a WPP of the WPR. The WPT identifies a match if the PTM of the first circuit and the WPP of the switch network, the variable matching circuit, a modulator / demodulator block or an out-of-band communication block, and a control logic circuit of the WPT match the PTM and the WPP of the WPR to transmit power to the WPR based on the match.

Owner:WIPQTUS

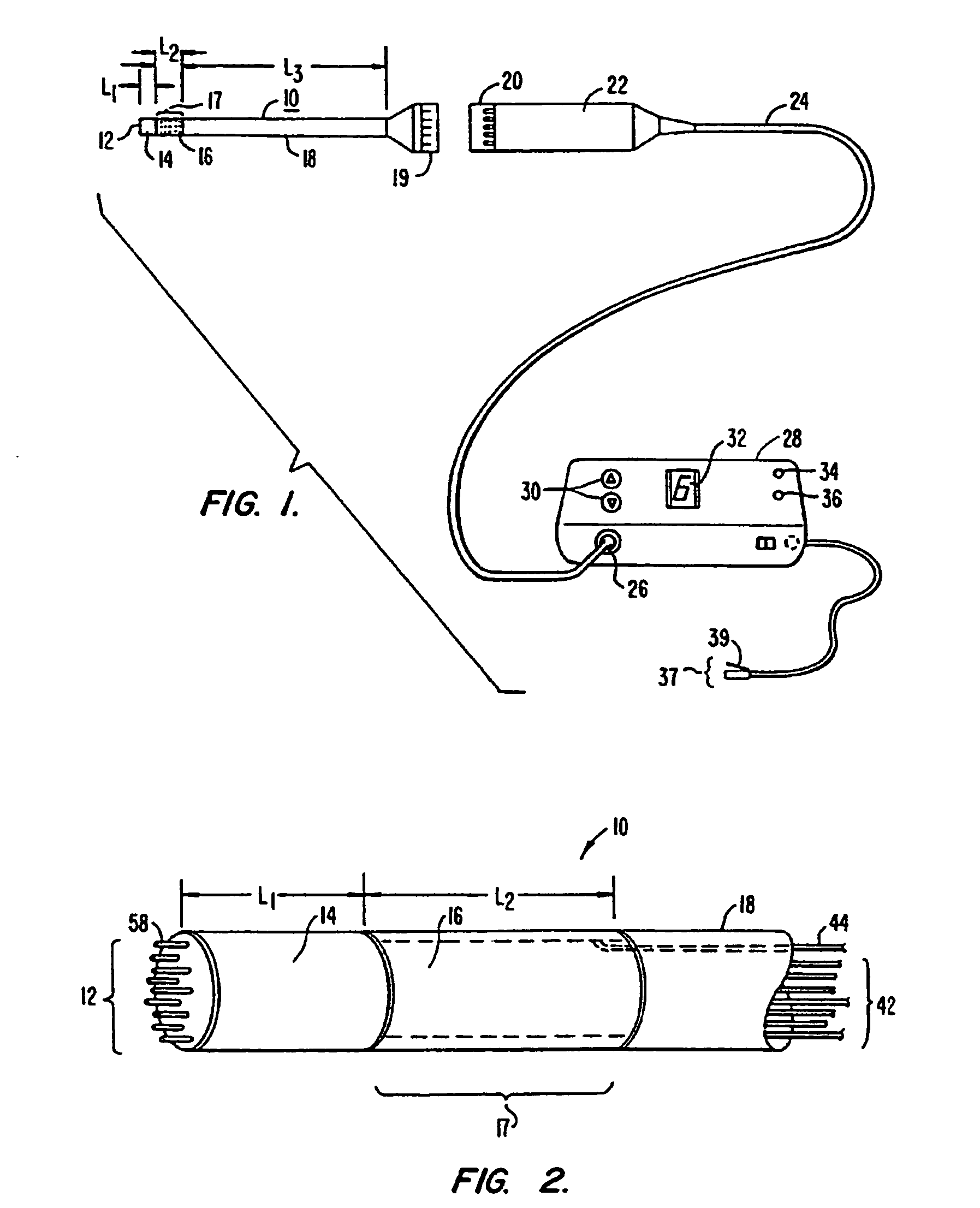

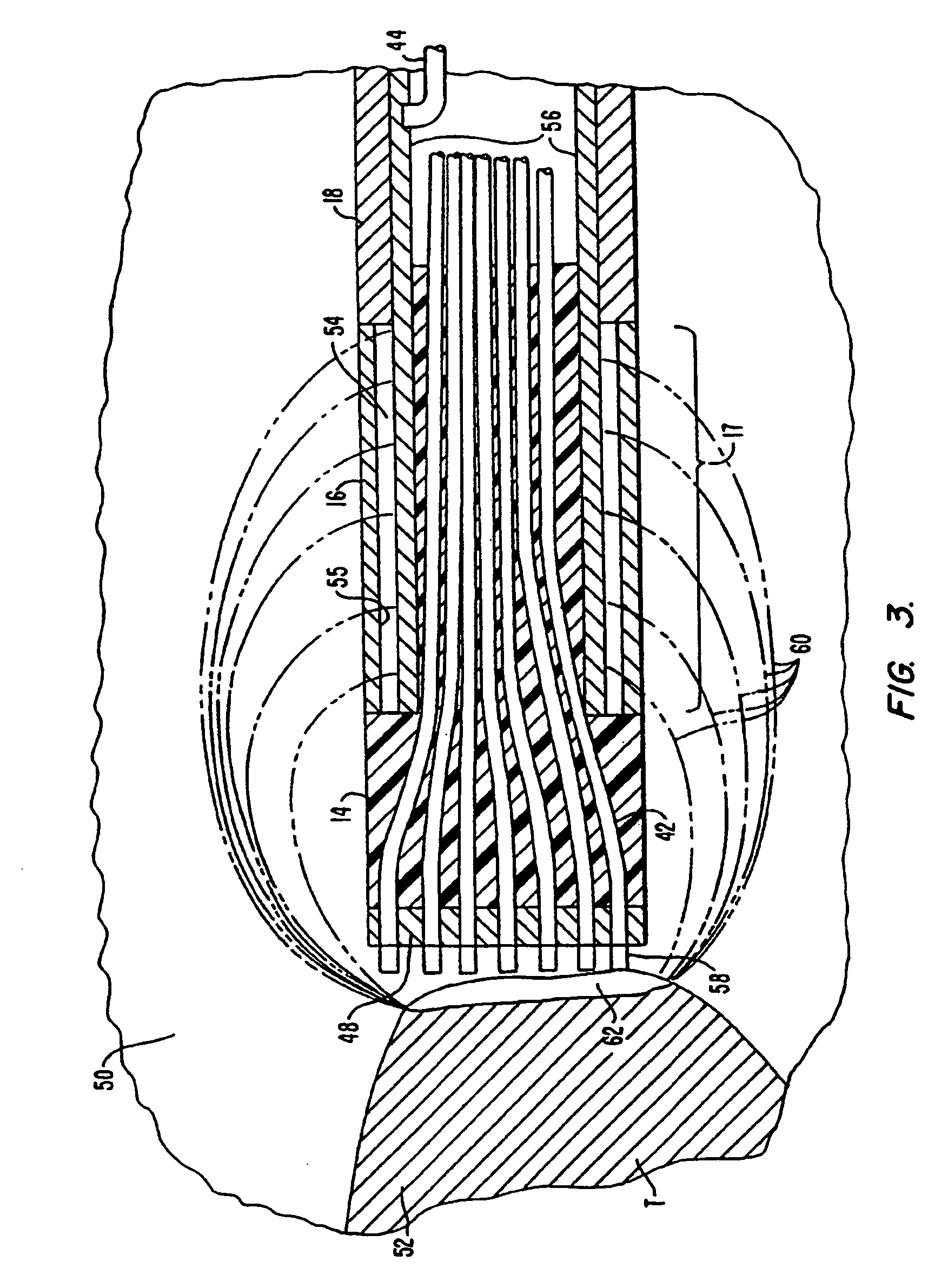

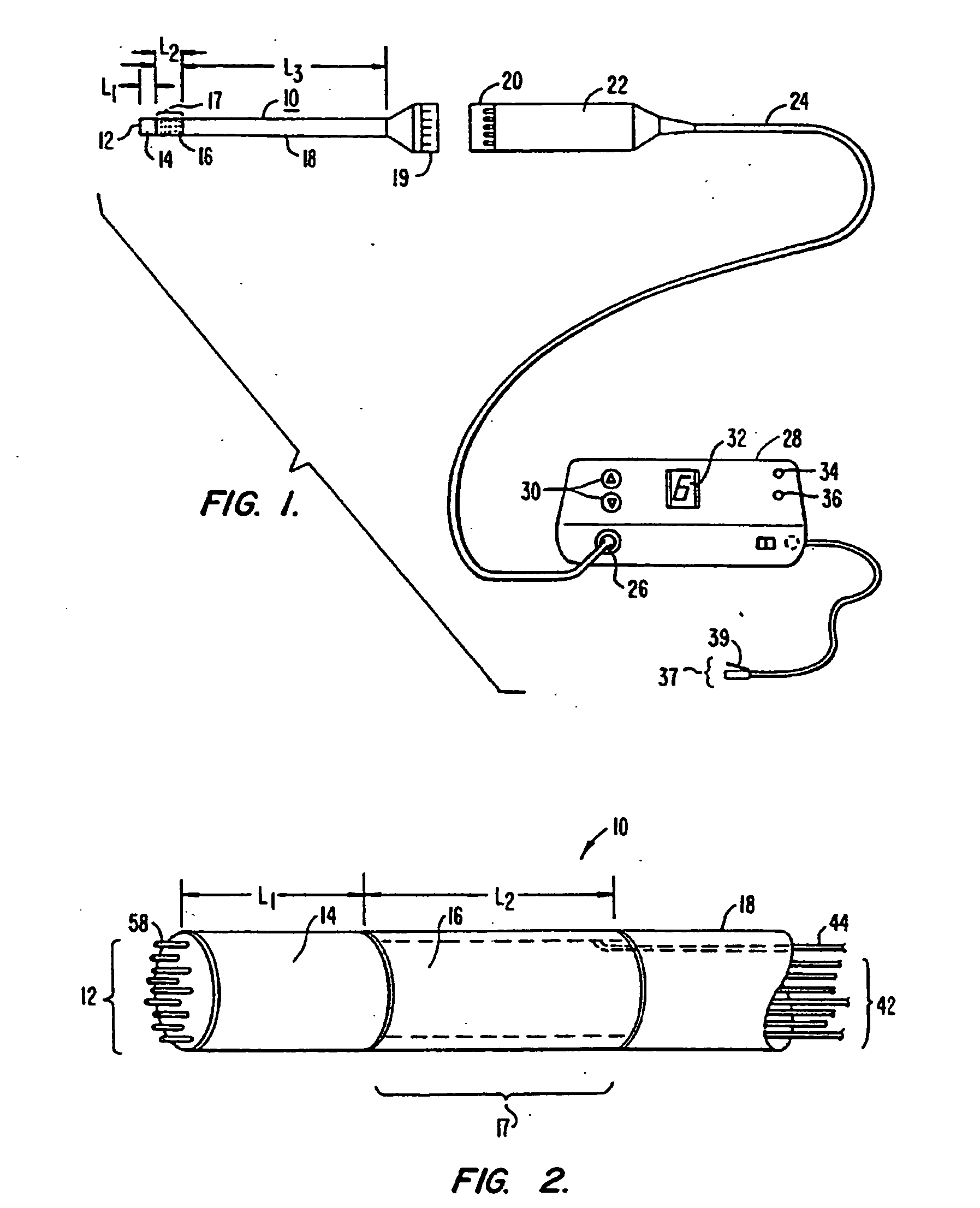

Methods for electrosurgical tissue treatment in electrically conductive fluid

InactiveUS7169143B2Control depthReducing power delivery and ablation rateDiagnosticsHeart valvesTarget tissueLow impedance

An electrosurgical probe comprises a shaft having at least one electrode terminal at its distal end and a connector at its proximal end. The electrode terminal may be spaced from a return electrode such that when the electrode terminal is brought adjacent a tissue structure immersed in an electrically conductive fluid from outside the body, the electrically conductive fluid completes a conduction path between the electrode terminal and the return electrode. By applying high frequency electrical energy to the electrode terminal, target tissue may be cut or ablated while heat dissipation through low impedance paths, such as blood and normal saline, will be minimized. Related methods are disclosed.

Owner:ARTHROCARE

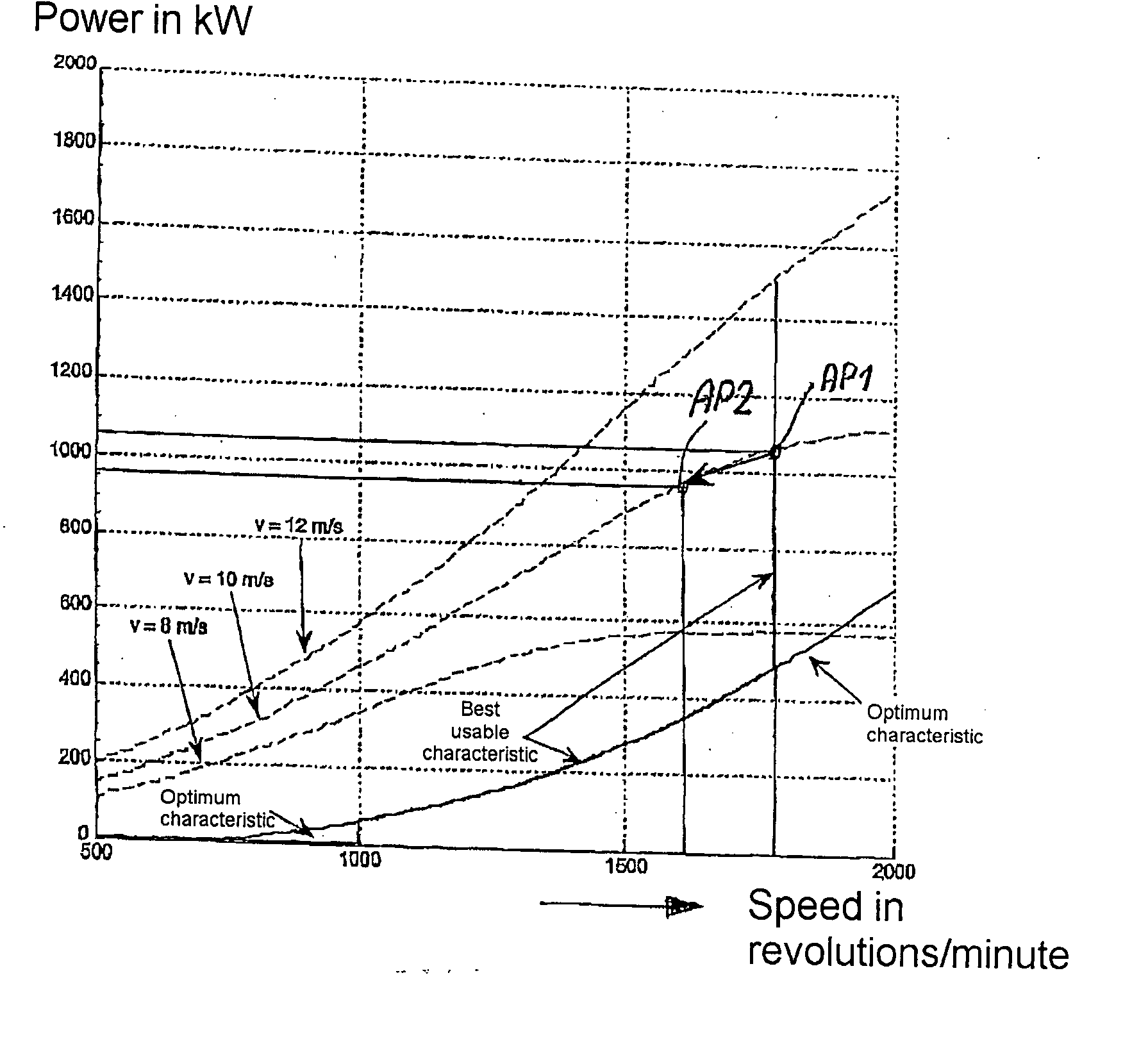

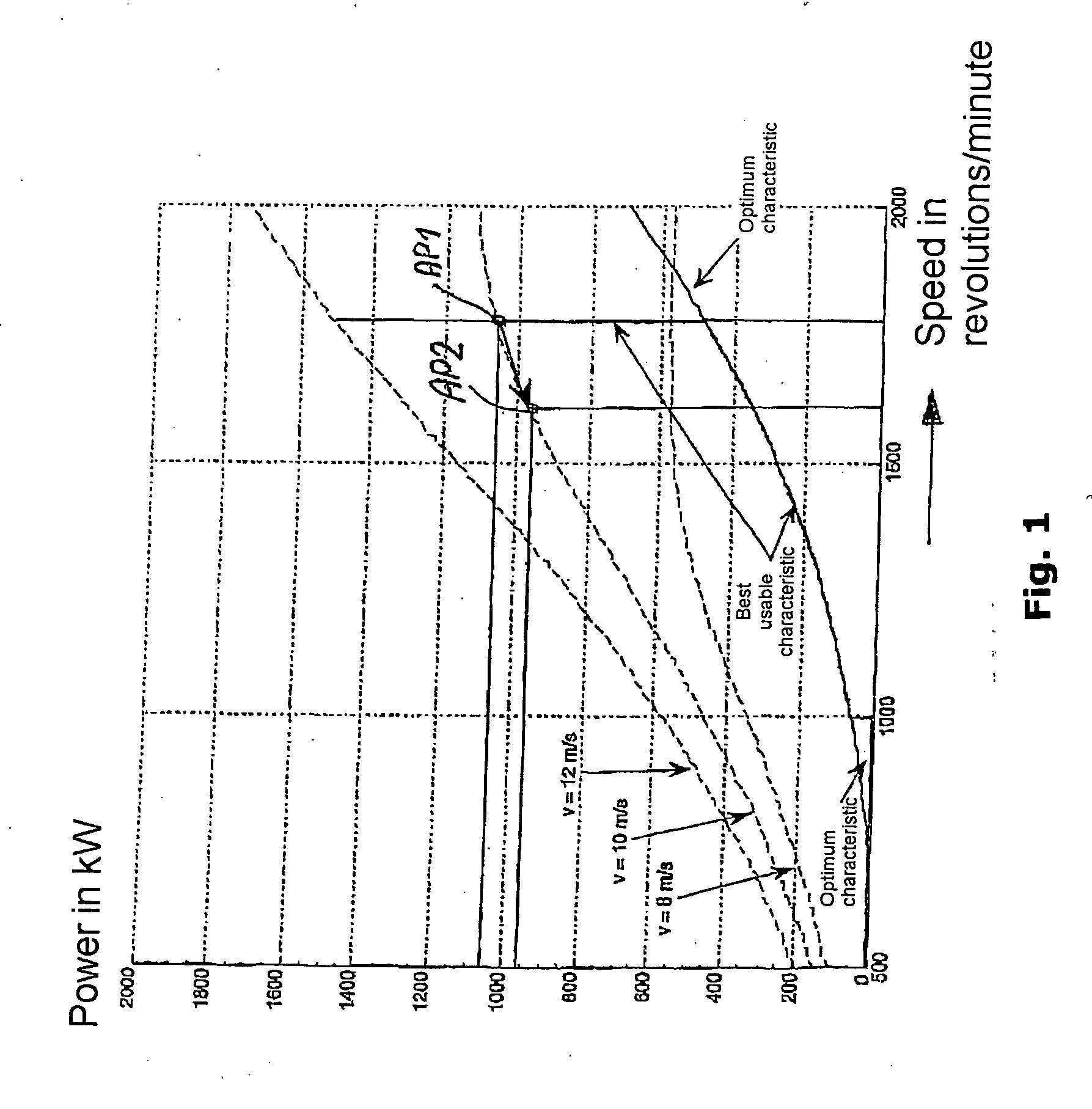

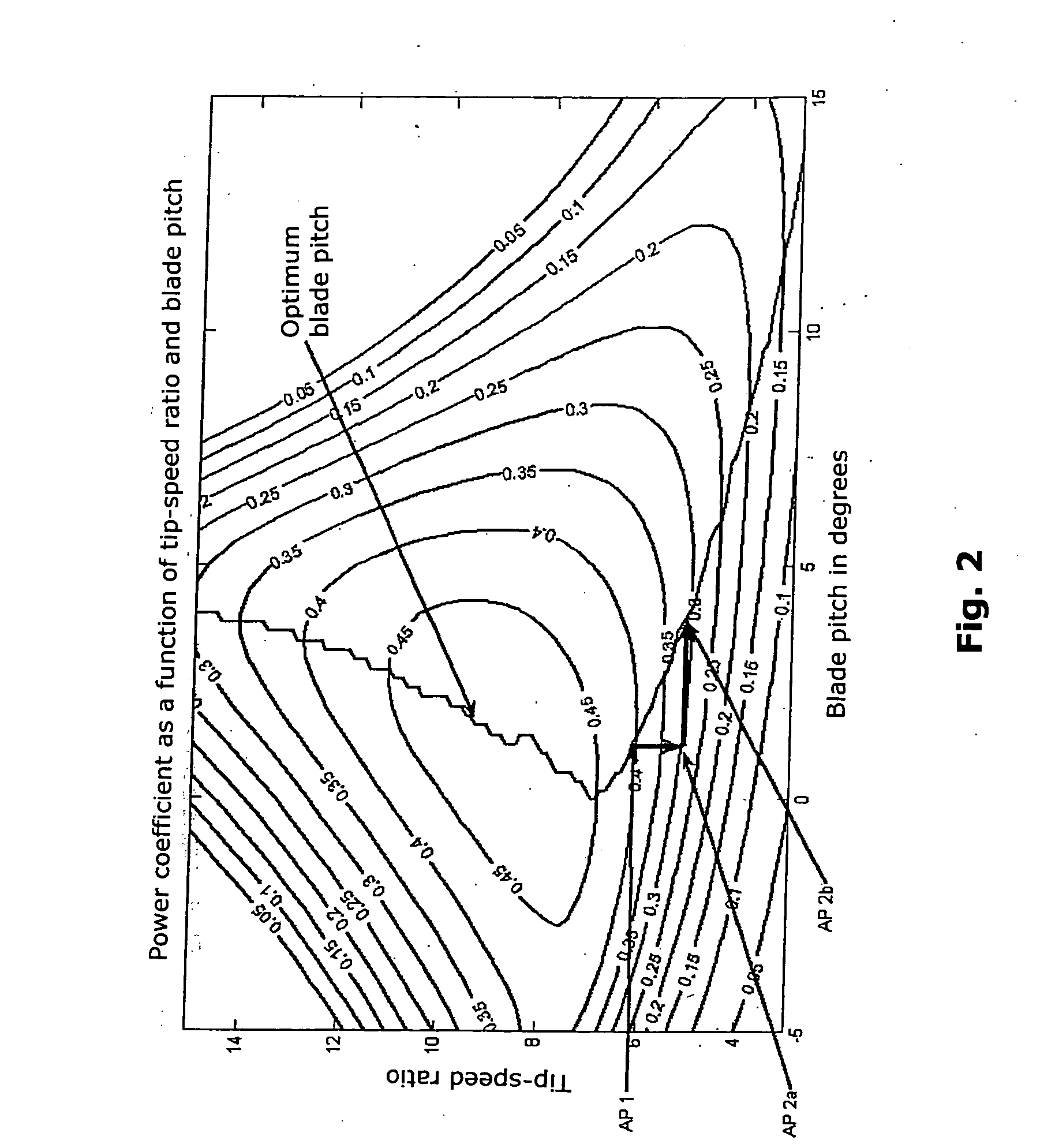

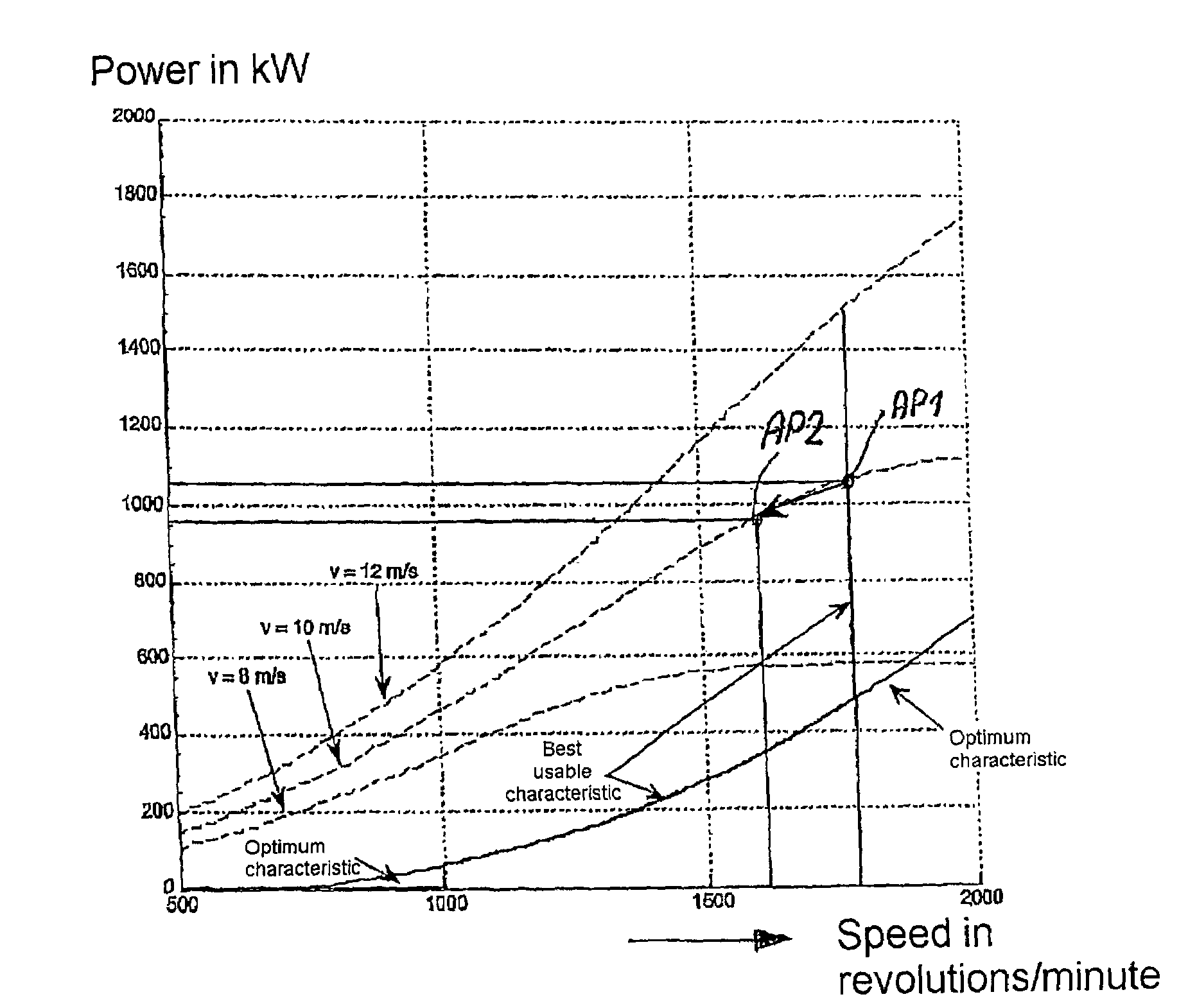

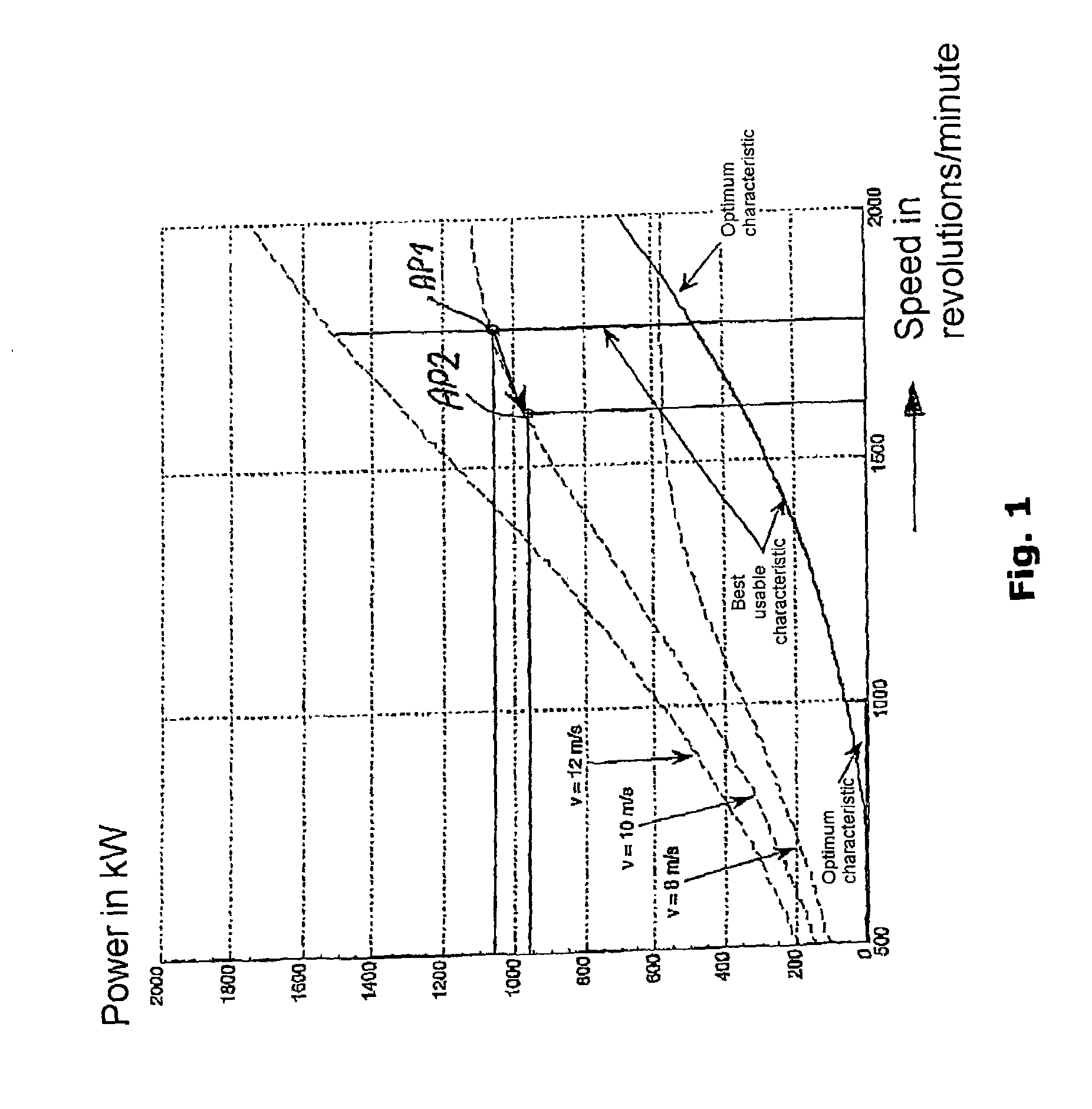

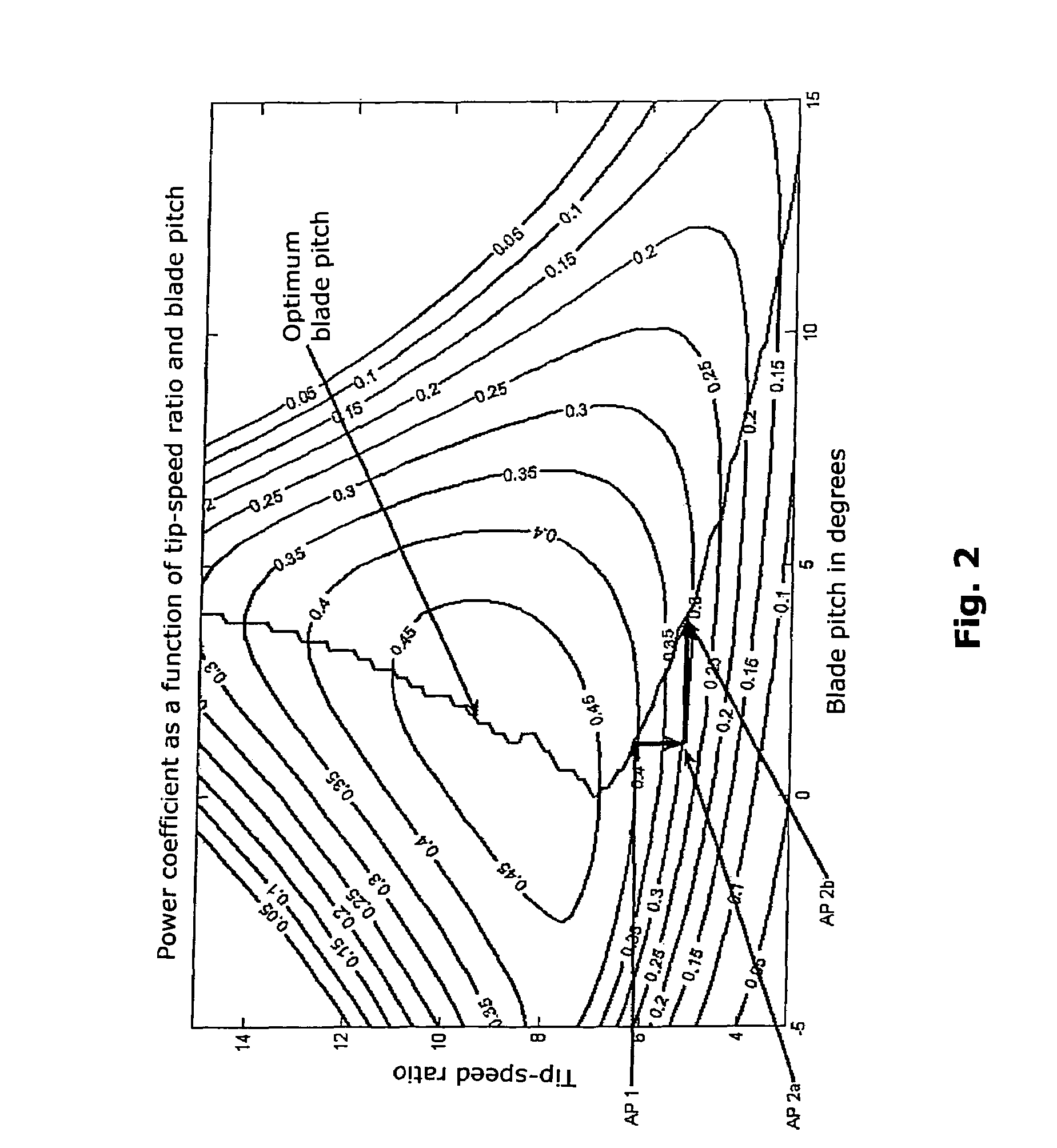

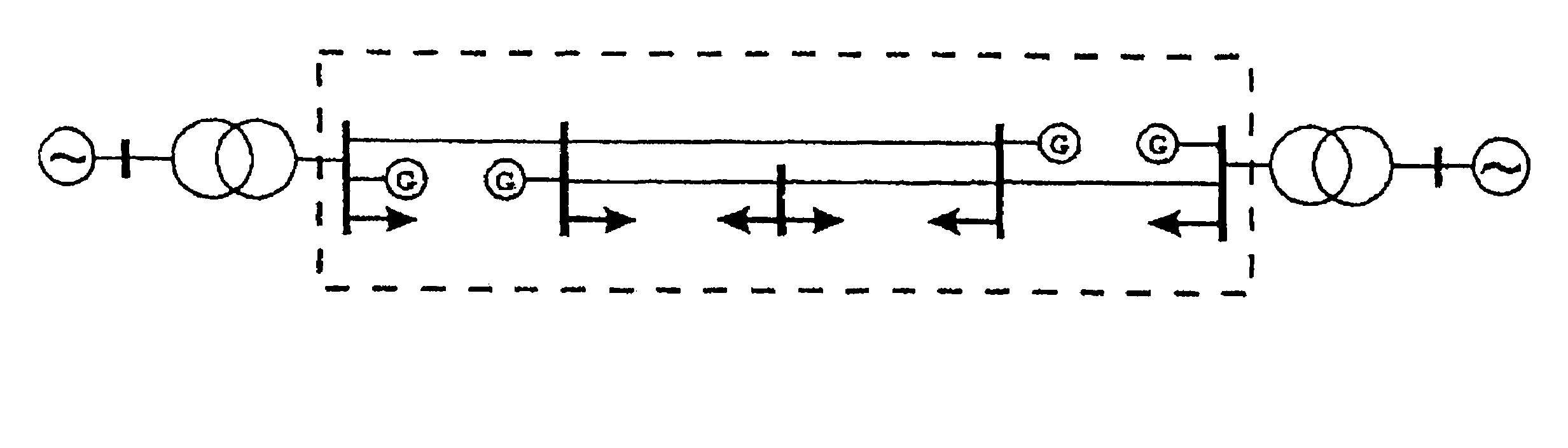

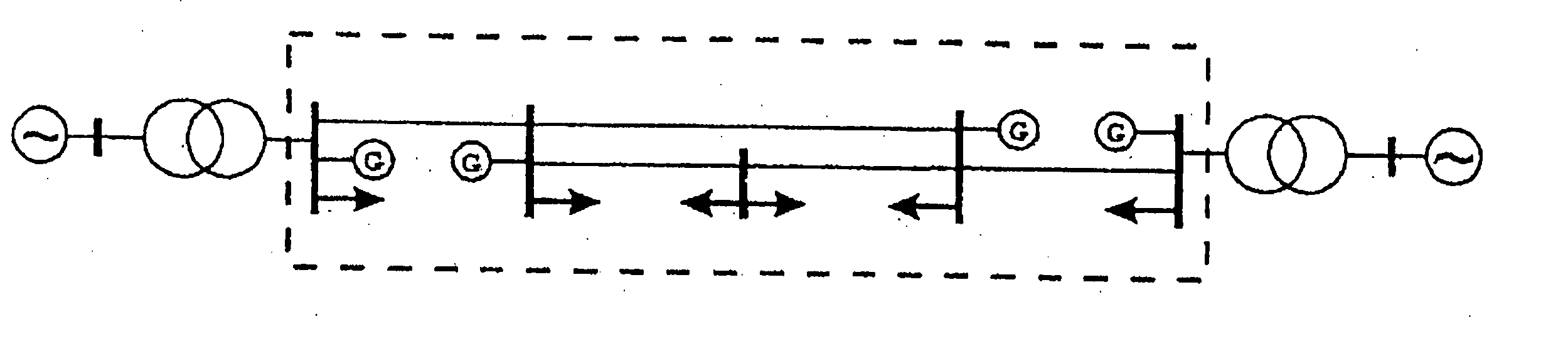

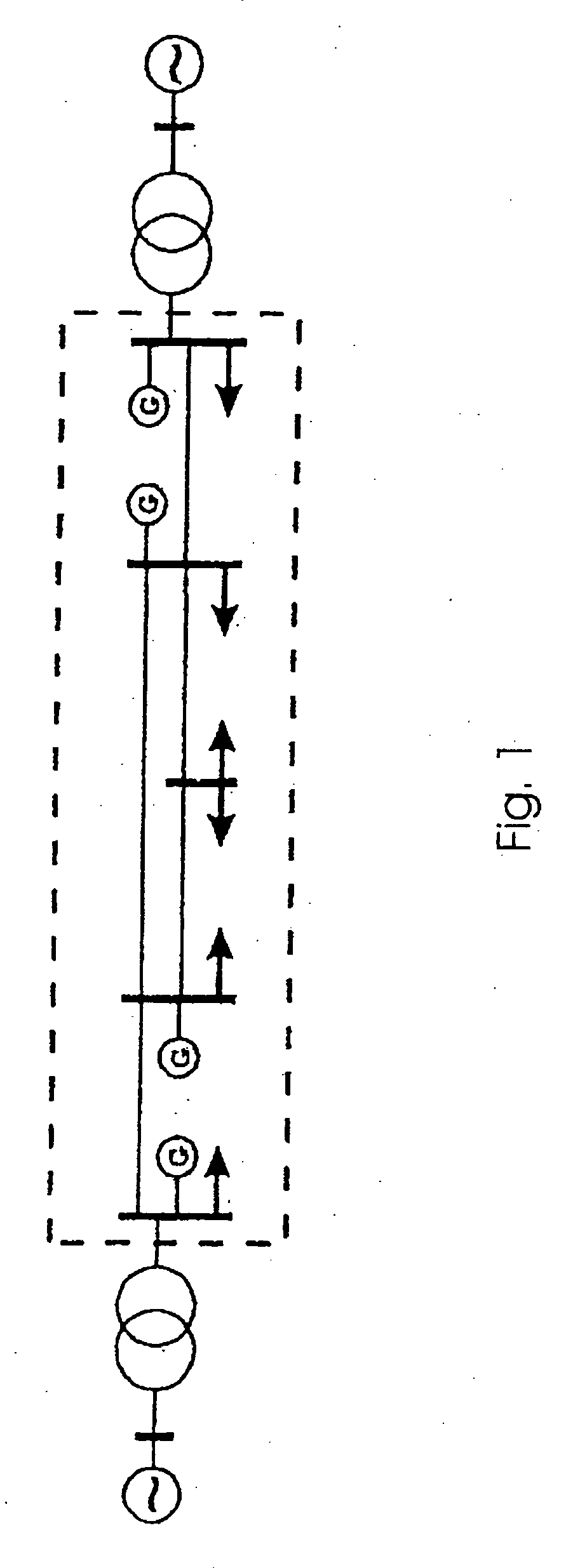

Method for operating or controlling a wind turbine and method for providing primary control power by means of wind turbines

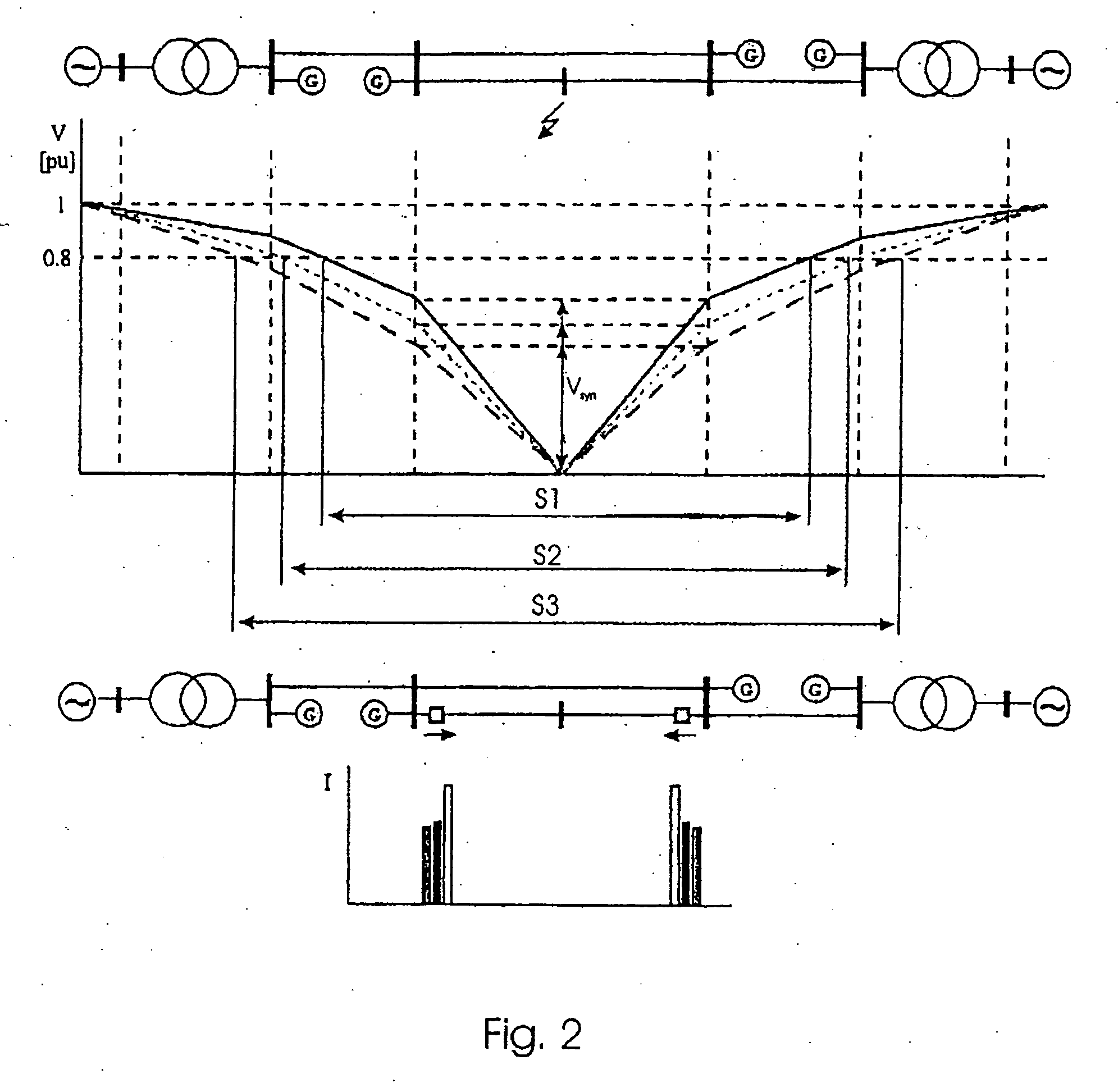

ActiveUS20070085343A1Reduce yield lossImprove power transmissionWind motor controlSingle network parallel feeding arrangementsElectric forcePower station

A method for operating at least one wind turbine with a rotor and an electric generator coupled to the rotor for delivering electrical power into an energy distribution system with the aid of a control device ensures that the wind turbine operates within its operating range. The wind turbine is controlled in response to the change of a system operating parameter and for a period of time, in such a manner that a higher power is fed into the system than belongs to the operating range of the steady-state operation. The same conditions also apply to a method for providing control power or primary control power for an electric energy generator and distributor system to which a multiplicity of power stations including wind turbines is connected, and to a wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

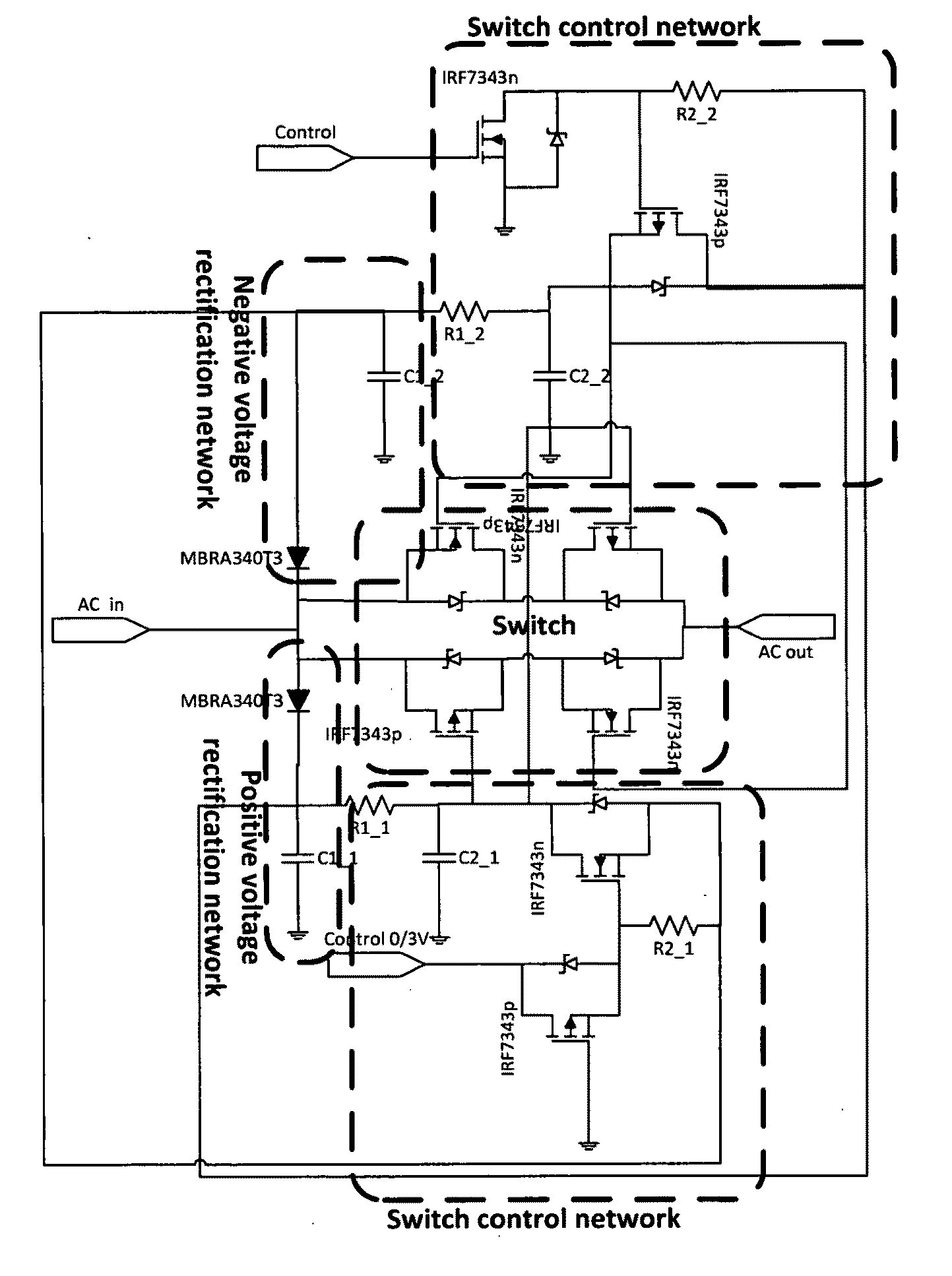

Miniature high voltage/current ac switch using low voltage single supply control

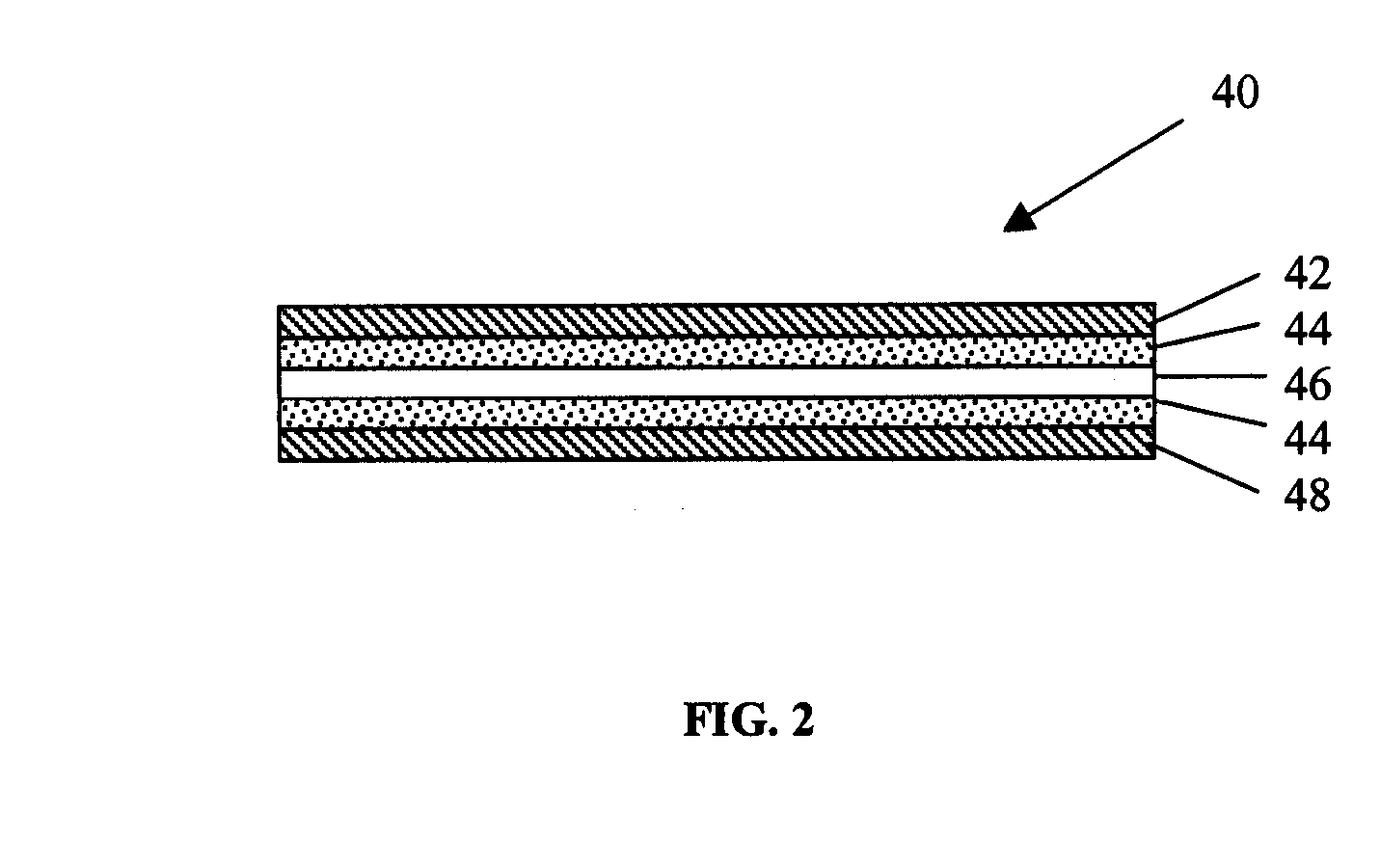

InactiveUS20100110741A1Improve efficiencyAvoid heatingAc-dc conversionSafety/protection circuitsElectric power transmissionHigh voltage igbt

Embodiments of the invention pertain to a method and apparatus for planar wireless power transfer where the receiver switches off and / or performs a duty cycle. In an embodiment, the switch can be used in a system that having a high voltage / current solid state switch, without having a high voltage control signal. An embodiment provides a switch that is capable of breaking, or greatly reducing, the connection of the receiver coil and the receiver circuitry in order to enable the receiver to decouple from the power transfer system. This embodiment can allow the transmitter to put out more power to other devices without providing power to the switched device. When the switch is used for a fully charged device, the switching can prevent or reduce damage to the fully charged device.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

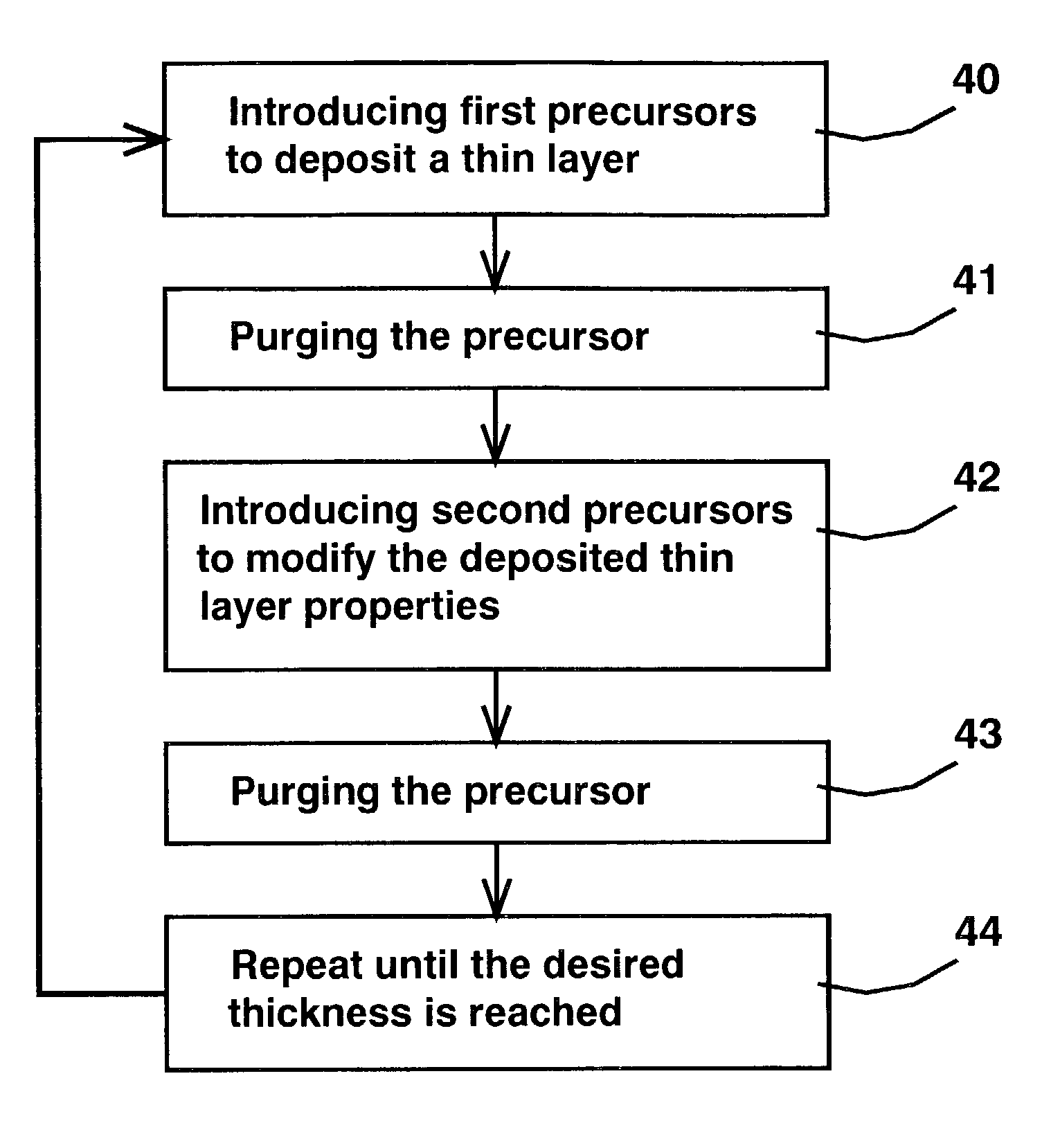

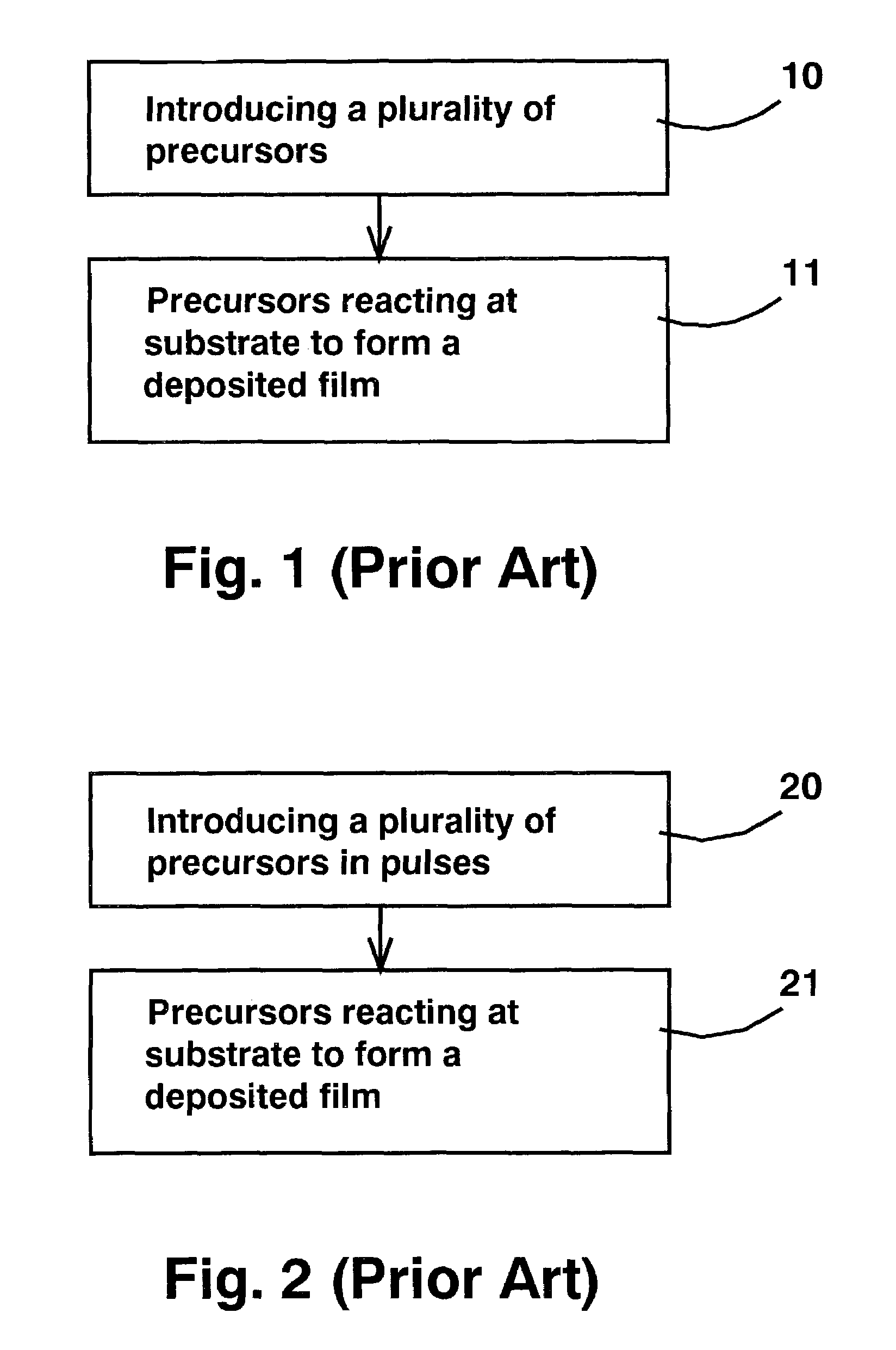

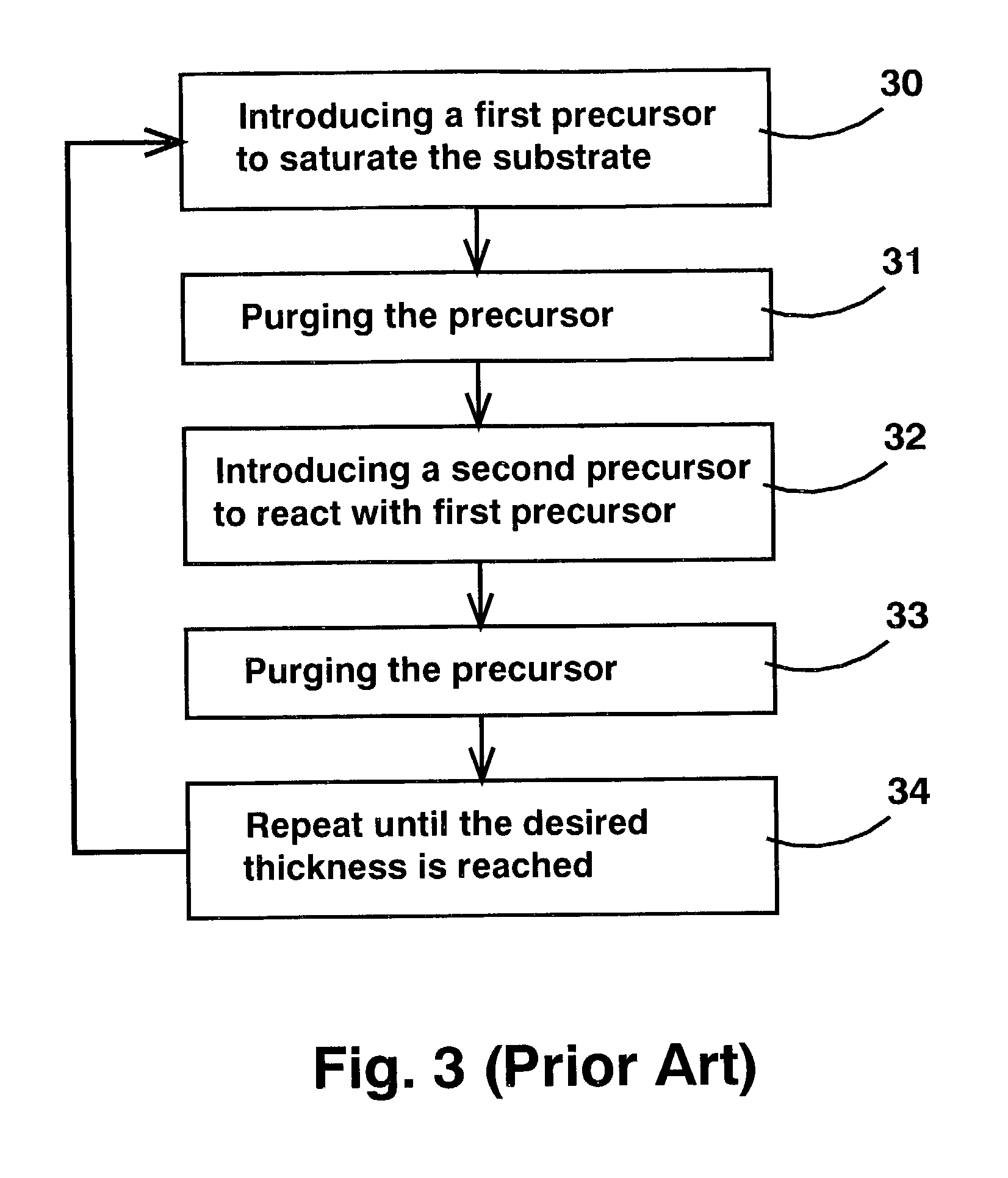

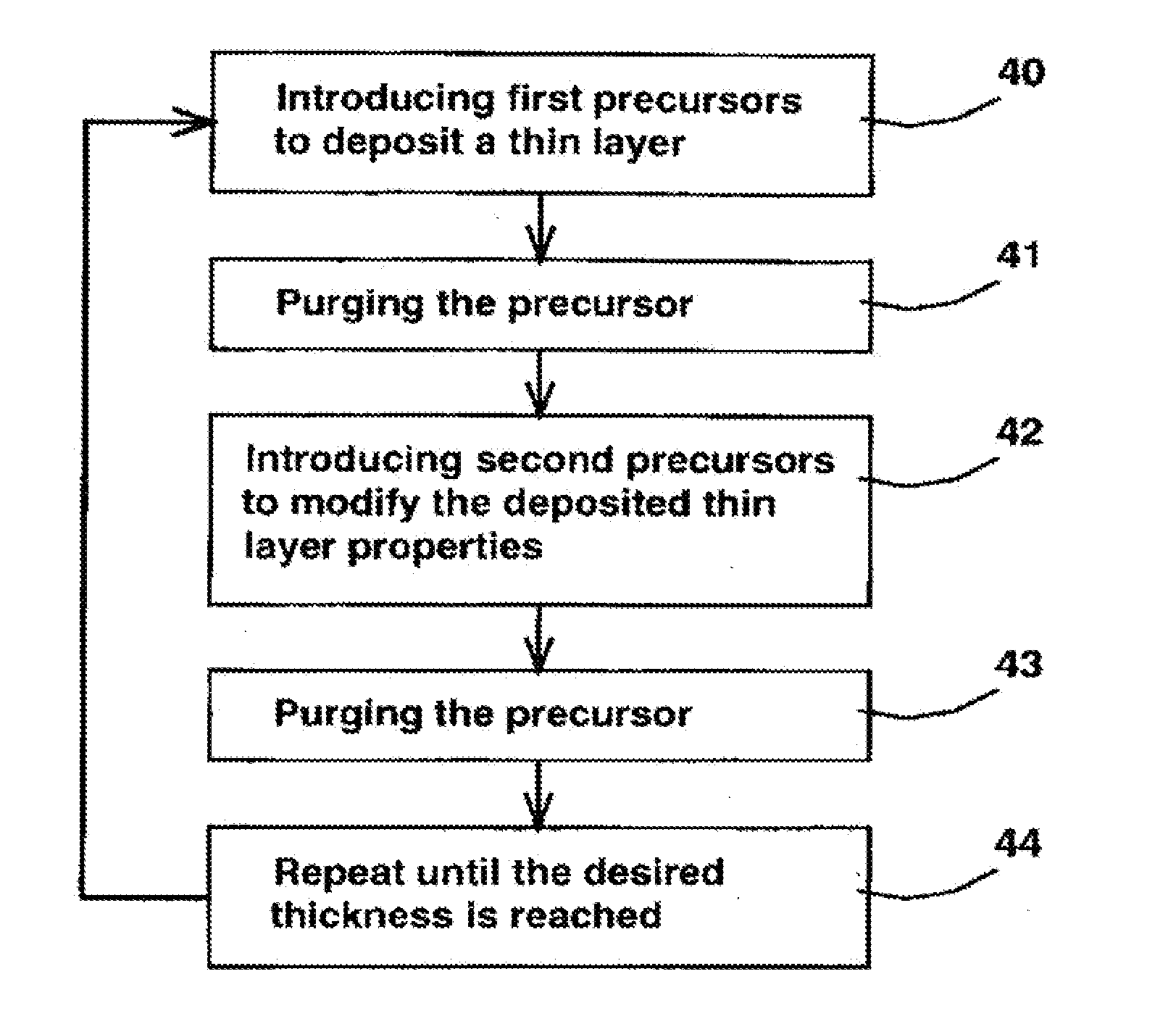

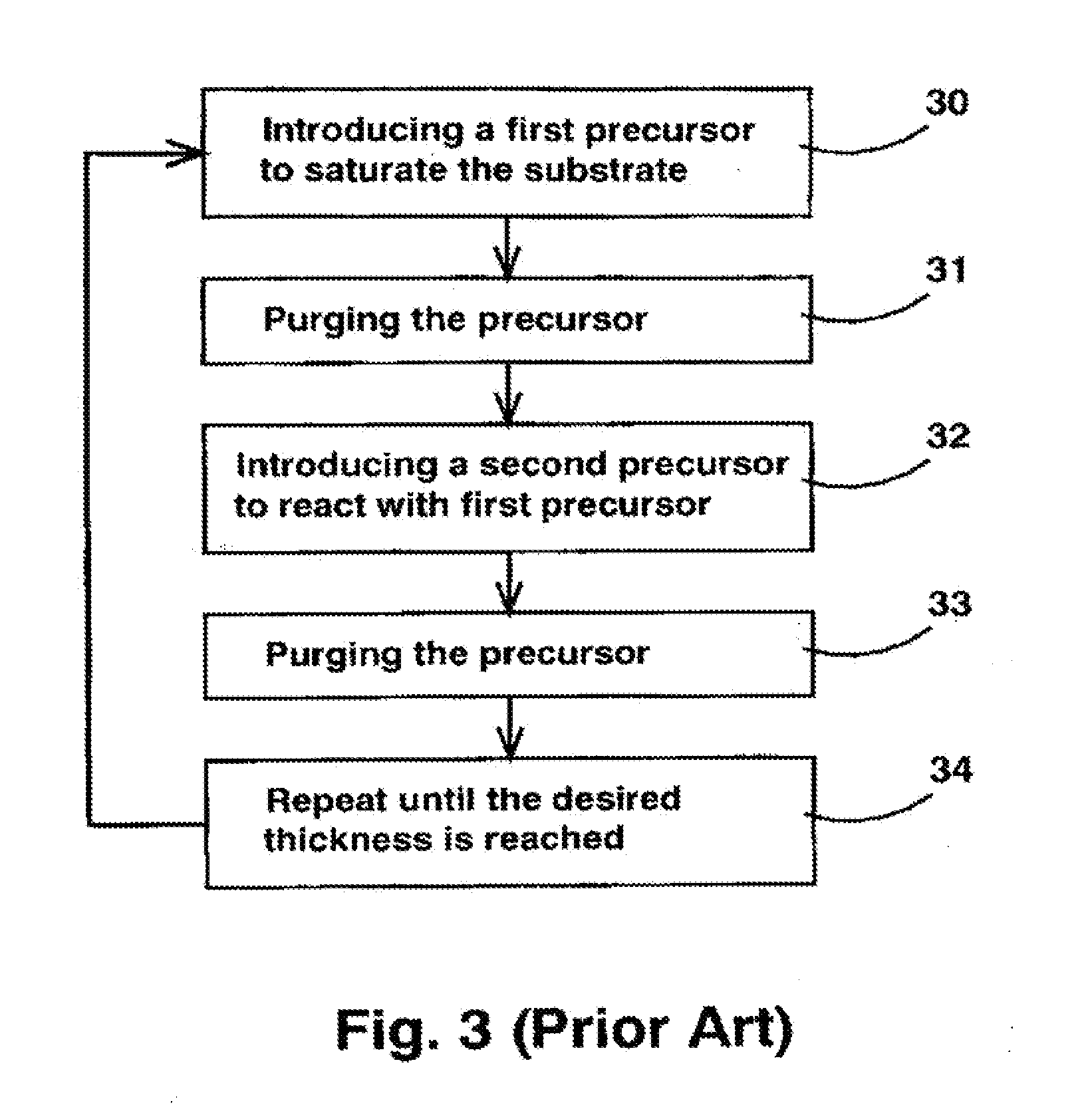

Nanolayer deposition process

InactiveUS7713592B2High energyIncrease powerMaterial nanotechnologyLiquid/solution decomposition chemical coatingSelf limitingDeposition process

A hybrid deposition process of CVD and ALD, called NanoLayer Deposition (NLD) is provided. The nanolayer deposition process is a cyclic sequential deposition process, comprising the first step of introducing a first plurality of precursors to deposit a thin film with the deposition process not self limiting, then a second step of purging the first set of precursors and a third step of introducing a second plurality of precursors to modify the deposited thin film. The deposition step in the NLD process using the first set of precursors is not self limiting and is a function of substrate temperature and process time. The second set of precursors modifies the already deposited film characteristics. The second set of precursors can treat the deposited film such as a modification of film composition, a doping or a removal of impurities from the deposited film. The second set of precursors can also deposit another layer on the deposited film. The additional layer can react with the existing layer to form a compound layer, or can have minimum reaction to form a nanolaminate film.

Owner:ASM INTERNATIONAL

Method for operating or controlling a wind turbine and method for providing primary control power by means of wind turbines

ActiveUS7528496B2Improve power transmissionHigh yieldWind motor controlSingle network parallel feeding arrangementsEngineeringDistributor

A method for operating at least one wind turbine with a rotor and an electric generator coupled to the rotor for delivering electrical power into an energy distribution system with the aid of a control device ensures that the wind turbine operates within its operating range. The wind turbine is controlled in response to the change of a system operating parameter and for a period of time, in such a manner that a higher power is fed into the system than belongs to the operating range of the steady-state operation. The same conditions also apply to a method for providing control power or primary control power for an electric energy generator and distributor system to which a multiplicity of power stations including wind turbines is connected, and to a wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

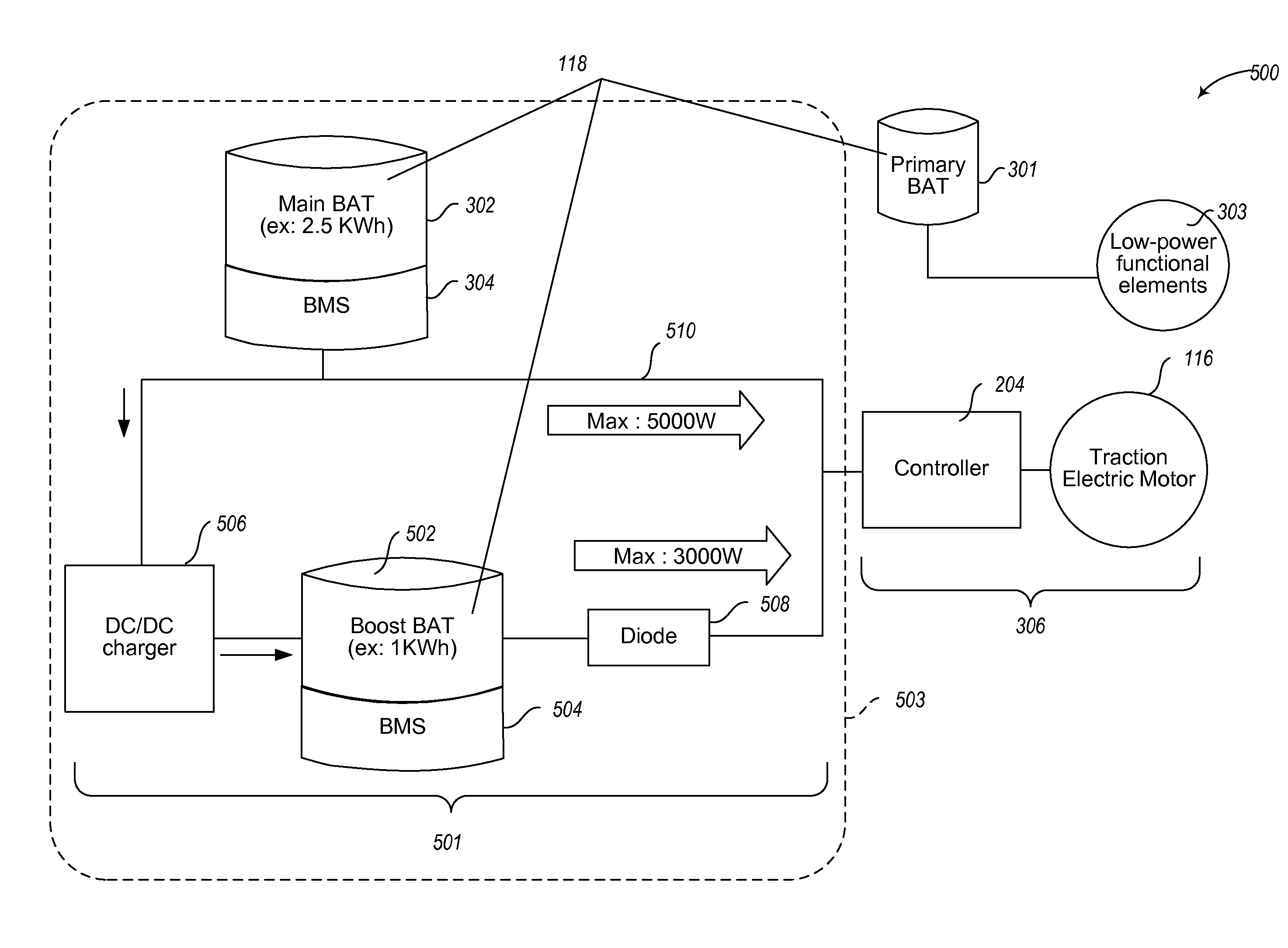

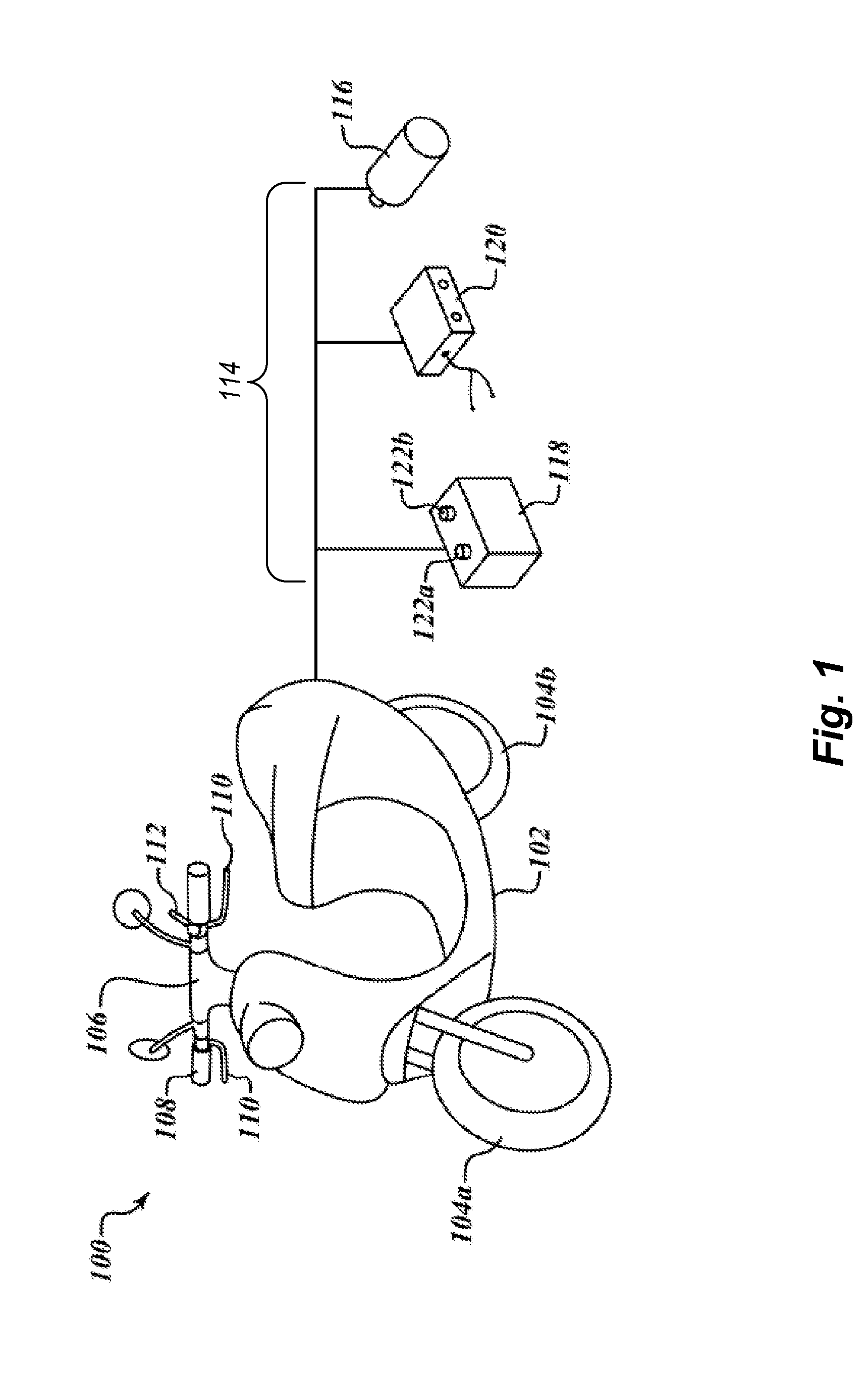

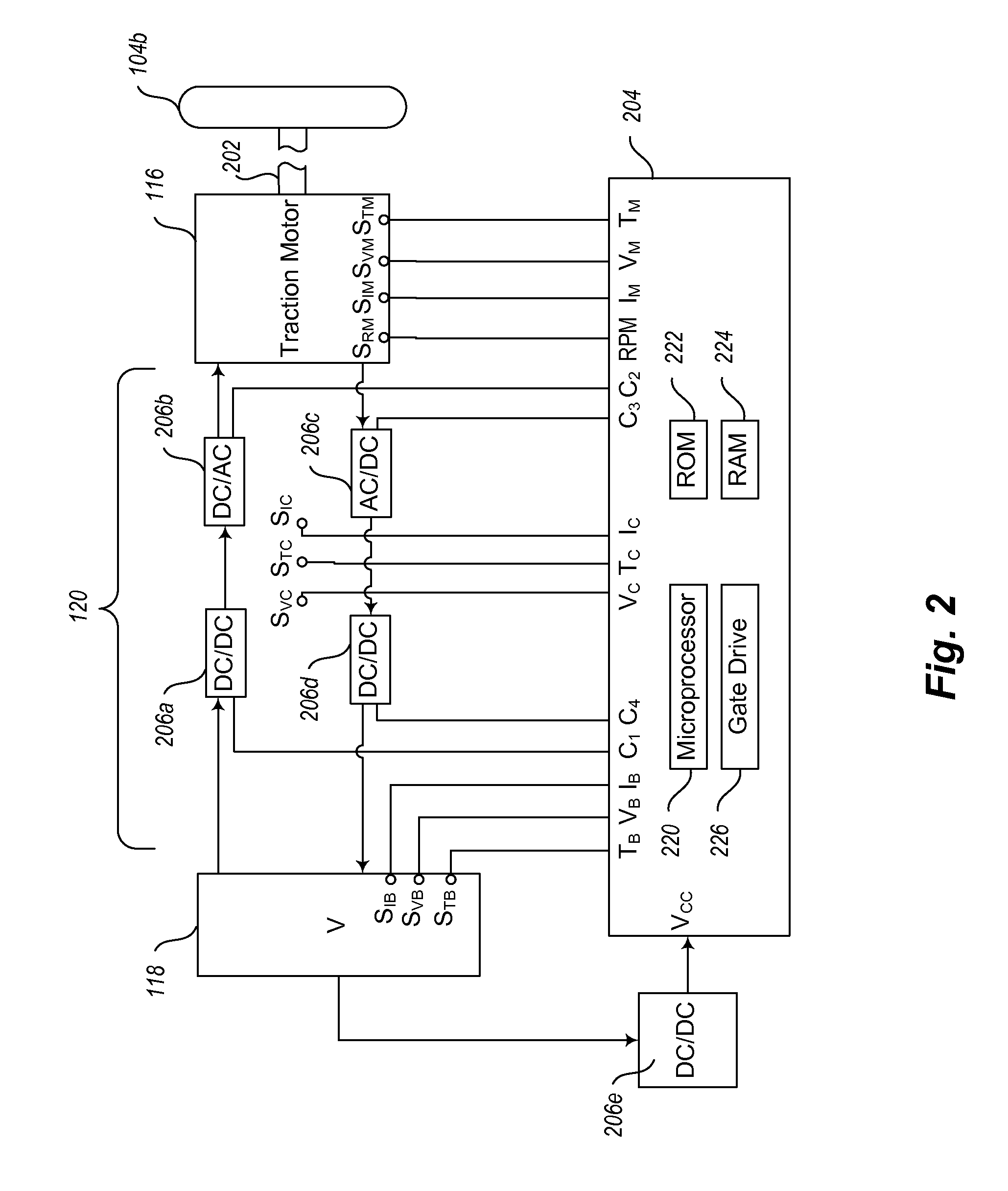

Battery configuration for an electric vehicle

ActiveUS20140111121A1Long rangeEfficient managementPropulsion by batteries/cellsVehicular energy storageAutomatic controlNormal load

A power delivery system for an electric vehicle provides efficient power management for either continuous or intermittent high-performance operation, using a boost stage and an on-board charging circuit. A main battery, configured as a high-capacity power source, supplies power to the electric motor under normal load conditions. An auxiliary boost battery assists the main battery in supplying a high-level current at a higher discharge rate thereby causing the motor to operate in a high-performance drive mode. A charging circuit recharges the boost battery from the main battery during operation of the motor. The charging circuit also maintains a charge balance between the boost battery and the main battery when the two batteries have different chemistries. In one embodiment, participation of the boost battery in powering the electric motor can be controlled automatically according to sensed changes in the load. In another embodiment, power management can be based on timed intervals.

Owner:GOGORO

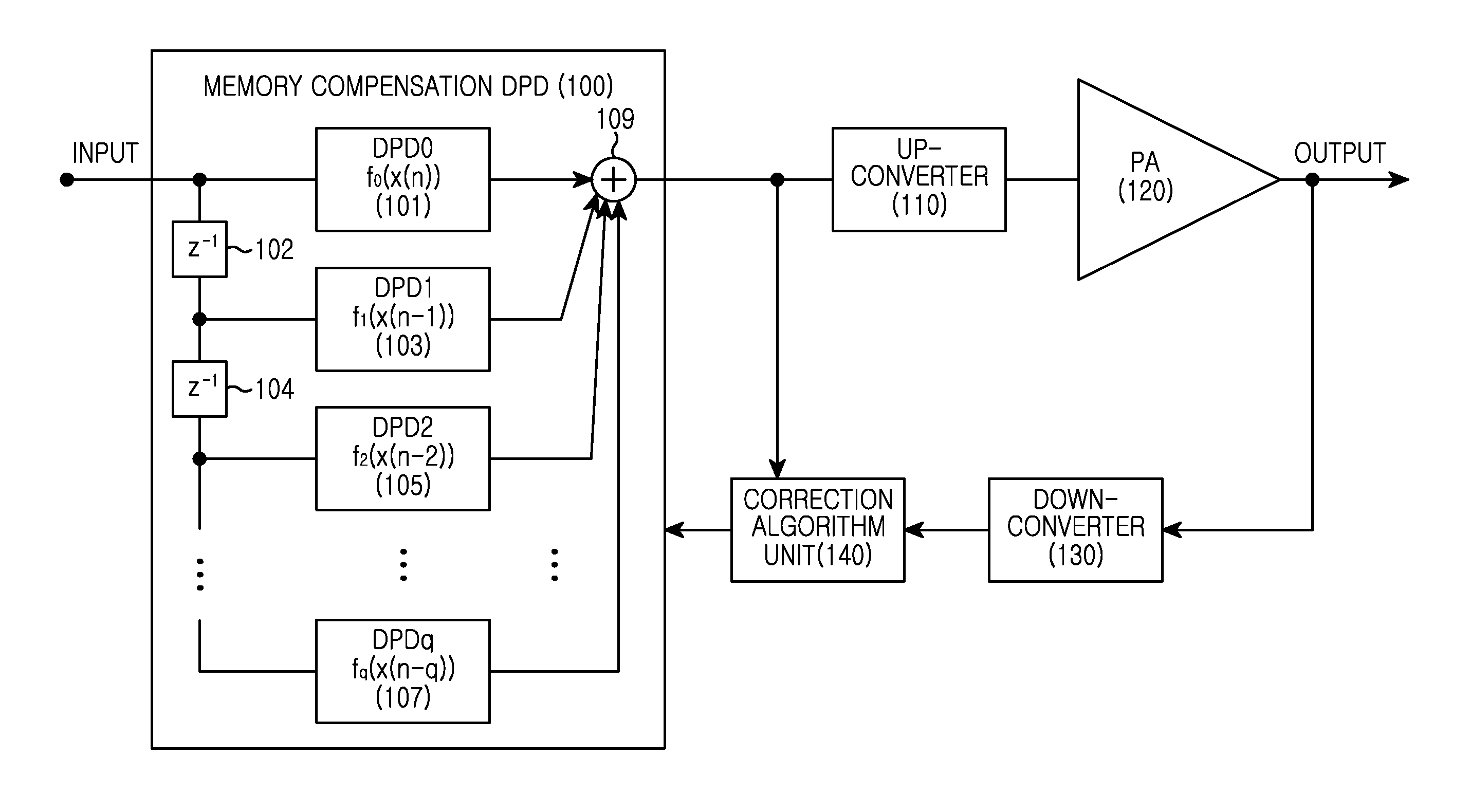

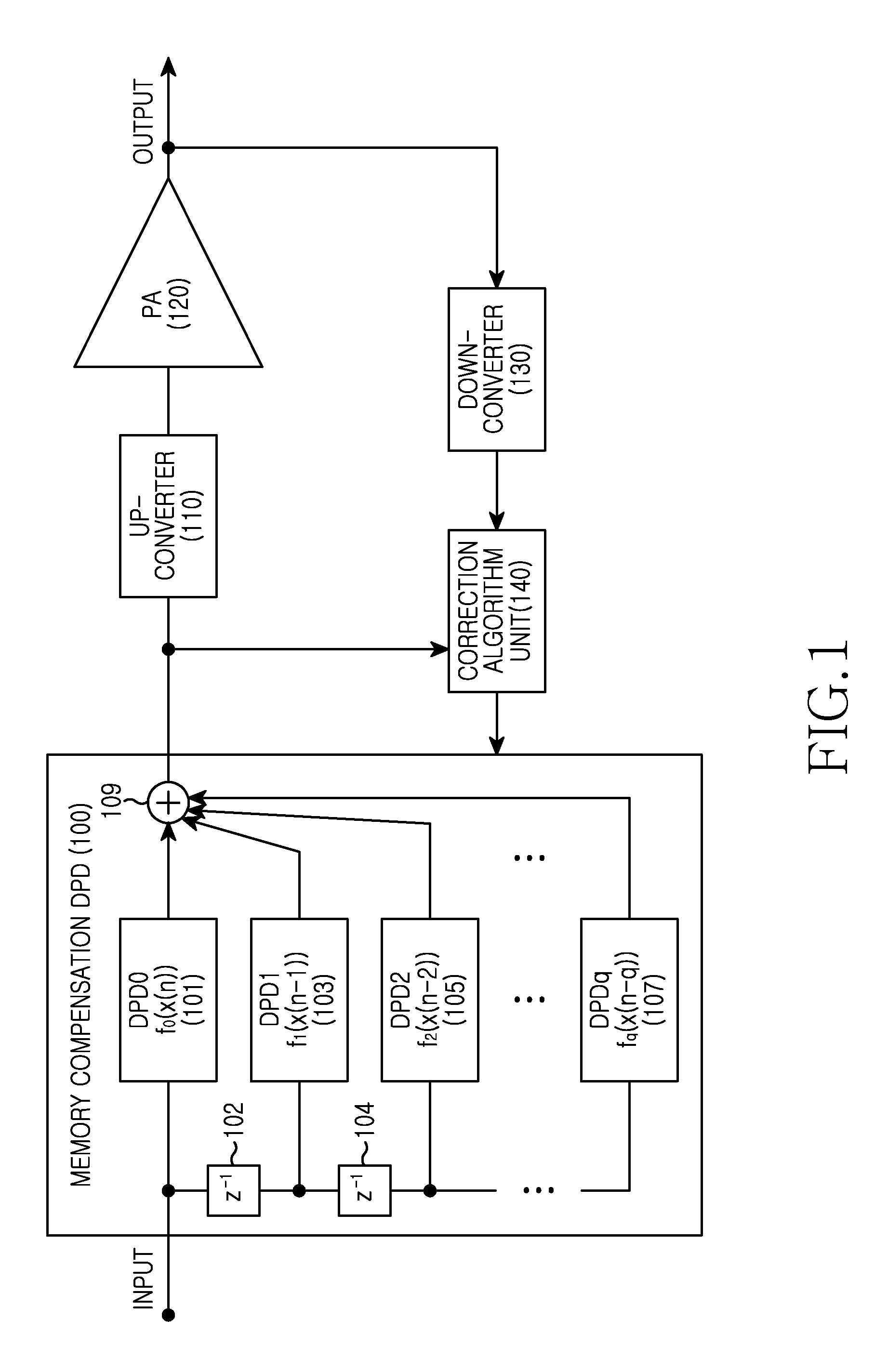

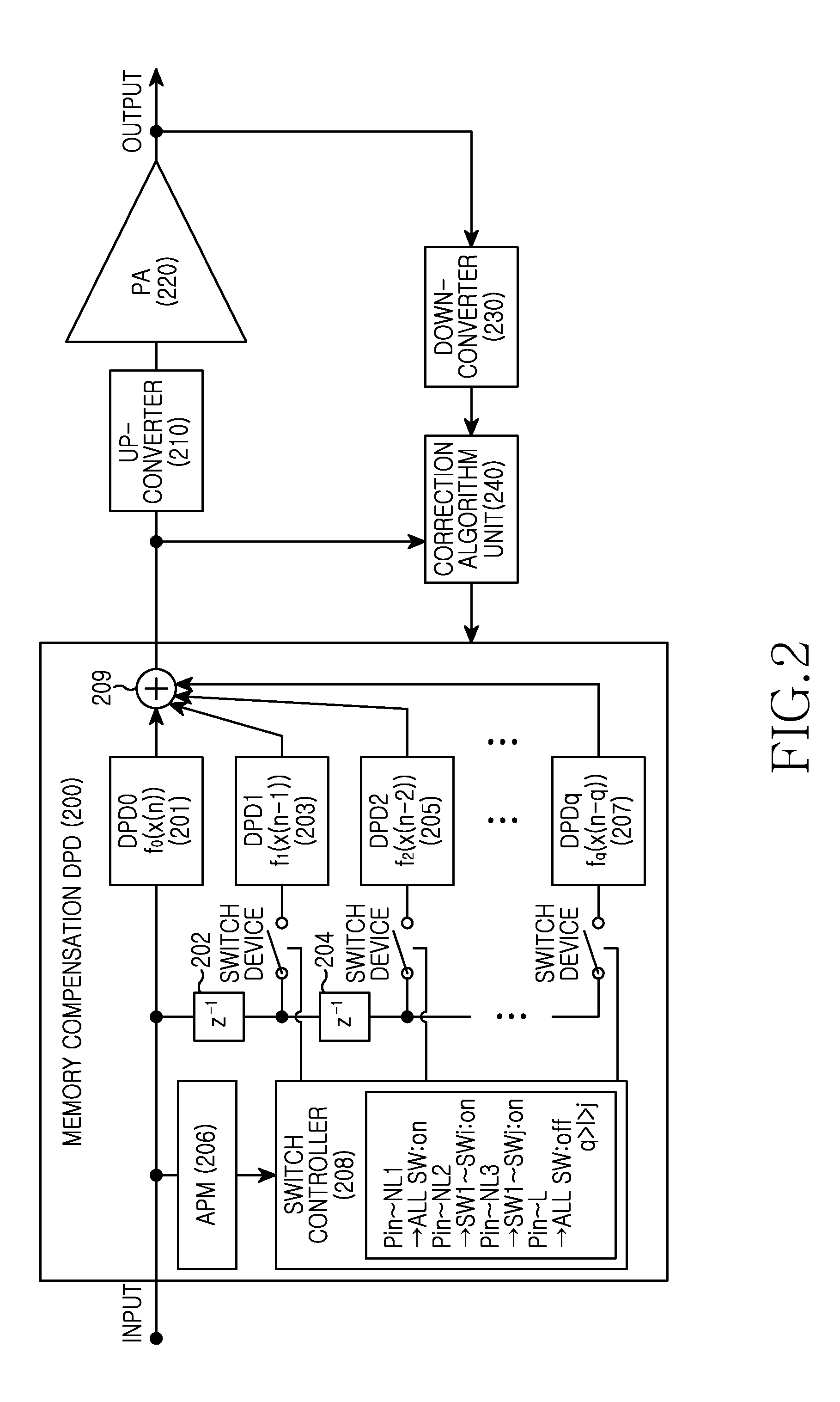

Digital pre-distortion method and apparatus thereof for changing memory degree depending on input level

ActiveUS20130100991A1Improve power transmissionSimple structureAmplifier modifications to reduce non-linear distortionModulated-carrier systemsElectrical and Electronics engineeringPre distortion

An apparatus and a method for operating a memory compensation Digital Pre-Distortion (DPD) are provided. In the method for operating a memory compensation DPD system, an input signal is received. An input average power of the input signal is determined. When the input average power of the input signal belongs to a non-linear section of the input average power, DPD is performed on a previous signal corresponding to a memory degree set depending on at least one non-linear section of the input average power.

Owner:SAMSUNG ELECTRONICS CO LTD

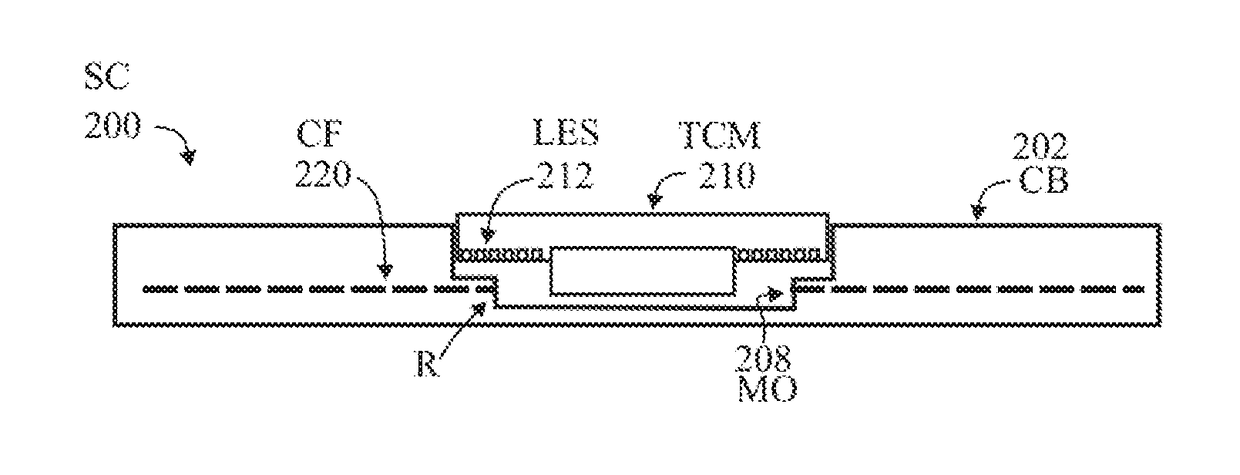

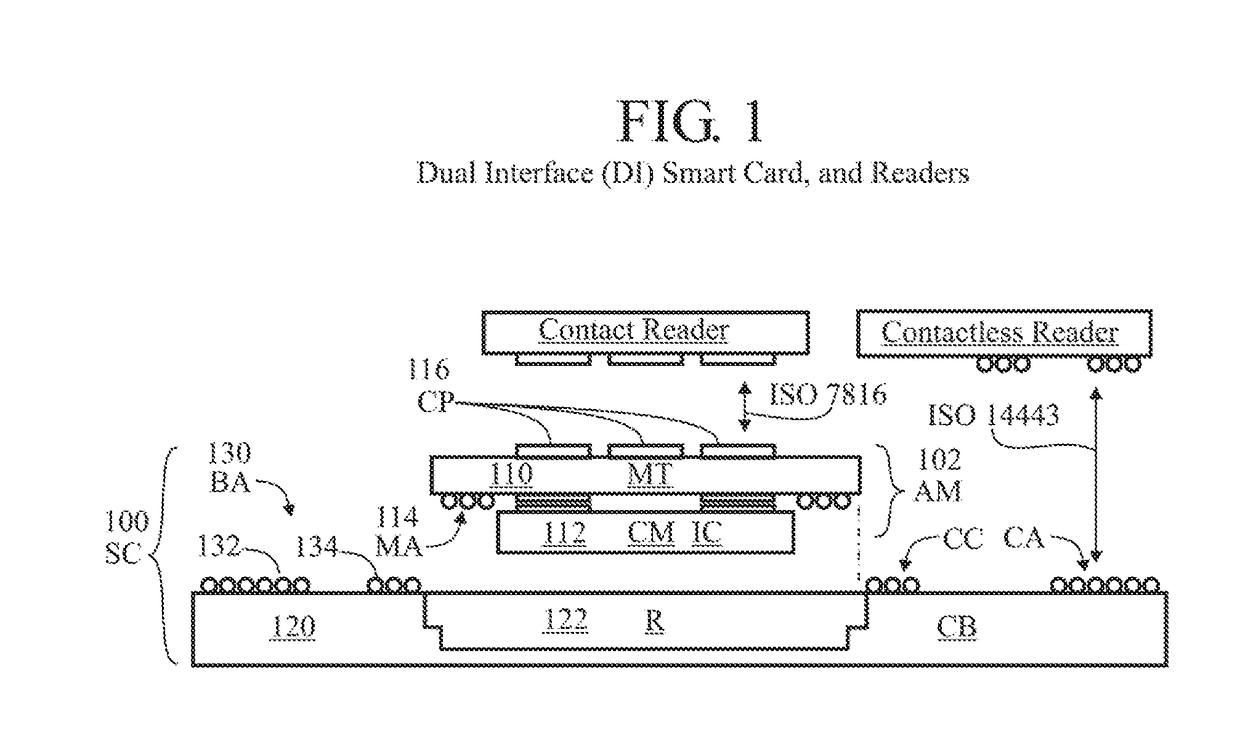

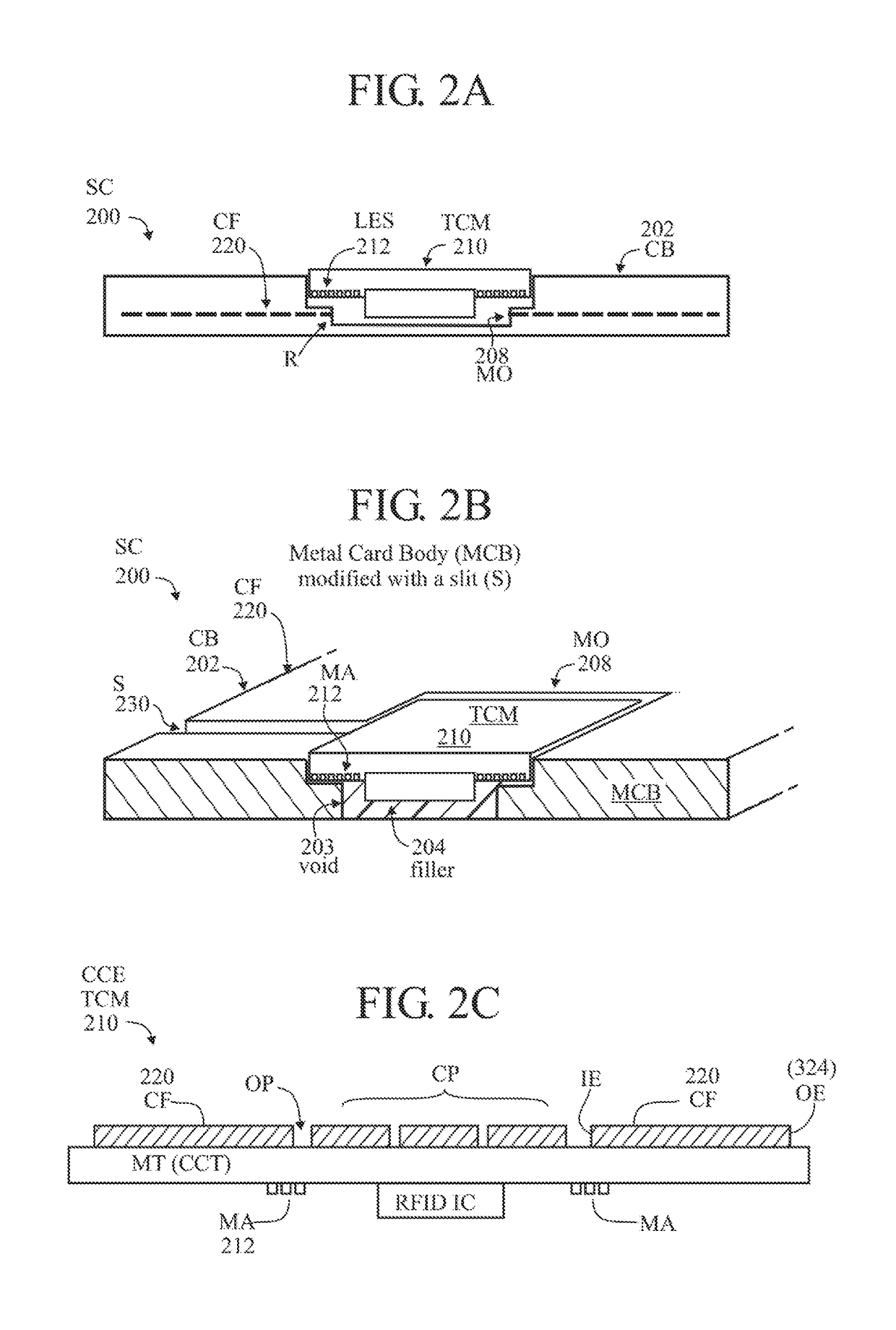

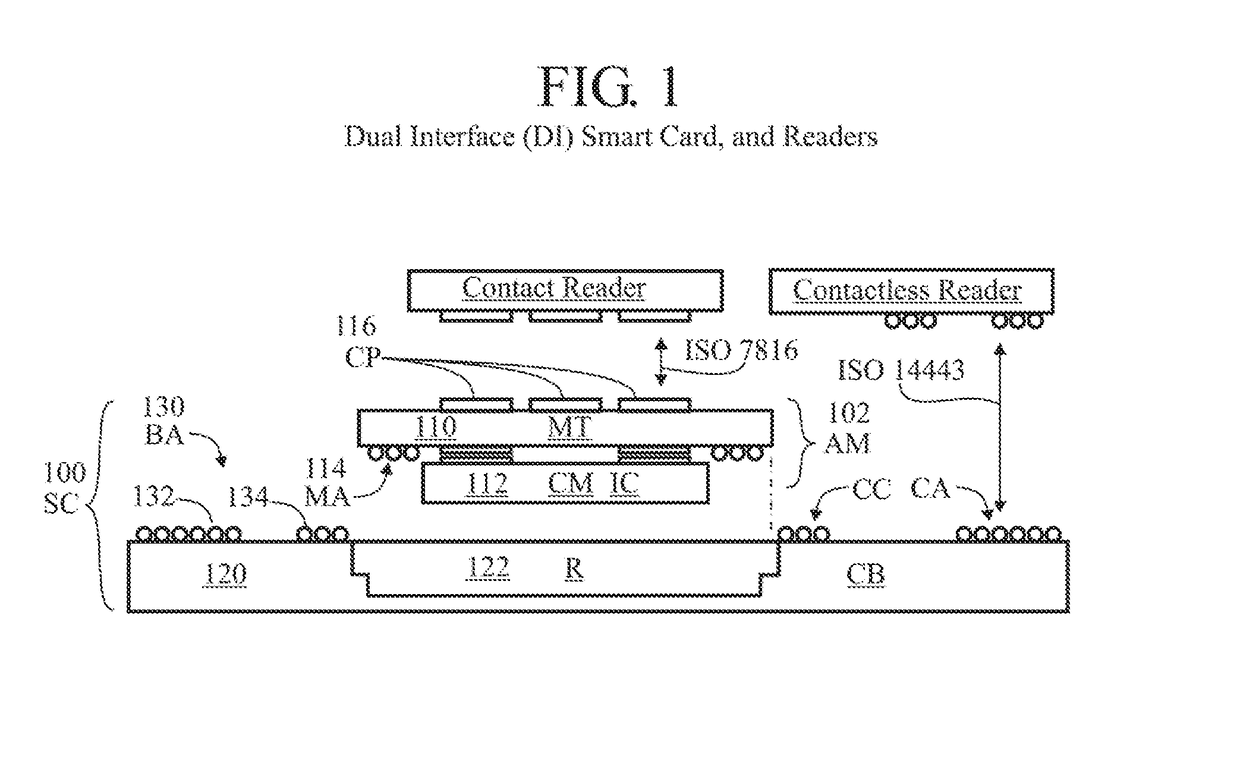

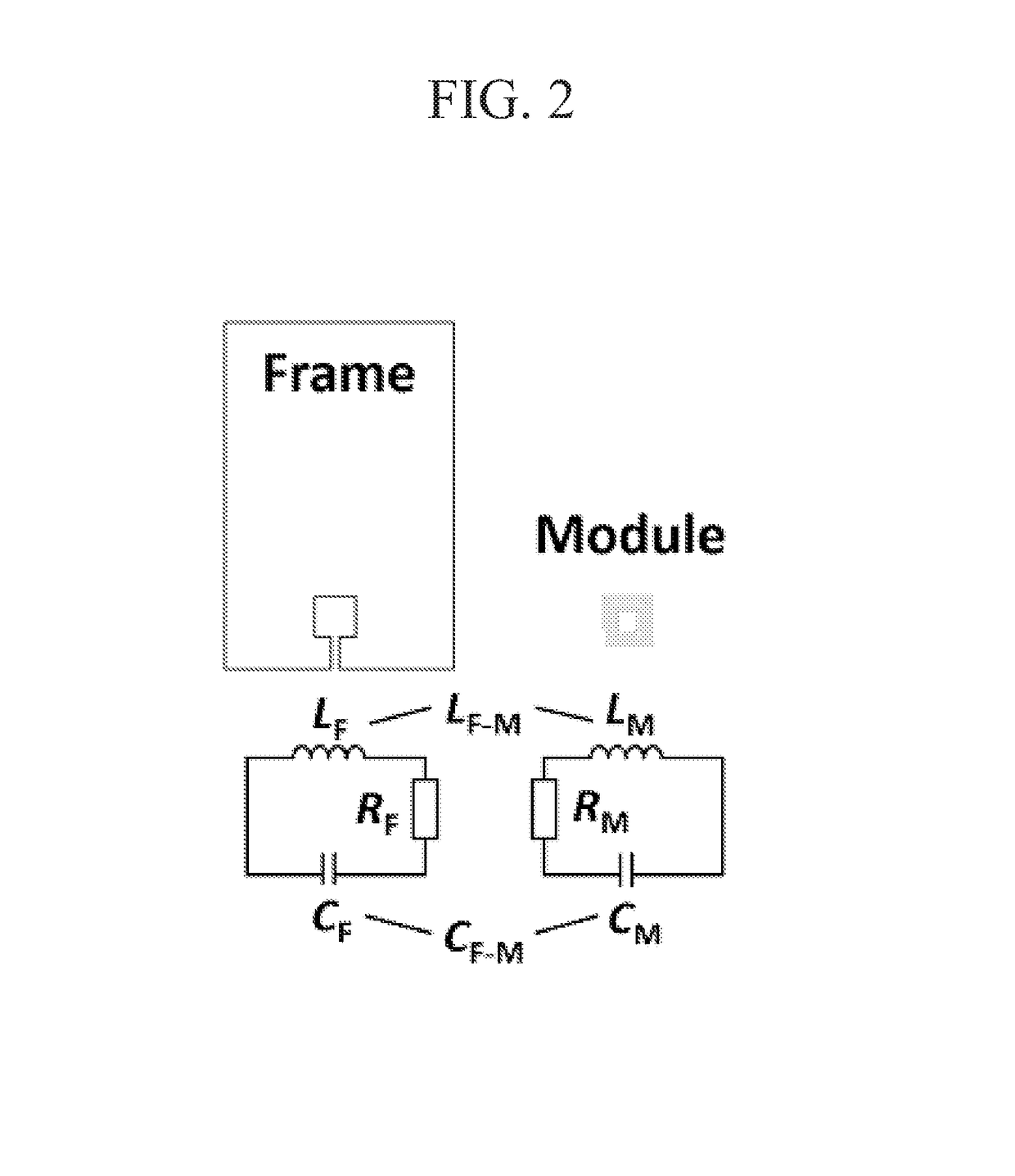

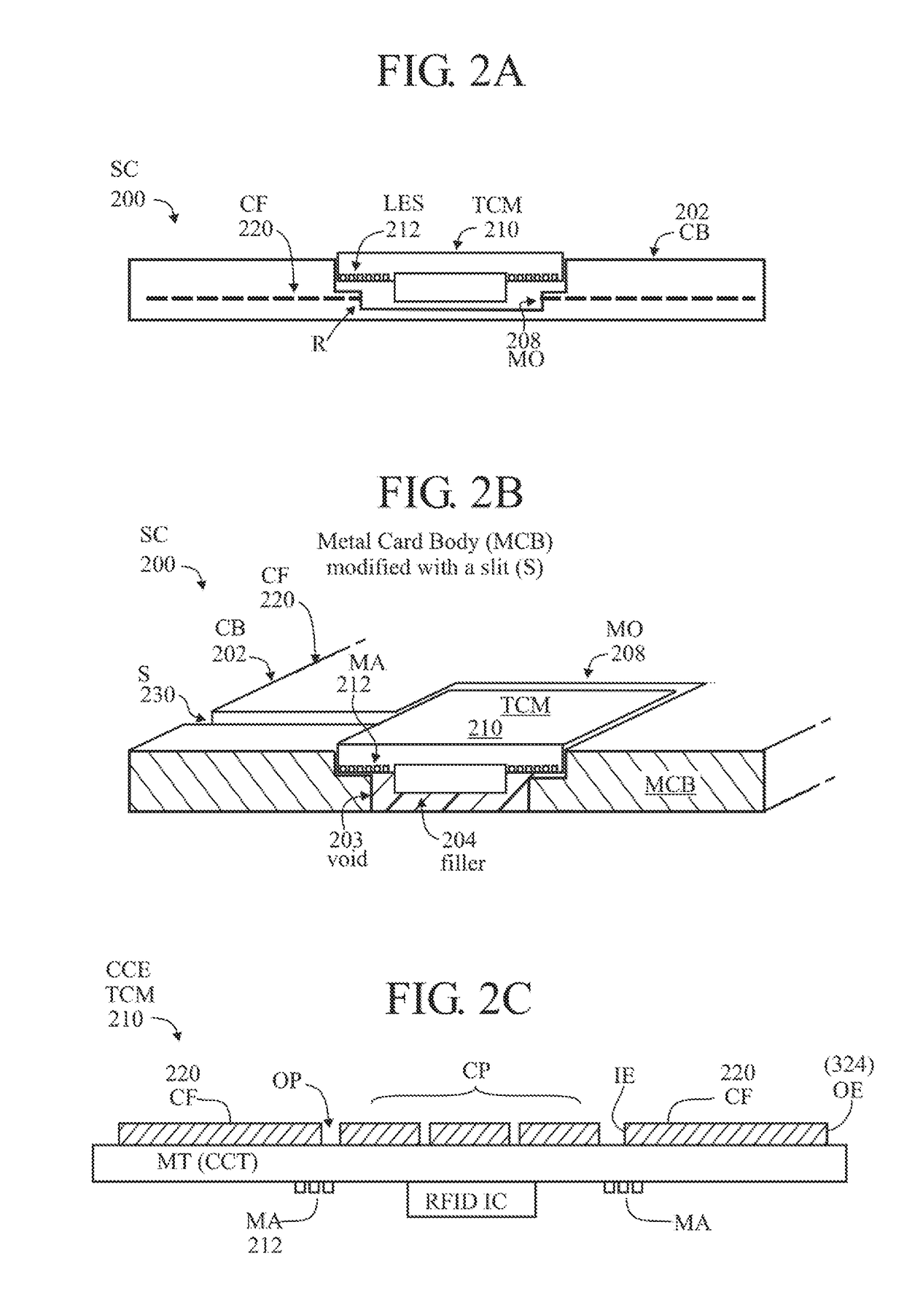

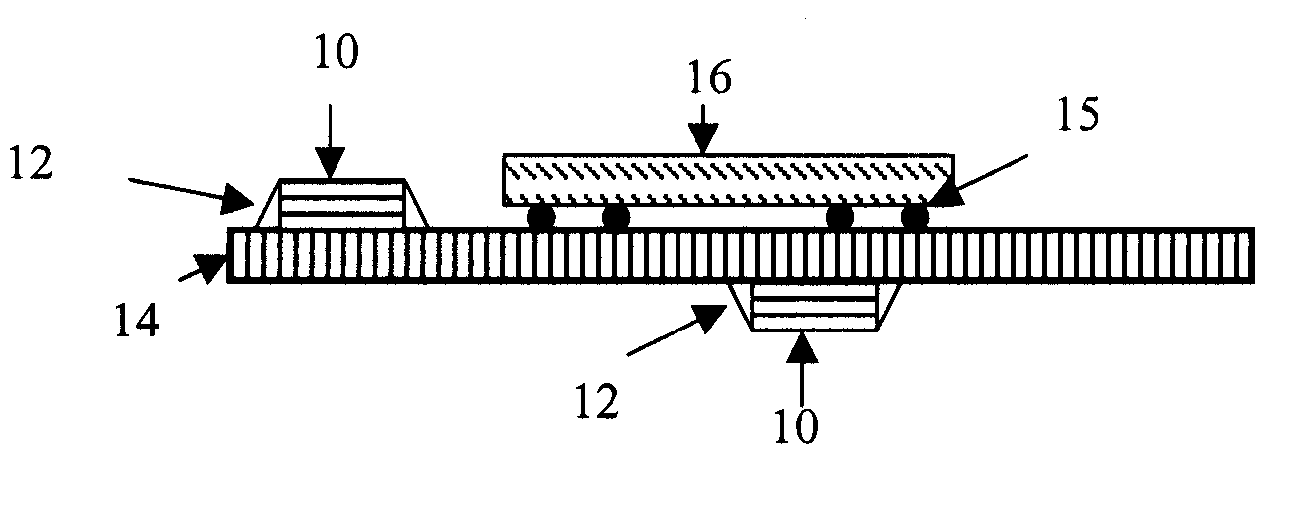

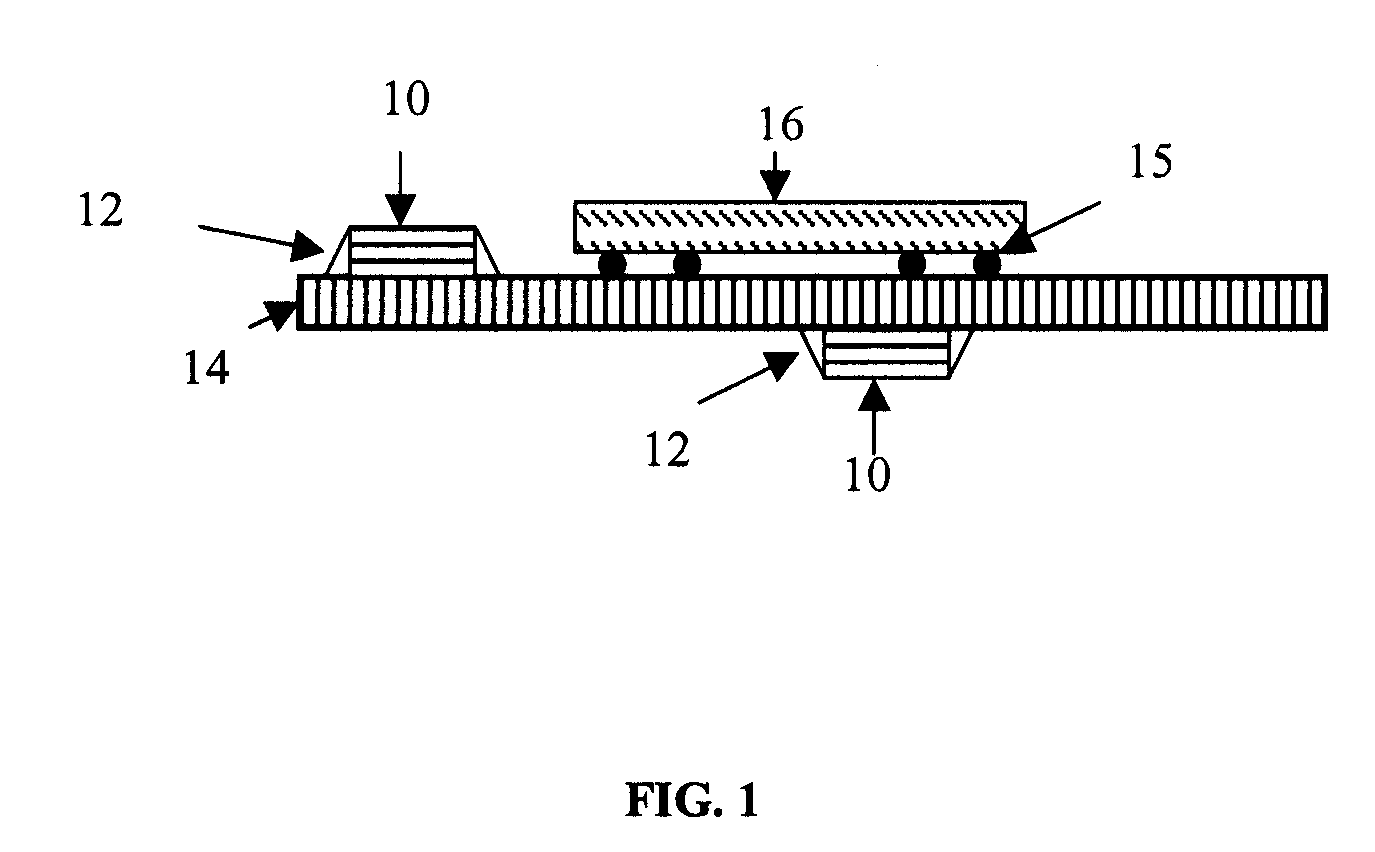

Smartcards, RFID devices, wearables and methods

ActiveUS20180123221A1Improve performanceImprove the coupling effectAntenna supports/mountingsRadiating elements structural formsCapacitanceDiamond-like carbon

Coupling frames comprising a conductive (metal) surface with a slit (S) or non-conductive stripe (NCS) extending from an outer edge to an inner position thereof, and overlapping a transponder device. A coupling frame with slit for coupling with an inductive or capacitive device (inductor or capacitor) may be used at any ISM frequency band to concentrate surface current around the slit. The coupling frame can be tuned to operate at a frequency of interested by introducing a resistive, inductive or capacitive element. The resonance frequency of the coupling frame can be matched to that of the transponder chip module to achieve optimum performance. Coupling frames with or without a transponder device may be integrated, overlapping, stacked or placed adjacent to one another to enhance system performance. Multiple coupling frames may be electrically isolated from one another by the application of a dielectric coating such Diamond Like Carbon (DLC).

Owner:AMATECH GRP LTD

Power supply

InactiveUS7304872B1High value coupling impedanceLow impedance loadAc-dc conversion without reversalSwitch power arrangementsLow voltageEngineering

A modular, low weight impedance dropping power supply with battery backup is disclosed that can be connected to a high voltage AC source and provide electrical power at a lower voltage. The design can be scaled over a wide range of input voltages and over a wide range of output voltages and delivered power.

Owner:FIELDMETRICS

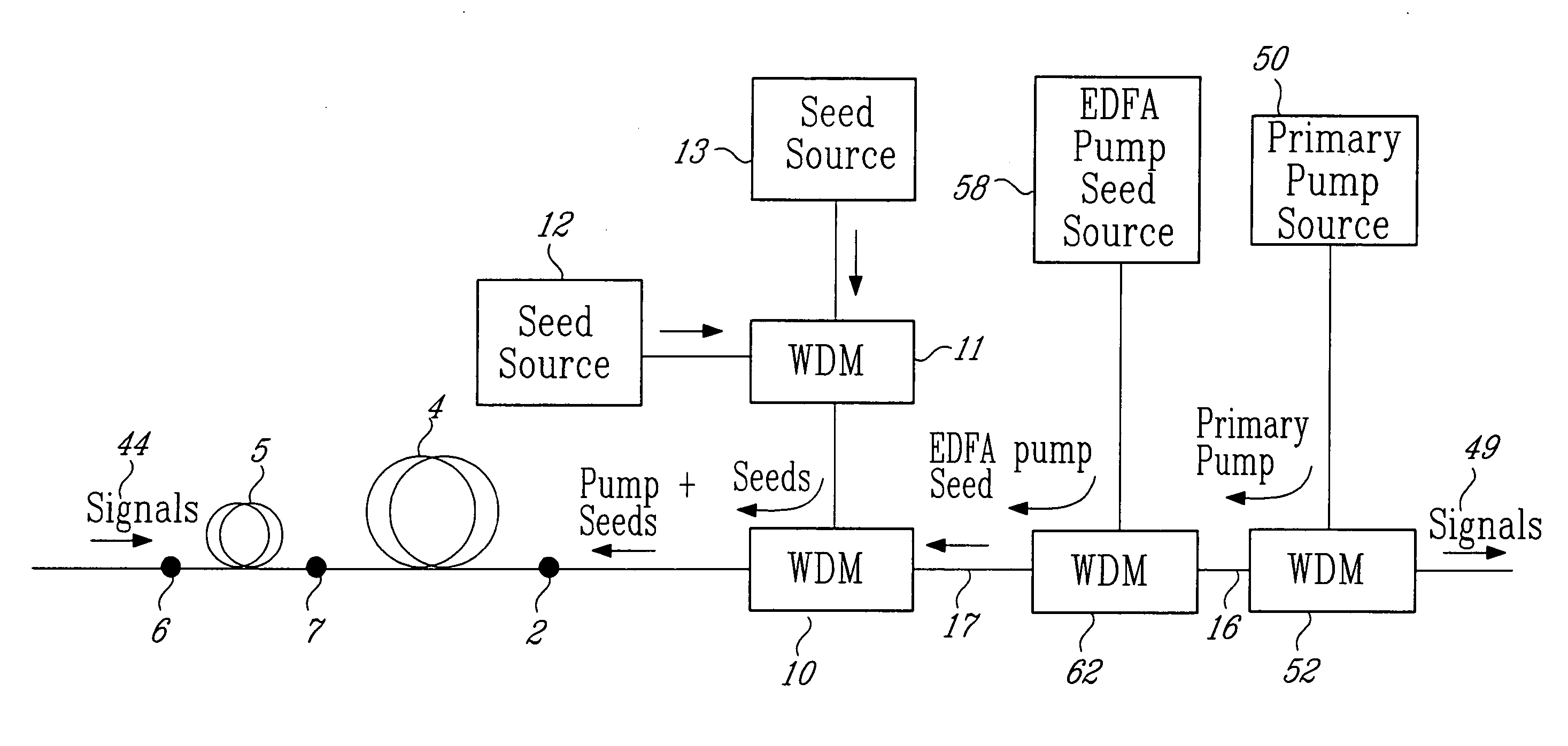

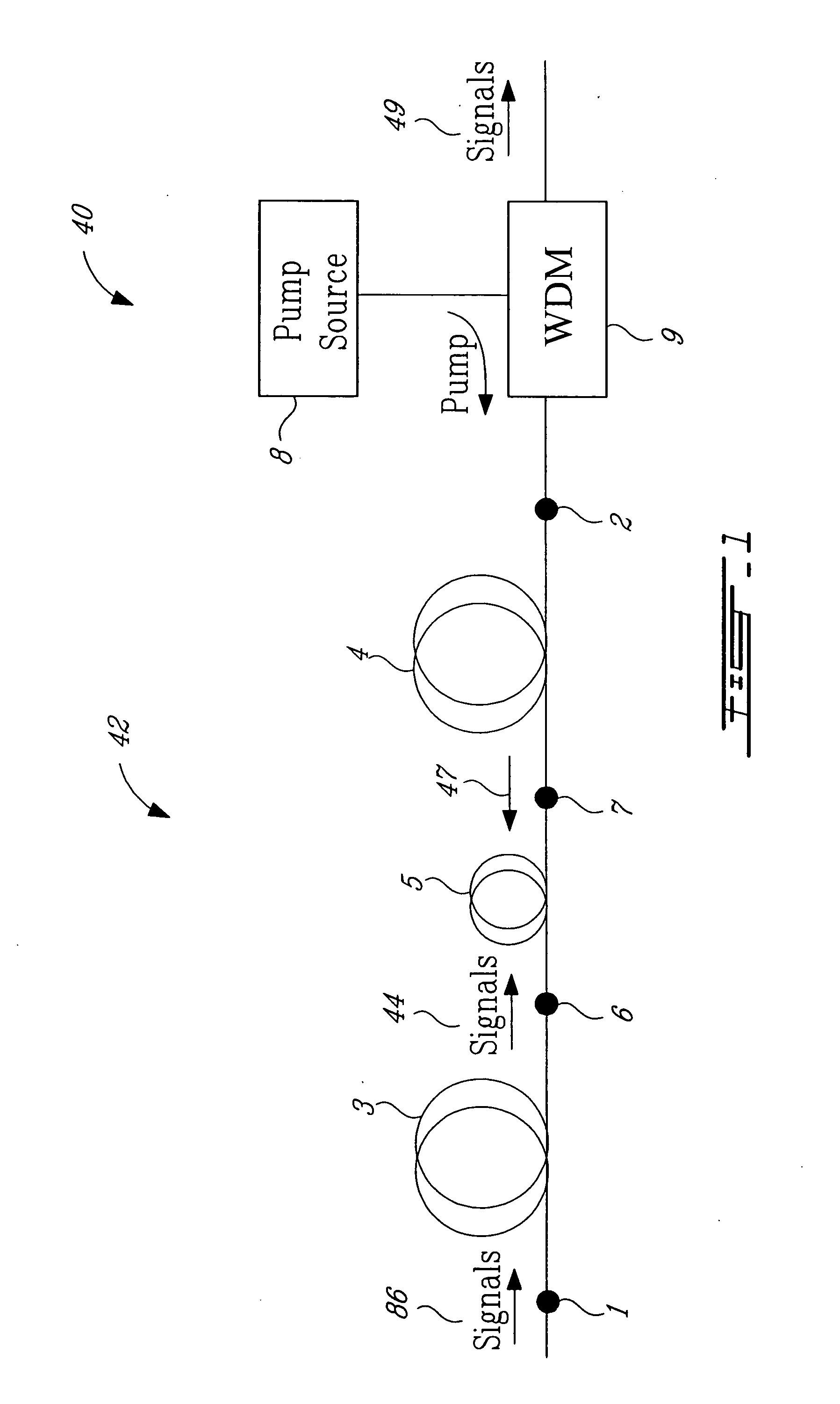

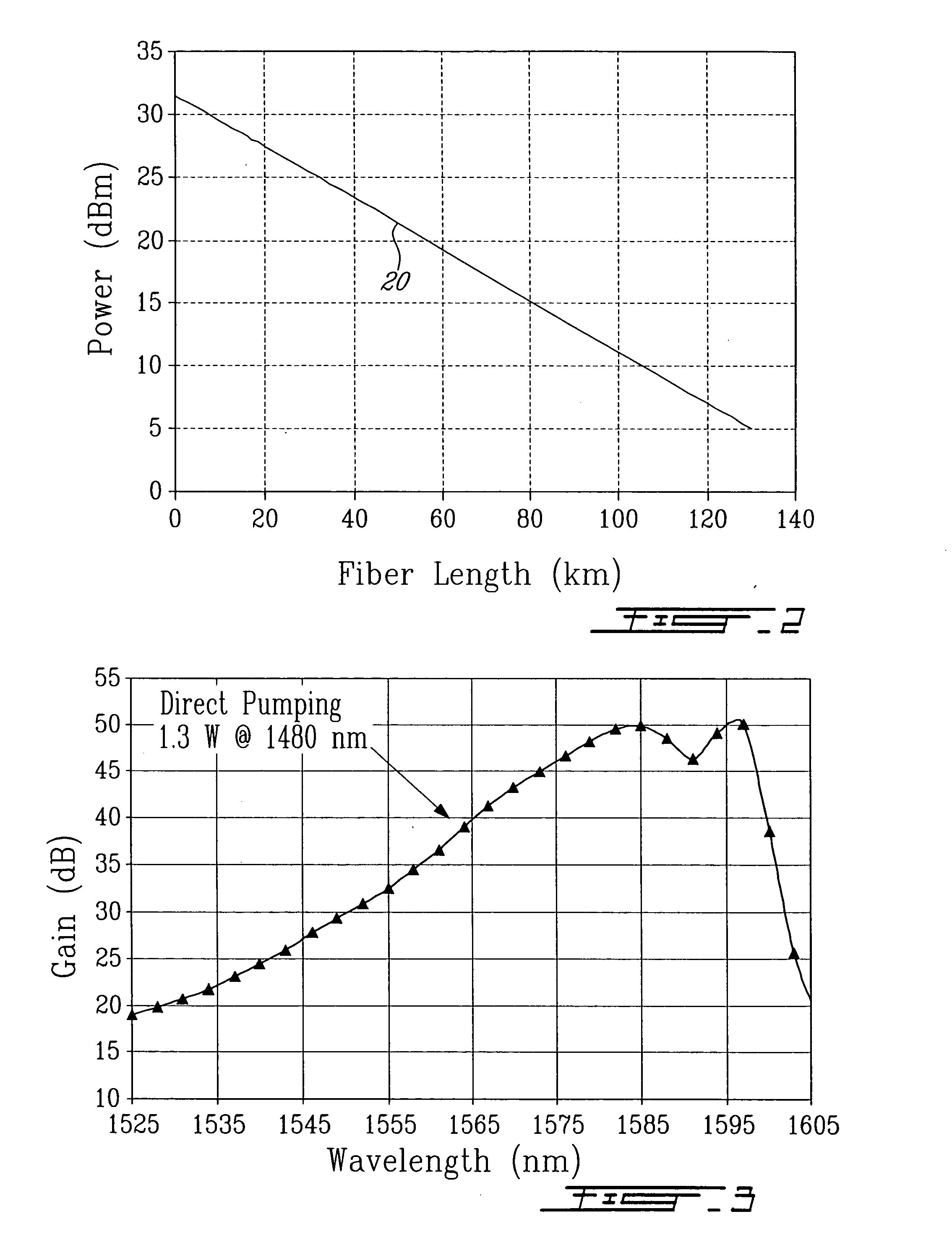

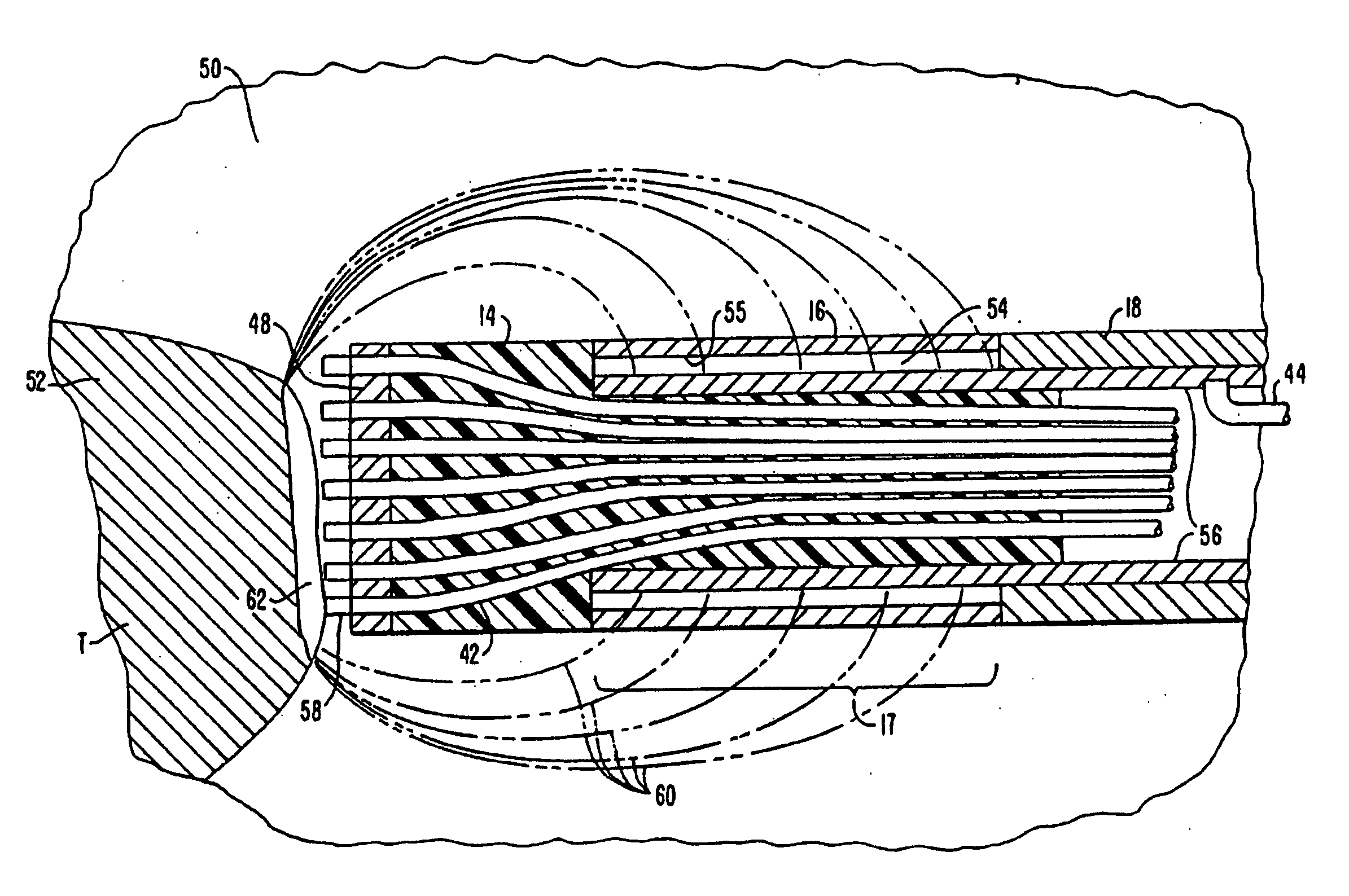

Cascaded pump delivery for remotely pumped erbium-doped fiber amplifiers

ActiveUS20060209394A1Increase volumeWeaken energyLaser detailsFibre transmissionErbium dopingEngineering

A method for pumping remote optically-pumped fiber amplifiers (ROPAs) in fiber-optic telecommunication systems is disclosed which uses cascaded Raman amplification to increase the maximum amount of pump power that can be delivered to the ROPA. According to the prior art, high power at the ROPA pump wavelength, λp, is launched directly into the fiber and the maximum launch power is limited by the onset of pump depletion by Raman noise and oscillations due to the high Raman gain at ˜(λp+100) nm. In preferred embodiments of the present invention, a ‘primary’ pump source of wavelength shorter than λp is launched into the delivery fiber along with two or more significantly lower-power ‘seed’ sources, among which is included one at λp. The wavelength and power of the seed source(s) are chosen such that, when combined with the high-power primary source, a series, n, where n≧2, of Raman conversions within the fiber ultimately leads to the development of high power at λp. In another embodiment, one or more of the seed sources at wavelengths shorter than λp are replaced by reflecting means to return, into the fiber, backward-travelling amplified spontaneous Raman scattered light resulting from high power in the fiber at a wavelength one Raman shift below the particular seed wavelength. In either case, the high power at λp is developed over a distributed length of the fiber, reaching its maximum some distance into the fiber and exceeding the maximum power possible at that point with the prior art.

Owner:MPB COMM

Smartcards, RFID devices, wearables and methods

ActiveUS10193211B2Improve power transmissionIncrease rangeAntenna supports/mountingsRadiating elements structural formsCapacitanceDiamond-like carbon

Owner:AMATECH GRP LTD

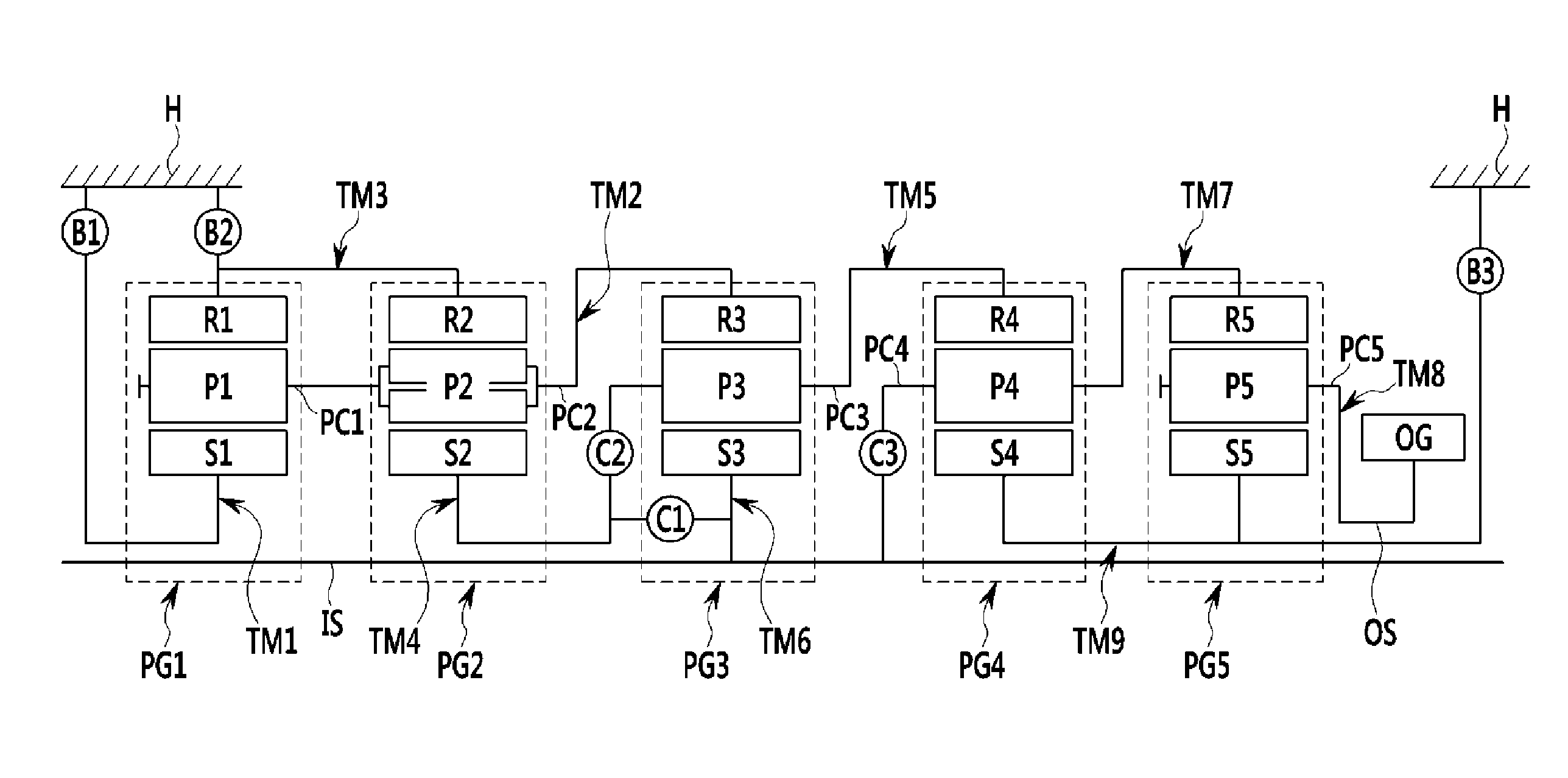

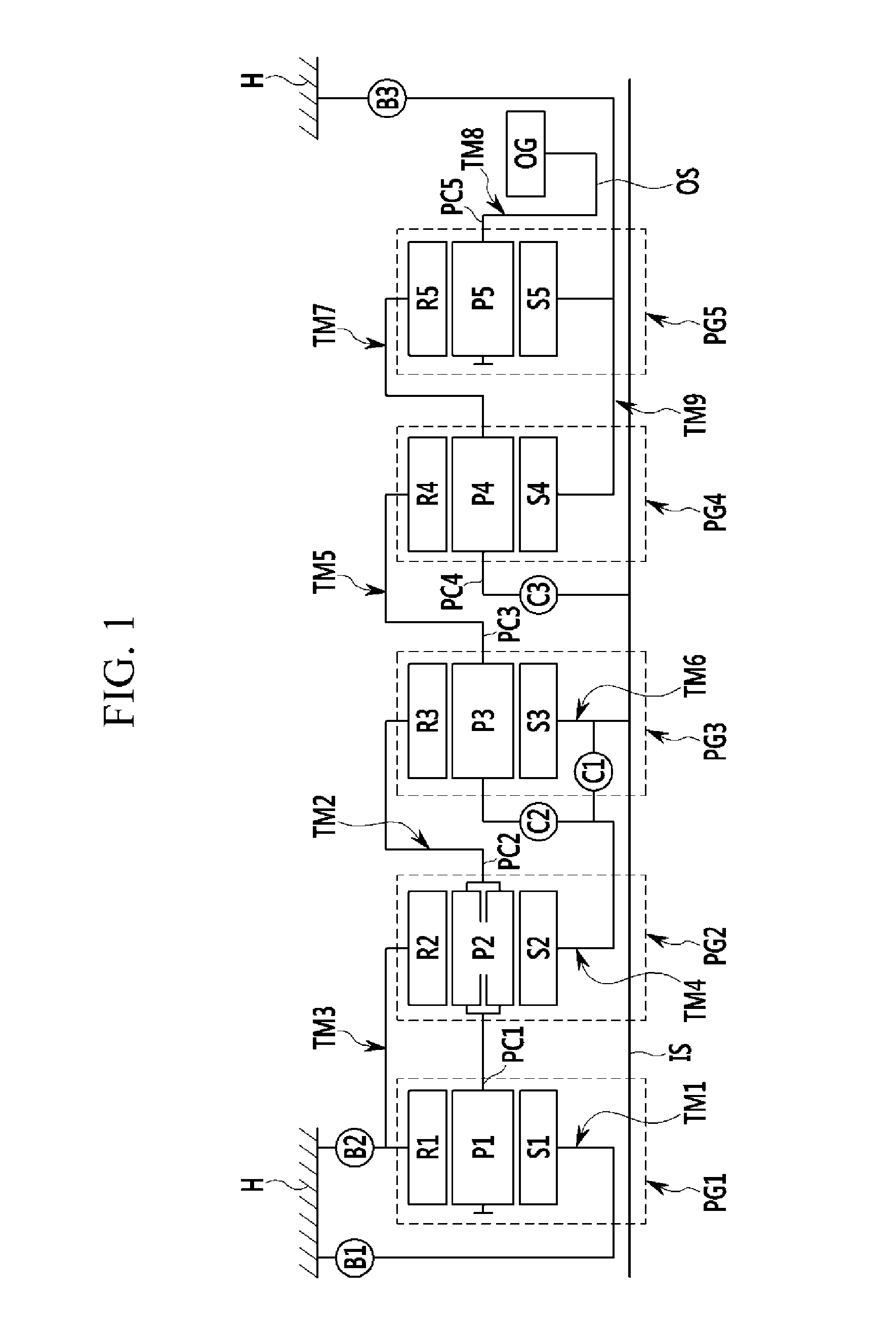

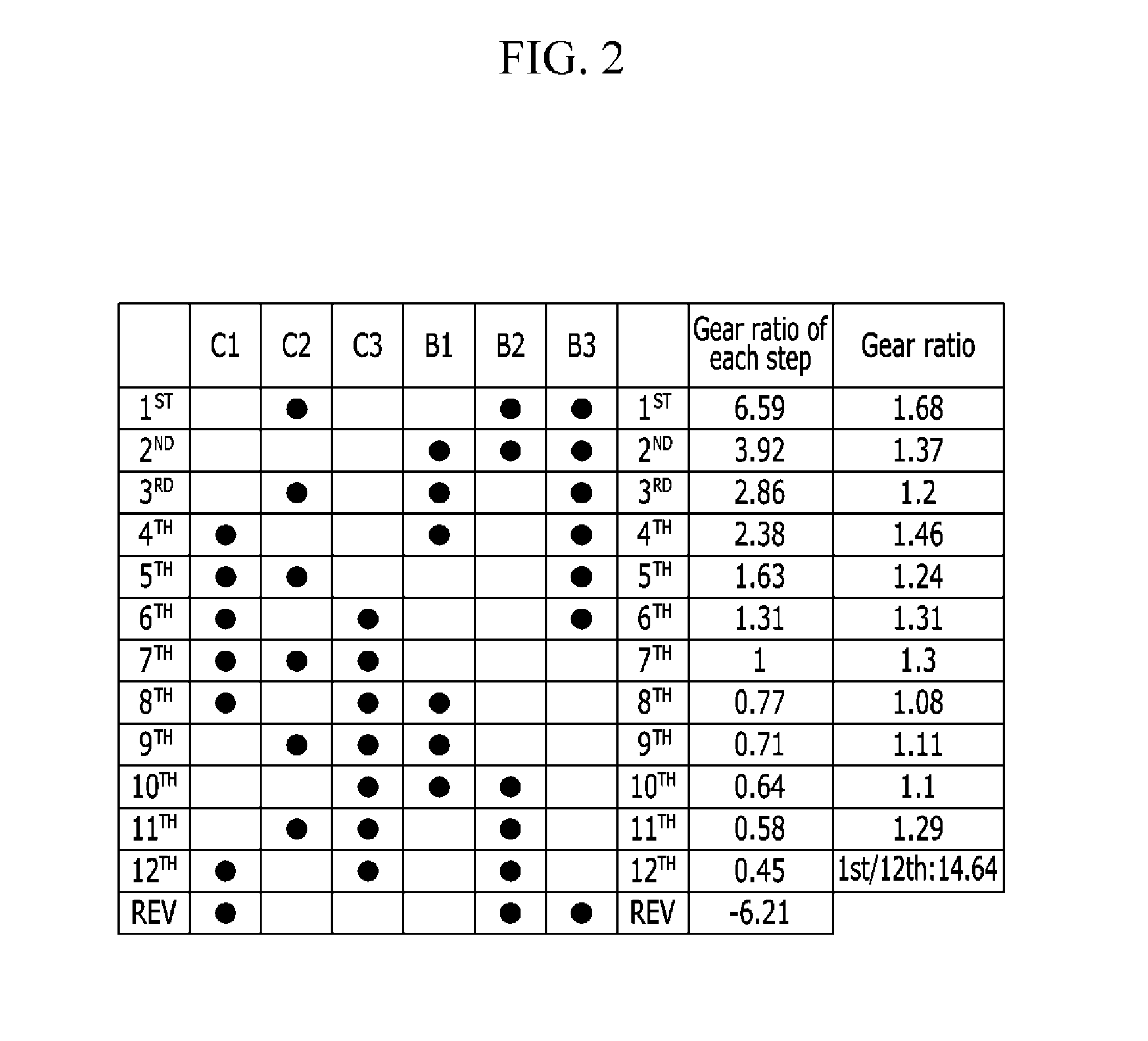

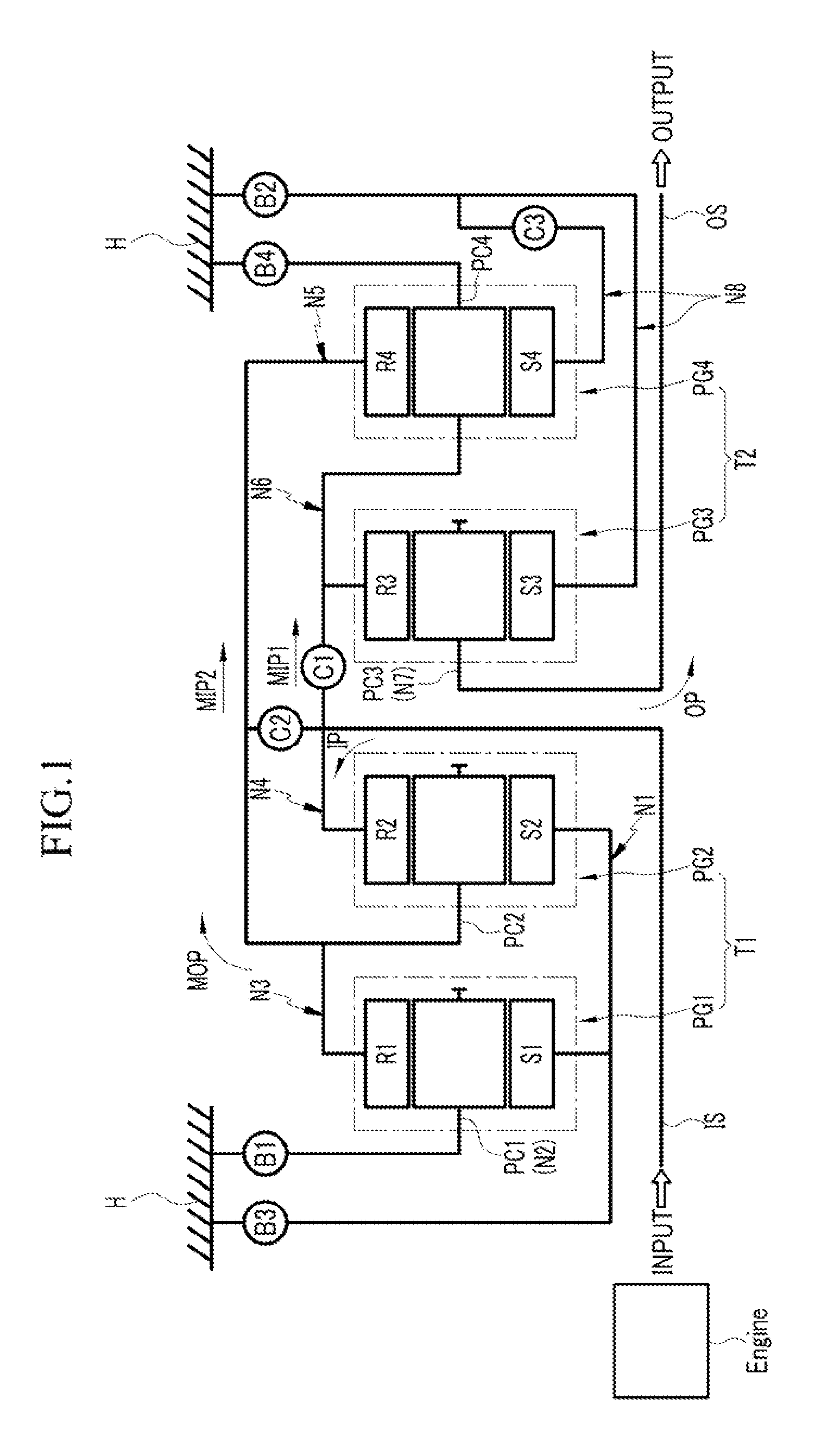

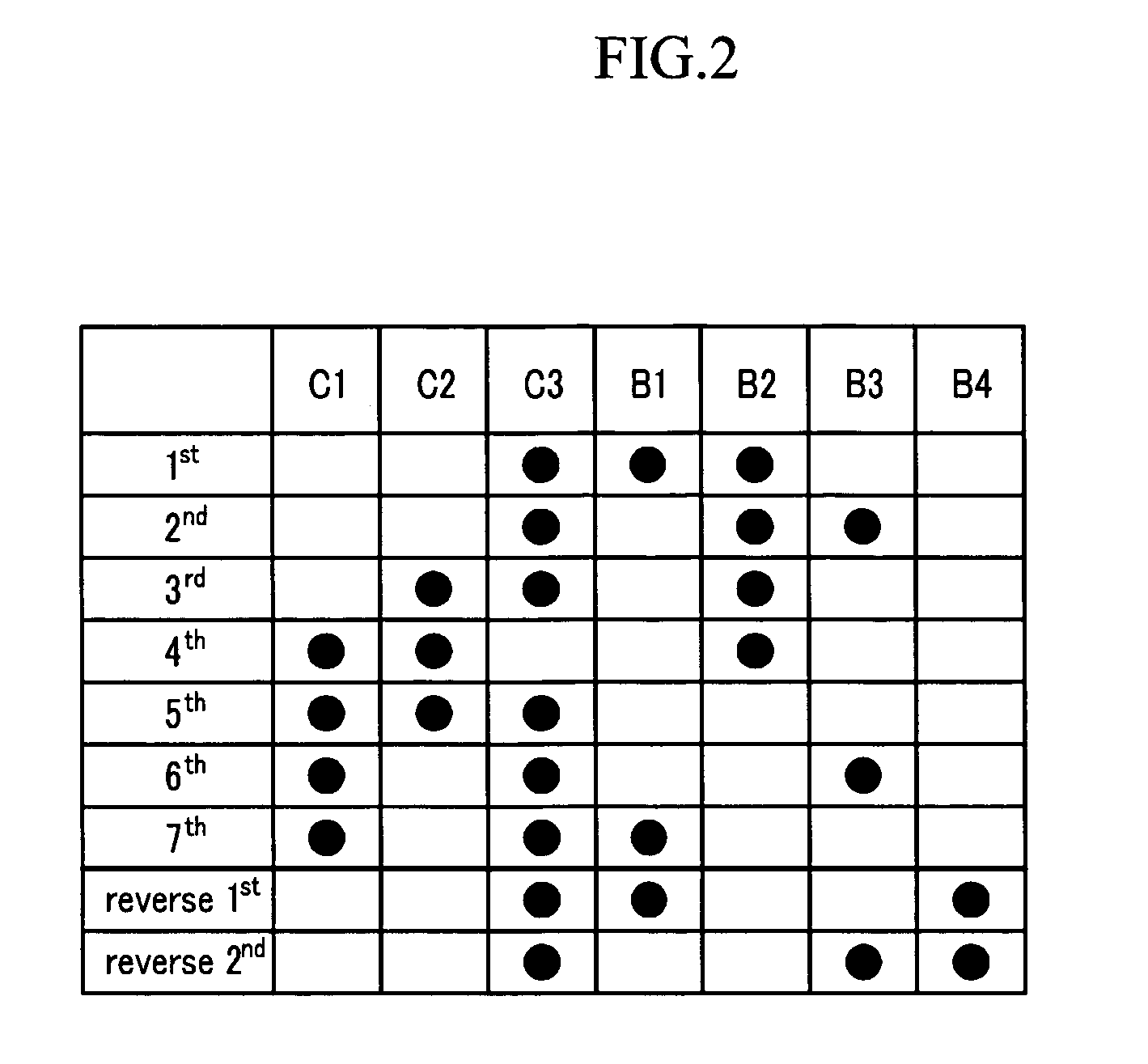

Planetary gear train of automatic transmission for vehicles

ActiveUS9163705B1Reduces drag torqueImprove power transmissionToothed gearingsTransmission elementsAutomatic transmissionEngineering

A planetary gear train of an automatic transmission may include an input shaft, a first planetary gear set including a first sun gear, a first planetary carrier, and a first ring gear, a second planetary gear set including a second sun gear, a second planetary carrier, and a second ring gear, a third planetary gear set including a third sun gear, a third planetary carrier, and a third ring gear, a fourth planetary gear set including a fourth sun gear, a fourth planetary carrier, and a fourth ring gear, a fifth planetary gear set including a fifth sun gear, a fifth planetary carrier, and a fifth ring gear, first to ninth rotational shafts, and six friction elements selectively connecting the rotational shafts and the rotational shaft and the transmission housing.

Owner:HYUNDAI MOTOR CO LTD

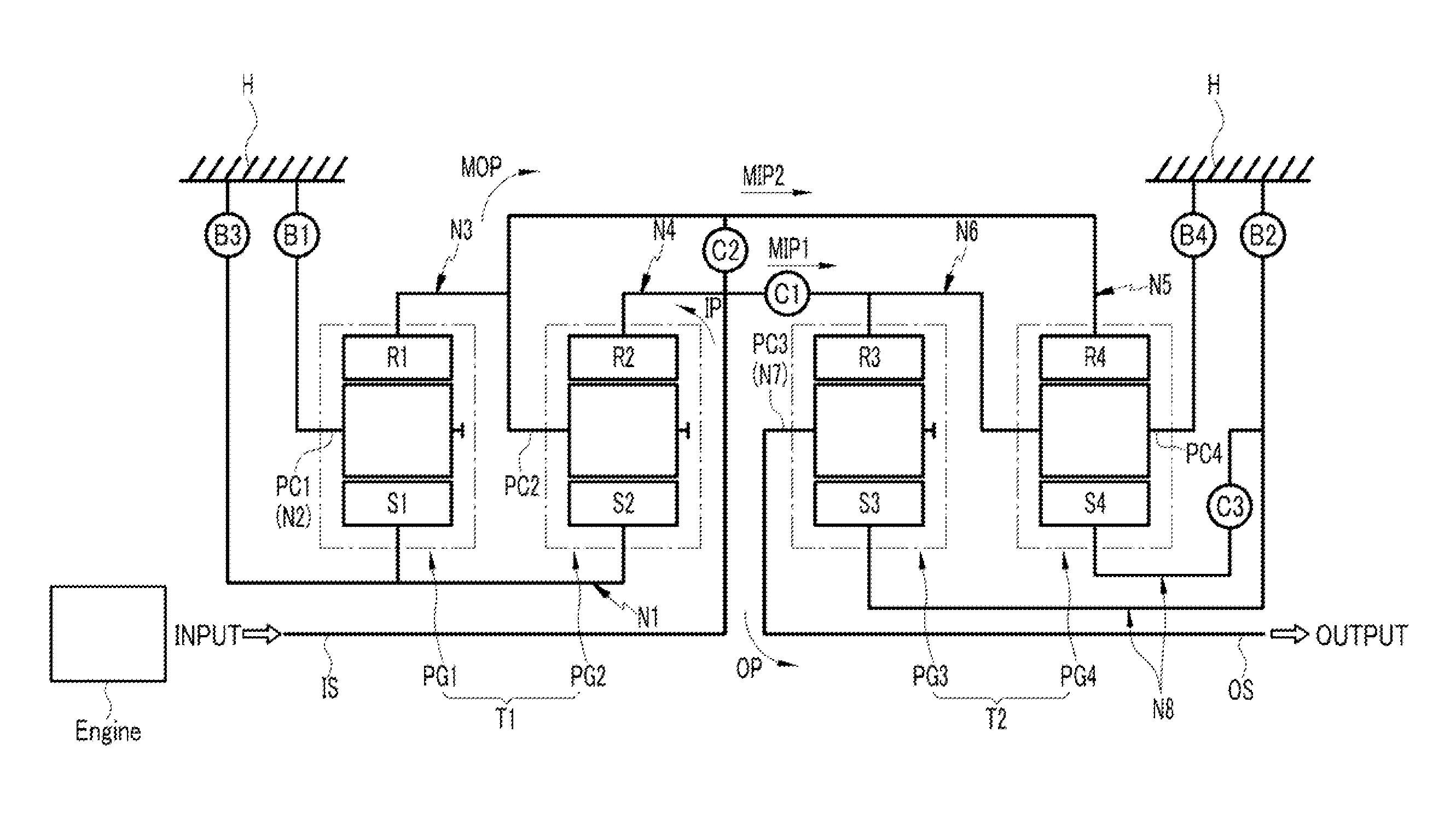

Gear train of an automatic transmission for a vehicle

InactiveUS7614975B2Improve power transmissionReduce fuel consumptionToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A gear train of an automatic transmission for a vehicle includes first and second shifting sections and a plurality of friction members, wherein: the first shifting section includes first and second simple planetary gear sets forming a first input path for directly receiving an input shaft rotation speed and an intermediate output path for outputting a reduced speed of the first shifting section; and the second shifting section includes third and fourth simple planetary gear sets forming a first intermediate input path for variably receiving an input shaft rotation speed, a second intermediate input path for receiving the reduced speed of the first shifting section through the intermediate output path and also for variably receiving an input shaft rotation speed, and a final output path for outputting a modified speed of the second shifting section.

Owner:HYUNDAI MOTOR CO LTD

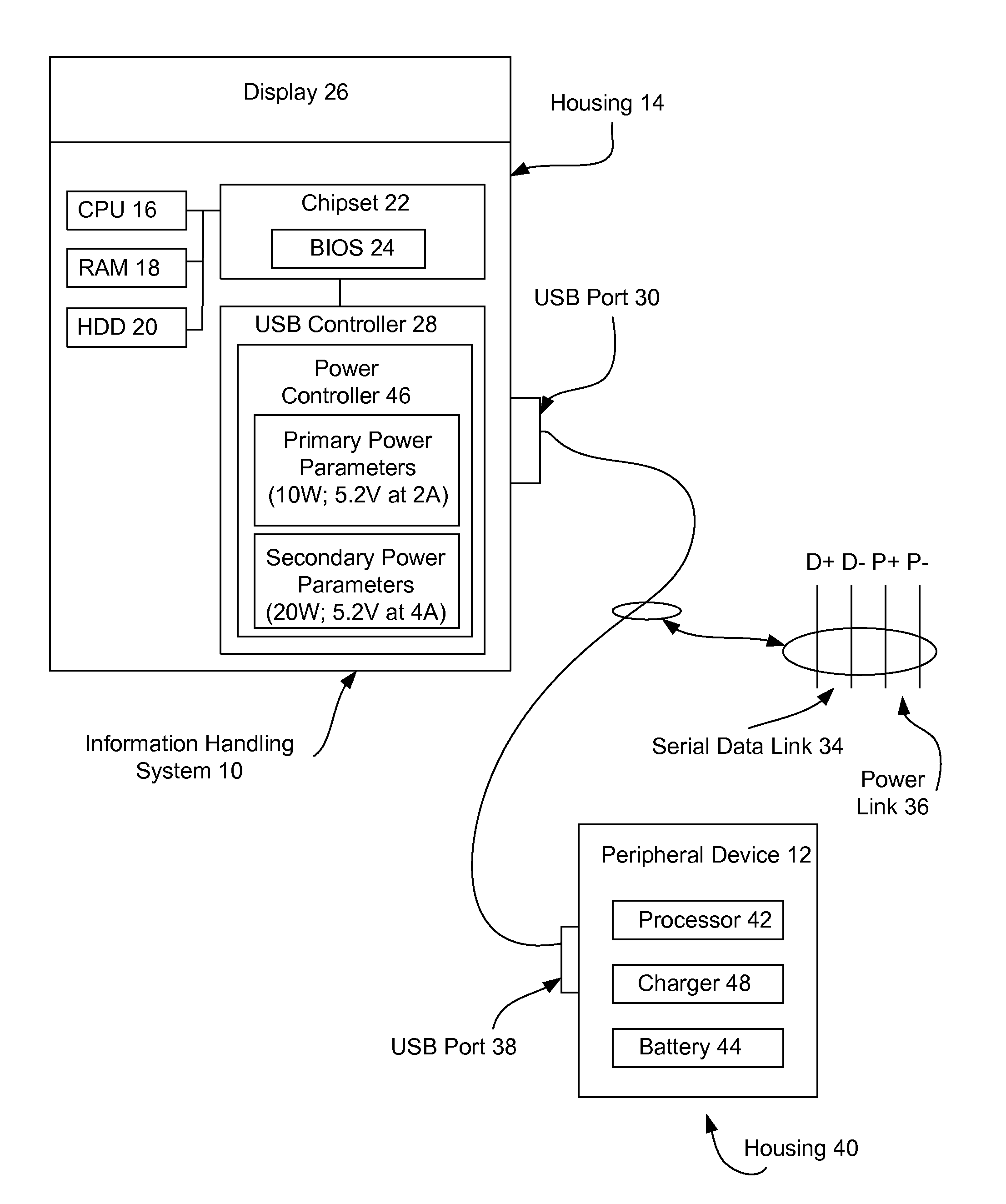

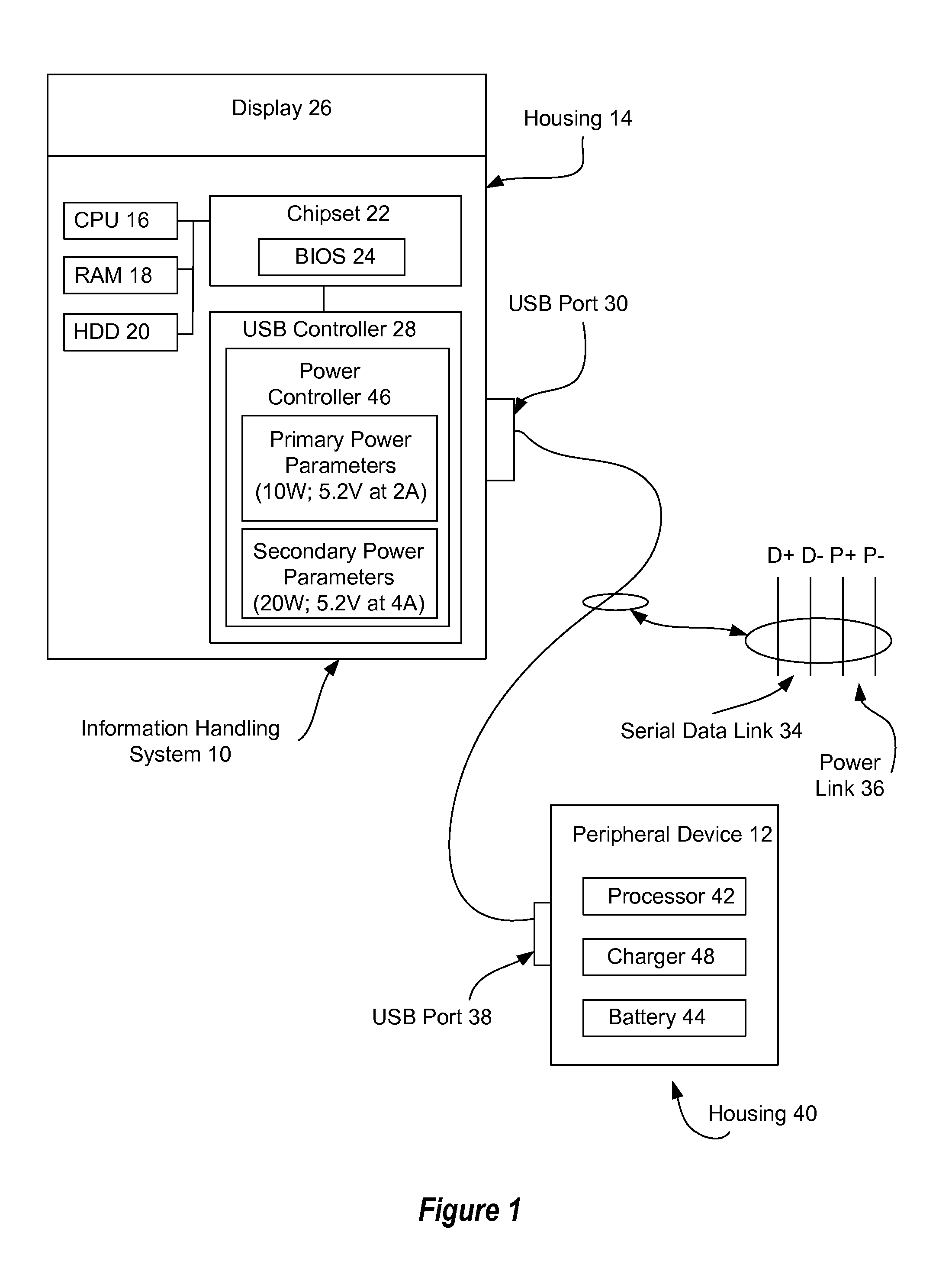

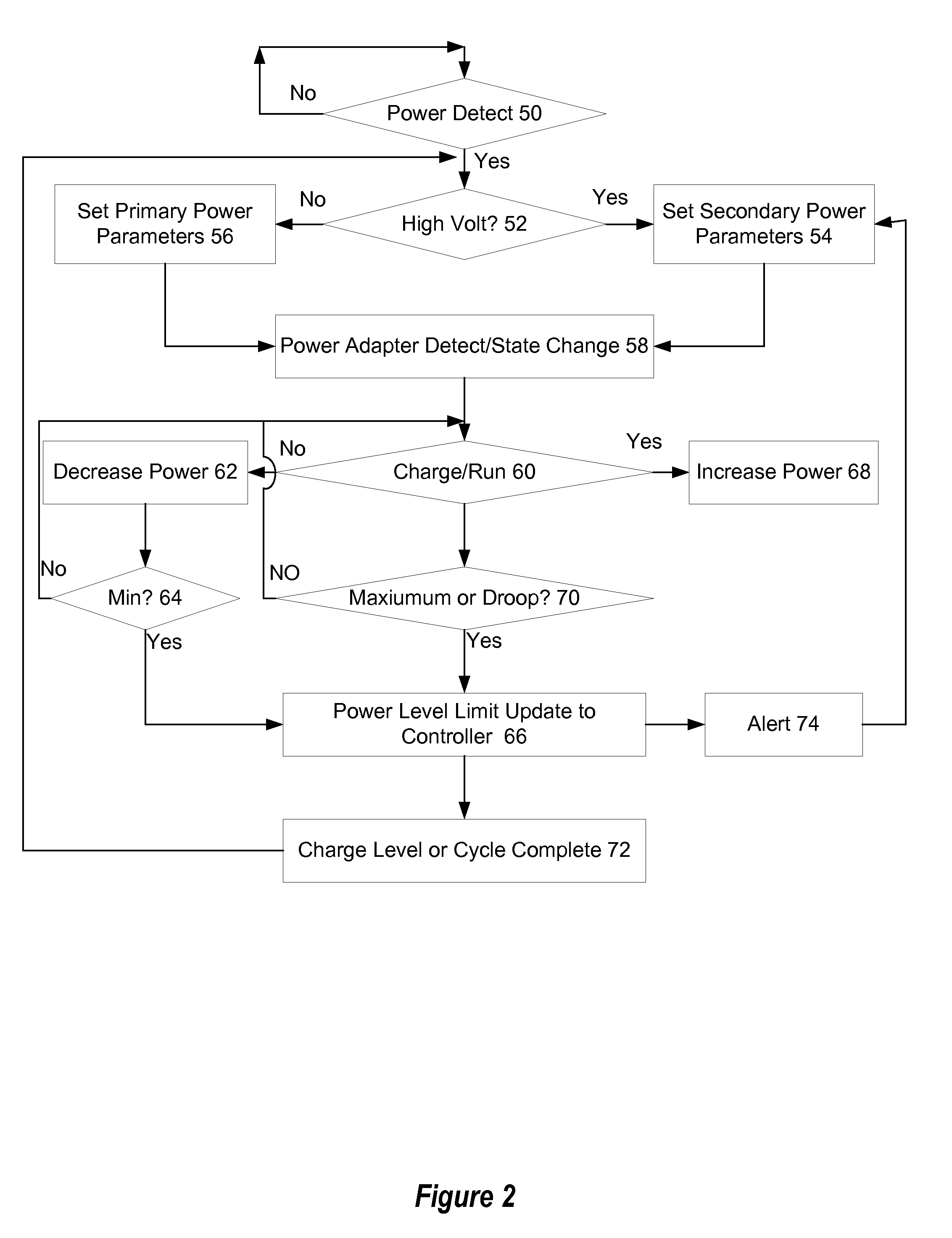

Information handling system adaptive high performance power delivery

ActiveUS20140095899A1Improve power transmissionShorten charging timeVolume/mass flow measurementPower supply for data processingElectric power transmissionPower parameter

An information handling system provides power to a peripheral though a peripheral interface, such as a USB interface, by communicating power availability with a primary set of power parameters through a data link and communicating power availability with a secondary set of power parameters through a power link. If a peripheral device has the capability to draw power at the second power parameters, it does so while monitoring for a fold back of host power that indicates power is not available at the second power parameters.

Owner:DELL PROD LP

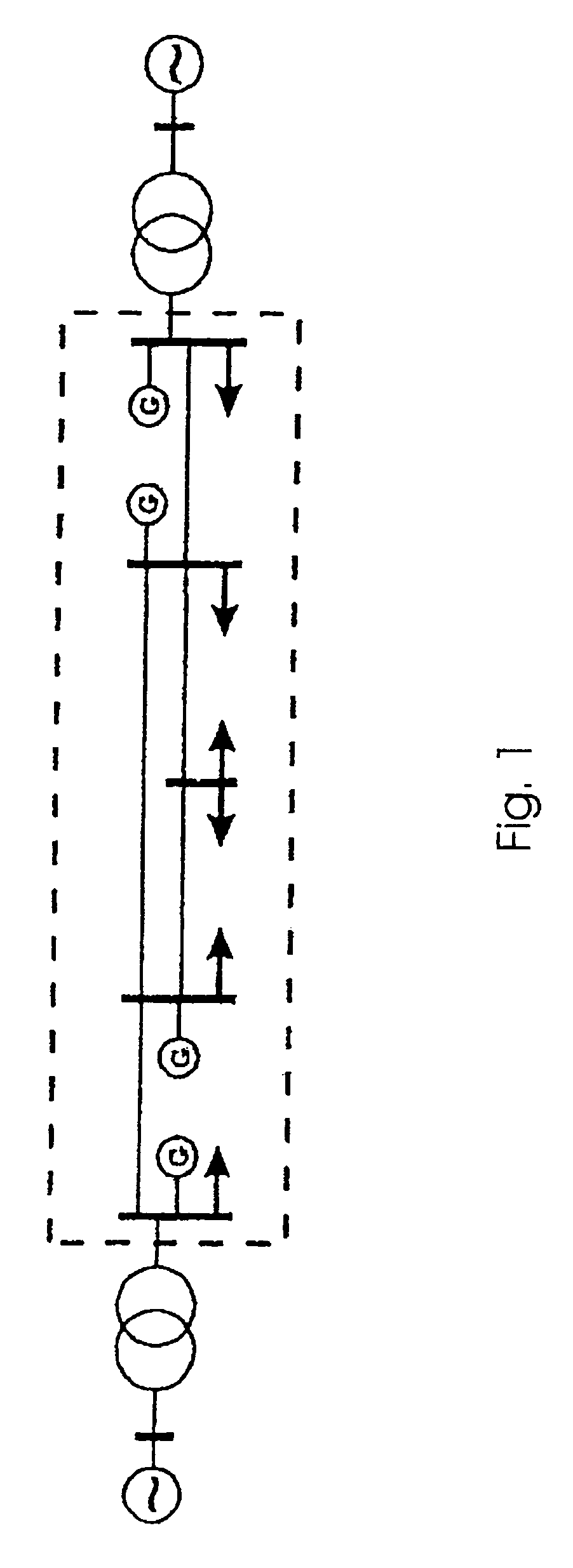

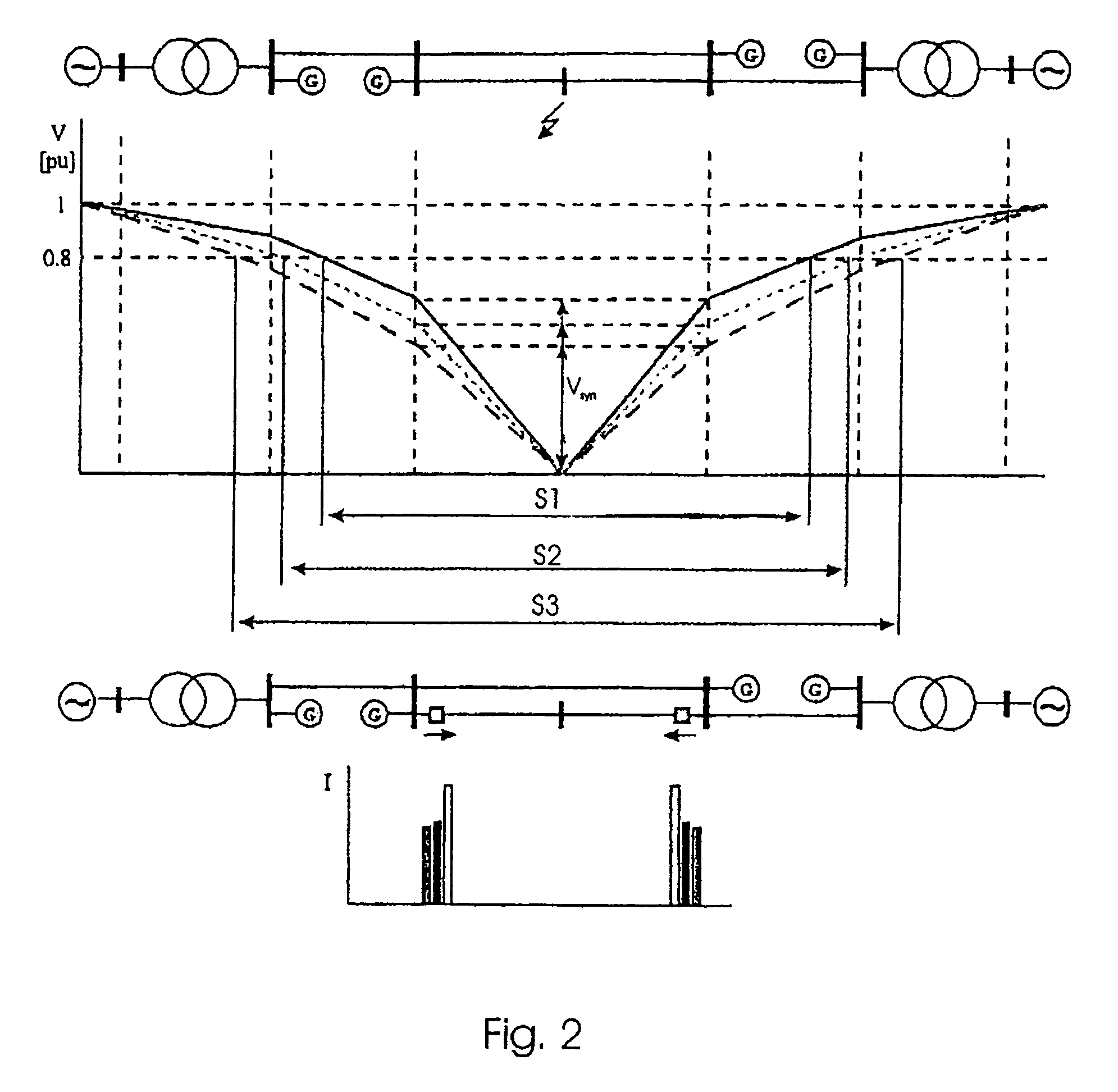

Method for operating a wind turbine during a disturbance in the grid

ActiveUS7525208B2Increase power levelIncrease valueWind motor controlContigency dealing ac circuit arrangementsPower gridEngineering

There is provided a method of operating a wind power installation. Under first operating conditions in a normal operating mode the wind power installation delivers a first power to a connected electrical network. That first power is proportional to the wind speed. The wind power installation is controlled in such a way that upon the occurrence of a disturbance it remains on the connected electrical network and delivers to the connected electrical network a second power which is lower than the first power. Upon cessation of the disturbance and under the first operating conditions a third power is briefly delivered to the connected electrical network, the third power being significantly higher than the first power.

Owner:WOBBEN ALOYS

Nanolayer deposition process

InactiveUS20100190353A1Achieve intuitiveLess preparationMaterial nanotechnologySemiconductor/solid-state device manufacturingSelf limitingDeposition process

A hybrid deposition process of CVD and ALD, called NanoLayer Deposition (NLD) is provided. The nanolayer deposition process is a cyclic sequential deposition process, comprising the first step of introducing a first plurality of precursors to deposit a thin film with the deposition process not self-limiting, then a second step of purging the first set of precursors and a third step of introducing a second plurality of precursors to modify the deposited thin film. The deposition step in the NLD process using the first set of precursors is not self limiting and is a function of substrate temperature and process time. The second set of precursors modifies the already deposited film characteristics. The second set of precursors can treat the deposited film such as a modification of film composition, a doping or a removal of impurities from the deposited film. The second set of precursors can also deposit another layer on the deposited film. The additional layer can react with the existing layer to form a compound layer, or can have minimum reaction to form a nanolaminate film.

Owner:ASM INTERNATIONAL

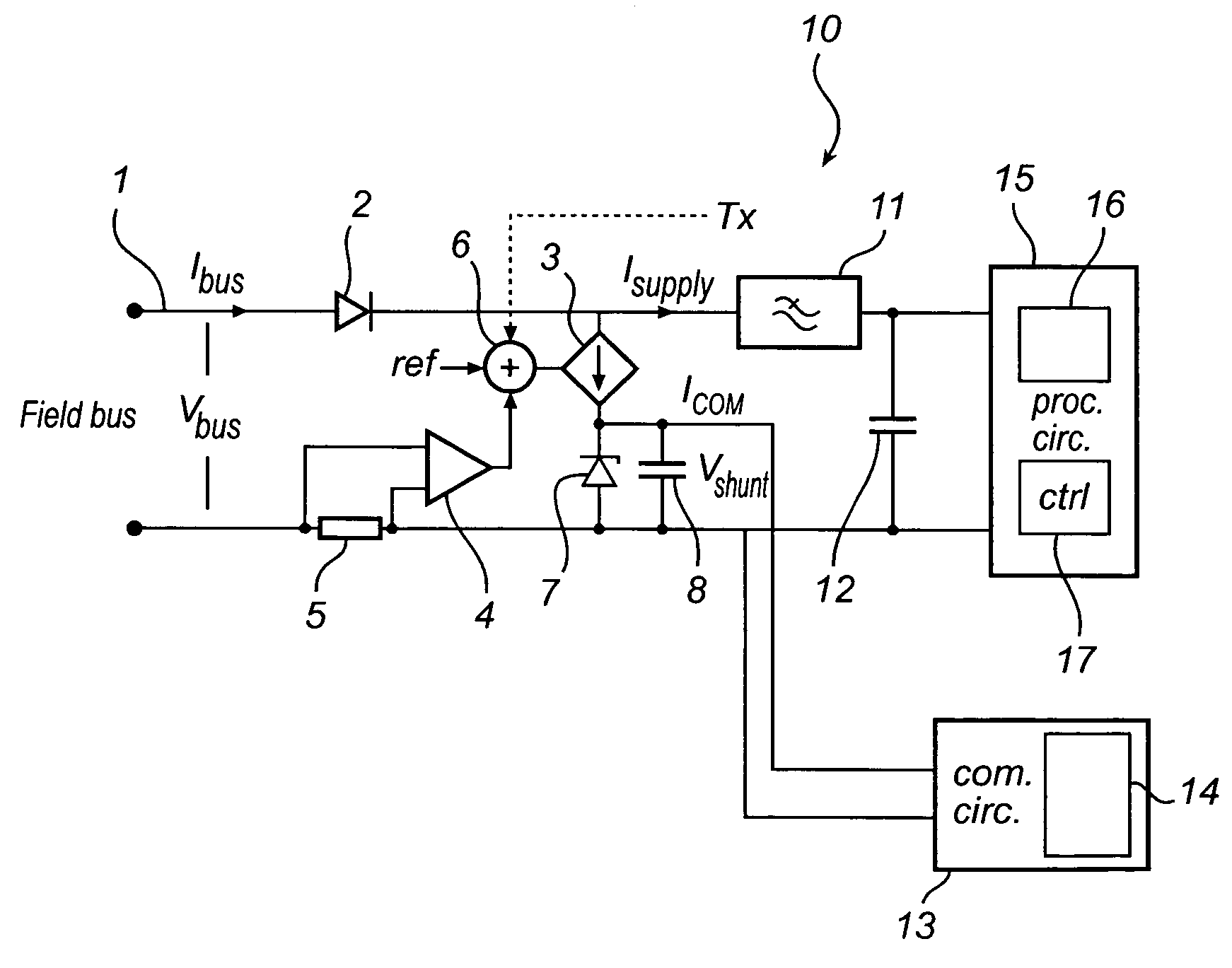

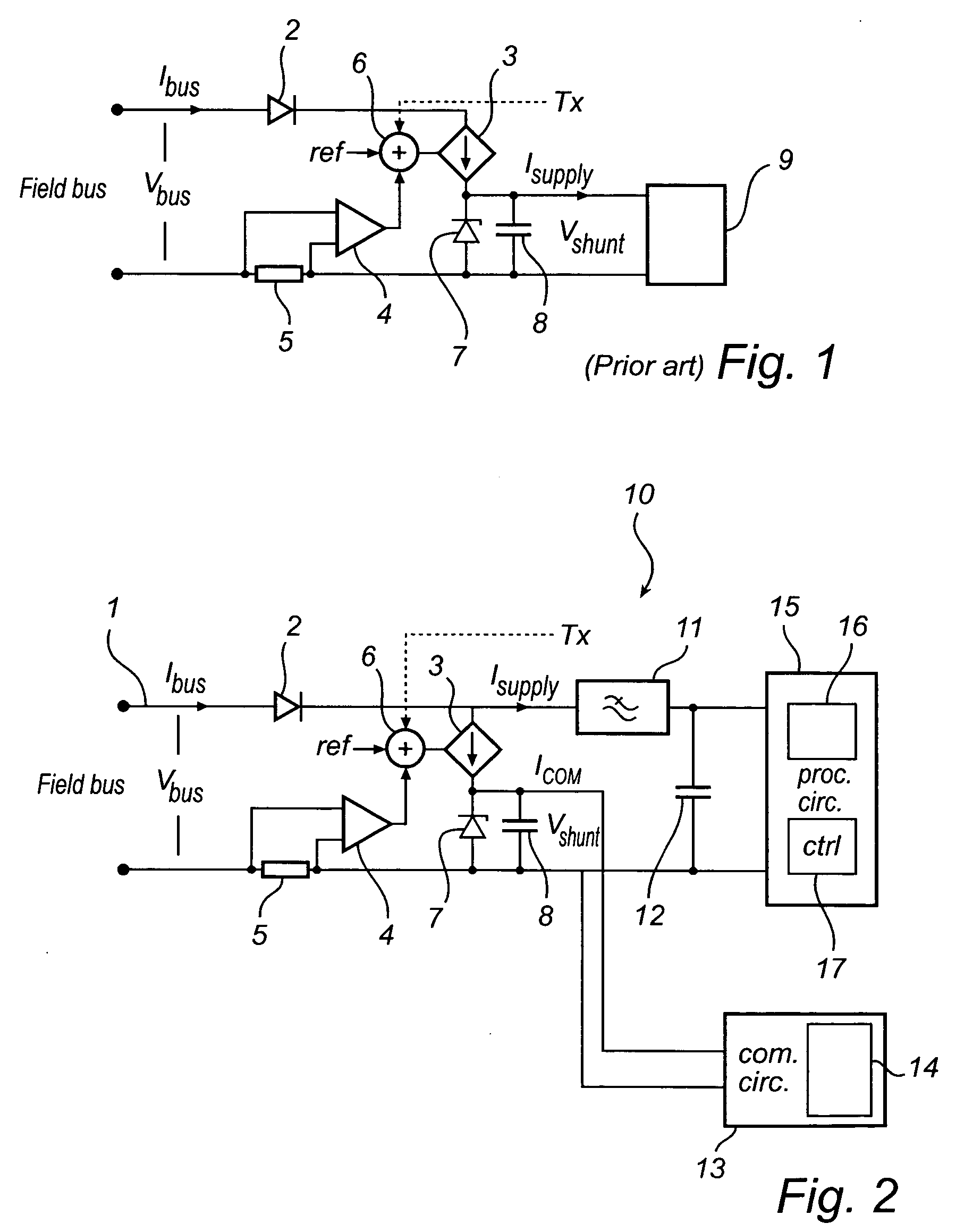

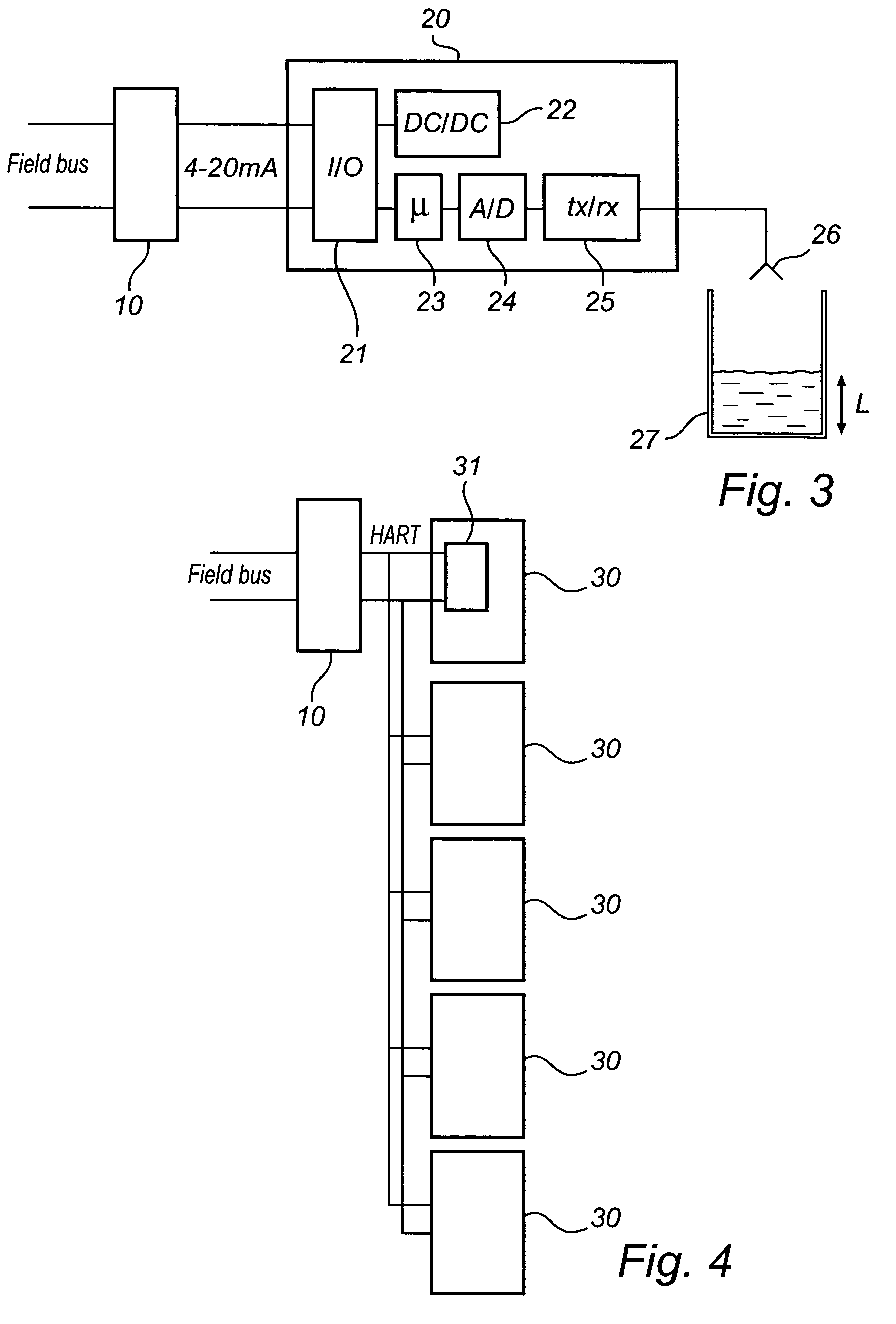

Field bus interface

InactiveUS20080174178A1Improve radar performanceImprove performanceDc network circuit arrangementsLevel indicatorsLower limitEngineering

A field bus interface for connecting a device to a field bus, comprising communication circuitry for providing communication via the field bus, first power supply circuitry arranged to provide said communication circuit with a predefined communication power at a predefined drive voltage, and second power supply circuitry arranged to provide a processing circuitry with processing power at said bus voltage only when a power available from said field bus exceeds said communication power.More specifically, the power provided to the processing circuitry at a given bus current will be decided by the power actually available, instead of a power level decided by the lower limit of the voltage range of the field bus specification. The first circuitry and the communication circuitry will ensure that the field bus requirements are met in a case when the bus voltage falls close to the lower limit of the bus voltage range.

Owner:ROSEMOUNT TANK RADAR

Method for operating a wind turbine during a disturbance in the grid

ActiveUS20070159737A1Increase power levelIncrease valueWind motor controlEmergency protective circuit arrangementsPower gridElectricity delivery

There is provided a method of operating a wind power installation. Under first operating conditions in a normal operating mode the wind power installation delivers a first power to a connected electrical network. That first power is proportional to the wind speed. The wind power installation is controlled in such a way that upon the occurrence of a disturbance it remains on the connected electrical network and delivers to the connected electrical network a second power which is lower than the first power. Upon cessation of the disturbance and under the first operating conditions a third power is briefly delivered to the connected electrical network, the third power being significantly higher than the first power.

Owner:WOBBEN ALOYS

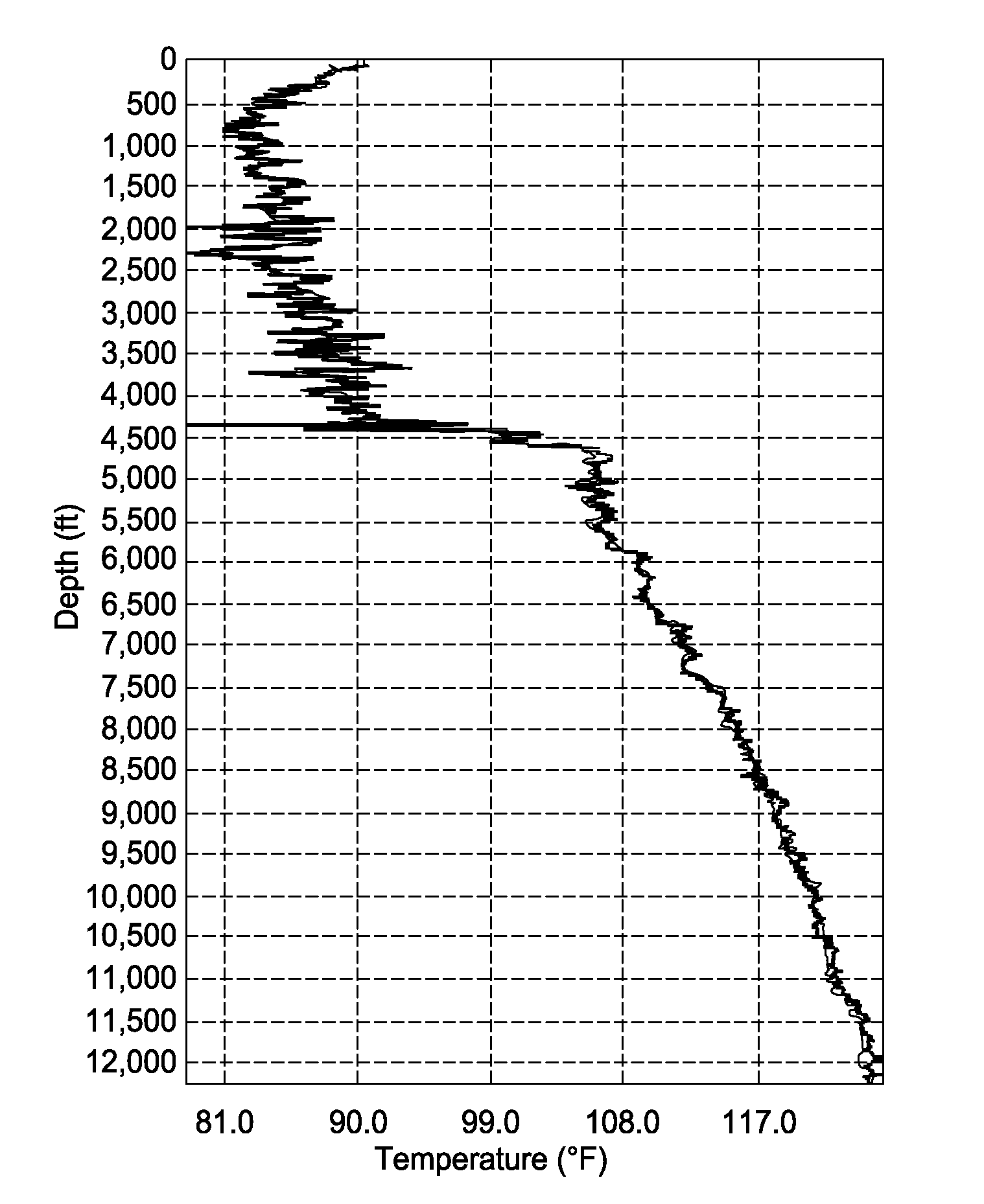

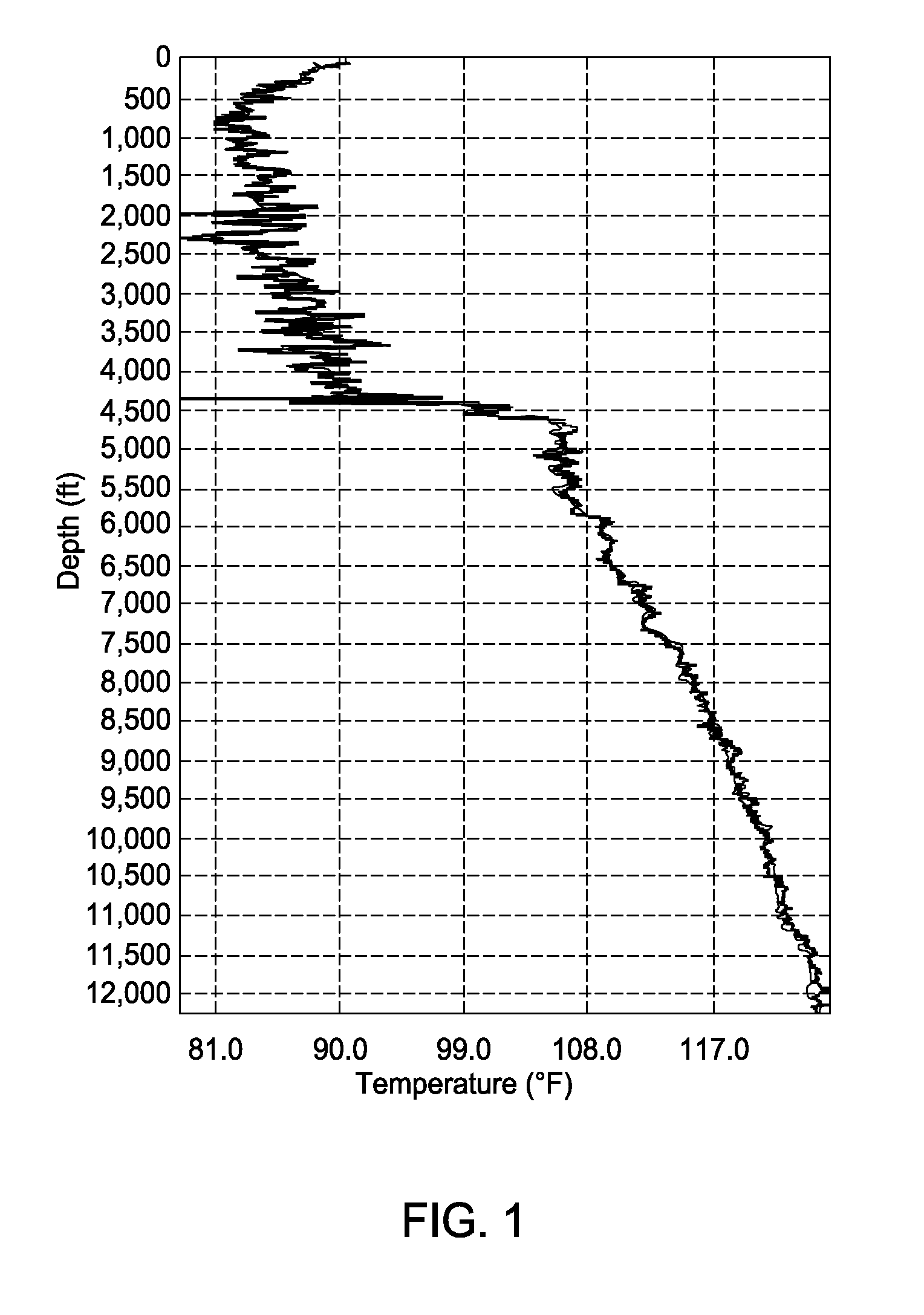

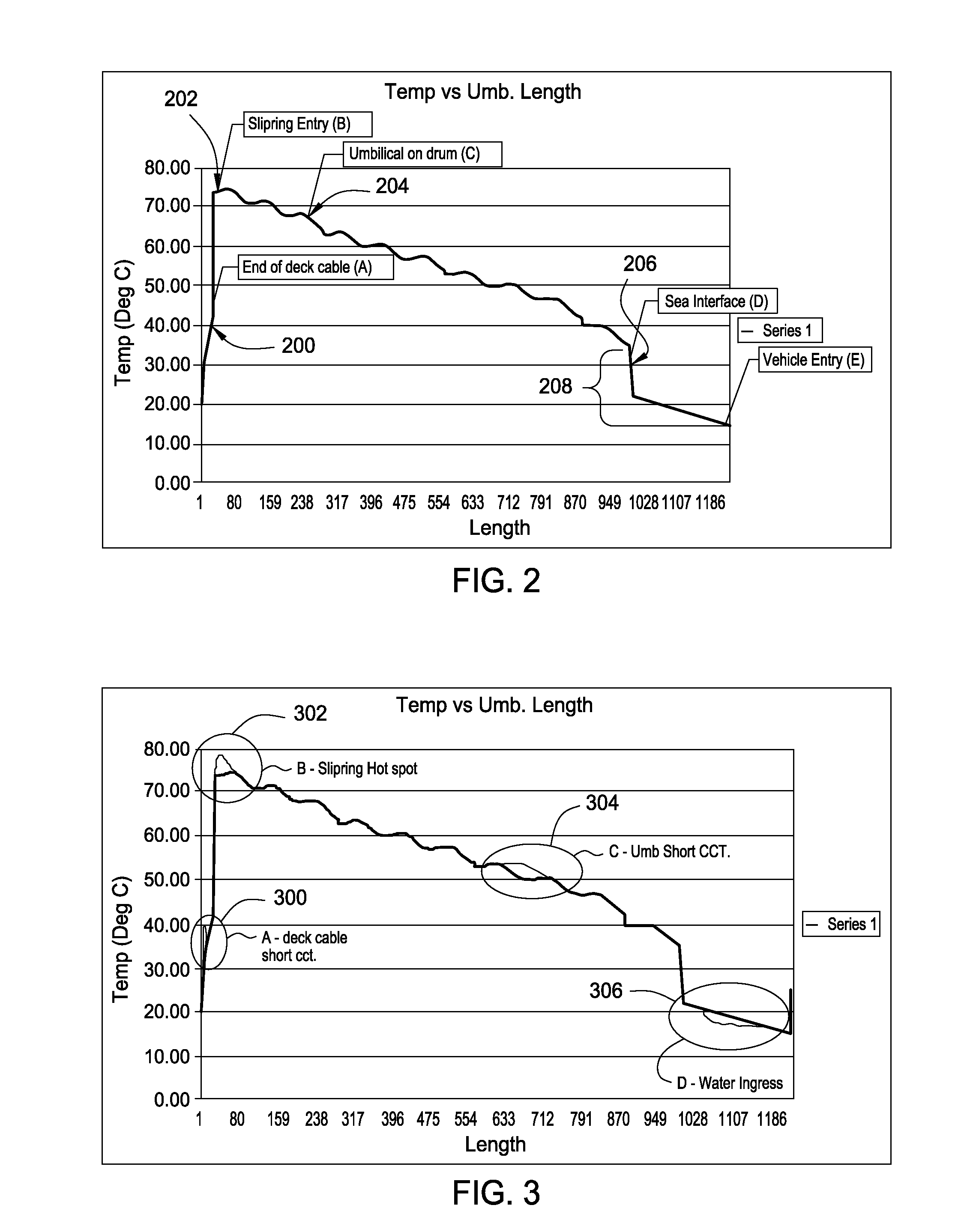

Distributed temperature sensing in a remotely operated vehicle umbilical fiber optic cable

ActiveUS20080110389A1CloserImprove power transmissionTowing/pushing equipmentThermometers using physical/chemical changesTemperature senseEngineering

Owner:WEATHERFORD TECH HLDG LLC

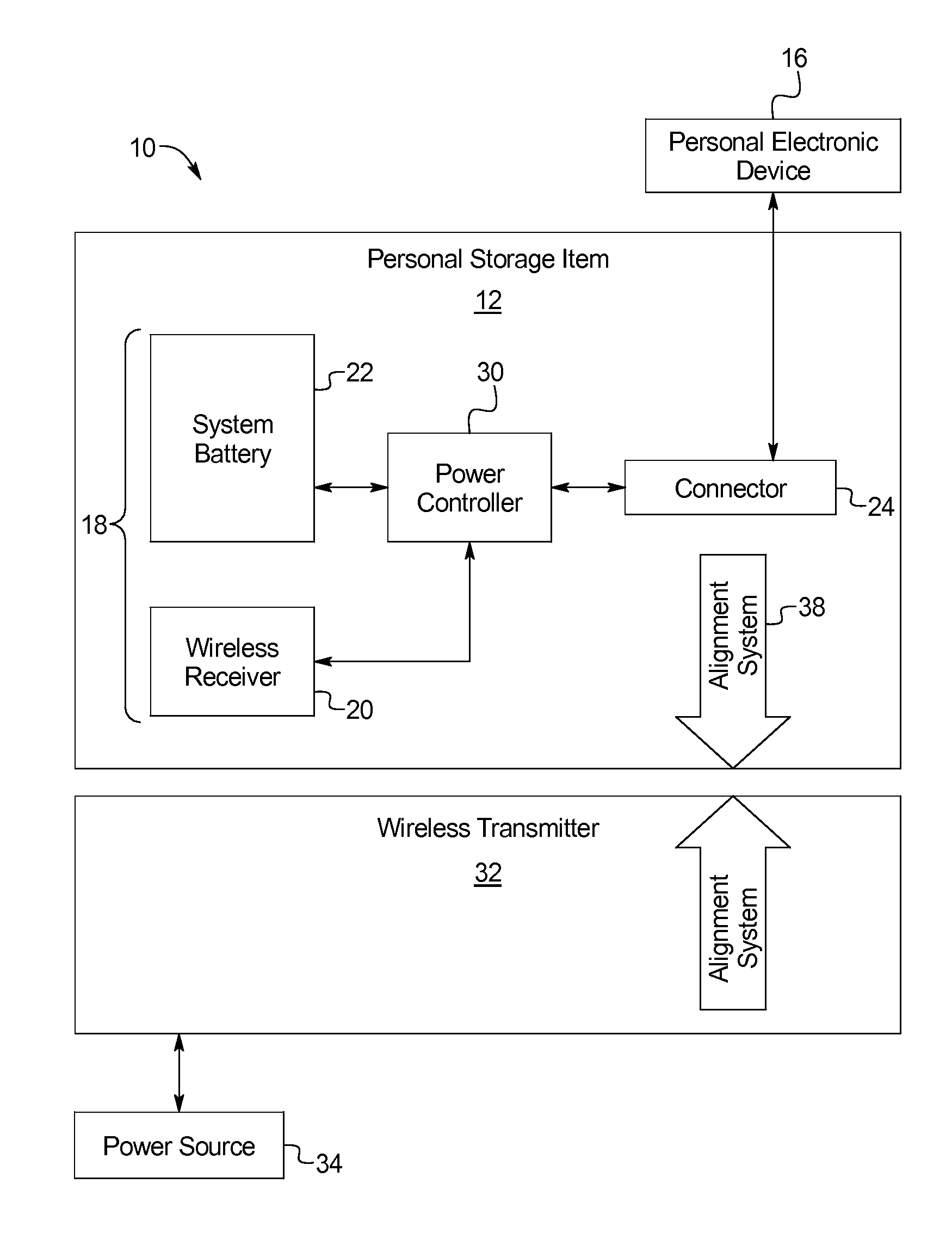

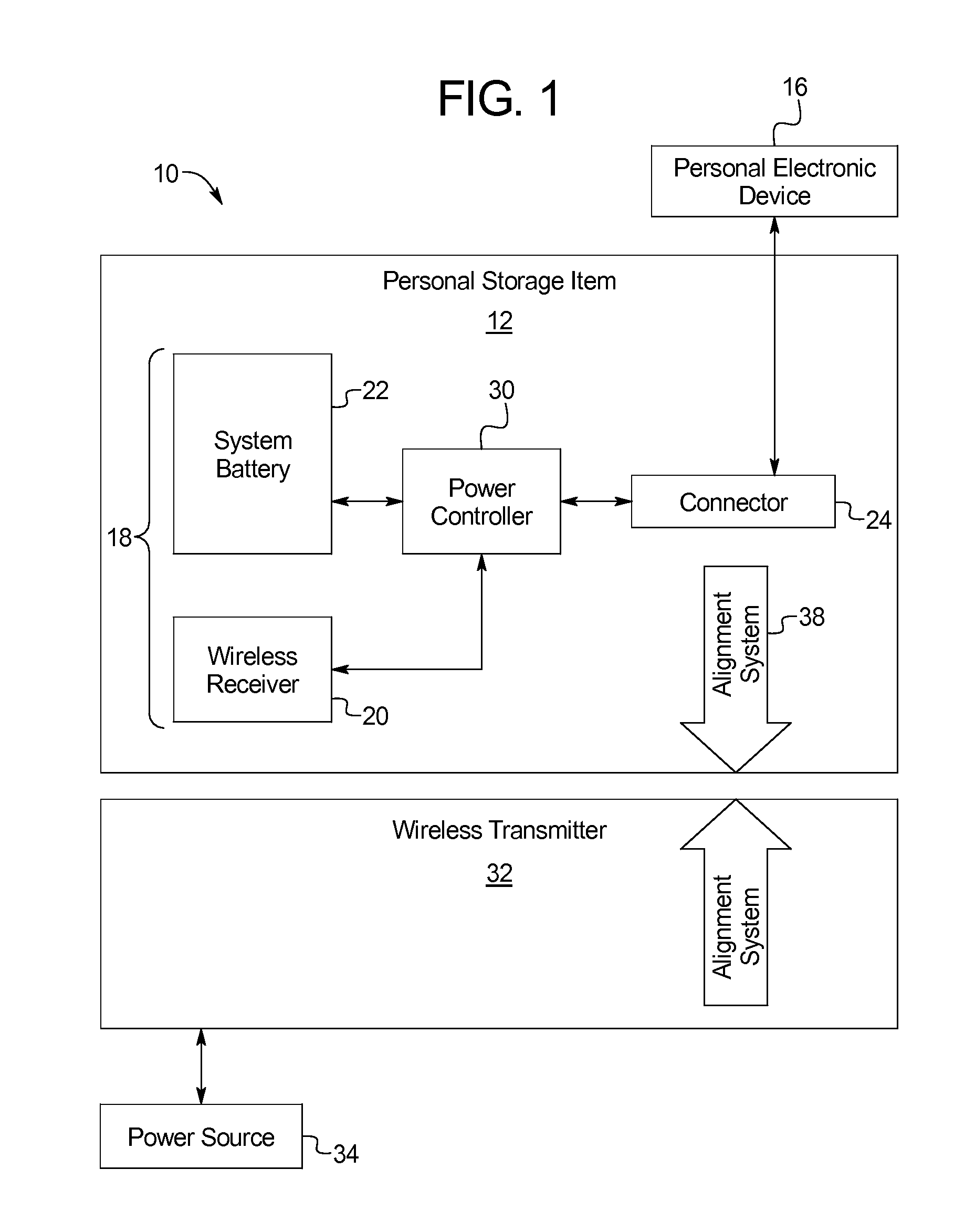

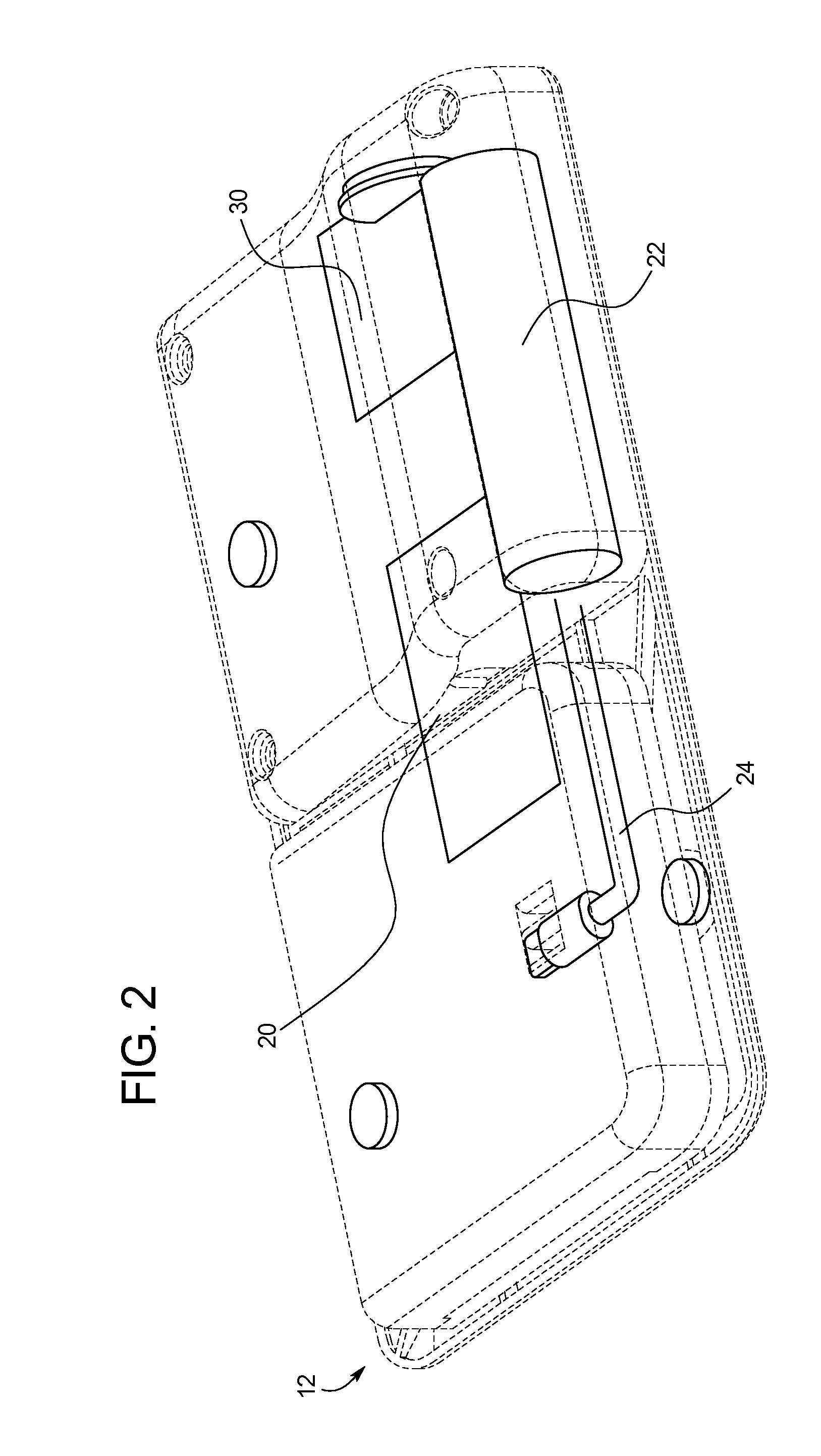

Personal Wireless Charging System

ActiveUS20150015196A1Extend battery lifeEasy to chargeBatteries circuit arrangementsElectric powerElectricityElectrical battery

The present disclosure provides wireless personal electronic charging systems including a personal storage item including a storage location for a portable electronic device, the personal storage item further includes a power section including a wireless induction charger receiver and a system battery configured to receive and store power from the wireless induction charger receiver. The personal storage item further includes a connector in electrical communication with the power section and, when a portable electronic device including a device battery is located within the storage location, in electrical communication with the device battery, wherein the connector transfers power from the power section to the device battery when the connector is connected to the portable electronic device.

Owner:EVERPURSE

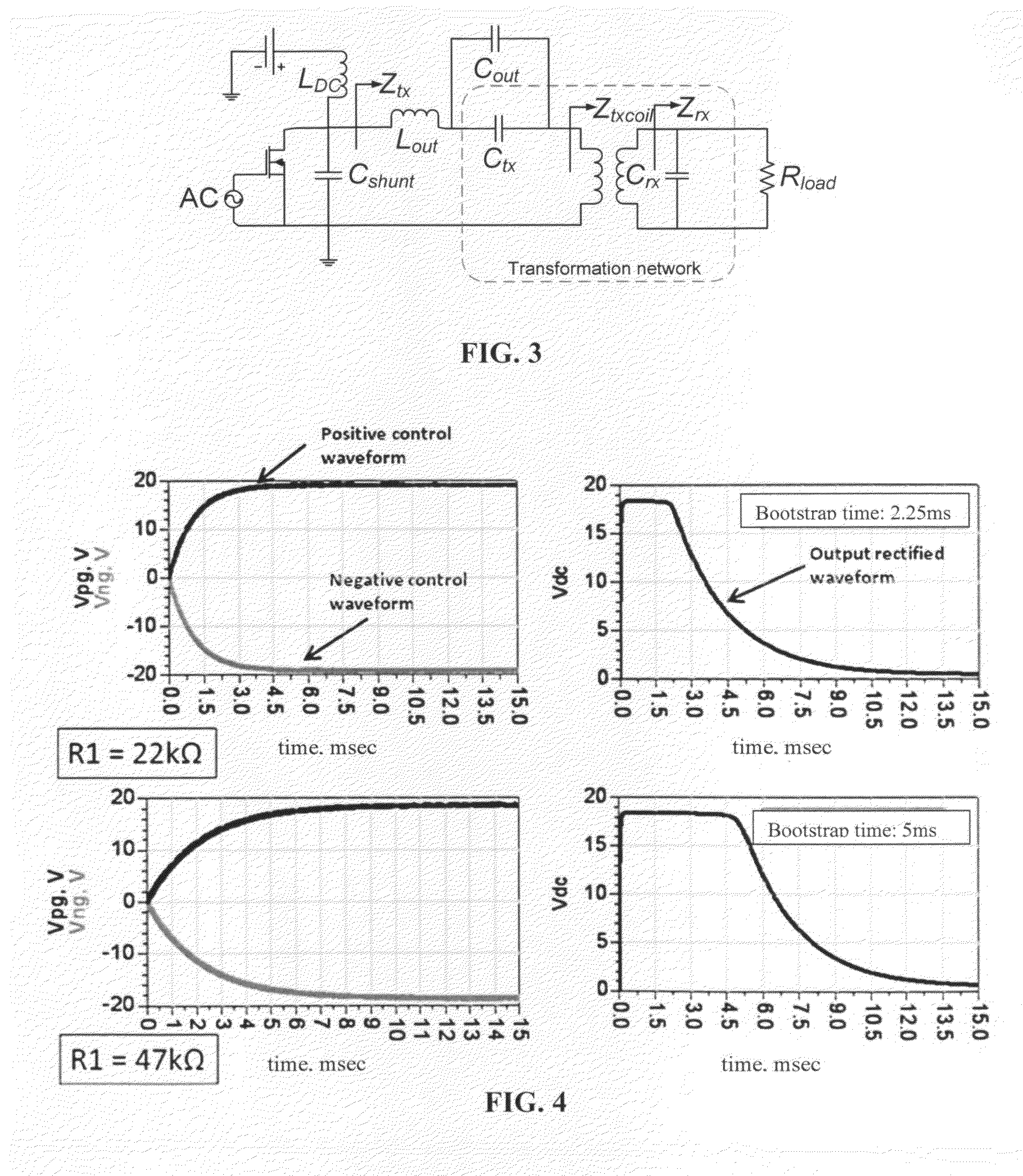

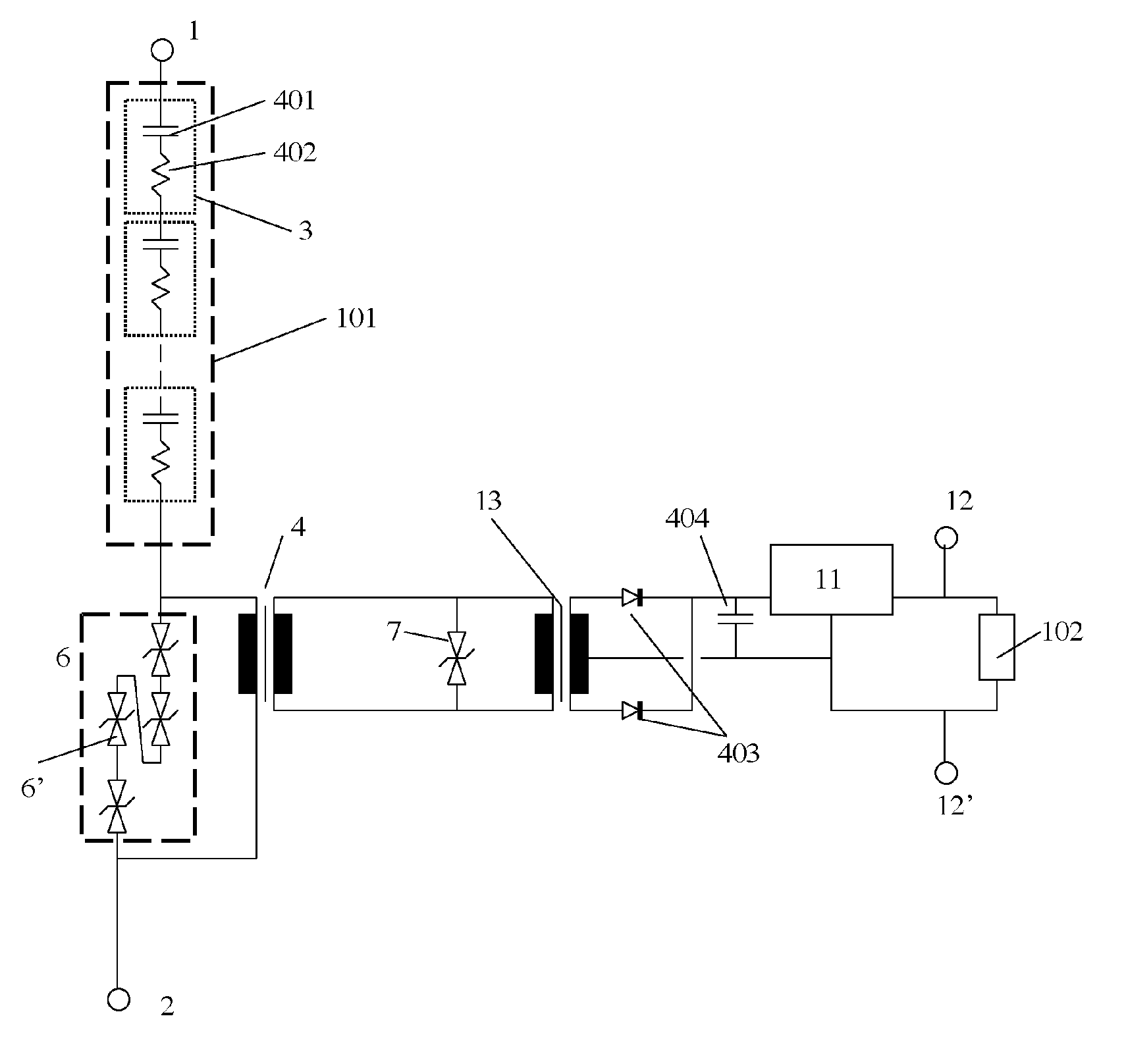

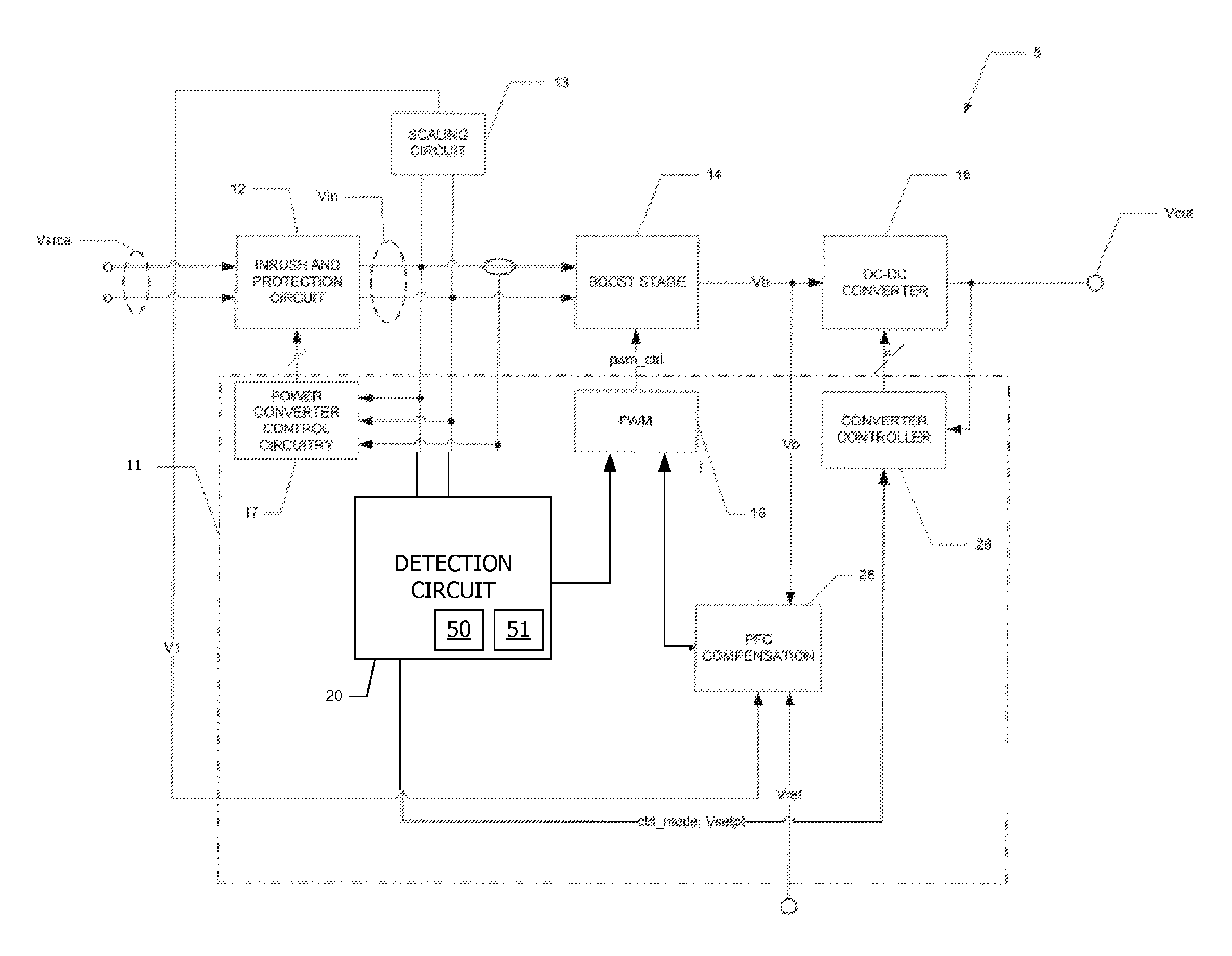

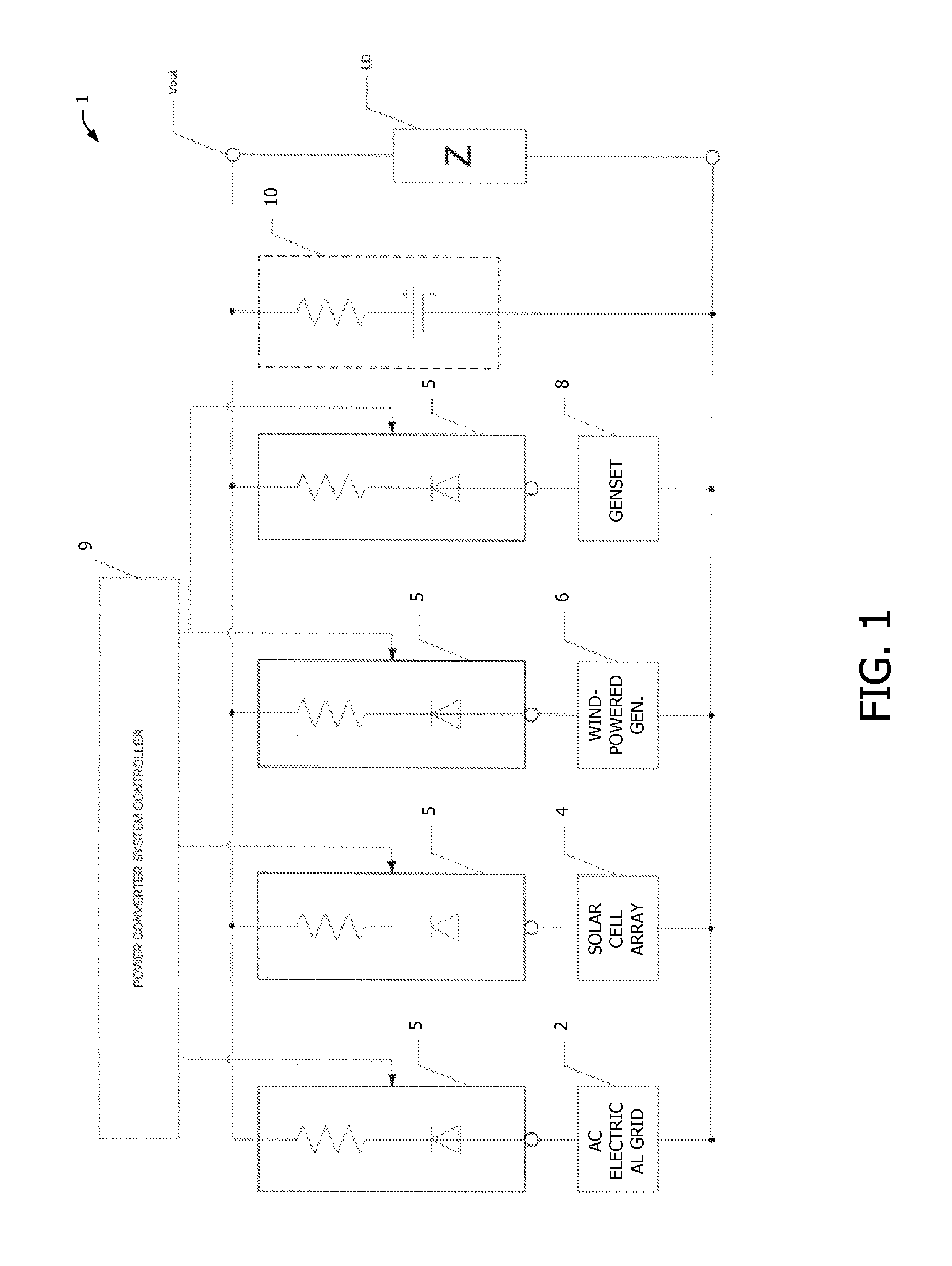

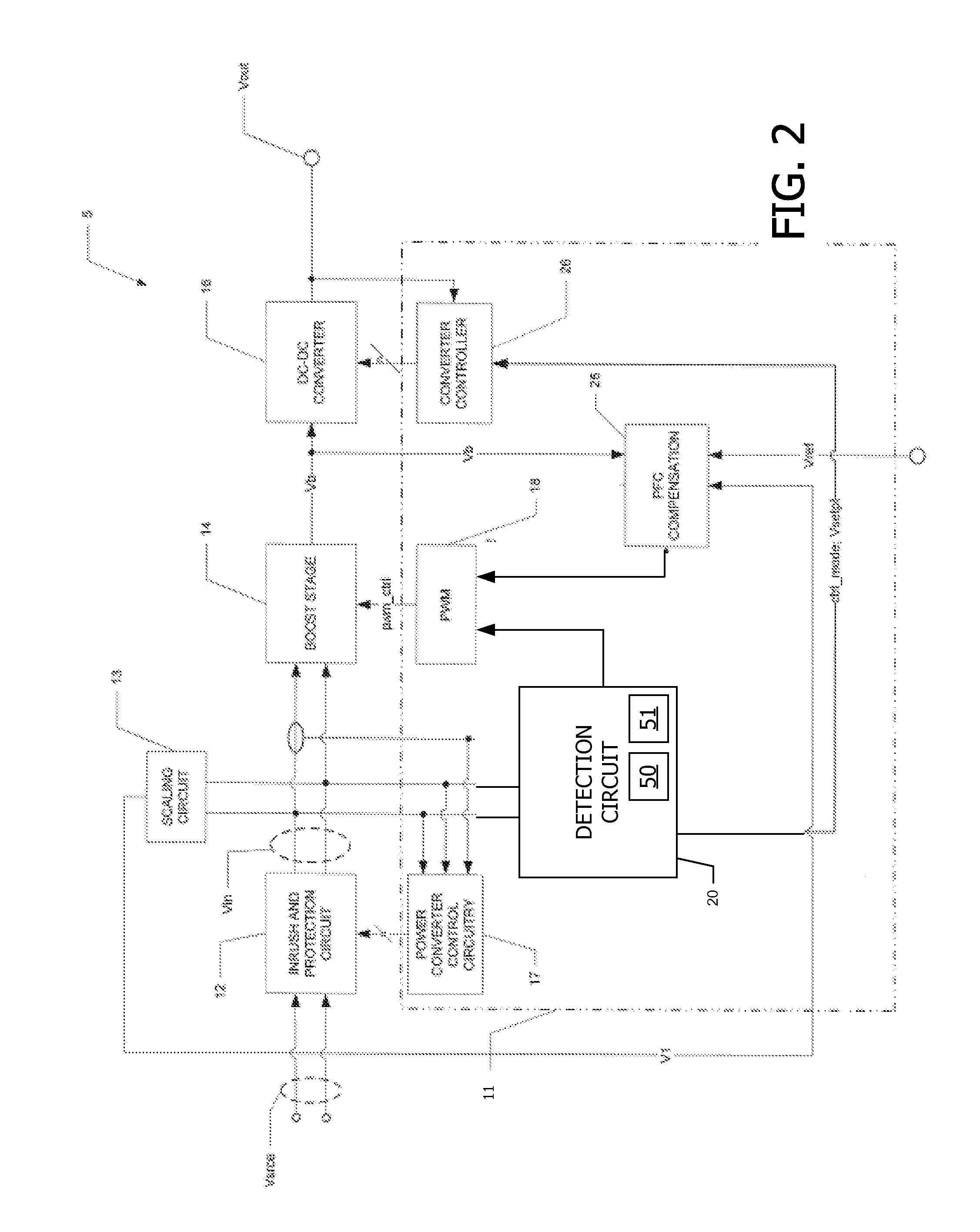

Power converter and methods for increasing power delivery of soft alternating current power source

ActiveUS20140306526A1Improve power transmissionEfficient power electronics conversionSingle network parallel feeding arrangementsOperating pointSource type

A power converter is provided that includes a detection circuit configured to determine a power source type based on at least one characteristic of power received from a power source. The detection circuit is also configured to determine an operating edge of the soft AC source by monitoring at least one parameter as the soft AC power source approaches a power limit, and assign an operating point to the soft AC power source based on the operating edge to increase power delivery of the soft AC power source.

Owner:ABB (SCHWEIZ) AG

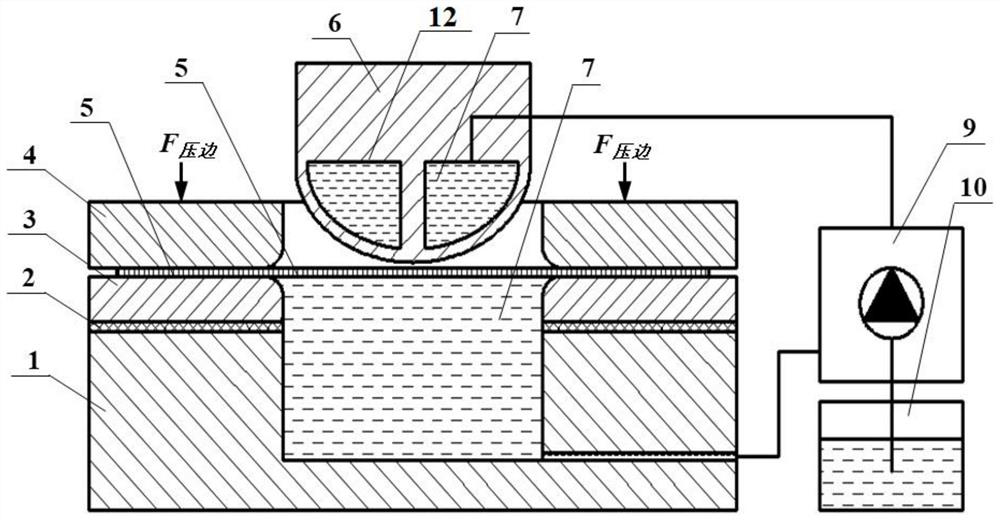

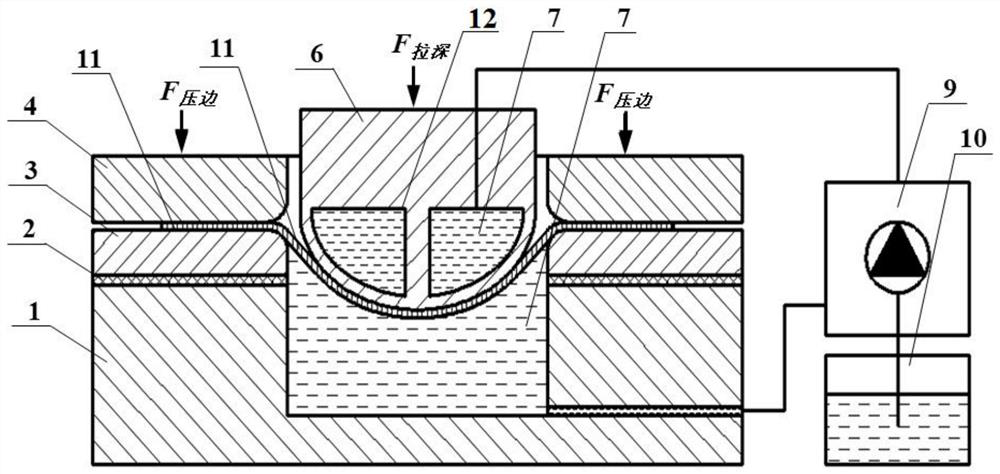

Ultralow-temperature deep drawing forming method for aluminum alloy thin-wall curved surface part

PendingCN111940583AGood formabilityAvoid easy cracking problemsShaping toolsDeep drawingMaterials science

The invention discloses an ultra-low temperature deep drawing forming method for an aluminum alloy thin-wall curved surface part. The ultra-low temperature deep drawing forming method comprises the following steps: forming a deep-cavity thin-wall curved surface part in an aluminum alloy plate on the basis of an ultra-low temperature gradient distribution formability regulation and control and a flowing stress principle, putting the aluminum alloy plate on a female die, and closing a blank holder to compress a flange area of the aluminum alloy plate; filling the cavity of a female die socket with an ultralow-temperature medium to cool the female die area of the aluminum alloy plate to the set low temperature, and forming the ultralow-temperature gradient that the temperature of the female die area is lower than that of the flange area; applying set blank holder force to the blank holder, meanwhile, controlling a male die to move downwards to form a deep-cavity thin-wall curved surface part; and controlling the male die to move upwards, opening the blank holder, and taking out the formed deep-cavity thin-wall curved surface part. According to the method, the aluminum alloy plate in the female die area is cooled to the ultralow temperature through the ultralow-temperature medium, so that the aluminum alloy plate deforms at the ultralow temperature, the forming performance is remarkably improved, and the problems that the aluminum alloy deep-cavity thin-wall curved surface part is suspended in the traditional deep-drawing forming process and a fillet area is prone to cracking are avoided.

Owner:DALIAN UNIV OF TECH

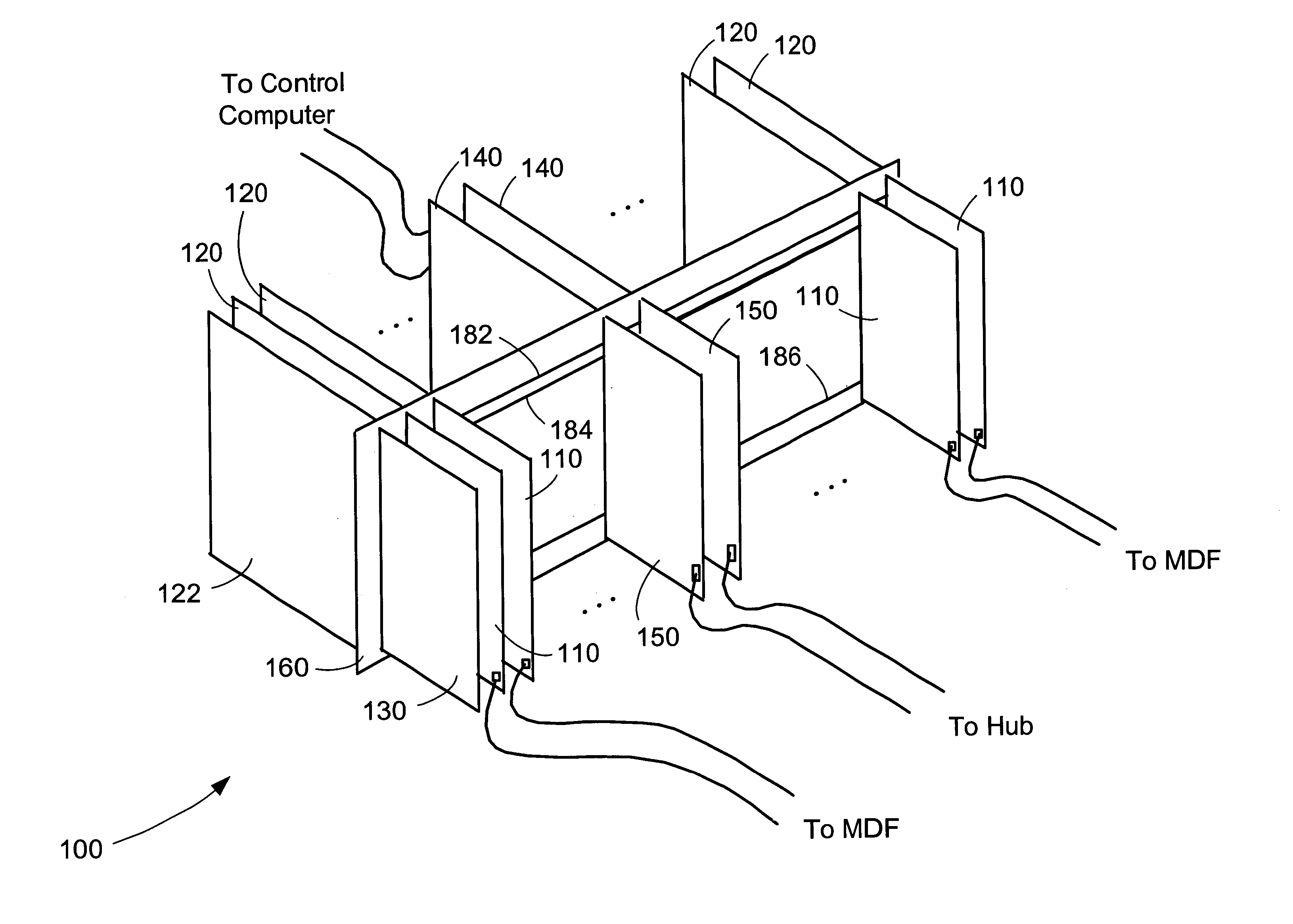

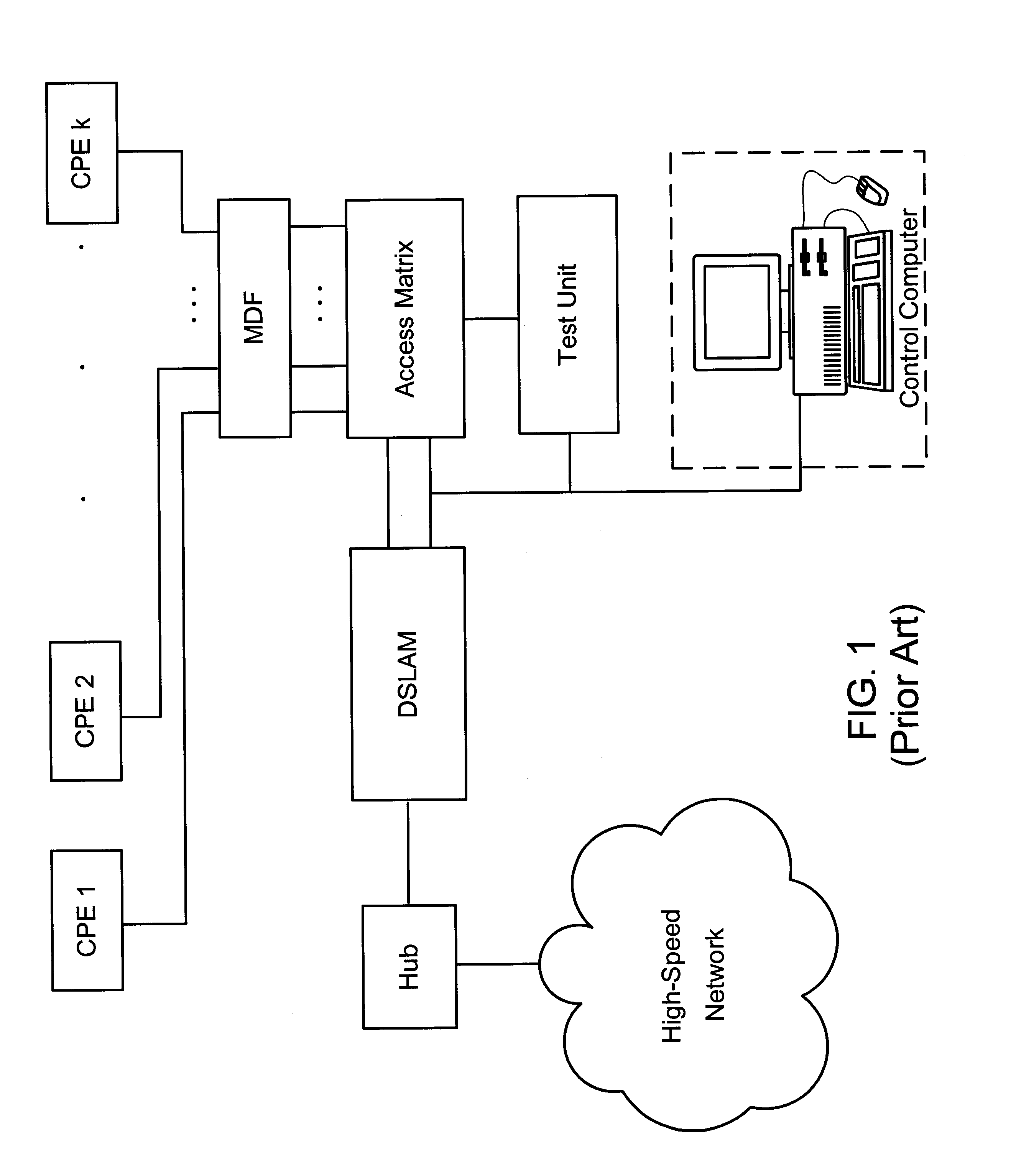

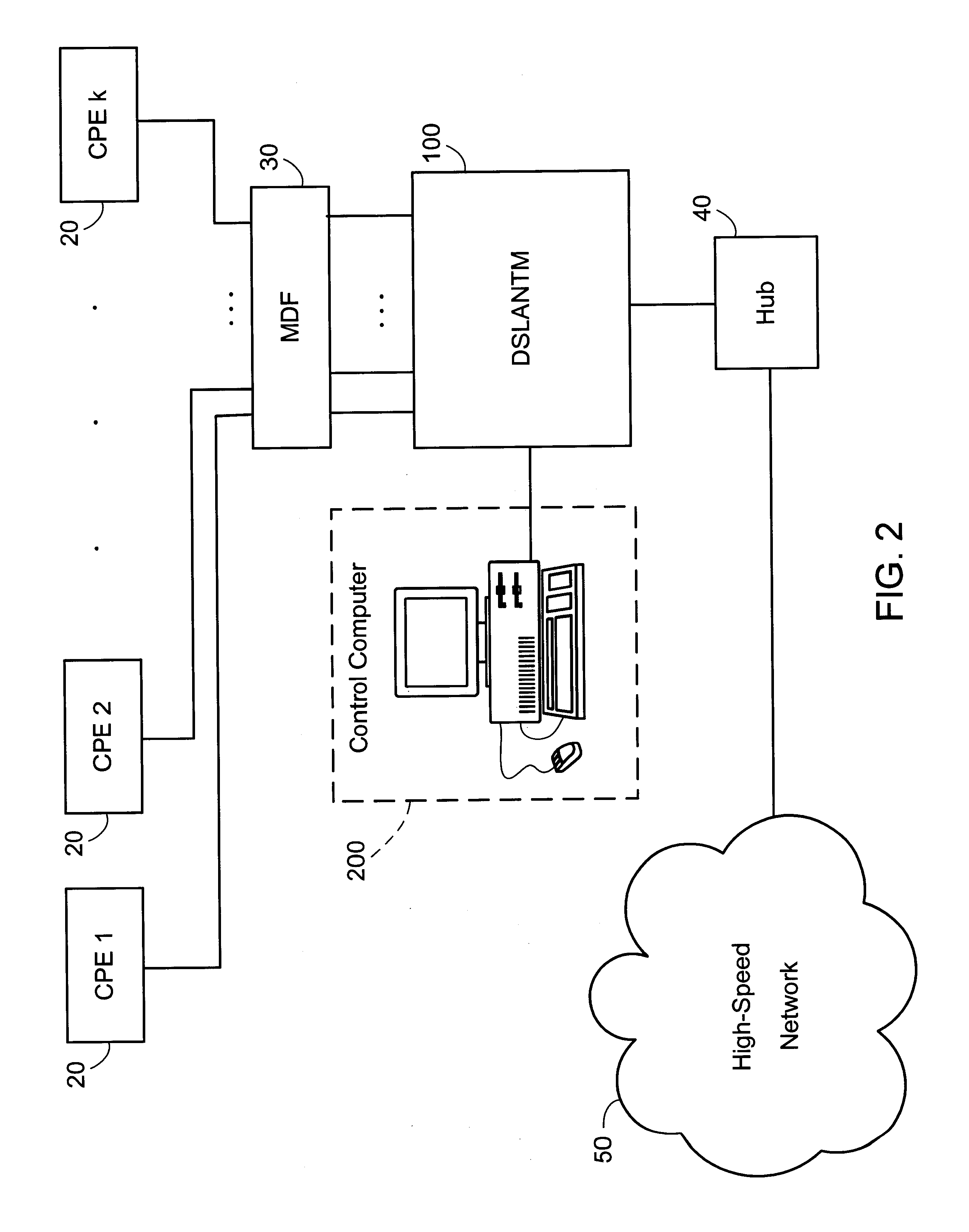

Digital subscriber line access and network testing multiplexer

InactiveUS6873685B2Highly compactCost efficientError preventionFrequency-division multiplex detailsNetwork testingLine card

A Digital Subscriber Line Access Multiplexer includes a set of line cards, a set of xDSL modem cards, a redundant xDSL modem card, a test and switching unit, a control unit, and a trunk unit. Each line card may include a switch, through which the control unit may selectively direct the line card to couple to a corresponding xDSL modem card or a redundancy bus. The test and switching unit is coupled to the redundancy bus, and includes a relay matrix and a Copper Loop Tester (CLT). In response to commands received from the control unit, the relay matrix may route redundancy bus signals to the CLT and / or the redundant xDSL modem card. The CLT performs tests to measure or determine subscriber loop electrical characteristics in response to control unit commands, and returns test results to the control unit.

Owner:SUNRISE TELECOM

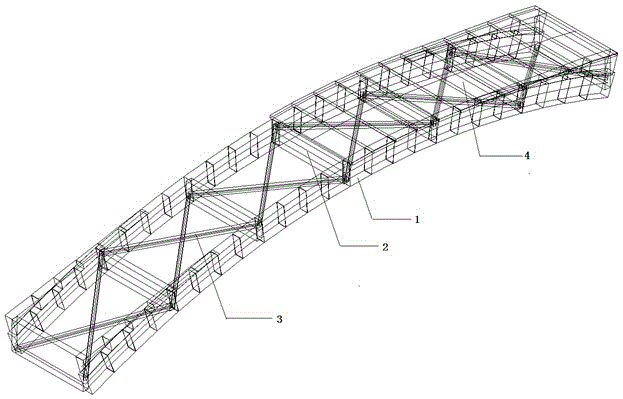

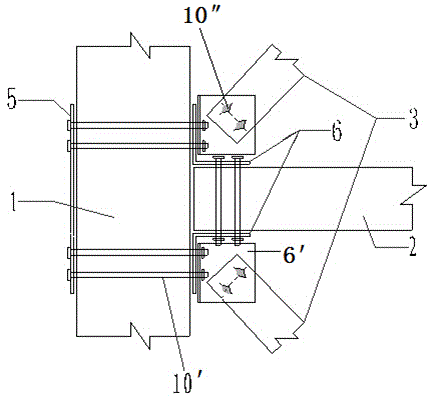

Modern arch type bamboo bridge and construction method thereof

InactiveCN104594175AImprove power transmissionImprove mechanical performanceBridge erection/assemblyArch-type bridgeDuctilityStructural element

The invention discloses a modern arch type bamboo bridge. The modern arch type bamboo bridge is characterized by comprising bamboo arch ribs, bamboo beams, diagonal bracings, bamboo panels and steel shoes, wherein the bamboo arch ribs, the bamboo beams, the diagonal bracings and the bamboo panels are made of reconsolidated bamboo materials; the steel shoes are made of steel materials. The invention further discloses a construction method of the modern arch type bamboo bridge. The construction method of the modern arch type bamboo bridge is characterized in that the bamboo arch ribs, the bamboo beams, the diagonal bracings, the bamboo panels and the steel shoes are prefabricated, installation of the steel shoes and a bridge abutment skewback is finished, then installation of the bamboo arch ribs and the steel shoes is finished, the bridge abutment skewback is poured, and finally the bamboo beams, the diagonal bracings and the bamboo panels are installed. The construction method of the modern arch type bamboo bridge has the advantages that the manufacturing process is simple, the cost is low, factorization and standardization of structural components are good, the assembly degree is high, the building time is short, the structural intensity is high, rigidity is large, ductility is good, and the seismic performance is good, and the obtained arch type bamboo bridge has the effects of being environmentally friendly and low in carbon.

Owner:CHONGQING JIAOTONG UNIVERSITY

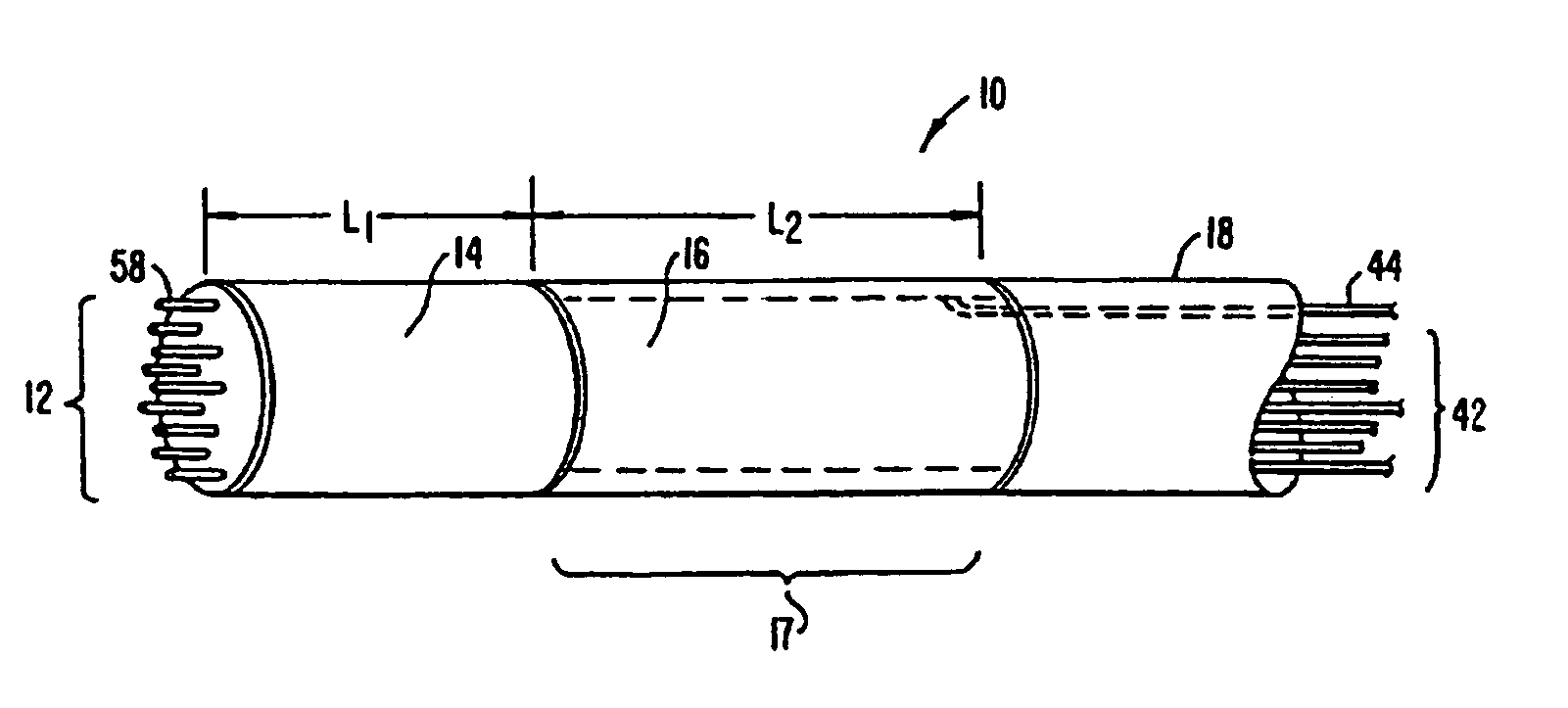

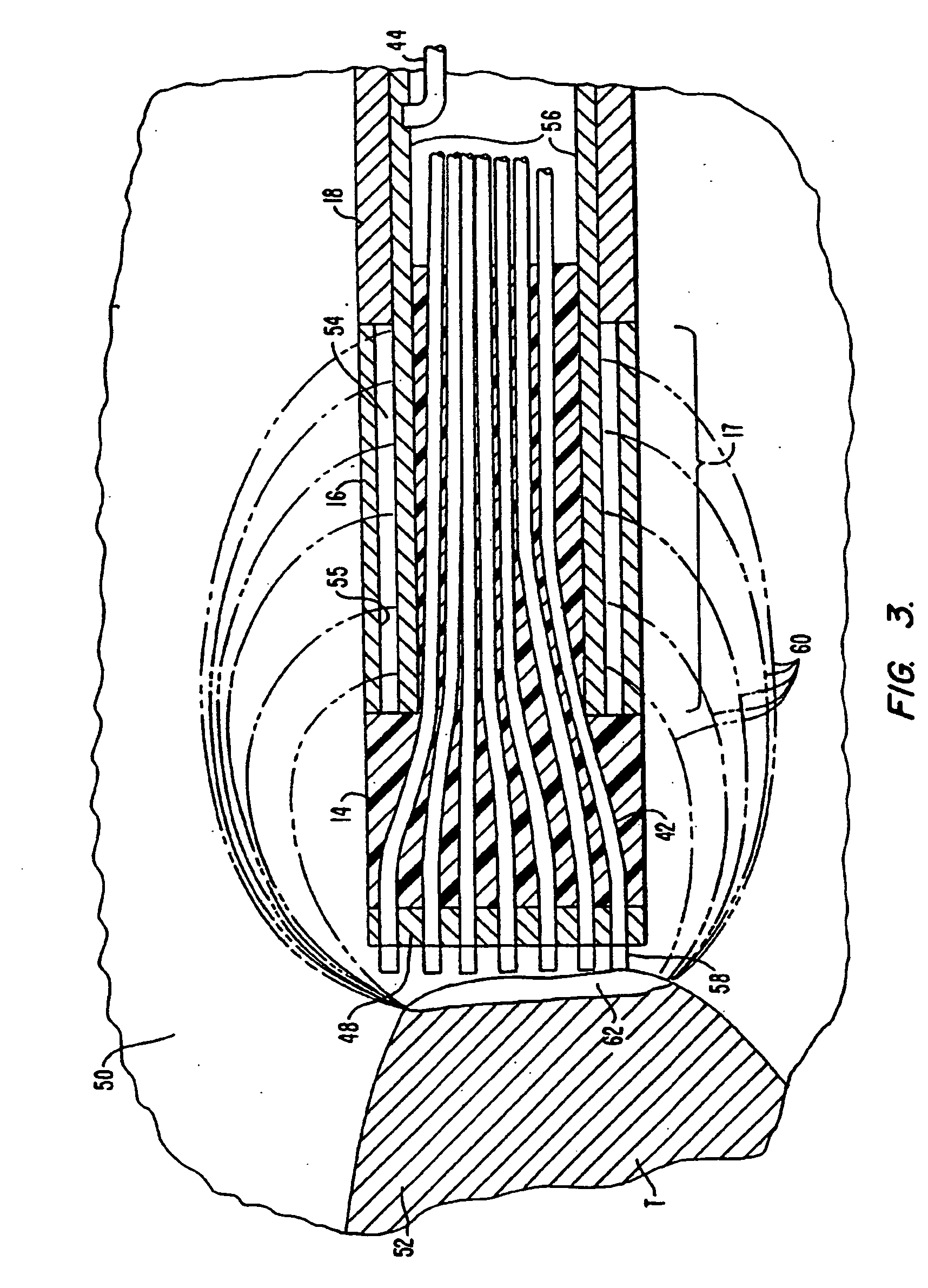

Methods for electrosurgical tissue treatment between spaced apart electrodes

InactiveUS20060041255A1Control depthReducing power delivery and ablation rateHeart valvesDiagnosticsElectrode arrayTarget tissue

As electrosurgical prove comprises a shaft having an electrode array (12) at its distal end and a connector at its proximal end. The array (12) includes a plurality of isolated electrode terminals, and an electrosurgical power supply (28) is provided with a multiplicity of independently limited or controlled current sources and a connector. The electrosurgical probe and the power supply may be connected through their respective connectors so that the independent current sources are connected to individual electrode terminals. By applying very high frequency electrical energy to the electrode array, target tissue may be cut or ablated while heat dissipation through low impedance paths, such as blood and normal saline, will be minimized.

Owner:ARTHROCARE

Integrated capacitor for wafer level packaging applications

InactiveUS20060258048A1Minimize the numberReduce device form factorSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

A capacitor design, which incorporates a material set that is adaptable to standard substrate or electronic packaging fabrication methods, uses copper as a base and electrode, mesoporous nanocomposite materials or other adhesion promoting materials combined with a high dielectric material specific to the application's capacitance requirements. This capacitor is then used as a basis for forming a capacitor in substrate or package or wafer level package or die or wafer.

Owner:EKUBIK CONSULTING

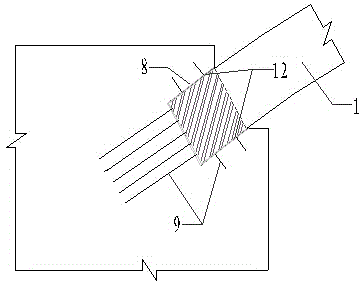

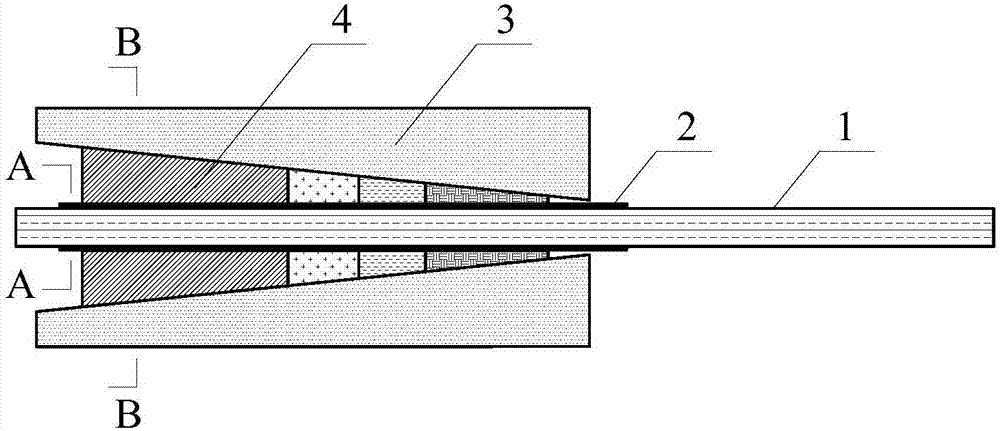

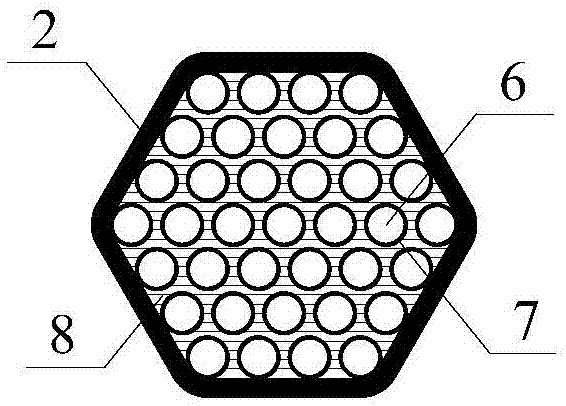

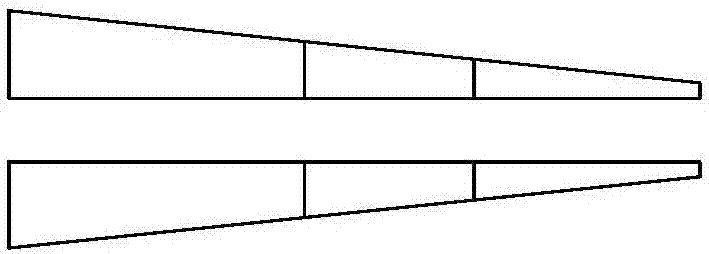

Large-tonnage FRP stay cable anchoring method

ActiveCN108004926AImprove anchoring efficiencyRelieve lateral stress concentrationBridge structural detailsBridge erection/assemblyYarnTransmission medium

The invention discloses a large-tonnage FRP stay cable anchoring method. The method comprises steps: forming a taper variable stiffness load transmission medium on a FRP stay cable anchoring region, wherein the variable stiffness load transmission medium being formed by fiber yarns which are winded along a length direction of the FRP stay cable anchoring region in a segmented manner through mouldpressing, heating, and solidifying, using fiber yarns in different kinds in different segments, to form variable stiffness load, the fiber yarns being soaked by resin before being winded; along an axial direction of the variable stiffness load transmission medium, cutting a plurality of kerfs; using a taper anchorage device matched with the taper variable stiffness load transmission medium to anchor. The anchoring method is advantaged by simple manufacturing, easy control, good coordination force property, high anchoring efficiency, continuous variation of load transmission medium stiffness, and more uniform load transmission medium stiffness. Fiber content and transverse stiffness of the variable stiffness load transmission medium gradually increase from a loading end to a free end, to relieve or eliminate notch effect of the loading end of the FRP stay cable, and prevent lateral shearing damages from preceding tensile damages of the large-tonnage FRP stay cable caused by stress concentration.

Owner:SOUTHEAST UNIV +1

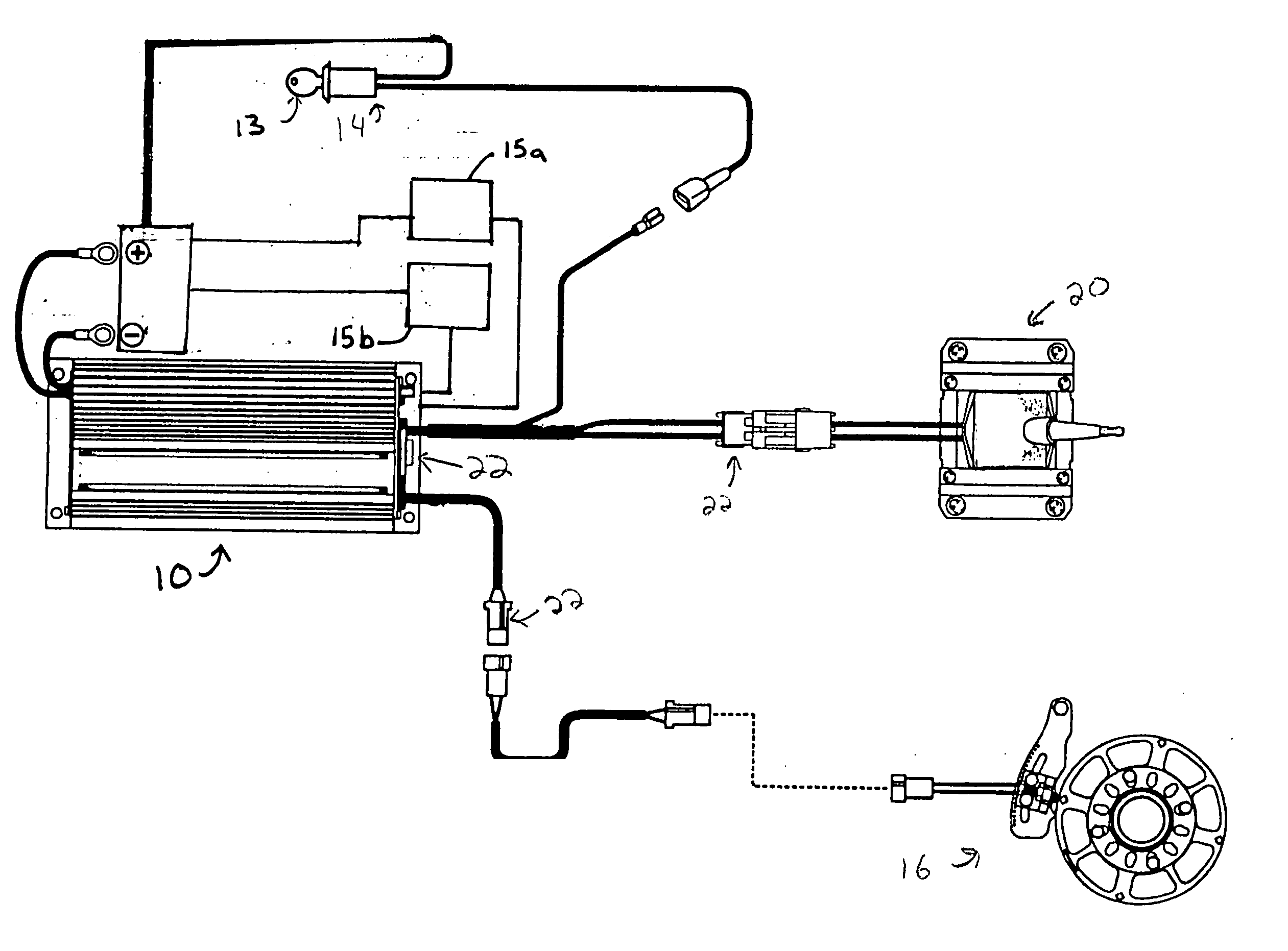

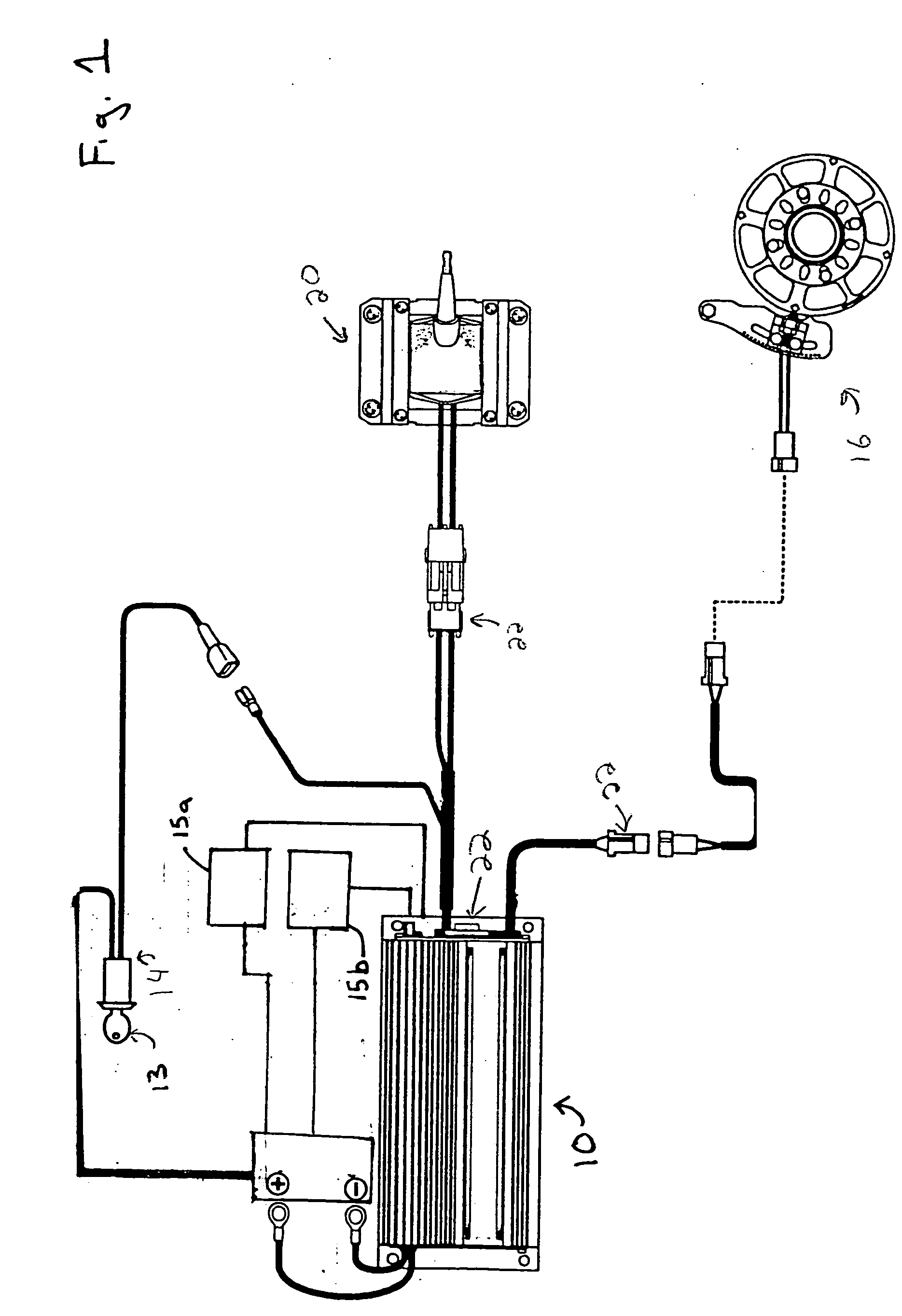

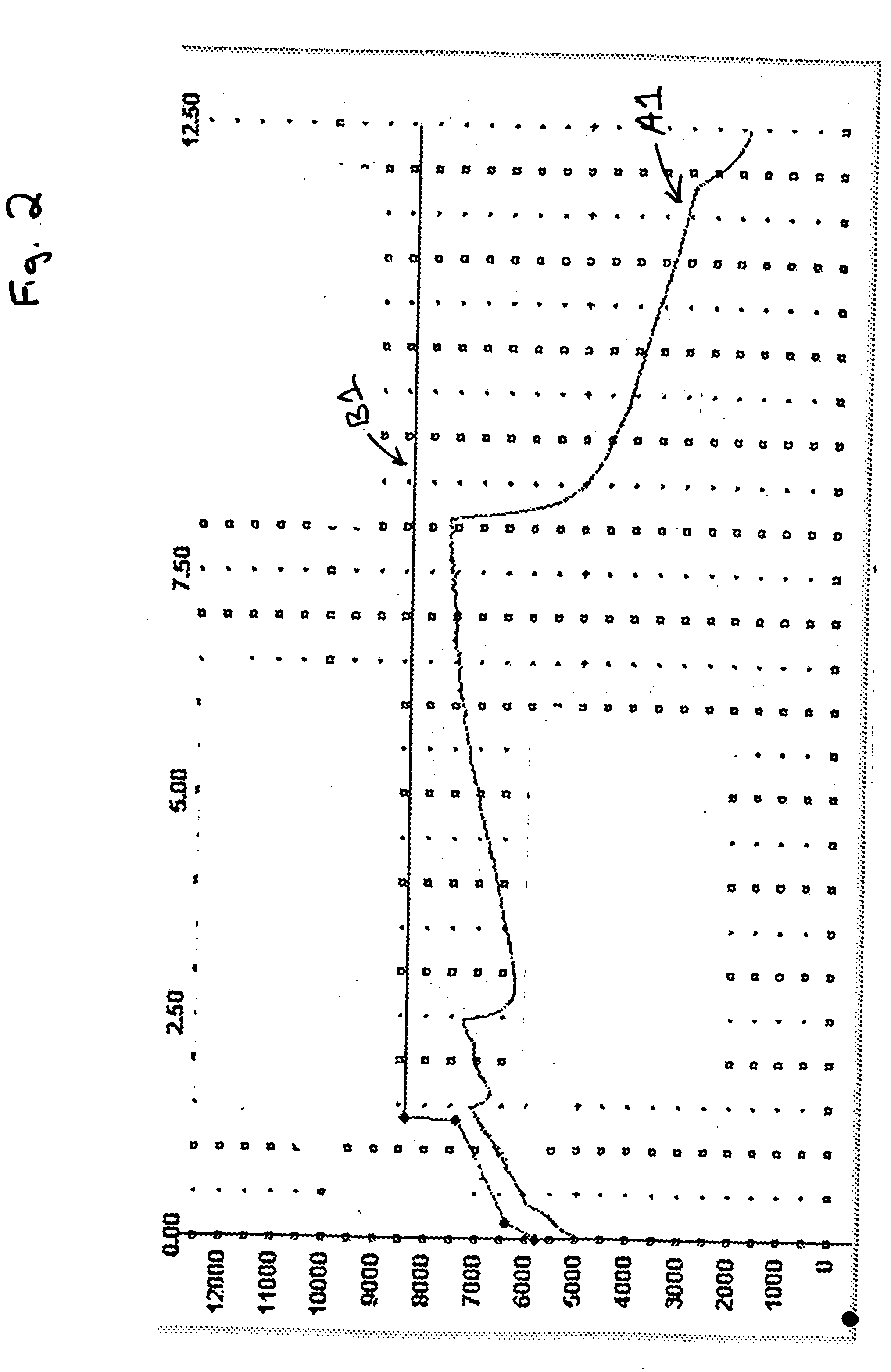

Slew rate revlimiter

ActiveUS20050216132A1Improve power transmissionAnalogue computers for vehiclesDigital data processing detailsElectrical resistance and conductanceSlew rate

A engine control device is disclosed for monitoring and controlling the RPM of an engine. The device restricts the over-revving of an engine due to a lack of resistance by monitoring the RPM and determining whether measured RPM indicate a likely lack of resistance causing over-revving of an engine, such as would occur if the tires are slipping relative to the road. The revlimiter may monitor the revolutions per minute of a crankshaft of an engine and, upon certain conditions, may slow the engine when the RPM exceed certain parameters. The revlimiter may slow the engine if the RPM of the crankshaft exceed a target RPM value. The programming of the device may be gear specific. In this manner, the revlimiter serves to prevent engine over-revving and serves as a form of traction control.

Owner:MSD LLC

Method for composite skid proof treatment for nail and anchor, and treating structure

InactiveCN1916297AEliminate overall and local instability of loose rock and soil slopes and landslidesEliminate potential safety hazardsCoastlines protectionExcavationsRebarReinforced concrete

The present invention discloses a nail-anchor combined anti-slide treatment method and its treatment structure. Said method includes the following steps: (1), leveling and ramming ground base; (2), setting reinforced concrete lattice, it is made up by combining lattice beams; (3), arranging anchor rods or anchor nails on the lattice beams; (4), setting anchor cable in every lattice corner point position respectively; and (5), applying prestressing force to every anchor cable.

Owner:陈洪凯 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com