Patents

Literature

118 results about "Sequential deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

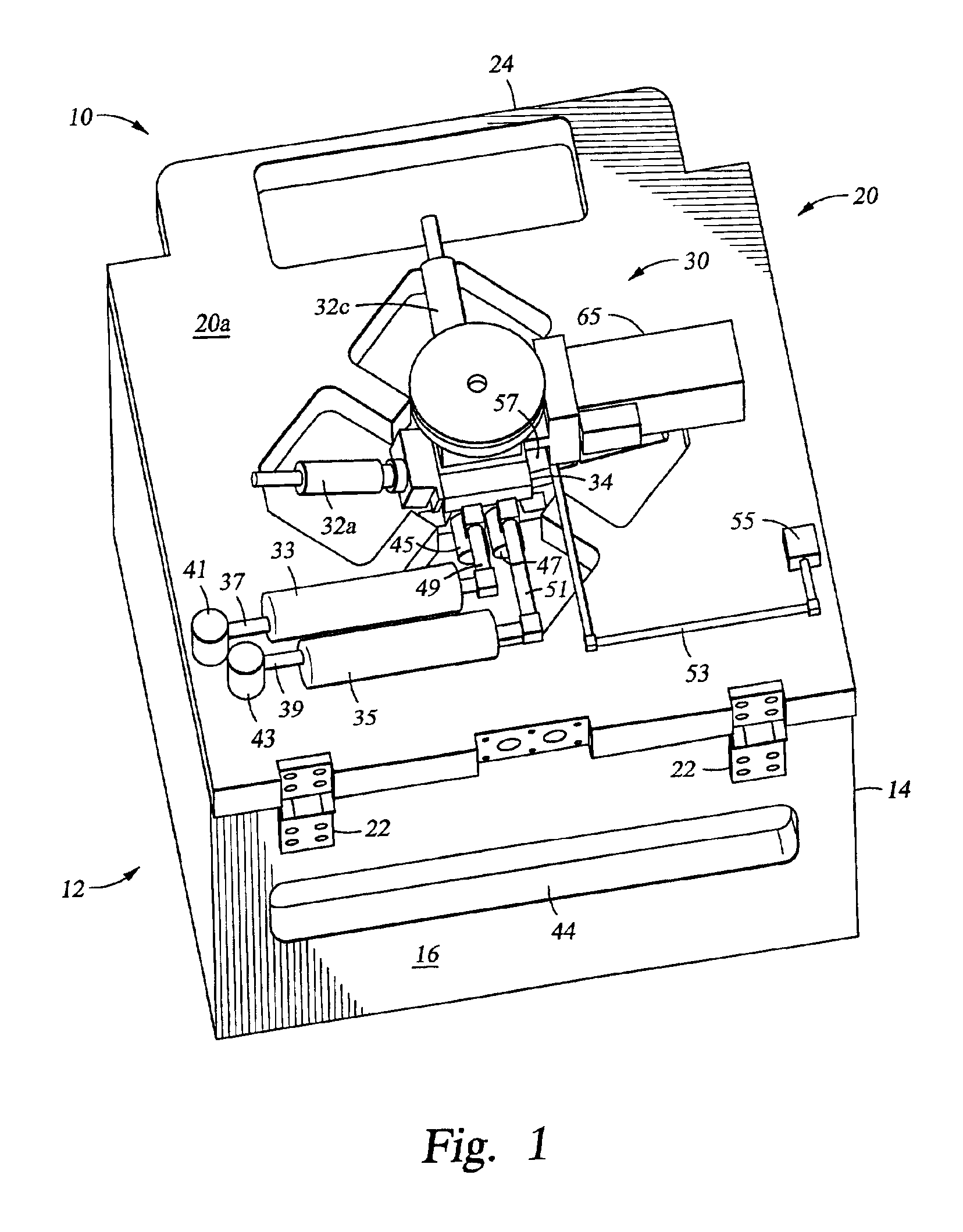

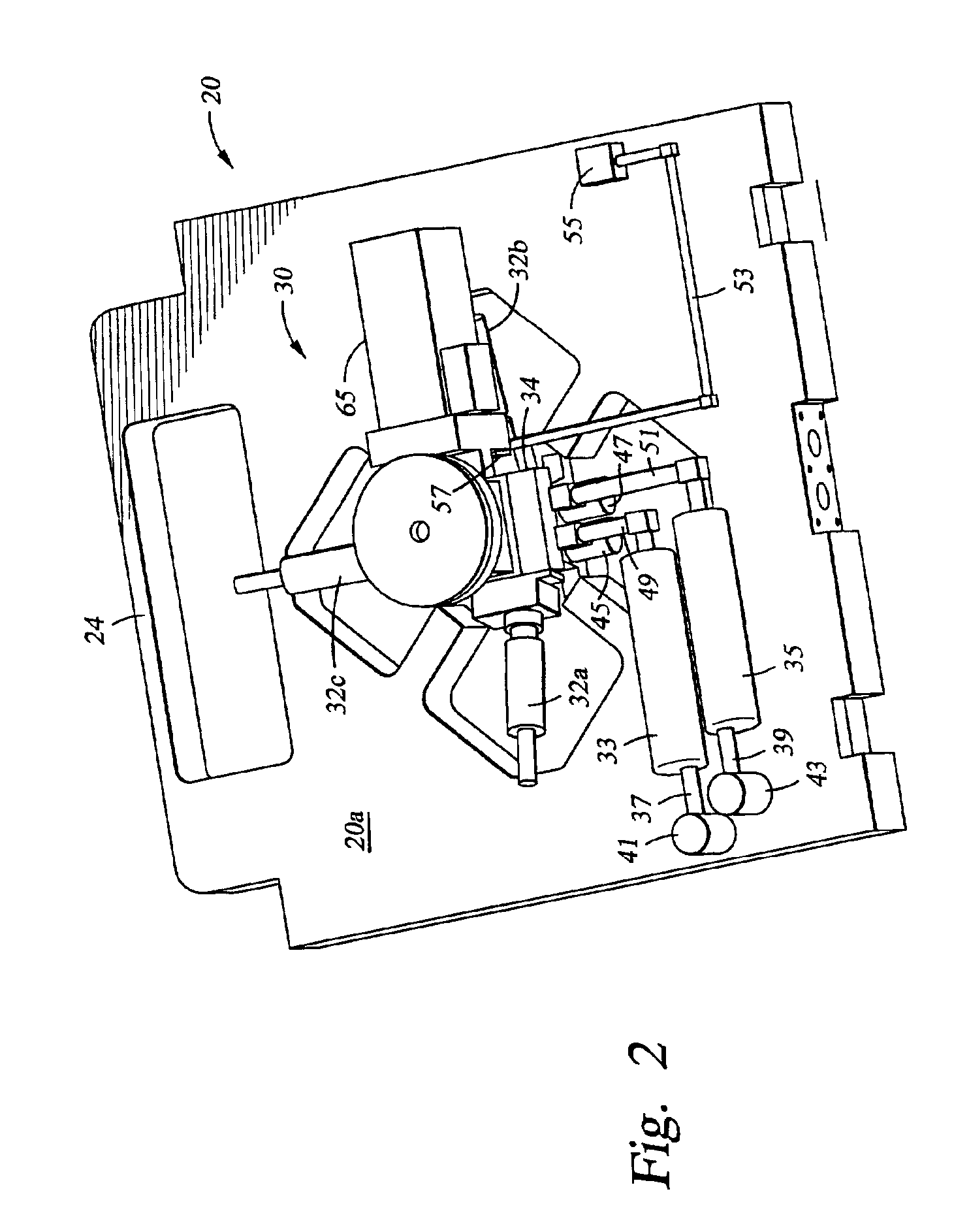

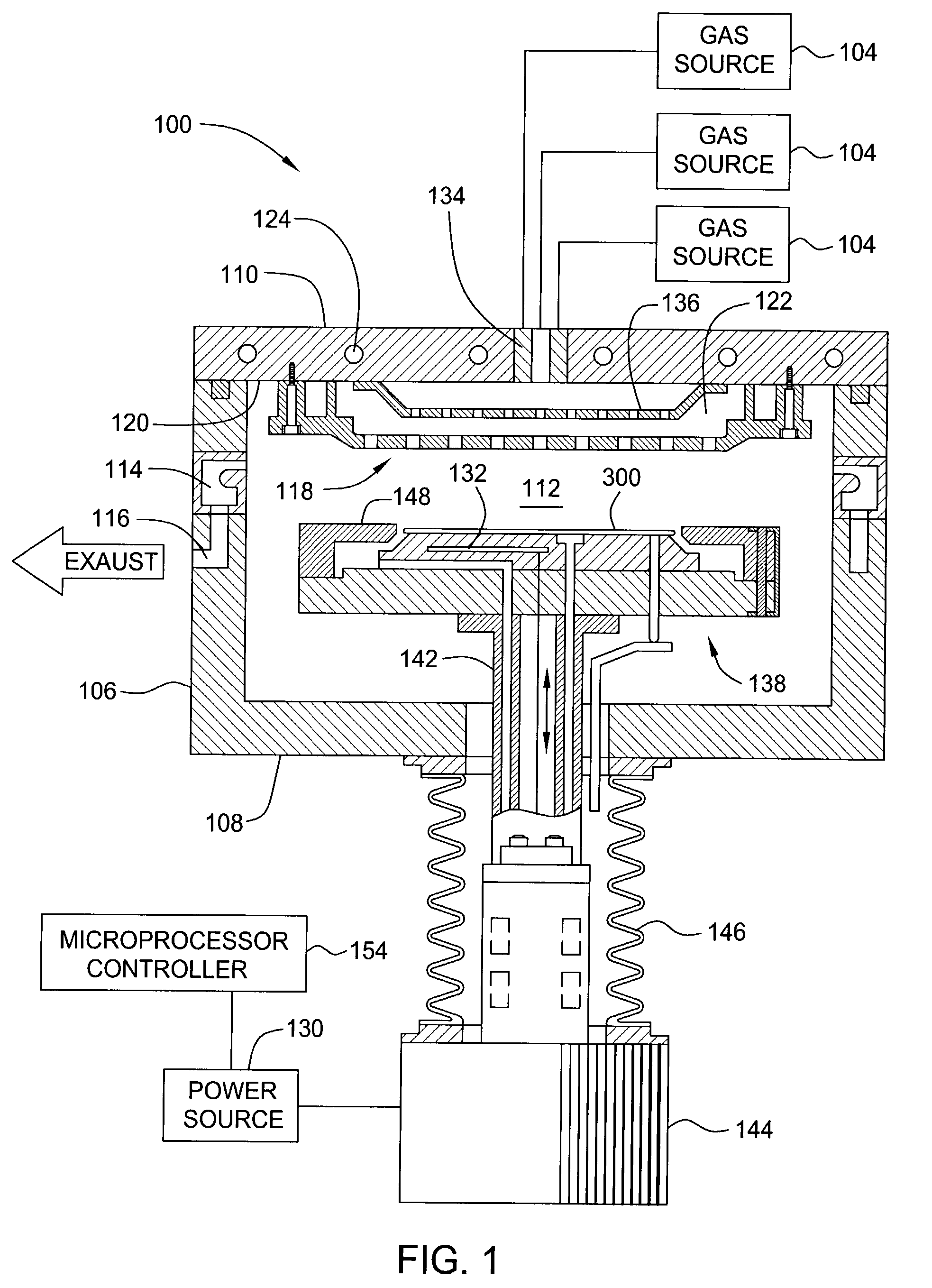

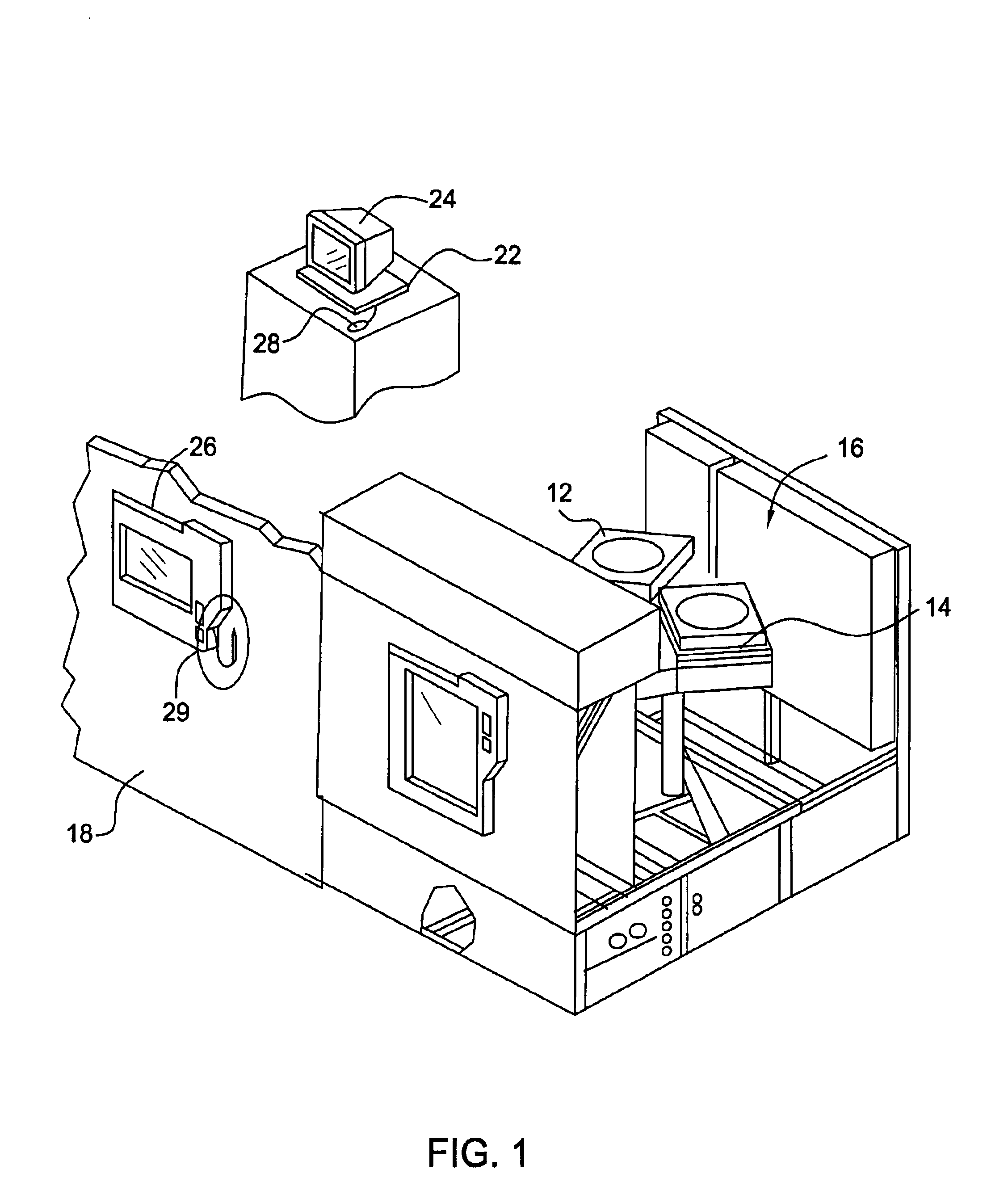

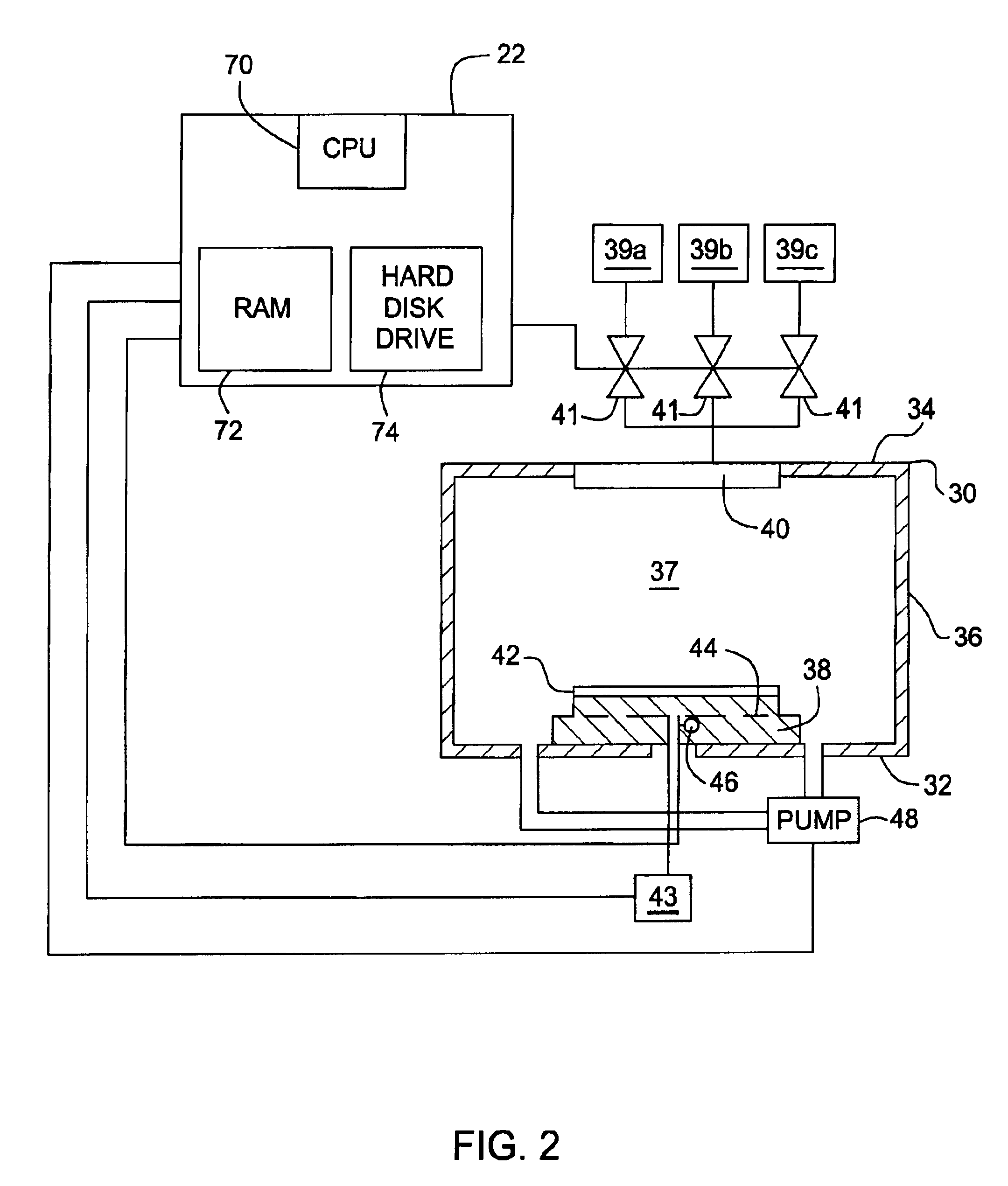

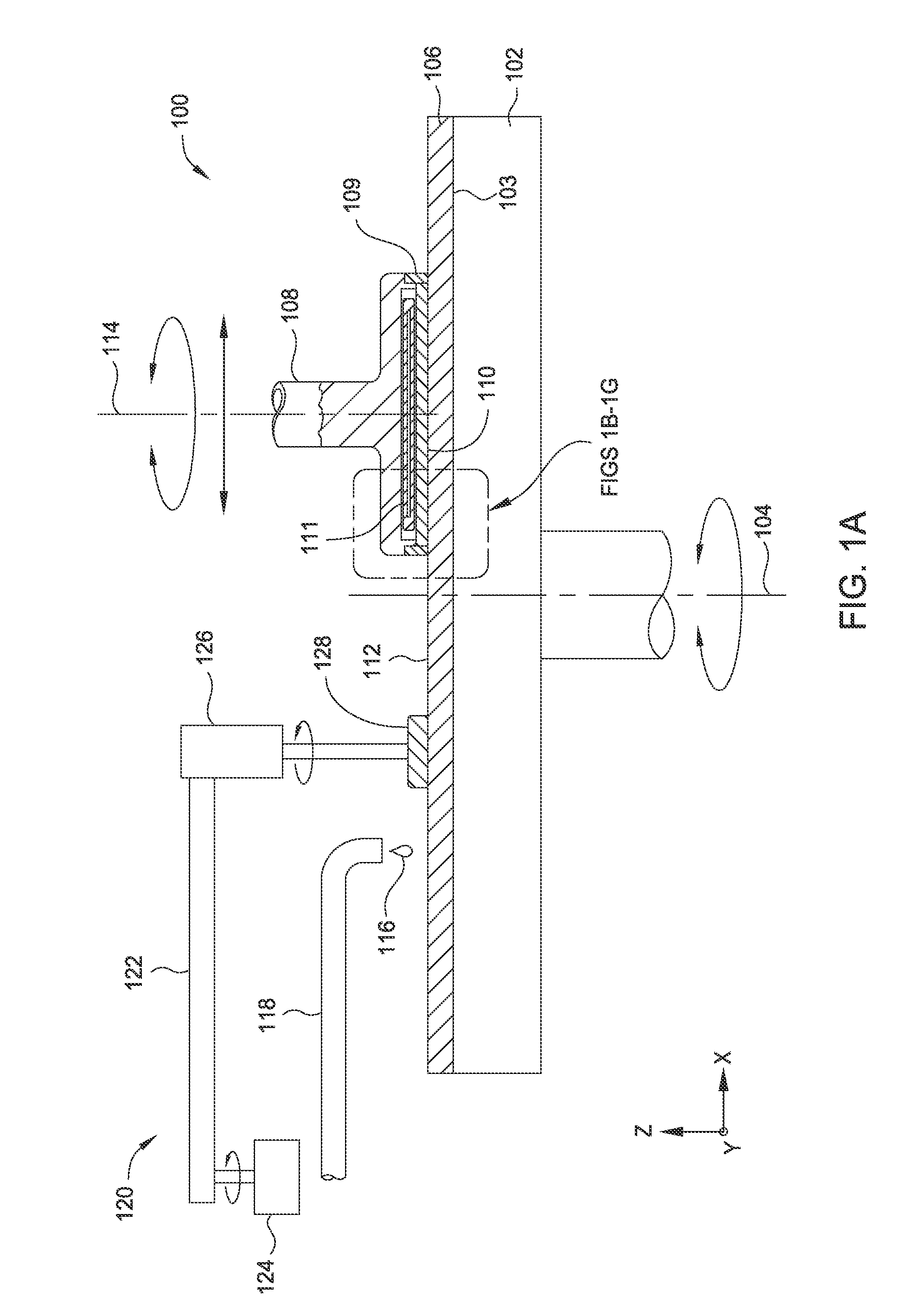

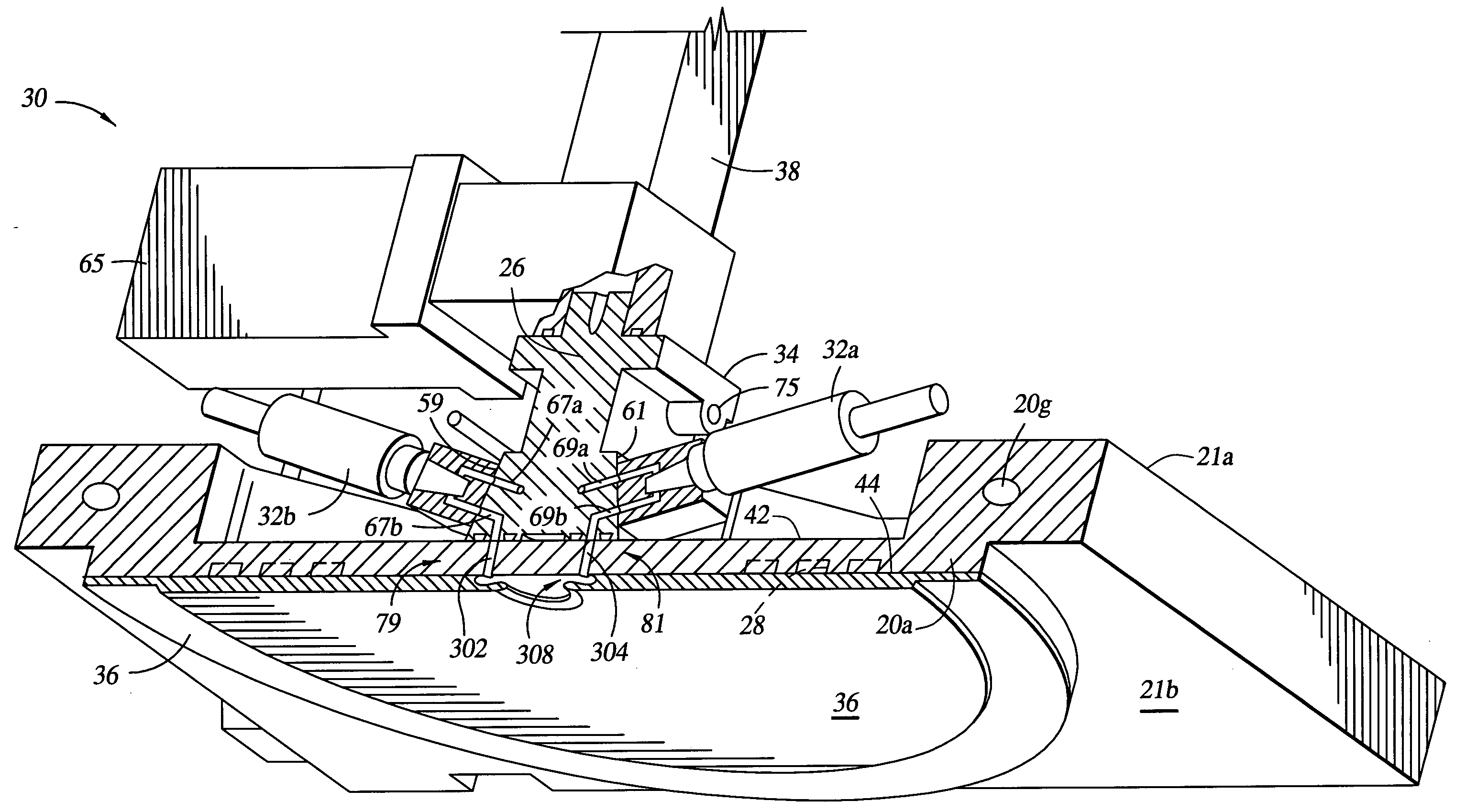

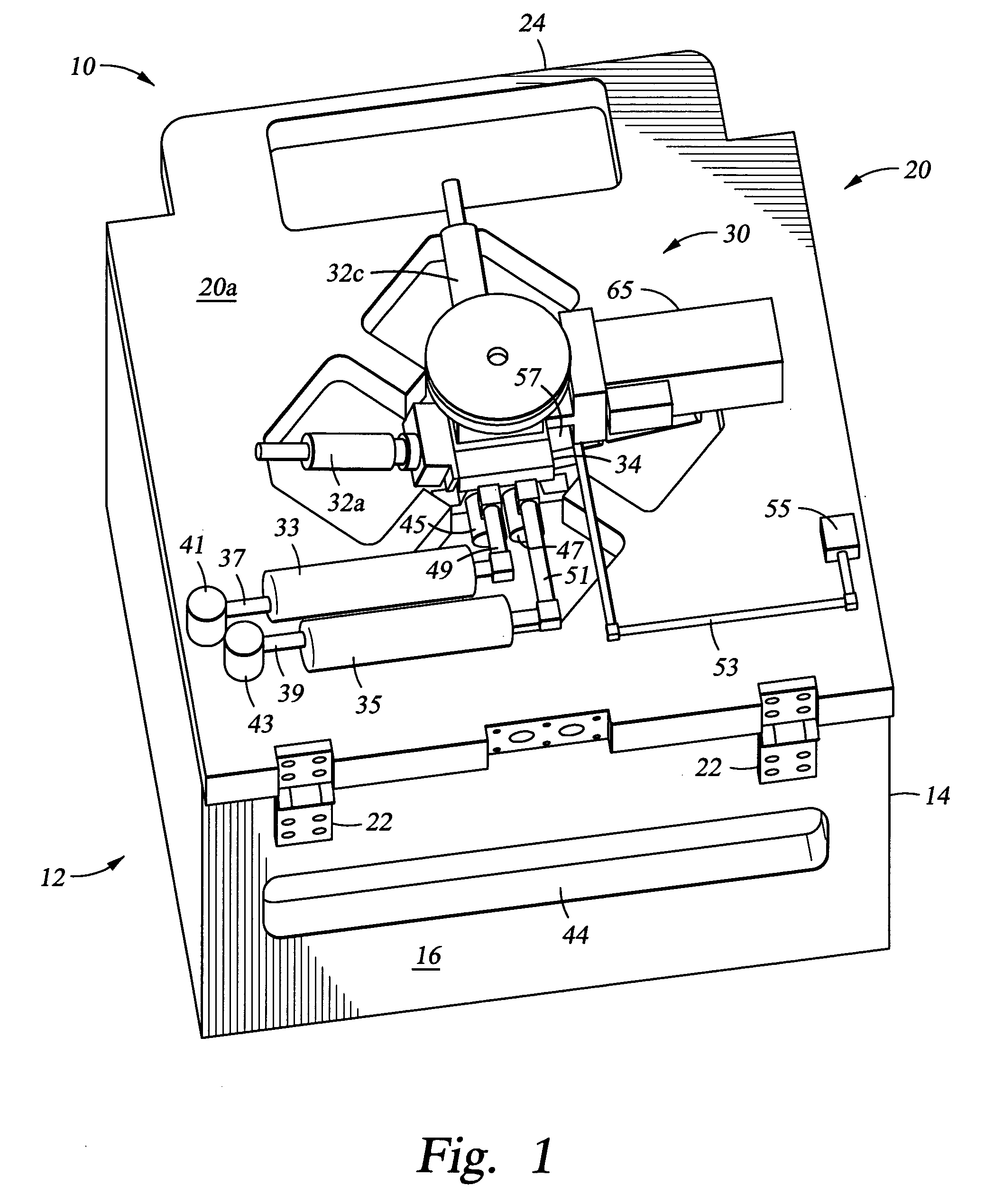

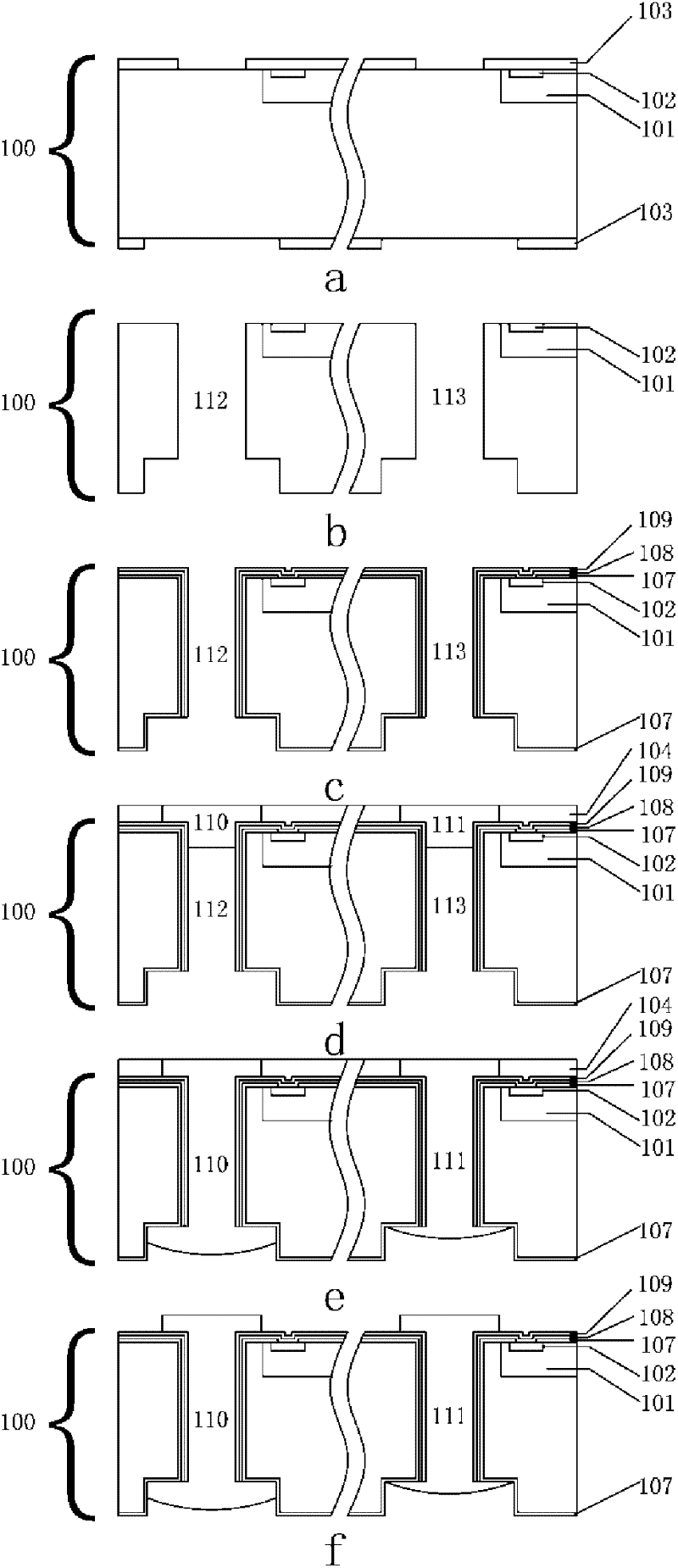

Lid assembly for a processing system to facilitate sequential deposition techniques

InactiveUS6878206B2Easy to controlIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHandling systemSequential deposition

A lid assembly for a semiconductor processing system is provided. The lid assembly generally includes a lid having a gas manifold mounted on a first side and a baffle plate mounted on a second side. The gas manifold is configured to deliver a plurality of gases to a plenum defined between the baffle plate and the lid. The gases are mixed within a recess formed in the baffle plate before exiting into the processing system through a singular passage.

Owner:APPLIED MATERIALS INC

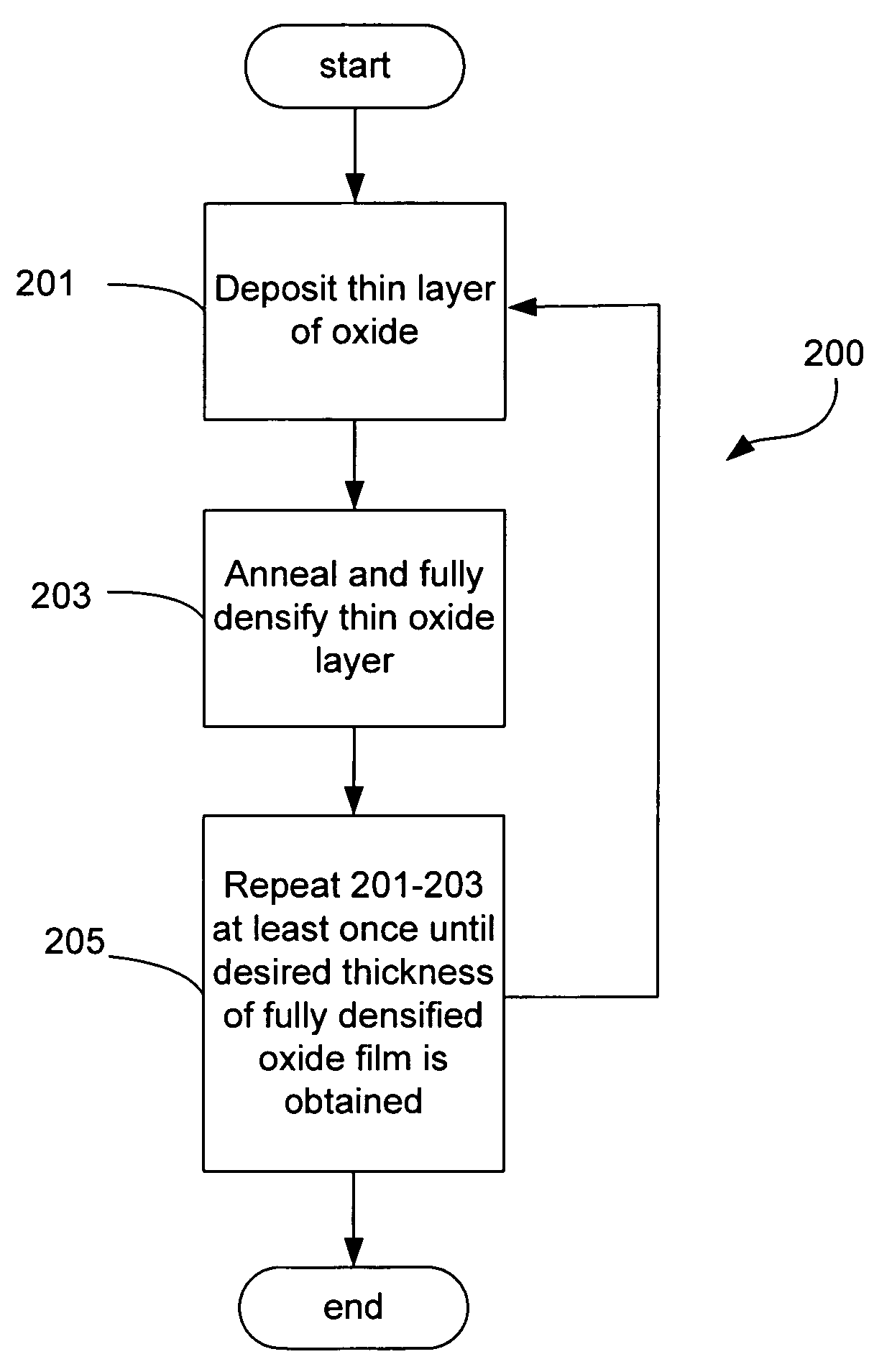

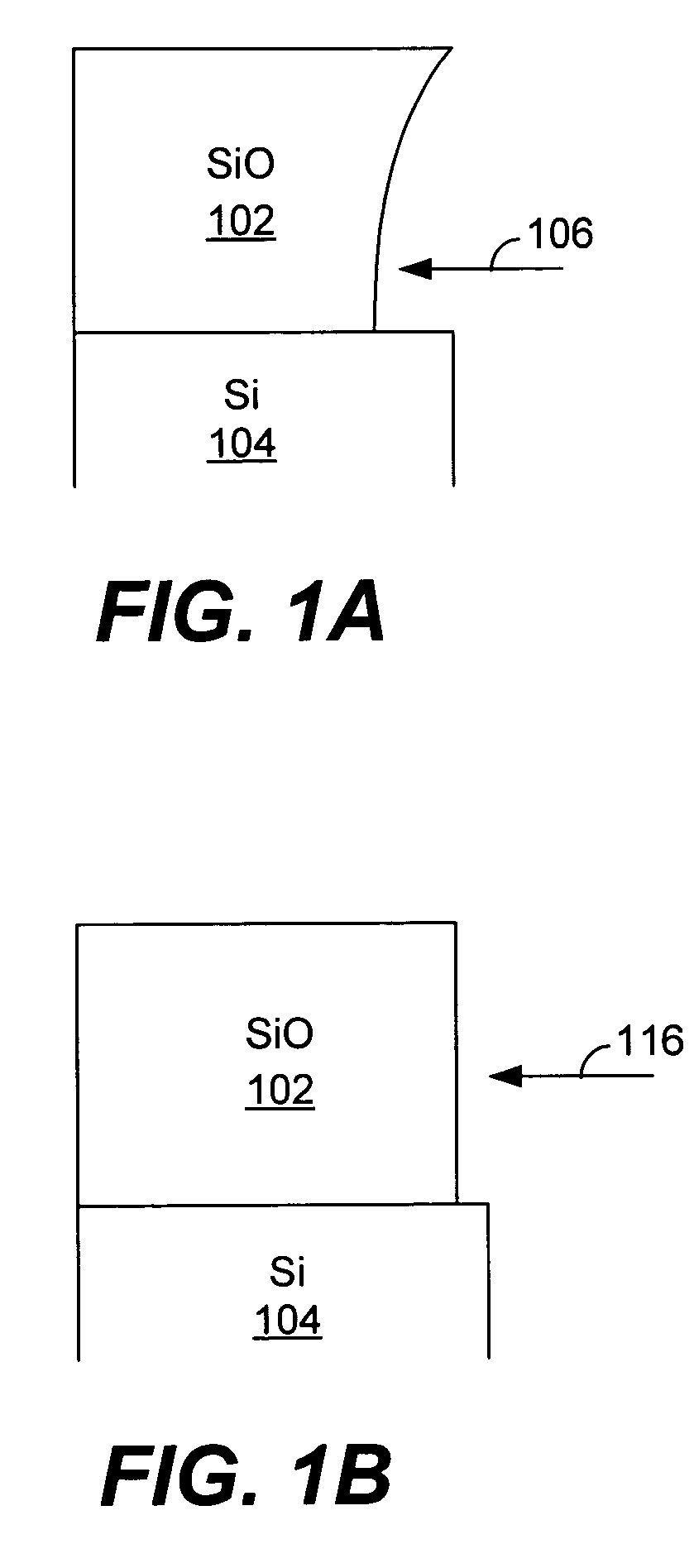

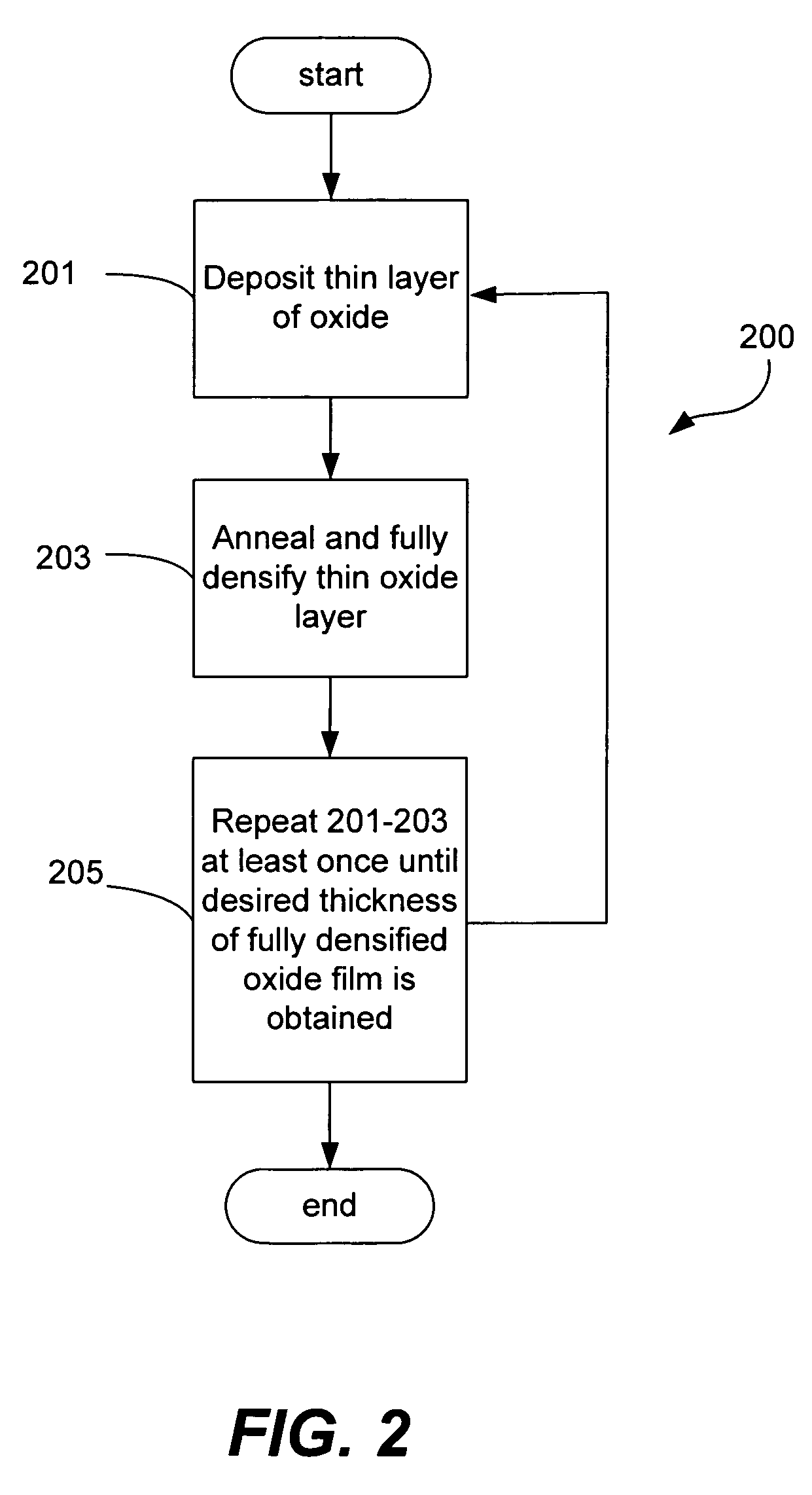

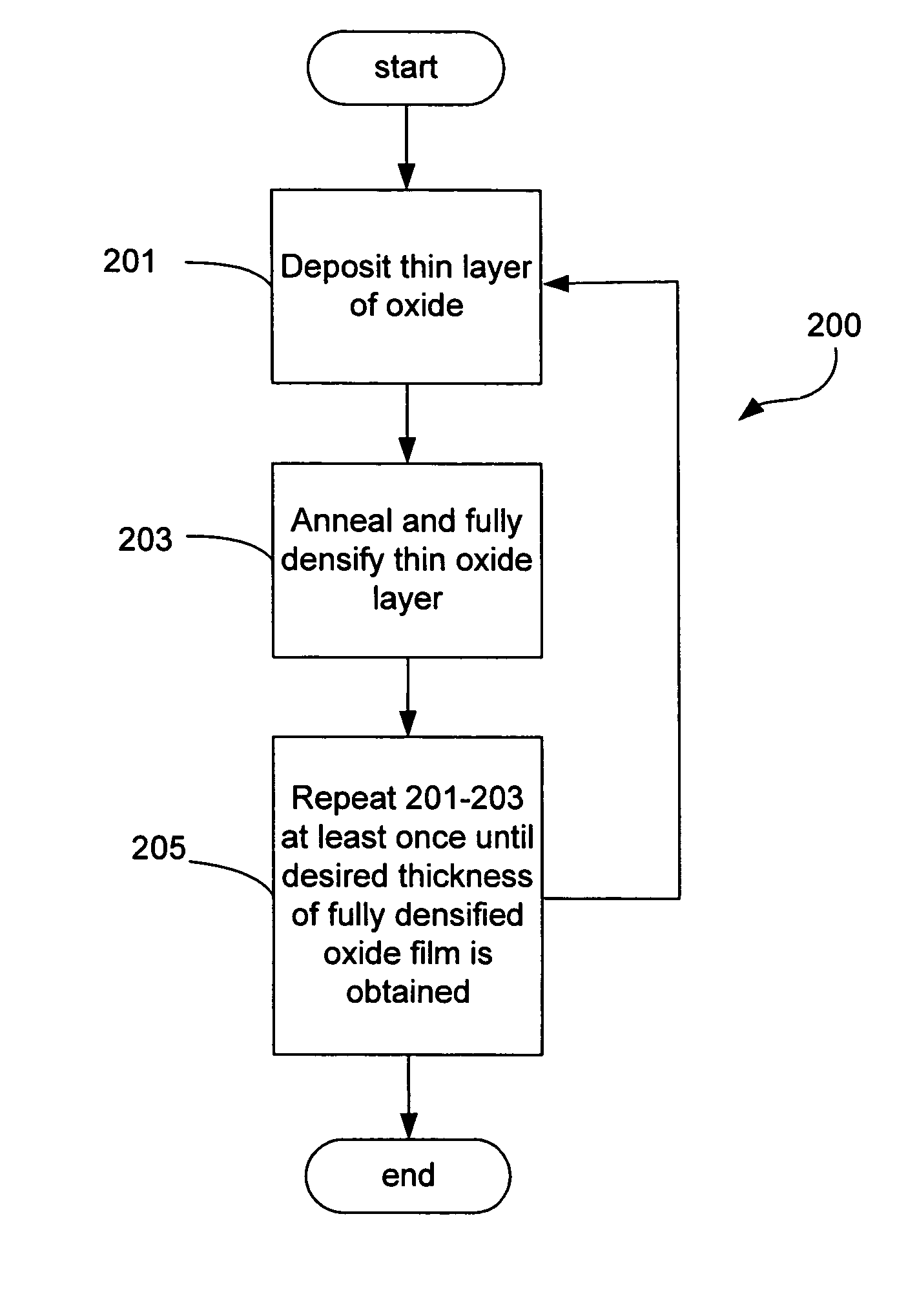

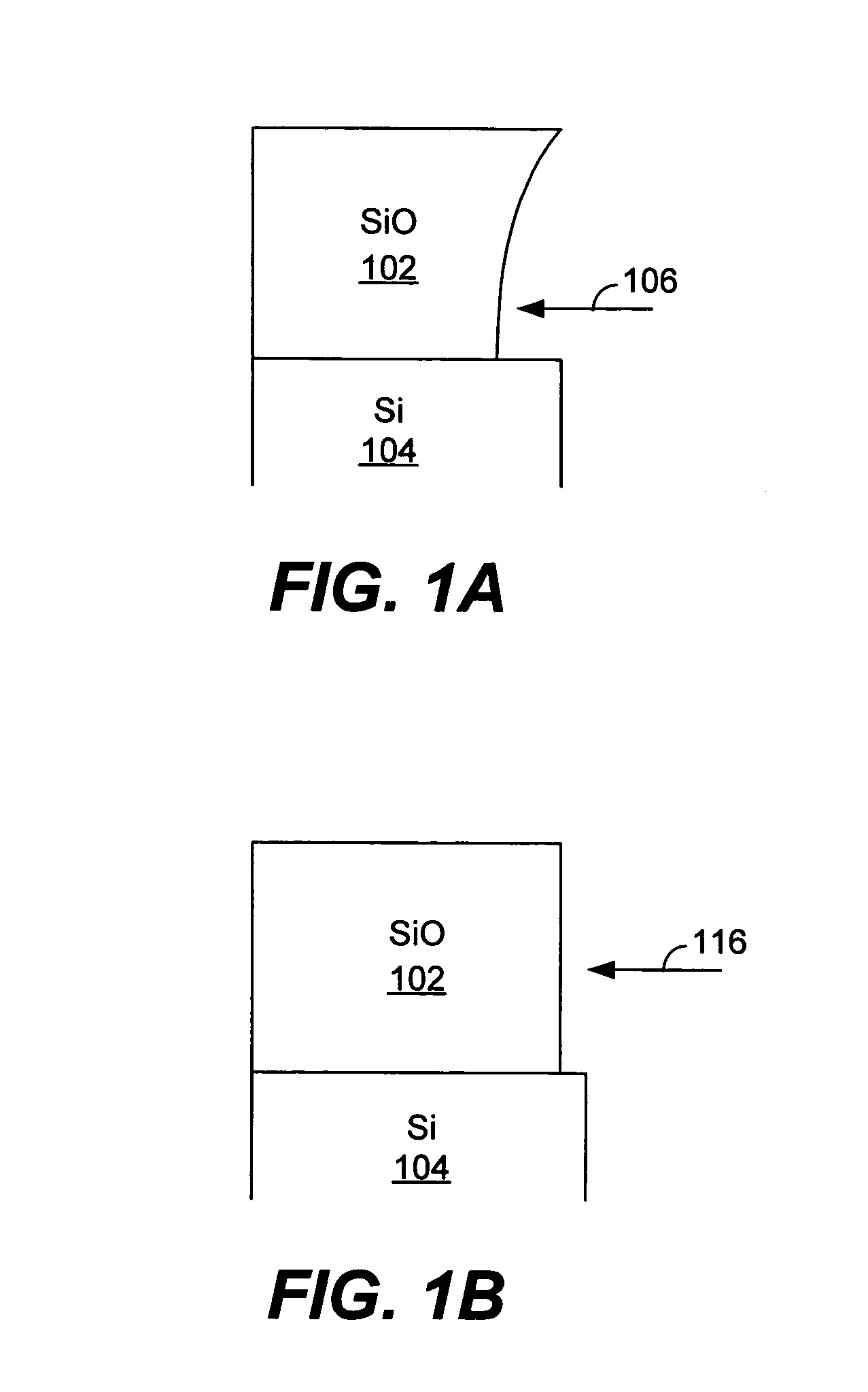

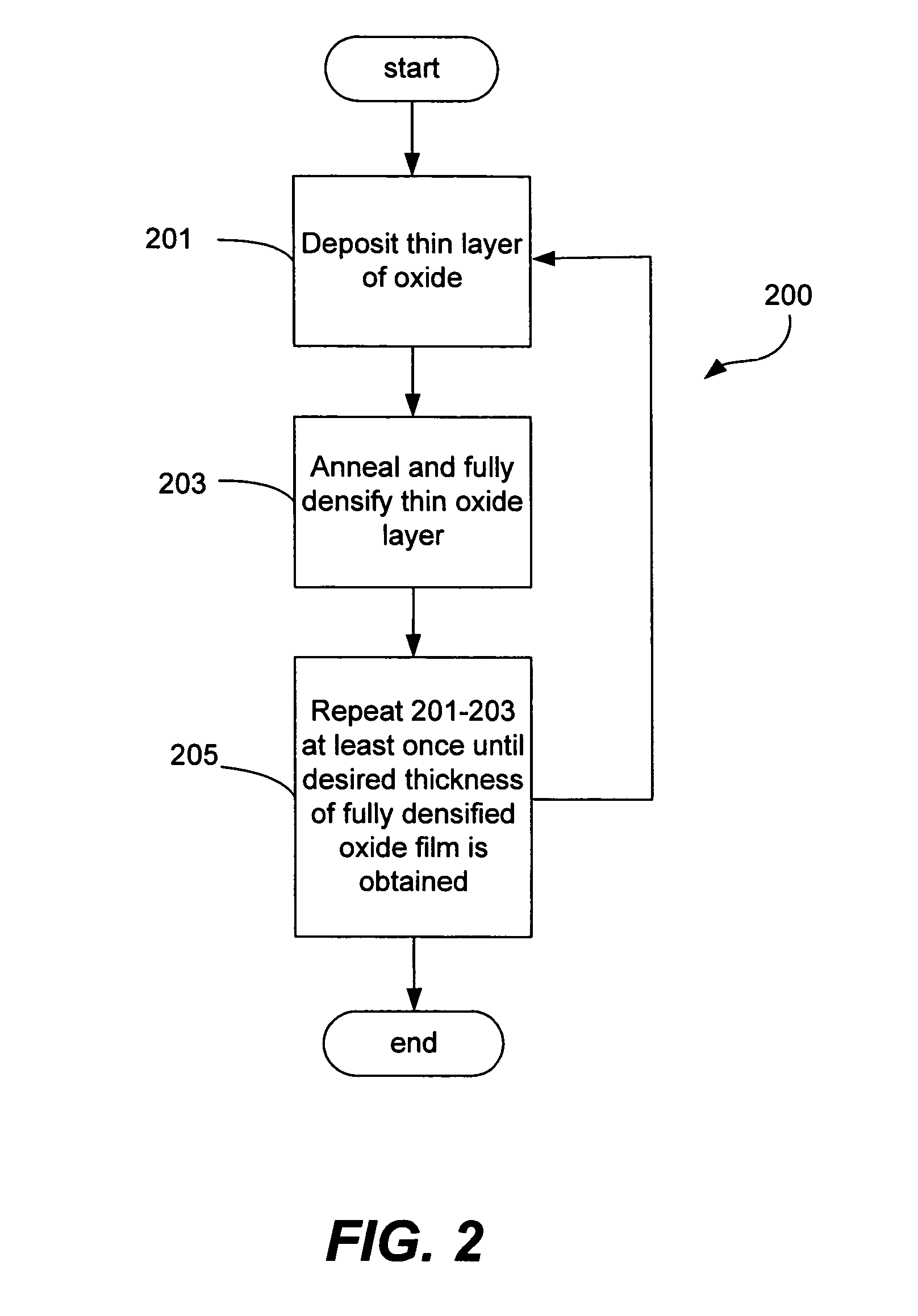

Sequential deposition/anneal film densification method

ActiveUS7790633B1Maintaining film propertyMaintain propertiesSemiconductor/solid-state device manufacturingProcedure AgentsOptoelectronics

A silicon dioxide-based dielectric layer is formed on a substrate surface by a sequential deposition / anneal technique. The deposited layer thickness is insufficient to prevent substantially complete penetration of annealing process agents into the layer and migration of water out of the layer. The dielectric layer is then annealed, ideally at a moderate temperature, to remove water and thereby fully densify the film. The deposition and anneal processes are then repeated until a desired dielectric film thickness is achieved.

Owner:NOVELLUS SYSTEMS

Sequential deposition/anneal film densification method

ActiveUS7148155B1Maintaining film propertyMaintain propertiesSemiconductor/solid-state device manufacturingDielectric membraneThin membrane

A silicon dioxide-based dielectric layer is formed on a substrate surface by a sequential deposition / anneal technique. The deposited layer thickness is insufficient to prevent substantially complete penetration of annealing process agents into the layer and migration of water out of the layer. The dielectric layer is then annealed, ideally at a moderate temperature, to remove water and thereby fully densify the film. The deposition and anneal processes are then repeated until a desired dielectric film thickness is achieved.

Owner:NOVELLUS SYSTEMS

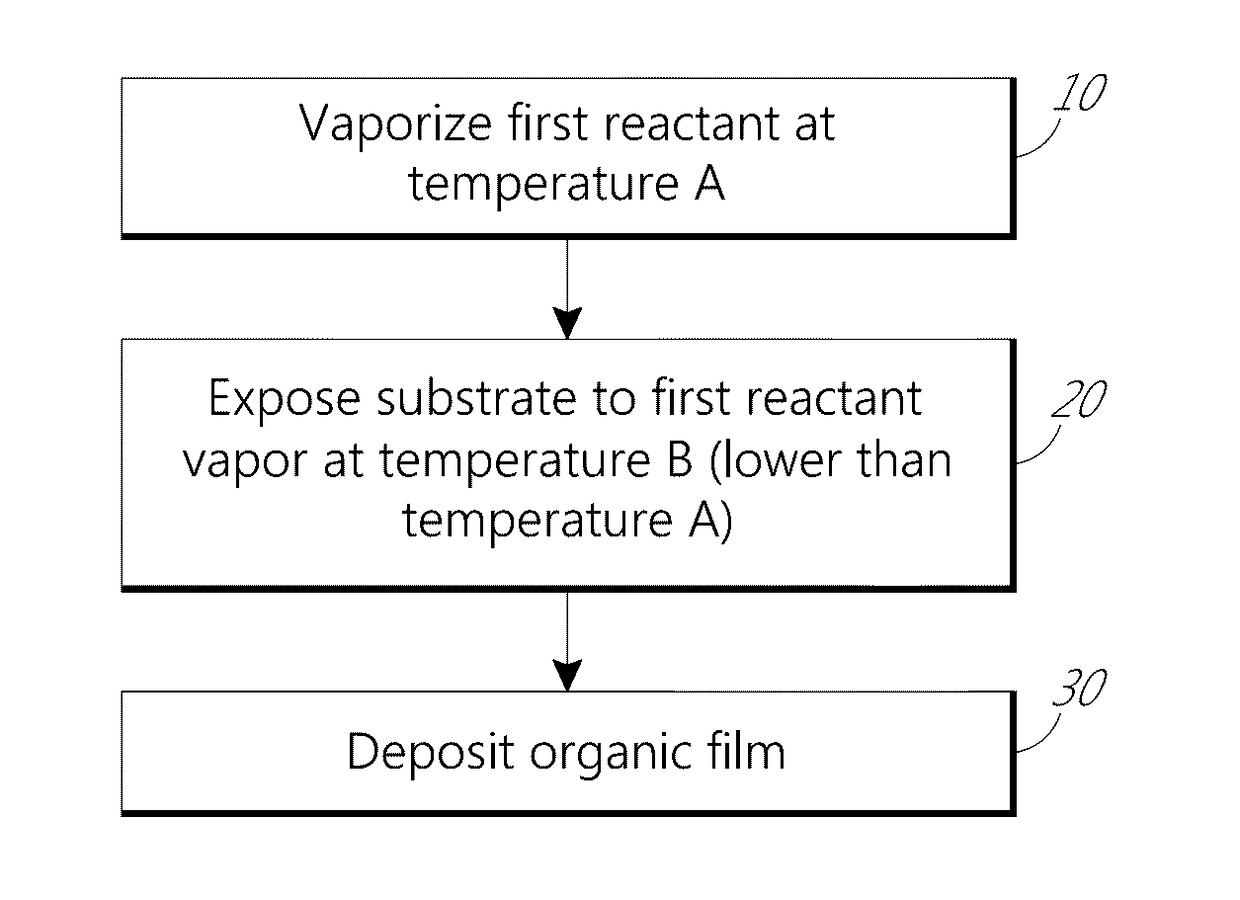

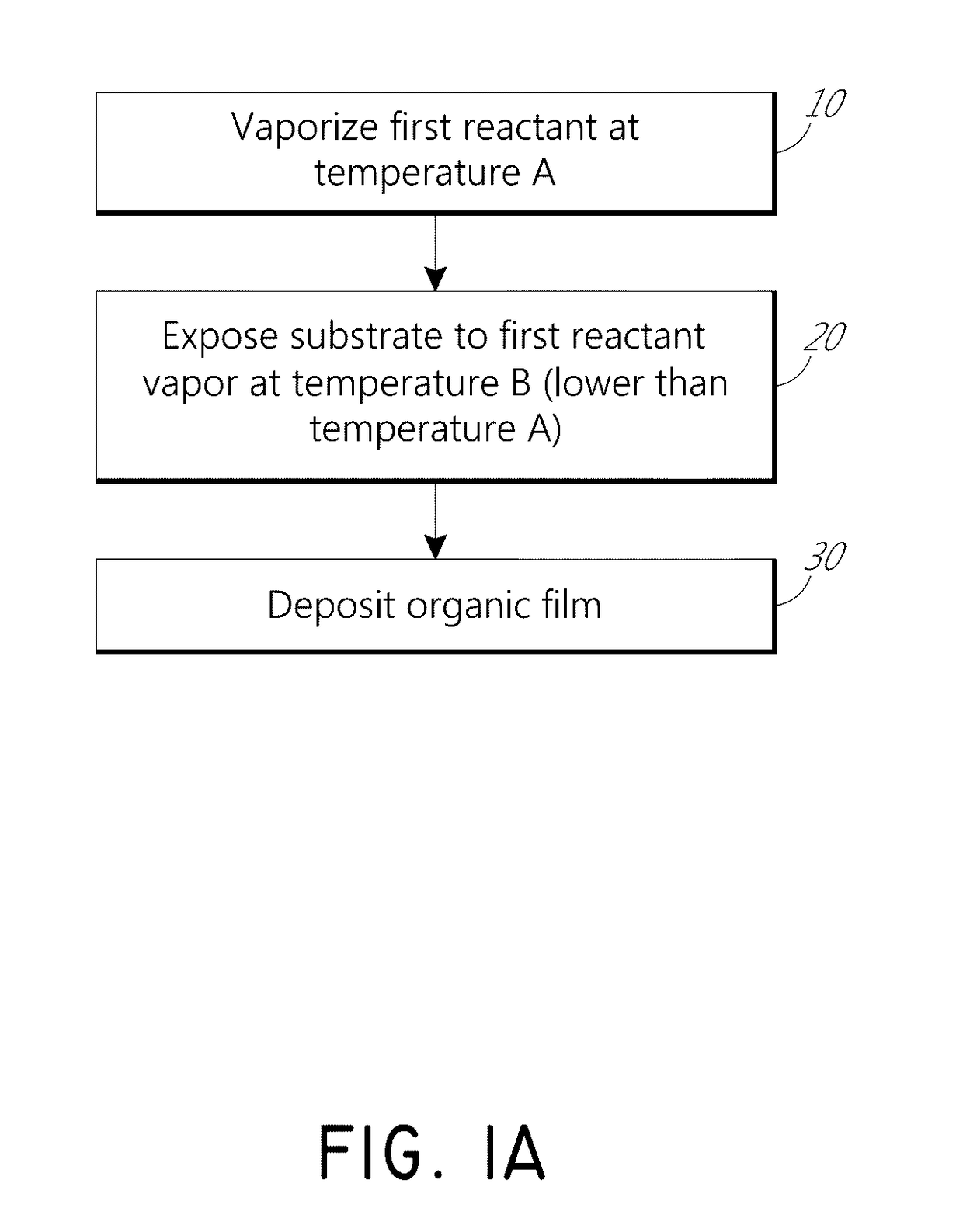

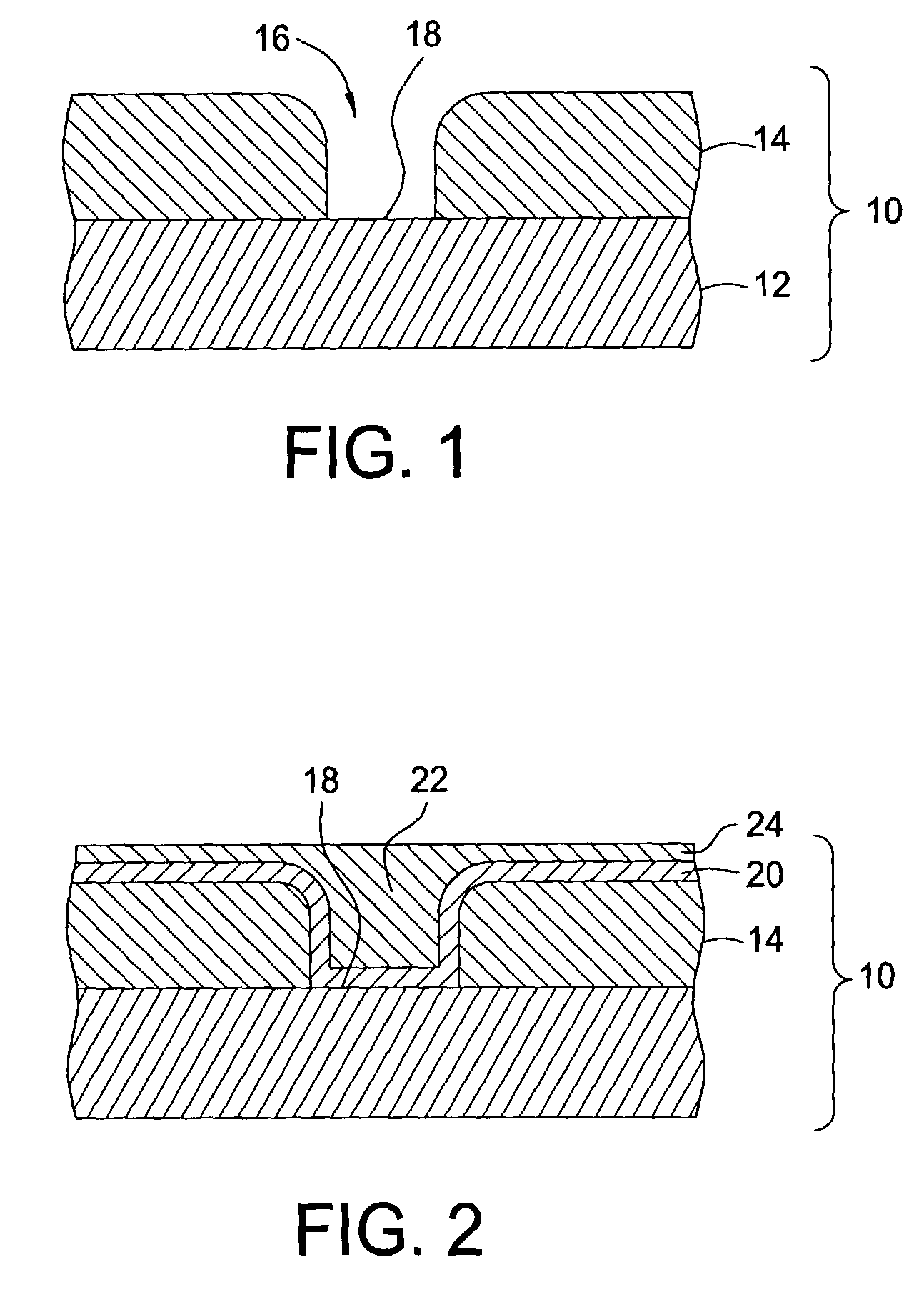

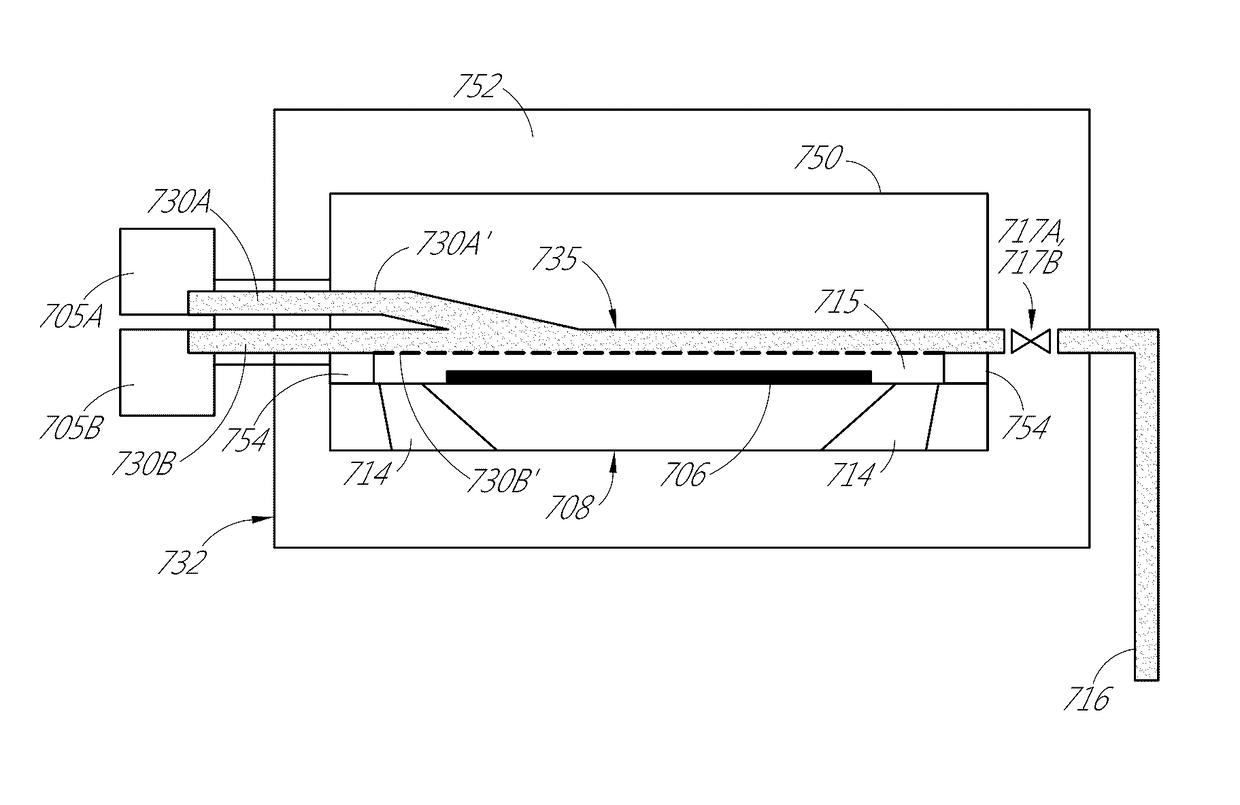

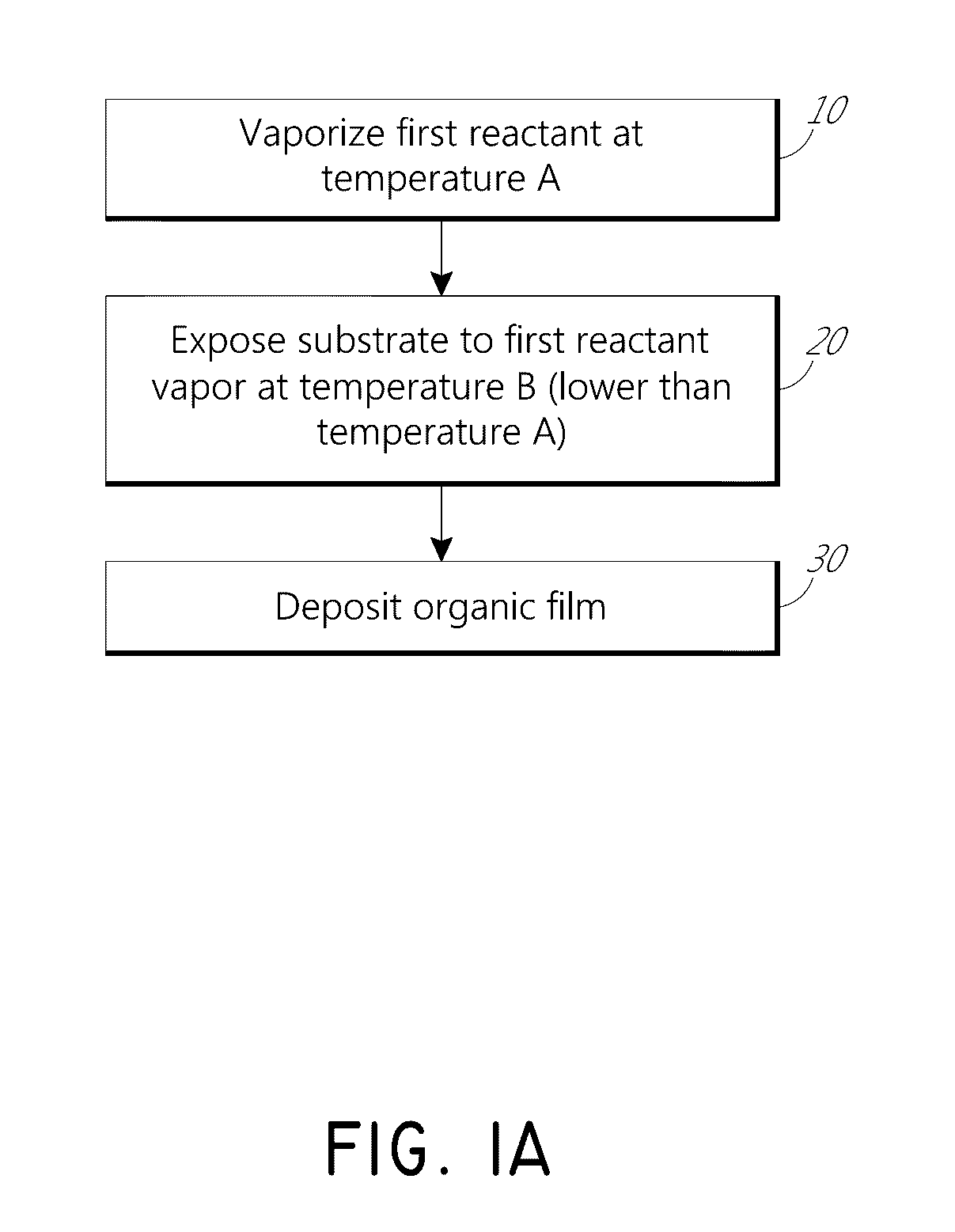

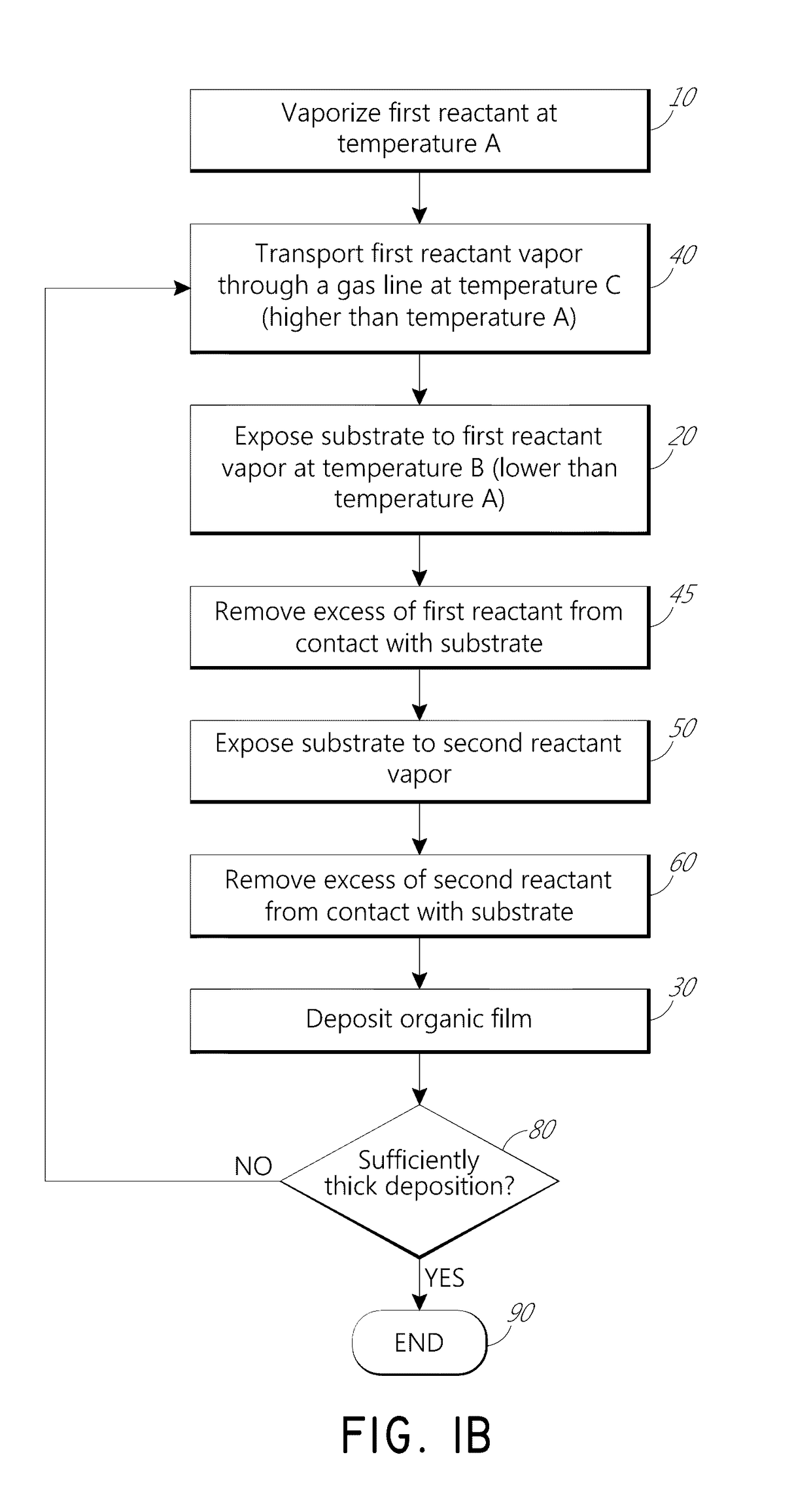

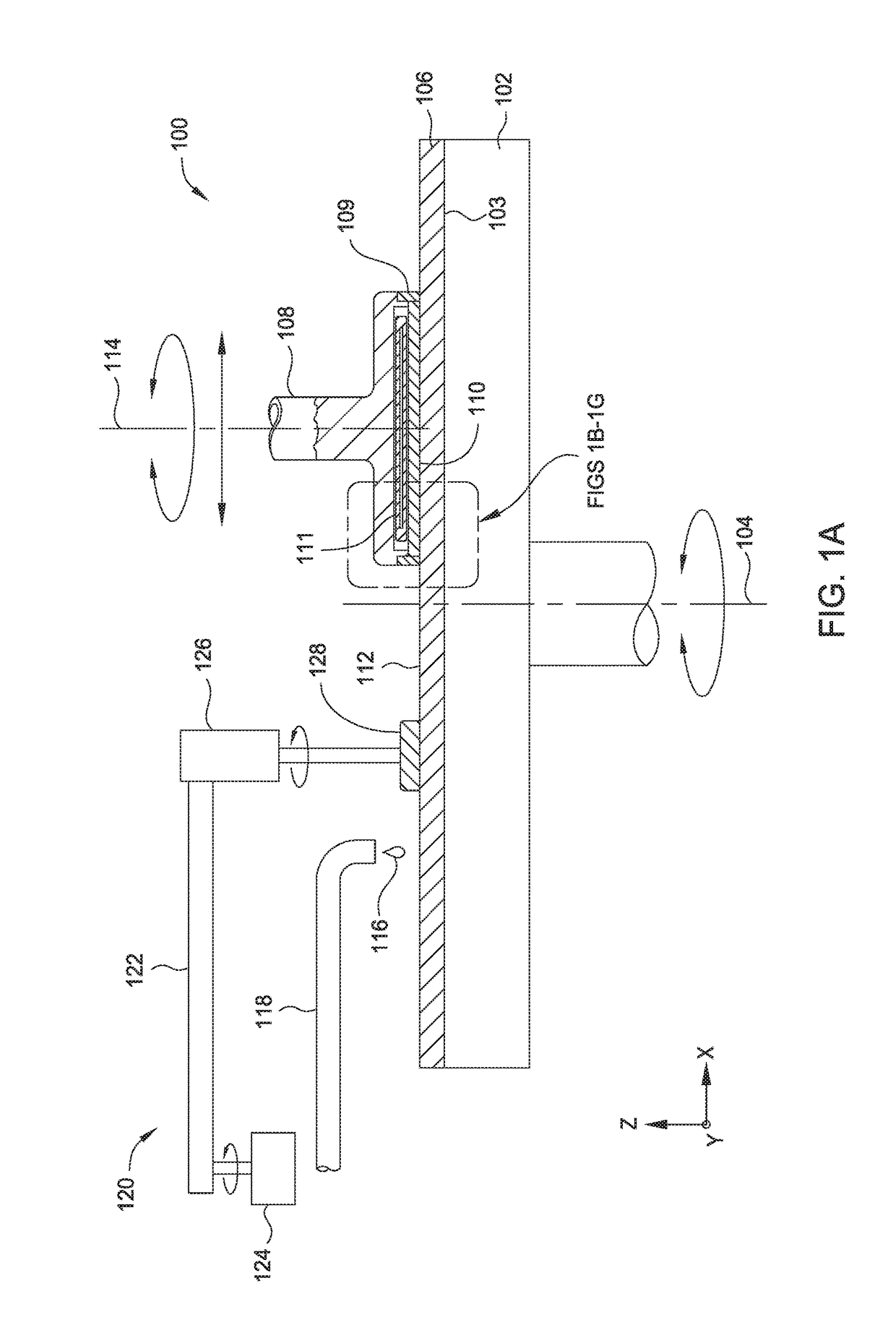

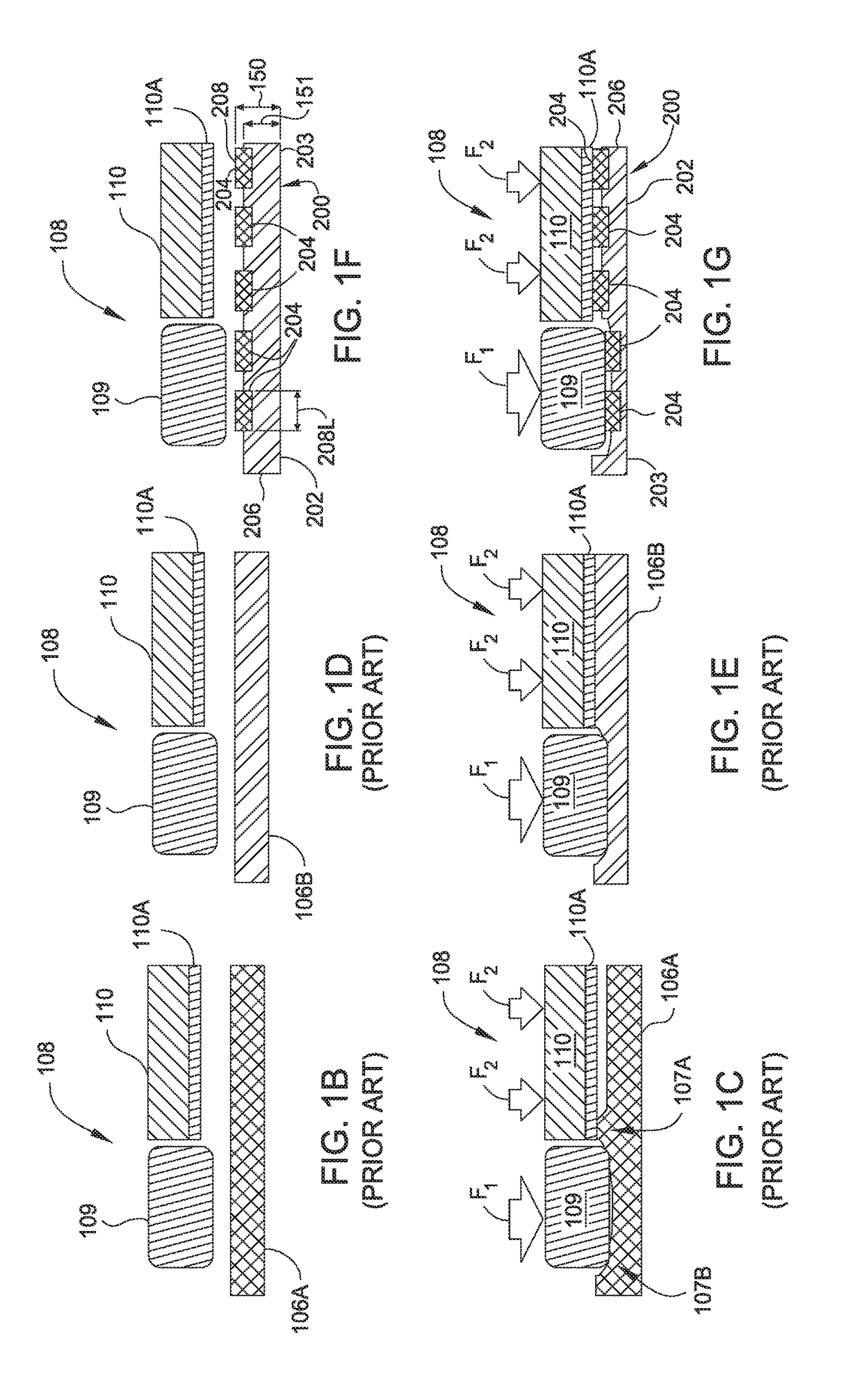

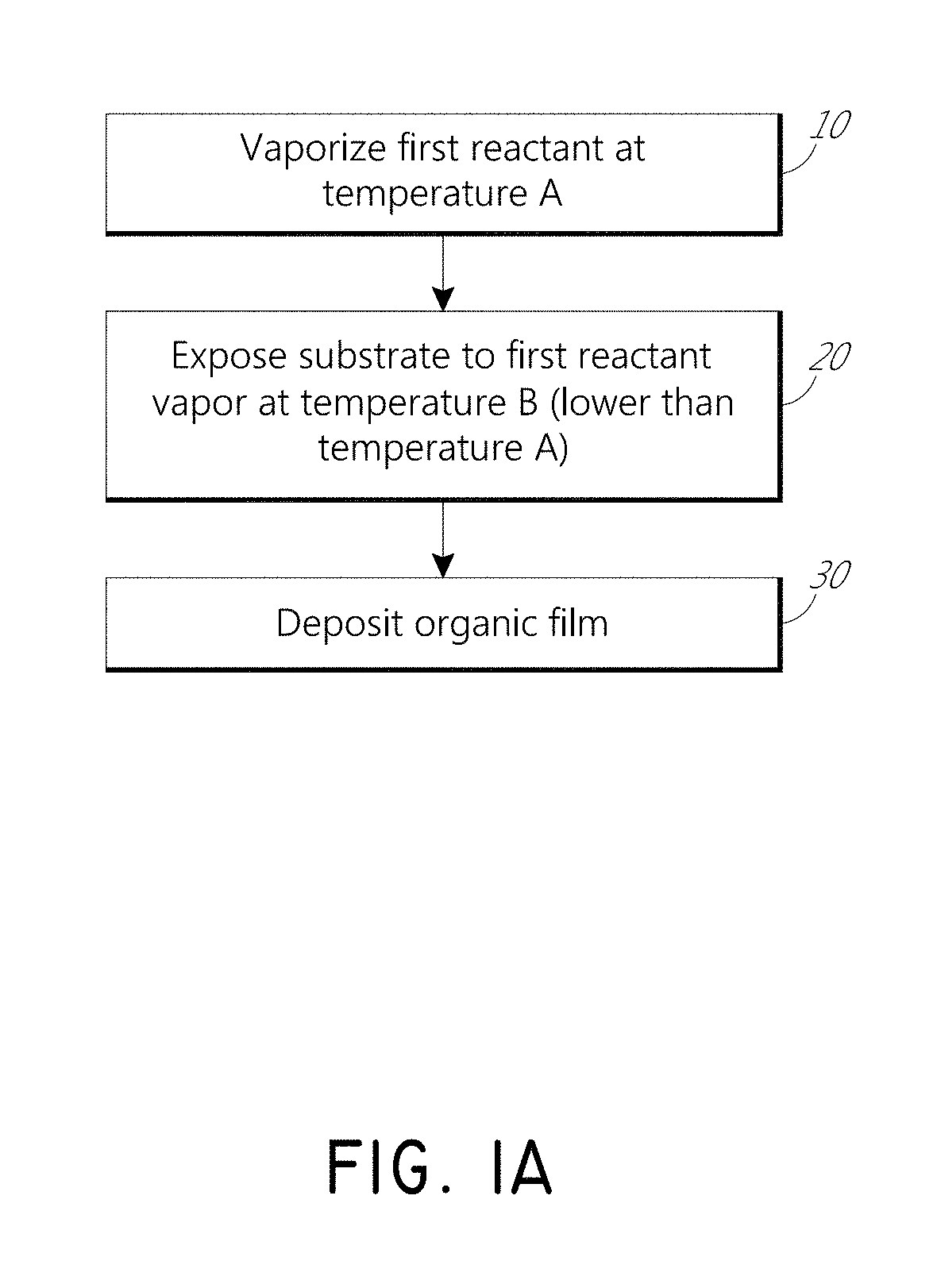

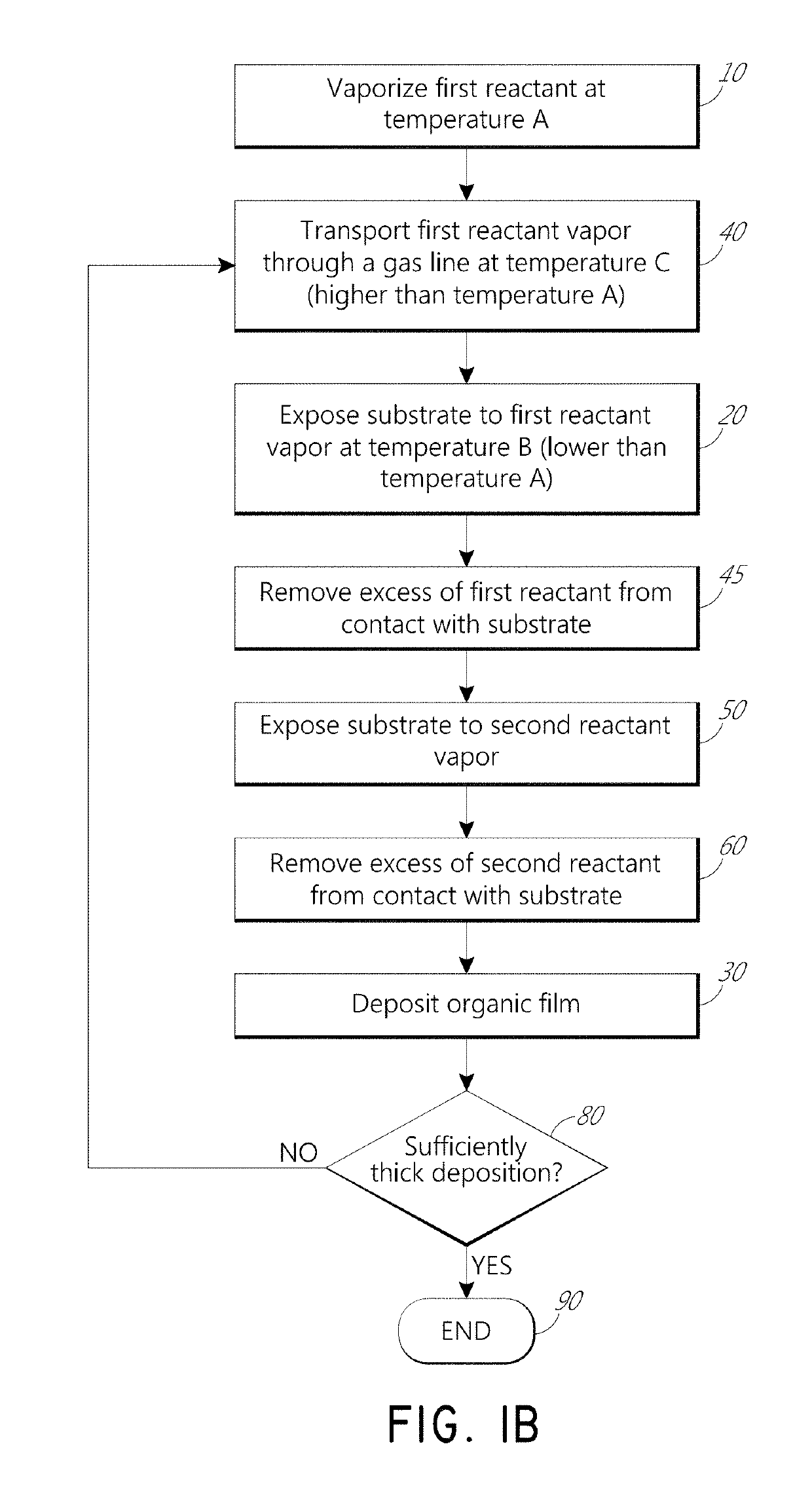

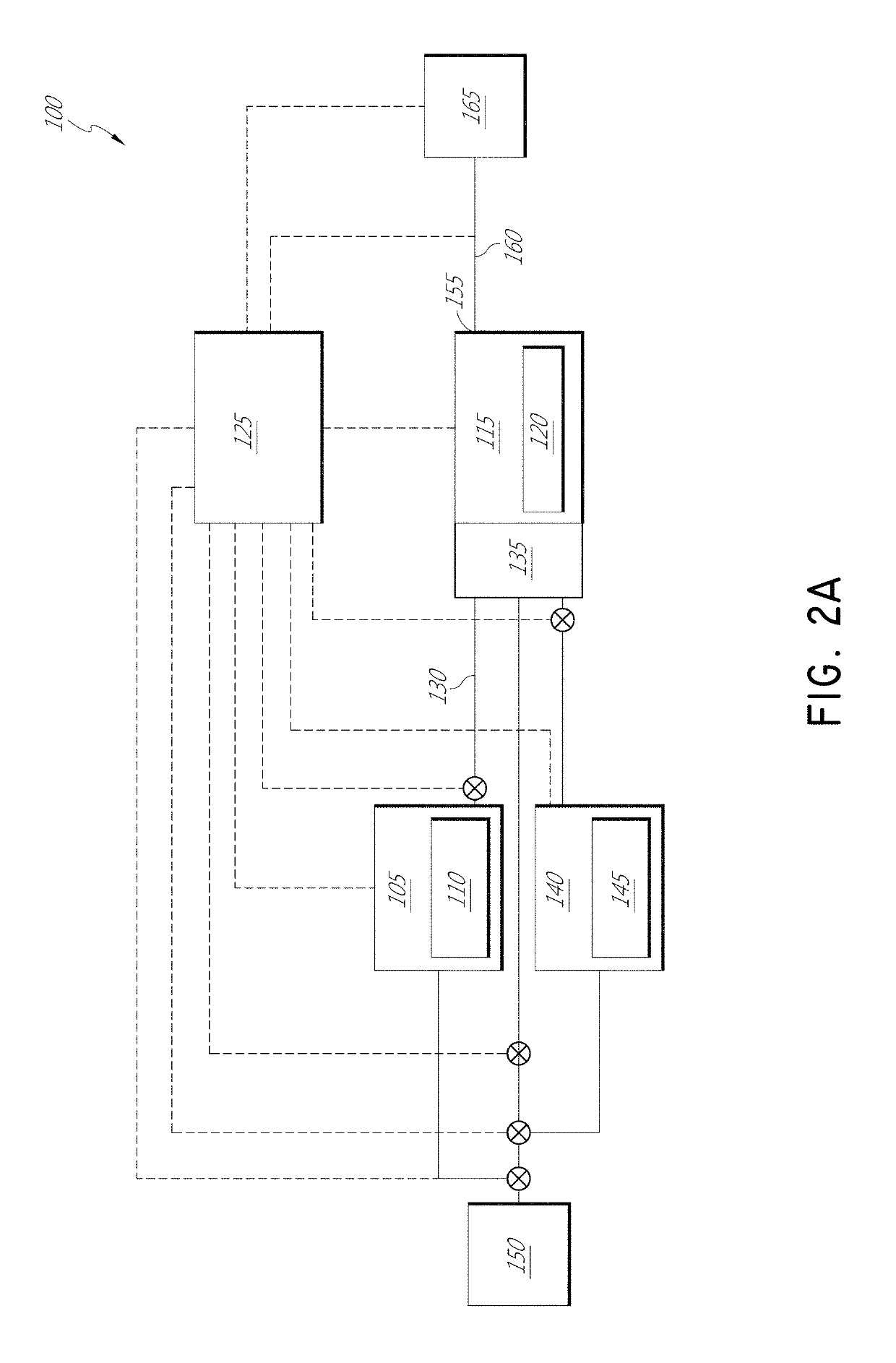

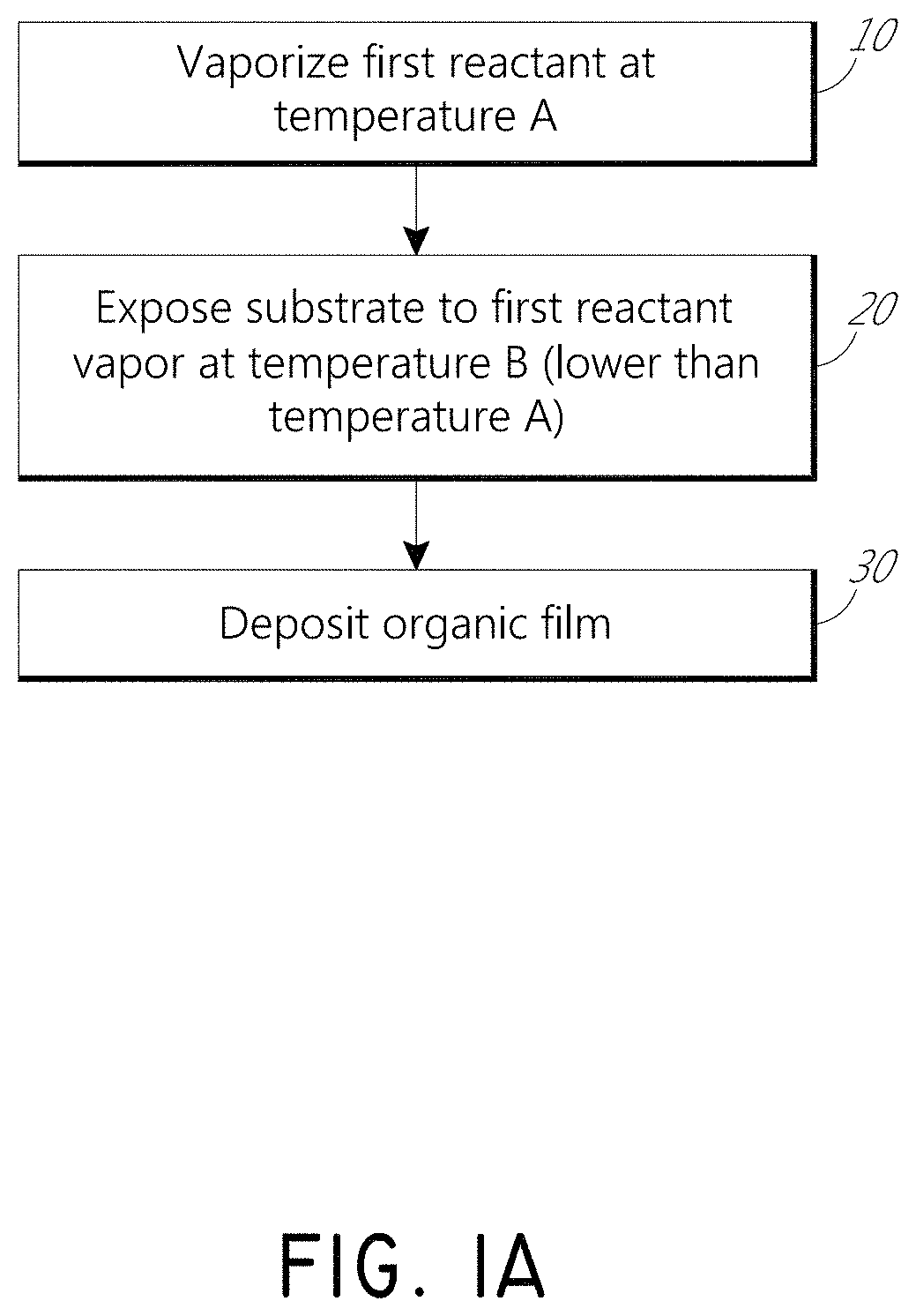

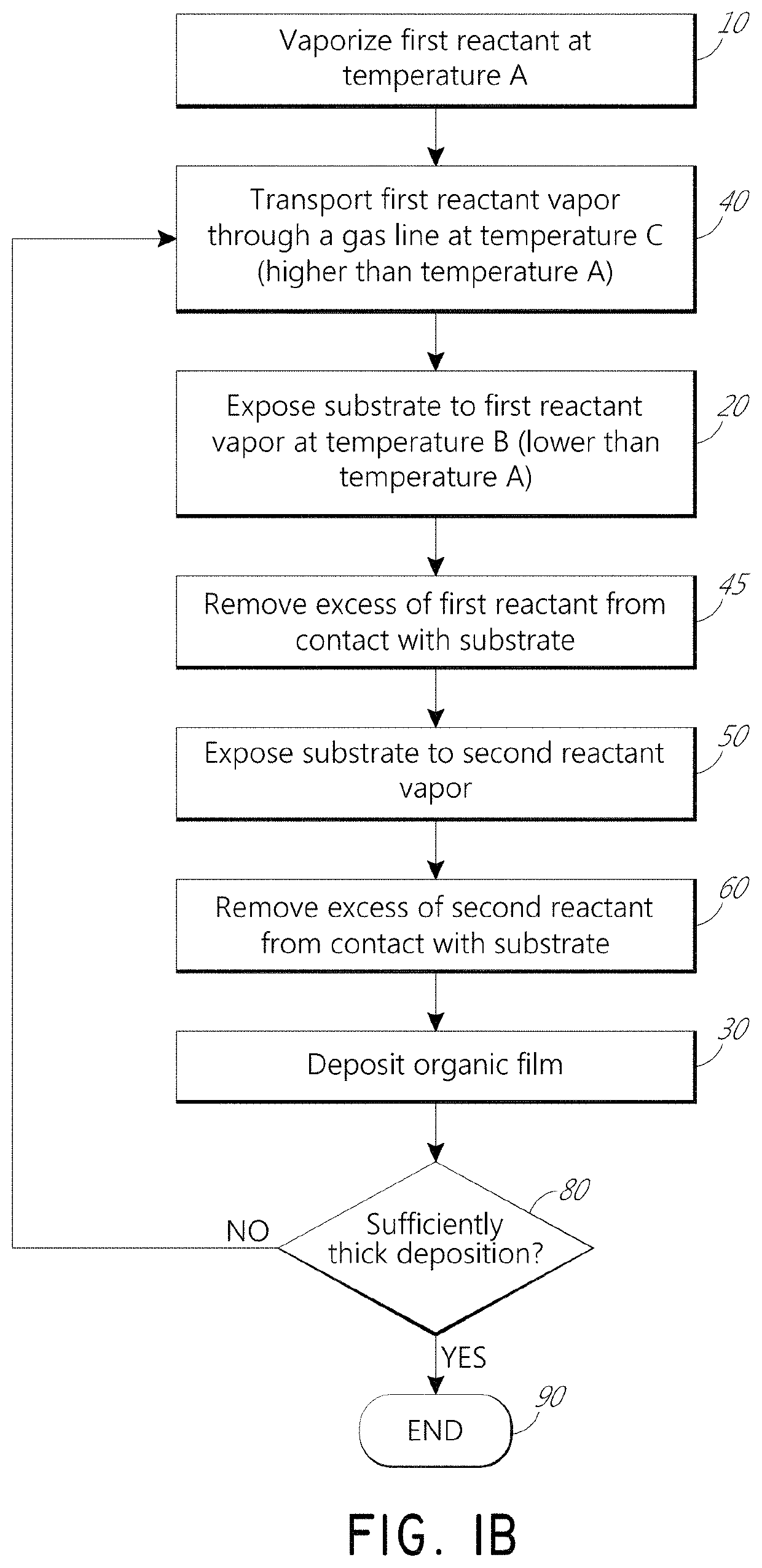

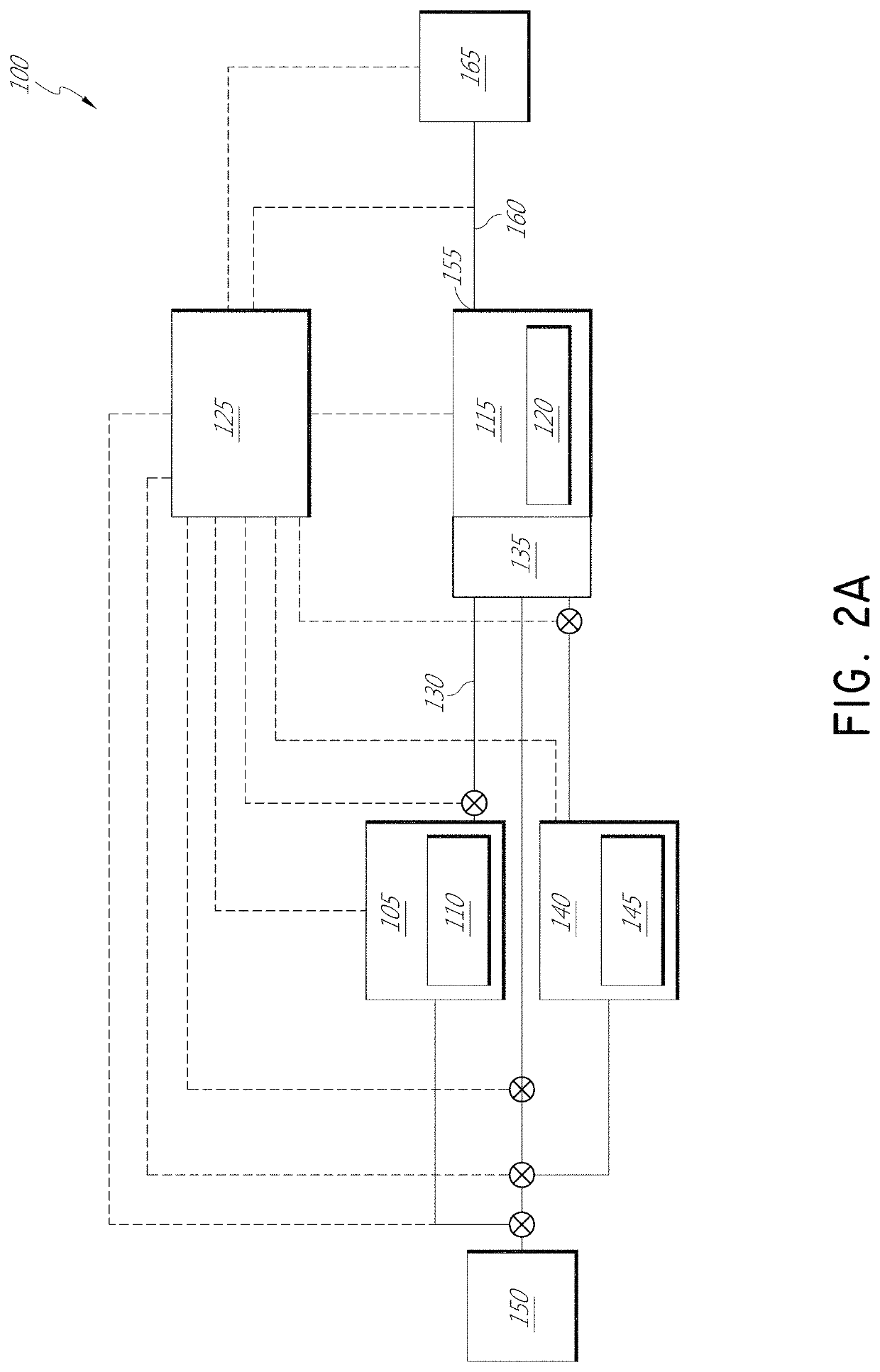

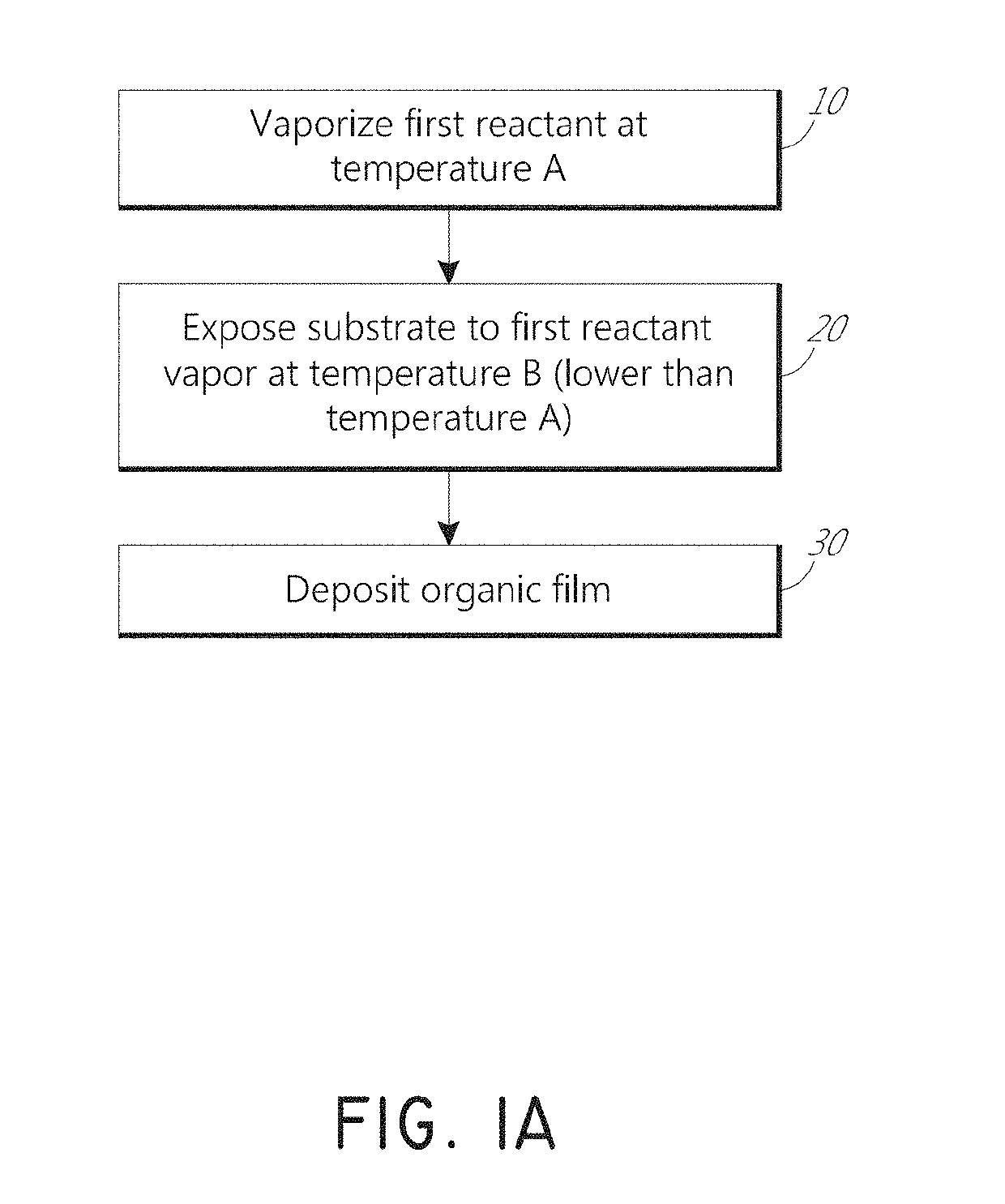

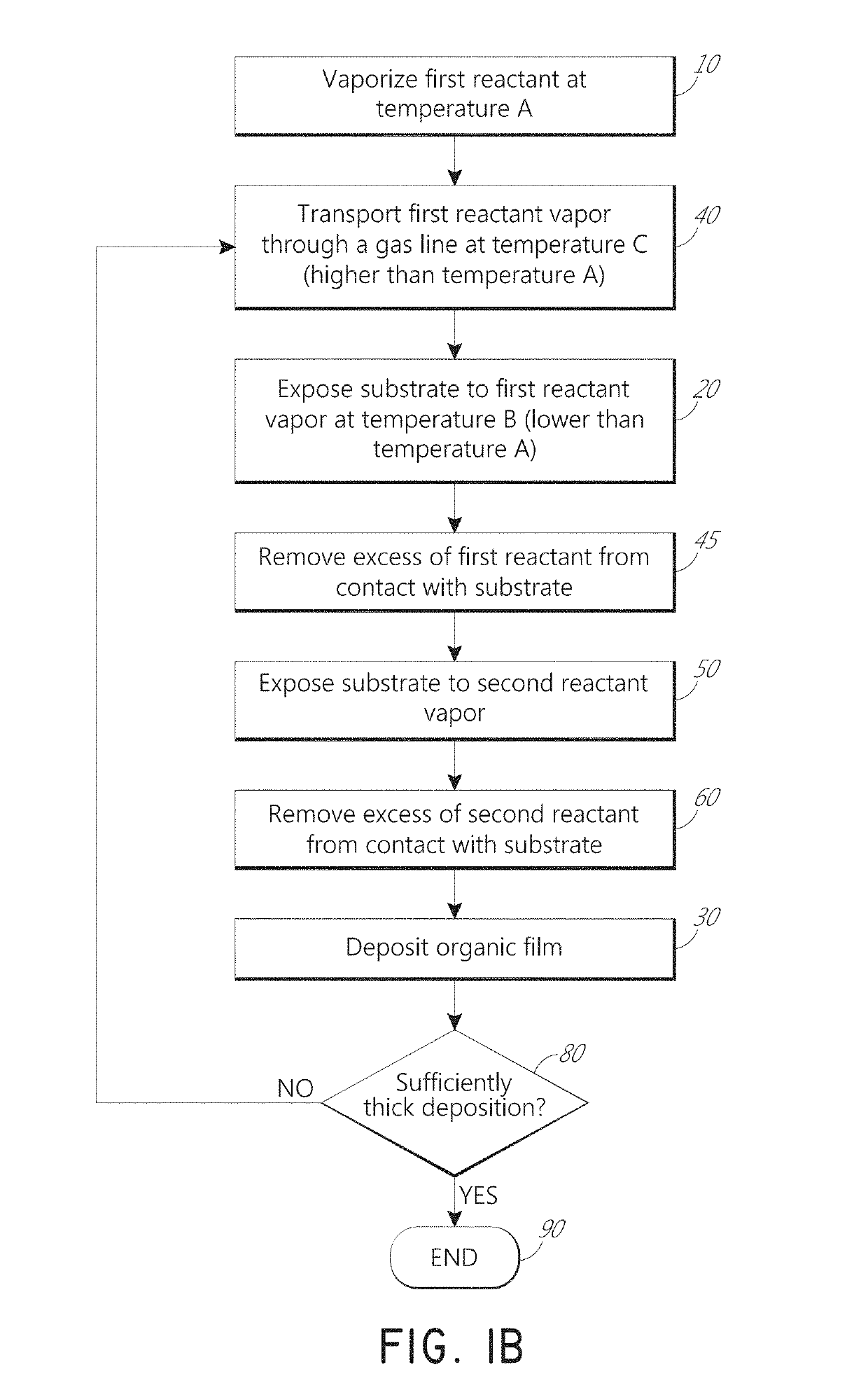

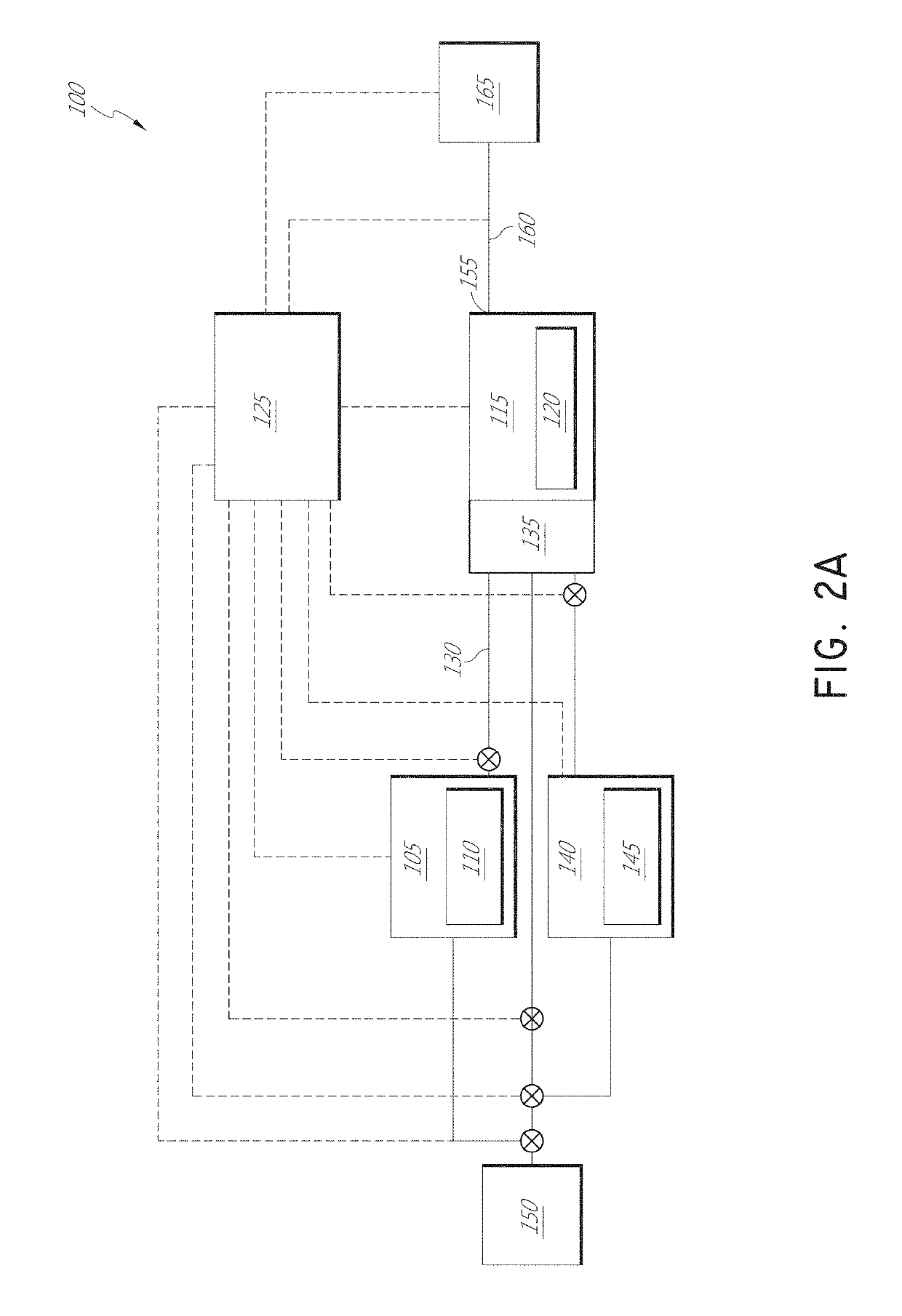

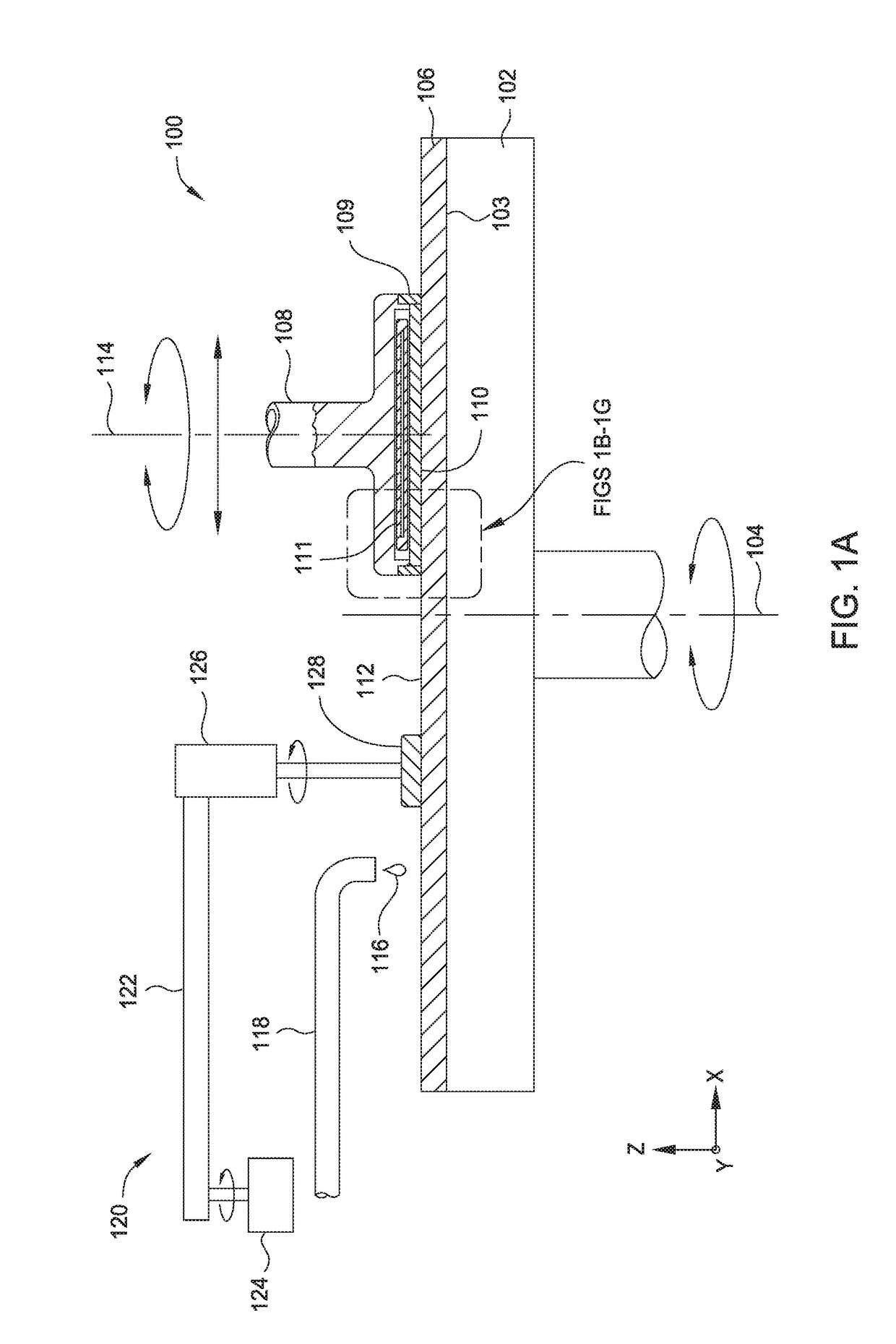

Vapor phase deposition of organic films

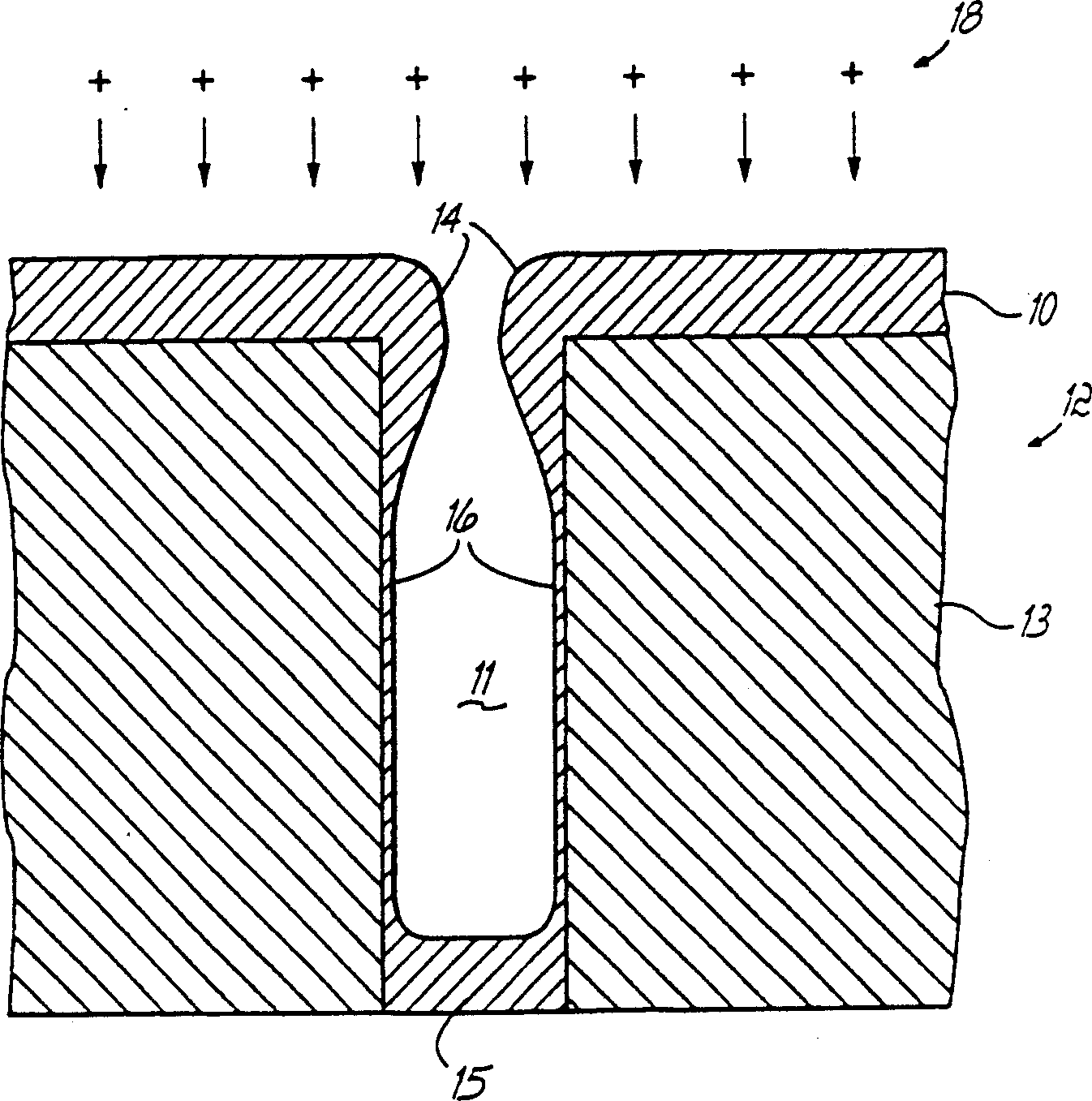

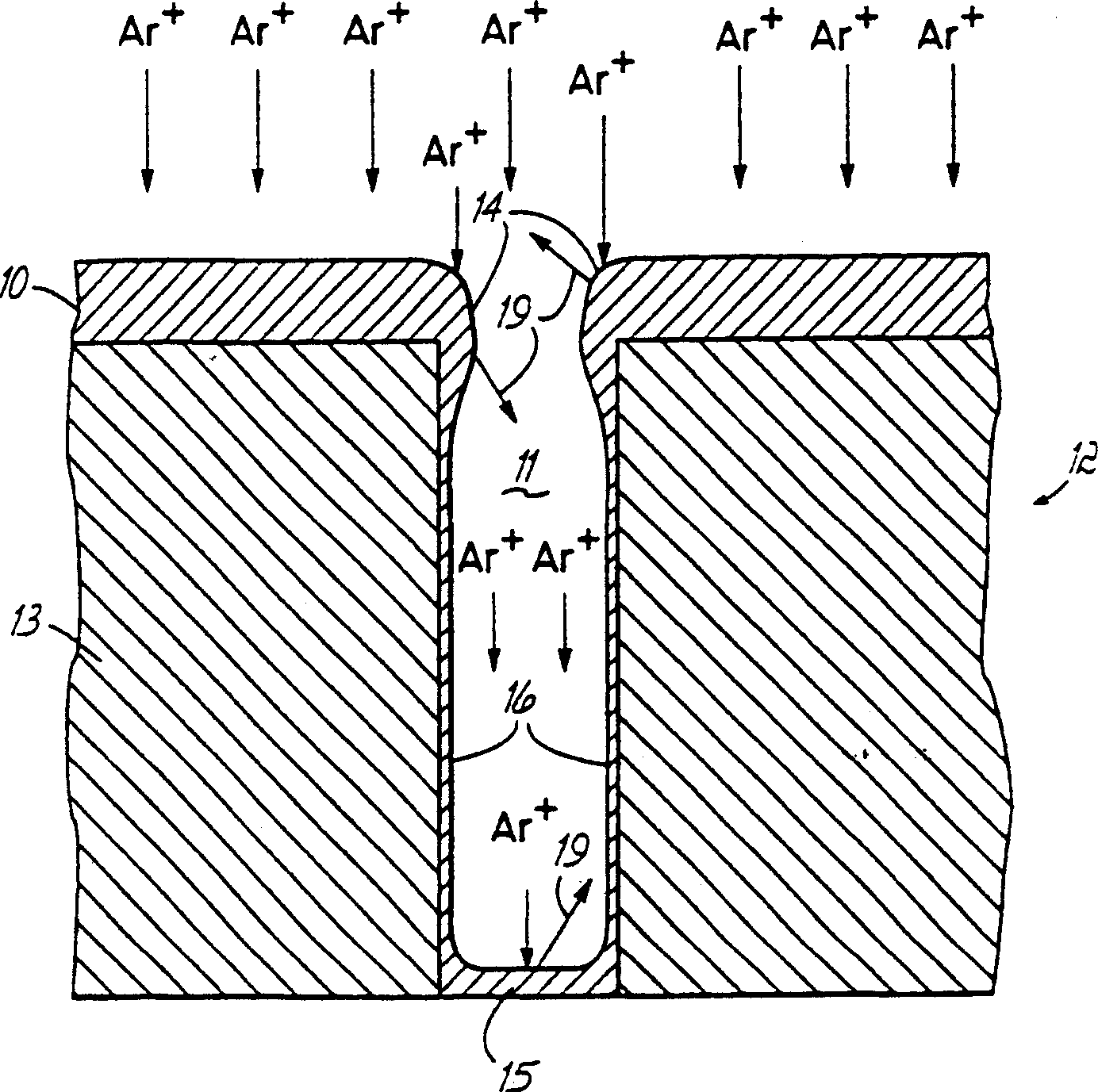

ActiveUS20170100742A1Reduce aspect ratioLiquid surface applicatorsChemical vapor deposition coatingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve.

Owner:ASM IP HLDG BV

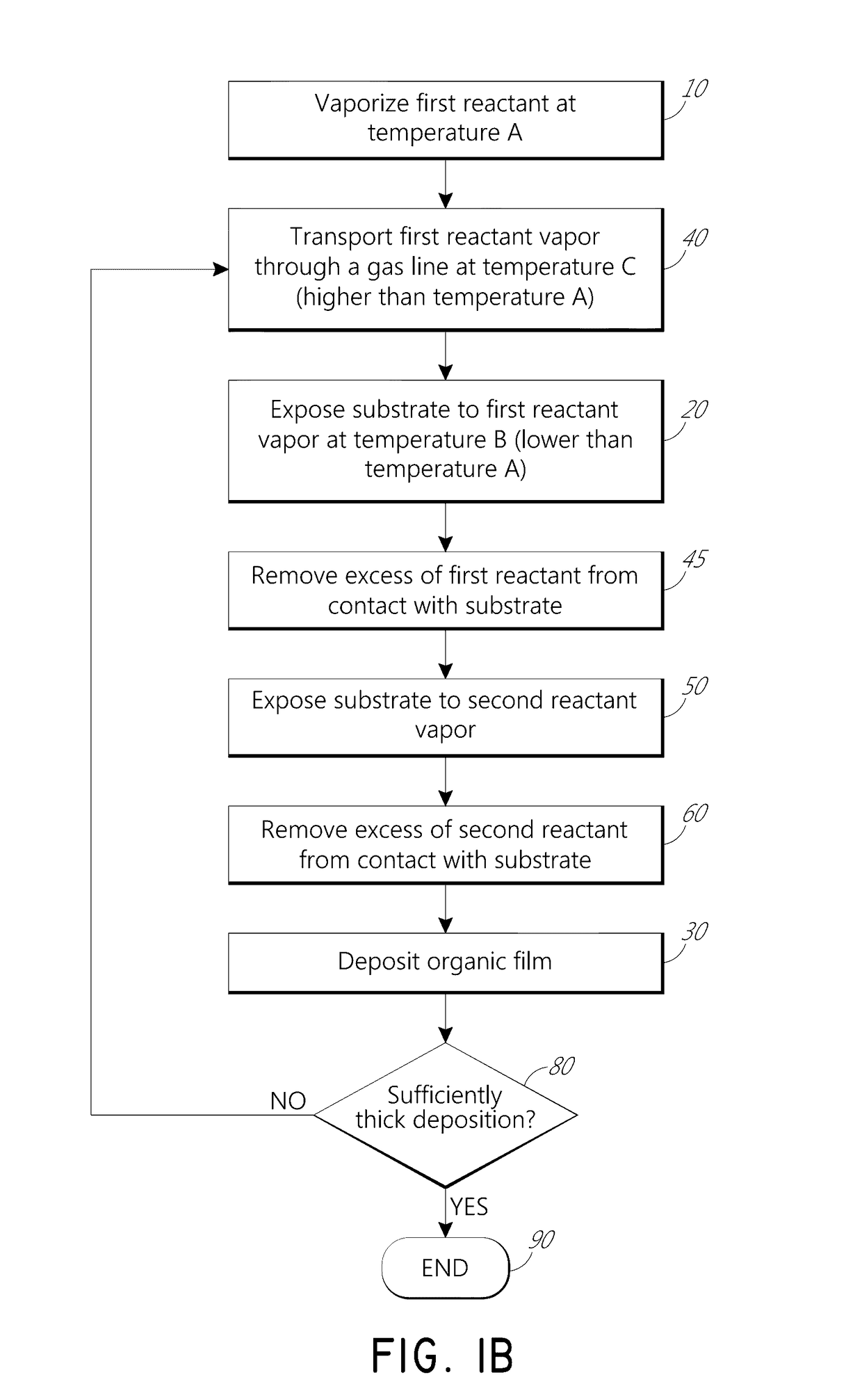

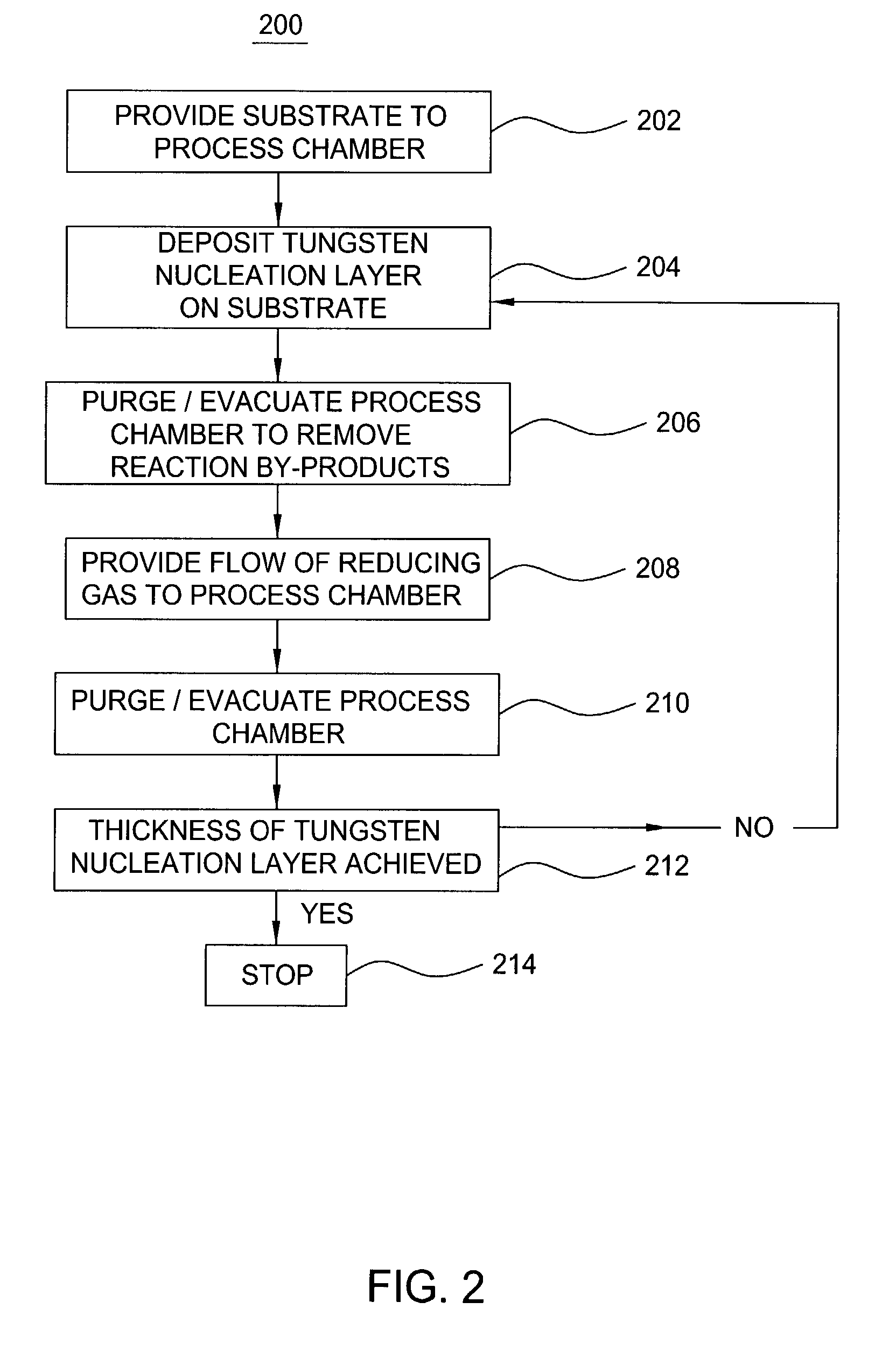

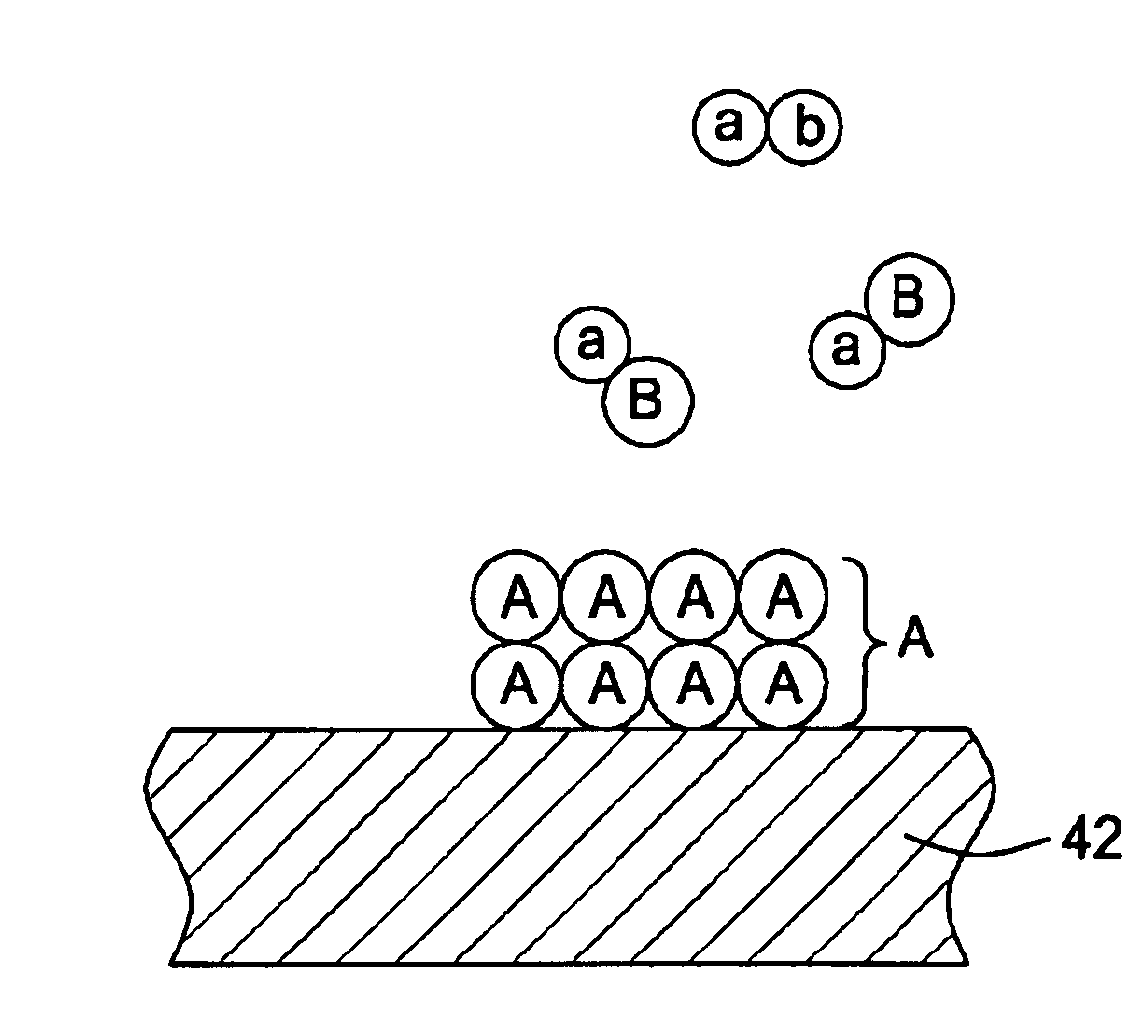

Pulsed nucleation deposition of tungsten layers

InactiveUS7211144B2Good step coveragePolycrystalline material growthSemiconductor/solid-state device manufacturingProduct gasDeposition process

A method of forming a tungsten nucleation layer using a sequential deposition process. The tungsten nucleation layer is formed by reacting pulses of a tungsten-containing precursor and a reducing gas in a process chamber to deposit tungsten on the substrate. Thereafter, reaction by-products generated from the tungsten deposition are removed from the process chamber. After the reaction by-products are removed from the process chamber, a flow of the reducing gas is provided to the process chamber to react with residual tungsten-containing precursor remaining therein. Such a deposition process forms tungsten nucleation layers having good step coverage. The sequential deposition process of reacting pulses of the tungsten-containing precursor and the reducing gas, removing reaction by-products, and than providing a flow of the reducing gas to the process chamber may be repeated until a desired thickness for the tungsten nucleation layer is formed.

Owner:APPLIED MATERIALS INC

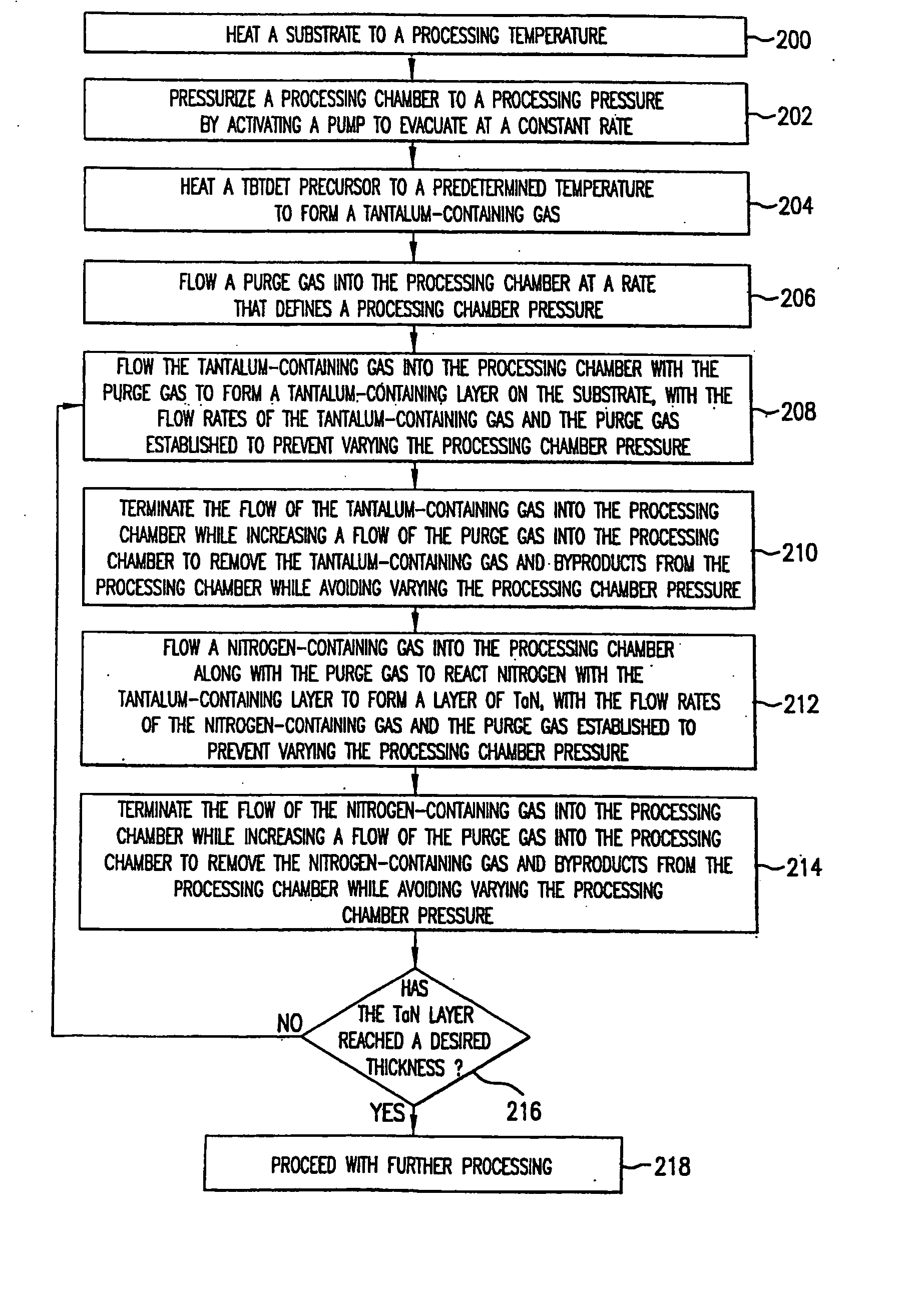

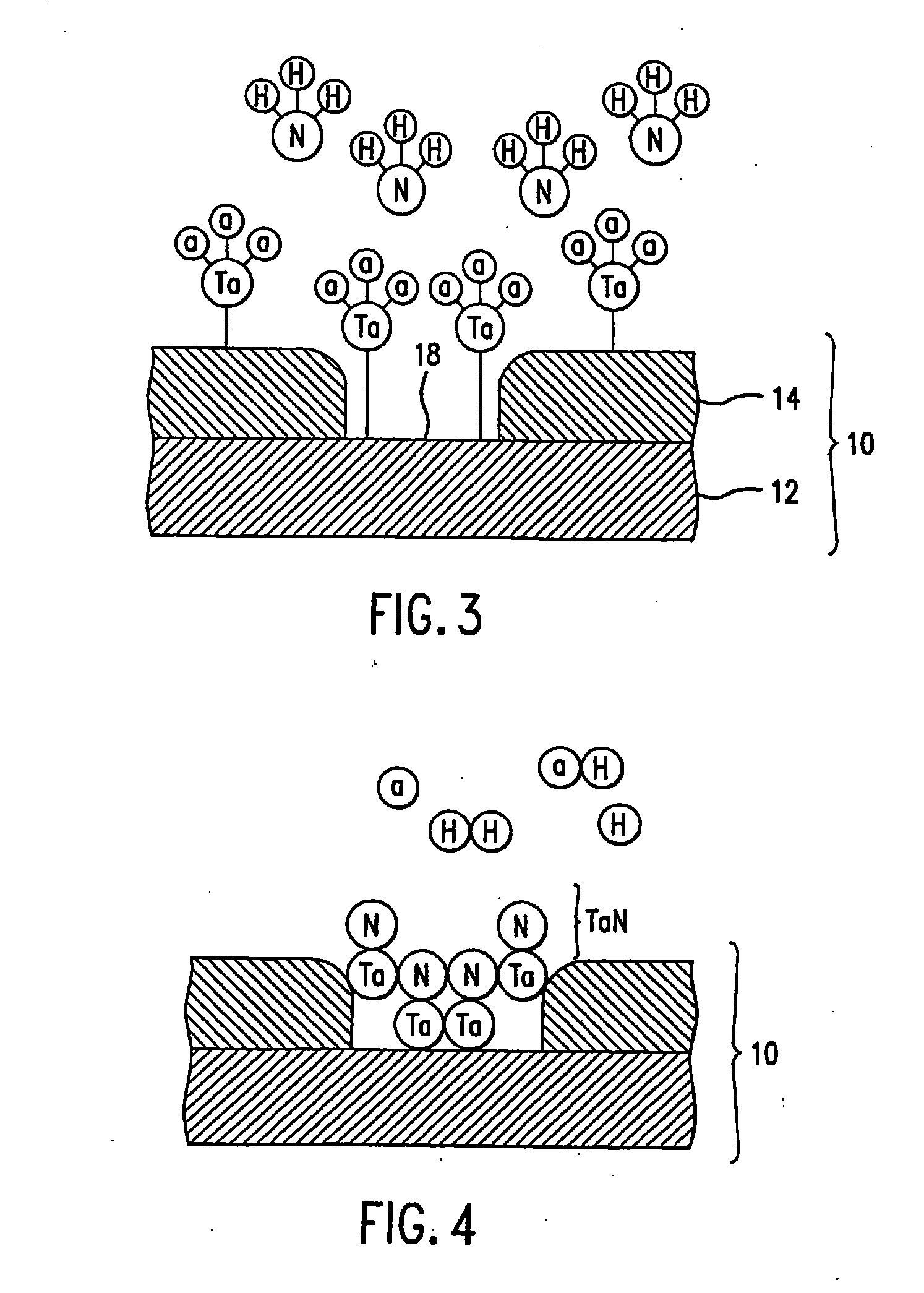

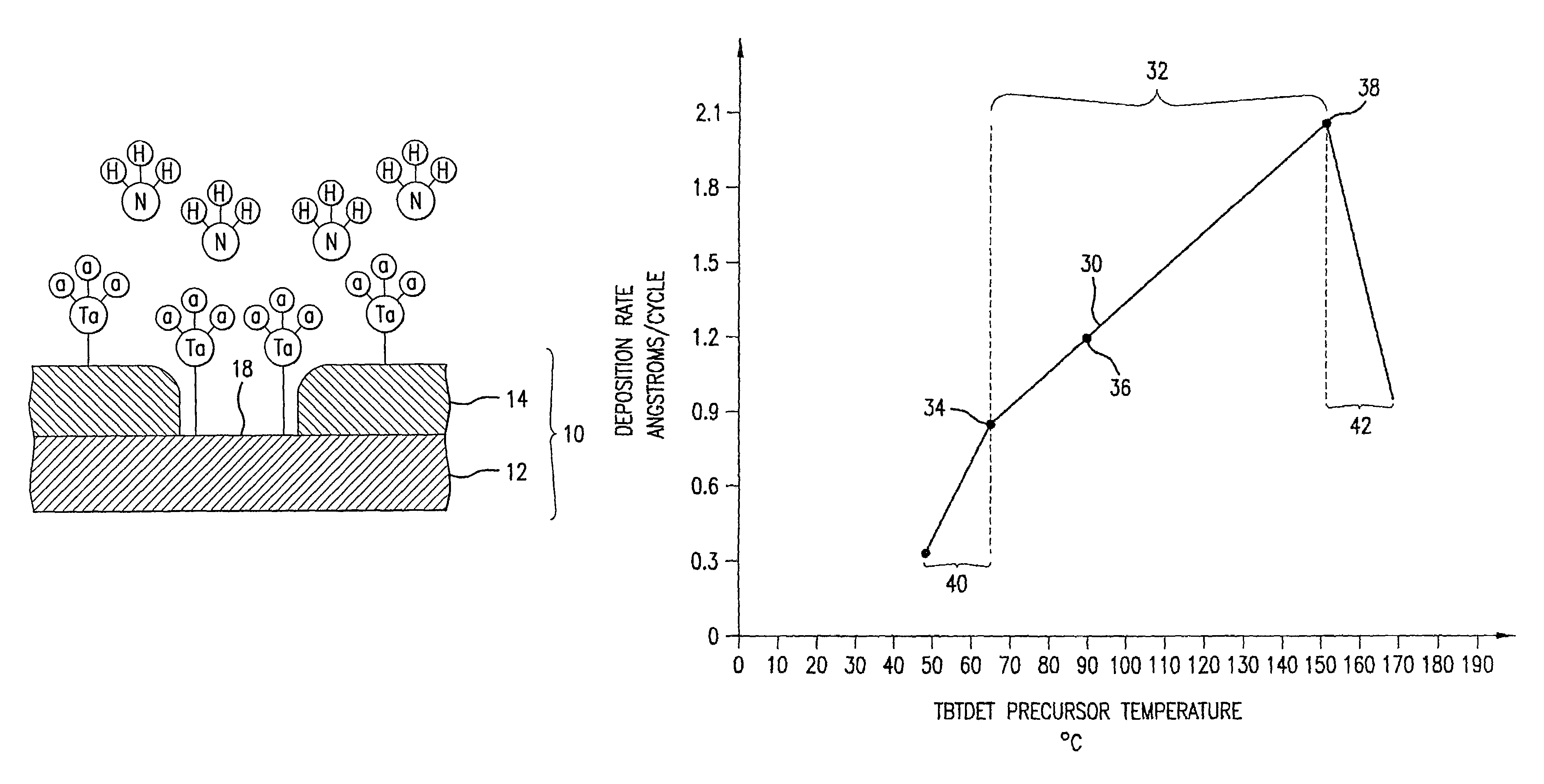

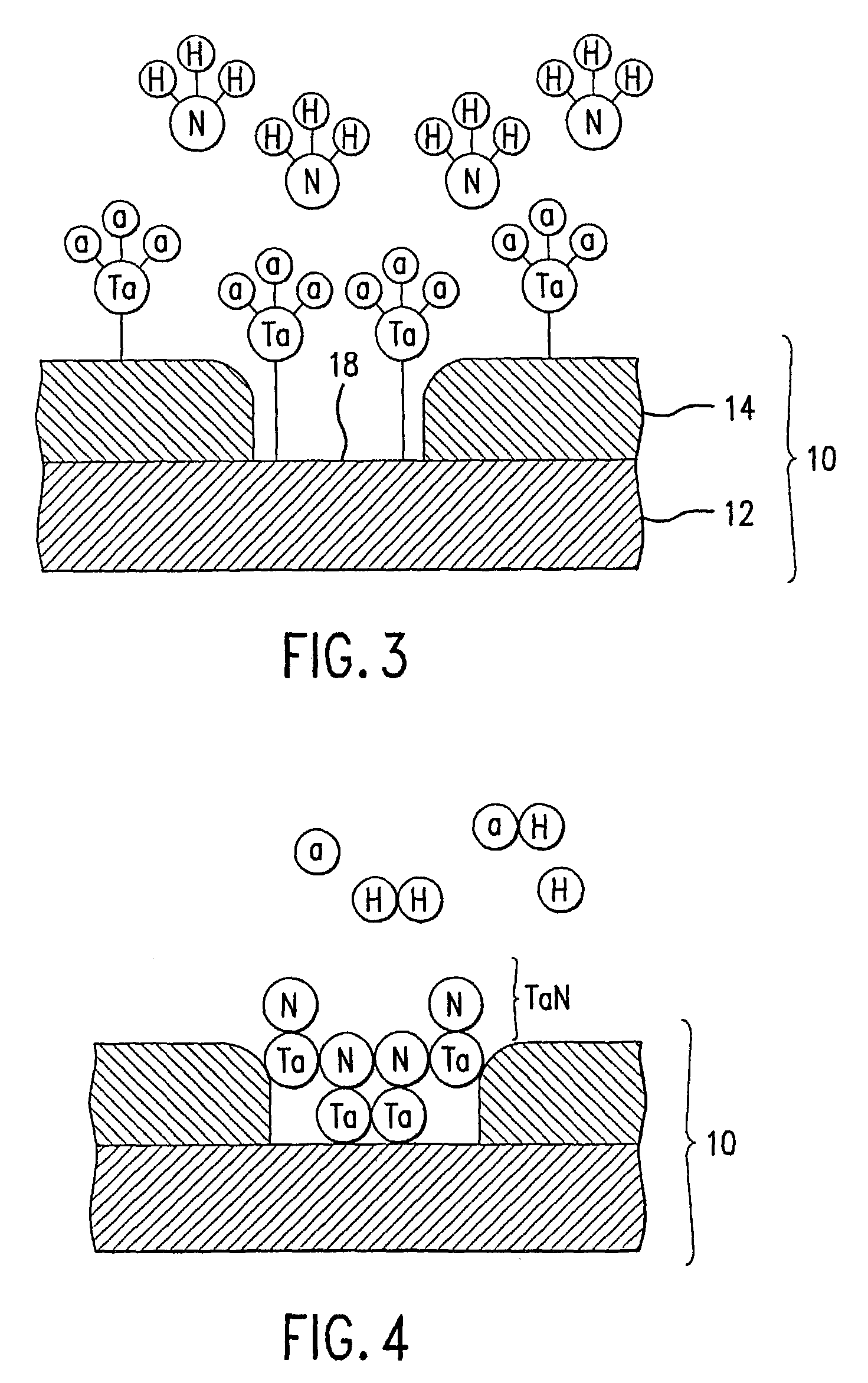

Sequential deposition of tantalum nitride using a tantalum-containing precursor and a nitrogen-containing precursor

InactiveUS20060019494A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

Embodiments of the invention provide a method for forming tantalum nitride materials on a substrate by employing an atomic layer deposition (ALD) process. The method includes heating a tantalum precursor within an ampoule to a predetermined temperature to form a tantalum precursor gas and sequentially exposing a substrate to the tantalum precursor gas and a nitrogen precursor to form a tantalum nitride material. Thereafter, a nucleation layer and a bulk layer may be deposited on the substrate. In one example, a radical nitrogen compound may be formed from the nitrogen precursor during a plasma-enhanced ALD process. A nitrogen precursor may include nitrogen or ammonia. In another example, a metal-organic tantalum precursor may be used during the deposition process.

Owner:APPLIED MATERIALS INC

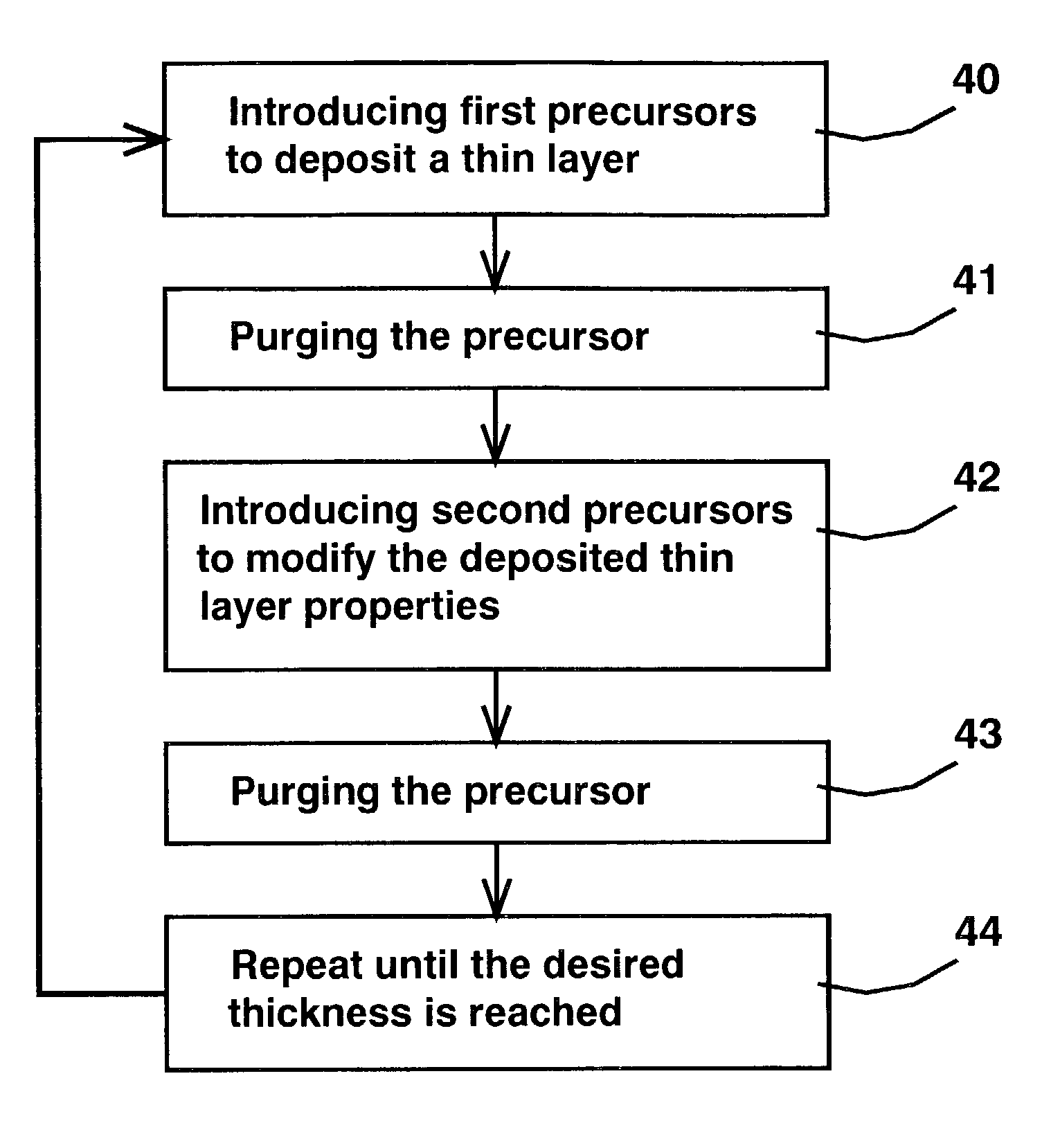

Nanolayer deposition process

InactiveUS7713592B2High energyIncrease powerMaterial nanotechnologyLiquid/solution decomposition chemical coatingSelf limitingDeposition process

A hybrid deposition process of CVD and ALD, called NanoLayer Deposition (NLD) is provided. The nanolayer deposition process is a cyclic sequential deposition process, comprising the first step of introducing a first plurality of precursors to deposit a thin film with the deposition process not self limiting, then a second step of purging the first set of precursors and a third step of introducing a second plurality of precursors to modify the deposited thin film. The deposition step in the NLD process using the first set of precursors is not self limiting and is a function of substrate temperature and process time. The second set of precursors modifies the already deposited film characteristics. The second set of precursors can treat the deposited film such as a modification of film composition, a doping or a removal of impurities from the deposited film. The second set of precursors can also deposit another layer on the deposited film. The additional layer can react with the existing layer to form a compound layer, or can have minimum reaction to form a nanolaminate film.

Owner:ASM INTERNATIONAL

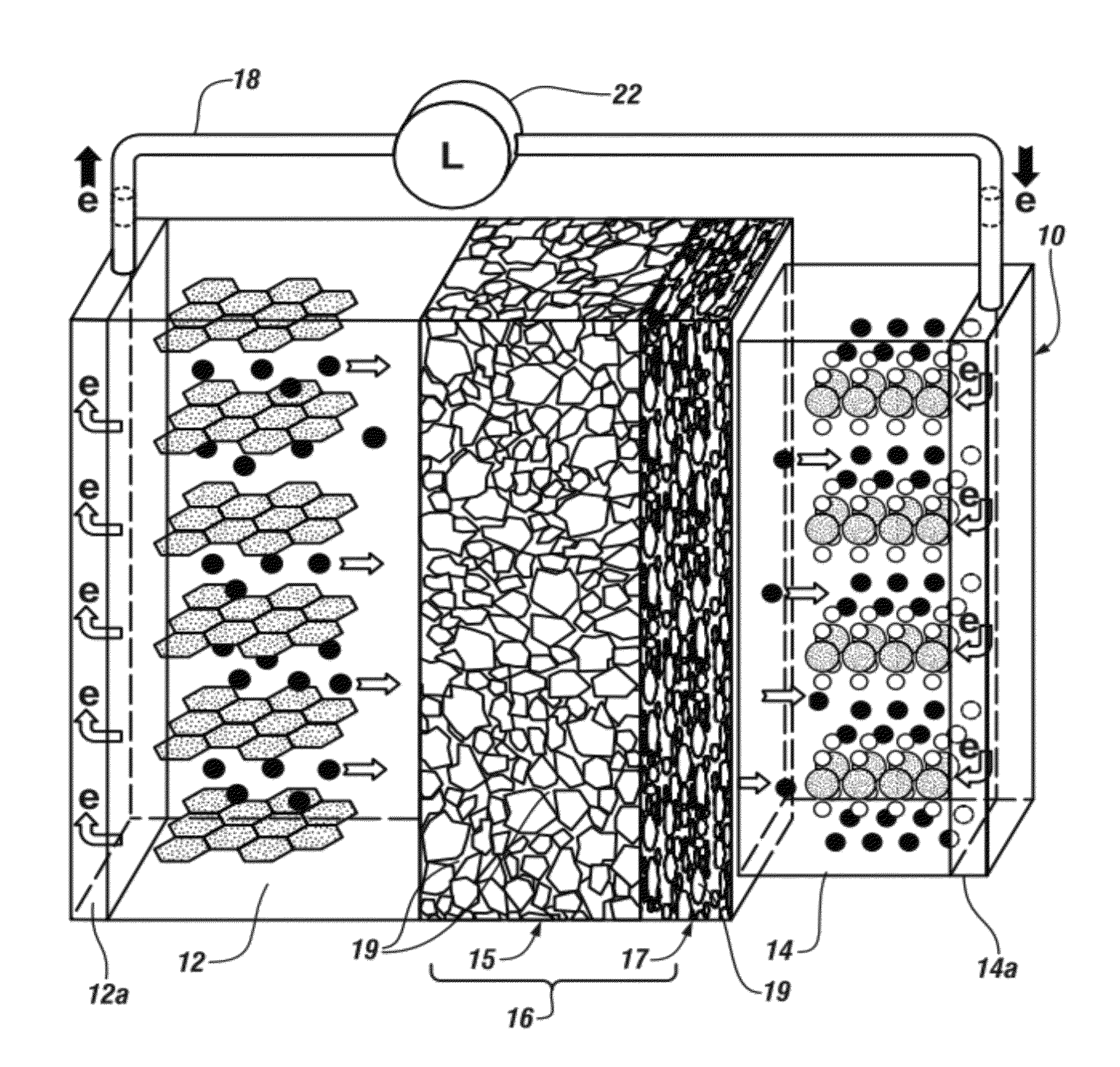

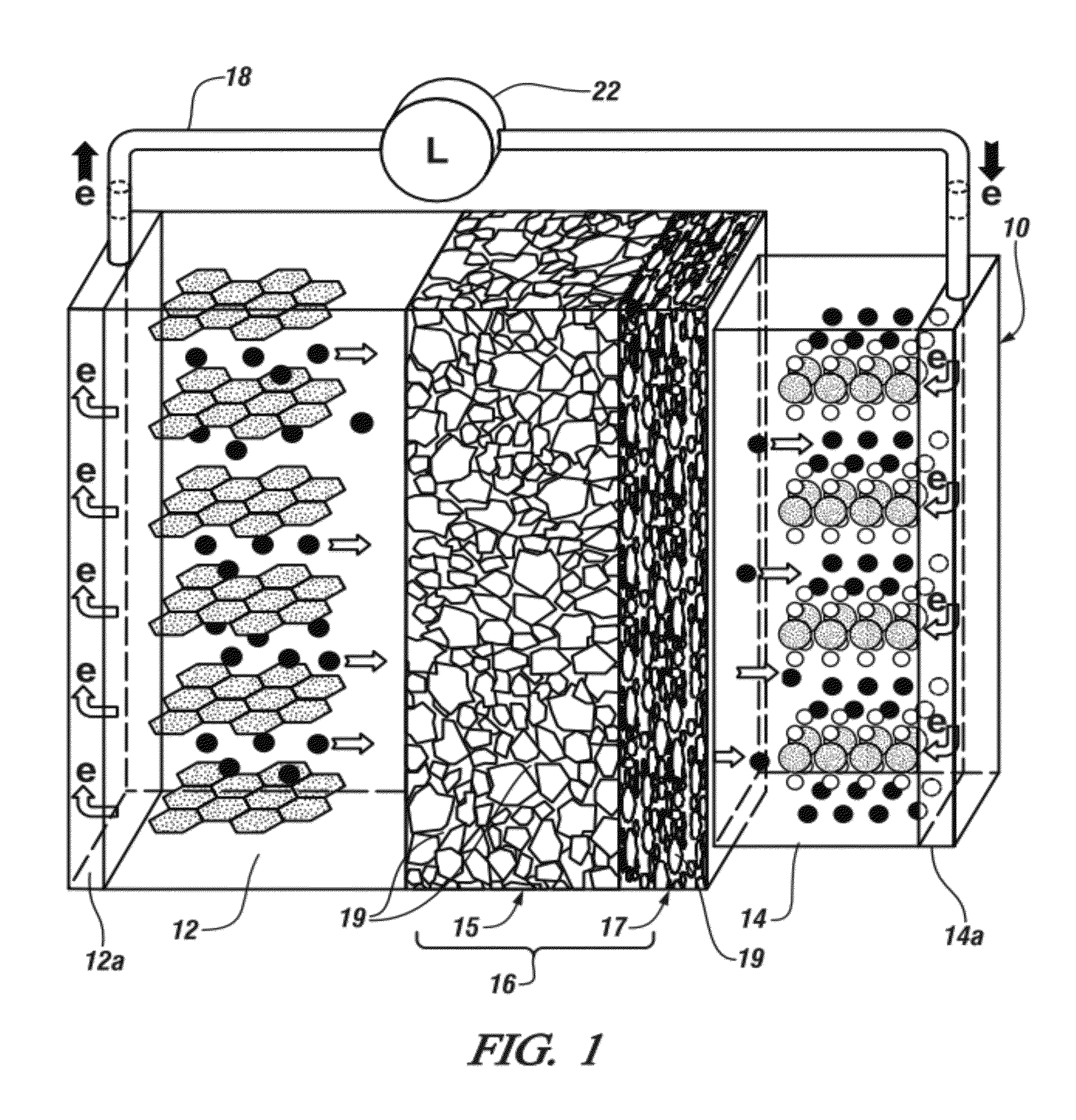

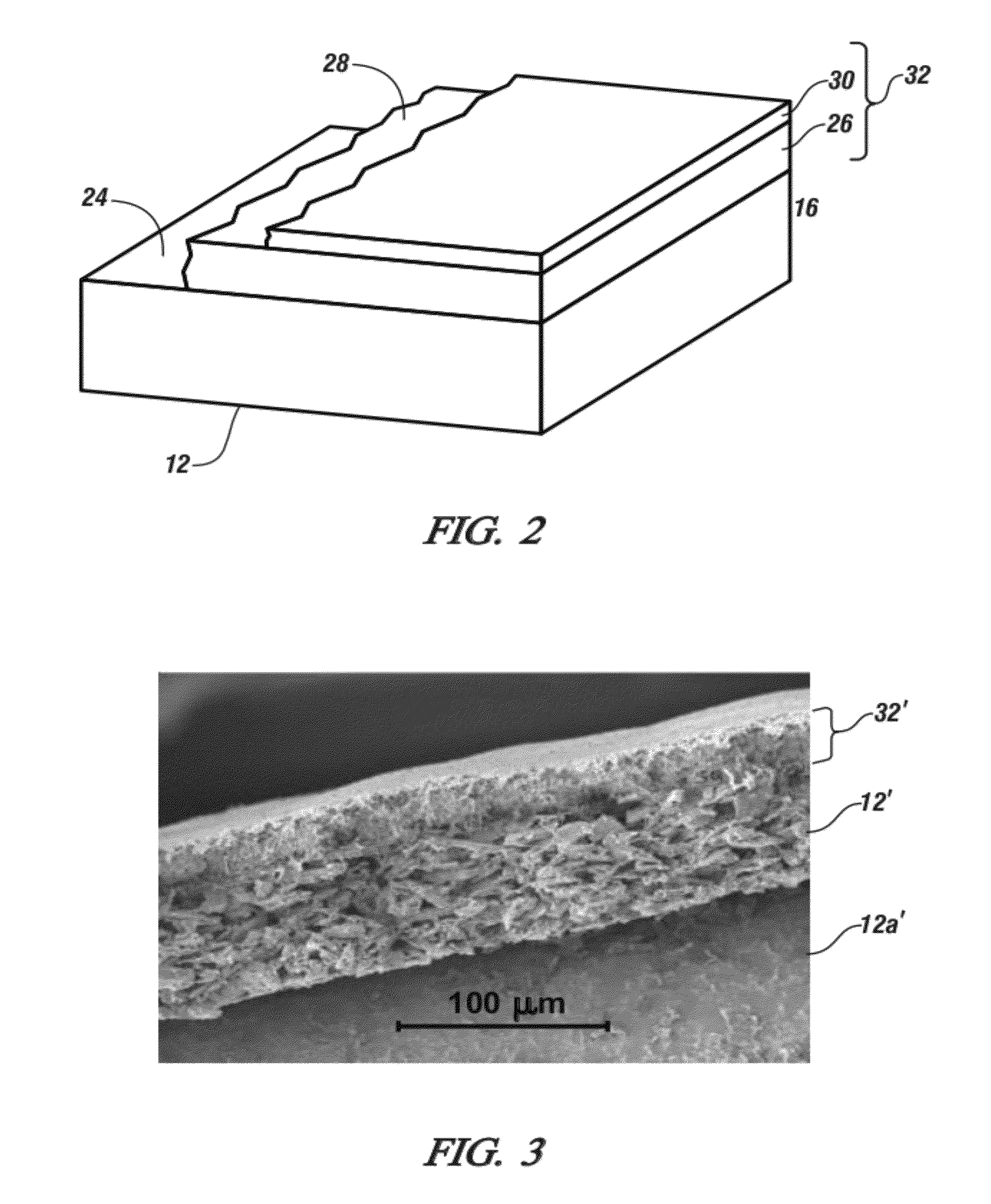

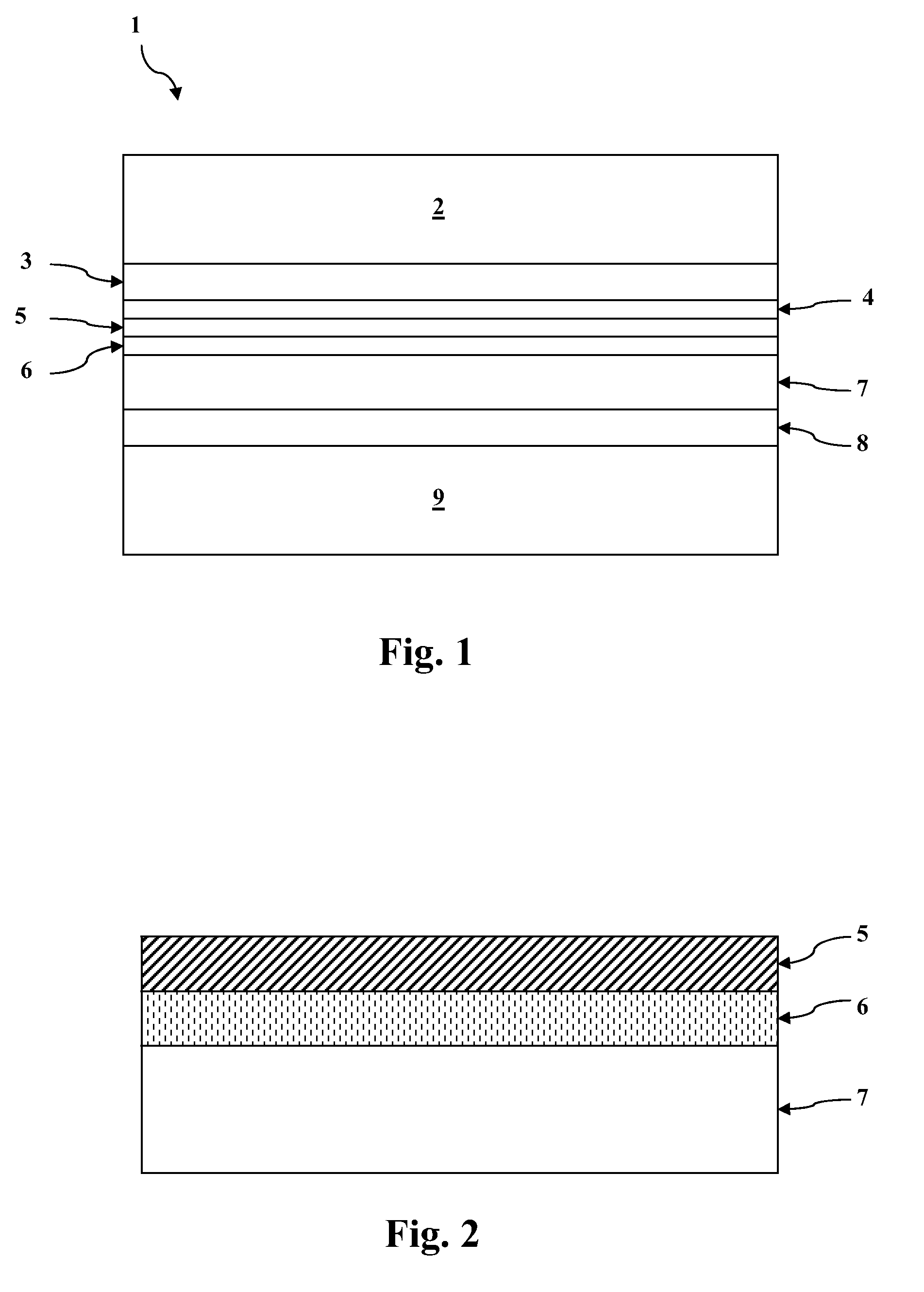

Integral bi-layer separator-electrode construction for lithium-ion batteries

InactiveUS20120231321A1Improve temperature resistanceImprove the immunityFinal product manufacturePrimary cellsEvaporationSlurry

A porous bi-layer separator composed of a first layer with a contacting array of non-conducting particles overlaid with a second layer of a microporous polymer layer, may be fabricated on the electrode surface of the anode of a lithium-ion battery to form an integral electrode-separator construction. The bi-layer separator may prevent development of a direct electronic path between the anode and cathode of the battery while accommodating electrolyte solution and enabling passage of lithium ions. Such an integral separator should be mechanically robust and tolerant of elevated temperatures. Exemplary bi-layer separators may be fabricated by sequential deposition of solvent-containing slurries and polymer solutions with subsequent controlled evaporation of solvent. The elevated temperature performance of lithium-ion battery cells incorporating such integral electrode-bi-layer separators was demonstrated to exceed the performance of similar cells using commercial and experimental single layer polymer separators.

Owner:GM GLOBAL TECH OPERATIONS LLC

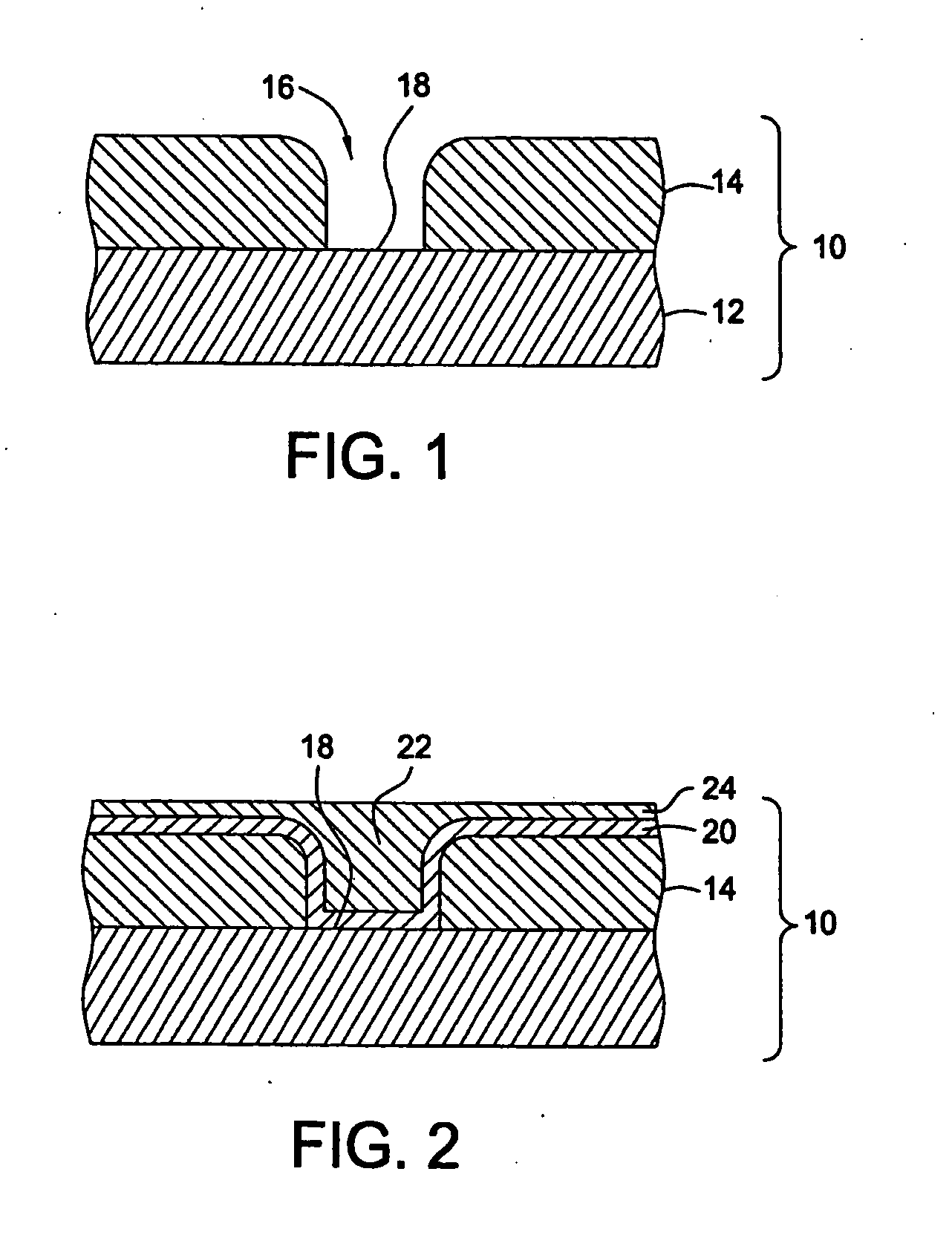

Copper technology for ULSI metallization

InactiveUS6919266B2Reduce diffuseFew process stepsSemiconductor/solid-state device detailsSolid-state devicesTungsten nitrideElectroless deposition

A copper damascene structure formed by direct patterning of a low-dielectric constant material is disclosed. The copper damascene structure includes a tungsten nitride barrier layer formed by atomic layer deposition using sequential deposition reactions. Copper is selectively deposited by a CVD process and / or by an electroless deposition technique.

Owner:MICRON TECH INC

Sequential deposition of tantalum nitride using a tantalum-containing precursor and a nitrogen-containing precursor

ActiveUS6972267B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

Disclosed is a method and apparatus that features deposition of tantalum films employing sequential deposition techniques, such as Atomic Layer Deposition (ALD). The method includes serially exposing a substrate to a flow of a nitrogen-containing gas, such as ammonia NH3, and a tantalum containing gas. The tantalum-containing gas is formed from a precursor, (tBuN)Ta(NEt2)3 (TBTDET), which is adsorbed onto the substrate. Prior to adsorption of TBTDET onto the substrate layer, the TBTDET precursor is heated within a predefined temperature range.

Owner:APPLIED MATERIALS INC

Vapor phase deposition of organic films

ActiveUS20170100743A1Reduce aspect ratioSemiconductor/solid-state device manufacturingPretreated surfacesOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve. Deposition reactors conducive to depositing organic films are provided.

Owner:ASM IP HLDG BV

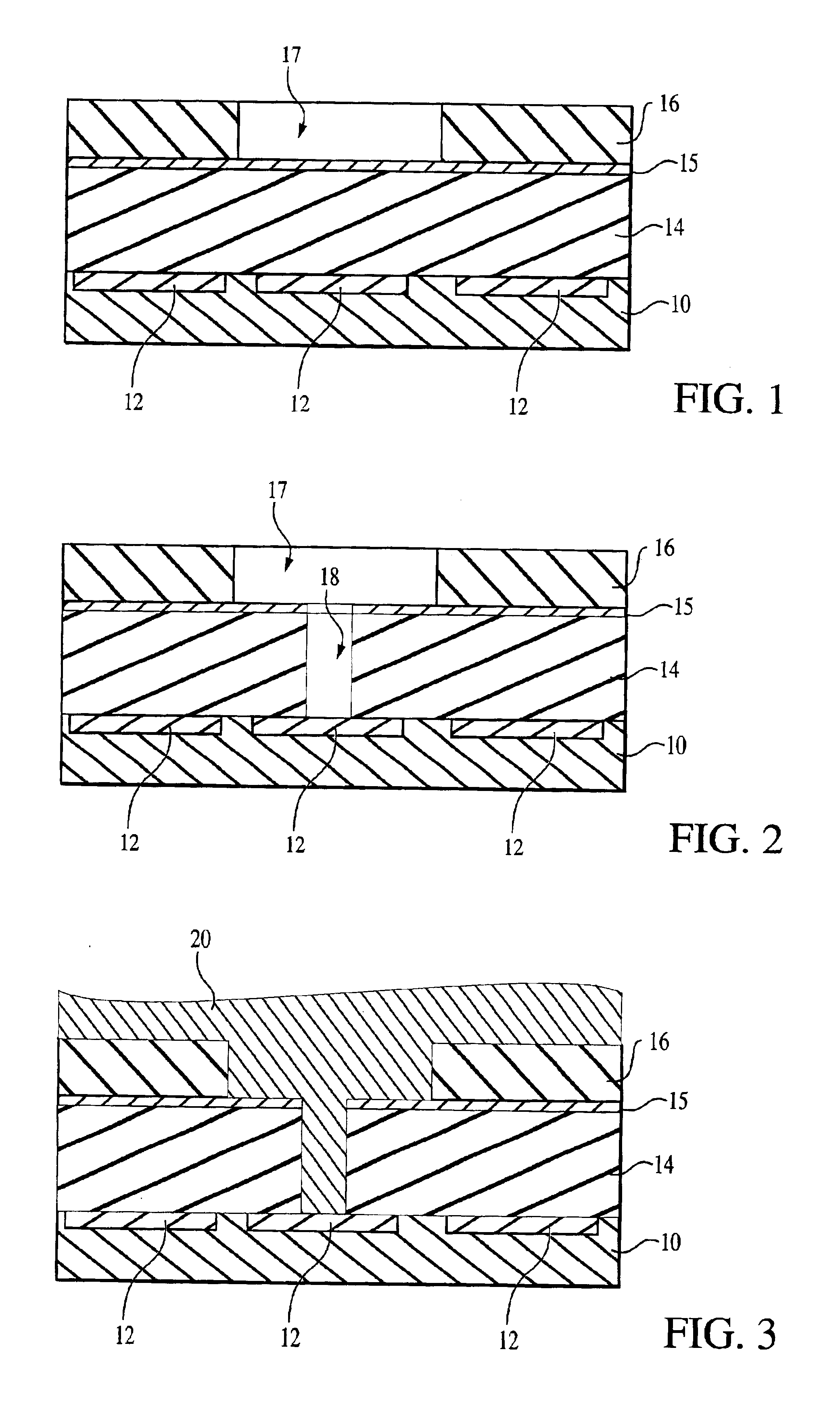

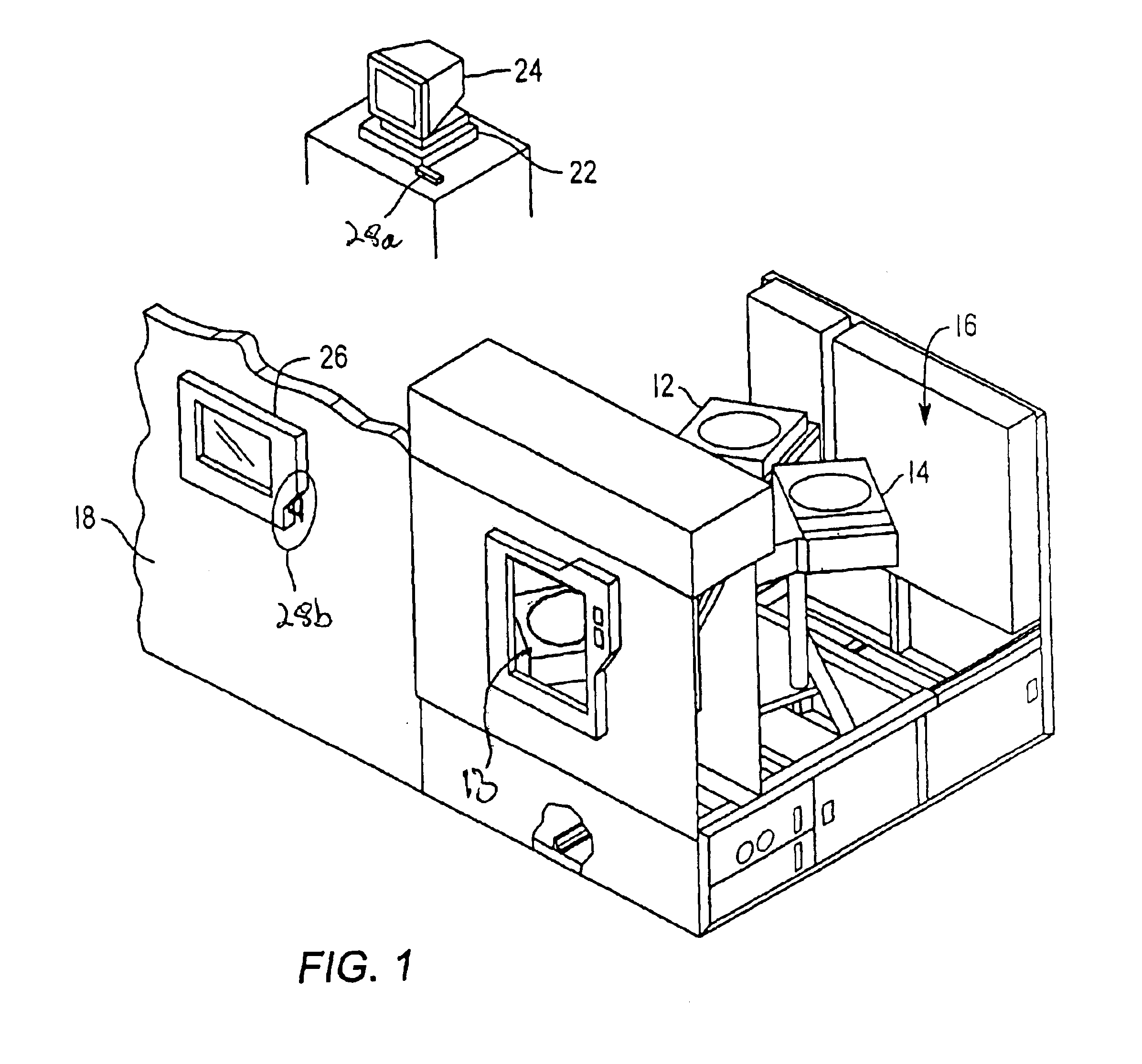

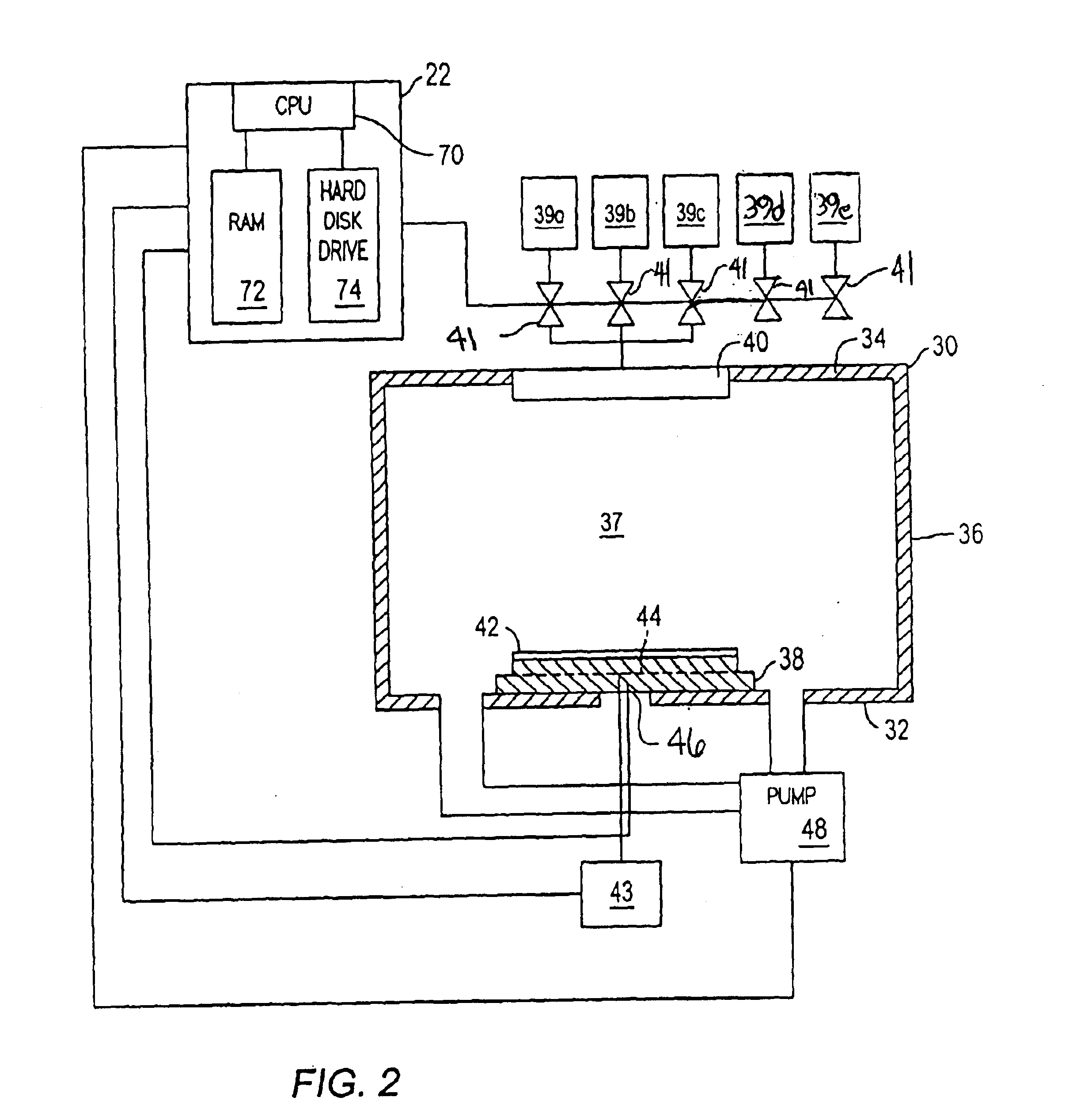

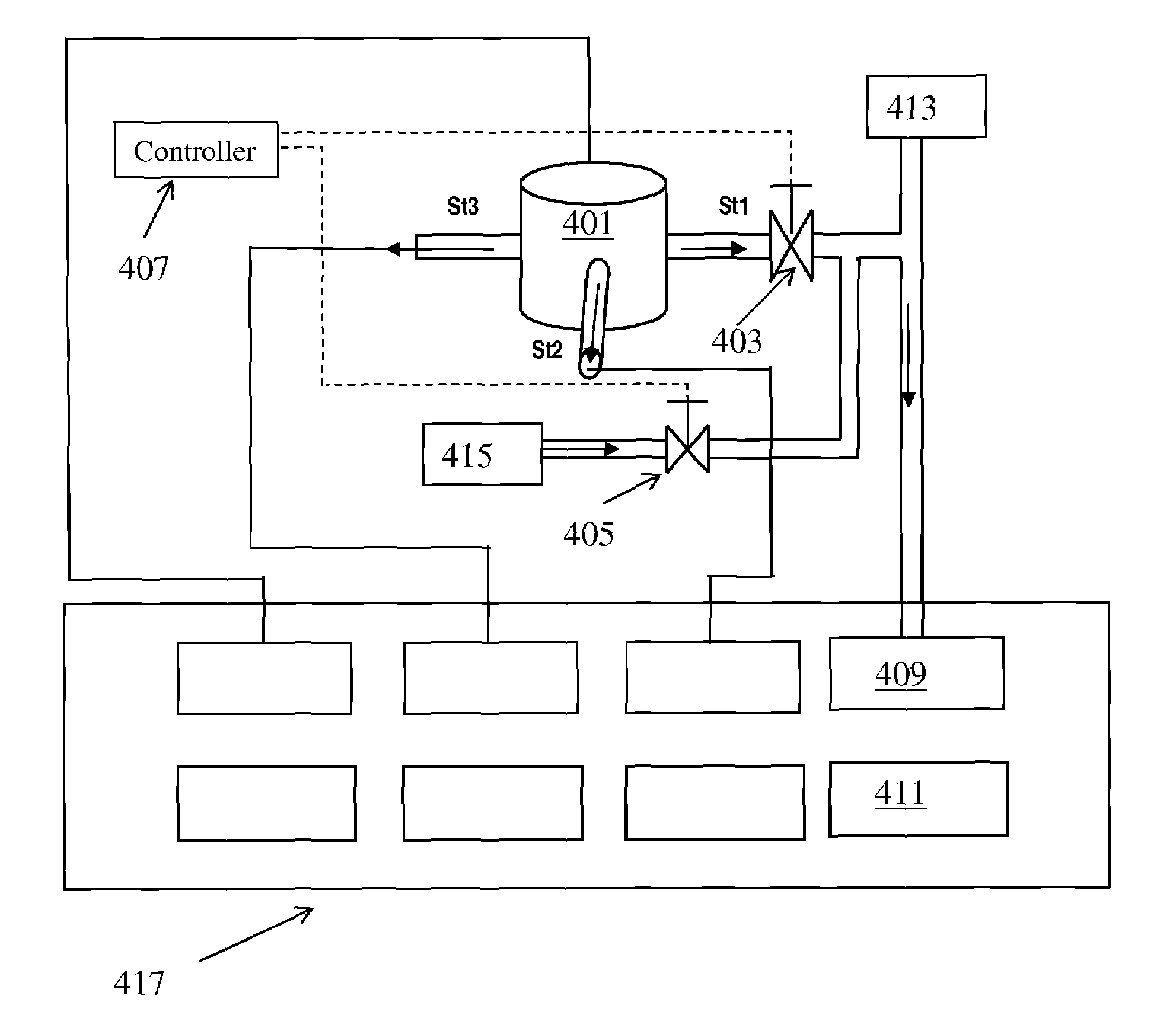

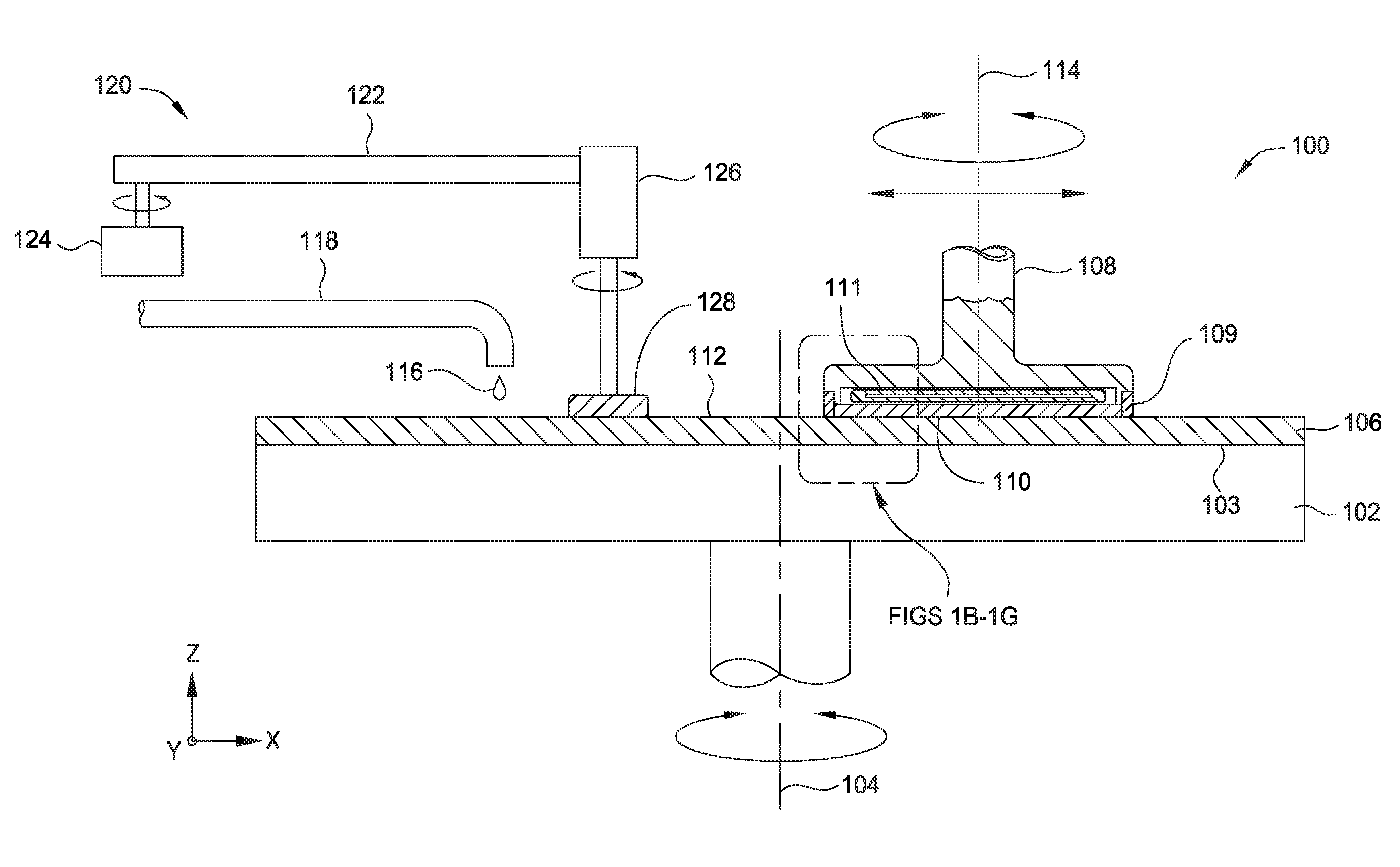

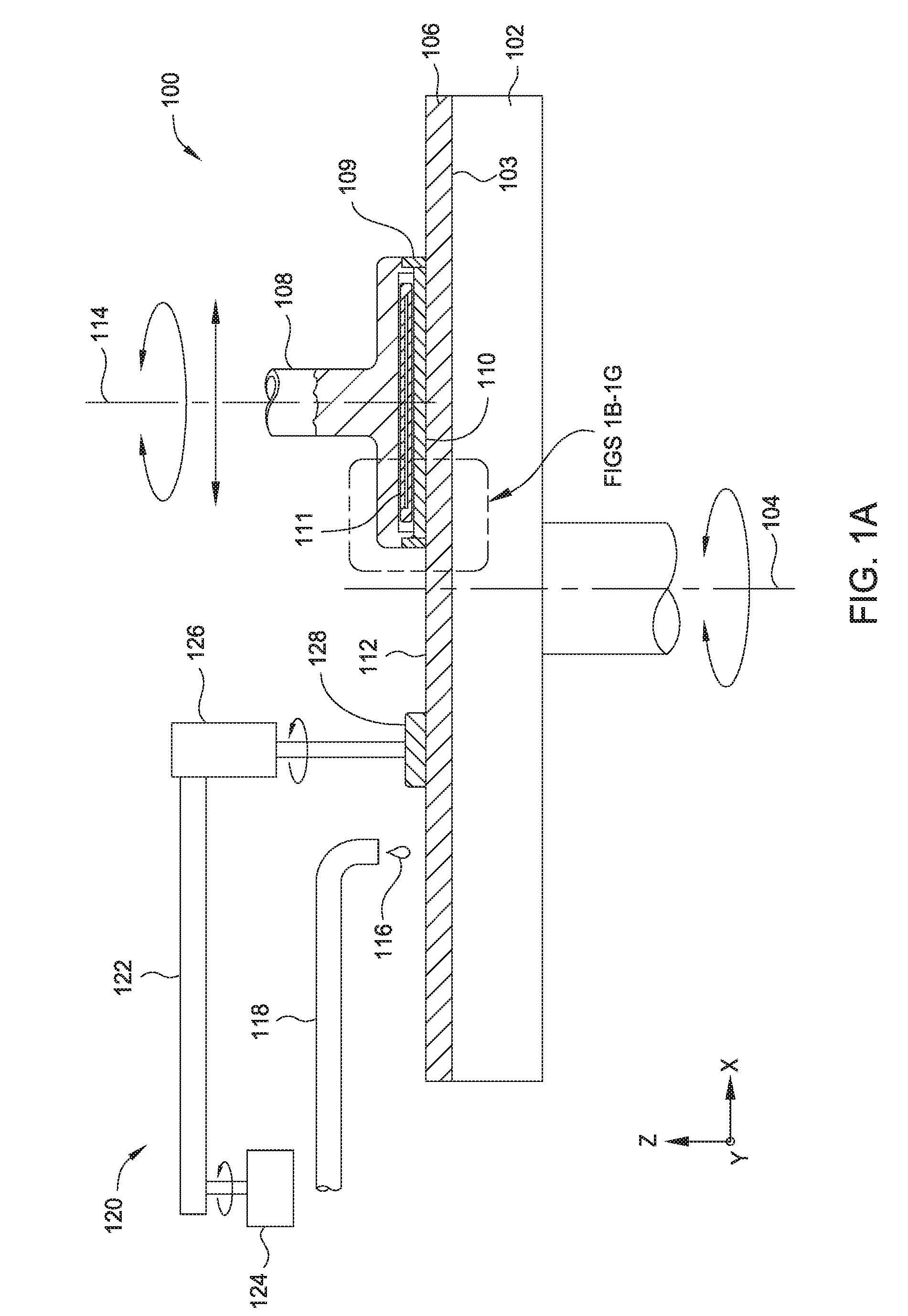

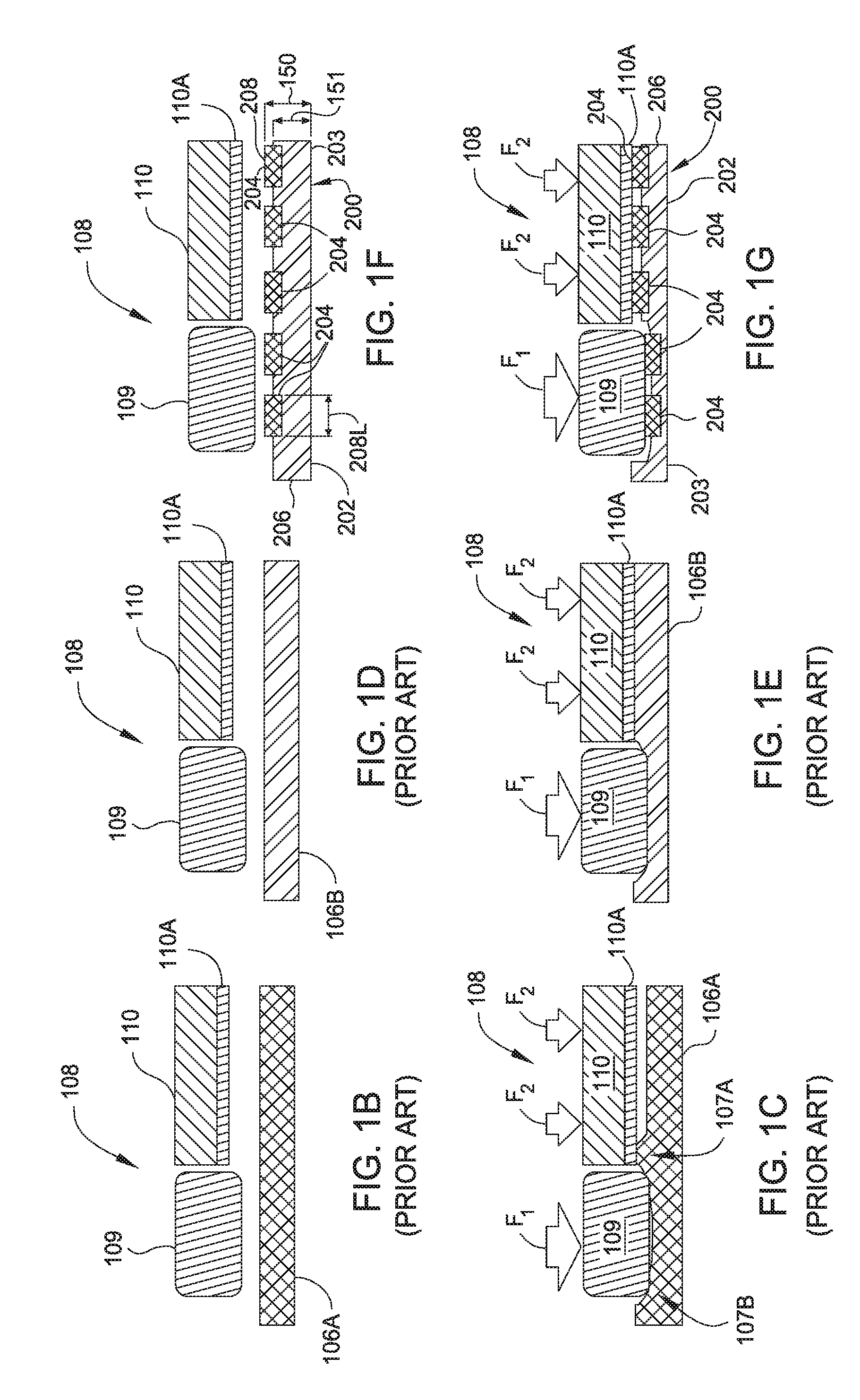

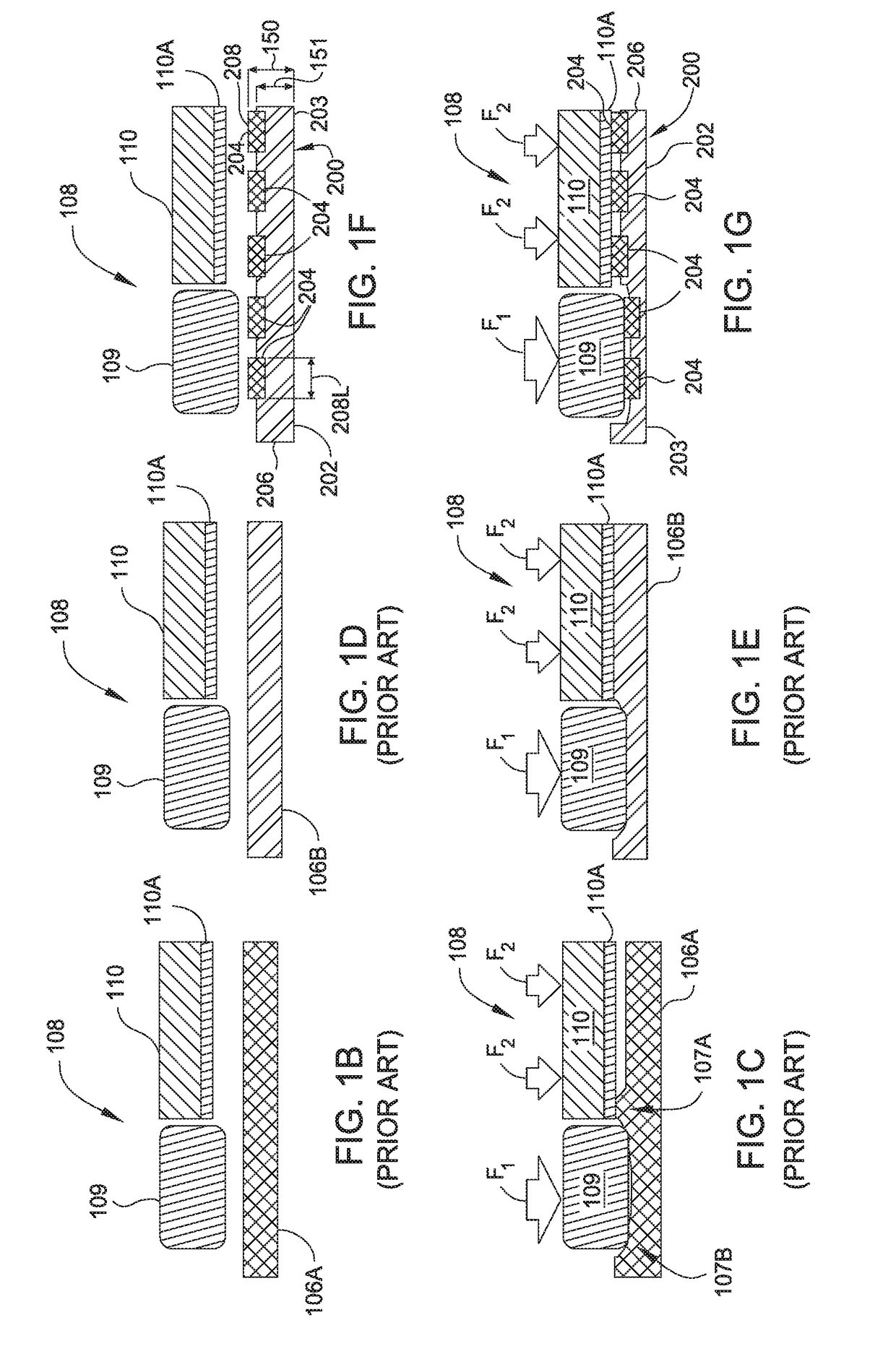

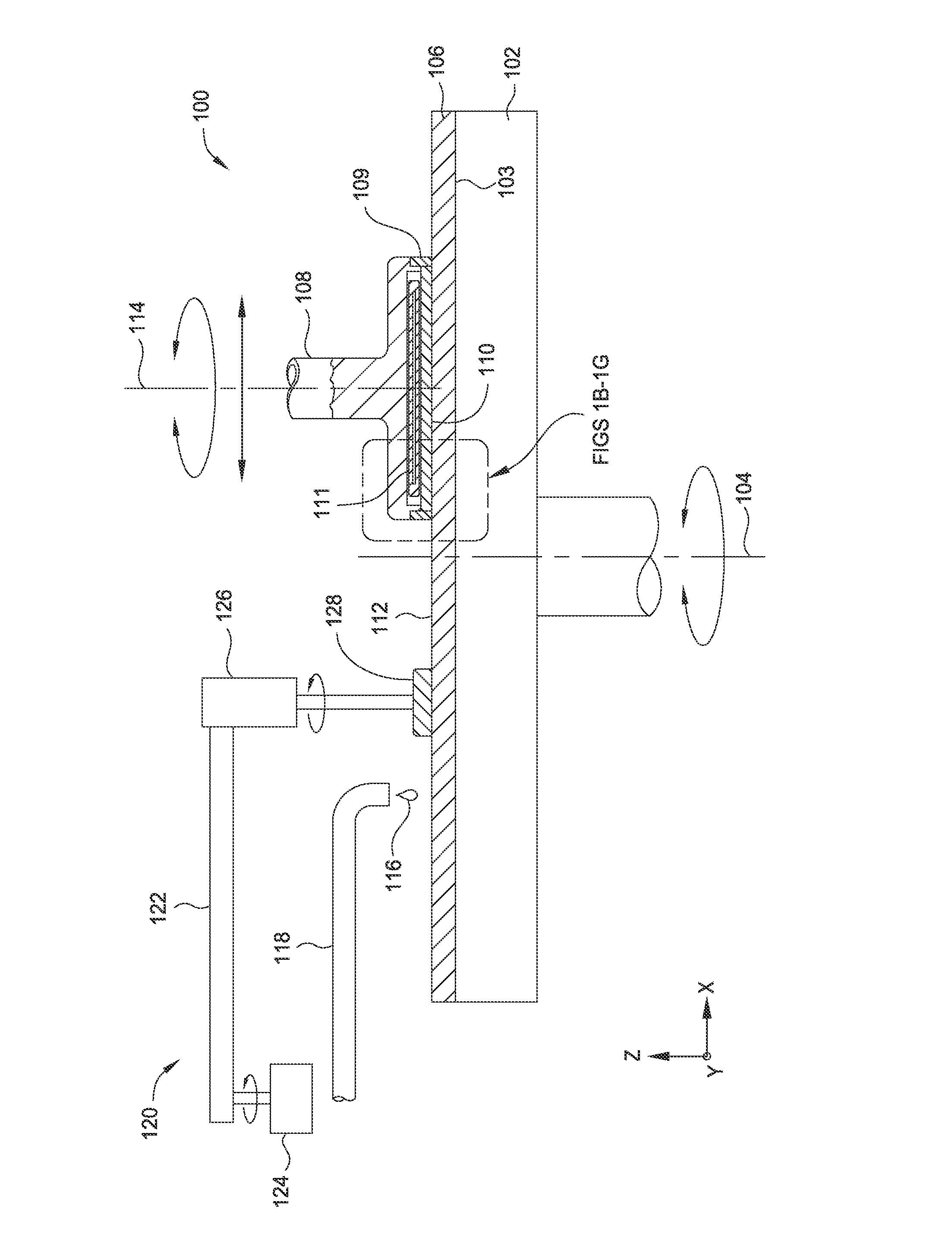

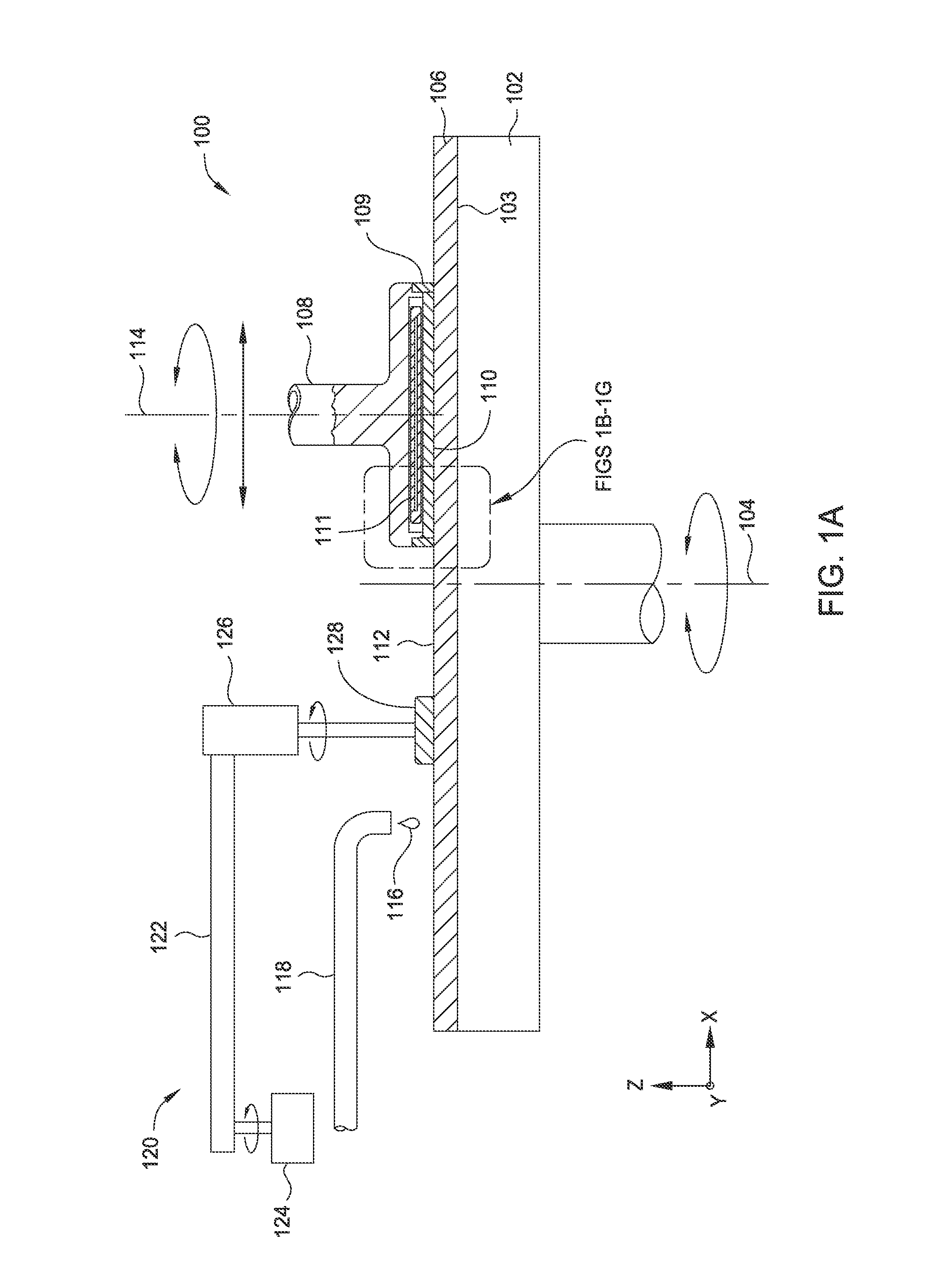

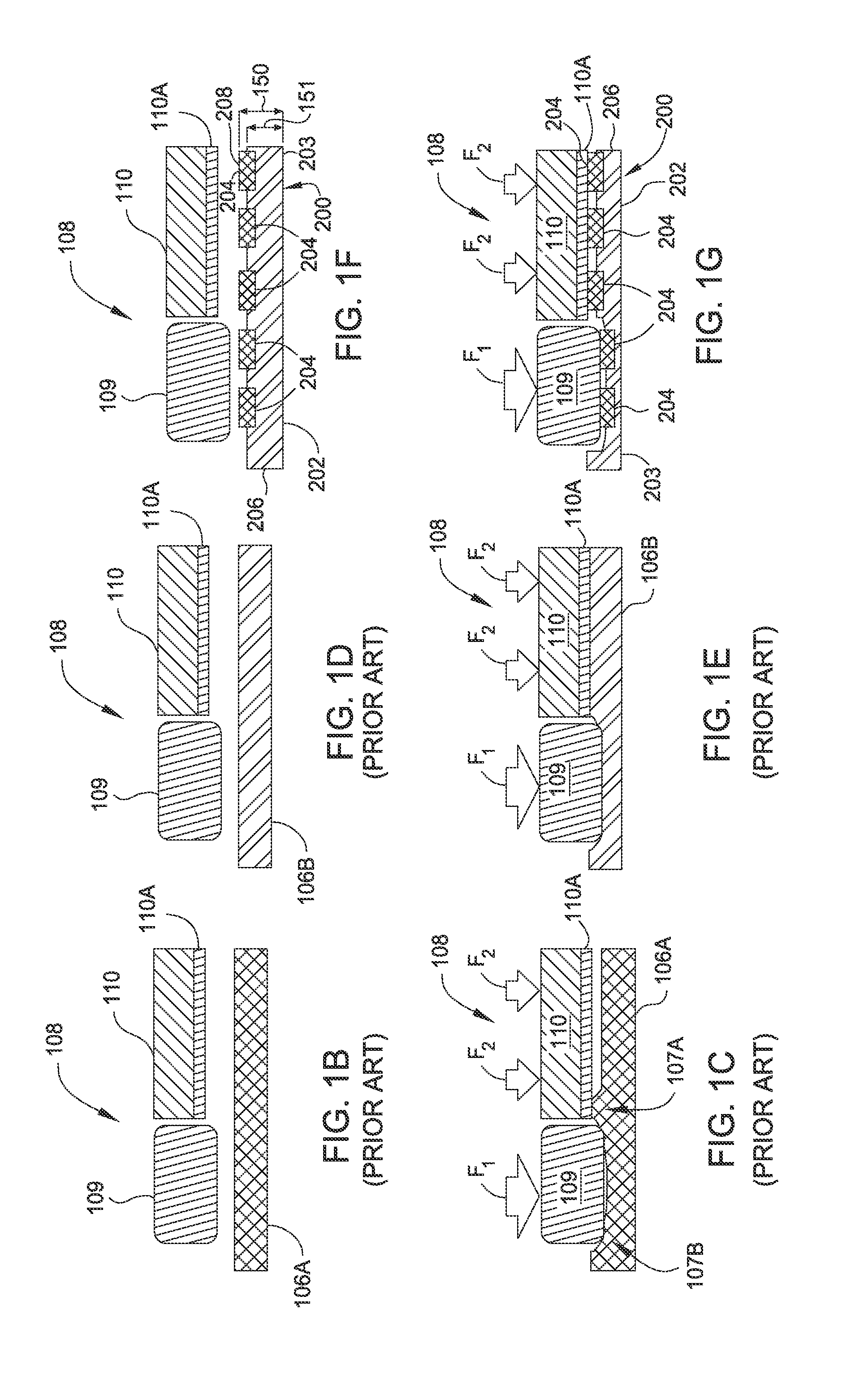

System and method to form a composite film stack utilizing sequential deposition techniques

InactiveUS6849545B2Semiconductor/solid-state device detailsSolid-state devicesComposite filmReactive gas

A system and method to form a stacked barrier layer for copper contacts formed on a substrate. The substrate is serially exposed to first and second reactive gases to form an adhesion layer. Then, the adhesion layer is serially exposed to third and fourth reactive gases to form a barrier layer adjacent to the adhesion layer. This is followed by deposition of a copper layer adjacent to the barrier layer.

Owner:APPLIED MATERIALS INC

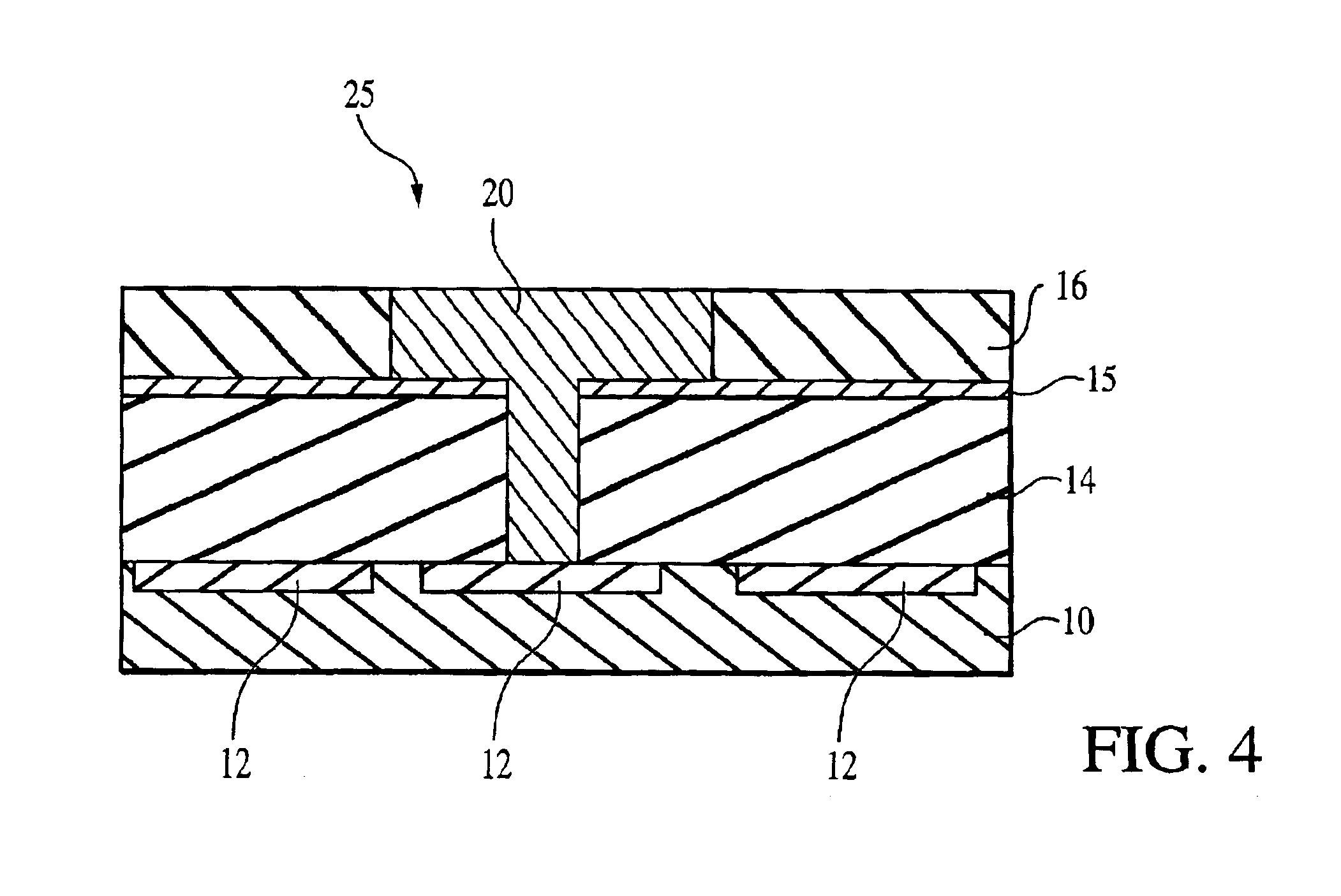

Method and apparatus for depositing refractory metal layers employing sequential deposition techniques to form a nucleation layer

InactiveUS7101795B1Pretreated surfacesSemiconductor/solid-state device manufacturingReactive gasNucleation

A method and system to form a refractory metal layer on a substrate features nucleating a substrate using sequential deposition techniques in which the substrate is serially exposed to first and second reactive gases followed by forming a layer, employing vapor deposition, to subject the nucleation layer to a bulk deposition of a compound contained in one of the first and second reactive gases.

Owner:APPLIED MATERIALS INC

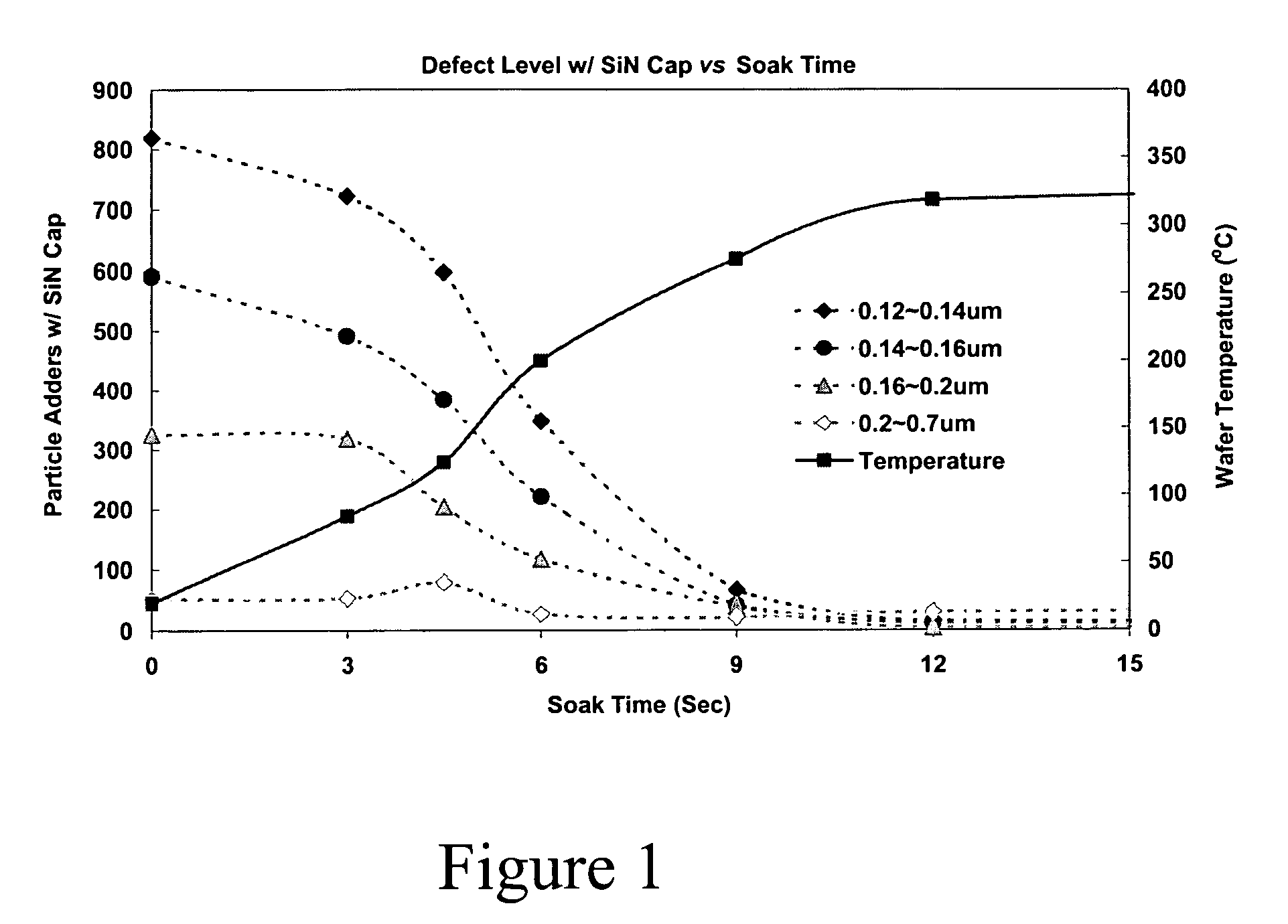

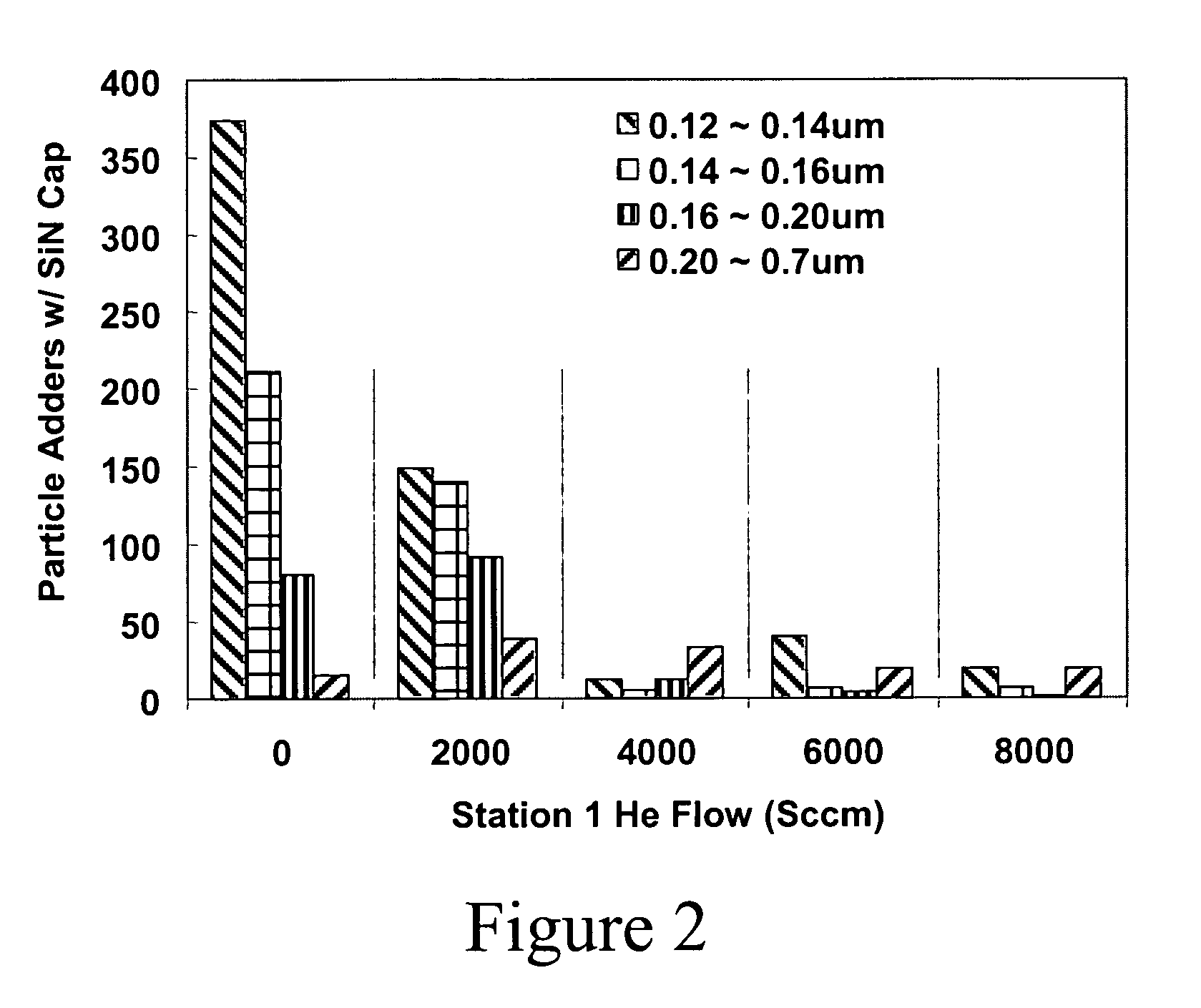

Method of eliminating small bin defects in high throughput TEOS films

ActiveUS7704894B1Improve throughputReduce in quantitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSequential deposition

This invention provides a high throughput PECVD process for depositing TEOS films in a multi-station sequential deposition chamber. The methods significantly reduce the number of particles in the TEOS films, thereby eliminating or minimizing small bin defects. The methods of the invention involve dedicating a first station for temperature soak while flowing purge gas. Stopping the flow of reactant gas and flowing the purge gas for station 1 eliminates TEOS condensation on a cold wafer surface and significantly reduces the number of defects in the film, particularly for short temperature soaks.

Owner:NOVELLUS SYSTEMS

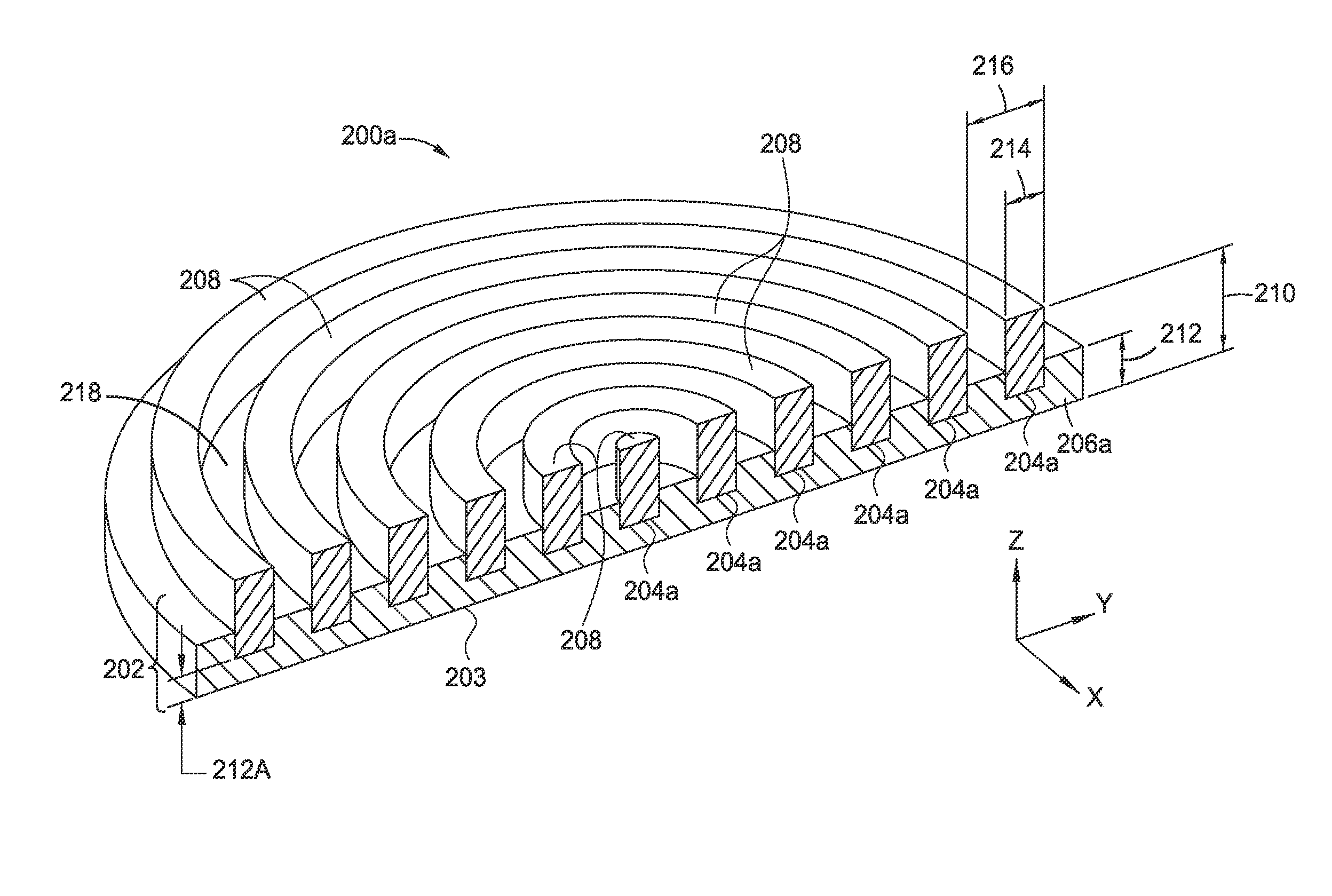

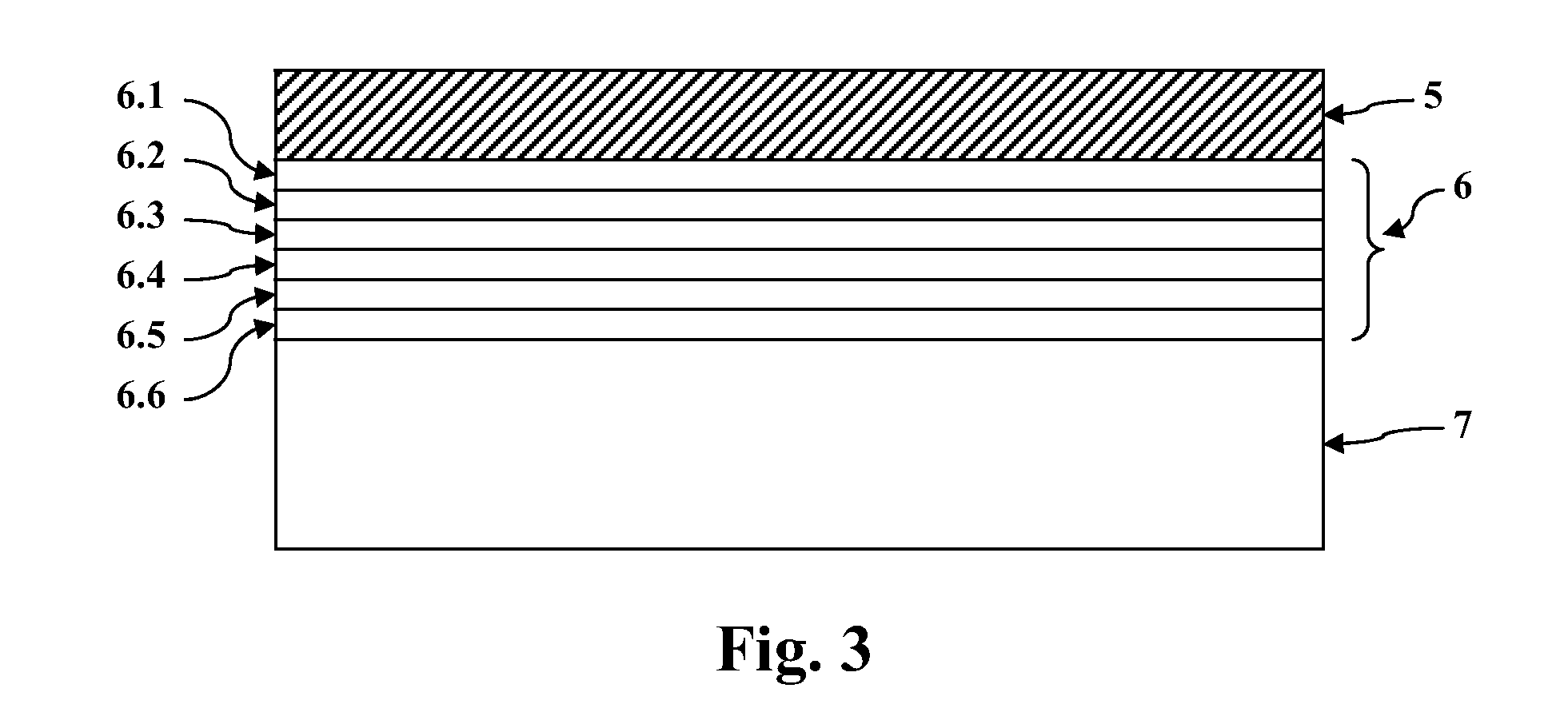

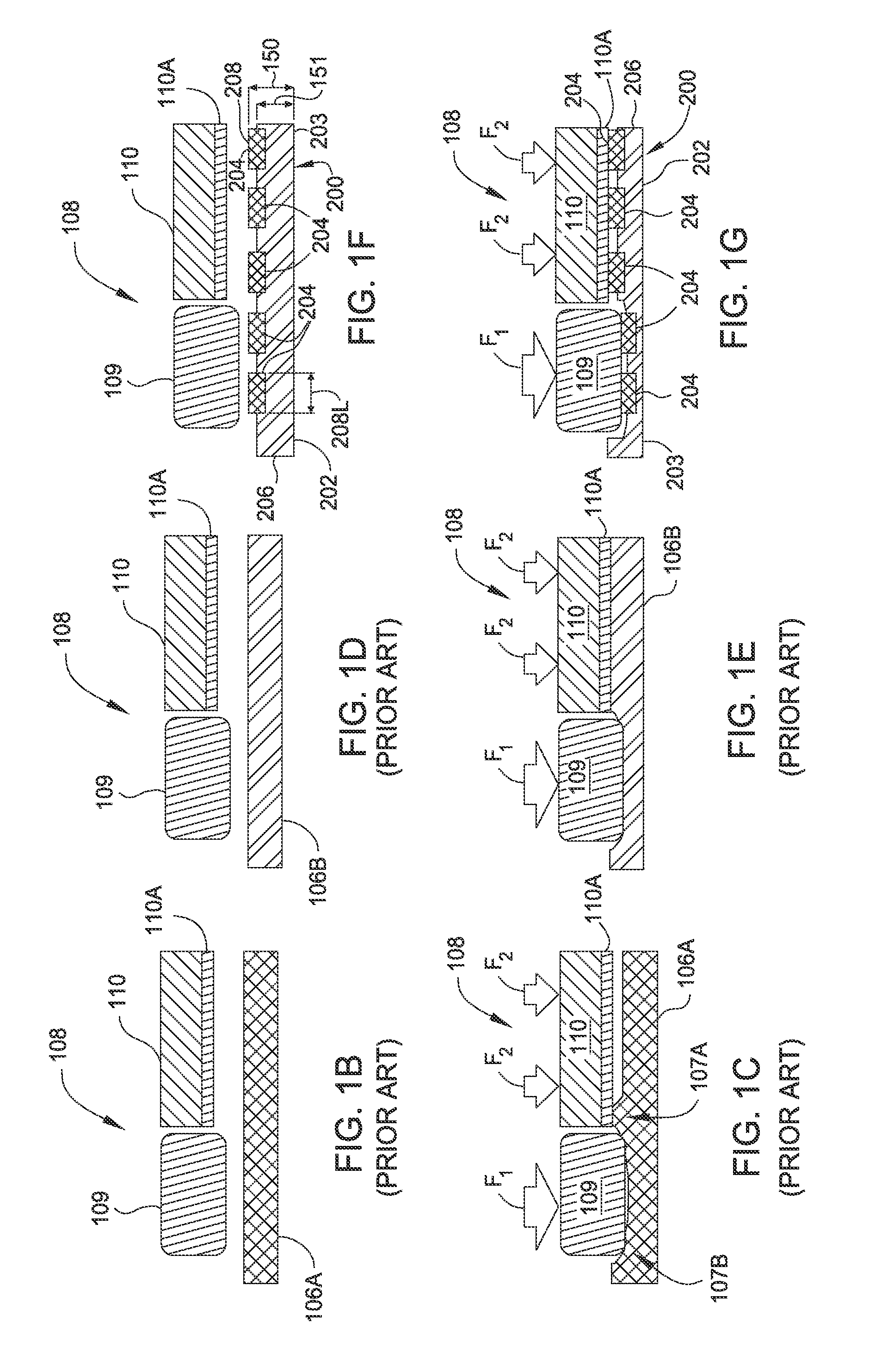

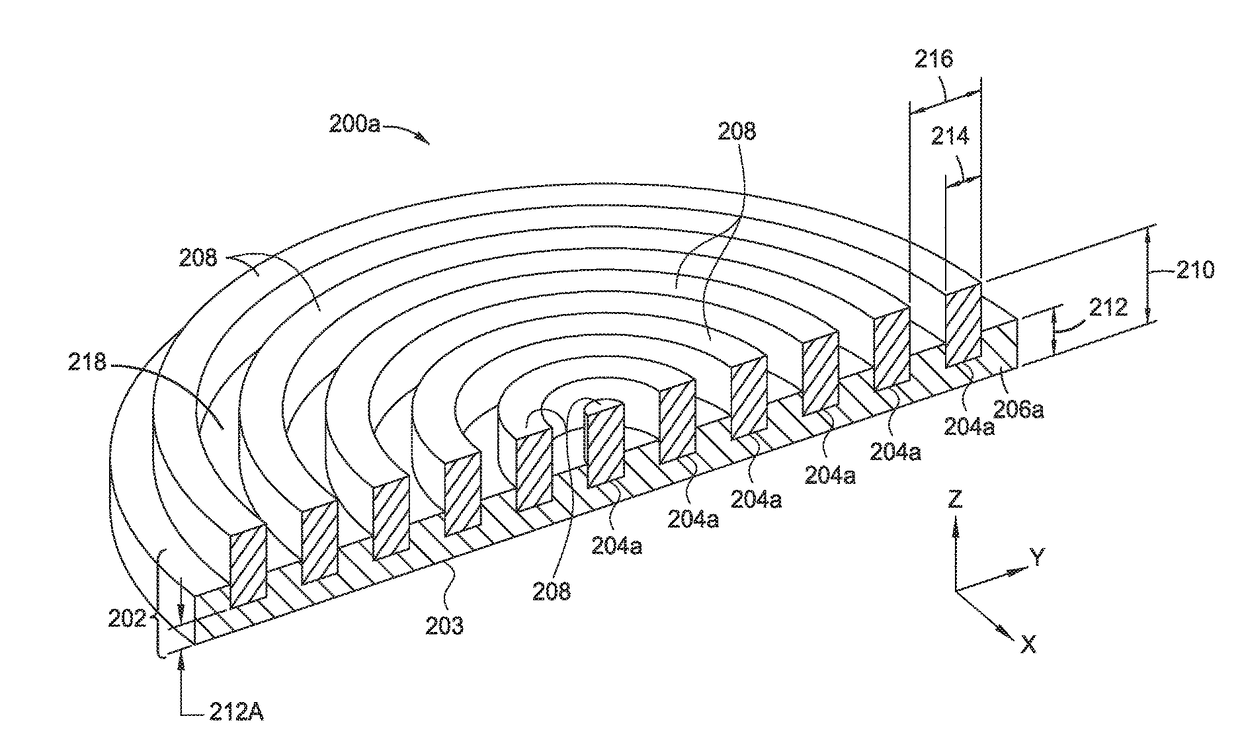

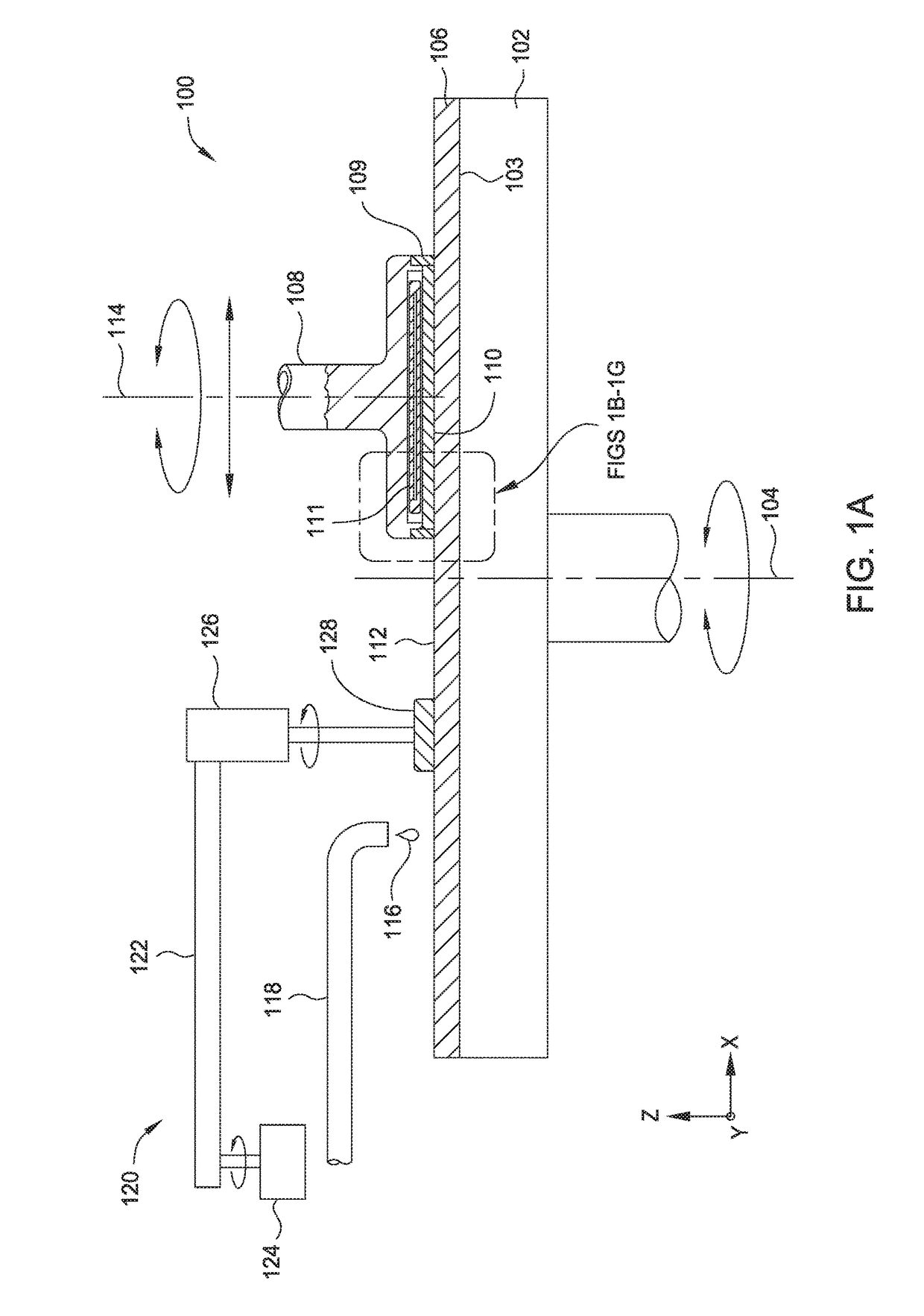

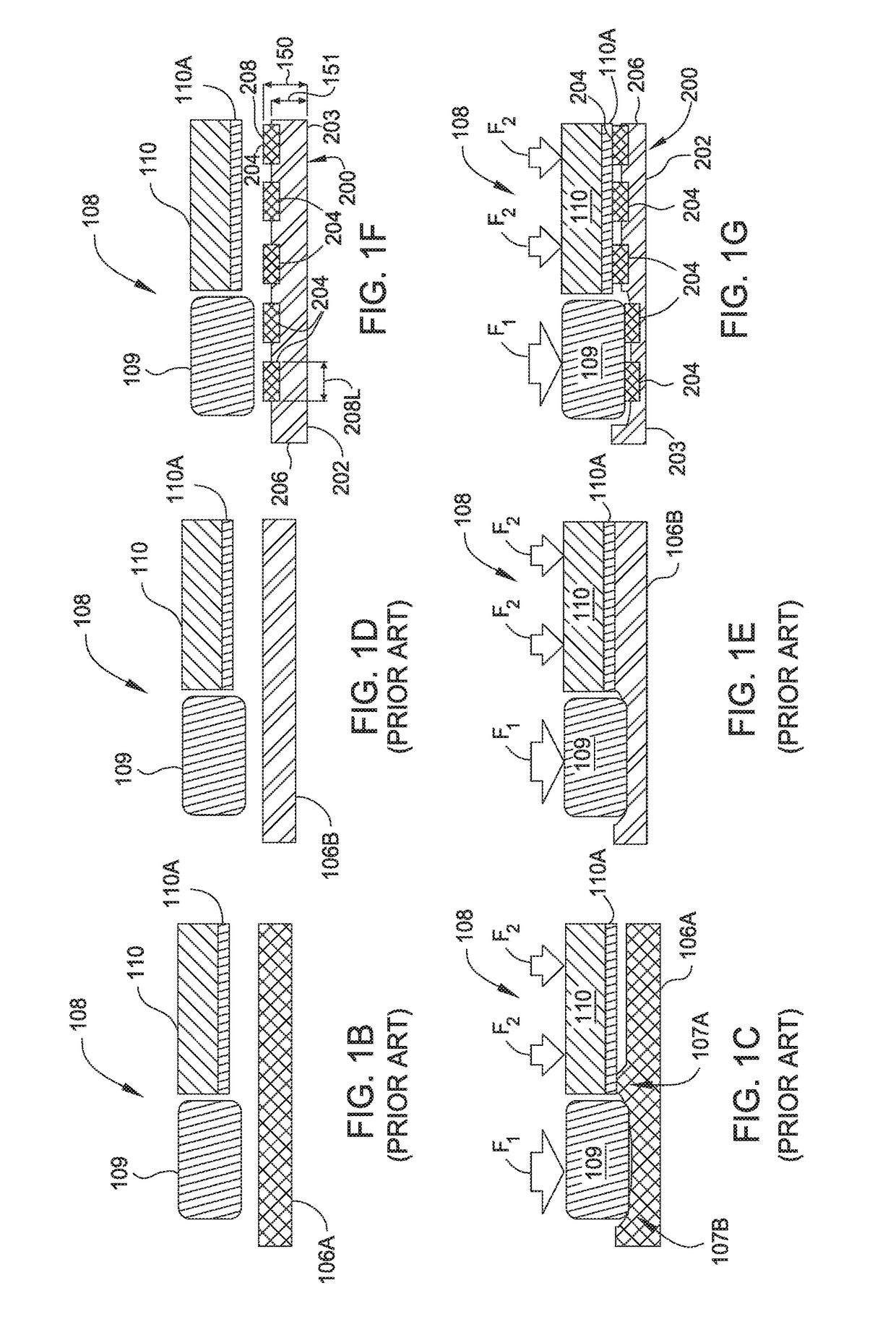

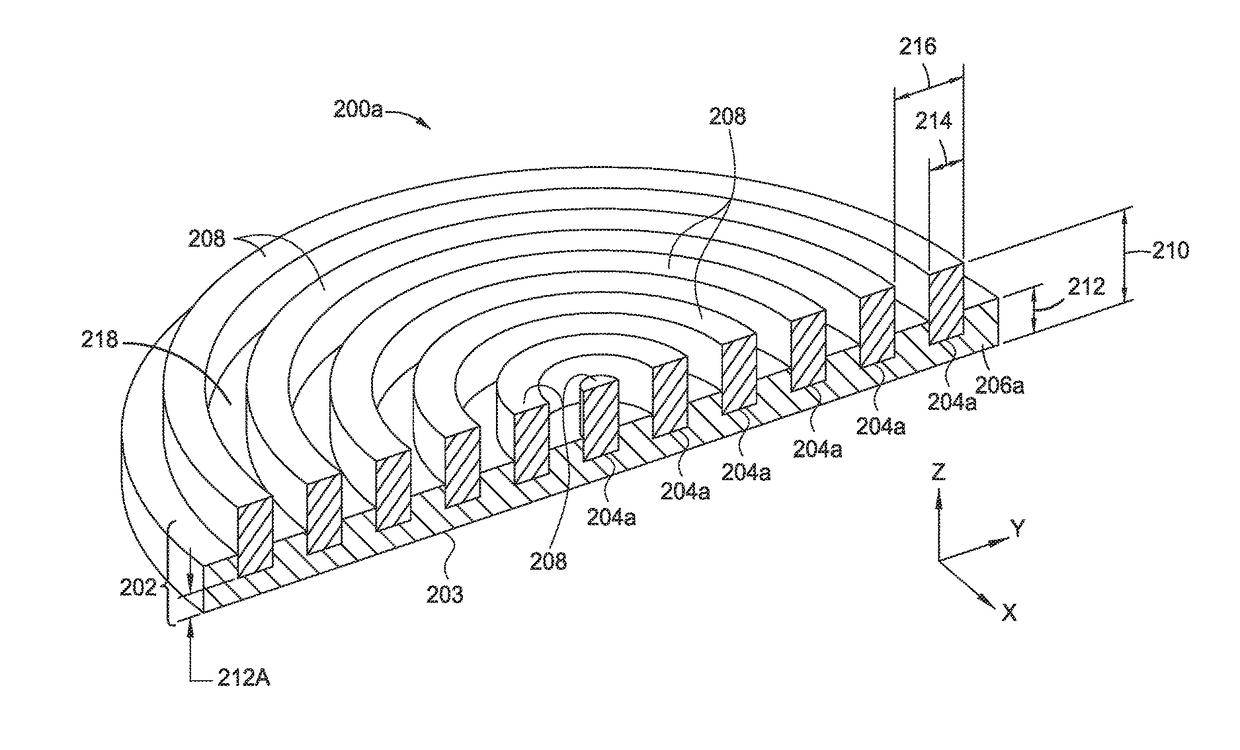

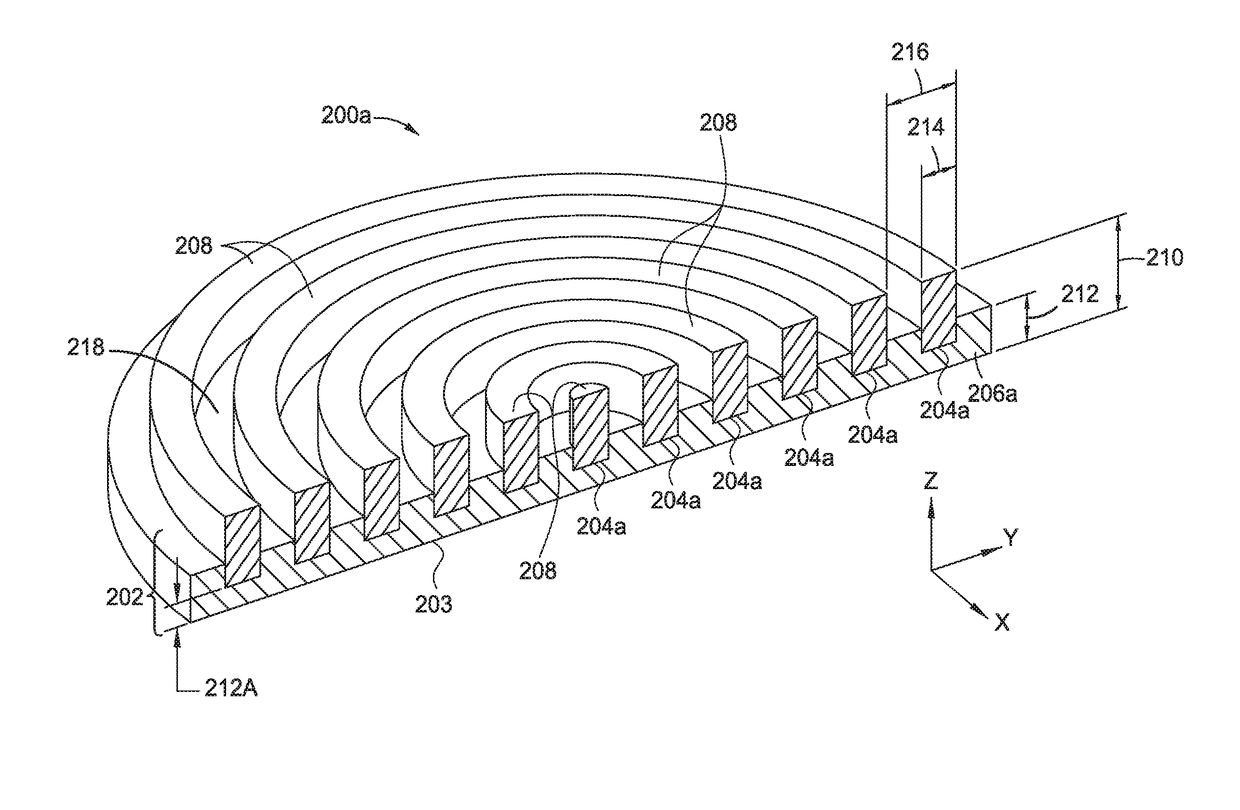

Polishing pads produced by an additive manufacturing process

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one resin precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions.

Owner:APPLIED MATERIALS INC

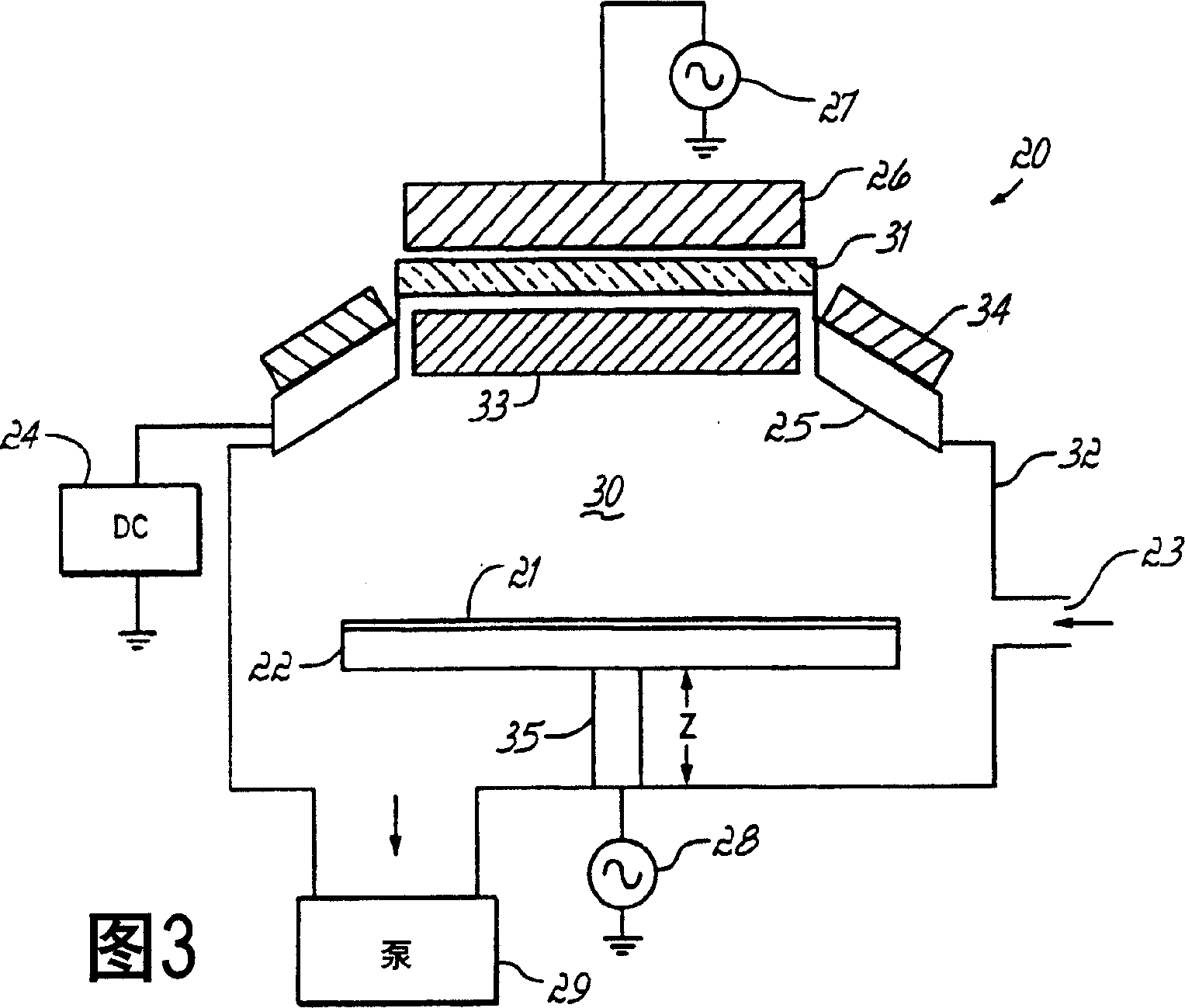

Ionized PVD with sequential deposition and etching

InactiveCN1552097AIncrease productionExcellent channel structure metallizationElectric discharge tubesVacuum evaporation coatingEtchingHigh density

Owner:TOKYO ELECTRON LTD

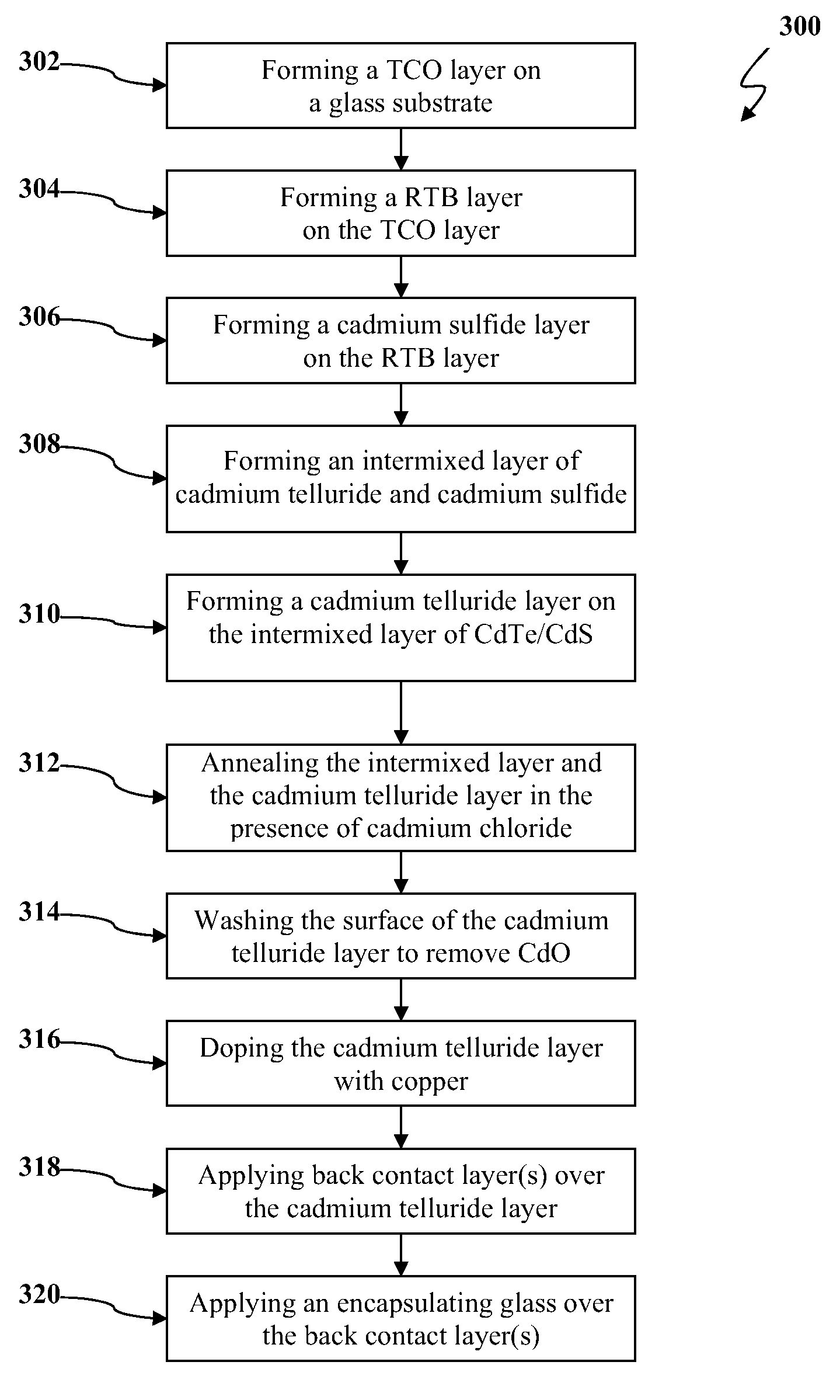

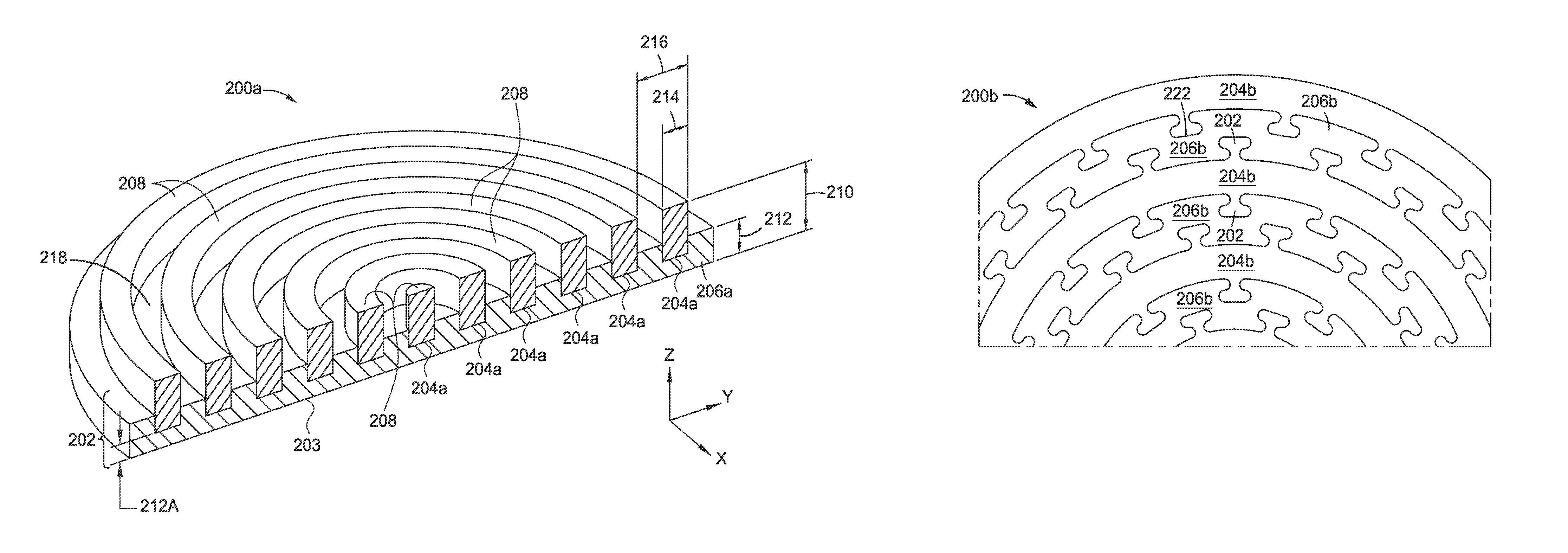

Systems and methods of intermixing cadmium sulfide layers and cadmium telluride layers for thin film photovoltaic devices

ActiveUS7939363B1Increasing tellurium concentrationReduce the concentration of sulfurFinal product manufactureVacuum evaporation coatingSource materialTe element

A process for manufacturing a cadmium telluride based thin film photovoltaic device having an intermixed layer is provided. The process can include introducing a substrate into a deposition chamber, wherein a window layer (e.g., a cadmium sulfide layer) is on a surface of the substrate. A sulfur-containing gas can be supplied to the deposition chamber. In addition, a source vapor can be supplied to the deposition chamber, wherein the source material comprises cadmium telluride. The sulfur-containing gas and the source vapor can be present within the deposition chamber to form an intermixed layer on the window layer. In one particular embodiment, for example, the intermixed layer generally can have an increasing tellurium concentration and decreasing sulfur concentration extending away from the window layer.An apparatus for sequential deposition of an intermixed thin film layer and a sublimated source material on a photovoltaic (PV) module substrate is also provided.

Owner:FIRST SOLAR INC (US)

Polishing pads produced by an additive manufacturing process

ActiveUS20160114458A1Additive manufacturing apparatusOther chemical processesOligomerReactive diluent

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one resin precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions.

Owner:APPLIED MATERIALS INC

Advanced polishing pads having compositional gradients by use of an additive manufacturing process

Owner:APPLIED MATERIALS INC

Advanced polishing pad materials and formulations

ActiveUS20160136787A1Additive manufacturing apparatusOther chemical processesOligomerCompound (substance)

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one resin precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions.

Owner:APPLIED MATERIALS INC

Method and apparatus for forming porous advanced polishing pads using an additive manufacturing process

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, addition polymer precursor compounds, catalysts, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one polymer precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions. Embodiments of the disclosure further provide a polishing pad with polymeric layers that may be interpenetrating polymer networks.

Owner:APPLIED MATERIALS INC

Vapor phase deposition of organic films

ActiveUS10343186B2Reduce aspect ratioPretreated surfacesSemiconductor/solid-state device manufacturingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve. Deposition reactors conducive to depositing organic films are provided.

Owner:ASM IP HLDG BV

Vapor phase deposition of organic films

ActiveUS10695794B2Reduce aspect ratioLiquid surface applicatorsSolid-state devicesOrganic filmThin membrane

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve.

Owner:ASM IP HLDG BV

Vapor phase deposition of organic films

ActiveUS20190283077A1Reduce aspect ratioPretreated surfacesSemiconductor/solid-state device manufacturingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve. Deposition reactors conducive to depositing organic films are provided.

Owner:ASM IP HLDG BV

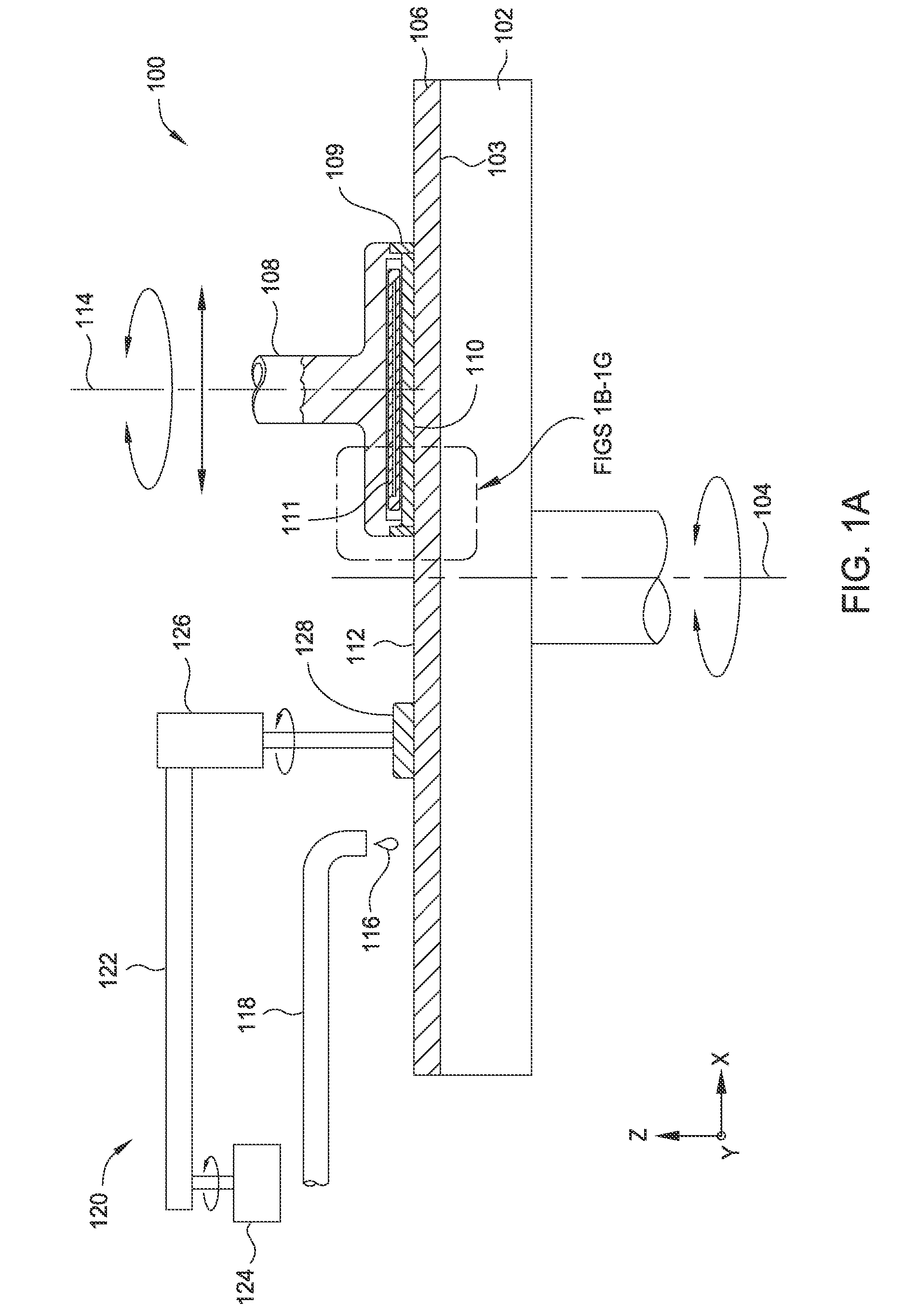

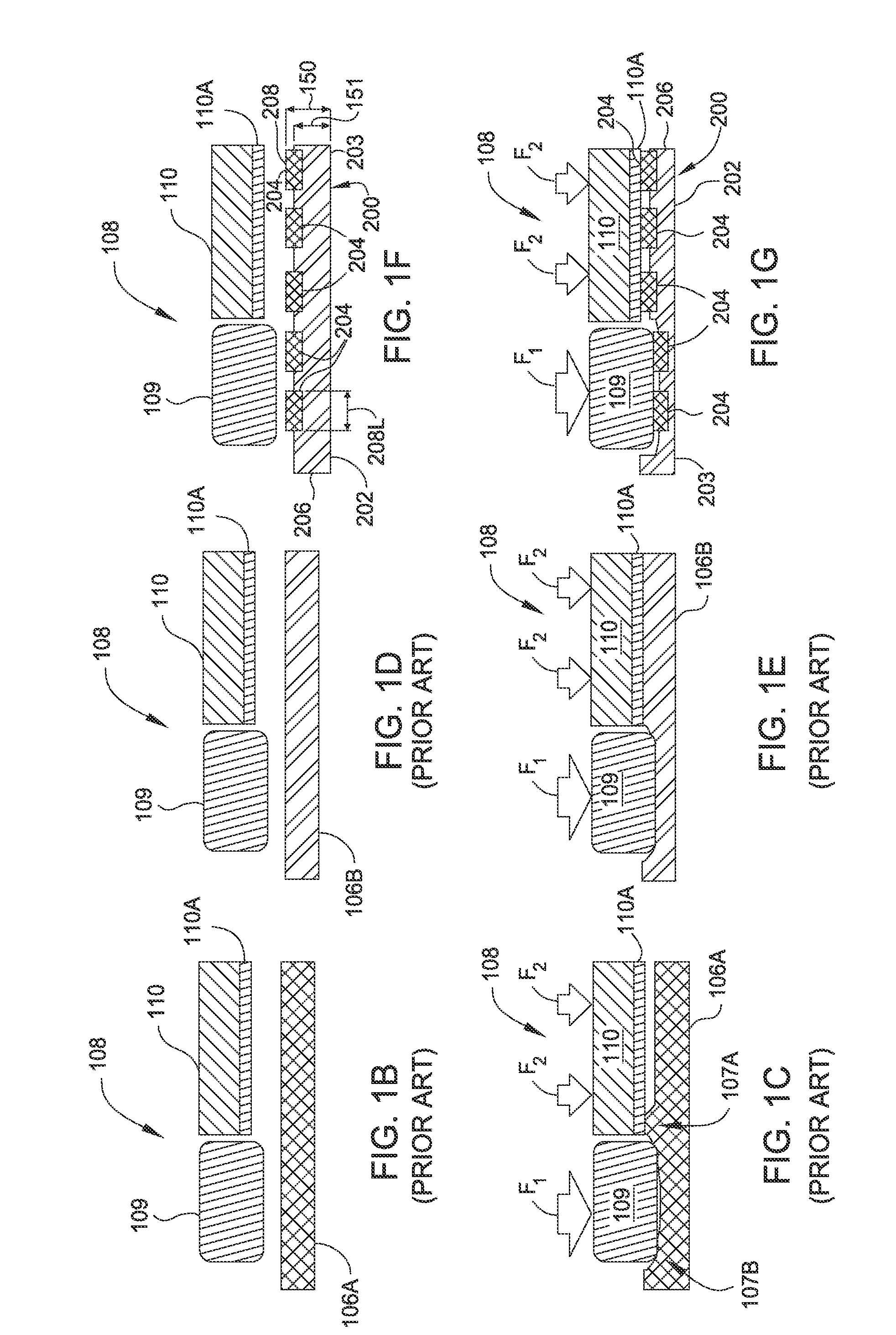

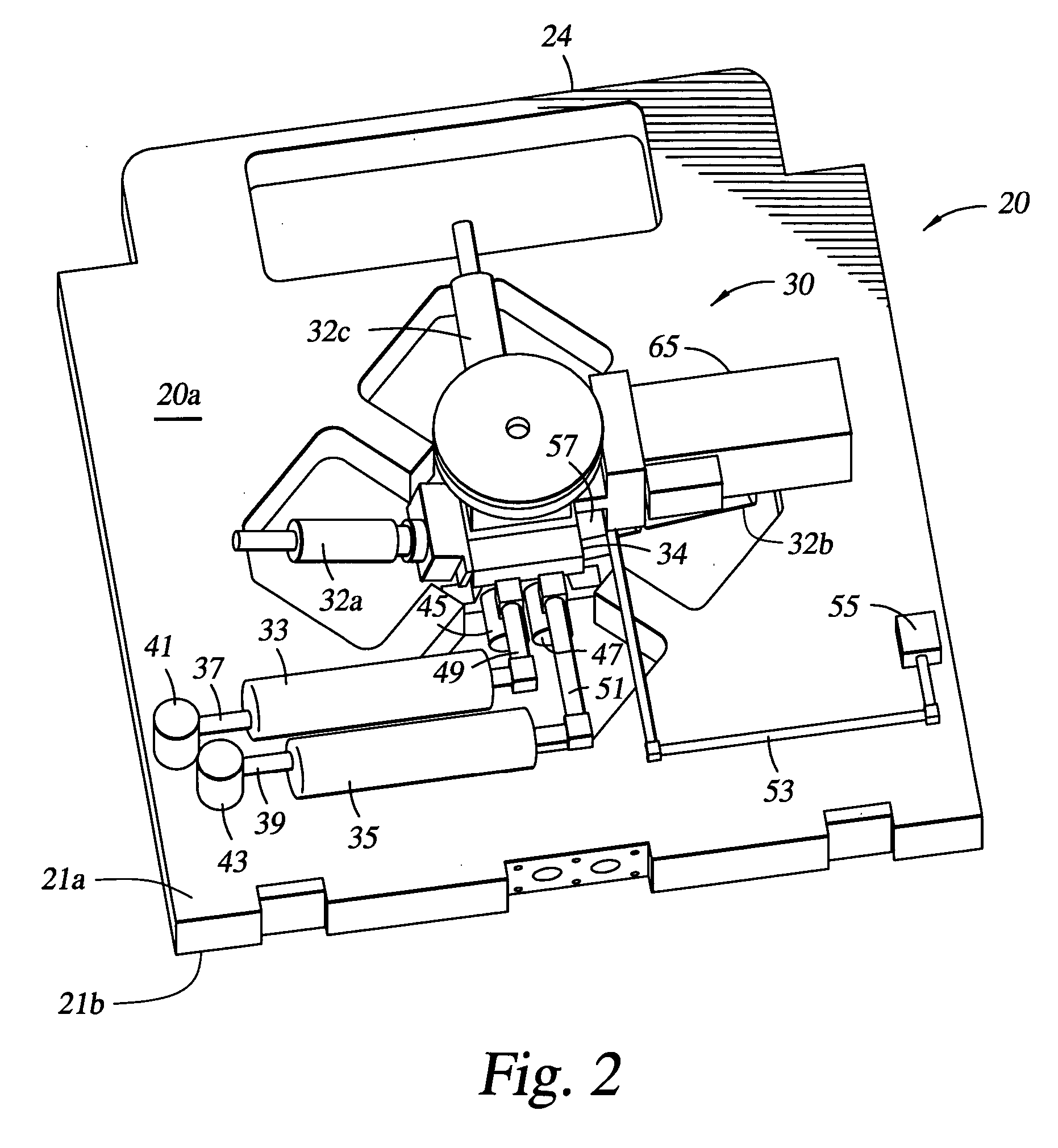

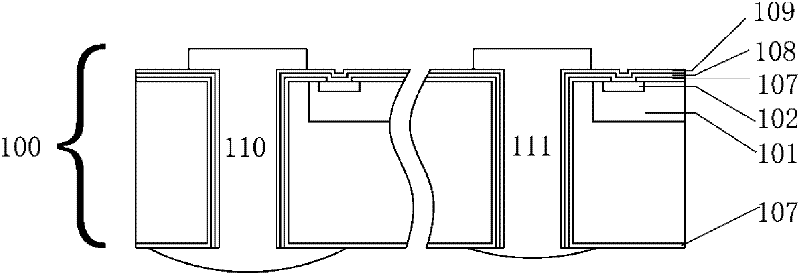

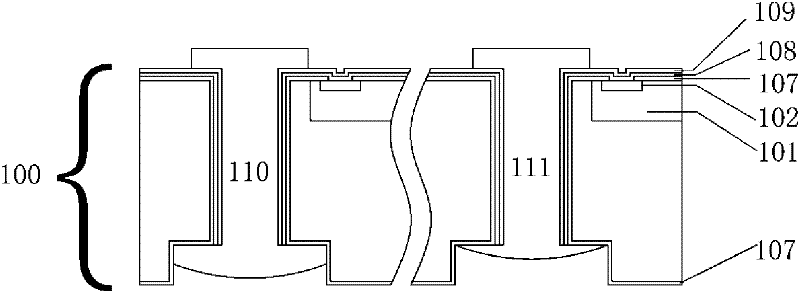

Lid assembly for a processing system to facilitate sequential deposition techniques

InactiveUS20050115675A1Easy to controlIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingControl systemEngineering

A lid assembly for a semiconductor processing system is provided. The lid assembly generally includes a lid having first and second opposed surfaces, a plurality of controllable flow channels extending from the first and second opposed surfaces and a gas control system disposed on the first surface and operably opening and closing the channels. The gas control system includes a gas manifold disposed on the lid, at least one valve coupled to the gas manifold and adapted to control a flow through one of the flow channels, a reservoir fluidly connected to the gas manifold, and a precursor source fluidly connected to the reservoir.

Owner:APPLIED MATERIALS INC

Apparatus and method of forming a polishing pads by use of an additive manufacturing process

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, addition polymer precursor compounds, catalysts, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one polymer precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions. Embodiments of the disclosure further provide a polishing pad with polymeric layers that may be interpenetrating polymer networks.

Owner:APPLIED MATERIALS INC

Polishing pads produced by an additive manufacturing process

ActiveUS20160107295A1Additive manufacturing apparatusOther chemical processesOligomerReactive diluent

Embodiments of the present disclosure relate to advanced polishing pads with tunable chemical, material and structural properties, and new methods of manufacturing the same. According to one or more embodiments of the disclosure, it has been discovered that a polishing pad with improved properties may be produced by an additive manufacturing process, such as a three-dimensional (3D) printing process. Embodiments of the present disclosure thus may provide an advanced polishing pad that has discrete features and geometries, formed from at least two different materials that include functional polymers, functional oligomers, reactive diluents, and curing agents. For example, the advanced polishing pad may be formed from a plurality of polymeric layers, by the automated sequential deposition of at least one resin precursor composition followed by at least one curing step, wherein each layer may represent at least one polymer composition, and / or regions of different compositions.

Owner:APPLIED MATERIALS INC

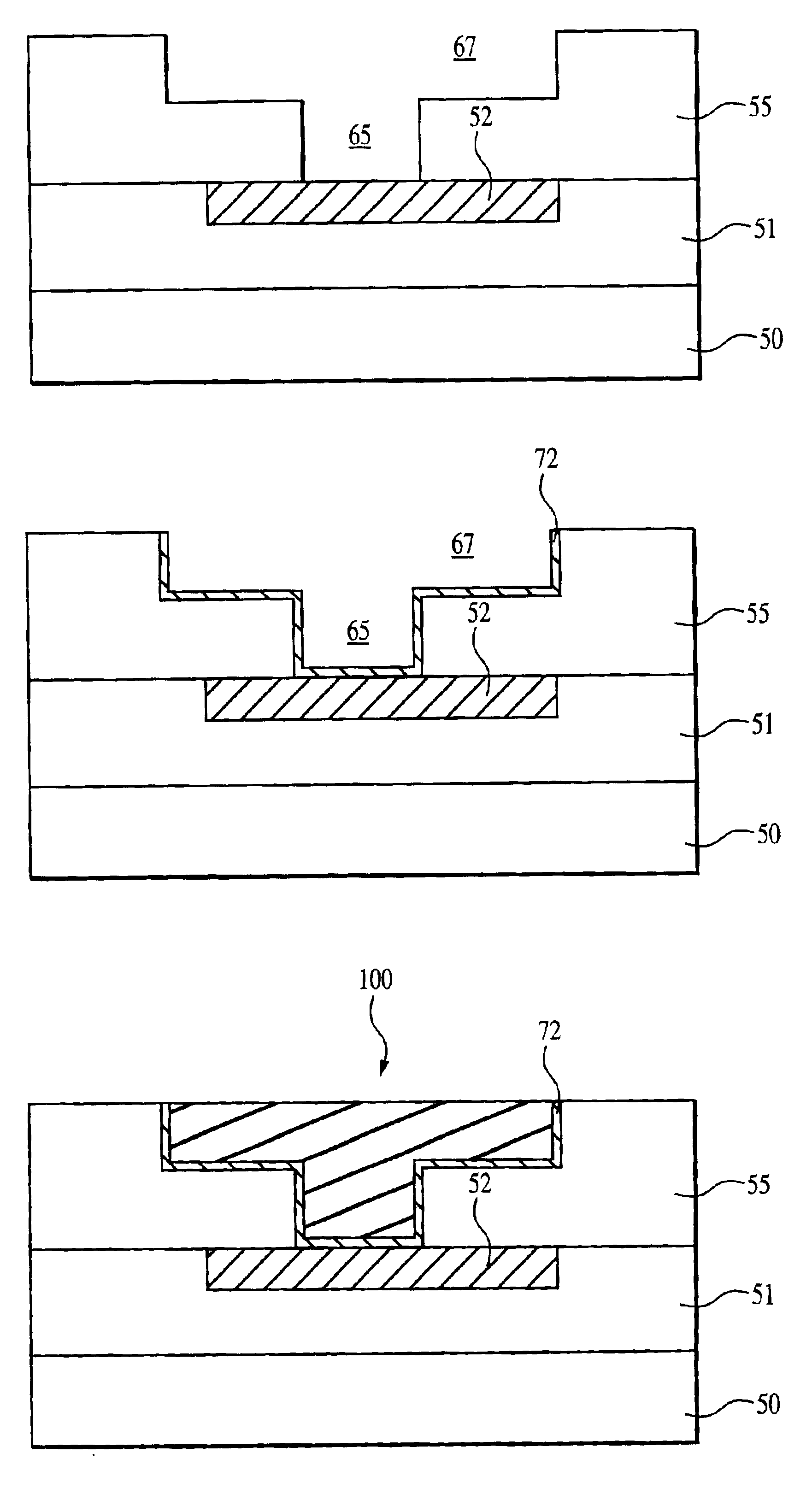

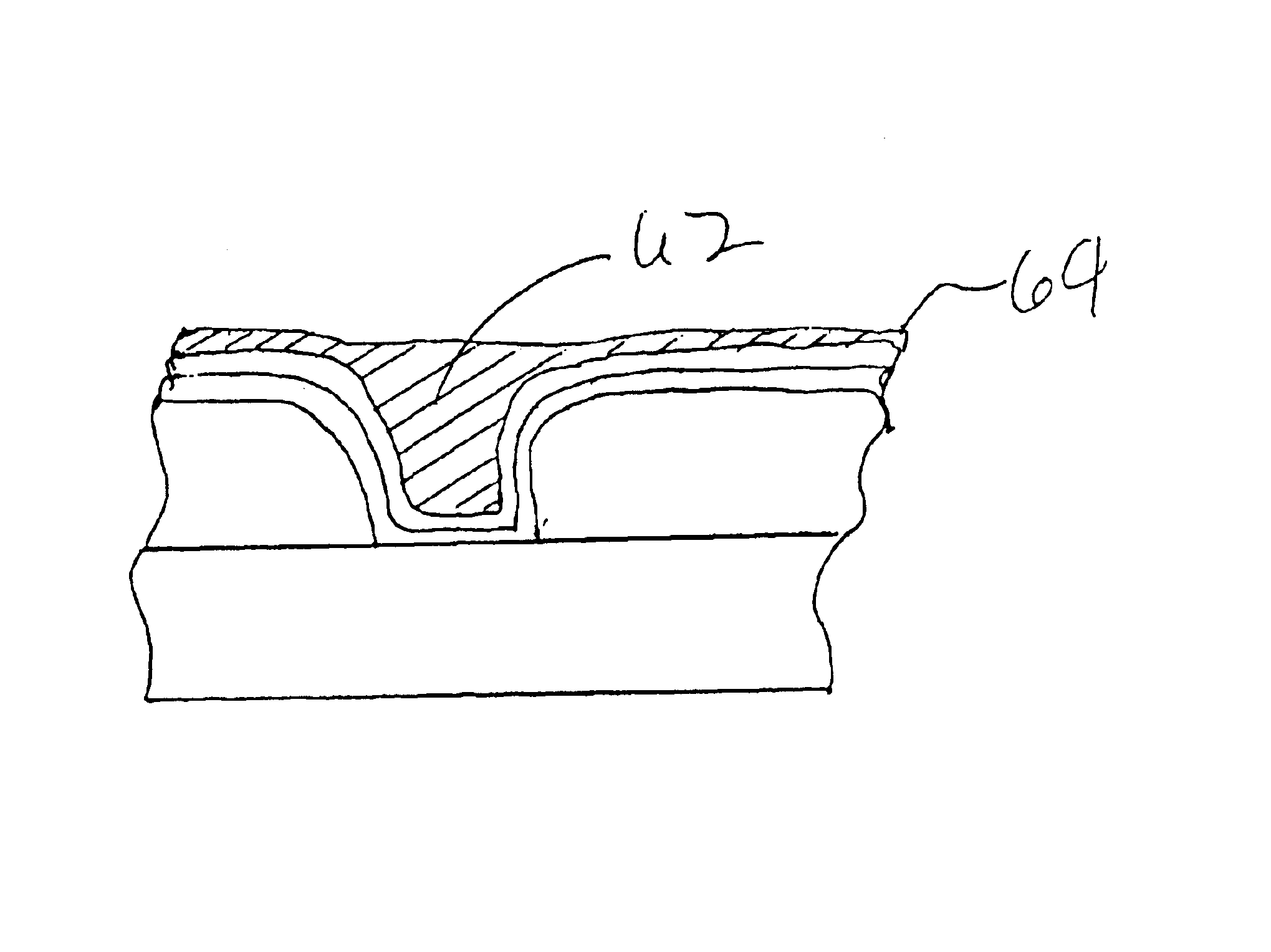

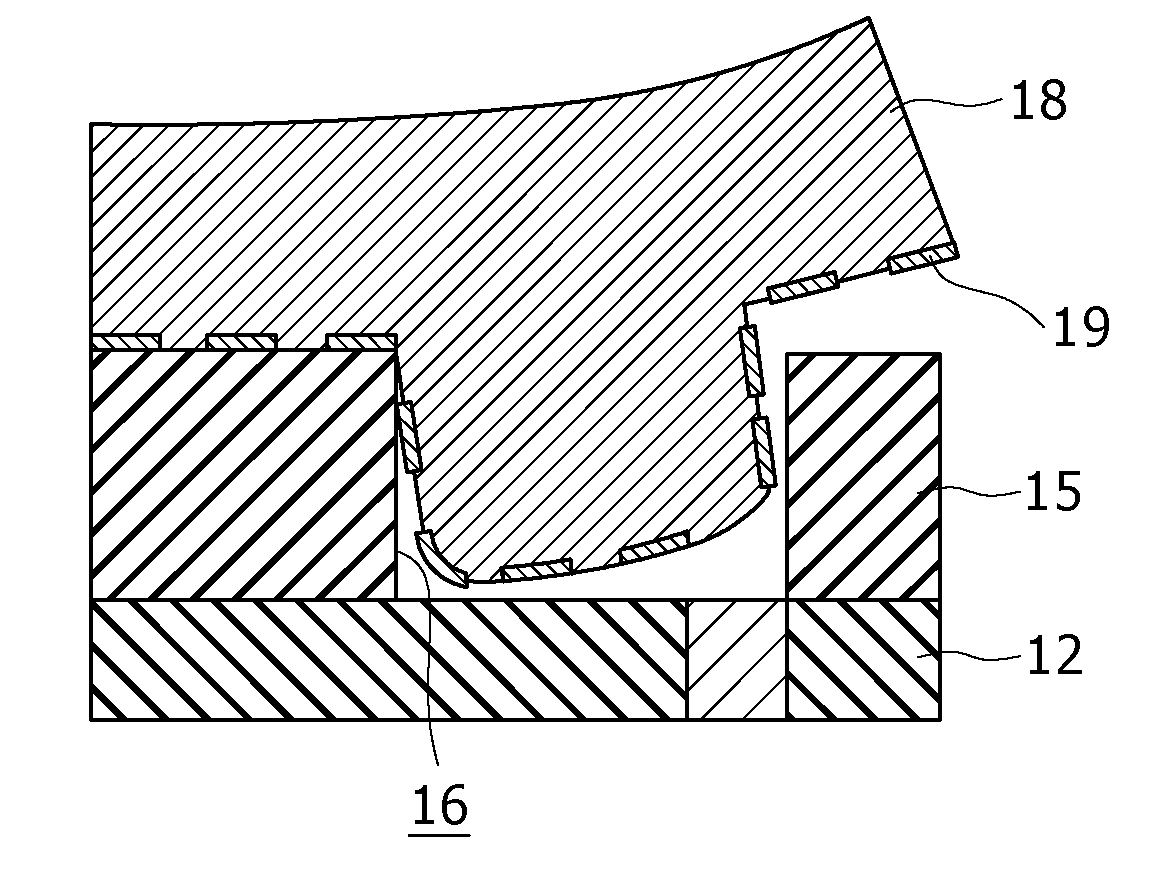

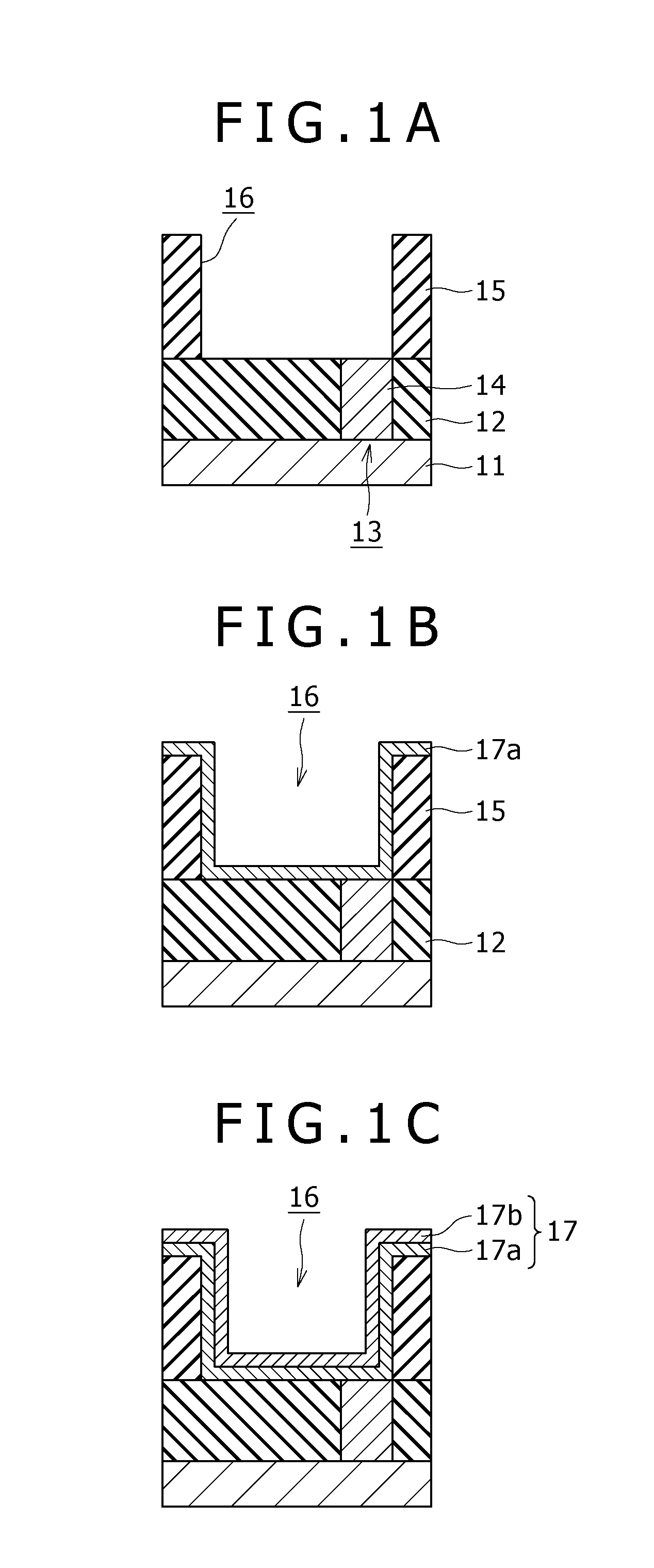

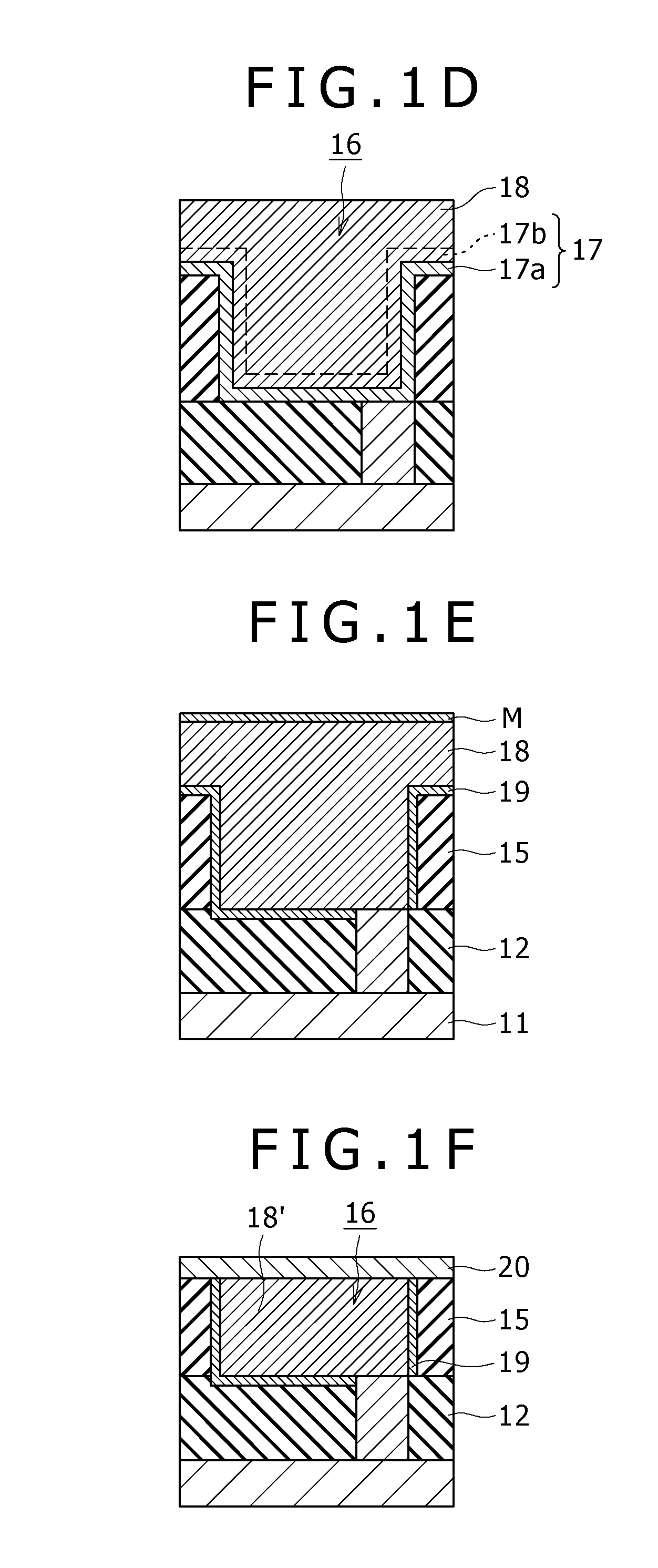

Through silicon hole structure with step and manufacture process of through silicon hole

InactiveCN102376689AReduce current densitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

The invention discloses a through silicon hole structure with a step, which comprises a semiconductor substrate and a through hole penetrating through the semiconductor substrate and having the step, wherein an insulation layer, an adhesion layer and a barrier layer are sequentially deposited on the side wall of the step through hole; a metal conductor is filled in the through hole; an interconnecting structure formed by sequential deposition of the insulation layer, the adhesion layer, the barrier layer and a conductive layer is deposited on the surface of the semiconductor substrate; and the conductive layer in the interconnecting structure is connected with the metal conductor. The invention also provides a manufacture process of the through silicon hole structure. The step in the through silicon hole can allow copper cylinder protruding height difference caused by local electroplating rate difference in an electroplating hole-filling process, and avoids silicon wafer breakage caused by the problem in a chemical mechanical polishing (MCP) process and a bonding process.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing semiconductor device

InactiveUS20080173547A1Avoid separationImprove uniformitySemiconductor/solid-state device detailsSolid-state devicesAlloyCopper

Disclosed herein is a method for manufacturing a semiconductor device, the method including the steps of: forming a recess in an insulating film provided over a substrate; forming a plating seed layer in such a way that an inner wall of the recess is covered, the plating seed layer arising from sequential deposition of an alloy layer composed of copper and a metal other than copper and a conductive layer composed mainly of copper; burying a conductive layer composed mainly of copper by plating in the recess on which the plating seed layer is provided; and carrying out heat treatment to cause the metal in the alloy layer to react with a constituent in the insulating film, to thereby form a barrier film composed of a metal compound having a copper diffusion barrier function at an interface between the alloy layer and the insulating film.

Owner:SONY CORP

Cr/CrAlN gradient coating technology of supercritical water-cooled reactor fuel can surface

InactiveCN102787300ARelieve heat stressEnhanced interface bindingVacuum evaporation coatingSputtering coatingOxidation resistantAustenite

The invention belongs to the surface modification technology of a nuclear reactor structure material, and concretely relates to a Cr / CrAlN gradient coating technology of a supercritical water-cooled reactor fuel can surface. The technology comprises the steps of treating before plating, bias backwashing, arc ion reinforced reaction magnetron sputtering, sequential deposition of a Cr transition coating and a CrAlN gradient coating on the surface of an austenitic stainless steel matrix, and coating thermal treatment. The Cr / CrAlN gradient coating technology enables the oxidation resistant temperature of the Cr / CrAlN gradient coating to reach above 700DEG C, the hardness of the Cr / CrAlN gradient coating to reach above 2200Hv, the adhesion of the Cr / CrAlN gradient coating to reach above 35N, and the high temperature oxidation resistance, the combination force, the thermal shock resistance and the mechanical performances of the supercritical water-cooled reactor fuel can surface to be good, so the coordination and the unification of the structure and the functions of the surface coating are realized, thereby the use performances and the service life of the supercritical water-cooled reactor fuel are effectively improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com