Patents

Literature

621 results about "Tantalum nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum nitride (TaN) is a chemical compound, a nitride of Tantalum. There are multiple phases of compounds, stoichimetrically from Ta₂N to Ta₃N₅ including TaN. As a thin film TaN find use as a diffusion barrier and insulating layer between copper interconnects in the back end of line of computer chips. Tantalum nitrides are also used in thin film resistors.

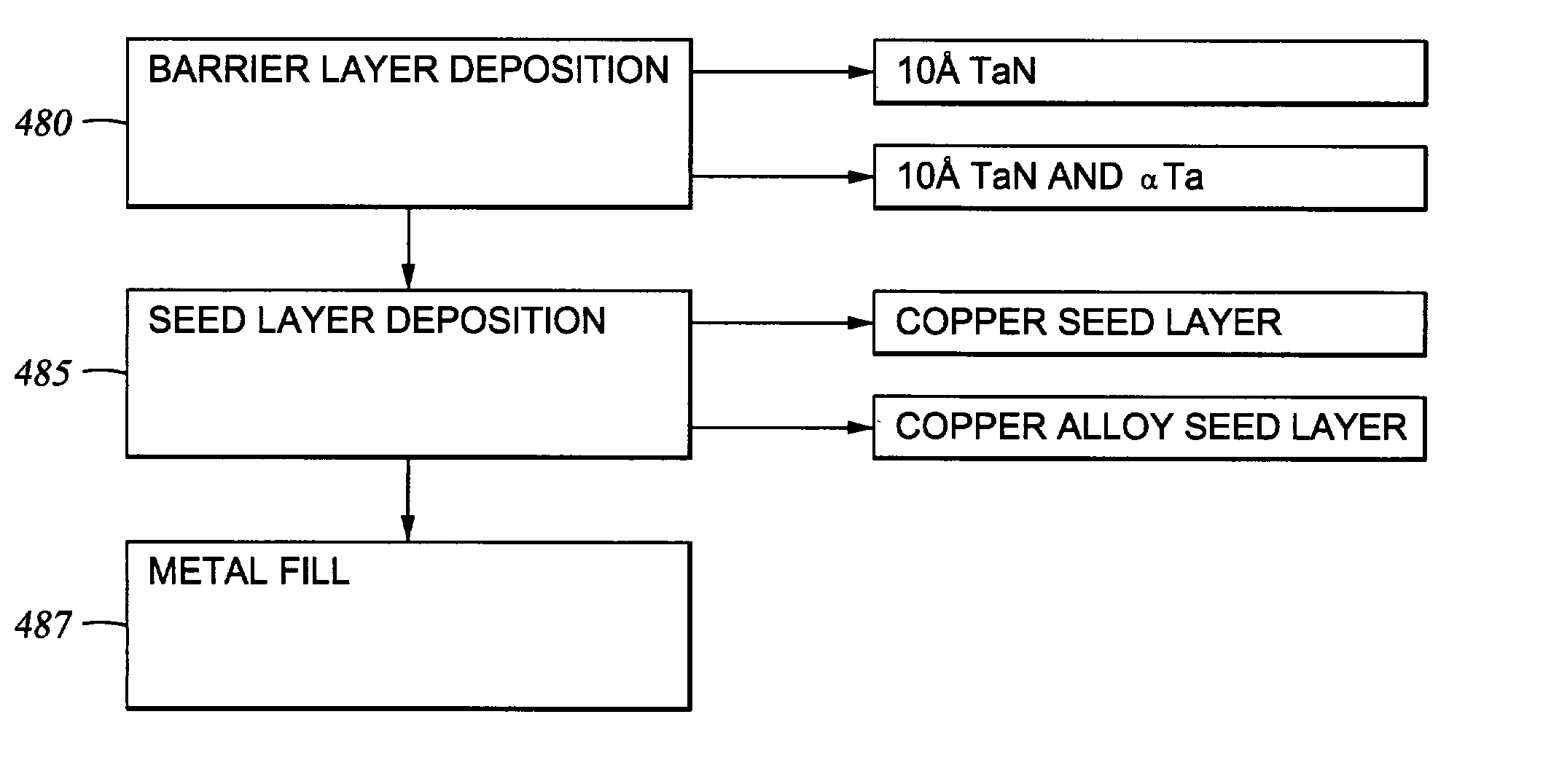

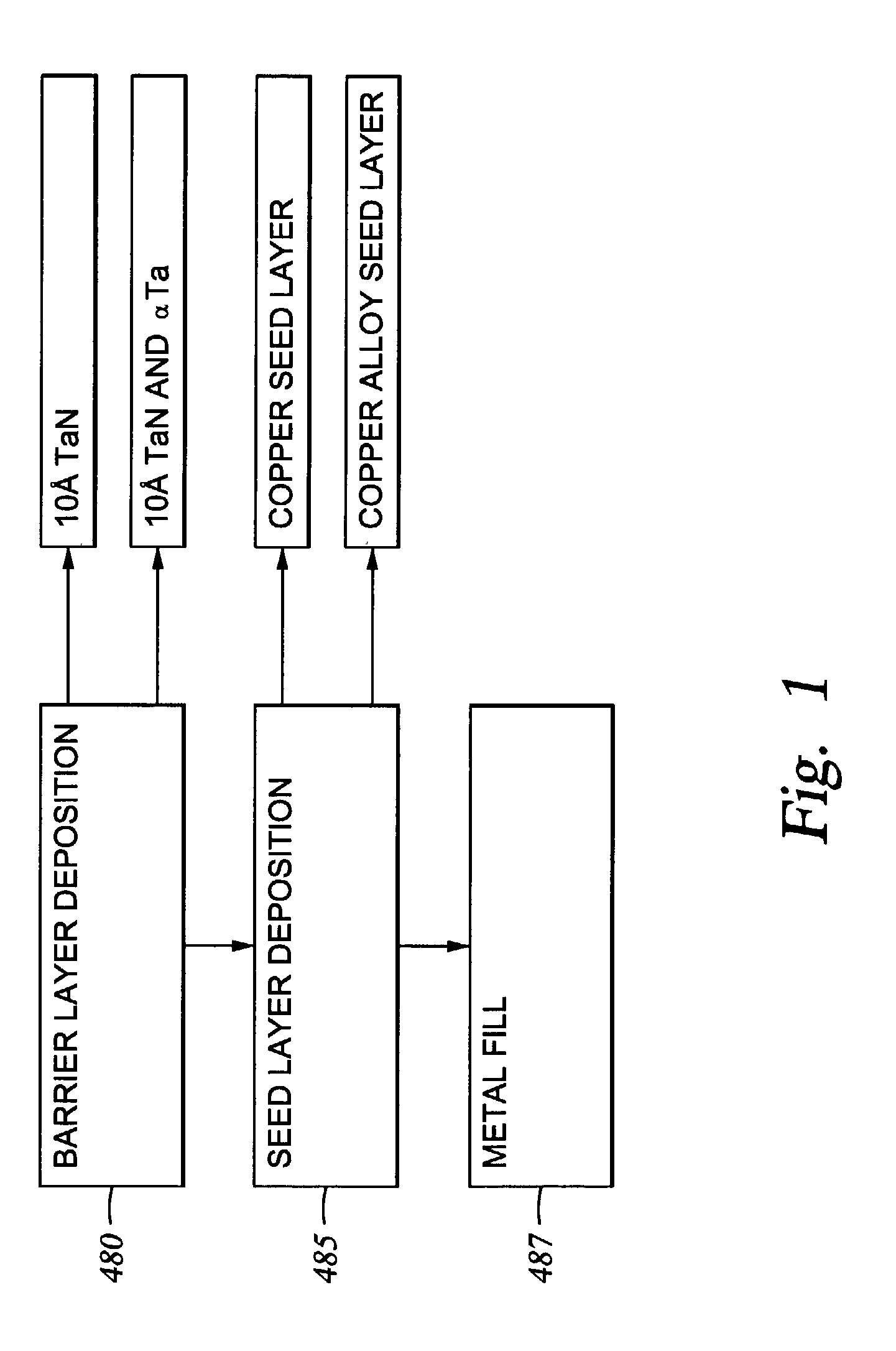

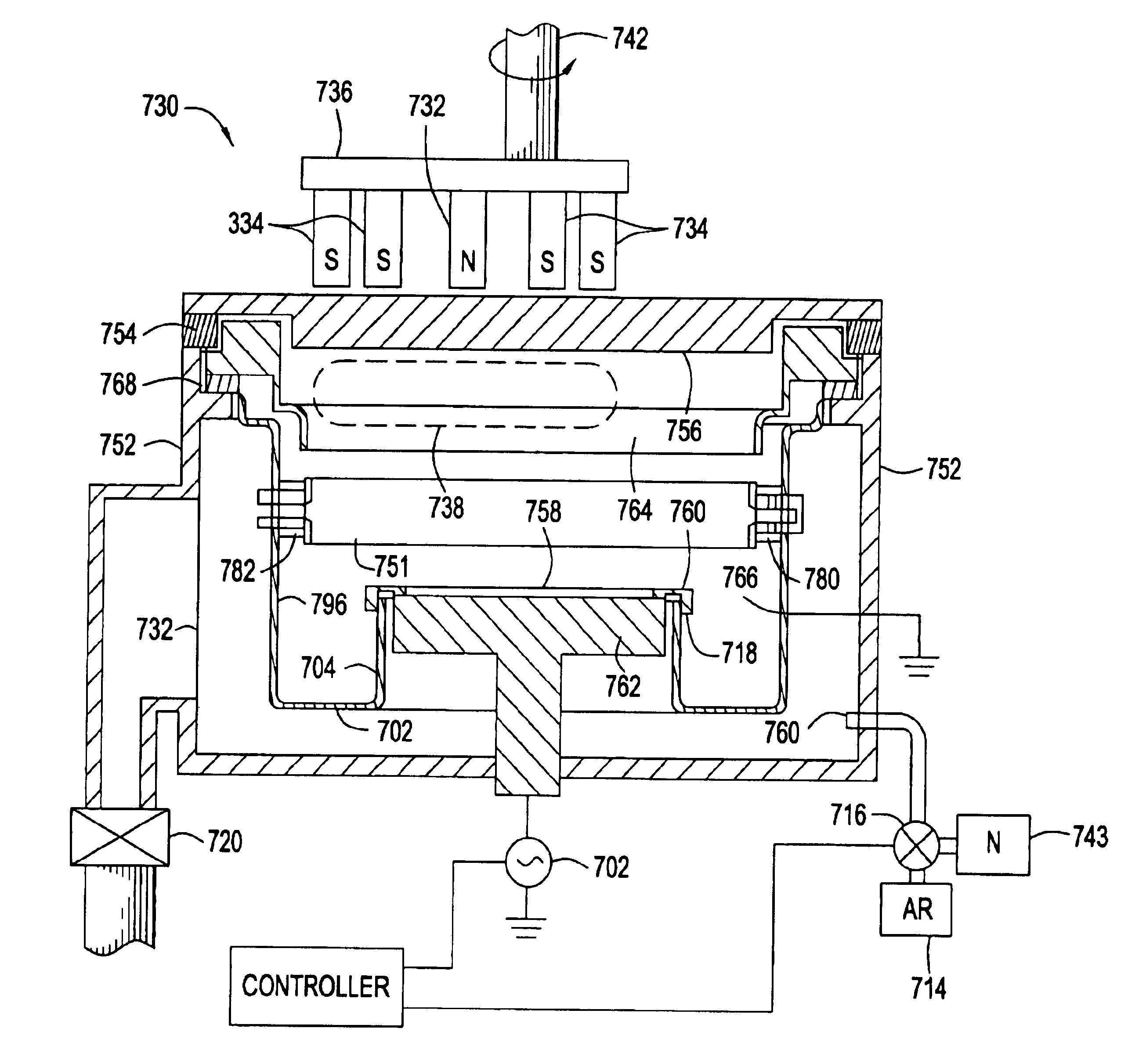

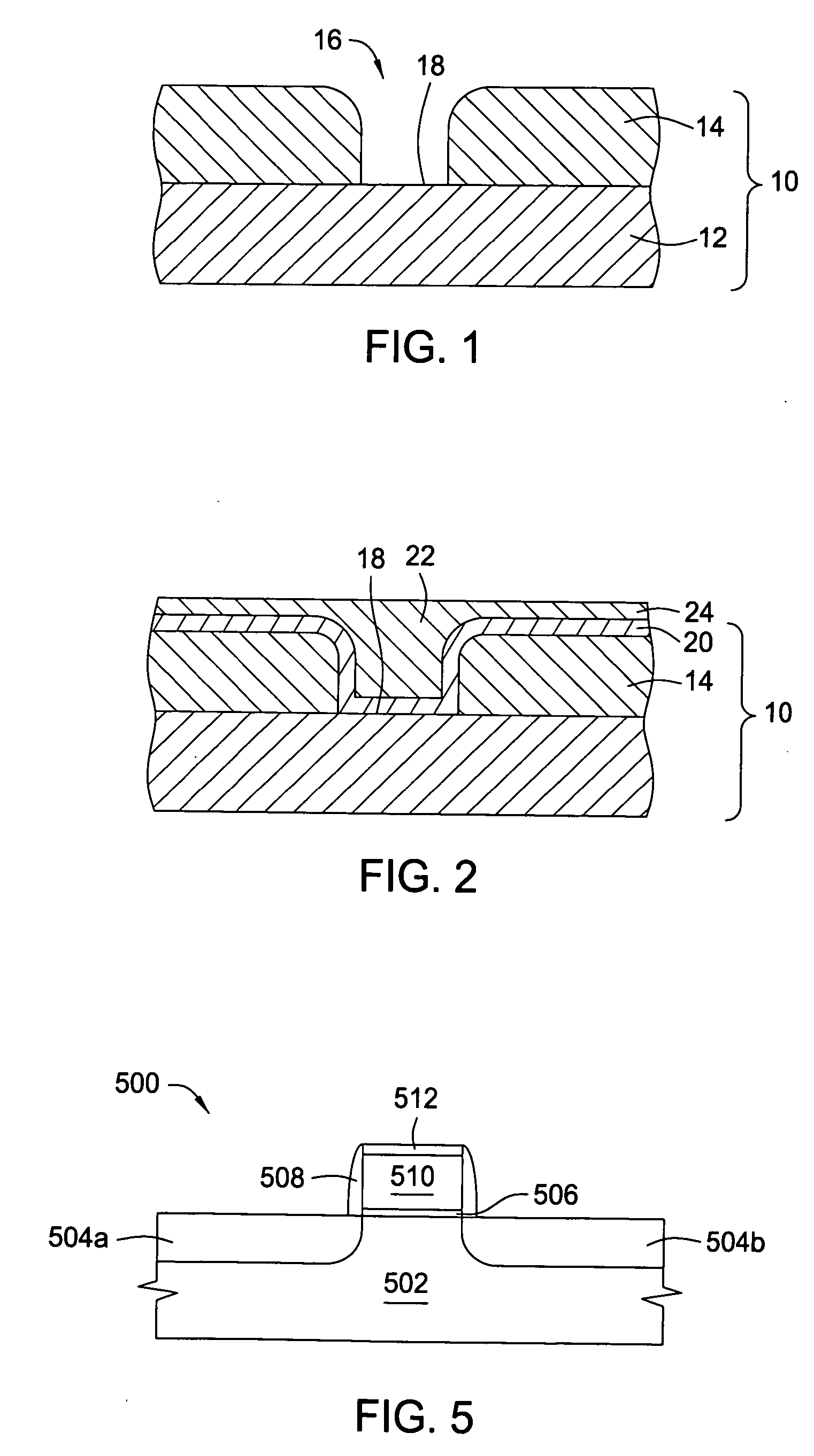

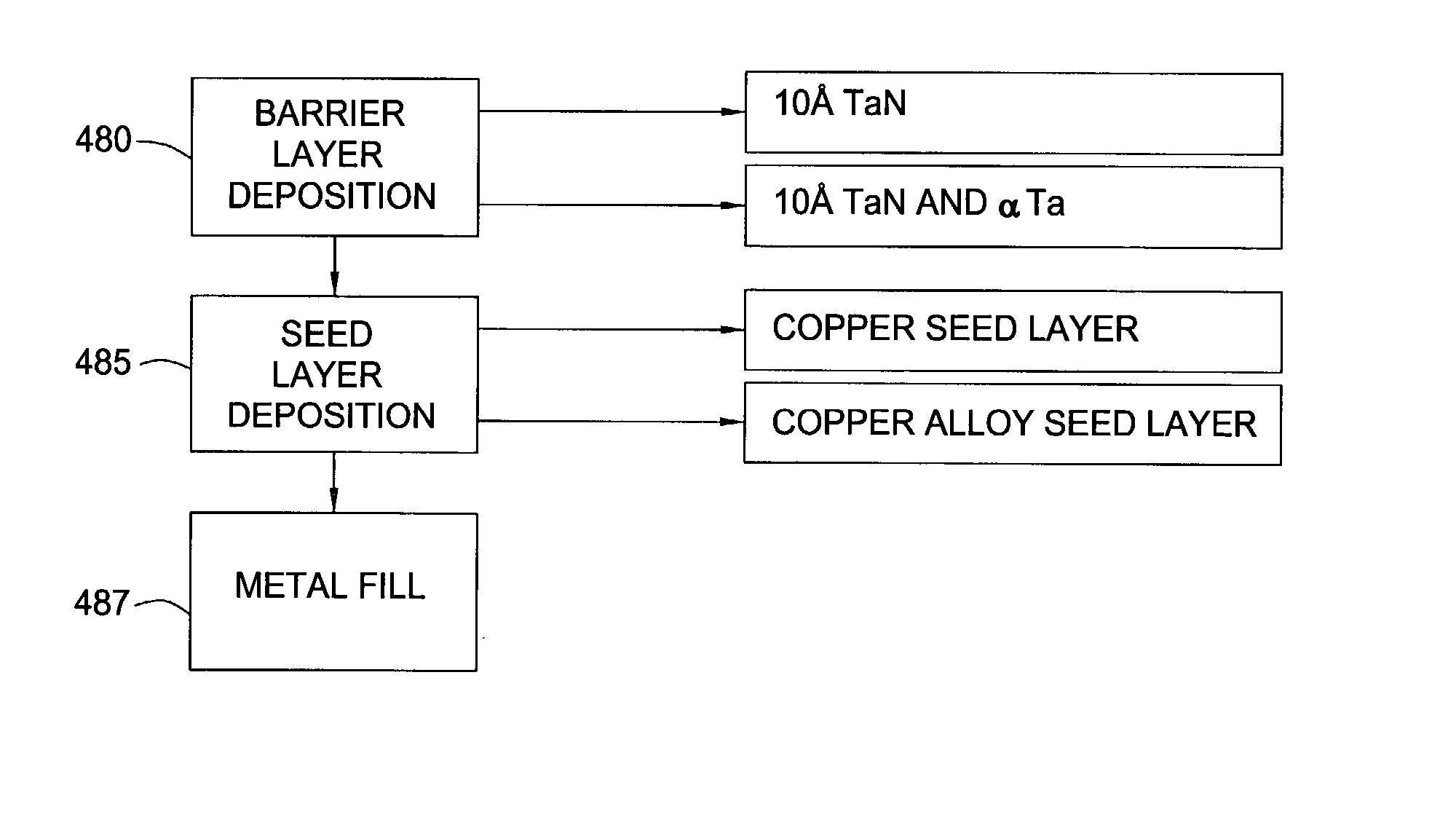

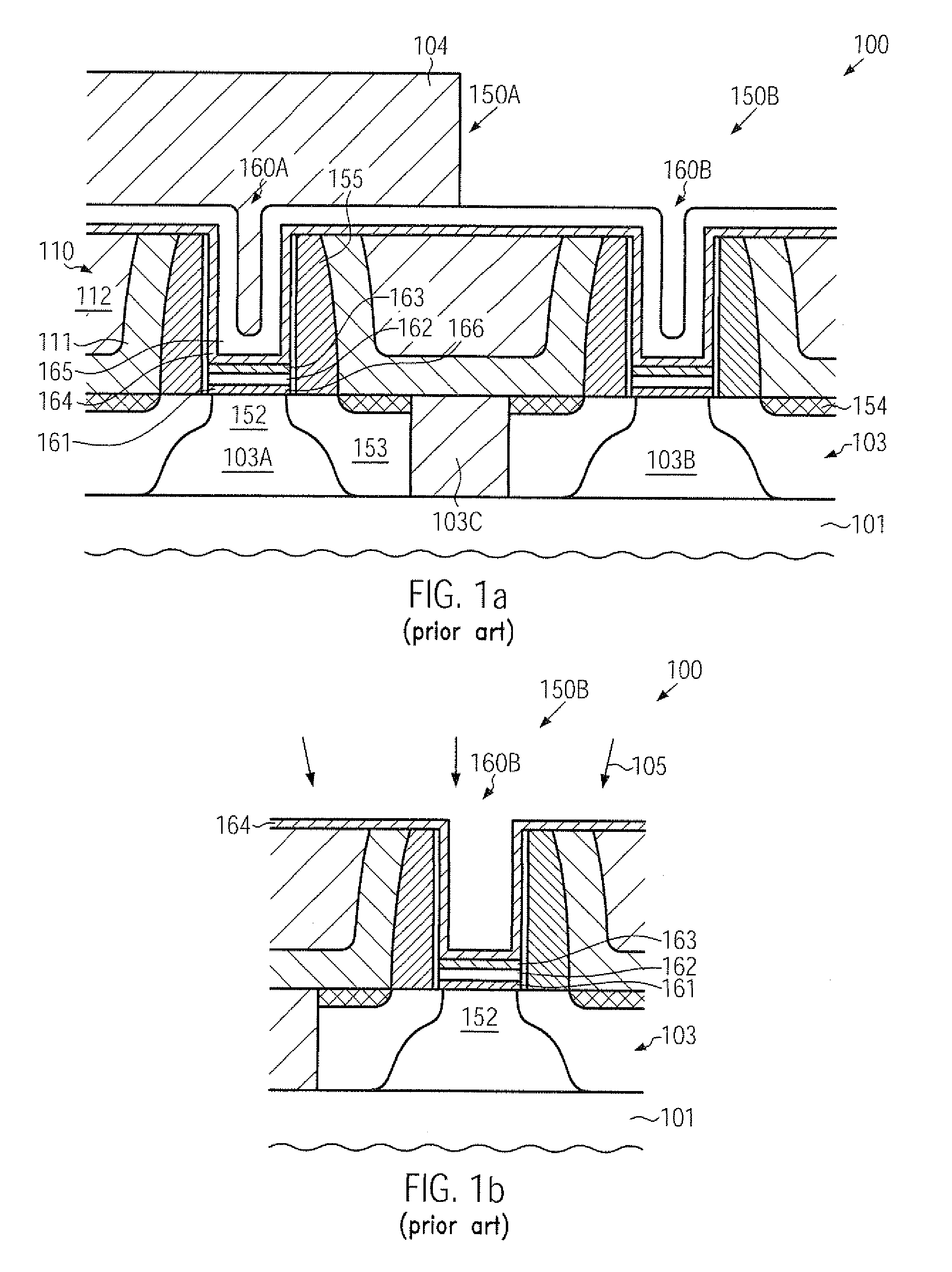

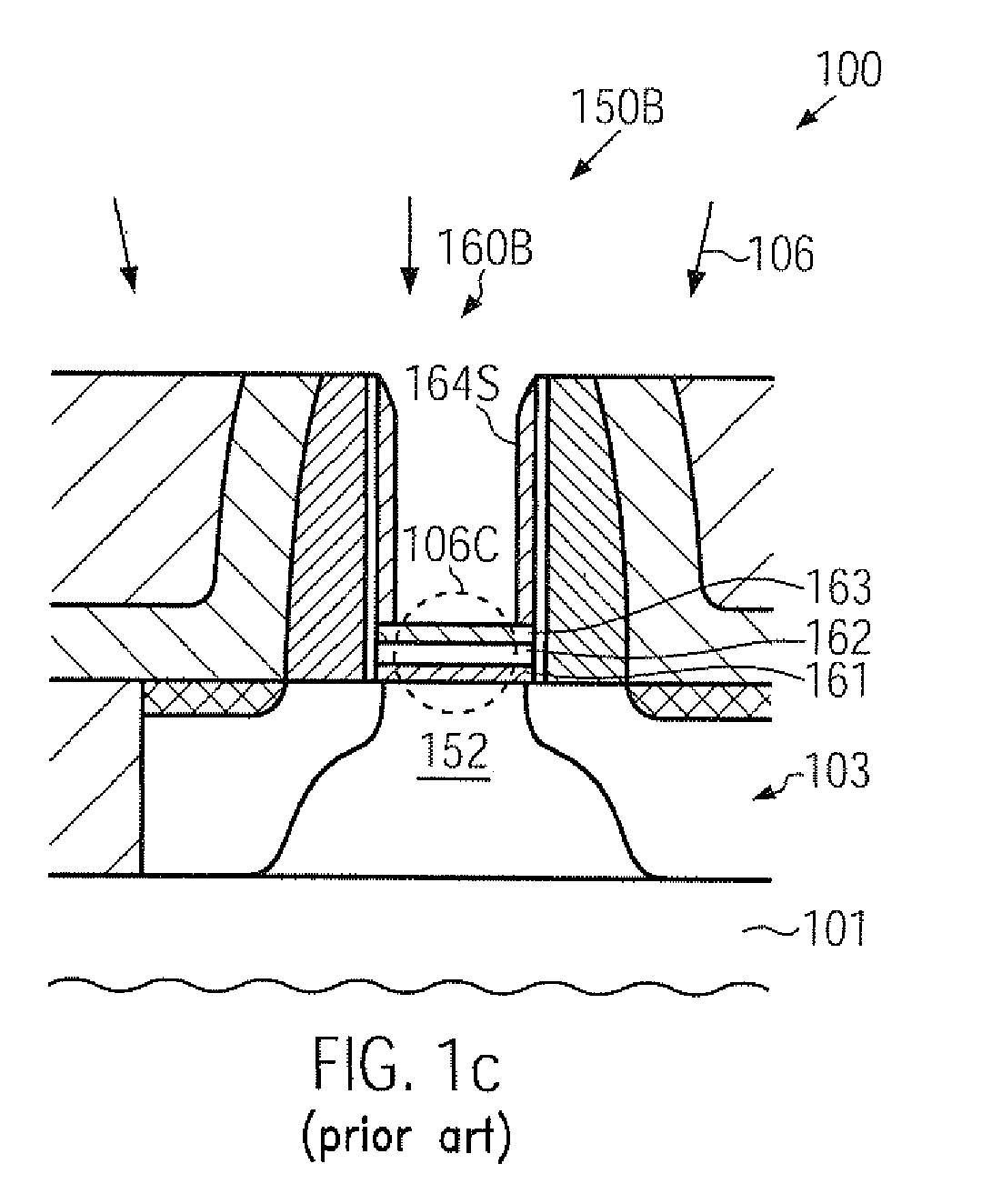

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

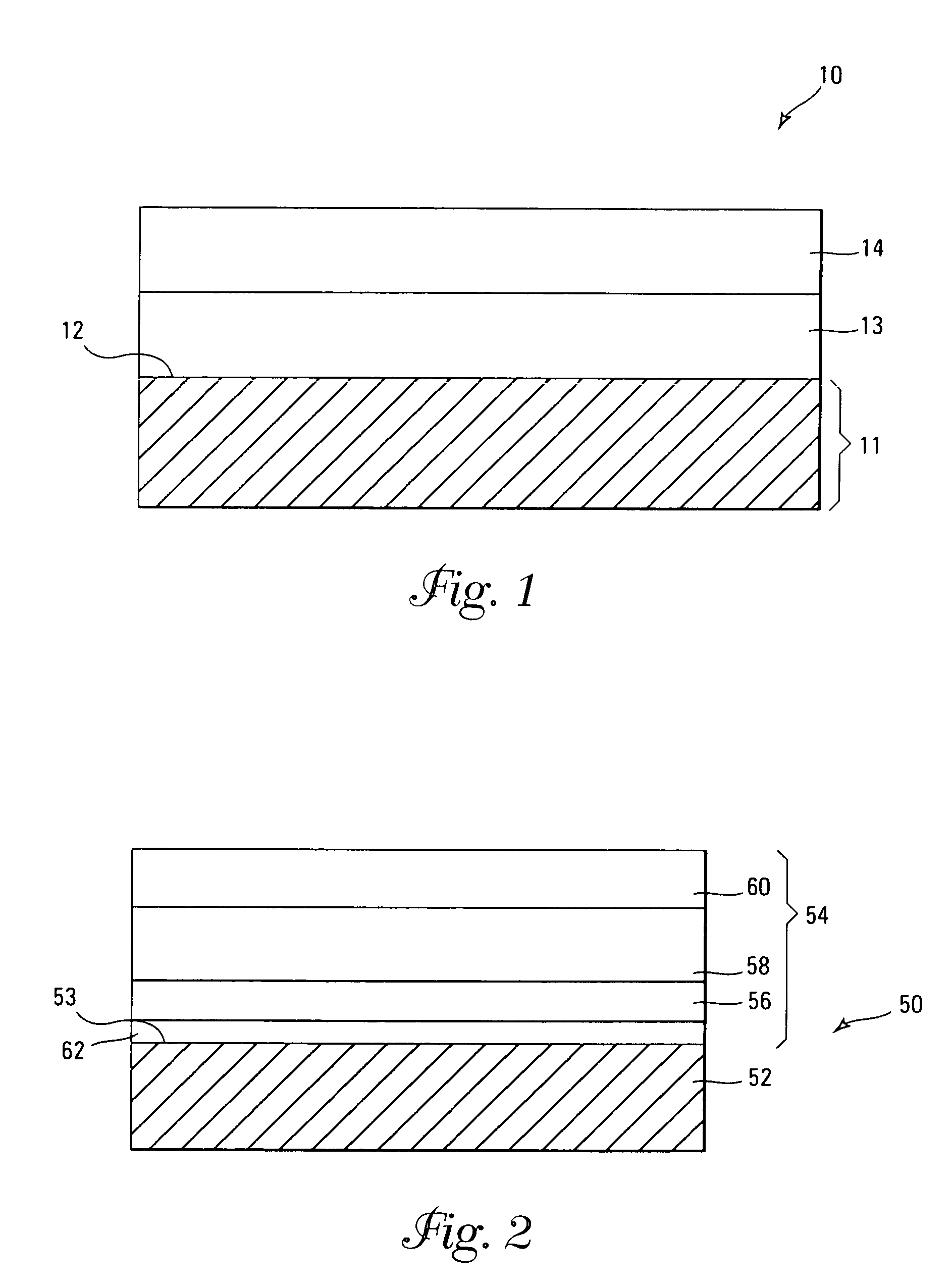

InactiveUS20030082307A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

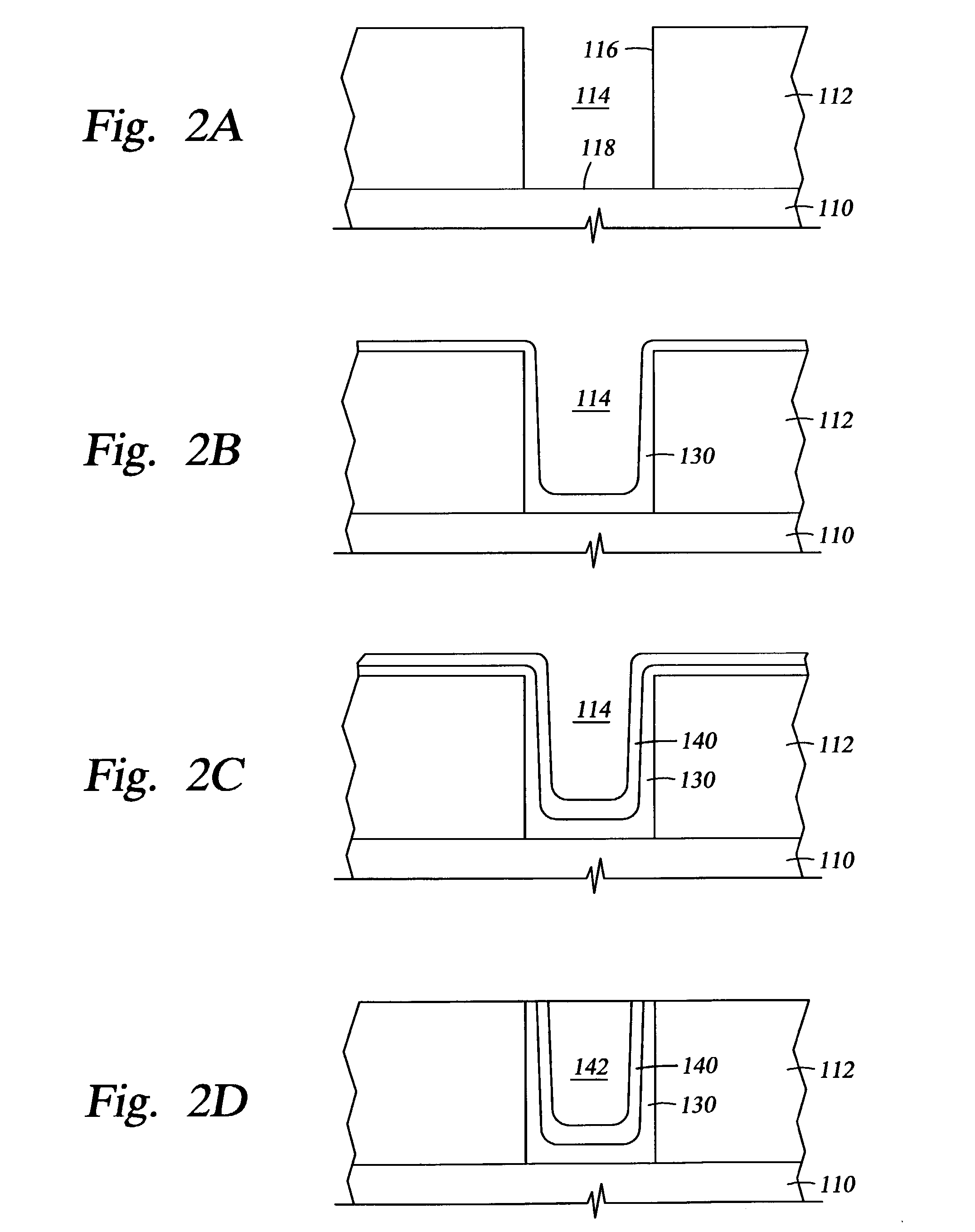

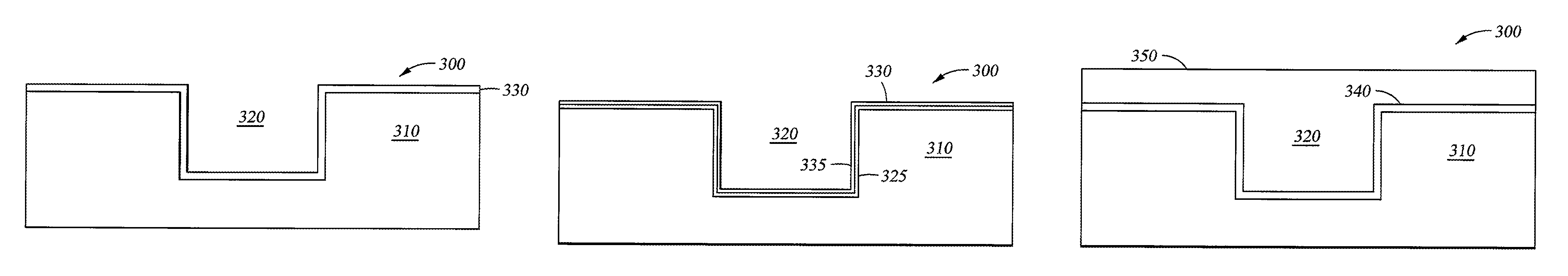

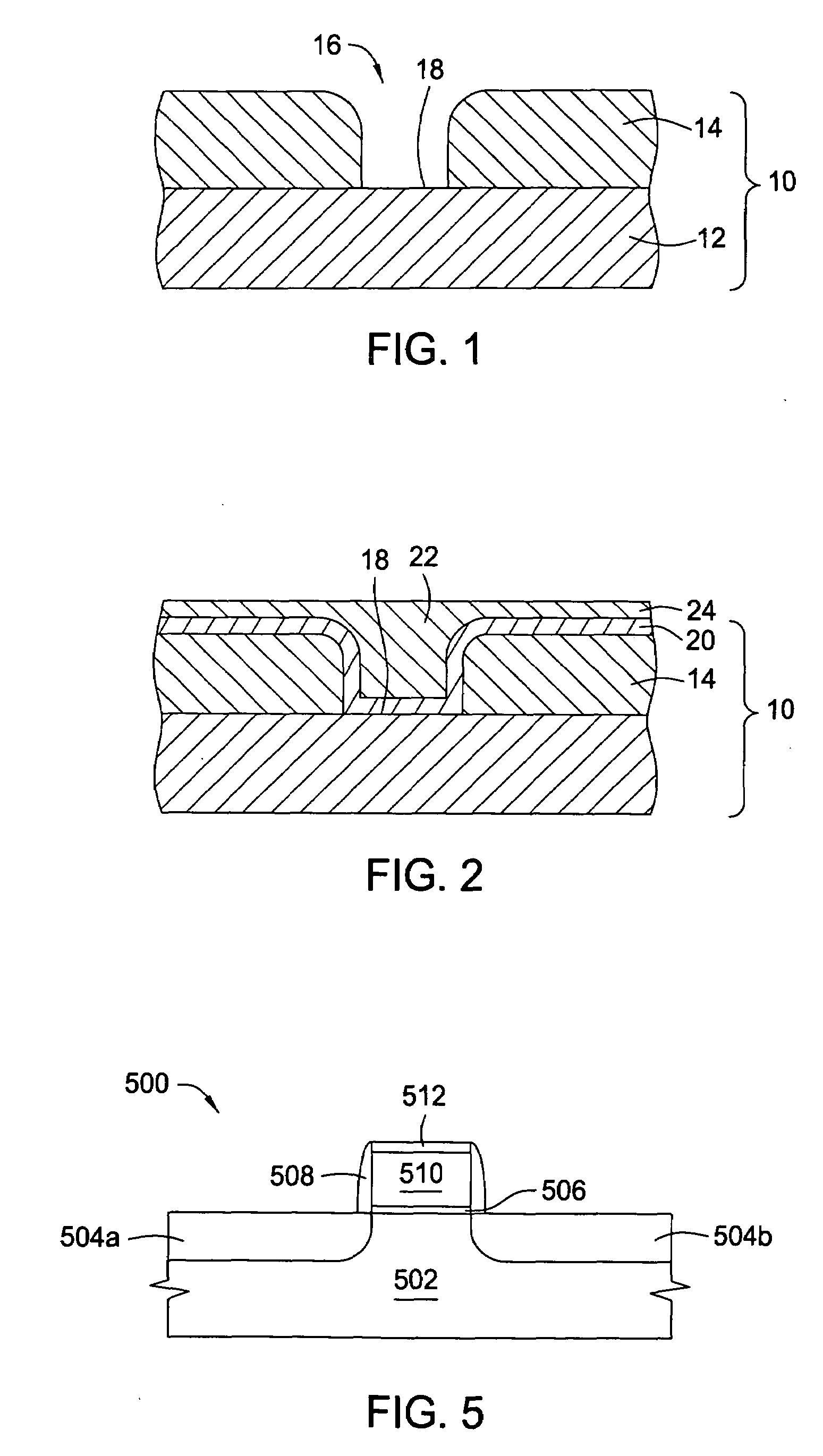

A method for forming a metal interconnect on a substrate is provided. The method includes depositing a refractory metal-containing barrier layer having a thickness less than about 20 angstroms on at least a portion of a metal layer by alternately introducing one or more pulses of a metal-containing compound and one or more pulses of a nitrogen-containing compound. The method also includes depositing a seed layer on at least a portion of the barrier layer, and depositing a second metal layer on at least a portion of the seed layer. The barrier layer provides adequate barrier properties and allows the grain growth of the metal layer to continue across the barrier layer into the second metal layer thereby enhancing the electrical performance of the interconnect.

Owner:APPLIED MATERIALS INC

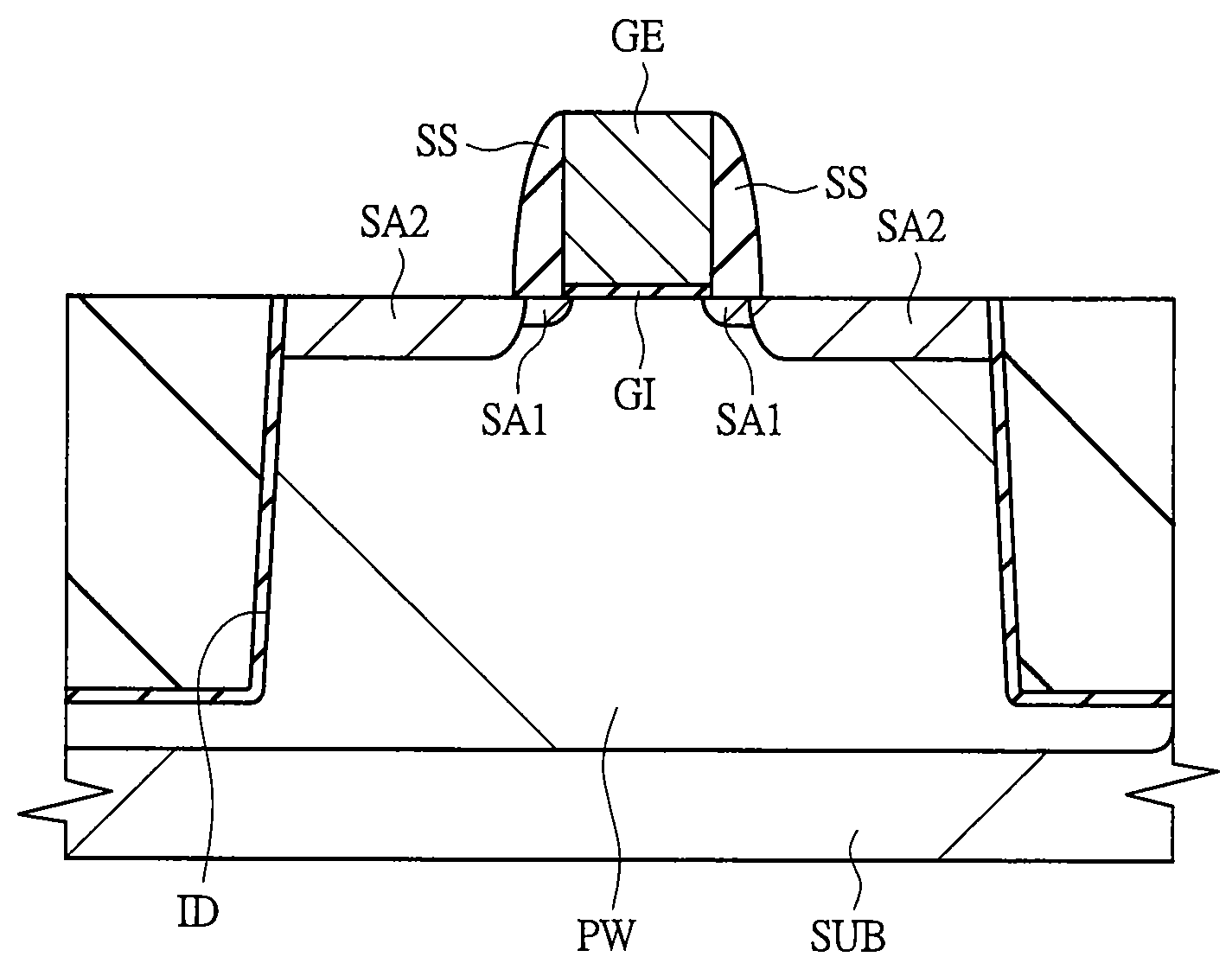

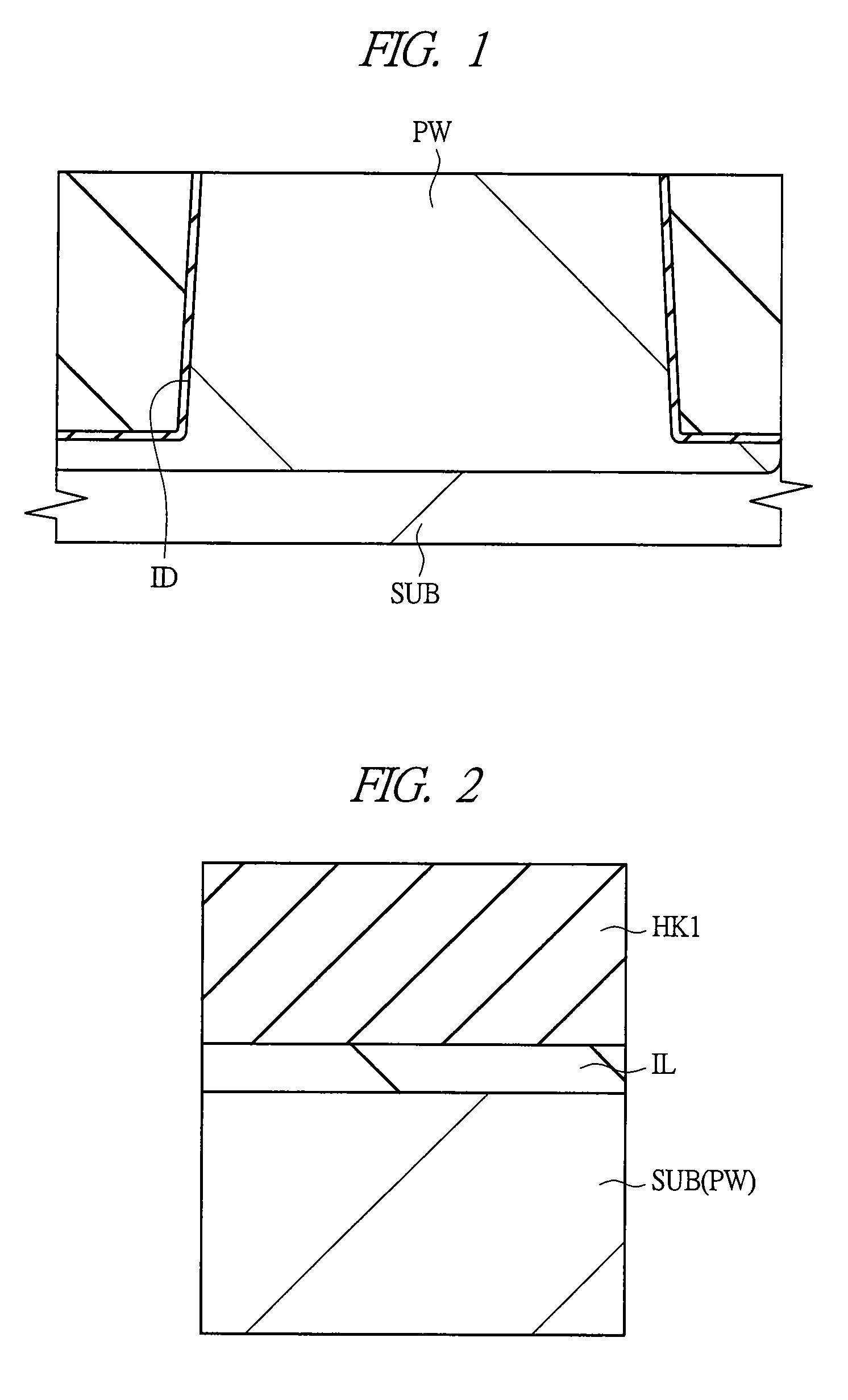

Manufacturing method of semiconductor device

InactiveUS20090011608A1Reduce hypoxiaSuppression of interface silicon oxide growthSemiconductor/solid-state device manufacturingSemiconductor devicesTantalum nitrideSilicon oxide

The transistor characteristics of a MIS transistor provided with a gate insulating film formed to contain oxide with a relative dielectric constant higher than that of silicon oxide are improved. After a high dielectric layer made of hafnium oxide is formed on a main surface of a semiconductor substrate, the main surface of the semiconductor substrate is heat-treated in a non-oxidation atmosphere. Next, an oxygen supplying layer made of hafnium oxide deposited by ALD and having a thickness smaller than that of the high dielectric layer is formed on the high dielectric layer, and a cap layer made of tantalum nitride is formed. Thereafter, the main surface of the semiconductor substrate is heat-treated.

Owner:RENESAS TECH CORP

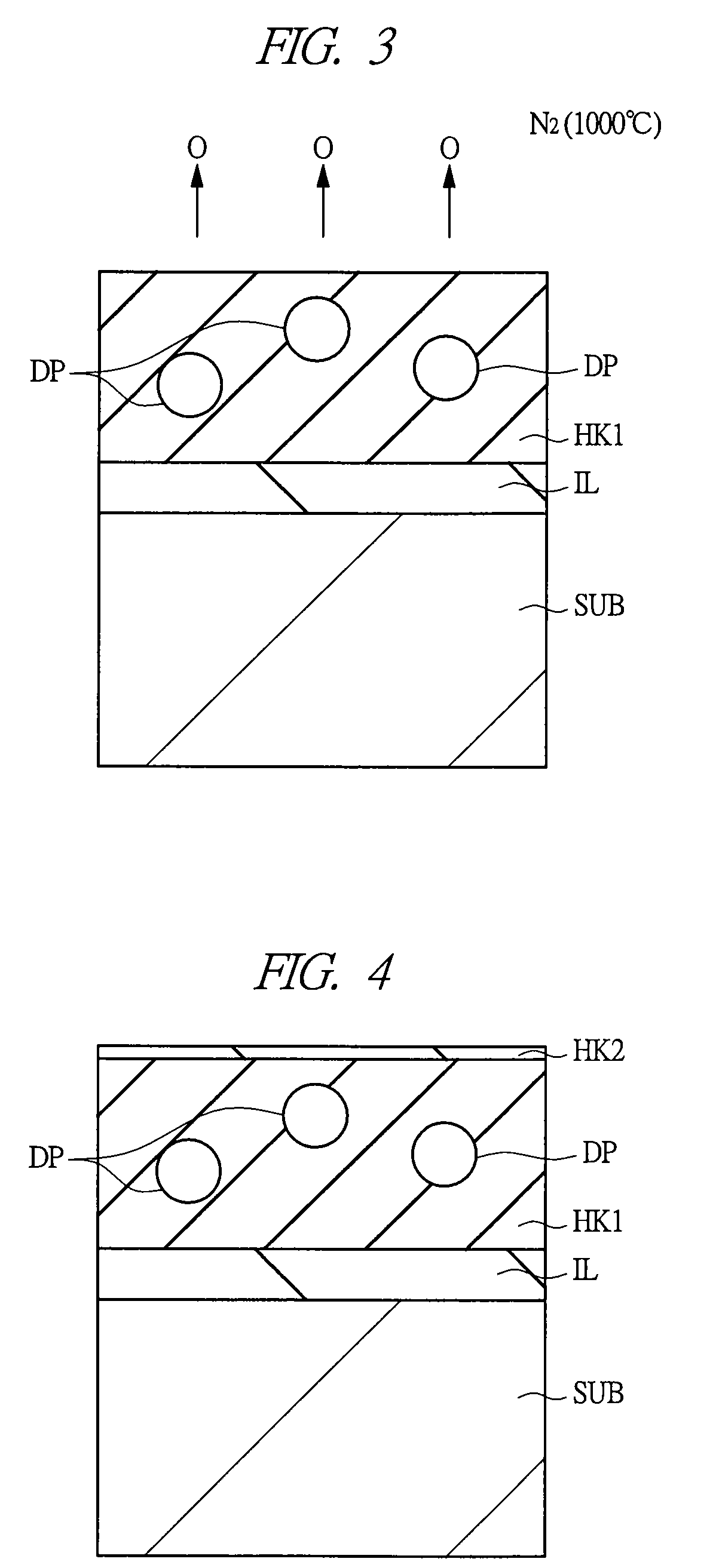

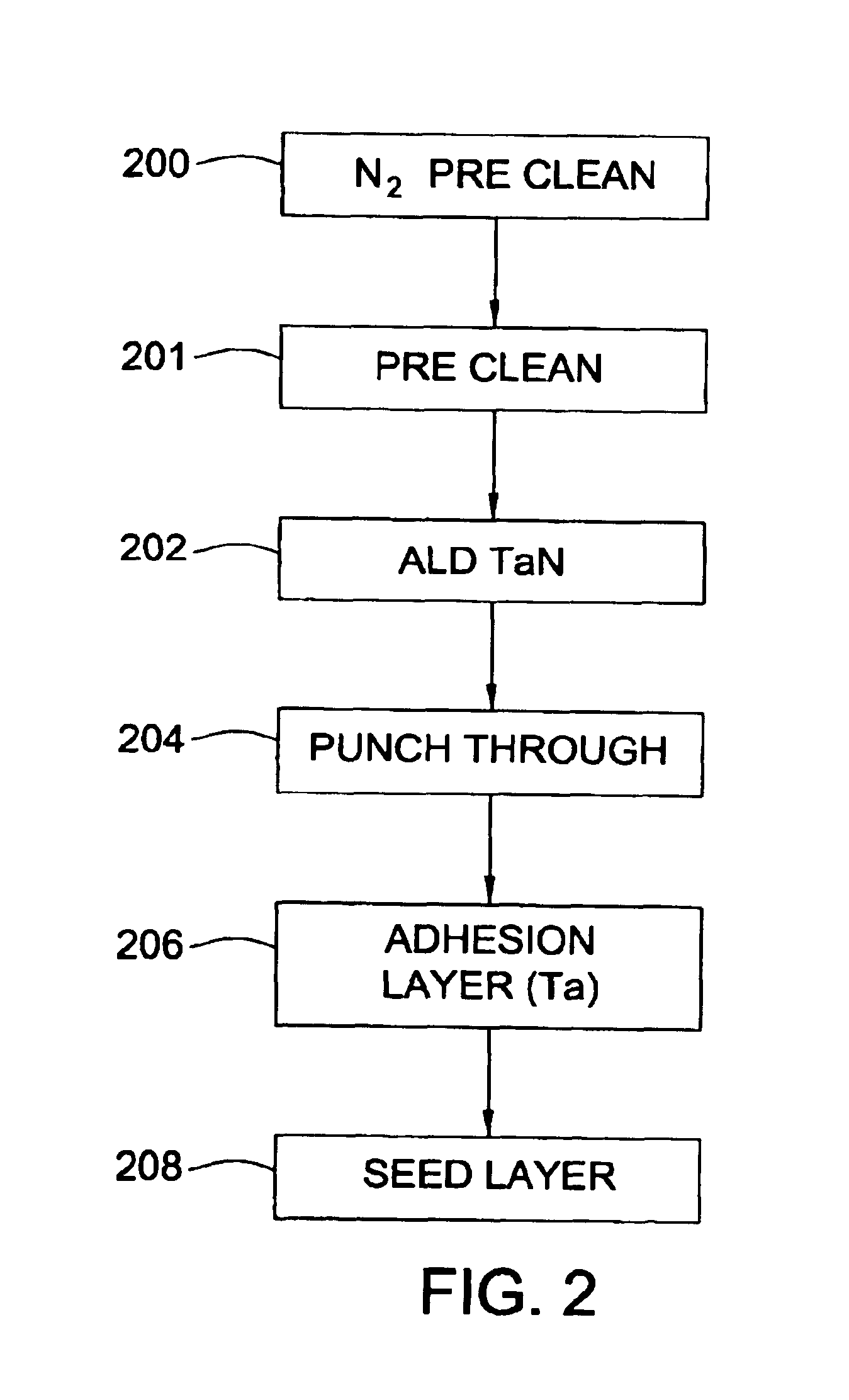

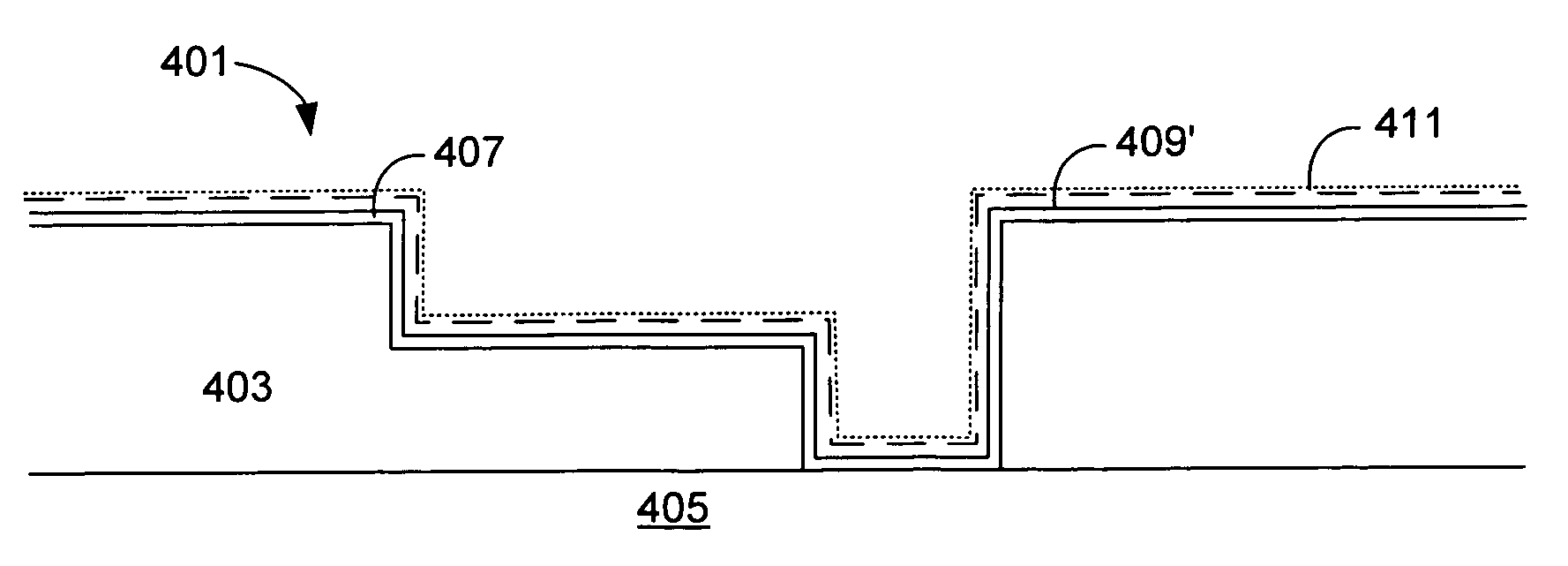

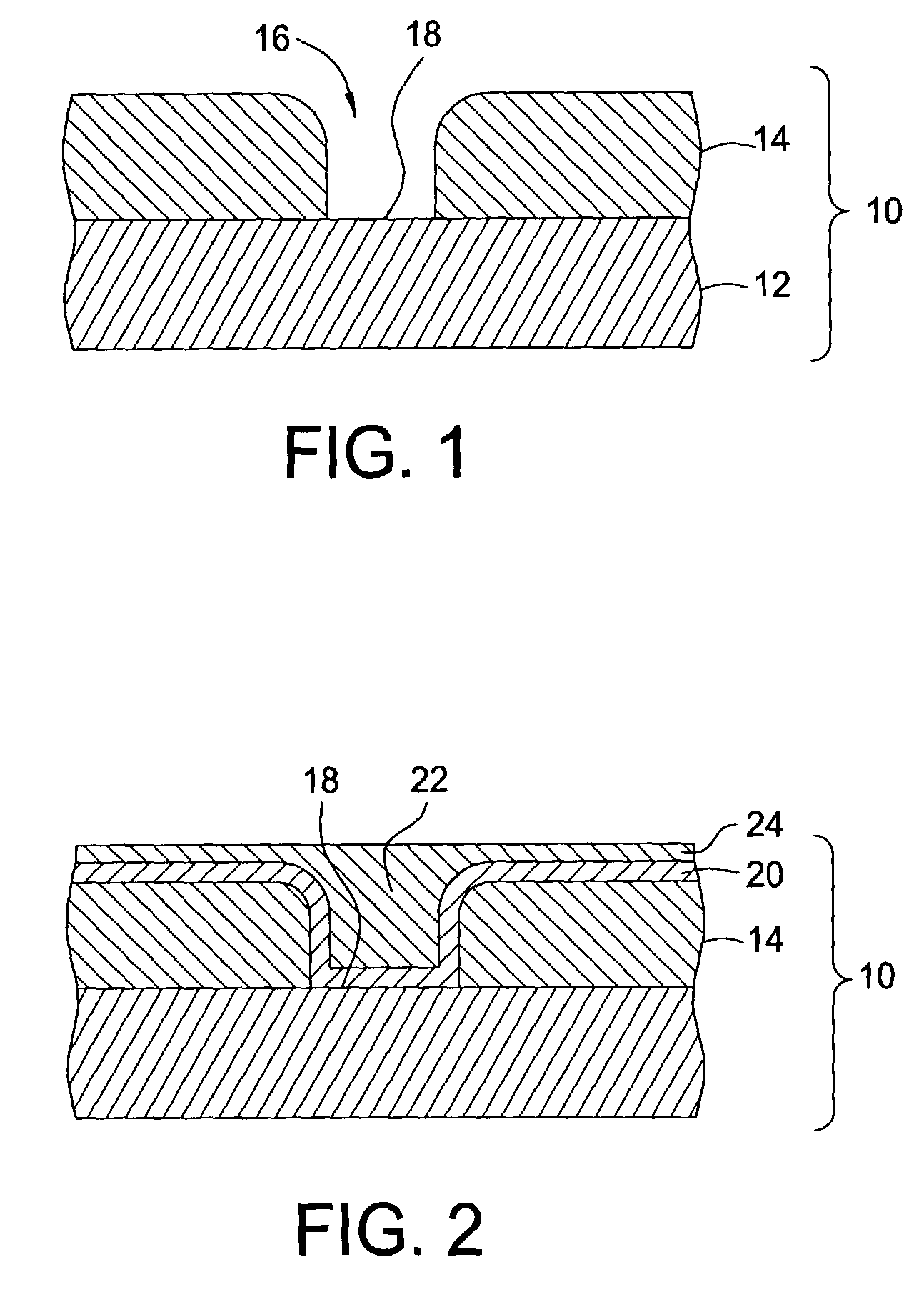

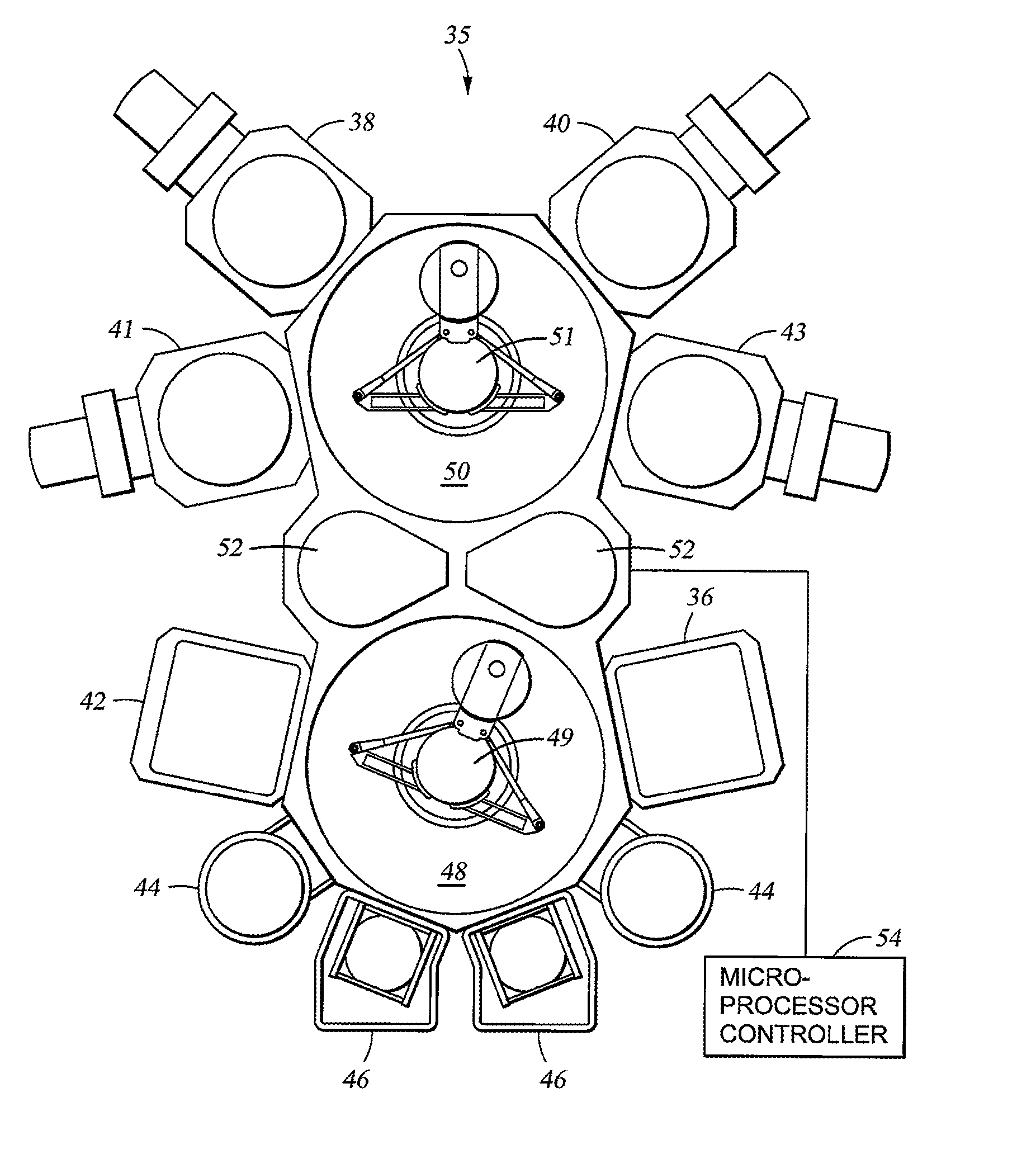

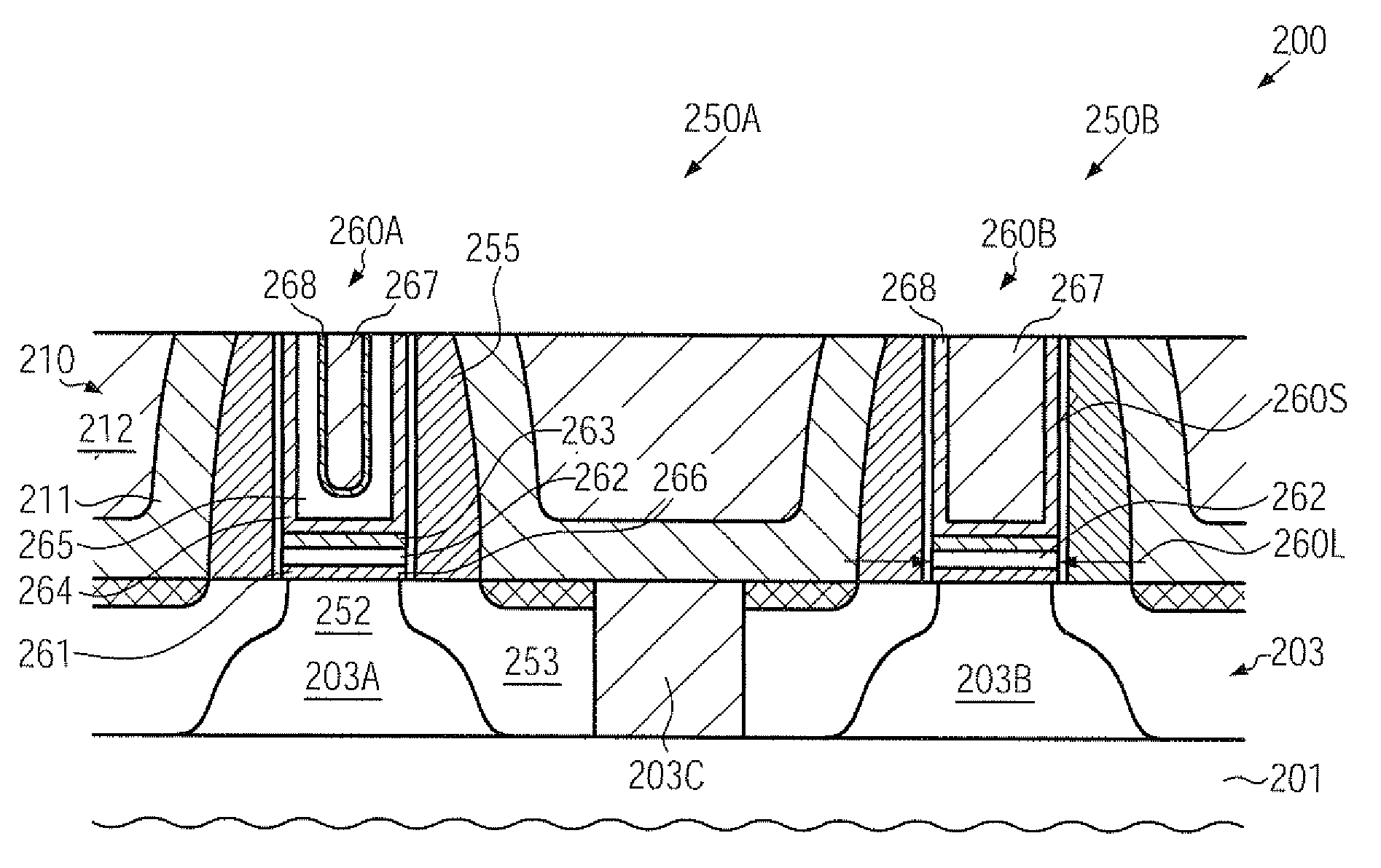

Integration of ALD tantalum nitride for copper metallization

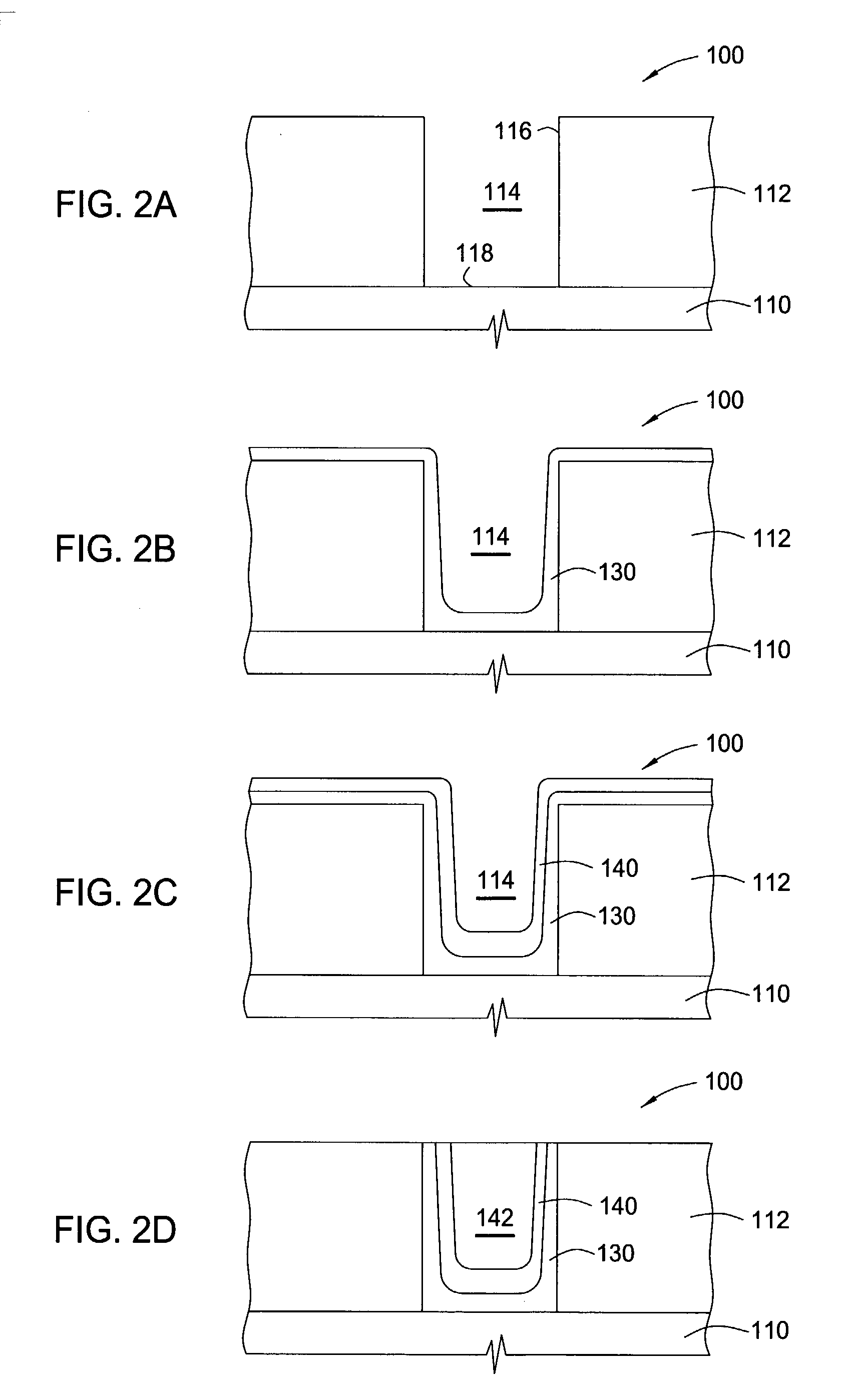

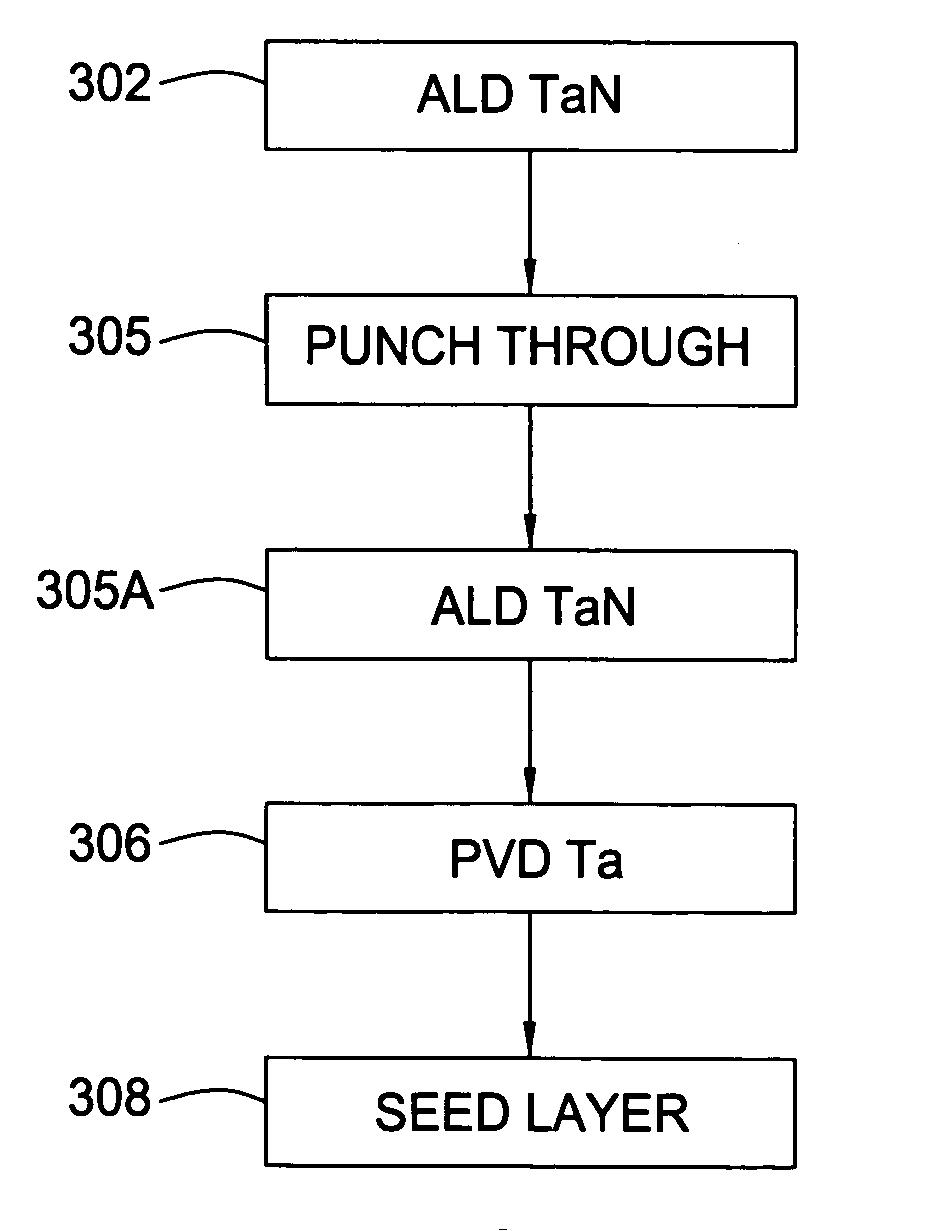

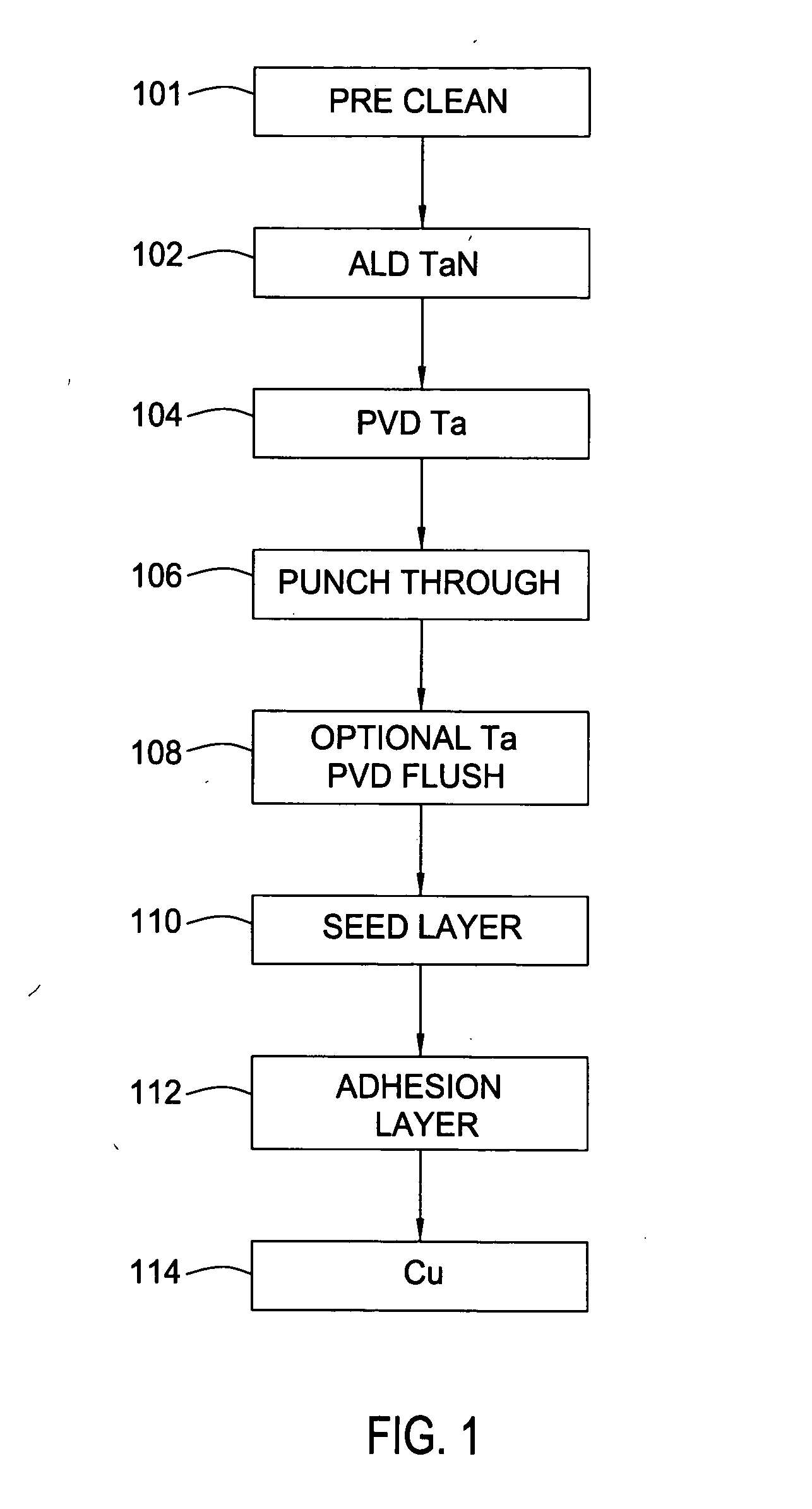

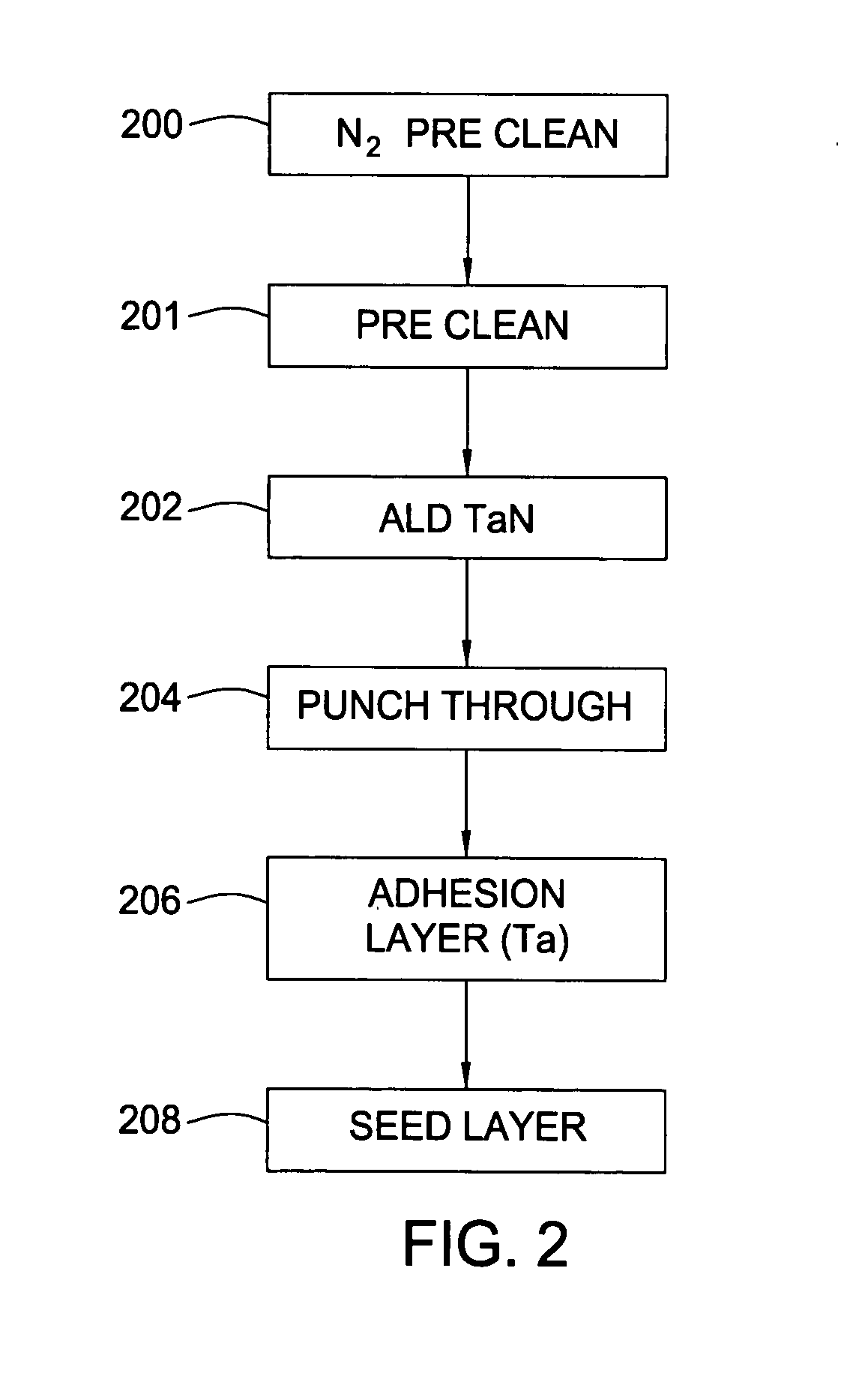

InactiveUS7049226B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideConductive materials

A method and apparatus for depositing a tantalum nitride barrier layer is provided for use in an integrated processing tool. The tantalum nitride is deposited by atomic layer deposition. The tantalum nitride is removed from the bottom of features in dielectric layers to reveal the conductive material under the deposited tantalum nitride. Optionally, a tantalum layer may be deposited by physical vapor deposition after the tantalum nitride deposition. Optionally, the tantalum nitride deposition and the tantalum deposition may occur in the same processing chamber.

Owner:APPLIED MATERIALS INC

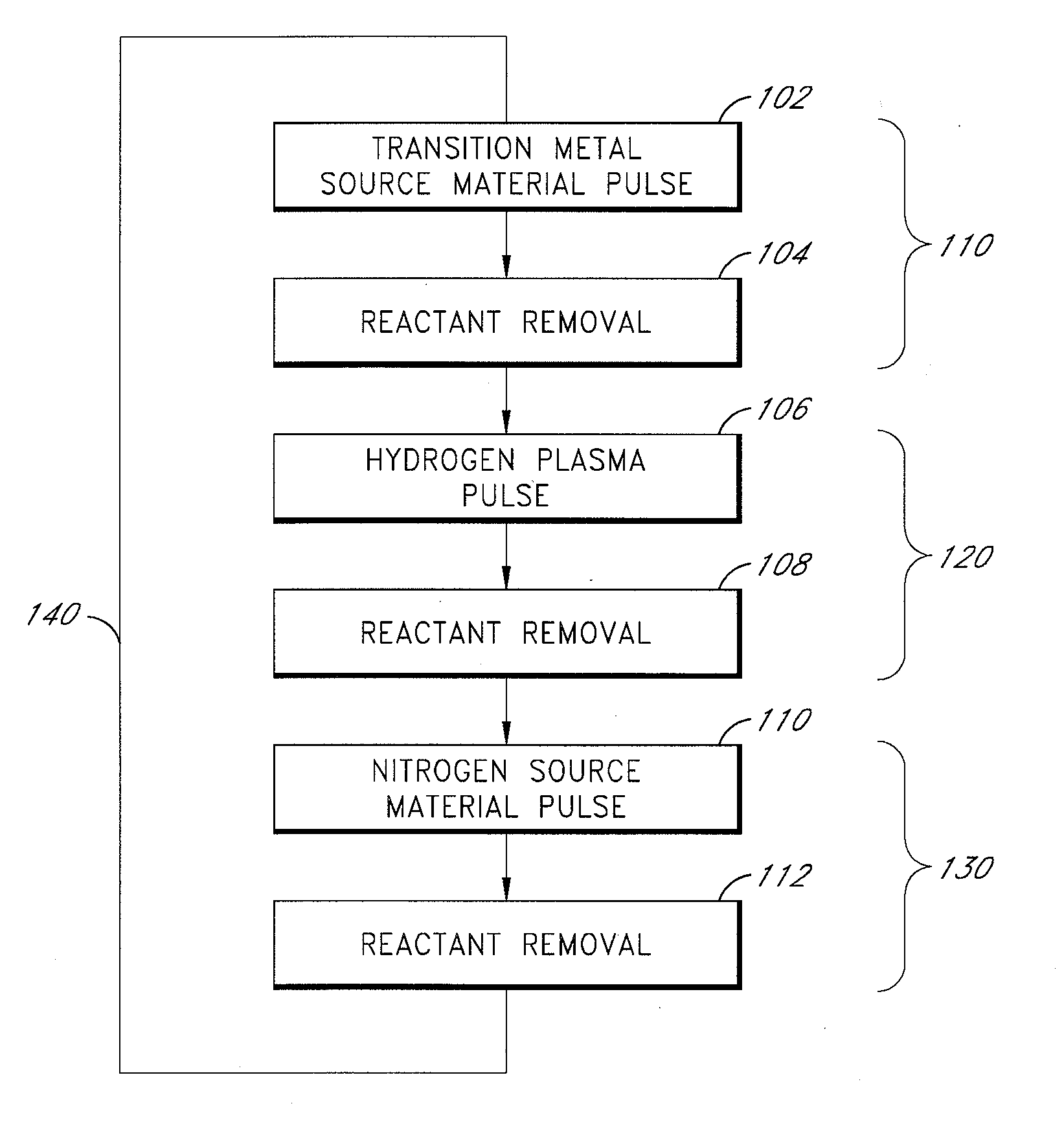

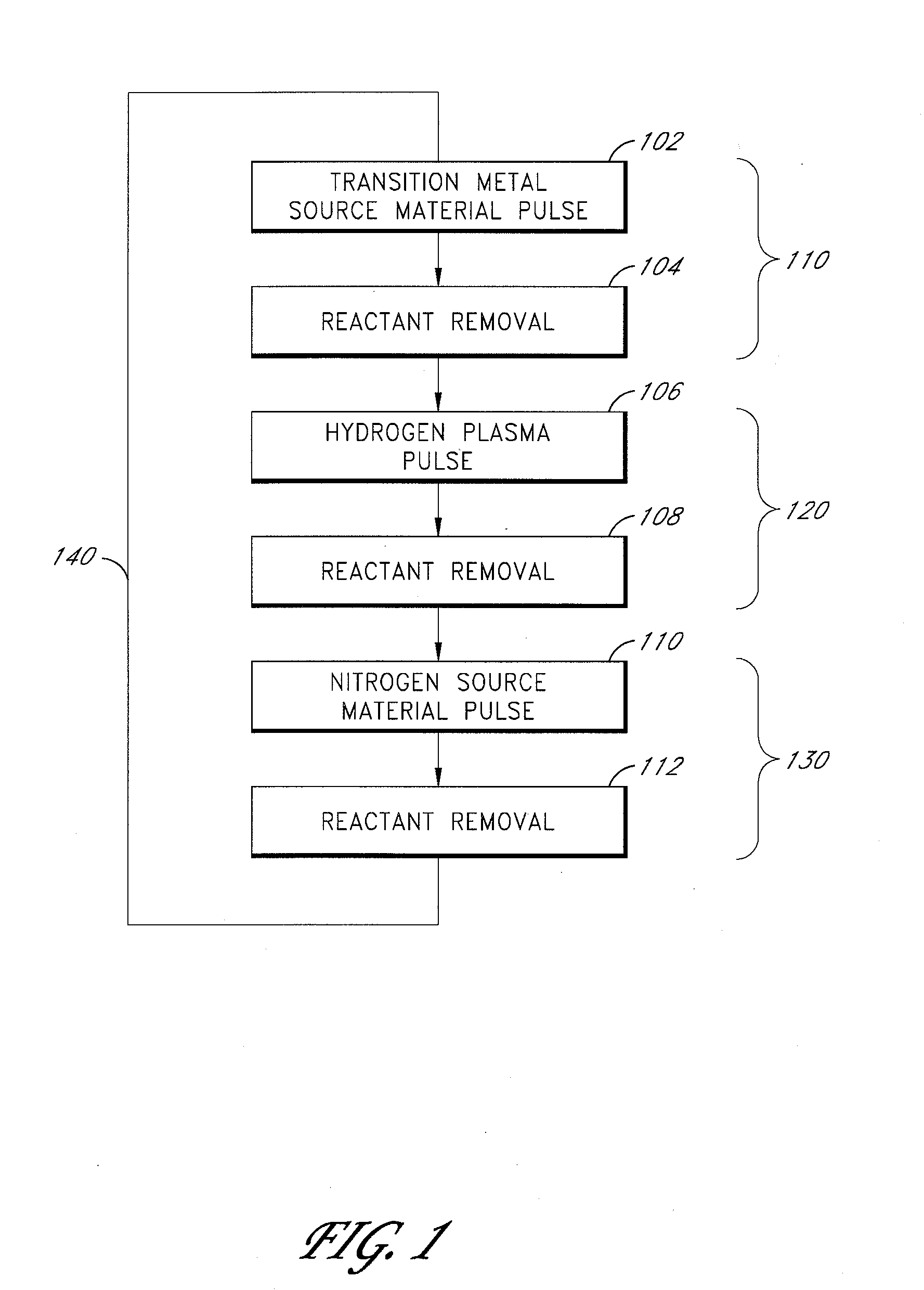

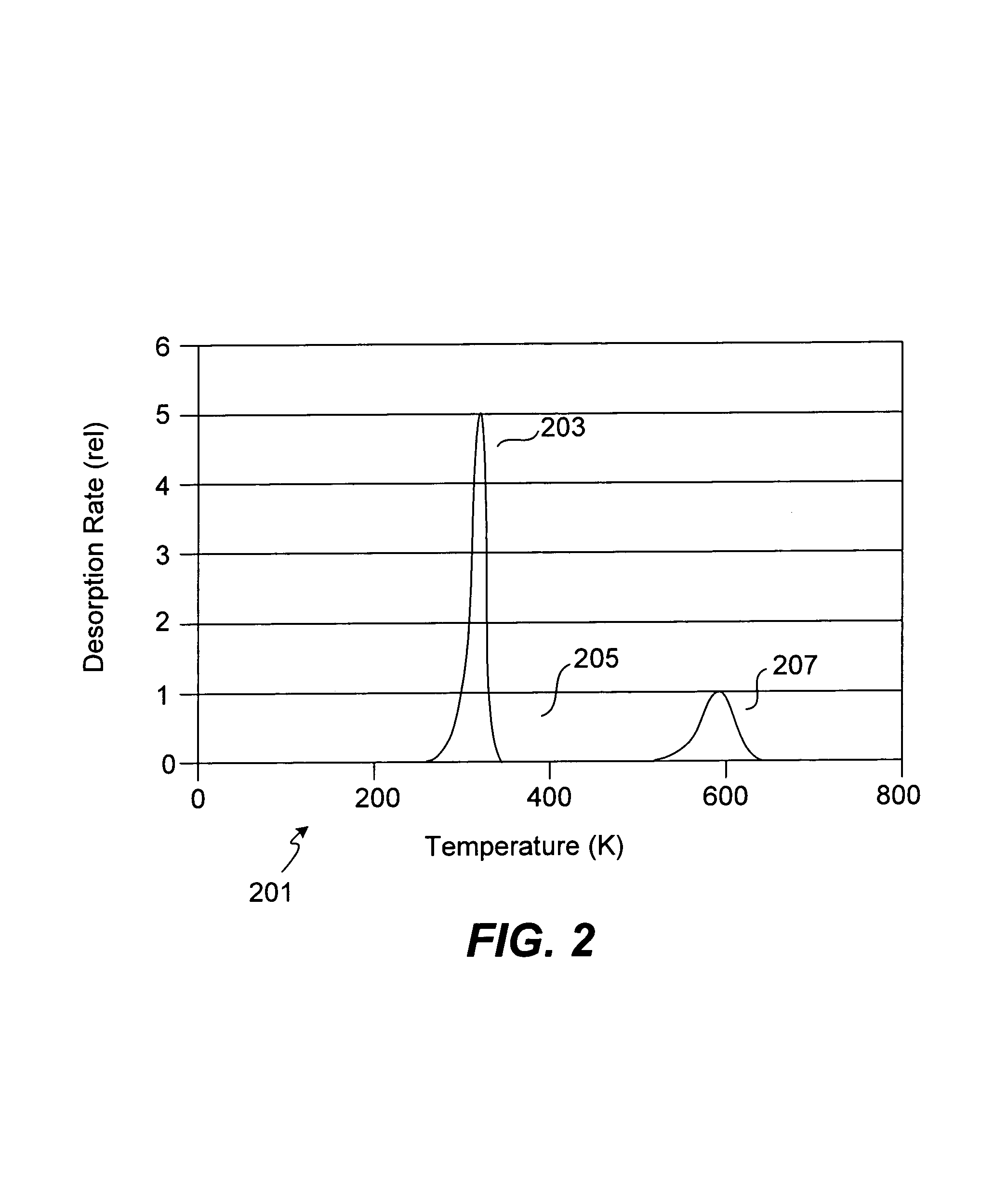

Plasma-enhanced ald of tantalum nitride films

ActiveUS20080182411A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSource material

Methods of controllably producing conductive tantalum nitride films are provided. The methods comprise contacting a substrate in a reaction space with alternating and sequential pulses of a tantalum source material, plasma-excited species of hydrogen and nitrogen source material. The plasma-excited species of hydrogen reduce the oxidation state of tantalum, thereby forming a substantially conductive tantalum nitride film over the substrate. In some embodiments, the plasma-excited species of hydrogen react with and removes halide residues in a deposited metallic film.

Owner:ASM IP HLDG BV

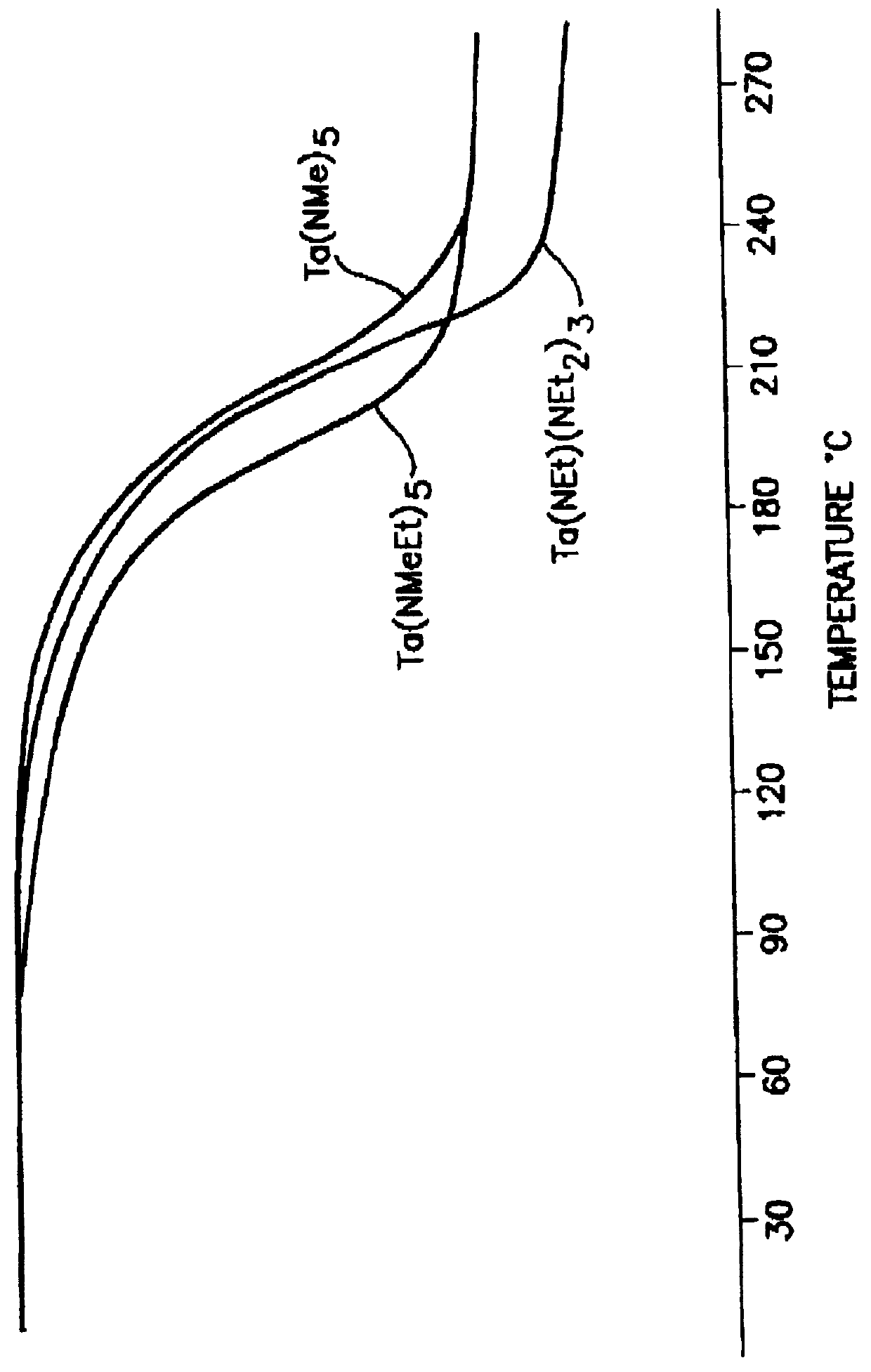

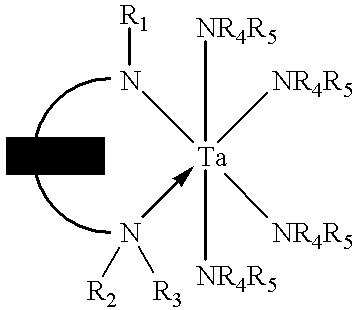

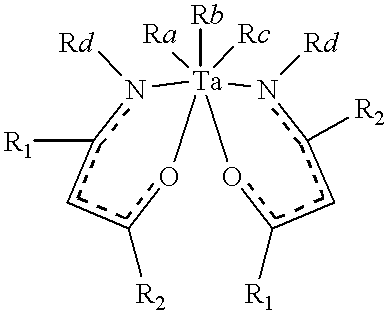

Tantalum amide precursors for deposition of tantalum nitride on a substrate

InactiveUS6015917ARapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

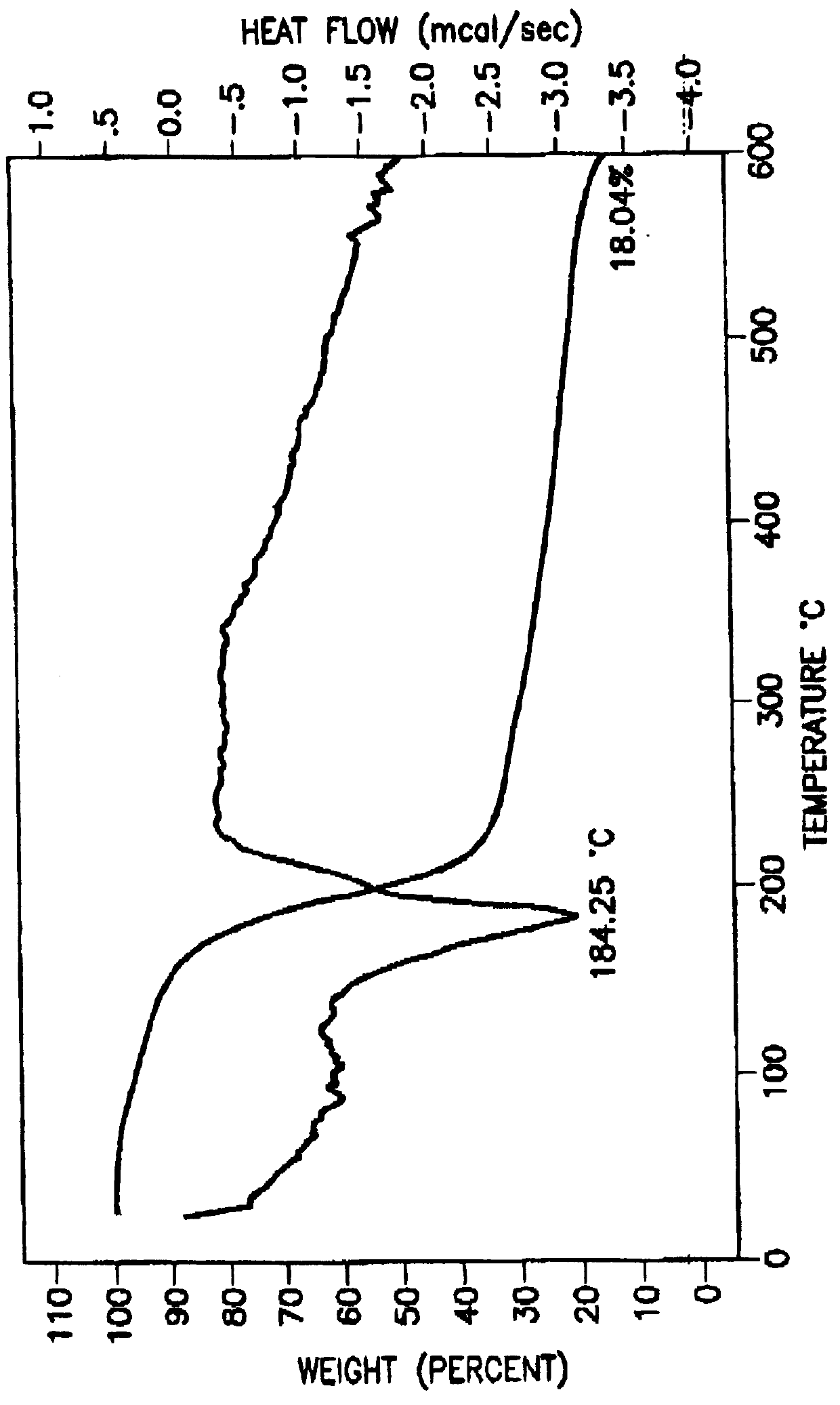

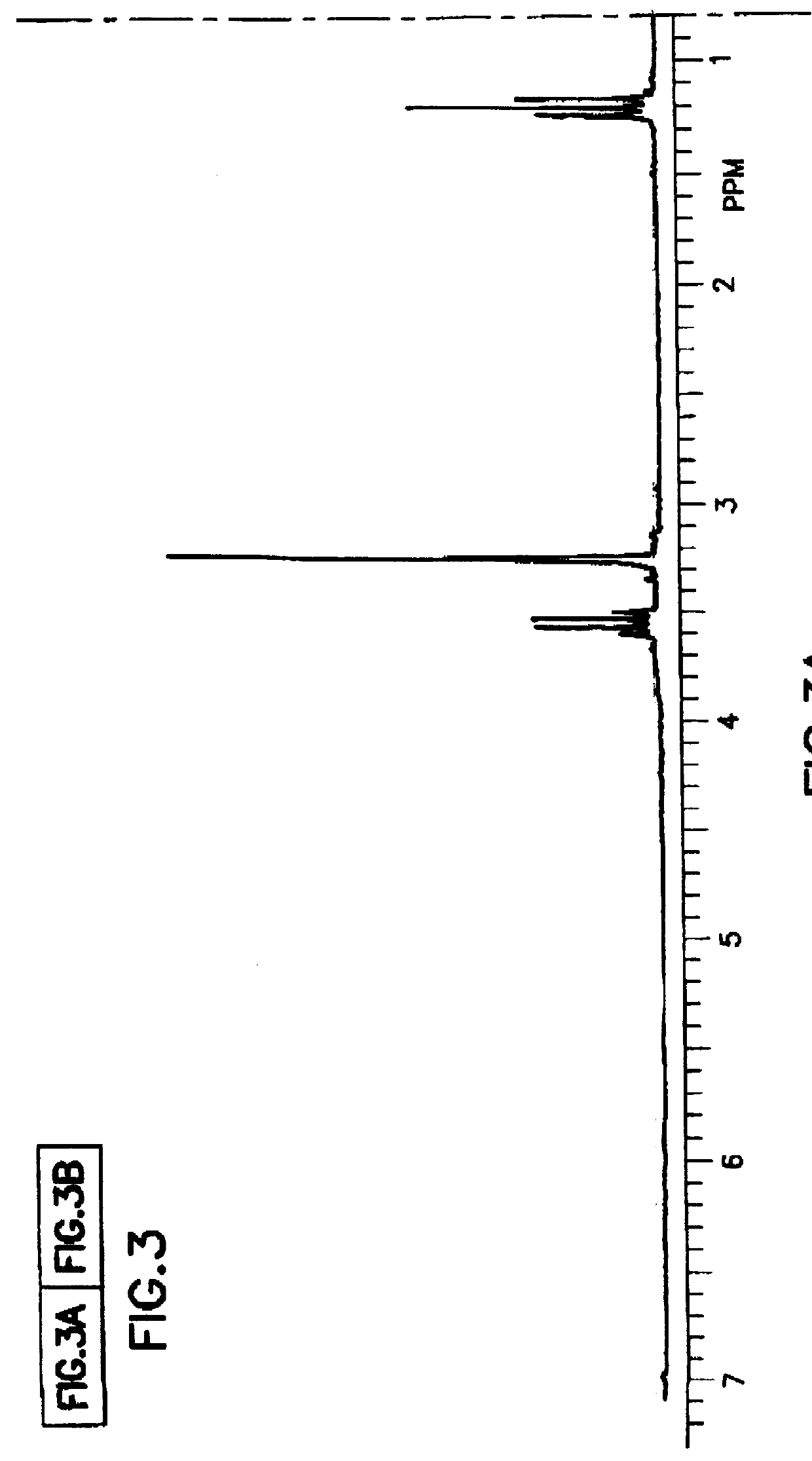

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microlectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ENTEGRIS INC

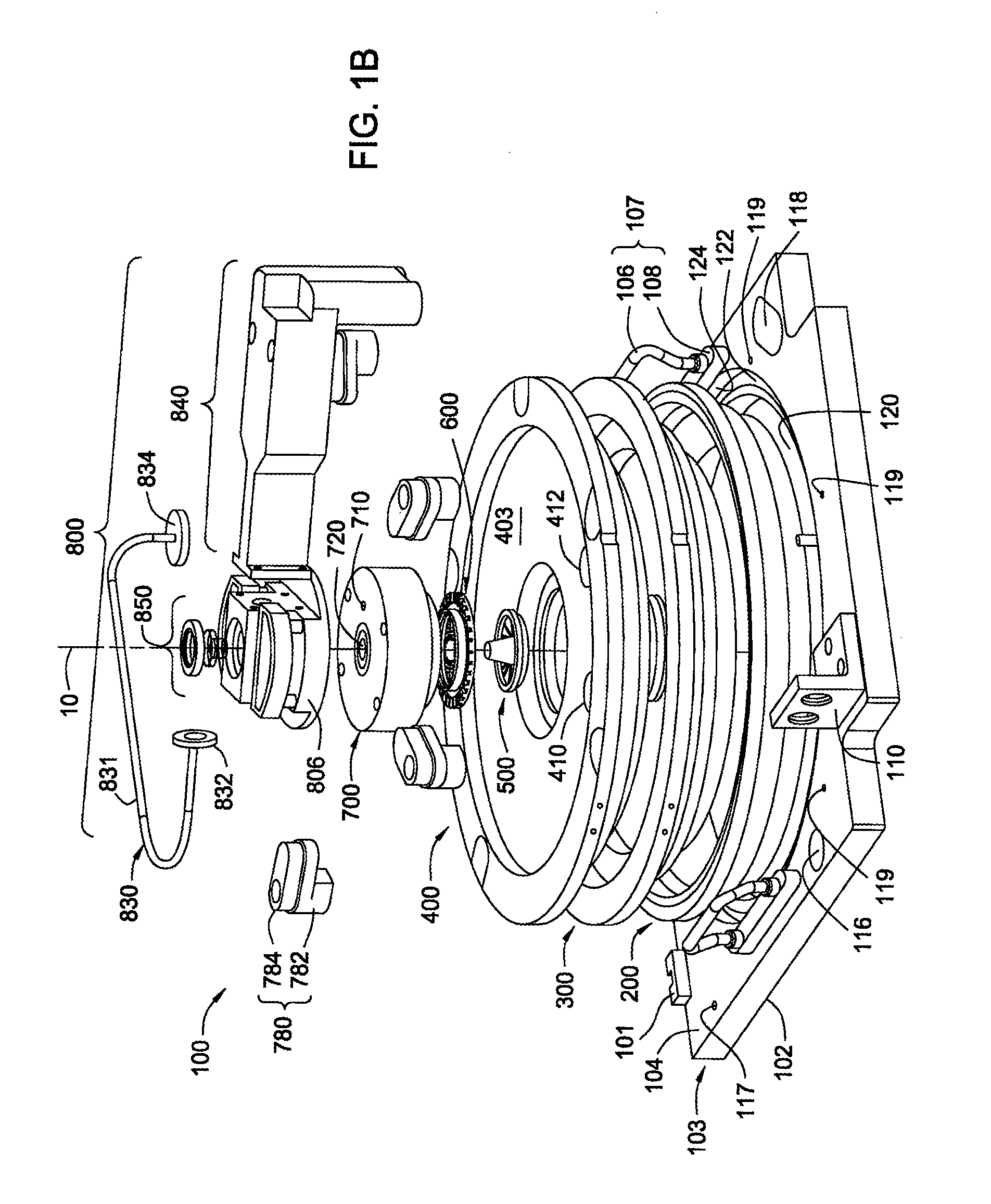

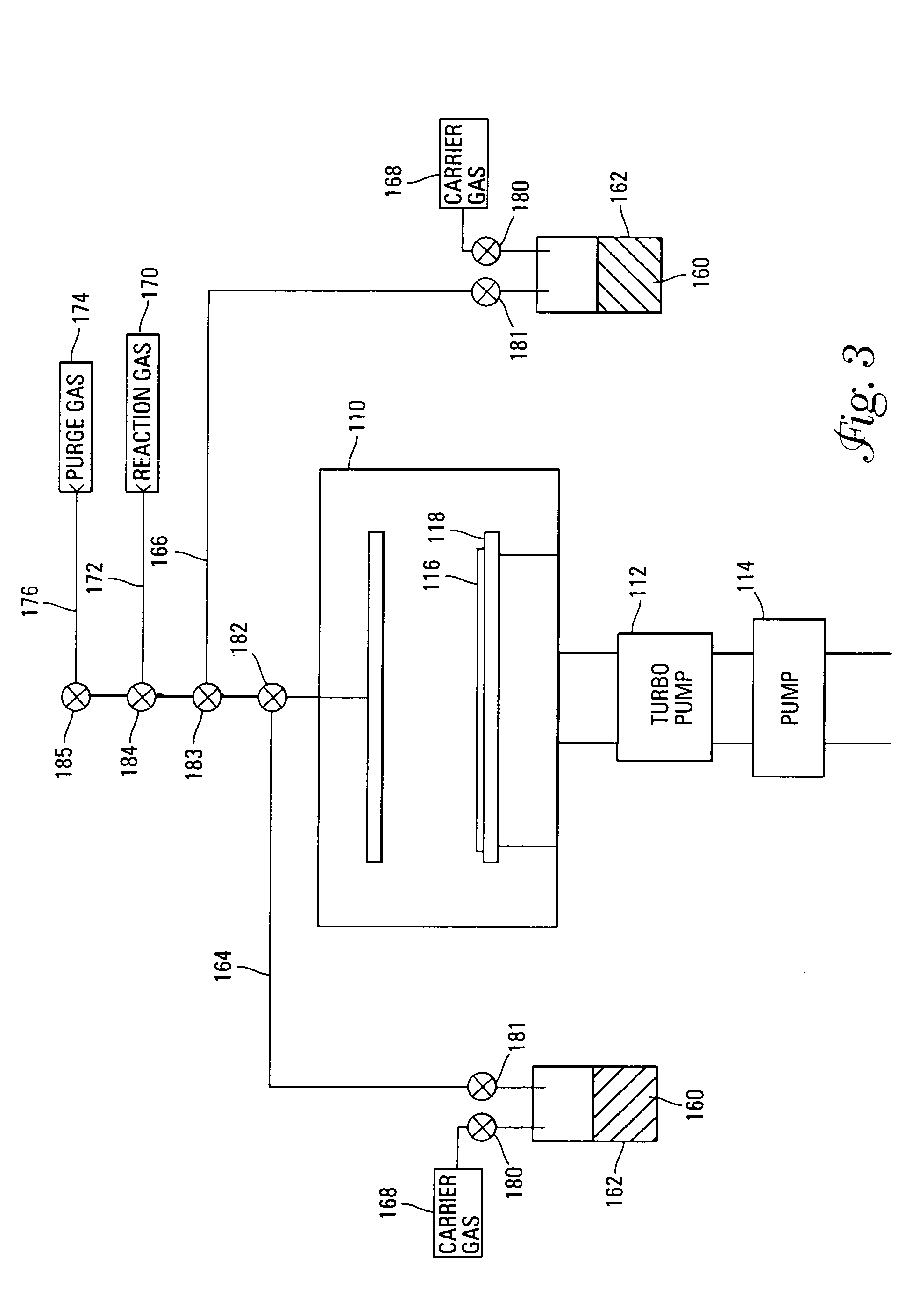

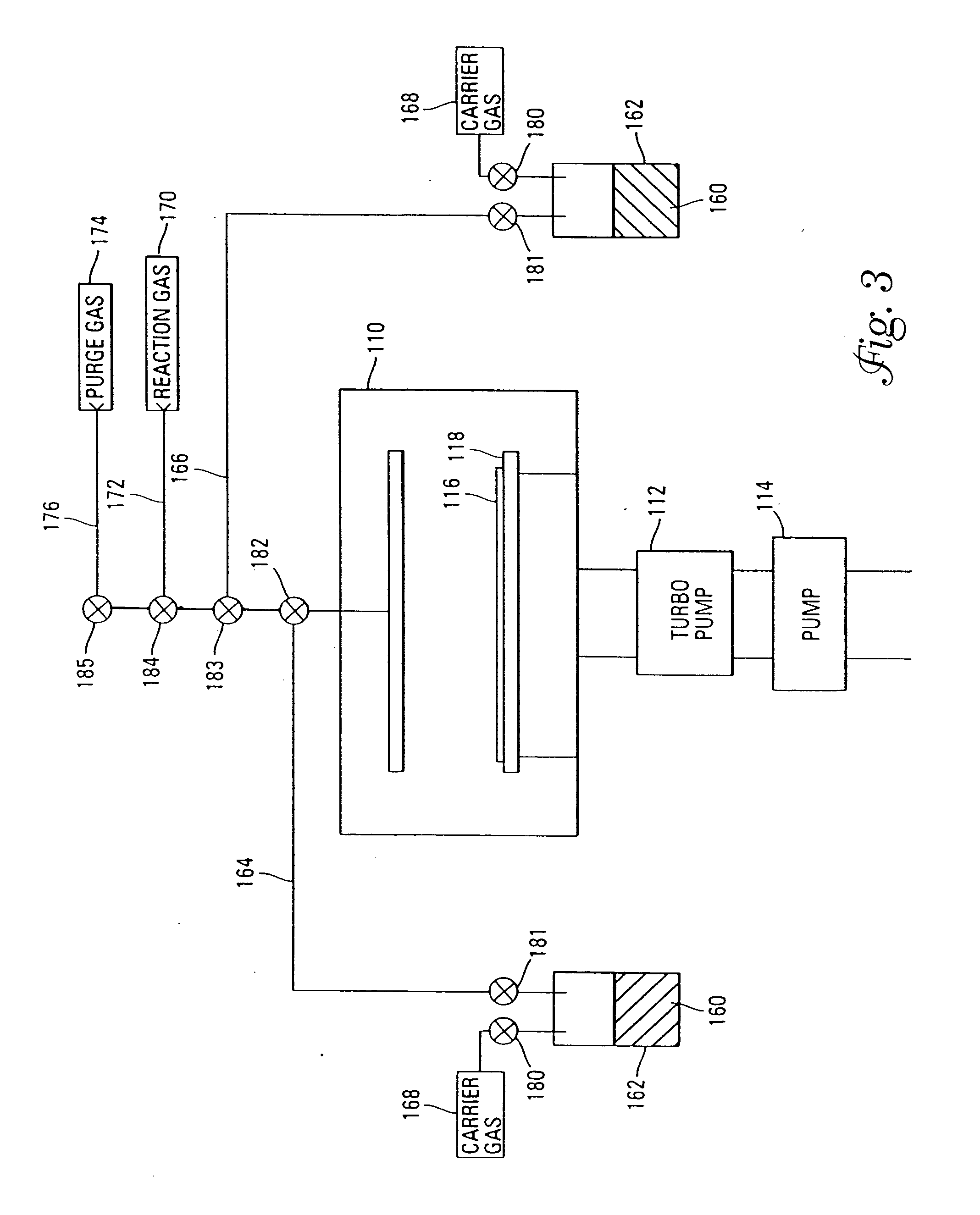

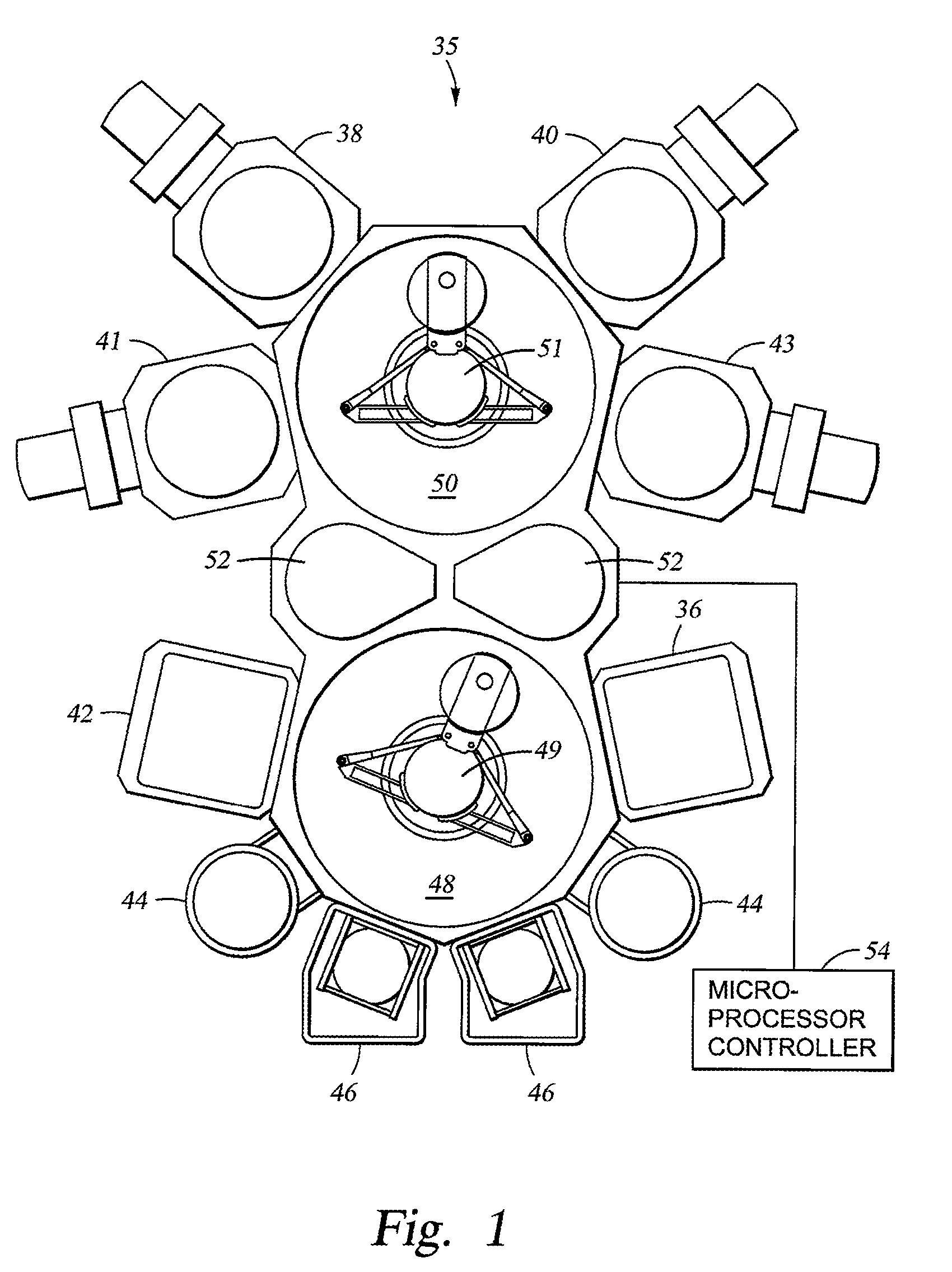

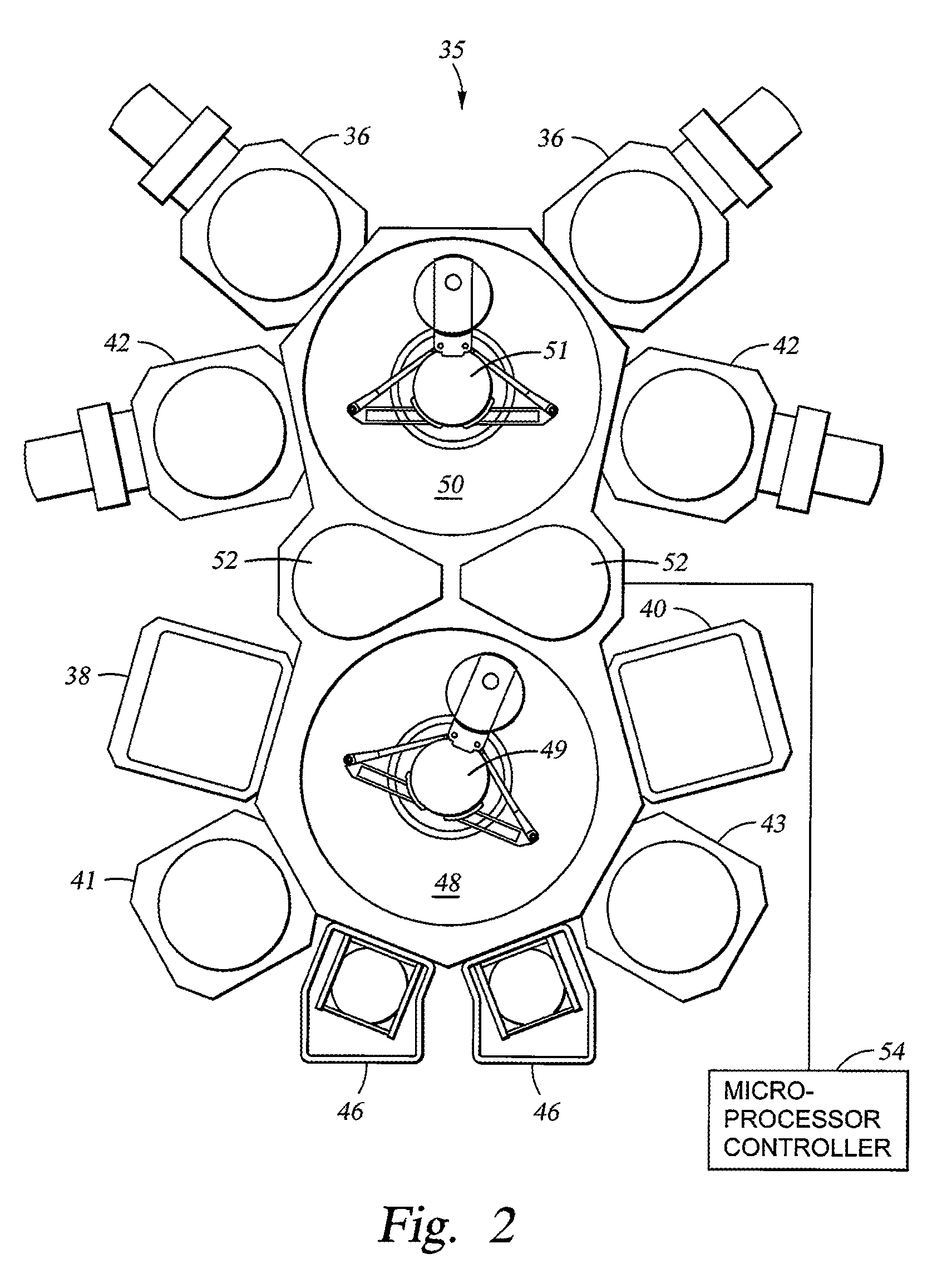

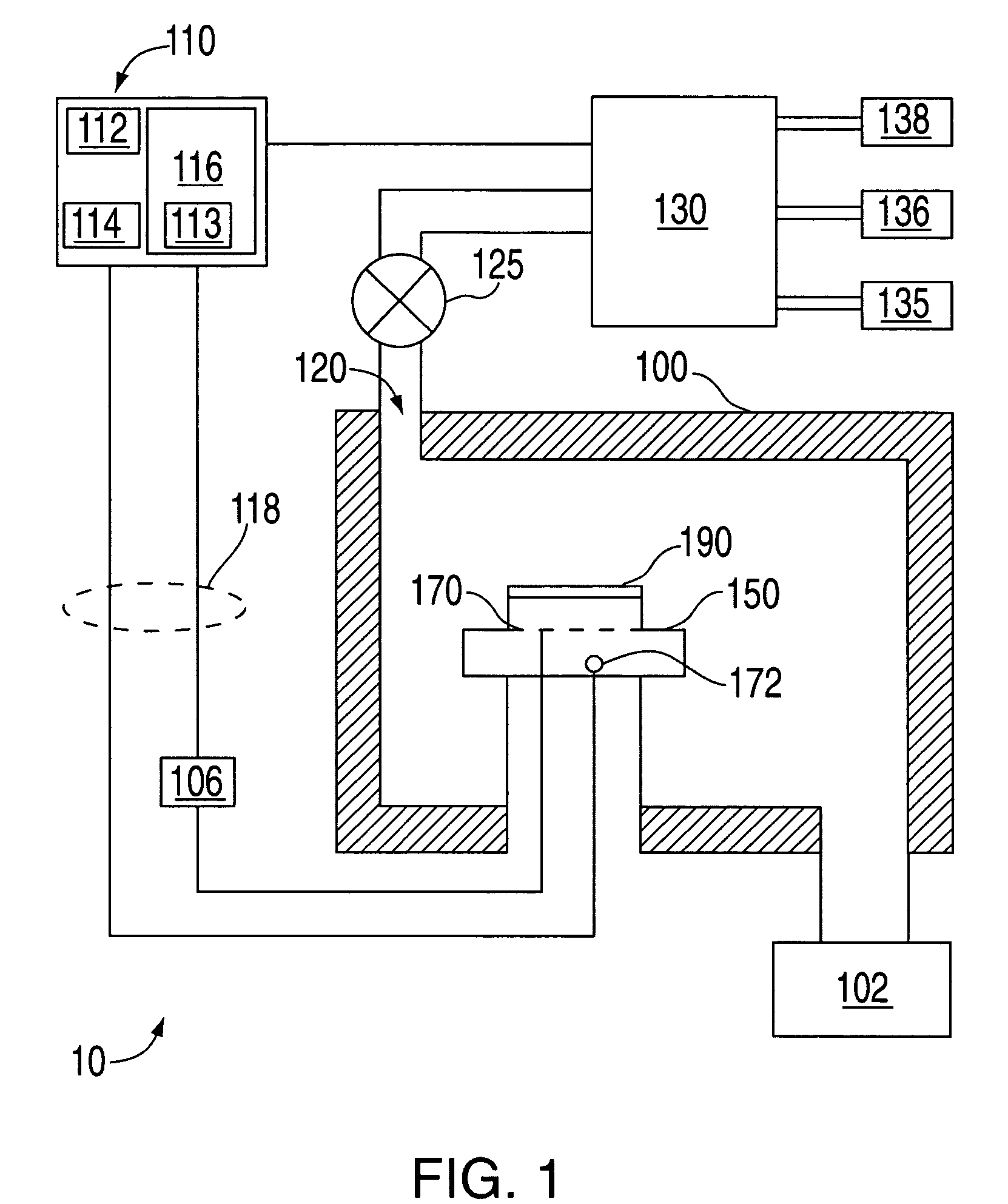

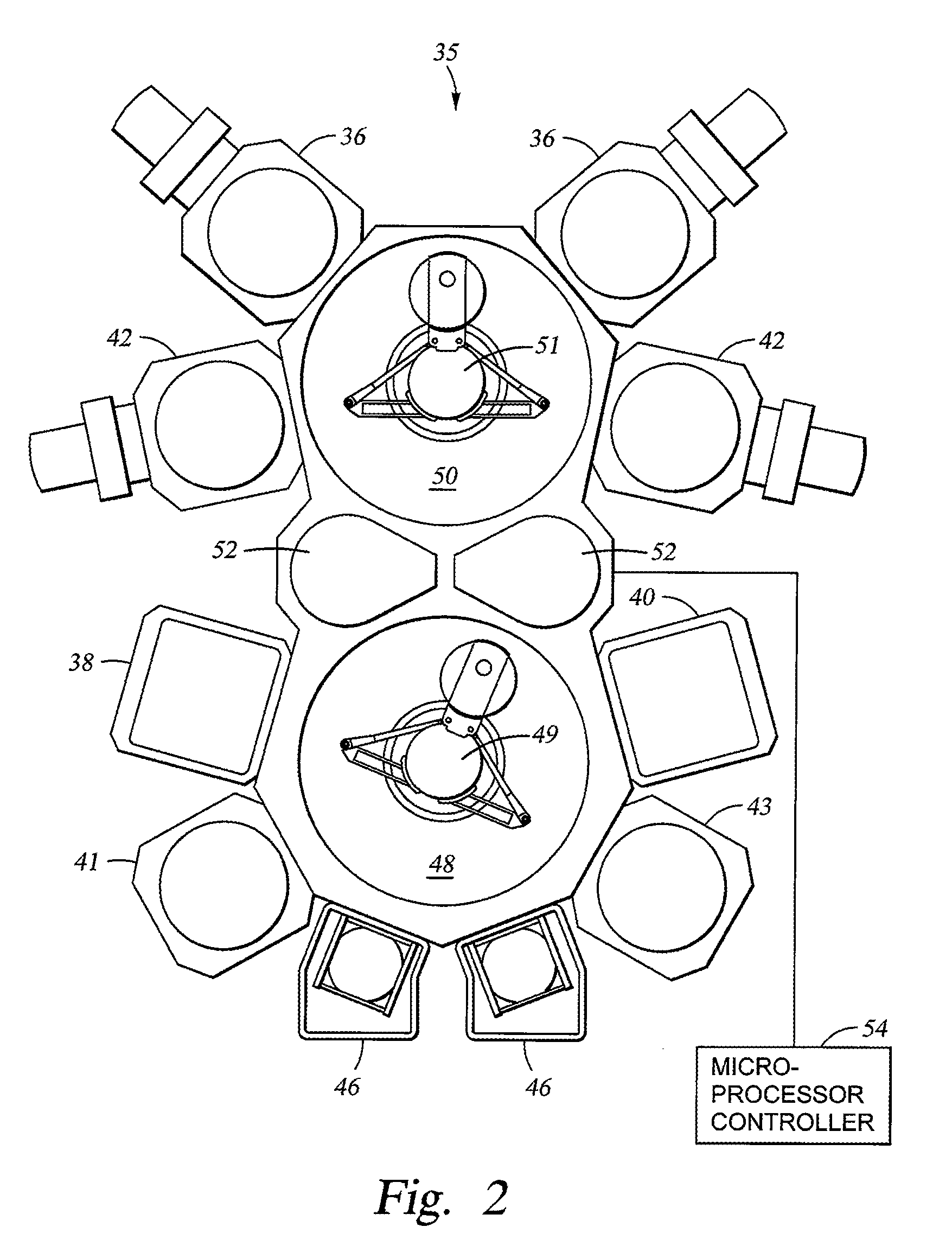

Apparatus and process for plasma-enhanced atomic layer deposition

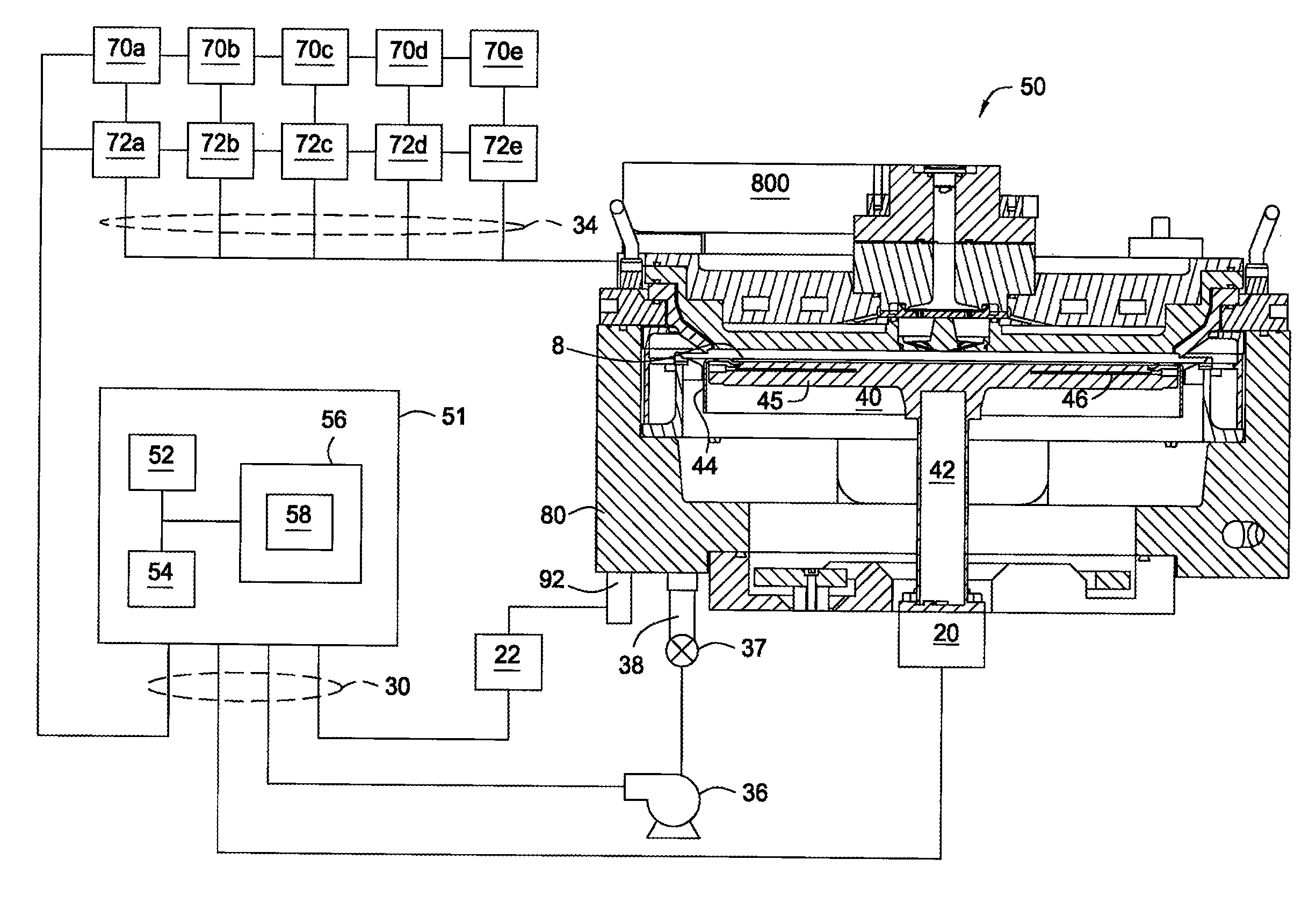

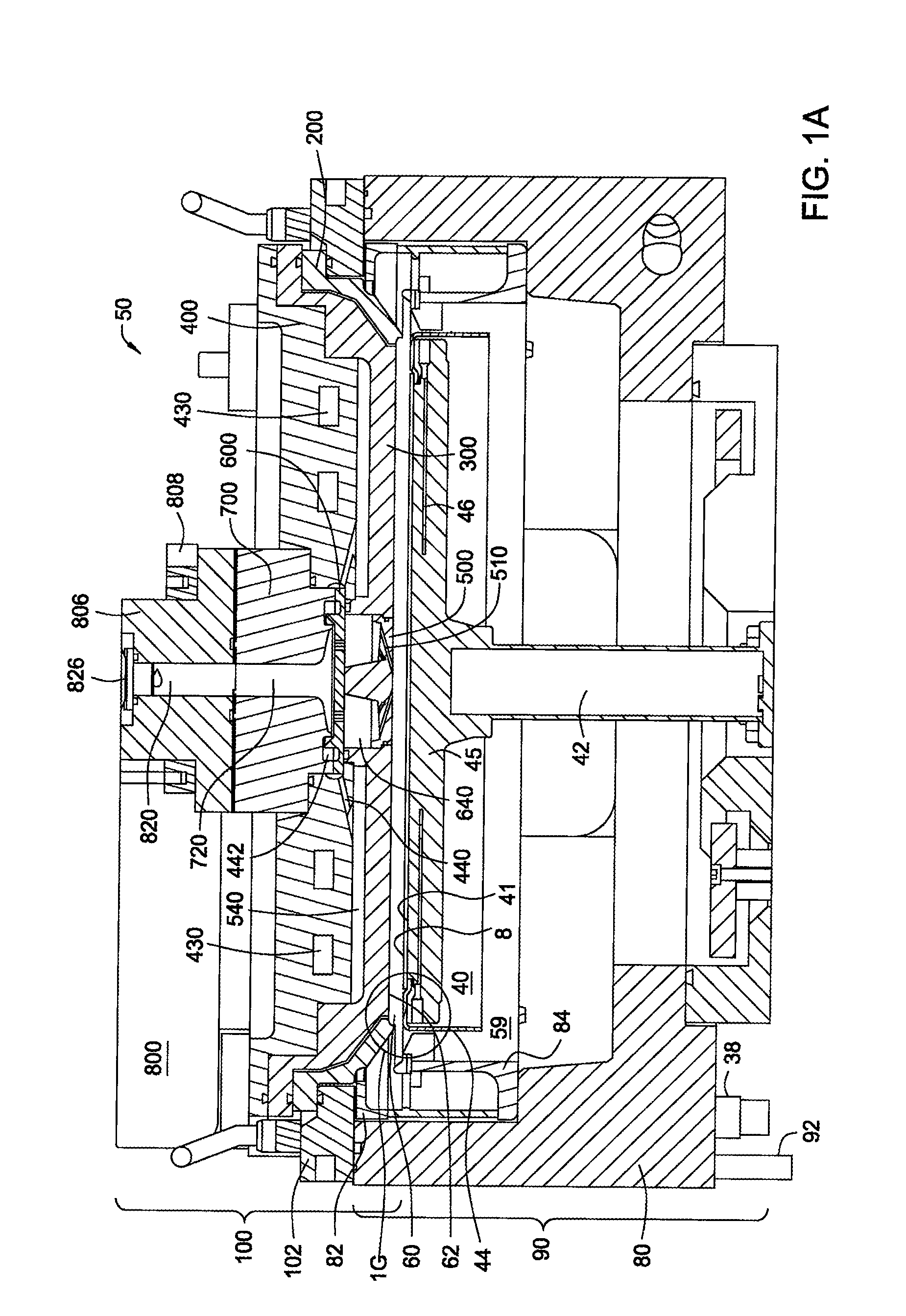

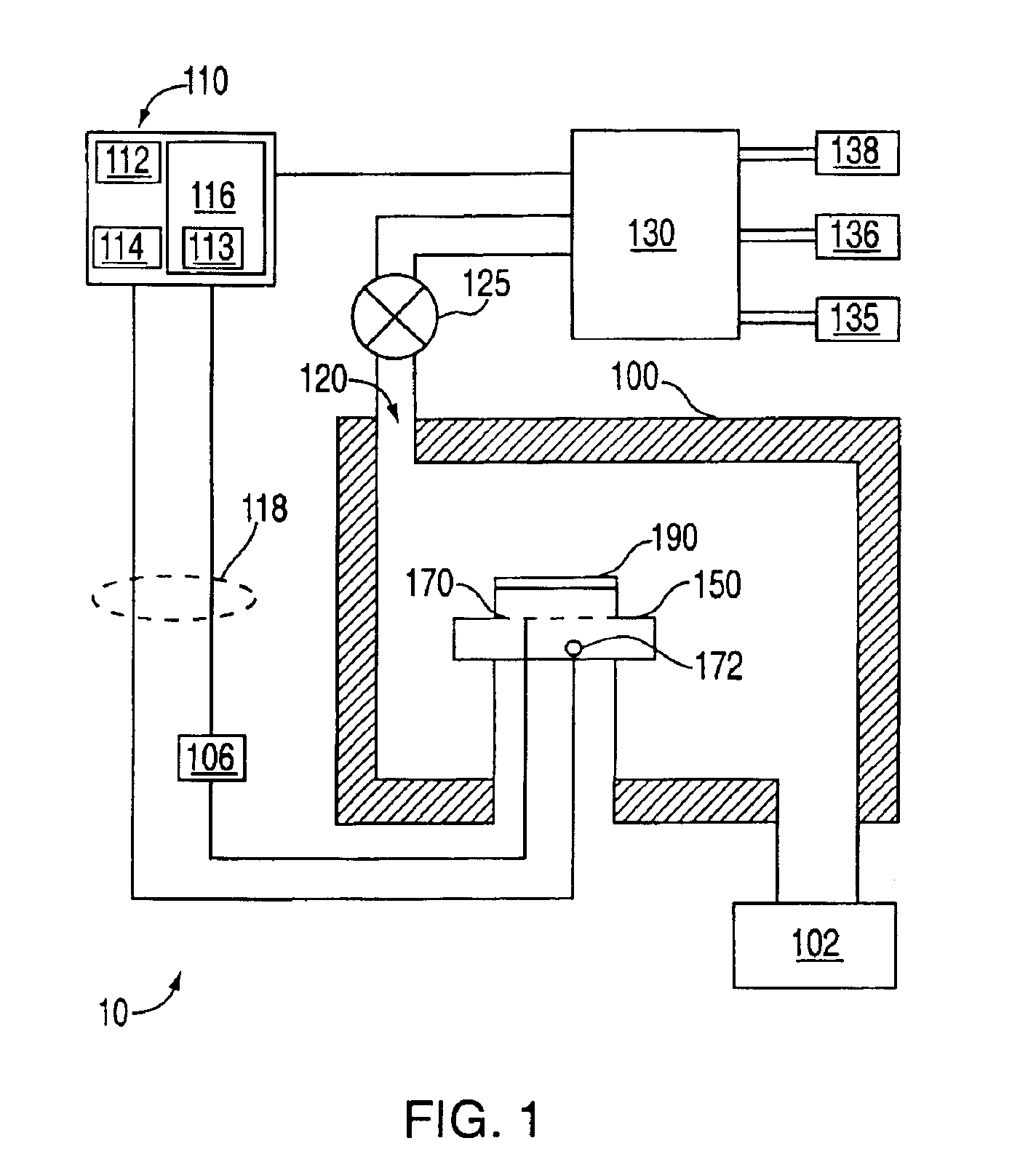

Embodiments of the invention provide a method for forming a material on a substrate during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a method is provided which includes flowing at least one process gas through at least one conduit to form a circular gas flow pattern, exposing a substrate to the circular gas flow pattern, sequentially pulsing at least one chemical precursor into the process gas and igniting a plasma from the process gas to deposit a material on the substrate. In one example, the circular gas flow pattern has circular geometry of a vortex, a helix, a spiral, or a derivative thereof. Materials that may be deposited by the method include ruthenium, tantalum, tantalum nitride, tungsten or tungsten nitride. Other embodiments of the invention provide an apparatus configured to form the material during the PE-ALD process.

Owner:APPLIED MATERIALS INC

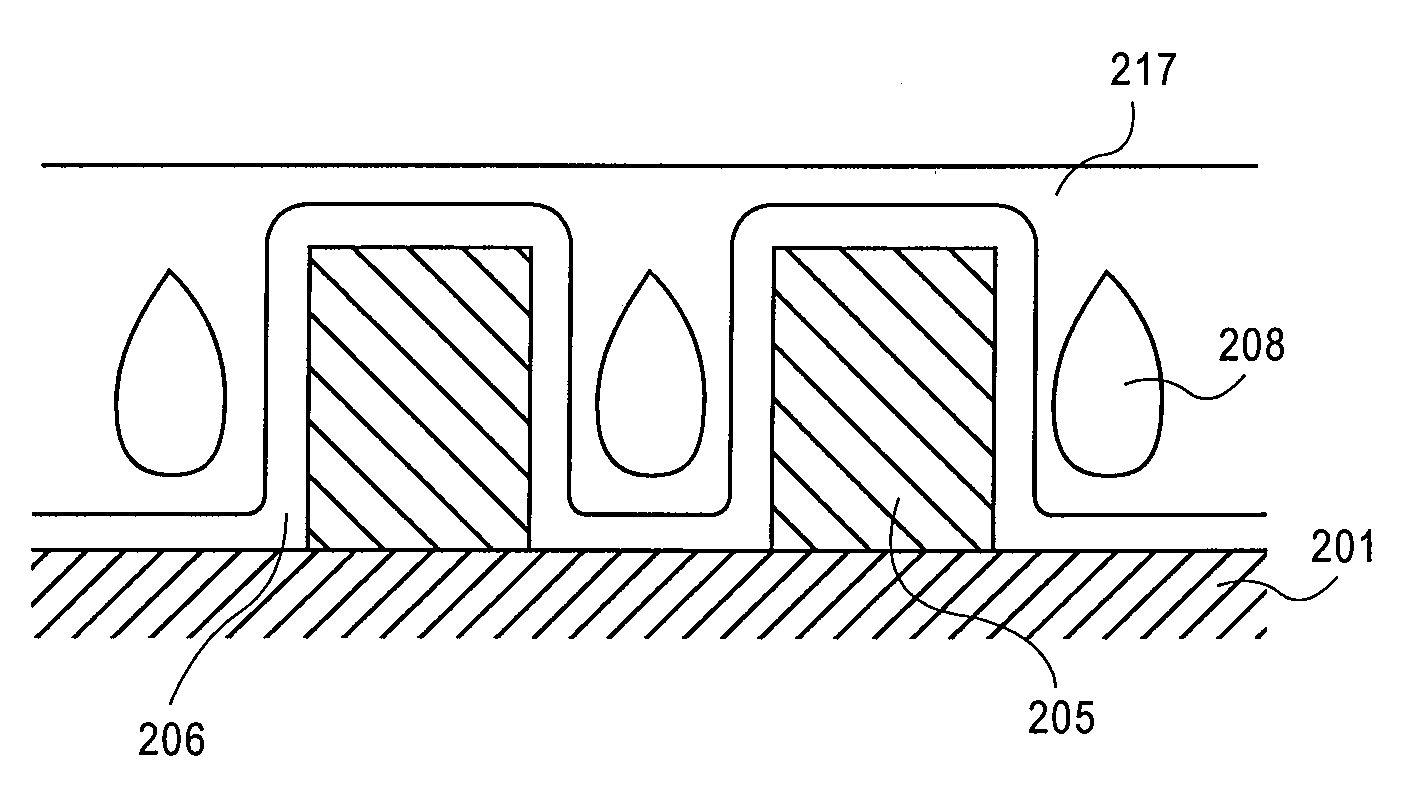

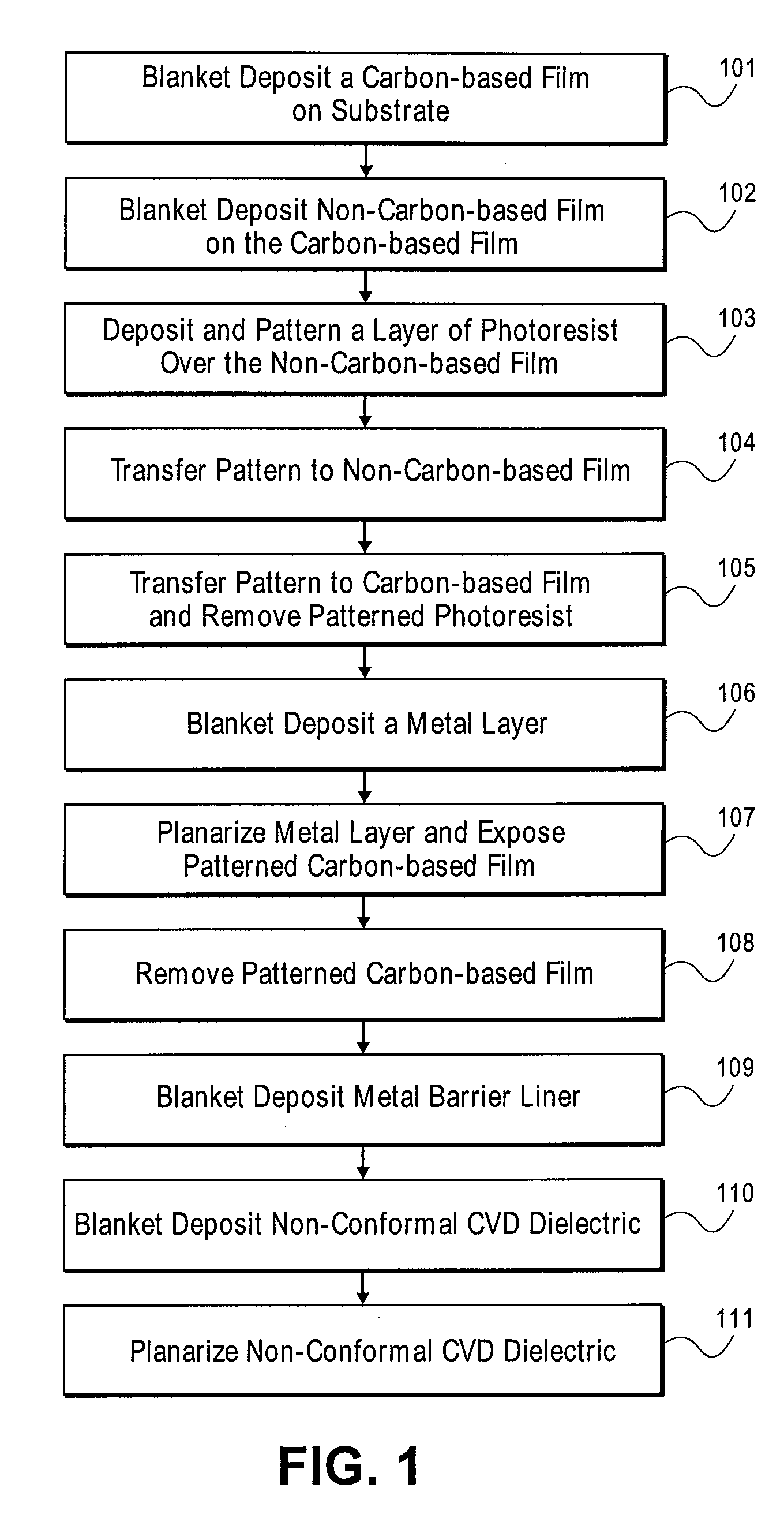

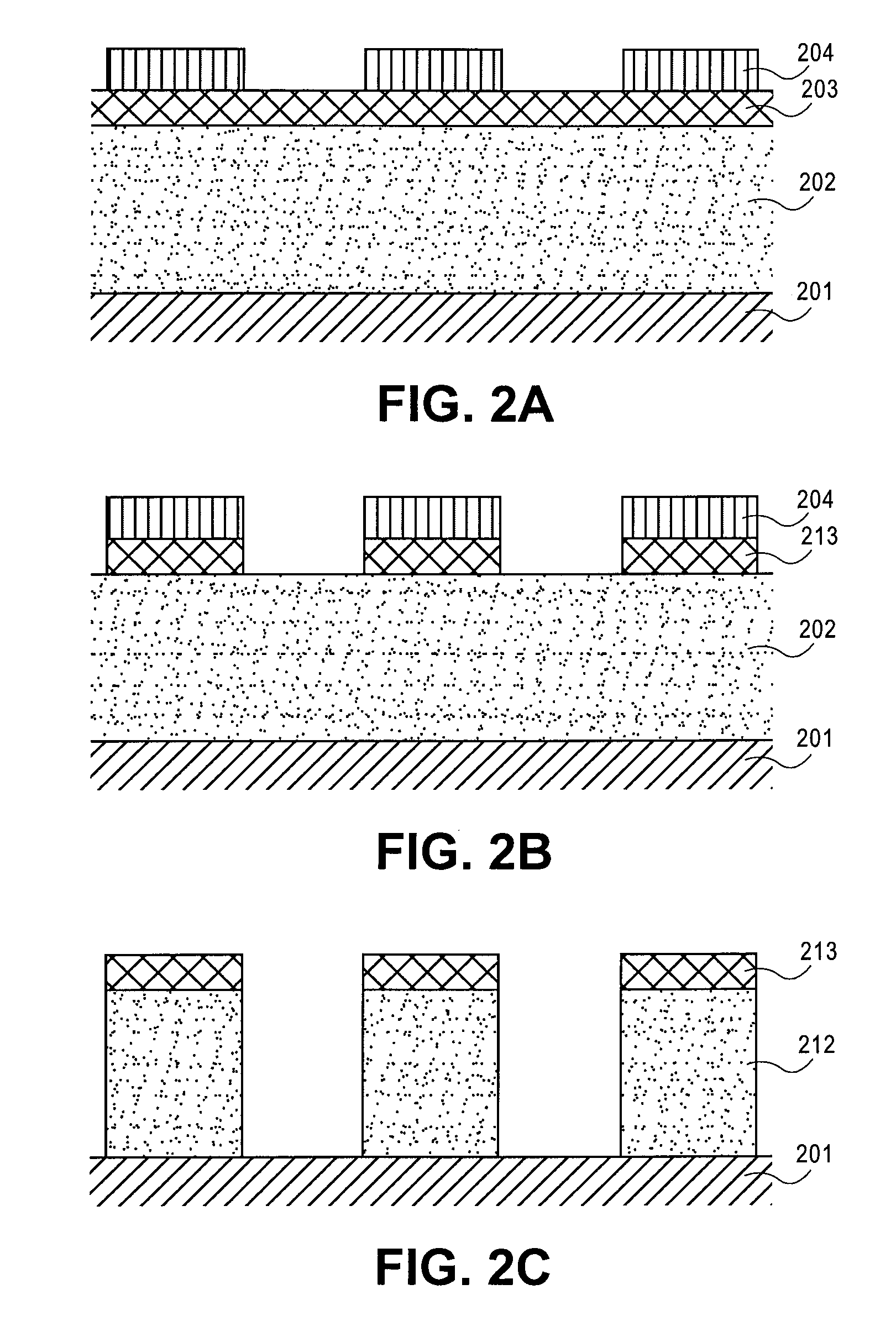

Air gap interconnects using carbon-based films

InactiveUS20100093168A1Improve electrical isolationSemiconductor/solid-state device manufacturingMetal interconnectPorous carbon

A method of forming an interconnect structure comprising: forming a sacrificial inter-metal dielectric (IMD) layer over a substrate, wherein the sacrificial IMD layer comprising a carbon-based film, such as amorphous carbon, advanced patterning films, porous carbon, or any combination thereof; forming a plurality of metal interconnect lines within the sacrificial IMD layer; removing the sacrificial IMD layer, with an oxygen based reactive process; and depositing a non-conformal dielectric layer to form air gaps between the plurality of metal interconnect lines. The metal interconnect lines may comprise copper, aluminum, tantalum, tungsten, titanium, tantalum nitride, titanium nitride, tungsten nitride, or any combination thereof. Carbon-based films and patterned photoresist layers may be simultaneously removed with the same reactive process. Highly reactive hydrogen radicals processes may be used to remove the carbon-based film and simultaneously pre-clean the metal interconnect lines prior to the deposition of a conformal metal barrier liner.

Owner:APPLIED MATERIALS INC

Atomic layer deposition of tantalum-containing materials using the tantalum precursor taimata

InactiveUS20060019495A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideBoron nitride

In one example of the invention, a method for depositing a tantalum-containing material on a substrate in a process chamber is provided which includes exposing the substrate to a tantalum precursor that contains TAIMATA and to at least one secondary precursor to deposit a tantalum-containing film during an atomic layer deposition (ALD) process. The ALD process is repeated until the tantalum-containing film is deposited with a predetermined thickness. Usually, the TAIMATA is preheated prior pulsing the tantalum precursor into the process chamber. A metal layer, such as tungsten or copper, may be deposited on the tantalum-containing material. The tantalum-containing material may include tantalum, tantalum nitride, tantalum silicon nitride, tantalum boron nitride, tantalum phosphorous nitride or tantalum oxynitride. The tantalum-containing material may be deposited as a barrier or adhesion layer within a via or as a gate electrode material within a source / drain device.

Owner:APPLIED MATERIALS INC

Tantalum amide precursors for deposition of tantalum nitride on a substrate

InactiveUS6379748B1Rapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microelectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ADVANCED TECH MATERIALS INC

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030124262A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

Owner:APPLIED MATERIALS INC

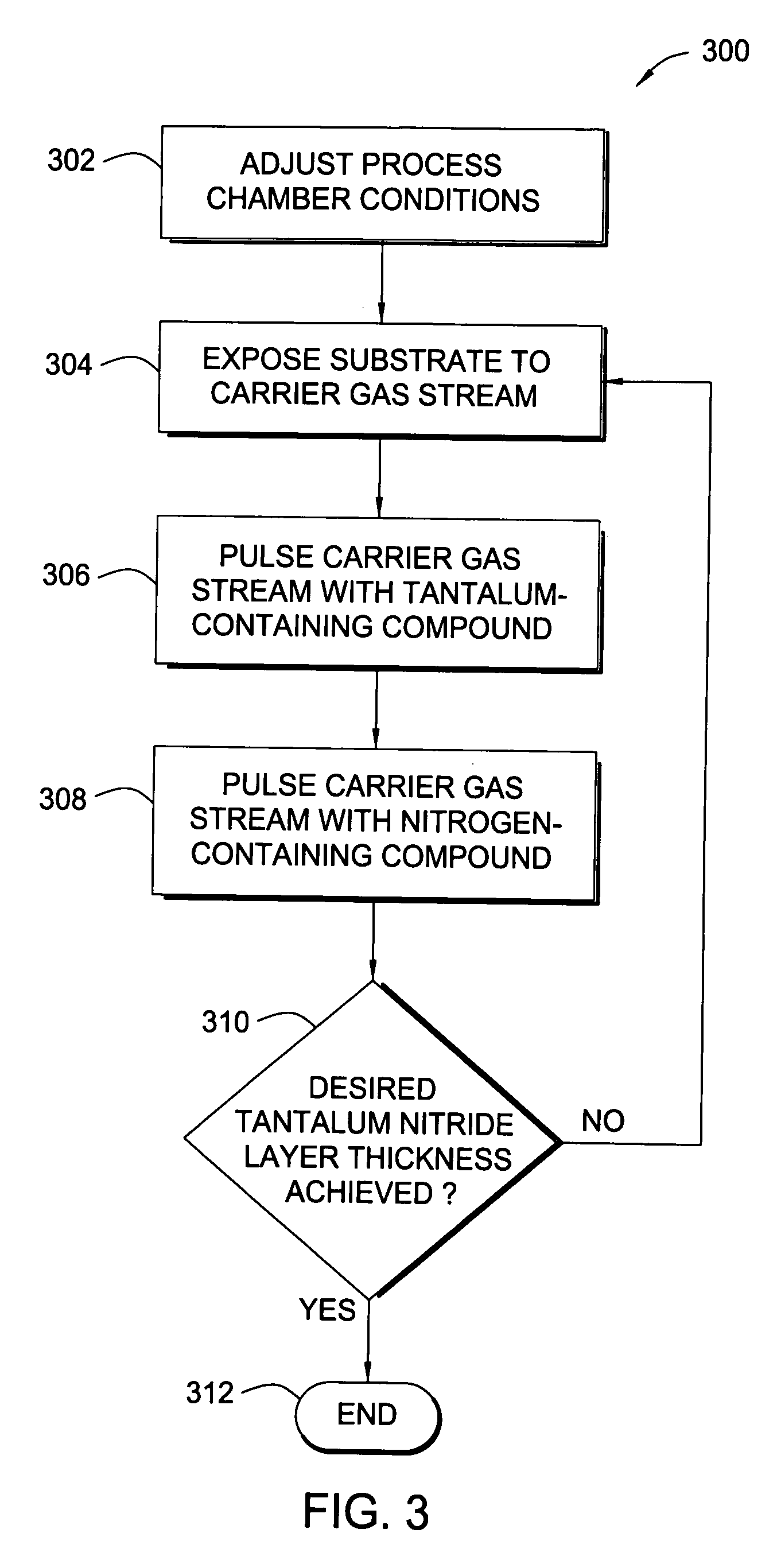

Integration of ALD tantalum nitride for copper metallization

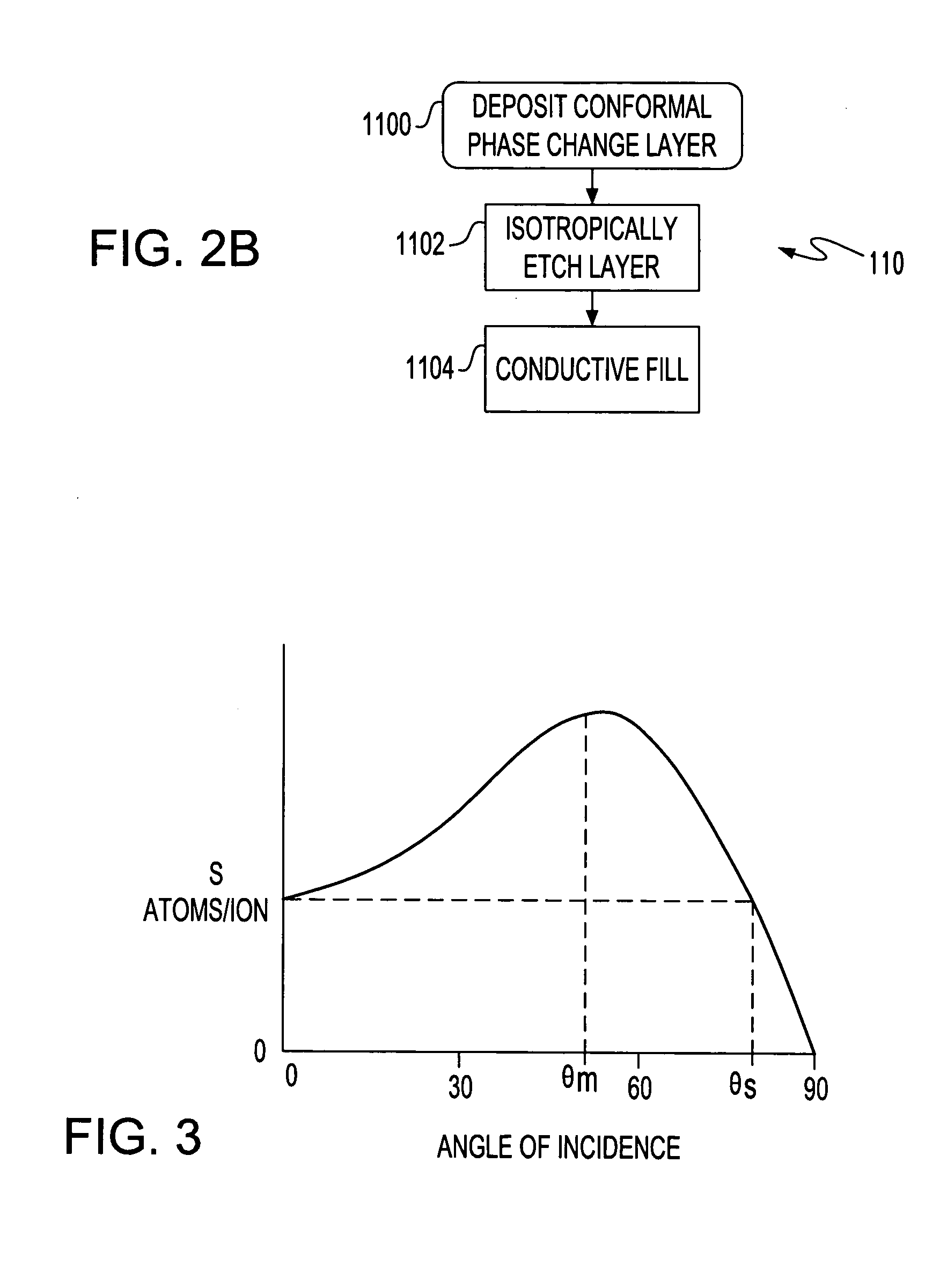

InactiveUS20050106865A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideConductive materials

A method and apparatus for depositing a tantalum nitride barrier layer is provided for use in an integrated processing tool. The tantalum nitride is deposited by atomic layer deposition. The tantalum nitride is removed from the bottom of features in dielectric layers to reveal the conductive material under the deposited tantalum nitride. Optionally, a tantalum layer may be deposited by physical vapor deposition after the tantalum nitride deposition. Optionally, the tantalum nitride deposition and the tantalum deposition may occur in the same processing chamber.

Owner:APPLIED MATERIALS INC

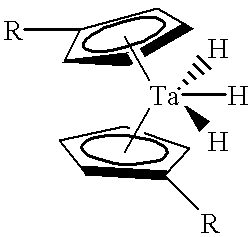

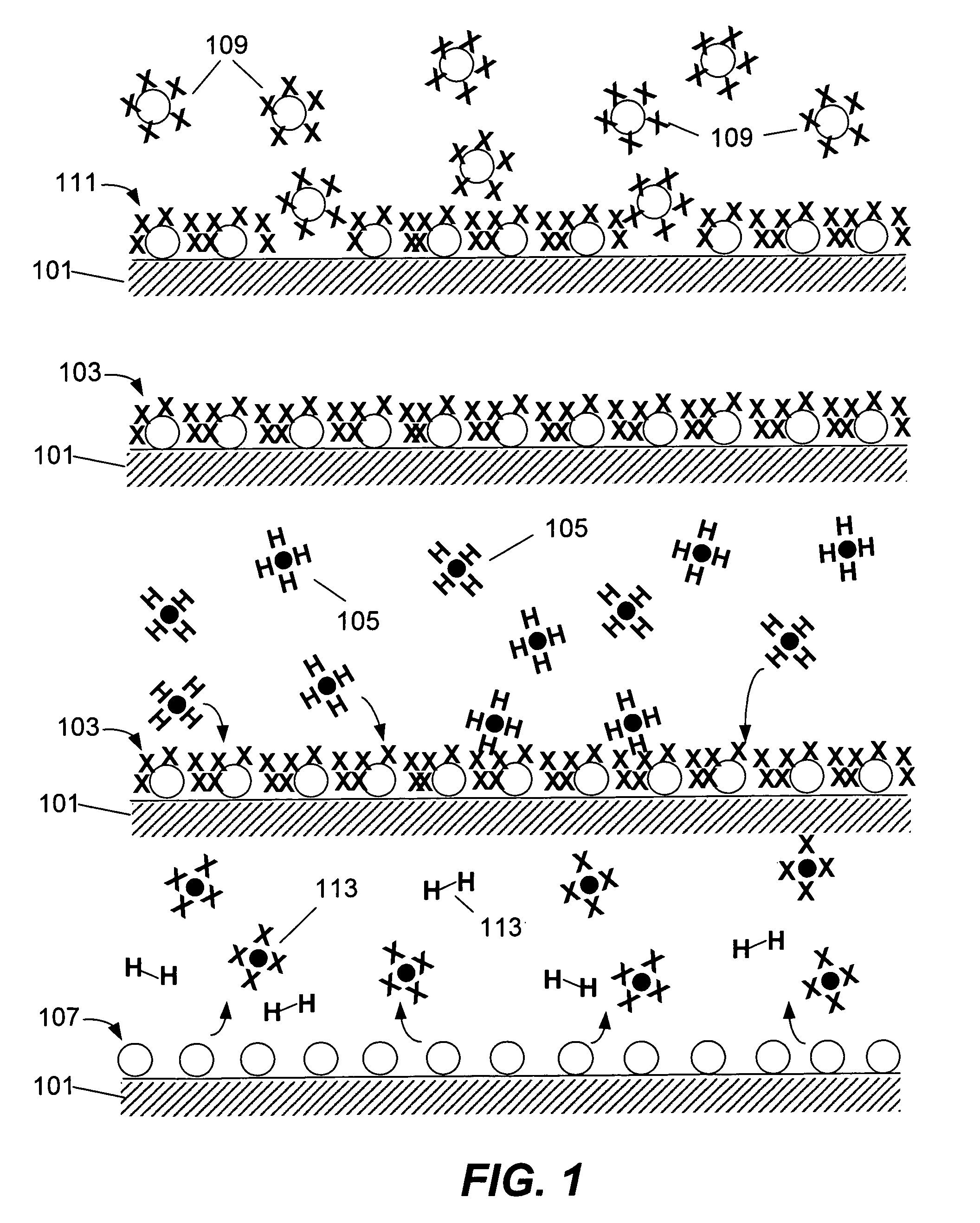

ALD of tantalum using a hydride reducing agent

InactiveUS7144806B1Reducing hydrideSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenTantalum nitride

An ALD method deposits conformal tantalum-containing material layers on small features of a substrate surface. The method includes the following principal operations: depositing a thin conformal and saturated layer of tantalum-containing precursor over some or all of the substrate surface; using an inert gas or hydrogen plasma to purge the halogen byproducts and unused reactants; reducing the precursor to convert it to a conformal layer of tantalum or tantalum-containing material; using another purge of inert gas or hydrogen plasma to remove the halogen byproducts and unused reactants; and repeating the deposition / reduction cycles until a desired tantalum-containing material layer is achieved. An optional step of treating each newly formed surface of tantalum containing material with a nitrogen-containing agent can be added to create varying amounts of tantalum nitride.

Owner:NOVELLUS SYSTEMS

Systems and methods for forming refractory metal nitride layers using organic amines

InactiveUS6967159B2Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsTantalum nitrideDeposition process

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum nitride barrier layer, on a substrate by using an atomic layer deposition process (a vapor deposition process that includes a plurality of deposition cycles) with a refractory metal precursor compound, an organic amine, and an optional silicon precursor compound.

Owner:MICRON TECH INC

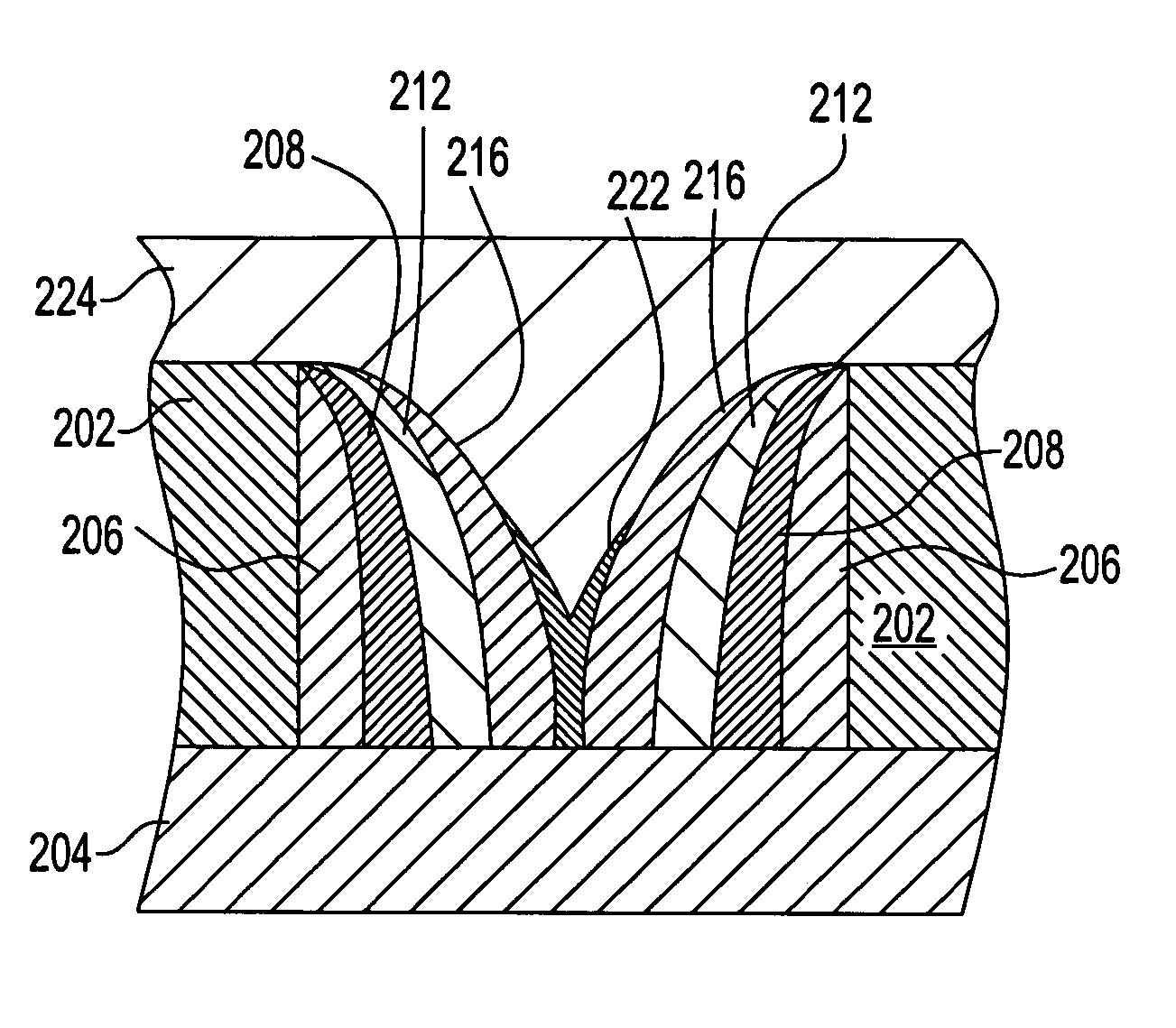

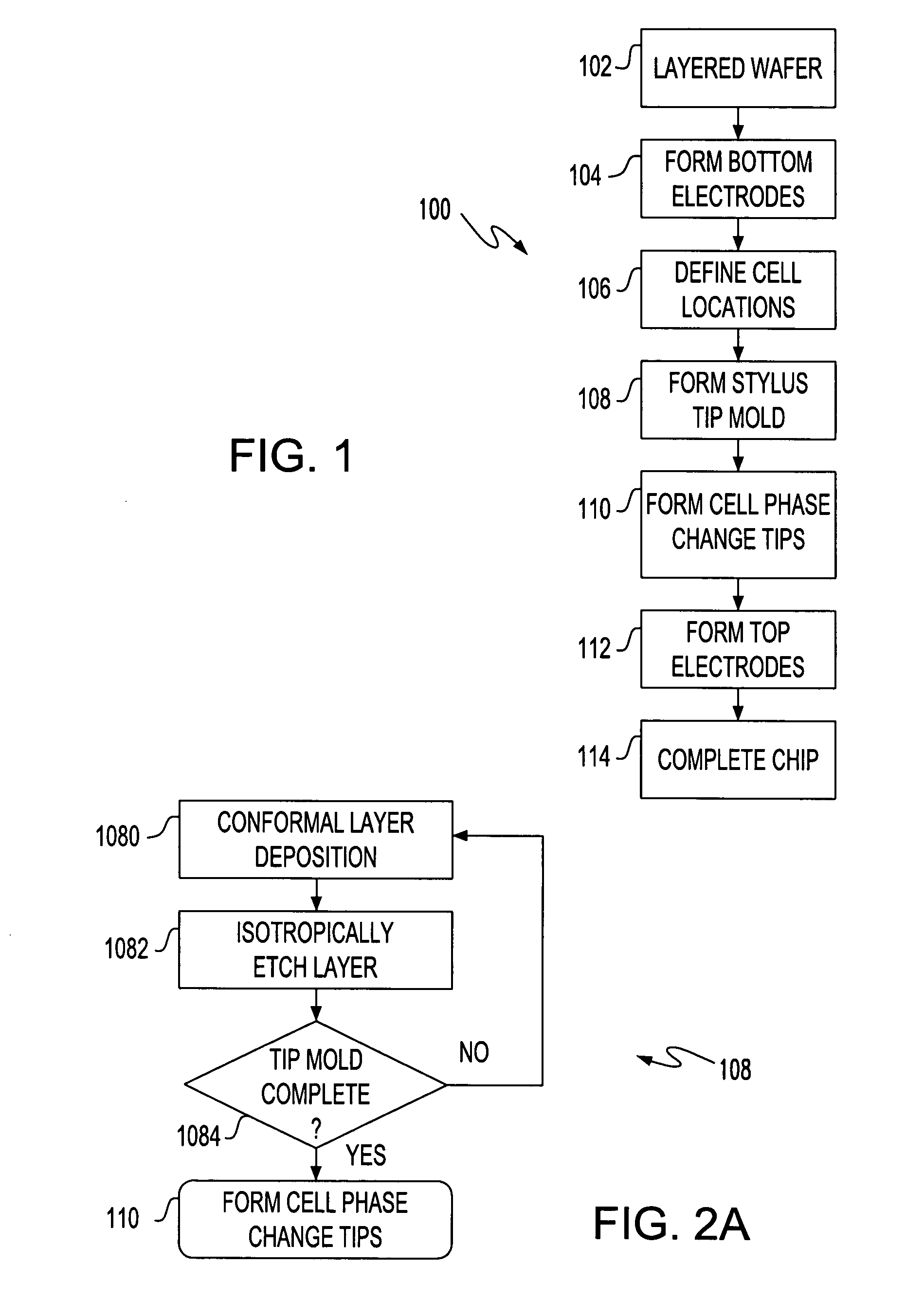

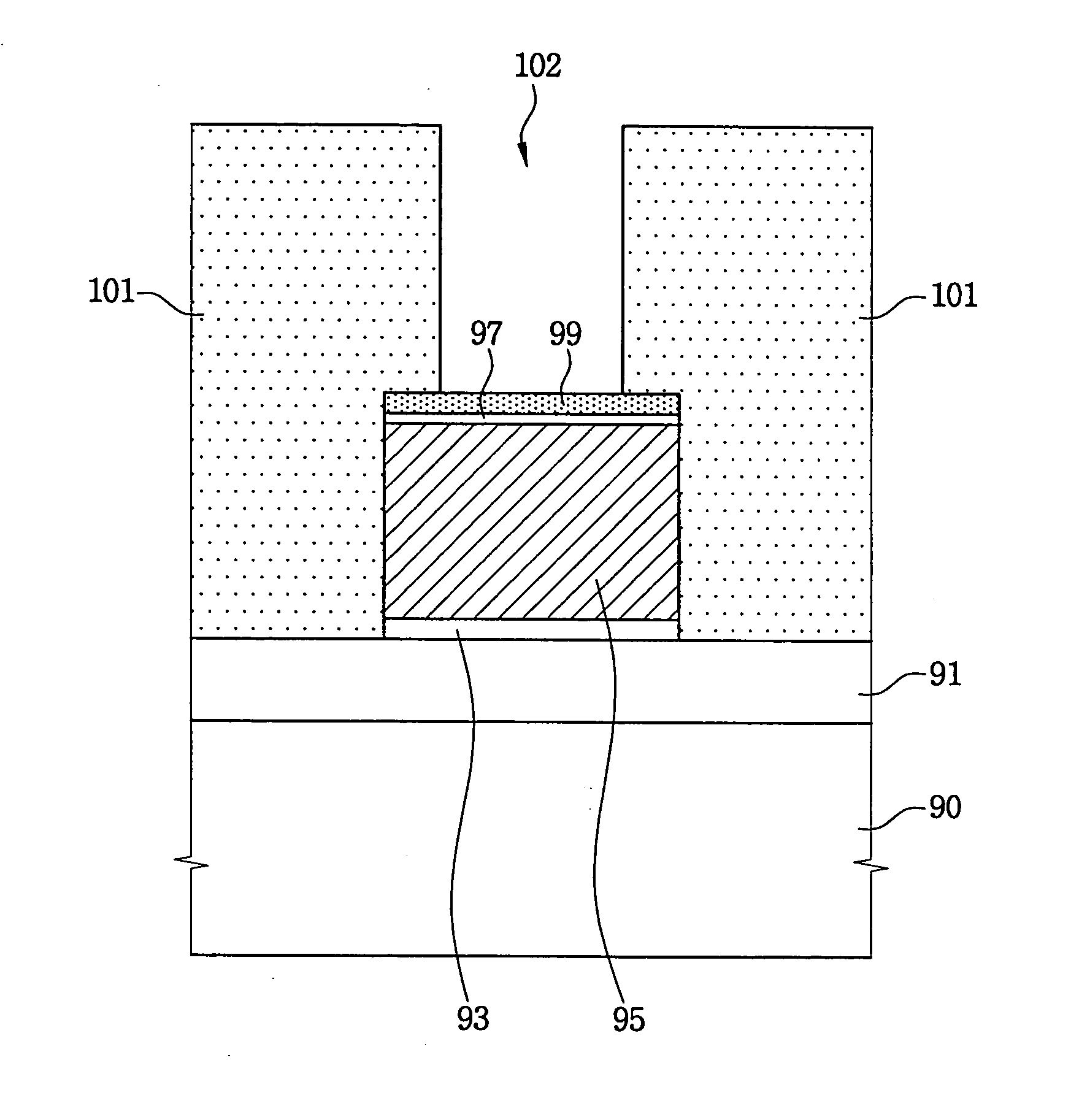

Phase change tip storage cell

ActiveUS20050127349A1Reduce the required powerSolid-state devicesDigital storageTitanium nitrideTe element

A storage cell, integrated circuit (IC) chip with one or more storage cells that may be in an array of the storage cells and a method of forming the storage cell and IC. Each storage cell includes a stylus, the tip of which is phase change material. The phase change tip may be sandwiched between an electrode and conductive material, e.g., titanium nitride (TiN), tantalum nitride (TaN) or n-type semiconductor. The phase change layer may be a chalcogenide and in particular a germanium (Ge), antimony (Sb), tellurium (Te) (GST) layer.

Owner:GLOBALFOUNDRIES US INC

Method for forming a wiring of a semiconductor device, method for forming a metal layer of a semiconductor device and apparatus for performing the same

InactiveUS20050059240A1Good step coverageThe process parameters are simpleSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical reactionDevice material

In a method for forming a wiring of a semiconductor device using an atomic layer deposition, an insulating interlayer is formed on a substrate. Tantalum amine derivatives represented by a chemical formula Ta(NR1)(NR2R3)3 in which R1, R2 and R3 represent H or C1-C6 alkyl group are introduced onto the insulating interlayer. A portion of the tantalum amine derivatives is chemisorbed on the insulating interlayer. The rest of tantalum amine derivatives non-chemisorbed on the insulating interlayer is removed from the insulating interlayer. A reacting gas is introduced onto the insulating interlayer. A ligand in the tantalum amine derivatives chemisorbed on the insulating interlayer is removed from the tantalum amine derivatives by a chemical reaction between the reacting gas and the ligand to form a solid material including tantalum nitride. The solid material is accumulated on the insulating interlayer through repeating the above processes to form a wiring.

Owner:SAMSUNG ELECTRONICS CO LTD

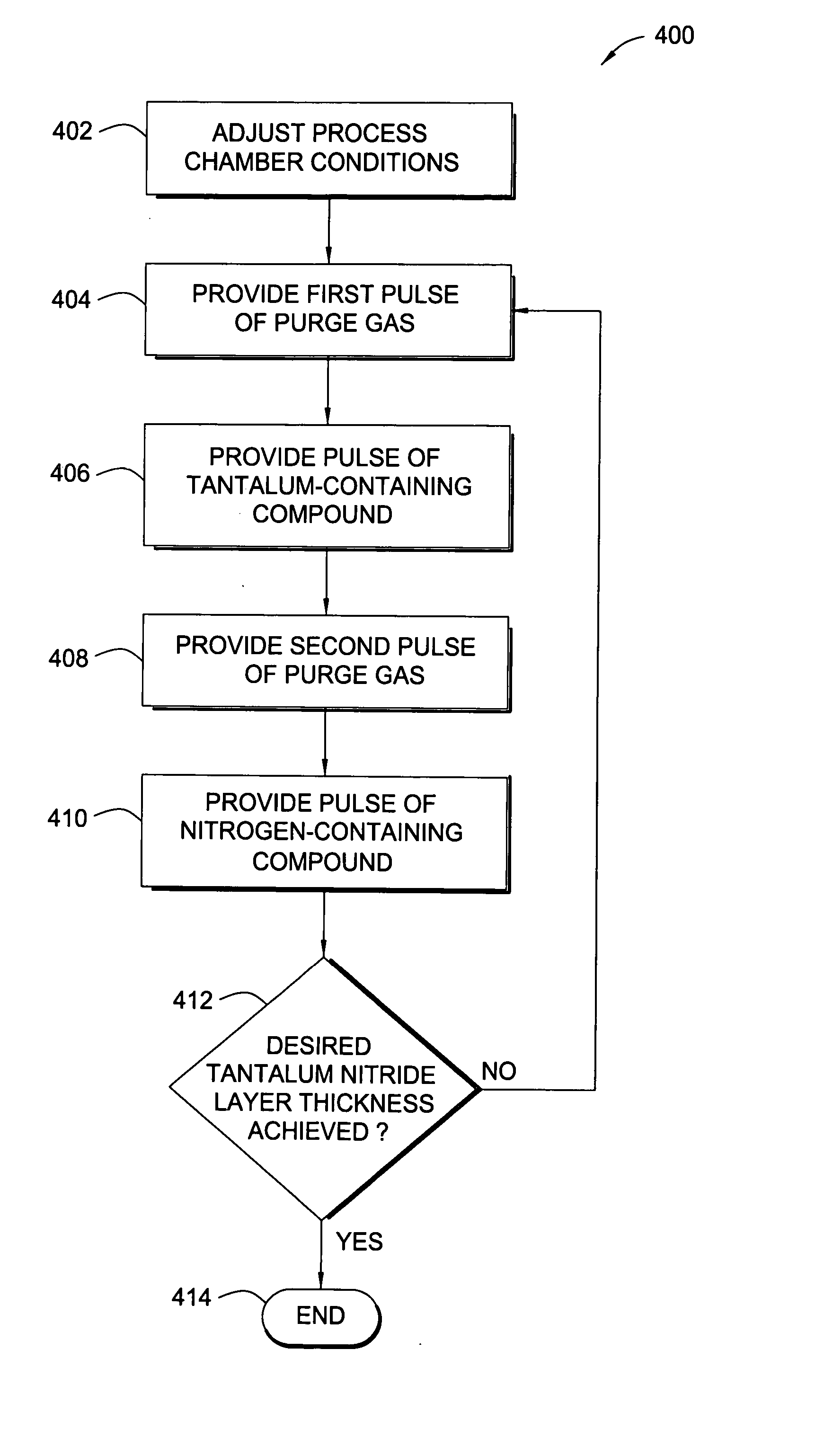

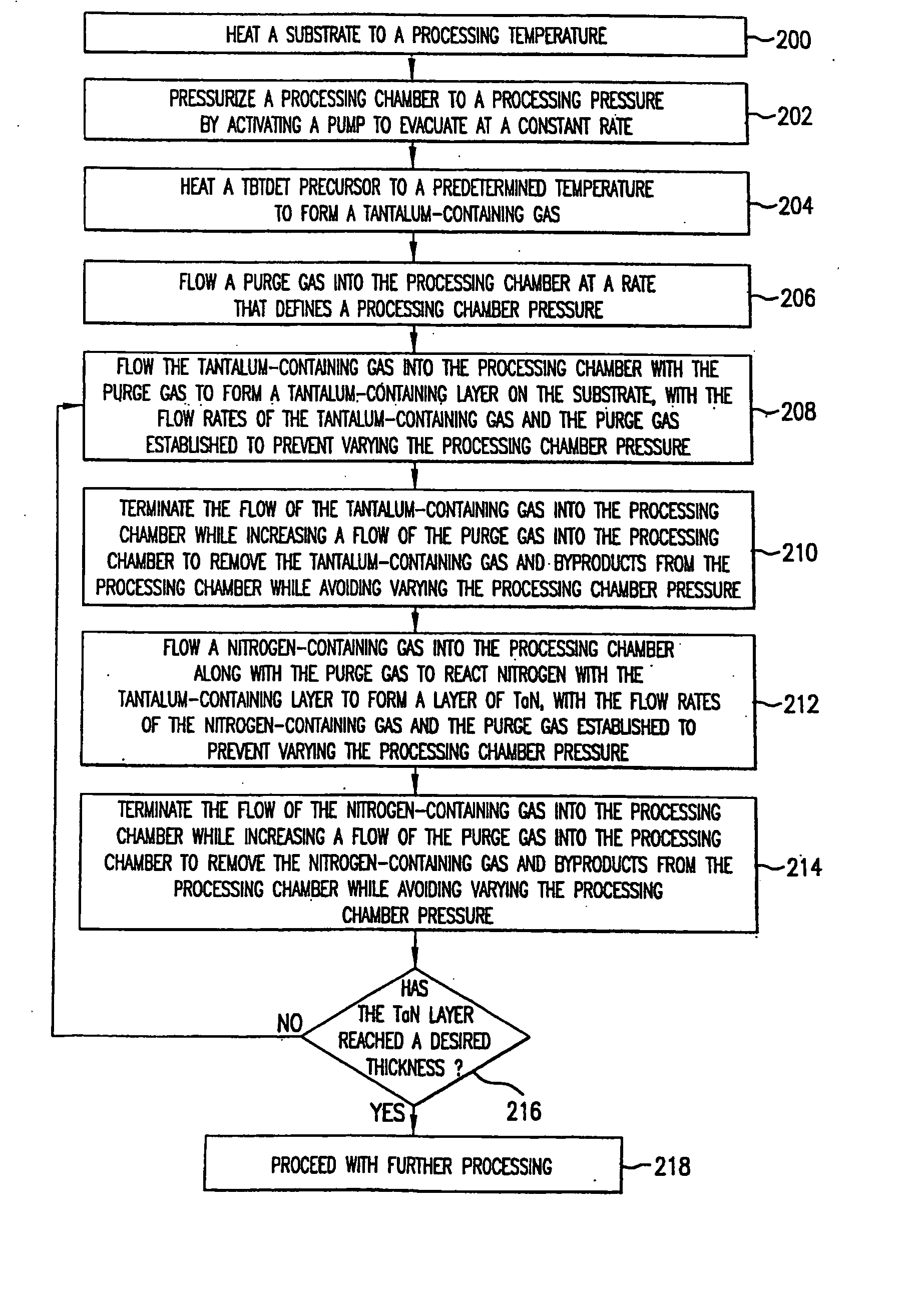

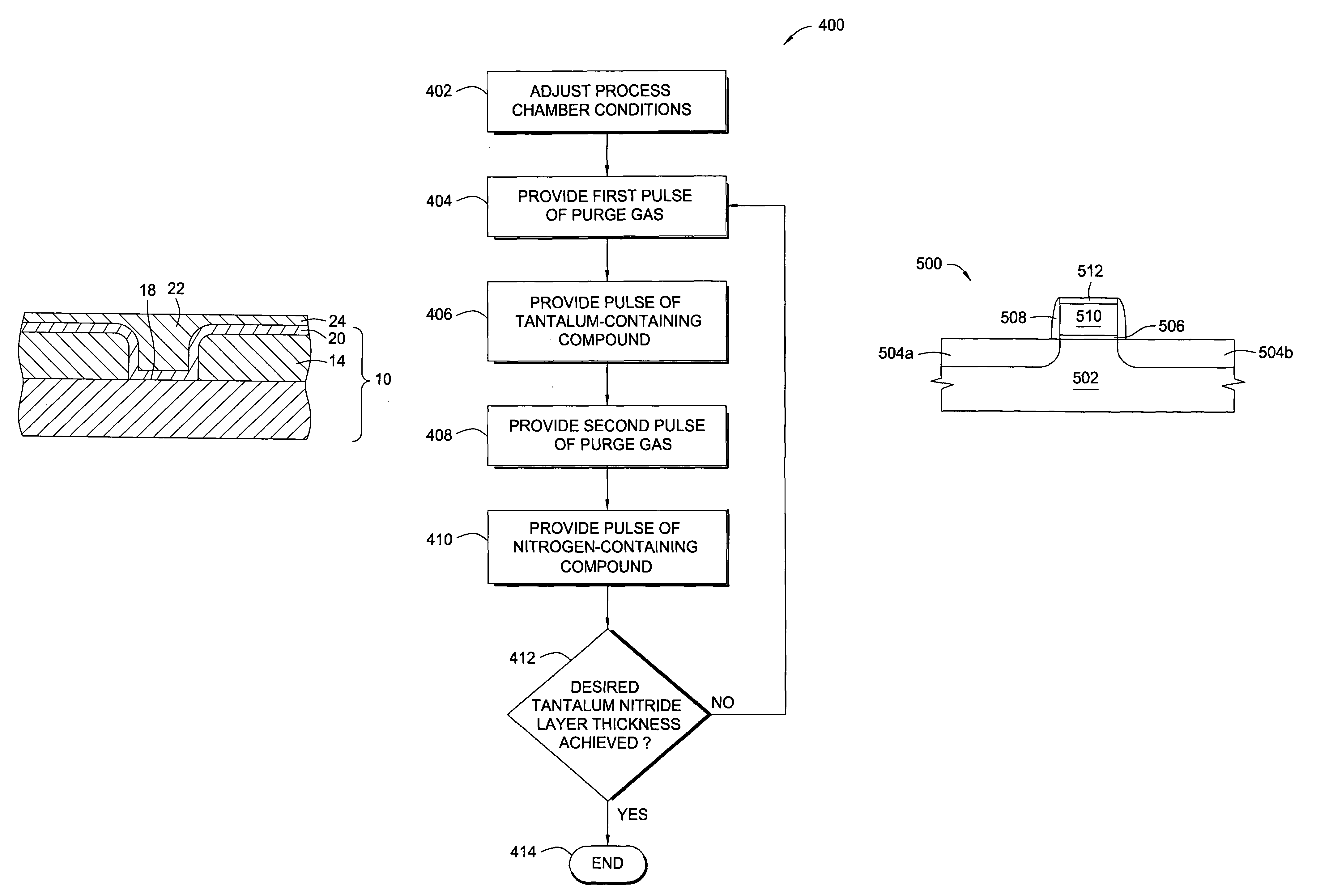

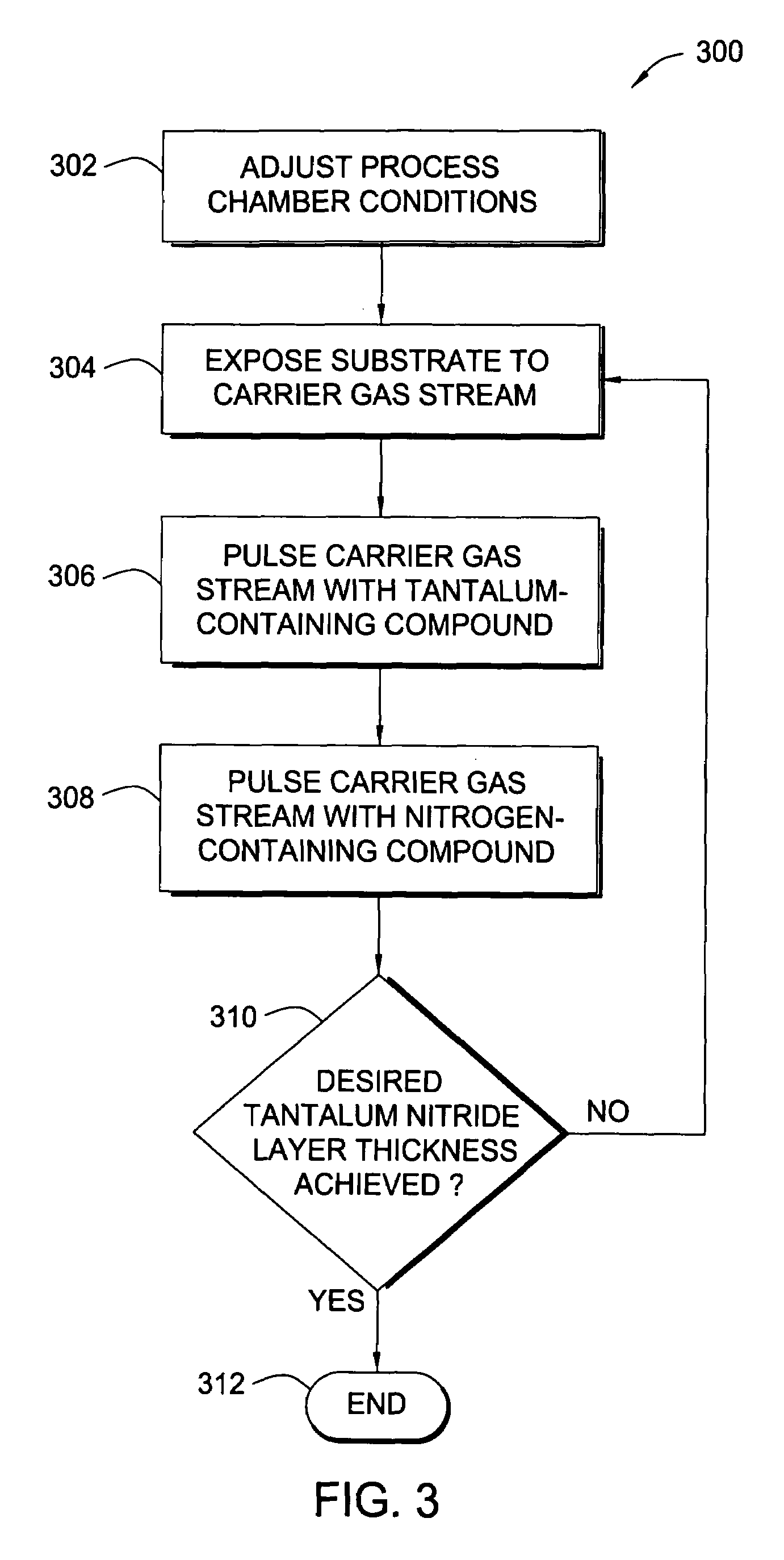

Sequential deposition of tantalum nitride using a tantalum-containing precursor and a nitrogen-containing precursor

InactiveUS20060019494A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

Embodiments of the invention provide a method for forming tantalum nitride materials on a substrate by employing an atomic layer deposition (ALD) process. The method includes heating a tantalum precursor within an ampoule to a predetermined temperature to form a tantalum precursor gas and sequentially exposing a substrate to the tantalum precursor gas and a nitrogen precursor to form a tantalum nitride material. Thereafter, a nucleation layer and a bulk layer may be deposited on the substrate. In one example, a radical nitrogen compound may be formed from the nitrogen precursor during a plasma-enhanced ALD process. A nitrogen precursor may include nitrogen or ammonia. In another example, a metal-organic tantalum precursor may be used during the deposition process.

Owner:APPLIED MATERIALS INC

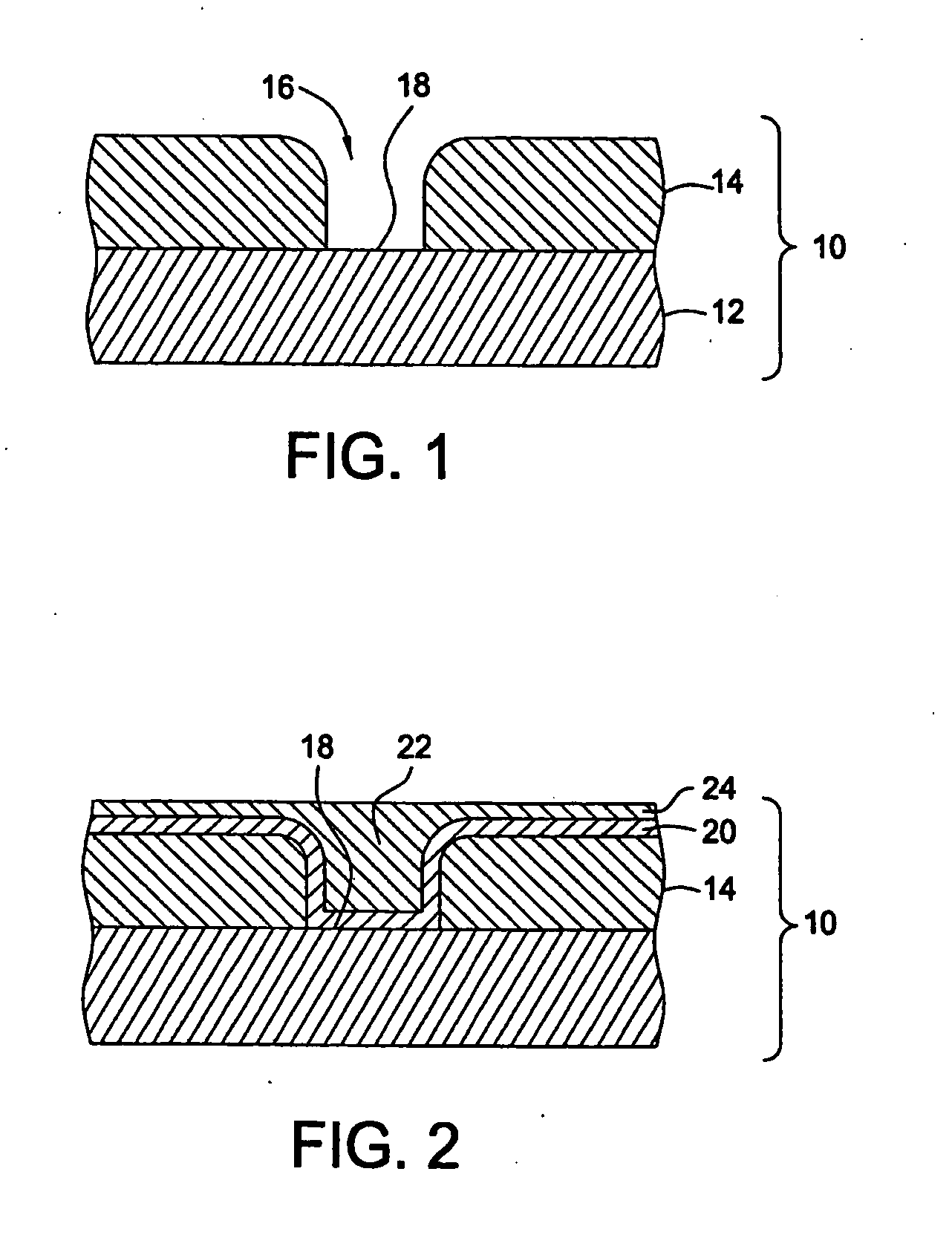

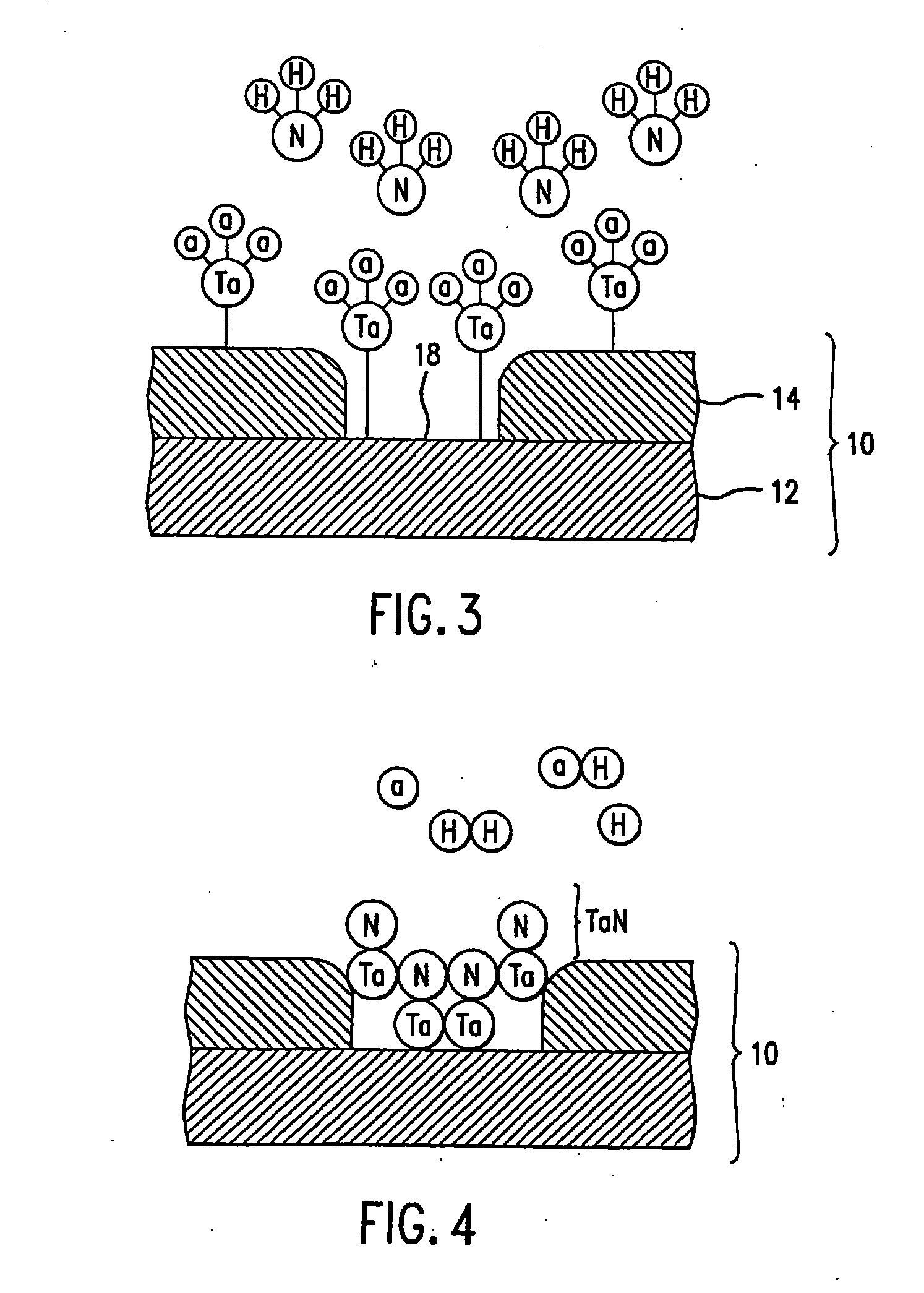

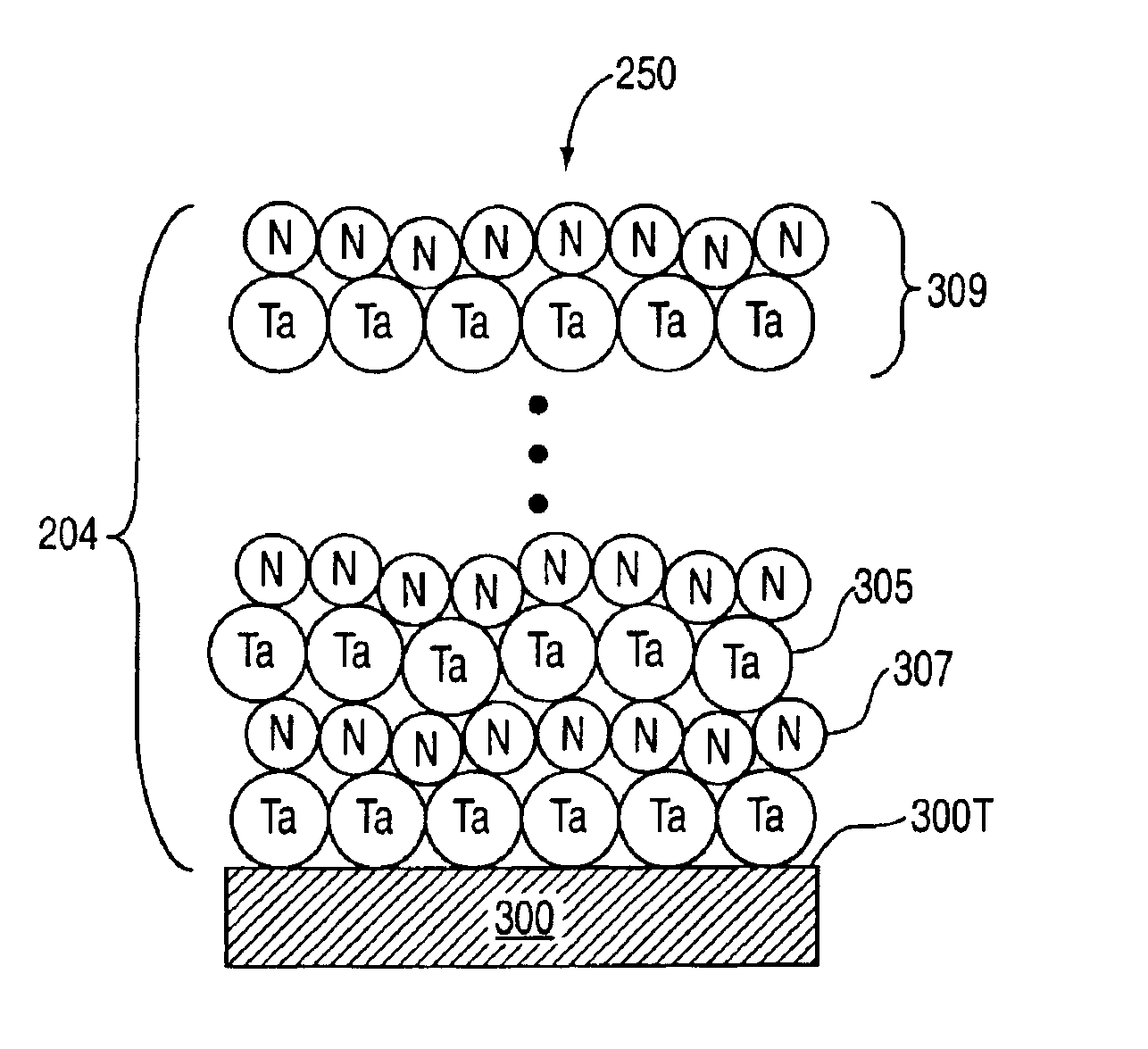

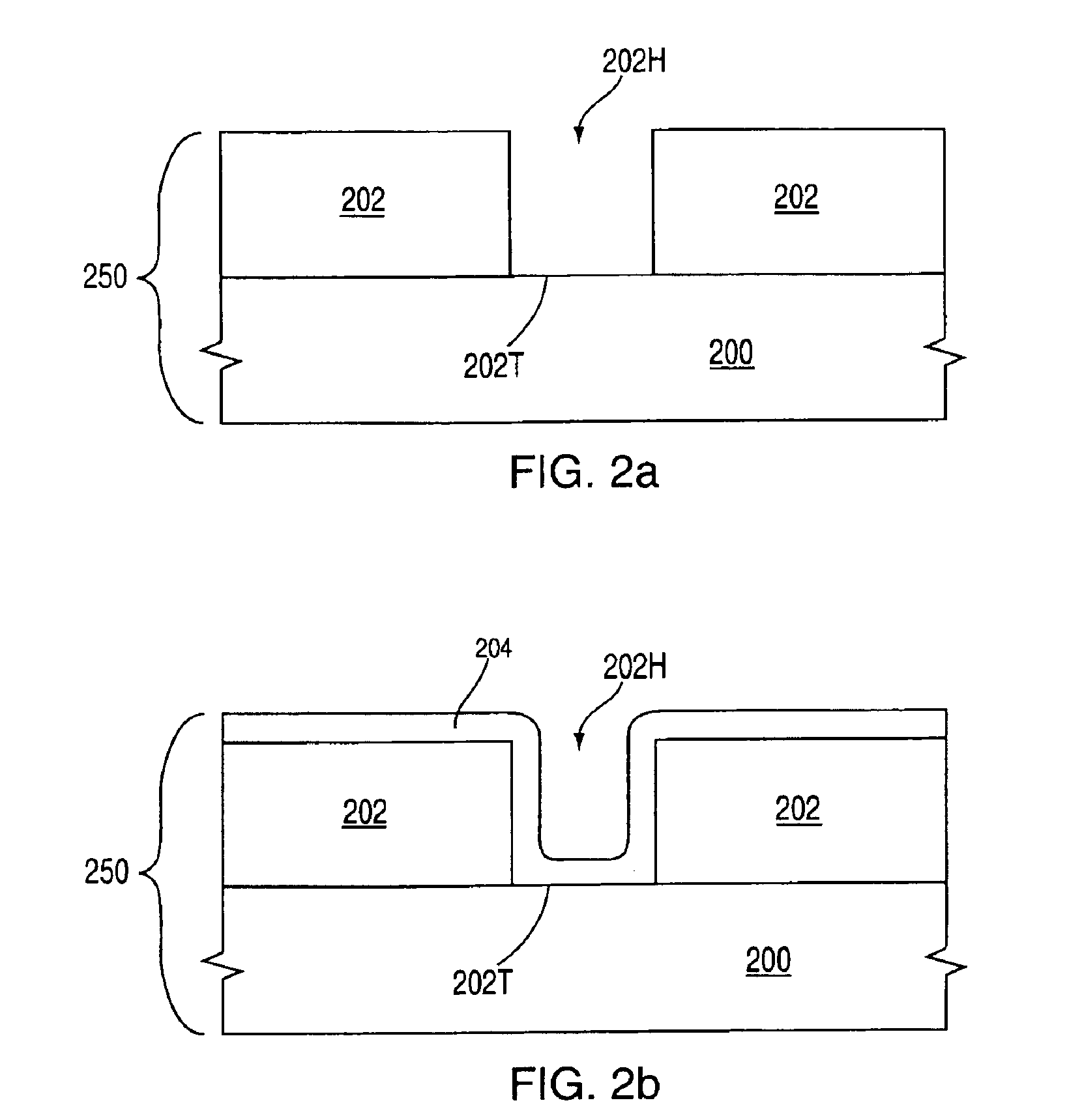

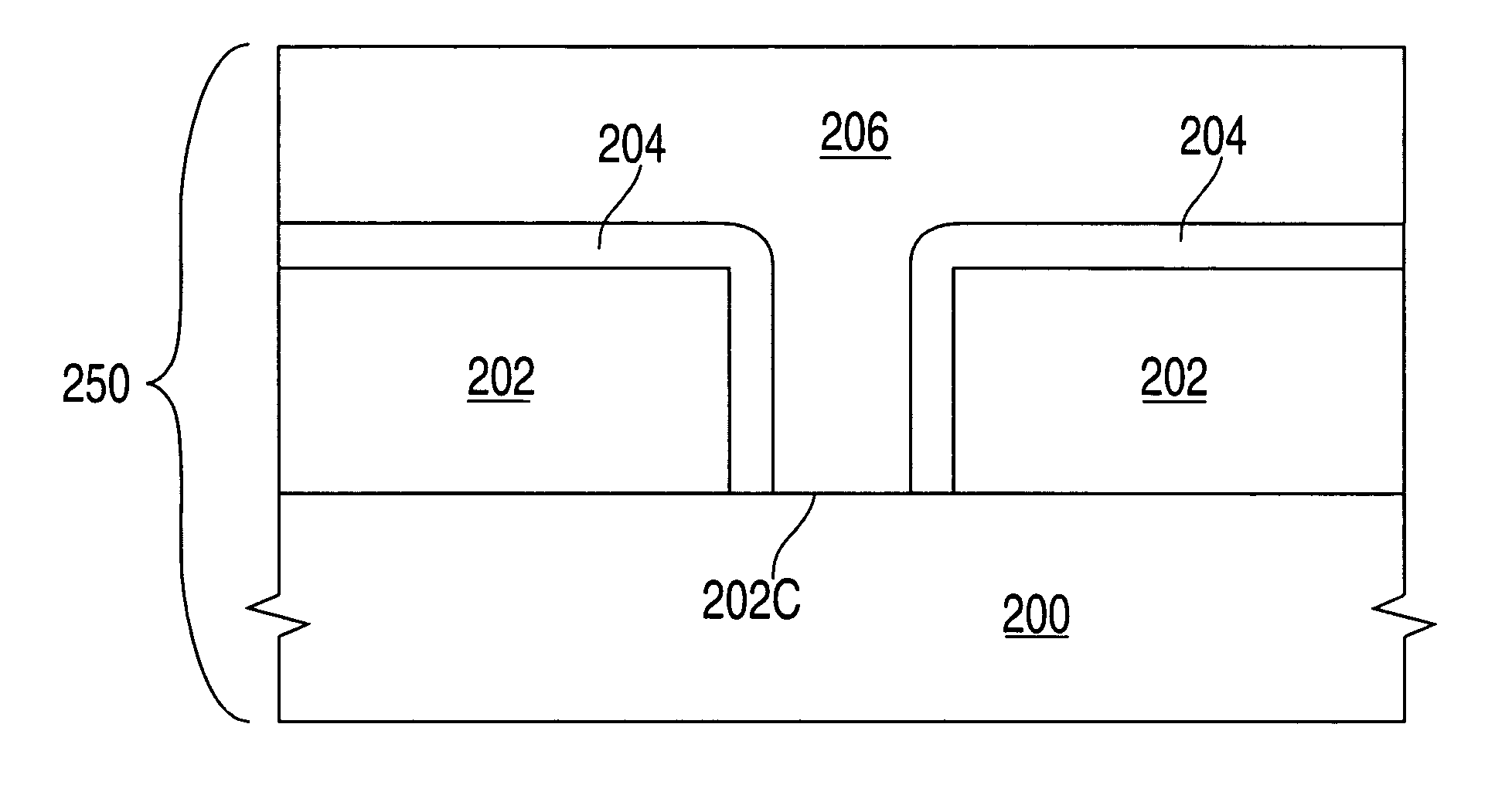

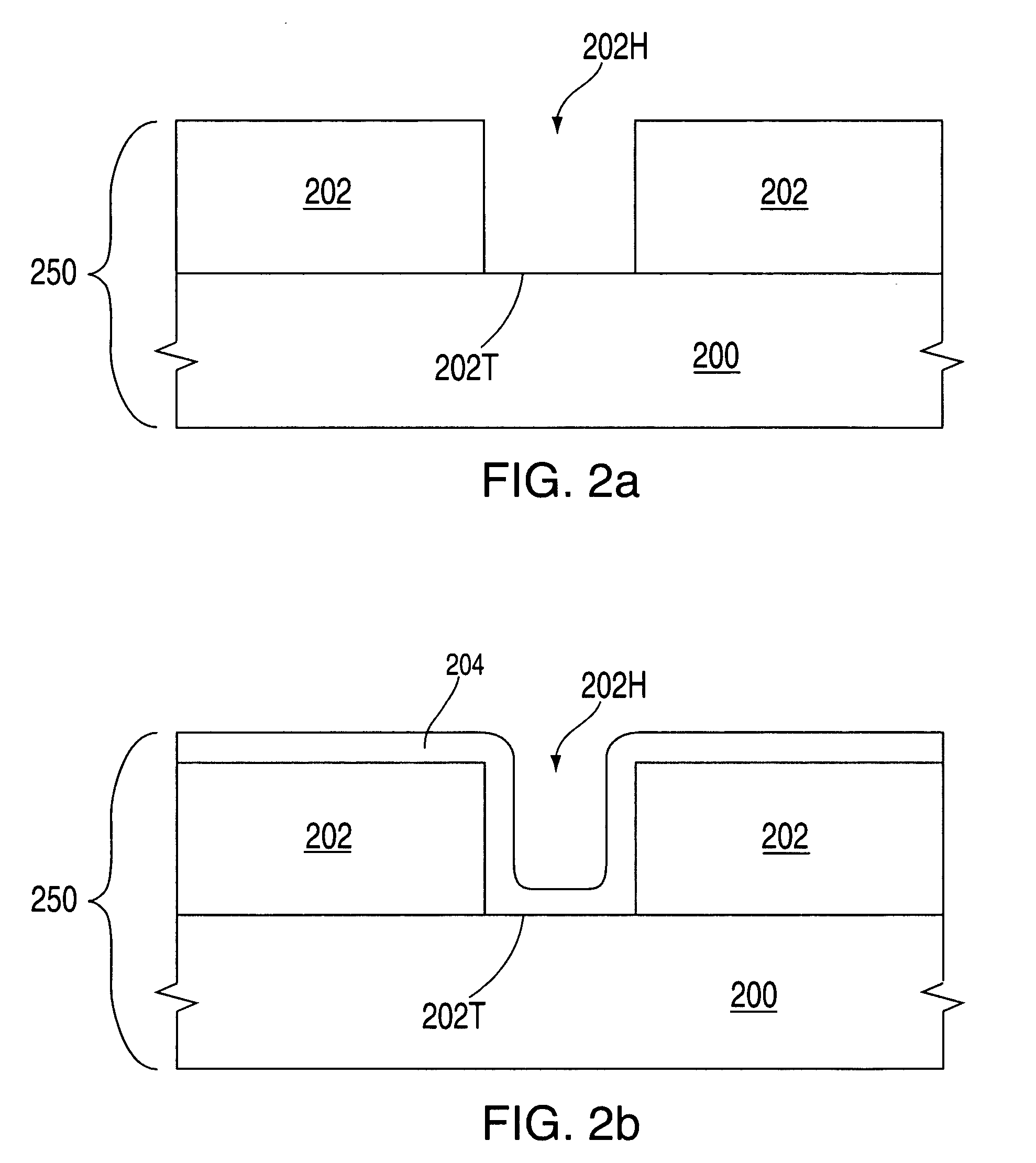

Formation of a tantalum-nitride layer

InactiveUS6951804B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal interconnectTantalum nitride

A method of forming a tantalum-nitride layer (204) for integrated circuit fabrication is disclosed. Alternating or co-reacting pulses of a tantalum containing precursor and a nitrogen containing precursor are provided to a chamber (100) to form layers (305, 307) of tantalum and nitrogen. The nitrogen precursor may be a plasma gas source. The resultant tantalum-nitride layer (204) may be used, for example, as a barrier layer. As barrier layers may be used with metal interconnect structures (206), at least one plasma anneal on the tantalum-nitride layer may be performed to reduce its resistivity and to improve film property.

Owner:APPLIED MATERIALS INC

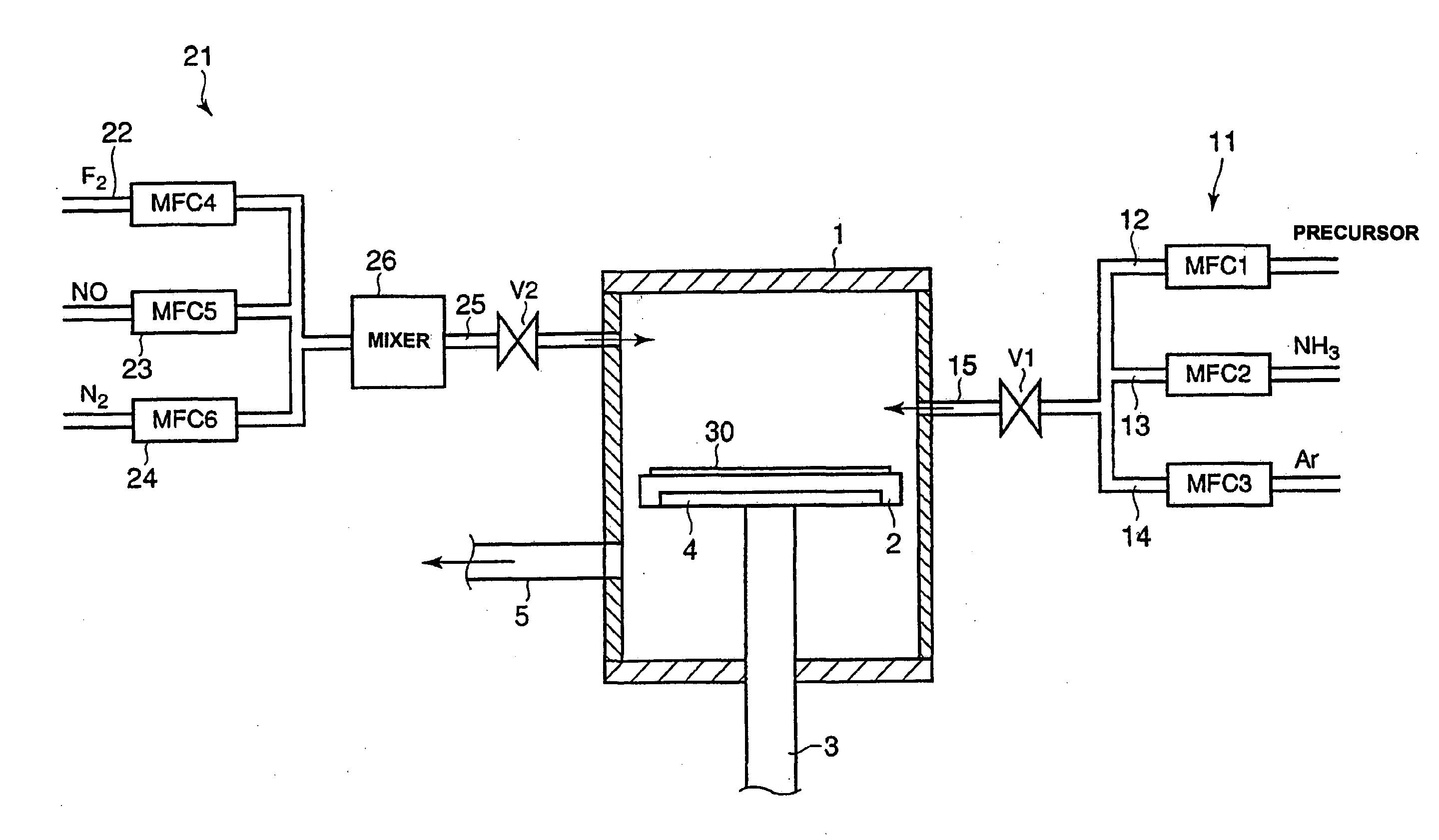

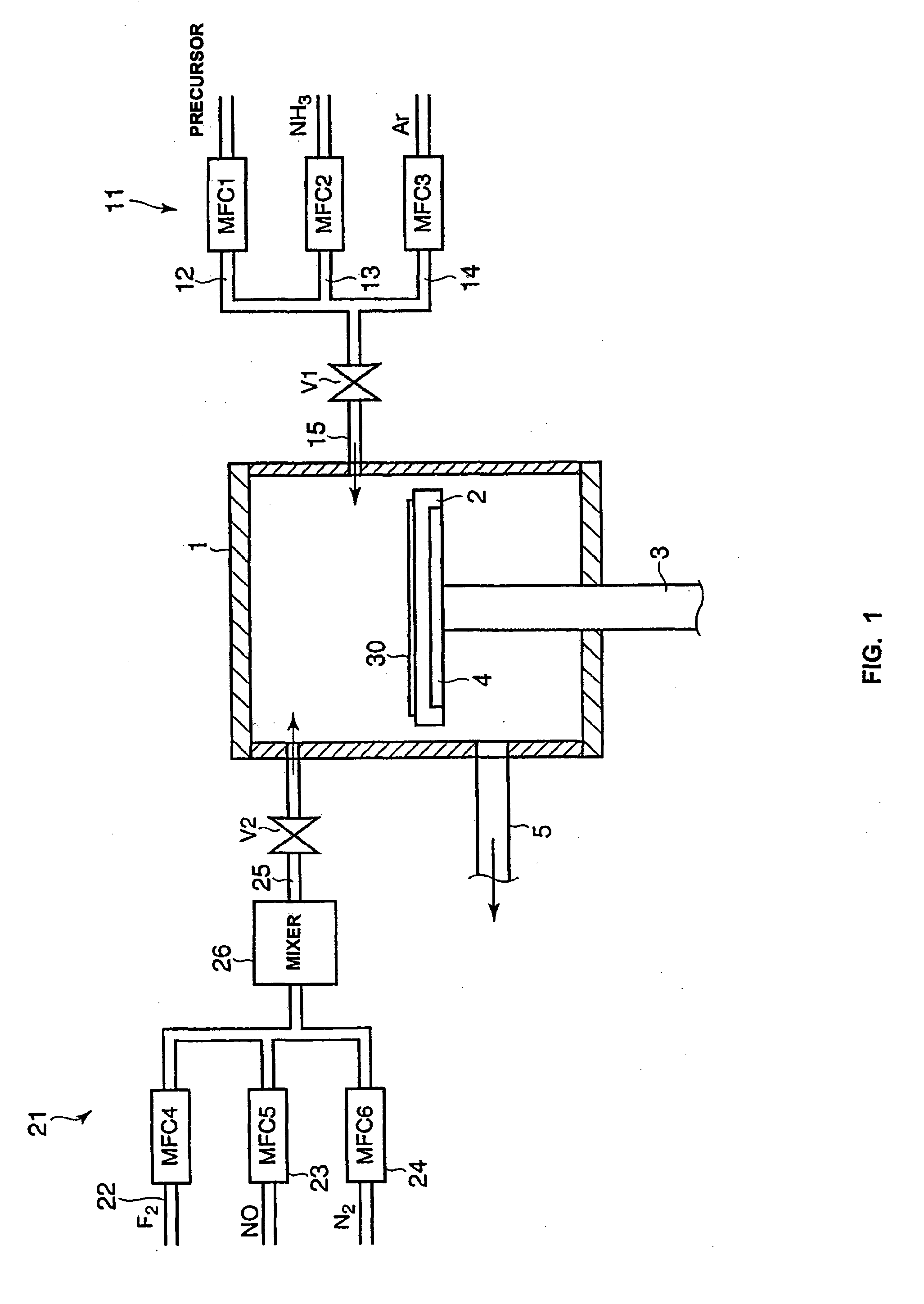

Method of cleaning film forming apparatus and film forming apparatus

InactiveUS20100012153A1Increase etch rateUniform removalHollow article cleaningChemical vapor deposition coatingTantalum nitrideTitanium nitride

To provide a method of cleaning a film forming apparatus capable of uniformly removing a deposit containing tantalum nitride, titanium nitride, tantalum, or titanium adhering to a wall of a processing chamber of the film forming apparatus at a high etching rate without use of plasma. A method of cleaning a film forming apparatus for removing a deposit containing tantalum nitride, titanium nitride, tantalum, or titanium deposited on a processing chamber of the film forming apparatus after it is used for forming a thin film made of tantalum nitride, titanium nitride, tantalum, or titanium, the cleaning method comprising: a step of supplying process gas containing fluorine gas into the processing chamber of the film forming apparatus; and a step of heating the processing chamber.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

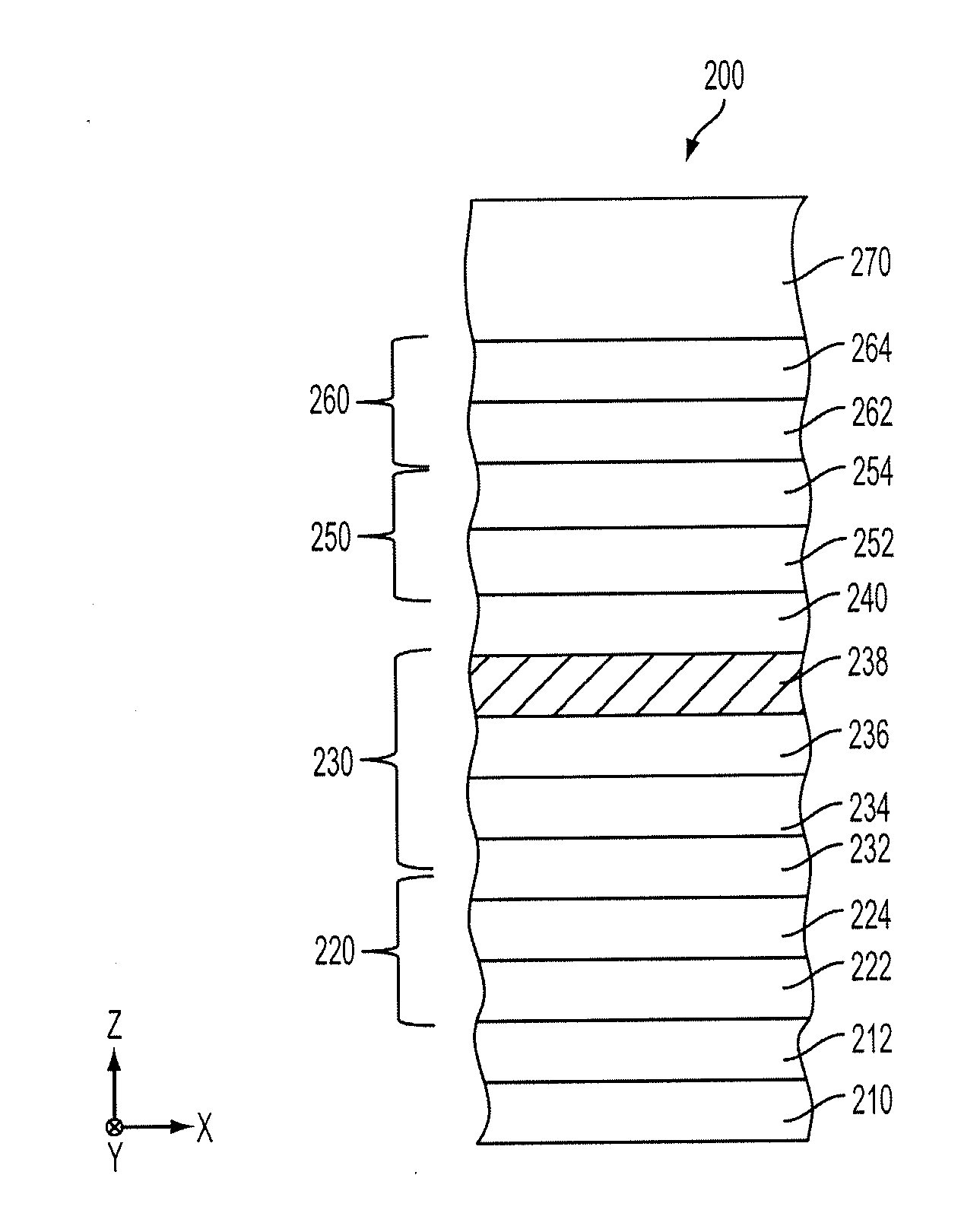

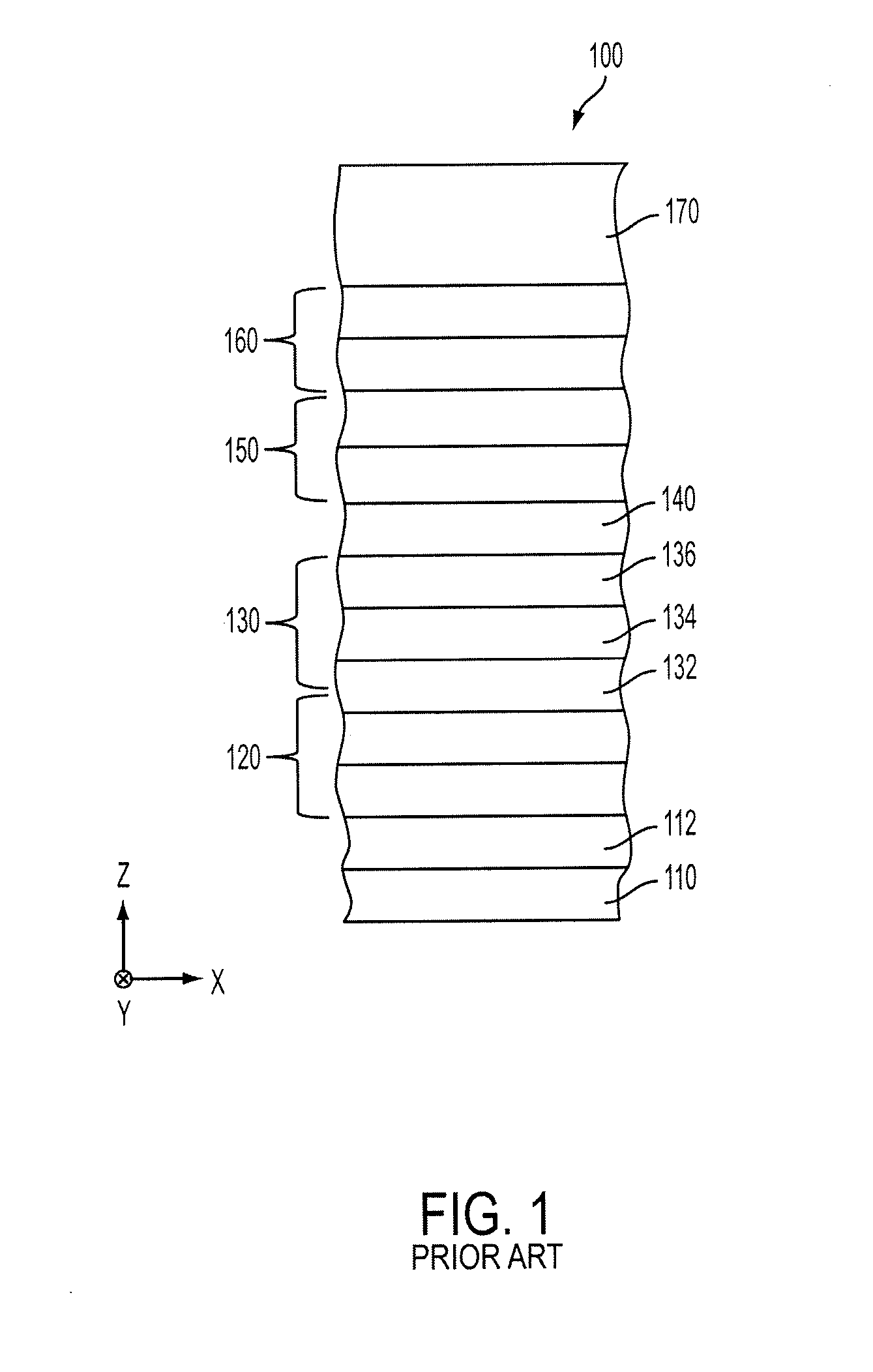

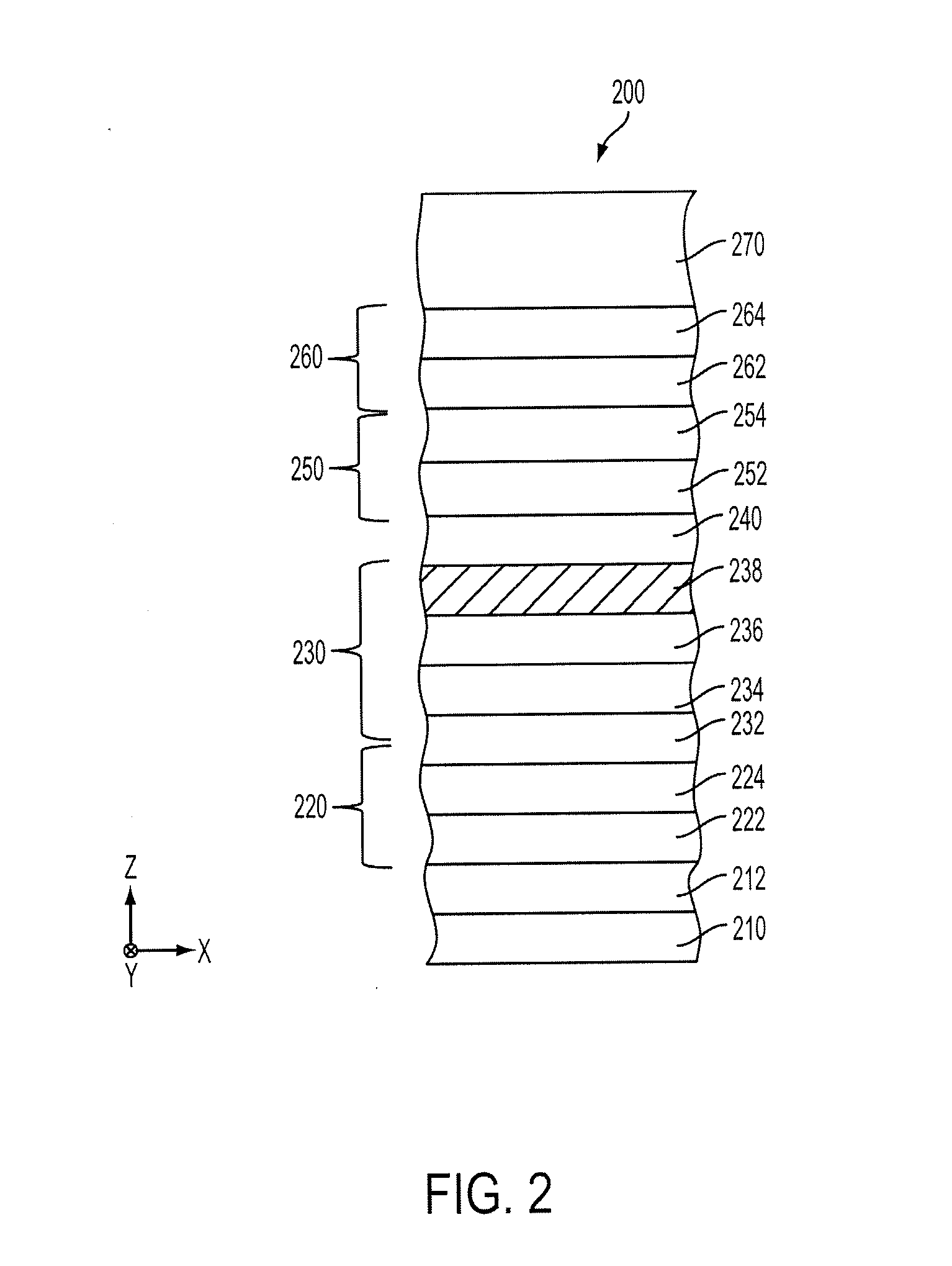

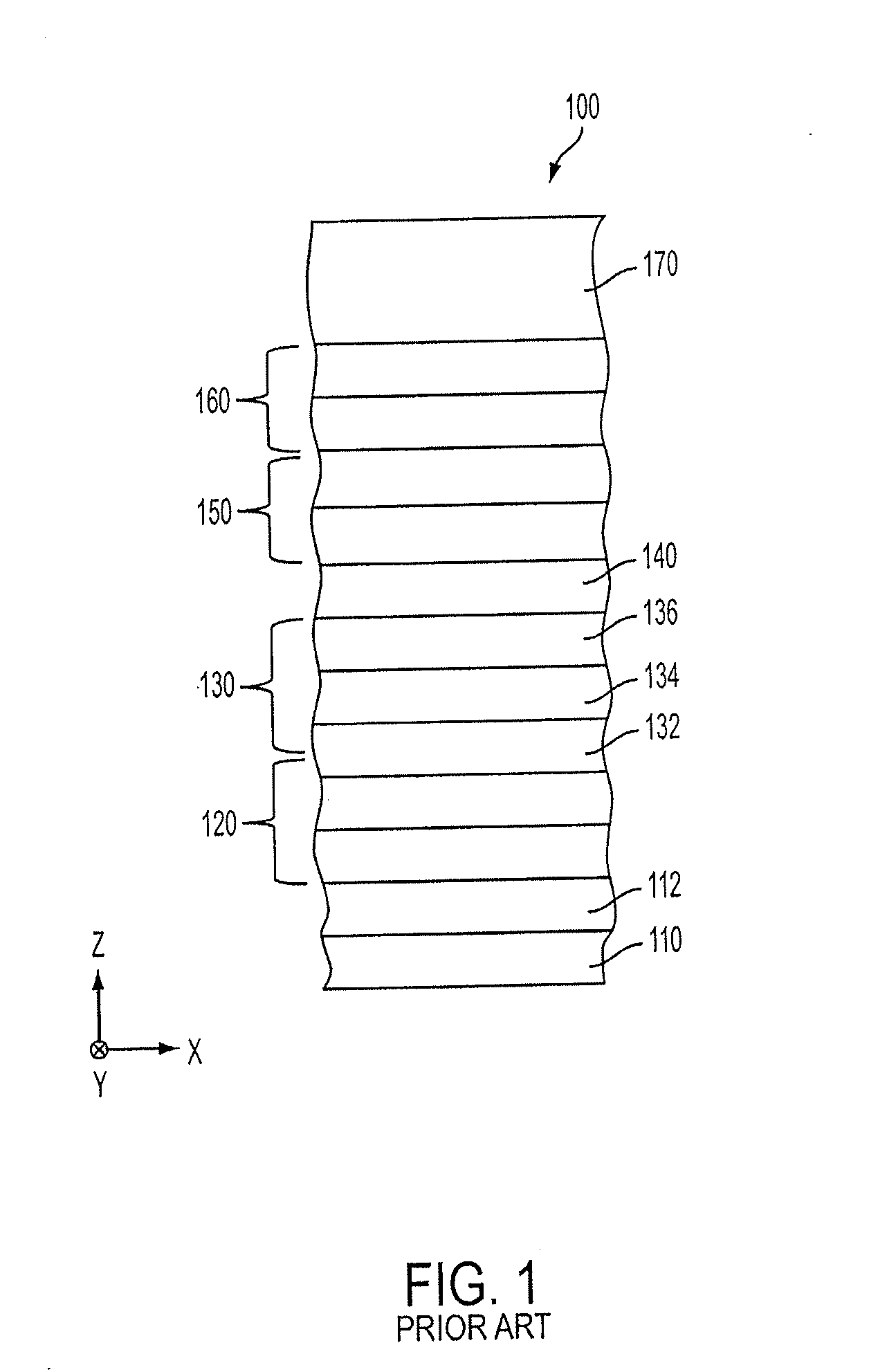

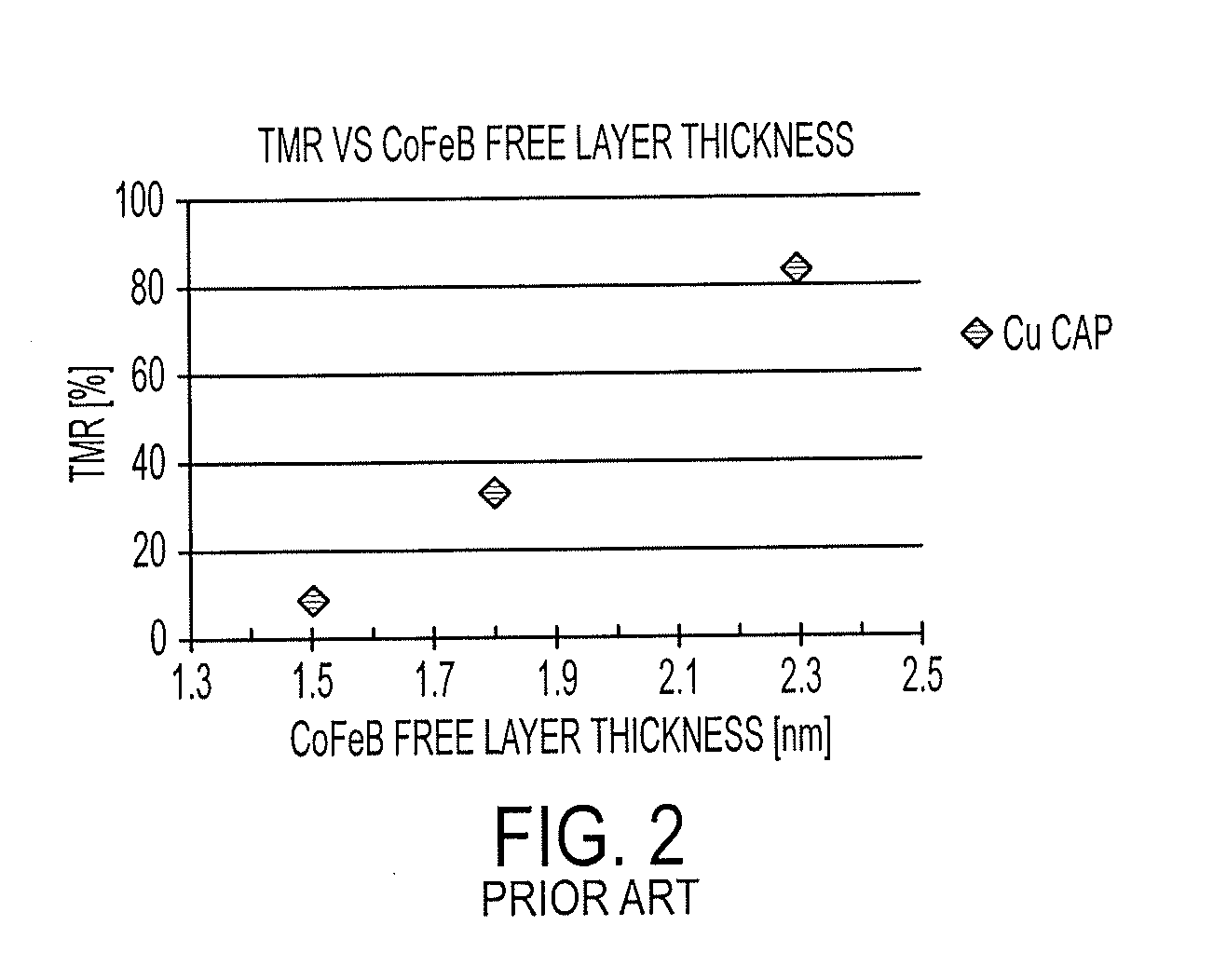

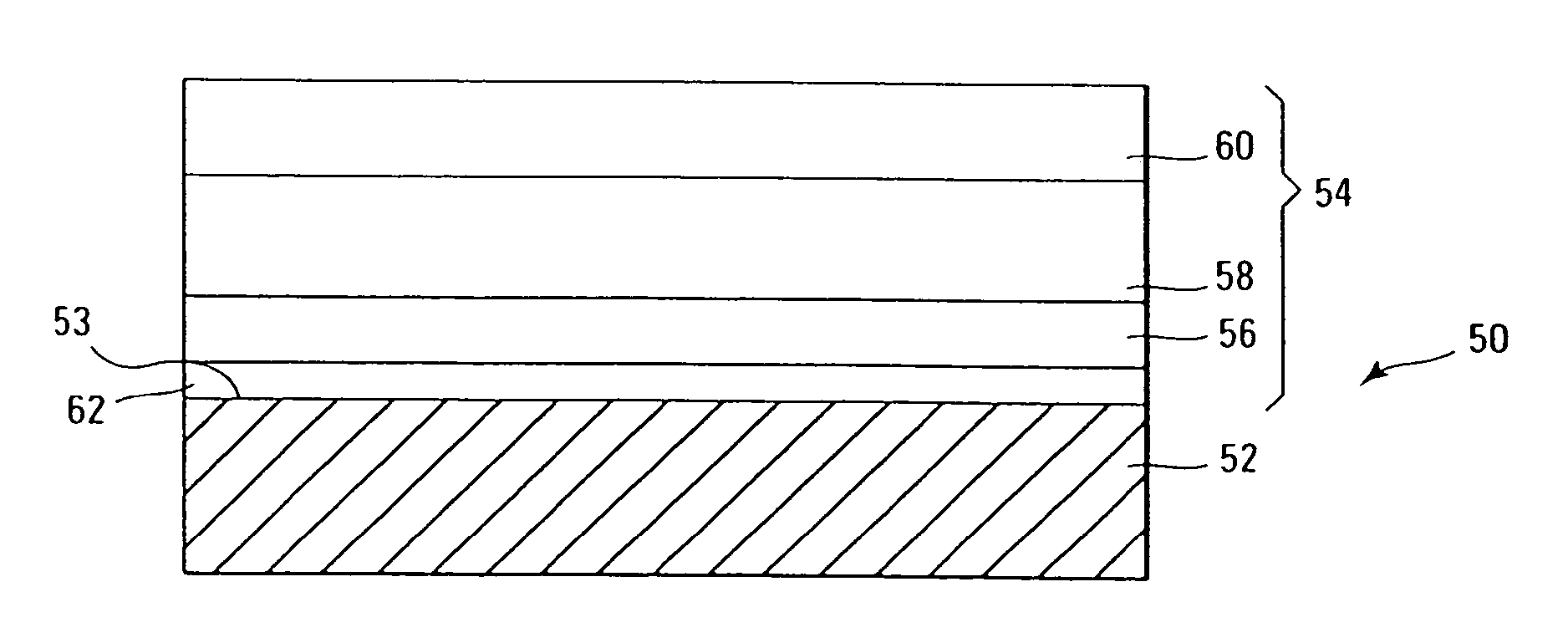

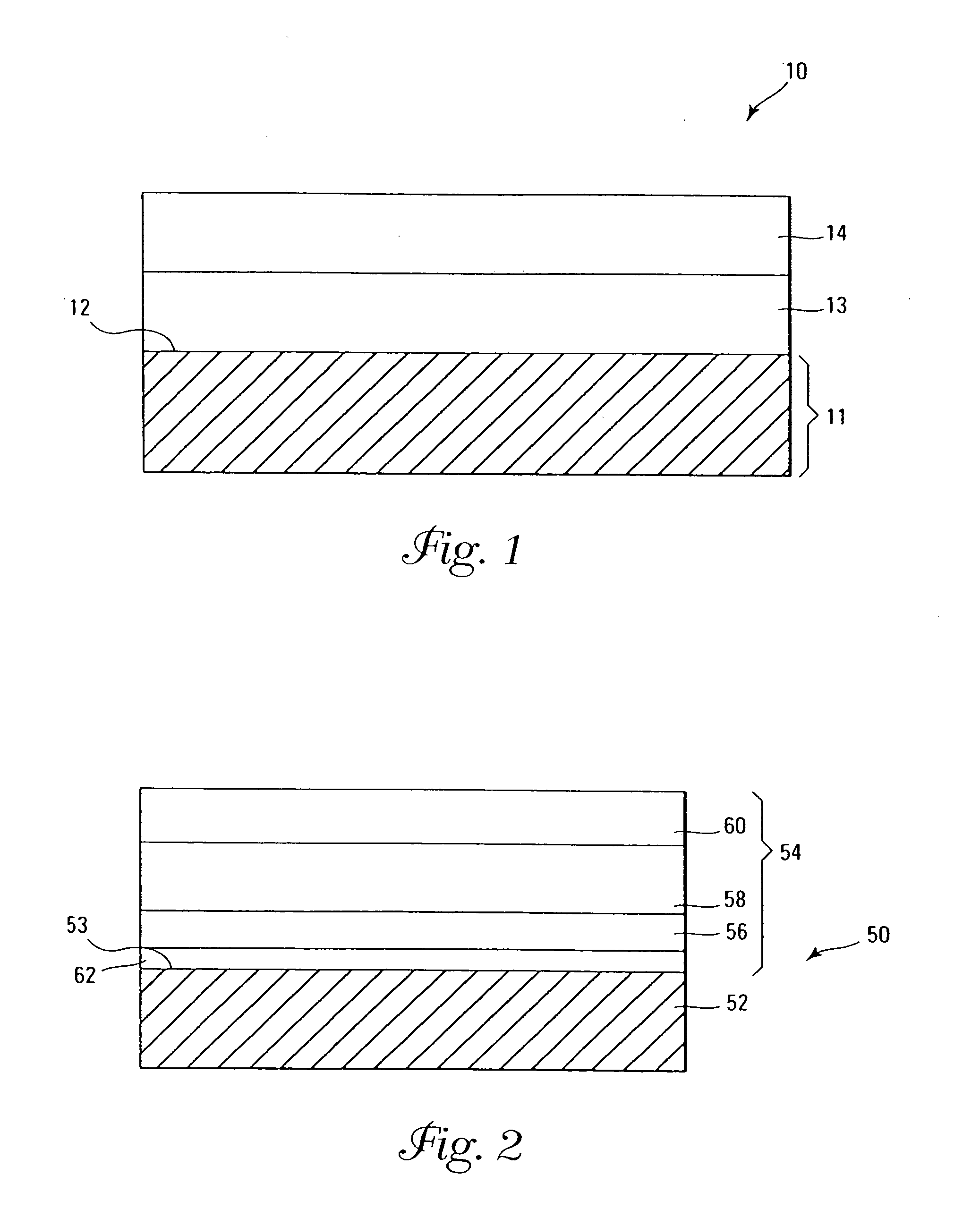

Magnetic tunnel junction for MRAM device

InactiveUS20150279904A1Improve performanceSwitching currentMagnetic-field-controlled resistorsSolid-state devicesTantalum nitrideSoftware engineering

A magnetoresistive random-access memory device with a magnetic tunnel junction stack having a significantly improved performance of the free layer in the magnetic tunnel junction structure. The memory device includes an antiferromagnetic structure and a magnetic tunnel junction structure disposed on the antiferromagnetic structure. The magnetic tunnel junction structure includes a reference layer and a free layer with a barrier layer sandwiched therebetween. Furthermore, a capping layer including a tantalum nitride film is disposed on the free layer of the magnetic tunnel junction structure.

Owner:SPIN MEMORY INC

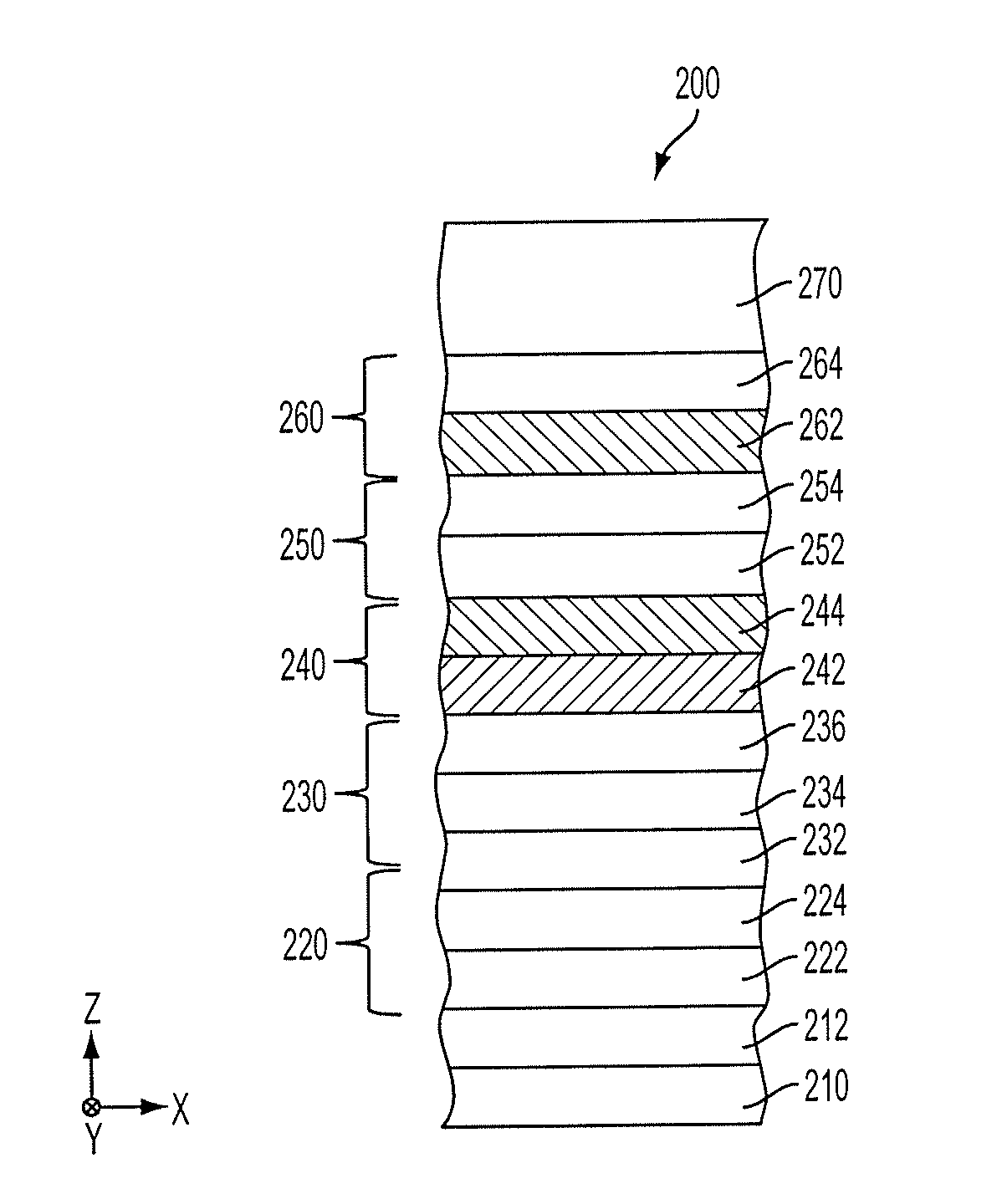

Magnetic tunnel junction structure for MRAM device

ActiveUS20160087193A1Increase TMR valueOptimized free layer magnetic propertiesNanomagnetismSolid-state devicesTantalum nitridePolarizer

A magnetic tunnel junction stack is provided that includes nonmagnetic spacer layers between the free layer and the polarizer layer formed from magnesium oxide and tantalum nitride materials that balance the spin torques acting on the free layer. The design provided enables a deterministic final state for the storage layer and significantly improves the tunneling magnetoresistance value and switching characteristics of the magnetic tunnel junction for MRAM applications.

Owner:INTEGRATED SILICON SOLUTION CAYMAN INC

Systems and methods of forming refractory metal nitride layers using organic amines

InactiveUS20050287804A1Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsGas phaseTantalum nitride

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum nitride barrier layer, on a substrate by using an atomic layer deposition process (a vapor deposition process that includes a plurality of deposition cycles) with a refractory metal precursor compound, an organic amine, and an optional silicon precursor compound.

Owner:MICRON TECH INC

Deposition methods for barrier and tungsten materials

Embodiments are provided for a method to deposit barrier and tungsten materials on a substrate. In one embodiment, a method provides forming a barrier layer on a substrate and exposing the substrate to a silane gas to form a thin silicon-containing layer on the barrier layer during a soak process. The method further provides depositing a tungsten nucleation layer over the barrier layer and the thin silicon-containing layer during an atomic layer deposition process and depositing a tungsten bulk layer on the tungsten nucleation layer during a chemical vapor deposition process. In some examples, the barrier layer contains metallic cobalt and cobalt silicide, or metallic nickel and nickel silicide. In other examples, the barrier layer contains metallic titanium and titanium nitride, or metallic tantalum and tantalum nitride.

Owner:APPLIED MATERIALS INC

Atomic layer deposition of tantalum-containing materials using the tantalum precursor TAIMATA

InactiveUS7241686B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron nitrideAtomic layer deposition

In one example of the invention, a method for depositing a tantalum-containing material on a substrate in a process chamber is provided which includes exposing the substrate to a tantalum precursor that contains TAIMATA and to at least one secondary precursor to deposit a tantalum-containing material during an atomic layer deposition (ALD) process. The ALD process is repeated until the tantalum-containing material is deposited having a predetermined thickness. Usually, the TAIMATA is preheated prior to pulsing the tantalum precursor into the process chamber. Subsequently, a metal layer, such as tungsten or copper, may be deposited on the tantalum-containing material. The tantalum-containing material may contain tantalum, tantalum nitride, tantalum silicon nitride, tantalum boron nitride, tantalum phosphorous nitride, or tantalum oxynitride. The tantalum-containing material may be deposited as a barrier or adhesion layer within a via or as a gate electrode material within a source / drain device.

Owner:APPLIED MATERIALS INC

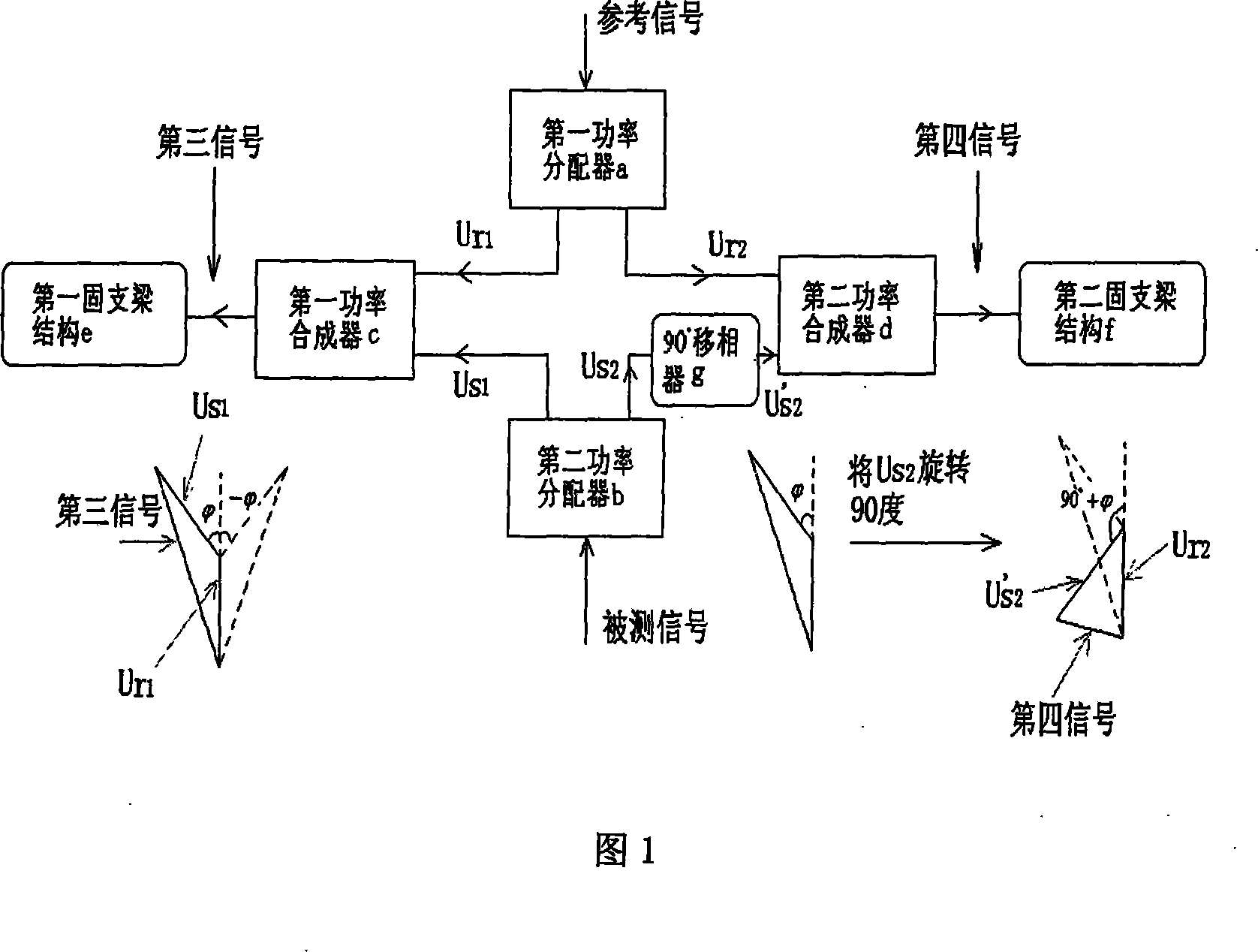

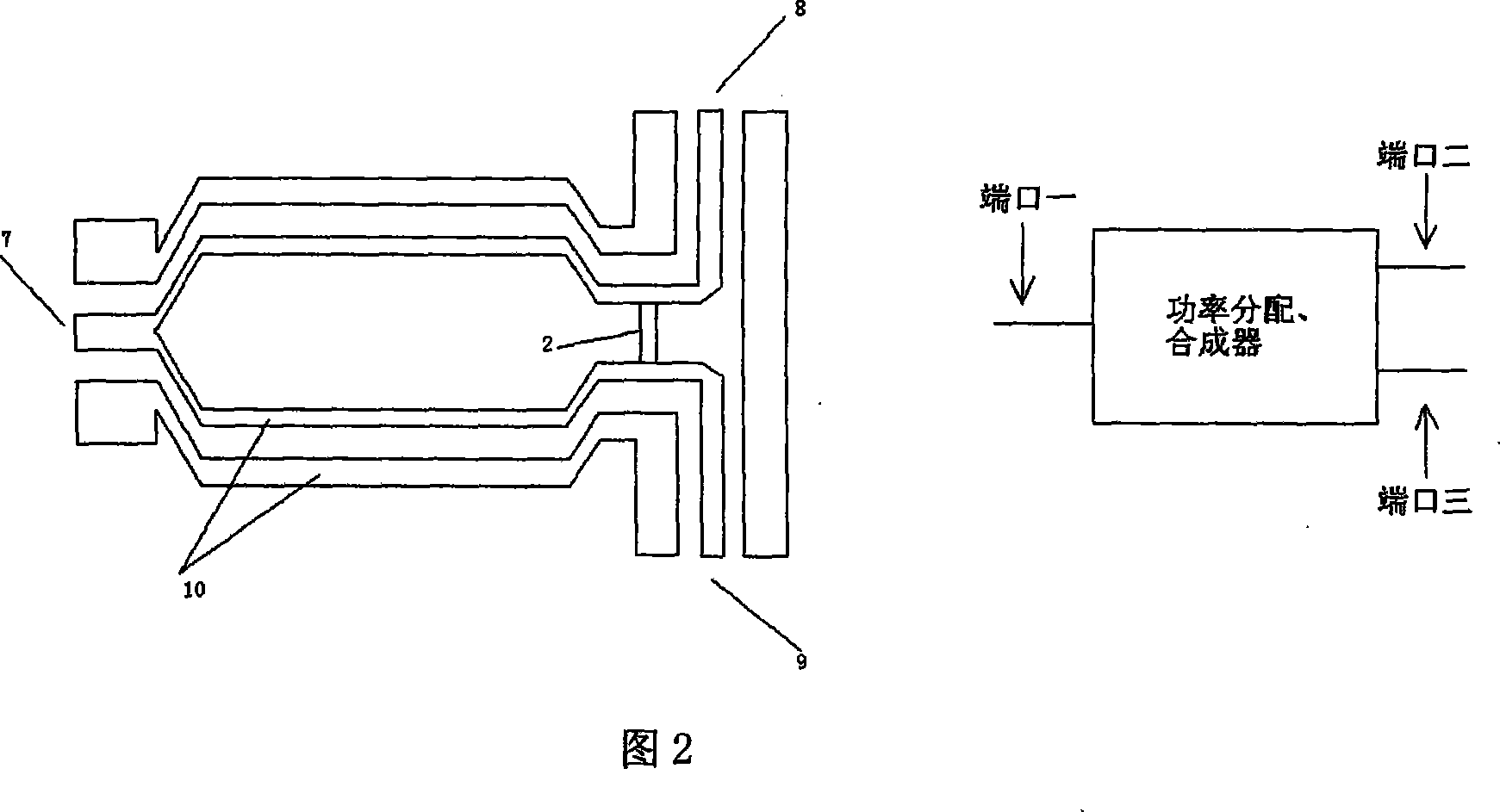

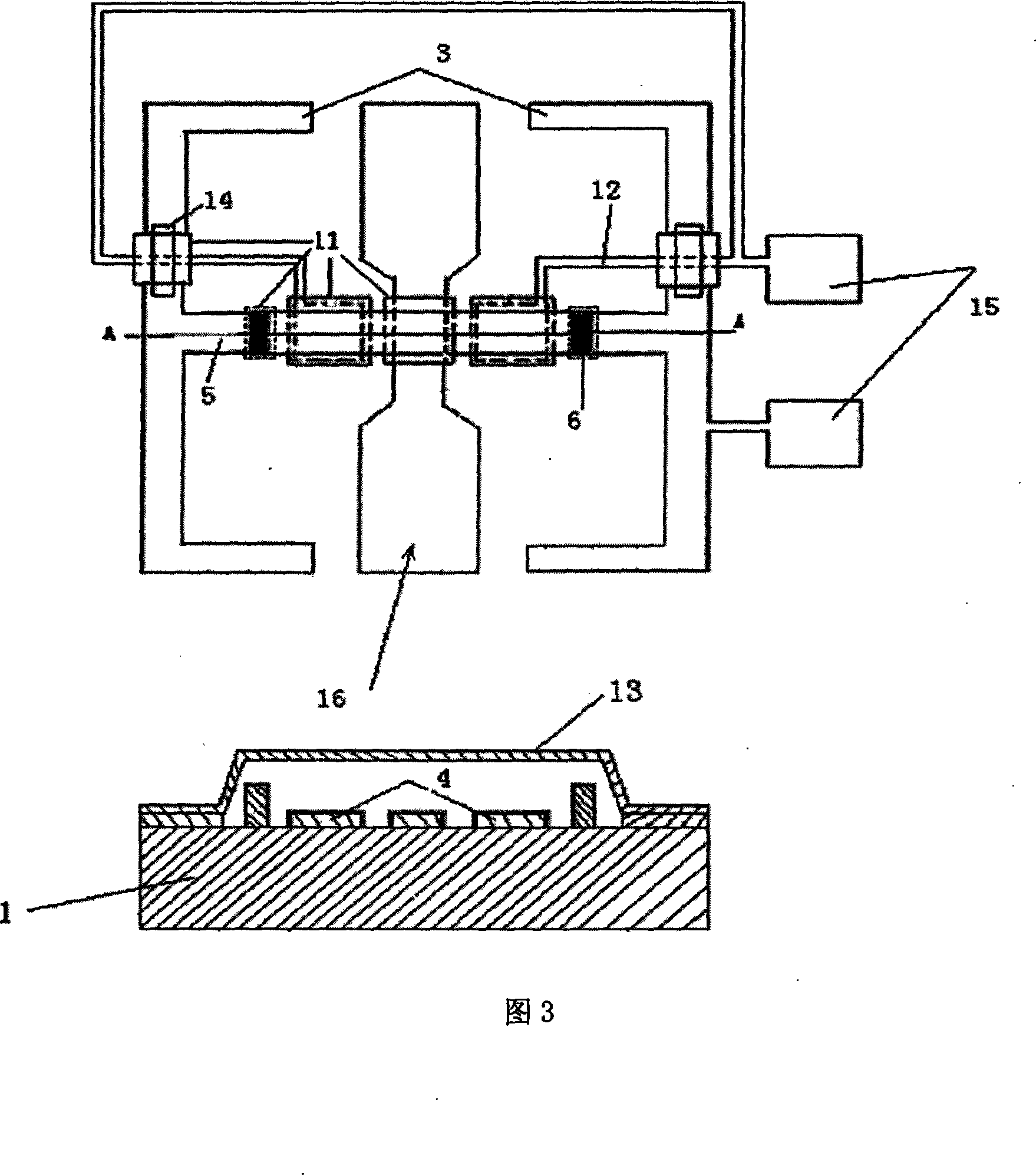

Microelectronic machinery orthogonal double channels microwave phase online detector and manufacturing method therefor

InactiveCN101034122AIncreaseIncreased bandwidthElectromagentic field characteristicsCapacitancePower combiner

this invention relates to power in direct-current circuits. The invention takes gallium arsenide as foundation (1). On the foundation has power divider, power synthesizer, 90deg phaser, solid beam structure. Power divider and power synthesizer composed by port one (7), port two(8), port three(8), dissymmetry coplane band line(10), nitride tantalum electric resistance. Solid beam structure includes signal input port(16), pier(5), solid beam(13), pedestal structure(6), sensing electrode(4), sensing electrode leader(12), capacitance detecting port(15), air bridge(14). There are nitriding silicon medium layer on the transmission line, pedestal structure and sensing electrode under solid beam, and sensing electrode leader under Air Bridge.

Owner:SOUTHEAST UNIV

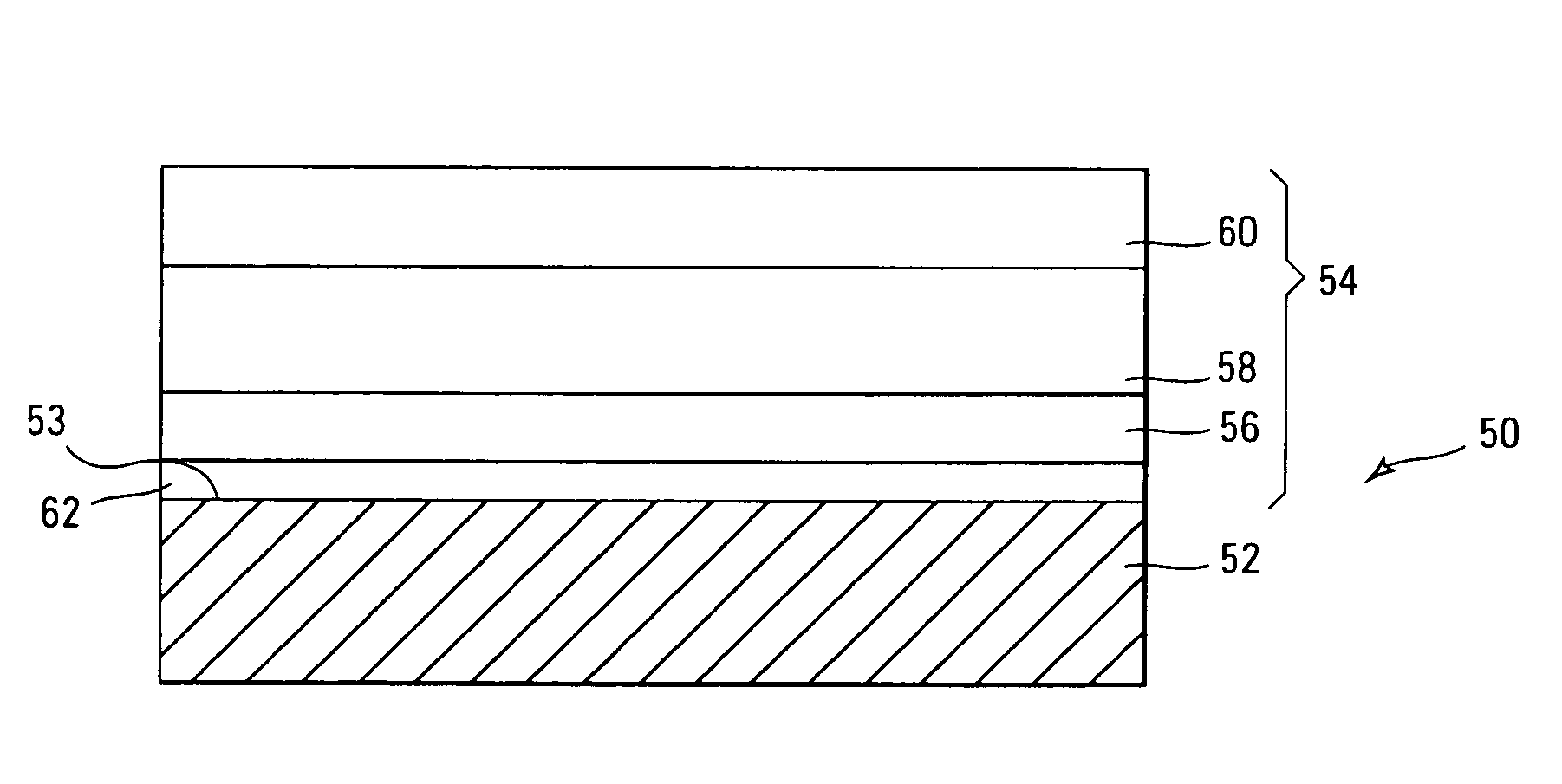

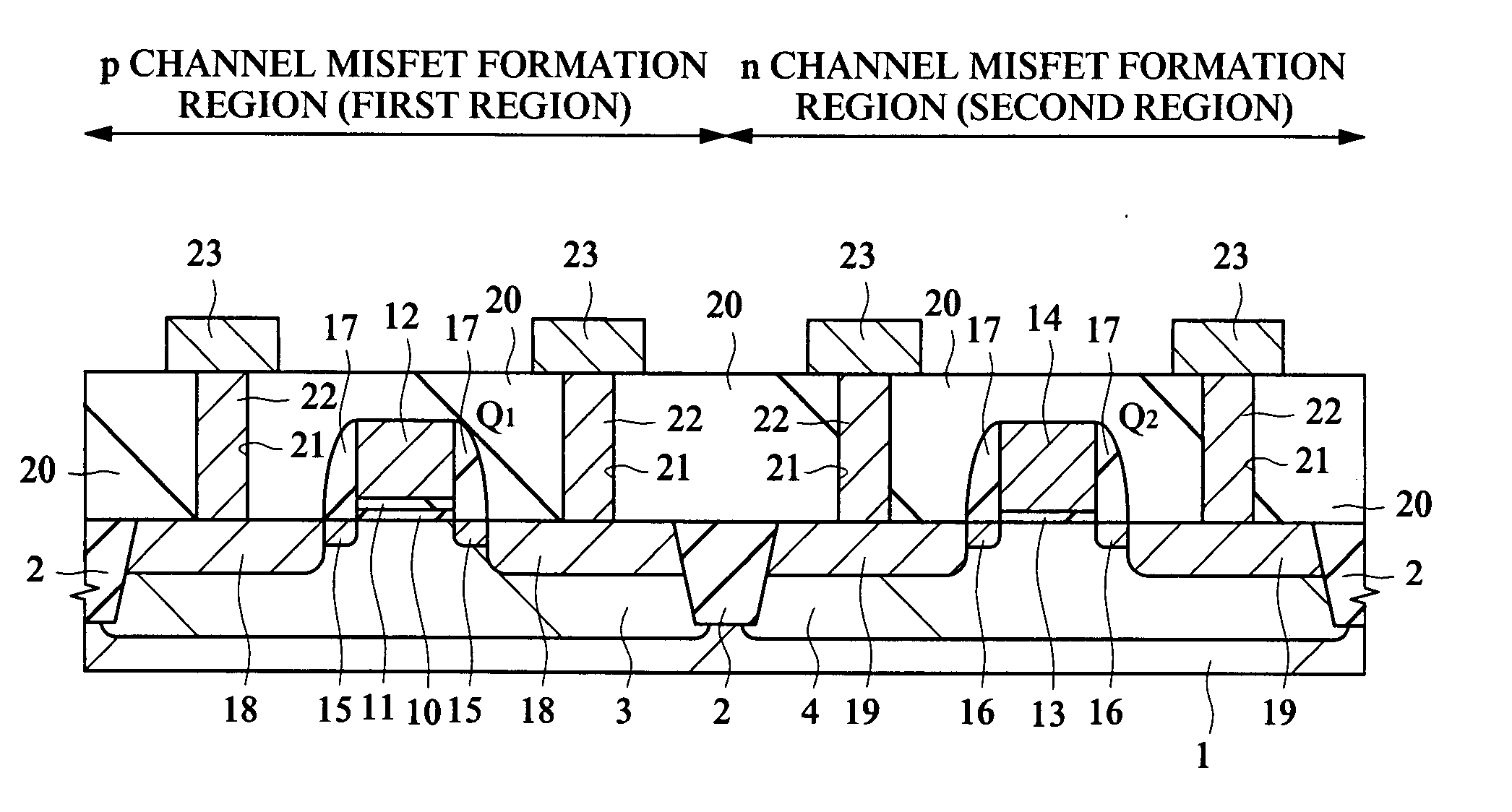

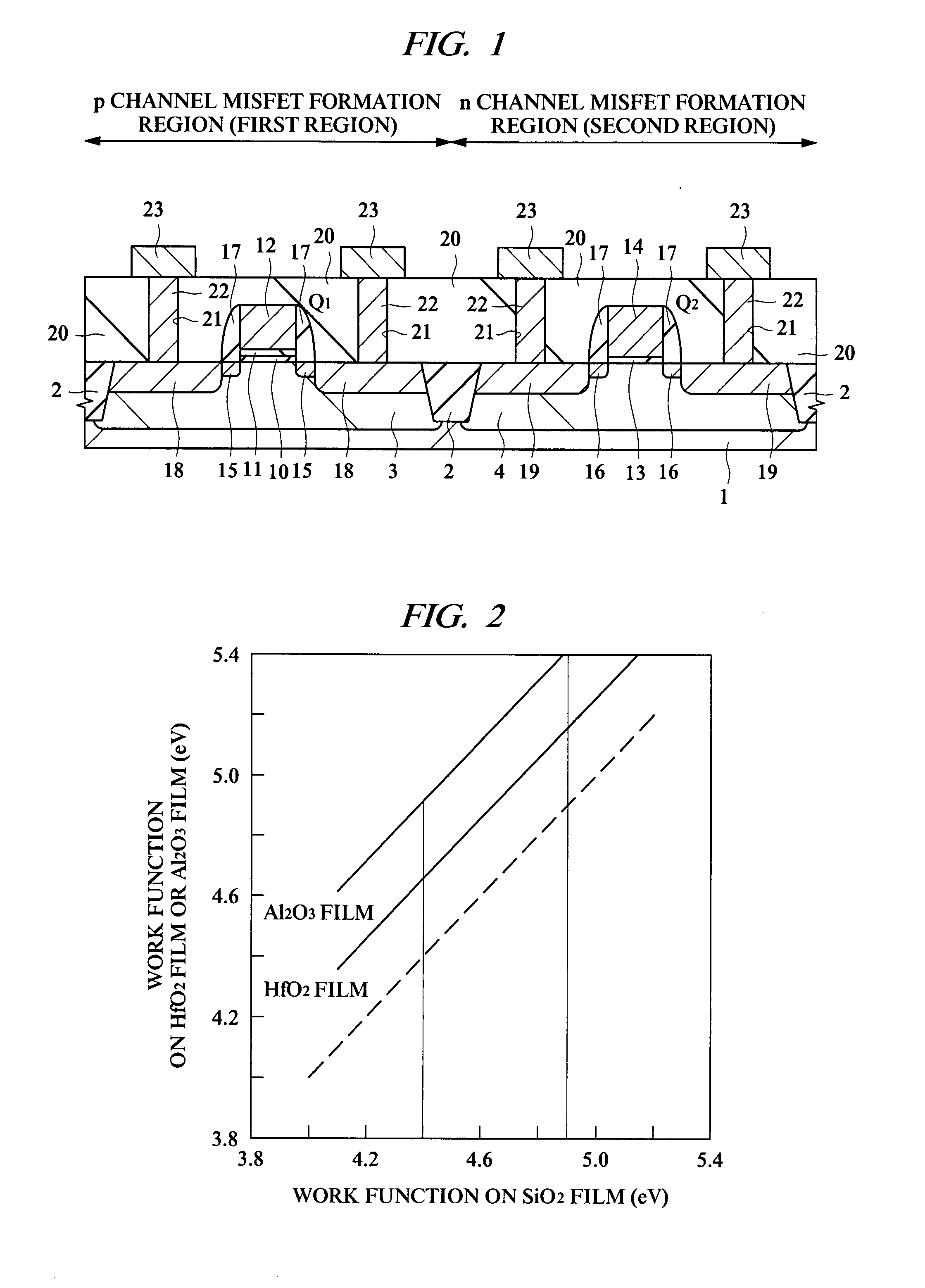

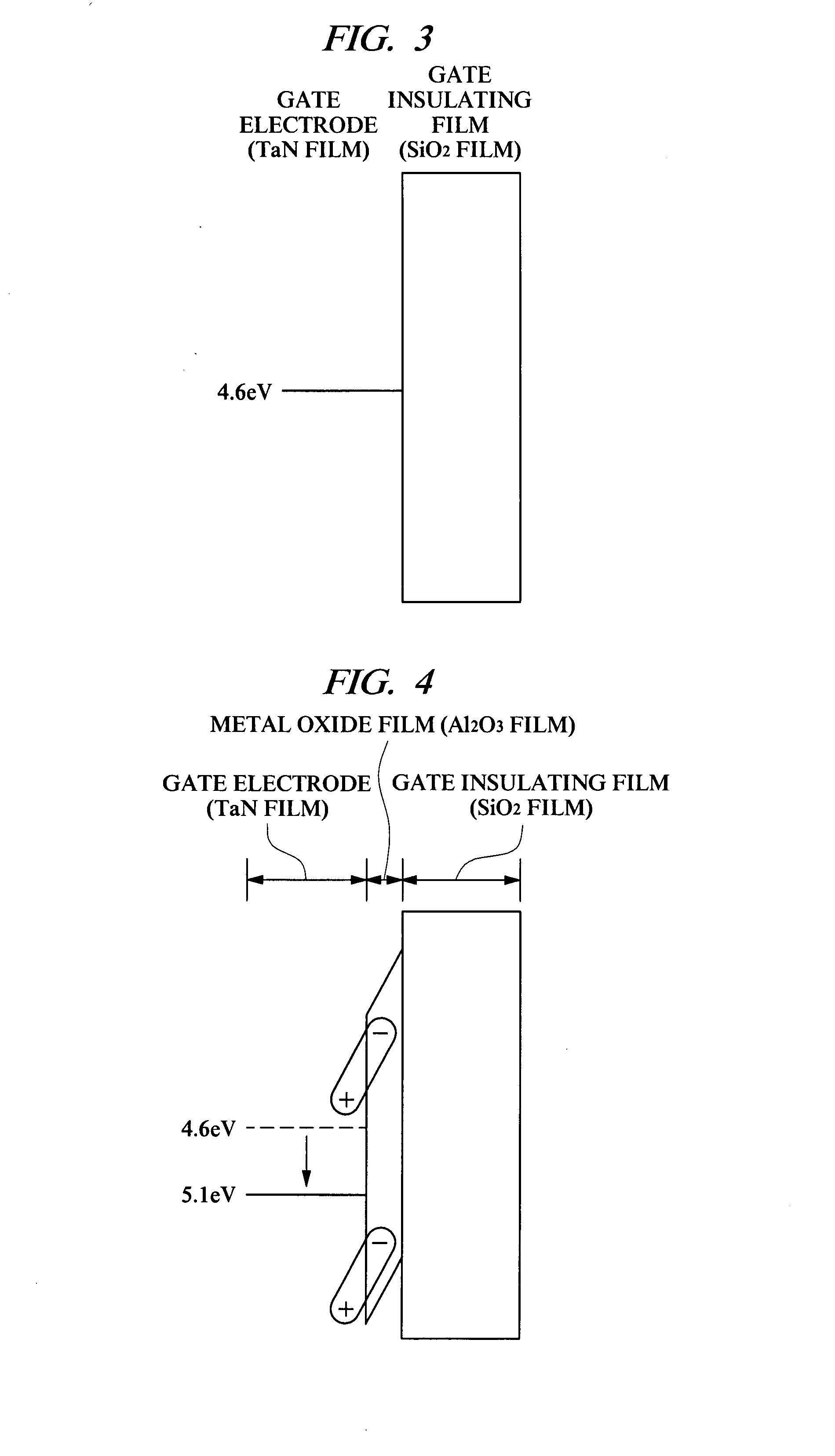

Semiconductor device and semiconductor device manufacturing method

InactiveUS20070210354A1Increased physical film thicknessReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSilicon oxide

Provided is a technology capable of improving the productivity of a p channel MISFET using a high dielectric-constant film as a gate insulating film and a conductive film containing metal as a gate electrode. In this technology, a threshold voltage of the p channel MISFET can be decreased even if a work function value of the conductive film containing metal at the time of contacting a silicon oxide film is away from a value near a valence band of silicon. A p channel MISFET formed on a semiconductor substrate has a gate insulating film formed of a hafnium oxide film, a metal oxide film formed of an aluminum oxide film on this gate insulating film, and a gate electrode formed of a tantalum nitride film on this metal oxide film. The metal oxide film has a function to shift a work function value of the gate electrode.

Owner:RENESAS TECH CORP

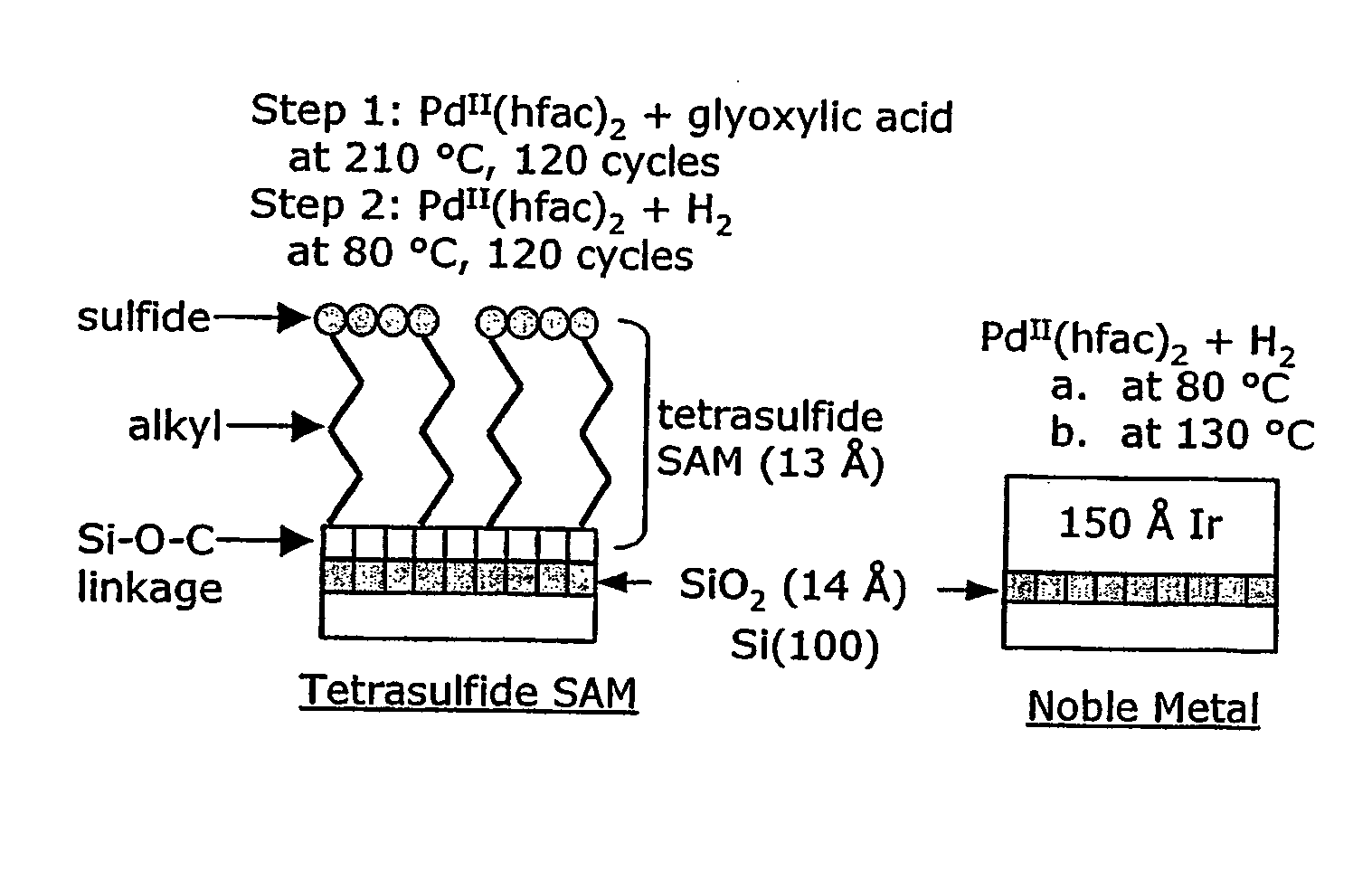

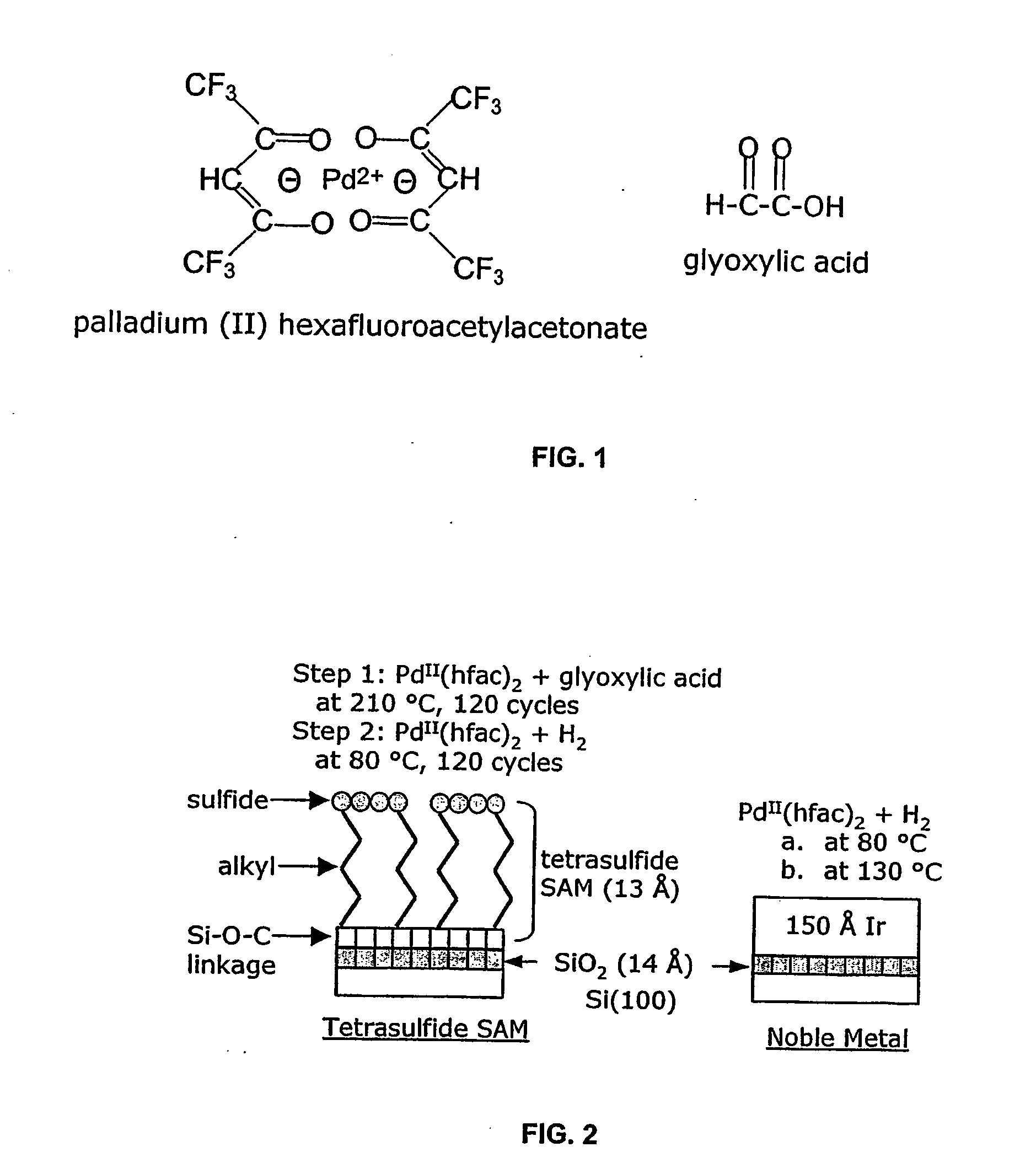

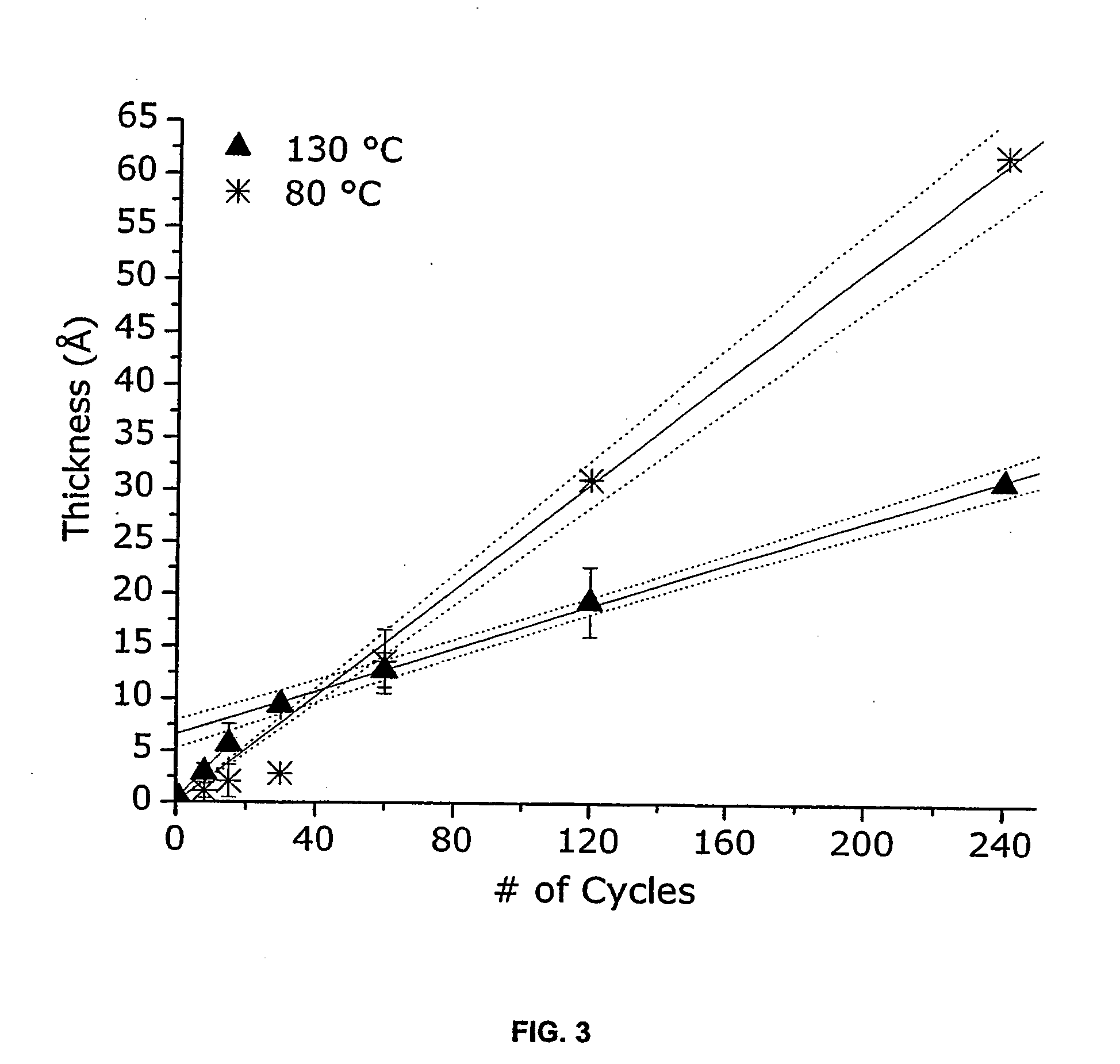

Atomic layer deposition of noble metals

The present invention relates to ALD processes for deposition of a metal selected from Pd, Rh, Ru, Pt and Ir wherein a layer including the metal is formed on a surface composed of a material selected from W, Ta, Cu, Ni, Co, Fe, Mn, Cr, V Nb, tungsten nitride, tantalum nitride, titanium nitride, dielectrics and activated dielectrics at a temperature ranging from >60° C. to <260° C. The layer is formed by sequentially pulsing into a chamber containing the surface a precursor for the metal and a reducing gas selected from hydrogen, glyoxylic acid, oxalic acid, formaldehyde, 2-propanol, imidazole and plasma-activated hydrogen.

Owner:SENKEVICH JOHN JOSEPH +1

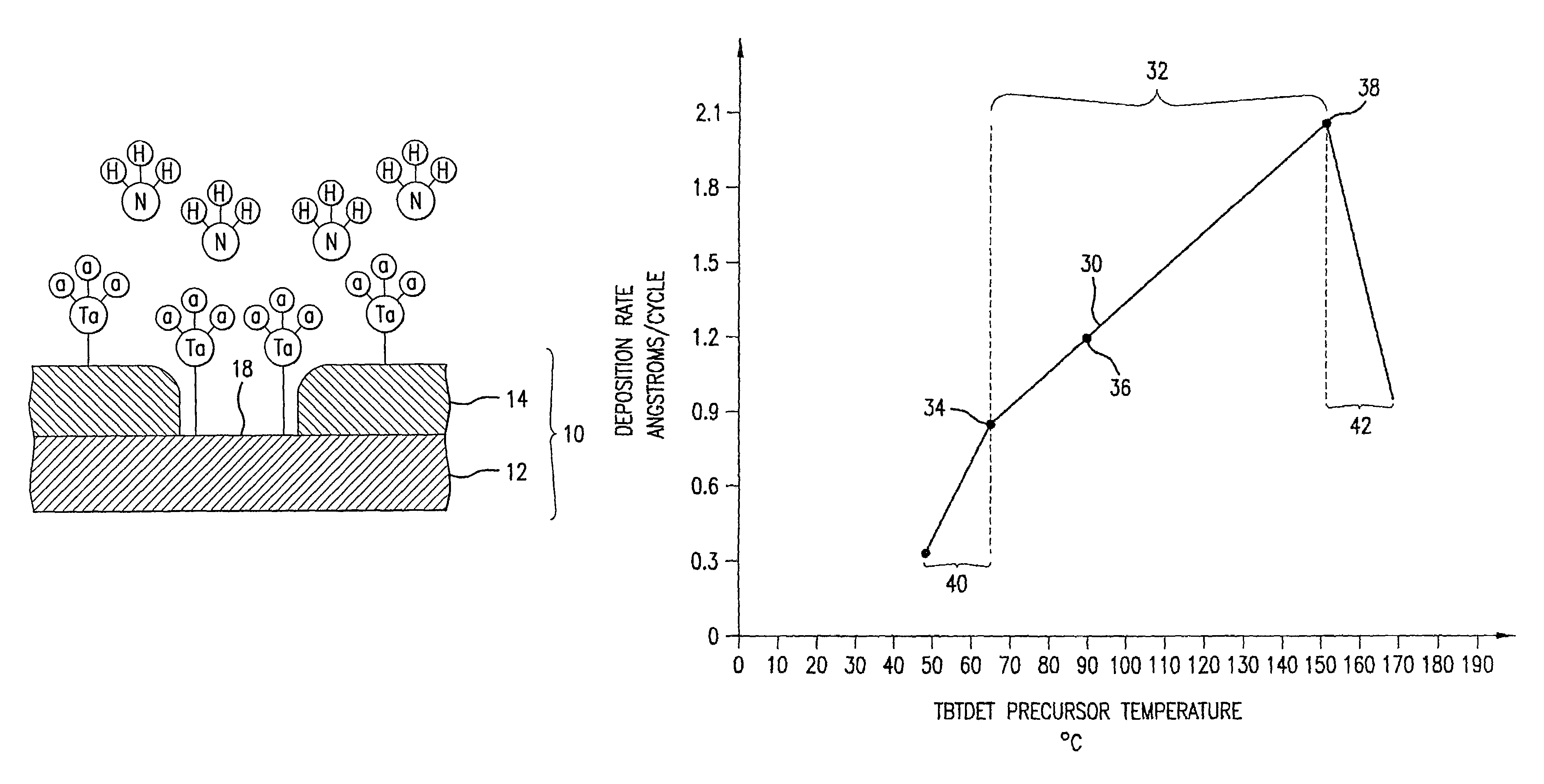

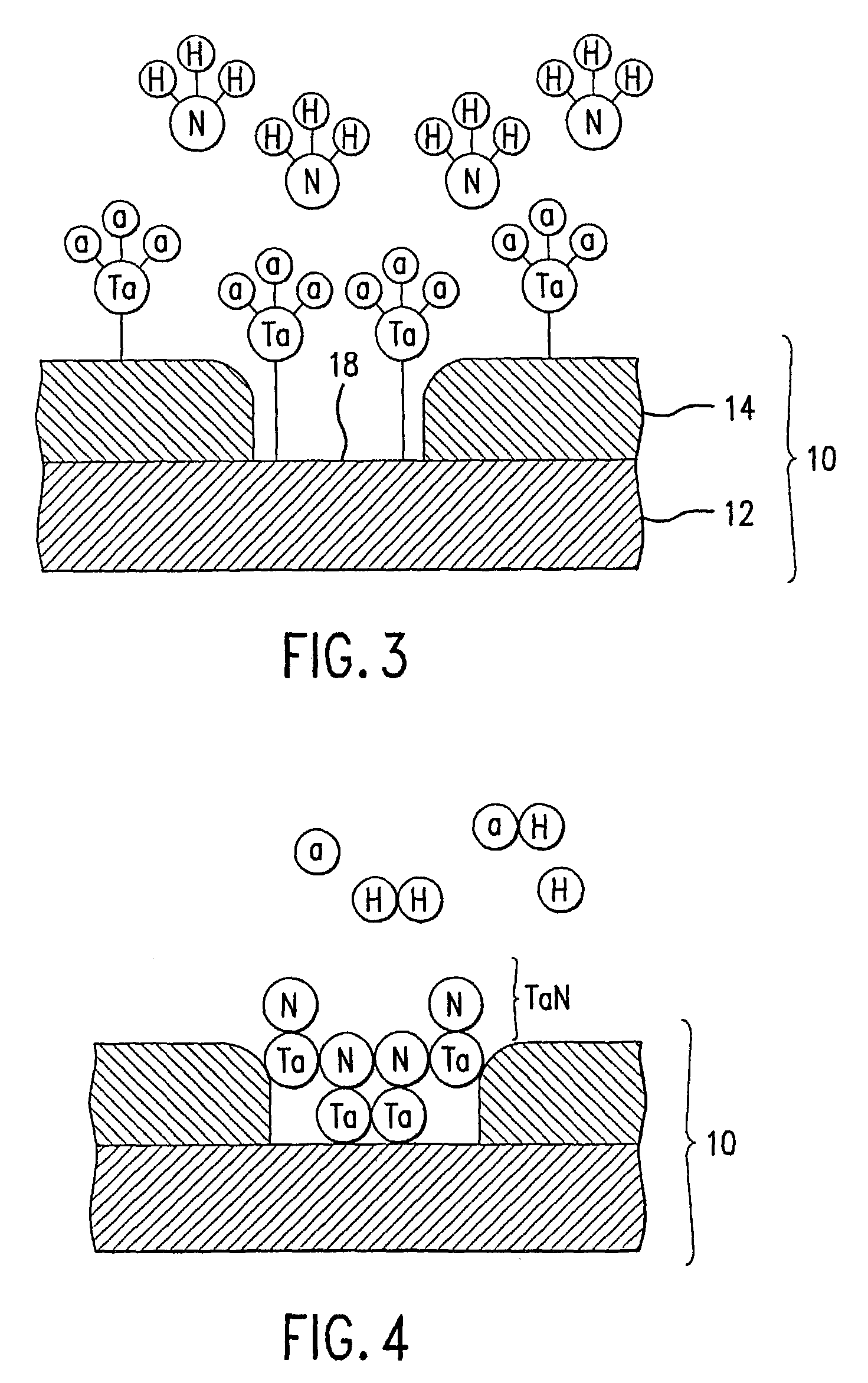

Sequential deposition of tantalum nitride using a tantalum-containing precursor and a nitrogen-containing precursor

ActiveUS6972267B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

Disclosed is a method and apparatus that features deposition of tantalum films employing sequential deposition techniques, such as Atomic Layer Deposition (ALD). The method includes serially exposing a substrate to a flow of a nitrogen-containing gas, such as ammonia NH3, and a tantalum containing gas. The tantalum-containing gas is formed from a precursor, (tBuN)Ta(NEt2)3 (TBTDET), which is adsorbed onto the substrate. Prior to adsorption of TBTDET onto the substrate layer, the TBTDET precursor is heated within a predefined temperature range.

Owner:APPLIED MATERIALS INC

Formation of a tantalum-nitride layer

InactiveUS20050164487A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

A method of forming a tantalum nitride layer for integrated circuit fabrication is disclosed. In one embodiment, the method includes forming a tantalum nitride layer by chemisorbing a tantalum precursor and a nitrogen precursor on a substrate disposed in a process chamber. A nitrogen concentration of the tantalum nitride layer is reduced by exposing the substrate to a plasma annealing process. A metal-containing layer is then deposited on the tantalum nitride layer by a deposition process.

Owner:APPLIED MATERIALS INC

Deposition methods for barrier and tungsten materials

Embodiments are provided for a method to deposit barrier and tungsten materials on a substrate. In one embodiment, a method provides forming a barrier layer on a substrate and exposing the substrate to a silane gas to form a thin silicon-containing layer on the barrier layer during a soak process. The method further provides depositing a tungsten nucleation layer over the barrier layer and the thin silicon-containing layer during an atomic layer deposition process and depositing a tungsten bulk layer on the tungsten nucleation layer during a chemical vapor deposition process. In some examples, the barrier layer contains metallic cobalt and cobalt silicide, or metallic nickel and nickel silicide. In other examples, the barrier layer contains metallic titanium and titanium nitride, or metallic tantalum and tantalum nitride.

Owner:APPLIED MATERIALS INC

Work function adjustment in high-k metal gate electrode structures by selectively removing a barrier layer

ActiveUS20100301427A1Degree of improvementImprove uniformityTransistorSolid-state devicesTantalum nitrideWork function

In a replacement gate approach in sophisticated semiconductor devices, a tantalum nitride etch stop material may be efficiently removed on the basis of a wet chemical etch recipe using ammonium hydroxide. Consequently, a further work function adjusting material may be formed with superior uniformity, while the efficiency of the subsequent adjusting of the work function may also be increased. Thus, superior uniformity, i.e., less pronounced transistor variability, may be accomplished on the basis of a replacement gate approach in which the work function of the gate electrodes of P-channel transistors and N-channel transistors is adjusted after completing the basic transistor configuration.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com