Patents

Literature

5954 results about "Ta element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum is a chemical element with symbol Ta and atomic number 73. Previously known as tantalium, its name comes from Tantalus, a villain from Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant.

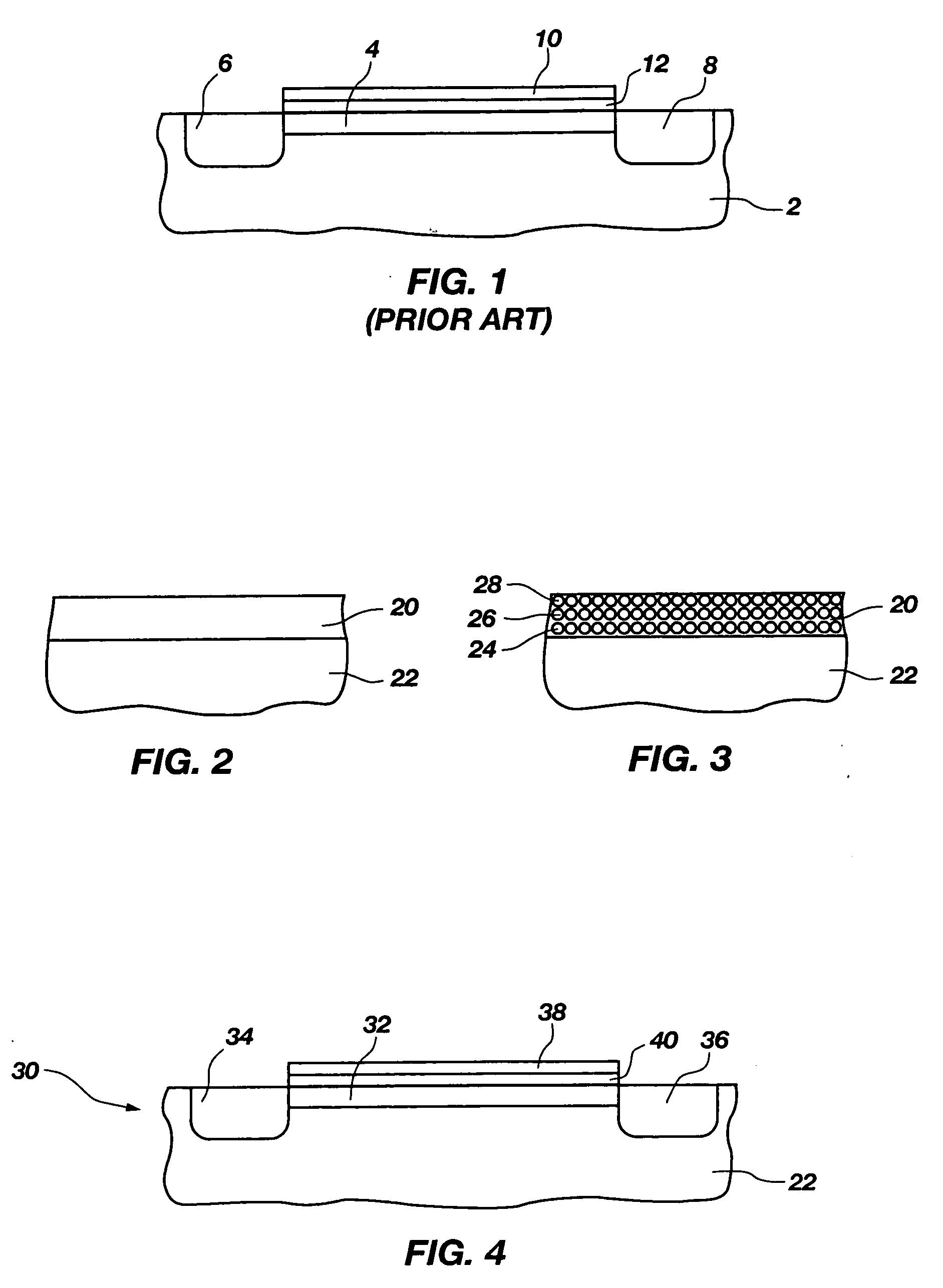

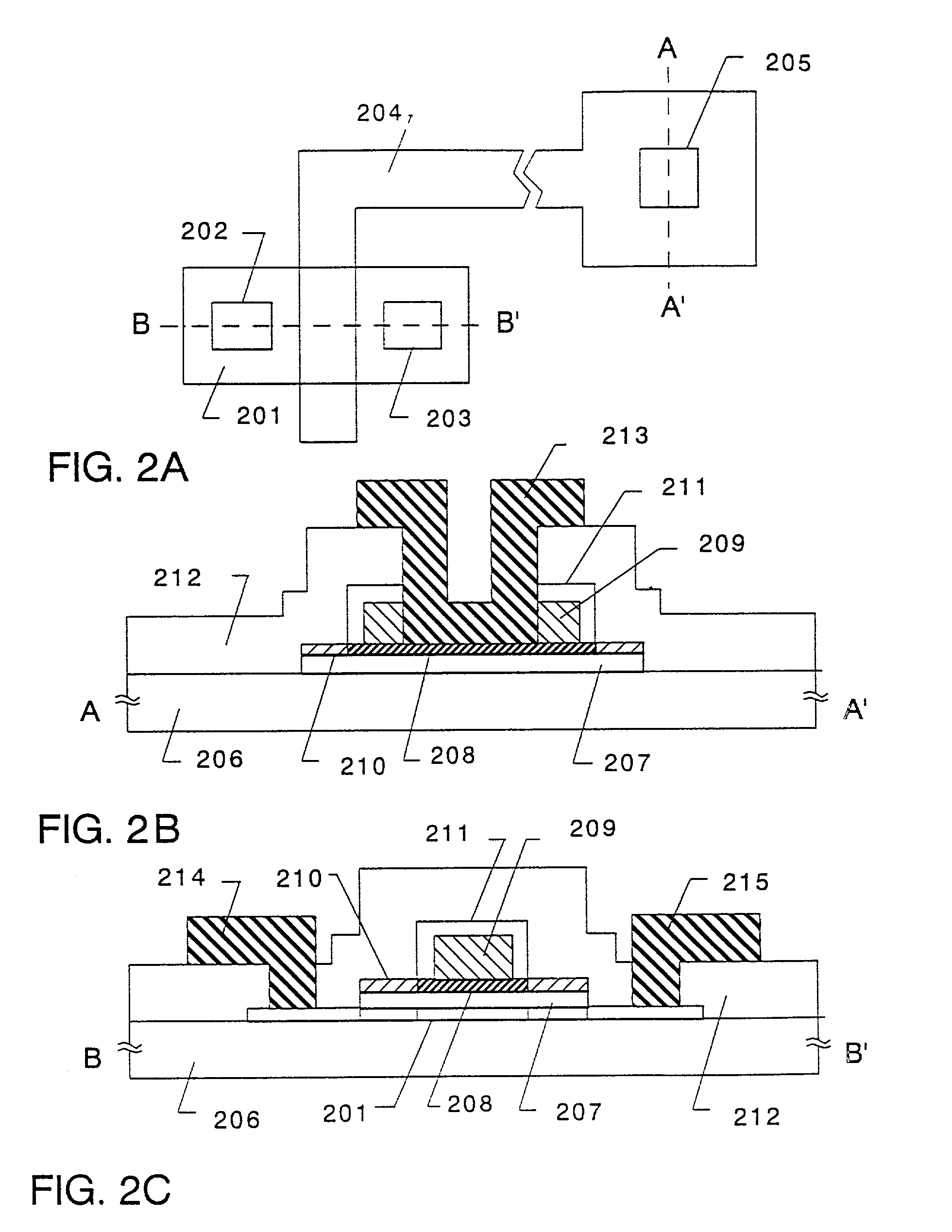

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

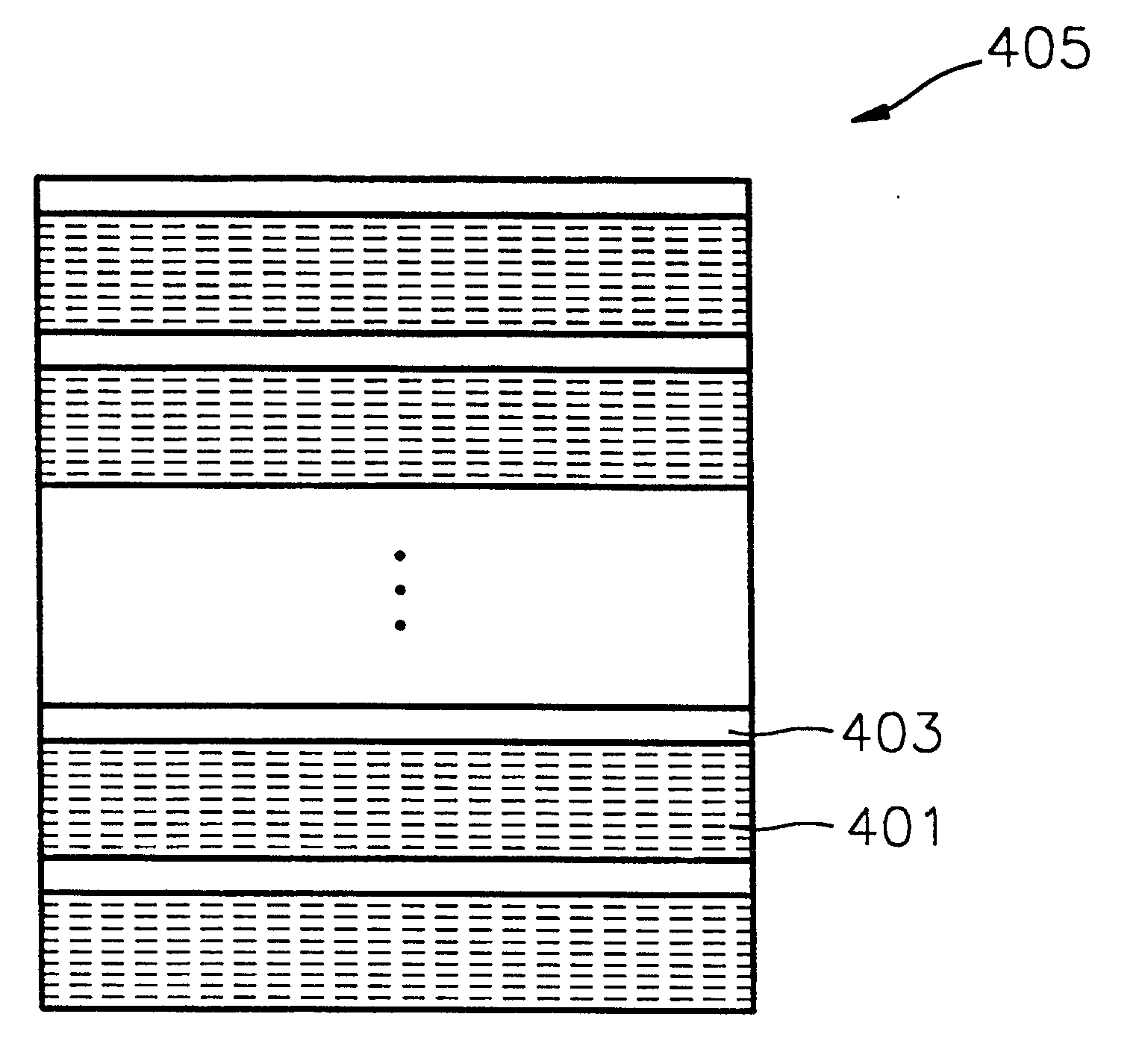

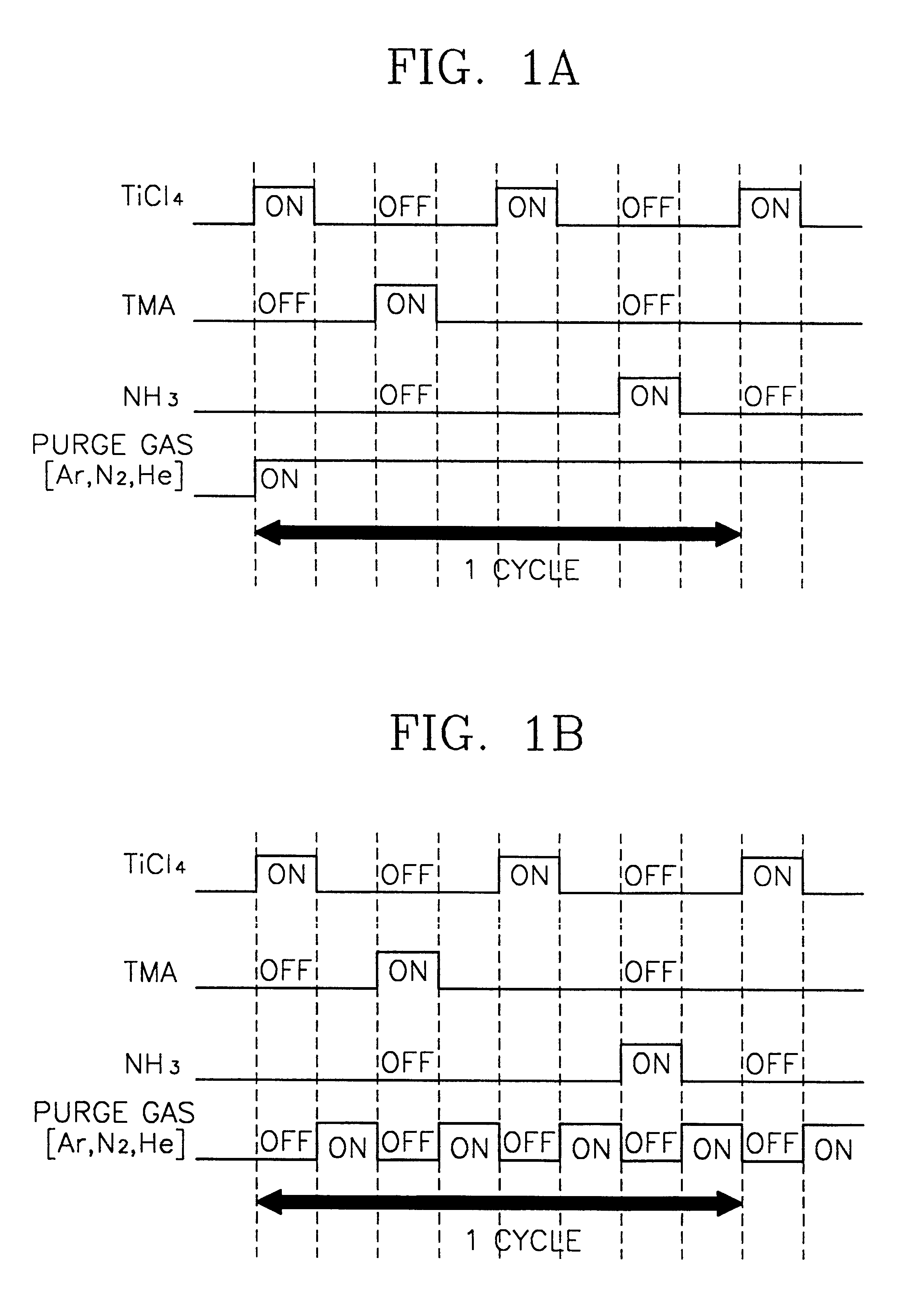

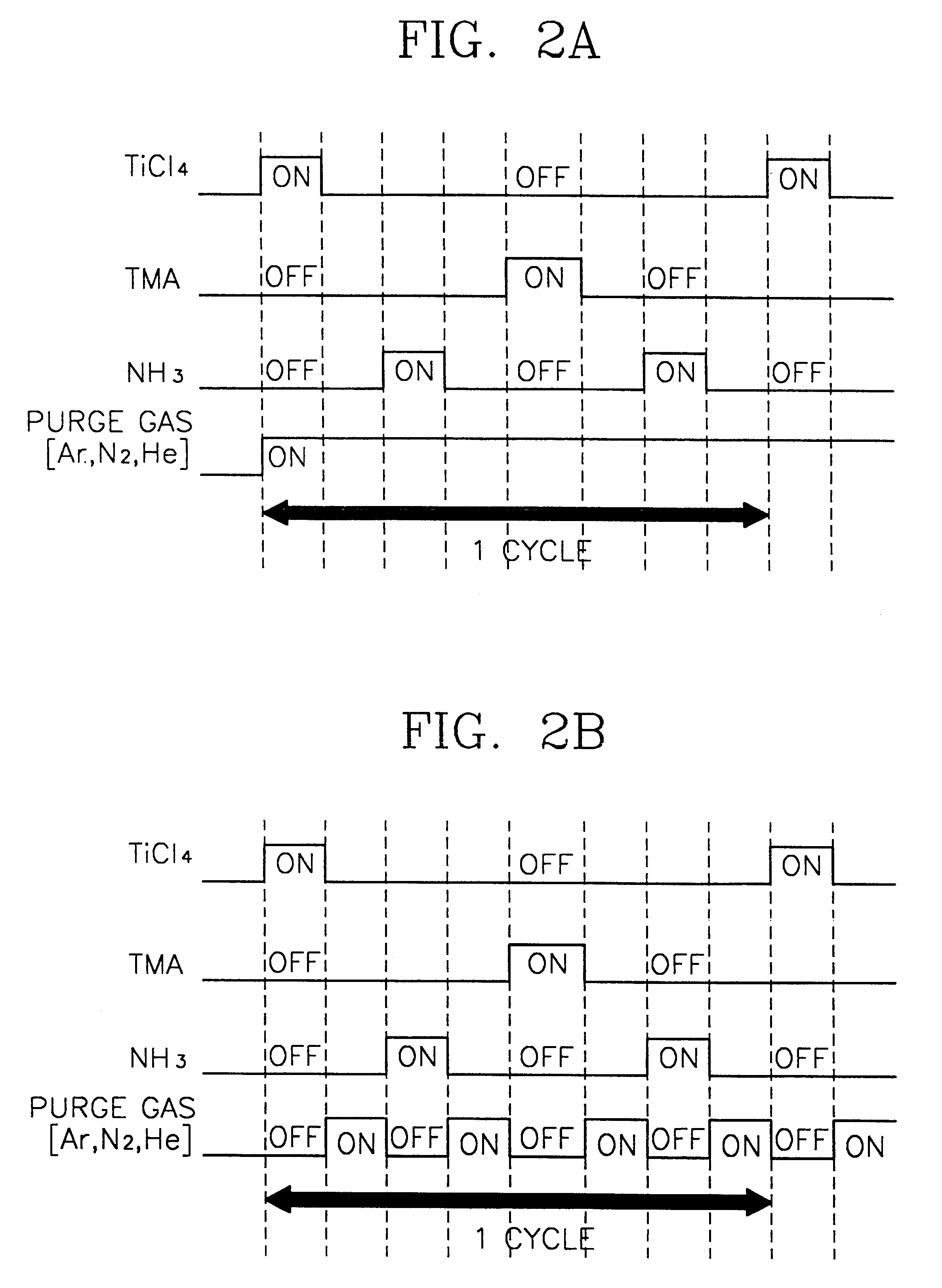

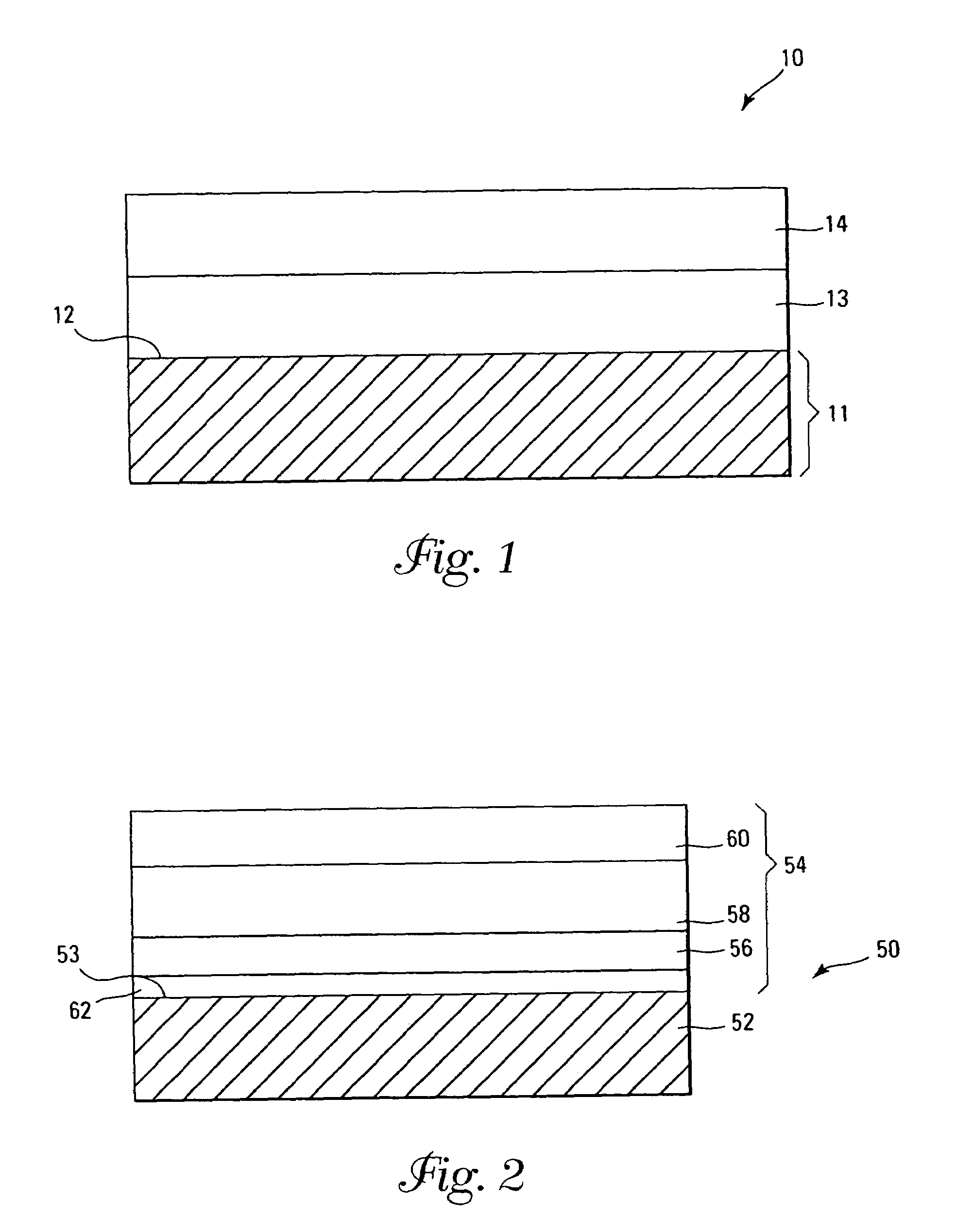

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

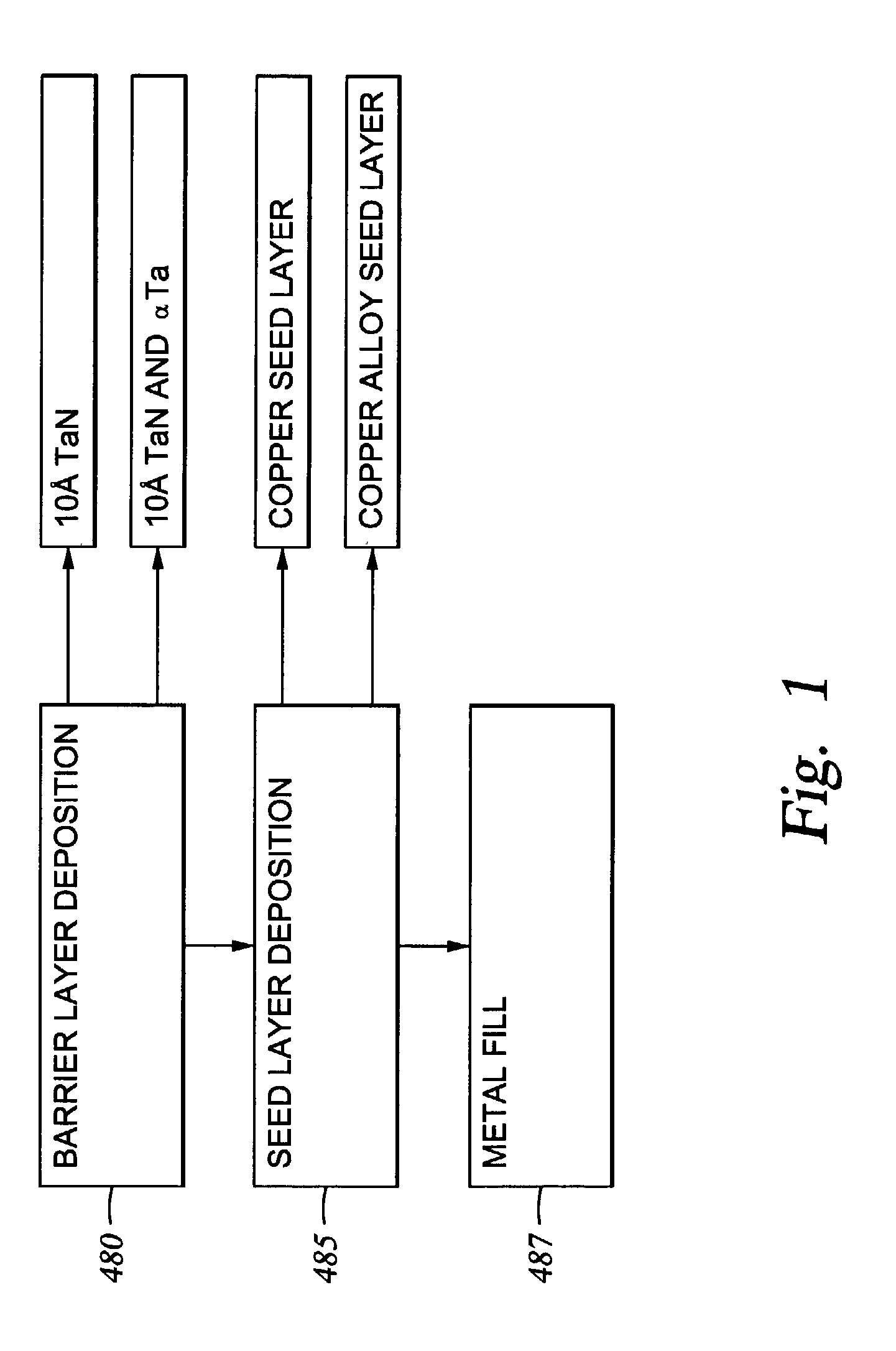

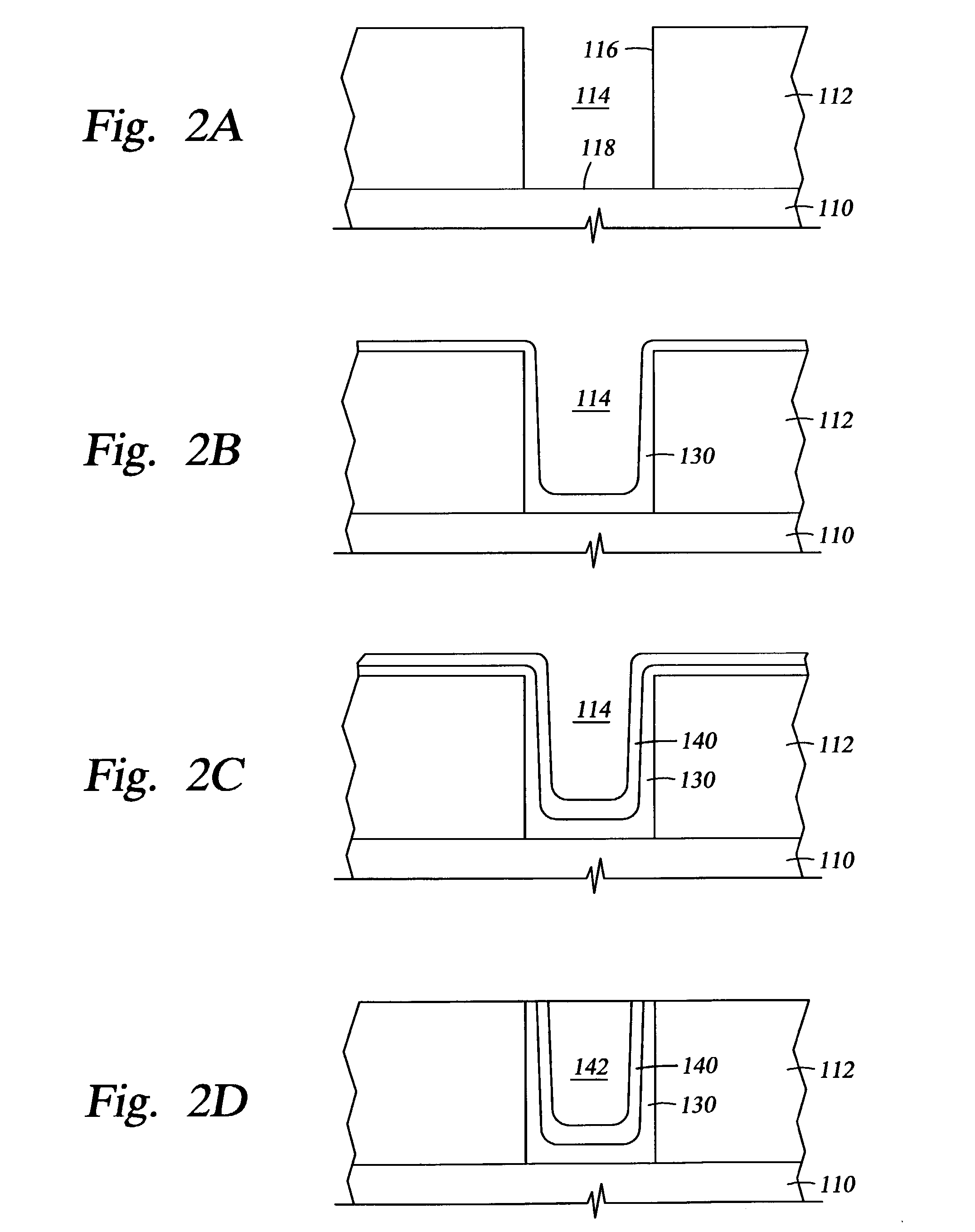

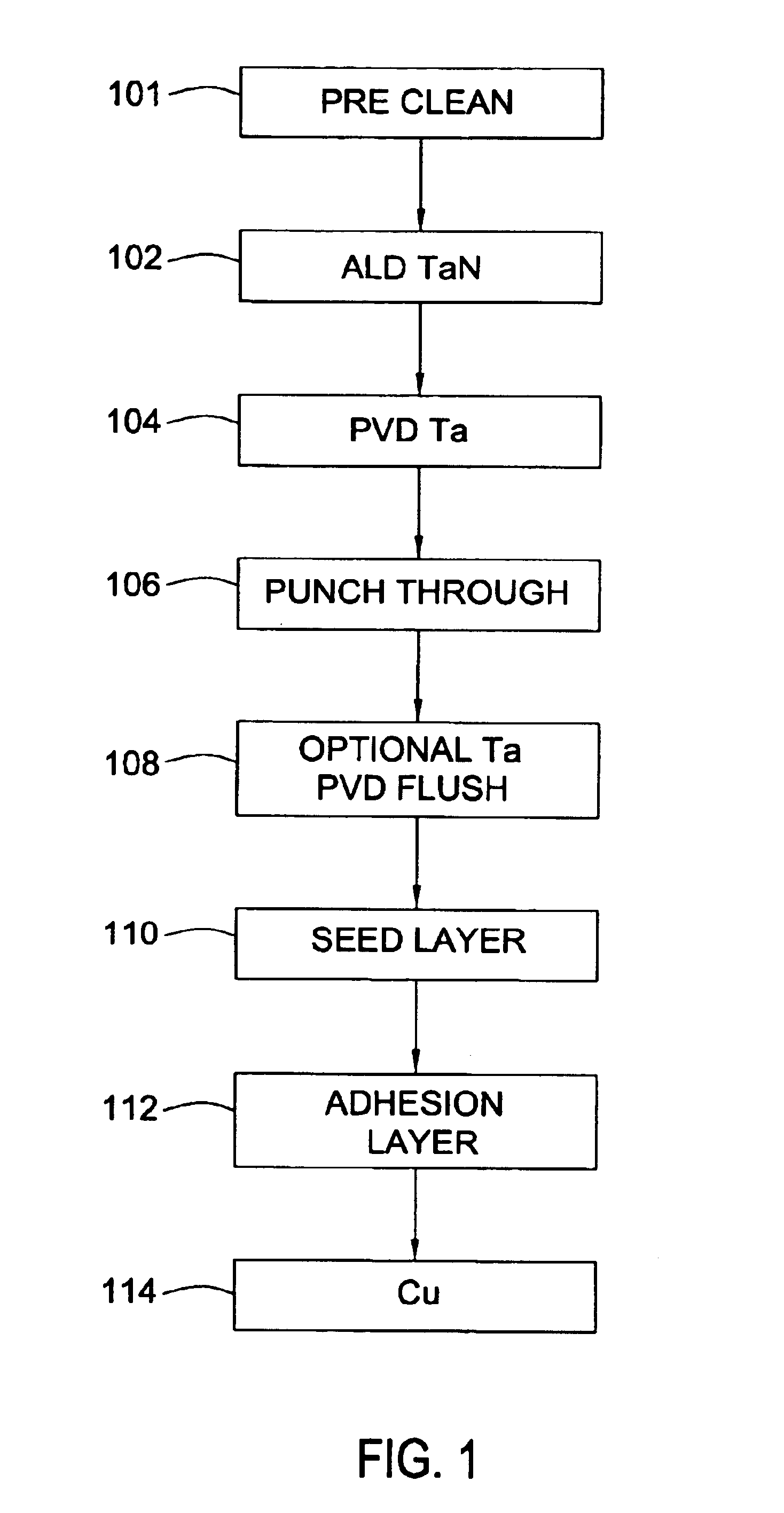

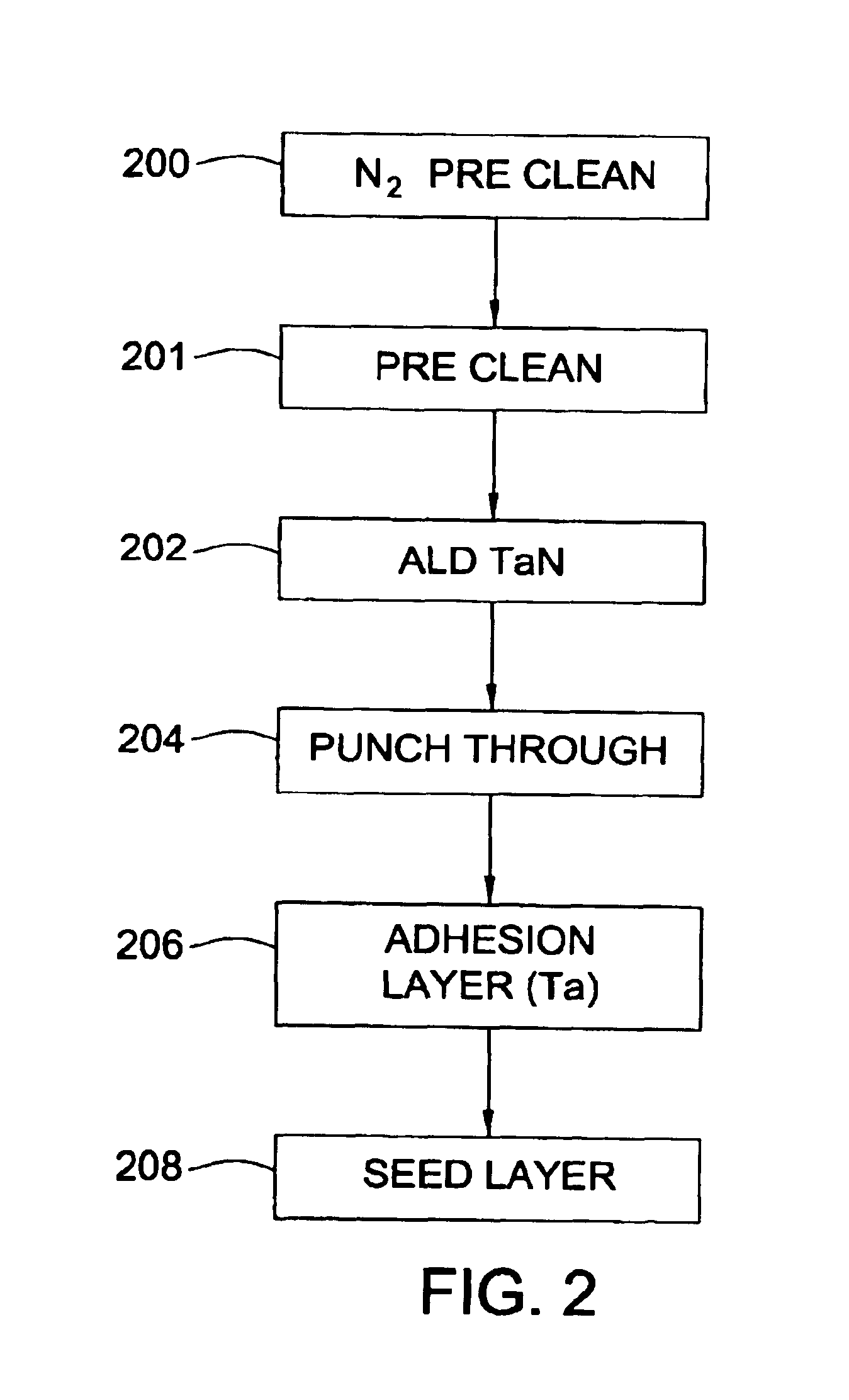

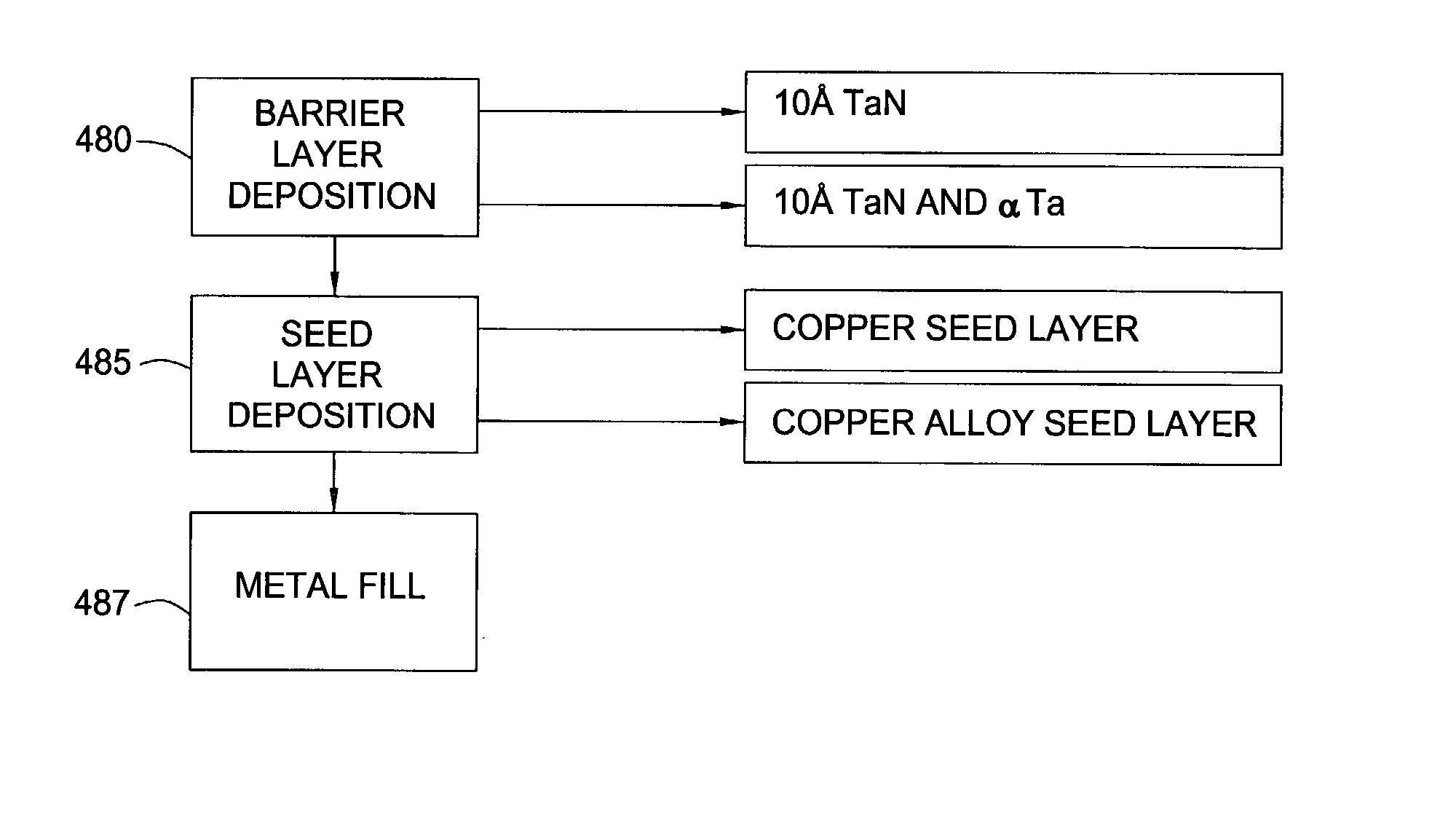

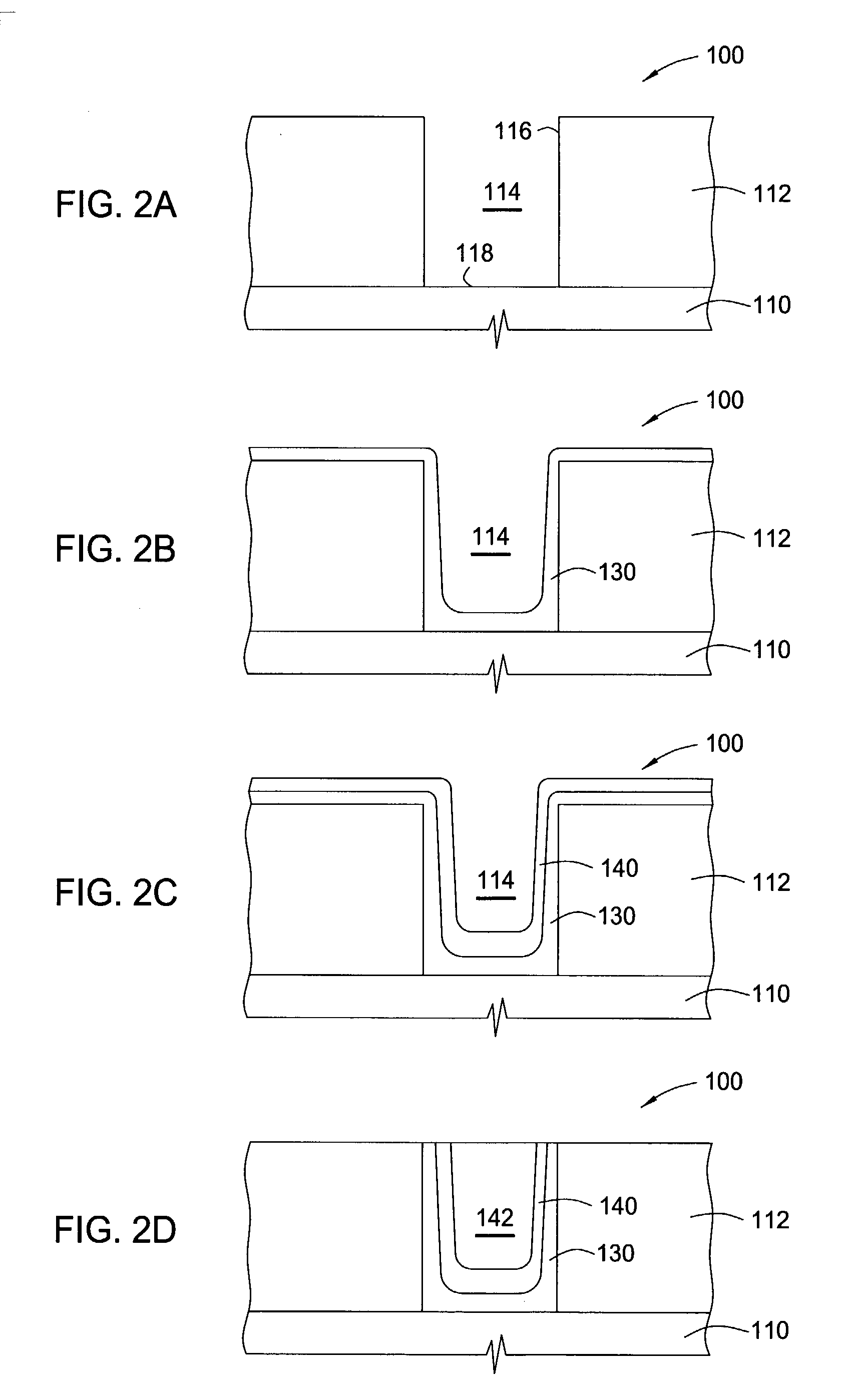

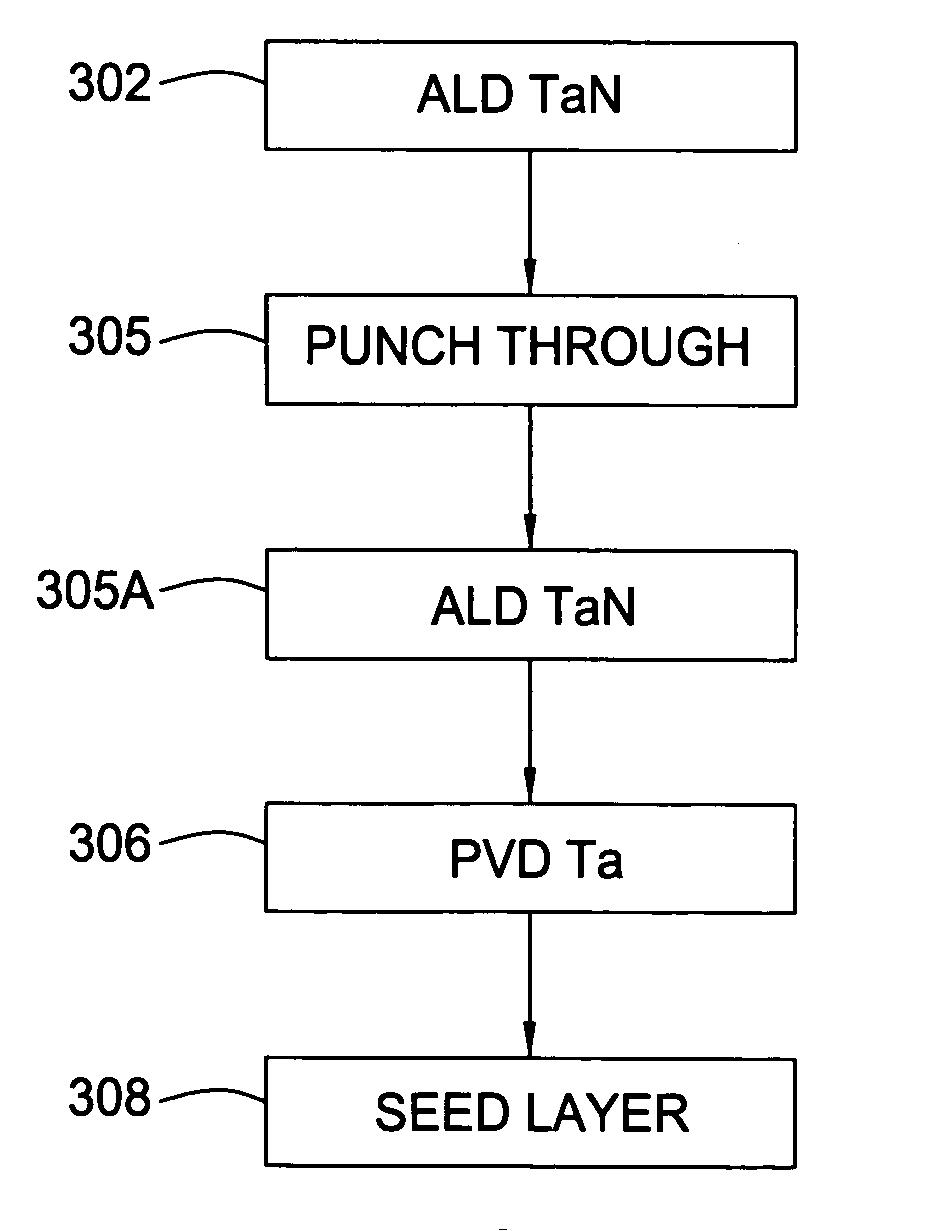

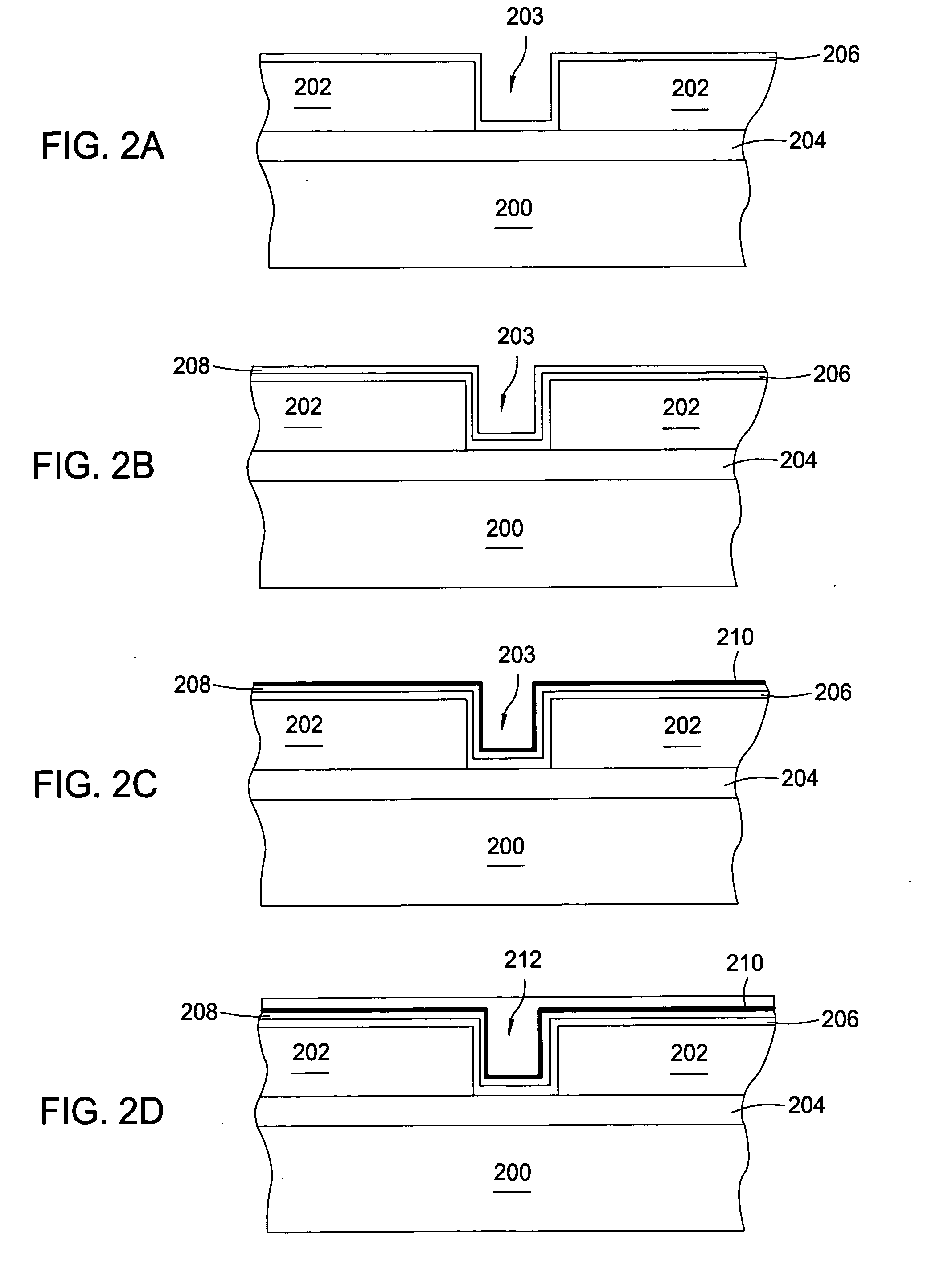

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030082307A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

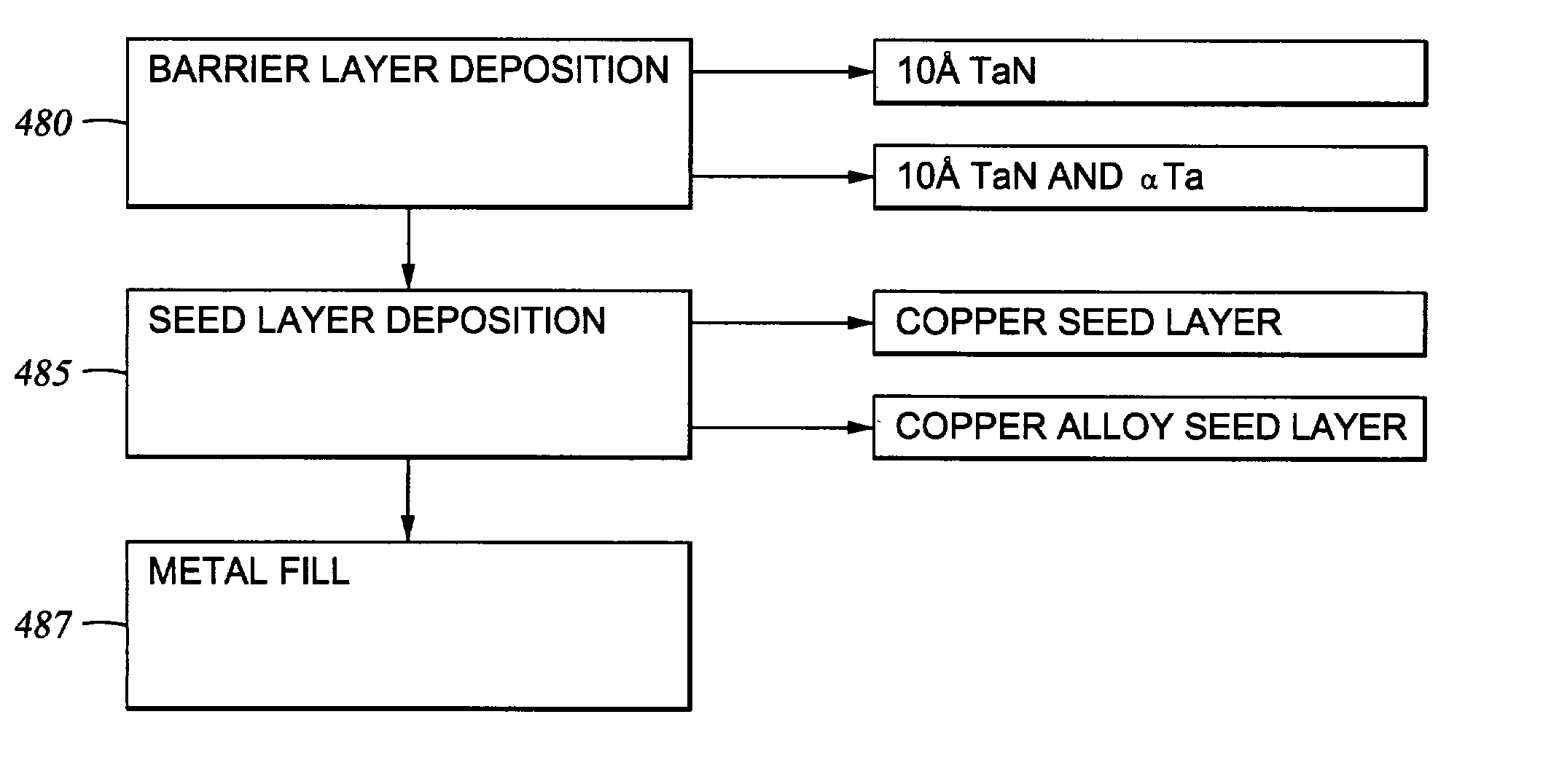

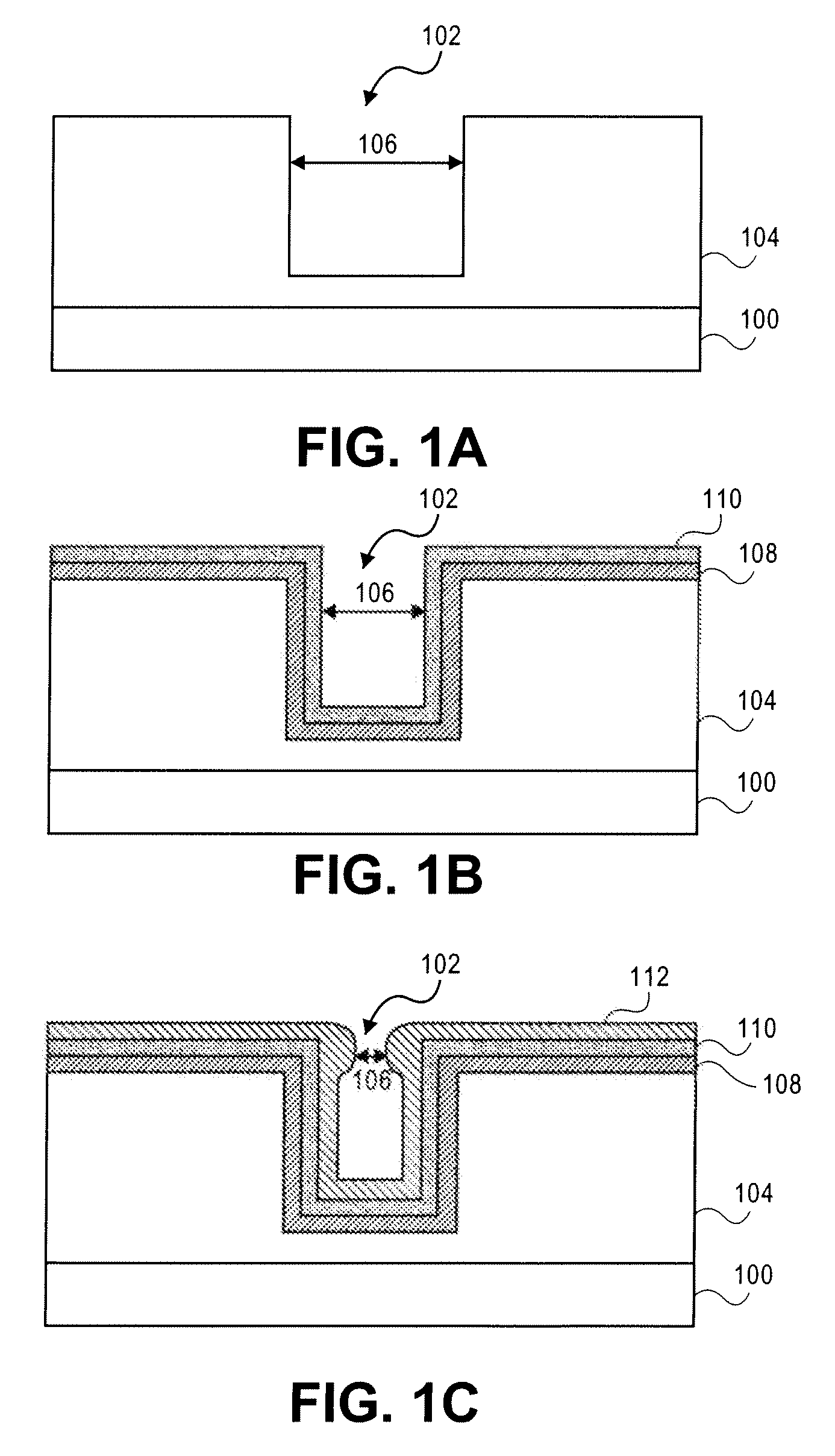

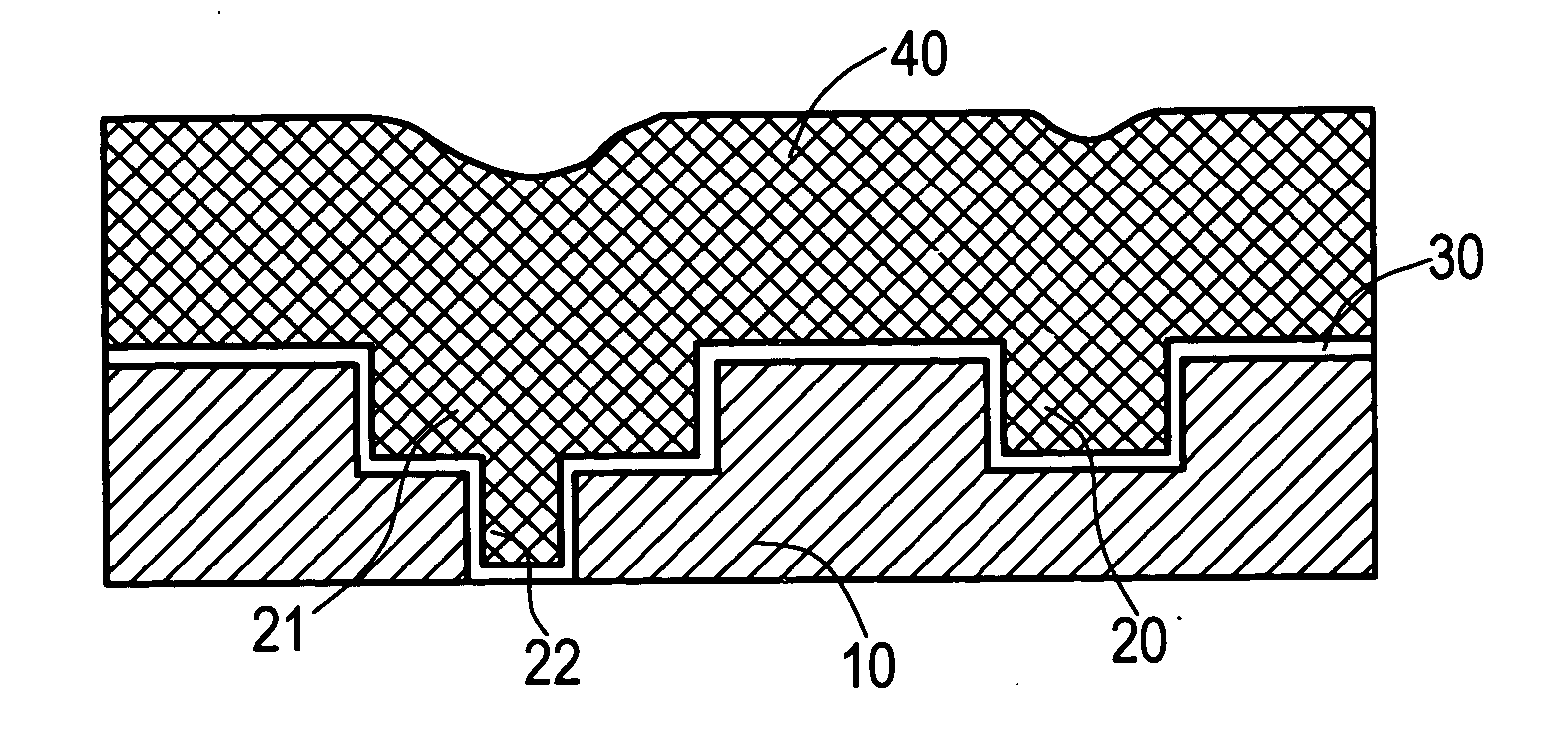

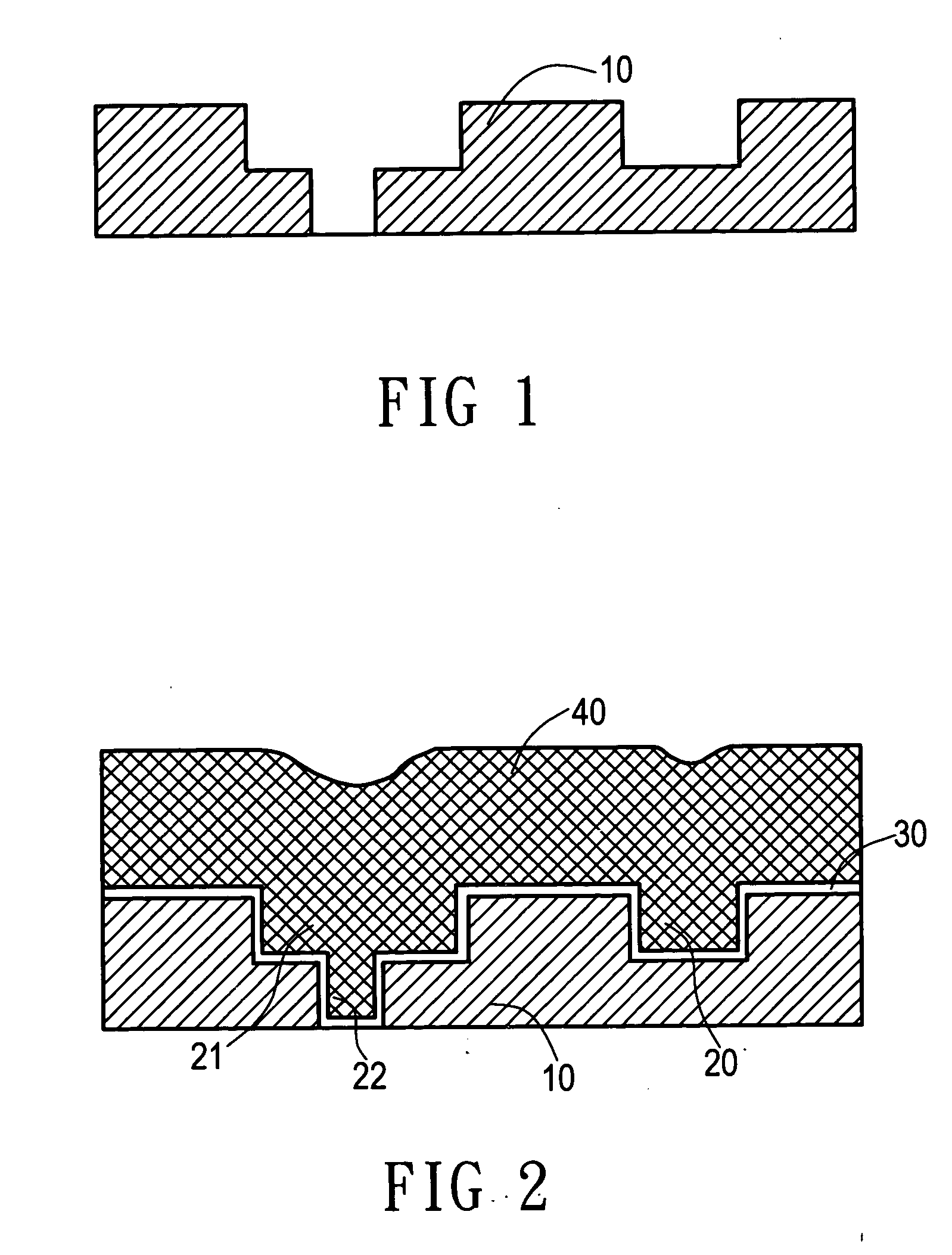

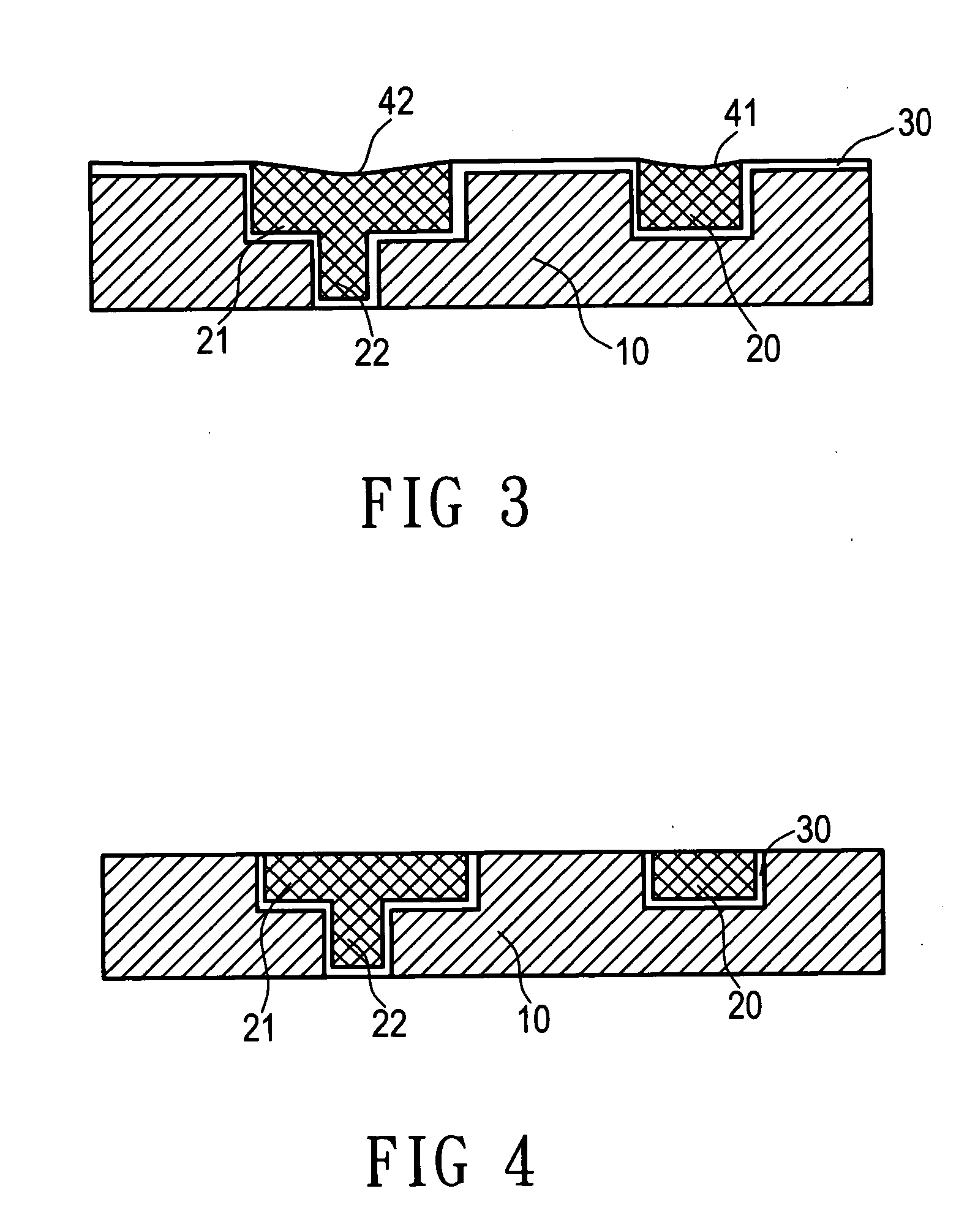

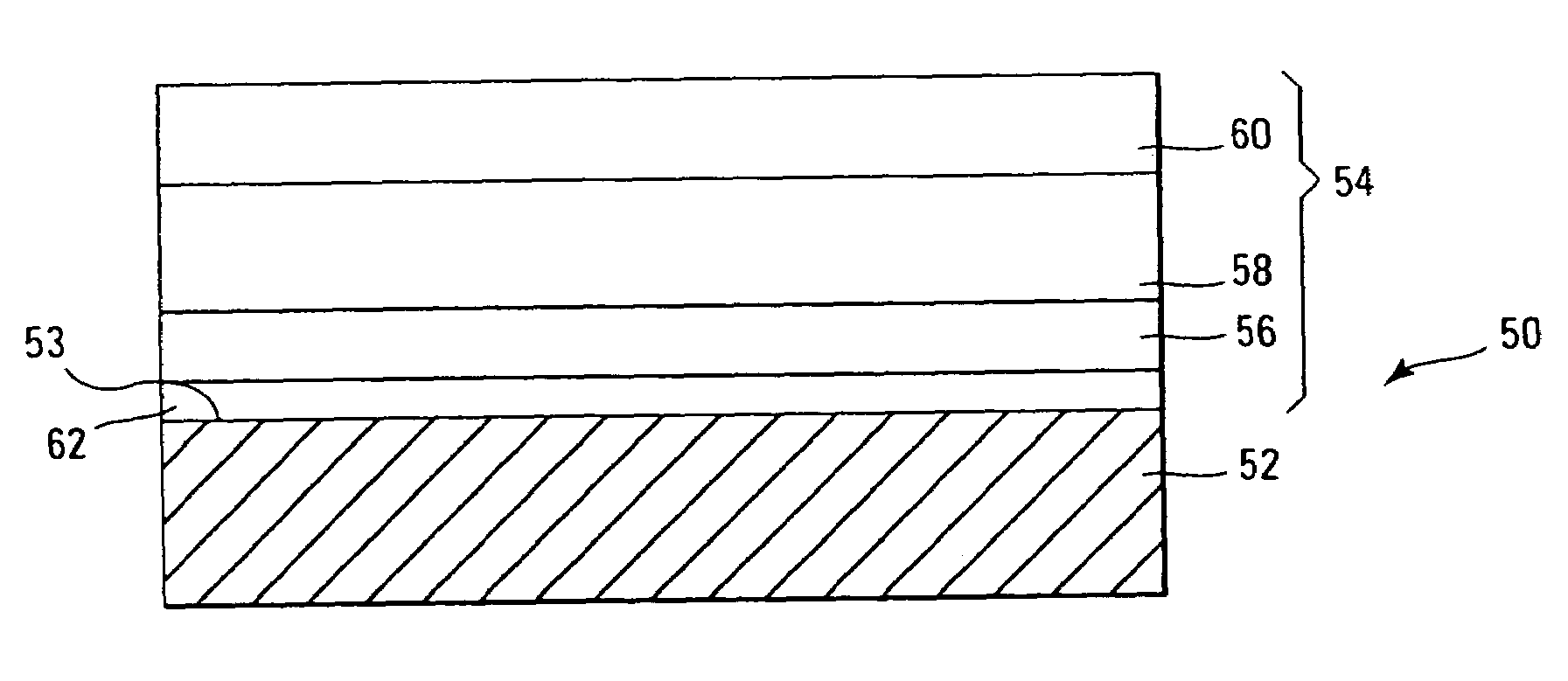

A method for forming a metal interconnect on a substrate is provided. The method includes depositing a refractory metal-containing barrier layer having a thickness less than about 20 angstroms on at least a portion of a metal layer by alternately introducing one or more pulses of a metal-containing compound and one or more pulses of a nitrogen-containing compound. The method also includes depositing a seed layer on at least a portion of the barrier layer, and depositing a second metal layer on at least a portion of the seed layer. The barrier layer provides adequate barrier properties and allows the grain growth of the metal layer to continue across the barrier layer into the second metal layer thereby enhancing the electrical performance of the interconnect.

Owner:APPLIED MATERIALS INC

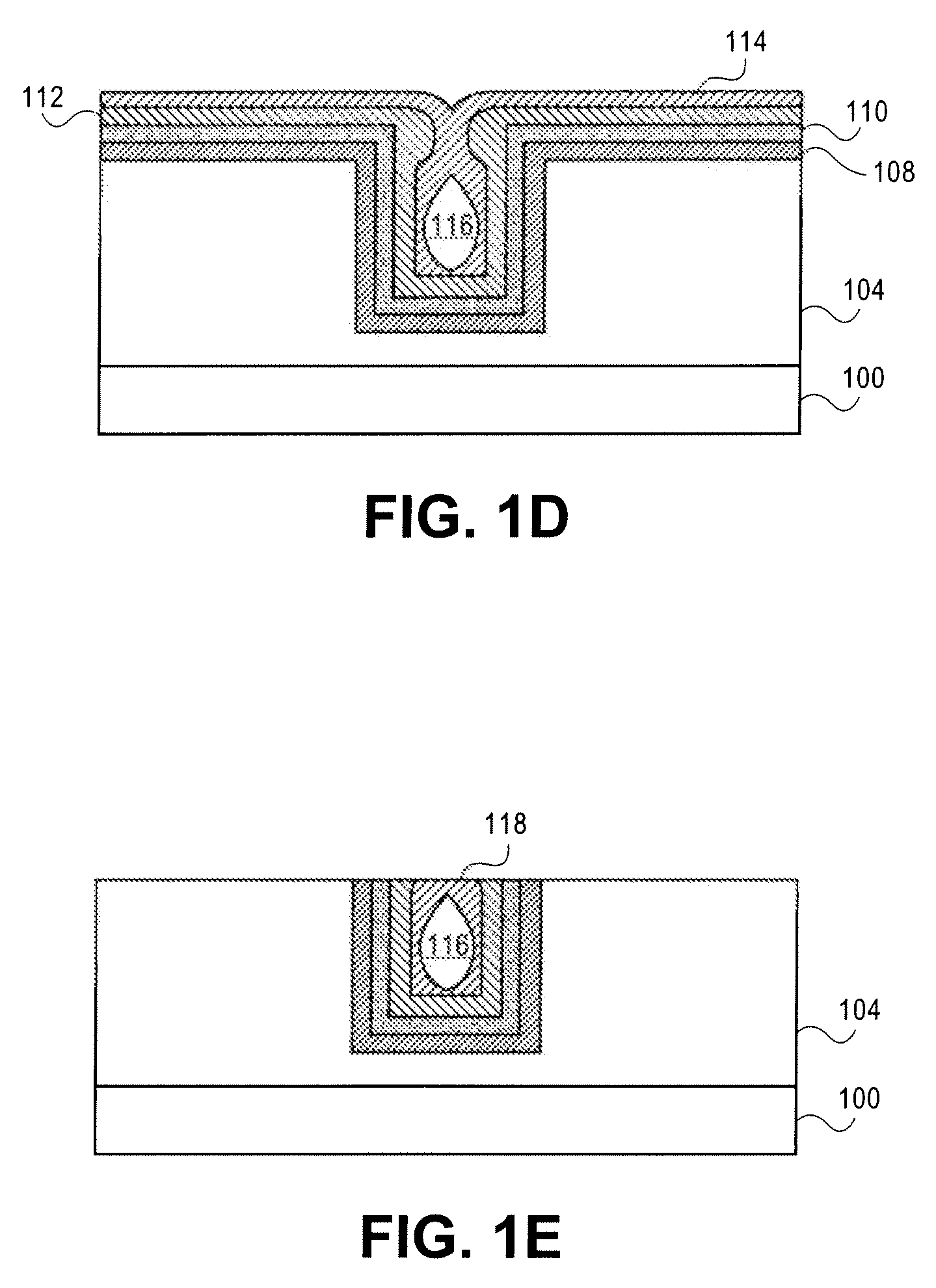

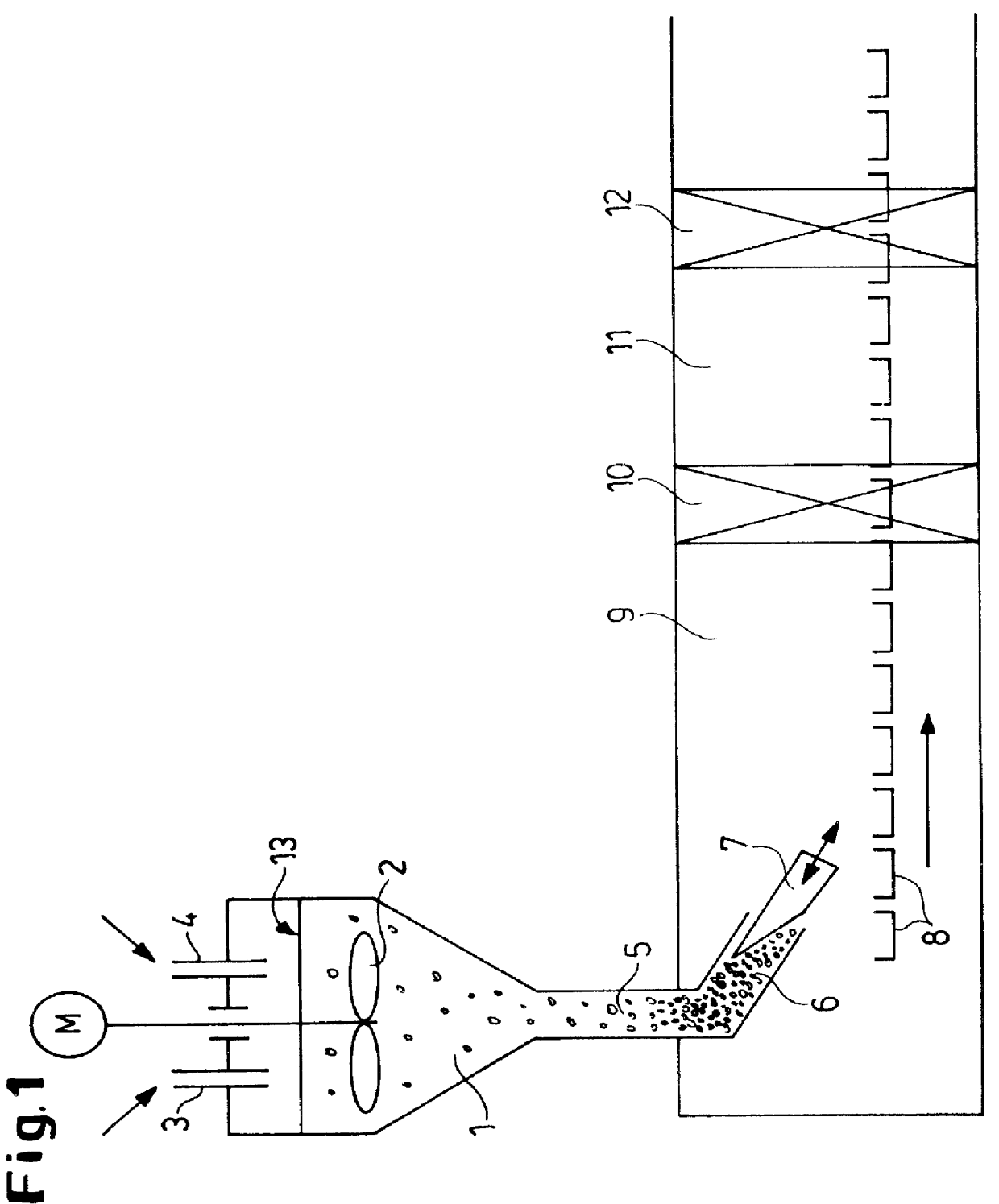

Ampoule with a thermally conductive coating

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

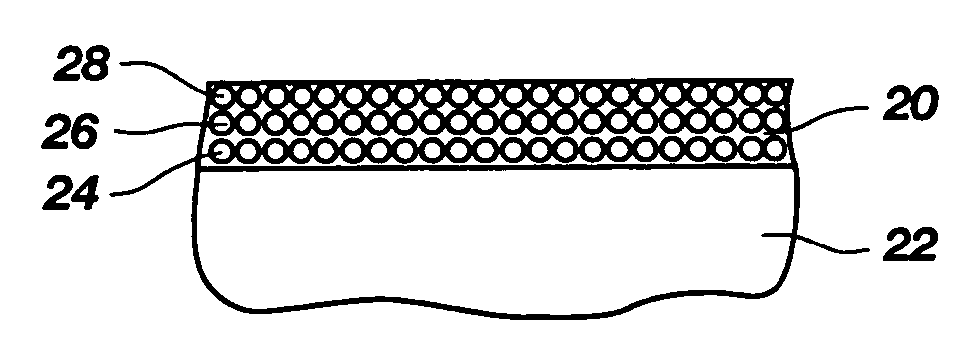

Atomic layer deposition of metal oxynitride layers as gate dielectrics

InactiveUS20060051925A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricHafnium

A metal oxynitride layer formed by atomic layer deposition of a plurality of reacted monolayers, the monolayers comprising at least one each of a metal, an oxide and a nitride. The metal oxynitride layer is formed from zirconium oxynitride, hafnium oxynitride, tantalum oxynitride, or mixtures thereof. The metal oxynitride layer is used in gate dielectrics as a replacement material for silicon dioxide. A semiconductor device structure having a gate dielectric formed from a metal oxynitride layer is also disclosed.

Owner:AHN KIE Y +1

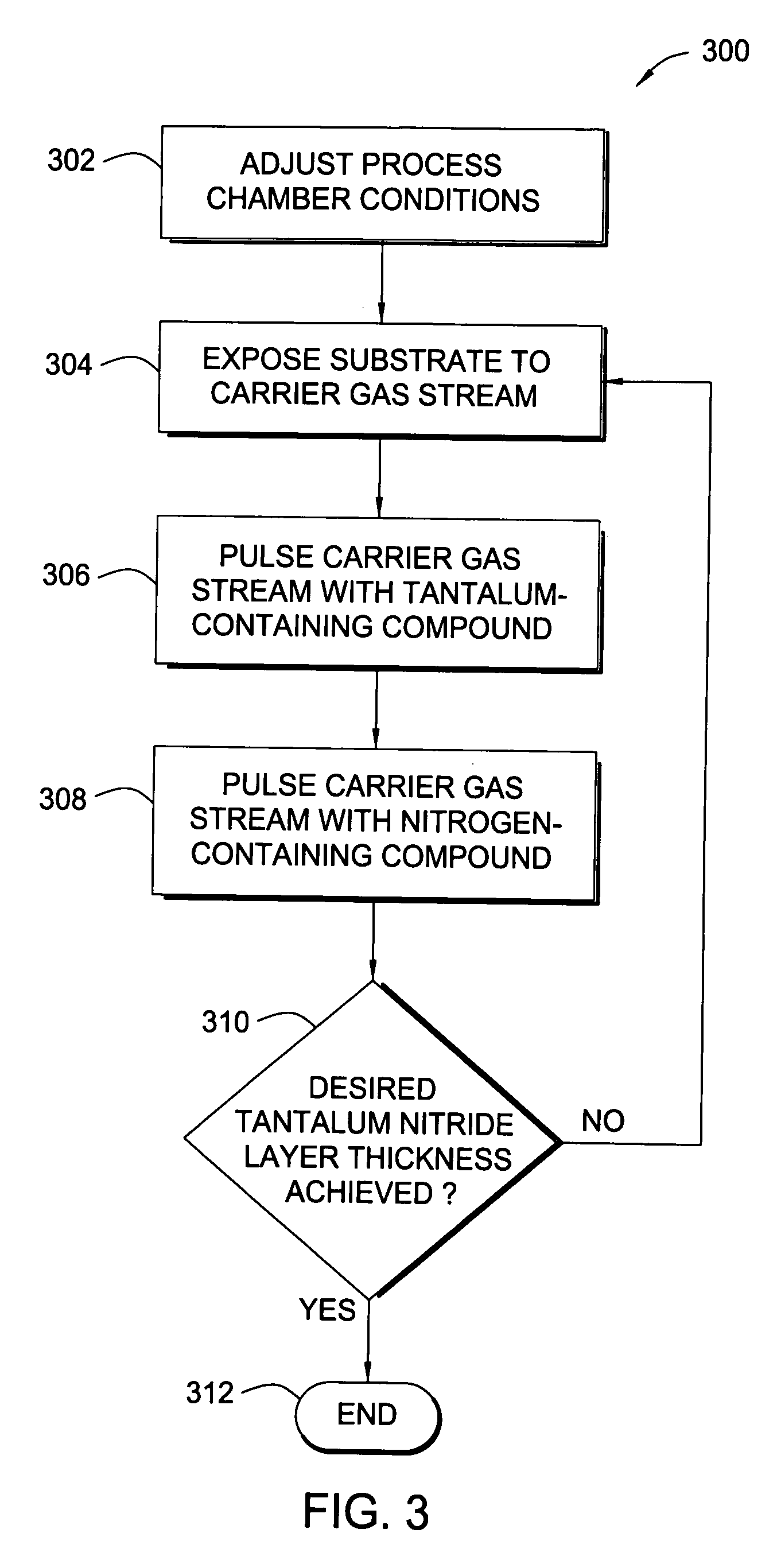

Integration of ALD tantalum nitride for copper metallization

InactiveUS7049226B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideConductive materials

A method and apparatus for depositing a tantalum nitride barrier layer is provided for use in an integrated processing tool. The tantalum nitride is deposited by atomic layer deposition. The tantalum nitride is removed from the bottom of features in dielectric layers to reveal the conductive material under the deposited tantalum nitride. Optionally, a tantalum layer may be deposited by physical vapor deposition after the tantalum nitride deposition. Optionally, the tantalum nitride deposition and the tantalum deposition may occur in the same processing chamber.

Owner:APPLIED MATERIALS INC

Methods of forming atomic layers of a material on a substrate by sequentially introducing precursors of the material

InactiveUS7201943B2Easy to integrateHigh dielectric constantVacuum evaporation coatingSemiconductor/solid-state device manufacturingGate dielectricTitanium

A thin film is formed using an atomic layer deposition process, by introducing a first reacting material including tantalum precursors and titanium precursors onto a substrate. A portion of the first reacting material is chemisorbed onto the substrate. Then, a second reacting material including oxygen is introduced onto the substrate. A portion of the second reacting material is also chemisorbed onto the substrate, to form an atomic layer of a solid material on the substrate. The solid material may be used as a dielectric layer of the capacitor and / or a gate dielectric layer of the transistor.

Owner:SAMSUNG ELECTRONICS CO LTD

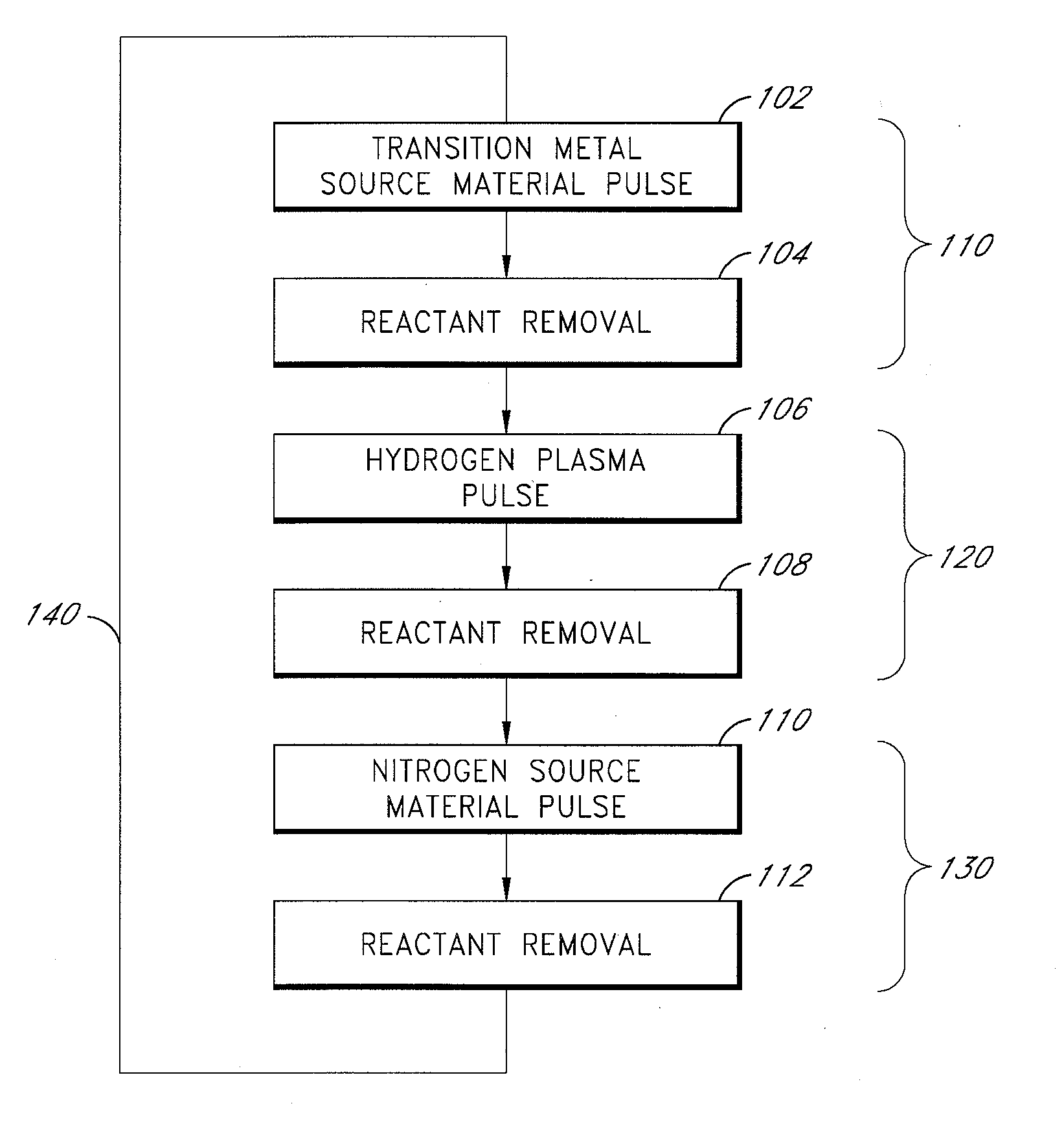

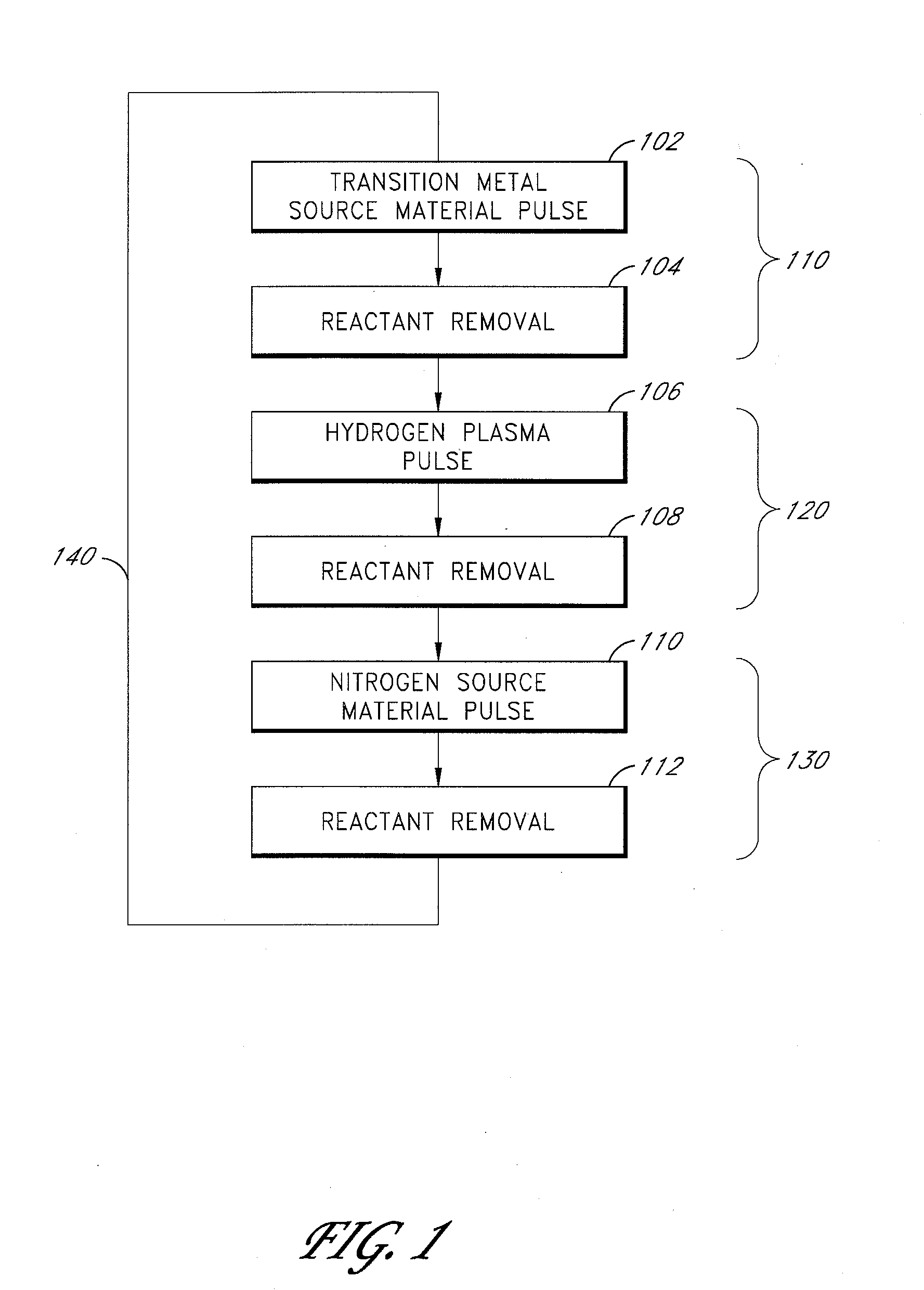

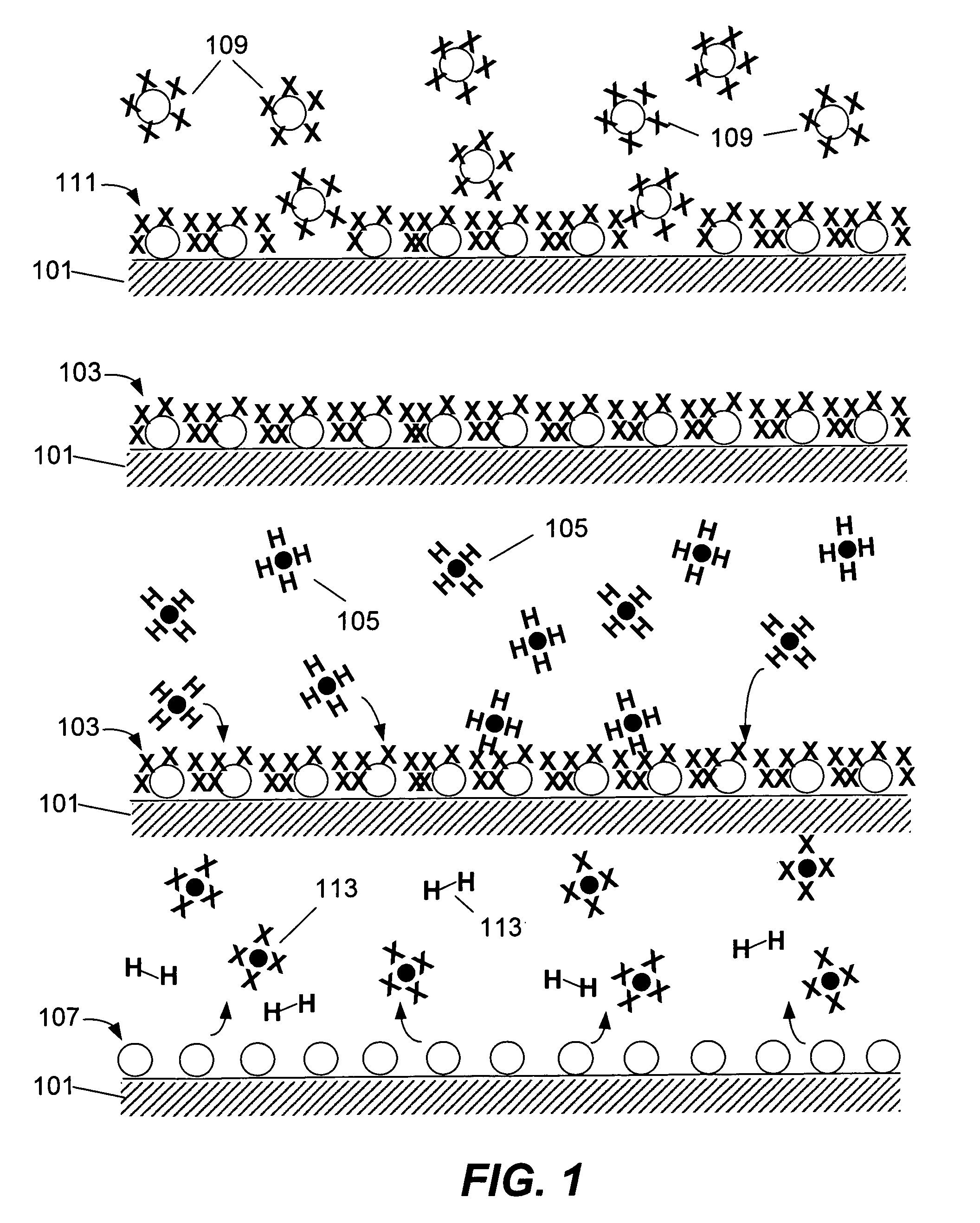

Plasma-enhanced ald of tantalum nitride films

ActiveUS20080182411A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenSource material

Methods of controllably producing conductive tantalum nitride films are provided. The methods comprise contacting a substrate in a reaction space with alternating and sequential pulses of a tantalum source material, plasma-excited species of hydrogen and nitrogen source material. The plasma-excited species of hydrogen reduce the oxidation state of tantalum, thereby forming a substantially conductive tantalum nitride film over the substrate. In some embodiments, the plasma-excited species of hydrogen react with and removes halide residues in a deposited metallic film.

Owner:ASM IP HLDG BV

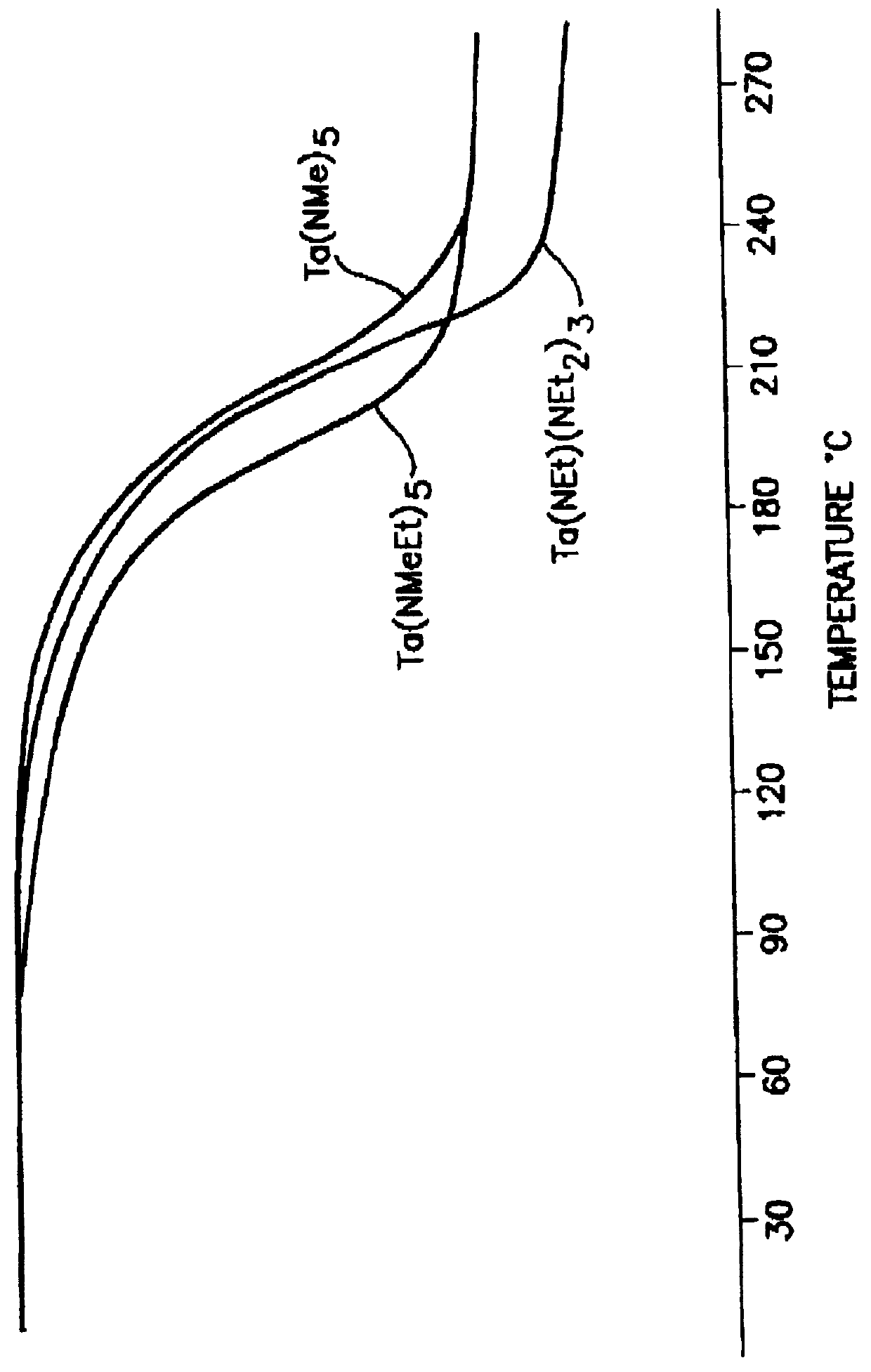

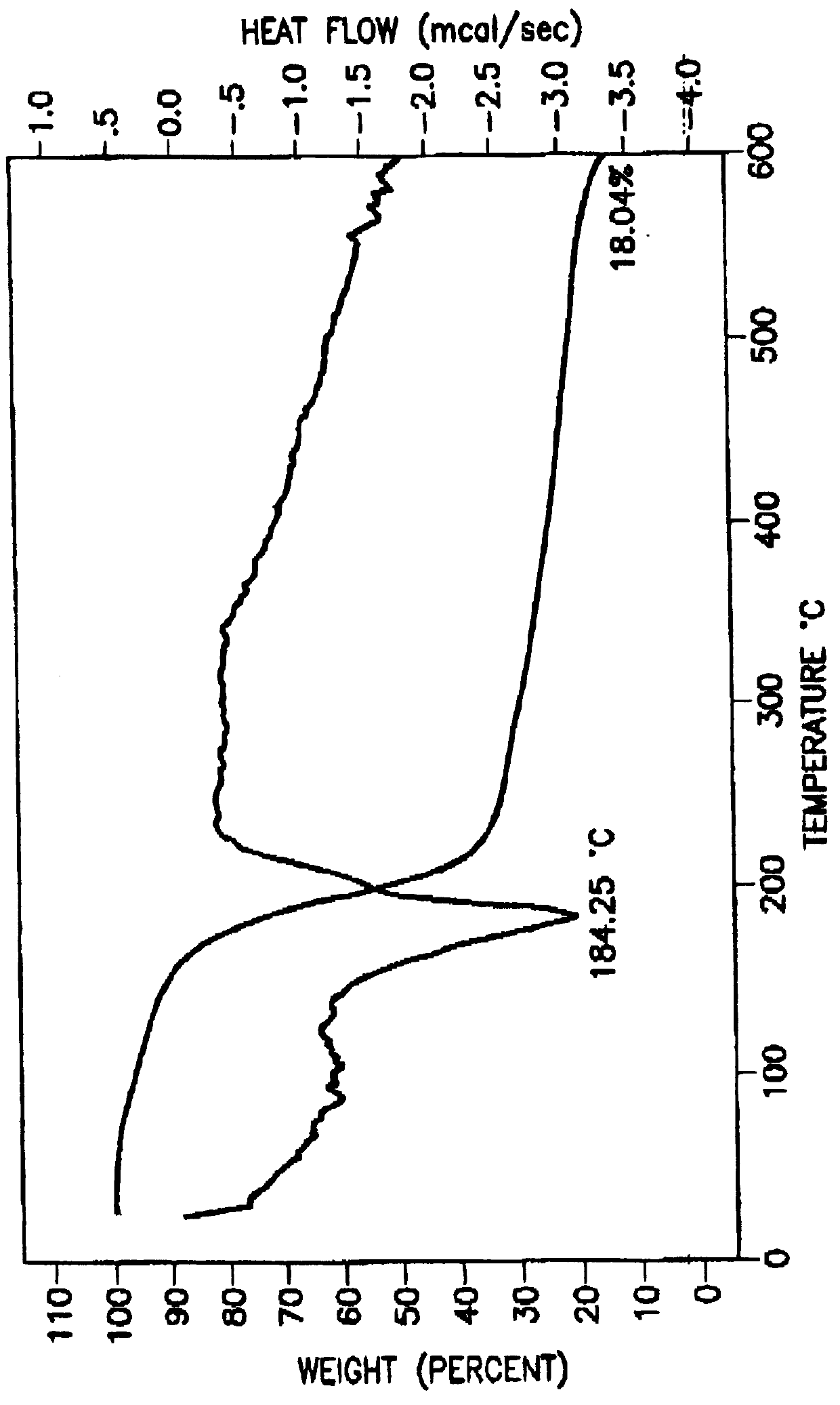

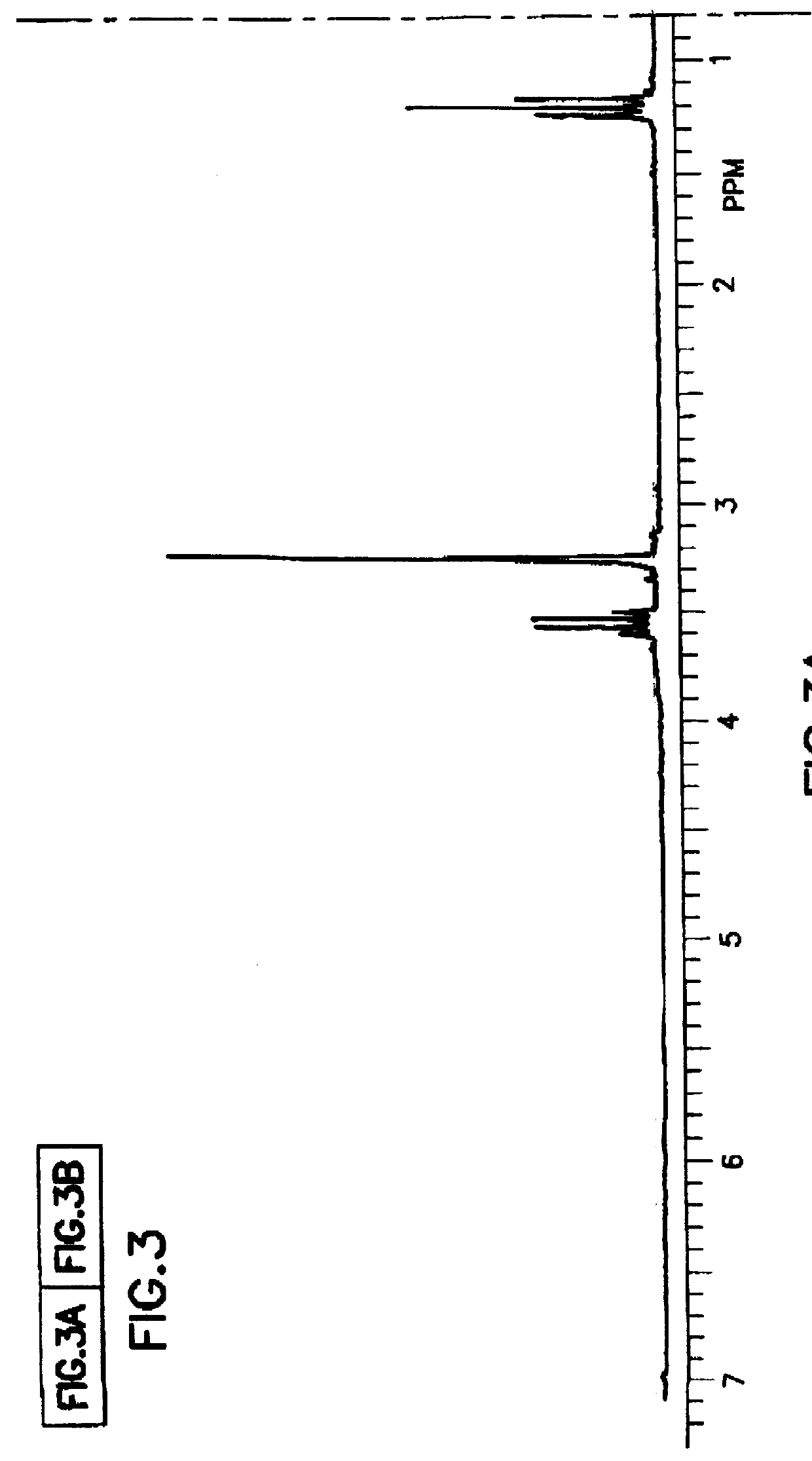

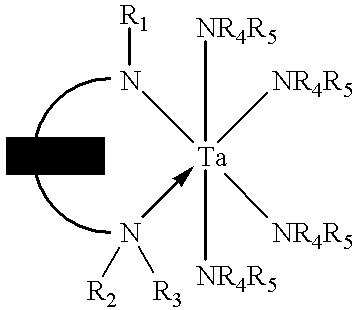

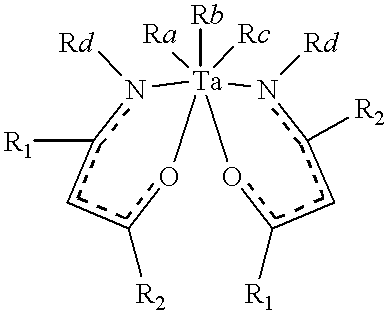

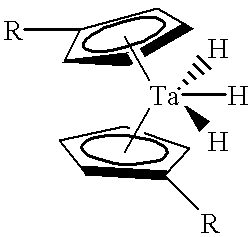

Tantalum amide precursors for deposition of tantalum nitride on a substrate

InactiveUS6015917ARapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microlectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ENTEGRIS INC

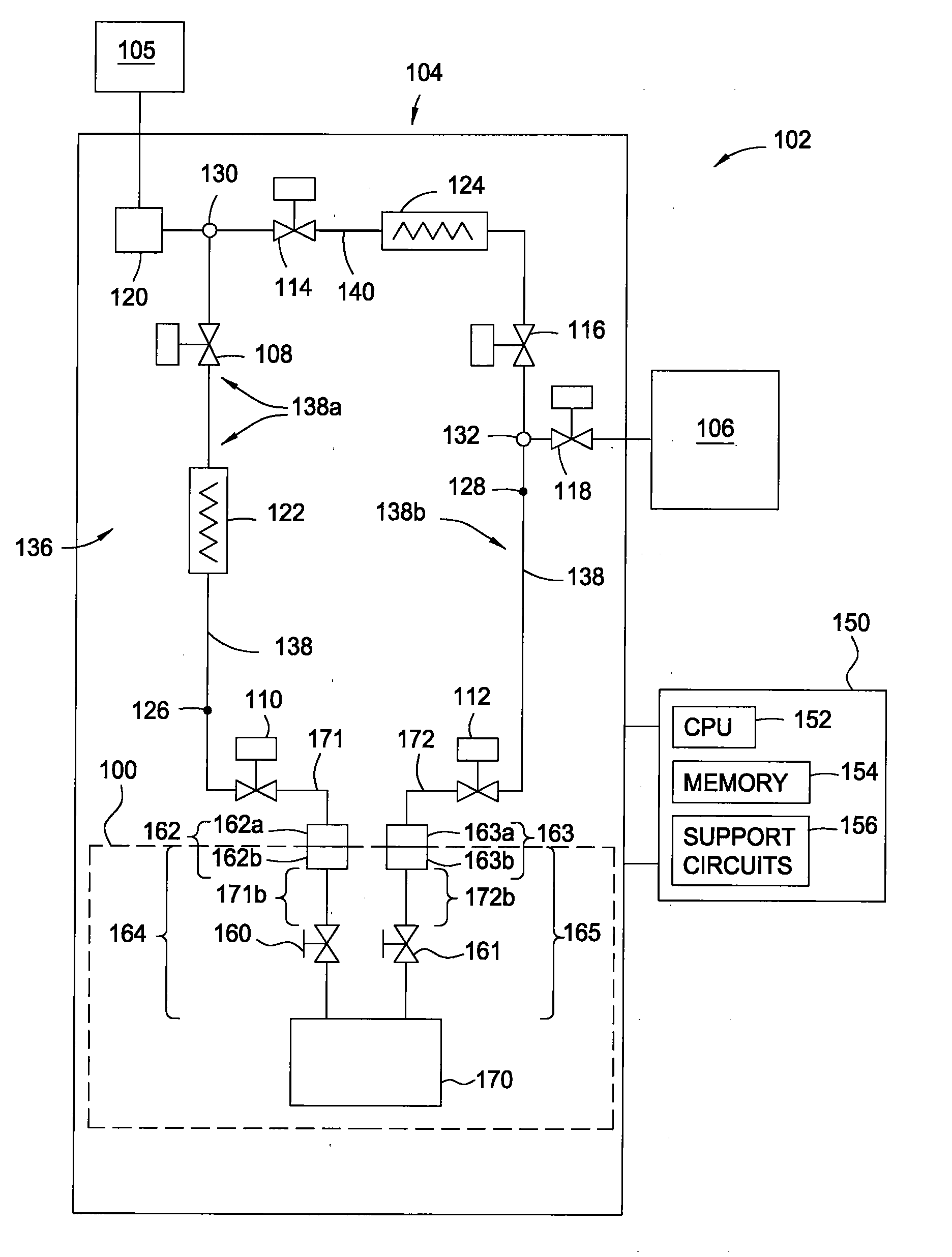

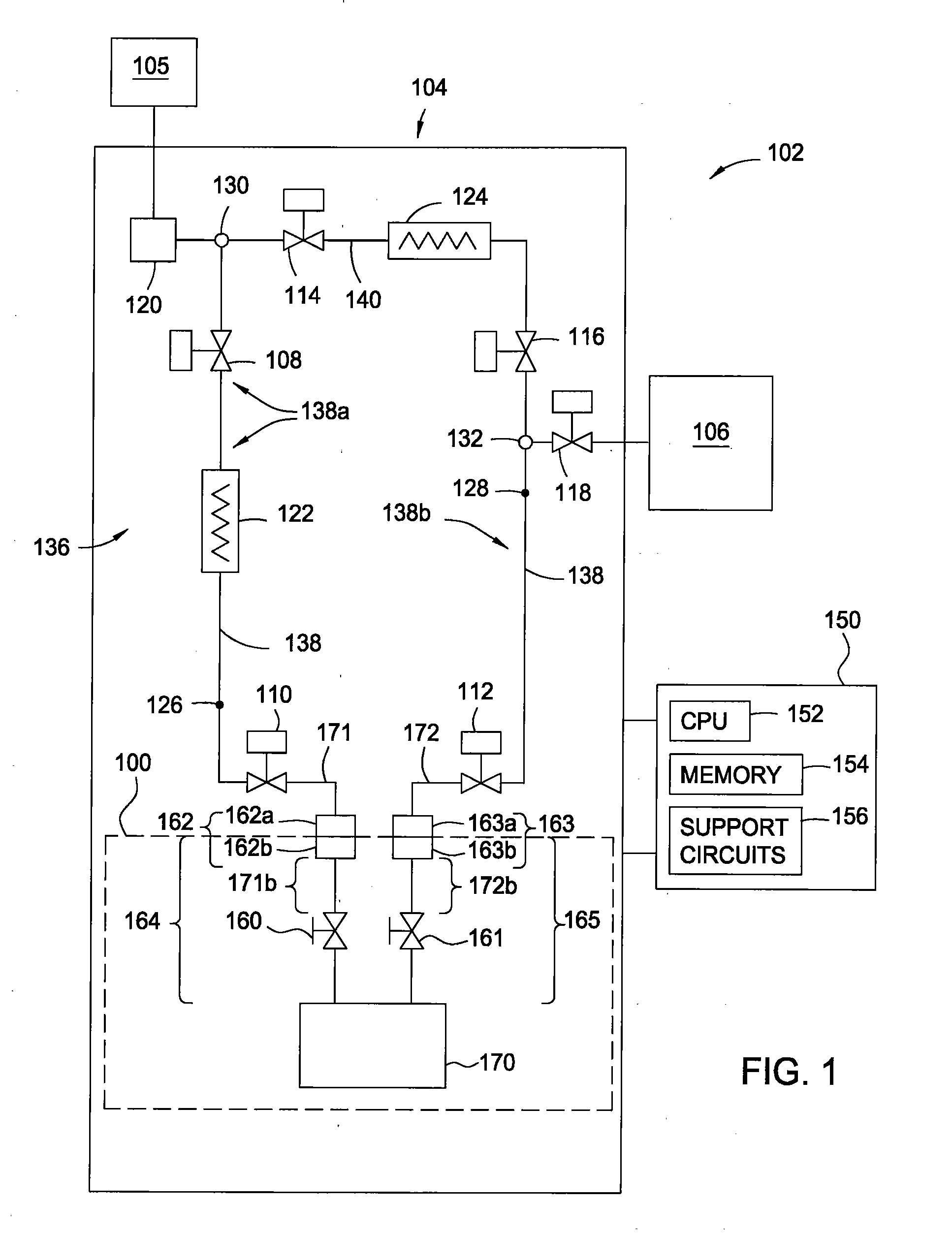

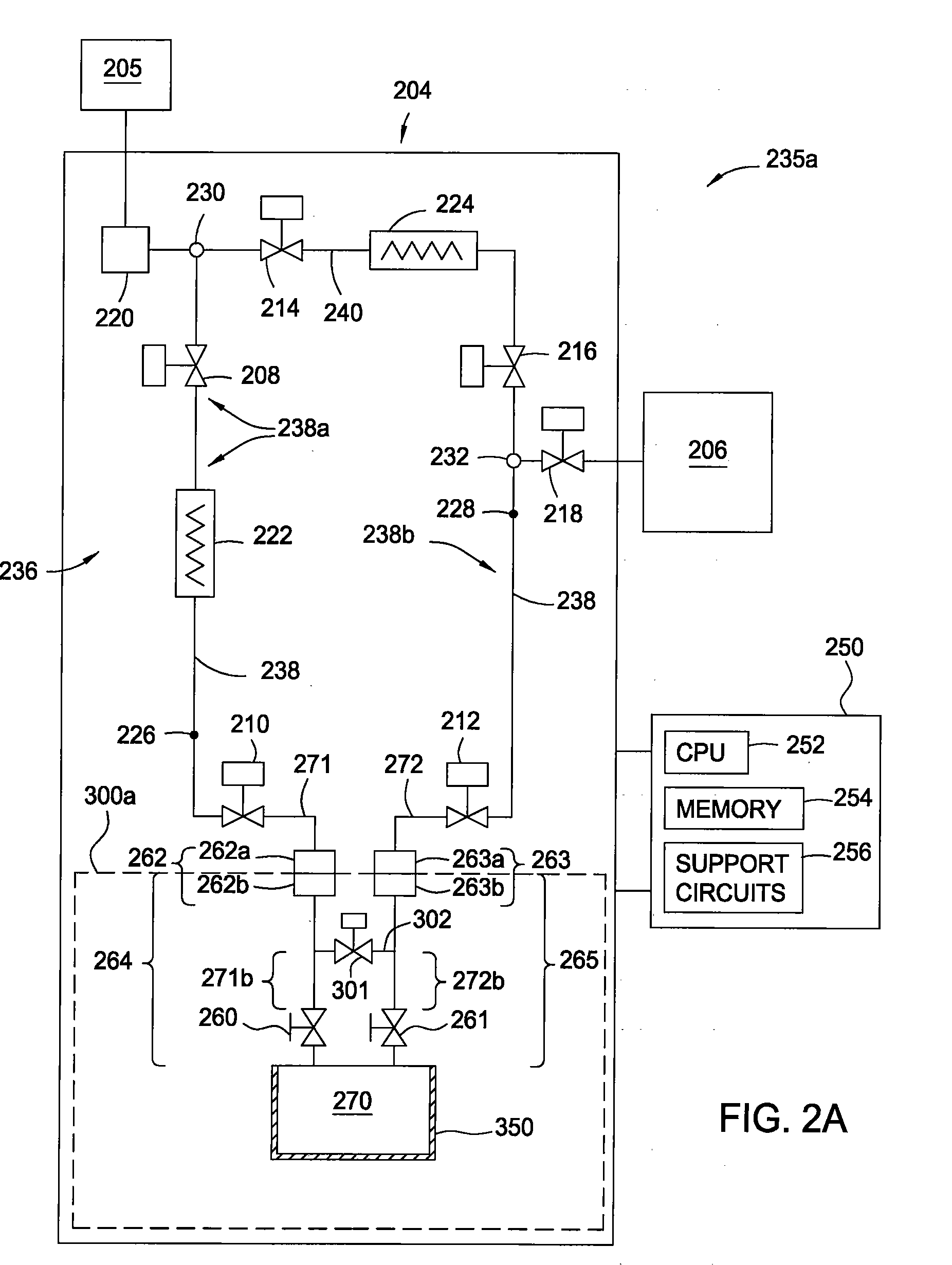

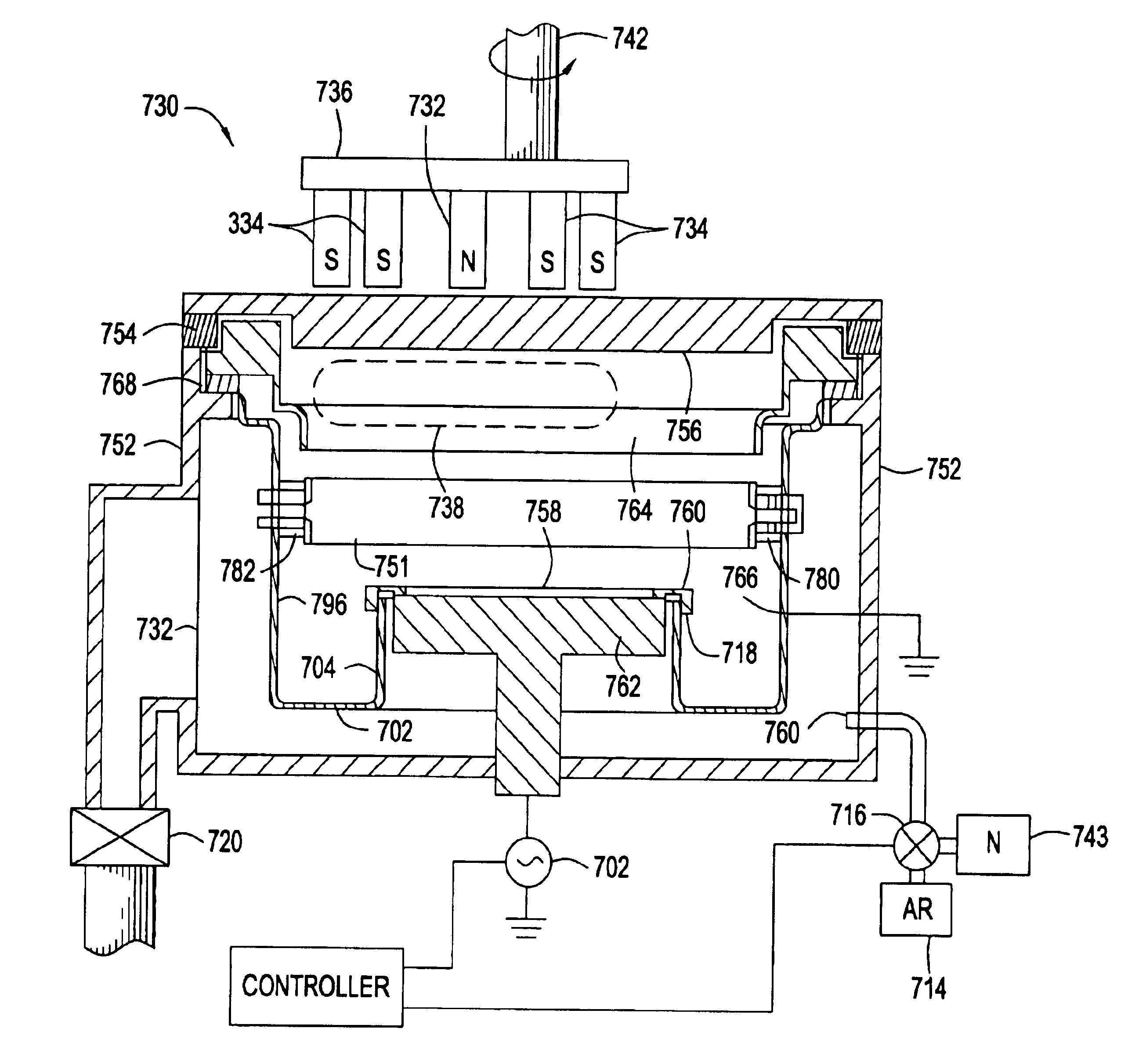

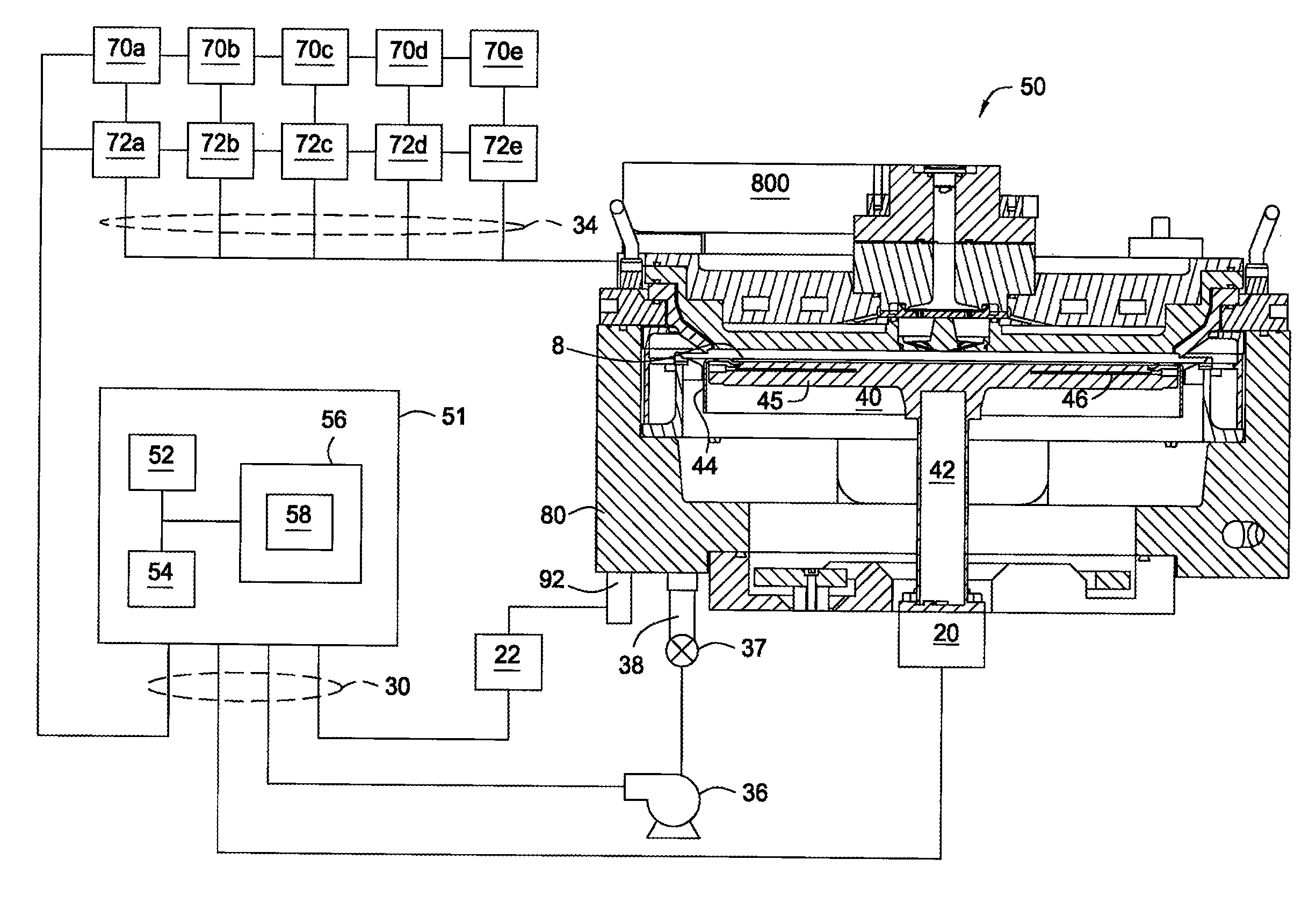

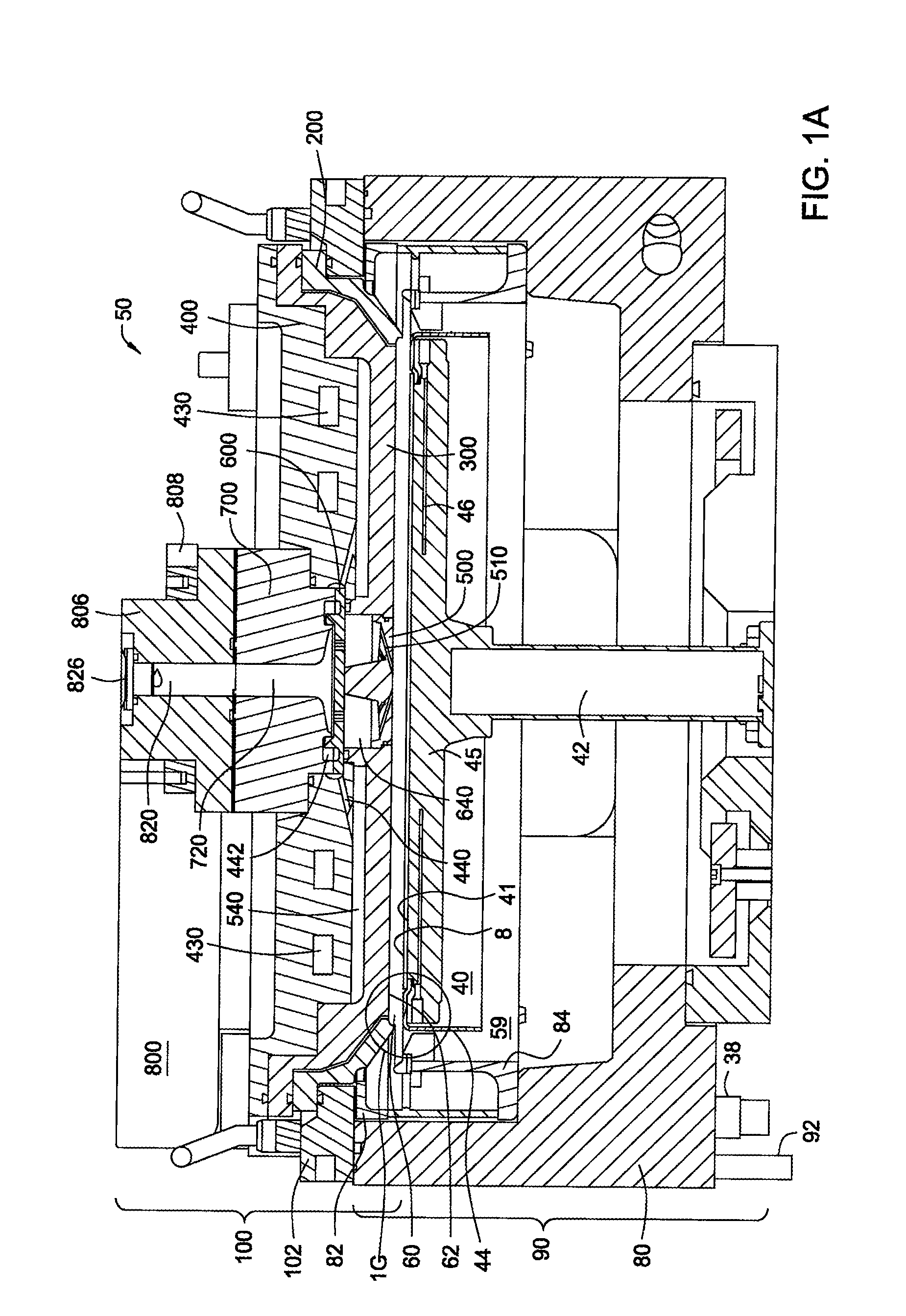

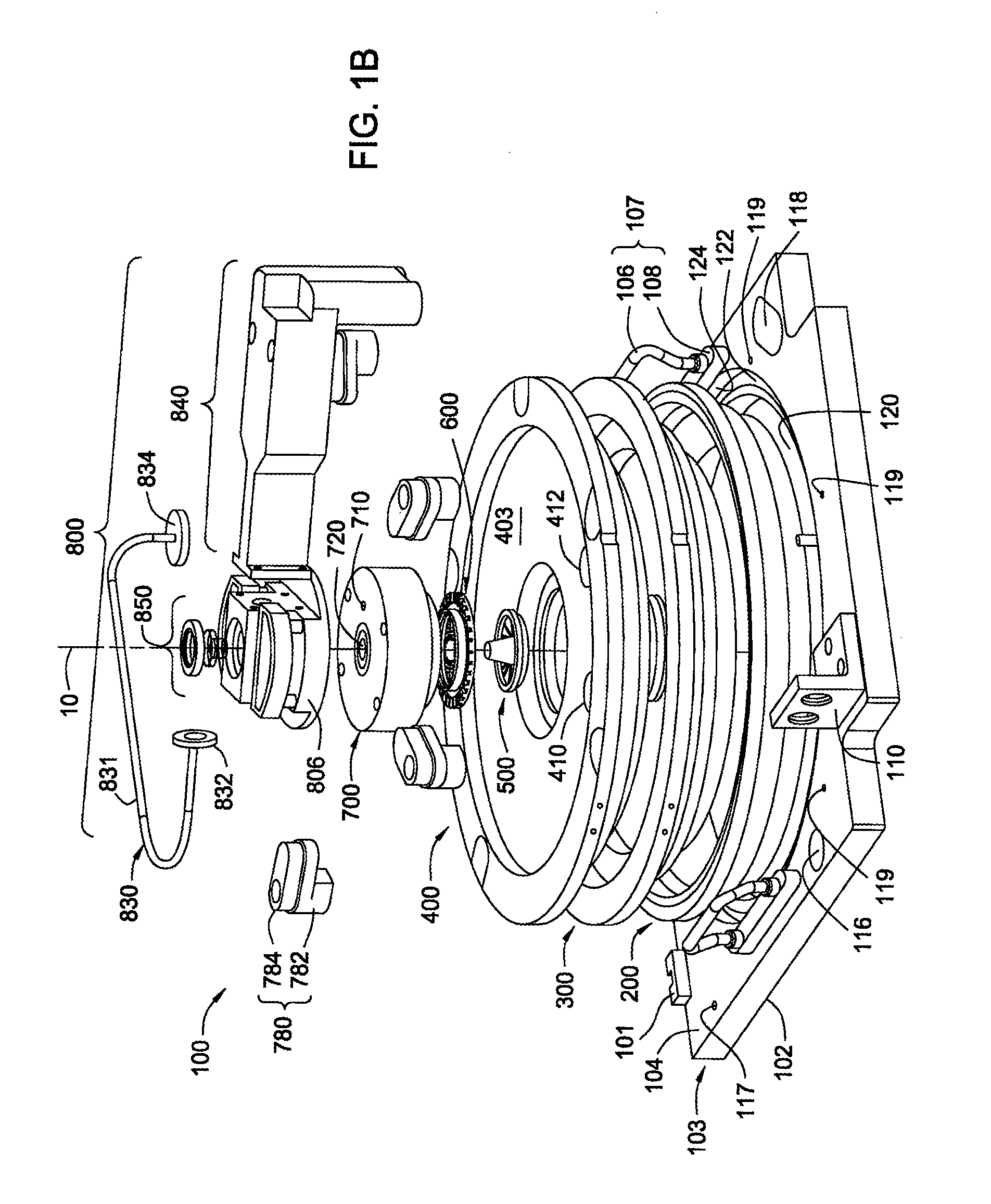

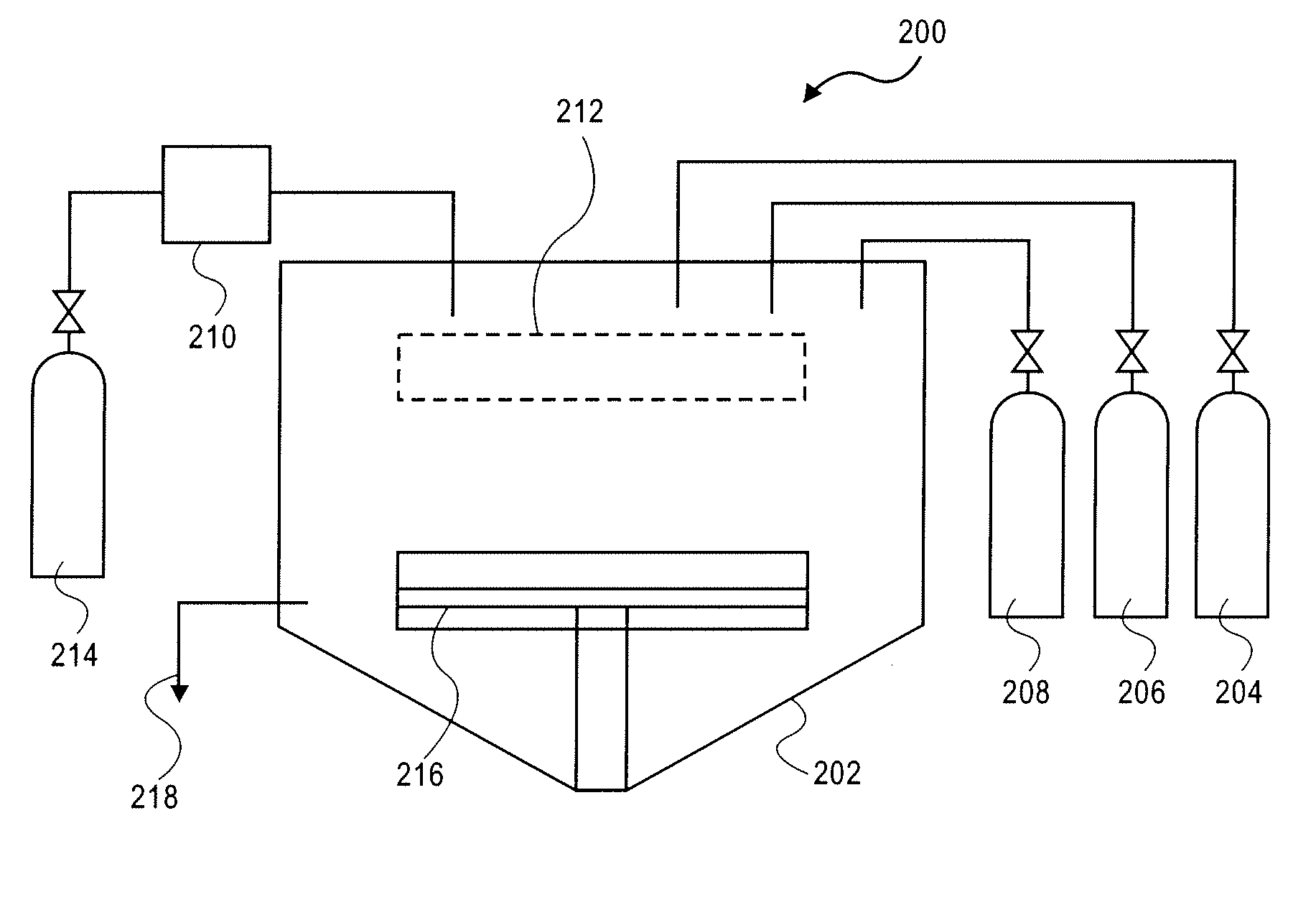

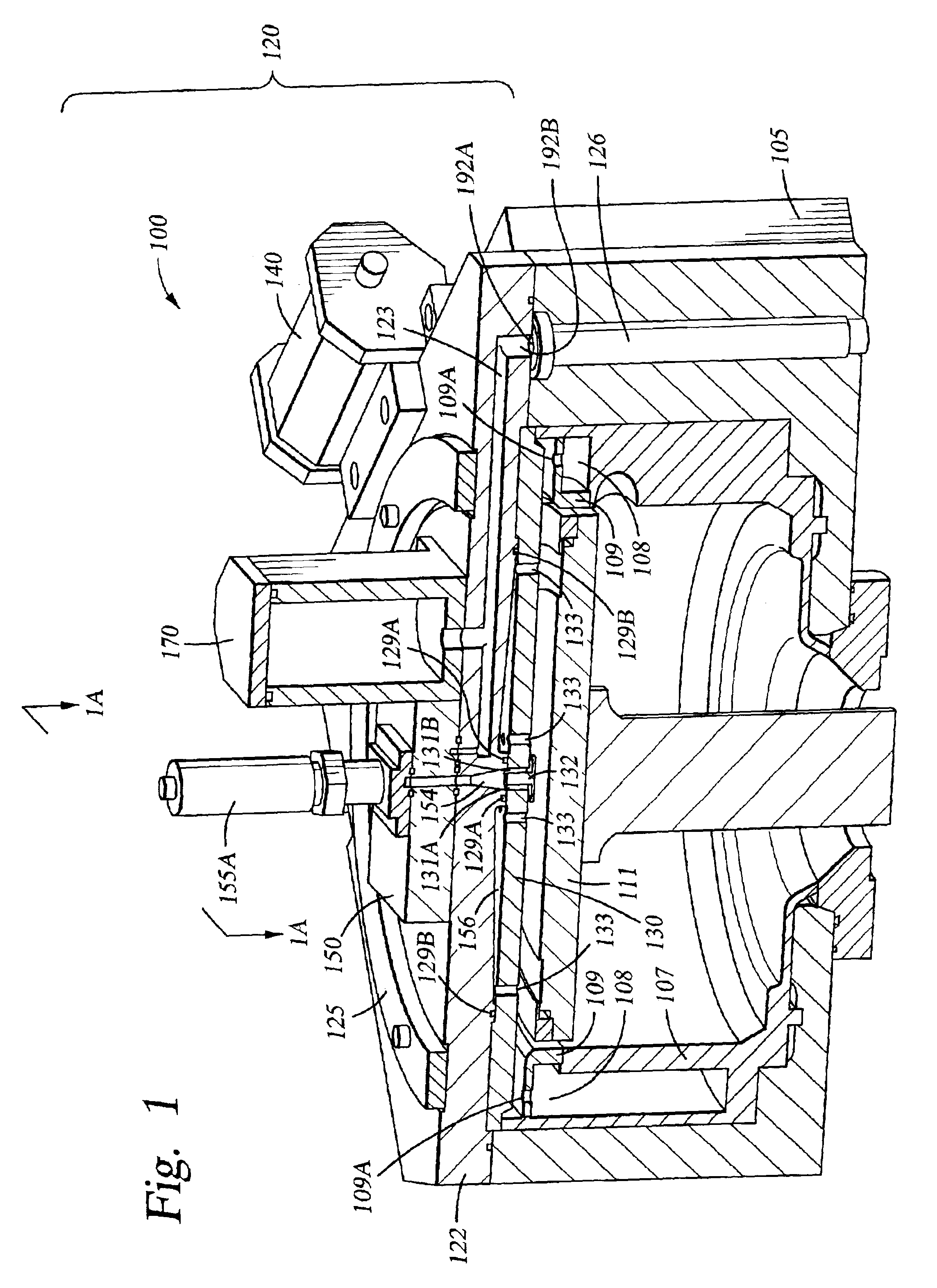

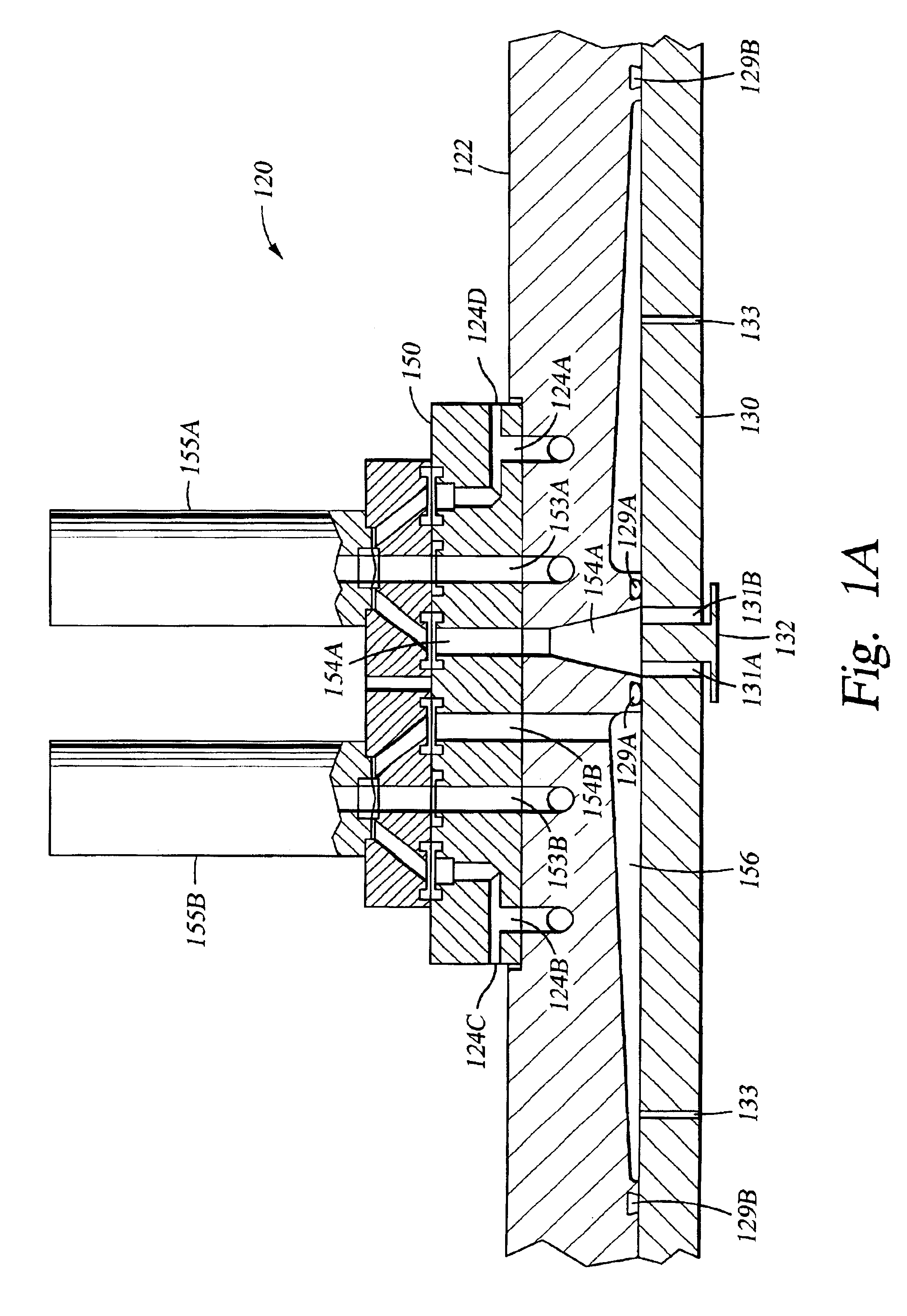

Apparatus and process for plasma-enhanced atomic layer deposition

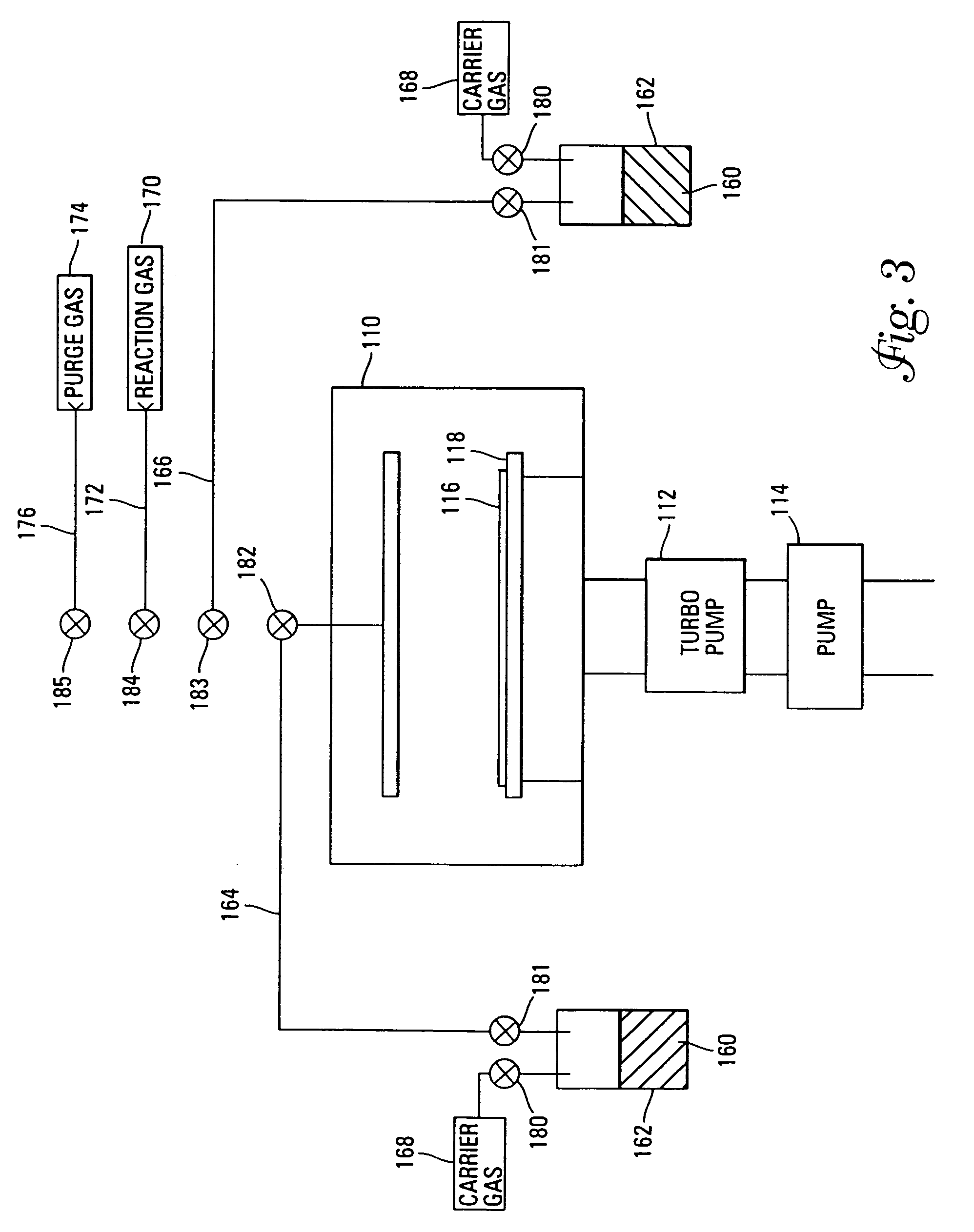

Embodiments of the invention provide a method for forming a material on a substrate during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a method is provided which includes flowing at least one process gas through at least one conduit to form a circular gas flow pattern, exposing a substrate to the circular gas flow pattern, sequentially pulsing at least one chemical precursor into the process gas and igniting a plasma from the process gas to deposit a material on the substrate. In one example, the circular gas flow pattern has circular geometry of a vortex, a helix, a spiral, or a derivative thereof. Materials that may be deposited by the method include ruthenium, tantalum, tantalum nitride, tungsten or tungsten nitride. Other embodiments of the invention provide an apparatus configured to form the material during the PE-ALD process.

Owner:APPLIED MATERIALS INC

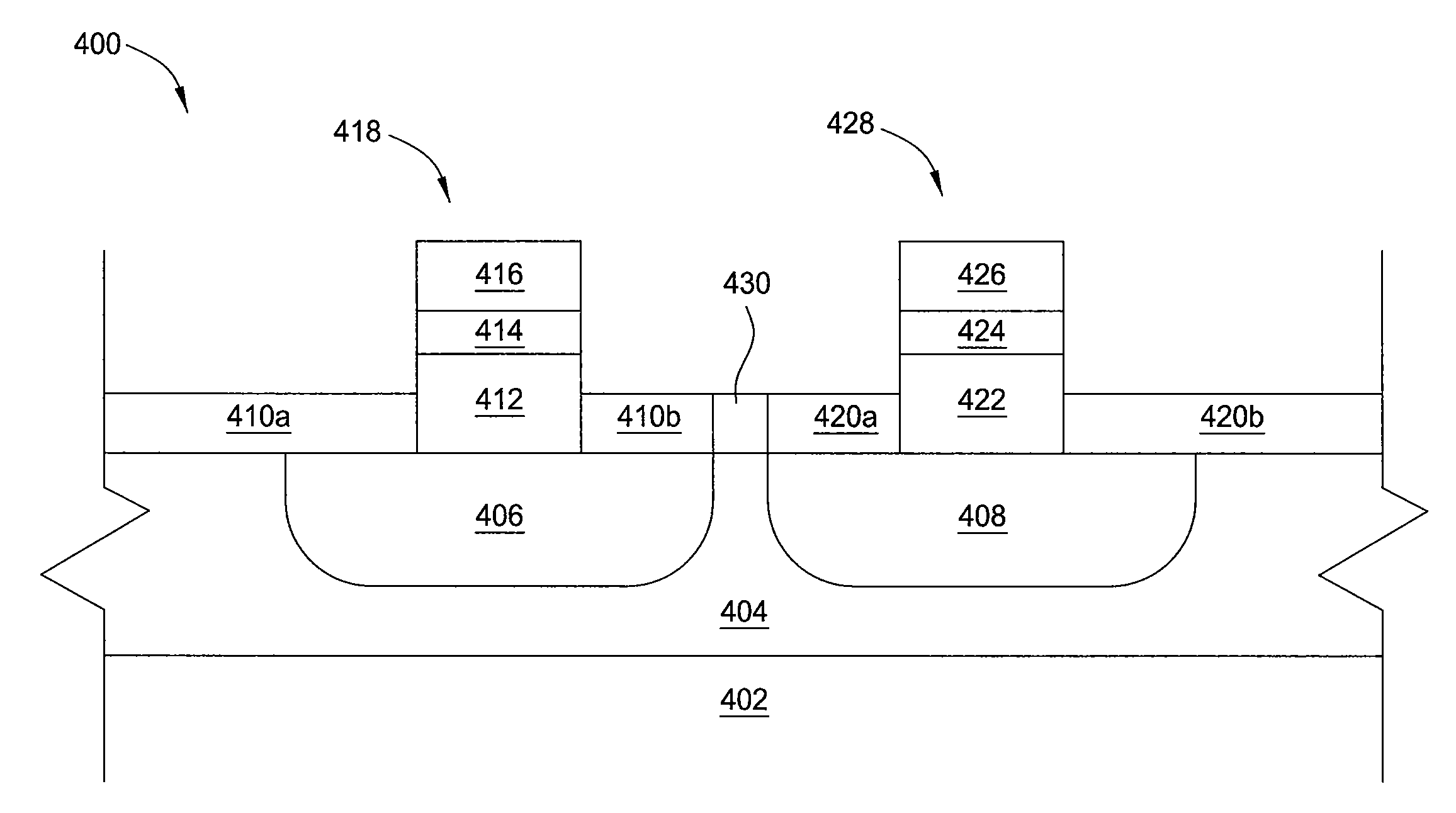

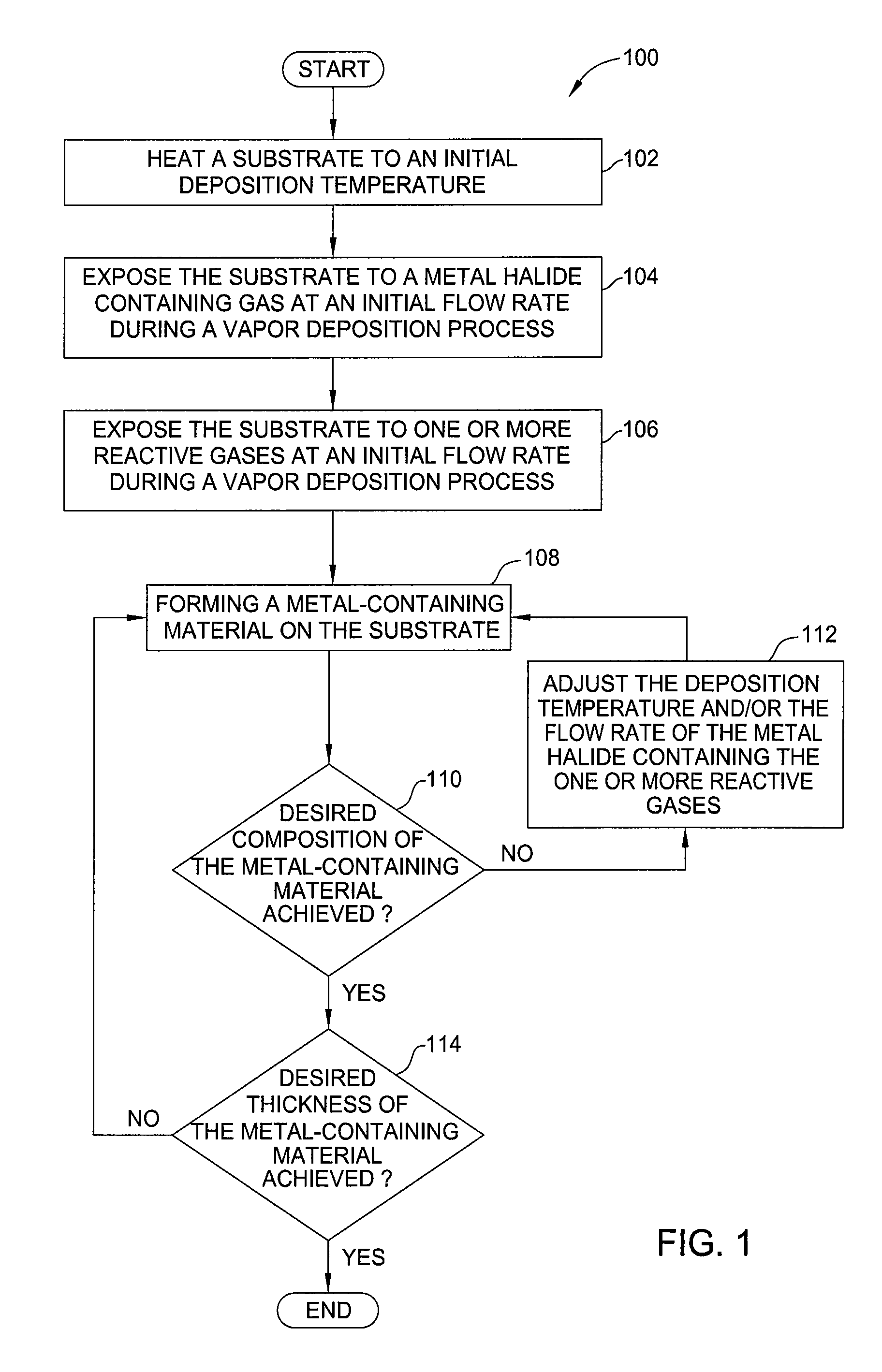

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

Organometallic precursors for seed/barrier processes and methods thereof

InactiveUS20080194105A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseRuthenium

Organometallic precursors and methods for deposition on a substrate in seed / barrier applications are herein disclosed. In some embodiments, the organometallic precursor is a ruthenium-containing, tantalum-containing precursor or combination thereof and may be deposited by atomic layer deposition, chemical vapor deposition and / or physical vapor deposition.

Owner:INTEL CORP

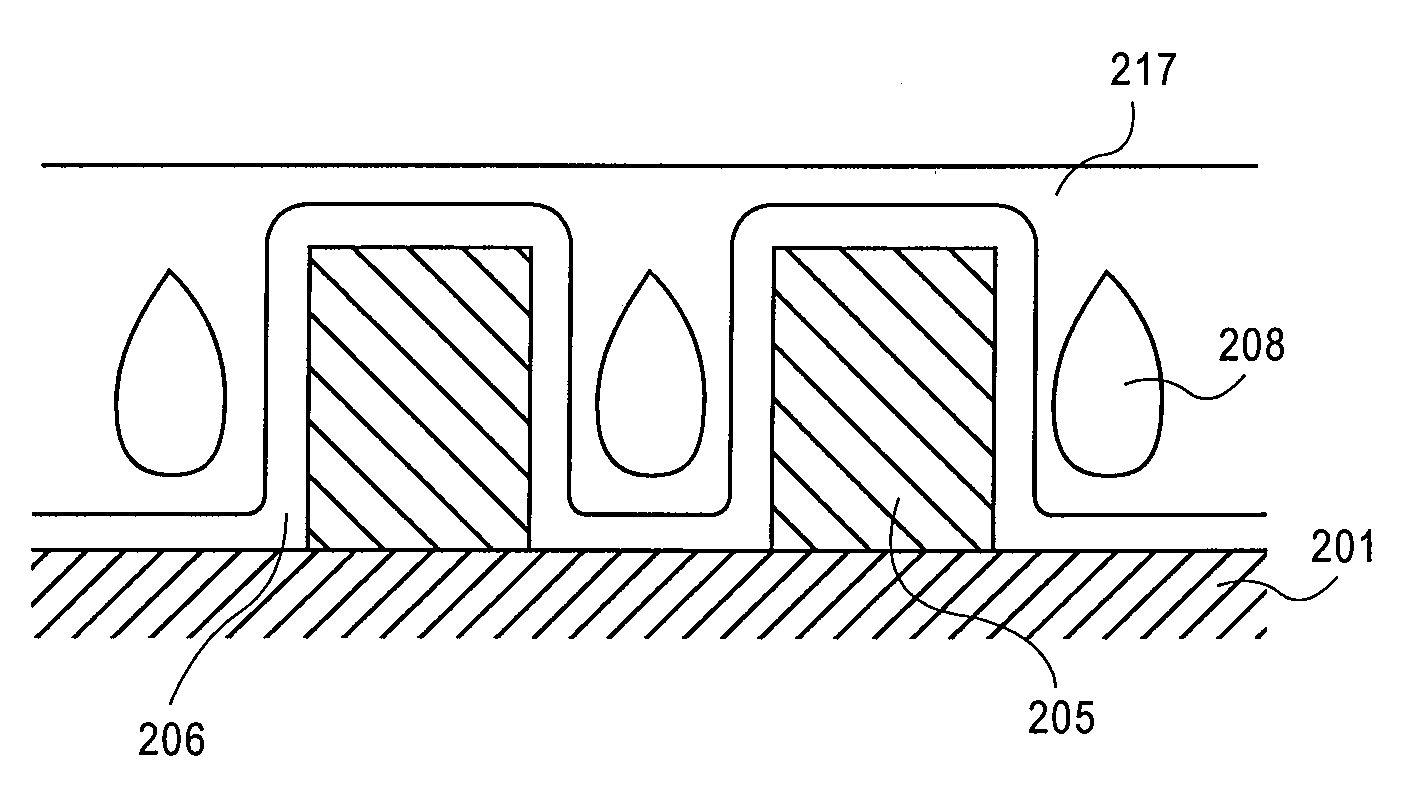

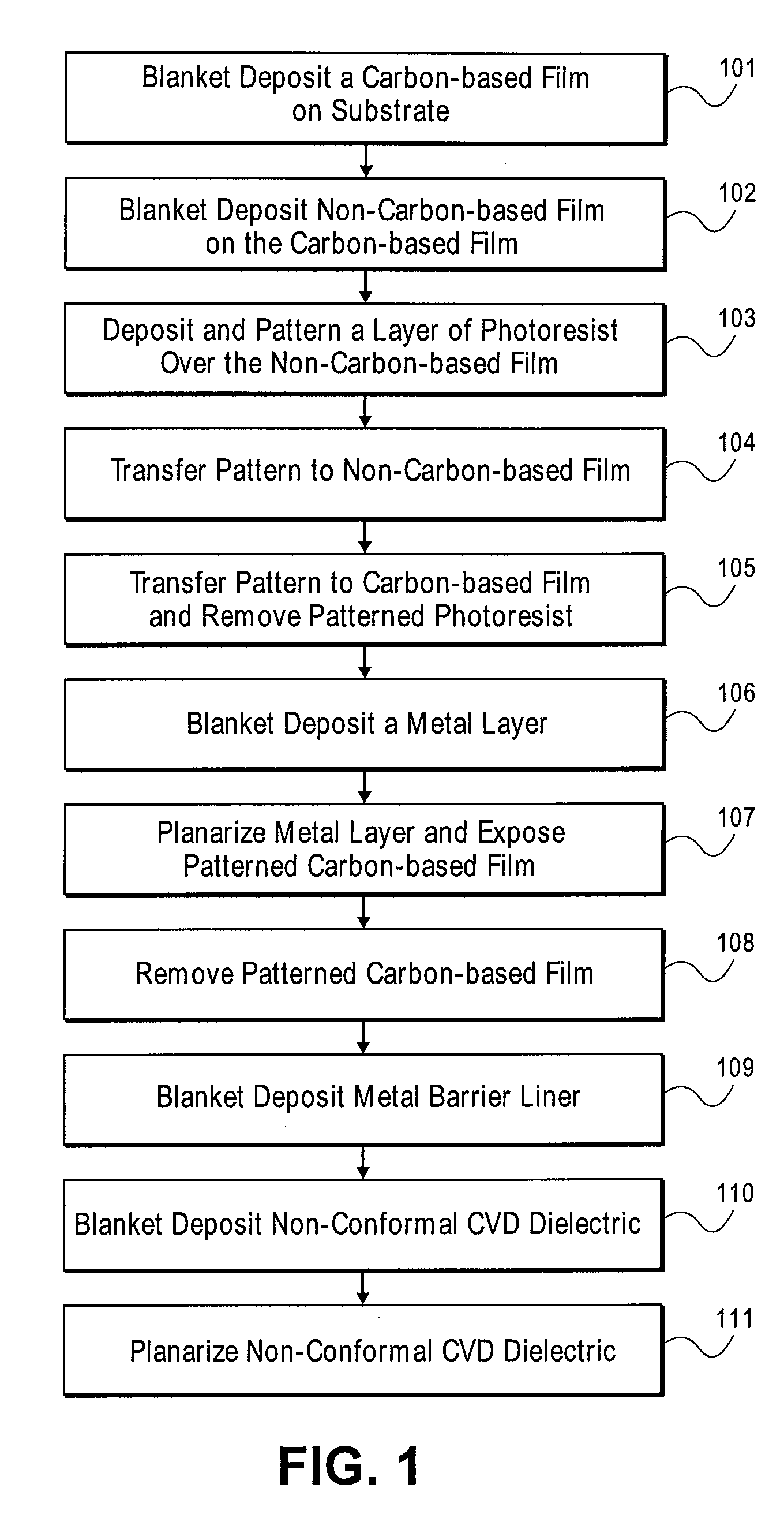

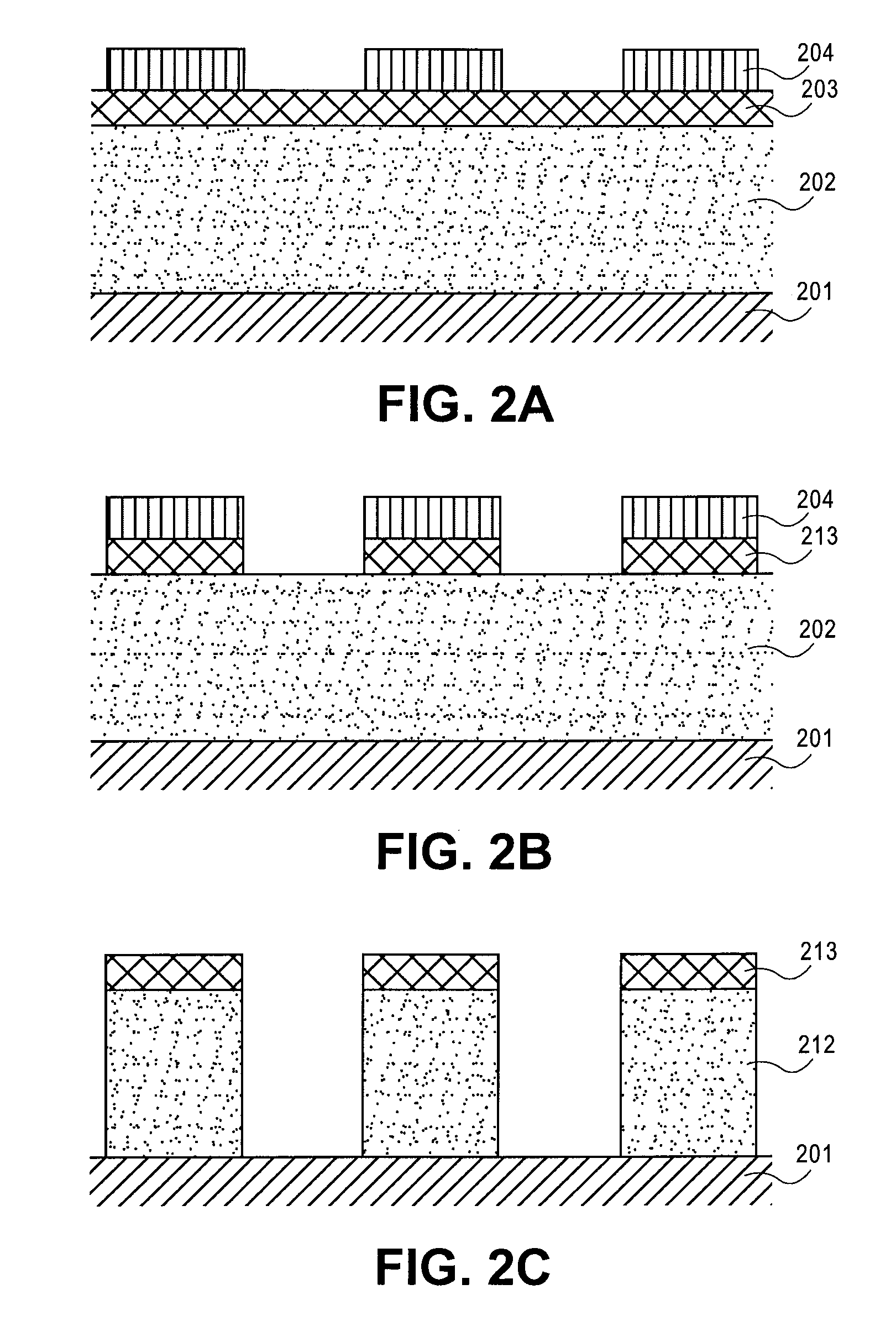

Air gap interconnects using carbon-based films

InactiveUS20100093168A1Improve electrical isolationSemiconductor/solid-state device manufacturingMetal interconnectPorous carbon

A method of forming an interconnect structure comprising: forming a sacrificial inter-metal dielectric (IMD) layer over a substrate, wherein the sacrificial IMD layer comprising a carbon-based film, such as amorphous carbon, advanced patterning films, porous carbon, or any combination thereof; forming a plurality of metal interconnect lines within the sacrificial IMD layer; removing the sacrificial IMD layer, with an oxygen based reactive process; and depositing a non-conformal dielectric layer to form air gaps between the plurality of metal interconnect lines. The metal interconnect lines may comprise copper, aluminum, tantalum, tungsten, titanium, tantalum nitride, titanium nitride, tungsten nitride, or any combination thereof. Carbon-based films and patterned photoresist layers may be simultaneously removed with the same reactive process. Highly reactive hydrogen radicals processes may be used to remove the carbon-based film and simultaneously pre-clean the metal interconnect lines prior to the deposition of a conformal metal barrier liner.

Owner:APPLIED MATERIALS INC

Atomic layer deposition of tantalum-containing materials using the tantalum precursor taimata

InactiveUS20060019495A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideBoron nitride

In one example of the invention, a method for depositing a tantalum-containing material on a substrate in a process chamber is provided which includes exposing the substrate to a tantalum precursor that contains TAIMATA and to at least one secondary precursor to deposit a tantalum-containing film during an atomic layer deposition (ALD) process. The ALD process is repeated until the tantalum-containing film is deposited with a predetermined thickness. Usually, the TAIMATA is preheated prior pulsing the tantalum precursor into the process chamber. A metal layer, such as tungsten or copper, may be deposited on the tantalum-containing material. The tantalum-containing material may include tantalum, tantalum nitride, tantalum silicon nitride, tantalum boron nitride, tantalum phosphorous nitride or tantalum oxynitride. The tantalum-containing material may be deposited as a barrier or adhesion layer within a via or as a gate electrode material within a source / drain device.

Owner:APPLIED MATERIALS INC

Slurry compositions for chemical mechanical polishing of copper and barrier films

InactiveUS20050090104A1High selectivityShorten the counting processSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurryPolymer

Owner:INNOVATIUM TECH

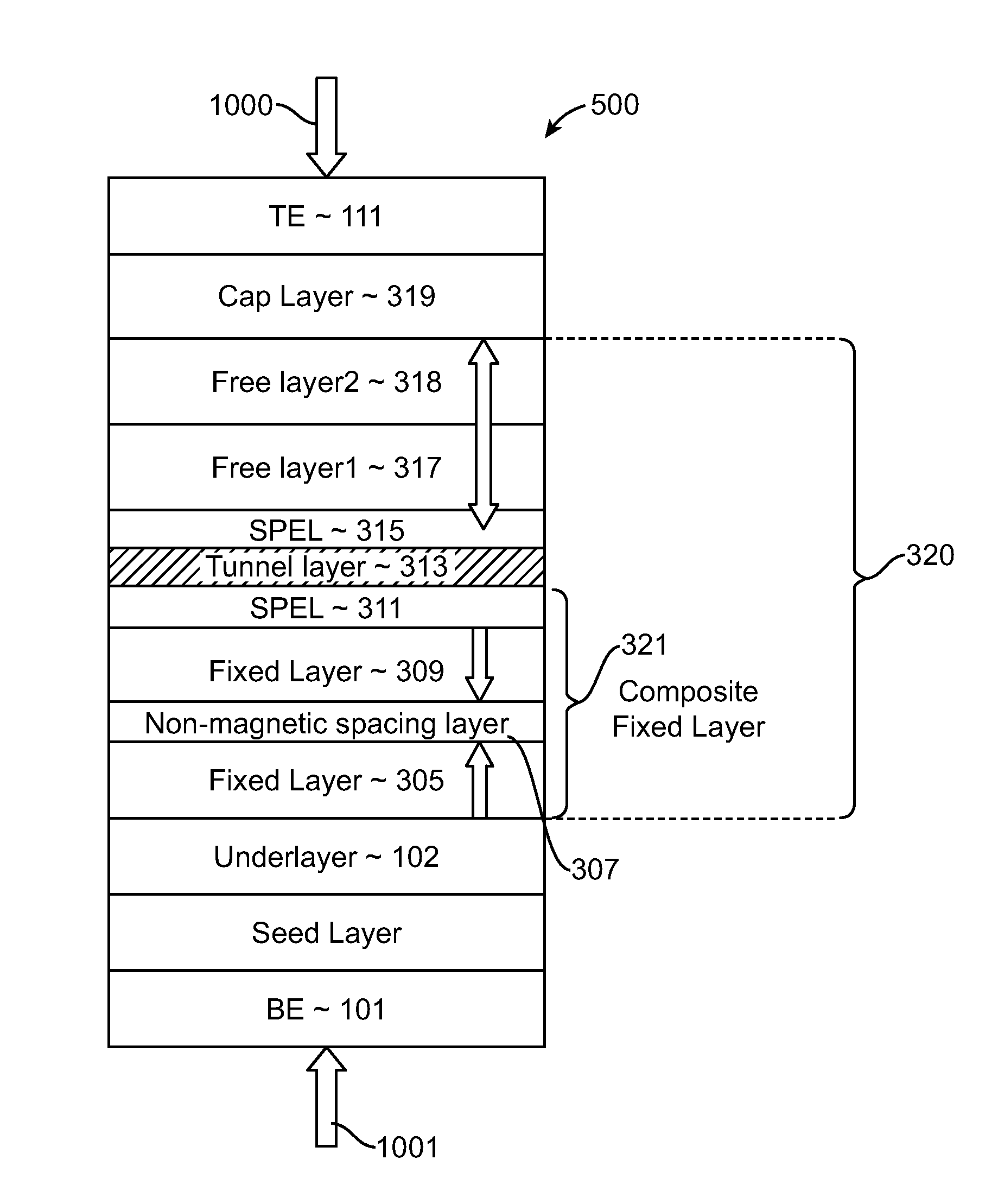

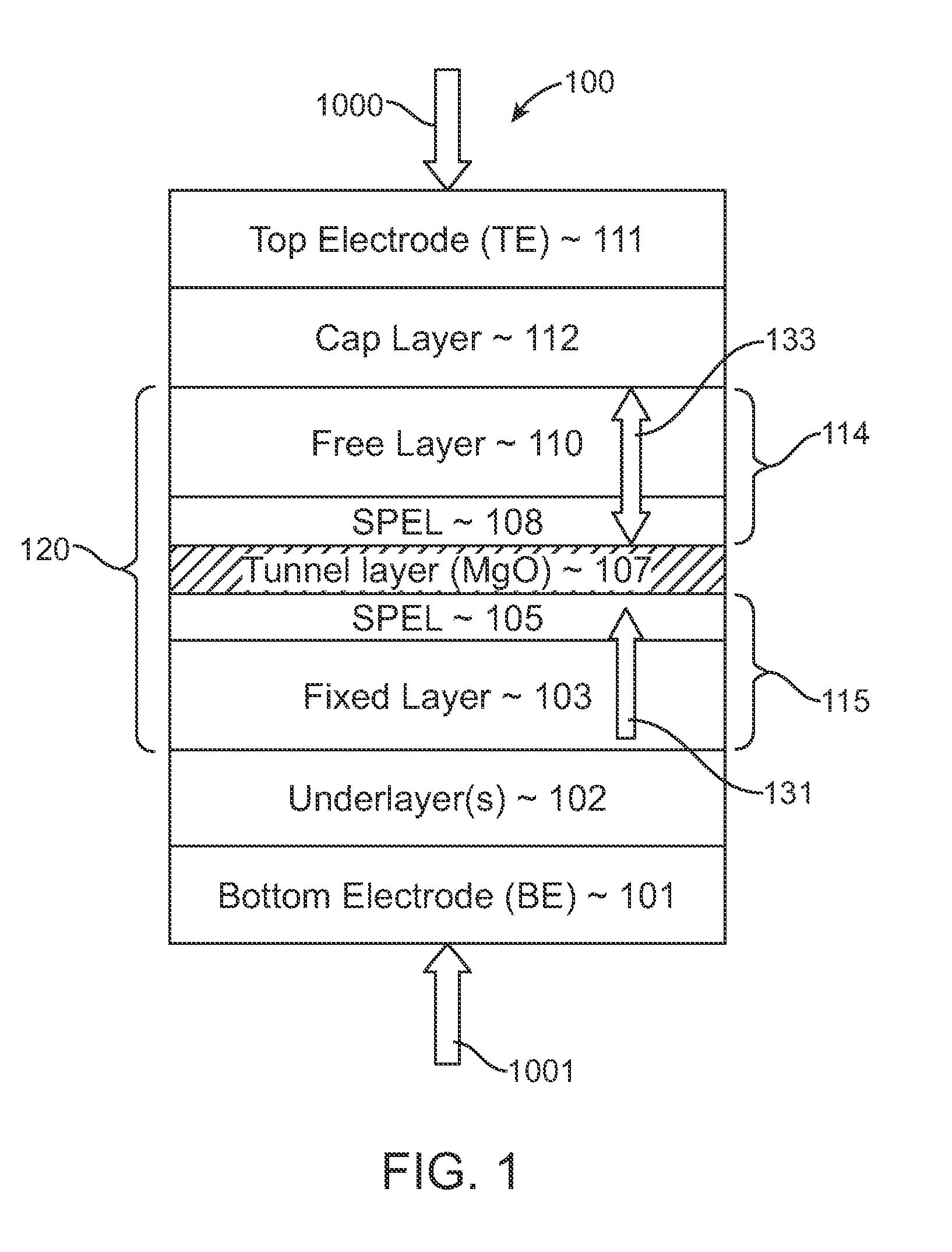

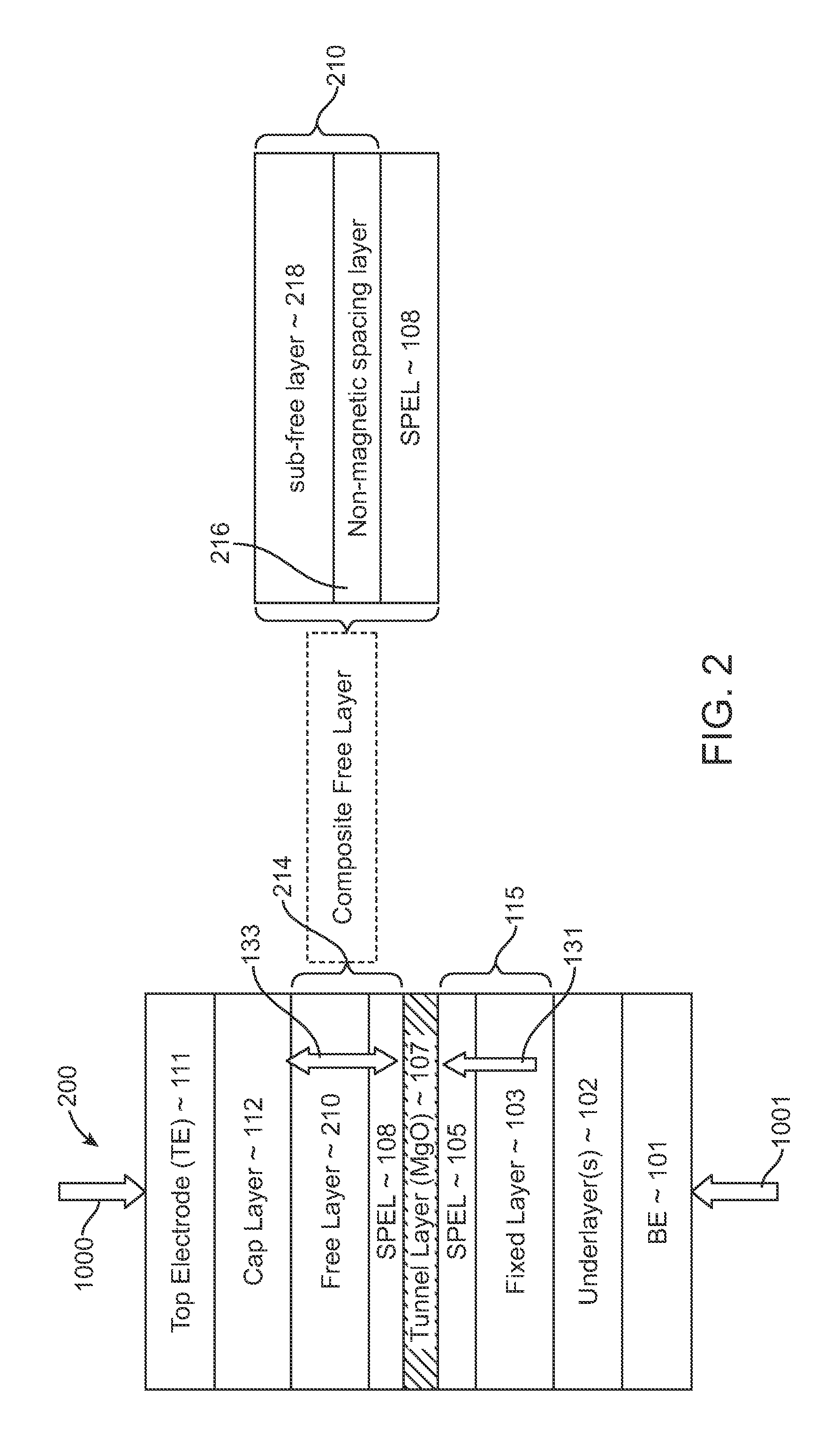

Spin-transfer torque magnetic random access memory having magnetic tunnel junction with perpendicular magnetic anisotropy

A spin-torque transfer memory random access memory (STTMRAM) element includes a fixed layer formed on top of a substrate and a a tunnel layer formed upon the fixed layer and a composite free layer formed upon the tunnel barrier layer and made of an iron platinum alloy with at least one of X or Y material, X being from a group consisting of: boron (B), phosphorous (P), carbon (C), and nitride (N) and Y being from a group consisting of: tantalum (Ta), titanium (Ti), niobium (Nb), zirconium (Zr), tungsten (W), silicon (Si), copper (Cu), silver (Ag), aluminum (Al), chromium (Cr), tin (Sn), lead (Pb), antimony (Sb), hafnium (Hf) and bismuth (Bi), molybdenum (Mo) or rhodium (Ru), the magnetization direction of each of the composite free layer and fixed layer being substantially perpendicular to the plane of the substrate.

Owner:AVALANCHE TECH

Tantalum amide precursors for deposition of tantalum nitride on a substrate

InactiveUS6379748B1Rapid heat treatmentSilicon organic compoundsPolycrystalline material growthFerroelectric thin filmsChemical vapor deposition

Tantalum and titanium source reagents are described, including tantalum amide and tantalum silicon nitride precursors for the deposition of tantalum nitride material on a substrate by processes such as chemical vapor deposition, assisted chemical vapor deposition, ion implantation, molecular beam epitaxy and rapid thermal processing. The precursors may be employed to form diffusion barrier layers on microelectronic device structures enabling the use of copper metallization and ferroelectric thin films in device construction.

Owner:ADVANCED TECH MATERIALS INC

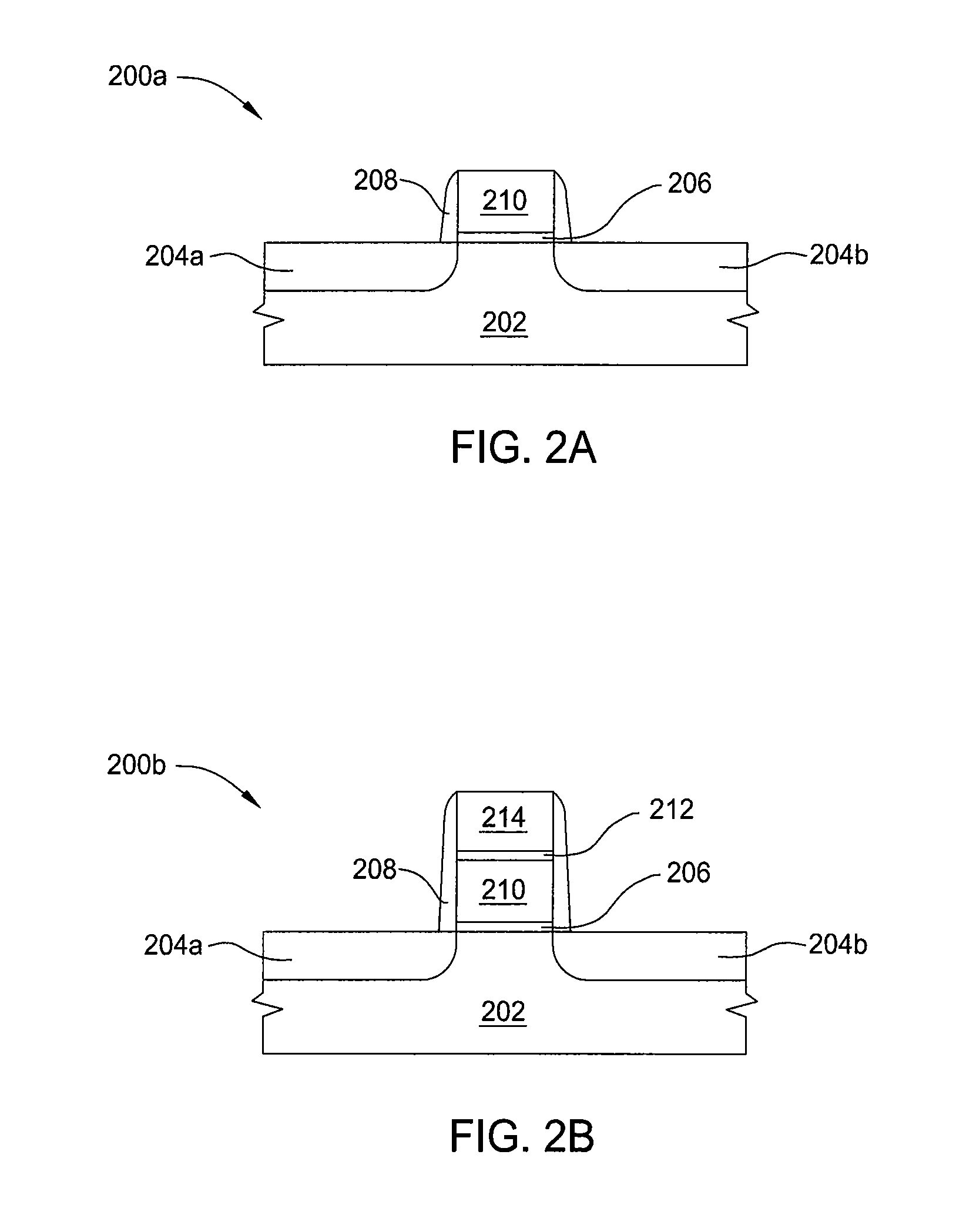

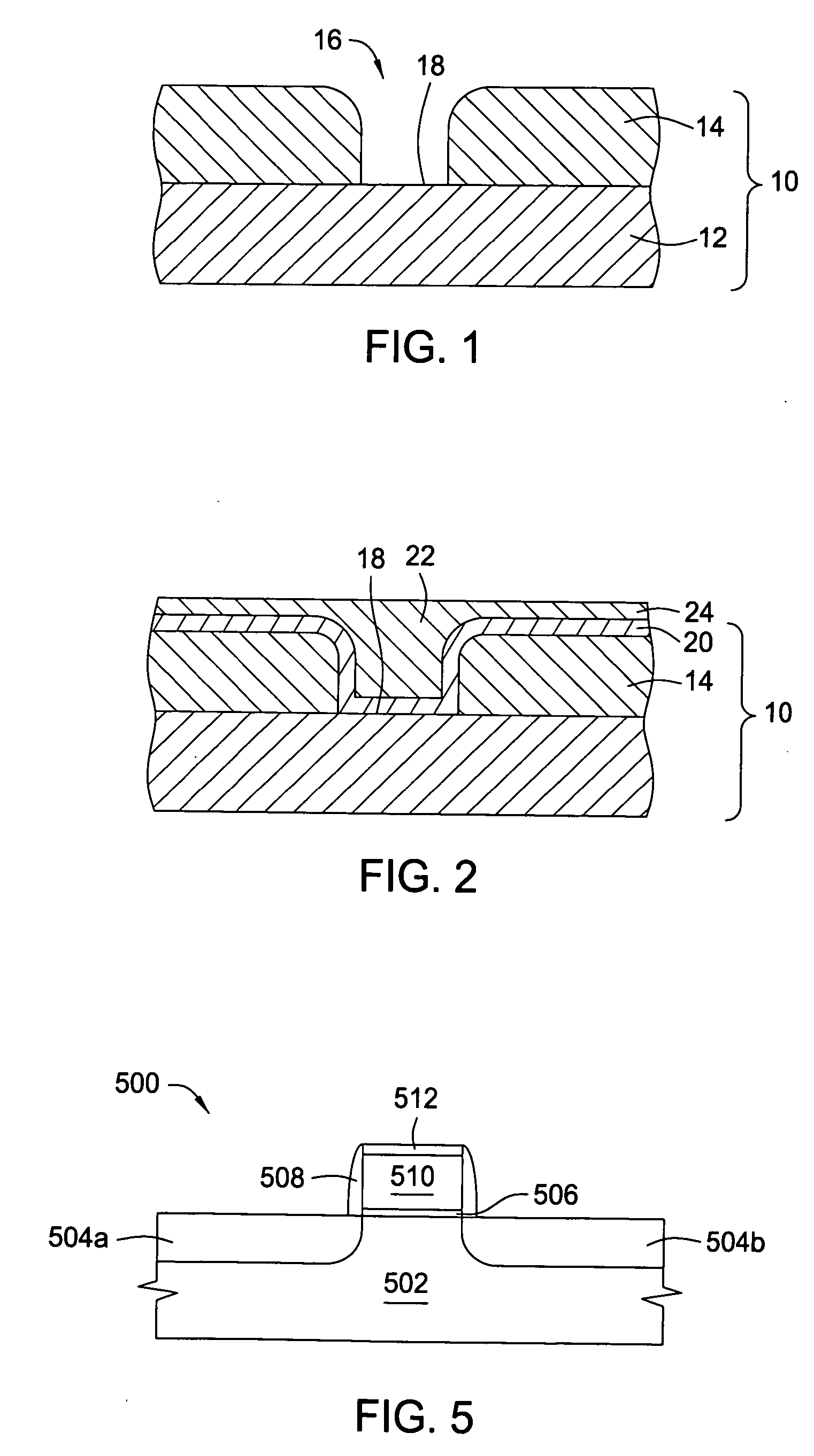

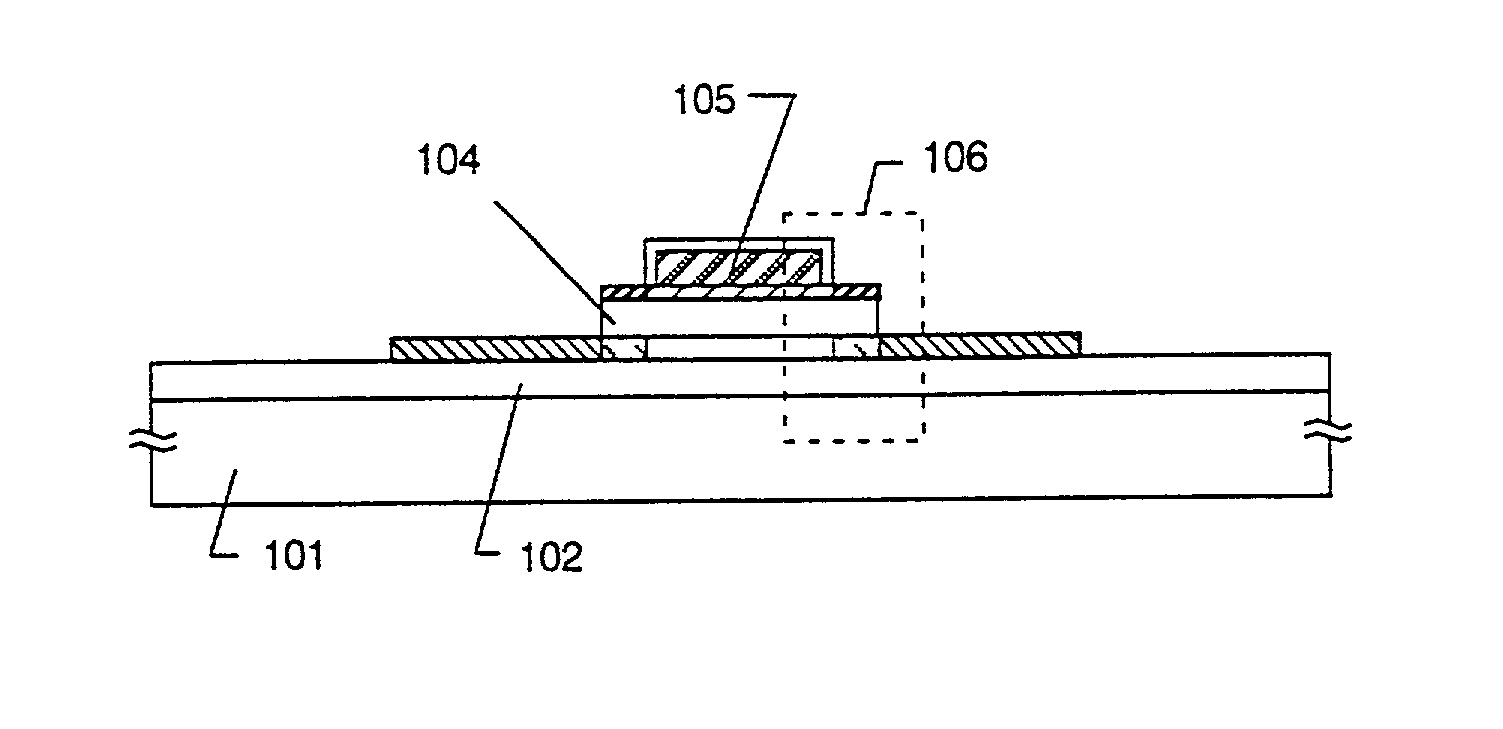

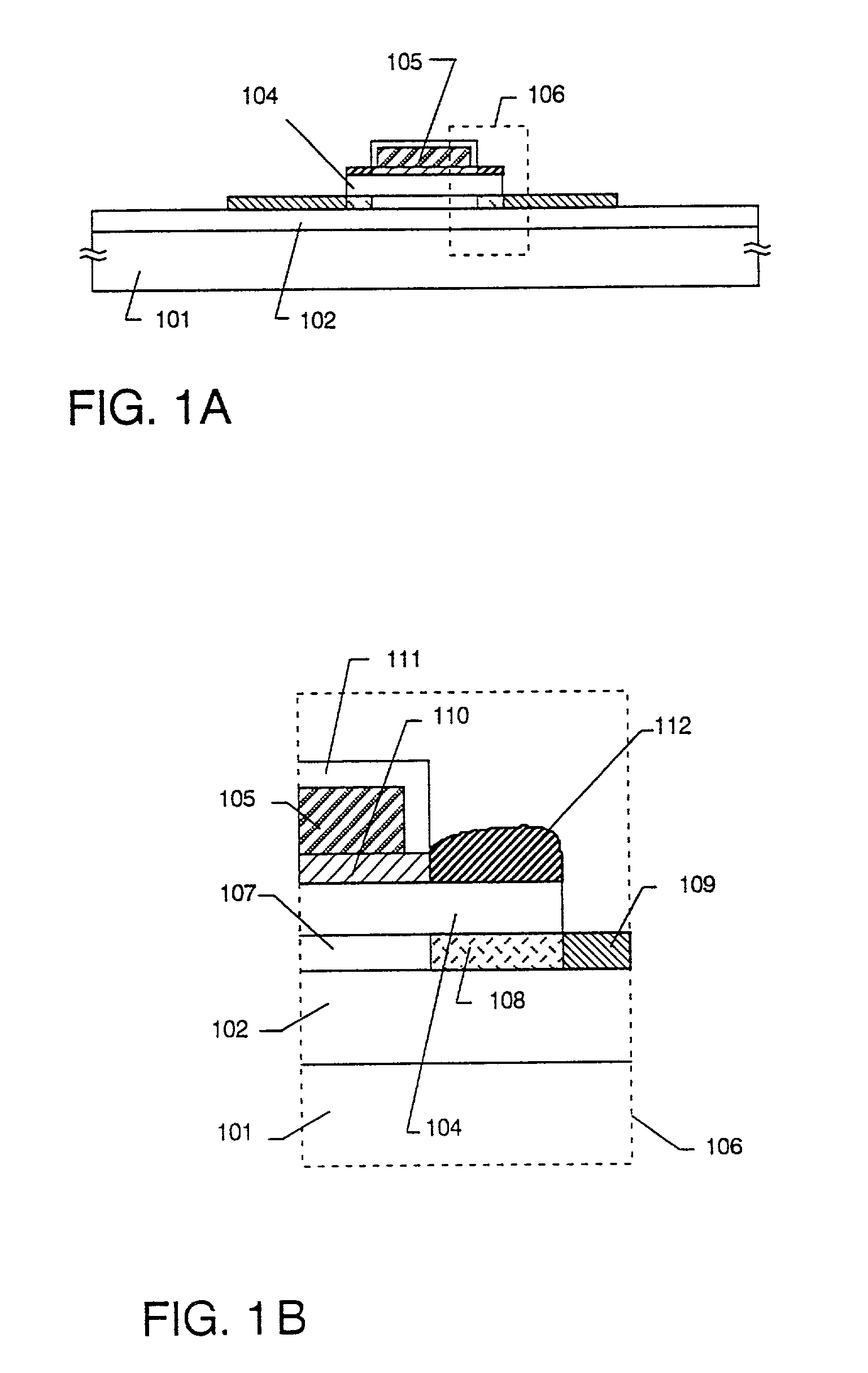

Semiconductor device and method of manufacturing the semiconductor device

InactiveUS20020096681A1TransistorSemiconductor/solid-state device manufacturingActive layerIon implantation

A TFT using an aluminum material for a gate electrode is manufactured at a high yield factor. The gate electrode provided over an active layer and a gate insulating film is constituted by a lamination film of a tantalum layer and an aluminum layer. In this structure, the tantalum layer functions as a stopper, so that it is possible to prevent a constituent material of the aluminum layer from intruding into the gate insulating film. An end portion of the tantalum layer is transformed into tantalum oxide, which has an effect to lower damage at ion implantation to the gate insulating film in the formation of an LDD region.

Owner:SEMICON ENERGY LAB CO LTD

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

Niobium powder and a process for the production of niobium and/or tantalum powders

InactiveUS6136062APrevent local overheating effectStirring speed is fastElectrolytic capacitorsTantalum compoundsMischmetalRare earth

The process comprises the reduction of niobium and / or tantalum oxides by means of alkaline earth metals and / or rare earth metals, wherein the first reduction stage is carried out as far as an average composition corresponding to (Nb, Ta)Ox where x=0.5 to 1.5 and before the second stage the reduction product from the first stage is freed from alkaline earth oxides and / or rare earth metal oxides which are formed (and optionally from excess alkaline earth metal and / or rare earth metal) by washing with mineral acids.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

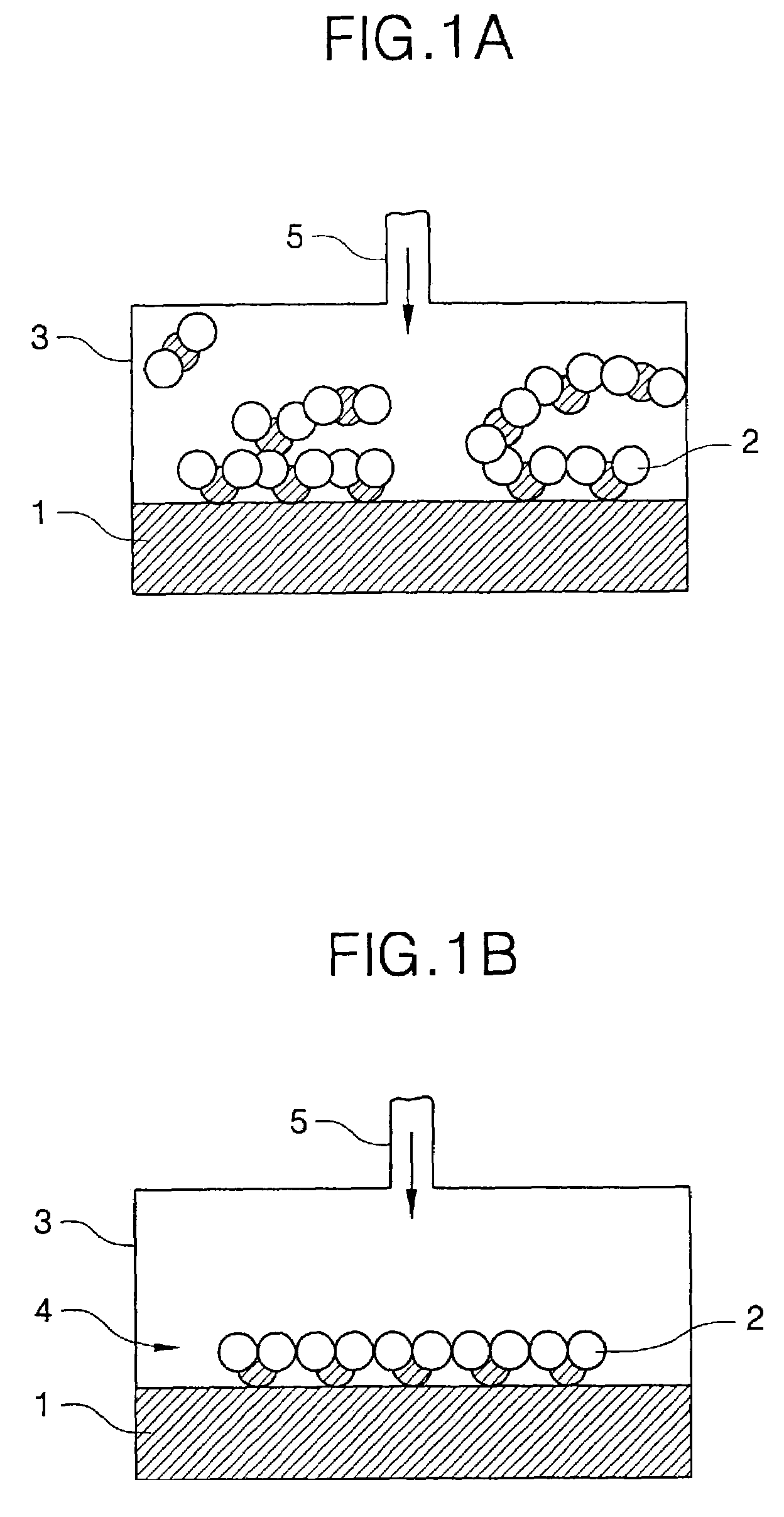

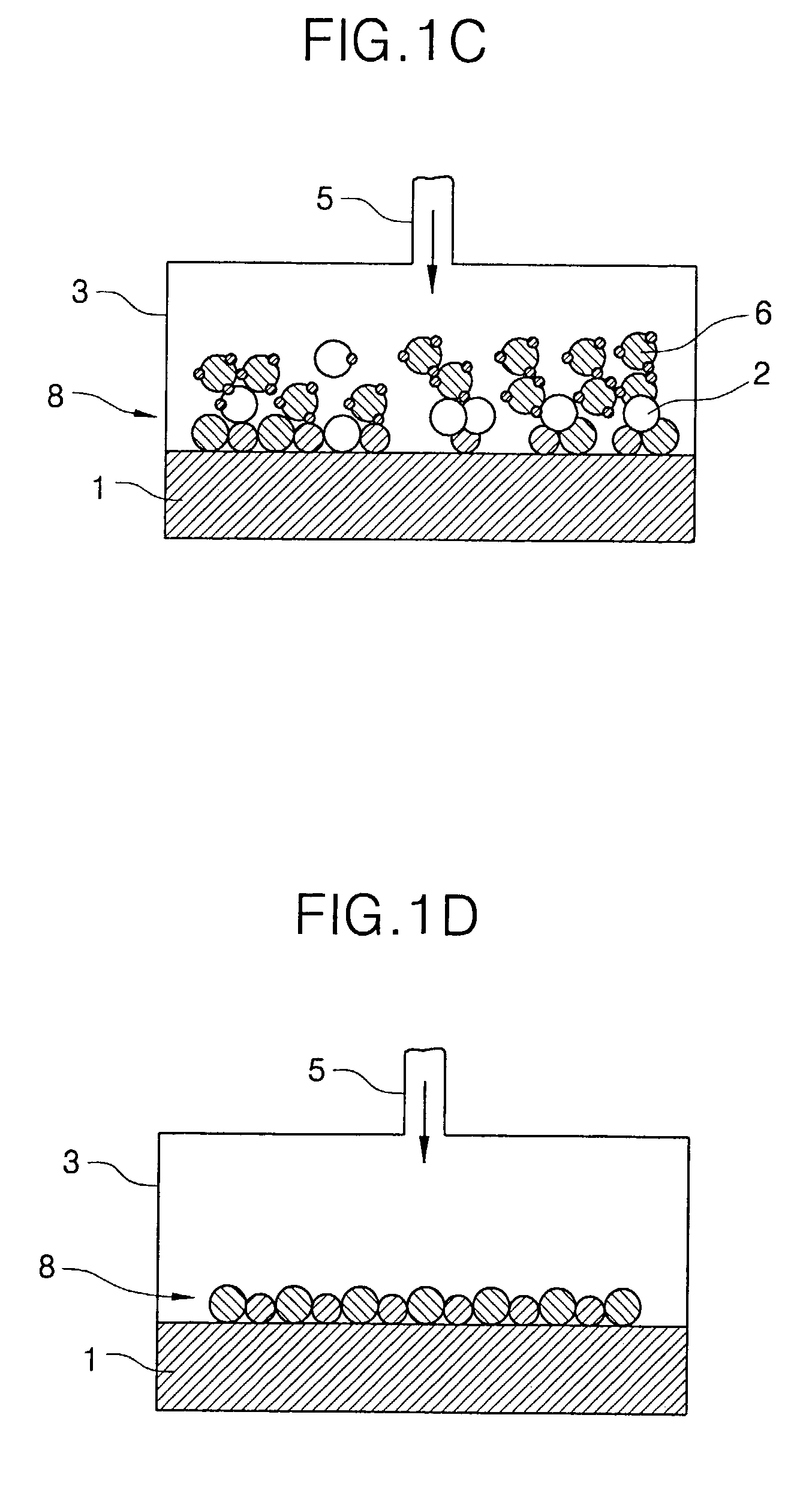

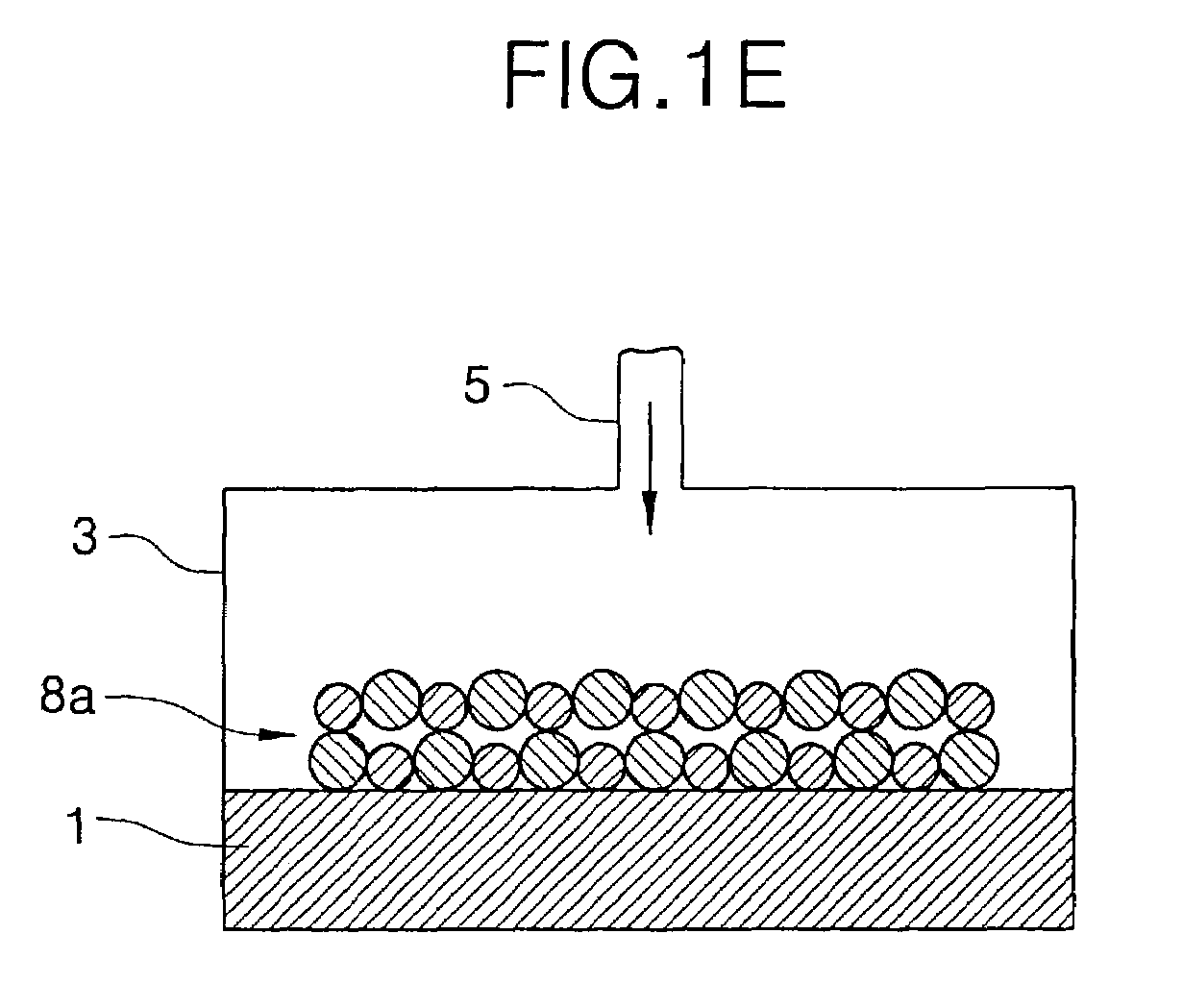

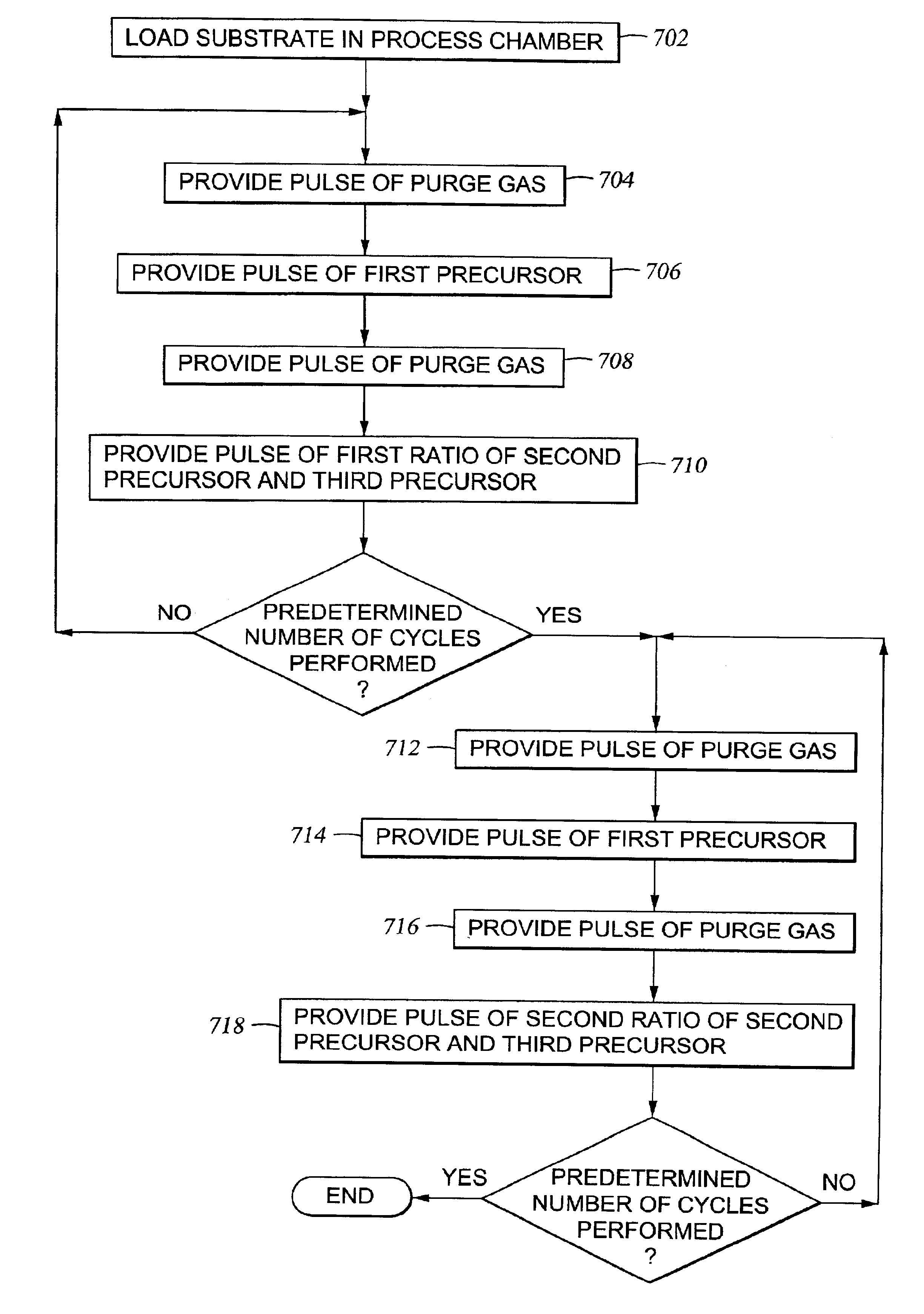

Multiple precursor cyclical deposition system

Embodiments of the present invention relate to an apparatus and method of cyclical deposition utilizing three or more precursors in which delivery of at least two of the precursors to a substrate structure at least partially overlap. One embodiment of depositing a ternary material layer over a substrate structure comprises providing at least one cycle of gases to deposit a ternary material layer. One cycle comprises introducing a pulse of a first precursor, introducing a pulse of a second precursor, and introducing a pulse of a third precursor in which the pulse of the second precursor and the pulse of the third precursor at least partially overlap. In one aspect, the ternary material layer includes, but is not limited to, tungsten boron silicon (WBxSiy), titanium silicon nitride (TiSixNy), tantalum silicon nitride (TaSixNy), silicon oxynitride (SiOxNy), and hafnium silicon oxide (HfSixOy). In one aspect, the composition of the ternary material layer may be tuned by changing the flow ratio of the second precursor to the third precursor between cycles.

Owner:APPLIED MATERIALS INC

Integration of ALD tantalum nitride and alpha-phase tantalum for copper metallization application

InactiveUS20030124262A1Pretreated surfacesSemiconductor/solid-state device manufacturingMetal interconnectTantalum nitride

Owner:APPLIED MATERIALS INC

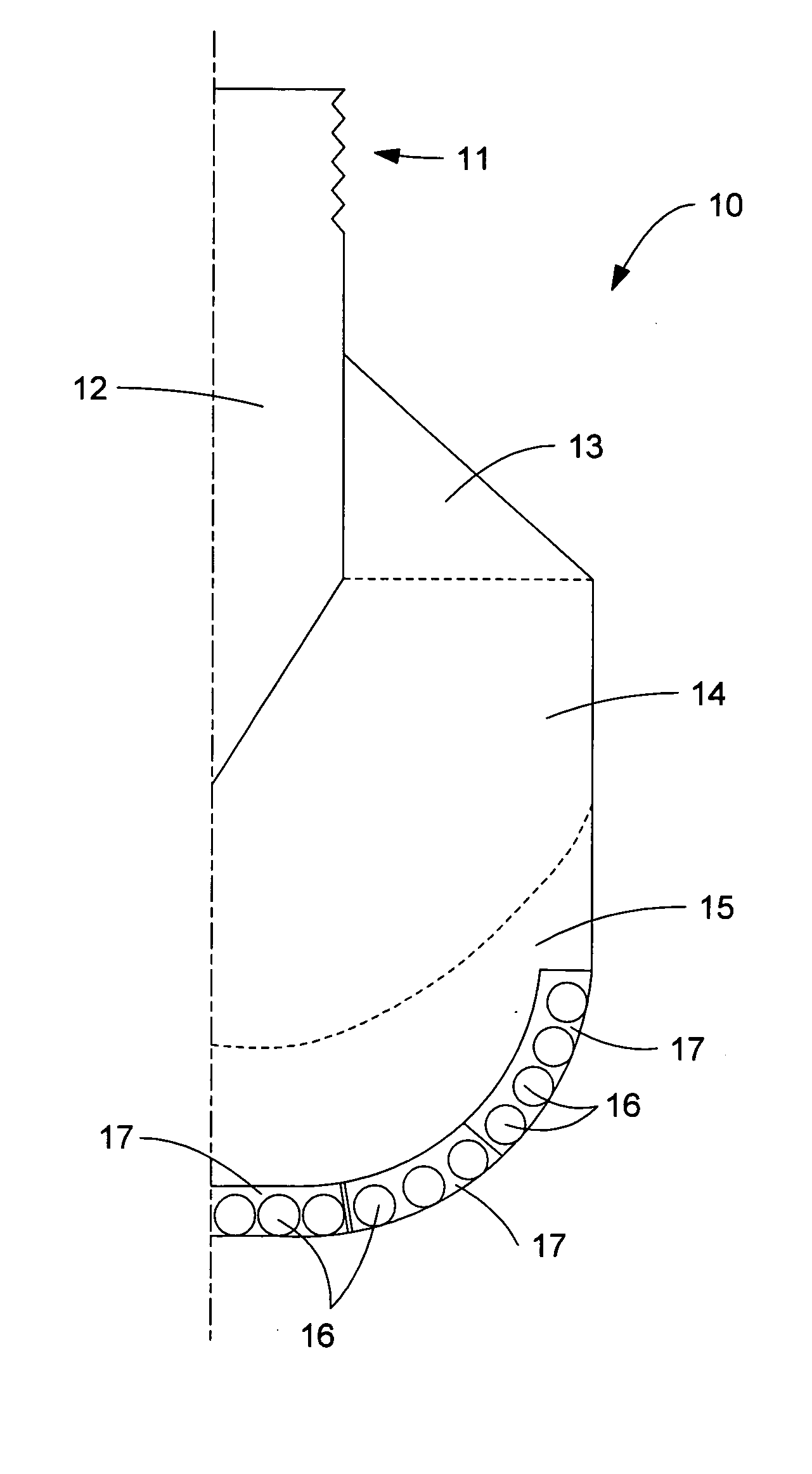

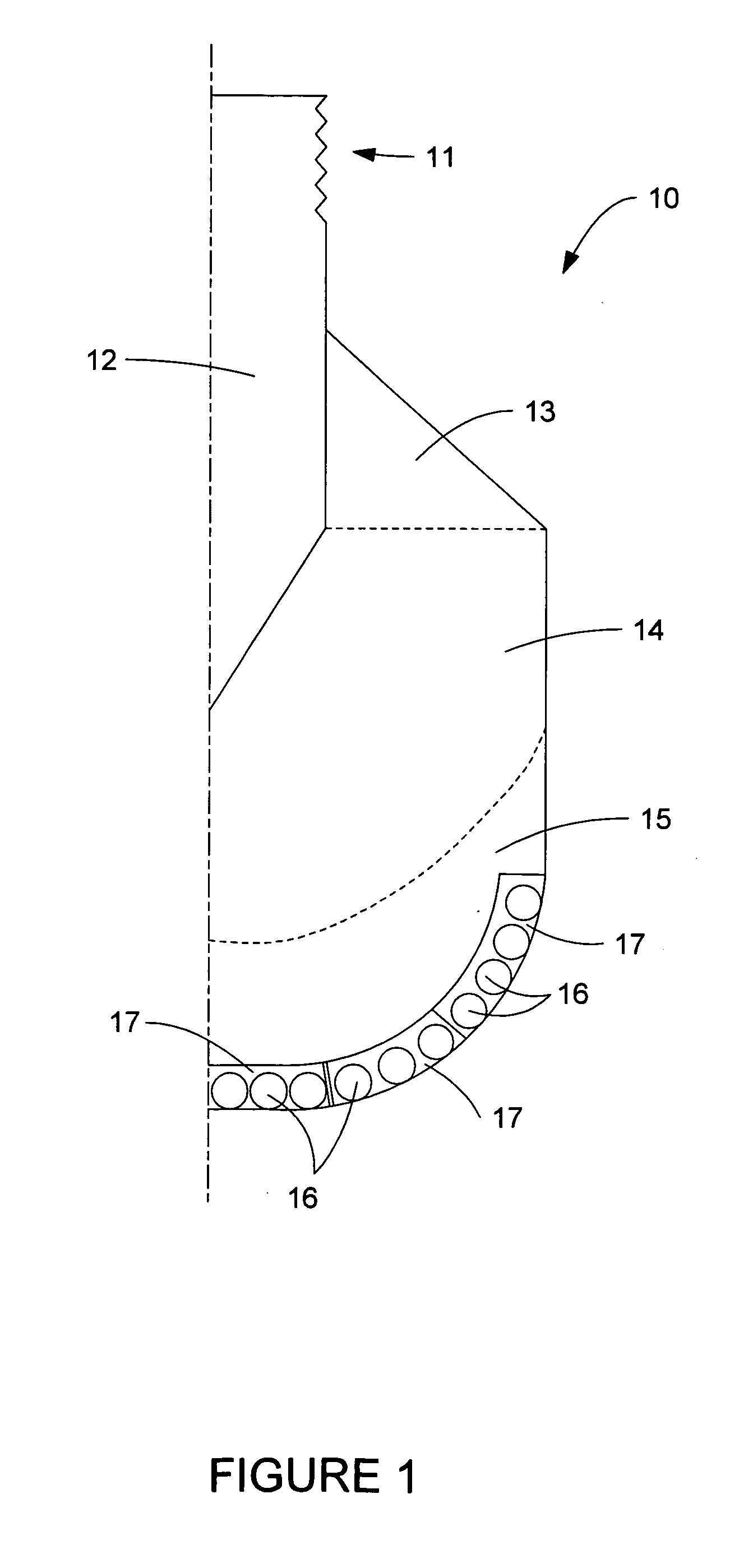

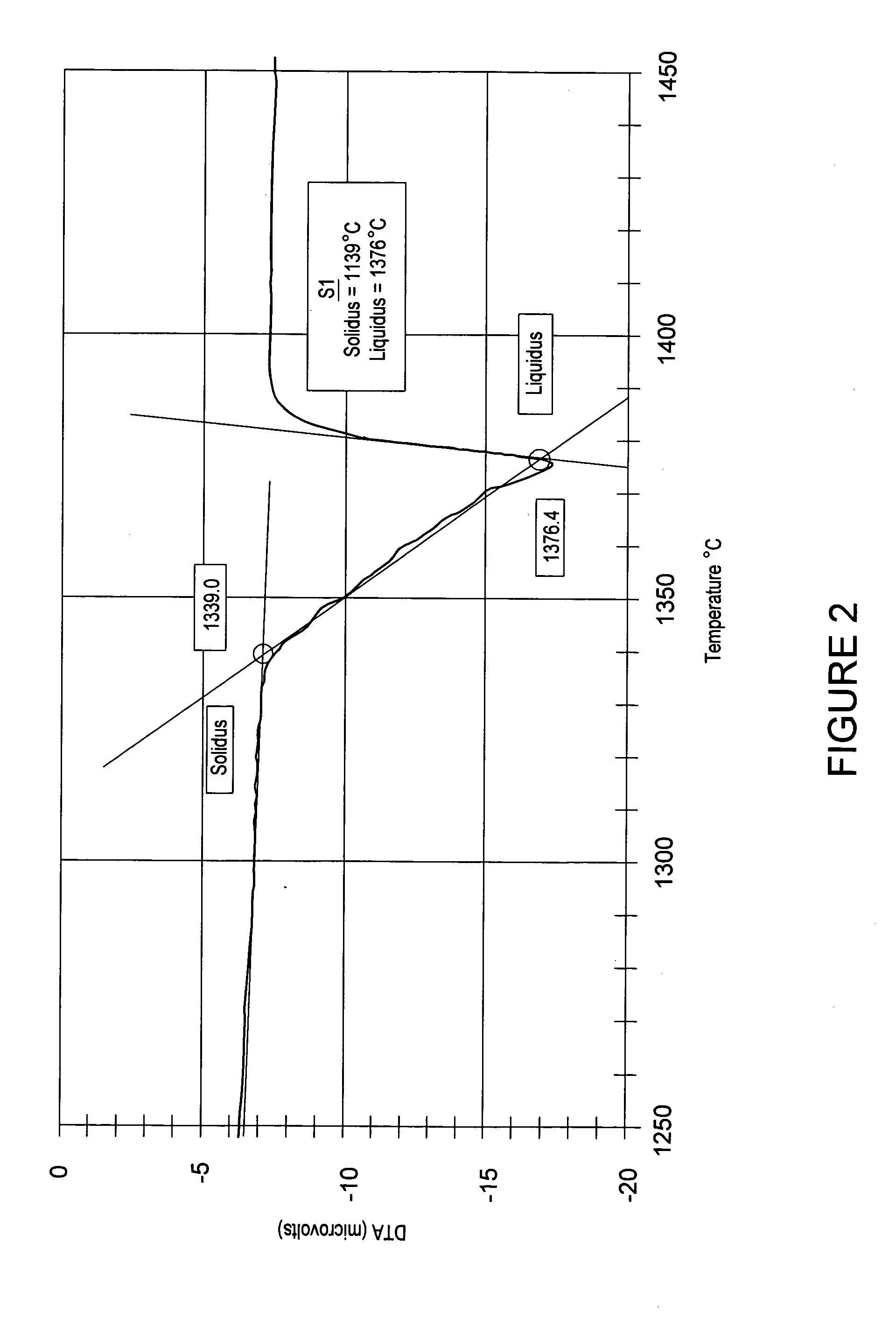

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

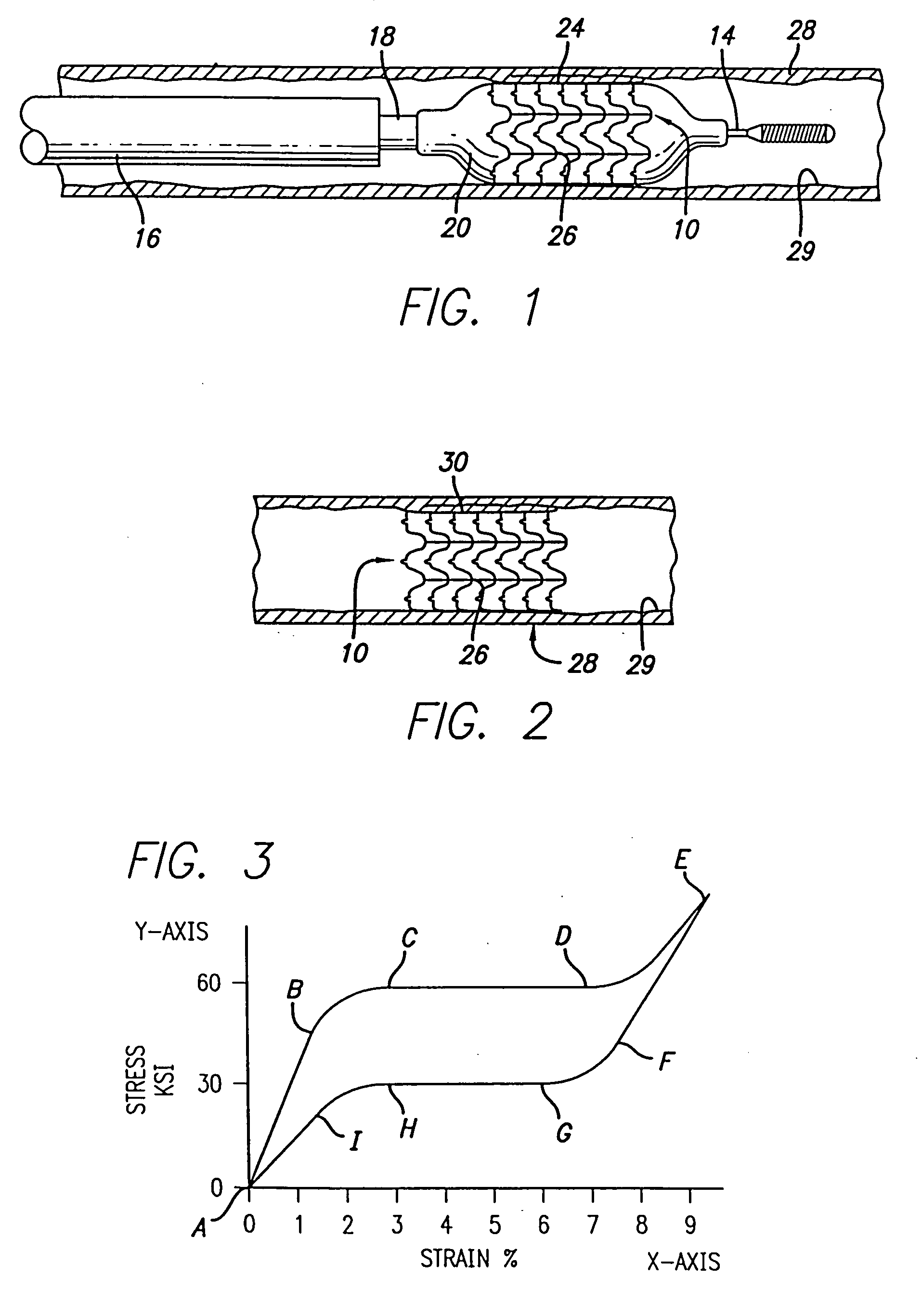

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

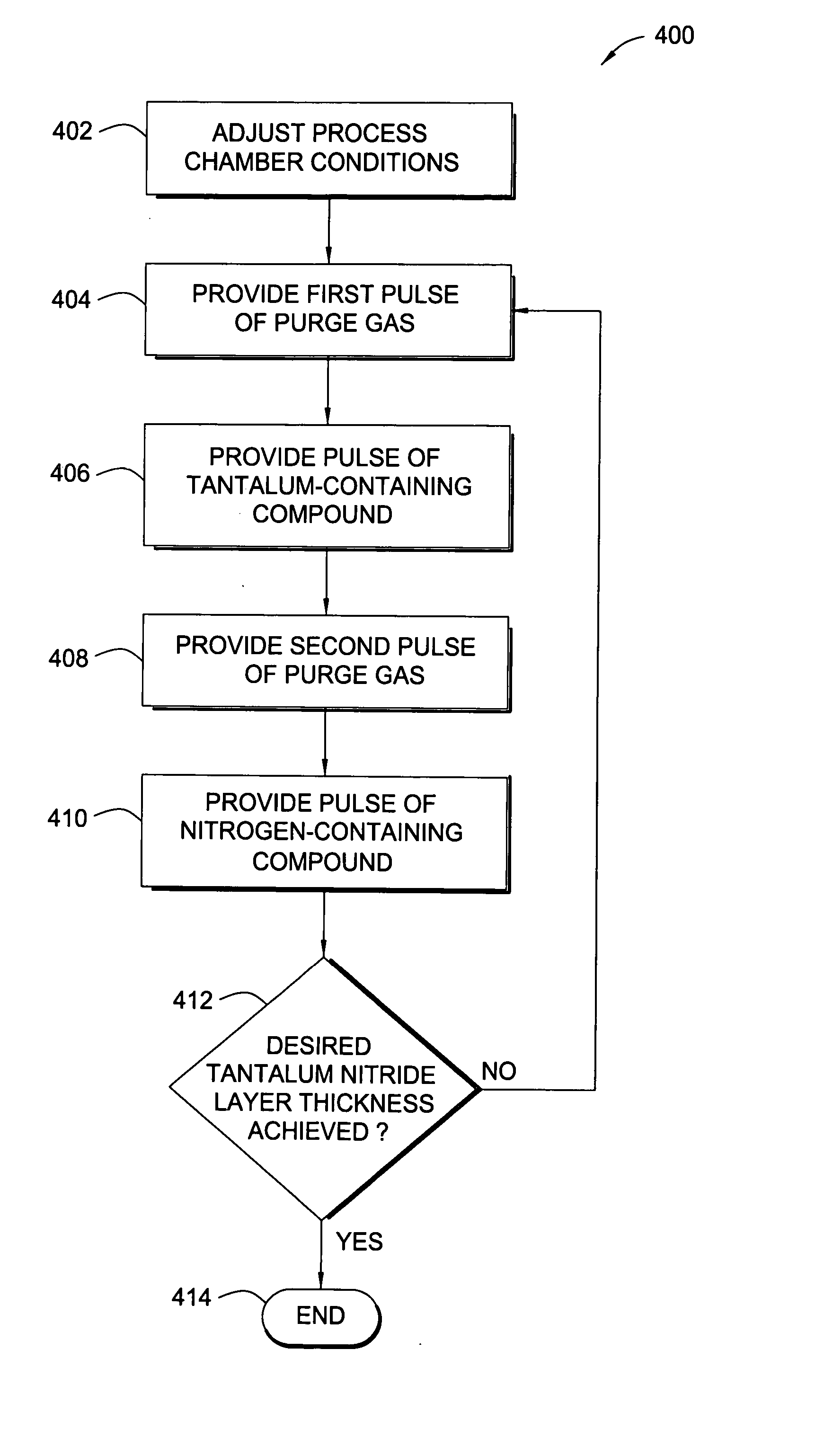

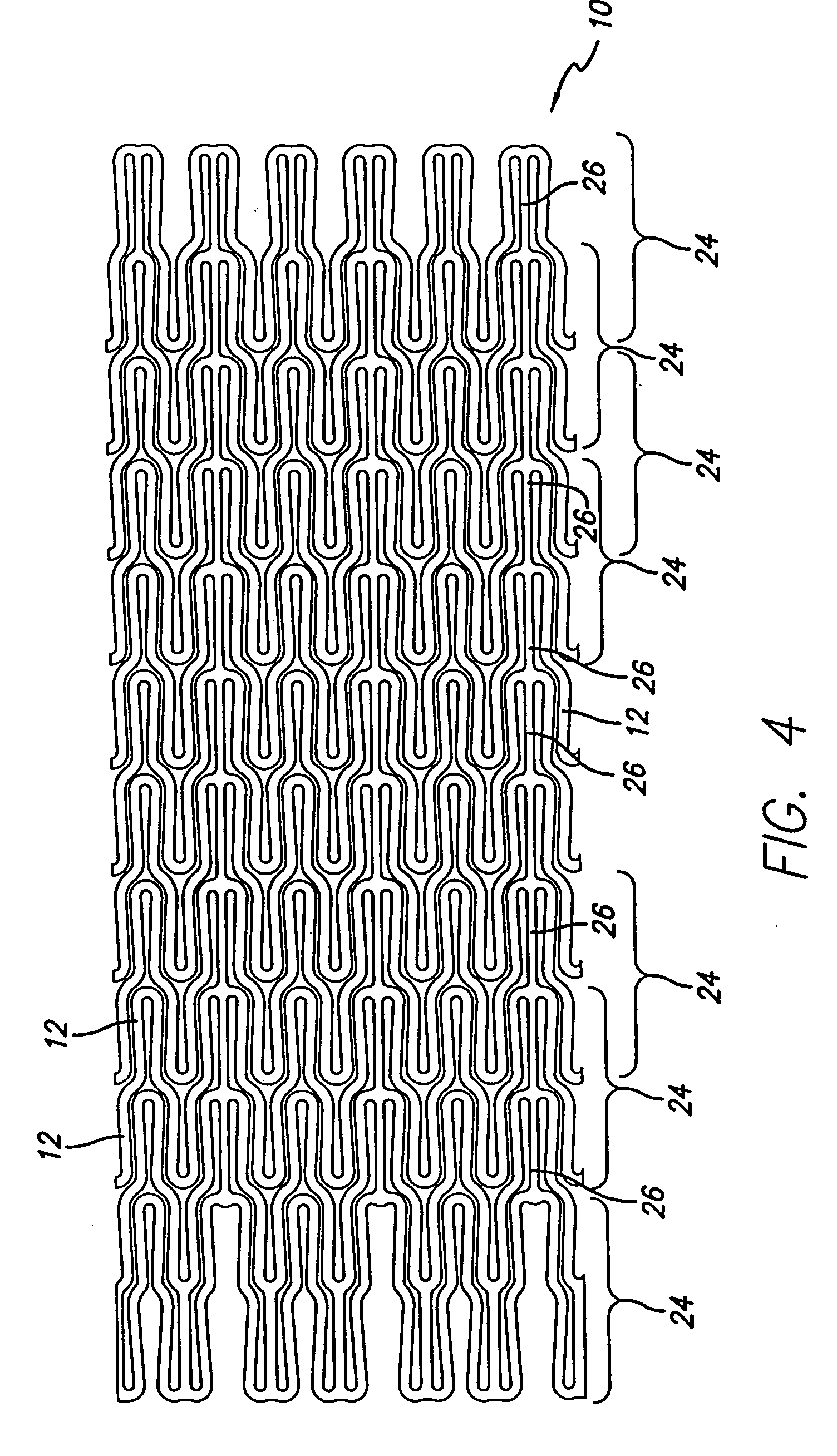

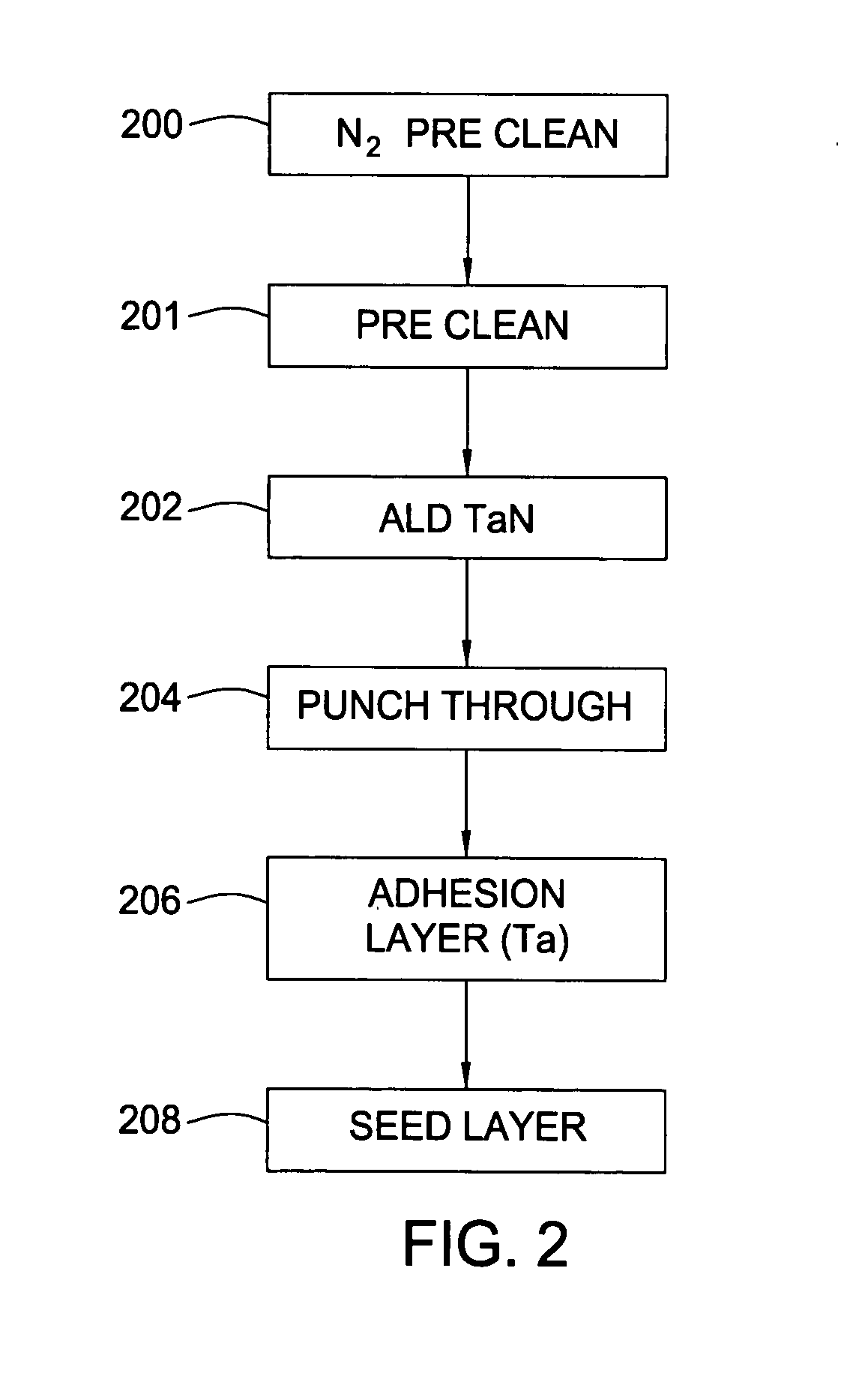

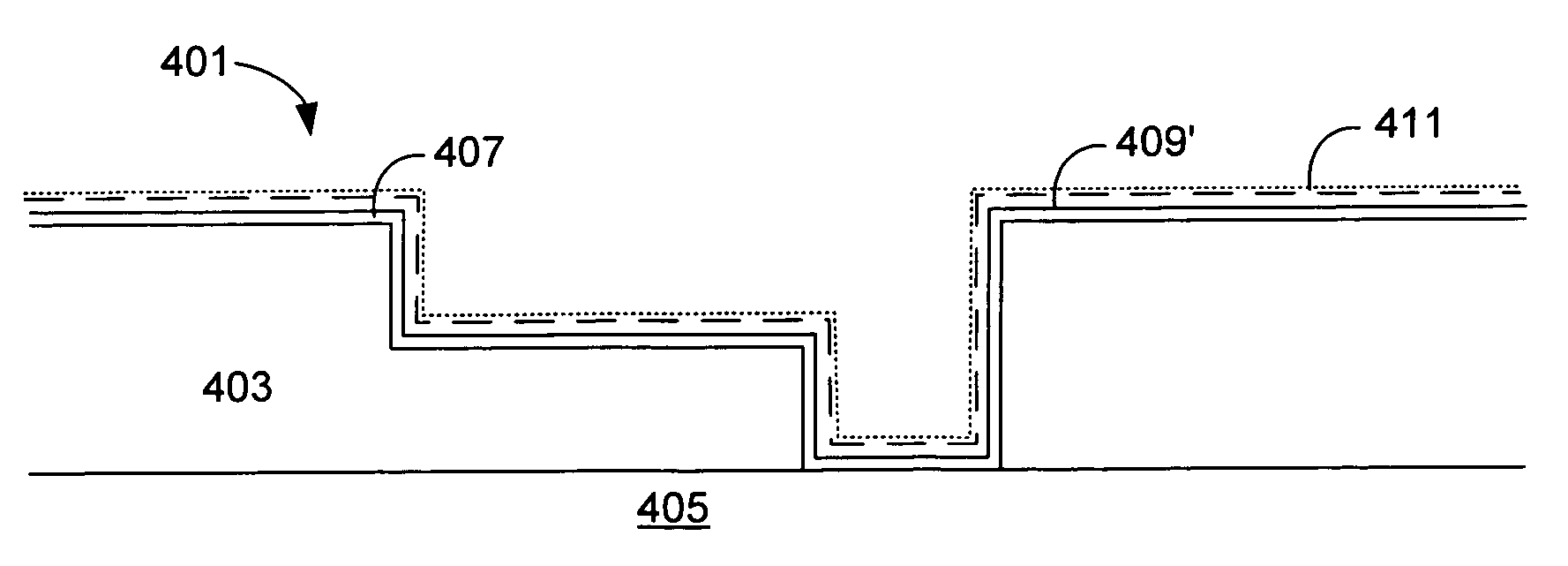

Integration of ALD tantalum nitride for copper metallization

InactiveUS20050106865A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideConductive materials

A method and apparatus for depositing a tantalum nitride barrier layer is provided for use in an integrated processing tool. The tantalum nitride is deposited by atomic layer deposition. The tantalum nitride is removed from the bottom of features in dielectric layers to reveal the conductive material under the deposited tantalum nitride. Optionally, a tantalum layer may be deposited by physical vapor deposition after the tantalum nitride deposition. Optionally, the tantalum nitride deposition and the tantalum deposition may occur in the same processing chamber.

Owner:APPLIED MATERIALS INC

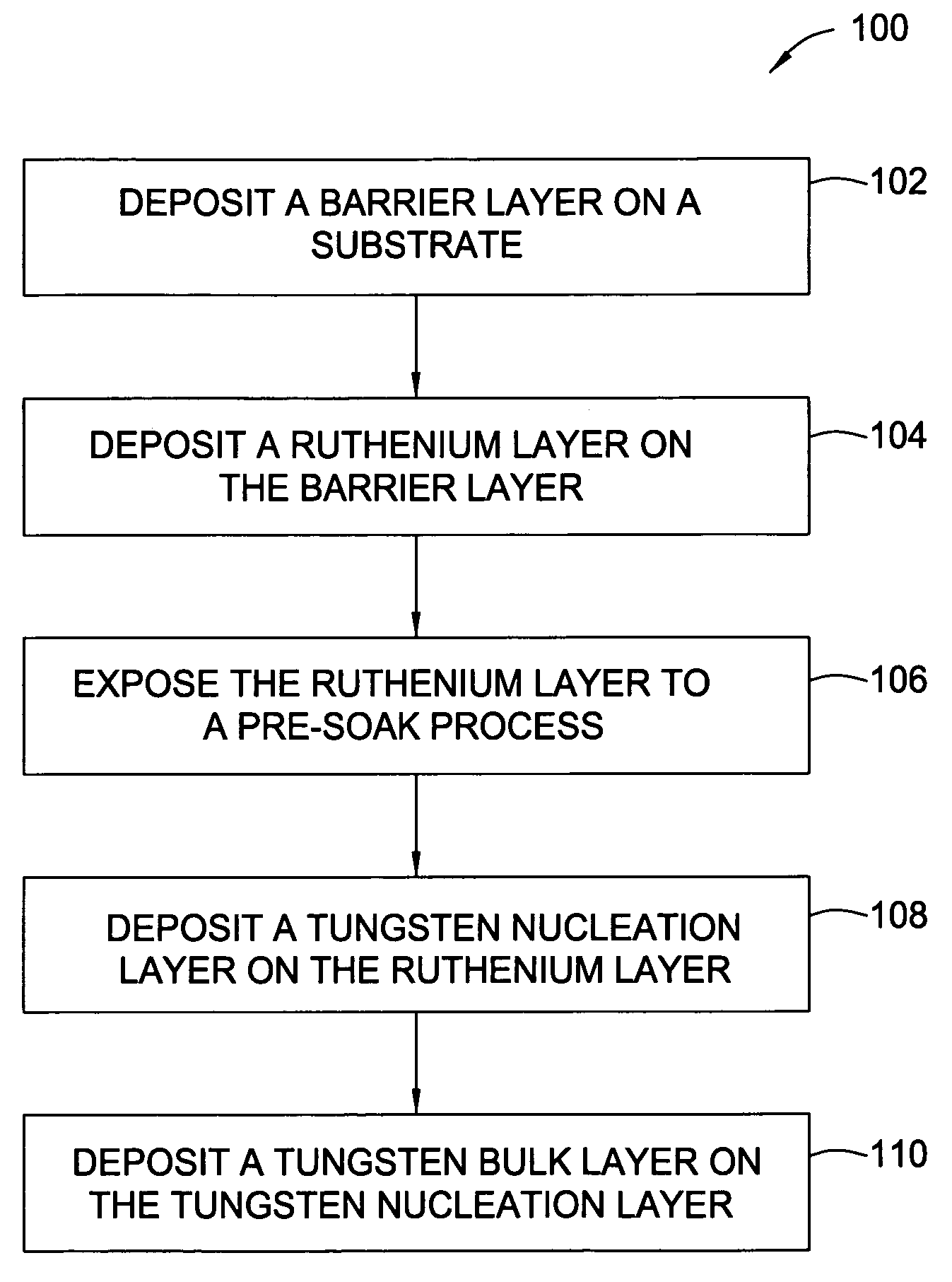

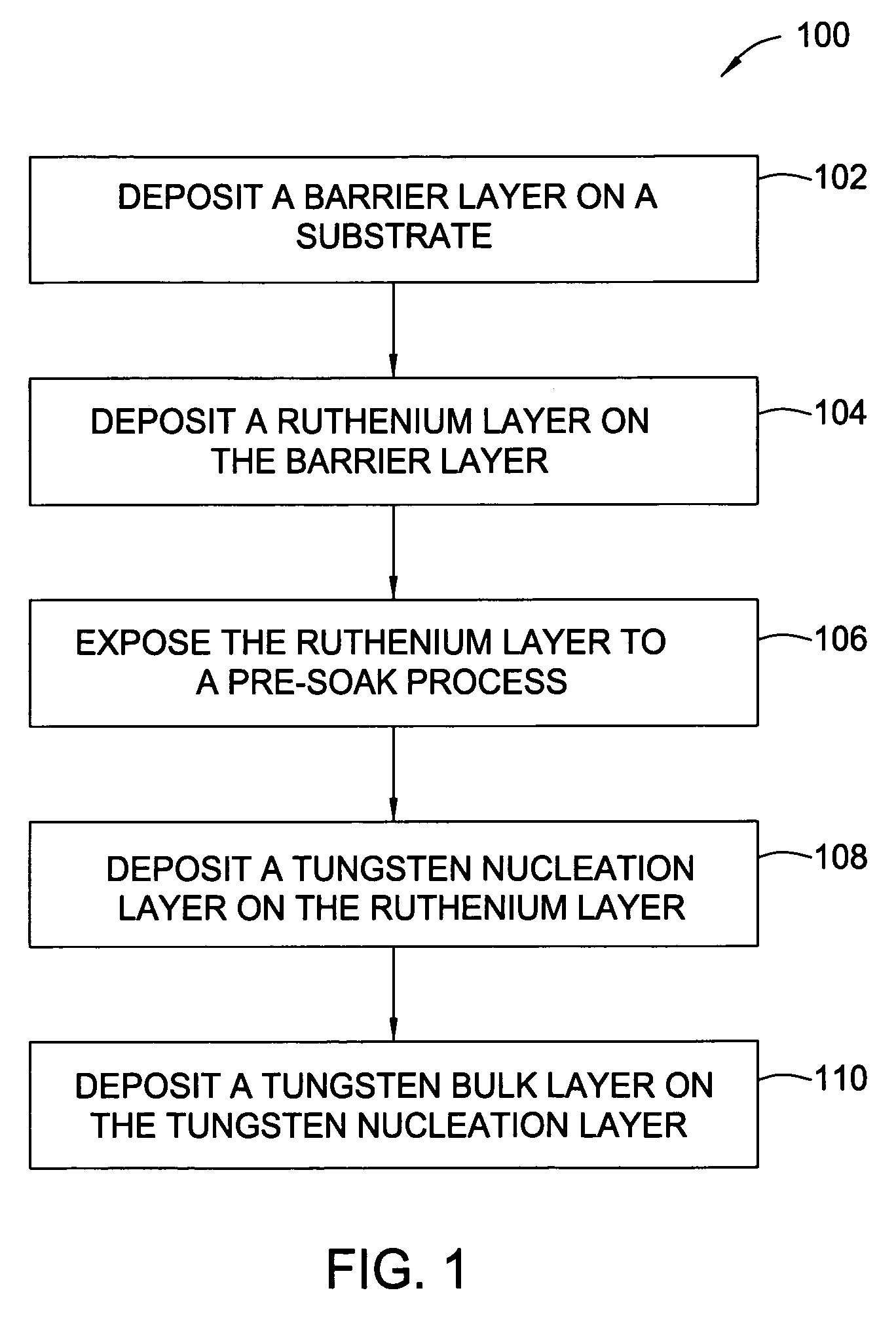

Ruthenium as an underlayer for tungsten film deposition

InactiveUS20060128150A1Semiconductor/solid-state device manufacturingSpecial surfacesRutheniumTitanium

In one embodiment, a method for depositing a tungsten-containing film on a substrate is provided which includes depositing a barrier layer on the substrate, such as a titanium or tantalum containing barrier layer and depositing a ruthenium layer on the barrier layer. The method further includes depositing a tungsten nucleation layer on the ruthenium layer and depositing a tungsten bulk layer on the tungsten nucleation layer. The barrier layer, the ruthenium layer, the tungsten nucleation layer and the tungsten bulk layer are independently deposited by an ALD process, a CVD process or a PVD process, preferably by an ALD process. In some examples, the substrate is exposed to a soak process prior to depositing a subsequent layer, such as between the deposition of the barrier layer and the ruthenium layer, the ruthenium layer and the tungsten nucleation layer or the tungsten nucleation layer and the tungsten bulk layer.

Owner:APPLIED MATERIALS INC

Systems and methods of forming refractory metal nitride layers using disilazanes

InactiveUS7122464B2Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsGas phaseDeposition process

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum (silicon) nitride barrier layer, on a substrate by using a vapor deposition process with a refractory metal precursor compound, a disilazane, and an optional silicon precursor compound.

Owner:MICRON TECH INC

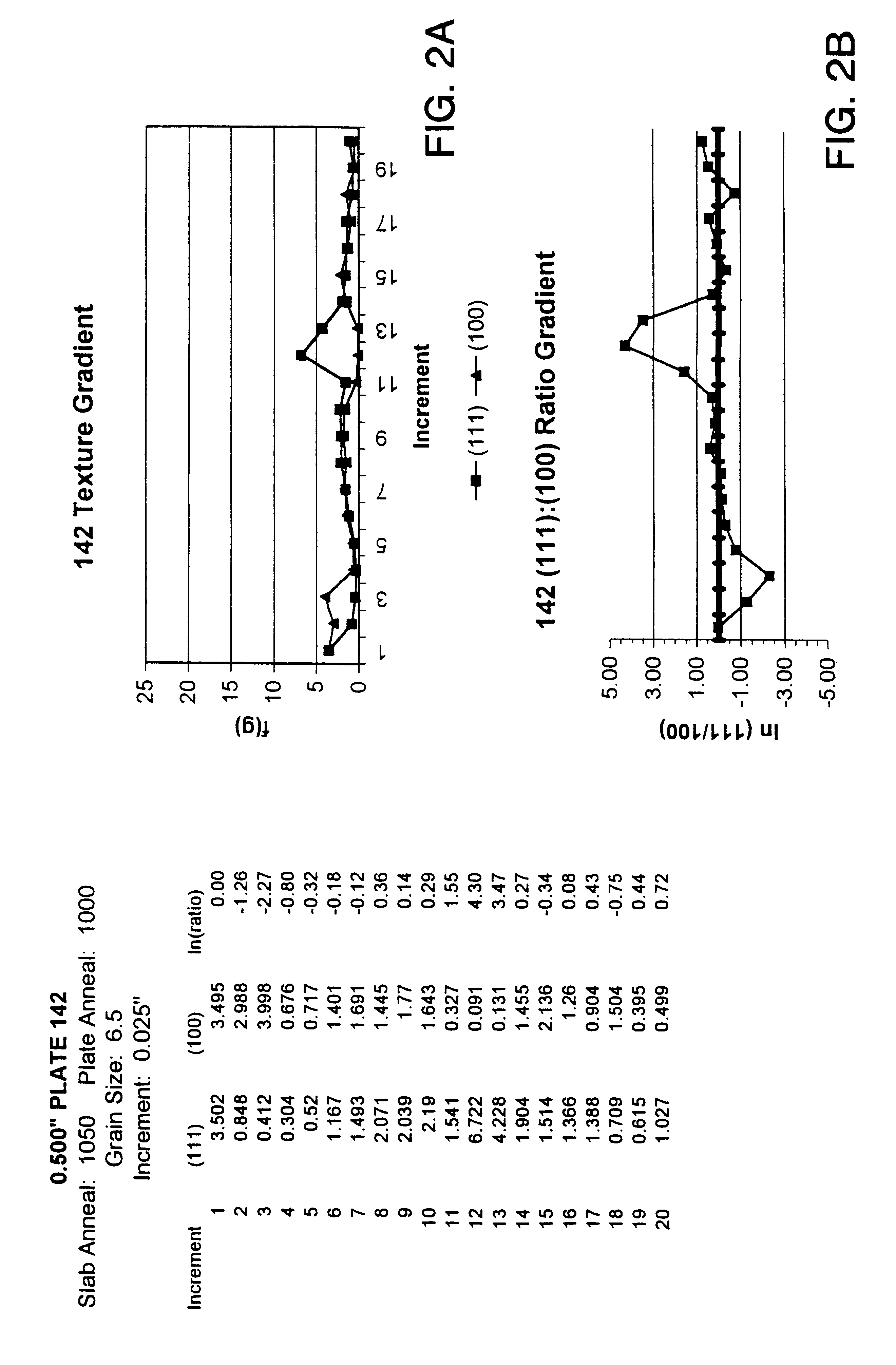

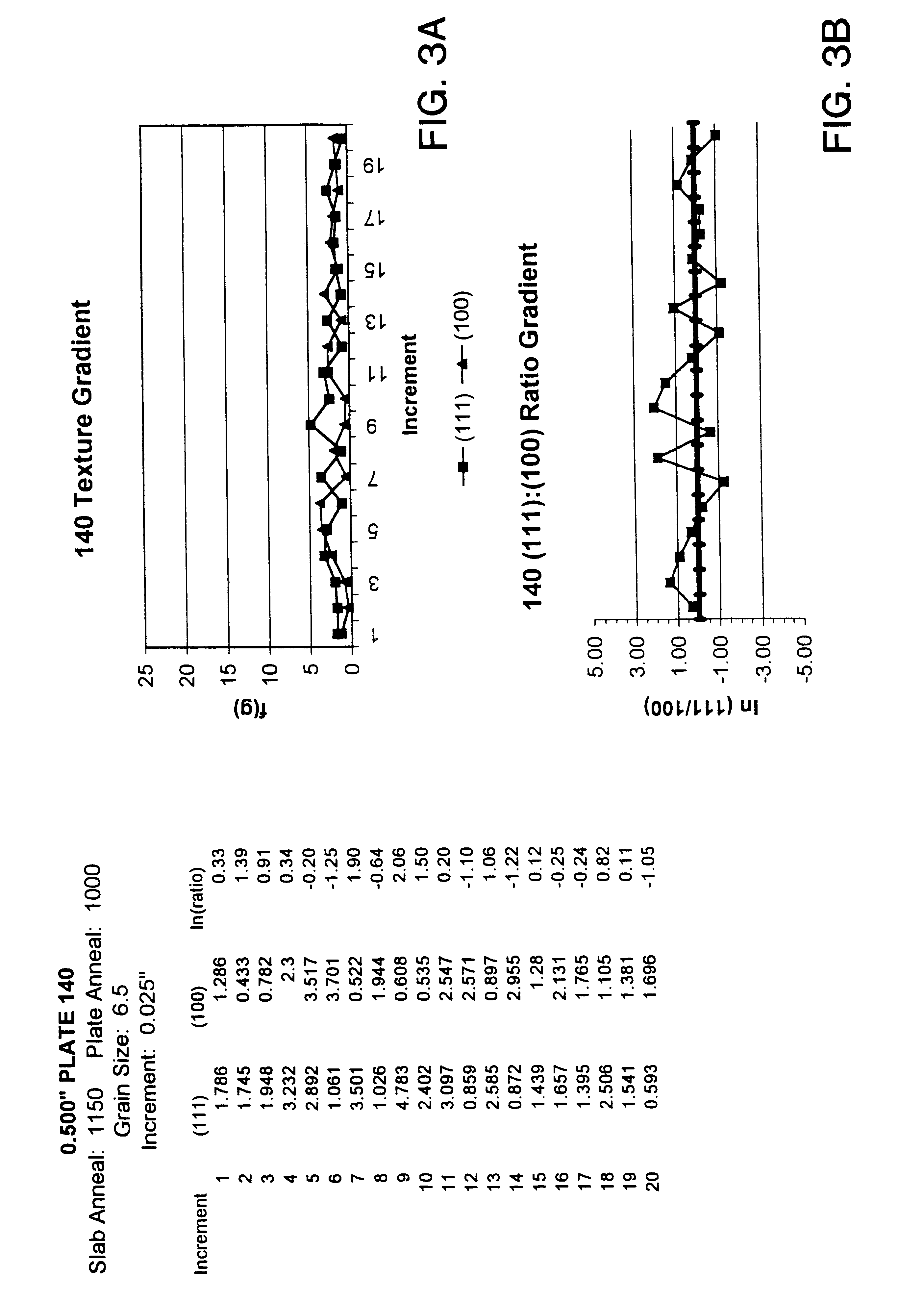

High purity tantalum, products containing the same, and methods of making the same

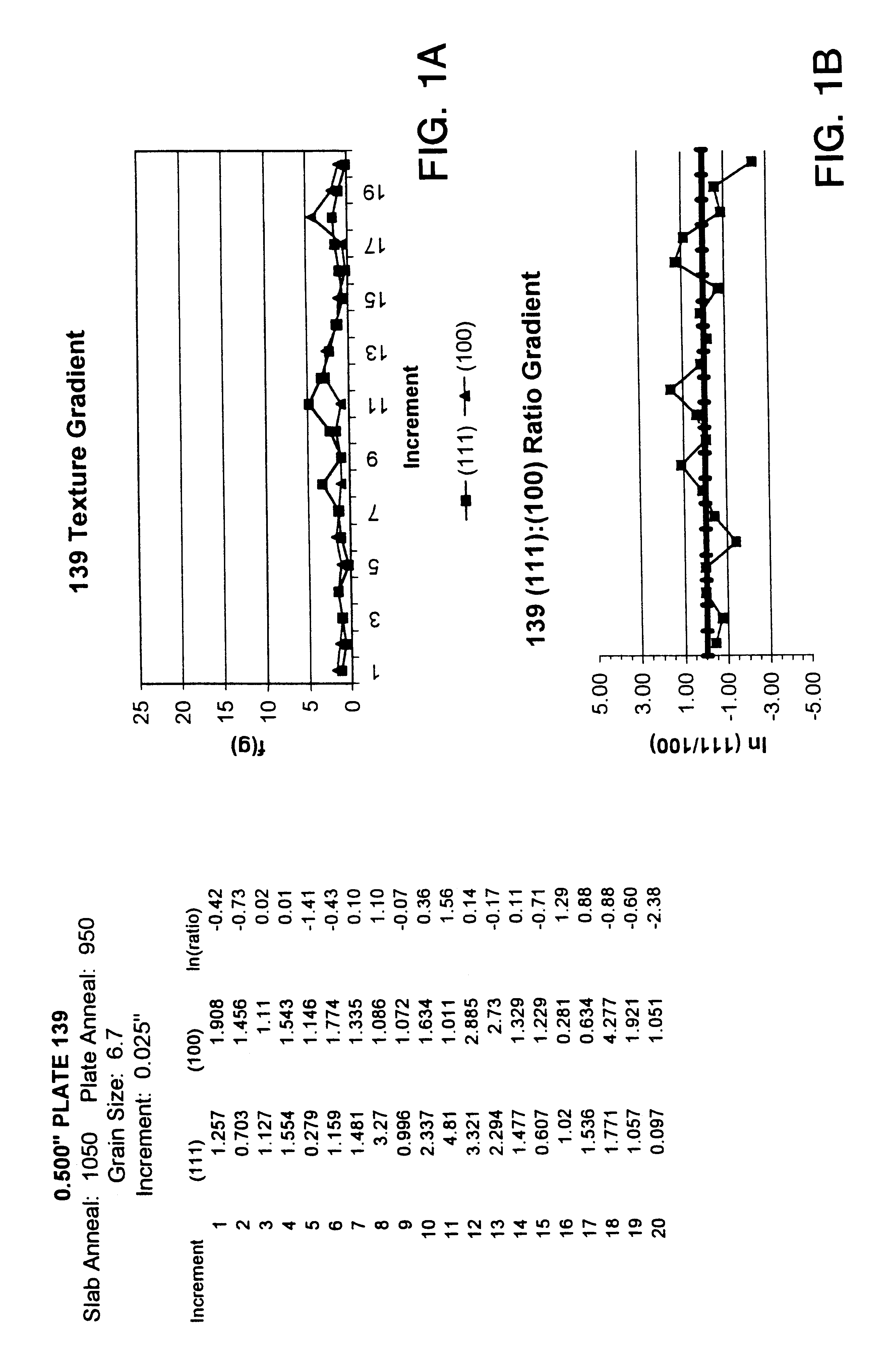

InactiveUS6348113B1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingMetallic materialsUltimate tensile strength

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995% and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

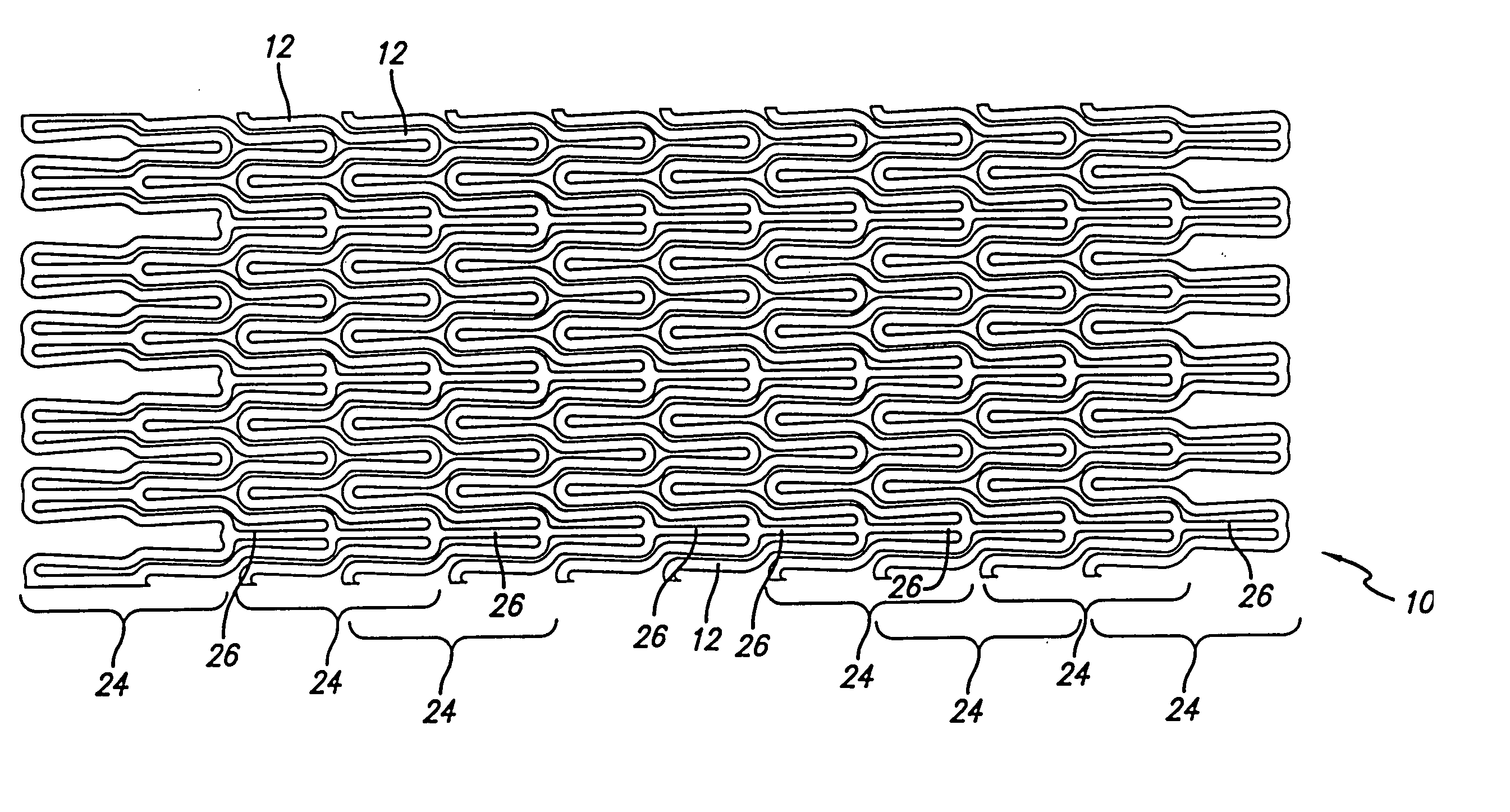

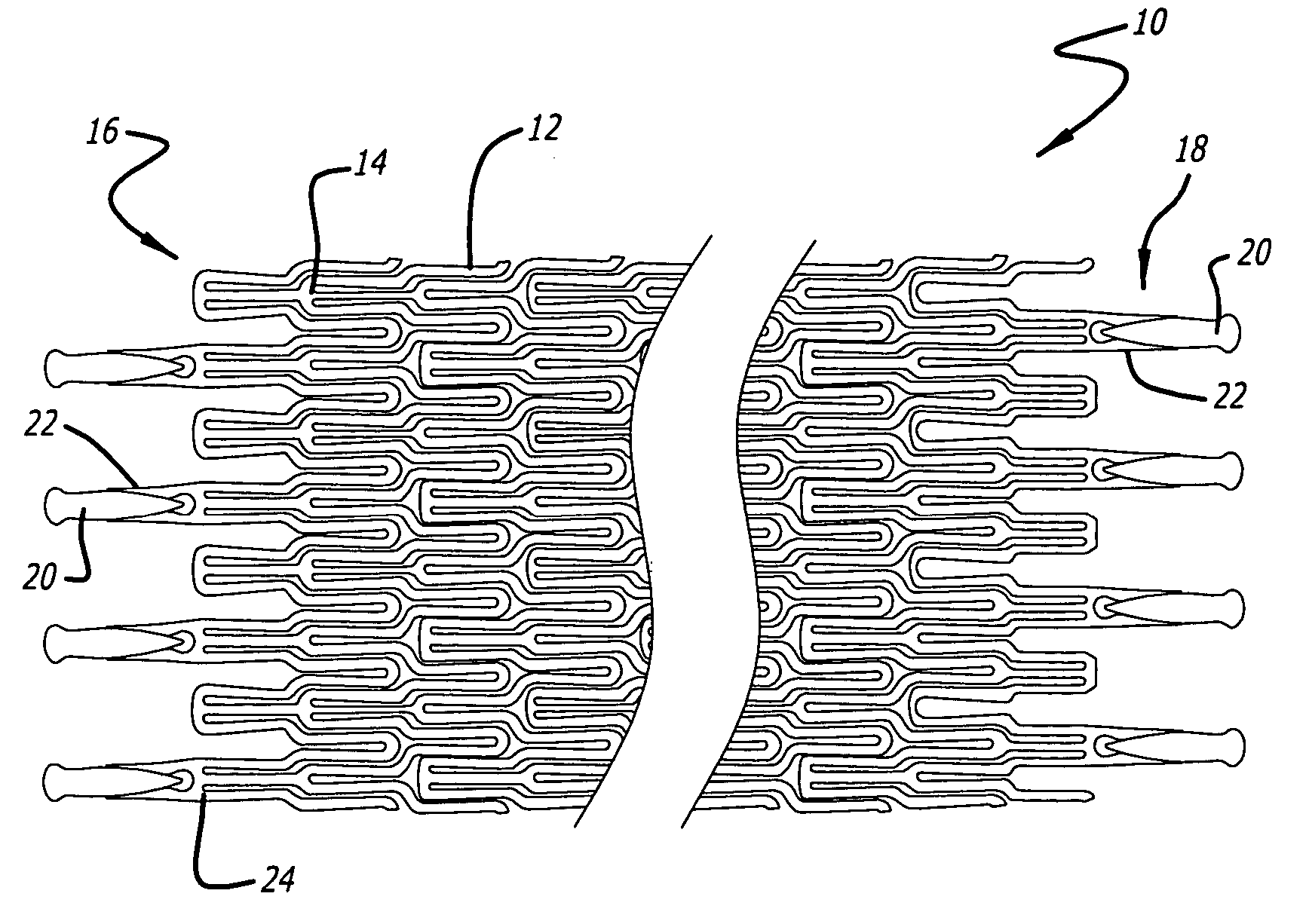

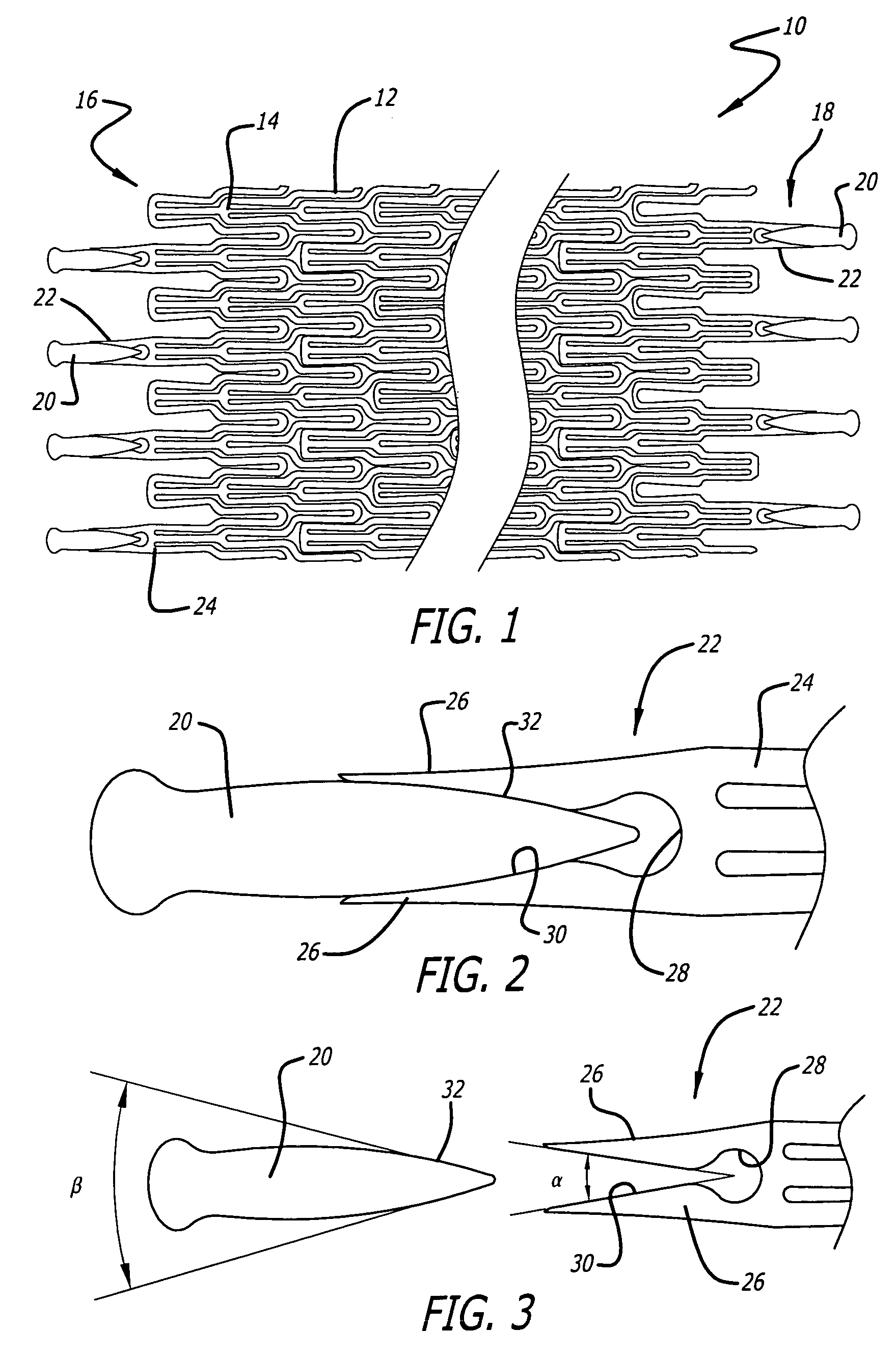

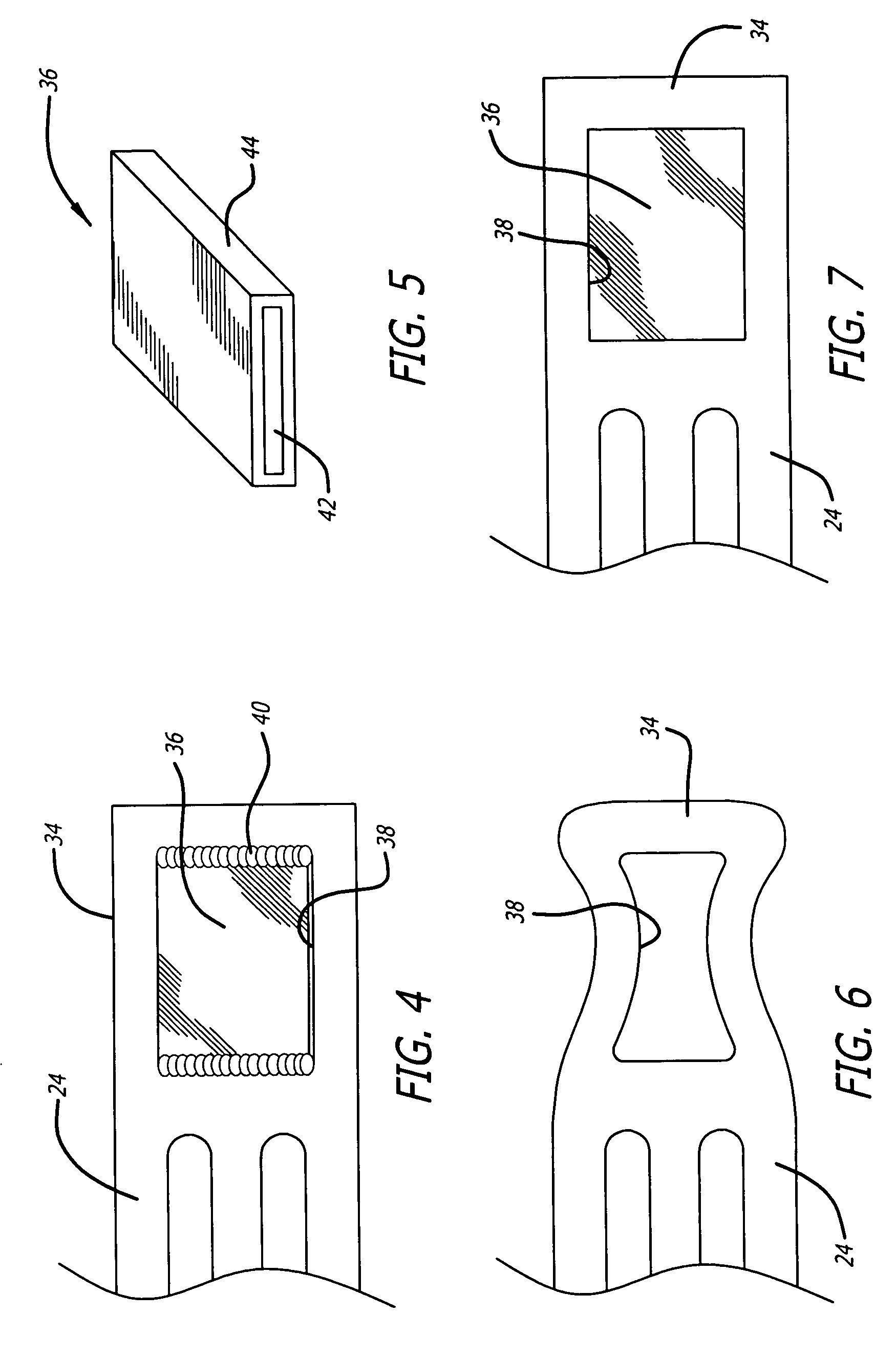

Radiopaque markers for medical devices

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

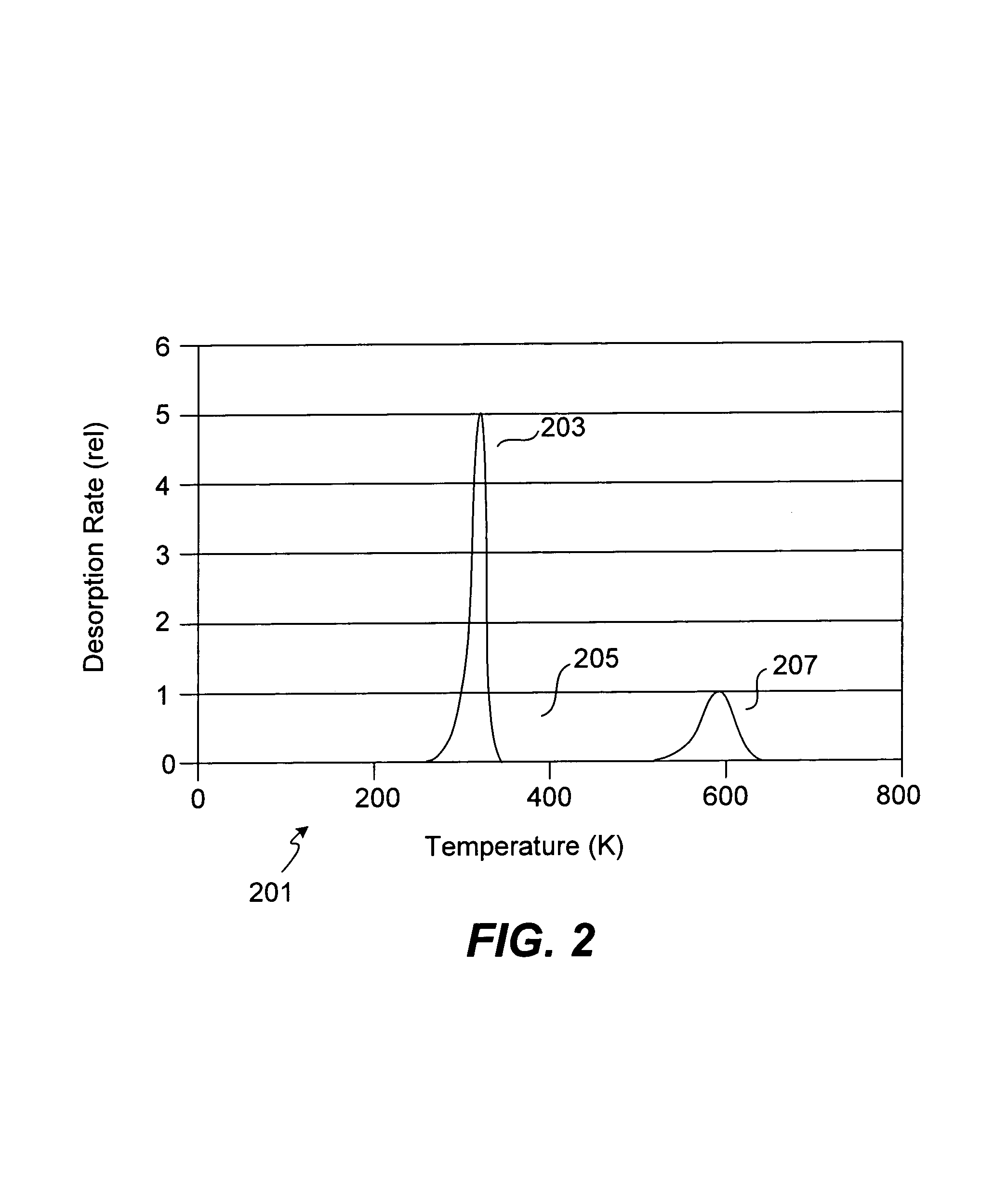

ALD of tantalum using a hydride reducing agent

InactiveUS7144806B1Reducing hydrideSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenTantalum nitride

An ALD method deposits conformal tantalum-containing material layers on small features of a substrate surface. The method includes the following principal operations: depositing a thin conformal and saturated layer of tantalum-containing precursor over some or all of the substrate surface; using an inert gas or hydrogen plasma to purge the halogen byproducts and unused reactants; reducing the precursor to convert it to a conformal layer of tantalum or tantalum-containing material; using another purge of inert gas or hydrogen plasma to remove the halogen byproducts and unused reactants; and repeating the deposition / reduction cycles until a desired tantalum-containing material layer is achieved. An optional step of treating each newly formed surface of tantalum containing material with a nitrogen-containing agent can be added to create varying amounts of tantalum nitride.

Owner:NOVELLUS SYSTEMS

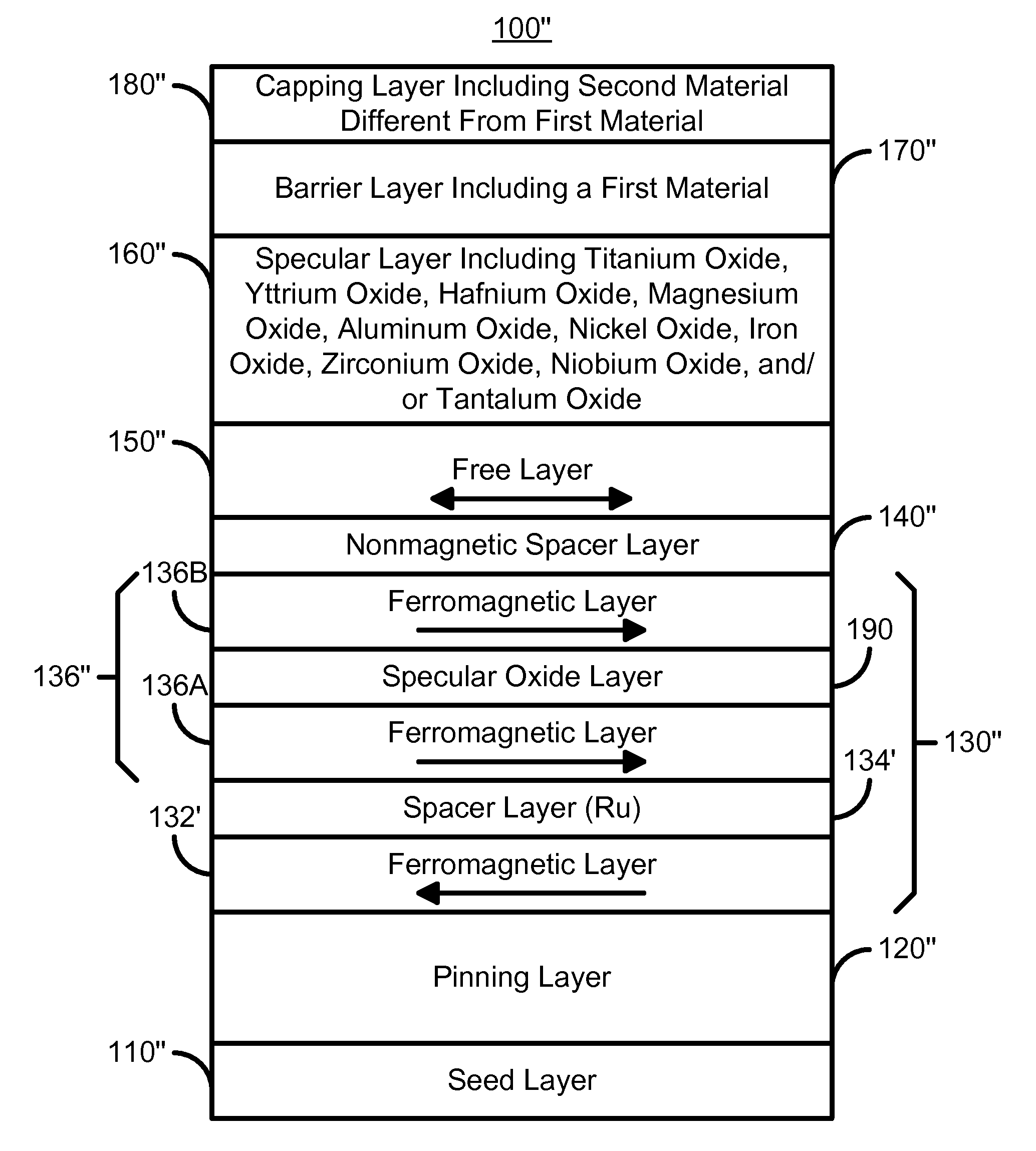

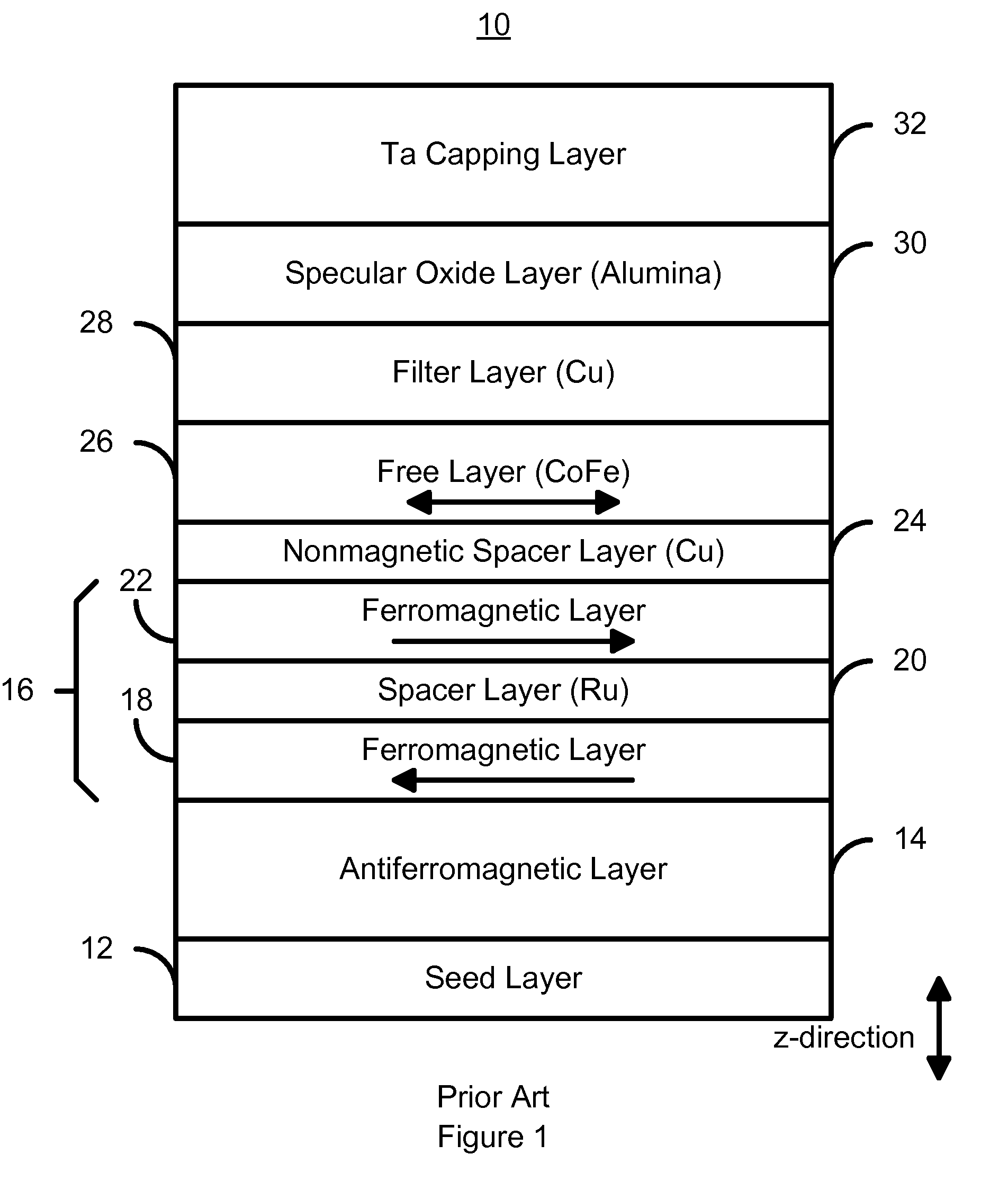

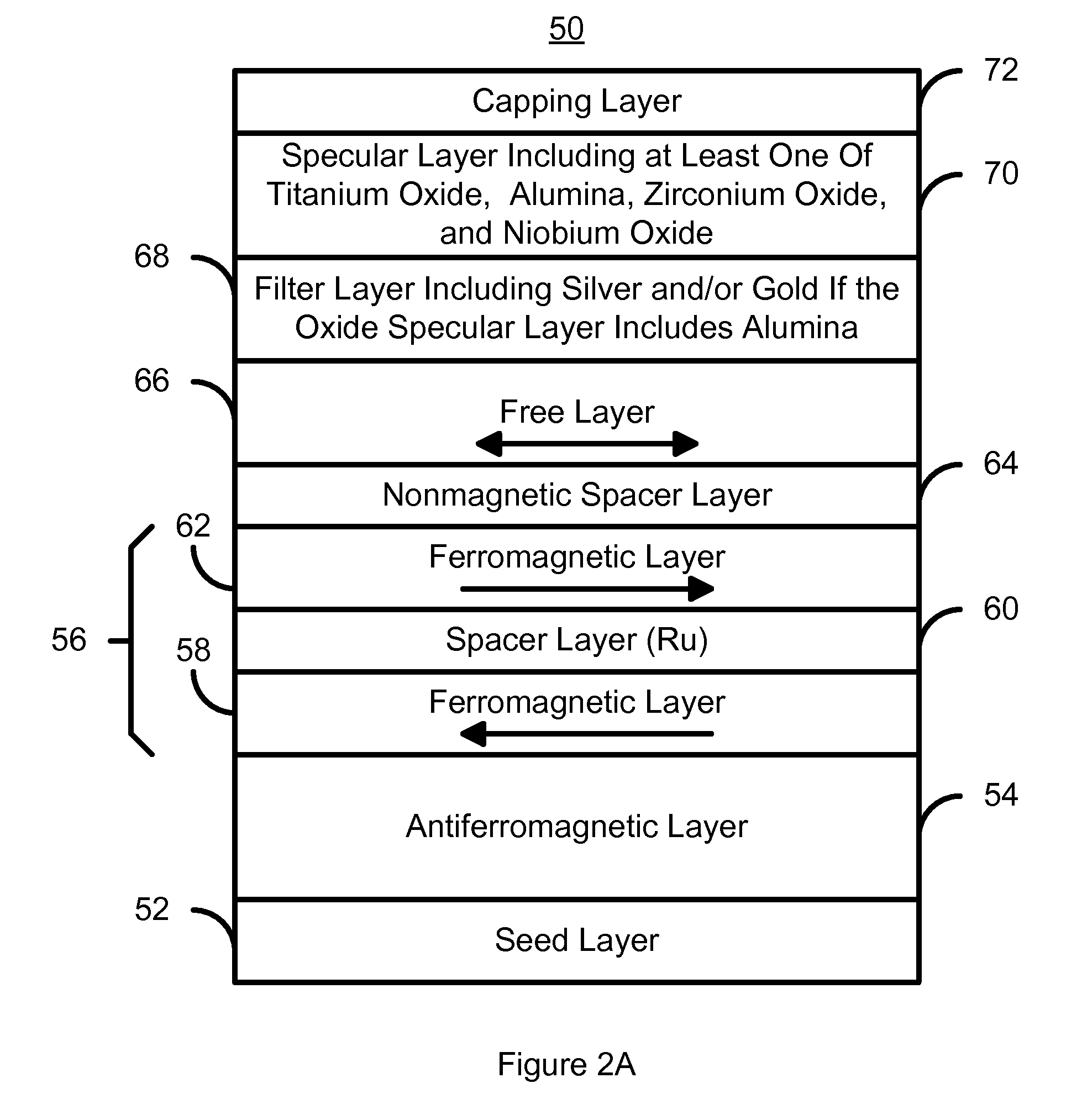

Magnetoresistive structure having a novel specular and barrier layer combination

InactiveUS7684160B1Magnetic-field-controlled resistorsConductive/insulating/magnetic material on magnetic film applicationYttriumTitanium oxide

A method and system for providing a magnetoresistive structure is disclosed. The magnetoresistive structure includes a pinned layer, a nonmagnetic spacer layer, a free layer, a specular layer, a barrier layer, and a capping layer. The spacer layer resides between the pinned layer and the free layer. The free layer is electrically conductive and resides between the specular layer and the nonmagnetic spacer layer. The specular layer is adjacent to the free layer and includes at least one of titanium oxide, yttrium oxide, hafnium oxide, magnesium oxide, aluminum oxide, nickel oxide, iron oxide, zirconium oxide, niobium oxide, and tantalum oxide. The barrier layer resides between the specular layer and the capping layer. The barrier layer is nonmagnetic and includes a first material. The capping layer includes a second material different from the first material.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com