Patents

Literature

5030results about How to "Good formability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

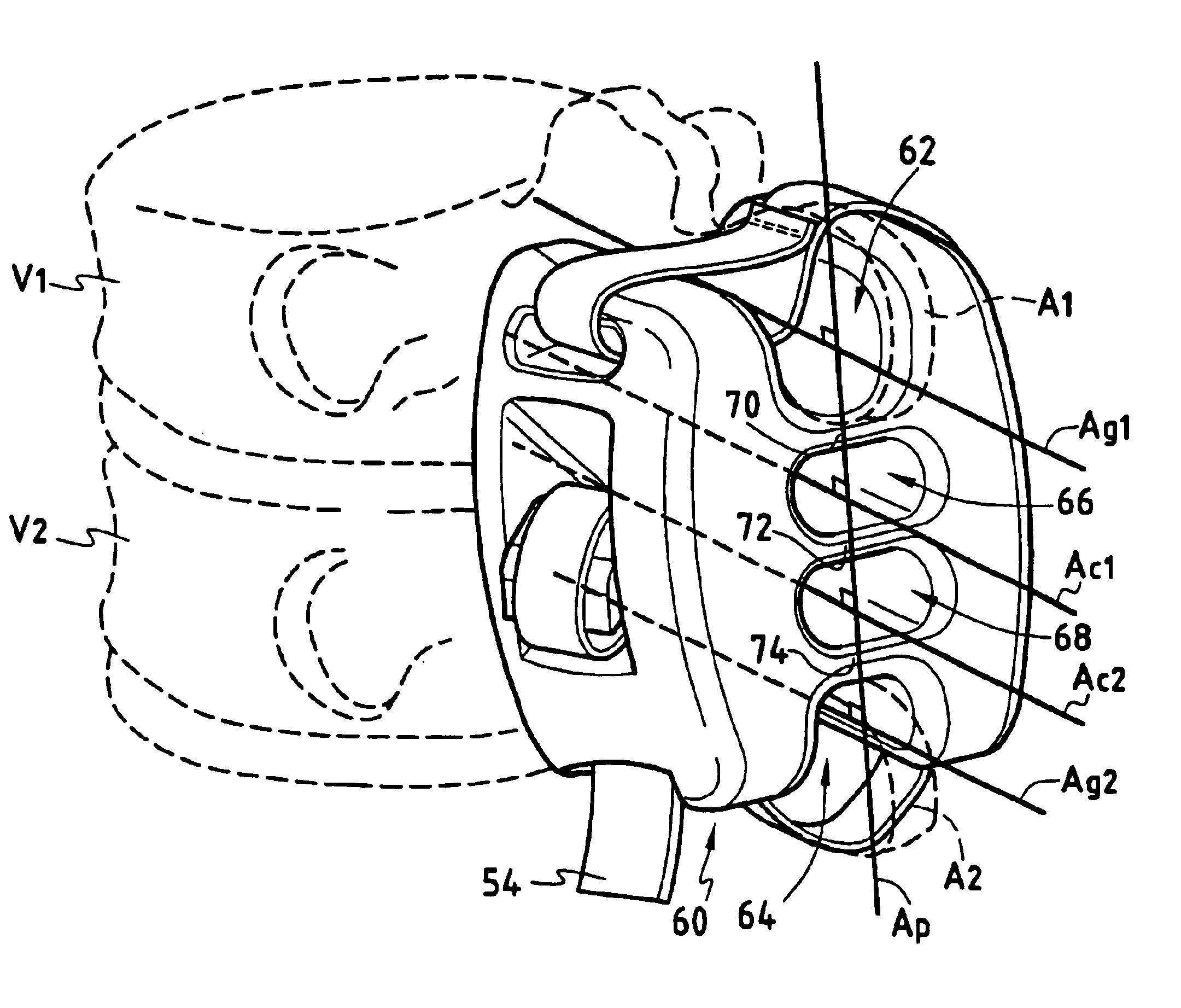

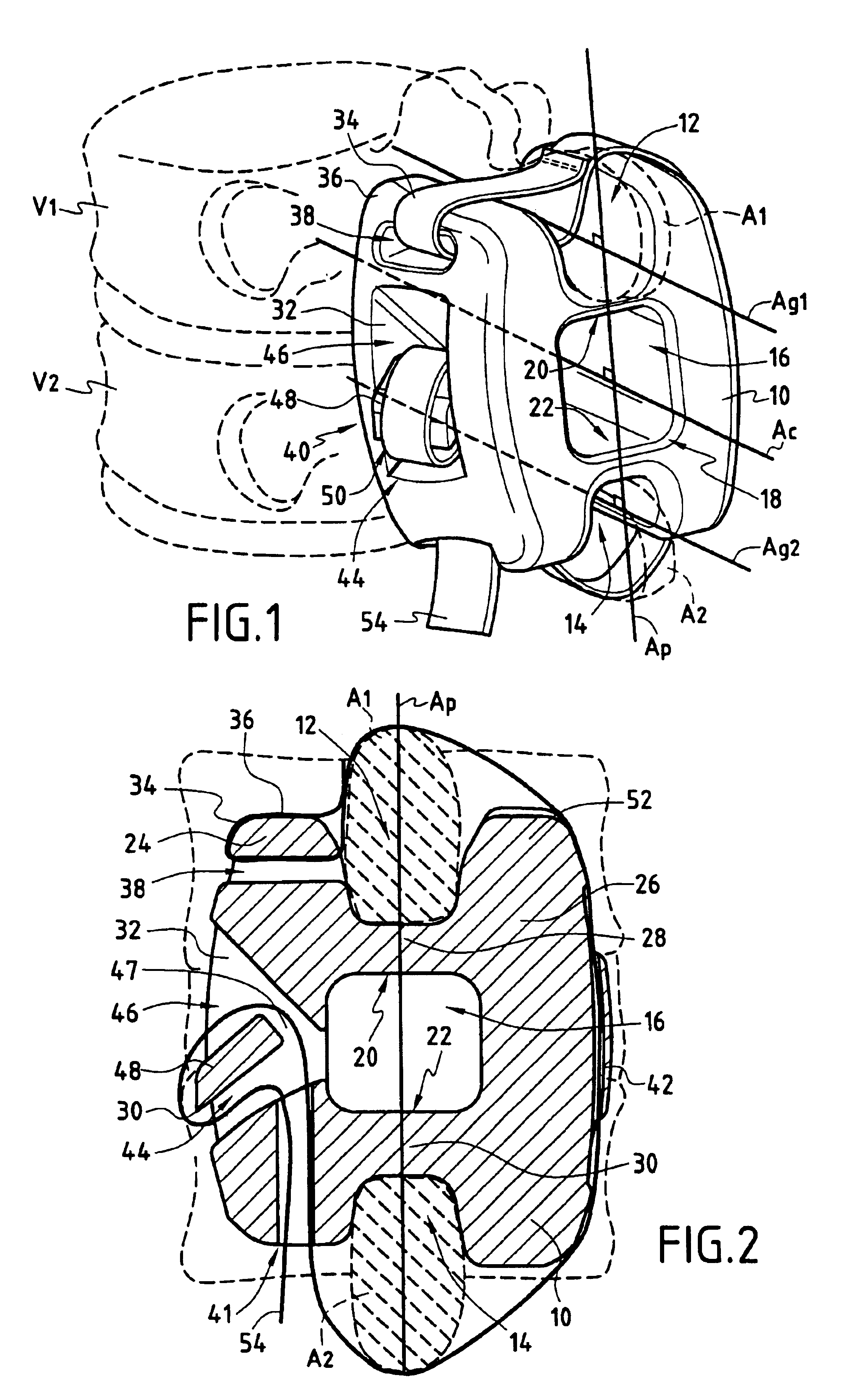

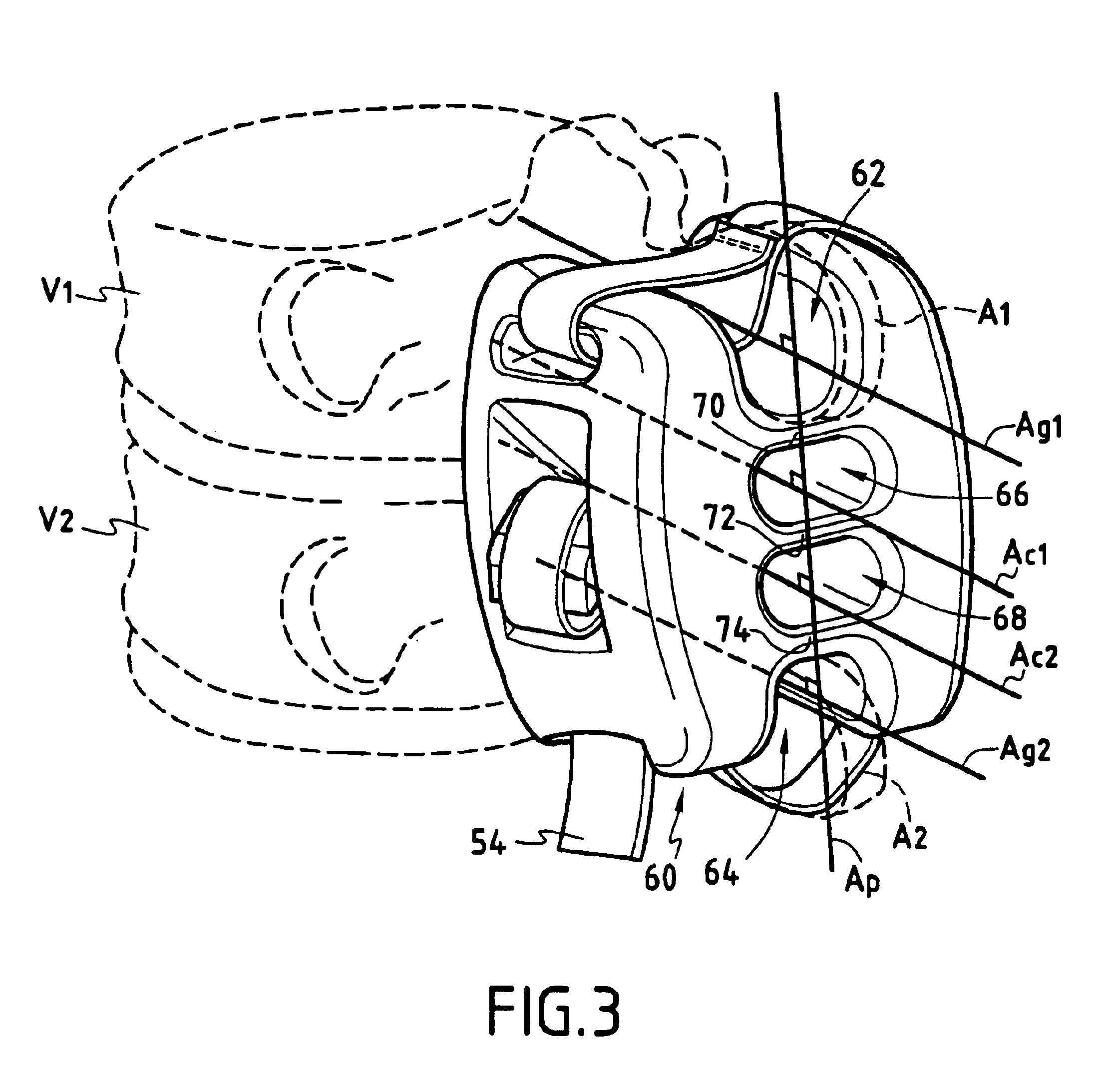

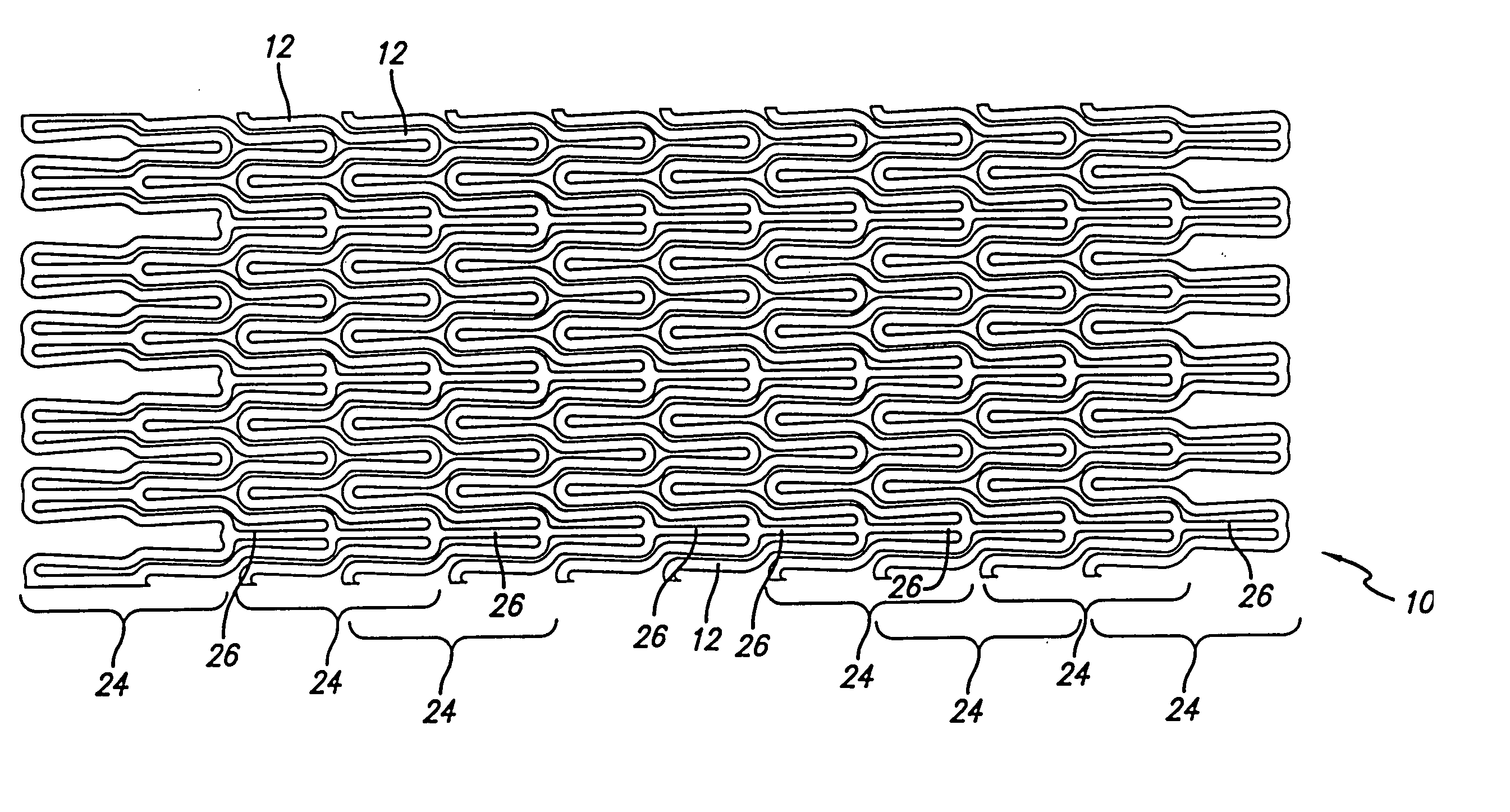

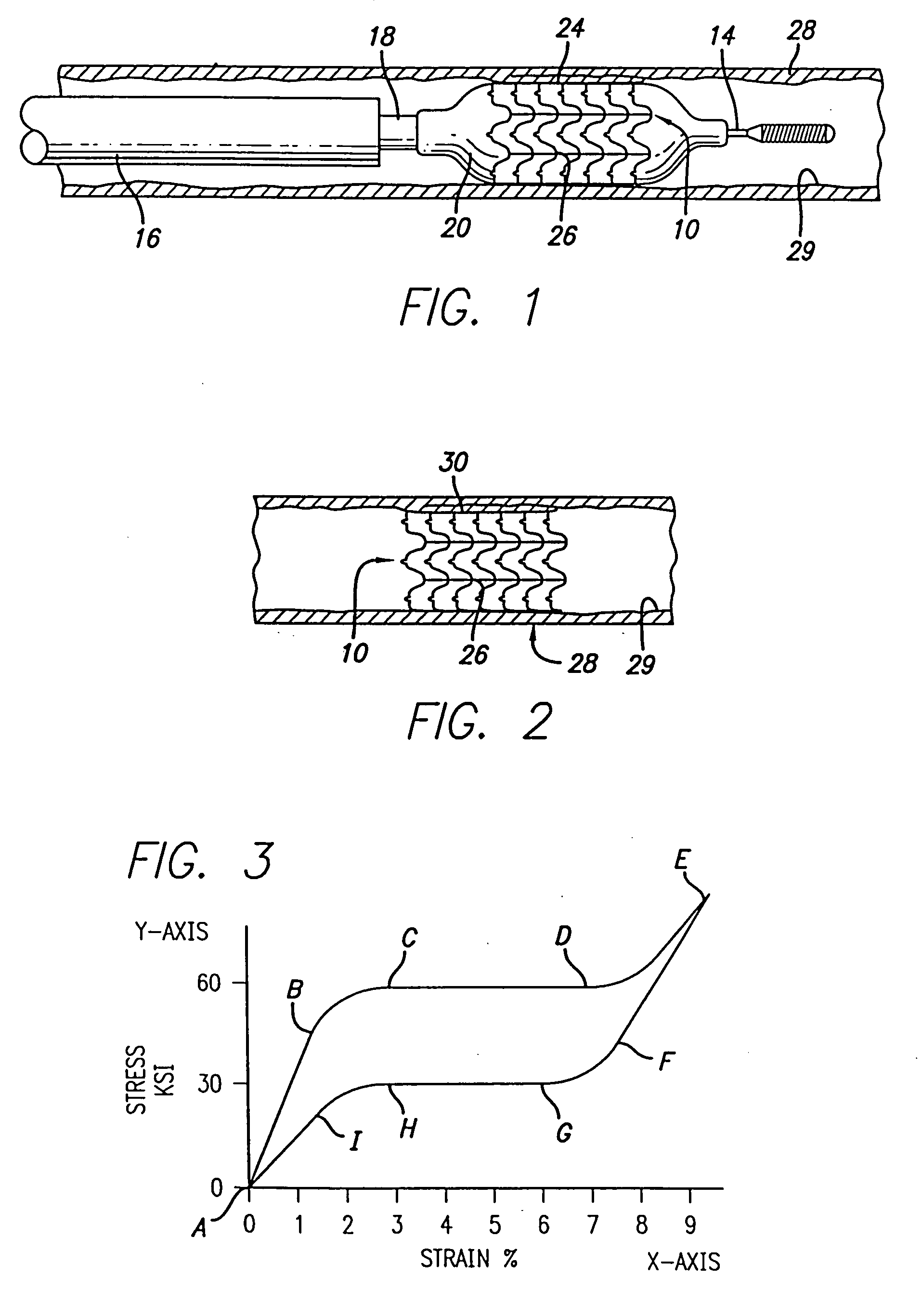

Intervertebral implant with deformable wedge

InactiveUS6946000B2Easy to manufactureCost advantageInternal osteosythesisJoint implantsBiomedical engineeringSpinous process

The invention relates to an intervertebral implant including a wedge which is inserted between two spinous processes and has two opposite grooves in which said spinous processes engage, which grooves have substantially parallel axes, and each of which grooves is defined by two flanges. The wedge has at least one central opening between said two grooves and said central opening passes completely through said wedge along an axis Ac substantially parallel to the axes Ag1 and Ag2 of said grooves, which renders said wedge elastically deformable.

Owner:ZIMMER SPINE INC

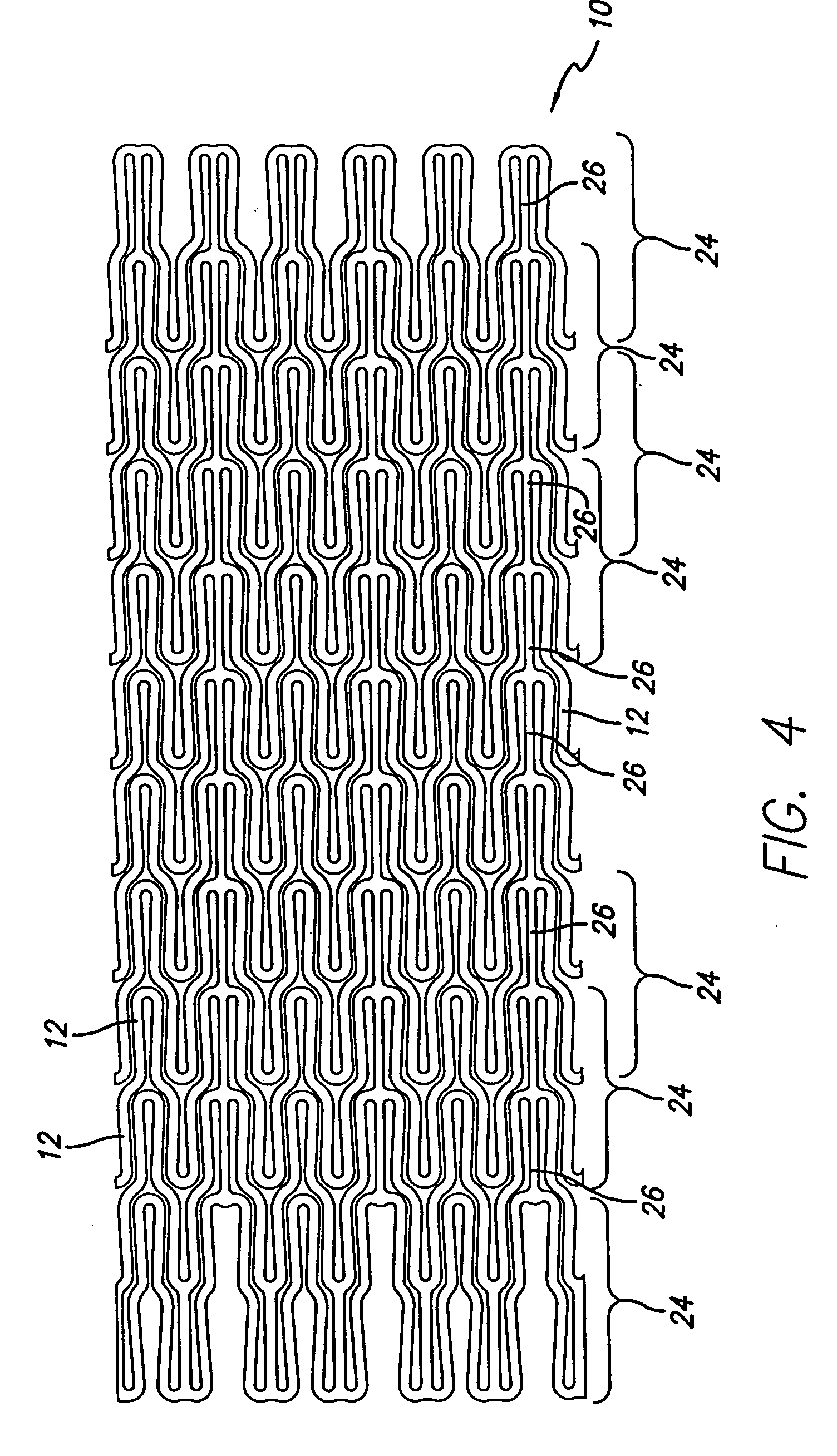

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

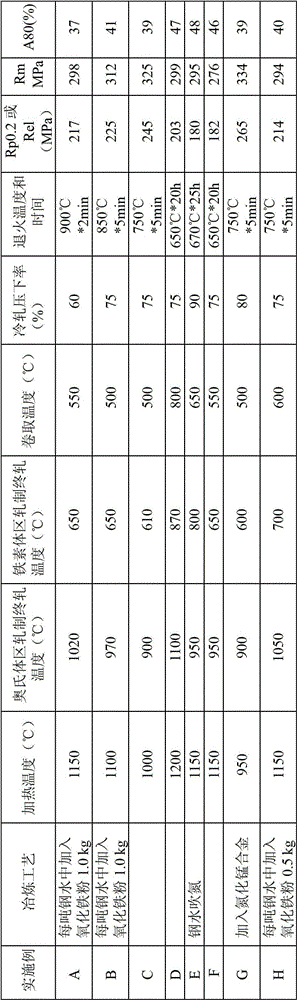

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Metal foil with resin and metal-clad laminate, and printed wiring board using the same and method for production thereof

InactiveUS20050121229A1Cost efficiency and handlingCircuit formability highInsulating substrate metal adhesion improvementSynthetic resin layered productsElectrical conductorMetal foil

The present invention provides a metal clad laminate or a resin coated metal foil having a metal foil whose both surfaces are not substantially roughening-treated and an insulating resin composition layer using generally used insulating resin, and a printed wiring board and a manufacturing method thereof, in which the metal clad laminate or the resin coated metal foil is used, the reliability and circuit formability are high, and the conductor loss is extremely low.

Owner:HITACHI CHEM CO LTD

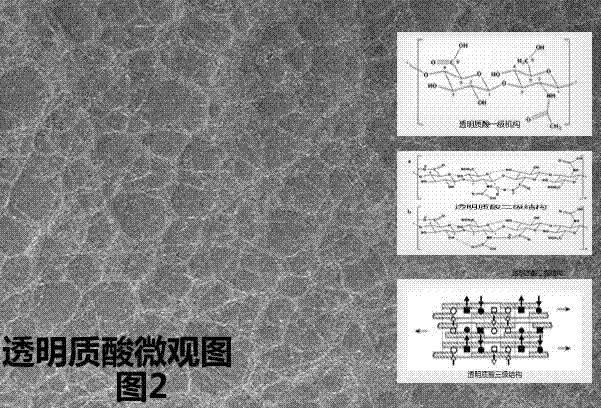

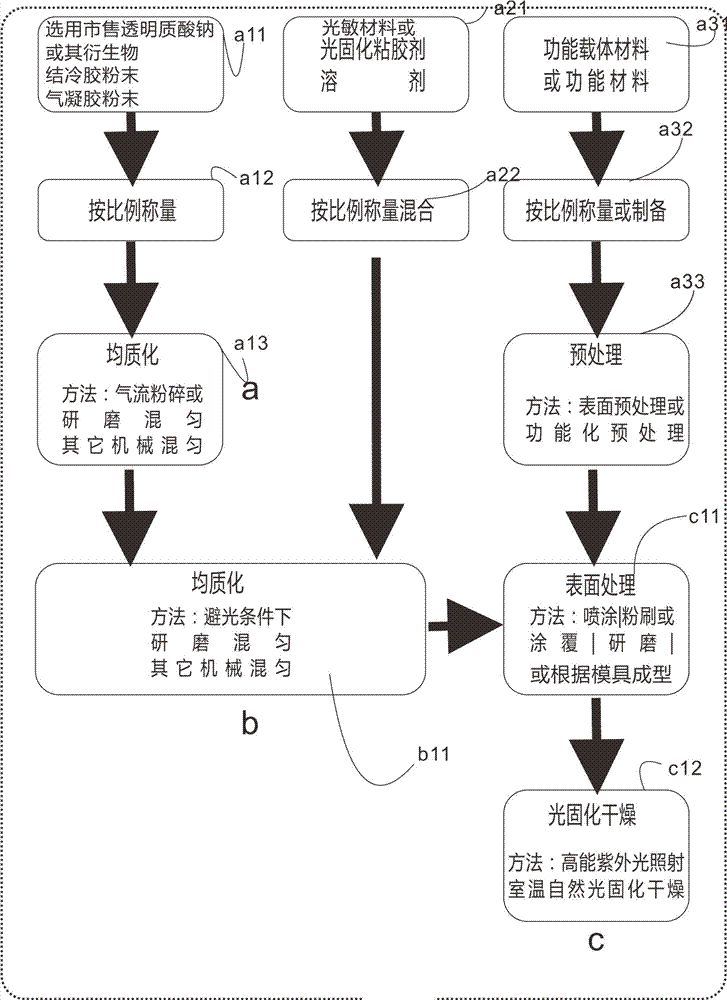

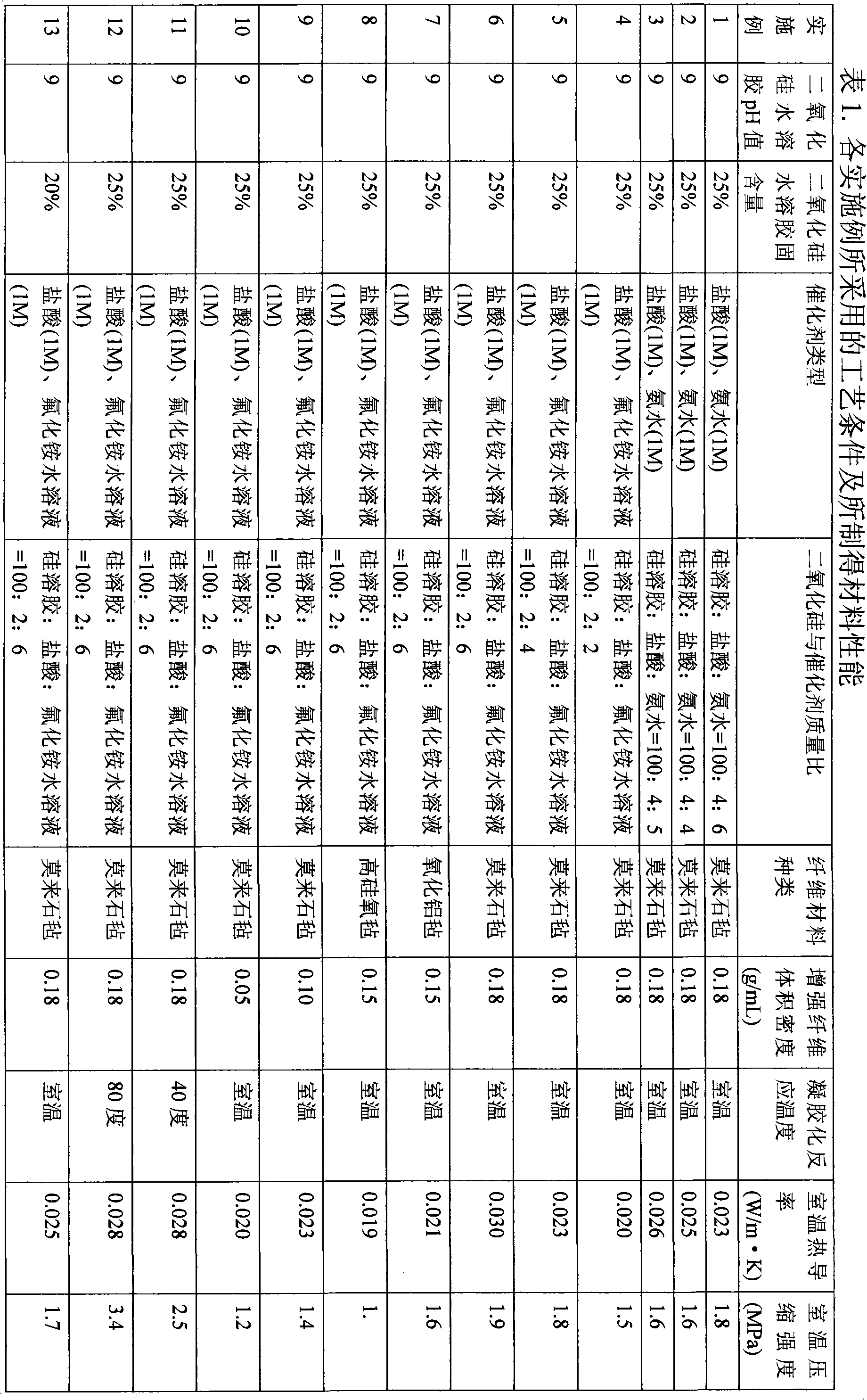

Novel aerogel multifunctional material and preparation method thereof

InactiveCN106928908AGood material uniformityGood formabilityHeat-exchange elementsAerogel preparationWeather resistanceChemistry

The invention provides a novel aerogel multifunctional material and a preparation method thereof. The multifunctional aerogel composite is prepared from gellan gum, hyaluronic acid as well as derivatives or mixture of the gellan gum and the hyaluronic acid, aerogel, a novel light-sensitive material, a novel solvent or novel ionic liquid or a novel mixed solvent formred by the above solvents or essential oil and the like by a high-energy photocuring method. The composite material has the characteristics of low density, low heat-conducting coefficient, high weather resistance, environmental friendliness and the like. A functional carrier or a functional material coated with the composite material has high heat-isolating, heat-insulating, cold-accumulating, moisturizing, moisture-proof, moisture-retaining and anti-haze characteristics, and the characteristics and the use range of the materials can be improved. The multifunctional material is extremely widely applied, and can be widely applied in the fields of haze prevention and control, disease diagnosis and treatment, medicine, military industry, chemical industry, spaceflight, navigation, aviation, high-speed train, paper making, printing, water treatment, agriculture and animal husbandry, a cold chain system, food and cosmetic safety.

Owner:广州市芯检康生物科技有限公司

Nonwoven fabric for separator of non-aqueous electrolyte battery and non-aqueous electrolyte battery using the same

InactiveUS6200706B1Uniform and efficient productionImprove various performanceOrganic electrolyte cellsPaper/cardboardSurface roughnessEngineering

The object of the present invention is to provide a nonwoven fabric for separators of non-aqueous electrolyte batteries which is superior in adhesion to electrodes, causes no breakage of the separator and neither slippage nor space between electrode and the separator at the time of fabrication of battery, provides superior battery processability such as rollability with electrodes, causes no internal short-circuit due to contact between electrodes caused by shrinking or burning of the nonwoven fabric even when electrodes generate heat owing to external short-circuit, whereby ignition of the battery can be inhibited, has no pin holes and is superior in retention of electrolyte and penetration of electrolyte, and which can give non-aqueous electrolyte batteries superior in capacity, battery characteristics and battery storage characteristics. Specifically, the nonwoven fabric for separators of non-aqueous electrolyte batteries according to the present invention has a thickness non-uniformity index (Rpy) of 1000 mV or less or a center surface average roughness SRa of 6 mum or less in whole wavelength region as measured using a tracer method three-dimensional surface roughness meter.

Owner:MITSUBISHI PAPER MILLS LTD

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

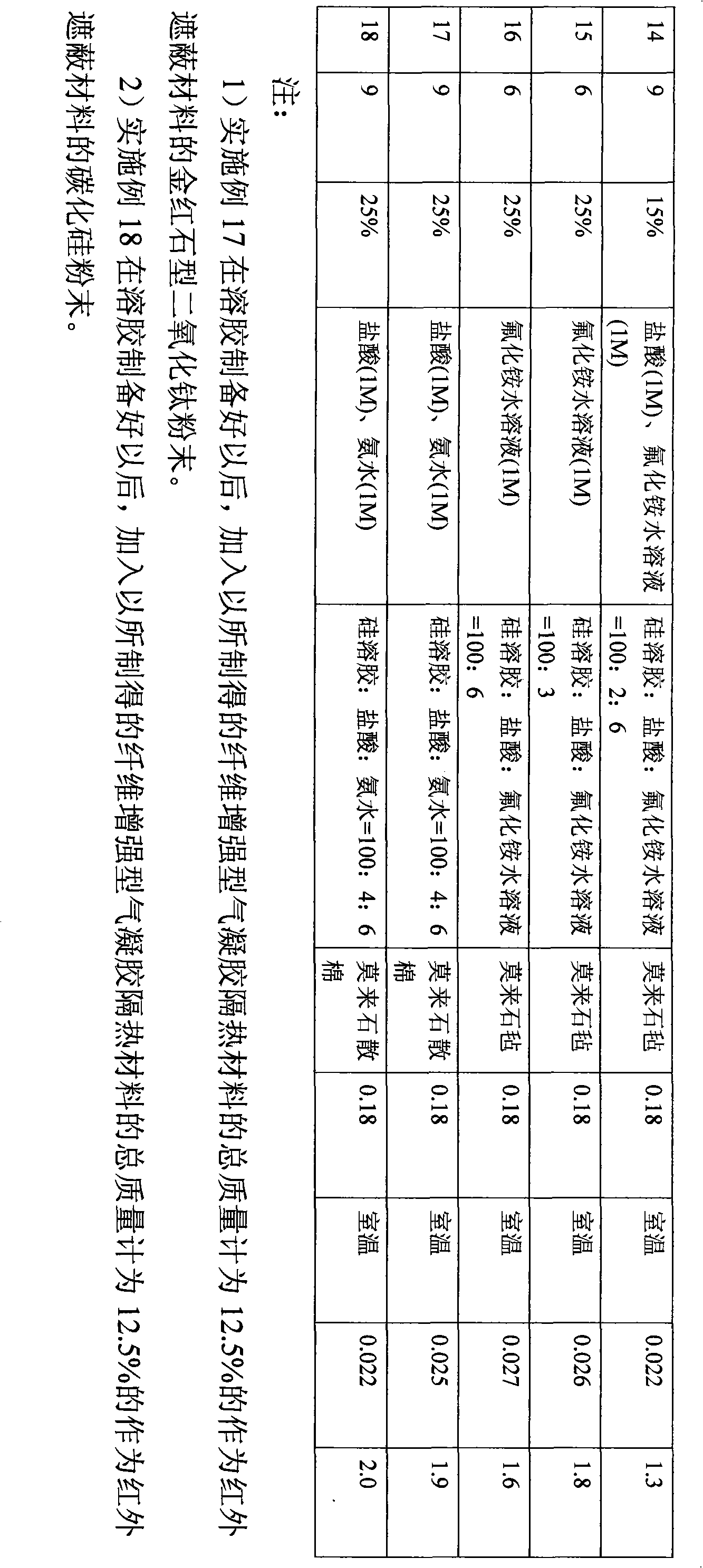

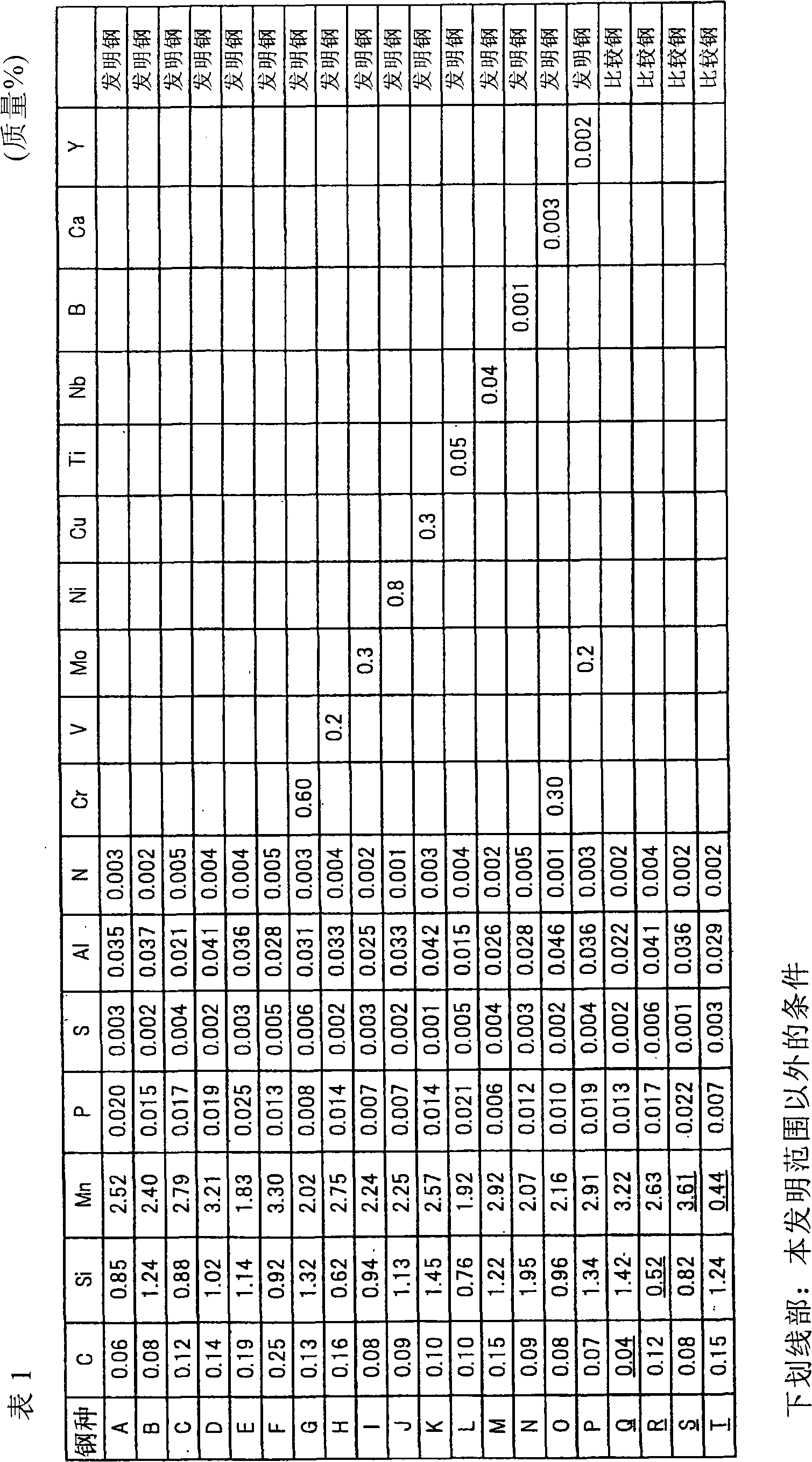

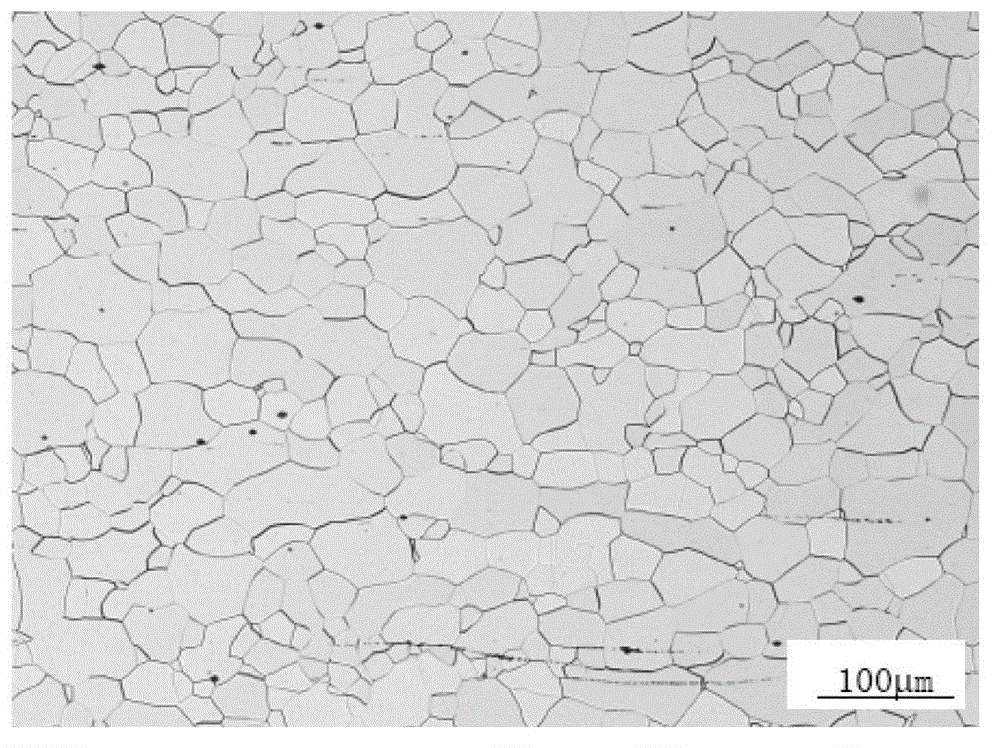

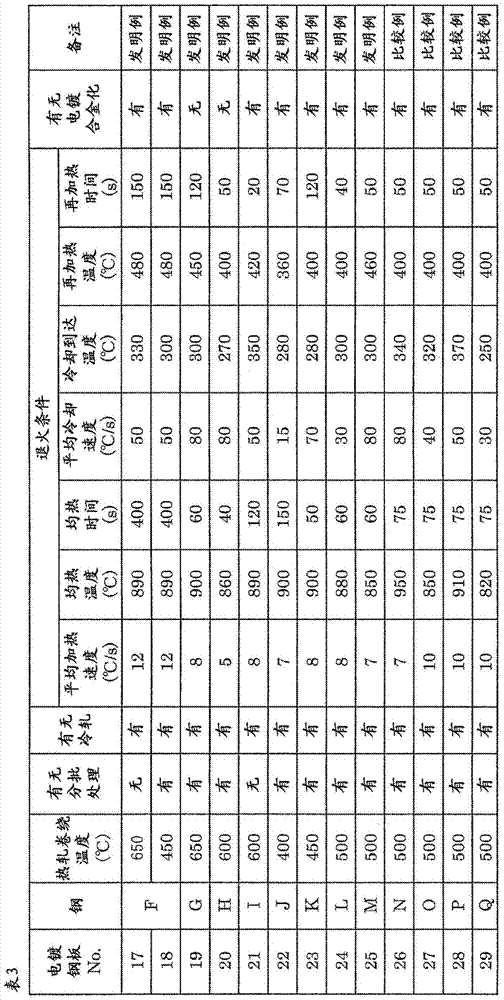

Hot-dip galvanized steel sheet and production thereof

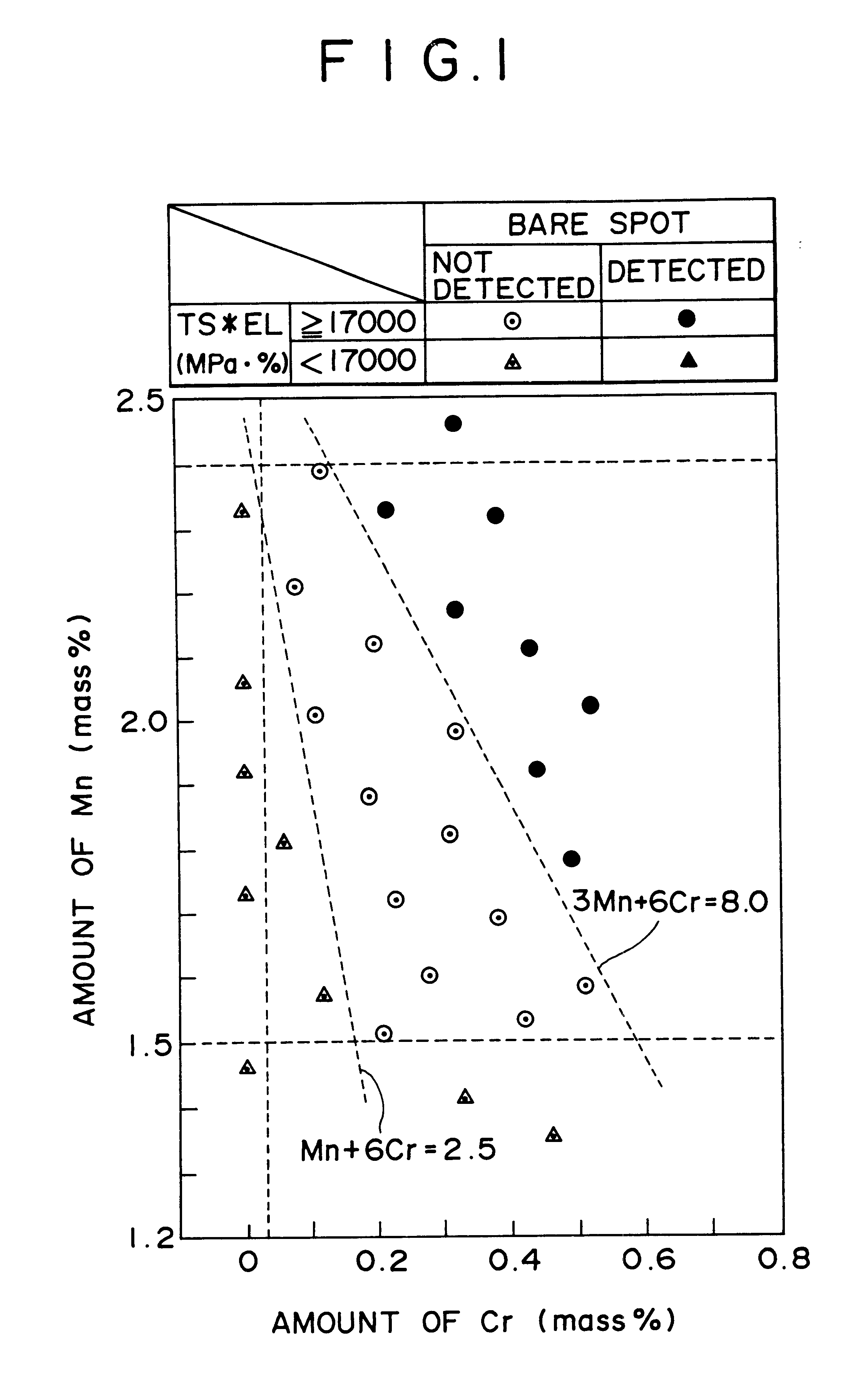

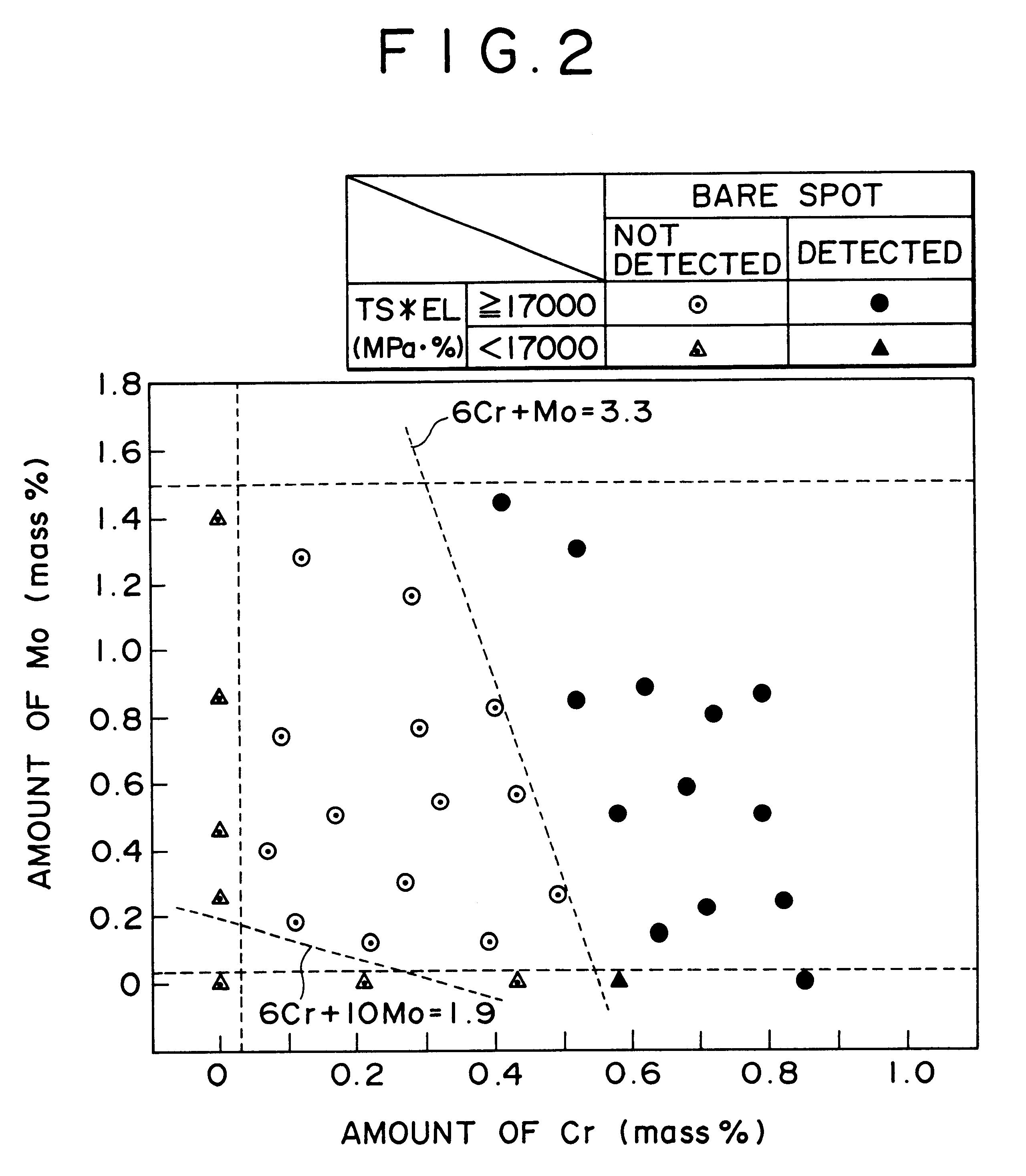

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

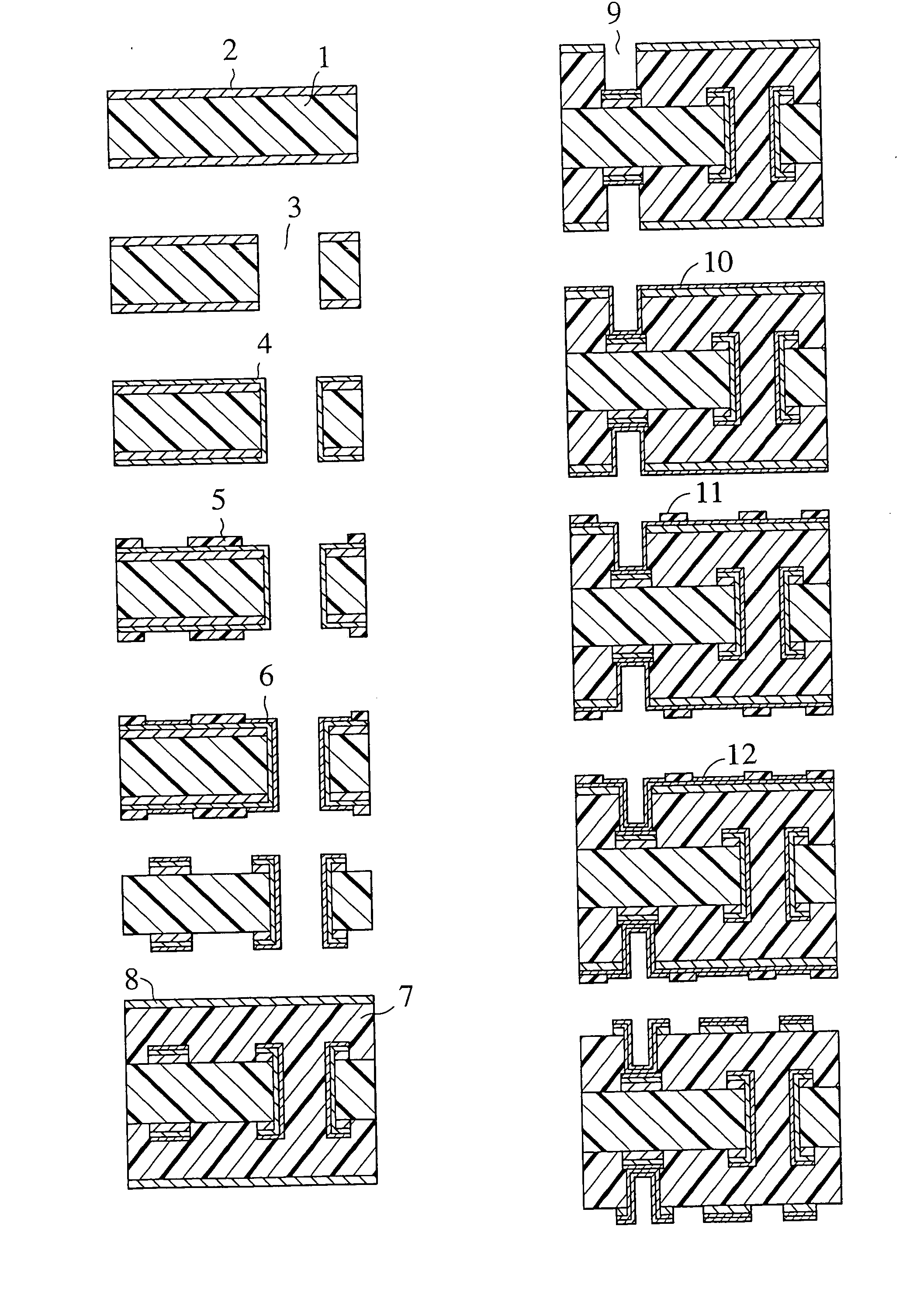

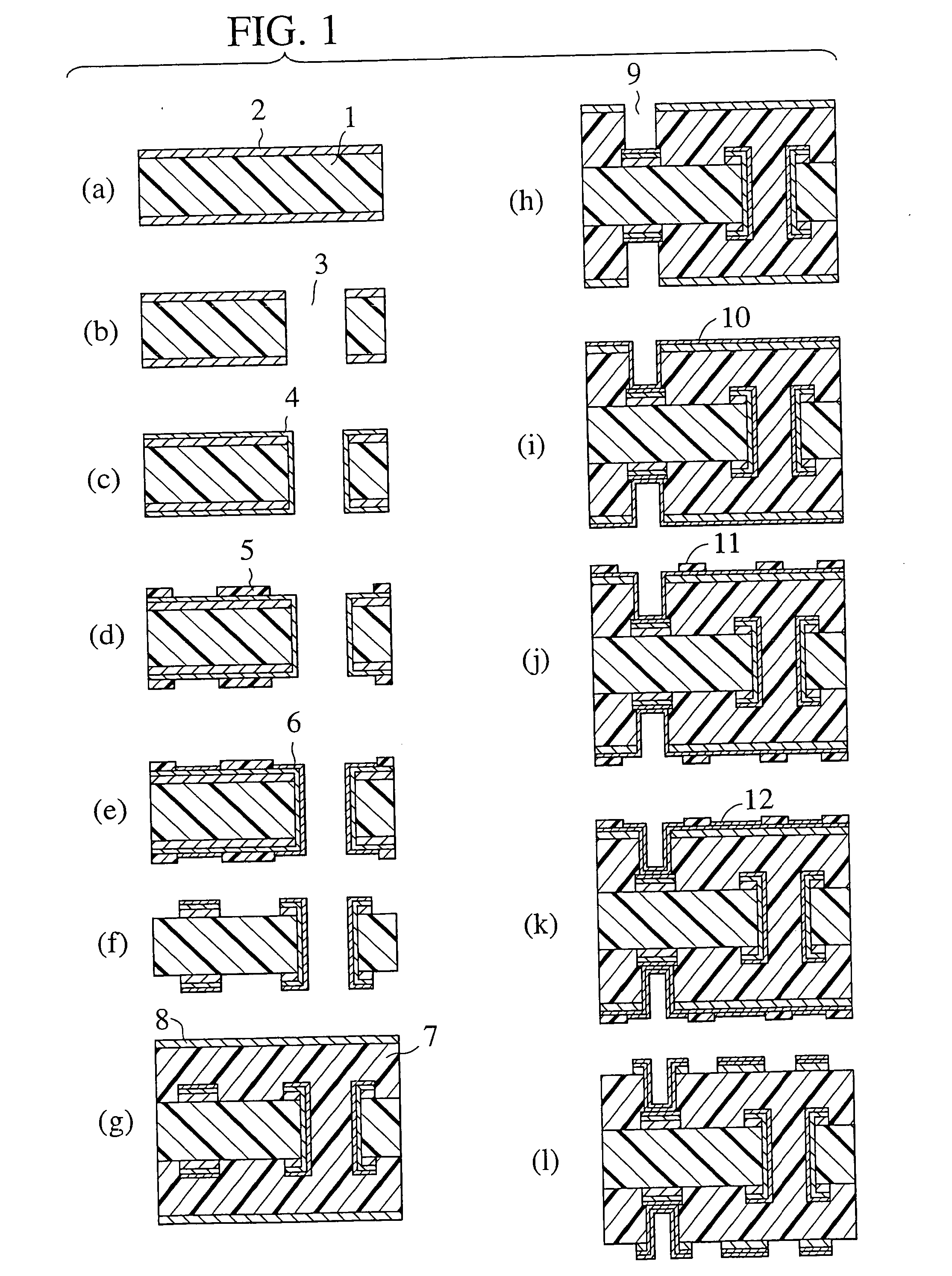

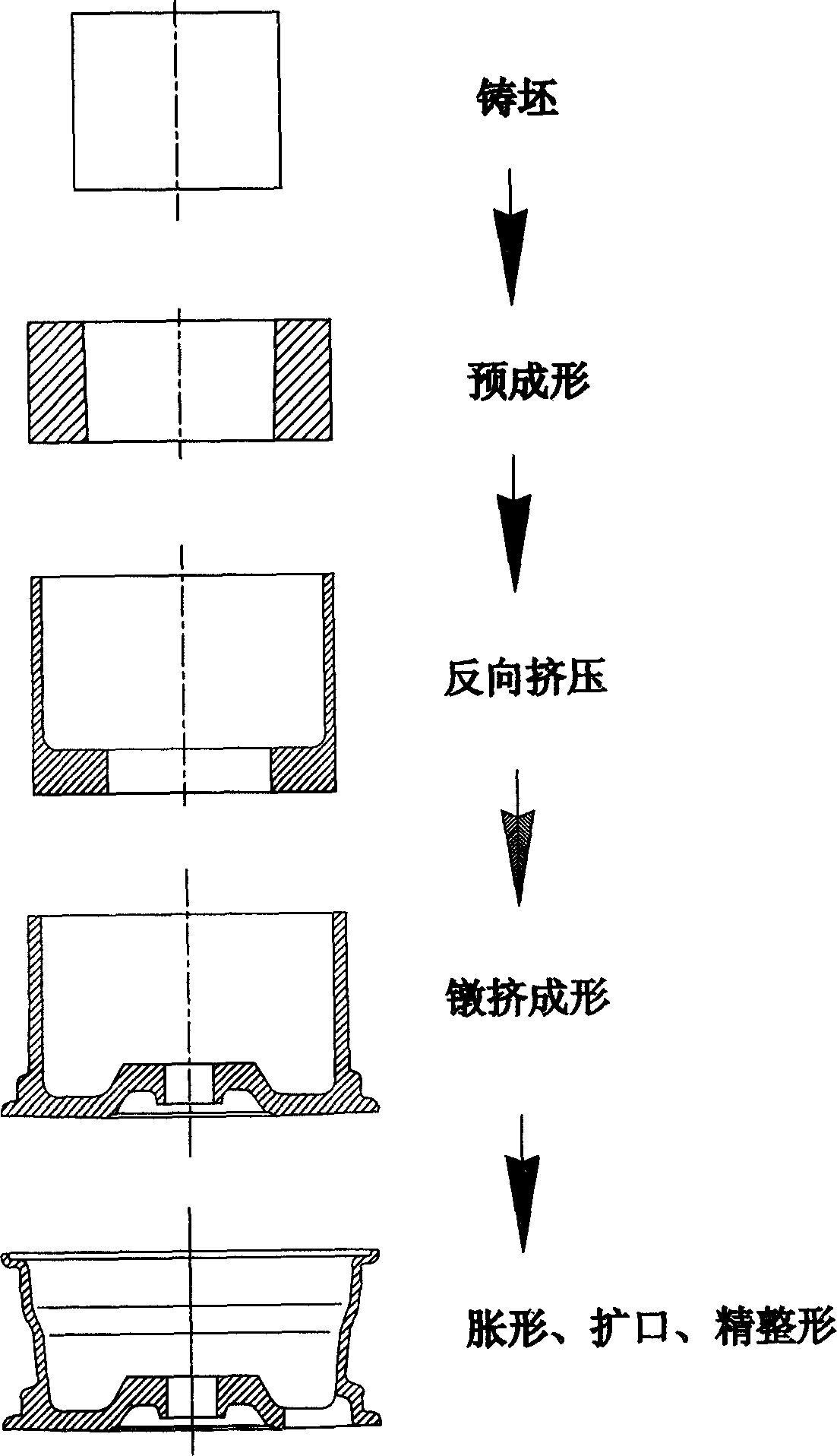

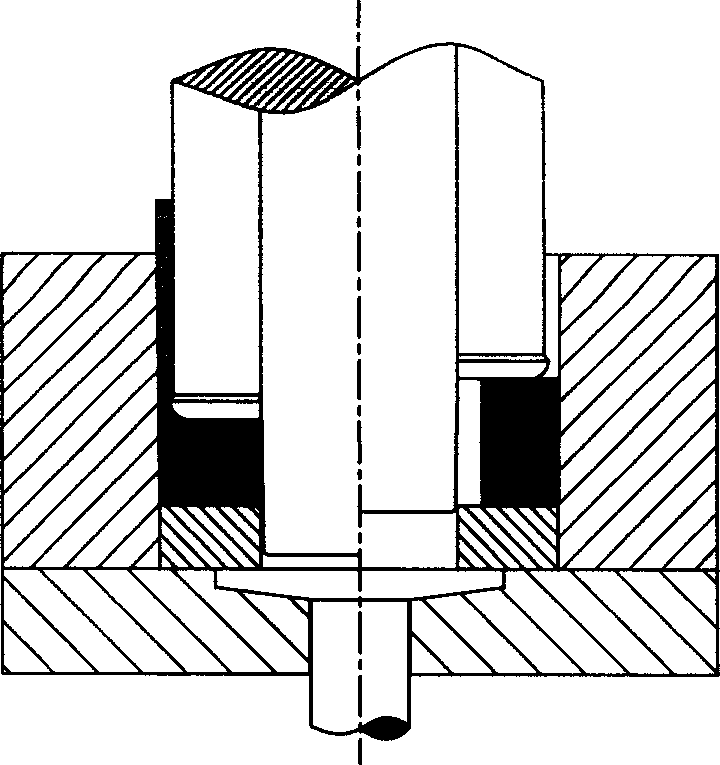

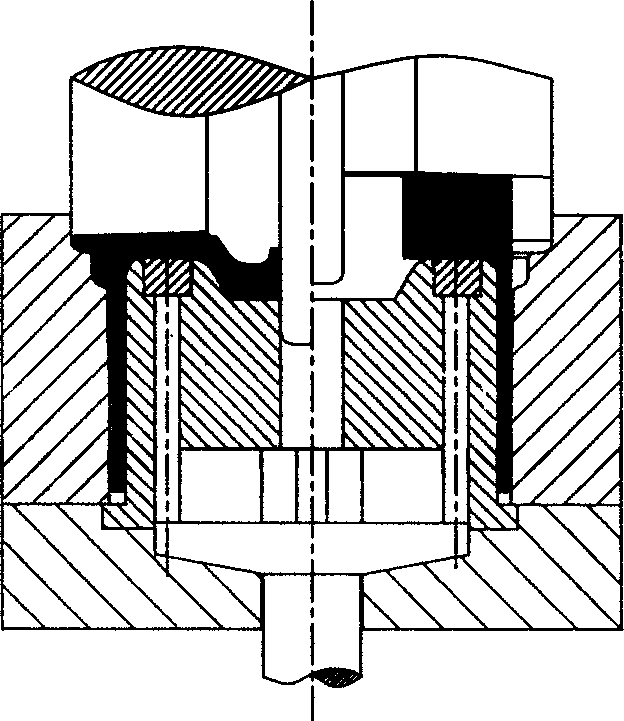

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

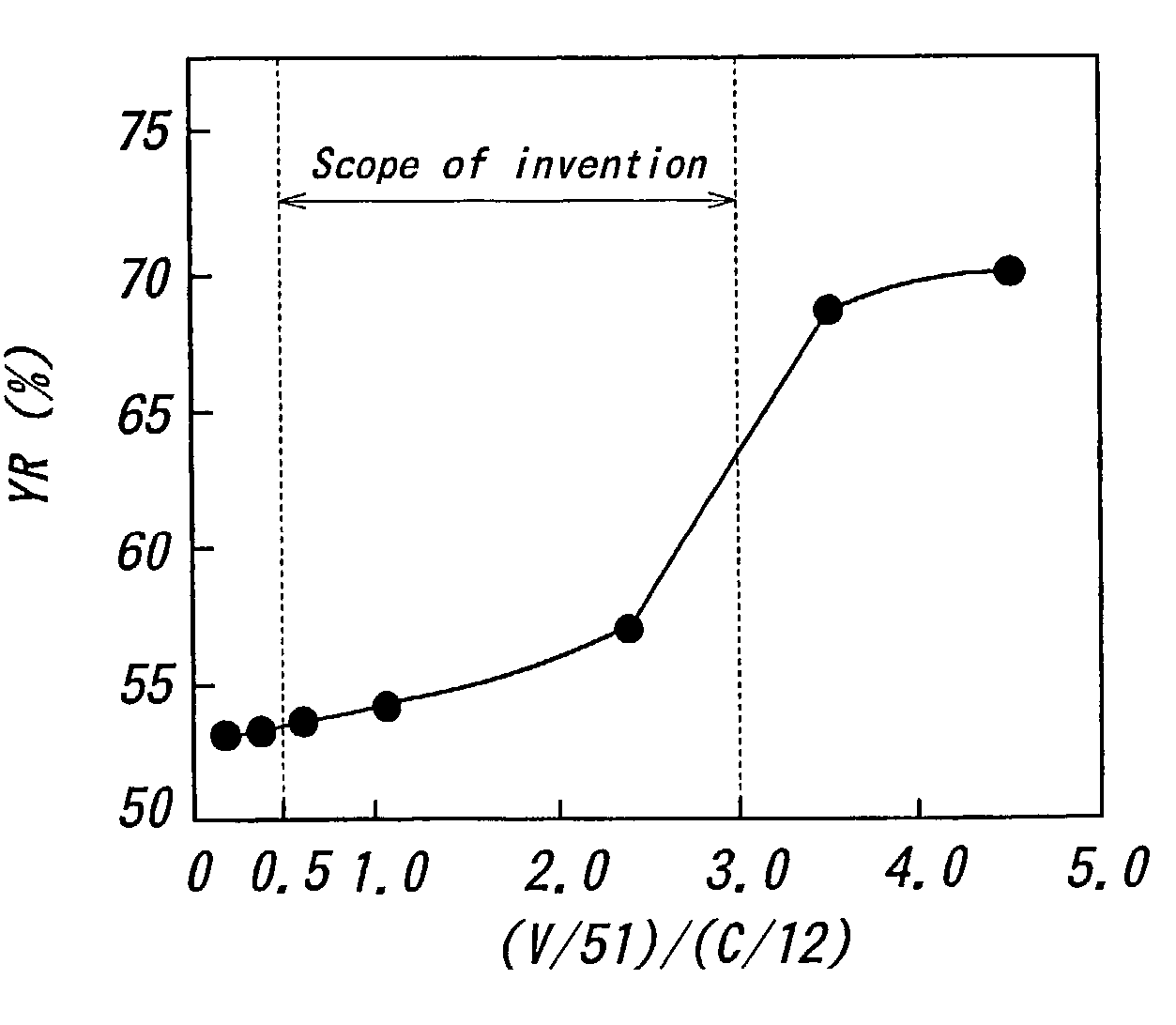

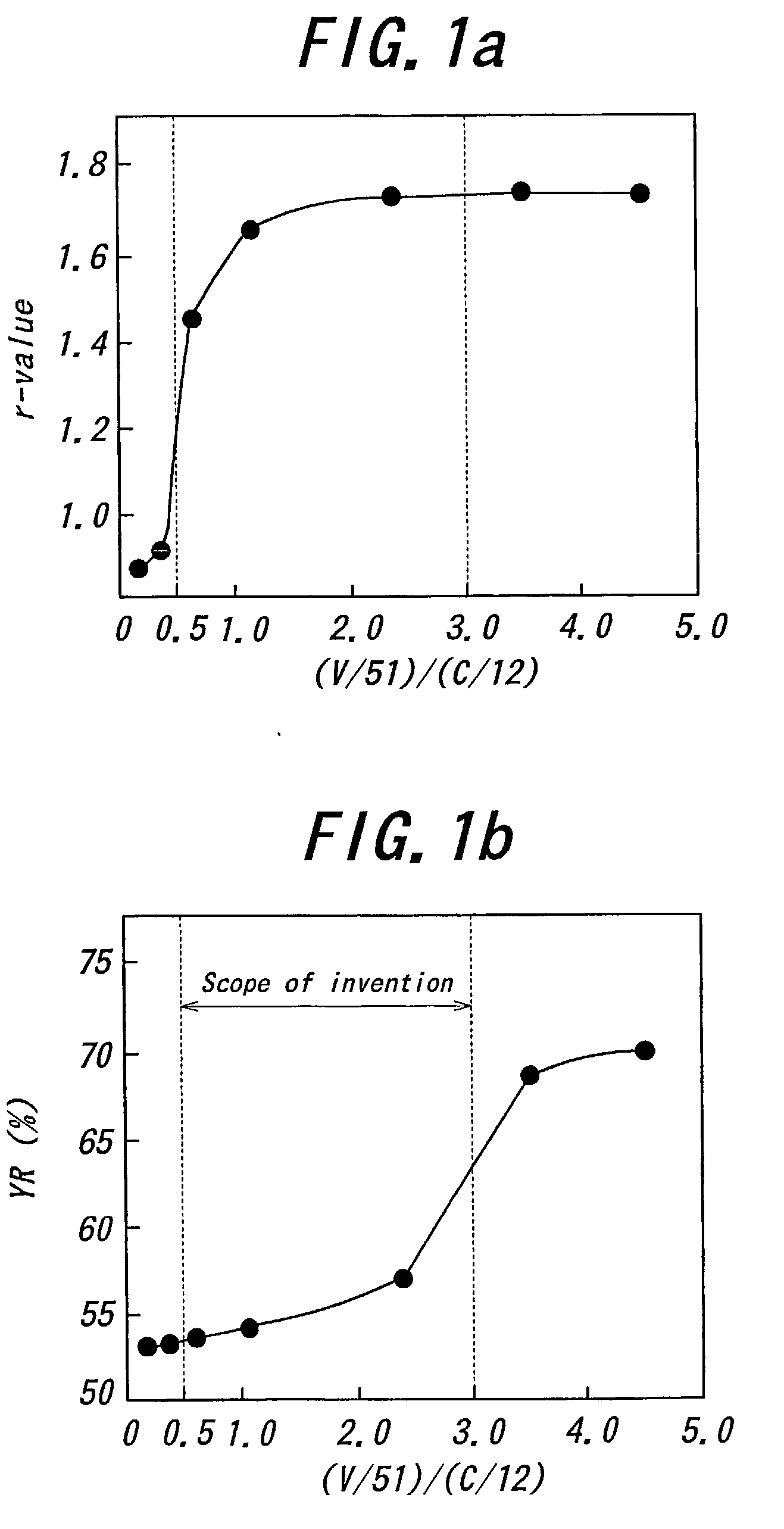

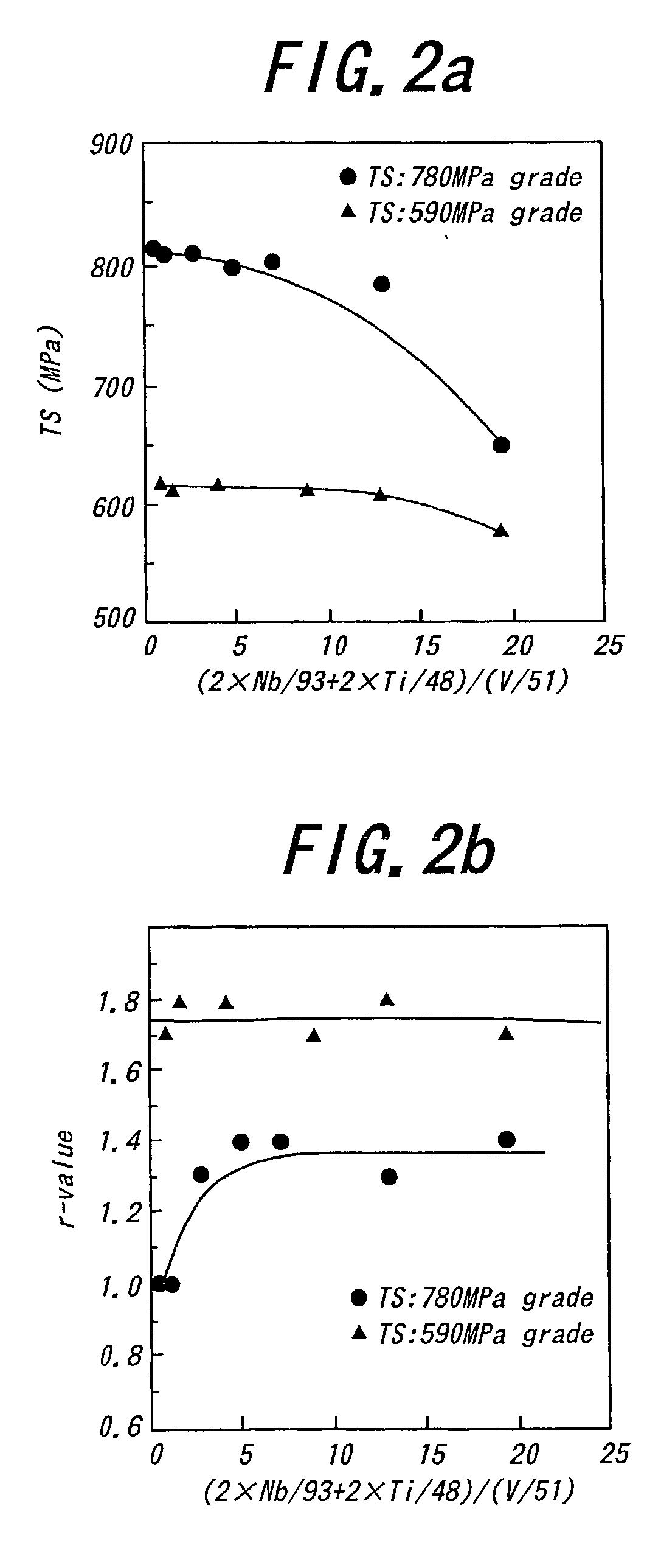

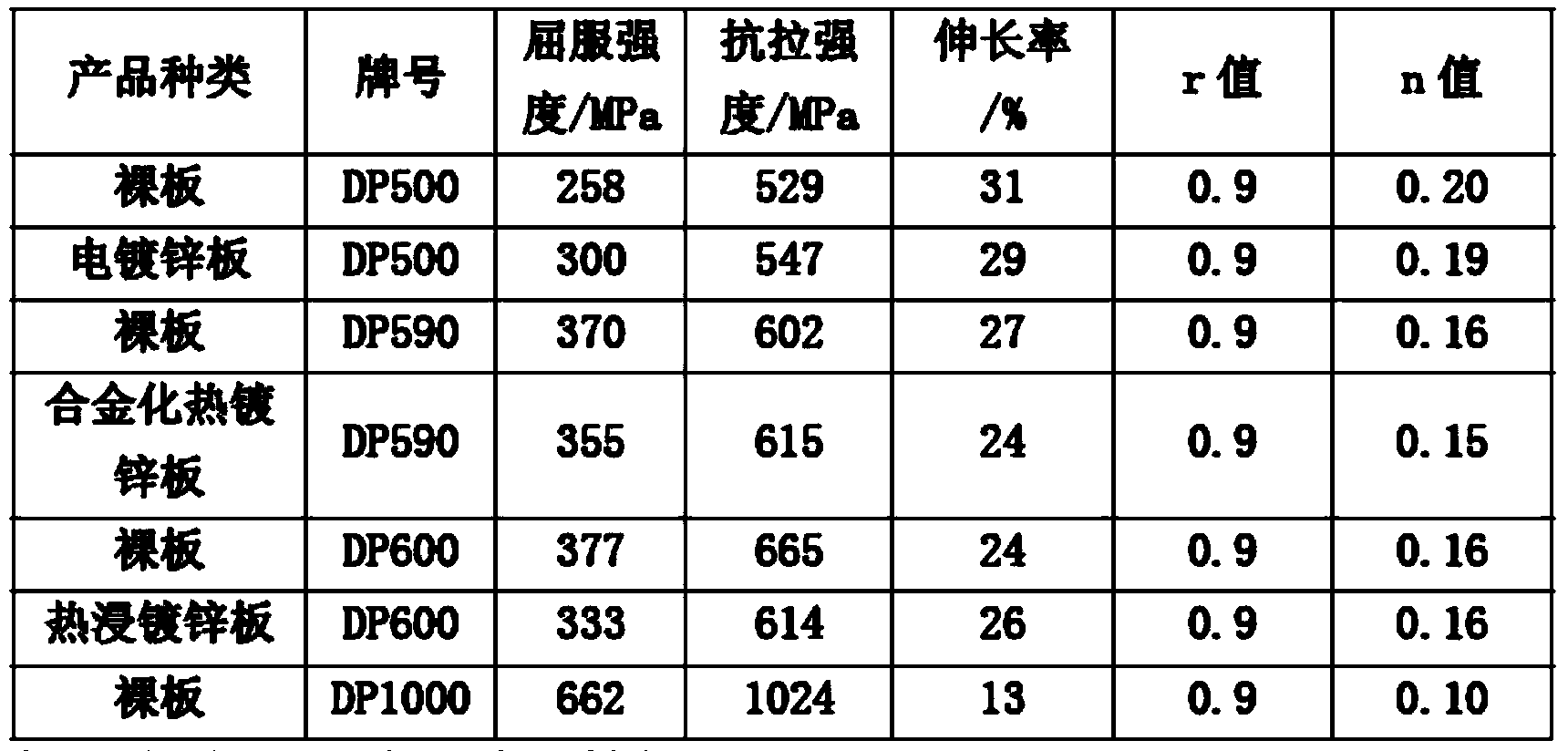

Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

InactiveUS20030129444A1Lower yield stressImprove ductilityHot-dipping/immersion processesThin material handlingSheet steelHigh intensity

The invention proposes a high-strength dual-phase cold rolled steel sheet having an excellent deep drawability, wherein the steel sheet has a composition comprising C: 0.01-0.08 mass %, Si: not more than 2.0 mass %, Mn: not more than 3.0 mass %, P: not more than 0.10 mass %, S: not more than 0.02 mass %, A1: 0.005-0.20 mass %, N: not more than 0.02 mass % and V: 0.01-0.5 mass %, provided that V and C satisfy a relationship of 0.5xC / 12<=V / 51<=3xC / 12, and the remainder being Fe and inevitable impurities, and has a microstructure consisting of a ferrite phase as a primary phase and a secondary phase including martensite phase at an area ratio of not less than 1% to a whole of the microstructure and a high-strength dual-phase galvanized steel sheet comprising a galvanized coating on the above steel sheet as well as a method of producing the same.

Owner:JFE STEEL CORP

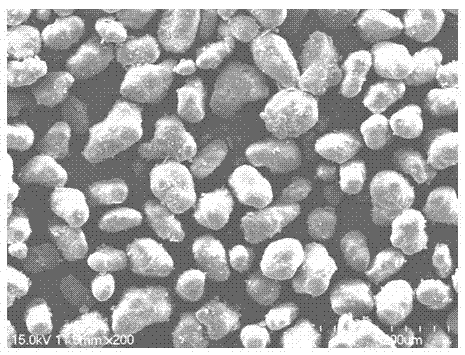

High-molecular composite powder material for SLS and preparation method therefor

ActiveCN103709737AExcellent physical and chemical propertiesImprove mechanical propertiesErbium lasersMacromolecule

The invention discloses a high-molecular composite powder material for SLS. The composite powder material comprises the following ingredients, by weight, 85%-99% of high-molecular powder, 0.1%-10% of laser absorbents, 0.1%-3% of flow promoters and 0.1%-2% of anti-oxidants. The preparation method for the composite powder material is advantaged by simple technology, environmental protection and easy implementation, and a high-molecular composite powder material with excellent molding performances can be obtained. The composite powder material can perform SLS molding through a fiber laser, the product precision is improved effectively, and application of the SLS technology in many fields is promoted.

Owner:ZRAPID TECH CO LTD

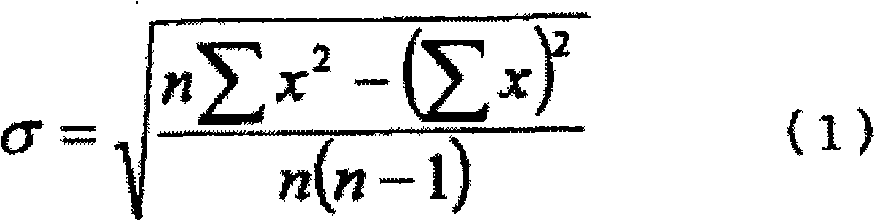

Retardation film, polarizing element, liquid crystal panel, and liquid crystal apparatus

InactiveUS20060177607A1Good molding effectImproved display property displayLiquid crystal compositionsThin material handlingIn planeLength wave

There is provided a retardation film including a stretched film of a polymer film having an absolute value of photoelastic coefficient (m2 / N) of 50×10−12 or less measured by using light of a wavelength of 550 nm at 23° C., which satisfies the following expressions (1) and (2):Re[450]<Re[550]<Re[650] (1)Rth[550]<Re[550] (2).In the expressions (1) and (2): Re[450], Re[550], and Re[650] respectively represent in-plane retardation values measured by using light of wavelengths of 450 nm, 550 nm, and 650 nm at 23° C.; and Rth[550] represents a thickness direction retardation value measured by using light of a wavelength of 550 nm at 23° C.

Owner:NITTO DENKO CORP

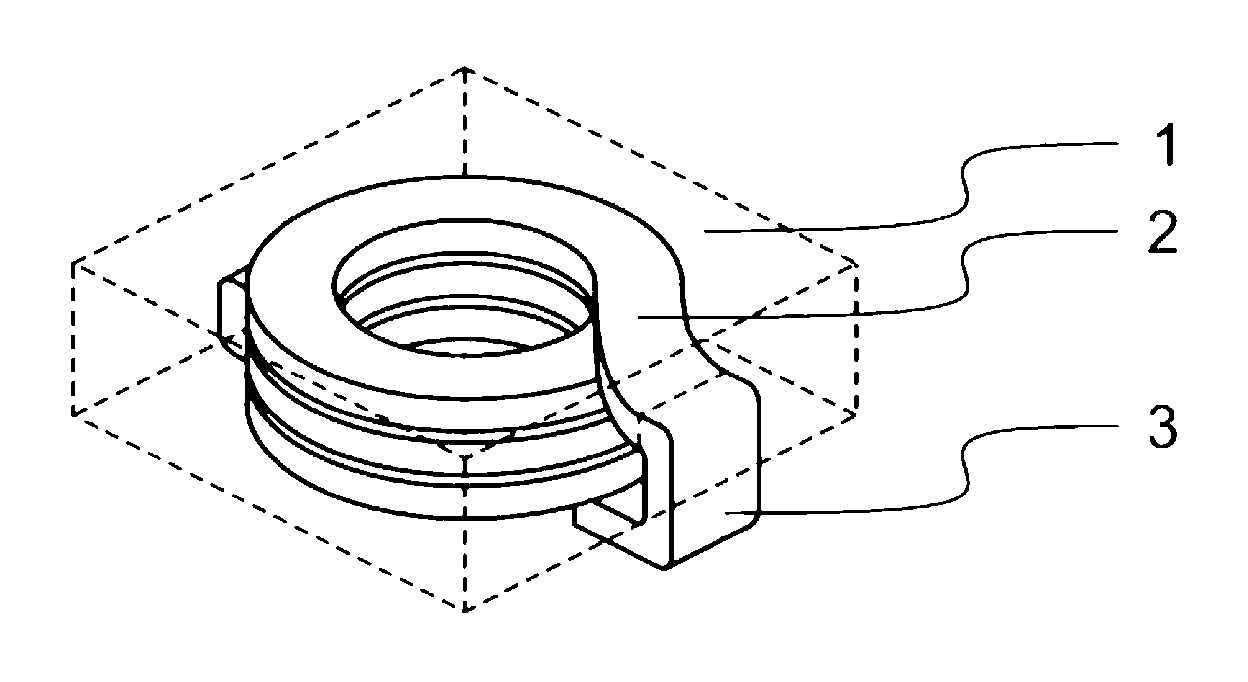

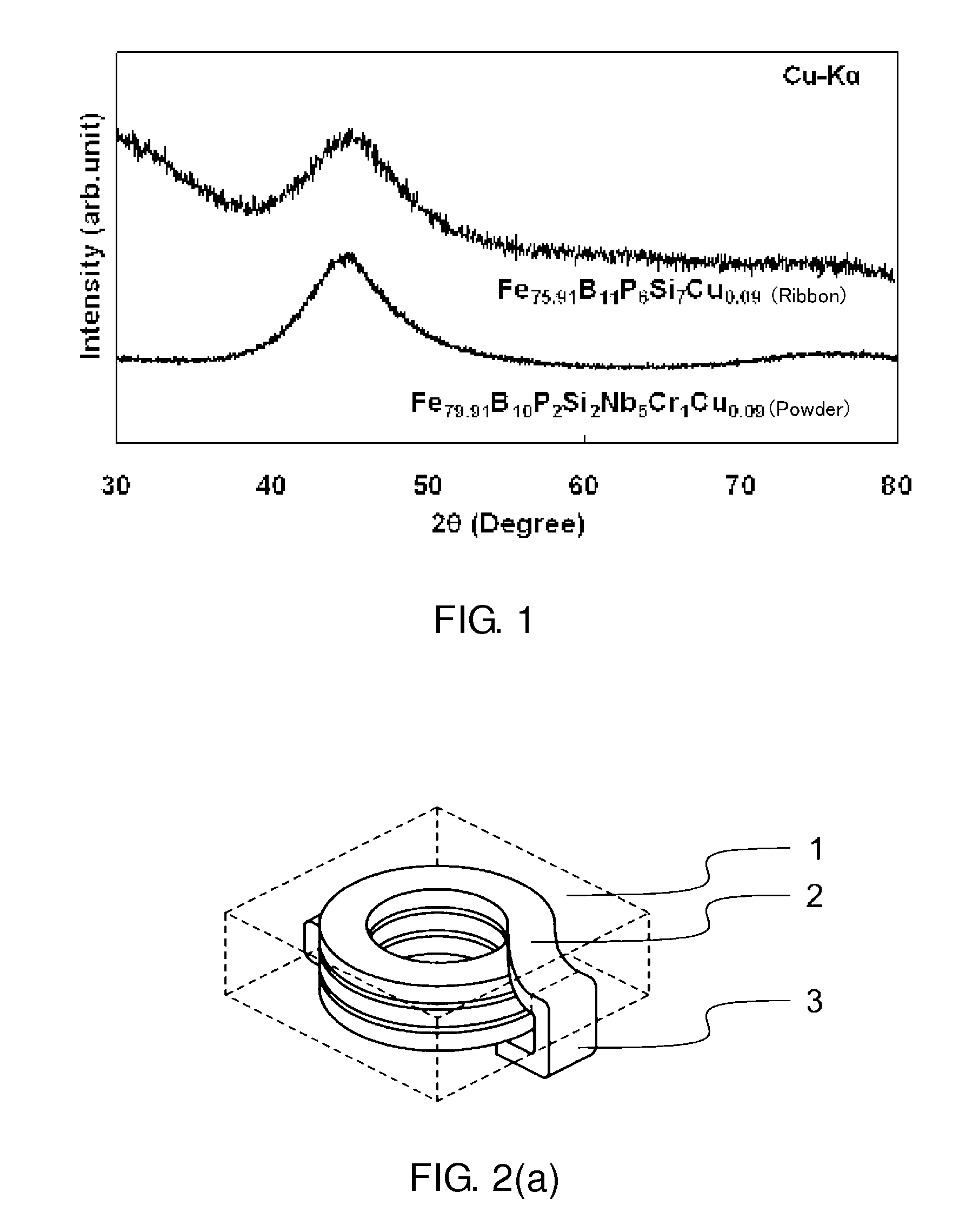

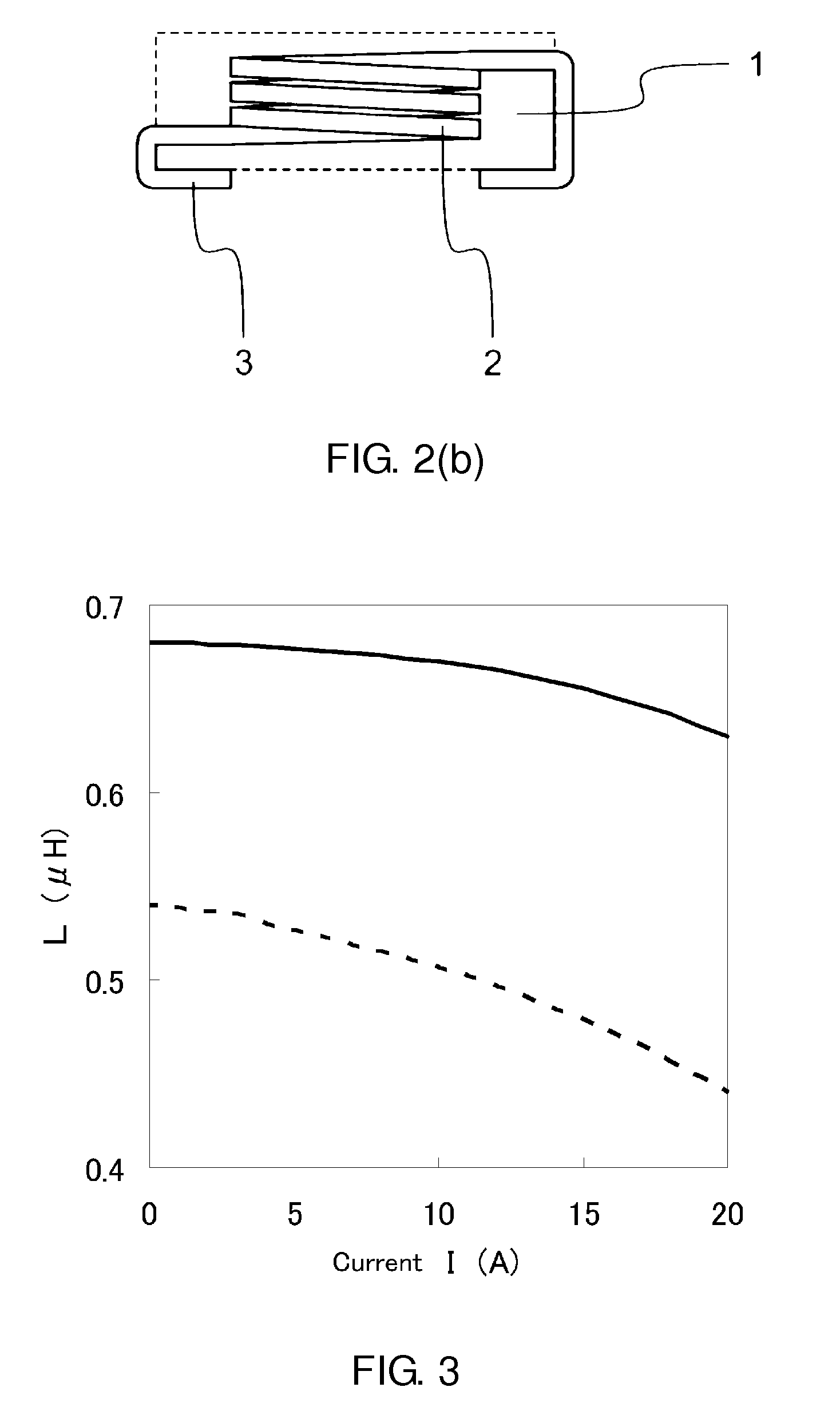

Soft magnetic alloy, magnetic component using the same, and thier production methods

ActiveUS20100097171A1Excellent soft magnetic propertiesGood formabilityTransportation and packagingMetal-working apparatusFe basedMagnetic alloy

A soft magnetic alloy contains P, B, and Cu as essential components. As a preferred example, an Fe-based alloy contains Fe of 70 atomic % or more, B of 5 atomic % to 25 atomic %, Cu of 1.5 atomic % or less (excluding zero), and P of 10 atomic or less (excluding zero).

Owner:TOKIN CORP +2

Packaging film or sheet

InactiveUS6416832B1Good formabilityExcellent gas barrier propertiesFlexible coversWrappersCopolymerPolymer chemistry

The invention provides a single-layer or multi-layer packaging film or sheet having at least one layer formed of a polyamide resin composition, wherein the layer formed of the polyamide resin composition is a layer (A) formed of a polyamide resin composition comprising a copolymer nylon (c) composed of an aliphatic nylon (co)polymer component (1) and an aromatic nylon (co)polymer component (2) in a proportion of at least 5 wt. %.

Owner:KUREHA KAGAKU KOGYO KK

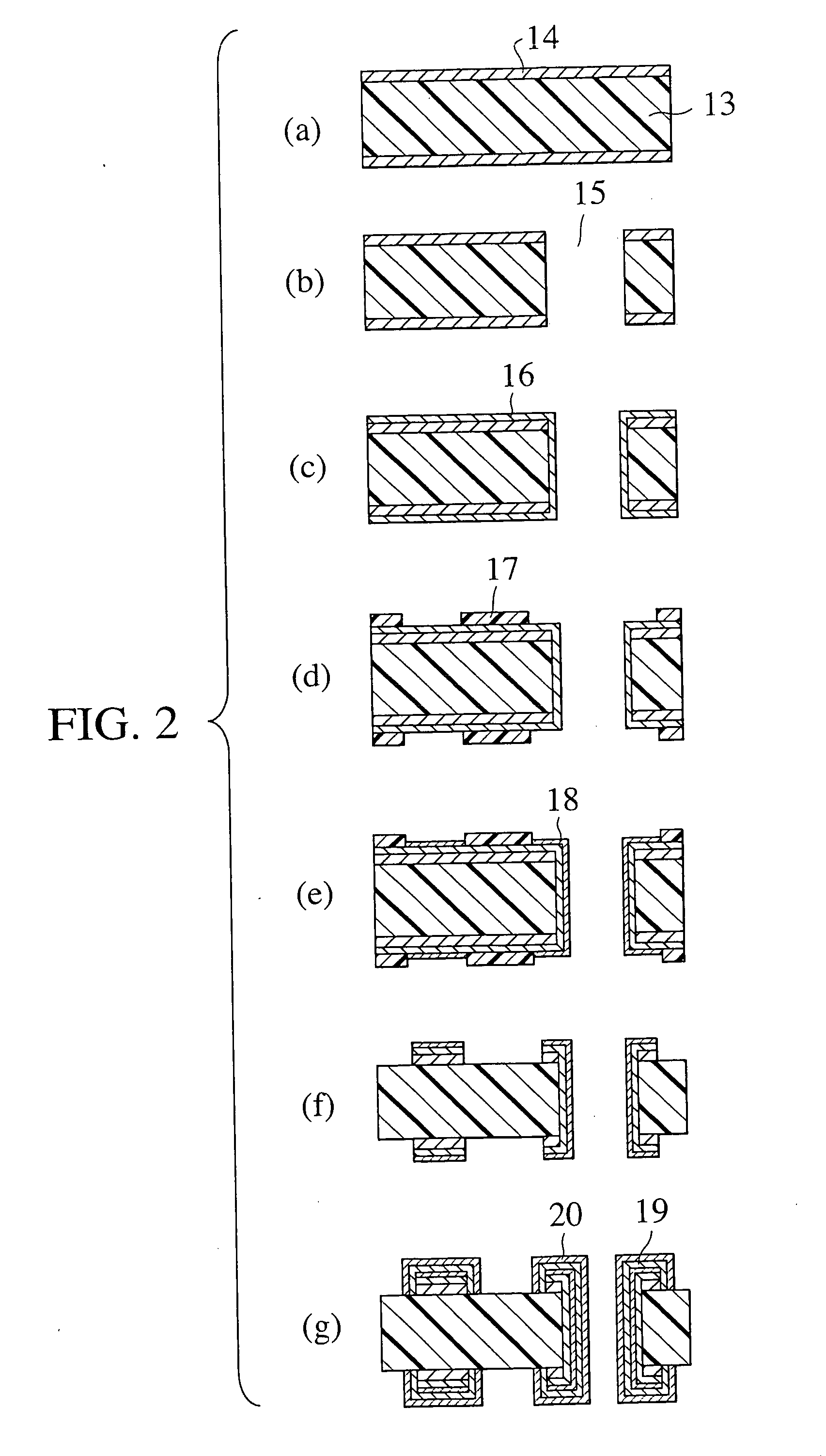

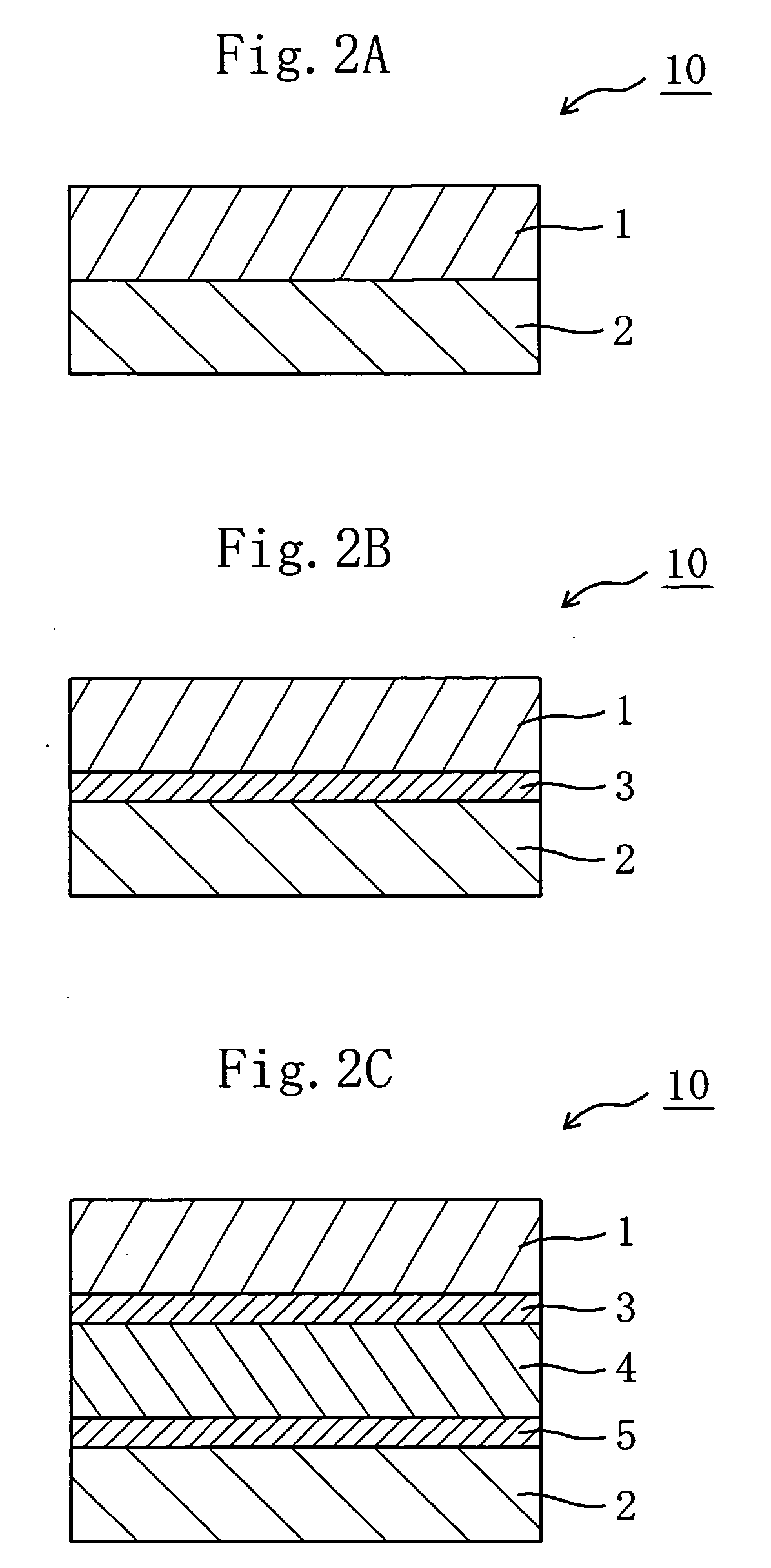

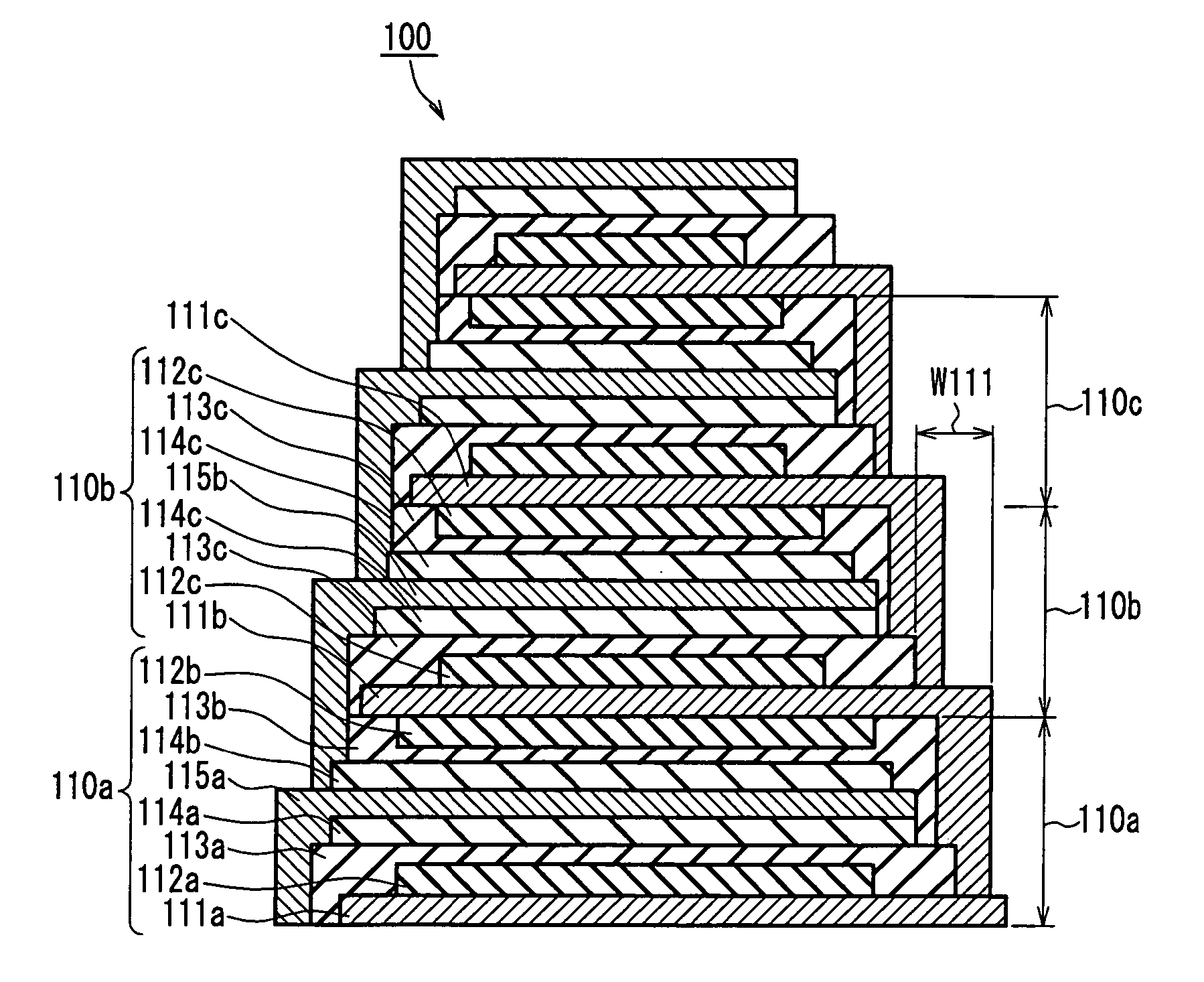

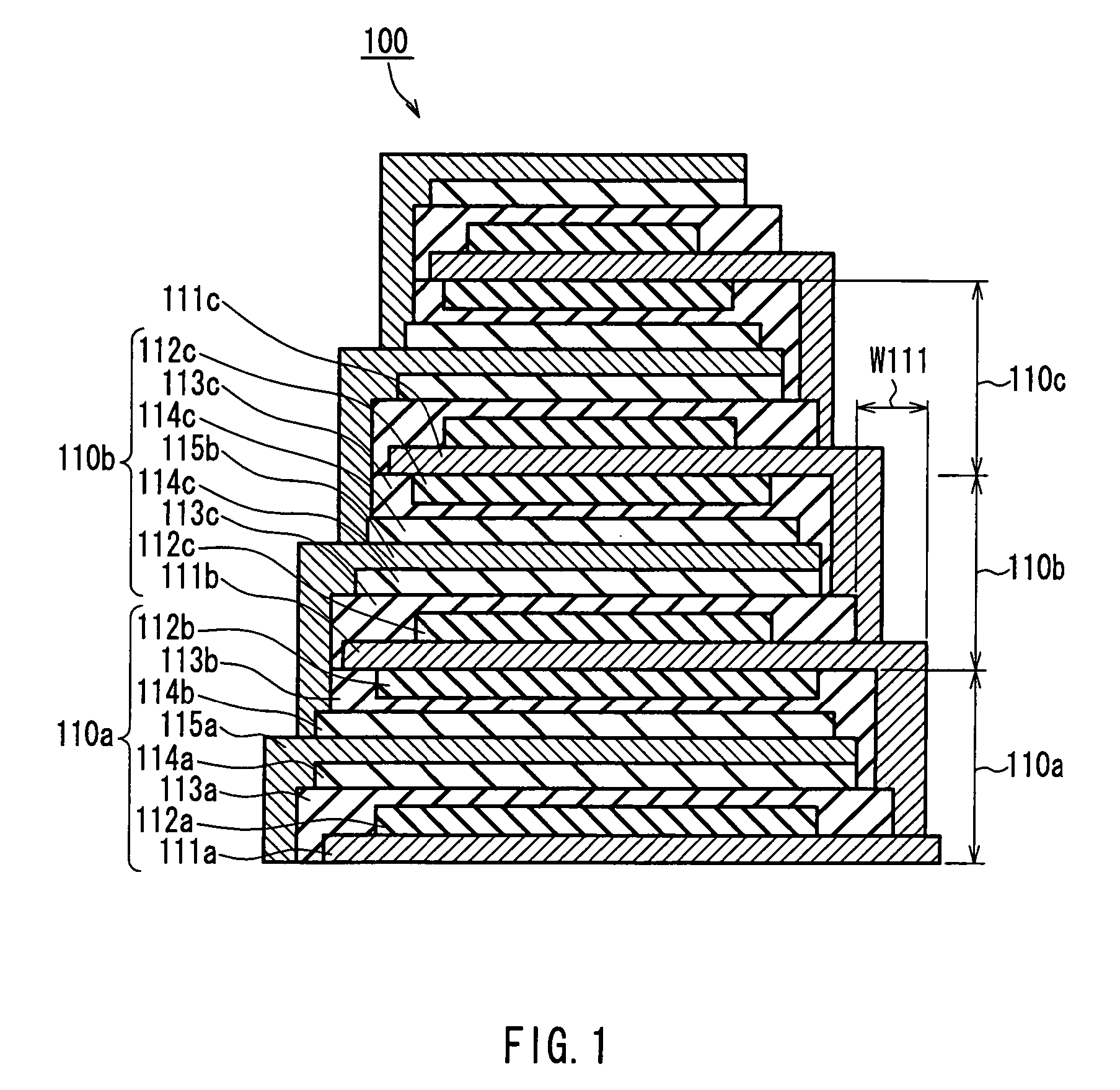

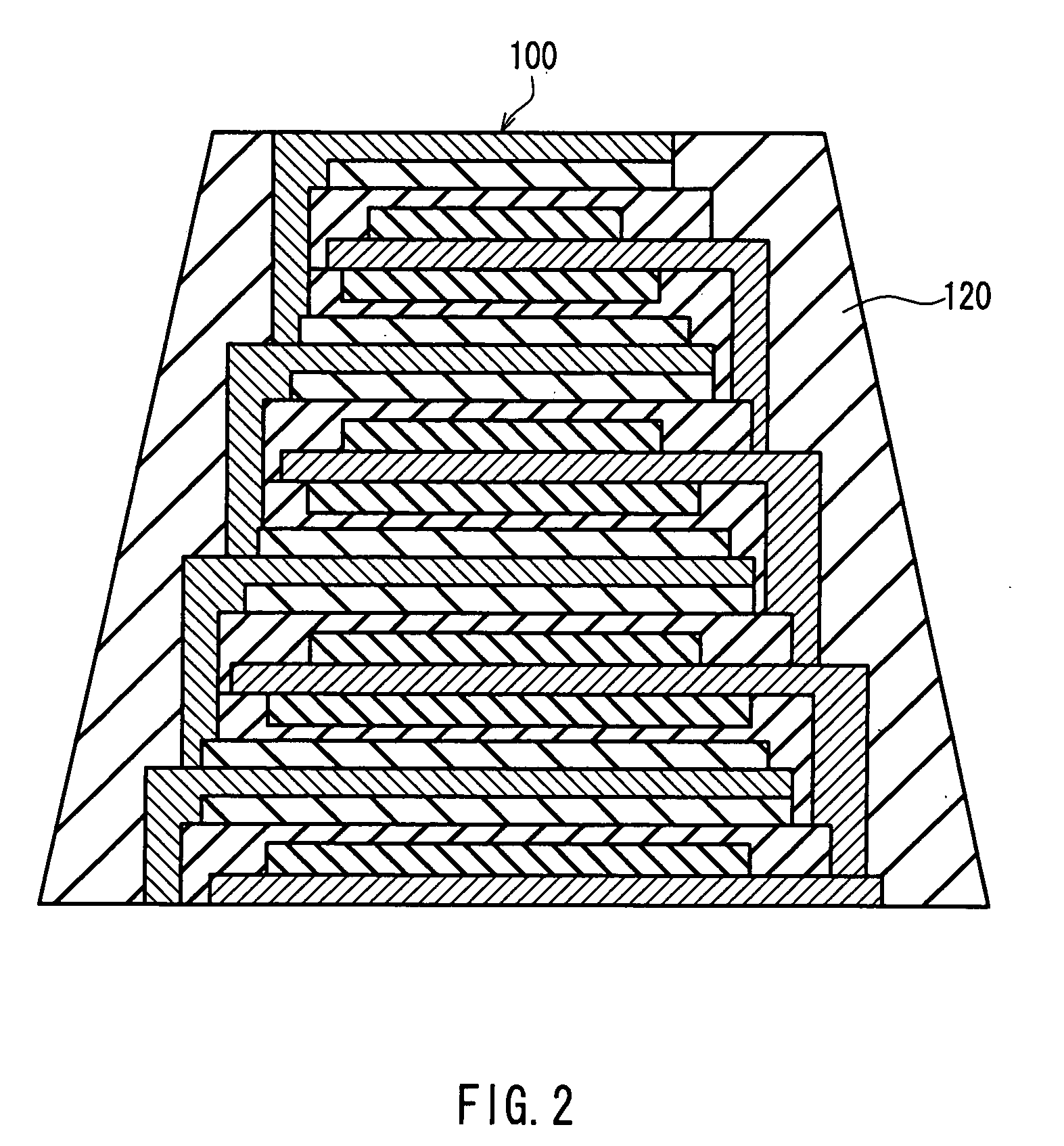

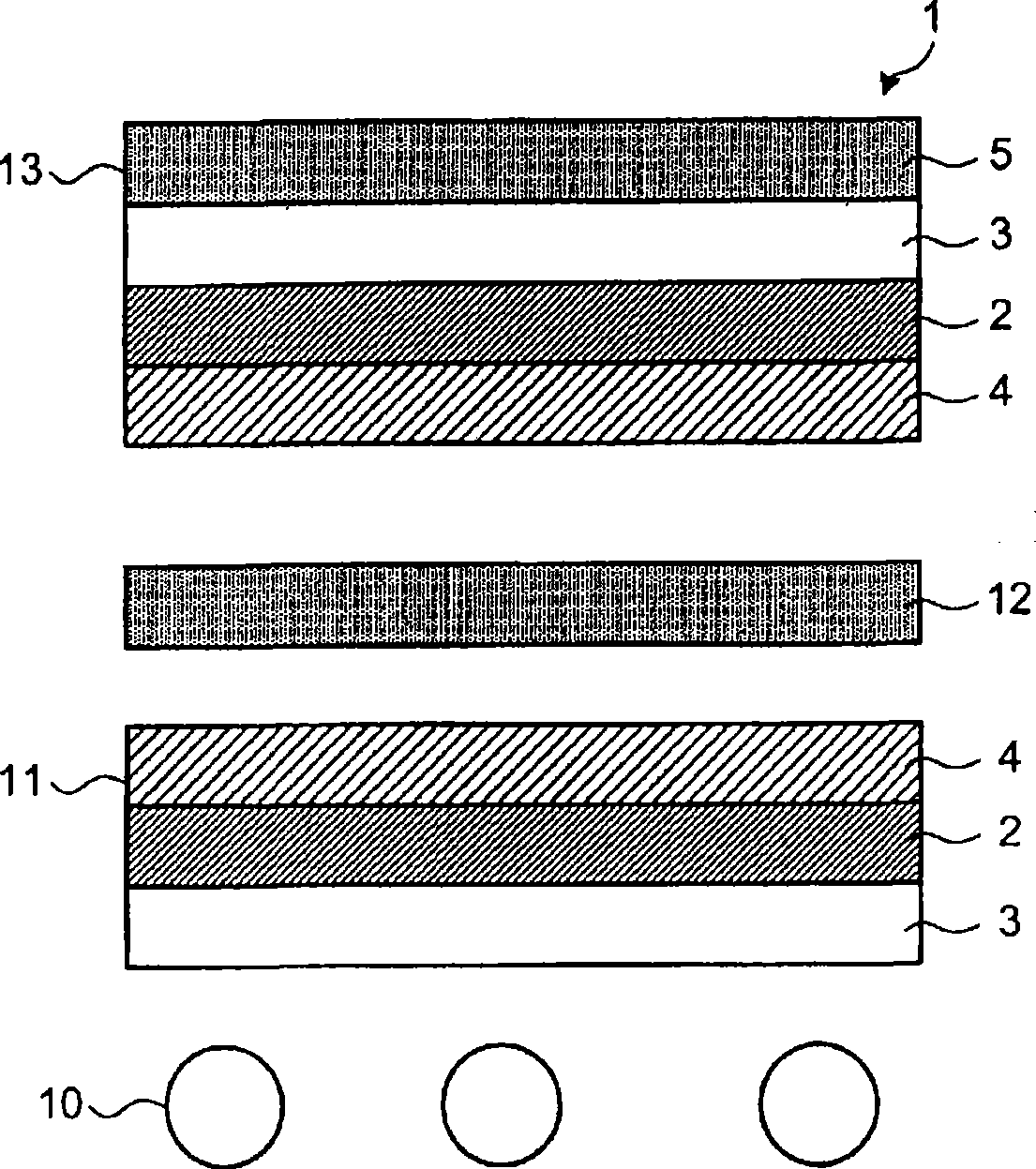

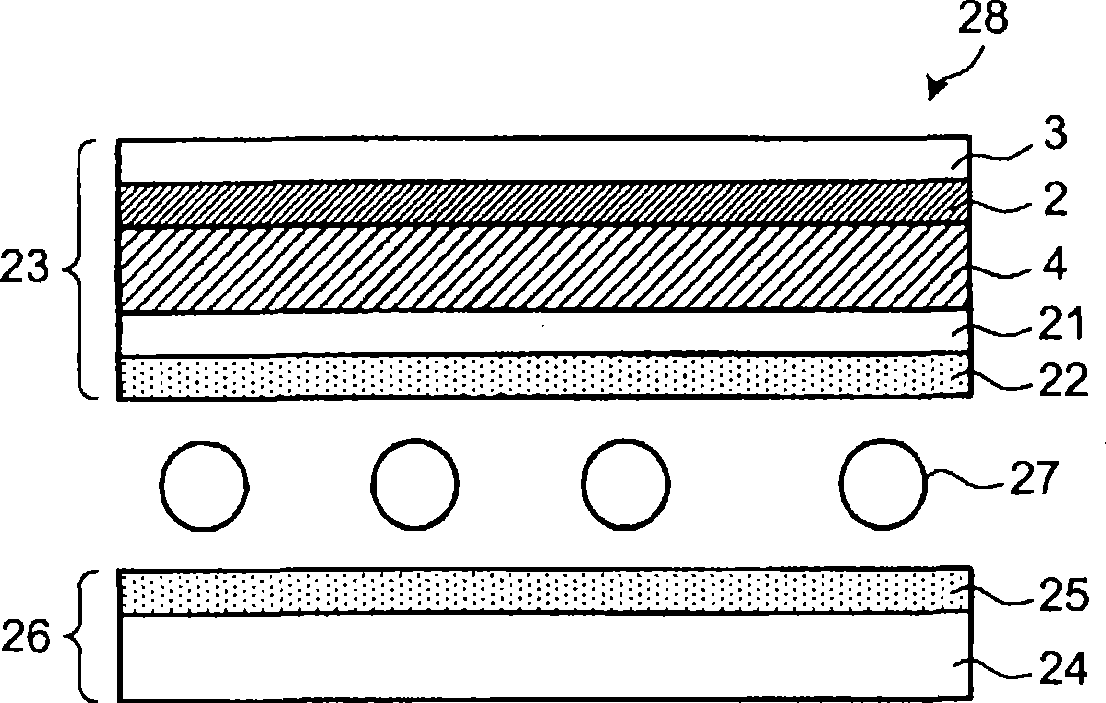

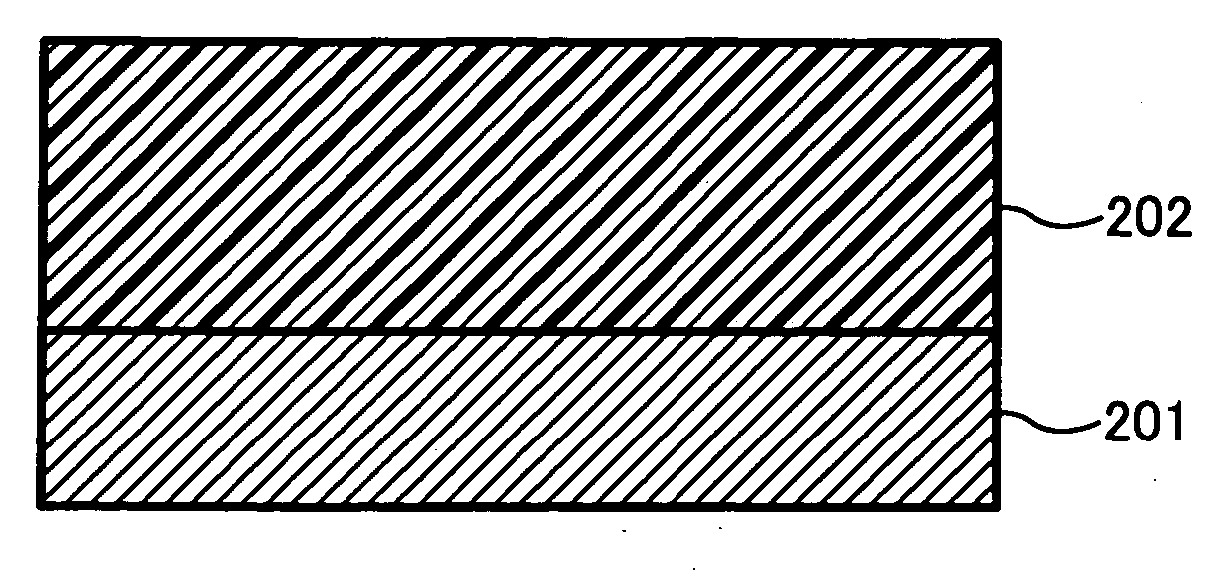

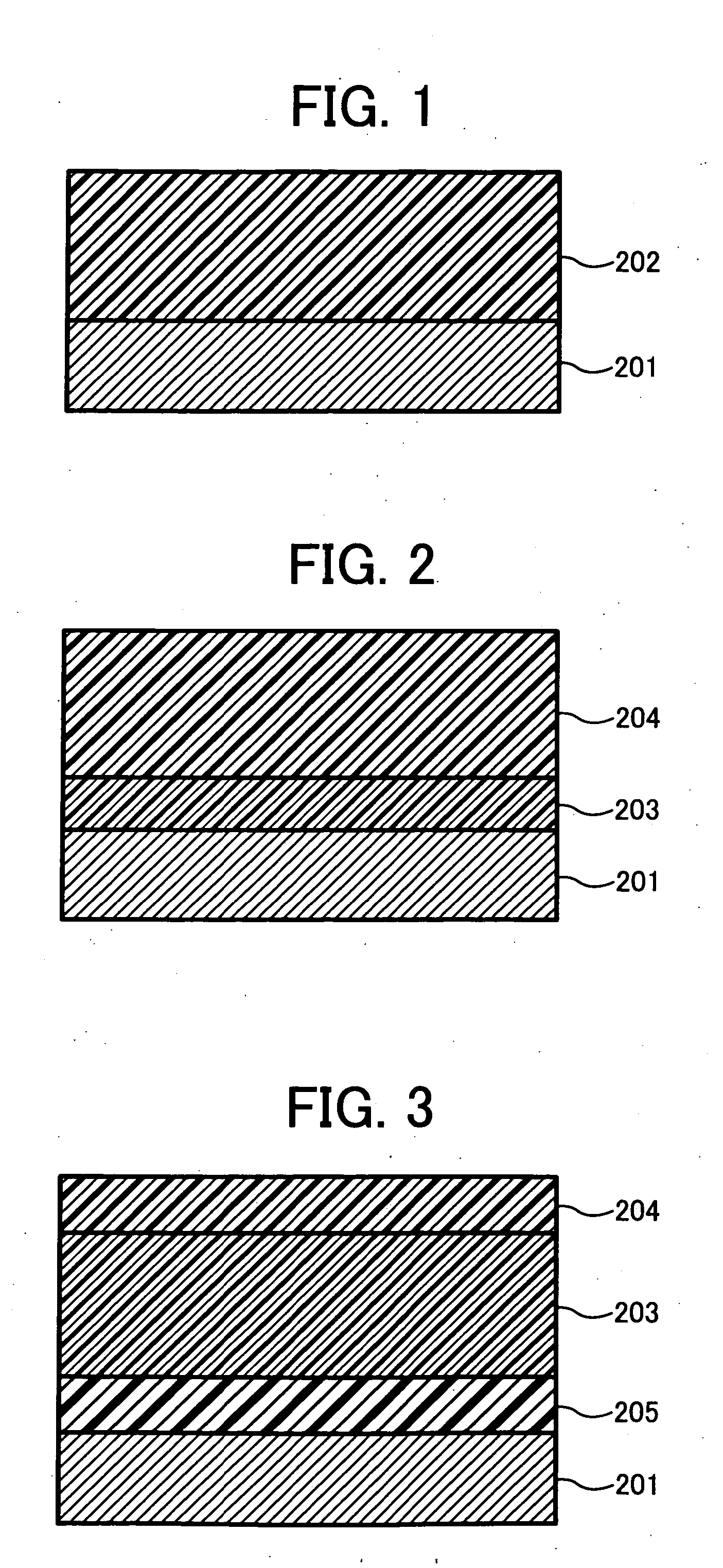

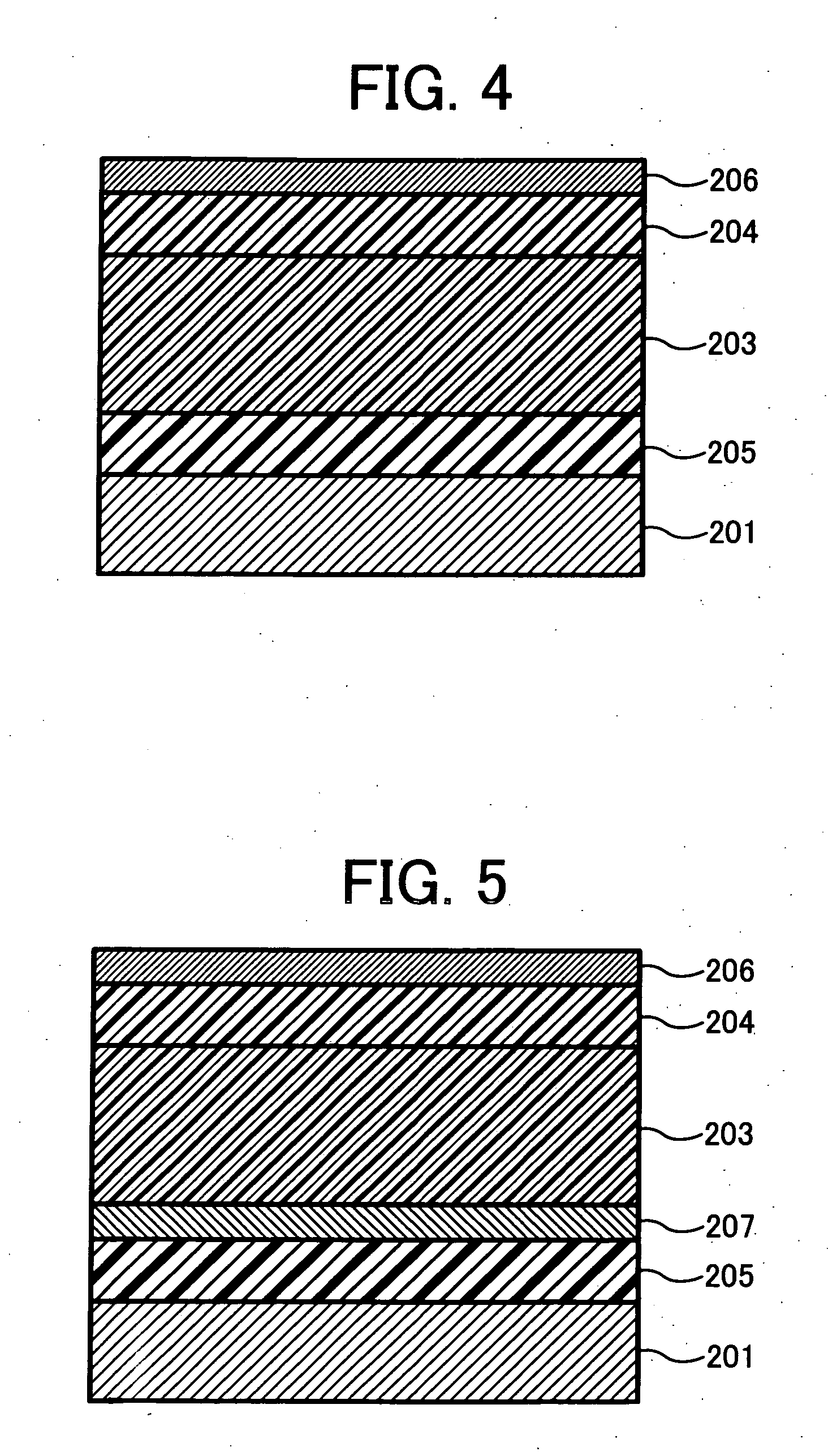

Thin-film laminated body, thin-film cell, capacitor, and method and equipment for manufacturing thin-film laminated body

InactiveUS20050141170A1Improve connection reliabilityQuality improvementCell electrodesFinal product manufactureEngineeringAdhesion strength

A thin film layered product is composed of at least two deposition units, each of which includes at least a first thin film layer and a second thin film layer. At least one of the first thin film layer and the second thin film layer in each of the at least two deposition units is laminated so as to have an area decreased in a direction from a lower layer toward an upper layer. Thus, the reliability of connection between layers can be improved, and when a protective layer is formed on side faces, the formability and adhesion strength can be improved.

Owner:PANASONIC CORP

High Strength Thin-Gauge Steel Sheet Excellent in Elongation and Hole Expandability and Method of Production of Same

InactiveUS20080000555A1High strengthHigh elongationFurnace typesMetal rolling arrangementsSectilityHigh intensity

The present invention provides high strength thin-gauge steel sheet with excellent elongation and hole expandability having a tensile strength of 500 MPa or more and a method of production of high strength thin-gauge steel sheet with excellent elongation and hole expandability enabling production of this on an industrial scale, that is, high strength thin-gauge steel sheet comprised of, by mass %, C: 0.03 to 0.25%, Si: 0.4 to 2.0%, Mn: 0.8 to 3.1%, P≦0.02%, S≦0.02%, Al≦2.0%, N≦0.01%, and a balance of Fe and unavoidable impurities and having a microstructure comprised of ferrite with an area fraction of 10 to 85% and residual austenite with a volume fraction of 1 to 10%, an area fraction of 10% to 60% of tempered martensite, and a balance of bainite.

Owner:NIPPON STEEL CORP

Fire-retardant polyolefin based wood plastic composite material and preparation method thereof

ActiveCN102321374AGood smoke suppression performanceExcellent flame retardancy and mechanical propertiesPolyolefinEnvironmentally friendly

The invention discloses a fire-retardant polyolefin based wood plastic composite material and a preparation method thereof, and relates to a wood plastic composite material and a preparation method thereof, and the composite material and method provided by the invention can be used for solving problems that the existing fire-retardant wood plastic composite material has high heat release efficiency in burning and high smoke production, and can generate CO harmful gas easily. The flame-retardant polyolefin based wood plastic composite material is prepared from wood fiber materials, plastics, acoupling agent, a lubricant, an antioxidant, a nano inorganic fire retardant and a mineral filler. The method comprises the following steps: putting the wood fiber materials, the coupling agent and the lubricant into a high-speed mixing machine for hot mixing; then putting into a cold mixing machine for cold mixing, sending the plastics, the antioxidant, the nano inorganic fire retardant and the mineral filler into the cold mixing machine and then mixing; and then carrying out fusing and extruding for granulation by adopting extruding, injection, hot compressing or mold compression for molding, thus the fire-retardant polyolefin based wood plastic composite material is obtained. The wood plastic composite material provided by the invention has low heat release rate in burning and less smoke production, and is healthy and environmentally-friendly, and can be widely applied to the fields of indoor construction, decoration and furnishing materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Ultraviolet-cured hydrophilic coating composition and preparation method thereof

InactiveCN102585691AHigh content of hydrophilic substancesCreate pollutionPolyurea/polyurethane coatingsPolyether coatingsHydrophilic coatingPolymer science

The invention relates to a highly-hydrophilic transparent ultraviolet-cured coating composition and a preparation method thereof. The ultraviolet-cured hydrophilic coating composition comprises light-cured resin, a polymerization monomer, a reactive diluent, a light initiator, an auxiliary and pigment. The preparation method comprises accurately weighing the light-cured resin according to a formula and pouring the light-cured resin into a mixing kettle, sequentially adding the polymerization monomer, the reactive diluent and the auxiliary into the mixing kettle, and stirring the mixture for 20-45 minutes; adding the light initiator into the mixing kettle, mixing for 15-35 minutes to obtain ultraviolet-cured hydrophilic coating, and storing the ultraviolet-cured hydrophilic coating away from the light; and when the ultraviolet-cured hydrophilic coating is used, adding the pigment and performing even mixing. The ultraviolet-cured hydrophilic coating composition can be coated on base materials of plastic, metal, glass and the like. An ultraviolet-cured coating has excellent hydrophilcity and good physical performance, adhesive force, hydrolytic resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

Polarizing plate, liquid crystal display and protective film

ActiveCN101460306AImprove scratch resistanceHigh mechanical strengthSynthetic resin layered productsPolarising elementsVisibilityTectorial membrane

Disclosed is a polarizing plate having high mechanical strength, while being excellent in flexibility and abrasion resistance. This polarizing plate is not deteriorated in visibility even under high temperature, high humidity conditions, and hardly suffers from visibility obstacles such as color shading due to dimensional change. Also disclosed is a liquid crystal display using such a polarizing plate. A film mainly containing a thermoplastic resin and composed of a plurality of layers is employed as a first protective film used on the viewer side of the polarizing plate, and at least one surface layer of the first protective film is mainly composed of an acrylic resin. A second protective layer having specific characteristics is arranged on the liquid crystal cell side.

Owner:ZEON CORP

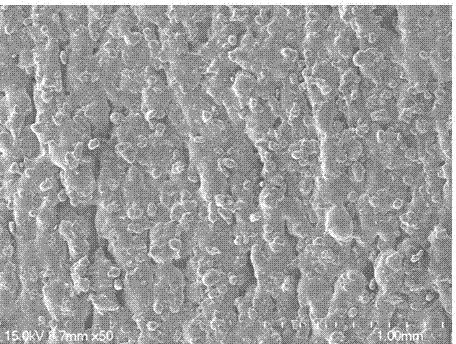

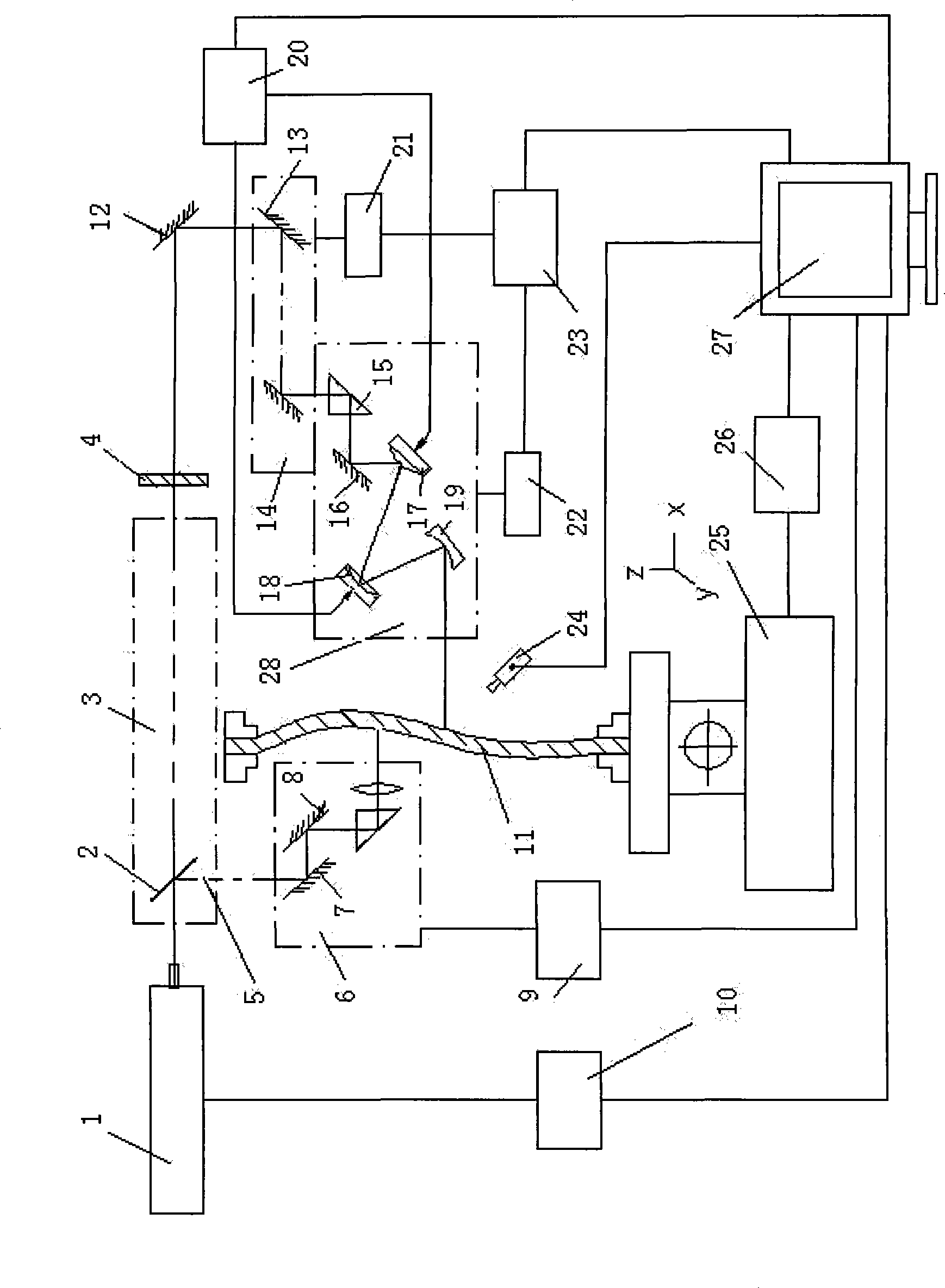

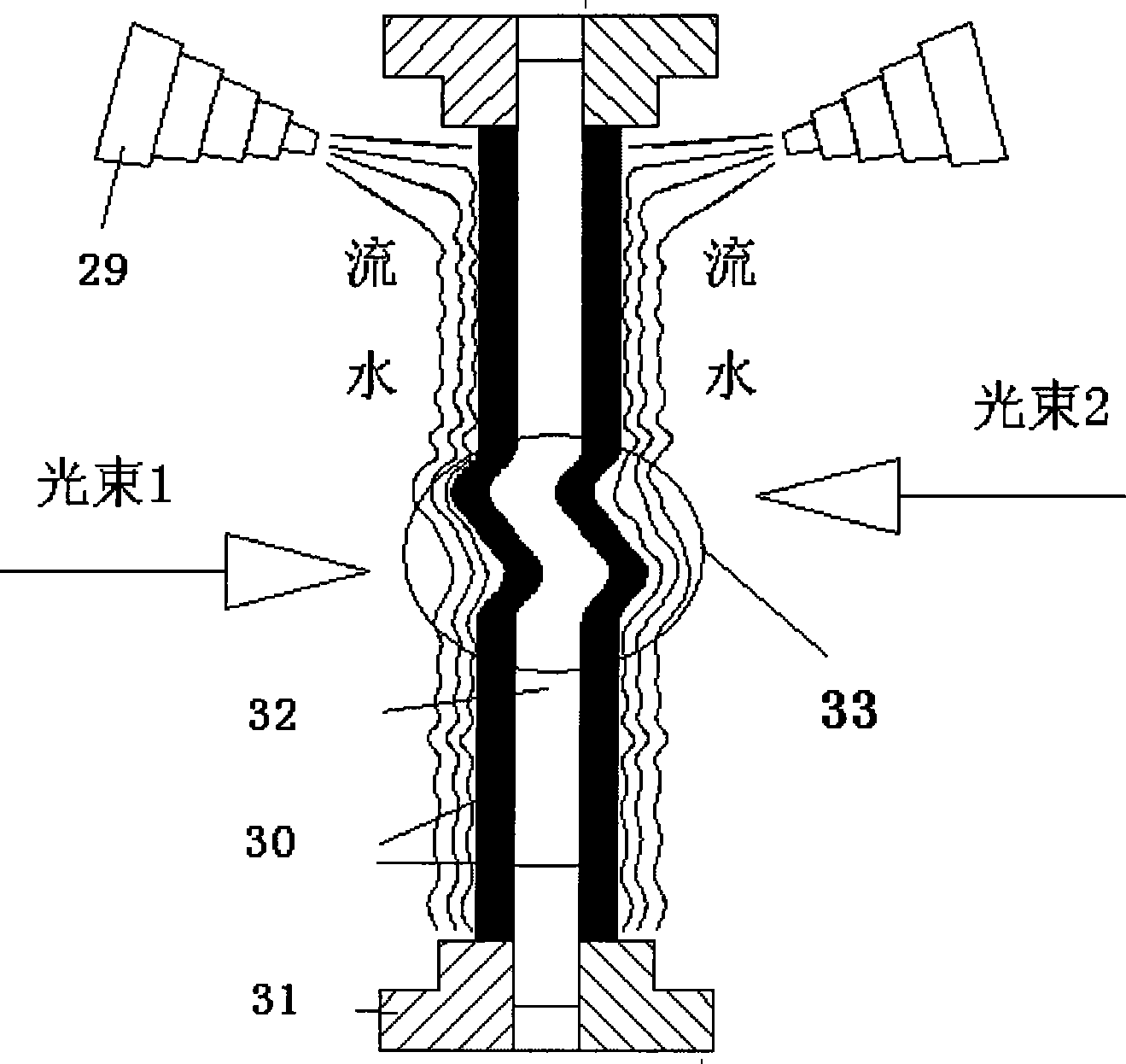

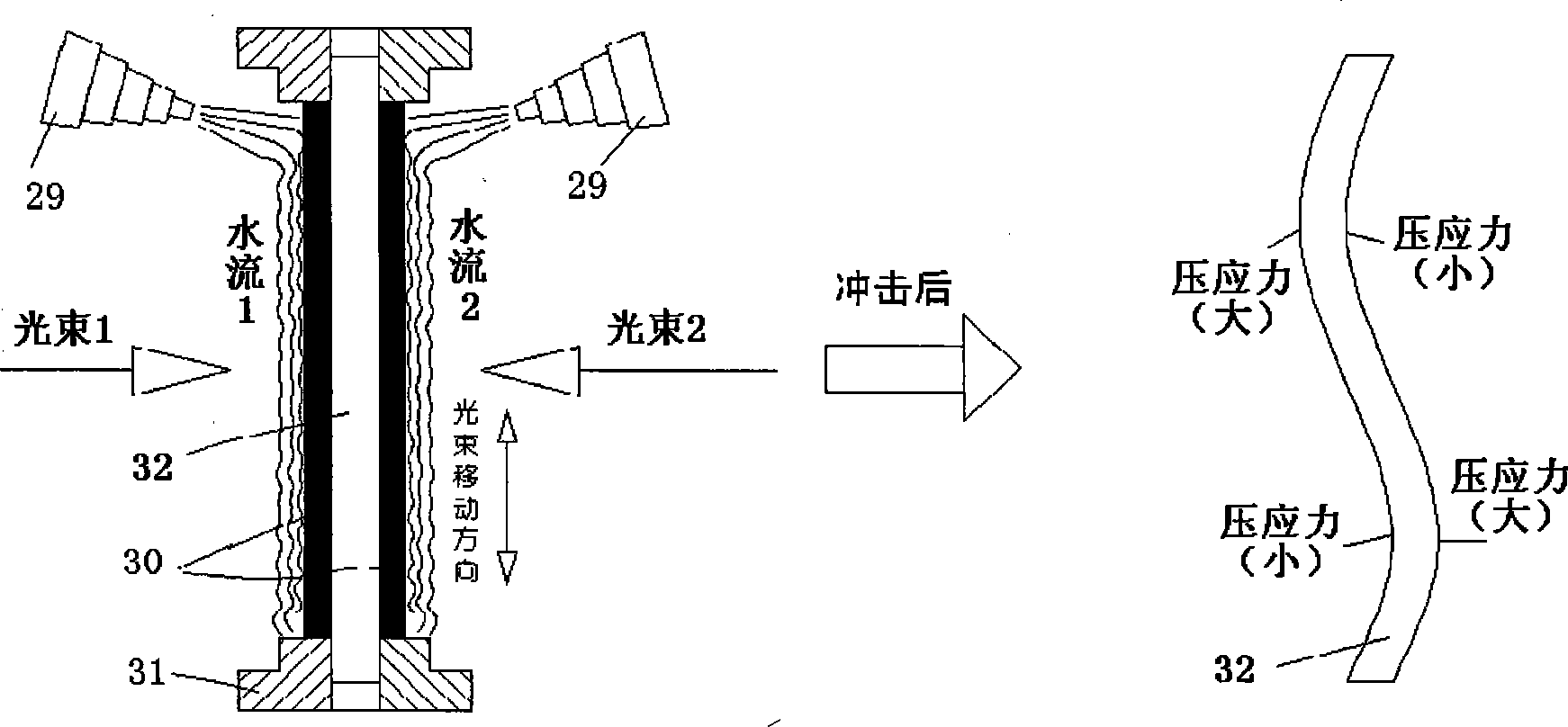

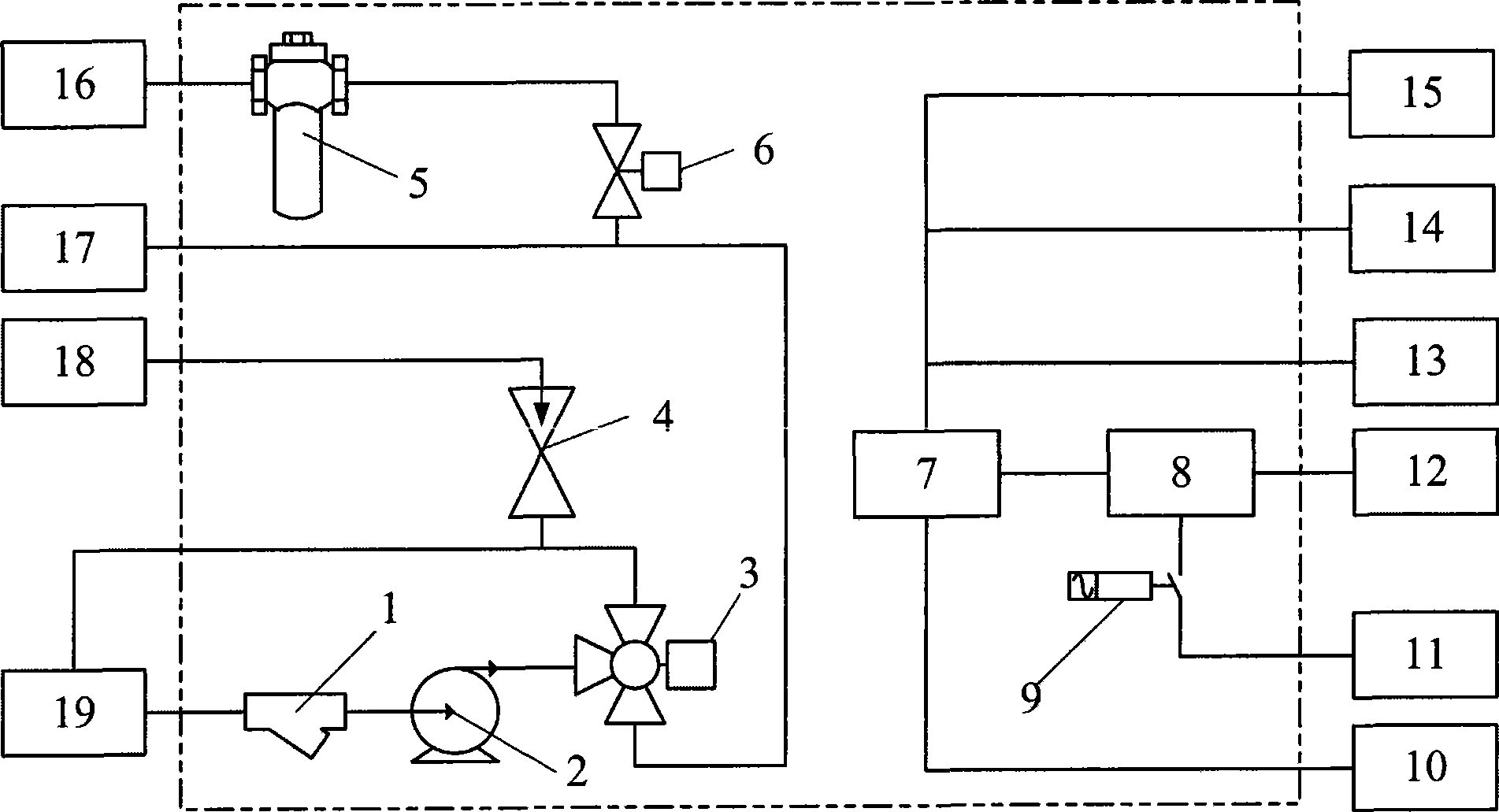

Sheet material double face precise forming method and apparatus based on laser blast wave effect

InactiveCN101249588AImprove surface propertiesPrecise workpiece contourLaser beam welding apparatusEnergy absorptionOptical processing

The invention relates to the field of laser processing manufacture, in particular to a laser shock precision forming method and a device. The device comprises a laser, an outer light path system, a laser shock head system A, a flying optical processing system with a laser shock head system B, a test sample system, a detection feedback system, a multi-axis link machine tool and a tool fixture system, a central control processor and a control system. A laser beam emitted by the laser is split by the outer light path system and are respectively transmitted to the front and the rear surfaces of a workpiece to subject the front and the rear surfaces of the double-sided workpiece with an energy absorption layer and a confinement layer to laser-induced shock wave. According to the requirements of the shape and the formation rule of a plate material, the double-sided laser shock head can execute simultaneous and non-simultaneous shock, counter shock, staggered shock, shocks with same and different energy, etc., so that the plate material is formed by generating a certain plastic deformation and a stress field distribution and that a certain residual stress is formed on the surface of the plate material. The method can achieve accurate quantitative formation, good repeatability and high forming efficiency, and can easily achieve automatic production.

Owner:JIANGSU UNIV

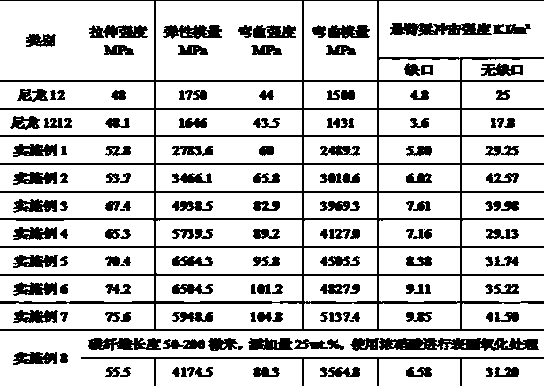

Carbon fiber reinforced resin powder material for selective laser sintering

The invention relates to a carbon fiber reinforced resin powder material for selective laser sintering (SLS). The powder material comprises 48-88 parts by mass of resin powder, 10-50 parts by mass of carbon fibers, 0.5-1.2 parts by mass of antioxidants, 0.2-1 part by mass of flow promoting agent and 0.2-0.6 parts by mass of dispersant per 100 parts by mass of the reinforced material. The carbon fiber reinforced resin powder material for selective laser sintering is obtained by configuring the each component sequentially according to a certain process. The strength and modulus of SLS molded parts made of the resin powder material disclosed by the invention, compared with SLS molded parts made of the matrix resin material, are greatly enhanced and the requirements on the mechanical performance of the molded parts directly as end products can be met better.

Owner:HUNAN FARSOON HIGH TECH CO LTD

High-strength hot dip zinc plated steel sheet having excellent moldability, and method for production thereof

ActiveCN101641456AGood formabilityHot-dipping/immersion processesNanotechnologySheet steelChemical composition

Disclosed is a high-strength hot dip zinc plated steel sheet having excellent moldability, which has a ¢TS OE(total elongation)! value of 15000 MPa % or more and a ¢TS OE(hole expanding rate)! value of 45000 MPa % or more as measured on a steel having a tensile strength of 780 MPa or more under such conditions where the amount of Al added is at the same level as employed in the conventional deoxidization. Also disclosed is a method for producing the steel sheet. Specifically disclosed is a high-strength hot dip zinc plated steel sheet having excellent moldability, which has the following chemical composition (by mass): C: 0.05 to 0.3%, Si: more than 0.60% and not more than 2.0%, Mn: 0.50 to 3.50%, P: 0.003 to 0.100%, S: 0.010% or less, Al: 0.010 to 0.06%, and N: 0.007% or less, with the remainder being Fe and unavoidable impurities, wherein the steel sheet structure has a standard deviation of the nano-hardness of 1.50 GPa or less.

Owner:JFE STEEL CORP

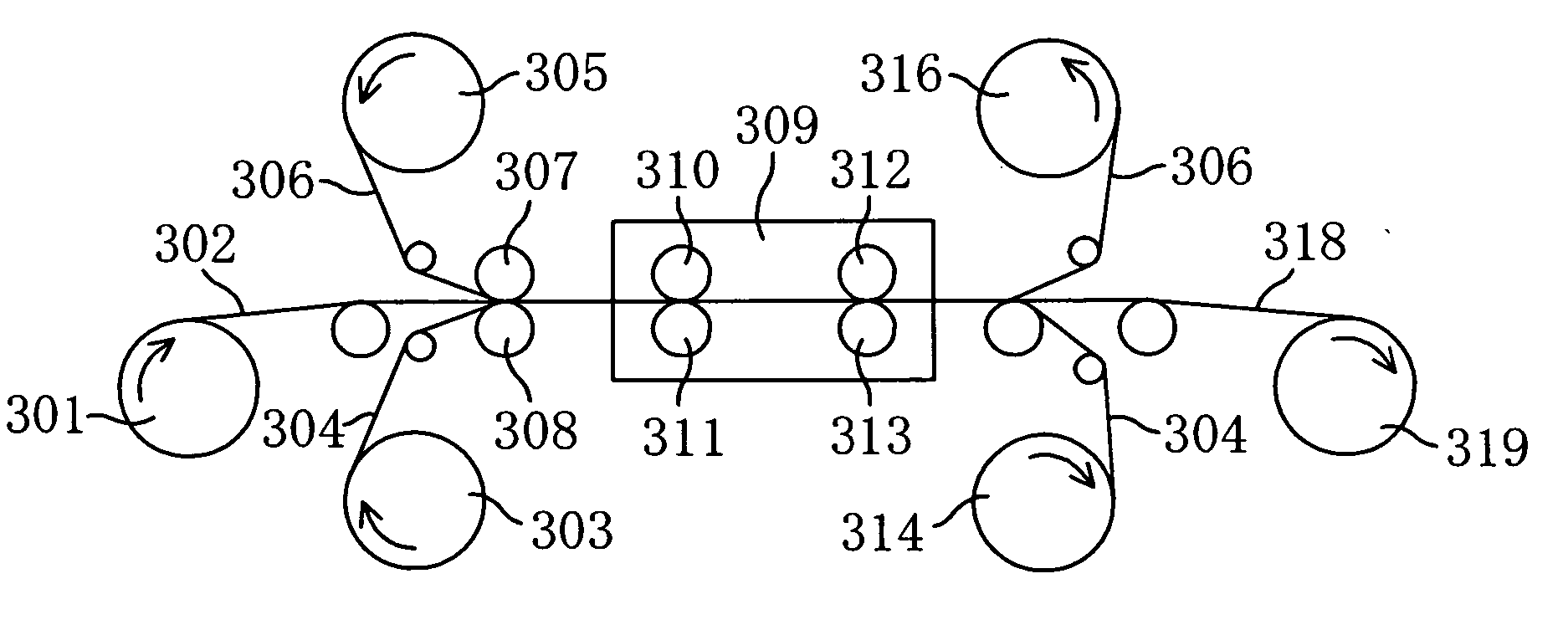

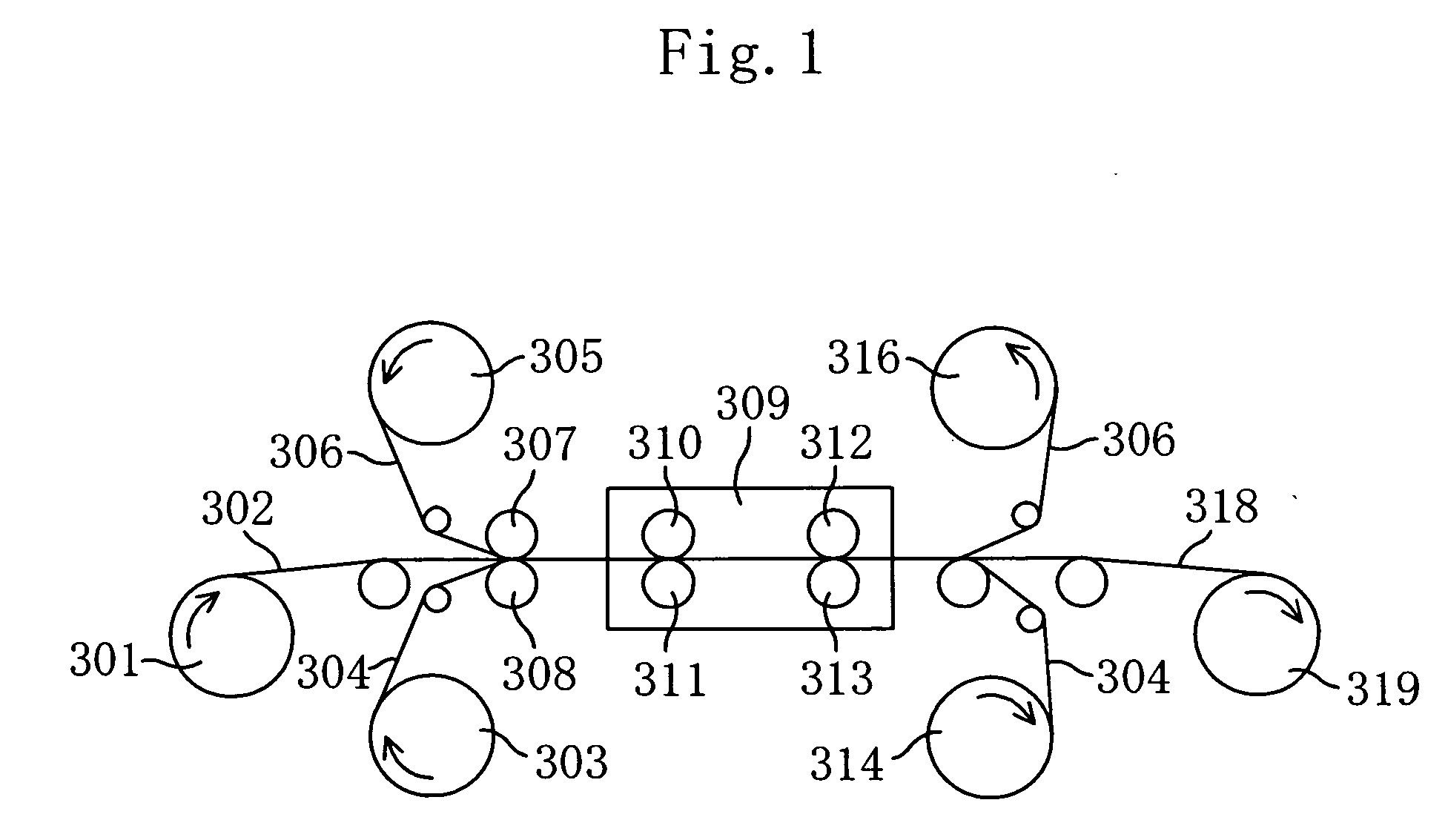

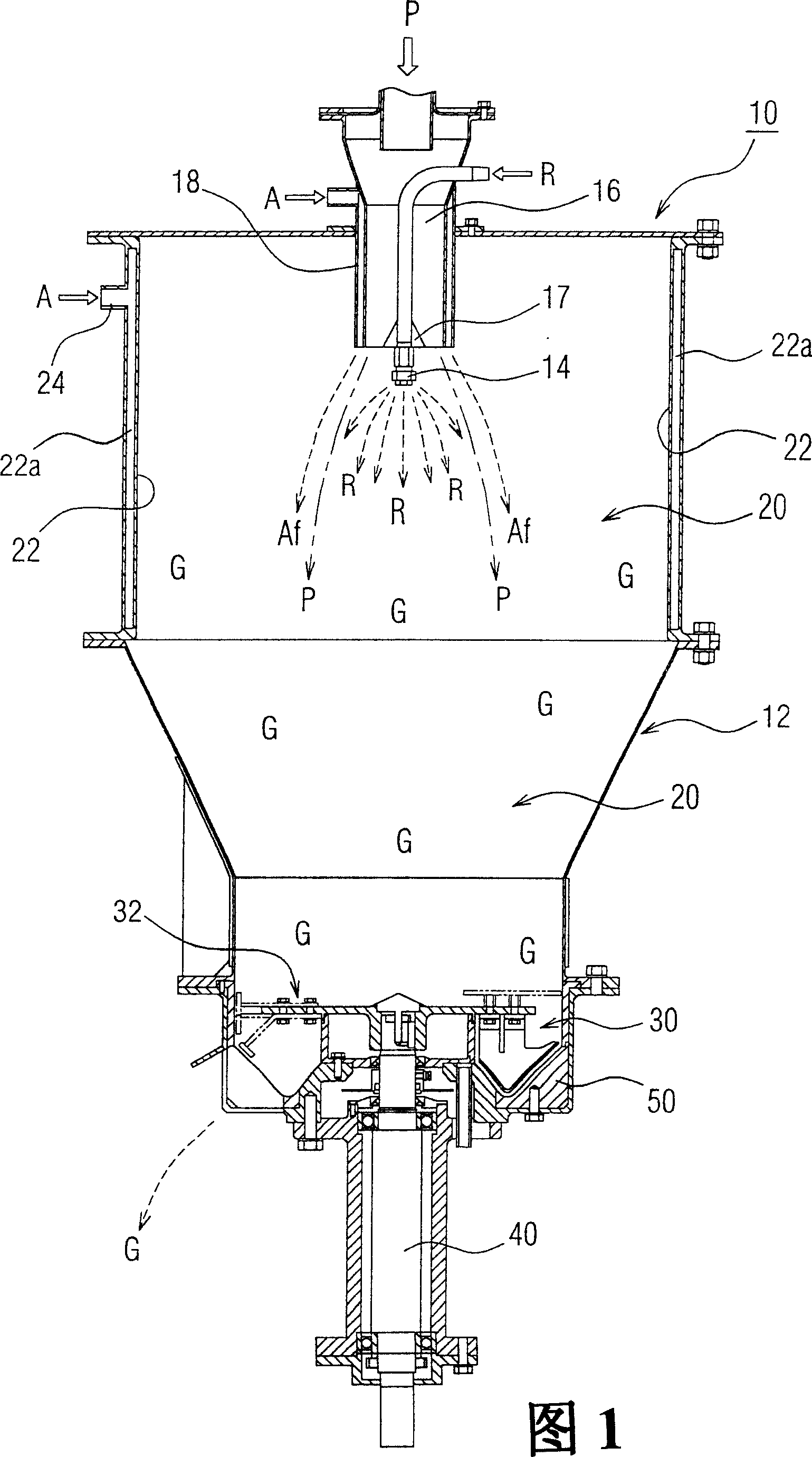

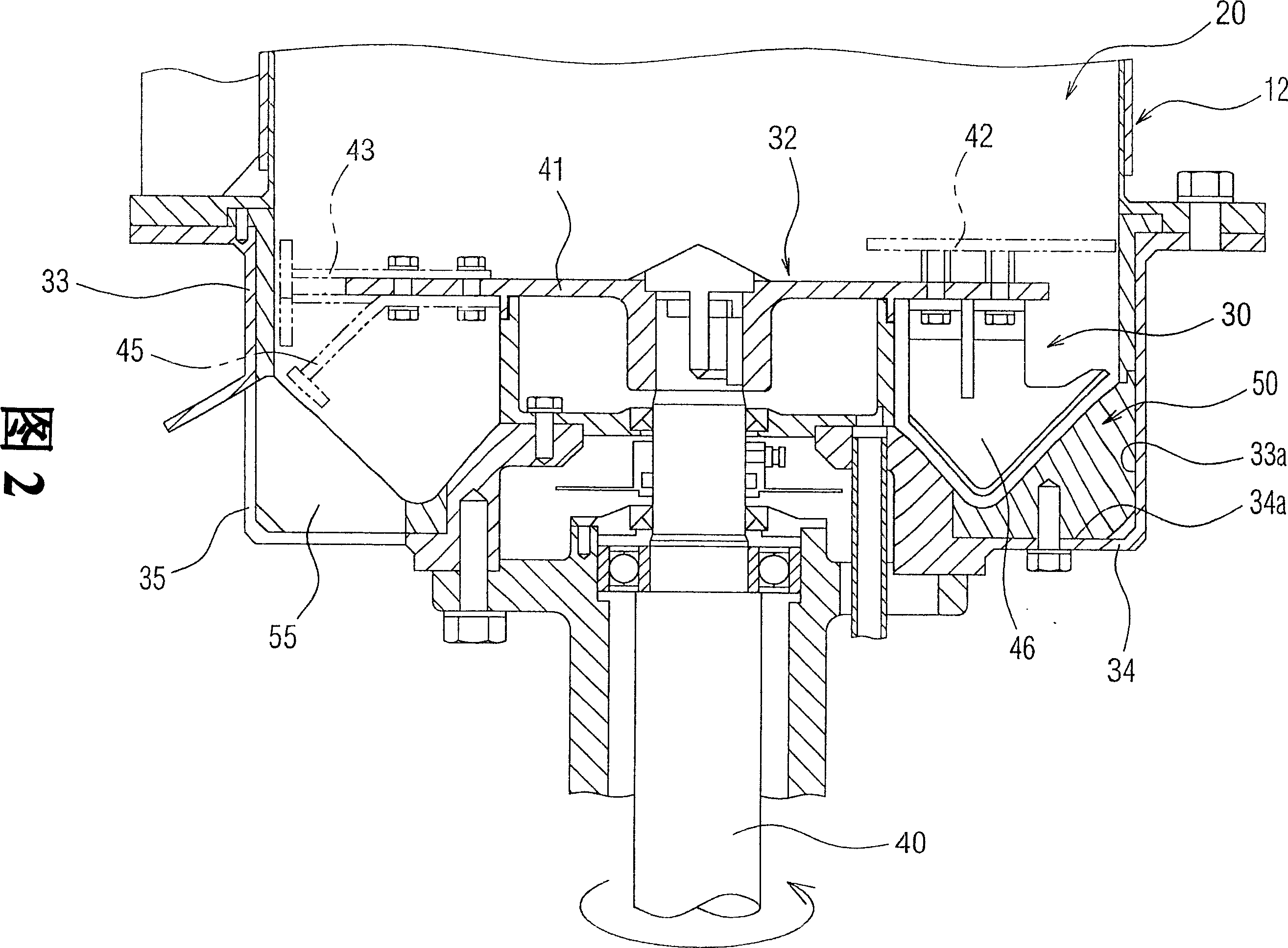

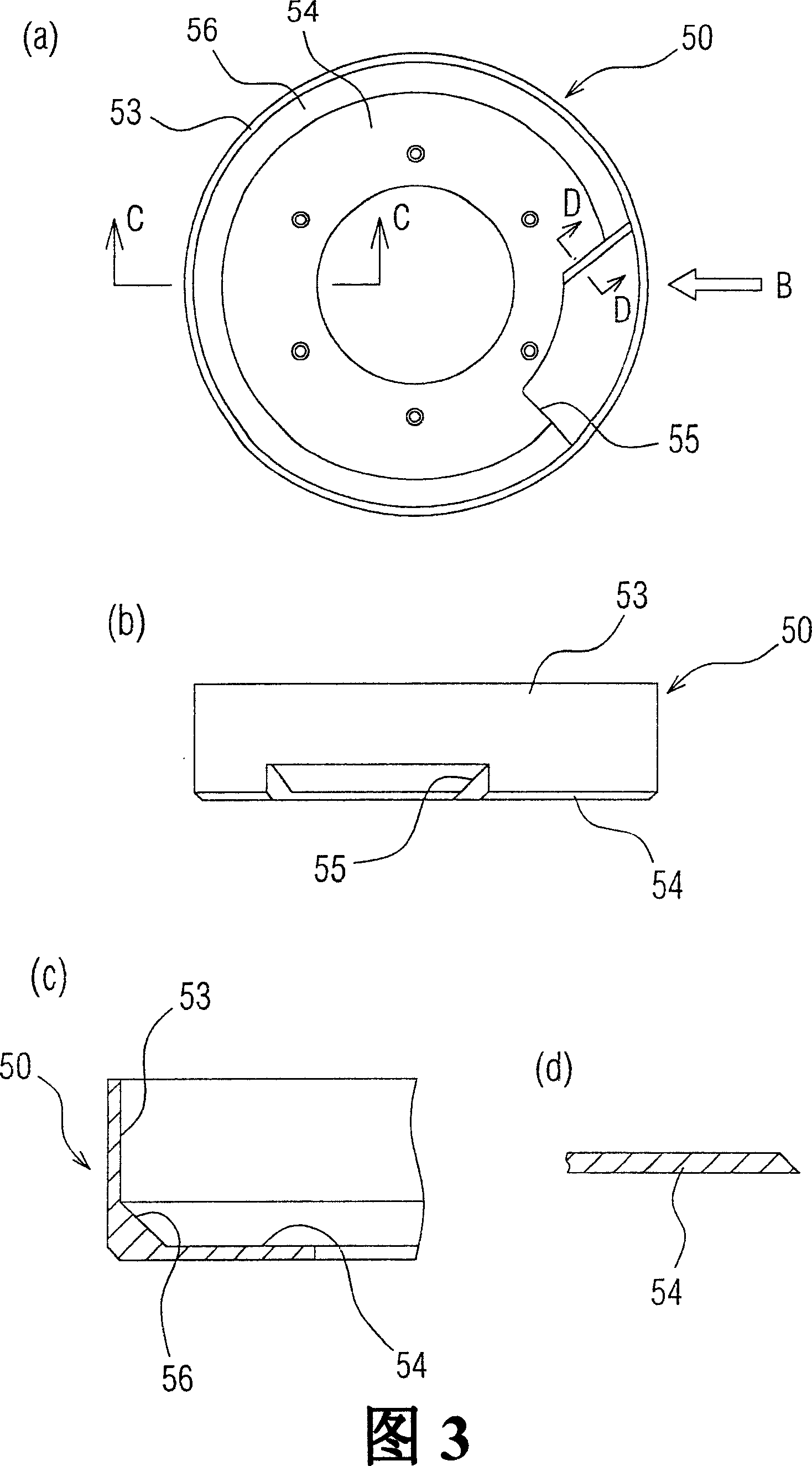

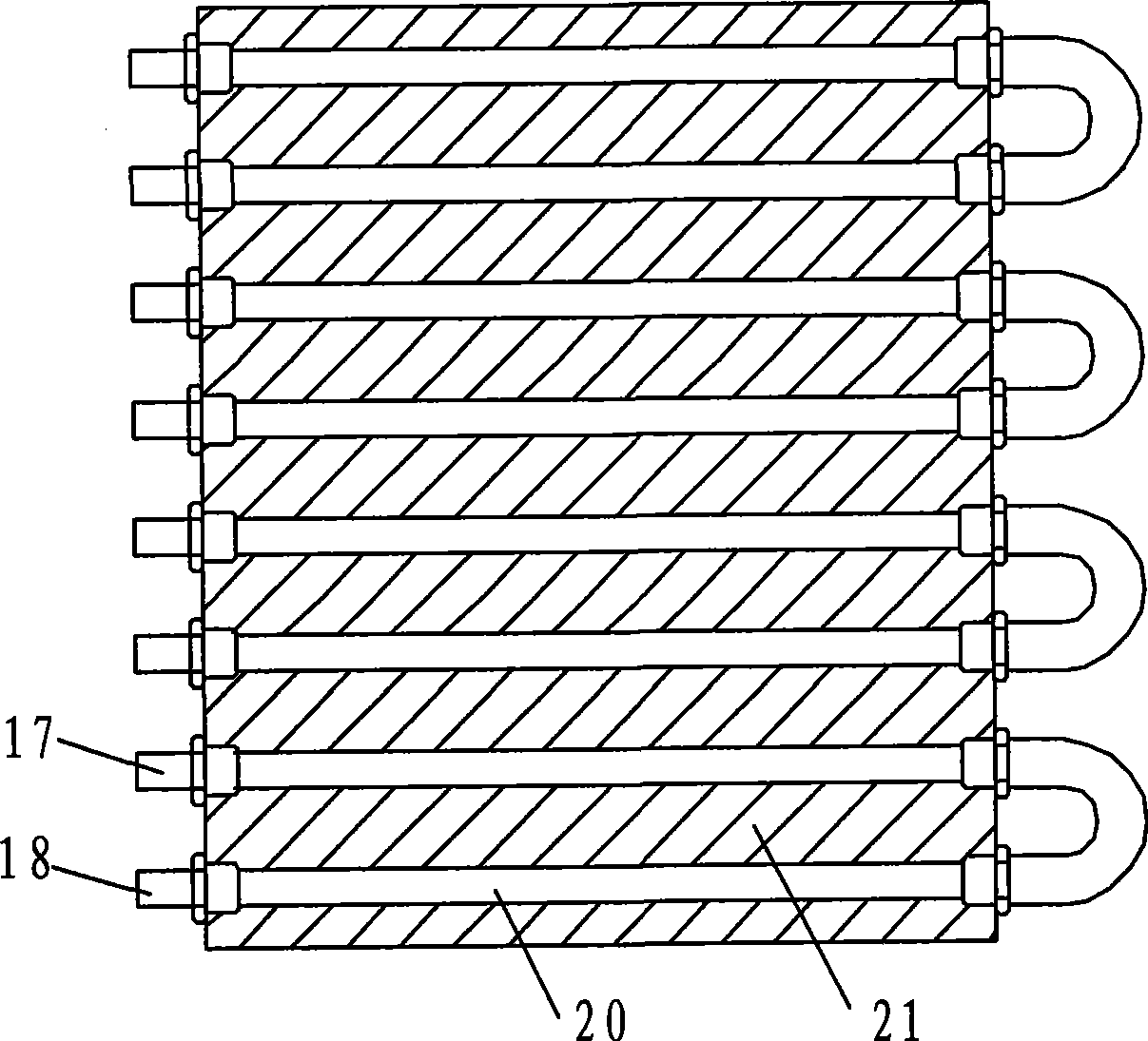

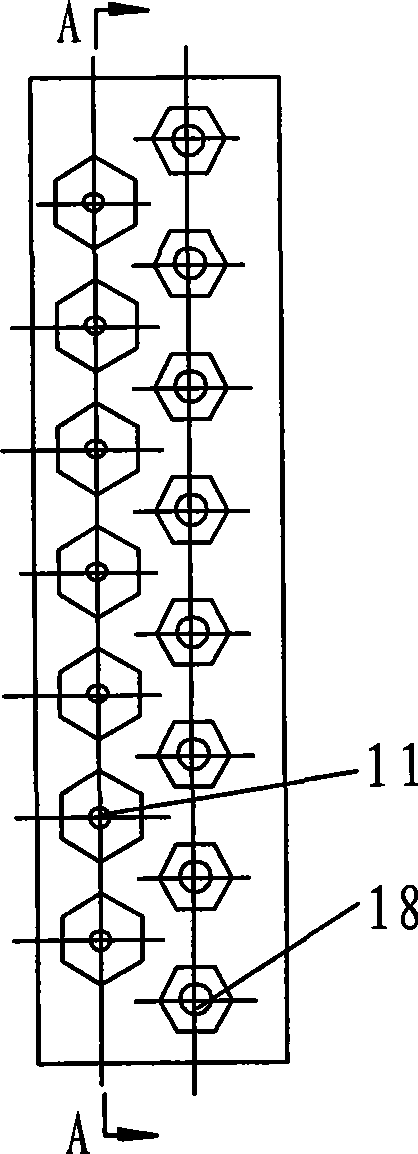

Method and apparatus for granulating by mixing powder and liquid continuously

ActiveCN1927437AImprove yieldWide applicabilityFlow mixersGranulation in rotating dishes/pansManufacturing cost reductionEngineering

The invention relates to a method of powder / liquid continuous mixing particle production. Wherein, said method comprises that sealing the top of hopper mixed particle producing room (12); the center at the top uses ejector (14) to continuously eject liquid downwards; the powder outlet (16) at the circumference of ejector disperses the atomized liquid to the powder; and the gas ejector (18) at the circumference of powder outlet feeds gas as the protective air film (Af) that avoiding dispersing the fed powder; therefore, the powder and liquid can continuously contact to form mixed particle (G); and the bottom of room (12) via the rotation of mixing disc (32) can make the air passive pressure, to generate eddy flow, to accelerate the particle (G) generation, and shear or mix the particle (G), to form and discharge uniform particles (G).

Owner:FUNKEN POWTECHS

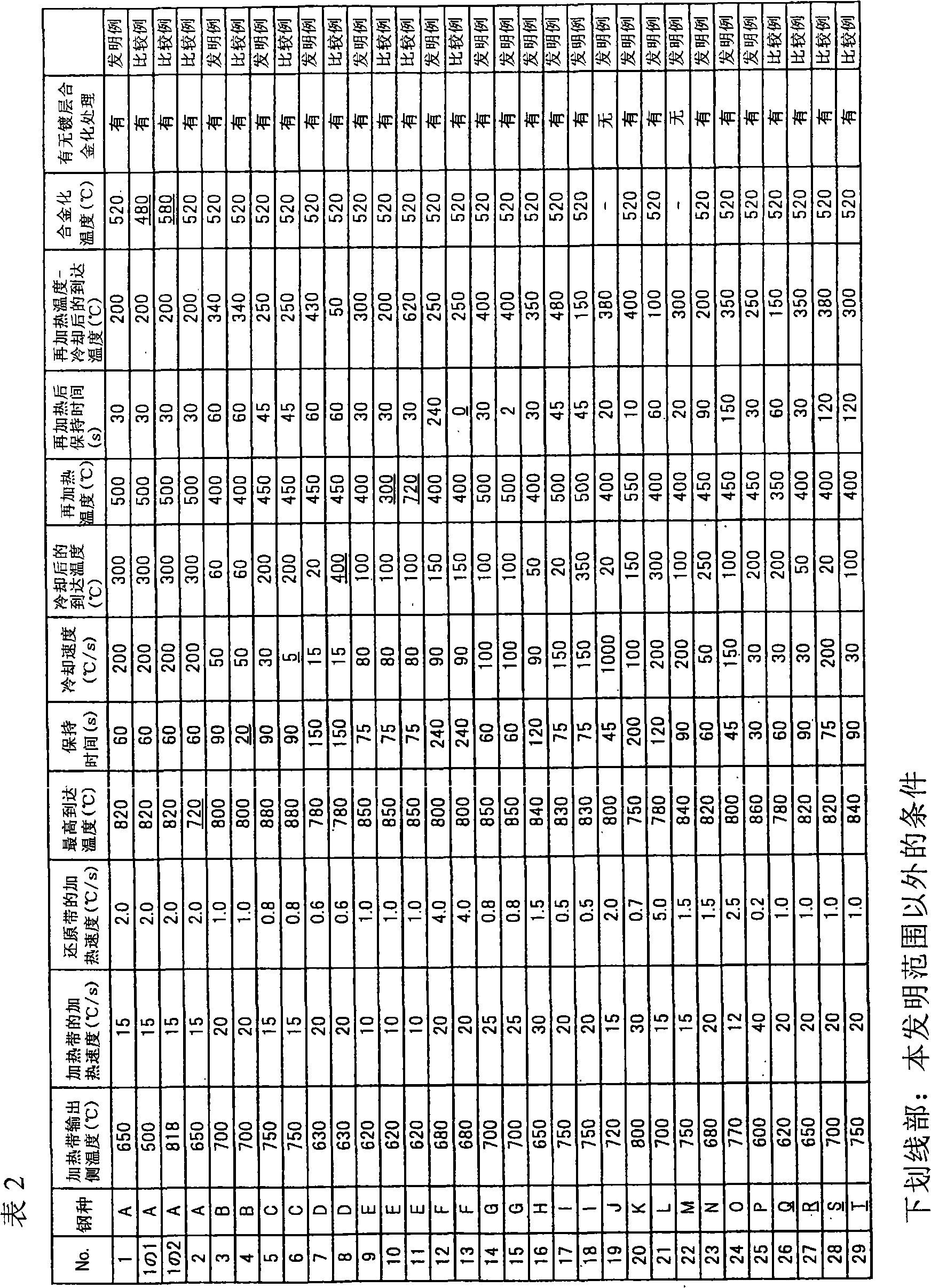

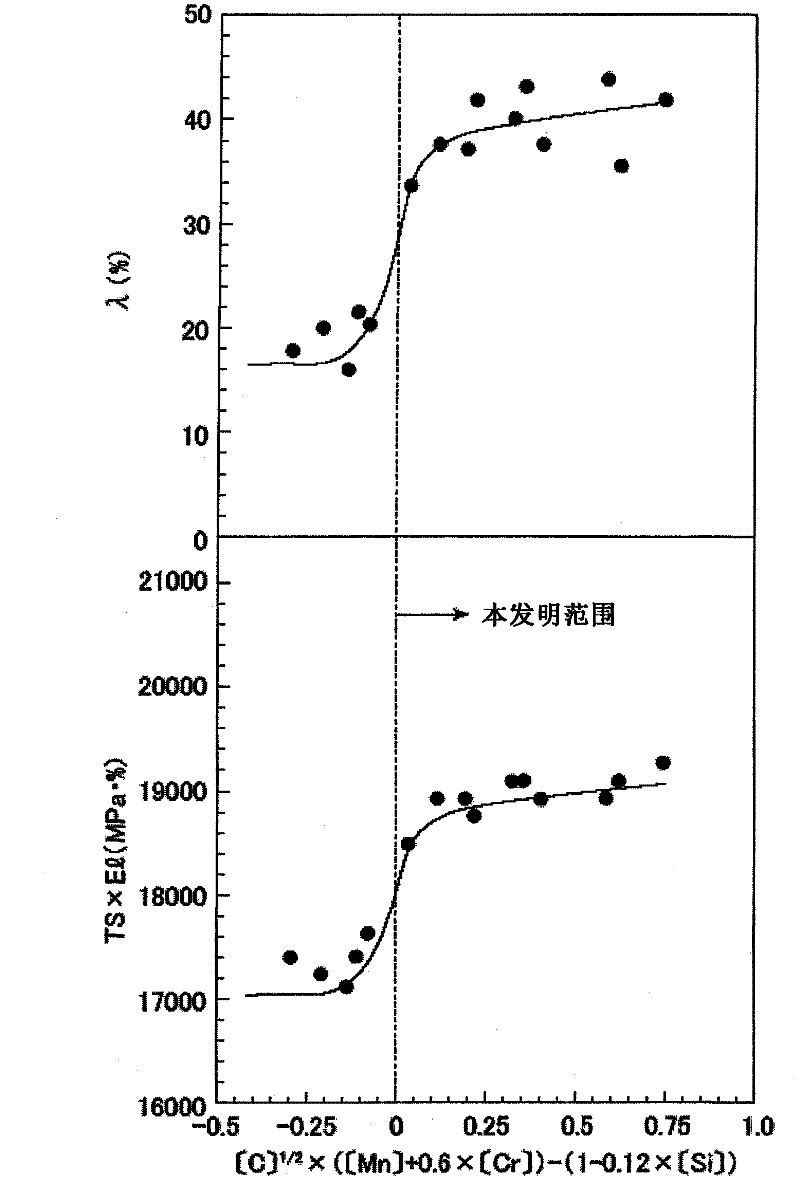

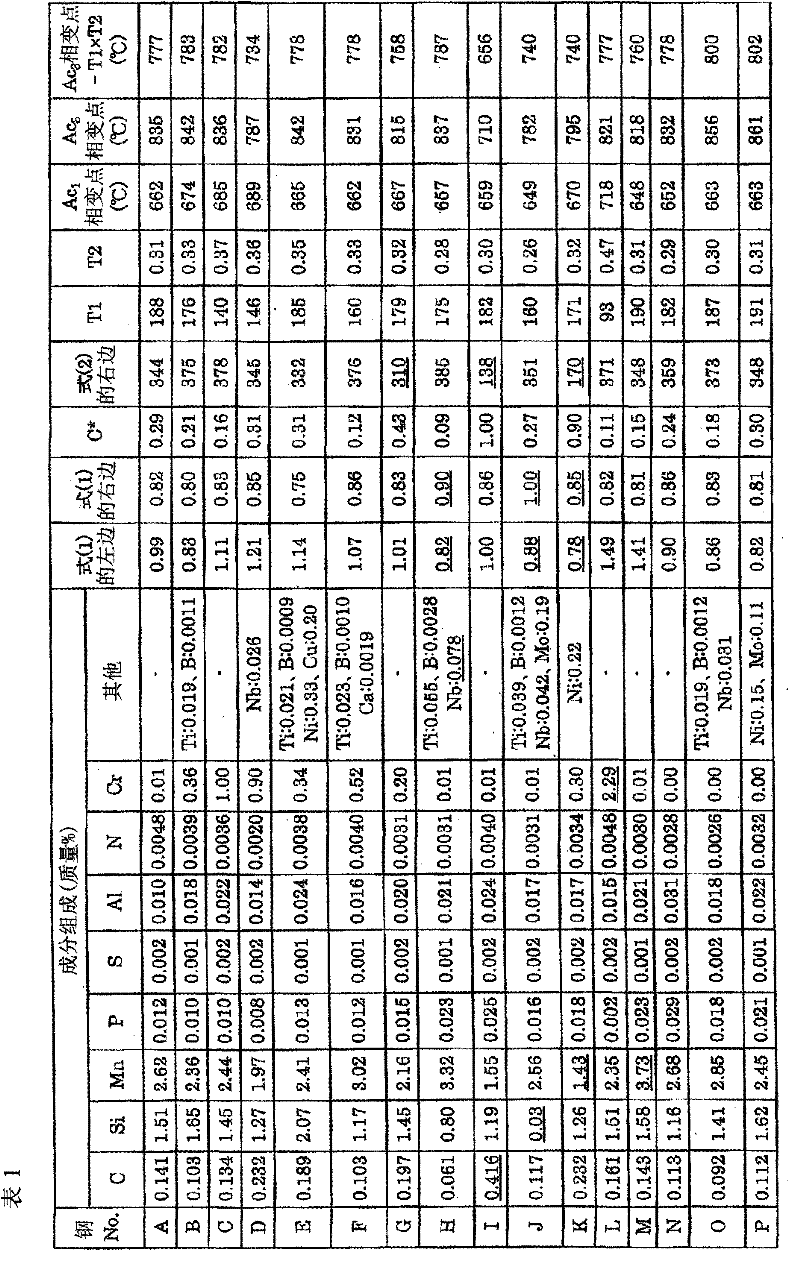

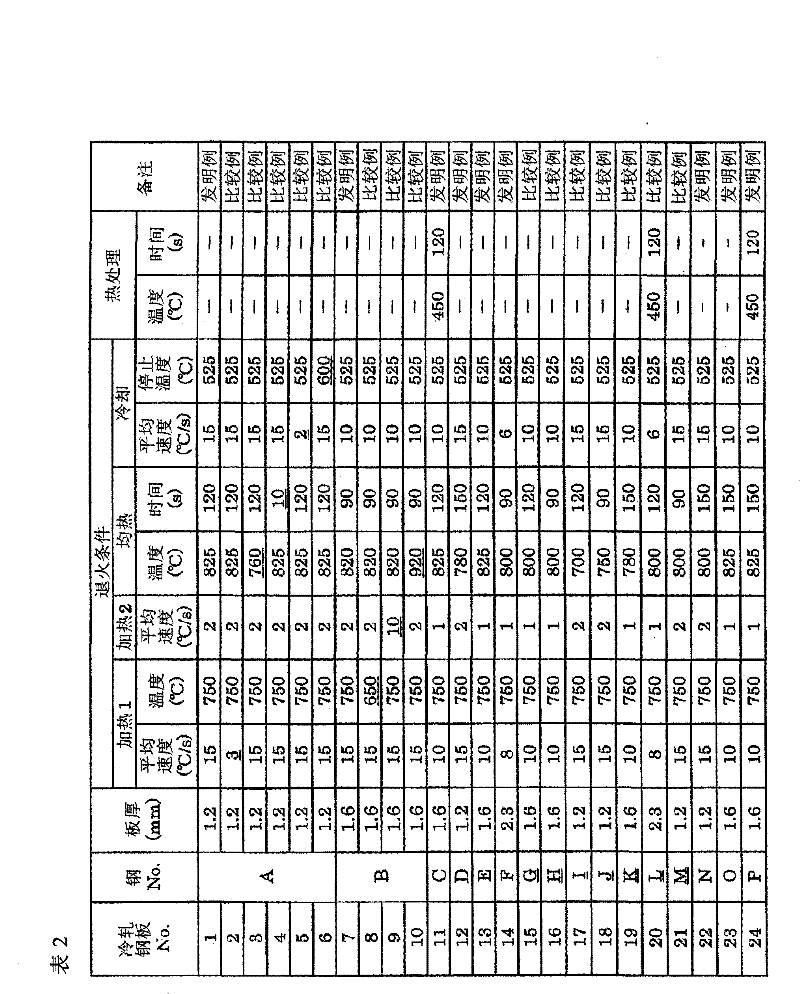

High-strength cold-rolled steel sheet having excellent workability, molten galvanized high-strength steel sheet, and method for producing same

ActiveCN102227511AExcellent hole expandabilityImprove bending performanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

The invention provides a high-strength cold-rolled steel sheet having a TS of 1,180 MPa or greater and excellent workability, such as stretch flange workability and bendability. Also provided are a molten galvanized high-strength steel sheet, and a method for producing the same. The high-strength cold-rolled steel sheet having excellent workability has a composition that comprises, by mass%, C: 0.05 to 0.3, Si: 0.5 to 2.5, Mn: 1.5 to 3.5, P: 0.001 to 0.05, S: 0.0001 to 0.01, Al: 0.001 to 0.1, N: 0.0005 to 0.01, and Cr: 1.5 or less (including 0) and satisfies formulas (1) and (2), with the balance being Fe and inevitable impurities. The steel sheet has a microtexture wherein there is a ferrite phase and a martensite phase, the percentage of the texture total surface area occupied by martensite phase is 30% or greater, (the surface area occupied by martensite phase) / (surface area occupied by ferrite phase) exceeds 0.45 but is less than 1.5, and the average particle diameter of the martensite phase is 2 microns or larger. [C]1 / 2*([Mn]+0.6*[Cr])> / =1-0.12*[Si] (1), and 550-350*C*-40*[Mn]-20*[Cr]+30*[Al]> / =340 (2), wherein C*=[C] / (1.3*[C]+0.4*[Mn]+0.45*[Cr]-0.75).

Owner:JFE STEEL CORP

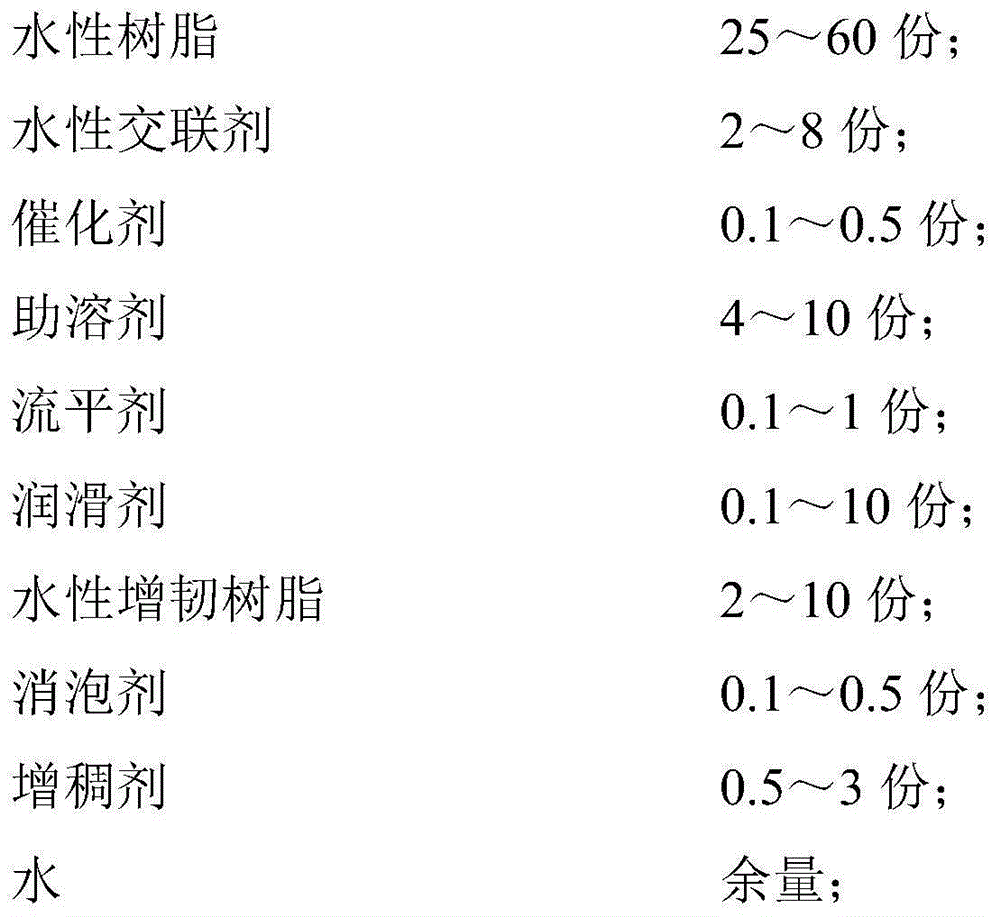

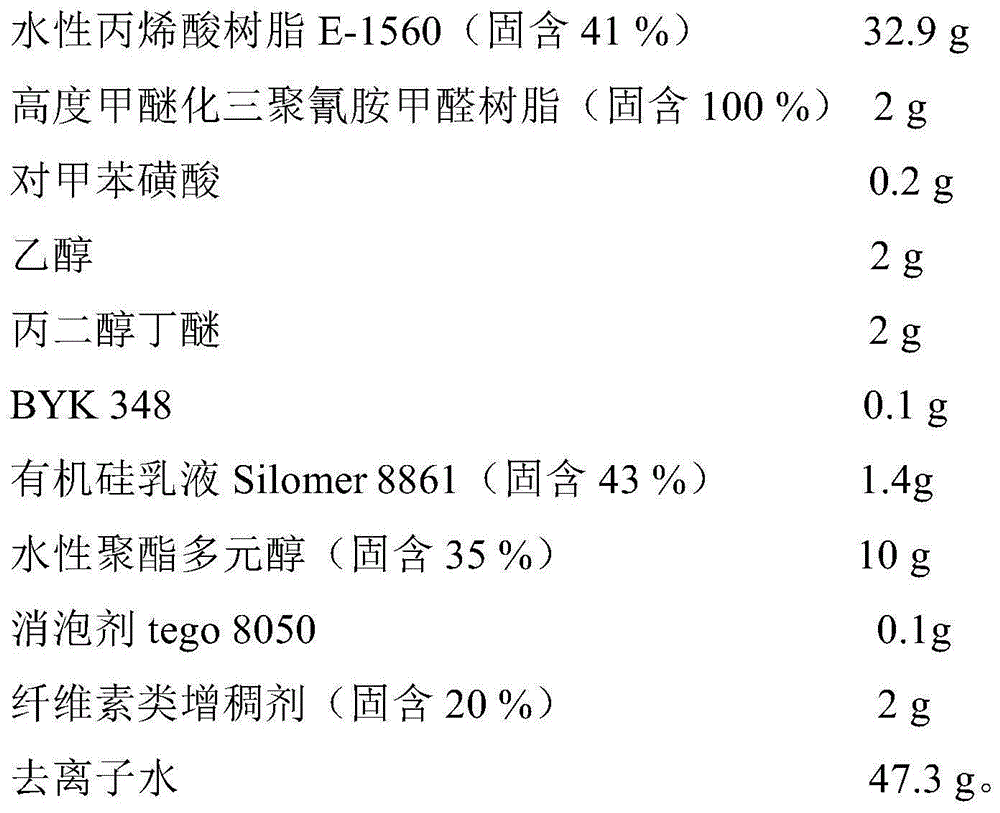

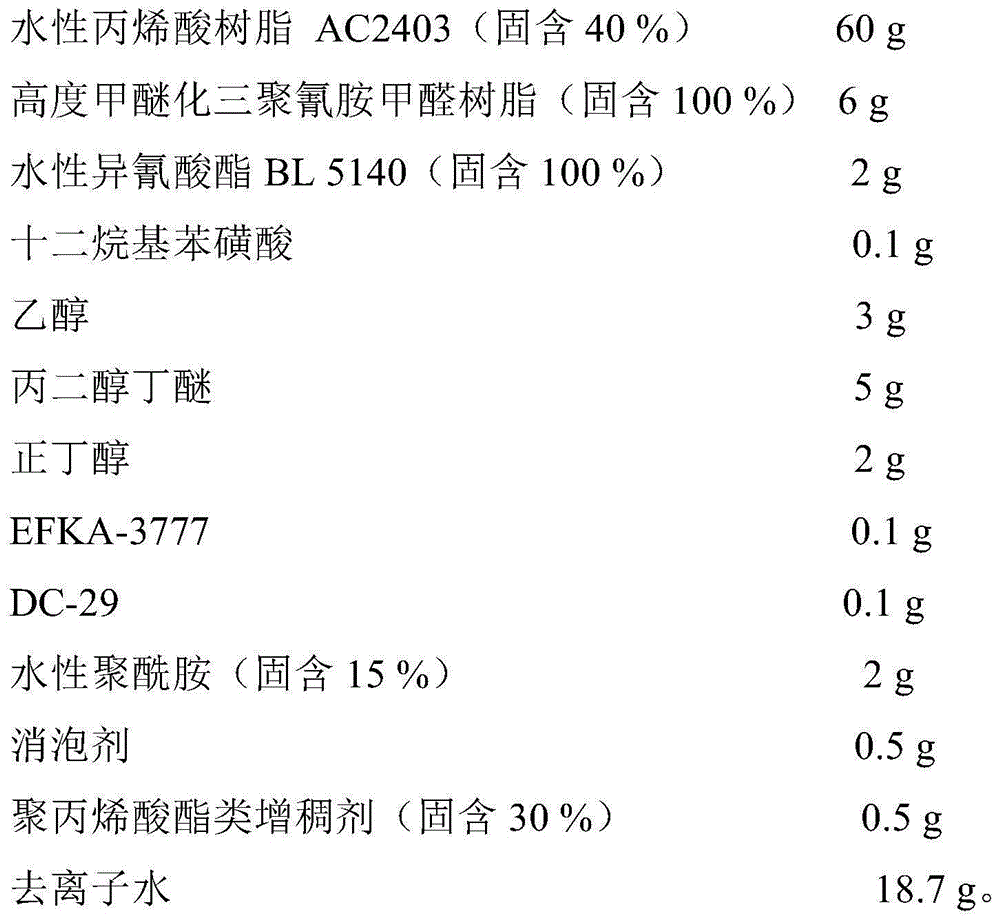

Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

ActiveCN105038464AEmission reductionReduce pollutionPretreated surfacesAnti-corrosive paintsWater basedMicrometer

The invention belongs to the technical field of surface corrosion prevention and discloses a water-based high-corrosion-resistance coating with excellent stamping performance and a preparing method and application of the water-based high-corrosion-resistance coating. The coating comprises, by mass, 25-60 parts of water-based resin, 2-8 parts of water-based cross-linking agent, 0.1-0.5 part of catalyst, 4-10 parts of cosolvent, 0.1-1 part of flatting agent, 0.1-10 parts of lubricating agent, 2-10 parts of water-based toughening resin, 0.1-0.5 part of defoaming agent, 0.5-3 parts of thickening agent and the balance water, and the total mass parts of the components are 100 parts. According to the water-based high-corrosion-resistance coating, the water-base resin serves as film forming matter, so that good construction performance is achieved, curing is quick, super corrosion resistance can be obtained when the thickness of the coating is 2-5 micrometers, the performance of resisting neutral salt mist is longer than 2,000 hours, resistance to acid salt mist is longer than 500 h, the corrosion grade can reach 9.8 or higher, and the salt mist resisting performance of the coating is maintained unchanged after stamping or bending is carried out.

Owner:GUANGZHOU HUMAN CHEM

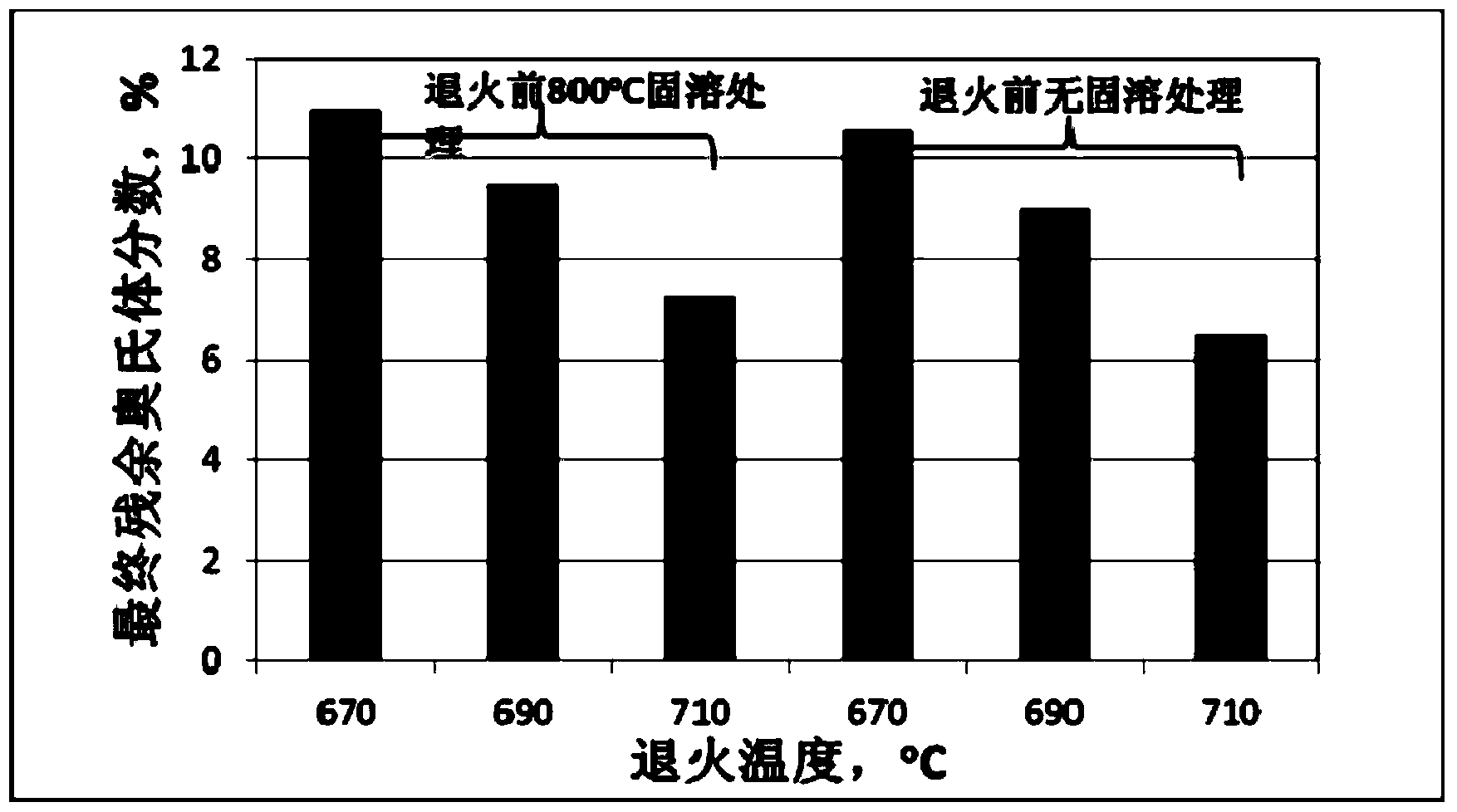

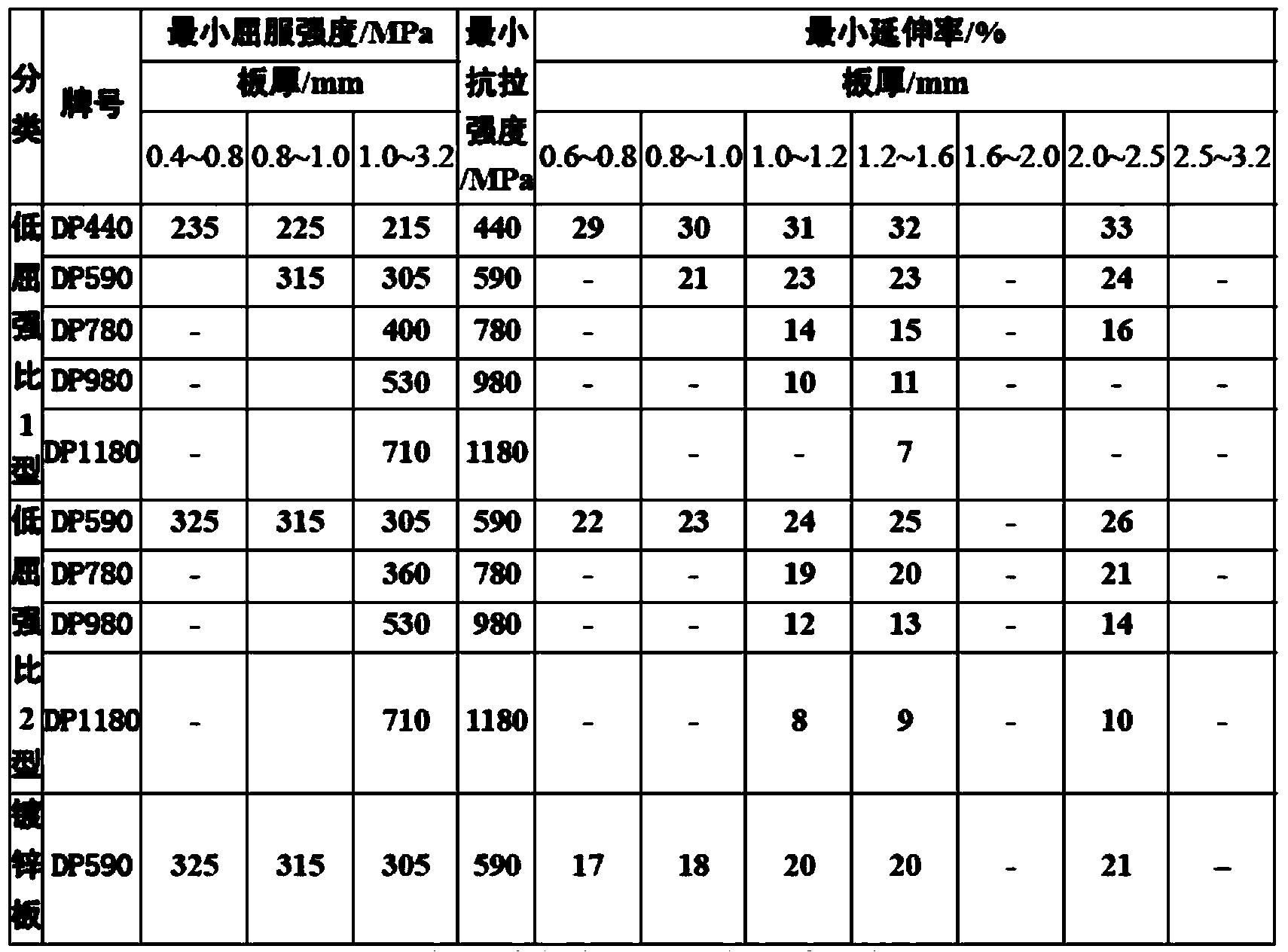

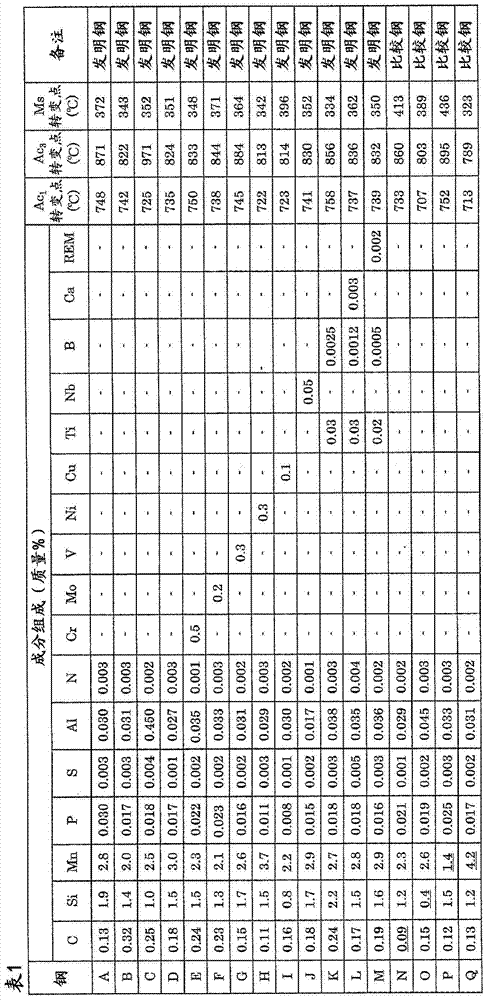

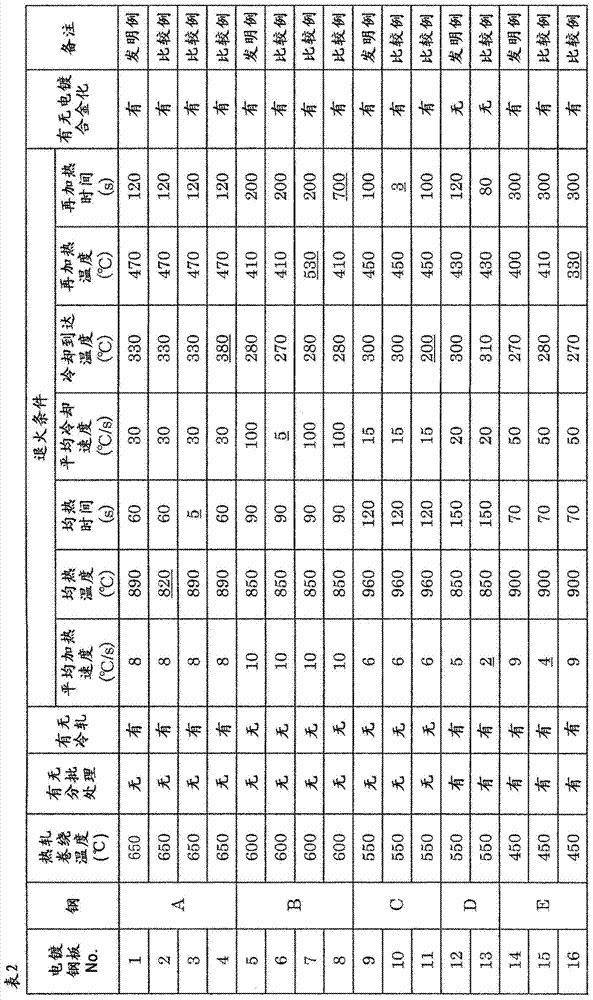

Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

The invention discloses a two-phase automobile steel plate with low yield-strength ratio and high strength and a production method of the two-phase automobile steel plate, belonging to the technical field of steel for automobiles. The two-phase automobile steel plate comprises the following chemical components: 0.1-0.40wt% of C, 3.0-8.0wt% of Mn, less than or equal to 0.020wt% of P and less than or equal to 0.02wt% of S; on the basis, the two-phase automobile steel plate can be additionally provided with one or more of the following elements: 0.1-3.0wt% of Ni, 0.2-3.0wt% of Cr, 0.1-0.8wt% of Mo, 0.3-2.3wt% of Si, 0.5-2.0wt% of Cu, 0.0005-0.005wt% of B, 0.02-0.10wt% of Nb, 0.002-0.25wt% of [N], 0.05-0.25wt% of Ti, 0.02-0.25wt% of V, 0.015-0.060wt% of Al, 0.002-0.005wt% of RE (Rare Earth) and 0.005-0.03wt% of Ca. The two-phase automobile steel plate has the advantages that the two-phase automobile steel plate with low yield strength, high tension strength and favorable elongation can be produced through annealing within short time; the performance indexes of the two-phase automobile steel plate are as follows: two-phase steel with the tension strength of 980MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 22%, and two-phase steel with the tension strength of 1180MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 17%.

Owner:CENT IRON & STEEL RES INST

Steel for enamel and production method thereof

The invention discloses a steel for enamel, and is characterized by comprising the following chemical elements by mass: not more than 0.020% of C, not more than 0.05% of Si, 0.10-0.50% of Mn, not more than 0.03% of P, 0.003-0.050% of S, 0.001-0.03% of Al, 0.001-0.015% of N, 0.005-0.050% of O, not more than 0.005% of Ca, not more than 0.005% of Mg, not more than 0.10% of Cu, not more than 0.10% of Cr, not more than 0.10% of Ni, not more than 0.10% of Mo, at least one of 0.0005-0.003% of B, not more than 0.01% of Nb, not more than 0.02% of V, and 0.001-0.05% of Ti, and the balance of Fe and other inevitable impurities, wherein N(%)*Ti(%) is not more than 3*10<-4>. Correspondingly, the invention further discloses a production method of the steel for enamel. The steel for enamel has excellent comprehensive performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Electrostatic latent image bearer, and image forming method, image forming apparatus and process cartridge using the electrostatic latent image bearer

InactiveUS20060199092A1High resistanceGood electrophotographic image formabilityElectrographic process apparatusElectrographic processes using charge patternEngineeringParticulate material

An electrostatic latent image bearer, including a substrate and a photosensitive layer located overlying the substrate, wherein an outermost layer of the electrostatic latent image bearer includes a binder resin and an electroconductive particulate material, wherein the electroconductive particulate material has the following formula: MxSbyOz wherein M represents a metallic element; and x, y and z represent molar ratios for respective elements.

Owner:RICOH KK

High-strength hot-dip galvanized steel sheet having excellent moldability and shape fixability, and method for manufacturing same

ActiveCN104508163AExcellent formability and settabilityGood formabilityHot-dipping/immersion processesFurnace typesSheet steelExpansion ratio

Provided is a high-strength hot-dip galvanized steel sheet having: a tensile strength (TS) no less than 1180 MPa; a total elongation (EL) no less than 14%; a hole expansion ratio (lambda) no less than 30%; and a yield ratio (YR) no greater than 70%, and having excellent moldability and shape fixability. Also provided is a method for manufacturing the high-strength hot-dip galvanized steel sheet. A high-strength hot-dip galvanized steel sheet having excellent moldability and shape fixability, characterized in having a component composition comprising, by mass, 0.10 to 0.35% of C, 0.5 to 3.0% of Si, 1.5 to 4.0% of Mn, 0.100% or less of P, 0.02% or less of S, and 0.010 to 0.5% of Al, with the remainder made up by Fe and unavoidable impurities; the microstructure containing, by area ratio, 0 to 5% of polygonal ferrite, 5% or more of bainitic ferrite, 5 to 20% of martensite, 30 to 60% of tempered martensite, and 5 to 20% of residual austenite; and the average particle diameter of prior austenite being no greater than 15 mum.

Owner:JFE STEEL CORP

Thermal punch forming technique and forming mold for super-strength steel

The invention provides an ultra-high strength steel thermal punching molding process and a molding die thereof. Before the thermal punching molding of ultra-high strength steel sheet, the thermal punching molding process is used for heating parts which are in contact with the ultra-high strength steel sheet in a die and need to be punched, so as to lead the surface temperature of the parts to reach or exceed martensite temperature of the ultra-high strength steel. Then, the ultra-high strength steel sheet which is heated to be totally austenitized is put in the die to be punched and molded. When closed, the thermal punching die is cooled. The die parts which are in contact with the molded parts are utilized for quenching the molded parts. The thermal punching molding die comprises a convex die, a concave die and a control unit. An electrothermal element and a cooling water channel are arranged in the convex die and the concave die. A temperature sensor is arranged in the convex die and the concave die. A reset switch and a pressure plate are respectively arranged on lateral sides of the concave die and the convex die. The ultra-high strength steel thermal punching molding process and the molding die thereof avoid cracks on surfaces and at the inner parts of the molded parts, eliminate the part molding resilience and ensure the precision and the quality of products.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com