Patents

Literature

2456results about "Insulating substrate metal adhesion improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of electroless plating copper on nitride barrier

InactiveUS6436816B1Insulating substrate metal adhesion improvementSolid-state devicesCopper platingElectroless deposition

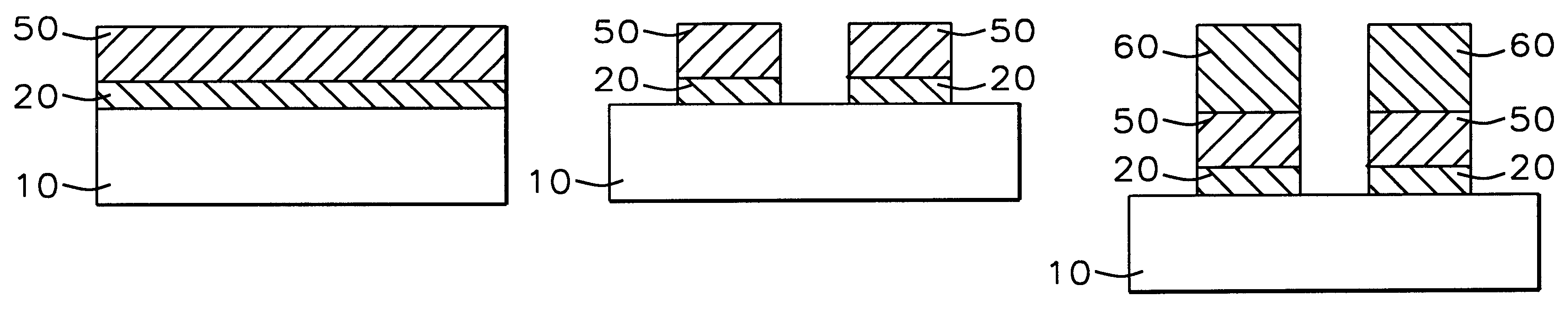

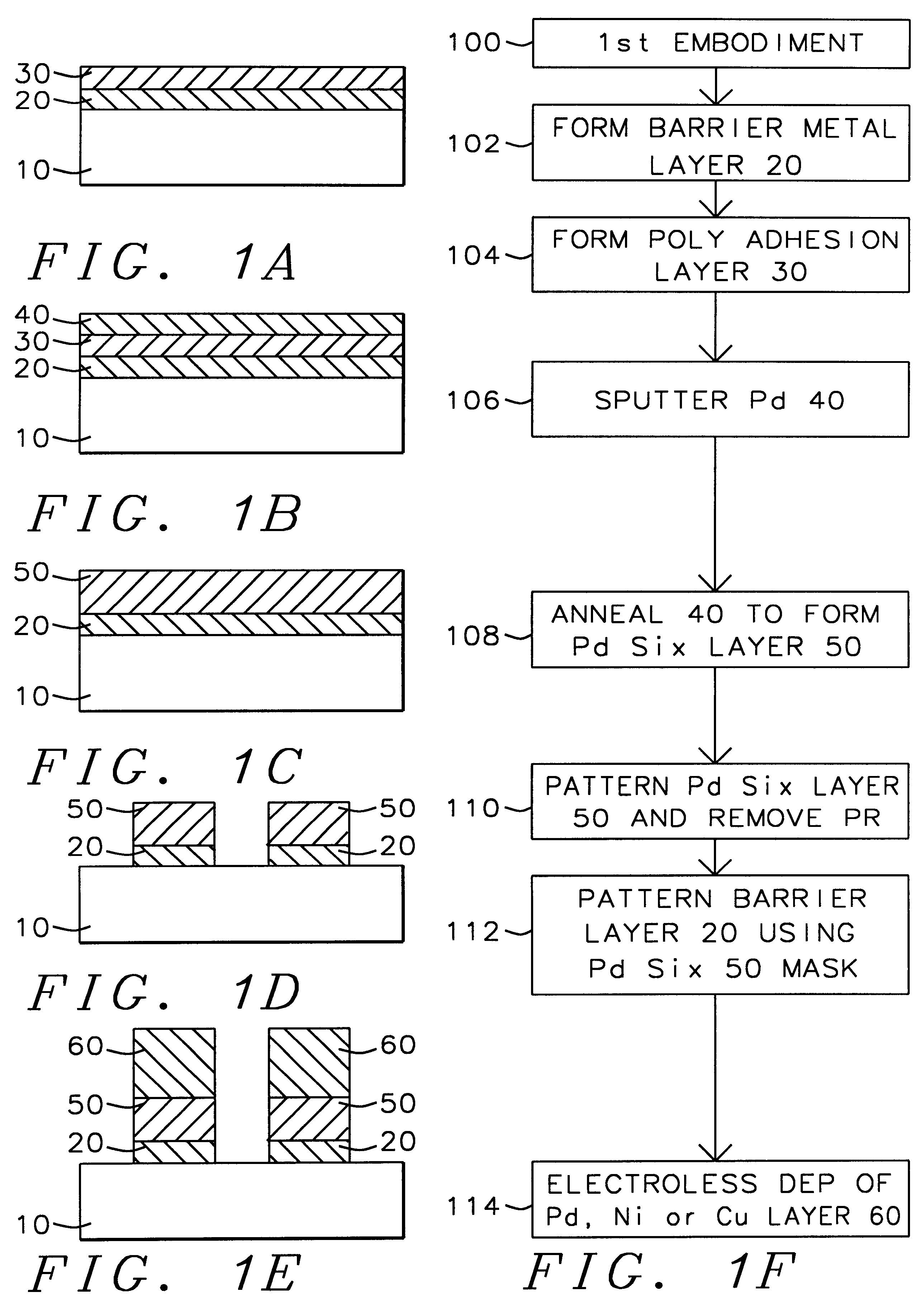

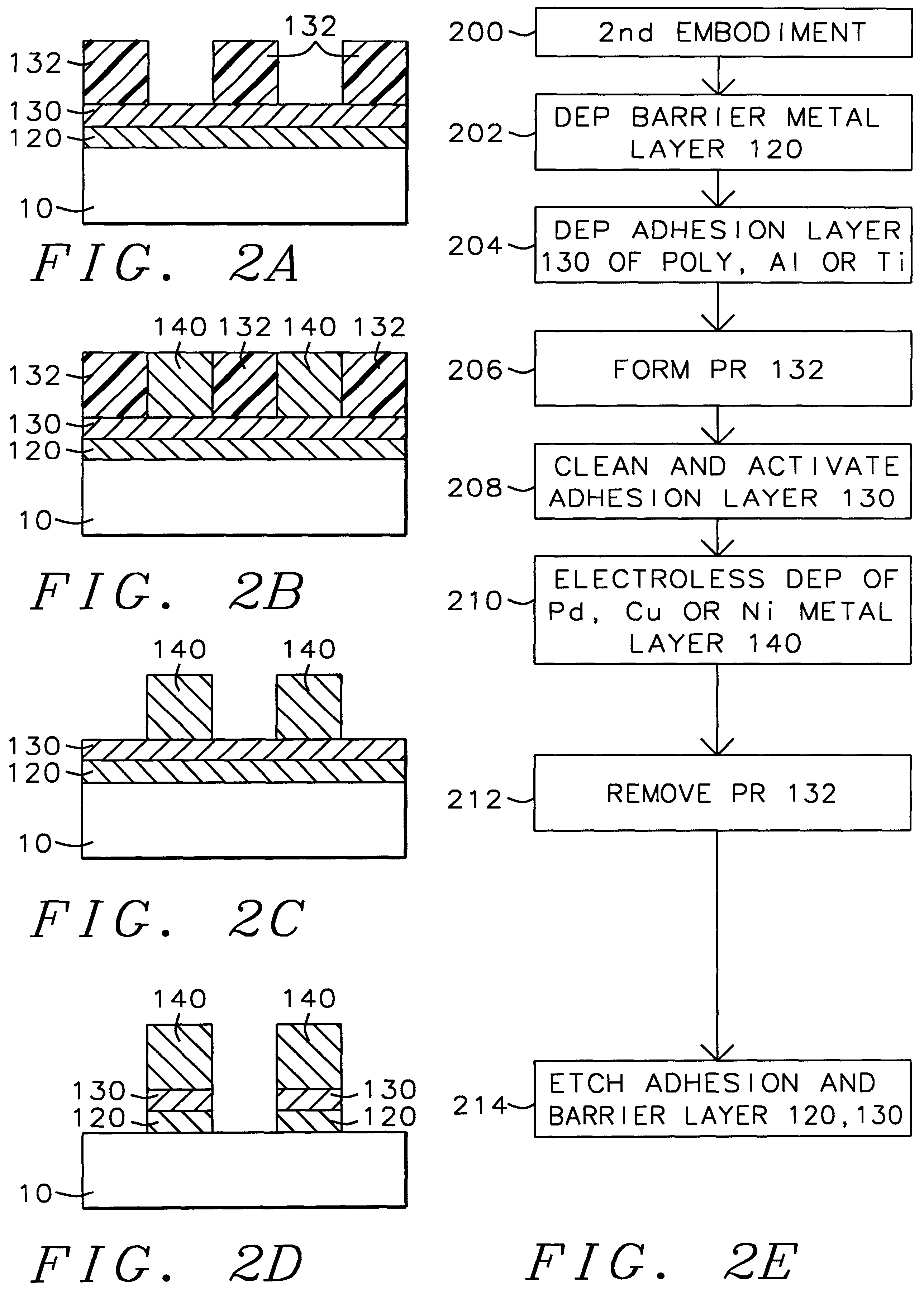

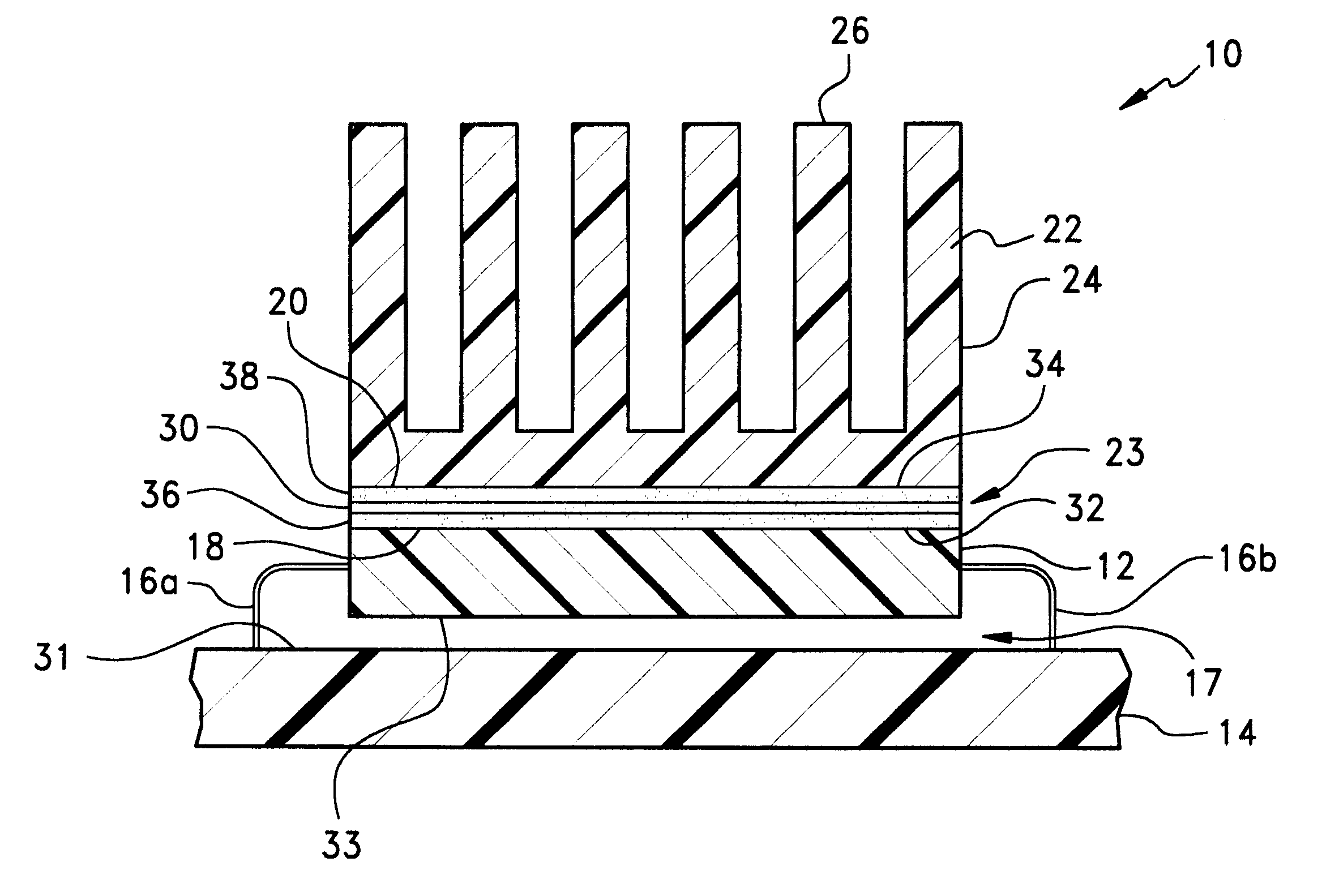

A method with three embodiments of manufacturing metal lines and solder bumps using electroless deposition techniques. The first embodiment uses a PdSix seed layer 50 for electroless deposition. The PdSix layer 50 does not require activation. A metal line is formed on a barrier layer 20 and an adhesion layer 30. A Palladium silicide seed layer 50 is then formed and patterned. Ni, Pd or Cu is electroless deposited over the Palladium silicide layer 50 to form a metal line. The second embodiment selectively electrolessly deposits metal 140 over an Adhesion layer 130 composed of Poly Si, Al, or Ti. A photoresist pattern 132 is formed over the adhesion layer. A metal layer 140 of Cu or Ni is electrolessly deposited over the adhesion layer. The photoresist layer 132 is removed and the exposed portion of the adhesion layer 130 and the underlying barrier metal layer 120 are etched thereby forming a metal line. The third embodiment electroless deposits metal over a metal barrier layer that is roughen by chemical mechanical polishing. A solder bump is formed using an electroless deposition of Cu or Ni by: depositing an Al layer 220 and a barrier metal layer 230 over a substrate 10. The barrier layer 230 is polished and activated. Next, the aluminum layer 220 and the barrier metal layer 230 are patterned. A metal layer 240 is electroless deposited. Next a solder bump 250 is formed over the electroless metal layer 240.

Owner:TAIWAN SEMICON MFG CO LTD

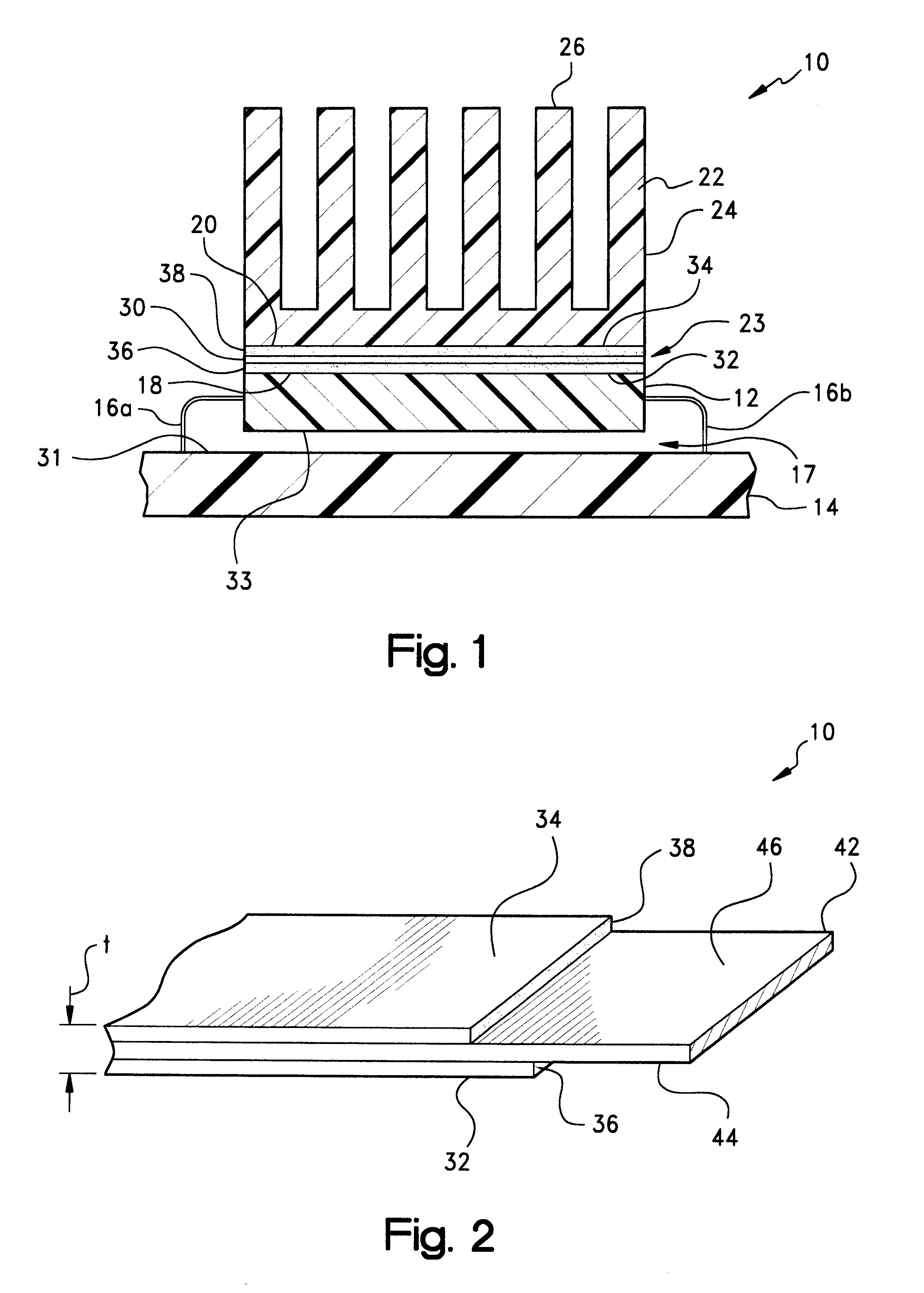

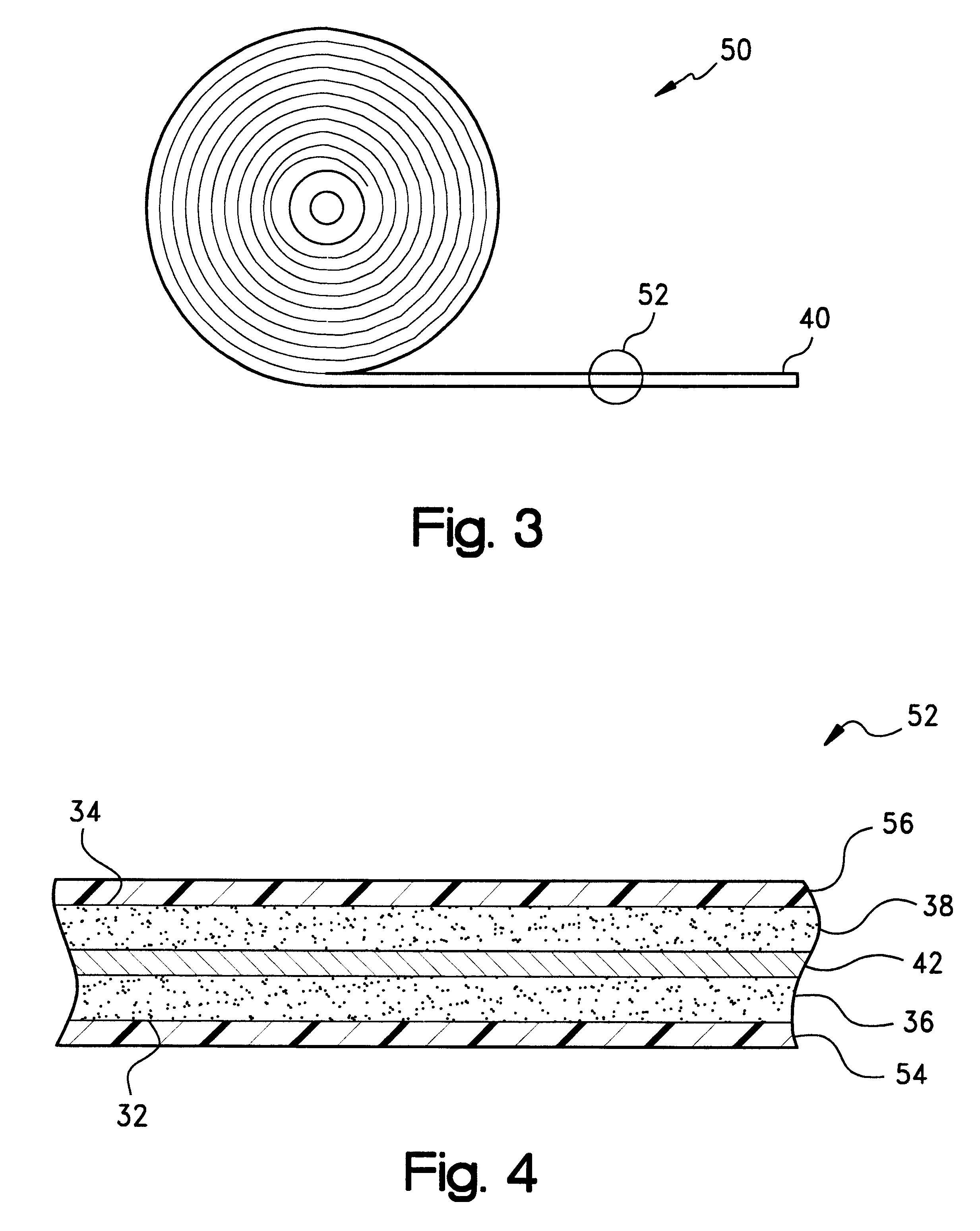

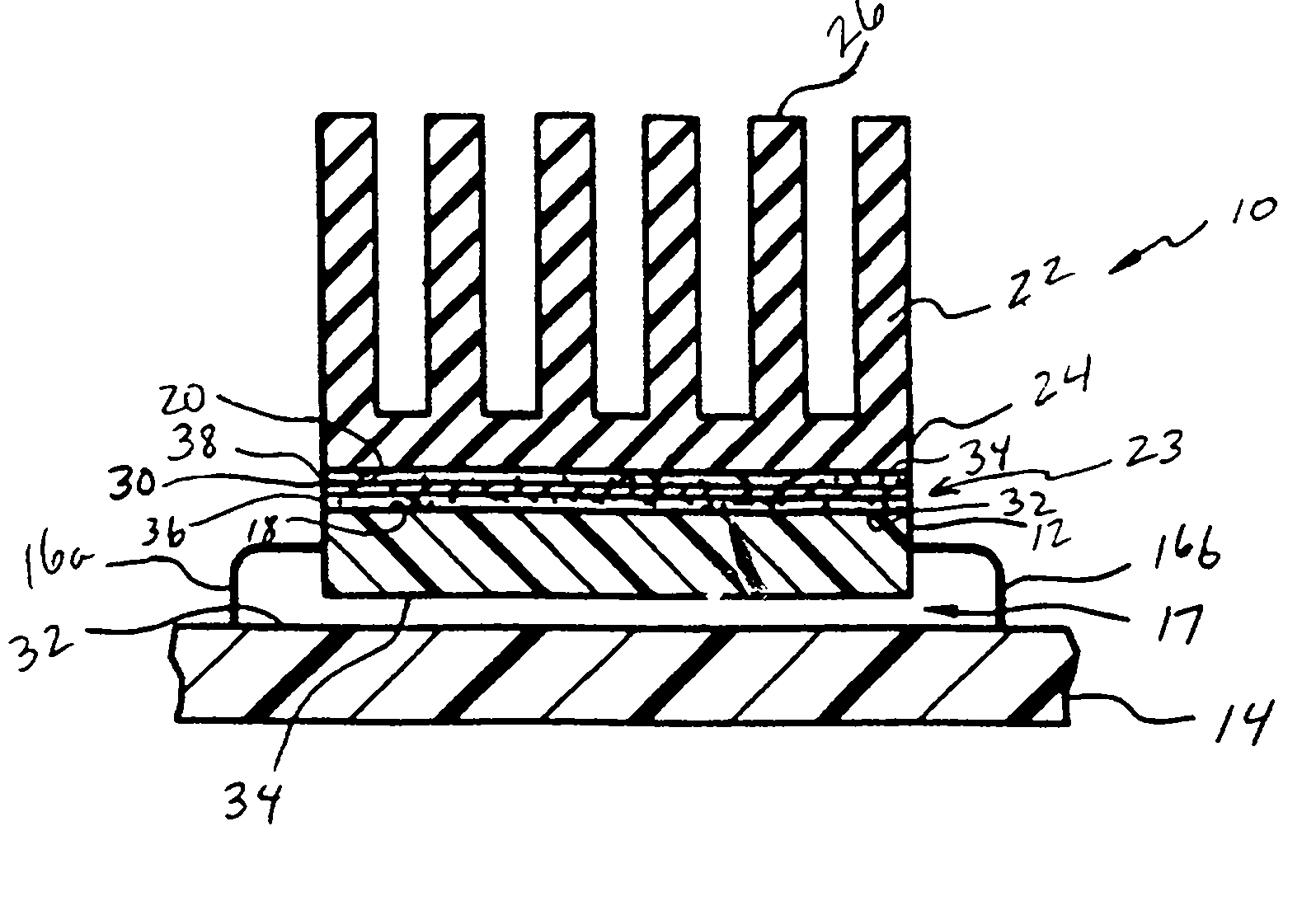

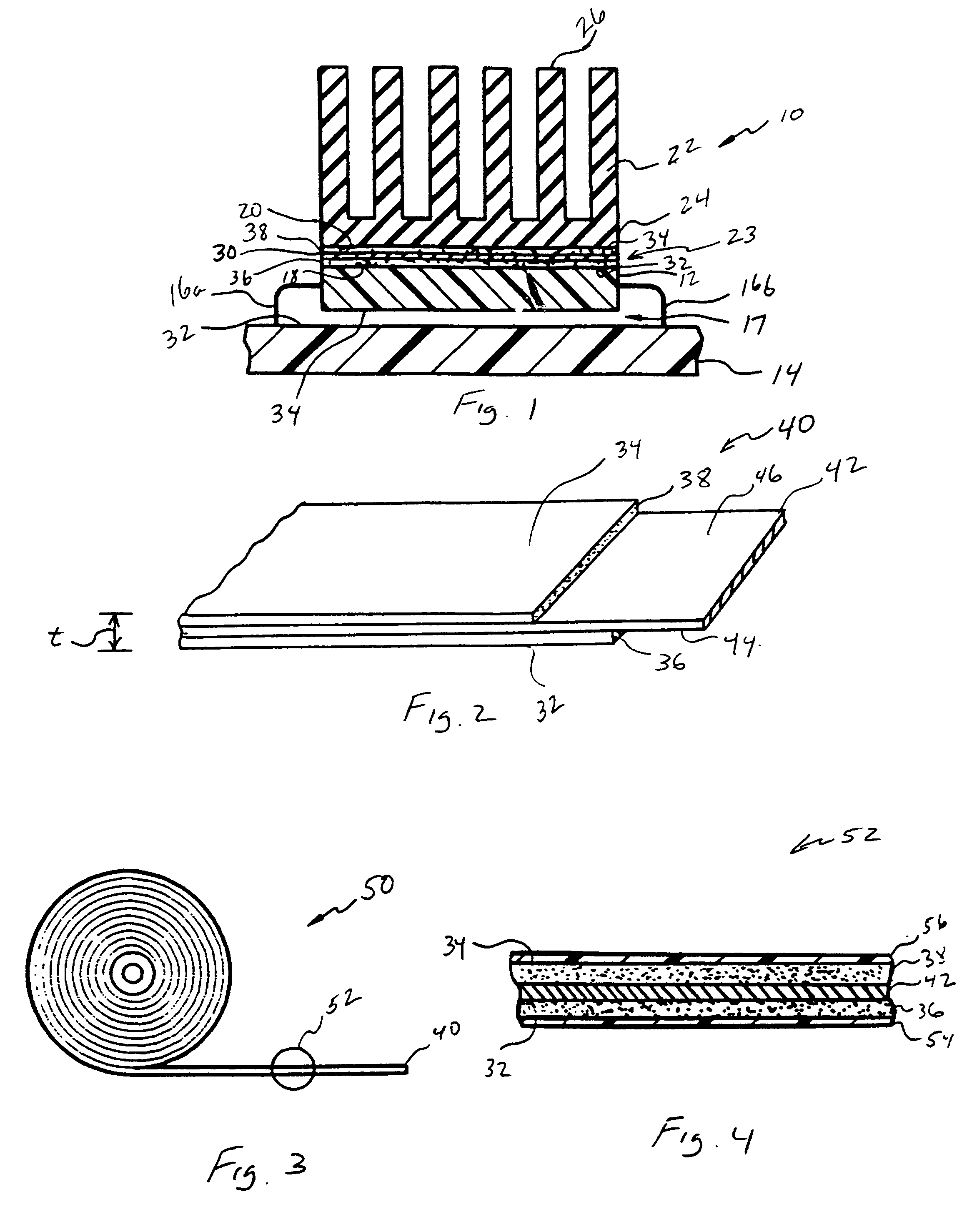

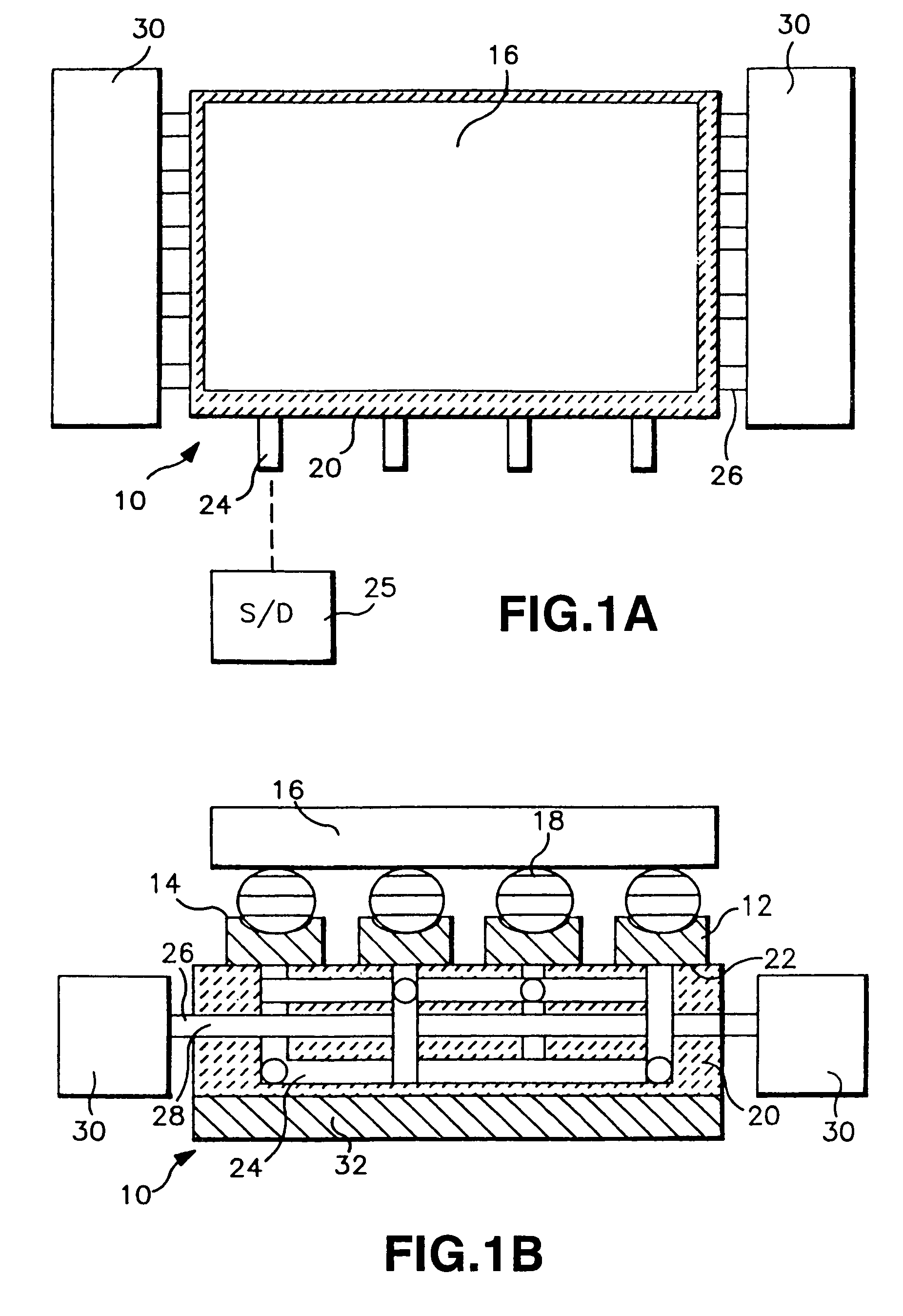

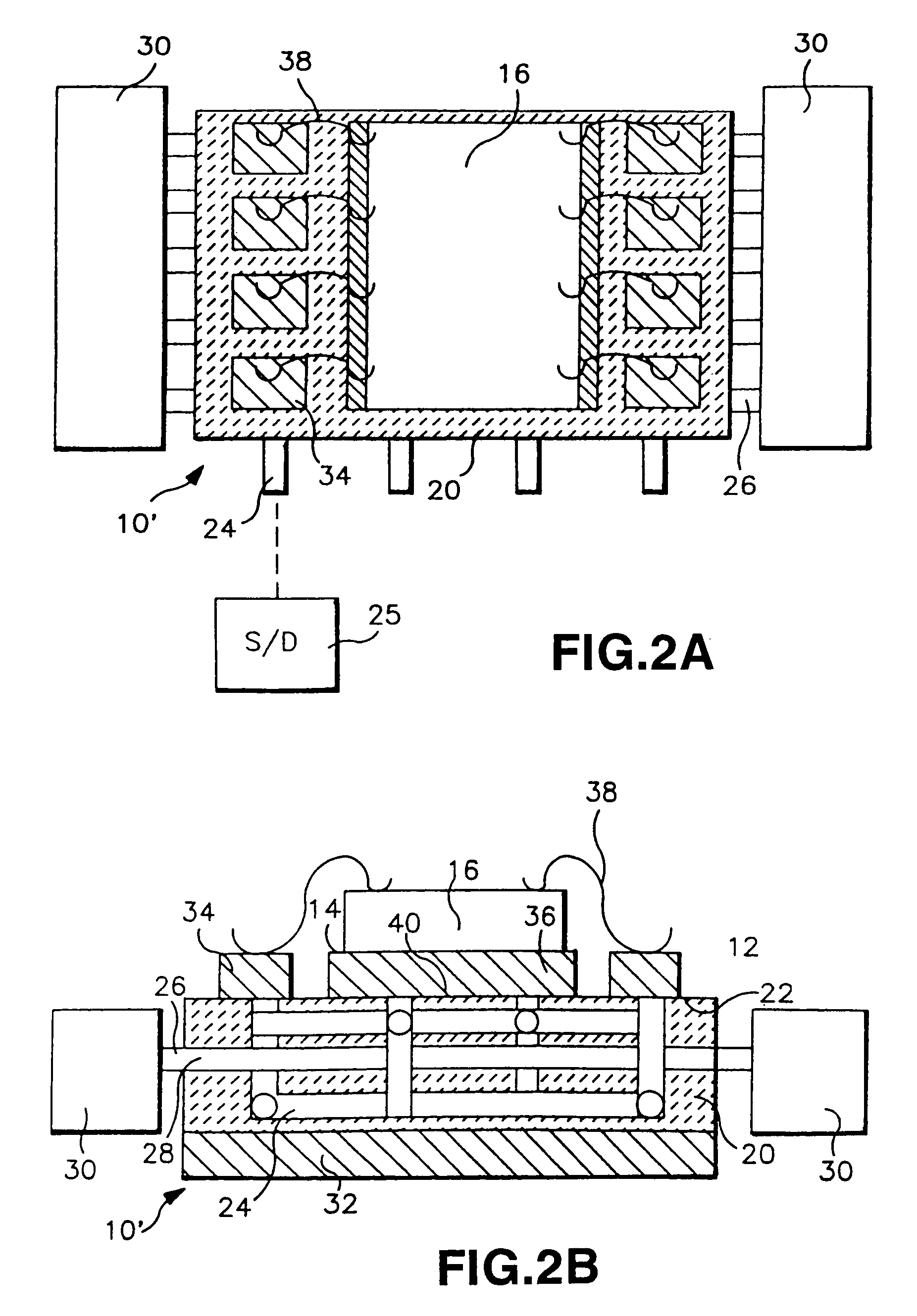

Double-side thermally conductive adhesive tape for plastic-packaged electronic components

InactiveUS6432497B2Easy `` peel and stick '' installationPrecise thermal and adhesive propertiesInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringHeat sink

A thermally conductive interface, which may be in the form of a double-sided, pressure sensitive adhesive tape, disposable intermediate a heat-generating source having a first heat transfer surface formed of a first material having a low surface energy, and a thermal dissipation member having a second heat transfer surface which is formed of a second material having a surface energy substantially higher than the surface energy of the first material, and which is disposable opposite the first heat transfer surface of the heat-generating source in a spaced-apart, heat transfer adjacency therewith. The interface includes a first pressure sensitive adhesive (PSA) surface which is bondable under pressure to at least a portion of the first heat transfer surface of the heat-generating source, and an opposing second pressure sensitive adhesive (PSA) surface bondable under pressure to at least a portion of the second heat transfer surface of the heat-generating source. The first PSA surface is presented from a layer of a thermally-conductive, first pressure sensitive adhesive composition, preferably silicone-based, having an affinity to the first heat transfer surface of the heat generating source. In turn, the second PSA surface is presented from a layer of a second pressure sensitive adhesive composition, preferably acrylic-based, different from the first composition and having an affinity to the second heat transfer surface of the thermal dissipation member. The interface is particularly adapted for bonding a plastic packaged electronic component to a metal heat sink.

Owner:PARKER INTANGIBLES LLC

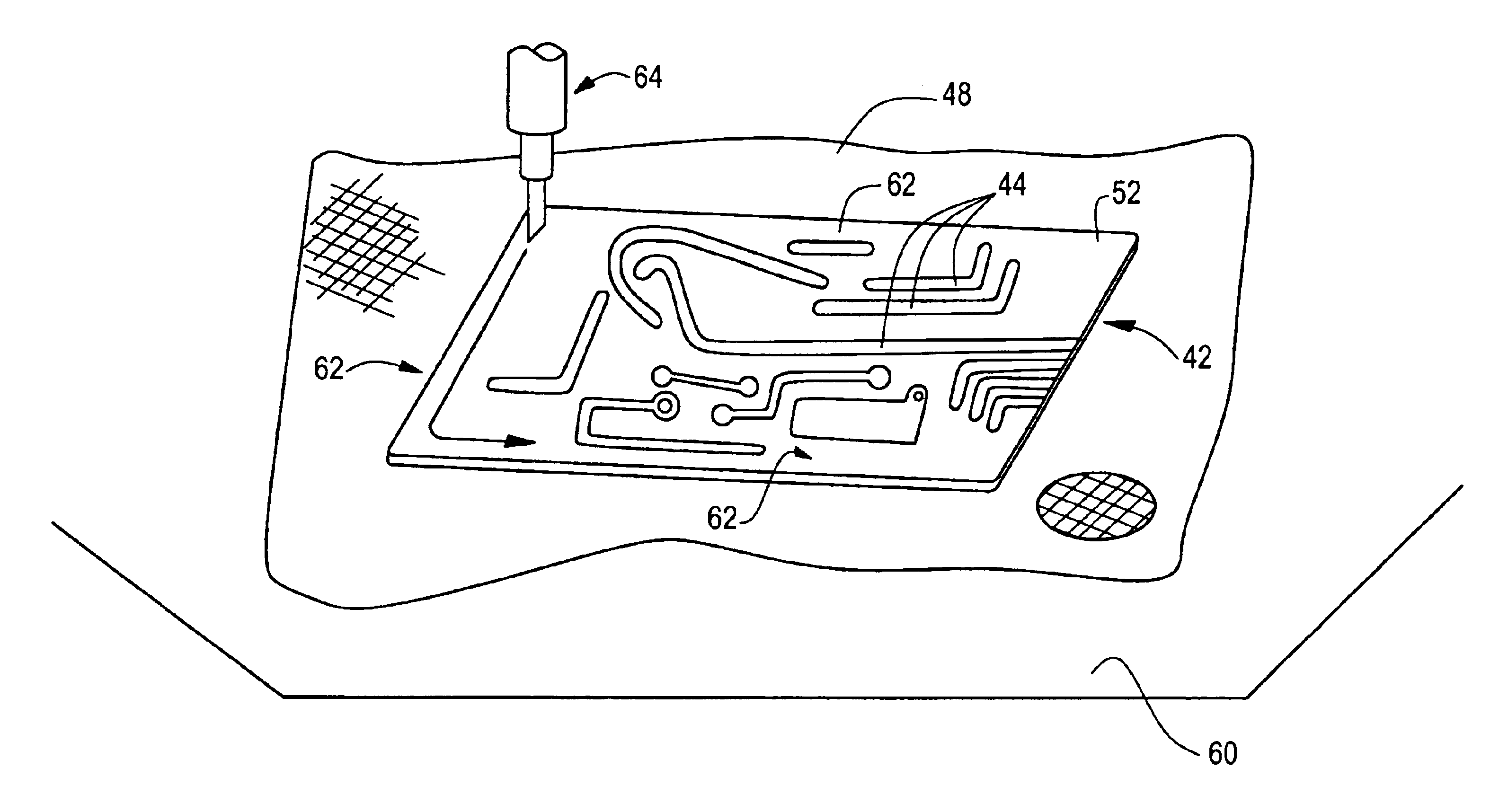

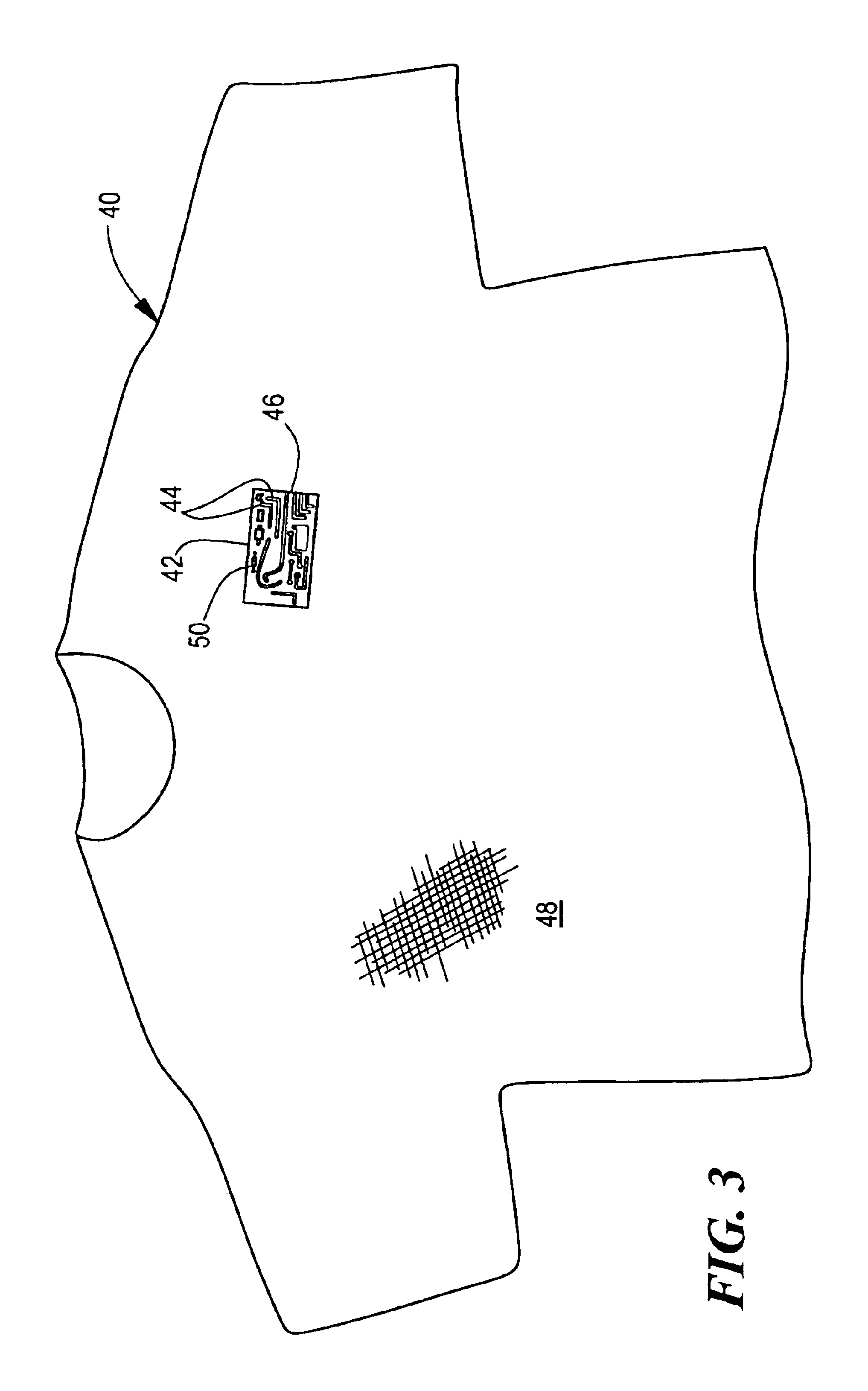

Method of manufacturing a fabric article to include electronic circuitry and an electrically active textile article

InactiveUS6729025B2Low-profileEliminate needLayered productsSemiconductor/solid-state device detailsEngineeringElectron

A method of manufacturing a fabric article to include electronic circuitry in which a flex circuit is assembled to include conductive traces and pads on a flexible substrate, a fabric article is placed on a rigid surface, and the substrate of the flex circuit is secured to the fabric article. Also disclosed is a fabric article which includes electronic circuitry and an electrically active textile article.

Owner:FOSTER-MILLER

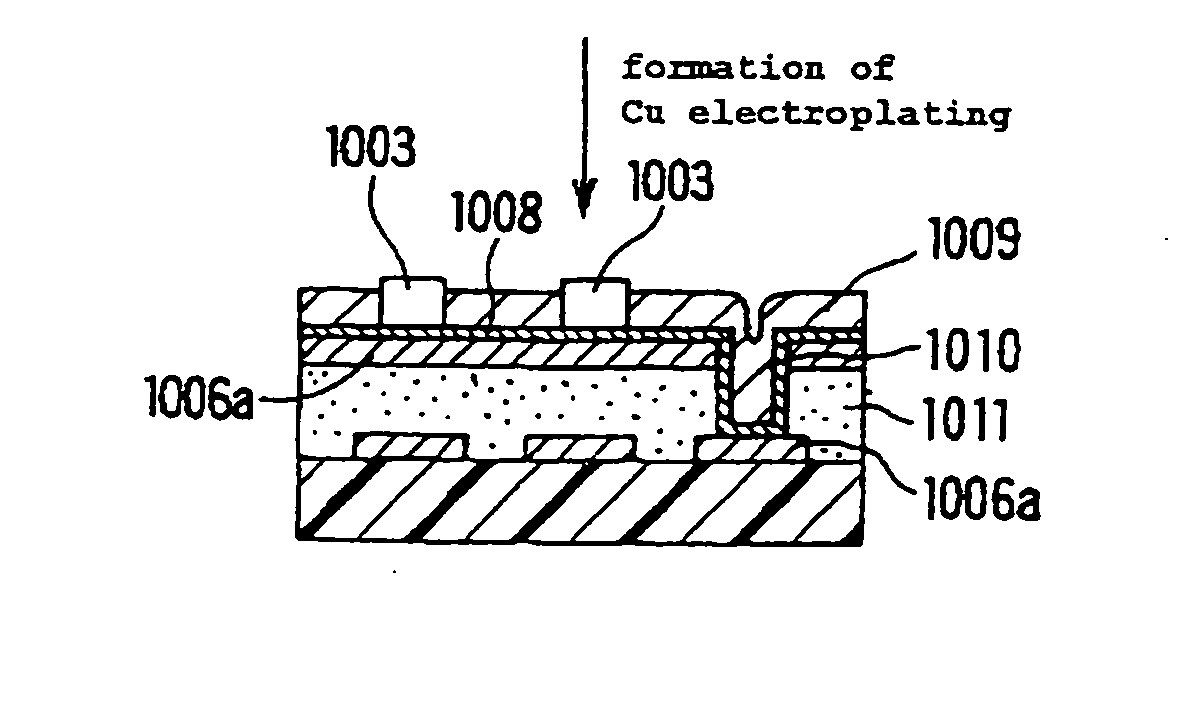

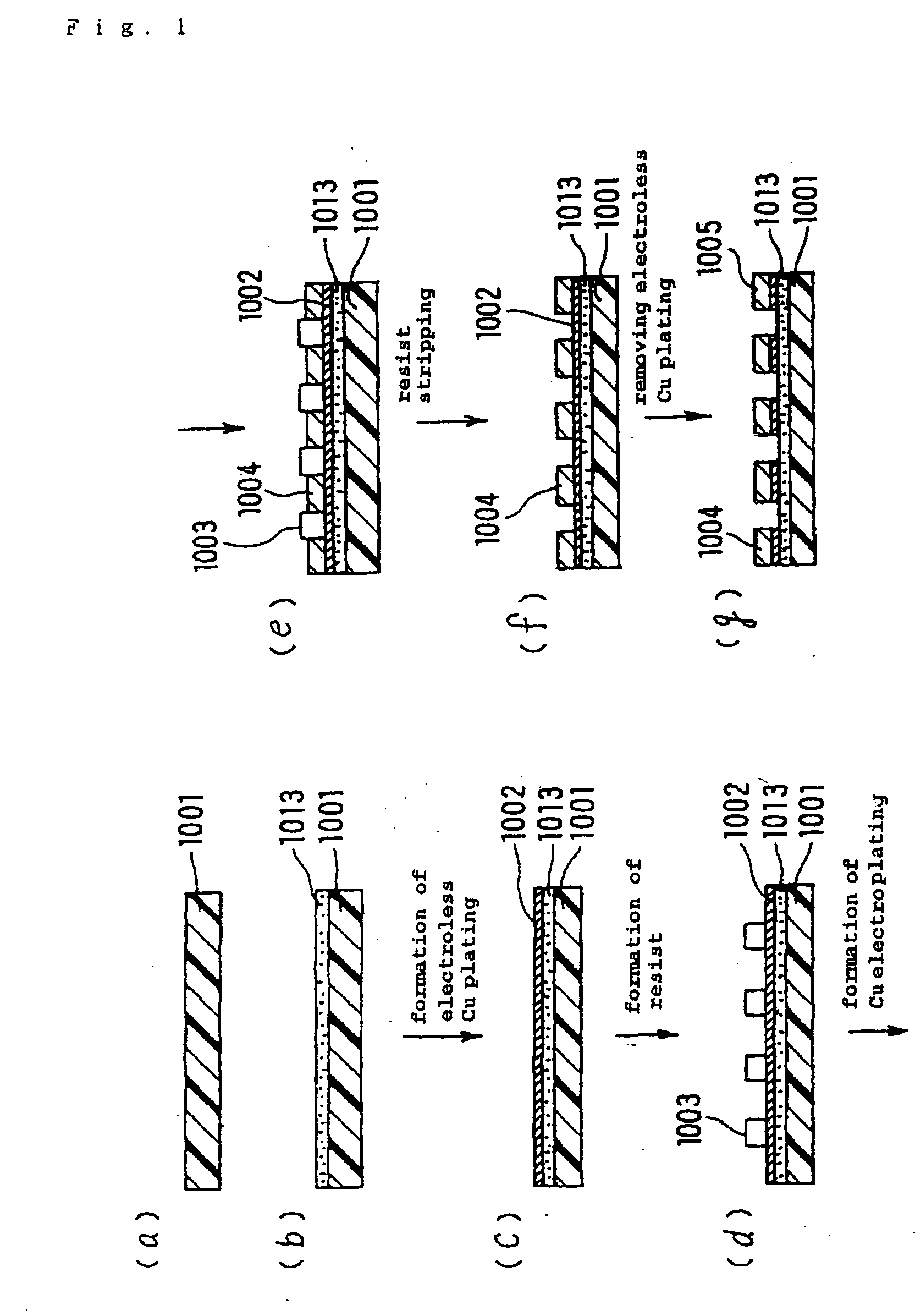

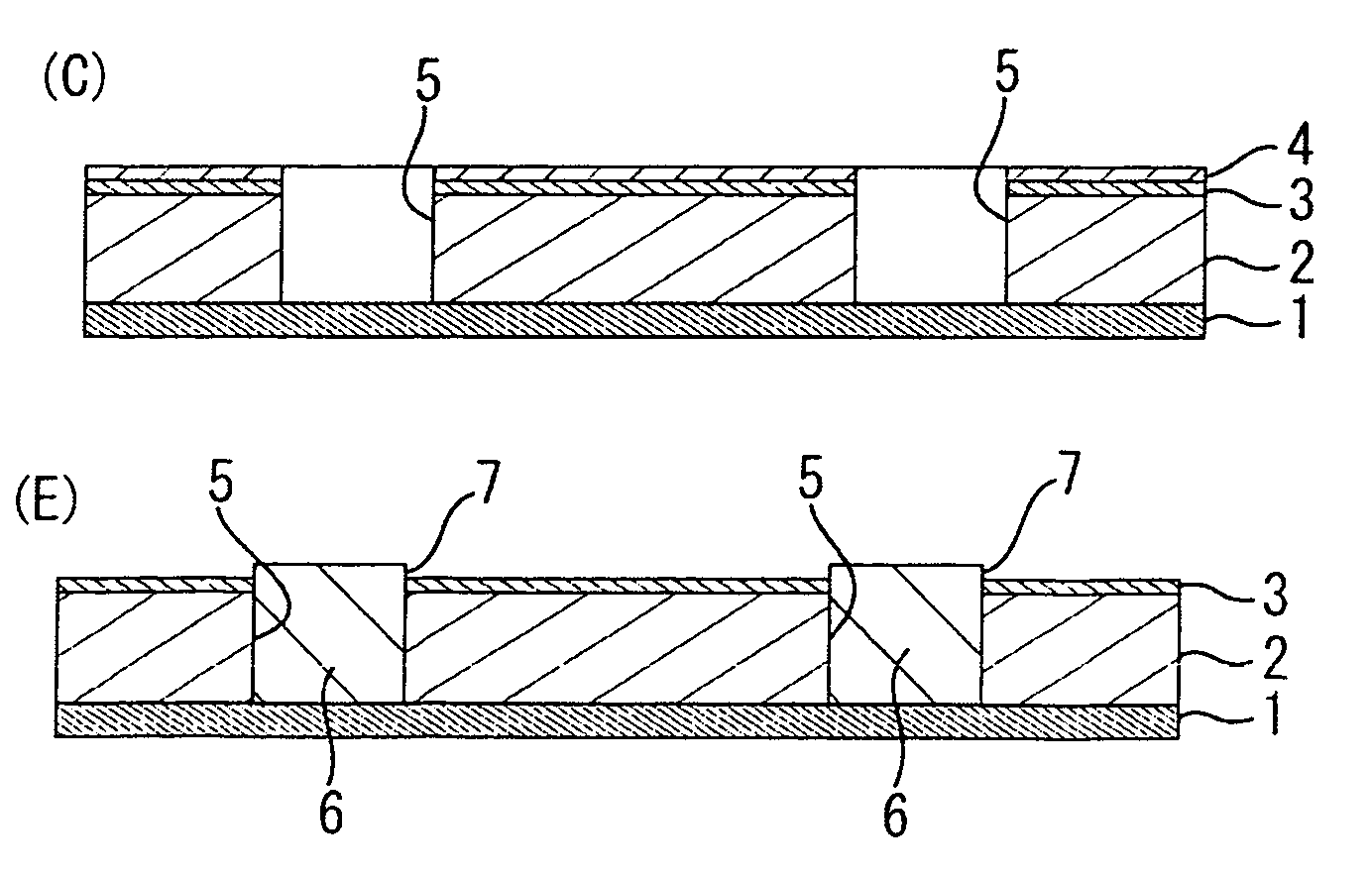

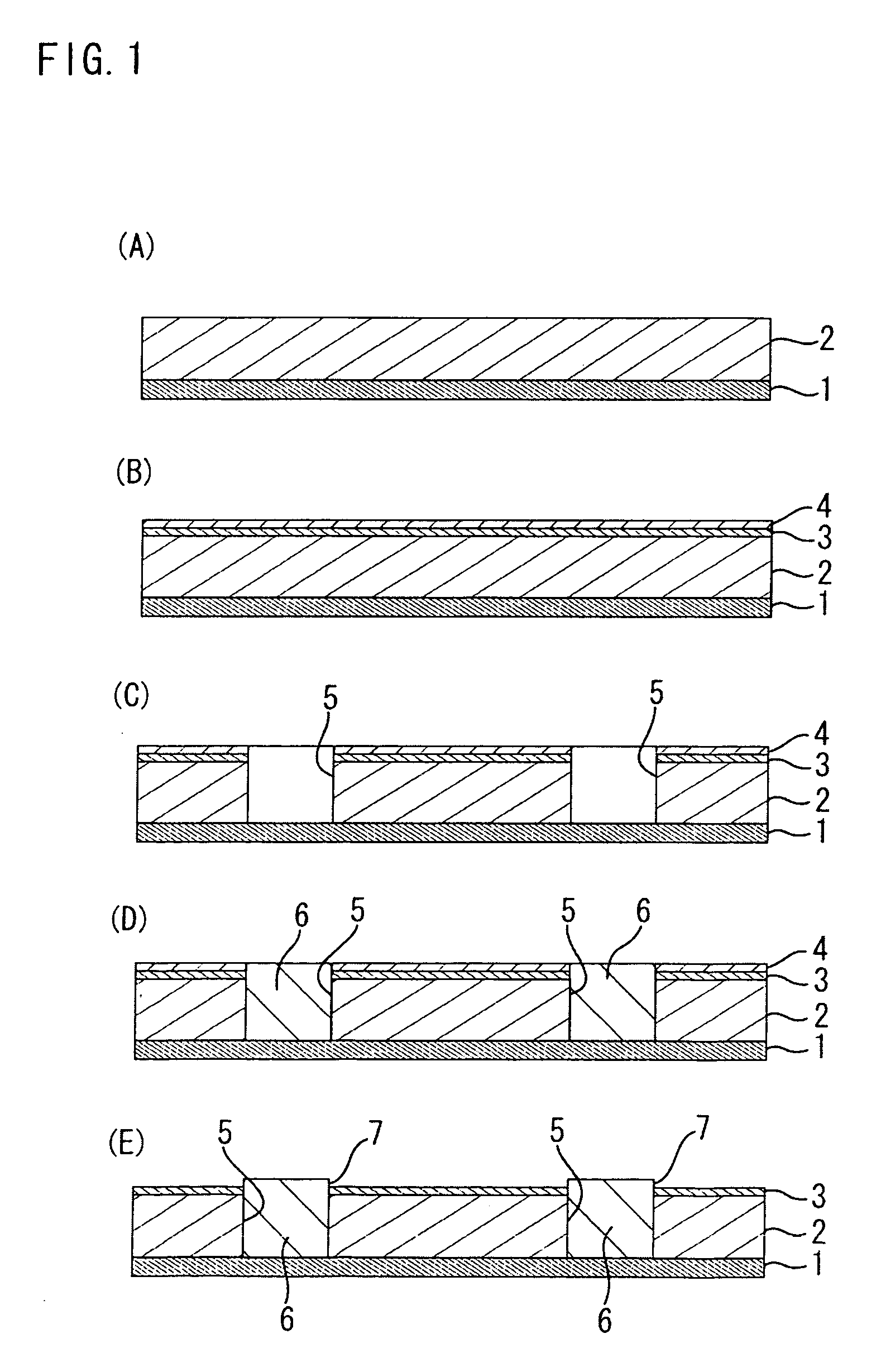

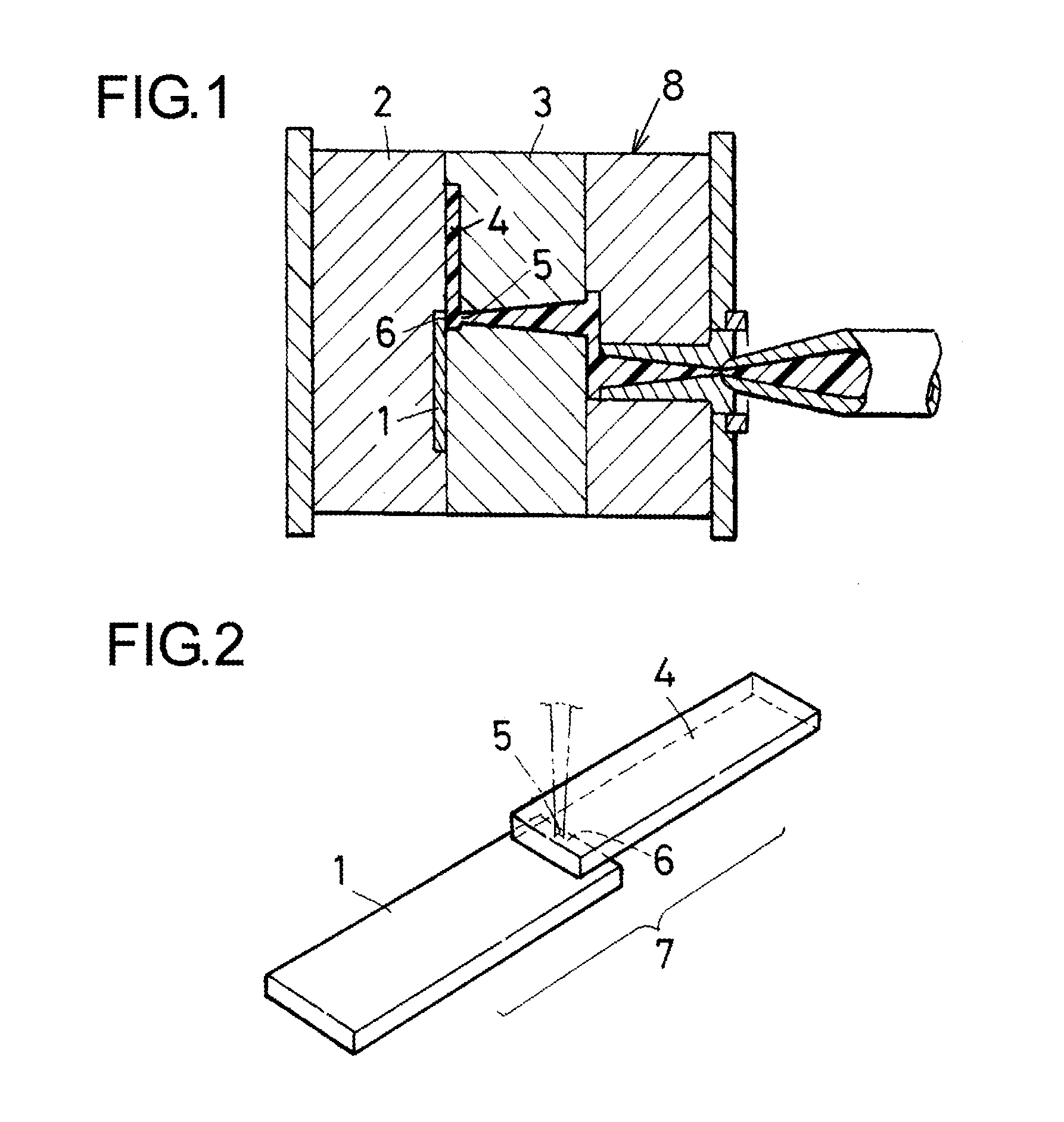

Printed wiring board and its manufacturing method

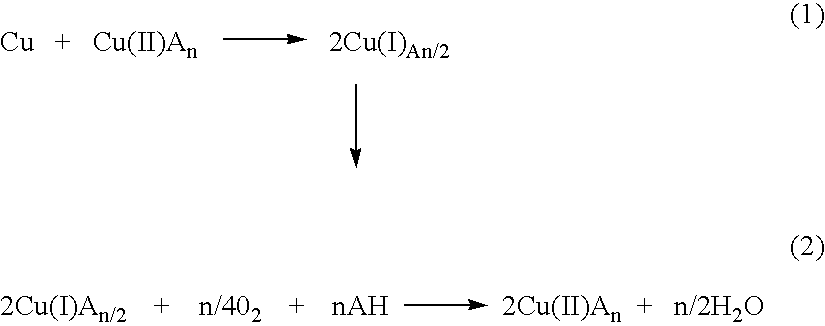

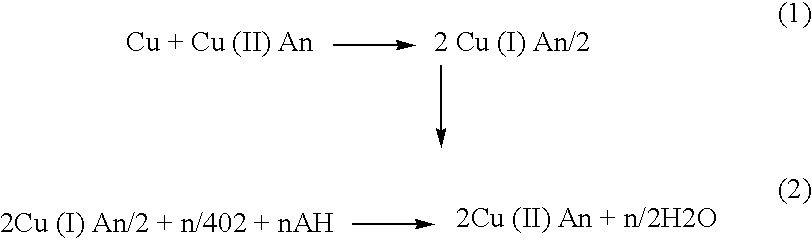

The present invention has for its object to provide a process for manufacturing multilayer printed circuit boards which is capable of simultaneous via hole filling and formation of conductor circuit and via holes of good crystallinity and uniform deposition can be constructed on a substrate and high-density wiring and highly reliable conductor connections can be realized without annealing. The present invention is related to a process for manufacturing multilayer printed circuit boards which comprises disposing an interlayer resin insulating layer on a substrate formed with a conductor circuit, creating openings for formation of via holes in said interlayer resin insulating layer, forming an electroless plated metal layer on said interlayer resin insulating layer, disposing a resist thereon, performing electroplating, stripping the resist off and etching the electroless plated metal layer to provide a conductor circuit and via holes, wherein the electroplating is performed intermittently using said electroless plated metal layer as cathode and a plating metal as anode at a constant voltage between said anode and said cathode.

Owner:IBIDEN CO LTD

Structure having laser ablated features and method of fabricating

InactiveUS6919514B2Dense configurationInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOptoelectronicsMetal

Embedded flush circuitry features are provided by providing a conductive seed layer on the sidewalls and bottom of laser ablated trench features plating a layer of conductive metal onto the seed layer and depositing a layer of dielectric material.

Owner:META PLATFORMS INC

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

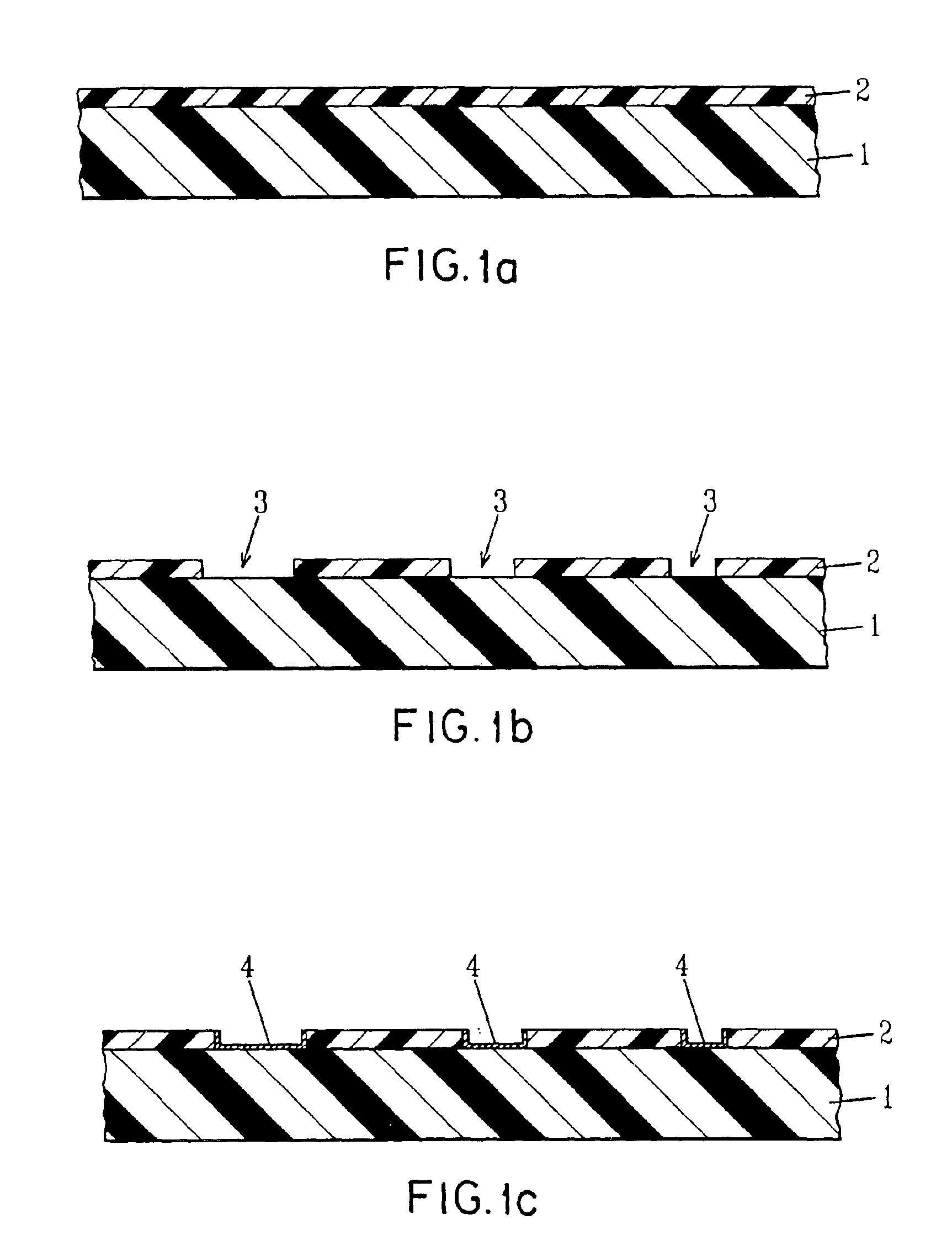

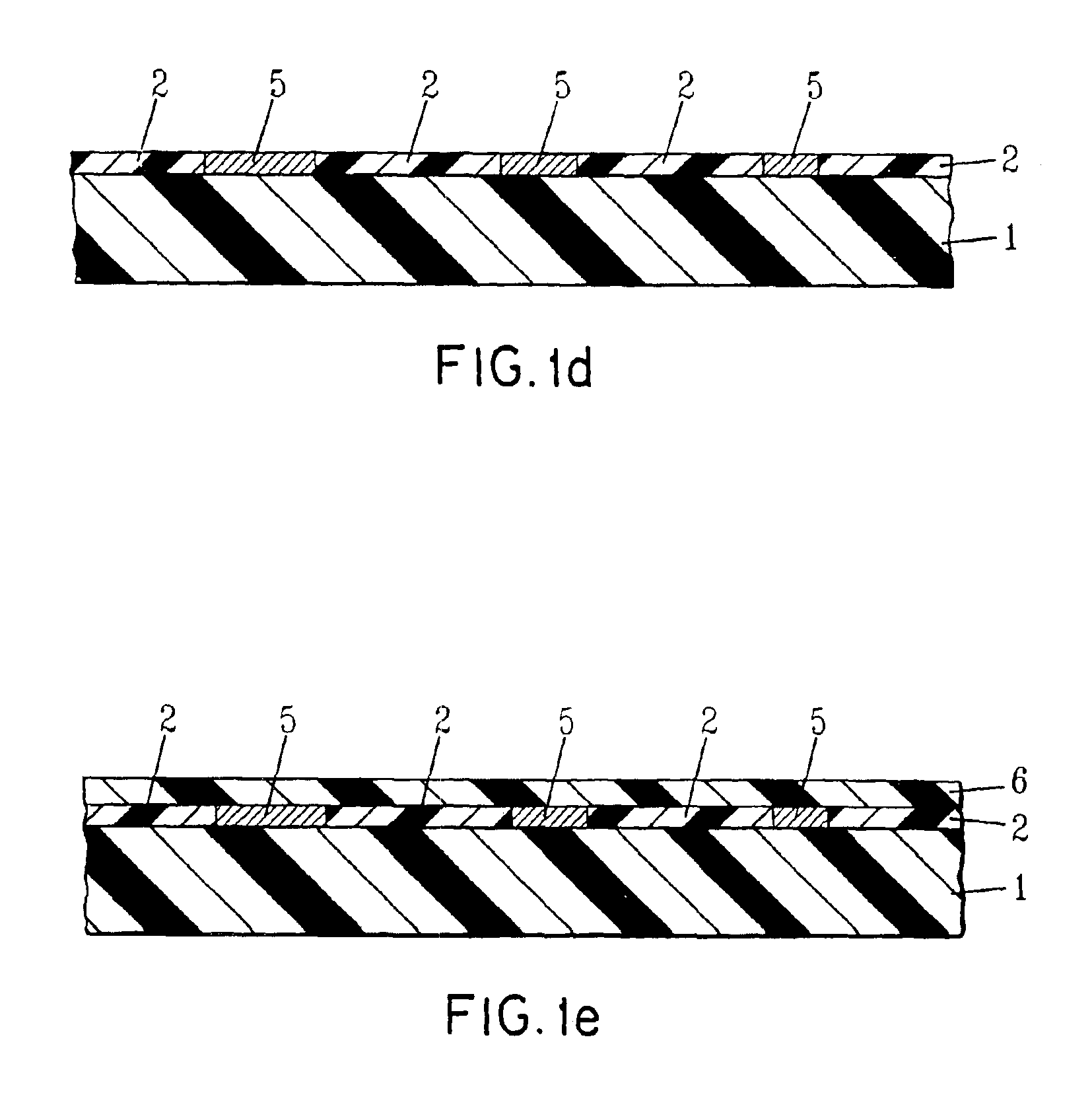

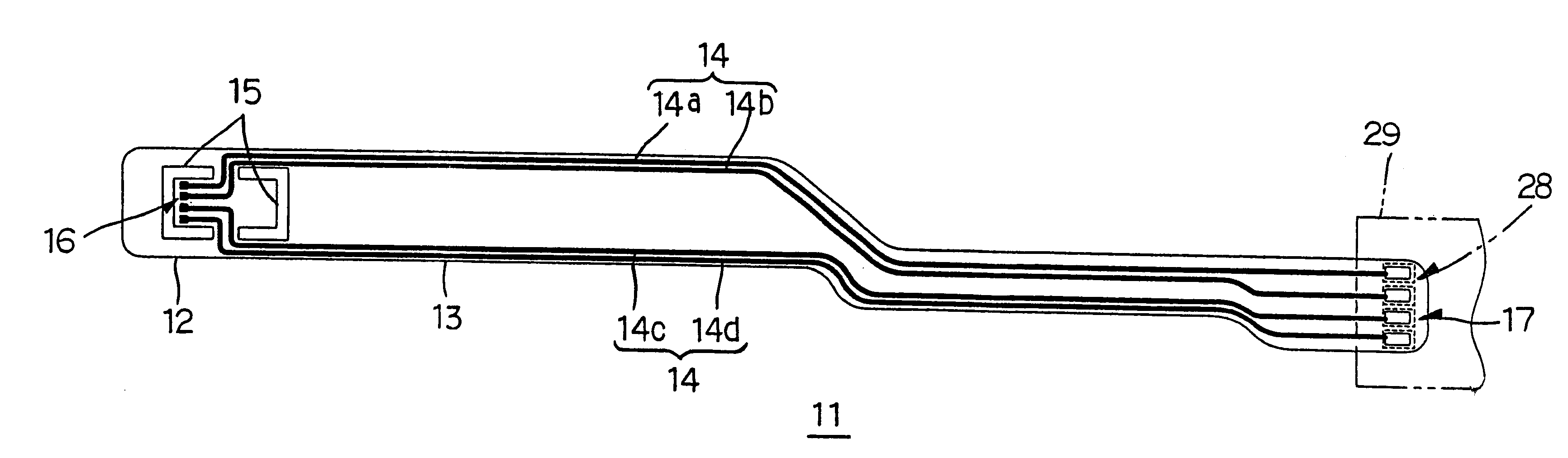

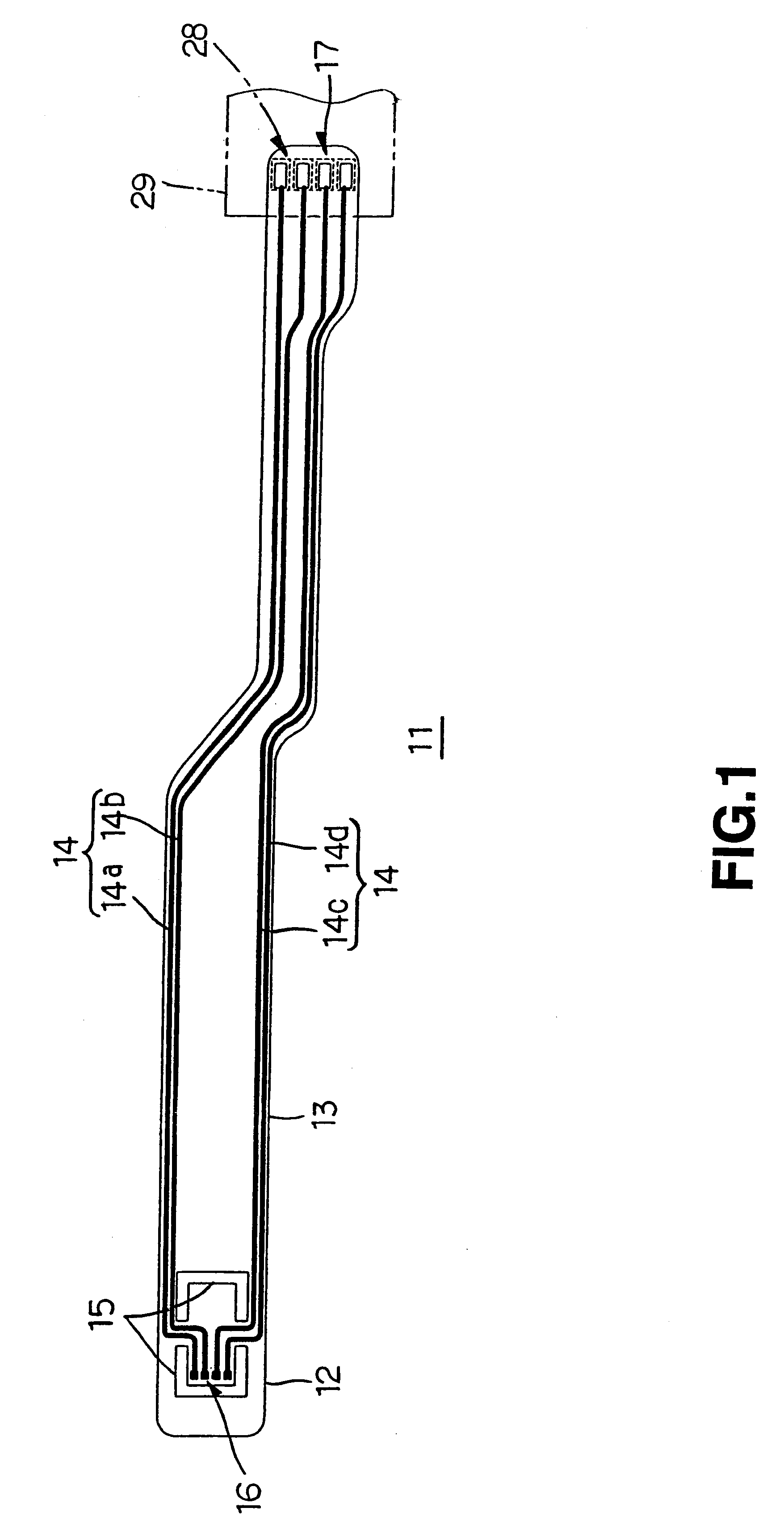

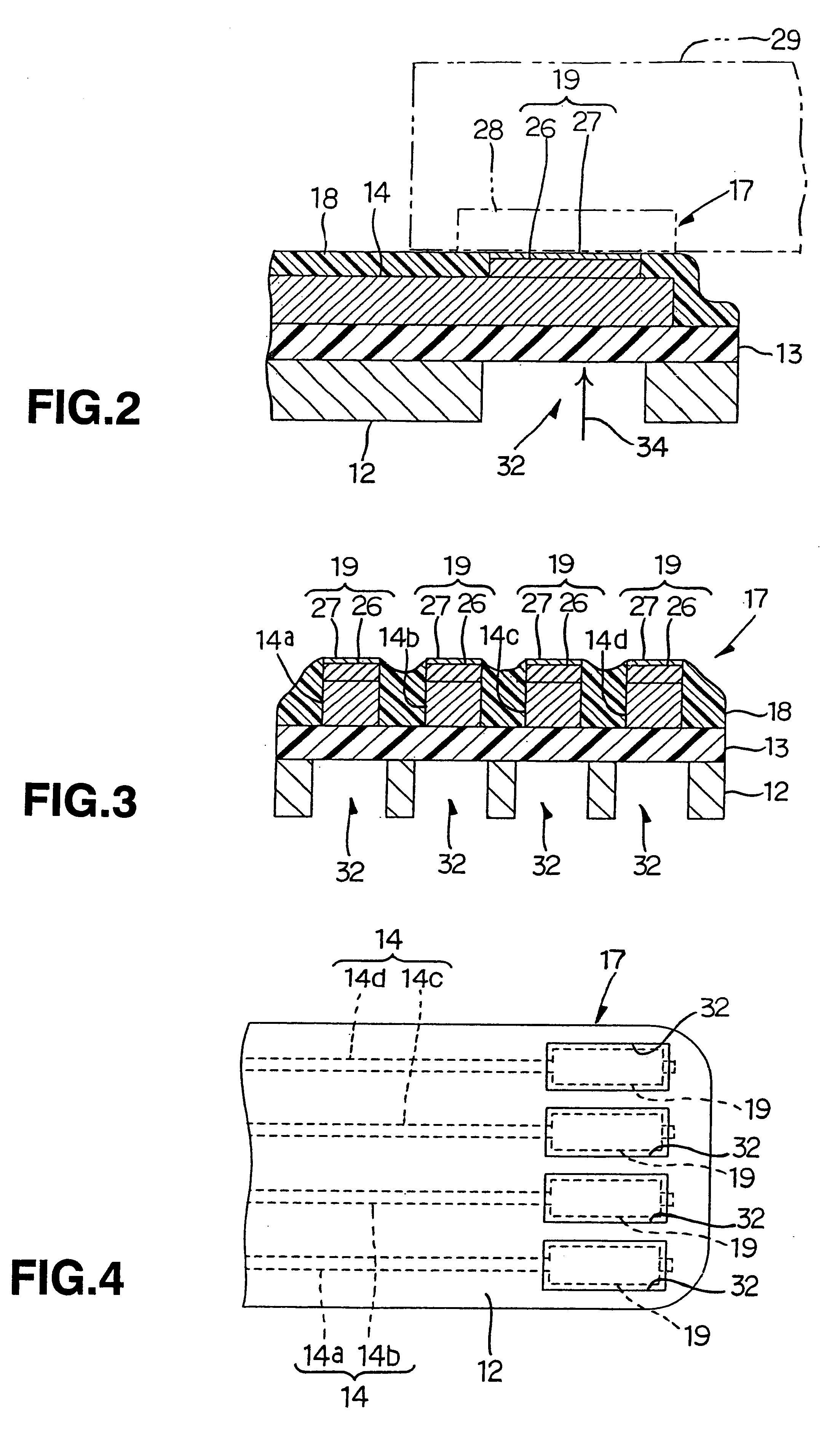

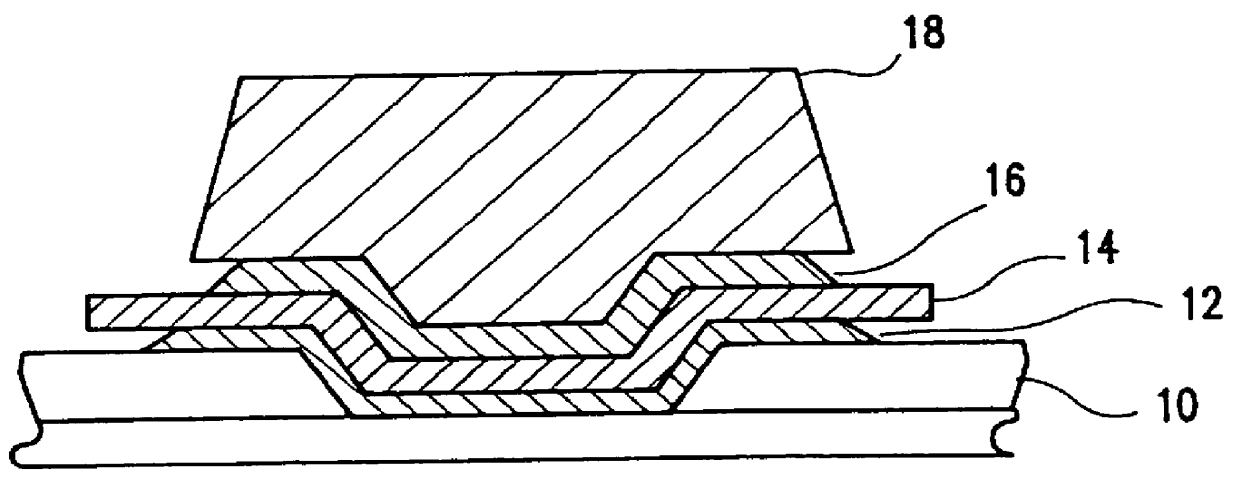

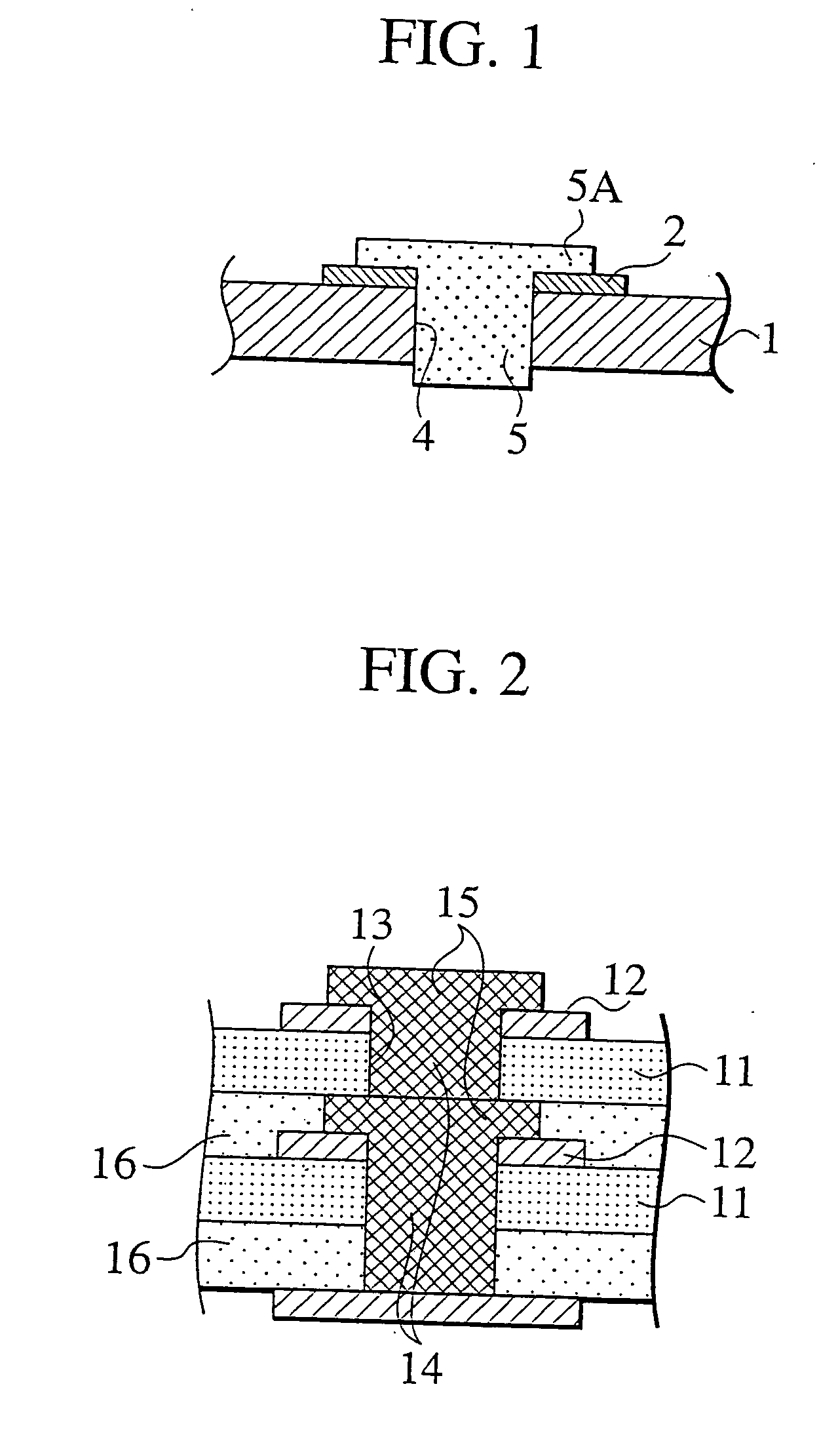

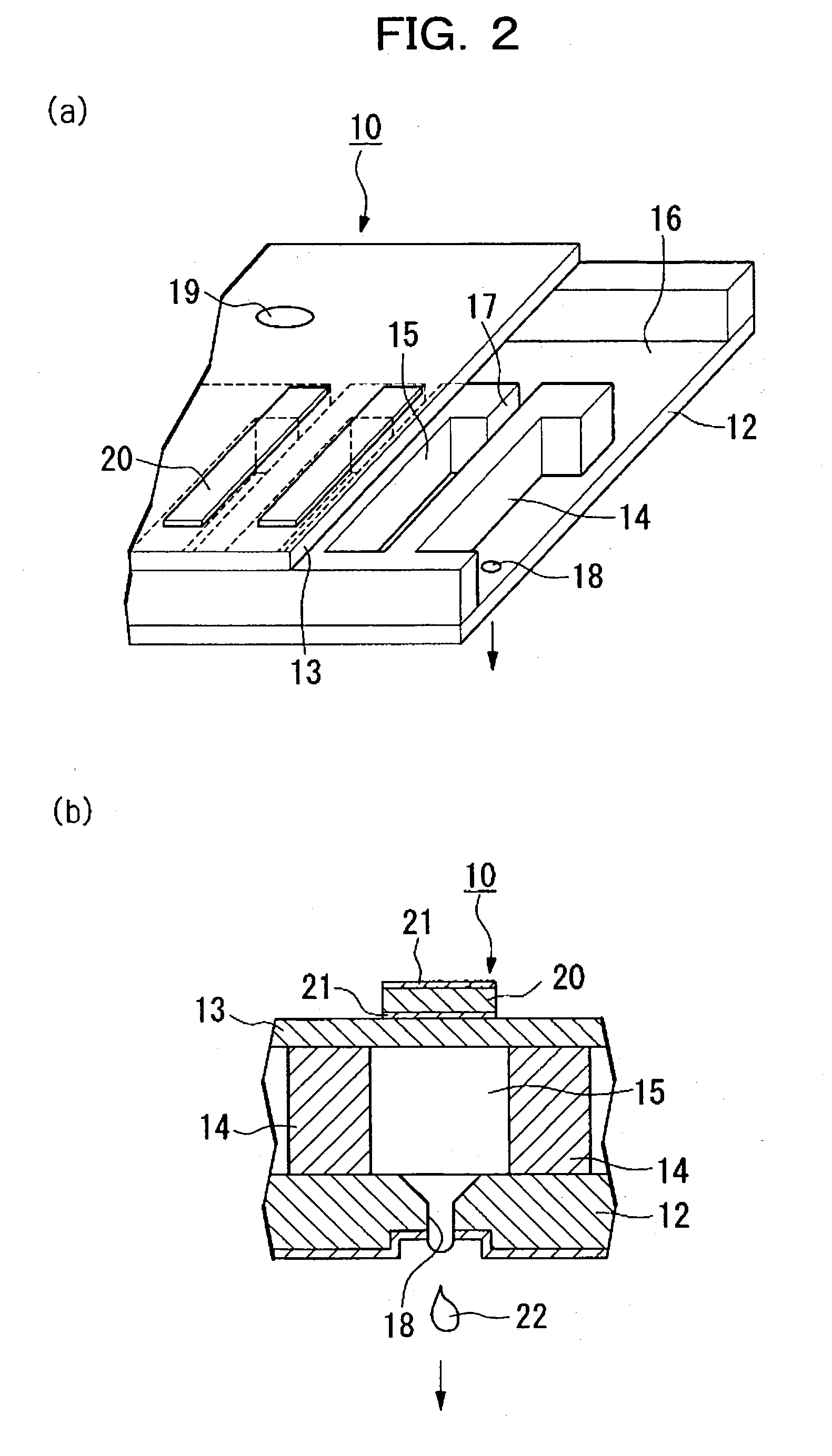

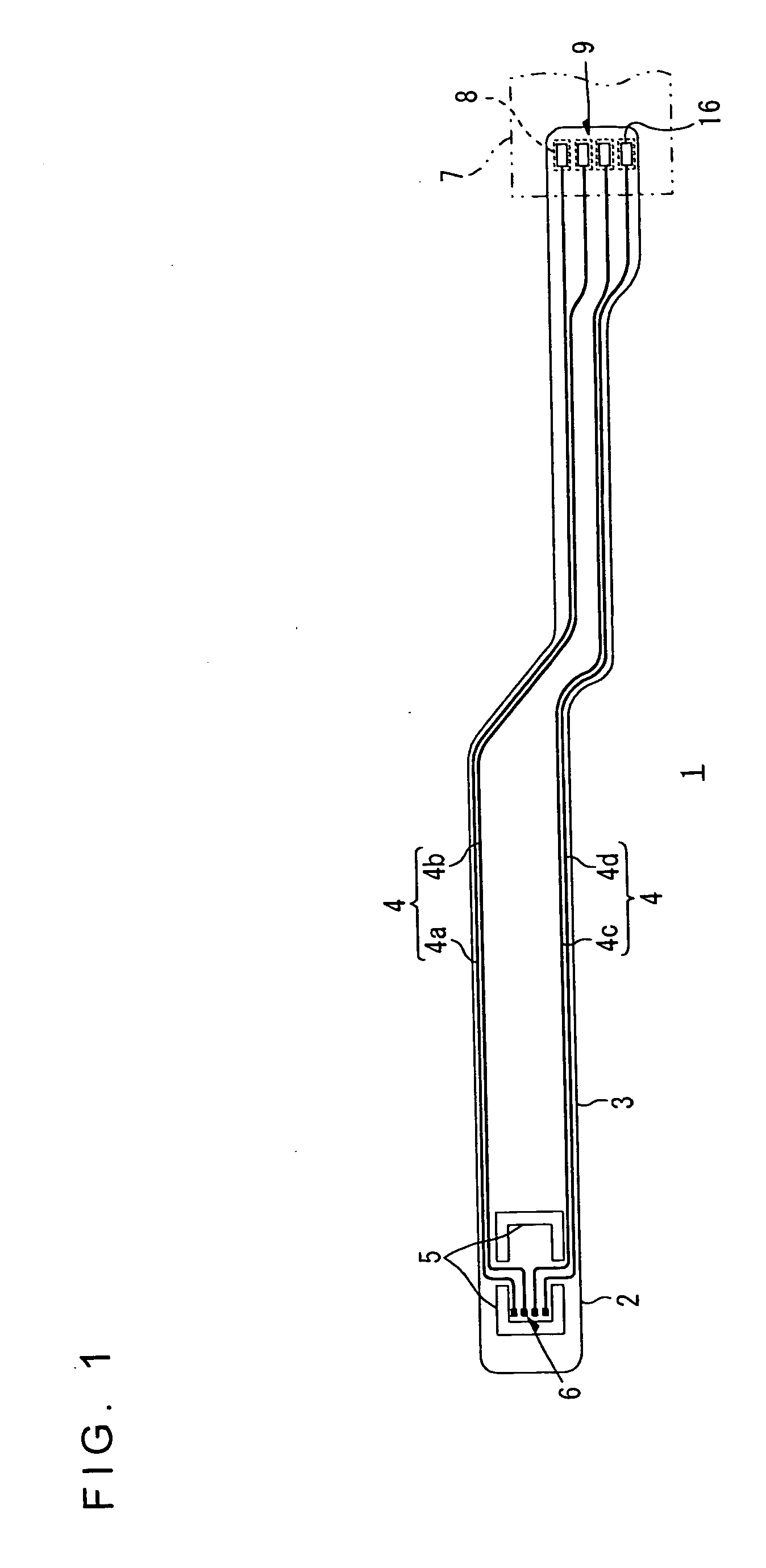

Suspension board with circuit

InactiveUS6399899B1High strengthSimple structureRelieving strain on wire connectionRecord information storageExternal connectionEngineering

To provide a suspension board with circuit that enables its terminals to be bonded to the other terminals with sufficient strength with simple structure, to ensure sufficient bonding reliability, the suspension board with circuit 11 includes a suspension board 12, a base layer 13 formed on the suspension board 12, and a conductive layer 14 formed on the base layer 13 and a cover layer 18 with which the conductive layer 14 is covered, wherein external connection terminals 17 to be bonded to terminals 28 of a read / write board 29 are formed without the suspension board 12 and / or the base layer 13 being formed.

Owner:NITTO DENKO CORP

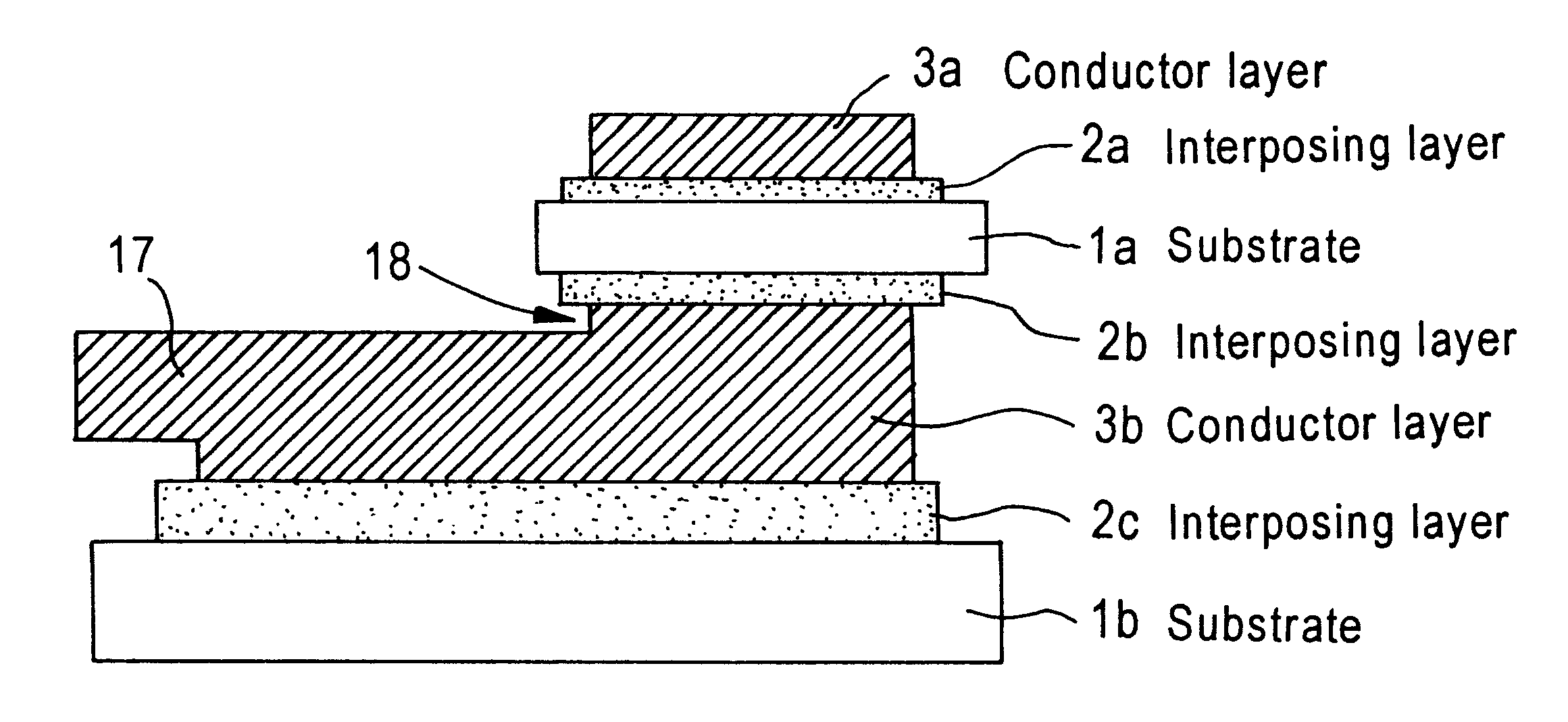

Copper circuit junction substrate and method of producing the same

InactiveUS6261703B1Avoid discharge phenomenonHigh concentration of thermal stressInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorCopper oxide

A highly reliable copper circuit-joined board that, in mounting a semiconductor element, a lead frame or the like on a ceramic substrate, enables the semiconductor element, the lead frame or the like to be strongly joined to the substrate without breaking or deformation of the substrate found in conventional joining methods, such as brazing and joining using a copper / copper oxide eutectic crystal. Any one of an interposing layer comprising a brazing material layer comprising silver and / or copper as a main component and an active metal or an interposing layer having a two-layer structure comprising a first interposing layer comprising the brazing material layer or a high-melting metallizing layer and a second interposing layer, having a melting point of 1000.degree. C. or below, comprising Ni, Fe, Cu as a main component in that order from the substrate side, is formed on a ceramic substrate, and a conductor layer, comprising copper as a main component, which, in both the lengthwise and widthwise directions, is at least 0.05 mm shorter than the interposing layer, is formed on the interposing layer to prepare a copper circuit-joined board. The copper circuit-joined board may comprise the base board having thereon an outer layer comprising Ni as a main component. A semiconductor element is mounted on the copper circuit-joined board to prepare a semiconductor device.

Owner:SUMITOMO ELECTRIC IND LTD

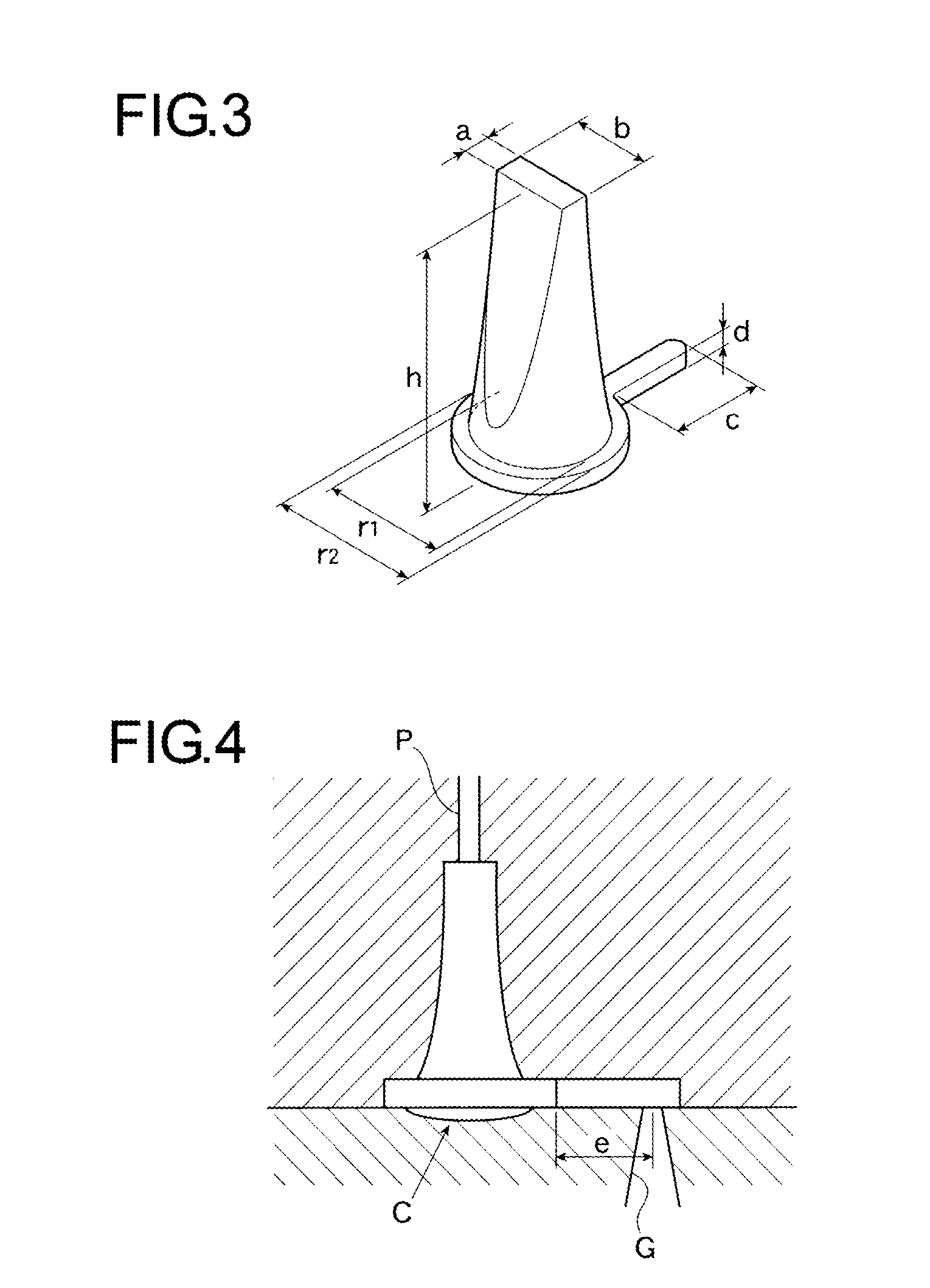

Ball limiting metalization process for interconnection

InactiveUS6111321APrinted circuit assemblingInsulating substrate metal adhesion improvementResistSemiconductor chip

A two-step masking process is disclosed for forming a ball limiting metallurgy (BLM) pad structure for a solder joint interconnection used between a support substrate and a semiconductor chip. A solder non-wettable layer and a solder wettable layer are deposited on the surface of a support substrate or semiconductor chip which are to be connected. A phased transition layer is deposited between the wettable and non-wettable layers. A thin photo-resist mask defines an area of the solder wettable and phased layers which are etched to form a raised, wettable frustum cone portion. A second mask is deposited on the surface of the support substrate or semiconductor chip, and has an opening concentrically positioned about the frustum cone. Solder is deposited in the opening and covers the frustum cone and the area about its periphery. When solidified, the solder, acting as a mask, is used to sub-etch the underlying solder non-wettable layer thereby defining the BLM pad. When reflowed, the solder beads away from the surface of the solder non-wettable layer to form a ball which securely adheres about the frustum cone.

Owner:IBM CORP

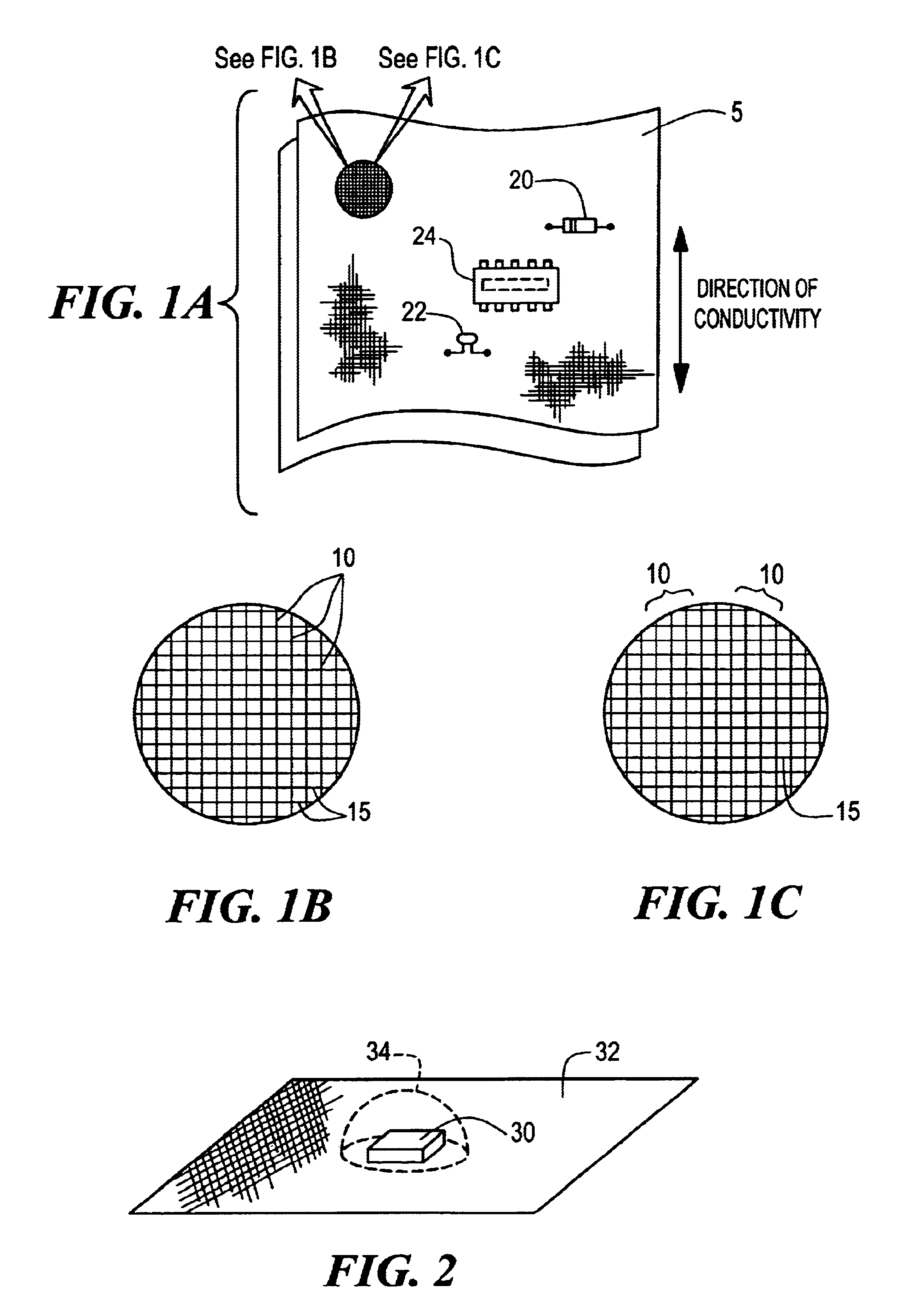

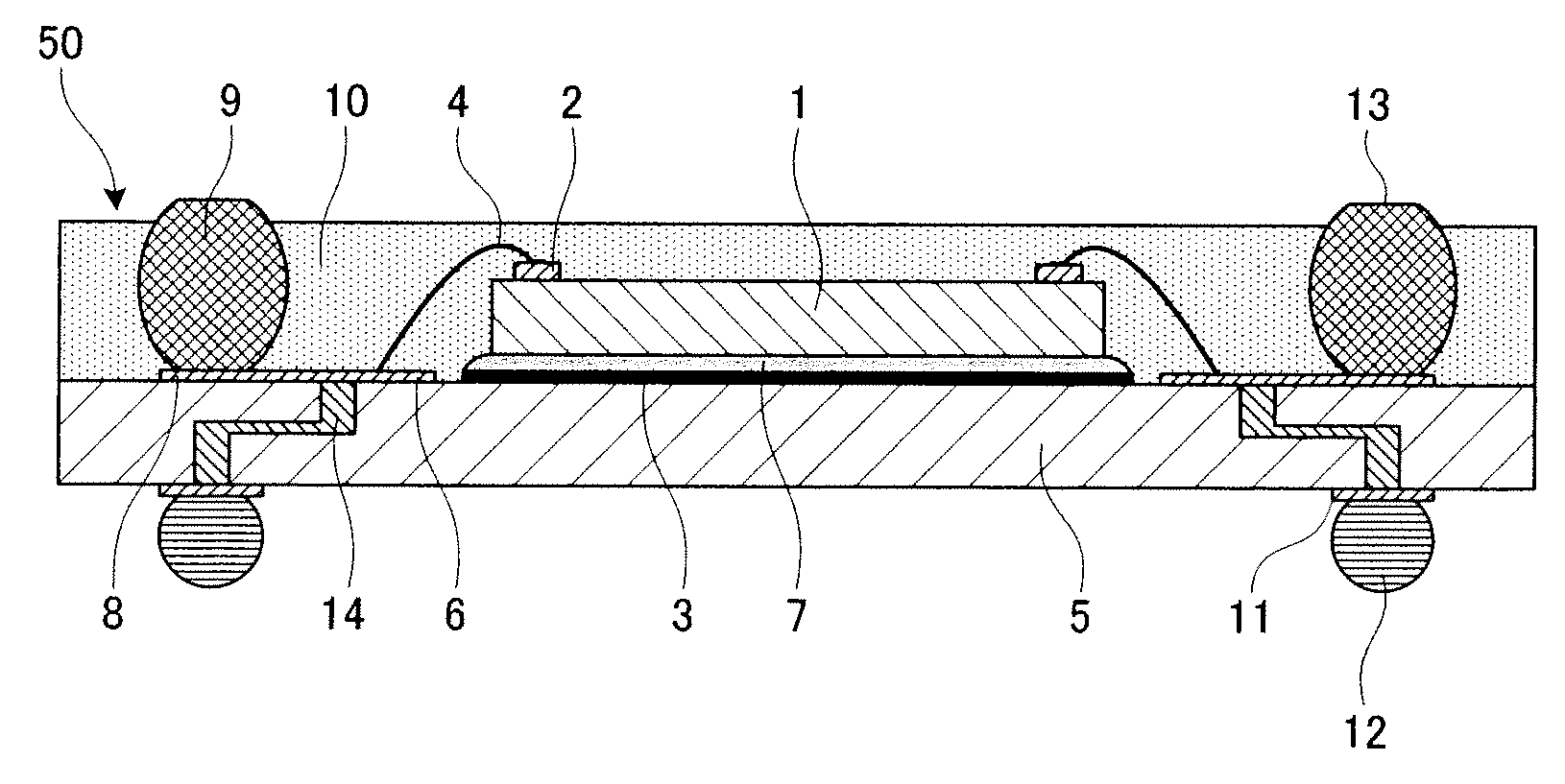

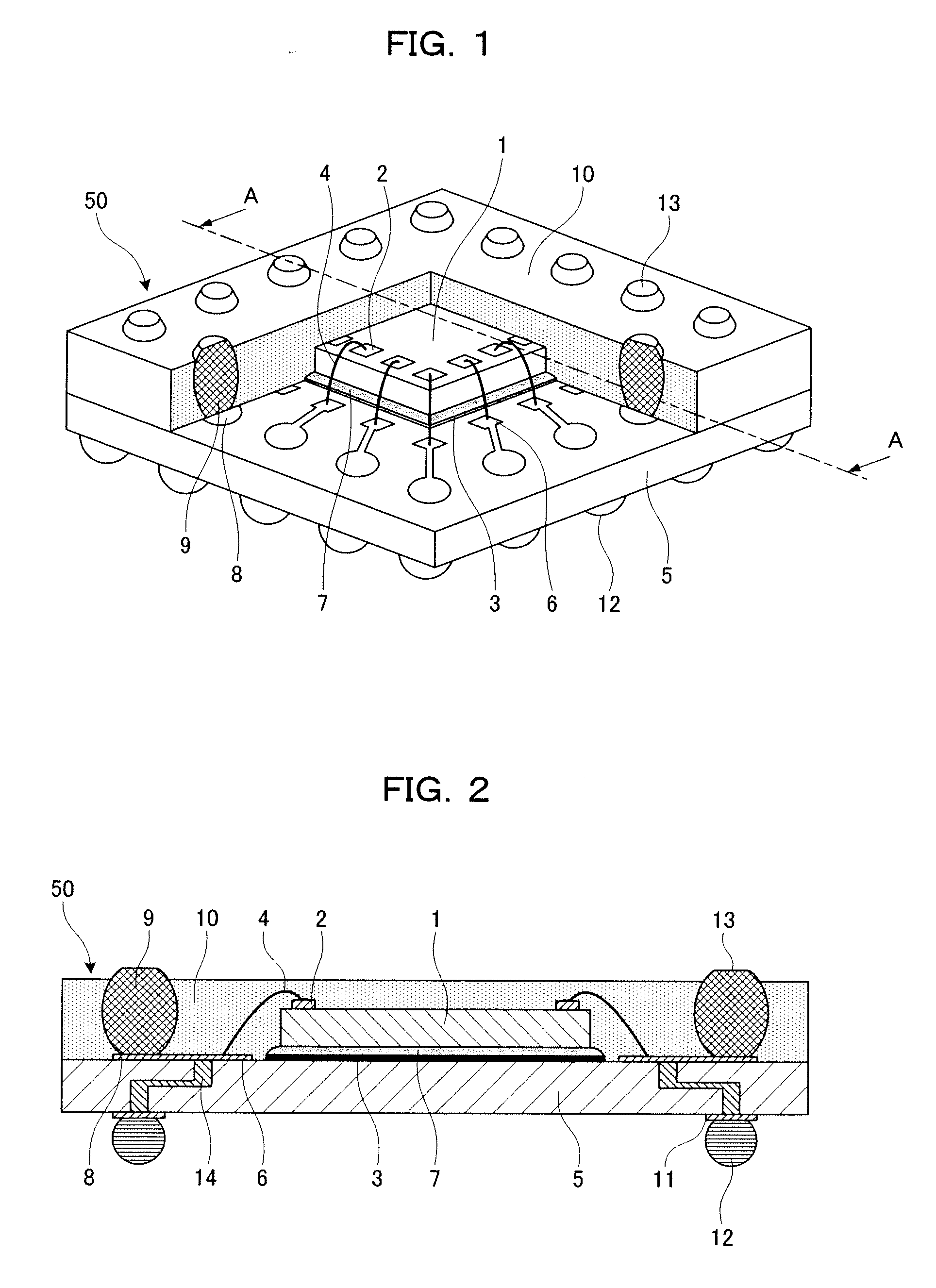

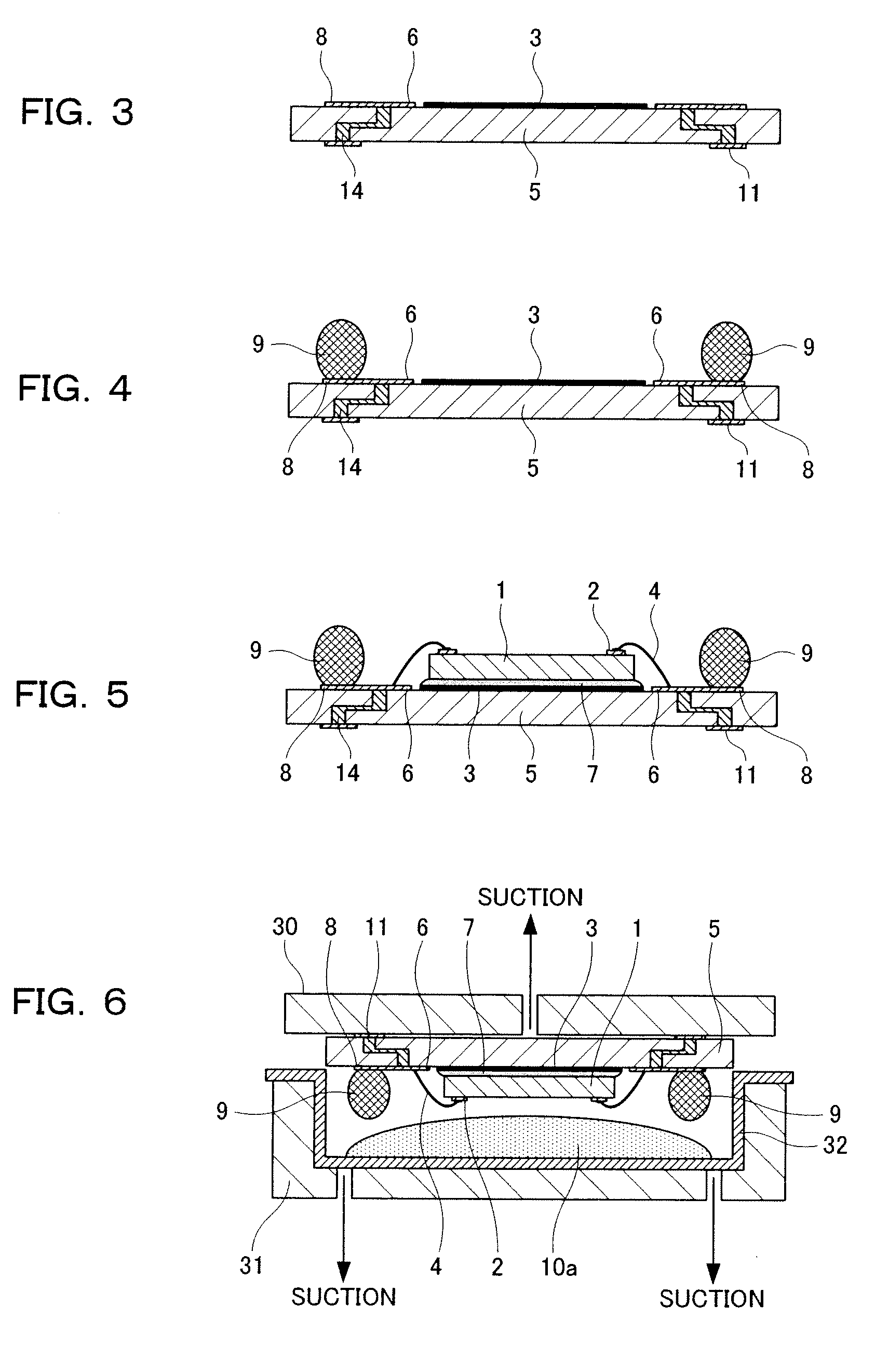

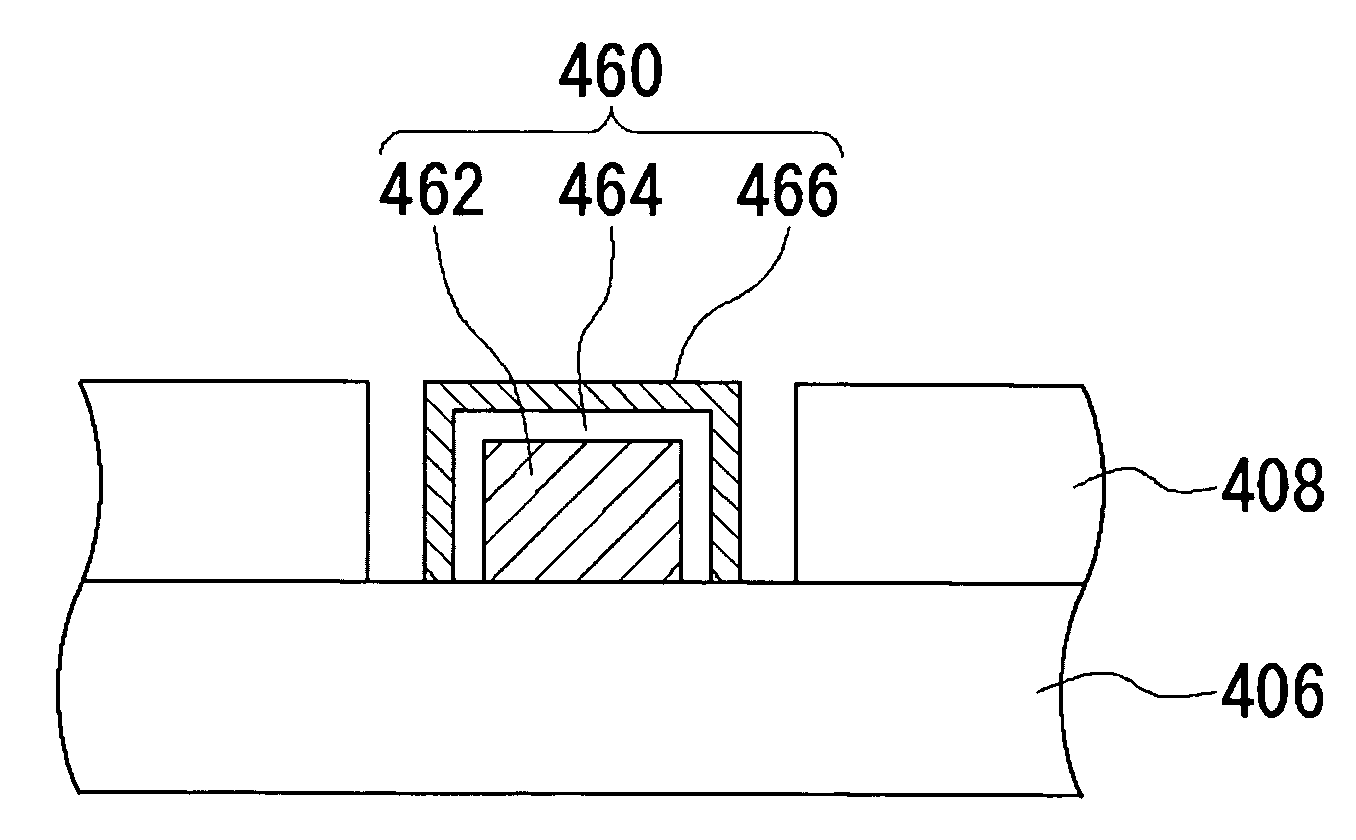

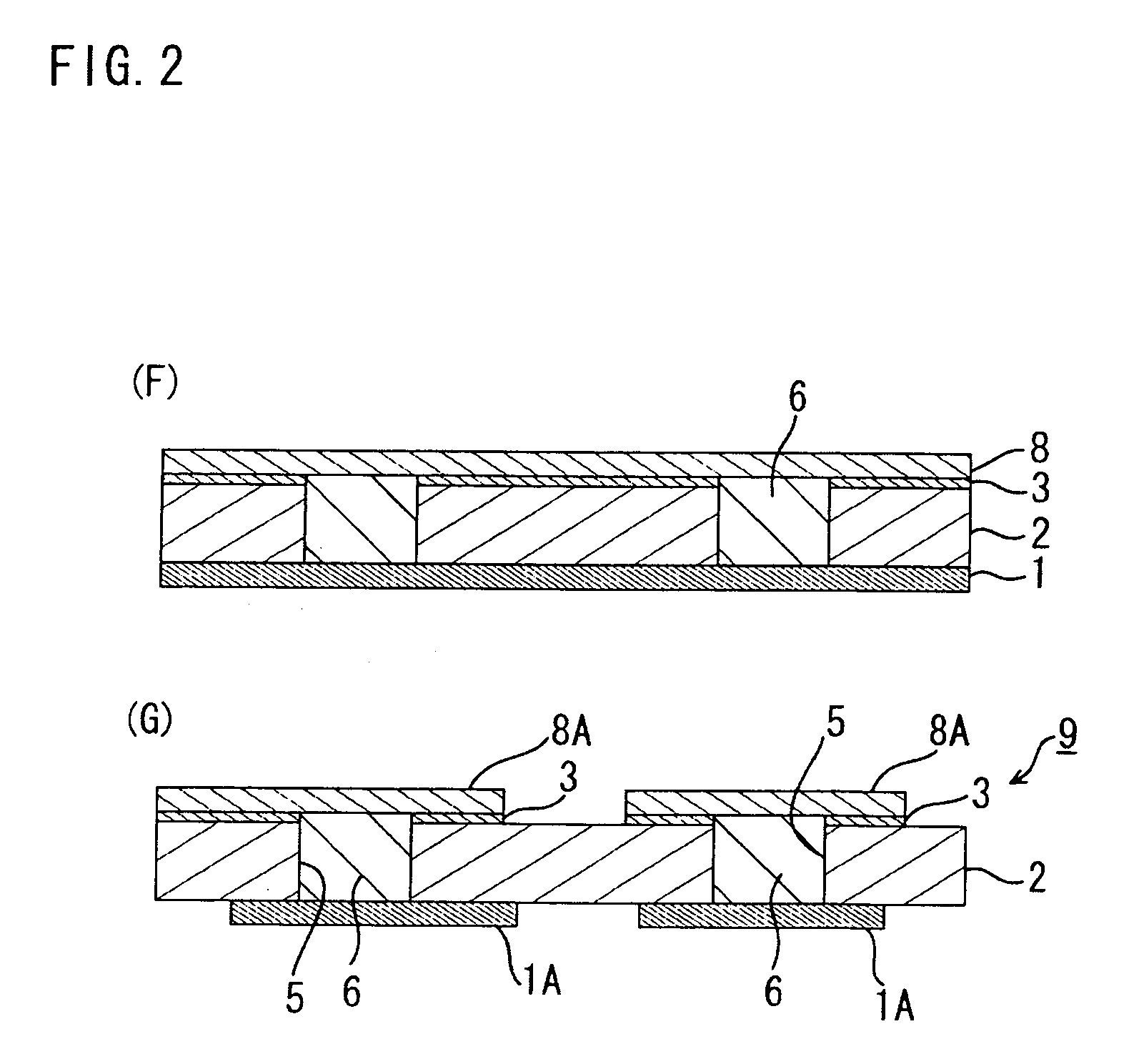

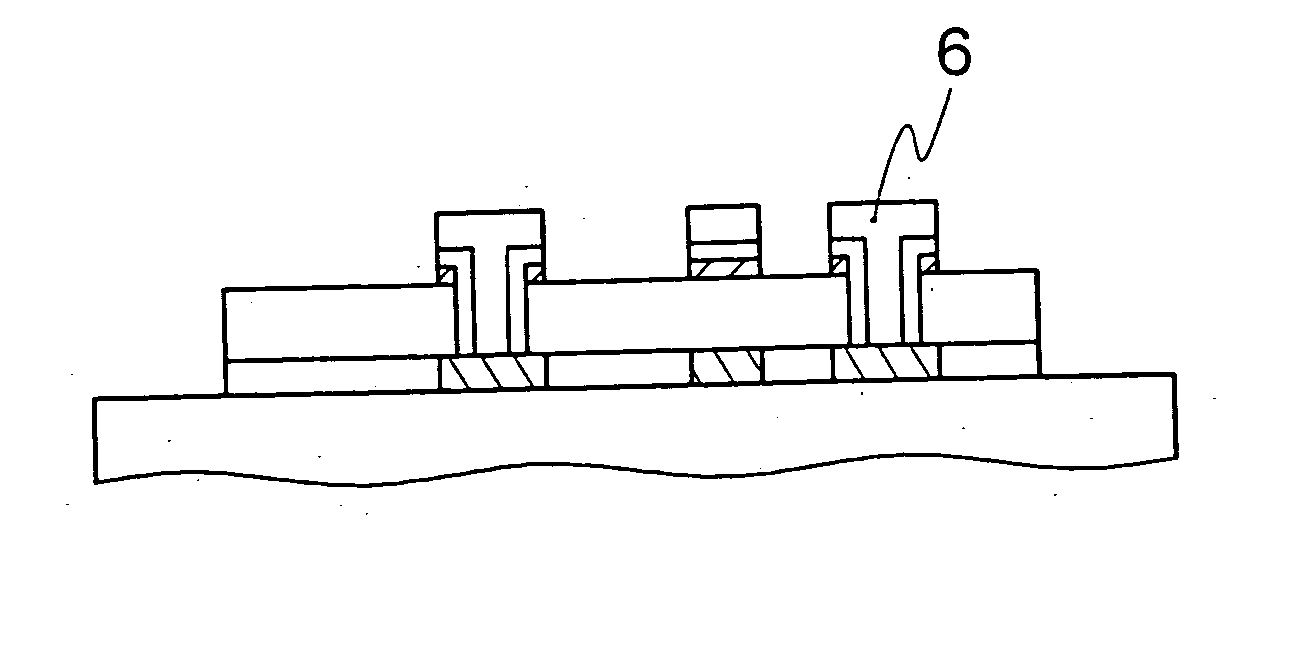

Semiconductor device and method of manufacturing the same

ActiveUS20090146301A1Highly reliable three-dimensional mounting structureOptimizationInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device capable of realizing highly reliable three-dimensional mounting, and a method of manufacturing the same, are provided. A projected electrode 9 is formed in a region outside of an element mounting region of a substrate 5. The projected electrode 9 includes a protruding portion that protrudes from the front face of a molding resin portion 10. The distal end of the protruding portion is a flat face 13. In addition, a portion of the projected electrode 9 whose cross section is larger than the protruding portion is positioned inside the molding resin portion 10.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

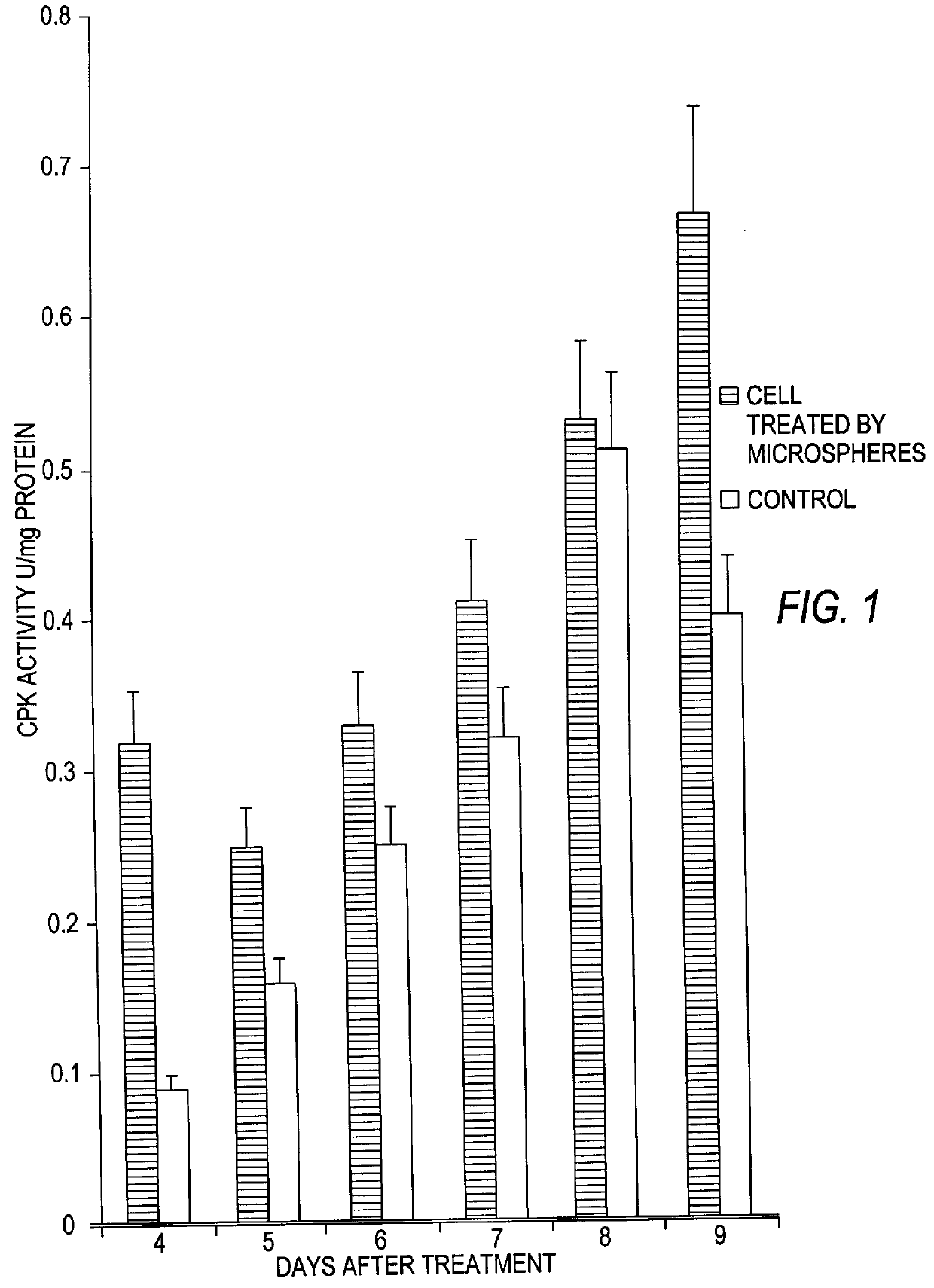

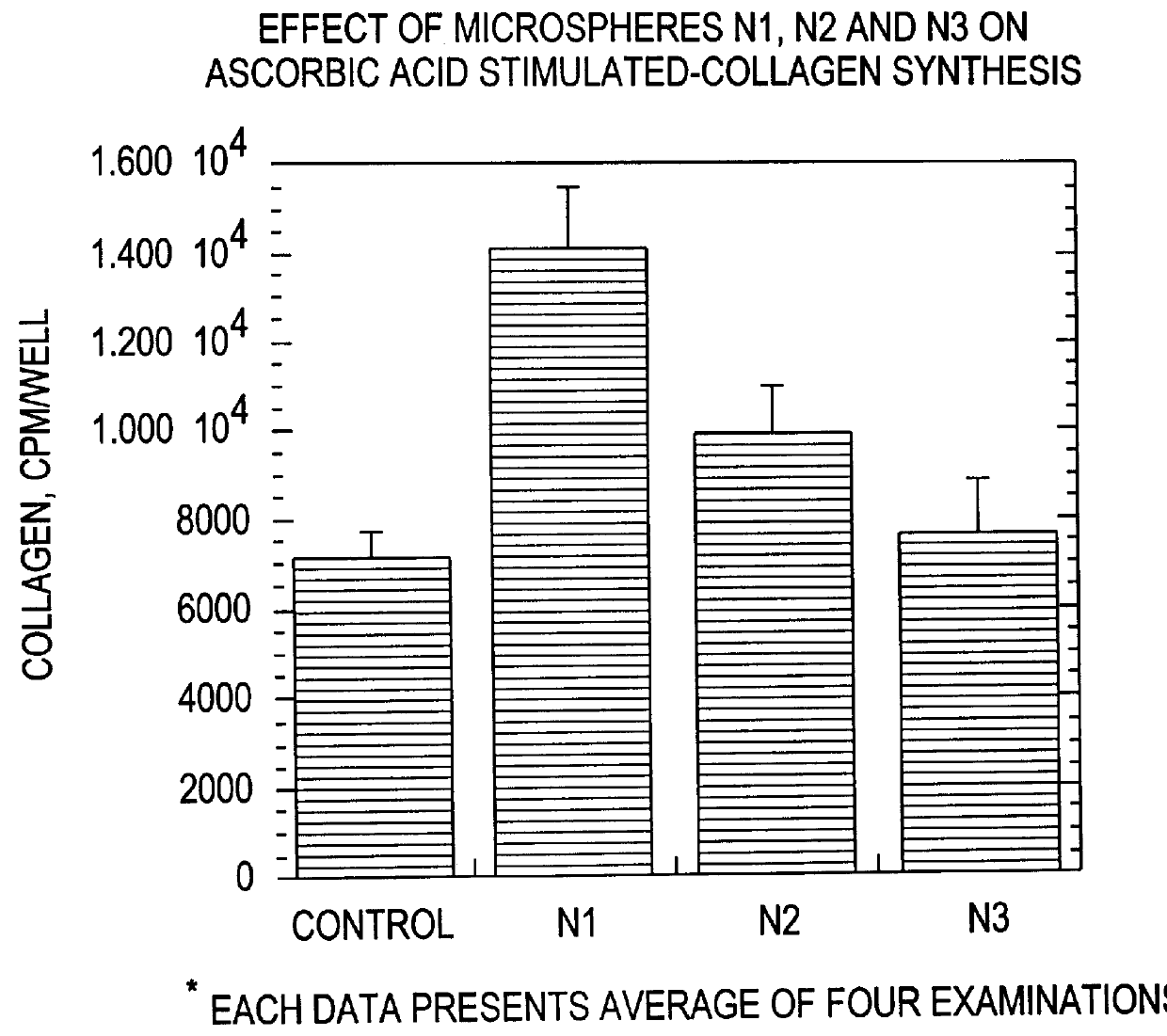

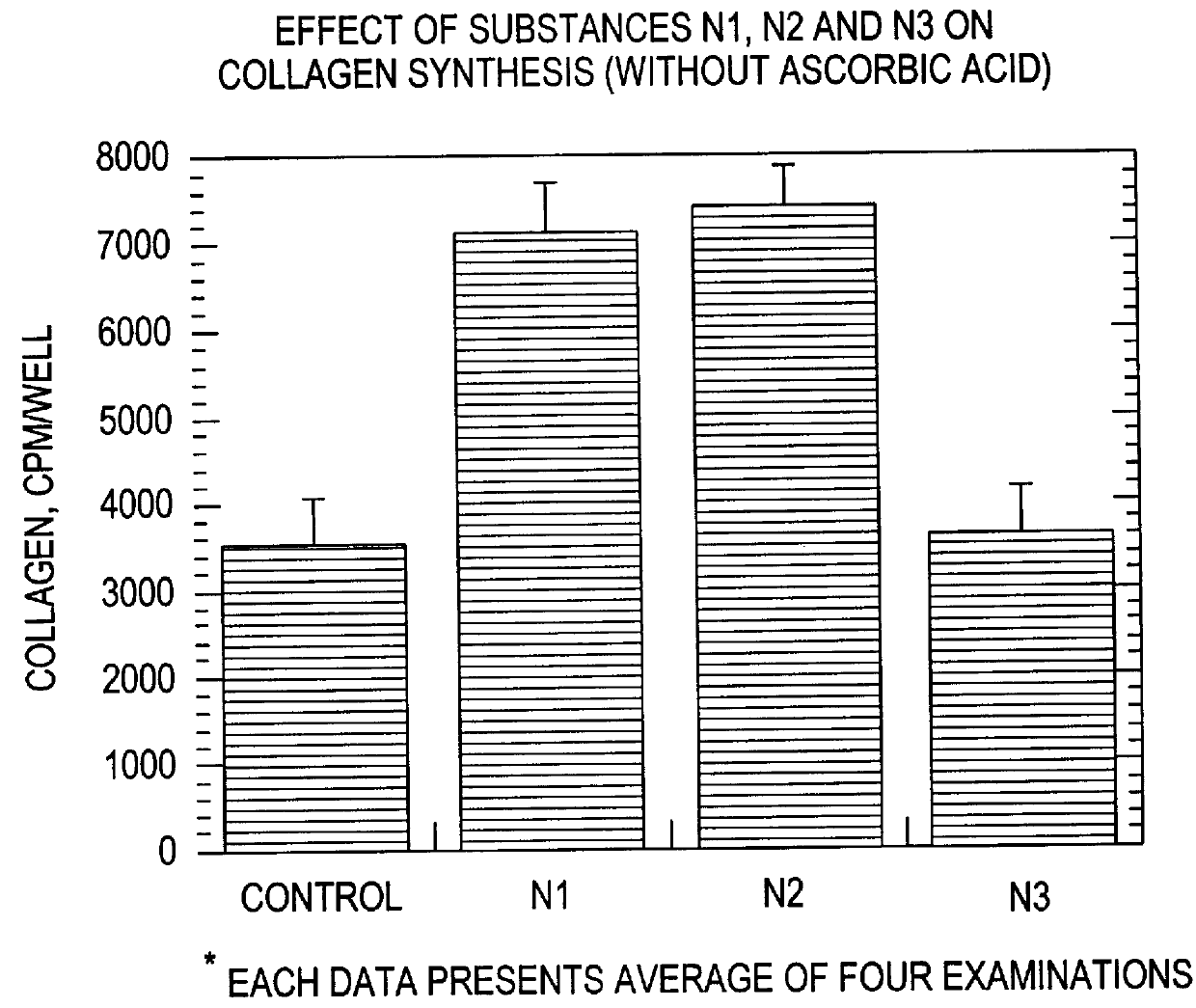

Compositions of microspheres for wound healing

InactiveUS6086863AHigh activityReduce pollutionCosmetic preparationsOrganic active ingredientsWound healingMicrosphere

Therapeutic compositions of microspheres for application to wounds and / or lesions for accelerating wound healing and muscle regeneration. The microspheres are made up of non-biodegradable material having a substantial surface charge. The therapeutic composition further includes a pharmaceutically acceptable carrier in which the microspheres are insoluble and a container for holding the composition. The therapeutic composition further contains pharmacologic agents or biologics that accelerate the wound healing process.

Owner:POLYHEAL

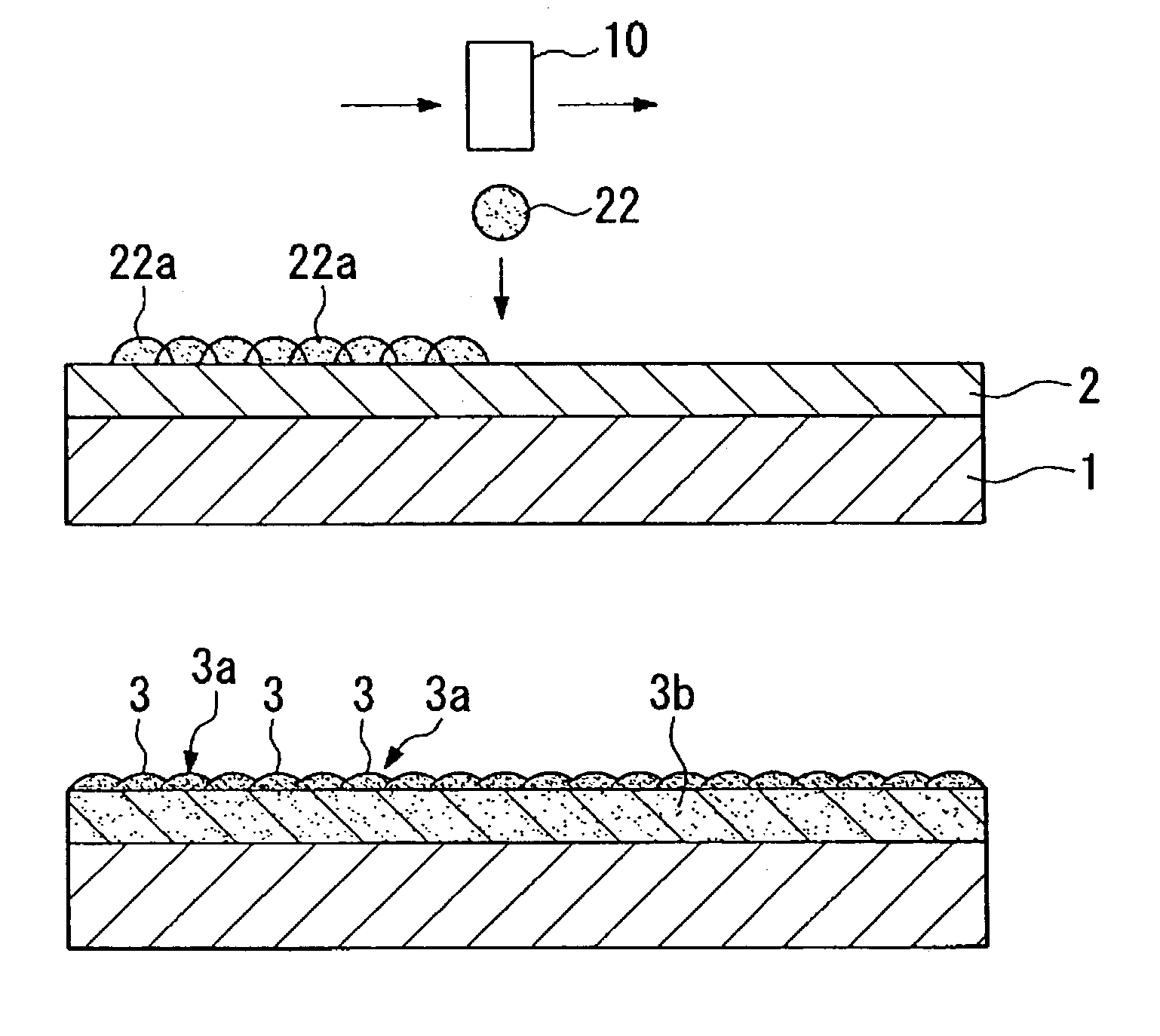

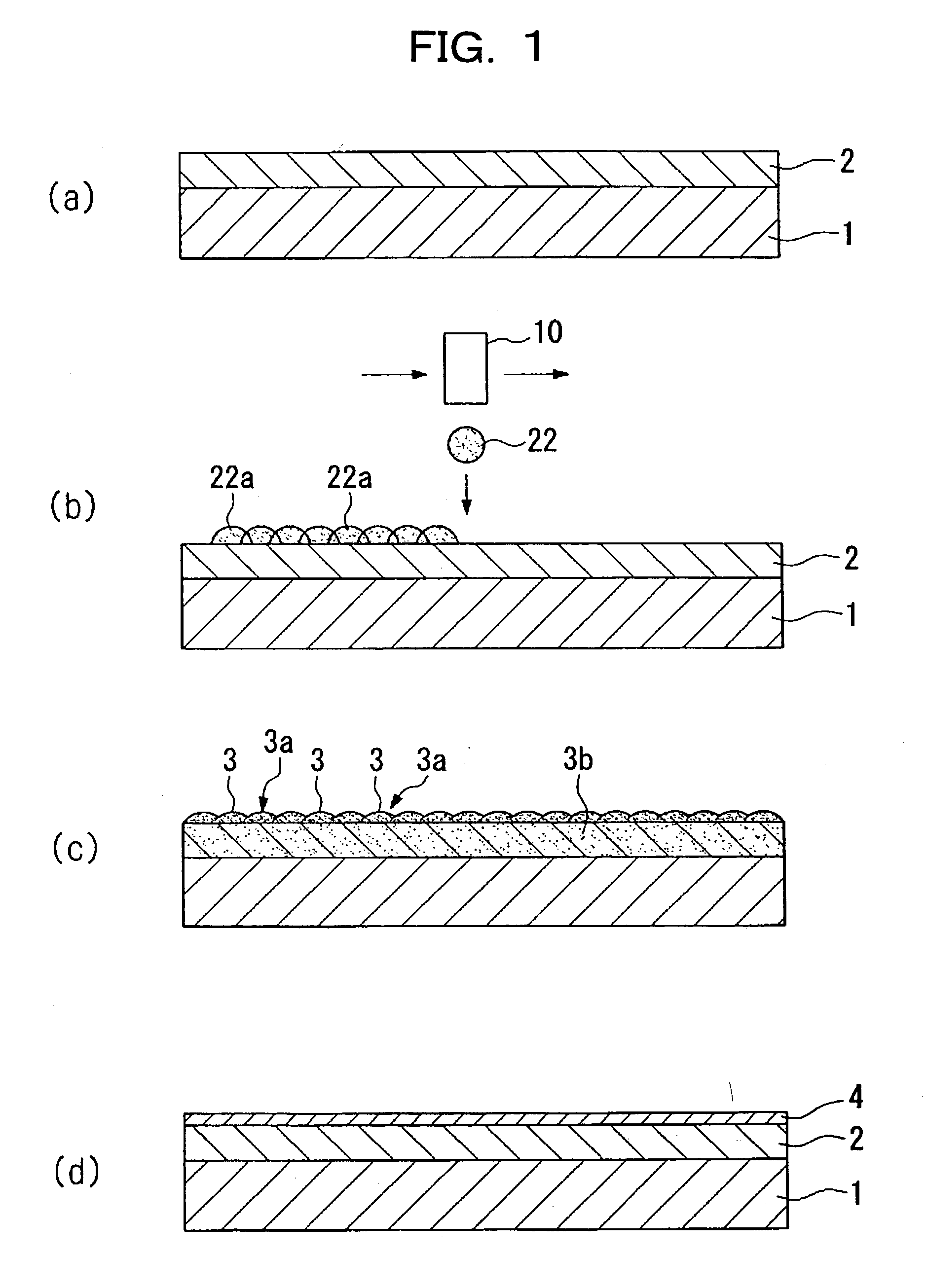

Metal foil with resin and metal-clad laminate, and printed wiring board using the same and method for production thereof

InactiveUS20050121229A1Cost efficiency and handlingCircuit formability highInsulating substrate metal adhesion improvementSynthetic resin layered productsElectrical conductorMetal foil

The present invention provides a metal clad laminate or a resin coated metal foil having a metal foil whose both surfaces are not substantially roughening-treated and an insulating resin composition layer using generally used insulating resin, and a printed wiring board and a manufacturing method thereof, in which the metal clad laminate or the resin coated metal foil is used, the reliability and circuit formability are high, and the conductor loss is extremely low.

Owner:HITACHI CHEM CO LTD

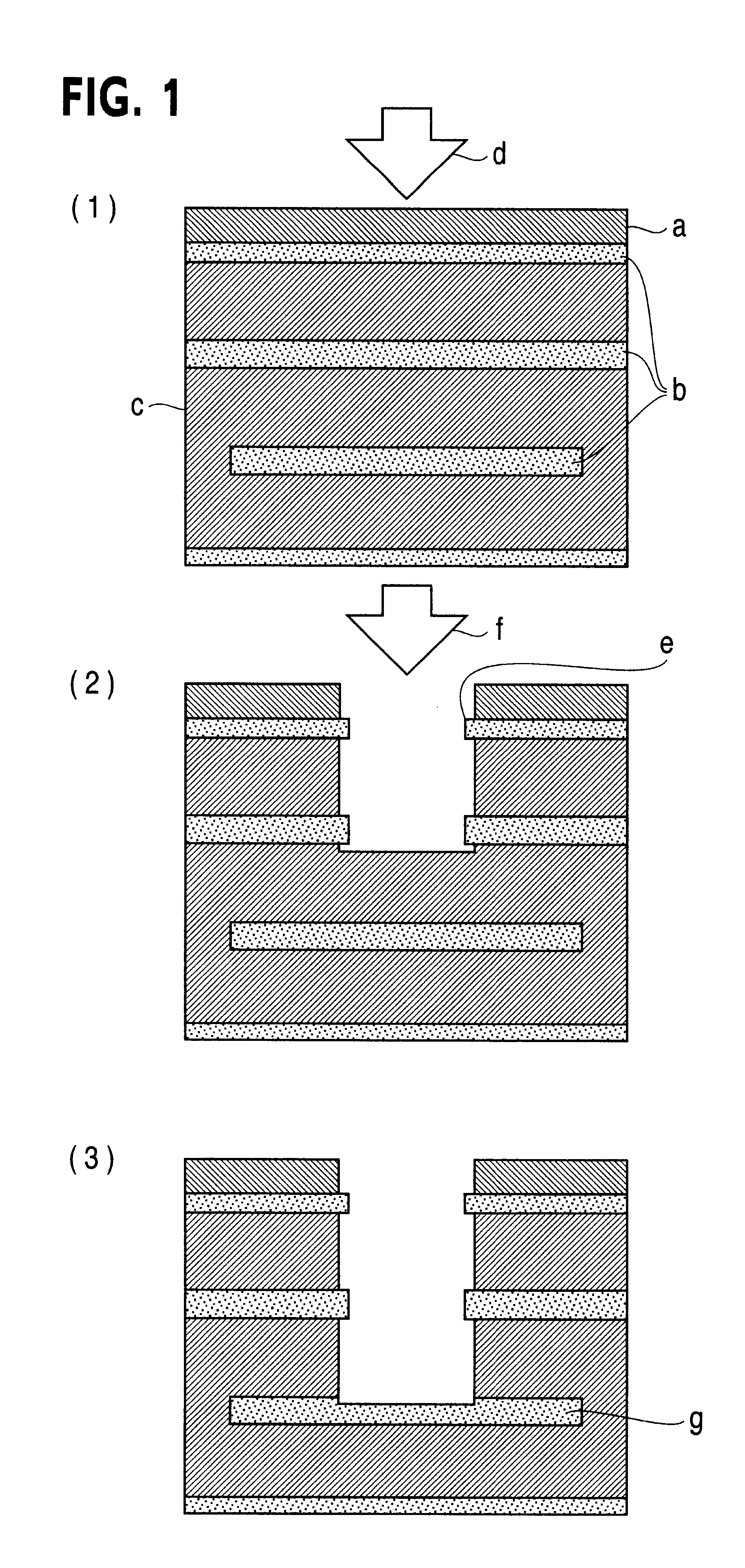

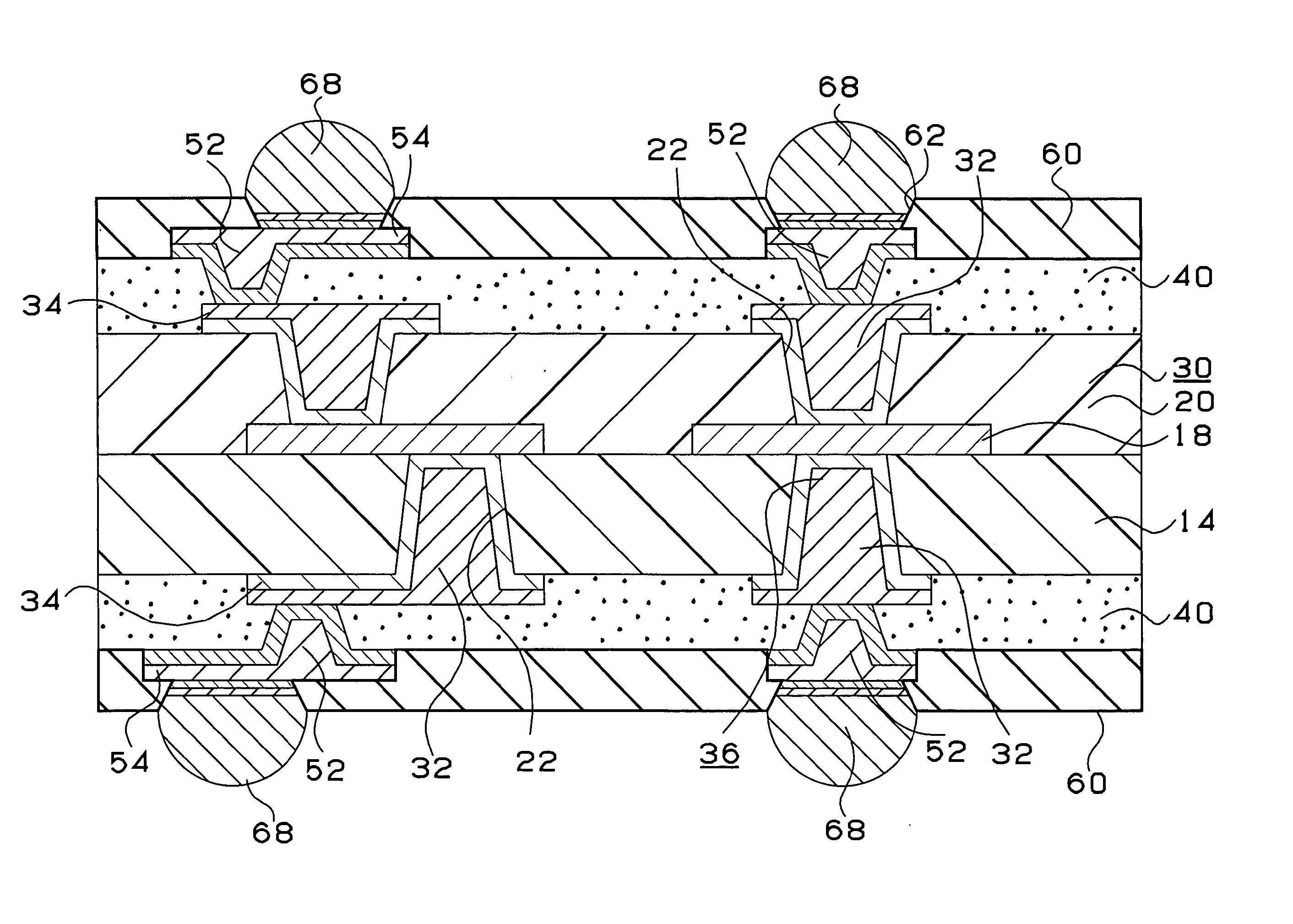

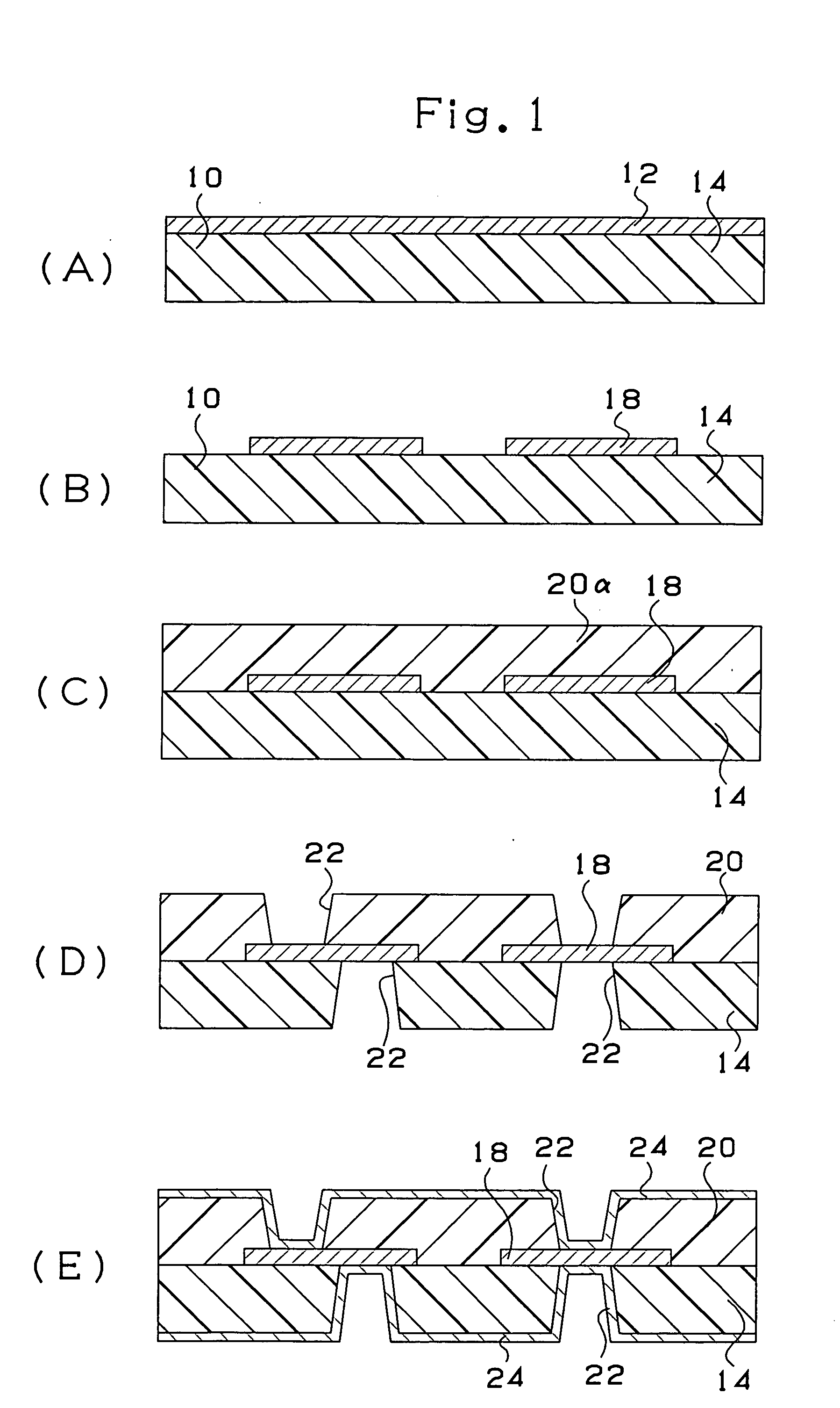

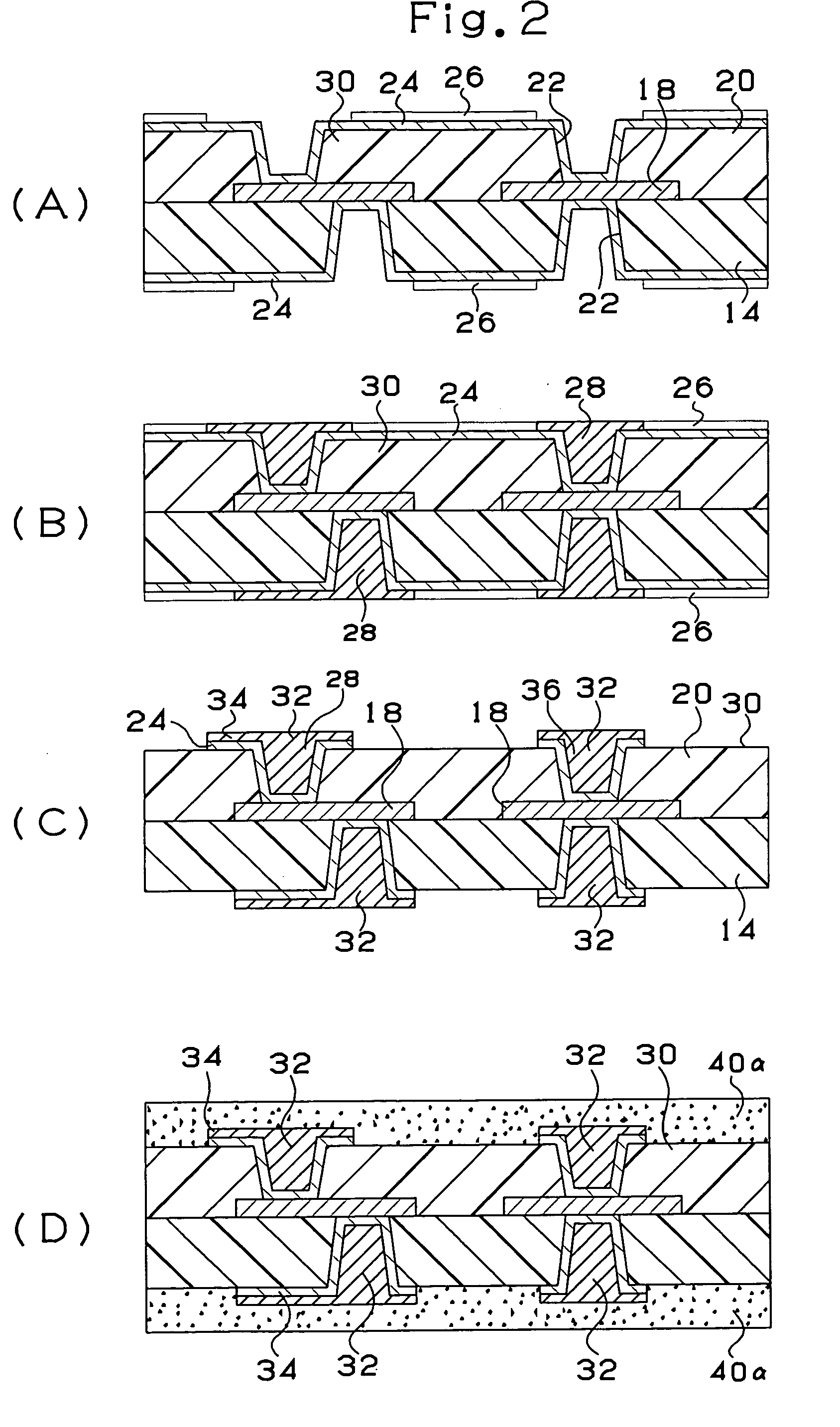

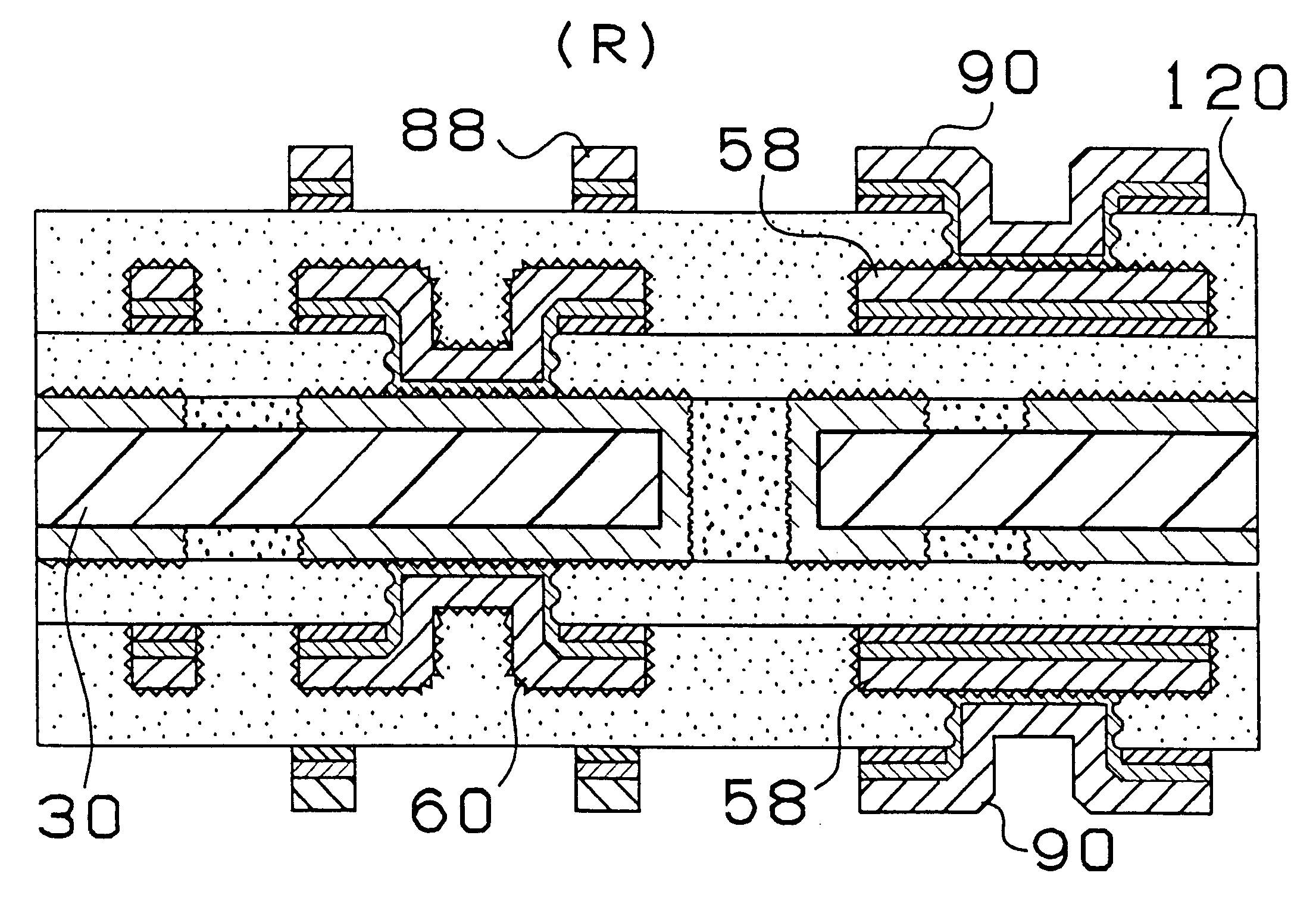

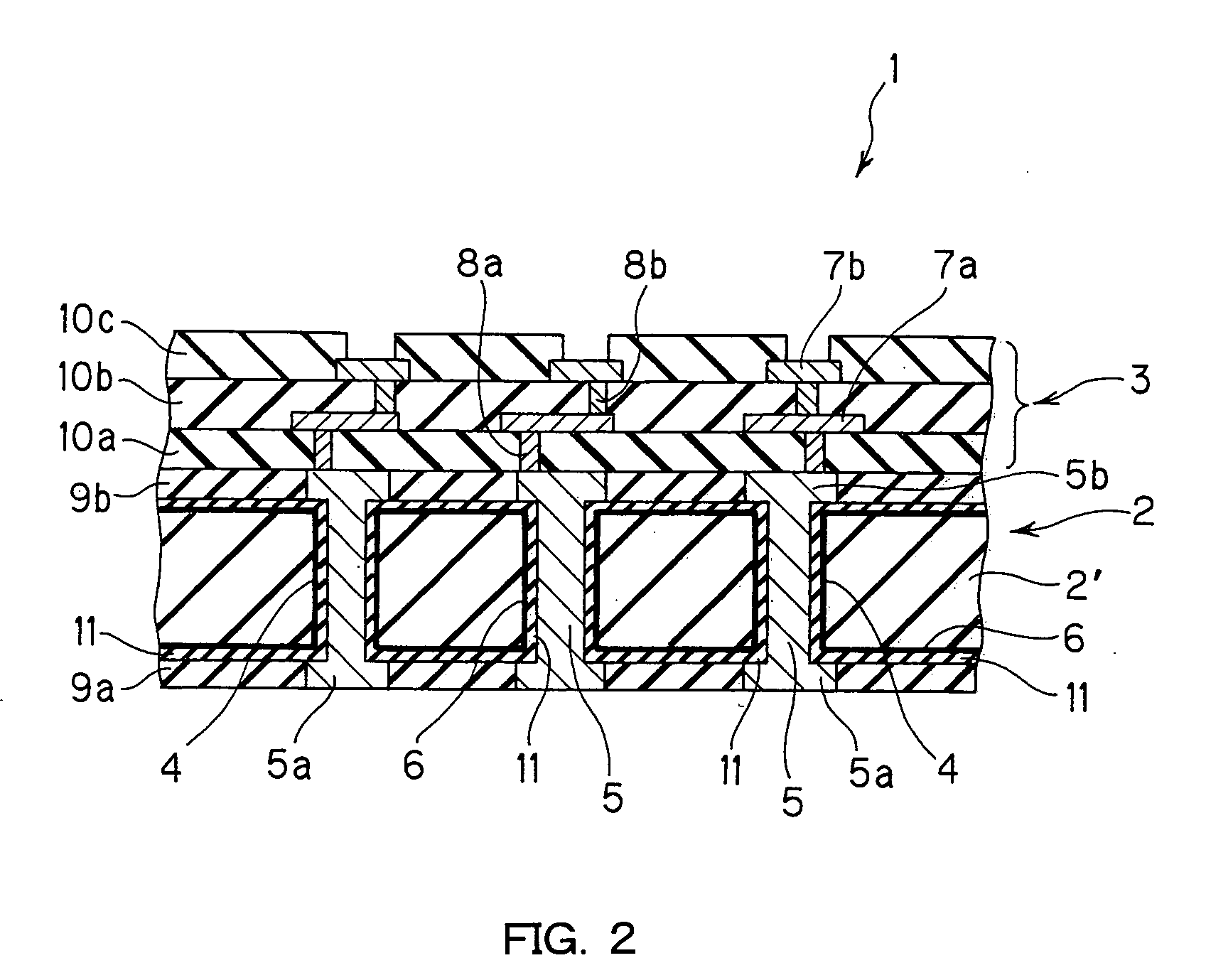

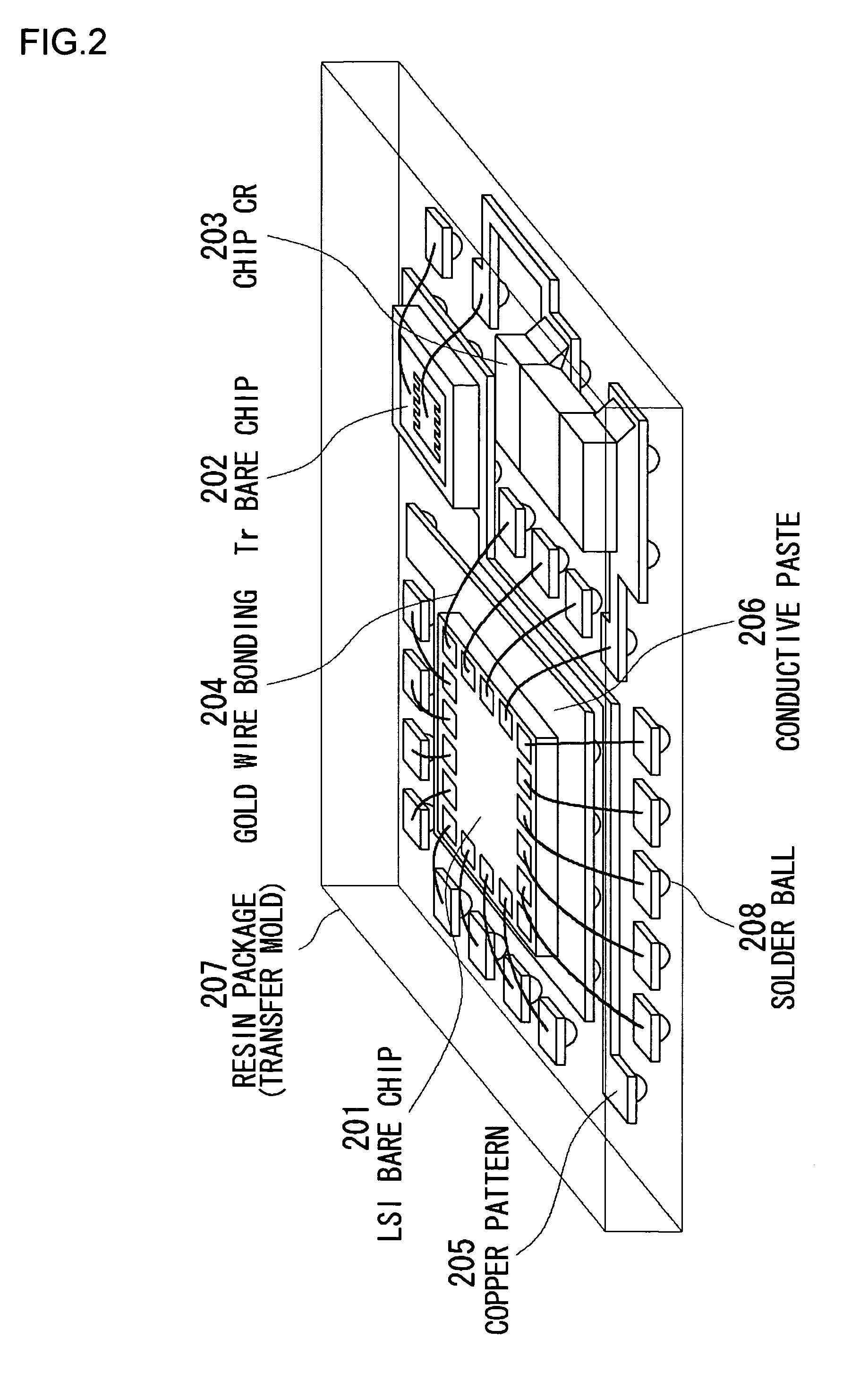

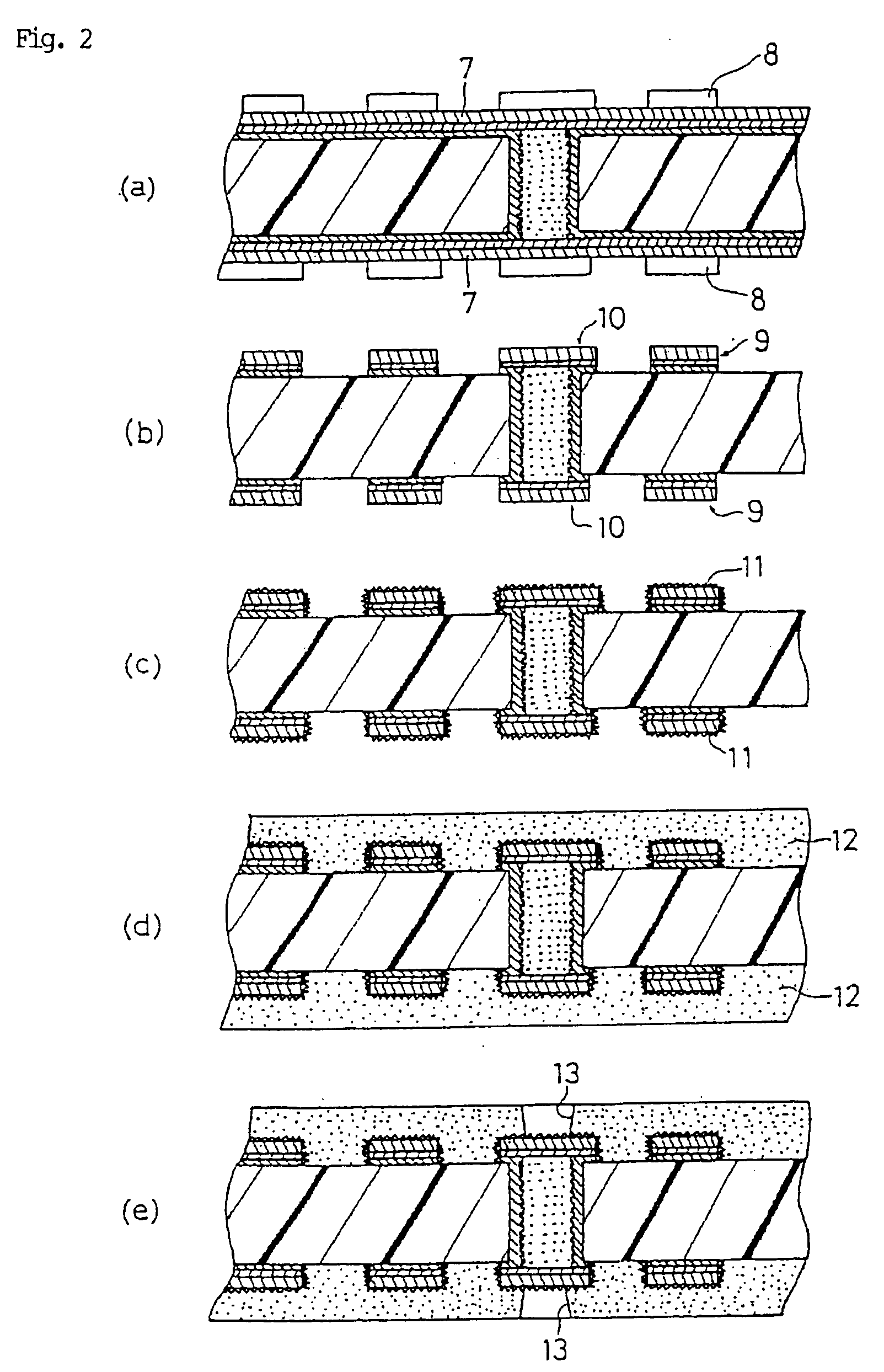

Multi-layer printed circuit board and method of manufacturing multi-layer printed circuit board

InactiveUS20050039948A1Shorten the timeSmall diameterInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringPrinted circuit board

A metal layer 18 is sandwiched between insulating layers 14 and 20 so that required strength is maintained. Hence it follows that the thickness of a core substrate 30 can be reduced and, therefore, the thickness of a multi-layer printed circuit board can be reduced. Formation of non-penetrating openings 22 which reach the metal layer 18 in the insulating layers 14 and 20 is simply required. Therefore, small non-penetrating openings 22 can easily be formed by applying laser beams. Thus, through holes 36 each having a small diameter can be formed.

Owner:IBIDEN CO LTD

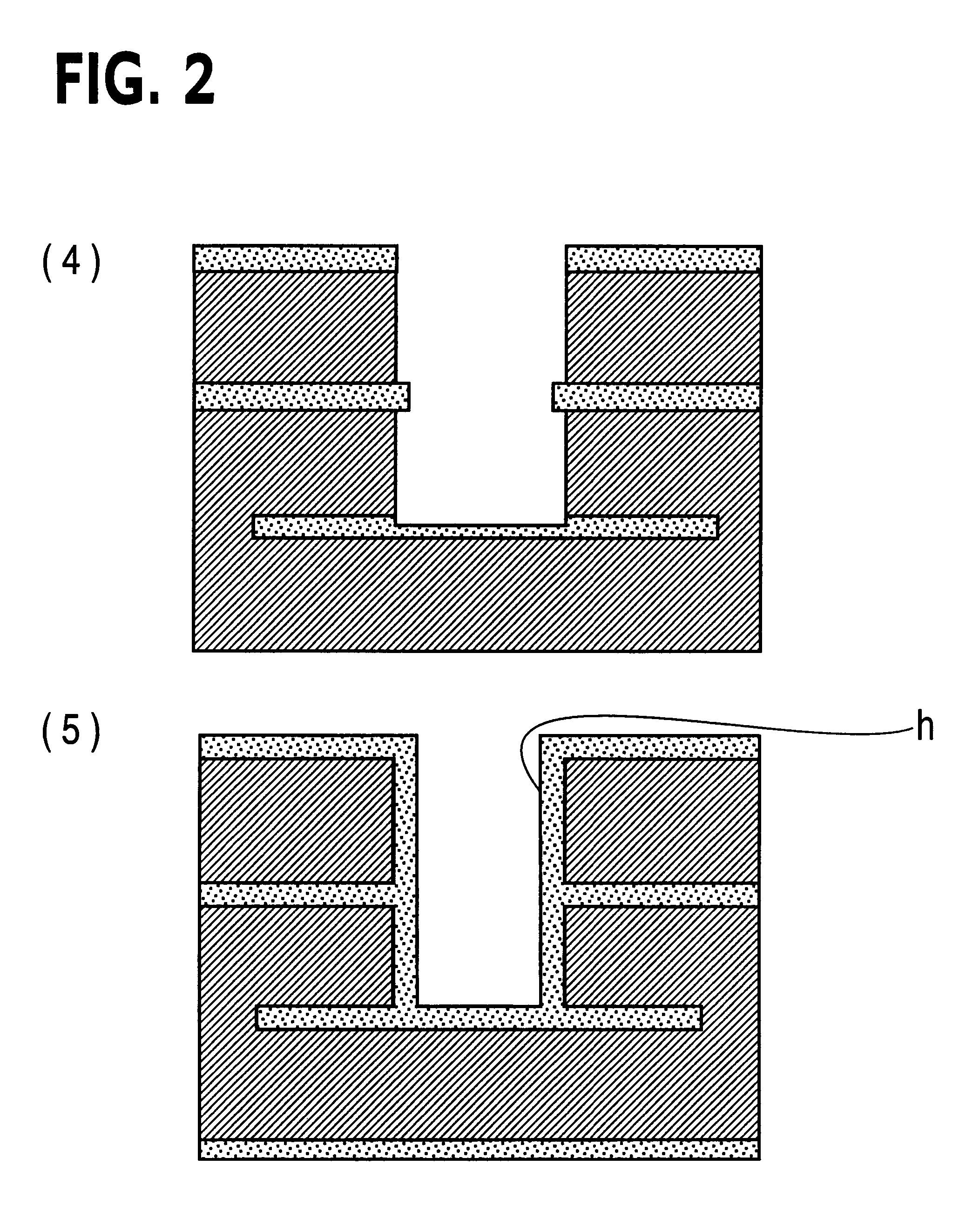

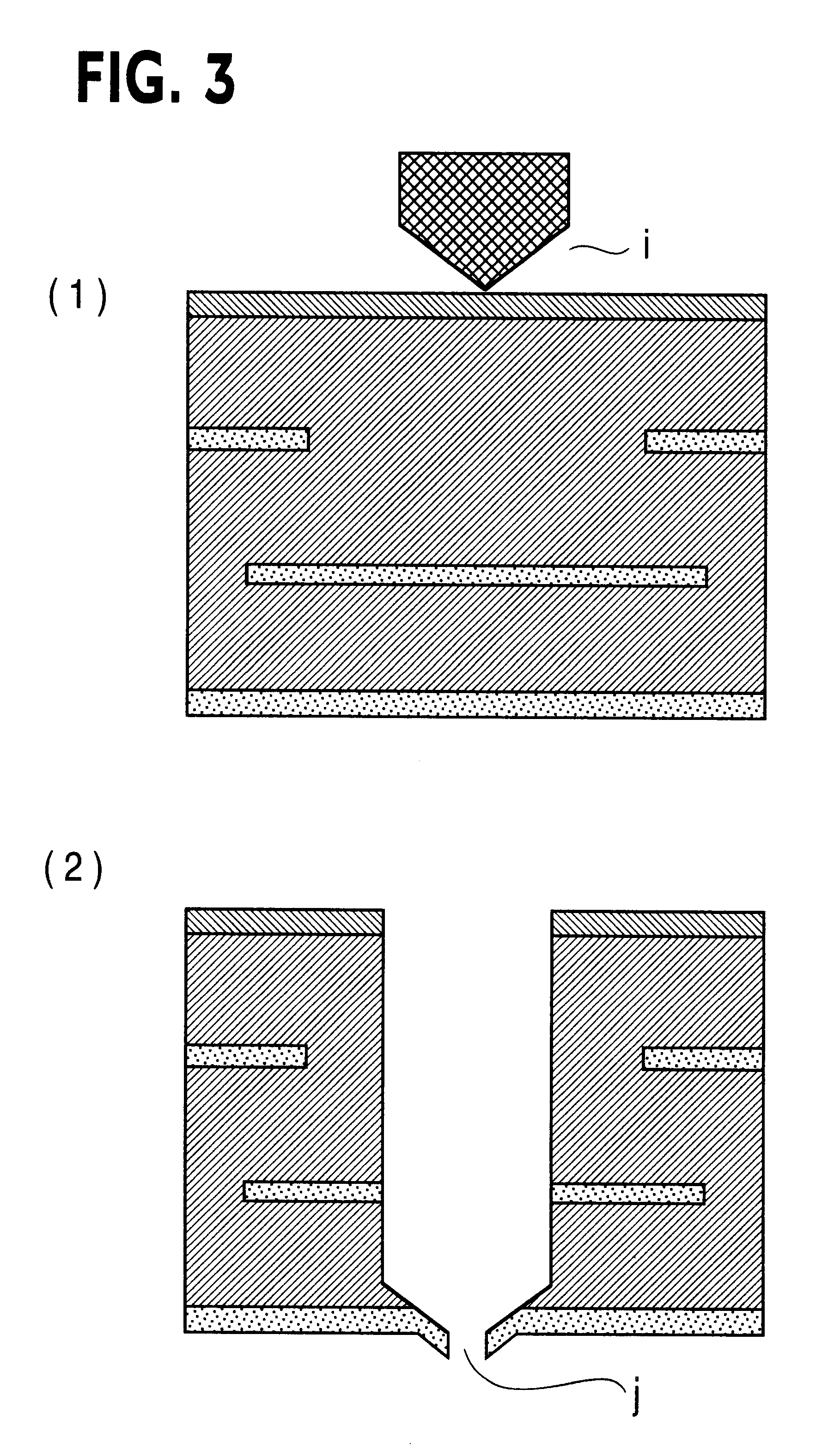

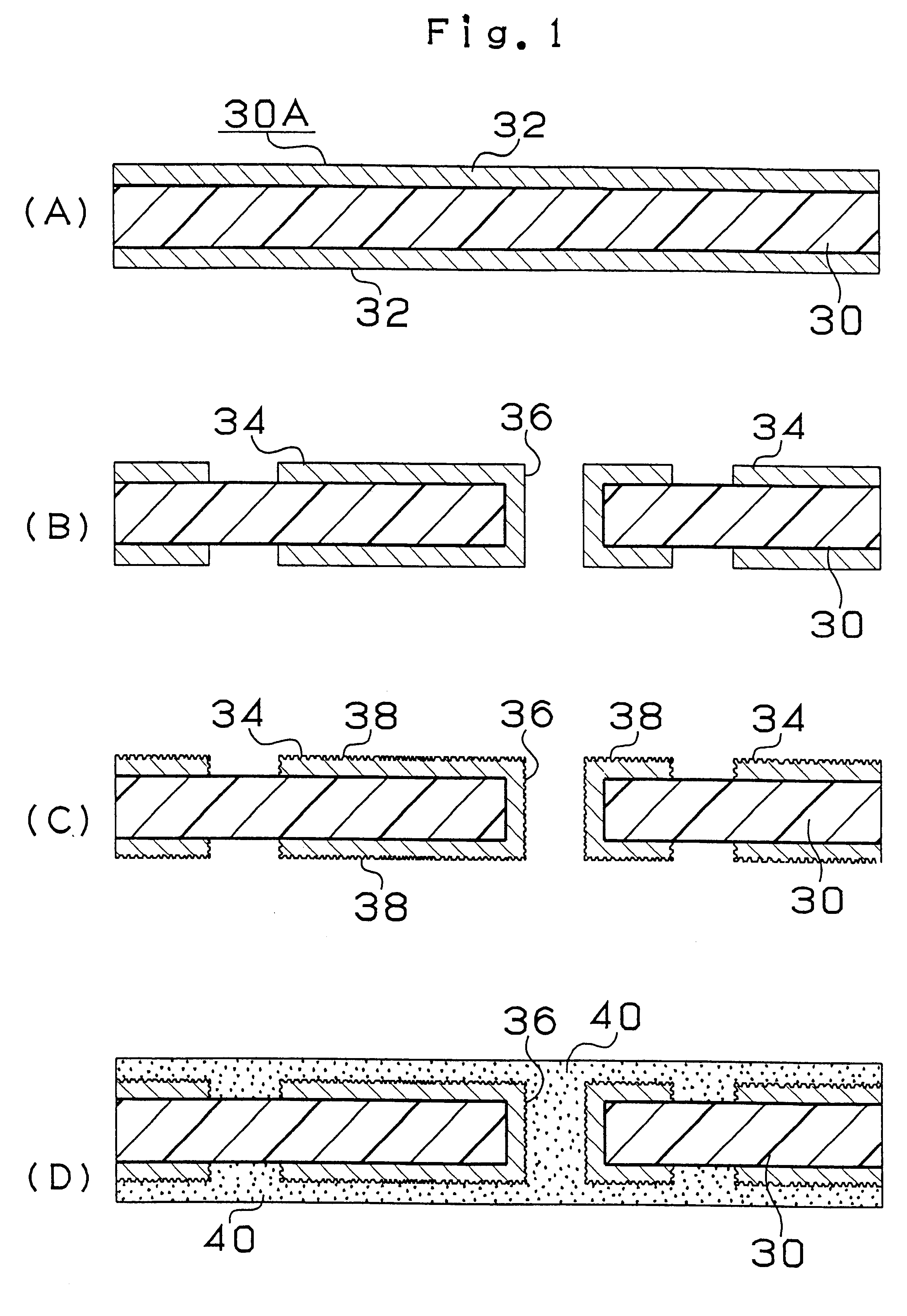

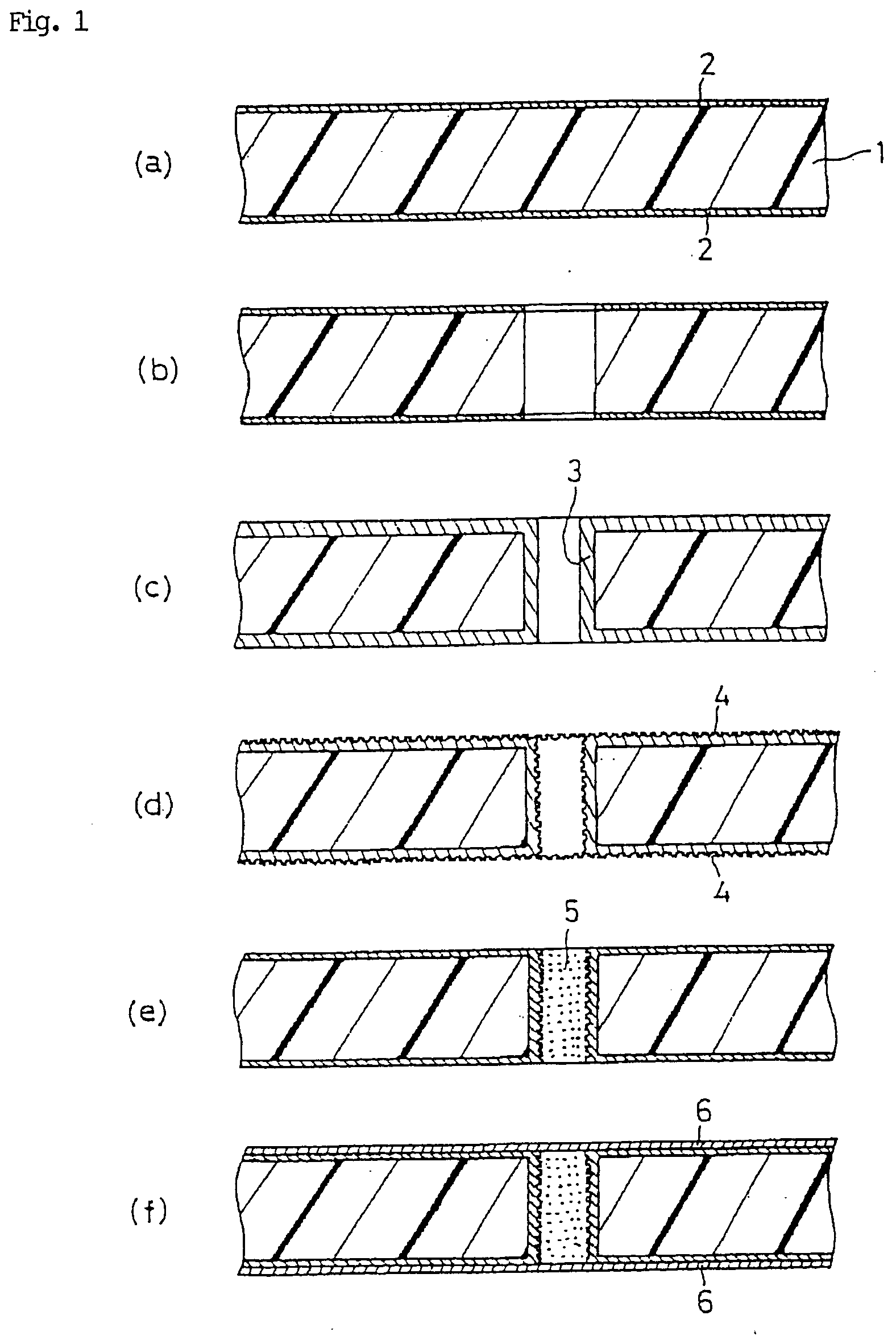

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

Multilayer wiring board and manufacture method thereof

ActiveUS20050012217A1Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringThermal expansion

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

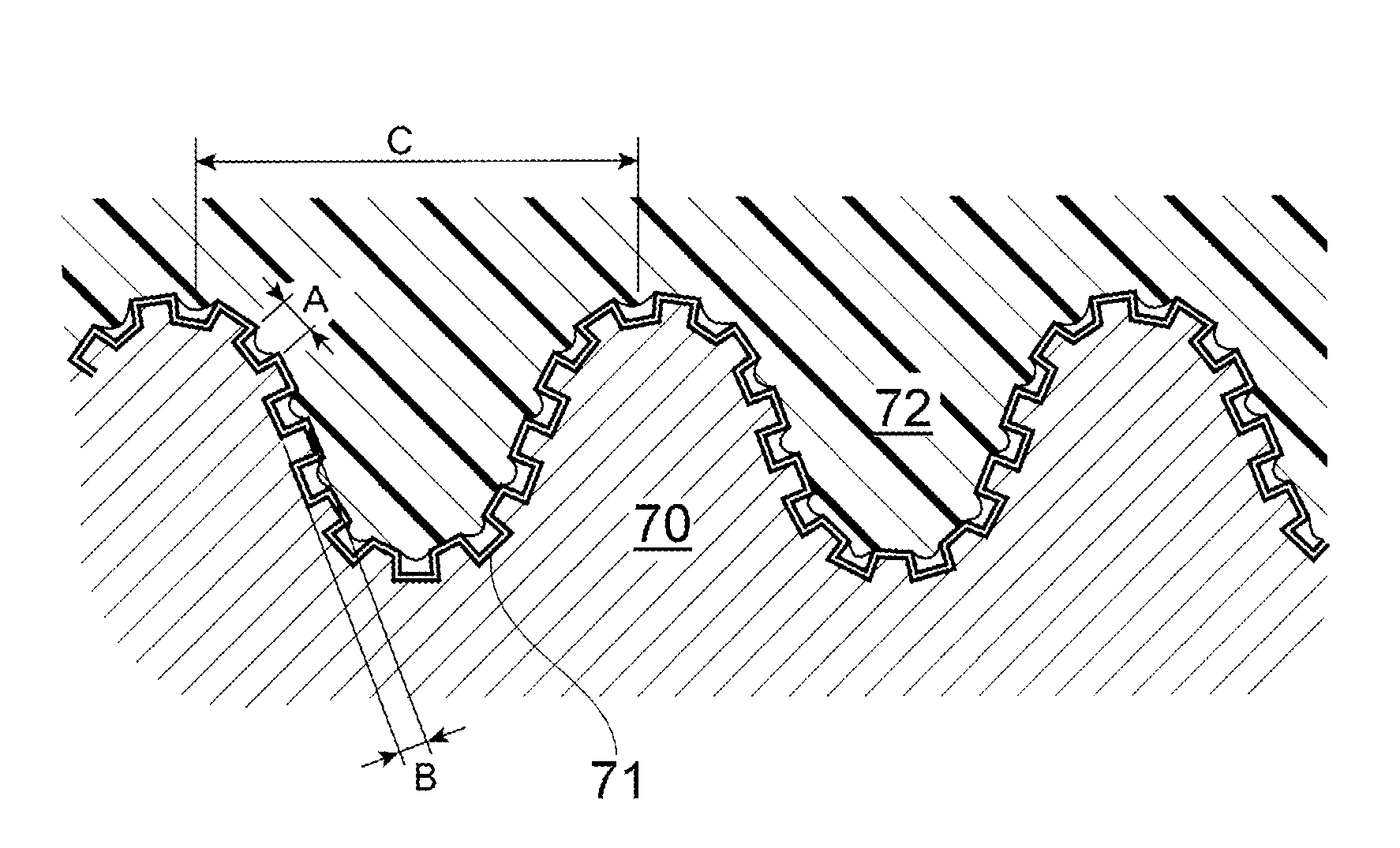

Non-chrome plating on plastic

InactiveUS20050199587A1Insulating substrate metal adhesion improvementDecorative surface effectsPERMANGANATE IONBiological activation

The invention comprises a process of preparing a non-conductive substrate for subsequent metalization. The process replaces the traditional chromic acid etching step with an etching solution comprising a permanganate and a mineral acid. The process also includes a novel activation solution comprising a palladium salt and an amine complexor. The new process of the invention is more environmentally friendly than the traditional chromic acid etching solutions but achieves a comparable result on most non-conductive substrates.

Owner:MACDERMID INC

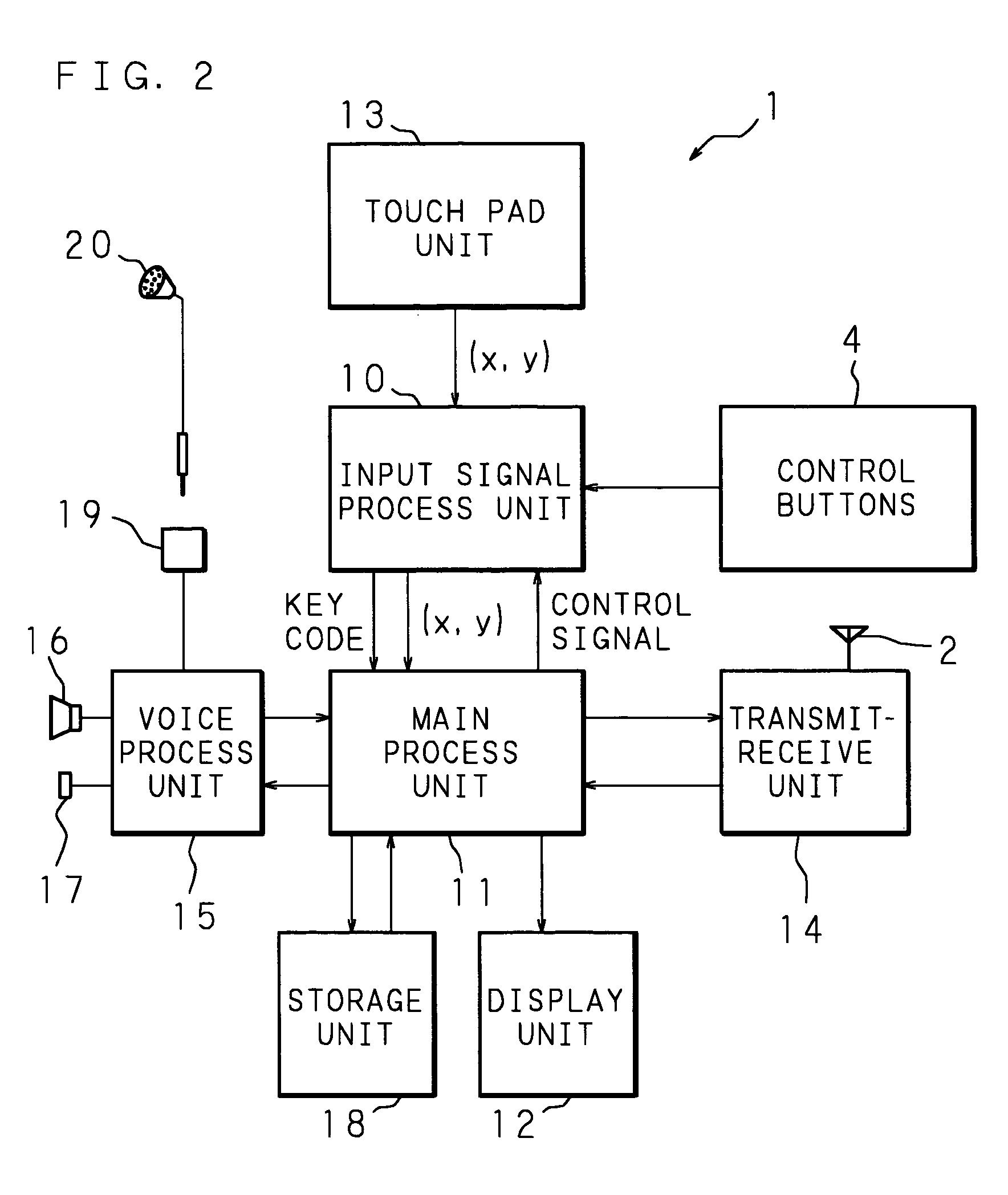

Input device, mobile telephone, and mobile information device

InactiveUS20050129199A1Reduce investmentEasy to operateInput/output for user-computer interactionInsulating substrate metal adhesion improvementLocation detectionInformation device

An input device having touched position detecting means for outputting a signal indicating a touched position during a period of time of touch when the touched position detecting means is touched, wherein a character and a symbol are inputted to be displayed on a display screen. Provided are: a virtual keyboard in which each virtual key corresponding to a plurality of characters or symbols is arranged corresponding to each divided area on the touched position detecting means; means for outputting, during the period of time of touch, a code signal indicating a character or a symbol of a virtual key corresponding to an area including the touched position; means for temporarily displaying on the display screen a character or a symbol of the outputted code signal; and means for determinately displaying the character or the symbol on the display screen when the code signal has disappeared.

Owner:KATHENAS

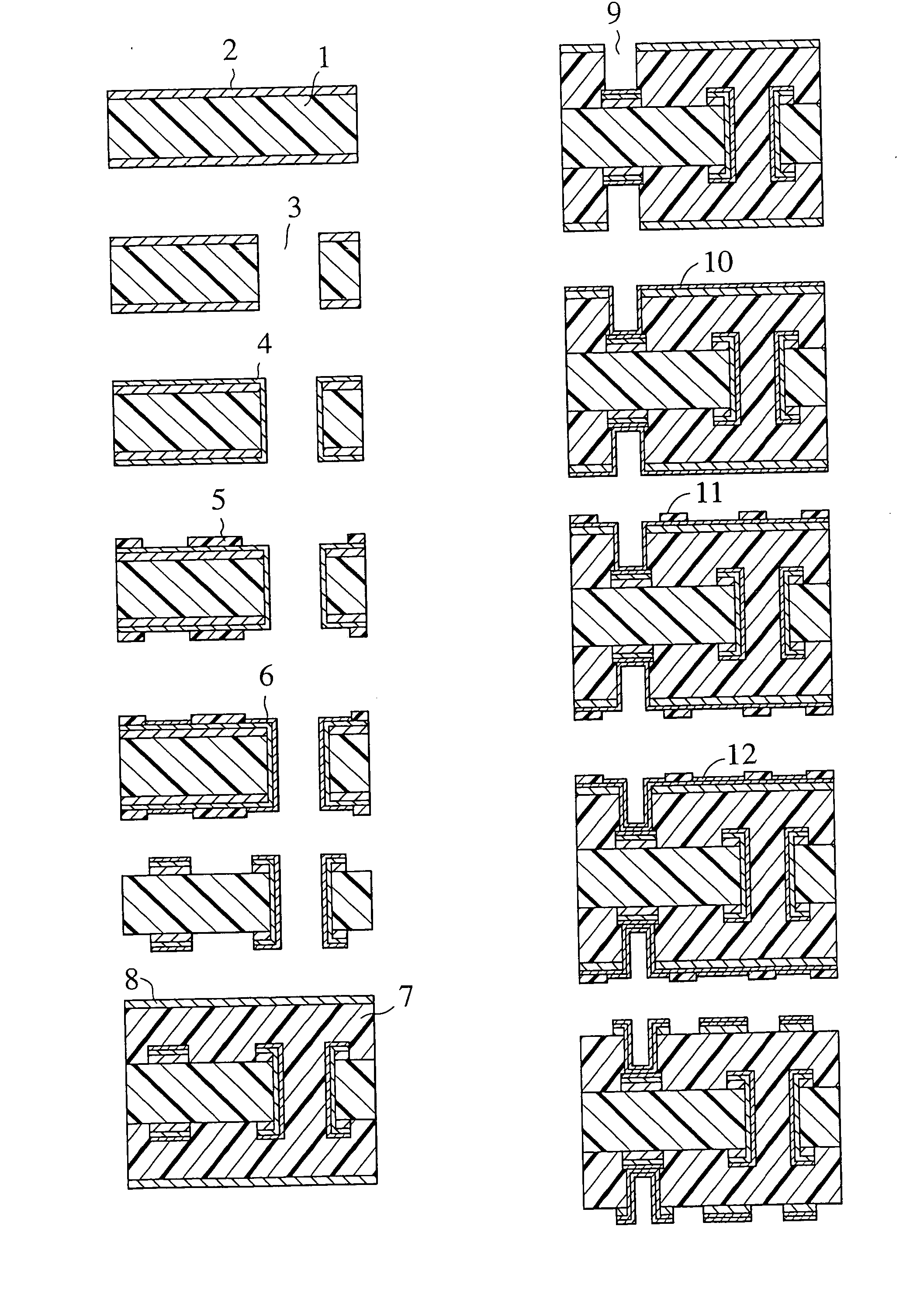

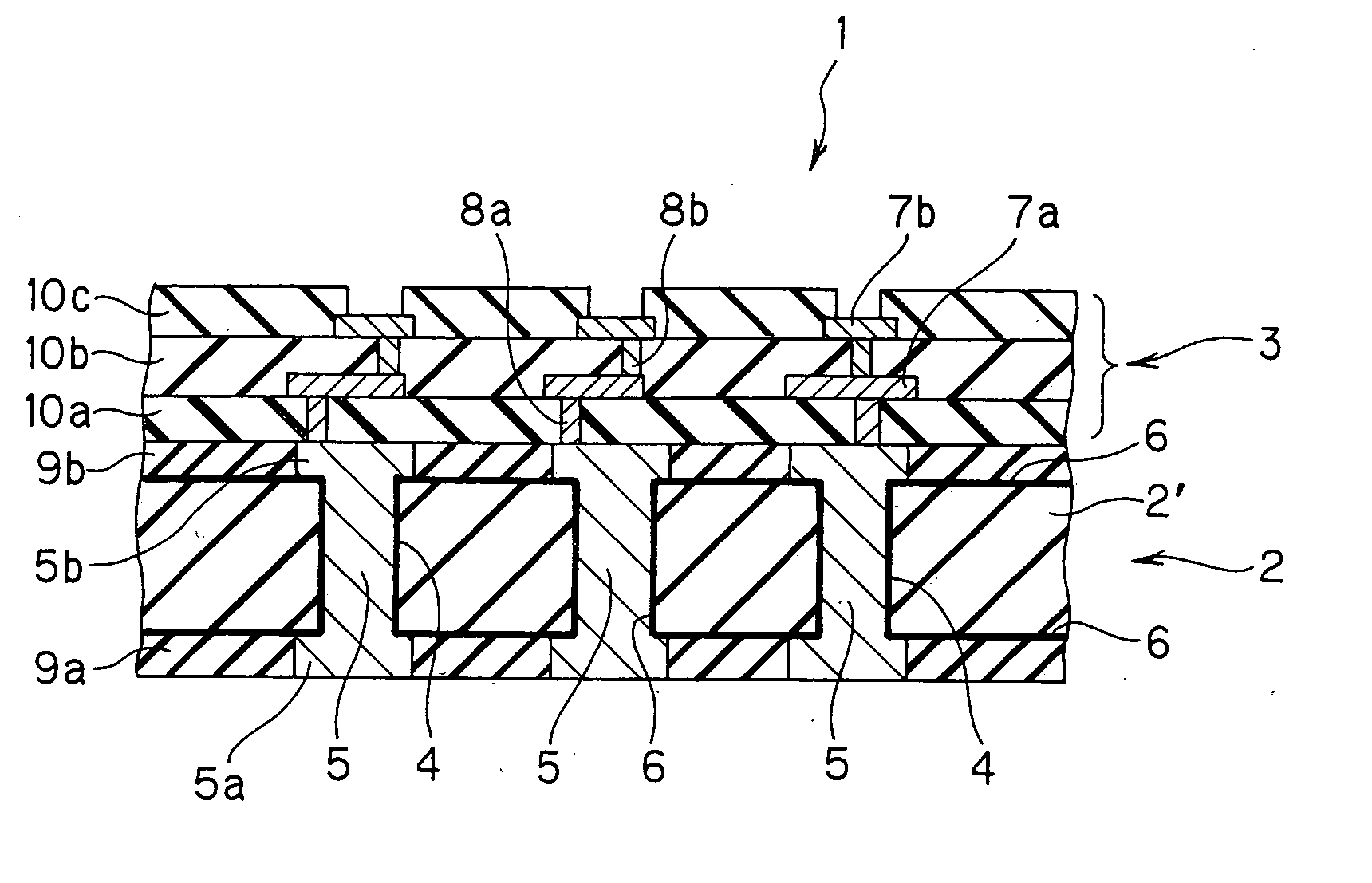

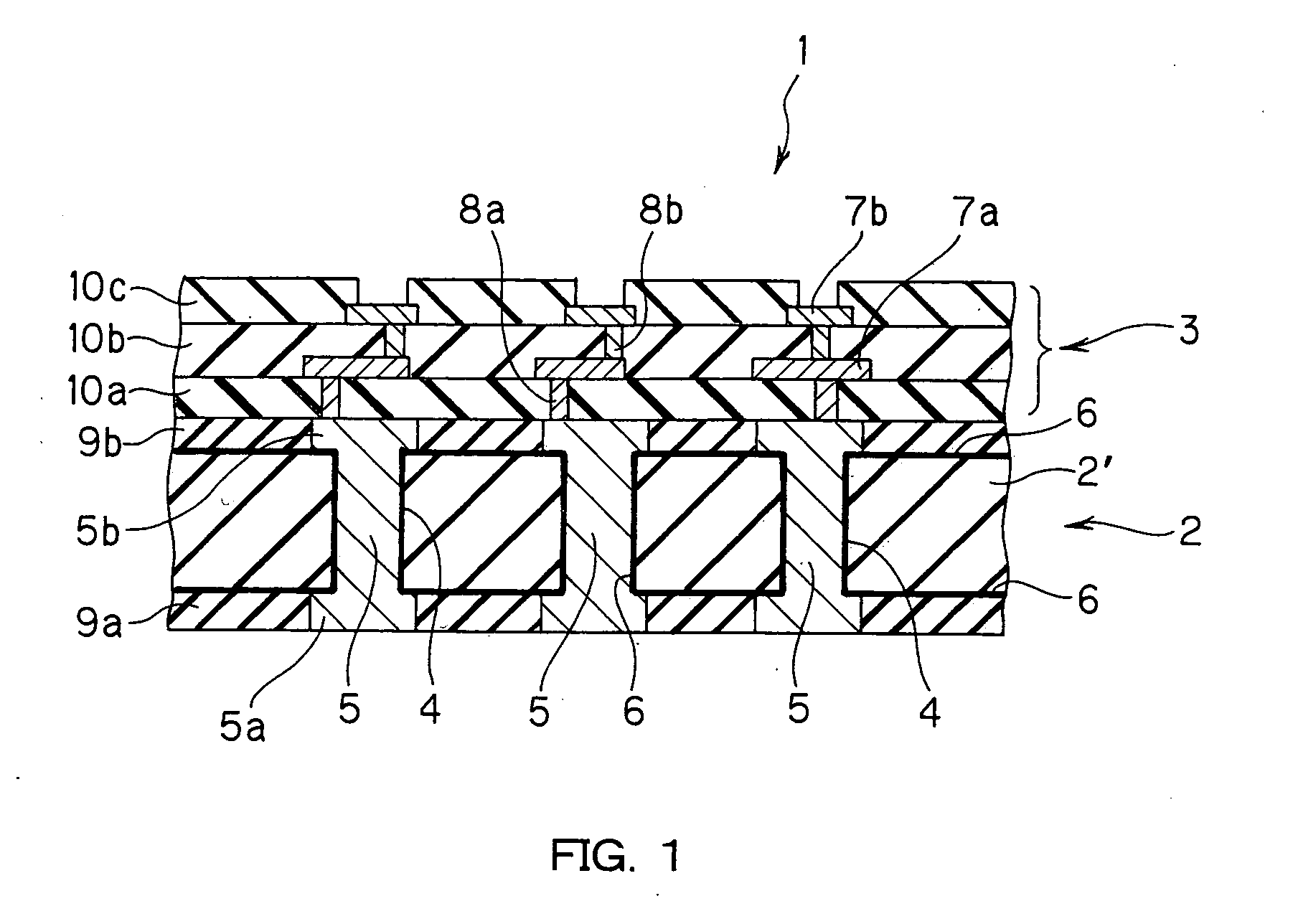

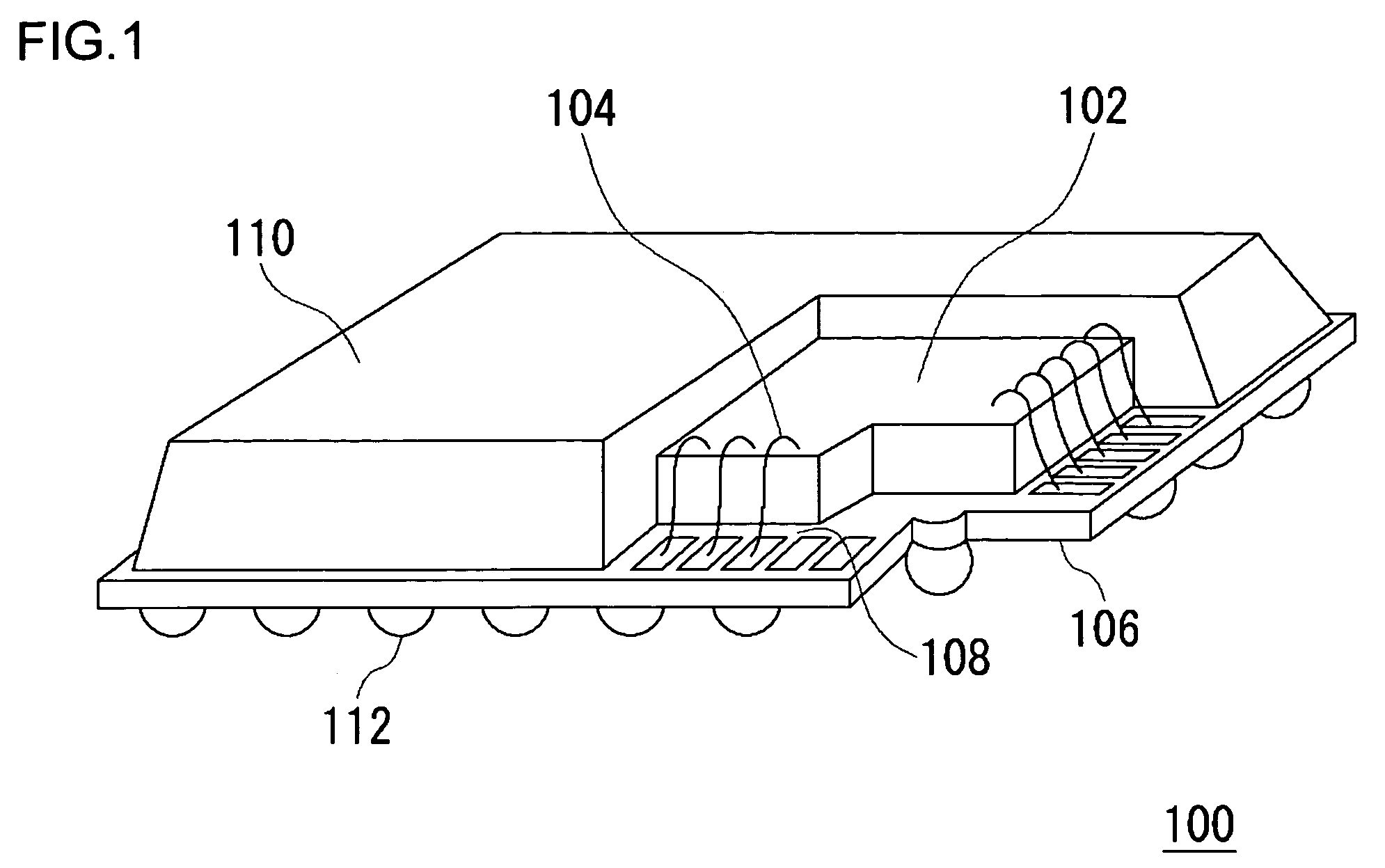

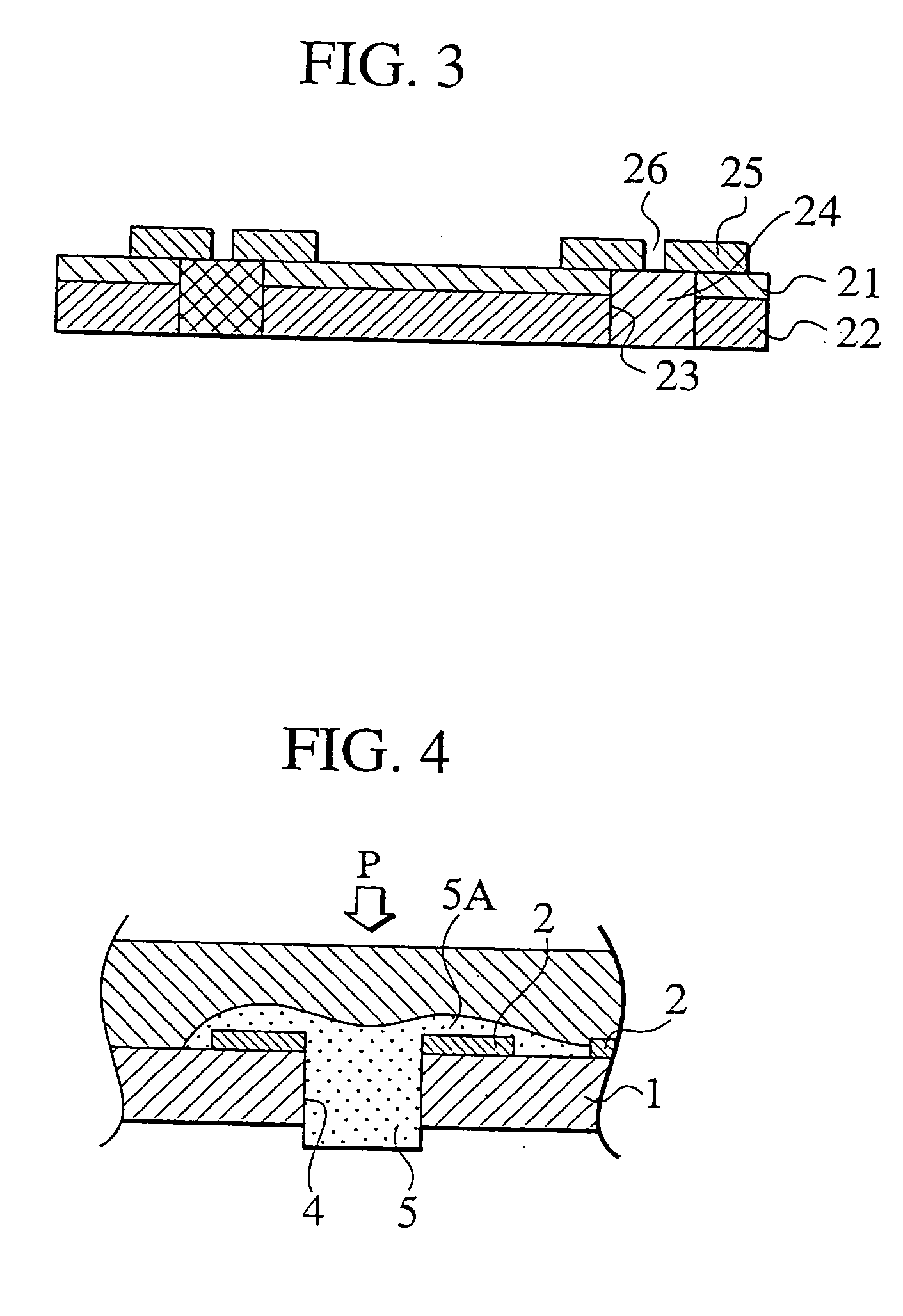

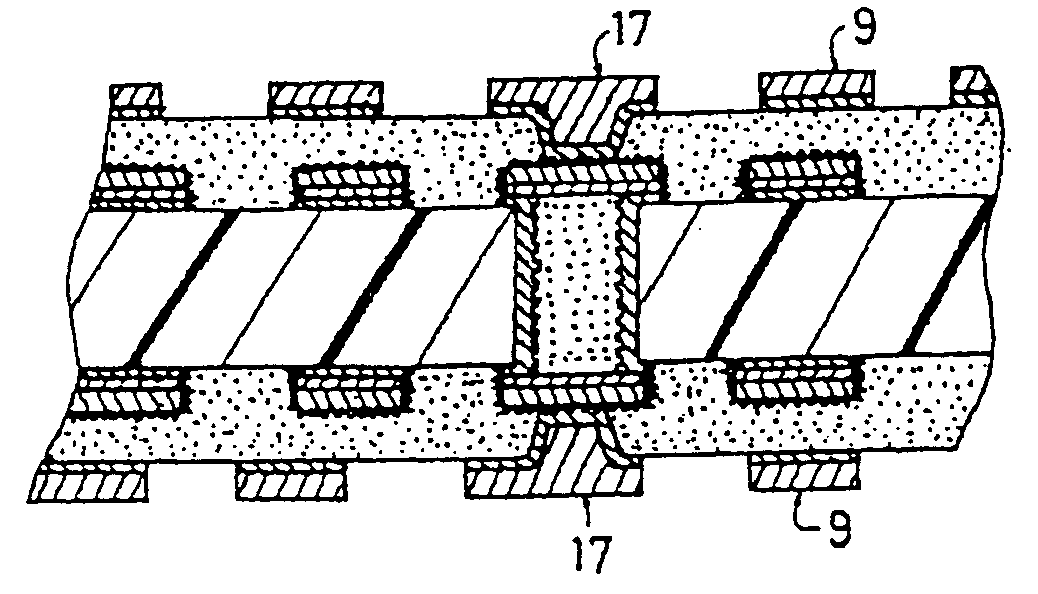

Semiconductor device containing stacked semiconductor chips and manufacturing method thereof

InactiveUS7405484B2Suppress bad connectionElement reliabilityPrinted circuit assemblingInsulating substrate metal adhesion improvementSemiconductor chipAlloy

An adhesive film is formed on an electrode film, and a coating film is formed thereon. Nickel, chrome, molybdenum, tungsten, aluminum or an alloy of them is used as a constituent material of the adhesive film. Gold, silver, platinum or an alloy of them is used as a constituent material of the coating film.

Owner:SANYO ELECTRIC CO LTD

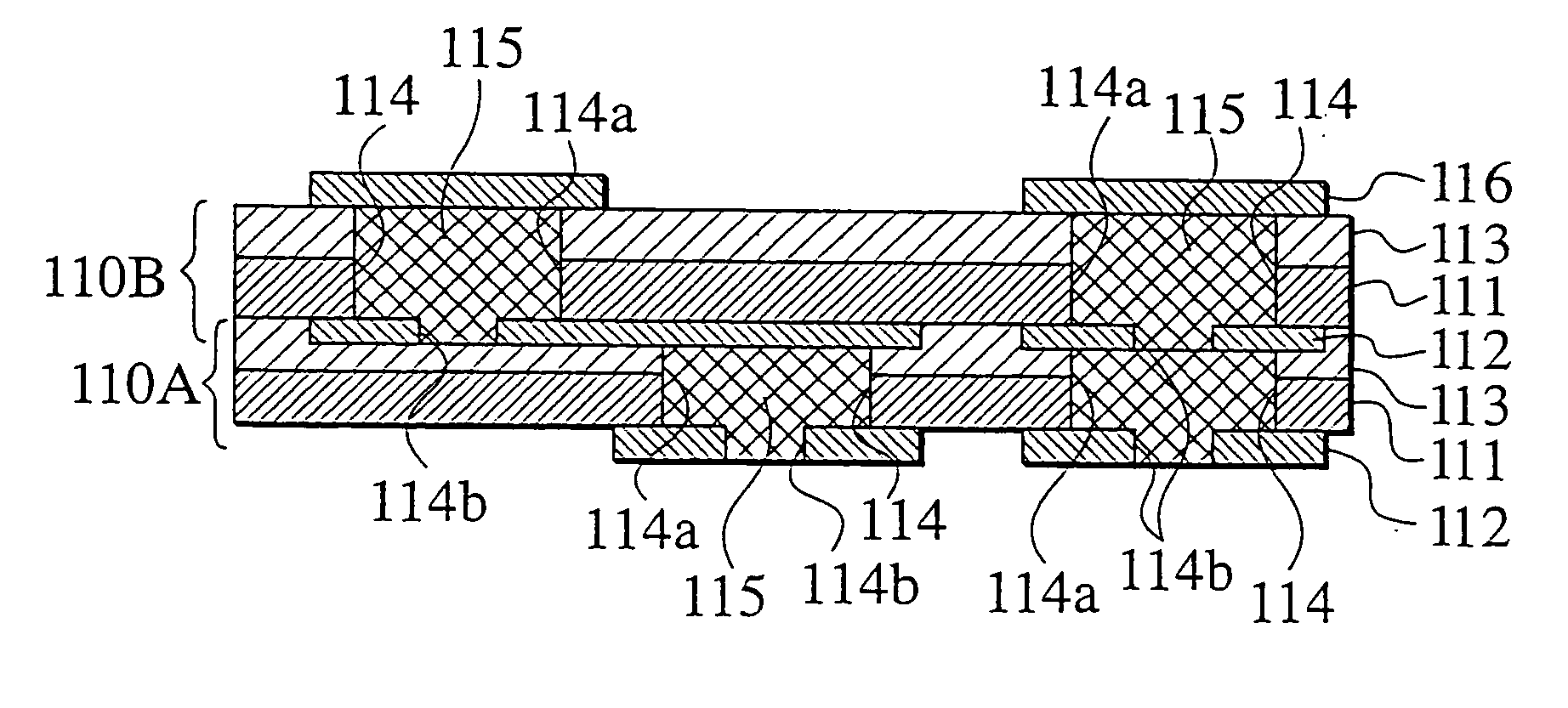

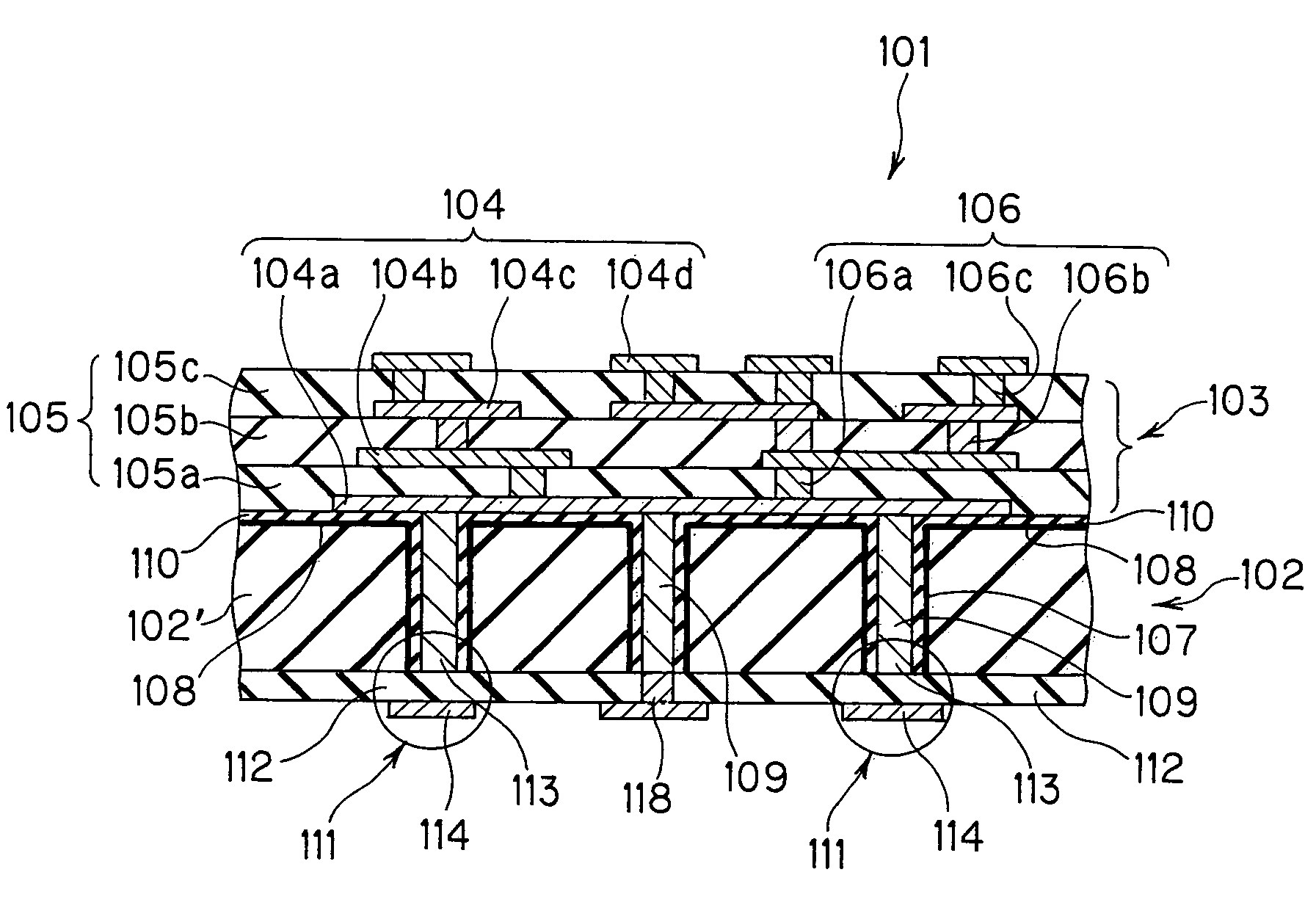

Multilayer wiring board, base for multilayer wiring board, printed wiring board and its manufacturing method

InactiveUS20050155792A1Solve the real problemIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionInterconnection

A multilayer wiring board assembly component comprises: an insulating substrate component (the insulating resin layer 111); a conductive layer 112 formed on one surface of said insulating substrate component 111 in the form of an electrode pattern; an adhesive layer 113 formed on the other surface of said insulating substrate component 111; and a conductive resin composition 115 with which is filled a through hole passing through said insulating substrate component 111, said adhesive layer and said conductive layer in order to make interlayer interconnection. The bore diameter of the conductive layer portion 114b of the through hole 114 is smaller than the bore diameter of the insulating resin layer portion and the adhesive layer portion 114a to establish electrical connection between the conductive resin composition 115 and the conductive layer 112 by the rare surface 112a of the conductive layer 112.

Owner:THE FUJIKURA CABLE WORKS LTD

Conductive layer pattern and method for forming the same, wiring board, electronic device, electronic appliances and noncontact card medium

InactiveUS20030213614A1Eliminate effectiveQuality improvementPorous dielectricsConductive layers on insulating-supportsConductive materialsEngineering

Owner:SEIKO EPSON CORP

Double-side thermally conductive adhesive tape for plastic-packaged electronic components

InactiveUS20020012762A1Easy `` peel and stick '' installationPrecise thermal and adhesive propertiesInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringElectronic component

A thermally conductive interface, which may be in the form of a double-sided, pressure sensitive adhesive tape, disposable intermediate a heat-generating source having a first heat transfer surface formed of a first material having a low surface energy, and a thermal dissipation member having a second heat transfer surface which is formed of a second material having a surface energy substantially higher than the surface energy of the first material, and which is disposable opposite the first heat transfer surface of the heat-generating source in a spaced-apart, heat transfer adjacency therewith. The interface includes a first pressure sensitive adhesive (PSA) surface which is bondable under pressure to at least a portion of the first heat transfer surface of the heat-generating source, and an opposing second pressure sensitive adhesive (PSA) surface bondable under pressure to at least a portion of the second heat transfer surface of the heat-generating source. The first PSA surface is presented from a layer of a thermally-conductive, first pressure sensitive adhesive composition, preferably silicone-based, having an affinity to the first heat transfer surface of the heat generating source. In turn, the second PSA surface is presented from a layer of a second pressure sensitive adhesive composition, preferably acrylic-based, different from the first composition and having an affinity to the second heat transfer surface of the thermal dissipation member. The interface is particularly adapted for bonding a plastic packaged electronic component to a metal heat sink.

Owner:PARKER INTANGIBLES LLC

Printed wiring board and method for producing the same

InactiveUS20050258522A1Satisfactory in adhesionSatisfactory in dielectric constantInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorPolyolefin

The present invention has for its object to provide a multilayer printed circuit board which is very satisfactory in facture toughness, dielectric constant, adhesion and processability, among other characteristics. The present invention is directed to a multilayer printed circuit board comprising a substrate board, a resin insulating layer formed on said board and a conductor circuit constructed on said resin insulating layer, wherein said resin insulating layer comprises a polyolefin resin.

Owner:IBIDEN CO LTD

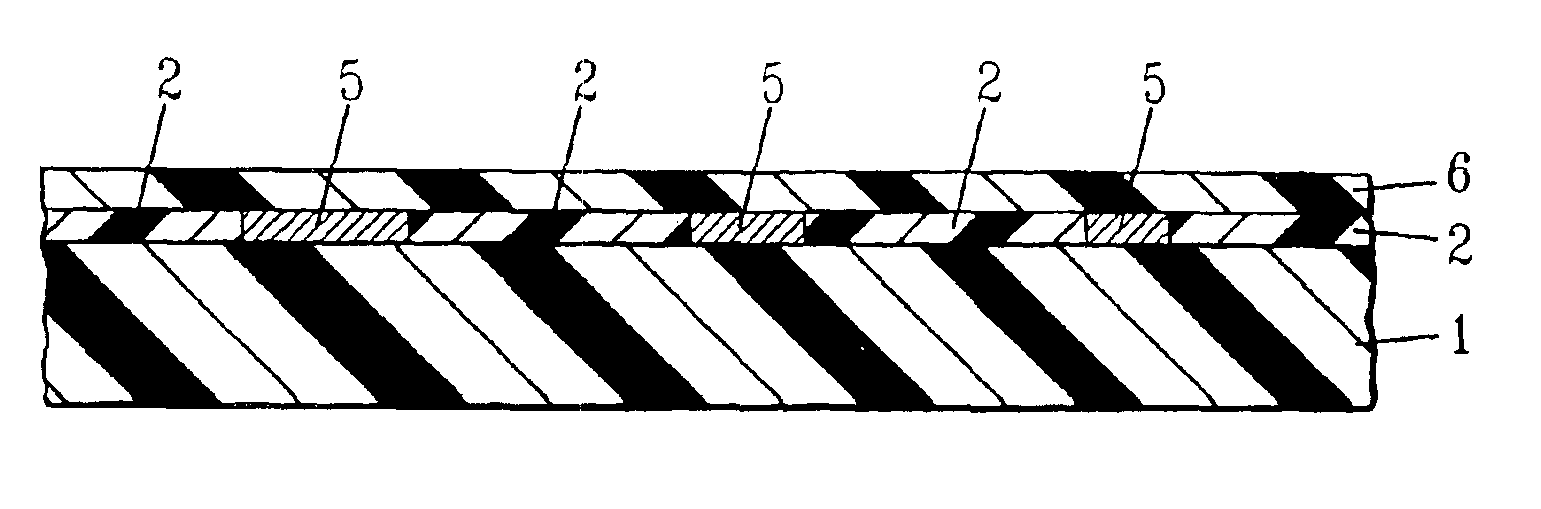

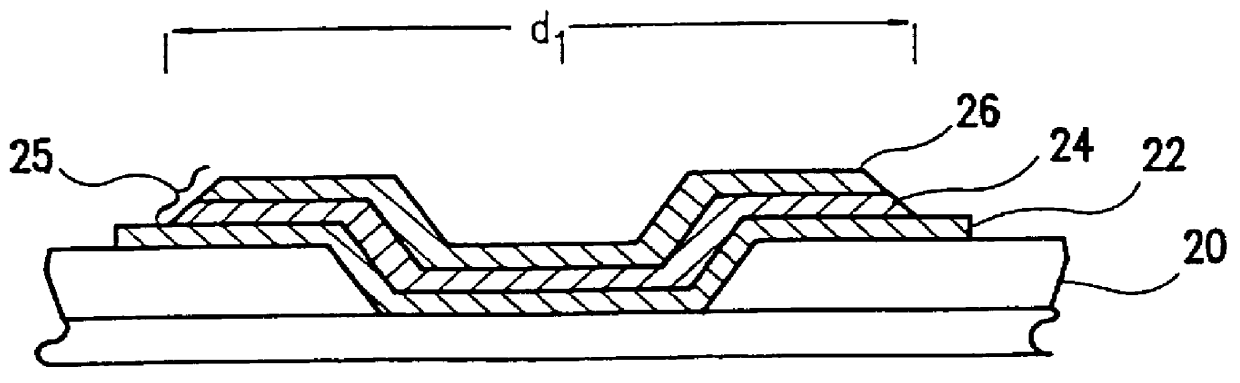

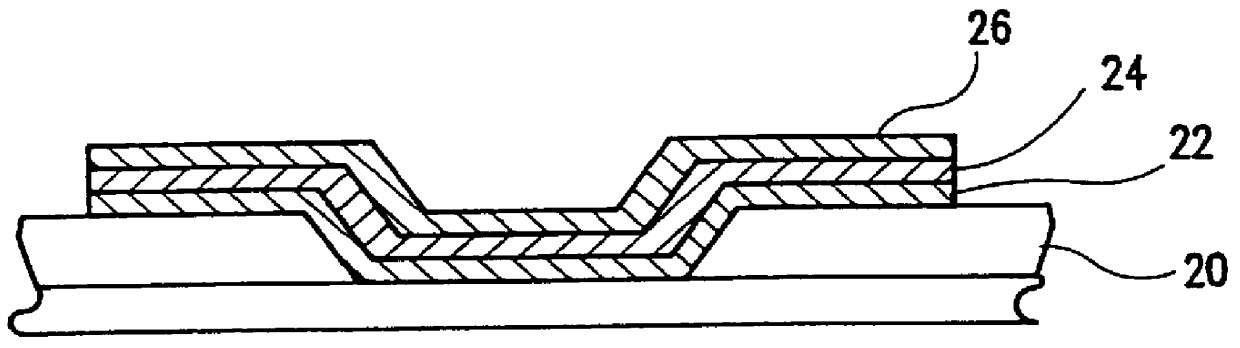

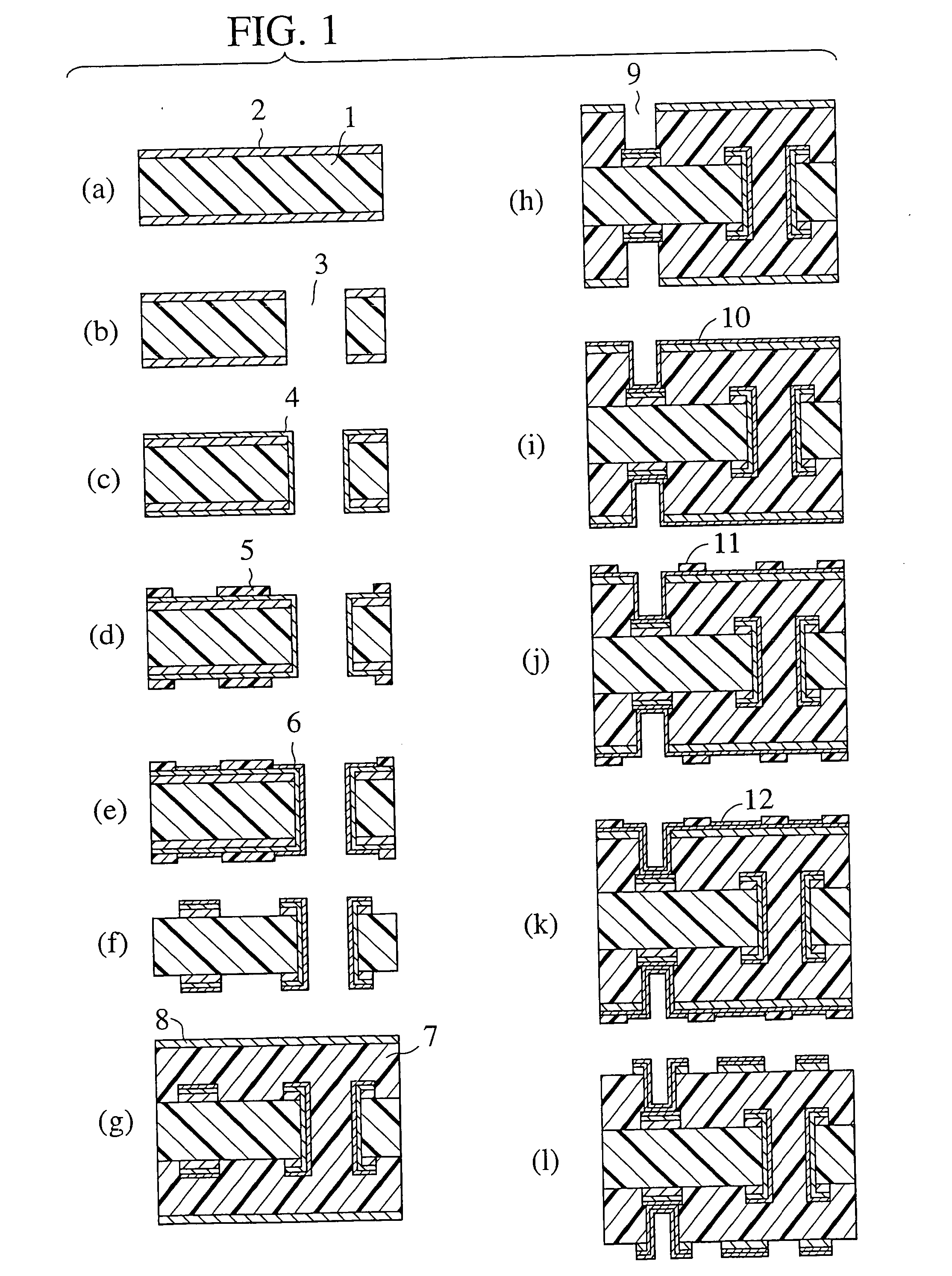

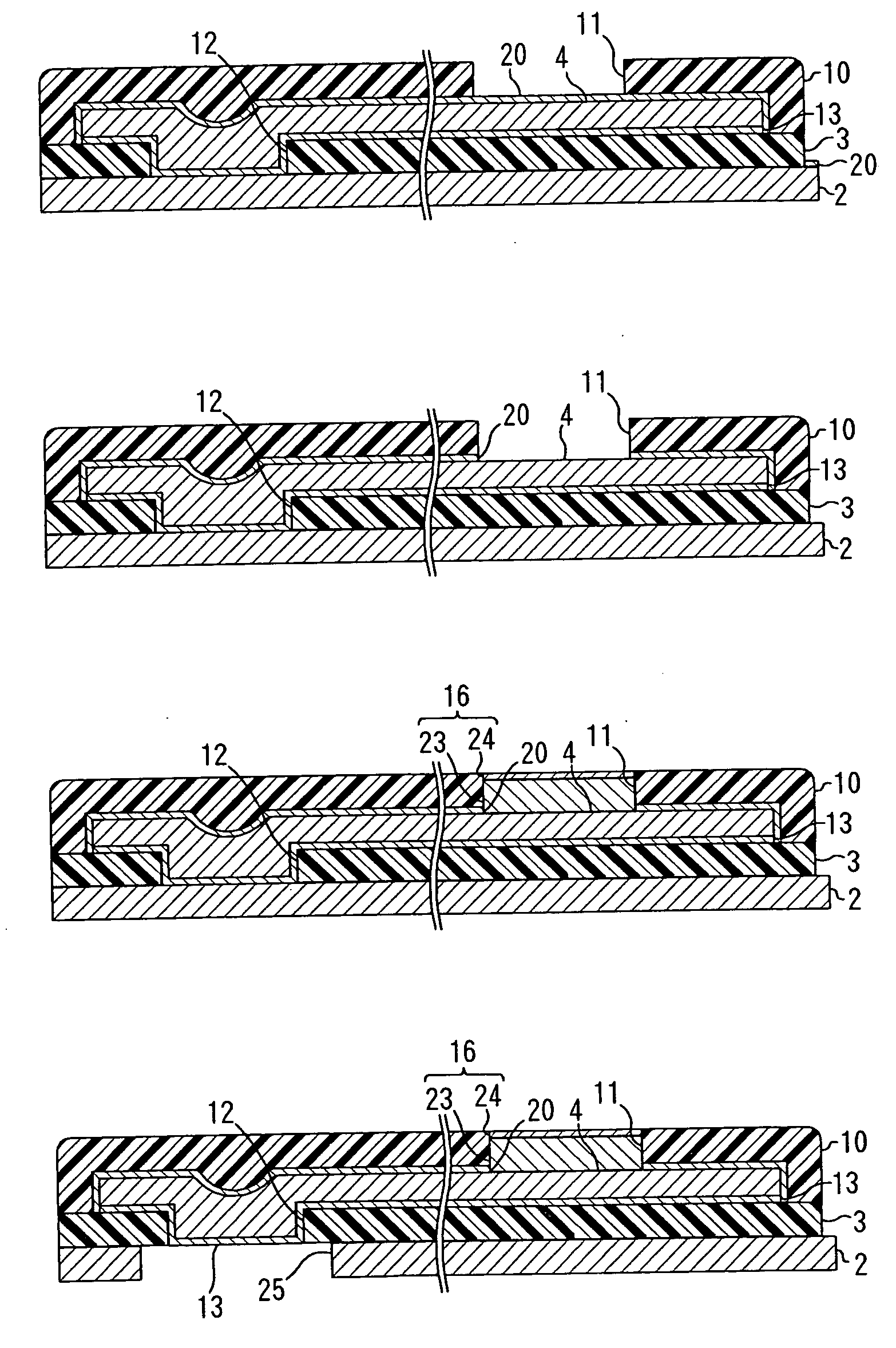

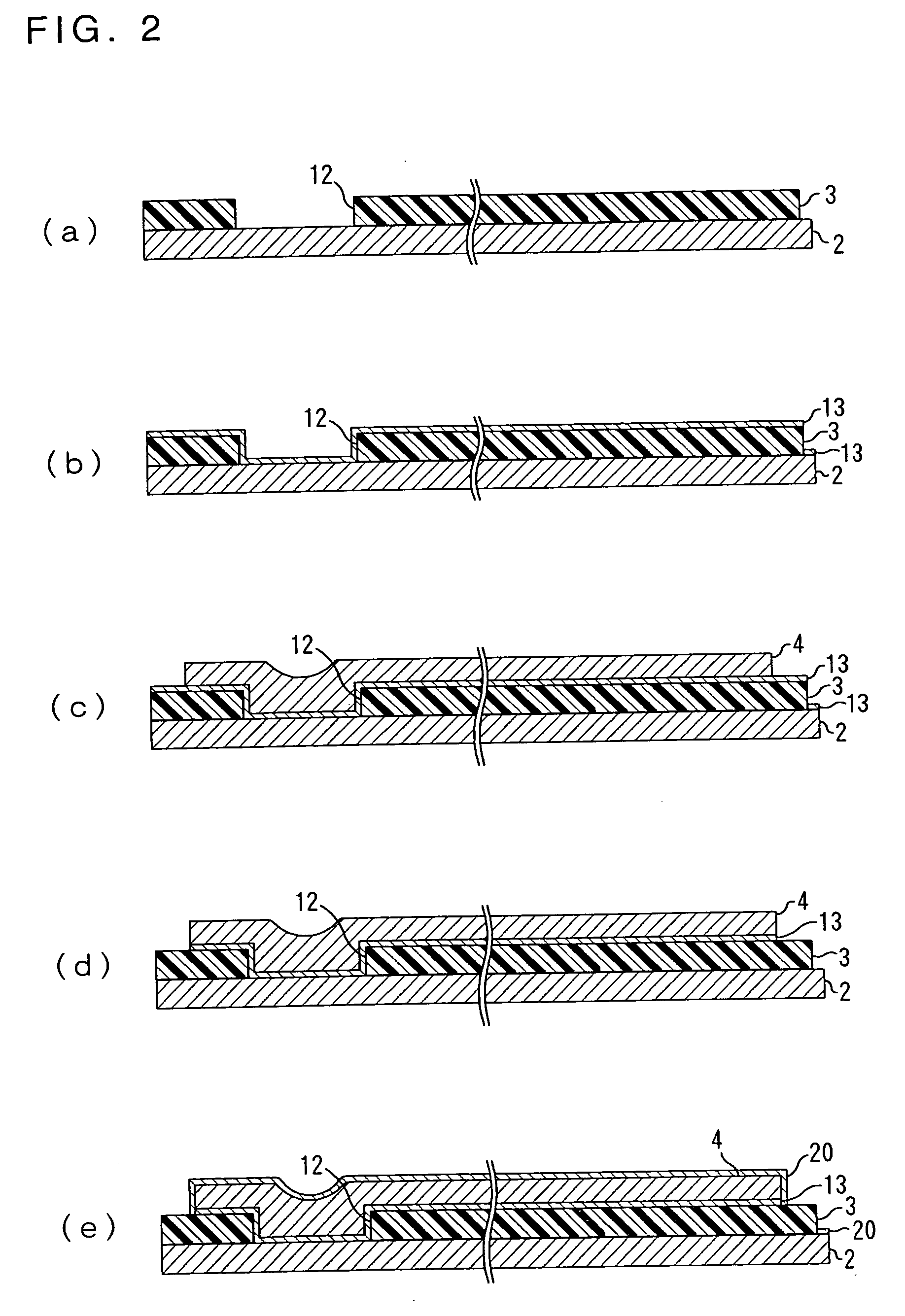

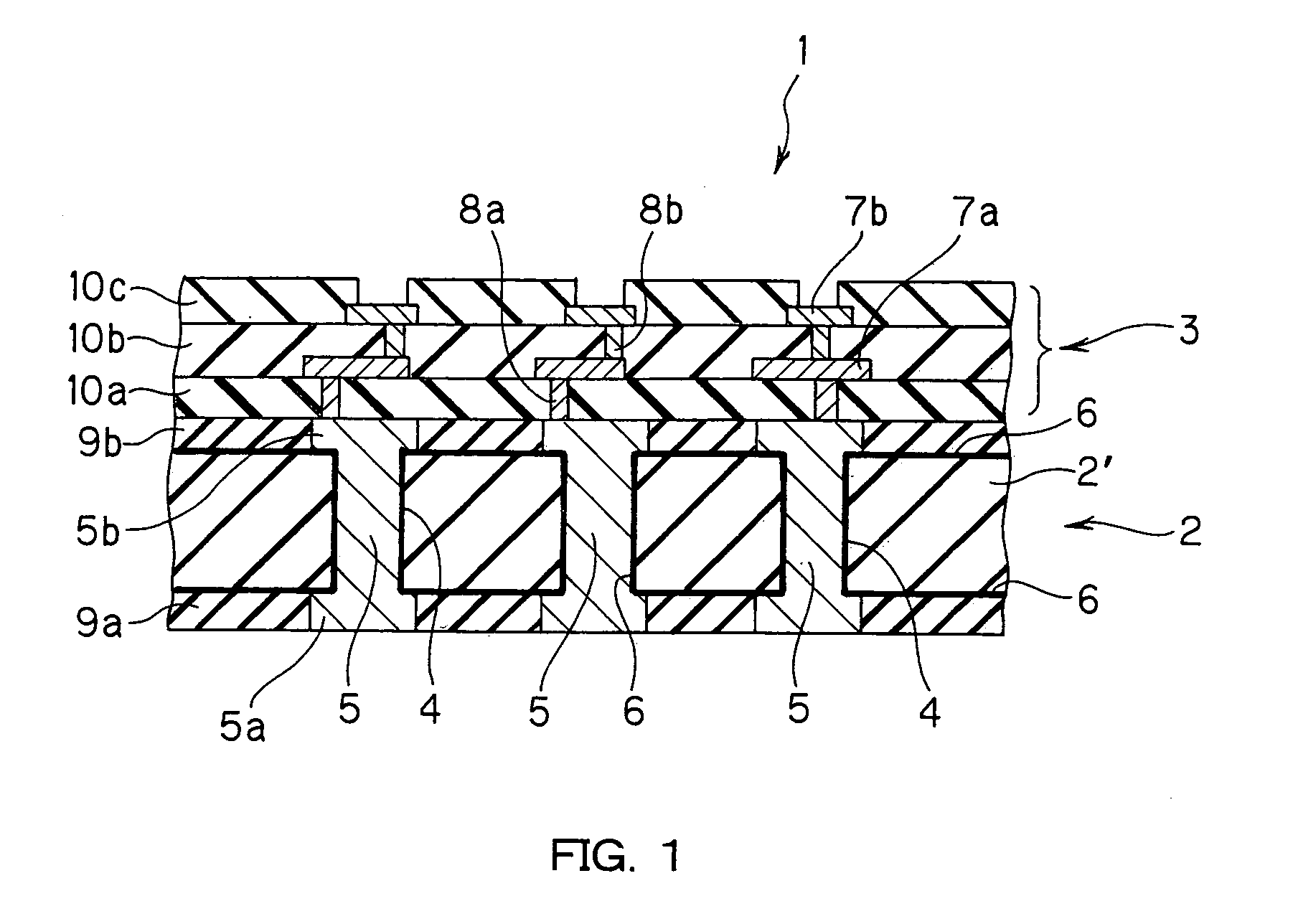

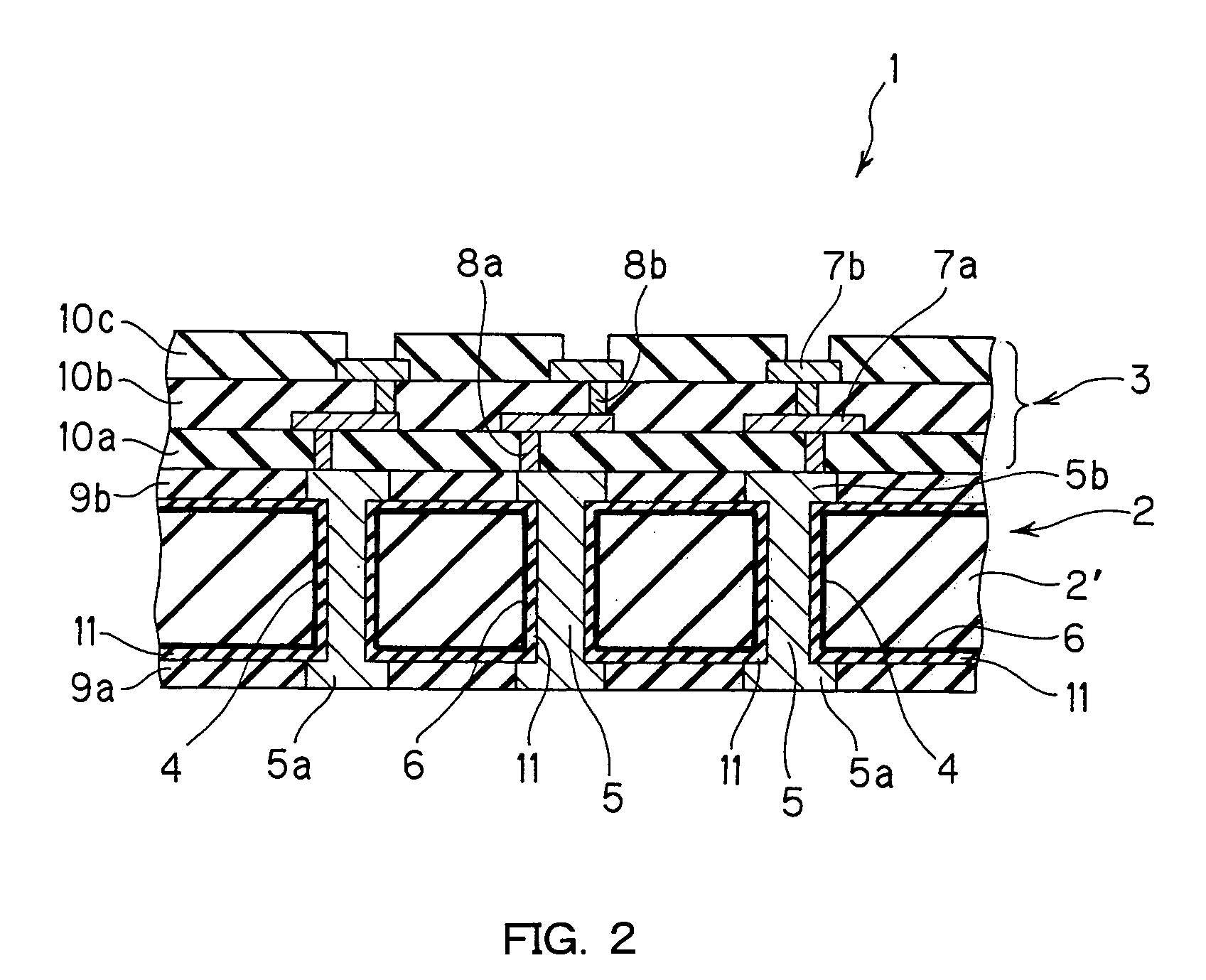

Suspension board with circuit and procuding method thereof

ActiveUS20050061542A1Increase productivityLow costInsulating substrate metal adhesion improvementCircuit arrangements on support structuresThin metalElectrical conductor

A producing method of a suspension board with circuit that can permit a terminal portion to be formed by electrolysis plating without exposing a conductor layer to outside and also can reduce the number of processes, and the suspension board with circuit produced by the same producing method. After an insulating base layer 3 is formed on a suspension board 2 in a specific pattern in which a second opening 12 is formed, a thin metal film 13 is formed on an entire surface of the insulating base layer 3 and on a surface of the suspension board 2 including the second opening 12 exposed from the insulating base layer 3.Then, a conductor layer 4 is formed in the form of a wired circuit pattern on the thin metal film 13. Thereafter, the insulating cover layer 10 is formed in such a manner that a pad opening 11 is formed in the insulating cover layer 10 and then a pad portion 16 is formed in the pad opening 11 using the suspension board 2 as a lead portion of the electrolysis plating. Thereafter, a first opening 25 larger than the second opening 12 is formed in the suspension board 2 at a portion thereof corresponding to the second opening 12.

Owner:NITTO DENKO CORP

Method of manufacturing printed-circuit board

InactiveUS6889433B1Reduced connection reliabilityHigh densityLine/current collector detailsInsulating substrate metal adhesion improvementConductive pasteEngineering

By filling a predetermined amount of conductive paste into an opening for forming a through hole or a VH formed in a resin insulating layer of a circuit board, and pressurizing the filled conductive paste under the condition of reduced pressure, removing air bubble strapped in the conductive paste.

Owner:IBIDEN CO LTD

Multilayer wiring board and manufacture method thereof

InactiveUS7091589B2Improve electrical performanceBroaden your optionsInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsEngineeringConductive materials

In a multilayer wiring board comprising a core board, and a wiring layer and an electrically insulating layer that are stacked on one surface of said core board, a thermal expansion coefficient of said core board in XY directions falls within a range of 2 to 20 ppm, a core member for said core board is a core member selected from silicon, ceramics, glass, a glass-epoxy composite, and metal, said core board is provided with a plurality of through holes that are made conductive between the front and the back by a conductive material, and a capacitor is provided on one surface of said core board, wherein said capacitor comprises an upper electrode being the conductive material in said through hole, and a lower electrode disposed so as to confront said upper electrode via a dielectric layer.

Owner:DAI NIPPON PRINTING CO LTD

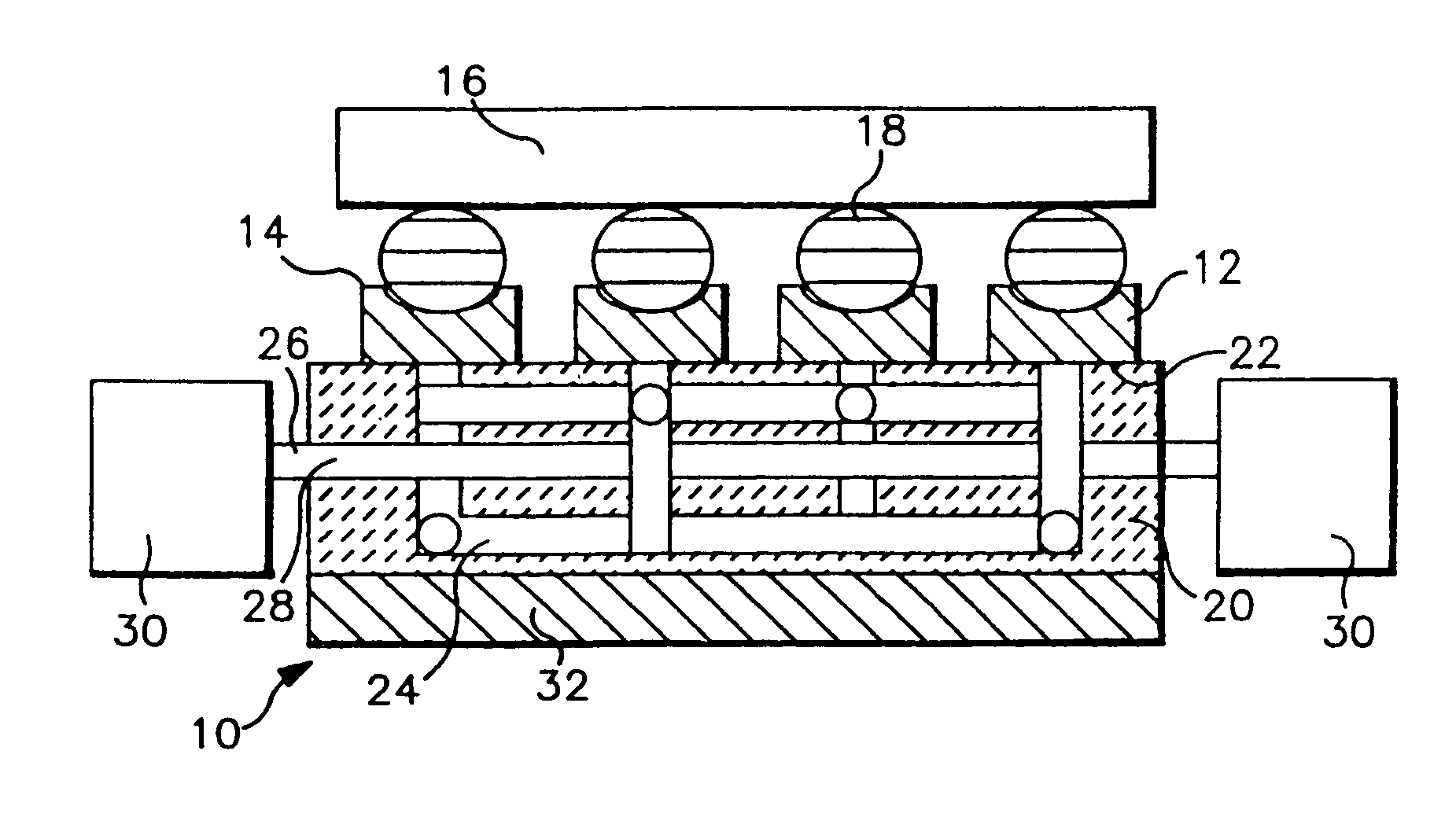

Method of manufacture of ceramic composite wiring structures for semiconductor devices

InactiveUS7047637B2Increase volume fractionEasy to removeSemiconductor/solid-state device detailsSolid-state devicesDielectricCeramic composite

Method of manufacture of a composite wiring structure for use with at least one semiconductor device, the structure having a first conductive member upon which the semiconductor device can be mounted for electrical connection thereto. A dielectric member, made of ceramic or organo-ceramic composite material, is bonded to the first conductive member and contains embedded therein a conductive network and a thermal distribution network. A second conductive member may be incorporated with the composite wiring structure, with a capacitor electrically connected between the conductive network and the second conductive member. Bonding between the dielectric member and the conductive members may be in the form of a direct covalent bond formed at a temperature insufficient to adversely effect the structural integrity of the conductive network and the thermal distribution network.

Owner:L PIERRE DEROCHEMONT C2 TECH

Bonded body of galvanized steel sheet and adherend, and manufacturing method thereof

InactiveUS20110008644A1Firmly connectedGood adhesionHot-dipping/immersion processesLiquid surface applicatorsPolyolefinSheet steel

The invention is a technique for strongly integrating a galvanized steel sheet and a resin molded article. A hot-dip galvanized steel sheet “Z18” is immersed in an aqueous solution for aluminum degreasing at 75° C. for 7 minutes, to form roughness having an RSm of 0.8 to 2.3 μm and an Rz of 0.3 to 1.0 μm on the surface. The surface is covered with convex protrusions having a diameter of about 100 nm, and a chromate treatment layer appears in the surface. In other words, three conditions suitable for bonding are satisfied thereby. A resin composition comprising 70 to 97 wt % of polyphenylene sulfide and 3 to 30 wt % of a polyolefin resin is injected onto the surface. The resin composition penetrates into ultra-fine irregularities and is cured in that state, whereby a composite in which the galvanized steel sheet and the resin molded article are strongly integrated is obtained. The shear rupture strength of the composite is extremely high, in excess of 20 MPa.

Owner:TAISEI PLAS CO LTD

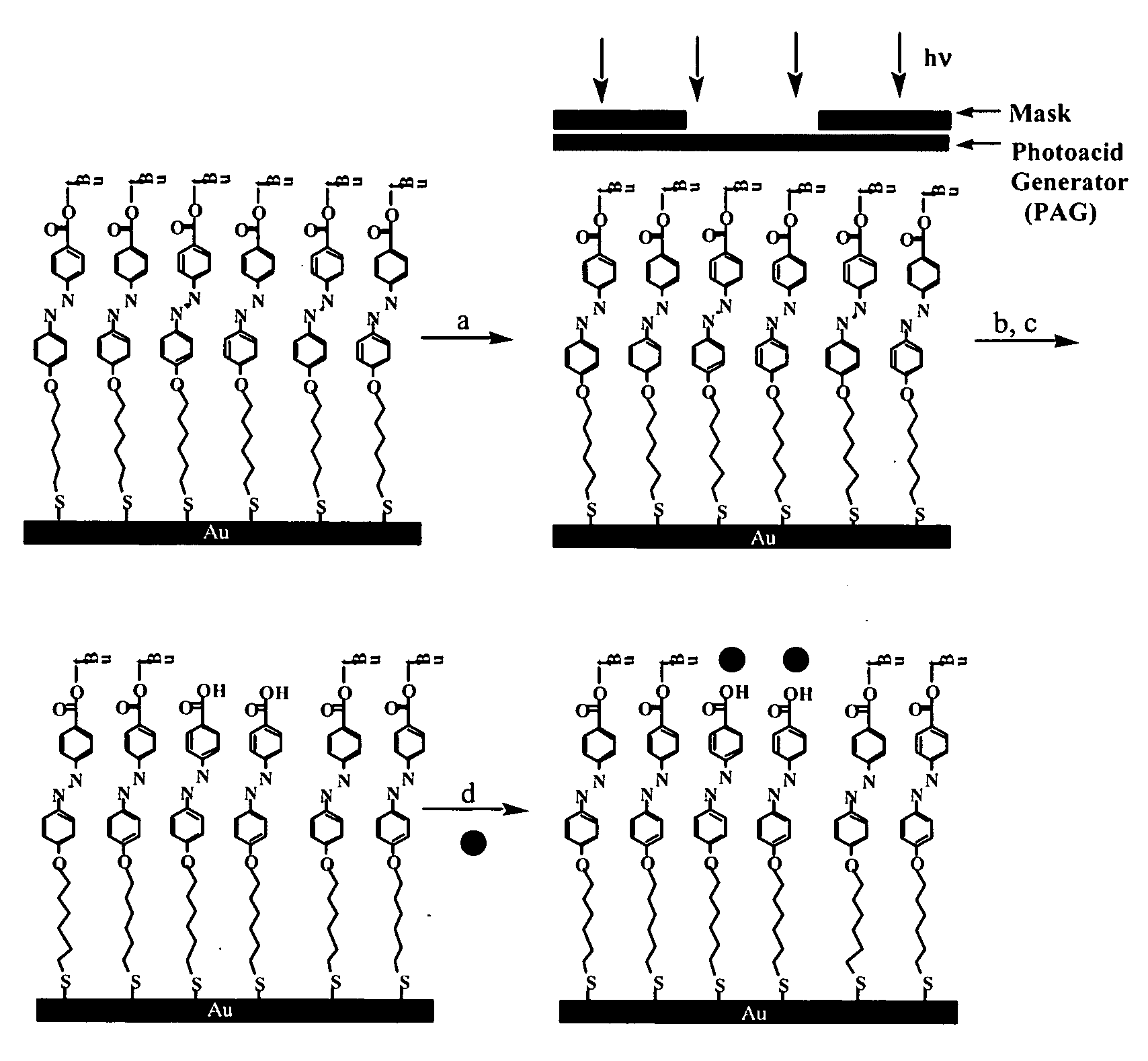

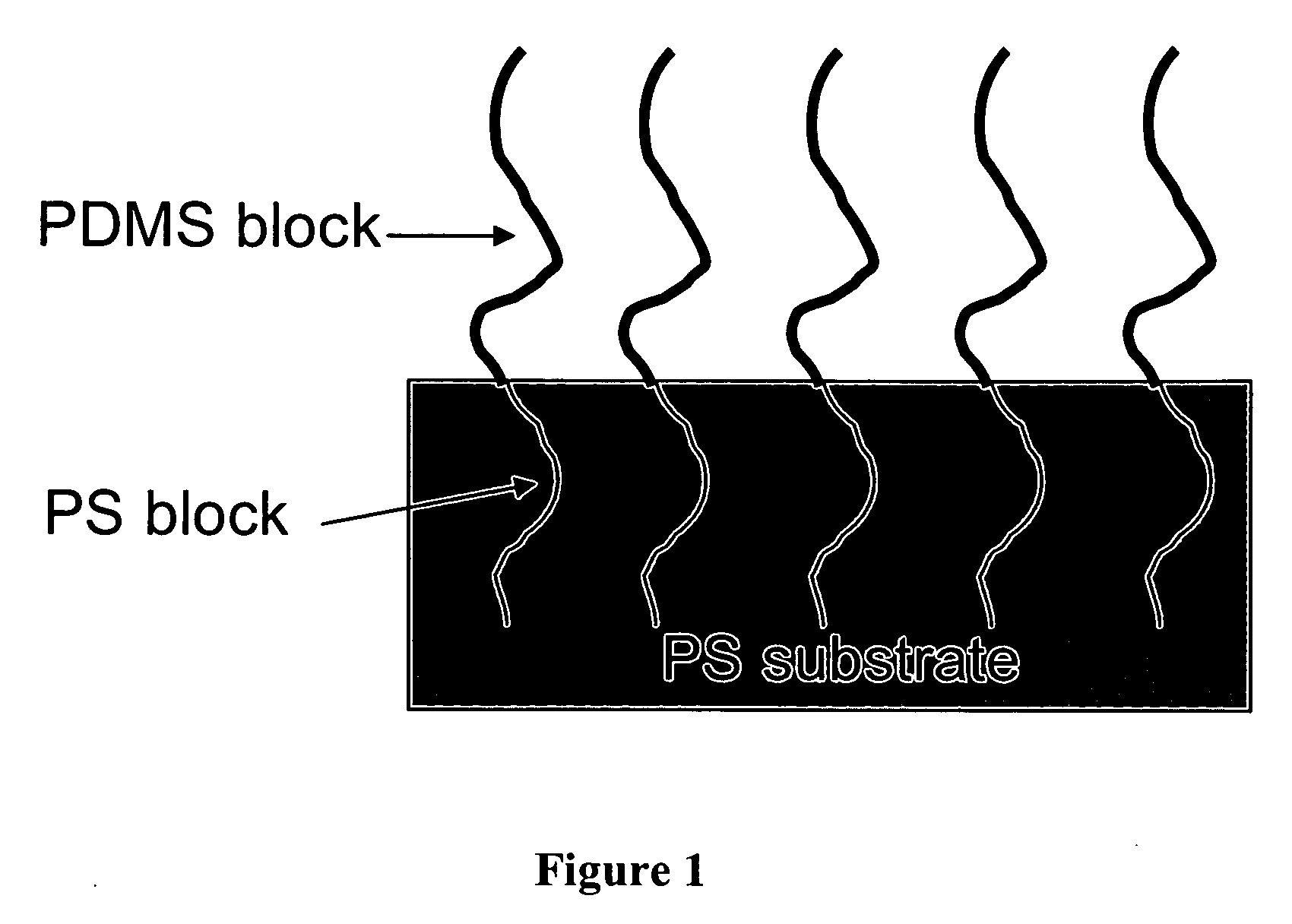

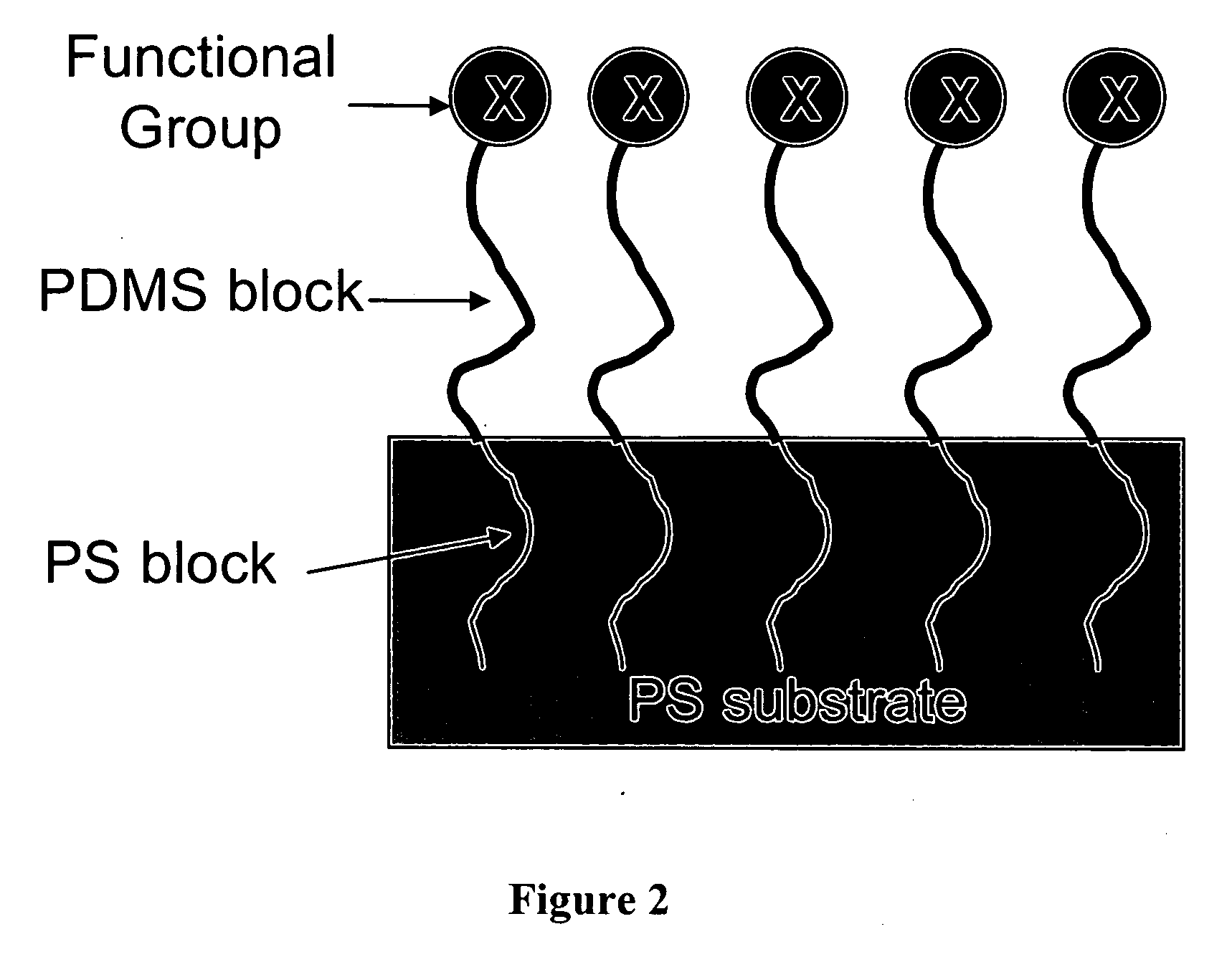

Methods for modifying surfaces

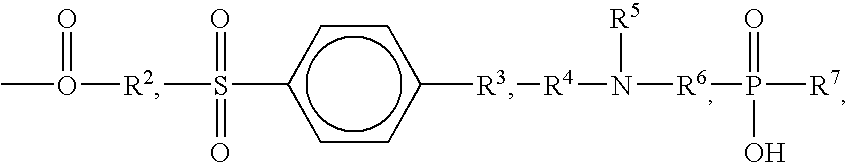

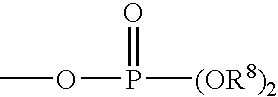

InactiveUS20070134420A1Material nanotechnologyInsulating substrate metal adhesion improvementActive polymerSURFACTANT BLEND

The present invention is directed to methods for coating monolayer films of surface-active polymers onto substrates of arbitrary shape. The present invention also provides molecular-based methods and processes that can be used to control the chemical and physical nature of surfaces and interfaces. The present invention is directed to methods for modifying functional groups in a homogenous way and controlling the spatial distributions of surface functional groups. The invention is directed to methods for modifying a substrate having a surface comprising coating a macromolecular surfactant comprising a modifiable functional group onto the surface of the substrate, wherein the modifiable functional group assembles to the air-coating interface, thereby modifying the surface of the substrate; wherein if the substrate comprises a first polymer and the macromolecular surfactant comprises a second polymer having a modifiable functional group, then the group is not modifiable by an acid to functionally modify the surface of the substrate. The invention is directed to devices made by these methods.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

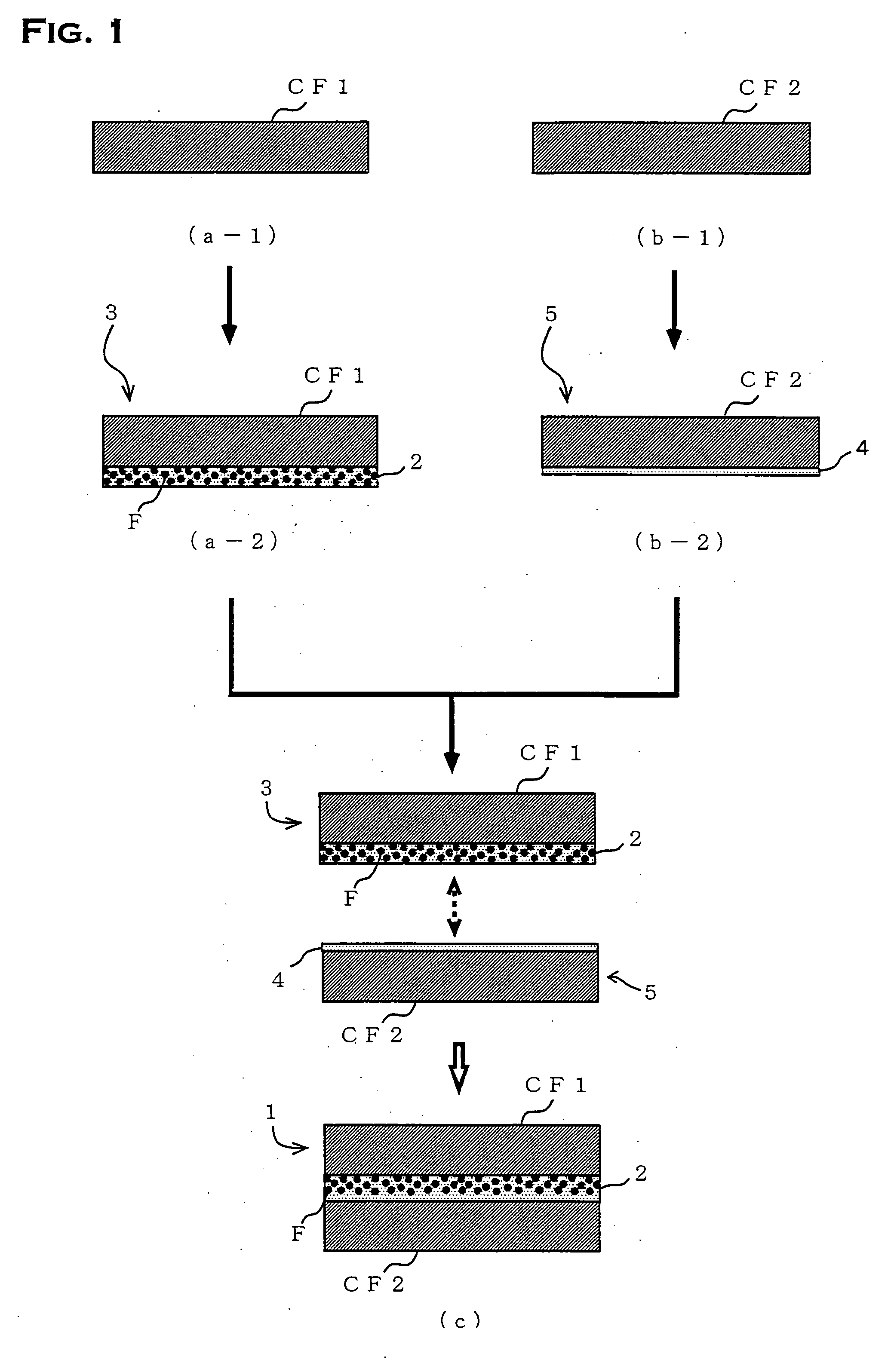

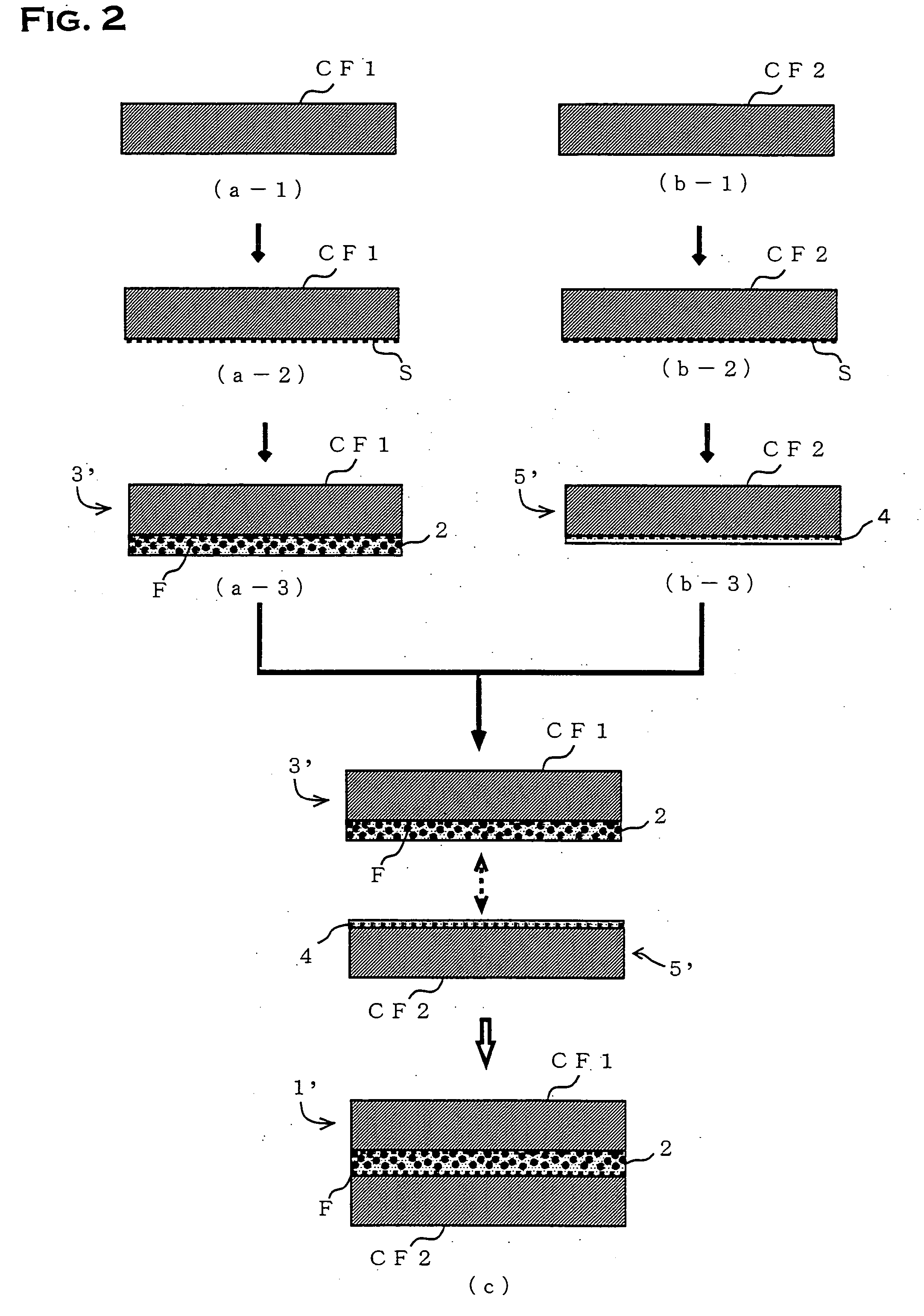

Laminate and its producing method

InactiveUS20040231141A1Improve surface smoothnessImprove adhesionPrinted circuit assemblingInsulating substrate metal adhesion improvementMetal coatingHigh density

A laminate is prepared by forming metal layer A on one face of a polymer film by dry plating method. When circuit is formed by using the laminate according to the semi-additive method, a high-density printed wiring board having excellent circuit shape, insulating property between the circuits and adhesion with the substrate can be obtained. By forming an adhesive layer on the other side of the polymer film of the laminate, an interlayer adhesive film is prepared. By thermally fusing or curing the adhesive layer after laminating the interlayer adhesive film on the inner layer circuit board, a multi-layer printed wiring board can be prepared. When preparing the circuit board by etching the first metal coating, an etchant which selectively etches the first metal coating is preferably used.

Owner:KANEKA CORP

Method of forming polymide coating containing dielectric filler on surface of metallic material process for producing copper clad laminate for formation of capacitor layer for printed wiring board and copper clad laminate obtained by the process

InactiveUS20050161149A1Avoid damageIncrease flexibilityInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsMetallic materialsMaterials science

A method of forming a dielectric layer containing dielectric filler, which is excellent in film thickness uniformity, from a polyimide electrodeposition liquid containing dielectric filler. In particular, a method of forming a polyimide coating container dielectric filler on a surface of metallic material according to the electrodeposition coating technique, characterized in that as the dielectric filler, use is made of dielectric powder of perovskite structure in approximately spherical form which has an average particle diameter (D1A) of 0.05 to 1.0 μm and a weight cumulative particle diameter (D50), measured in accordance with the laser diffraction scattering type particle size distribution measuring method, of 0.1 to 2.0 μm and further exhibits an aggregation degree, in terms of D50 / D1a wherein D50 and D1a represent a weight cumulative particle diameter and an average particle diameter obtained by image analysis, respectively, of 4.5 or less.

Owner:MITSUI MINING & SMELTING CO LTD

Popular searches

Semiconductor/solid-state device manufacturing Liquid/solution decomposition chemical coating Conductive pattern formation Semiconductor devices Laminating printed circuit boards Thin material handling Circuit susbtrate materials Metal layered products Electrical connection printed elements Electrical components

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com