Patents

Literature

61results about How to "Satisfactory productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

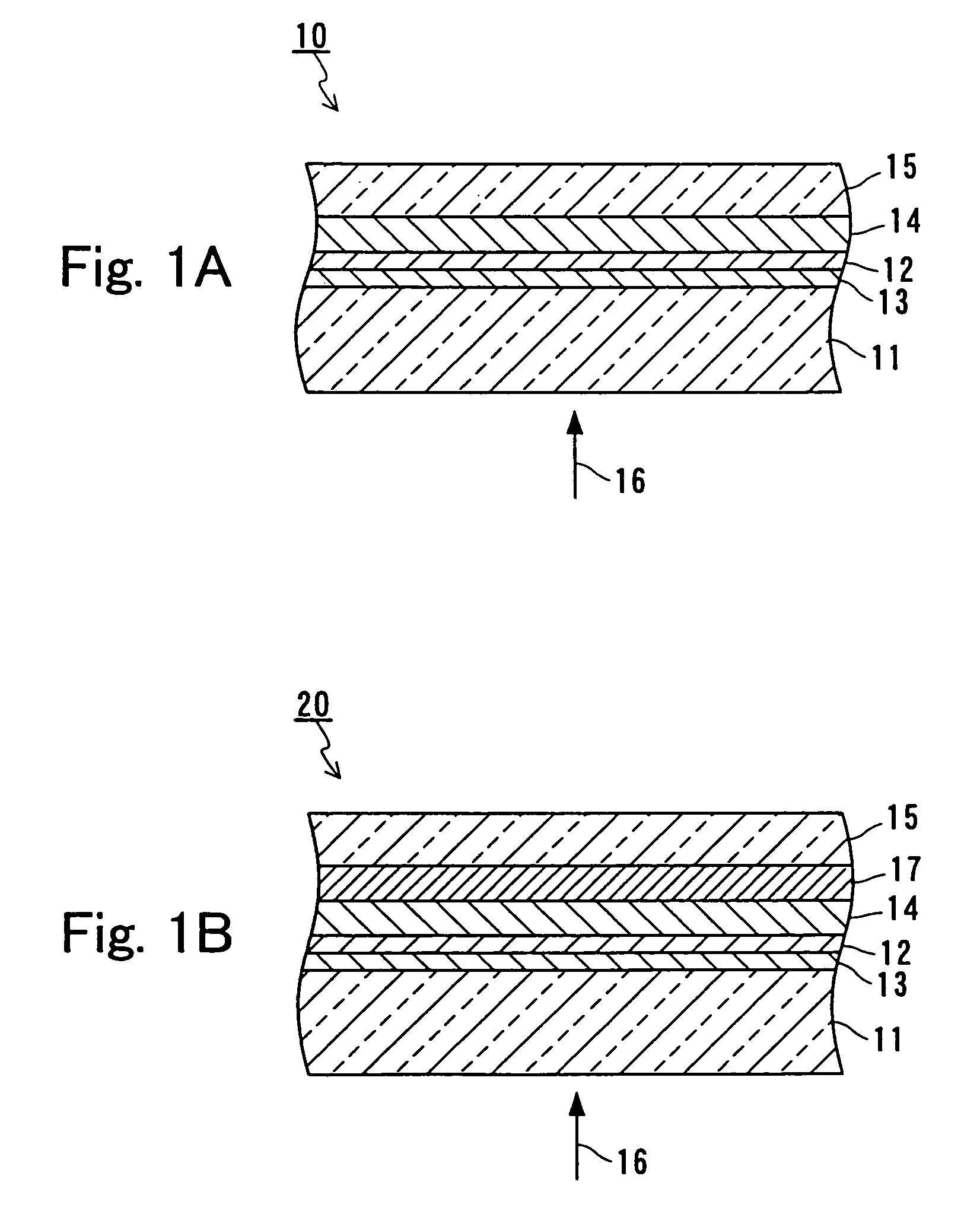

Process for producing multilayered gas-barrier film

InactiveUS20120003500A1Satisfactory productivityExcellent gas barrier performanceLiquid surface applicatorsSynthetic resin layered productsPolymer scienceThin membrane

Provided are a method for producing a film, which is satisfactory in productivity, exhibits high gas-barrier property immediately after production, and has excellent adhesive strength between constituent layers while maintaining the excellent gas-barrier property, and a gas-barrier film, which is obtained by the method. The method for producing a gas-barrier film includes the steps of; (1) forming an inorganic thin film by a vacuum deposition method on at least one surface of a base film; (2) forming a thin film by a plasma CVD method on the inorganic thin film formed in the step (1); and (3) forming an inorganic thin film by the vacuum deposition method on the thin film formed in the step (2), in which each of the steps (1) and (3), and the step (2) are sequentially carried out at a pressure of 1×10−7 to 1 Pa, and at a pressure of 1×10−3 to 1×102 Pa, respectively.

Owner:MITSUBISHI PLASTICS INC

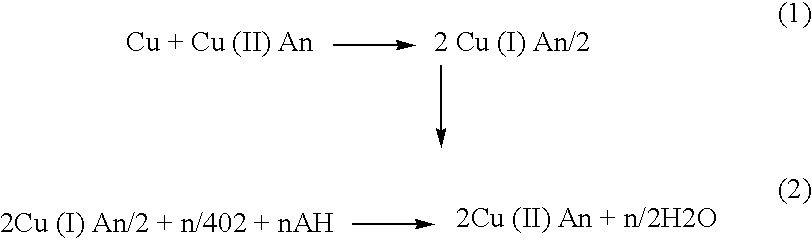

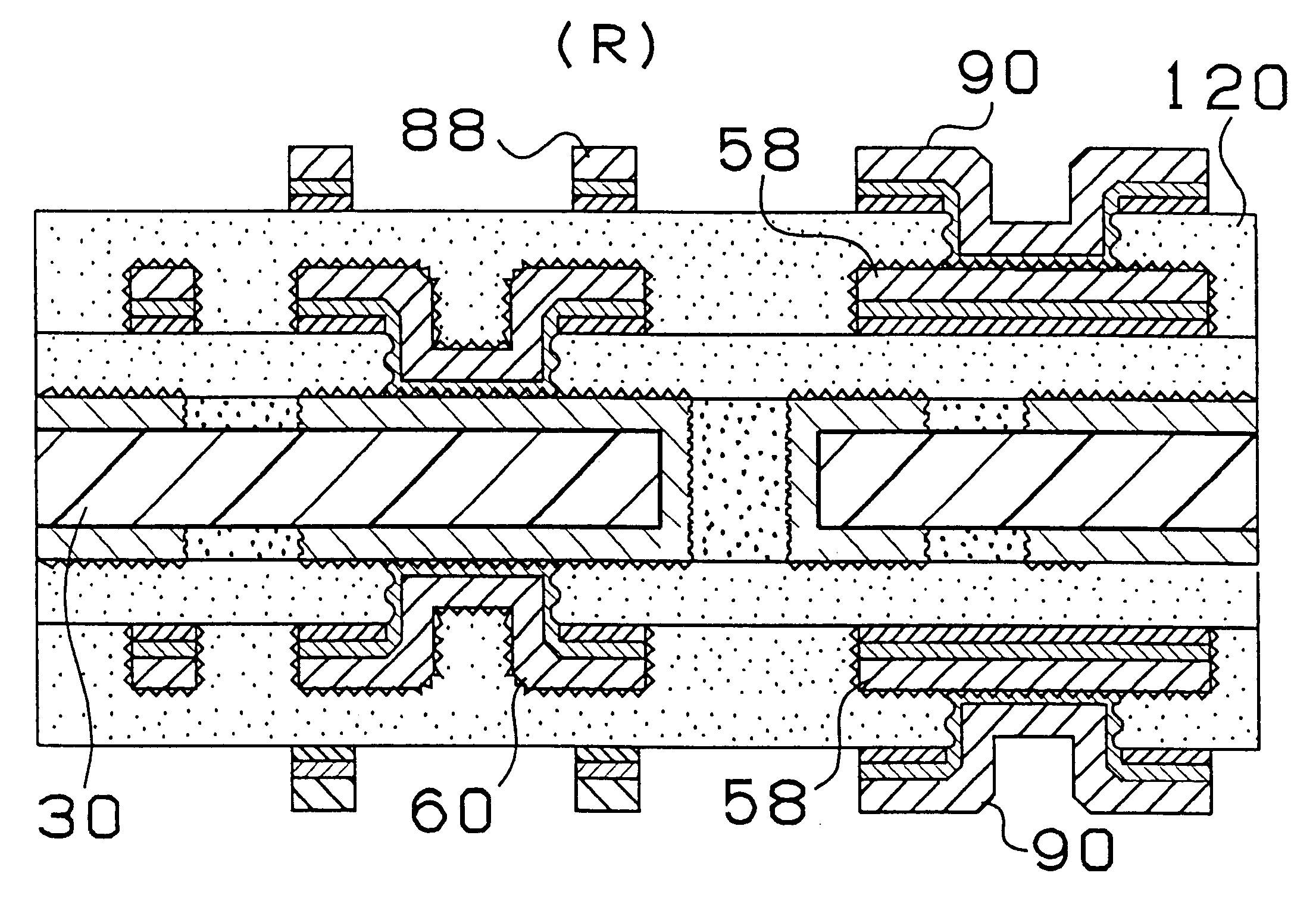

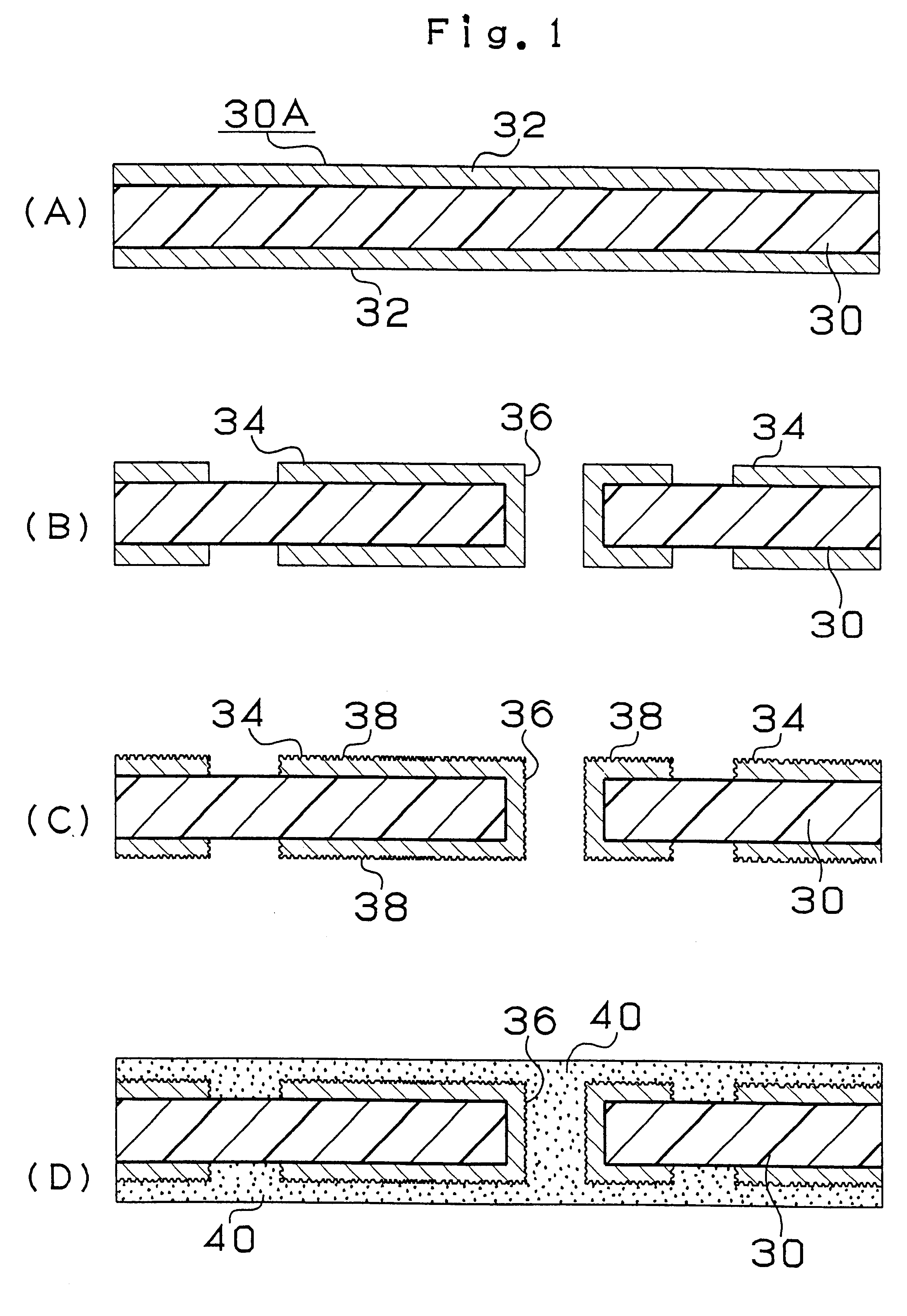

Manufacturing method of a multilayered printed circuit board having an opening made by a laser, and using electroless and electrolytic plating

InactiveUS6591495B2Satisfactory productivityAvoid separationSolid-state devicesInsulating layers/substrates workingCopper foilPulse shaping

An opening is formed in resin by a laser beam so that a via hole is formed. Copper foil, the thickness of which is reduced to 3 mum by etching to lower the thermal conductivity, is used as a conformal mask. Therefore, an opening is formed in the resin and the number of irradiation of pulse-shape laser beam is reduced. Thus, occurence of undercut of the resin, which forms an interlayer insulating resin layer, can be prevented and the reliability of the connection of the via holes can be improved.

Owner:IBIDEN CO LTD

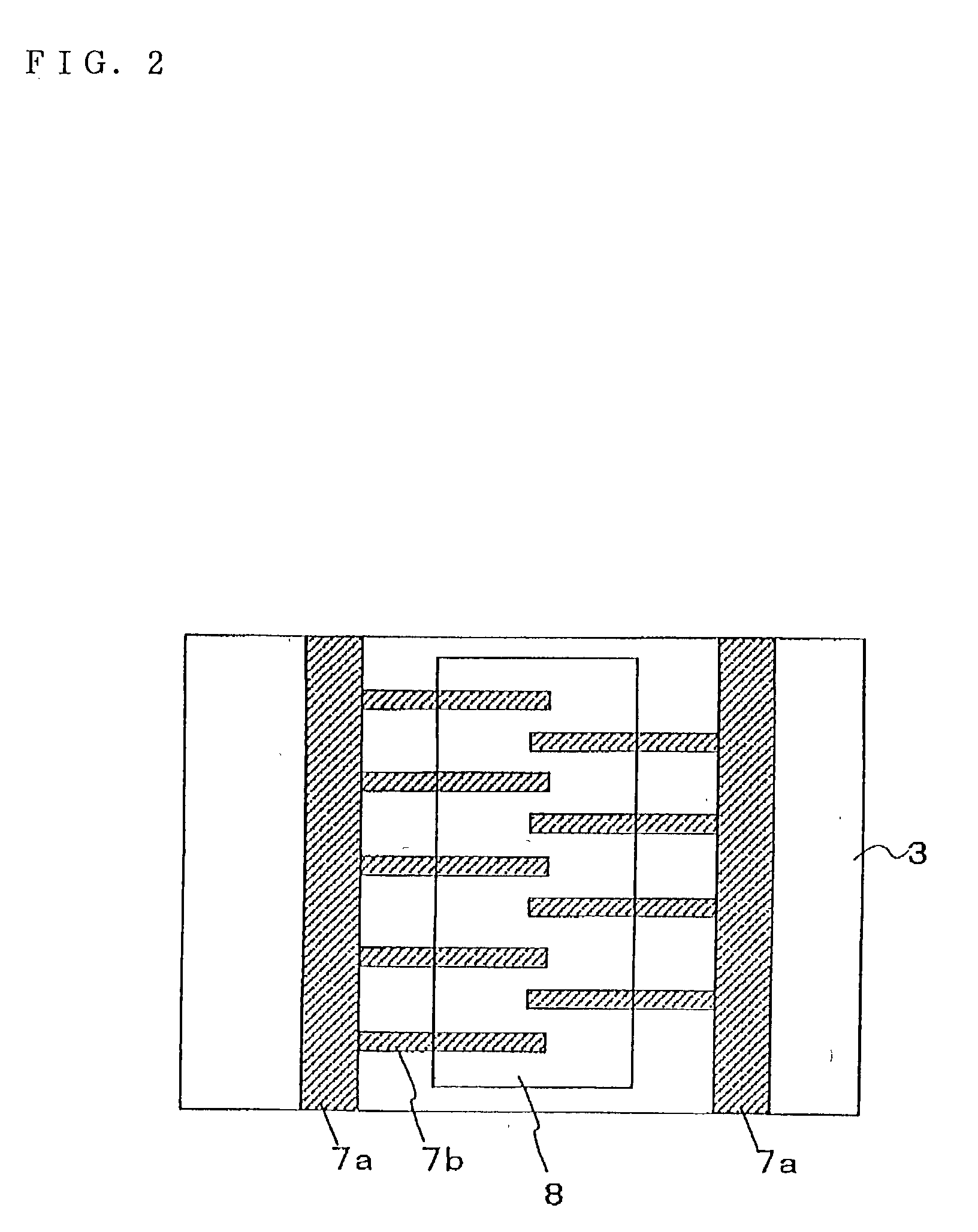

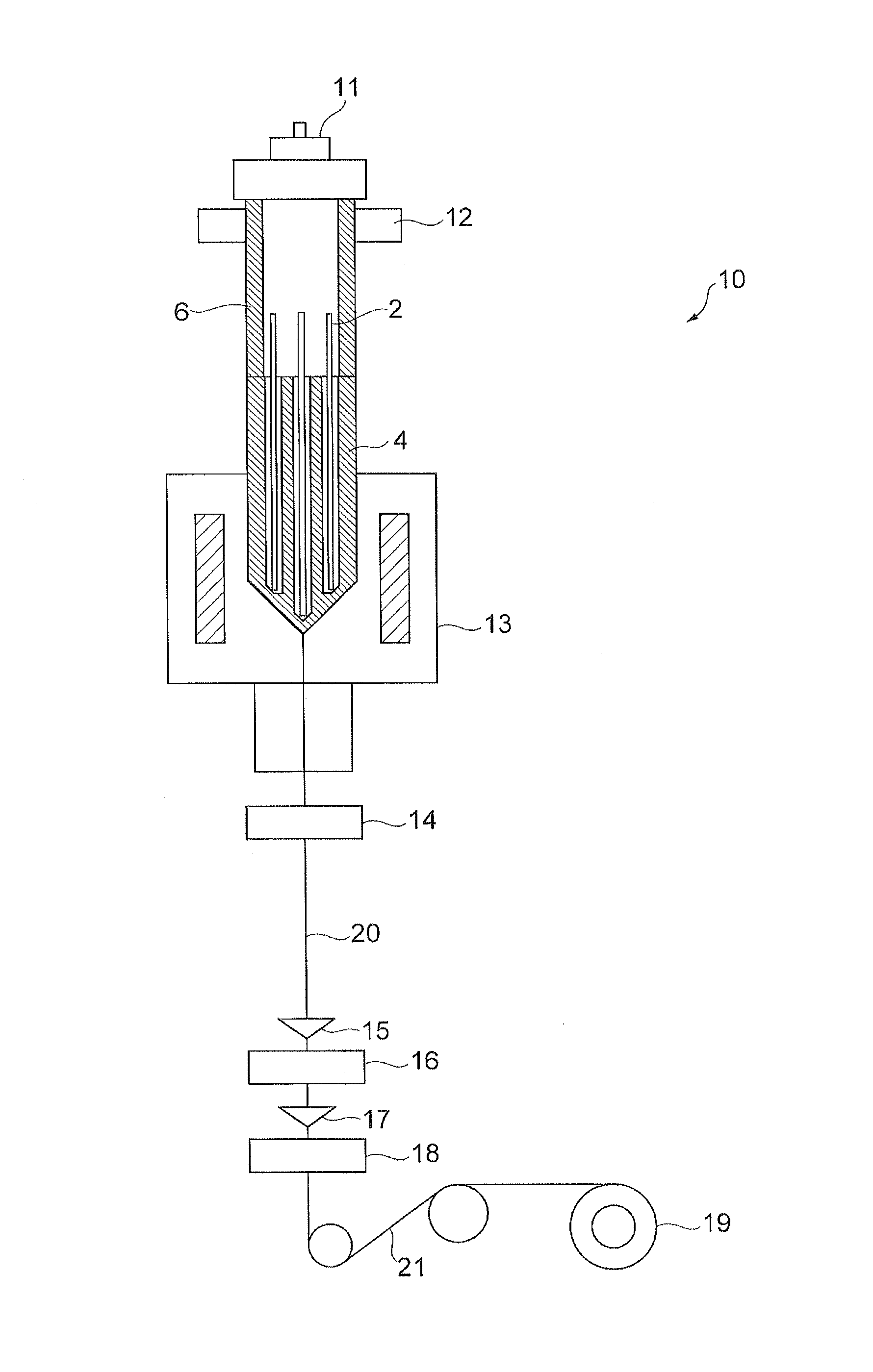

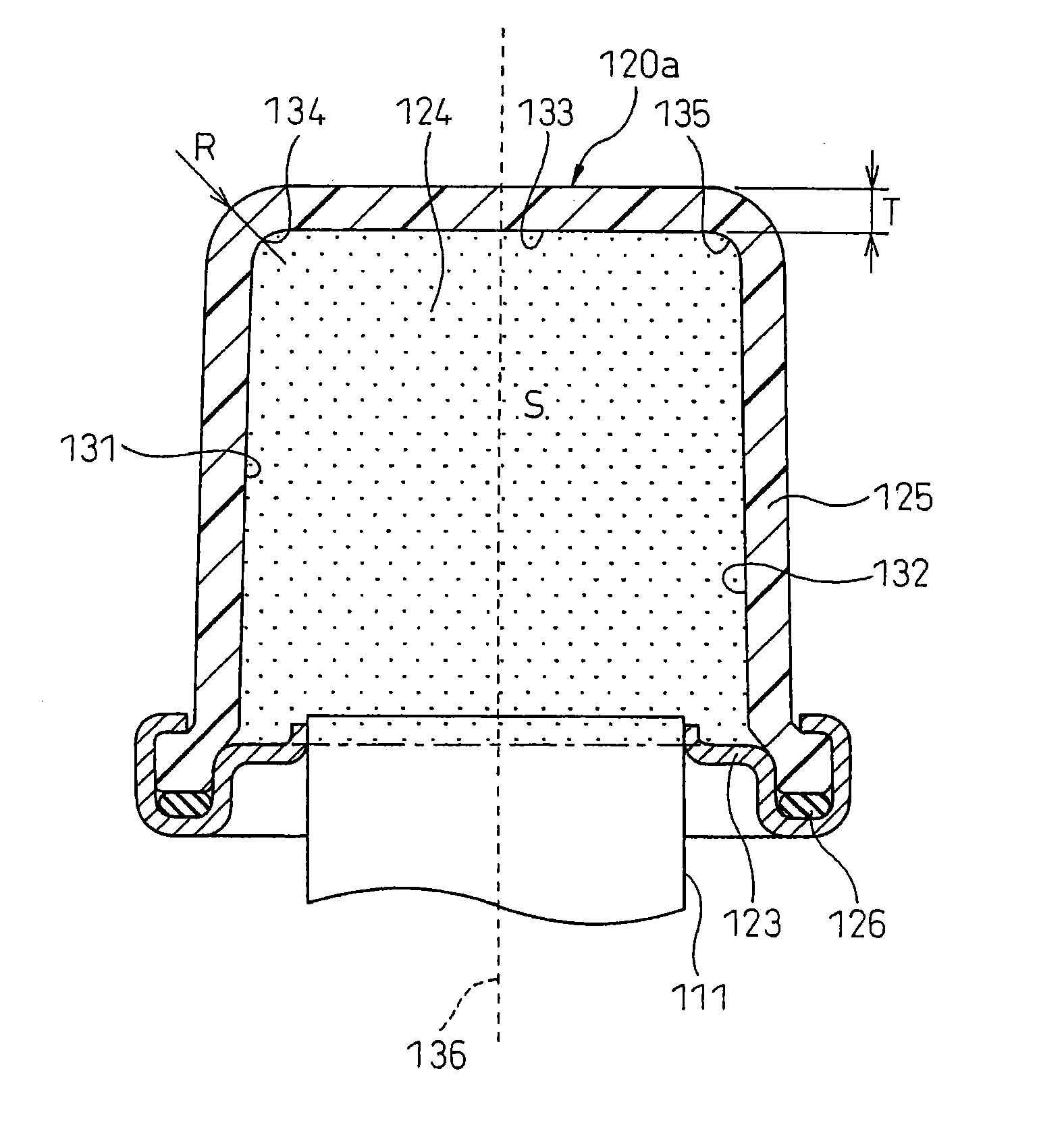

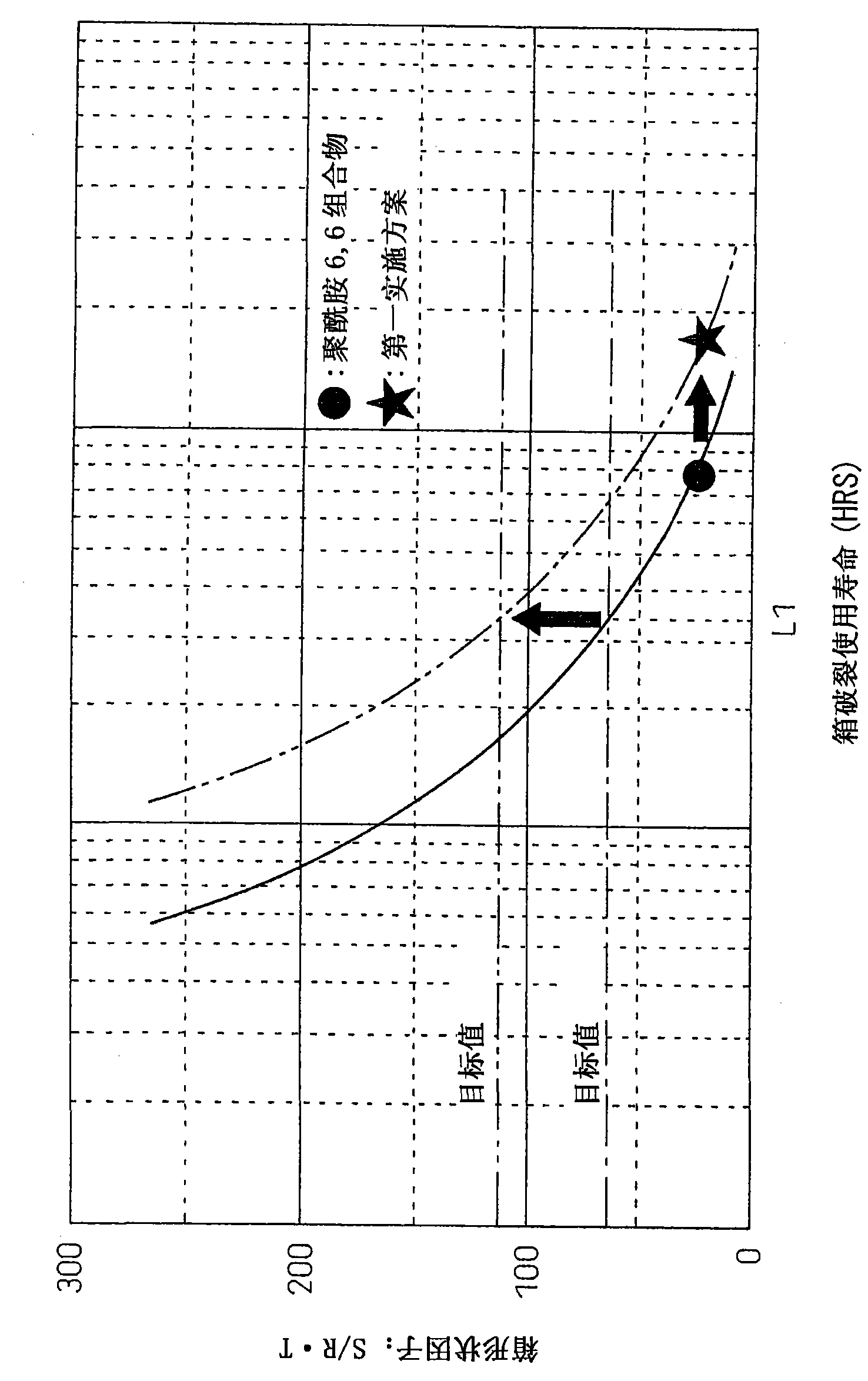

Electric double layer capacitor and process for its production

InactiveUS6906911B2Increase capacitance densityMaintained satisfactorilyHybrid capacitor separatorsHybrid capacitor electrodesEngineeringElectric double-layer capacitor

An electric double layer capacitor includes, contained in a casing, an electrolyte, a positive electrode and a negative electrode each being an electrode containing carbon black, to form an electric double layer at the interface with the electrolyte, and a separator interposed between the positive electrode and the negative electrode. At least one electrode of the positive electrode and the negative electrode has protruded portions or bent portions formed continuously in the height direction against the bottom face of the casing. Further, a space due to the height of the protruded portions or the bent portions is formed between the at least one electrode and the separator.

Owner:MITSUBISHI ELECTRIC CORP +1

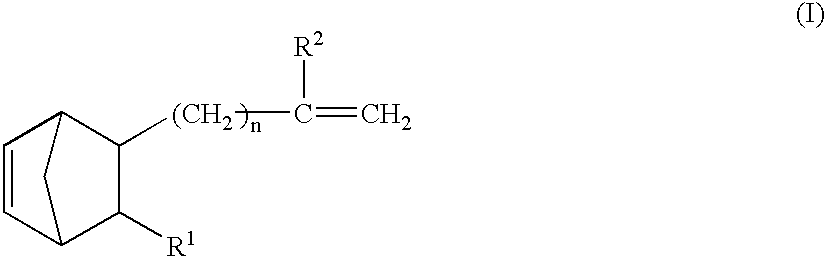

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition.

Owner:MITSUI CHEM INC

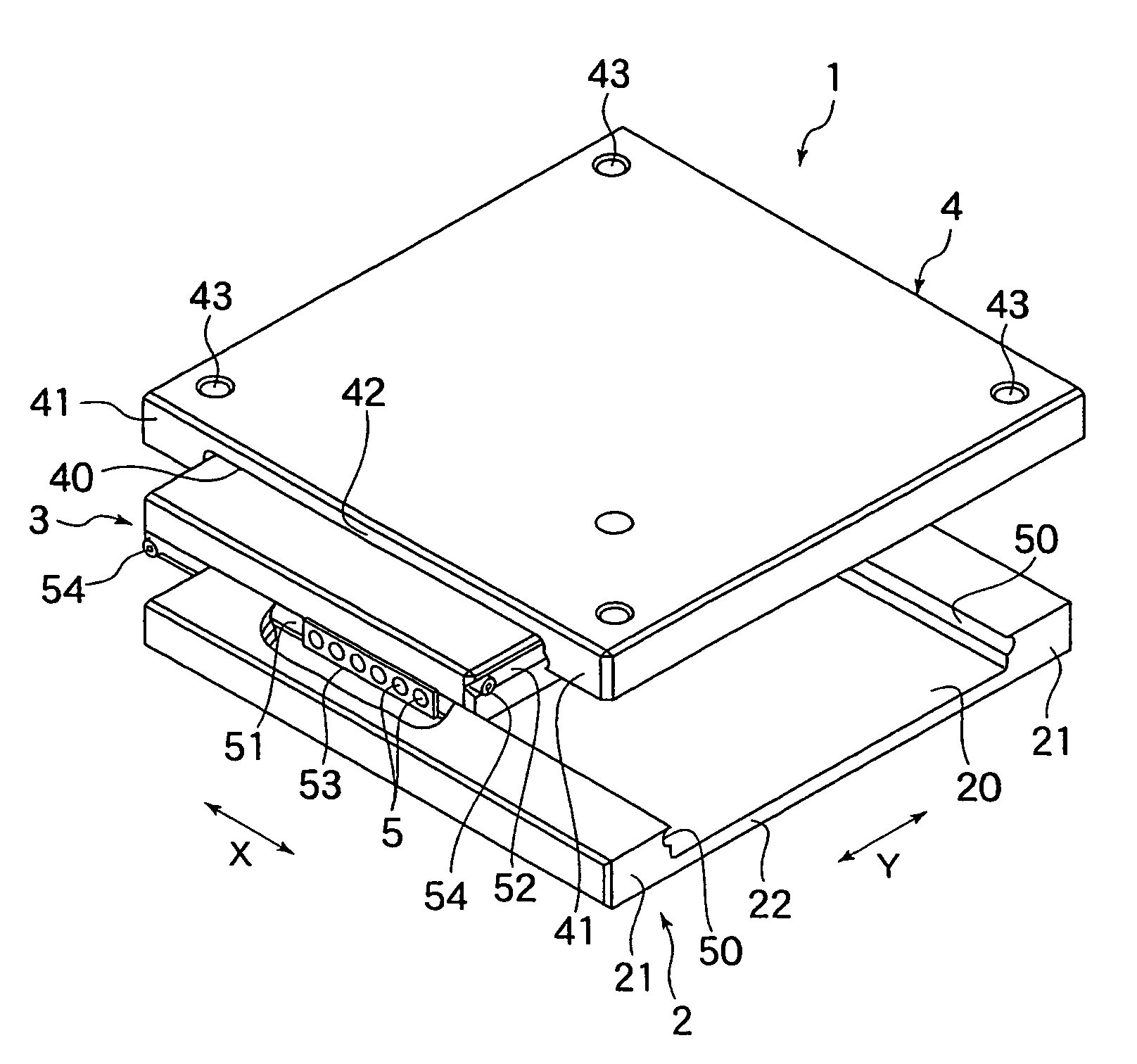

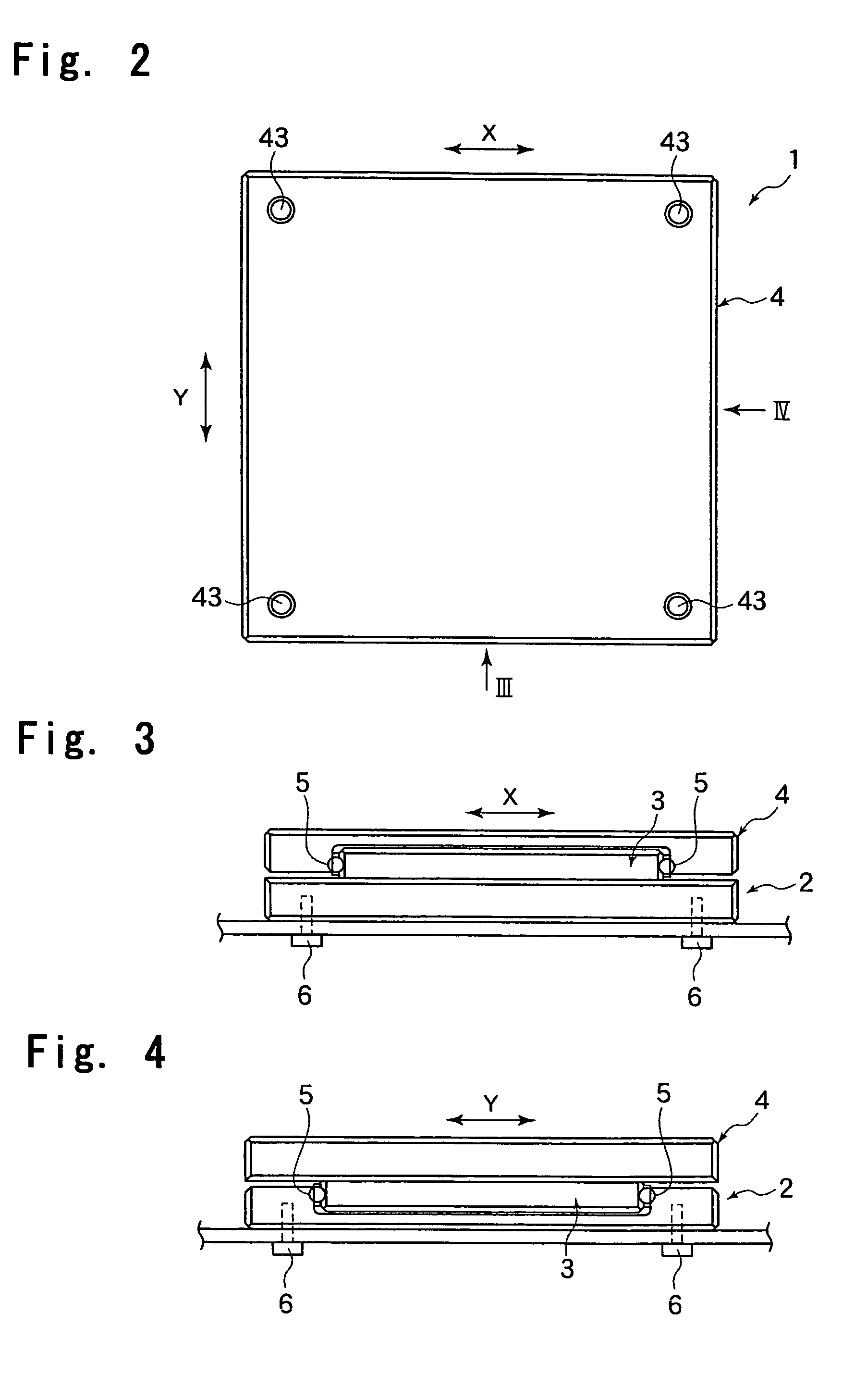

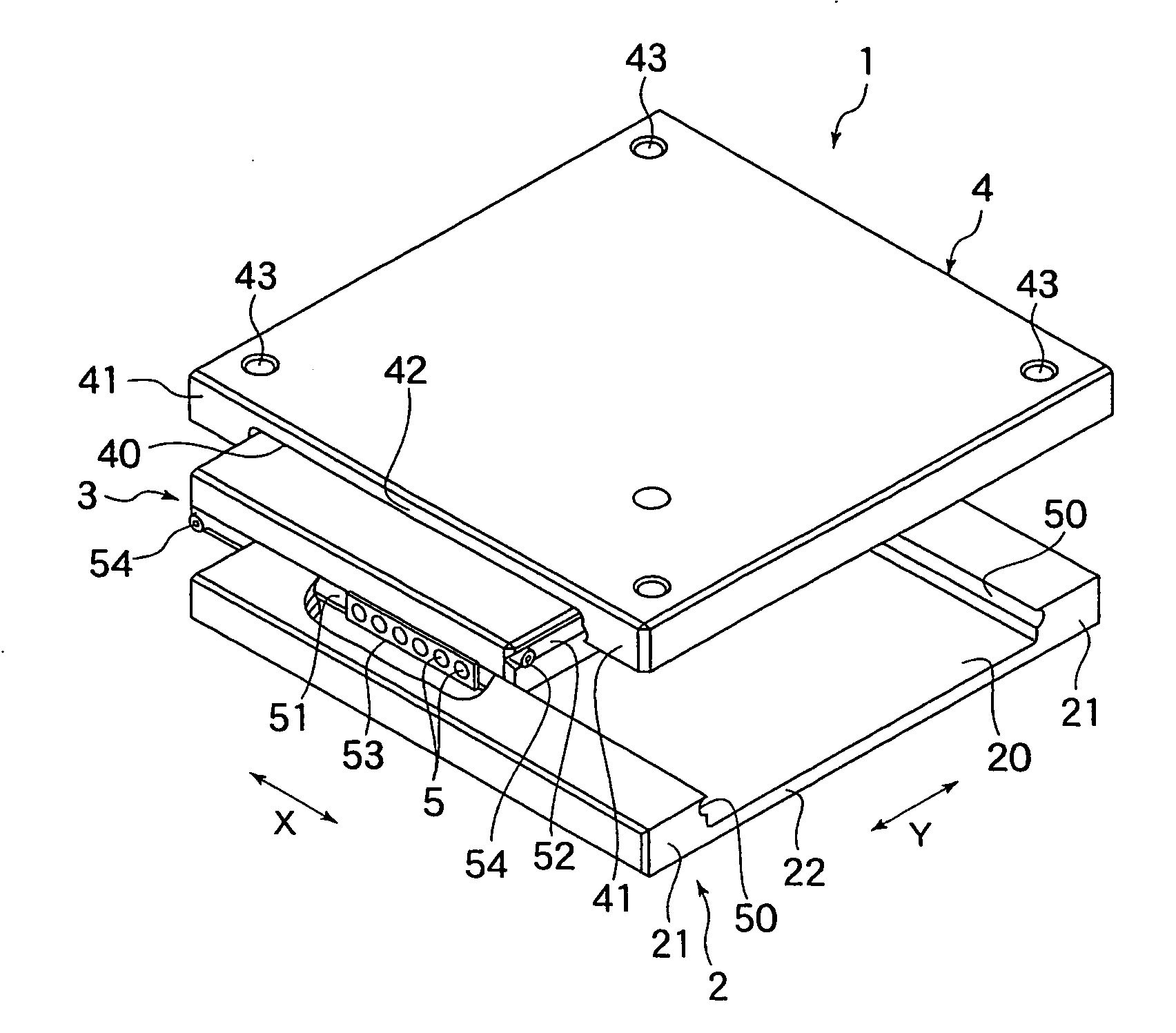

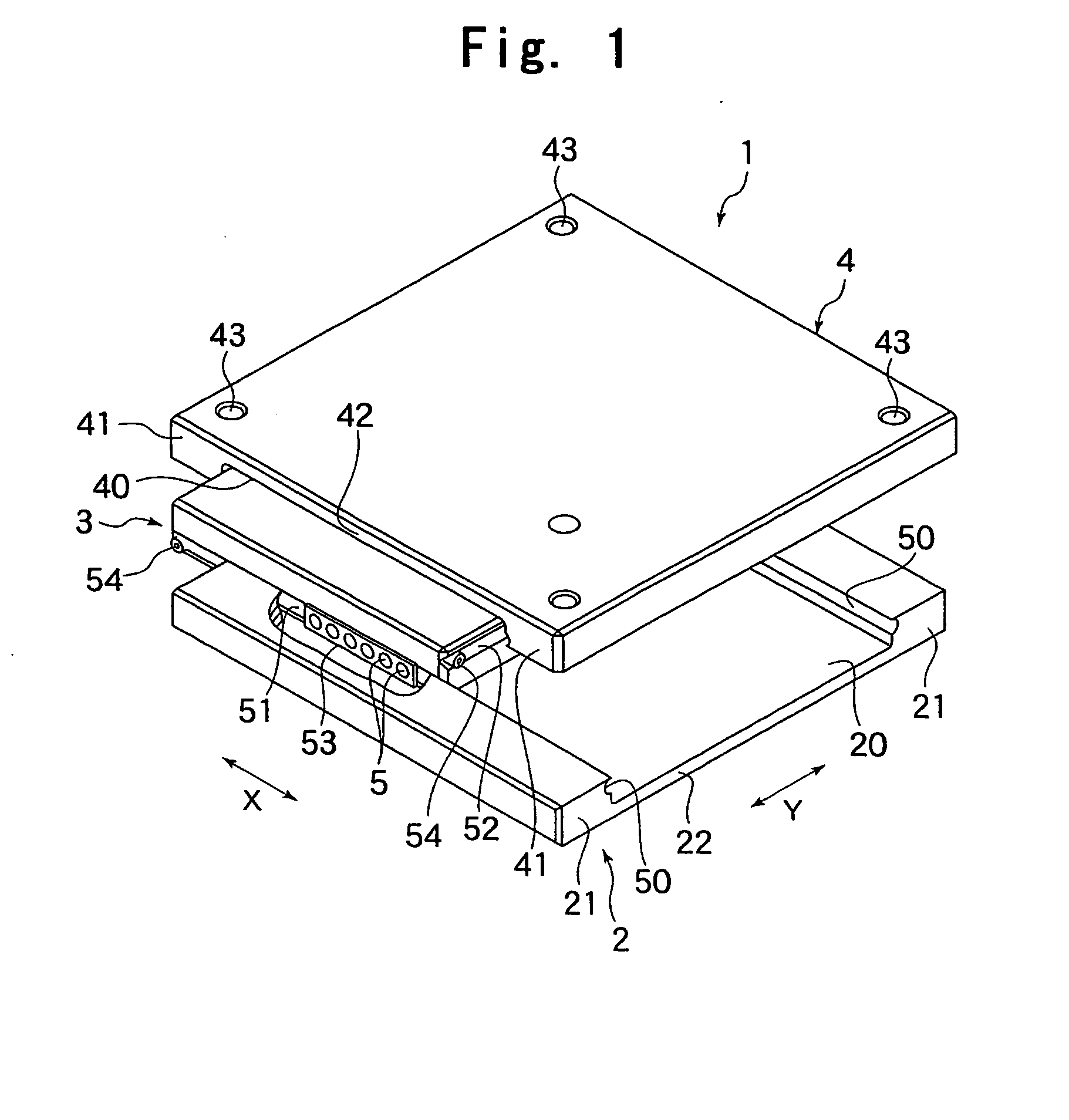

XY guide table

ActiveUS7637487B2Prevent rattlingImprove rigidityLinear bearingsGearingEngineeringMechanical engineering

Owner:THK CO LTD

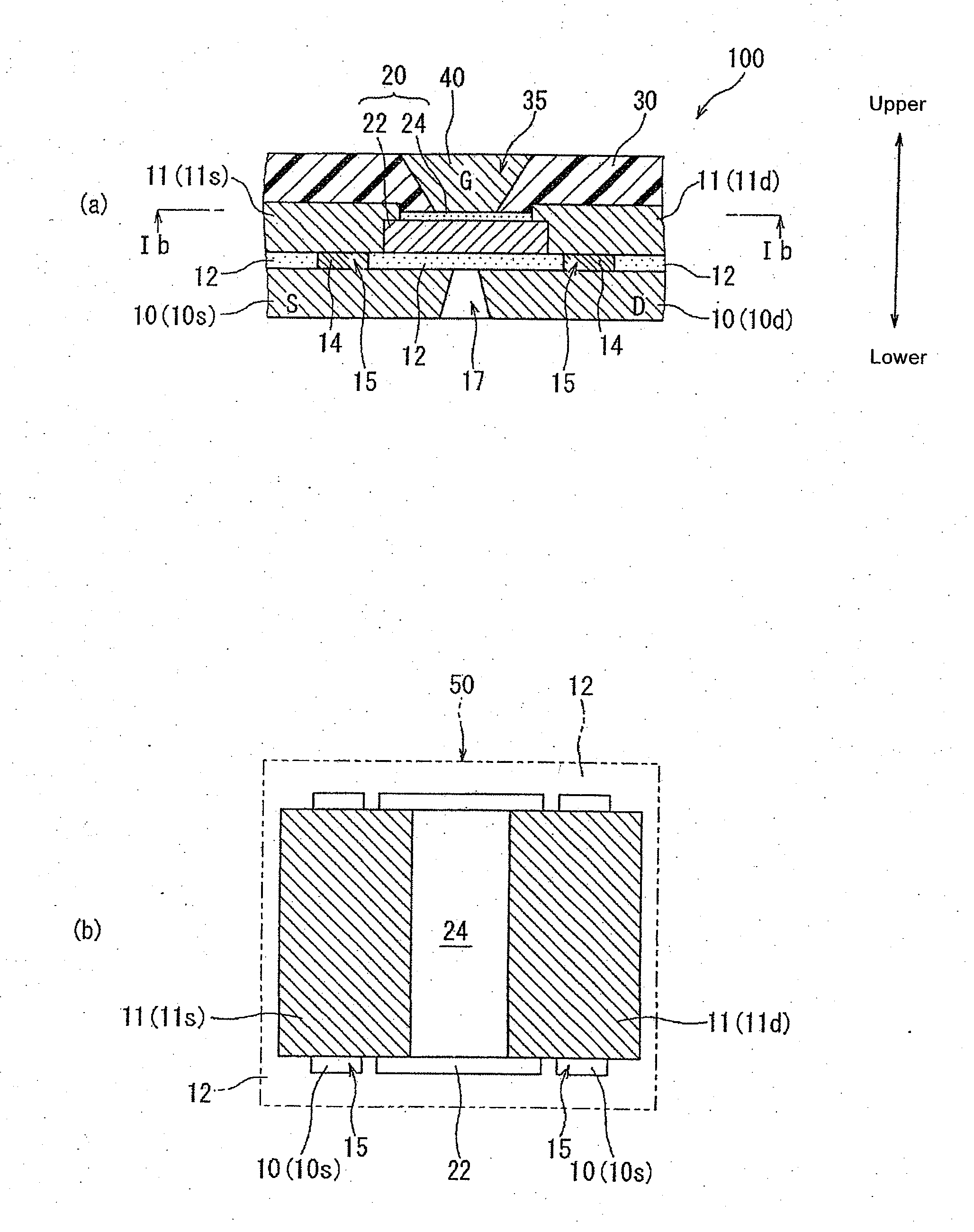

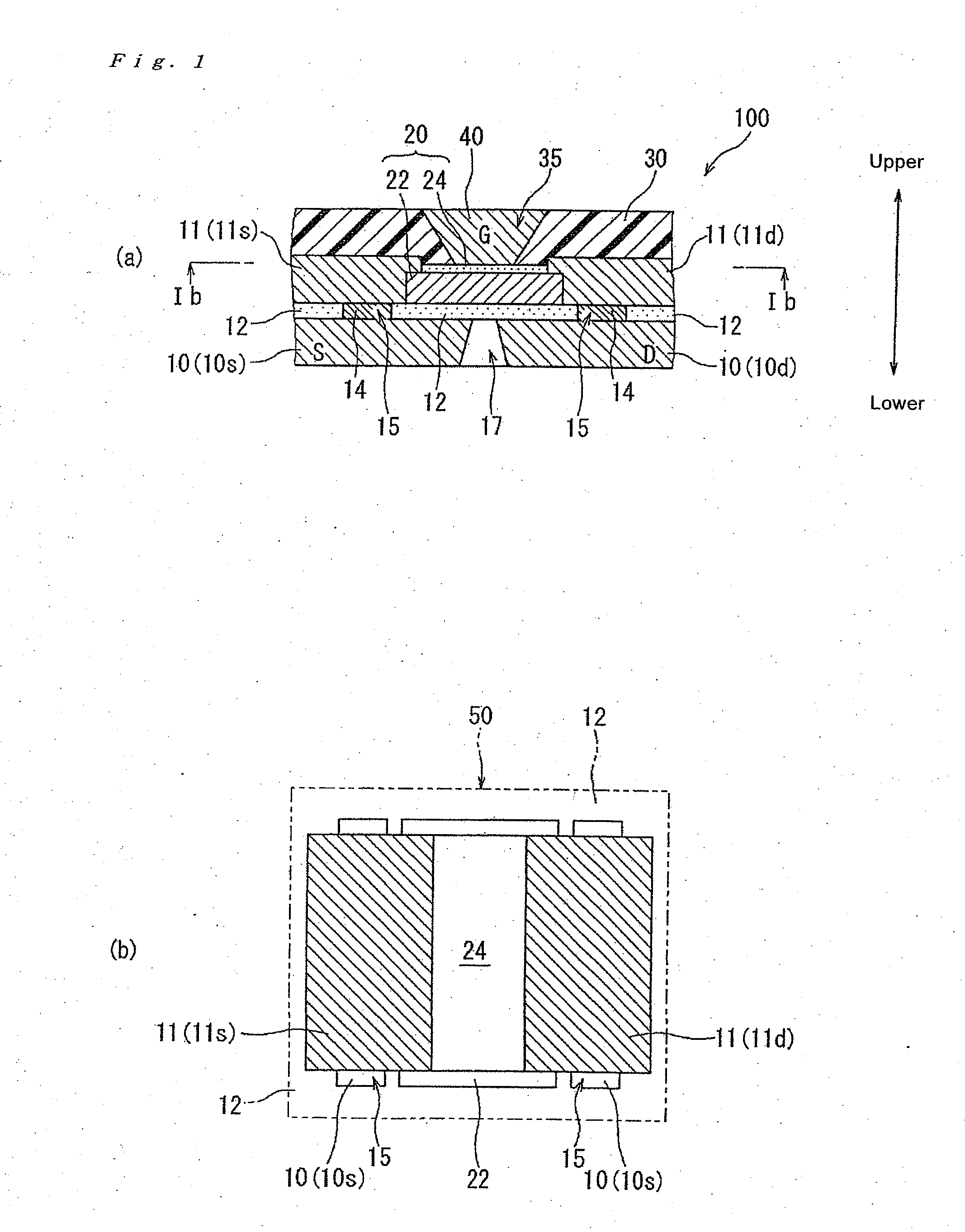

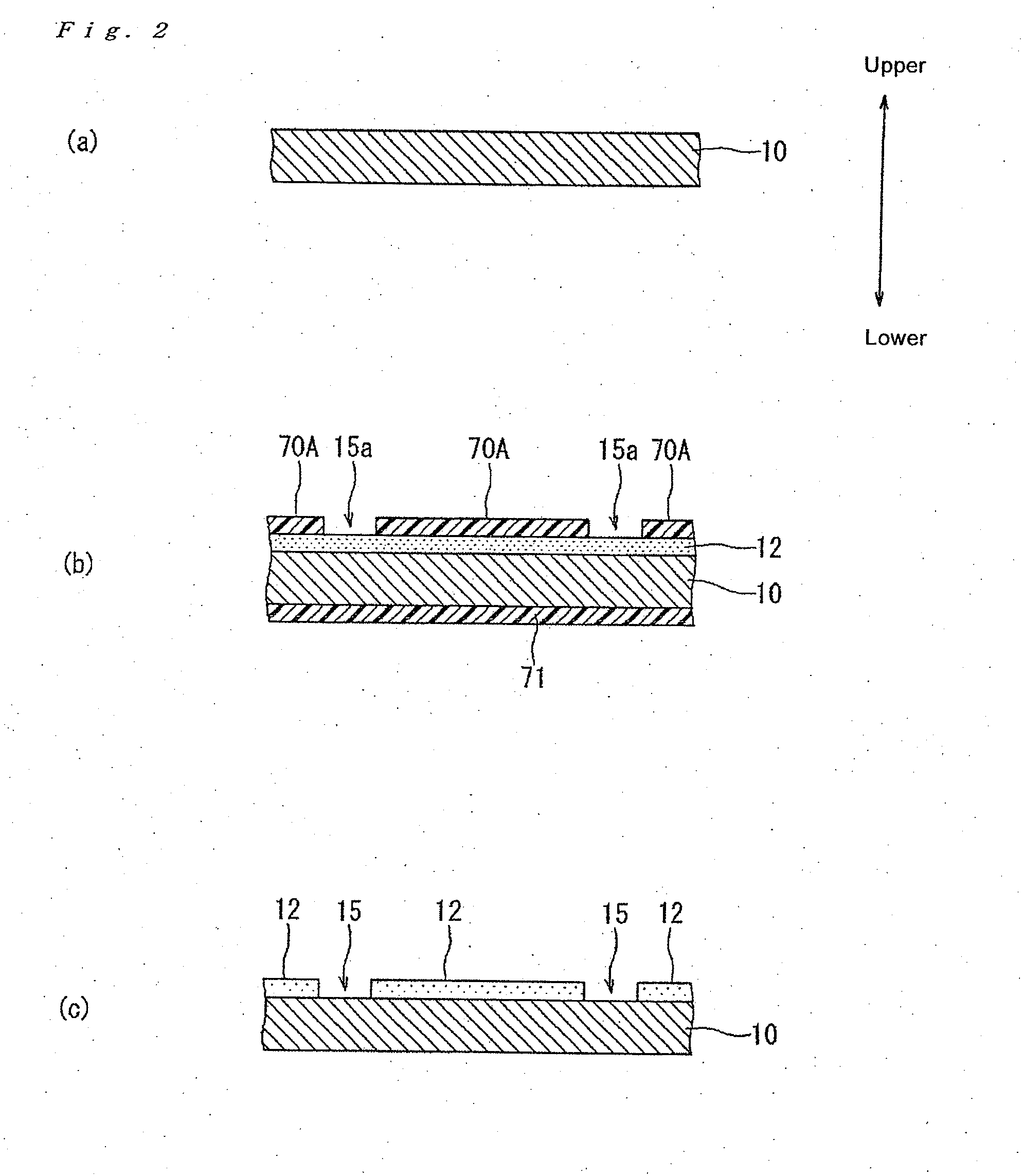

Flexible semiconductor device and method for manufacturing same

ActiveUS20120001173A1Improve performanceSatisfactory productivityTransistorSolid-state devicesEngineeringSemiconductor structure

There is provided a flexible semiconductor device. The flexible semiconductor device of the present invention comprising a support layer, a semiconductor structure portion formed on the support layer, and a resin film formed on the semiconductor structure portion. The resin film comprises an opening formed by a laser irradiation therein, and also an electroconductive member which is in contact with the surface of the semiconductor structure portion is disposed within the opening of the resin film.

Owner:PANASONIC CORP

Image forming apparatus

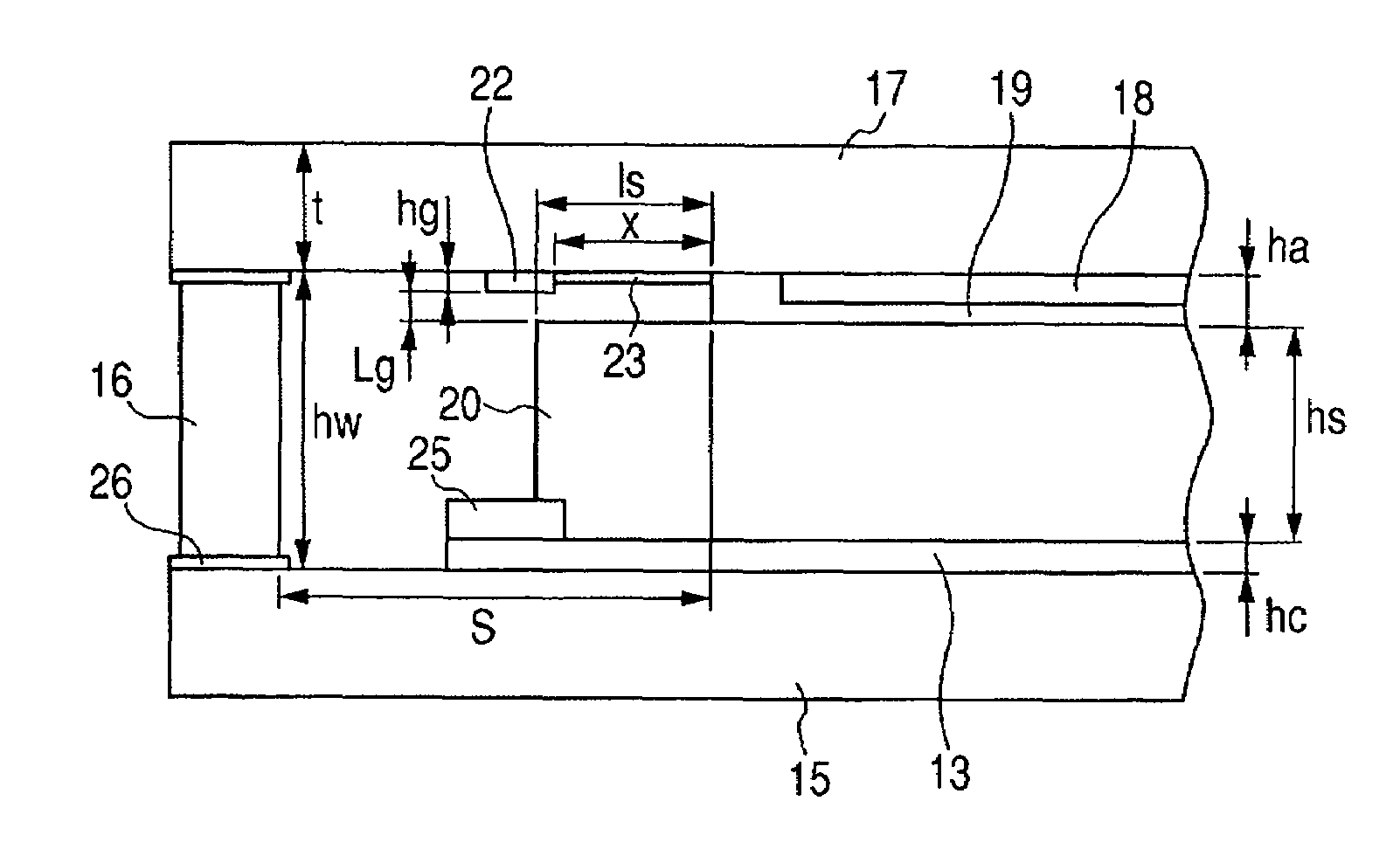

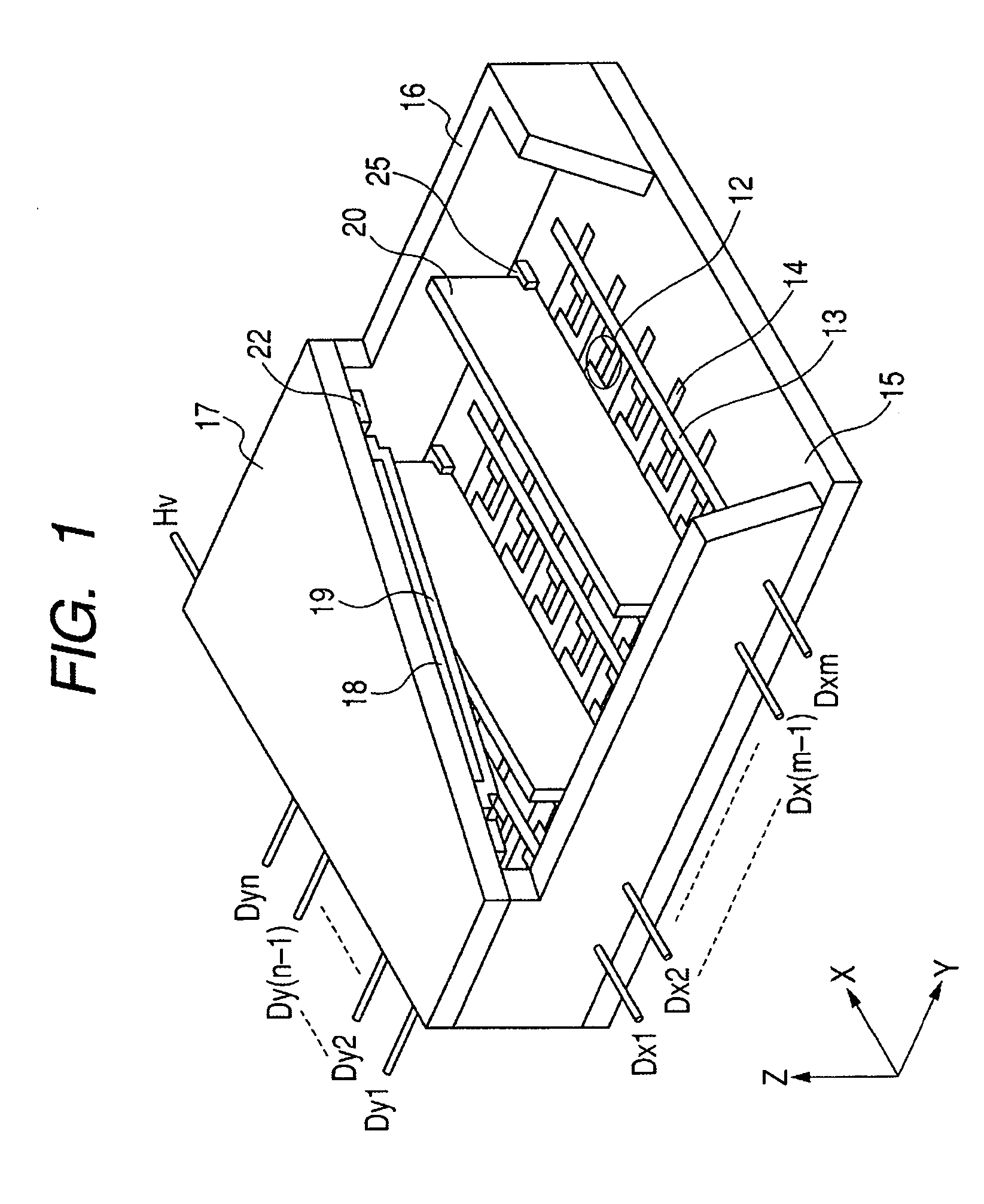

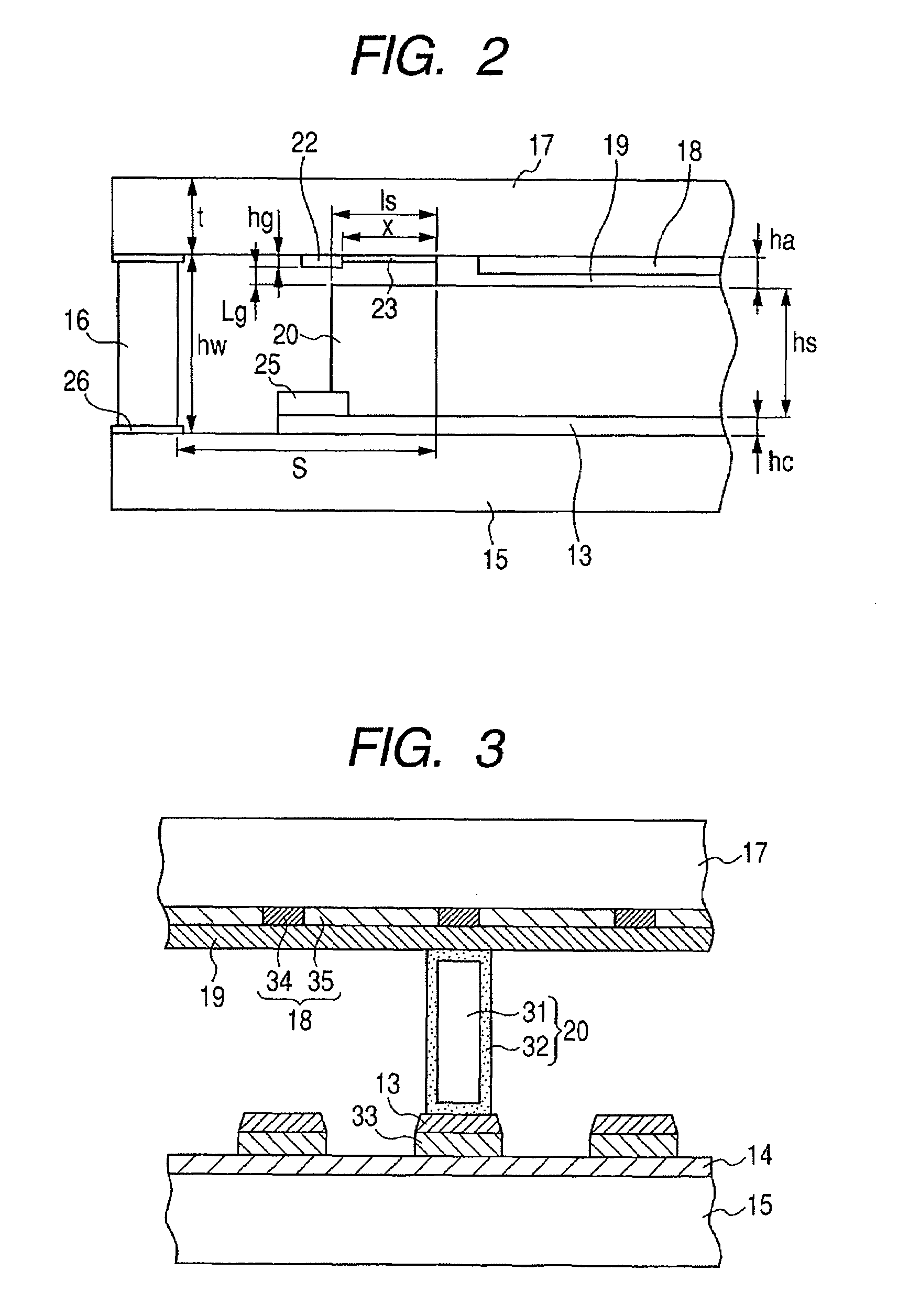

InactiveUS7247981B2Satisfactorily preventedSatisfactory productivityCathode-ray/electron-beam tube vessels/containersAlternating current plasma display panelsImage formationOptoelectronics

In an image forming apparatus utilizing an electron emitting device, a guard electrode for preventing a creepage discharge from an anode electrode is provided without causing an abnormal discharge with a spacer. A guard electrode positioned at a predetermined distance (x) from a metal back constituting an anode electrode is positioned at such a distance (Lg) from a spacer as not to cause a discharge according to a ratio (x / hs) of the distance x and a height (hs) of a spacer.

Owner:CANON KK

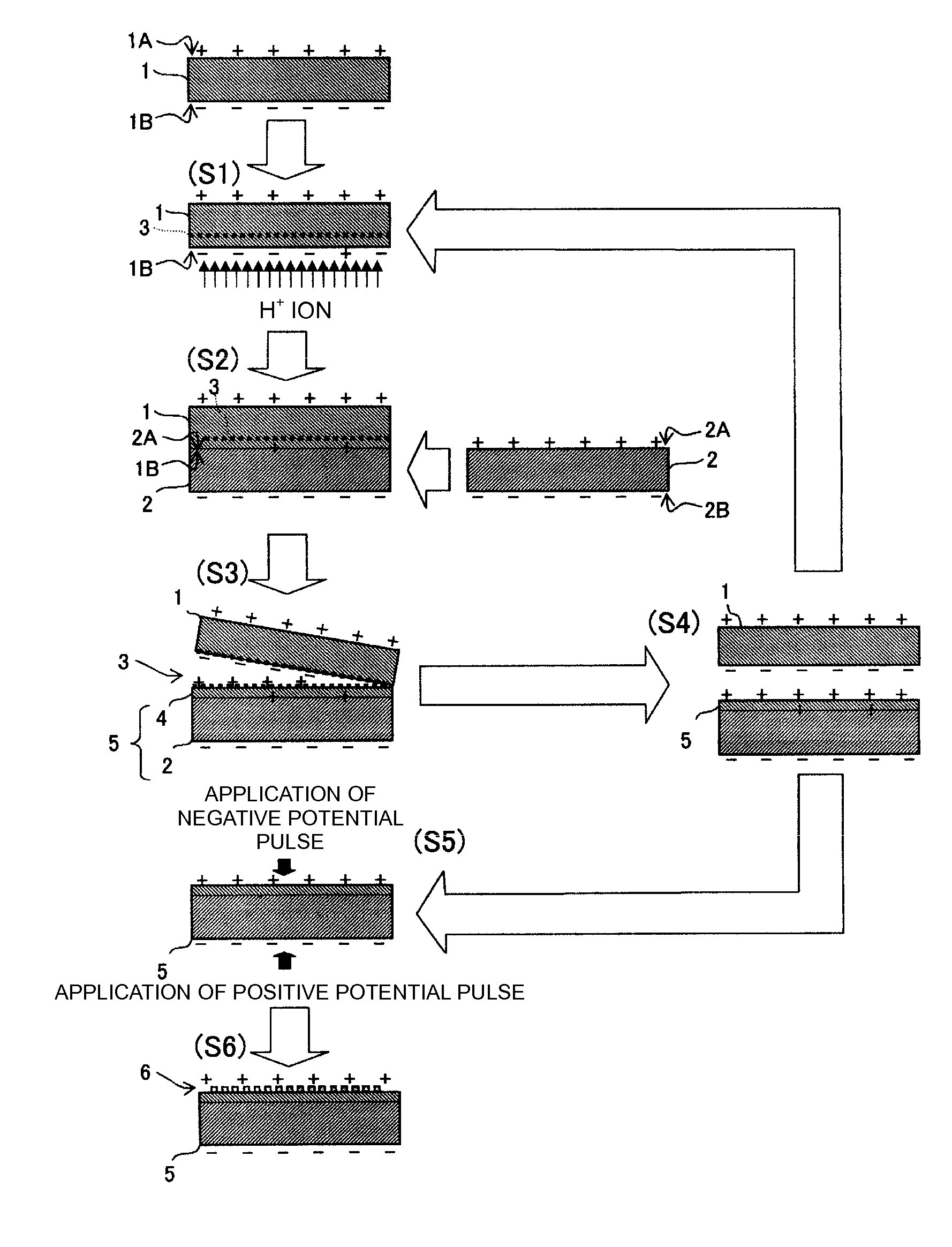

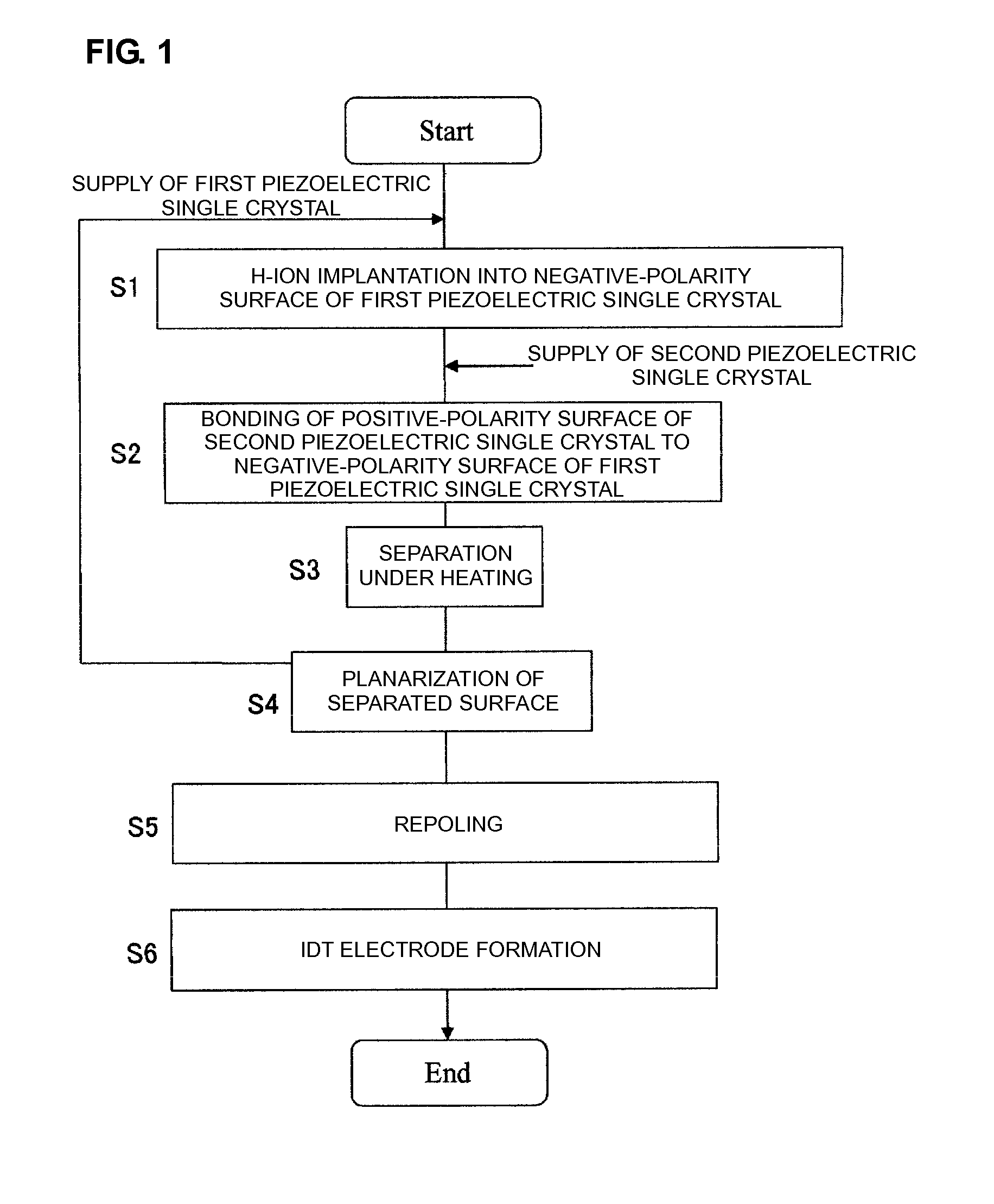

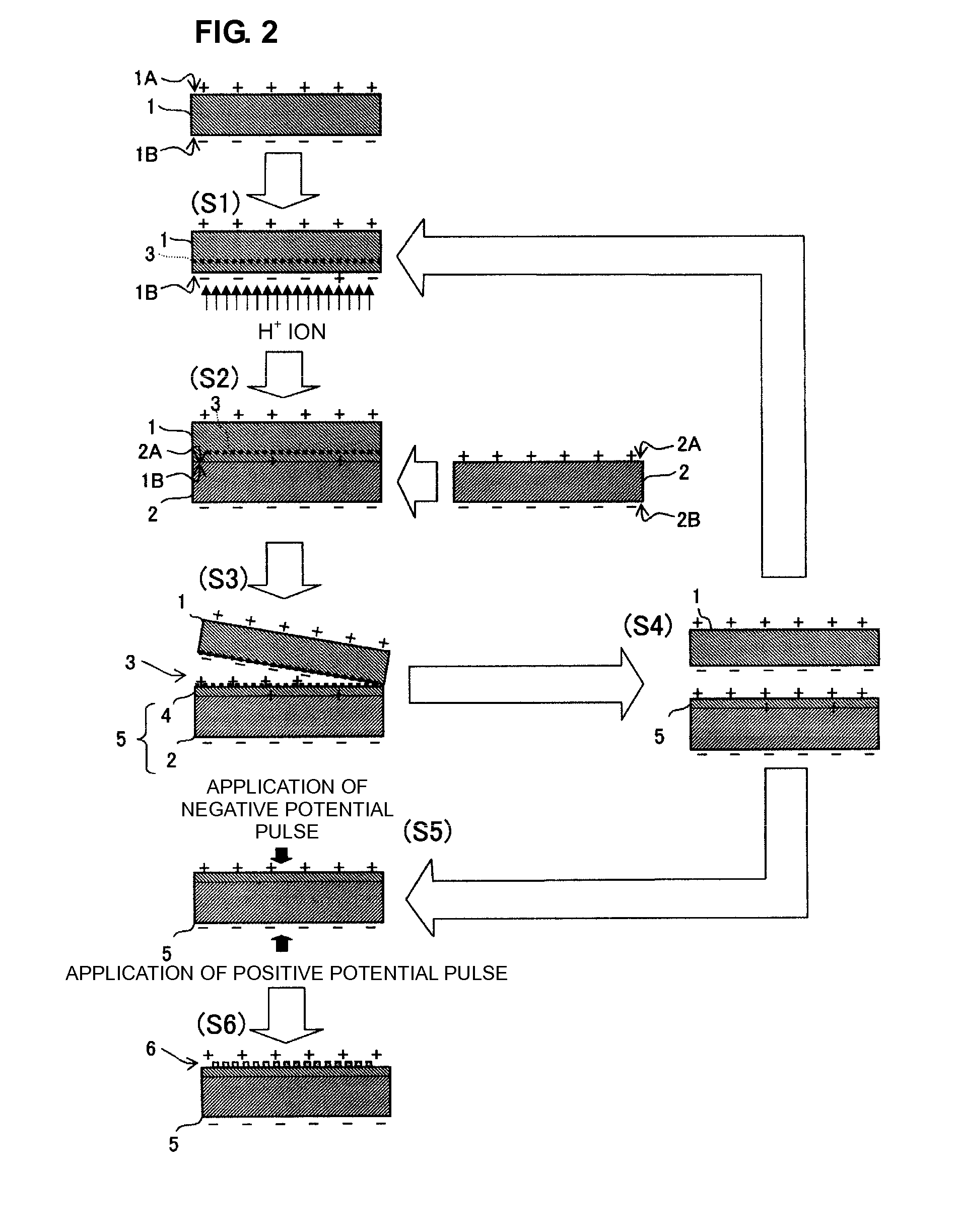

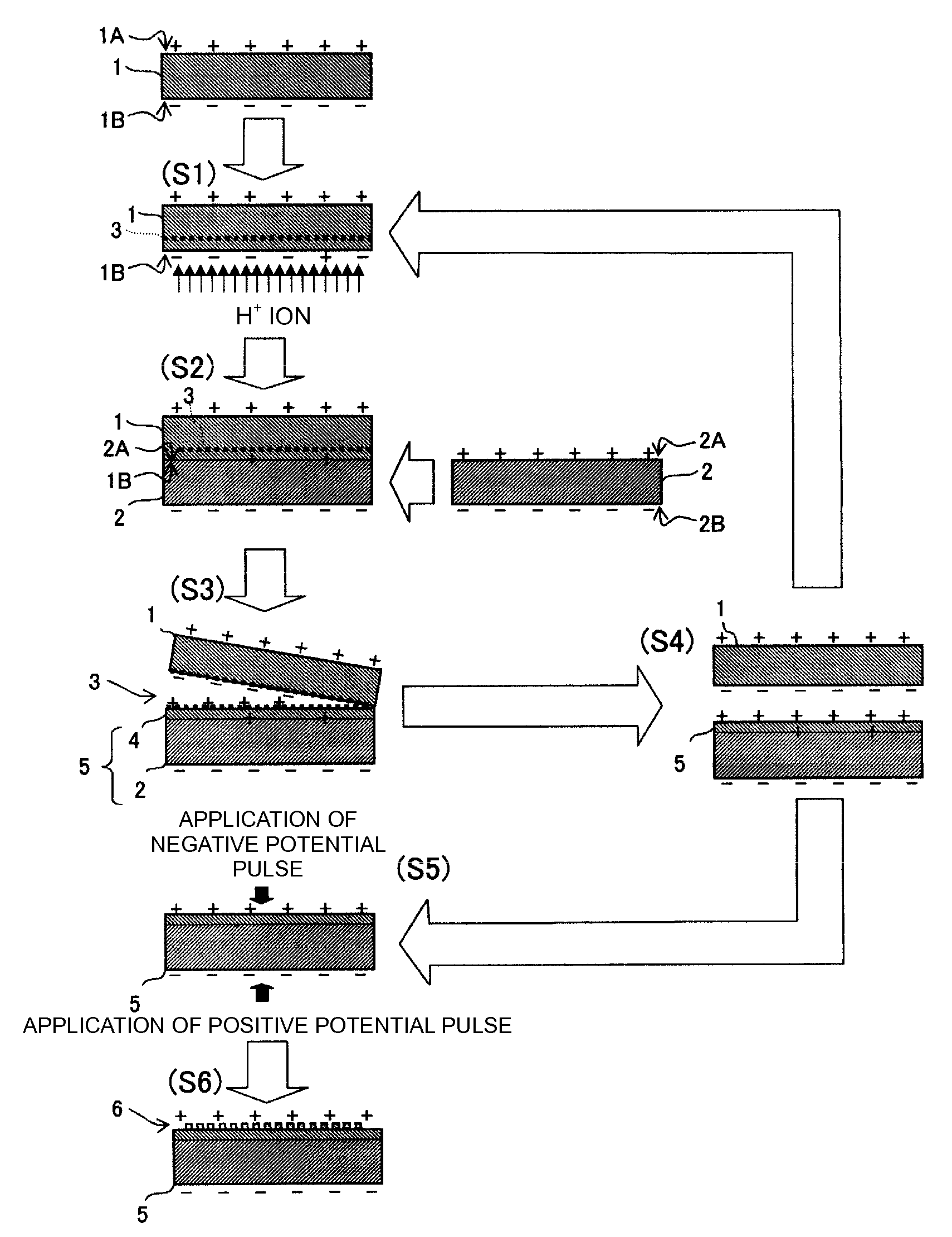

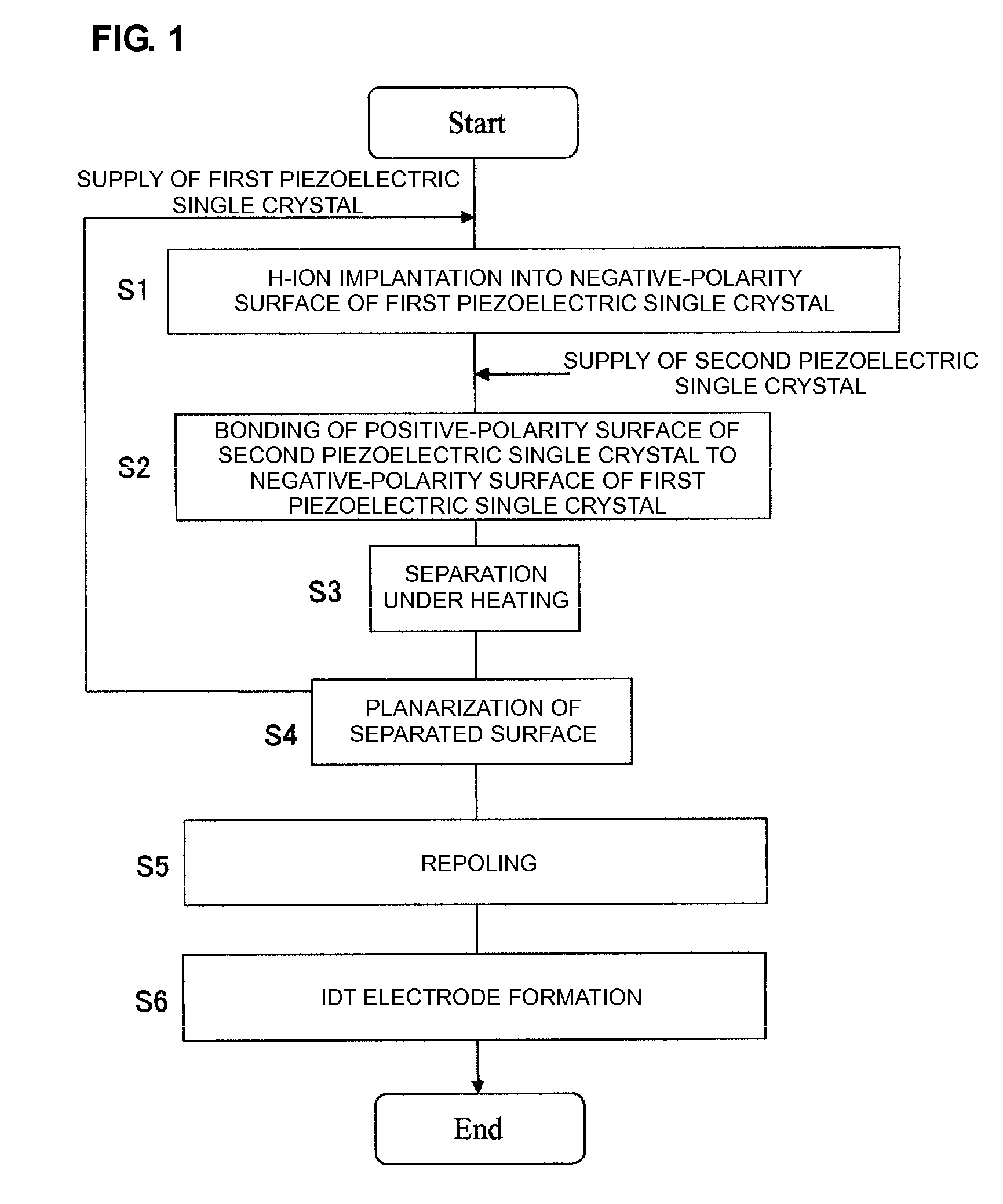

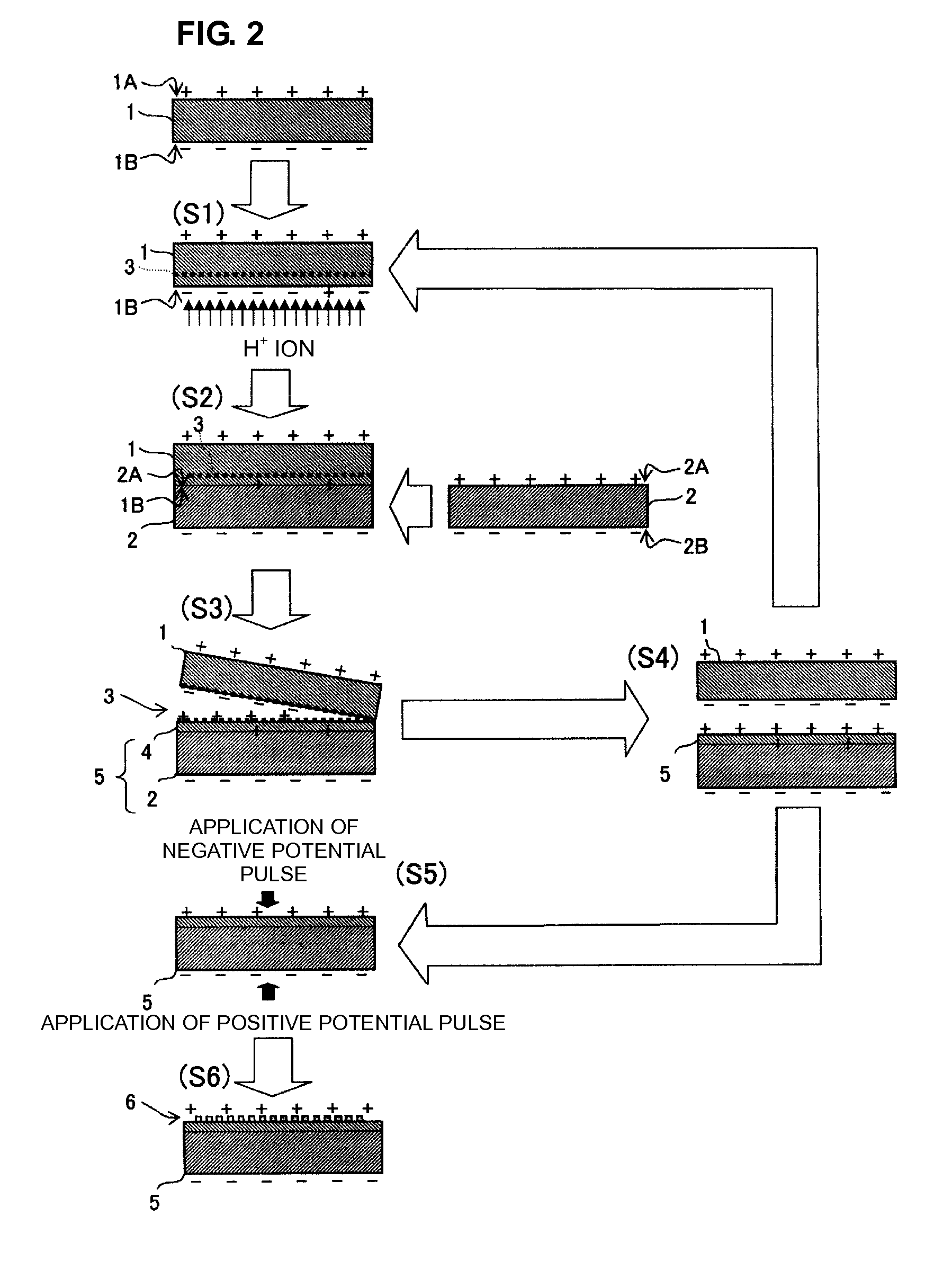

Method for producing piezoelectric composite substrate and method for producing piezoelectric element

ActiveUS20110220275A1Improve productivityLittle pyroelectricityPiezoelectric/electrostrictive device manufacture/assemblyAfter-treatment detailsProduction rateSingle crystal

A method for producing a piezoelectric composite substrate with satisfactory productivity controls the inclination of the crystal axis and the polar axis of a single-crystal thin film and prevents an adverse effect due to pyroelectricity in a production process. The method for producing a piezoelectric composite substrate provided with a plurality of piezoelectric materials includes an ion-implantation step, a bonding step, and a separation step. In the ion-implantation step, H+ ions are implanted into a piezoelectric single crystal material. In the bonding step, the piezoelectric single crystal material is bonded to a piezoelectric single crystal material. At this time, the polarity of the polar surface of the piezoelectric single crystal material is opposite to the polarity of the polar surface of the piezoelectric single crystal material, the polar surfaces being bonded to each other. In the separation step, a separation layer of the piezoelectric single crystal material is divided by heating to separate a piezoelectric single-crystal thin film.

Owner:MURATA MFG CO LTD

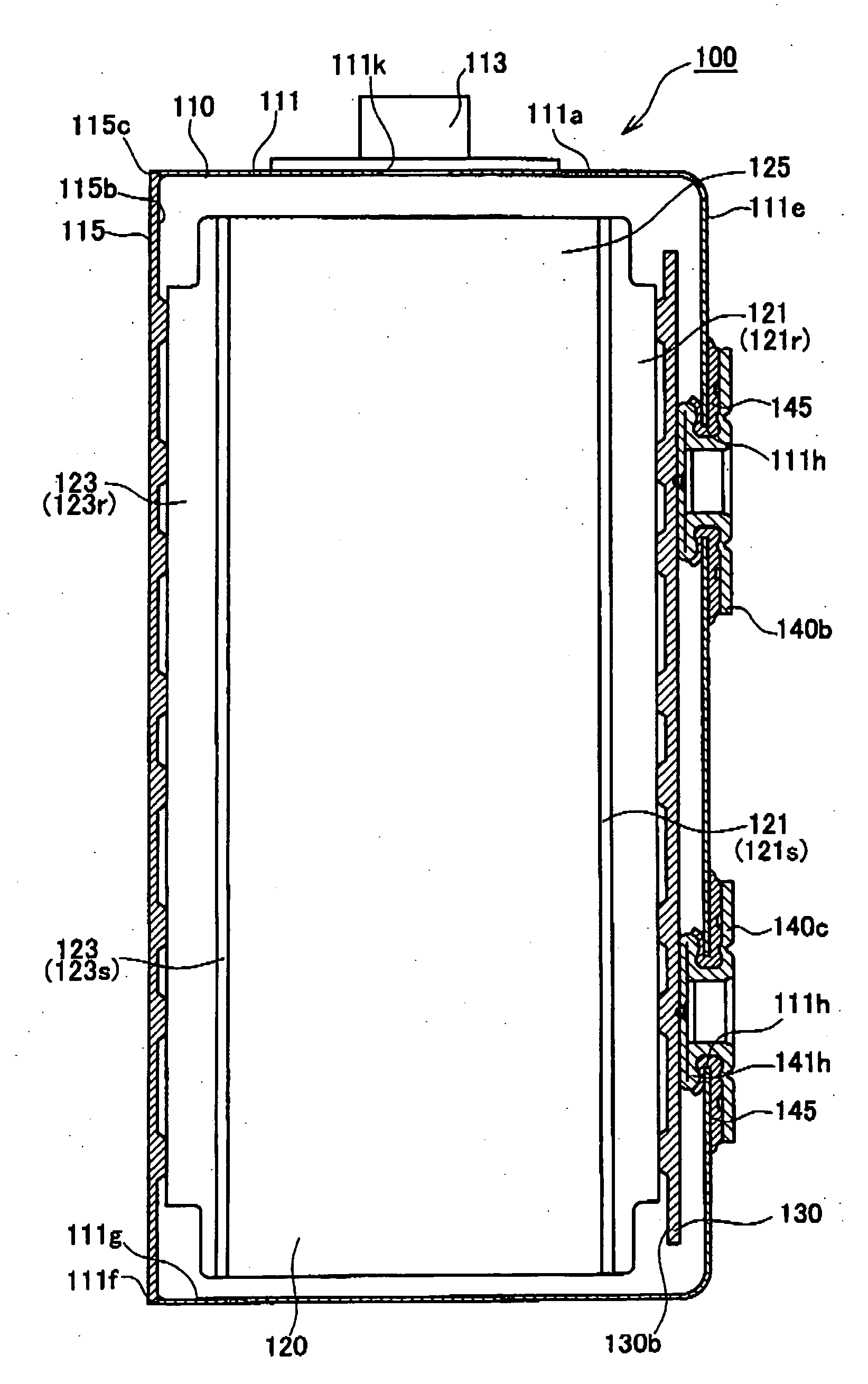

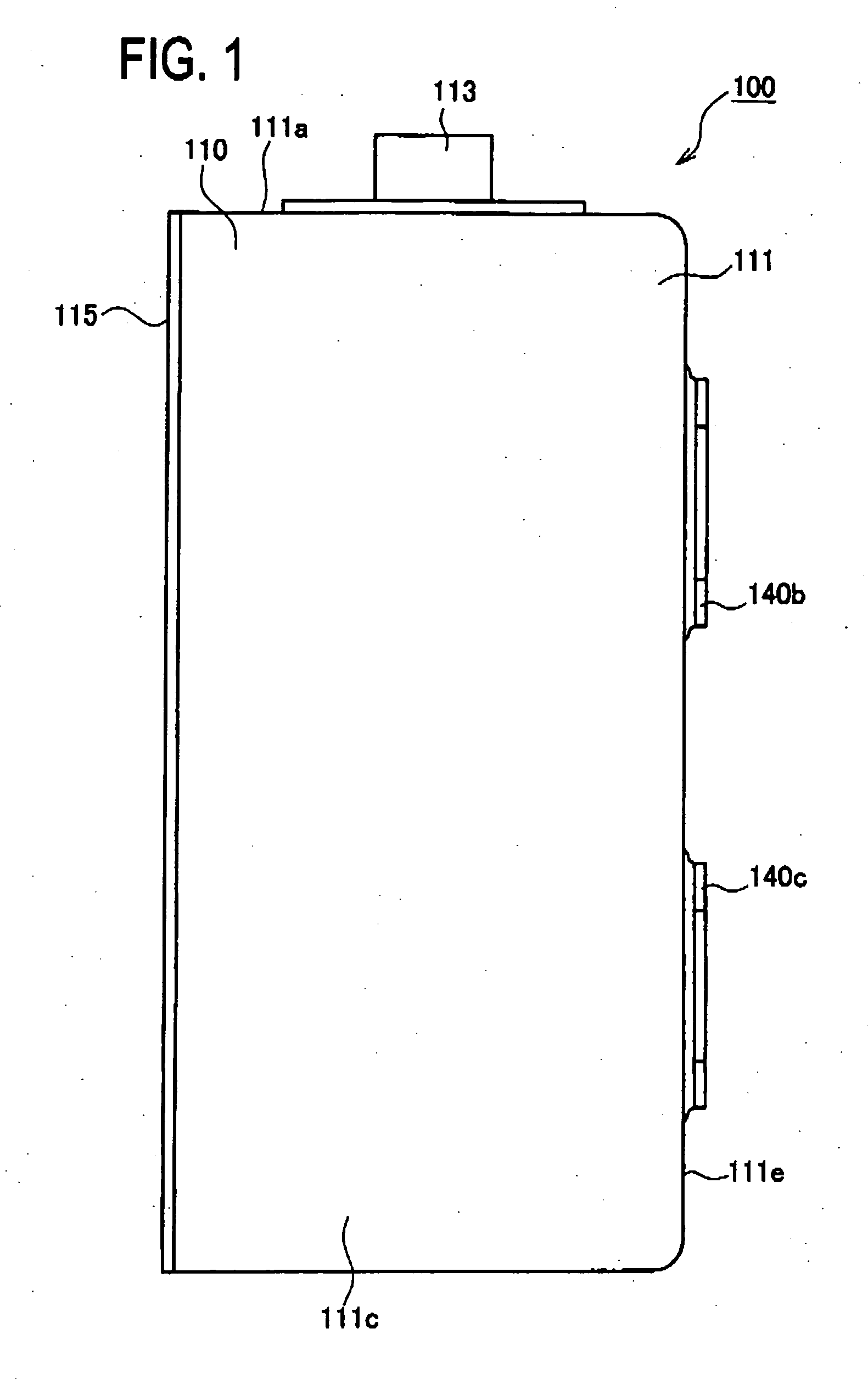

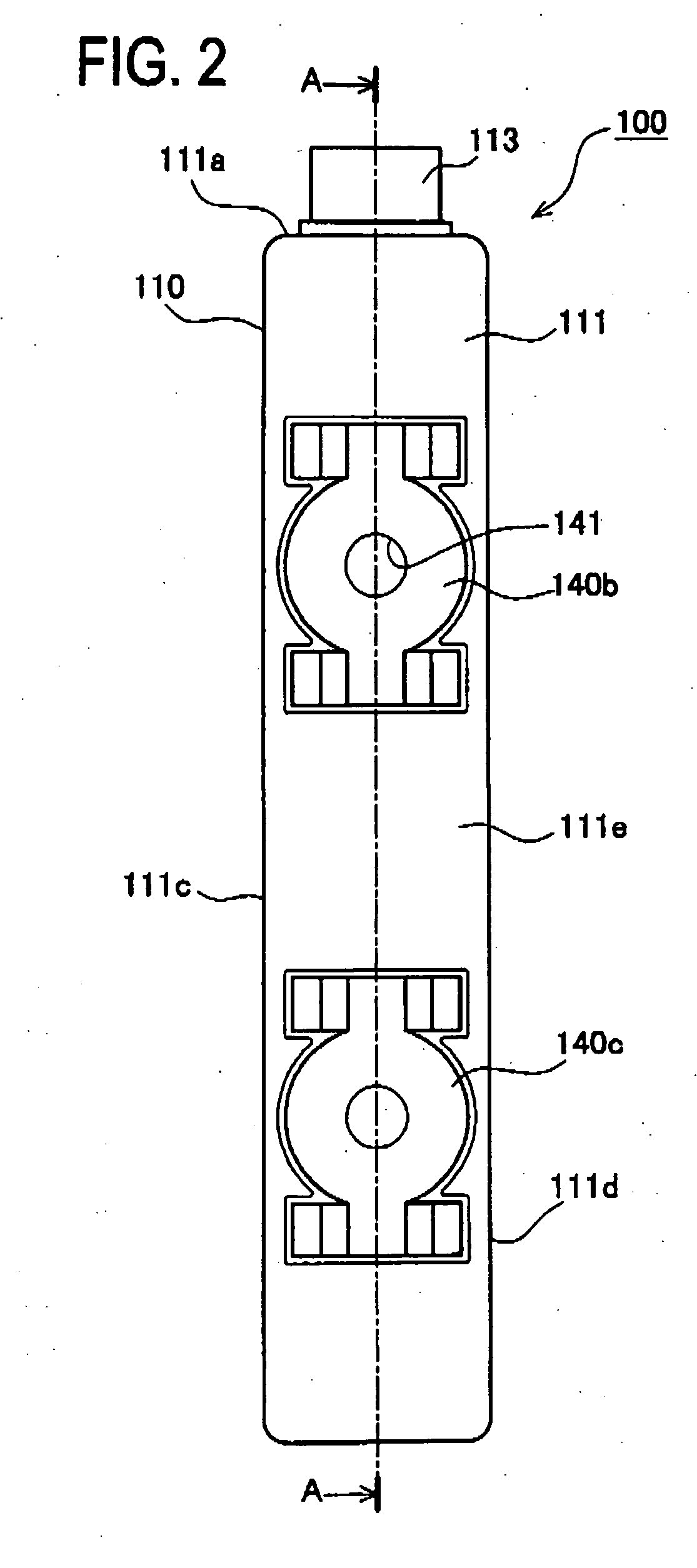

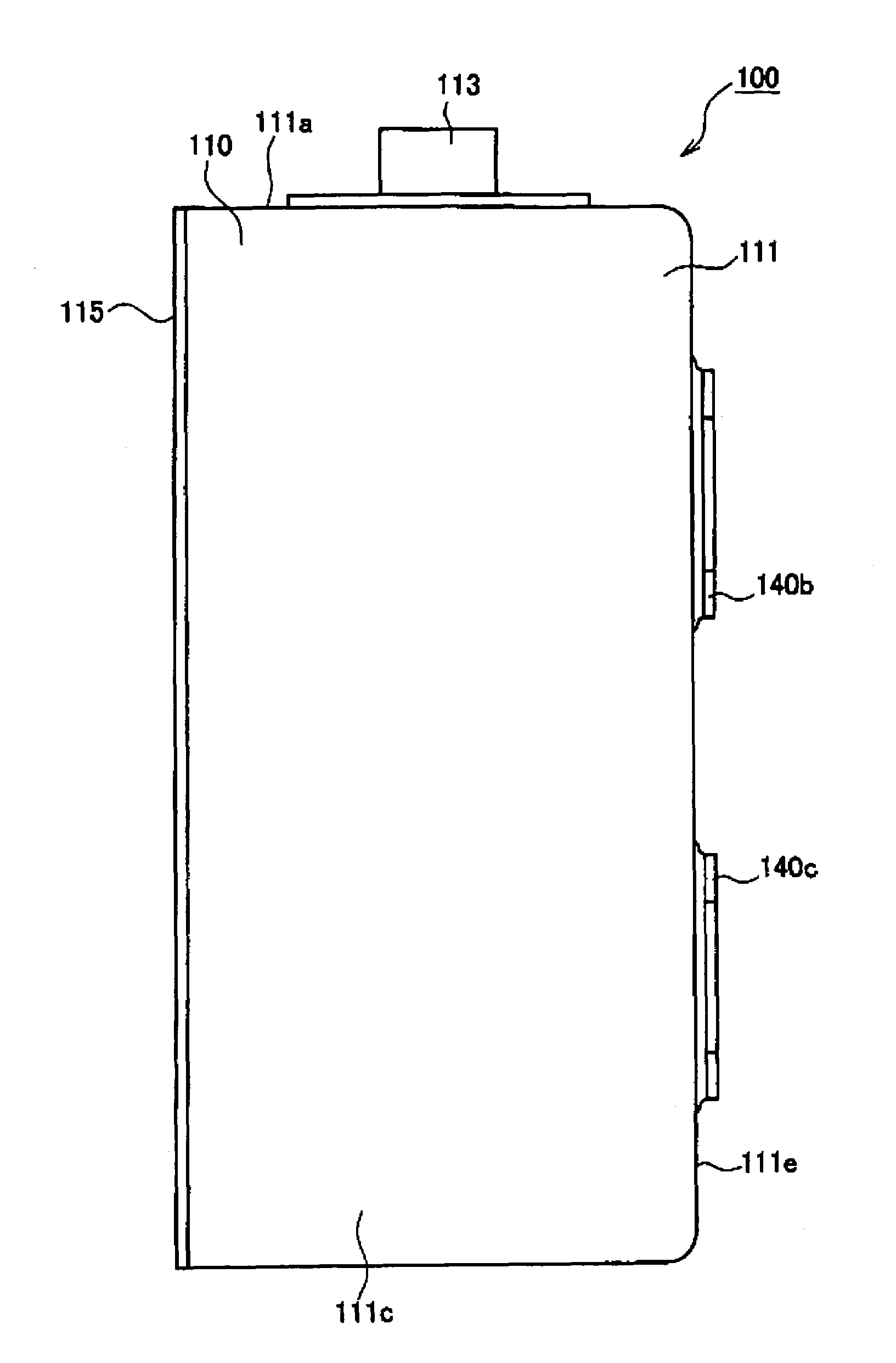

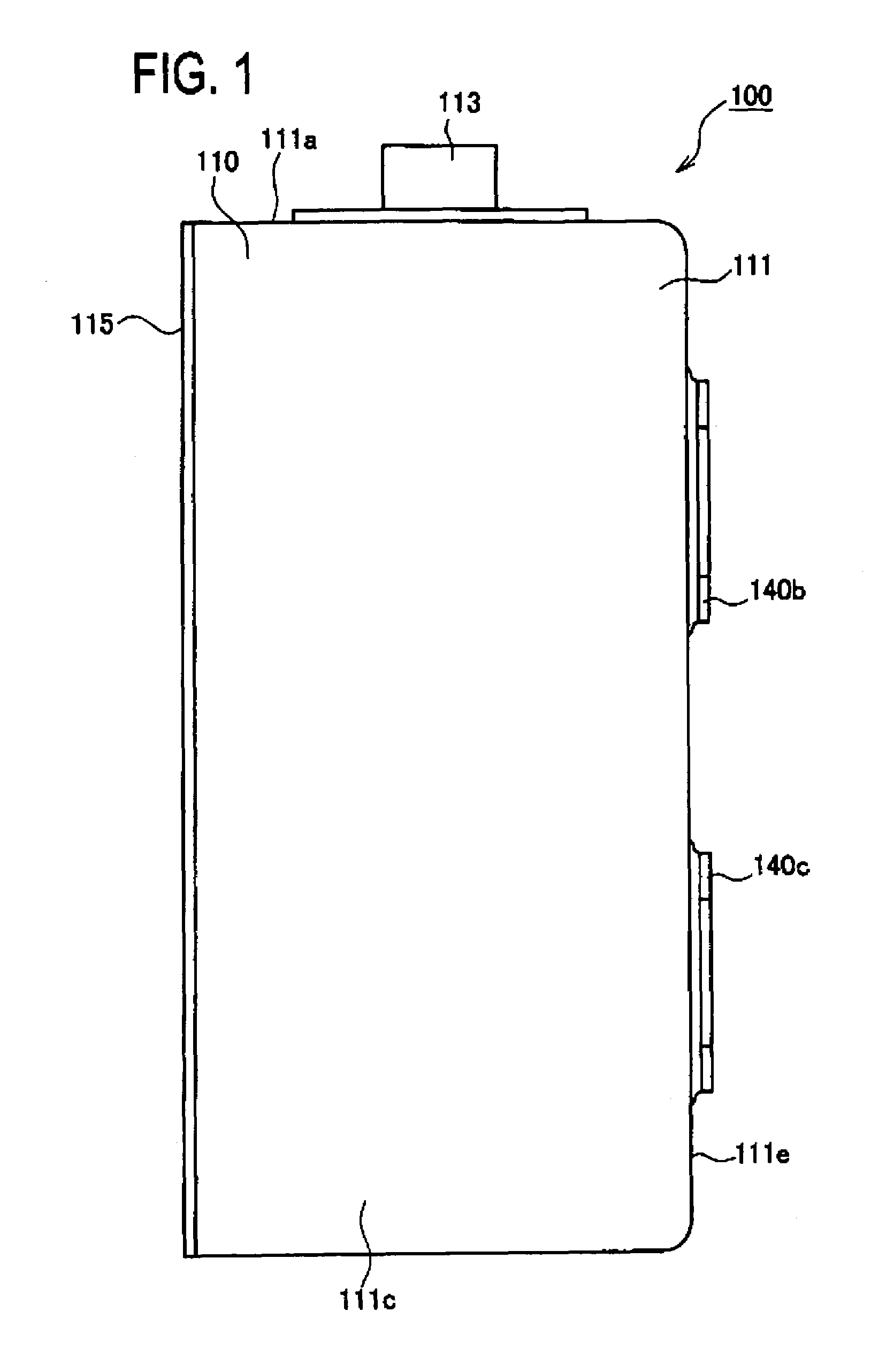

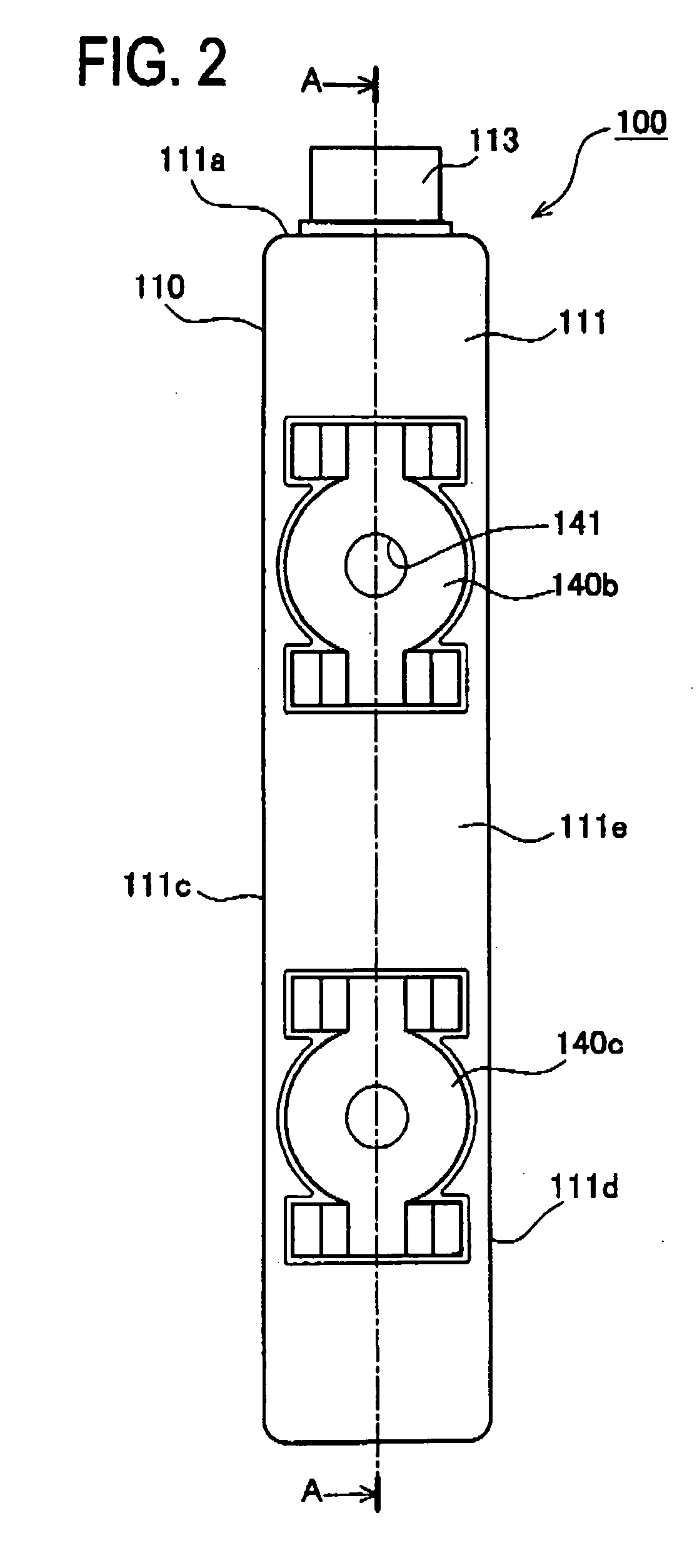

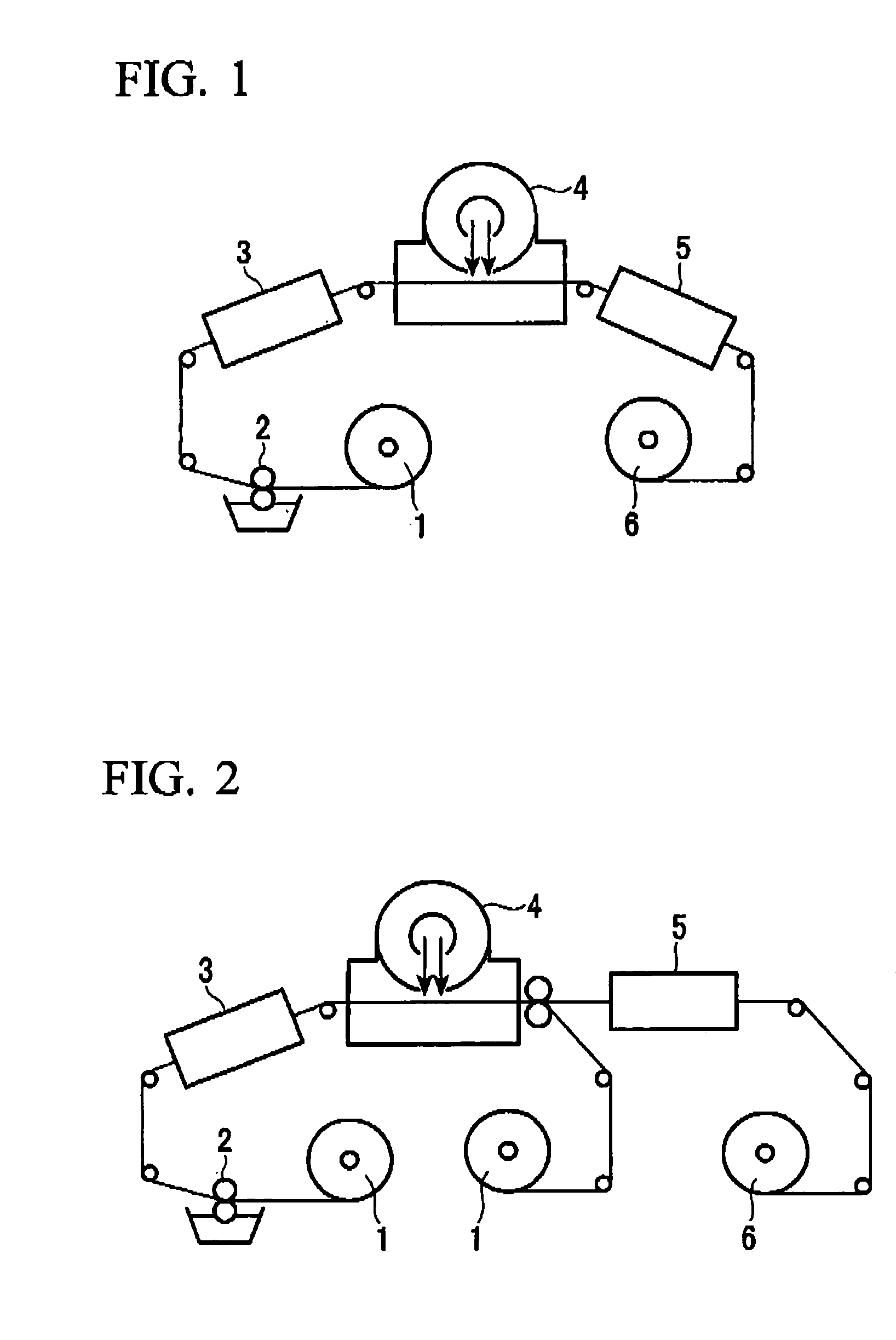

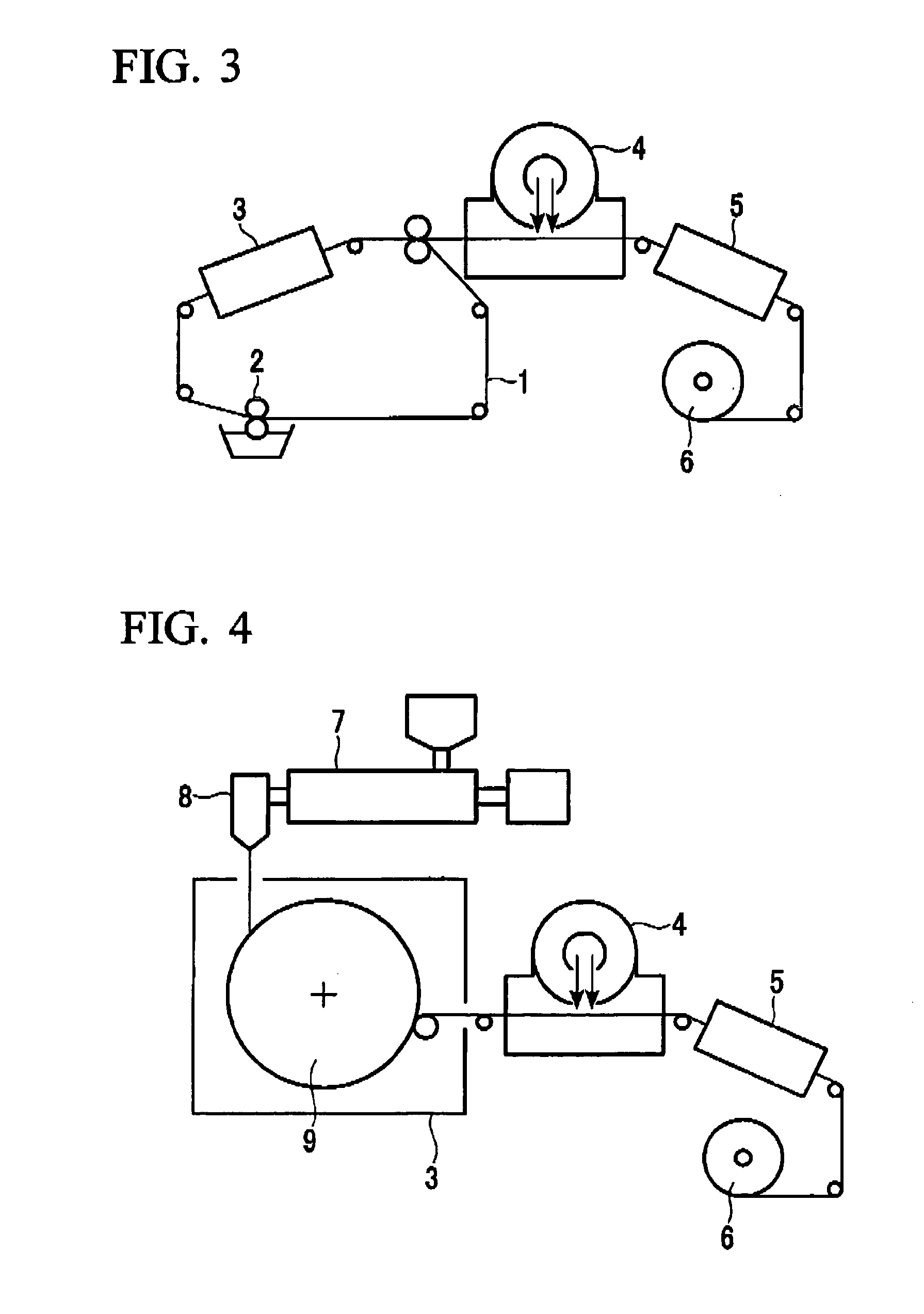

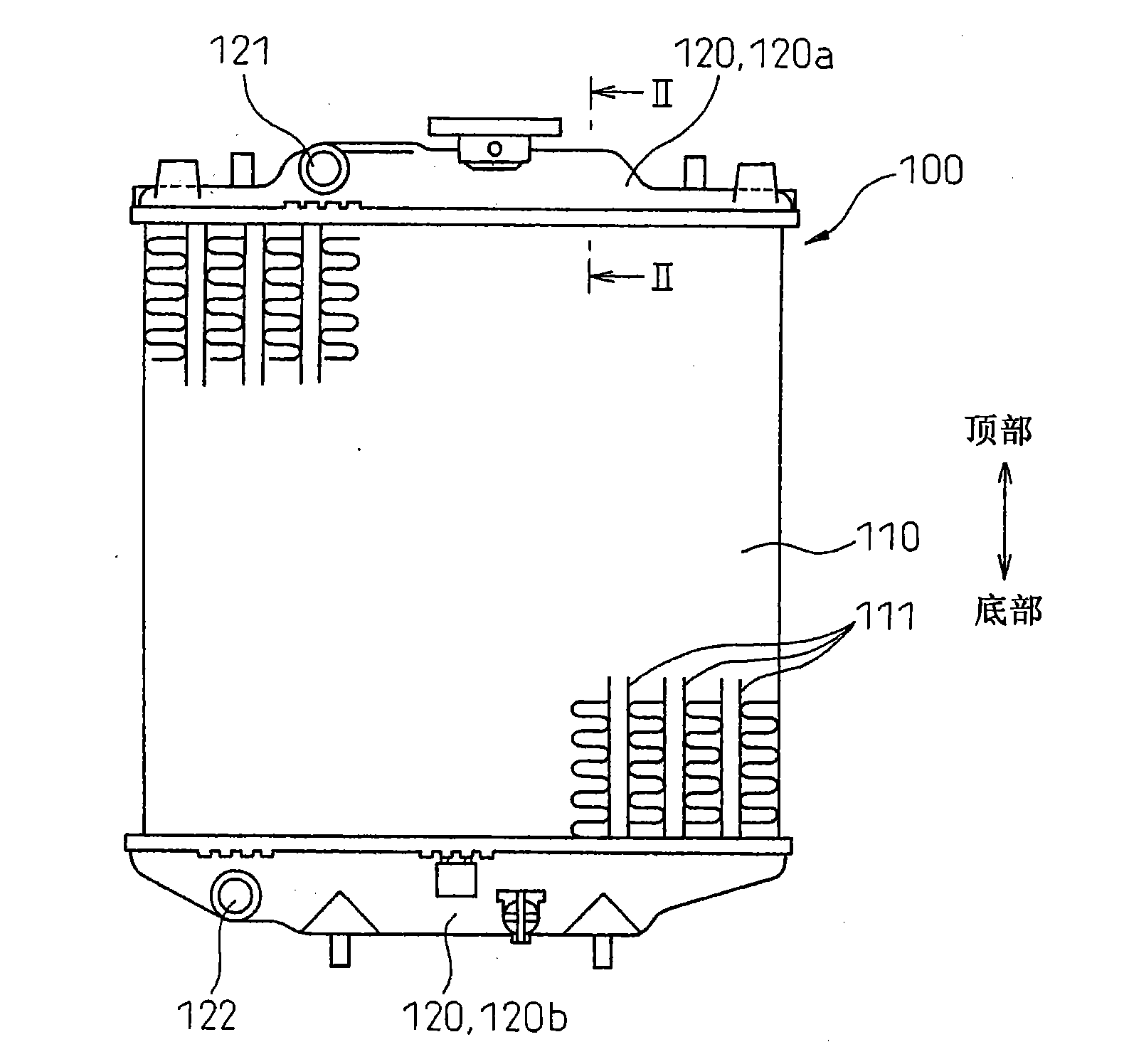

Manufacturing method of secondary battery, restraining jig for secondary battery, charging/discharging device for secondary battery, and charging device for secondary battery

ActiveUS20060200972A1Low costSwiftlyBatteries circuit arrangementsFinal product manufactureInternal pressureElectrical and Electronics engineering

A manufacturing method of a secondary battery according to the present invention includes a charging / discharging process wherein the secondary battery is arranged to a restraining jig, that restricts an expansion caused on the battery case with respect to at least a part of the battery case and that is configured to be removable from a charging / discharging device with the secondary battery arranged thereto regardless of the magnitude of the internal pressure in the secondary battery; a charging / discharging is performed to the secondary battery with the restraining jig mounted to the charging / discharging device; and after the completion of the charging / discharging, the restraining jig is removed from the charging / discharging device with the secondary battery arranged to the restraining jig.

Owner:TOYOTA JIDOSHA KK

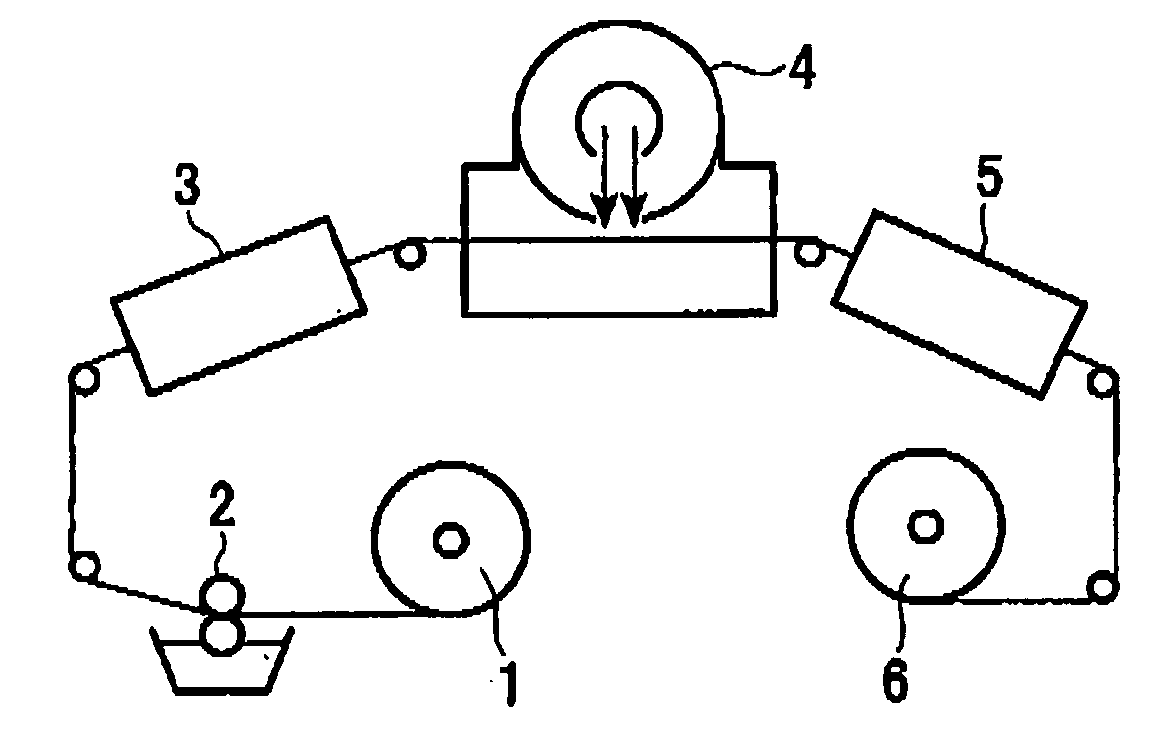

Manufacturing method of secondary battery, restraining jig for secondary battery, charging/discharging device for secondary battery, and charging device for secondary battery

ActiveUS7586288B2Fast charge and dischargeSatisfactory productivityBatteries circuit arrangementsFinal product manufactureInternal pressureEngineering

A manufacturing method of a secondary battery according to the present invention includes a charging / discharging process wherein the secondary battery is arranged to a restraining jig, that restricts an expansion caused on the battery case with respect to at least a part of the battery case and that is configured to be removable from a charging / discharging device with the secondary battery arranged thereto regardless of the magnitude of the internal pressure in the secondary battery; a charging / discharging is performed to the secondary battery with the restraining jig mounted to the charging / discharging device; and after the completion of the charging / discharging, the restraining jig is removed from the charging / discharging device with the secondary battery arranged to the restraining jig.

Owner:TOYOTA JIDOSHA KK

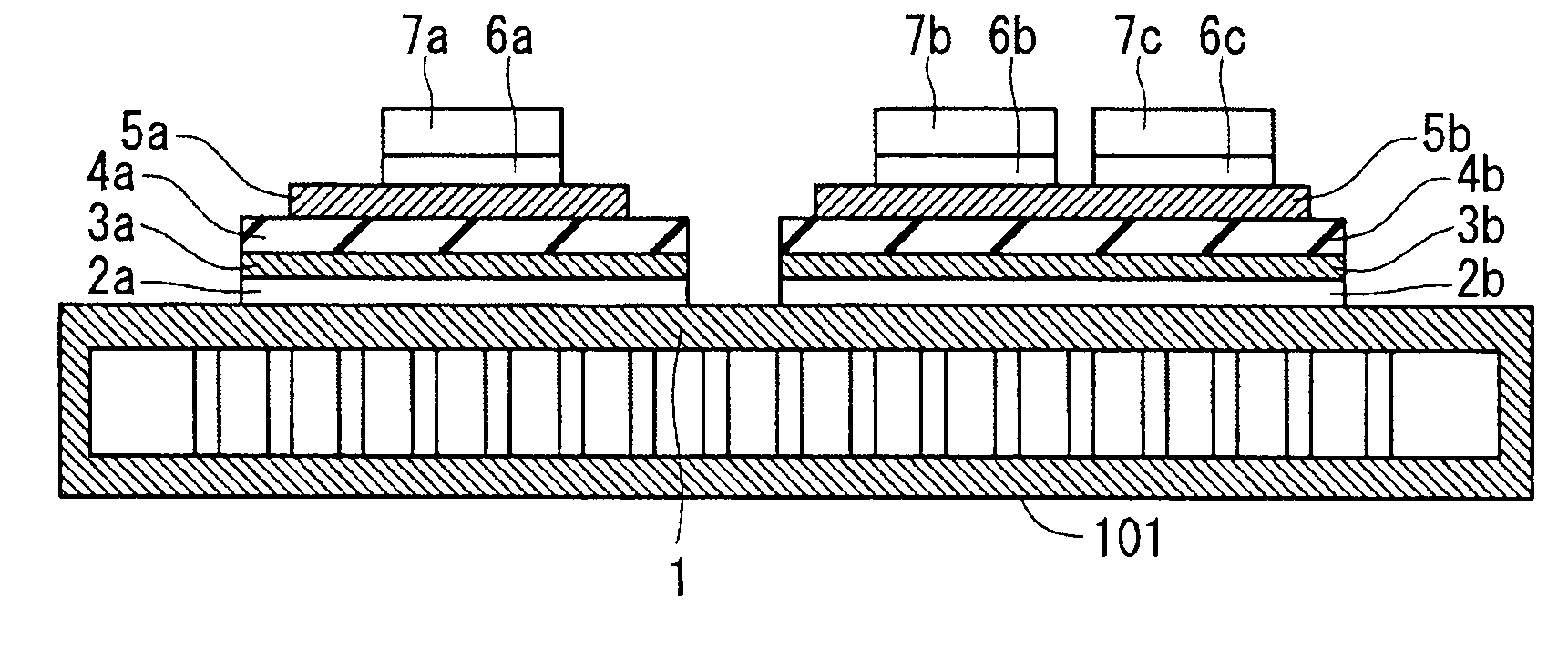

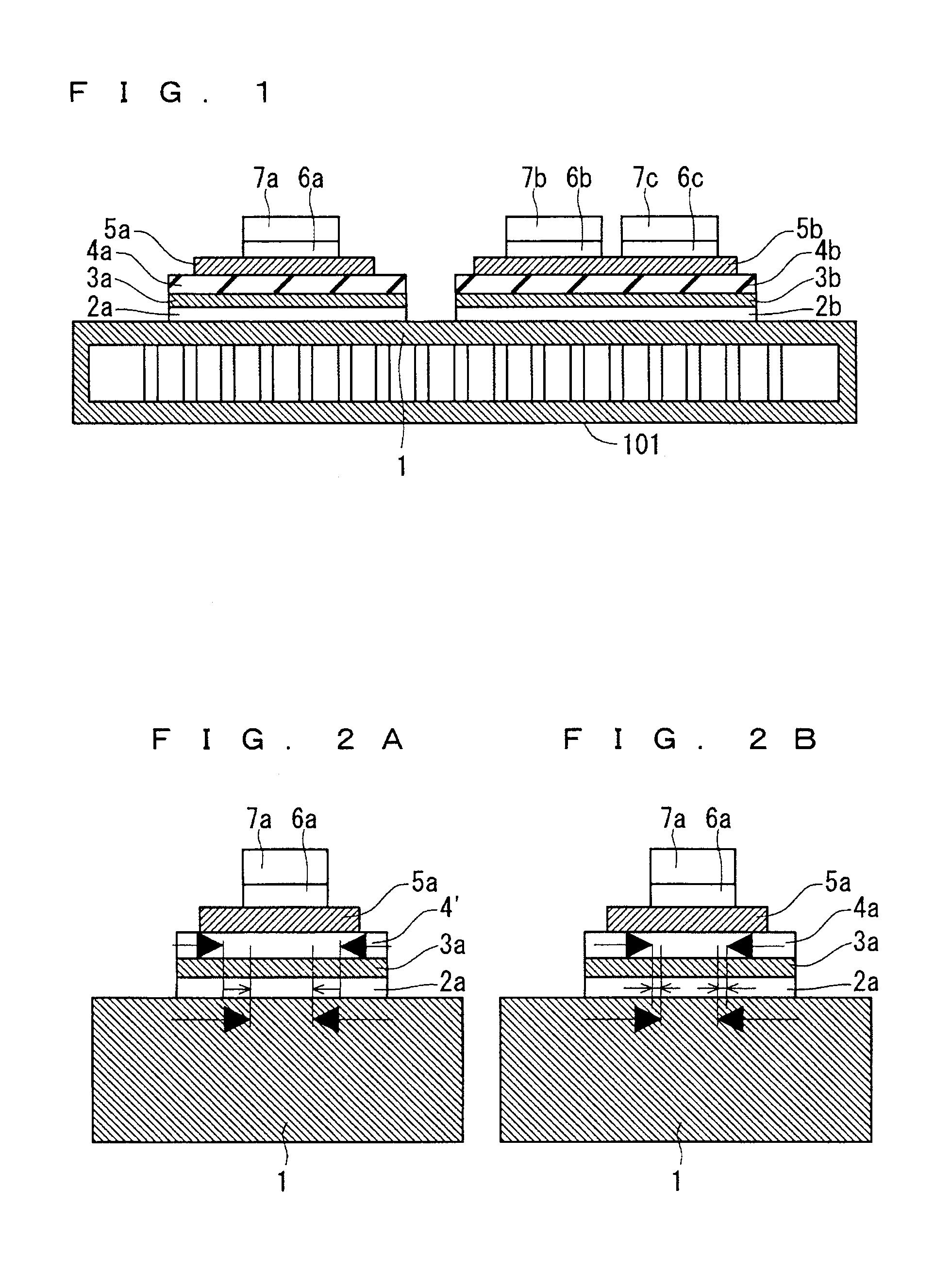

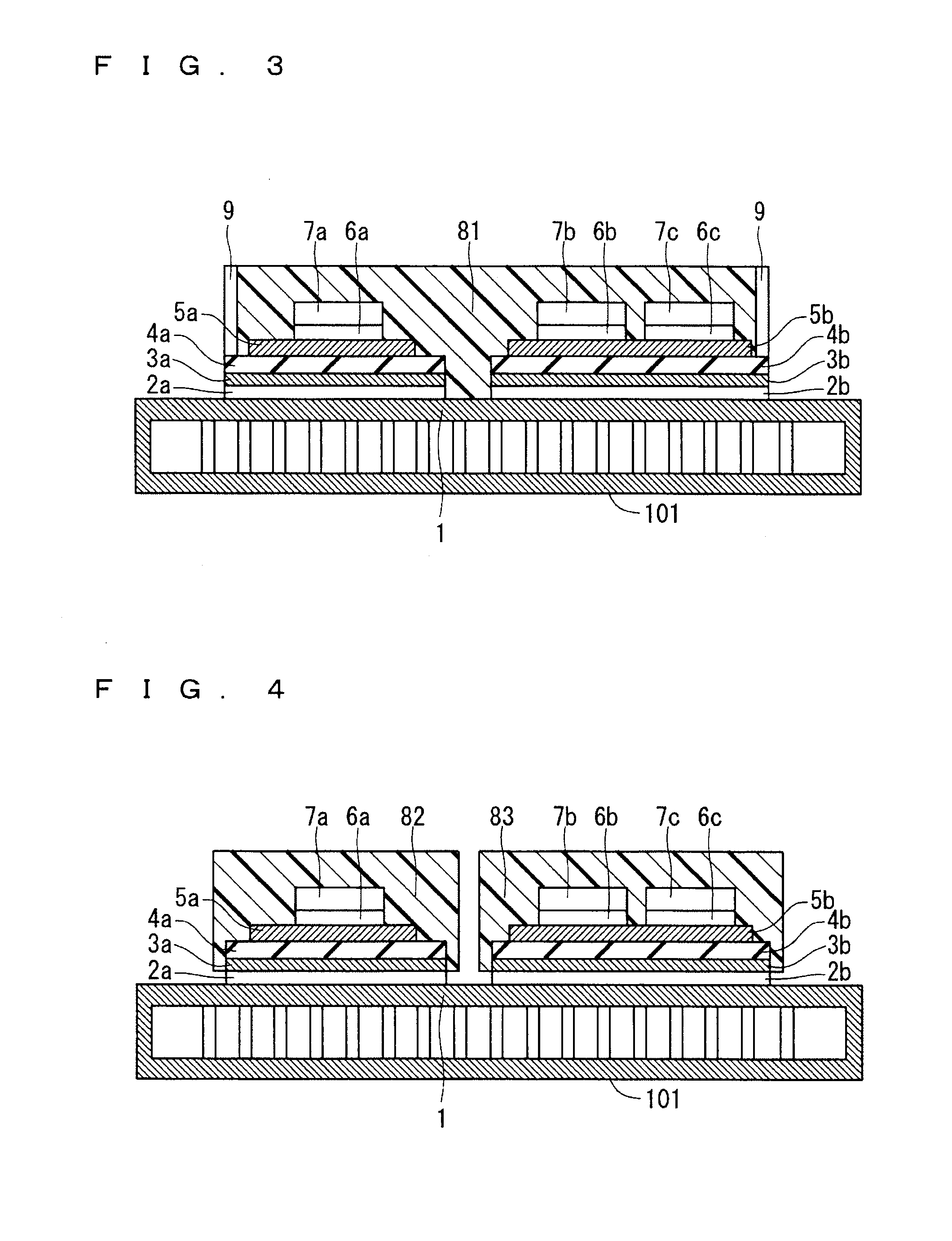

Semiconductor device and method of manufacturing the same

InactiveUS20120138946A1Reliably responding to temperature changeSatisfactory productivitySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceMaterials science

A semiconductor device includes a cooler having a main surface constructed of a metal base, joined layers fixed on the metal base through joining layers, insulating layers fixed on the joined layers and which contain an organic resin as a base material, metal layers provided on the insulating layers, and semiconductor elements provided on the metal layers. A stacked structure with the joined layers, the insulating layers, and the metal layers is divided into parts containing one or the plurality of semiconductor elements, and is fixed through the joining layers on the metal base.

Owner:MITSUBISHI ELECTRIC CORP

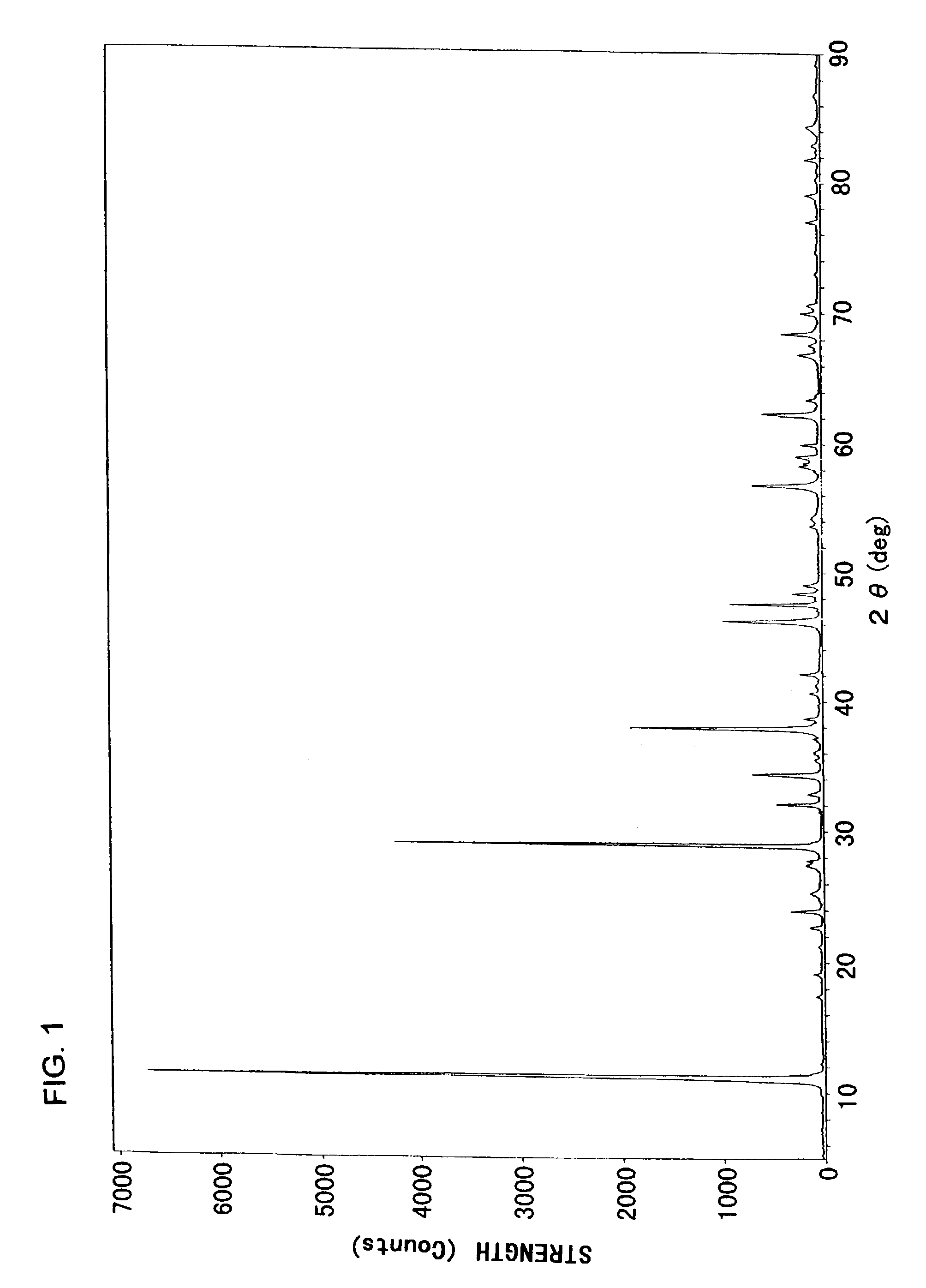

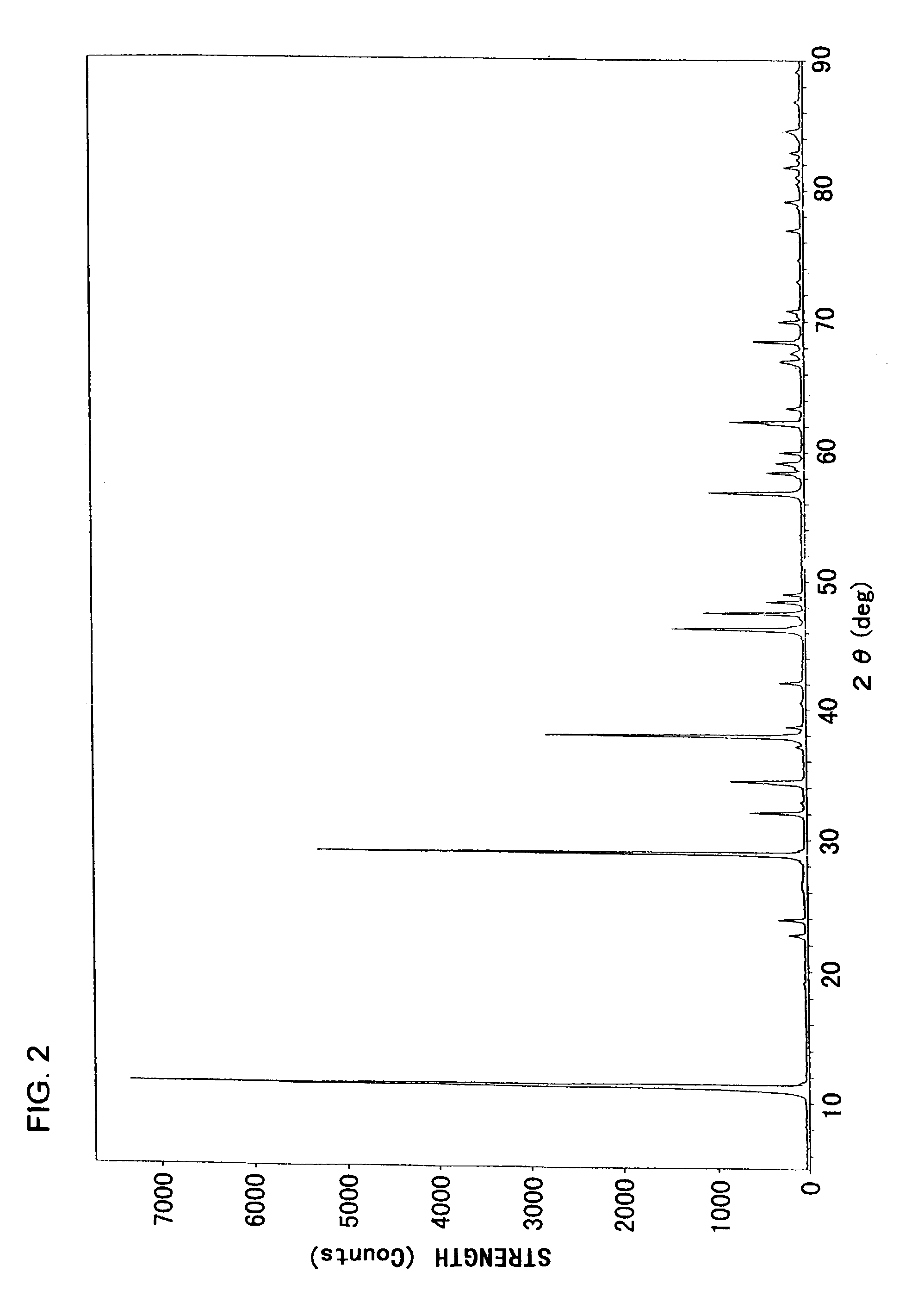

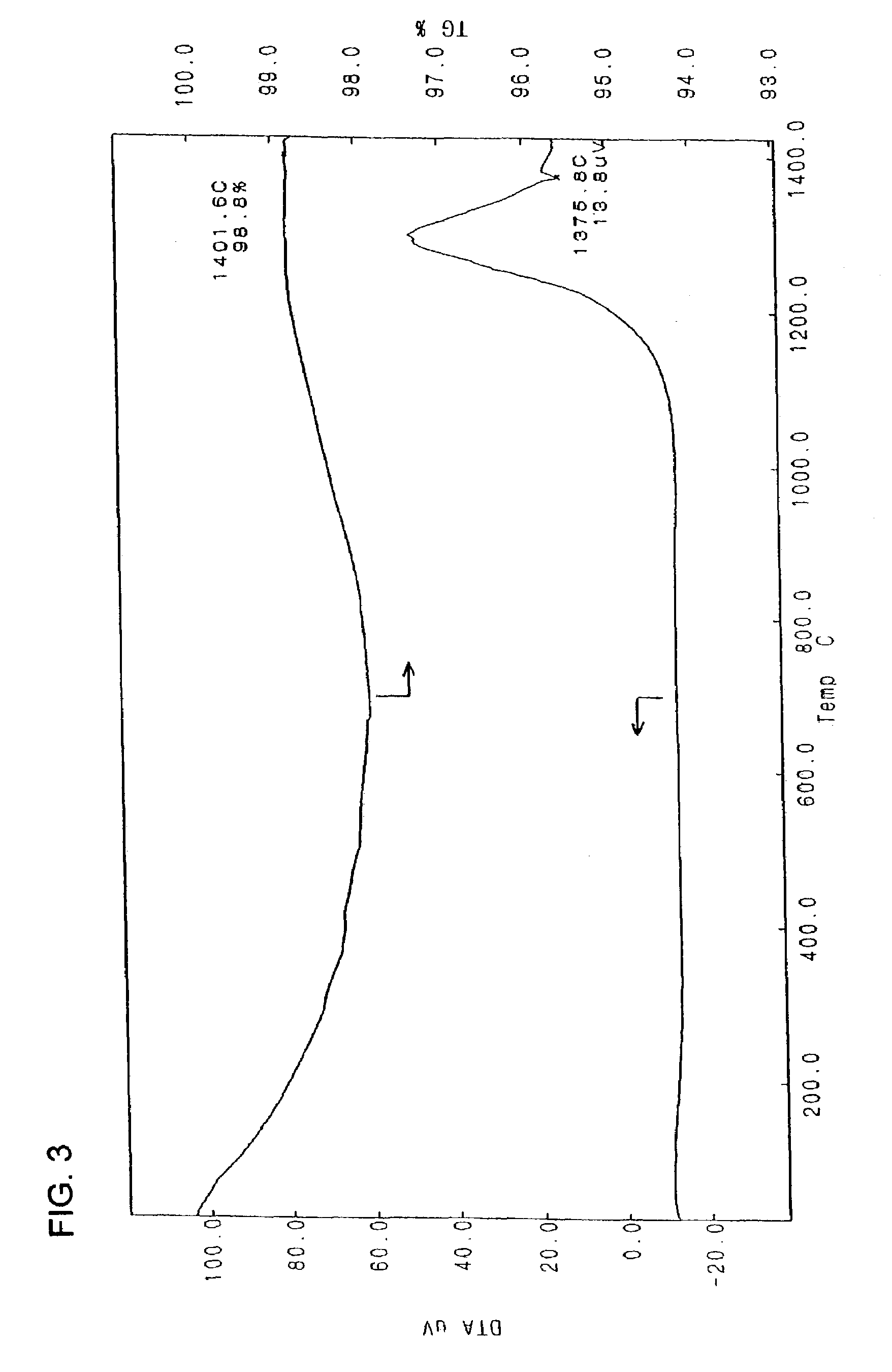

Lepidocrocite potassium magnesium titanate, method for manufacturing the same and friction material

InactiveUS7307047B2Improve propertiesIncrease resistanceOther chemical processesBearing componentsAcid treatmentPotassium

Lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.2-0.7Mg0.4Ti1.6O3.7-4 and obtainable by subjecting an aqueous slurry of lepidocrocite potassium magnesium titanate having a composition represented by the formula K0.8Mg0.4Ti1.6O4 to an acid treatment and subsequent calcination.

Owner:OTSUKA CHEM CO LTD

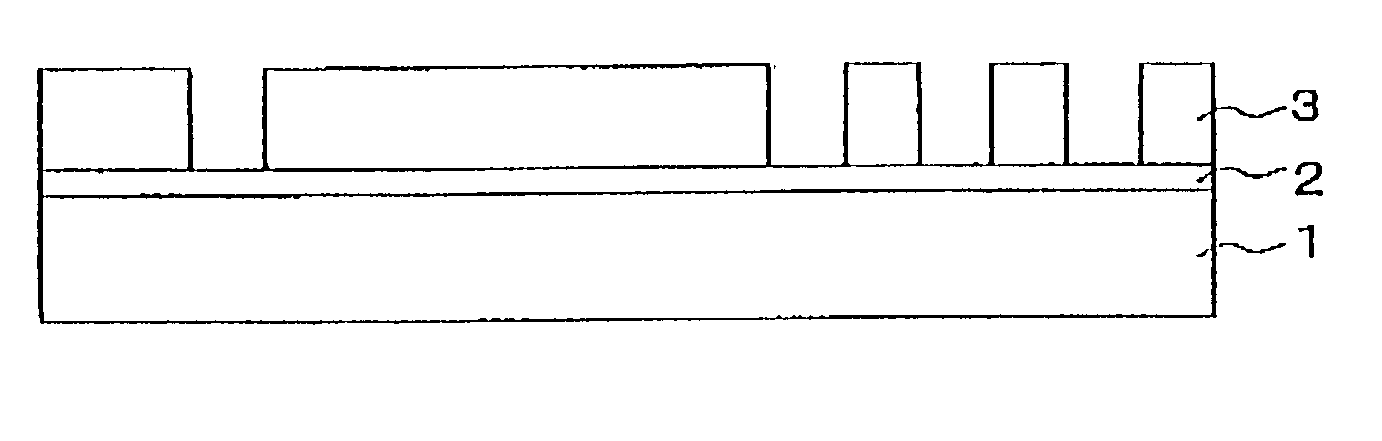

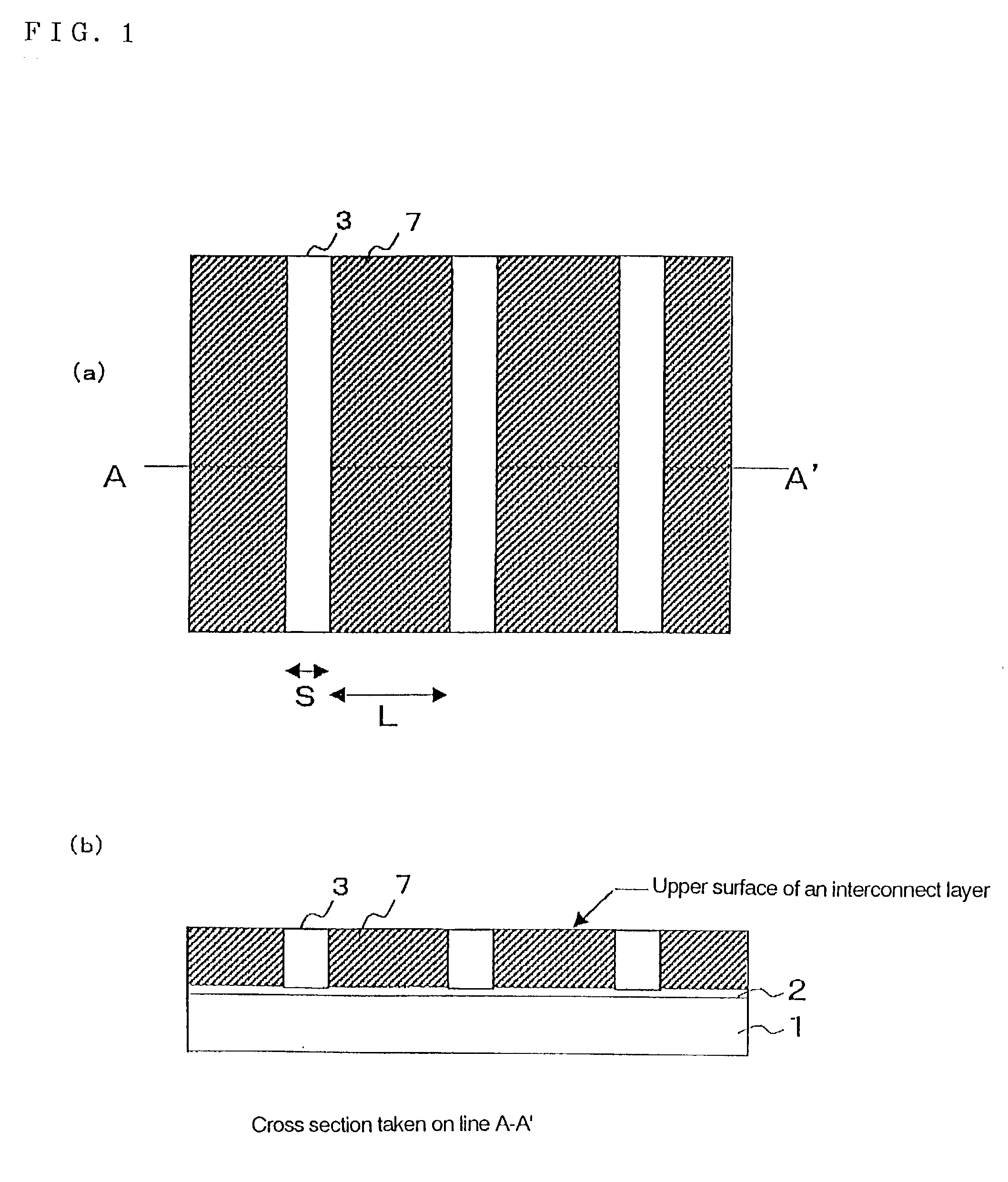

Semiconductor device

InactiveUS20030104690A1Avoid erosionMinimize increaseSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectSemiconductor

There is disclosed a semiconductor device comprising a copper interconnect layer 7 where a copper film is buried in a concave in an insulating film 3 via a barrier metal film, wherein the copper interconnect layer 7 has a line / space ratio of 4.5 or less and an interconnect occupancy of 10 to 60%. It can effectively prevent dishing and erosion, as well as increase and dispersion in an interconnect resistance when forming damascene copper interconnects.

Owner:NEC ELECTRONICS CORP

Xy Guide Table

ActiveUS20080217828A1Rigid enoughEliminate gapsLinear bearingsGearingMechanical engineeringLower half

Provided is an XY guide table in which rigidity of portions thereof where ball rolling surfaces are formed is enhanced to thereby eliminate clearances between balls and ball rolling grooves making it possible to guide an upper plate in an X-direction and Y-direction with respect to a lower plate without involving any rattling, and which can be formed in a very thin shape. The XY guide table includes the lower plate, an intermediate plate, and the upper plate assembled with each other through intermediation of the balls. Each of the lower plate and the upper plate has a pair of rail bodies of a substantially rectangular sectional configuration and a storage groove sandwiched between the rail bodies, and is formed in a substantially channel-like configuration. The ball rolling groove is formed in a side surface of each rail body facing the storage groove. The plates are stacked together, with the storage grooves being opposed and orthogonal to each other. The intermediate plate is formed in a substantially rectangular configuration, and has the lower half thereof loosely fitted into the storage groove of the lower plate and the upper half thereof loosely fitted into the storage groove of the upper plate.

Owner:THK CO LTD

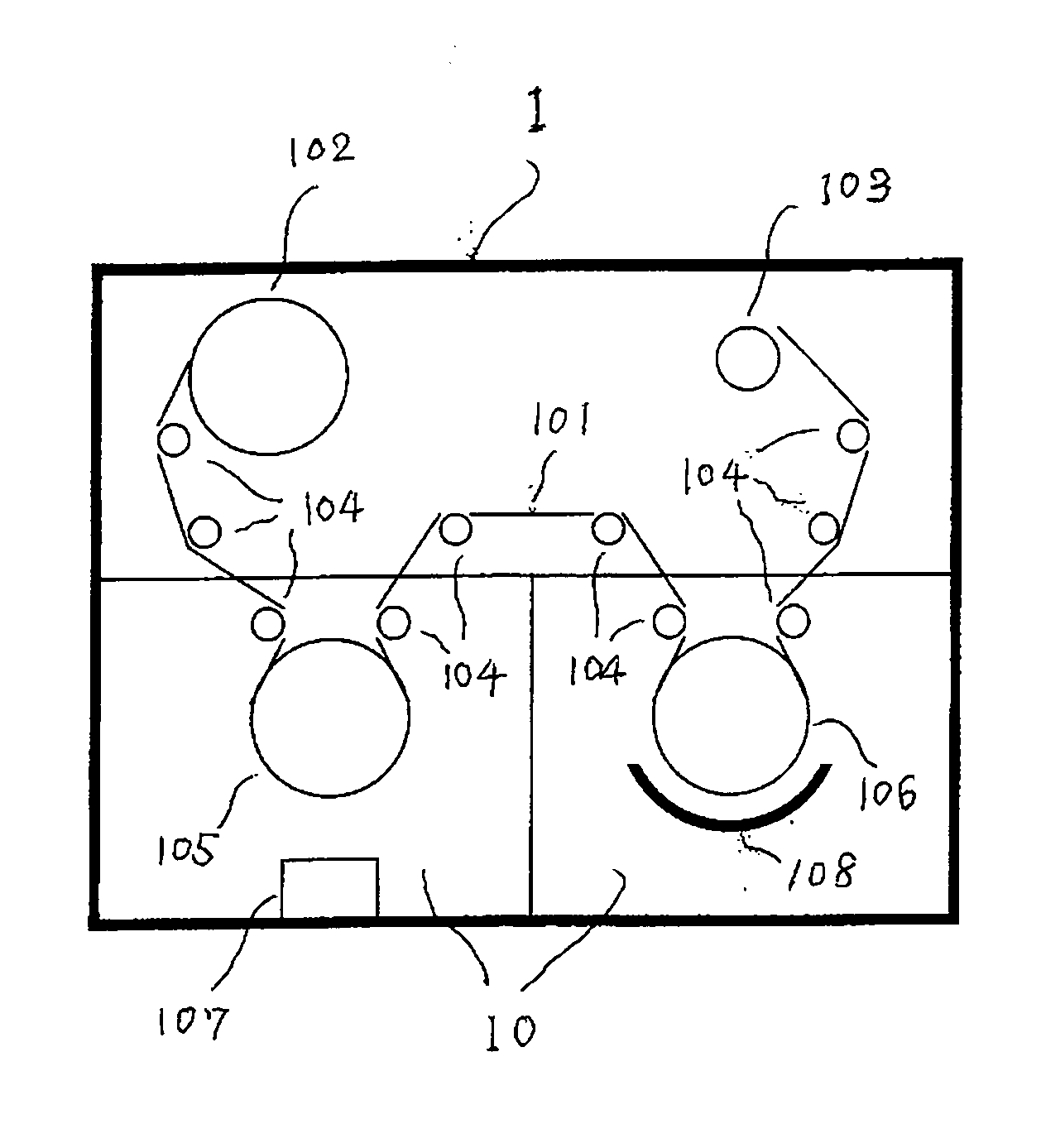

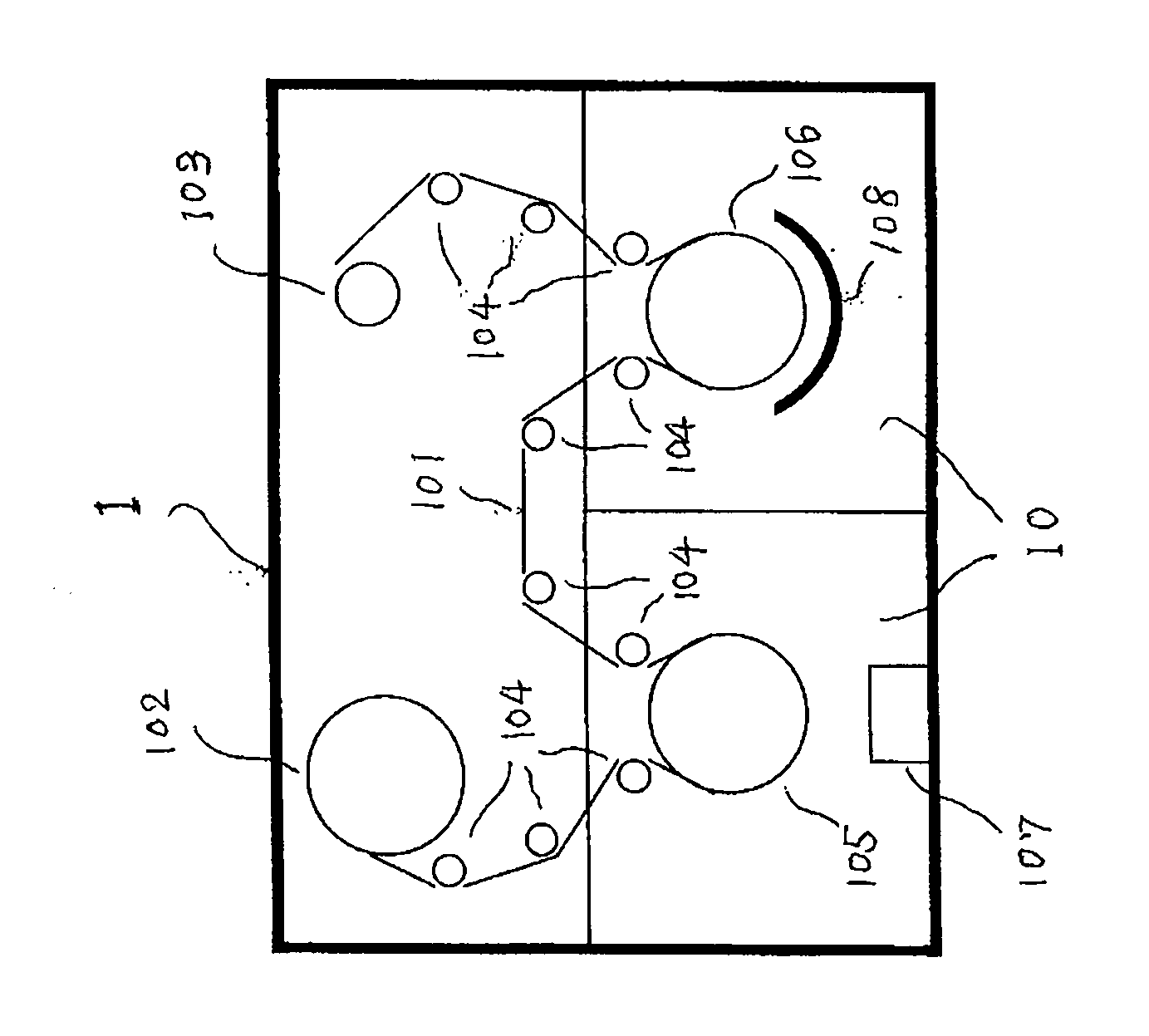

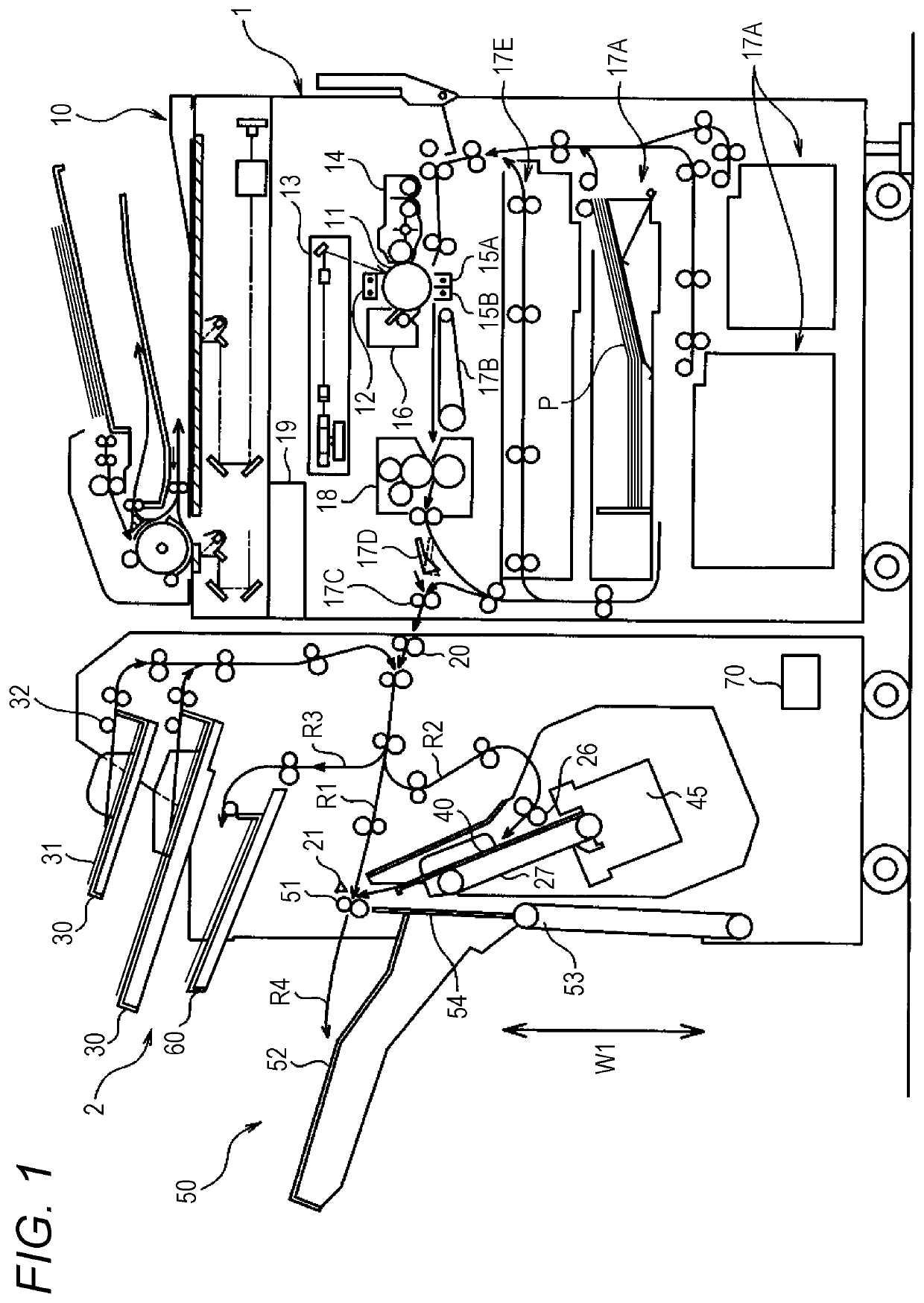

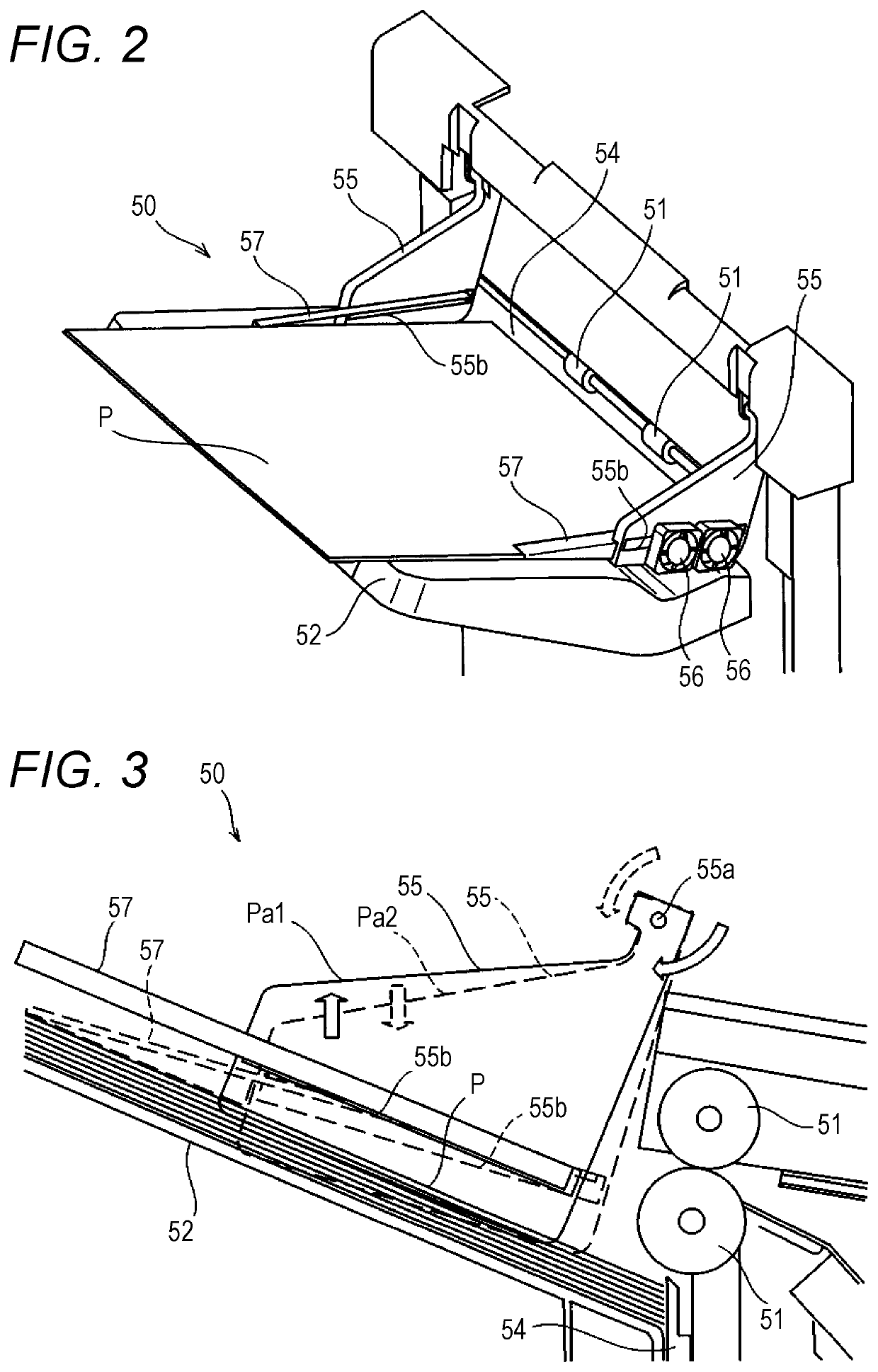

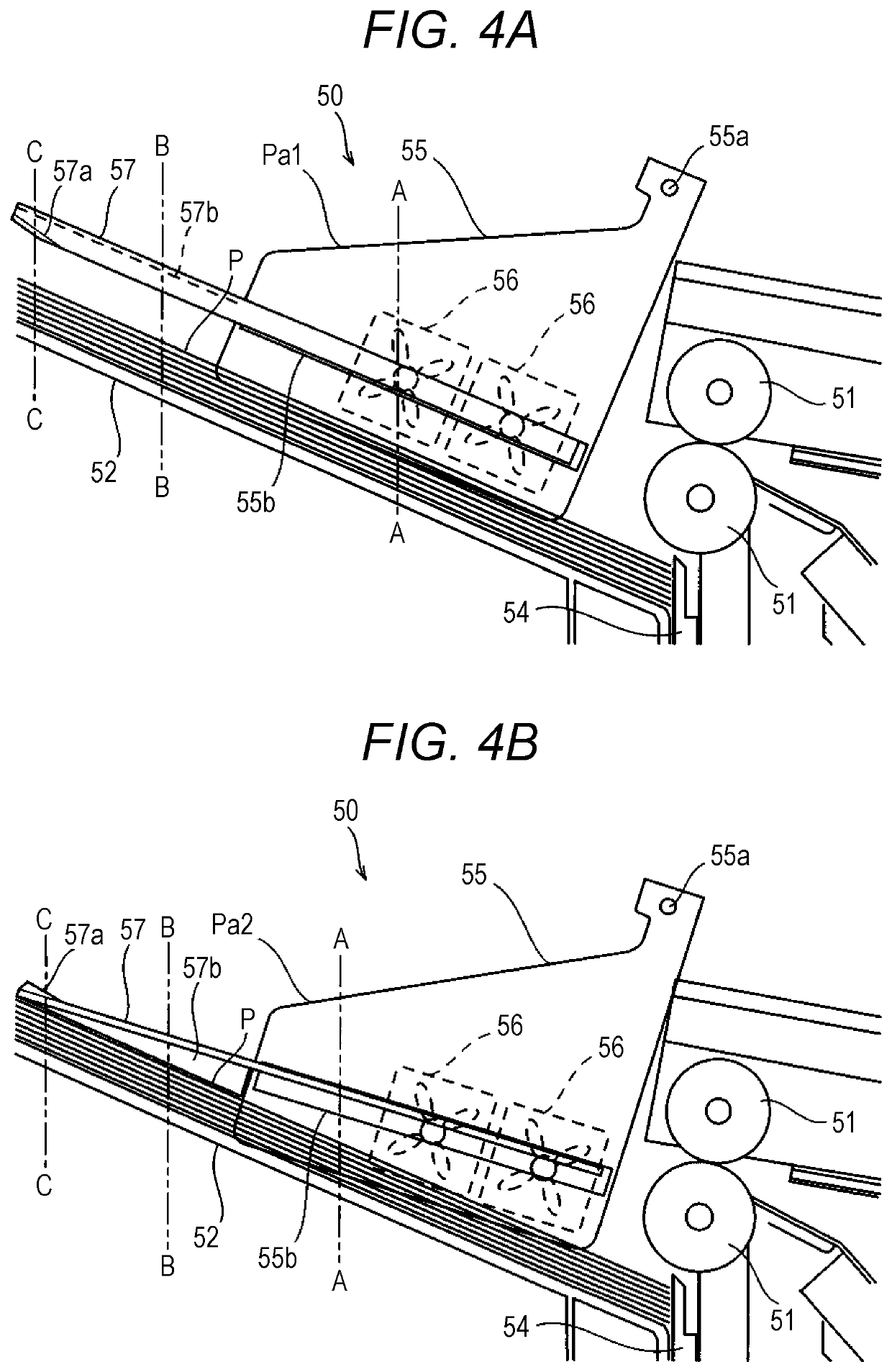

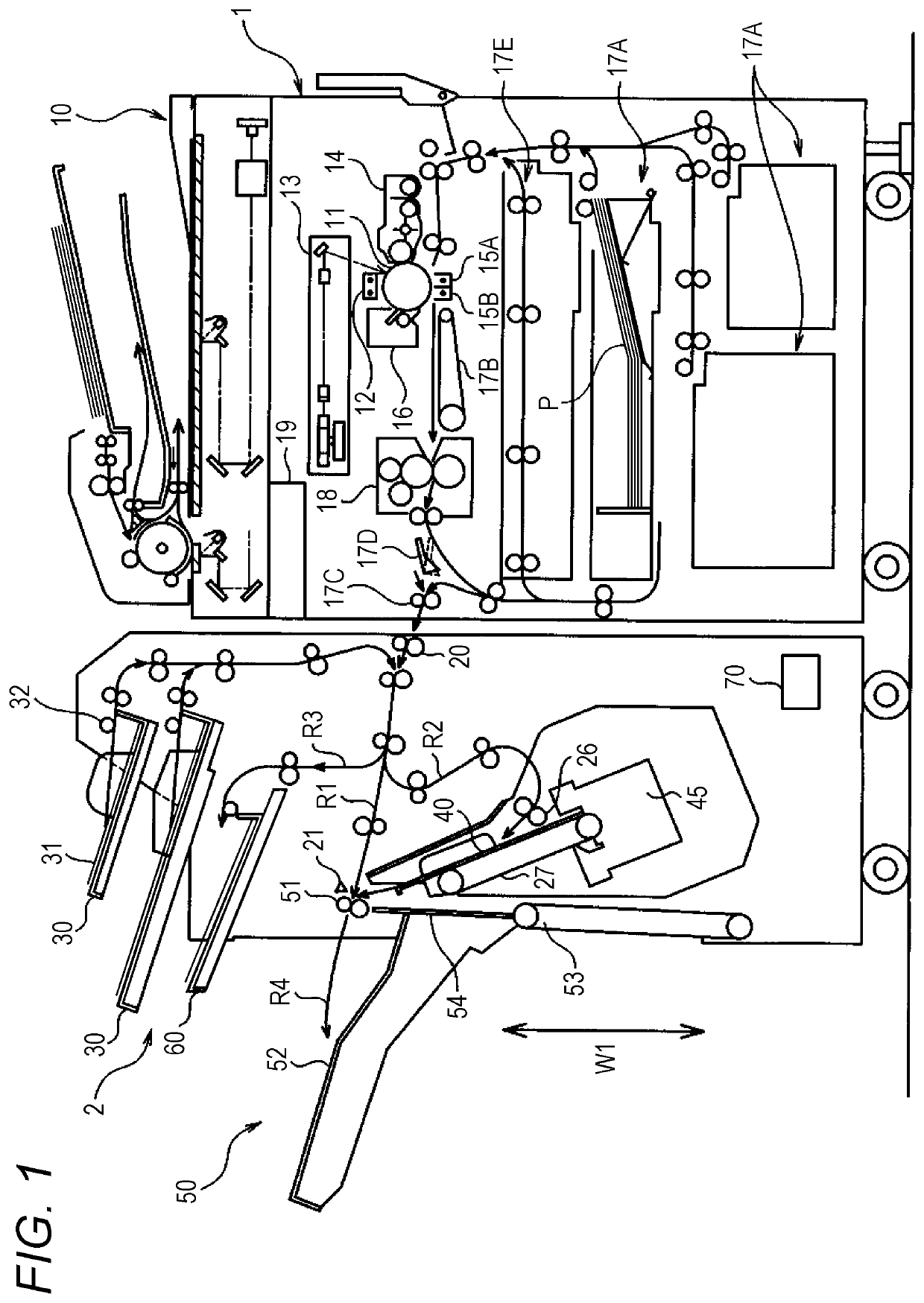

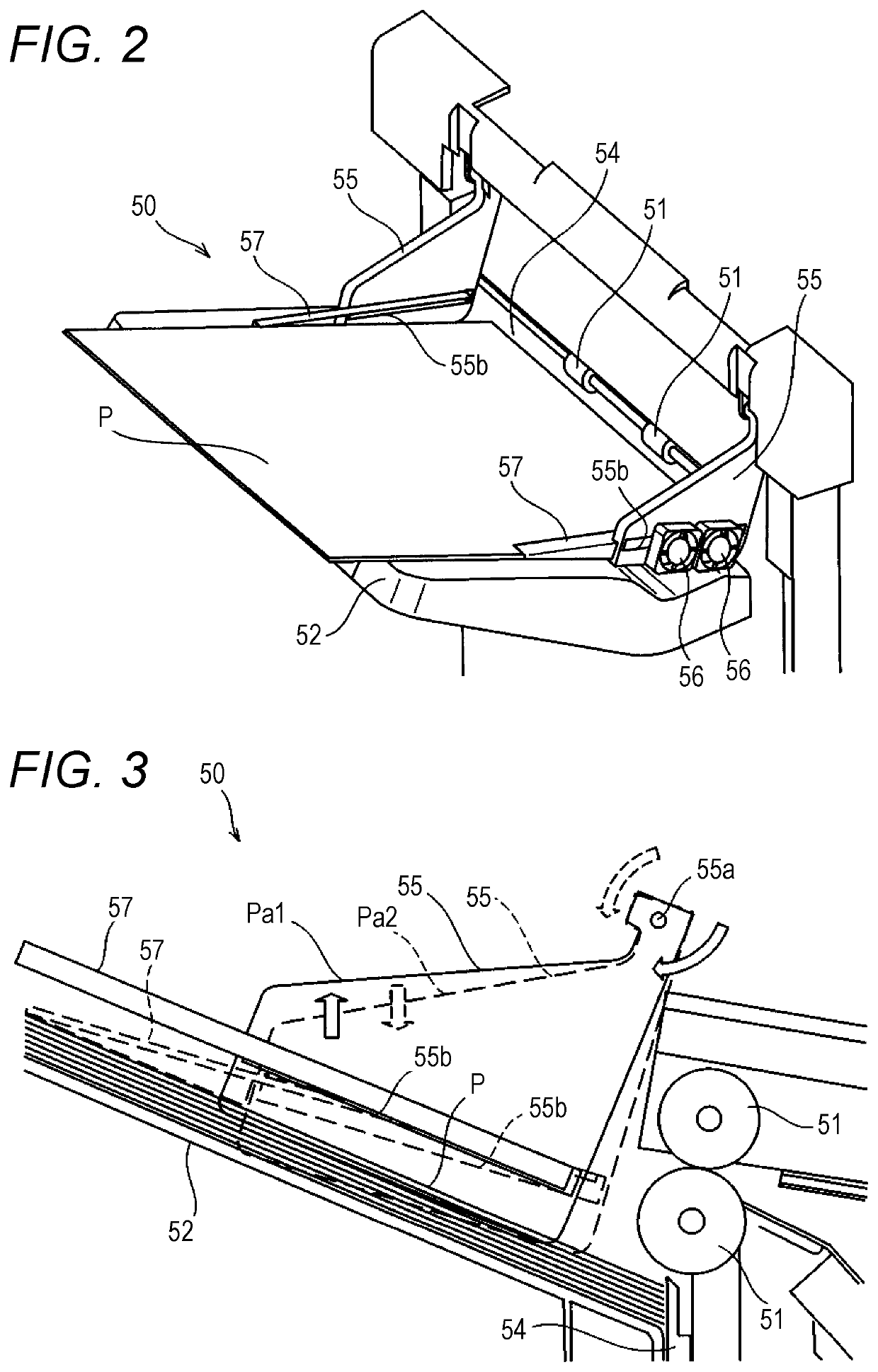

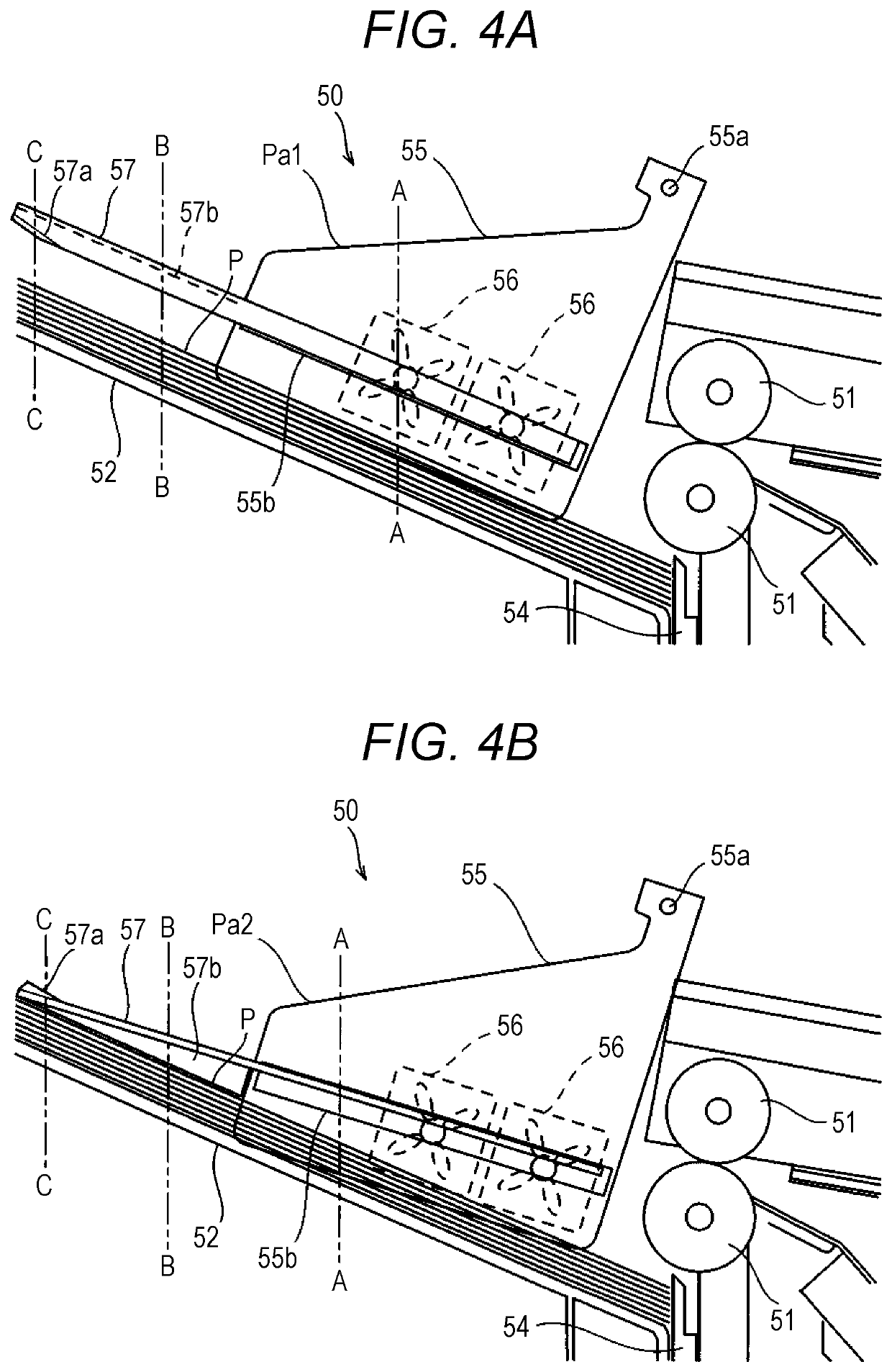

Paper stacking device and image forming system

ActiveUS11084679B2Satisfactory productivityInhibit adhesionFunction indicatorsElectrographic process apparatusEngineeringStructural engineering

A paper stacking device includes: a stacker on which paper is stacked; a paper ejector that ejects the paper; an aligning plate that is provided on a side of the paper, and aligns a side end of the paper; a paper floating member that is provided in the aligning plate, and supports, from below, the side end of the paper; and a blower that is provided on the side of the paper across the aligning plate, and blows air, wherein the aligning plate includes a blowing opening through which air from the blower is blown, the paper floating member is switched between: a paper floating position; and a retreat position, when the paper floating member is located in the paper floating position, the blowing opening is opened, and when the paper floating member is located in the retreat position, the blowing opening is shielded.

Owner:KONICA MINOLTA INC

Silane crosslinkable rubber composition and silane crosslinked rubber molded body, method of producing the same, and silane crosslinked rubber molded article

A silane crosslinkable rubber composition having a silane crosslinkable rubber in which a silane coupling agent is grafted onto a base rubber containing 61 to 99 mass % of ethylene-α-olefin rubber and 1 to 39 mass % of polypropylene-based resin, and with respect to 100 parts by mass of the base rubber, 0.3 to 400 parts by mass of inorganic filler, and 0.0001 to 0.5 parts by mass of silanol condensation catalyst; a silane crosslinked rubber molded body obtained by bringing the rubber composition into contact with water after molding; a silane crosslinked rubber molded article including the rubber molded body; and a method of producing a silane crosslinkable rubber composition and a silane crosslinked rubber molded body.

Owner:FURUKAWA ELECTRIC CO LTD

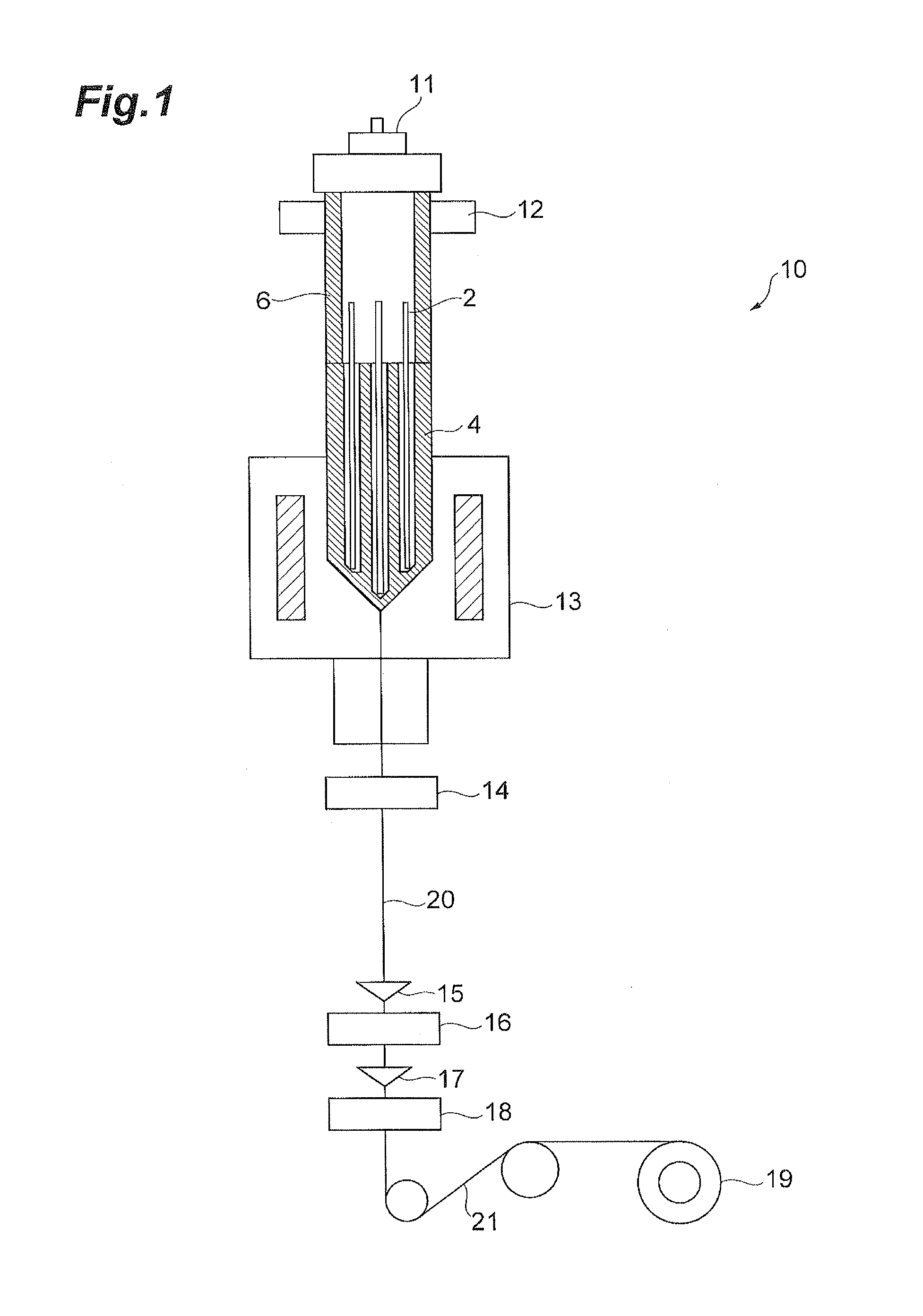

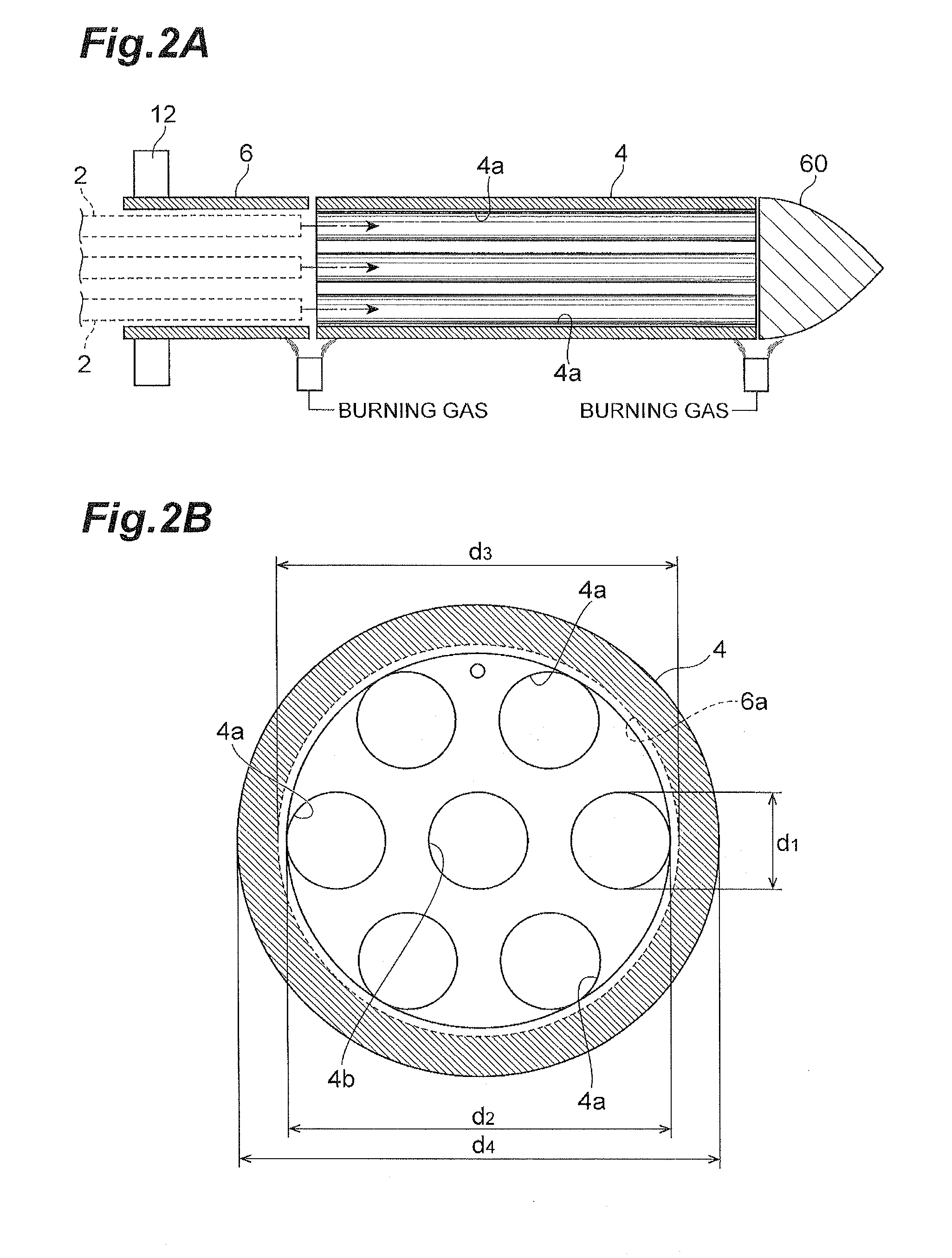

Method for manufacturing multi-core optical fiber

InactiveUS20150274577A1Satisfactory economic efficiencySatisfactory productivityMaterial analysis using wave/particle radiationGlass fibre drawing apparatusOptical powerDiameter ratio

A manufacturing method according to an embodiment of the invention includes a step of calculating Pj0.1 satisfying (62.6×JOH+1175)×Pj=0.1, where Pj is an optical power ratio at the wavelength 1383 nm of a portion corresponding to a cladding material of an MCF after drawn, and an outer diameter ratio Pcc0.1 of core portions to core rods to obtain Pj0.1. The core rods have an outer diameter 2R0.1 satisfying the condition that a ratio Pcc is not less than the ratio Pcc0.1, and the cladding material has holes formed in a diameter larger by C (not less than 0.15 mm and not more than 1.5 mm) than the outer diameter of the core rods.

Owner:SUMITOMO ELECTRIC IND LTD

Paper stacking device and image forming system

ActiveUS20200156896A1Satisfactory productivityInhibit adhesionFunction indicatorsElectrographic process apparatusStructural engineeringIndustrial engineering

A paper stacking device includes: a stacker on which paper is stacked; a paper ejector that ejects the paper; an aligning plate that is provided on a side of the paper, and aligns a side end of the paper; a paper floating member that is provided in the aligning plate, and supports, from below, the side end of the paper; and a blower that is provided on the side of the paper across the aligning plate, and blows air, wherein the aligning plate includes a blowing opening through which air from the blower is blown, the paper floating member is switched between: a paper floating position; and a retreat position, when the paper floating member is located in the paper floating position, the blowing opening is opened, and when the paper floating member is located in the retreat position, the blowing opening is shielded.

Owner:KONICA MINOLTA INC

Conductive coating film-forming agent, method for producing the same, and molded article using the same

InactiveUS20120193587A1Improve solubilityEasy to handleConductive materialOrganic conductorsImideSolubility

This conductive coating film-forming agent contains a coating film-forming component having a polyol structure, and at least one kind of a compound selected from bis(fluorosulfonyl)imide salts represented by (FSO2)2N.X, which is easy to handle while maintaining solubility in the coating film-forming component, and exerts no influence on the environment and also has excellent conductivity even in the use-environment at high temperature.

Owner:MITSUBISHI MATERIALS CORP +1

Foam sheet and production process thereof

InactiveUS20090130419A1Simple processImprove efficiencySemi-permeable membranesMembranesBoiling pointPhotochemistry

A foam sheet produced from a foamable composition containing an acid generator that generates acid or a base generator that generates base due to the action of an active energy beam, and containing a compound having decomposing foamable functional group that decomposes and eliminates at least one type of low boiling point volatile substance by reacting with acid or base, makes it possible to obtain a microcellular thin foam that was considered to be difficult to produce thus far, thereby greatly expanding the range of fields in which foams can be used and significantly contributing to industry.

Owner:OJI HLDG CORP

Removable pressure sensitive adhesive compositions and sheets

InactiveUS7374815B2Easy to disassembleSolve the lack of cohesionPolyureas/polyurethane adhesivesSynthetic resin layered productsPeel forceMelamine

A removable pressure sensitive adhesive composition includes at least (A) a hydroxyl-group-containing acrylic polymer, (B) an amine compound containing plural hydroxyl groups, and (C) a polyisocyanate compound and has a gel fraction of equal to or more than 70% by weight after drying or curing. A removable pressure sensitive adhesive sheet has a removable pressure sensitive adhesive layer including the removable pressure sensitive adhesive composition formed on one or both sides of a base material. The sheet may have a 180° peel force with respect to a melamine-faced steel sheet of 5 N / 20-mm or less and may have a 180 ° peel force after adhesion at 50° C. for 48 hours of 1.2 times or less the initial adhesion (after adhesion at 23° C. for 20 minutes), as determined at a pulling rate of 300 mm / minute, 23° C. and 50% relative humidity.

Owner:NITTO DENKO CORP

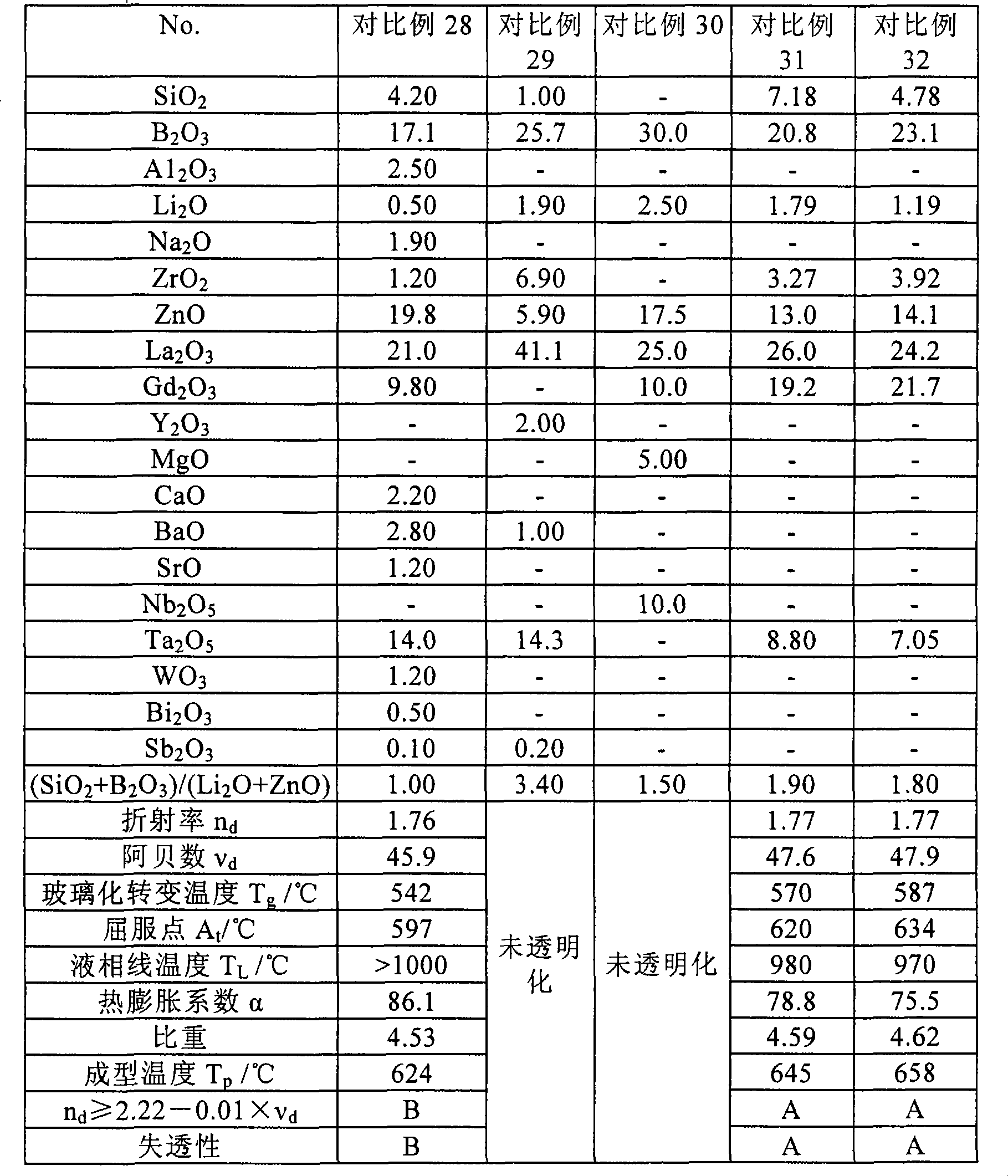

Optical glass and lens using the same

InactiveCN101466647AHigh refractive indexSmall dispersionOptical elementsOptical glassLanthanum compounds

Disclosed is an optical glass which comprises the following components (% by mass in terms of an oxide): B2O3: 13-27%; La2O3: 20-35%; Gd2O3: 5-25%; ZnO: 5-20%; Li2O: 0.5-3%; Ta2O5: 0.5-15%; and WO3: 0.5-10%, and which has a mass-based ratio between the total amount of SiO2 and B2O3 and the total amount of ZnO and Li2O (i.e., a (SiO2+B2O3) / (ZnO+Li2O) ratio) of 1.35 to 1.65. Also disclosed is a lens comprising the optical glass.

Owner:AGC INC

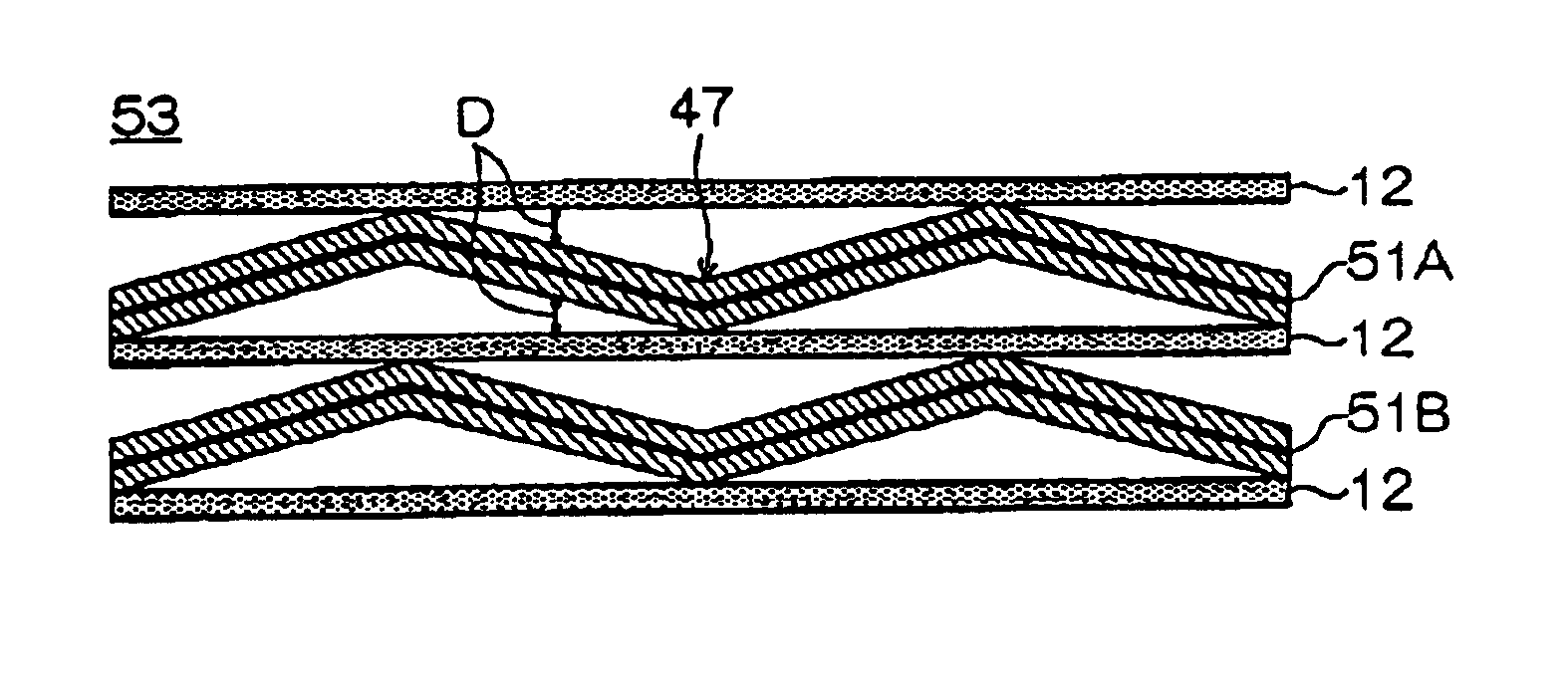

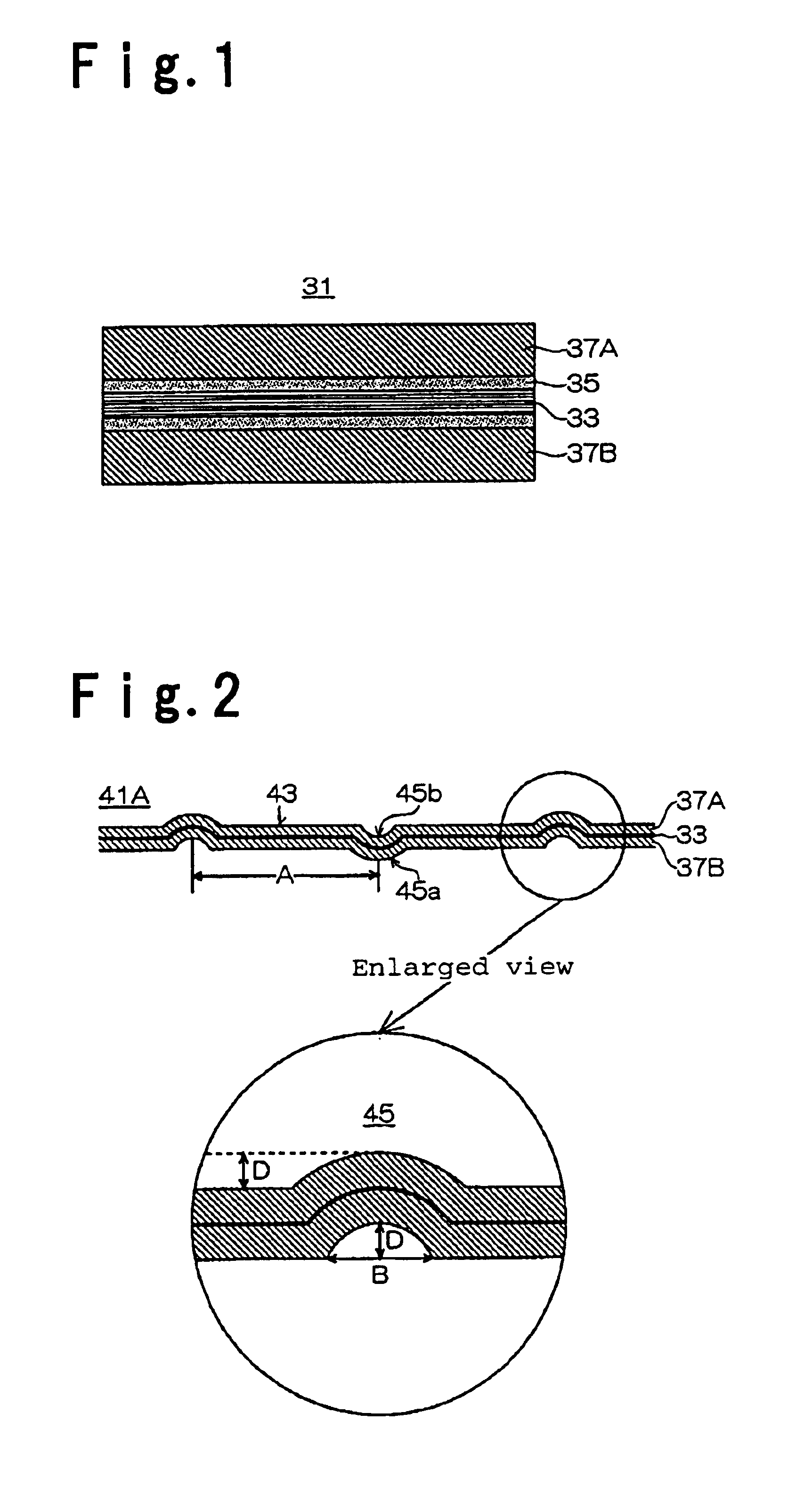

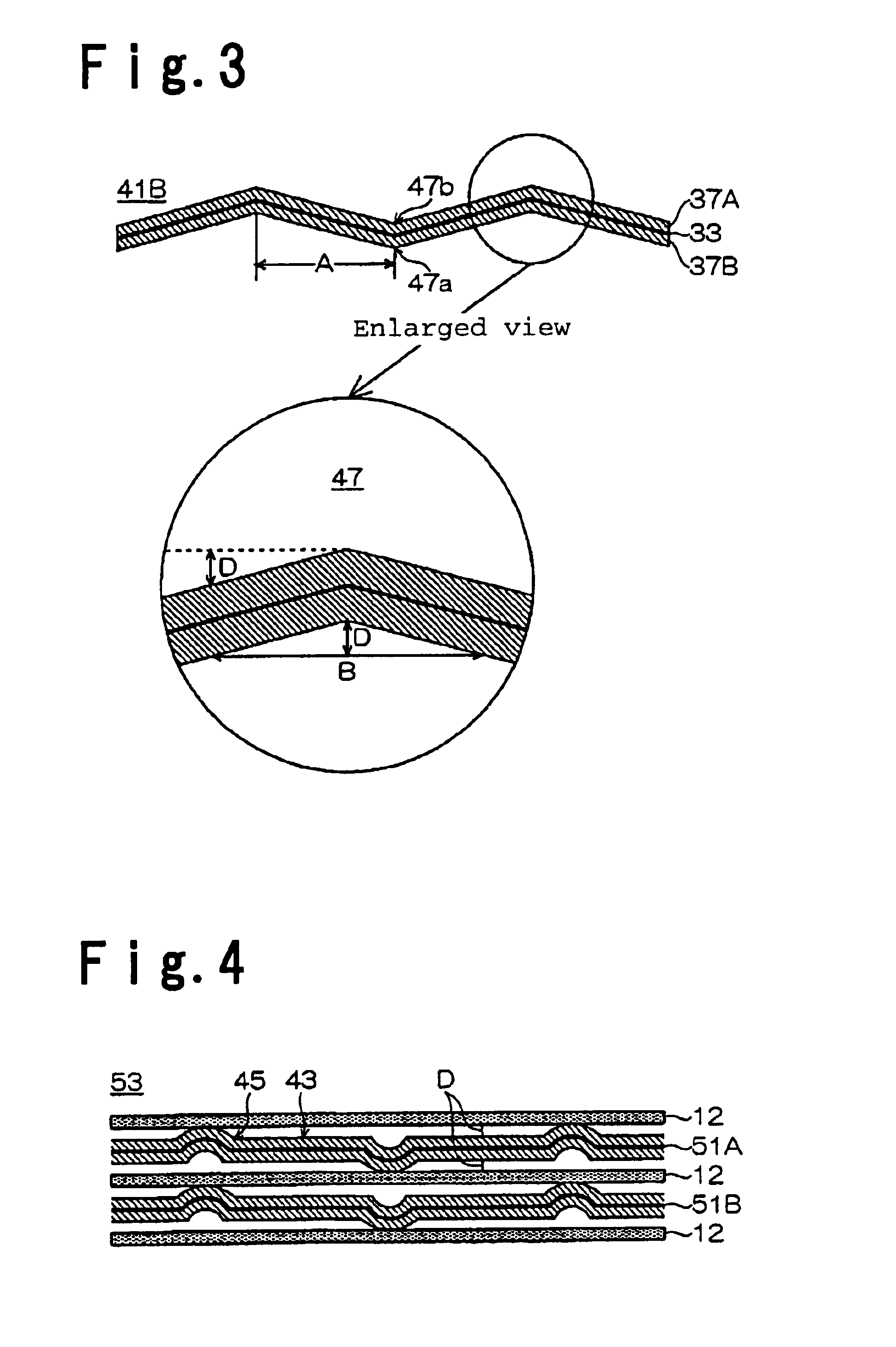

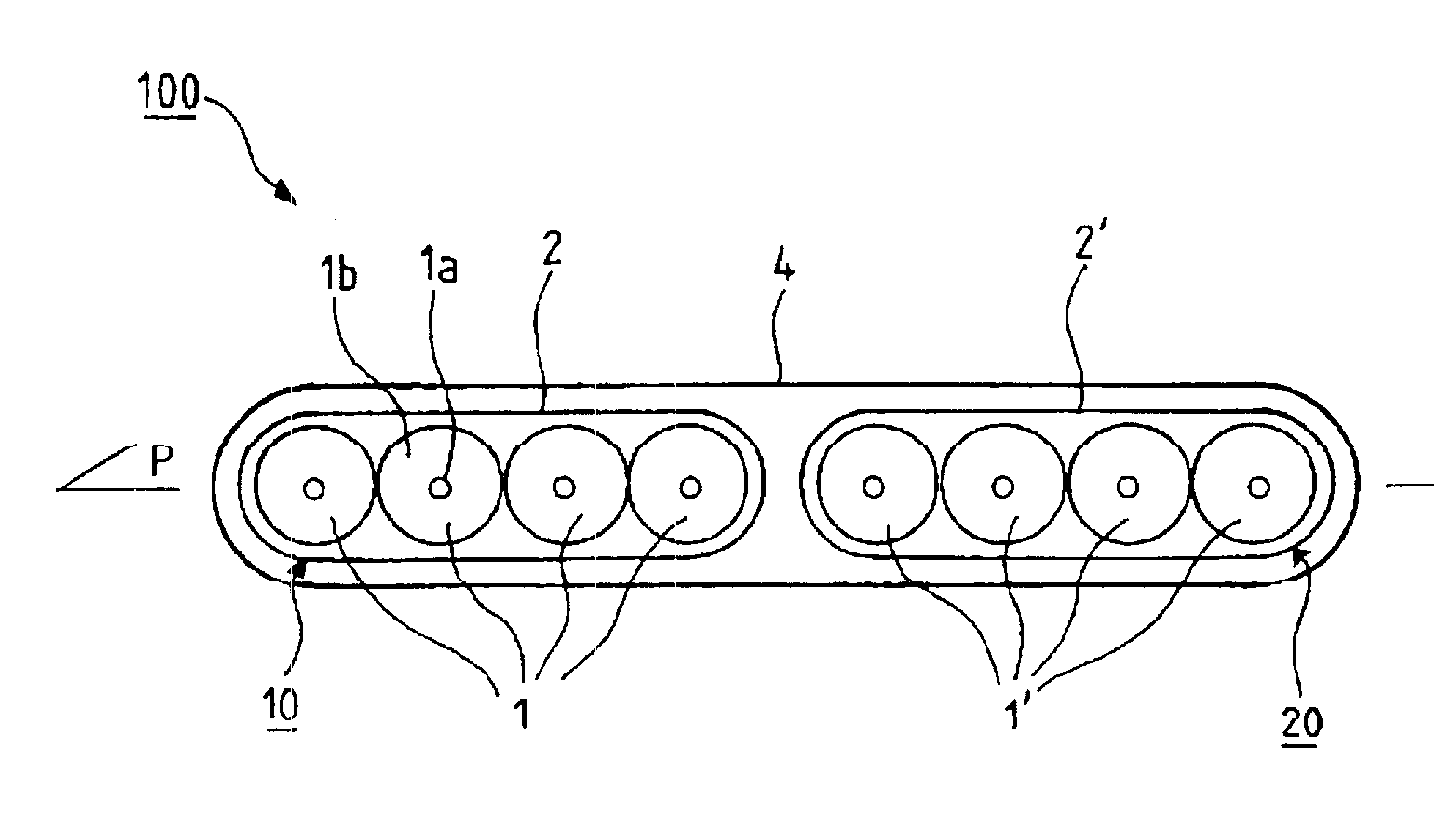

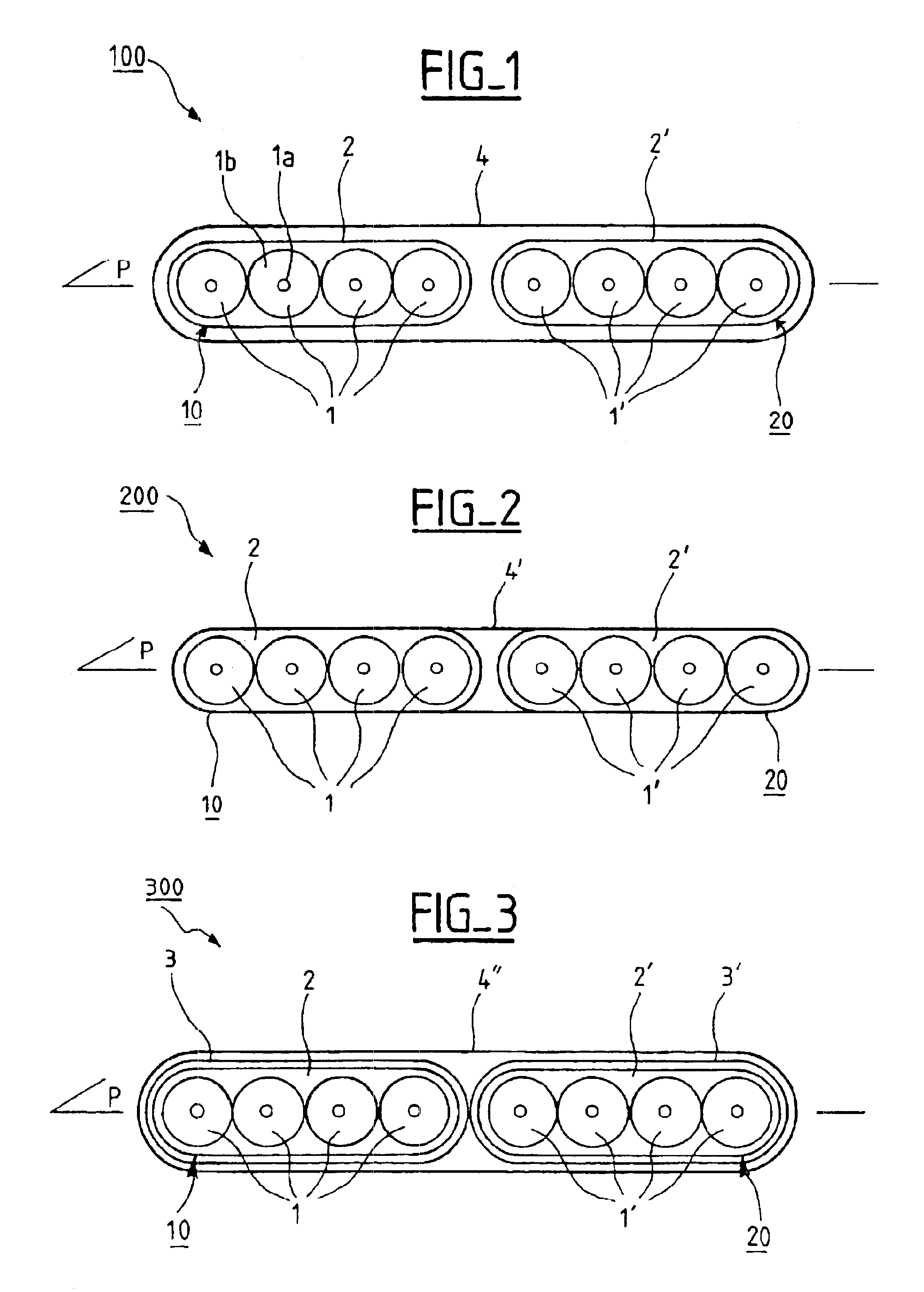

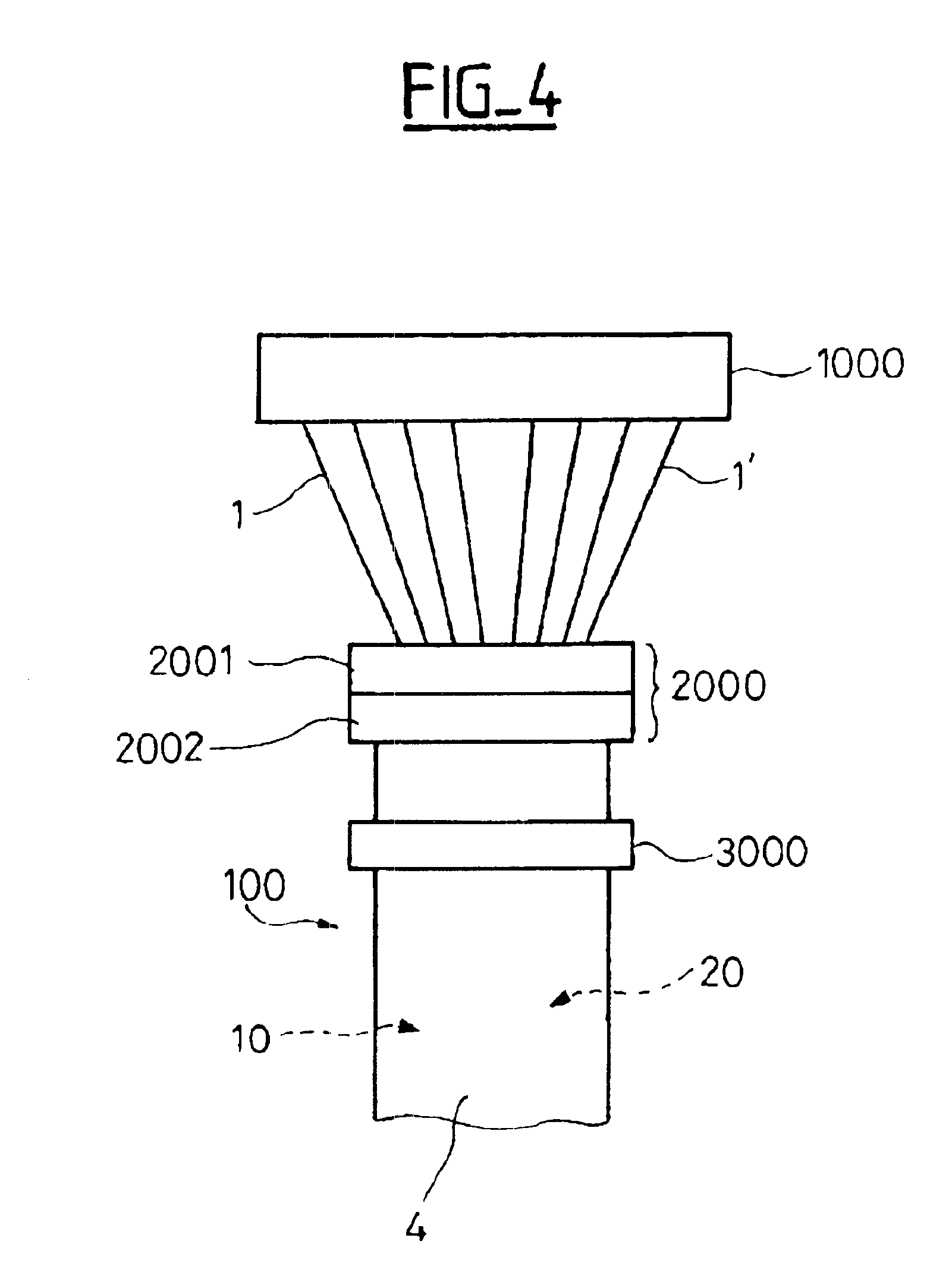

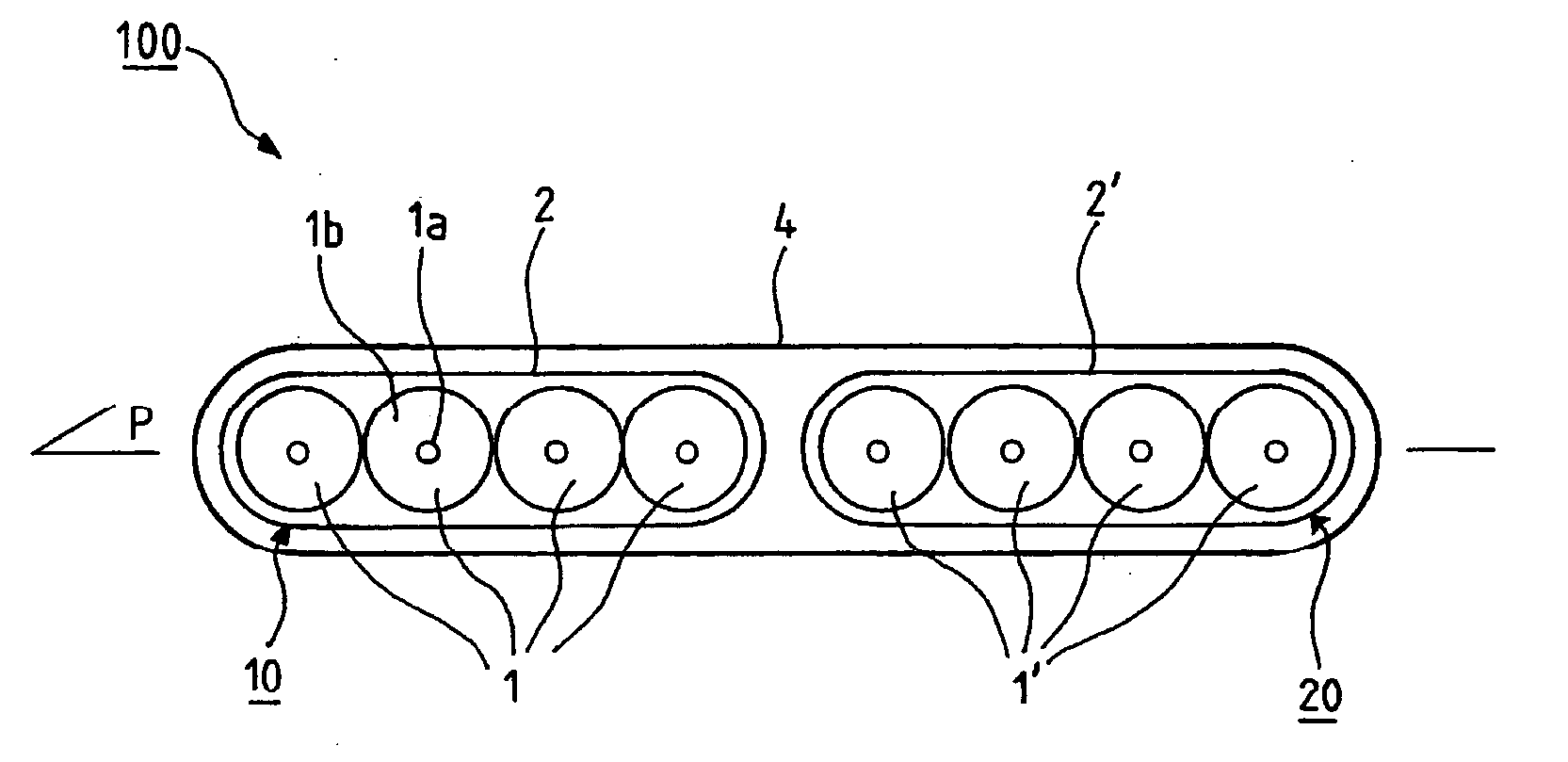

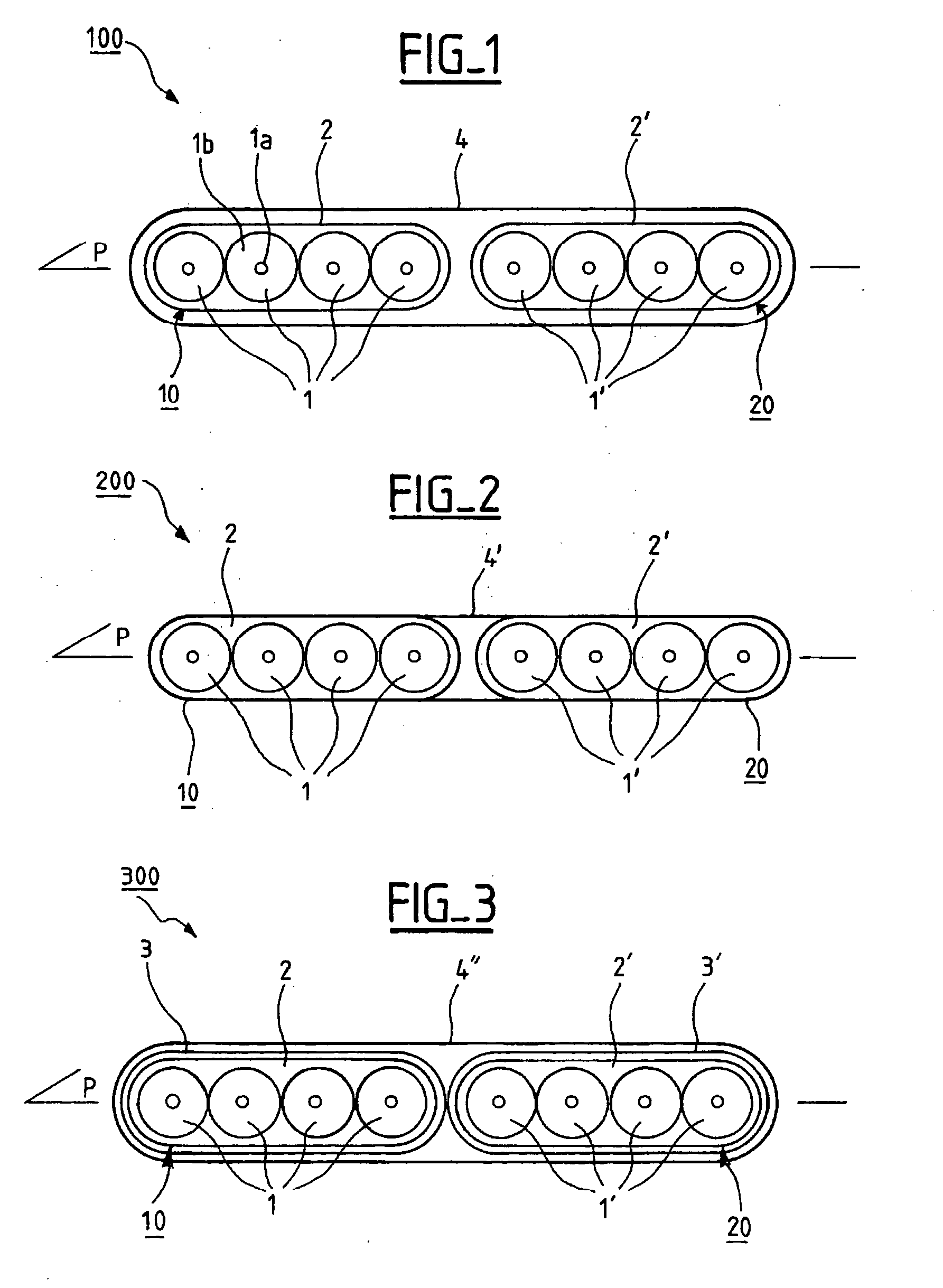

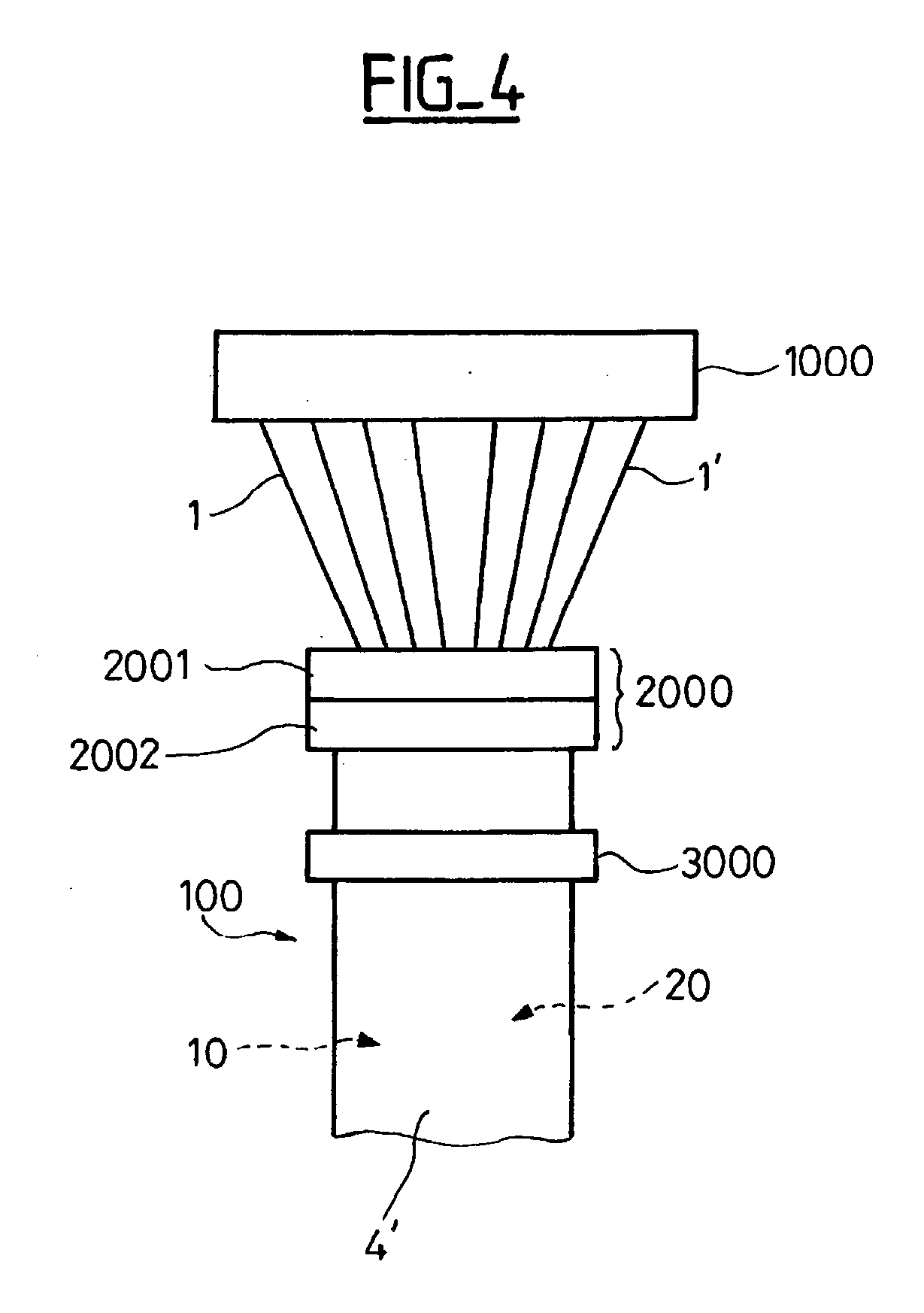

Method of manufacturing an optical fiber ribbon, and an optical ribbon

InactiveUS6859593B2Reducing time and costSatisfactory productivityCommunication cablesFibre mechanical structuresFiberEngineering

The present invention relates to a method of manufacturing an optical fiber ribbon comprising the following steps: arranging N groups of optical fibers so that the fibers in any one group are disposed in the same plane, applying a first layer of a first liquid resin settable under the action of UV type radiation onto each group of optical fibers to form first casings, applying a second layer of a second liquid resin settable under the action of UV type radiation disposed to link together the adjacent first casings, and applying a single irradiation step to the second layer and the first layers using UV type radiation in order to form the first matrices and to form the “link” second matrix.

Owner:NEXANS

Method for producing piezoelectric composite substrate and method for producing piezoelectric element

ActiveUS8572825B2Satisfactory productivityProducing a piezoelectric elementPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyProduction rateSingle crystal

A method for producing a piezoelectric composite substrate with satisfactory productivity controls the inclination of the crystal axis and the polar axis of a single-crystal thin film and prevents an adverse effect due to pyroelectricity in a production process. The method for producing a piezoelectric composite substrate provided with a plurality of piezoelectric materials includes an ion-implantation step, a bonding step, and a separation step. In the ion-implantation step, H+ ions are implanted into a piezoelectric single crystal material. In the bonding step, the piezoelectric single crystal material is bonded to a piezoelectric single crystal material. At this time, the polarity of the polar surface of the piezoelectric single crystal material is opposite to the polarity of the polar surface of the piezoelectric single crystal material, the polar surfaces being bonded to each other. In the separation step, a separation layer of the piezoelectric single crystal material is divided by heating to separate a piezoelectric single-crystal thin film.

Owner:MURATA MFG CO LTD

Method of manufacturing an optical fiber ribbon, and an optical fiber ribbon

InactiveUS20040131319A1Reducing time and costSatisfactory productivityCommunication cablesFibre mechanical structuresFiberEngineering

The present invention relates to a method of manufacturing an optical fiber ribbon comprising the following steps: arranging N groups of optical fibers so that the fibers in any one group are disposed in the same plane, applying a first layer of a first liquid resin settable under the action of UV type radiation onto each group of optical fibers to form first casings, applying a second layer of a second liquid resin settable under the action of UV type radiation disposed to link together the adjacent first casings, and applying a single irradiation step to the second layer and the first layers using UV type radiation in order to form the first matrices and to form the "link" second matrix.

Owner:NEXANS

Highly adhesive pressure sensitive adhesive compositions and sheets

InactiveUS7371460B2Increase stickinessPrevent and suppressPolyureas/polyurethane adhesivesSynthetic resin layered productsPeel forceAcrylic polymer

A highly adhesive pressure sensitive adhesive composition includes at least (A) a hydroxyl-group-containing acrylic polymer, (B) an amine compound containing plural hydroxyl groups, and (C) a polyisocyanate compound and has a gel fraction of equal to or more than 10% by weight and less than 70% by weight after drying or curing. A highly adhesive pressure sensitive adhesive sheet has a highly adhesive pressure sensitive adhesive layer including the highly adhesive pressure sensitive adhesive composition formed on one or both sides of a base material. The sheet preferably has a 180° peel force with respect to a stainless steel sheet of 10 N / 20-mm or more as determined at a pulling rate of 300 mm / minute, 23° C. and 50% relative humidity.

Owner:NITTO DENKO CORP

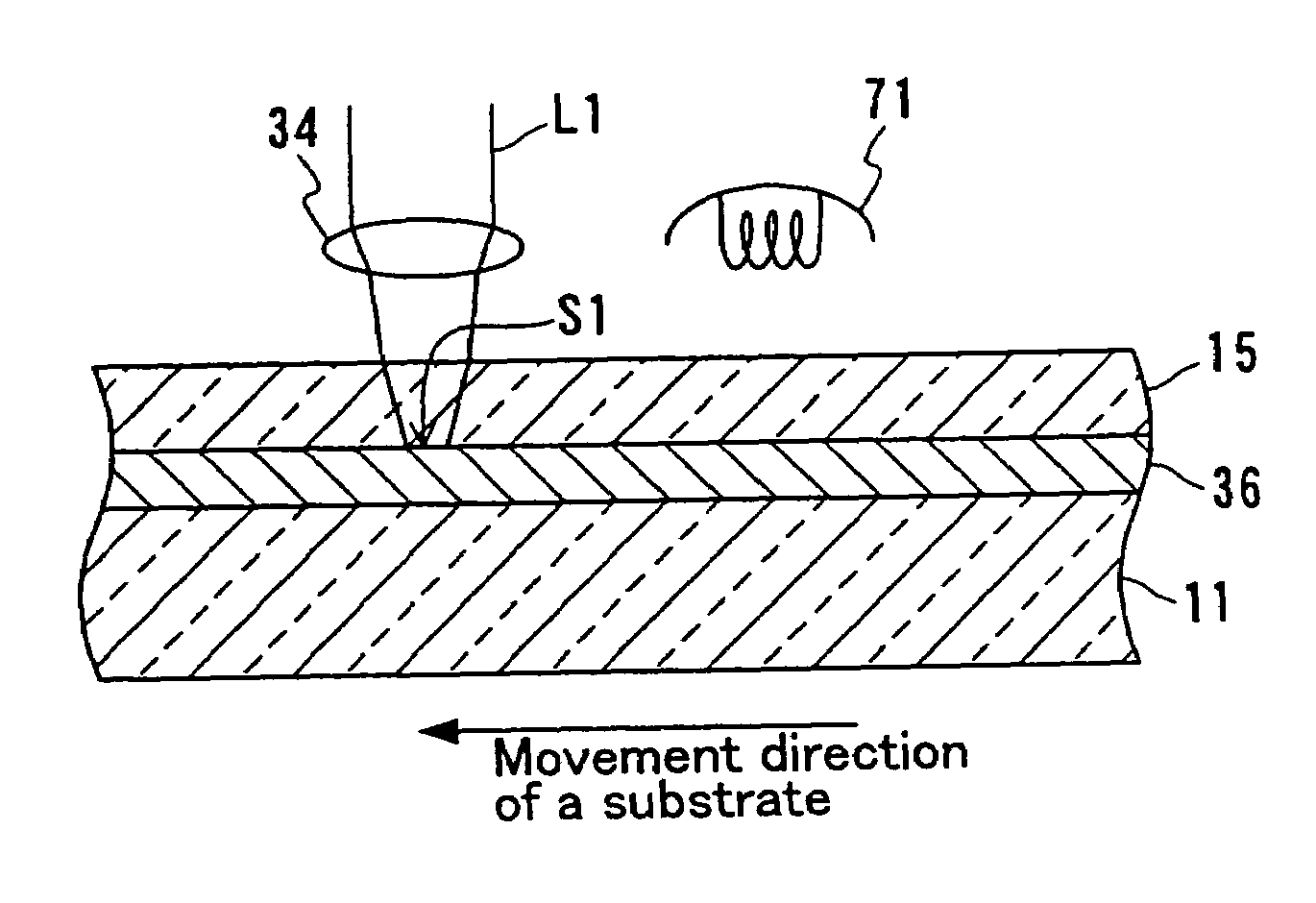

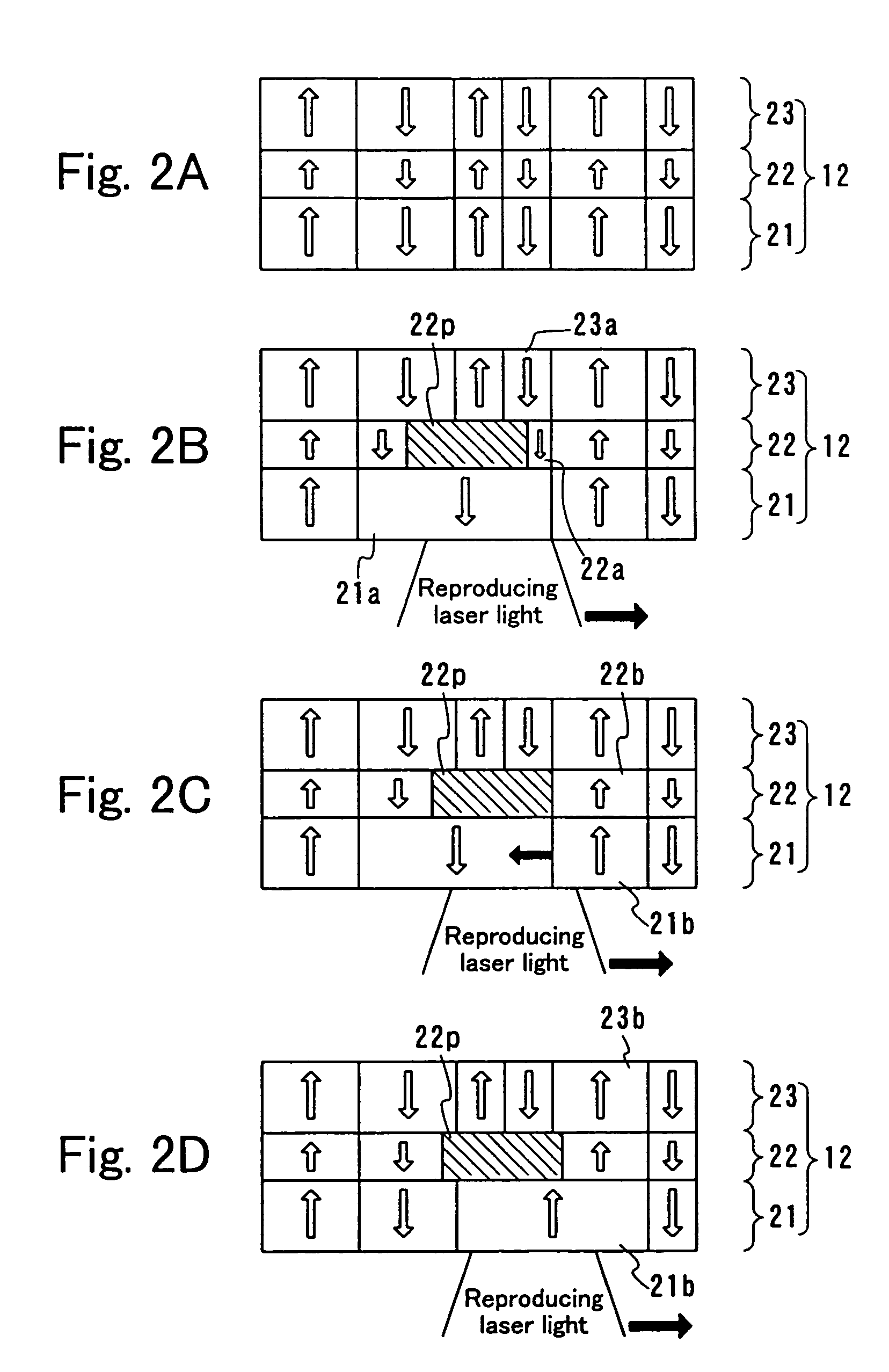

Magneto-optical recording medium for use in domain wall displacement detection system, and method for producing the same

InactiveUS6975564B2Improve recording densityReduce couplingLayered productsRecord information storageRefractive indexLength wave

An optical disk of the present invention includes a substrate and a recording layer disposed above the substrate, and reproduces an information signal by a DWDD system, using light incident from the substrate side. The optical disk further includes a first dielectric layer disposed between the substrate and the recording layer and a second dielectric layer disposed on the recording layer opposite to the substrate, wherein the recording layer is initialized with light having a wavelength λ incident from the second dielectric layer side, and the thickness of the second dielectric layer is in a range of λ / (12×n) to λ / (2×n) (where n is a refractive index of the second dielectric layer).

Owner:PANASONIC CORP

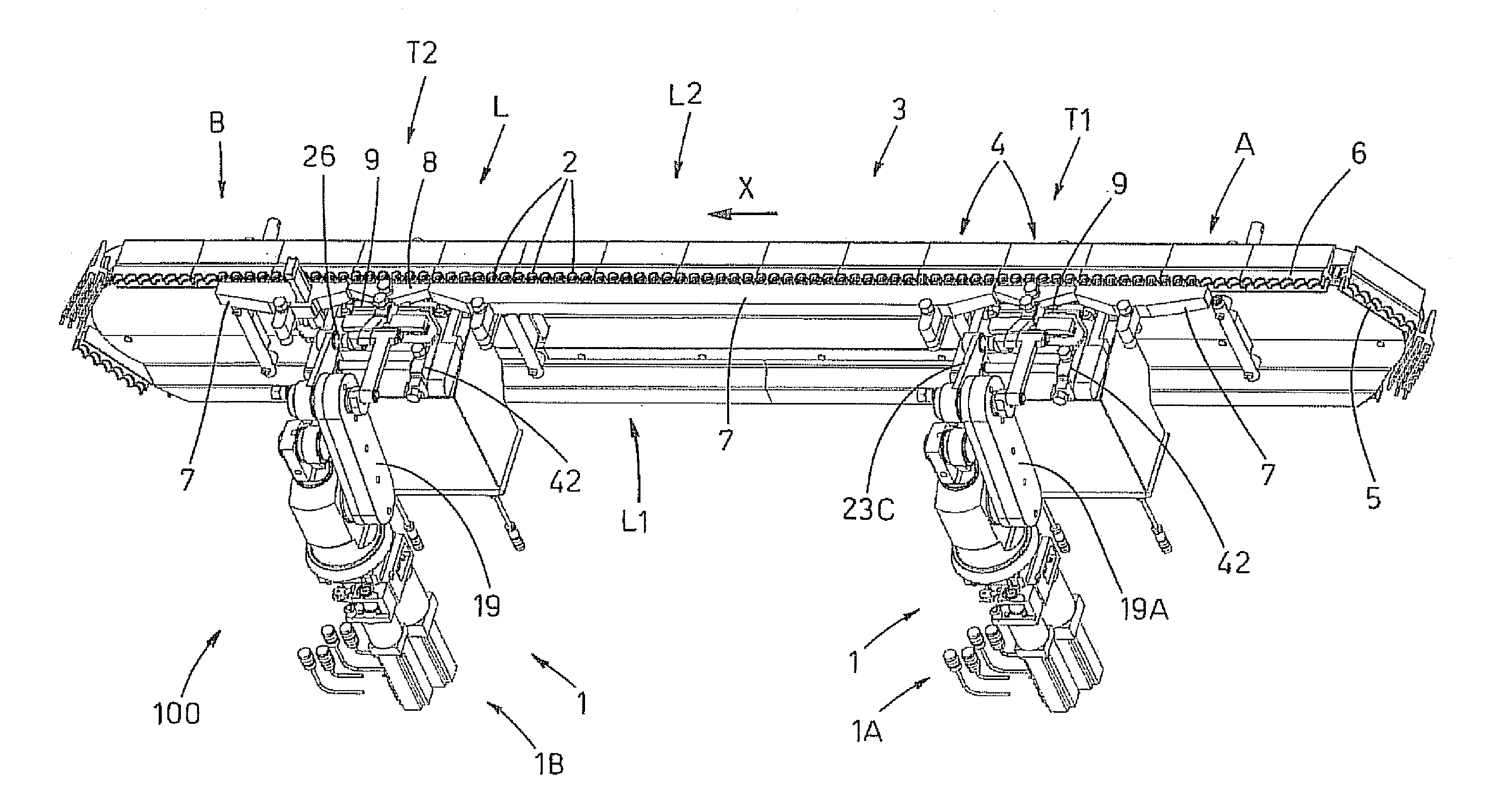

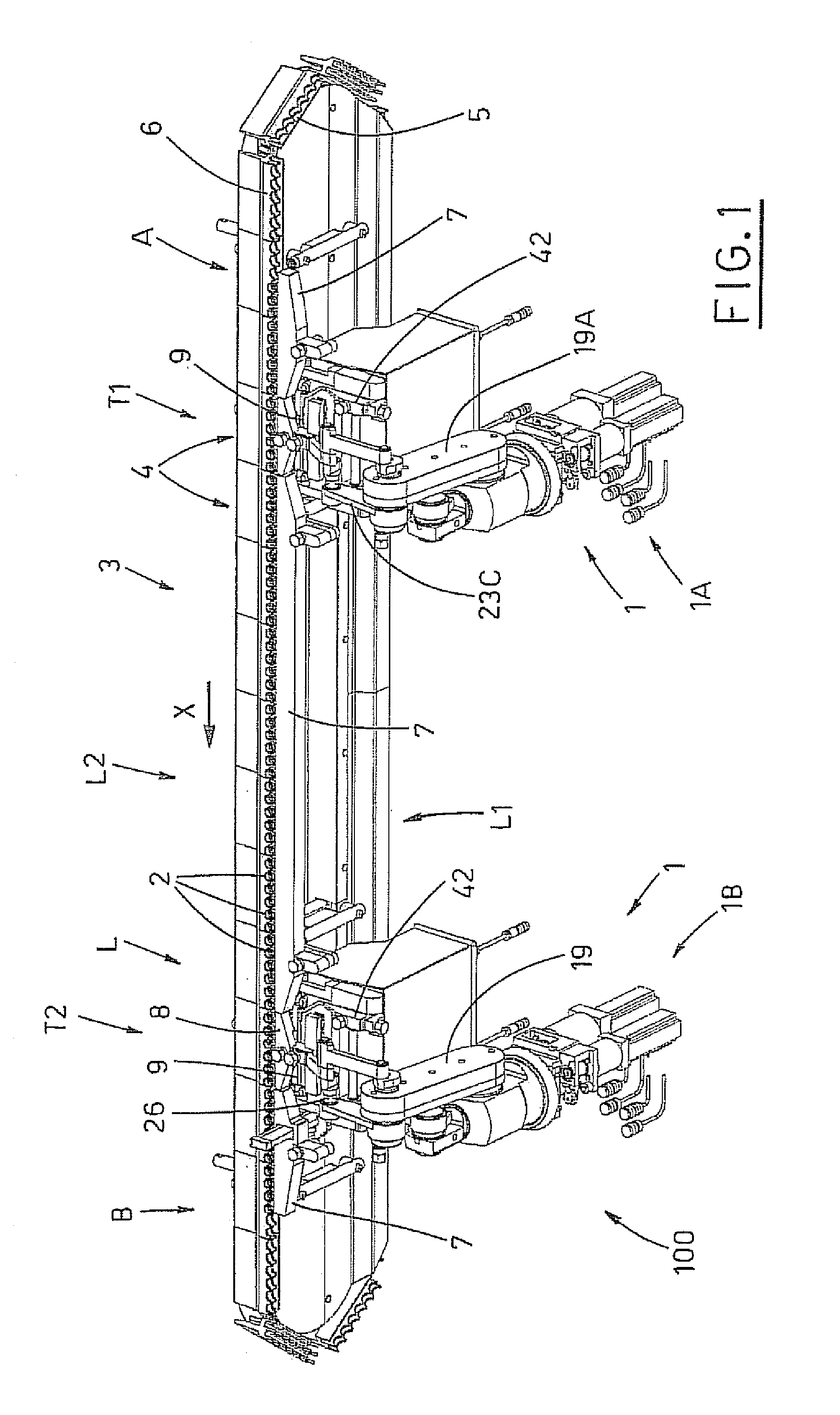

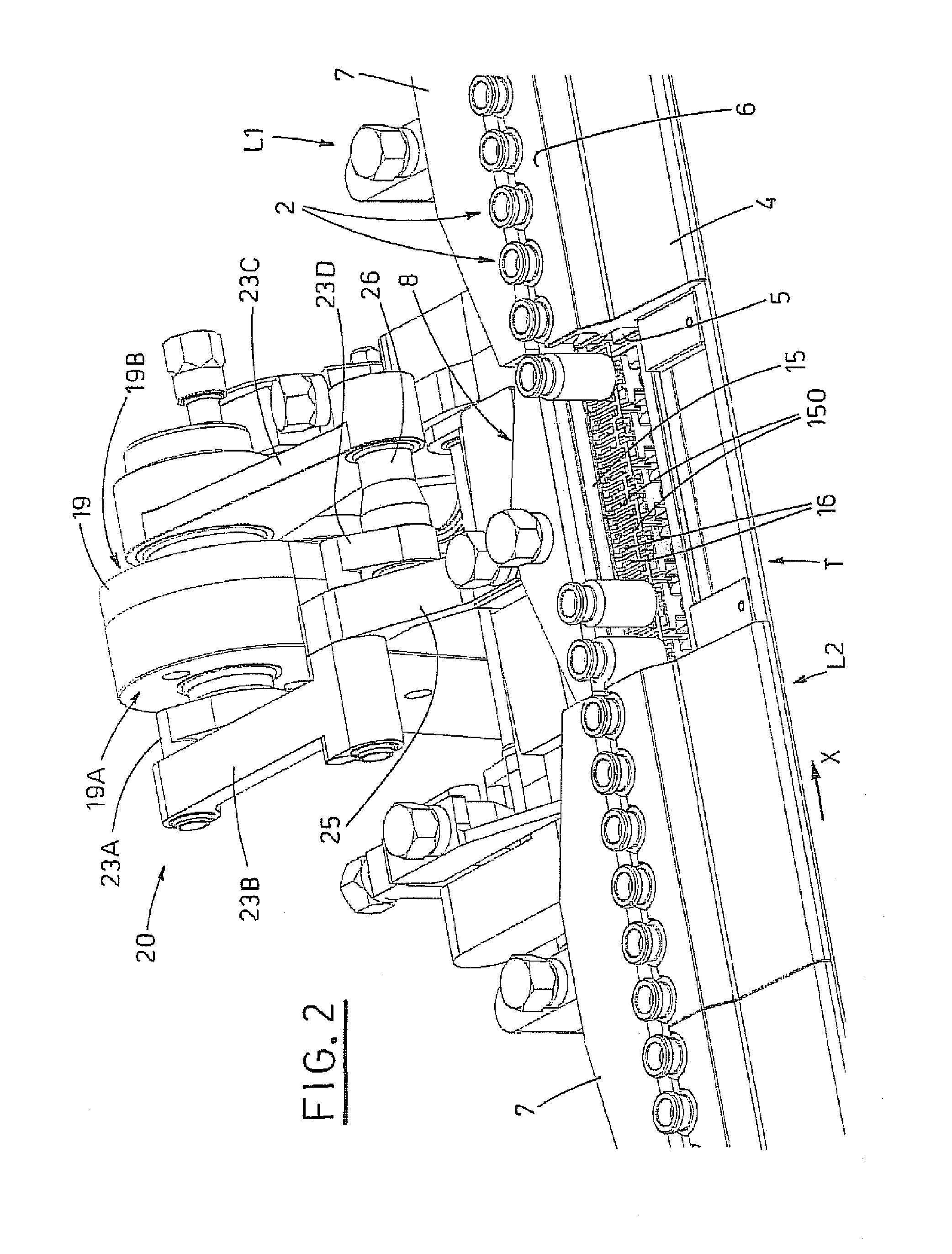

Method for weighing containers which are supplied along a conveying line and a device for actuating the method

ActiveUS20120043181A1Satisfactory productivityLow costMetal sawing devicesFeeding devicesEngineeringMechanical engineering

The invention relates to a device and a method for weighing containers (2) supplied along a conveying line (L). The device comprises: first weighing means (MP1) arranged on a first side (L1) of a stretch (T) of the conveying line (L) of containers (2) in a proximal position thereto; second weighing means (MP2) arranged at a side of the stretch (T) of the conveying line (L) of containers (2) in a distal position thereto; a supporting member (8) activatable between a first position (P1) in which it is arranged at the stretch (T) of the conveying line (L) for receiving the containers (2), a second position (P2) in which it engages with the first weighing means (MP1), and a third position (P3) in which it engages with the second weighing means (MP2); and first guide means (9) activatable between a guide configuration (C1), in which they are arranged at the stretch (T) in order to guide the containers (2) along the conveying line (L), and a disengaged position (C2). The method comprises steps of: activating the support member (8) in order to bring the containers (2) received from the conveying line (L) into the third position (P3); activating the second weighing means (MP2) order to weigh the containers (2); activating the first guide means (9) in order to reach the guide configuration (C1) in phase relation with the movement of the support member (8).

Owner:IMA LIFE SRL

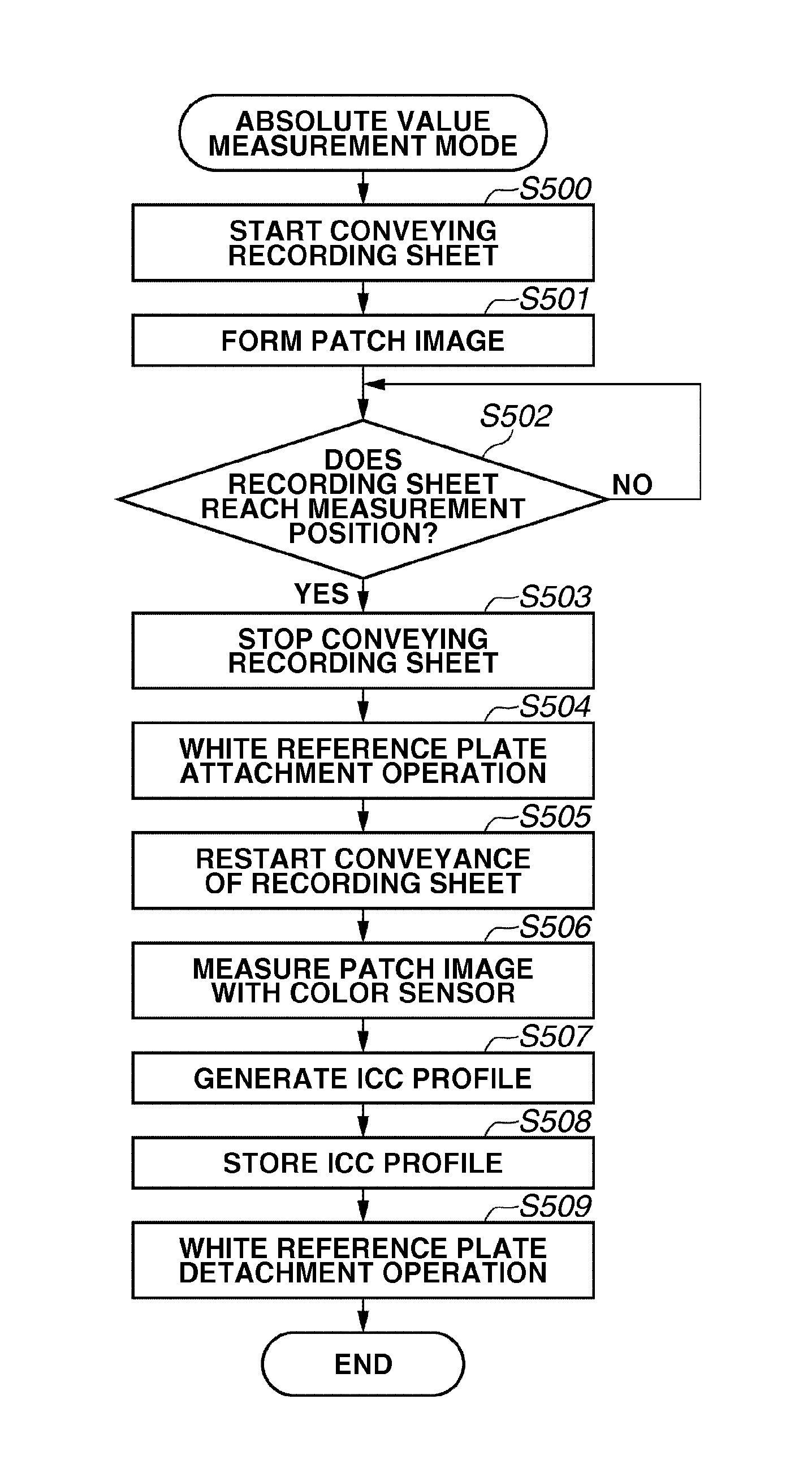

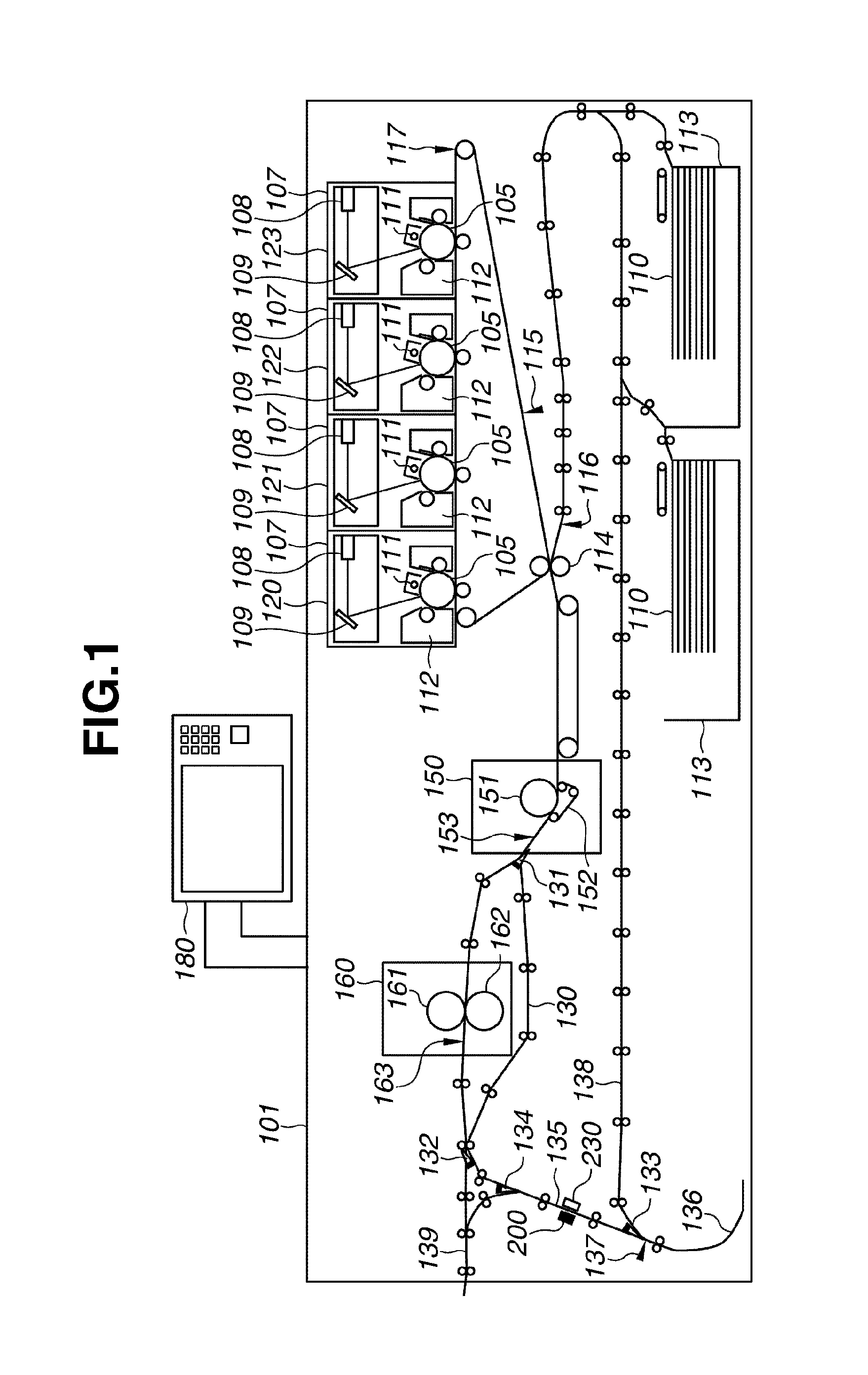

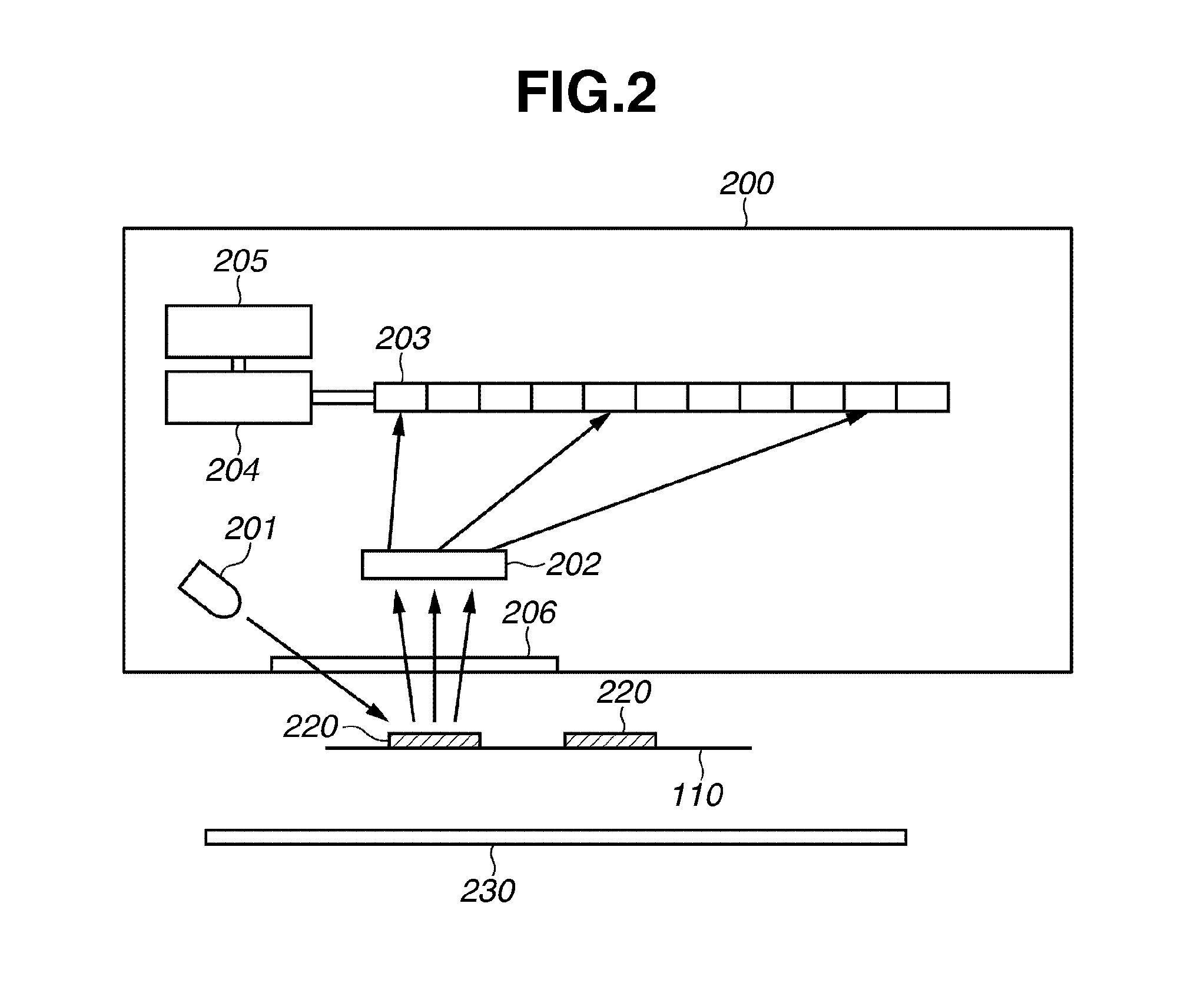

Image forming apparatus and control method thereof

InactiveUS8909072B2Improve accuracySatisfactory productivityElectrographic process apparatusElectrographic processes using charge patternElectrical and Electronics engineeringEngineering

Owner:CANON KK

Constituent part of cooling system for motor vehicle

ActiveCN101636571ASatisfactory productivitySatisfactory calcium chloride resistanceLiquid coolingIndirect heat exchangersGlass fiberPolyamide

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com