Patents

Literature

568 results about "Reaction inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reaction inhibitor is a substance that decreases the rate of, or prevents, a chemical reaction. A catalyst, in contrast, is a substance that increases the rate of a chemical reaction.

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

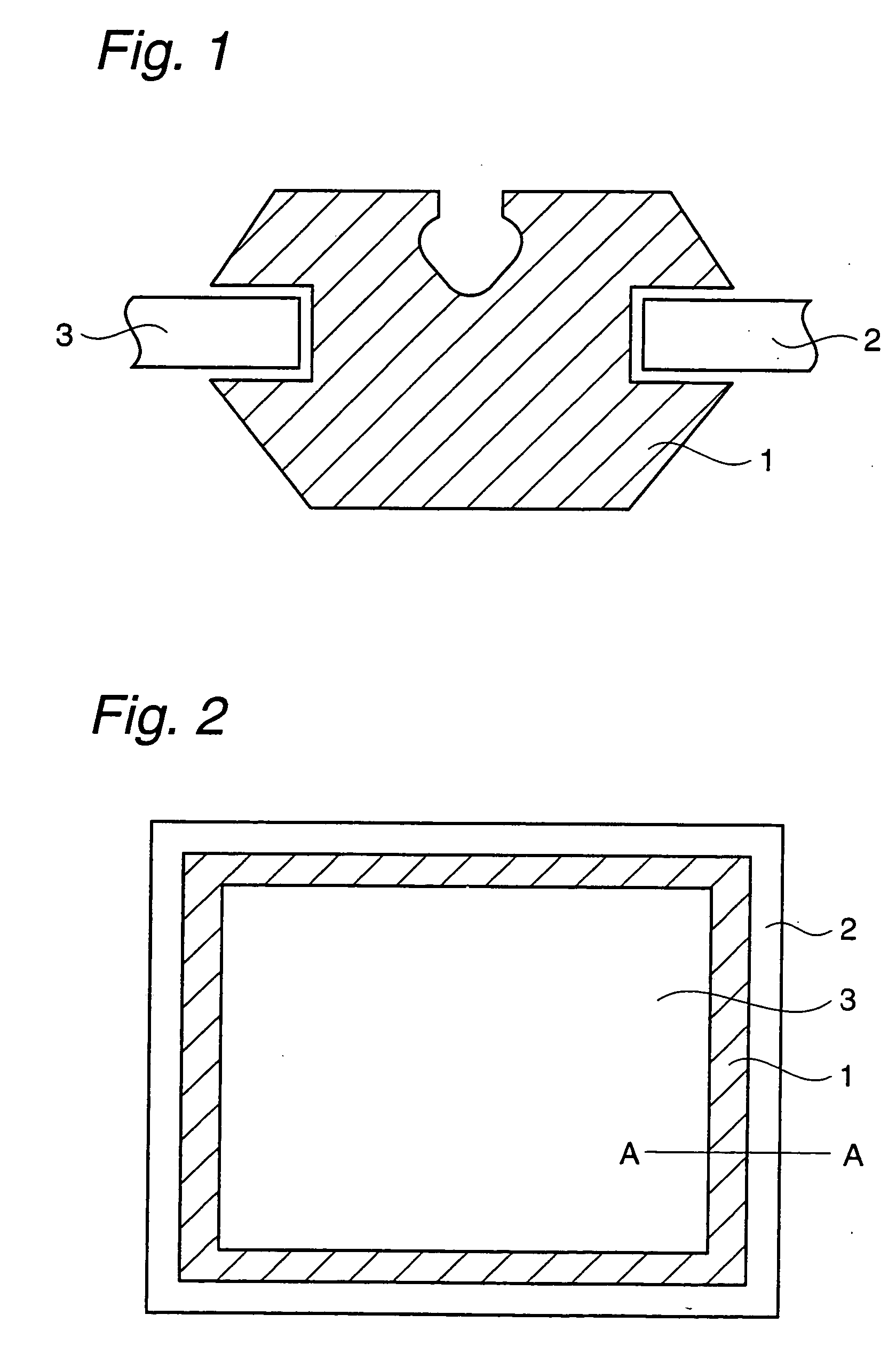

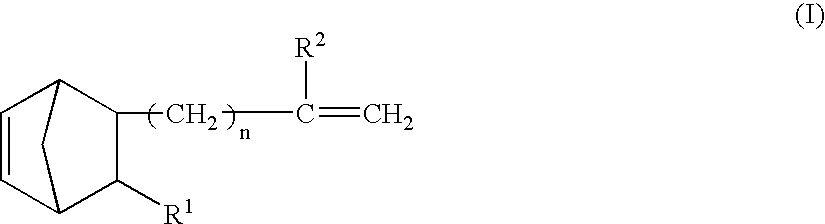

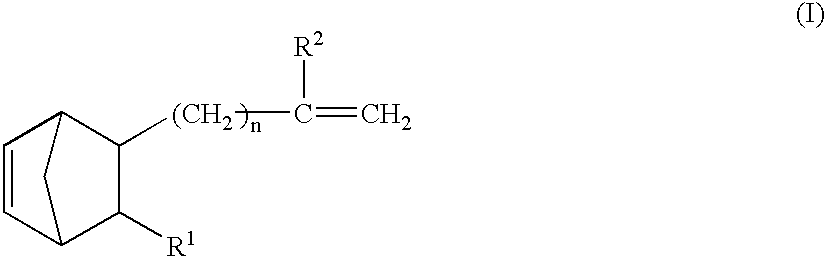

Crosslinkable rubber compositions and use thereof

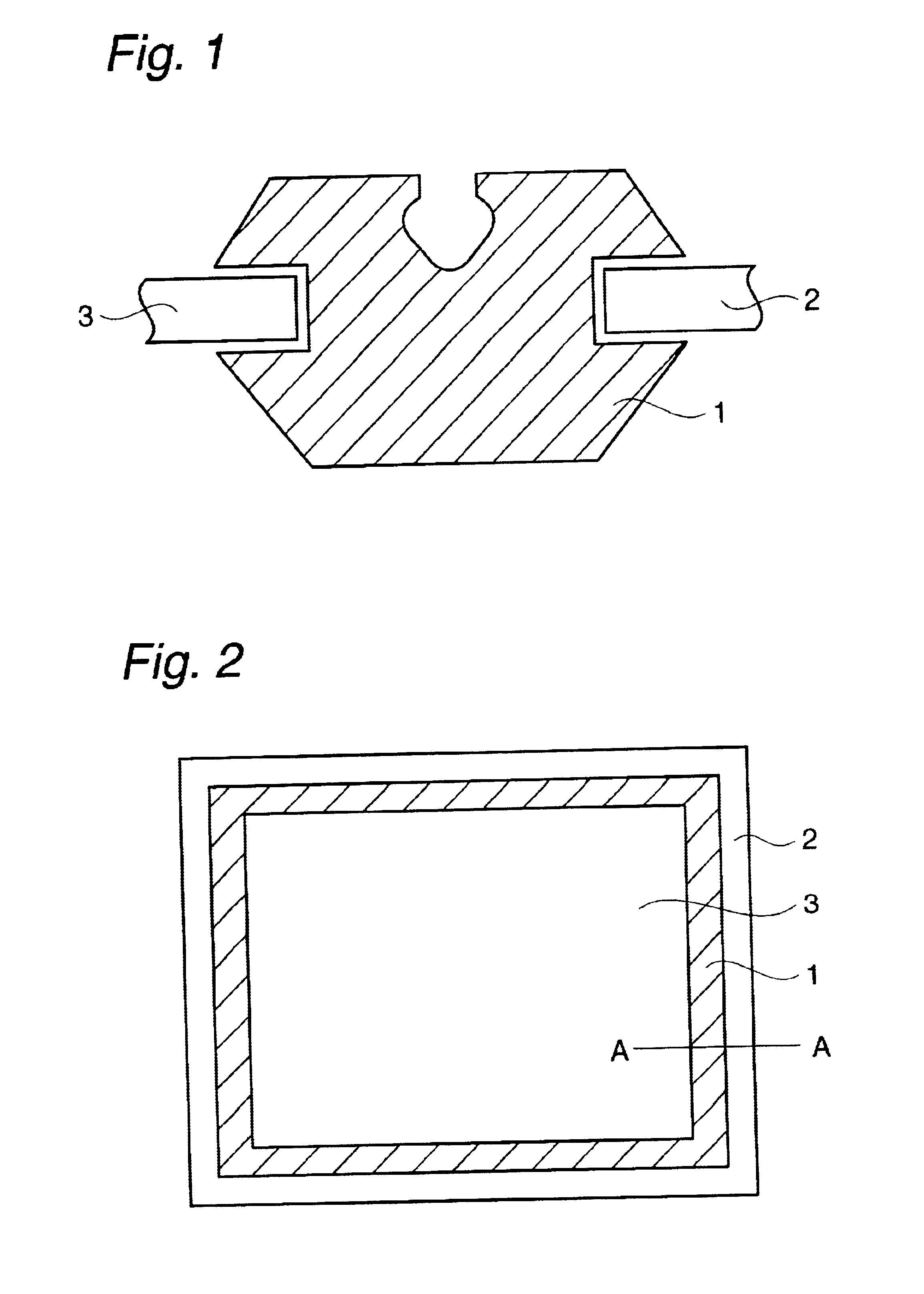

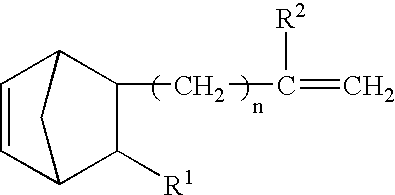

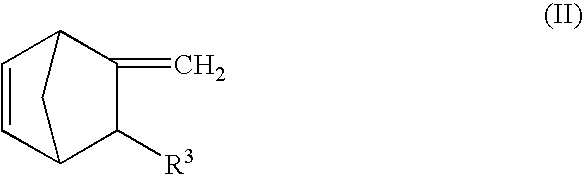

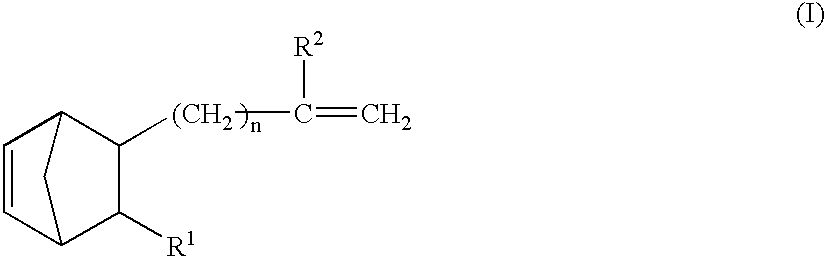

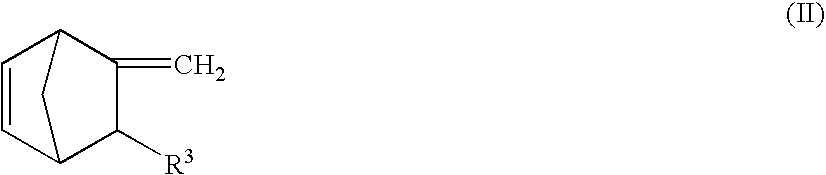

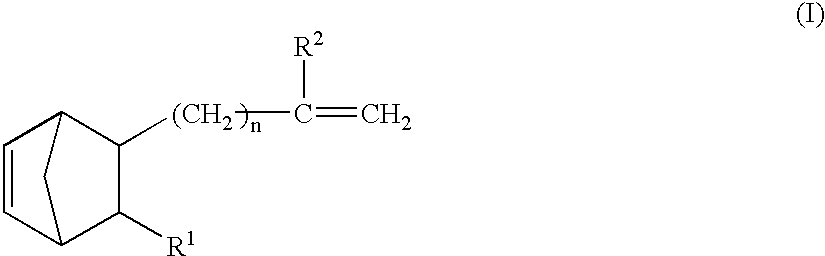

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC +1

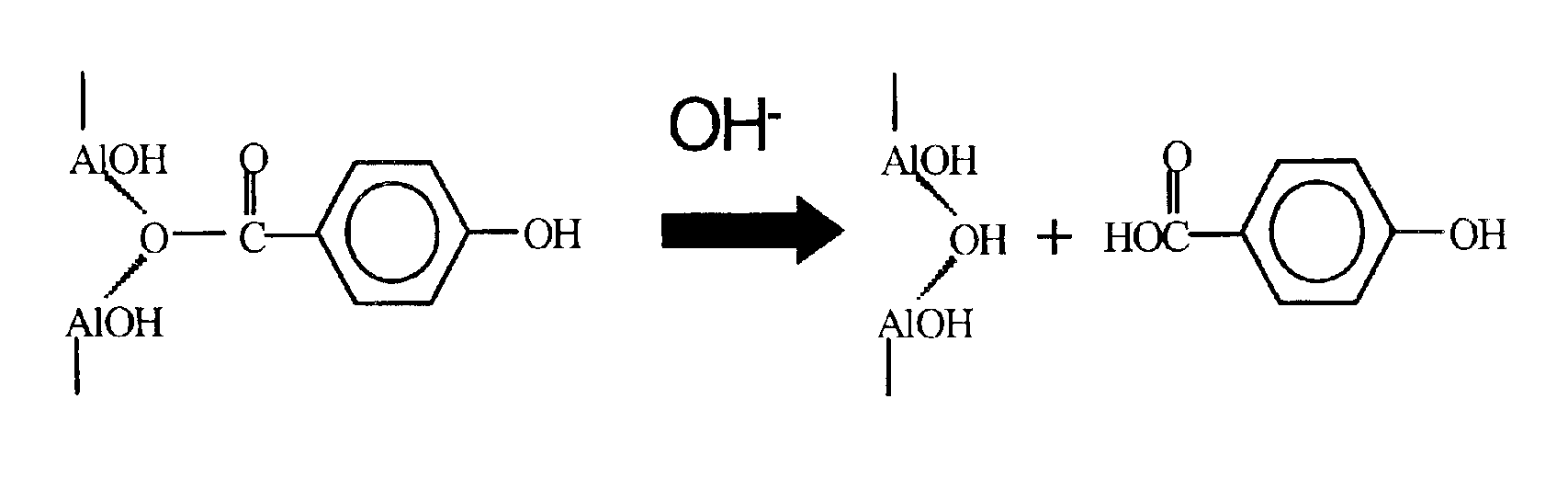

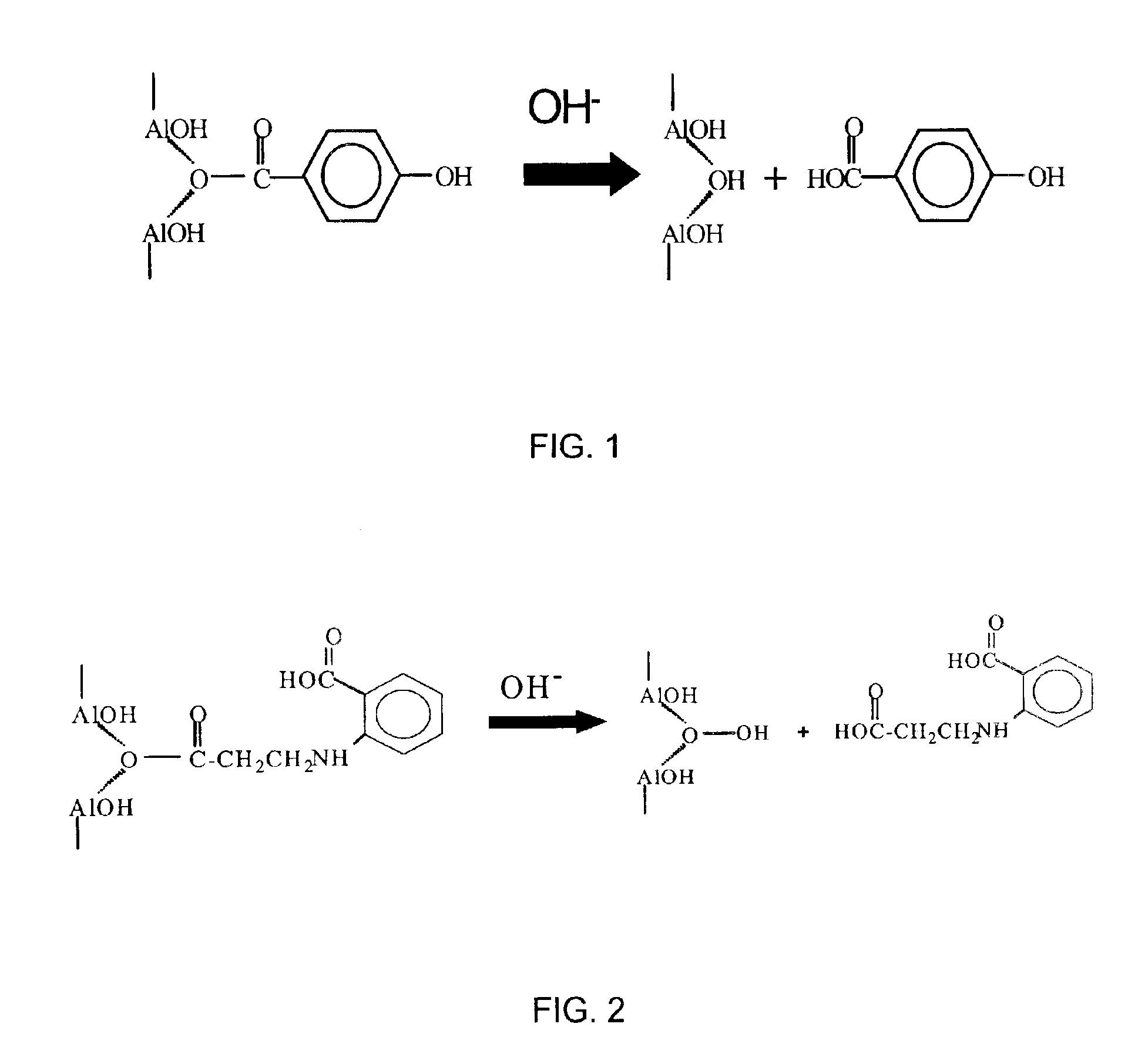

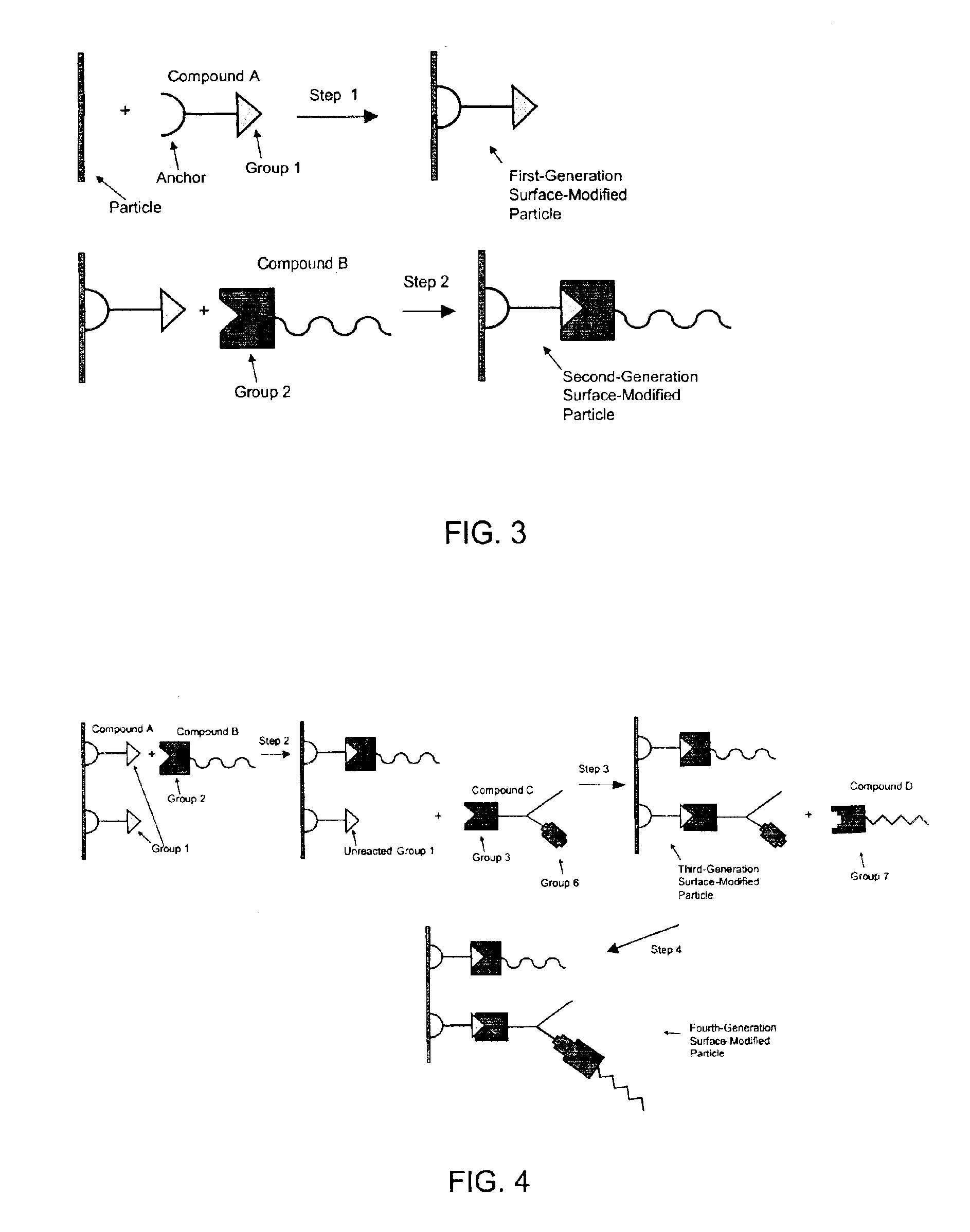

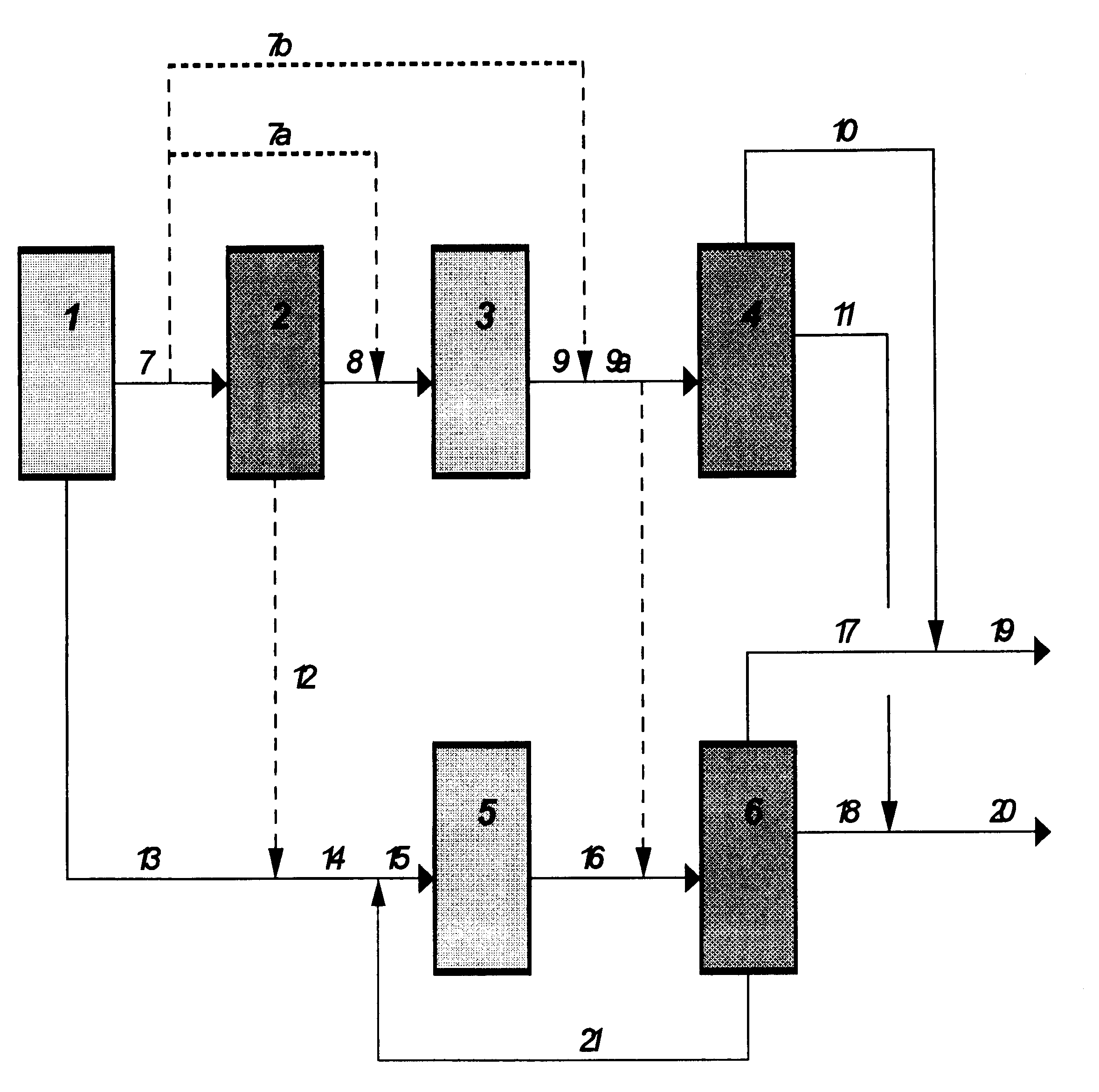

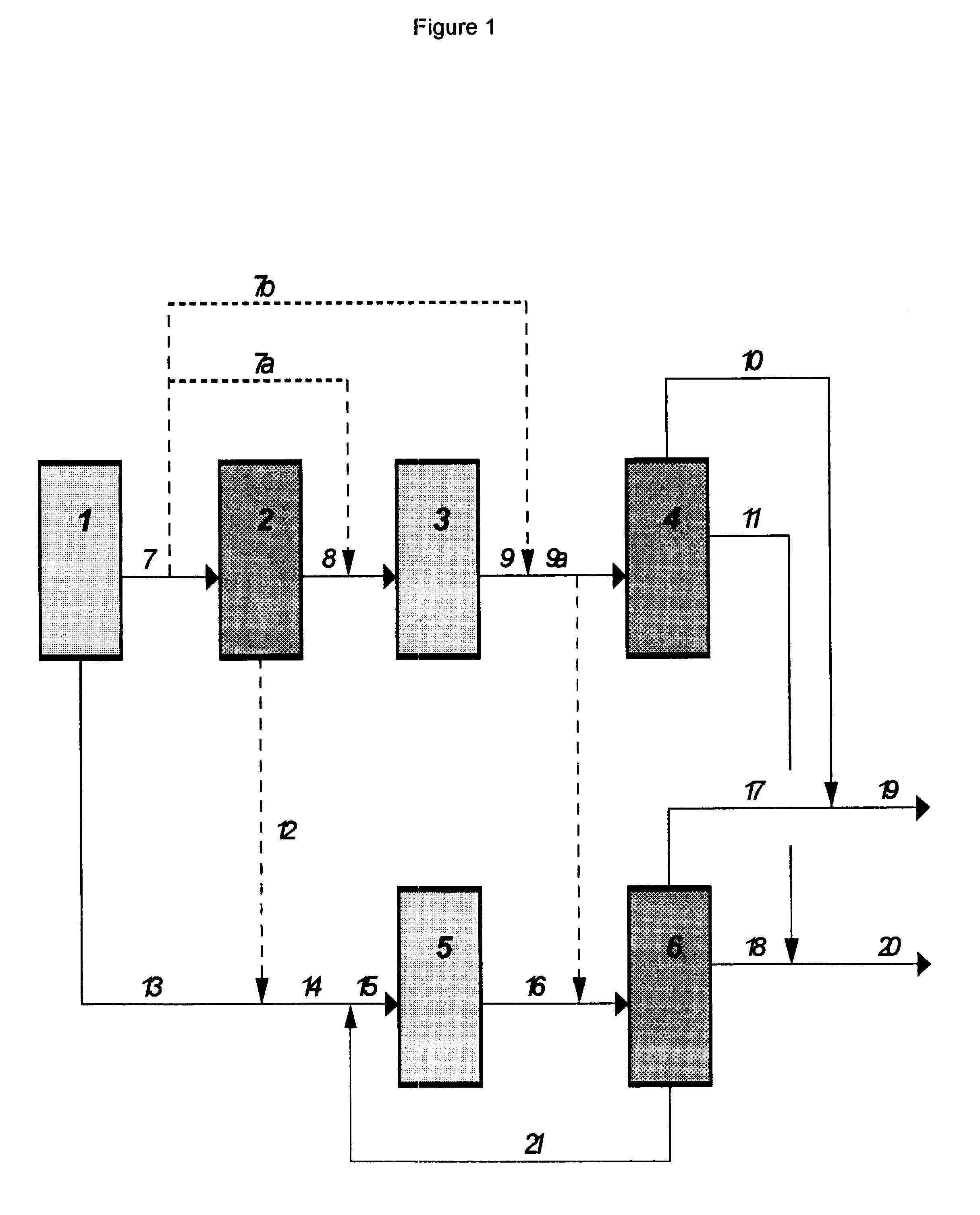

Releasable corrosion inhibitor compositions

InactiveUS6933046B1Without degrading physical property and performance of coatingReduce impactMaterial nanotechnologyPigmenting treatmentCarboxylic acidMetal

A new class of releasable corrosion inhibiting materials for protective coatings, methods of making the same, methods of using the same, and coatings containing the same are provided. The materials comprise one or more corrosion inhibitors that are chemically anchored to the surface of a particle having an aluminum oxyhydroxide surface through a carboxylate bond. The carboxylate / aluminum-oxyhydroxide-surface bond breaks under corrosion-causing conditions (for example the presence of high levels of hydroxide ions generated by the cathodic oxygen reduction reaction on metals such as iron and aluminum) thereby allowing the corrosion inhibitors to detach from the particle surface when corrosion is present.

Owner:TDA RES

Process for producing synthetic naphtha fuel and synthetic naphtha fuel produced by that process

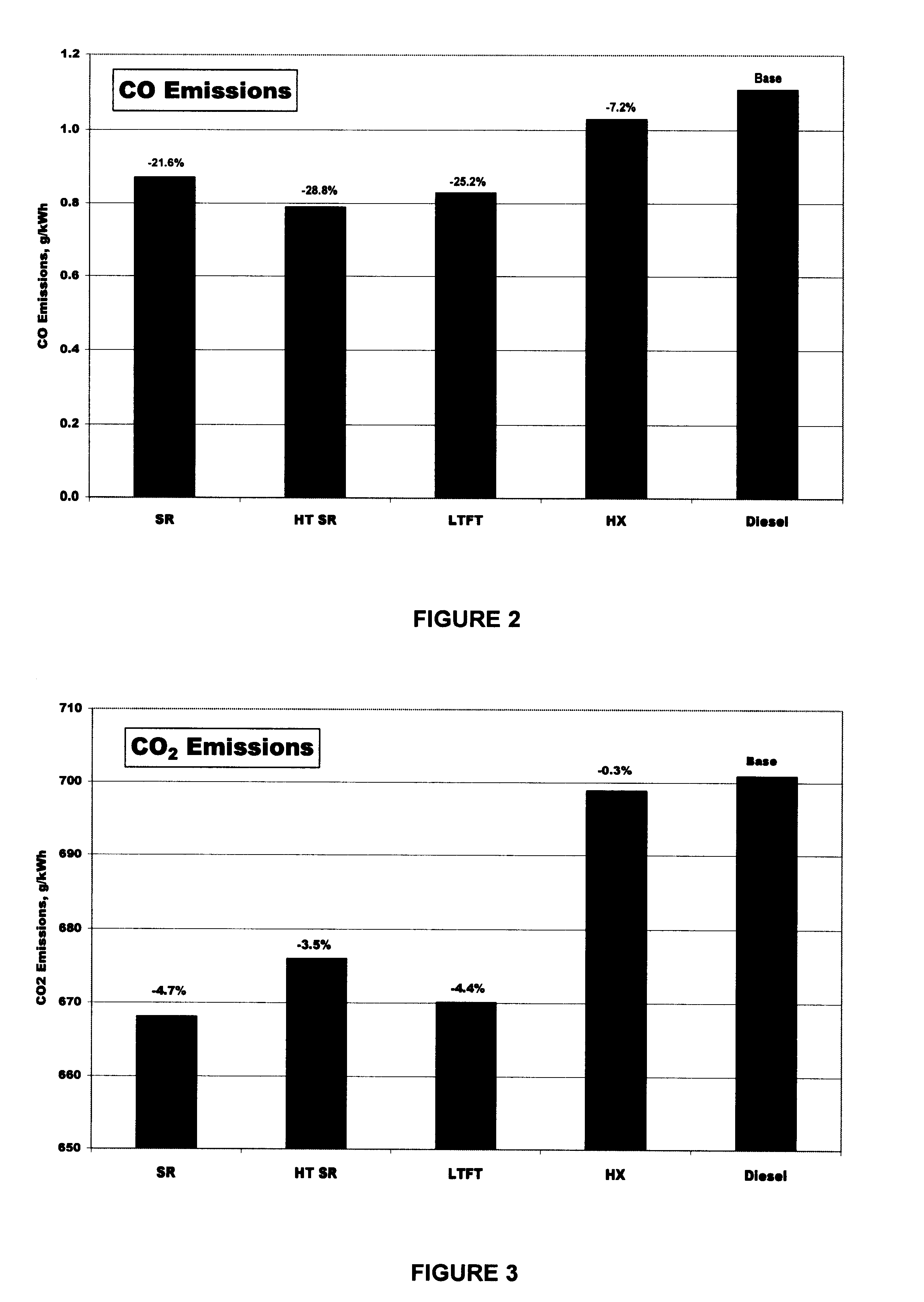

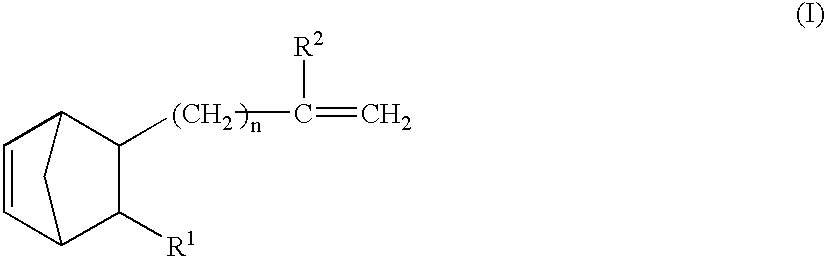

InactiveUS6475375B1Treatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyNaphthaEngineering

The invention provides a process for the production of a synthetic naphtha fuel suitable for use in compression ignition (CI) engines, the process including at least the steps of hydrotreating at least a fraction of a Fischer-Tropsch (FT) synthesis reaction product of CO and H2, or a derivative thereof, hydrocracking at least a fraction of the FT synthesis product or a derivative thereof, and fractionating the process products to obtain a desired synthetic naphtha fuel characteristic. The invention also provides a synthetic naphtha fuel made by the process as well as a fuel composition and a Cloud Point depressant for a diesel containg fuel composition, said fuel composition and said depressant including the synthetic naphtha of the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD +1

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition. The rubber composition has a high crosslinking rate at room temperature and excellent productivity, and can prepare crosslinked rubber molded products (including foamed products) having excellent weathering resistance, ozone resistance, heat aging resistance and compression set at low cost. Further, it is suitable for use of electric and electronic parts, transportation machines, civil engineering and construction materials, medical appliances and goods for leisure activities.

Owner:MITSUI CHEM INC

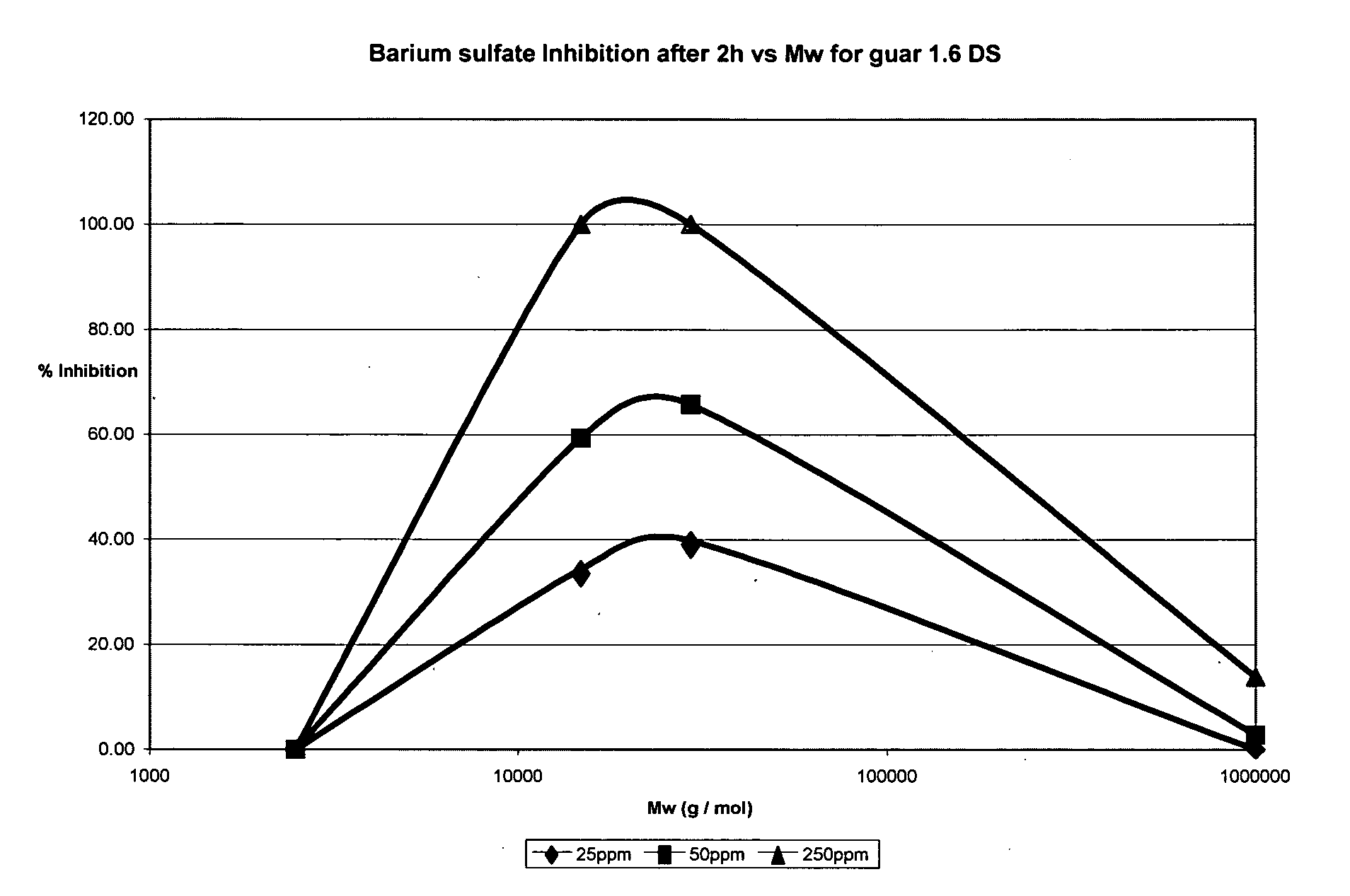

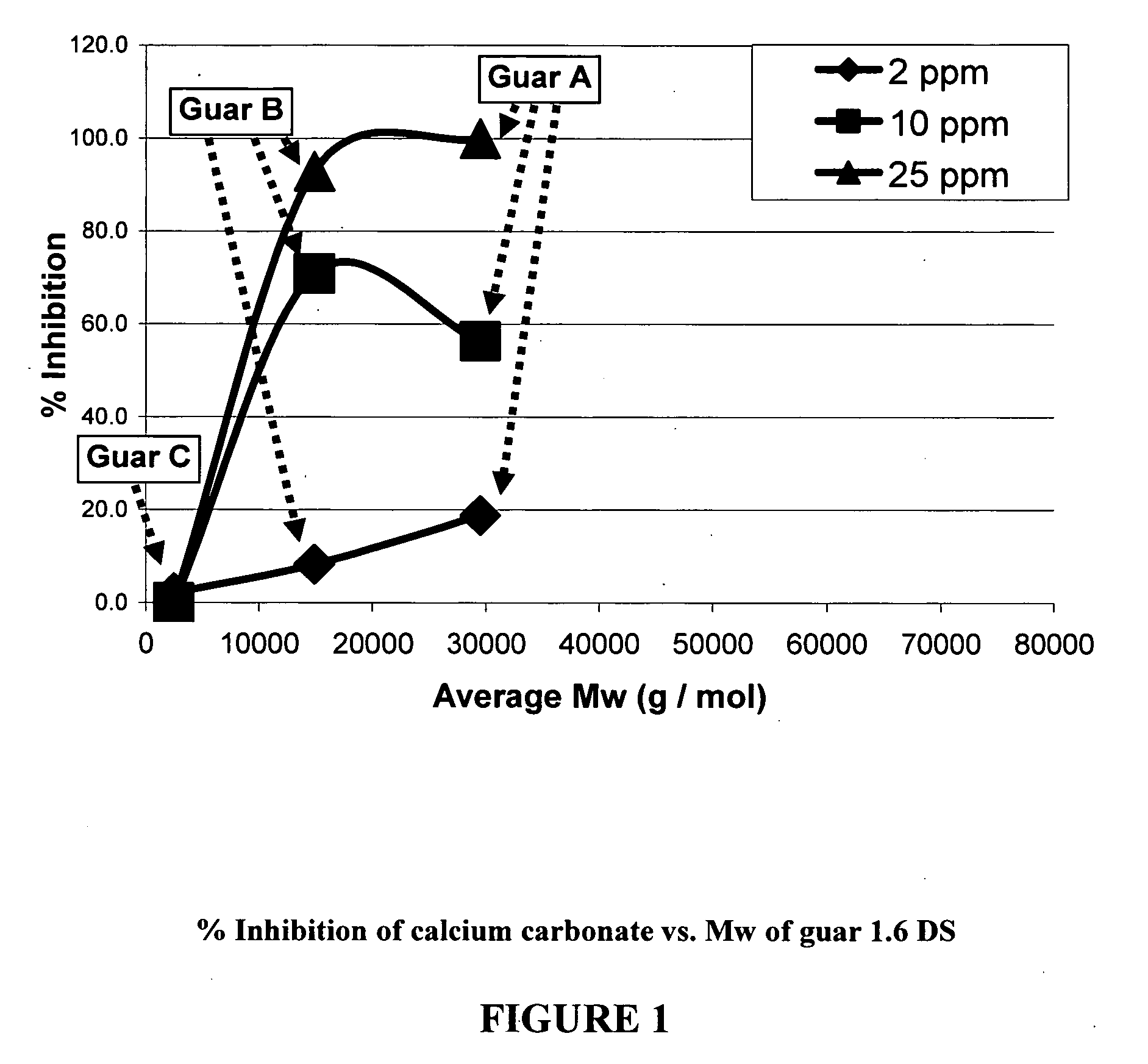

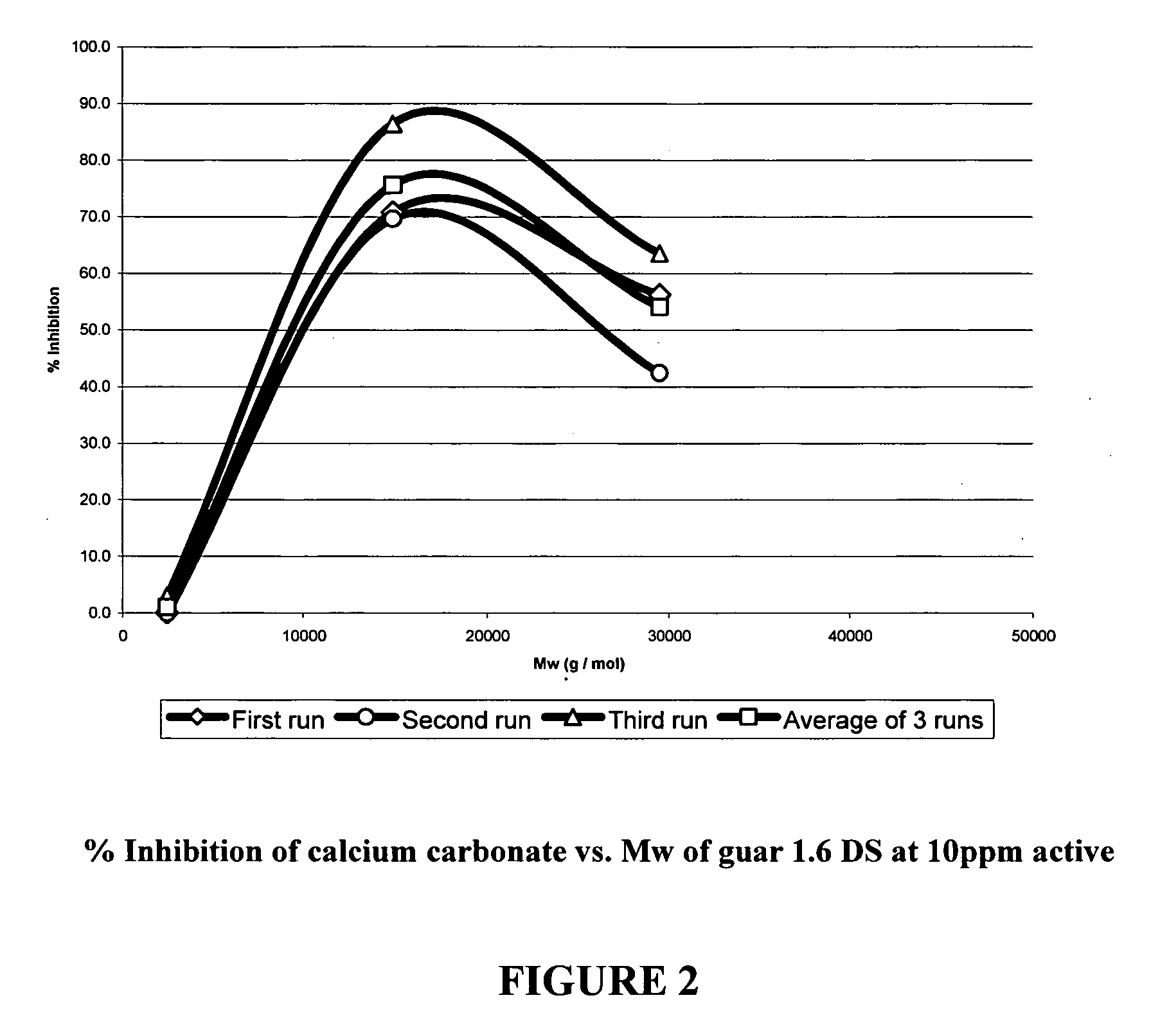

Polysaccharide based scale inhibitor

ActiveUS20080277620A1Reduce and prevent productionPrevent scalingWaste water treatment from quariesInorganic/elemental detergent compounding agentsSulfateDegree of substitution

A depolymerized-carboxyalkyl polysaccharide formed by de polymerizing a polysaccharide having from 0.5 to 3.0 degrees of substitution and reducing the molecular weight of said polysaccharide before or after said depolymerizing provides a biodegradable scale inhibitor useful to prevent deposition of scale comprising, for example, calcium, barium, sulfate and salts thereof. The depolymerized carboxyalkyl polysaccharide is particularly useful in off shore oil production squeeze treatments and in the treatment of scale formed in industrial water treatment.

Owner:RHODIA OPERATIONS SAS

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition of the invention is crosslinkable by hot air, and a hot-air crosslinked rubber sheet thereof has no scratch on the surface in a hardness test using a pencil of HB and has a compression set of not more than 70% after a heat treatment at 150° C. for 22 hours. The rubber composition comprises an ethylene / α-olefin / non-conjugated polyene random copolymer rubber comprising a specific vinyl end group-containing norbornene compound, a SiH group-containing compound having at least two SiH groups in one molecule, and if necessary, an addition reaction catalyst comprising a platinum group element and a reaction inhibitor. The automobile weatherstrip, hose, rubber vibration insulator, belt, sealing material, expanded product, covered electric wire, electric wire joint, electric insulating part and household rubber product according to the invention comprise the above-mentioned rubber composition. The rubber composition has a high crosslinking rate and excellent productivity to produce crosslinked rubber molded products, is capable of undergoing hot-air crosslinking such as HAV or UHF and is capable of providing crosslinked rubber molded products having excellent compression set resistance, strength properties, heat resistance, weathering resistance and abrasion resistance.

Owner:MITSUI CHEM INC

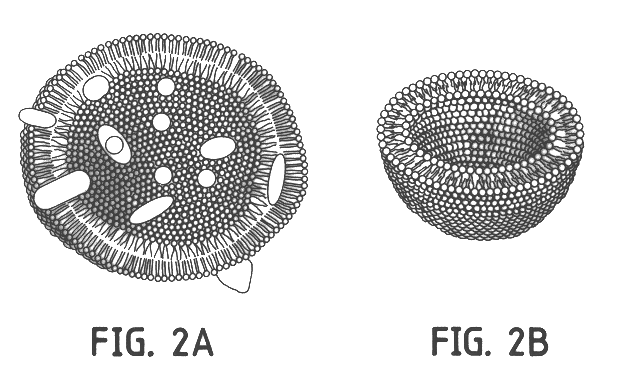

Direct colorimetric detection of biocatalysts

InactiveUS6468759B1Rapid optical signalFast response timeMaterial nanotechnologyColor measuring devicesAnalyteColor changes

The present invention relates to methods and compositions for the direct detection of membrane conformational changes through the detection of color changes in biopolymeric materials. In particular, the present invention allows for the direct colorimetric detection of membrane modifying reactions and analytes responsible for such modifications and for the screening of reaction inhibitors.

Owner:RGT UNIV OF CALIFORNIA

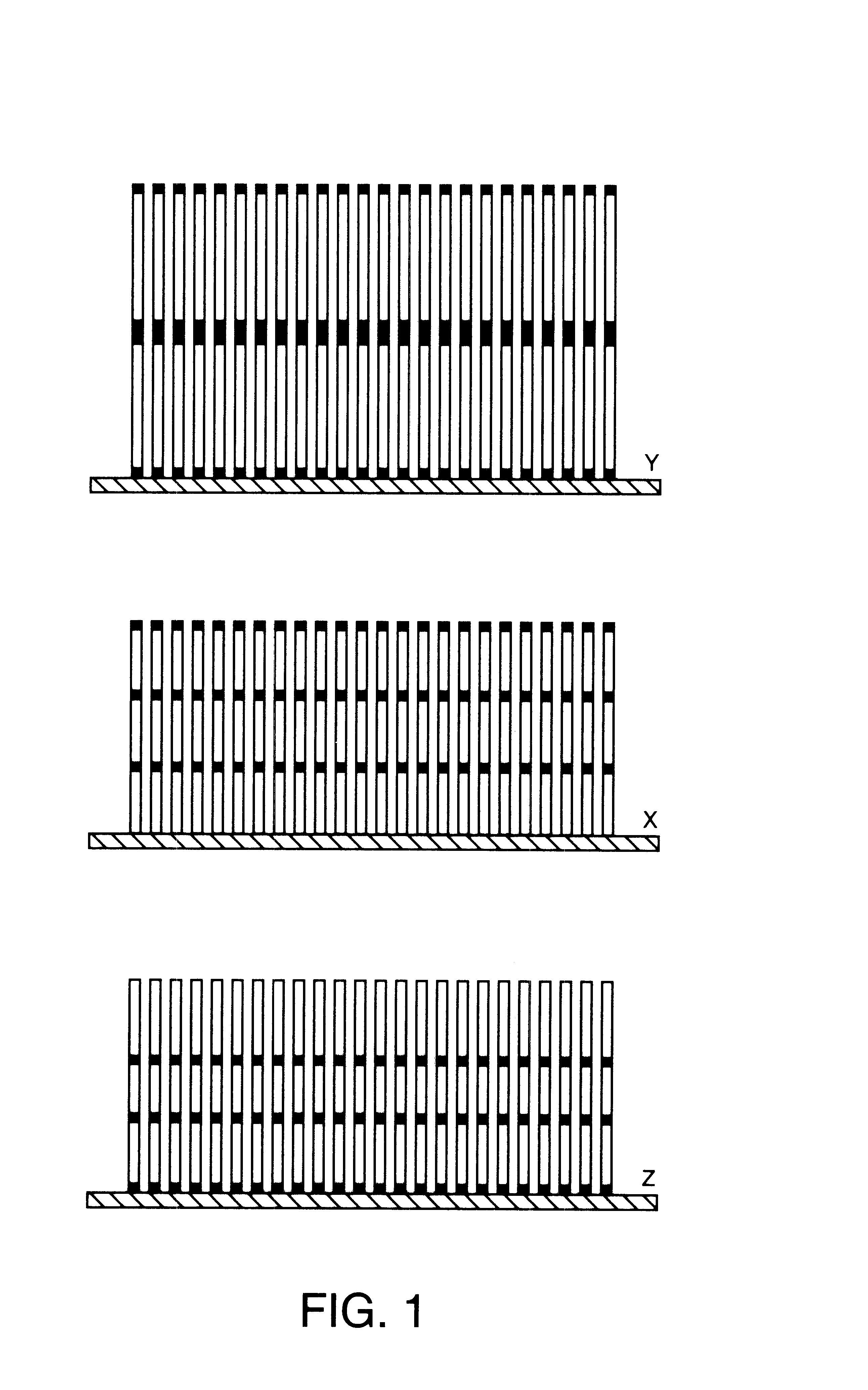

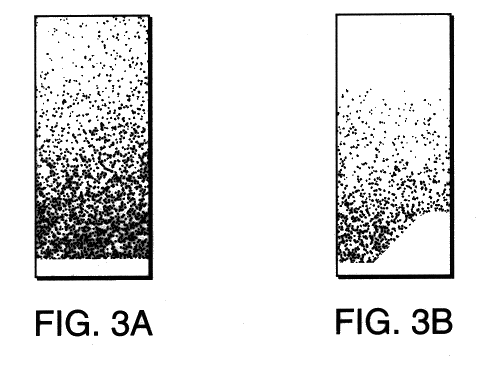

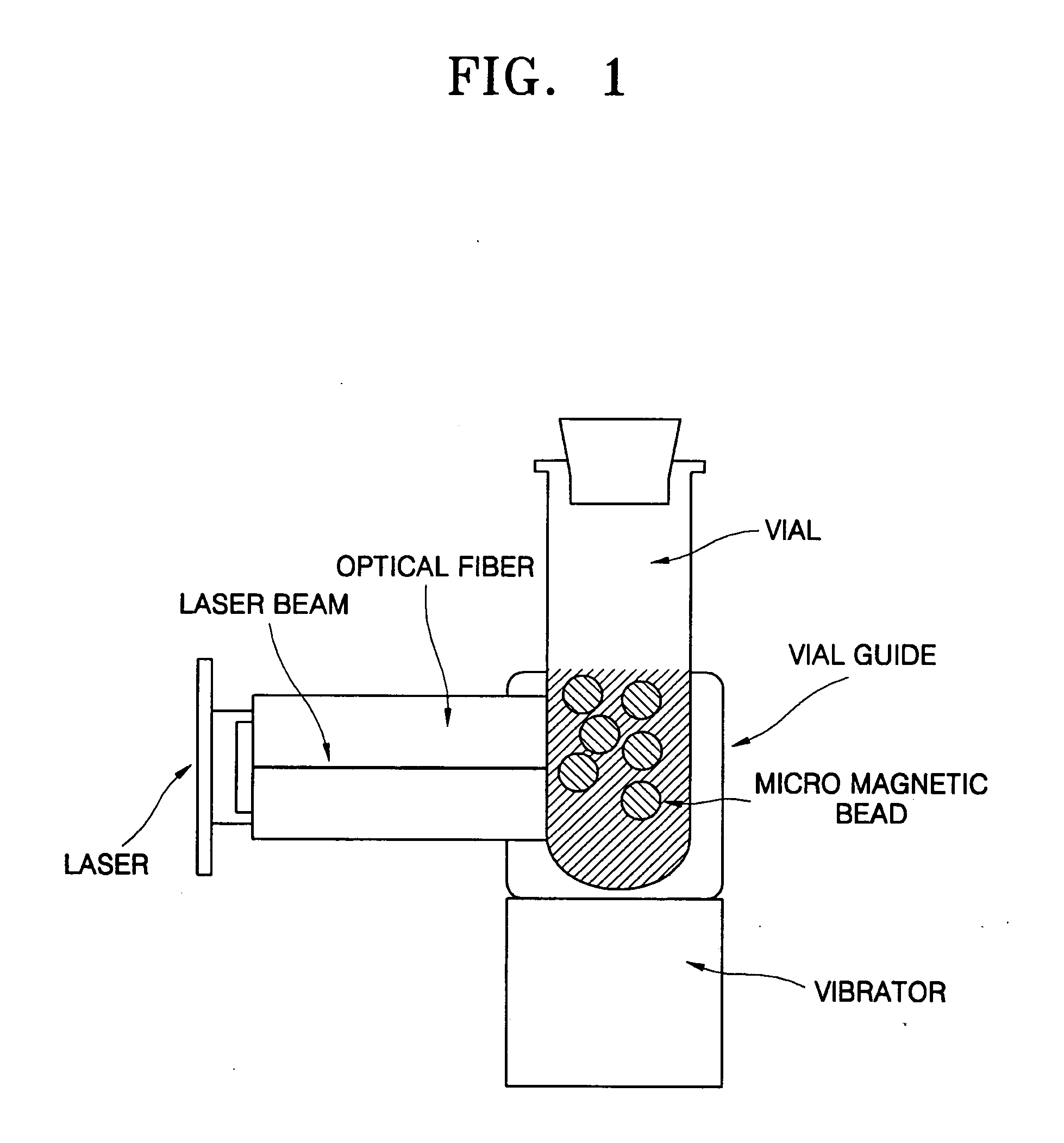

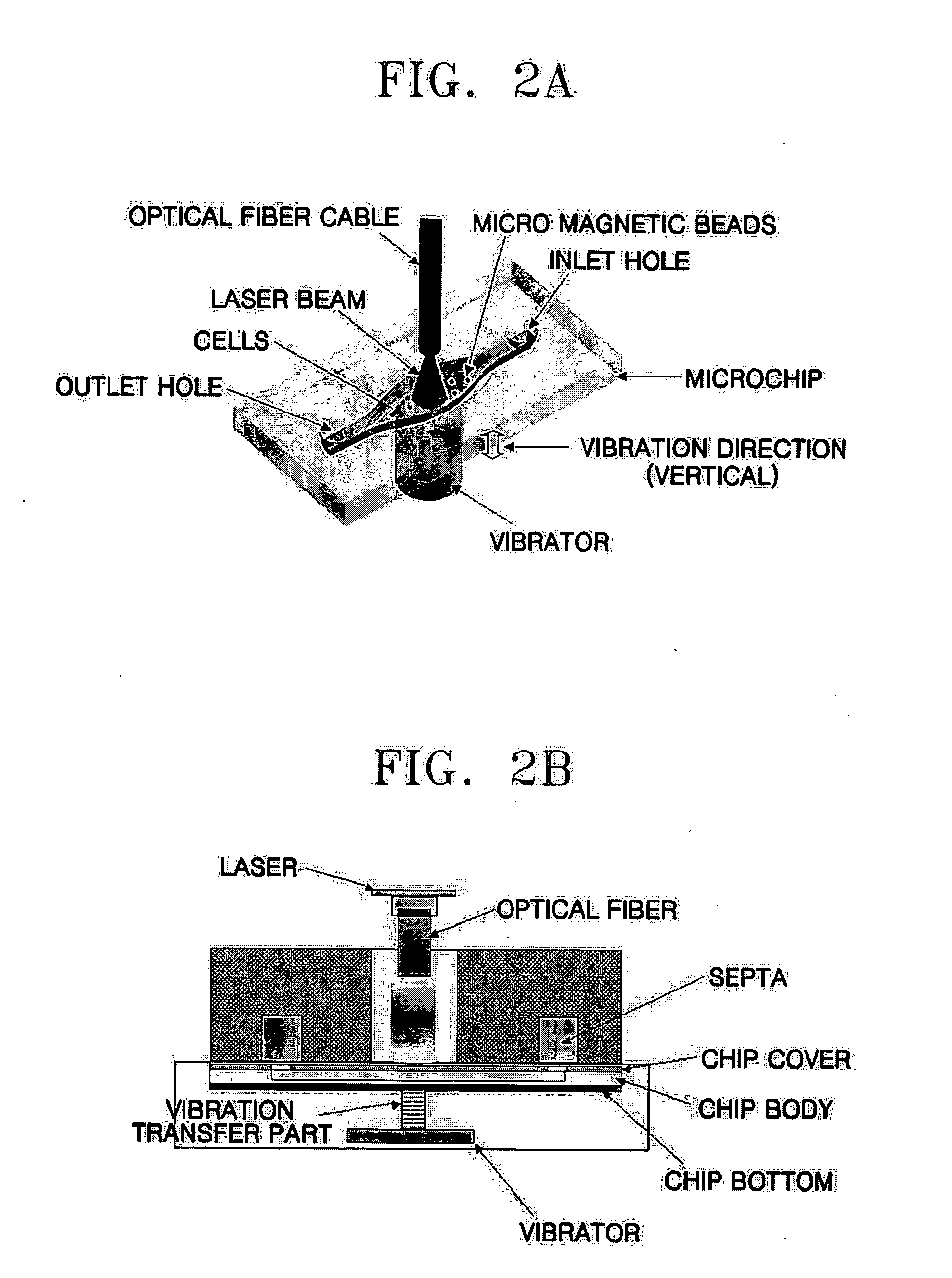

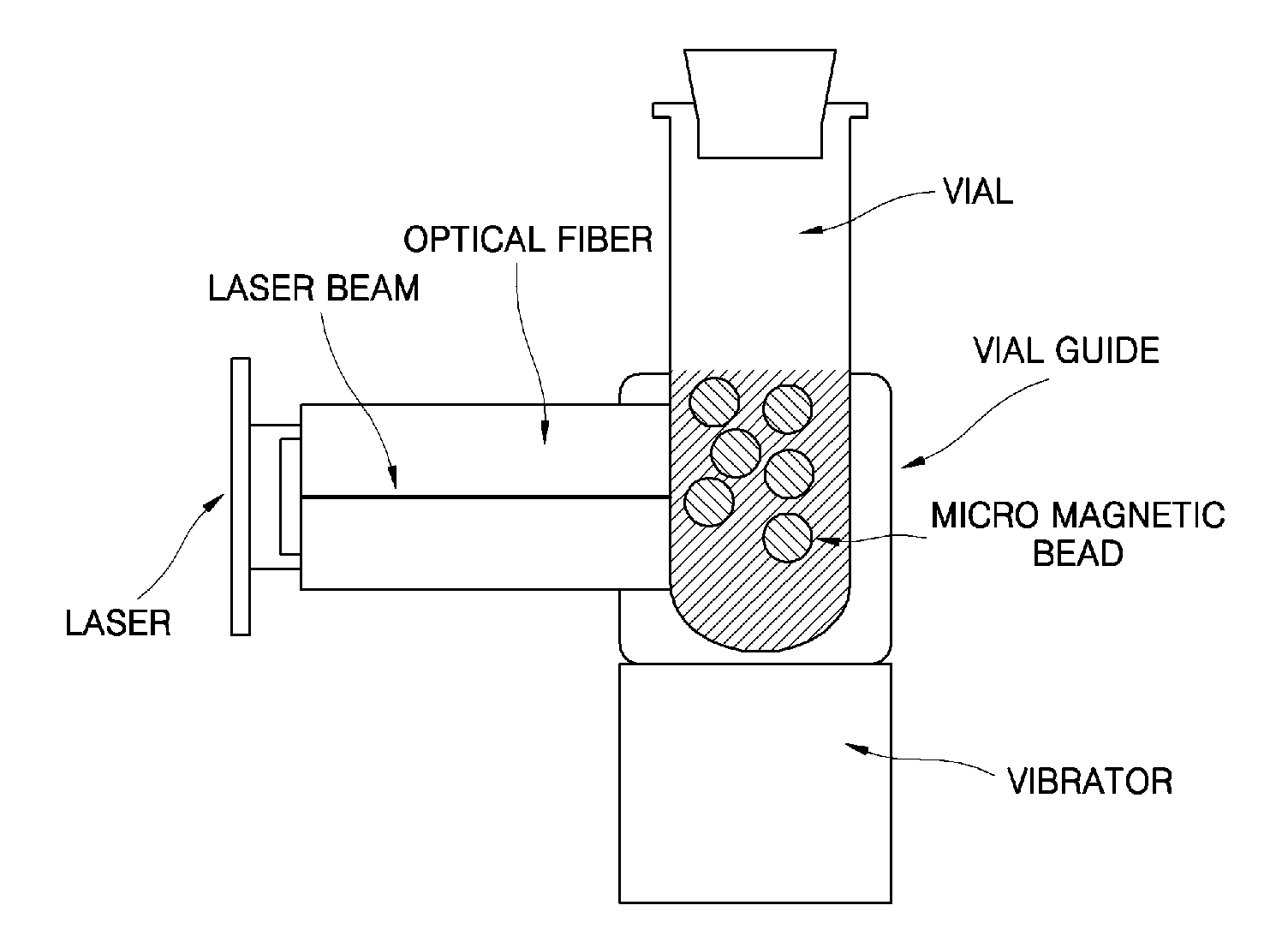

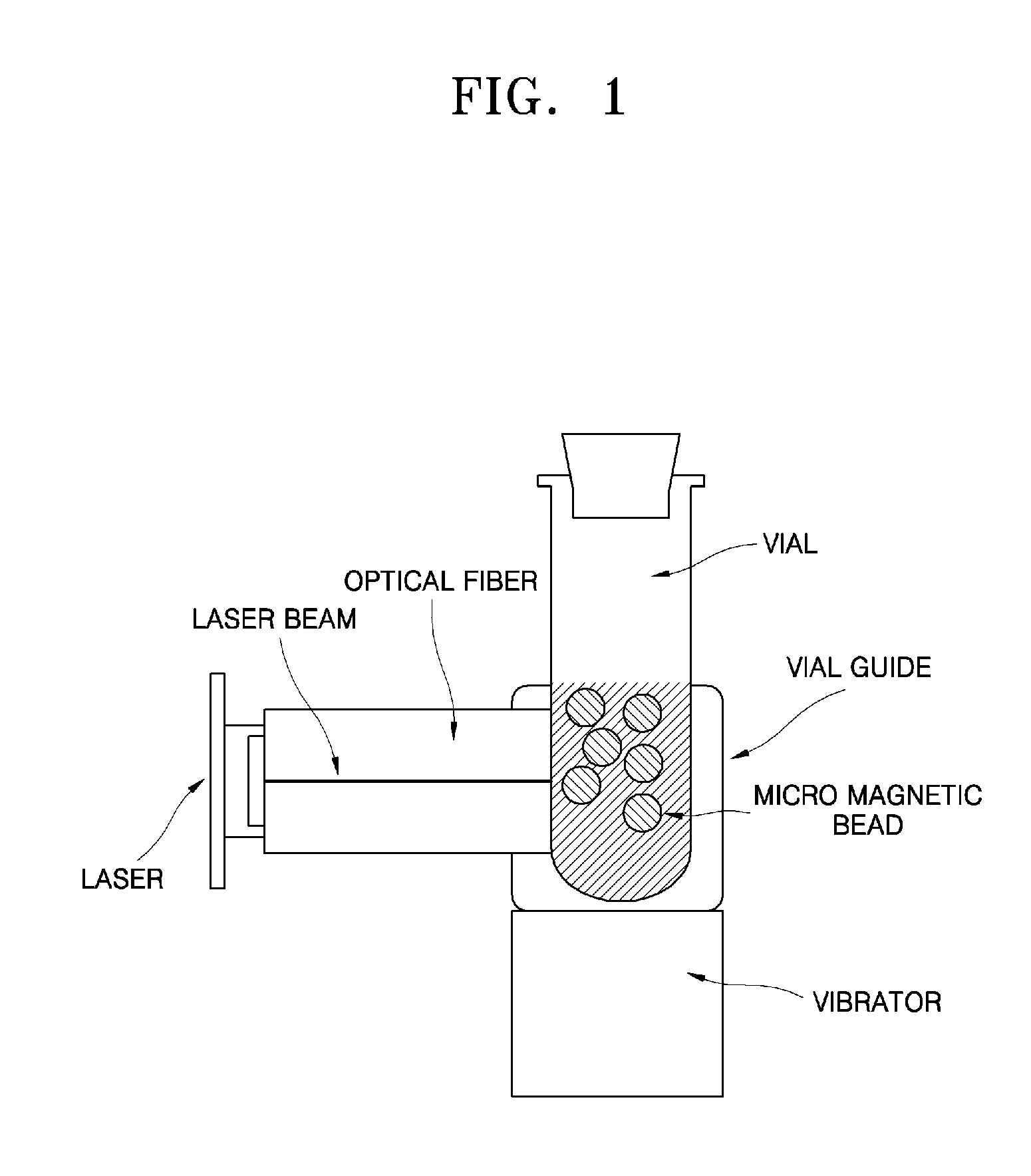

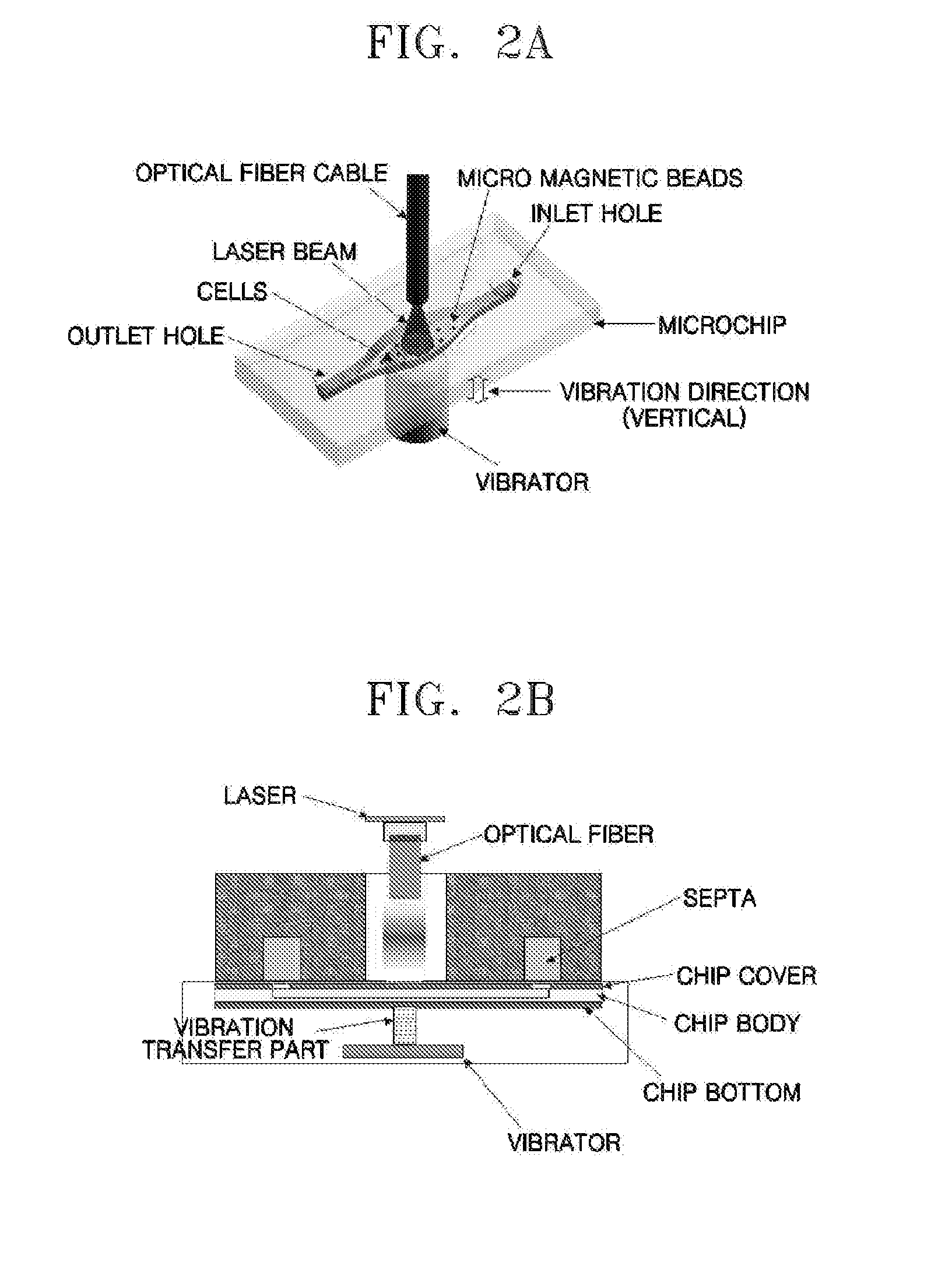

Method and apparatus for the rapid disruption of cells or viruses using micro magnetic beads and laser

ActiveUS20060084165A1Efficient releaseEfficient amplificationBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersRough surfaceLysis

A method and apparatus for a rapid disruption of cells or viruses using micro magnetic beads and a laser are provided. According to the method and apparatus for a rapid disruption of cells or viruses using micro magnetic beads and a laser, cell lysis within 40 seconds is possible, the apparatus can be miniaturized using a laser diode, a DNA purification step can be directly performed after a disruption of cells or viruses, and a solution containing DNA can be transferred to a subsequent step after cell debris and beads to which inhibitors of a subsequent reaction are attached are removed with an electromagnet. In addition, by means of the cell lysis chip, an evaporation problem is solved, vibrations can be efficiently transferred to cells through magnetic beads, a microfluidics problem on a rough surface is solved by hydrophobically treating the inner surface of the chip, and the cell lysis chip can be applied to LOC.

Owner:SAMSUNG ELECTRONICS CO LTD

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition.

Owner:MITSUI CHEM INC

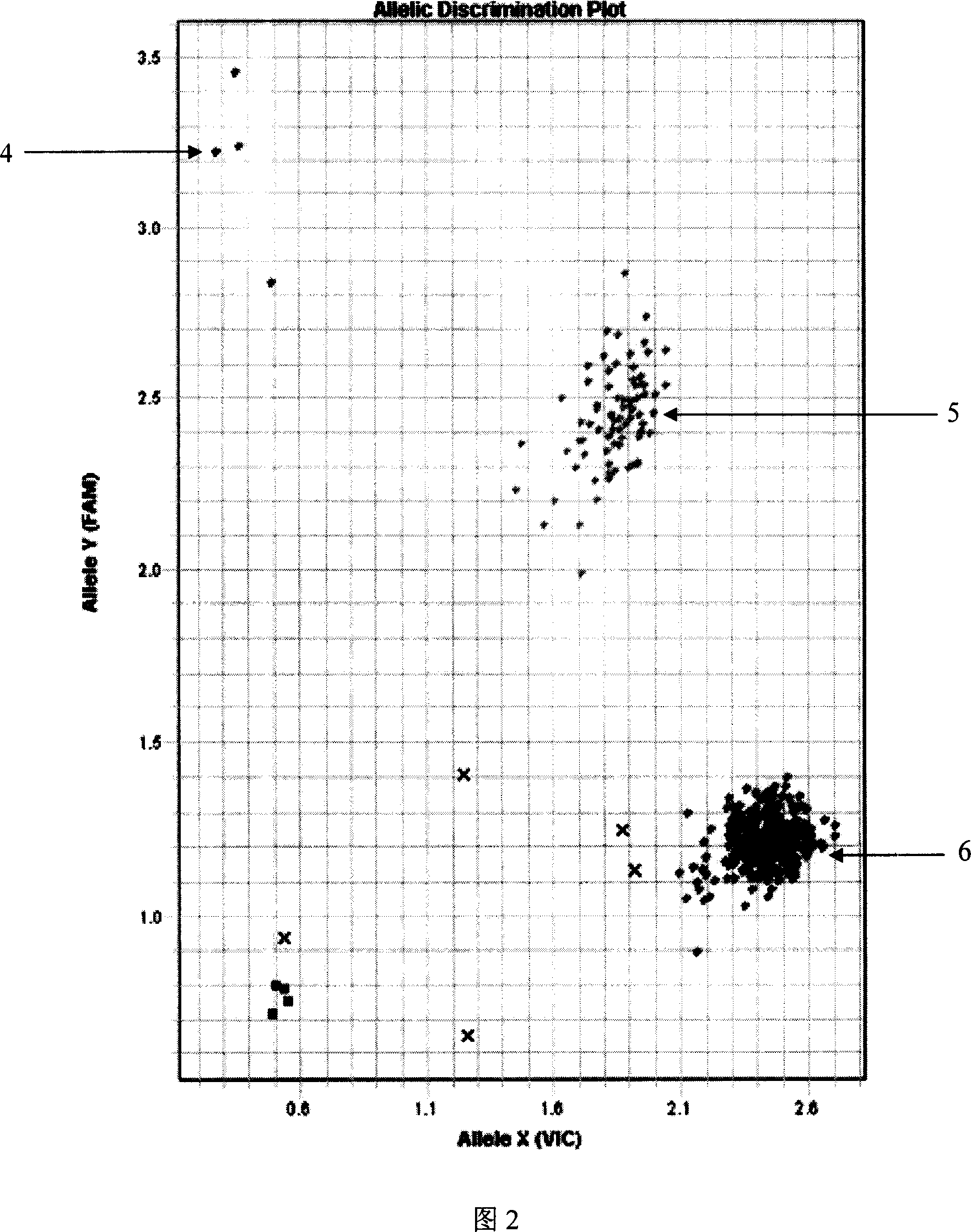

Reagent case for predicting action effect of angiotensin conversion enzyme inhibitor medicament

ActiveCN101063166APredictive validityPredict safetyMicrobiological testing/measurementWild typeBiology

The invention discloses an agent box, which is characterized by the following: utilizing the relation between mononucleotide polymorphism site E112D genetype of important enzyme praline carboxypeptidase gene on vessel or esoderma regulating access and ACEI medical effect; forecasting ACEI medical effect; possessing good ACEI medical effect when genetype as 112EE pure wild-type; possessing bad effect when the genetype as 112ED heterozygous type or 112DD pure saltant; incorporating polymorphism parting oligonucleotide of E112D polymorphism site genetype with praline carboxypeptidase gene to test biological sample and related agent. This invention improves effectiveness and safety of clinic medicine, which provides criterion for new medicine of high blood pressure.

Owner:SHENZHEN AUSA PHARM CO LTD +1

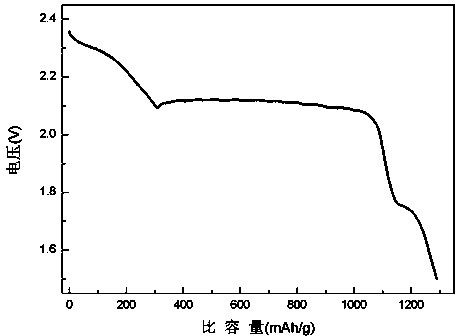

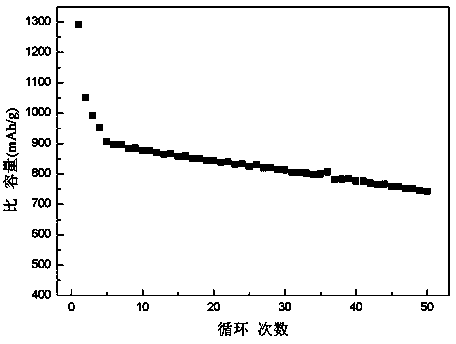

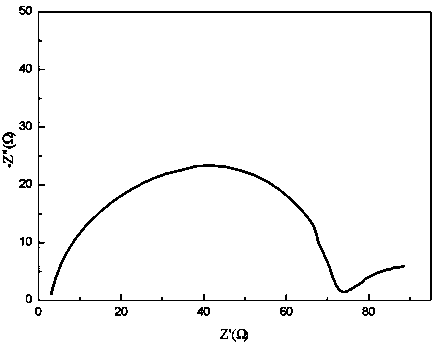

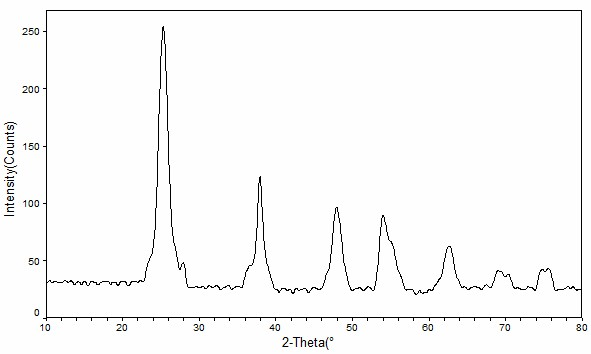

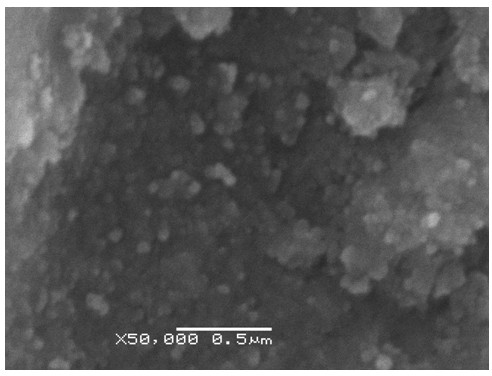

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

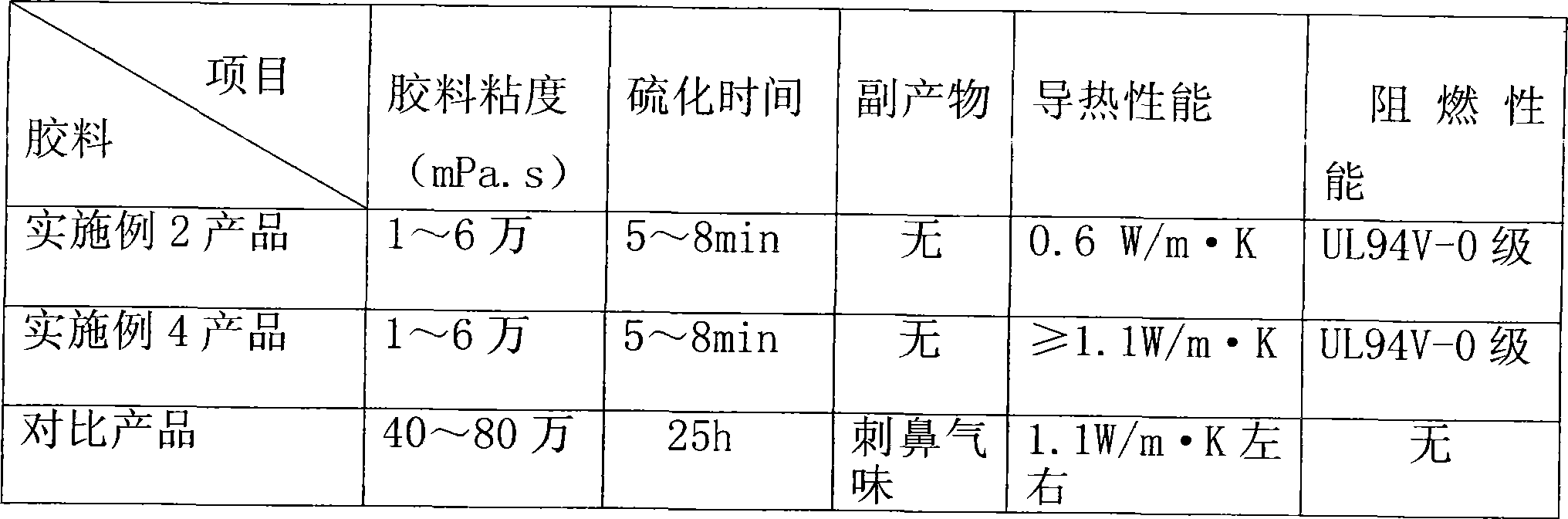

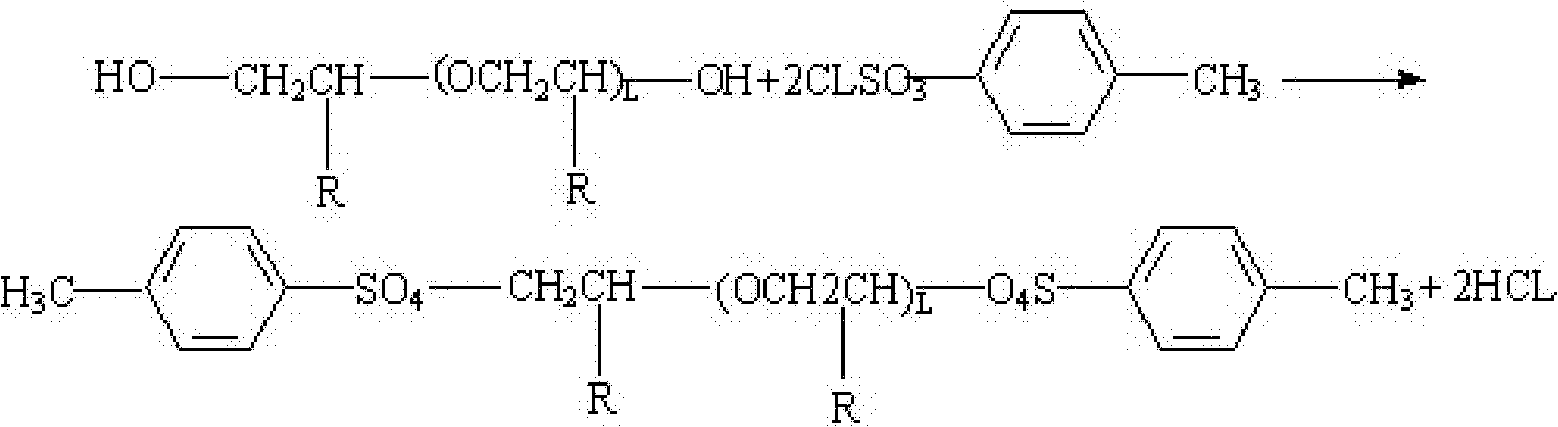

Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

InactiveCN101168620AReduce consumptionIncrease demandHeat-exchange elementsVulcanizationHeat conducting

The invention discloses heat conduction flame retardant liquid silica gel, which comprises components with the following parts by weight: 10 to 40 parts of vinyl end organopolysiloxane with 500 to 5000 mPa.s polymeric viscosity in 25 DEG C, 10 to 40 parts of vinyl end organopolysiloxane with 10000 to 50000 mPa.s in 25 DEG C, and 1 to 5 parts of hydrogen-containing polymethylsiloxane, 2 to 8 parts of alkyl disilazane, 20 to 50 parts of surface hydrophobicity Al2O3 powder with average particle diameter of 5 to 20 microns, 10 to 50 parts of Al(OH)3 powder with average particle diameter of 5 to 20 microns, 0.3 to 2 parts of addition solidification catalyst, 0.01 to 0.06 part of alkynol depressant and 0.5 to 2 parts of distilled water, wherein, R is methyl, ethyl, propyl or butyl. The invention is prepared by the way of addition type heat vulcanization, toxic substance or irritant gas is not produced in the production process, the vulcanization rate is quick, and the energy saving, the consumption decreasing and the environmental protection requirements are conformed. The storage stability of the product is good, the viscosity is moderate, the operability is good, the product integrates the heat conduction, insulation and flame retardant performances into a whole, and the performance-price ratio is high.

Owner:兆舜科技(广东)有限公司

Crosslinkable rubber composition and use thereof

A rubber composition which is crosslinkable with hot air or a hot press and gives a hot-air-crosslinked rubber sheet which receives no scratch on the surface in an HB pencil hardness test and has a compression set of 70% or lower through 22-hour heat treatment at 150 DEG C. The composition comprises: an ethylene / alpha -olefin / unconjugated polyene random copolymer rubber wherein the unconjugated polyene is a specific norbornene compound terminated by a vinyl group; and a compound having two or more SiH groups per molecule. It may optionally contain an addition reaction catalyst comprising a platinum-group metal and a reaction inhibitor.

Owner:MITSUI CHEM INC +1

Electrode material and electrode containing the electrode material

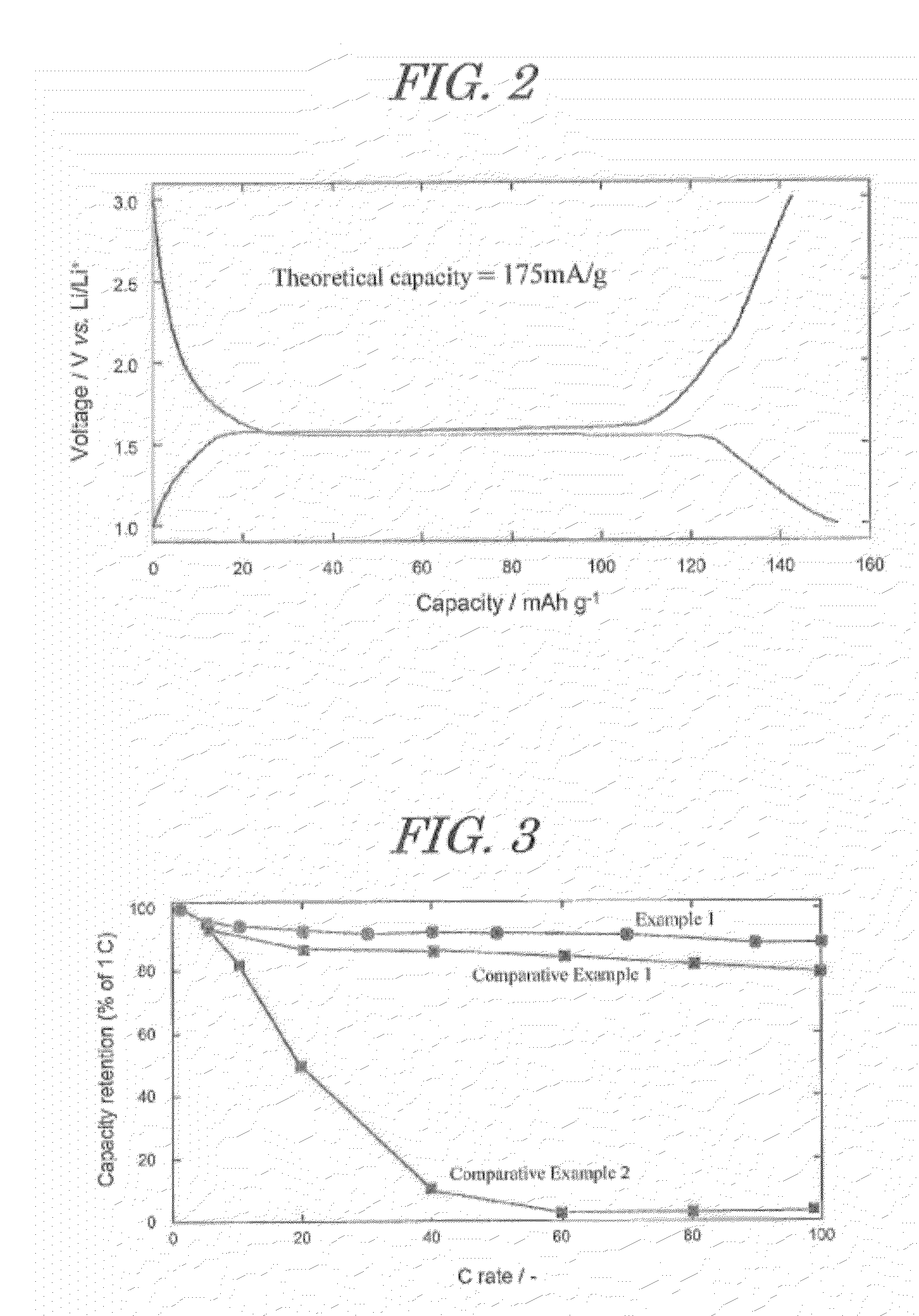

InactiveUS20120132861A1Small particle sizeInhibit aggregationNon-metal conductorsAlkali titanatesChemical reactionMetal oxide nanoparticles

The electrode material includes metal oxide nanoparticles formed by applying shear force and centrifugal force to reactants containing a reaction inhibitor in a rotating reaction vessel during a chemical reaction; and carbon nanotubes with a specific area of 600 to 2600 m2 / g to which shear force and centrifugal force are applied for dispersion in the rotating reaction vessel during the chemical reaction. The metal oxide particles are highly dispersed and carried on the carbon nanotubes. Preferably, the metal oxide is lithium titanate.

Owner:NIPPON CHIMI CON CORP +1

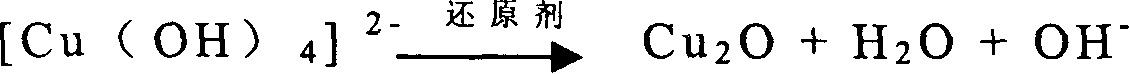

Method for preparing stable nanometer cuprous oxide whiskers with chemical precipitation method

InactiveCN1490439ASimple processEasy to controlPolycrystalline material growthSingle crystal growth detailsHydrazine compoundAntioxidant

A process for preparing the stable nano-class cuprous oxide crystal whisker by chemical deposition method includes such steps as using reducer chosen from glucose, hydrazine hydrate, hydroxyamin hydrochloride, sodium borohydride and sulfite to reduce the 2-valence Cu ions to Cu2O in water medium, preparing micron (or nano) powder, adding crystalline growth inhibitor, controlling reaction time and condition, and treating with antioxidizing agent to obtain bar and / or needle whisker.

Owner:HUAZHONG NORMAL UNIV

Nylon and preparation method thereof

ActiveCN103102486AHigh degree of polymerizationReduce the degree of polymerizationPolymer scienceAntioxidant

The invention belongs to the technical field of polymer processing, and relates to nylon and a preparation method thereof. The nylon is prepared from the following components: 1 part of dicarboxylic acid, diamine, a catalyst, a blocking agent, exchange reaction inhibitor, a nucleating agent and antioxidant, wherein the diamine and the dicarboxylic acid are equal in molar weight; the catalyst accounts for 0.001-0.1wt% of the total weight of the dicarboxylic acid and diamine; the blocking agent accounts for 0.05-1mol% of the total molar weight of the dicarboxylic acid and diamine; the exchange reaction inhibitor accounts for 0.1-5wt% of the total weight of the dicarboxylic acid and diamine; the nucleating agent accounts for 0.1-1wt% of the total weight of the dicarboxylic acid and diamine; and the antioxidant accounts for 0.001-1wt% of the total weight of the dicarboxylic acid and diamine. According to the invention, a primary polymerization product is low in viscosity, and the pressure in a kettle is high, so that pressure spray can be easily realized to prepare dry nylon polymer powder; and further polycondensation can be performed on the low-polymerization-degree nylon through melt polycondensation. Thus, the materials do not need to be further subjected to a long-time solid-phase tackifying process, thereby shortening the reaction time and improving the performance of the high-temperature nylon.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Sulphydryl acid and imidazoline salts as inhibitors of carbon corrosion of iron and ferrous metals

InactiveUS6395225B1Inhibit static corrosionHigh salinityDrilling compositionBorehole/well accessoriesCarbon corrosionFerric

The invention concerns inhibitor compositions based on fatty sulphydryl acid and poly(ethyleneamino)imidazoline salts for considerably reducing the corrosive effect of carbon brine on iron and ferrous metals. These compositions are as efficient when the corrosive medium is driven with a high flowrate and in biphasic brine / oil medium.

Owner:CECA SA

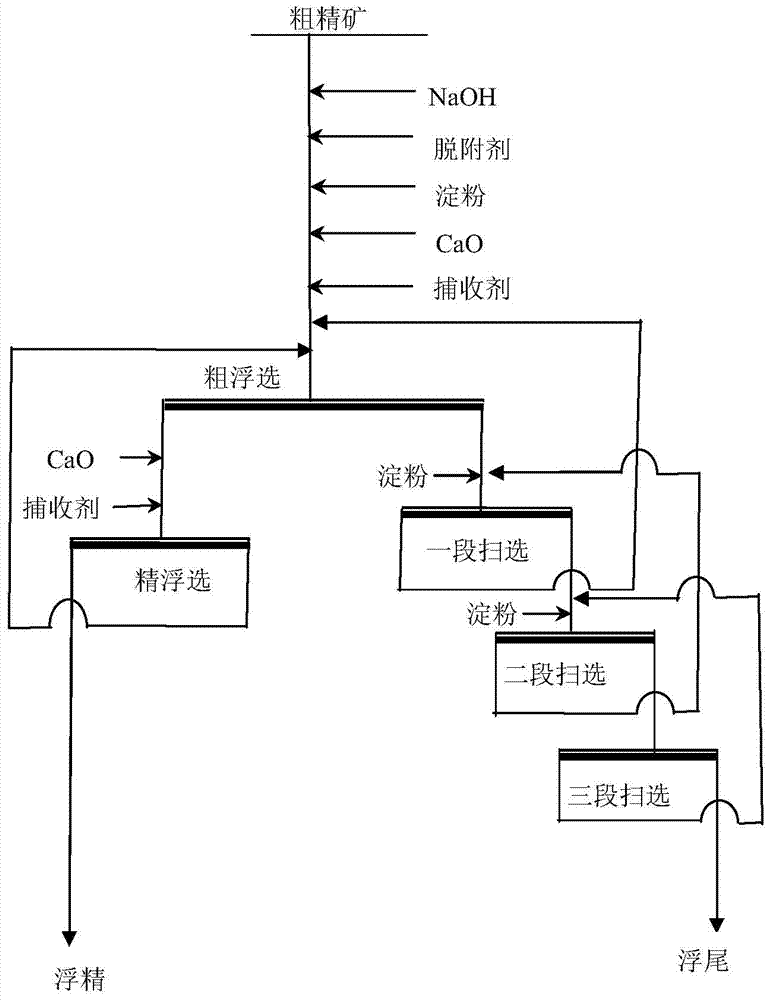

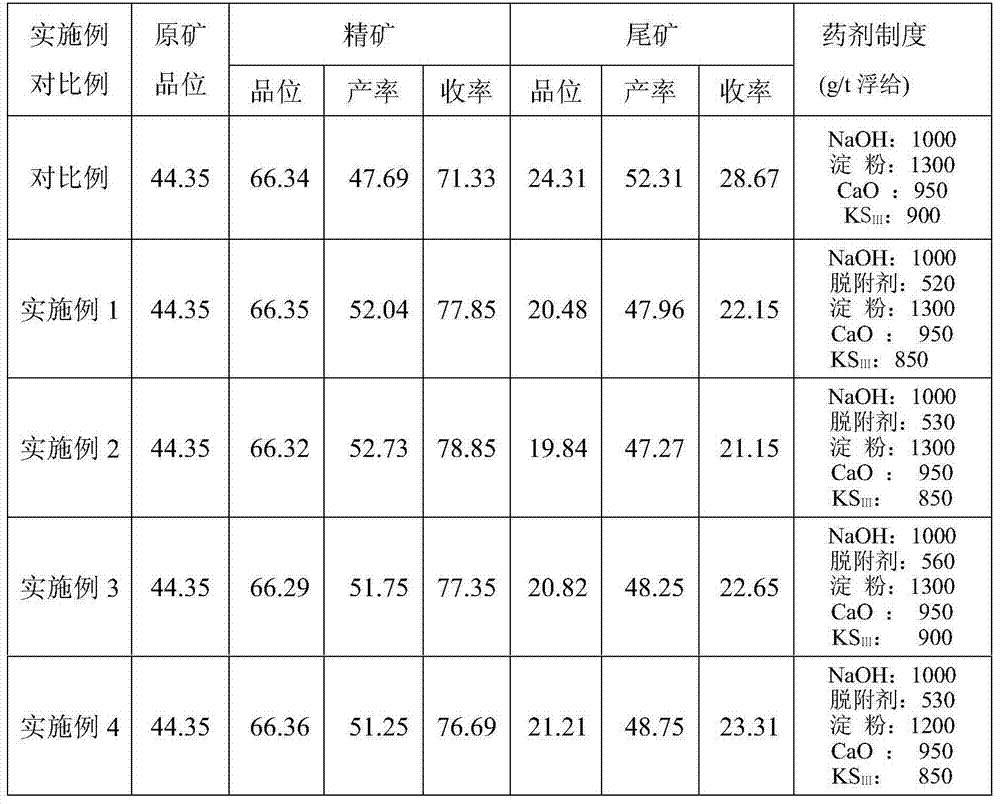

Agent for reverse flotation of iron ore and combination use method

The invention provides an agent for reverse flotation of iron ore and a combination use method. The agent is composed of pH regulator sodium hydroxide, desorption agents, inhibitor causticity corn starch, activator calcium oxide and fatty acid collectors and is characterized in that the desorption agents are composed, by weight, of 40-42 parts of water glass, 4-6 parts of carboxymethyl cellulose and 7-9 parts of polycarboxylate. When the desorption agents are used, all raw material components are dissolved respectively according to the weight proportion and mixed, water is added, and therefore a desorption agent solution with the mass concentration of 0.04-0.06% is prepared. The desorption agents are applied to a reverse flotation process including one-time rough separation, one-time fine separation and three-time scavenging and a stage agent addition manner is adopted, so that the selective inhibition function on iron minerals by inhibitors in an original reverse flotation process is obviously enhanced, selectivity of the collectors is obviously enhanced, the tailing grade is reduced, the metal recovery rate is improved, fine-grain metal losses are reduced, emission reduction, yield increasing and efficiency increasing are achieved, the resource utilization rate is improved, and a new approach is provided for improvement of the micro-fine-particle iron ore reverse flotation technical index.

Owner:ANSTEEL GRP MINING CO LTD

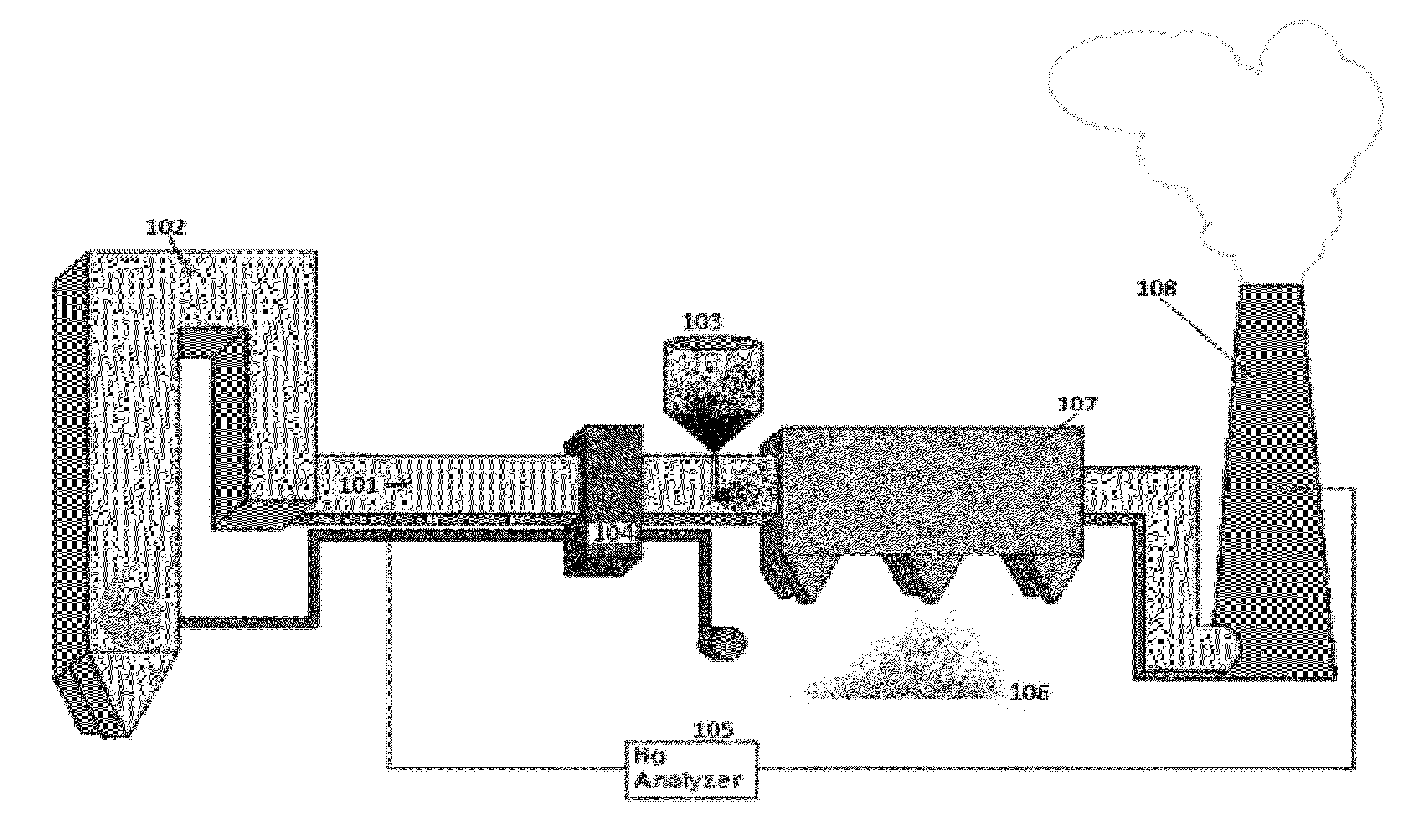

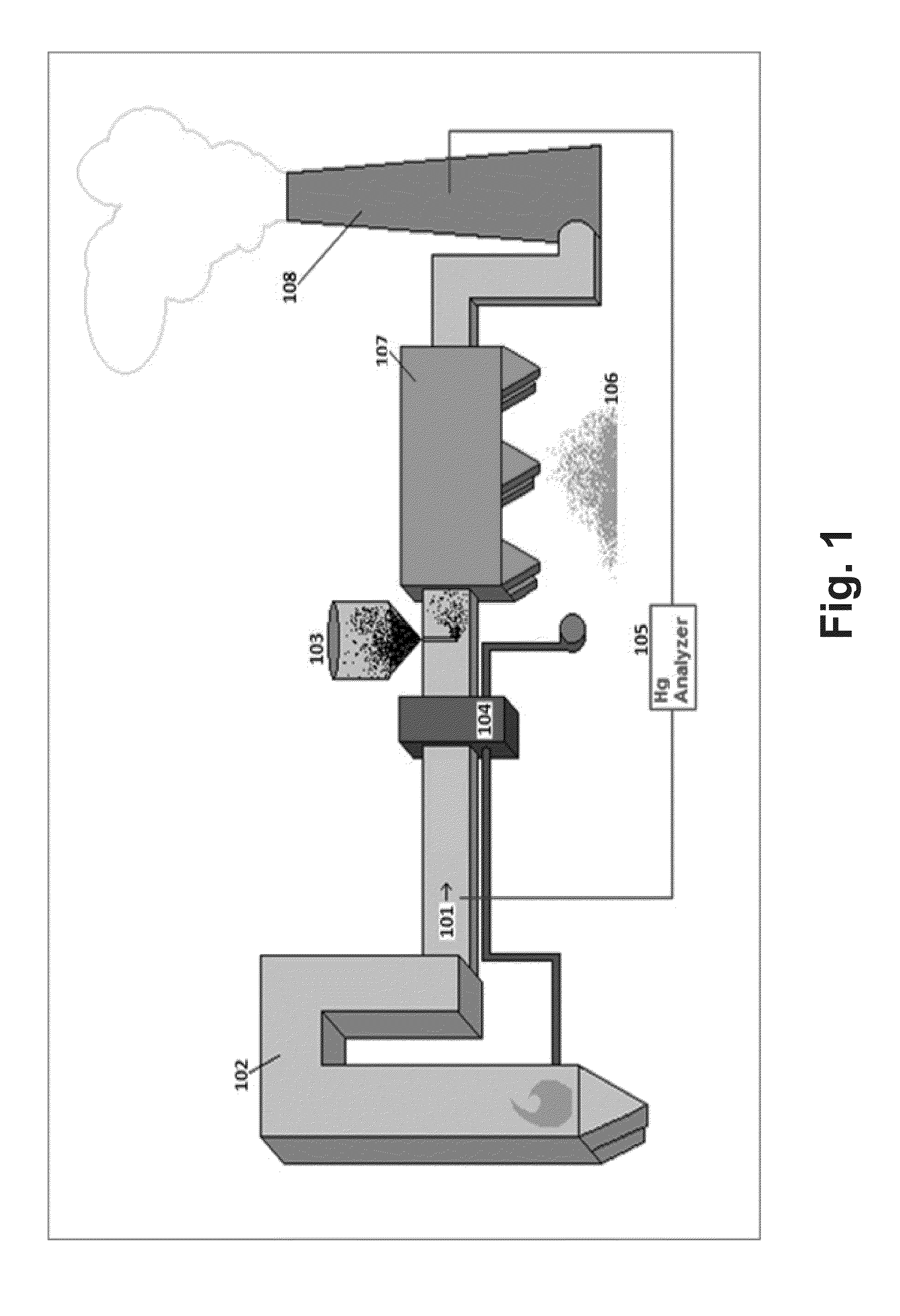

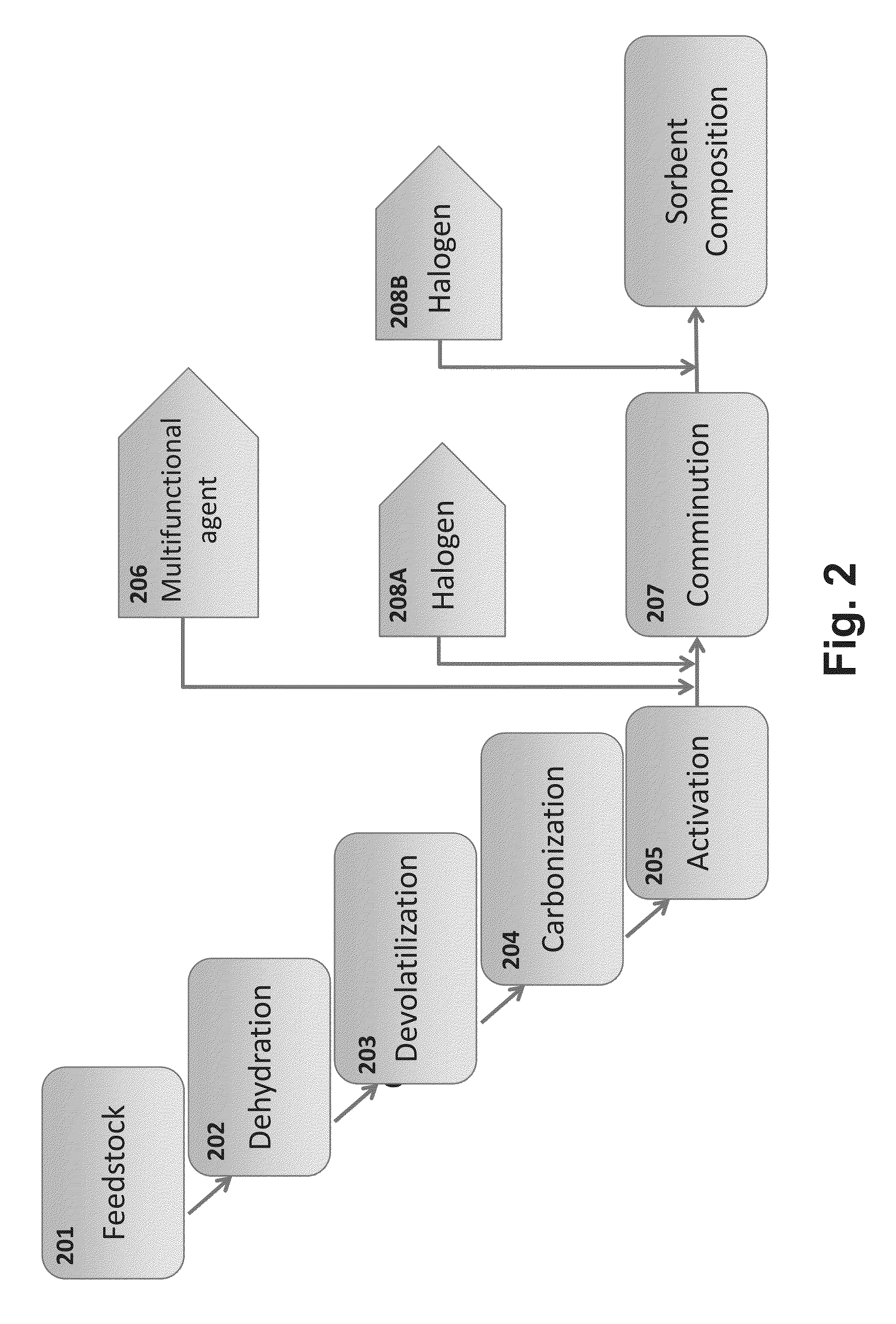

Composition for acid gas tolerant removal of mercury from a flue gas

InactiveUS20140186625A1Increase relative volatilityAdd equipmentOrganic/inorganic per-compounds compounding agentsGlass/slag layered productsHigh concentrationActivated carbon

Method and compositions useful for removal of mercury from a flue gas stream with relatively high concentrations of acid gas precursors and / or acid gases. The method includes contacting the flue gas stream with a multi-functional agent, where the multi-functional agent includes a salt having a cation of valency 3 or higher. A composition comprises a (1) sorbent material such as powdered activated carbon which will ultimately capture and sequester oxidized mercury, (2) a multi-functional agent that protects the sorbent core from unfavorable reaction conditions or inhibitors, oxidizes or helps catalyze the oxidation of elemental mercury, and / or amalgamates with elemental mercury to make it easier to capture, among other benefits, and optionally (3) a halogen such as in the form of a halide salt that helps facilitate the oxidation of elemental mercury into its oxidized form.

Owner:ADA CARBON SOLUTIONS

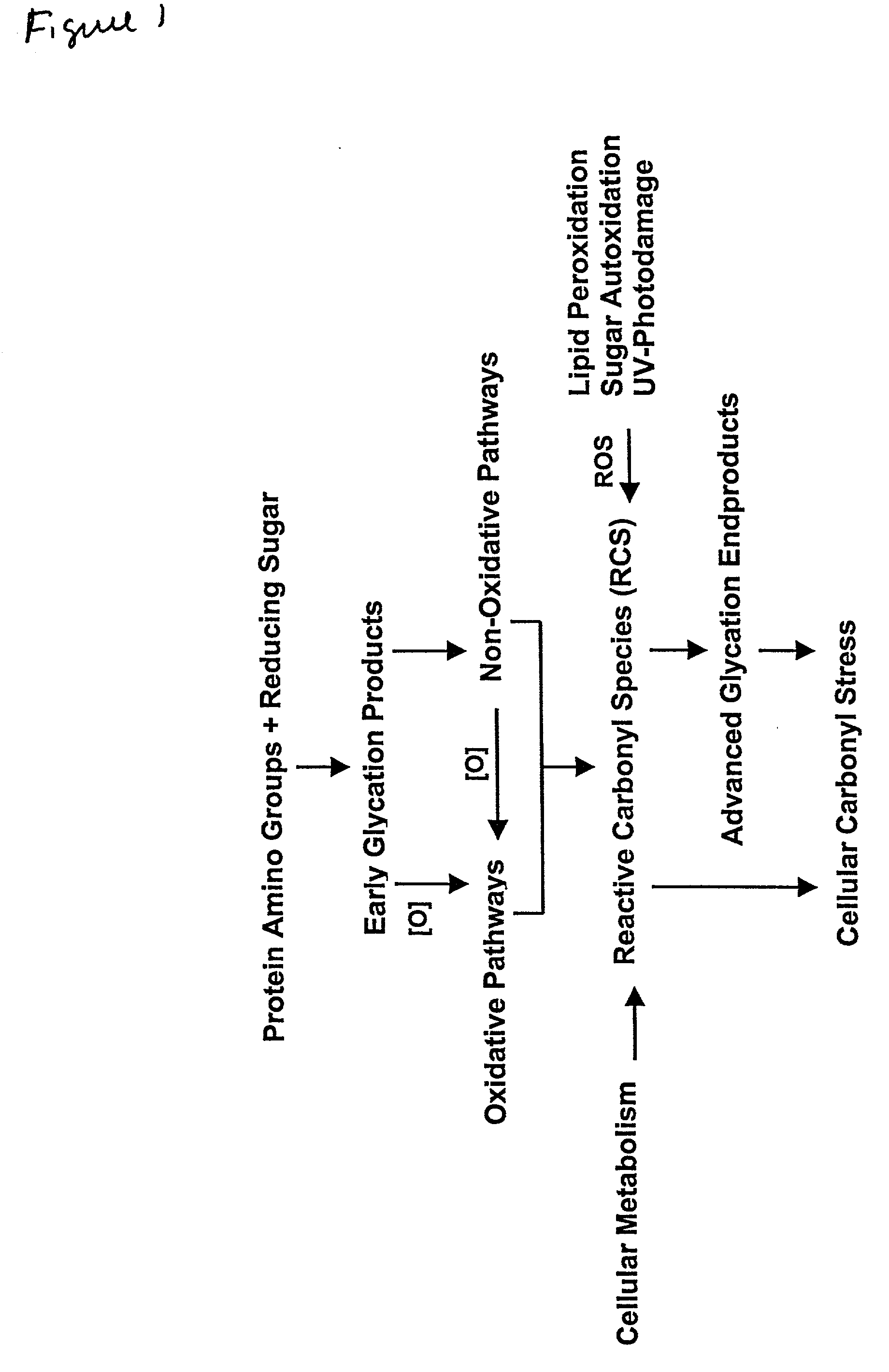

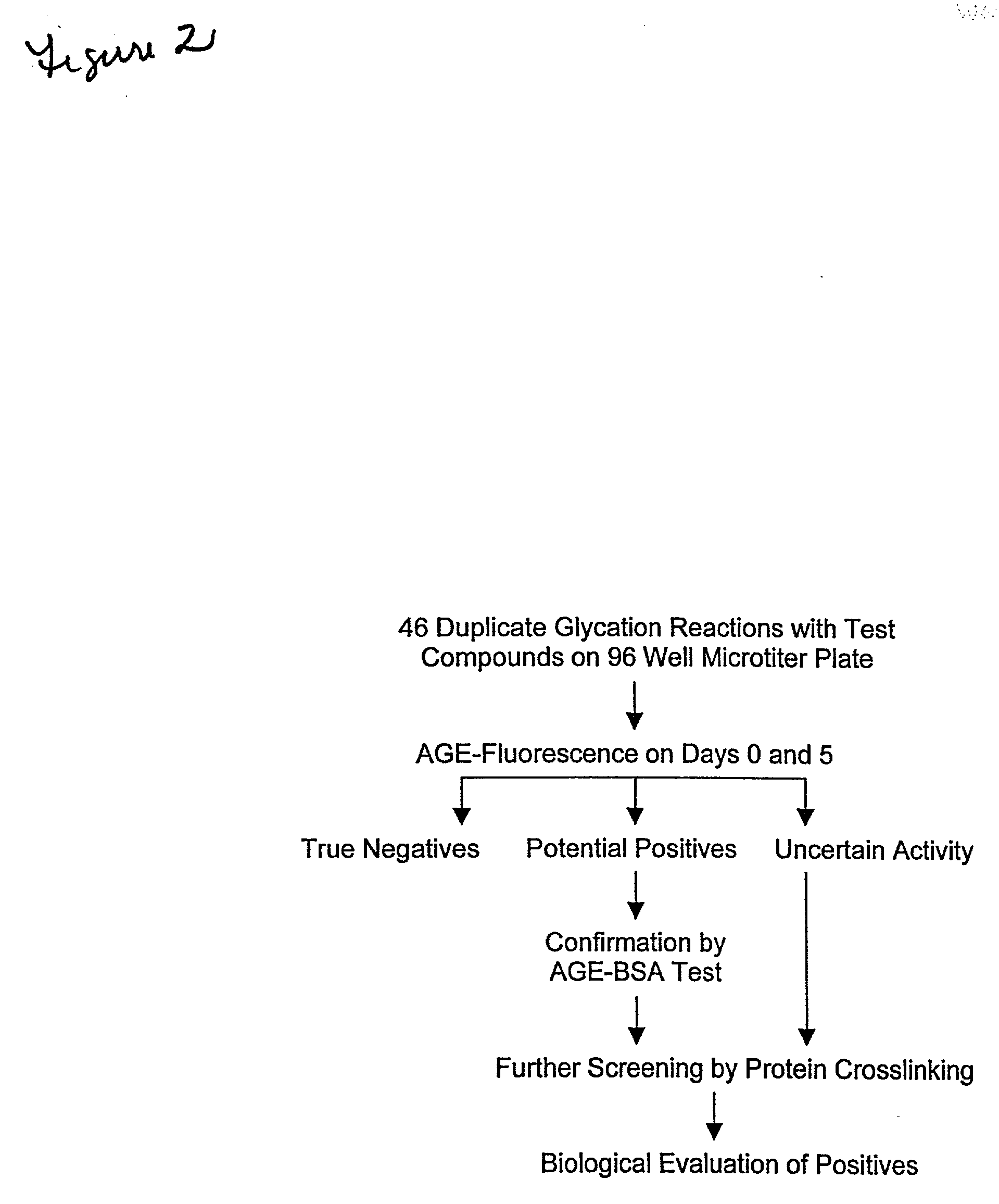

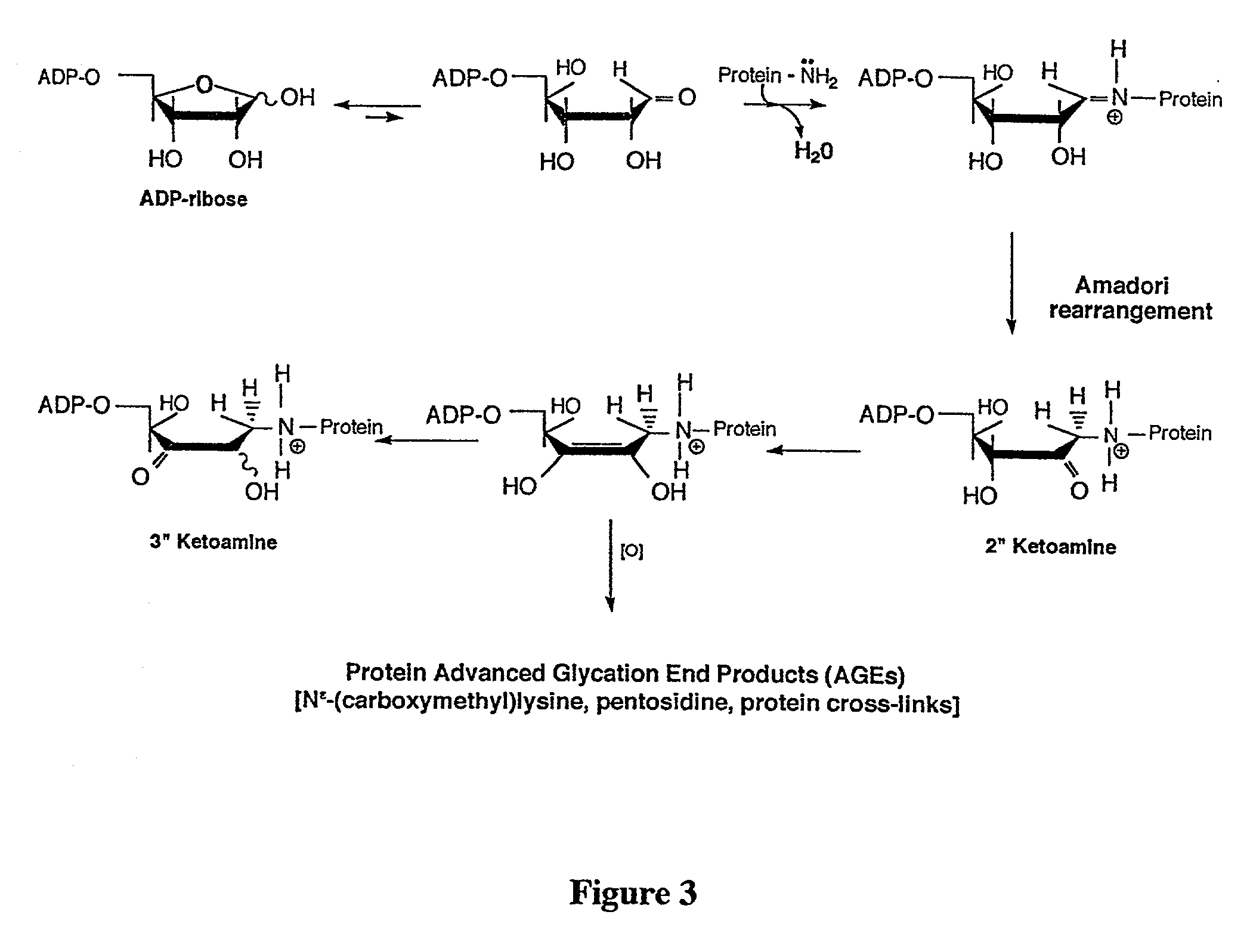

Method for identifying regulators of protein-advanced glycation end product (protein-AGE) formation

InactiveUS20020037496A1Material analysis by observing effect on chemical indicatorMicrobiological testing/measurementScavengerProtein insertion

The invention relates to methods for identifying compounds which affect cellular stress. In particular, the method relates to identifying compounds which inhibit protein advanced glycation end product formation, where the compounds are carbonyl scavengers which inhibit the formation. The assay involves combing the substance of interest with histone H1 and ADP-ribose, and then measuring fluorescence and protein cross linking. Various inhibitors ofprotein AGE glycation have been identified, using this assay.

Owner:UNIV OF KENTUCKY RES FOUND

Method and apparatus for the rapid disruption of cells or viruses using micro beads and laser

InactiveUS20080199930A1Prevent evaporationBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersRough surfaceLysis

A method and apparatus for rapid disruption of cells or viruses using beads and a laser are provided. According to the method and apparatus for rapid disruption of cells or viruses using beads and a laser, cell lysis within 40 seconds is possible, the apparatus can be miniaturized using a laser diode, a DNA purification step can be directly performed after a disruption of cells or viruses, and a solution containing DNA can be transferred to a subsequent step after cell debris and beads to which inhibitors of a subsequent reaction are attached are removed with an electromagnet. In addition, by means of the cell lysis chip, an evaporation problem is solved, vibrations can be efficiently transferred to cells through magnetic beads, a microfluidics problem on a rough surface is solved by hydrophobically treating the inner surface of the chip, and the cell lysis chip can be applied to LOC.

Owner:SAMSUNG ELECTRONICS CO LTD

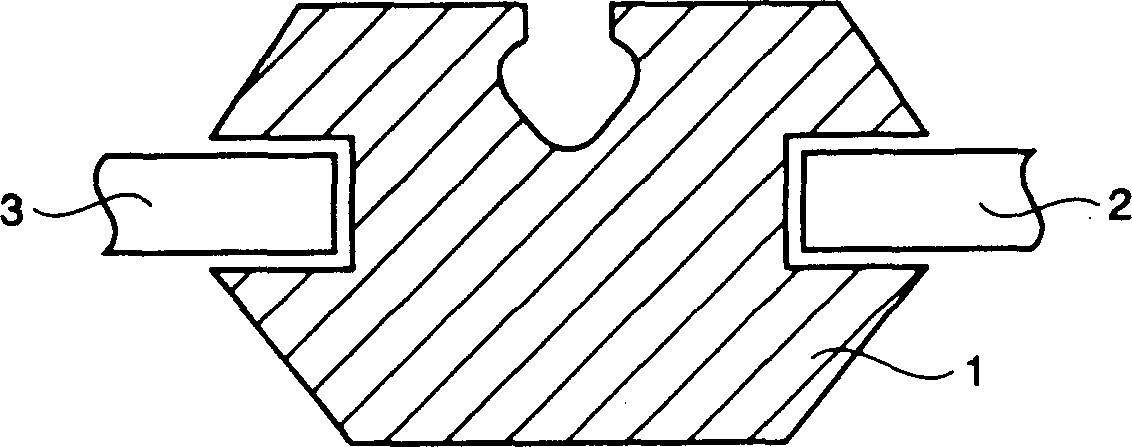

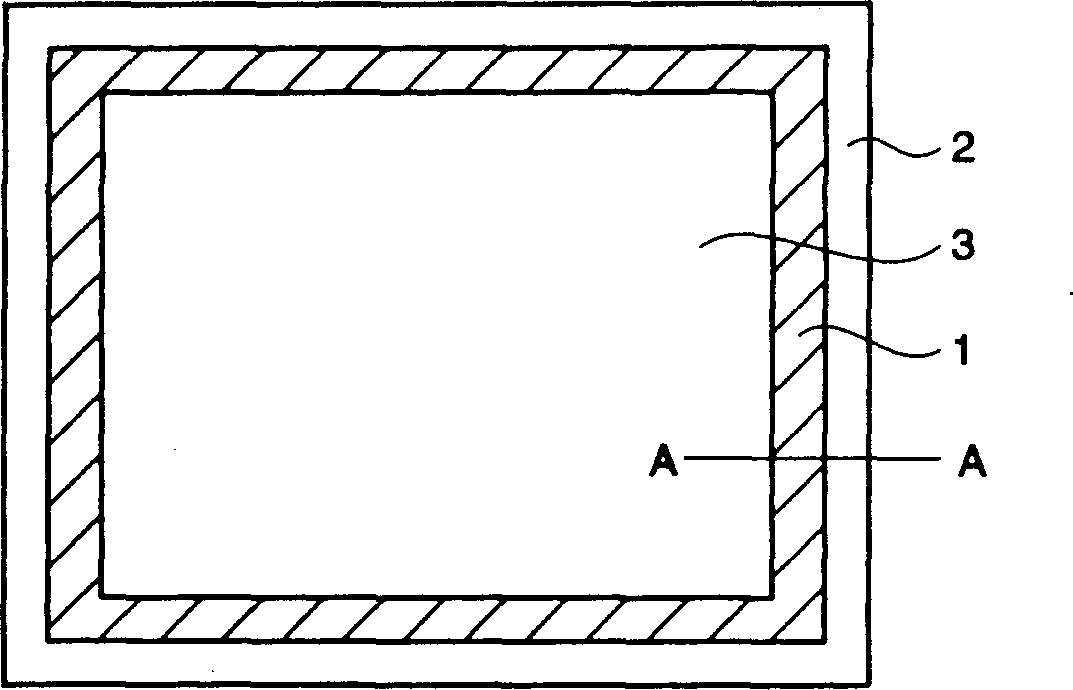

Organosilicon sealant for LED (light-emitting diode) packaging

The invention relates to an organosilicon sealant for LED (light-emitting diode) packaging, belonging to the technical field of organosilicon sealants. The organosilicon sealant comprises a component A and a component B. The component A comprises 15-25 parts of divinyl polydimethylsiloxane silicon resin and 2-6 parts of platinum catalyst. The component B comprises 50-58 parts of divinyl polydimethylsiloxane silicon resin, 50-88 parts of methylhydropolysiloxane, 2-8 parts of reaction inhibitor, 30-40 parts of fumed silica, 2-10 parts of additive KH-560 and 20-25 parts of TiO2. The vinyl silicon resin, hydrogen-containing silicon oil and tetramethyltetravinylcyclosiloxane are subjected to addition reaction under the condition of the platinum catalyst to prepare the organosilicon electronic packaging adhesive with favorable comprehensive properties. The sealant is very suitable for LED packaging.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Separating method for isocyanate monomer of urethane curing agent

A method for separating isocyanic ester from polyurethane-curing agent includes; adding acid 0.01 - 0.5% as reaction inhibitor, adding distillation agent 8 -60%, carrying out three-stage separation in an internally or externally cooling membrane distiller, pumping remains separated after second or third stage to pass them into a diluting container with solvent in, heating solvent up to 80 - 140deg.C, and stirring solvent with solid remains 35 - 85% to obtain curing agent with high solid content, low isocyanic ester content, and low viscosity.

Owner:SOUTH CHINA UNIV OF TECH

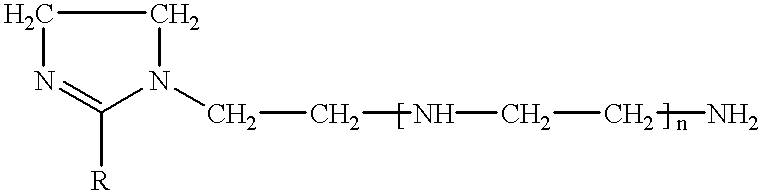

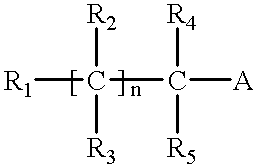

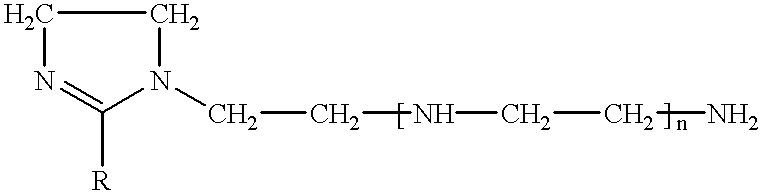

Polyamine inhibitor for drilling fluids and method for preparing polyamine inhibitor

InactiveCN102504065AImprove performancePrevent hydrationOrganic compound preparationDrilling compositionWater basedDistillation

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Resin used for polyurethane cold-resistant flexible middle/low-density shoes and preparation method thereof

ActiveCN102504181AIt is not suitable to break the bottomRaw materials are readily availableFootwearPolyesterChemical reaction

The invention relates to a resin used for polyurethane cold-resistant flexible middle / low-density shoes and a preparation method of the resin, and belongs to the technical field of polyurethane resin preparation. The method comprises the following steps of: mixing compositions A and B, foaming the mixture with a polyurethane low-pressure foaming machine, injecting into a shoe mould and molding. The composition A is a mixture of polyester polyol A1, polyester polyol A2, a diol chain extender, a catalyst, an organic silicon foam stabilizer and water; the composition B is a prepolymer obtained by chemical reaction of polyisocyanate, polyester polyol A1, polyether glycol B1, polyether glycol B2 and a secondary reaction inhibitor. The product provided by the invention can maintain flexible and cold-resistant properties in case of low density, so that the shoe is flexible and the sole is not liable to break in winter. The invention has the advantages of easily-accessible raw materials, simple process, good product reproducibility and low cost, and can achieve mass production. The foaming process adopts only water, so that the whole production process is environment-friendly.

Owner:无锡双象新材料有限公司

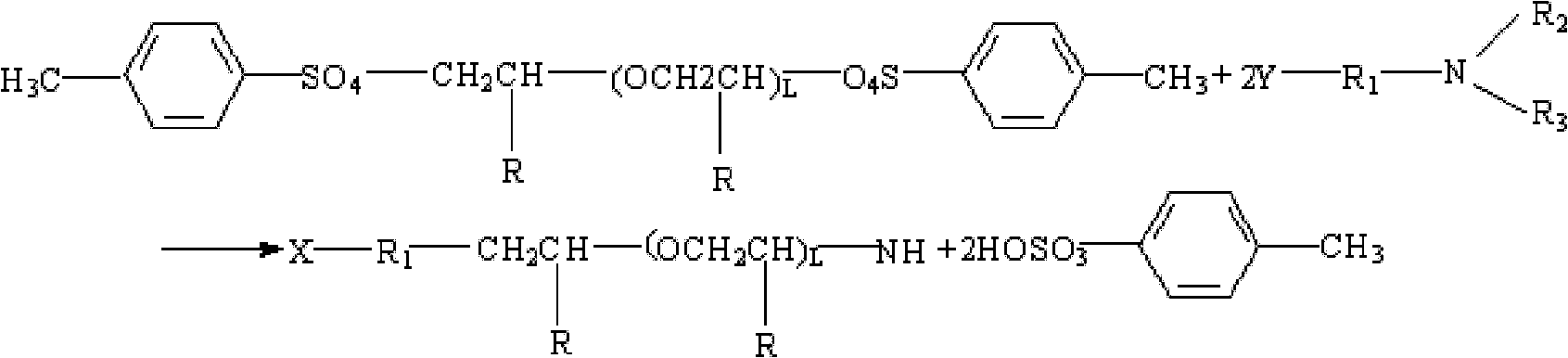

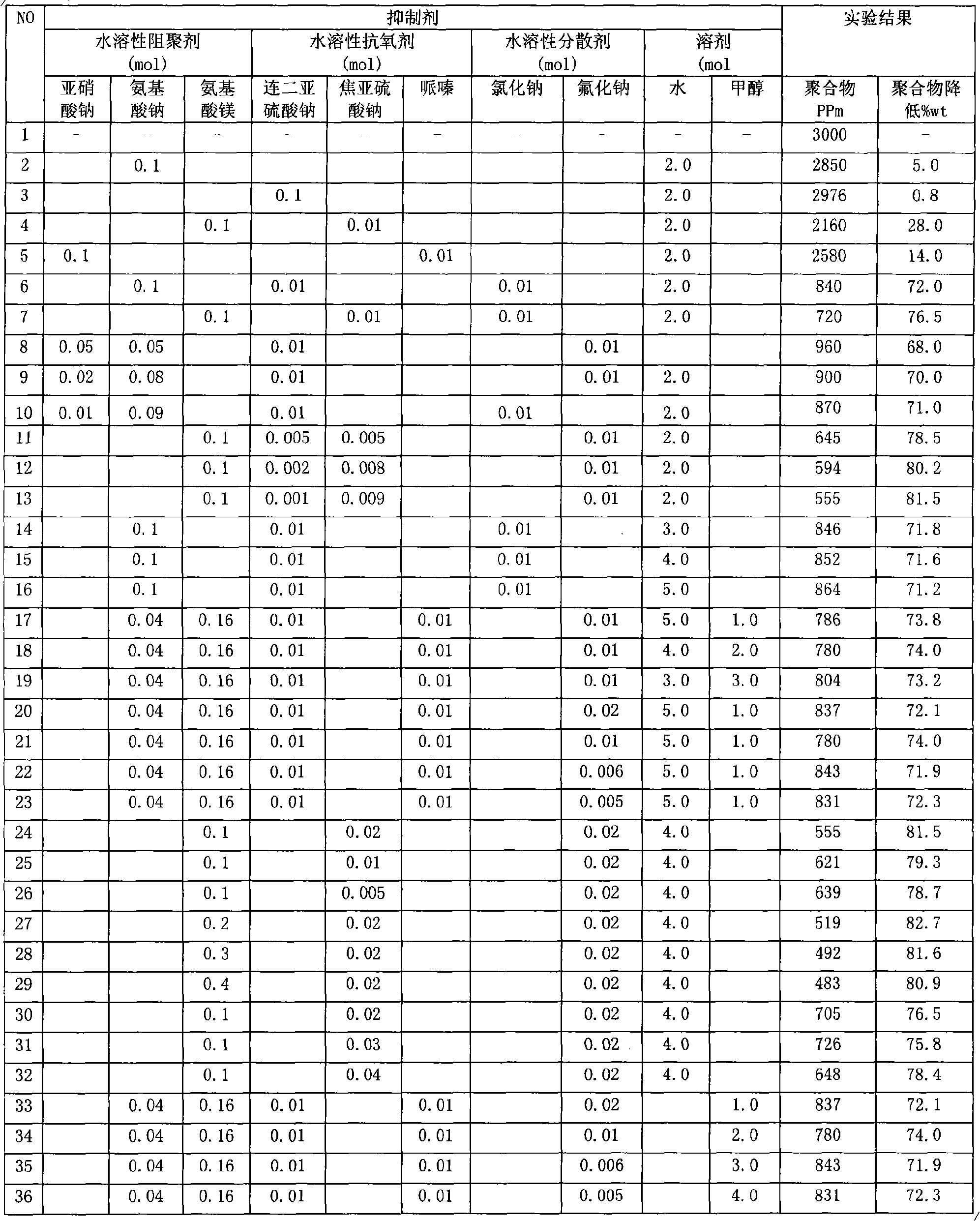

Inhibitor of polymerization reaction in hydrocarbon cracking and alkaline cleaning operation

ActiveCN101358144AInhibition of polymerizationEnhanced inhibitory effectThermal non-catalytic crackingAntioxidantKetone

The present invention relates to inhibitor which can inhibit the polyreaction of carbonyl compounds, such as aldehyde and ketone, and unsaturated olefin in the pyrolysis gas of the hydrocarbon cracking technique in the process of alkali cleaning. The inhibitor is composed of water-soluble polymerization inhibitor, water-soluble antioxidant, solvent and water-soluble dispersant; wherein, the molar ratio of the water-soluble antioxidant and the water-soluble polymerization inhibitor is 1 : 2 to 20; the molar ratio of the water-soluble polymerization inhibitor and the solvent is 1 : 1 to 100; the molar ratio of the dispersant and the water-soluble polymerization inhibitor is 1 : 1 to 20; the water-soluble dispersant is selected from Ca Cl2, CaF2, NaCl or NaF or any combination thereof. The inhibitor can effectively inhibit the polyreaction of carbonyl compounds, such as aldehyde and ketone, and unsaturated olefin in the pyrolysis gas in the process of alkali cleaning, and can resolve the produced polymers.

Owner:PETROCHINA CO LTD

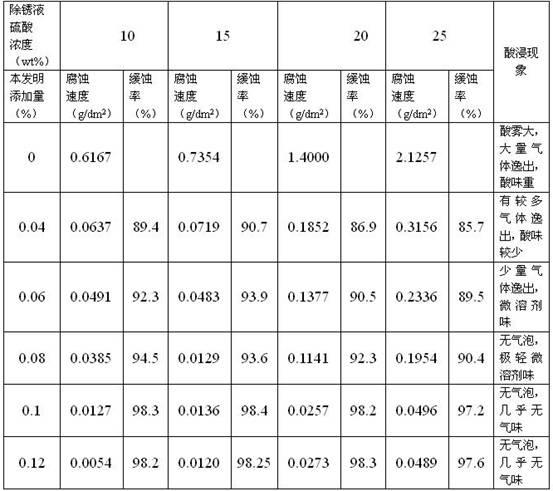

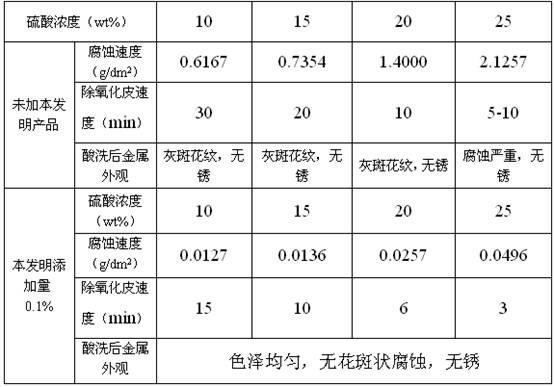

Sulfuric acid washing corrosion-retarding fog inhibitor and preparation method thereof

InactiveCN101851761AThe effect of suppressing acid mist is obviousThe effect of acid mist is obviousEthylenediamineGallic acid ester

The invention discloses a sulfuric acid washing corrosion-retarding fog inhibitor and a preparation method thereof. The sulfuric acid washing corrosion-retarding fog inhibitor comprises an inhibitor, a complexing agent and a wetting agent, wherein the inhibitor comprises di-o-tolyl-thiourea, o-toluidine, sulfonated protein and ethylene diamine tetraacetic acid; the complexing agent comprises sodium citrate, sodium tartrate, hydroxyacetic acid and gallic acid; and the wetting agent comprises sodium sulfonate, sodium carboxylate, L-548 and OP-10. The sulfuric acid washing corrosion-retarding fog inhibitor can retard the excessive corrosion of sulfuric acid to steel matrix, also can be used as an acid washing fog inhibitor, and has good stability at high temperature; and the capability of inhibiting acid fog can reach over 95 percent, the highest corrosion-retarding capability can reach over 98 percent, and the stability is no less than 5 hours.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

Neutral multifunctional steel surface treating agent and preparation method

The invention discloses a neutral multifunctional steel surface treating agent, which does not generate waste acid, is environmental-friendly, and comprises the following raw materials in percentage by mass: 12-43 percent of organic acid, 0.2-4 percent of catalyst, 12-43 percent of multivalent nitrogen compound, 0.01-3 percent of inhibitor, 0.5-5 percent of film-forming agent, 0.5-4 percent of surface active agent, and the balance water. A preparation method comprises the following steps of: adding the catalyst, the multivalent nitrogen compound and the water with calculated quantity into the organic acid; starting to stir and heating in a reaction kettle, wherein the temperature is controlled to be 80-120 DEG C, and the reaction time is 2-4h; generating amide through a reaction product, wherein the amide is not acid and has a pH value being 6-7; adding the inhibitor, the film-forming agent and the surface active agent; and uniformly stirring.

Owner:DALIAN JIESHI CLEANING PRODS

Method for preparing nano titanium dioxide by sol process at low temperature

InactiveCN102674452AHigh purityEasy to wash and filterNanotechnologyTitanium dioxideWater bathsHYDROSOL

The invention relates to a preparation method of a catalyst, particularly a method for preparing nano titanium dioxide by a sol process at low temperature, which comprises the following steps: by using titanium salt as a raw material, alcohol as an organic solvent and acid as a reaction inhibitor, stirring in a reactor at room temperature to react; after reacting for some time, obtaining a sol solution; and refluxing the sol solution in a water bath for some time, washing, separating, and drying to obtain the nano titanium dioxide powder. The nano titanium dioxide prepared by the sol-gel process does not need high-temperature calcination technology, has the advantages of good product quality, simple experimental operation steps, simple experimental facilities, easily controlled reaction steps and energy-saving preparation process, and is suitable for mass production, thereby being advanced technology for preparing nano materials by a sol-gel process.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com