Agent for reverse flotation of iron ore and combination use method

A technology of reverse flotation and iron ore, applied in flotation, solid separation, etc., can solve the problem of poor pertinence in the separation of fine iron ore, heavy metal loss of fine iron ore, and inhibition of iron ore Insufficient and other problems, to achieve reasonable and efficient flotation process, improve metal recovery rate, reduce the effect of fine metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

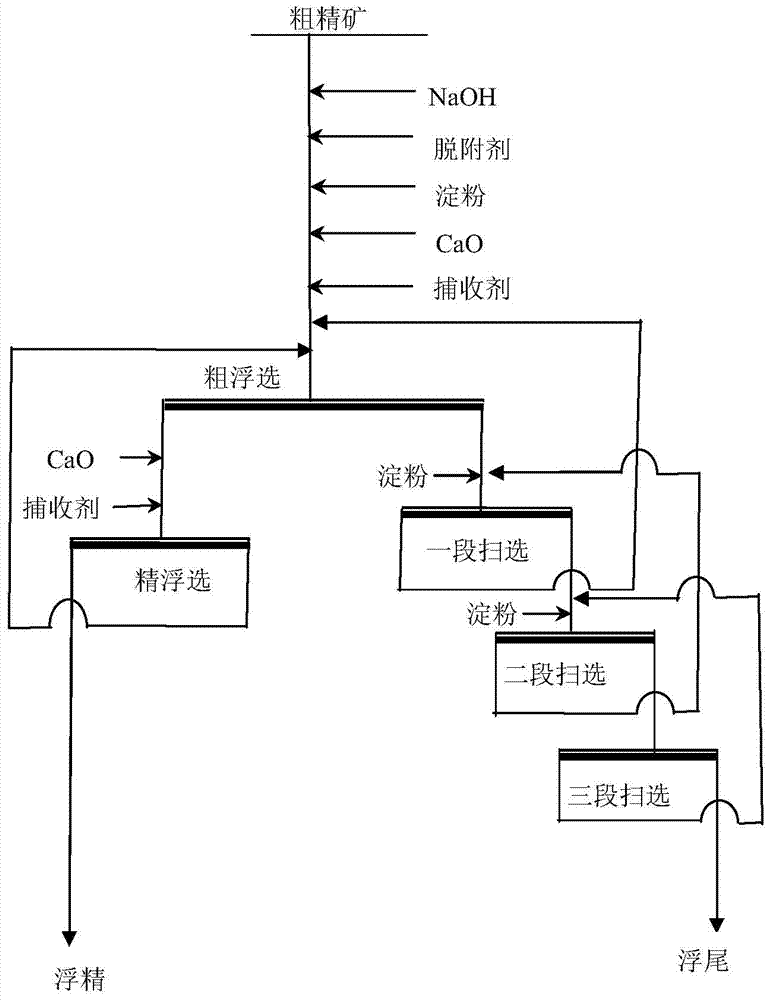

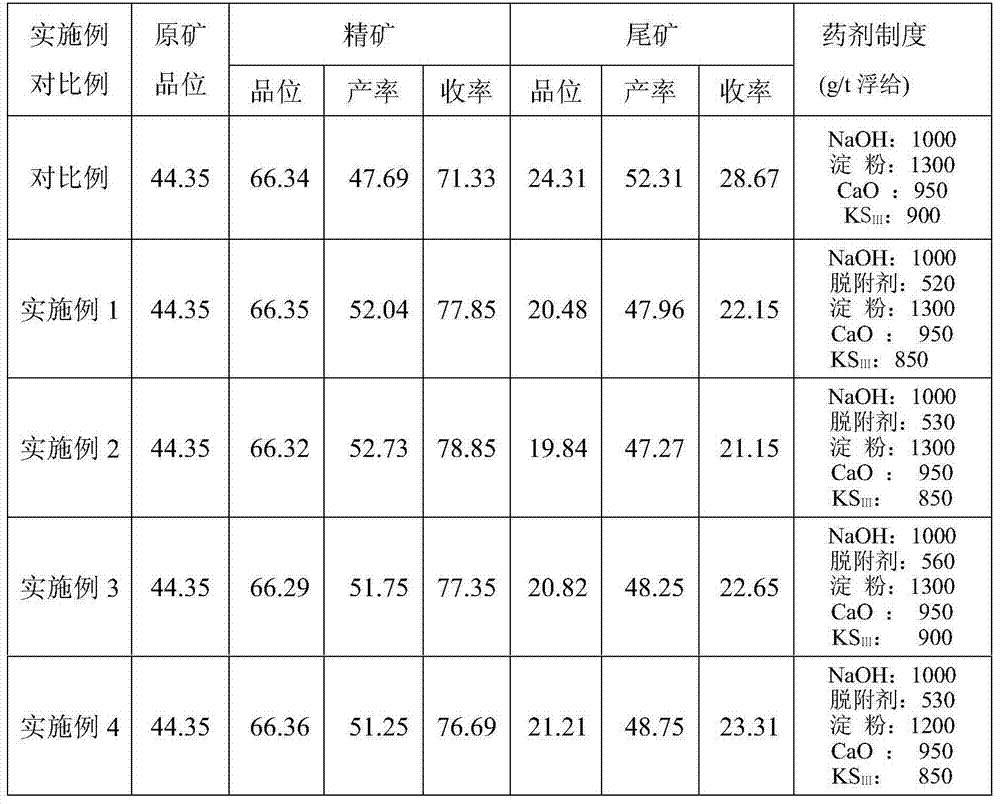

[0027] The method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] As shown in Figure 1 and Embodiments 1 to 4:

[0029] The medicament for reverse flotation of iron ore of the present invention comprises pH adjusting agent sodium hydroxide, desorbing agent, inhibitor caustic cornstarch, activator calcium oxide and fatty acid collector,

[0030] Described desorbent is made of the following raw material components by weight:

[0031] 40 parts of water glass, 5 parts of carboxymethyl cellulose, 8 parts of polycarboxylate;

[0032] Among them, the modulus of water glass is 1-2, the viscosity of carboxymethyl cellulose is 800-1200mPa·s, the degree of substitution is ≥0.9, the molecular weight of polycarboxylate is 3000-4000, and the solid content is 40%;

[0033] Preparation method and usage amount: Firstly, dissolve the raw material components of the desorbent according to the weight ratio respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com