Patents

Literature

7387 results about "Corn starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

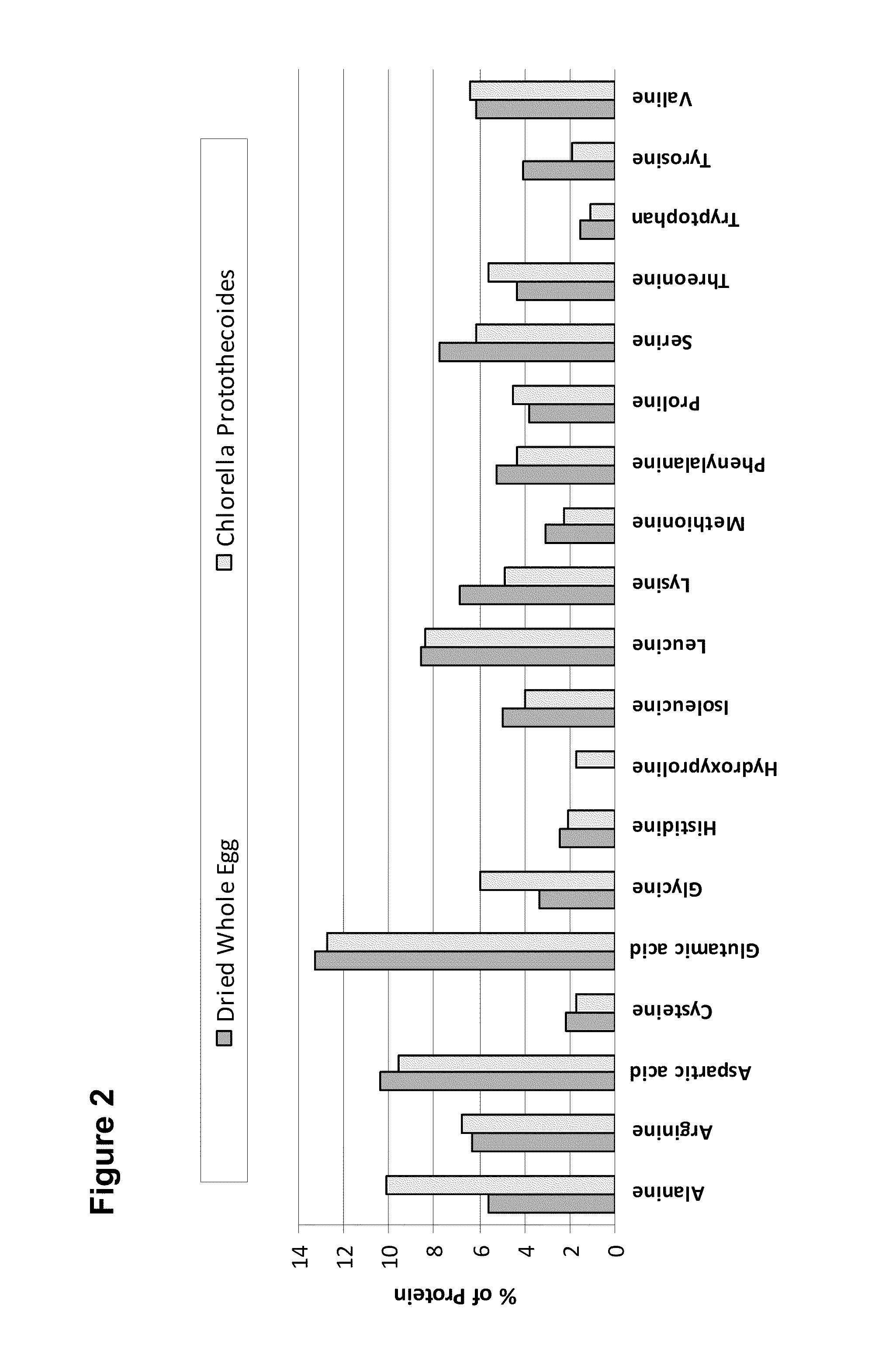

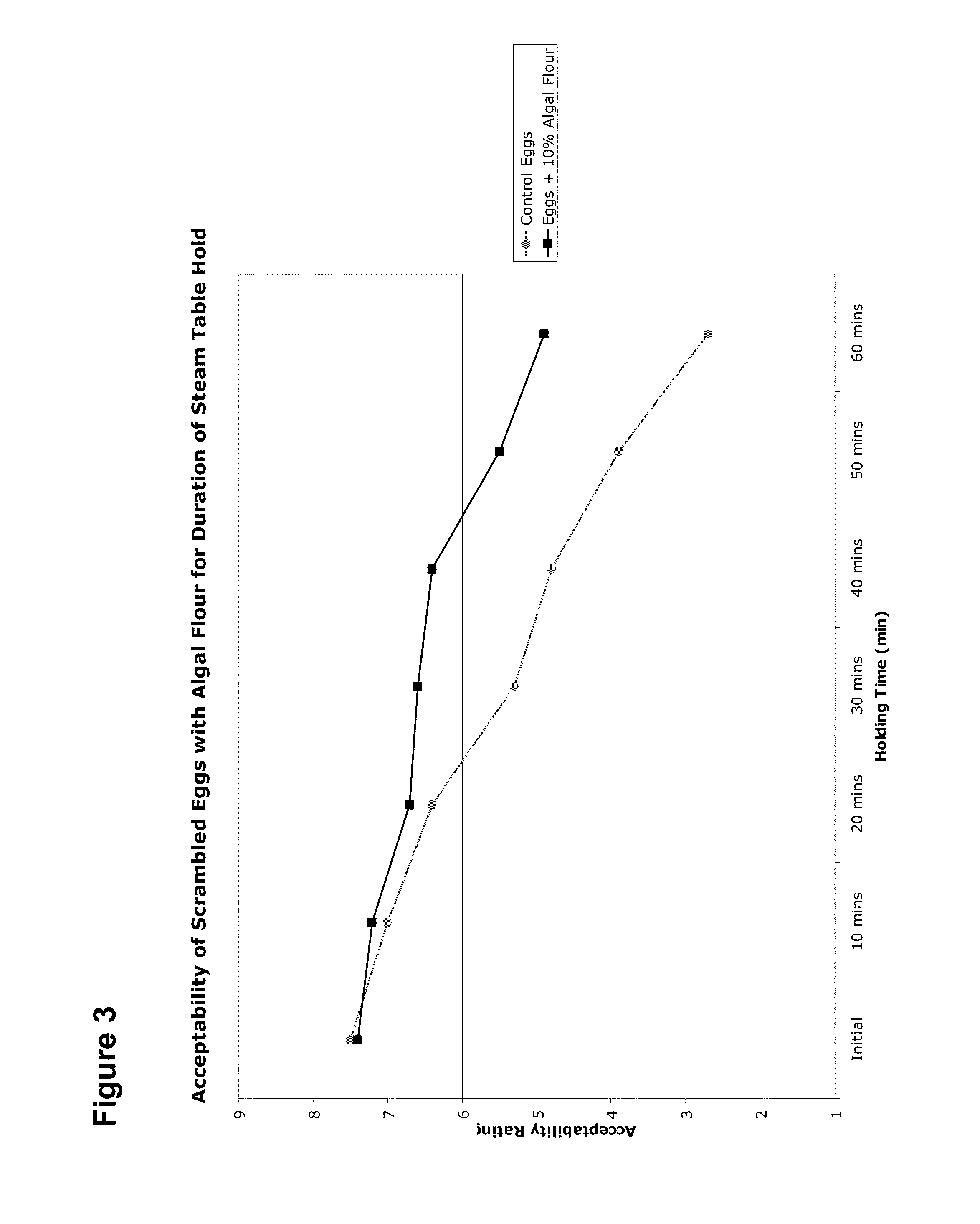

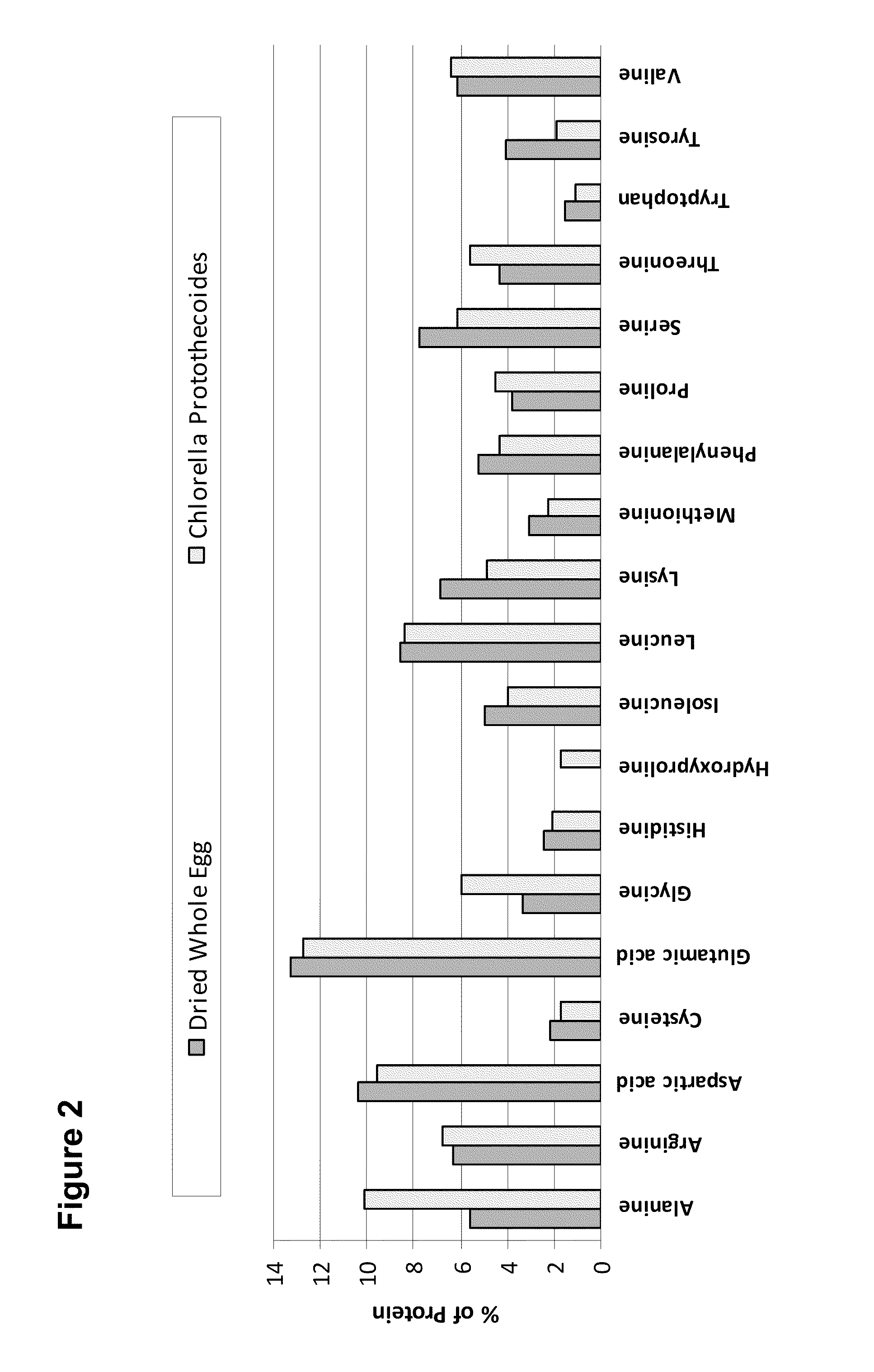

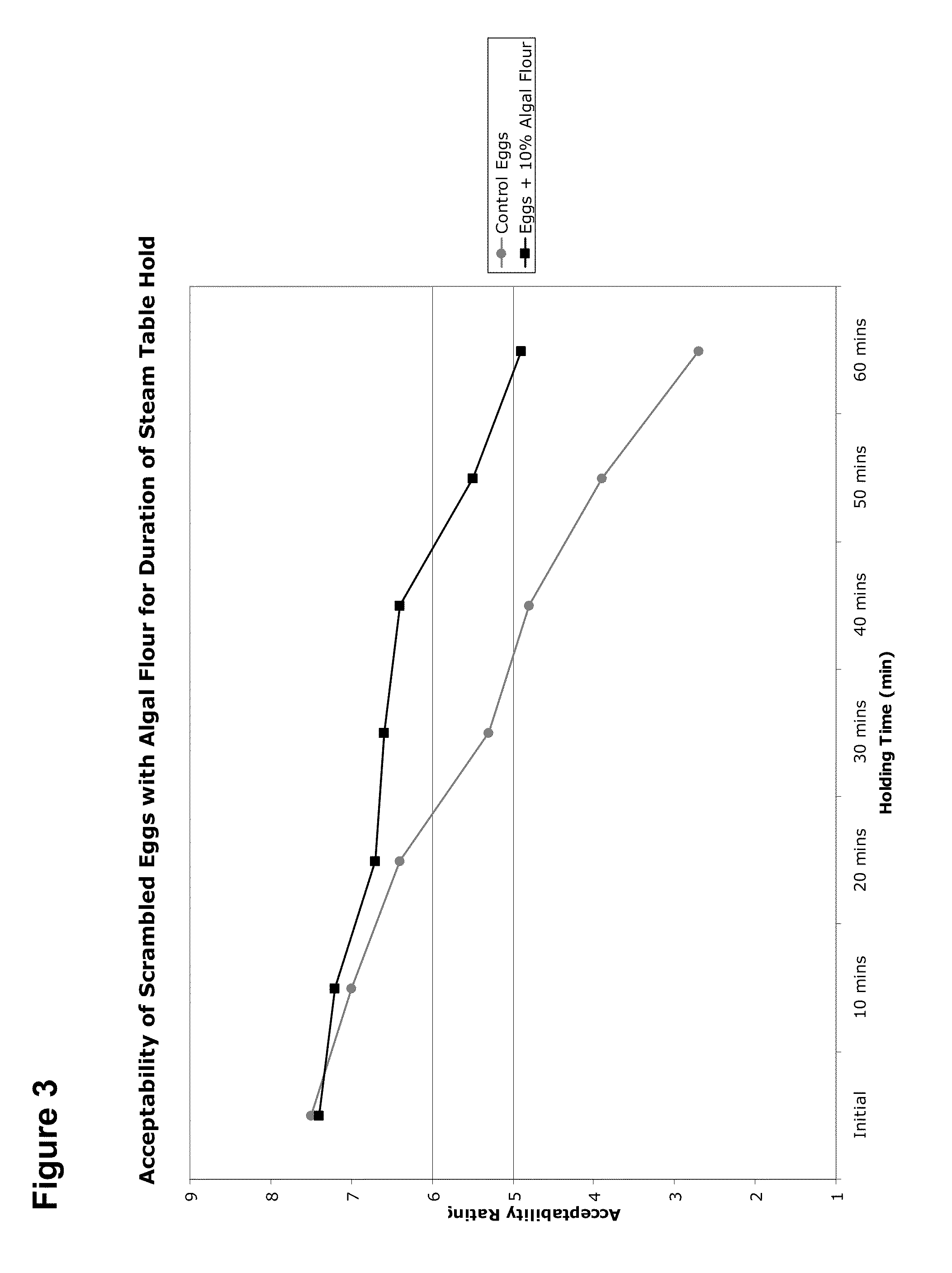

High Protein and High Fiber Algal Food Materials

The disclosed inventions include microalgal biomass high in protein and fiber, wherein the biomass has been manufactured through heterotrophic fermentation. The materials provided herein are useful for the manufacture of meat substitutes and meat enhancers, as well as other food products that benefit from the addition of digestible protein and dietary fiber. Structural properties of foods are enhanced through the use of such materials, including texture and water retention properties. High in protein and fiber food materials of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose.

Owner:TERRAVIA HLDG INC

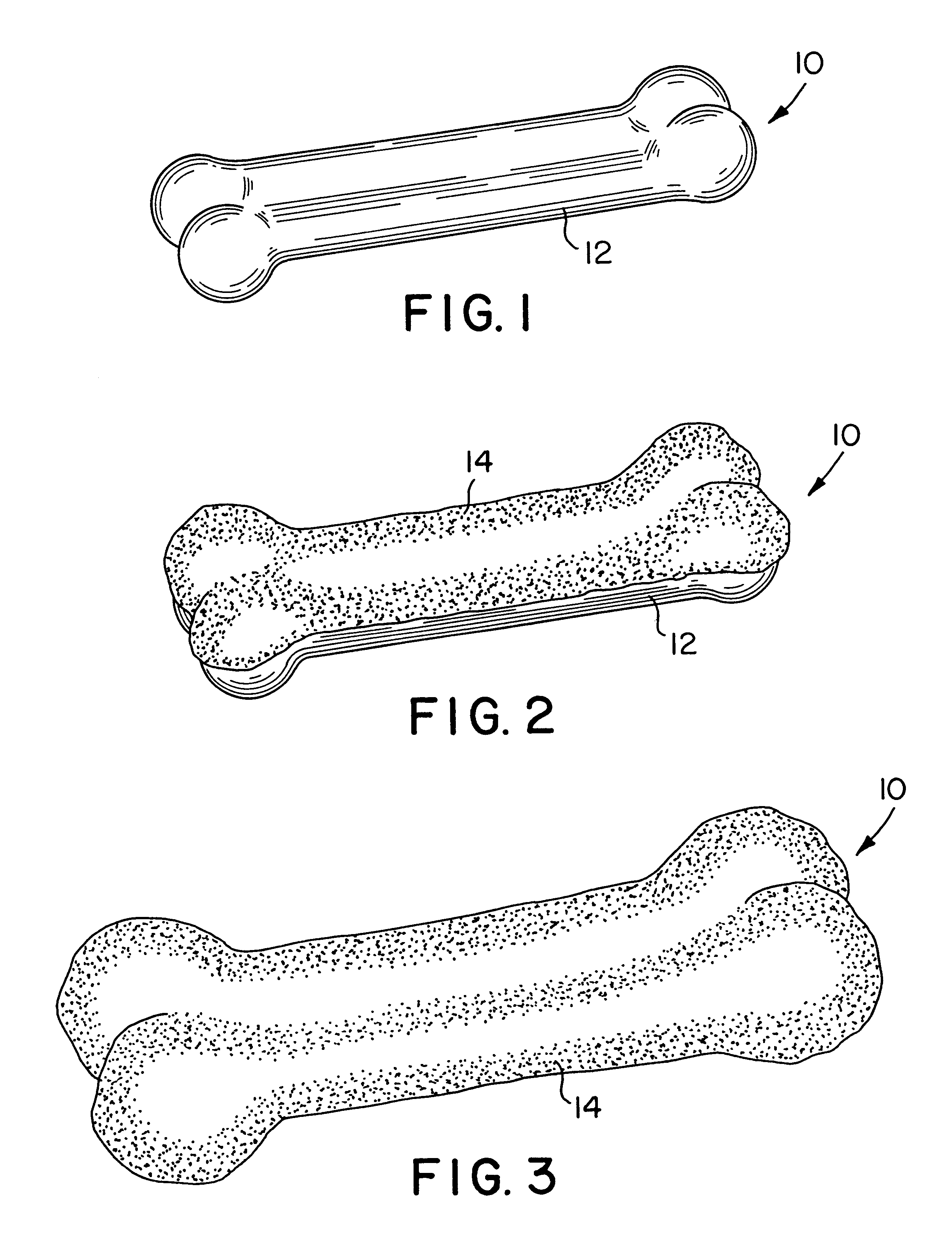

Heat modifiable edible dog chew

A completely digestible highly nutritious dog chew formulated primarily of beaded corn starch or a mixture of beaded corn starch and potato starch, and calcium carbonate, the texture of hardness or which is easily modified to suit a particular dog by the dog owner. By irradiating the chew in a microwave oven, the chew is caused to expand and is thereby rendered more easily chewable.

Owner:T F H PUBLICATIONS

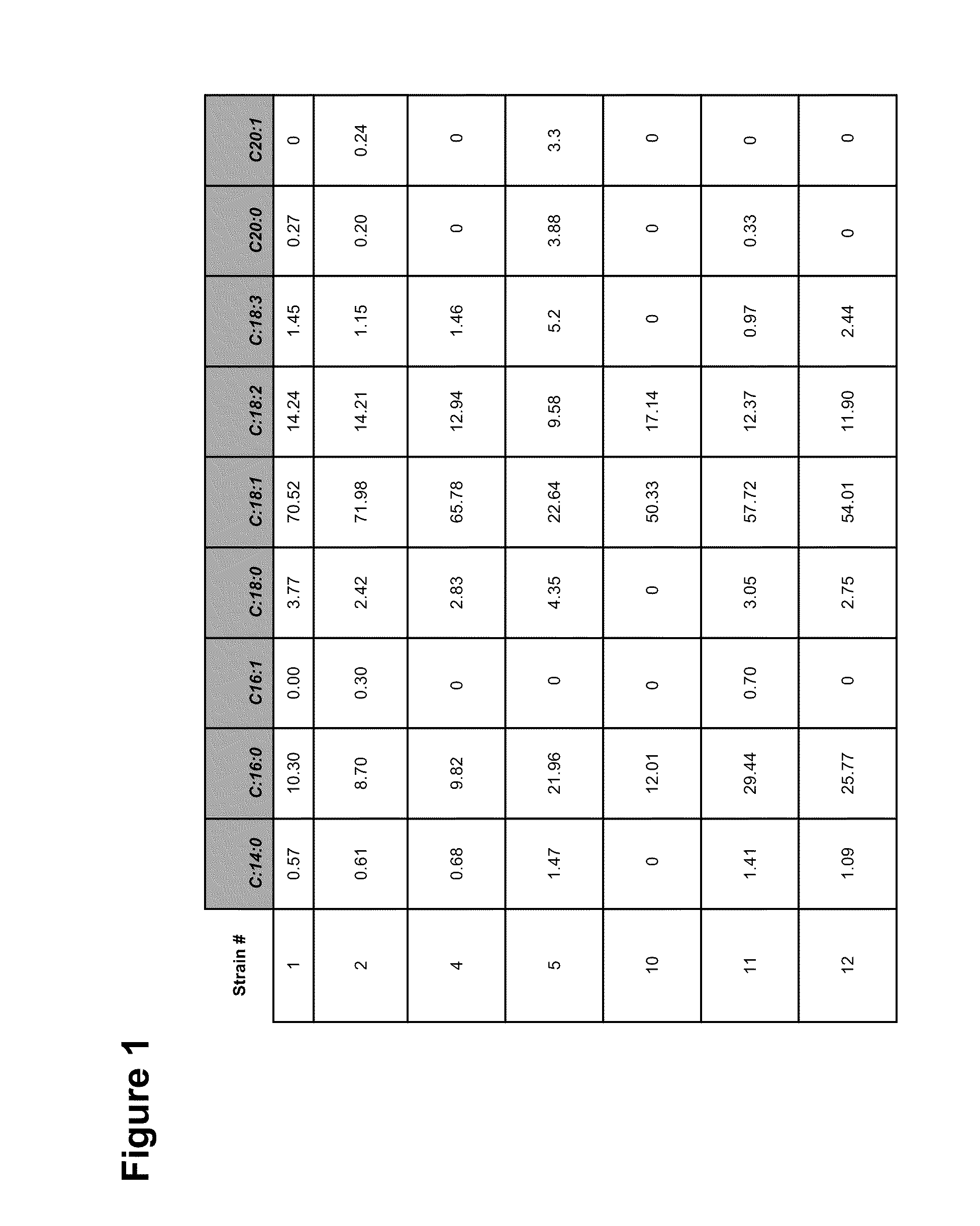

Edible Oil and Processes for Its Production from Microalgae

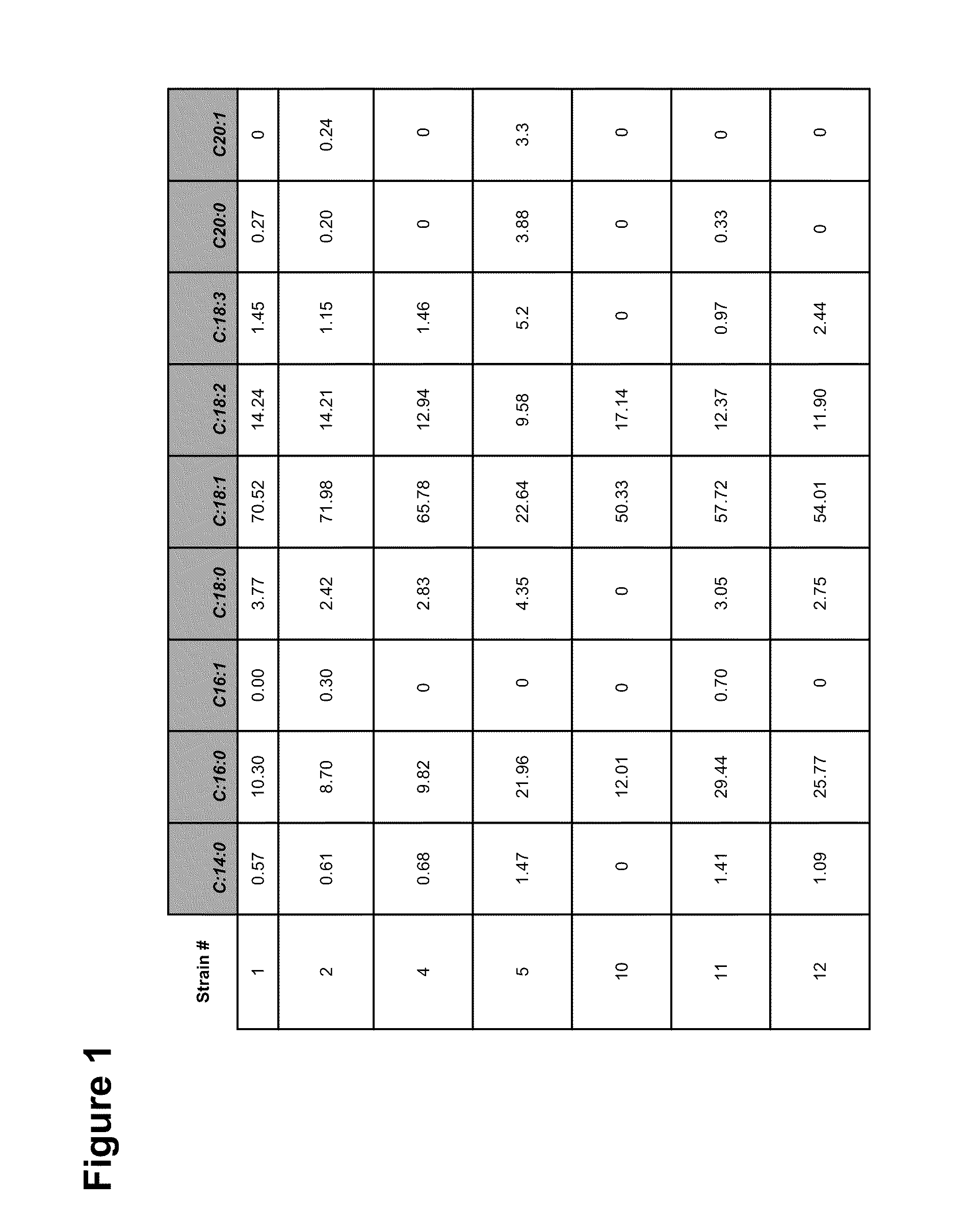

InactiveUS20100303957A1Simple preparation conditionsFatty acid hydrogenationReady-for-oven doughsCelluloseBiotechnology

Novel triglyceride oils are provided for human consumption. Traditionally, agricultural materials such as canola, soybean, and olives have been the sources of edible oils, and such materials are limited by the geography in which these crops can be cultivated. Oils of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose that are purpose-grown or byproducts of existing agricultural processes from an extremely broad diversity of geographic regions. The food oils disclosed herein are low in saturates, high in monounsaturates, and can be manufactured in reduced pigment form through the use of pigment-reduced microalgae strains. The food oils disclosed herein can be manufactured through the use of a variety of different types of oil-producing microalgae.

Owner:TERRAVIA HLDG INC

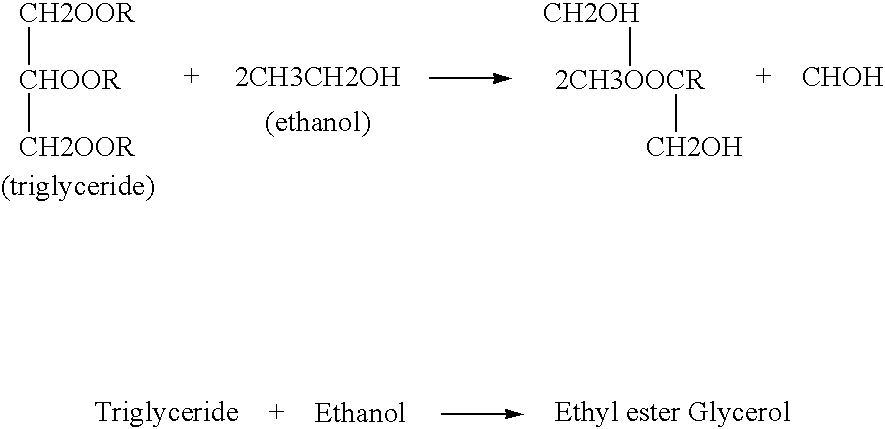

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

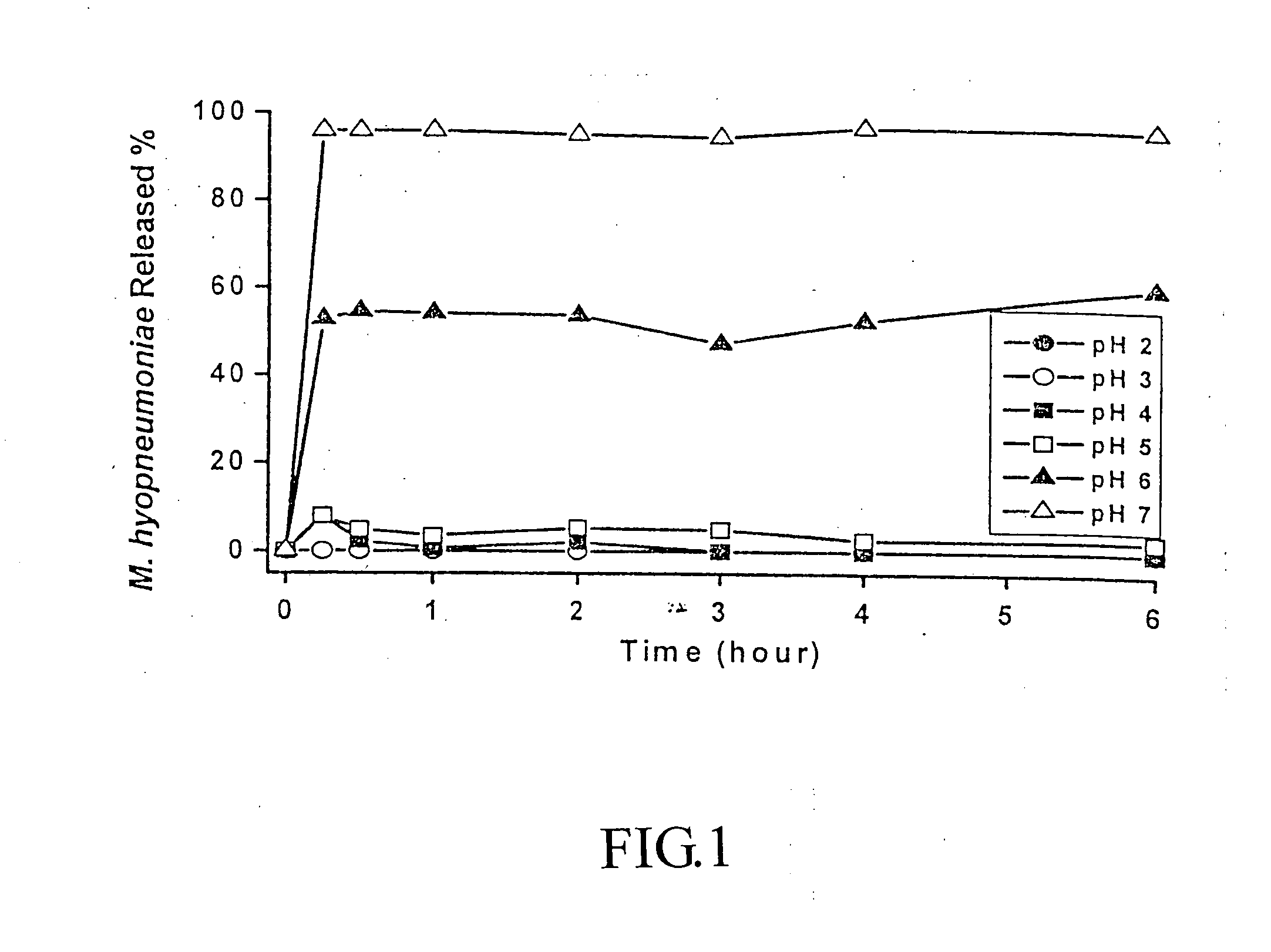

Probiotic composition having acid-resistant enteric coating

InactiveUS20070059296A1Improve digestibilityImproving resistance against diseaseOrganic active ingredientsBiocideBiotechnologyTalc

A probiotic composition essentially comprises 15 to 20 wt % of milk powder, 25 to 30 wt % of corn starch, 8 to 15 wt % of modified starch (capsul), 10 to 15 wt % of ethylcellulose, 5 to 15 wt % of bacterial broth, and 10 to 15 wt % of talc. The probiotic composition is microencapsulated to form a plurality of microencapsule coated with an acid-resistant enteric coating for improving the enteric acid-resistance, the probiotic survival rate, the antimicrobial property, the stability, the moisture-proof property, and the mobility of the probiotic composition preventing from coagulation in a moist environment and for being used as an additive applied to livestock feed.

Owner:BION TECH INC

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

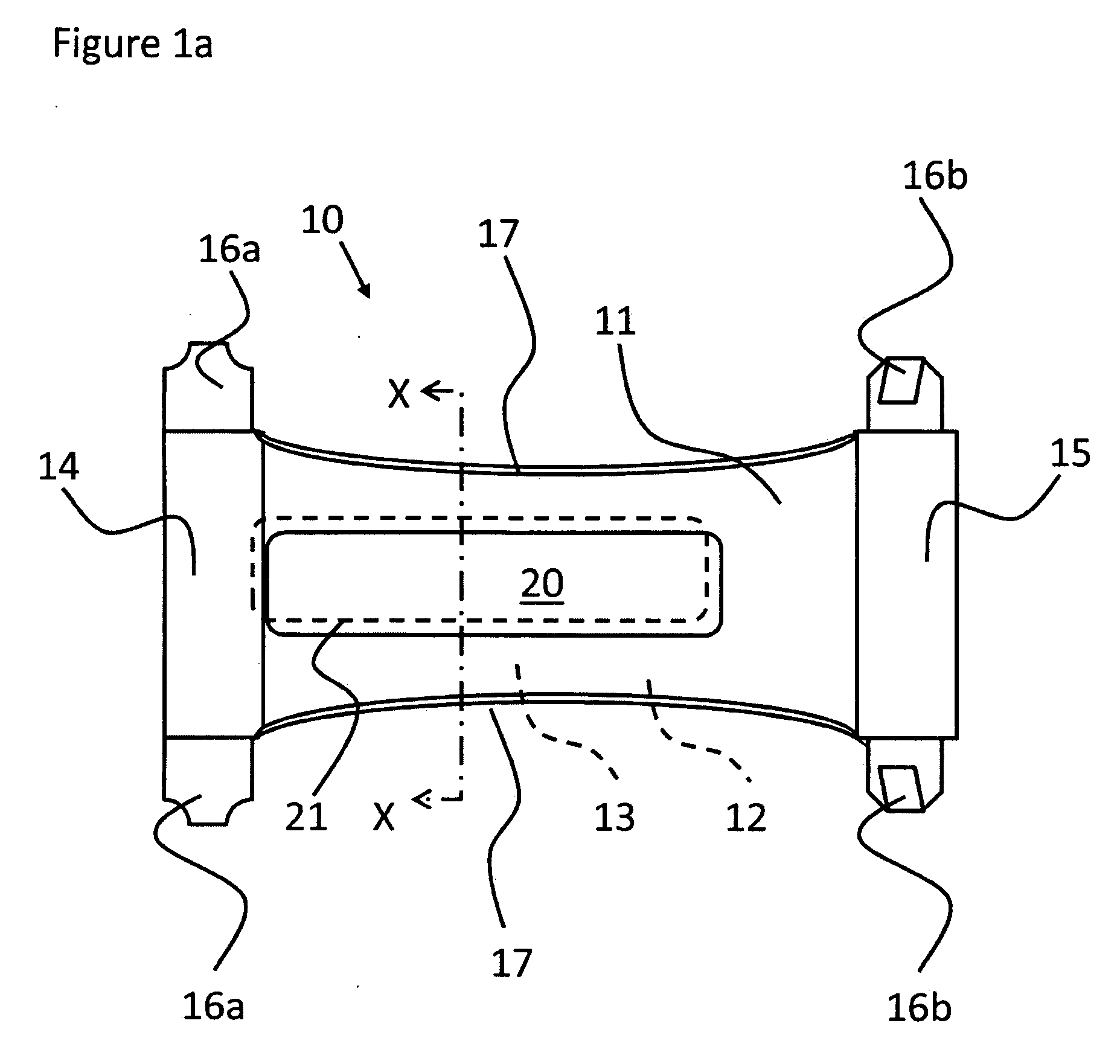

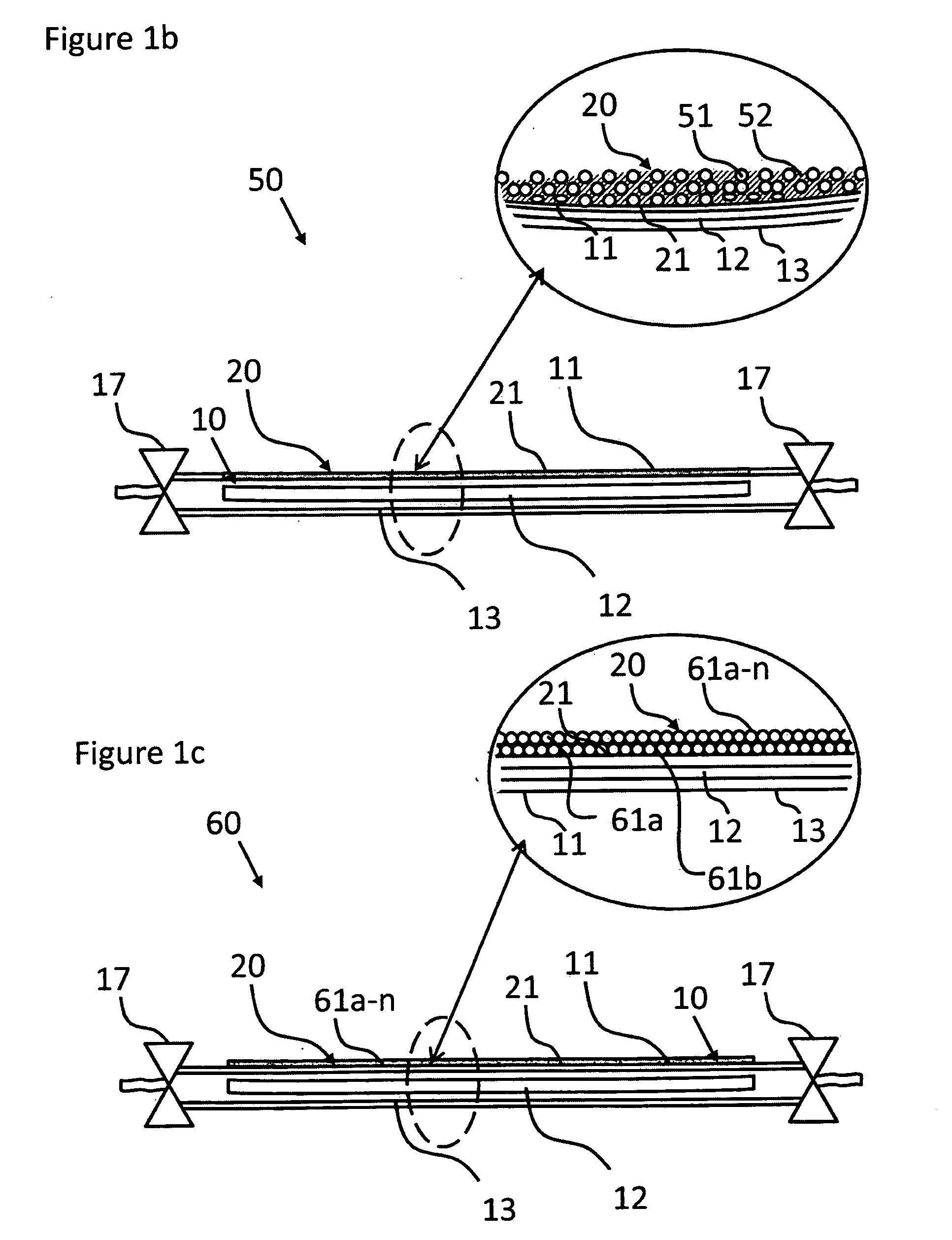

Diapers, diaper wipes and diapaer pads with active ingredients integrated therein

InactiveUS20090264849A1Improve protectionReduce development riskBoard cleaning devicesCarpet cleanersSkin contactDry skin

The present invention provides a diaper, diaper pad insert and / or a diaper wipe with active ingredients integrated therein, including ointments for treating diaper rash, baby oils and lotions for treating dry skin, and / or powder treatments for absorbing moisture, including baby powder, corn starch powders and the like. In a first embodiment, the invention provides a diaper having a active ingredients integrated therein comprising a skin-contact surface appointed for contact with an infant's bottom, at least one inner absorption layer, an outer most layer, and a active ingredients segment. The active ingredient segment includes active ingredients associated therewith and is adapted for contact and direct delivery to the infant's bottom when the diaper is placed on and worn by the infant. The active ingredient may be applied as a coating or integrate as fine particles within the skin-contact surface. As the infant wears the diaper and moves around, or the active ingredient wipe is wiped on the infant, the skin-contact surface comes into contact with the infant's body, transferring active ingredients associated with the active ingredient segment onto the infant's body.

Owner:LA CROIX TIMOTHY MATTHEW

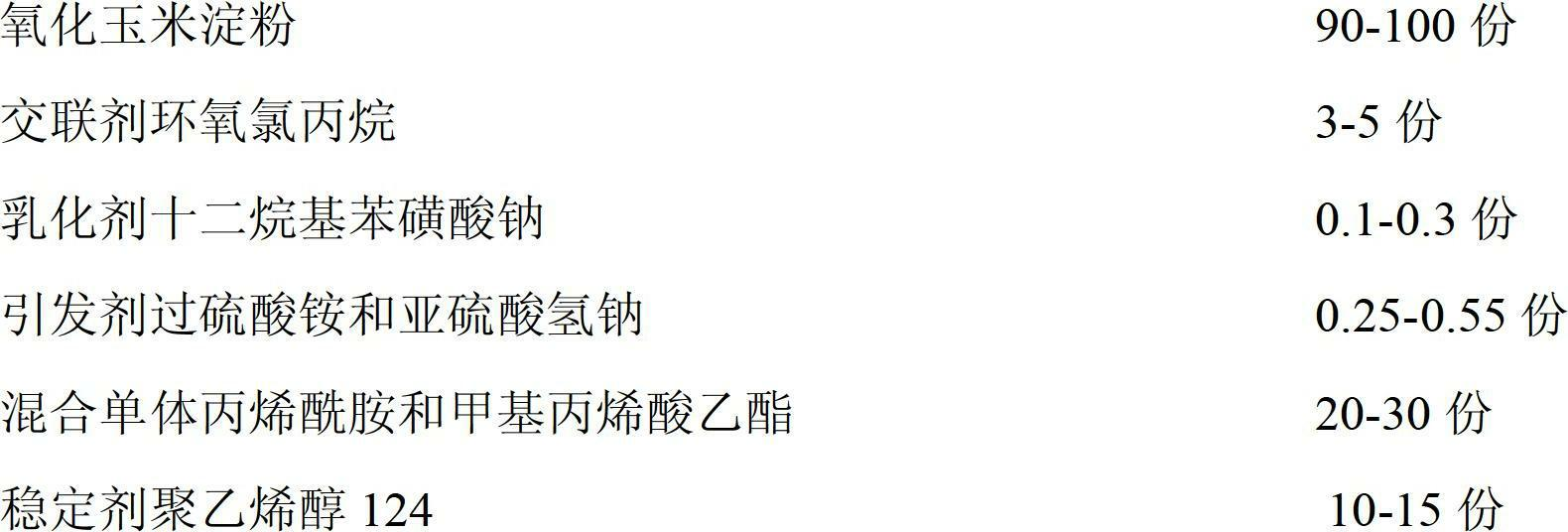

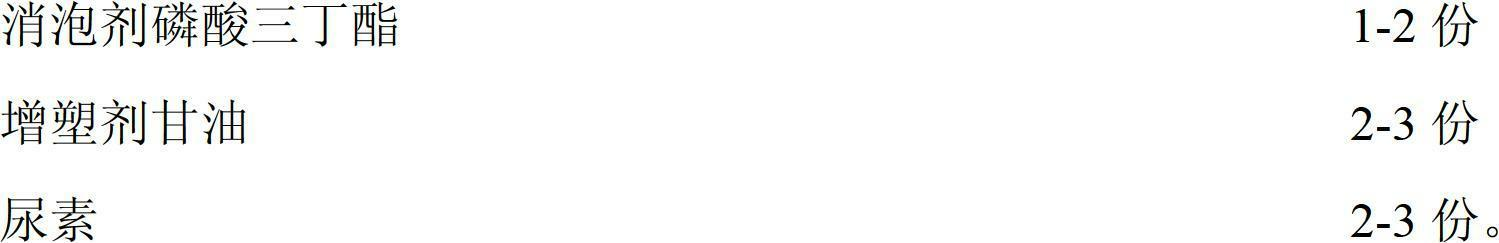

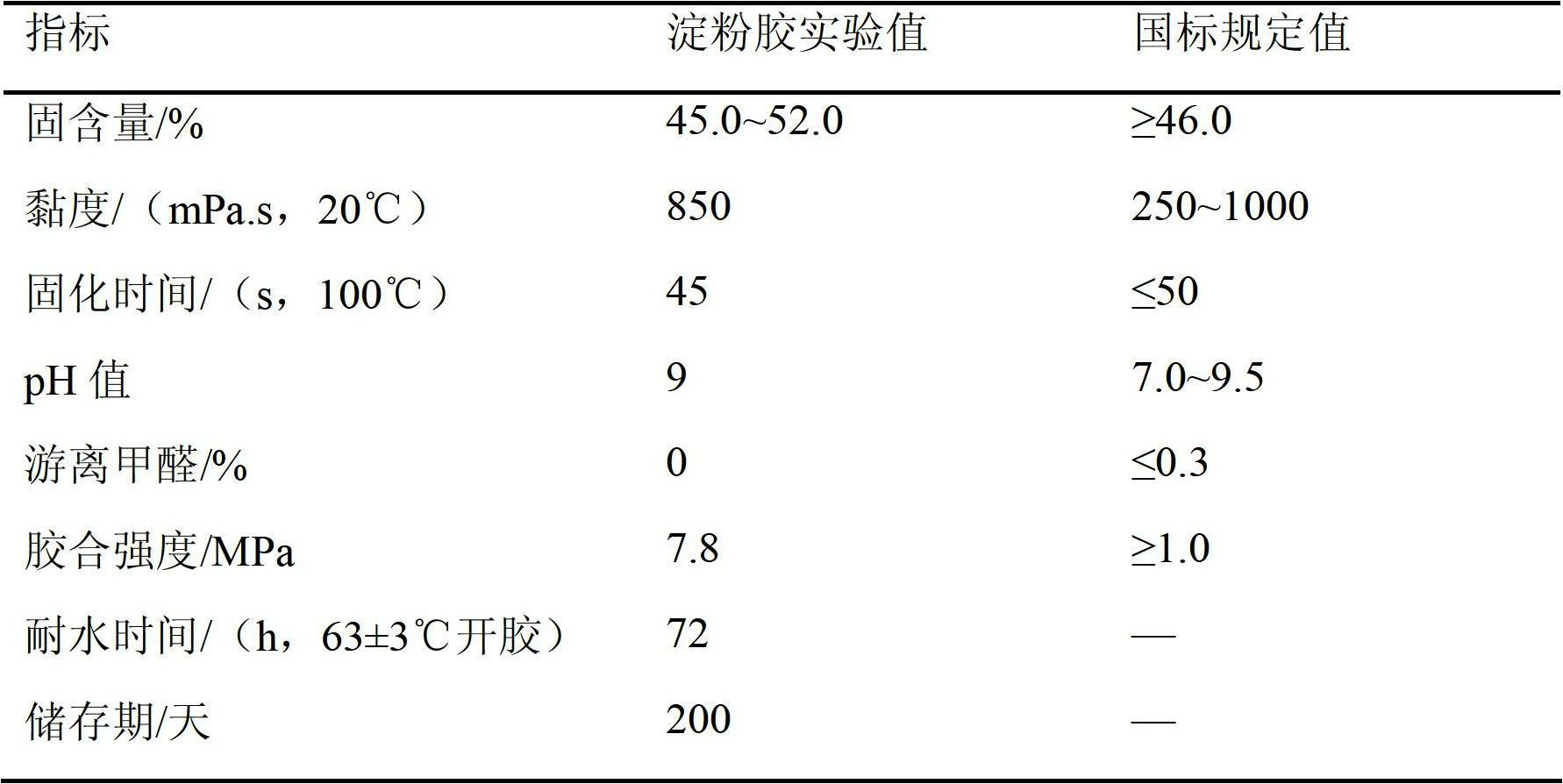

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

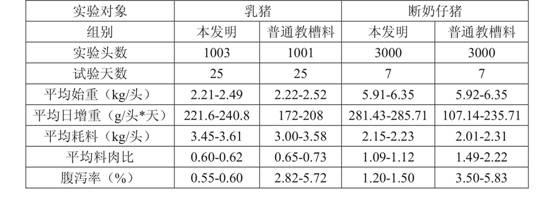

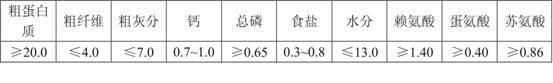

Compound feed for teaching piglets to eat foods other than breast milk

InactiveCN102178115AHealthy micro-ecological balance environmentAvoid damageFood processingAnimal feeding stuffDiseaseSucrose

The invention provides compound feed for teaching piglets to eat foods other than breast milk, which is used for weaning piglets and teaching the piglets to eat foods other than breast milk, and comprises the following components in part by weight: 212.4 parts of corn starch, 154.0 parts of bulked corn, 100.0 parts of 46 percent of bulked bean pulp, 40 parts of fish meal, 100 parts of wheat flour, 5 parts of calcium powder, 21 parts of calcium hydrophosphate, 2 parts of table salt, 20 parts of soybean oil, 5 parts of lysine, 2 parts of threonine, 1.5 parts of choline chloride, 10 parts of premix, 0.2 part of complex enzyme, 0.3 part of pig Duowei, 0.2 part of sweetener, 0.3 part of flavouring agent, 3 parts of baking soda, 20 parts of cane sugar, 30 parts of glucose, 50 parts of egg powder, 70 parts of soy protein concentrate, 50 parts of fermented bean pulp, 6 parts of acidizer, 100 parts of whey powder, 0.5 part of mould removing agent, 0.3 part of antioxidant and 0.3 part of mildewpreventive. In the invention, the problems of incomplete immune functions, low disease resistance, inadequate digestive ferment, incomplete upper gastrointestinal development, low digestion and absorption ability, susceptibility to diarrhea and the like of piglets.

Owner:AGRI SCI & TECH INST CO LTD OF CHENGDU WEST HOPE GRP

Preparation method of edible film with antibacterial and antioxidant functions

InactiveCN103159970AHas antibacterial propertiesAntioxidantFlexible coversWrappersAntioxidantGlycerol

The invention relates to a preparation method of an edible film with antibacterial and antioxidant functions, and belongs to the technical field of edible packaging materials. The preparation method disclosed by the invention comprises the following steps: 1) dissolving and gelatinizing corn starch; 2) dissolving gelatin; 3) dissolving chitosan; 4) adding glycerin and plant essential oil or essential oil components; 5) mixing, homogenizing and refining; 6) degassing; 7) tape-casting; and 8) drying and stripping the film. The preparation method disclosed by the invention has the beneficial effects that the chitosan, the corn starch and the gelatin are taken as base materials of the edible film, the sources of the raw materials are wide, the cost is low, and the prepared edible film has the advantages of strong mechanical properties, high barrier performance and great transparency. Oregano oil, carvacrol and cinnamaldehyde are taken as an antibacterial agent and an antioxidant so as to be added into the edible film, the processing process is simple and easy to operate, the cost is low, the edible film is non-toxic and safe to eat, and the prepared edible film has great antibacterial and antioxidant properties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Environmental-friendly white emulsion

InactiveCN103725229AOptimal temperature timeImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDioxyethylene EtherBenzioc acid

The invention discloses an environmental-friendly white emulsion. The environmental-friendly white emulsion is prepared from the components in percentage by weight: 1.8-2.5 percent of polyvinyl alcohol PVA, 23-27 percent of vinyl acetate VAC, 0.3-0.8 percent of acrylic acid AA, 0.8-1.5 percent of acryl amide AM, 0.1-0.15 percent of ammonium persulfate, an anionic emulsifier A-102, alkyl polyoxyethylene ether LCN-287, a nonionic emulsifier, 5-7 percent of corn starch, a transparent powder, a plasticizer, 2.5-4 percent of diethylene glycol dibenzoate, 0.2-0.3 percent of preservative KSG-201, 0.1-0.2 percent of sodium hydroxide NaOH, 0.3-0.5 percent of methanol, 3-6 percent of functional filler, 0.15-0.3 percent of compound emulsifier and 56-58 percent of water. The environmental-friendly white emulsion is strong in the adhesive force and the adhesive strength, is low in the production cost and is good in the environmental protection performance.

Owner:GUANGZHOU YIJIANG CHEM CO LTD

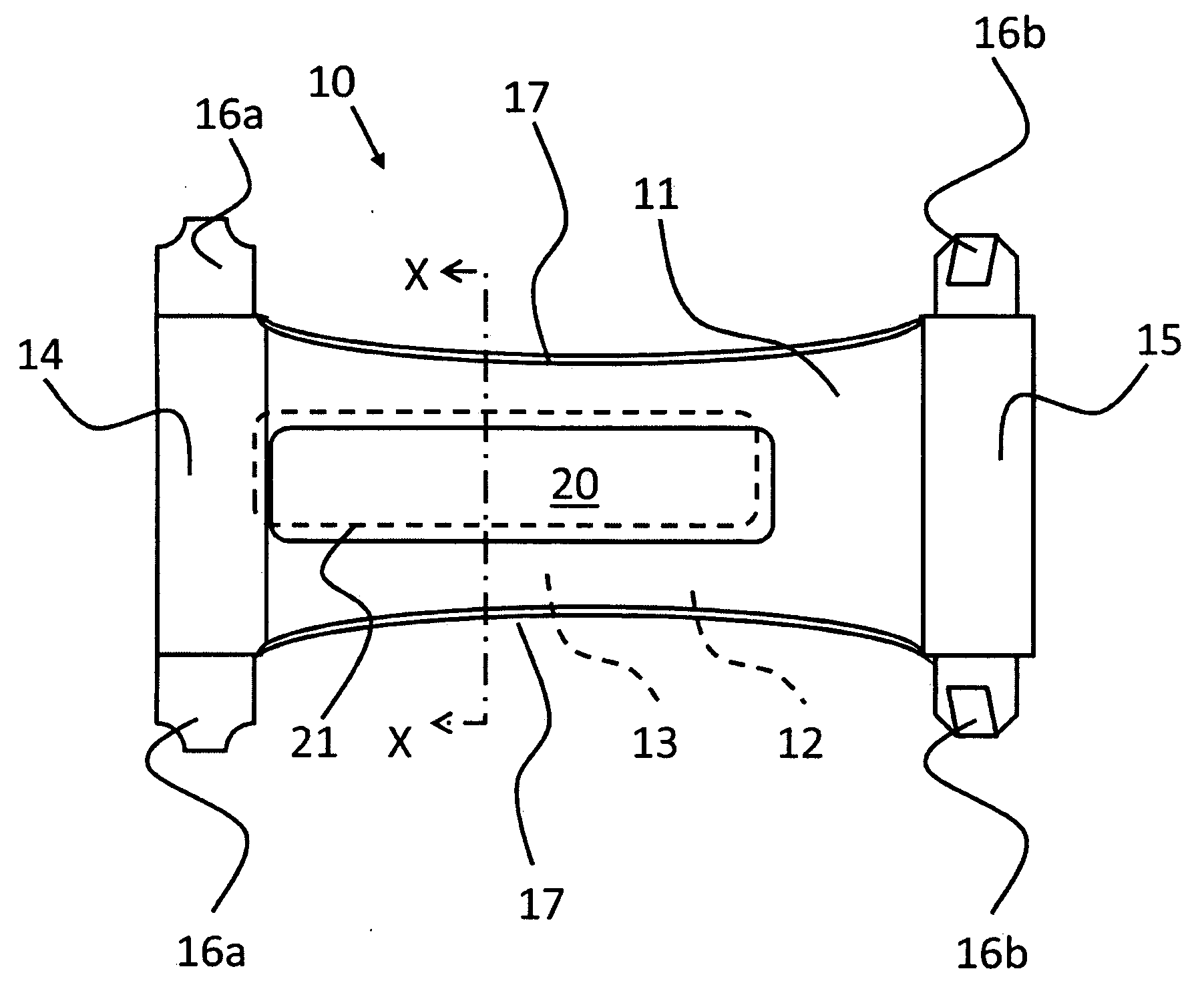

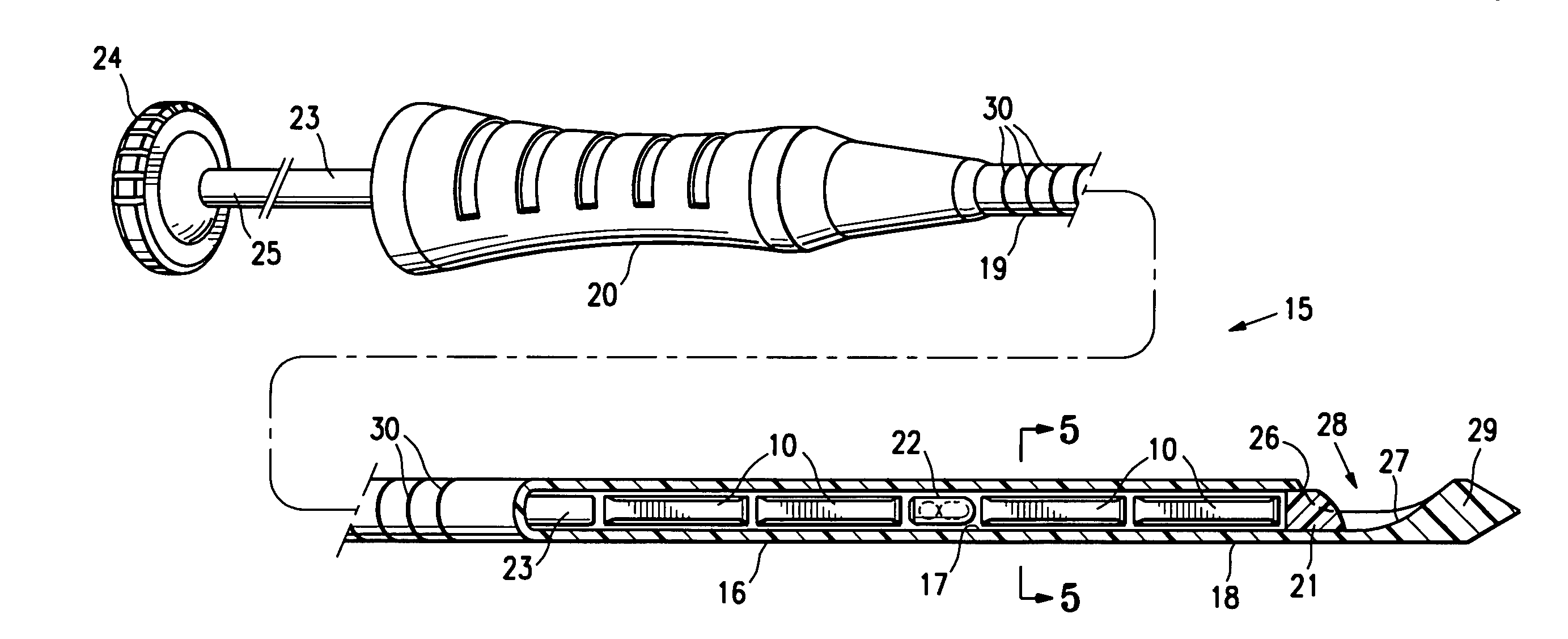

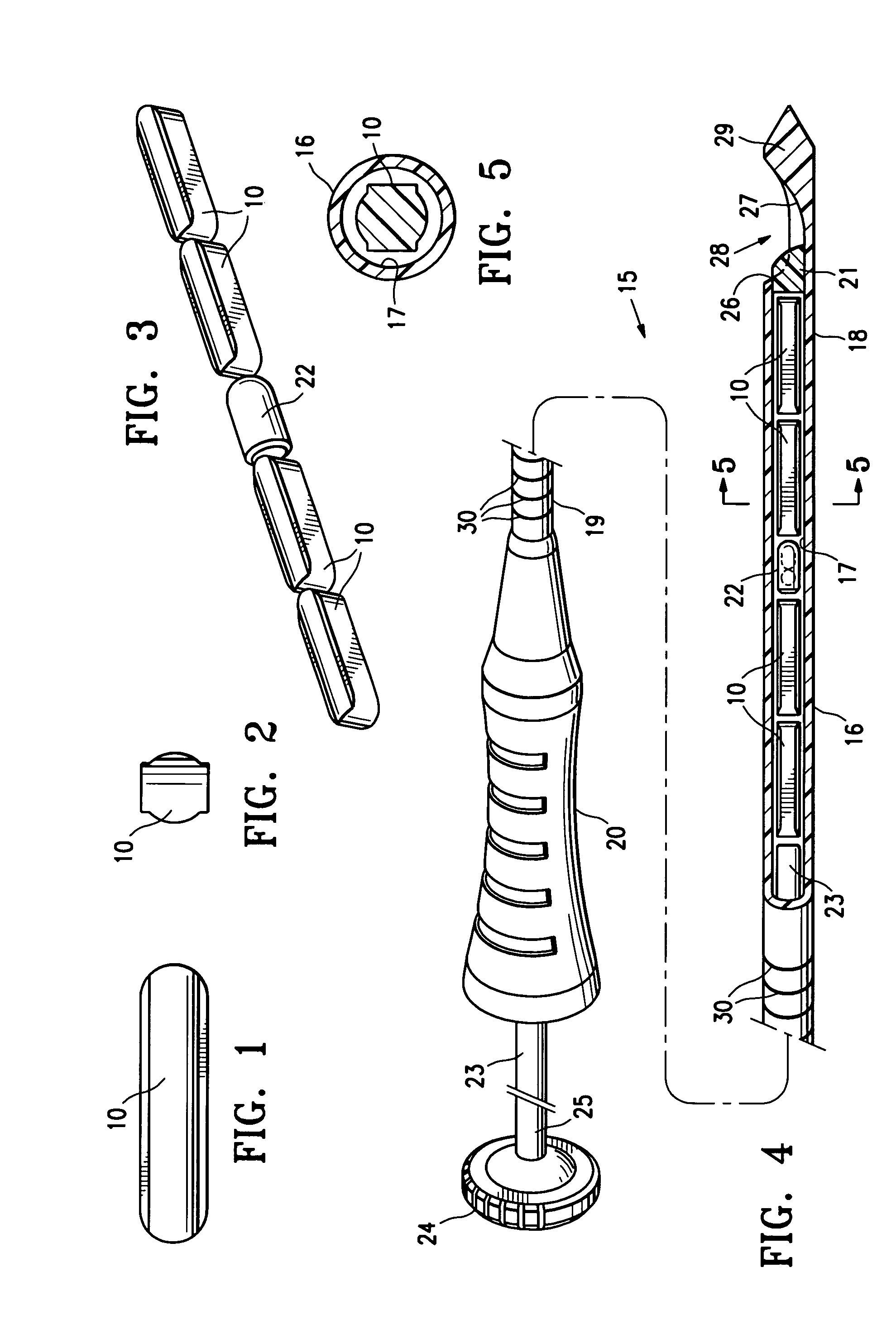

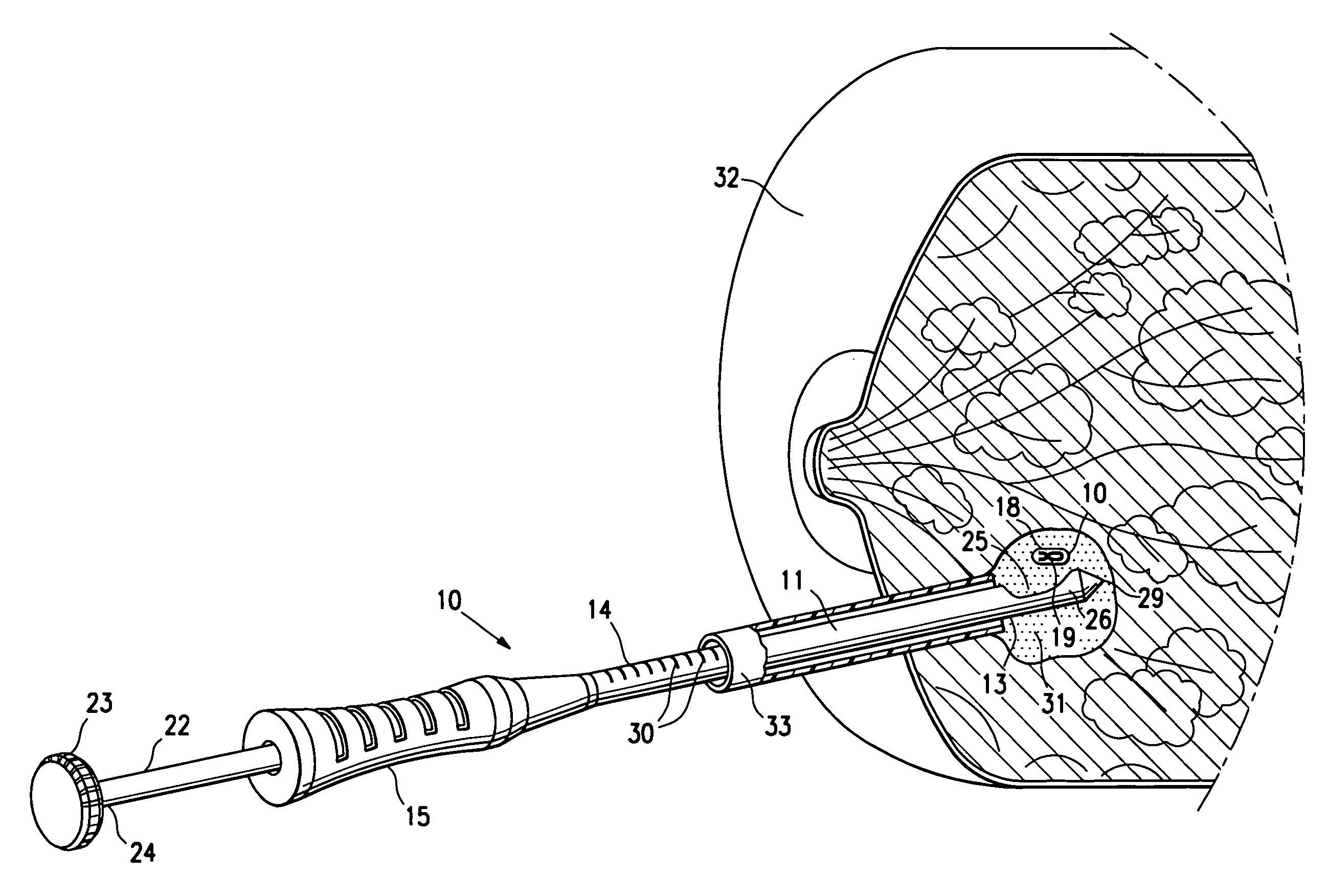

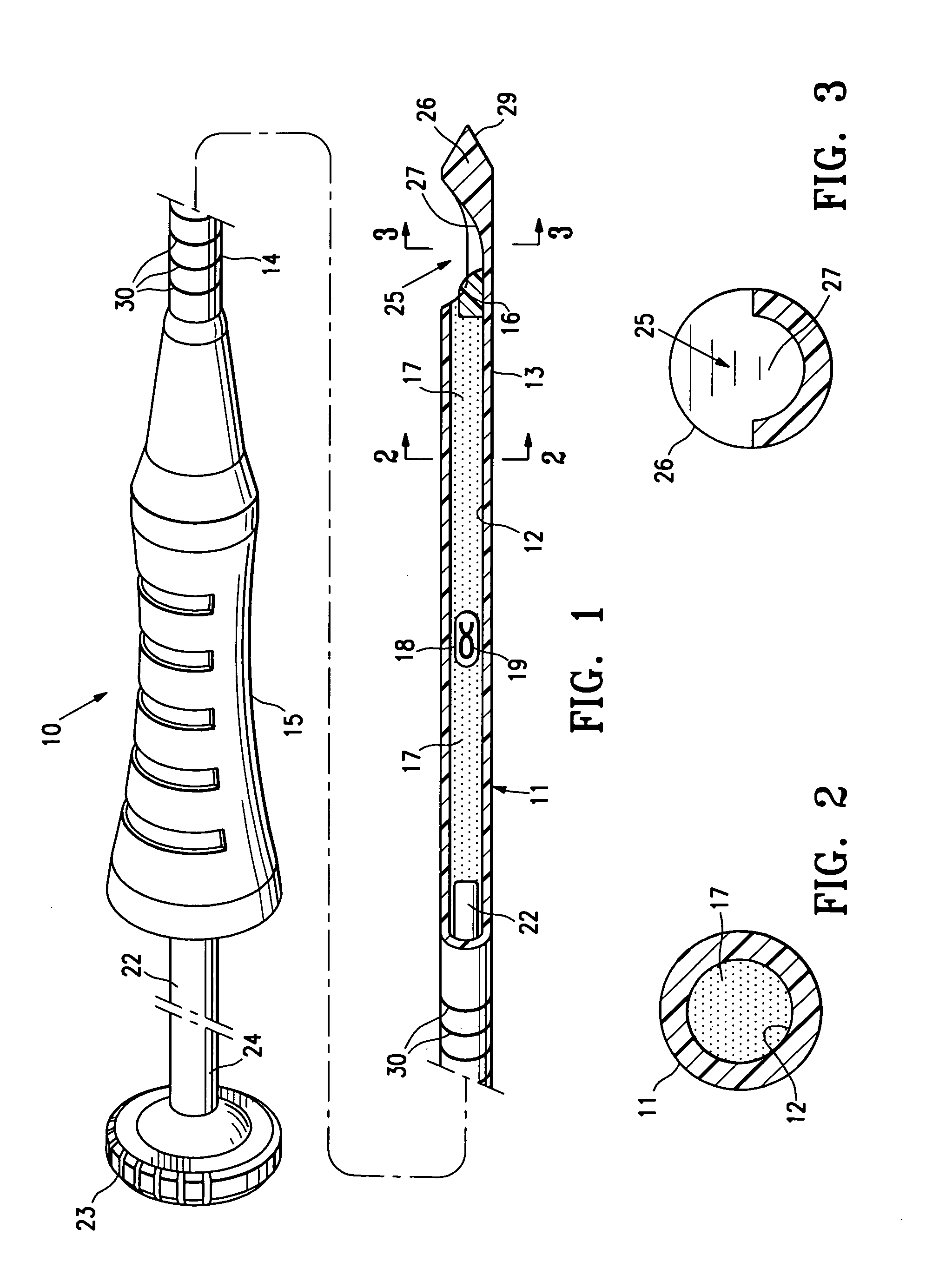

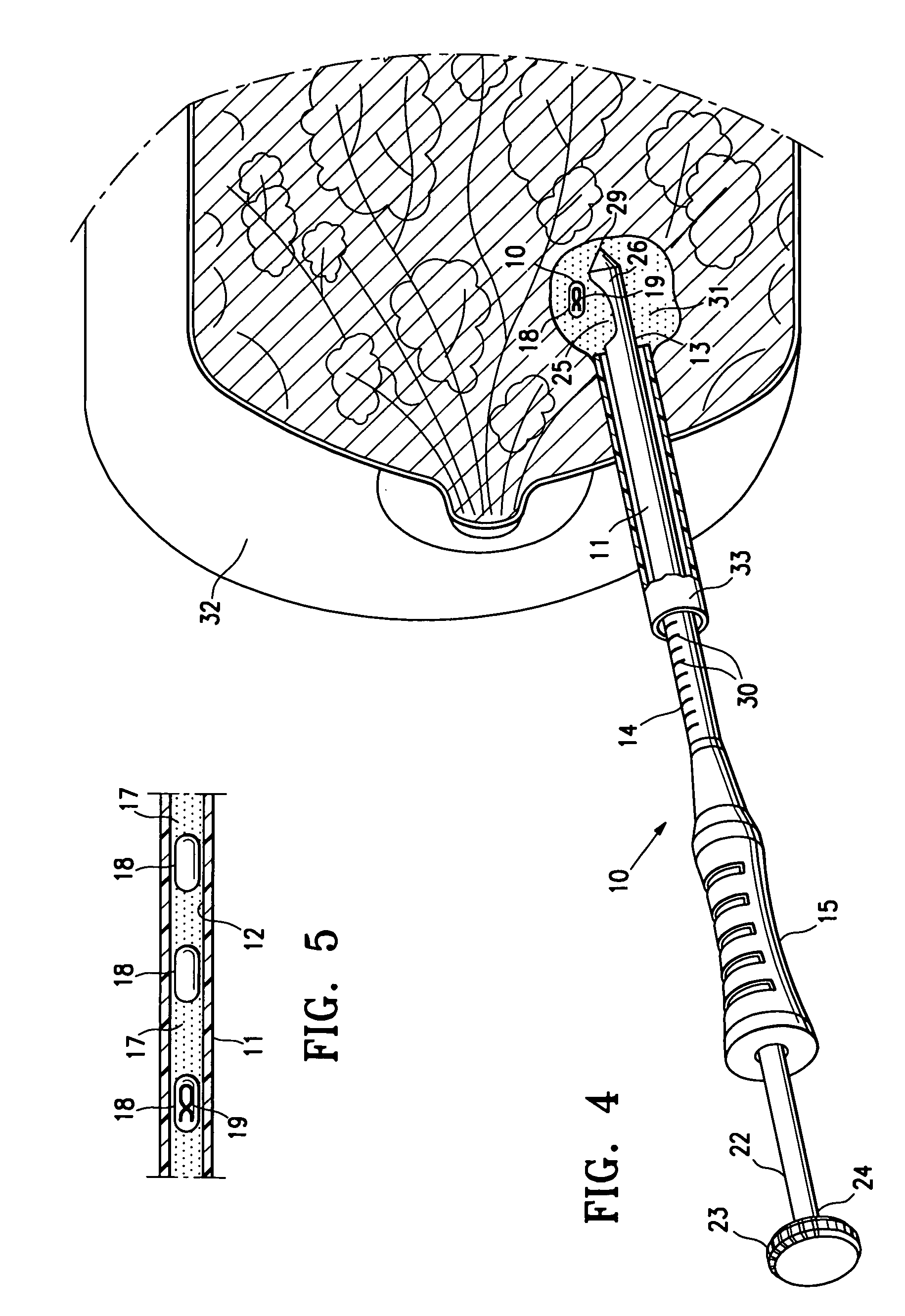

Deployment of polysaccharide markers

InactiveUS20090030309A1High strengthEasy dischargeSurgeryPharmaceutical delivery mechanismPotato starchPolysaccharide

The marker member delivery system described has a plurality of marker members disposed within a delivery tube or cannula which contain a suitable polysaccharide such as starch (e.g. corn starch or potato starch) and a binder such as methylcellulose. These marker members are preferably press-formed from powders. The system has preferably has at least one other marker member formed of bioabsorbable material with a radiopaque element attached to or incorporated therein. The marker with a radiopaque marker element is preferably disposed within the delivery tube between two marker members formed of polysaccharide and is preferably formed of a bioabsorbable material other than a polysaccharide.

Owner:SENORX

Nonreactive health powdered suckling pig creep compound feed and preparation method thereof

InactiveCN102885236AIncrease feed intakeImprove Gut HealthFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses a nonreactive health powdered suckling pig creep compound feed and a preparation method thereof, wherein the feed is prepared from the following materials: corn, broken rice, puffed corn starch, puffed soybean meal, dehulling soybean meal, fermented soybean meal, white fish meal, flour, plasma protein flour, whey powder, fruit sugar, glucose monohydrate, bean oil, calcium formate, calcium biphosphate, salt, enveloped slow release acidulant, choline chloride, suckling pig compound premix, zinc oxide, yeast cell wall polysaccharides, sodium glutamate, arazyme, lipidase, Clostridium butyricum, essential oils, L-lysine hydrochloride, DL methionine, L-threonine, tryptophan and phytase. Based on the physiological characteristics of suckling pig and by the combination of various materials, the feed is supplementary in nutrition and high in design of amino acid and daily ration of energy without adding antibiotics, and Clostridium butyricum and various essential oils are used for protecting the health; therefore, the feed intake of suckling pig can be increased, the weight growth rate is increased, the diarrhea rate after ablactation is reduced, the intestine health of suckling pig can be improved, the immunity is improved, and the survival rate of suckling pig is increased.

Owner:HUAIAN ZHENGCHANG FEED

Powdered marker

InactiveUS20090171198A1Easy to identifyStable and fastSurgeryDiagnostic markersPolysaccharideDelivery system

The marker delivery system described has a delivery tube or cannula which has a bioabsorbable powdered mass and a radiographically detectable element within an inner lumen thereof. The powdered material is a starch such as USP (corn) starch or other suitable polysaccharide. The radiographically detectable element may be disposed within or coupled to a bioabsorbable pellet.

Owner:SENORX

Flammulina velutipes noodles

The invention belongs to the field of foods, relates to noodles and particularly relates to flammulina velutipes noodles which comprise the following components in parts by weight: 200-300 parts of flammulina velutipes powder, 50-100 parts of purple sweet potato powder, 40-80 parts of flour, 20-60 parts of corn starch, 20-60 parts of sorghum flour, 10-40 parts of millet flour, 20-60 parts of sticky rice flour, 5-20 parts of edible additive, 5-10 parts of auxiliary material, 20-60 parts of peanut protein powder, 30-90 parts of vegetable juice, 20-50 parts of buckwheat flour, 20-60 parts of bean flour and10-40 parts of milk powder. The noodles prepared by adopting the formula have better intrinsic viscoelasticity and good mouthfeel, and is pliable; the quality of the noodle does not change after the noodle is stored for a long time, and better taste and flavor can be maintained; and as the flammulina velutipes in the noodle has an intelligence promoting function, and anti-tumor and anti-oxidized activities, people can ingest various intelligence promoting nutritive components after eating the noodles provided by the invention.

Owner:山东创新源农业技术开发有限公司

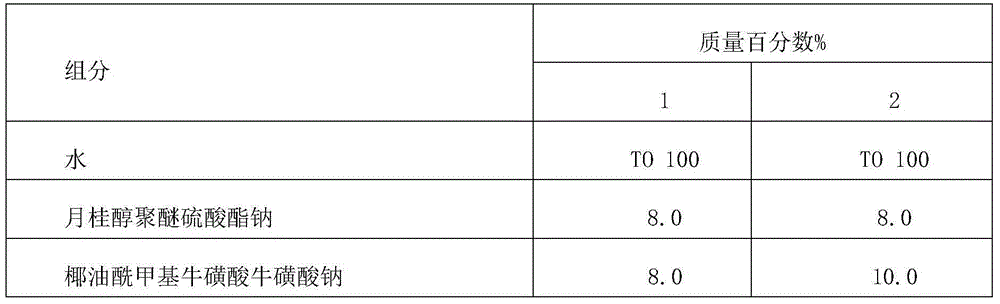

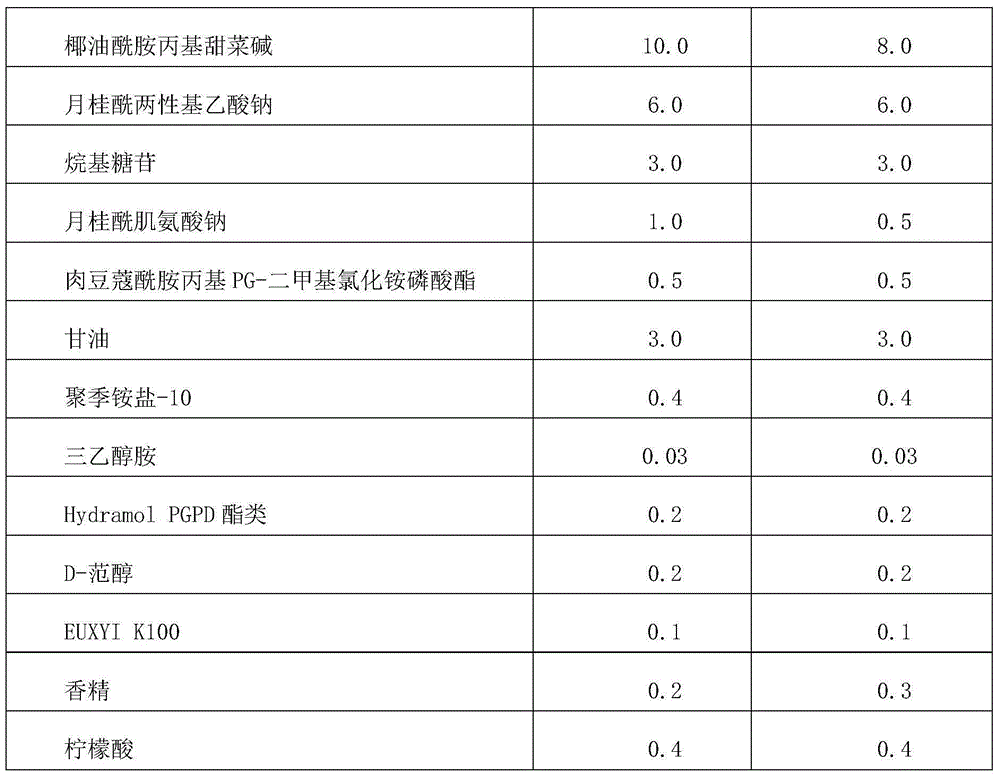

Liquid shampoo without silicon oil and with hair caring effect and preparation method thereof

ActiveCN104921989AReduce hair lossHigh viscosityCosmetic preparationsHair cosmeticsIrritationPiroctone olamine

The invention relates to liquid shampoo without silicon oil and with the hair caring effect. The liquid shampoo comprises, by mass, 5-50% of mild surfactants and 0.1-10% of hair caring agents. The mild surfactants are mixtures of more than three of sodium methyl cocoyl taurate, sodium methyl cocoyl taurate, sodium lauroyl sarcosinate, sodium lauroyl glutamate, sodium cocoyl alaninate, cocamidopropyl betaine, sodium lauroamphoacetate, decyl glucoside, tea saponin and sapindus mukurossi peel extracts. The hair caring agents are mixtures of more than two of hydrolyzed corn starch, sodium pyrrolidonecarboxylate, poly (sodium glutamate), piroctone olamine, ginger root extracts, camelina oilseeds, pipewort extracts, raspberry juice and spicy mint leaf extracts. The liquid shampoo is mild and free of irritation, the scalp can feel comfortable, the hair follicle is healthy, the hair root is stable, and the functions of caring hair and reducing hair loss are achieved.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

Fish paste and preparation method

The invention relates to a fish paste and a preparation method. The fish paste is characterized by comprising main raw materials and auxiliary raw materials, wherein the main raw materials comprise fish filet, lard oil, corn starch, fresh eggs and water, and the auxiliary raw materials comprise refined salt, a natural aromatic condiment, sodium glutamine, sorbitol and vegetable protein. The fish paste is prepared by the special processes of stewing, sterilizing and caking. The fish paste has the characteristics of high protein content, low fat content, long retention period, delicate quality, smooth and soft mouth feel, good toughness after being sliced into a flaky shape and convenient eating, can be preserved for 5 months at ordinary temperature, can be eaten in a cooking way, a swilling way, a stewing way, a cold way or a hot way and is a delicious food which is suitable for all the people, and the quality of the fish paste can be preserved for 4 months at ordinary temperature.

Owner:黄啟付

Maize oligopeptide and method for preparing same

ActiveCN101531700AIncrease contentImprove enzymatic hydrolysis efficiencyPeptide preparation methodsFermentationAlkaline waterEnzymatic hydrolysis

The invention relates to a maize oligopeptide and a method for preparing same, belonging to the field of biological technology. The method takes the byproduct, namely corn protein powder (also called maize yellow powder containing about 60% of protein) in corn starch production as a raw material, removes the impurities such as starch, grease and the like by the treatment of alkaline water and obtains high-purity corn protein slag; furthermore, the corn protein slag is taken as enzymatic hydrolysis substrate and treated by the following process of pre-treatment, enzymatic hydrolysis, multi-step separation and purification, concentrating, drying and the like so as to prepare the maize oligopeptide powders with edible value and various health-care functions. The method for preparing maize oligopeptide has the advantages of easily obtaining raw material, simple process and higher industrial feasibility. The prepared maize oligopeptide sample has high crude protein content and small molecular weight, has various physiological activities of prompting immunity adjustment, anti-fatigue and the like, and can be used as new functional nutritional compounding and widely applied to the development and production of products such as foods, health-care foods and the like.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

A kind of health vermicelli and preparation method

The invention discloses health care silk noodles and a manufacturing method thereof. The health care silk noodles comprise the following ingredients in percentage by weight: 50 percent of tapioca, 8 to 10 percent of jujube powder, 5 percent of black fungus powder, 8 percent of arrowroot, 10 percent of corn starch, 5 percent of mung bean flour, 7 percent of yam flour and 5 to 7 percent of pumpkin powder. The health care silk noodles disclosed by the invention are not added with any preservative, contain substances such as vitamins, trace elements, proteins and the like, not only can improve heat, but also can supplement iron and reduce blood lipid, have the health care effect on prevention of heart cerebrovascular diseases and have the simple manufacturing method. The silk noodles manufactured by the method are not broken, are not sticky and have soft and elastic taste.

Owner:姚存利

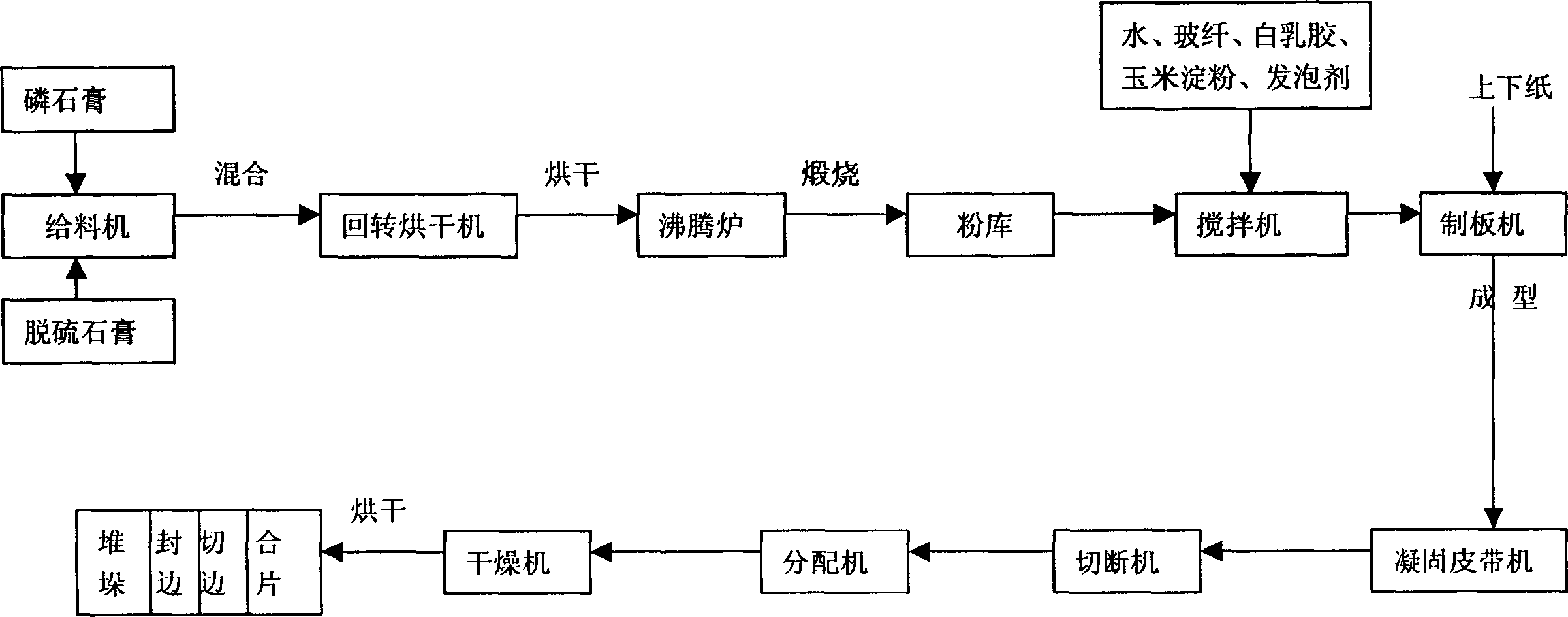

Method for producing paper gypsum board using desulfurated gypsum and ardealite

The invention discloses a making method of paper plaster board, which comprises the following steps: mixing the phosphogypsum and desulfuration plaster according to the weight ratio at 50-90:50-10; drying until the free water content under 5 percent; sintering the plaster at 160-220 DEG C continually to form the calcined gypsum powder with 5-9 percent crystal water; cooling in the bin; placing to obtain the architecture plaster powder; stirring the plaster powder with white corn starch latex, foaming agent, glass fiber and water evenly into material paste; compounding the roof and bottom of paper plaster board through plate-typed molder. The invention saves the natural plaster resource and cost, which improves the product property.

Owner:TAISHAN GYPSUM CO LTD

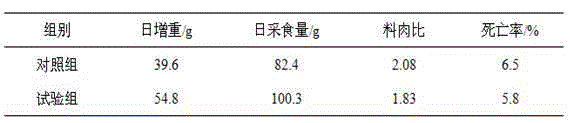

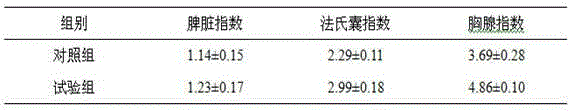

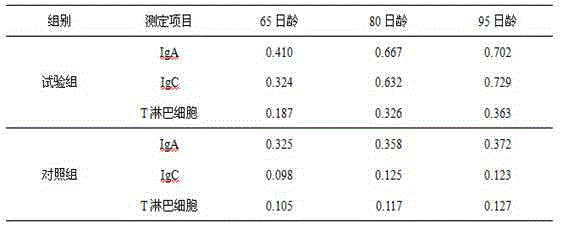

Composite microorganism preparation and preparation method thereof

The invention discloses a composite microorganism preparation including the active components as follows: at least two of enterococcus faecalis, saccharomyces cerevisiae and bacillus subtilis, and as well as zymosan and corn starch. The preparation is composed of, by weight, 0.1-15 parts of powder of the enterococcus faecalis, 0.1-15 parts of powder of the saccharomyces cerevisiae, 0.1-10 parts of powder of the bacillus subtilis, 0.1 parts of the zymosan and 59.9-74.9 parts of the corn starch. Compared with the prior art, the enterococcus faecalis, saccharomyces cerevisiae and bacillus subtilis are organically combined so that advantages of the bacteria can be achieved completely. The preparation can adapt different hosts and conditions, can partially, even completely replace antibiotics, and can regulate ecologic balance in gastrointestinal tracts, promote growth, increase conversion rate of feeds and enhance immunity. The preparation can improve enteric microorganism environment in animals, inhibit growth of harmful bacteria and promote reproduction of beneficial bacteria, improves animal immunity and enhances disease resistance, supplies nutrients to animals, improves utilization rate of feed and promotes growth of the animals.

Owner:HENAN HUITONGTIANXIA ANIMAL MEDICINE

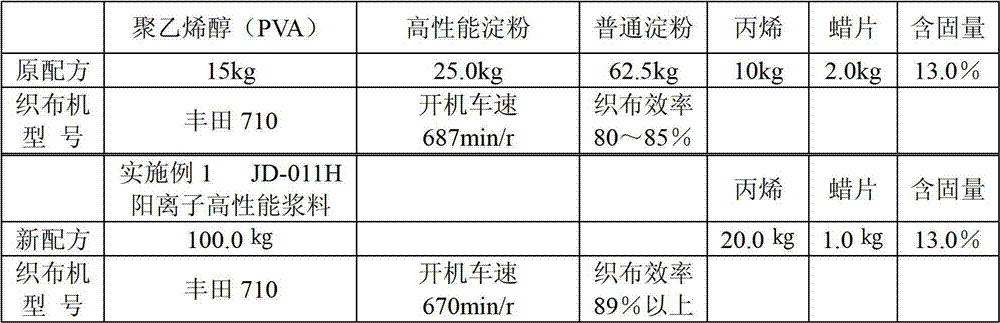

Multi-component high-performance sizing agent

The invention discloses a multi-component high-performance sizing agent. The sizing agent is prepared from various raw materials by a mixing reaction, wherein the raw materials comprise corn starch, phosphate, tween, persulfate, and at least one of phosphorus oxychloride and epoxy chloropropane. The sizing agent has the characteristics that the adhesion force is high, the film-forming ability is high, a serous film is coriaceous, the elasticity is high, the bending resistance (fatigue resistance) is improved by 3 to 4 times compared with a common modified starch sizing agent, and the abrasion resistance and the ageing resistance are high. The serous liquid is not frozen, caked or layered at normal temperature, and has high liquidity and stable viscosity. The sizing agent has no polyvinyl alcohol; when the sizing agent is sized on spinning cotton yarns; for the variety with general tightness, the polyvinyl alcohol does not need to be used for less than 50 yarns; or no or less polyvinyl alcohol is used for sizing on polyester cotton or over 50 cotton yarns; the yarns are easy to desize; the serous liquid waste water is easy to treat; the environment pollution is low; and the production process has zero pollution emissions.

Owner:YIXING JUNDA SLURRY TECH

Cation high performance slurry

The invention discloses cation high performance slurry. The slurry is formed by commixture reaction of raw materials including corn starch, sodium hydroxide, trimethylamine hydrochloride and persulfate with the following quality content: 80-95% of the corn starch, 1-10% of the sodium hydroxide, 1-15% of the trimethylamine hydrochloride, and 0.1-15% of persulfate. The cation high performance slurry has the advantages of strong adhesive force, good film formation property, tenacious chorion and good elasticity, the flexibility (anti-fatigue property) is improved by 3-4 times compared with common modified starch slurry, the cation high performance slurry has good wear-resisting property and ageing resistance, and a serous fluid has good liquidity and stable viscosity under an I normal temperature condition; and the slurry contains no polyvinyl alcohol, when a spinning purified cotton yarn is subjected to a sizing process, a variety with 60 yarns with common compactness can be processed without polyvinyl alcohol, when sash cotton or purified cotton yarn with more than 60 yarns is subjected to sizing process, little polyvinyl alcohol or no polyvinyl alcohol is used, desizing is easy, waste water of serous fluid is easy to process, pollution of the waste water to the environment is small, and zero-pollution discharge in the production process is realized.

Owner:YIXING JUNDA SLURRY TECH

Cation high-performance size

The invention discloses cation high-performance size which is made from the following raw materials: corn starch, hydroxides, trimethylamine hydrochloride and persulfate through a hybrid reaction, wherein corn starch accounts for 80%-95% by weight, calcium hydroxide and / or magnesium hydroxide account(s) for 1%-10% by weight, trimethylamine hydrochloride accounts for 1%-15% by weight, and persulfate accounts for 0.1%-15% by weight. The cation high-performance size has the advantages of strong adhesive ability, good film forming property, tough size film, and excellent elasticity; the flexibility (fatigue endurance) is improved by 3-4 times in comparison with common modified starch size; the cation high-performance size is excellent in wear-resisting and anti-aging properties; and the size has good flowability under the condition of normal temperature, and is stable in viscosity. Polyvinyl alcohol is not used. When pure cotton yarns are sized during spinning, 60-count yarns of common tightness do not need polyvinyl alcohol, and when polyester or pure cotton yarns higher than 60-count are sized, no polyvinyl alcohol is needed or only a small amount of polyvinyl alcohol is needed, so that desizing is easy, the size waste is easy to process and causes small pollution to the environment; and zero pollution emission is realized in a production process.

Owner:YIXING JUNDA SLURRY TECH

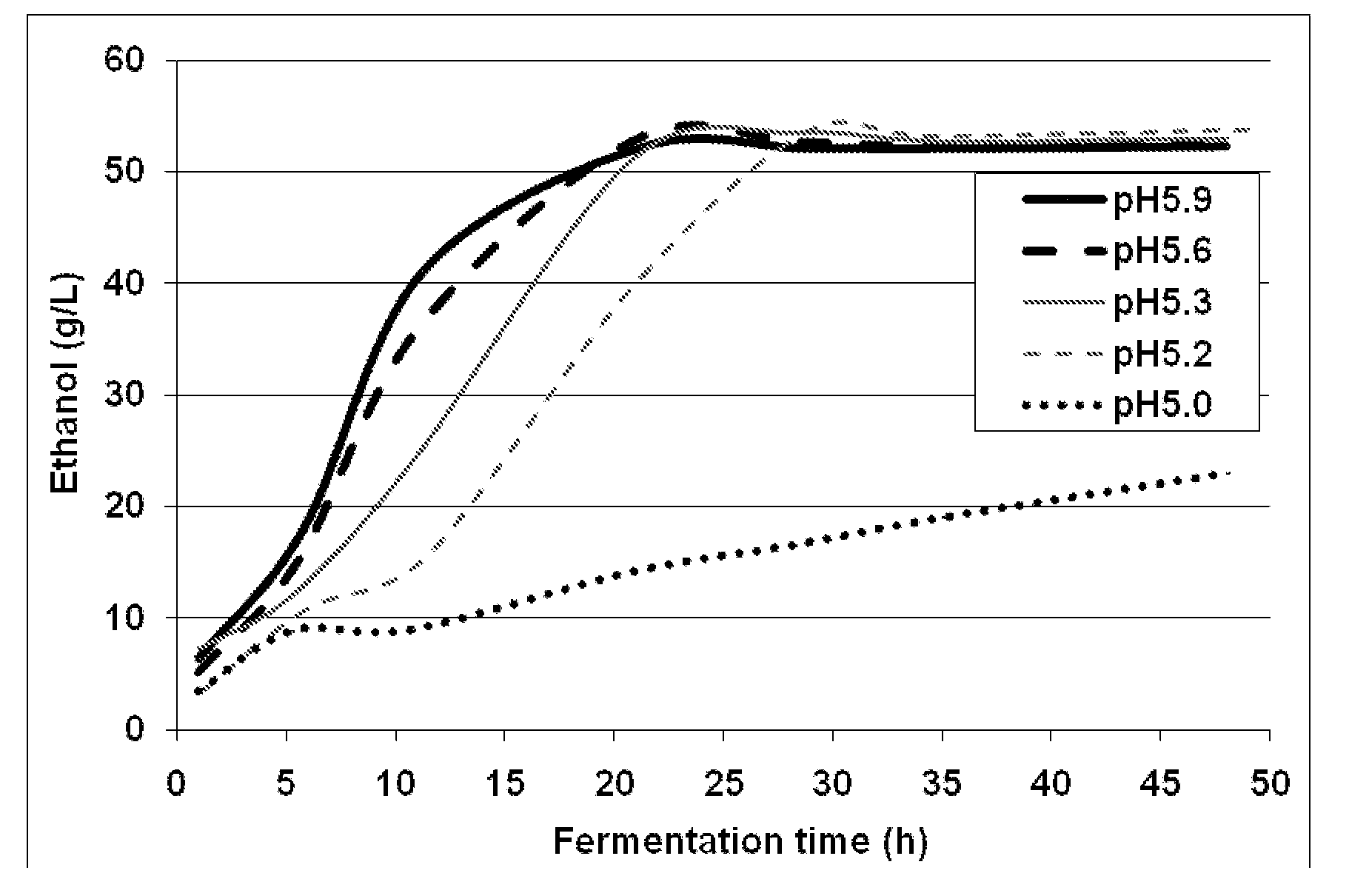

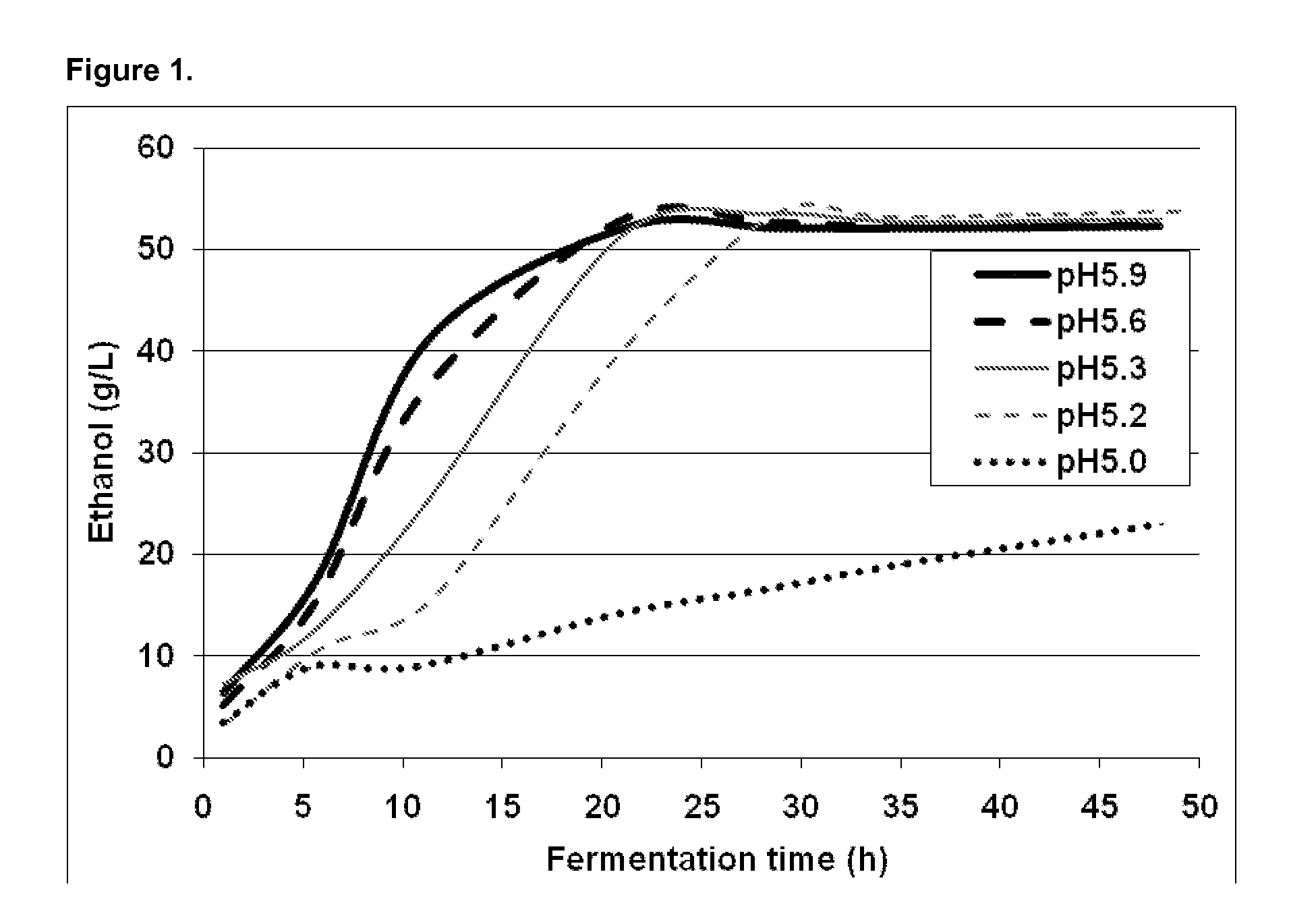

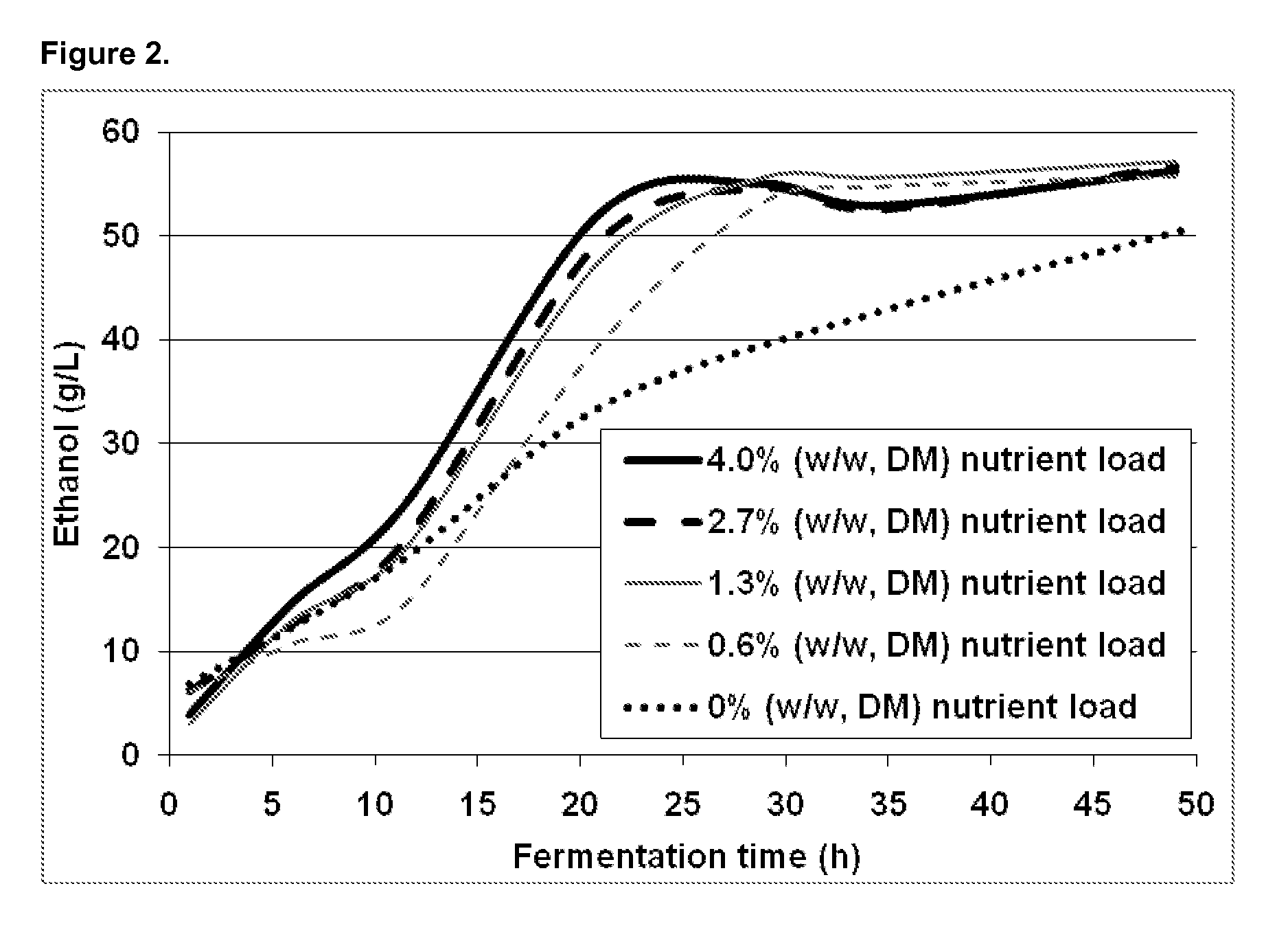

Process for alcoholic fermentation of lignocellulosic biomass

InactiveUS20100159552A1Lower cost of capitalReduce operating costsBiofuelsFermentationCelluloseHydrolysate

A process for the production of ethanol wherein a hydrolyzed lignocellulosic biomass is fermented in the presence of a stillage residue. The fermentation of cellulosic hydrolysates is improved by adding prior to and / or during fermentation a stillage residue side stream from a corn starch-to-ethanol process as a nutrient source for the yeast organisms used in the fermentation. Stillage residues from the grain dry mill ethanol producing process, including the whole stillage, wet cake, thin stillage, and / or syrup are added to assist as a nitrogen and nutrient source for the fermentive processes. The stillage residue is produced by any grain-to-ethanol process.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Water-thinned isocyanate adhesive with corn starch as main material and its prepn process

The present invention belongs to the field of adhesive technology, and features that the present invention is double component no-aldehyde waterproof timber adhesive comprising main adhesive component, which is prepared with corn starch and through esterification to form emulsion and copolymerization with grafting stabilizer under certain pH condition, and curing agent, which is prepared with polyisocyanate through closing the isocyanate radical. The present invention has the features of unique composition, no environmental pollution, low cost, etc. and is used in various timber products.

Owner:时君友

Low cost bio-based full degradable film and preparation method thereof

The present invention discloses a low cost bio-based full degradable film and preparation method thereof, the ratio of each component in parts by mass of the film is as follows: 15-25 parts of a polyglycolic acid, 25-35 parts of corn starch, 35-55 parts of poly(butylene adipate-co-terephthalate), 5 parts of a compatilizer, 3.75-12.25 parts of a starch plasticizer, 0.5-0.7 part of citric acid, 0.75-1.25 parts of acetyl tributyl citrate, 0.3-0.5 part of maleic anhydride, 0.2 part of antioxidant 164, and 0.2 part of 2-(2″-hydroxyl-5″-methylphenyl)benzotriazole. The low cost bio-based full degradable film provided by the present invention has a bio-based content, which can reach 30% or more, a lower cost, and a tensile strength exceeding a traditional PE thin film, and has very important significance for solving the problem of “white pollution” and promoting the popularization and application of full biodegradable materials.

Owner:JIANGSU JINJU ALLOY MATERIAL

Degradable fertilizer coating liquid and manufacturing method thereof

InactiveCN101045656AGood controlled release effectIncrease profitFertiliser formsFertilizer mixturesAcetic acidThiourea

A degradable coating liquid for fertilizer is proportionally prepared from chitosan, PVA, oxidized starch or corn starch, benton or talc powder or diatomite or clay, formaldehyde, gelatin, N-butylthiophosphoryl triamine (NBPT) or dicyandiamide (DCD), thiourea or urea, glacial acetic acid, and distilled water. Its preparing process is also disclosed.

Owner:SHENYANG AGRI UNIV

Degradable plastic packaging bag

InactiveCN104927318AHigh tensile strengthLow moisture permeabilityFlexible coversWrappersArray data structurePolyvinyl alcohol

The present invention belongs to the field of plastic products, and particularly relates to a biodegradable plastic packaging bag which is characterized by comprising the following components by weight: 5-15 parts of ethyl cellulose, 10-20 parts of polyethylene, 15-30 parts of modified starch, 15-30 parts of corn starch, 15-30 parts of sweet potato starch, 20-40 parts of polylactic acid, 2-10 parts of calcium carbonate powder, 1-5 parts of a lubricant, 1-5 parts of a plasticizer, 1-3 parts of a toughening agent, 1-10 parts of a degradation accelerator, 1-5 parts of polyvinyl alcohol, 2-5parts of chitosan, 1-5 parts of a compatibilizing agent and 2-6 parts of polycaprolactone. The biodegradable plastic packaging bag begins to thin, lose in weight, reduce in strength, then gradually splits into fragments after being exposed to the environment for two months, when these fragments are buried in garbage or soil, the degradation effect is very obvious; by addition of the plasticizer and the calcium carbonate powder, the added ingredients may enhance the tensile strength of the plastic packing tape, reduce the air and moisture permeability, and maintain the original characteristics of the plastic packaging bag.

Owner:TIANJIN YOUZHI TECH CO LTD

Soup block compound flavourings and preparation method thereof

InactiveCN101390601ARich flavorNutritional diversityFood preparationMonosodium glutamateAdditive ingredient

Disclosed are a soup-block composite seasoning and a preparation method; as the existing domestic composite seasoning has single major nutrient and edible approach and is mainly used as the ingredient in cooking and instant food, the invention discloses a soup-block composite seasoning composed of seasoning ingredient, seasoning accessory, spice and other ingredients; wherein, the seasoning ingredient mainly comprises iodized salt, cane sugar and monosodium glutamate; the seasoning accessory is mainly composed of animal, seafood, vegetable and other extracts and determines the flavor of the seasoning; the spice mainly comprises ginger powders, cumin powders and onion powders; and other ingredients mainly refer to corn starch and maltodextrin. The soup-block seasoning has pure delicious taste and is rich in amino acids, protein and other nutrients, which can be used in catering as ingredient and can also be directly consumed as soup after being dissolved in hot water.

Owner:安徽省芬格欣食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com