Method for producing paper gypsum board using desulfurated gypsum and ardealite

A paper-faced gypsum board, desulfurized gypsum technology, used in ceramic molding machines, manufacturing tools, etc., can solve the problem of difficult to control dry powder conveying, metering, feeding performance, weak bonding performance between gypsum board surface and board core, and board. The problem of poor adhesion between the core and the cover paper can improve the drying effect and the utilization rate of heat energy, avoid over-burning of the side wall powder, and shorten the setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

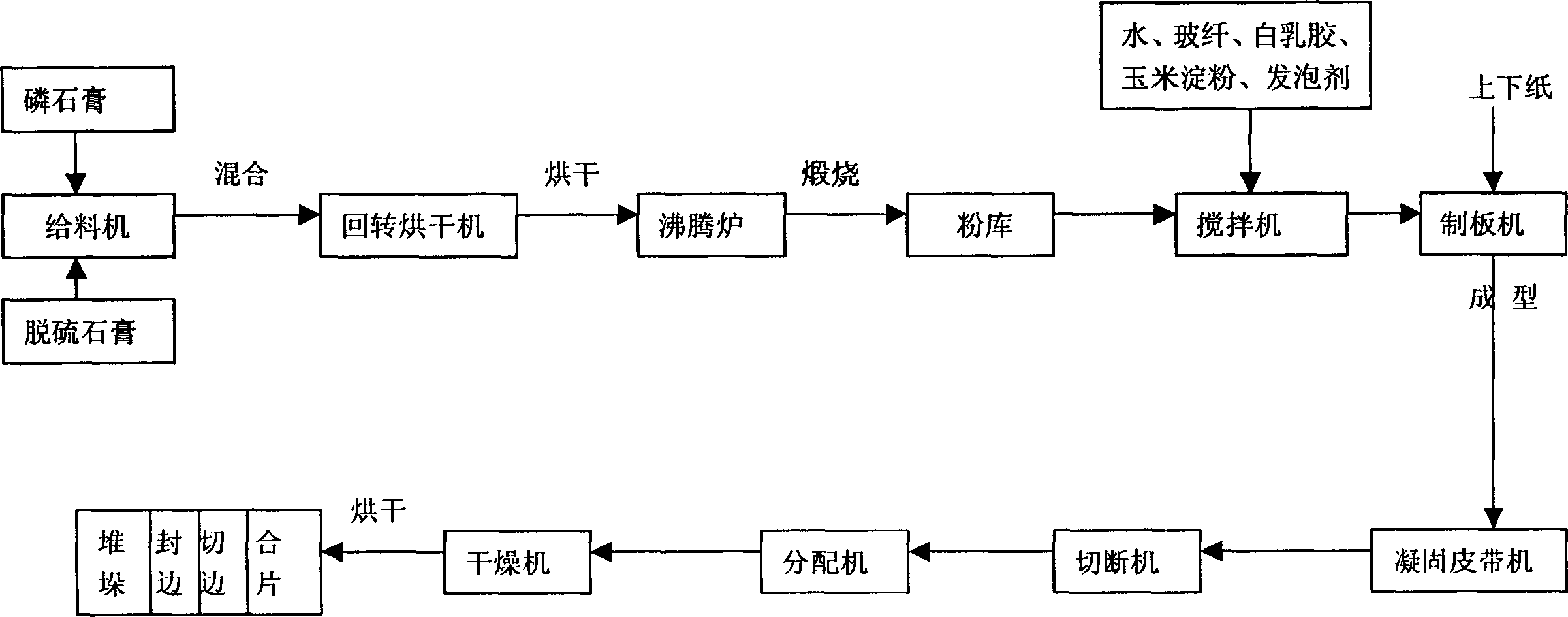

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] 1. Send 70 parts of phosphogypsum and 30 parts of desulfurized gypsum to the feeder according to the weight ratio of spare industrial by-product gypsum, and then transport them to the drum rotary dryer heated by the hot blast stove for drying , the drying temperature is controlled at 100°C, and mixed while drying. When the free moisture in the mixture is below 5%, it is sent to the silo through the belt conveyor and elevator;

[0020] 2. Sieve the material in the silo and send it to the hot flue gas fluidized furnace for continuous calcination at 200°C. When the crystal water in the mixture drops to 8%, it will be sent to the powder warehouse by belt conveyor for cooling and aging ;

[0021] 3. Accurately weigh 100 parts by weight of the aged powder through an electronic belt scale and send it to the mixer, and add 6 parts by weight of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com