Patents

Literature

2841 results about "Phosphogypsum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphogypsum refers to the calcium sulfate hydrate formed as a by-product of the production of fertilizer from phosphate rock. It is mainly composed of gypsum (CaSO₄·2H₂O). Although gypsum is a widely used material in the construction industry, phosphogypsum is usually not used, but is stored indefinitely because of its weak radioactivity. The long-range storage is controversial.

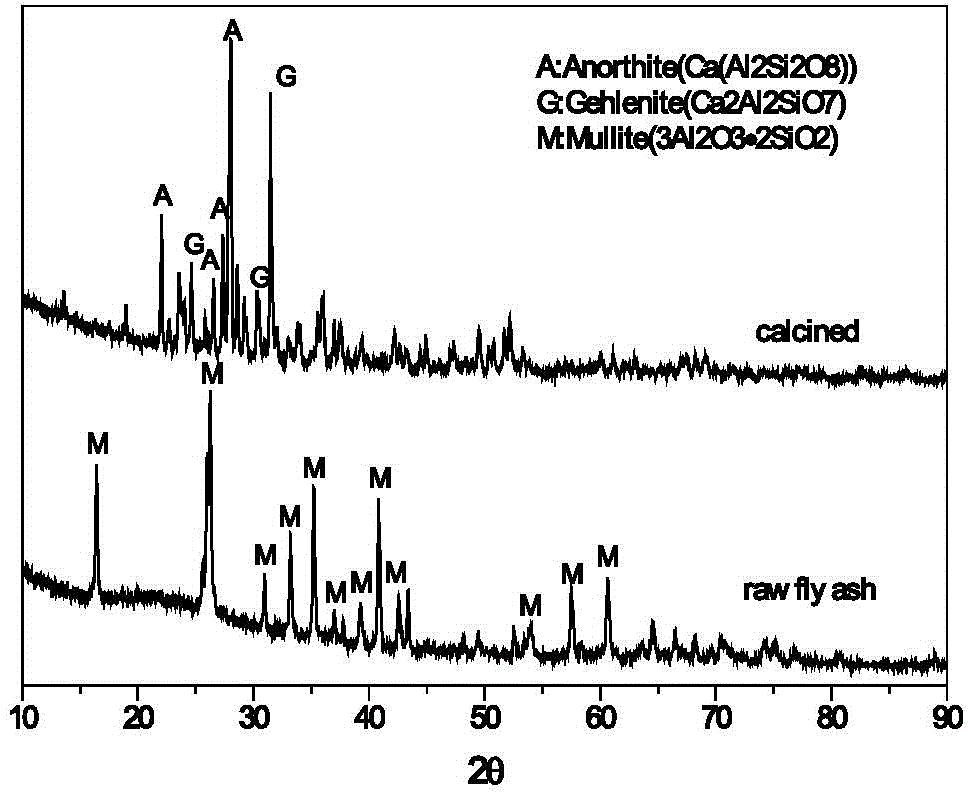

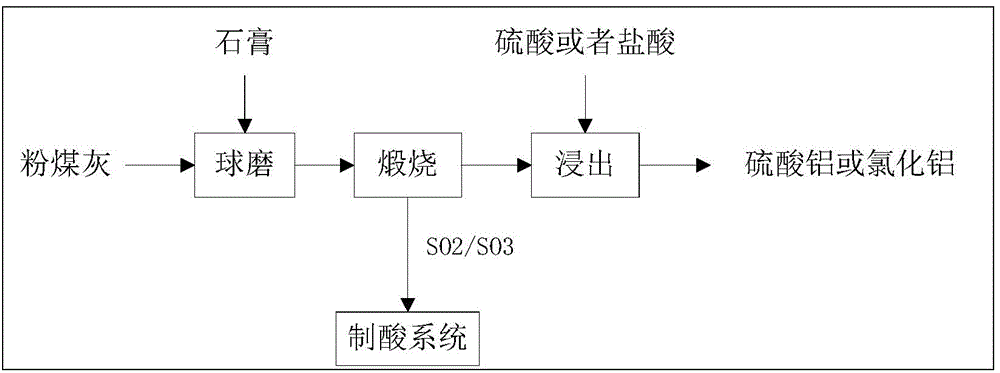

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

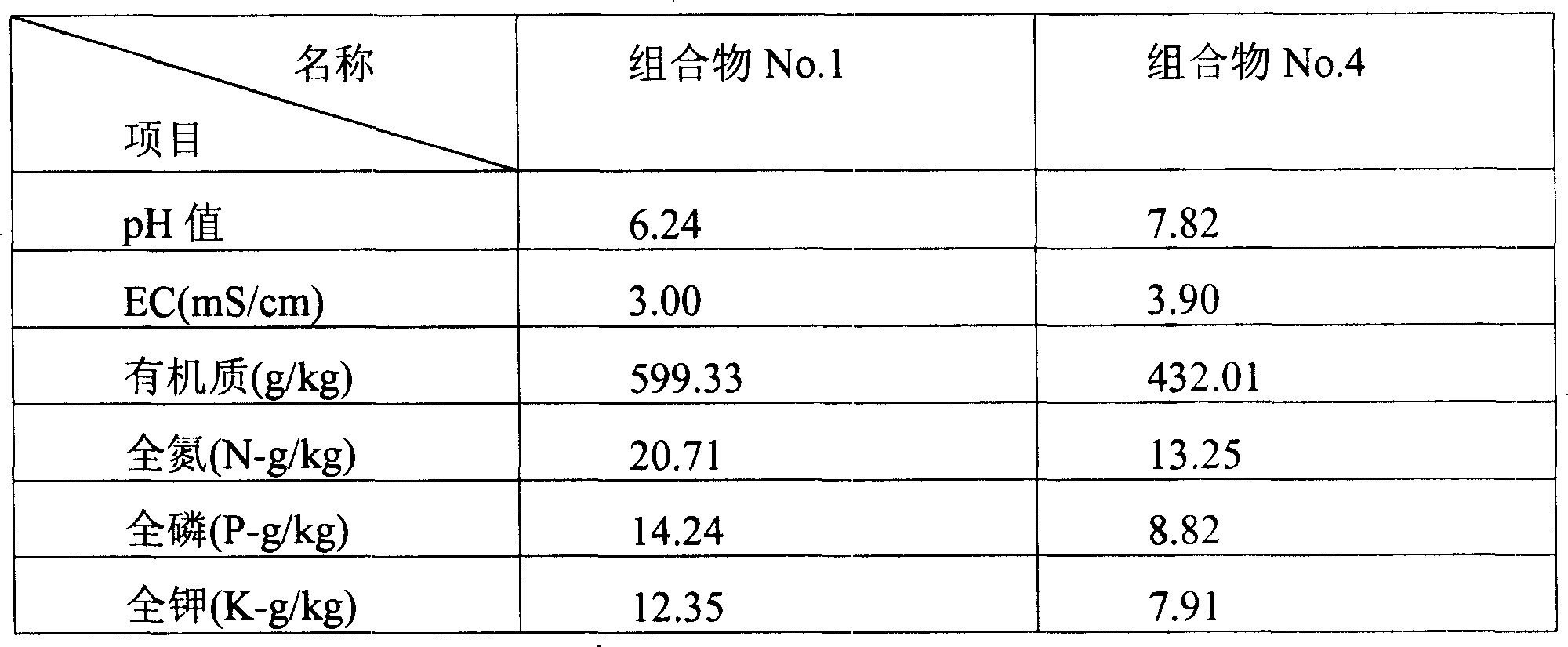

Alkali soil modification fertility intensifying amendment and preparation method thereof

The invention discloses a fertilizing and conditioning agent for improving the saline alkali soil, and the fertilizing and conditioning agent includes an organic material, an inorganic material and a regulator for the plant growth, wherein, the weight proportion between the organic material and the inorganic material is 3:2 to 1:1. The organic material is fermented and maturated by one or a plurality of such organic matters as town living sludge, excrements of livestock and poultry, and furfural slag; and the inorganic material is formed by one or a plurality of such industrial waste and materials as desulfurized gypsum, phosphogypsum, and ammonium sulphate. Moreover, appropriate growth regulator for plant which is added according to the growing requirements can not only improve the saline alkali soil and fertilize the soil, but also can improve the plant growth and promote the plant to grow well as well as providing an effective path for promoting the recycling of the waste resources and reducing the secondary pollution to the town and the country.

Owner:天津市北方绿业生态科技有限公司

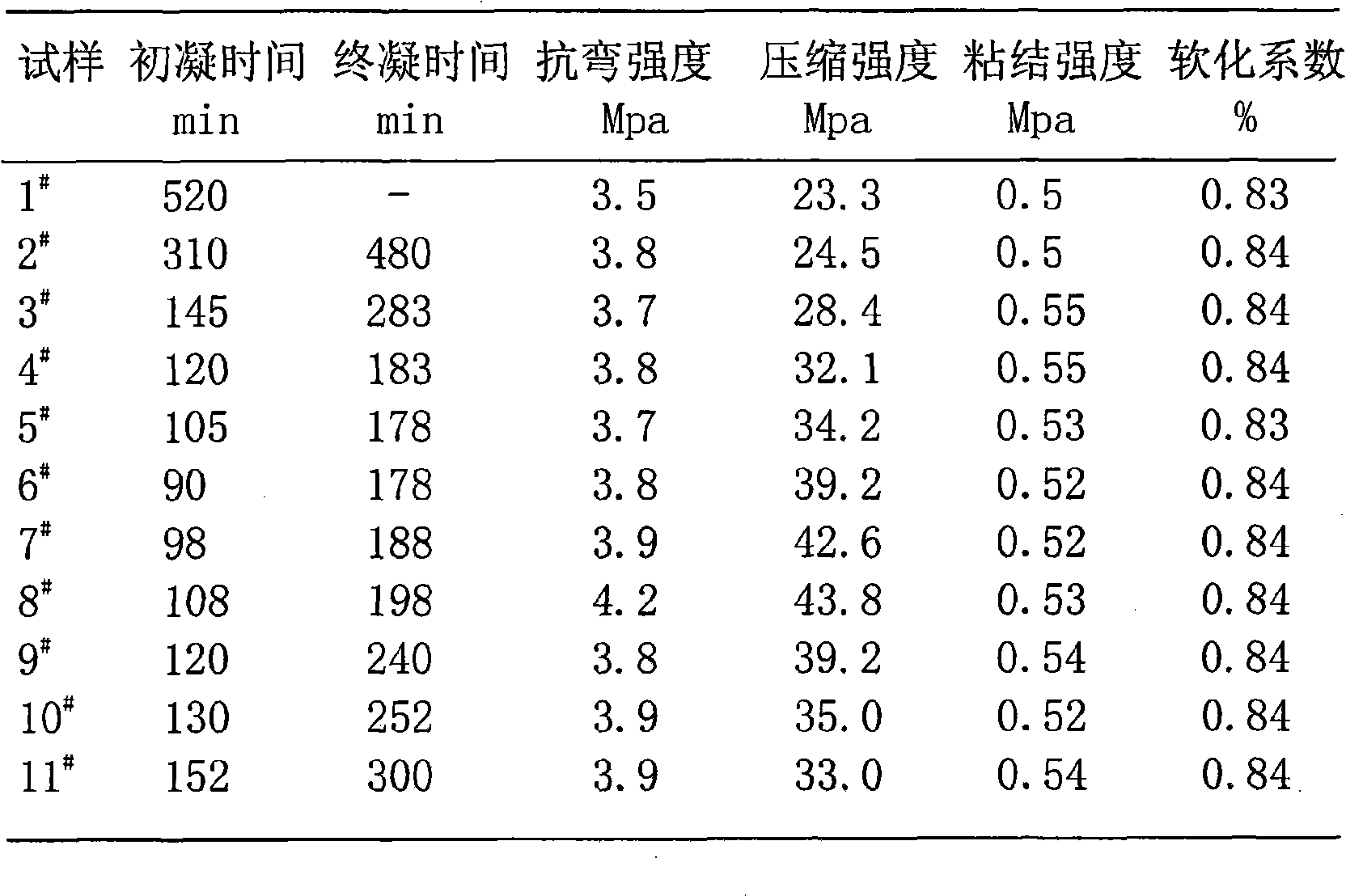

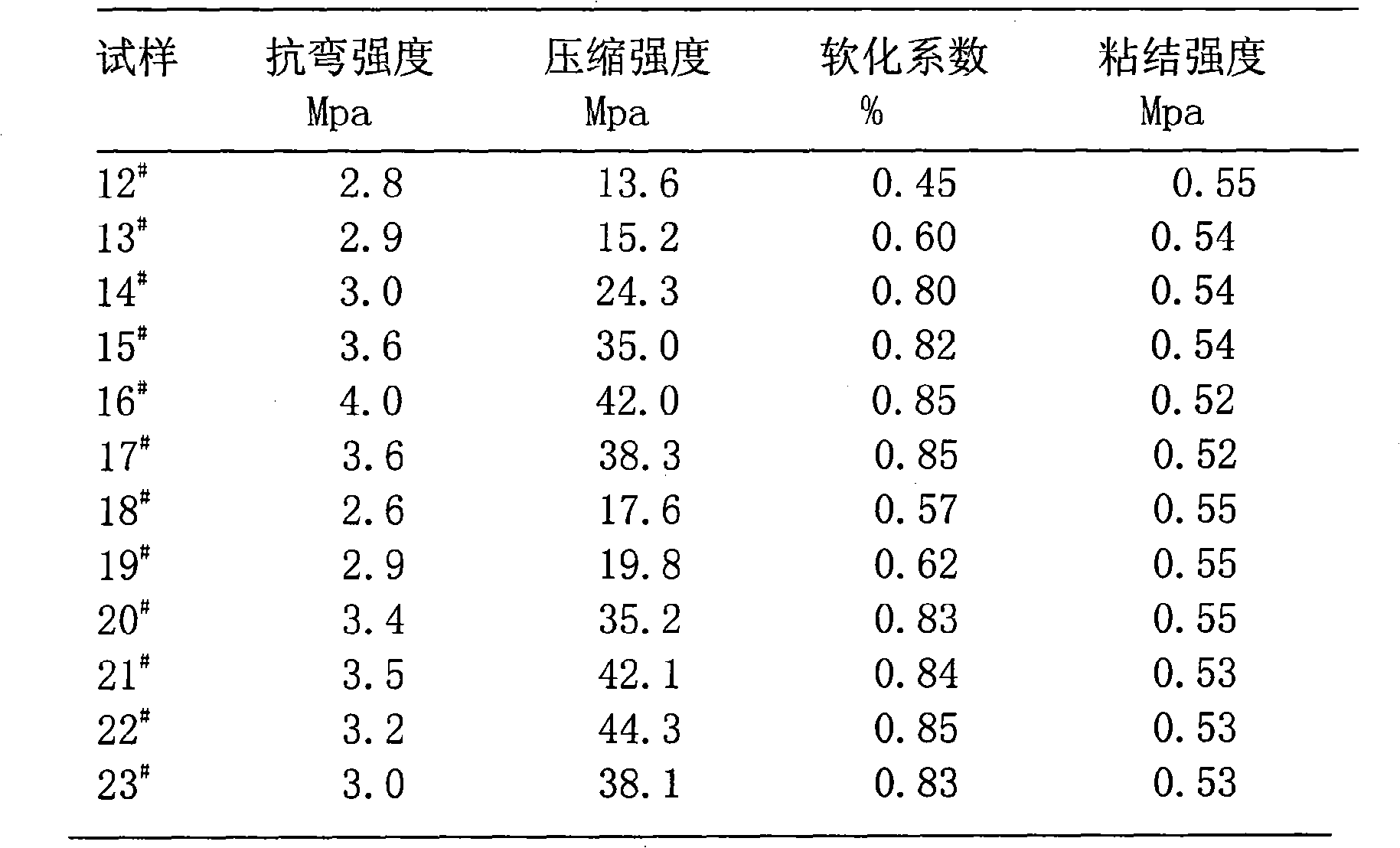

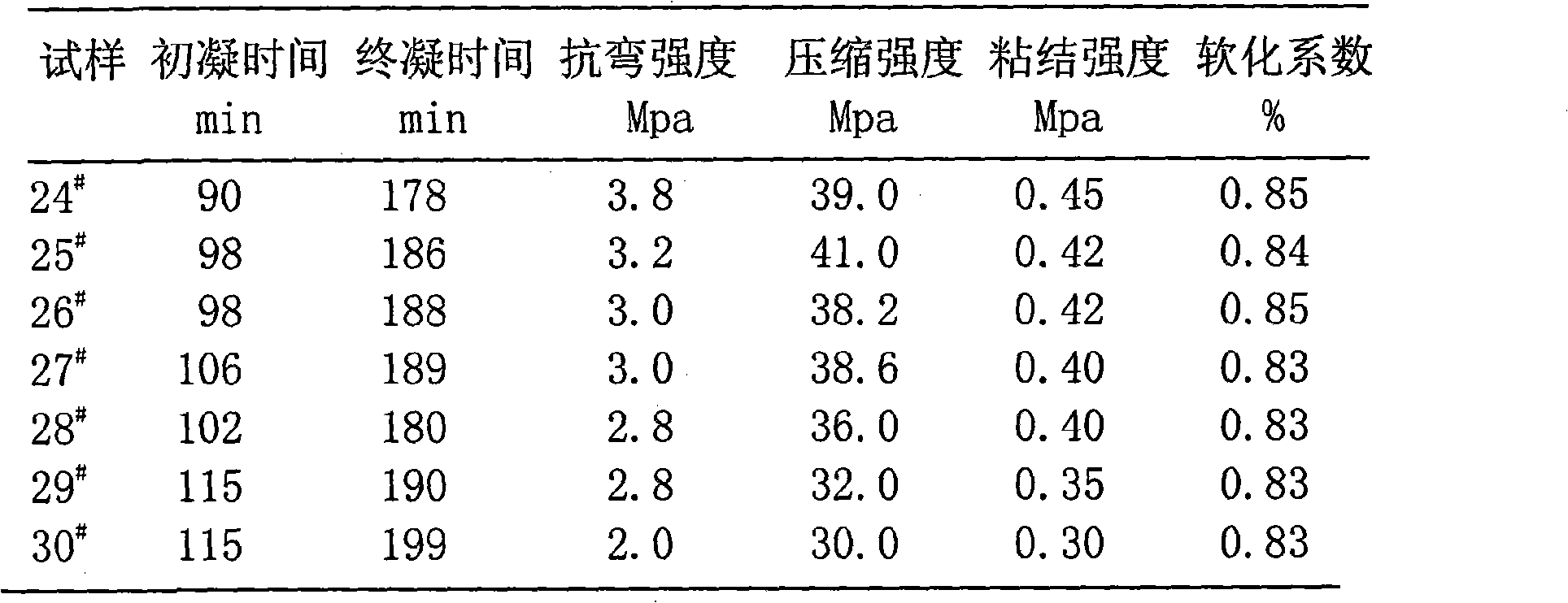

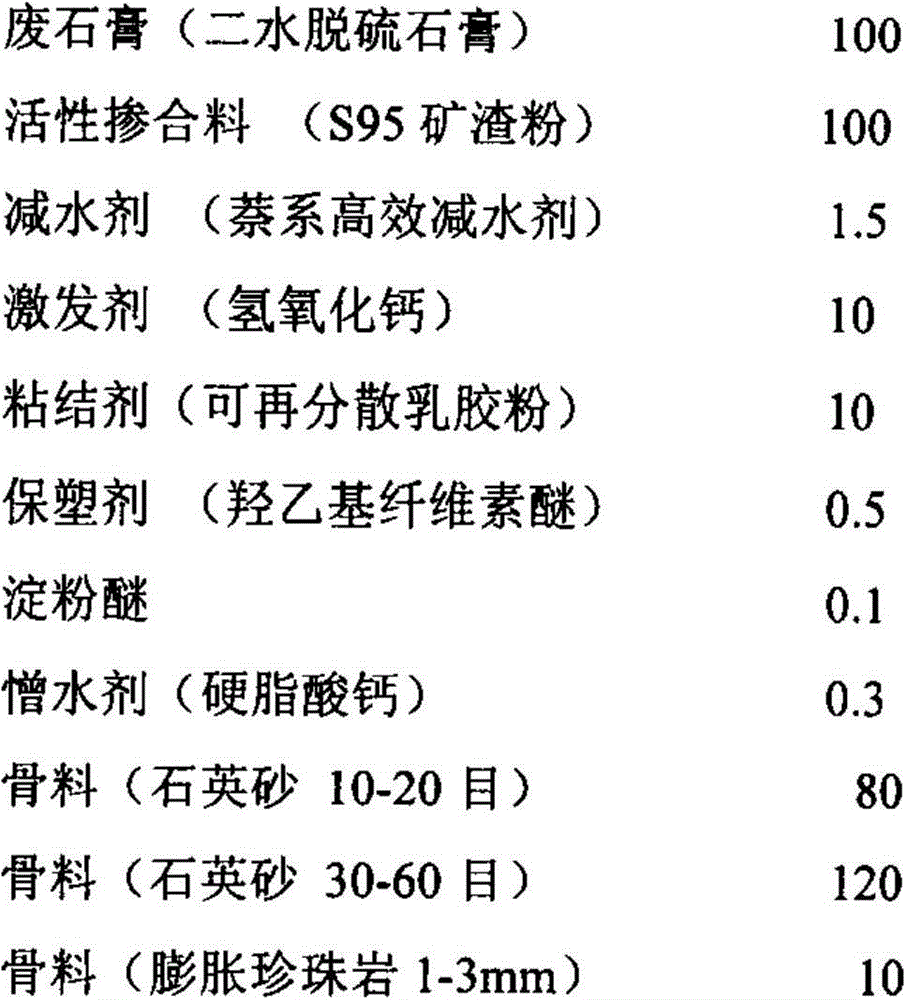

High-strength water-resistant plastering gypsum and producing method thereof

The invention relates to a high-strength water-proof gypsum plaster and a production method thereof. The inventive high-strength water-proof gypsum plaster is made from the following materials in weight proportions: 10-99% of gypsum-based composite binding agent, 0-90% of aggregates, 0.08-4% of additives and 0-16.1% of adsorbent. The production method comprises the following steps: weighing raw materials at the given ratio, drying the aggregates, mixing all raw materials, and packaging. The inventive high-strength water-proof gypsum plaster has high strength and good water resistance; can be made from chemical gypsum materials without needing calcination, such as desulfurized gypsum, phosphogypsum, fluorgypsum and citric acid gypsum; and has the advantages of low production cost, energy conservation, discharge reduction and environmental friendliness.

Owner:长沙归一新材料科技股份有限公司

Preparation of composite high-expansion cementing material by using industrial slag and preparation technique thereof

The invention relates to a preparation process of using industrial slag to prepare composite cementing materials with high expansibility. The cementing materials consist of four components. The first component includes three parts: one or a plurality of combinations of fly ashes, slag, etc., which contain aluminosilicate; one or a plurality of combinations of phosphogysum, fluorine gypsum, etc., which contain calcium sulfate; one or a plurality of combinations of carbide, alkaline residue, quick lime or slaked lime. The second component includes: one or a plurality of combinations of alkaline composition, such as the quick lime or slaked lime, the carbide slag, etc.. The third component includes one or a plurality of combinations of the phosphogypsum, fluorine gypsum, etc., which contain the calcium sulfate. The preparation method is: firstly, to evenly mix the raw materials of the first component which are grinded to be with the surface area of 200-500m<2> / kg through the steam curing of four hours to ten days at 50-100 DEG C and the calcining of 0.5-24h at the high temperature of 400-1000 DEG C to obtain the first component; secondly, to dry and grind the raw materials of the second and the third component to be with the surface area of 200-500m<2> / kg to obtain the second and the third component; thirdly, to evenly mix the first, the second and the third component.

Owner:BEIHANG UNIV

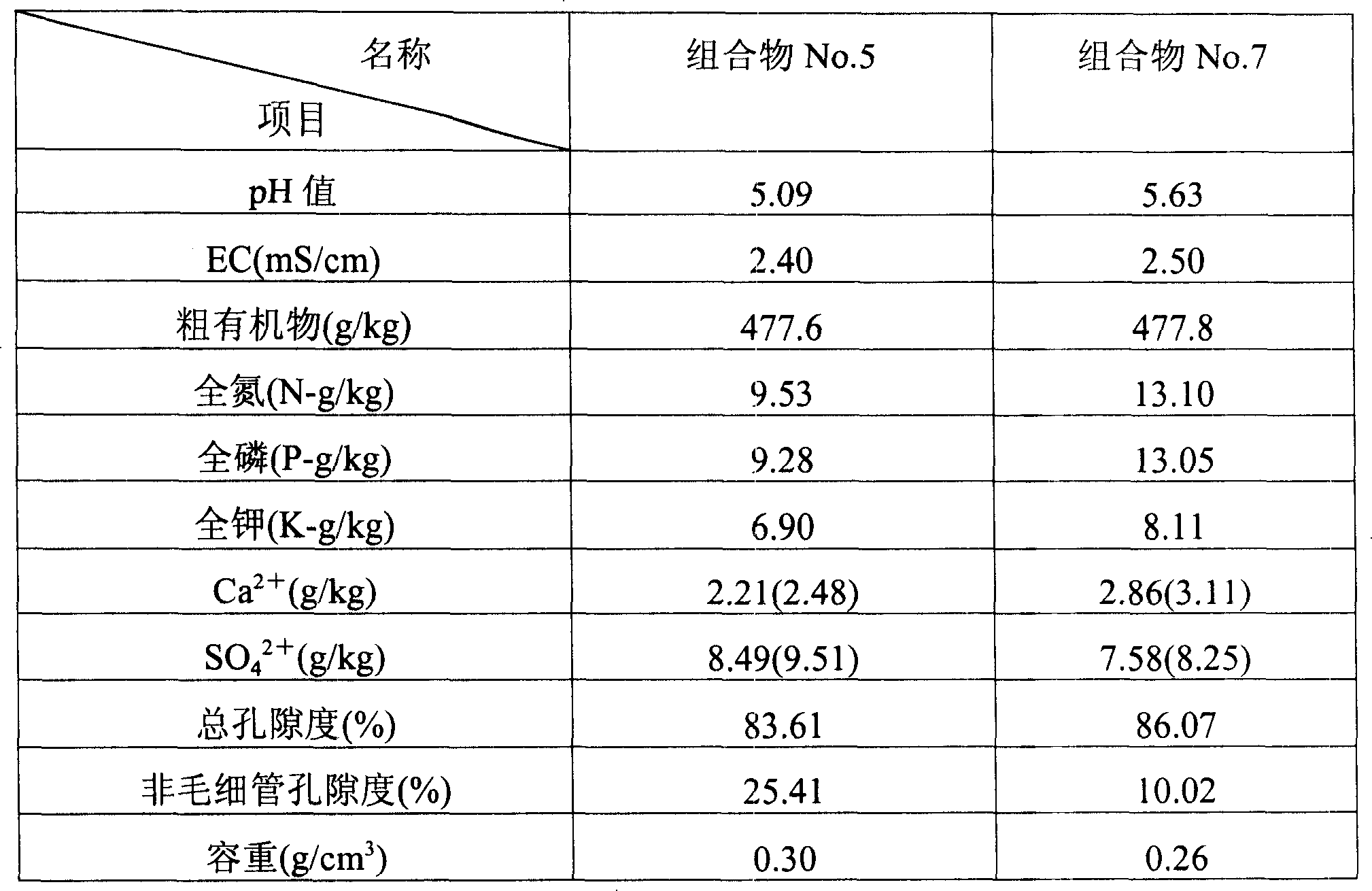

Salination soil modifying agent composition and use thereof

The invention discloses a new-typed salted soil modifier composition and making method, which comprises the following parts: superphosphate, calcium sulfate, poromeric material, decomposed rough organics, phosphogypsum, rough stream and macromolecular (water retention) agent for alkali soil of littoral area.

Owner:魏凤巢 +4

Method for using phosphogypsum as polyvinyl chloride resin filler

The invention discloses a method for using phosphogypsum as a polyvinyl chloride resin filler. The method is as follows: the phosphogypsum is subjected to modified treatment; a coupling agent is added in a milling process, so as to obtain the product which can be used as the polyvinyl chloride resin filler. The method comprises following concrete processes: (1) screening; (2) calcining; (3) grinding and adding the coupling agent; and (4) mixing, so as to obtain an aluminate ester modified phosphogypsum filler. The method has the advantages that (1) organic impurities and crystal water are removed by screening and calcining the phosphogypsum; the whiteness is improved; the grain sizes of the grains are controlled in a grinding manner; the method meets the requirements of the polyvinyl chloride (PVC) filler, and is low in cost; (2) the method is even to modify, and good in effect; no externally added water enters inside; the bubbling of the PVC in a machining process is avoided; (3) the method is simple in process, low in cost, good in processing rheological property and easy to mold, and the plasticization of the phosphogypsum in the PVC resin can be accelerated. The method is suitable for reinforcing and toughening of a polymer material, not only can be applied to the PVC resin, but also can be used as fillers of the materials such as polyethylene (PE), polypropylene (PP) and polystyrene (PS).

Owner:贵州开磷遵义碱厂

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

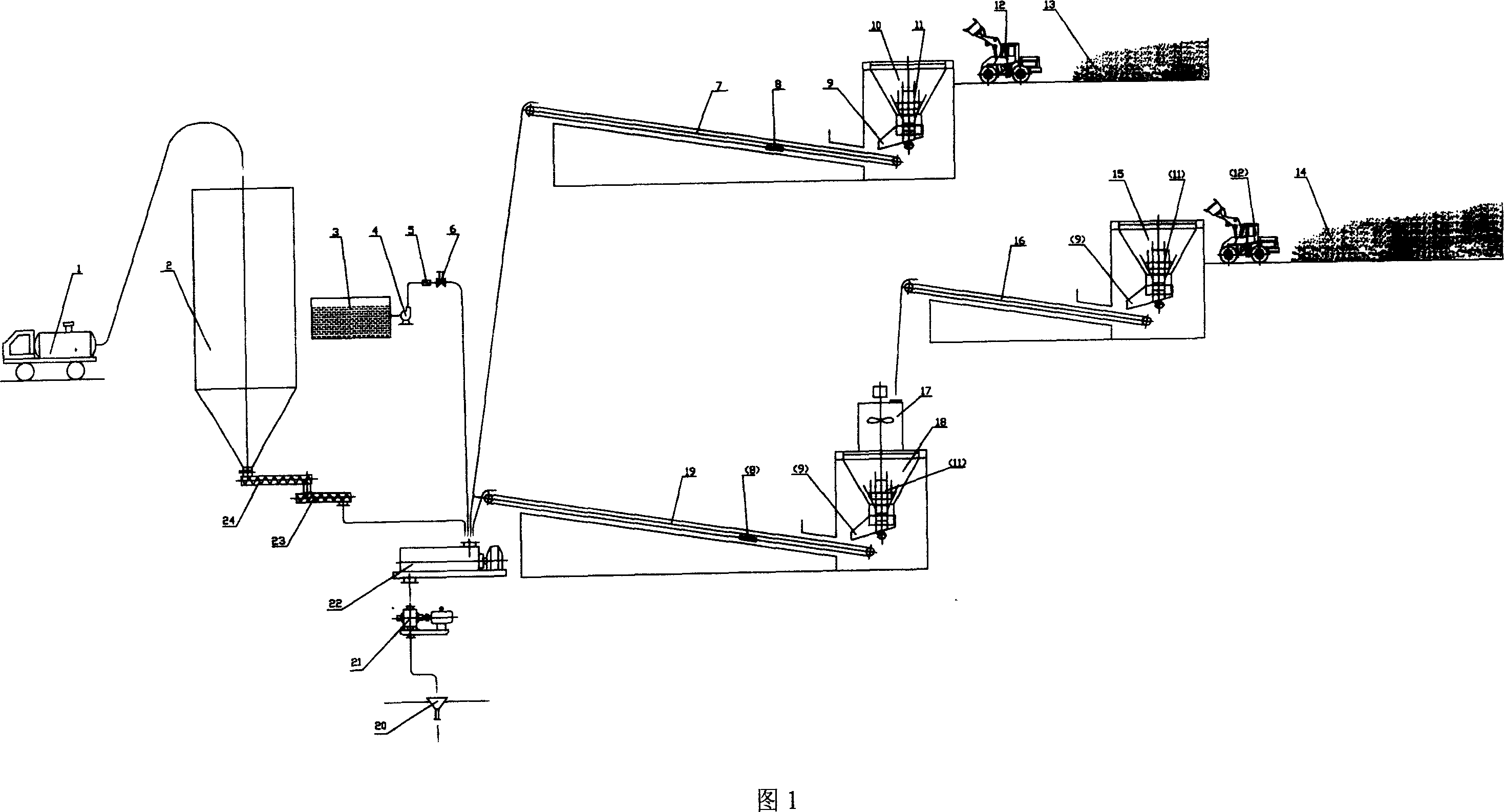

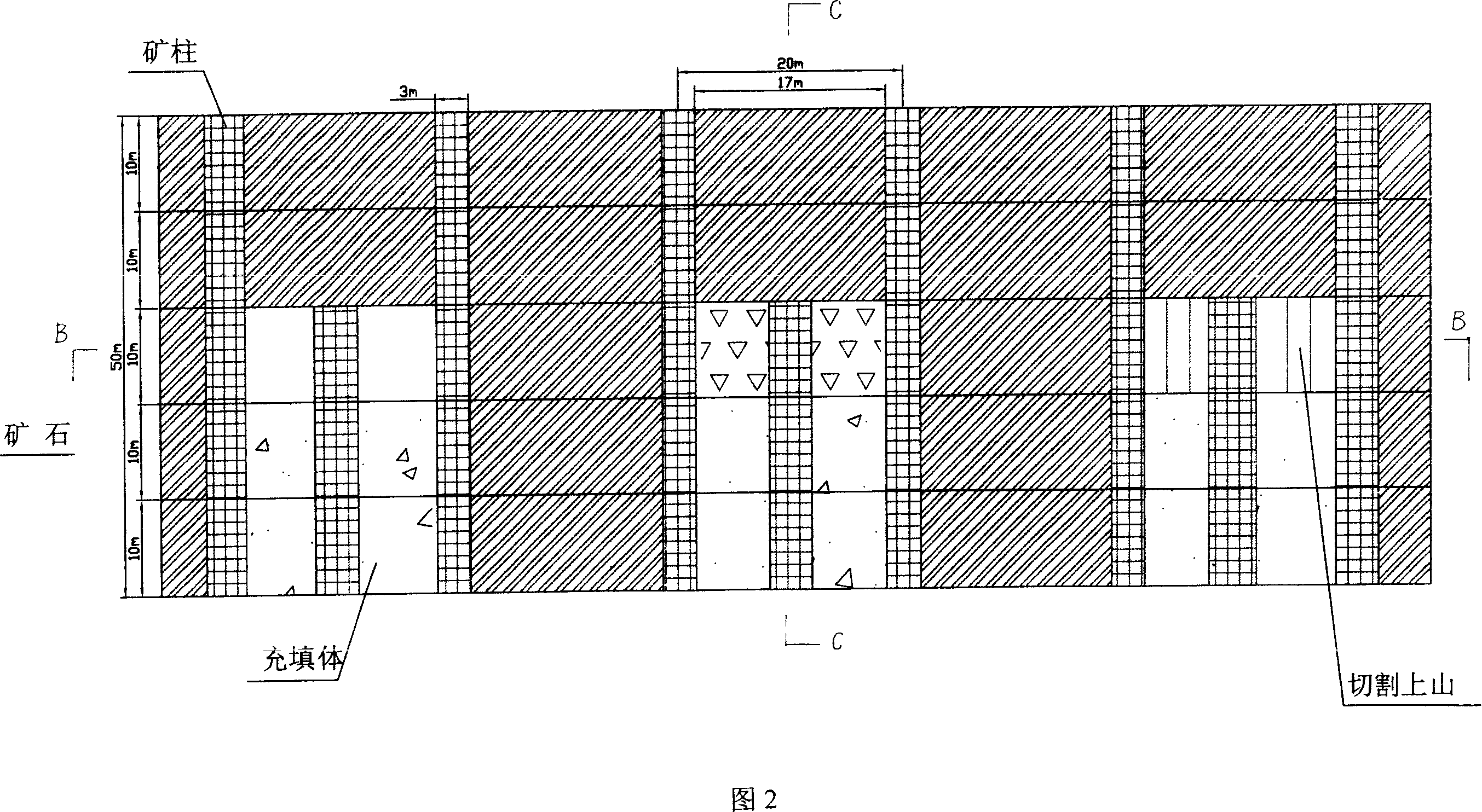

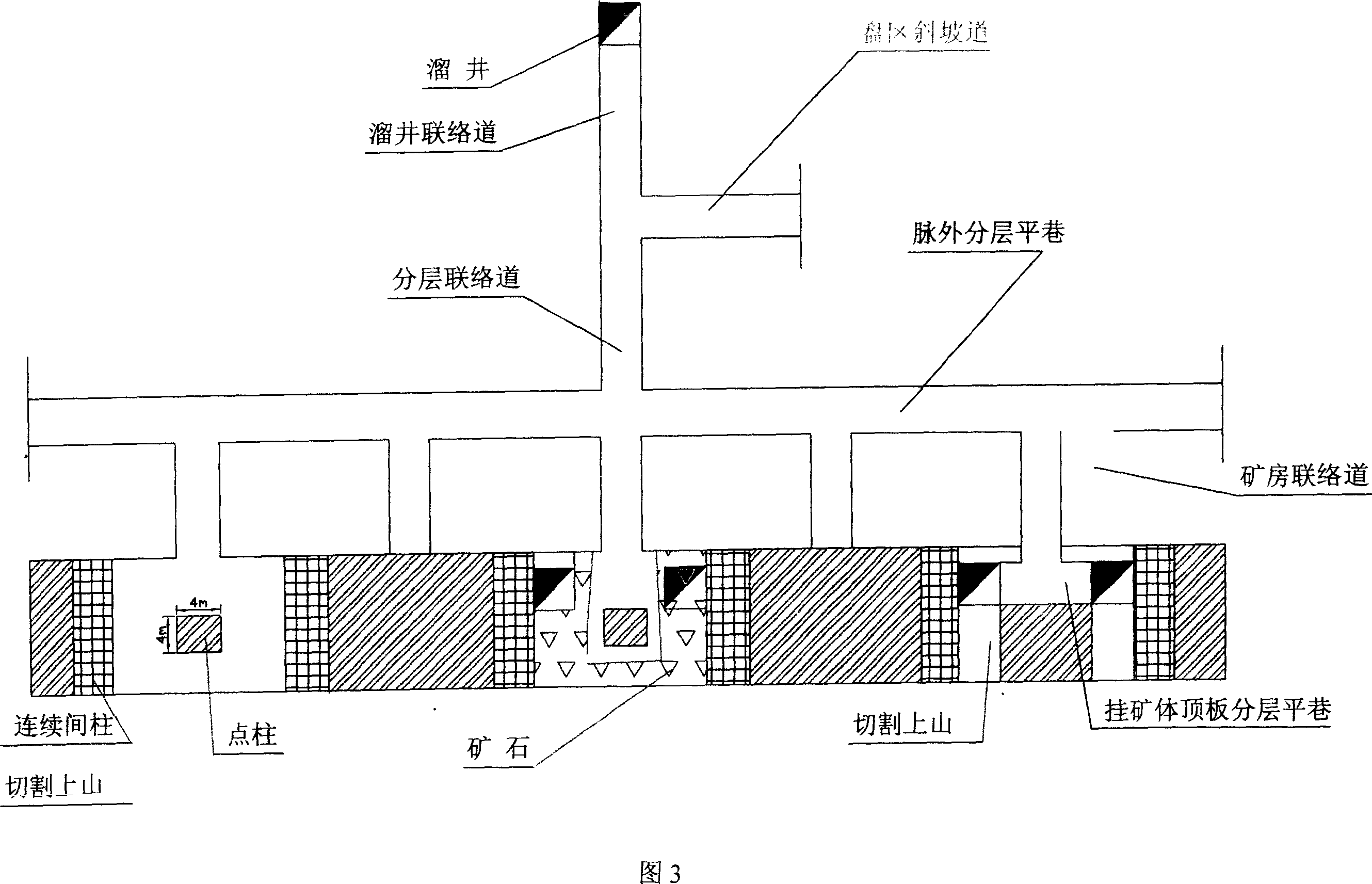

Phosphogypsum cementing and post-filling mining method and pulping technology thereof

ActiveCN101008316ASolve problems that are difficult to handle in large blocksIncrease profitMaterial fill-upAdhesivePhosphorite

The invention discloses a stuff mining method when the ardealite adhesive is solidified and relative pulp production. The stuff mining method comprises that preparing mine house, stuffing preparation, preparing pulp, and stuffing. The pulp preparation comprises that using ardealite, coal powder / dolostone and cement as the stuff material to be added into water and mixed into stuff pulp; the stuff pulp via the stuff drill hole or the pump station is input to the upper outer flat channel of the mining field via the stuff tube, to be fed into the mining field. The inventive stuff mining method can confirm the yield and stability of mine, to improve the recycle rate of mineral and protect the environment.

Owner:贵州开磷设计研究院有限责任公司

Method for production of phosphoric acid and combined production of a-hemihydrate gypsum through dehydrate-hemihydrate wet phosphoric acid technology

ActiveCN103086335AIncrease concentrationHigh recovery rateCalcium/strontium/barium sulfatesPhosphorus compoundsO-Phosphoric AcidSulfate radicals

The invention discloses a method for the production of phosphoric acid and the combined production of a-hemihydrate gypsum through a dehydrate-hemihydrate wet phosphoric acid technology. A dehydrate part production technology is characterized in that the reaction tank temperature is 70-80DEG C, the retention time is 1.5-3h, the free sulfate radical concentration is 1-2%, and the produced wet phosphoric acid concentration omega(P2O5) is 35-39%. A hemihydrate part production technology is characterized in that the reaction tank temperature is 86-94DEG C, the retention time is 1-2h, and the mass concentration of free sulfate radicals is 6-8%. Phosphoric acid produced through the hemihydrate technology has a concentration omega(P2O5) of 10-15% and is used as a recycle acid of the dehydrate part, the crystal water content of the combined-production hemihydrate gypsum is 5-7%, the mass percentage of free P2O5 in gypsum is less than 0.4%, and the crystal form of the produced hemihydrate gypsum is a-hemihydrate gypsum. Compared with the dehydrate technology, the method disclosed in the invention improves the phosphoric acid concentration and improves the phosphorus recovery rate to above 98%, and the combined-production a-hemihydrate gypsum can be directly used as a building gypsum product, so energy consumption saving is realized.

Owner:WENGFU (GRP) CO LTD

Soil heavy metal passivator, preparation method thereof, and passivation method thereof on soil cadmium

ActiveCN105802637AImprove adsorption capacityStrong chelationContaminated soil reclamationOrganic fertilisersSoil heavy metalsPhosphogypsum

The invention belongs to the technical field of heavy metal pollution soil restoration, and particularly relates to a soil heavy metal passivator, a preparation method thereof, and a passivation method thereof on soil cadmium. The soil heavy metal passivator provided by the invention is prepared from the following materials in parts by weight: 30 to 50 parts of modified alkali minerals, 10 to 15 parts of rotten agriculture and forestry wastes, 1 to 10 parts of soil conditioners, 1 to 5 parts of pH sensitive gel, 1 to 5 parts of phosphogypsum, and 0.1 to 5 parts of graphene. The soil heavy metal passivator provided by the invention has stronger adsorbing and chelating functions, can effectively fix heavy metal cadmium in the soil, and prevents effective cadmium from entering into crops; regulation can be carried out according to the soil pH, so that the utilization ratio and the long-term stability of the soil heavy metal passivator are improved; meanwhile, with an added soil conditioner, the soil environment can be improved, and the soil fertility is improved. The passivator provided by the invention can better meet the urgent demand of heavy metal pollution soil restoration in China currently on strong stability, no secondary pollution, and durable and stable effect.

Owner:SICHUAN SHILIWANG AGRI SCI & TECH DEV CO LTD

Method for reducing and decomposing phosphogypsum by sulfur

ActiveCN101708826AImprove recovery rateReduce reaction energy consumptionSulfur compoundsReduction rateSlag

The invention discloses a method for reducing and decomposing phosphogypsum by sulfur, which comprises the following steps: putting the phosphogypsum into a reactor, and raising the temperature to between 500 and 900DEGC for preheating for 10 to 30 minutes at an inert atmosphere; introducing gaseous sulfur in a molar percentage of 10 to 50 percent to perform reduction reaction with the phosphogypsum for 1 to 2 hours; grinding obtained a calcium sulfide block, and uniformly mixing the ground calcium sulfide with the phosphogypsum in a molar ratio of 1-1.5:3; sintering at a temperature between 1,000 and 1,400 DEG C for 0.5 to 3 hours at a non-oxidizing atmosphere; and taking CaO in the obtained solid slag as a cement clinker for cement production, taking the generated tail gas SO2 as a raw material gas for producing sulphuric acid. The reduction rate of CaSO4 is high, the decomposition ratio of the phosphogypsum can reach over 98 weight percent, the desulfurization ratio of the phosphogypsum can reach over 95 weight percent, and the method has the advantages of low energy consumption, simple and mature process, short production period, easy control and convenient promotion.

Owner:SICHUAN UNIV

Method for preparing light calcium carbonate and co-producing ammonium sulfate from phosphogypsum

ActiveCN101993105AAchieve separationAvoid secondary pollutionCalcium/strontium/barium carbonatesSolid waste disposalAtherion elymusCarbonization

The invention discloses a method for preparing light calcium carbonate and co-producing ammonium sulfate from phosphogypsum, which comprises the steps of: firstly, converting phosphogypsum into a soluble calcium ion solution through phase transfer reaction; secondly, adding a carburizer in the soluble calcium ion solution, settling and separating to obtain calcium carbonate and filtrate; and thirdly, cooling and crystallizing or evaporating the filtrate to obtain the ammonium sulfate. The invention has the advantages of short process procedure and no need of strong acid leaching and twice carbonization, and avoids the secondary pollution of CO2 to the environment; and the prepared light calcium carbonate accords with the requirement on national corresponding product standards and lays the research foundation for the industrialized massive production.

Owner:HEFEI UNIV OF TECH

Method for producing high-admixture water resistant phosphogypsum product

InactiveCN101492275AIncrease dosageImprove water resistanceSolid waste managementCeramic shaping apparatusMass ratioWater vapor

The invention discloses a method for producing high addition-amount water-resistant ardealite building material. The method comprises the following steps that: ardealite accounting for 70 to 80 percent of the total weight, hydraulic cementing material accounting for 20 to 30 percent of the total weight and alkaline exciting agent accounting for 1 to 10 percent of the total weight are taken as raw materials and well mixed at a water-ash ratio (mass ratio) of between 0.18 and 0.22 so as to give a mixed material; a die is filled with the mixed material; the mixed material is molded under the pressure of between 10 and 20 MPa so as to prepare blank; the prepared blank is maintained for 1 to 3 days at normal temperature under normal pressure and then put into an autoclave for maintenance; and a medium of steaming-pressing maintenance is water vapor, wherein the steaming-pressing temperature is between 180 and 220 DEG C, and the heat preservation time is between 8 and 12 hours; the mixed material is discharged from the autoclave; and a high addition-amount water-resistant ardealite product can be obtained. The method has the advantages of raising the addition amount of ardealite and remarkably improving the water resistance of the gypsum product.

Owner:WENGFU (GRP) CO LTD

Alkaline soil improver

InactiveCN1664064AImprove compactionThe improved effect is excellentOrganic fertilisersSoil conditioning compositionsCrop cultivationPhosphogypsum

The invention provides a new modifying agent formulation for alkaline soil, which can improve the alkaline soil modifying efficiency by calcium sulfate and phosphogypsum, and the product can be also used in alkali and arid area. The product comprises the following components by weight: calcium sulfate 1,straw 0.5-1.5, urea 0.01-0.08. The important contribution of the invention is that it takes the advantage of straw and mixes with calcium sulfate or with fertilizer industrial waste which combines the chemical modifying with physical modifying, which can improves the soil consolidation essentially, and the modifying effect is obviously better than simple chemical modifying on the condition of not proceeding eluting. The product can not only be used in the ground-crop cultivation proceeding irrigation and draining, but also can be used in forest plantation which not proceeding manual irrigation.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

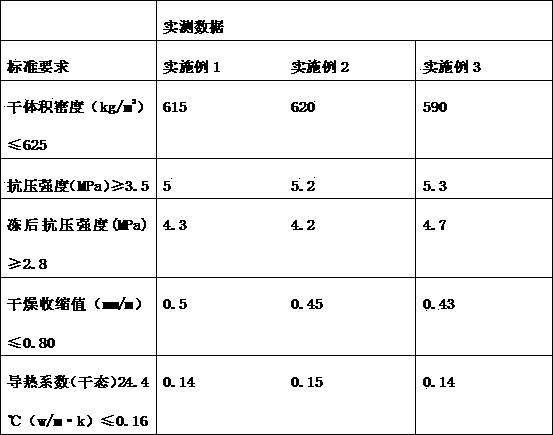

Aerated concrete building block and preparation technology thereof

ActiveCN102206095AHigh tensile strengthHigh impact strengthCeramicwarePhosphogypsumUltimate tensile strength

The invention discloses an aerated concrete building block. The aerated concrete building block comprises, by weight, 65-72 parts of fly ash, 15-20 parts of quick lime, 5-10 parts of cement, 2.83-3.83 parts of phosphogypsum, 0.1 parts of aluminum powers, 0.05 parts of a foam stabilizer and 0.02 parts of a polypropylene fibre. The modified polypropylene fiber is added to the concrete structure material, such that tensile strength and anti-impact strength of the concrete structure material are improved, a drying shrinkage value of the concrete structure material is reduced, and cracks are prevented from formation and extension during cement solidification. During a green body structural strength formation, a plurality of microcracks are generated due to a plastic shrinkage of the green body, such that during a later autoclaved process, larger cracks are easily generated from the microcracks when the aerated concrete structure extends; meanwhile, because a gradient variation of humidity of the aerated concrete material is large, cracks in the aerated concrete material are easily generated during humidity changing. Therefore, the internal structure of the aerated concrete provided by the present invention can enable improving the disadvantages of generation of aerated concrete wall cracks through an enhancement of the polypropylene fibre.

Owner:俞华贵

Denatured ardealite brick and its application as cement retardant

The present invention relates to a modified phosphogypsum brick and its use as cement retarder. Said modified phosphogysum brick comprises 80-95 wt% of phosphogypsum, 2-15 wt% of reinforcing agent and 3-10 wt% of modifiying agent. Said material mixture (100 wt%) is undergone the processes of forming and naturally-drying to obtain the invented product. The water content of said modified phosphogypsum brick is less than 10 wt%, SO3 is greater than 35 wt%, pH is greater than 7, P2O5 is less than 0.1 wt%. Said modified phosphogypsum brick is convenient for storage and transportation, can be used as cement retarder for production of cement instead of natural gypsum, and can reduce cement cost and raise cement property.

Owner:WUHAN UNIV OF TECH +1

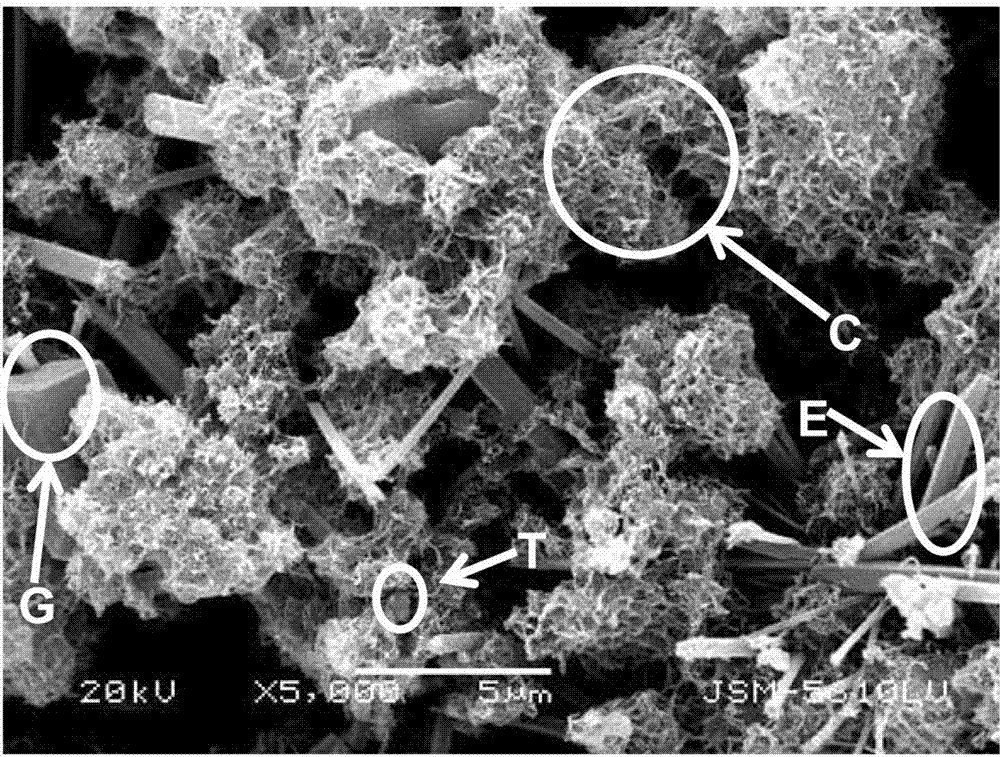

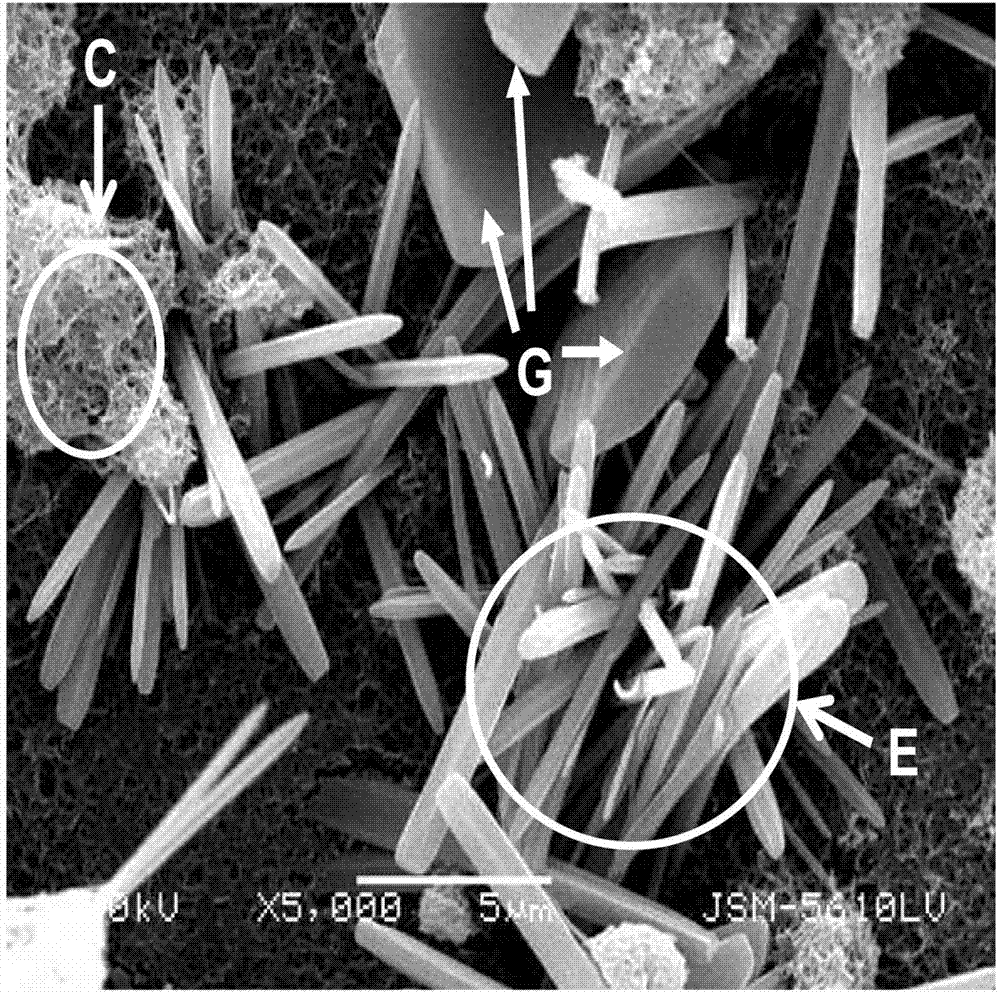

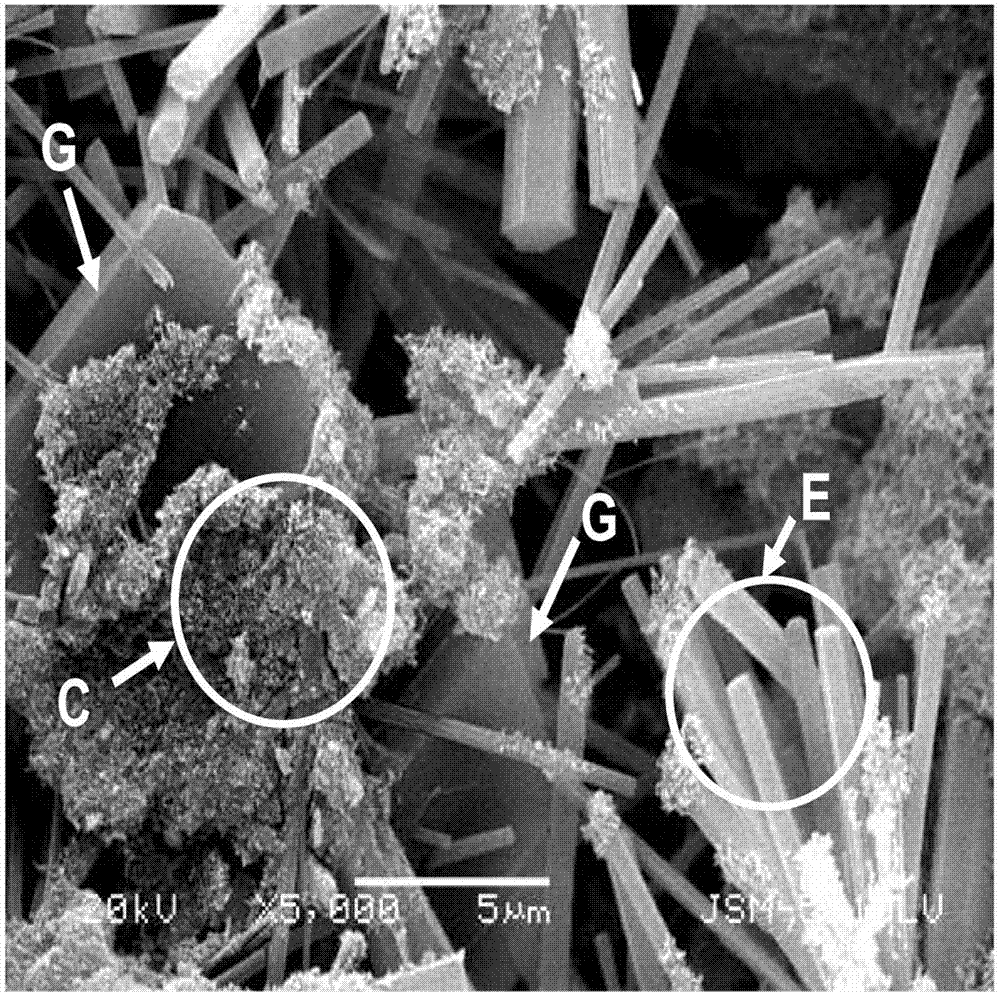

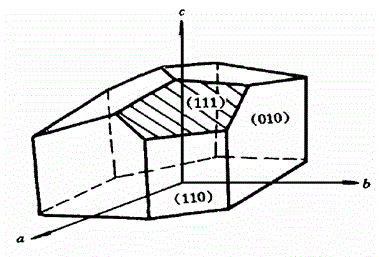

Method for preparing ultra-fine calcium sulfate crystal whisker by using phosphogypsum

ActiveCN101792932ALarge diameterSmall diameterPolycrystalline material growthSingle crystal growth detailsFiltrationWhiskers

The invention discloses a method for preparing ultra-fine calcium sulfate crystal whiskers by using phosphogypsum. The method comprises that the phosphogypsum is ultra-fine treated to powder with grain size of 0.1-100 mum, water is added into the powder to prepare slurry with weight percent of 5-15 percent, pH value is regulated to be 3-5, reaction is kept for 3-5h at 125-145 DEG C and under 2-3MPa, pumping filtration is conducted when the obtained product is hot, and the filtered product is dried at 120-250 DEG C to obtain the calcium sulfate crystal whiskers. Moreover, crystal promoter with weight 0.10-0.20 time of the weight of the phosphogypsum and seed crystal with weight 0.1-0.2 time of the weight of the phosphogypsum can be added. The invention has the advantages of low production cost, simple production method and good comprehensive performance.

Owner:WENGFU (GRP) CO LTD +1

Phosphogypsum-based gelling material and its application in mine tailing filling

ActiveCN104211313ARealize high-quality utilizationWide variety of sourcesMaterial fill-upRed mudPhosphogypsum

The invention relates to a gelling material for mine tailing filling. The gelling material for mine tailing filling used for improving the early stage strength of a filler and having good water segregation performance is obtained through the steps of respectively milling phosphogypsum, red mud, phosphorus residues and clinker to 800m<2> / kg, 700m<2> / kg, 300m<2> / kg and above 300m<2> / kg respectively, uniformly mixing the above milled raw materials, and adding an exciting agent. The gelling material is used to carry out mine tailing filling, and the raw materials are from various industrial waste residues, so the gelling material has the advantages of low cost, simple technology, strong maneuverability, low filling cost, effective utilization of various industrial waste residues of the metallurgy industry, energy saving, emission reduction and environmental protection.

Owner:CHINA THREE GORGES UNIV

Biological pesticidal organic fertilizer and preparation method thereof

InactiveCN103724139ASimple structureAddress organic matter declineFertilizer mixturesPaulownia coreanaNematode

The invention discloses a biological pesticidal organic fertilizer and a preparation method thereof. The biological pesticidal organic fertilizer is prepared from the following raw materials in parts by weight: 40-50 parts of pig manure, 20-30 parts of tea seed pulp, 10-15 parts of coffee grounds, 8-12 parts of paulownia sawdust, 5-10 parts of phosphogypsum, 4-8 parts of corn cob, 5-10 parts of pepper seed cake, 10-15 parts of mushroom dreg, 8-12 parts of wheat bran, 15-20 parts of bentonite, 10-15 parts of opoka, 2-3 parts of ferrous sulfate, 1-2 parts of manganese sulfate, 3-5 parts of humic acid, 1-2 parts of chinese tallow tree root and bark, 2-3 parts of sophora alopecuroides, 1-2 parts of stemona, 1-3 parts of Artemisia annua, 1.5-2.5 parts of ailanthus leaf, 2-3 parts of derris and 1-2 parts of Radix Euphorbiae Ebractealatae. The organic fertilizer disclosed by the invention has multiple effects of providing nutrients, improving the soil structure, preventing and treating pests and diseases and the like, can promote the crops to quickly grow, enhances the stress tolerance of the crops, can have favorable preventing and treating effects on nematodes and soil insects, reduces or avoids use of chemical pesticides, enhances the soil fertility, regulates the ecological equilibrium of soil, improves the quality of agricultural products, has no chemical residues, and implements yield increase and income increase of agricultural products.

Owner:青岛米品品服装有限公司

Modification and innocuous treatment method of phosphogypsum

The invention discloses a modification and innocuous treatment method of phosphogypsum, comprising the following steps: (1) cleaning, (2) neutralizing, (3) dehydrating, (4) calcining, and (5) packaging. The modified phosphogypsum prepared by the invention is a raw material for building material, can be used for preparing a phosphogypsum high strength cement fiberboard. The modified phosphogypsum sandwich panels prepared by the phosphogypsum high strength cement fiberboard can be applied in wall material, floor and roof panel, and has the advantages of good antifreezing performance, thermal insulation performance, heat shielding performance, corrosion resisting performance, fireproof performance, high intensity, light specific gravity, easiness in installation and the like. According to the invention, the waste residue phosphogypsum of phosphorus chemical enterprises are recycled through modification treatment and can be used for producing building materials after recycling, so that the national energy saving policy and the development direction of circular economy are satisfied; even temporarily unable use occurs because of investment or other reasons, the modified phosphogypsum can be stored in long term without environmental hazard, so that the harmlessness is realized.

Owner:GUIYANG PENGHONG HIGH NEW TECH DECORATION MATERIAL

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

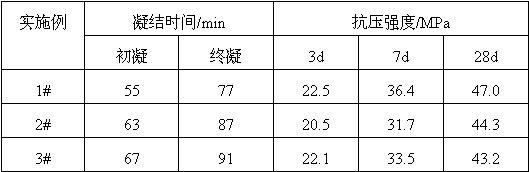

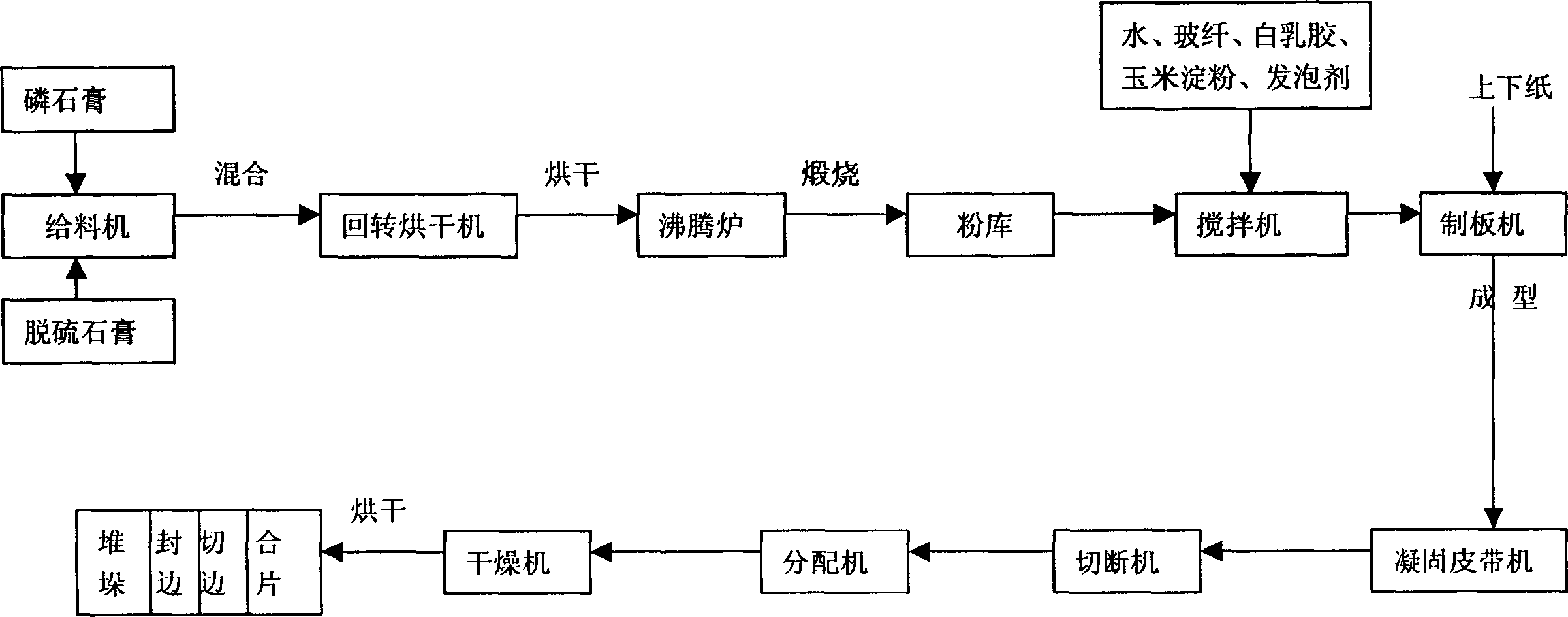

Method for producing paper gypsum board using desulfurated gypsum and ardealite

The invention discloses a making method of paper plaster board, which comprises the following steps: mixing the phosphogypsum and desulfuration plaster according to the weight ratio at 50-90:50-10; drying until the free water content under 5 percent; sintering the plaster at 160-220 DEG C continually to form the calcined gypsum powder with 5-9 percent crystal water; cooling in the bin; placing to obtain the architecture plaster powder; stirring the plaster powder with white corn starch latex, foaming agent, glass fiber and water evenly into material paste; compounding the roof and bottom of paper plaster board through plate-typed molder. The invention saves the natural plaster resource and cost, which improves the product property.

Owner:TAISHAN GYPSUM CO LTD

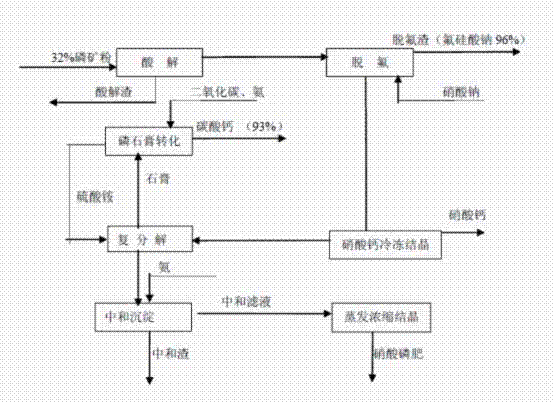

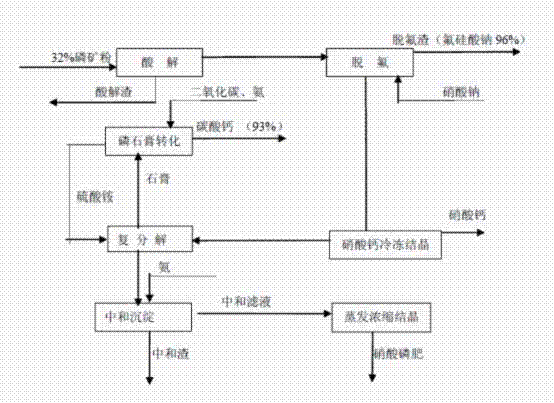

Method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing

InactiveCN102351590APromote absorptionImprove qualityCalcium/strontium/barium carbonatesFertilizer mixturesSolubilityChemical industry

The invention discloses a method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing. The high-water solubility nitrophosphate fertilizer is prepared from the processes of phosphorite nitrolysis, fluorine removal, calcium nitrate freezing separation, further removal of calcium in ammonium sulfate, ammonia liquor neutralization and deposition removal of impurities, and evaporation concentration and crystallization. Specially, the method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing comprises the following steps of 1, acidolysis, 2, fluorine removal, 3, calcium nitrate freezing crystallization, 4, double decomposition removal of calcium in ammonium sulfate,5, neutralization and deposition removal of impurities, 6, evaporation concentration and crystallization, and 7, phosphogypsum transformation. The high-water solubility nitrophosphate fertilizer prepared by the method has a dissolution rate great than or equal to 99.9% in water, wherein nitrate nitrogen is easy for be absorbed by drops, satisfies requirements of a few commercial crops, has a highutilization rate, and improves a crop yield by 8 to 25% and crop quality. The method reduces waste discharge, is environmentally friendly, can be utilized for structure adjustment and product upgradeand update of the traditional phosphorus chemical industry, and has good economic and environmental benefits.

Owner:GUIZHOU RES INST OF CHEM IND

Autoclaved aerated concrete block and manufacturing process thereof

InactiveCN103964781ASolve fair useAvoid influenceSolid waste managementEcological environmentPhosphate

The invention provides an autoclaved aerated concrete block and a manufacturing process thereof. The autoclaved aerated concrete block comprises the following raw materials by weight parts: 60-70 parts of coal ash (sand), 15-20 parts of lime, 5-10 parts of cement, 2-4 parts of gypsum and 5-8 parts of wastes, wherein aluminum powder accounts for 0.075% of the total weight of dry materials, and the water-material ratio is 0.6-0.65. The manufacturing process comprises the following steps: storing and processing the raw materials; dosing, stirring, and pouring; standing, cutting, and grouping; autoclaving to obtain a finished product of the autoclaved aerated concrete block. According to the process, industrial solid wastes-phosphogypsum are used as the raw materials, wastewater and leftover materials discharged in a production process are recycled, the produced aerated concrete block completely meets the national standards, the influence on the aerated concrete block caused by phosphate impurities in the phosphogypsum is avoided, the problems of reasonable utilization of the leftover materials and waste slurry are solved, the industrial solid wastes are treated and turn into wealth, the ecological environment is protected, and the novel process is energy-saving and environment-friendly.

Owner:FUZHOU HENGSHUN ENVIRONMENTAL PROTECTION BUILDINGMATERIALS CO LTD

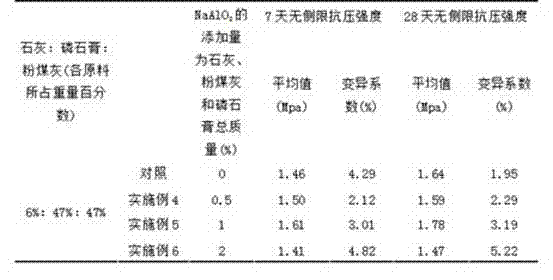

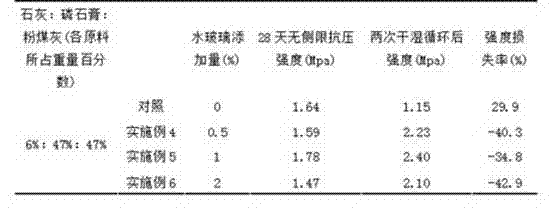

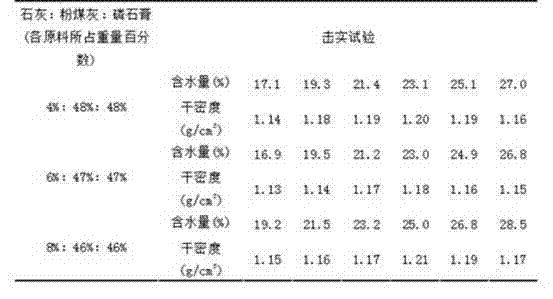

Roadbed filler for road and preparation method of roadbed filler

InactiveCN102690098AImprove early strengthImprove water stabilityRoadwaysPhosphogypsumPulverized fuel ash

The invention relates to a roadbed filler for a road and a preparation method of the roadbed filler. The roadbed filler for the road is characterized by being prepared from lime, pulverized fuel ash, phosphogypsum and stabilizer. The weight percentage of each material in the lime, the pulverized fuel ash and the phosphogypsum is 15% of lime, 30-50% of pulverized fuel ash and 35-60% of phosphogypsum; the sum of the weight percentages of the materials is 100%; the stabilizer is water glass or NaAlO2 (sodium metaaluminate); the adding amount of the water glass is 2-6% of total mass of the lime, the pulverized fuel ash and the phosphogypsum, and the adding amount of the NaAlO2 is 0.5-2% of total mass of the lime, the pulverized fuel ash and the phosphogypsum. Due to the roadbed filler for the road prepared by the method, not only can the early strength be improved, but also the problem of water stability can be solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

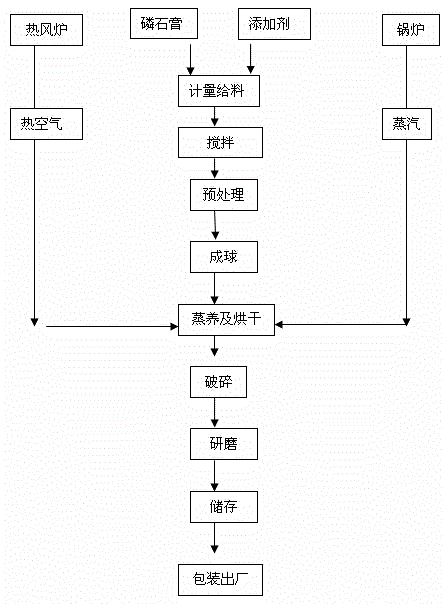

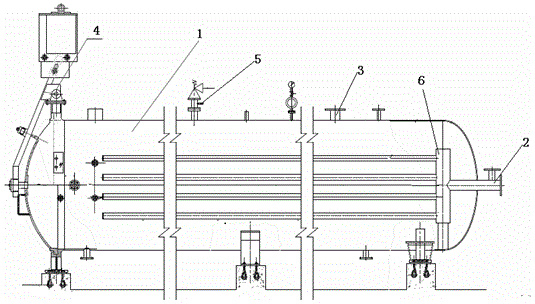

Method and device for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum

The invention discloses a method for preparing high-strength alpha hemihydrate gypsum by using phosphogypsum. The method comprises the following steps of: mixing the phosphogypsum, a pretreatment additive, water and a crystal modifier, stirring to be uniform, forming balls after aging treatment, then finishing steam curing and drying in a stilling kettle, and preparing the high-strength alpha hemihydrate gypsum. The method disclosed by the invention has the advantages that the process flow is simple, the industrialization is easy, the phosphogypsum can be greatly utilized and consumed, and the conversion rate is high; and simultaneously, the invention provides the stilling kettle capable of realizing integration of steam curing and drying, the alpha hemihydrate gypsum can be better prepared, and the high-quality building material or wall-body material can be better prepared.

Owner:KUNMING UNIV OF SCI & TECH

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

Gypsum-based door and window seam filling and sealing mortar as well as preparation method and application thereof

Owner:SHANGHAI LIVABLE BUILDING SCI & TECH CO LTD

Phosphogypsum light-weight partition wall board and building block and manufacturing method thereof

The invention discloses a phosphogypsum light-weight partition wall board and a building block and a manufacturing method thereof, which are characterized in that the phosphogypsum light-weight partition wall board and the building block consist essentially of raw materials according to the following weight percentages: 10-50% of phosphogypsum, 10-50% of magnesium oxide, 5-20% of magnesium chloride, 10-50% of water, 10-50% of packing, 0.1-3% of foaming agent and 0-5% of short fiber reinforced material. The phosphogypsum foamed building block or foamed wall board are light in weight, and good in sound insulation and heat preservation effects, thus being ideal energy-saving and environment-protective building materials; and main raw materials of phosphogypsum concrete can be obtained locally, the phosphogypsum concrete is simple and convenient in production, low in cost and pollution-free, and phosphogypsum concrete products not only can be widely used in mined-out areas of mines or tunnel backfilling, but also can be comprehensively utilized as surface layers, base layers and under layers of roads, and the like, thus having very broad application prospect.

Owner:杜庆贵

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com