Patents

Literature

7919results about How to "High impact strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

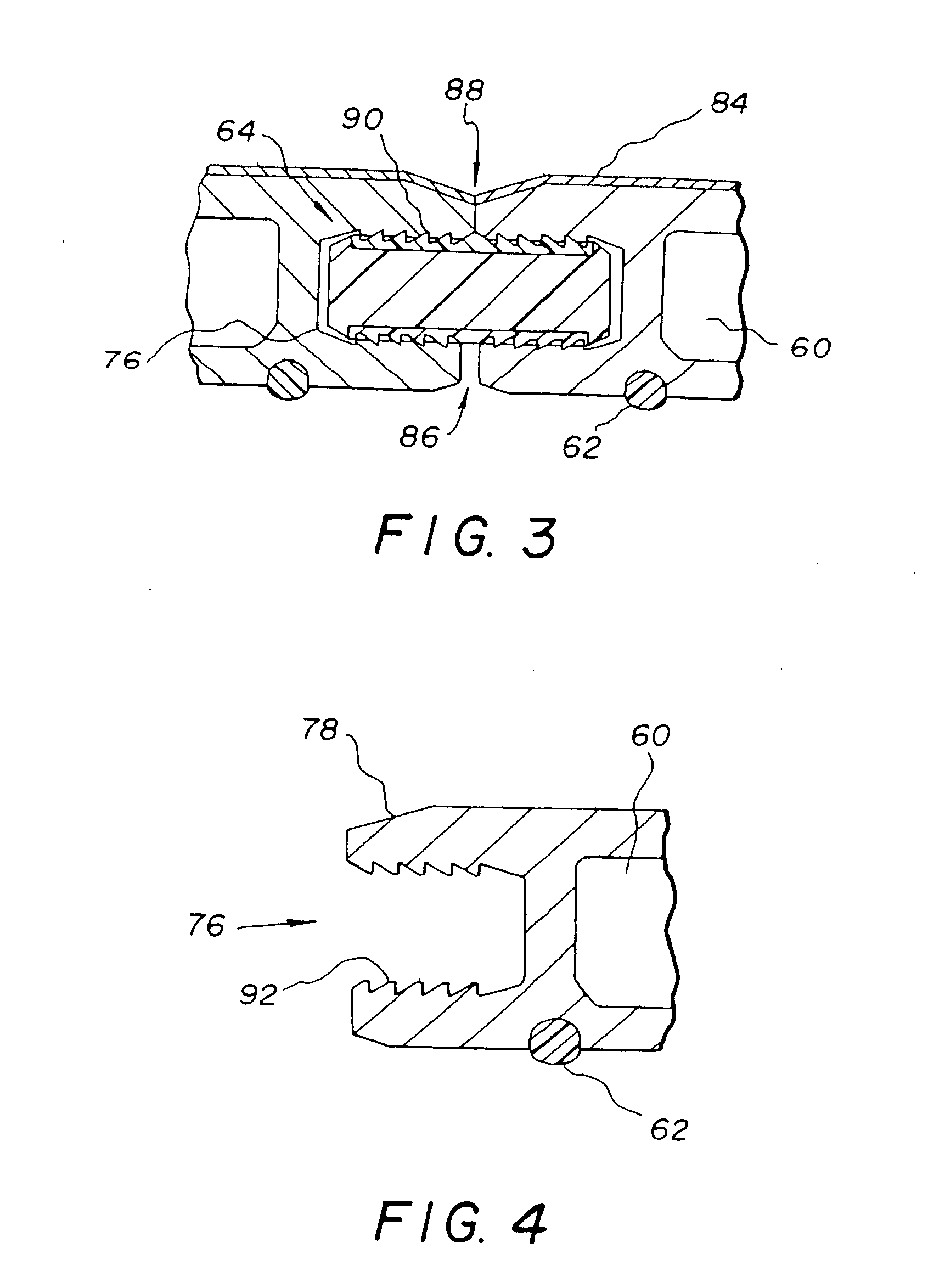

Polymerization catalysts and process for producing bimodal polymers in a single reactor

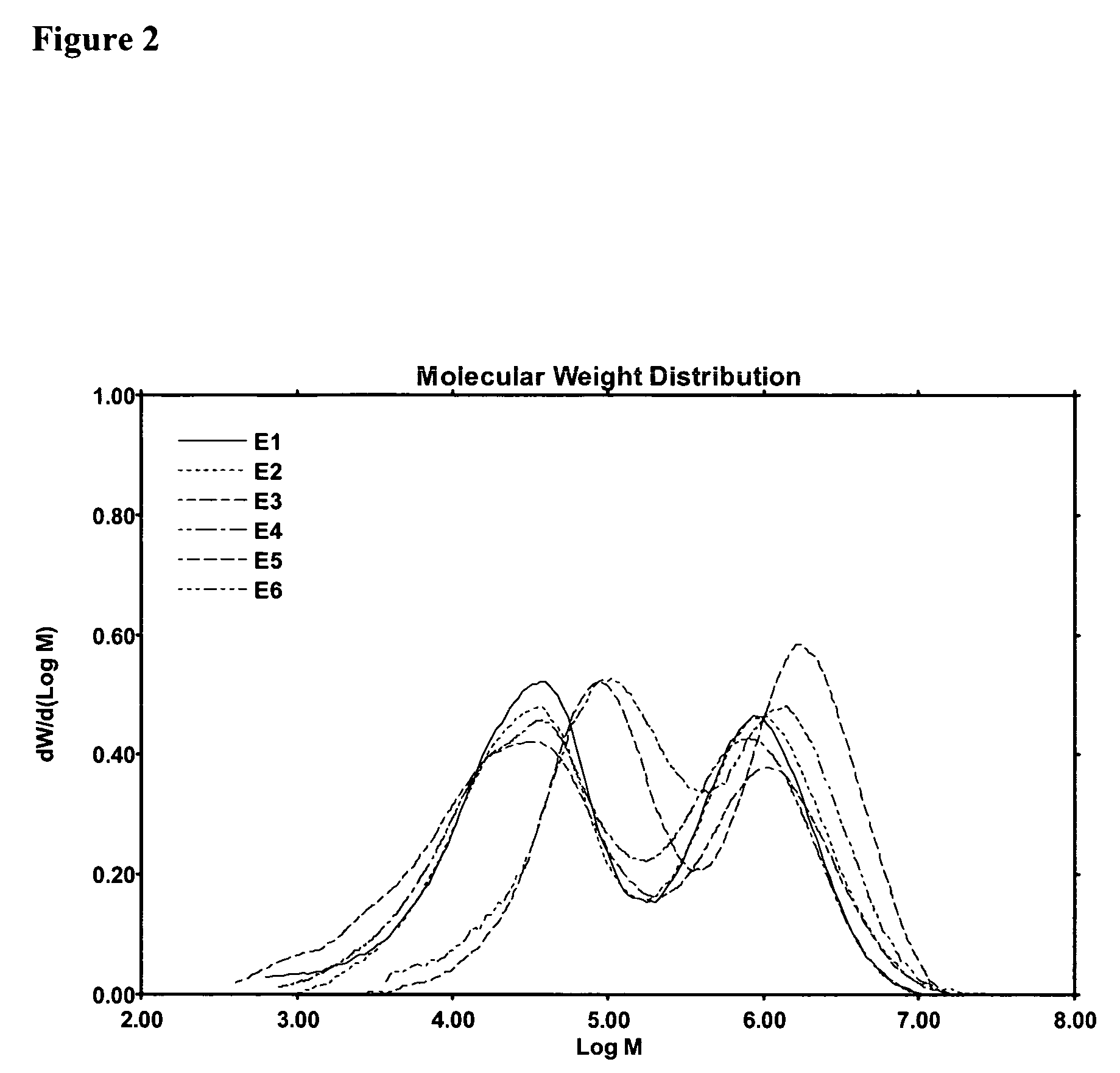

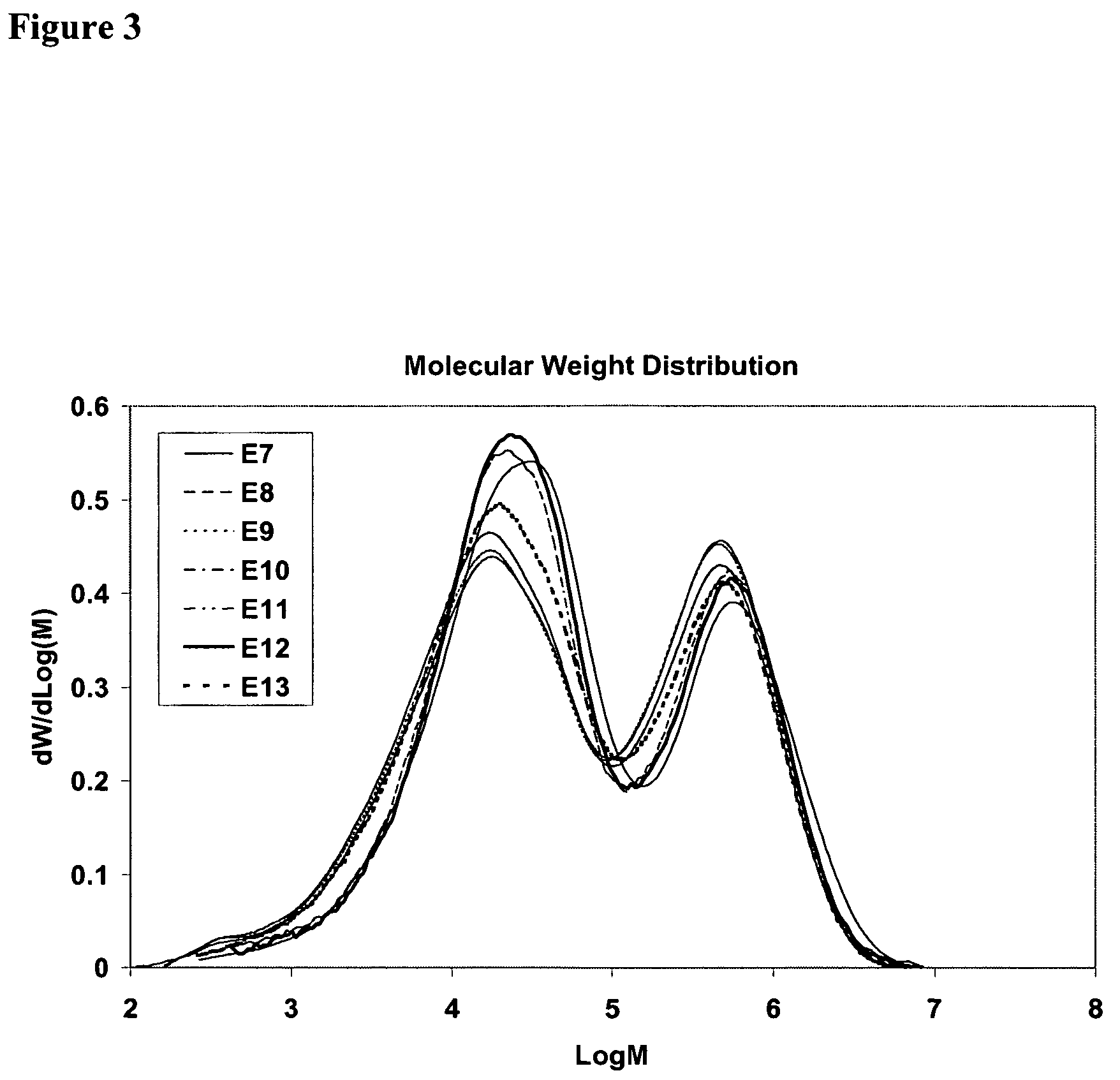

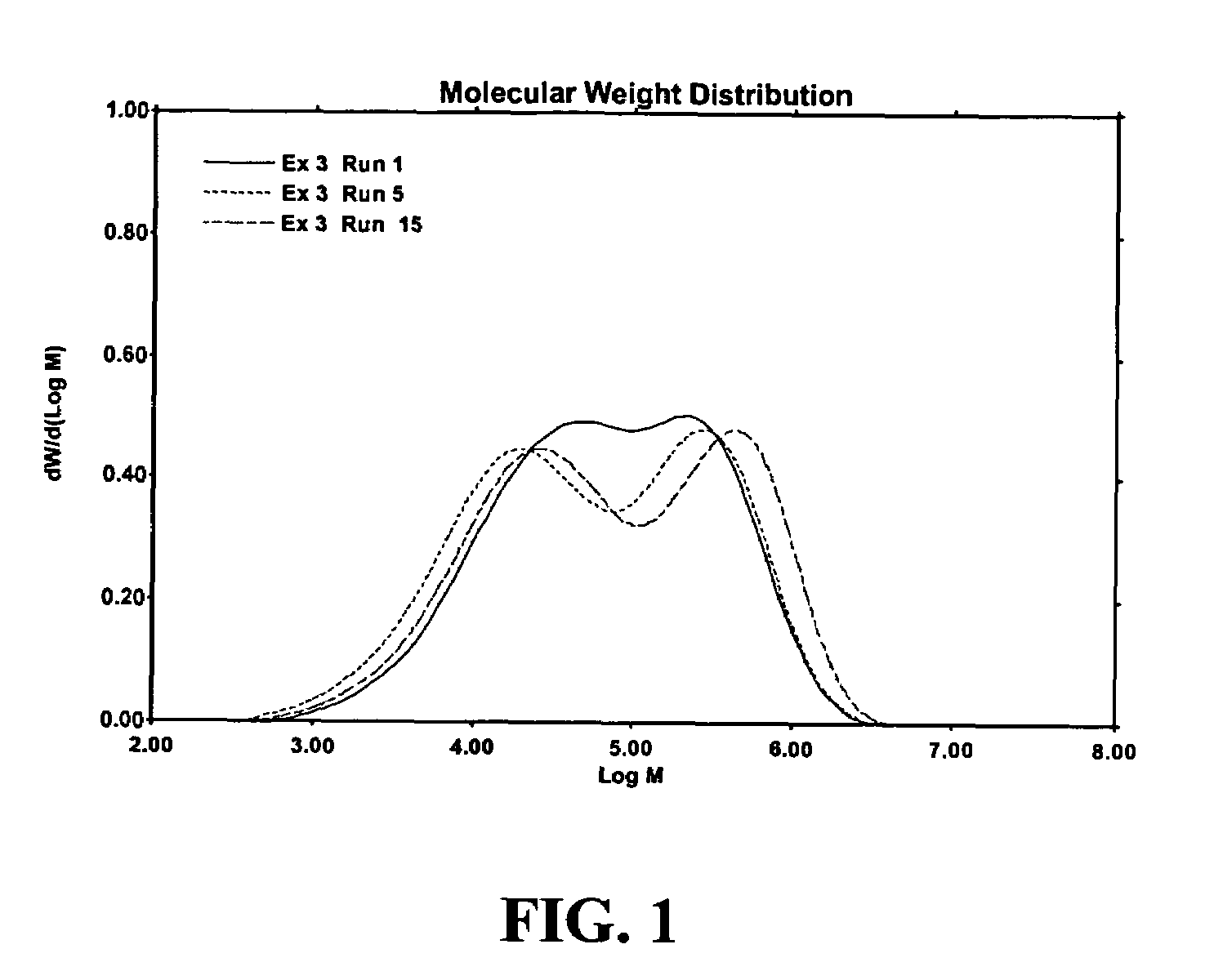

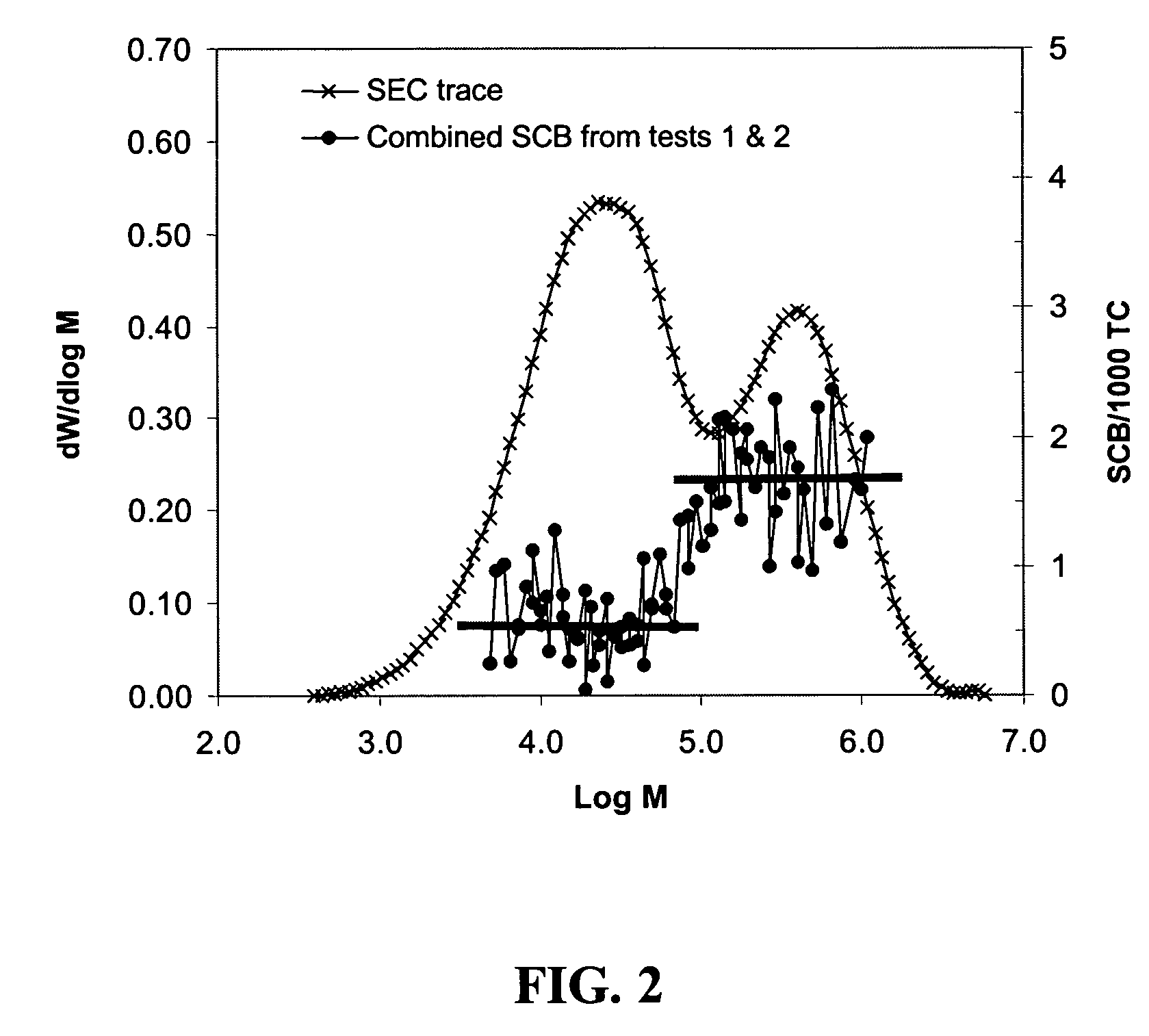

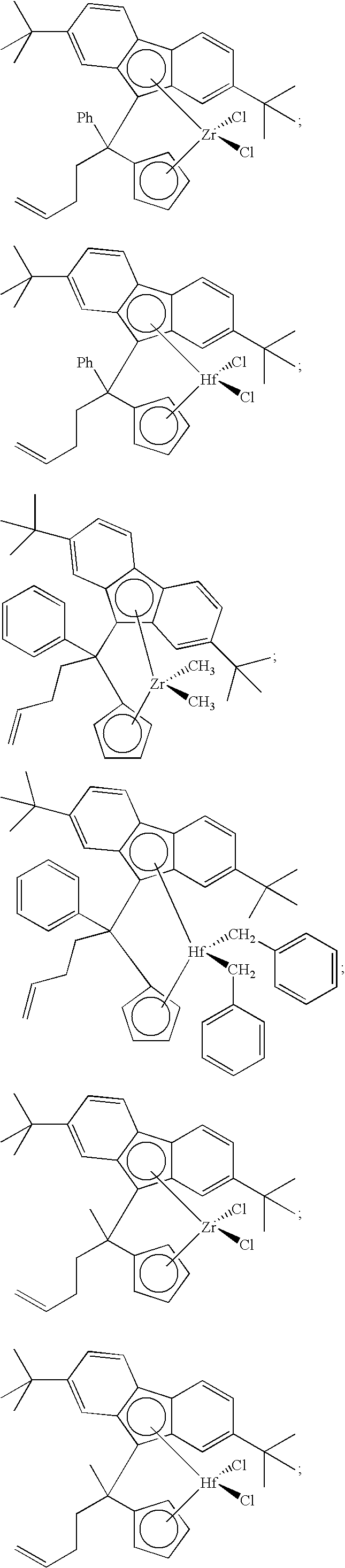

ActiveUS7226886B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinImproved method

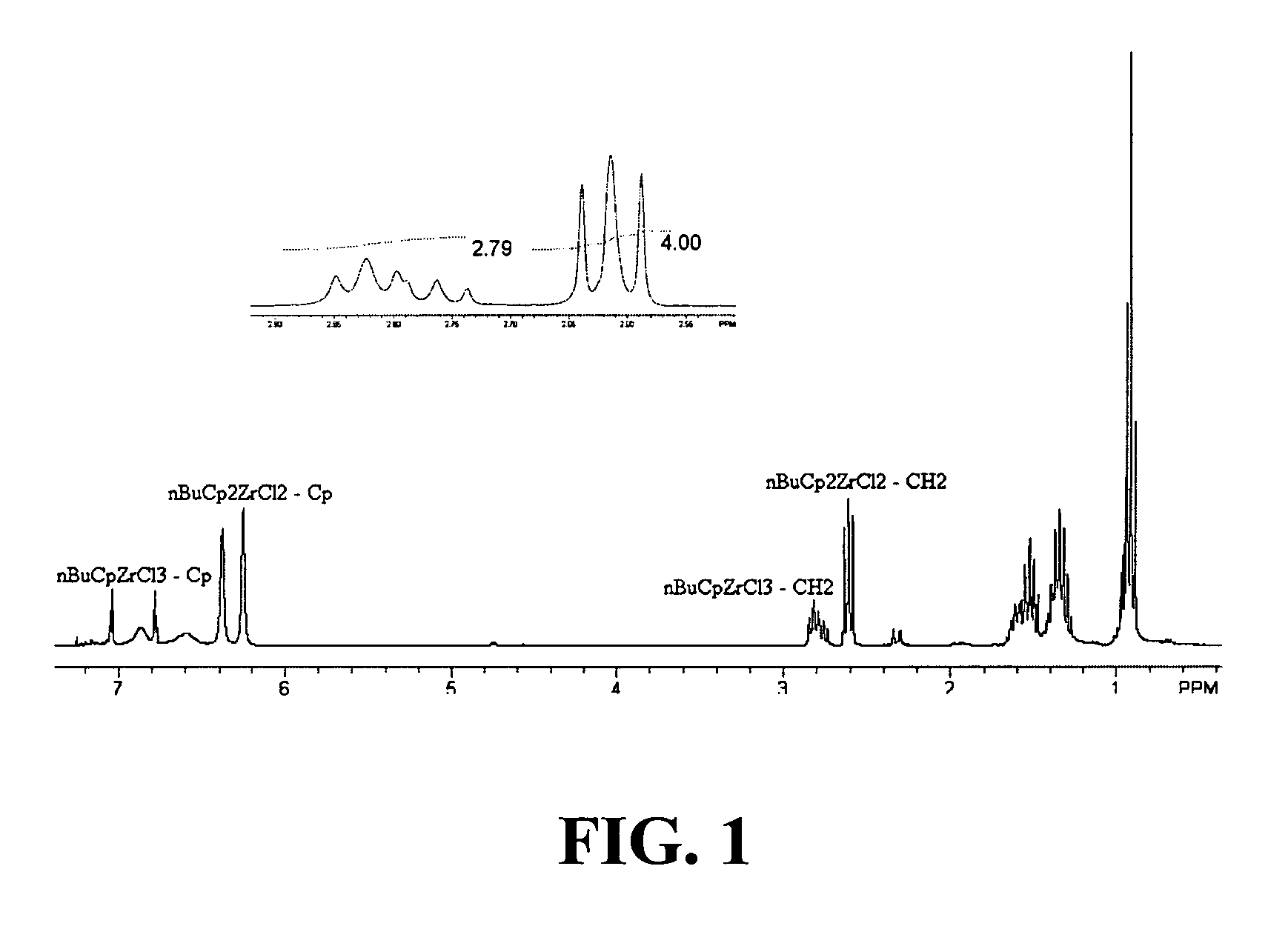

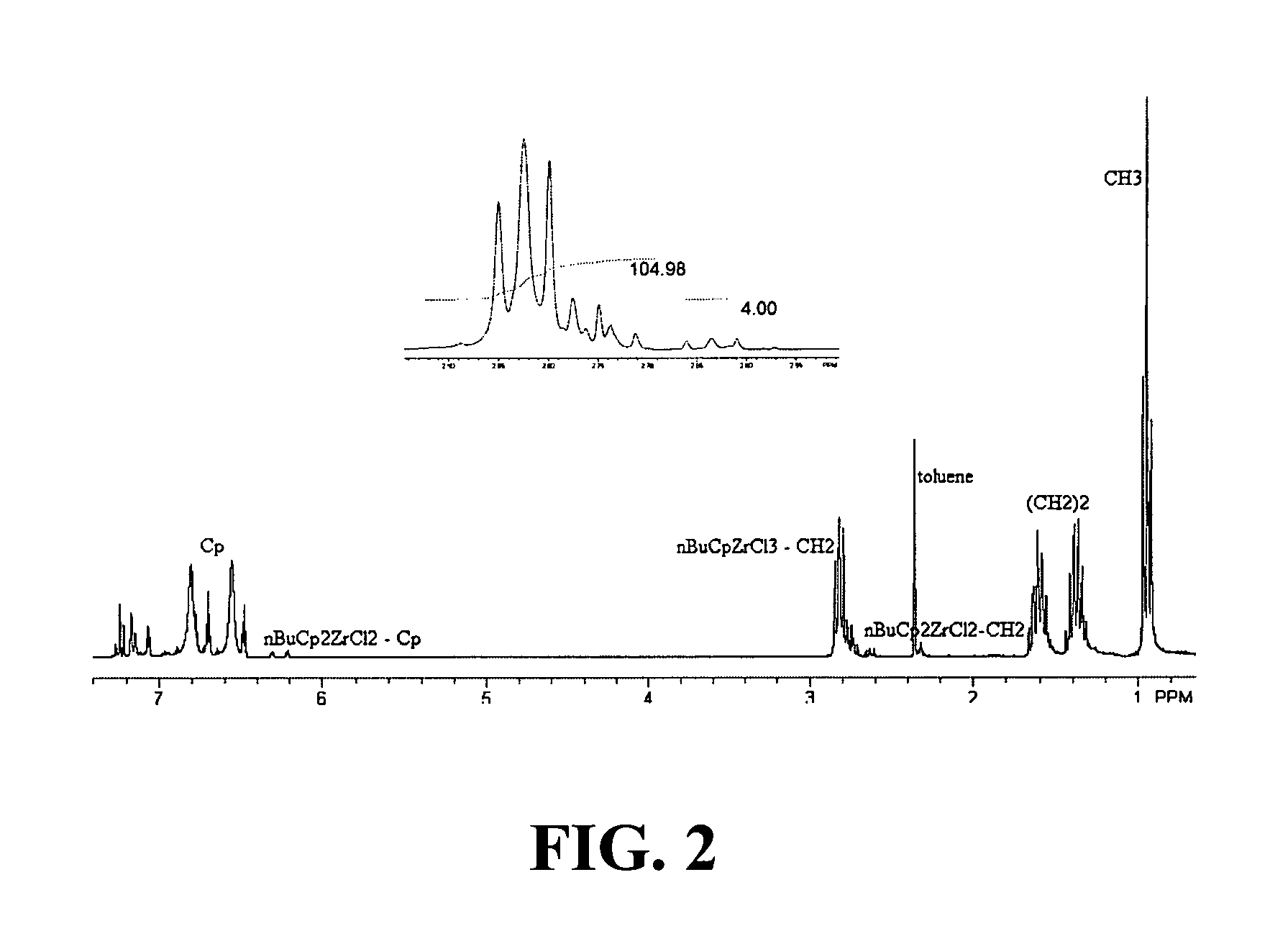

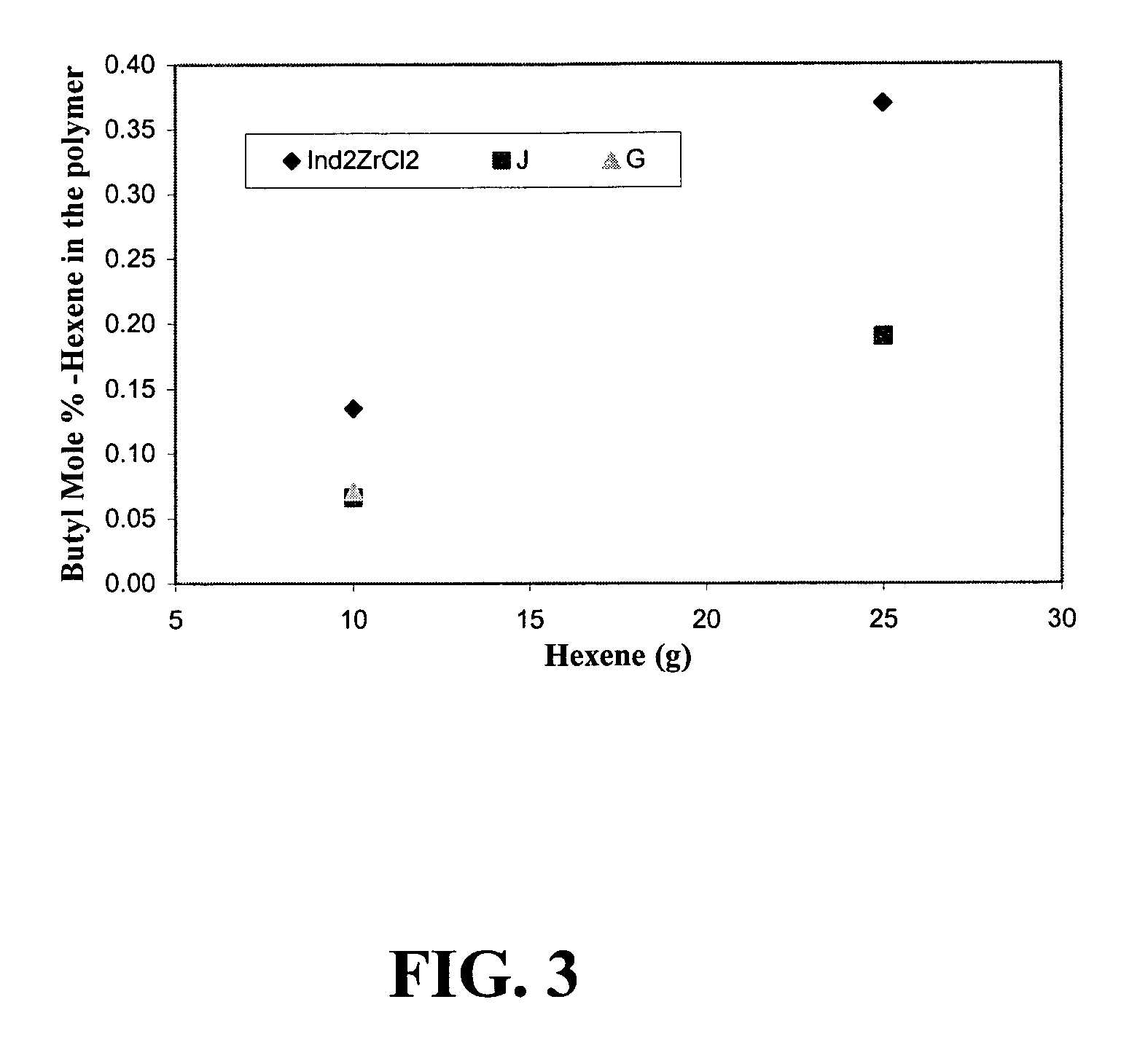

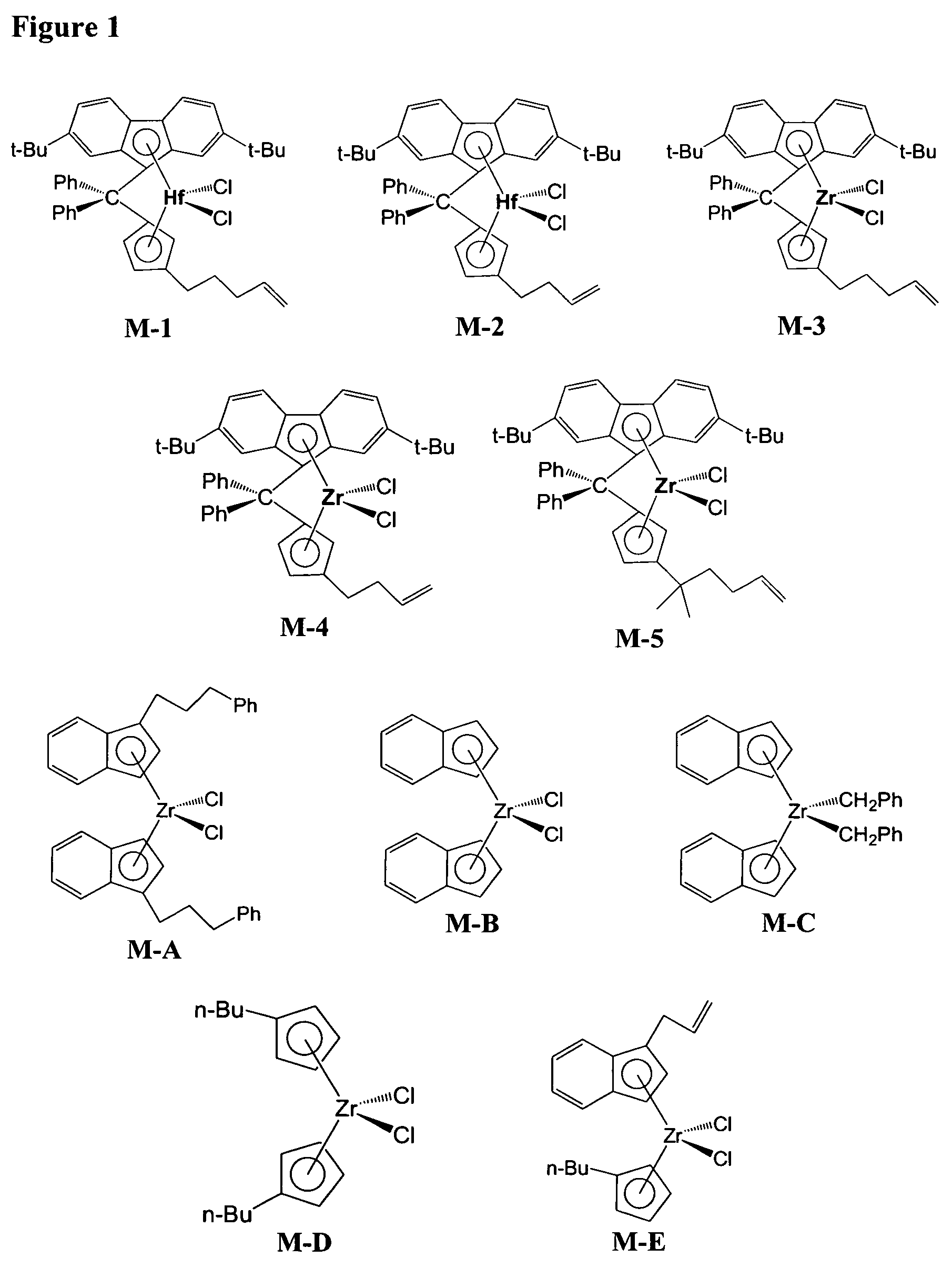

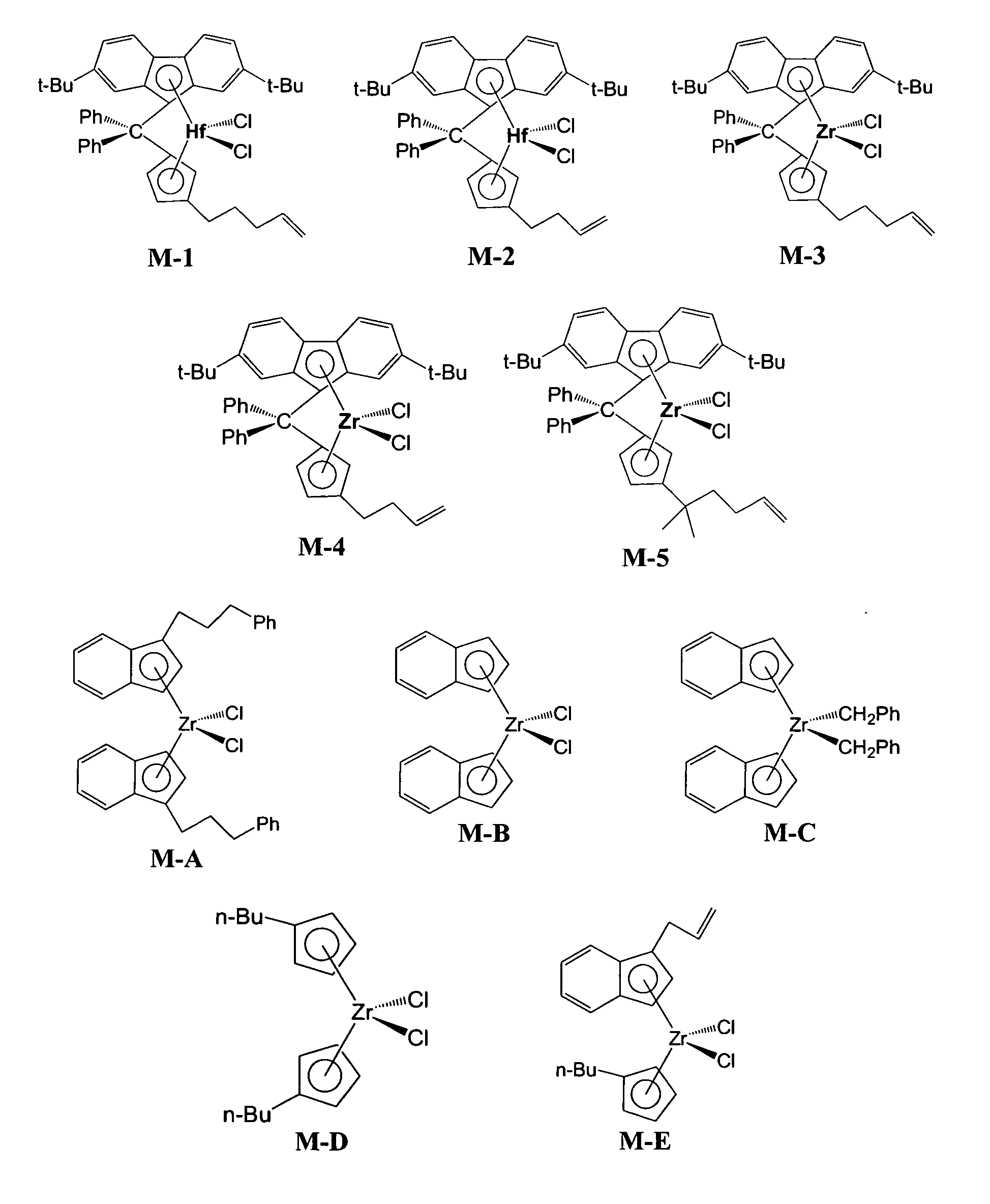

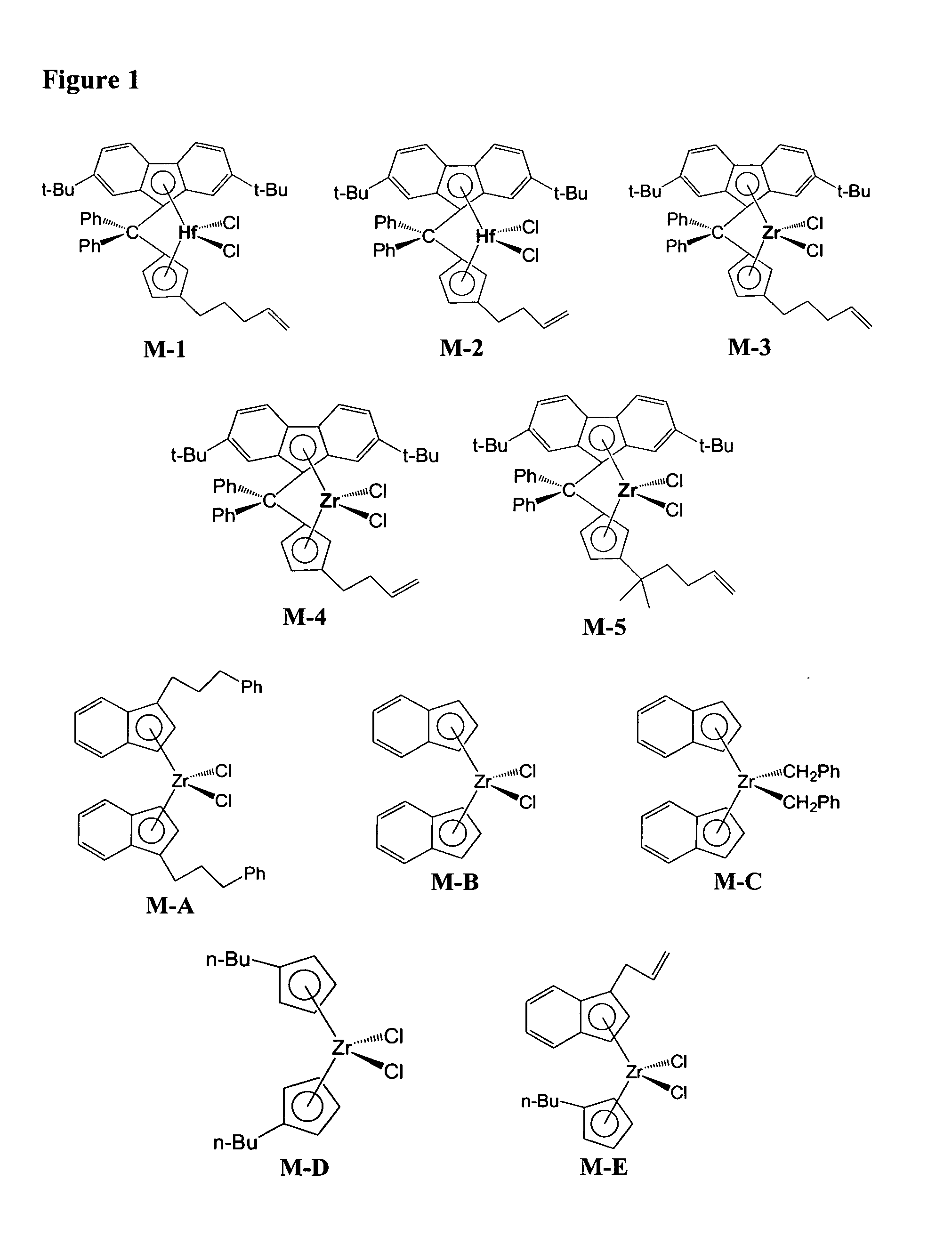

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. An improved method for preparing cyclopentadienyl complexes used to produce polyolefins is also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

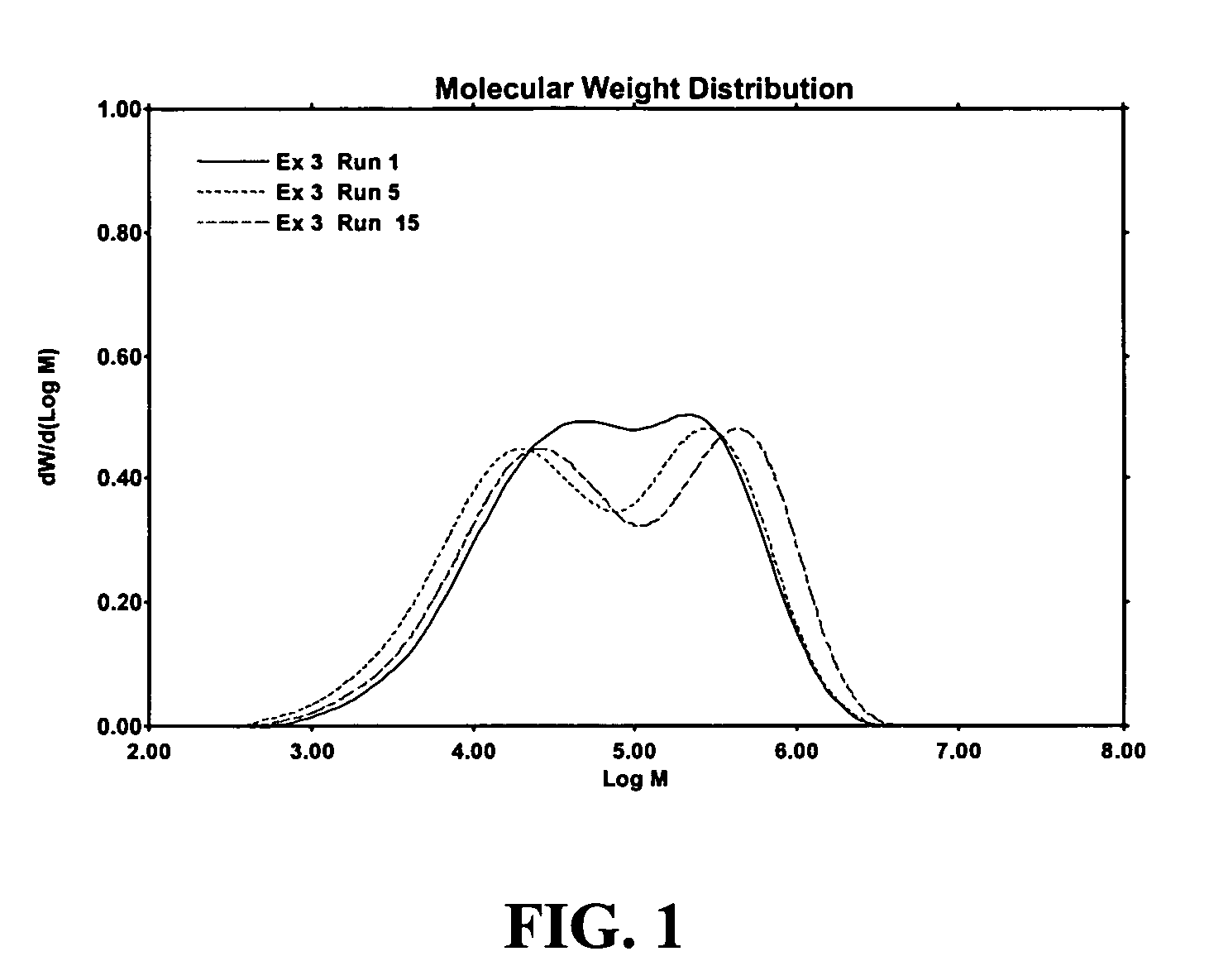

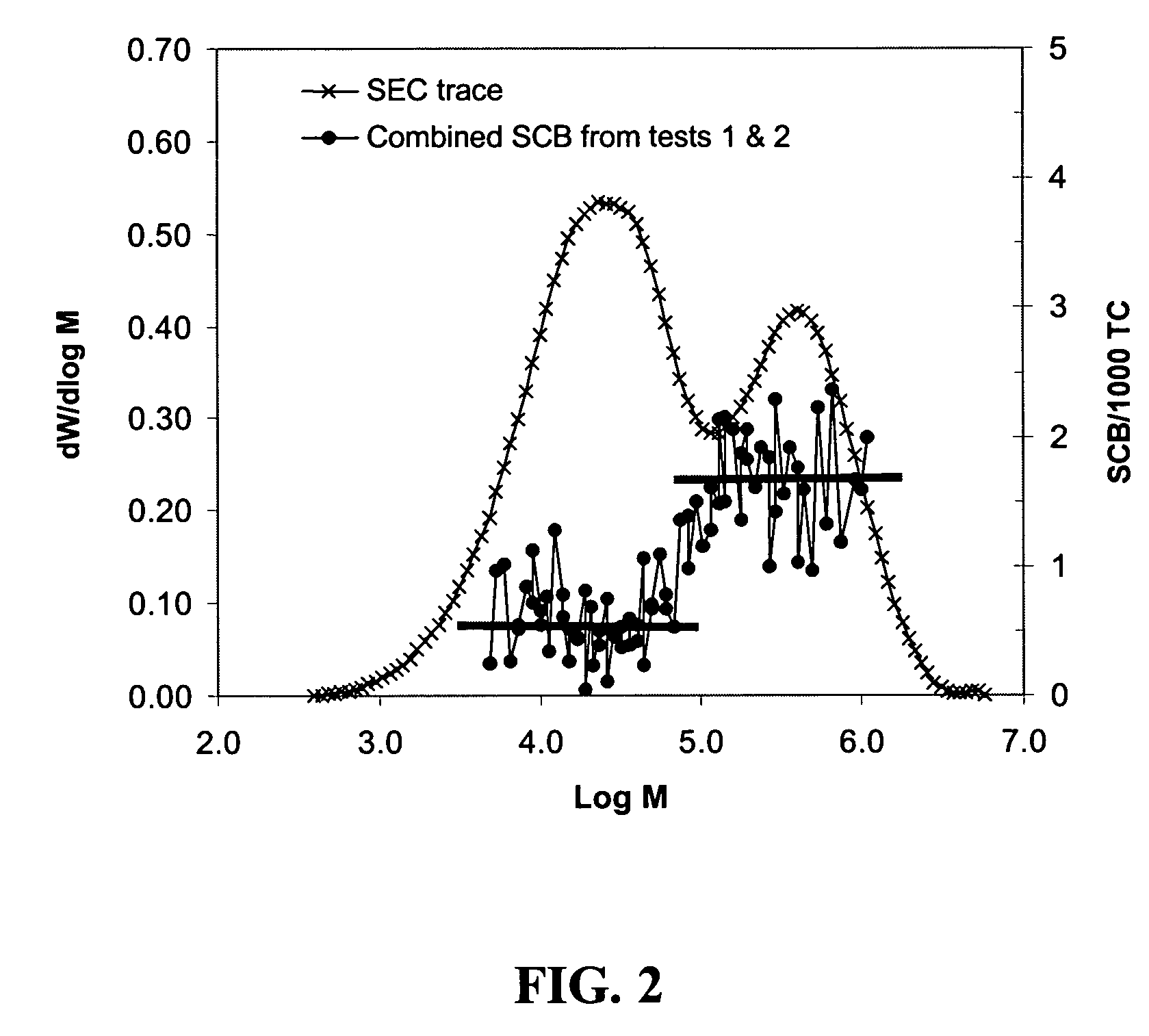

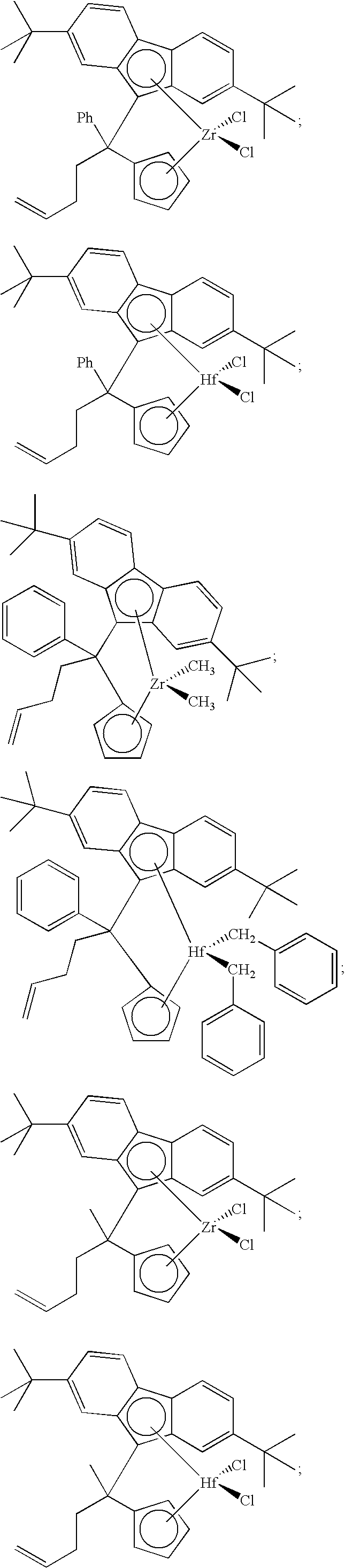

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS7619047B2Good balance of stiffnessHigh impact strengthGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEthylene PolymersEthylene

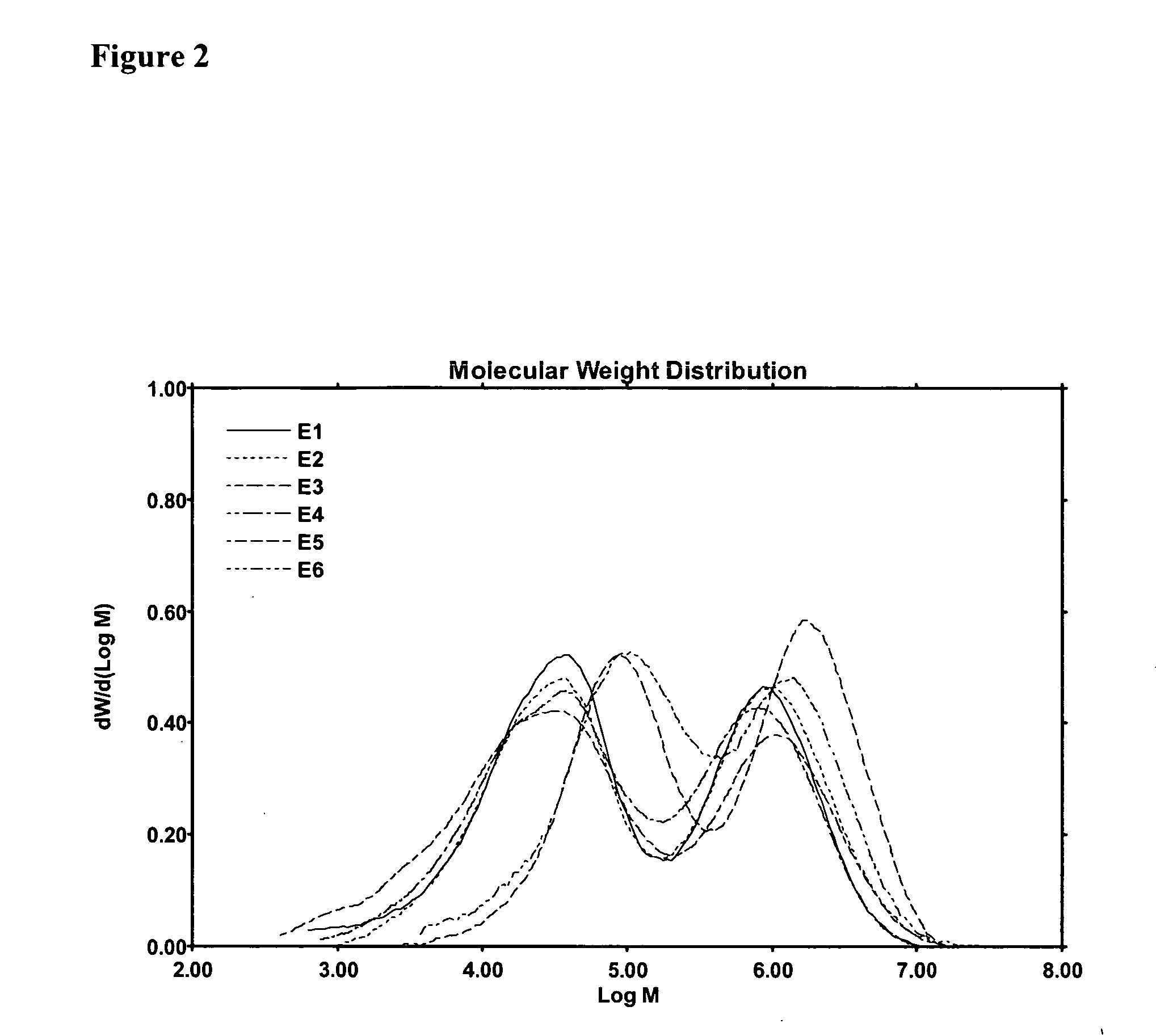

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7312283B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Mixtures of phenolic and inorganic materials with antimicrobial activity

InactiveUS6585989B2Excellent discoloration resistanceMaintain physical propertiesBiocideHeavy metal active ingredientsFiberAntibacterial activity

Plastic films, fibers and articles are provided long-term antimicrobial activity with a combination of certain phenolic and inorganic antimicrobial agents. The plastic films, fibers and articles with antimicrobial activity exhibit superior resistance to discoloration, may be processed at high temperature, and maintain physical properties upon weathering, especially upon exposure to ultraviolet radiation.

Owner:BASF SE

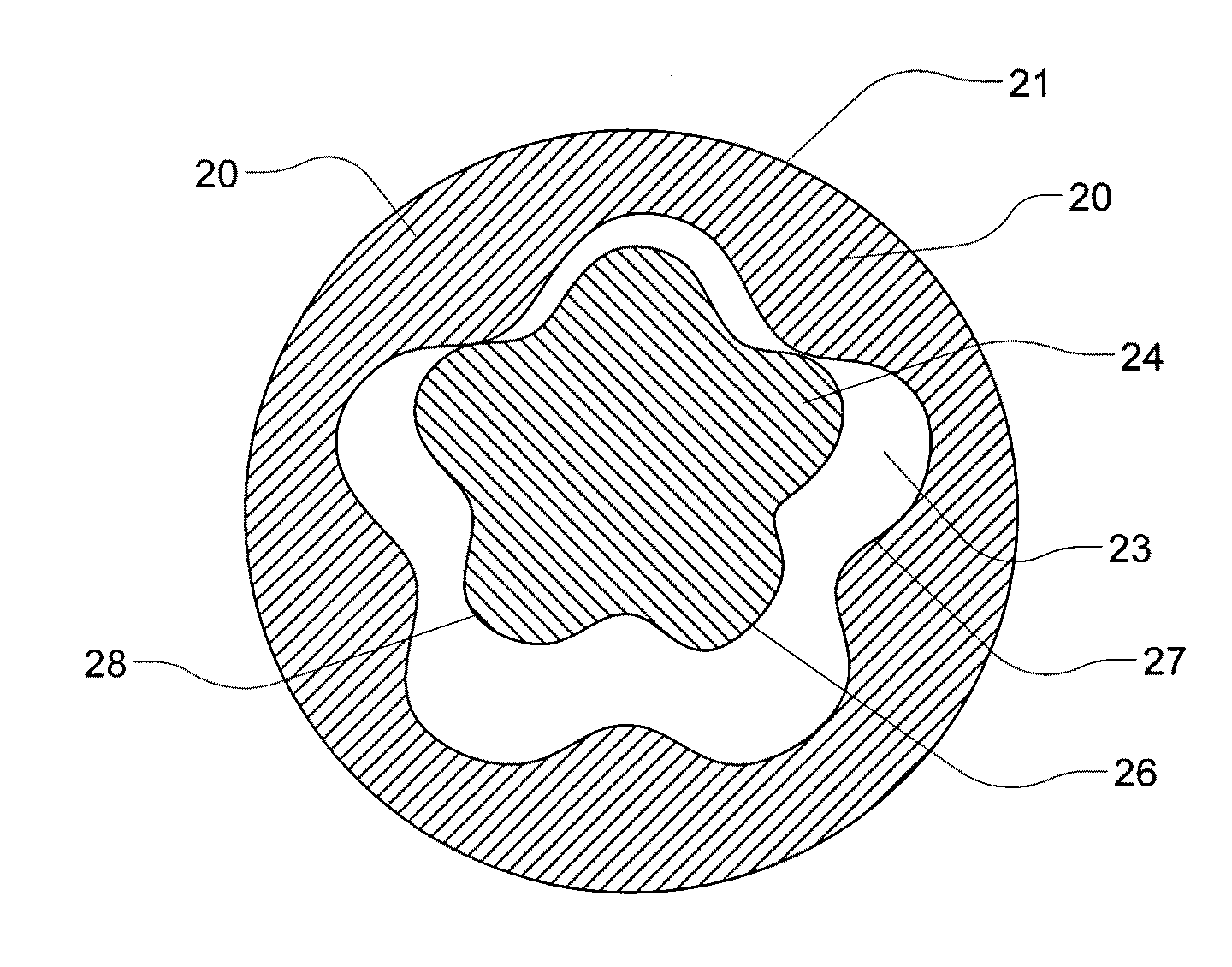

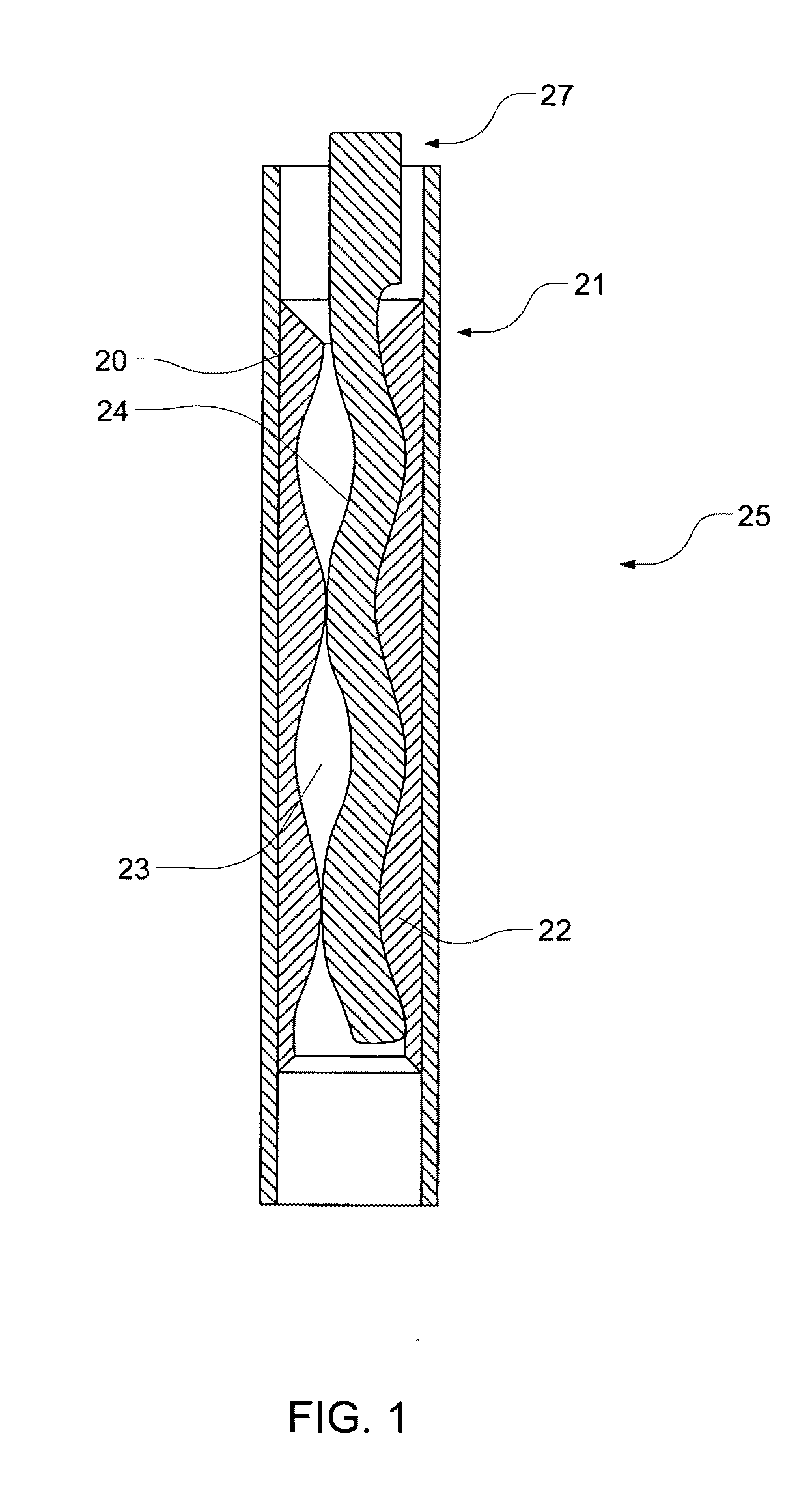

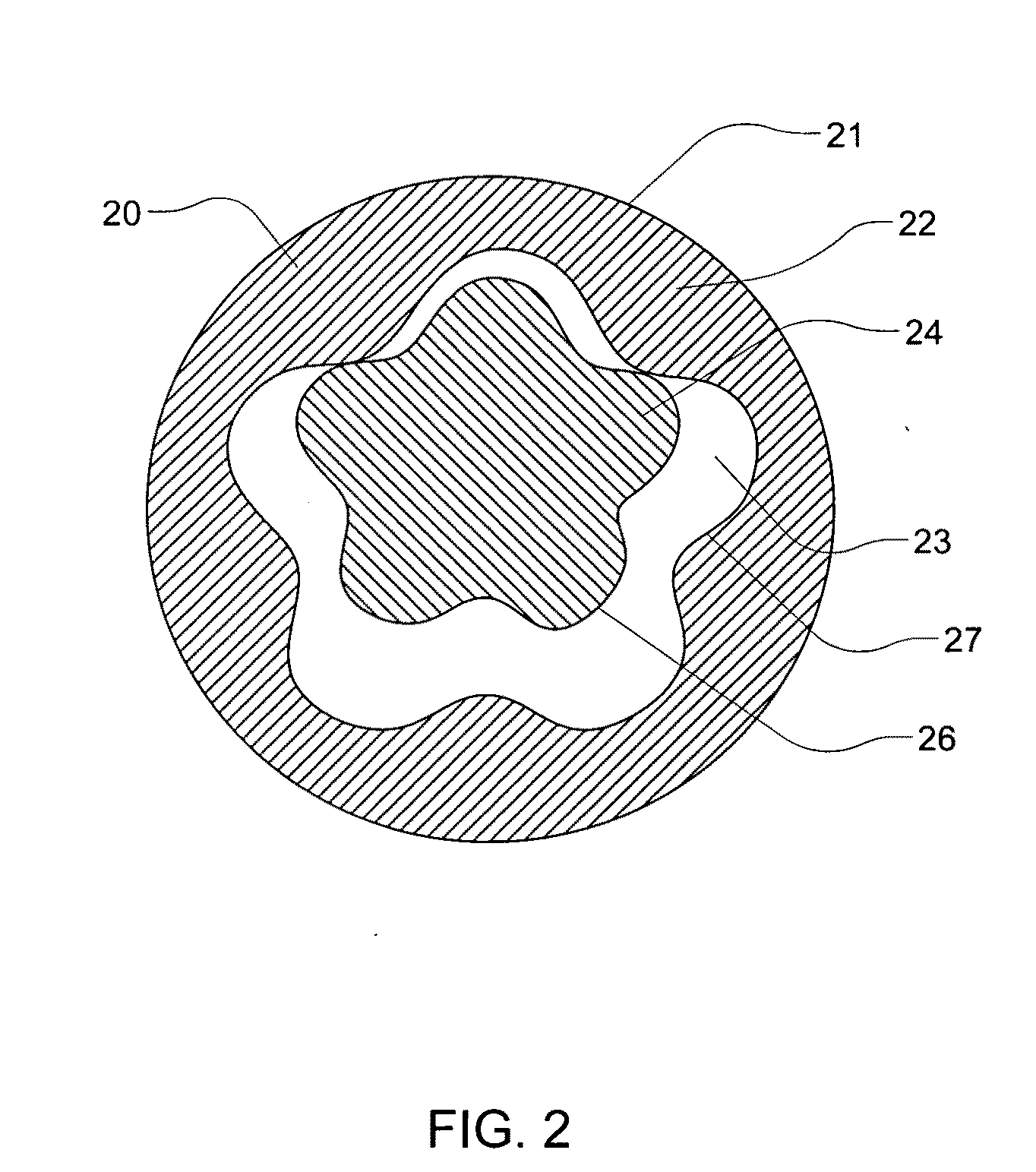

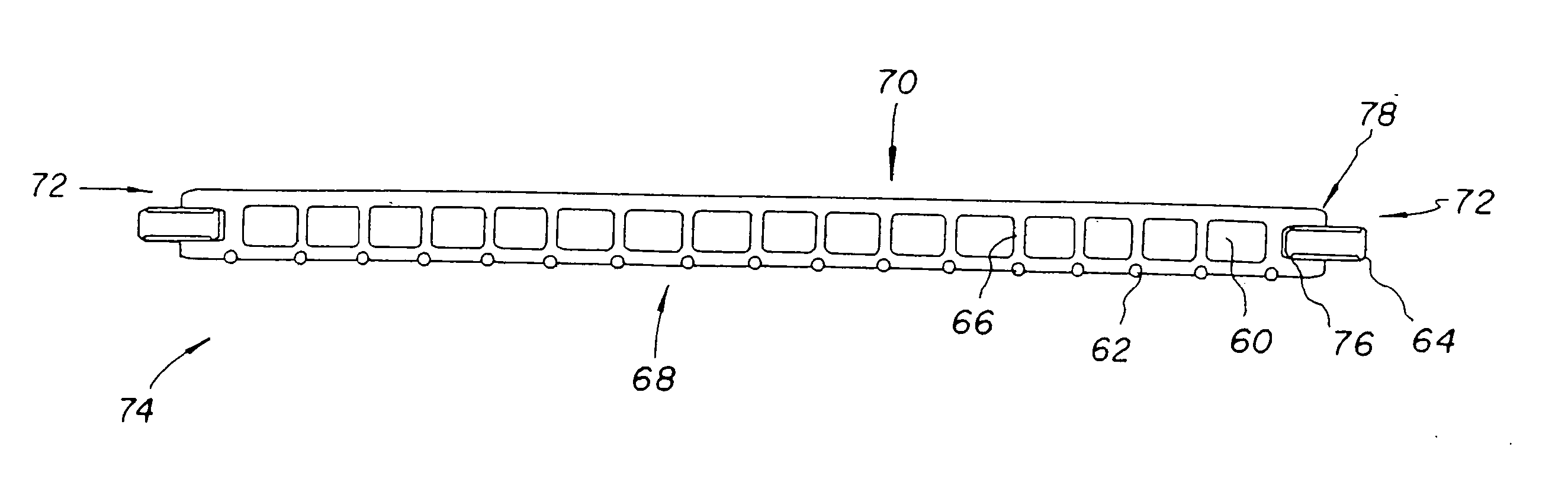

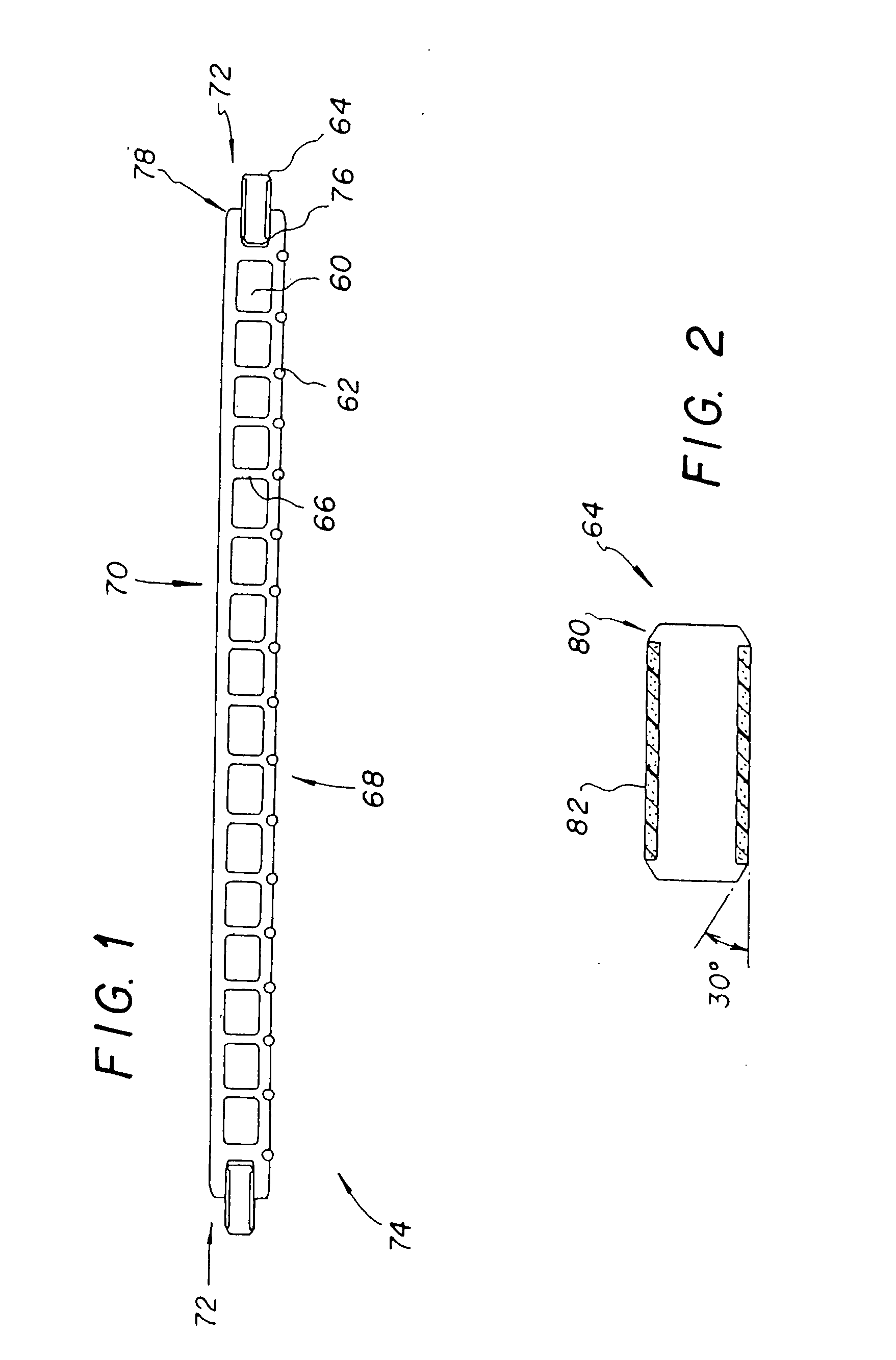

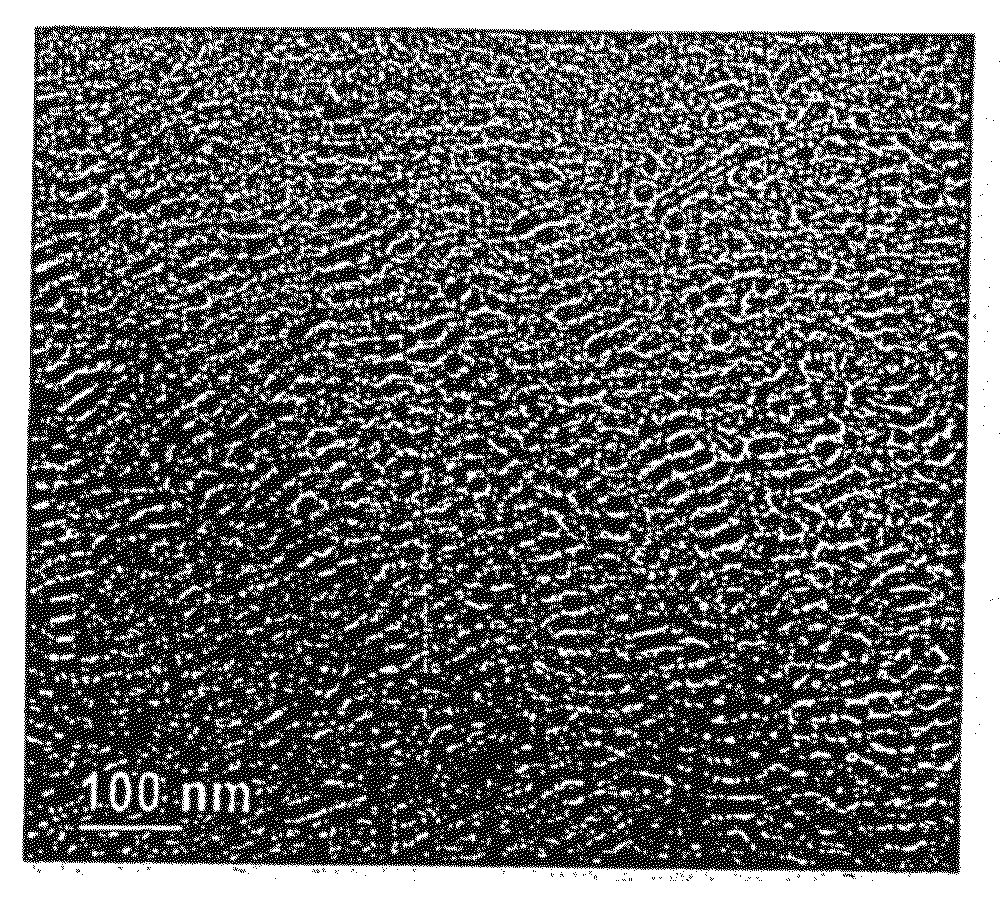

Nano particle reinforced polymer element for stator and rotor assembly

InactiveUS20090152009A1Interfacial interaction be improveImprove resistanceEngine of arcuate-engagement typeOscillating piston enginesNanometreNano sized particle

A nano particle reinforced polymer element of a stator and rotor assembly for a power section of a positive displacement fluid motor or a progressive cavity pump. Nano-sized particles are blended with an uncured polymer to improve the physical and chemical properties of the polymer. The use of nano-sized particles reduces the quantity of reinforcement material required to manufacture the polymer for the stator and rotor assembly and lowers the viscosity of the uncured polymer to improve manufacturing characteristics. The use of chemically functionalized nano particles improves the chemical and physical characteristics of the polymer.

Owner:HALLIBURTON ENERGY SERVICES INC

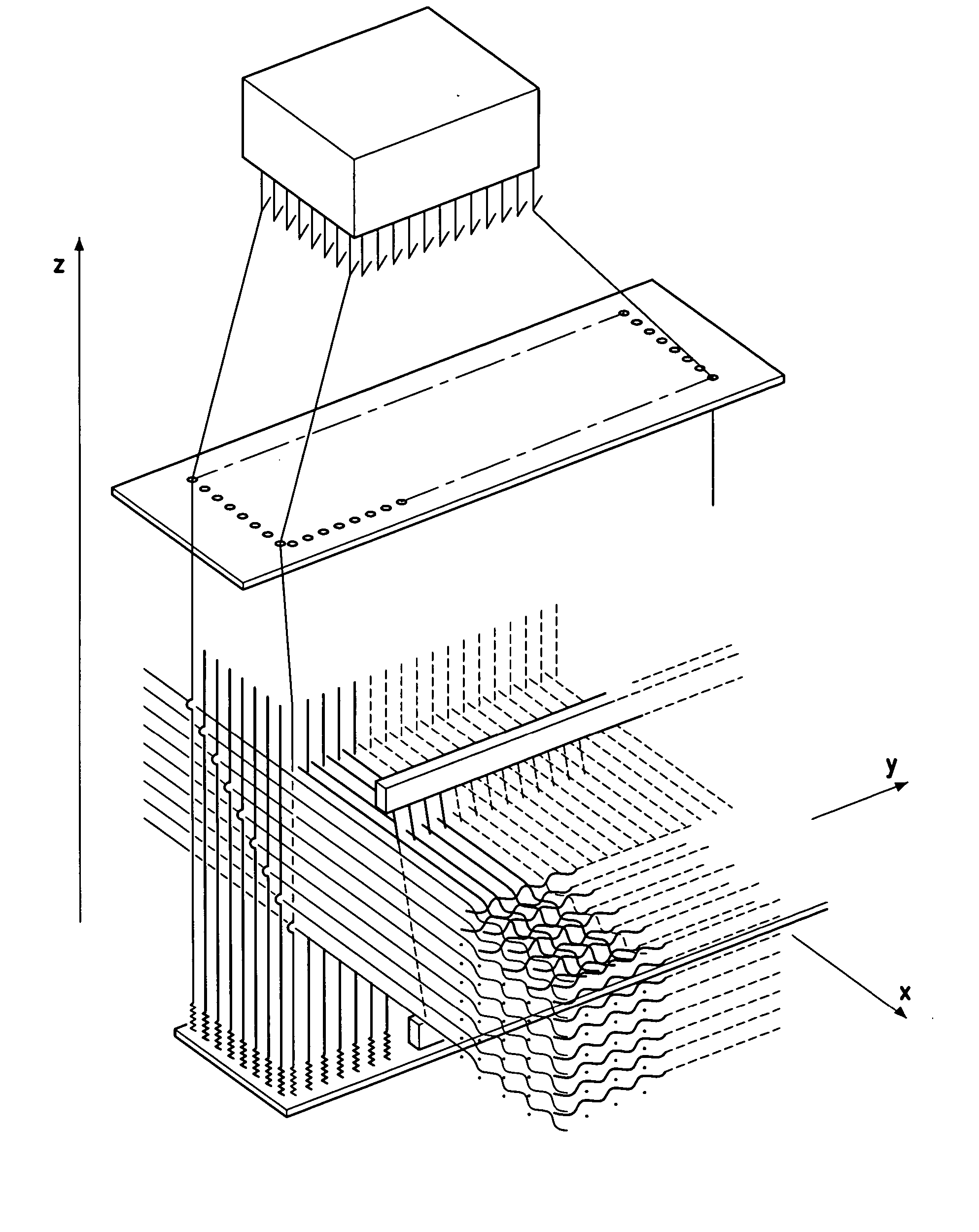

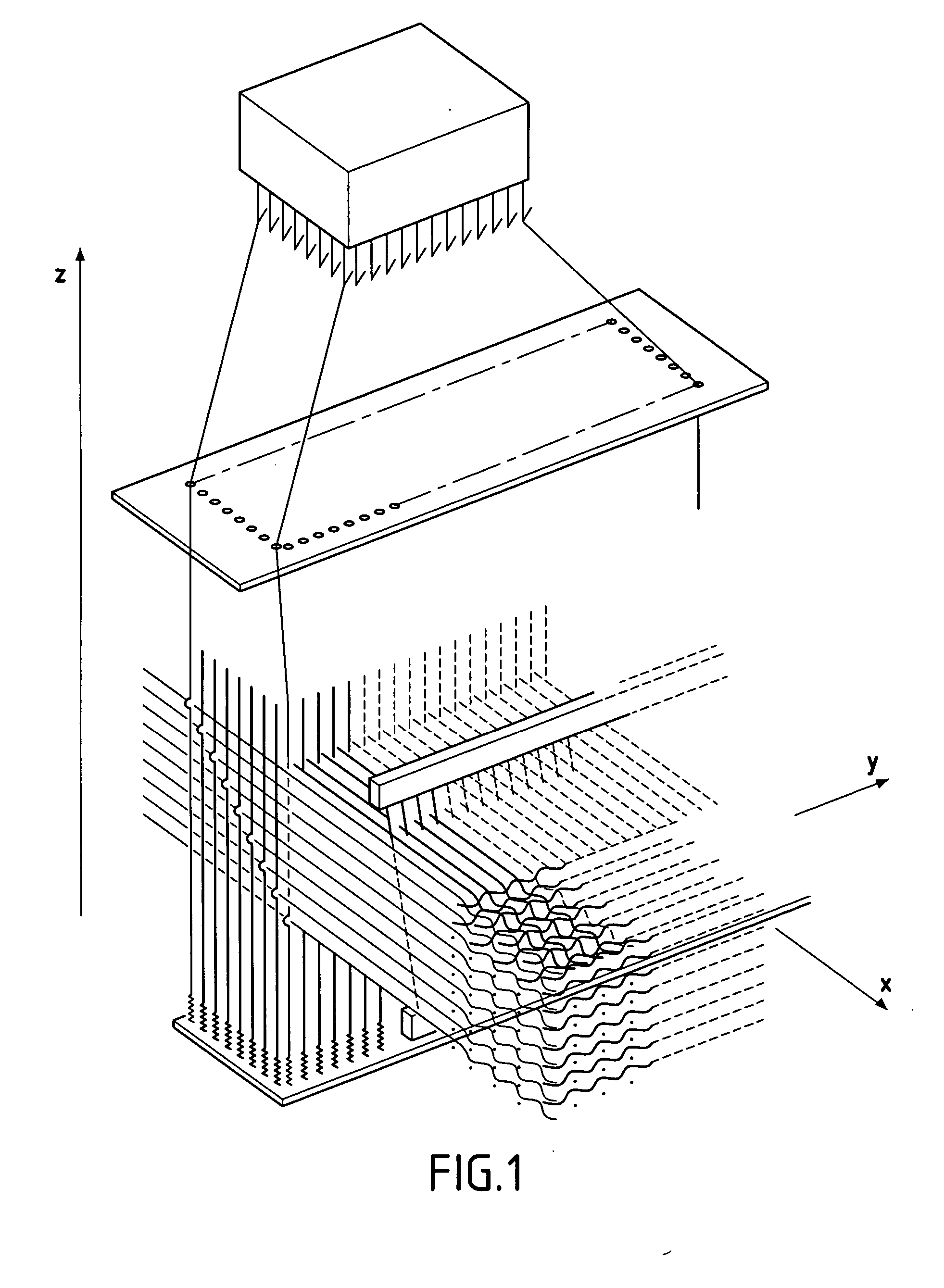

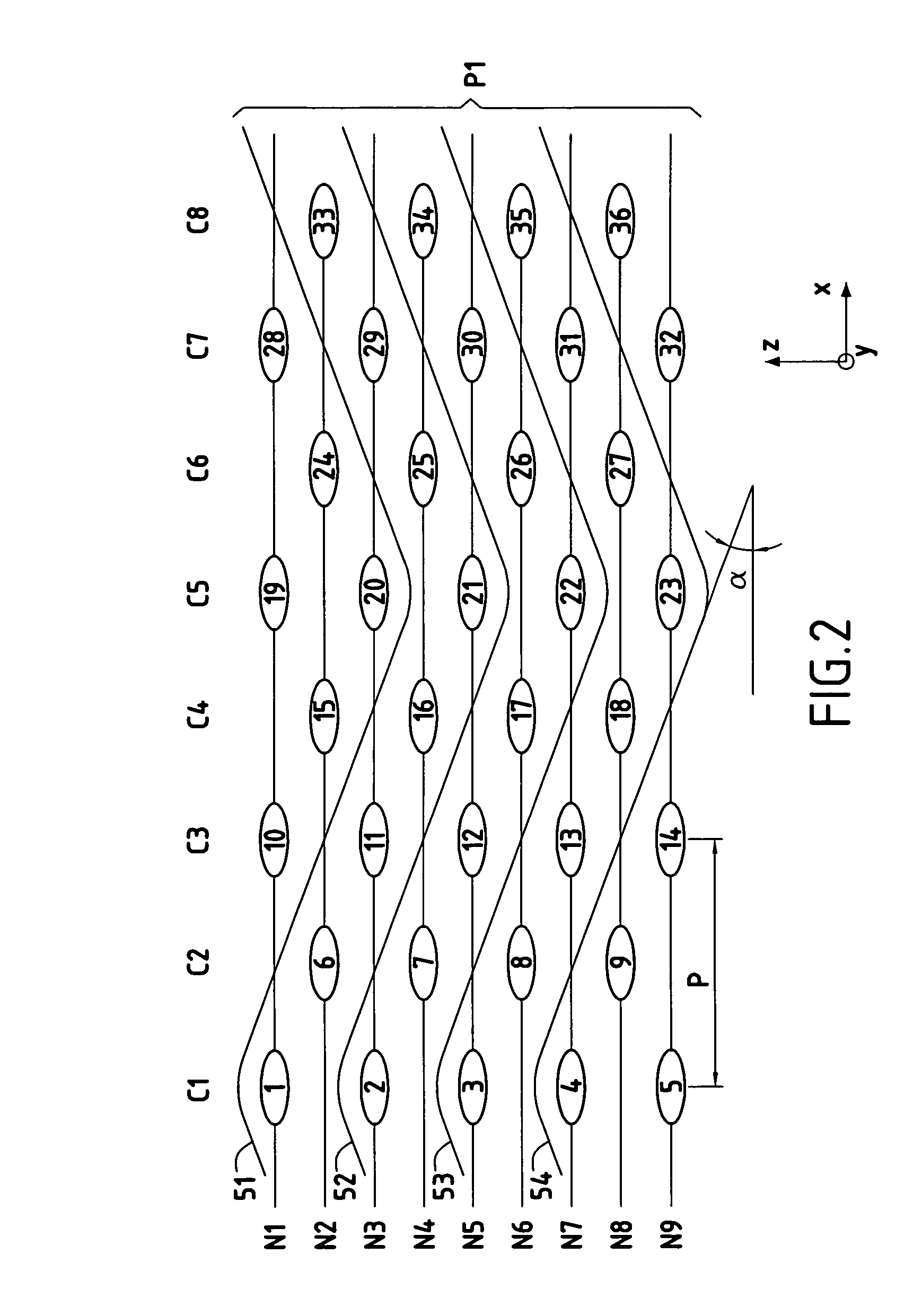

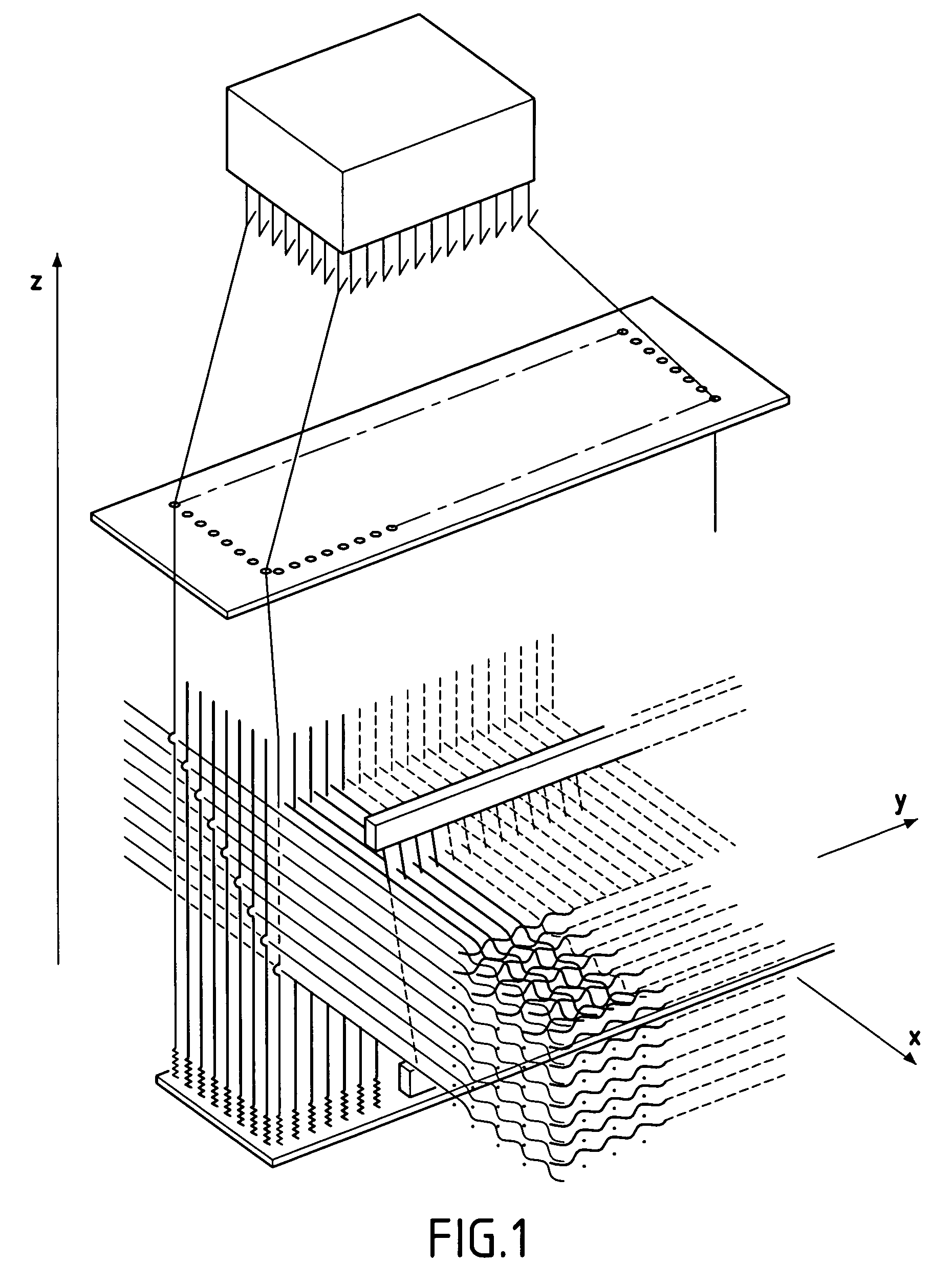

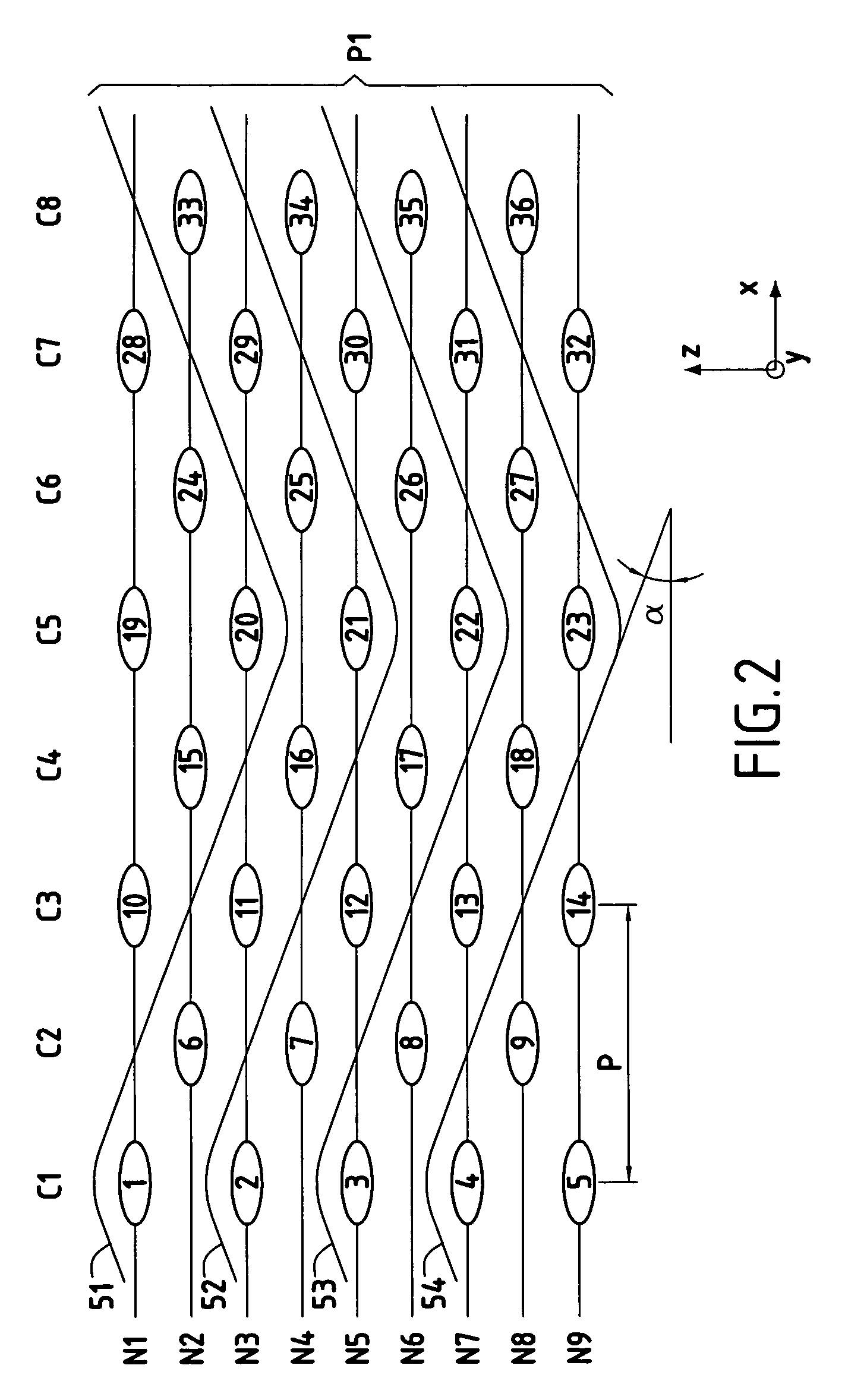

Turbomachine blade, in particular a fan blade, and its method of manufacture

The composite turbomachine blade of the present invention comprises a preform made of yarns or fibers woven in three dimensions and a binder maintaining the relative disposition between the yarns of the preform. Said preform is made up of warp yarns and of weft yarns, the direction of the warp yarns forming the longitudinal direction of the preform. In characteristic manner, said preform comprises at least a first portion made using a first weave forming the airfoil of the blade, and a second portion made using a second weave forming the root of the blade, and the first and second portions are united by a transition zone in which the first weave is progressively modified to end up with the second weave, thereby obtaining a reduction at least in the thickness of the blade between the second portion and the first portion. The invention is applicable to making a fan blade for a turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

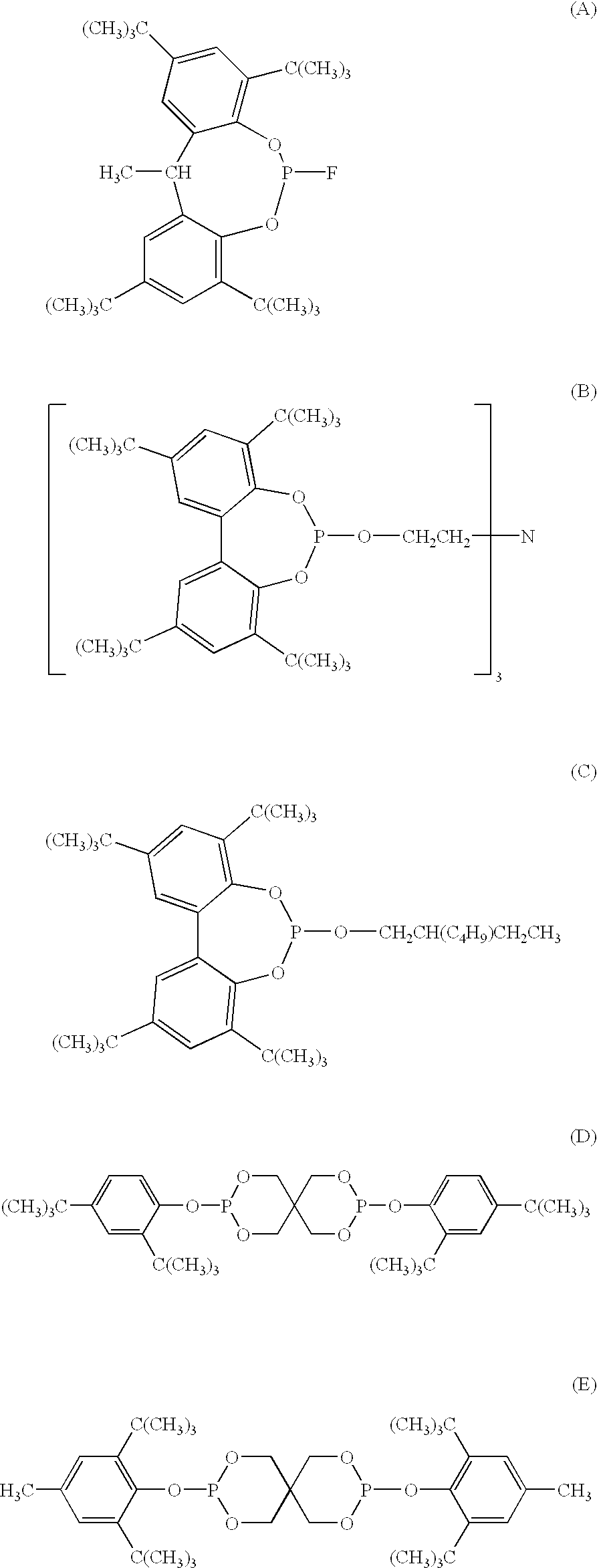

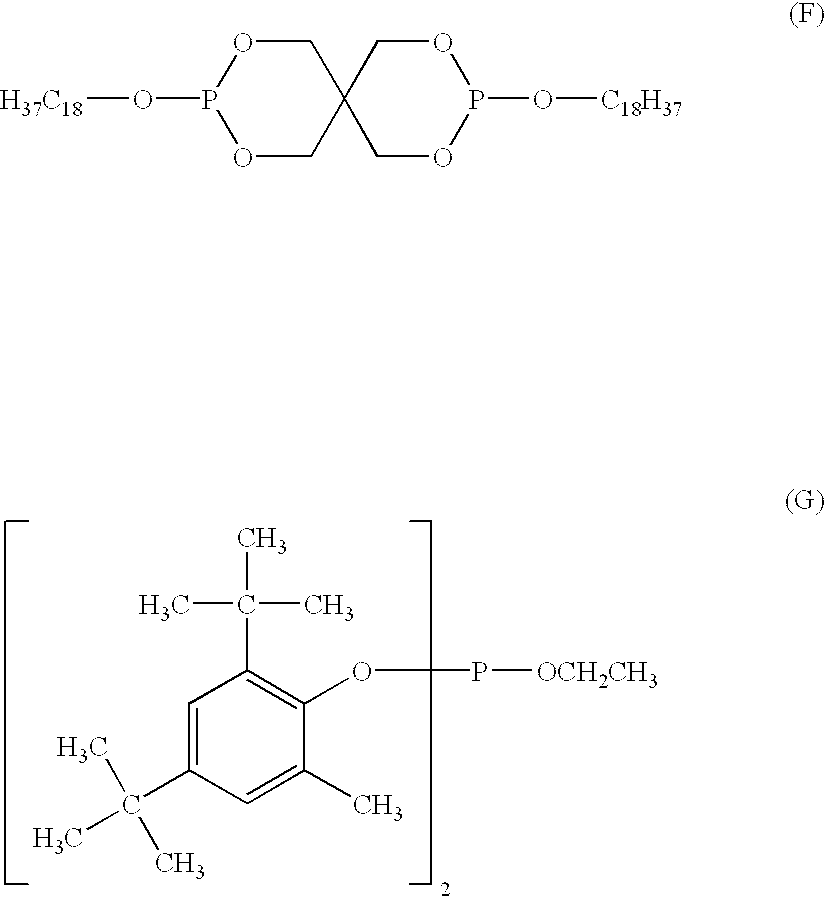

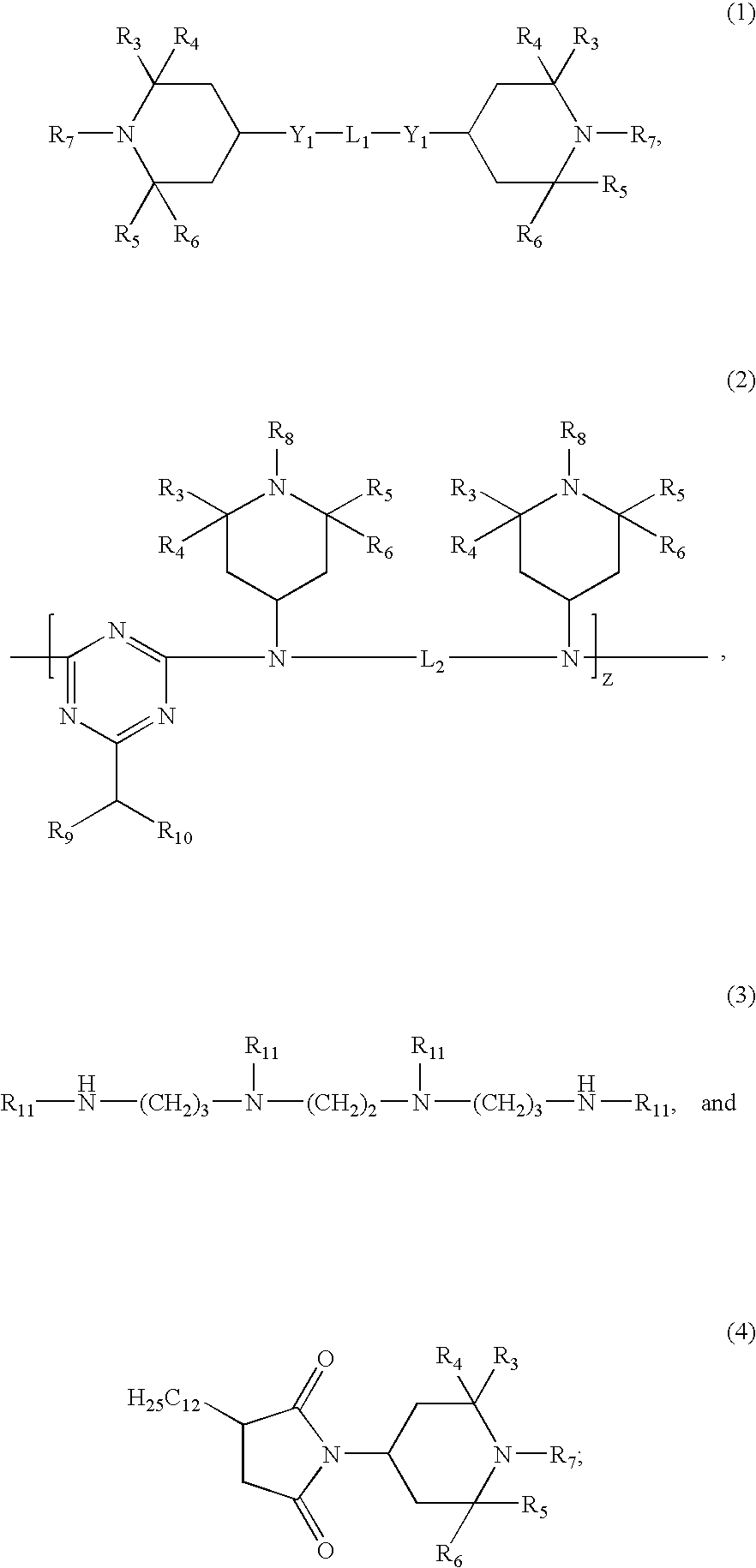

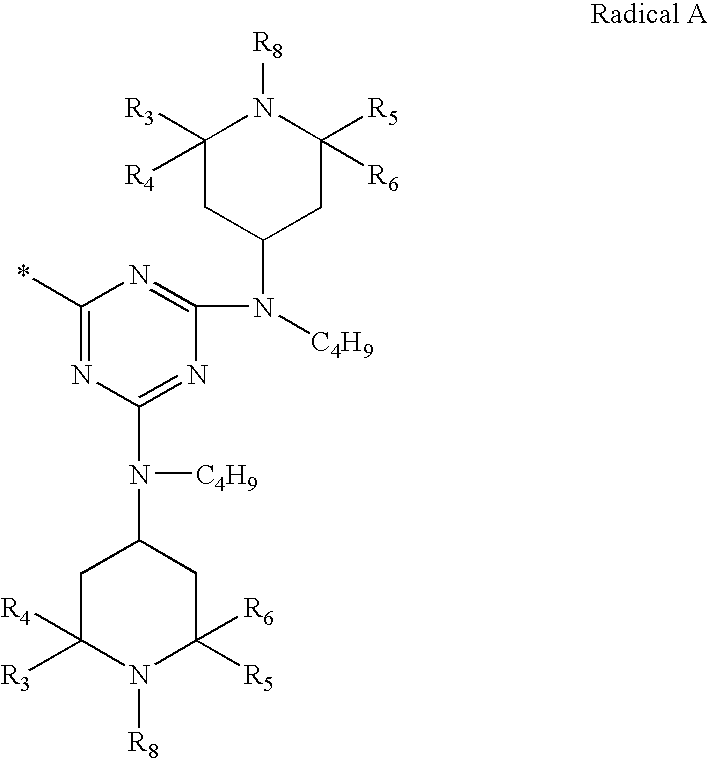

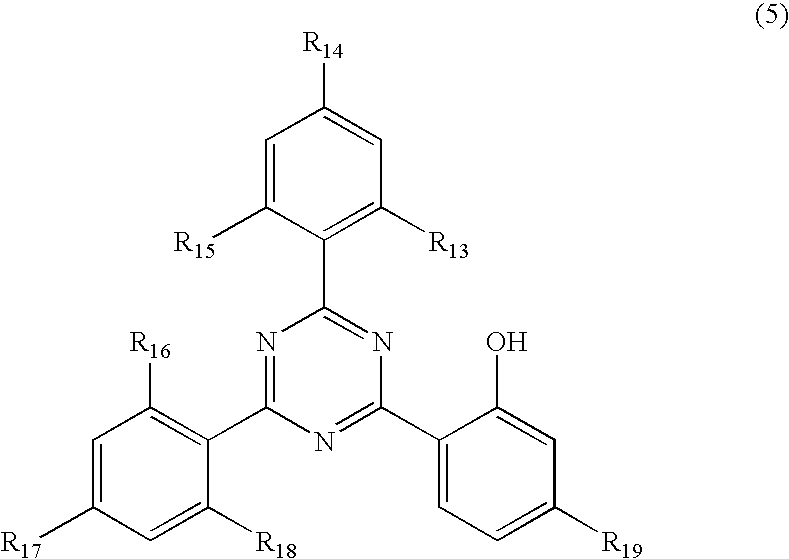

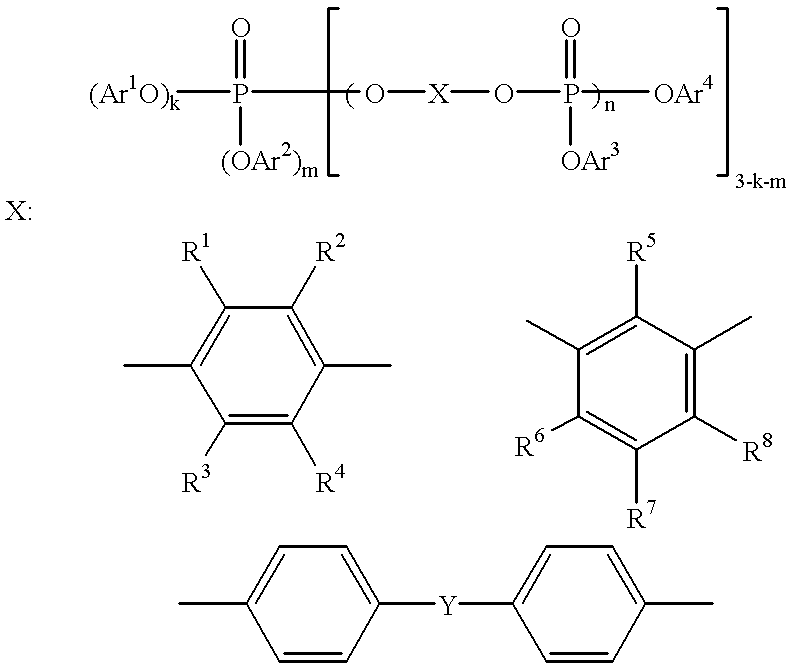

Stabilized aliphatic polyester compositions

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

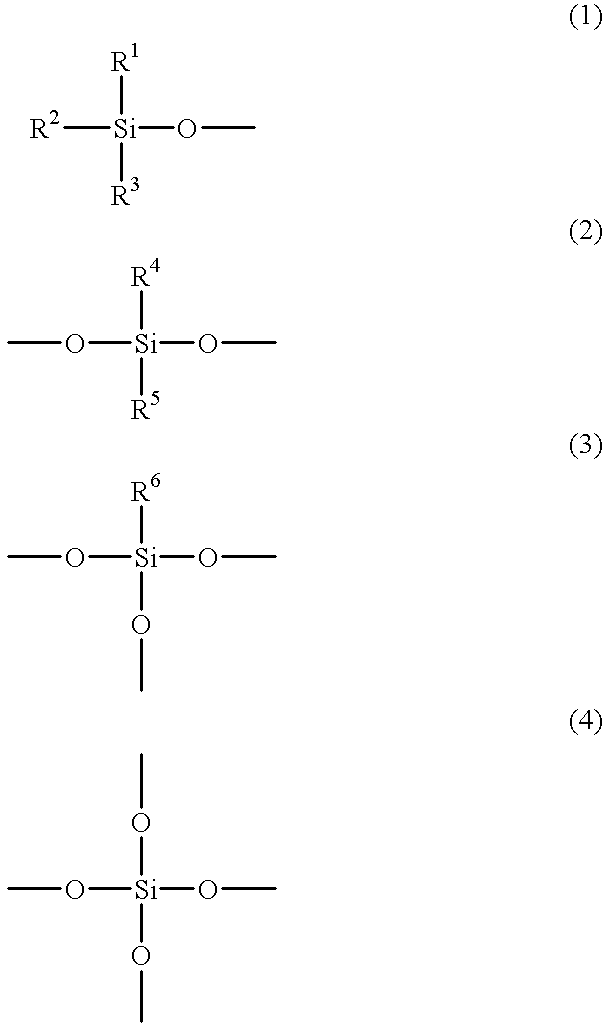

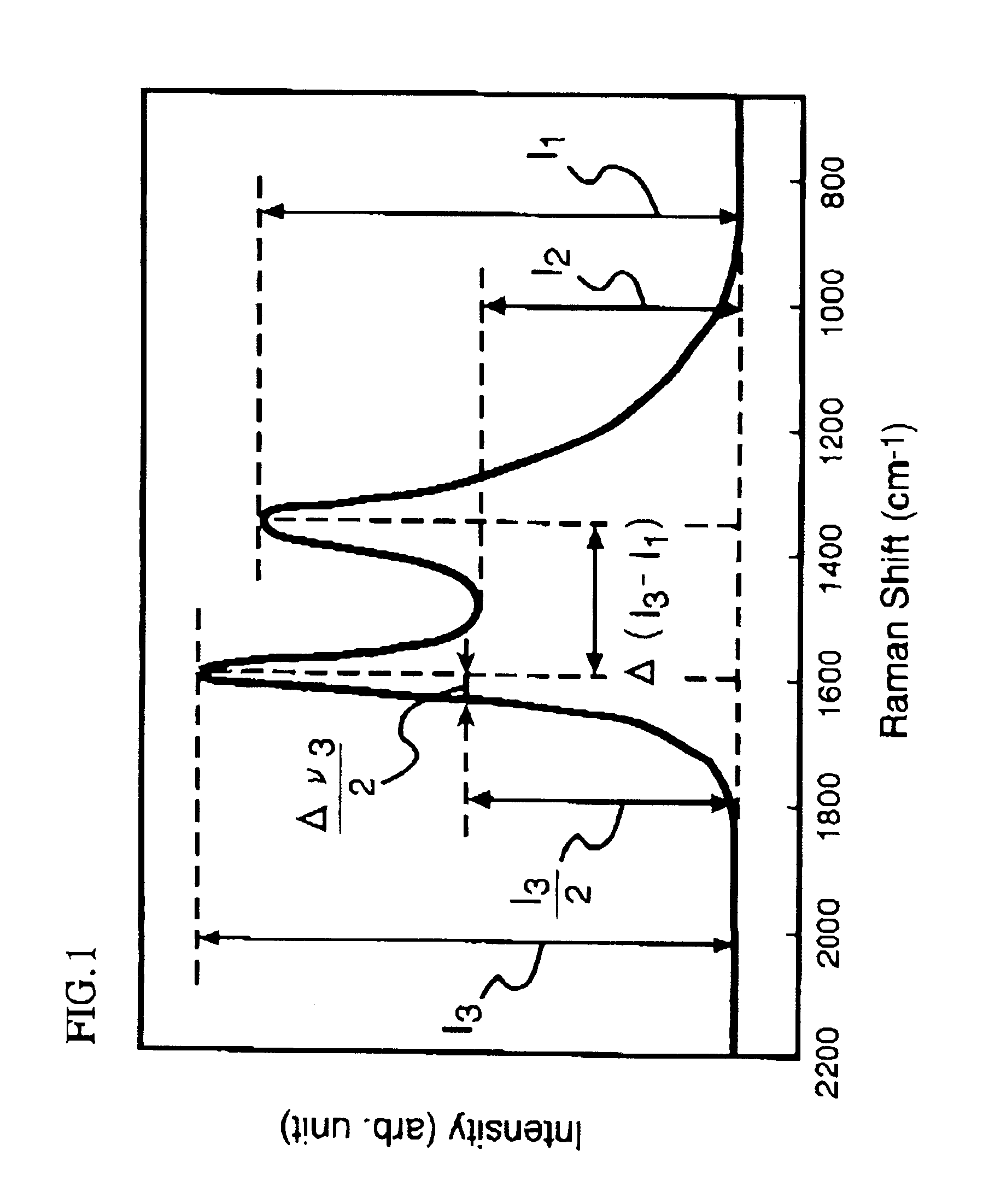

Thermoplastic resin composition, molding material, and molded article thereof

A thermoplastic resin composition capable of providing a thin walled molded article whose flame retardancy with a thickness of 1.6 mm ({fraction (1 / 16)} inch) in accordance with an UL 94 standard is V-0 or better, and which comprises the following components [A], [B] and [C], wherein the component [B] satisfies the following conditions (B1) and / or (B2):[A]: an electrically conductive fiber;[B]: a carbon powder;[C]: a thermoplastic resin;(B1): Raman scattering intensity ratio I2 / I1 is 0.55-0.8;(B2): Raman scattering intensity ratio I2 / I3 is 0.54-0.8; whereI1: local maximum value of Raman scattering intensity appearing near a Raman shift of 1360 cm-1;I2: local minimum value of the Raman scattering intensity appearing near a Raman shift of 1480 cm-1;I3: local maximum value of the Raman scattering intensity appearing neat a Raman shift of 1600 cm-1.

Owner:TORAY IND INC

Crystalline polypropylene resin composition and amide compounds

InactiveUS6235823B1Low melting pointLess force for deformation under heatingOrganic chemistryOrganic compound preparationPolypropylenePolymer chemistry

Disclosed are a crystalline polypropylene resin composition comprising a crystalline polyproplylene resin and a beta-nucleating agent, and a method of increasing the proportion of beta-form crystals in a crystalline polypropylene resin molding comprising molding the composition, the beta-nucleating agent being a diamide compound.

Owner:NEW JAPAN CHEM CO

Resin compositions with fluoropolymer filler combinations

InactiveUS20050143508A1Improve propertiesImprove mechanical propertiesSpecial tyresOrganic dyesDuctilityPolymer chemistry

A thermoplastic resin composition is disclosed which comprises a matrix polymer, and a combination of a fluoropolymer that can be at least partially encapsulated by an encapsulating polymer, and a filler. Methods for making the thermoplastic resin composition and articles made of such compositions are also disclosed. The composition and article can have improved tensile modulus, ductility and impact properties.

Owner:GENERAL ELECTRIC CO

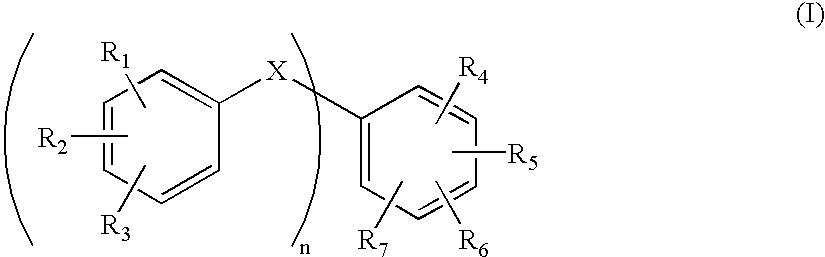

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS20070197374A1Good balanceSlow crack growthOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsChemistryMetal

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polypropylene-base resin composition and products of injection molding thereof

Owner:SUMITOMO CHEM CO LTD +1

Turbomachine blade, in particular a fan blade, and its method of manufacture

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Thermoplastic planks and methods for making the same

InactiveUS20050003160A1Improve moisture resistanceDamaged resistance propertyLamination ancillary operationsSynthetic resin layered productsEngineeringThermoplastic materials

A thermoplastic laminate plank is described wherein the thermoplastic laminate plank comprises a core, a print layer, and optionally an overlay. The core comprises at least one thermoplastic material and has a top surface and bottom surface wherein a print layer is affixed to the top surface of the core and an overlay layer is affixed to the top surface of the print layer. Optionally, an underlay layer can be located and affixed between the bottom surface of the print layer and the top surface of the core. In addition, a method of making the thermoplastic laminate plank is further described which involves extruding at least one thermoplastic material into the shape of the core and affixing a laminate on the core, wherein the laminate comprises an overlay affixed to the top surface of the print layer and optionally an underlay layer affixed to the bottom surface of the print layer.

Owner:VÄLINGE INNOVATION AB

Composite polypropylene material and its preparing method

The composite polypropylene material is prepared with polypropylene 10-100 weight portions, polyethylene 1-50 weight portions, inorganic rigid grain 1-50 weight portions, toughener 1-50 weight portions, coupling agent 0.01-10 weight portions and grafting compatilizer 1-50 weight portions. The composite polypropylene material has high rigidity, high impact strength and balanced rigidity and toughness, and compared with common automobile bumper material, it has 15-30 % higher bending modulus.

Owner:吴永刚

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS20070043176A1Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

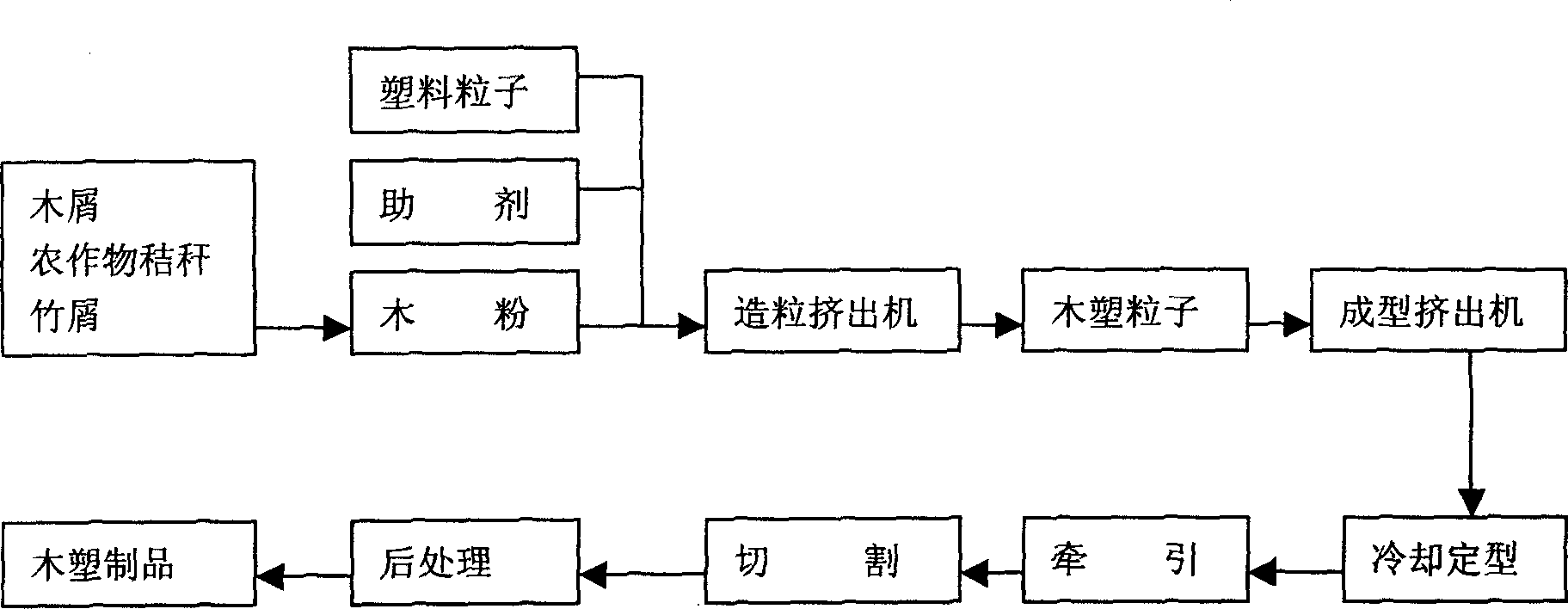

Making process of compound wood-plastic material product

The present invention discloses the making process of compound wood-plastic material product. Un-dried wood powder, plastic grain, compatibilizing agent, coupler, antioxidant, reinforcer, color powder and lubricant in certain proportion are fed to a pelletizing extruder for form granular material; and the granular material is extruded in a forming extruder and further processed through cooling to settle, drawing, cutting and decorating to produce the wood-plastic product. The present invention has the advantages of simple process, high production effect and rich material resource, and the product has timber-like texture, excellent performance and environment friendship.

Owner:浙江诚信包装有限公司

MBS impact modifiers

A process and composition for MBS modifiers having (A) a rubbery core, (B) an inner graft stage comprised mainly of a hard polymer, (C) an intermediate sealer stage comprised mainly of an alkyl acrylate monomer and / or a polyunsaturated crosslinker, and (D) an outer shell to provide compatibility of the core-shell polymer with the matrix polymer, is disclosed. A process for preparing MBS impact modifiers having suprisingly improved impact performance in matrix polymers is also disclosed. Articles prepared from blends of matrix polymers and the MBS core-shell polymers described herein are also disclosed.

Owner:ROHM & HAAS CO

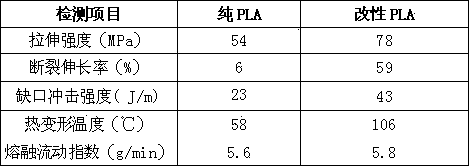

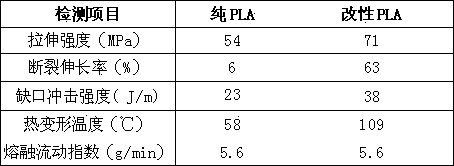

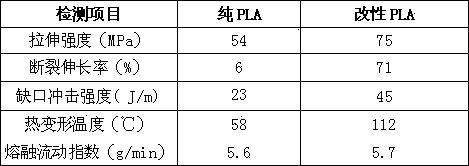

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

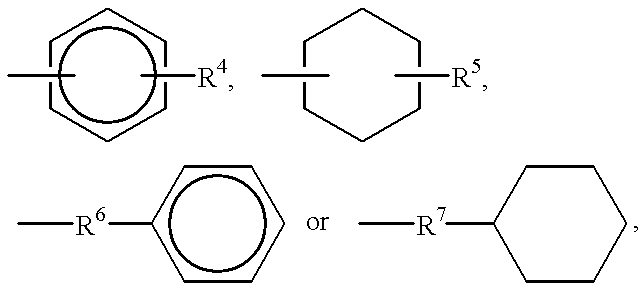

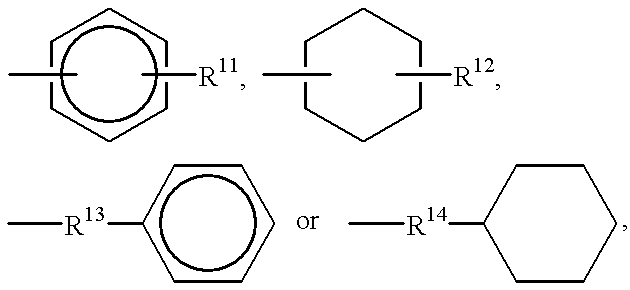

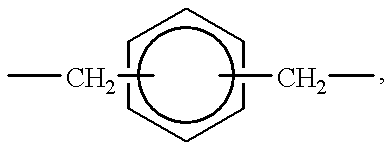

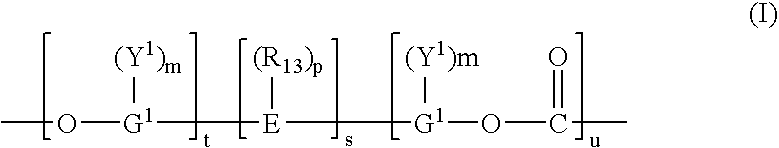

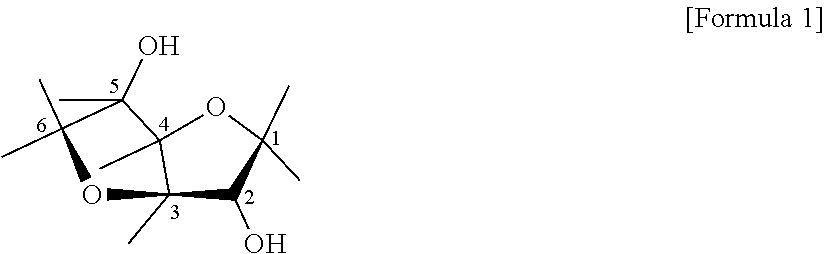

Polyester resin and method for preparing the same

InactiveUS20120177854A1Superior heat-resistanceHigh impact strengthBio-packagingSynthetic resin layered productsCyclohexanedimethanolDiol

A polyester resin copolymerized with isosorbide and 1,4-cyclohexane dimethanol and having an improved impact strength, and a method for preparing the same are disclosed. The copolymerized polyester resin has an alternating structure of acid moieties which are derived from acid components and diol moieties which are derived from diol components, wherein the acid components comprise terephthalic acid, and the diol components comprise (i) 5˜99 mol % of 1,4-cyclohexanedimethanol and (ii) 1˜60 mol % of isosorbide with respect to the total diol components.

Owner:SK CHEM CO LTD

Polymer blends with improved notched impact strength

ActiveUS7160977B2Well formedHigh impact strengthSynthetic resin layered productsCeramic shaping apparatusPolymer scienceUltimate tensile strength

This invention relates to a blend of biodegradable polymers comprising:(A) about 70% to about 80% by weight of at least one flexible biodegradable polymer (A) having a glass transition less than about 0° C.,(B) about 30% to about 20% by weight of at least one rigid biodegradable polymer (B) having a glass transition greater than about 10° C.;said percentages being based on the total weight of the polymer blend;wherein said polymer blend has a notched Izod impact strength according to ASTM D256 of at least 7.5 ft-lbs / in.

Owner:NOVAMONT SPA

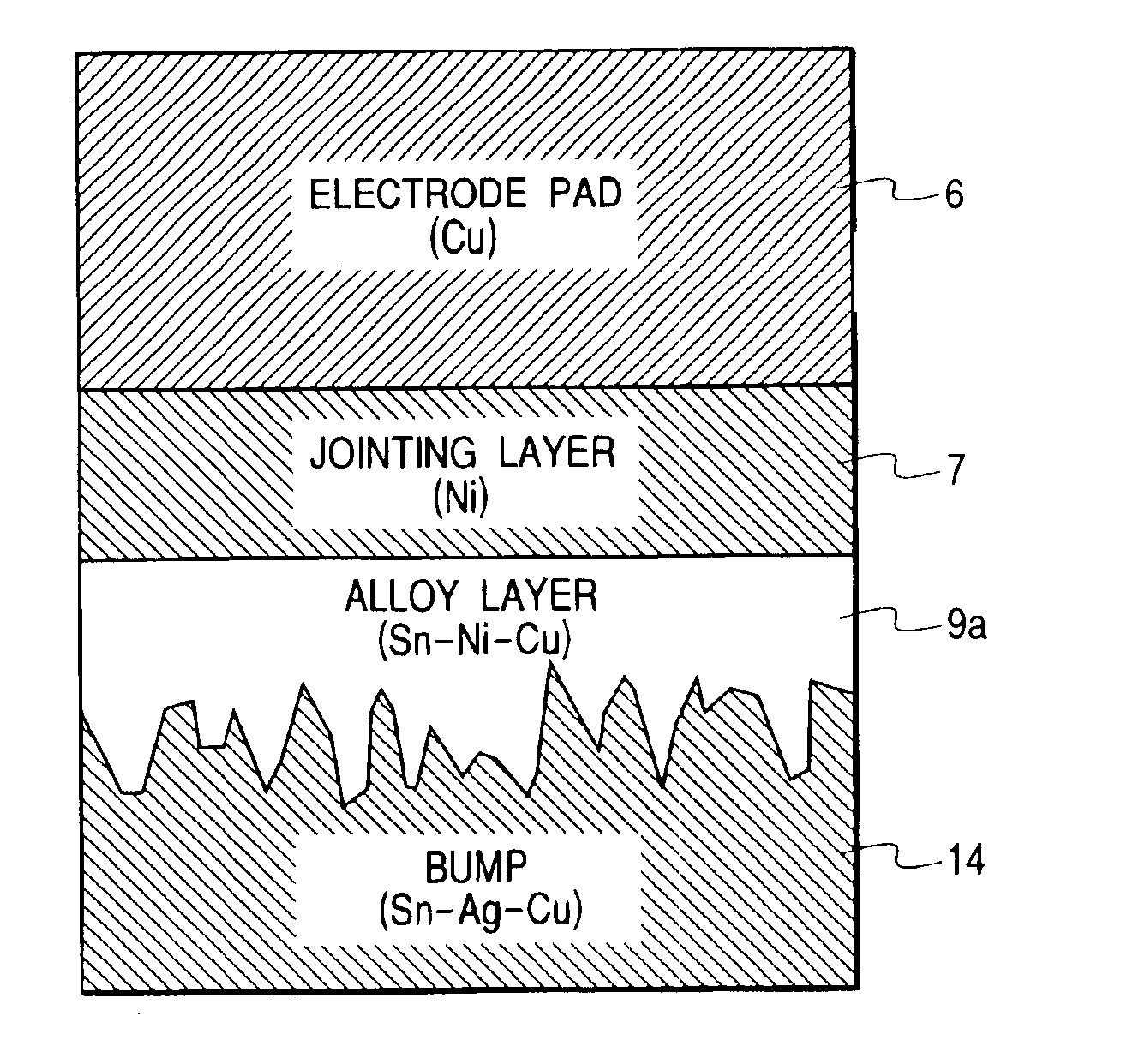

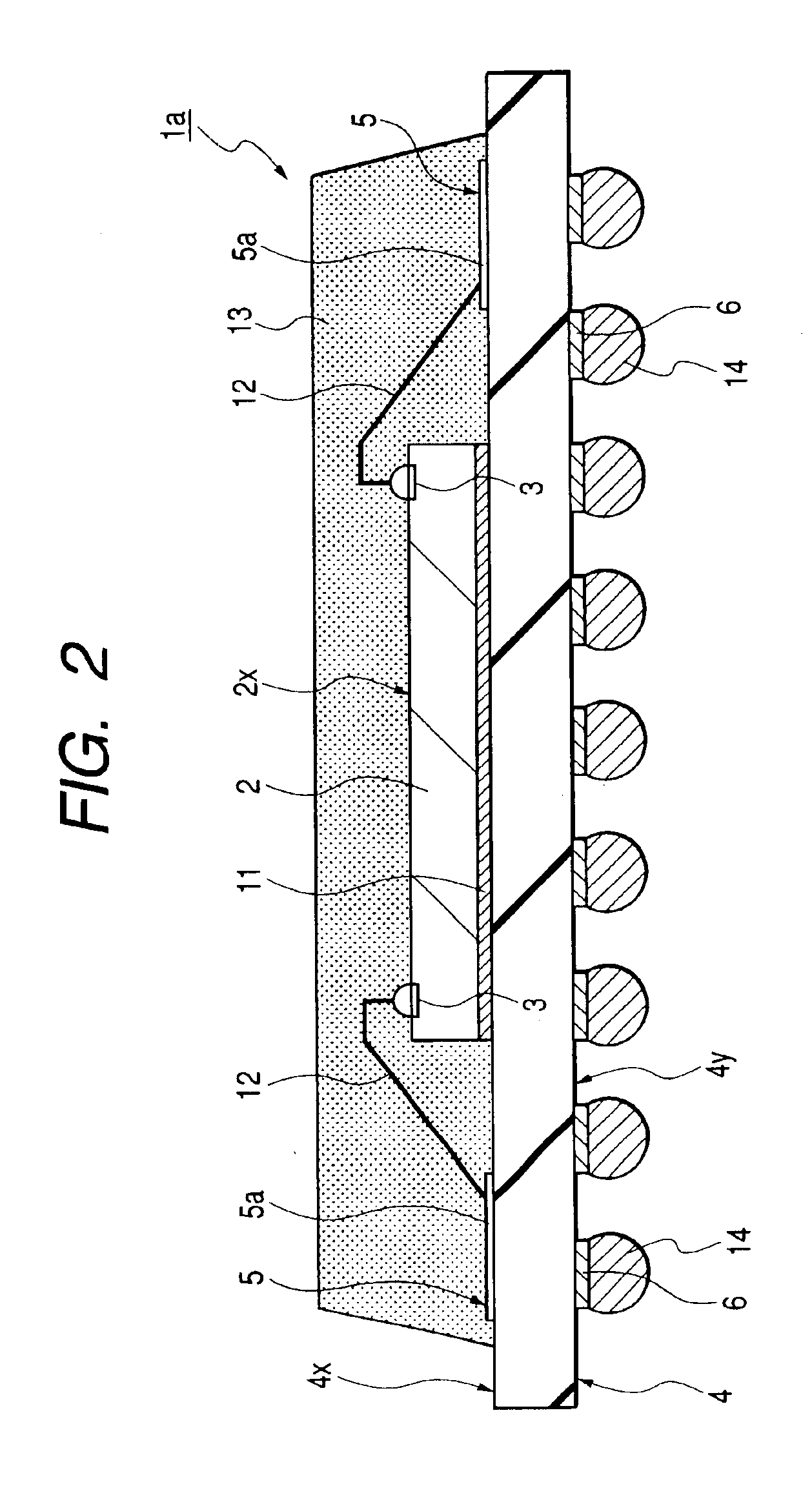

Semiconductor device with joint structure having lead-free solder layer over nickel layer

InactiveUS6879041B2Low melting pointImpact resistancePrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialSulfur

The impact strength resistance of a solder joint portion of a semiconductor device is improved. The semiconductor device has a joint structure wherein a jointing layer which does not contain sulfur substantially is arranged between an underlying conductive layer and a lead-free solder layer and further between the jointing layer and the lead-free solder layer is formed an alloy layer comprising elements of these layers.

Owner:RENESAS ELECTRONICS CORP

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

Weatherable multilayer articles and method for their preparation

InactiveUS20040253428A1Avoid insufficient thicknessRelieve stressSynthetic resin layered productsThin material handlingPolyesterPolymer science

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyester with structural units derived from at least one glycol and at least one dibasic carboxylic acid, and (iv) a substrate layer, wherein the coating layer is in contiguous contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Production of meta-block copolymers by polymer segment interchange

Meta-block copolymers and a process for preparing a product mixture comprising meta-block copolymers by contacting a metathesis catalyst under metathesis conditions with a composition comprising two or more ethylenically unsaturated polymers, said unsaturation defining one or more polymer segments in each ethylenically unsaturated polymer, at least one polymer segment in at least one ethylenically unsaturated polymer being chemically distinguishable from at least one polymer segment in at least one other ethylenically unsaturated polymer, characterized in that each meta-block copolymer in the product mixture comprises a random distribution of said chemically distinguishable polymer blocks.

Owner:DOW GLOBAL TECH LLC +1

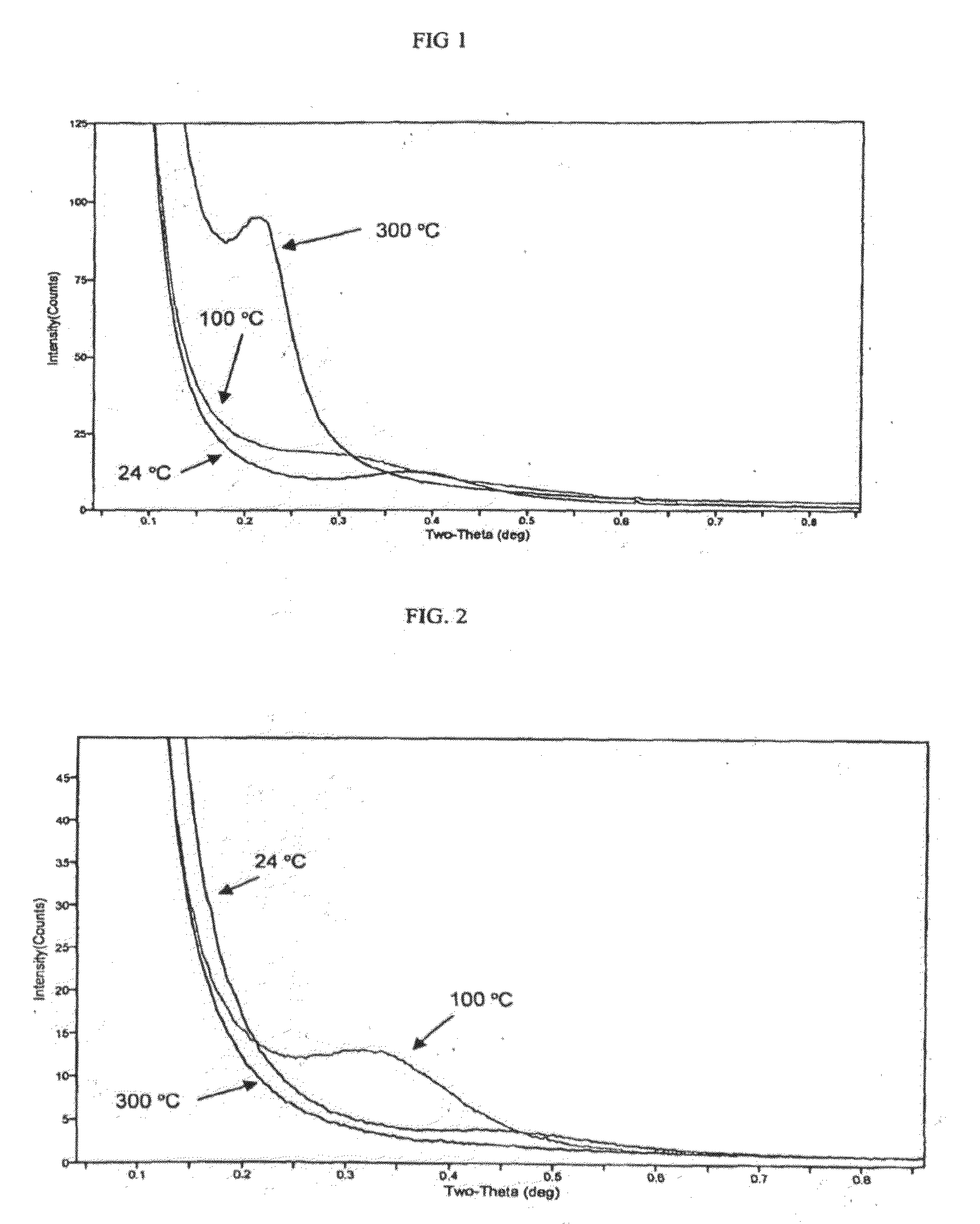

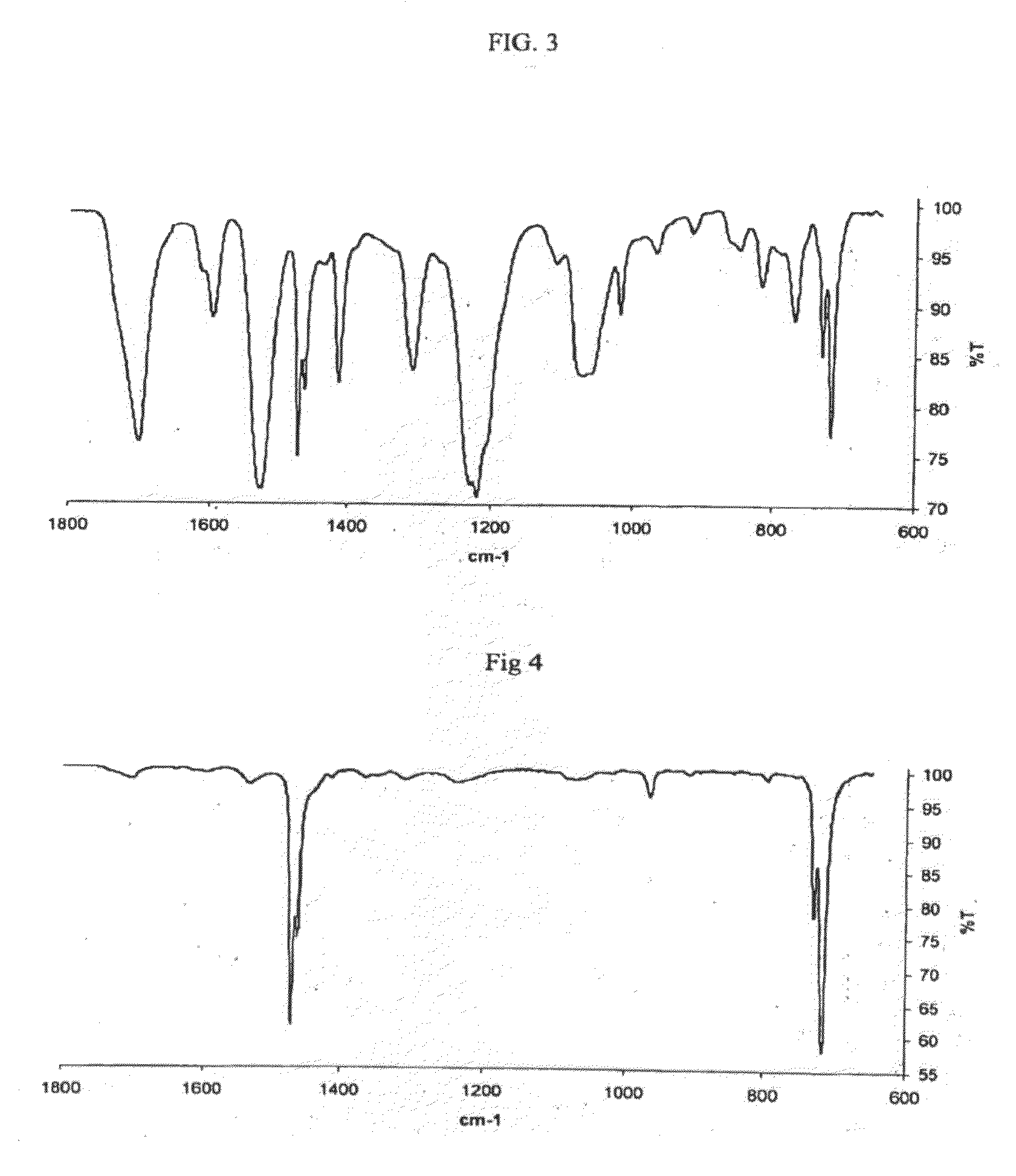

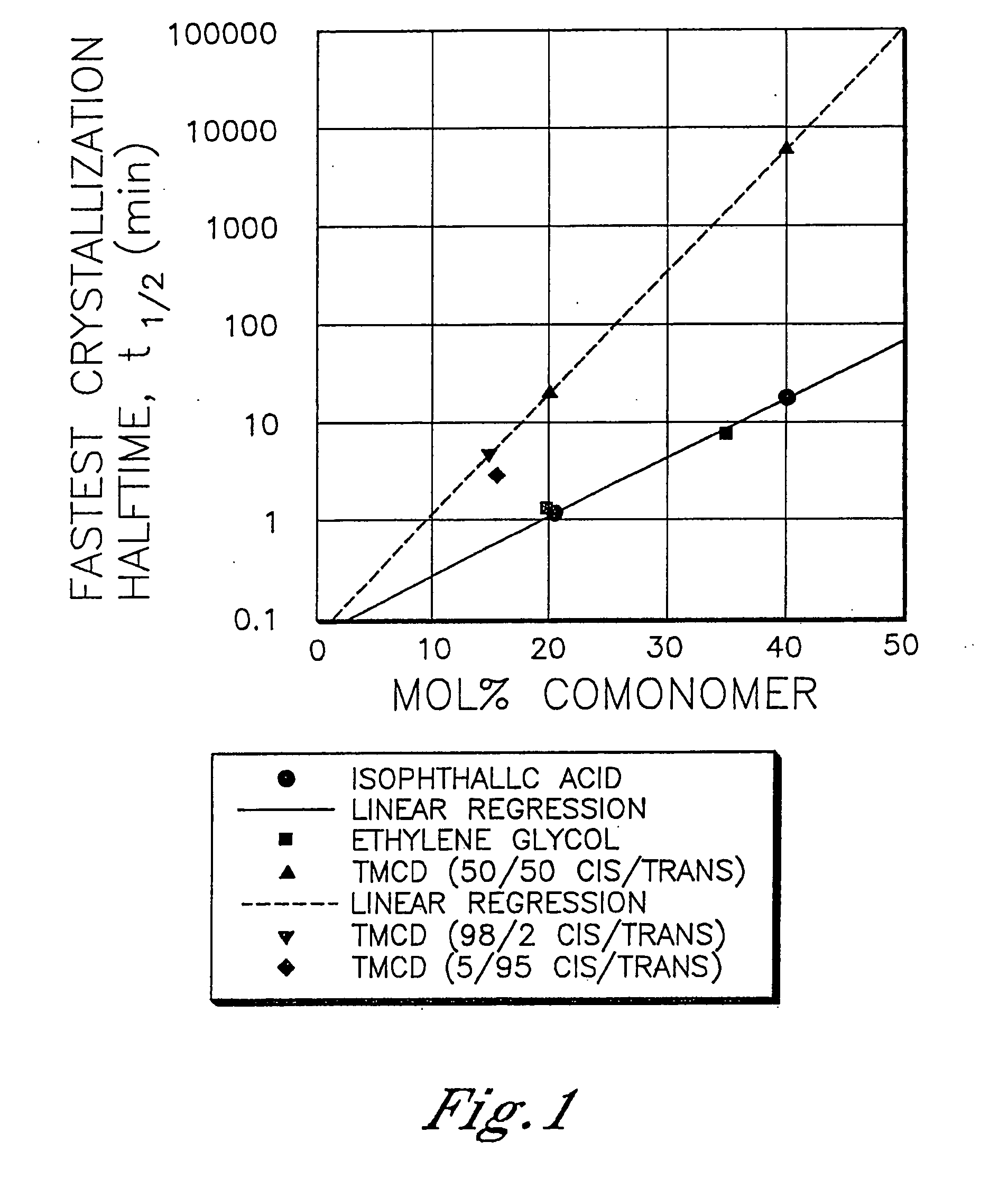

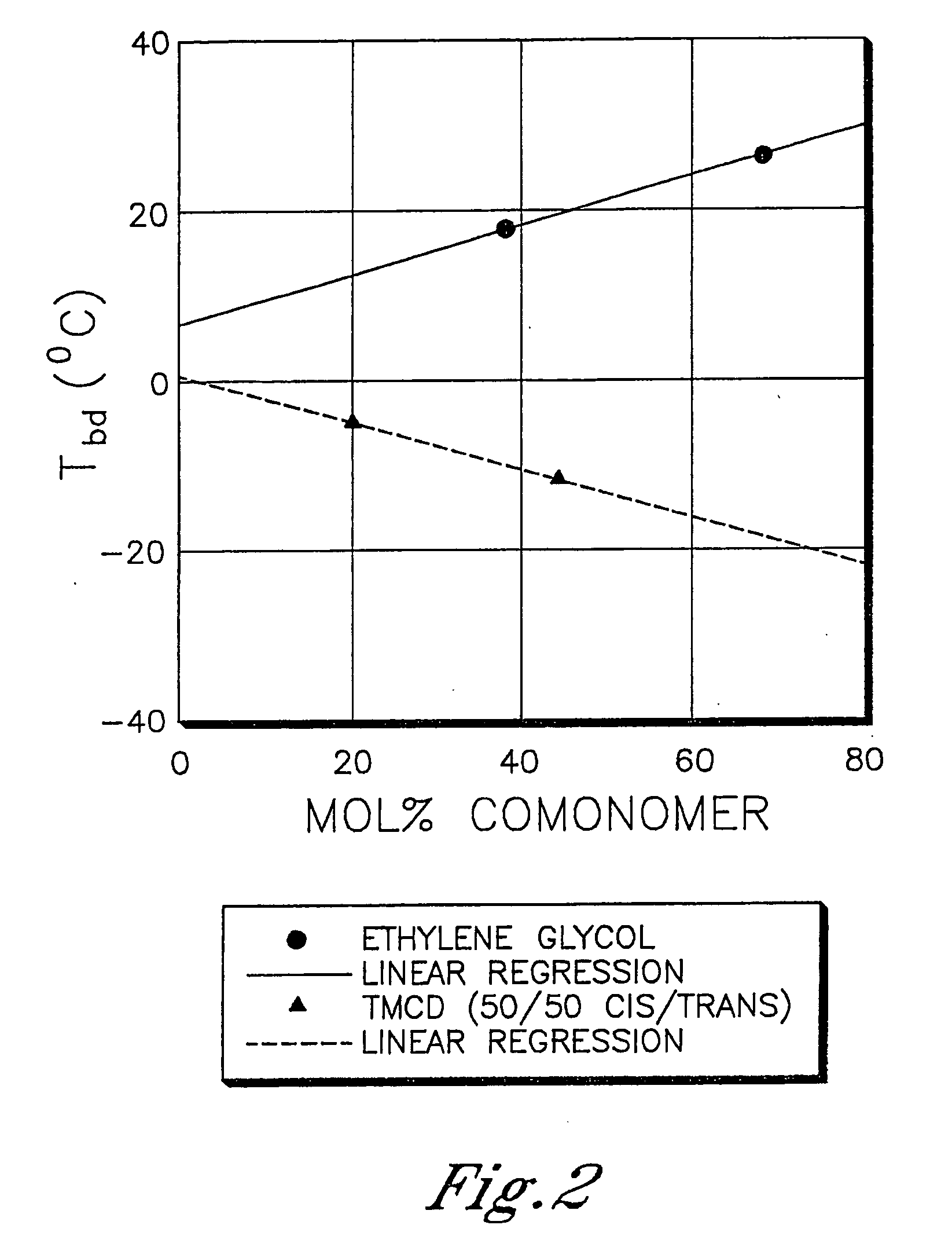

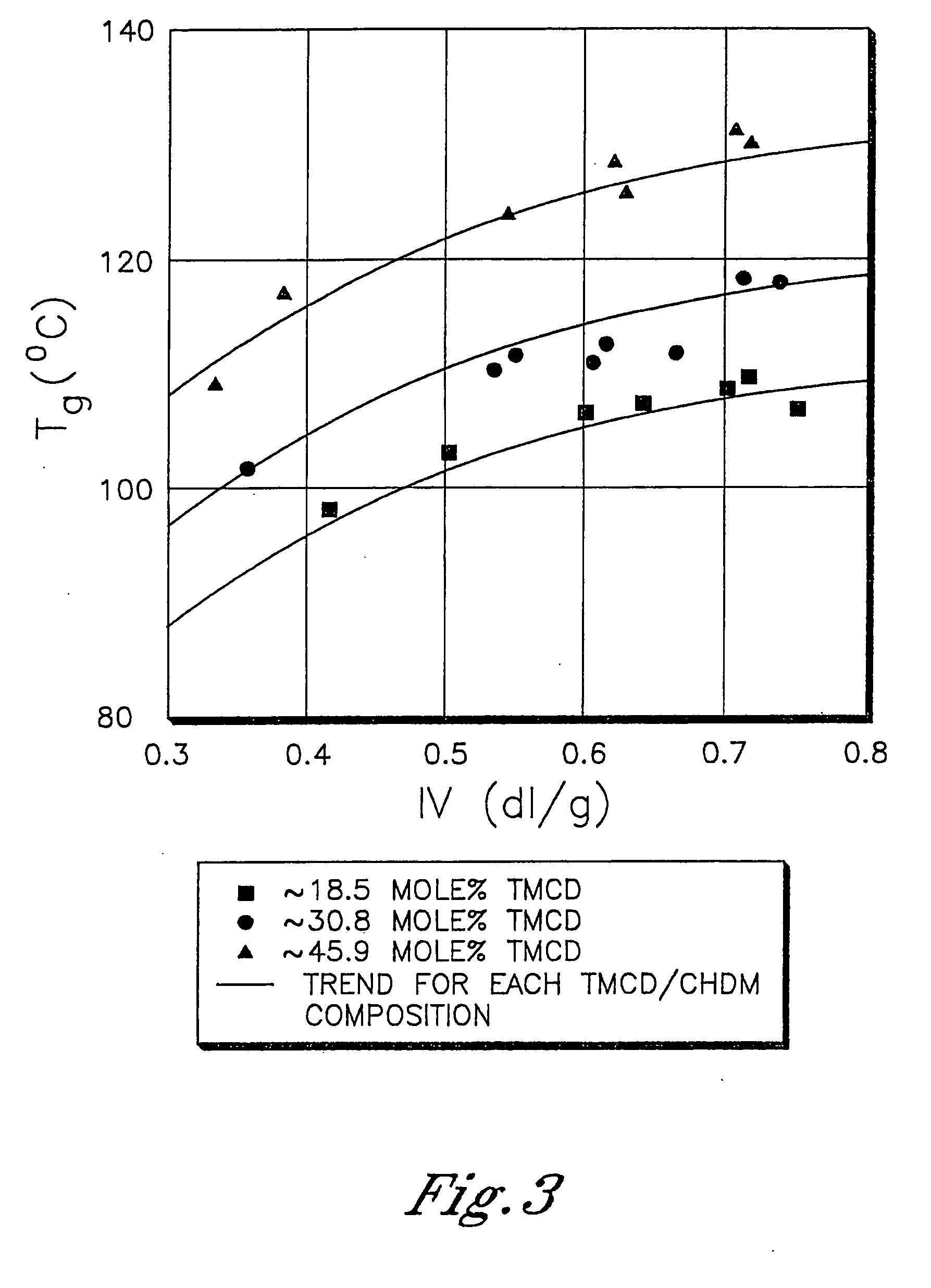

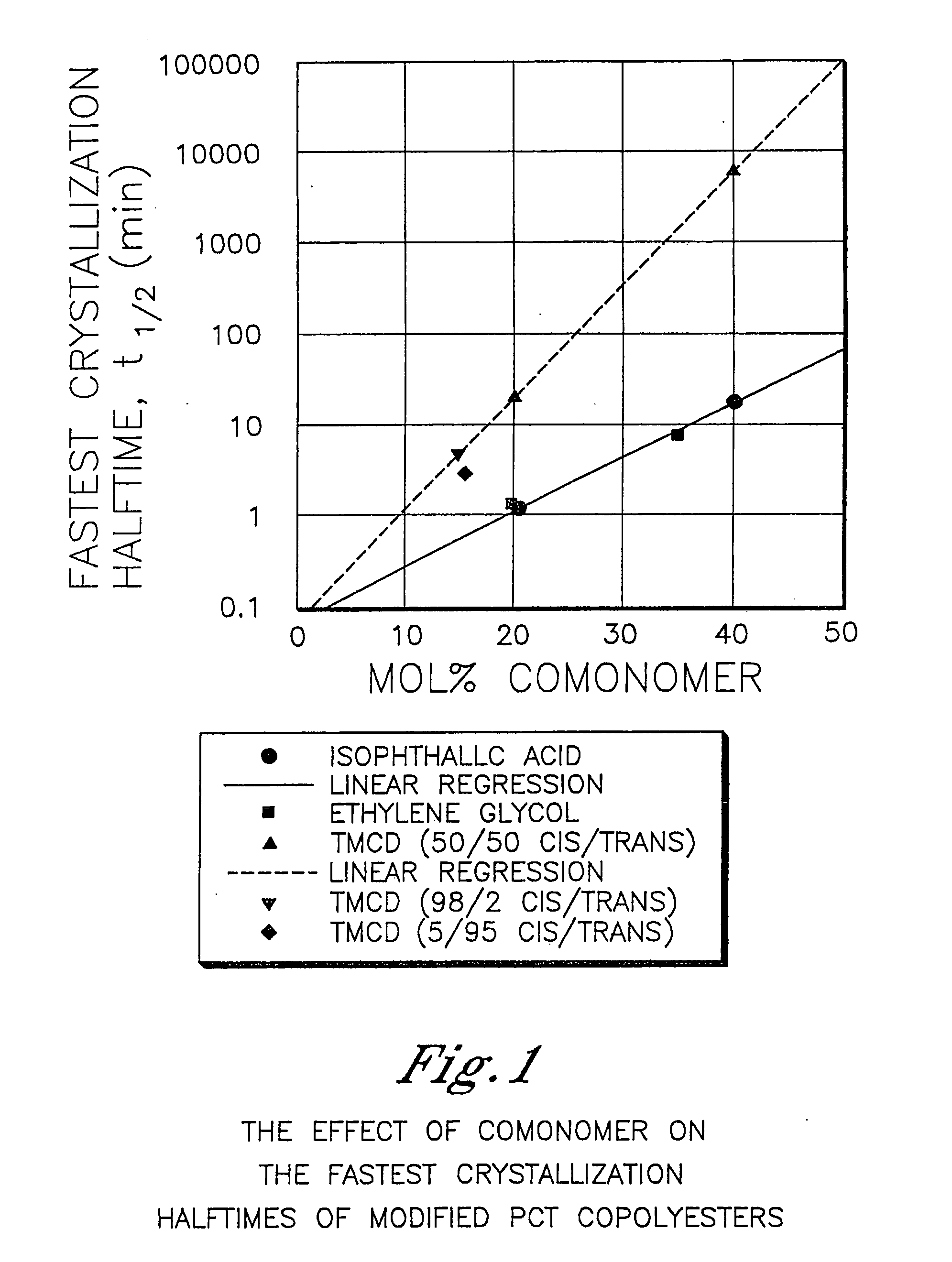

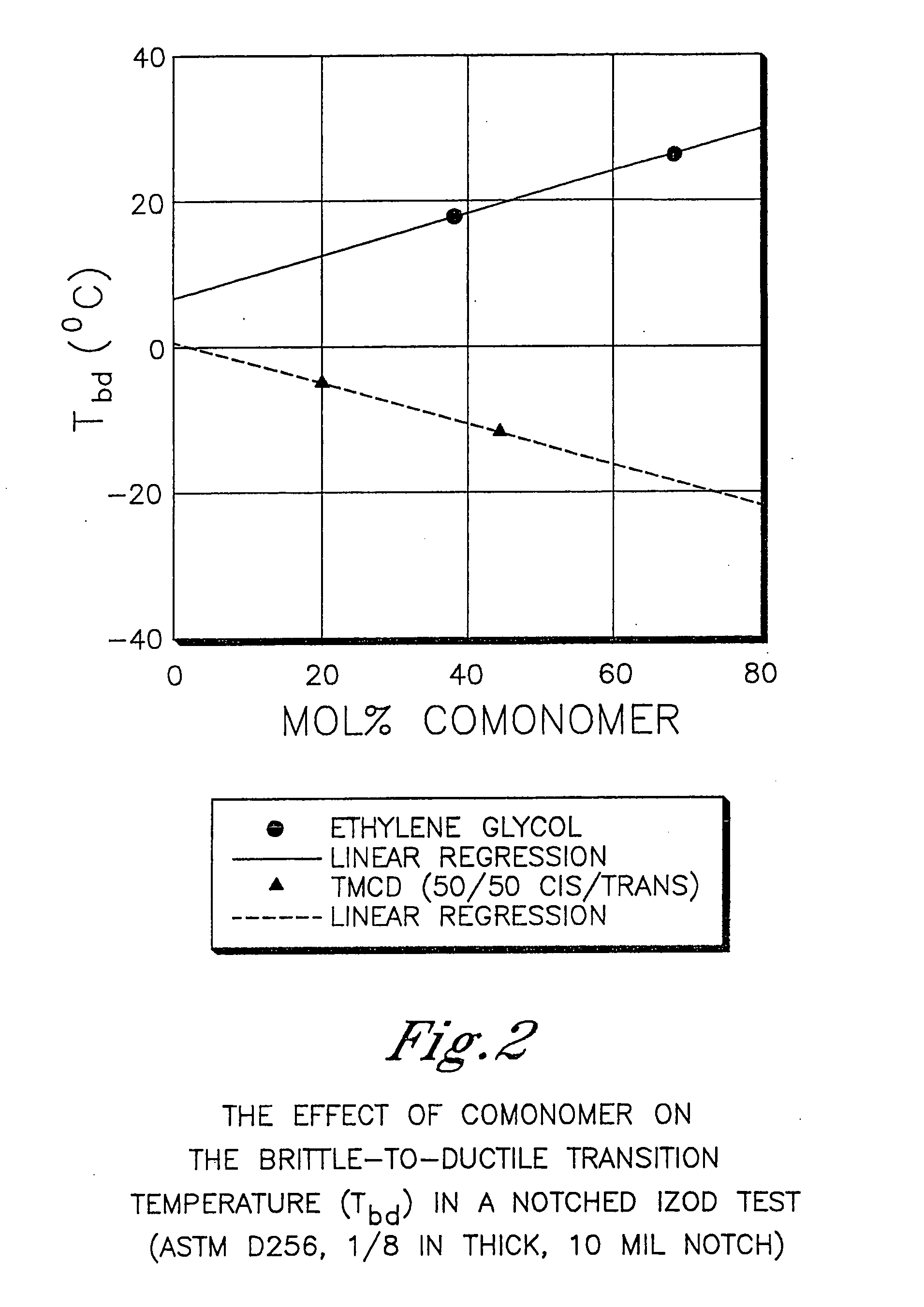

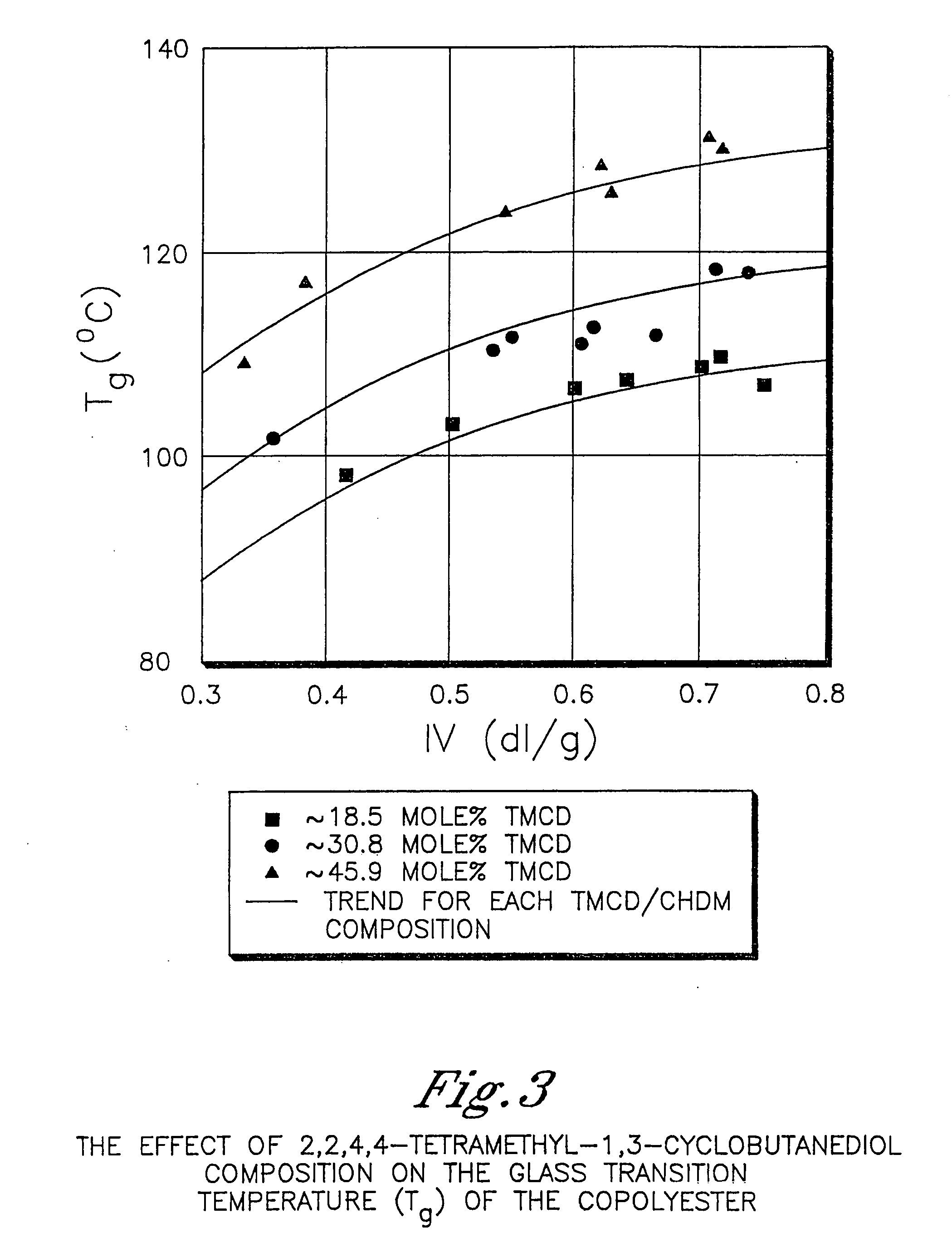

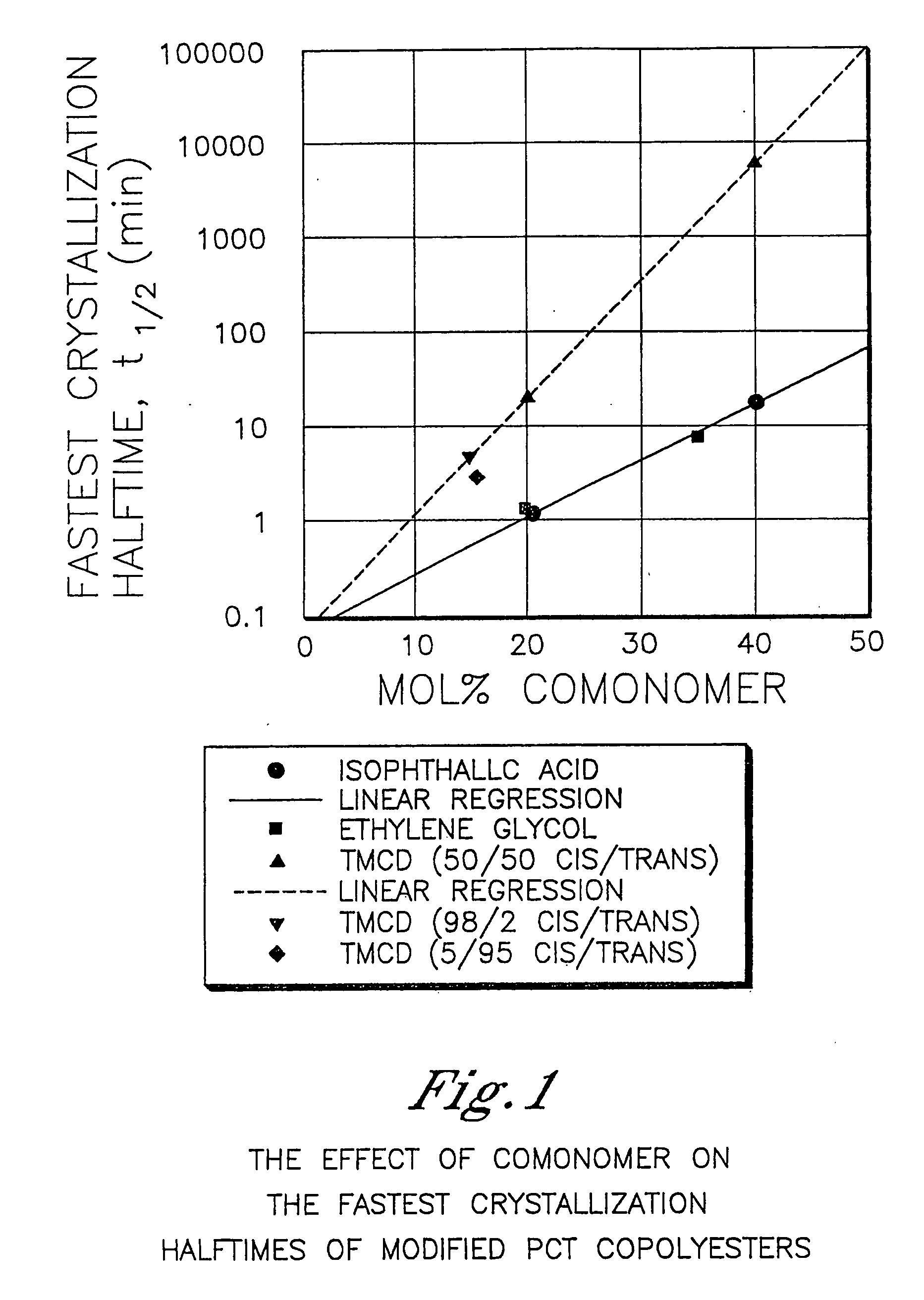

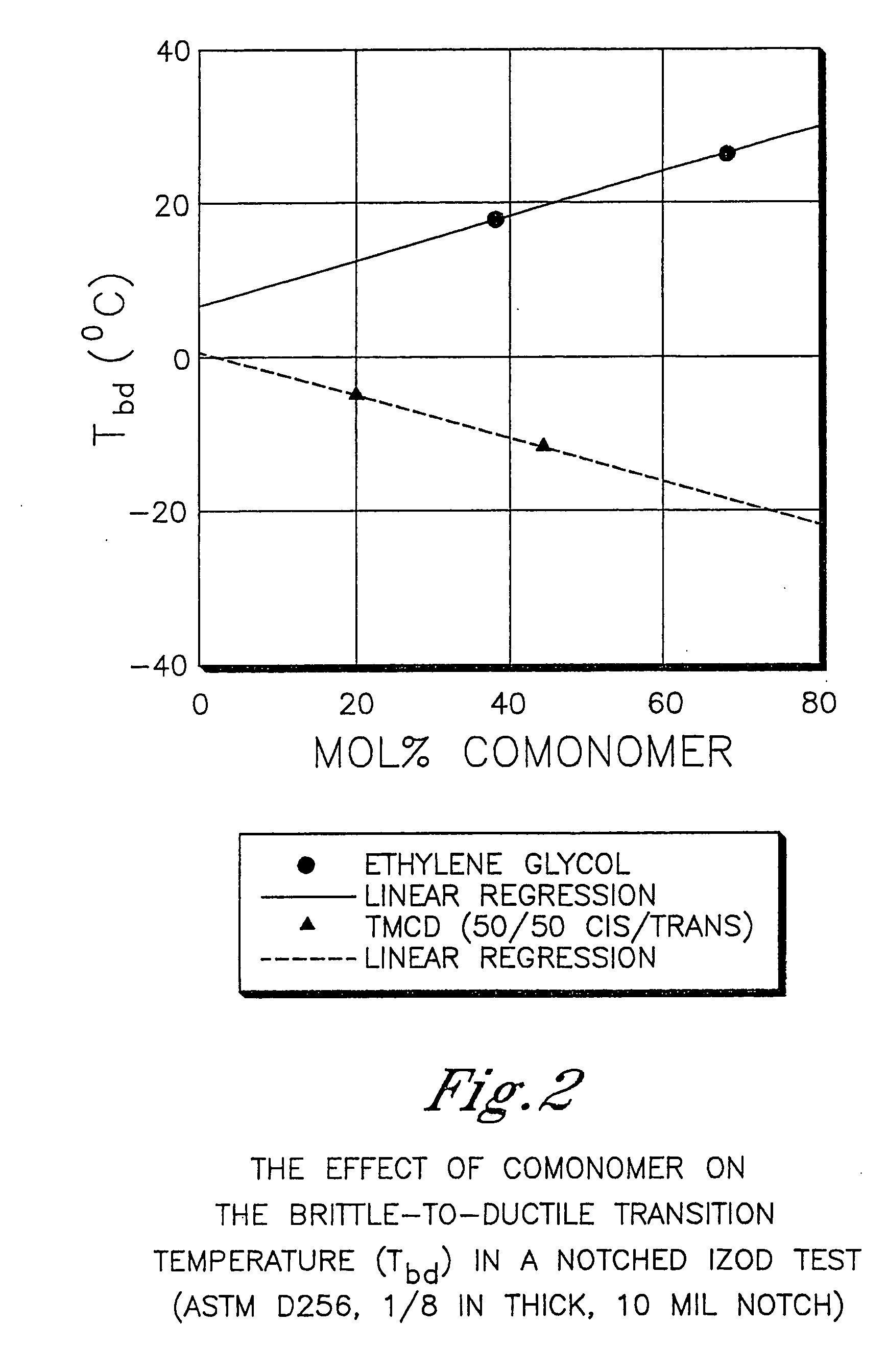

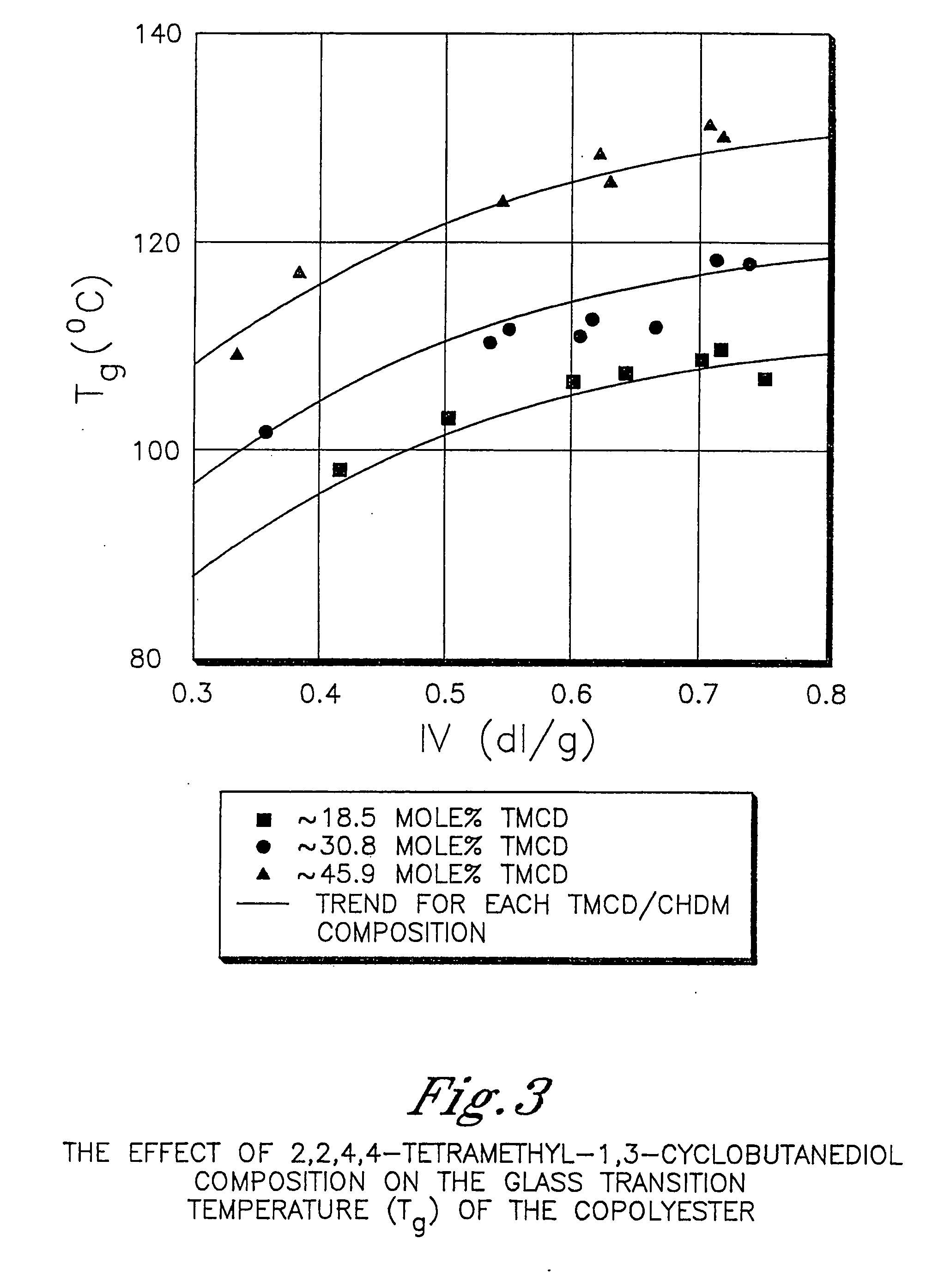

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

ActiveUS20060287482A1Good chemical resistanceHigh impact strengthDialysis systemsDialysisFiberPolymer science

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and 1,4-cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and moderate glass transition temperature and articles made therefrom

ActiveUS20060293495A1Easy to optimizeHigh impact strengthDialysis systemsDialysisFiberCyclohexanedimethanol

Described are polyesters comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

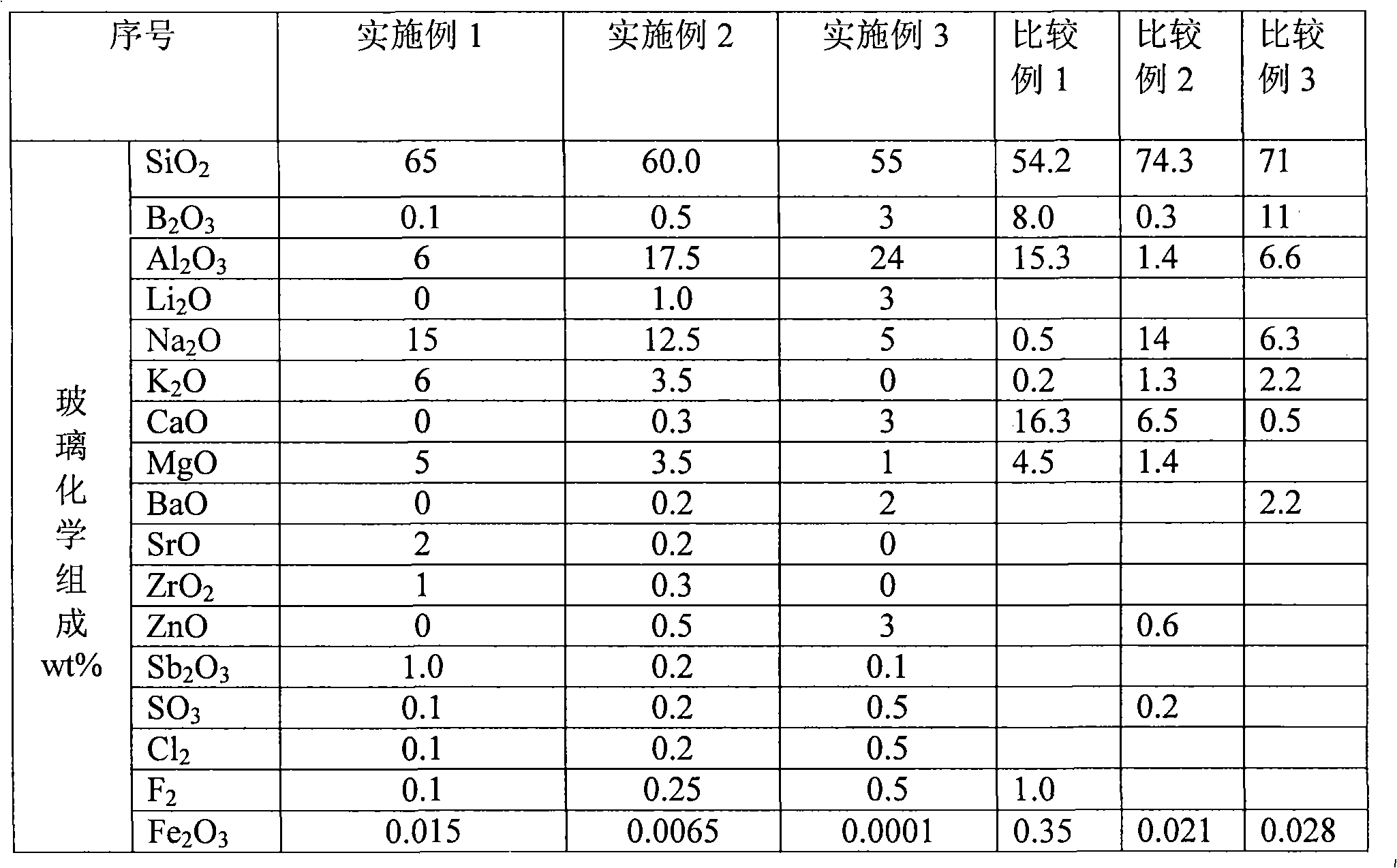

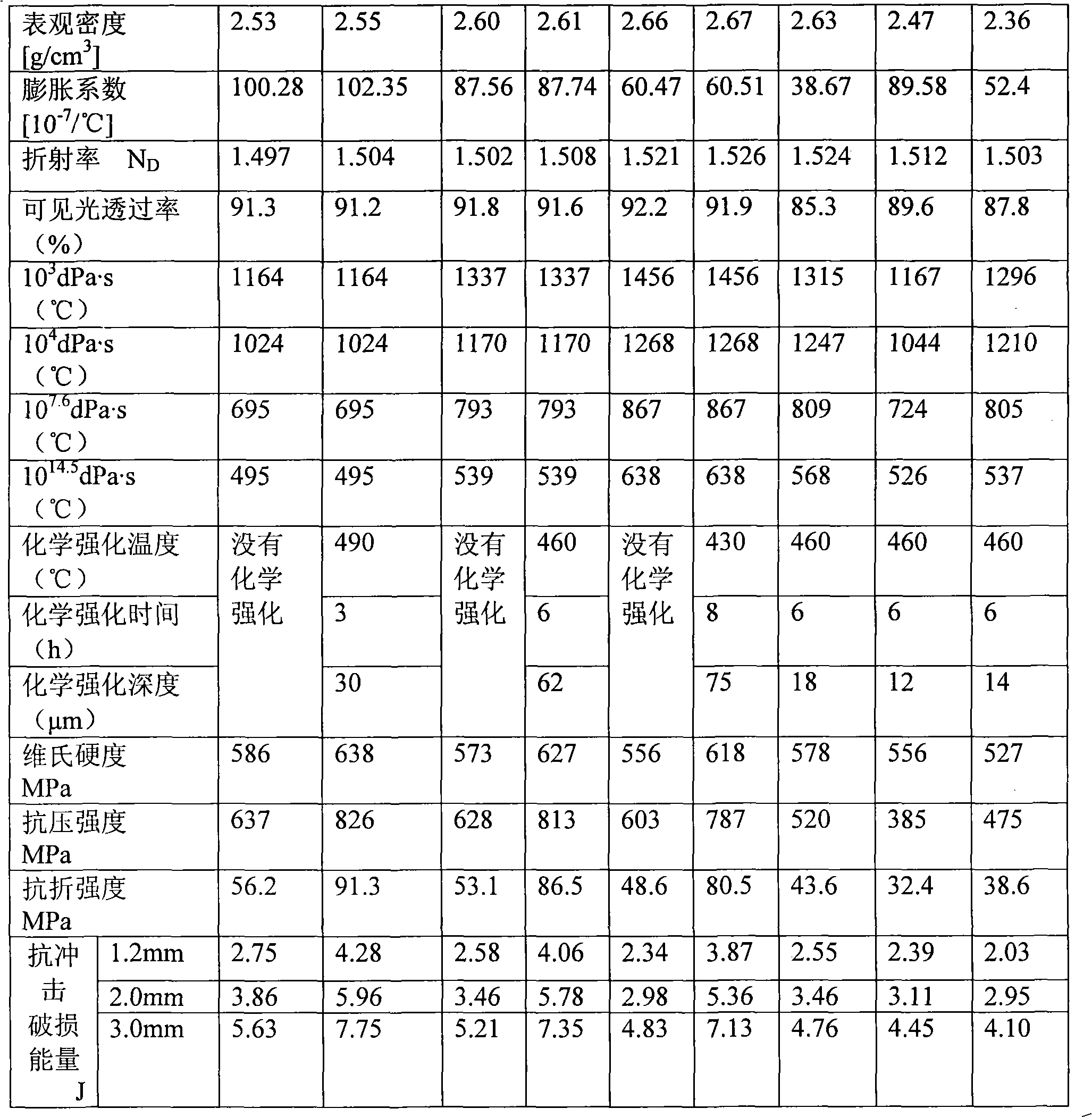

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com