Patents

Literature

332 results about "Progressive cavity pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

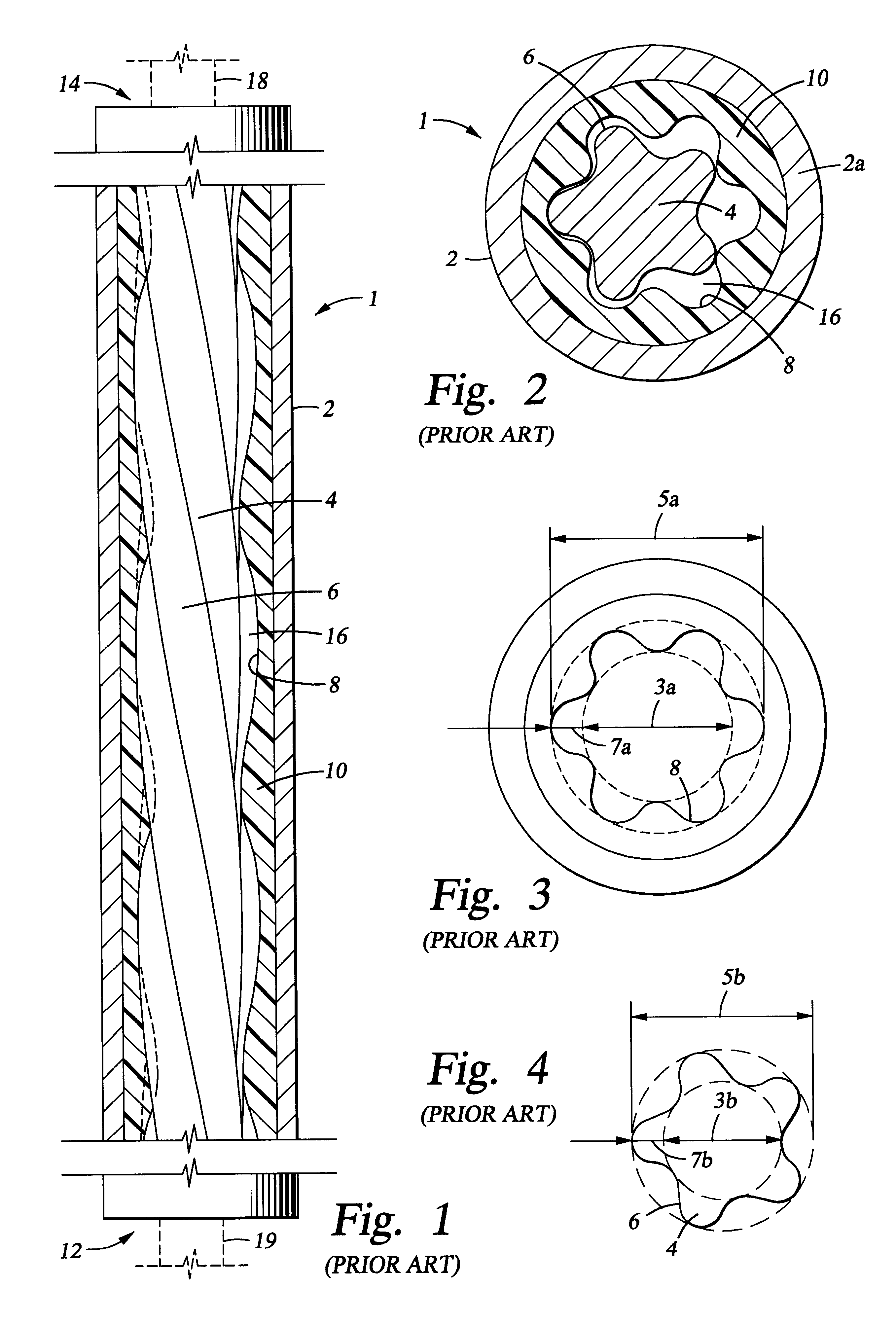

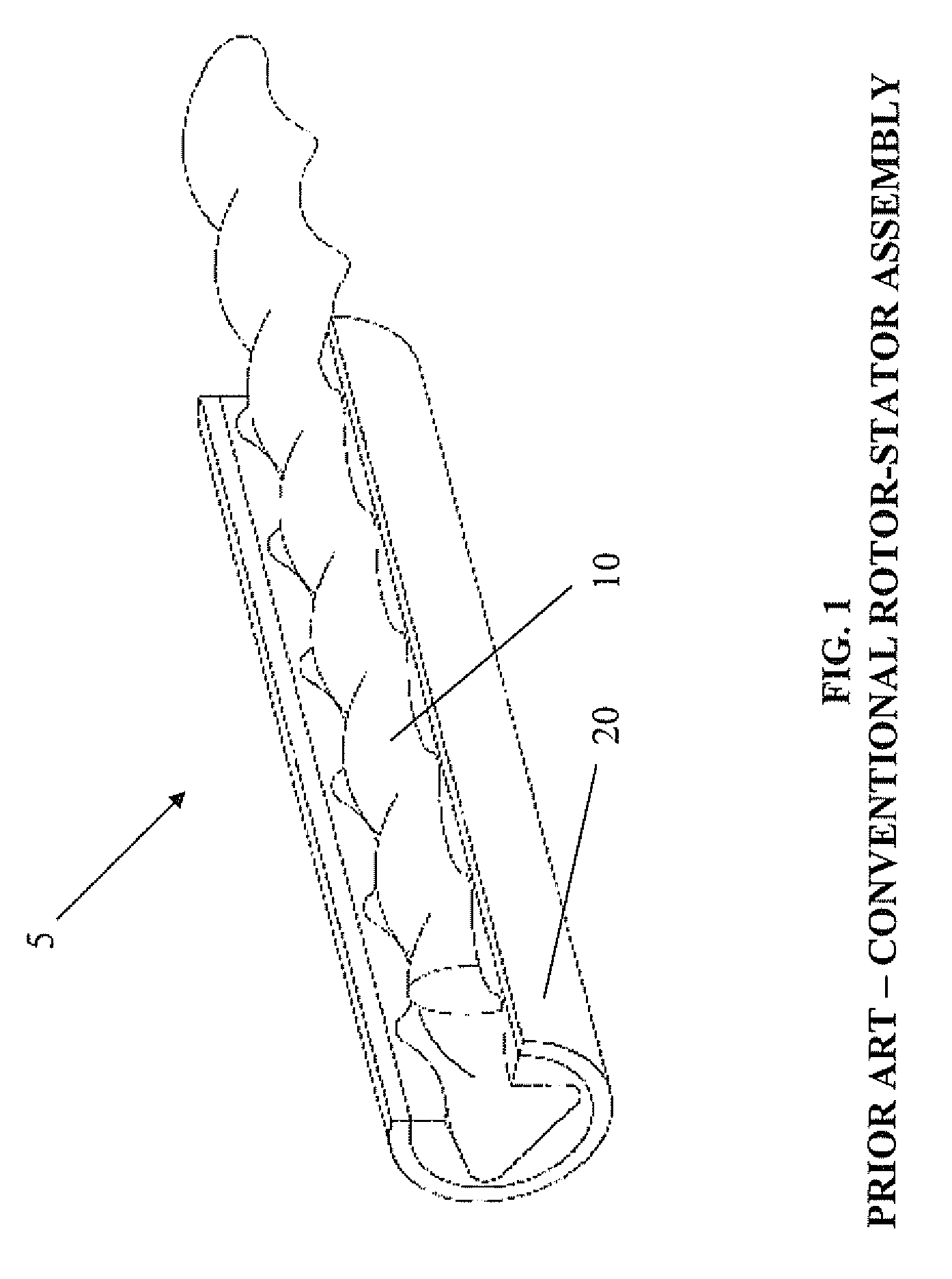

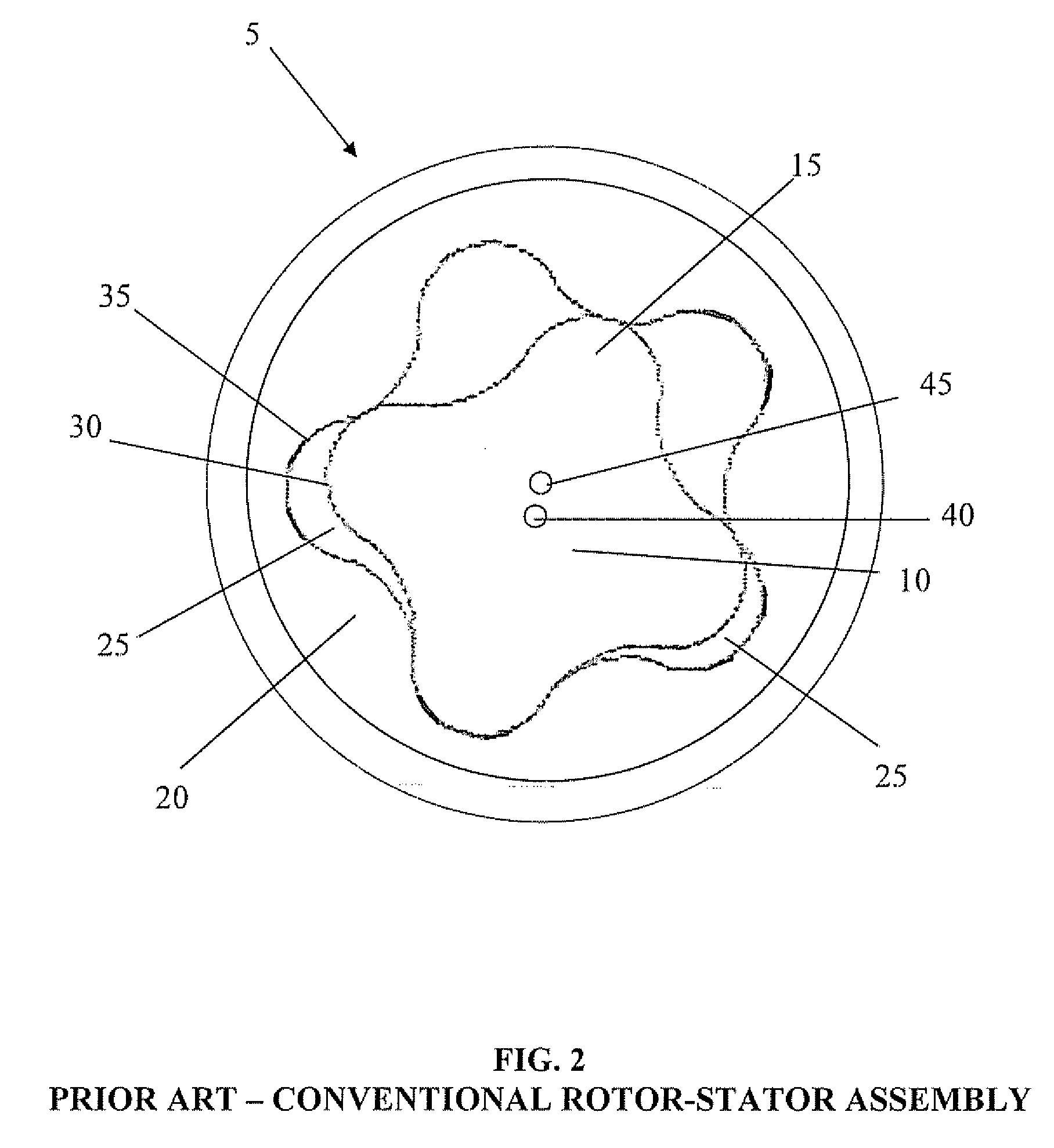

A progressive cavity pump is a type of positive displacement pump and is also known as a progressing cavity pump, progg cavity pump, eccentric screw pump or cavity pump. It transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned. This leads to the volumetric flow rate being proportional to the rotation rate (bidirectionally) and to low levels of shearing being applied to the pumped fluid. A common misconception among laymen is that the progressive cavity pump is a simple auger. This type of pump is by no means an auger. This misconception is usually caused by a lack of understanding of the basic principles of pump operation.

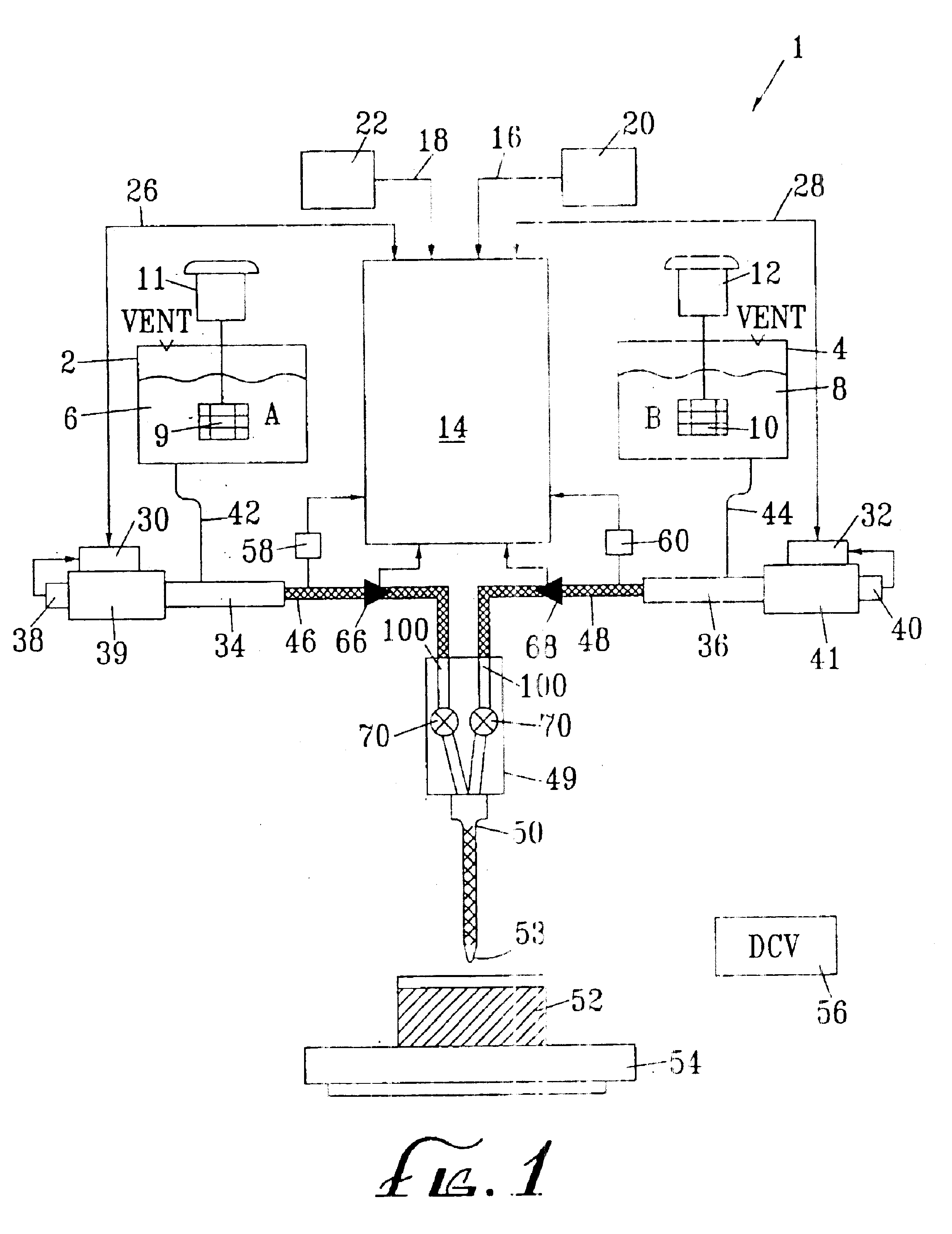

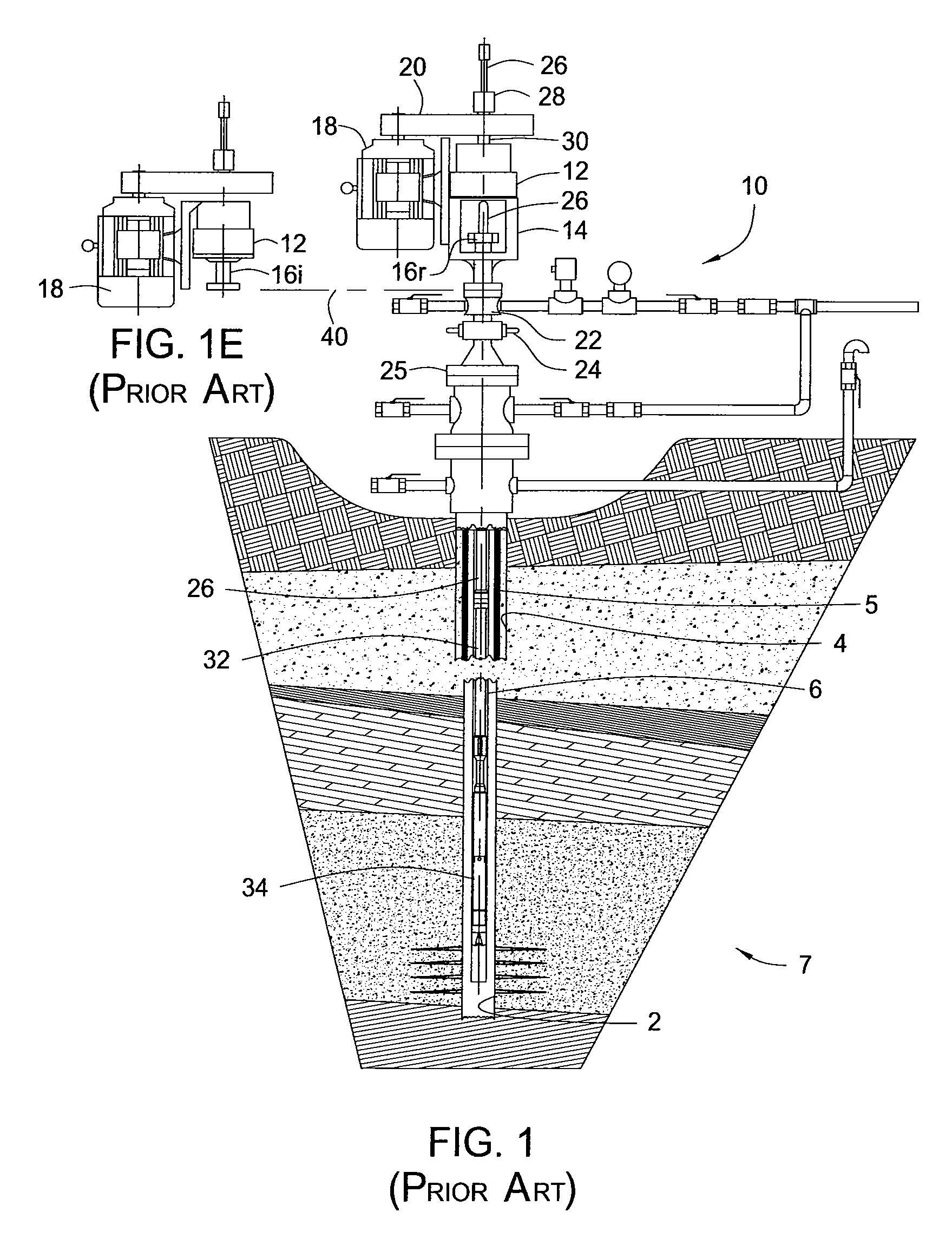

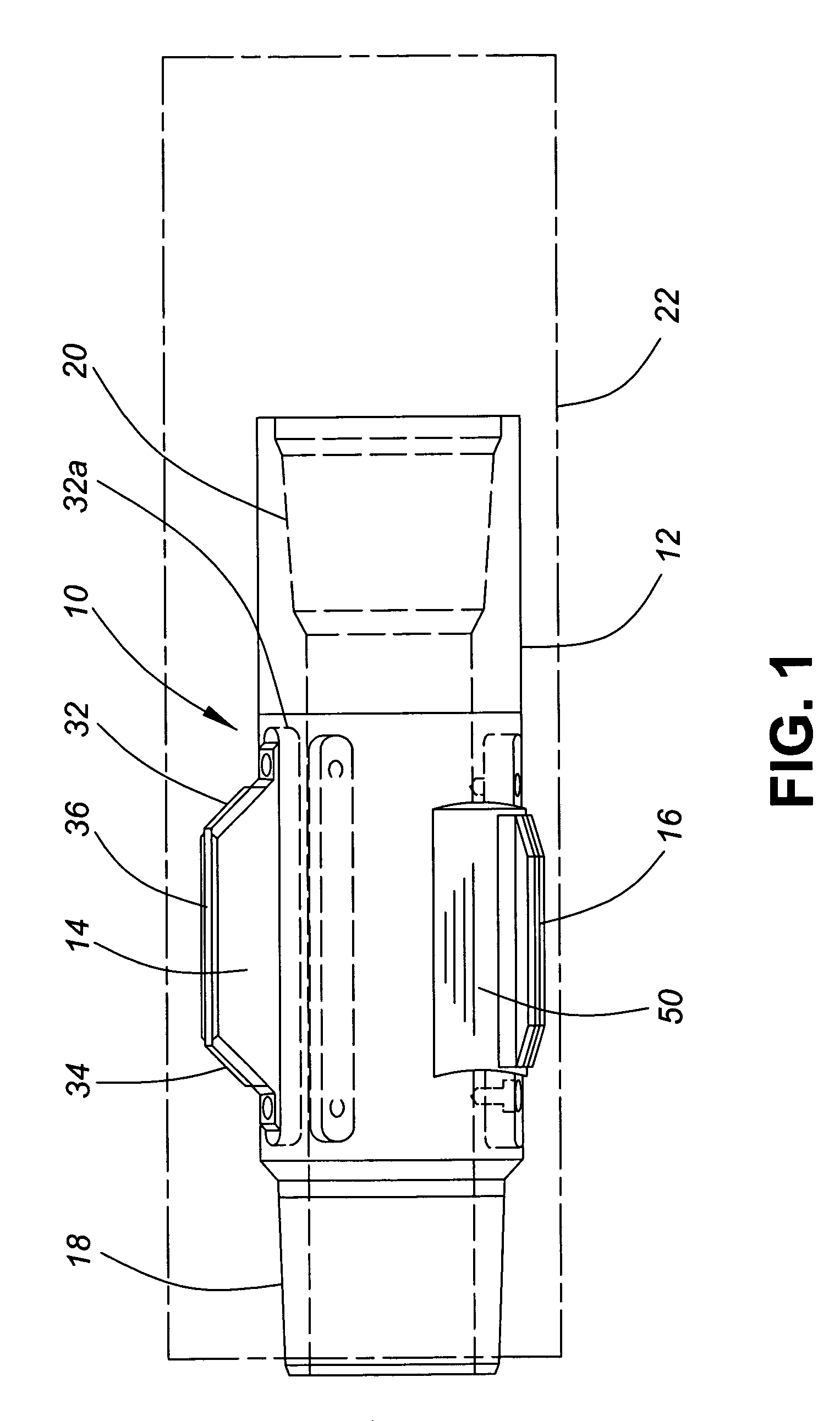

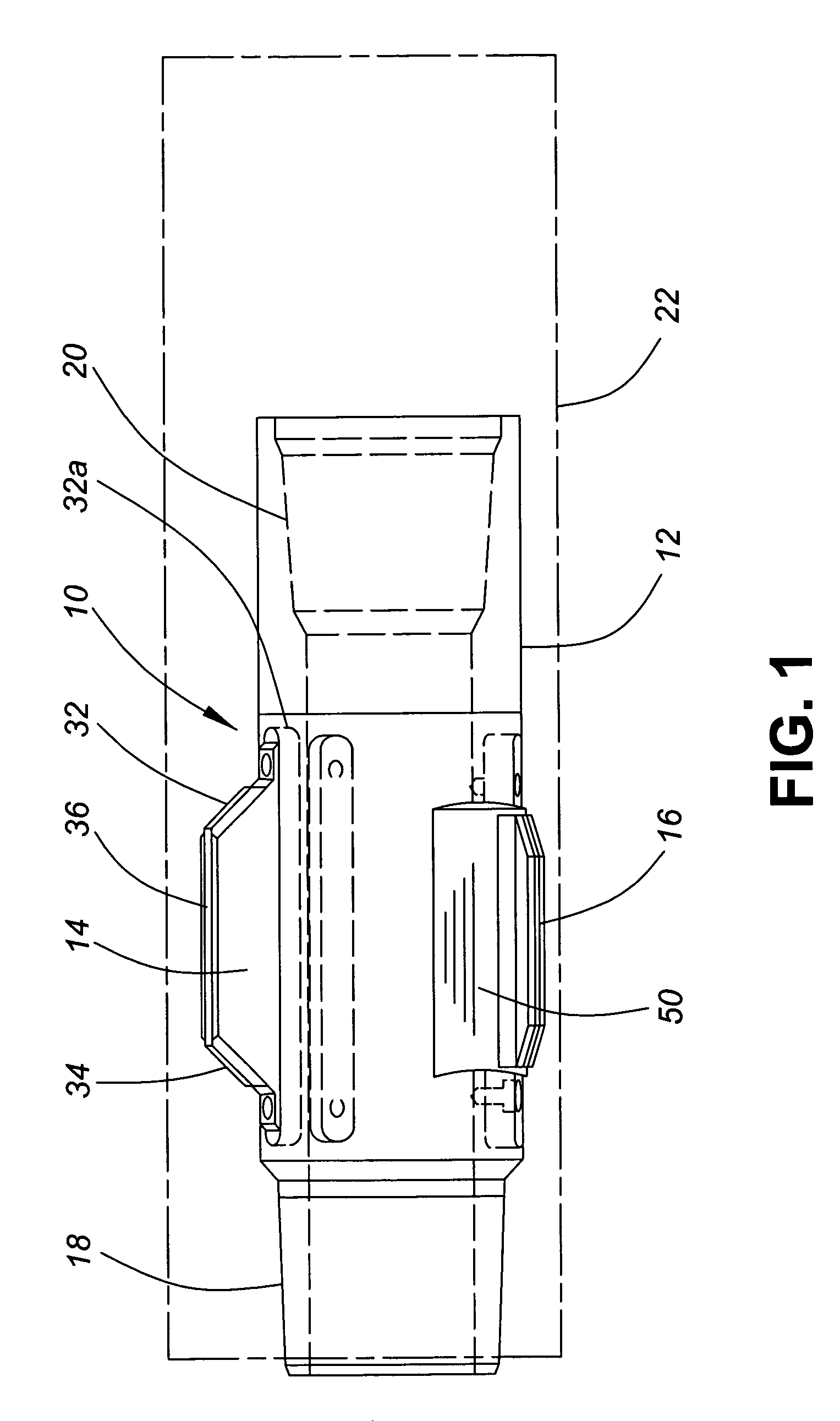

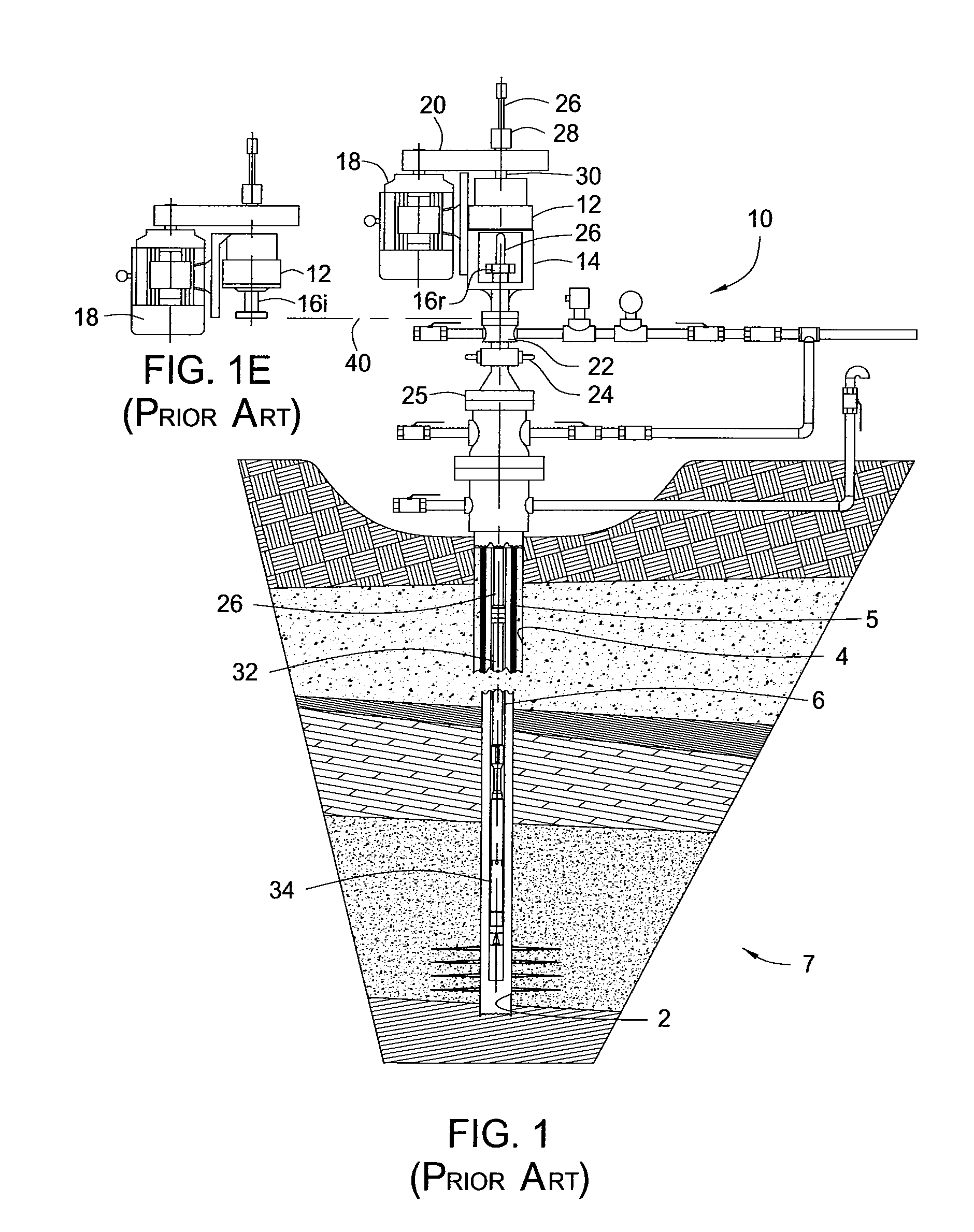

Method and apparatus for controlling a submergible pumping system

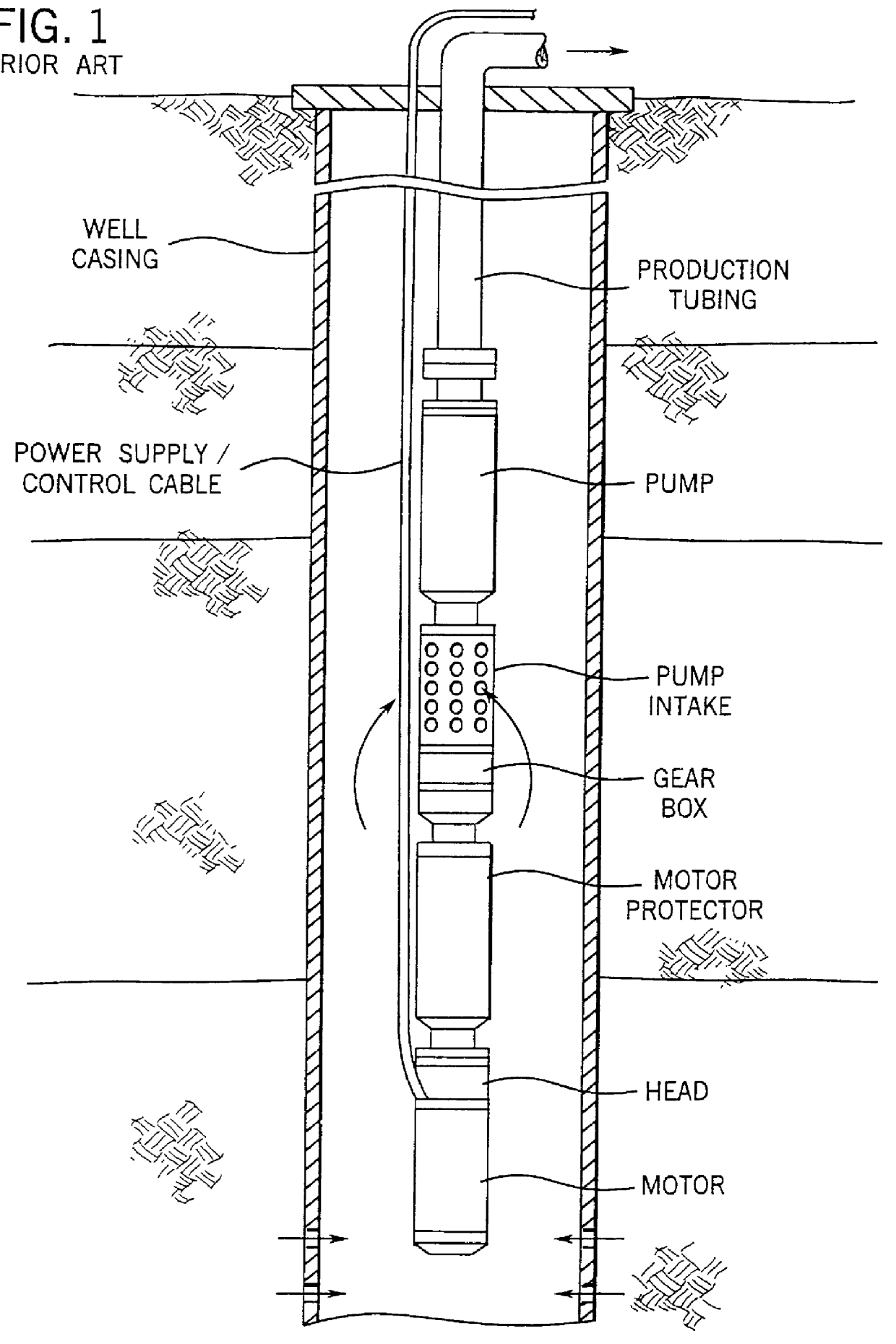

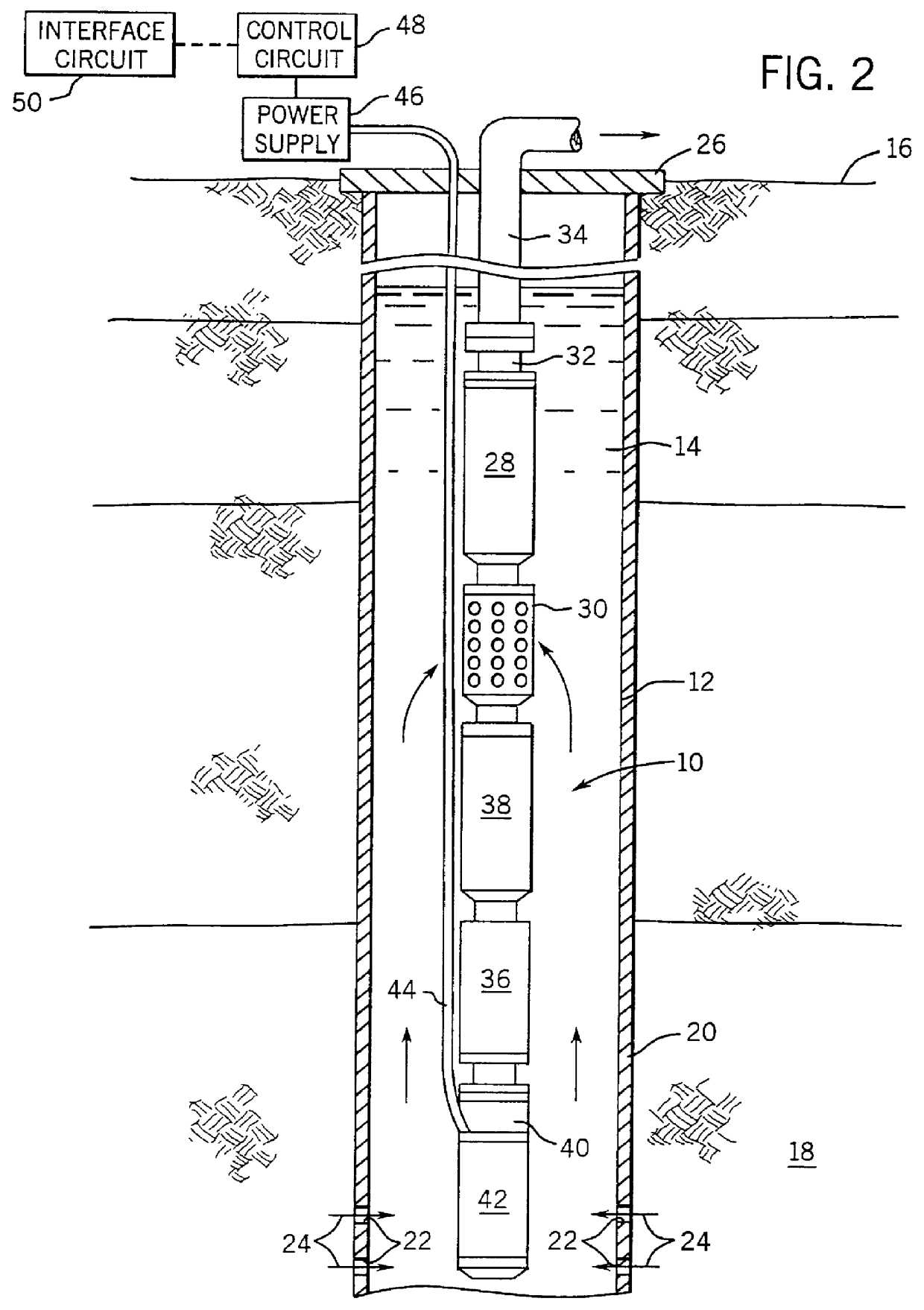

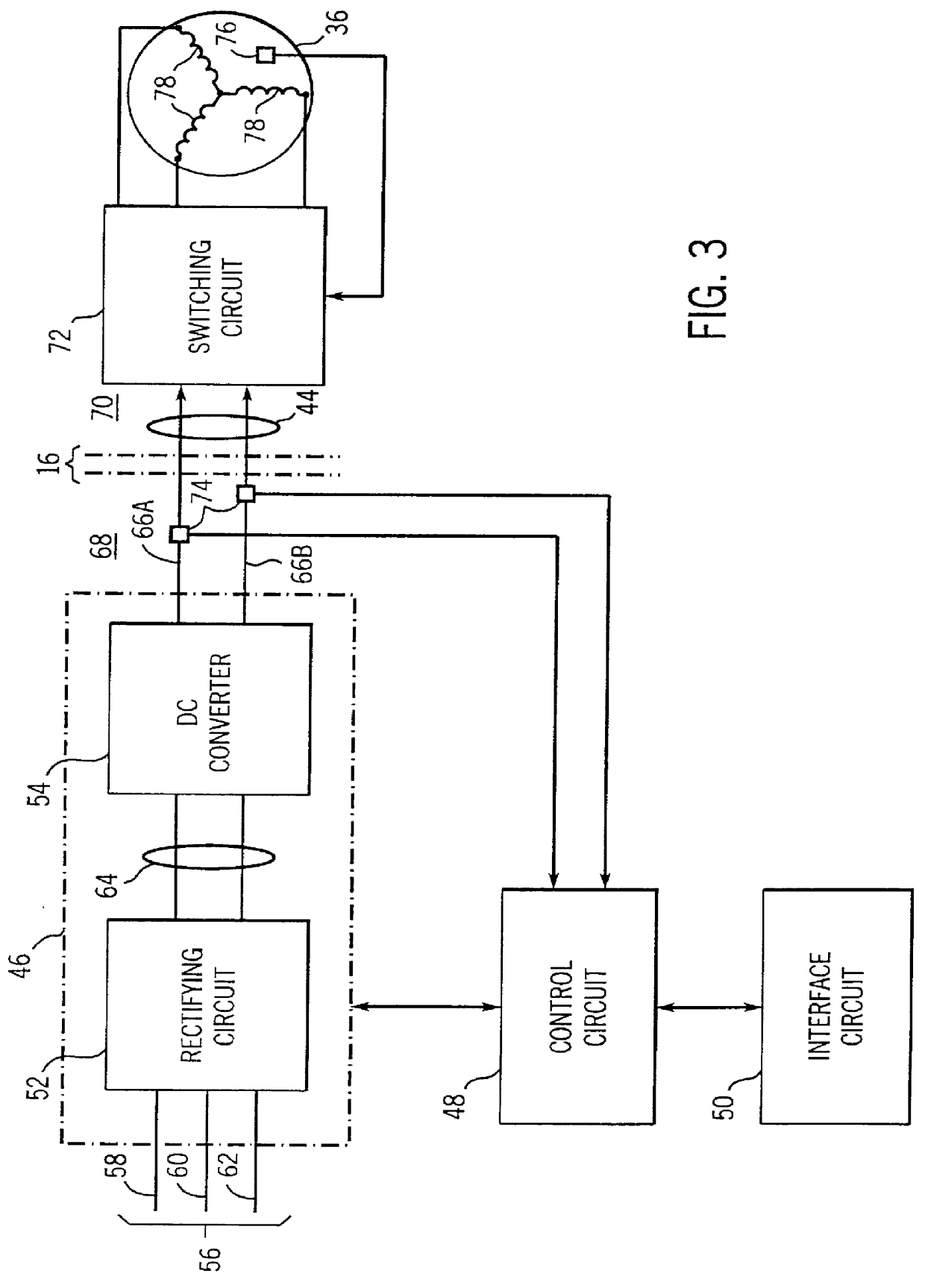

A submergible pumping unit for raising viscous fluids from a well is driven by an electronic drive and control system, a first portion of which is located above the well, and a second portion of which is coupled to the submergible pumping unit. The drive and control system includes a power supply circuit located above the well for converting AC power from a source to DC power having current and voltage levels. The DC power is transmitted to the pumping unit via a two-conductor DC bus cable. The pumping unit includes a switching circuit which receives the DC power for driving a submergible motor, such as a permanent magnet brushless motor. The speed of the motor, and of a pump coupled thereto, is proportional to the voltage of the DC power applied to the pumping unit. The pump is preferably a progressive cavity pump, and the drive and control circuitry provides sufficient torque to start the pump from a static condition. A control circuit is provided for transmitting configuration and desired flow rate and speed data to the power supply.

Owner:CAMCO INT

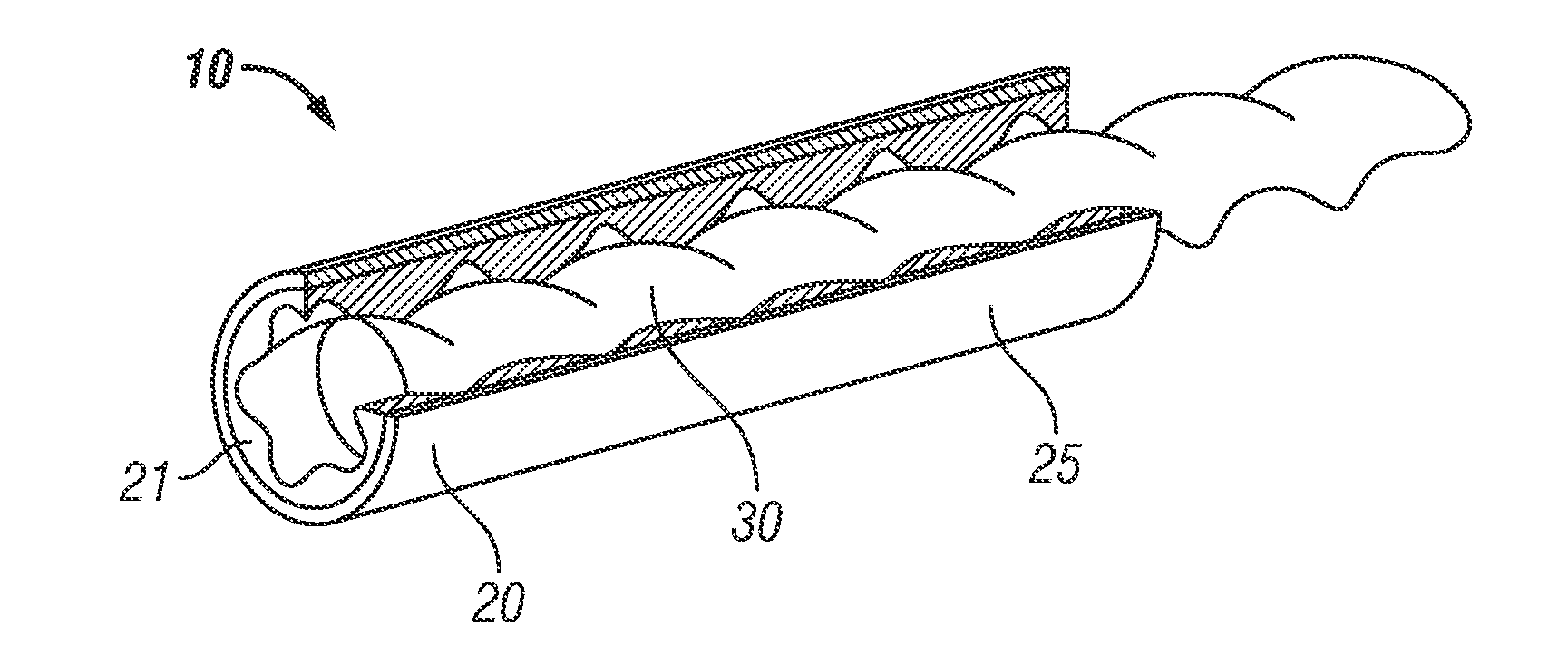

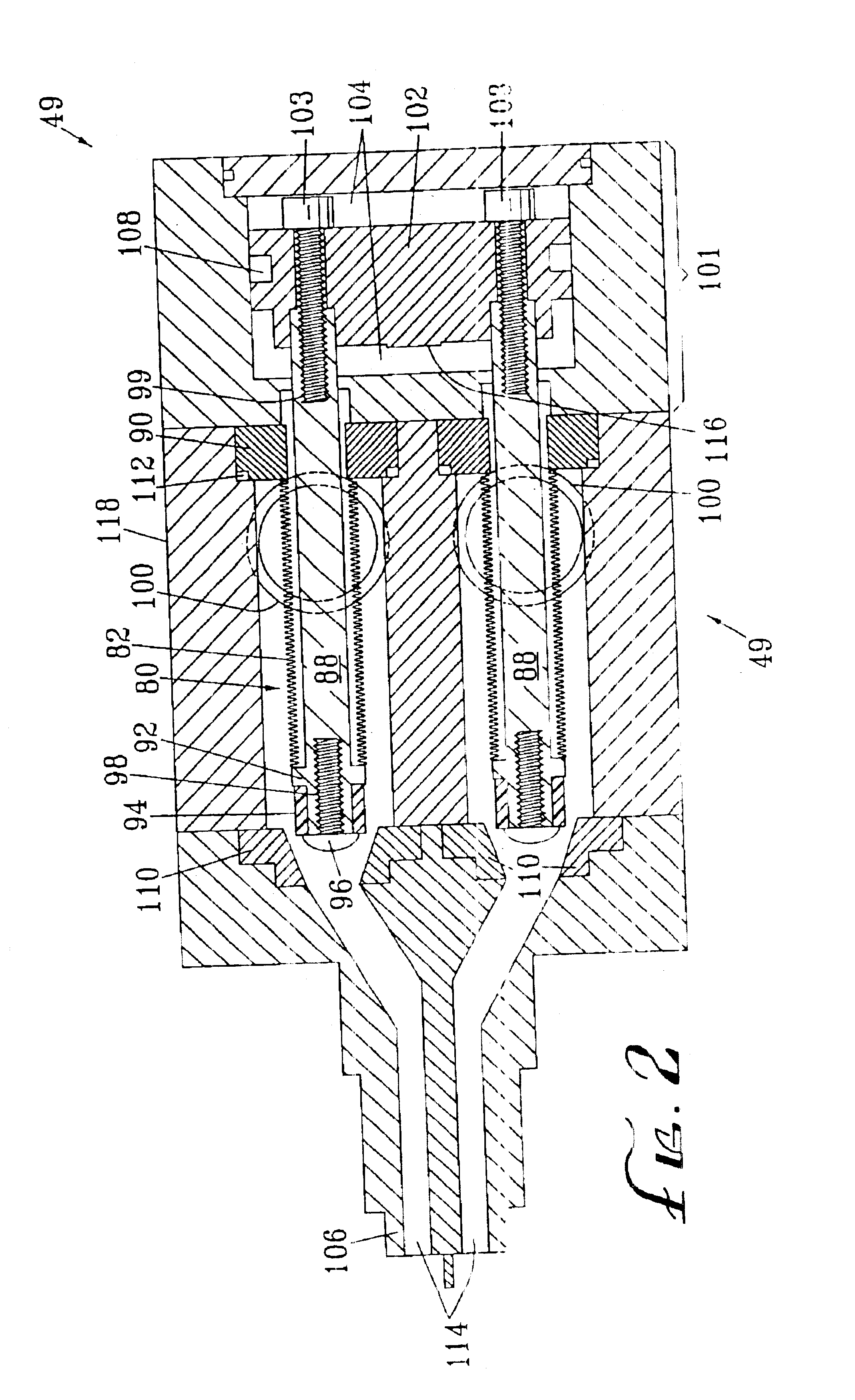

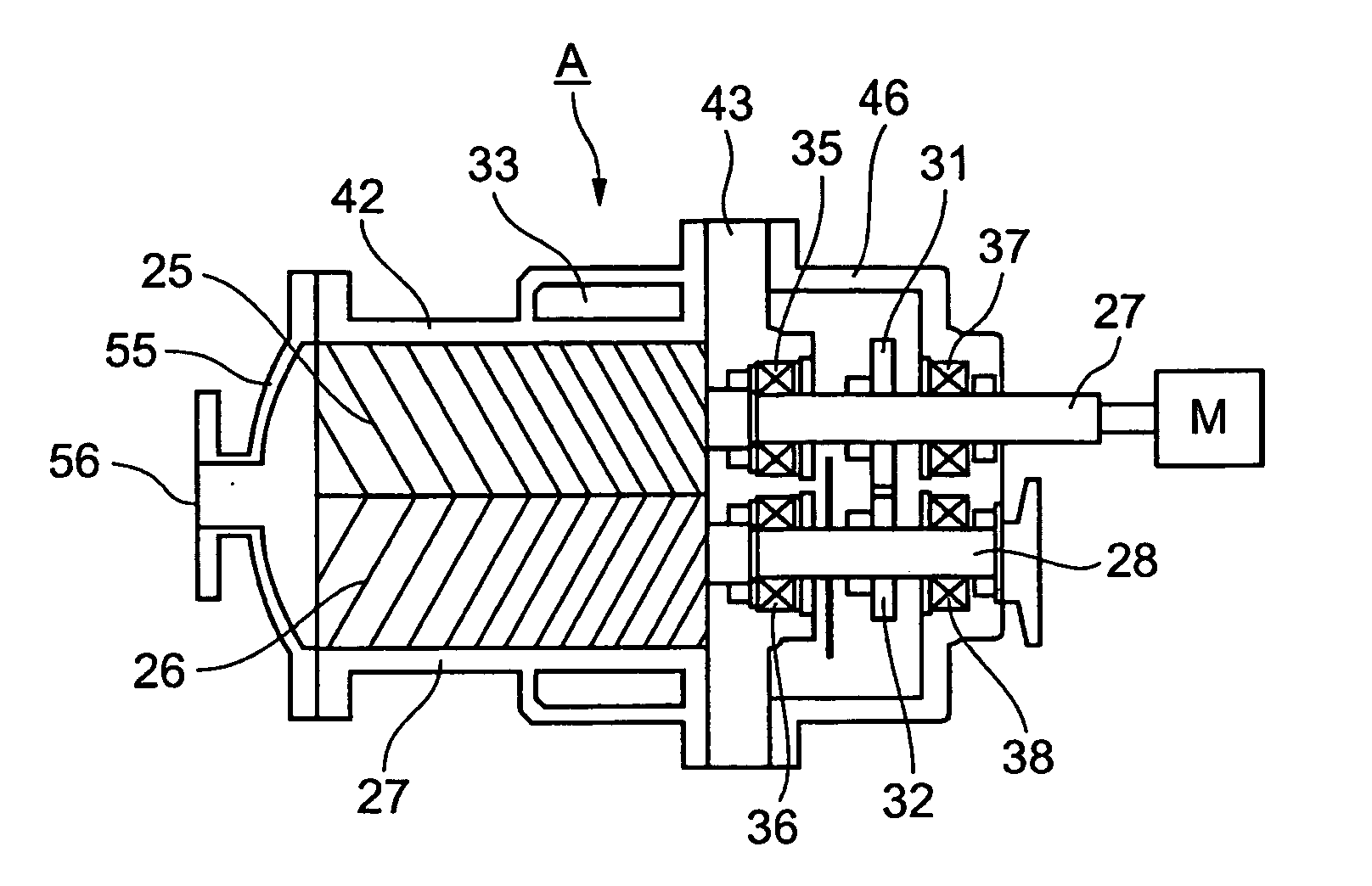

Direct drive linear flow blood pump

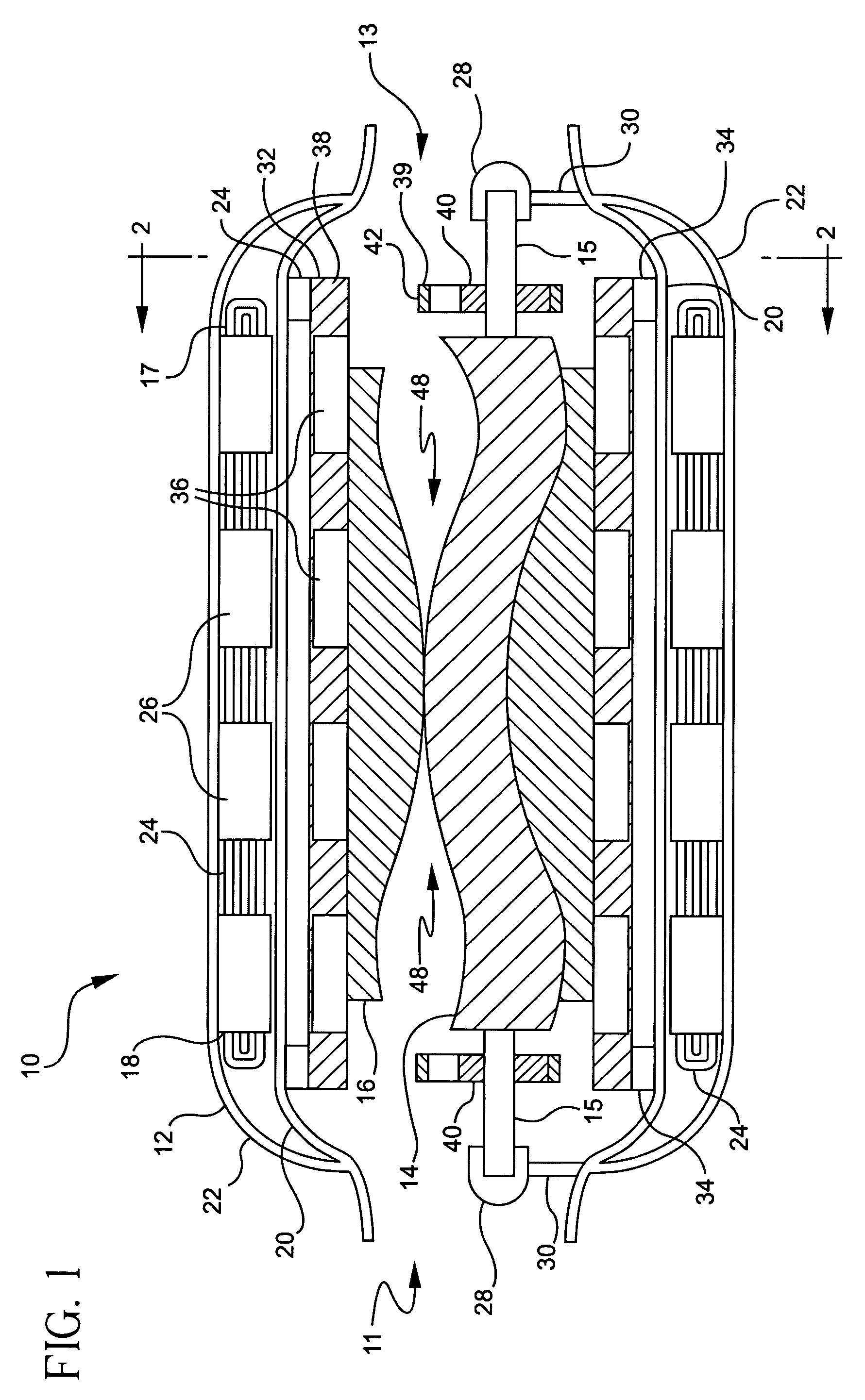

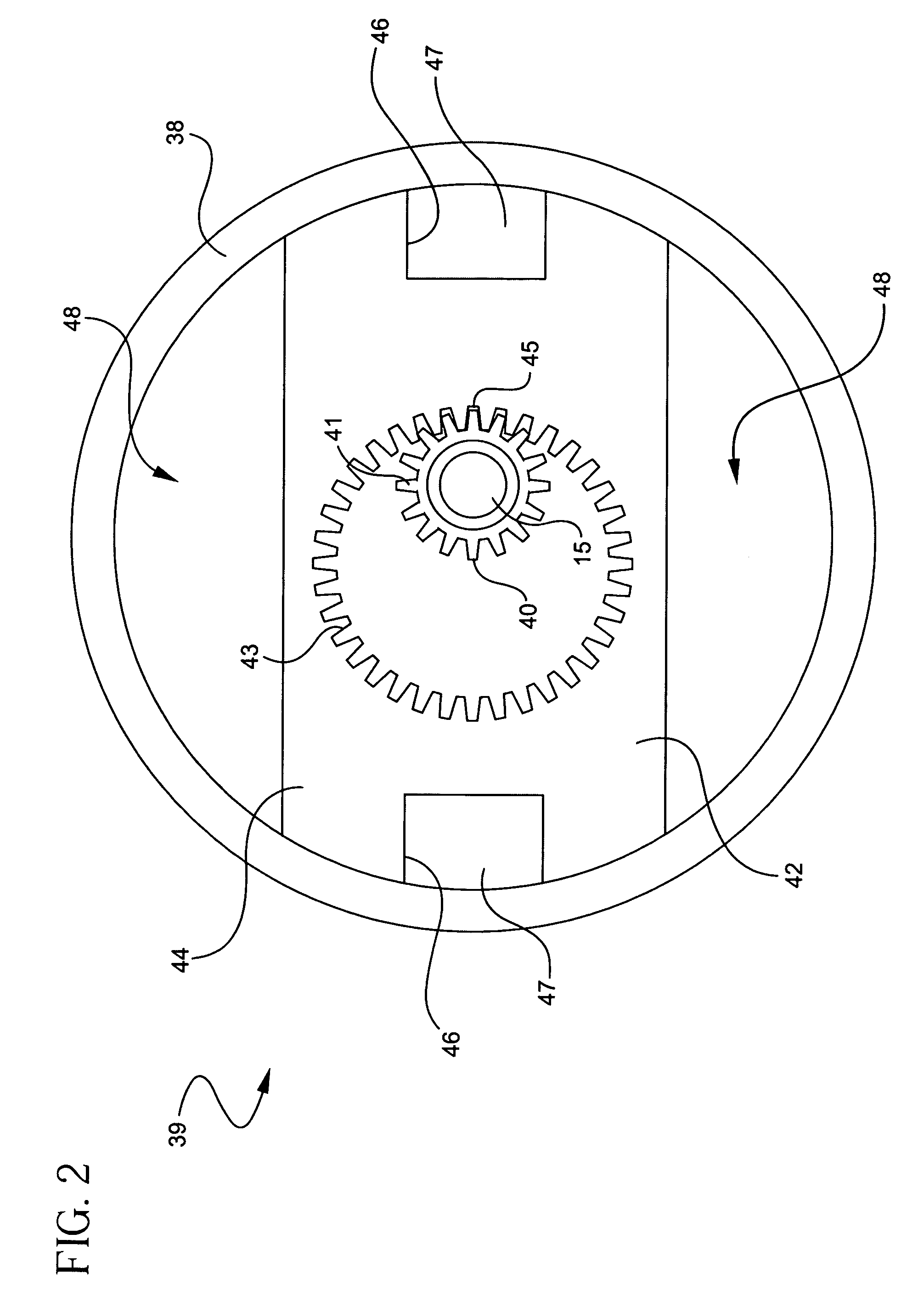

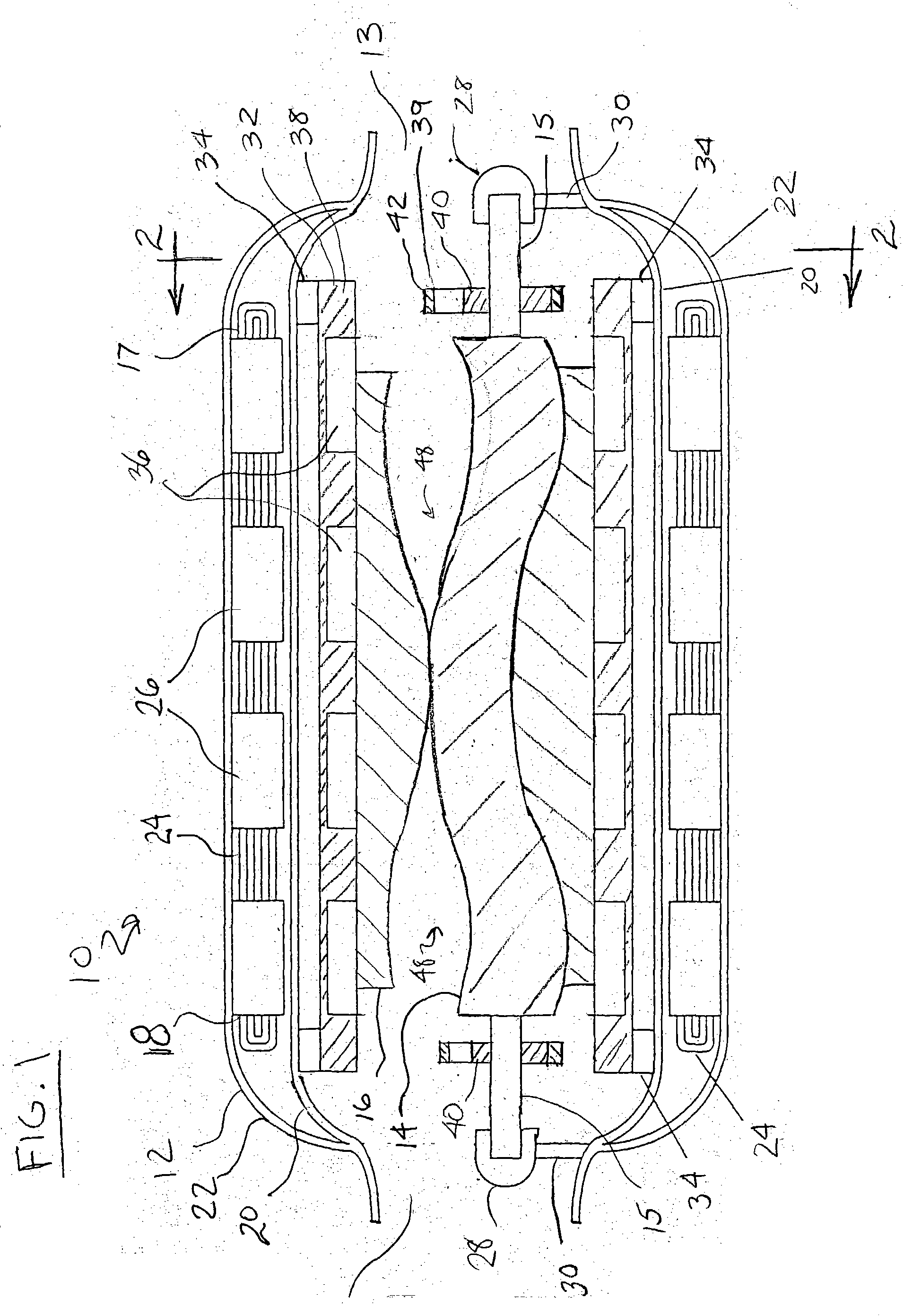

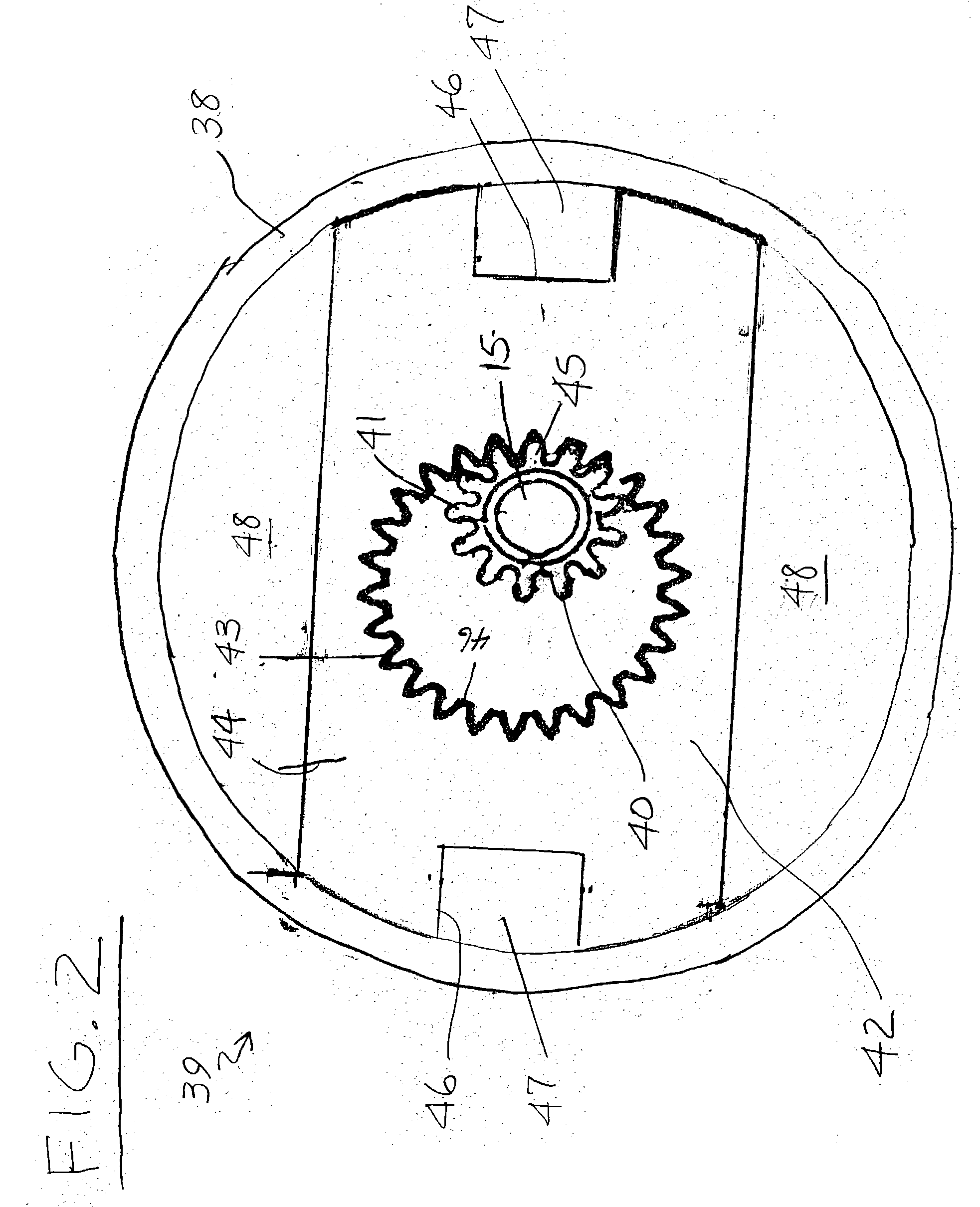

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

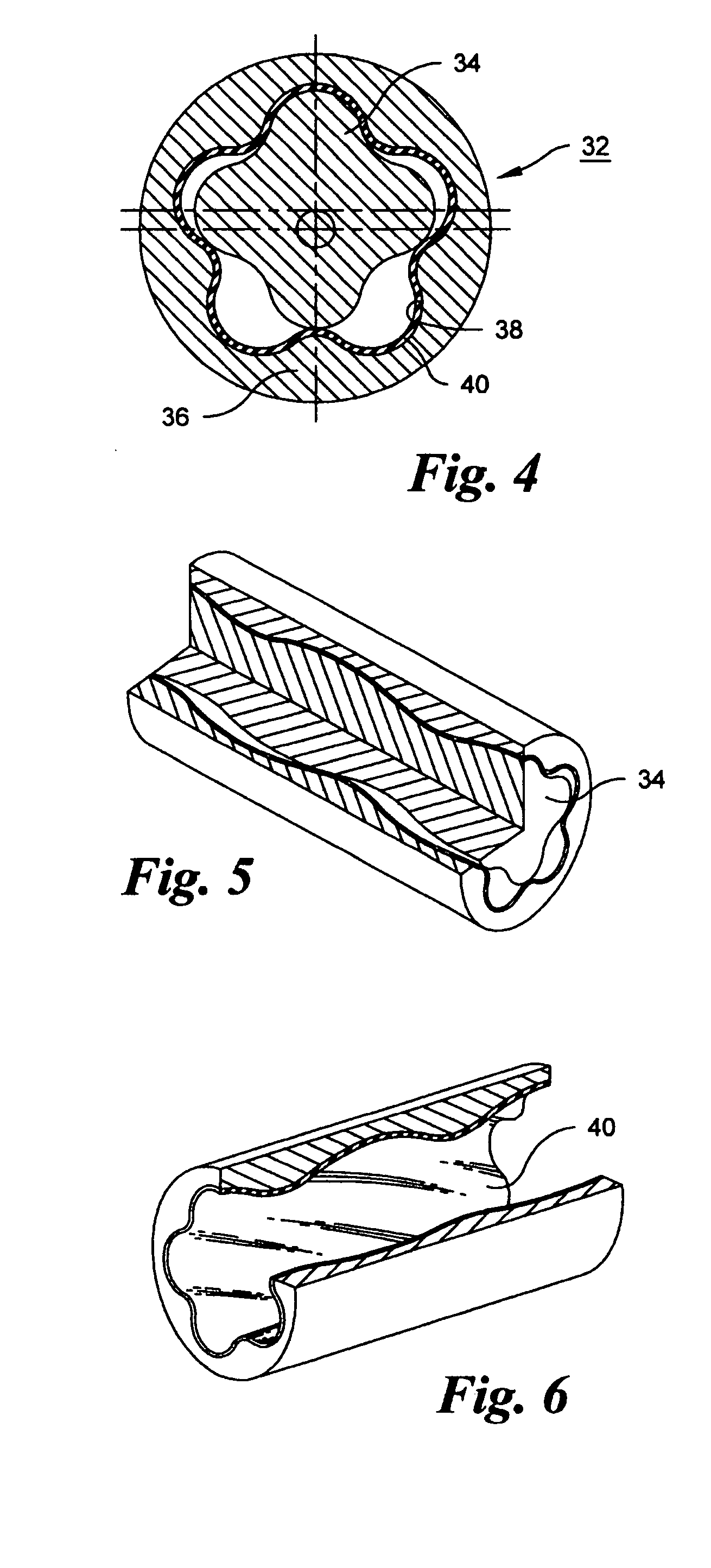

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

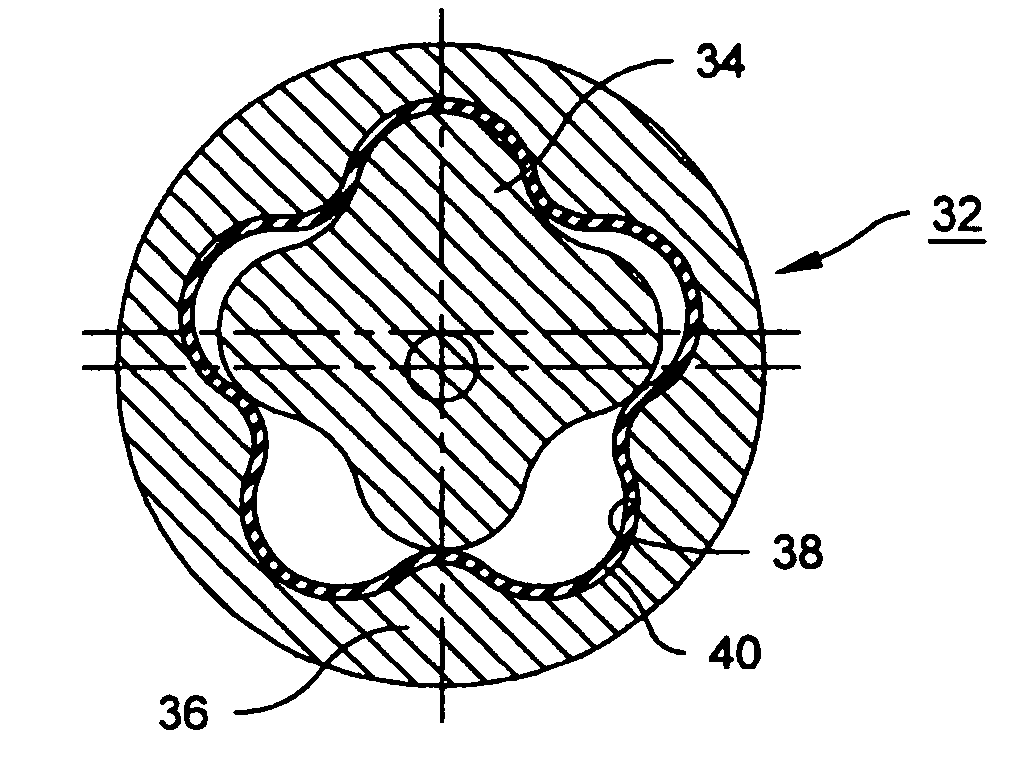

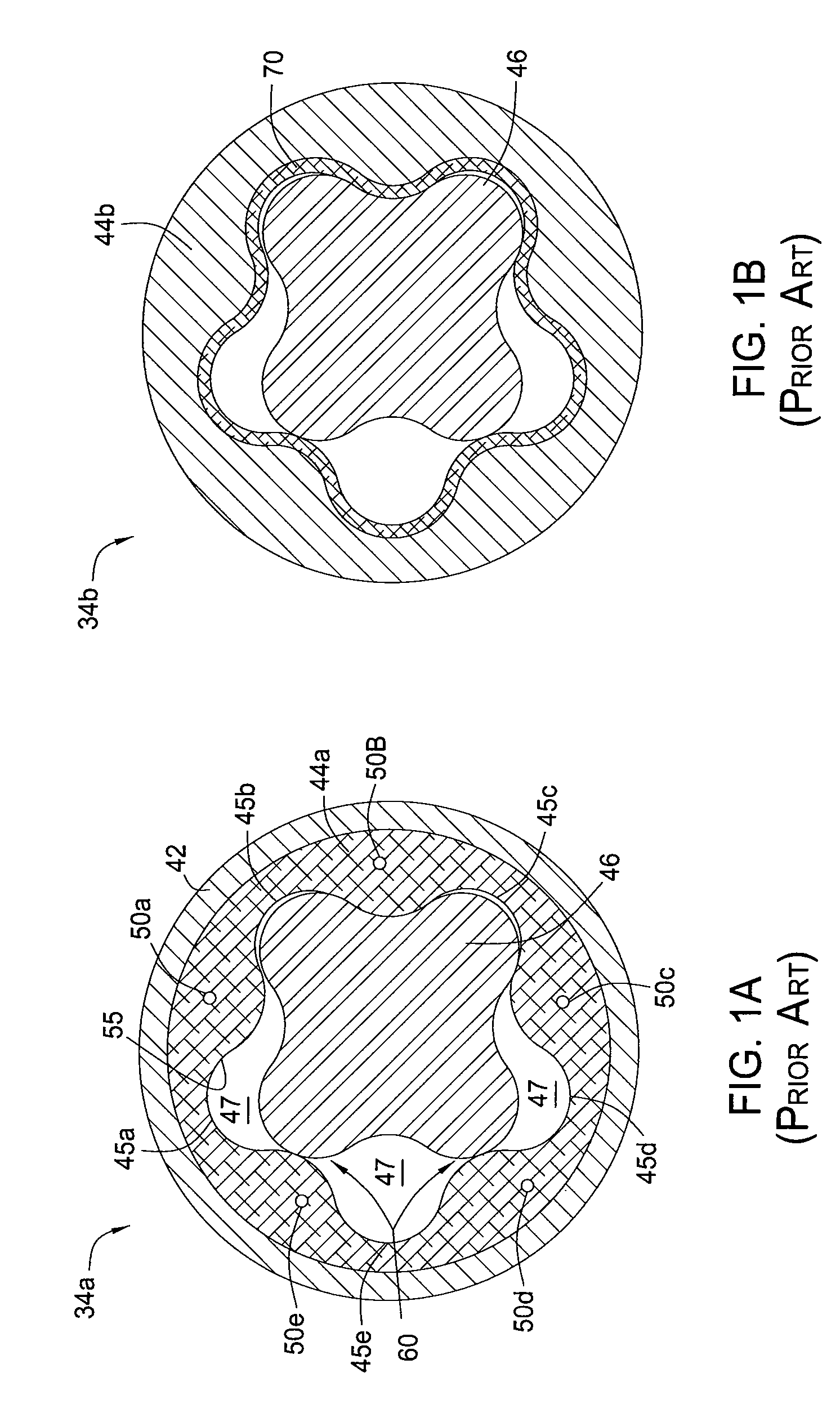

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

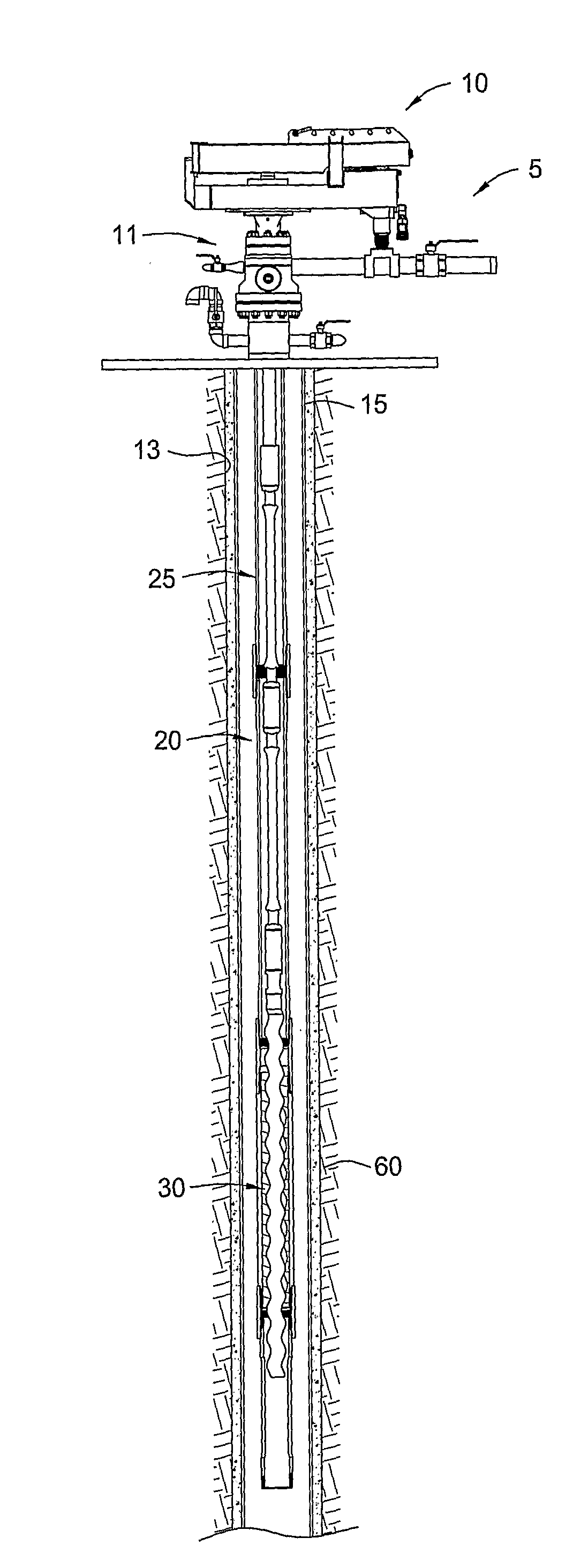

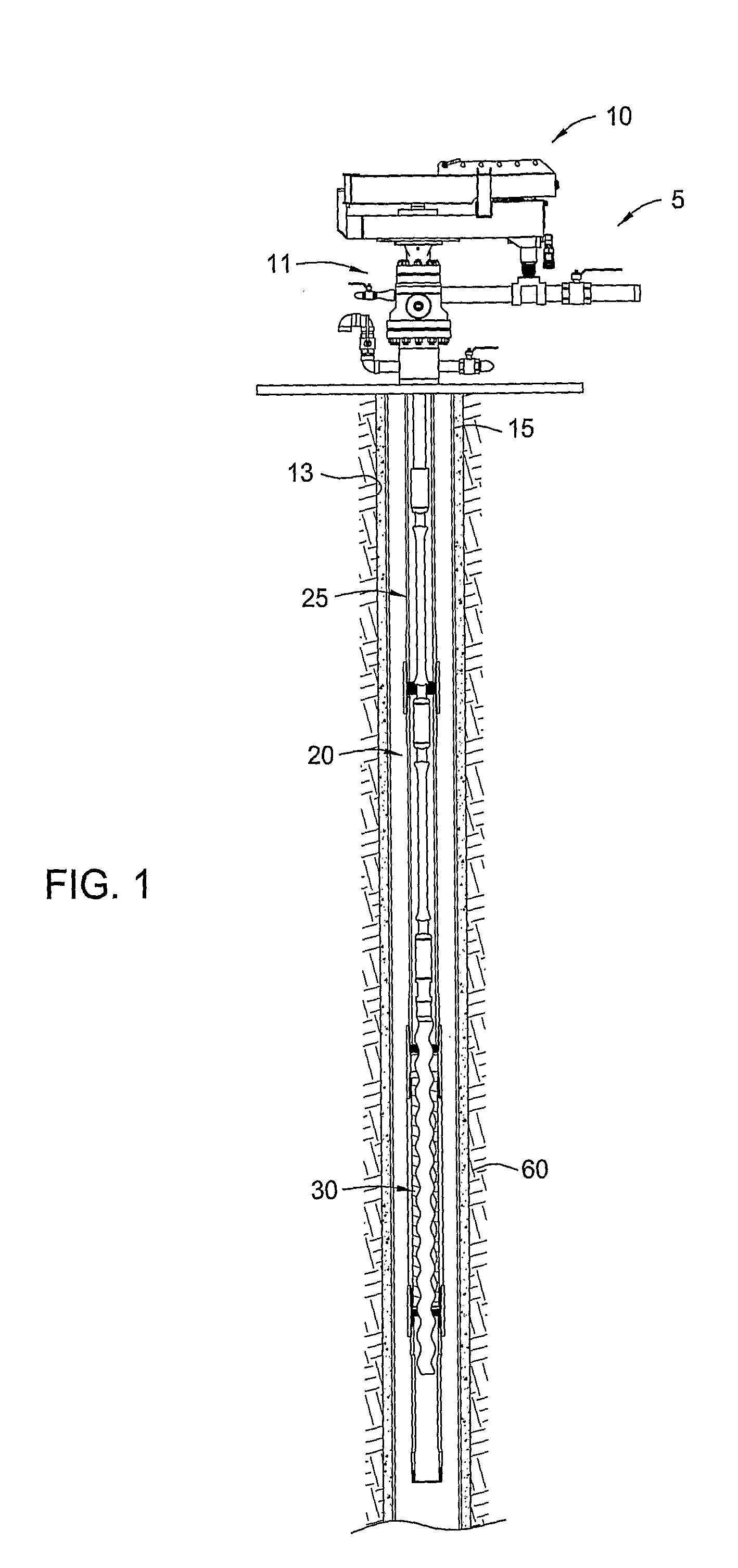

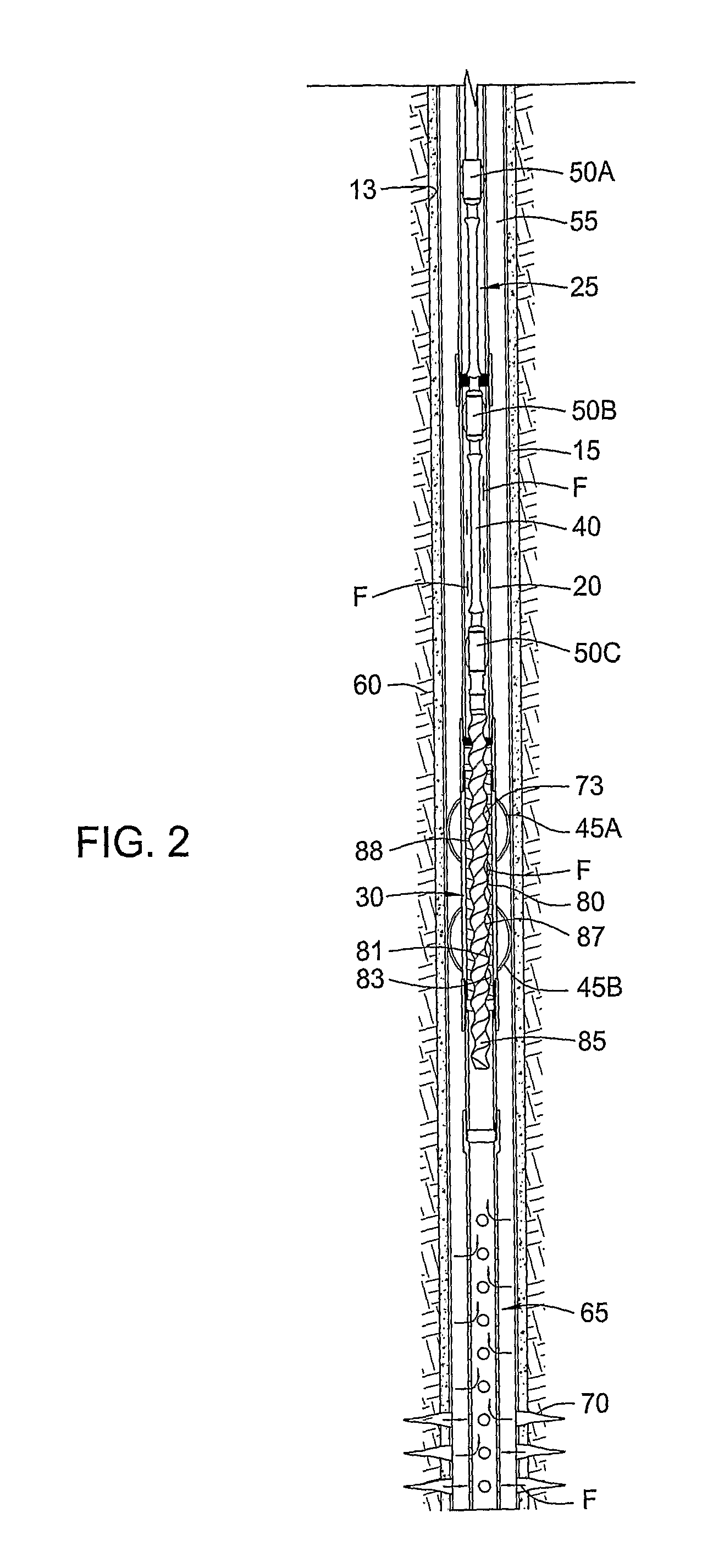

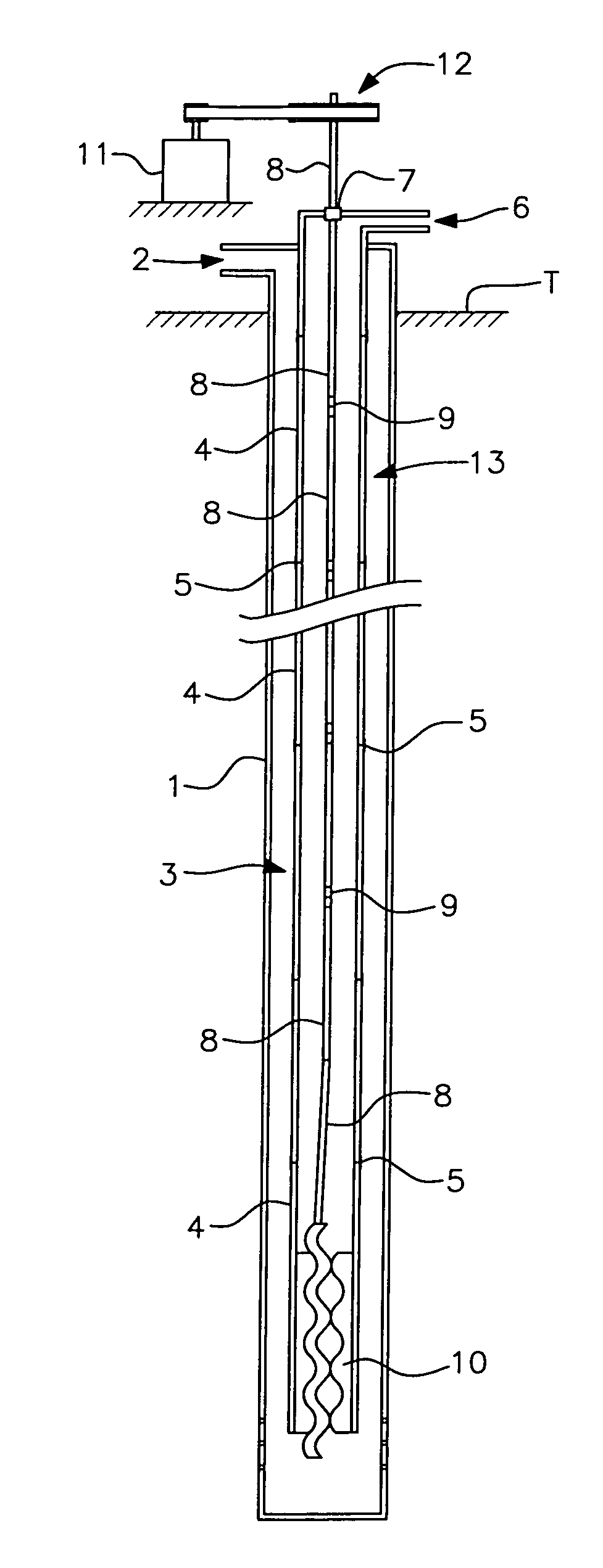

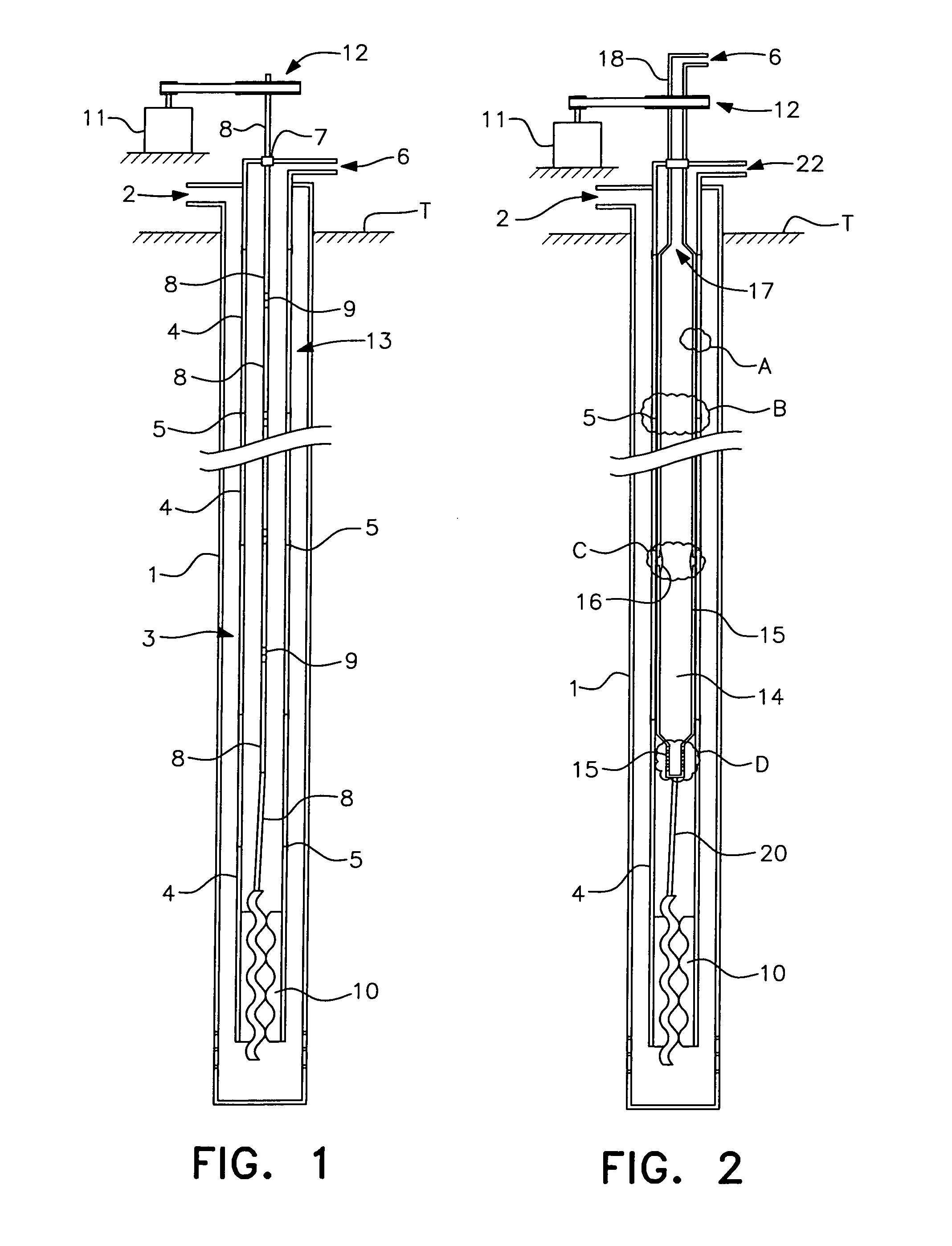

Artificial lift, concentric tubing production system for wells and method of using same

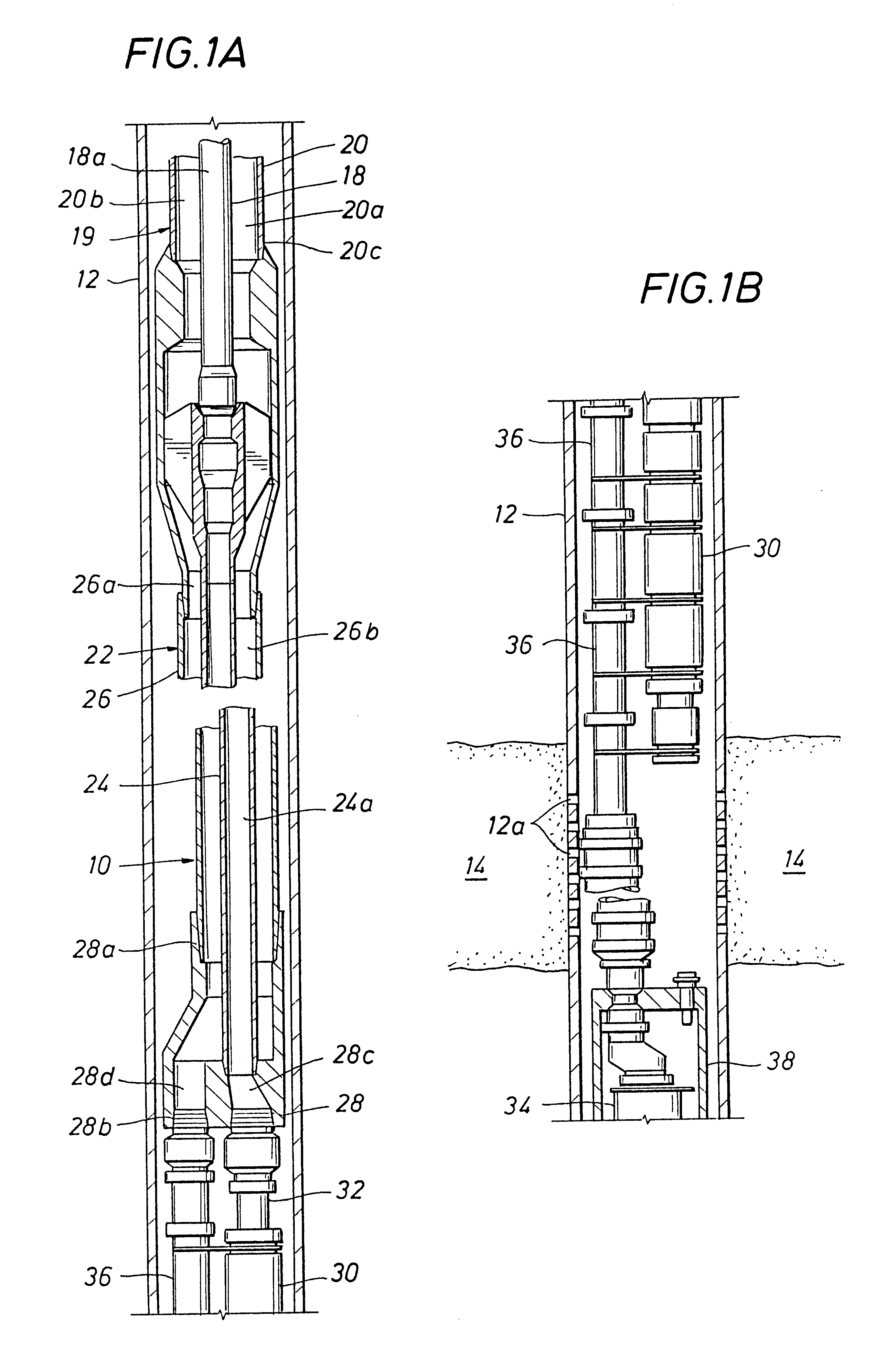

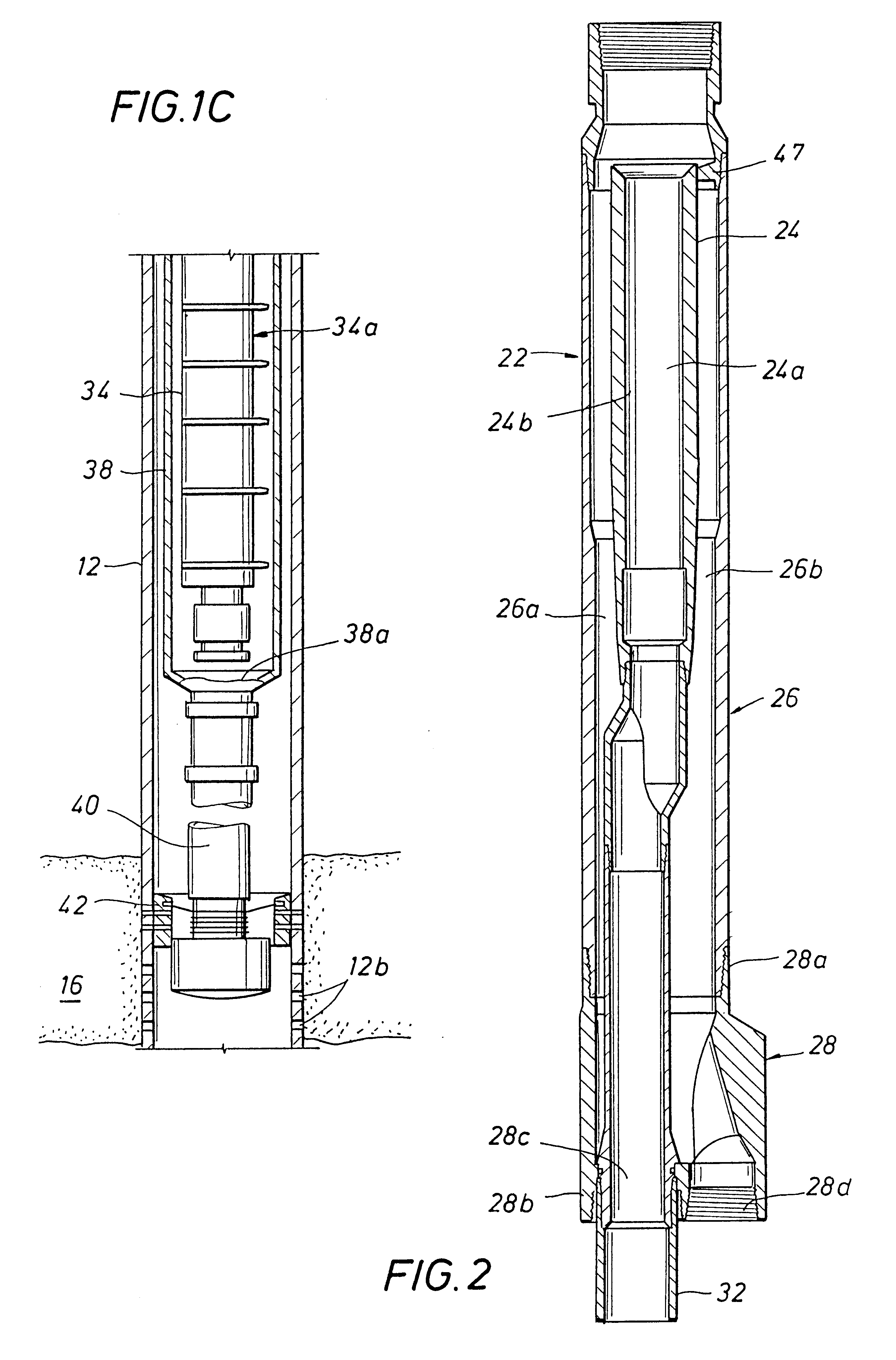

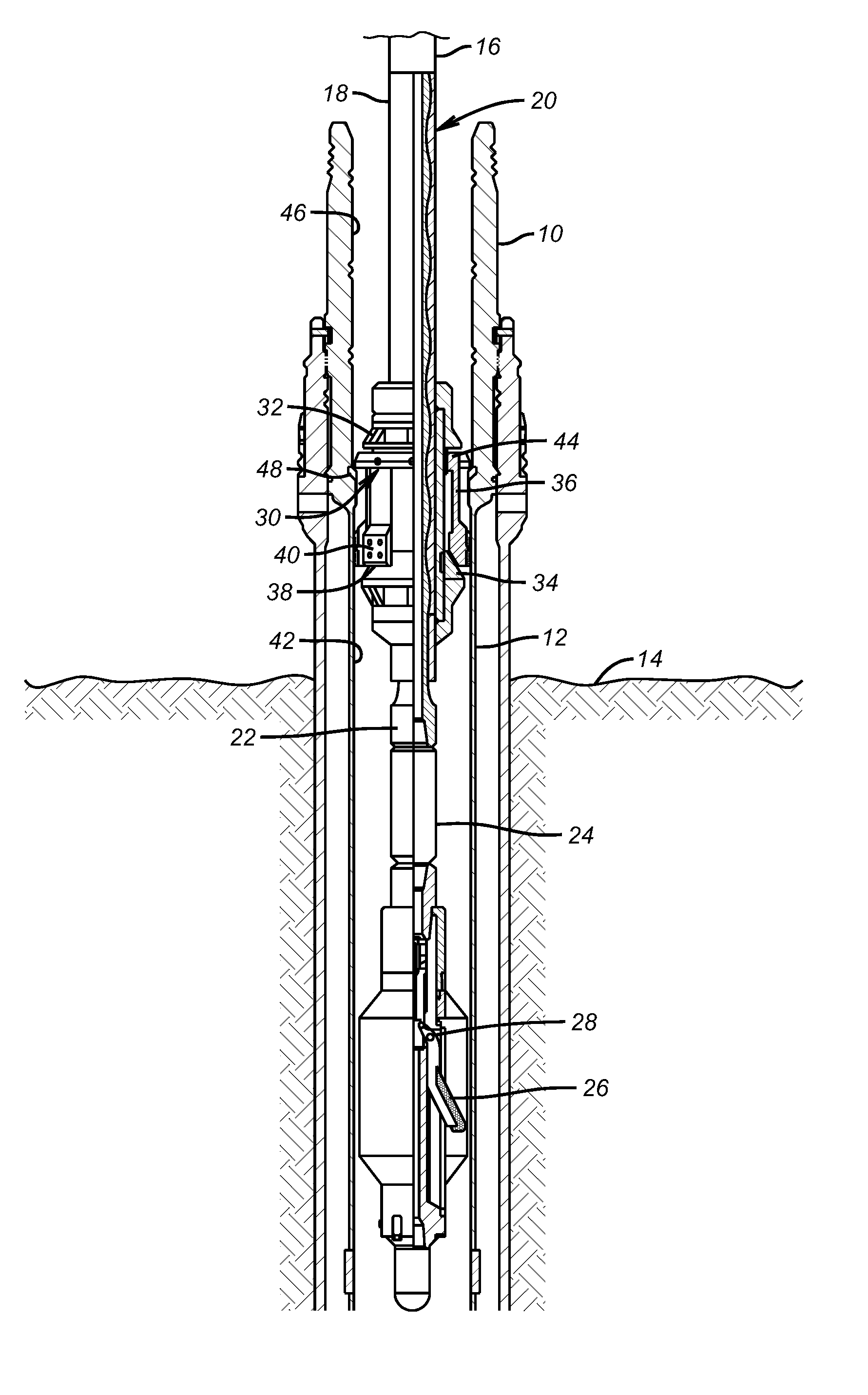

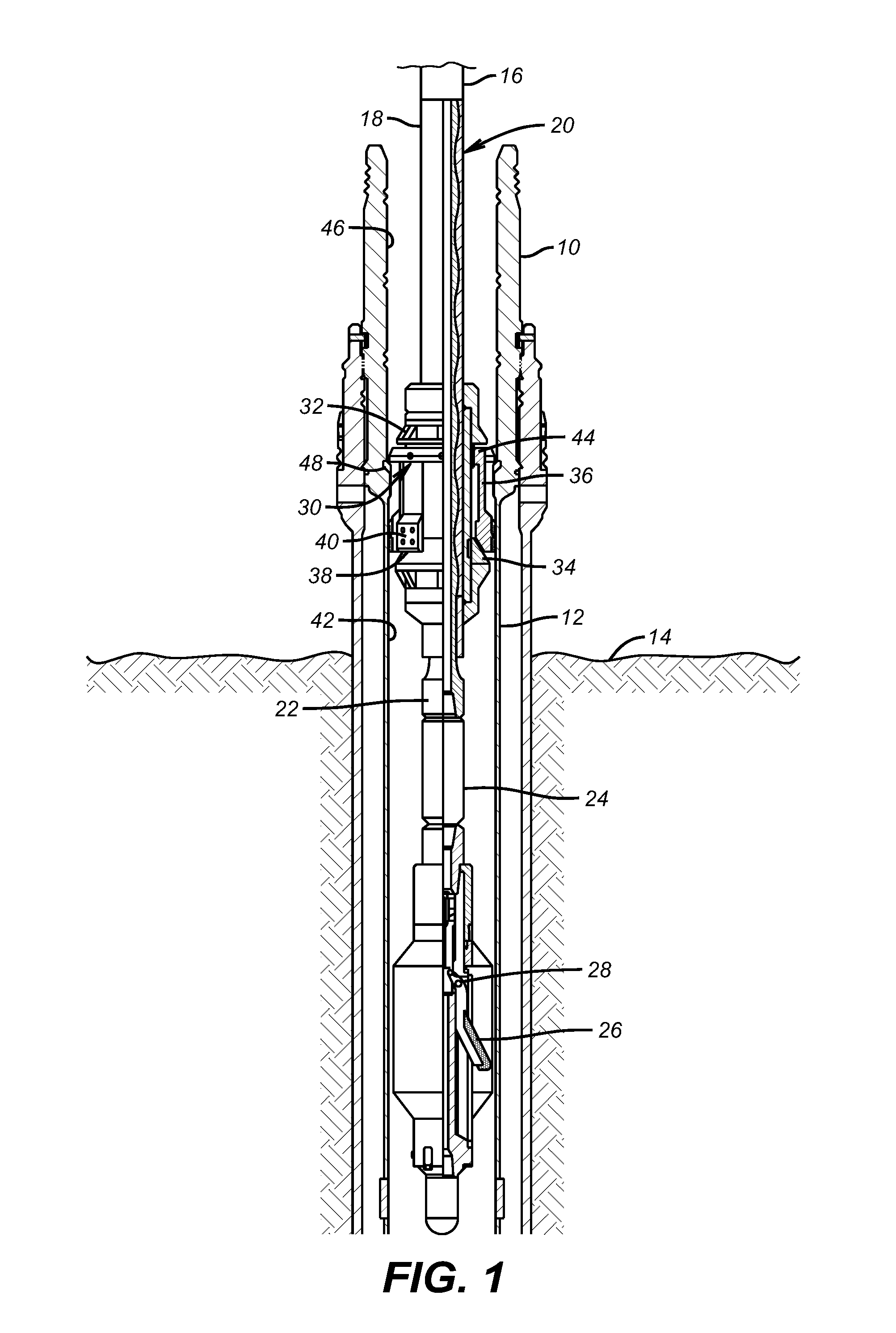

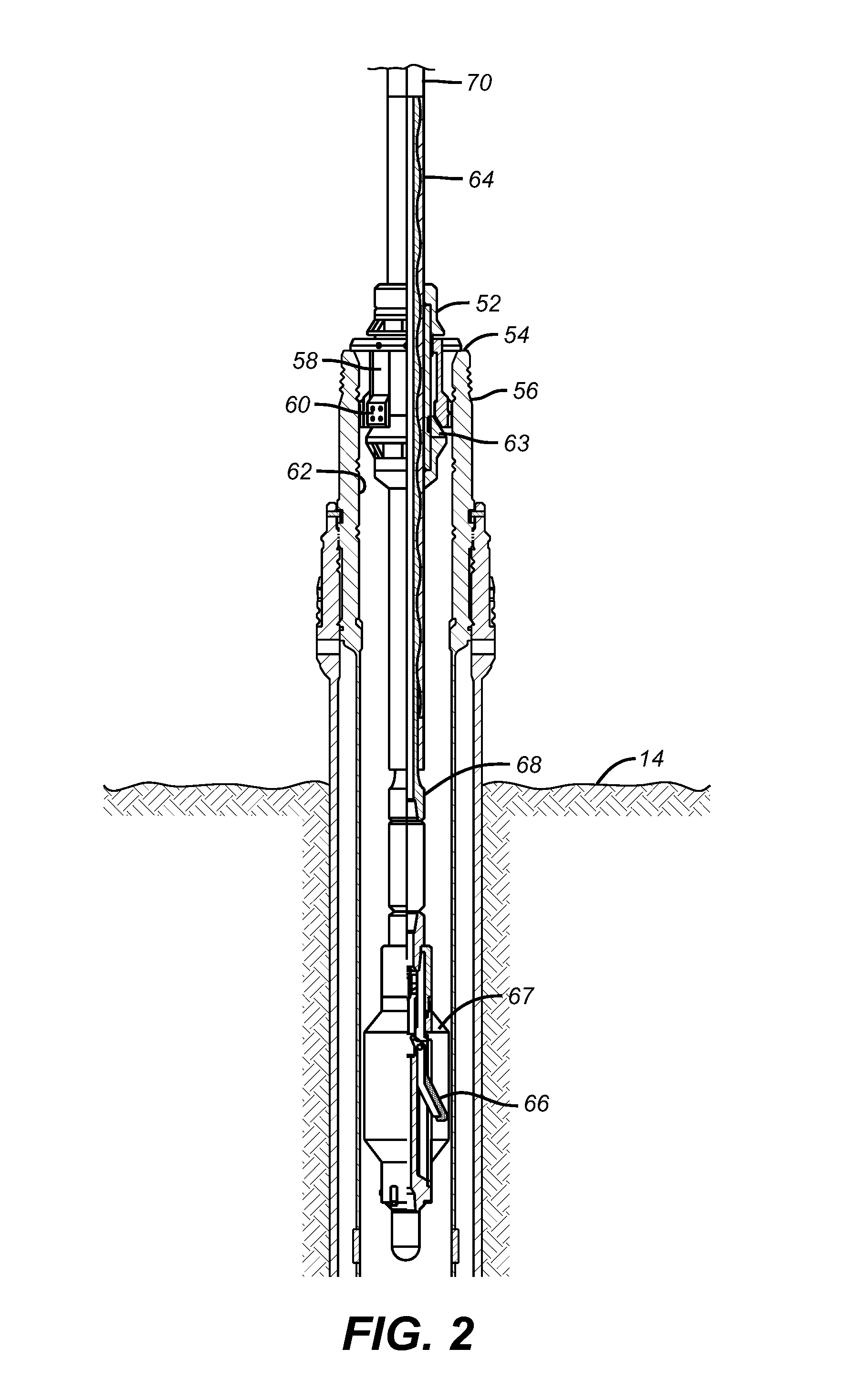

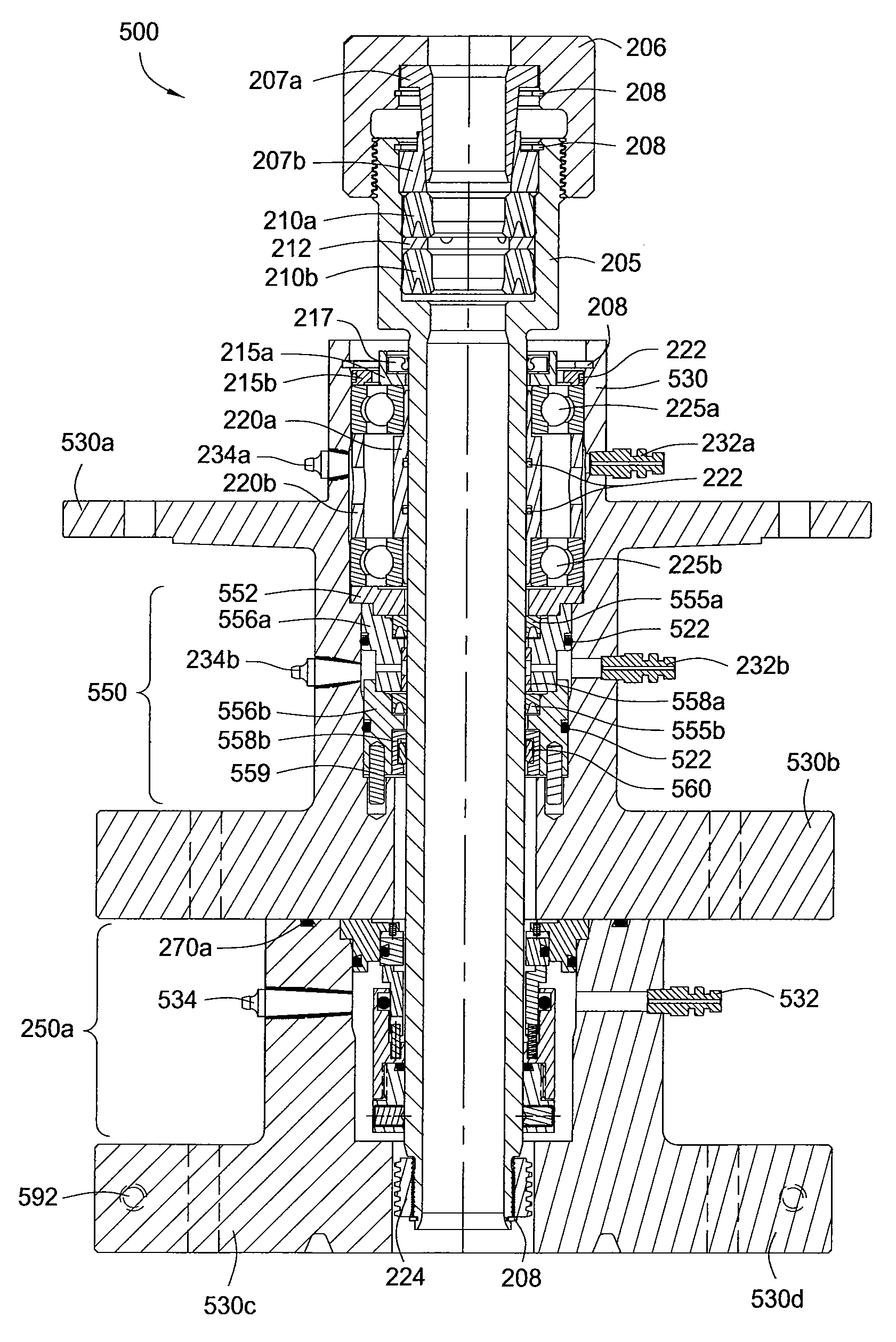

An artificial lift, concentric tubing production system for a well and method of using same. The system including an upper concentric tubing string portion comprising an inner production tubing string positioned within an outer production tubing string. A flow crossover assembly is connected to the upper concentric tubing string portion. The flow crossover assembly has first and second passageways. The inner production tubing string is in fluid communication with the first passageway and the outer production tubing string in fluid communication with the second passageway. An upper transducer is in fluid communication with one of the passageways of the flow crossover assembly and a lower apparatus is in fluid communication with the other of the passageways of the flow crossover assembly. The upper transducer may be a pump such as an electric submersible pump or a progressive cavity pump. The lower apparatus may be a pump, including an electric submersible pump, or a liquid / gas separator.

Owner:YPF INT

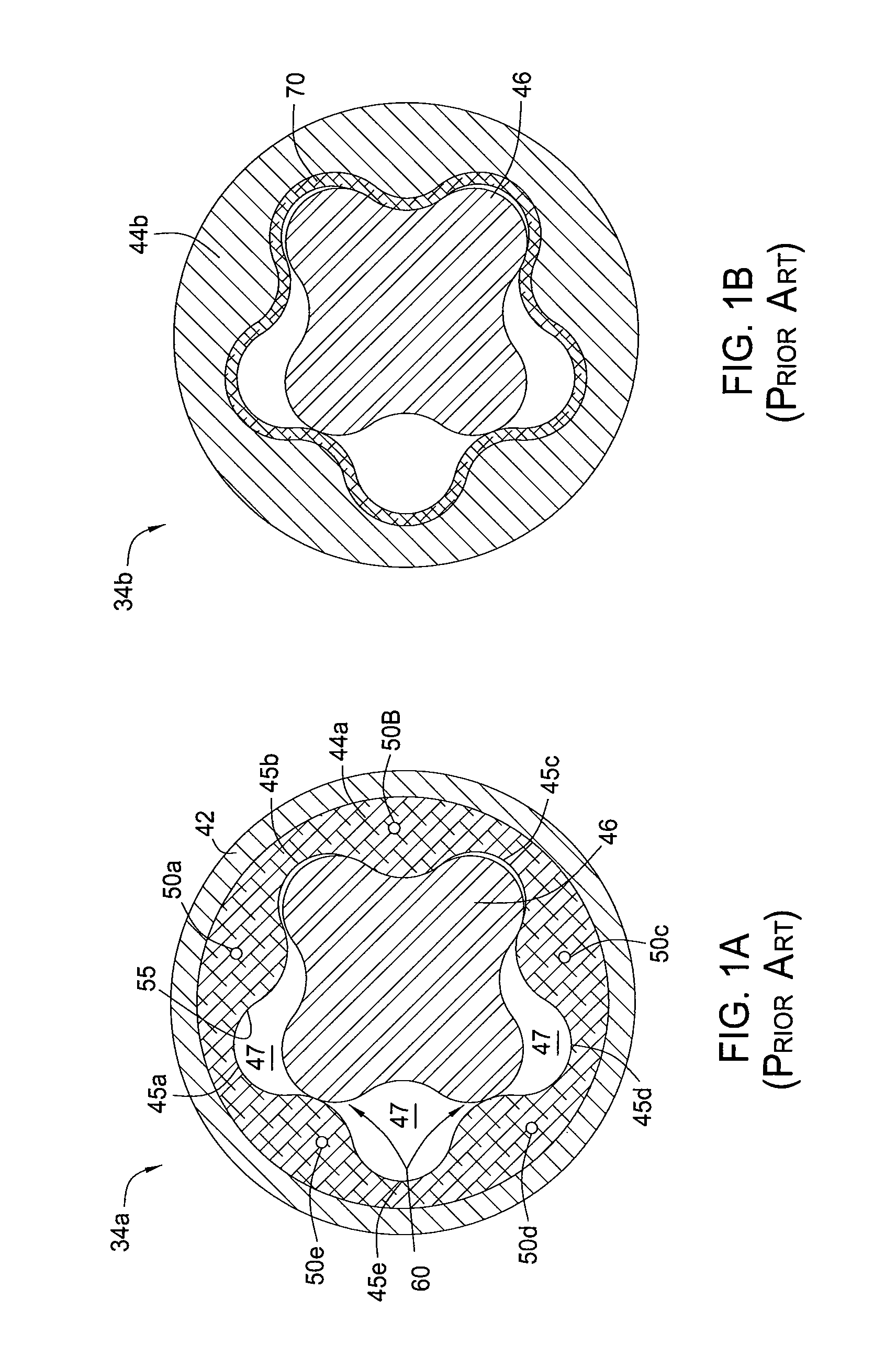

Progressive cavity pump/motor

InactiveUS6881045B2Accurate verificationOscillating piston enginesEngine of intermeshing engagement typeEngineeringDrill bit

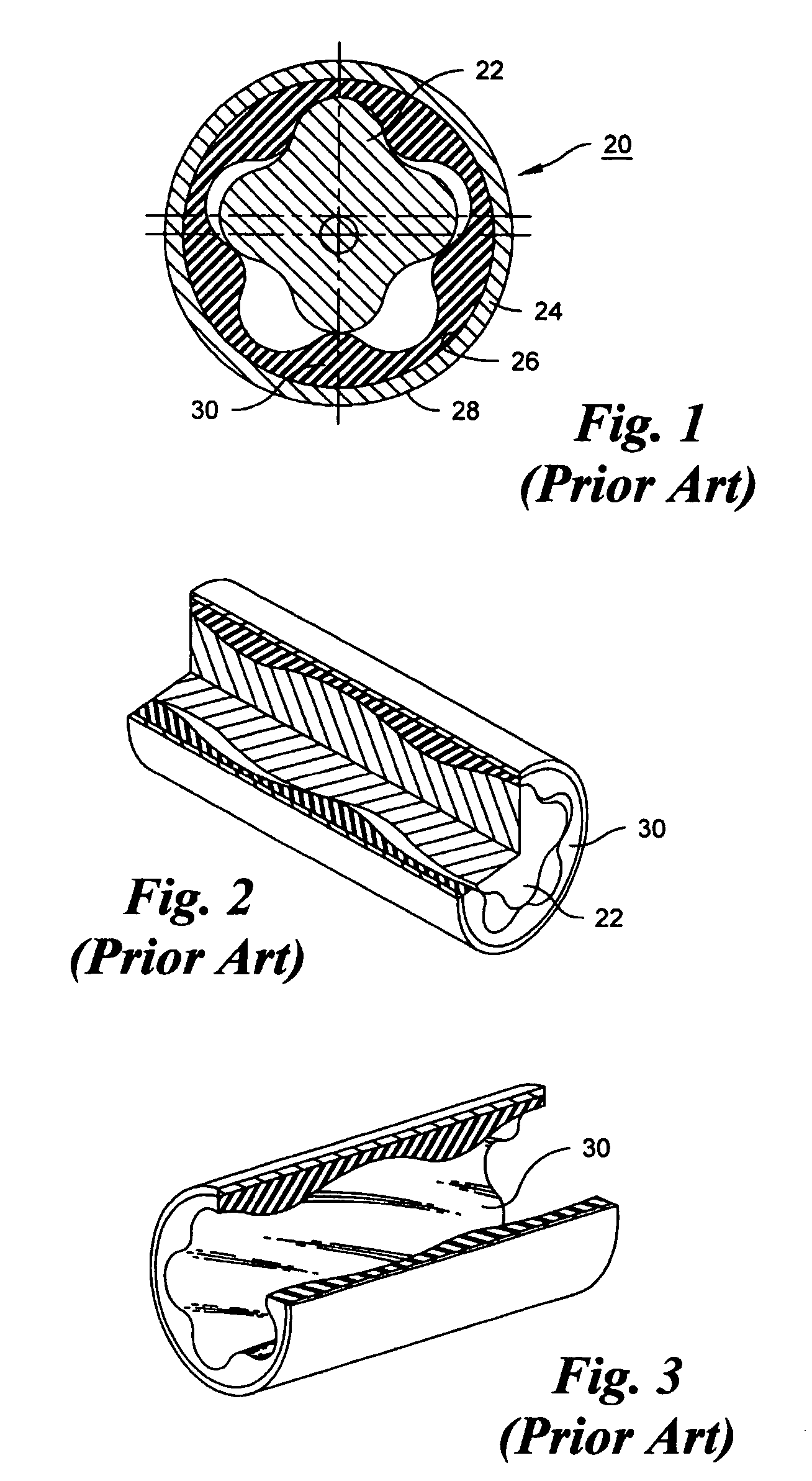

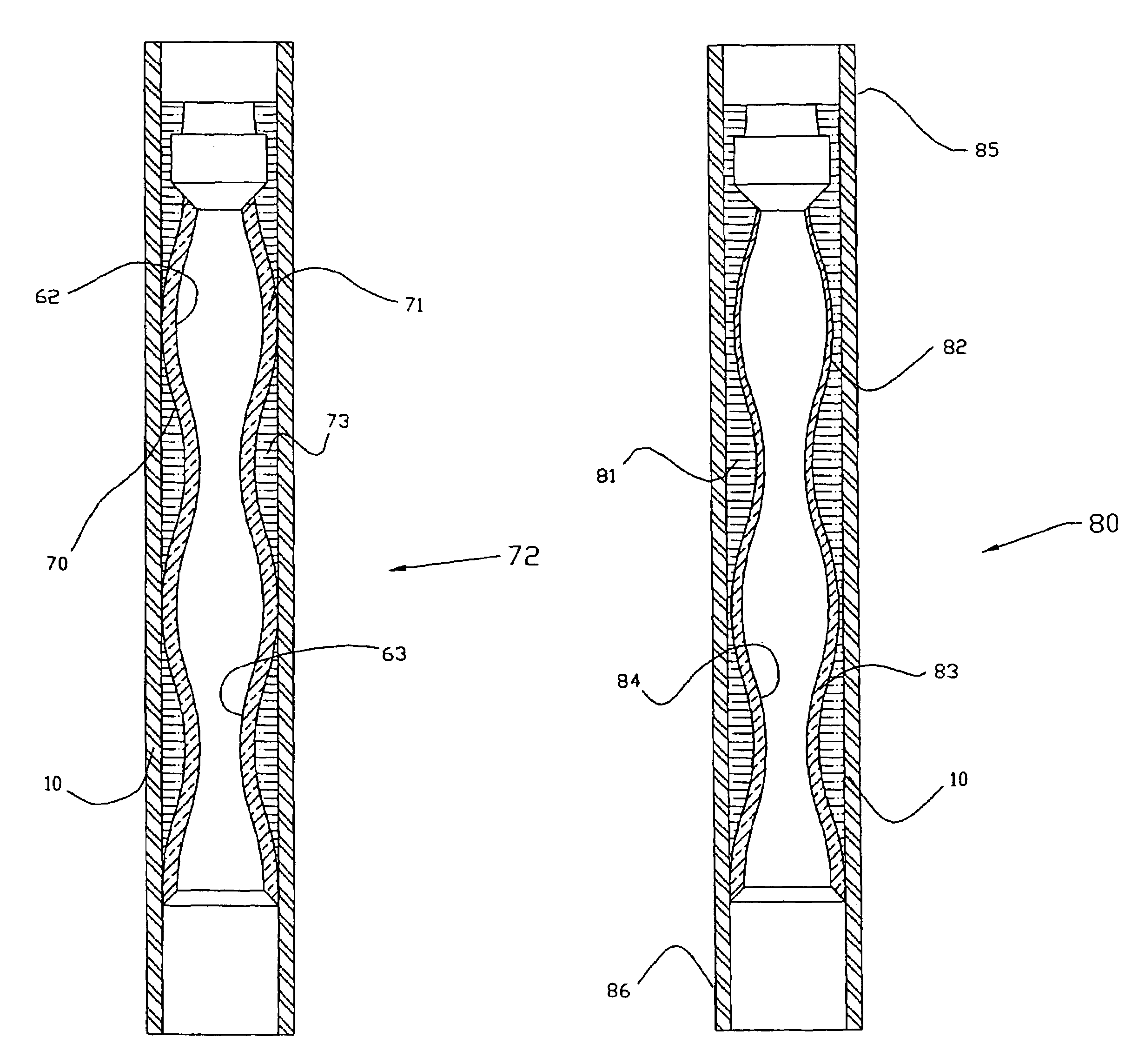

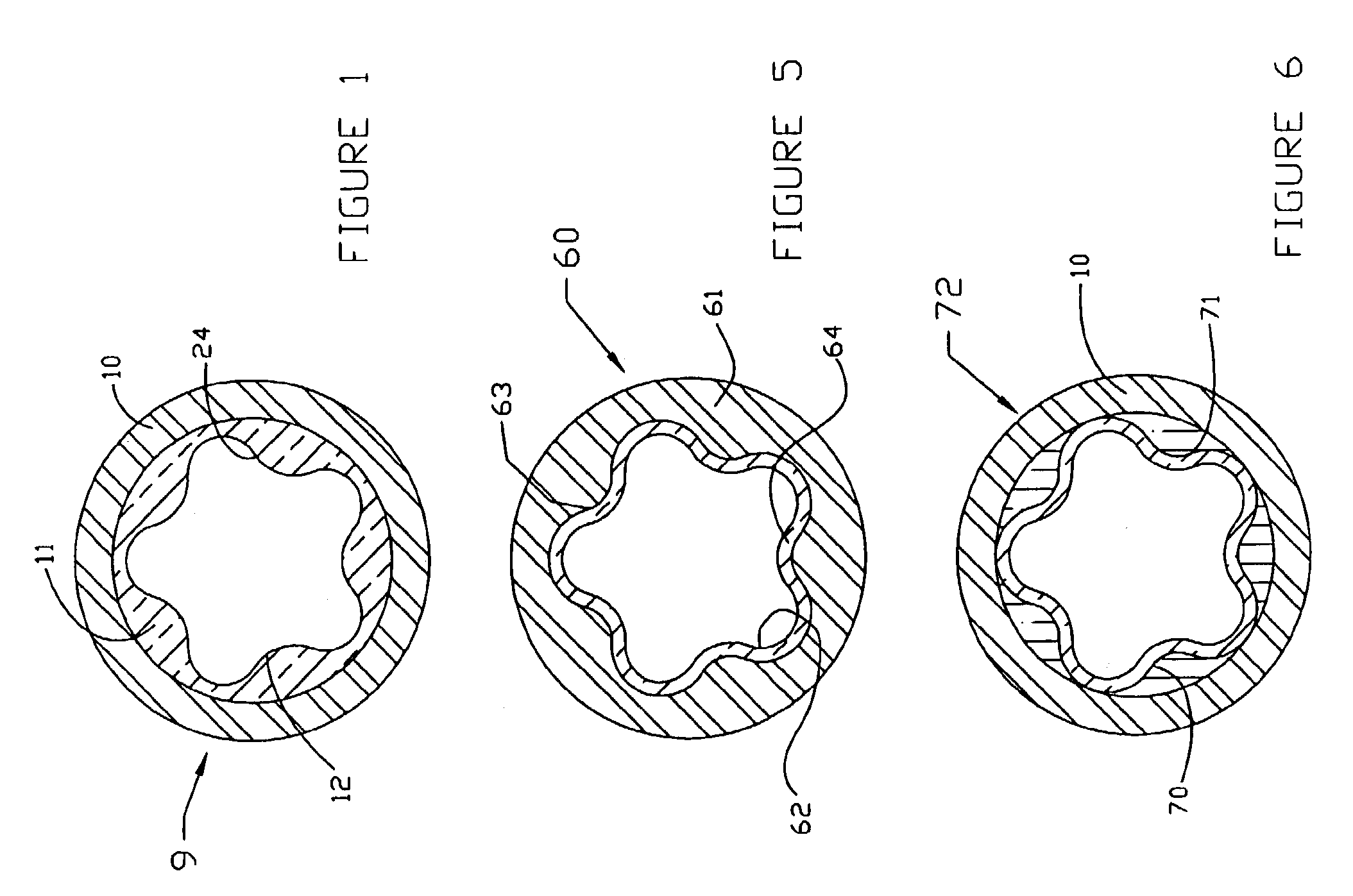

A progressive cavity pump or motor, particularly suitable for hydrocarbon recovery operations, includes a rotor 20 and a stator 10. Fluid pressure in cavities between the stator and the rotor create torque which rotates the bit. An interior surface of the stator is rigidly secured to the outer housing of the pump stator and defines an interior profile. A substantially uniform thickness elastomeric layer 62 is supported on the outer housing. The pump rotor has an exterior profile which corresponds with the interior profile of the elastomeric layer.

Owner:ROBBINS & MYERS ENERGY SYST

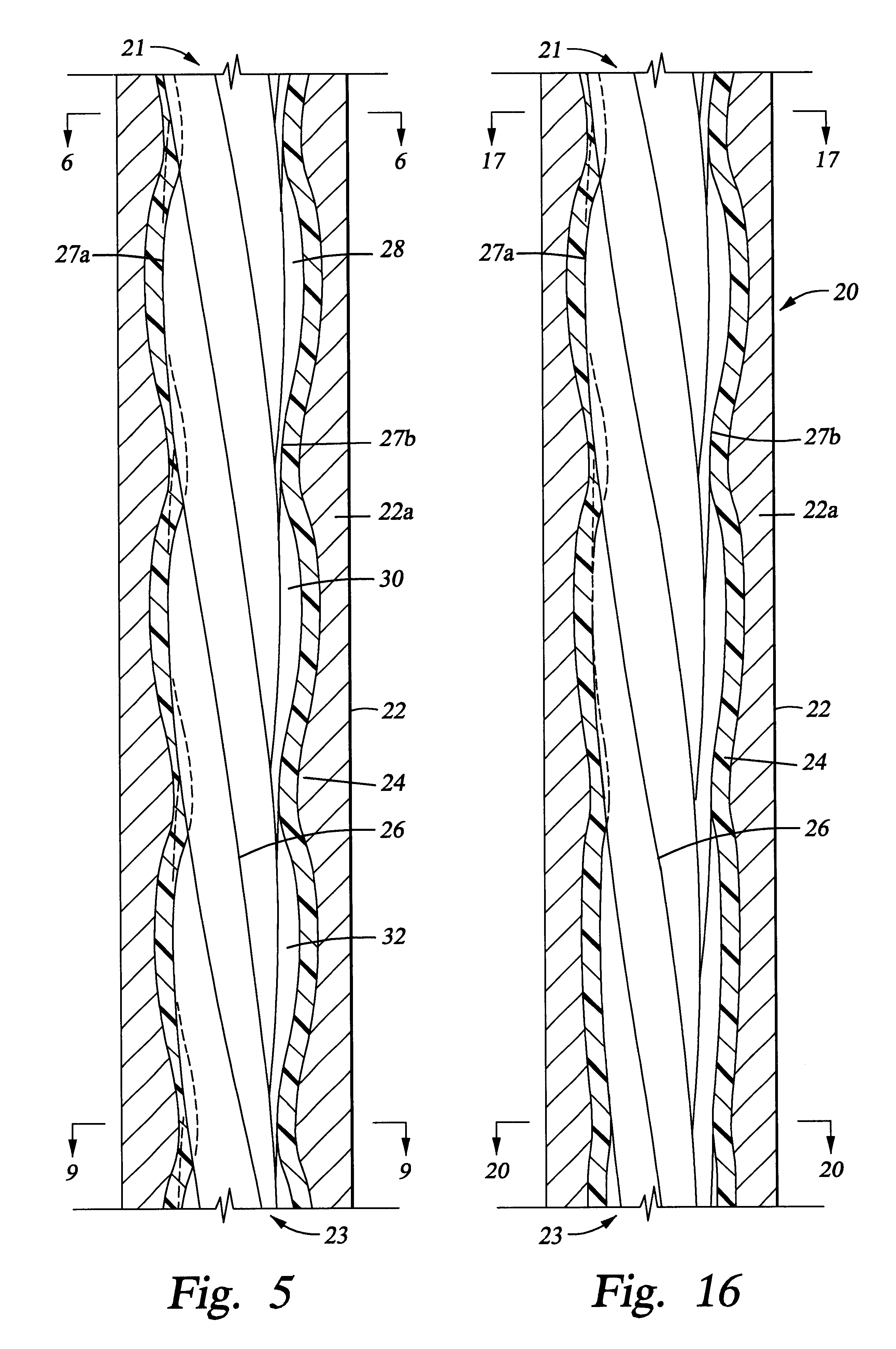

Adjustable fit progressive cavity pump/motor apparatus and method

InactiveUS6358027B1Oscillating piston enginesSealing arrangement for pumpsInterference fitEngineering

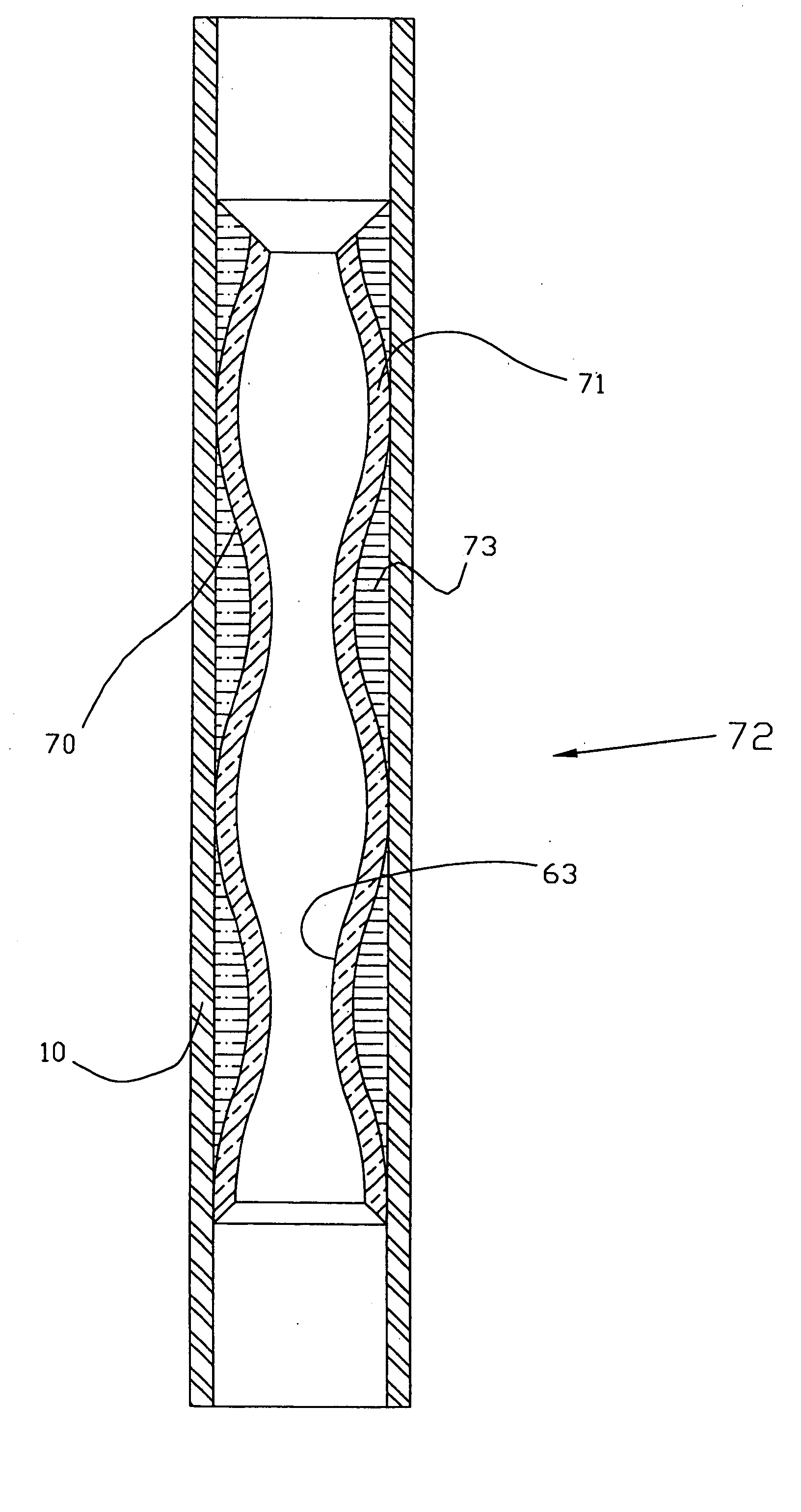

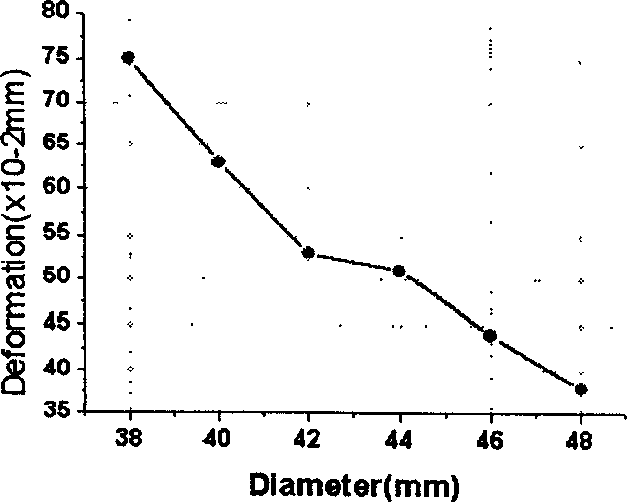

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. In one embodiment, the adjustment may occur while the PCP in mounted downhole in a wellbore. In another embodiment, the adjustment may occur automatically depending on sensor input of operating conditions of the PCP.

Owner:WEATHERFORDLAMB

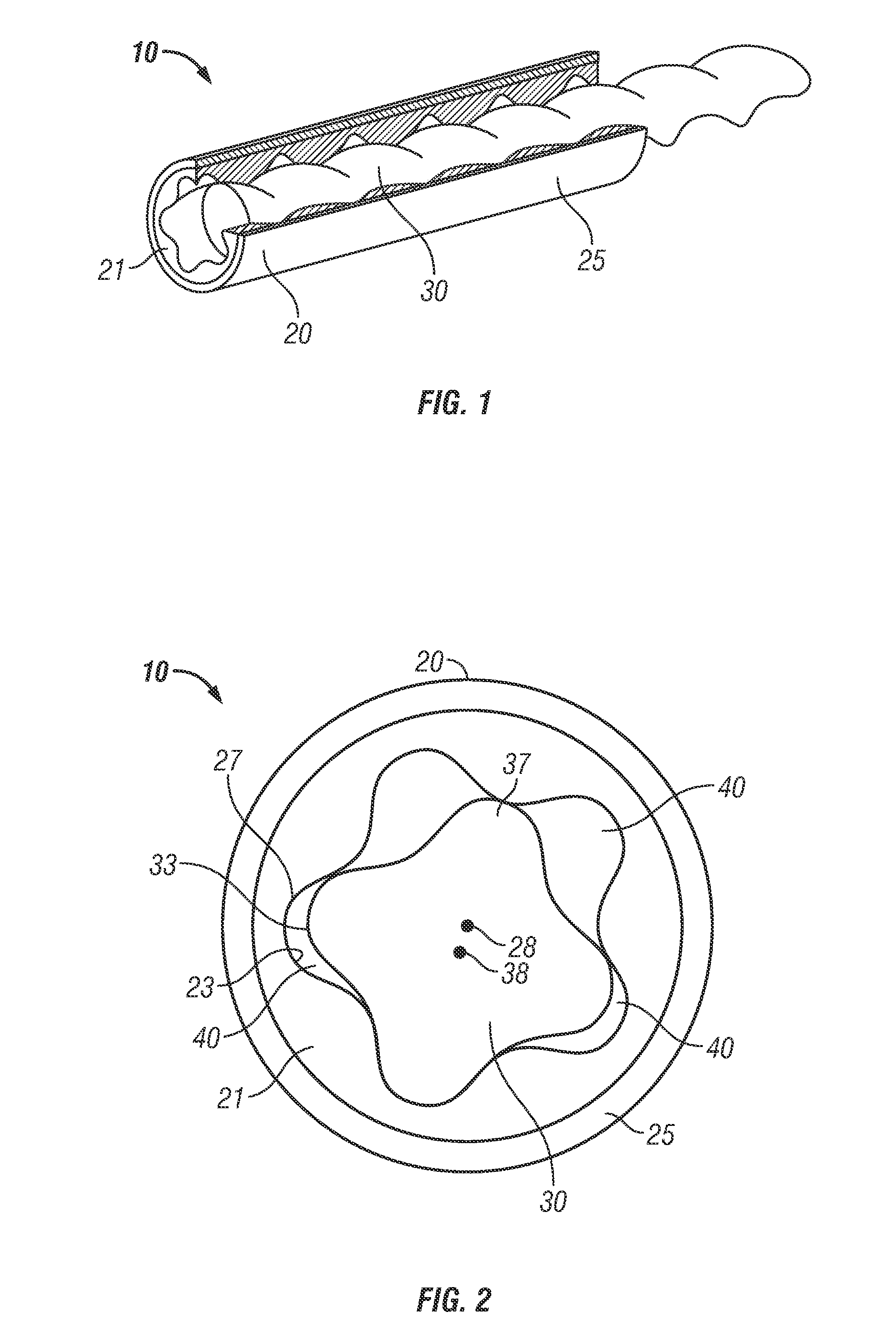

Reinforced Stators and Fabrication Methods

ActiveUS20130149182A1Readily apparentAdditive manufacturing apparatusOscillating piston enginesEngineeringMechanical engineering

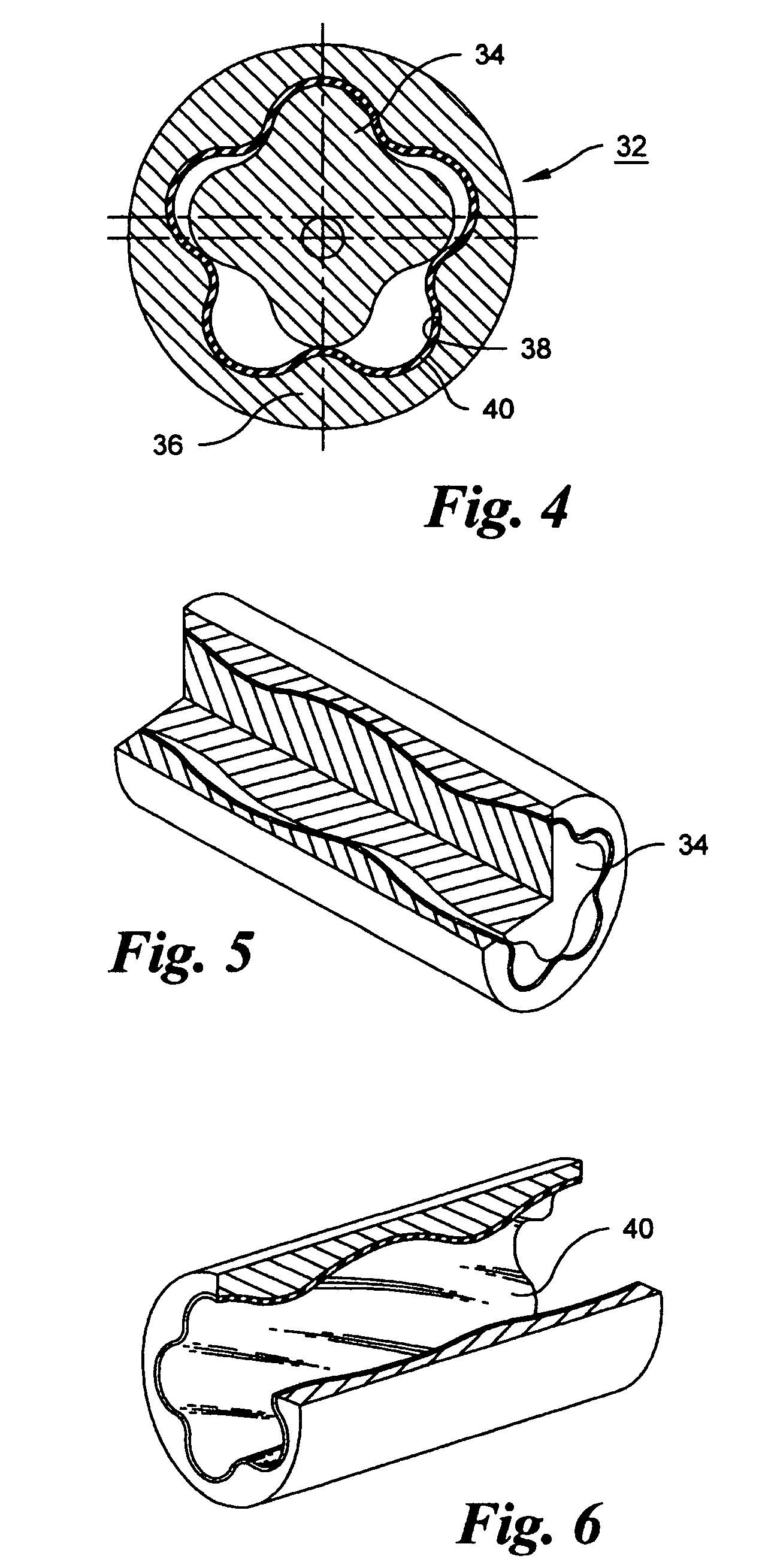

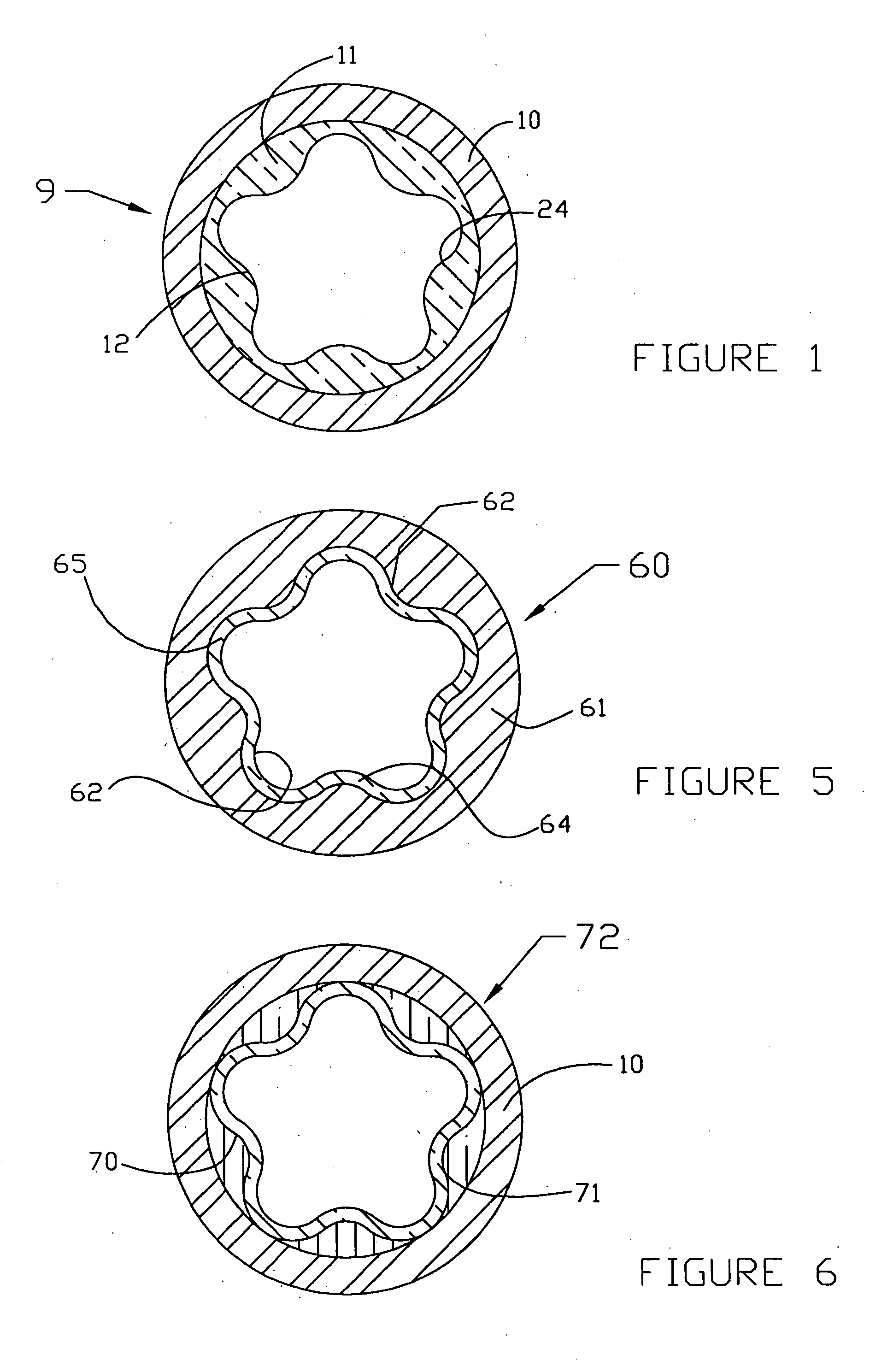

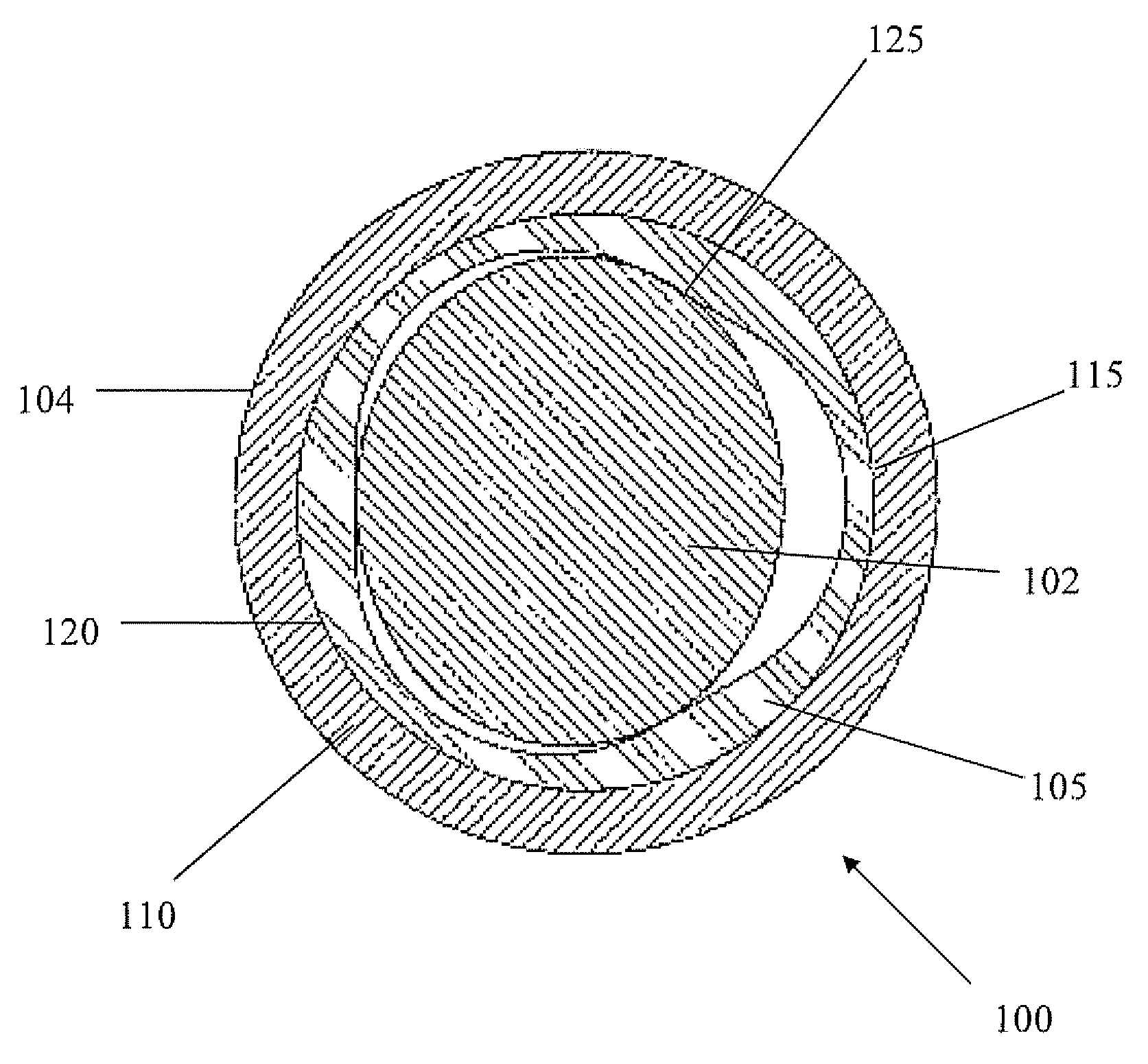

A stator for a progressive cavity pump or motor comprises a tubular housing having a central axis. In addition, the stator comprises a stator insert coaxially disposed within the housing. The stator insert has a radially outer surface that engages the housing and a radially inner surface defining a helical-shaped through bore extending axially through the stator insert. The stator insert includes an insert body and an insert liner attached to the insert body. The insert body is radially positioned between the housing and the insert liner. The insert body comprises a reinforcement structure and a plurality of voids dispersed within the reinforcement structure.

Owner:NAT OILWELL VARCO LP

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS20050079083A1Improve heat transfer performanceReduce adverse effectsOscillating piston enginesEngine of intermeshing engagement typeRough surfaceElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Apparatus for dispensing liquids and solids

InactiveUS6913166B2Avoid adjustmentAllocation is accurateLiquid transferring devicesFluid pressure control using electric meansSprayerDiagnostic system

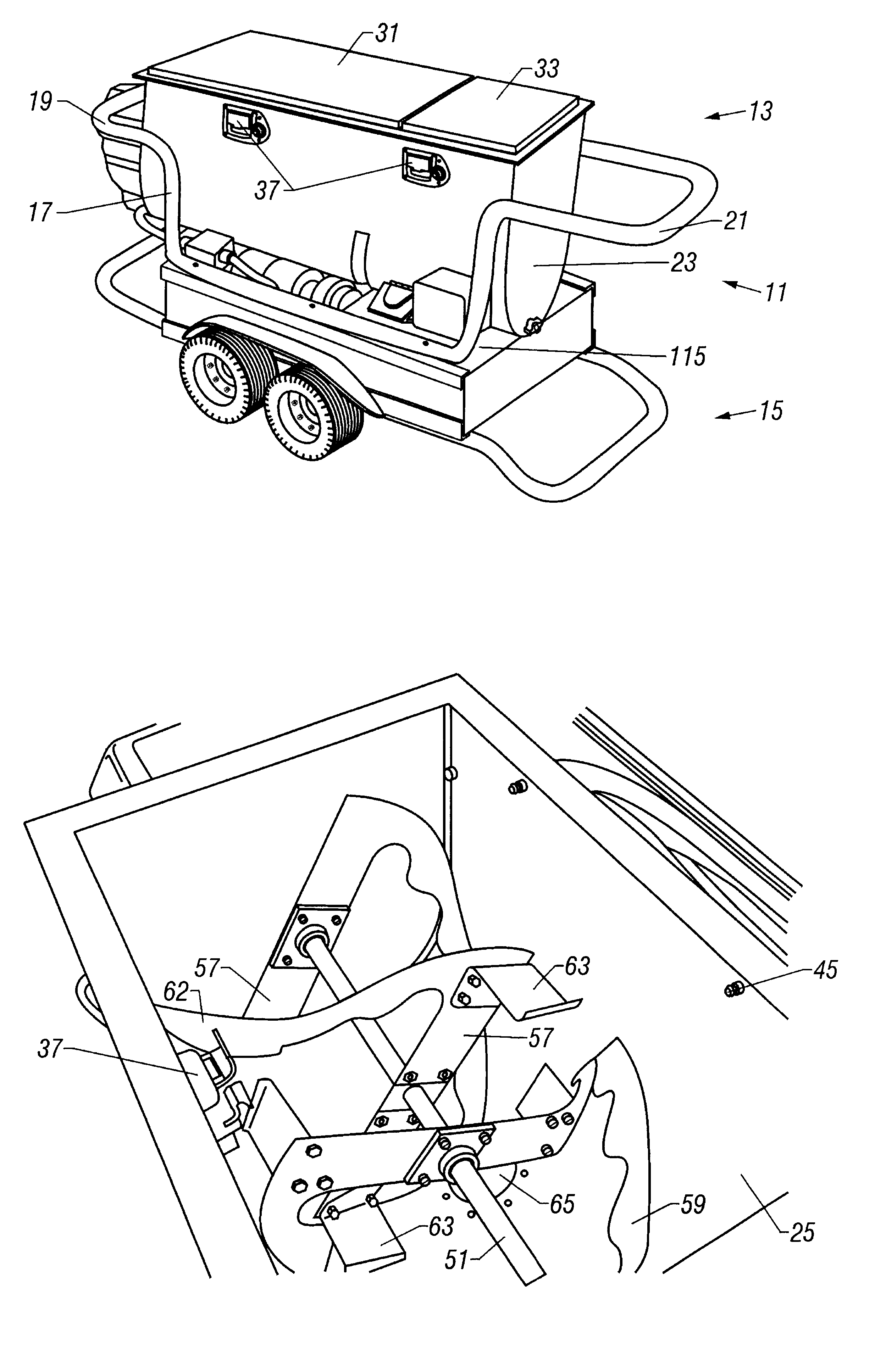

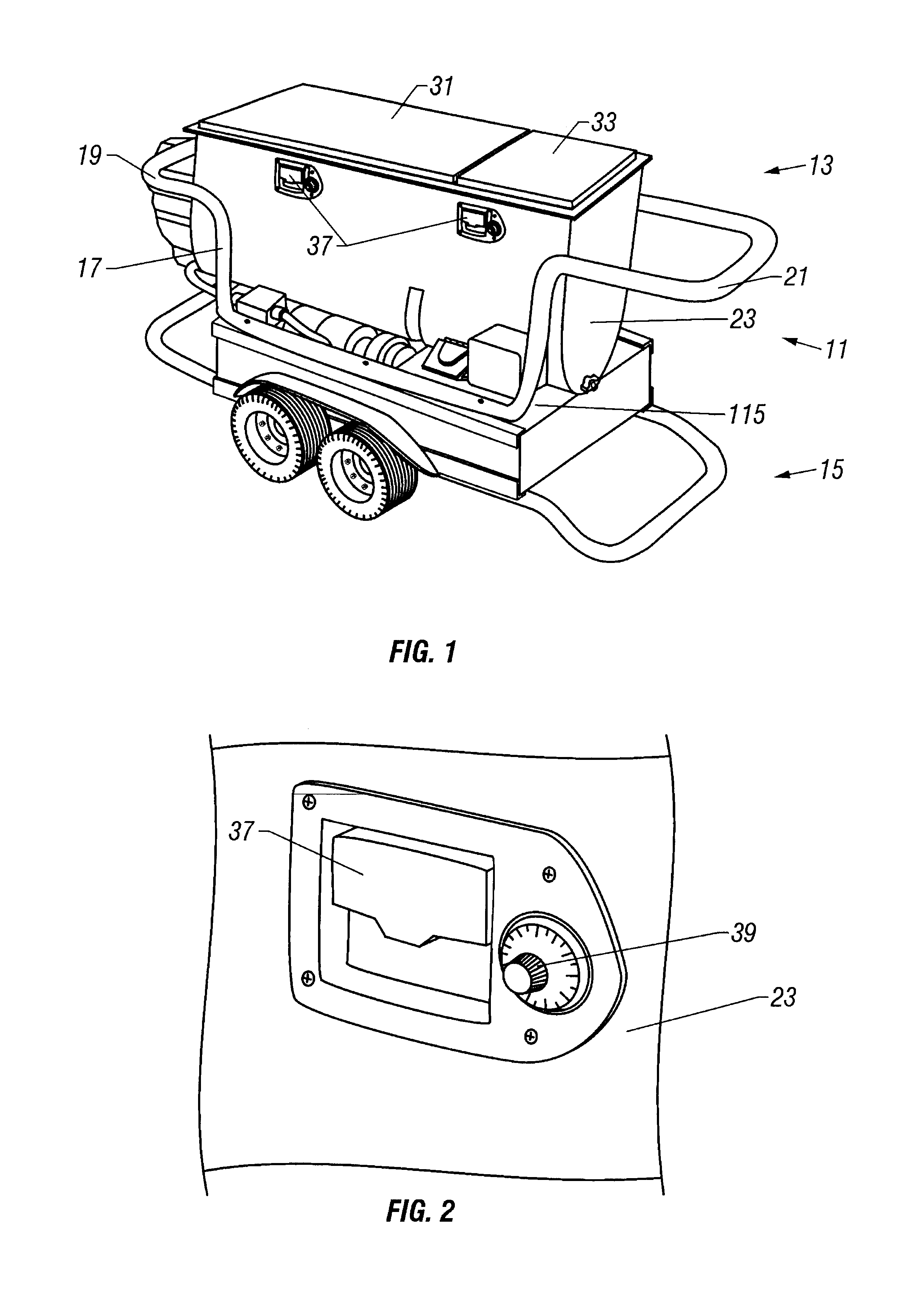

A system for metering and dispensing single and plural component liquids and solids as described herein. The dispensing system has a microprocessor-based control system and progressive cavity pumps which provide a very accurate control of component ratios, shot sizes, flow rates and dispense durations. The system has numerous feedback components for accurately controlling the pressure, flow rates, fluid levels and amounts of fluids dispensed. Where a valved nozzle is used, the pressure in the flow system is used to control the pumps rather than the valve. Such a system may be used as a sprayer with compressed air added. Drum rams are associated with the supply drums and the progressive cavity pumps may be placed on the drum ram. Maintenance of a steady state in the system is accomplished with back and forth movement of the pump, with compensation for pressure changes. Absolute rotational position of the pump can be monitored when a set pressure is maintained, to diagnose system conditions. A high flow system uses ball valves and a releasably coupled manifold. A mold charging system uses pressure to control the pumps which are cycled on and off to avoid overpressurizing the mold. The rate of pressure increase is used to control the rate of flow from the pumps as the mold approaches completion of the charge, again to avoid overpressurizing the mold. A signal controlled by a timer can indicate elapsed time as a warning that material within the mixer conduit is hardening to a condition such that flow cannot be reinitiated.

Owner:FLUID RES

Direct drive linear flow blood pump

InactiveUS20050008509A1Reduce unbalanced magnetic forceReduce magnetic forceOscillating piston enginesBlood pumpsMotor driveBlood pump

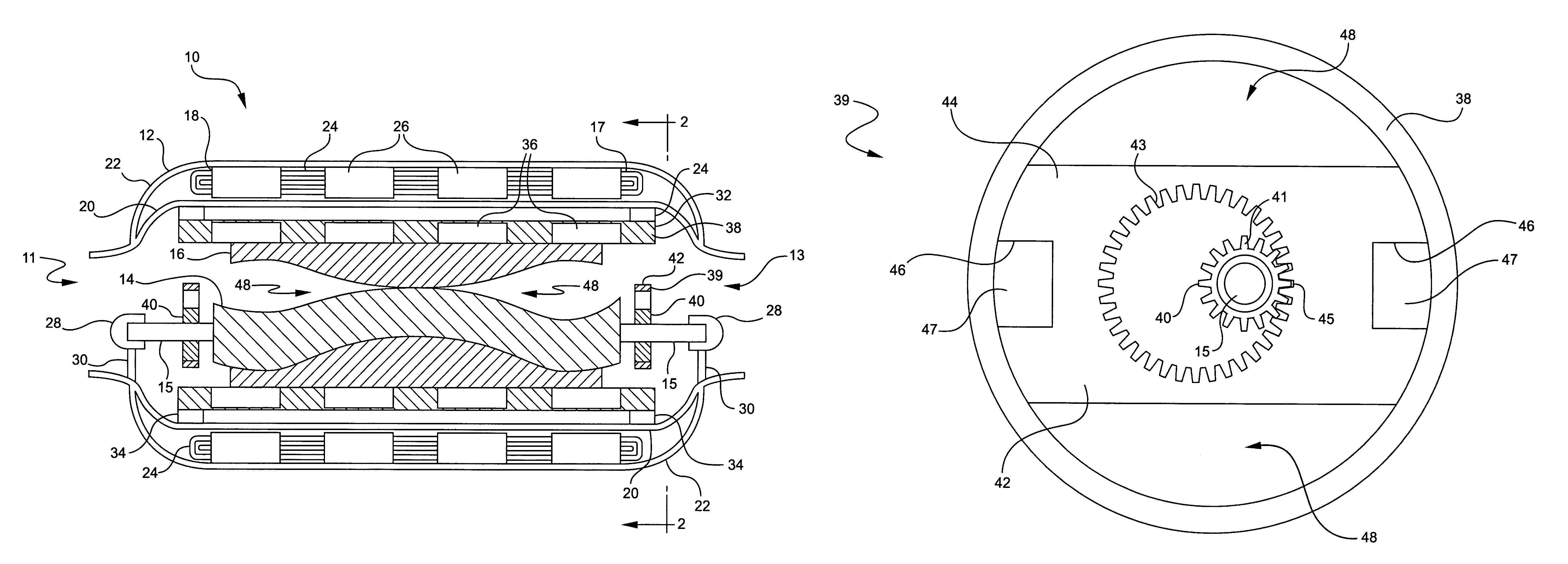

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

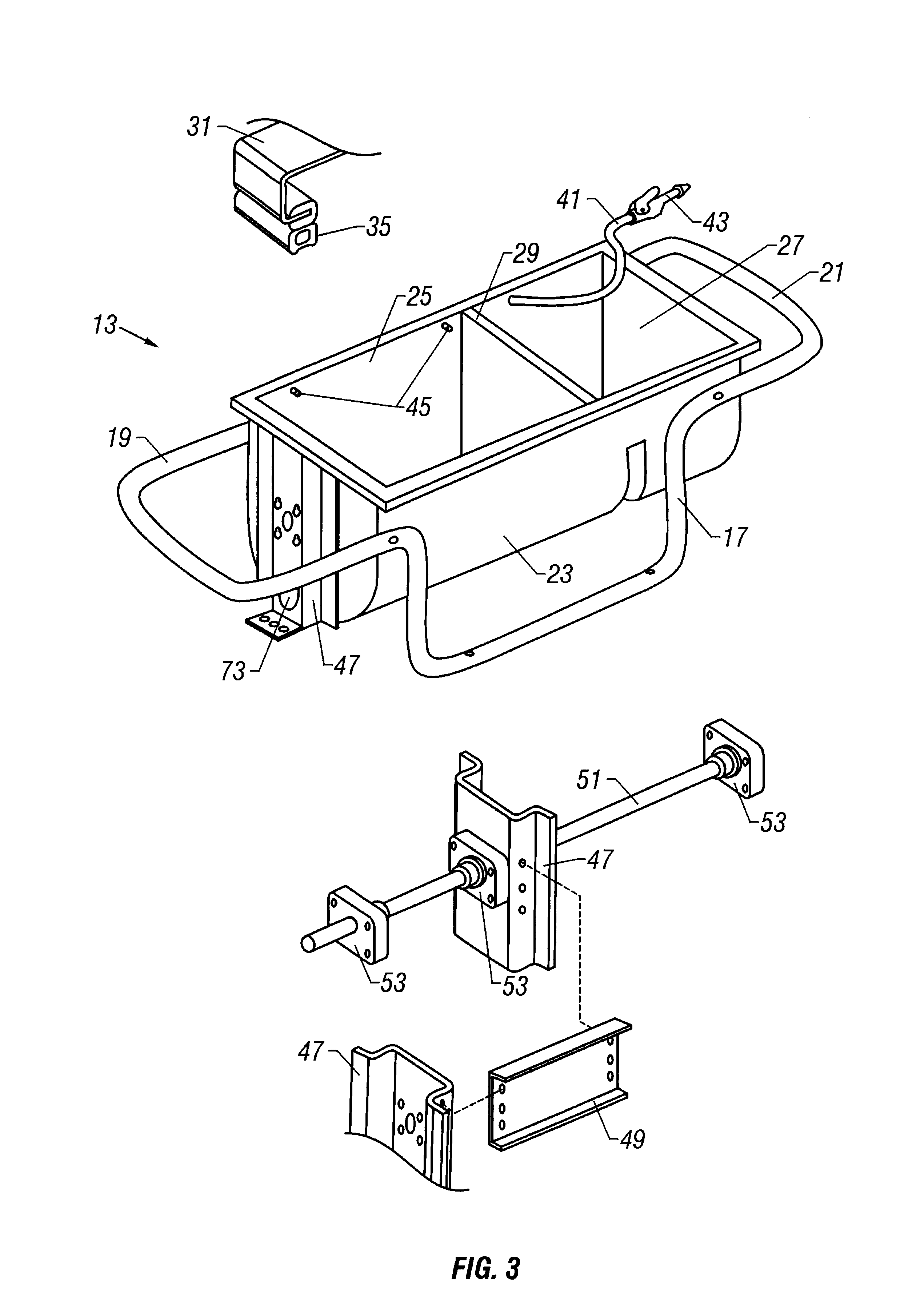

Apparatus for automated finishing of interior surfaces

An automated interior finishing apparatus has an upper section for mixing material, and a lower section for conveying the material. The upper section has a mixing compartment and a separate washing / storage compartment. Each compartment has a hinged lid that forms an air-tight seal. The mixing compartment has a shaft with an auger for mixing compound with water. The lower section has a motor for driving a progressive cavity pump, which receives mixed material from the mixing compartment. The pump delivers a smooth and uniform supply of material through an external supply hose. The apparatus is used as one component of an overall automated interior finishing system and method for completing surface finishes. For example, one end of the supply hose is connected to the outlet end of the pump for delivering mixed material to a hand tool at the opposite end, such as a flat taper.

Owner:RENEGADE TOOL

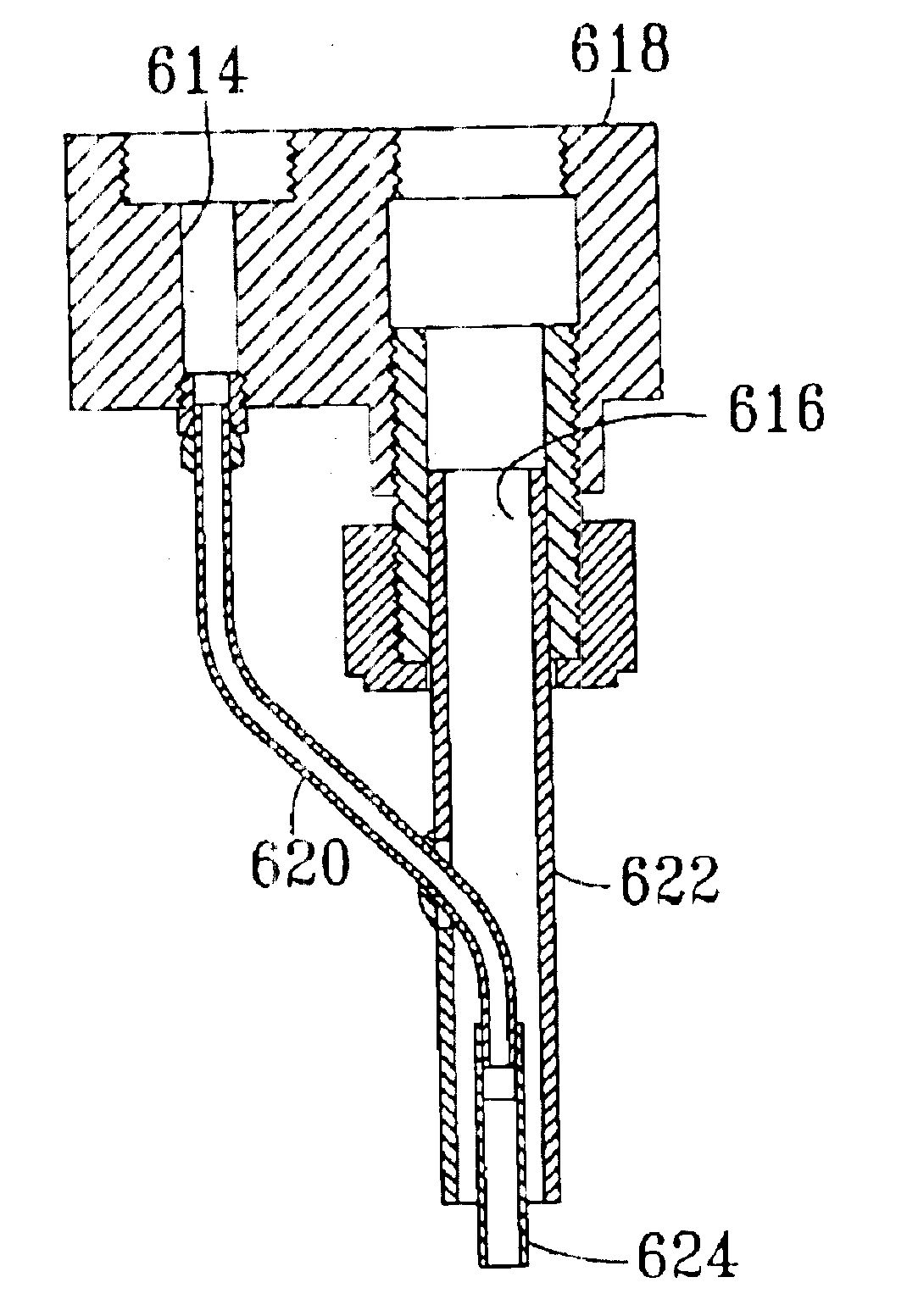

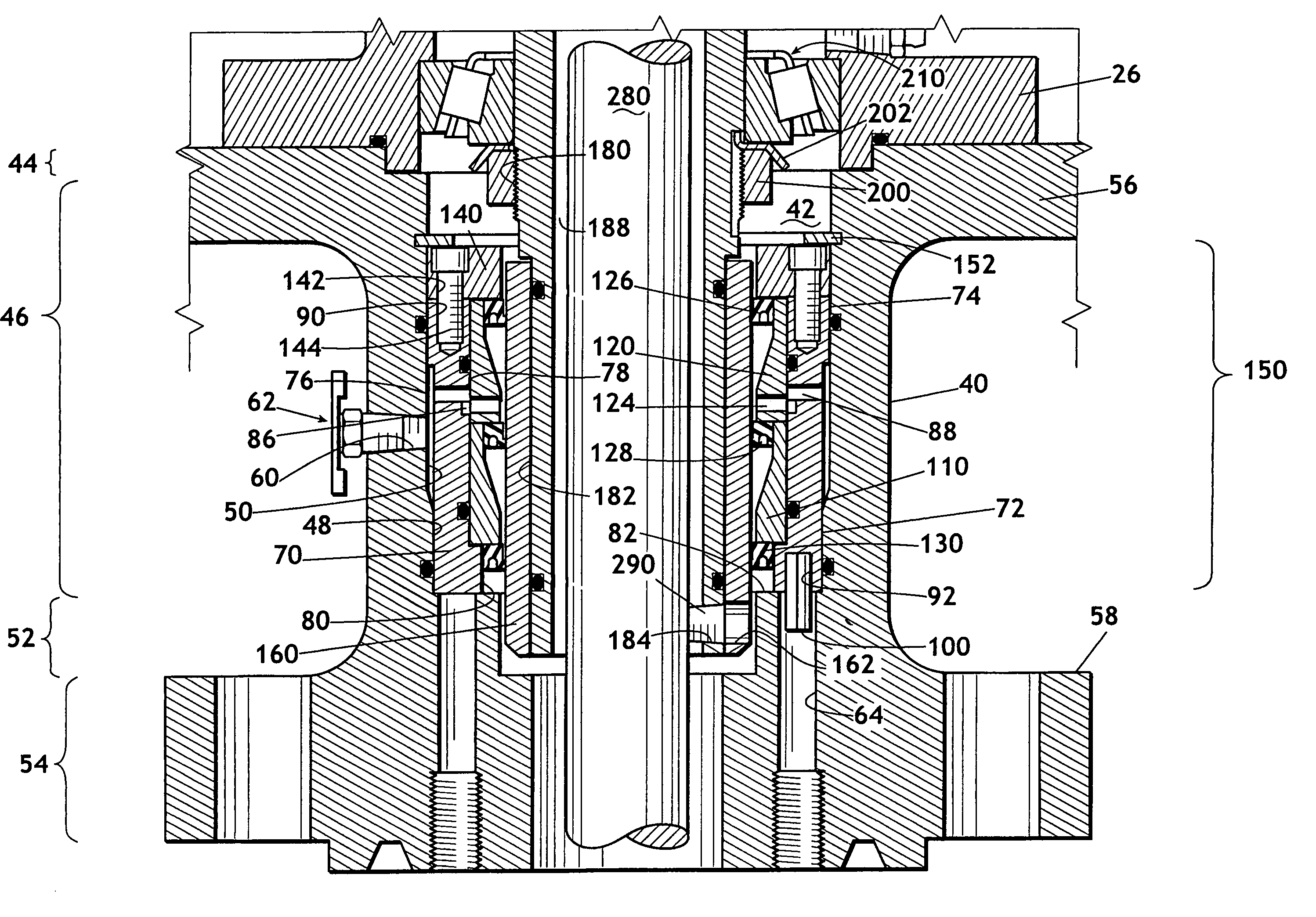

Convertible rotary seal for progressing cavity pump drivehead

ActiveUS7255163B2Eliminate wear and tearDetect failureDrilling rodsFluid removalLocking mechanismEngineering

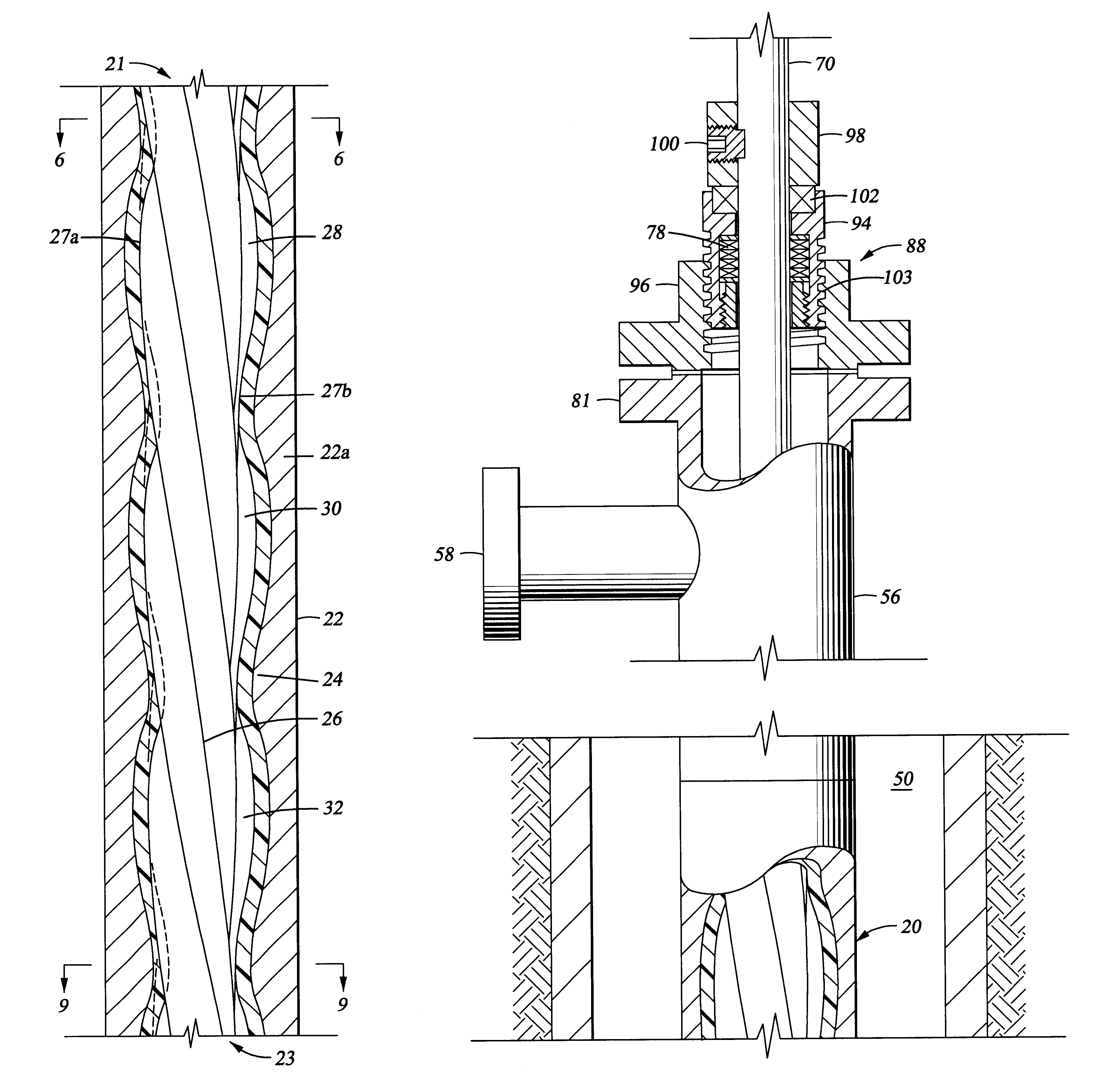

A convertible rotary seal has a housing for receiving a polish rod. A mandrel is rotatably mounted in the seal housing and surrounds the polish rod. A wear sleeve surrounding the mandrel engages a primary seal. A secondary seal engages the mandrel and polish rod and rotates therewith but may be converted for use as a static seal if necessary. A locking mechanism selectively secures the mandrel in a stationary orientation with respect to the seal housing. Fluid that leaks past the primary seal will be detectible through an external orifice. If a leak in the primary seal is detected via the external port, then the mandrel may be secured in a stationary orientation with respect to the housing and the secondary seal may be reconfigured to operate as a stationary seal until such time as the rotary sealing unit can be overhauled.

Owner:RAVDOS HLDG INC

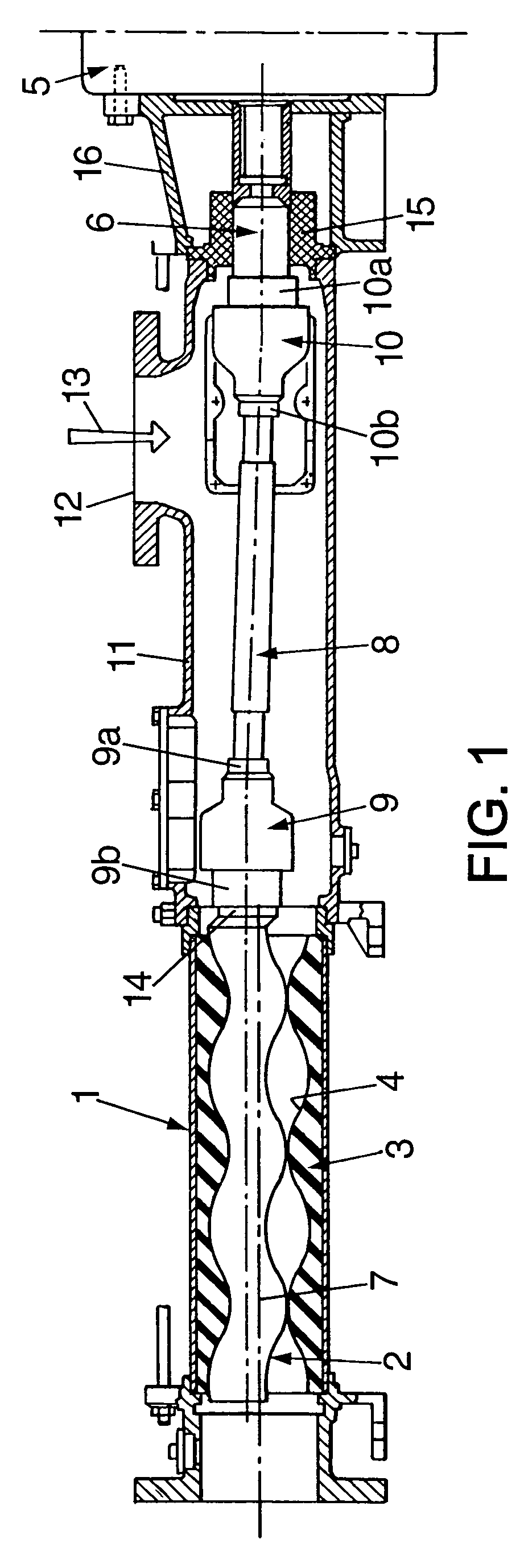

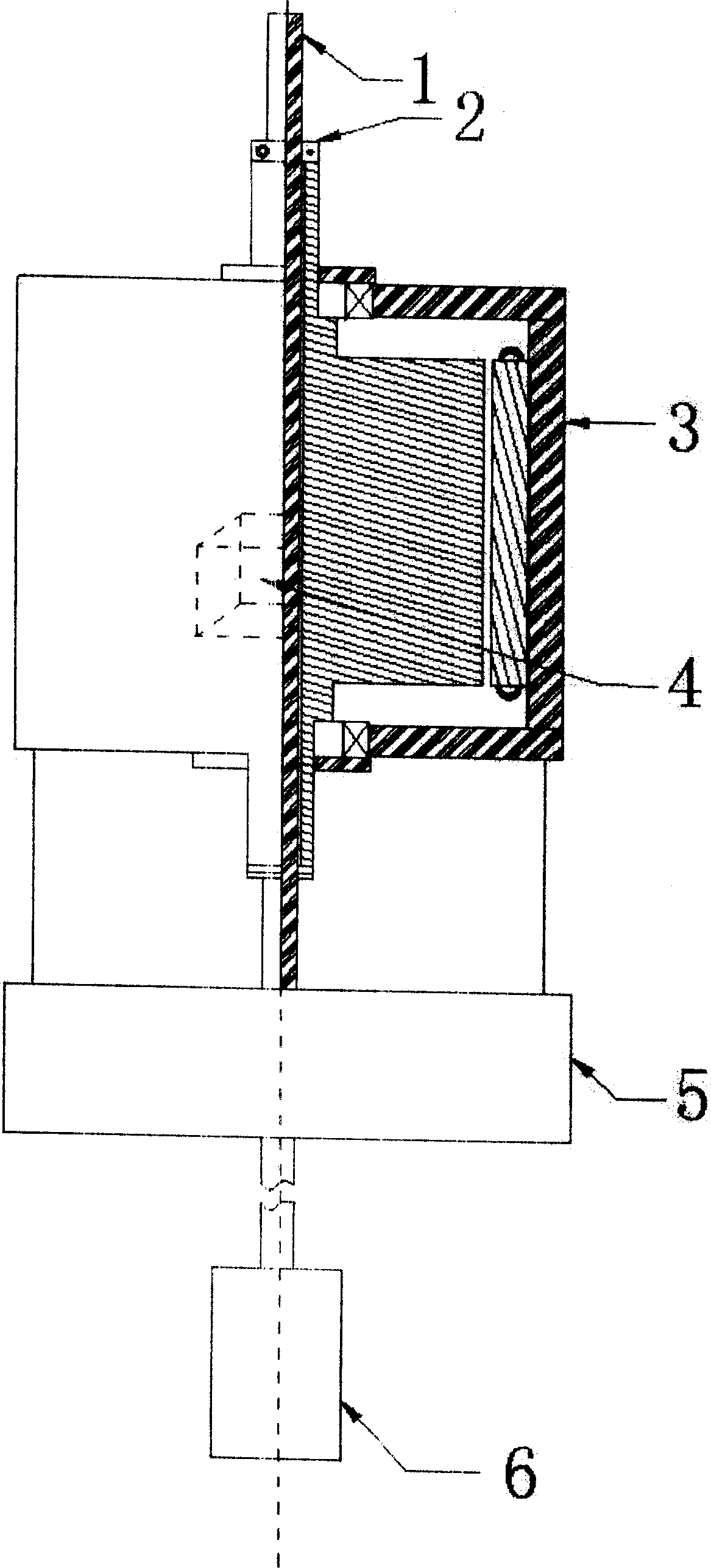

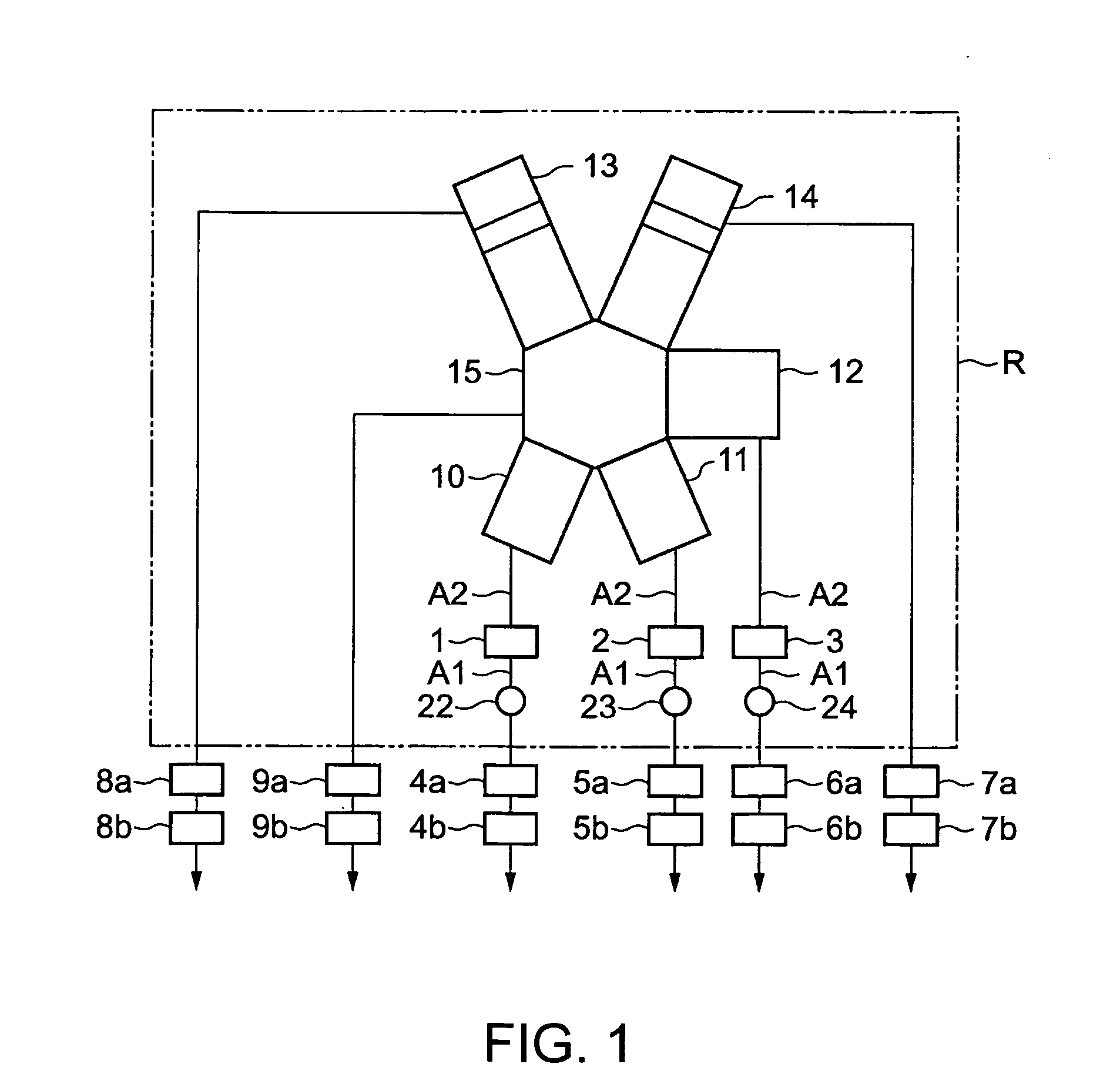

Progressing cavity pump

ActiveUS20050169779A1Improve system reliabilityImprove reliabilityPump componentsOscillating piston enginesTemperature controlEngineering

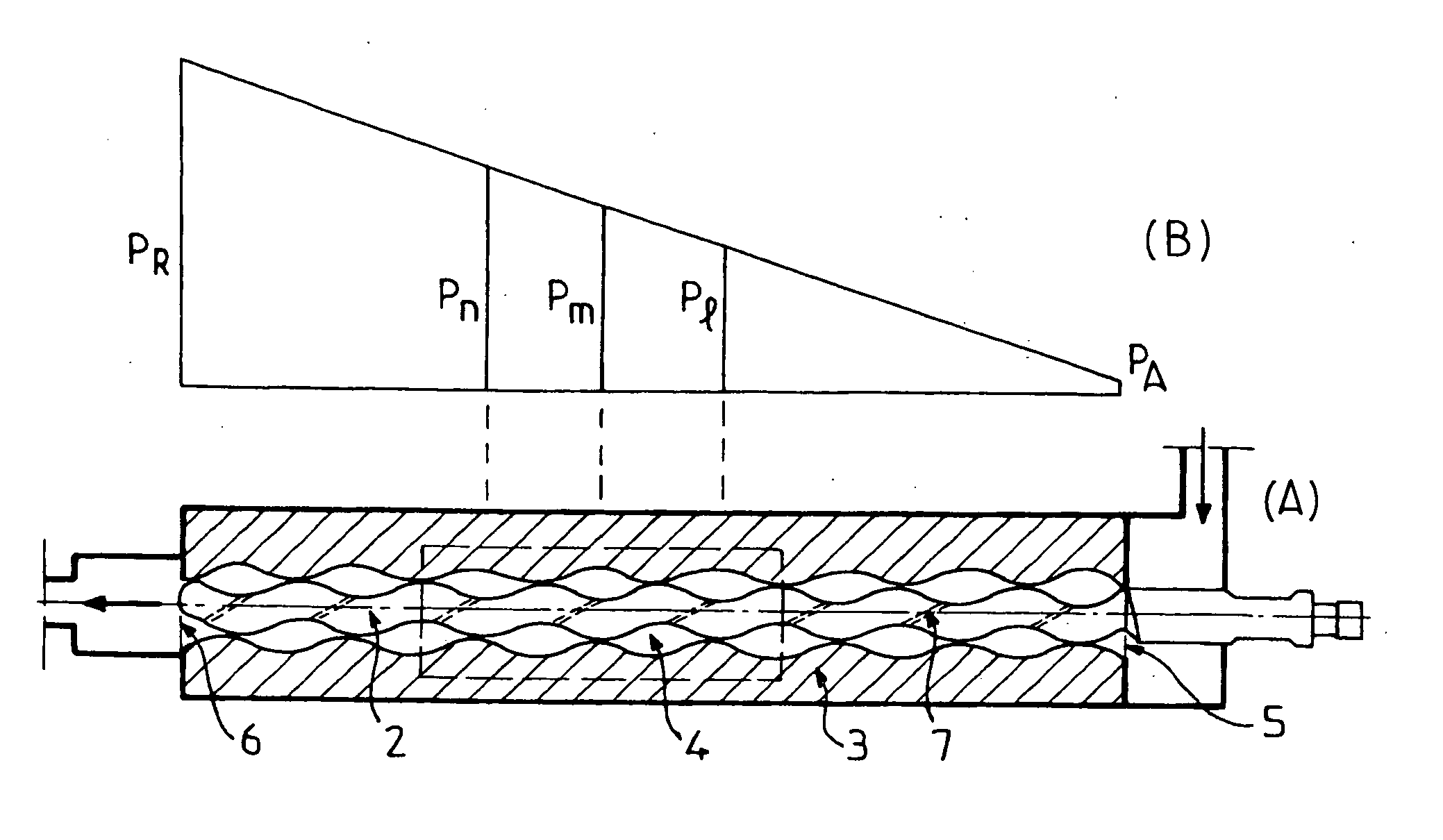

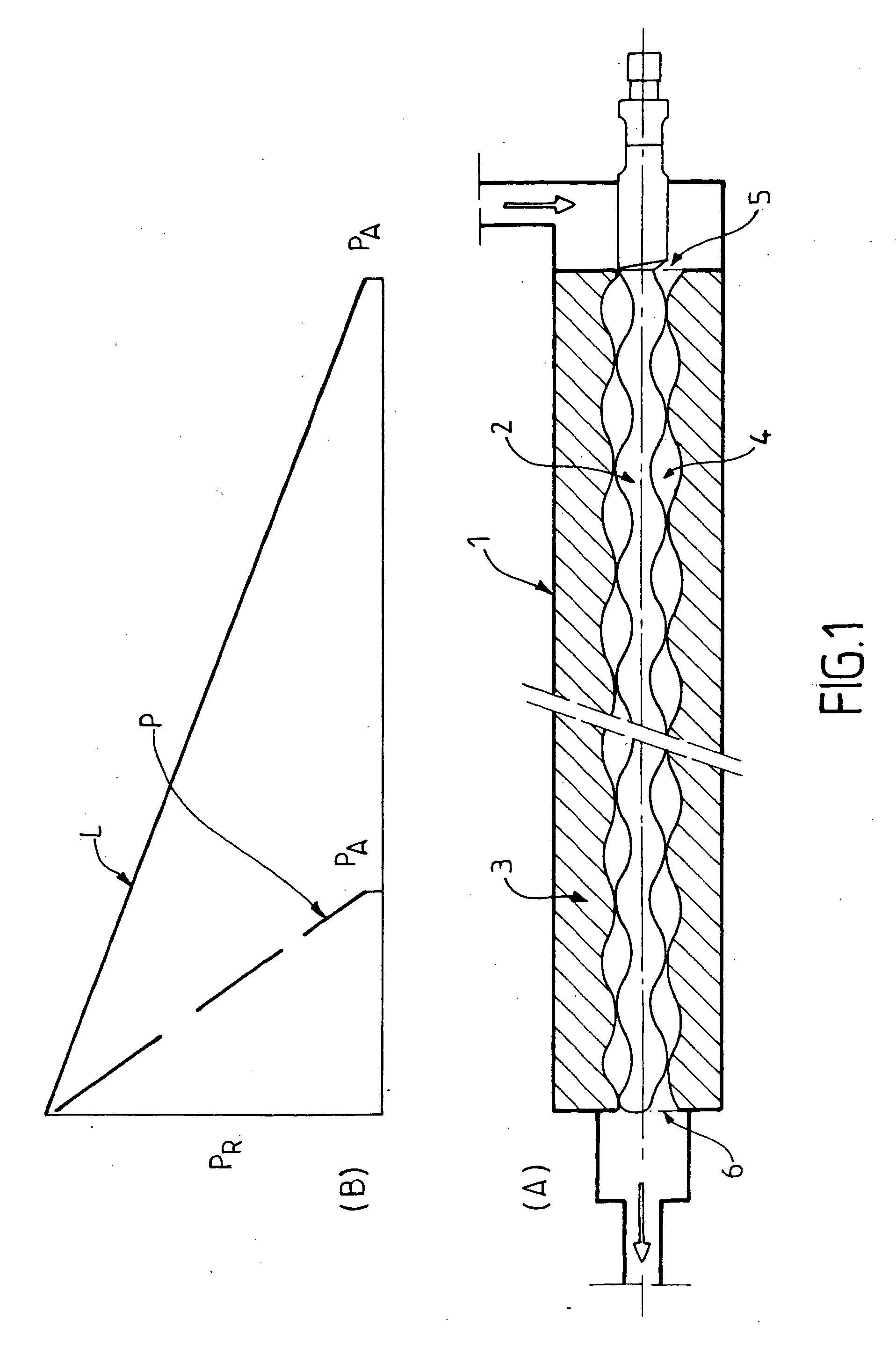

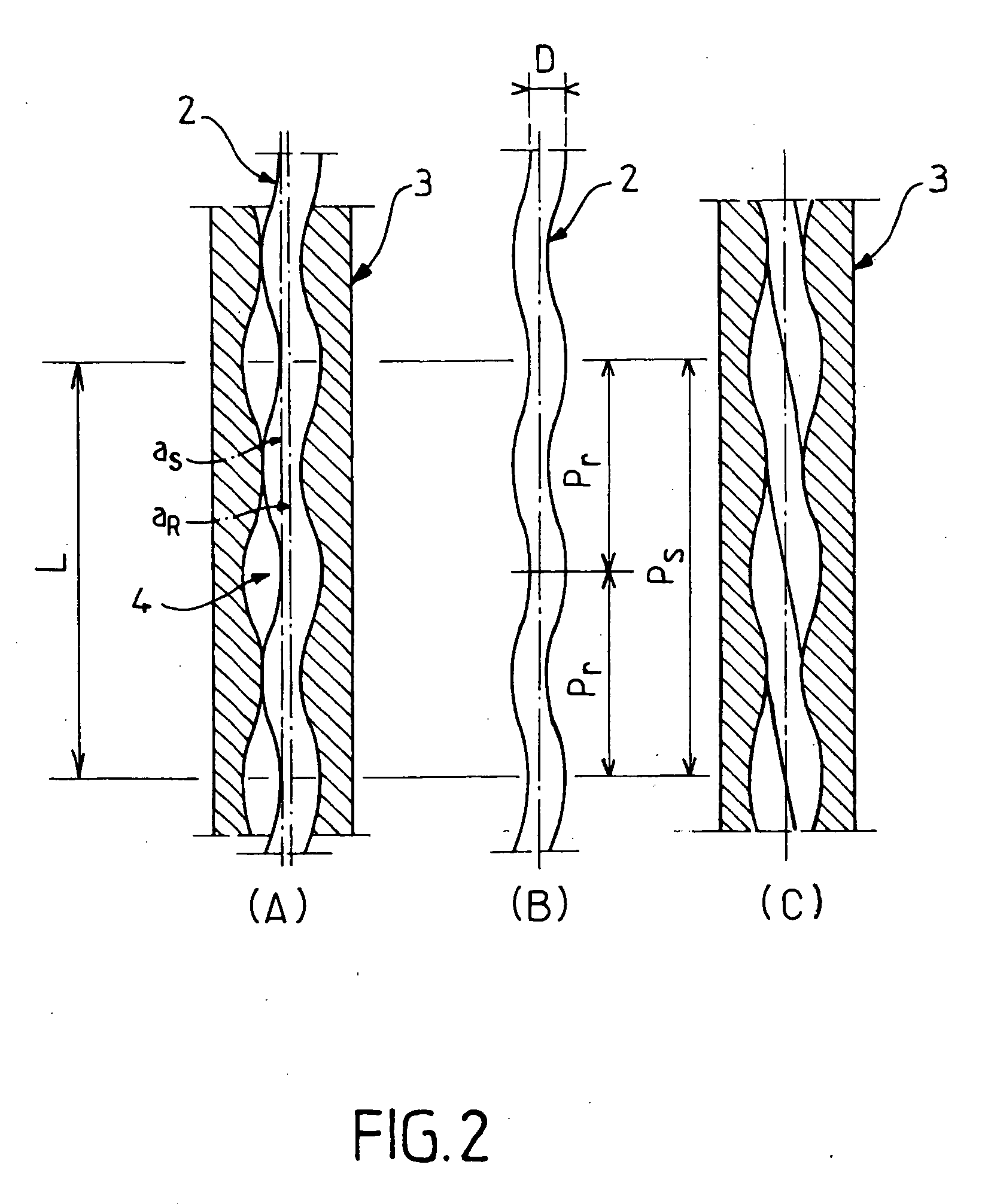

This progressing cavity pump including a helical rotor (2) mounted to turn inside a helical stator (3), said stator (3) and said rotor (2) being disposed such that the cavities (4) formed between said rotor (2) and said stator (3) move from the inlet (5) towards the outlet (6), is characterized by the fact that hydraulic regulation (HR) means are provided for obtaining internal recirculation of the pumped fluid between at least two of said cavities (4) under conditions capable of performing at least one function selected from: achieving the desired pressure distribution along the pump, stabilizing the temperatures, controlling the leakage flow rates, and compensating for the volumes of compressed gas.

Owner:PC MALL INC

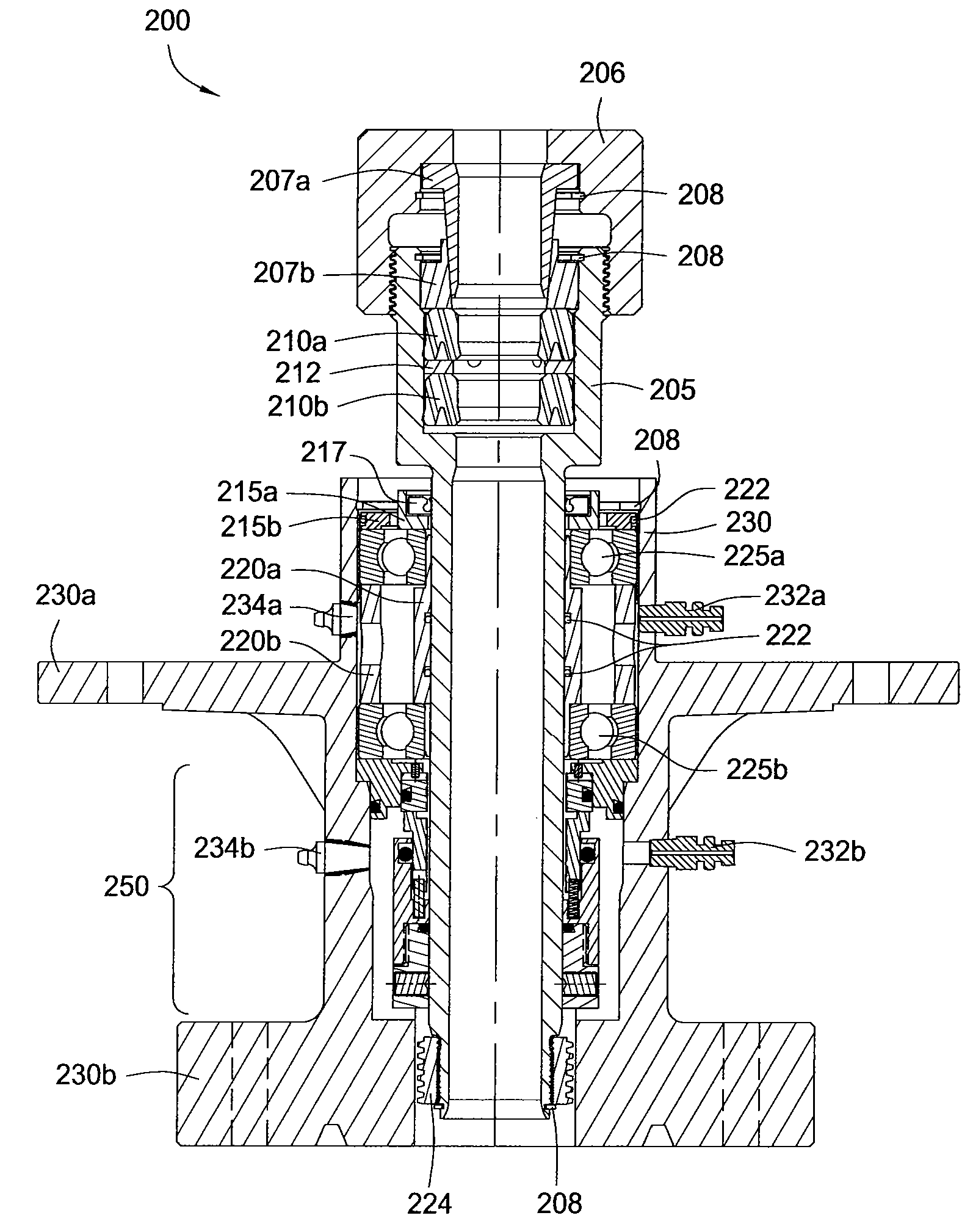

Progressive cavity pump (PCP) drive head stuffing box with split seal

The present invention relates to a split seal for a progressive cavity pump (PCP) drive head stuffing box. In one embodiment, a mechanical seal assembly for a pump is provided. The mechanical seal assembly includes a seal housing; first and second semi-annular mechanical seals, each at least partially disposed in the seal housing bore, and a seal sleeve rotatable relative to the seal housing; third and fourth semi-annular mechanical seals, each disposed at least partially in the seal sleeve bore, at least one of the third and fourth seals rotationally coupled to the seal sleeve; and one or more biasing members biasing the mechanical seals into engagement.

Owner:WEATHERFORD TECH HLDG LLC

Progressive cavity pump/motor

InactiveUS20050118040A1Rotary piston pumpsRotary piston liquid enginesHydrocotyle bowlesioidesEngineering

Owner:ROBBINS & MYERS ENERGY SYST

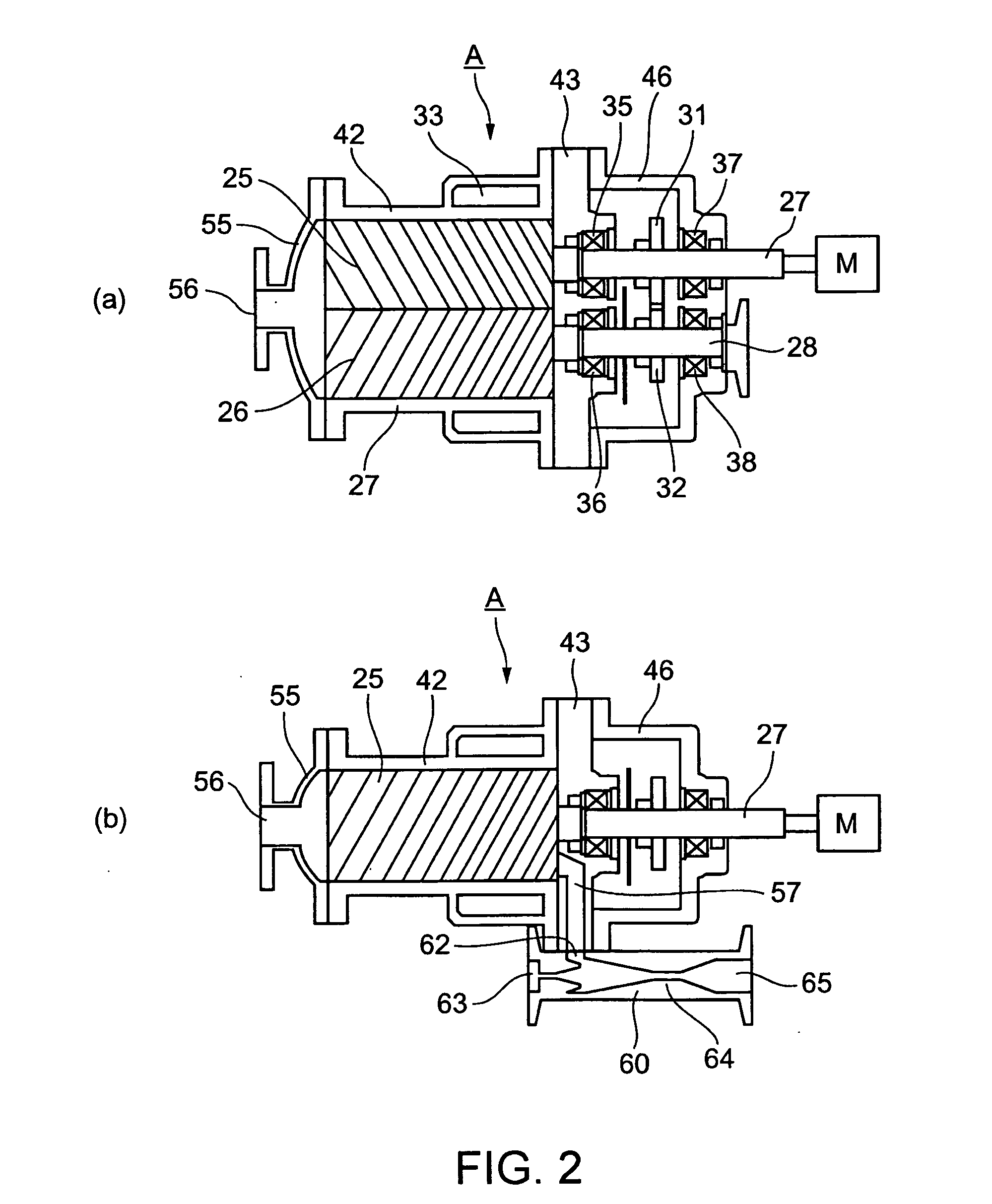

Pumping system with progressive cavity pump

InactiveUS7473082B2Made smallLess costlyEngine of intermeshing engagement typeRotary piston pumpsCouplingEngineering

Owner:PCM TECH

Positive displacement motor/progressive cavity pump

ActiveUS20070172371A1Low heat generationCost of manufactureOscillating piston enginesEngine of intermeshing engagement typeClassical mechanicsProgressive cavity pump

Disclosed is a progressive cavity device. In some embodiments, the device includes a stator with an inner surface having a number of lobes and a rotor disposed within the stator and having a different number of lobes. The stator lobes define a major diameter and a minor diameter, where the major diameter circumscribes the stator lobes and the minor diameter inscribes the stator lobes. A rotor-stator, defined as the major diameter divided by the minor diameter, is selected from the group consisting of 1.350 or less for a progressive cavity device with a stator having two lobes, 1.263 or less for three lobes, 1.300 or less for four lobes, 1.250 or less for five lobes, 1.180 or less for six lobes, 1.175 or less for seven lobes, 1.150 or for eight lobes, 1.125 or less for nine lobes, and 1.120 or less for ten lobes.

Owner:NAT OILWELL DHT

Torque anchor and method for using same

A torque anchor for use with progressive cavity pumps (PC Pumps) for preventing rotation of the PC Pumps and any related tool string within a well bore, possessing a connector constructed and adapted to connect a tube, which in a preferred embodiment is a diluent cable, between the two fixed slips. A method is also recited for running coiled tubing or a diluent cable downhole using the torque anchor.

Owner:TAZCO HLDG

Directly driving screw pump device

InactiveCN1683791AEliminate Oil Spill ProblemsEliminate lossesFlexible member pumpsFluid removalLow speedEngineering

The directly driven screw pump device consists of polished rod, shaft coupler, low speed motor, motor controller, fixing seat and screw pump body. It features the hollow low speed motor shaft penetrating through the polished rod to connect integrally with the polished rod; the polished rod penetrating through the central hole in the fixing seat to connect to the shaft of screw pump in well; the low speed motor fixed on the fixing seat; the fixing seat fixed on the well head through support; and coaxiality of the polished rod, the low speed motor and the fixing seat with the well head.

Owner:胜利油田胜利电器有限责任公司

Torque anchor

The invention describes a torque anchor for use with progressive cavity pumps (PC Pumps) for preventing rotation of the PC Pumps and any related tool string and tubing within a wellbore. The torque anchor includes at least one fixed rigid slip and one pivotable slip that in combination enhance the ability of the torque anchor to remain centered within wellbore casing and provide space between the torque anchor and wellbore casing for other tubing and / or other cabling or instruments to be run within the well and / or facilitate the passage of sand and other substances indigenous to many well formations past the torque anchor.

Owner:TAZCO HLDG

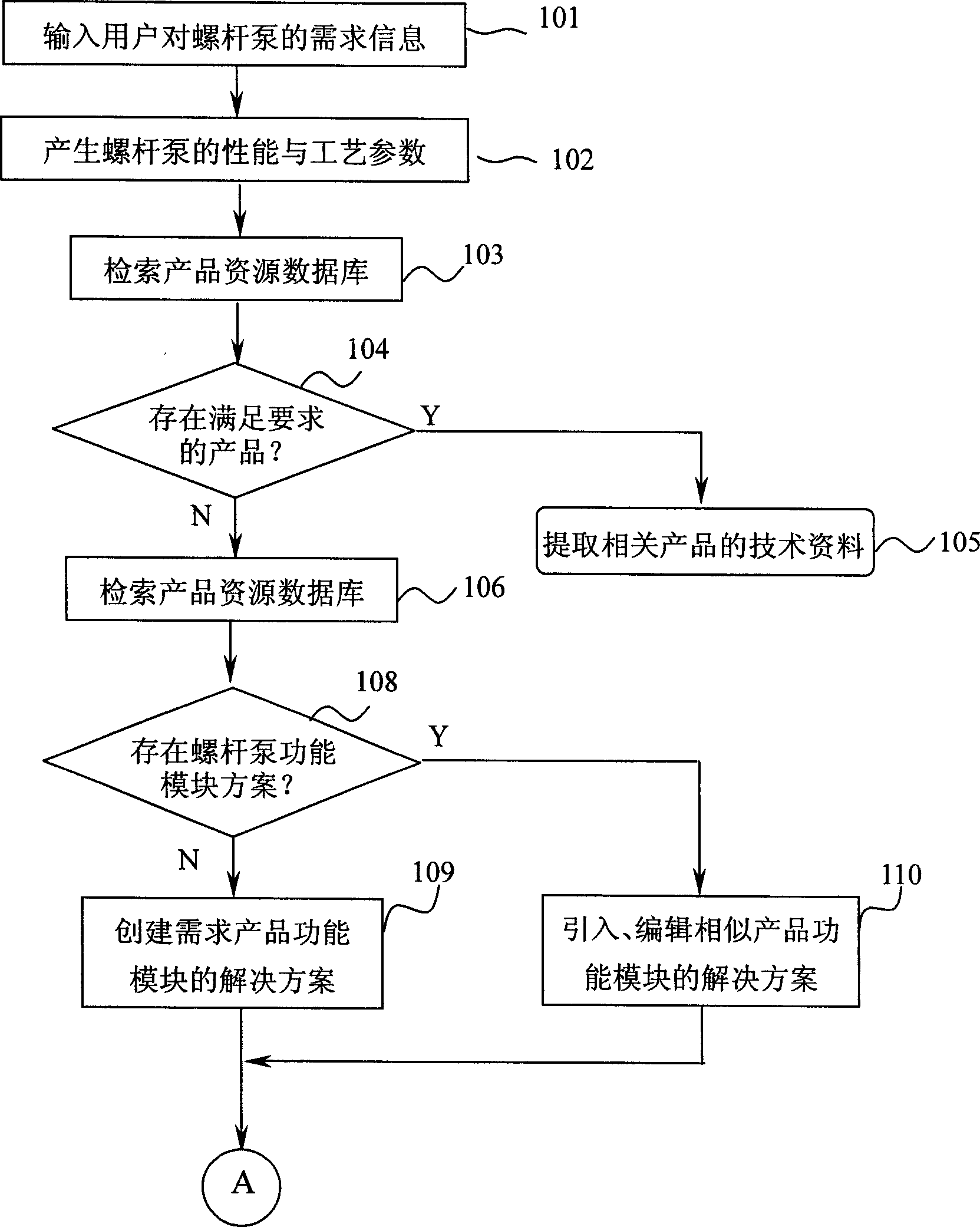

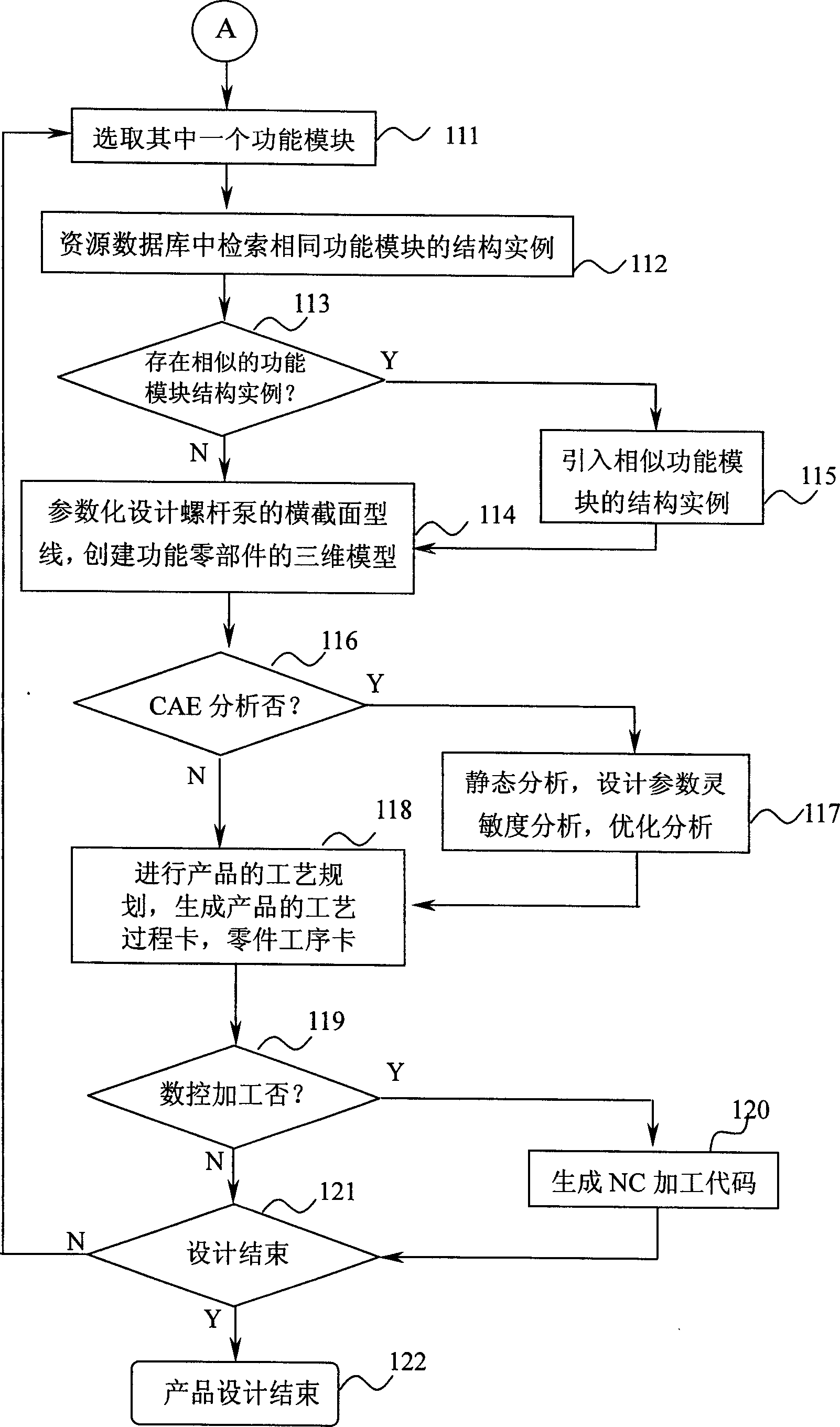

Method for integrated designing screw pump

InactiveCN1760876AImprove manufacturing levelRealize unified managementProgramme controlComputer controlNumerical controlElement analysis

Applying KBE, CBR etc. knowledge design, modularized and variable techniques, the method is built based on 3D CAD platform. The method includes following steps: (1) based on userí»s need, creating main parameters for preliminary design; (2) based on the said parameters, searching database to see whether there are products to meet userí»s need; (3) based on design scheme of functional module in the said products, searching structure instance of functional module in the said products to determine whether there is similar structure instance of functional module in the said products; (4) whether ANSYS finite element analysis is carried out for the said functional module; (5) based on structure of functional module, carrying out process planning, generating technological process sheet and operation sheet; using CAM subsystem generates NC machining codes for making module structure needed of using digital control machine-tool.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Combination motor casing and spear

A wellhead removal tool features a rotary cutter run by a Moyno type progressive cavity pump that is powered by fluid pumped through it. The stator of the motor has a gripping device with a series of collets or slip inserts that have grip features that face outwardly. A support shoulder on the grip assembly cooperates with a j-slot connection to the stator to allow a cone to be moved under the collets to push them into a grip position below or in a selected portion of the wellhead where the grip will not damage the wellhead internal components. Fluid pumped through the downhole motor causes the casing cutter blades to extend and rotate to cut the casing.

Owner:BAKER HUGHES INC

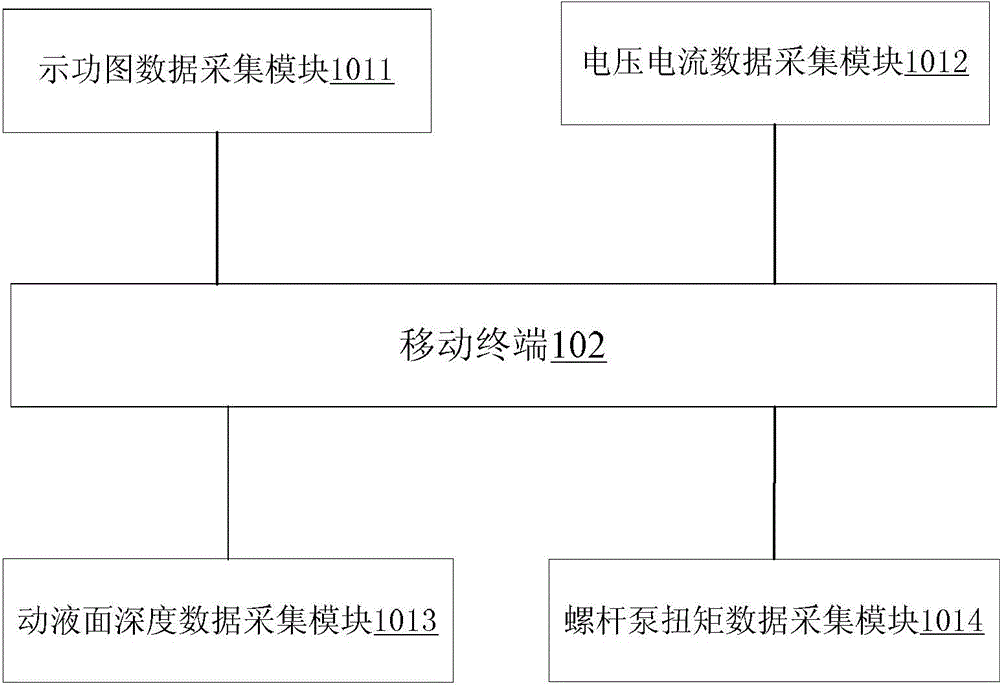

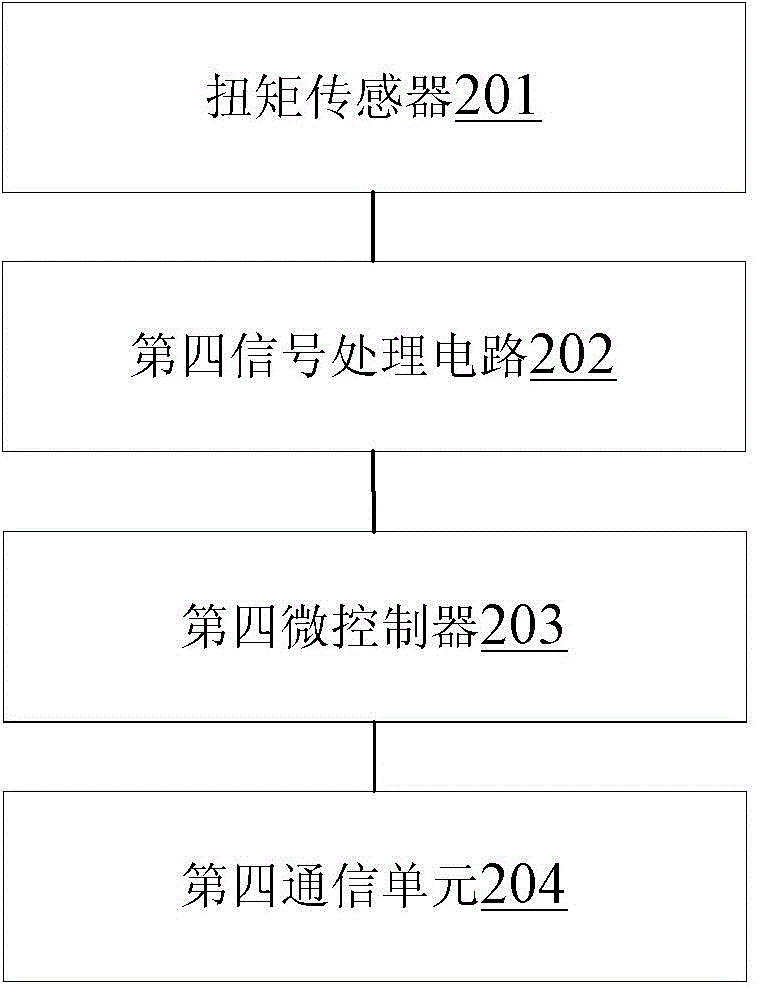

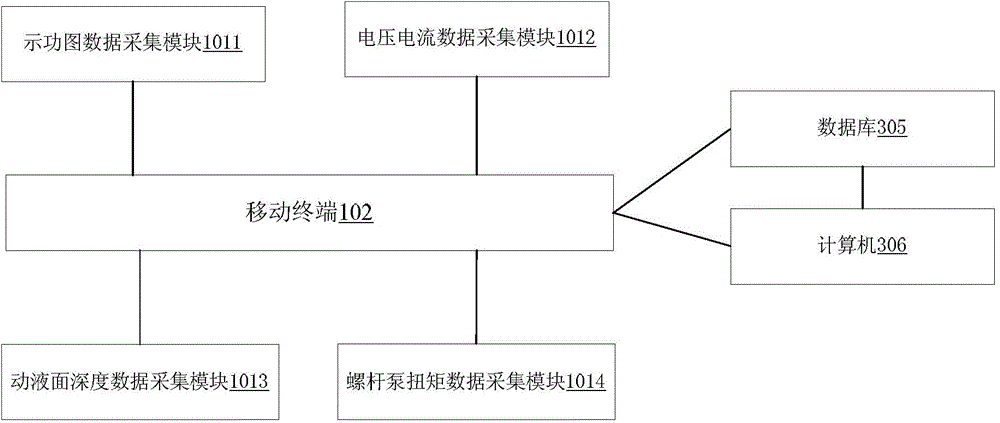

Oil well test and analysis system

The embodiment of the invention provides an oil well test and analysis system. The system comprises a data collection device, a voltage current data collection module, a working fluid level depth data collection module, a screw rod pump torsion data collection module and a mobile terminal; the data collection device is used for collecting multiple types of oil well parameters and transmitting the oil well parameters to the mobile terminal; the data collection device comprises an indicator diagram data collection module for collecting and analyzing the oil parameters needed by an indicator diagram of an oil well; the voltage current data collection module collects the voltage current data of the oil well; the working fluid level depth data collection module collects and analyzes the oil well parameters needed by the depth of a working fluid level of the oil well; the screw rod pump torsion data collection module collects the torsion data of a screw rod pump in the oil well; the mobile terminal receives and analyzes the oil well parameters transmitted from the data collection device for generating an image corresponding to each type of oil well parameter. The oil well test and analysis system disclosed by the embodiment realizes the test functions on diversified parameters, the accuracy of an analysis and diagnosis result of the oil well test parameters is favorably ensured, and meanwhile, the mobile terminal can finish the field analysis on the collected data and the optimal time for equipment regulation is prevented from being missed.

Owner:PETROCHINA CO LTD

Progressive cavity pump (PCP) drive head stuffing box with split seal

The present invention relates to a split seal for a progressive cavity pump (PCP) drive head stuffing box. In one embodiment, a mechanical seal assembly for a pump is provided. The mechanical seal assembly includes a seal housing; first and second semi-annular mechanical seals, each at least partially disposed in the seal housing bore, and a seal sleeve rotatable relative to the seal housing; third and fourth semi-annular mechanical seals, each disposed at least partially in the seal sleeve bore, at least one of the third and fourth seals rotationally coupled to the seal sleeve; and one or more biasing members biasing the mechanical seals into engagement.

Owner:WEATHERFORD TECH HLDG LLC

Vacuum device and vacuum pump

InactiveUS20060182638A1Suppress power consumptionReduce manufacturing costRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringVacuum pump

A vacuum apparatus has a vacuum chamber provided with a gas inlet and a gas outlet, and mechanical vacuum pumps in a plurality of stages for reducing a pressure inside the vacuum chamber and maintaining the pressure-reduced state. The vacuum apparatus has an ejector pump (60) connected to a discharge port (57) of a screw pump (A) as the vacuum pump at the last stage among the vacuum pumps. The vacuum apparatus is reduced in power consumption and used in the semiconductor manufacturing field and so on.

Owner:FOUND FOR ADVANCEMENT OF INT SCI

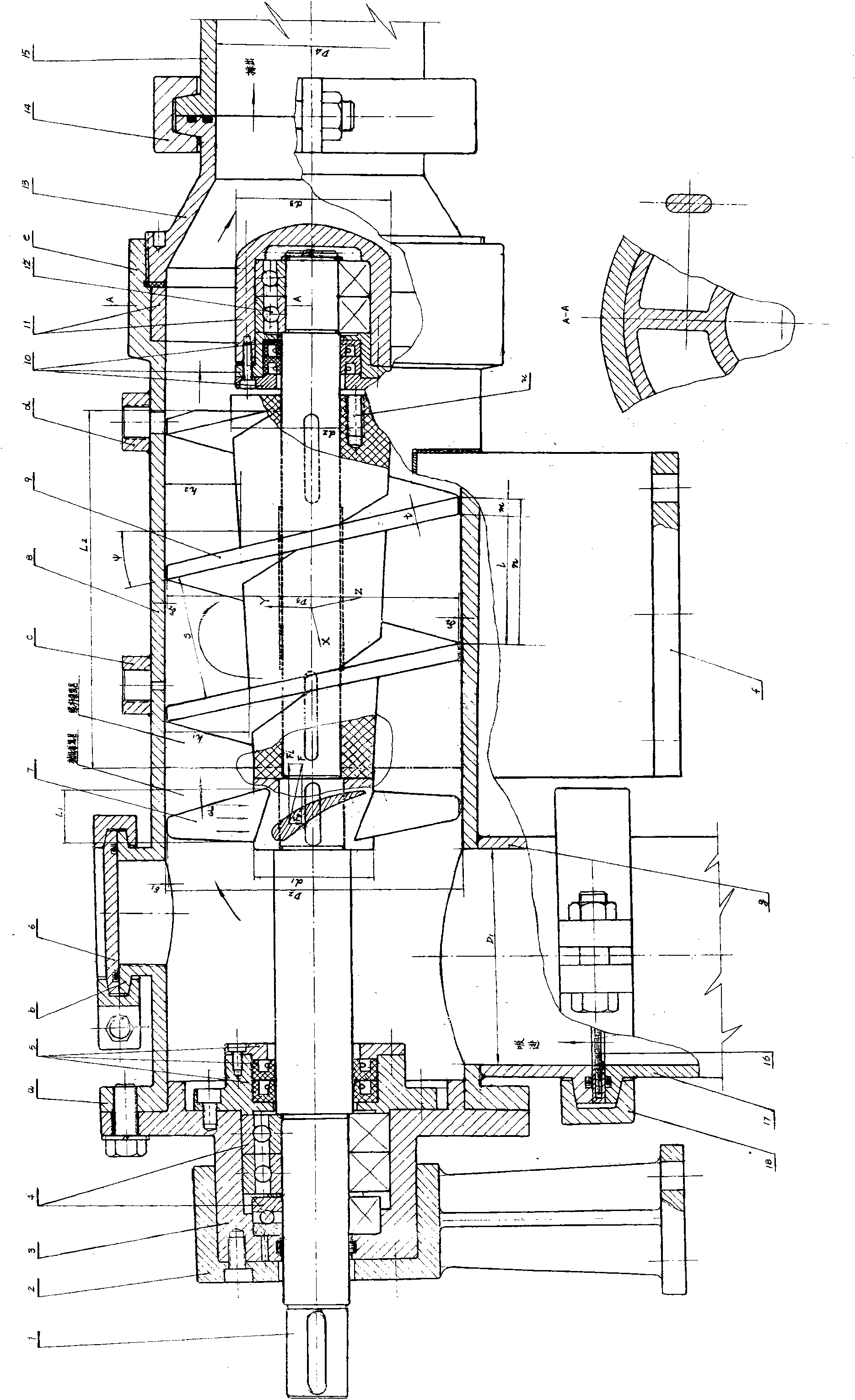

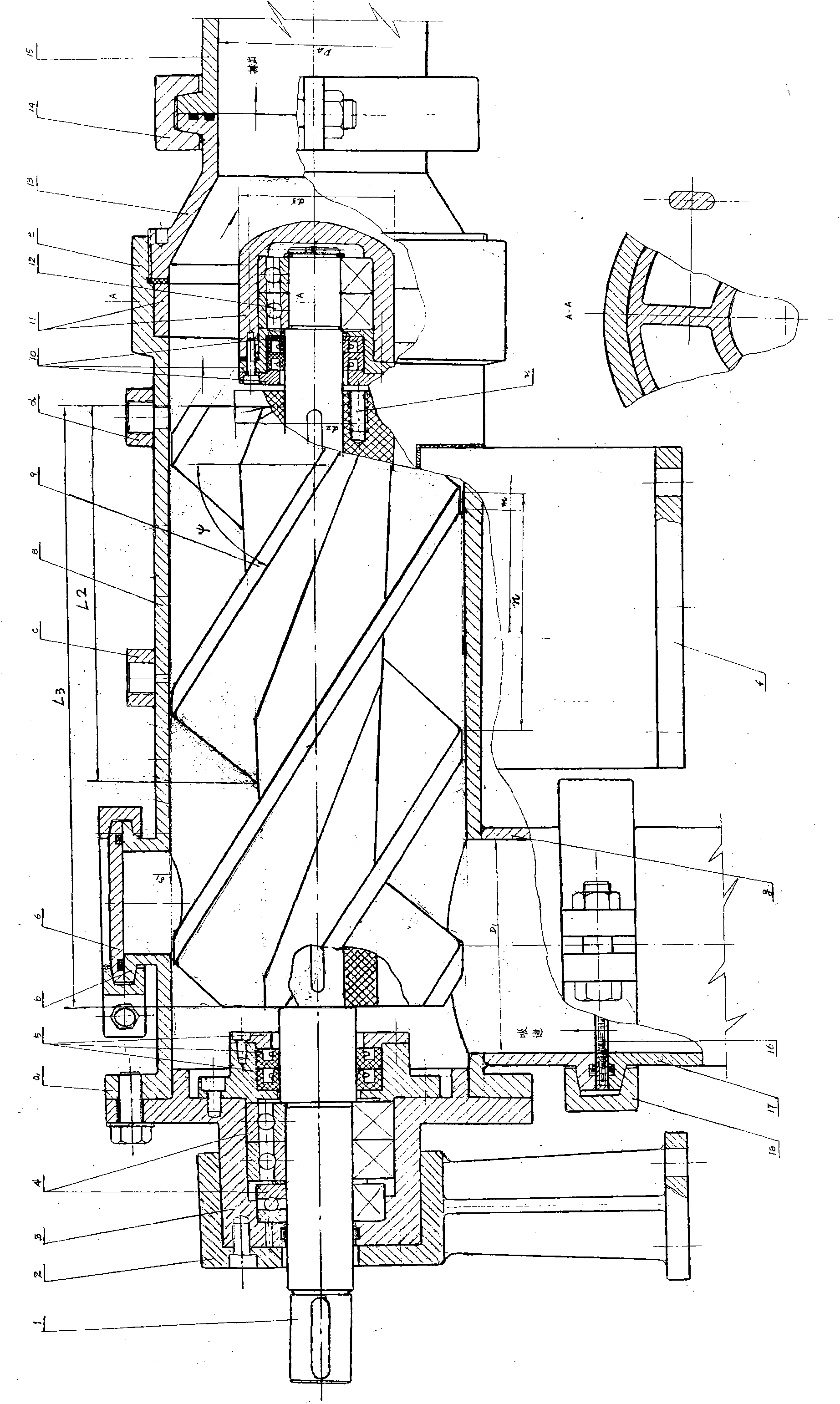

High-efficiency axial flow and screw combined pump for ship

InactiveCN102486169AGuaranteed coaxial accuracyImprove machining accuracyPropulsive elementsPump installationsAxial-flow pumpLow speed

The invention relates to a structure of a high-efficiency axial flow and screw combined pump. A large flow and a high pressure are obtained by high speed rotation. A transmission chain in a ship is greatly simplified. The high-efficiency axial flow and screw combined pump has light weight and is suitable for high-speed sailing. The high-efficiency axial flow and screw combined pump is characterized in that an axial flow pump impeller and a screw of a screw pump which are driven coaxially are arranged in a big sleeve to form a structure of an axial flow pump and the screw pump; if the positions of the axial flow pump and the screw pump are exchanged, a structure of the screw pump and the multi-stage axial pump is formed; and water is sucked from the front of the ship bottom, obtains kinetic energy through the front-mounted pump and then is fed to the rear-mounted pump to be boosted to be sprayed, so that the ship is propelled. One single screw is arranged and is provided with a plurality of heads; screw edges are very narrow and have large screw pitch, so that the depth of a screw thread gradually becomes shallow to achieve the effects of large flow and high pressure; and the axial flow pump is designed by combining excellent aerofoils according to a variable-circulation variable-axis surface. The pump has a very simple structure, has good manufacturability and is easy to manufacture; the high-efficiency axial flow and screw combined pump is convenient to install; the high-efficiency axial flow and screw combined pump rotates at the high speed, has small volume and light weight, is efficient and energy-saving; the high-efficiency axial flow and screw combined pump has the self-adsorption capability and the ship has high sailing speed; the high-efficiency axial flow and screw combined pump can be made to have large power; the high-efficiency axial flow and screw combined pump has double-injection capability, a steering engine is saved and the high-efficiency axial flow and screw combined pump has high performances which cannot be realized by a single low speed axial flow pump or mixed-flow pump injection propeller.

Owner:赵明

Well treatment using a progressive cavity pump

Embodiments of the present invention include methods and apparatus for treating a formation with fluid using a downhole progressive cavity pump (“PCP”). In one aspect, the direction of the PCP is reversible to pump treatment fluid into the formation. In another aspect, two or more PCP's are disposed downhole and reversible to allow a chemical reaction downhole prior to the treatment fluid entering the formation. In yet another aspect, embodiments of the present invention provide a method of flowing treatment fluid downhole using one or more downhole PCP's. Treatment of the formation with the fluid and production of hydrocarbon fluid from the formation may both be conducted using the same downhole PCP operating in opposite rotational directions. In an alternate embodiment, one or more downhole PCP's may be utilized in tandem with one or more surface pumps.

Owner:WEATHERFORD TECH HLDG LLC

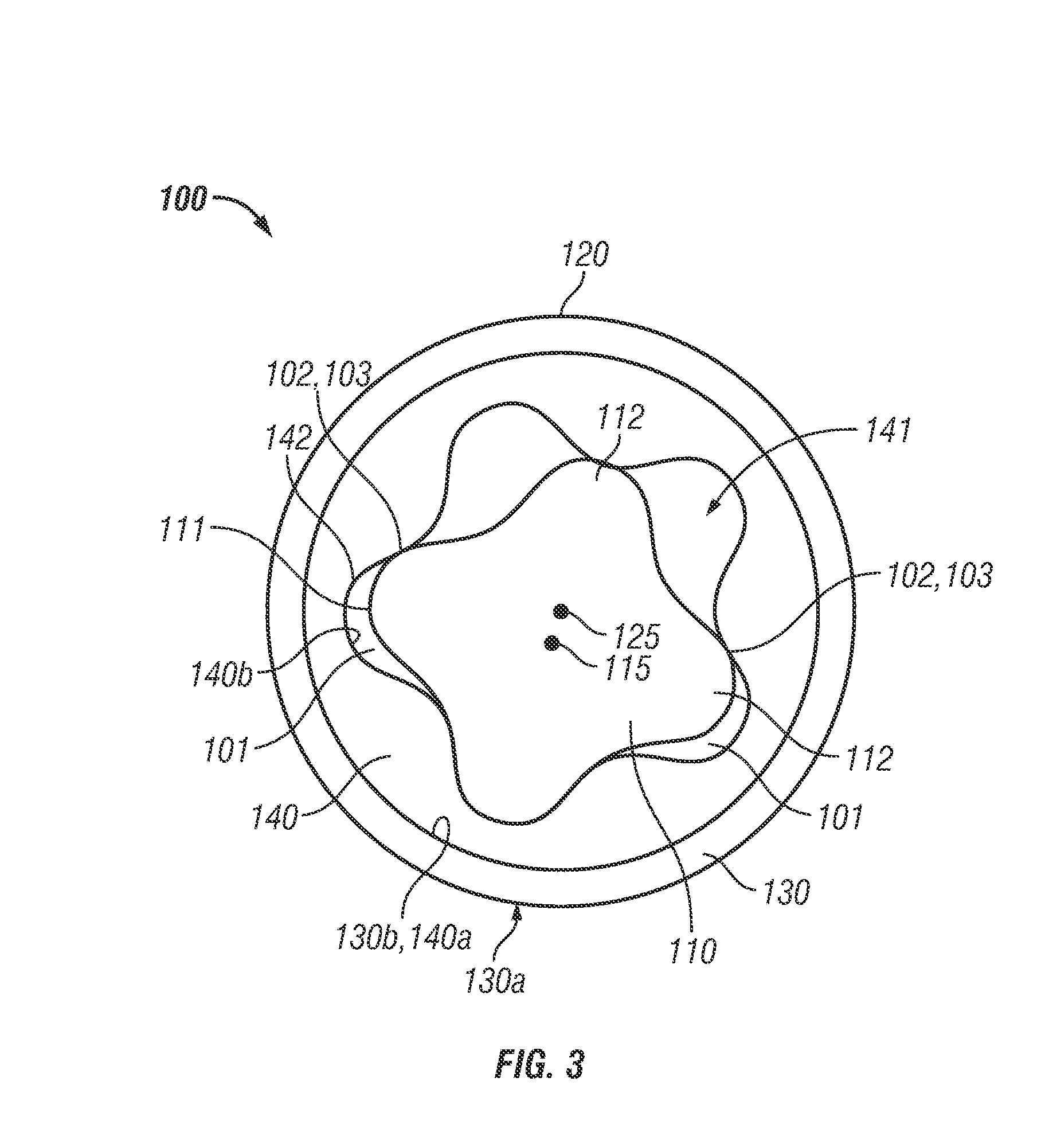

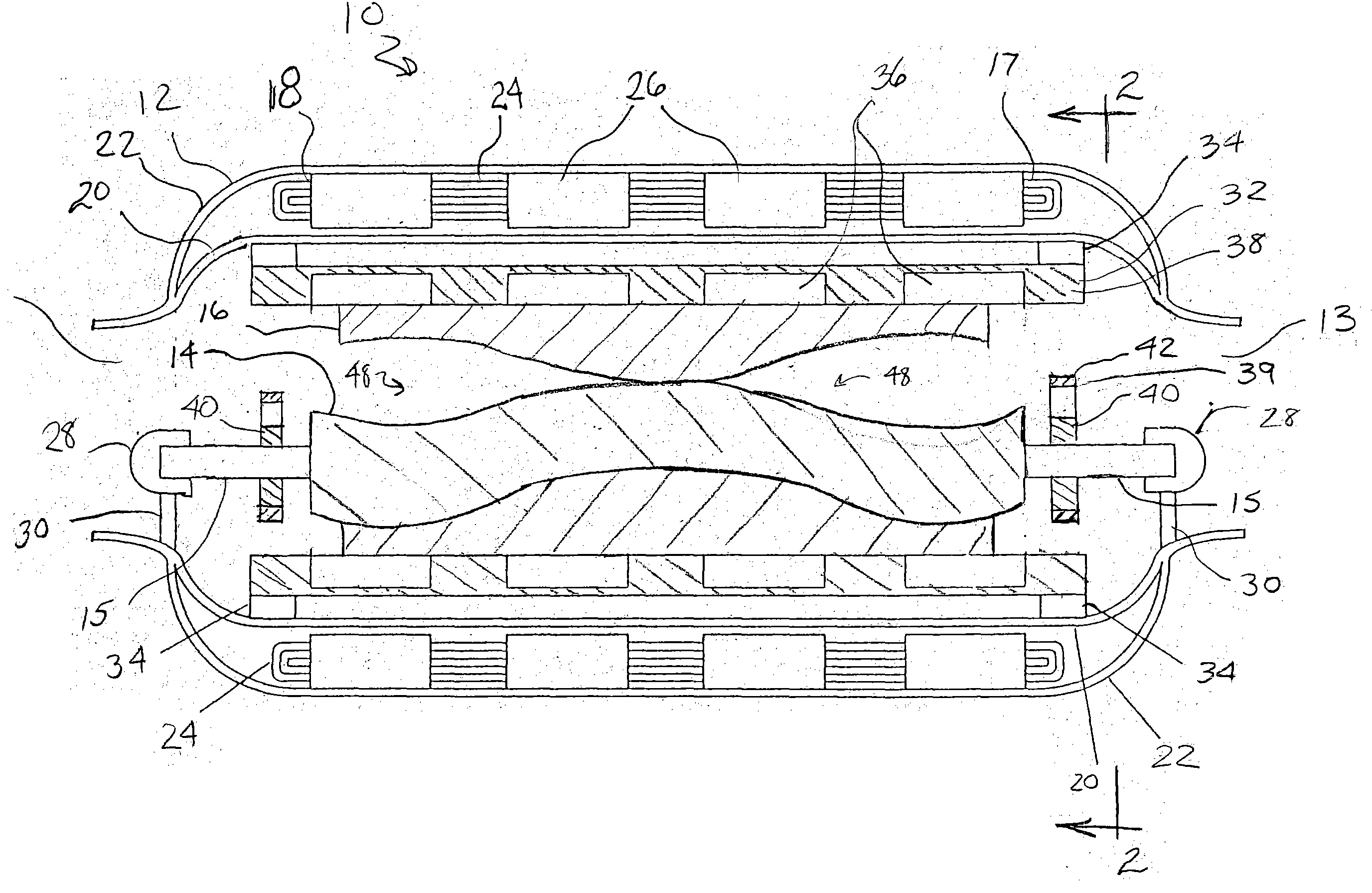

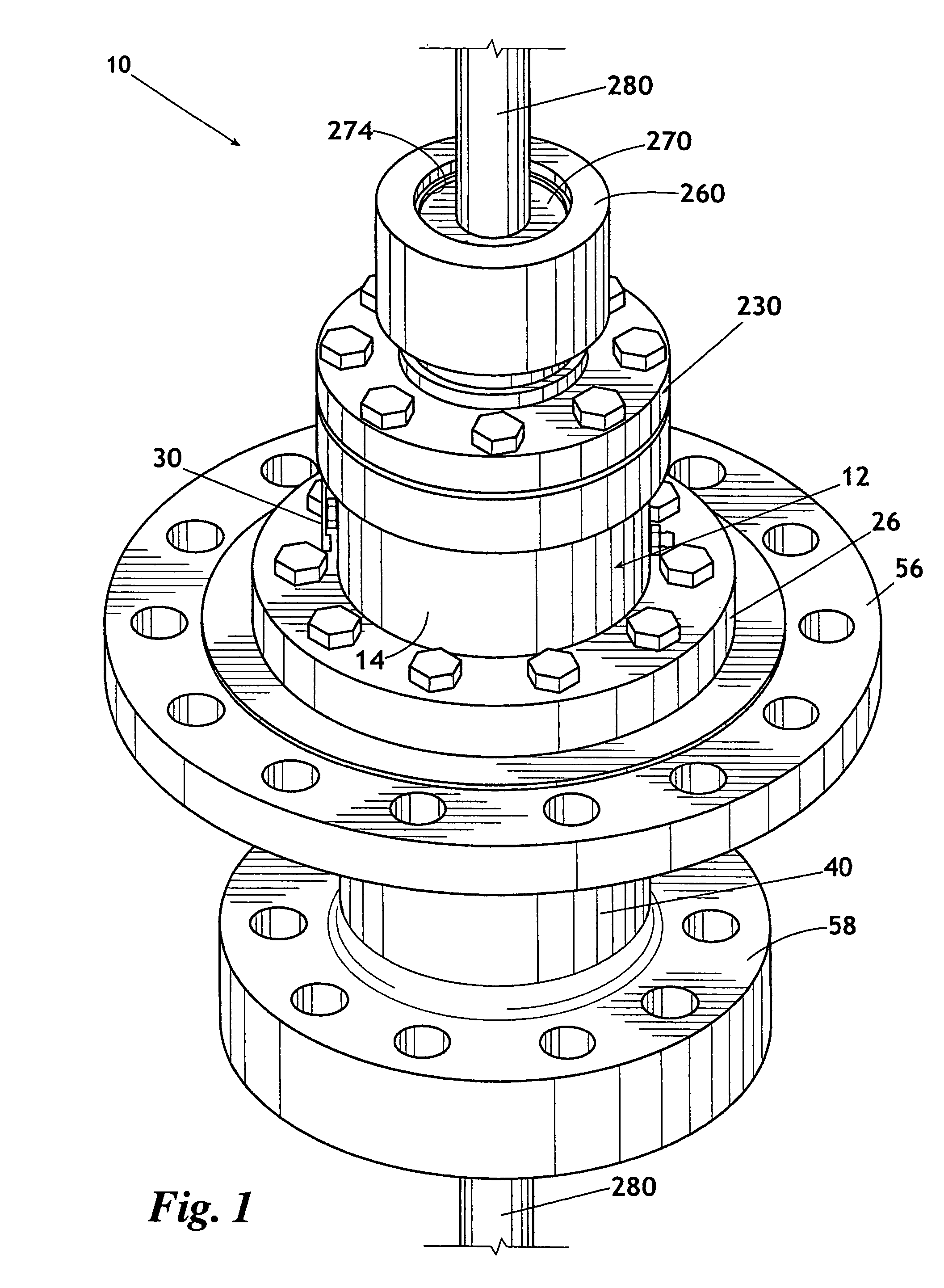

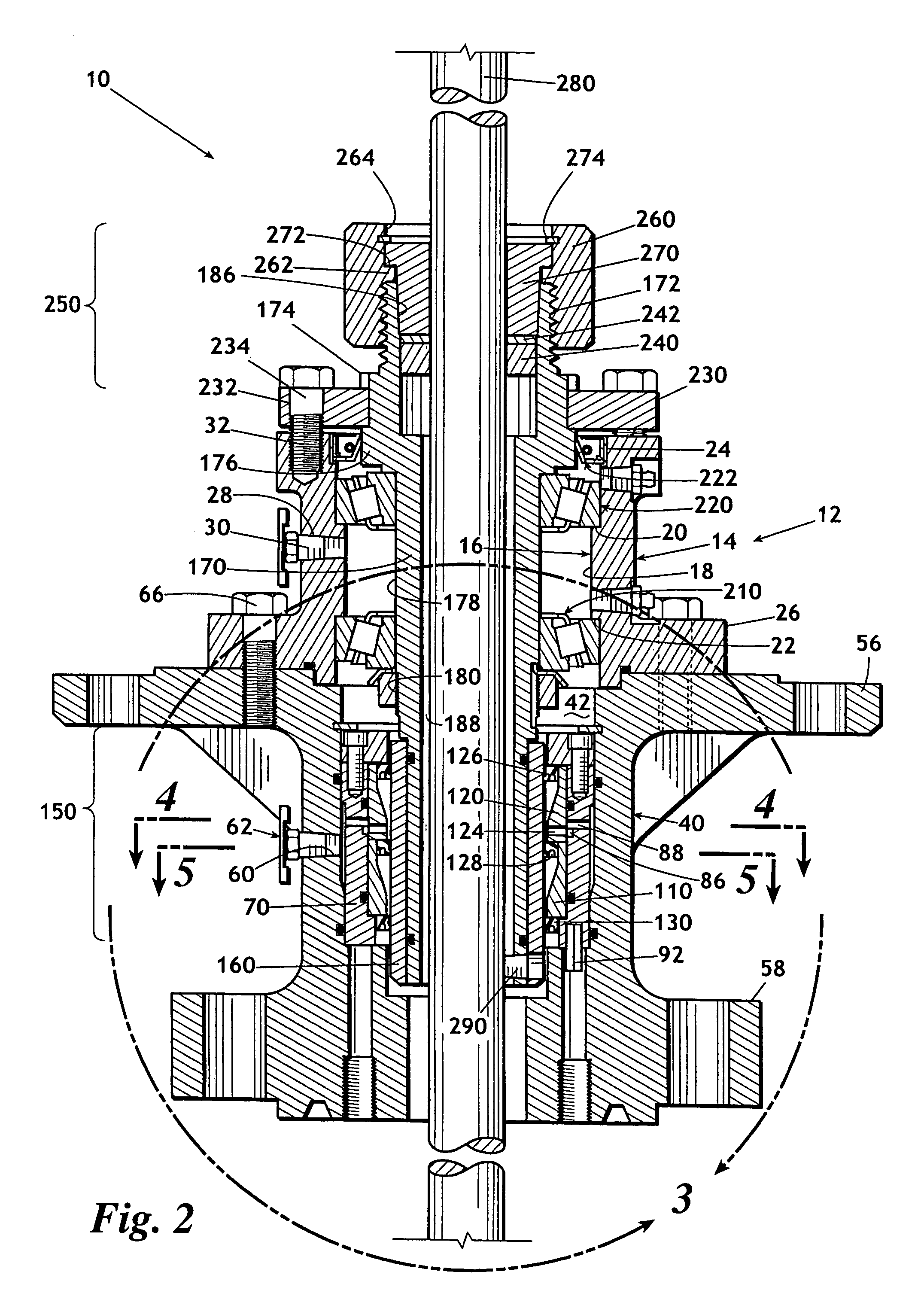

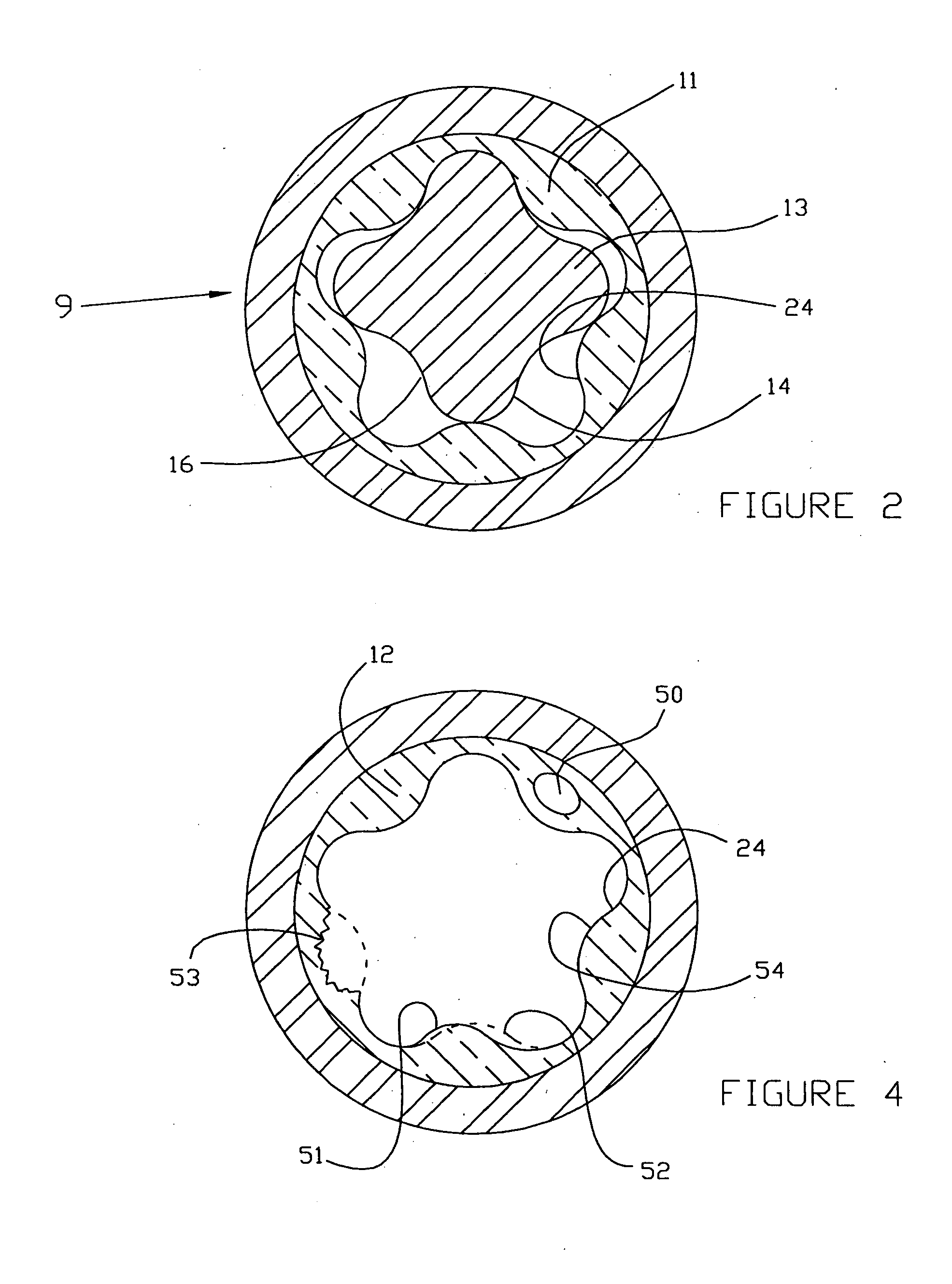

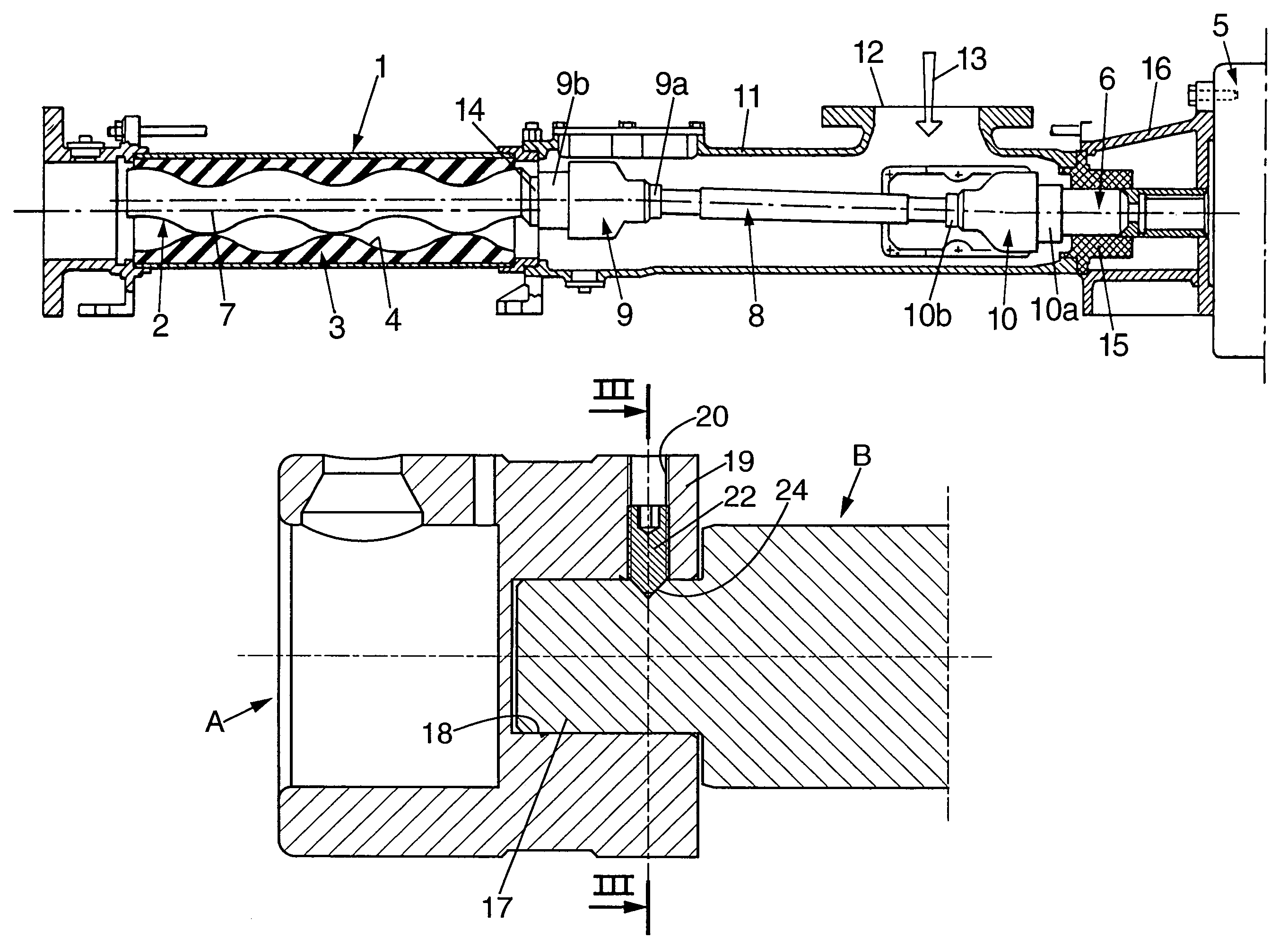

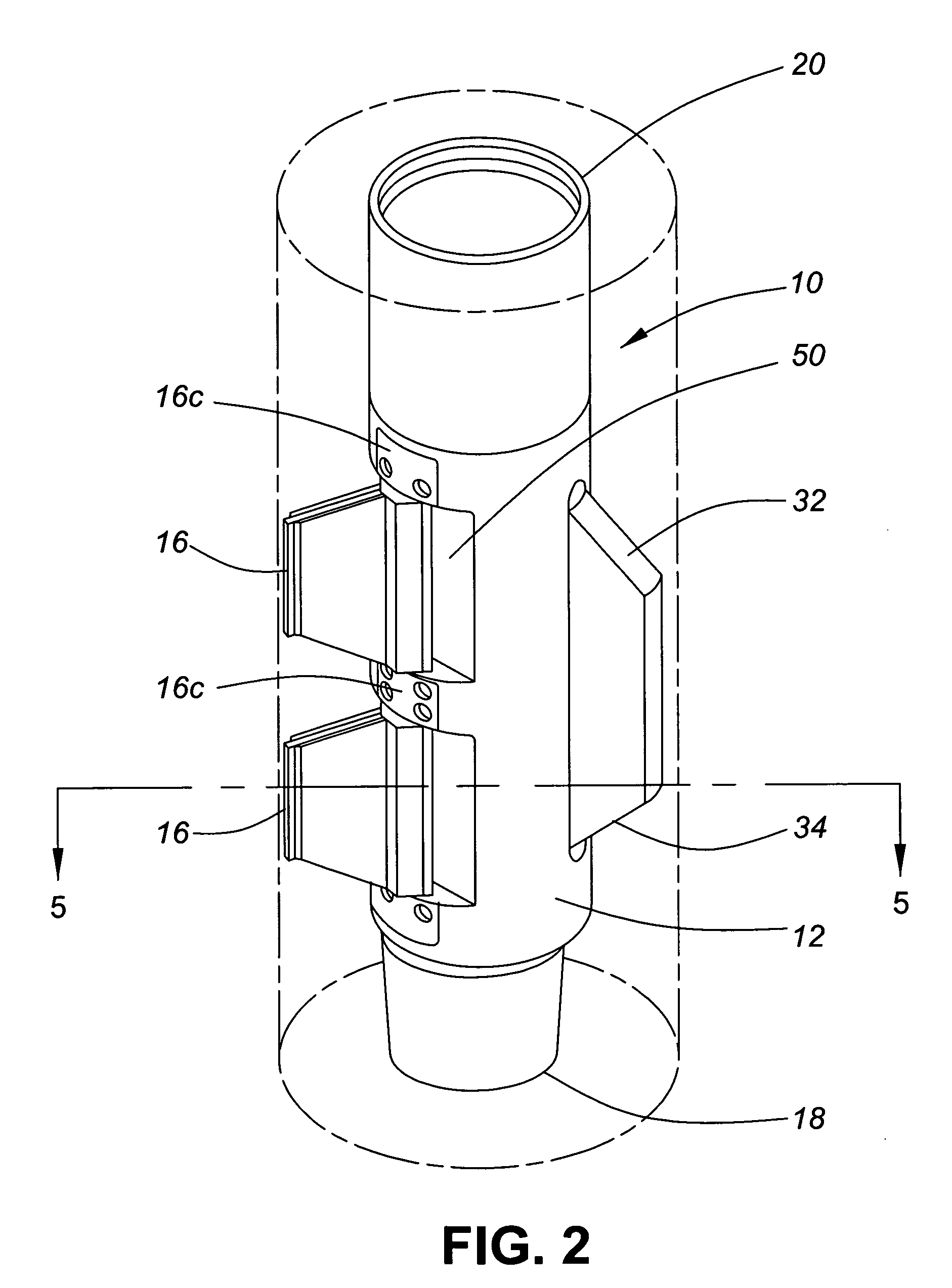

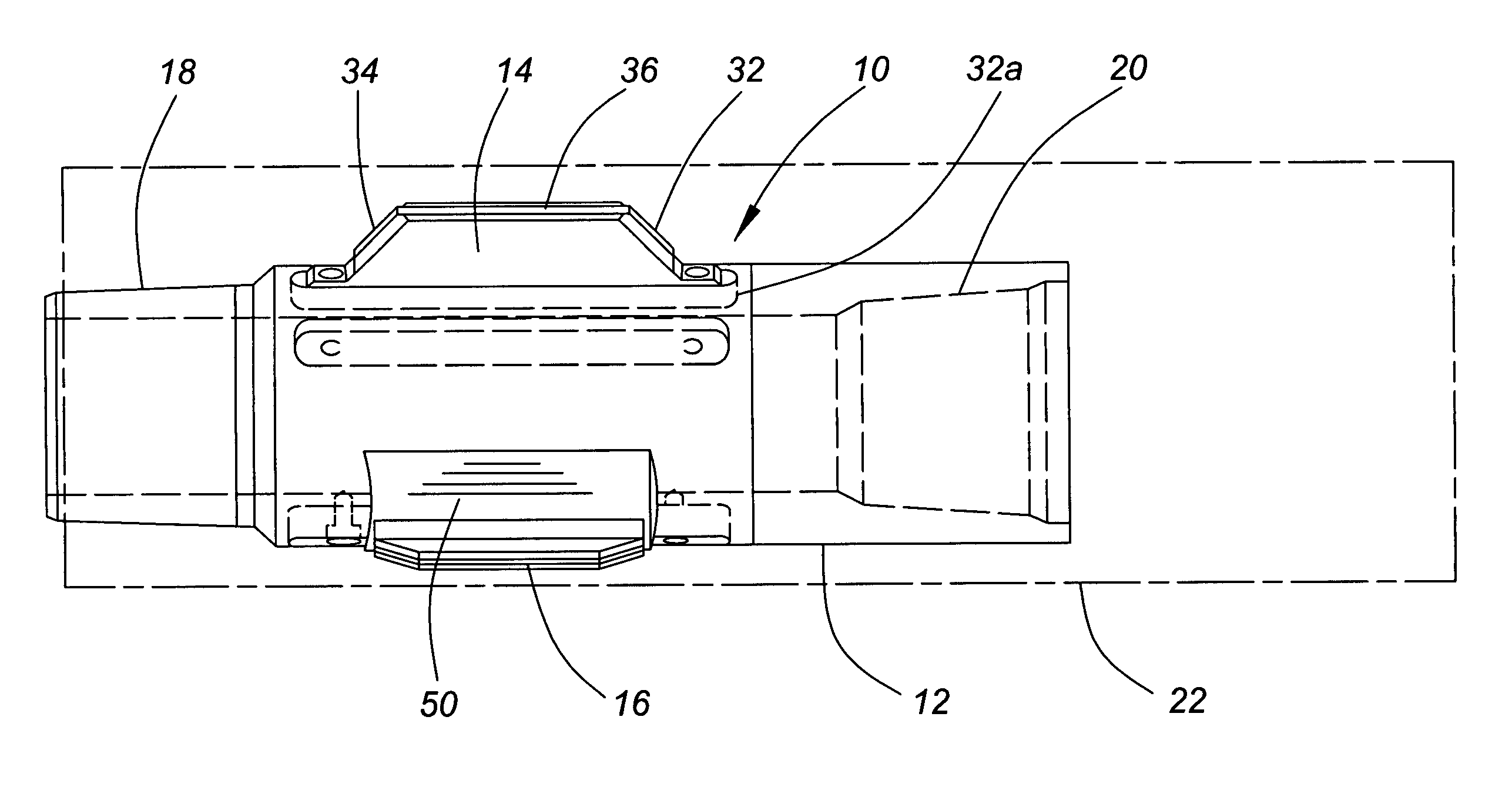

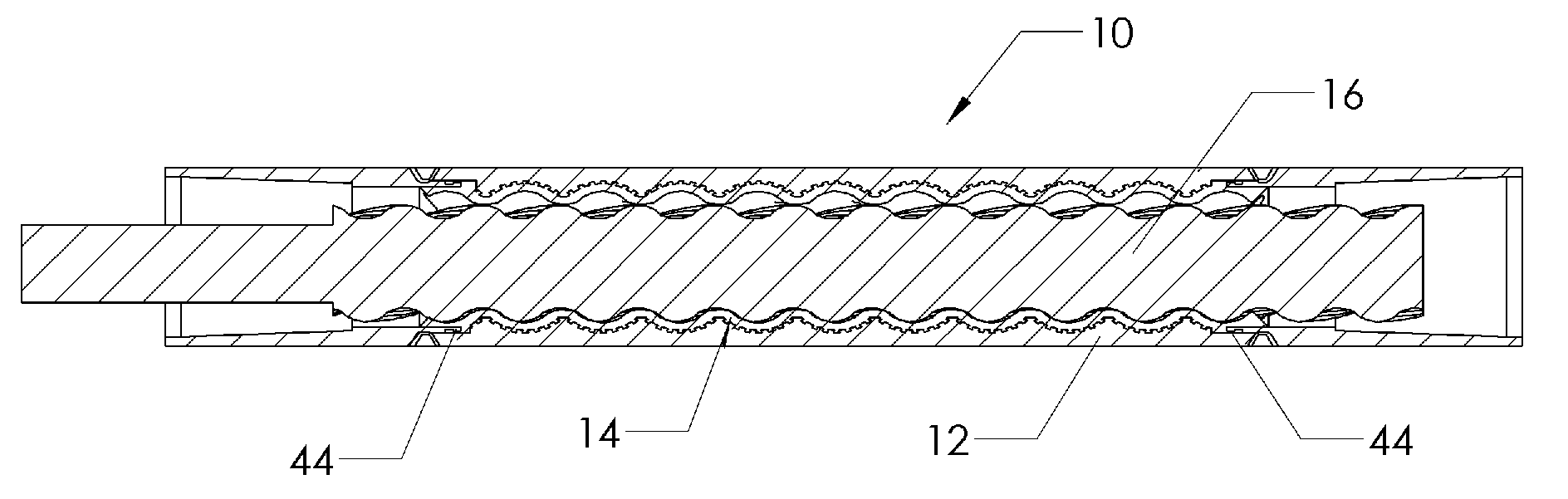

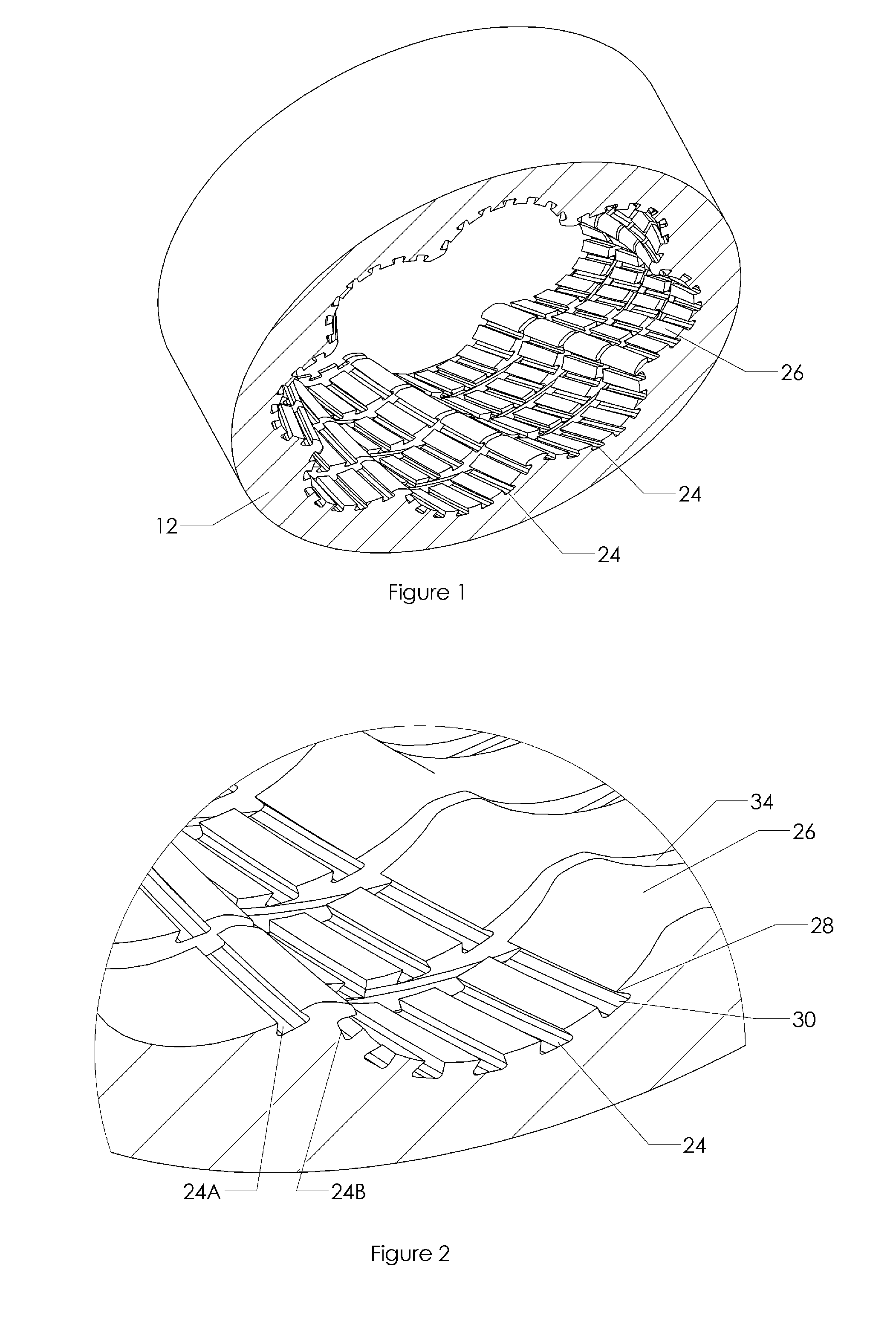

Progressing Cavity Pump/Motor

ActiveUS20120156078A1Oscillating piston enginesEngine of counter-engagement typeEngineeringMechanical engineering

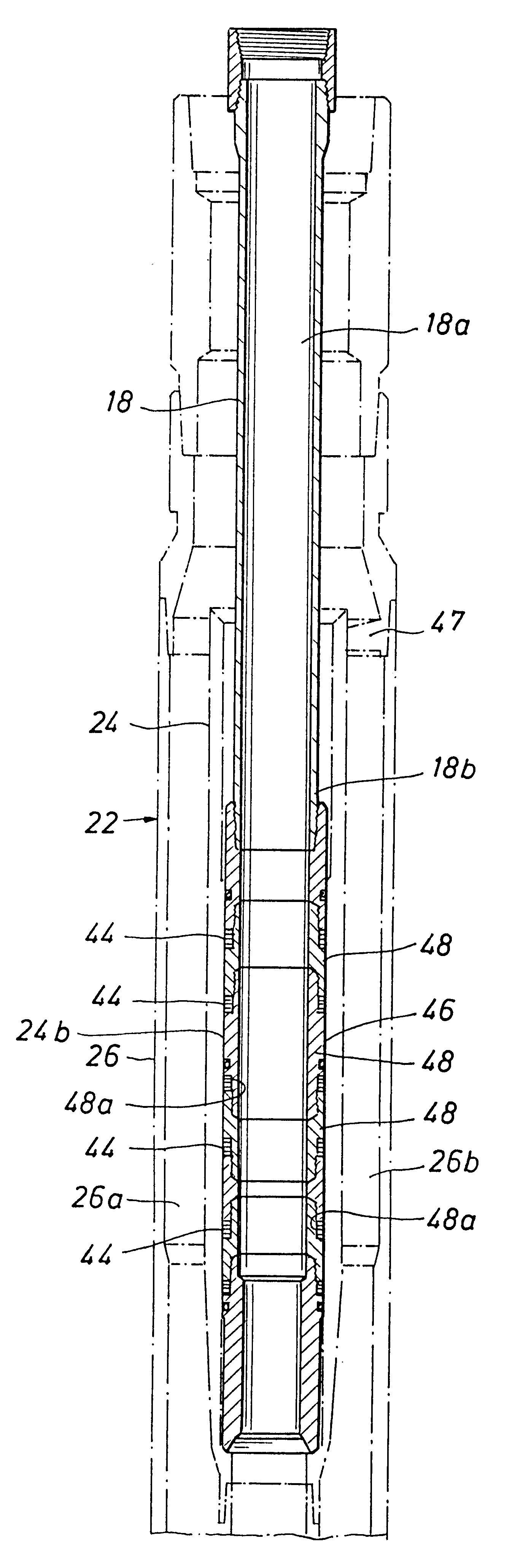

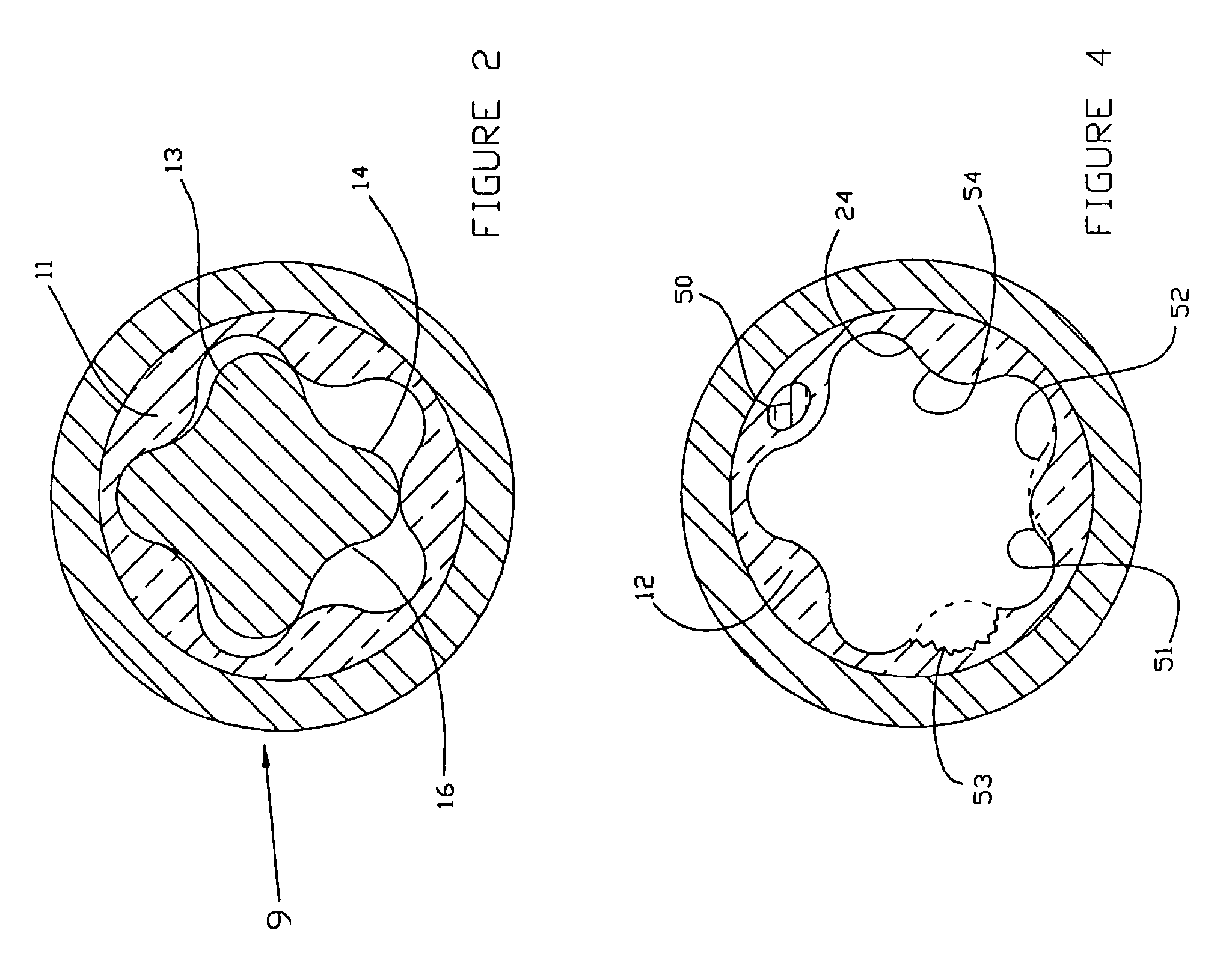

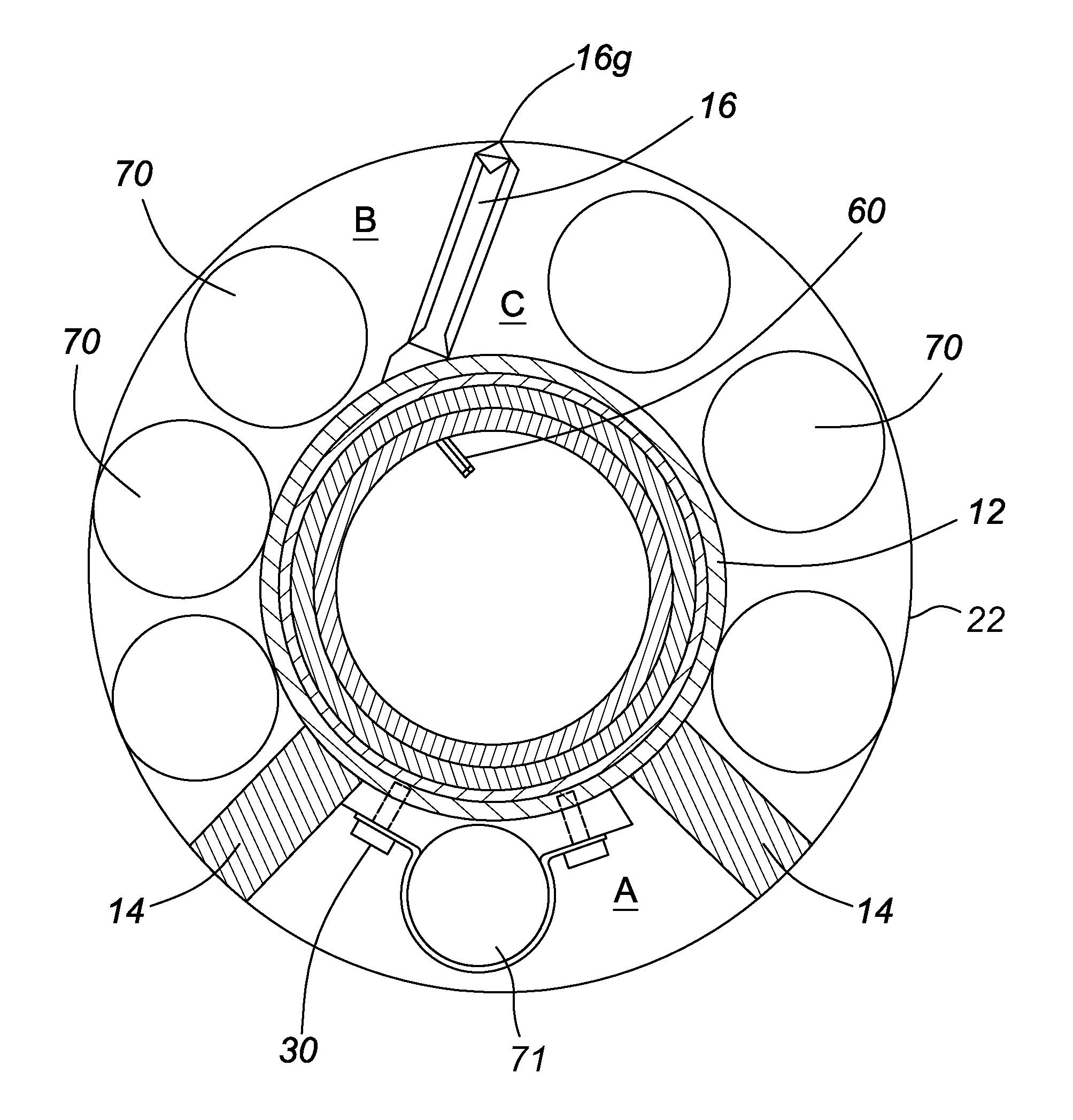

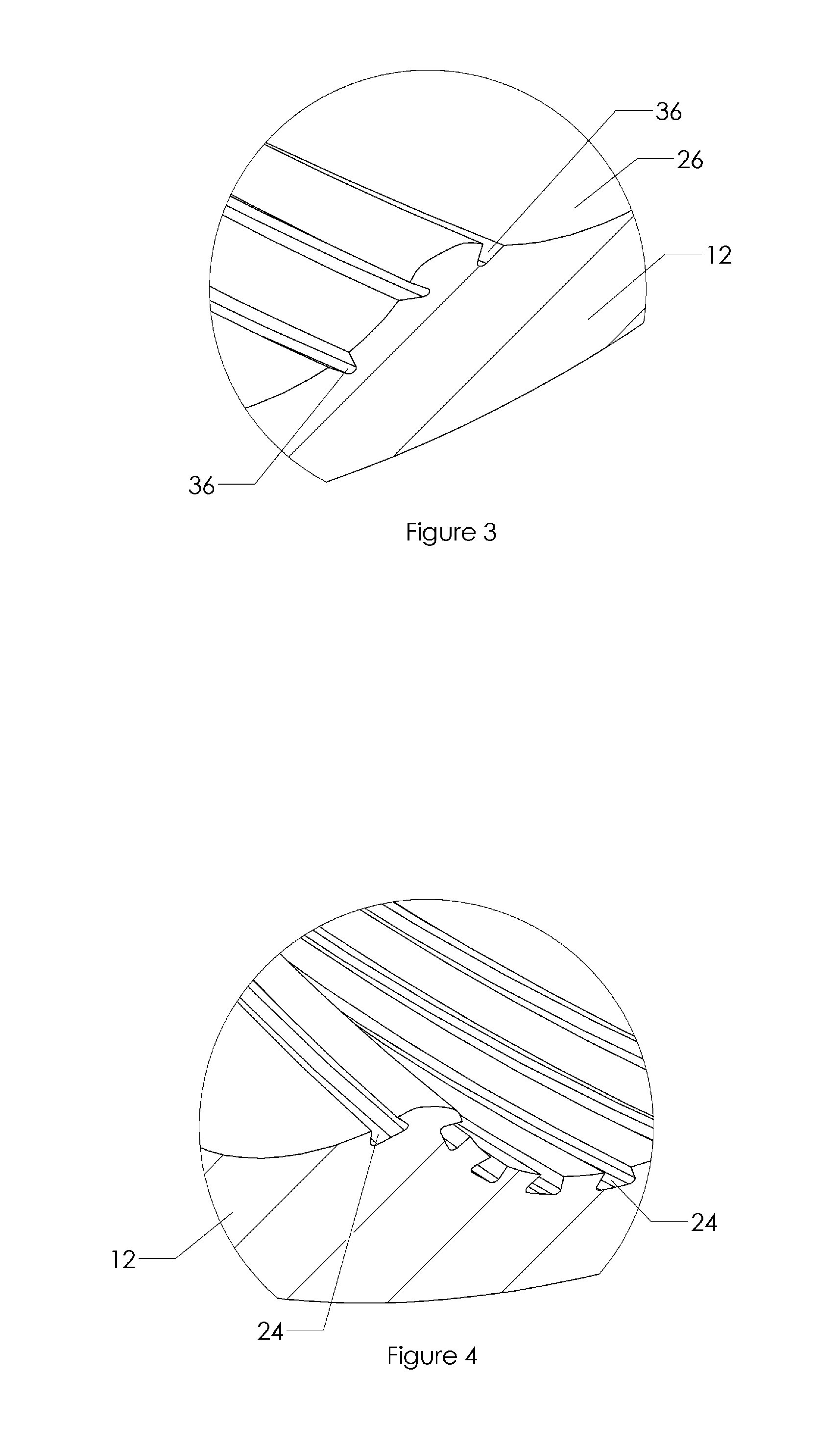

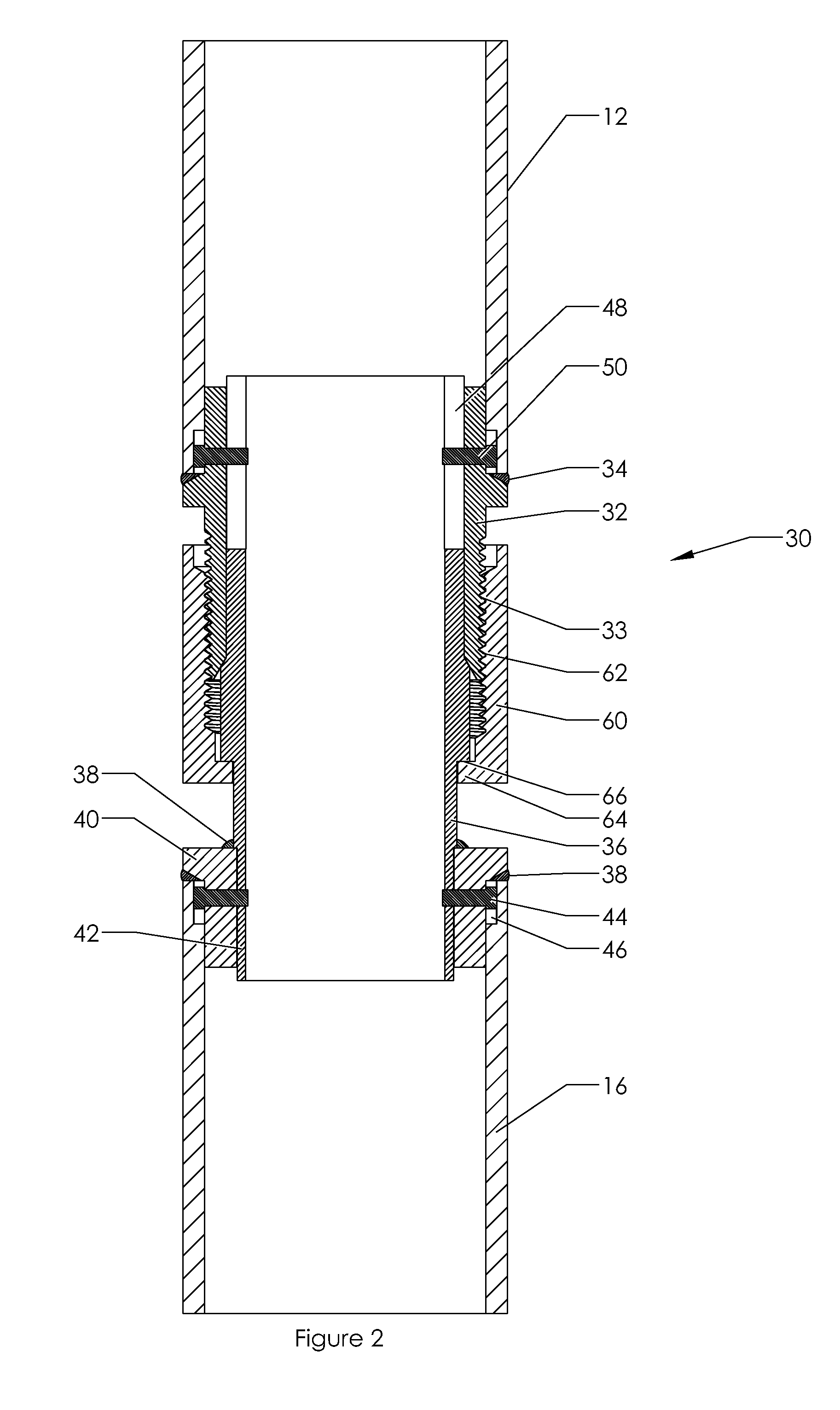

A progressing cavity pump / motor (10) includes a stator housing (12), a polymeric layer (14), and a rotor (16). A plurality of axially extending grooves (24) are formed in the interior surface of the stator housing for receiving polymeric material therein. At least one seal gland (46) adjacent an end of the polymeric layer maintains sealing between the stator housing and the polymeric layer.

Owner:ROBBINS & MYERS ENERGY SYST

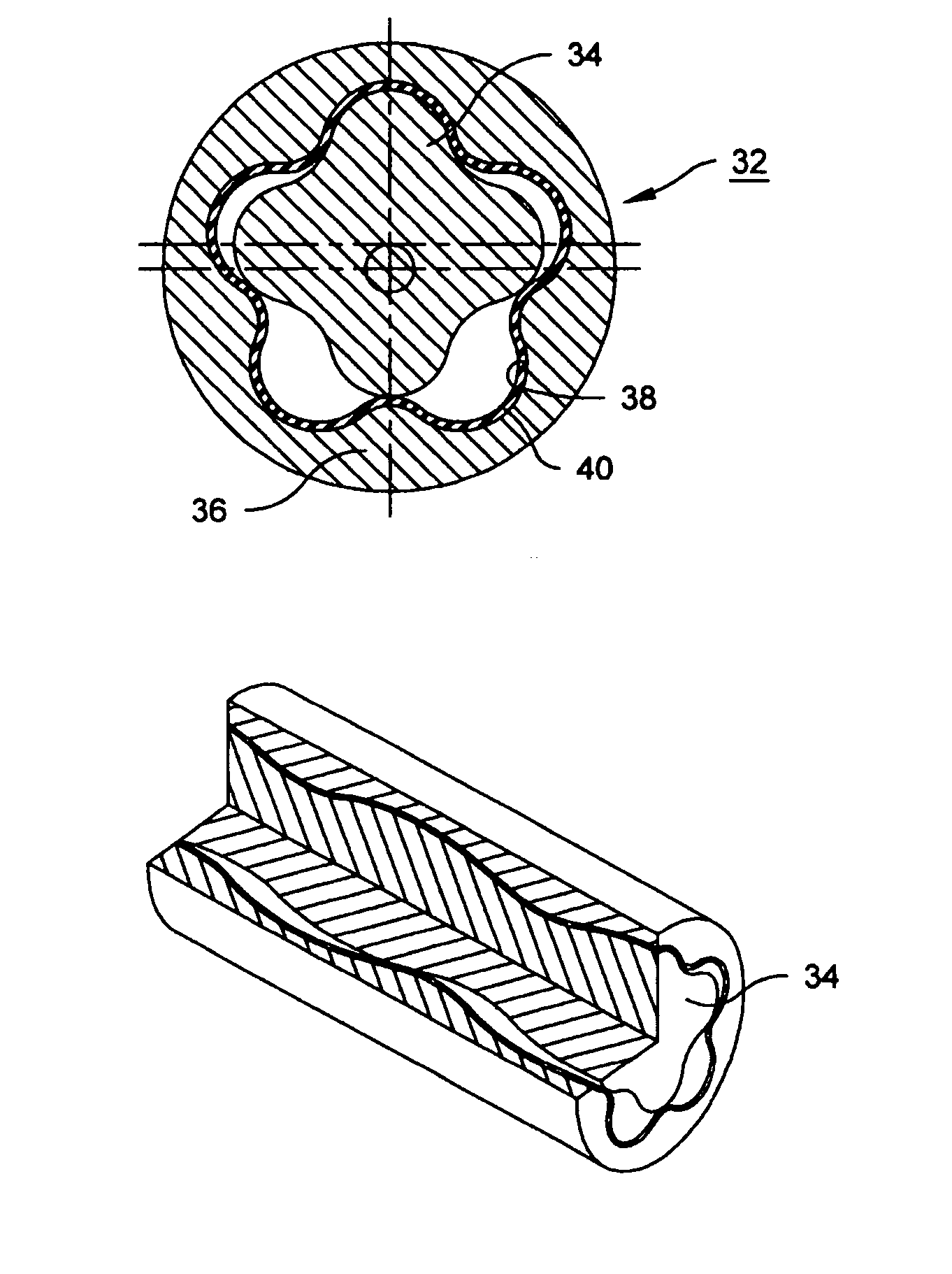

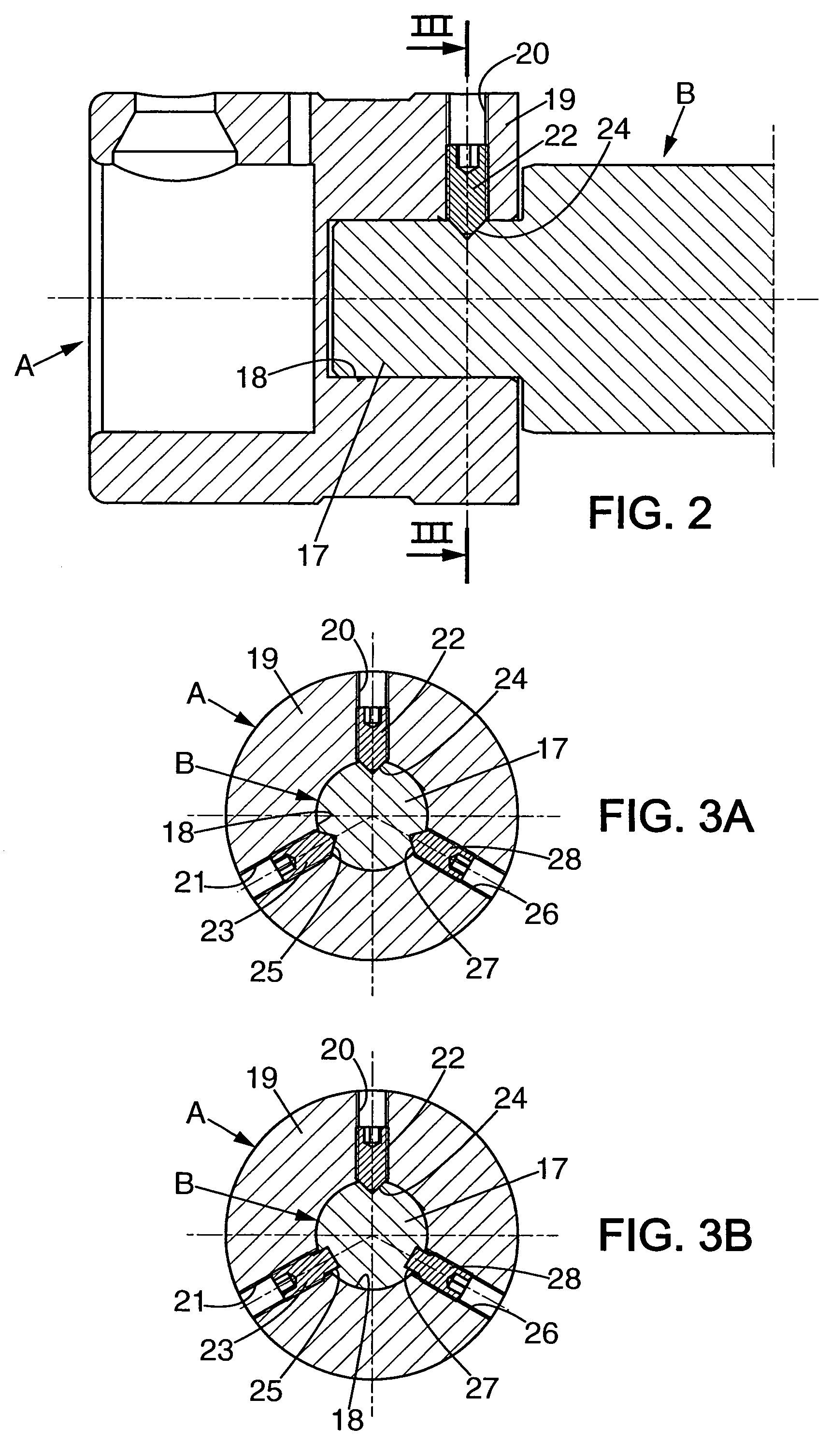

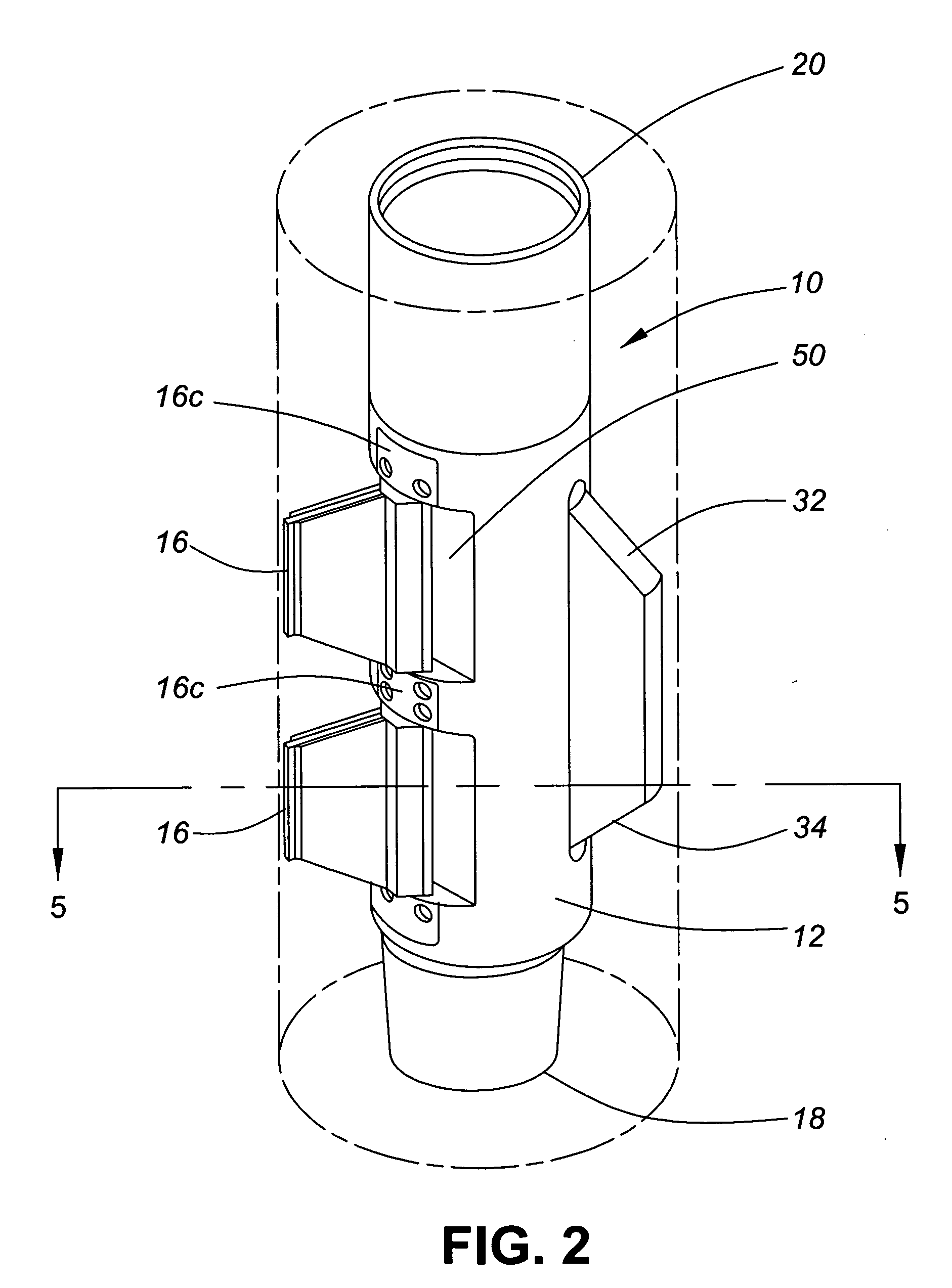

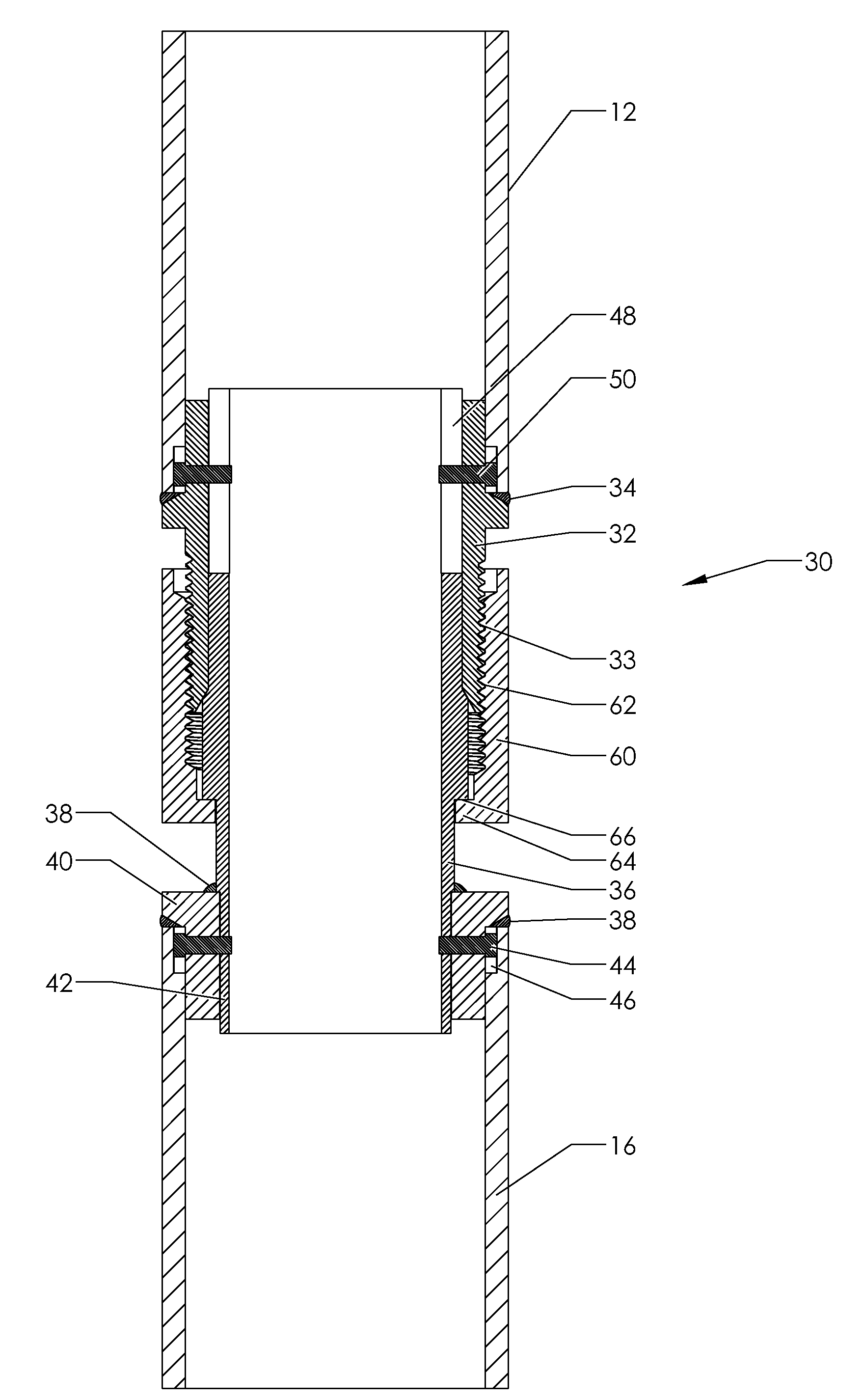

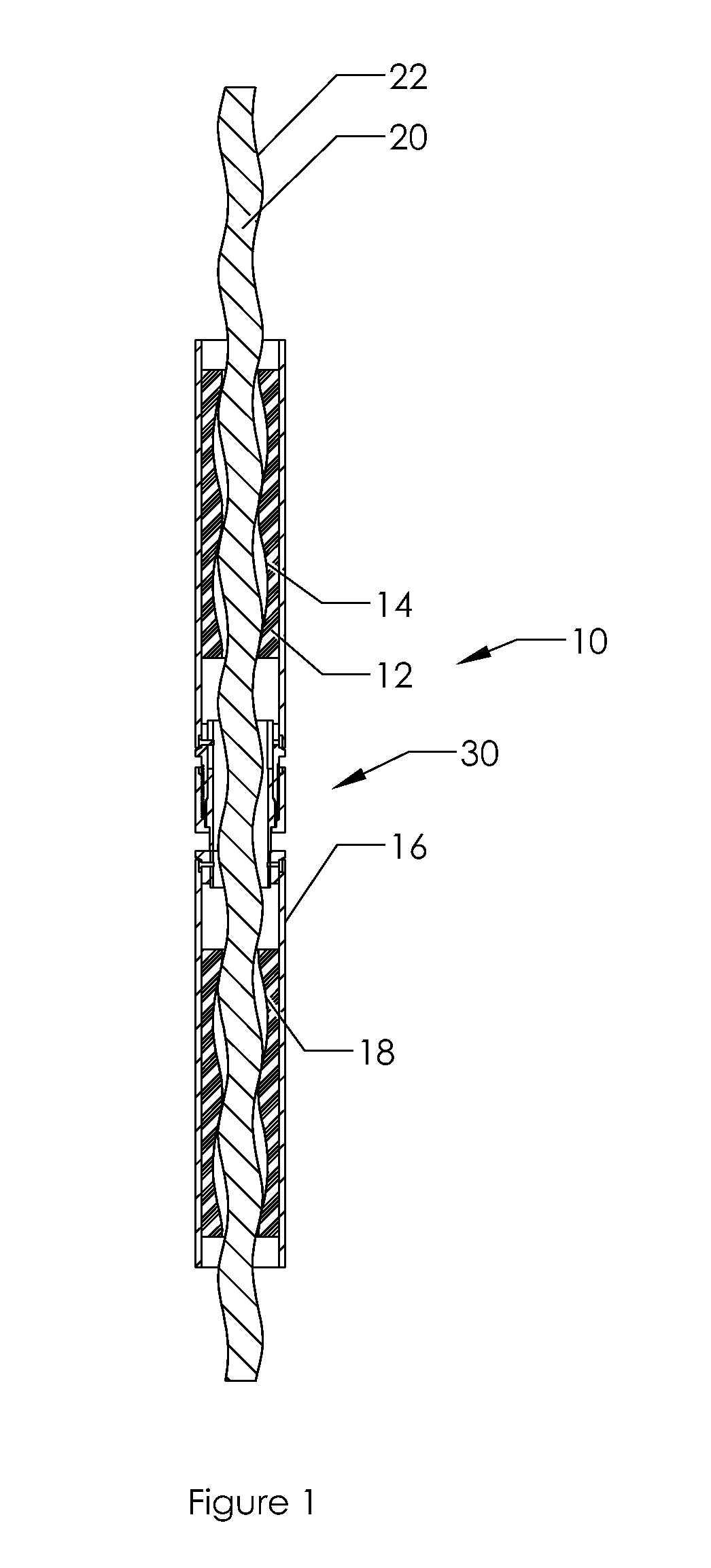

Progressing Cavity Pump/Motor

ActiveUS20100316518A1Oscillating piston enginesEngine of intermeshing engagement typeElectric machineCoupling

A progressing cavity pump / motor includes an upper stator tube (14), a lower stator tube (16), a rotor (20) sitting between the upper and lower stator tubes, and a coupling assembly (30) interconnecting the stator tubes comprising an outer sleeve (32), an inner sleeve (36) and a nut (60) for threaded engagement with at least one of the sleeves to bring a stop surface on the inner sleeve into mating engagement with the stop surface on the outer sleeve. The pump / motor is usually assembled in the field while maintaining precise axial and rotational positioning of the stator tubes.

Owner:ROBBINS & MYERS ENERGY SYST

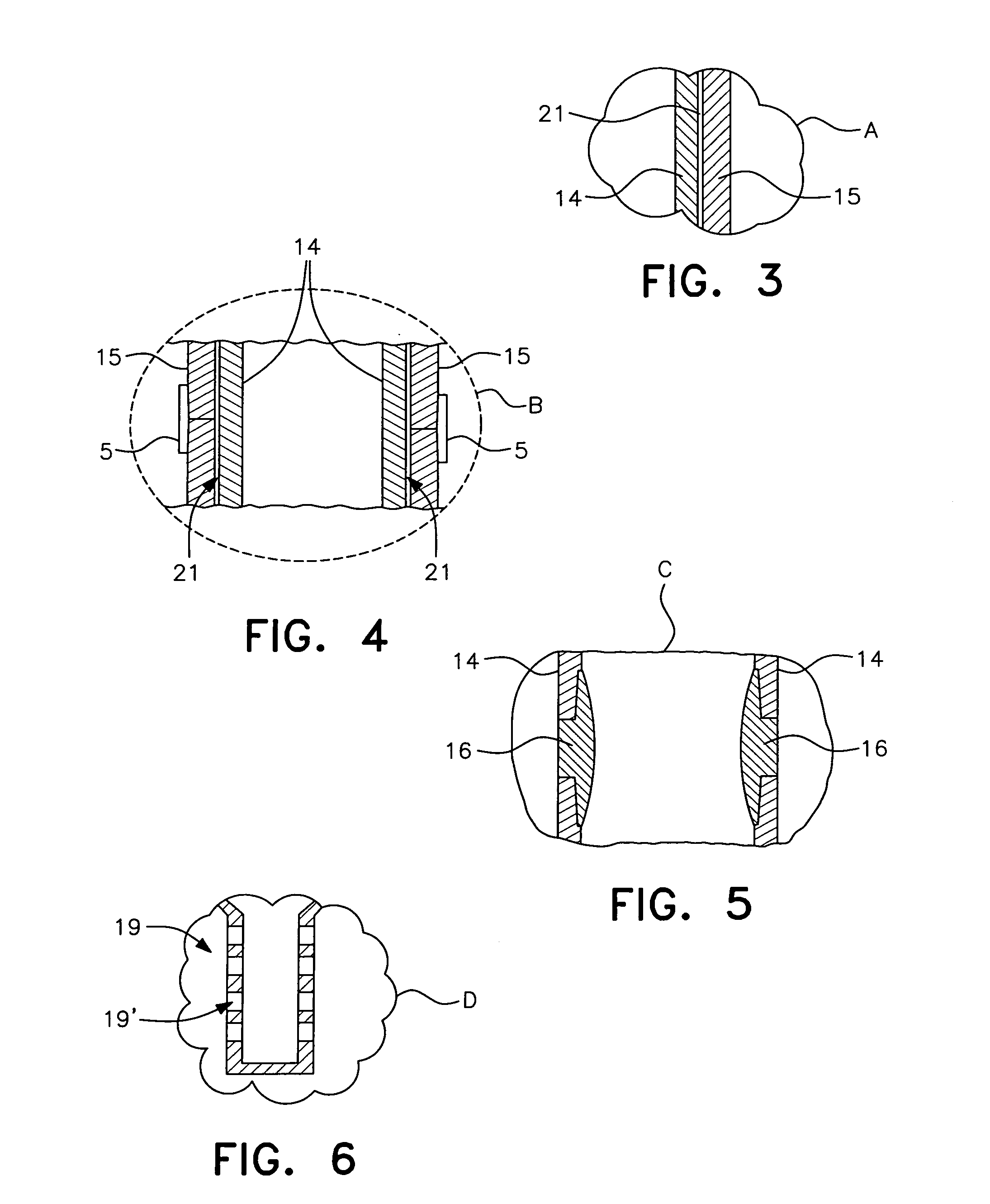

Arrangement for hydrocarbon extraction in wells using progressive cavity pumps

InactiveUS20120034120A1Reduce decreaseReduce wearDrilling rodsOscillating piston enginesHydrocotyle bowlesioidesEngineering

Arrangement for hydrocarbon extraction in wells using progressive cavity pumps which consists of a rotating tube located inside a fixed tube which extend along the well casing. The rotating tube carries fluid from the bottom of the well to the surface. Between the rotating tube and the fixed tube there is an “O” ring space into which an anti-friction lubricant is injected between the external face of the rotating tube and the internal face of the fixed tube. The bottom end of the rotating tube has a section holding holes through which fluid flows into it, it is connected to the progressive cavity pump by means of a rod, and its top end is connected to a production outlet and to its propelling motor mechanism. The upper section of the fixed tube is connected to an anti-friction lubricant injection pipe in the space left between the rotating and the fixed tubes. This arrangement prevents the wearing out, as a result of friction and corrosion, of conventional tubings used in field wells where fluid extraction is carried out by means of progressive cavity pumps.

Owner:COMPANIAS ASOCIADAS PETROLERAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com