Patents

Literature

157 results about "Axis surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

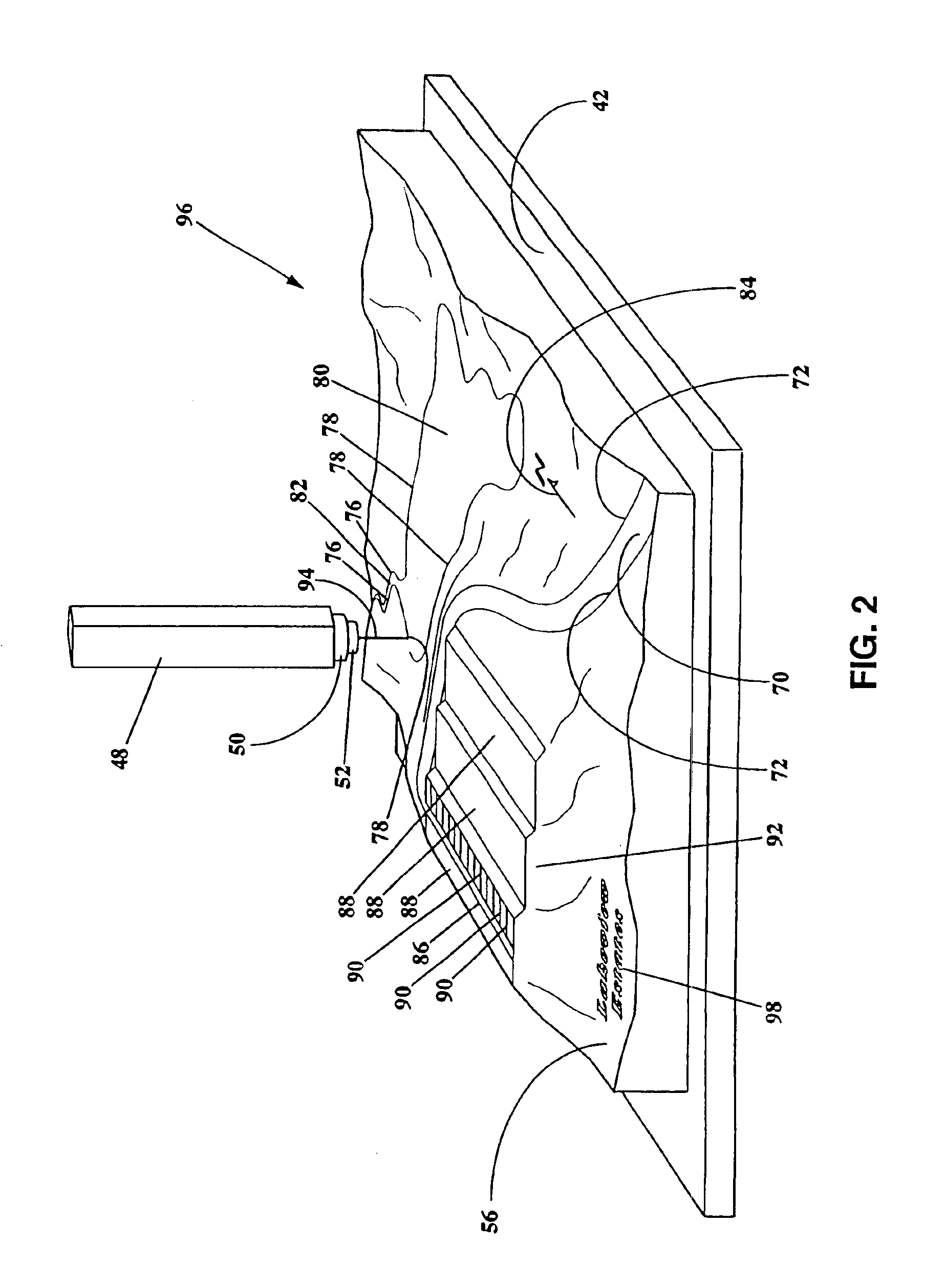

System And Method For Vascular Visualization Using Planar Reformation Of Vascular Central Axis Surface With Biconvex Slab

InactiveUS20070201737A1Efficient real-time processingAccurately present calcification and stenosisImage enhancementImage analysisData setEngineering

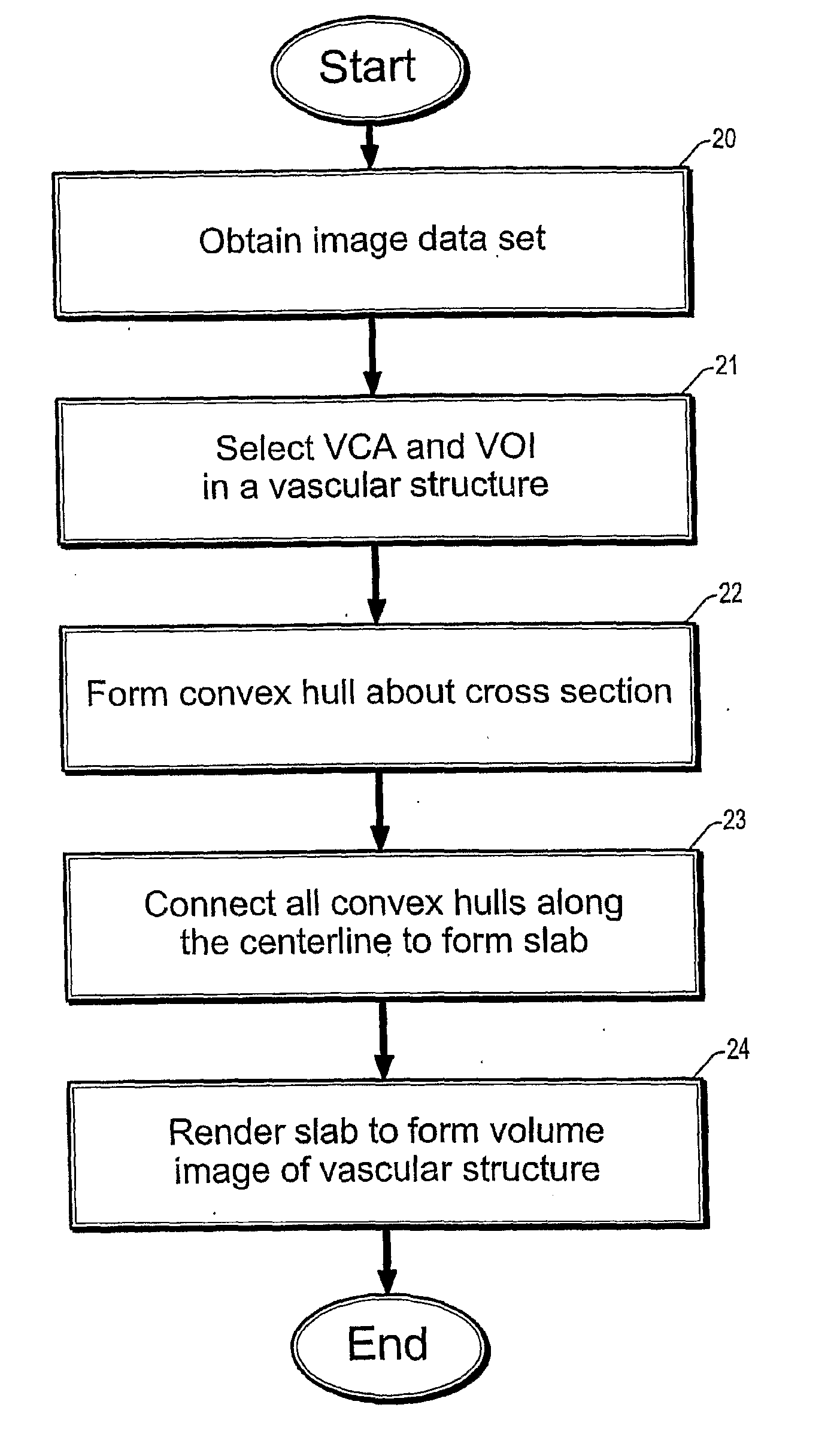

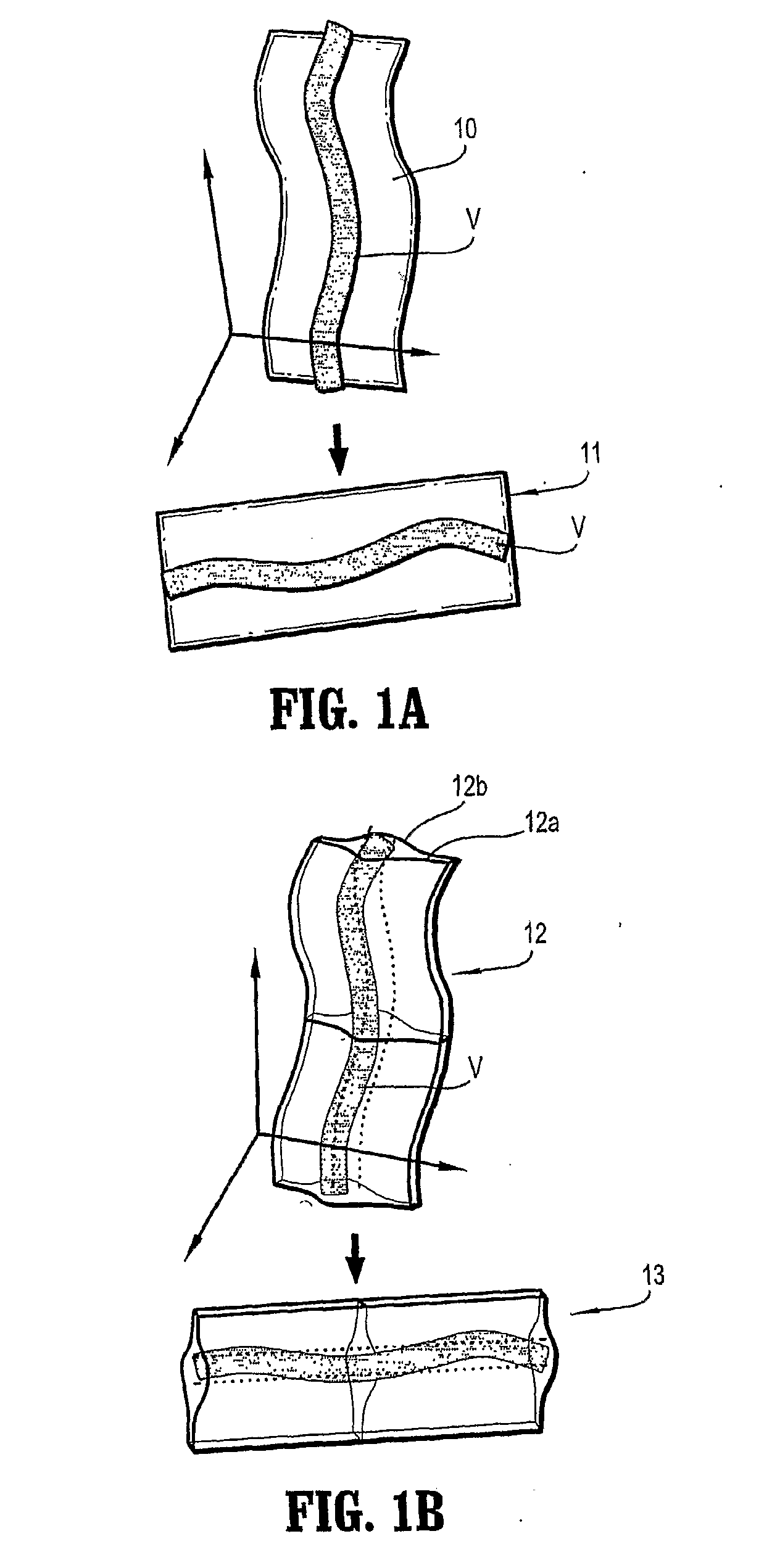

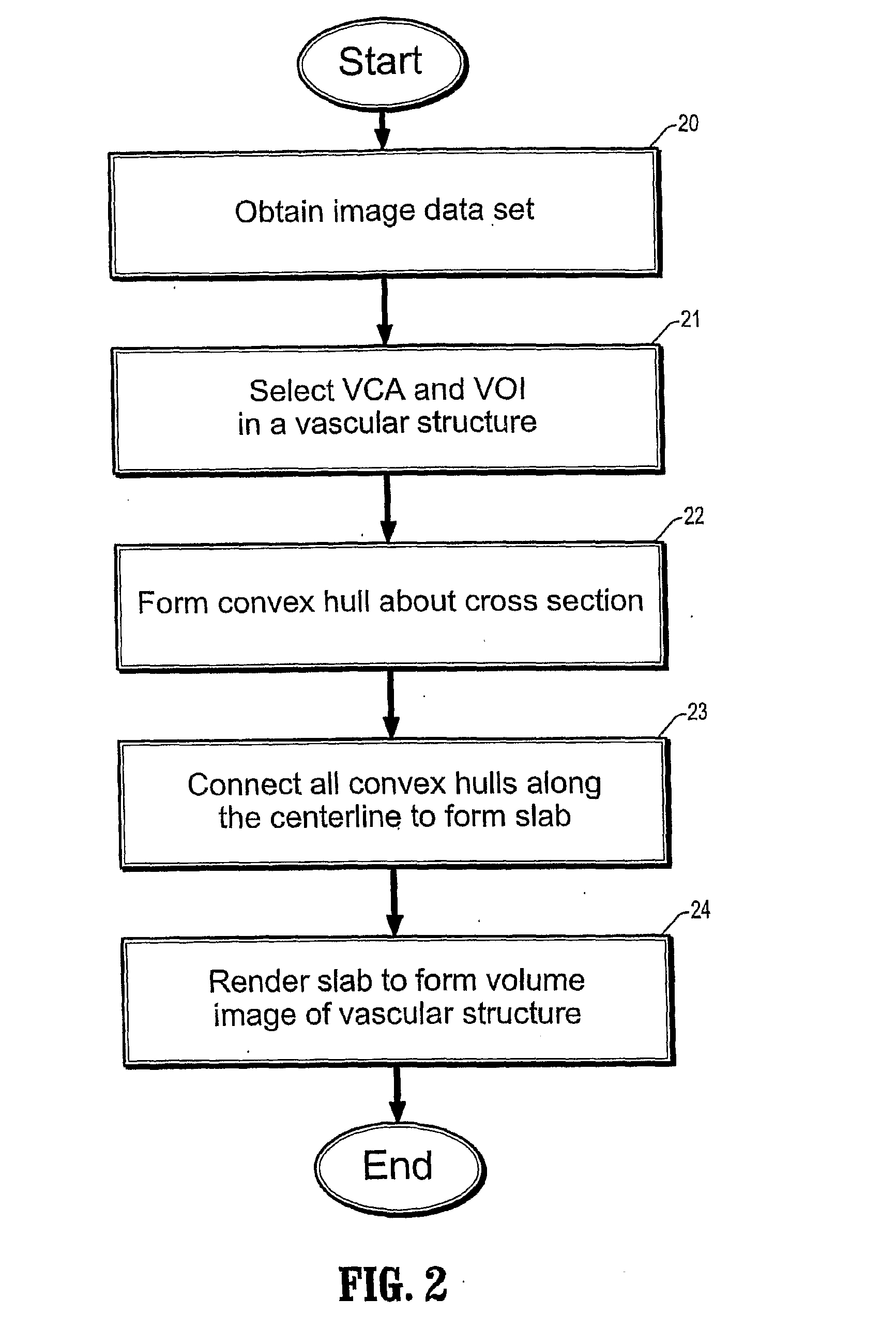

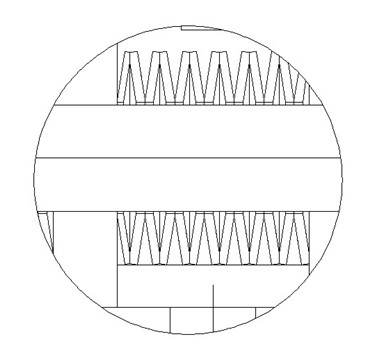

A method for visualizing a vascular structure includes obtaining an image dataset (step 20), selecting a vascular central axis (VCA) and a vector of interest (VOI) (step 21), forming a plurality of cross sections perpendicular to the vascular central axis, forming a convex hull to enclose each cross section (step 22), wherein the convex hull is oriented by the vector of interest and determined by the shape of the cross section, and connecting each convex hull to form a biconvex slab (step 23). The biconvex slab comprises two curved surfaces that enclose a 3D volume including the vascular structure 21 of interest. The volume within the biconvex slab can rendered to obtain a 3D view of the entire vascular structure (step 24). Since the biconvex slab is a 3D volume, volume rendering techniques can be used to render the 3D information and generate a resulting image of the vascular structure in a flattened plane having precise 3D spatial information.

Owner:VIATRONIX

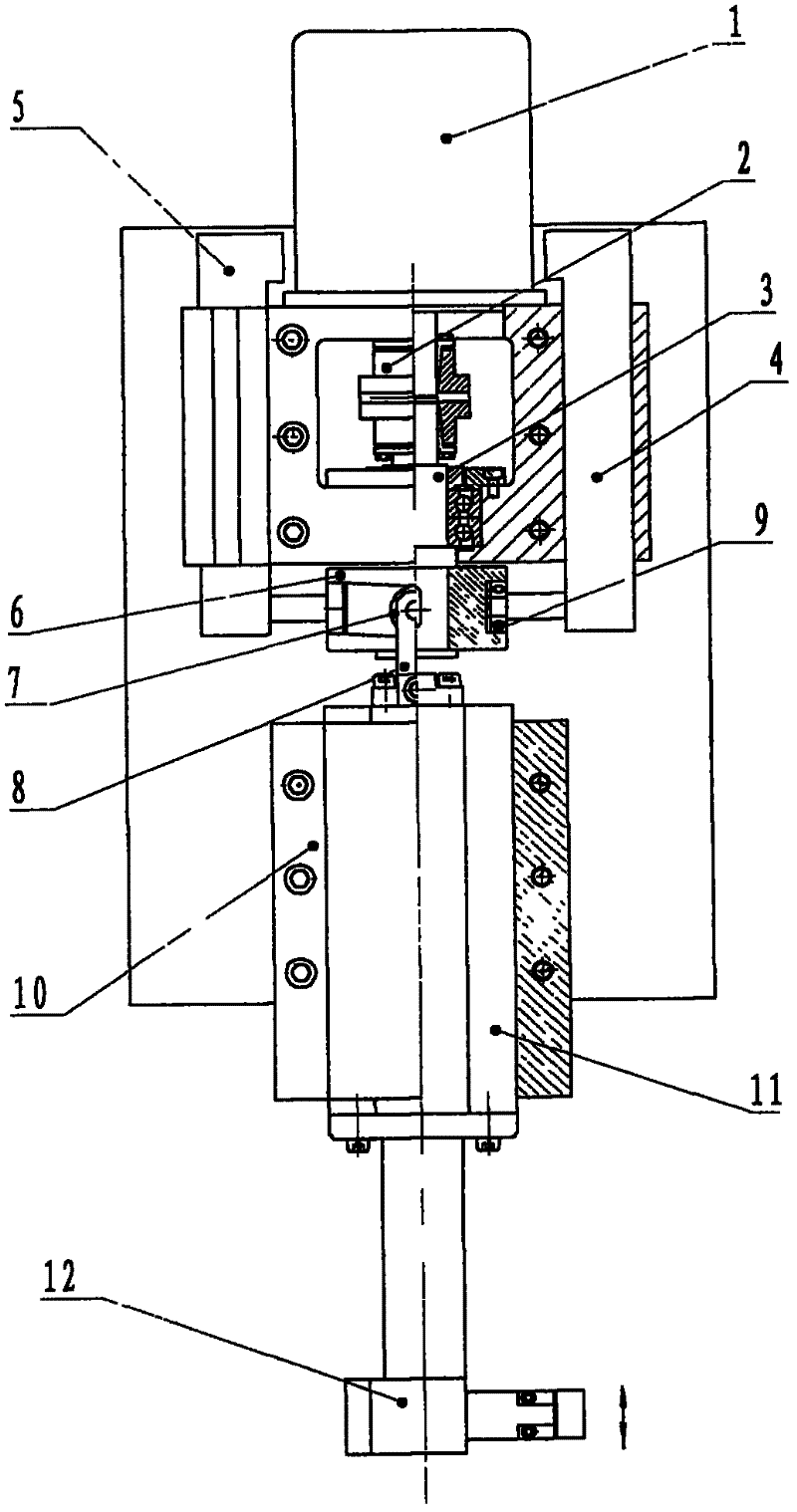

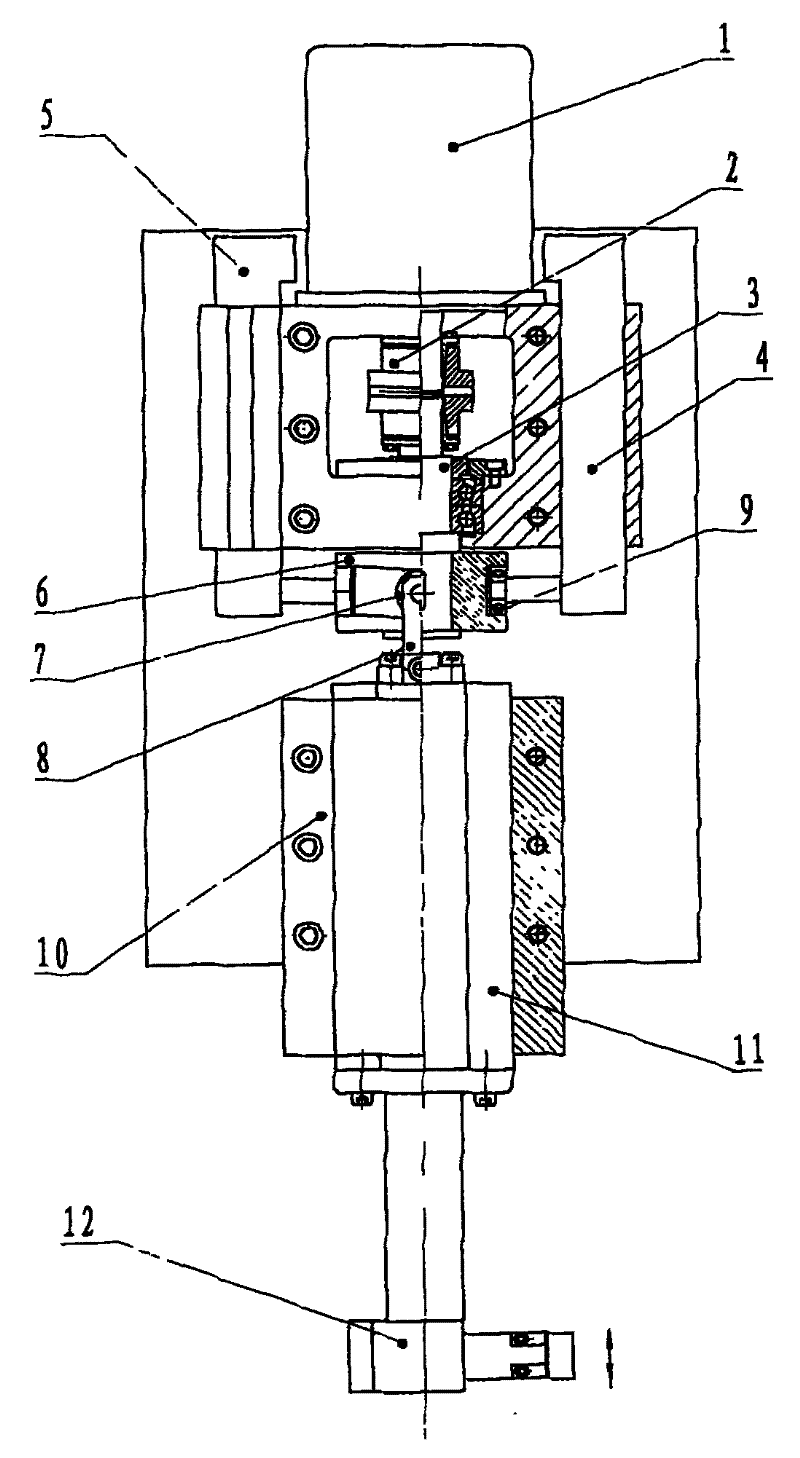

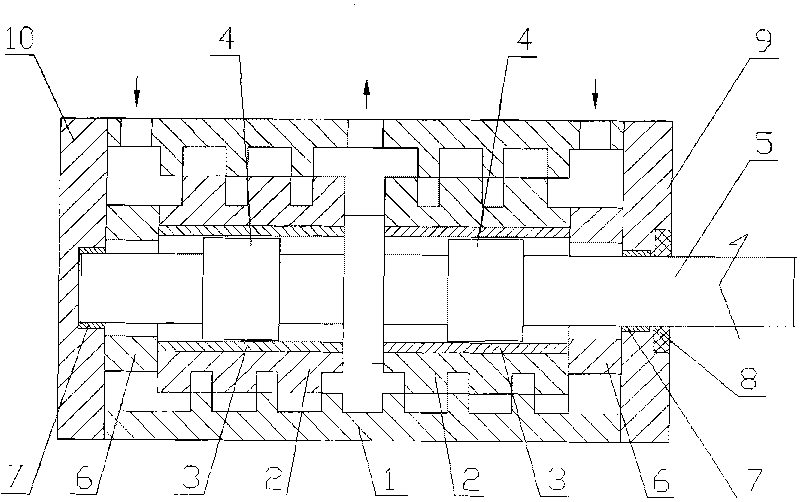

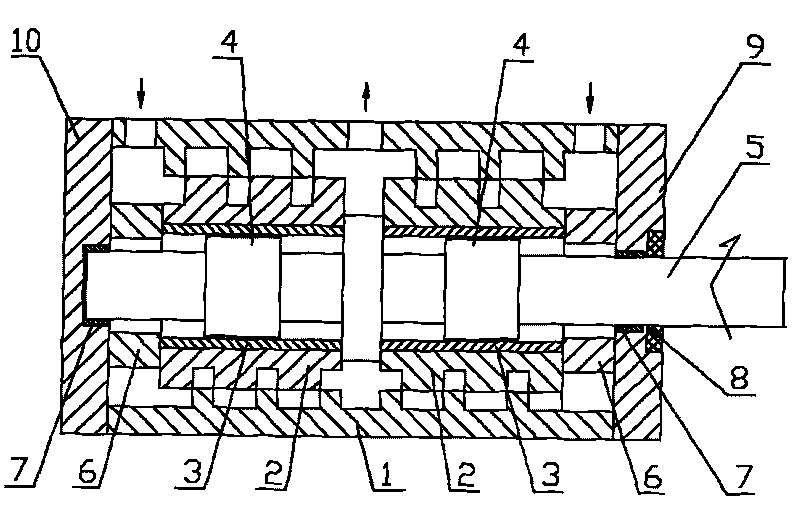

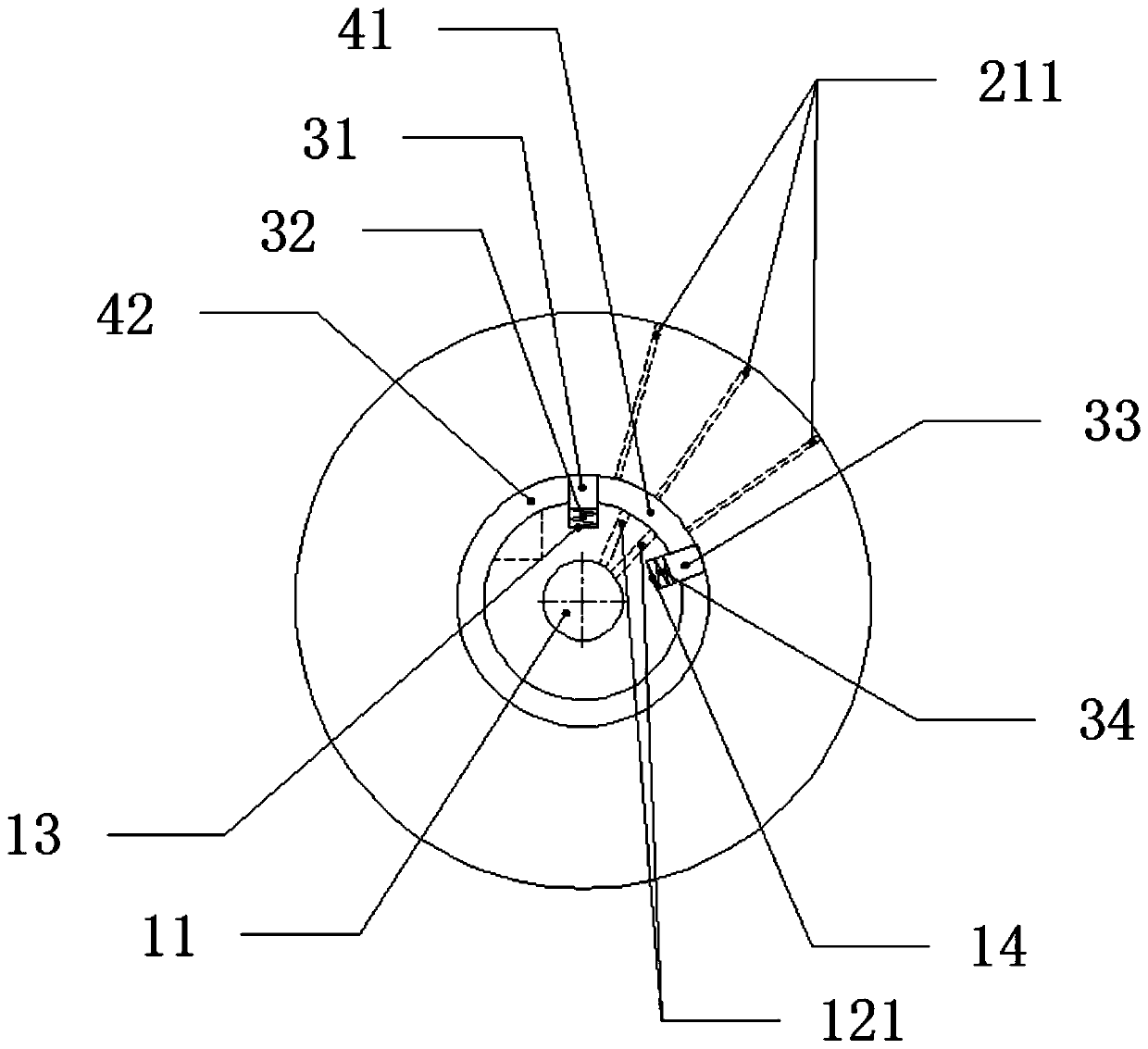

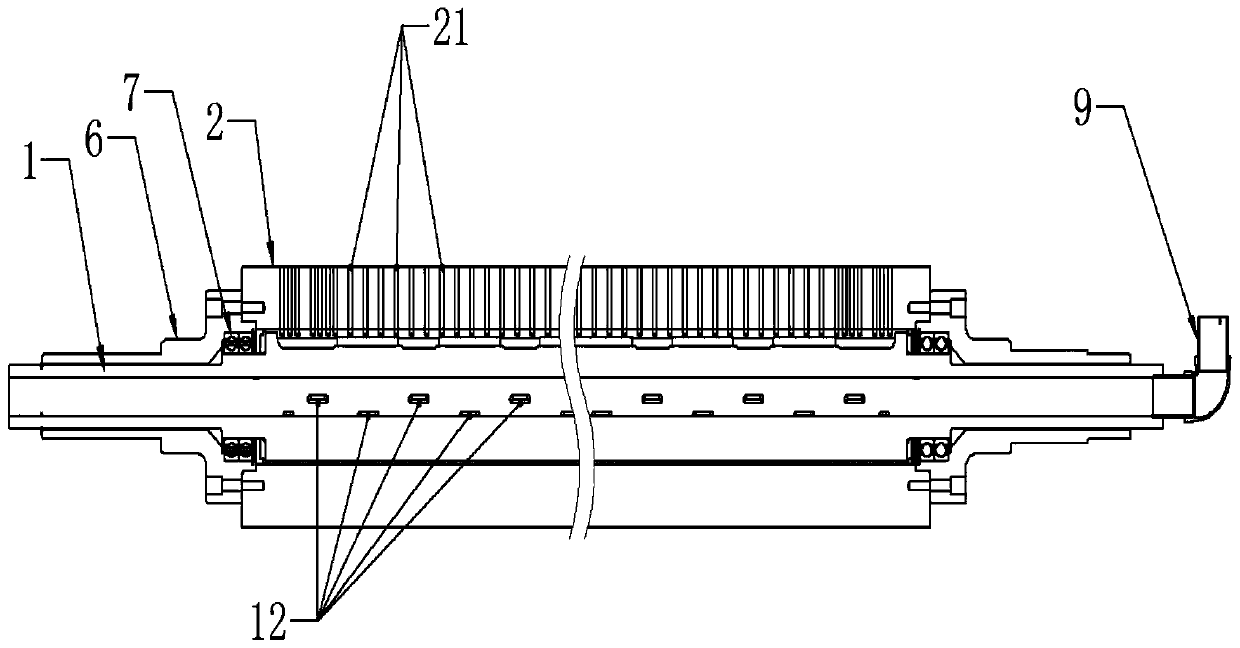

Mechanical-hydraulic bonding composite stepless speed regulating device

ActiveCN102155526ANot easy to damageExtended service lifeFluid gearingsEngineeringTransmission system

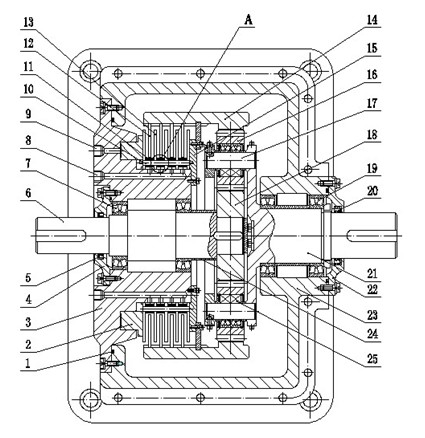

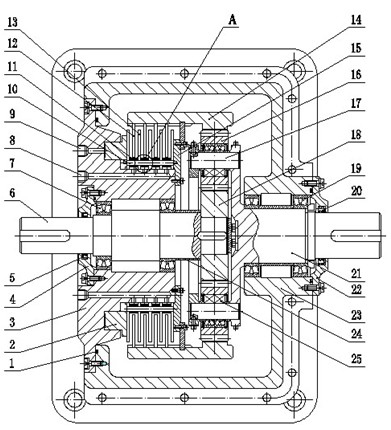

The invention discloses a mechanical-hydraulic bonding composite stepless speed regulating device which comprises a support block (3), an input shaft (6), a disc spring (11), an outer friction plate (12), an inner friction plate (13), a planet wheel (16), a planet shaft (17), a sun wheel (18) and an output shaft (21); one end of the input shaft (6) is fixedly connected with the sun wheel (18), a planet transmission system is formed by the sun wheel (18), the plant wheel (16), the output shaft (21) and an inner gear ring (14), and the plant wheel (16) is connected with the planet shaft (17) into a whole through a planet bearing (25) and arranged on the shaft surface in closed space of the output shaft (21); the inner gear ring (14) is meshed with the planet wheel (16) through an internal tooth, and the other end of the inner gear ring is assembled with the outer friction plate (12) through an internal spline; and the inner friction plate (13) is fixed between the support block (3) and a link stopper (15) through a pin roll (10). The device has the advantages of reasonable, simple and compact structure and long service life, and is suitable for speed regulation and soft start of high-power equipment.

Owner:苏州方德锐精密机电科技有限公司

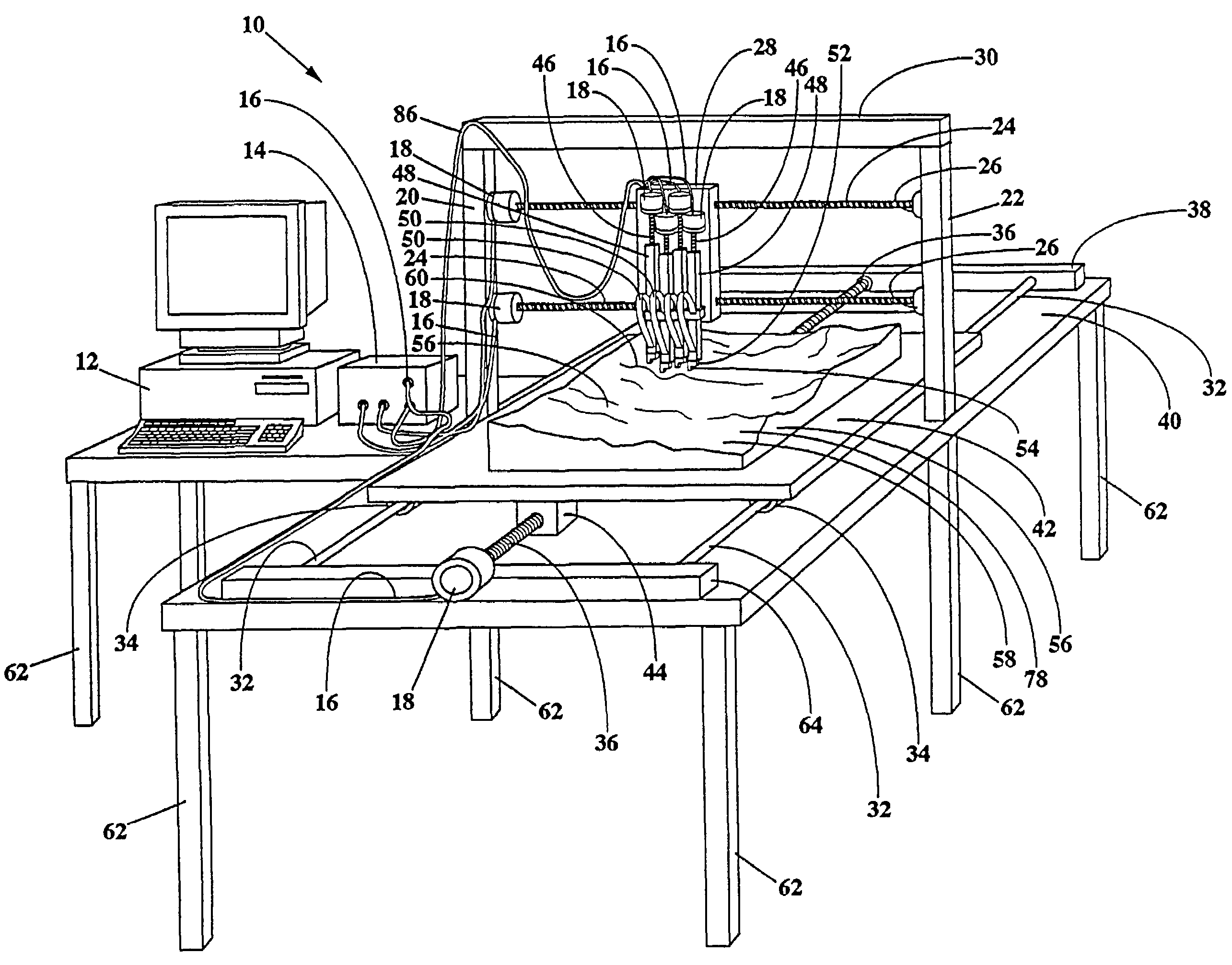

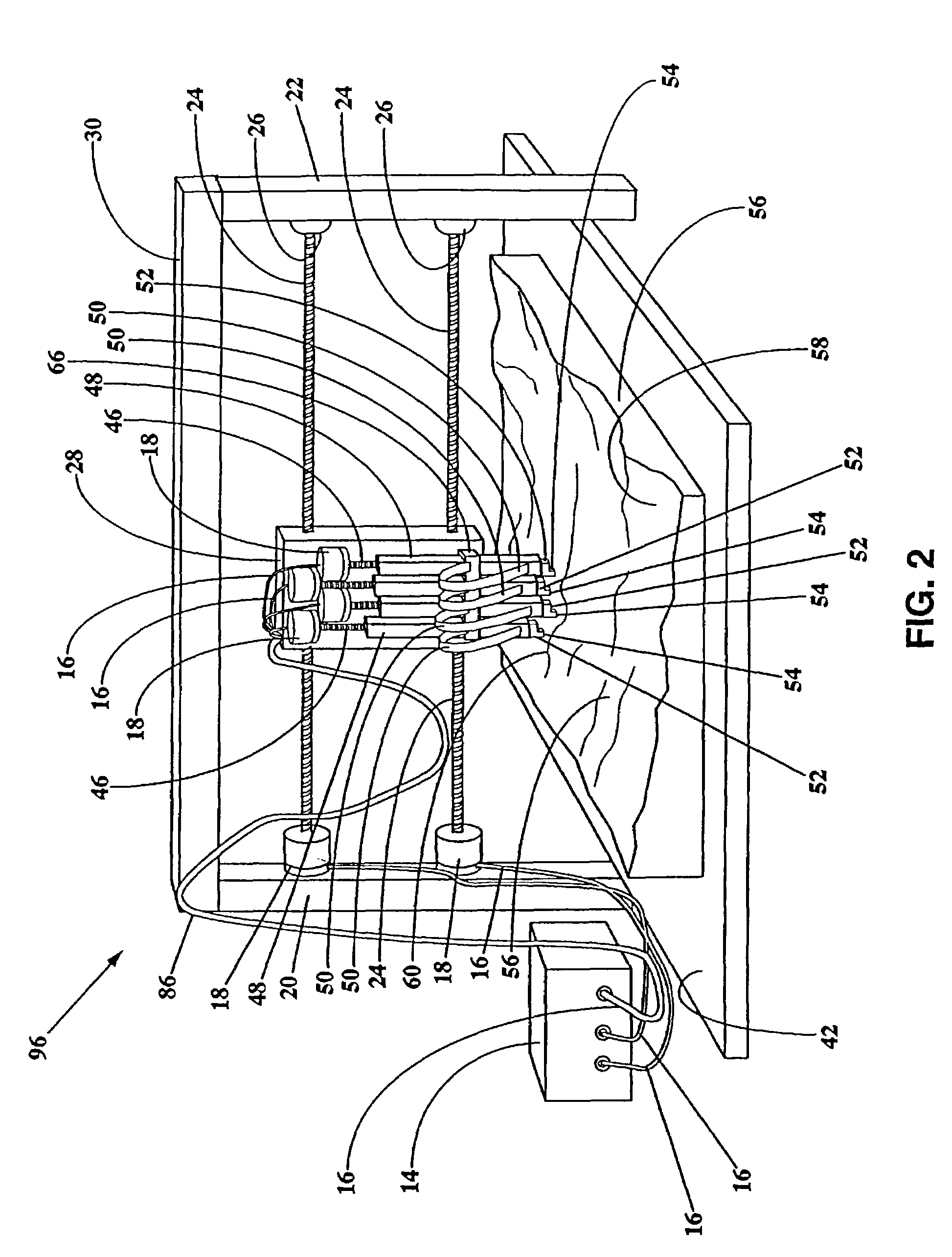

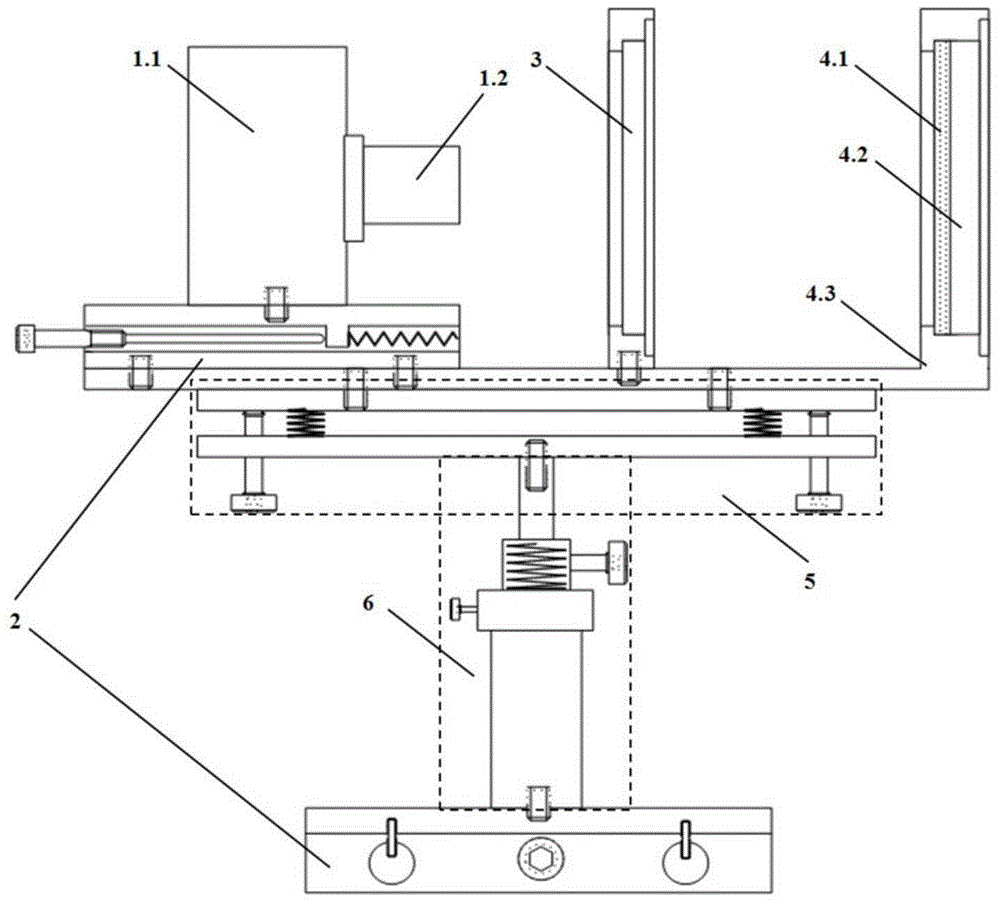

Hi-accuracy three-dimensional topographic modeling apparatus

InactiveUS7216003B2Accurate scaleSimple surfaceOrnamental structuresMilling machinesTerrainMaterial removal

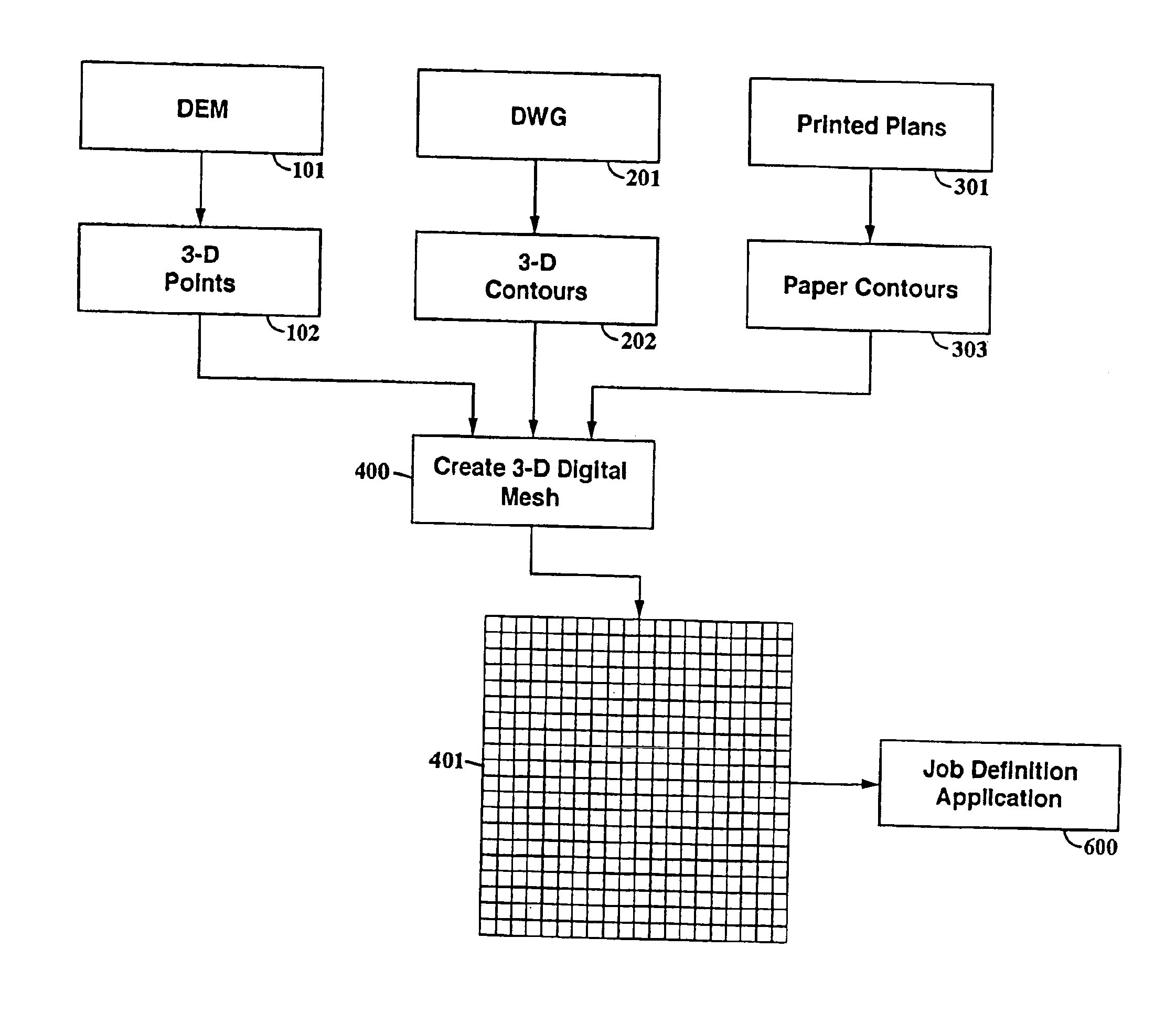

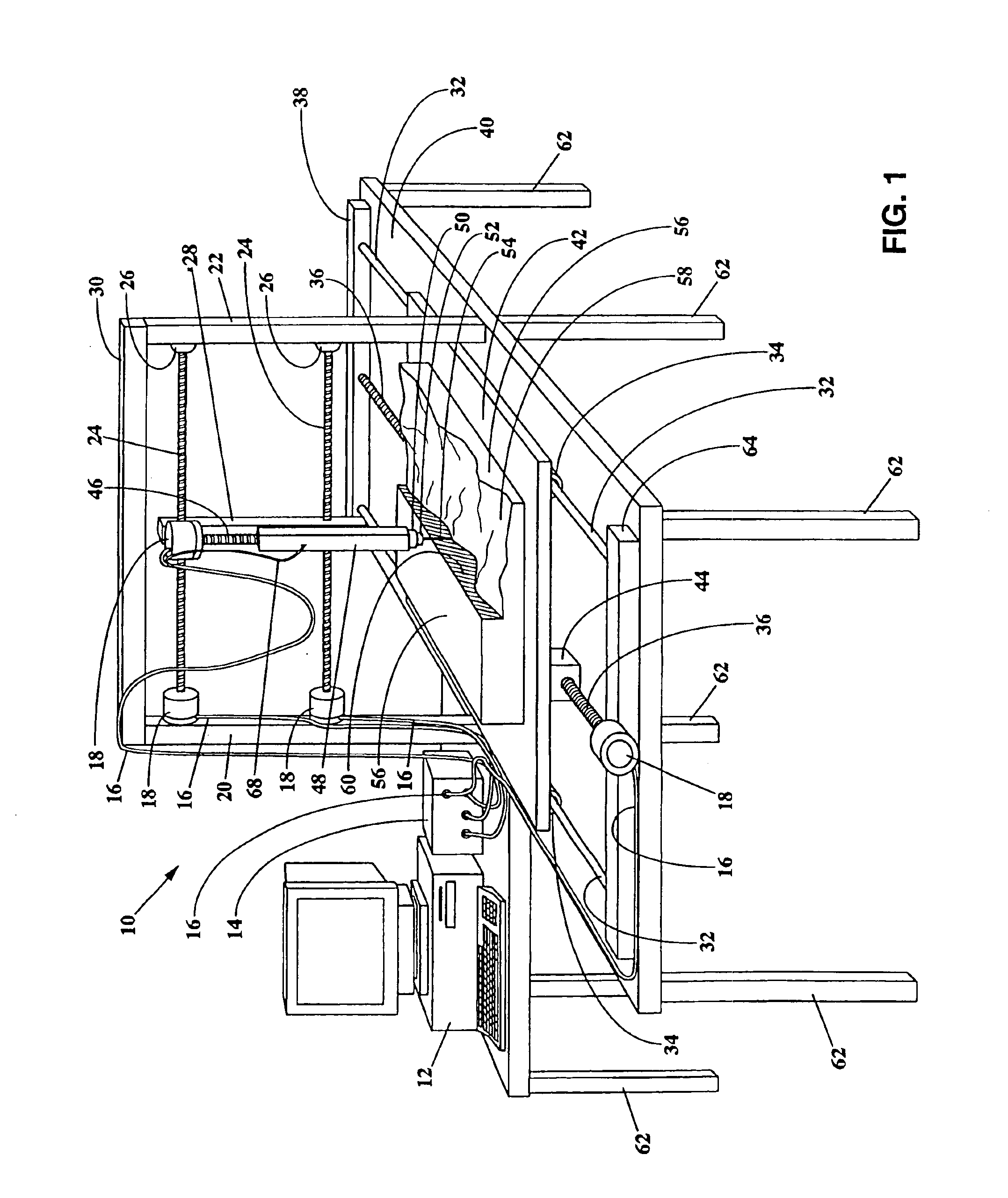

A cutting apparatus includes a hi-accuracy three-dimensional cutting apparatus for topographic modeling that is electronically coupled with a computer. The computer has a central processor that executes instructions, a memory for storing instructions to be executed, and non-volatile storage for storing the messages. The executable computer instructions of the system include one or more algorithms for converting the complex and randomly-occurring contours found in natural terrain into an efficient series of modeling material removal swaths defined in simplified 2-axis cross-sections that are cut adjacent and parallel to one another. The swaths are defined in a simplified 2-axis surface contour-following rotation cutting device moved by the system's CPU, driver software, driver circuitry and / or logic circuitry. This multi-axis control of the system assures that each of the swaths are seamlessly rendered next to one another while also maintaining an optimal proximity between the upper surface of the 3D model and the rotation cutting device.

Owner:SOLID TERRAIN MODELING

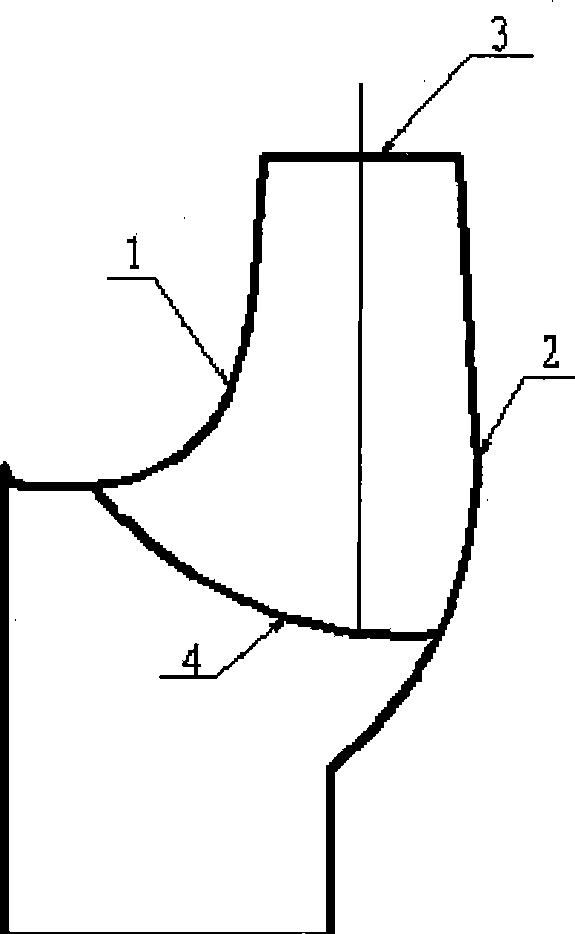

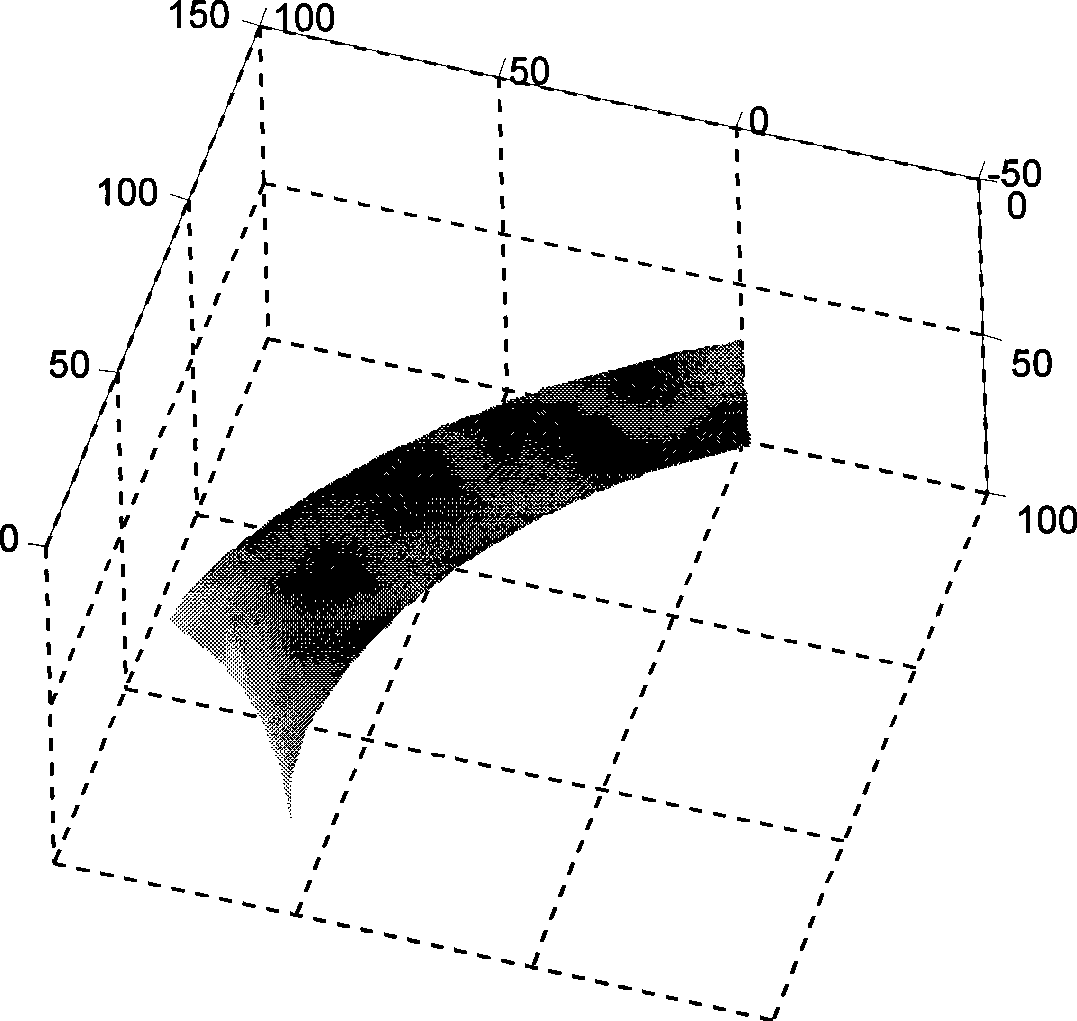

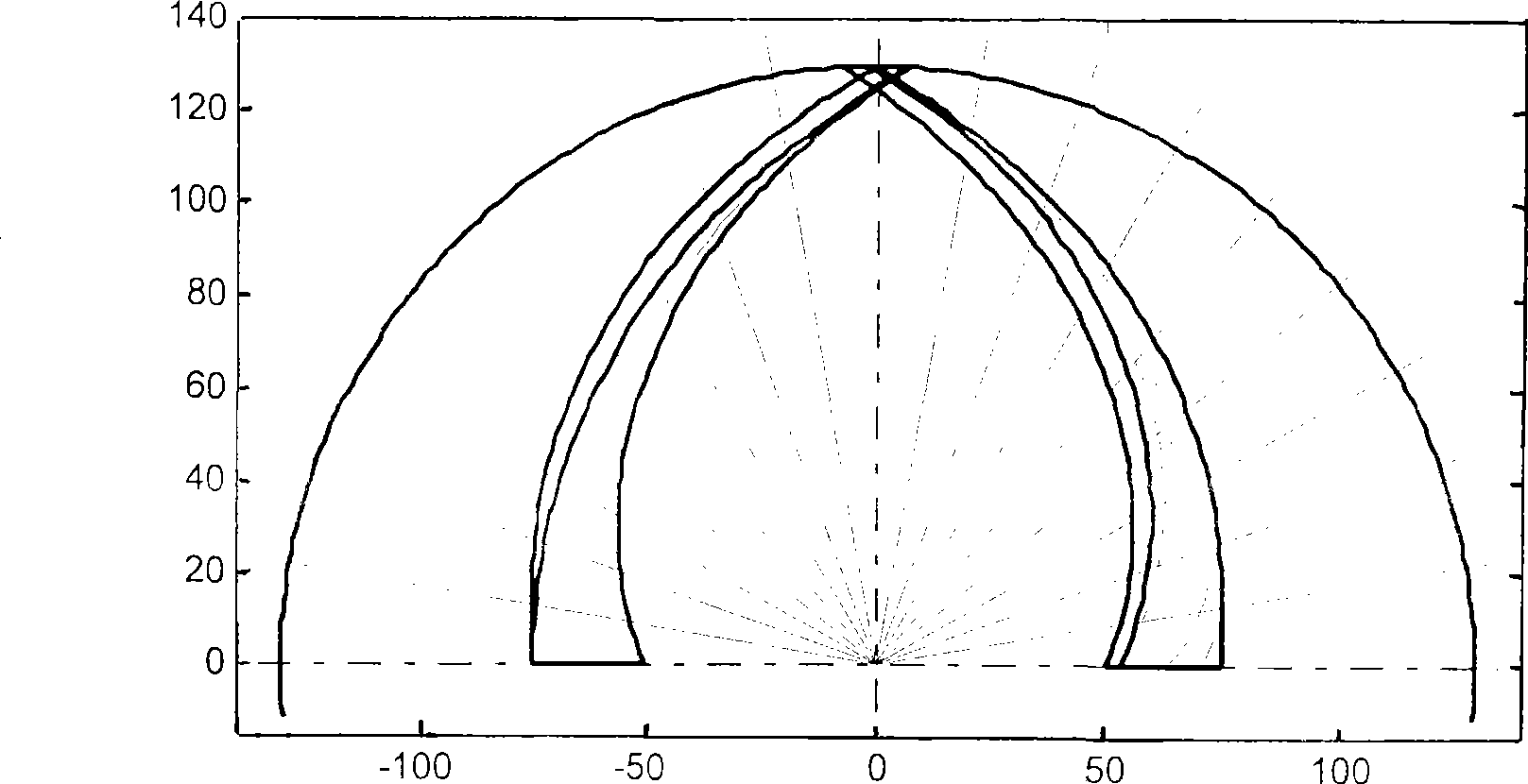

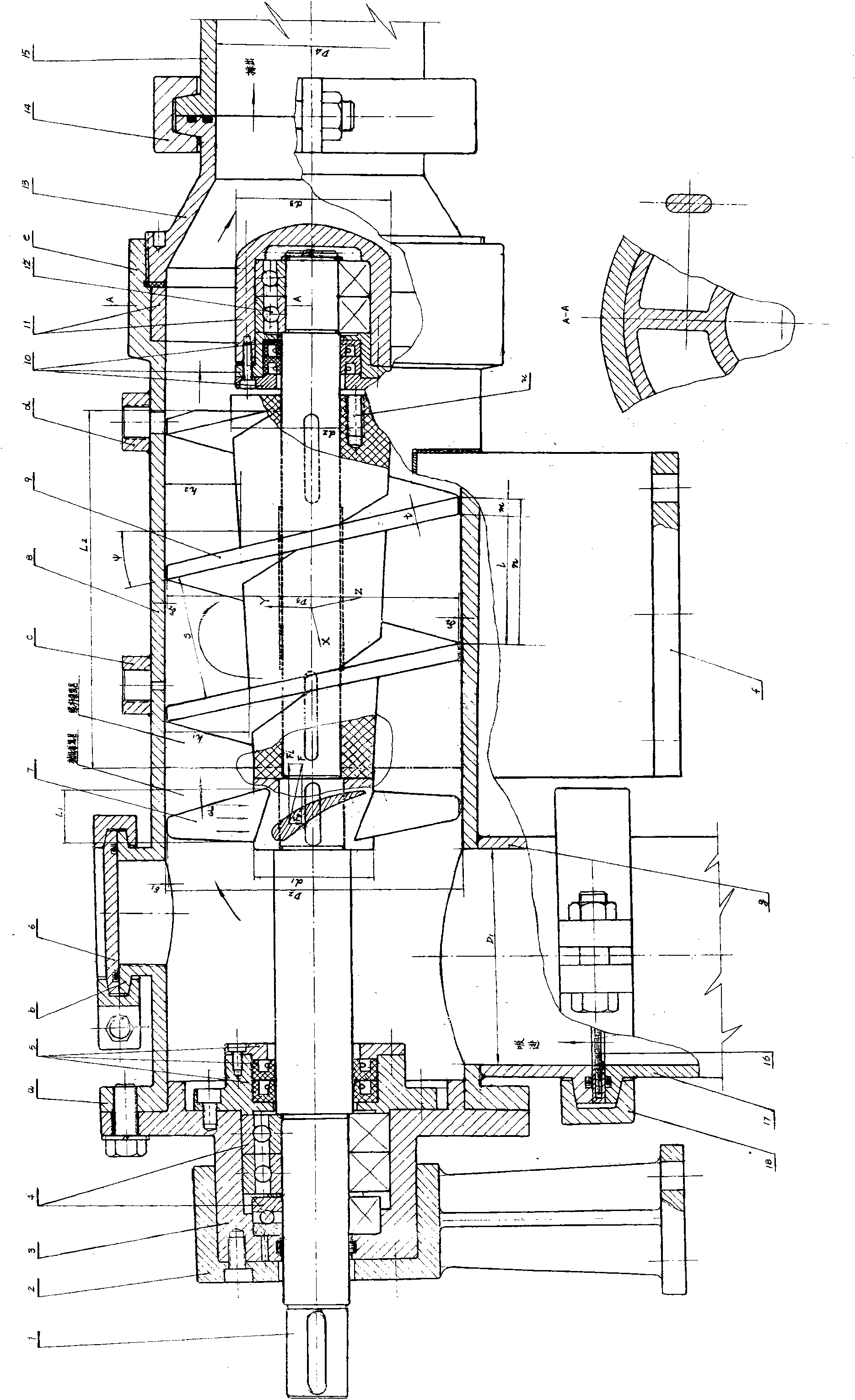

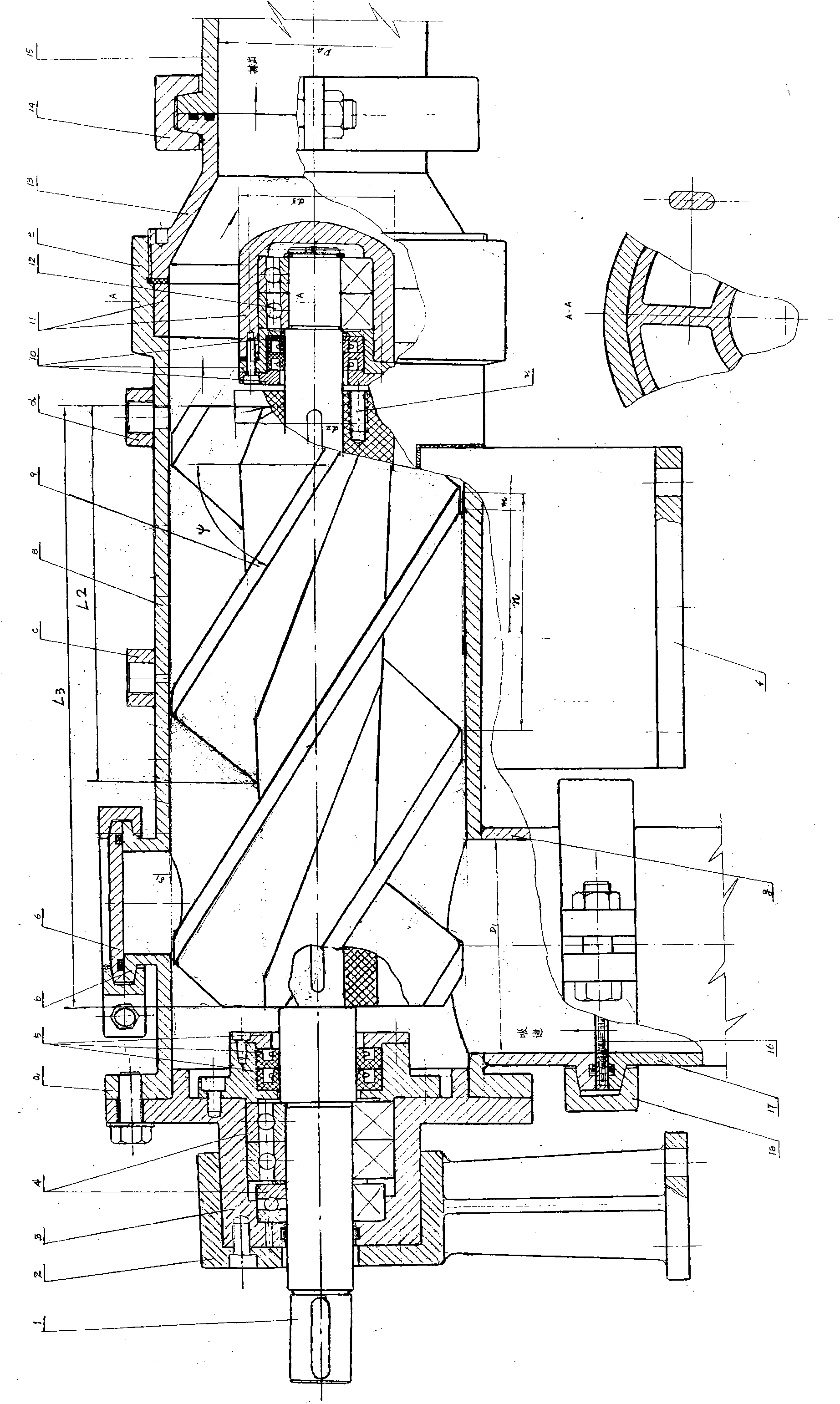

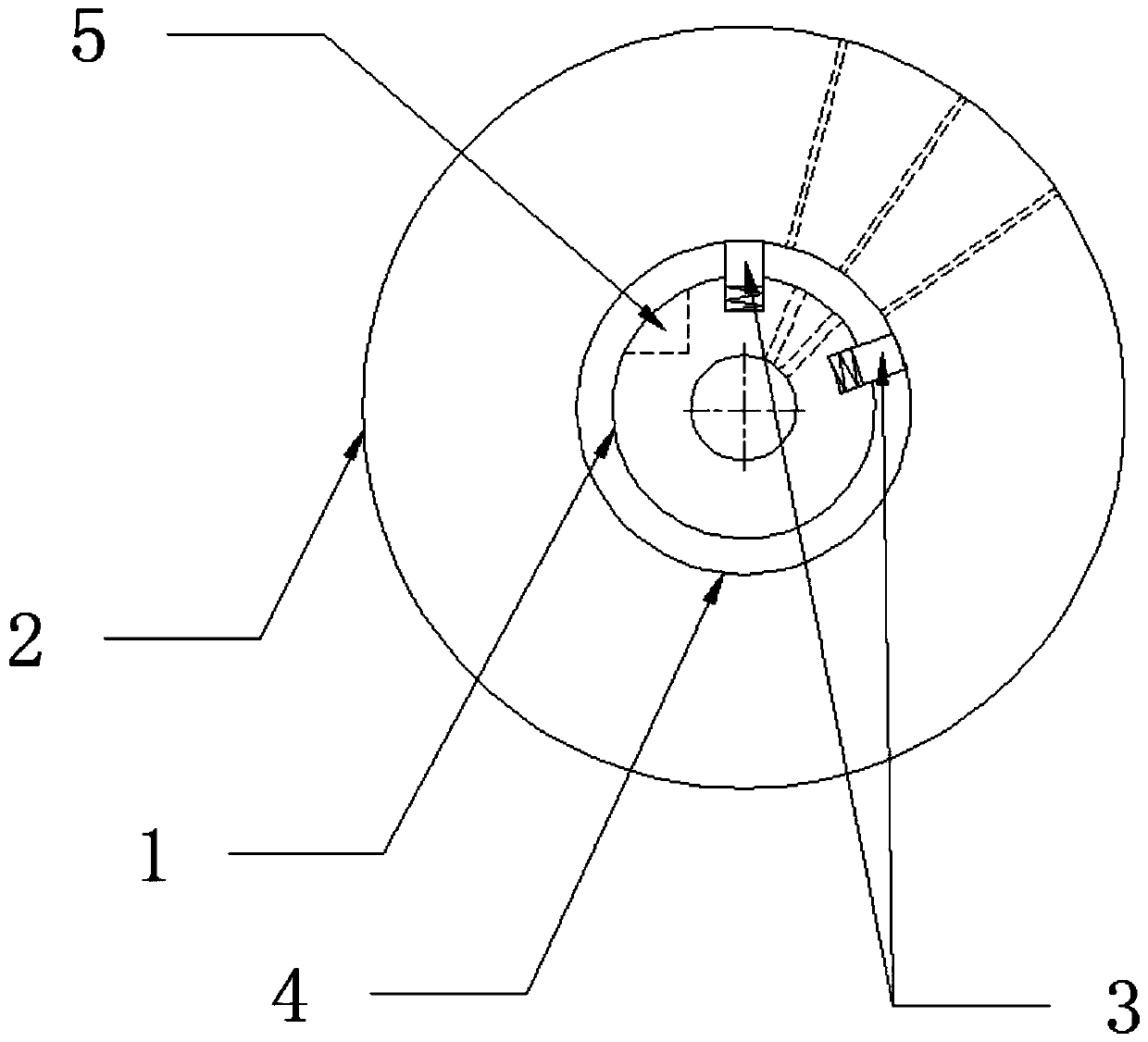

Reverse design method for impeller of centrifugal pump

InactiveCN101520052AOvercoming the Definition of GeometryOvercome many inconveniences such as modificationPump componentsPumpsBoundary value problemThree-dimensional space

The invention discloses a reverse design method for an impeller of a centrifugal pump, which comprises the following steps: according to a given impeller axial plane, a blade in a three-dimensional space can be actually expressed as X=X(z(u, v), r(u, v), theta(u, v)), the (z(u, v), r(u, v)) has been determined when a streamline of the impeller axial plane is given, and the space modeling of the blade can be determined by determining the theta(u, v) on the impeller axial plane. The reverse design method is characterized in that the reverse design method transforms a geometric design problem of the blade of the centrifugal pump into a boundary value problem of a partial differential equation to solve under the condition of the given impeller axial plane of the centrifugal pump. The reverse design method overcomes a lot of disadvantages such as the definition and modification of geometrical shape of the blade in the prior design method, can realize the parametric design of the blade, overcome the defects existing when a fussy two-dimensional form drawing is used for showing three-dimensional twisted blades in the prior method, can closely combine the hydraulic design of hydraulic machinery, three-dimensional solid modeling and the CFD analysis of flow field, and realize the quick and accurate solving of the reverse problem of the blade.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

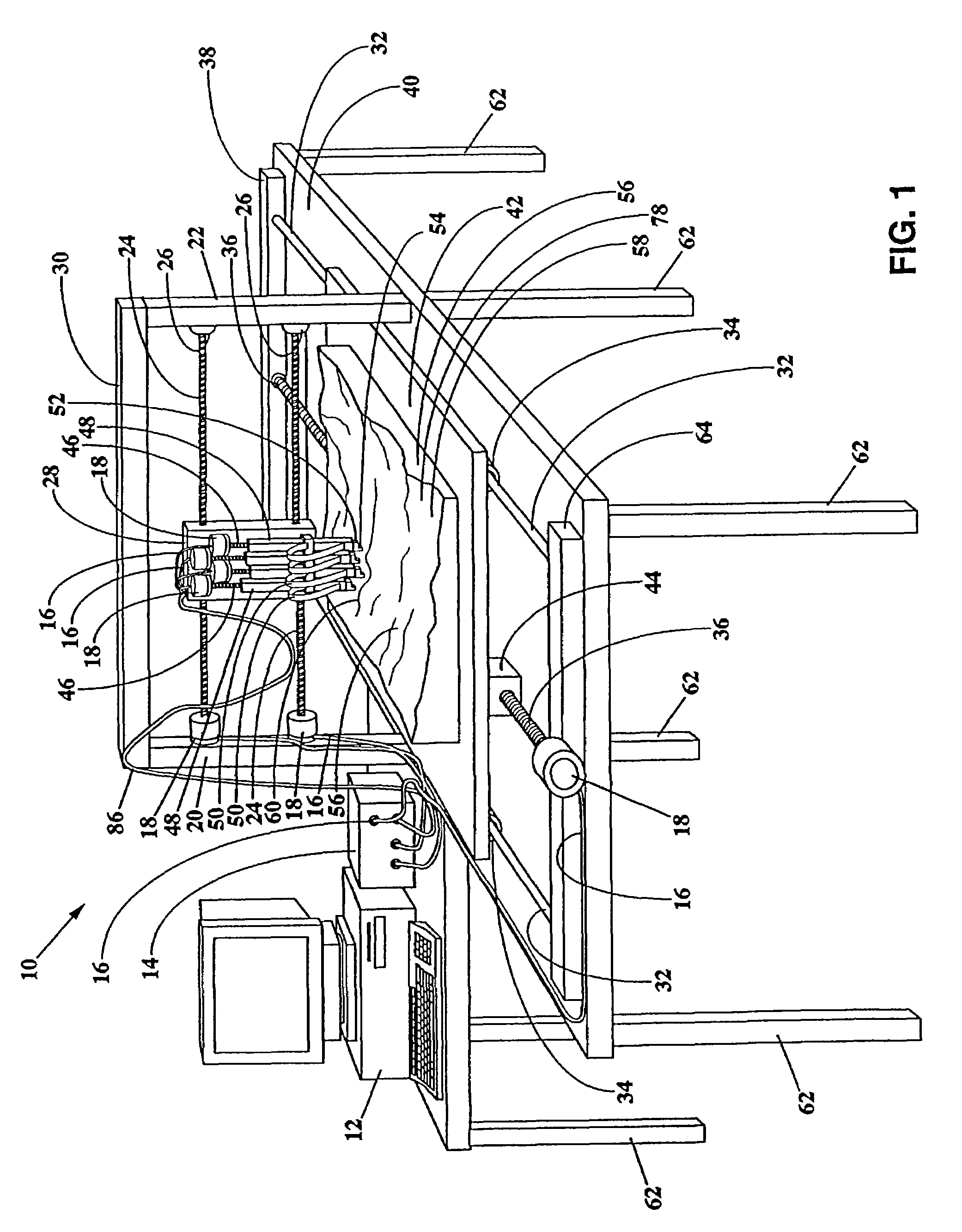

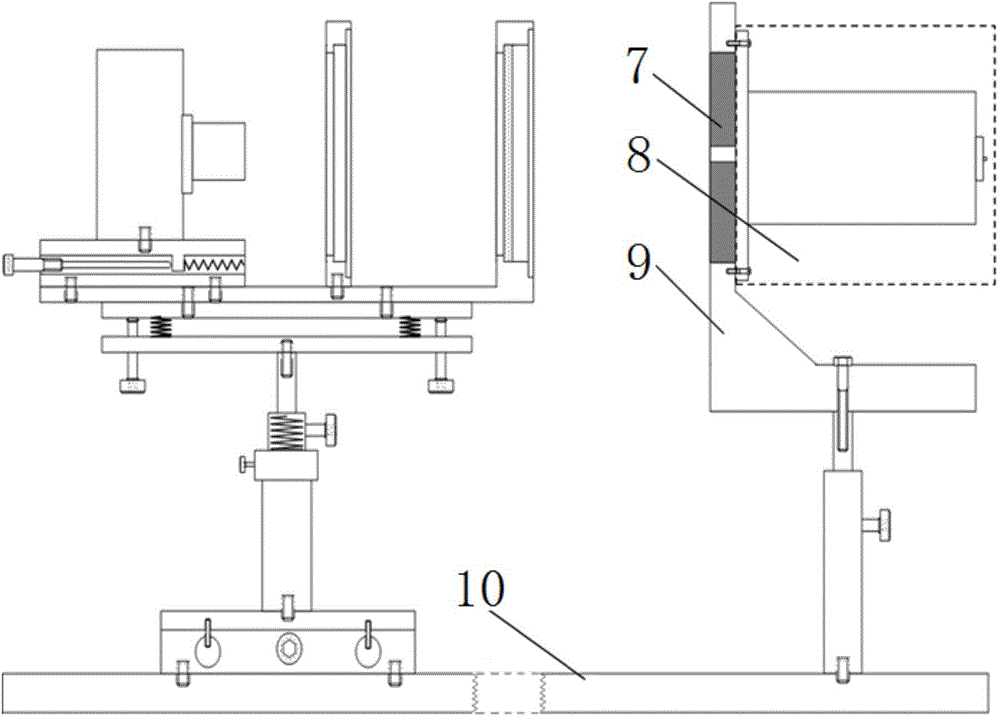

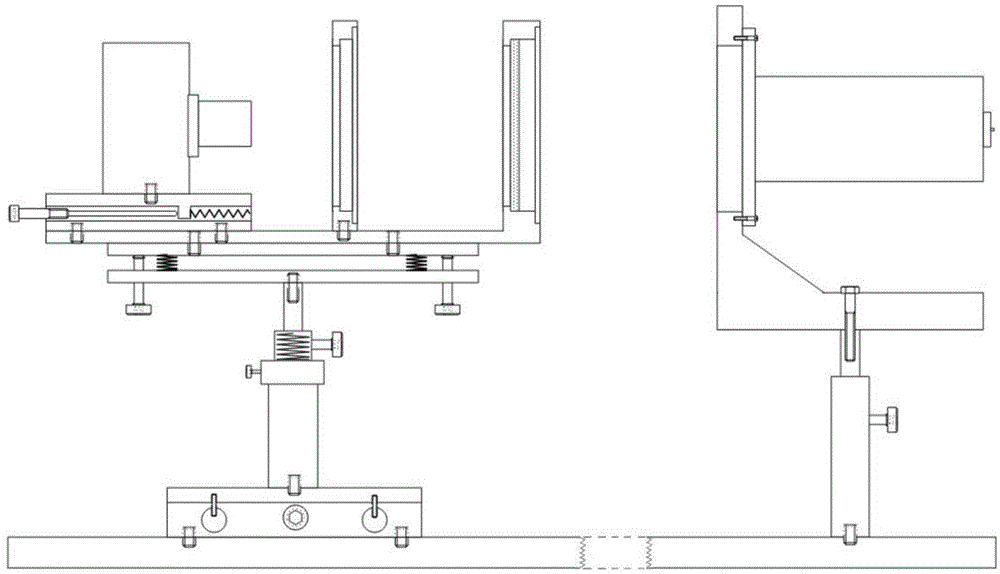

Hi-resolution three-dimensional imaging apparatus for topographic and 3d models

The present invention is directed to an automated system that includes a hi-resolution three-dimensional imaging apparatus for topographic modeling that is electronically coupled with a computer. The system incorporates one or more algorithms for converting the complex and randomly-occurring contours found in natural terrain into an efficient series of adjacent and parallel coloring-agent imaging paths or swaths (comprised of inks, dyes, paints, and / or pigments). The swaths are defined in simplified 2-axis surface contour-following printer-head movements by the system's CPU, printer driver software, driver circuitry and / or logic circuitry. This multi-axis control of the system assures that each of the swaths are seamlessly rendered next to one another while also maintaining an optimal proximity between the upper surface of the 3D model and the nozzle end of one or more hi-resolution printer. A single coloring-agent such as black ink, may be used solely, or in combination with a plurality of colors such as a Cyan, Magenta, Yellow and Black or “CMYK” combination. The system also incorporates algorithms for applying accurately registered indicia of a prescribed color, or colors, onto the surface of models including man-made boundaries such as property lines, easements, right-of-ways, land-development features; naturally occurring boundaries such as ridges and flow-lines, bodies of water, lakes, lake-beds, rivers, river-beds and forested areas including tree varieties; lettering including the accommodation of a variety of fonts; graphical embellishments; and cartographic elements.

Owner:SOLID TERRAIN MODELING

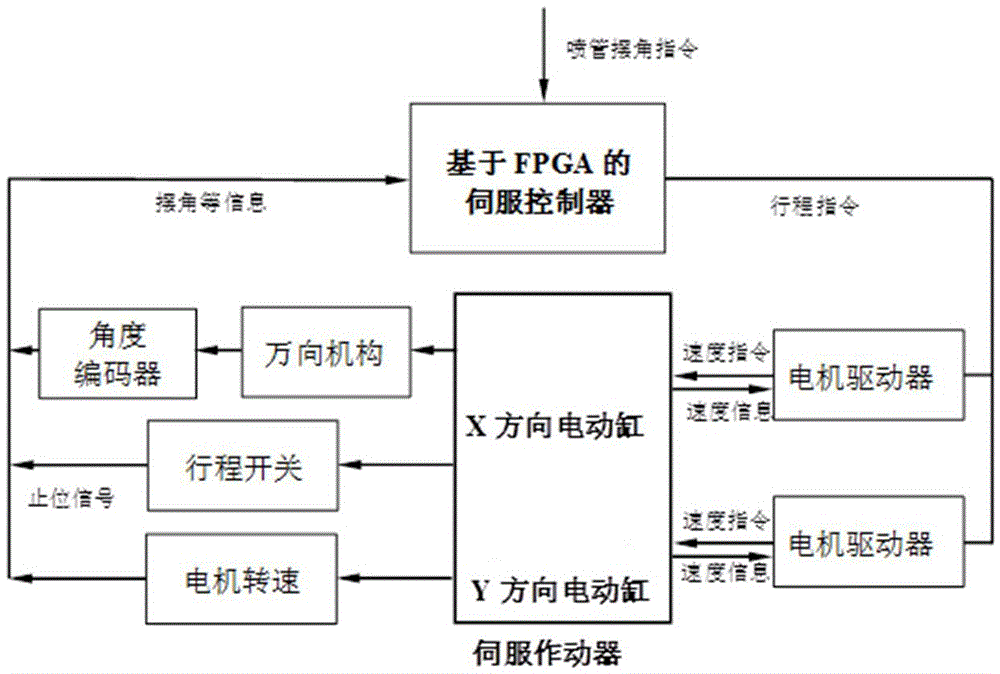

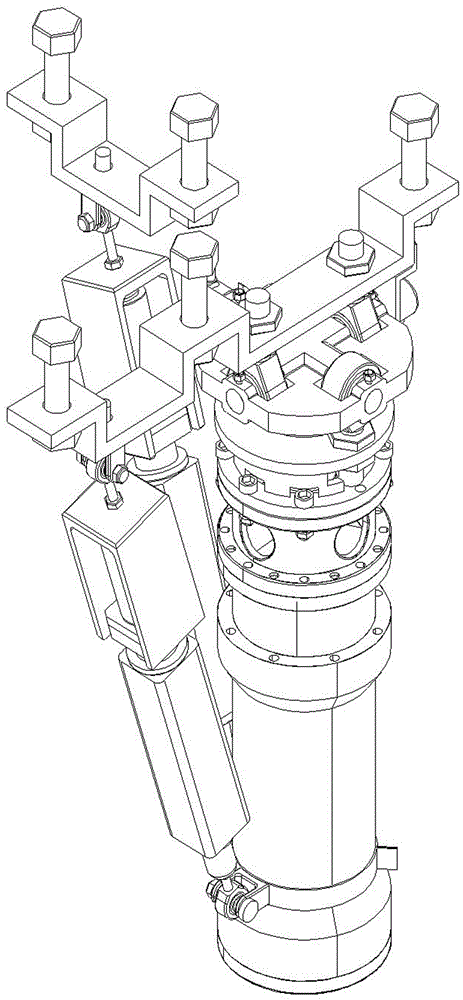

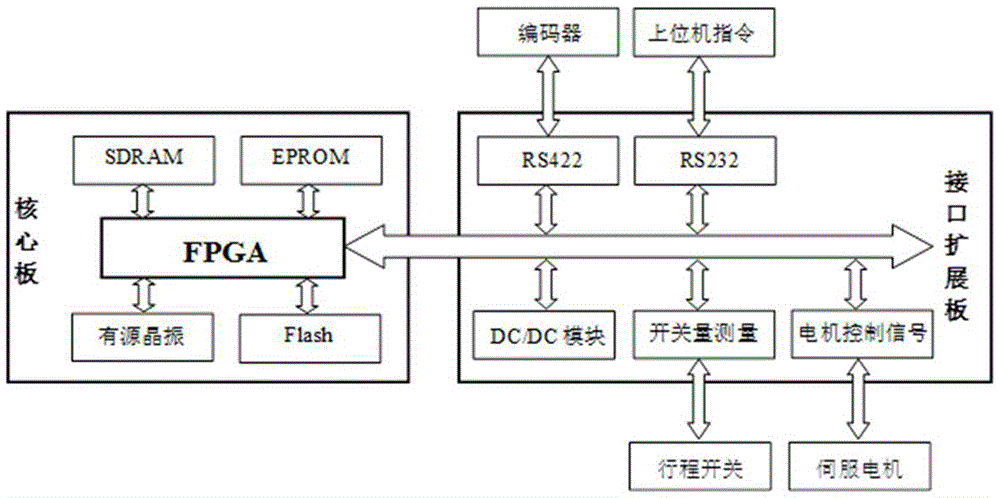

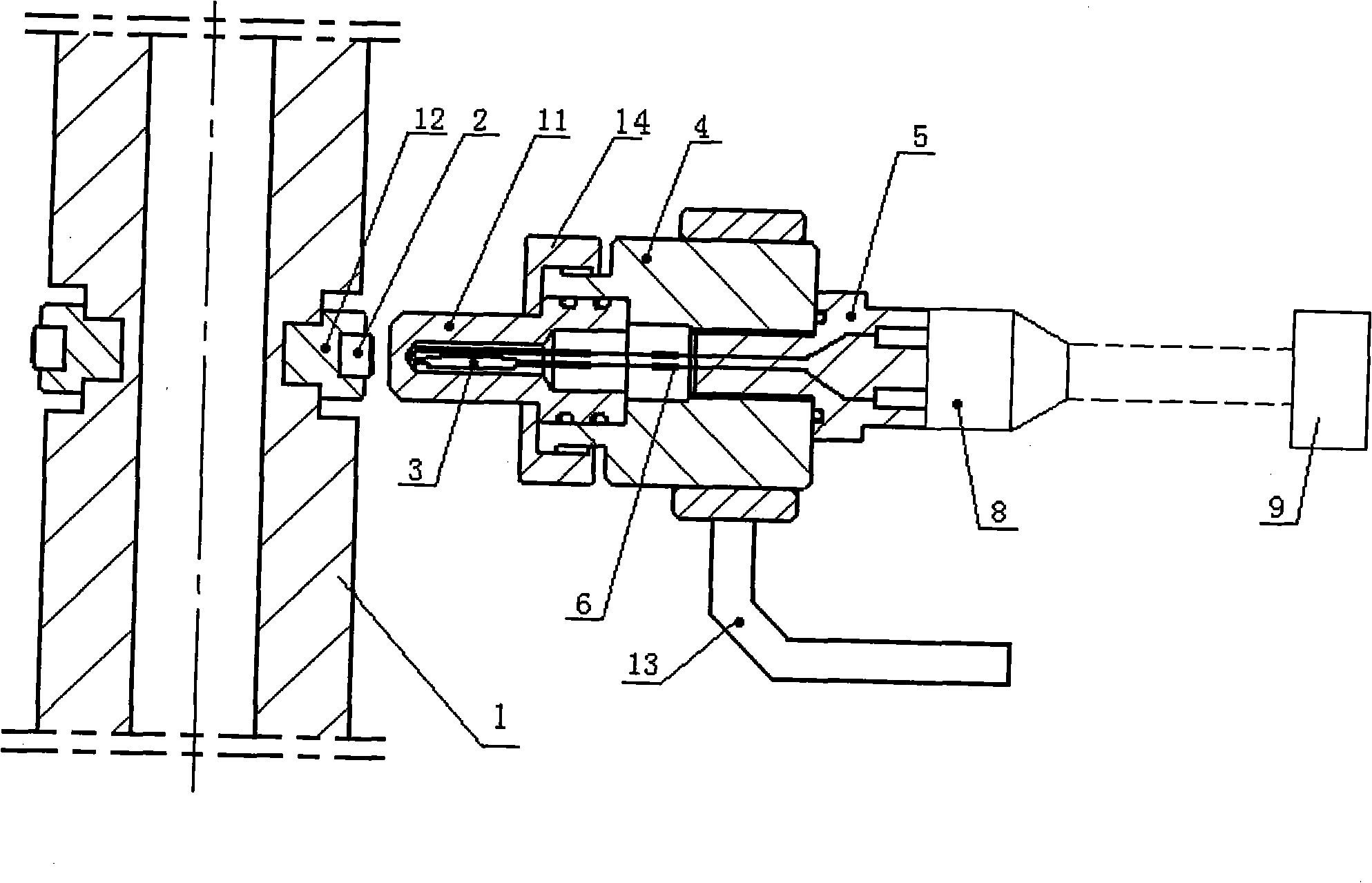

Small liquid/solid rocket thrust vectoring nozzle servo control system and method

The invention discloses a small liquid / solid rocket thrust vectoring nozzle servo control system. The system comprises a servo mechanism and a servo controller; the servo mechanism comprises two servo actuators, a cross-shaped omnidirectional mechanism, angle encoders and travel switches; the two servo actuators are respectively mounted on an X-axis surface and a Y-axis surface of a thrust vectoring nozzle; each travel switch is mounted in the middle of a push rod of the corresponding servo actuator; the angle encoders are mounted at shaft ends of two shafts, which are perpendicular to each other, of the cross-shaped omnidirectional mechanism; the servo controller comprises a core board and an interface extension board; and a CPU soft core is quickly established for the core board by an FPGA chip. By the control system and method, the size and the weight of the servo mechanism are greatly reduced because a mode of directly driving a lead screw by a motor is adopted, and reliability of the servo mechanism is improved; the FPGA-based core board and the peripheral interface extension board are adopted, instantaneity is good, computing efficiency is high, and extensibility is also high; and the servo mechanism and the servo controller are integrated, so that integration level is high, dynamic response is quick, and control precision is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

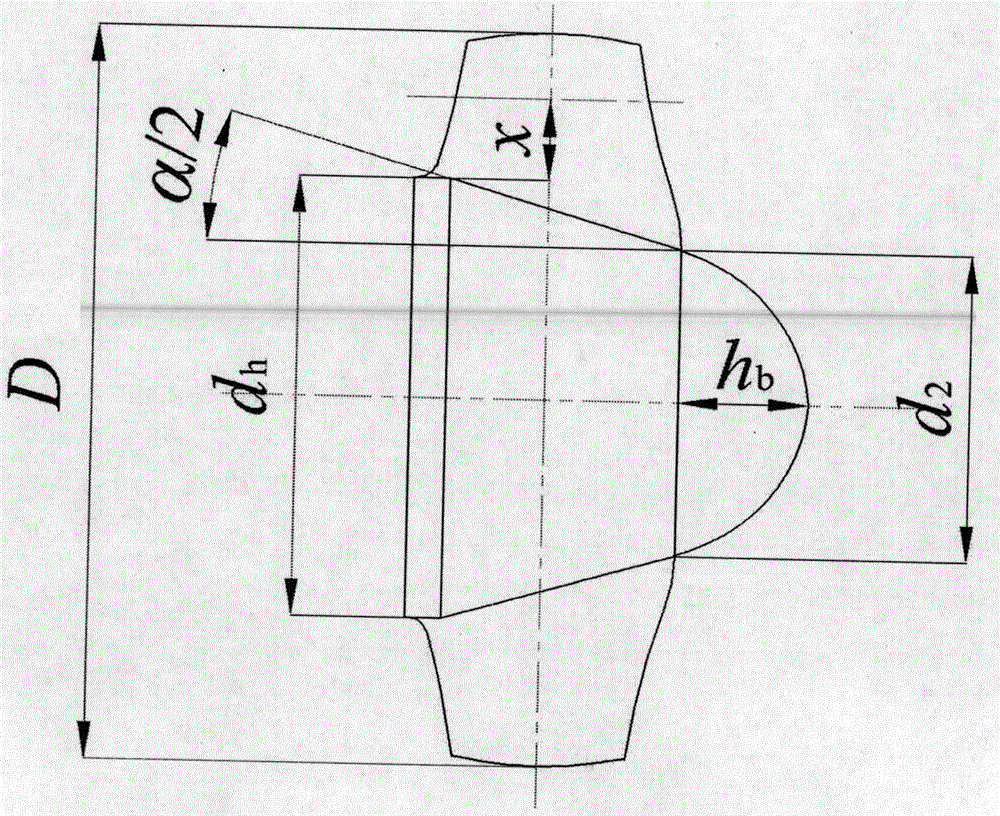

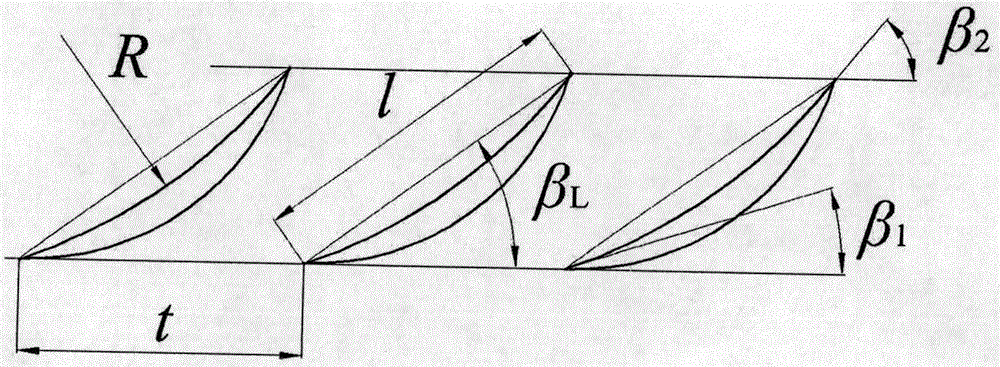

Hydraulic design method of high-lift axial flow pump impeller

The invention relates to a hydraulic design method of a high-lift axial flow pump impeller. Main geometric parameters of the impeller are provided, and include a maximum thickness delta max of axial flow pump blades, a molded line radius R, an impeller blade number z, an impeller hub side cascade solidity Sh, an impeller rim side cascade solidity S0, a blade inlet placing angle beta 1, a blade outlet placing angle beta 2, a blade inlet axial surface speed vm1, a blade outlet axial surface speed vm2, a blade outlet peripheral component speed vu2, an impeller diameter D, an impeller hub ratio Rd, an impeller lift coefficient psi, an impeller inlet hub diameter d2, an impeller hub dispersion angle alpha, an impeller round nut height hb, a blade outlet placing angle coefficient K beta 2, a blade inlet placing angle coefficient K beta 1, selection of wing sections with different sections of blades and the like. The designed axial flow pump impeller improves both the impeller lift and the cavitation resistance of an axial flow pump, facilitates computer programming, and can replace traditional similar design method and speed coefficient method of the axial flow pump to a greater extent.

Owner:JIANGSU UNIV

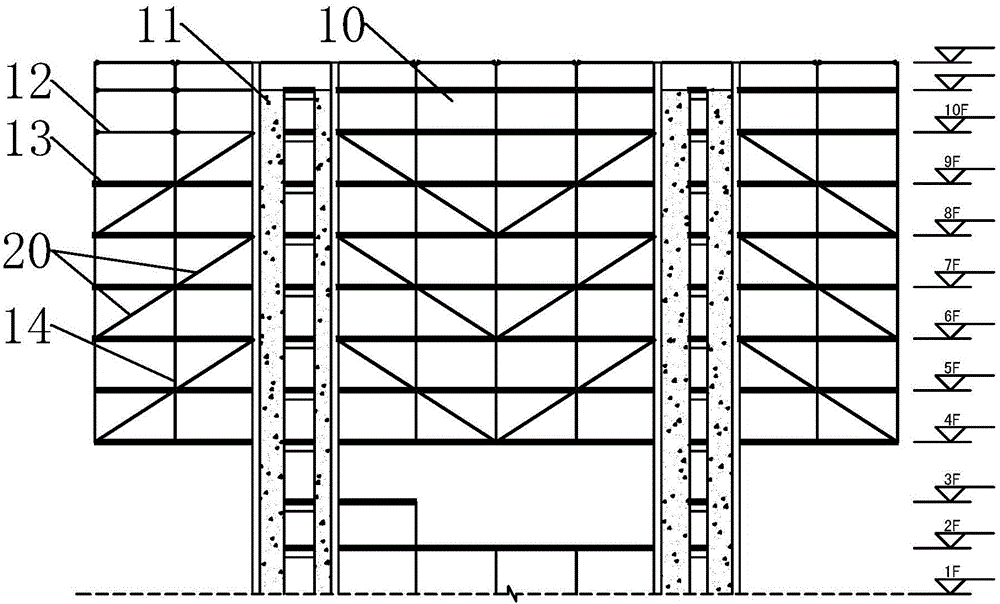

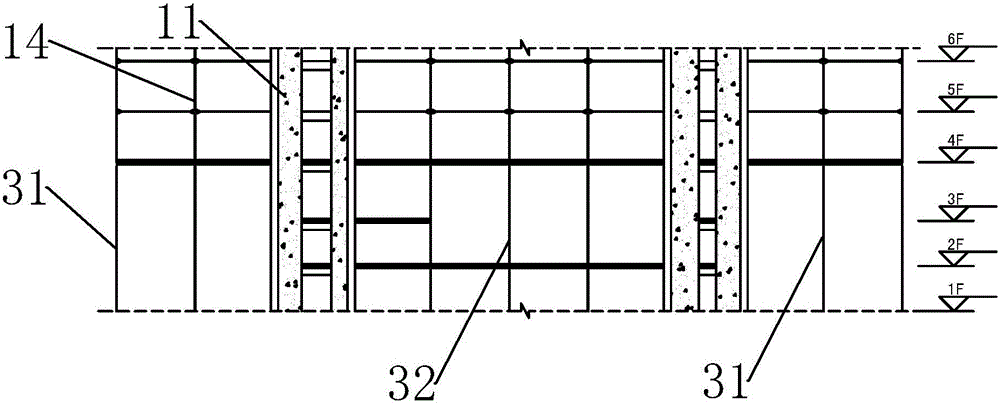

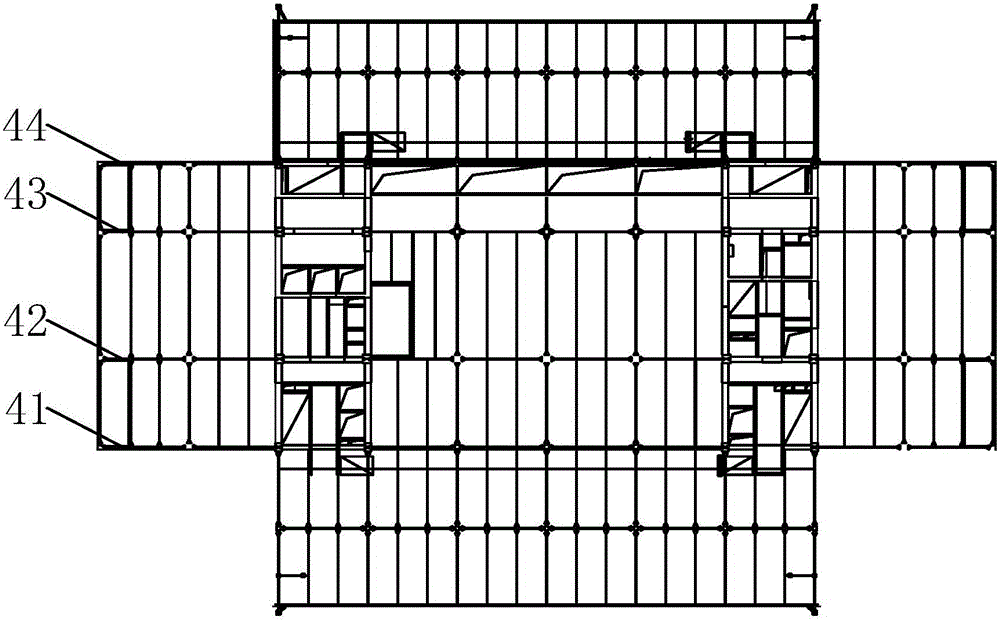

Large-cantilever steel frame structure with pull rod and construction method thereof

ActiveCN106088337AImprove installation accuracyImprove securityExtraordinary structuresBuilding material handlingSteel frameSteel columns

The invention discloses a large-cantilever steel frame structure with a pull rod and a construction method thereof. The steel frame structure comprises a core tube and N layers of steel frames erected on the core tube, wherein multiple layers of cantilever floors are arranged at the lower end of the side surface of a steel frame body; a temporary steel column support is arranged at the suspension point; multiple axial surfaces are longitudinally arranged on the steel frame body; the steel frames of upper and lower adjacent layers on the axial surfaces are fixed through a steel pull rod; and the steel pull rod is positioned on the outer side of the core tube and shows a slope shape with top inside and bottom outside. The method comprises the following steps: pouring the core tube, mounting the steel structures of the cantilever layers, erecting temporary steel column supports, setting up the steel pull rod, constructing a roof and a roof framework-layer steel frame and removing the temporary steel column support. The structure disclosed by the invention is suitable for hoisting a large cantilever structure and a steel structure with internal large space; and the whole structure is stable, the mounting precision is high, the safety coefficient is high, and overall construction difficulty is low.

Owner:CHINA 19TH METALLURGICAL CORP

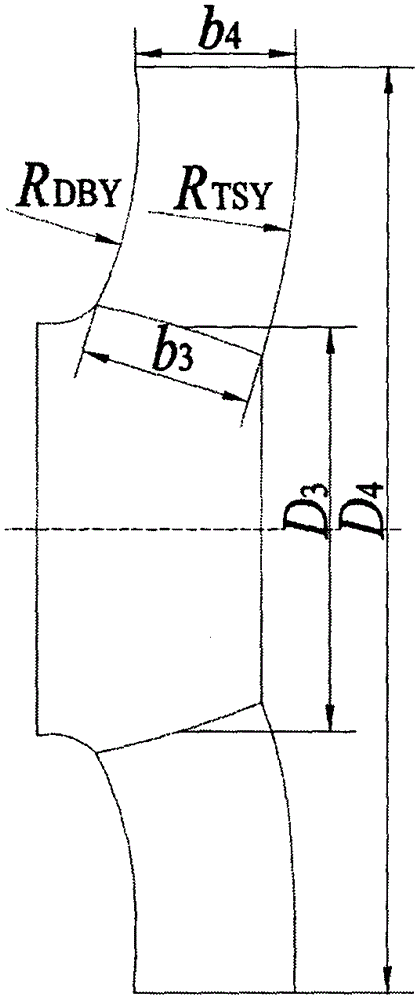

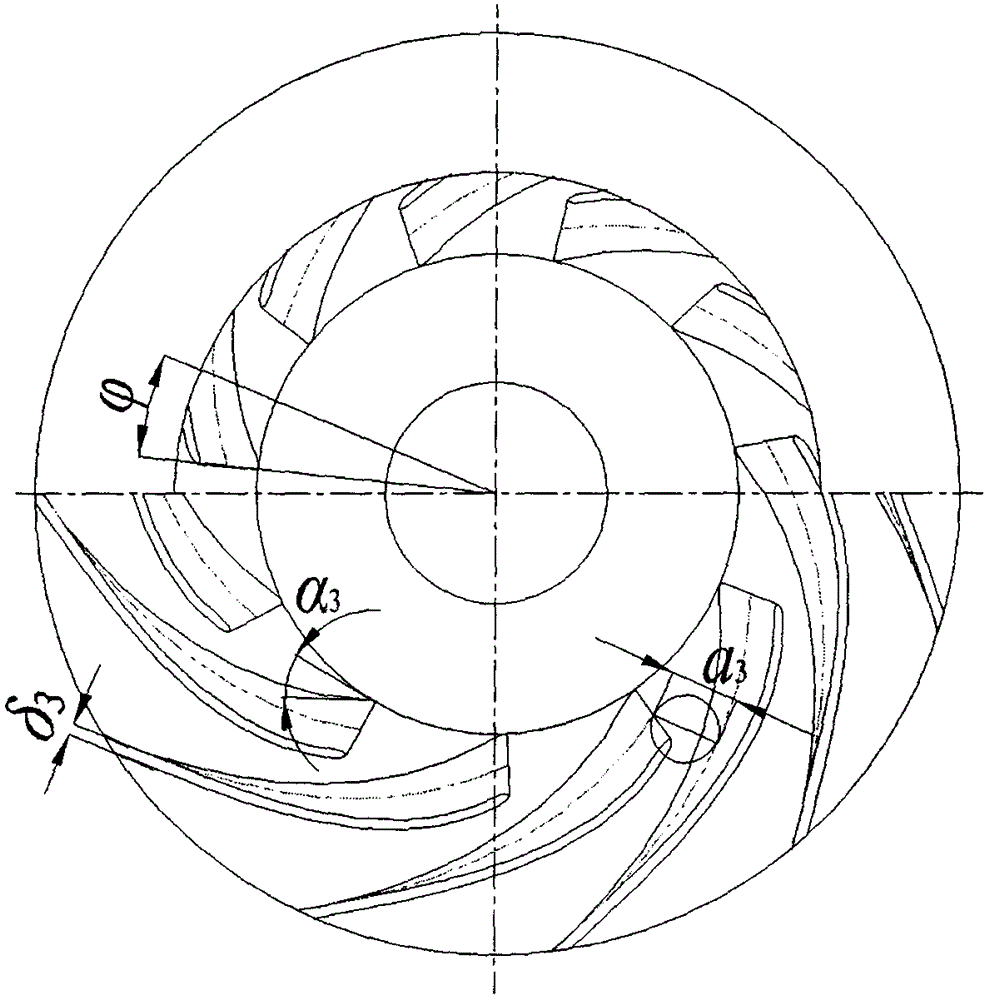

Hydraulic design method of radial guide blade of diagonal flow pump

The invention relates to a hydraulic design method of a radial guide blade of a diagonal flow pump. The method gives design formulas of main geometric parameters of the guide blade; and the main geometric parameters include a base circle diameter D3 of the guide blade of the diagonal flow pump, an inlet width (axial width) b3 of the guide blade, an inlet shaft surface speed vm3 of the guide blade, an exclusion coefficient omega 3, an inlet peripheral composite velocity vu3 of the guide blade, an inlet blade width coefficient KDBY of the guide blade, an inlet blade width b3' of the guide blade, a front cover plate round angle radius RDBY of the guide blade, a front cover plate round angle radius coefficient KTSY of the guide blade, a back cover plate round angle radius RTSY of the guide blade, an inlet liquid flowing angle alpha 3' of the guide blade, an inlet placing angle alpha 3 of the guide blade, a blade thickness delta 3 of the guide blade, a throat coefficient a 3 of the guide blade, a blade number z of the guide blade, a throat speed v3, a dispersion section outlet speed v4, an outlet diameter D4 of the guide blade, a dispersion angle phi, a dispersion section inlet area F3, a dispersion section outlet area F4 and the like. The method is different from a hydraulic design method of a radial guide blade of a common pump, improves the flowing conditions, and achieves the purposes of improving diversion and energy conversion.

Owner:江苏源泉泵业股份有限公司 +1

High-efficiency axial flow and screw combined pump for ship

InactiveCN102486169AGuaranteed coaxial accuracyImprove machining accuracyPropulsive elementsPump installationsAxial-flow pumpLow speed

The invention relates to a structure of a high-efficiency axial flow and screw combined pump. A large flow and a high pressure are obtained by high speed rotation. A transmission chain in a ship is greatly simplified. The high-efficiency axial flow and screw combined pump has light weight and is suitable for high-speed sailing. The high-efficiency axial flow and screw combined pump is characterized in that an axial flow pump impeller and a screw of a screw pump which are driven coaxially are arranged in a big sleeve to form a structure of an axial flow pump and the screw pump; if the positions of the axial flow pump and the screw pump are exchanged, a structure of the screw pump and the multi-stage axial pump is formed; and water is sucked from the front of the ship bottom, obtains kinetic energy through the front-mounted pump and then is fed to the rear-mounted pump to be boosted to be sprayed, so that the ship is propelled. One single screw is arranged and is provided with a plurality of heads; screw edges are very narrow and have large screw pitch, so that the depth of a screw thread gradually becomes shallow to achieve the effects of large flow and high pressure; and the axial flow pump is designed by combining excellent aerofoils according to a variable-circulation variable-axis surface. The pump has a very simple structure, has good manufacturability and is easy to manufacture; the high-efficiency axial flow and screw combined pump is convenient to install; the high-efficiency axial flow and screw combined pump rotates at the high speed, has small volume and light weight, is efficient and energy-saving; the high-efficiency axial flow and screw combined pump has the self-adsorption capability and the ship has high sailing speed; the high-efficiency axial flow and screw combined pump can be made to have large power; the high-efficiency axial flow and screw combined pump has double-injection capability, a steering engine is saved and the high-efficiency axial flow and screw combined pump has high performances which cannot be realized by a single low speed axial flow pump or mixed-flow pump injection propeller.

Owner:赵明

Superfine grinding oscillation mechanism

ActiveCN102328268AIncrease the oscillation frequencyReduce impactSuperfinishing machinesRotational axisDrive wheel

The invention discloses a superfine grinding oscillation mechanism which comprises an oscillation mechanism on a superfine grinding machine. Two balance wheels between left and right balance blocks are rotatably connected with a Geneva wheel together; the Geneva wheel is composed of two symmetric parts which are fixed on rotation shafts by bolts respectively; a drive wheel is mounted on the rotation shafts on the two sides of the Geneva wheel in a manner symmetrically protruding out of a shaft surface; and a transmission plate is coupled between the drive wheel and a ram. Through the invention, the oscillation frequency can be improved by more than one time, the oscillation conversion is smooth, the impact is obviously reduced, and the superfine grinding oscillation mechanism is favorable for improving the processing efficiency as well as surface accuracy and quality of products.

Owner:XINXIANG SUNRISE CNC BEARING EQUIP

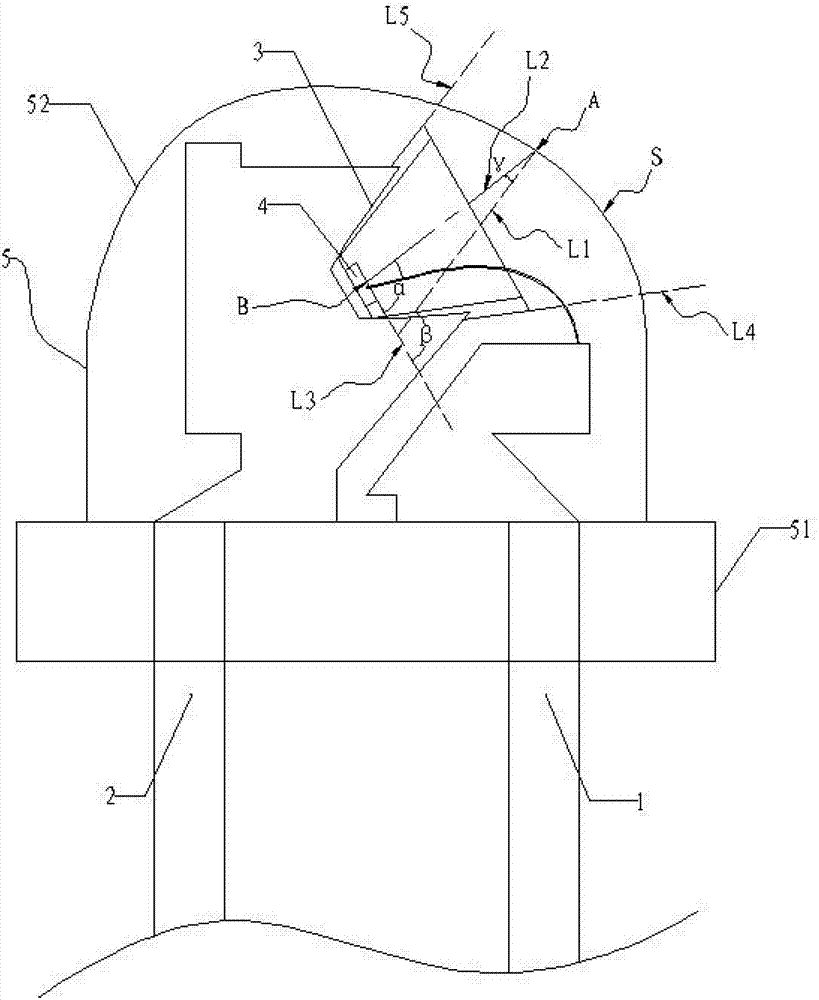

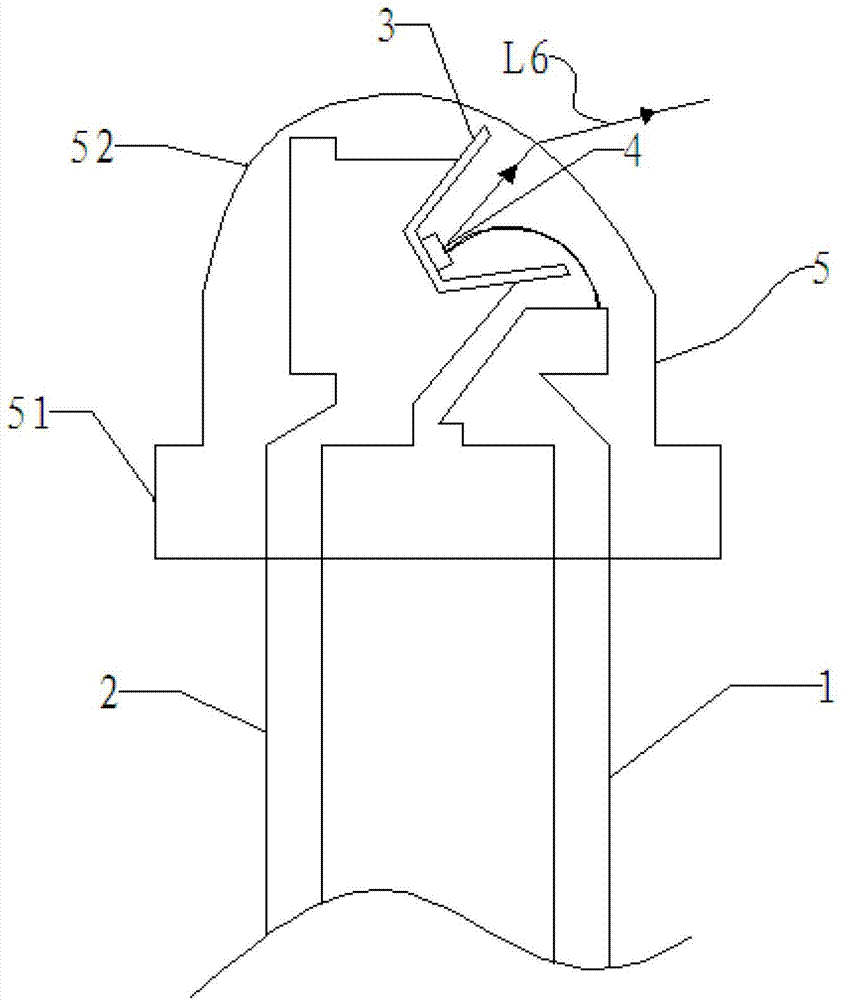

Detection method for decentered Gaussian beams emitted by fiber beam expanding collimating lens barrel

InactiveCN104537656AImprove reliabilityEfficient detectionImage enhancementImage analysisFiberGaussian beam

The invention provides a detection method for decentered Gaussian beams emitted by a fiber beam expanding collimating lens barrel. The detection method includes the three steps of constructing a CCD photographic device, adjusting a mechanical axis of the to-be-detected lens barrel to be perpendicular to an image acquisition plane and conducting image acquisition, processing and decentered detection. According to the method, uneven distribution of intensity of light perpendicular to the section of the mechanical axis caused by decentered Gaussian beams generated by off-axis imbalance of an optical element can be effectively detected, distribution data of the intensity of the light perpendicular to the section of the mechanical axis of the lens barrel can be accurately obtained, detection can be rapidly conducted, and distribution information of the intensity of the light perpendicular to the section of the mechanical axis in different directions can be obtained. The detection method has the advantages of being simple, practical, high in reliability and the like and can be applied and popularized in the cold atom research field, the fountain clock research field and laser transmission engineering.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

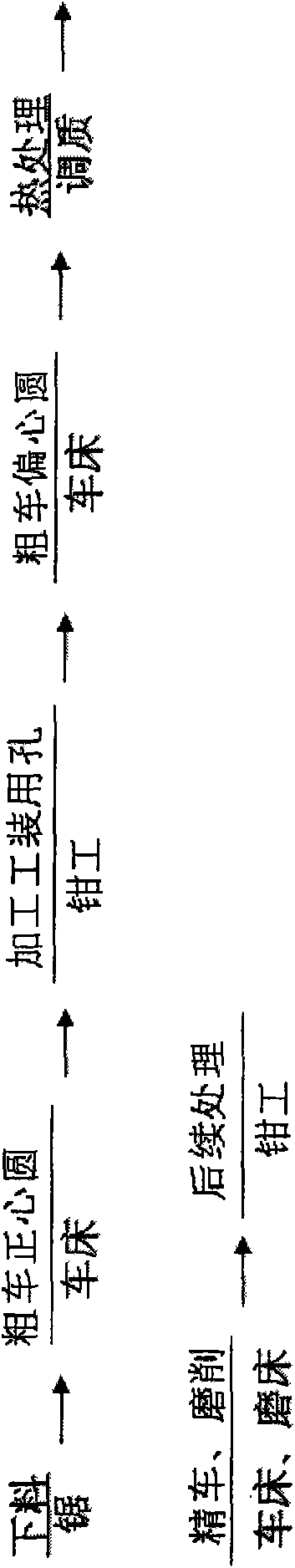

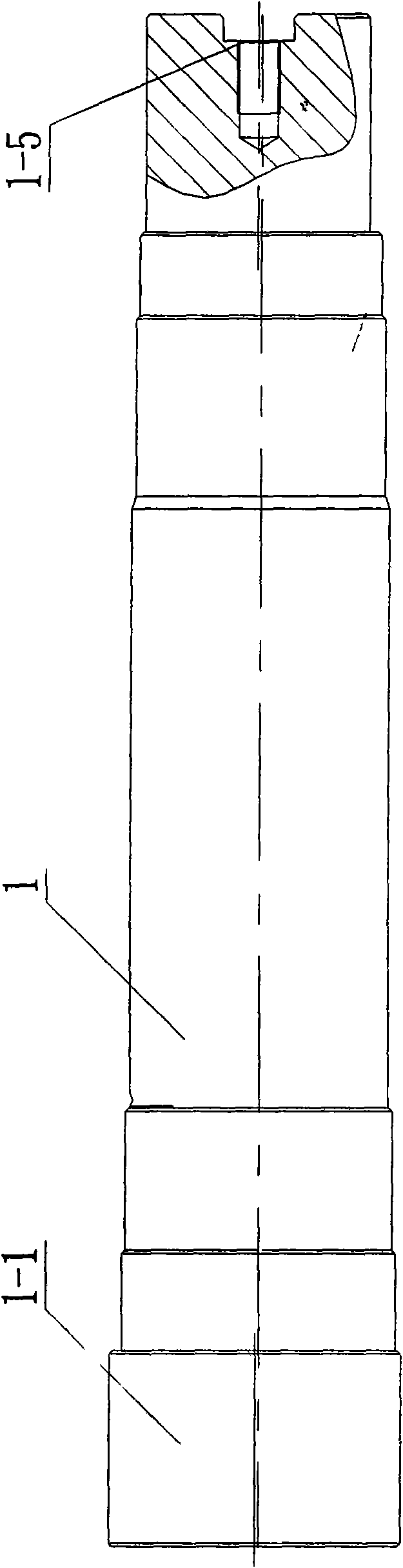

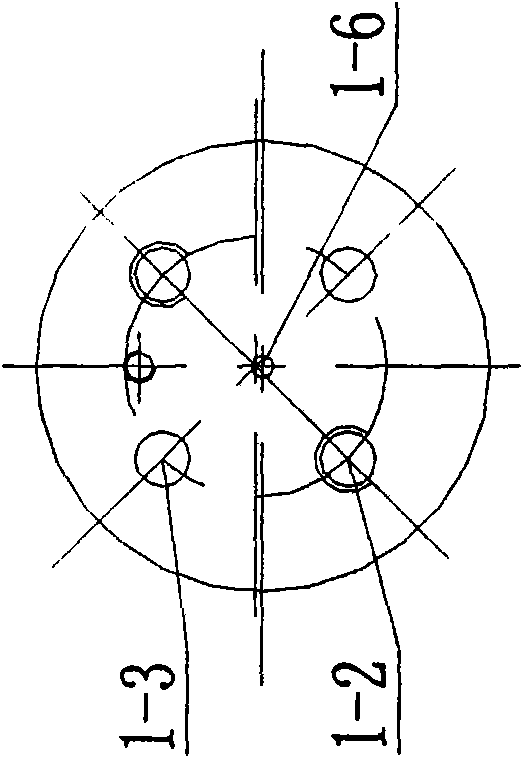

Method for processing shaft with small eccentricity

The invention relates to a method for processing a shaft with small eccentricity, which comprises the steps of processing a shaft blank and lathing a centric circle roughly and is characterized in that the process of the technique for processing the shaft with small eccentricity is as follows: an eccentric circle is roughly lathed; a point deviated from the center of the centric circle for a certain distance is taken as the center of the eccentric circle; a threaded hole is marked, drilled and tapped on the left end surface of the shaft; a threaded hole is drilled and tapped at a position deviating from the central line with the same distance on the right end surface of the shaft; a left card plate and a right card plate are respectively fixed on the left end surface and the right end surface of the shaft blank; and pin-hinging holes are drilled at the left card plate and the right card plate respectively. Both ends of a shaft assembly are provided with a special pallet which is fixed on the shaft assembly stably with bolts and pins; the eccentric holes on various pallets are used when the eccentric part is processed; the position of the bolts and the pin-hinging holes on the shaft assembly determines the eccentricity of the shaft assembly; and after the one-off survival of the centric shaft surface and the end surfaces is completed, the pallets are used for assisting to process the survival of the eccentric part; therefore, the technique process is completed. The method has the advantages of simplifying processing procedures, saving raw materials, improving the efficiency of mass production and ensuring the quality of workpieces.

Owner:TIANJIN SERI MACHINERY EQUIP

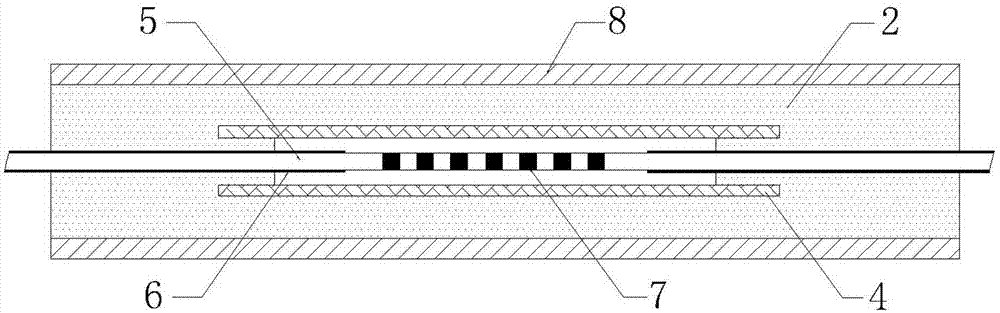

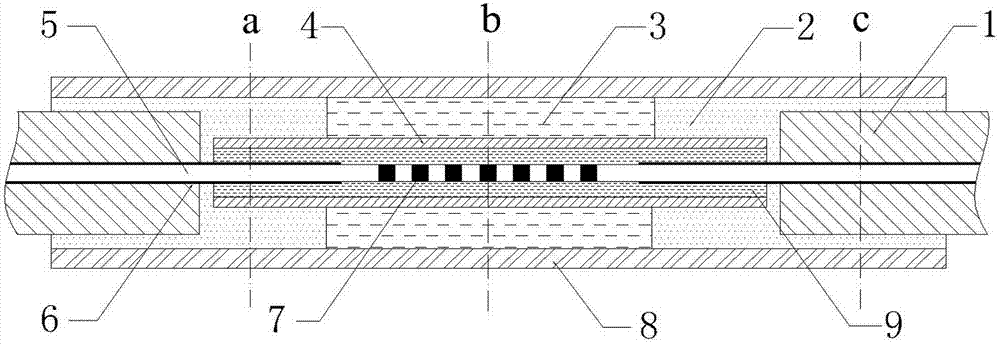

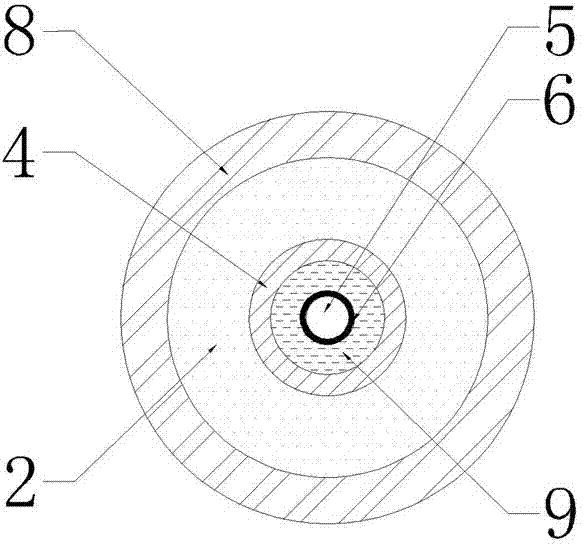

Testing system for internal temperature distribution in process of fusion cast forming of explosives

ActiveCN103487165ASolve the sensitive problem of wavelength shiftPackage structure is simpleThermometers using physical/chemical changesSensor arrayGrating

The invention discloses a testing system for internal temperature distribution in the process of fusion cast forming of explosives. The testing system is formed by an optical fiber Bragg grating sensor array, a signal detecting and demodulating device, a service and monitoring device and an explosive fusion casting device. The optical fiber Bragg grating sensor array is formed by optical fibers in an S-shaped arrangement mode, wherein a plurality of grating sensors are arranged on the optical fibers, and the optical fiber Bragg grating sensor array is fixed on one half of the central axis surface in the explosive fusion casting device. The grating sensors are arranged at intervals and distributed in an array mode. The signal detecting and demodulating device is located outside the explosive fusion casting device and is connected with the optical fibers. The service and monitoring device is in circuit connection with the signal detecting and demodulating device. The testing system effectively shelters the elasto-optical effect of Bragg grating to a thermal stress response, and can carry out sensing and measuring on temperature signals singly so as to carry out continuous multipoint monitoring on the change conditions of an internal temperature field in the process of fusion cast of the explosives.

Owner:ZHONGBEI UNIV

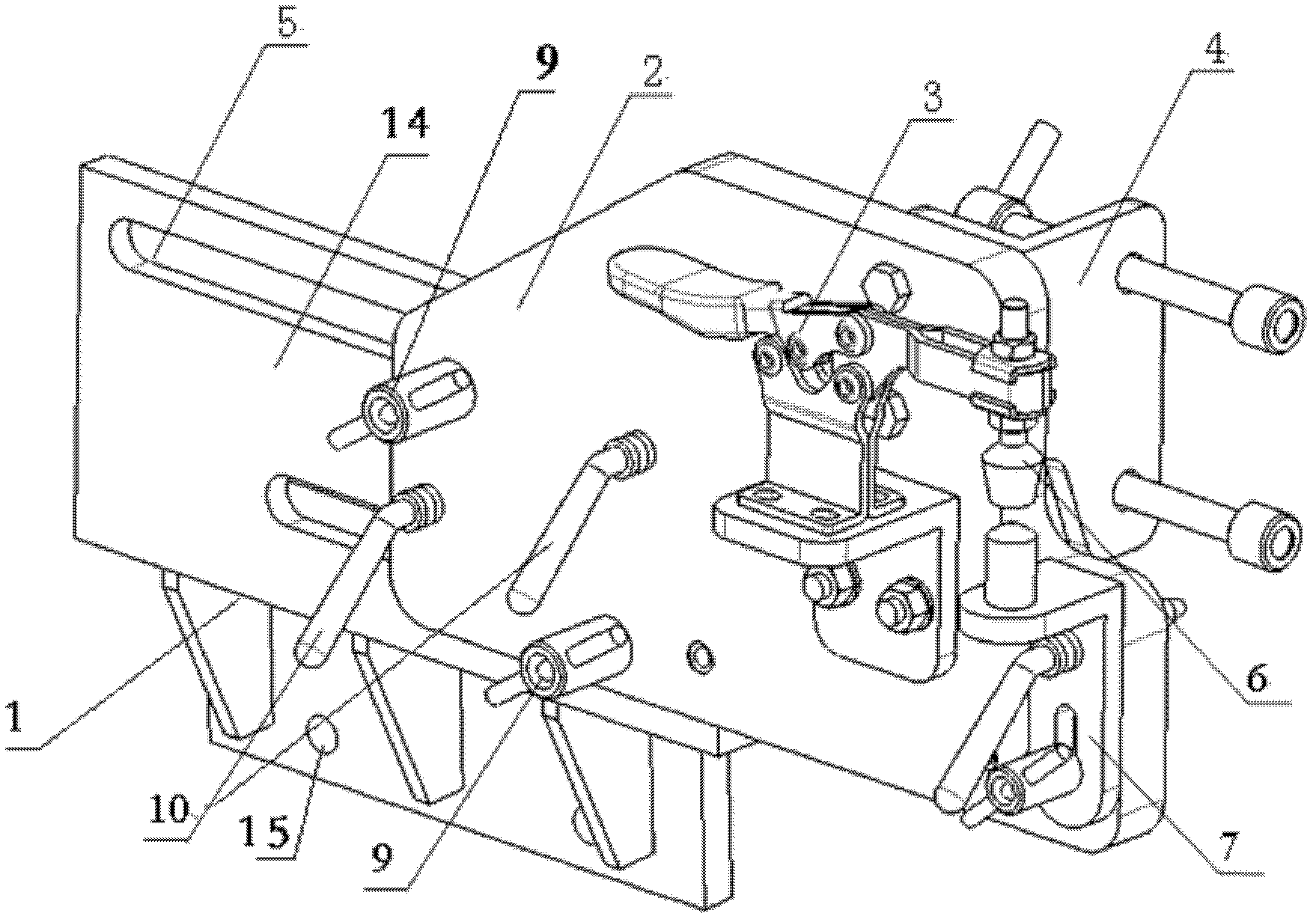

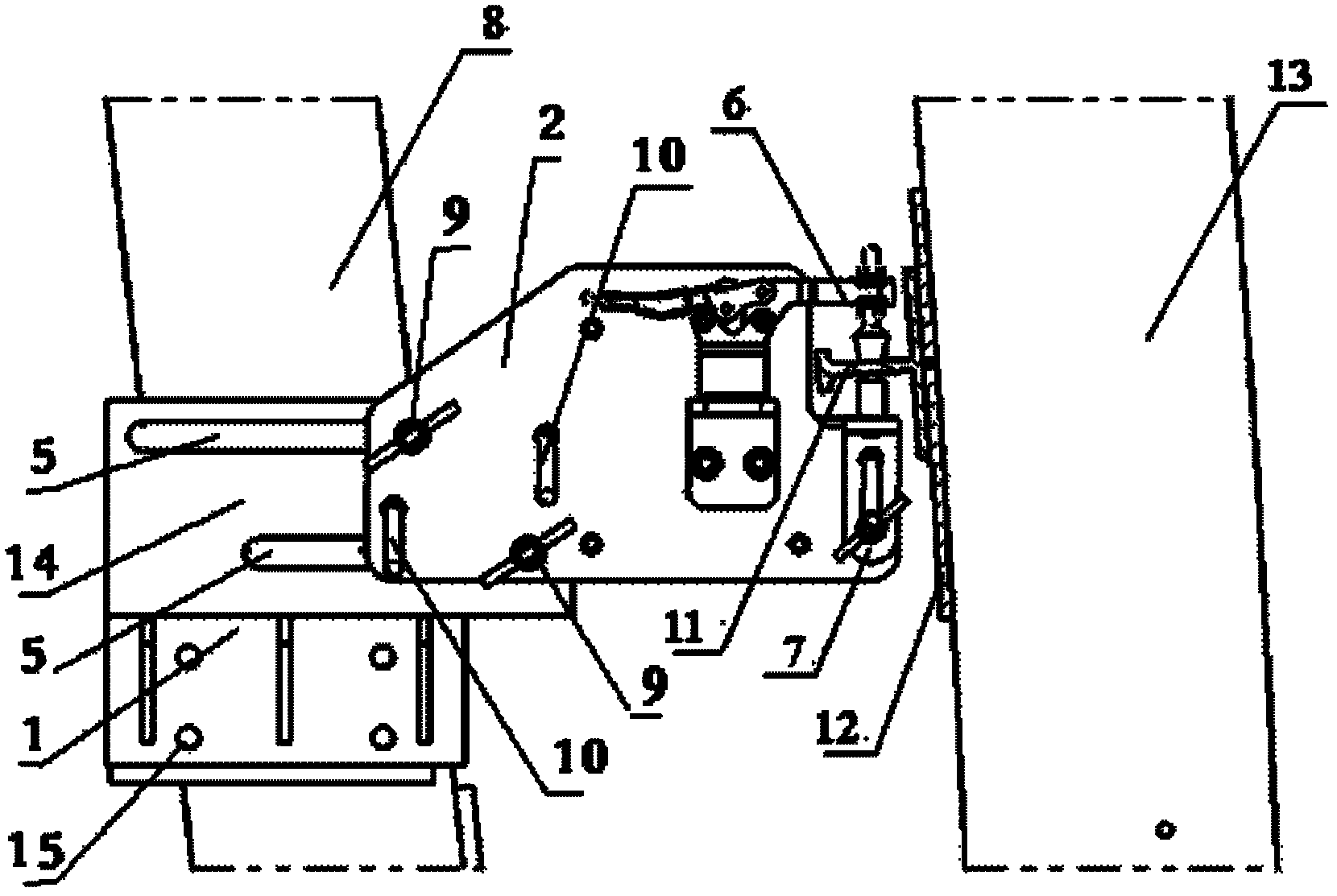

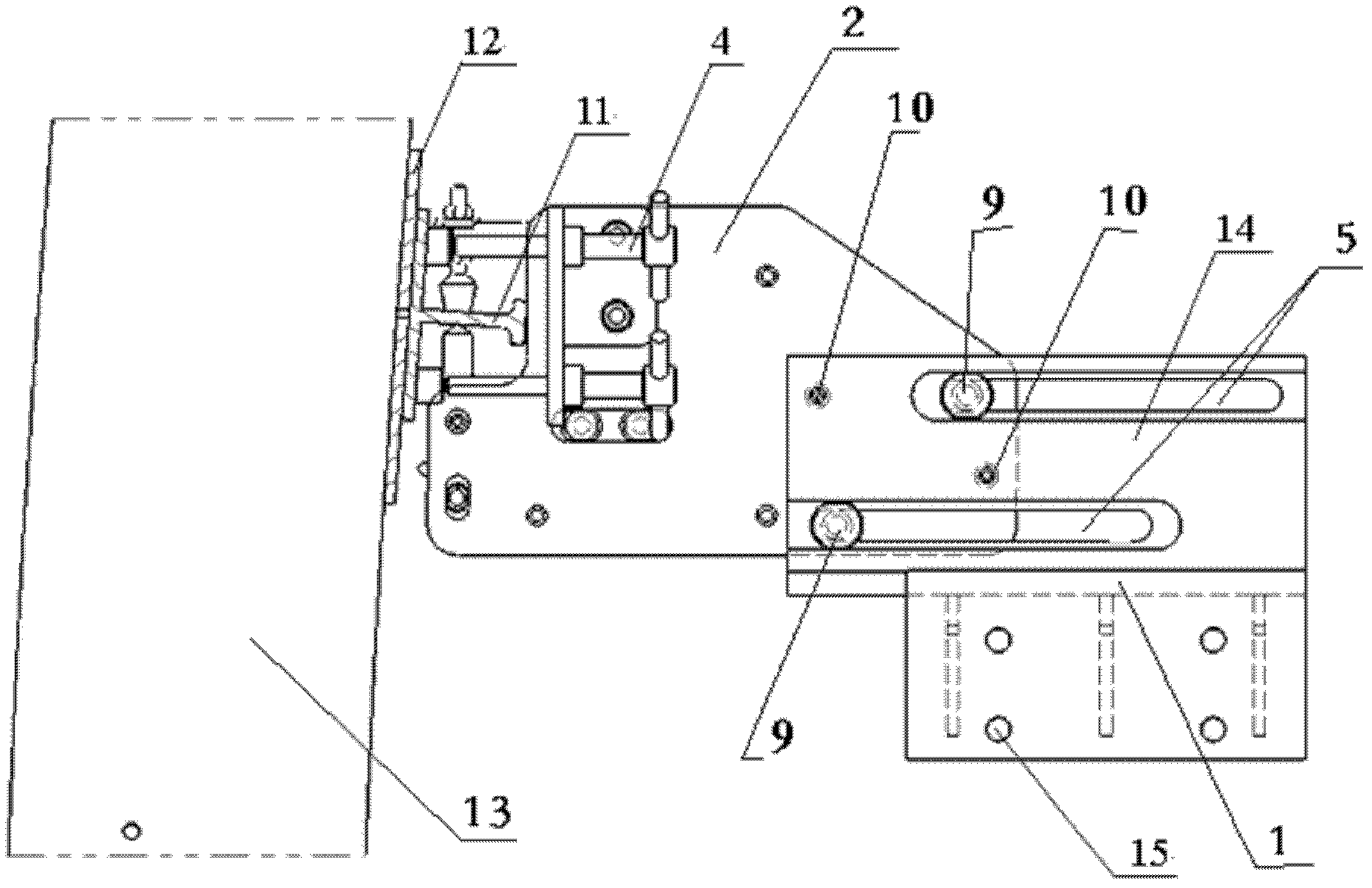

Aircraft wing wall panel butt joint stringer locating device

The invention discloses an aircraft wing wall panel butt joint stringer locating device comprising a base, a locating body, an axis surface locating and clamping assembly and an appearance compressor; a connecting plate of the base is provided with a guide sliding chute in an oblong hole shape, which is used as the guide for the movement of the locating body, and the axis surface locating and clamping assembly and the appearance compressor are respectively fixed on two sides of the locating body. The locating device is capable of accurately locating, clamping a butt joint stringer and conveniently moving so as to be beneficial for assembling a product, putting the product on the shelf and taking down the product from the shelf.

Owner:XIAN AIRCRAFT IND GROUP

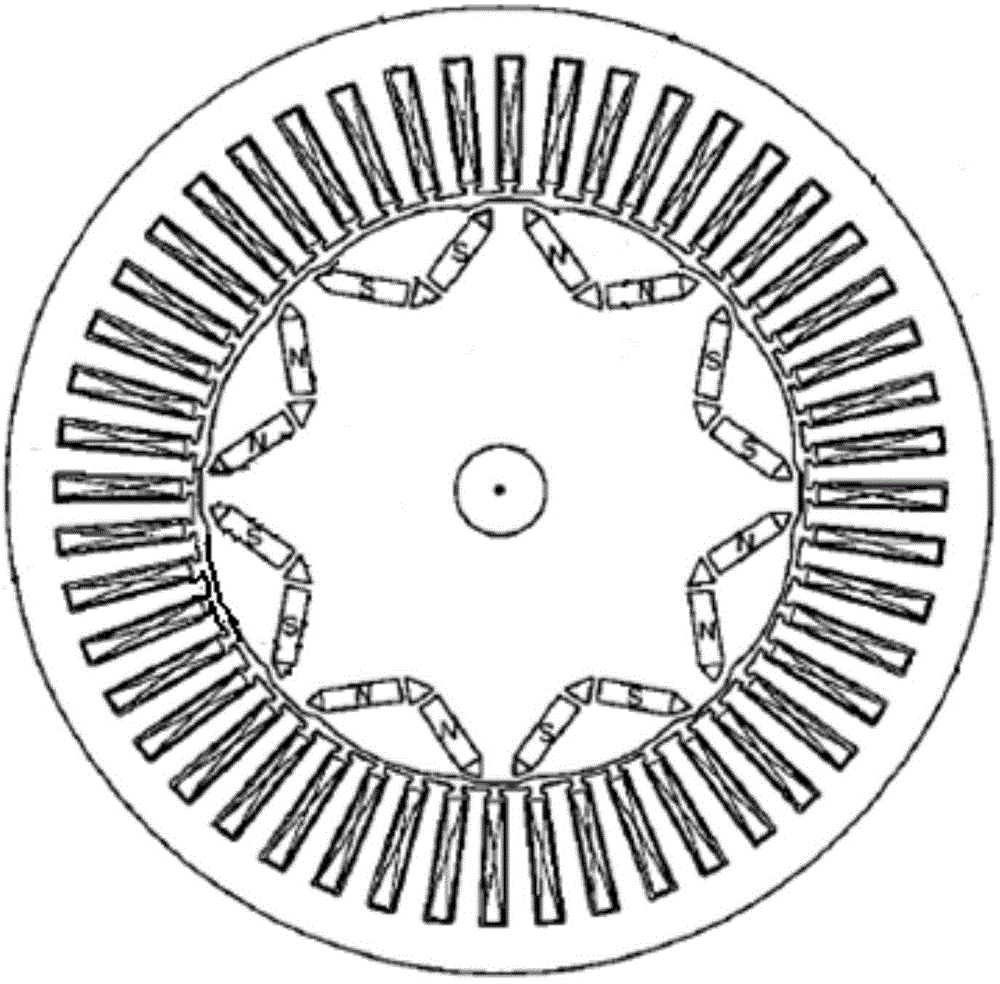

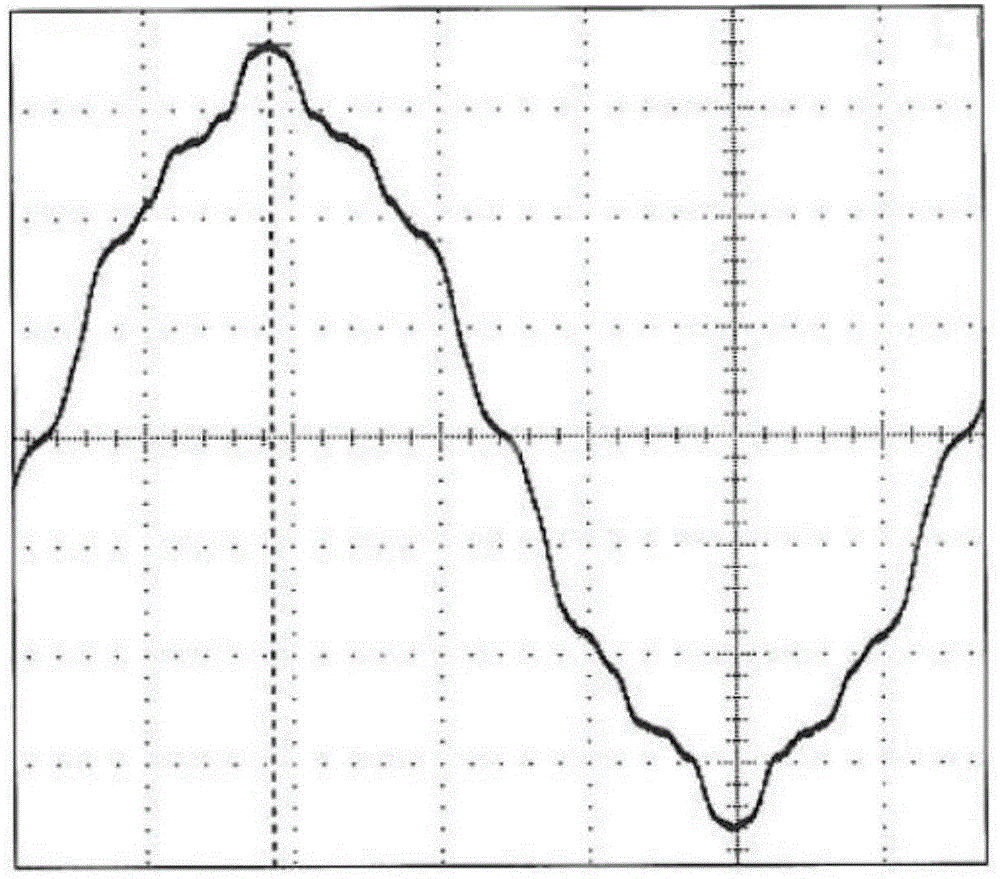

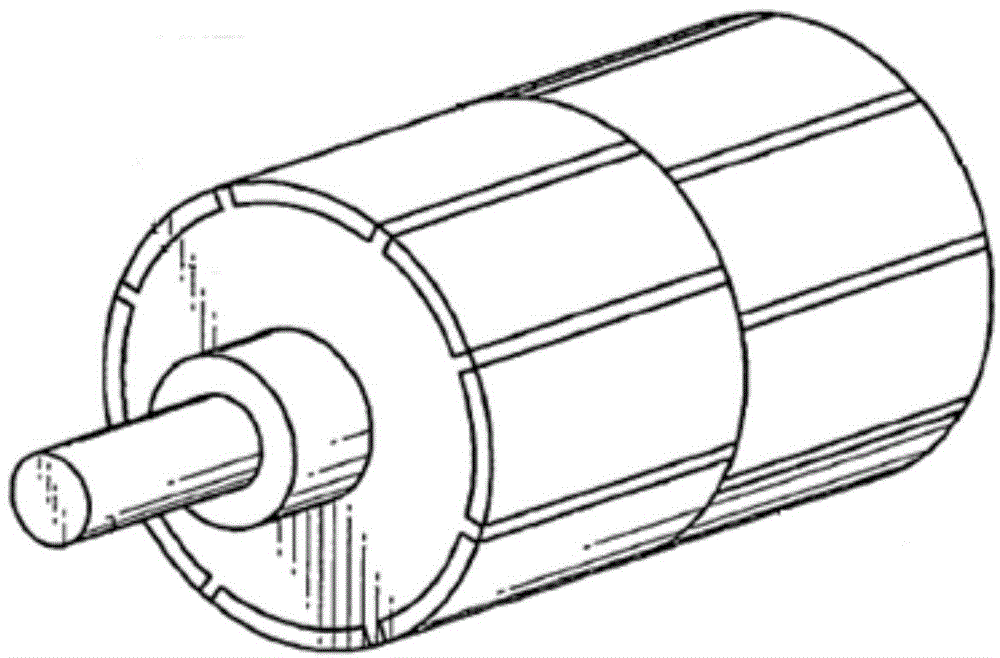

Permanent magnet synchronous motor and rotor thereof

ActiveCN103956872ALow costReduced torque ripple levelsMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a permanent magnet synchronous motor. A rotor of the permanent magnet synchronous motor comprises an iron core. The iron core is cylindrical. P S-pole magnetic steel sheets and p N-pole magnetic steel sheets are evenly arranged around the axis in the iron core, wherein p is a positive integer. The S-pole magnetic steel sheets and the N-pole magnetic steel sheets are arranged at intervals. Two d-axis surface grooves are formed in the portion, at the position of each magnetic steel sheet, of the surface of the iron core of the rotor. Every two d-axis surface grooves corresponding to the same magnetic steel sheet are symmetrically distributed on the two sides of the center line of the magnetic steel sheet. The distance between the axes of every two d-axis surface grooves corresponding to the same magnetic steel sheet is approximate to the width of the tooth end of a stator tooth of the permanent magnet synchronous motor. The invention further discloses the rotor of the permanent magnet synchronous motor. According to the permanent magnet synchronous motor and the rotor of the permanent magnet synchronous motor, torque fluctuation in a low-torque area can be reduced; in addition, the structure is simple, machining and manufacturing are easy, and cost is low.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

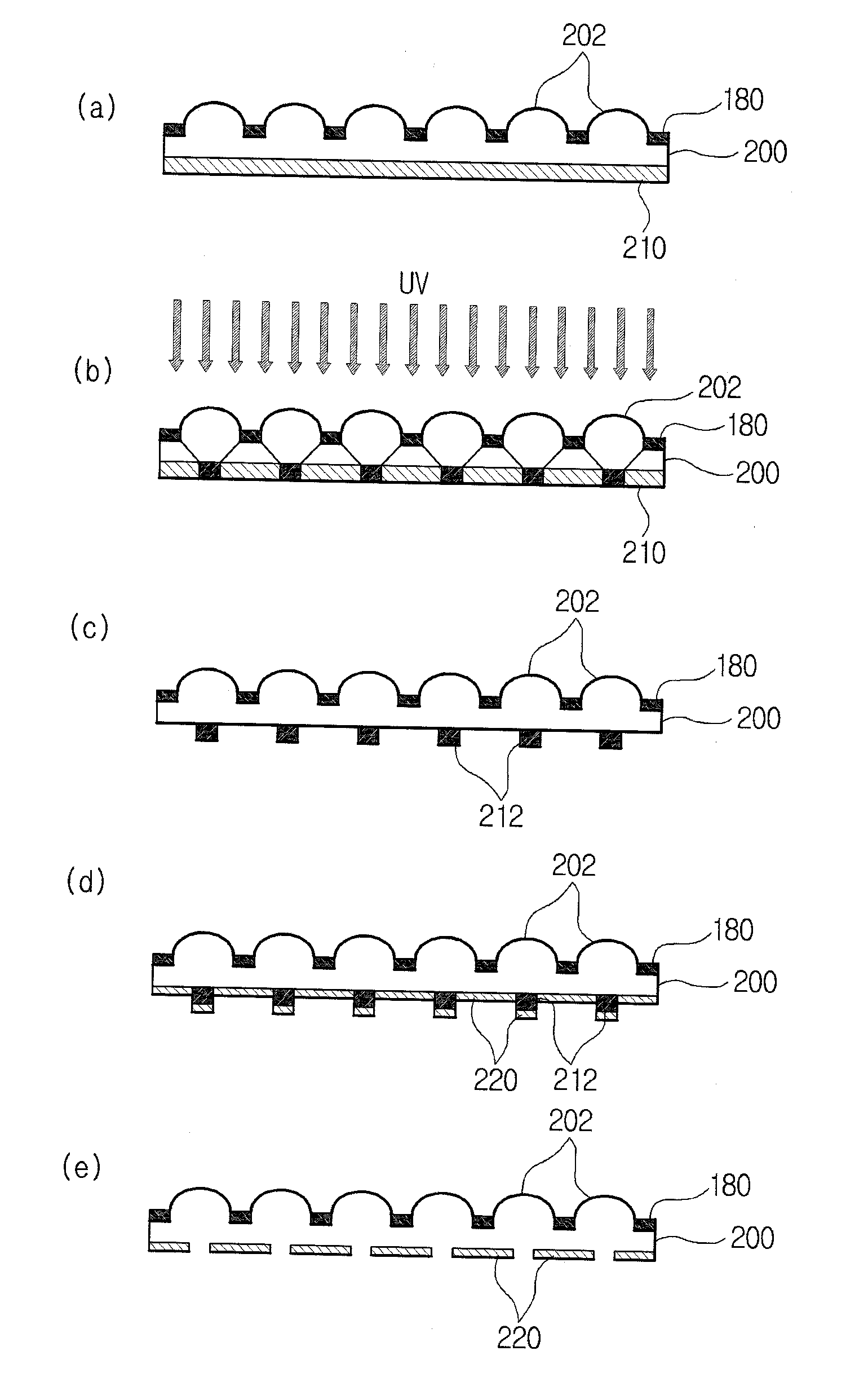

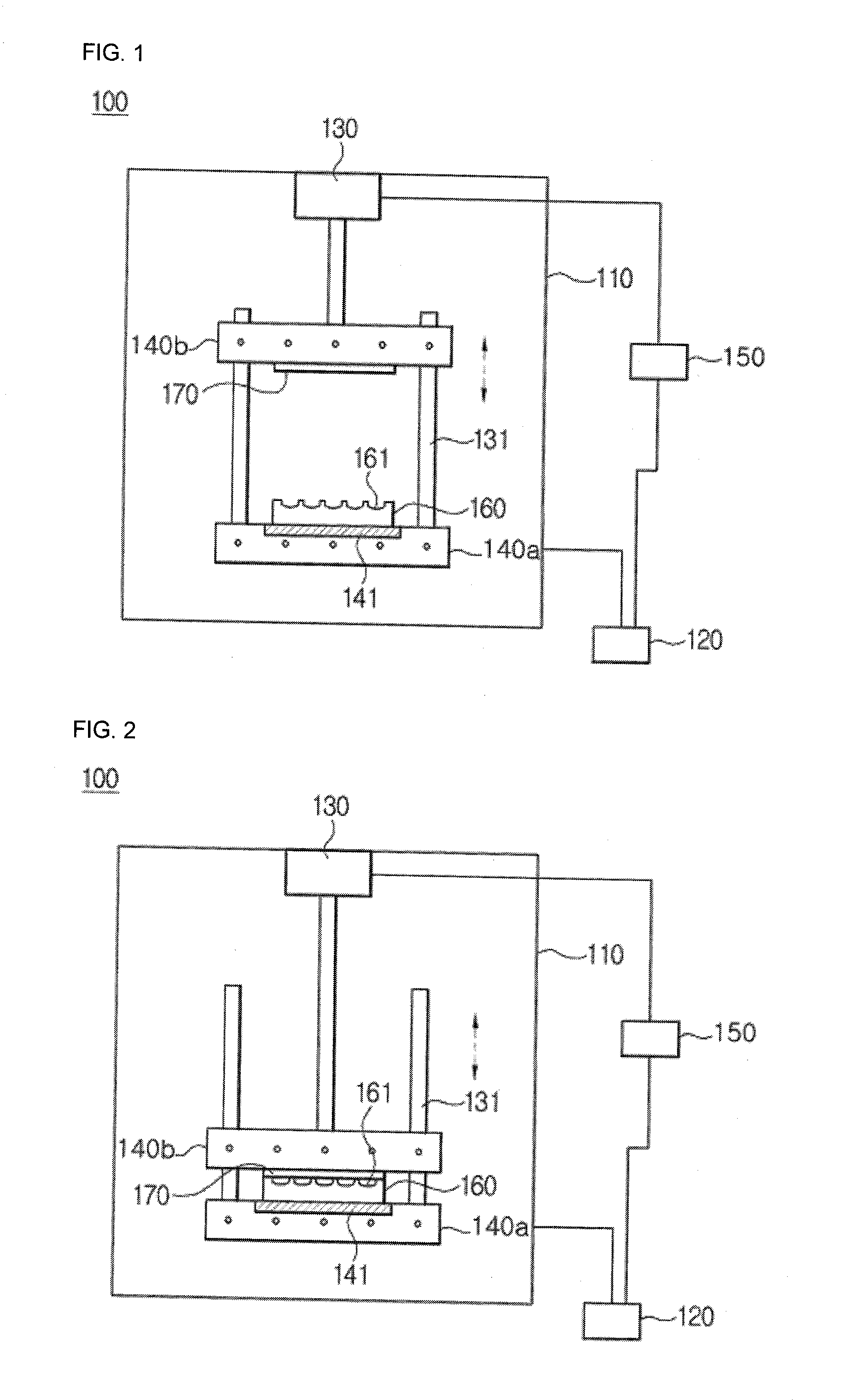

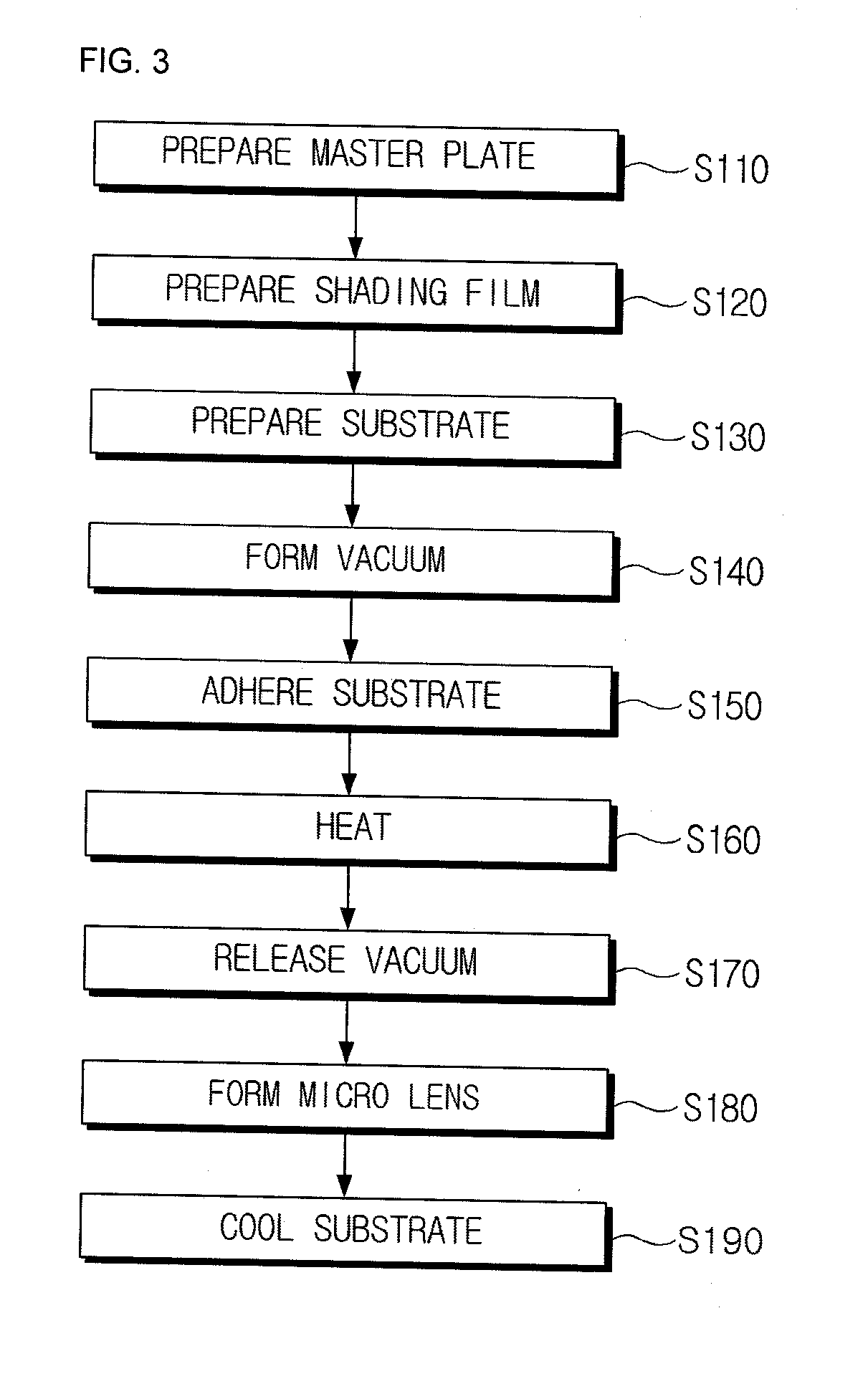

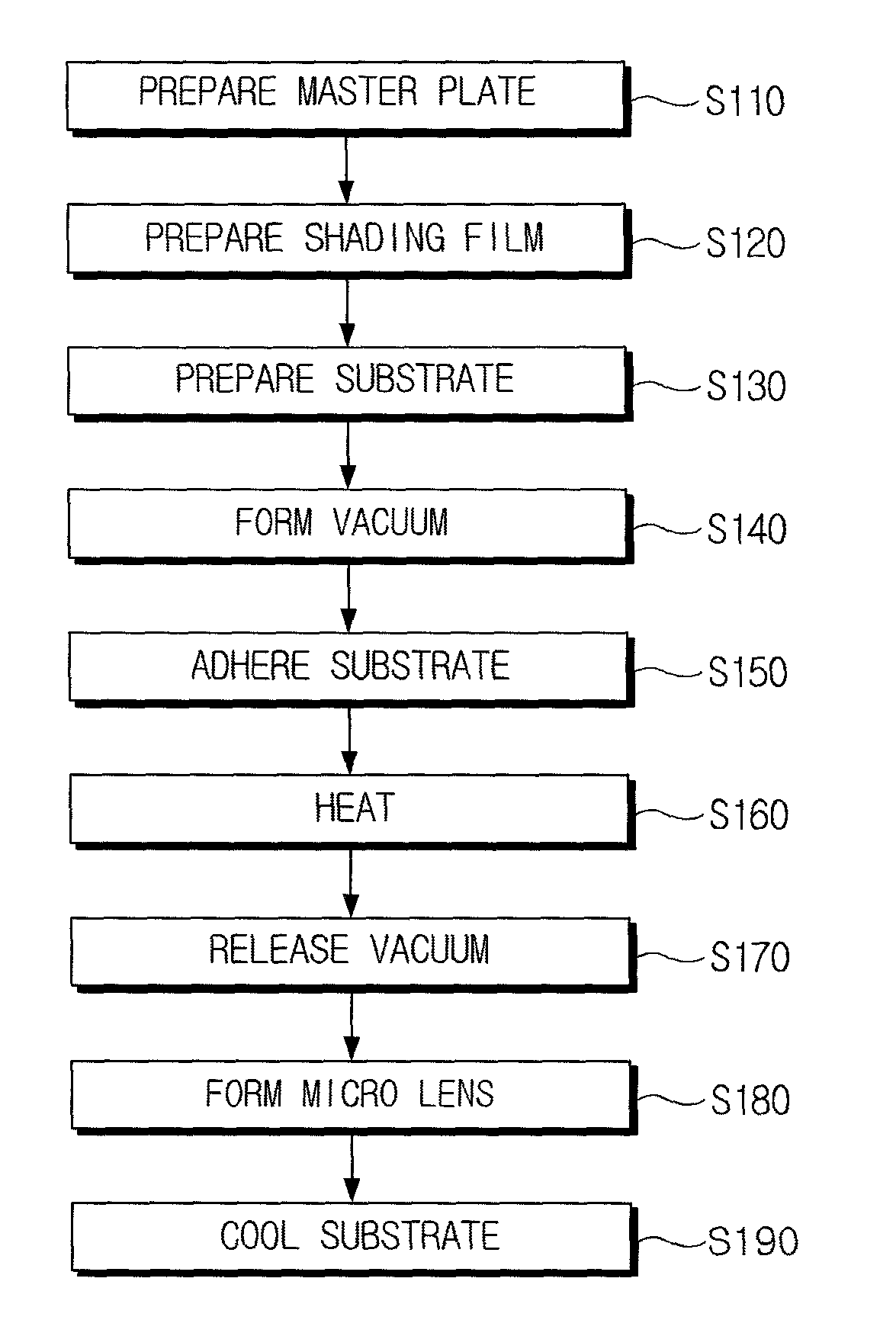

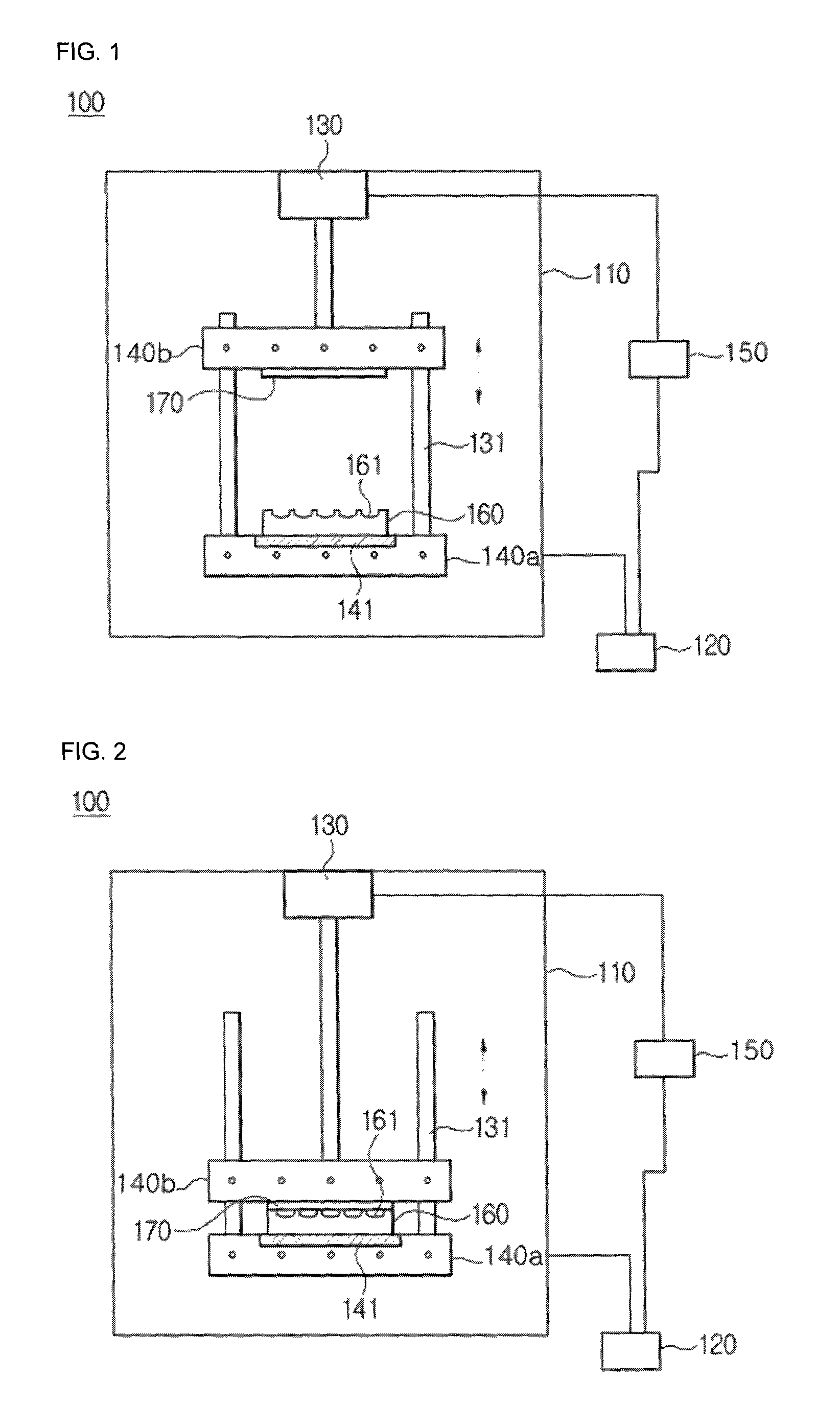

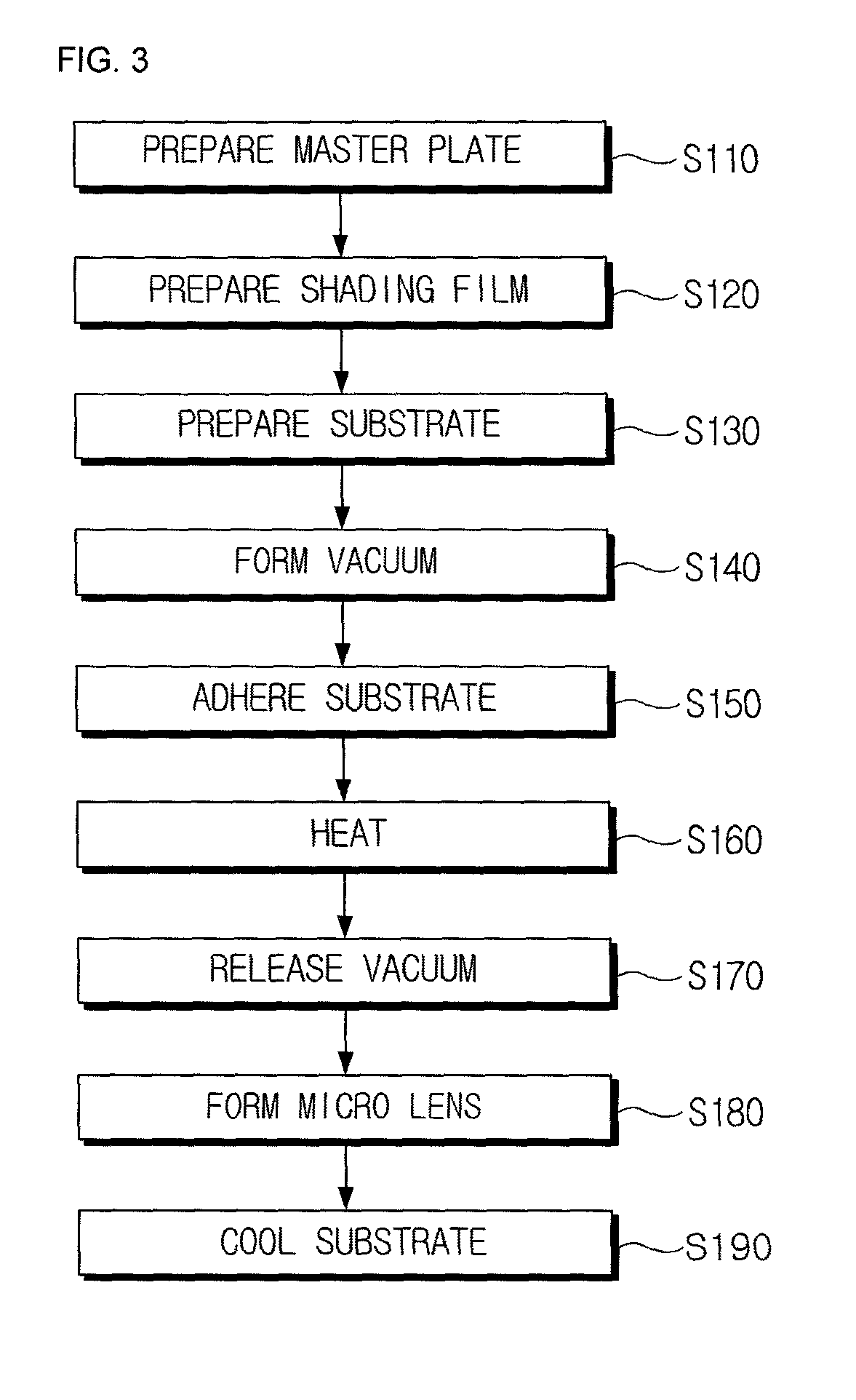

Method of manufacturing micro lens array

ActiveUS20120070785A1Reduce image qualityQuality improvementOptical articlesPhotomechanical exposure apparatusHigh numerical apertureLight beam

A method of manufacturing a micro lens array, wherein the quality of an image is prevented from being deteriorated as a beam on an off-axis surface reaches a focal plane of a micro lens by forming a shading film for preventing the beam from penetrating through a space between micro lenses of the micro lens array, a micro lens having a high numerical aperture or any shape, such as an aspheric shape, is quickly manufactured at a low cost, and the micro lenses and a mask pattern are easily aligned by forming a mask pattern on a focus region formed by the micro lenses of the micro lens array.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

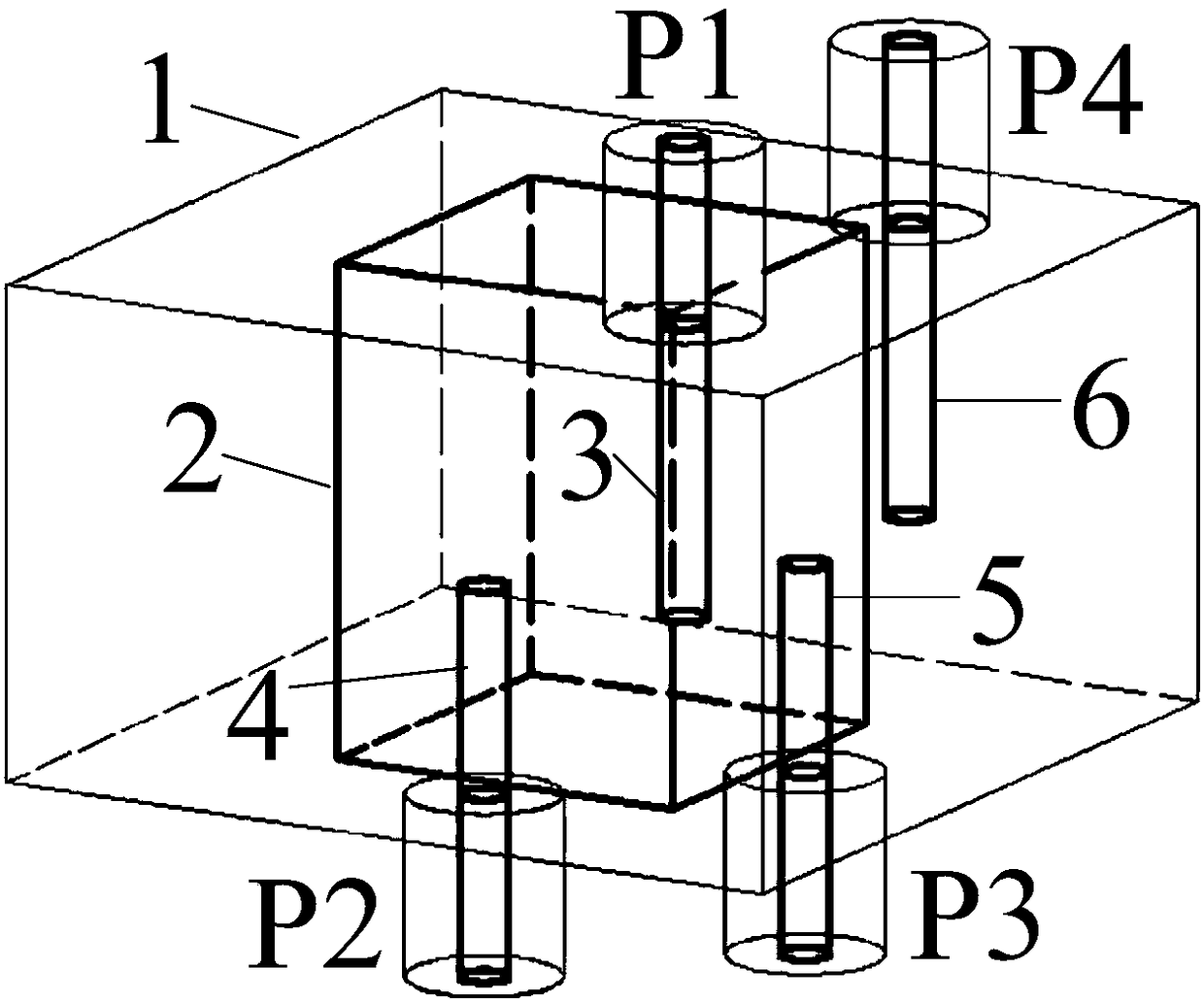

Narrow-band filtering annular coupler based on quadruple-mode dielectric resonator

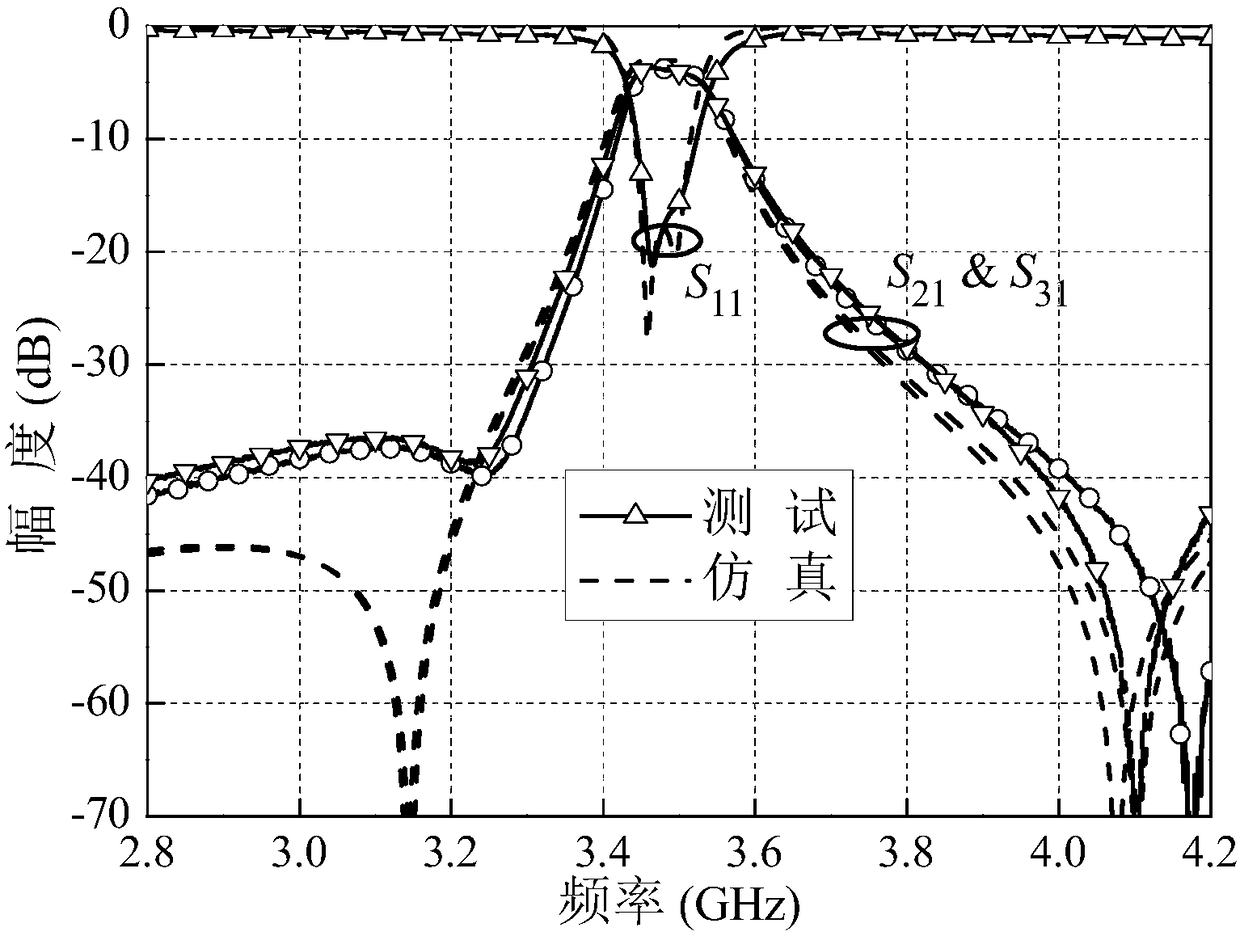

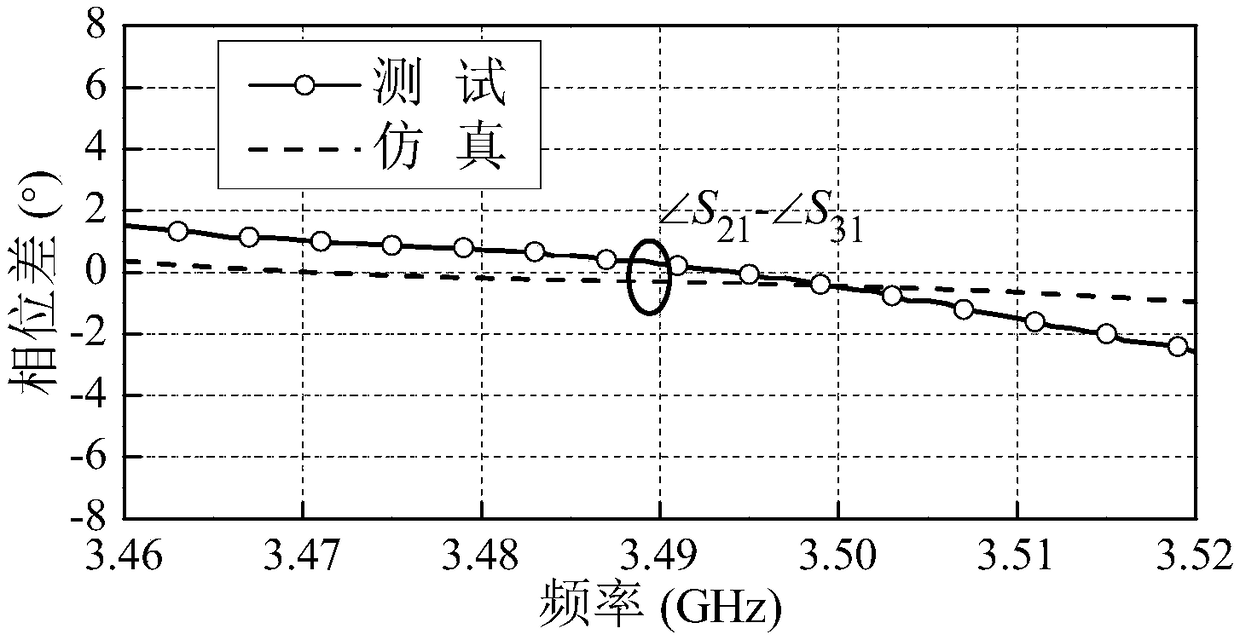

ActiveCN108493565AMiniaturizationWith miniaturizationCoupling devicesHigh level techniquesDielectric resonatorRat-race coupler

The invention discloses a narrow-band filtering annular coupler based on a quadruple-mode dielectric resonator, comprising a quadruple-mode dielectric resonator, a metal cavity and four feed metal rods, wherein the four feed metal rods get close to the quadruple-mode dielectric resonator in parallel, and form coupling with the quadruple-mode dielectric resonator; the four feed metal rods are respectively first, second, third and fourth metal rods, the connection line of the second metal rod and the center point of the metal cavity is vertical to the connection line of the third metal rod and the center point of the metal cavity, the first metal rod is located on the axis surfaces of the second and third metal rods, and the connection line of the fourth metal rod and the metal cavity is vertical to the connection line of the first metal rod and the center point of the metal cavity. The narrow-band filtering annular coupler has the characteristics of being miniaturized and high in integration degree, and has creativity and applicability.

Owner:SOUTH CHINA UNIV OF TECH

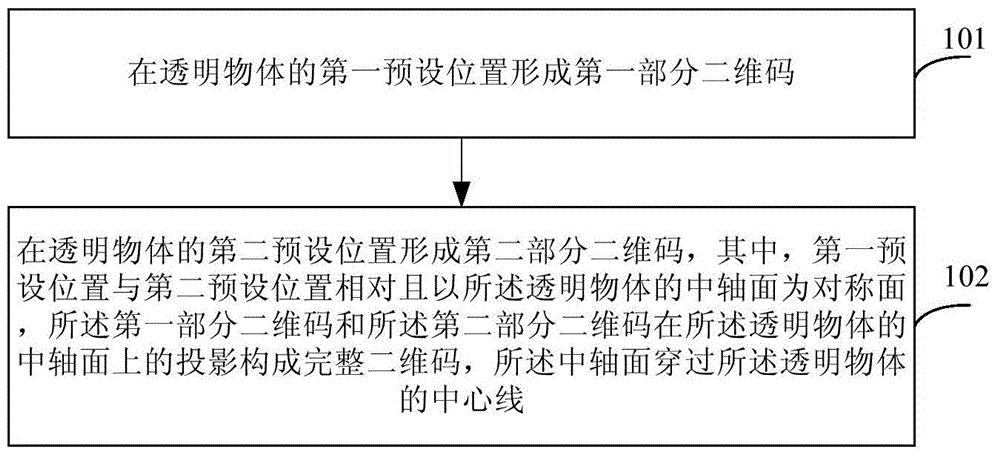

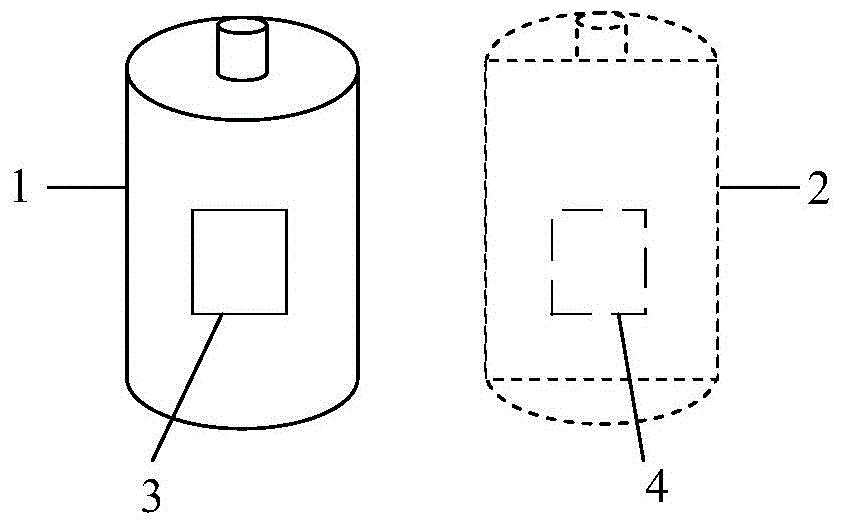

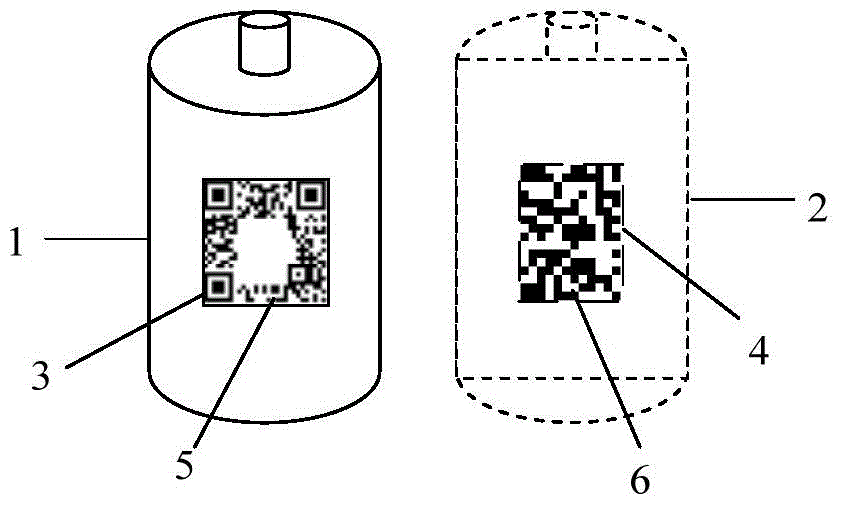

Two-dimensional code setting method and device, and transparent object

ActiveCN105488550AImprove convenienceAvoid gettingRecord carriers used with machinesSensing by electromagnetic radiationComputer scienceEncryption

The invention provides a two-dimensional code setting method and device, and a transparent object. A first part two-dimensional code is formed in a first preset position of a transparent object, a second part two-dimensional code is formed in a second preset position of the transparent object, wherein the first preset position is opposite to the second preset position and a central axis surface of the transparent object serves as a symmetrical surface, the central axis surface penetrates through a center line of the transparent object, and the first part two-dimensional code and the second part two-dimensional code form a complete two-dimensional code on the central axis surface of the transparent object. In the two-dimensional code setting method, the complete two-dimensional code is split and arranged in the opposite positions of the transparent object using the central axis surface thereof as the symmetrical surface, when liquid held in the transparent object exceeds the first preset position, two-dimensional coded scanned under a liquid refraction effect are combined to obtain an illegal two-dimensional code, when the transparent object is used for liquid commodity circulation, the two-dimensional code of the commodity can be prevented from being obtained by an illegal user, and no special means is needed for encryption, thereby improving convenience of use of the two-dimensional code.

Owner:NEW FOUNDER HLDG DEV LLC +1

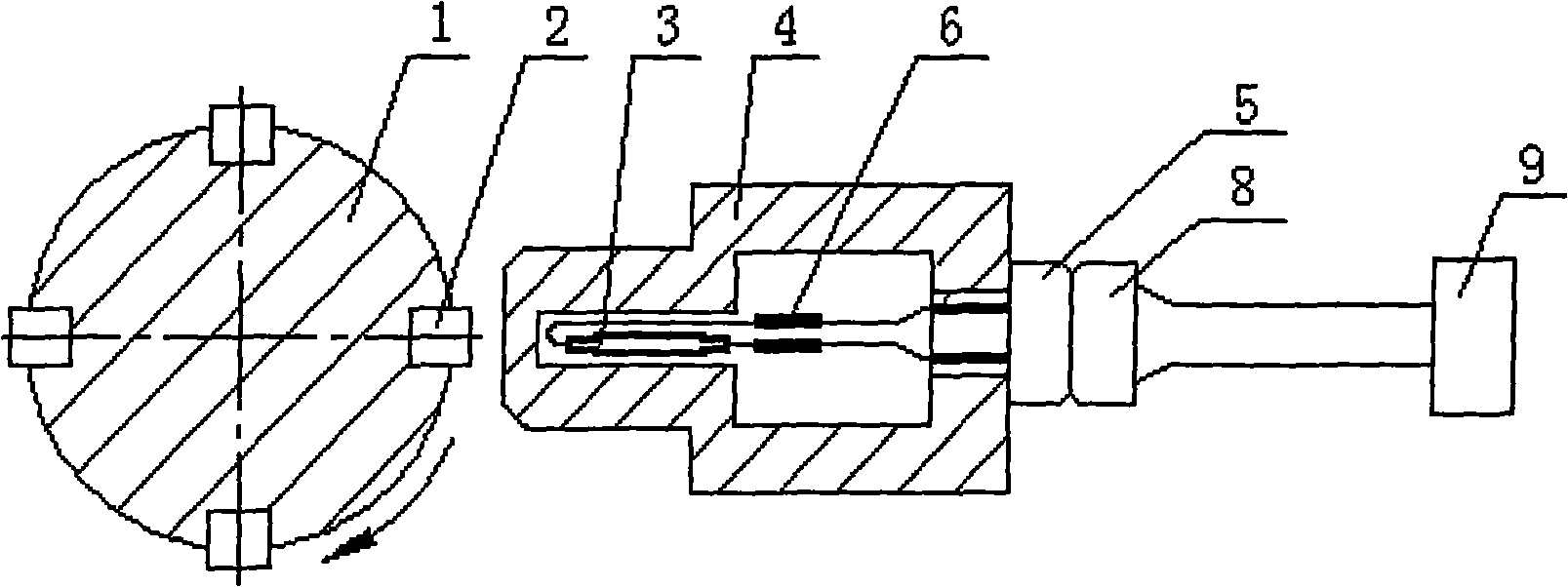

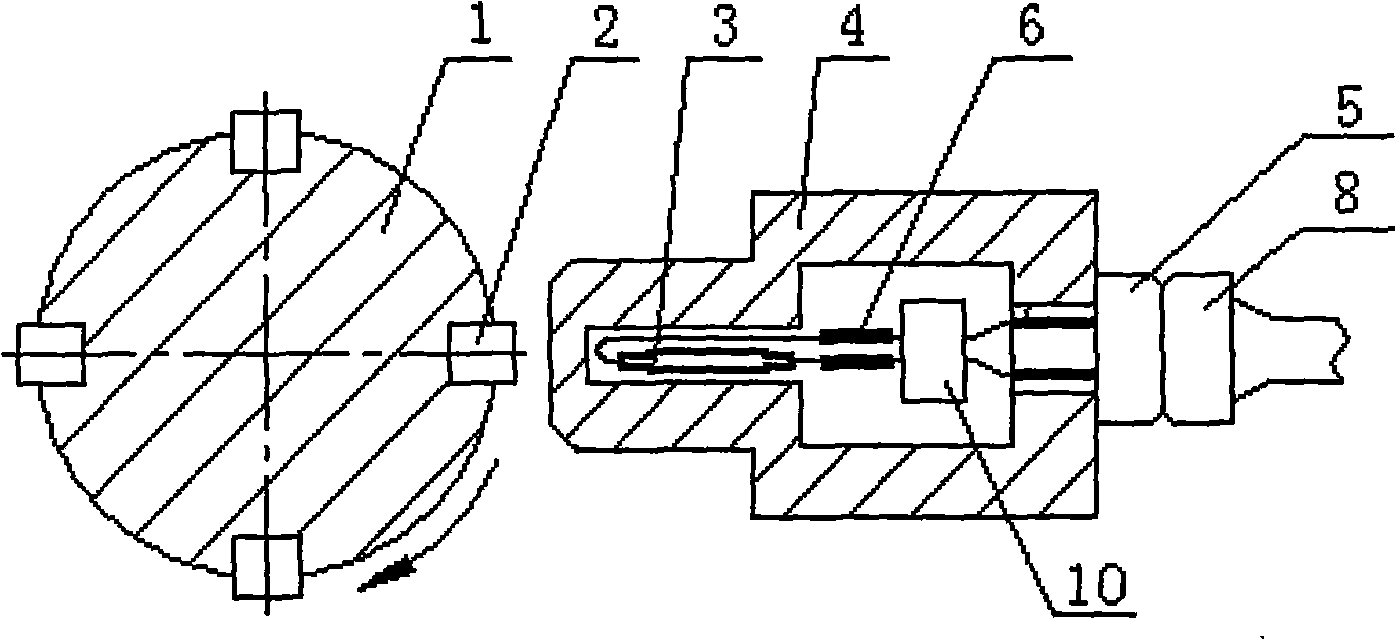

Non-contact type tachometric sensor

InactiveCN101256196ADoes not affect movementThe overall structure is simple and reliableLinear/angular speed measurementMagnetic/electric field switchesTransducerContact type

The invention discloses a non-contact revolution speed transducer, comprising a non-magnetic material shell with magnetoconductivity; a dry reed pipe sealed on the front end of the shell and connected with sensor signal output cable by connecting line of dry reed pipe; 1-N permanent magnets for controlling the switch of the dry reed pipe circuit being fixed on rotation axis surface of the motor to be measured. The structure is simple and the cost is low. The running of the rotation axis is not affected. The non-contact revolution speed transducer can measure rotate speed of rotational parts of a great variety of motors, especially used in abyssal environment and measure the rotate speed of rotational parts of abyssal motor.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

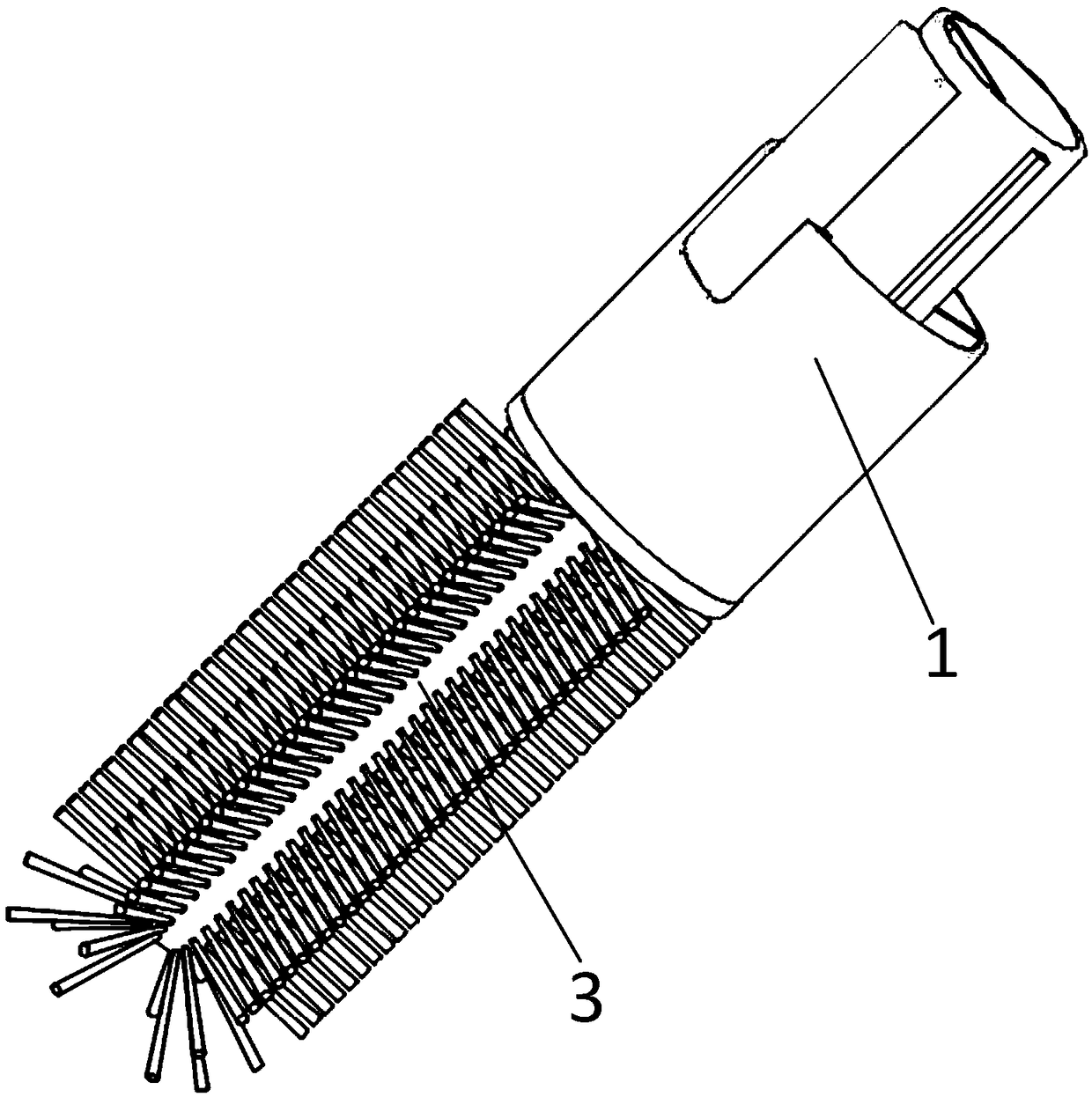

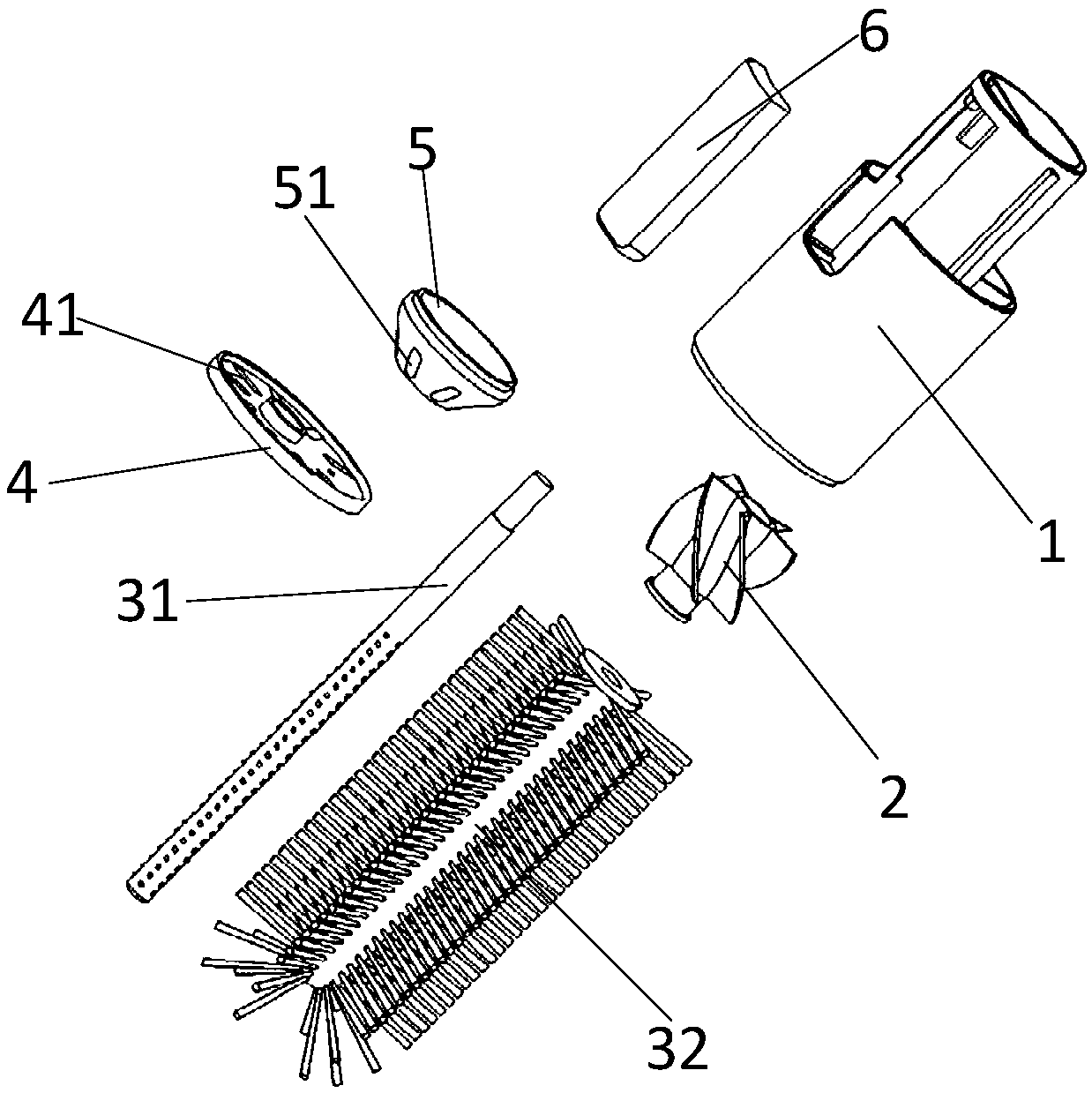

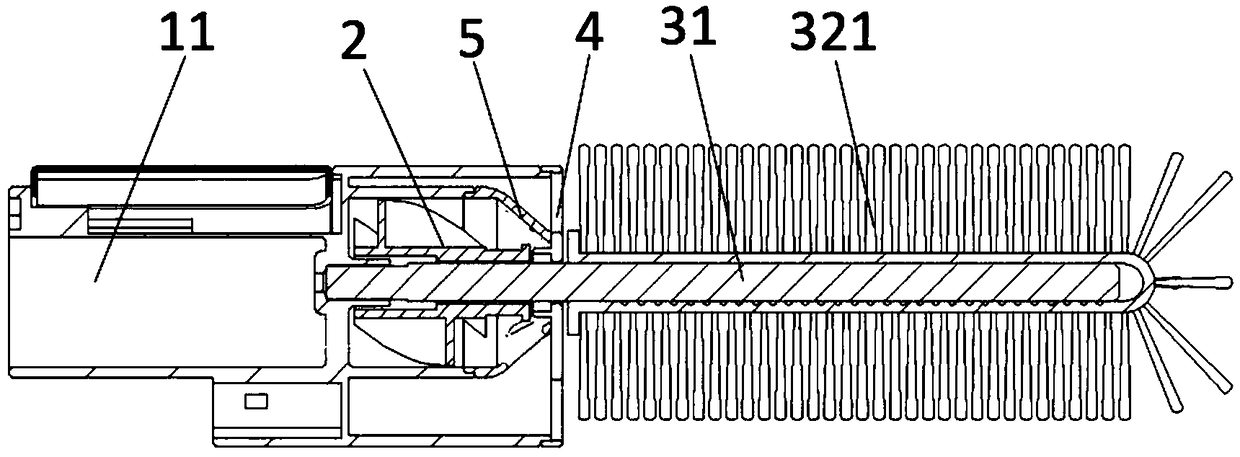

Brush head and vacuum cleaner

PendingCN109431370AReduce the difficulty of cleaningIncrease the cleaning areaSuction nozzlesEngineeringWind force

The invention relates to the field of vacuum cleaners, in particular to a brush head and a vacuum cleaner. The brush head consists of a joint pipe, a wind wheel and a rolling brush. The joint pipe isinternally provided with an air suction channel, one end of the joint pipe is connected with a negative pressure source, the wind wheel is arranged in the air suction channel, and wind force in the air suction channel drives the wind wheel to rotate, one end of the rolling brush is connected with the wind wheel, the rolling brush is driven by the wind wheel and rotates around the axis of the jointpipe, and the axial surface of the other end of the rolling brush is provided with brush hair extending outwards along the axial surface. The brush head has a large cleaning area, the cleaning effecton accumulated dust is good, meanwhile the inner walls of tubular parts can be cleaned, and the difficulty of cleaning the tubular parts is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Design method of double-rotor internal-rotation constant pressure pump

InactiveCN101737322ASolving the challenge of being a monolithic structureSolve the sealing problemRotary piston pumpsRotary piston liquid enginesLow noiseEngineering

The invention relates to a design method of a double-rotor internal-rotation constant pressure pump, which is characterized in that the inner surface of a pump body (1) is provided with two groups of spiral grooves with opposite rotary directions, the normal sections of the spiral grooves are rectangular, and two eccentric sleeves (4) with opposite eccentric directions are sleeved on the axial surface of an eccentric shaft (5); two groups of spiral groove bodies (2) with opposite rotary directions are sleeved between the pump body (1) and the eccentric shaft (5), and two circular tracks (6) are respectively fixed on end covers at the outer end faces of the two groups of spiral groove bodies (2) with opposite rotary directions; a liquid inlet is respectively arranged at both ends of the pump body (1) and a liquid outlet is arranged at the middle part of the pump body (1) between the two groups of spiral groove bodies (2); and the inner surfaces of the spiral groove bodies (2) and the outer surface of the eccentric sleeve (4) are connected by arcs, the eccentric shaft (5) is connected with an end cover body of the pump body (1) by a bearing, and a liquid inlet and a liquid outlet are arranged at both ends of the pump body (1) or on the end cover body. The invention has high output pressure, good internal sealing effect, small volume, low noise and low energy consumption, can change the flow rate at constant pressure and can carry out the mixed output of liquid and gas.

Owner:张中元

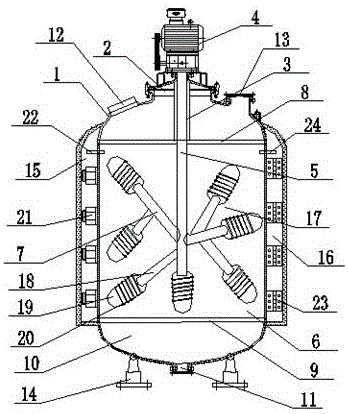

Juncao ganoderma lucidum dreg fermentation and extraction device

ActiveCN106136275AImprove the strength of forceRealize quantitative extractionFeeding-stuffEconomic benefitsElectric machinery

The invention discloses a Juncao ganoderma lucidum dreg fermentation and extraction device. The Juncao ganoderma lucidum dreg fermentation and extraction device comprises a tank body, a stirring chamber and a weighing unit, wherein the top of the tank body is connected with a power input shaft through a sealing element; one end of the power input shaft is connected with a driving motor; the other end of the power input shaft stretches into the tank body and is connected with a stirring shaft; the stirring shaft is mounted in the stirring chamber and a plurality of stirrer main bodies are distributed on a shaft surface; a weighing unit is connected with a discharging valve at the bottom of the tank body; a feeding hole is formed in one side of the top of the tank body and an air inlet is formed in the other side of the top of the tank body; a support is further mounted at the bottom of the tank body; one side of the tank body is connected with a heating chamber; and the other side of the tank body is connected with a humidification chamber. According to the Juncao ganoderma lucidum dreg fermentation and extraction device, a fermentation tank and an extracting tank are combined, so that fermentation and extraction of materials can be finished in the same tank body, an operation step is greatly simplified and the working efficiency is high; and quantitative extraction of the materials can be realized, the practicability is high, the enterprise cost is easily reduced and the economic benefits are improved.

Owner:内蒙古苁蓉实业有限责任公司

Polarized light type light-emitting diode (LED) straw hat lamp bead

ActiveCN102777793AImprove light utilizationPoint-like light sourceElectric lightingLED displayLight equipment

The invention relates to a polarized light type light-emitting diode (LED) straw hat lamp bead. The polarized light type LED straw hat lamp bead comprises a bracket with positive and negative pins and an inner reflector, an LED chip and an encapsulating lens for encapsulating the inner reflector, wherein the encapsulating lens comprises a lens base and a lens curve; the inner reflector is arranged on the upper part of the negative pin in an inclined manner and faces towards the positive pin; the lens curve is axial surface asymmetrical at C90-270 degrees and symmetrical at C0-180 degrees; and the curvature variation of the lens curve affects refraction of emergent rays from the inner reflector. The polarized light type LED straw hat lamp bead is good in light polarization effect and high in light source utilization rate, and can be widely applied to illumination equipment (such as a garden lamp) or display equipment (such as an LED display screen) mounted on a high position.

Owner:FUJIAN HONGBO OPTO ELECTRONICS TECH CO LTD

Vacuum adsorption roller used for folding machine

The invention discloses a vacuum adsorption roller used for a folding machine and belongs to the field of adsorption rollers. The vacuum adsorption roller comprises a core shaft and a roller body, wherein the core shaft is in the roller body; the core shaft and the roller body are coaxially and rotatably connected; a chamber is formed between the outer axial plane of the core shaft and the inner axial plane of the roller body; the vacuum adsorption roller for the folding machine further comprises a sealing device; and the sealing device is positioned between the core shaft and the roller bodyand divides the chamber into an adsorption cavity and a decompression cavity. The vacuum adsorption roller for the folding machine adopts the sealing device formed through combination of a spring anda sealing strip for sealing to replace the direct sealing manner of the single rubber sealing strip, the sealing effect is excellent, and the maintenance is convenient to achieve; in addition, only one vacuum pump is needed for working, so that the noise is small, and the energy consumption is low; and moreover, the vacuum pump continuously supplies pressure for air exhaust to reduce the time difference of intermittent air exhaust, so that the vacuumizing speed is further increased.

Owner:欧克科技股份有限公司

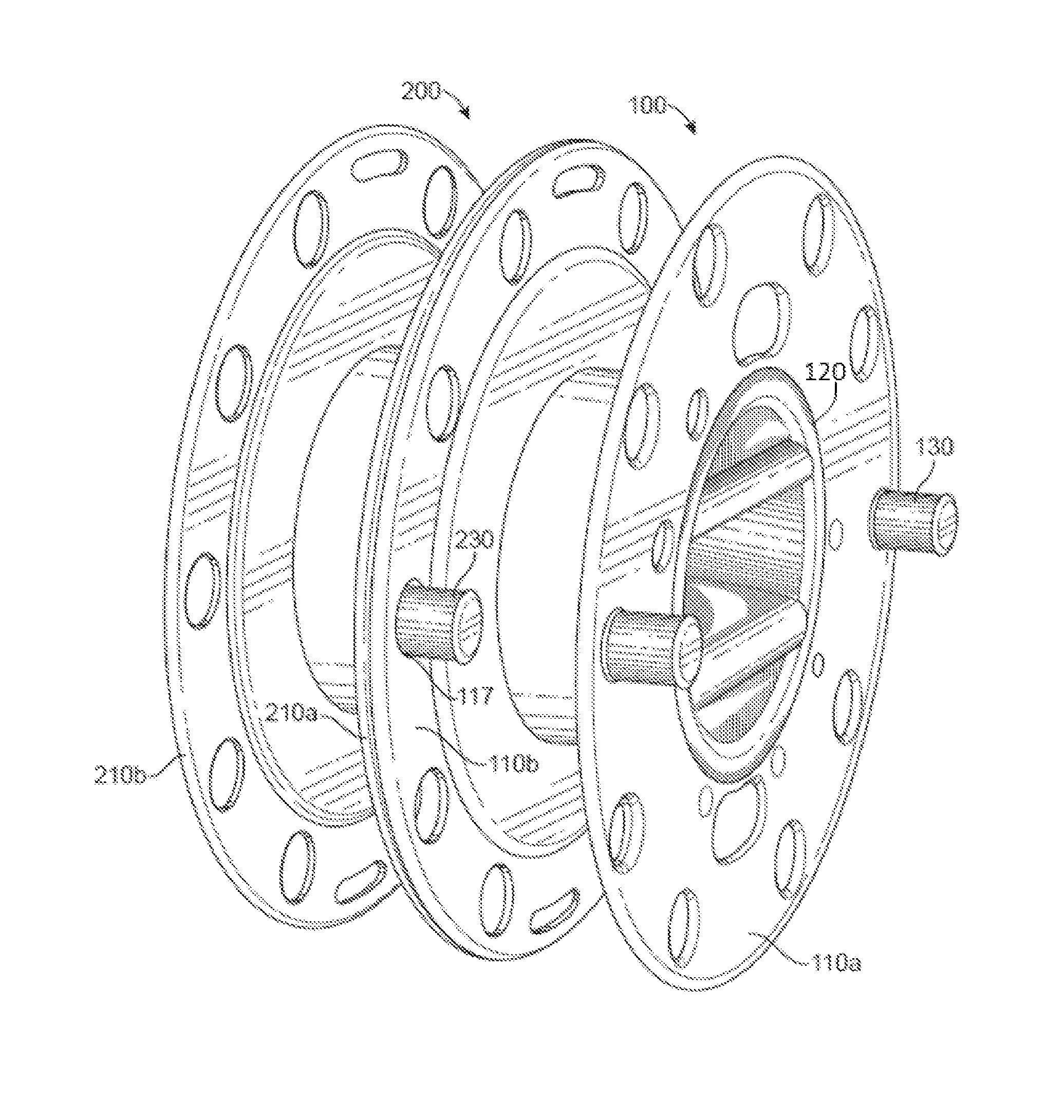

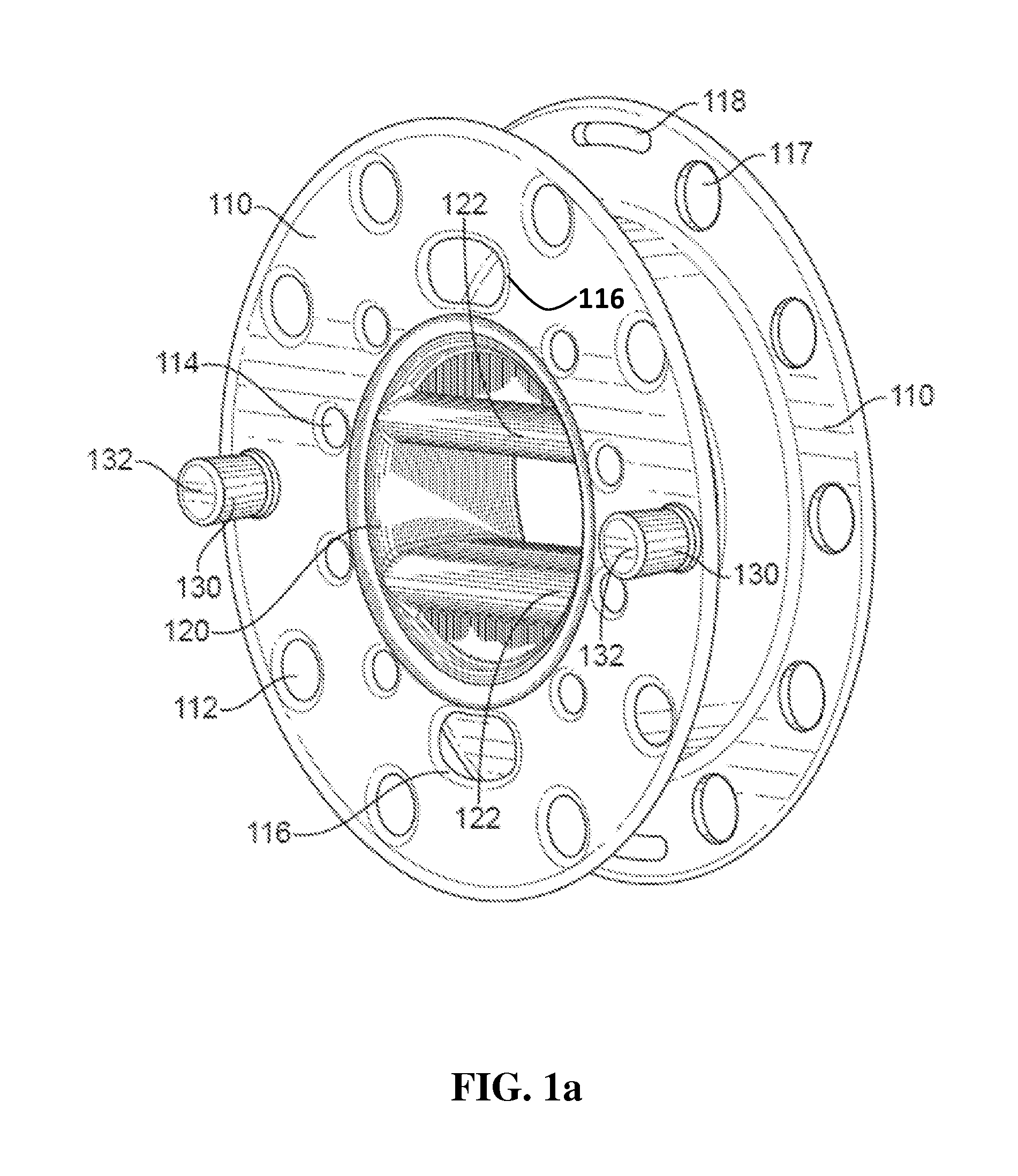

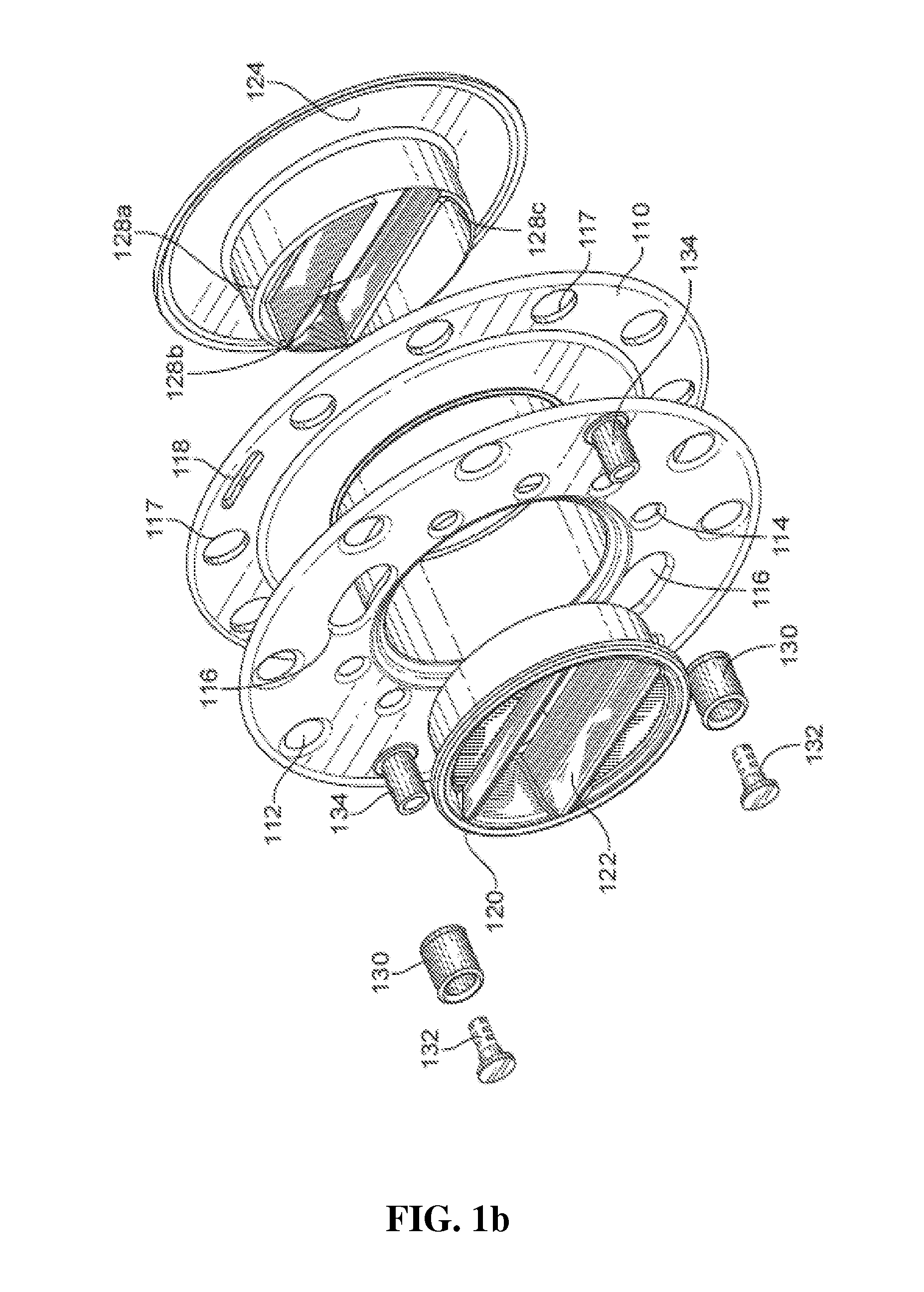

Hand held cable reel assembly

The present invention relates to a small lightweight hand held cable reel comprising a spool configured to rotate around a central ergonomic handle, wherein the spool comprises of two winder knobs for rotating the spool around the central ergonomic handle; smaller, larger locator holes and larger elongated slotted holes on the outer spool face for attaching a cable. The hand held cable reel further comprises elongated slotted holes on inner spool face for attaching to a webbing strap of clothing or equipment.

Owner:RUSLYN HLDG

Method of manufacturing micro lens array

ActiveUS8658347B2Quality improvementLarge numerical aperturePhotomechanical apparatusOptical articlesHigh numerical apertureLight beam

A method of manufacturing a micro lens array, wherein the quality of an image is prevented from being deteriorated as a beam on an off-axis surface reaches a focal plane of a micro lens by forming a shading film for preventing the beam from penetrating through a space between micro lenses of the micro lens array, a micro lens having a high numerical aperture or any shape, such as an aspheric shape, is quickly manufactured at a low cost, and the micro lenses and a mask pattern are easily aligned by forming a mask pattern on a focus region formed by the micro lenses of the micro lens array.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

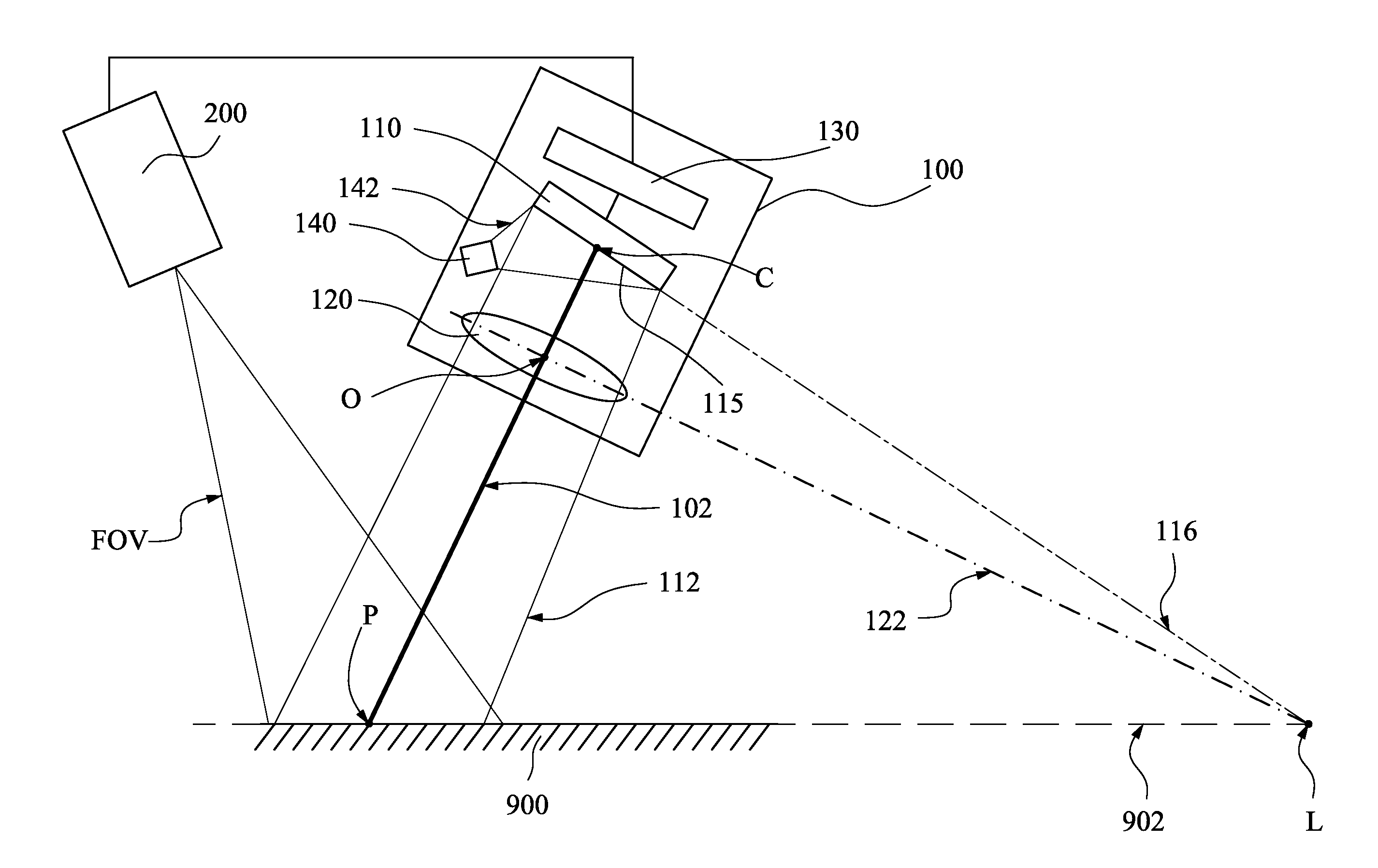

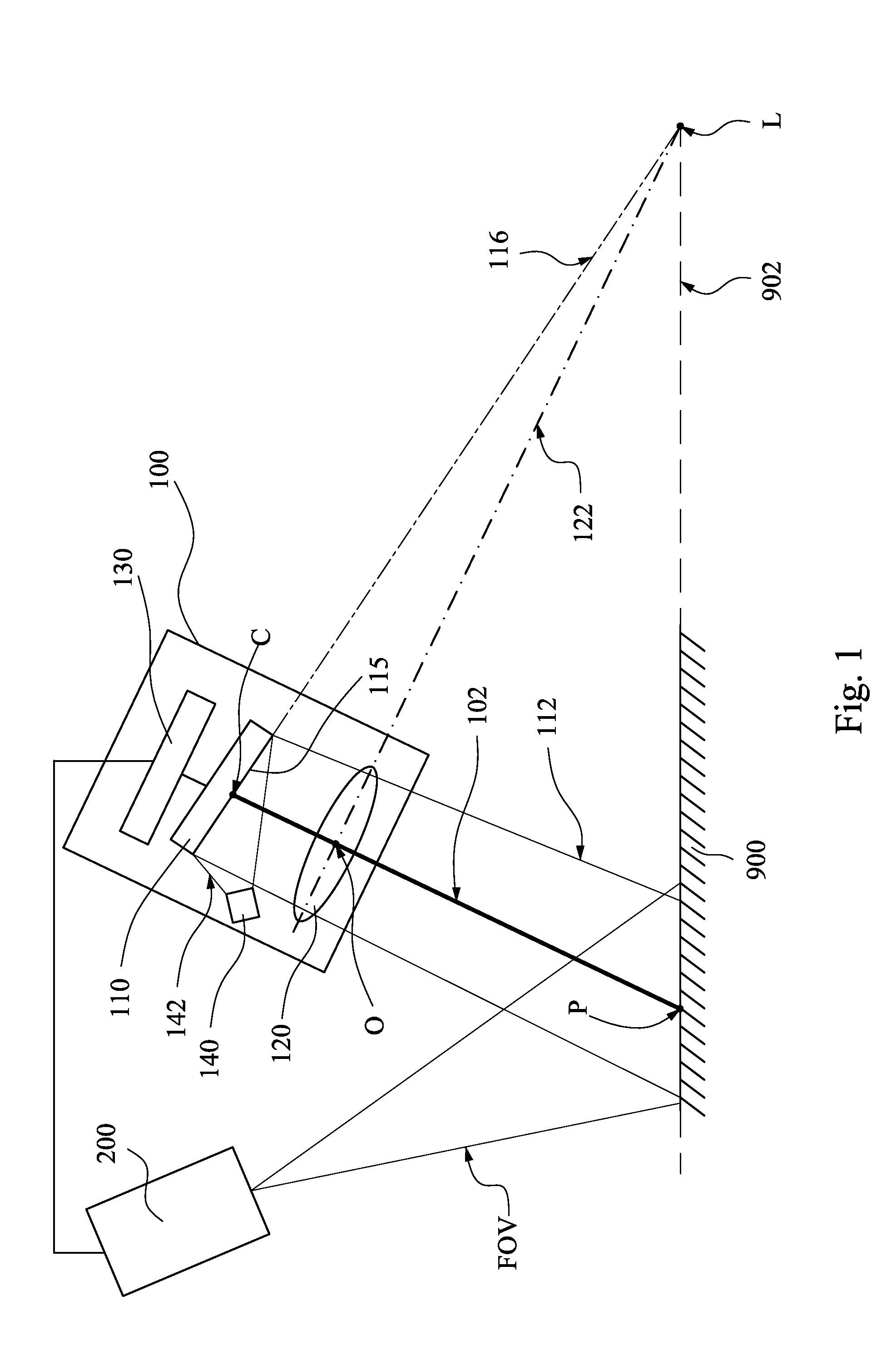

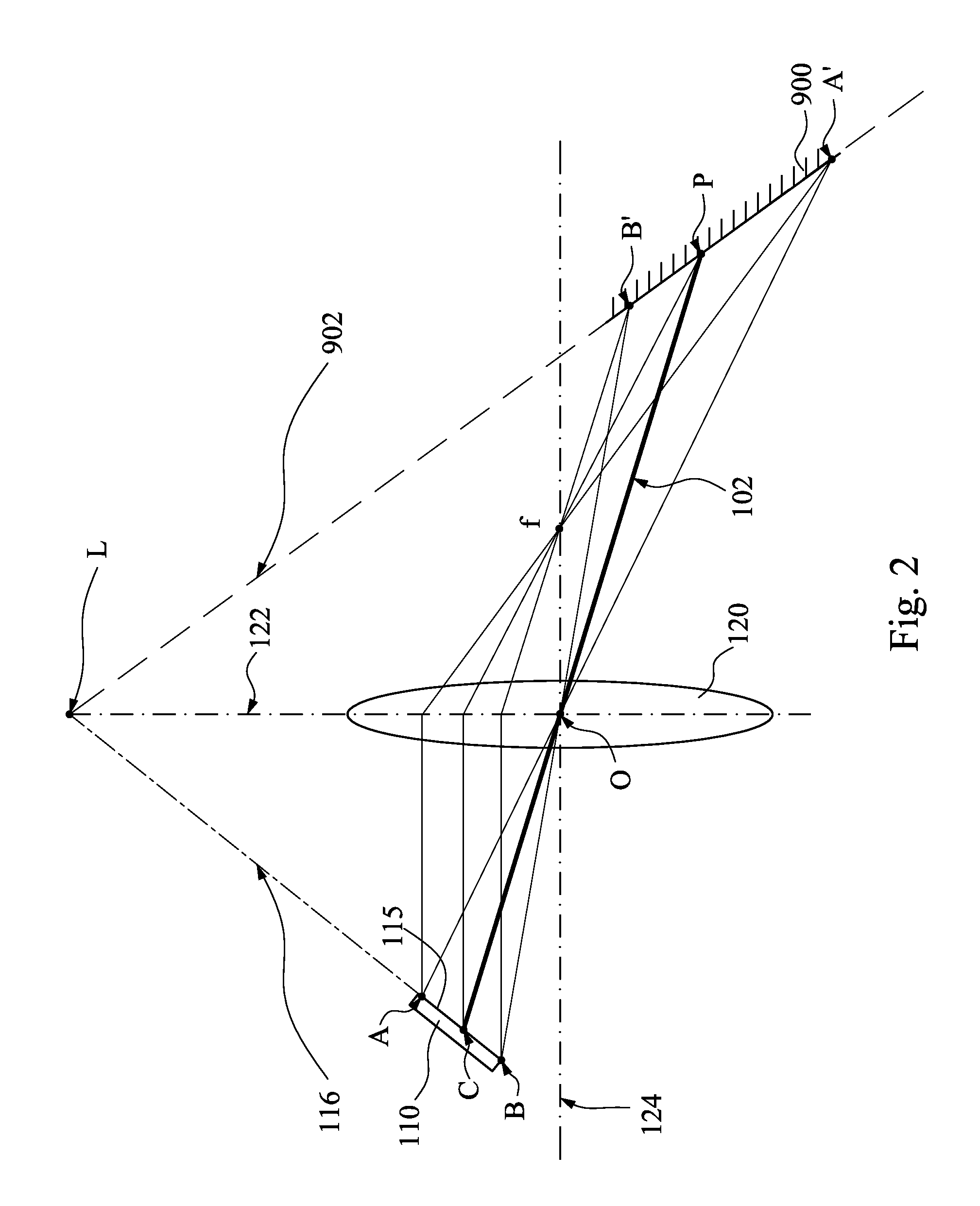

Optical system and image compensating method of optical apparatus

An optical system includes an optical apparatus. The optical apparatus is for projecting a first projection image to a plane or detecting a first detected image of the plane. The optical apparatus includes a first image device, and a lens group. The first image device has an image surface having an image center. The lens group is disposed between the first image device and the plane and has a lens axis surface and an optic center. The optic center and the image center form a connection line. The plane has a tangent surface to an intersecting point of the connection line. The lens axis surface, the tangent surface, and an extension surface of the image surface substantially intersect at a straight line.

Owner:TEST RES INC

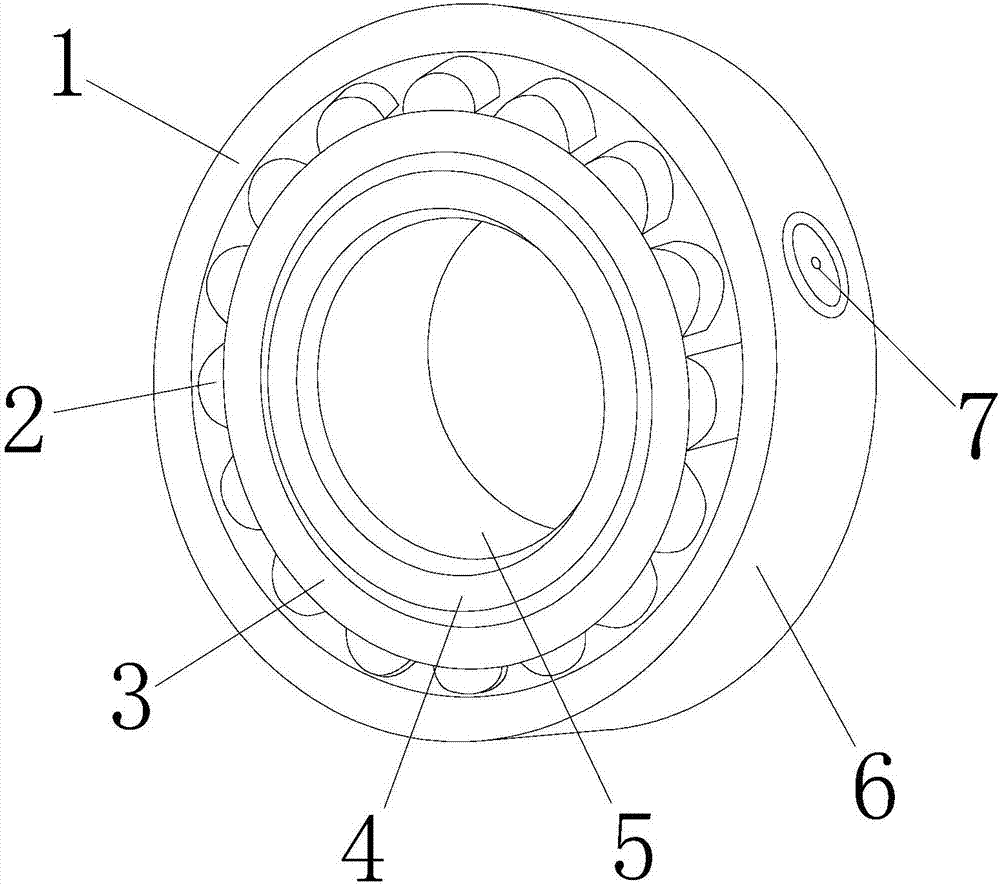

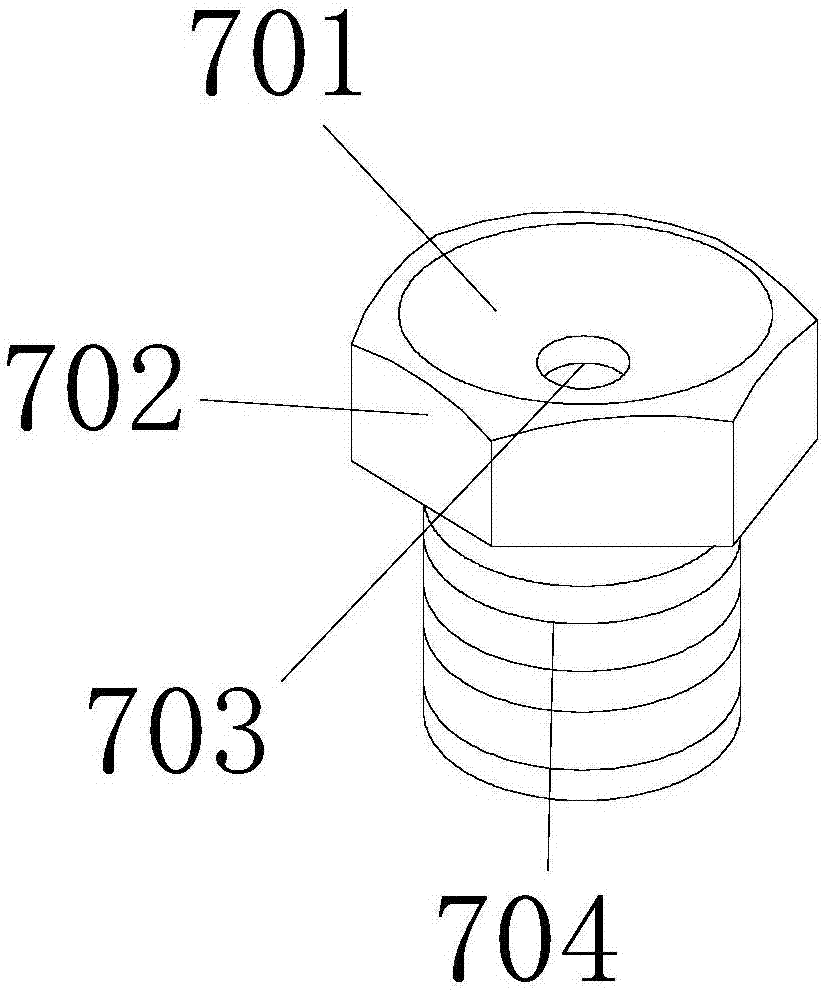

Bearing

InactiveCN107269684AEasy to useNot easy to rustBall bearingsBearing componentsInterference fitEngineering

The invention discloses a bearing, the structure of which comprises an outer ring, a sliding ball, a bearing protective cover, an inner ring protective cover, an inner ring, an axial surface, and a grease nipple. The outer ring has a circular structure, and an axial surface and In one structure, there are two protective sleeves parallel to each other. The protective sleeves are respectively nested on the left and right sides of the outer ring. There are more than two sliding balls. The sliding balls are evenly and equally spaced inside the outer ring with clearance fit. The ring protective sleeve has a circular structure, the inner ring protective sleeve is respectively nested on the inner side of the bearing protective sleeve, the inner ring is set in the middle of the outer ring as an integral structure, and the oil nozzle is nested on the shaft surface and has an interference fit. Beneficial effects: the structure is equipped with a grease nipple. When in use, the screw under the nut can be screwed into the inside of the shaft surface, and then the sliding ball inside the outer ring can be filled with lubricating oil through the grease nipple hole on the nut, so that it can be more Good use, not easy to rust, long service life.

Owner:广州市鹭江远科技有限公司

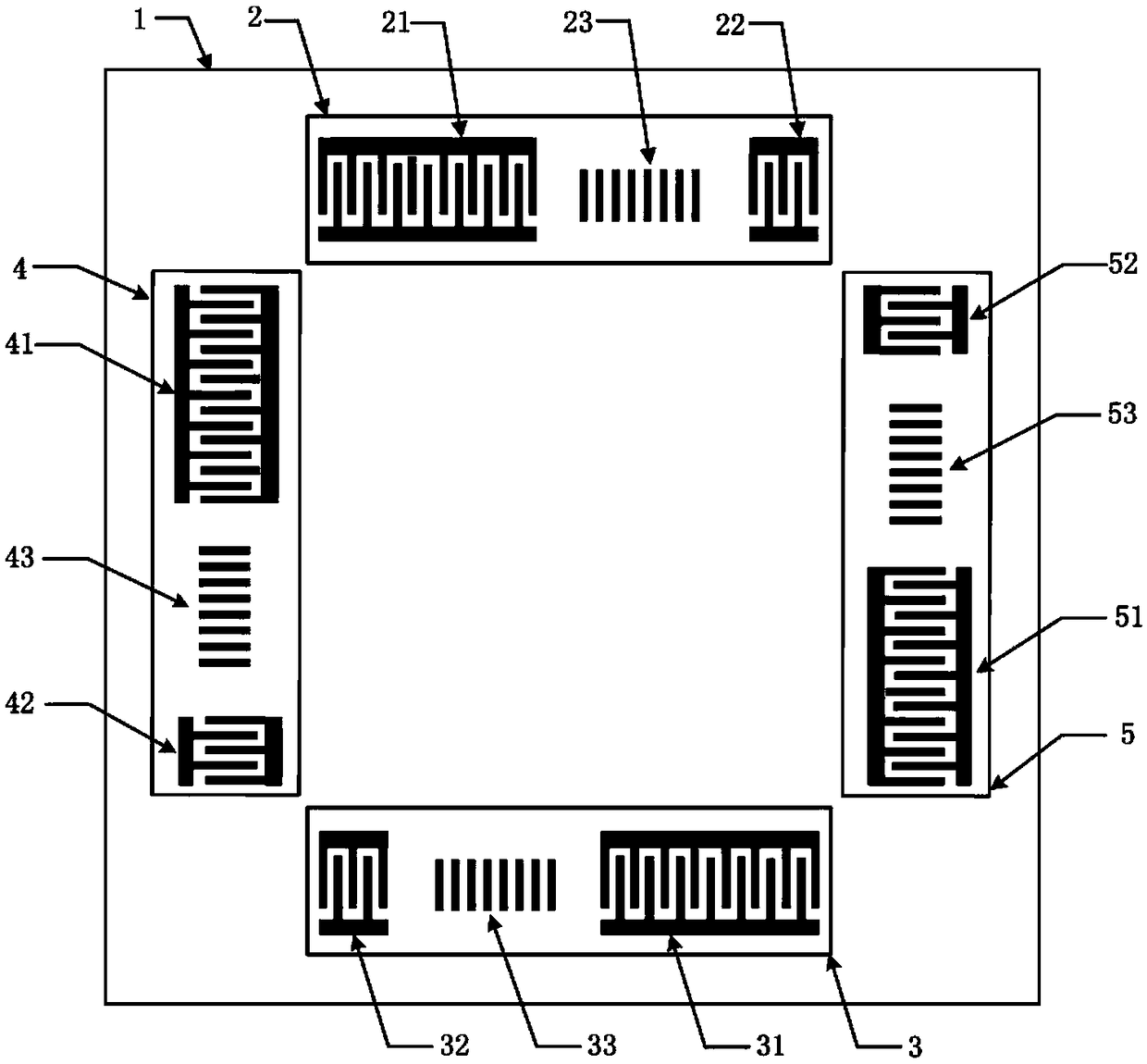

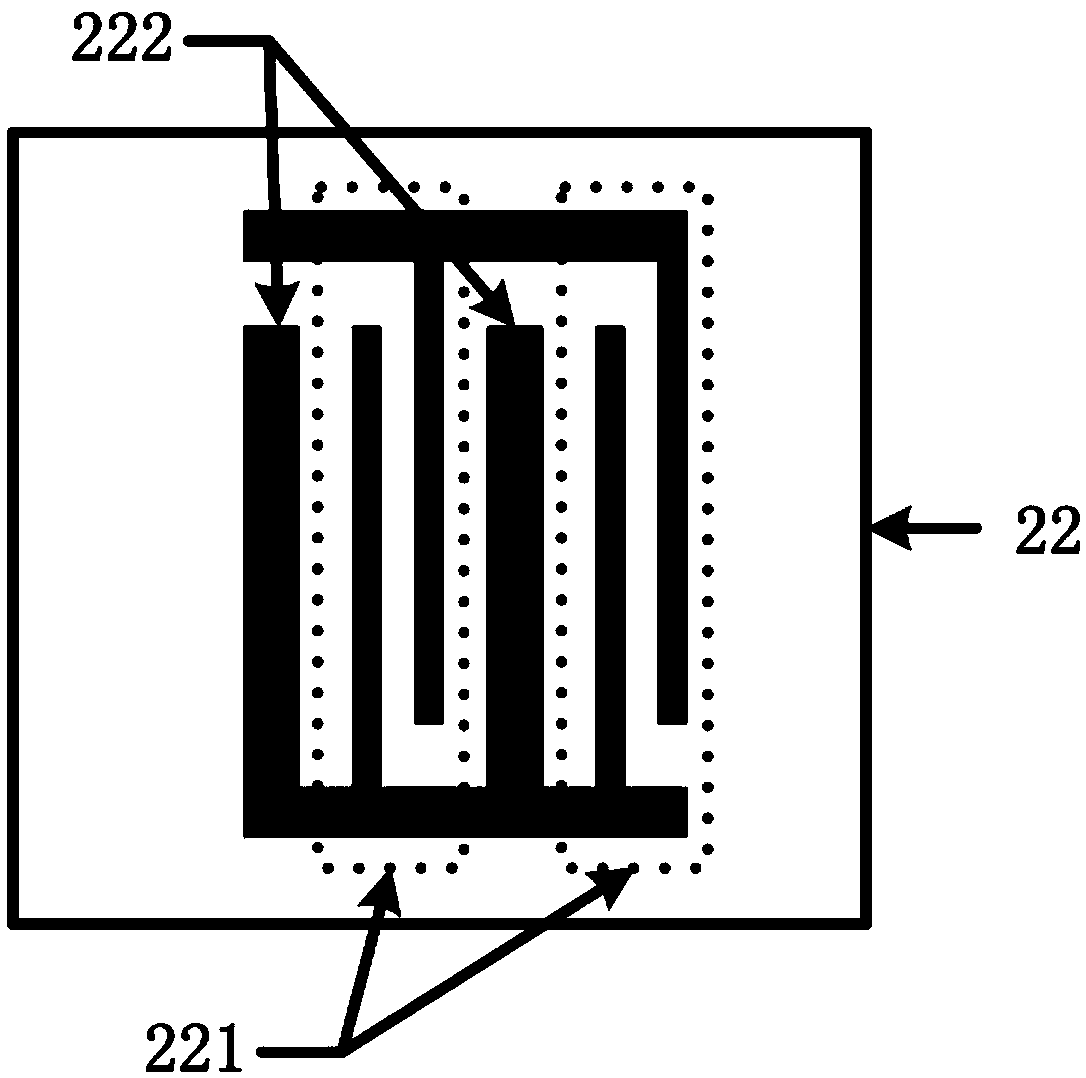

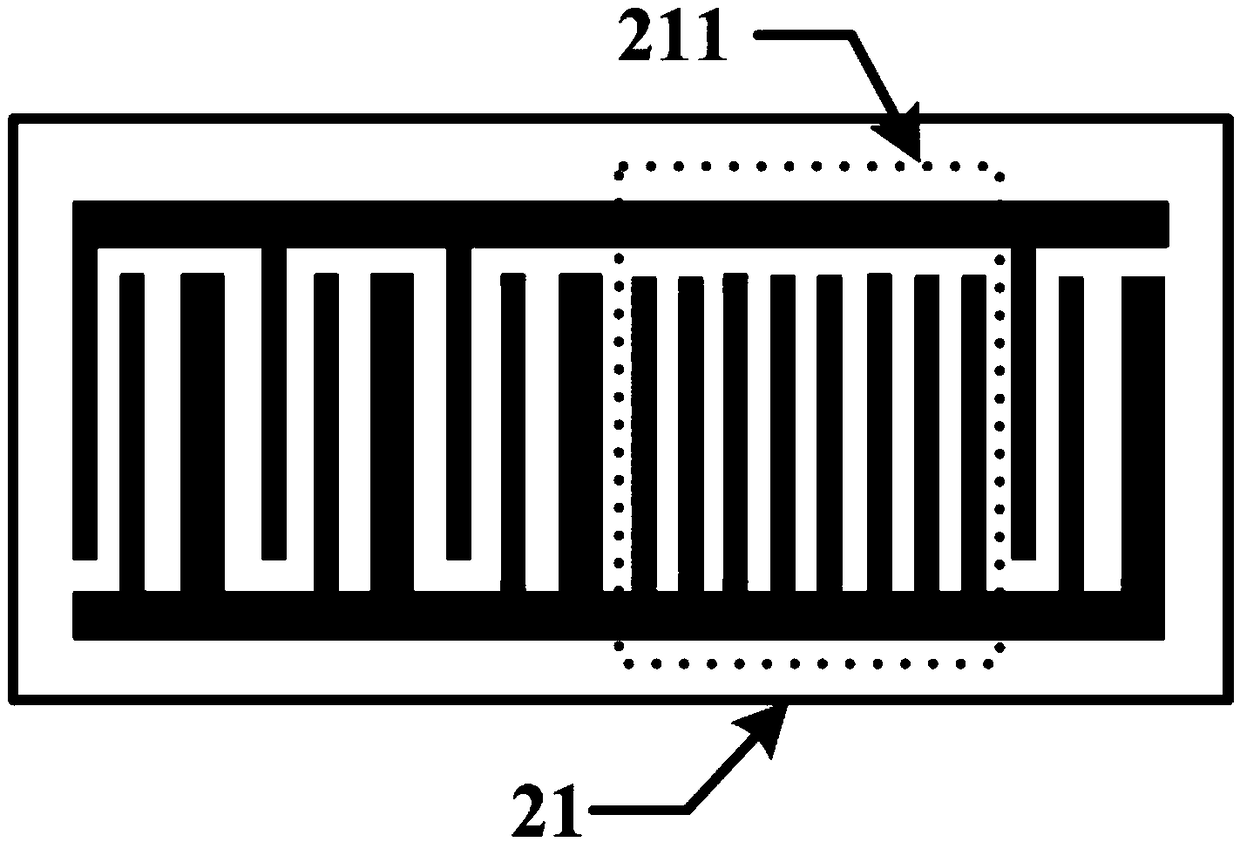

Double-axis surface acoustic wave angular rate sensor

ActiveCN108828253AHigh detection sensitivityRealize dual-axis angular rate detectionLinear/angular speed measurementElectricityAngular rate sensor

The invention discloses a double-axis surface acoustic wave angular rate sensor. The sensor is composed of a piezoelectric substrate and four surface acoustic wave delay lines disposed on the surfaceof the piezoelectric substrate. The structures of the first and the third surface acoustic wave delay lines are identical and are arranged in reverse and in parallel. The structures of the second andthe fourth surface acoustic wave delay lines are identical and are arranged in reverse and in parallel, and are distributed perpendicular to the first and the third surface acoustic wave delay lines.Metal grid arrays are distributed between input transducers and output transducers of the four surface acoustic wave delay lines. The first and third surface acoustic wave delay lines form a differential sensing structure so as to detect rotation angular rate along the y-axis direction. The second and the fourth surface acoustic wave delay lines form a differential sensing structure so as to detect rotation angular rate along the x-axis direction. When the sensor rotates at a specific angular rate, the metal grid arrays are subjected to Coriolis force effect and then the spread phase speed ofthe surface acoustic waves change. Therefore, detection of the angular rate is realized.

Owner:SHANDONG NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com