Patents

Literature

100 results about "Wing wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wing wall (also "wingwall" or "wing-wall") is a smaller wall attached or next to a larger wall or structure.

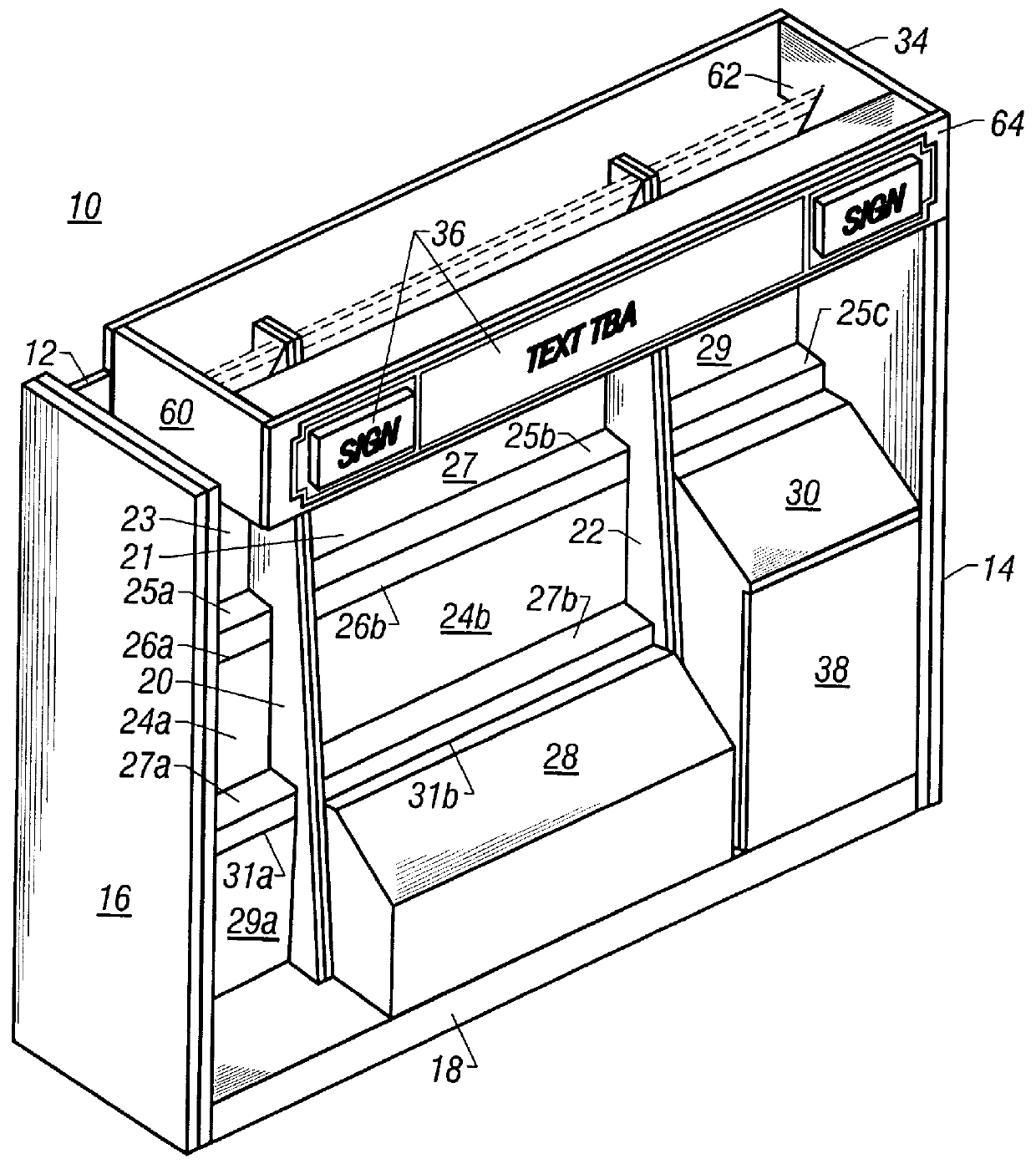

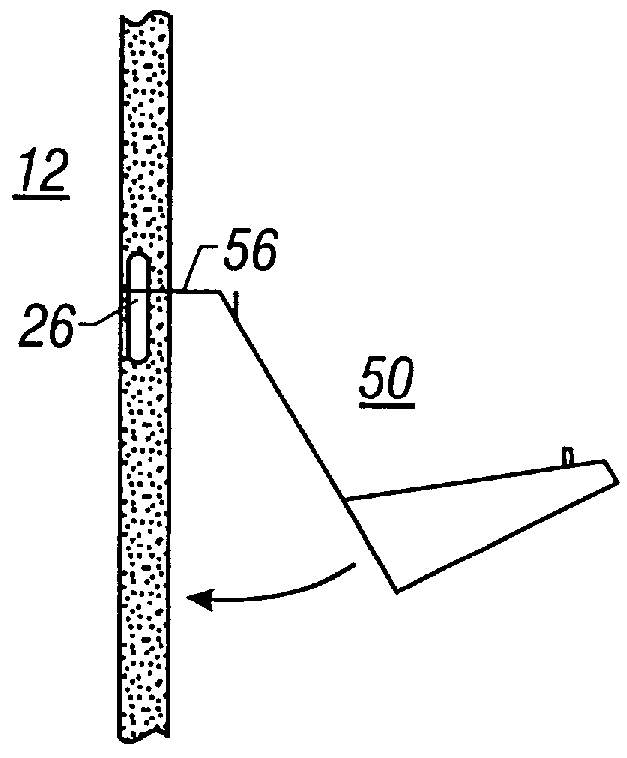

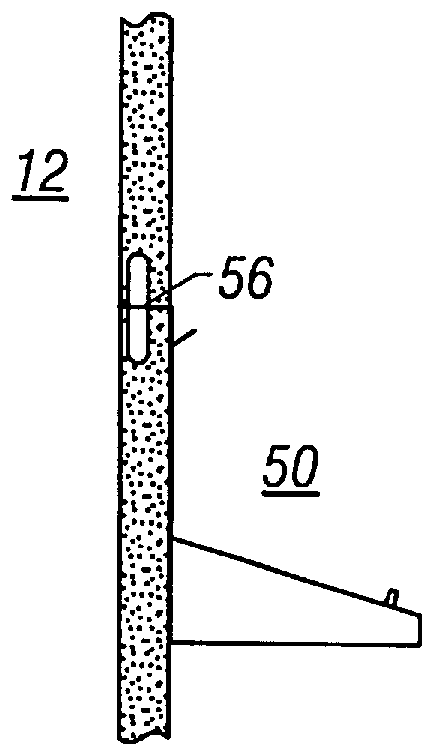

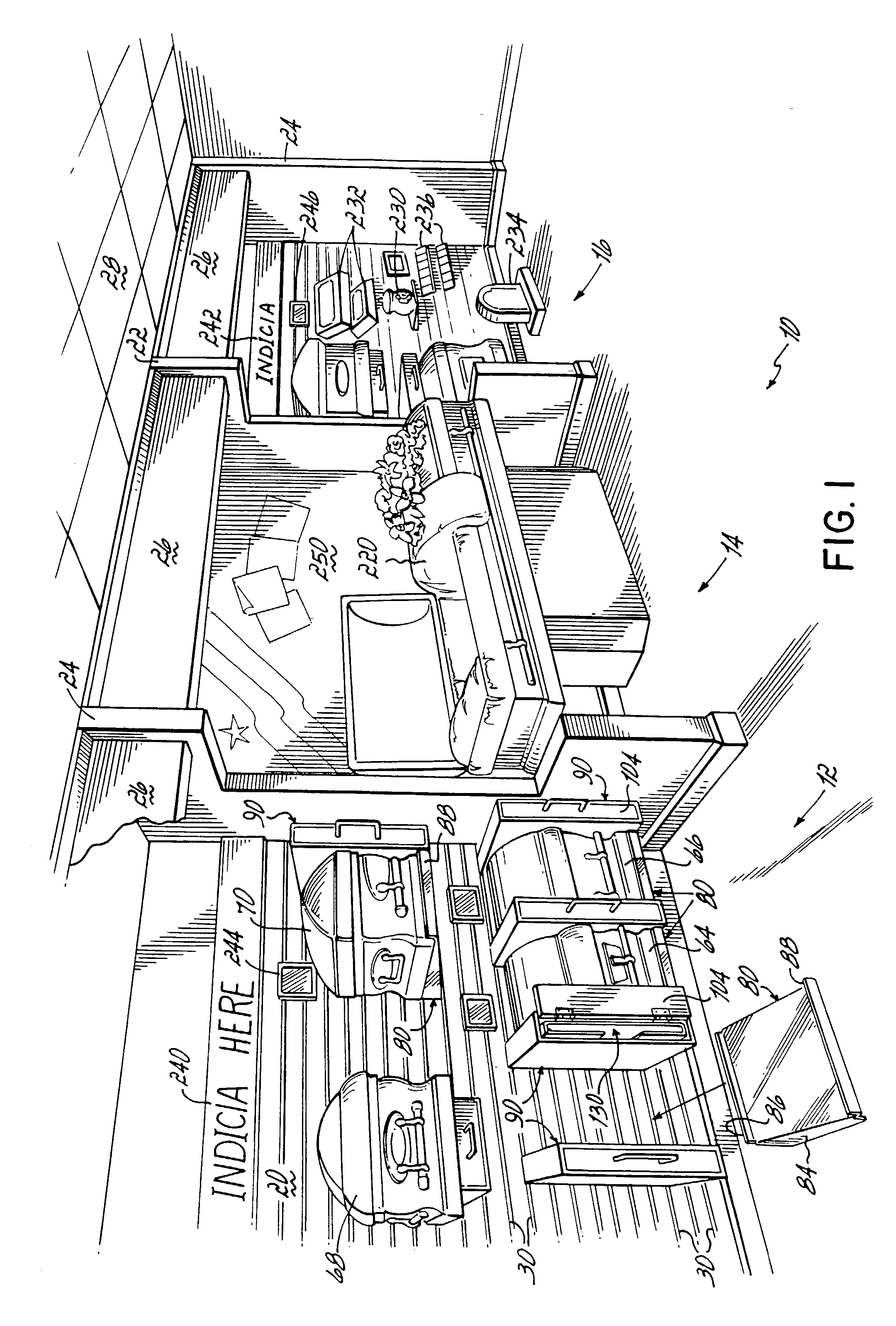

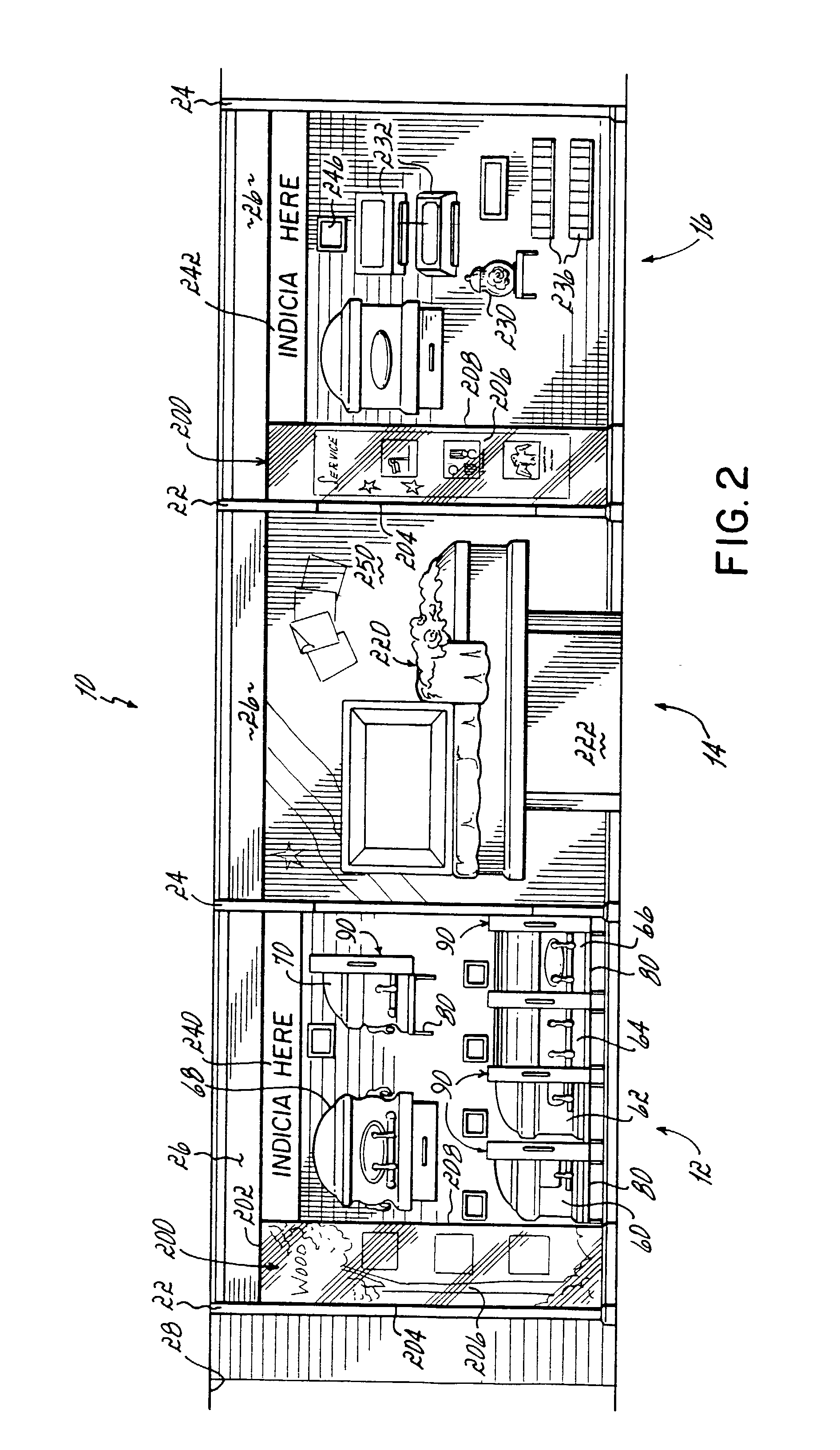

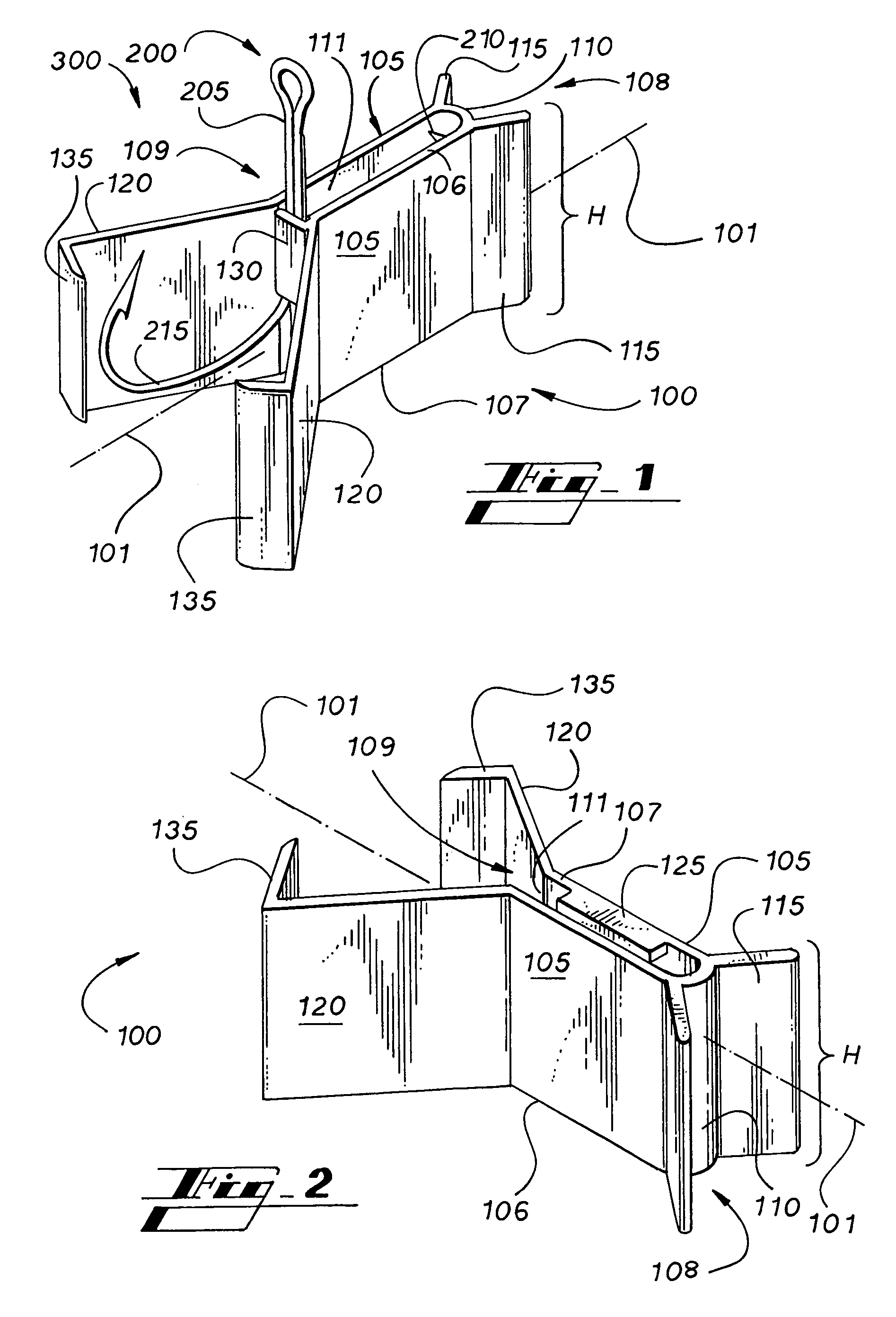

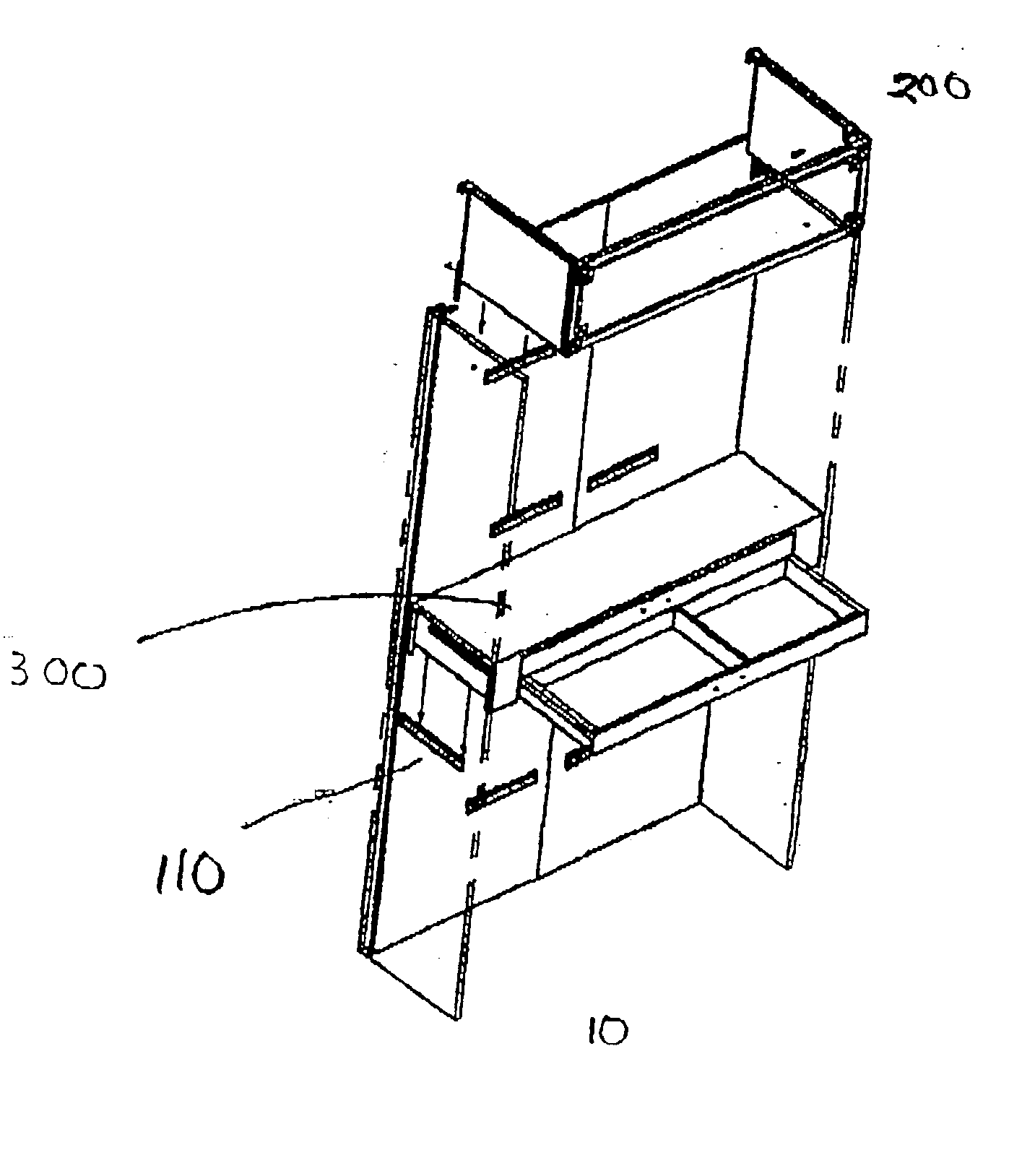

Integrated display system for death care merchandise

InactiveUS6145671ADetail of the adornments is not diminishedKitchen equipmentFolding cabinetsWing wall

A death care merchandise display unit maximizes the display of miniature death care merchandise products. The display unit has two vertical, parallel, spaced wing wall panels and a vertical back wall having lateral edges secured to the rear edges of the wing wall panels. Fixtures for holding miniature replicas of various death care merchandise articles are adfixed to the wall panels and the vertical back walls. One or more display surfaces are preferably further contained within the display unit.

Owner:MATTHEWS INT CORP

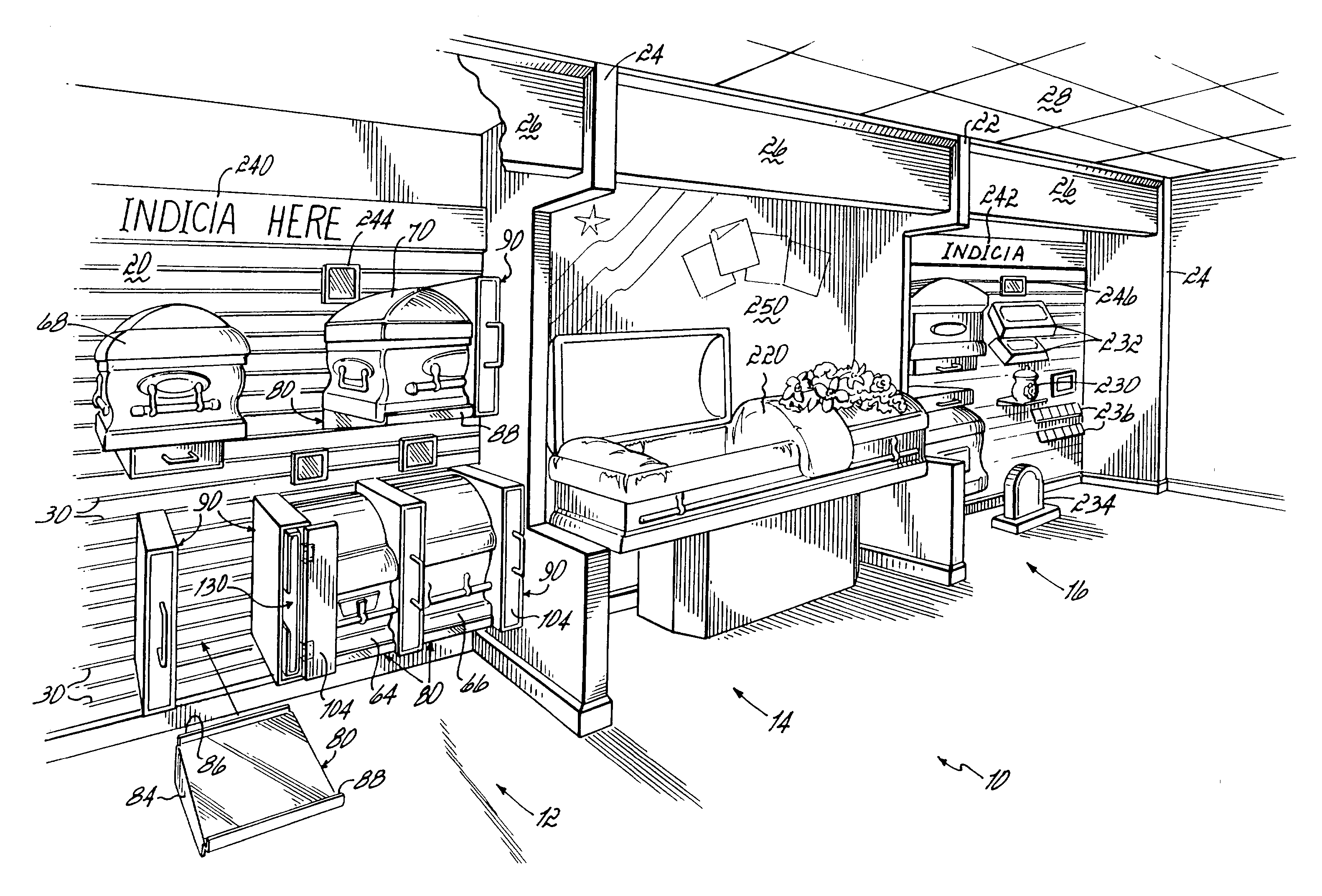

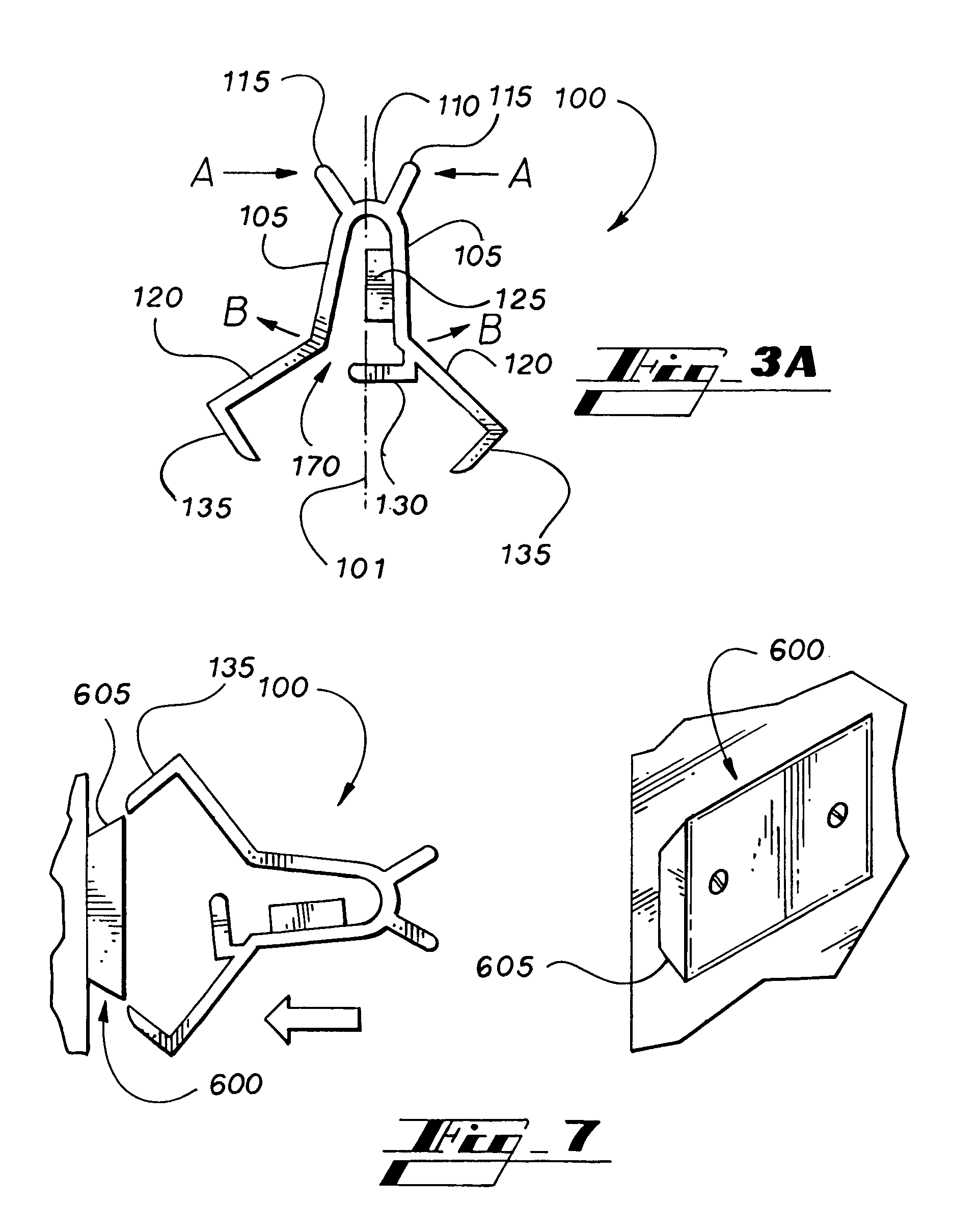

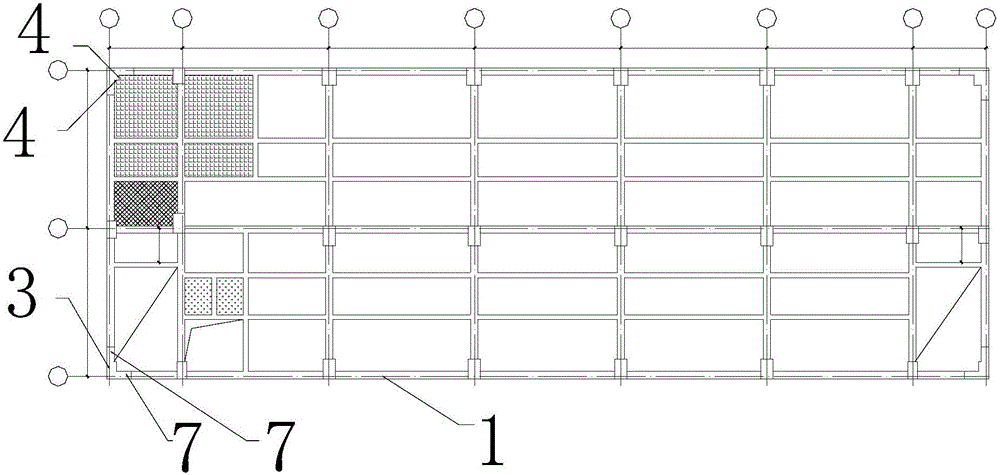

Display for a casket selection and/or viewing room

InactiveUS7036196B2High densityWithout compromising pleasing look and feelKitchen equipmentCoffinsDisplay deviceEngineering

A selection room display facilitates a casket selection by a customer of a funeral home. The display includes a vertical back wall and a pair of vertical, spaced apart wing walls cooperating with the back wall to form an alcove. A plurality of casket portions are displayed in the alcove. A vertical signage column may be positioned in the alcove. Information modules are also displayed in the alcove. The modules correspond to the casket portions. The casket portions are supported on shelves which are removably secured to the back wall. The information modules are similarly removably secured to the back wall. The display may incorporate “themes” to feature the various casket choices. The theme technique may also be utilized in the funeral home viewing room.

Owner:BATESVILLE SERVICES

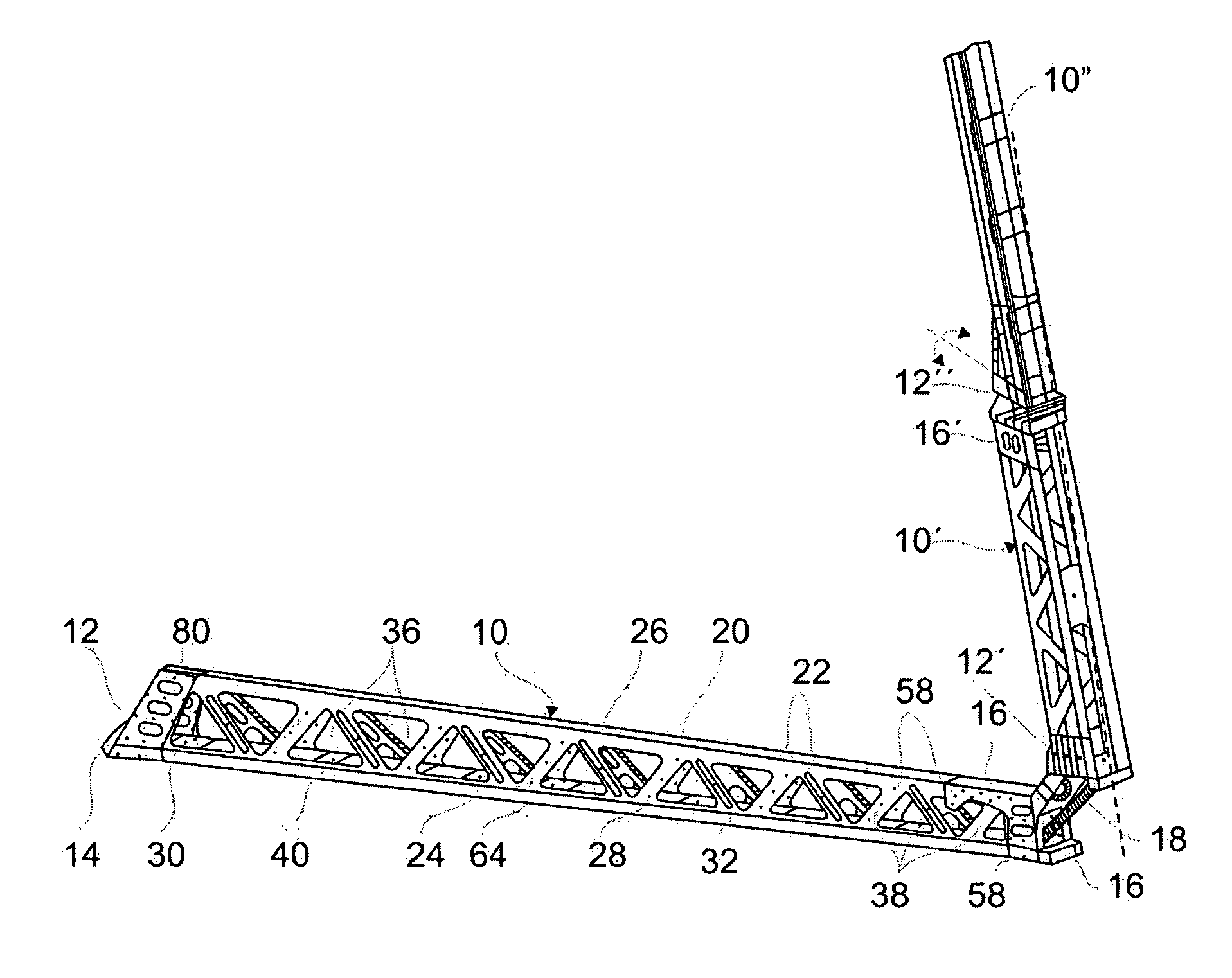

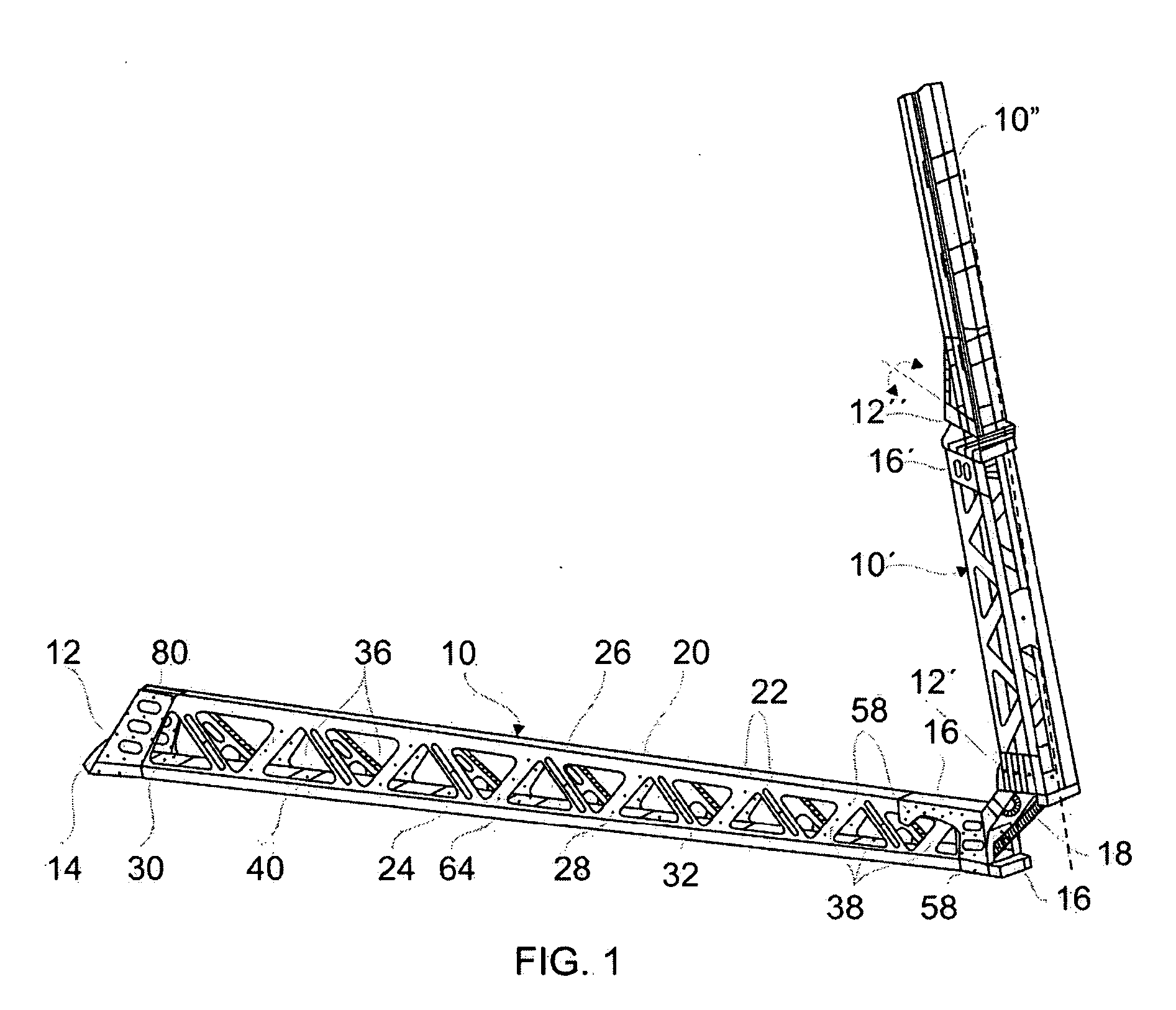

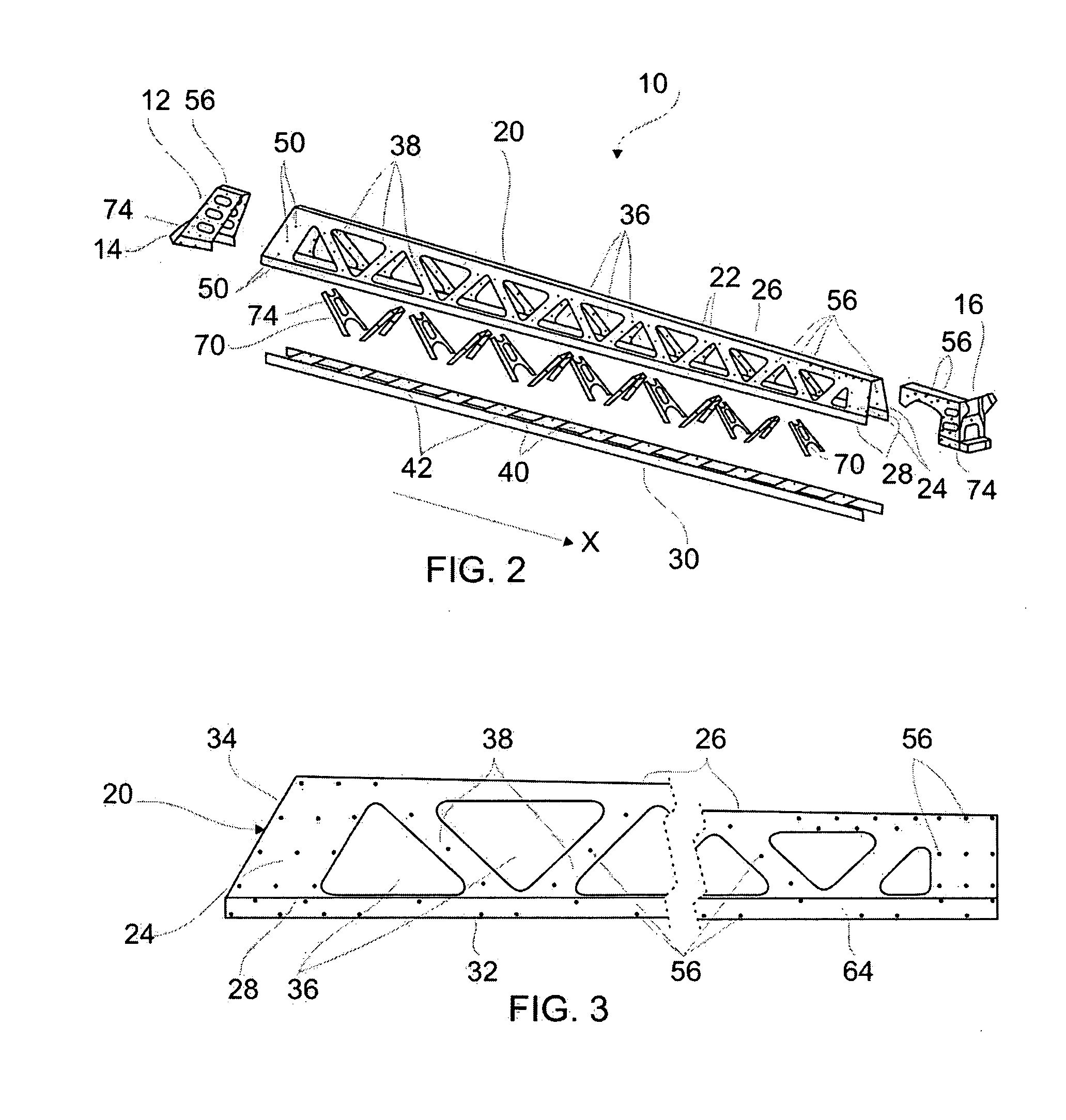

Agricultural sprayer boom and method of manufacture

Sprayer boom beam structure includes a girder member having an elongated profiled sheet structure including at least two folds or bends defining three portions in an inverted V- or U- or C-shaped cross-section, i.e. a pair of side or wing walls integrally joined by a top or bridge wall. Triangular orifices are punched out of the side walls, alongside one another in a longitudinal direction, alternating between inverted and upright triangles, leaving inclined strips of sheet material in between, and which absorb and transmit strains and stresses similar to a tubular lattice structure, and having benefits of a spatial lattice-like structure. Complementary beam members include a base plate joining longitudinal edges of sidewalls of the profiled member and close the open face of the profiled member, forming a sturdy box-like structure, and internal cross-platelets joined to inclined strips of the profiled-member sidewalls to further rigidify the beam structure.

Owner:CAIMAN SOC DE RESPONSABILIDAD

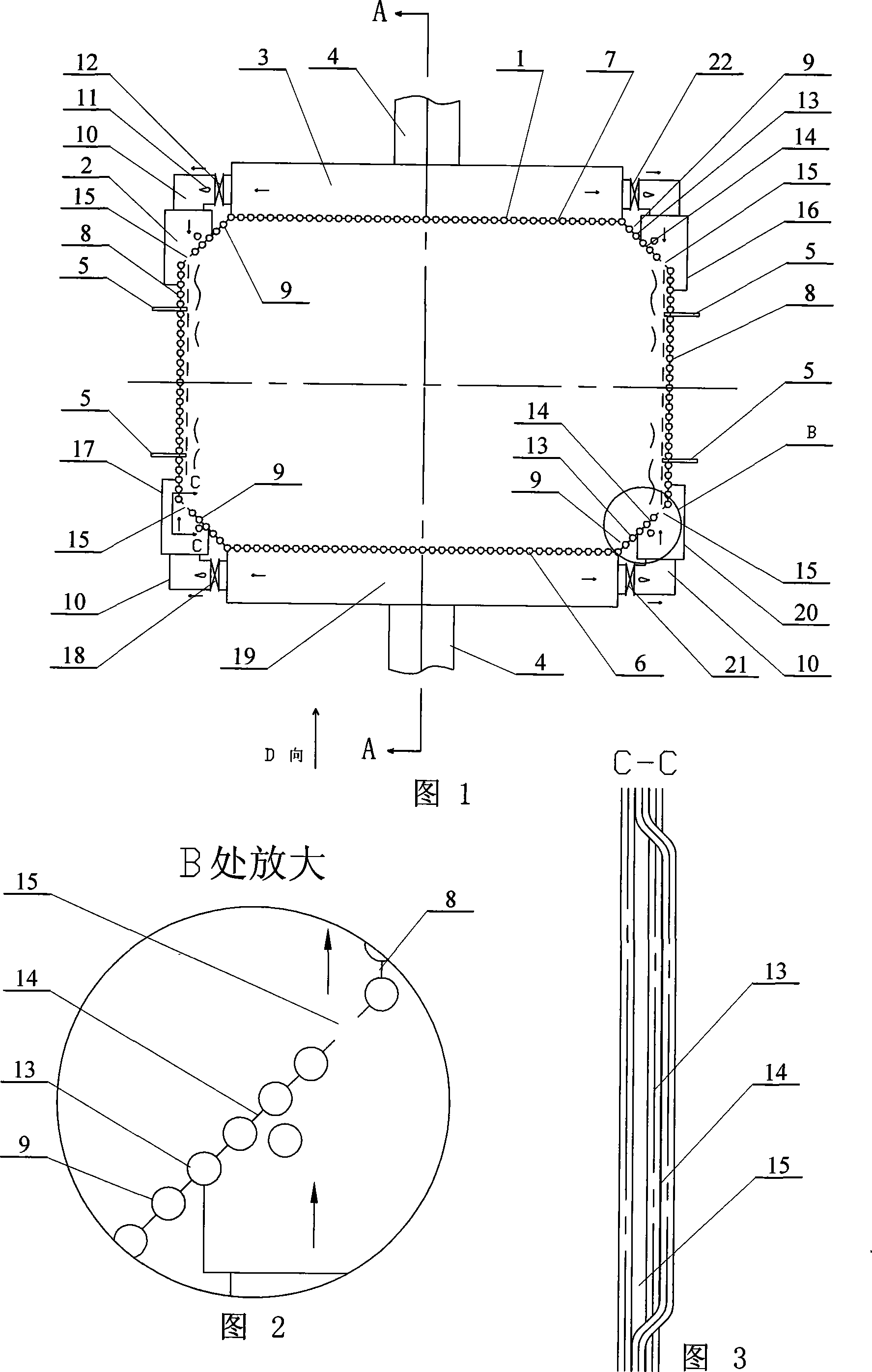

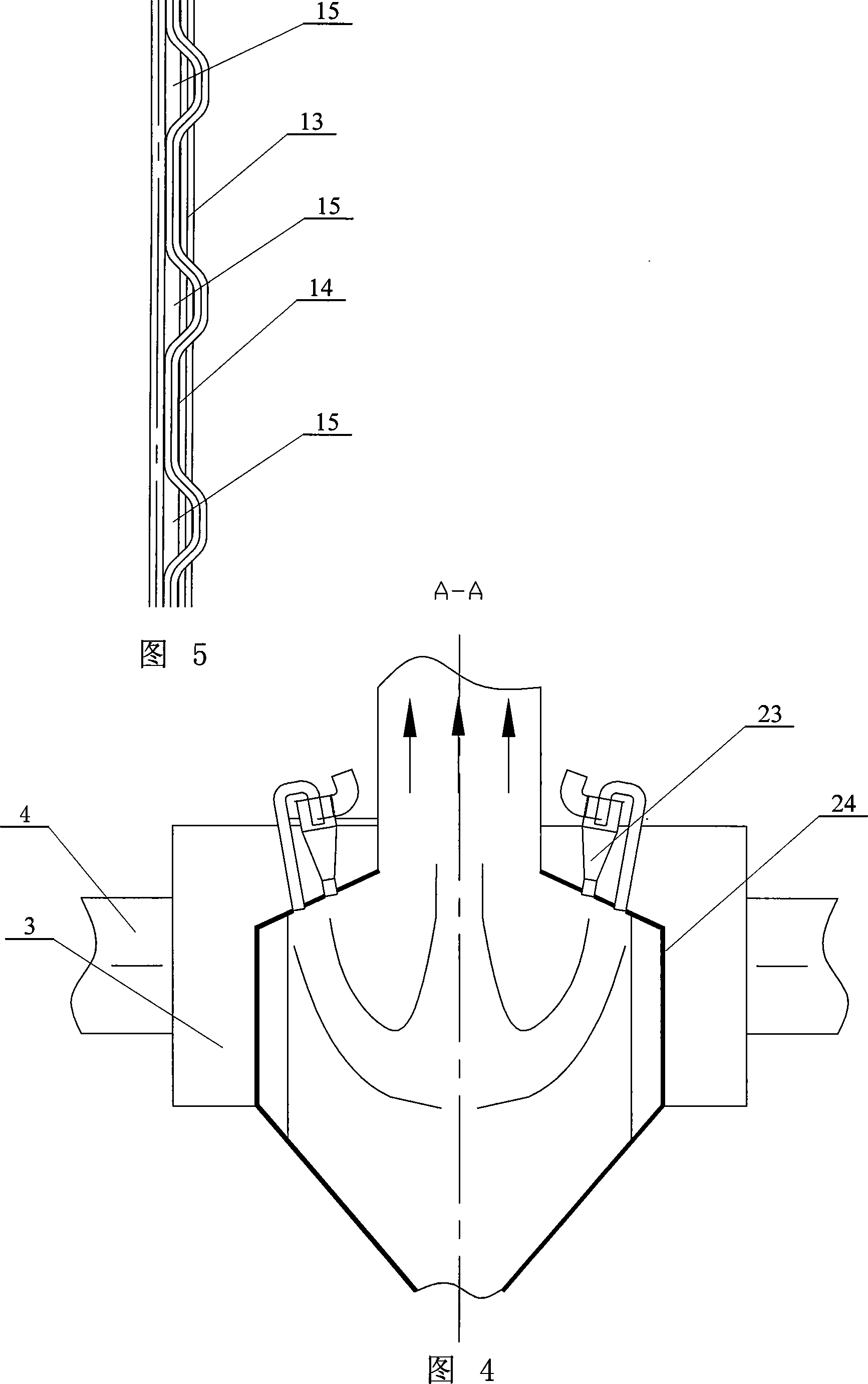

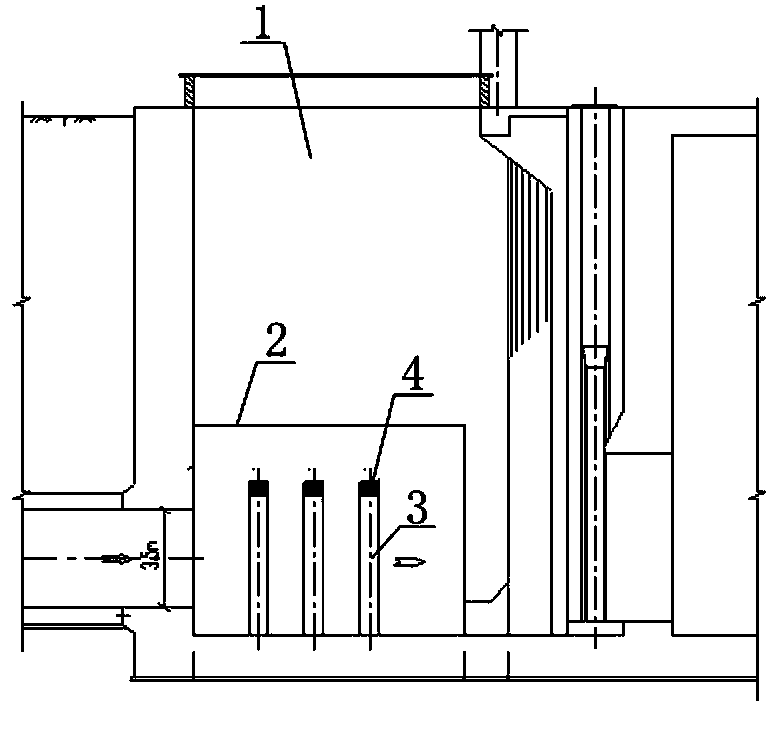

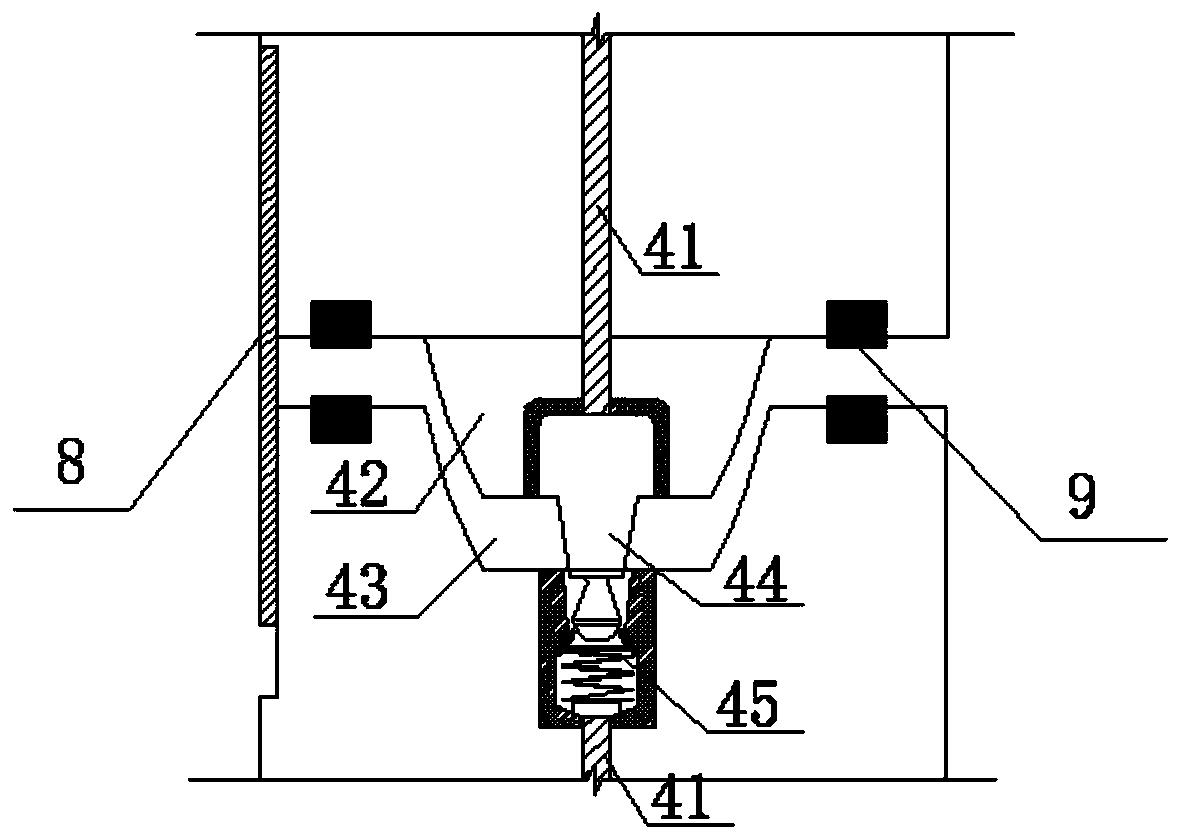

W-shape flame boiler for preventing side wall water cooling wall slagging scorification

ActiveCN101050854AAccelerated slagging problemReduce the temperatureSteam boilersCombustion chambersScarificationWing wall

A W type of flame boiler enabling to prevent water-cooled wall of wing walls from slagging scarification is prepared for setting four wall-wind fans separately on external sides of four wing walls and arranging ventilation gap on each of four wing walls.

Owner:HARBIN INST OF TECH

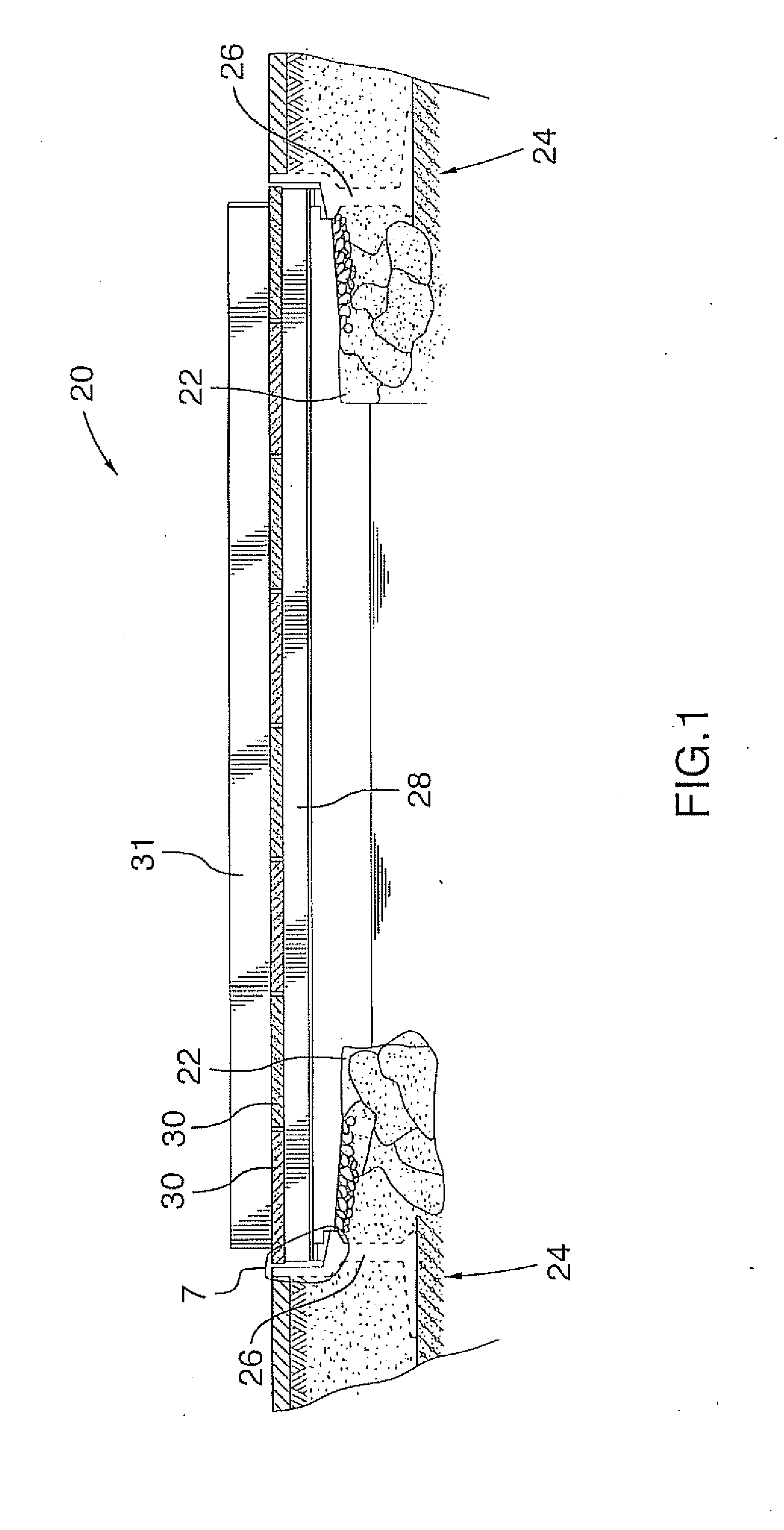

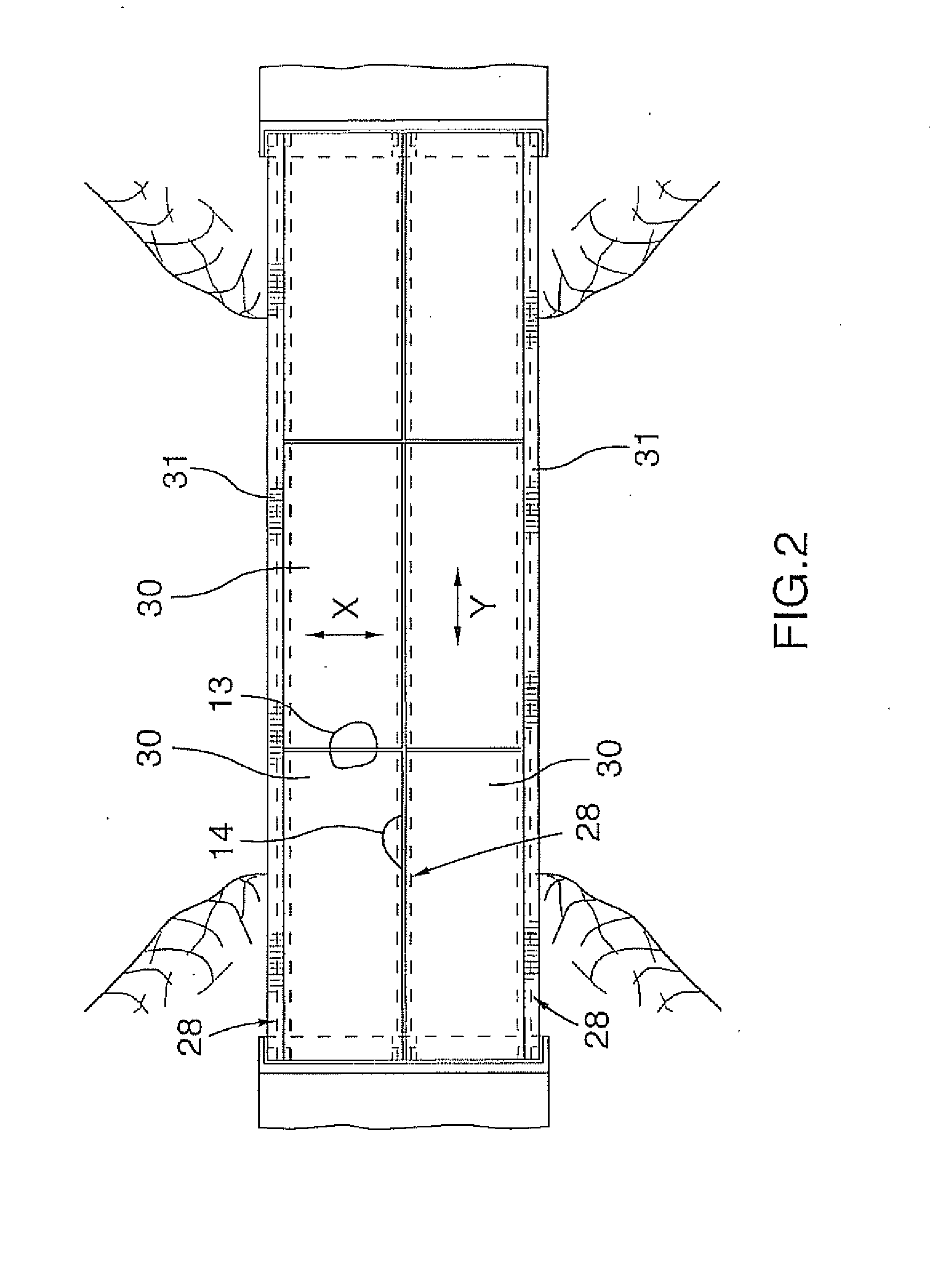

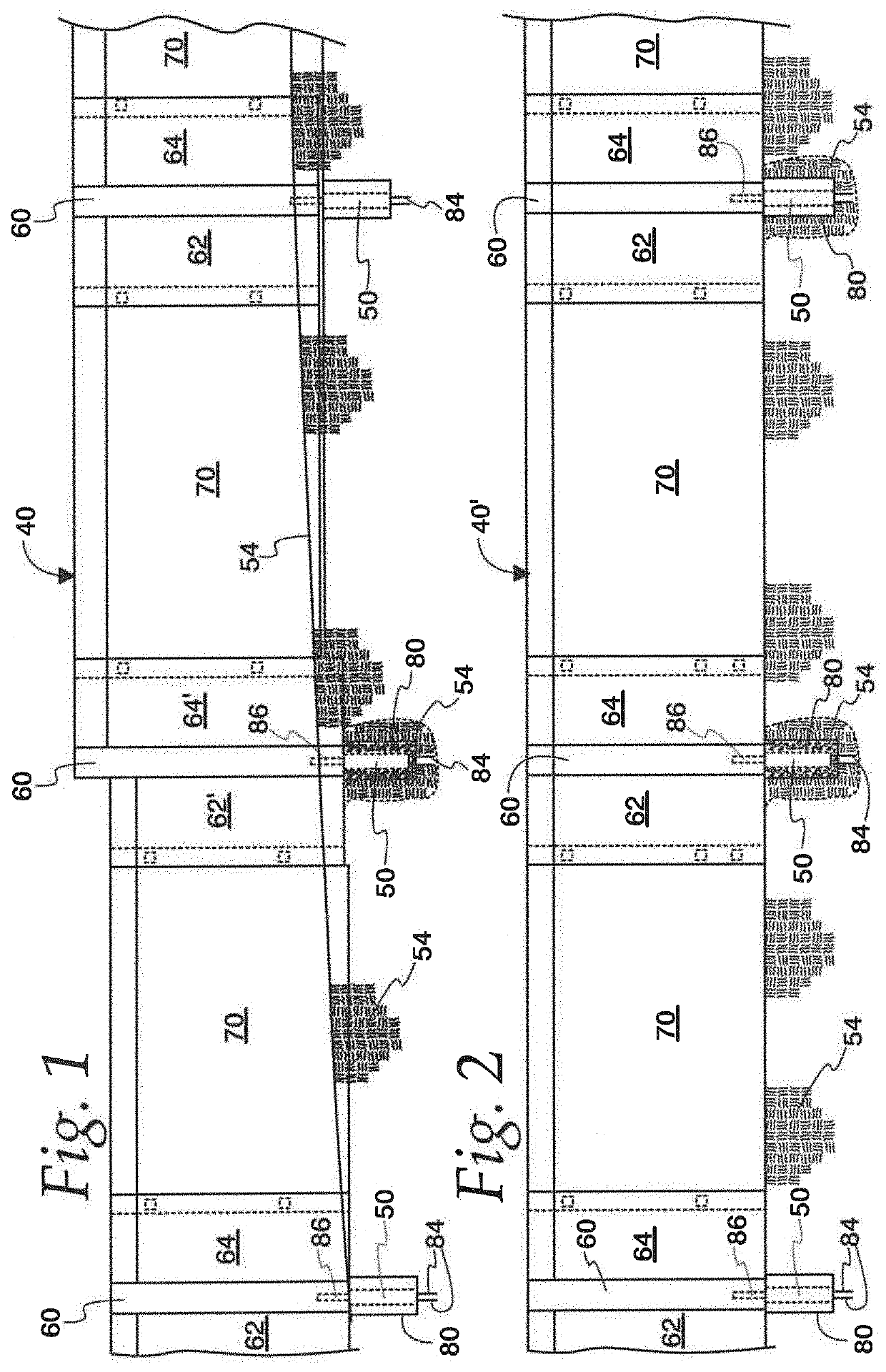

Bridge construction and method of replacing bridges

InactiveUS20110219554A1Reduce camberIncrease arcBridge structural detailsBridge erection/assemblyAbutmentReplacement method

A bridge replacement method is disclosed. The bridge includes a deck supported by a pair of abutments, each abutment having wing walls. The deck is removed, footings are cast in holes dug behind each abutment and a pier is provided on each footing. Substantially parallel and coplanar cambered beams are provided. Each beam spans between and is supported by the piers. A brace assembly reinforces the beam camber. On each adjacent pair of beams, precast deck elements are placed, such that each element of said plurality spans the beam pair, to define at least transverse gaps between the elements and put the upper surfaces of the elements in compression in a transverse direction. The gaps are grouted. After grout curing, the brace is adjusted to reduce the beam camber and cause the upper surface of the elements to also be put into compression in a direction parallel to the beams.

Owner:NEWTON BRIDGE SOLUTIONS

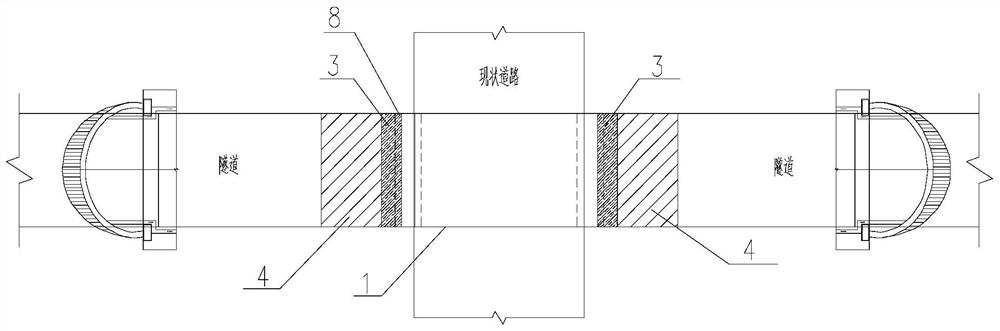

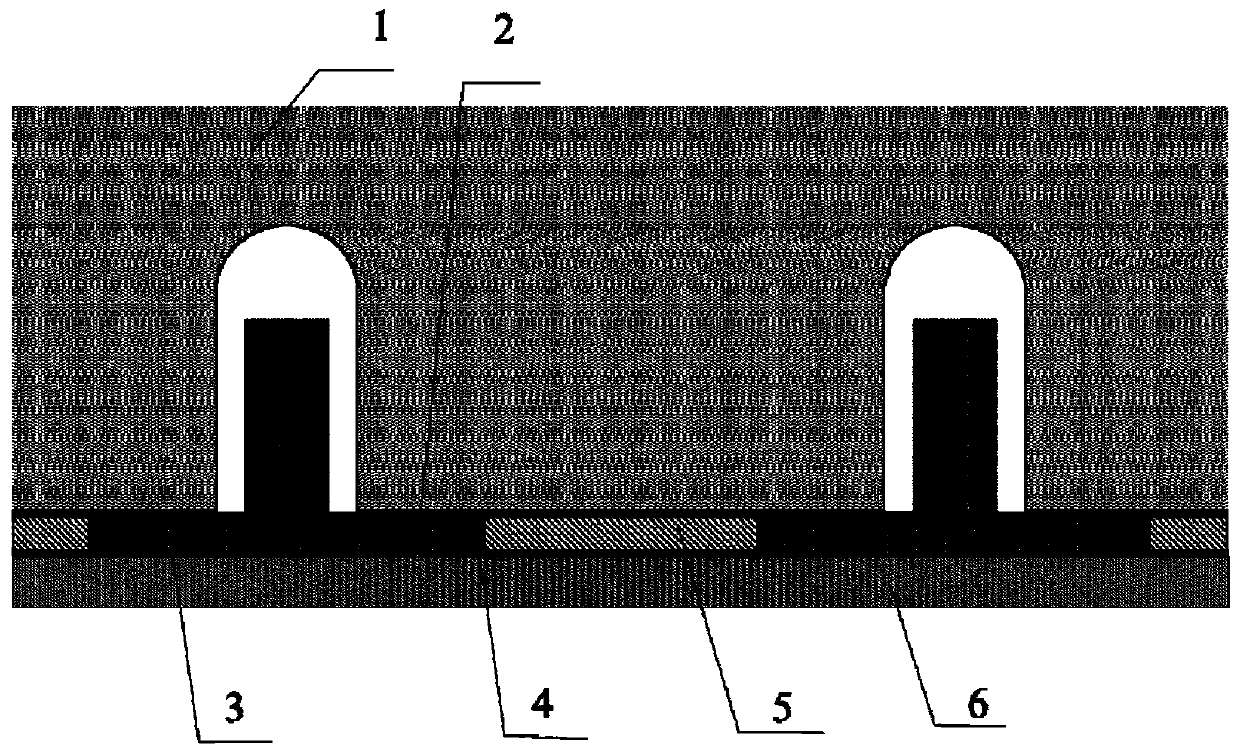

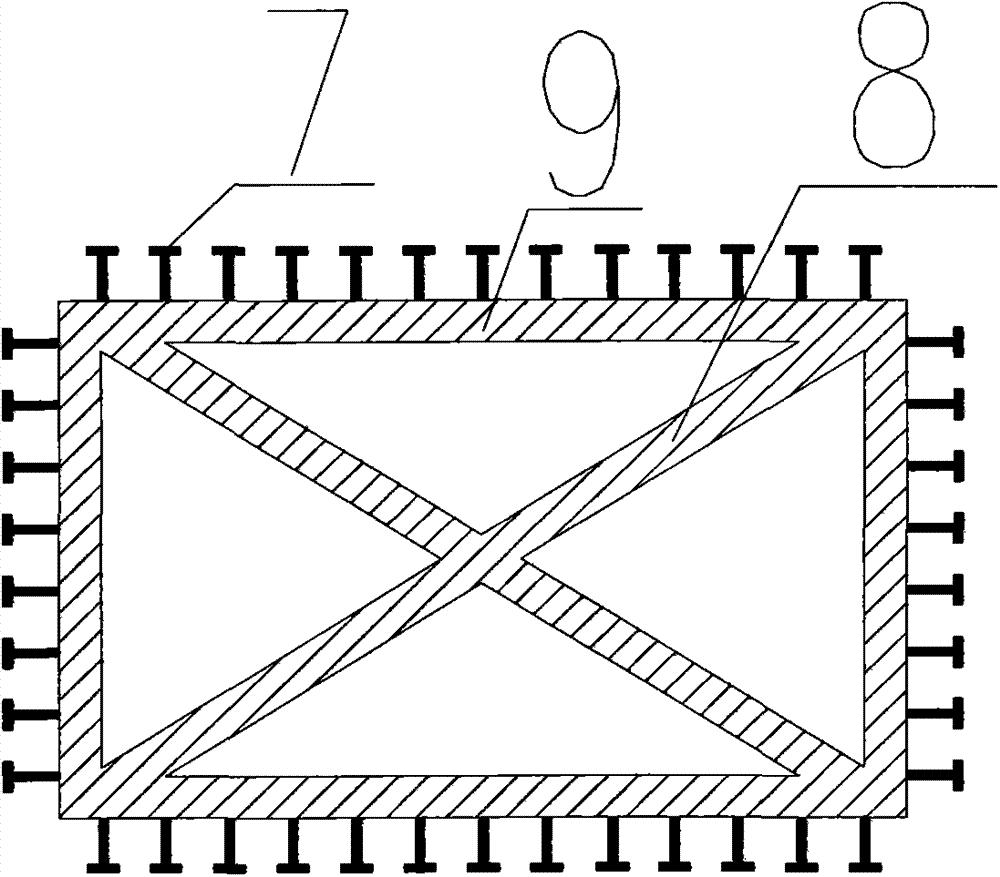

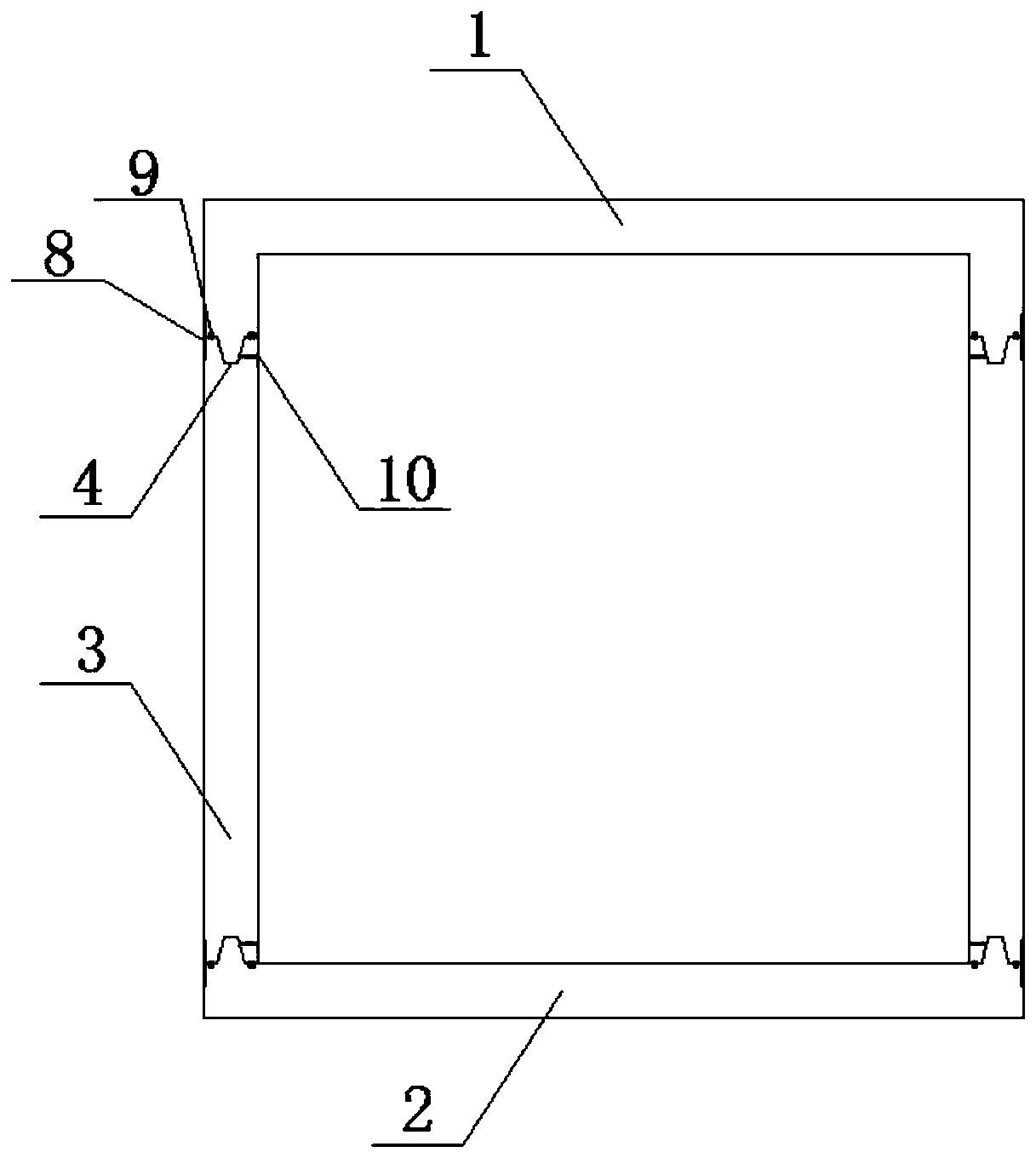

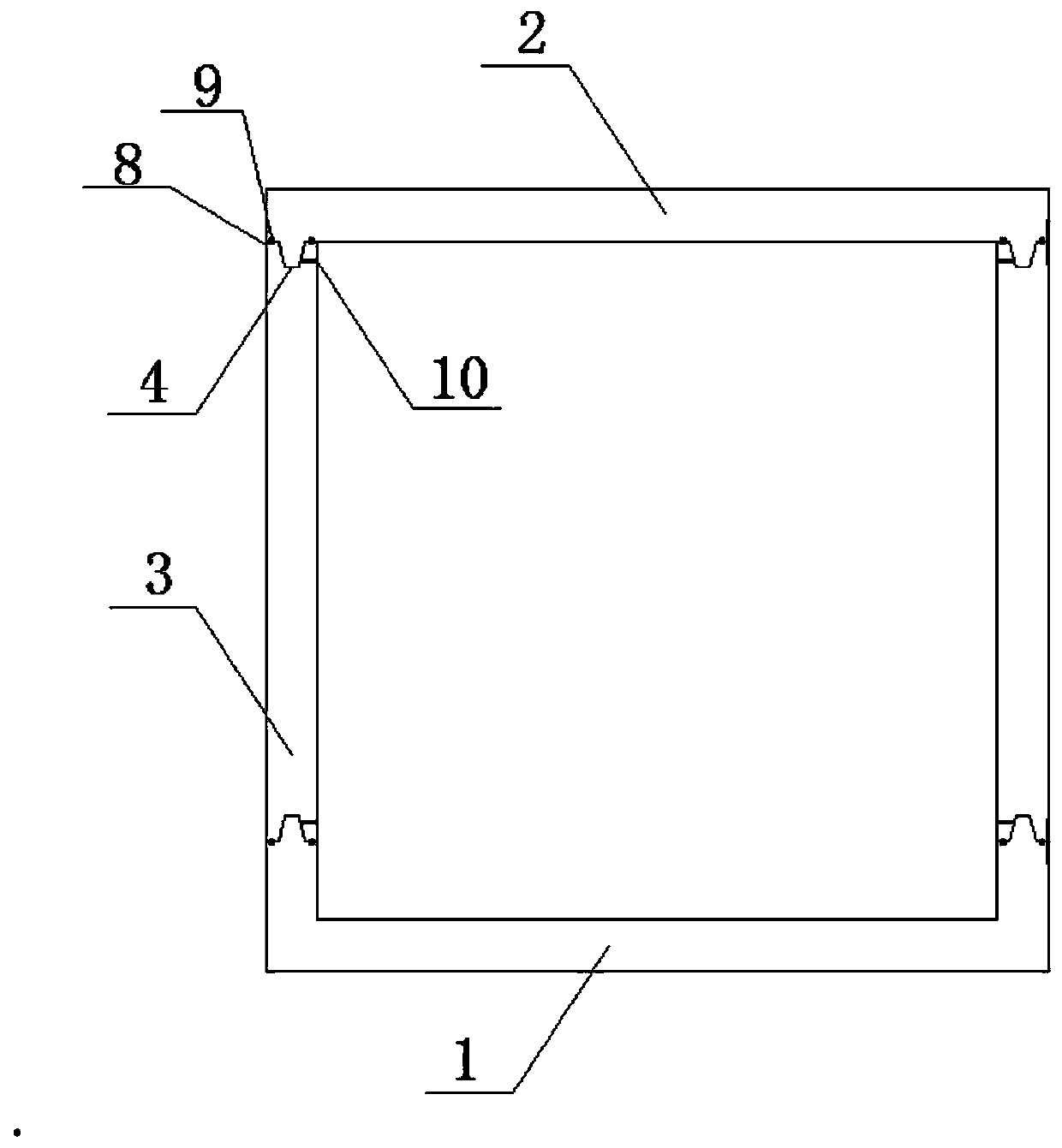

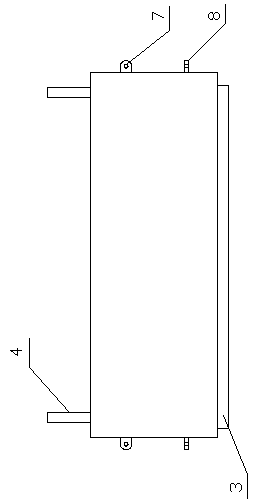

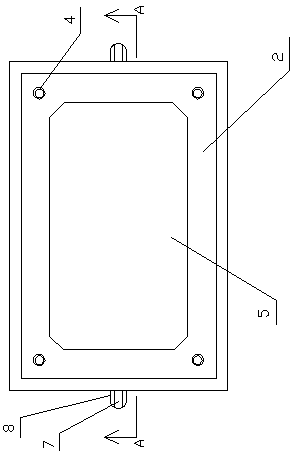

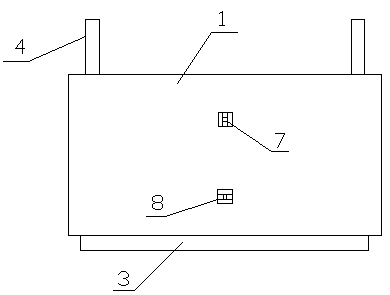

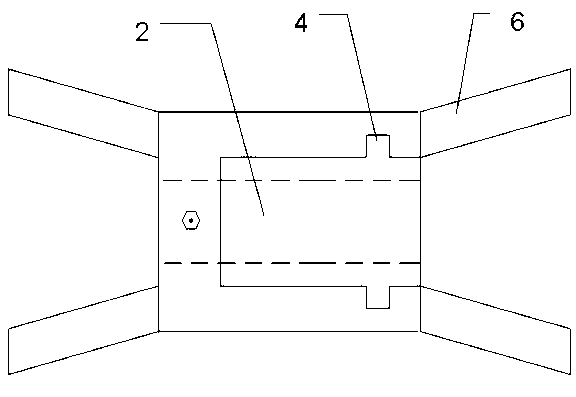

Prefabricated assembled box culvert and construction method thereof

InactiveCN102418319AImprove construction progressQuality assuranceGround-workRc framesArchitectural engineering

The invention discloses a prefabricated assembled box culvert and a construction method thereof. The box culvert is in an assembled structure and consists of a reinforced concrete culvert body, wing walls, a foundation and deformation joints, wherein the culvert body of the box culvert is in an integral closed-type reinforced concrete framework structure formed by combining transition culvert joints, non-standard culvert joints and standard culvert joints. The culvert body and the wing walls adopt assembly and construction. By utilizing the prefabricated assembled box culvert, batch production can be performed in a factory, field assembly is realized, the construction progress of the culvert is accelerated, the construction period is shortened and the quality of the culvert is ensured. Therefore, the problems of long culvert construction period and difficult control on the quality during the current road construction can be solved.

Owner:新疆交通科学研究院有限责任公司

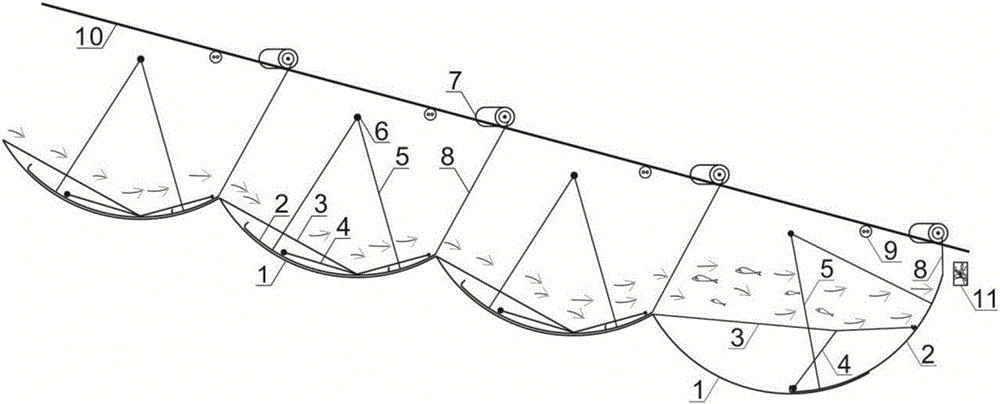

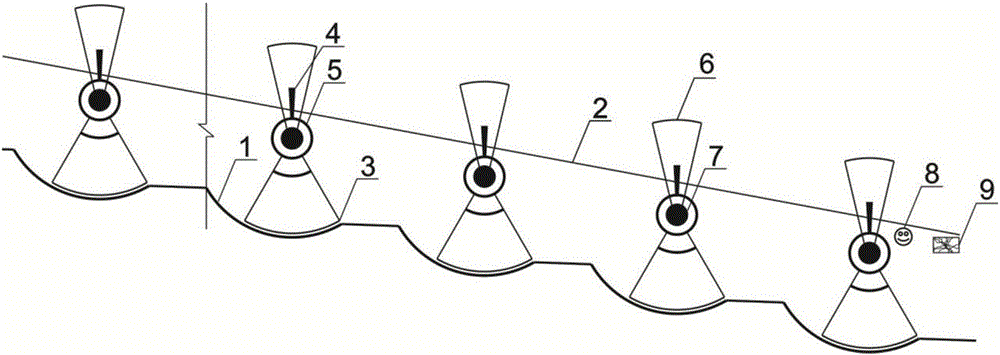

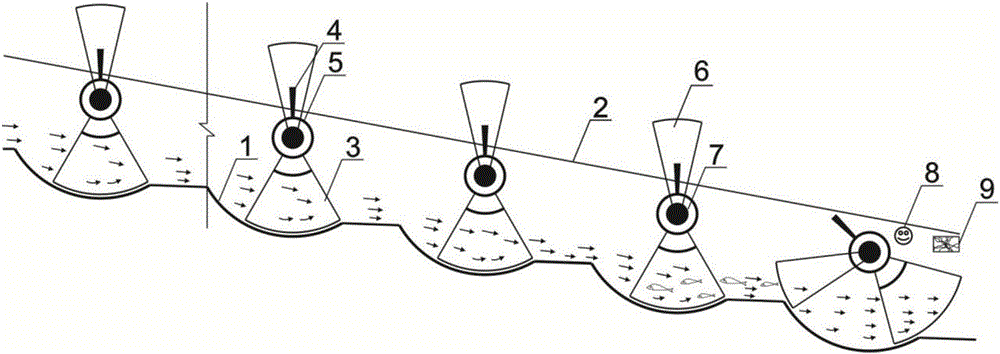

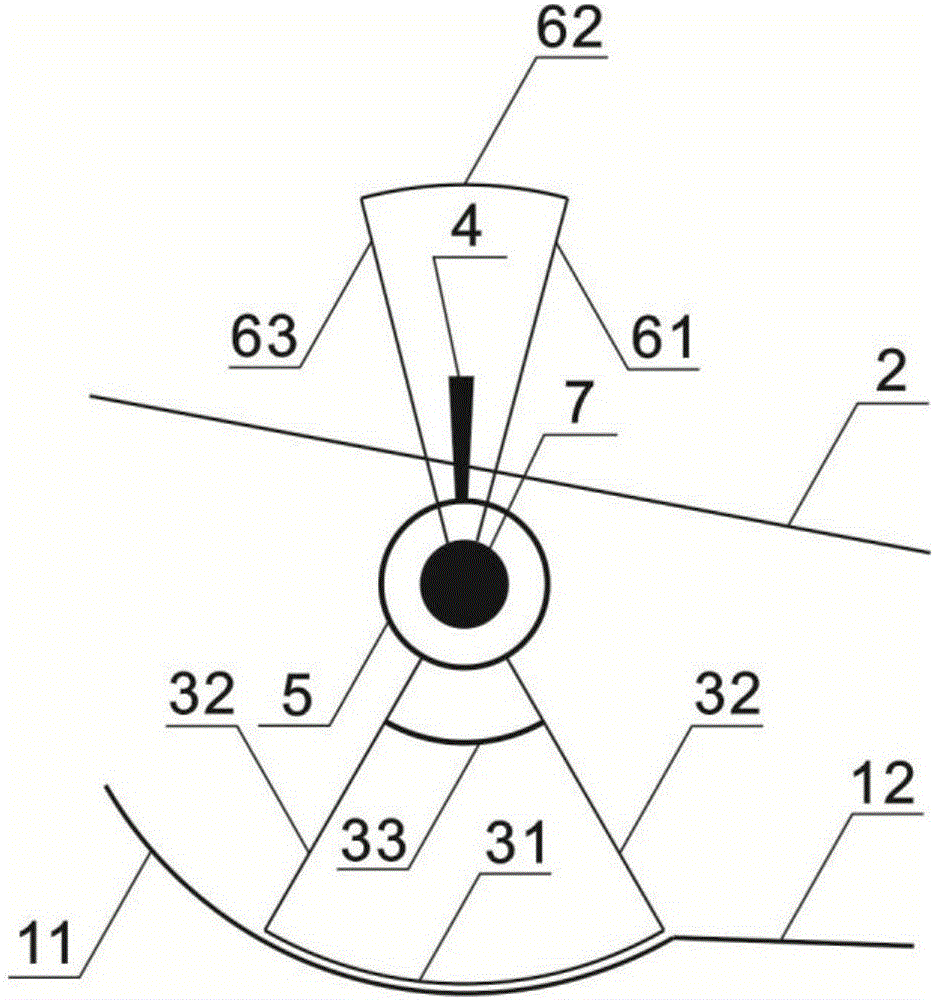

Multi-stage superimposed arc type fish passage and fish passing method

ActiveCN106702979AConducive to traceReduce flow bottom slopeBarrages/weirsClimate change adaptationWing wallEcological environment

Owner:ANHUI UNIV OF SCI & TECH

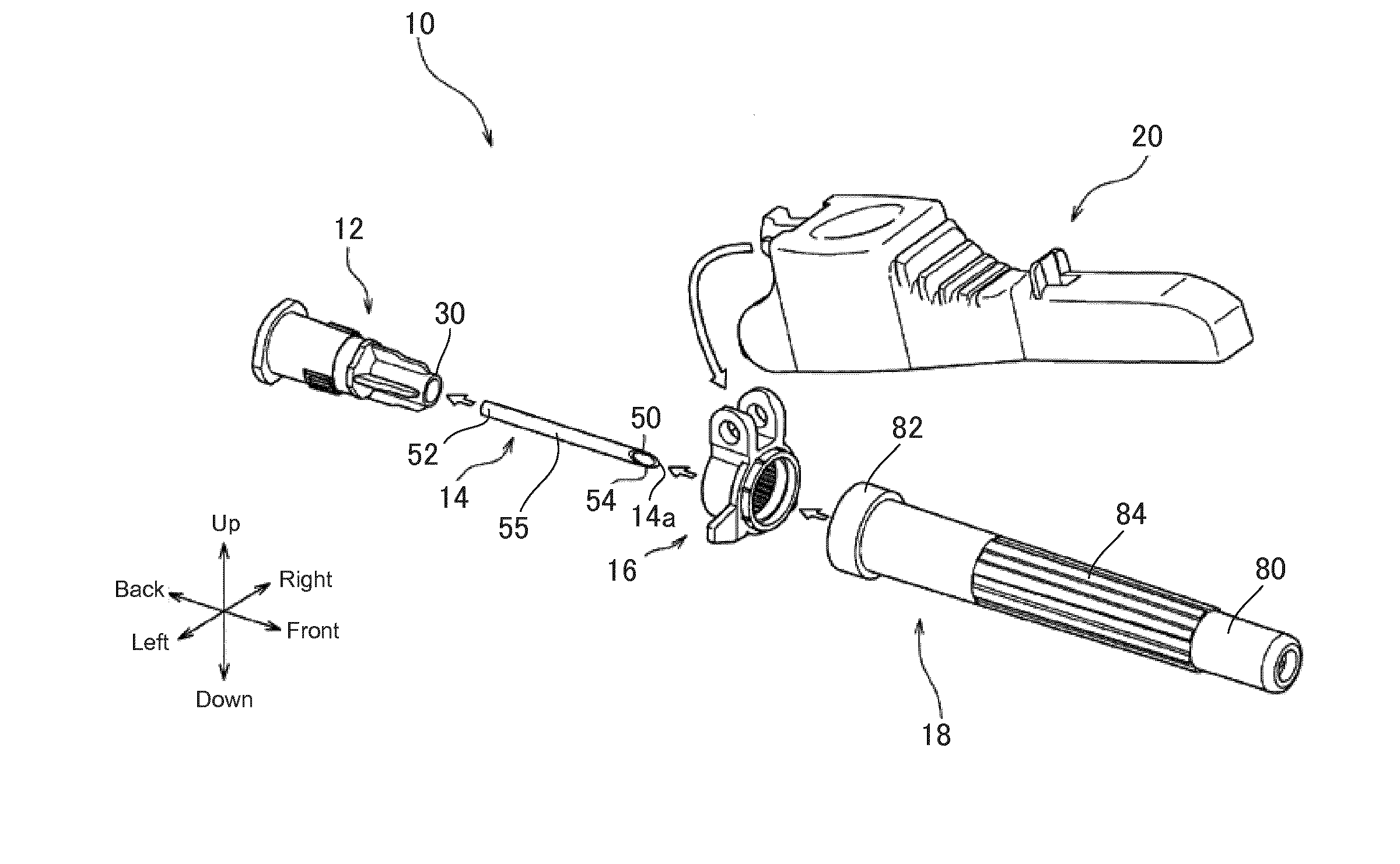

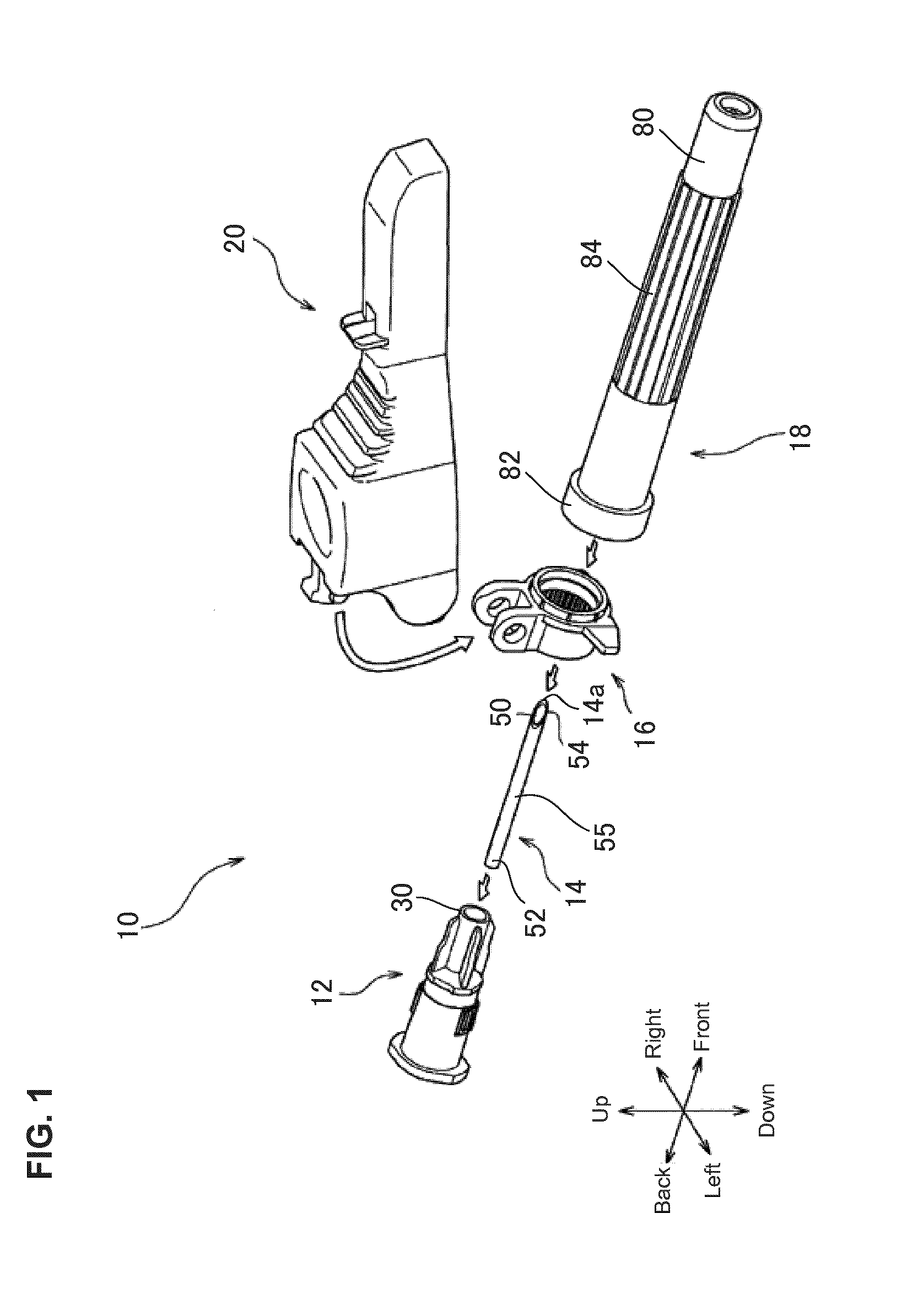

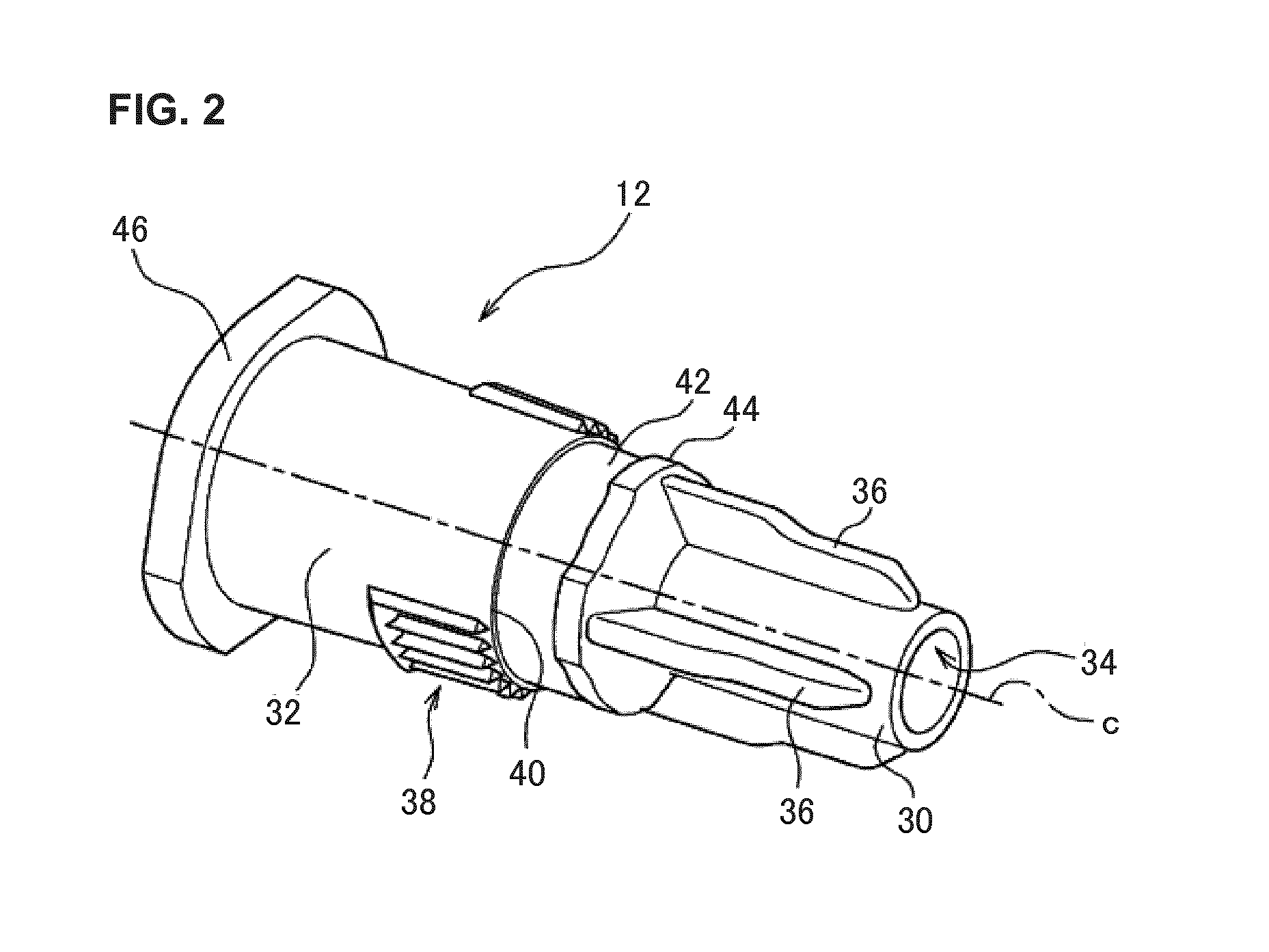

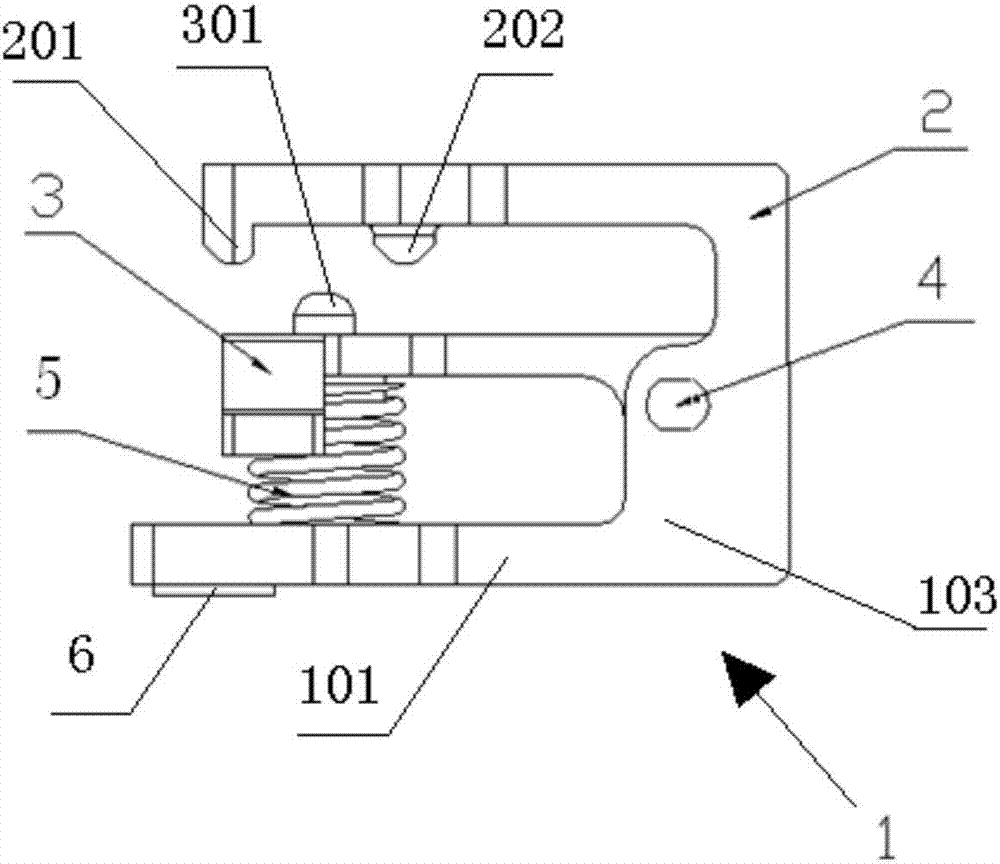

Safety needle assembly

InactiveUS20160220766A1Avoid reliabilitySafe and reliableMedical devicesInfusion needlesBiomedical engineeringWing wall

A safety needle assembly includes a hub including a proximal end and a distal end, the proximal end being connectable to a syringe, a cannula, a collar, a protector, and a sheath sheath including an opening extending in a longitudinal direction along at least a part of the sheath, the opening being configured to house the cannula, a cannula fixing part configured to fix the cannula with respect to the sheath, the cannula fixing part comprising a plurality of wing walls extending in a longitudinal direction along at least a part of the sheath; an attachment part configured to rotatably support the sheath with respect to the collar such that the attachment part is rotatable to a position at which the cannula is housed in the opening of the sheath; and a guide rib including a locking protrusion configured to lock the cannula inside the opening.

Owner:TERUMO KK

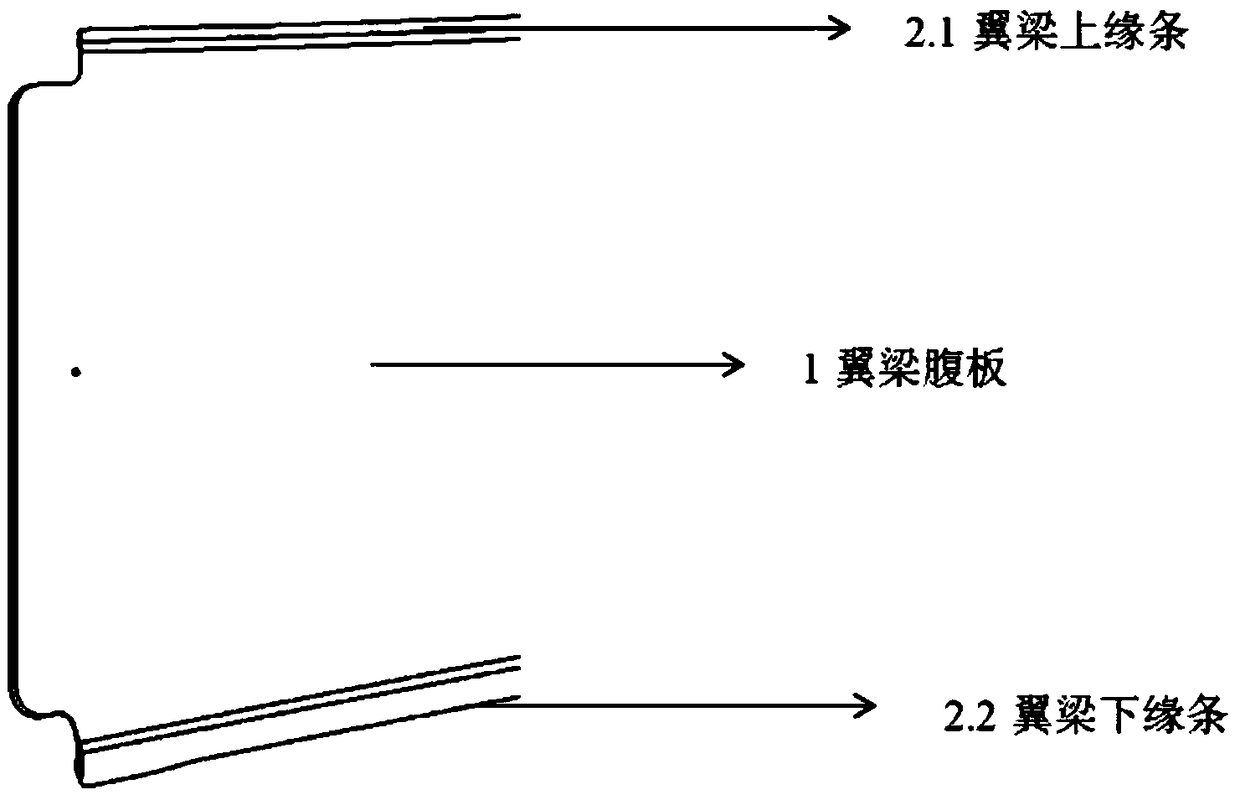

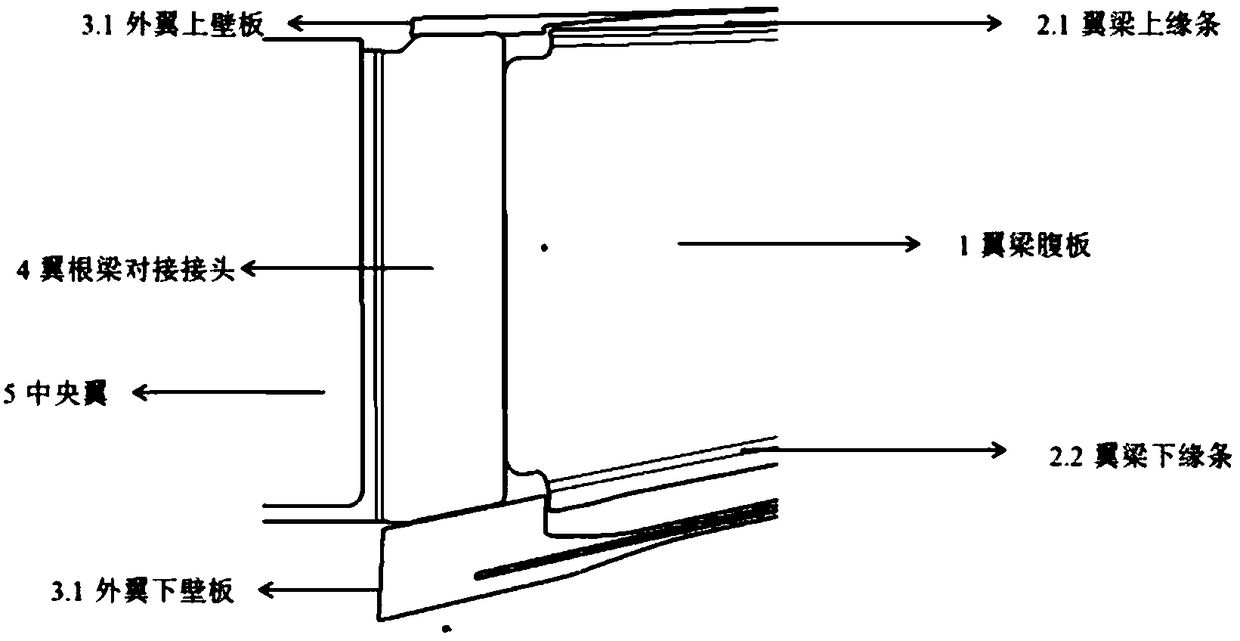

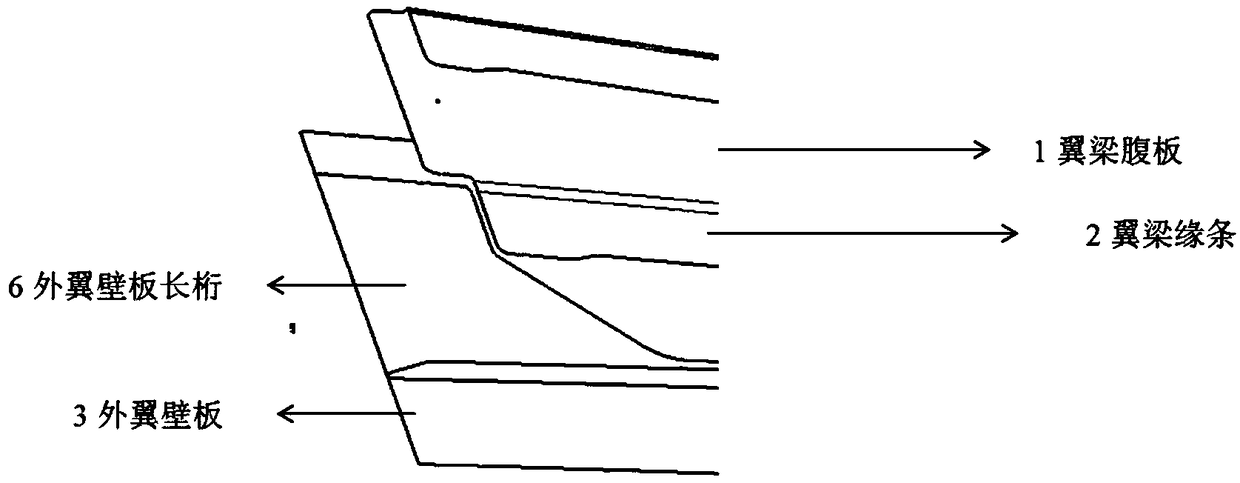

Aircraft composite material wing spar and wing butt zone connection structure

ActiveCN109484624ASimplify the power transmission pathSimplify efficiencySpars/stringersStress concentrationFiber

The invention provides an aircraft composite material wing spar and wing butt zone connection structure. In the structure, a wing spar has a C-type configuration, and is formed by a spar web, a spar upper flange and a spar lower flange; the composite material wing spar is prepared by adopting processes of manual pasting, automatic tape-laying with thermal diaphragm forming, automatic fiber-placement and the like; the wing spar is connected with an outer wing wall plate and a connection joint by adopting fastening parts; and the wing spar is arranged at the joint of a wing butt, is stopped in advance according to the butt joint requirement, is not directly butted with a wing butt, a wing rib or center wing spar, can be used for cutting an end socket to avoid stress concentration caused in avariable cross-section zone when load is transferred, and can perform fillet treatment on an edge zone.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

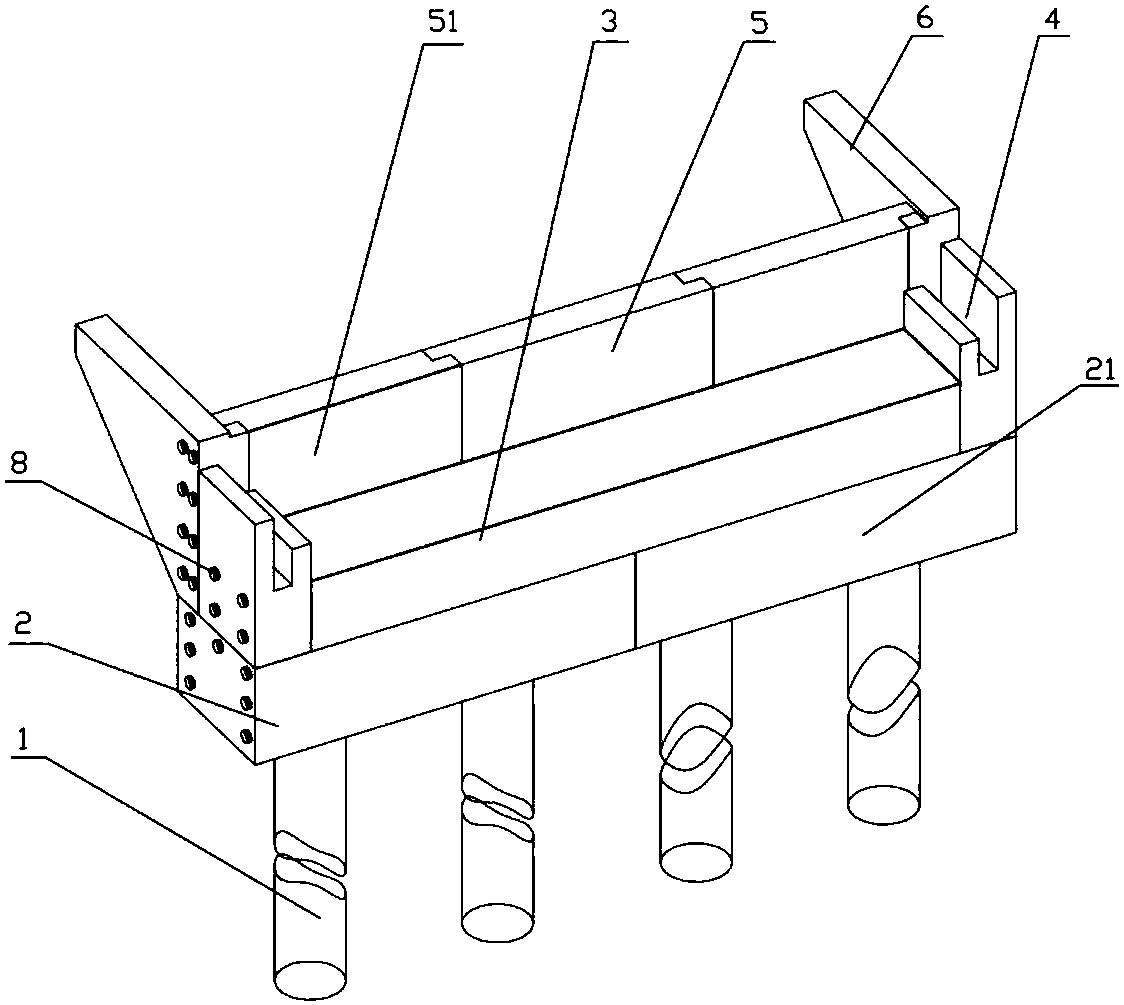

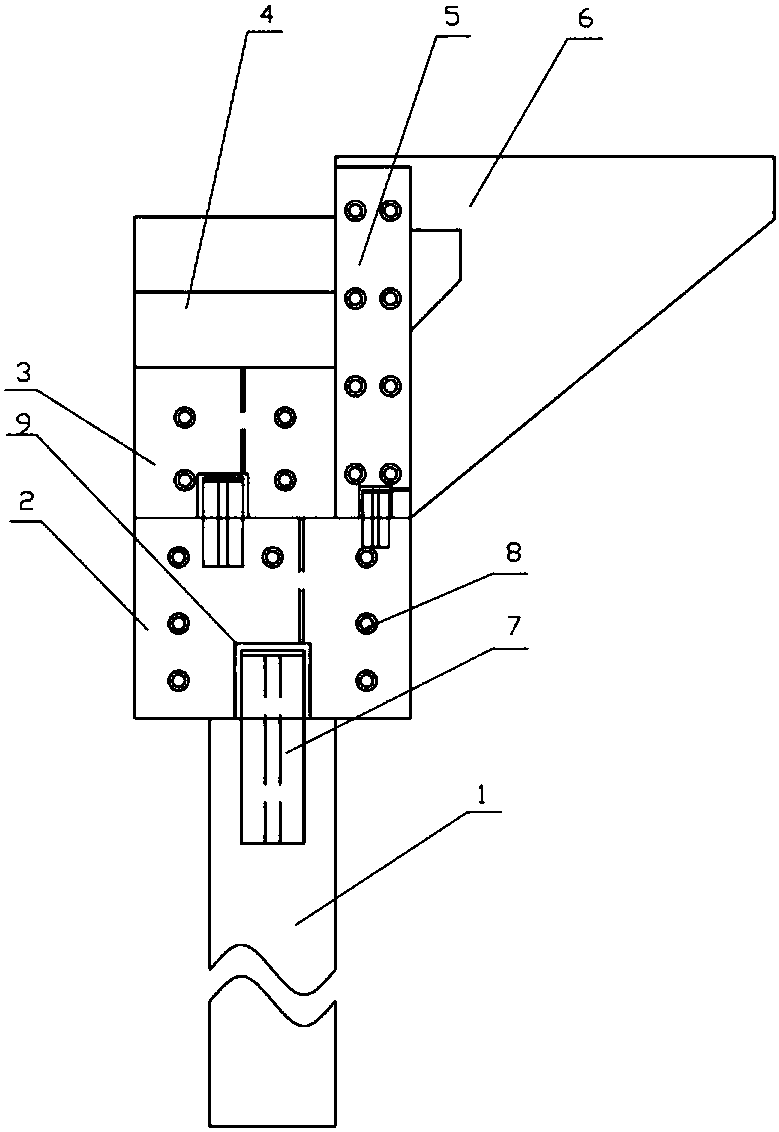

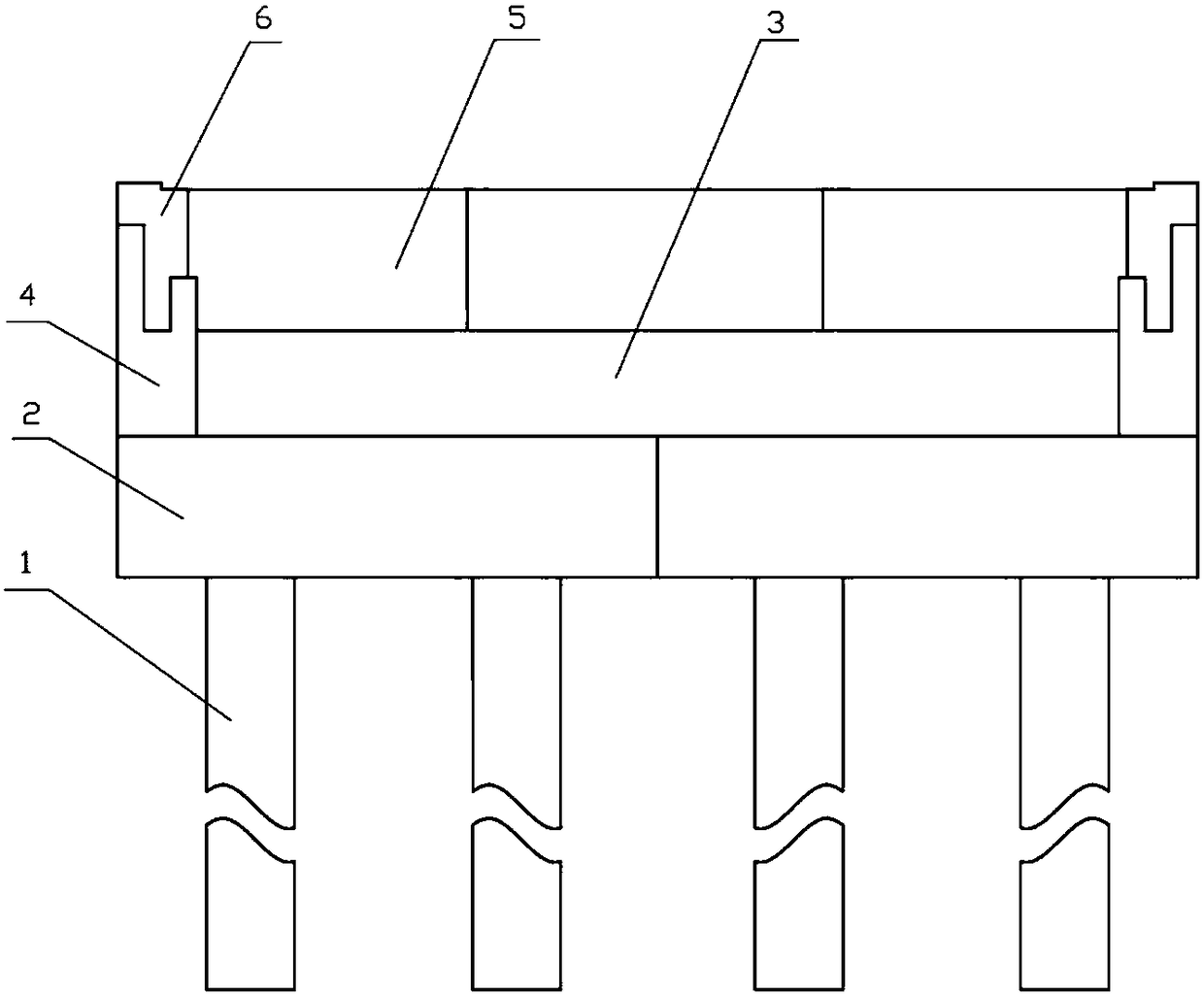

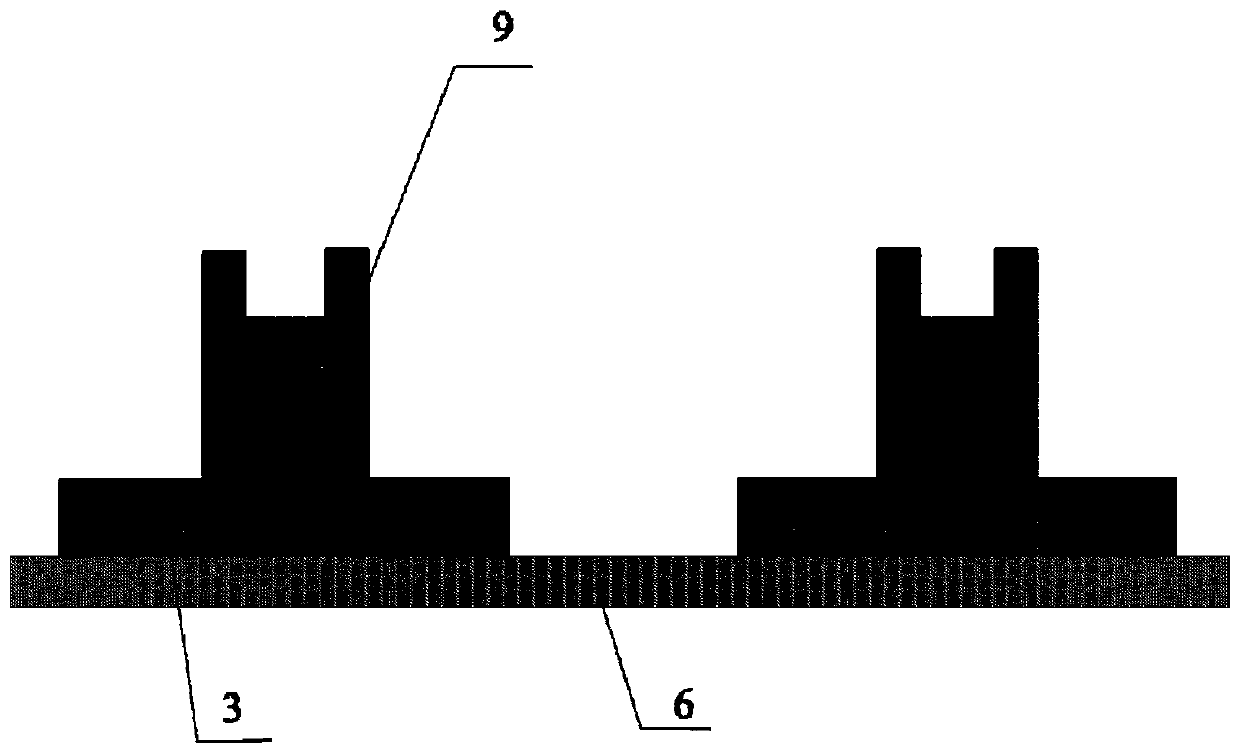

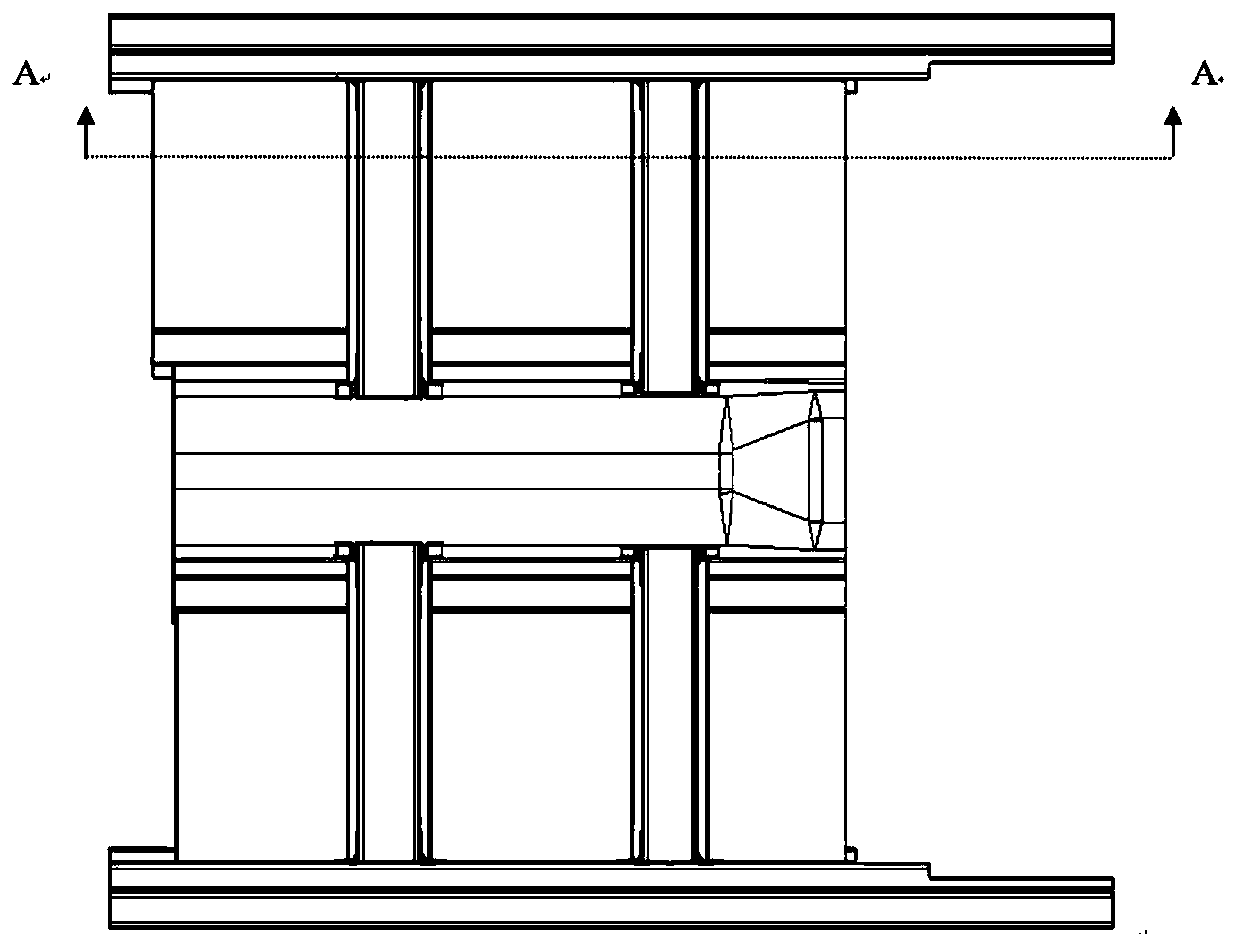

Fully assembled light abutment and construction method thereof

PendingCN108442239AHigh strengthLight weightBridge structural detailsBridge erection/assemblyPre stressAbutment

The invention discloses a fully assembled light abutment. The abutment comprises a pile foundation, a cushion cap, an abutment cap, double baffle blocks, a back wall bracket and a wing wall, the double baffle blocks are connected with the back wall bracket and installed on the cushion cap, the cushion cap, the abutment cap, the double baffle blocks, the back wall bracket and the wing wall are UHPCprefabricated components internally provided with reinforcement cages, the pile foundation is an NC prefabricated component or a UHPC prefabricated component internally provided with reinforcement cages, the cushion cap is connected with the pile foundation through an H-shaped steel plate with a sealing end cover plate, the abutment cap, the wing wall and the back wall bracket are connected withthe cushion cap through H-shaped steel plates with sealing end cover plates, the double baffle blocks are in tensile connection with the abutment cap through prestress reinforcing bars, and the back wall bracket is in tensile connection with the wing wall through prestress reinforcing bars; the construction method of the structure is included. According to the fully assembled light abutment, a fully assembled structure is adopted, the abutment has the advantages of being fast in construction speed, simple in process, easy to control in engineering project quality, less in occupation space of construction sites and the like, and the existing problem of slow construction process, the quality problem brought by hydration heat when large volume concrete construction is conducted, the problemsof large occupation space and environmental pollution and the like of traditional abutments can be effectively solved.

Owner:XIANGTAN UNIV

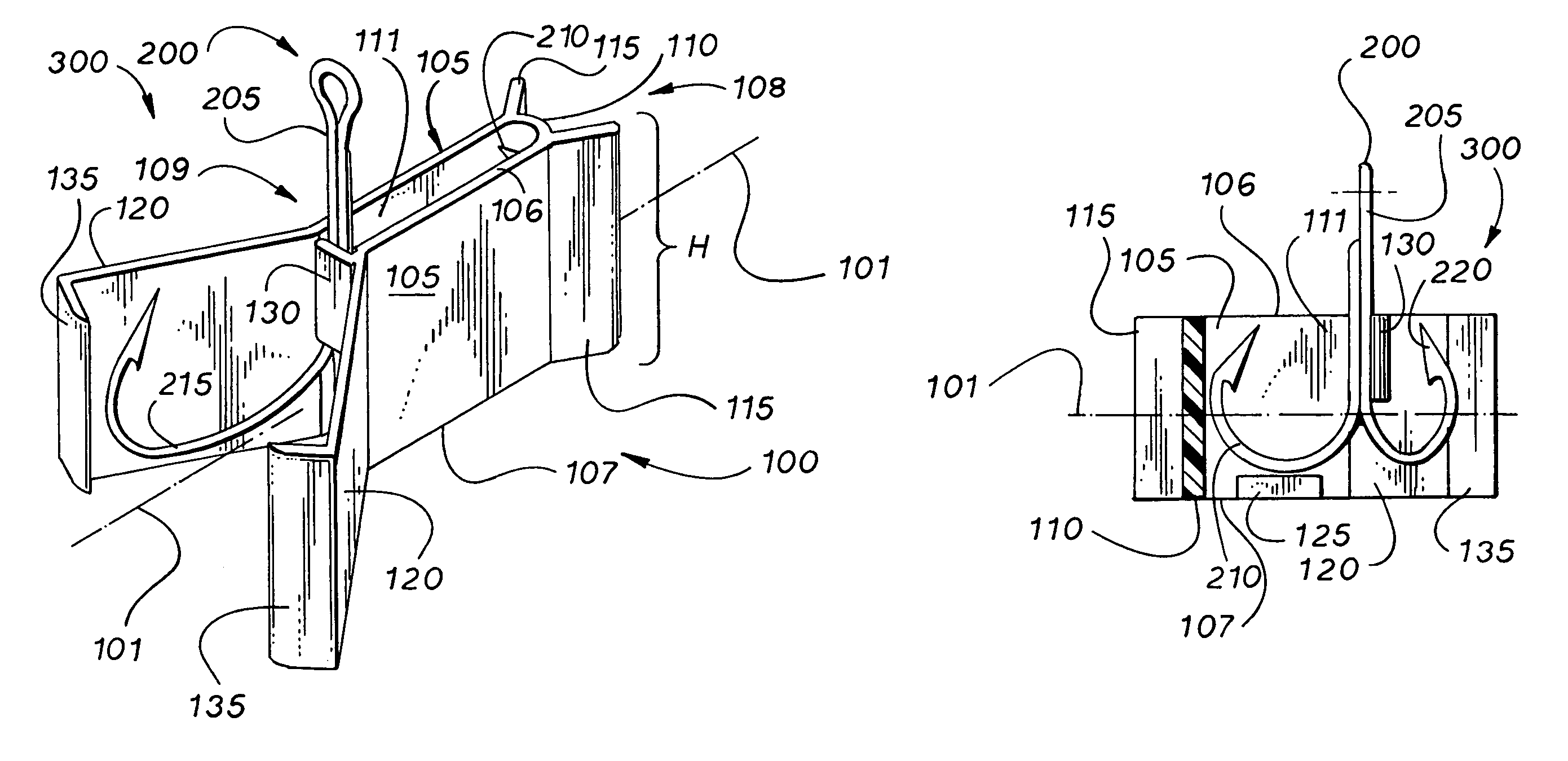

Treble hook protector apparatus

Owner:REPINE CHARLES EDWARD

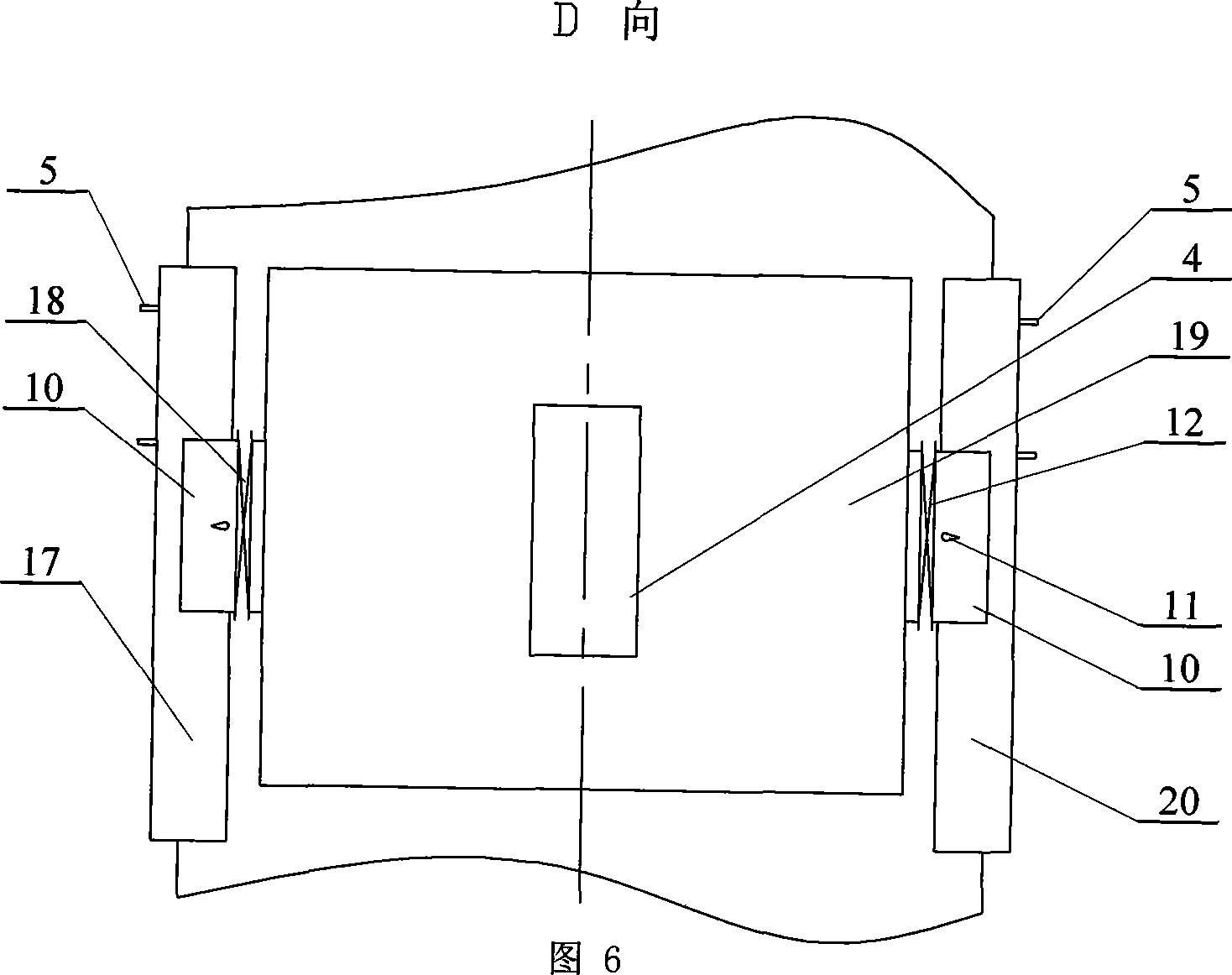

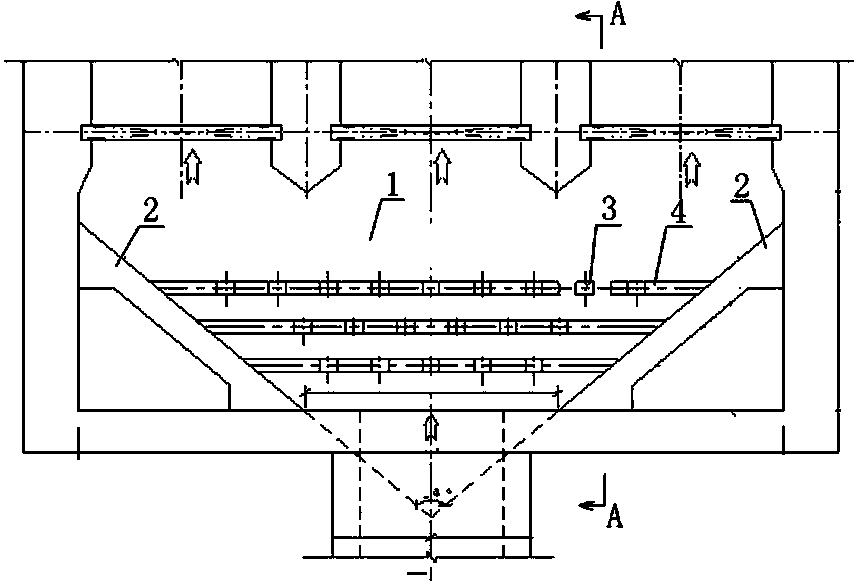

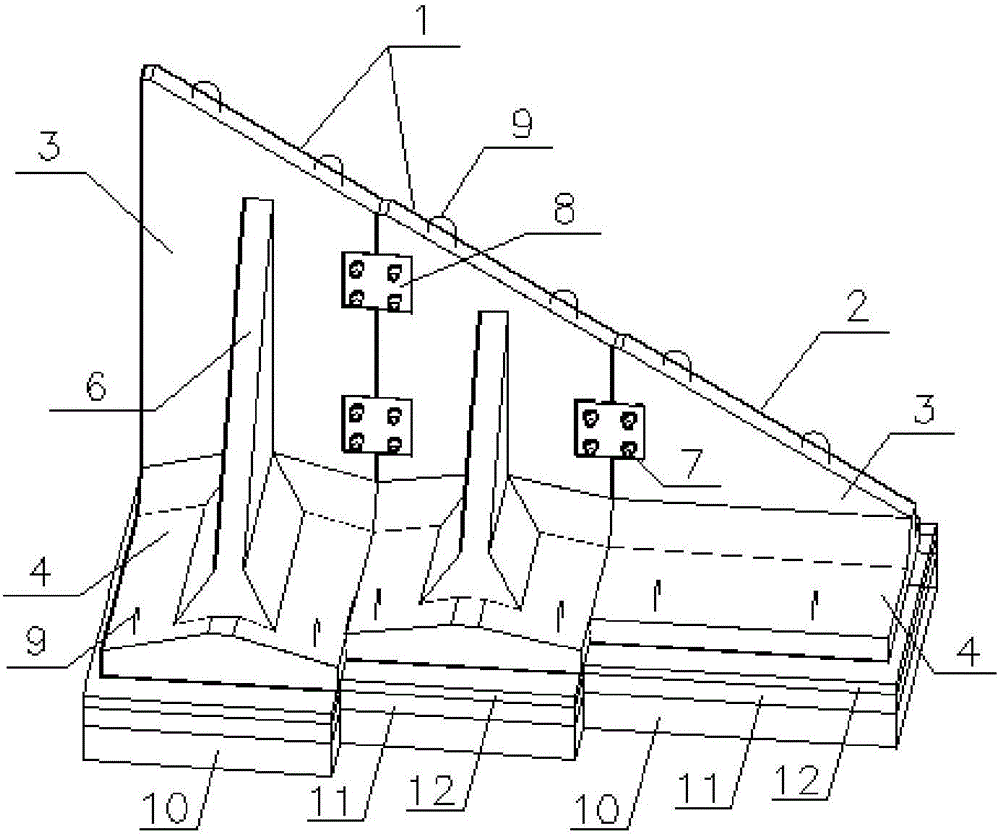

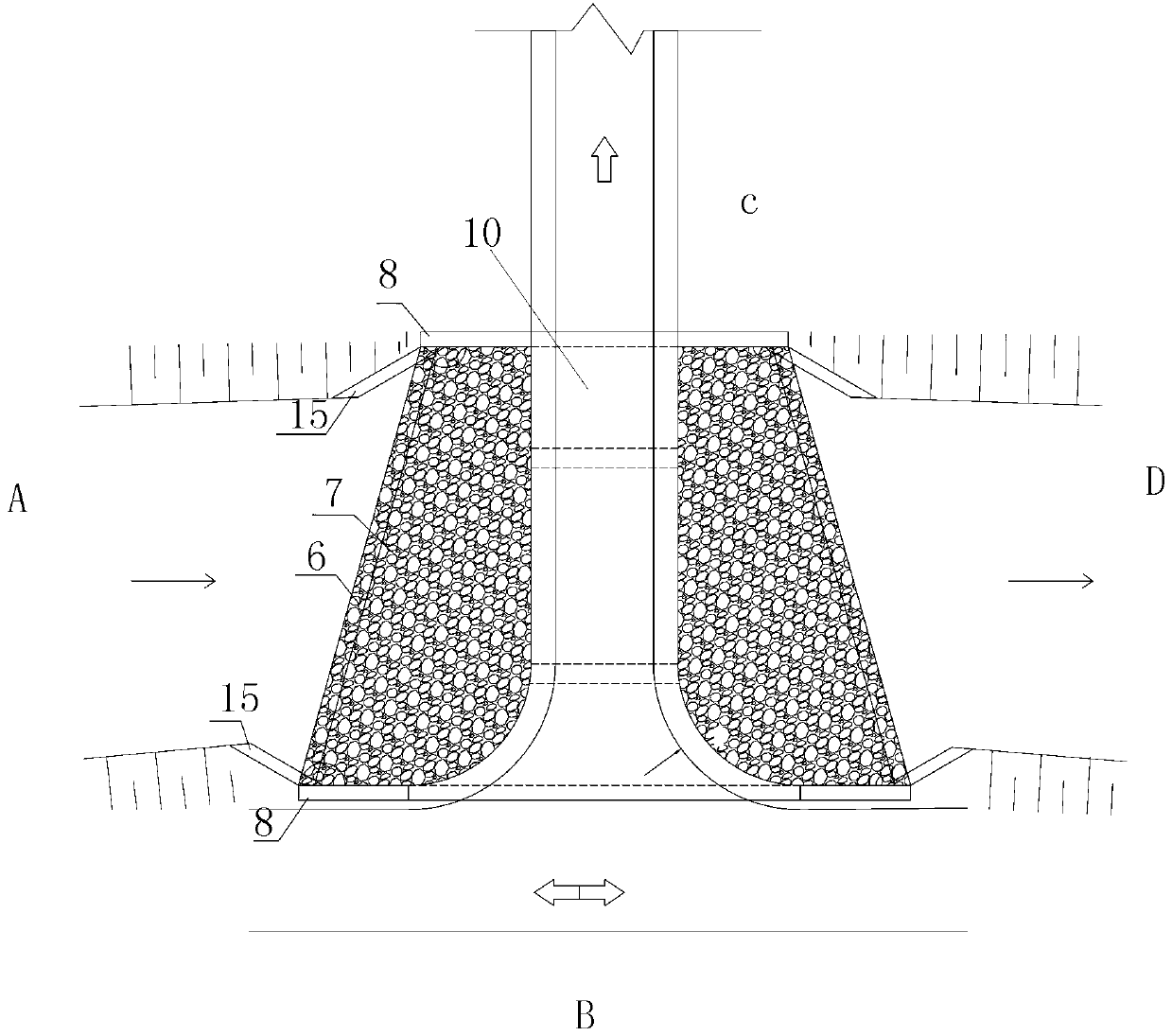

Flow distributing facility of front water feeding pond of large circulating water pump station of power plant and construction method for flow distributing facility

ActiveCN103669278AShorten the lengthSave engineering investmentHydraulic engineering apparatusPumping plantsWater flowEnvironmental engineering

The invention provides a flow distributing facility of a front water feeding pond of a large circulating water pump station of a power plant and a construction method for the flow distributing facility. The flow distributing facility comprises the front water feeding pond, wherein flow guiding wing walls which form an included angle of 60-90 degrees are respectively casted on two sides of the front water feeding pond; rows of flow distributing columns which are transversely arranged are arranged in the front water feeding pond and between the two flow guiding wing walls along the water feeding direction at least; each row of flow distributing columns consists of a plurality of square columns; the square columns of one row of flow distributing columns and the square columns of the adjacent rows of flow distributing columns are arranged in a staggered manner; the number of the square columns of each row of flow distributing columns is progressively increased along the water flow direction; and cross beams which are connected with the flow guiding wing walls on the two sides of the front water feeding pond are arranged on tops of the flow distributing columns. The construction method comprises the following steps of (a) constructing the flow distributing facility and a main body structure of an underground portion of the pump station together, and constructing the front water feeding pond of the pump station at first; (b) reserving anchor bars for casting the flow guiding wing walls according to two sides of the front water feeding pond and a bottom plate, and casting the flow guiding wing walls on the two sides of the front water feeding pond; (c) casting flow distributing square columns and forming the rows of flow distributing columns according to the anchor bars reserved on the bottom of the front water feeding pond after the flow guiding wing walls on the two sides of the front water feeding pond are constructed; and (d) casting the cross beams on the tops of the flow distributing columns, and connecting the cross beams and the flow guiding wing walls on the two sides of the front water feeding pond.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

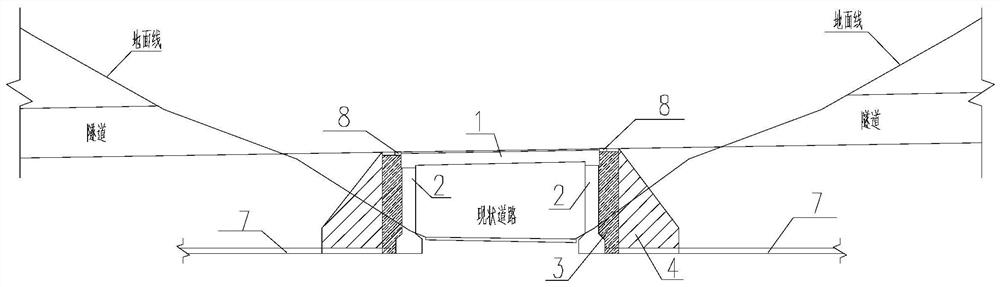

Novel bridge spanning structure between mountainous area tunnels and construction method thereof

PendingCN112482185AImprove economyIncreased durabilityBridge structural detailsBridge engineeringArchitectural engineering

The invention is suitable for the field of bridge engineering, and provides a novel bridge spanning structure between mountainous area tunnels and a construction method. The bridge spanning structurecomprises a bridge girder, abutment wing walls, a buffer layer and a cement macadam stable filling body. And the bridge girder is fixedly connected with the tops of the abutment wing walls to form a portal rigid frame. According to the bridge spanning structure, the economical efficiency and durability of the whole life cycle of the bridge structure are improved by adopting a portal rigid frame bridge mode. Meanwhile, the structure achieves the hidden drainage function, prevents water from flowing back into the tunnel, and improves the driving safety. Meanwhile, according to the construction method, disturbance to a tunnel mountain is small in the construction period, the influence on driving safety of an existing road spanning the bridge is small, the construction period is short, and efficiency is high.

Owner:深圳市综合交通与市政工程设计研究总院有限公司

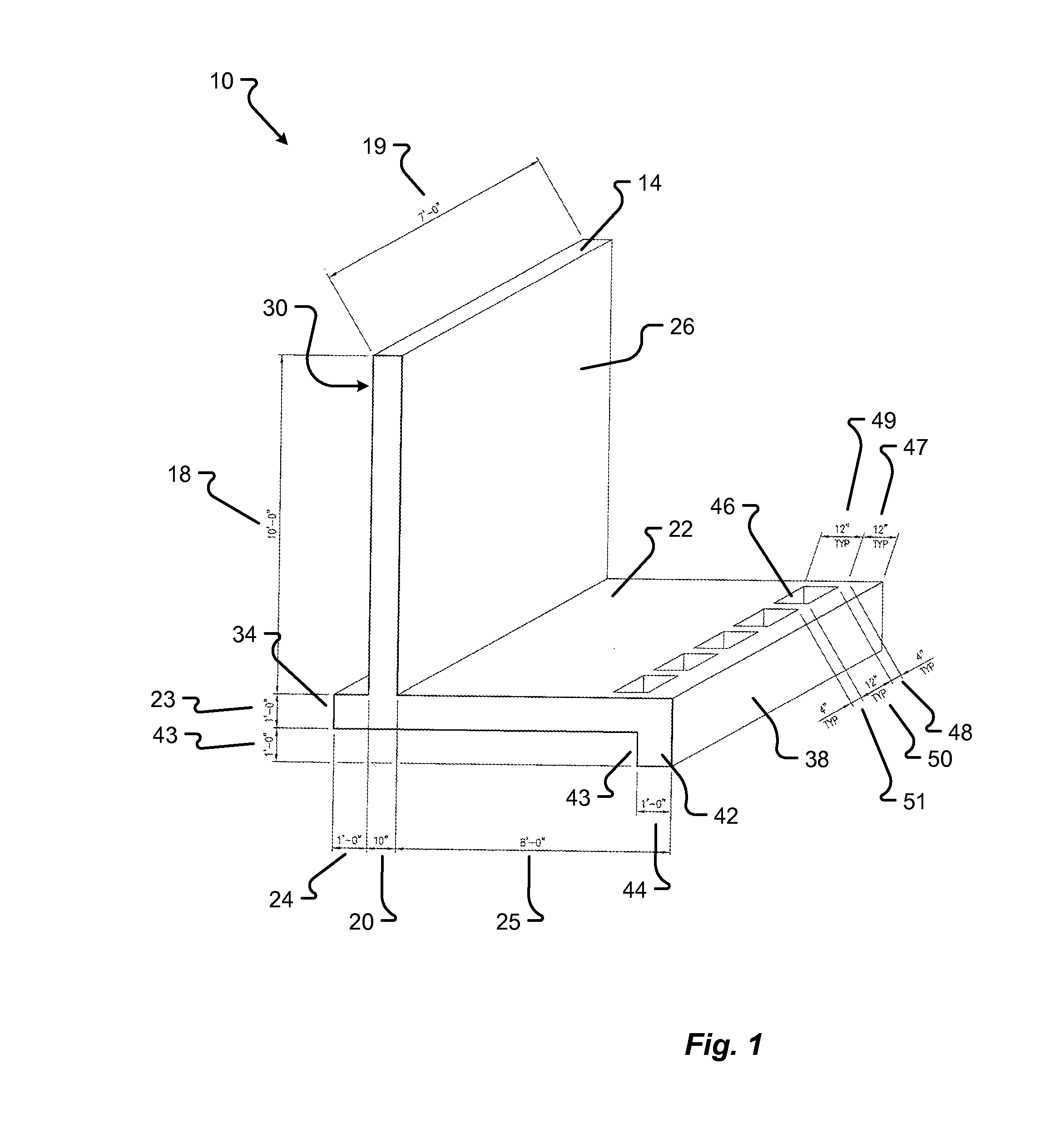

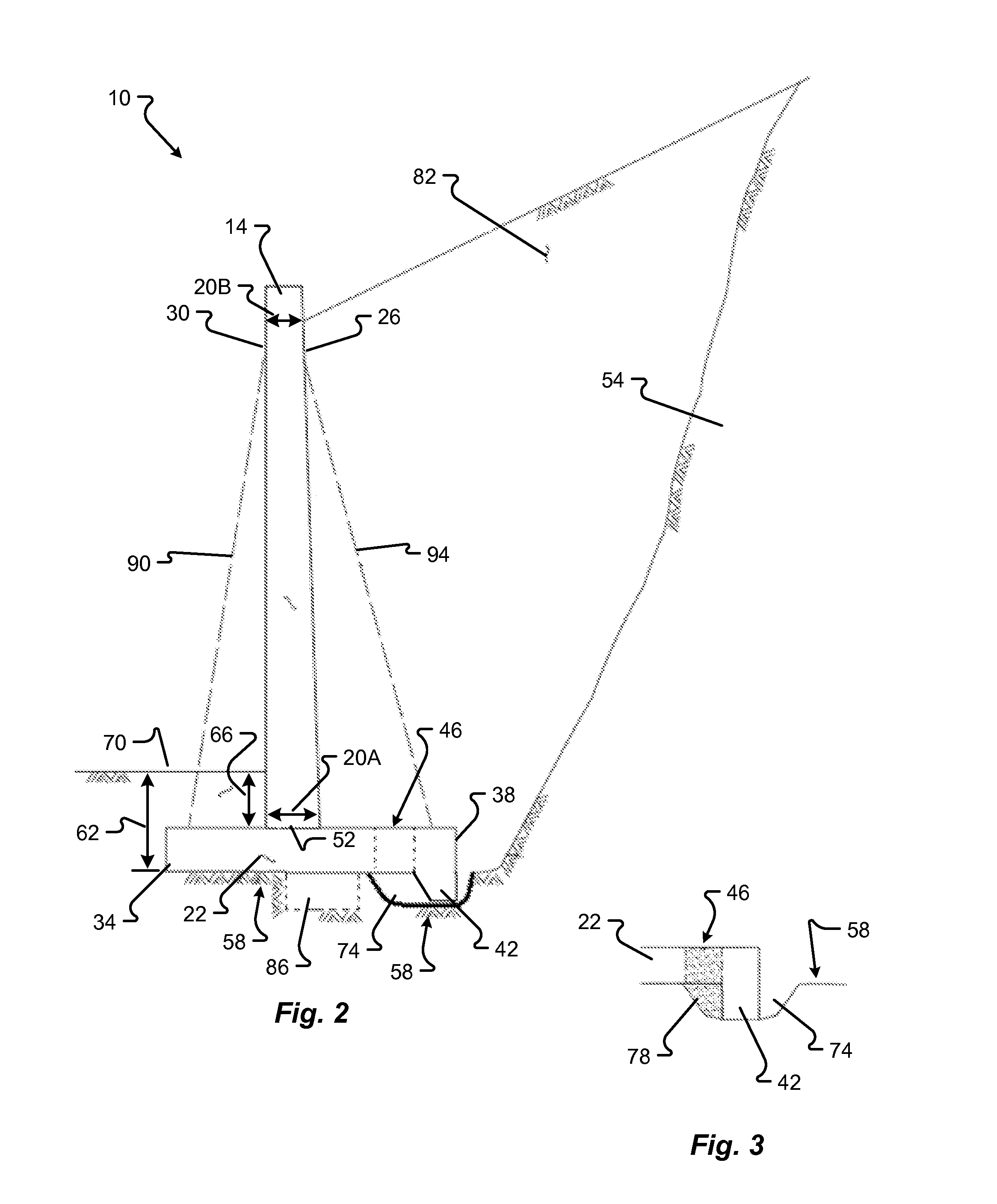

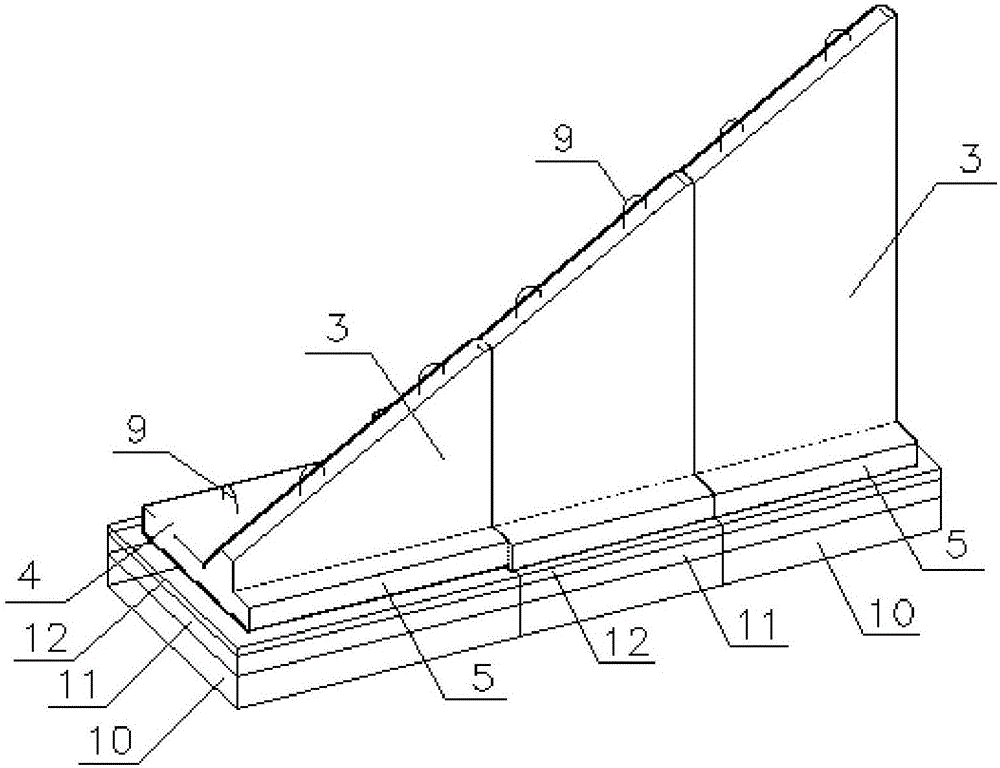

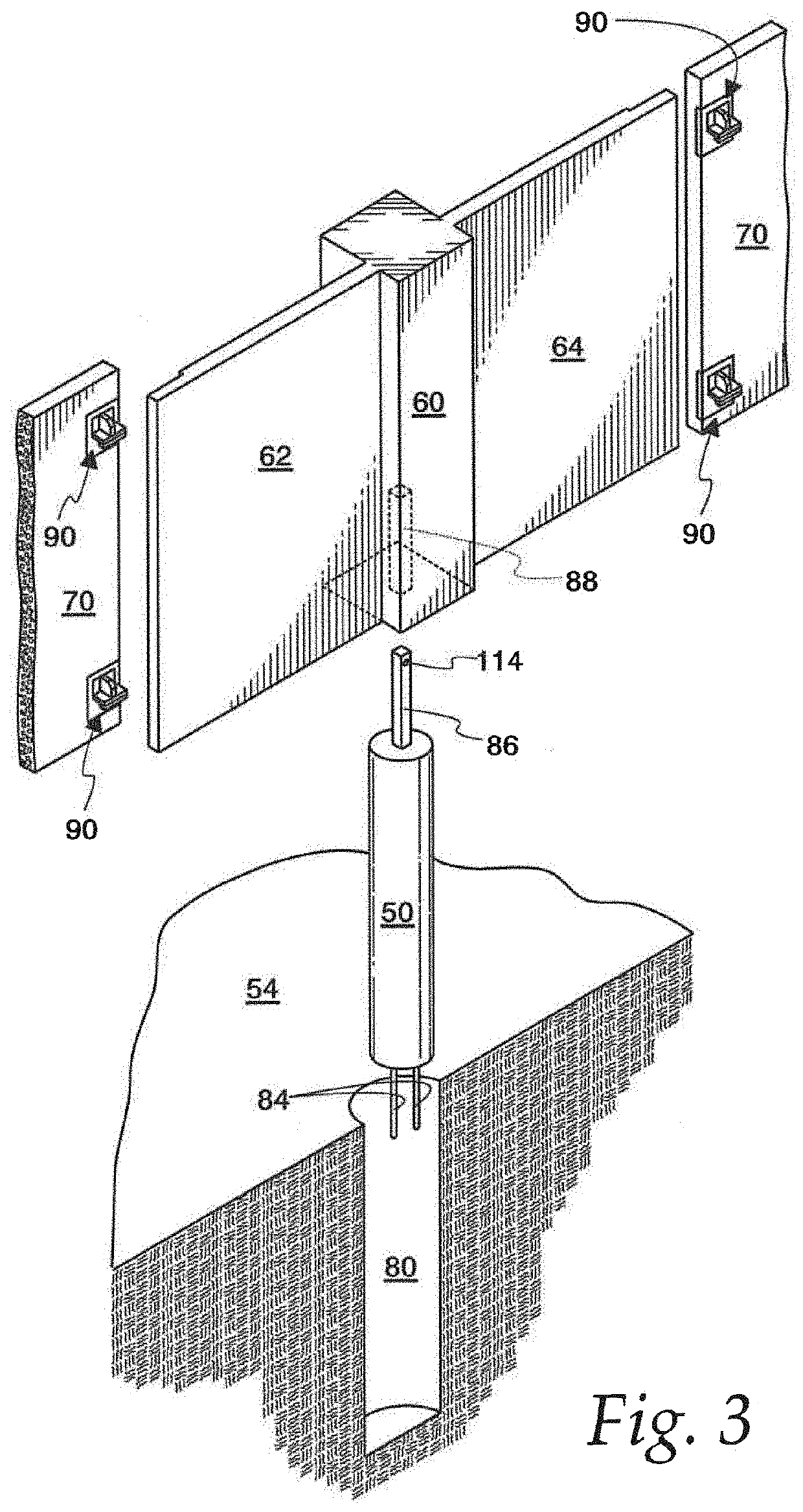

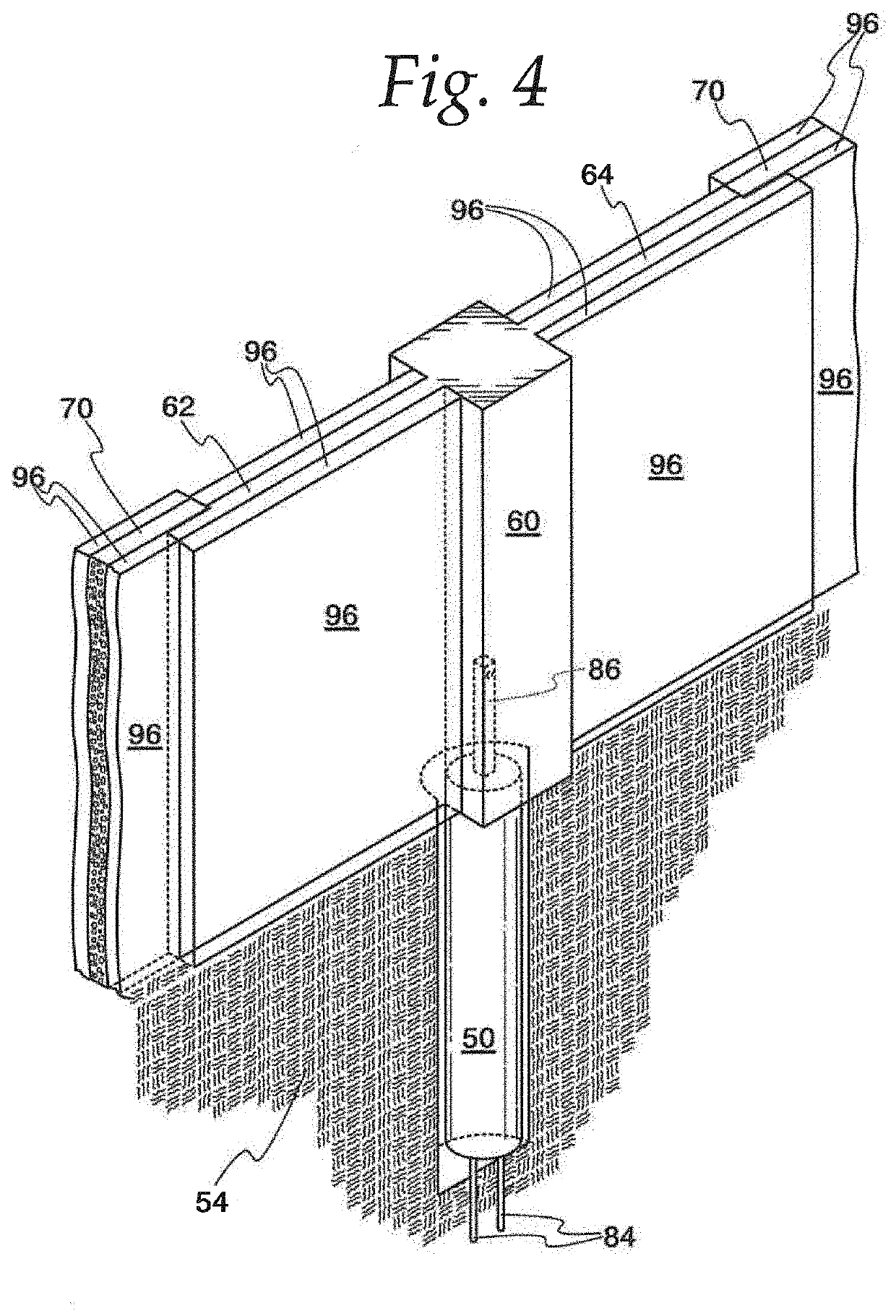

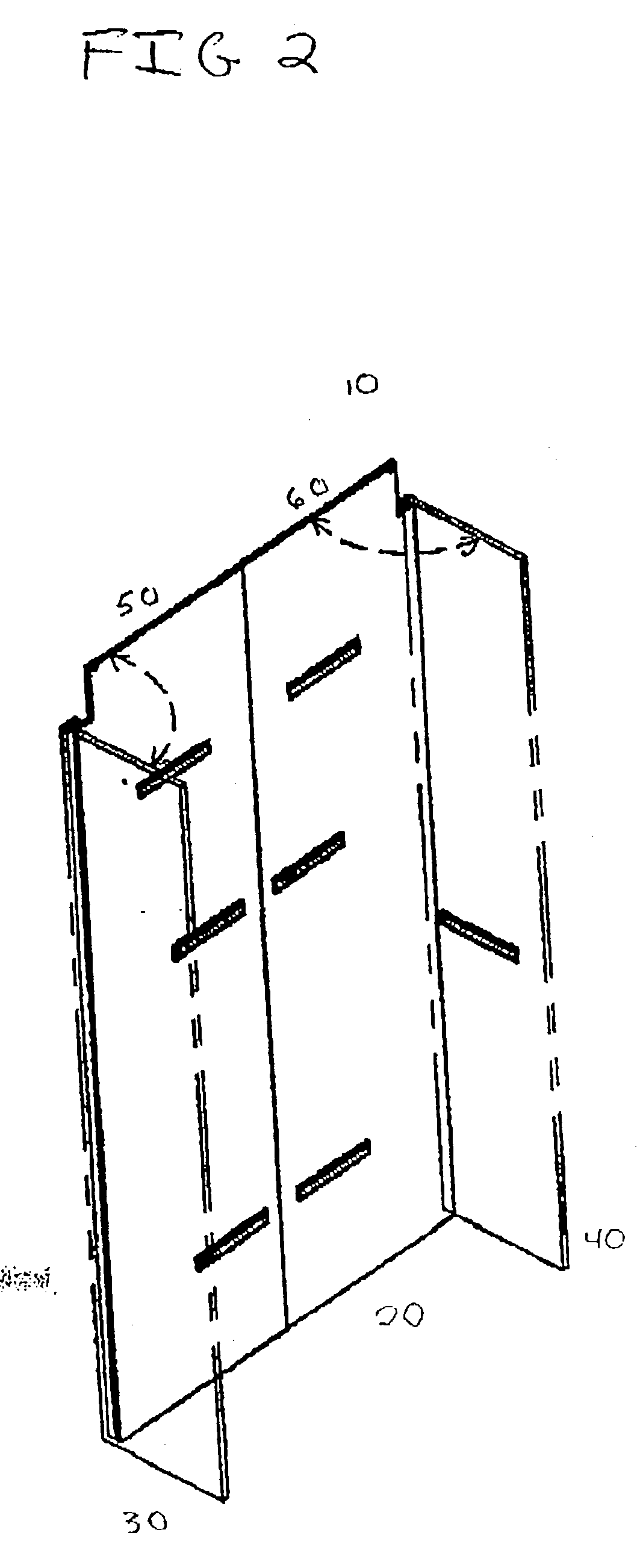

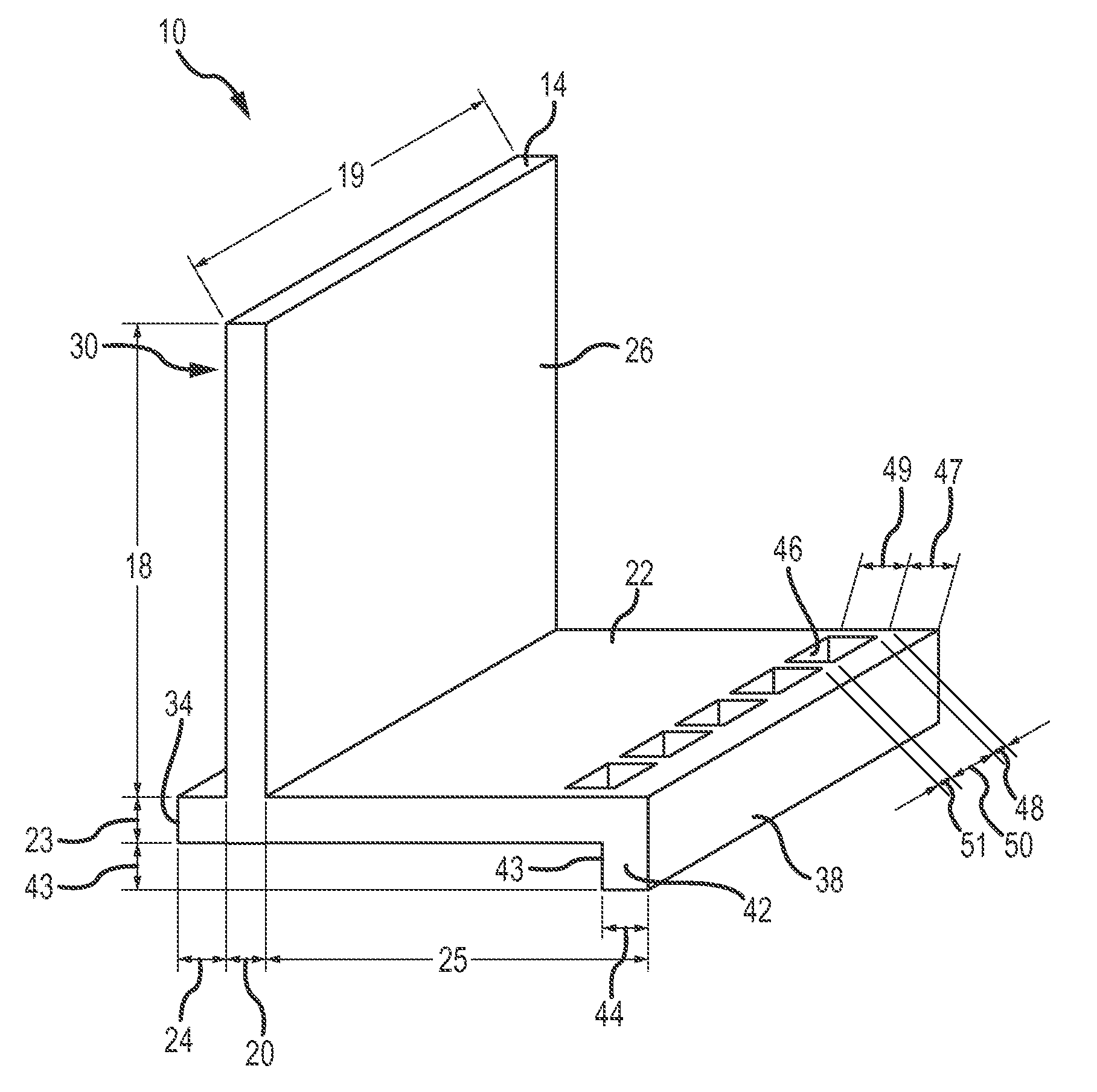

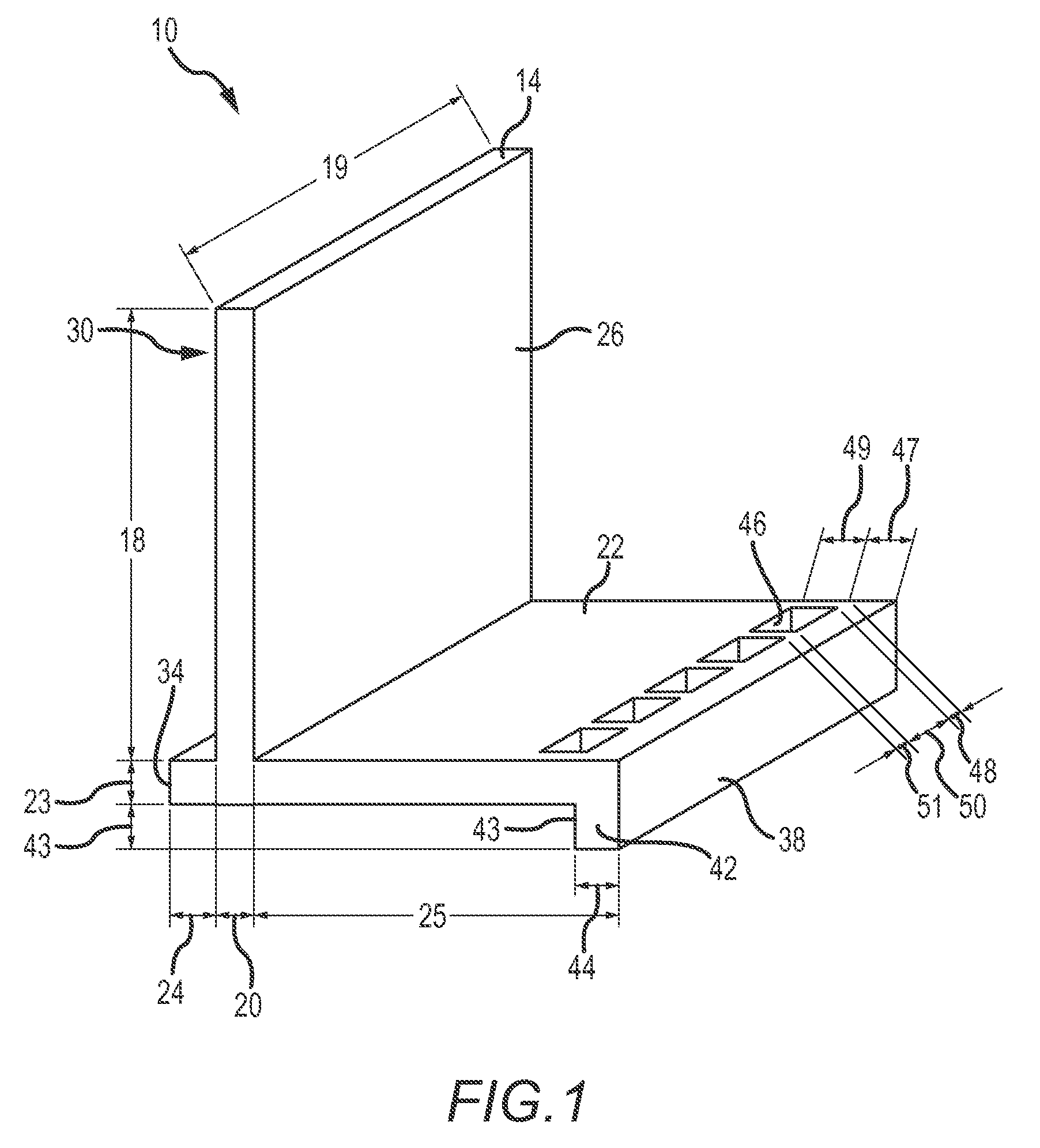

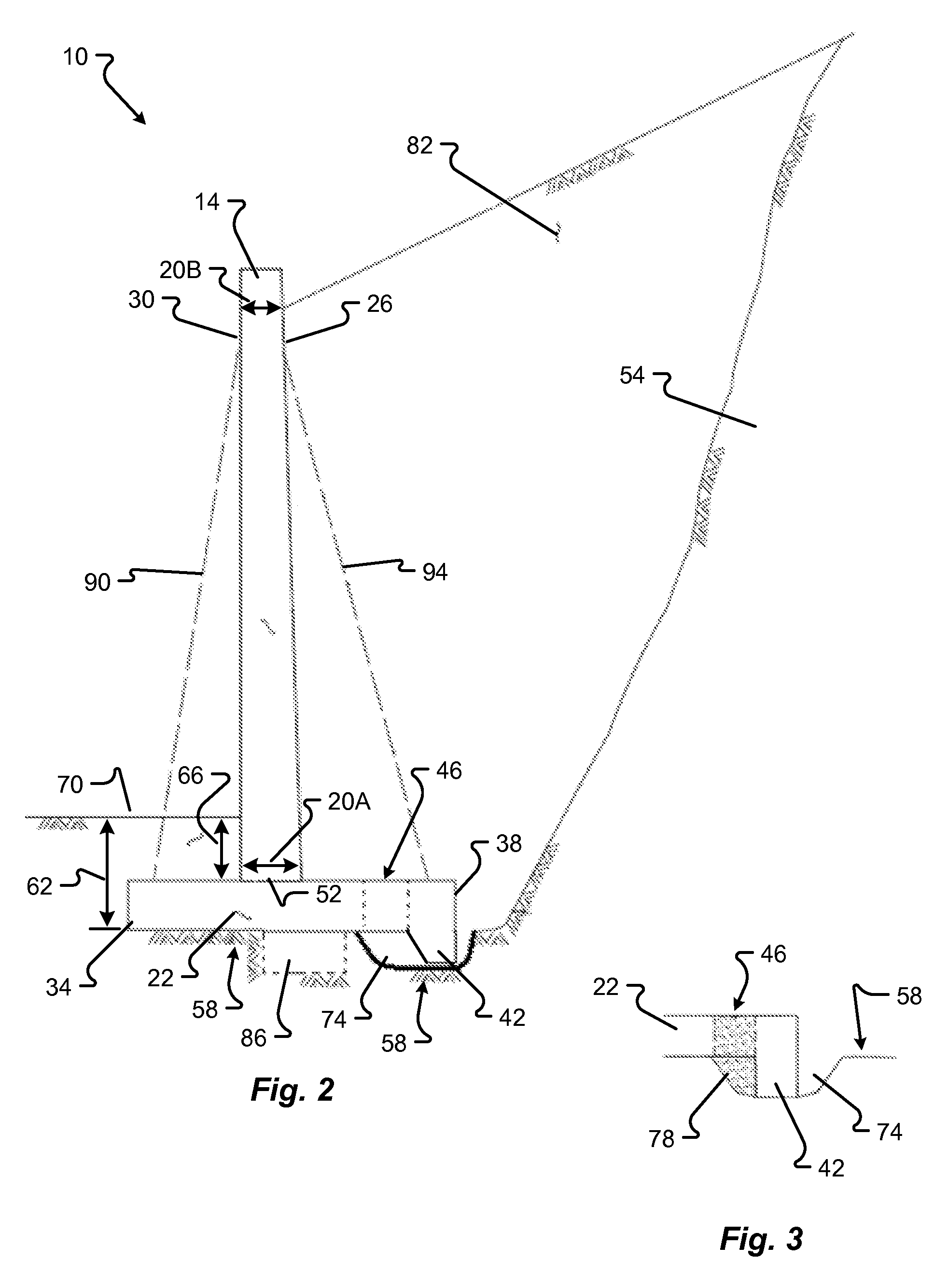

Cantilevered wing wall

ActiveUS20150117963A1Cost-effective fabricationVersatile in useArtificial islandsCeramic shaping apparatusRetaining wallWing wall

The present invention relates generally to precast cantilevered retaining walls. More specifically, the present invention relates to a cantilevered concrete retaining wall having a base shear key and blockouts for receiving a material that substantially impedes the wing wall from sliding or other inadvertent movement.

Owner:OLDCASTLE PRECAST

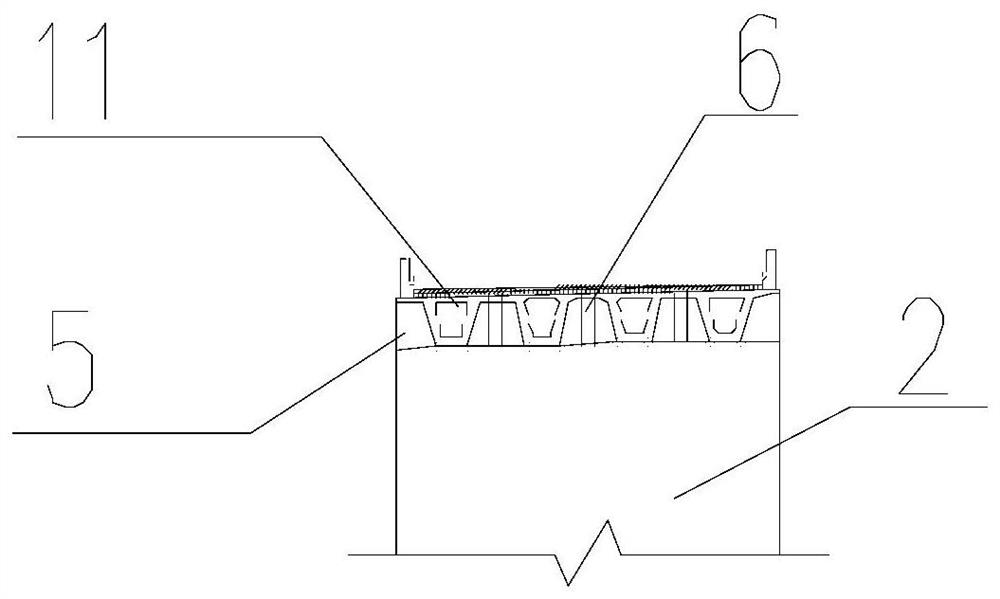

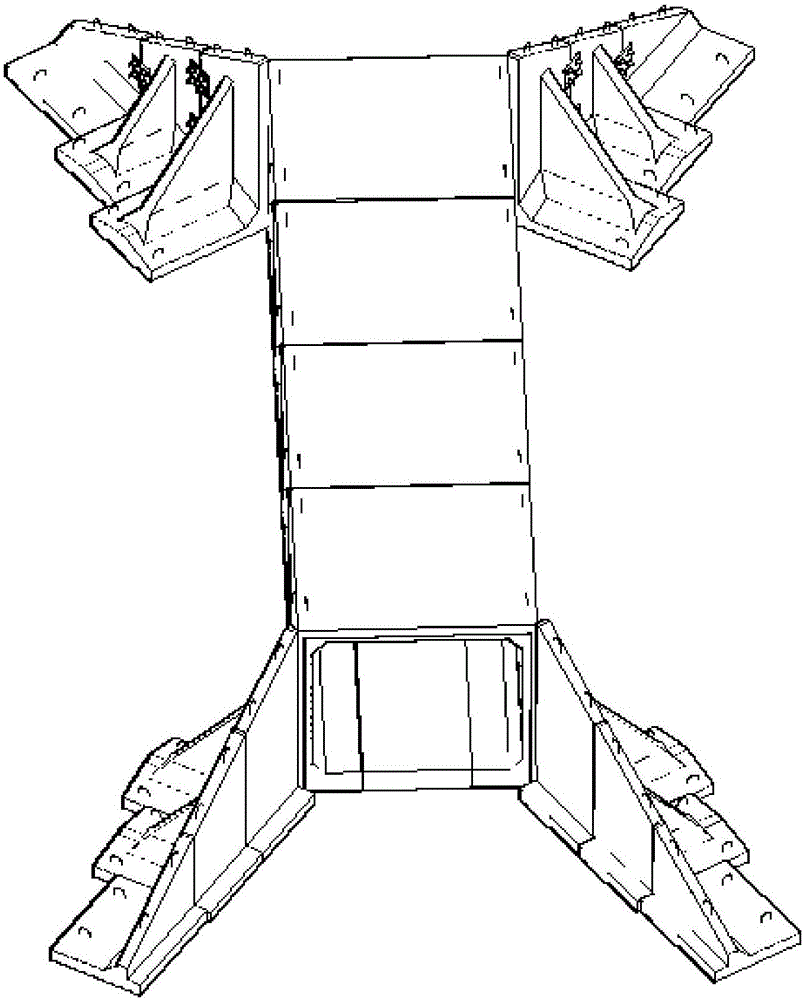

Assembly-type reinforced concrete splay wall-type inlet and outlet of culvert and construction method

The invention discloses an assembly-type reinforced concrete splay wall-type inlet and outlet of a culvert. The assembly-type reinforced concrete splay wall-type inlet and outlet of the culvert comprises wing walls arranged on both sides of the inlet and outlet of the culvert. Each side of the wing wall comprises a precast counterfort reinforced concrete retaining wall and a precast cantilever reinforced concrete retaining wall, and a plurality of precast counterfort reinforced concrete retaining walls and precast cantilever reinforced concrete retaining walls are combined and assembled one by one from the inlet and outlet outward to both sides. The precast counterfort reinforced concrete retaining wall is precast of vertical walls, vertical wall heel slabs, vertical wall toe boards and a counterfort. The precast cantilever reinforced concrete retaining wall is precast of the vertical walls, the vertical wall heel slabs and the vertical wall toe boards. The back of the vertical walls, near the side edge, are provided with pre-embedded bolts. The two vertical walls are connected and assembled by inter-segment connection steel plates, and each inter-segment connection steel plate is fixed through the pre-embedded bolts. The invention also discloses a construction method for assembly-type reinforced concrete splay wall-type inlet and outlet of the culvert. The assembly-type reinforced concrete splay wall-type inlet and outlet of the culvert adopts prefabricated components to realize assembly connection, thereby improving the project quality, shortening the construction period and reducing the project cost.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

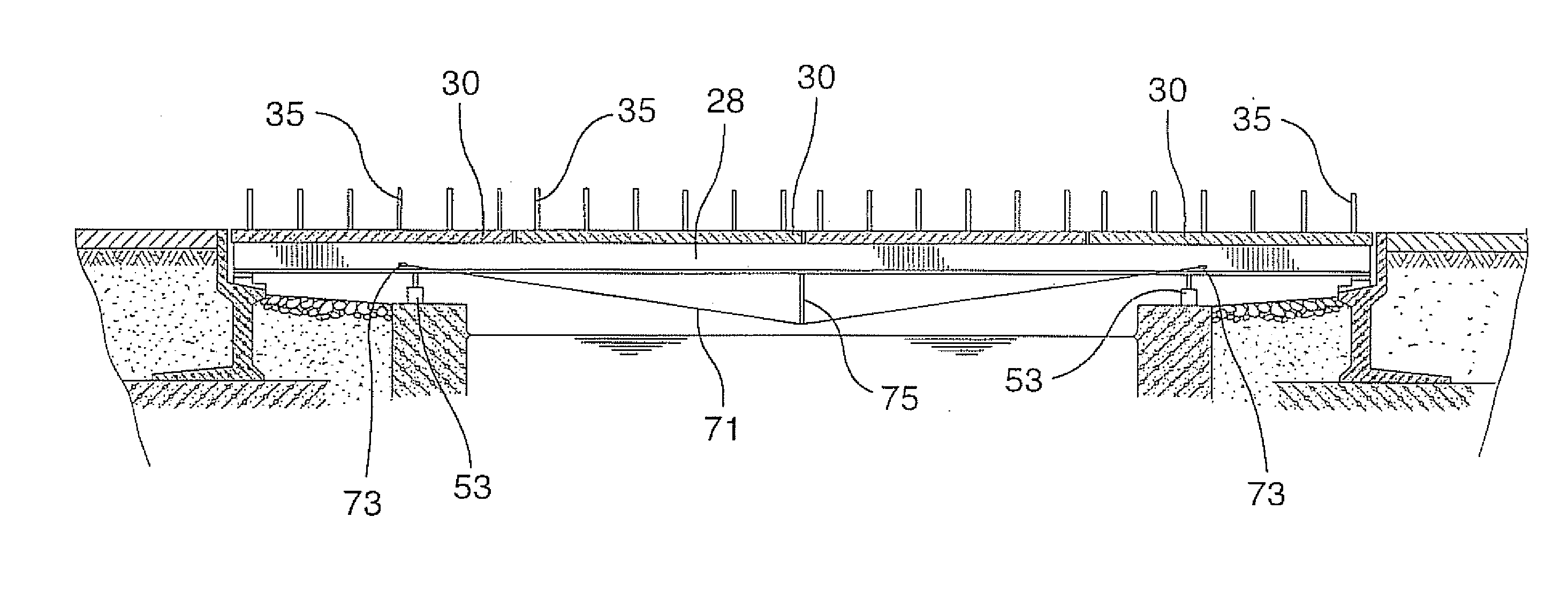

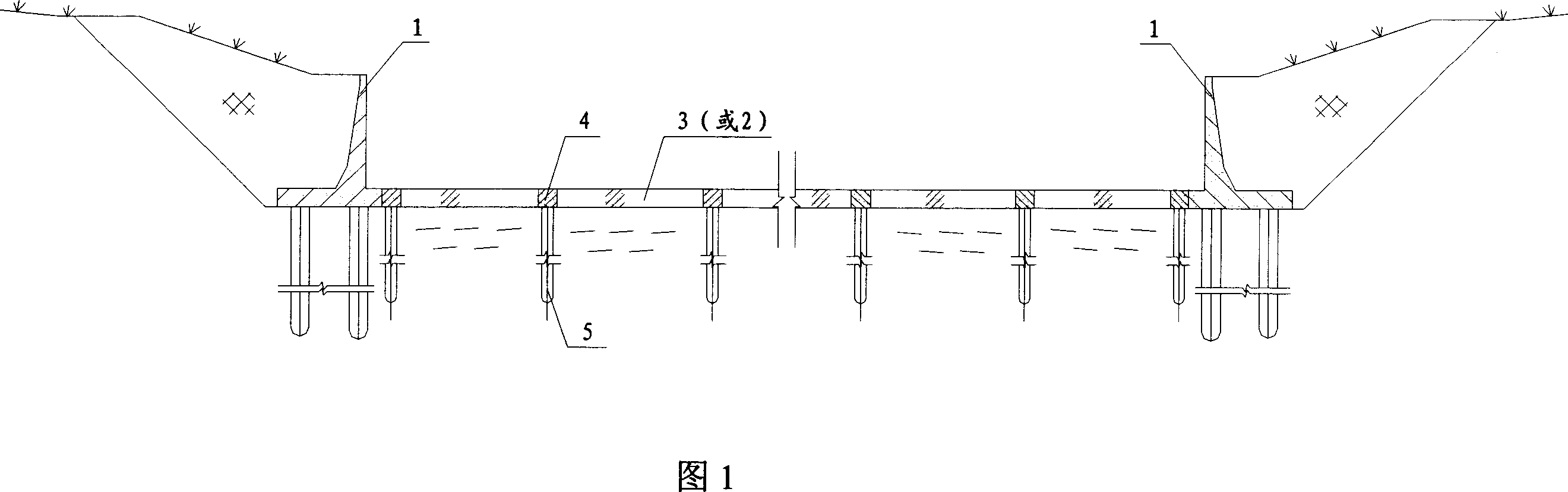

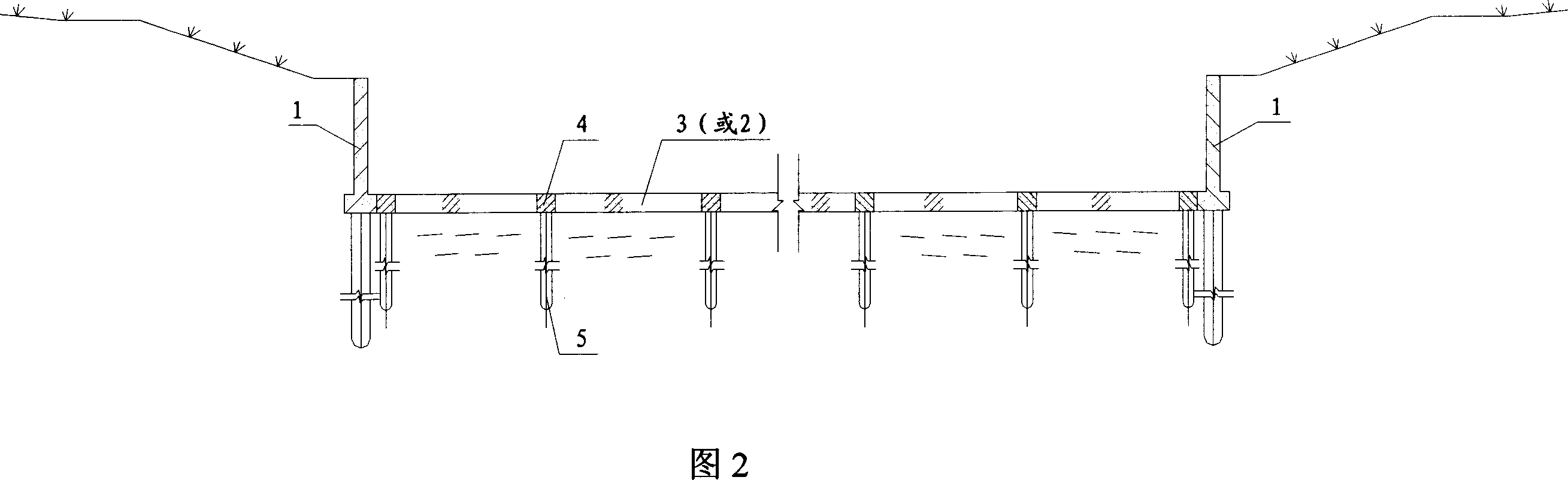

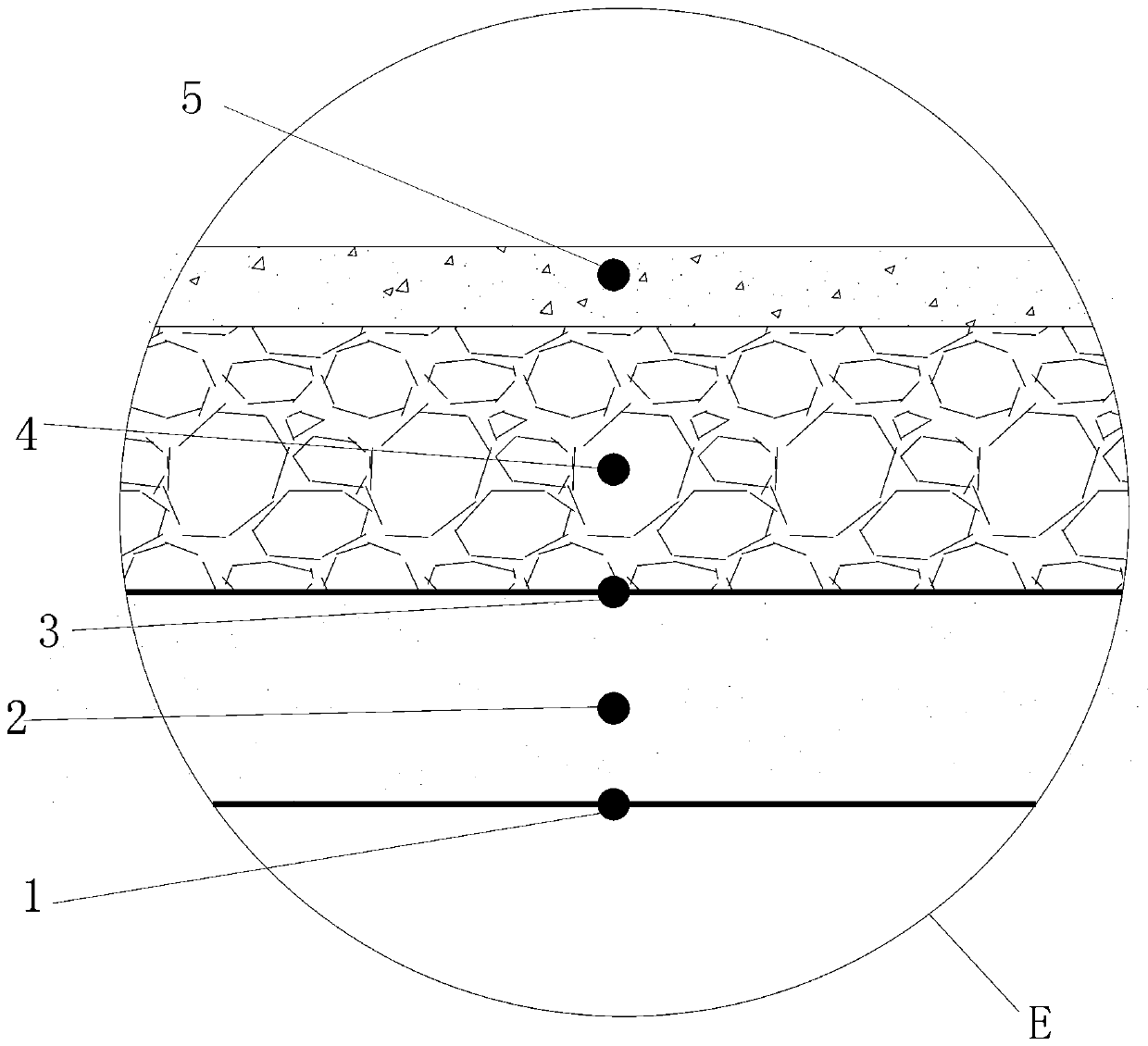

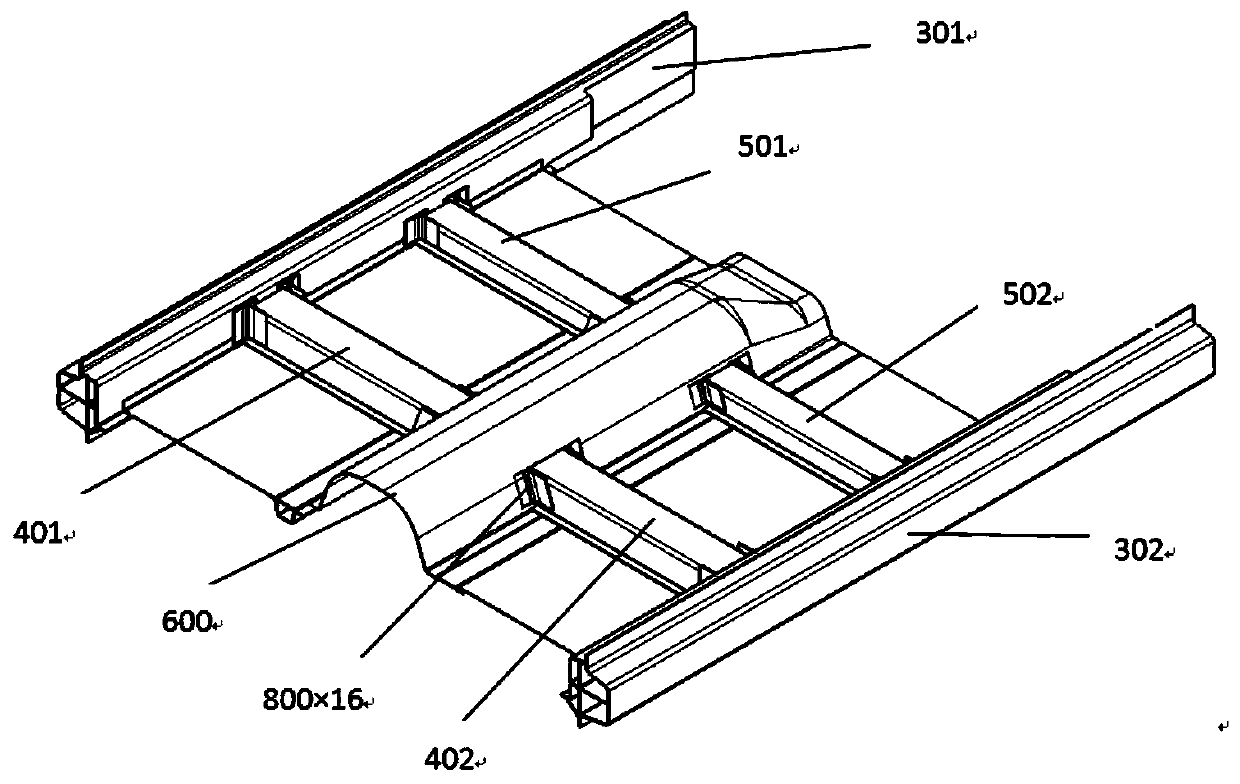

Three-dimensional space supportive gridiron for refraining from deflection of two side walls and wings walls of river

ActiveCN1920179AIncrease stiffnessSmall sizeArtificial islandsUnderwater structuresReinforced concreteThree-dimensional space

The invention relates to a three-dimension support beam structure for limiting the displacements of river bank and wing wall, wherein it combines the riverbed protective structure (masonry or steel bar concrete protector), arranges longitudinal and transverse steel bar concrete hidden beam, while two ends of transverse hidden beam are supported at the front finger of bottom plate, and the cross point of longitudinal and transverse hidden beams has short post below, to form vertical limit, to limit the deformation of compress rod caused by the axial pressure of two side support structures, to form three-dimension steel bar concrete support beam, wherein said bank and wing walls can be light one, suspended arm, held arm or low-rigidity support cam type. The invention can reduce the span of horizontal beam, increase the rigidity of beam, reduce the size of beam, and reduce the number of post foundations.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Noise attenuating barrier and method of installing same

A noise abating wall including piers with integral column members, columns each including two laterally extending wing walls, and a spandrel panel. The piers are secured in spaced ground holes with column members extending vertically from the pier securing the columns in a vertical orientation with the wing wall outer sides having a selected spacing from one wing wall of an adjacent column. The spandrel panels are wider than the selected spacing of wing walls of adjacent columns whereby the spandrel panel sides overlap the sides of adjacent wing walls. First connectors on the spandrel panel front face adjacent both of the panel opposite sides and second connectors on the wing wall rear faces adjacent the wing wall outer sides connect together to secure the overlapping walls and spandrel panels in substantially face to face contact.

Owner:ENGINUITY SYST LLC

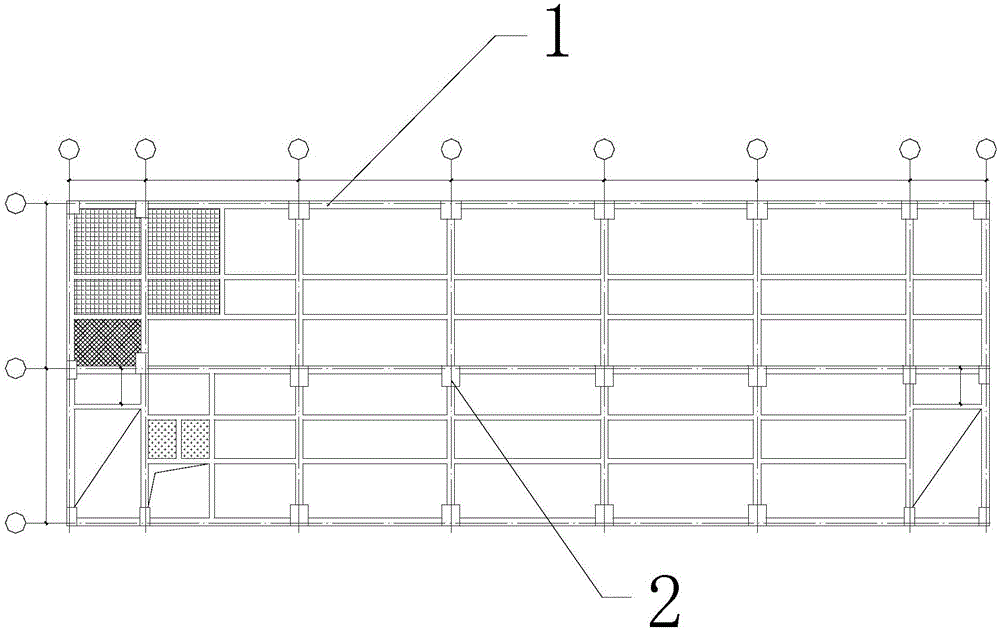

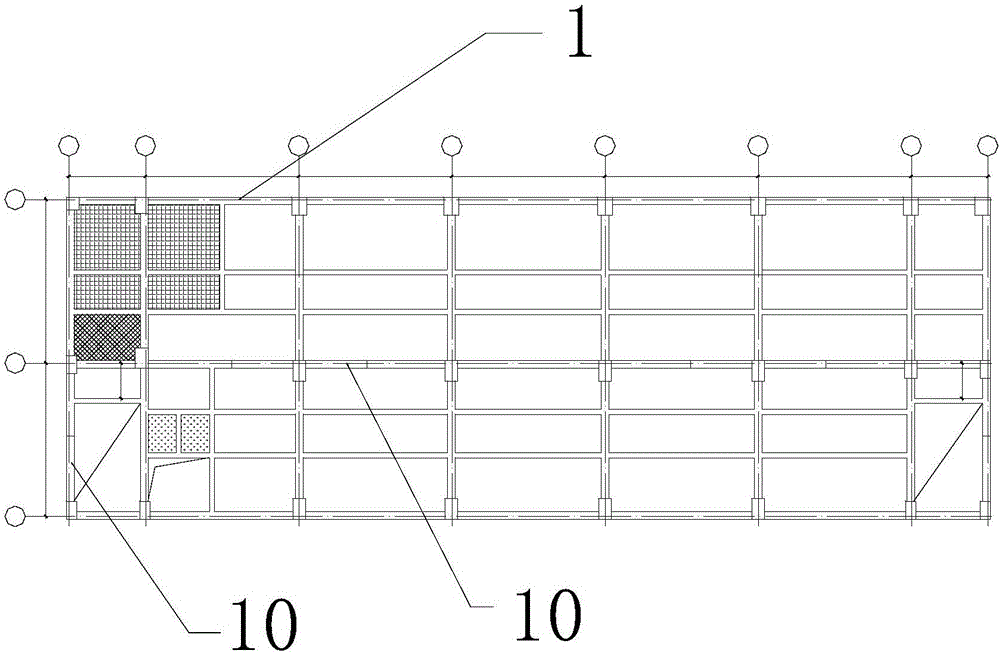

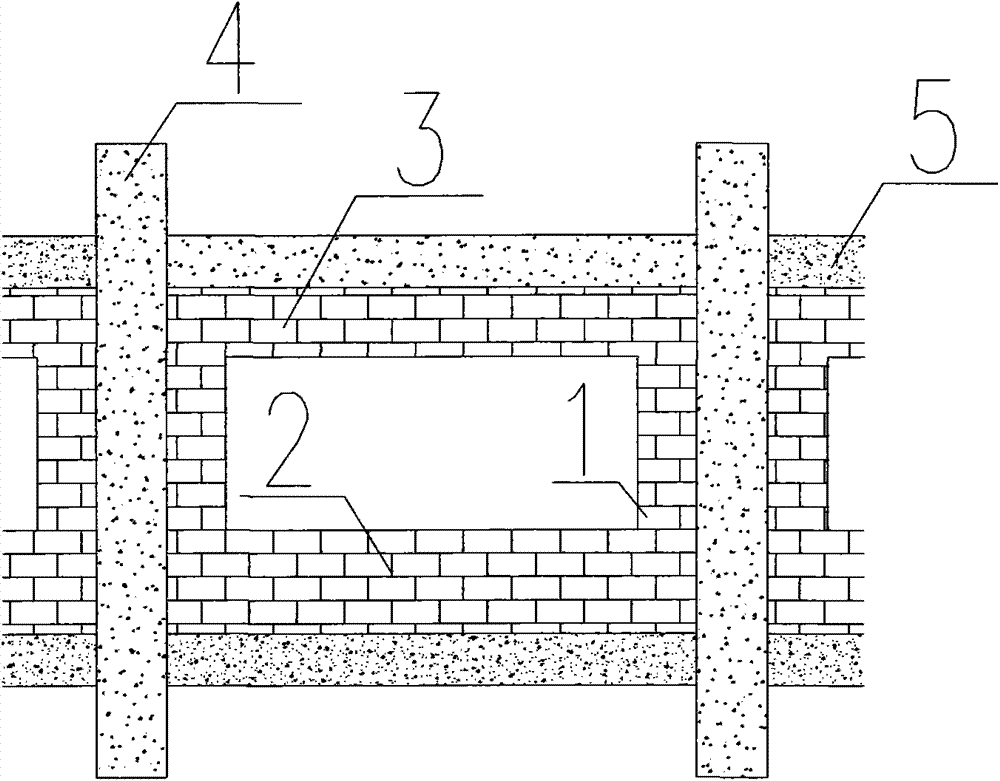

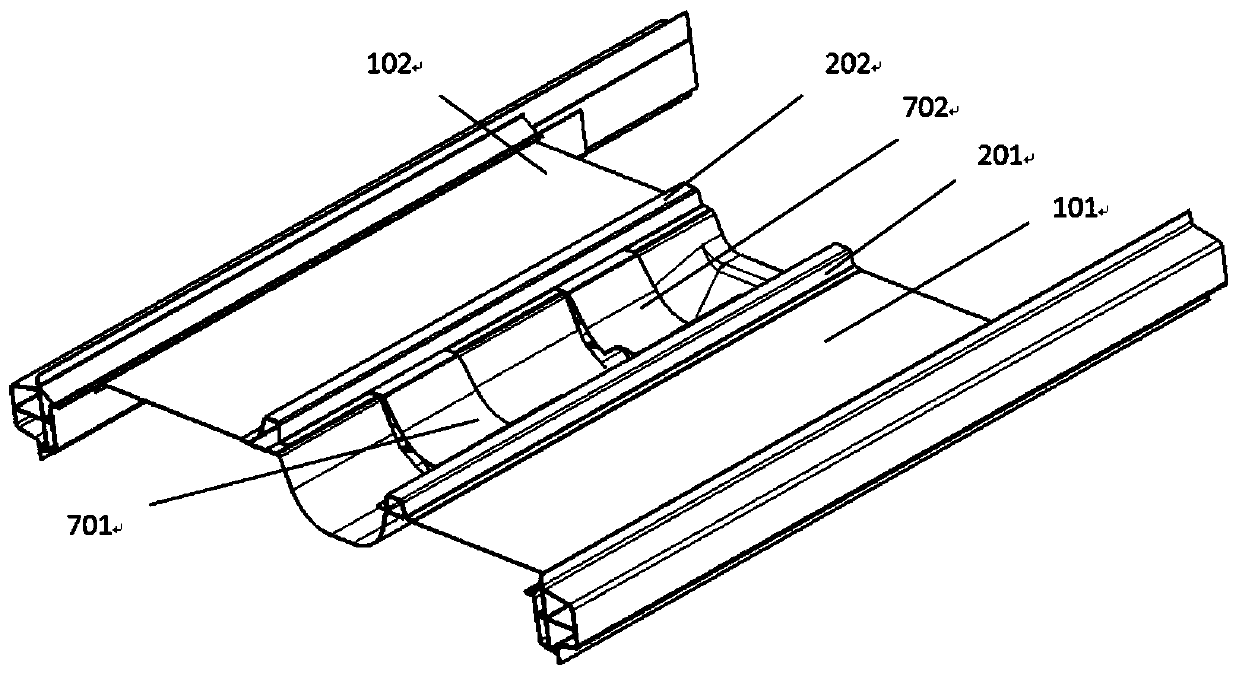

Frame structure for high intensity areas

InactiveCN106284650ANo internal impactNo material impact on internalBuilding constructionsProtective buildings/sheltersEngineeringHigh intensity

The invention discloses a frame structure for high intensity areas and especially relates to a frame structure for high intensity areas applied to the field of architectural structures. The invention provides the frame structure for high intensity areas. The frame structure for high intensity areas is low in engineering construction cost, has small influences on the architectural layout, use function and later reconstruction, can effectively enhance the stiffness of the frame structure, and can effectively prevent the condition that pillars at the four corners of the frame structure are easily damaged and difficultly repaired under strong earthquakes. The frame structure for high intensity areas comprises a main frame and frame pillars distributed in the main frame, and corner frame pillars are arranged at the four corner positions of the main frame. The frame structure for high intensity areas also comprises short wing walls, and the short wing walls are positioned at the four corners of the main frame and connected with the two inner sides of the corner frame pillars. According to the invention, a small amount of the short wing walls are arranged at the four corners of the frame structure, the stiffness of the structure is greatly increased, the deformation under the effect of earthquakes can be effectively decreased, and no substantial influence is caused on the interiors of buildings, use function, later space reconstruction and the like.

Owner:POWERCHINA CHENGDU ENG

Installation-free death care merchandise display unit

Owner:RIGA DENNIS J

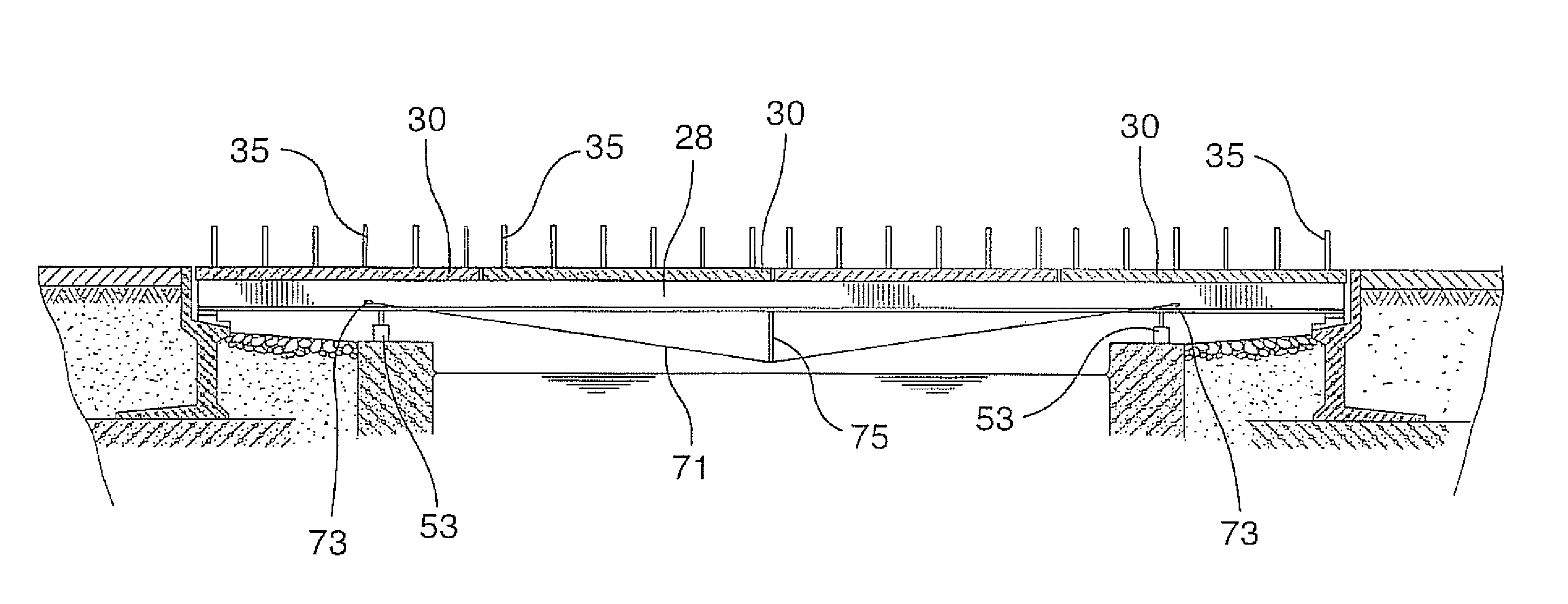

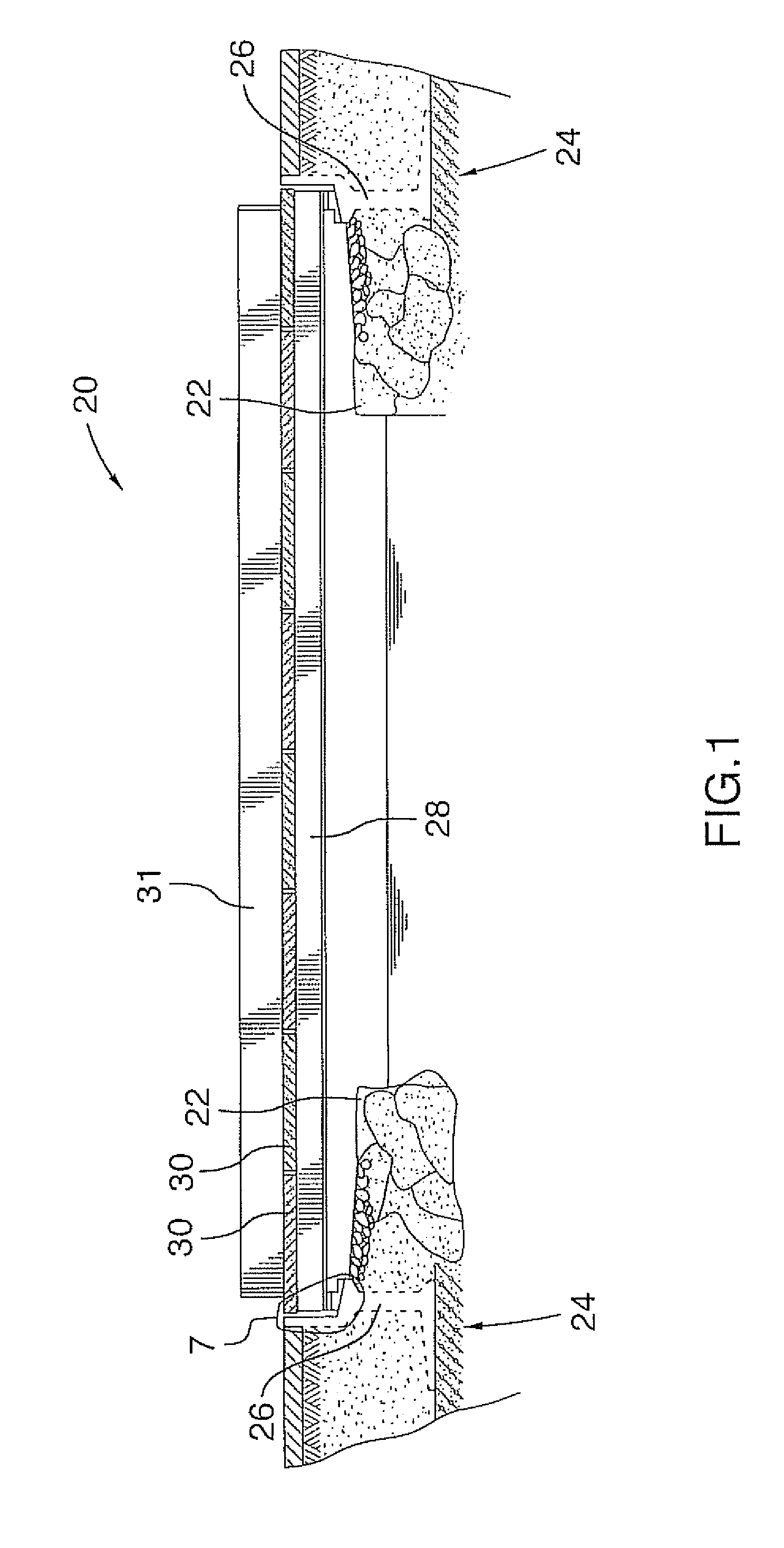

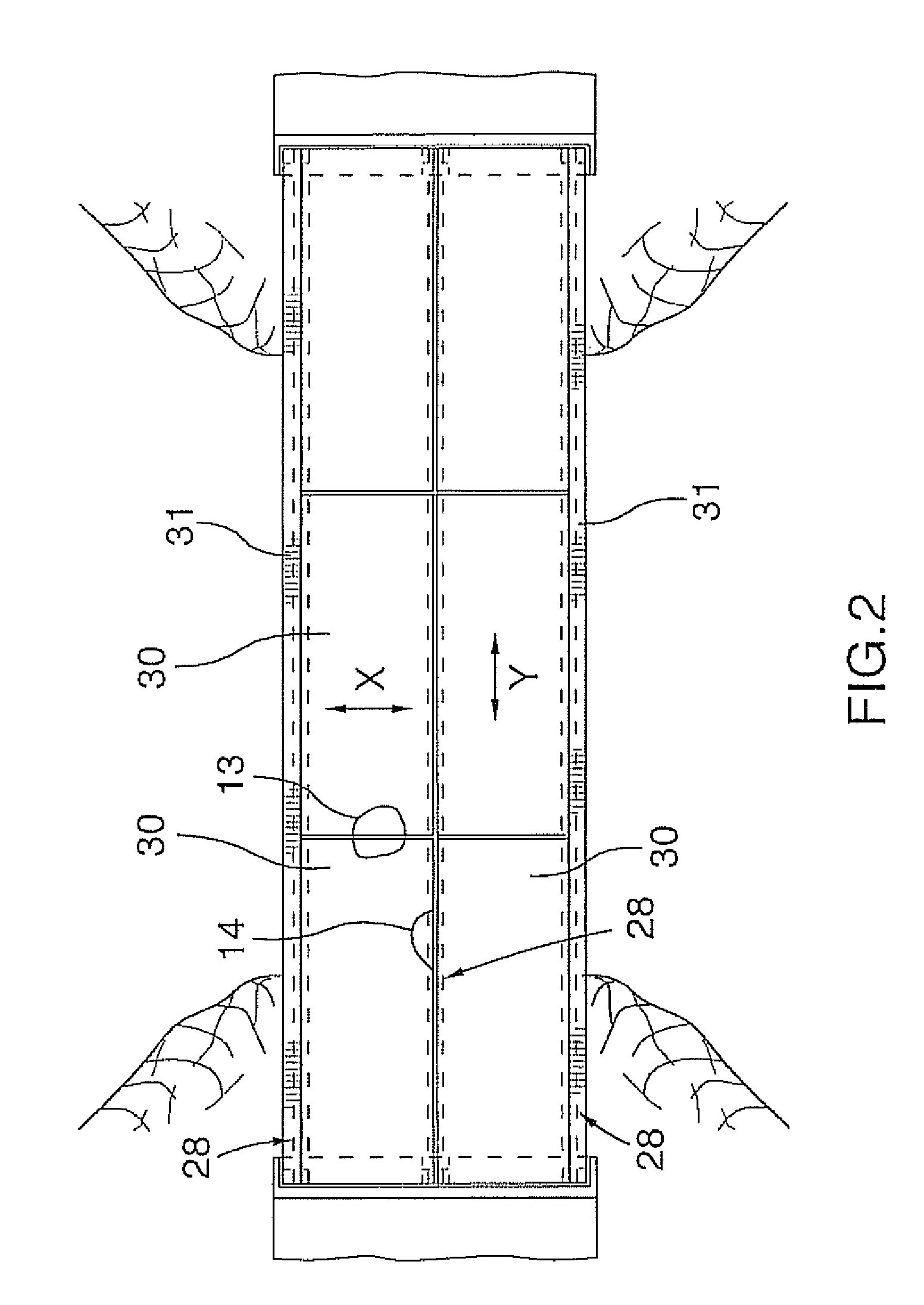

Bridge construction and method of replacing bridges

A bridge replacement method is disclosed. The bridge includes a deck supported by a pair of abutments, each abutment having wing walls. The deck is removed, footings are cast in holes dug behind each abutment and a pier is provided on each footing. Substantially parallel and coplanar cambered beams are provided. Each beam spans between and is supported by the piers. A brace assembly reinforces the beam camber. On each adjacent pair of beams, precast deck elements are placed, such that each element of said plurality spans the beam pair, to define at least transverse gaps between the elements and put the upper surfaces of the elements in compression in a transverse direction. The gaps are grouted. After grout curing, the brace is adjusted to reduce the beam camber and cause the upper surface of the elements to also be put into compression in a direction parallel to the beams.

Owner:NEWTON BRIDGE SOLUTIONS

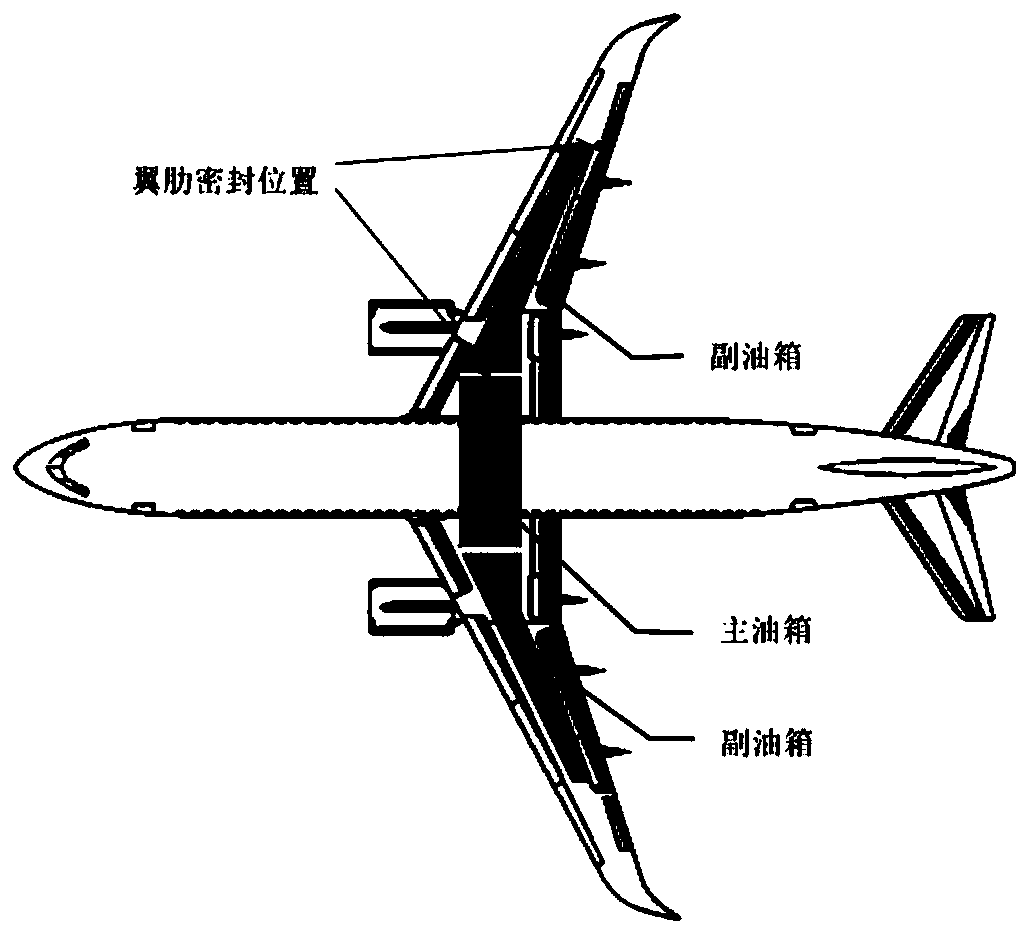

Method for sealing composite wing wall panel and metal wing rib based on co-bonding process

ActiveCN109849351AReduce manufacturing costReduce assembly processDomestic articlesGlass fiberManufacturing technology

The invention relates to the technical field of aircraft body manufacturing, and provides a method for sealing a composite wing wall panel and a metal wing rib based on a co-bonding process. The method comprises the steps that agap formed by a stringer edge strip of the wing wall panel and the metal wing rib is filled with glass fibers, specifically, the glass fibers form a sealing stopper; the stringer edge strip and the sealing stopper are connected with skin simultaneously in a co-bonding mode, before being cured, resin between the sealing stopper and the stringer edge strip is heated and then naturally flows for filling, and no gap exists after curing of the resin; a stringer, the sealing stopper and the skin form an integral structure; and the matching faces of the sealing stopper andthe metal wing rib are glued and sealed. Compared with the prior art, there is no need to separately manufacture a follow-up mold with theskin theoretical inner profile characteristics for the stopper, only a maintenance rubber stop mold is maintained, resin does not need to be separately cured in a hot pressure tank, and thus the cost is reduced; the sealing glue only needs to be applied to thematching faces of the stopper and the wing rib instead of being applied to the periphery of the stopper, so that the assembly procedure is simplified, and the sealing effect is improved; and the method is simple and practical, and has broad application prospects.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

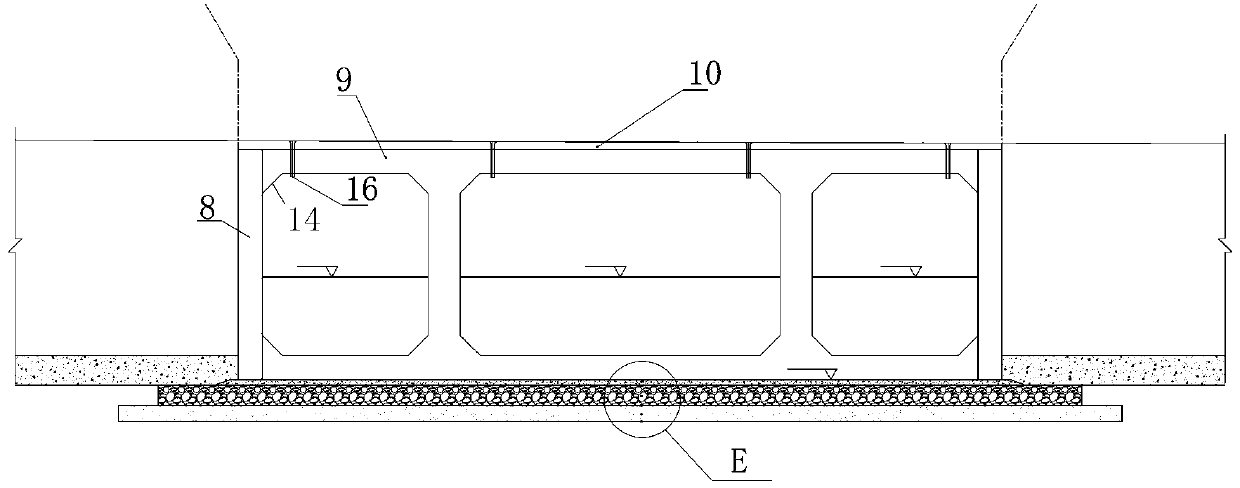

Water passing box culvert on soft soil foundation and construction method of water passing box culvert

ActiveCN110438914AMeet the bearing capacity requirementsNot prone to quality defectsGround-workSoil preservationRoad surfaceMechanical equipment

The invention discloses a water passing box culvert on a soft soil foundation and a construction method of the water passing box culvert. The water passing box culvert comprises a box culvert foundation, wherein the box culvert foundation sequentially comprises a reinforced filter net layer, a gravel soil layer, a durable reinforced filter net layer, a graded broken stone layer and a cushion layerfrom bottom to top, and the water passing box culvert is poured on the cushion layer; a body of the water passing box culvert is of a frame structure with a single box and three chambers, the frame with the single box and three chambers forms three water passing channels, a road pavement structure is arranged at the top of the water passing box culvert, a water separation wall is arranged on theupstream of the water passing tank culvert, and a paving layer is arranged on the downstream of the water passing tank culvert; and wing walls are arranged at joints between the water passing tank culvert and both sides of a river channel, and concrete protecting feet are arranged at the ends of each wing wall. The water passing box culvert is stable in foundation structure, not prone to generatequality diseases caused by uneven settlement of the foundation, lower in construction cost and easy to operate a construction technology, and does not need large-scale mechanical equipment for construction.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

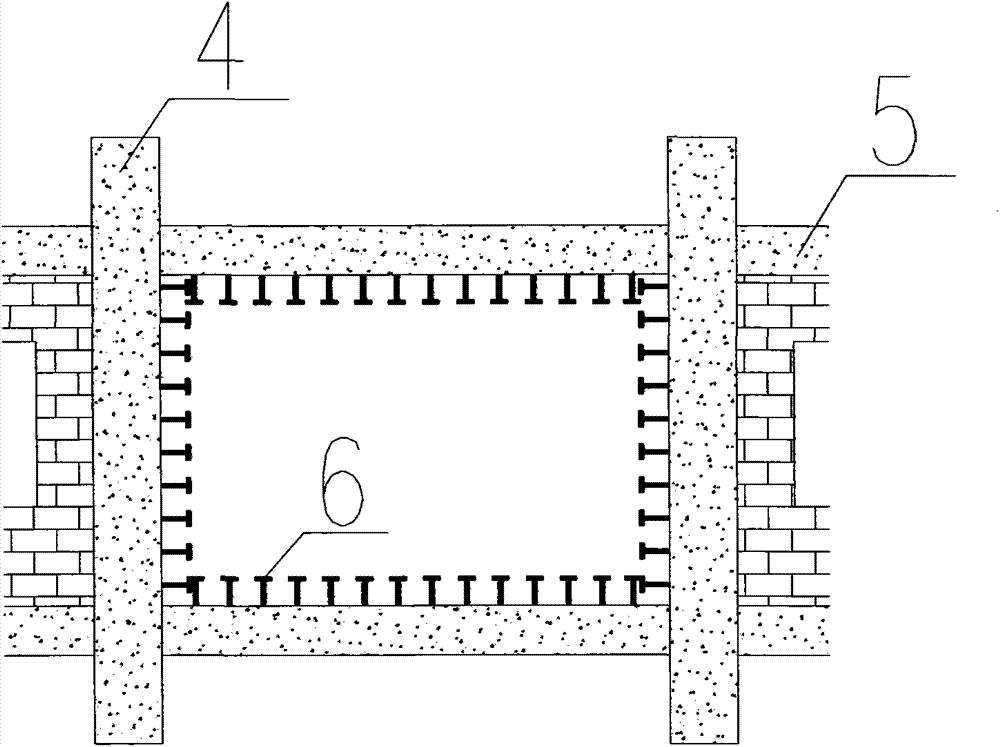

Method for strengthening existing frame additionally provided with steel support with border

ActiveCN103498573ASuitable for reinforcement repairEasy to operateBuilding repairsEngineeringWing wall

The invention relates to a method for strengthening an existing frame additionally provided with a steel support with a border, and belongs to the technical field of aseismic strengthening. The method comprises the steps of firstly, removing a crown wall, a waist wall and a wing wall inside the existing frame, reserving a concrete frame column and a concrete frame beam, embedding post-anchored bolts on the concrete frame column and the concrete frame beam, manufacturing the support with the steel border, welding toggle pins on the outer side of the profile steel border of the support with the steel border, embedding the support with the steel border into a frame structure, arranging spiral reinforcement bars at connection points, and pressing non-shrink mortar into the connection points. The method is easy to operate and reliable in maintenance effect, force can be transmitted to a building foundation through the added supporting member, and therefore the method for strengthening the existing frame is suitable for strengthening and maintenance of a whole building.

Owner:倡创(上海)咨询管理事务所

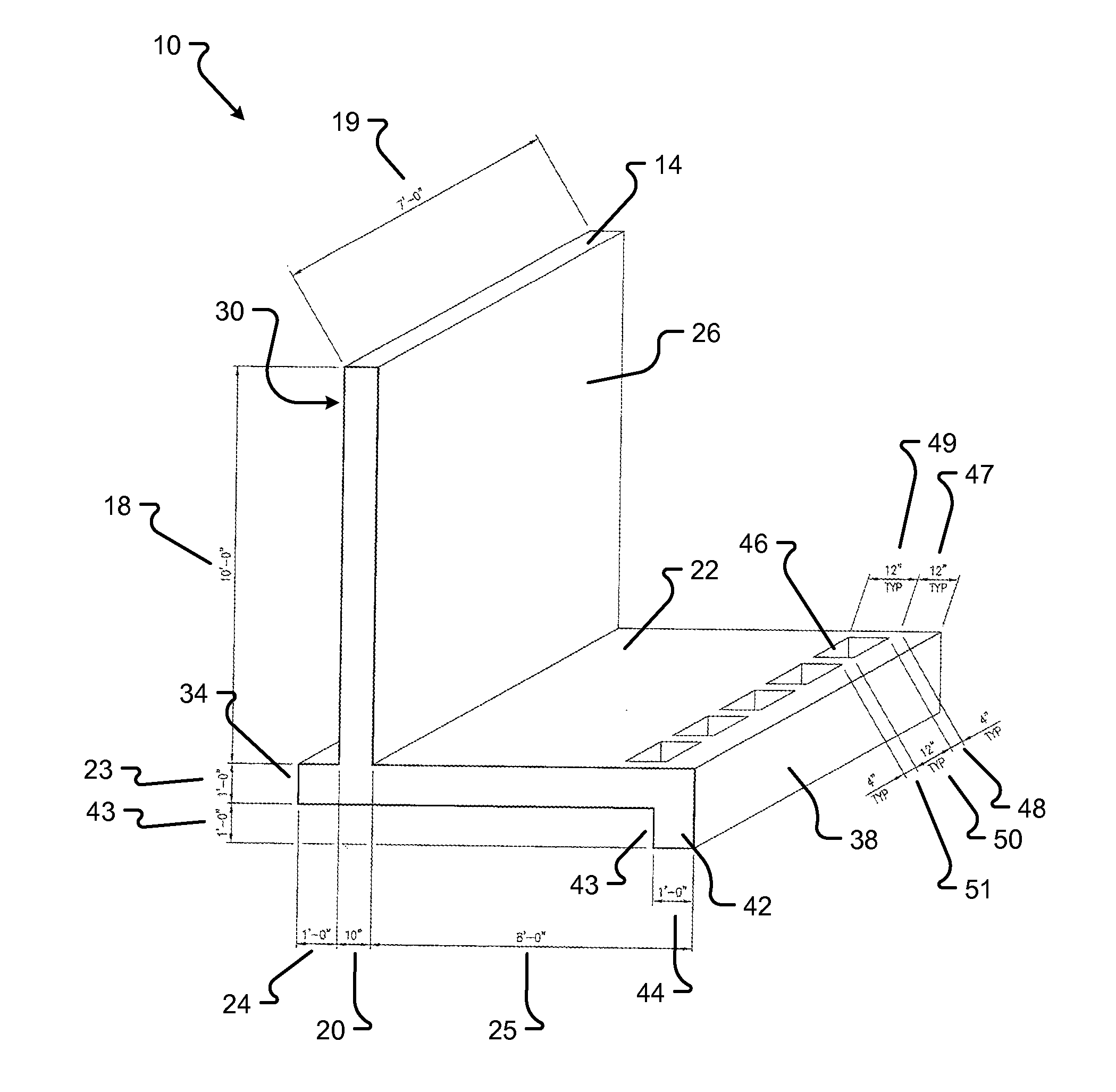

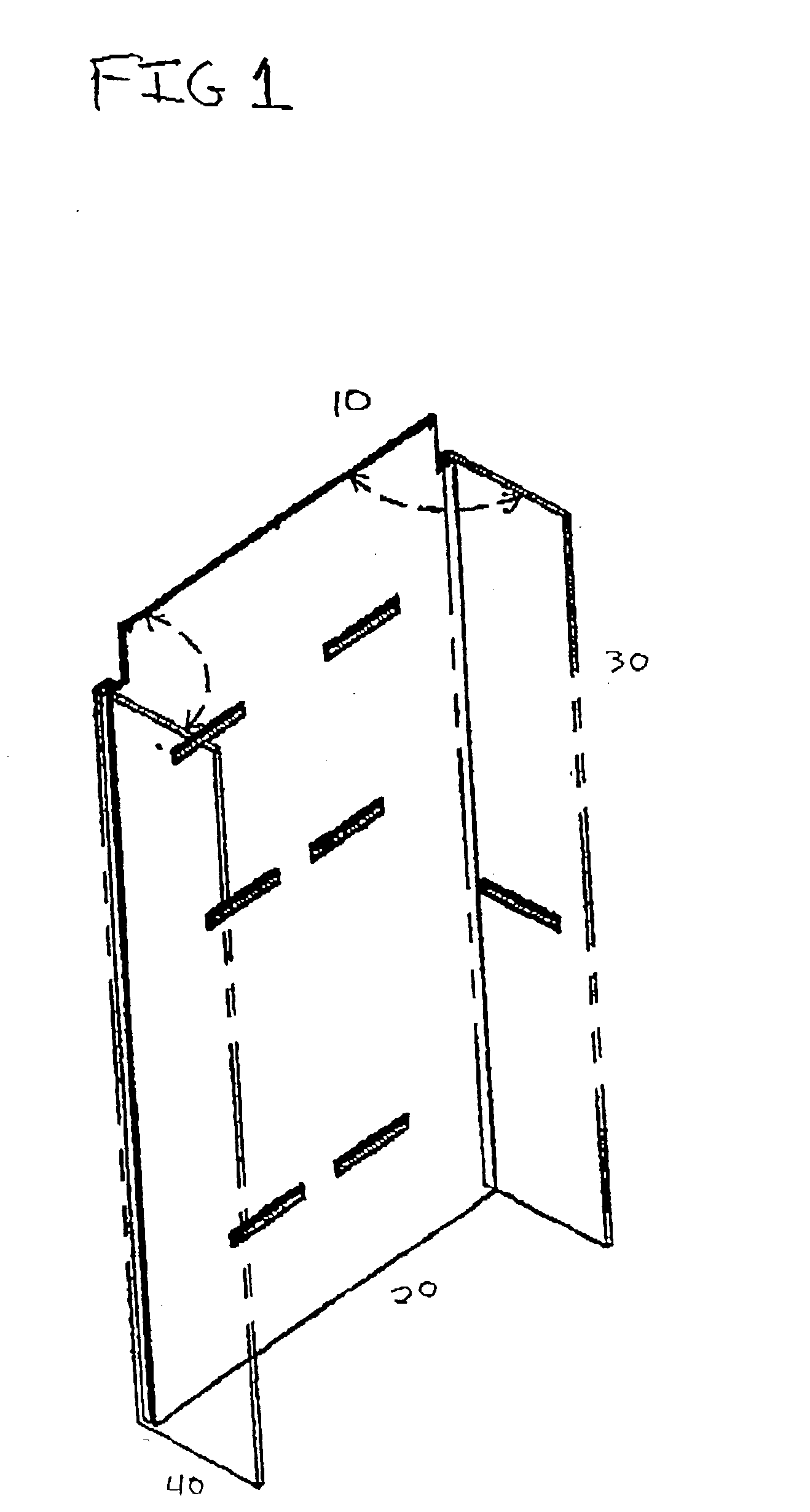

Cantilevered wing wall

ActiveUS9157211B2Cost-effective fabricationWide range of usesArtificial islandsCeramic shaping apparatusEngineeringPrecast concrete

The present invention relates generally to precast cantilevered retaining walls and methods of using and forming precast cantilevered retaining walls. More specifically, the present invention relates to a cantilevered concrete retaining wall having a base shear key and blockouts for receiving a material that substantially impedes the wing wall from sliding or other inadvertent movement, to a method of retaining a soil embankment with a cantilevered concrete retaining wall, and to a method of manufacturing a precast concrete cantilevered retaining wall.

Owner:OLDCASTLE PRECAST

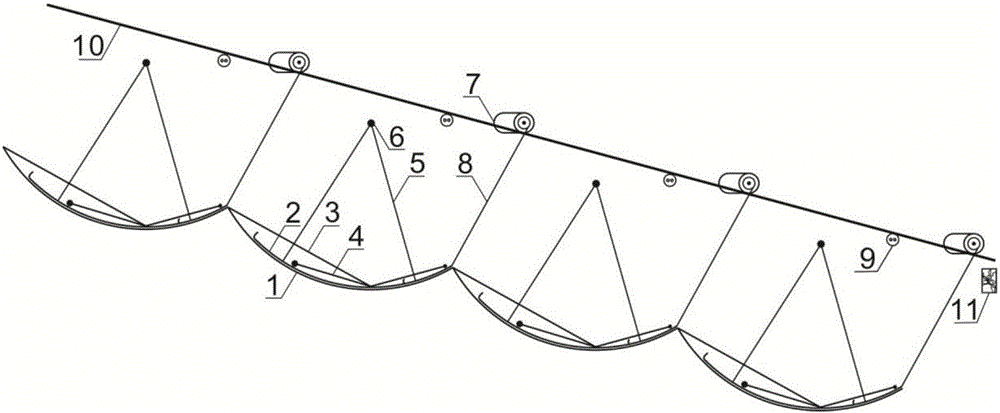

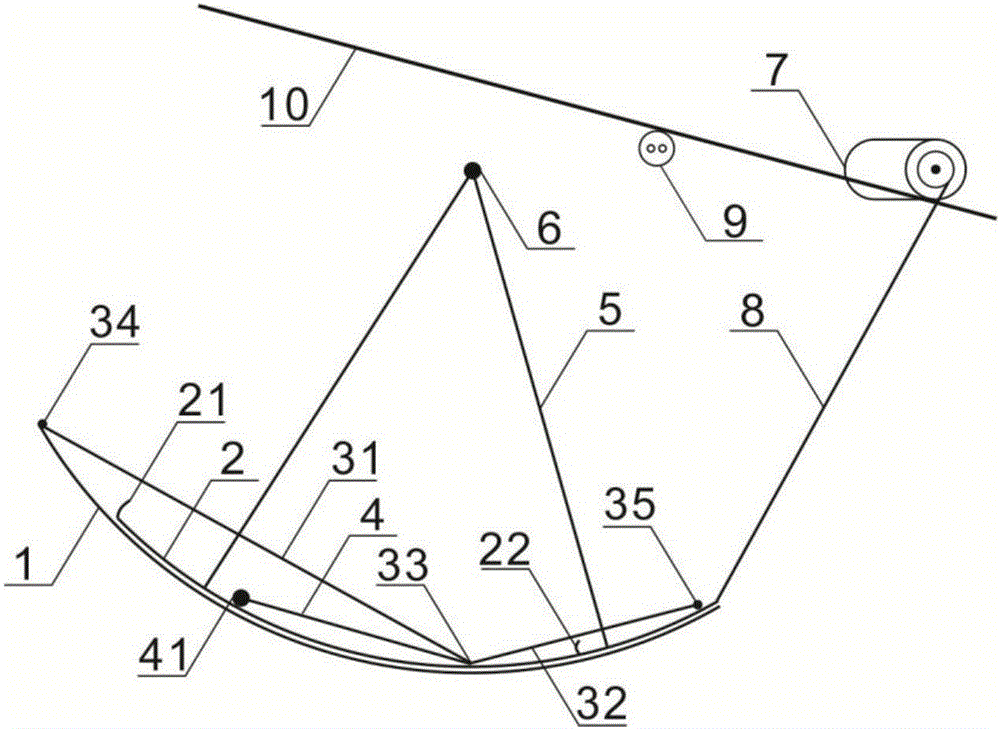

Superimposed arc type hydraulic-slope-variable fishway and fish passing method

ActiveCN106592542AGood for free spinsIncreased energy lossBarrages/weirsClimate change adaptationEcological environmentWater flow

The invention discloses a superimposed arc type hydraulic-slope-variable fishway and a fish passing method, and relates to the field of ecological environment of fish passing buildings and water conservancy and hydropower projects. The superimposed arc type hydraulic-slope-variable fishway is composed of a bottom plate with a plurality of steps, wing walls, a water retaining structure, a drive assisting structure, an inductor and a master controller, wherein the bottom plate and the water retaining structure can form a temporary pool so that the hydraulic slope of the fishway unit can be reduced and the hydrodynamic condition beneficial to upstream swimming of fish can be formed; and the drive assisting structure can assist fish in quickly and efficiently swimming upwards. Compared with a traditional fishway, the length of the fishway can be decreased, construction cost can be reduced, the waterflow condition of the fishway is easy to control, the fishway is suitable for dams with different delivery lifts to allow passing of fish, and the fishway has broad application prospects and remarkable economic and ecological benefits.

Owner:ANHUI UNIV OF SCI & TECH

Assemble rectangular ejecting tube section

PendingCN110685712AType of reductionSmall construction impactUnderground chambersTunnel liningWater stopEngineering

The invention discloses an assemble rectangular ejecting tube section. Each rectangular ejecting tube section is composed of two or more than two pieces of assemble prefabricated tube sheets, a convenient and fast joint or a step shear key, a pre-buried water stop steel pnd a sealed water stop rubber strip are arranged on each prefabricated tube sheet, quick positioning and connecting fixing are conducted on the splicing surface of each prefabricated tube sheet through the convenient and fast joint or the step shear key, the pre-buried water stop steel plate is arranged on the outer side of the slicing surface of each prefabricated tube sheet for water stopping, the grouting hole is reversed in the inner side of the splicing surface of each prefabricated tube sheet, the sealed water stop rubber strip is reversed at the splicing surface of each prefabricated tube sheet, and a waterproof system is formed jointly by the pre-buried water stop steel plate, the grouting hole and the sealed water stop rubber strip; and an inter-ring pre-buried water stop steel plate and a sealed water stop rubber strip are arranged between tube sections, and sealing is achieved through ejecting feeding pressure for ejecting. In addition, by being combined with use functions, a wing wall and / or a laminated plate is needed to be arranged in each ejecting tube section to form a space stable structure, atemporary supporting function is achieved during assembling, and the functional requirements of the use state are met.

Owner:北京中岩智泊科技有限公司

All aluminum alloy front floor assembly for automobile

InactiveCN110001792ALight in massImprove NVH performanceSuperstructure subunitsEngineeringInverted u

The invention discloses an all aluminum alloy front floor assembly for an automobile. The all aluminum alloy front floor assembly for the automobile comprises a front floor, an omega-shaped middle passage stamping panel, a multi-cavity inverted U-shaped middle through plate piece with a wing arm-shaped section, a front floor longitudinal beam with an extending wing arm and a square-shaped section,a threshold beam with a wing wall and an irregular four-square-shaped section and an irregular seat cross beam with an extending wing arm and an irregular square-shaped section. According to the allaluminum alloy front floor assembly for the automobile, each member adopts an aluminum alloy material, and the integral mass of the assembly is light; compared with a steel front floor, the the all aluminum alloy front floor assembly for the automobile has the advantages that the integral weight loss reaches up to 25-35%, the manufacturing is simple, the cost is saved, and the assembly can be completely recycled. According to the all aluminum alloy front floor assembly for the automobile, each member adopts a cementing and riveting mixed connecting mode so that the structural strength of the integral structural frame is high; and moreover, the integral NVH performance of the automobile is improved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Cement component crossing highway and mounting method

PendingCN110747762AImprove construction progressReduce slotting timeArtificial islandsGround-workPre stressArchitectural engineering

The inventio discloses a cement component crossing a highway and a mounting method and belongs to the field of road construction. At present, when a traditional cast-in-place manner is adopted for construction, the construction process is tedious, the construction plant requirement is high, the construction period is laggard, and the maintenance cost is high. The cement component crossing the highway comprises a fabricated box culvert (1), and a convex inserting groove (2) is machined in an end opening of a top mold of the fabricated box culvert; a convex clamping groove (3) with an annular gap is machined in a bottom end opening of the fabricated box culvert, and the convex clamping groove is inserted into the convex inserting groove in another fabricated box culvert; PE pipes (4) for forming prestressed tendon pore ducts are arranged at the four corners of the convex inserting groove, the PE pipes are linearly buried in the four corners of the upper portion of the fabricated box culvert, and then pore ducts (5) are preserved in the four corners of the pipe joints of the PE pipes; steel strands penetrate through the pore ducts, tensioning is carried out, and joint treatment and pore duct grouting are carried out after tensioning is completed; and then wing wall treatment and culvert side backfilling are carried out.

Owner:贾殿录

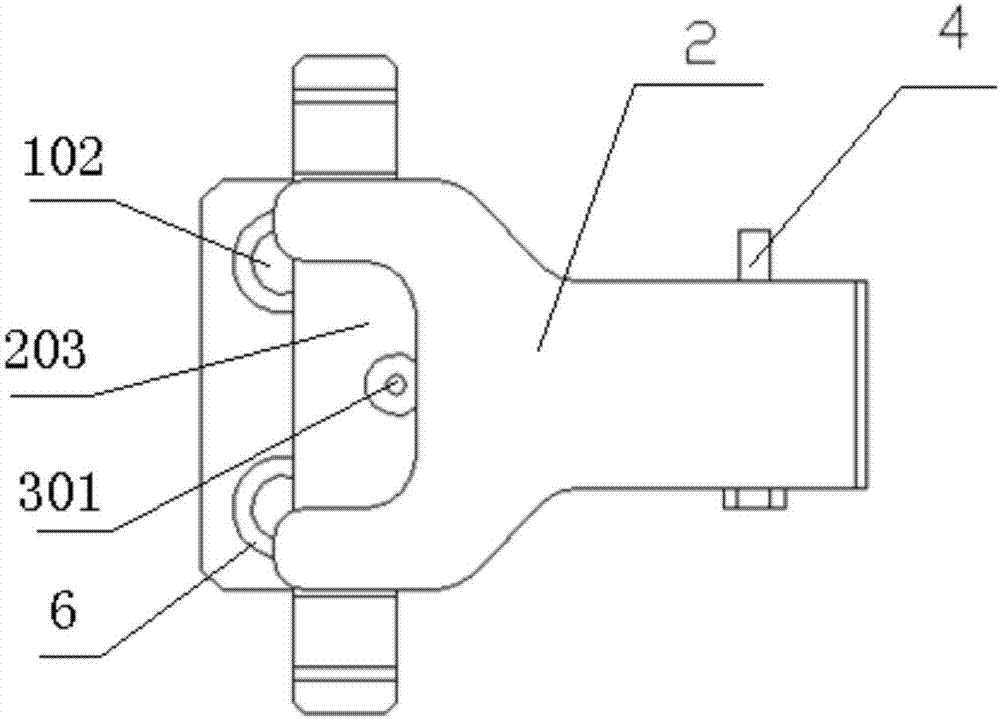

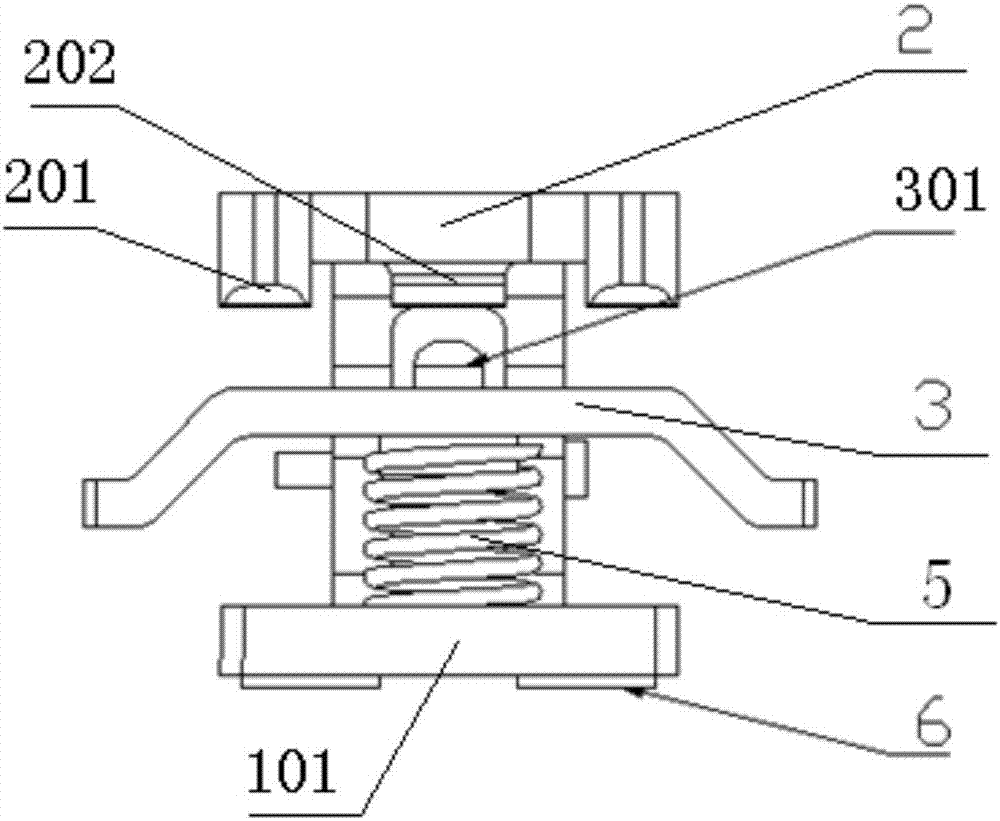

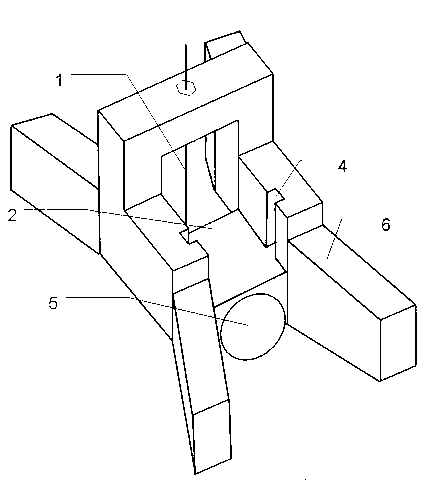

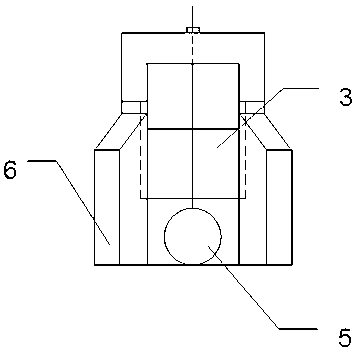

Measurement tool of edges and recesses of composite-material wing wall board

ActiveCN107167065AEasy to useImprove measurement efficiencyMechanical roughness/irregularity measurementsEngineeringWing wall

The invention discloses a measurement tool of edges and recesses of a composite-material wing wall board. The measurement tool comprises an installation seat, a first clamp plate, a second clamp plate and an elastic support piece. The installation seat is equipped with a target seat installation hole. The first clamp plate is fixedly connected with the installation seat. The second clamp plate is connected with the installation seat through a rotation shaft. The first clamp plate and the second clamp plate are oppositely arranged and a clamp space is arranged therebetween. The elastic support piece is installed between the second clamp plate and the installation seat and used for keeping the second clamp plate and providing clamping force. According to the invention, the measurement tool is simple and convenient to use, high in measurement efficiency, simple to manufacture, low in cost, and capable of achieving multi-point positioning and providing stable support.

Owner:ZHEJIANG UNIV

Open trench control drainage device for rice-wheat crop rotation farmlands

InactiveCN103015381AAvoid water damageIncrease profitConstructionsSoil drainageEutrophicationRetention time

The invention provides an open trench control drainage device for rice-wheat crop rotation farmlands. The device comprises a lock chamber, wherein the lock chamber is divided into upper and lower layers, and wing walls are respectively distributed at two ends of the lock chamber; a culvert pipe is distributed in the lower layer of the lock chamber, and a gate is arranged at the front end of the culvert pipe in the lower chamber; an overflow tank is formed into the upper layer of the lower chamber, and dam troughs are oppositely distributed at two sides of the wall at the rear end of the overflow tank; and a water retaining weir plate is inserted into the dam trough. Through the device, the retention time of the farmland drainage in the trench is increased, so that the pollutants in the trench are absorbed, adsorbed and degraded; the downstream water body pollution can be reduced; and the water eutrophication can be controlled. Because the device is permanently and fixedly arranged at the rear end of a drainage trench, the improvement on a drainage system of rice-wheat crop rotation can be avoided, and the water conservancy cost of the farmland is greatly reduced. The device is low in construction cost and maintenance cost, compact in structure, simple to operate, and easy for promoting in large area.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com