Patents

Literature

17555results about "Cranes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

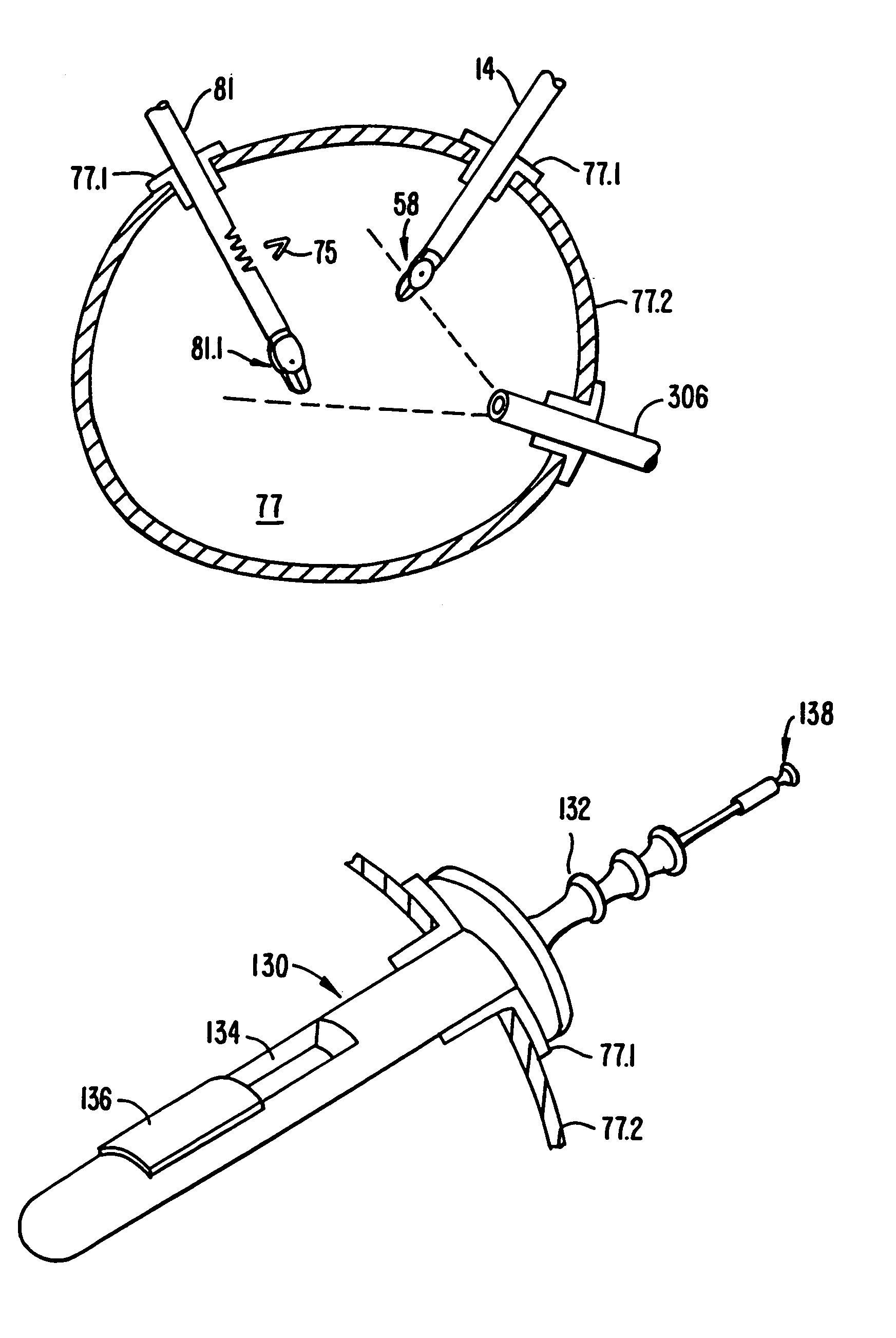

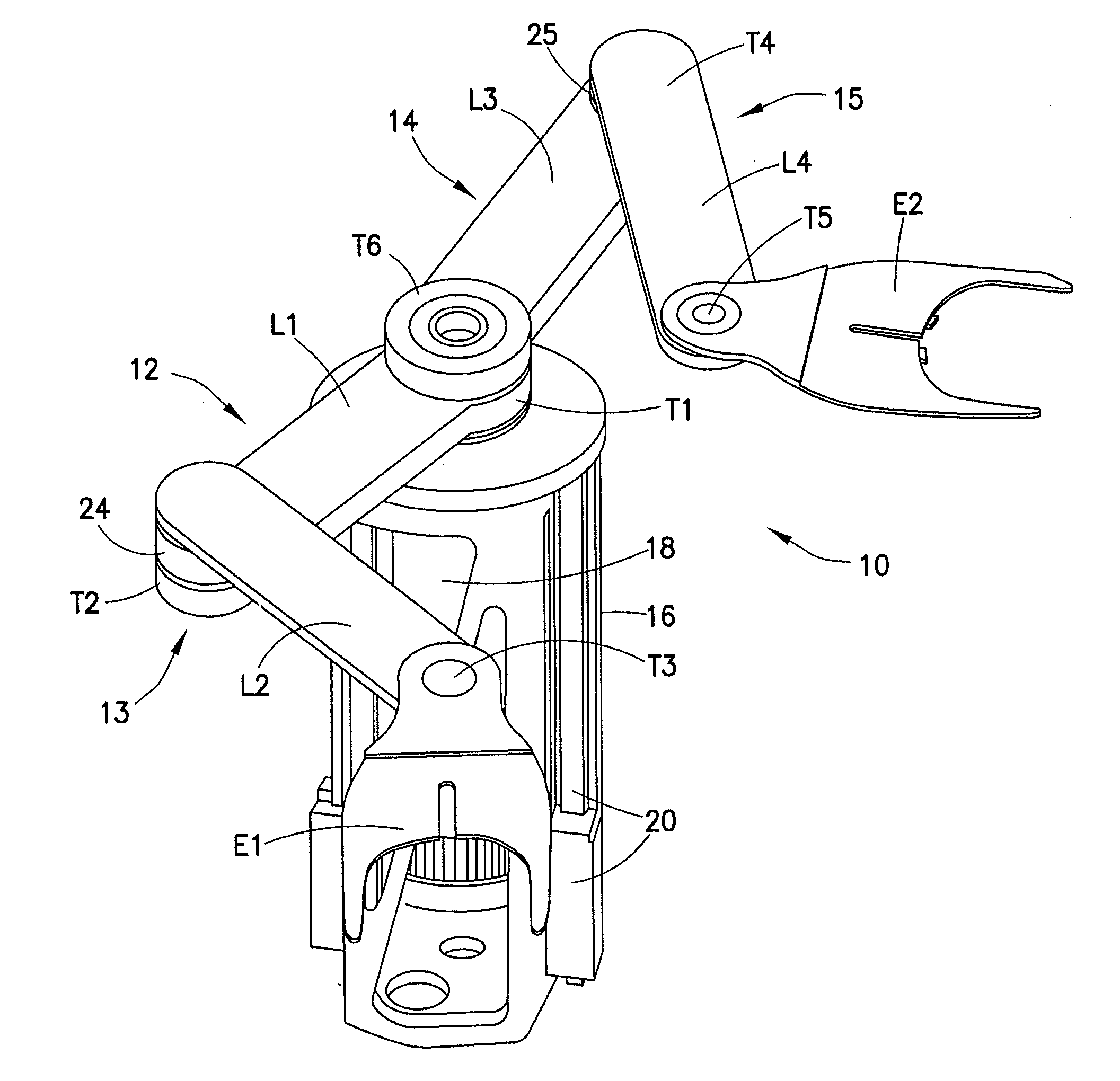

In vivo accessories for minimally invasive robotic surgery

InactiveUS7125403B2Reduce downtimeReduce needSuture equipmentsSurgical needlesSurgical siteEngineering

Owner:INTUITIVE SURGICAL OPERATIONS INC

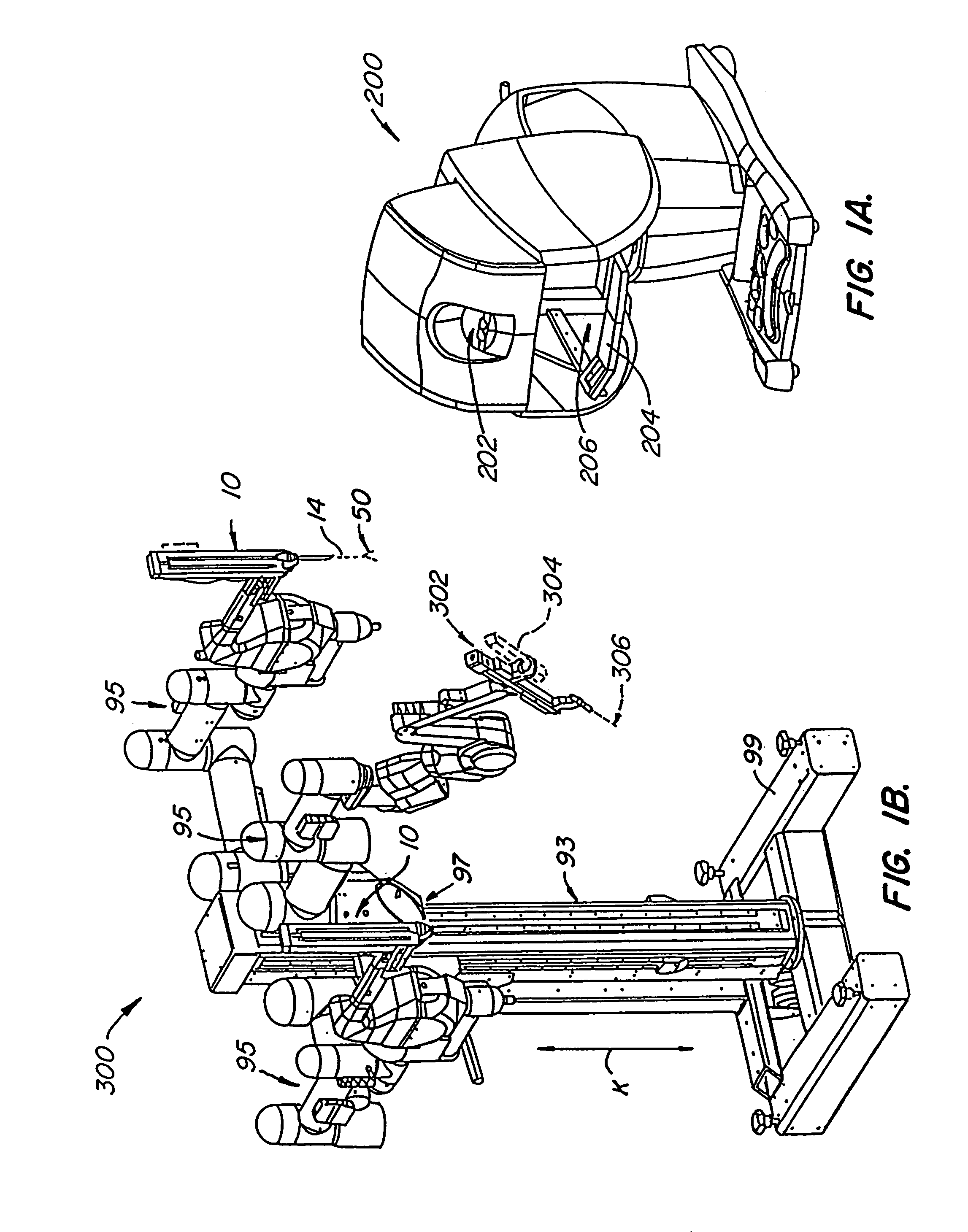

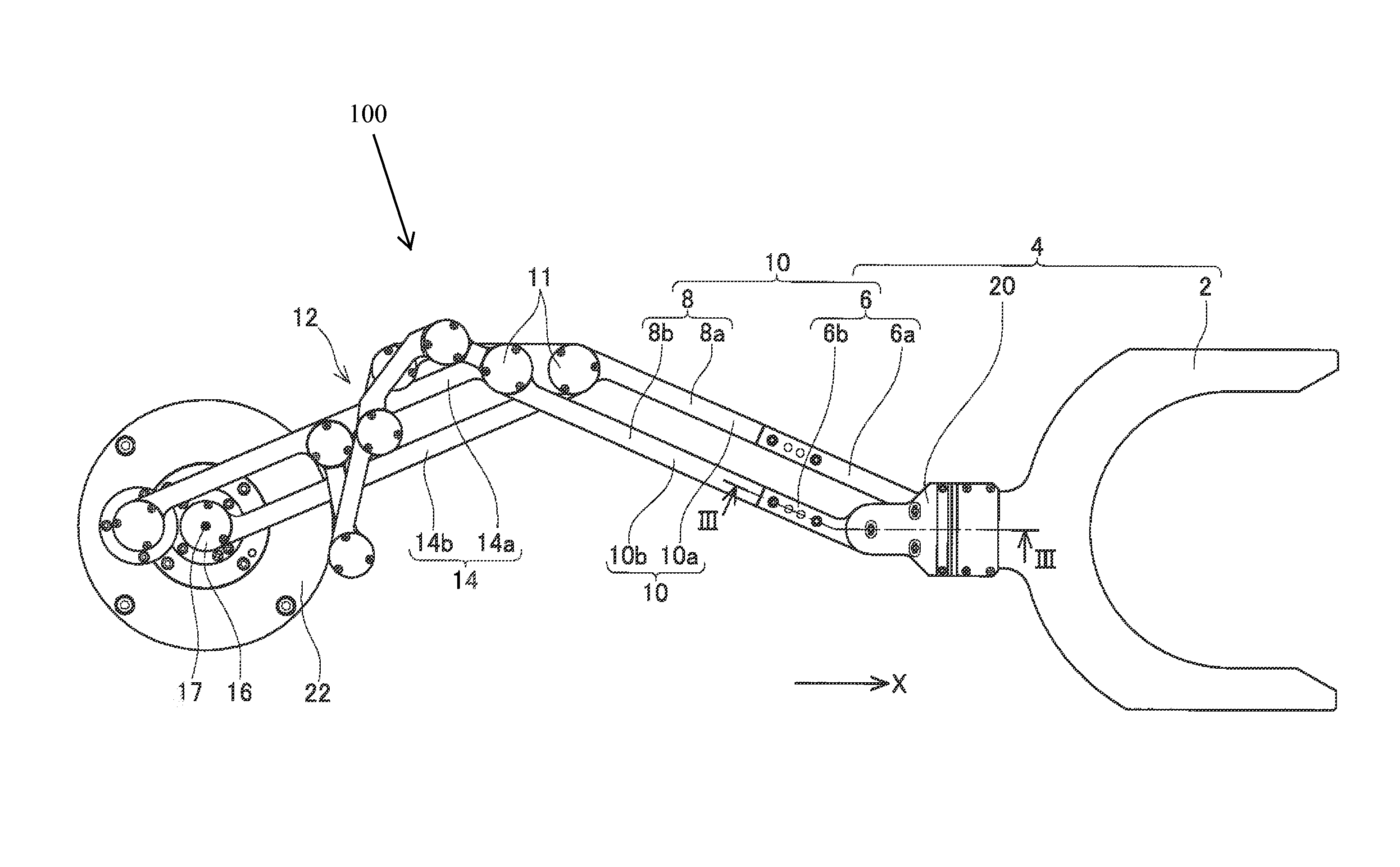

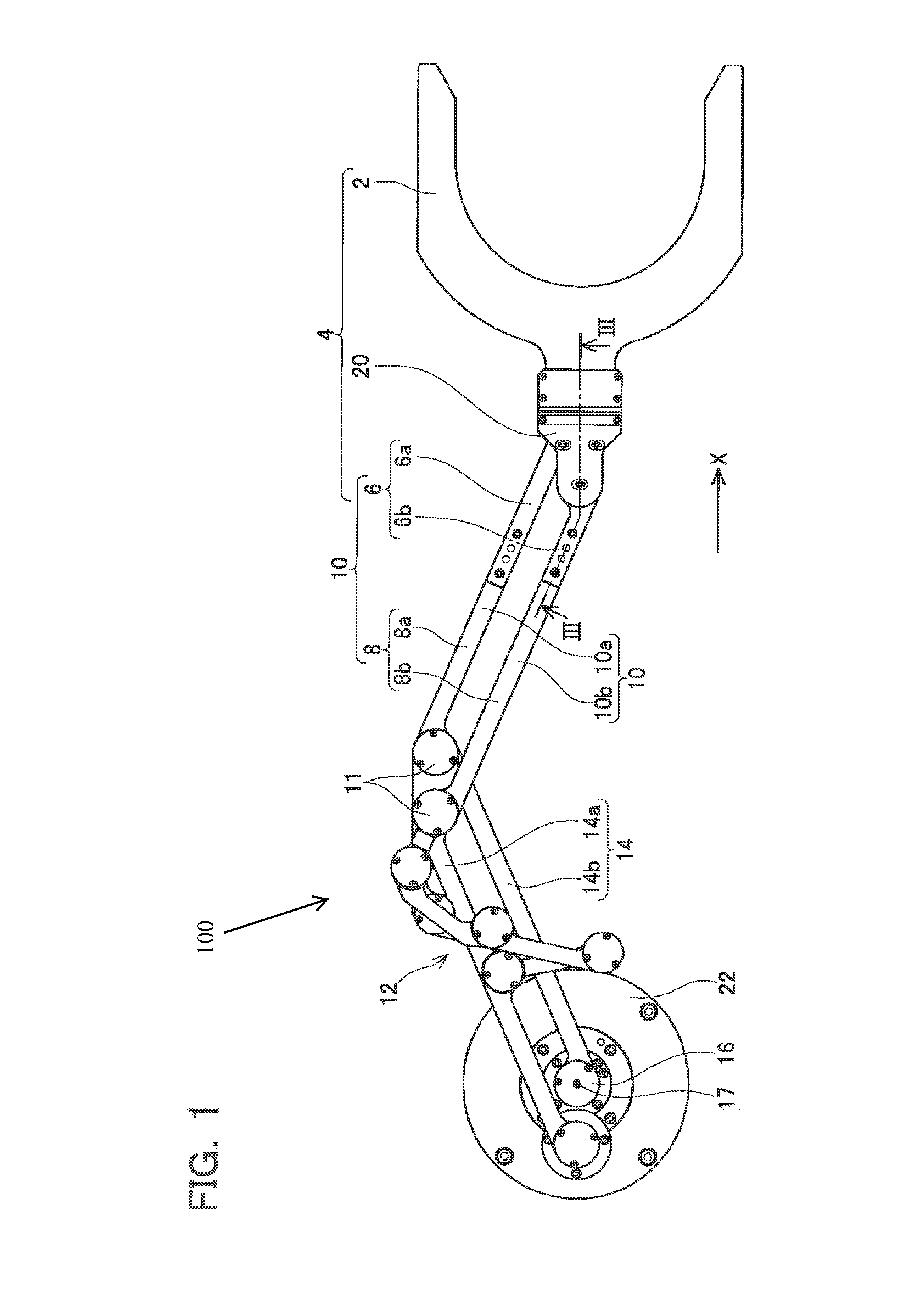

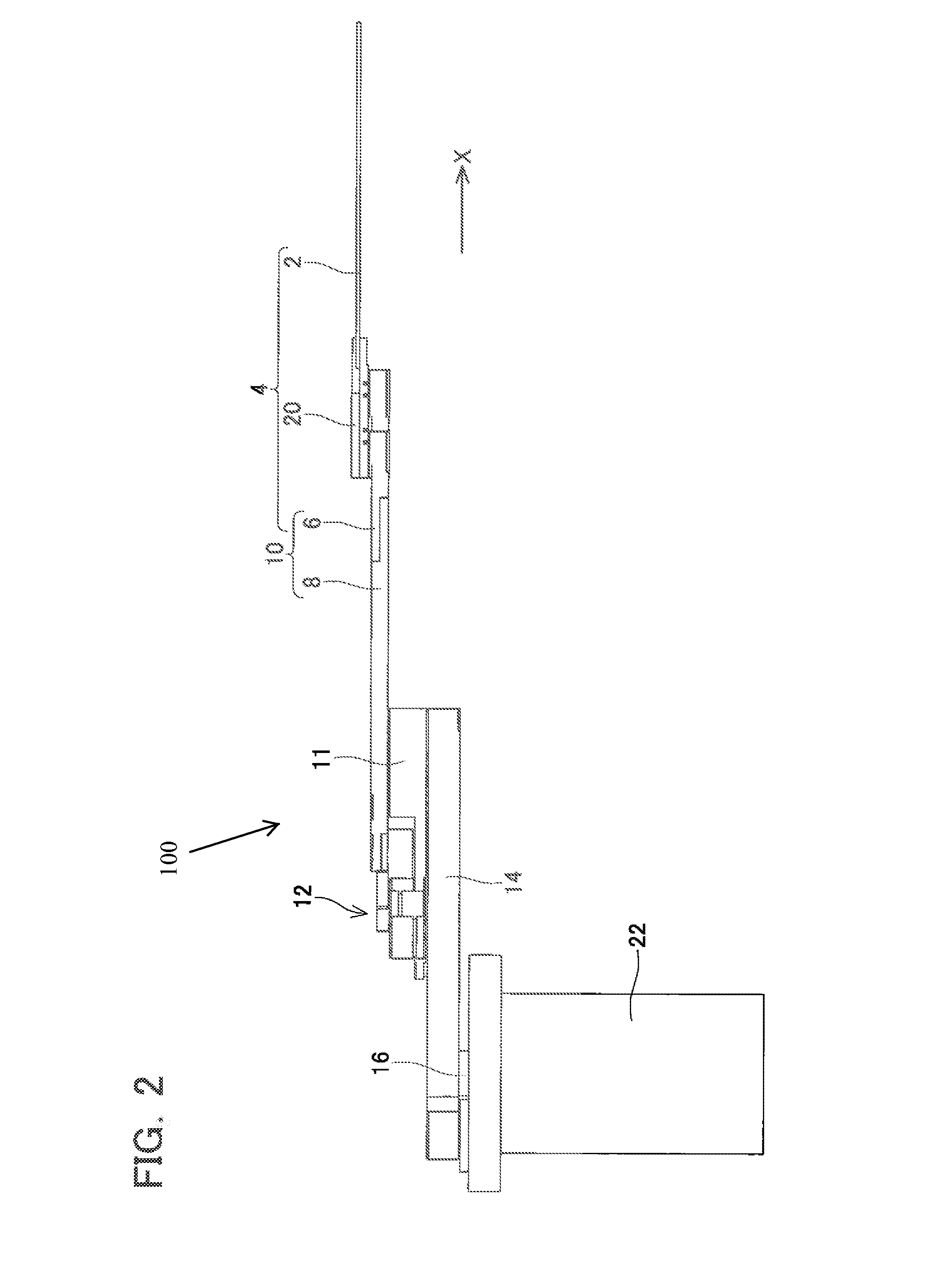

Transportation apparatus and drive mechanism

ActiveUS7837425B2Low costReduce weightProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

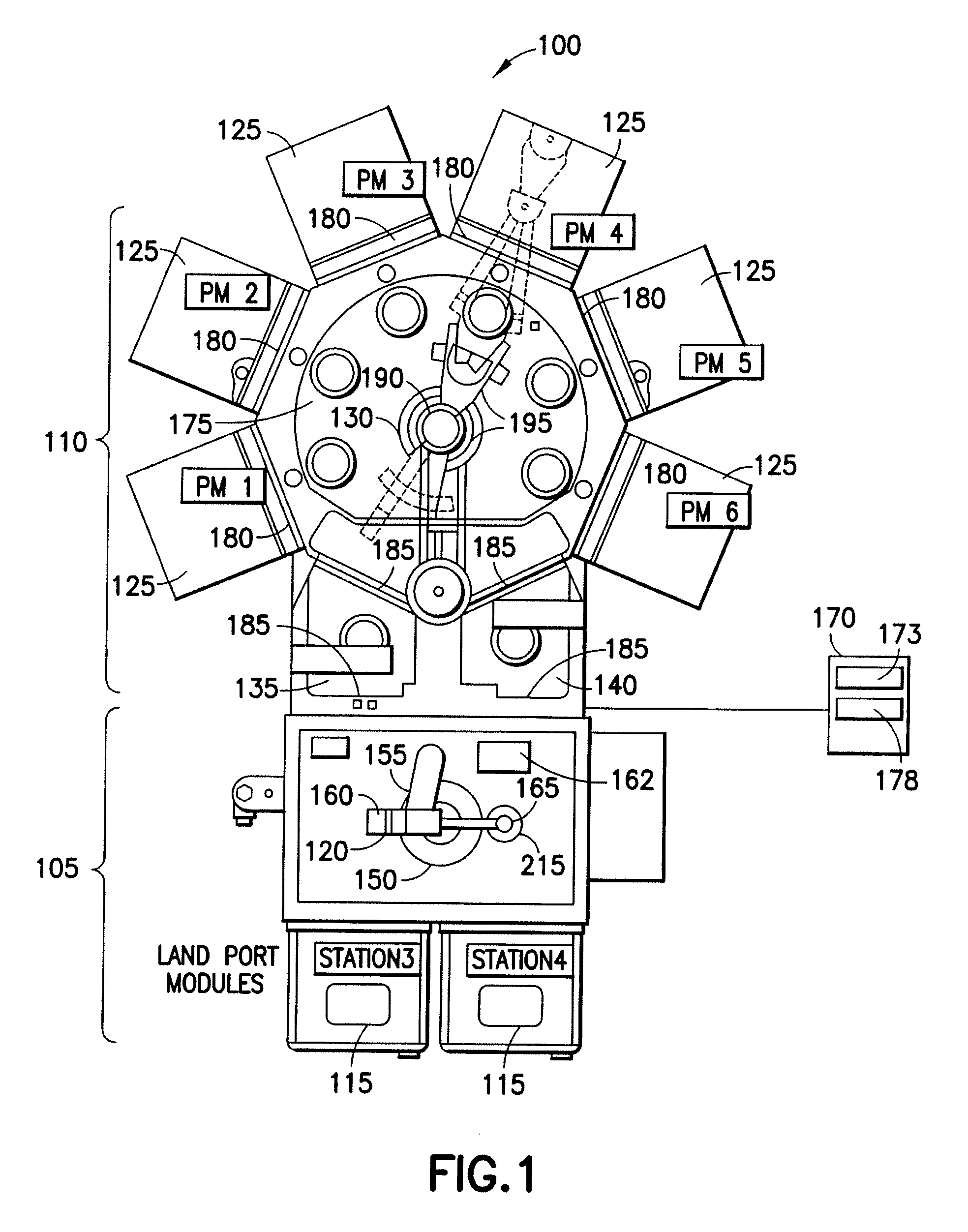

Owner:TOKYO ELECTRON LTD

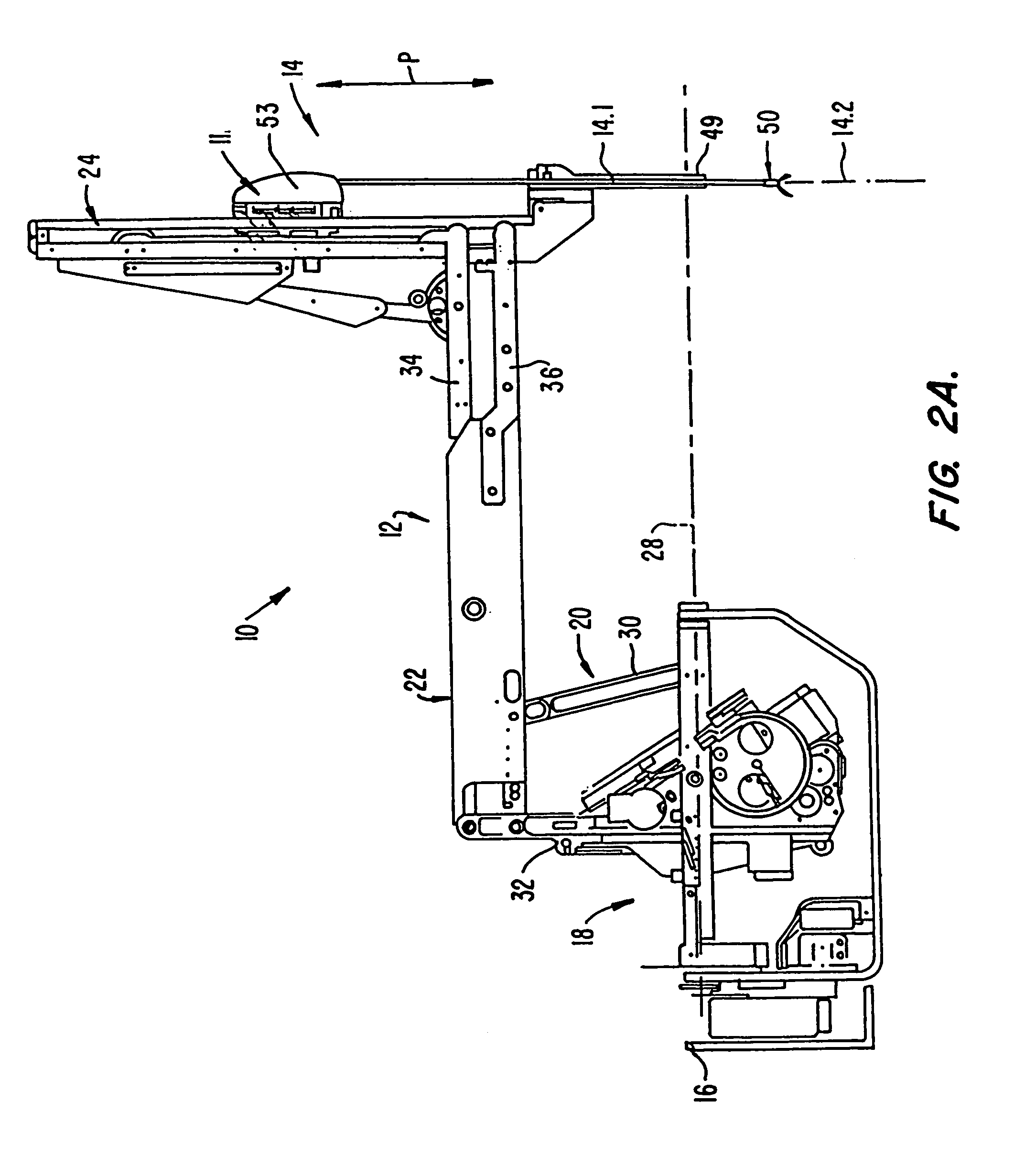

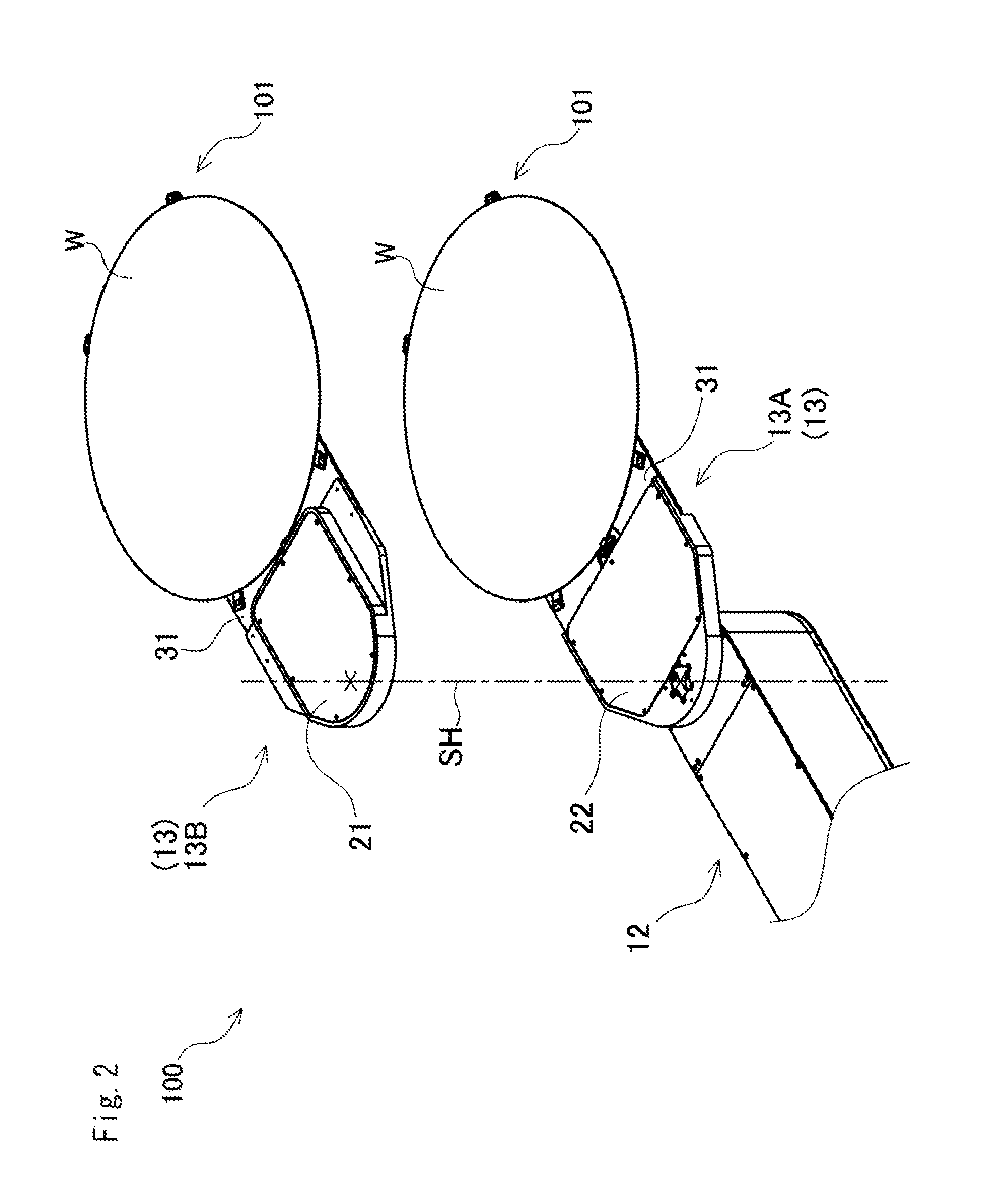

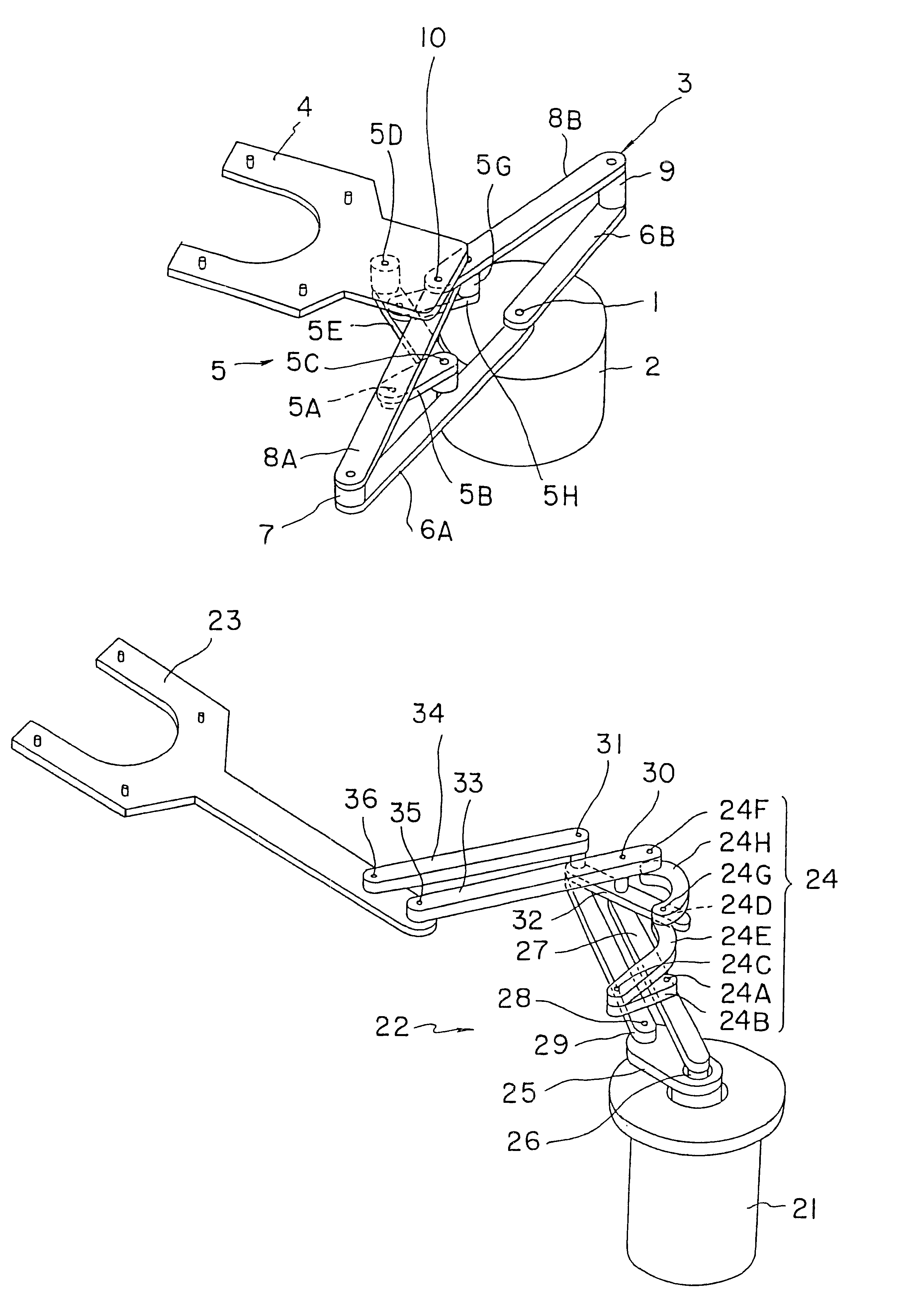

Clamping device and workpiece conveying robot

InactiveUS8764085B2High positionalImprove retentionGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SINFONIA TECHNOLOGY CO LTD

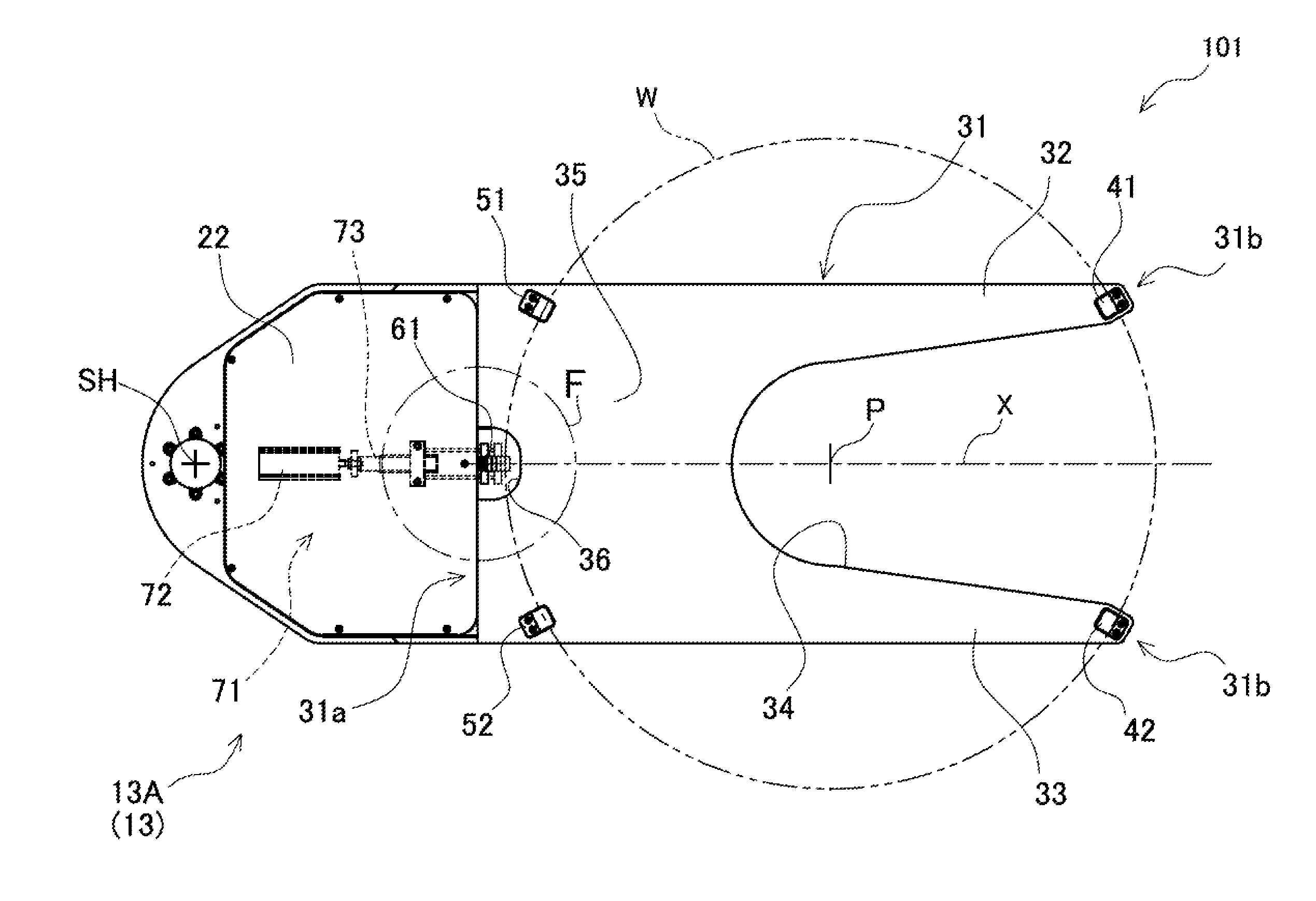

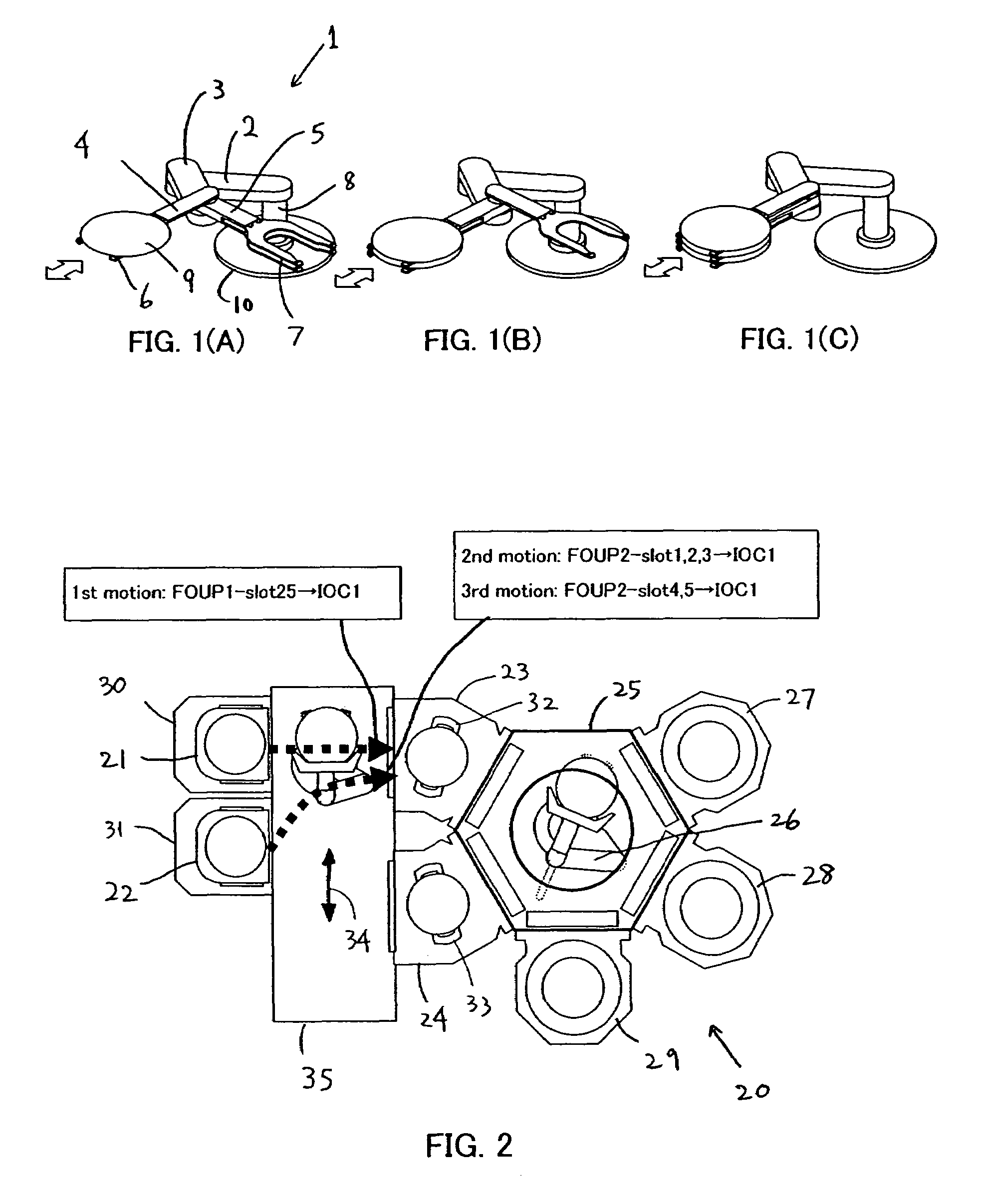

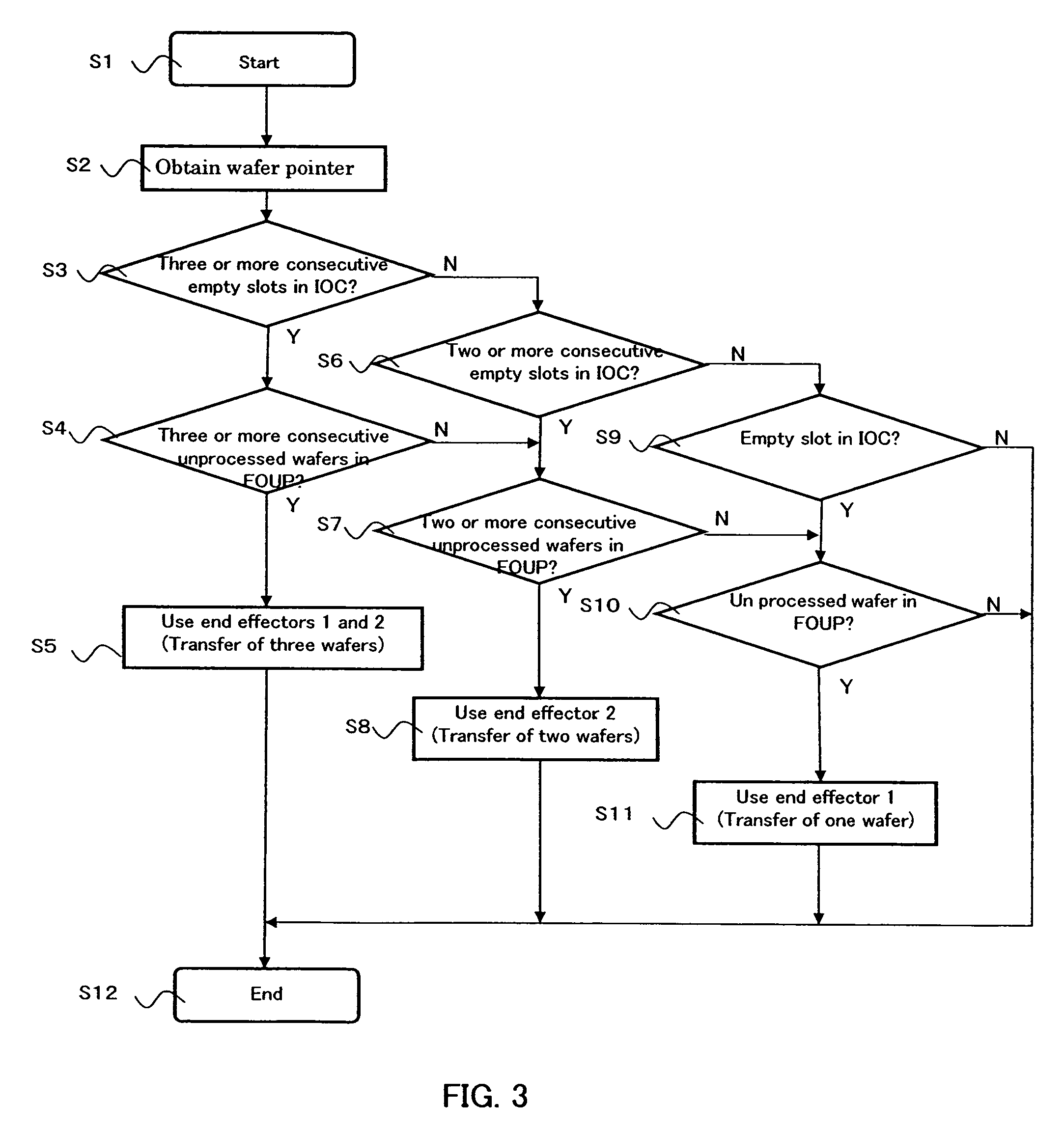

Semiconductor substrate transfer apparatus and semiconductor substrate processing apparatus equipped with the same

A semiconductor substrate transfer apparatus for transferring semiconductor substrates from a first container to a second container, includes: multiple end effectors; at least one robot arm with which the multiple end effectors are independently rotatably joined; and a controller storing software including instructions to judge which end effector or end effectors in the multiple end effectors are to be selected based on a distribution status of substrates stored in the first and second containers and to rotate the selected end effector(s) for unloading a substrate or substrates from the first container and loading the substrate or substrates to the second container.

Owner:ASM JAPAN

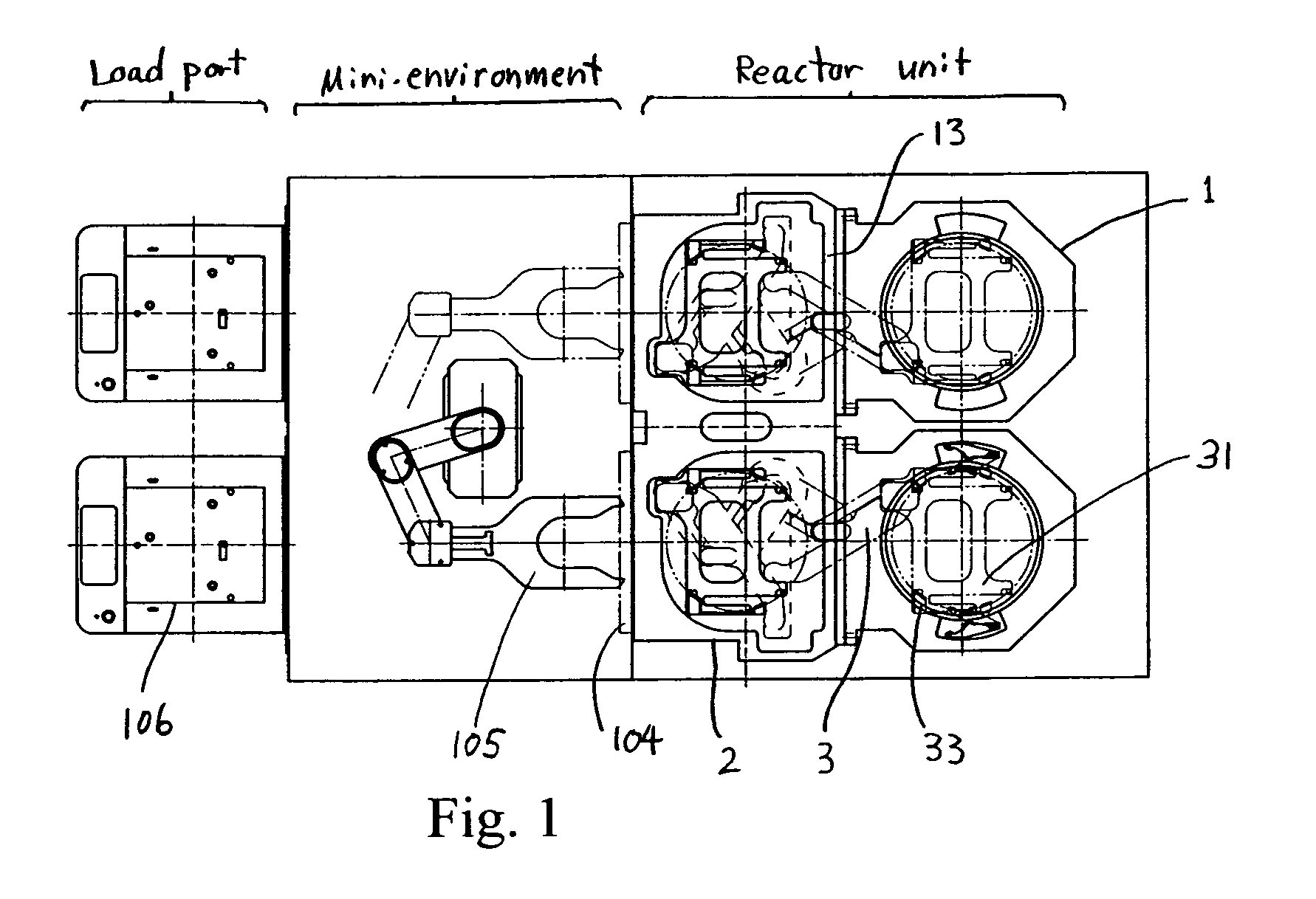

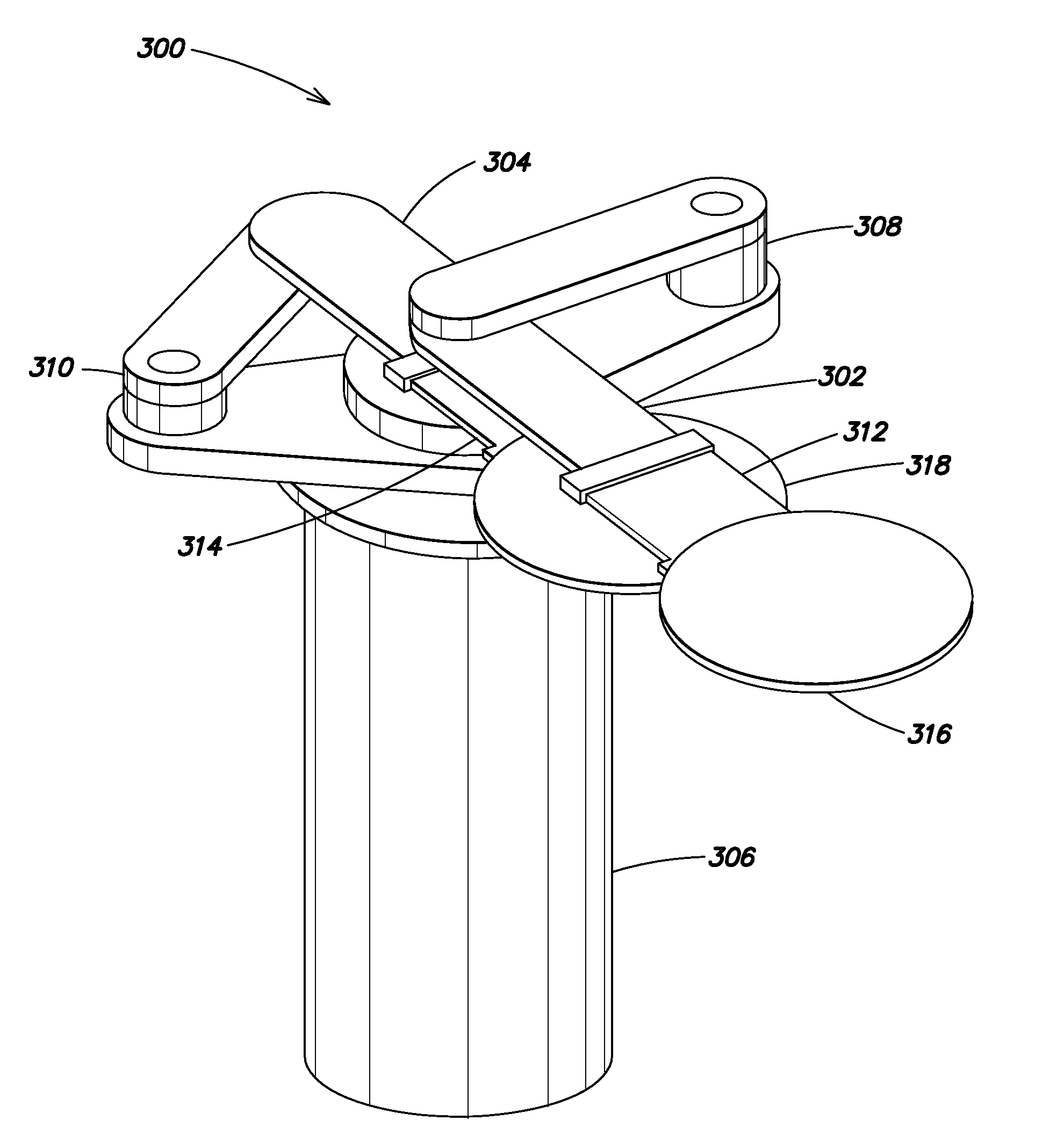

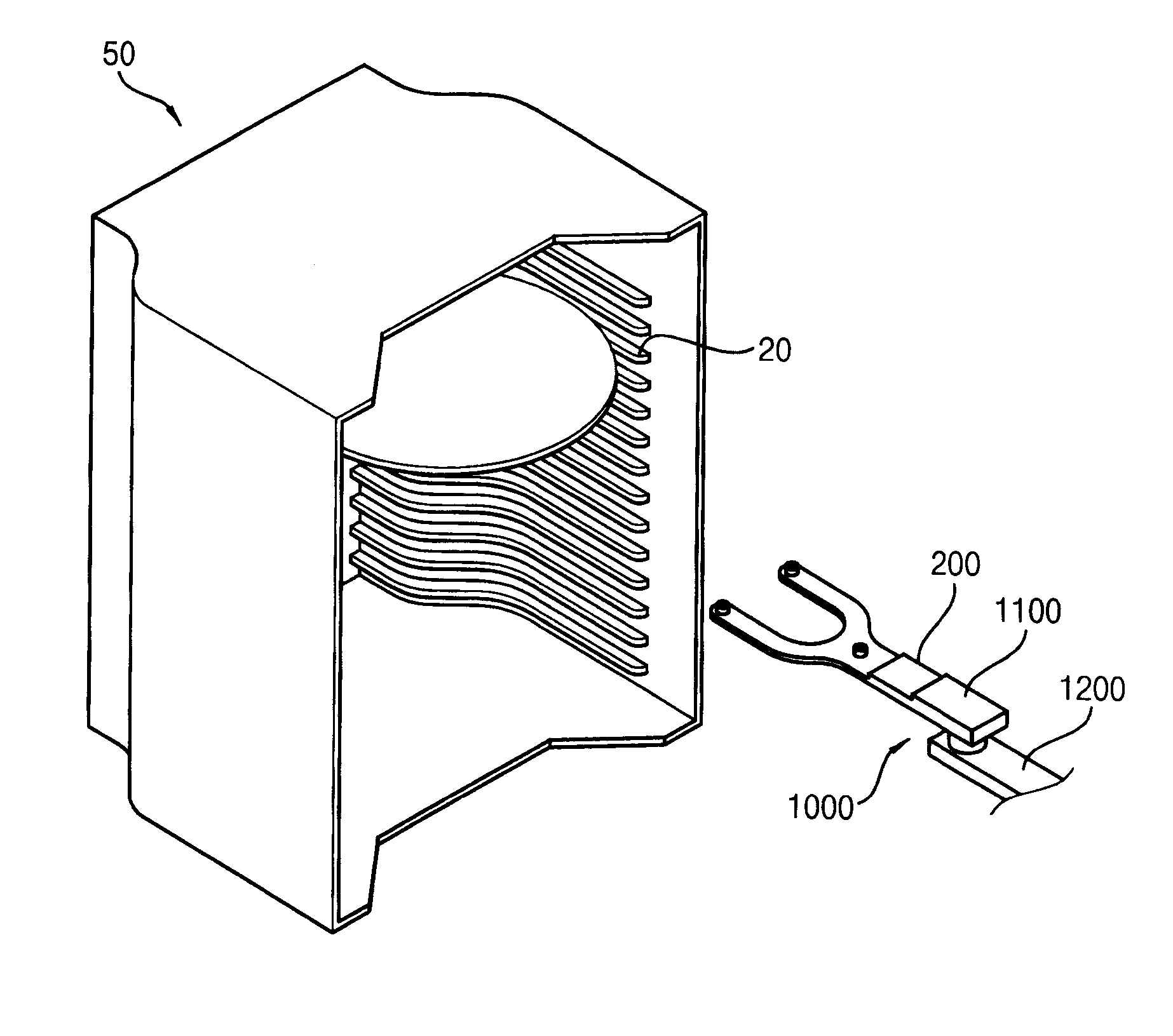

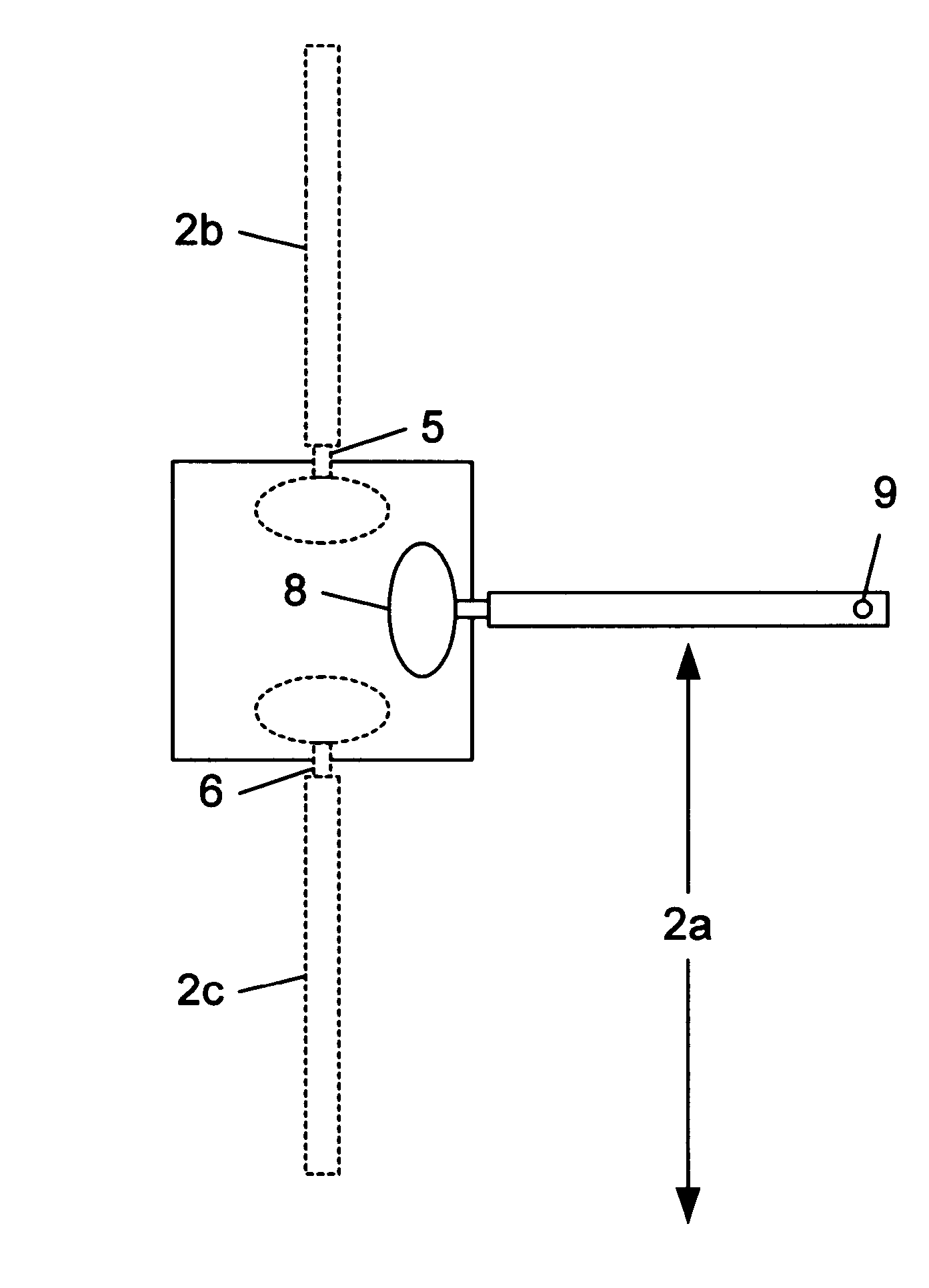

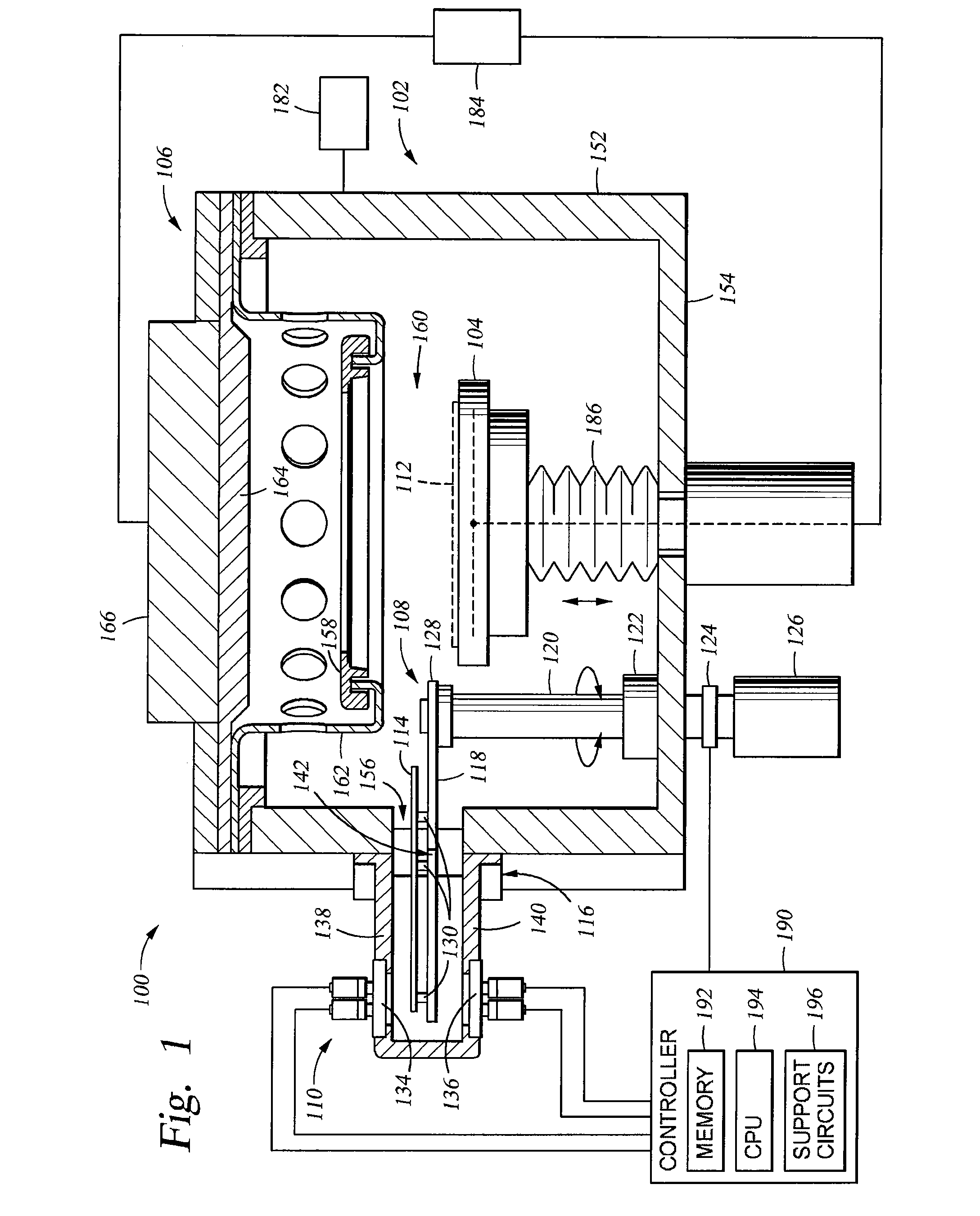

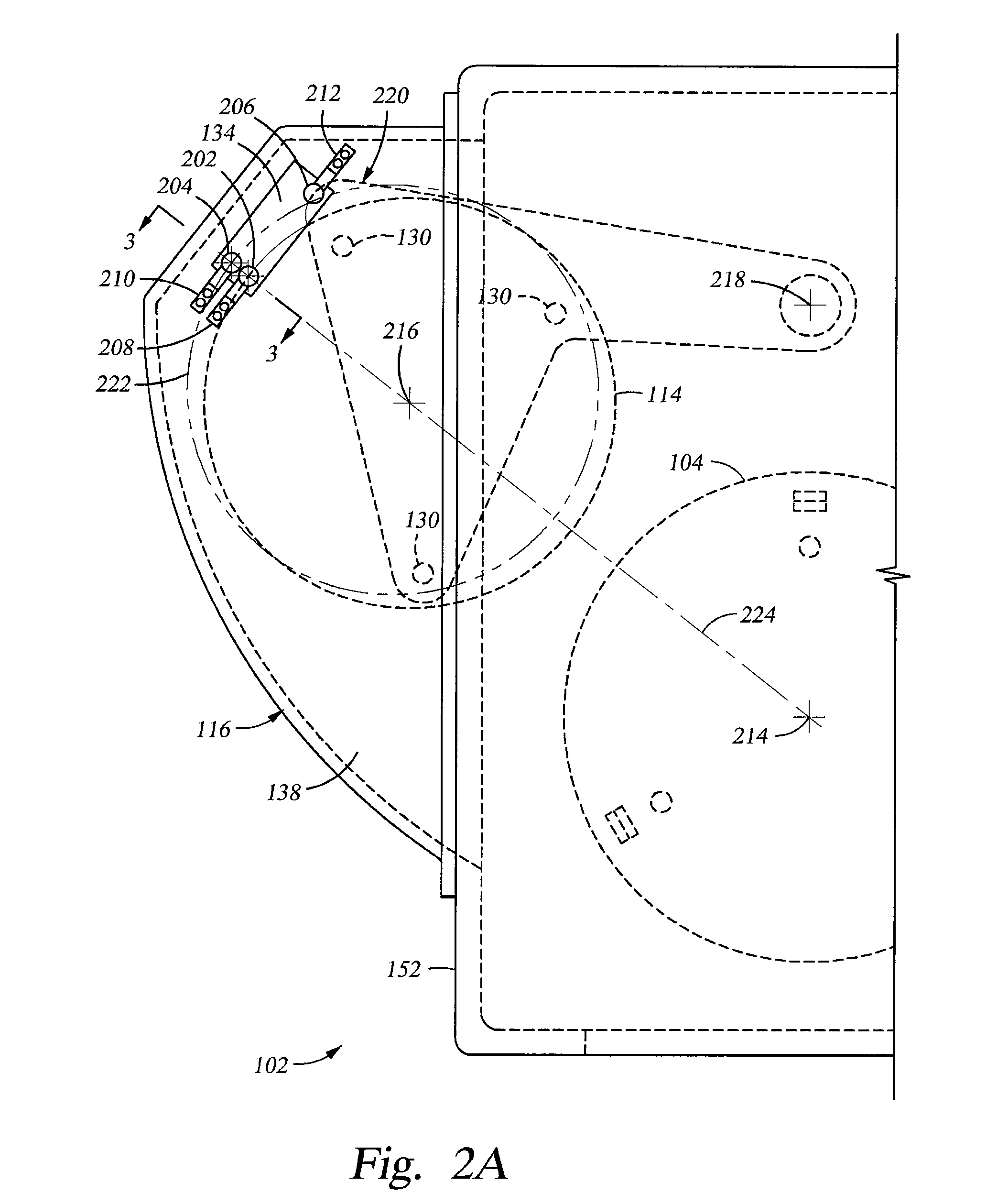

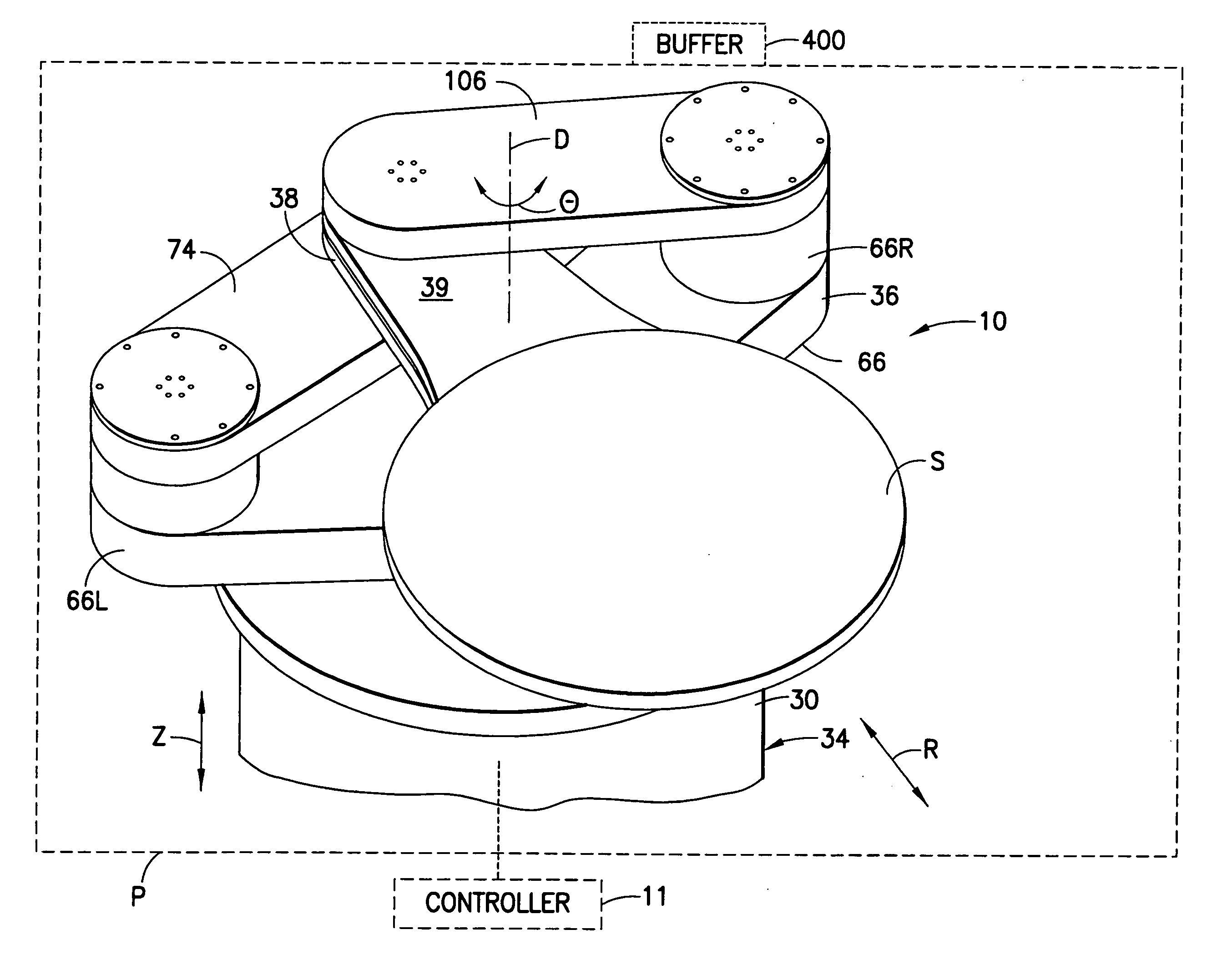

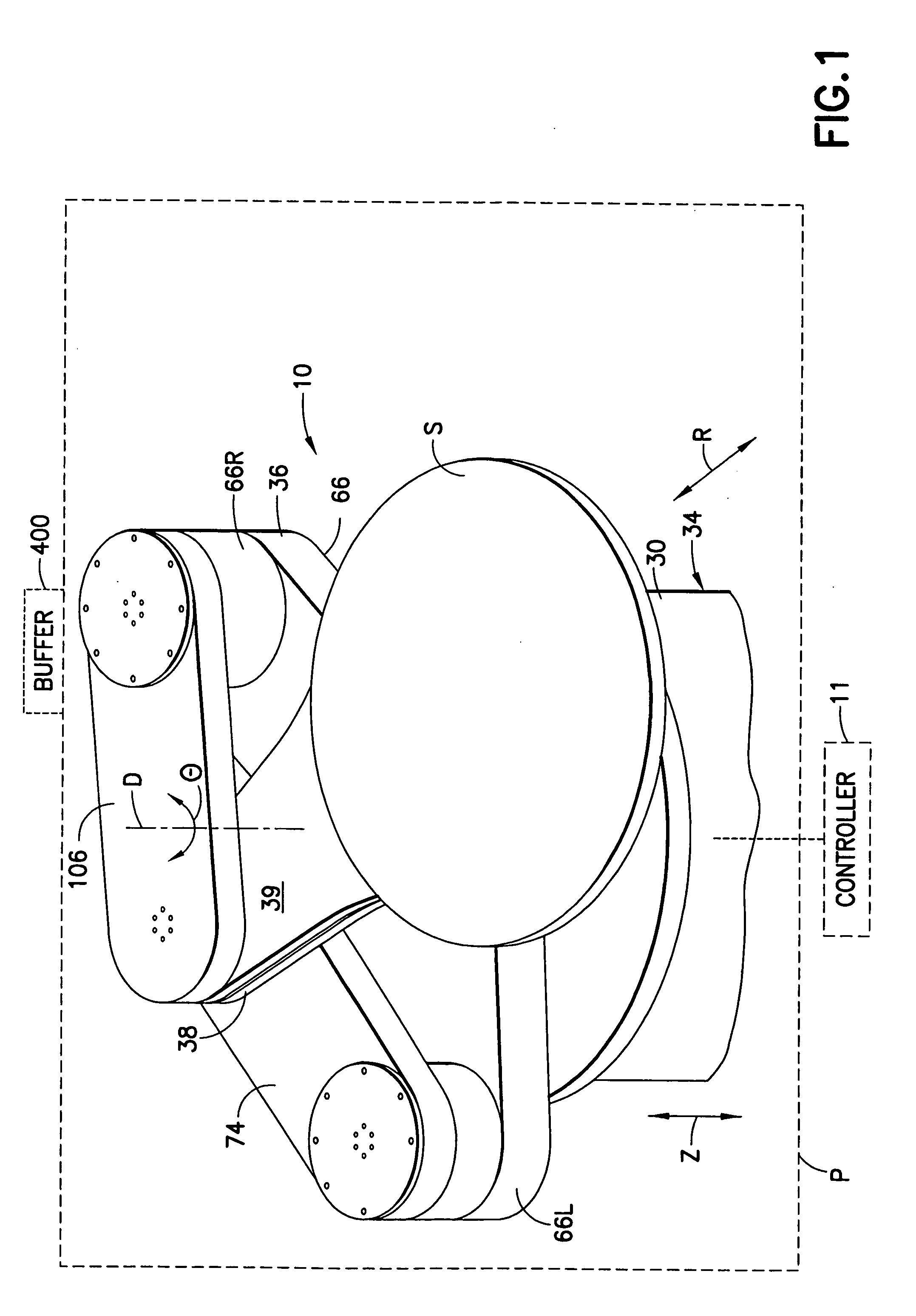

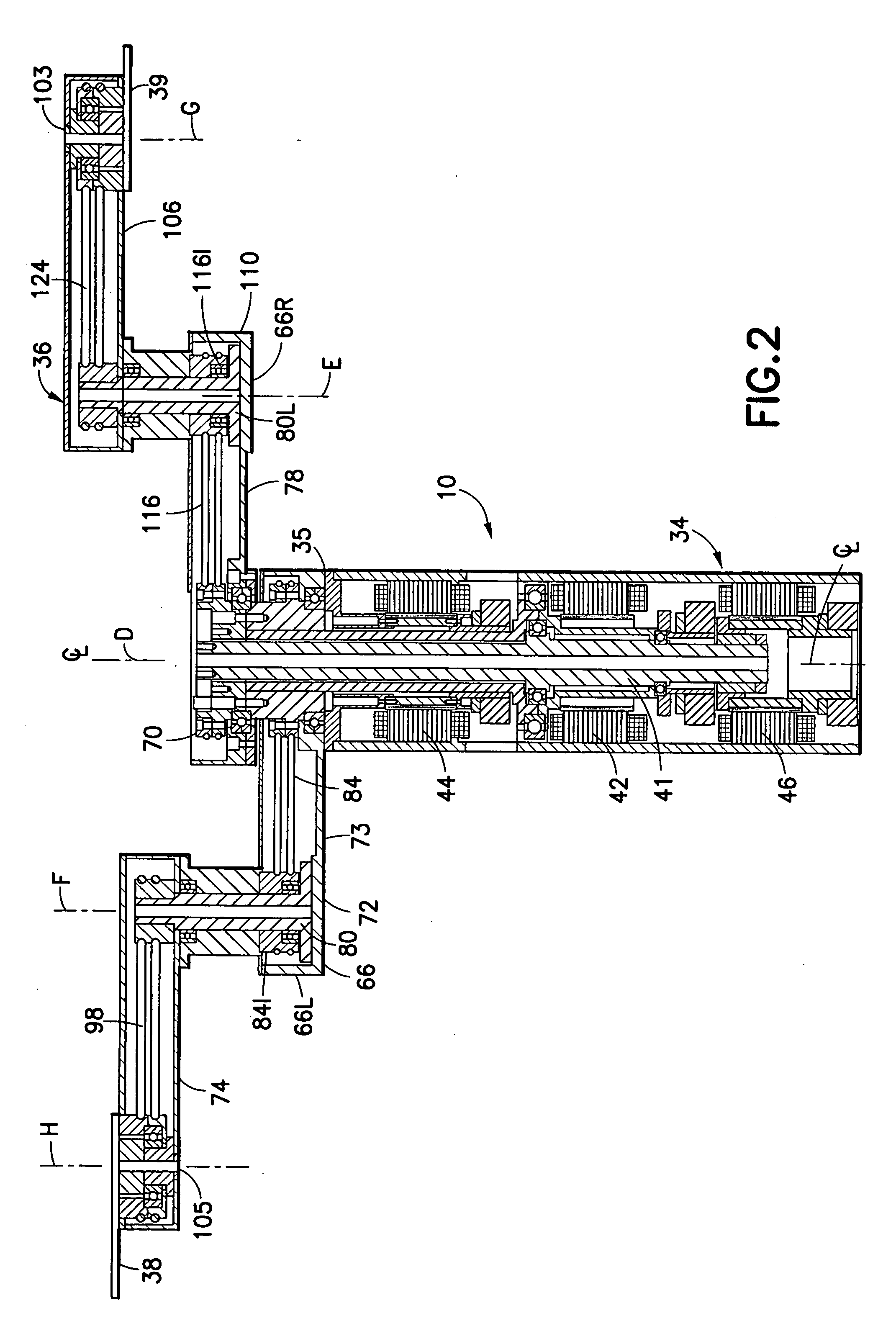

Substrate-processing apparatus with buffer mechanism and substrate-transferring apparatus

ActiveUS7690881B2Low costSmall footprintPliersSemiconductor/solid-state device manufacturingEngineeringActuator

A substrate transfer apparatus for loading and unloading substrates in a reaction chamber, includes: an arm having a distal end which is laterally movable in a straight line direction; and end-effectors for loading and unloading substrates in a reaction chamber, which include a lower end-effector and an upper end-effector. One of the lower end-effector or the upper end-effector is movably coupled to the arm at a distal end of the arm, and the other end-effector is fixed to the movably coupled end-effector. The fixed end-effector is fixed to the movably coupled end-effector.

Owner:ASM JAPAN

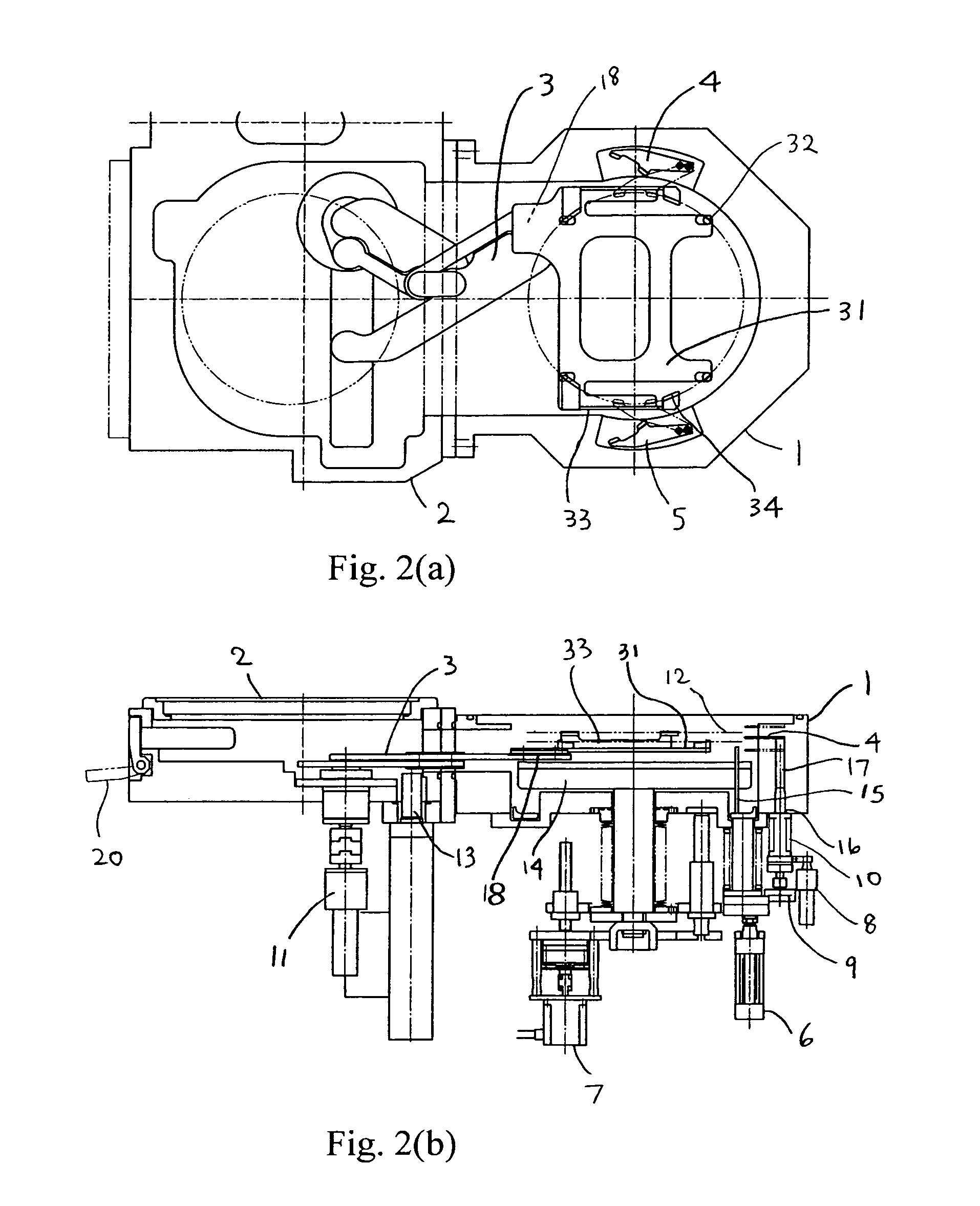

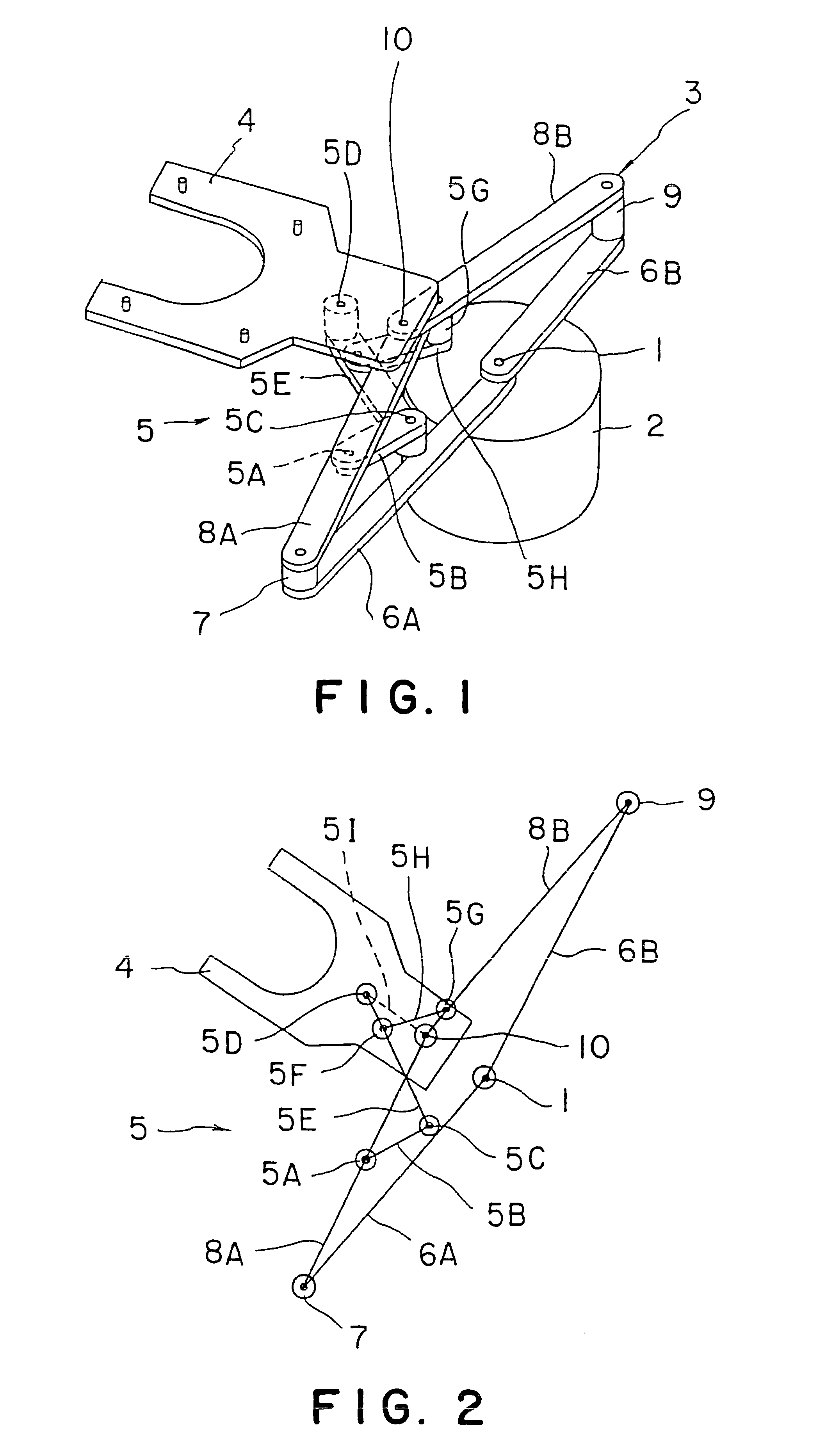

Conveyor system

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

Methods and apparatus for extending the reach of a dual scara robot linkage

ActiveUS20080298945A1Avoid interferenceProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

Methods and apparatus are provided for the use of a dual Selective Compliant Assembly Robot Arm (SCARA) robot. In some embodiments two SCARAs are provided, each including an elbow joint, wherein the two SCARAs are vertically stacked such that one SCARA is a first arm and the other SCARA is a second arm, and wherein the second arm is adapted to support a first substrate, and the first arm is adapted to extend to a full length when the second arm supports the first substrate, and wherein the first substrate supported by the second arm is coplanar with the elbow joint of the first arm, and the second arm is further adapted to move concurrently in parallel (and / or in a coordinated fashion) with the first arm a sufficient amount to avoid interference between the first substrate and the elbow joint of the first arm. Numerous other embodiments are provided.

Owner:APPLIED MATERIALS INC

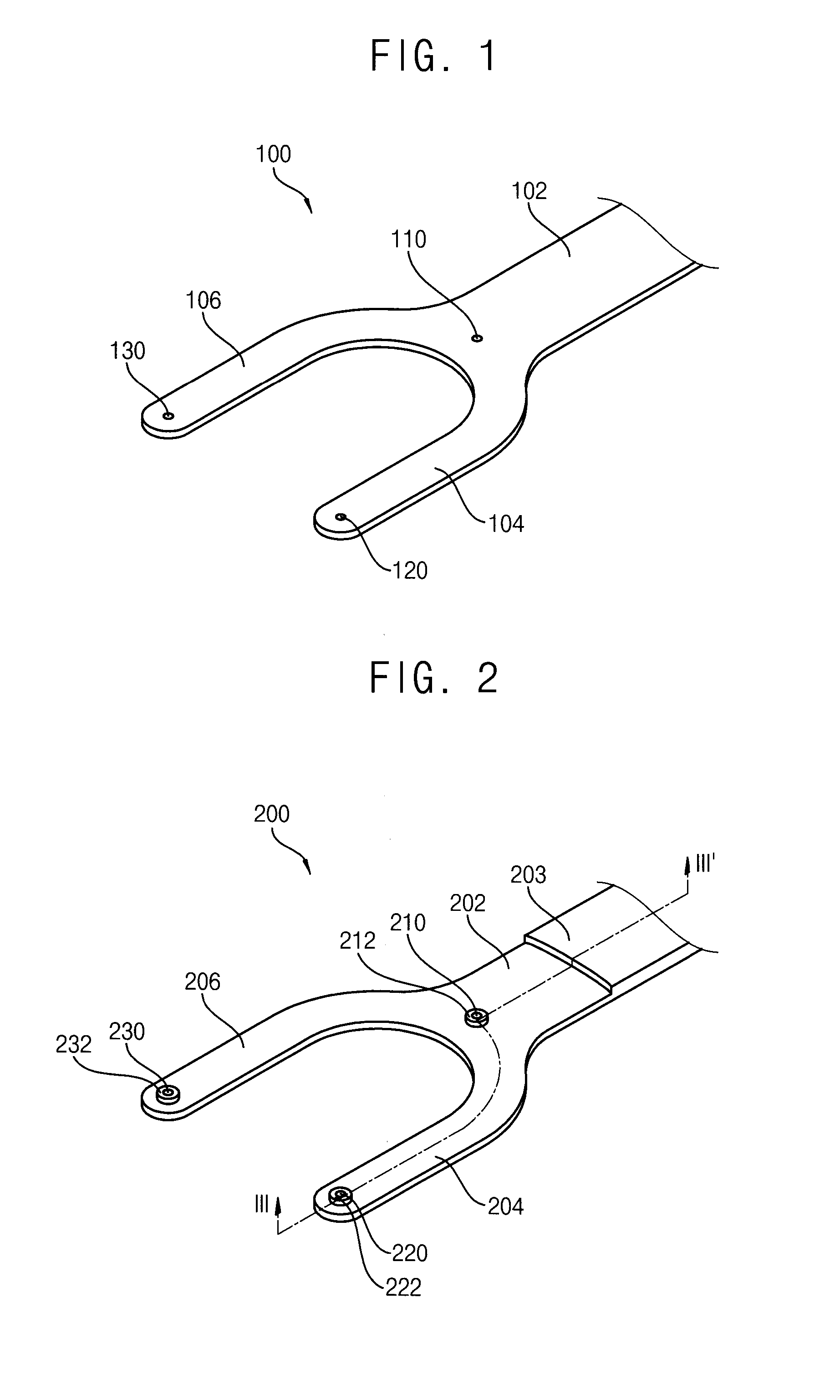

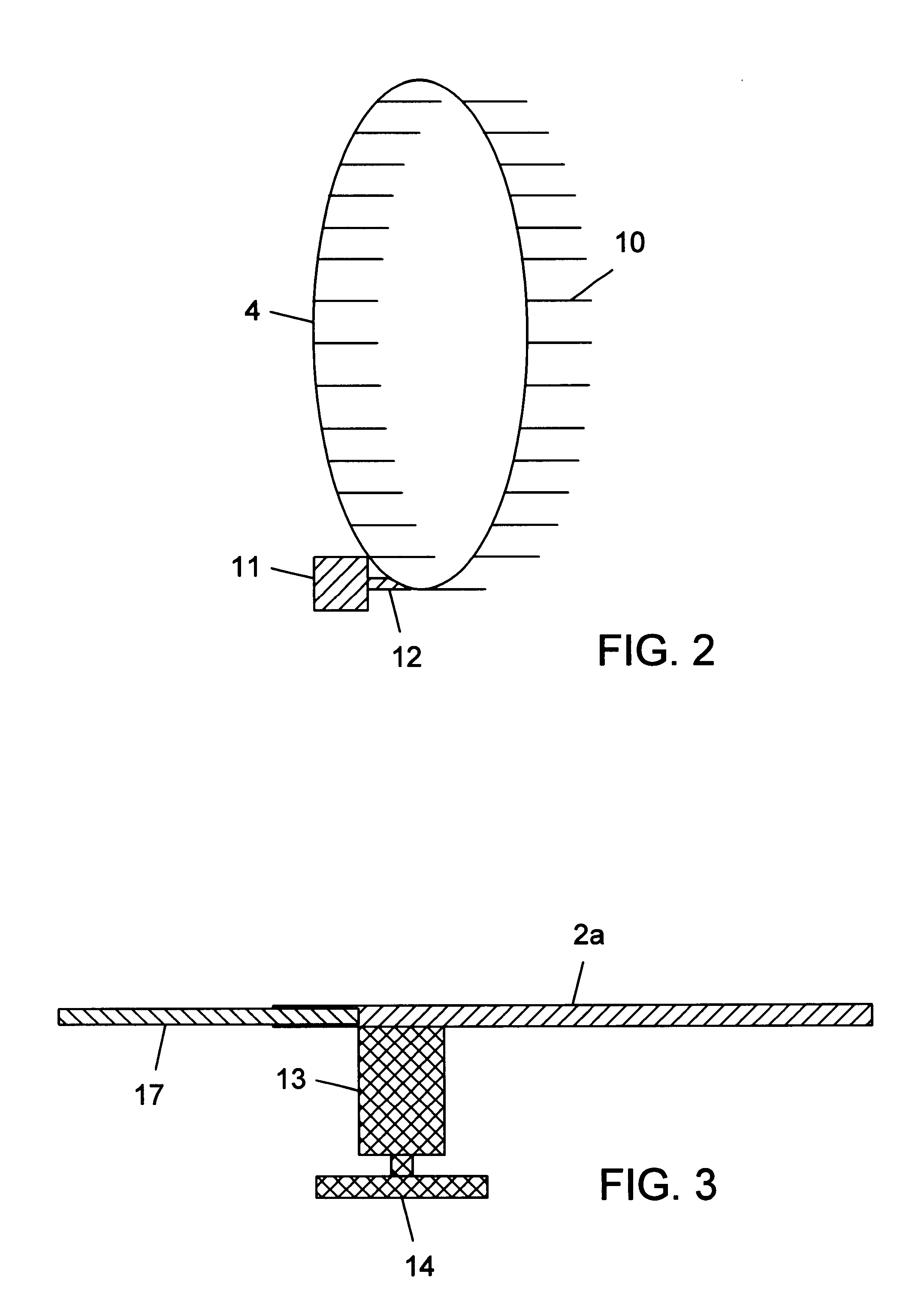

Wafer transfer blade and wafer transfer apparatus having the same

InactiveUS20140227072A1Damage is prevented and mitigatedDamage can be prevented and mitigatedGripping headsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

A wafer transfer blade including a body including metal oxide and configured to support a wafer, and an adsorbing part on the body, the adsorbing part having at least one therein and configured to apply vacuum pressure to attach the wafer on the body may be provided. The body may include metal oxide to prevent static electricity.

Owner:SAMSUNG ELECTRONICS CO LTD

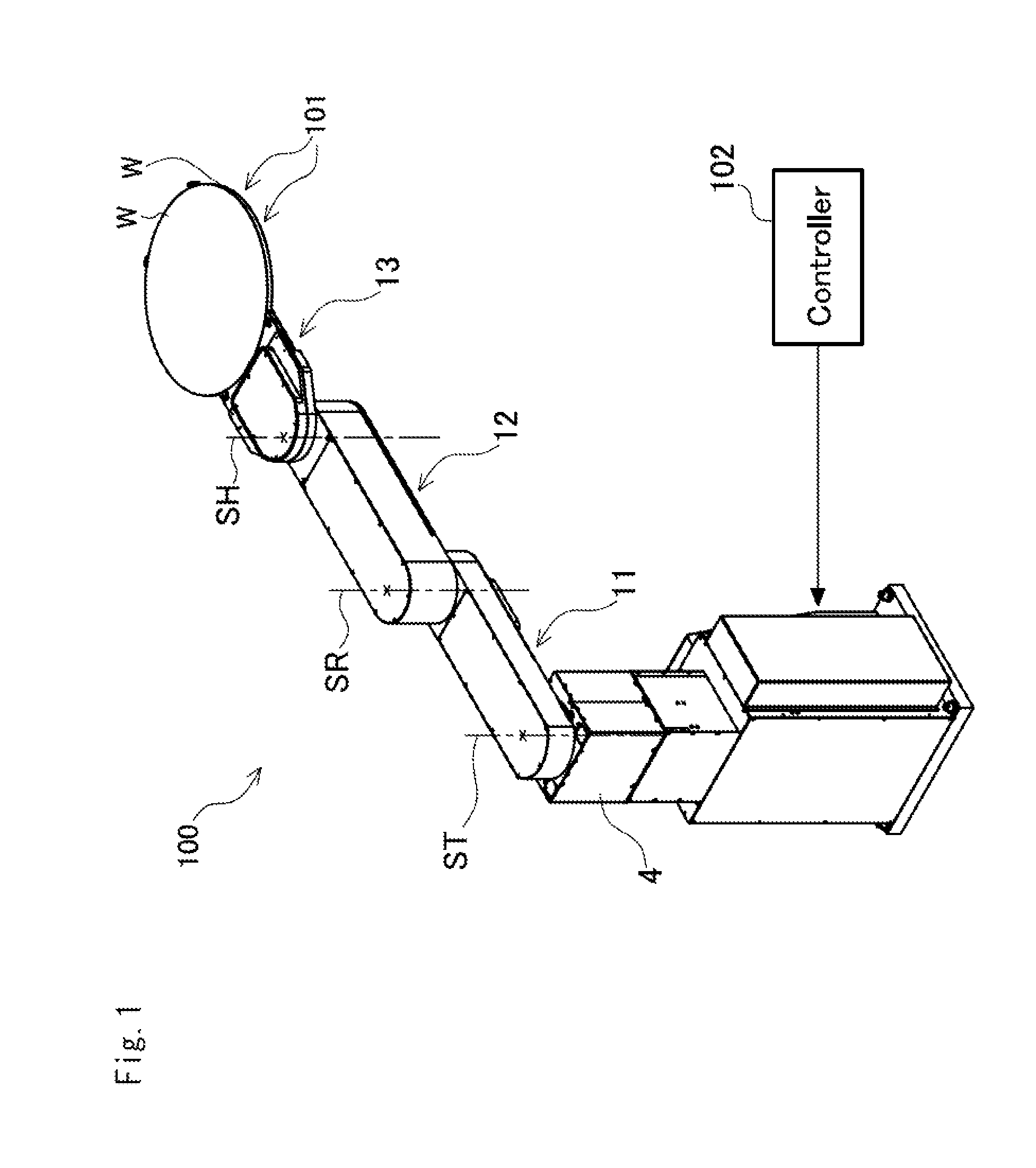

Robot arm

ActiveUS20130084156A1Precise positioningPollution suppressionProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingPhysical medicine and rehabilitationWafering

The robot arm of the present application is a robot arm that transports semiconductor wafers. The robot arm includes a hand, a lower arm link, and an upper arm link. The hand is connected to the lower arm link via a first joint. The upper arm link is connected to the lower arm link via a second joint. In the robot arm of the present application, the lower arm link is capable of being separated at a location between the first joint and the second joint.

Owner:NABLESCO CORP

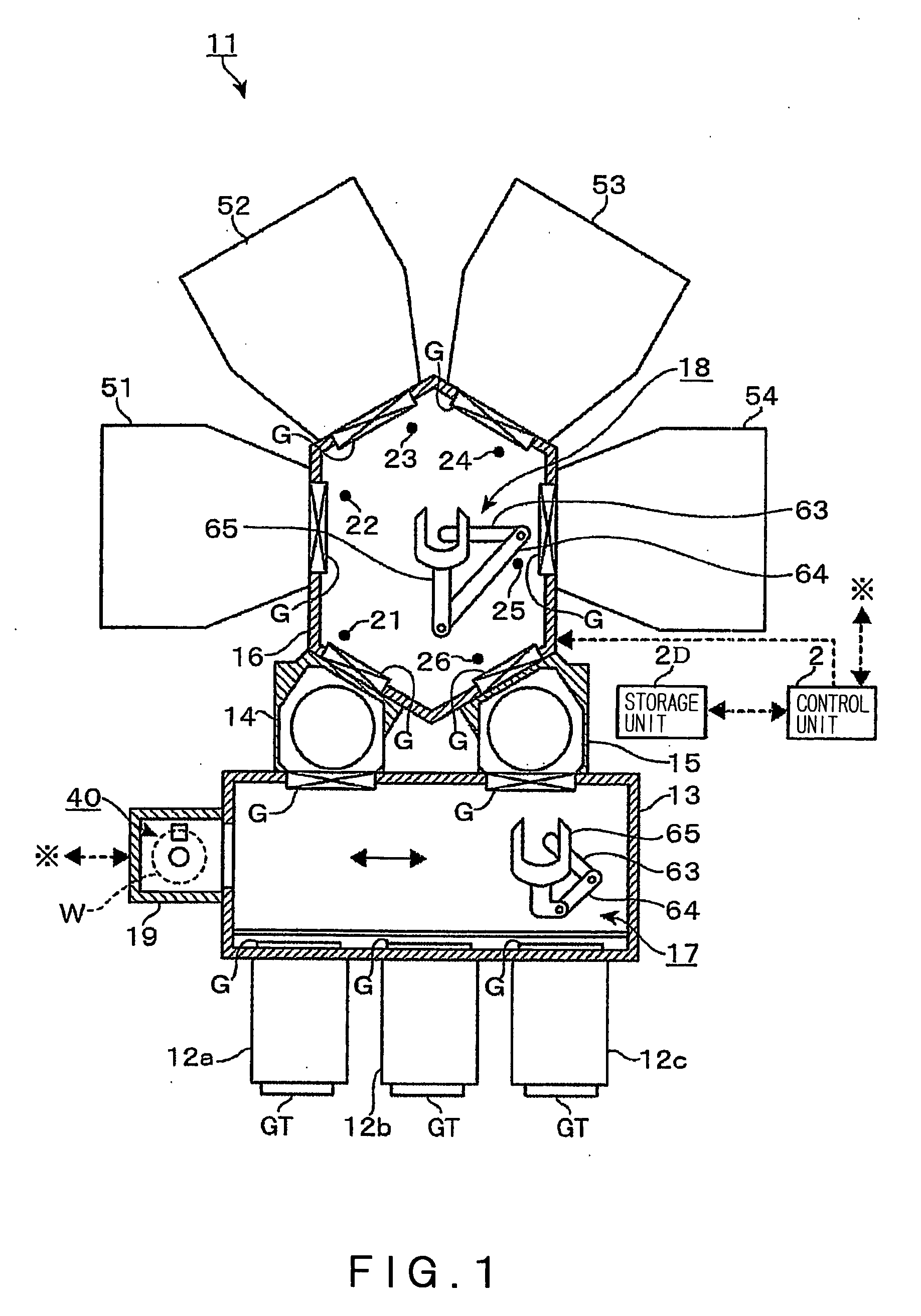

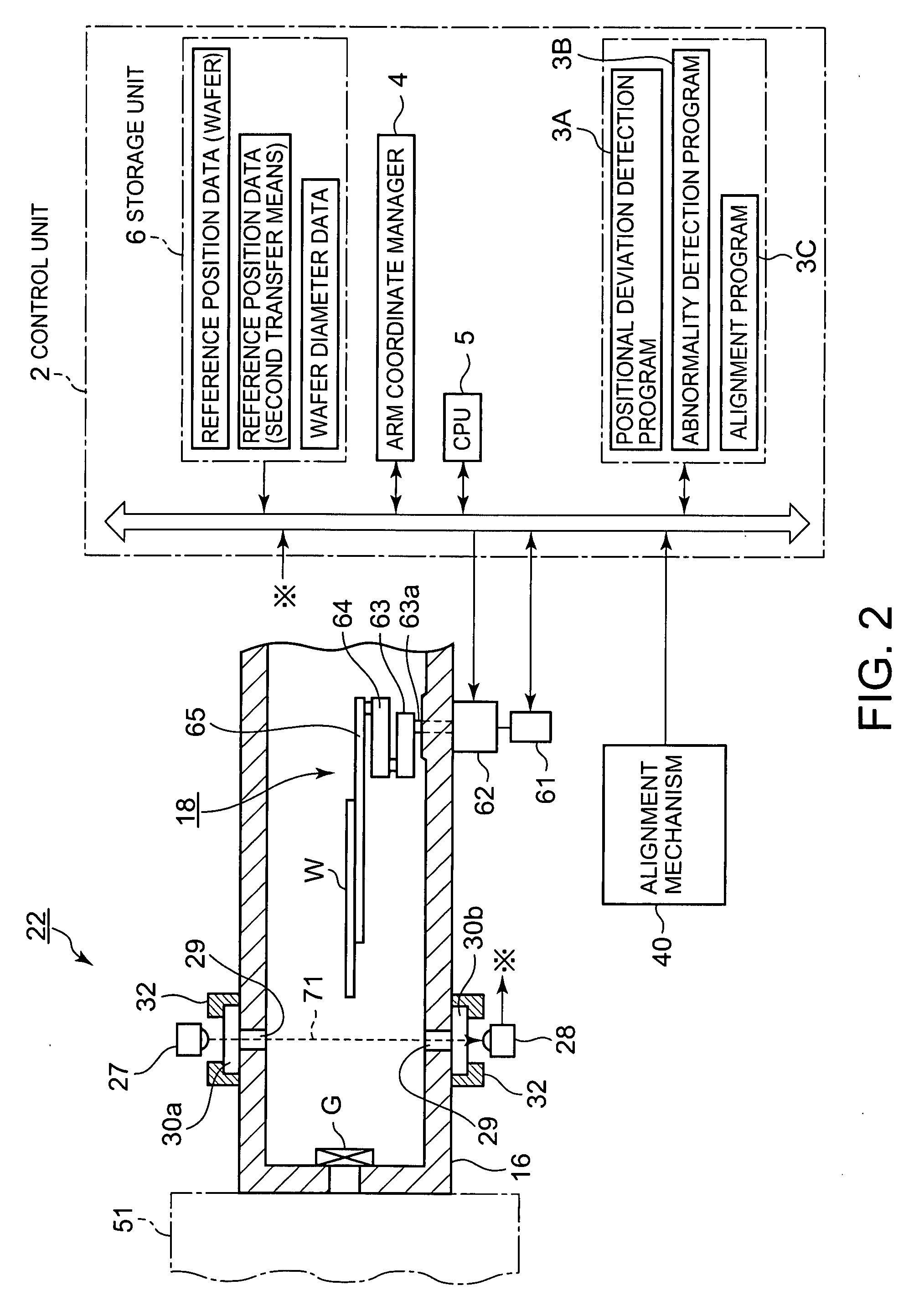

Wafer transfer apparatus, wafer transfer method and storage medium

ActiveUS20090053023A1Low costOptimize layoutDigital data processing detailsSemiconductor/solid-state device manufacturingEngineeringLight emission

One sensor constituted of a light emission element and a light-receiving element is provided in a path through which a wafer is transferred. The sensor is positioned so that the wafer passes through an area between the light emission element and the light-receiving element. Coordinates of the center of the wafer are calculated based on encoder values obtained when the wafer starts passing through the sensor and when the wafer completes passing through the sensor, position data of wafer transfer means corresponding to the encoder value, and the diameter of the wafer; and thereby the amount of positional deviation of the center of the wafer from a reference position is calculated.

Owner:TOKYO ELECTRON LTD

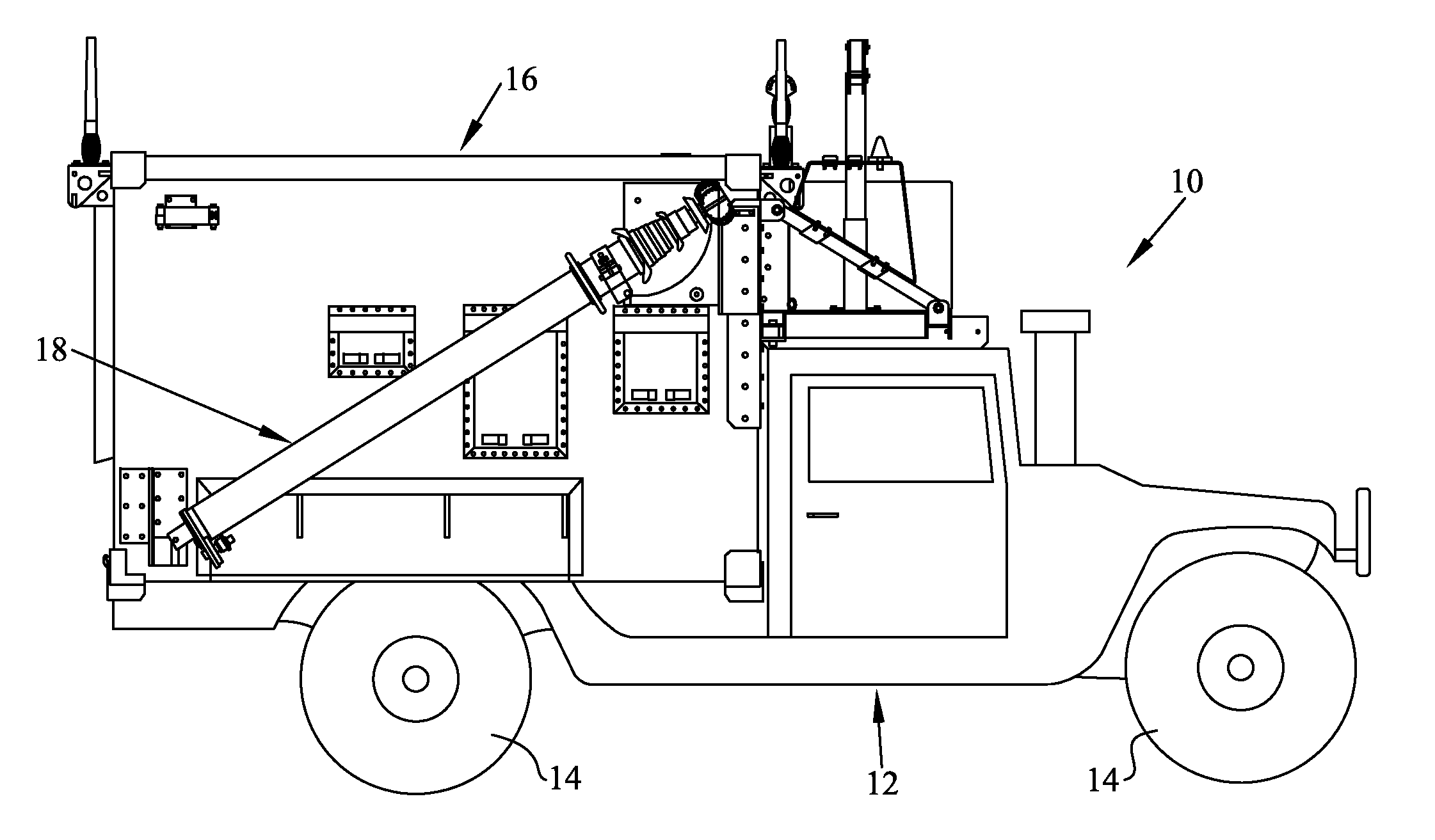

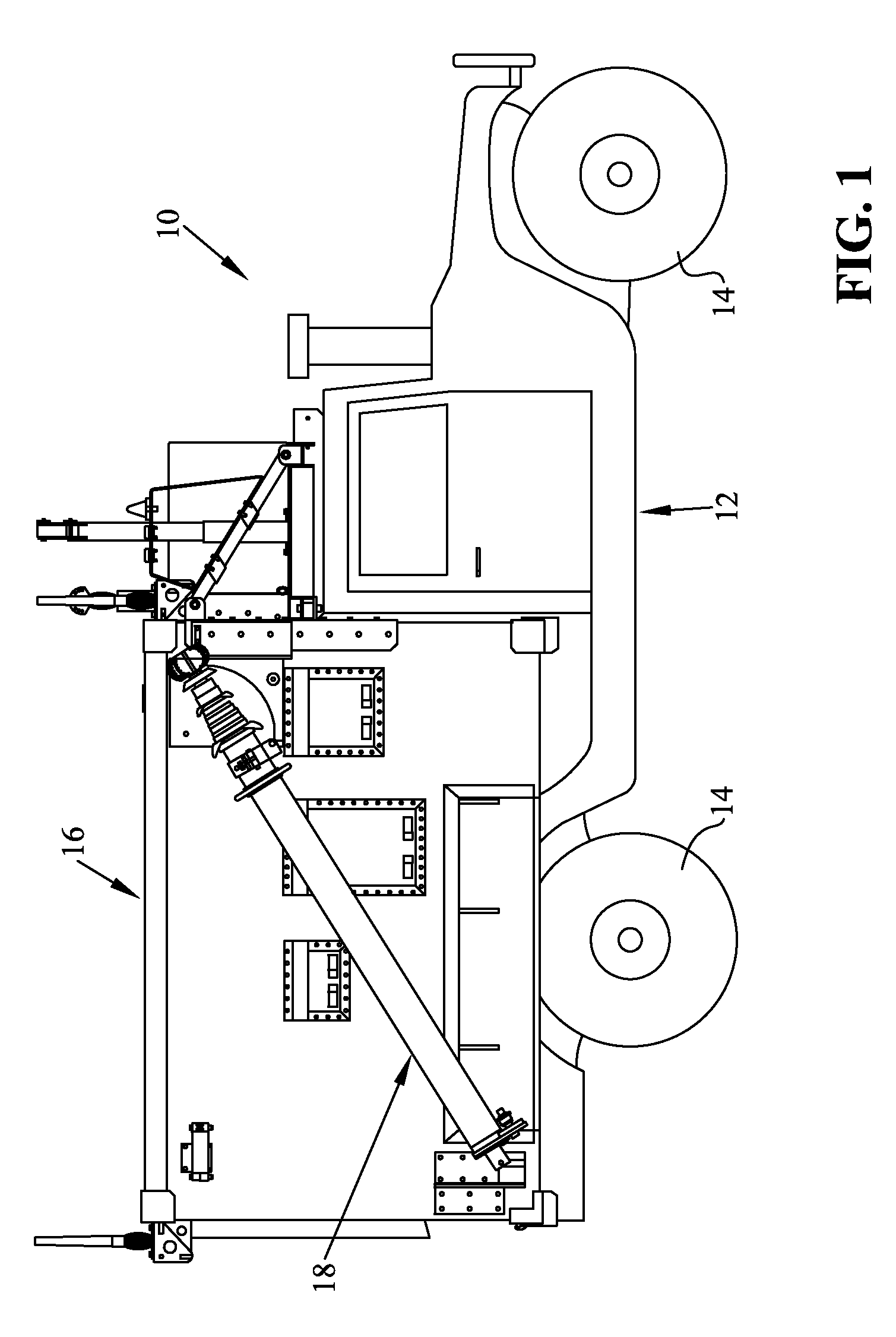

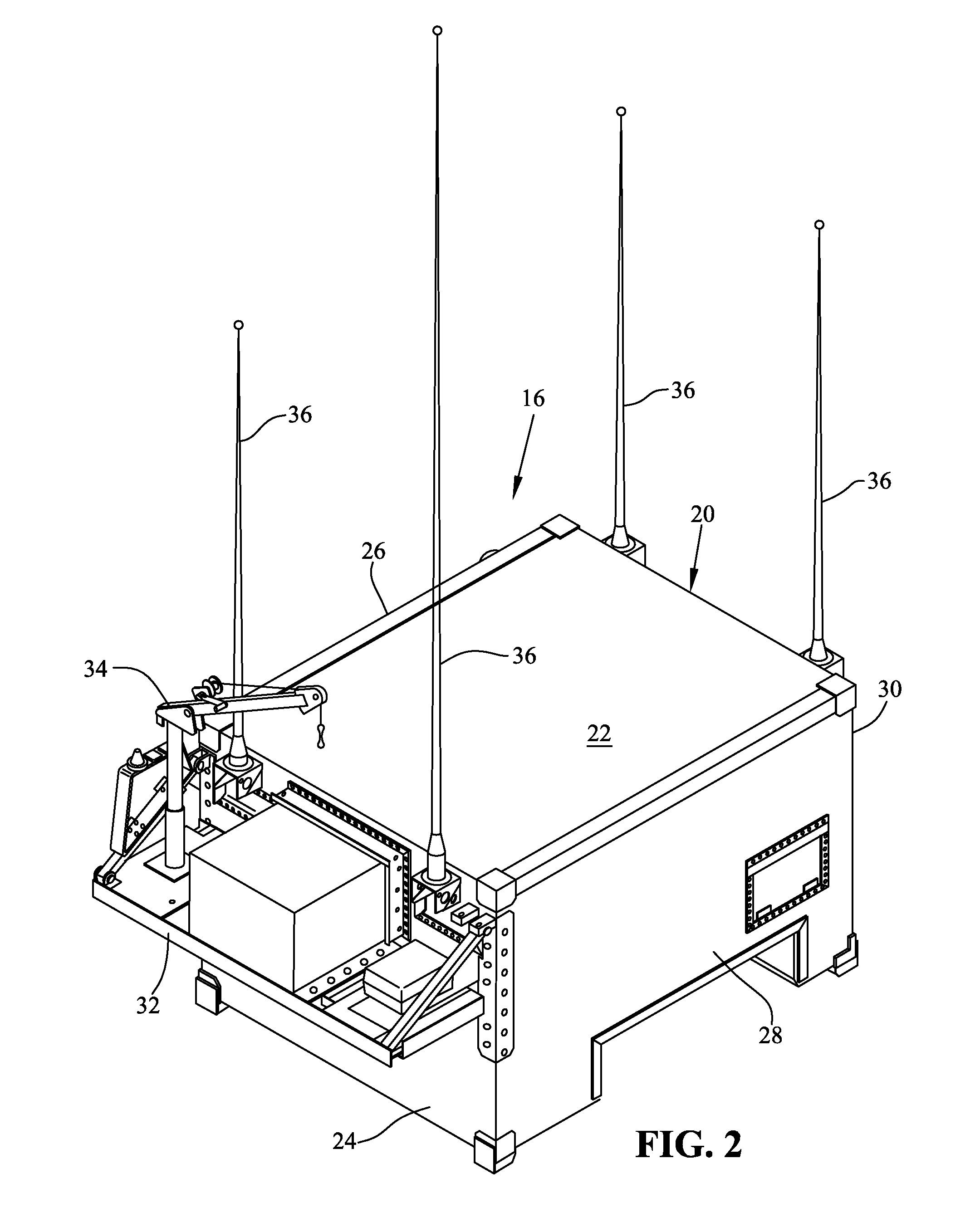

Vehicle and mast mounting assembly therefor

ActiveUS8276325B2Antenna supports/mountingsAntenna adaptation in movable bodiesEngineeringMechanical engineering

A vehicle is disclosed having a mast assembly mounted to a sidewall of the vehicle. The mast is pivotally mounted and can be held in a first stowed position by way of a first clamp member. The mast is pivotal relative to the sidewall, to an essentially vertical and erect position, and held in the second position by way of a second clamp.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Modular hybrid snake arm

ActiveUS20080302200A1Reduced arm manufacturing costImprove work performanceMechanical apparatusJointsModularitySimulation

An intelligent modular hybrid robot arm system is usable with mobile robots, and is applicable to stationary industrial arms. The intelligent modular hybrid robot arm system provides a large work envelope and a controlled and directed rotational movement for a flexible snake robot arm. The intelligent modular hybrid robot arm system has the ability to change end effector tools and sensors. The platform computers have the ability to interact with other subsystems for coordinated as well as independent tasks. The flexibly snake robot arm can be covered with a flexible sensor network, or “skin”. The intelligent modular hybrid robot arm system can manage its energy use, stores the arm in a compact shape and uses a central support tube offering unobstructed arm access to all sectors of its working envelope.

Owner:CYCOGS

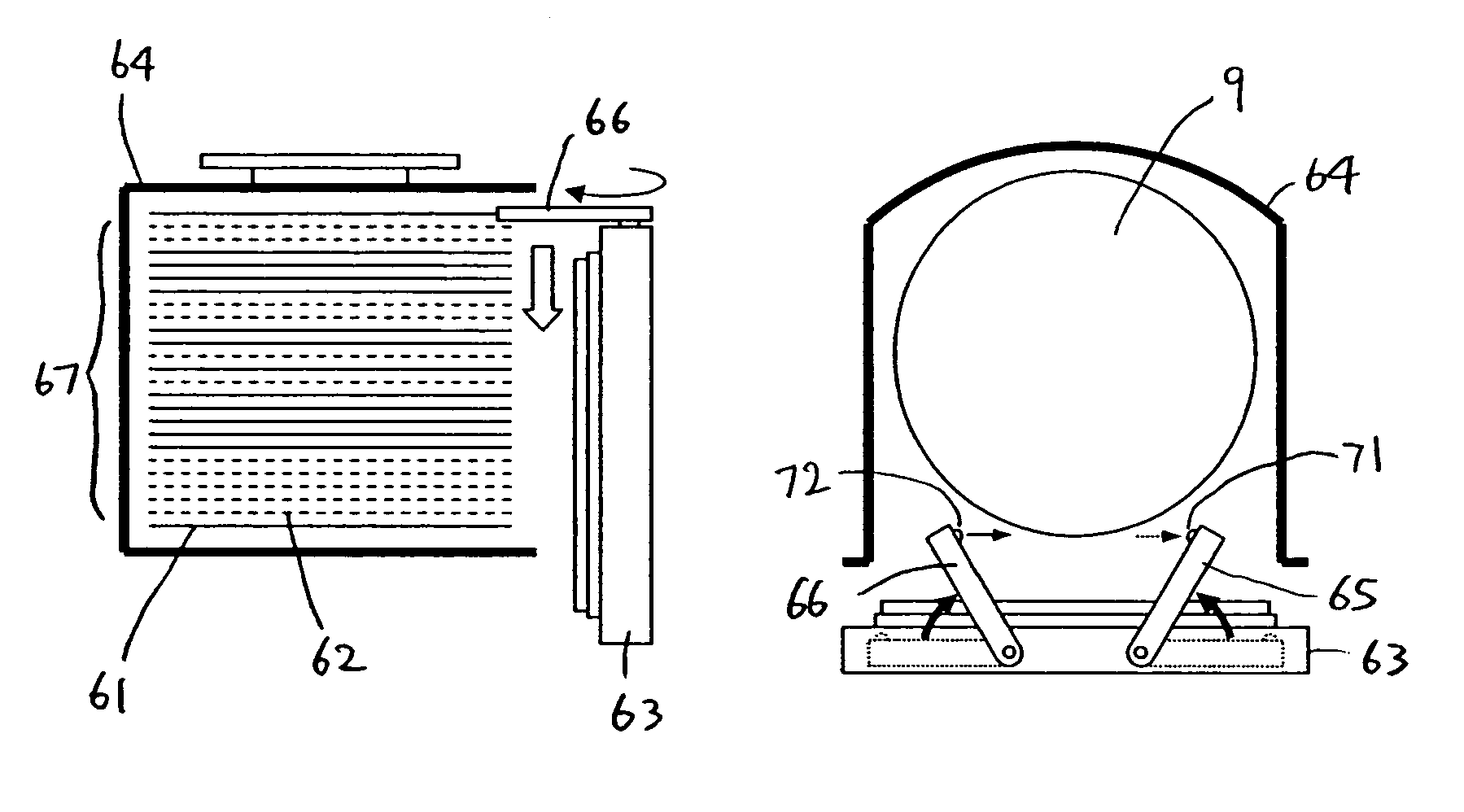

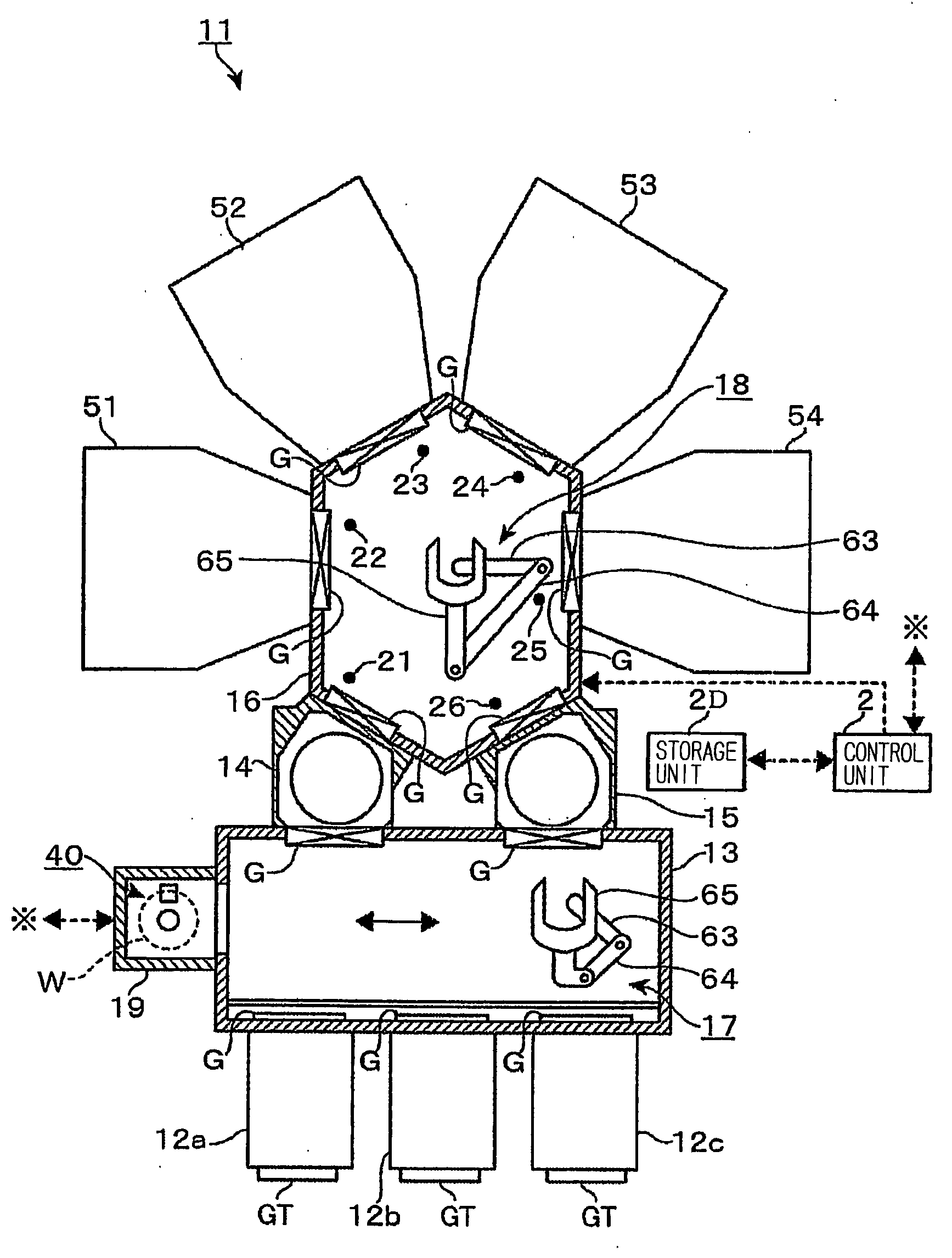

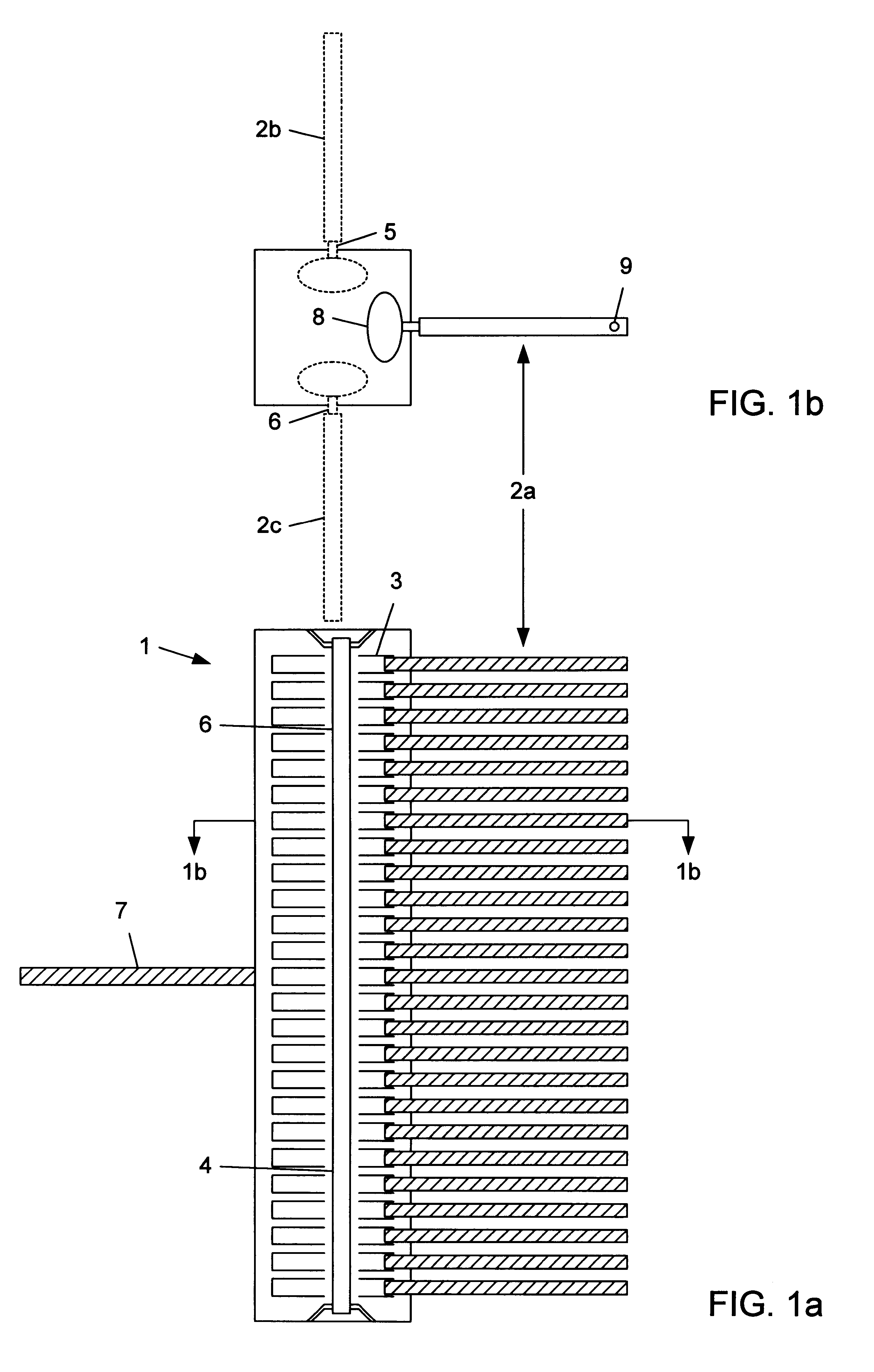

System for sorting multiple semiconductor wafers

InactiveUS6213708B1Semiconductor/solid-state device manufacturingArticle unpackingRobotic armEngineering

A wafer sorting system is provided. The wafer sorter system is used to simultaneously sort multiple semiconductor wafers of a cassette. The wafer sorter system includes multiple arms which extend from a tower. These arms are at different vertical locations along the tower. The wafer sorter system also comprises a robotic arm which may move the tower to a position where the arms contact wafers. These wafers are in different vertical slots of a cassette. Further included in the wafer sorter system is a belt which may rotate to move arms vertically through slots of the tower. Wafers may become attached to arms by applying a vacuum suction to each arm. The arms having wafers may be rotated to the belt in a clockwise or counterclockwise direction about a portion of the tower via a slot in the tower. The arms may then be attached to the belt. After the belt moves the arms to new levels of the tower, the arms may then be rotated back to their original positions. The rearranged wafers may then be placed in their original cassette, in several different cassettes, or in one different cassette via turning off the vacuum suction.

Owner:ADVANCED MICRO DEVICES INC

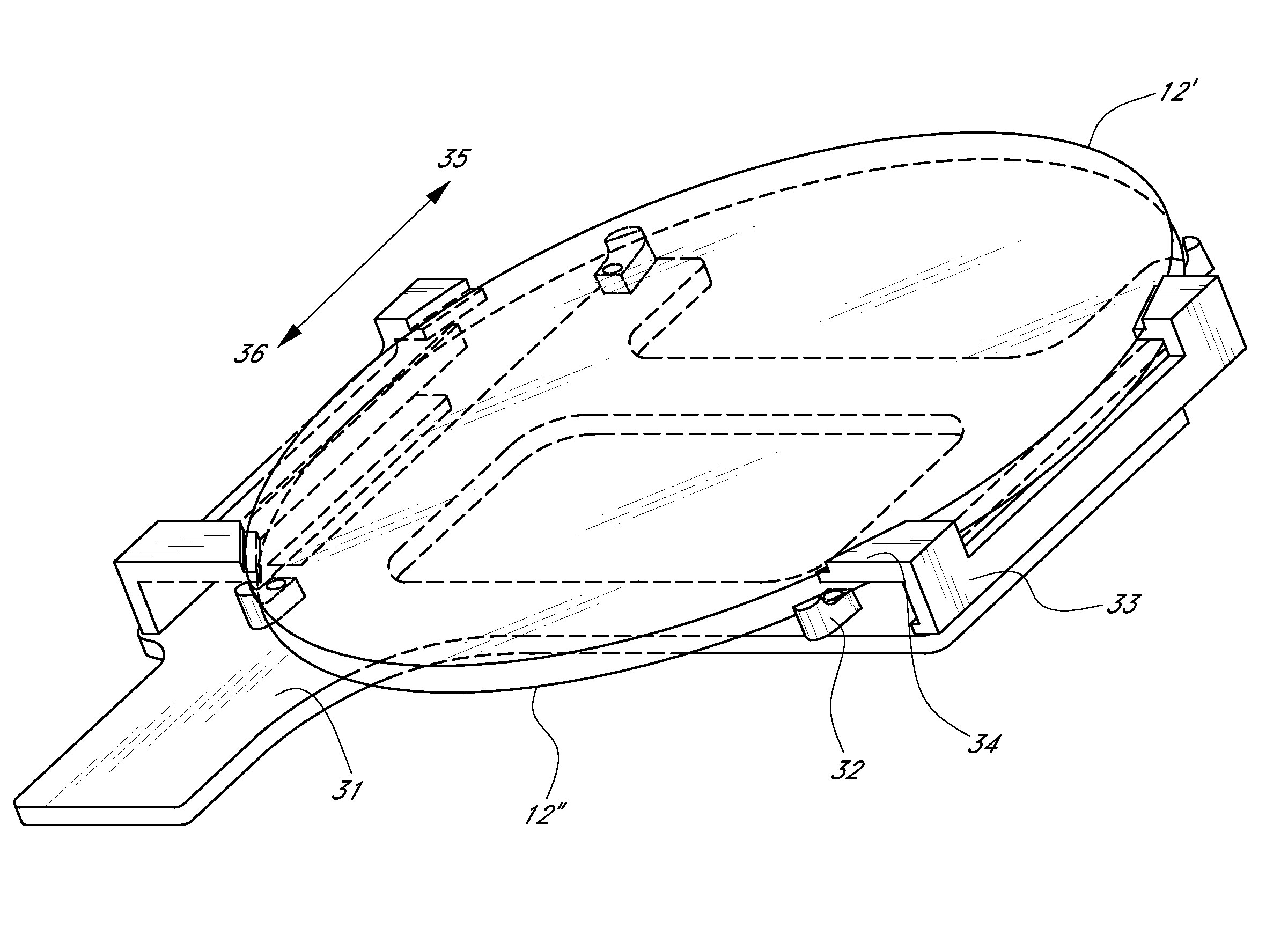

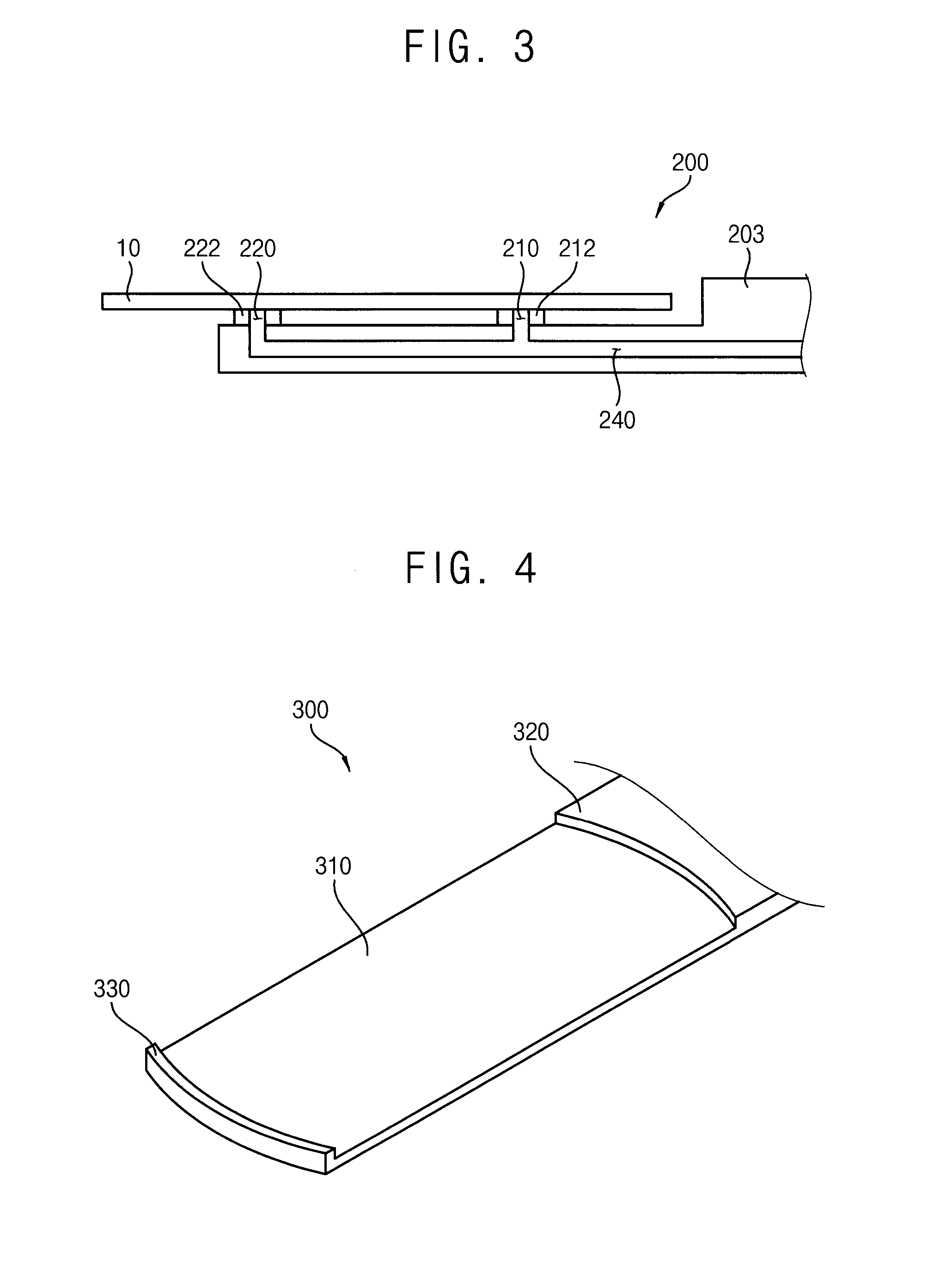

Shutter blade and robot blade with cte compensation

Processing chamber shutter blade and robot blade assemblies are constructed to eliminate thermal effects on the placement of elements in processing chambers. Such blade assemblies may contain at least two parts, which may include a positioning member including a low CTE material and a thermal compensating member including a high CTE material. The positioning member includes a coupling point and a reference point on a reference axis separated by a first distance. The thermal compensating member includes a connection point and a controlled point separated by another distance that is less than the first distance. A distance ratio of the first distance to the other distance is substantially equal to a CTE ratio of the high CTE material to the low CTE material, and the positioning member is joined to the thermal compensating member through the coupling point and the connection point.

Owner:APPLIED MATERIALS INC

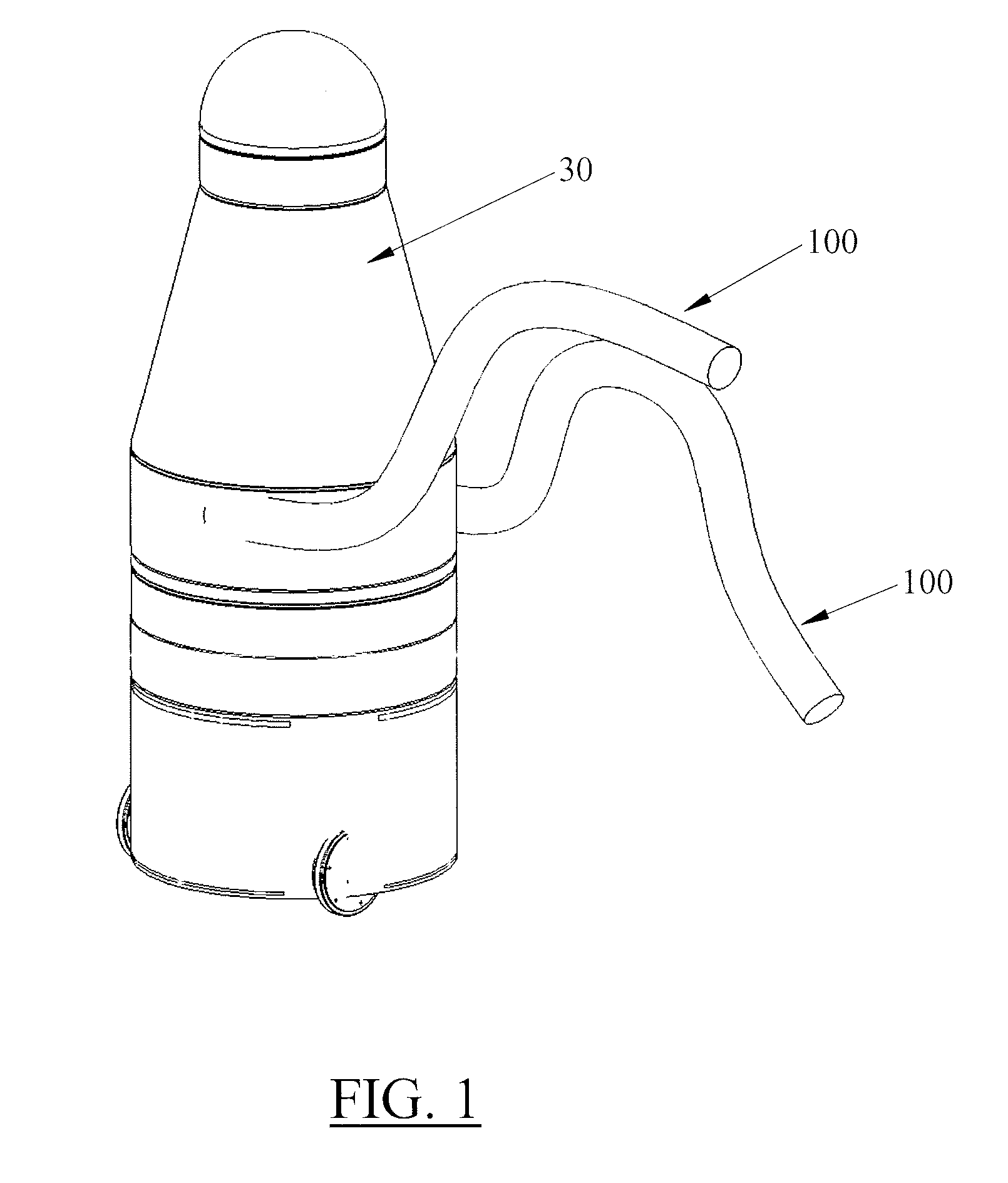

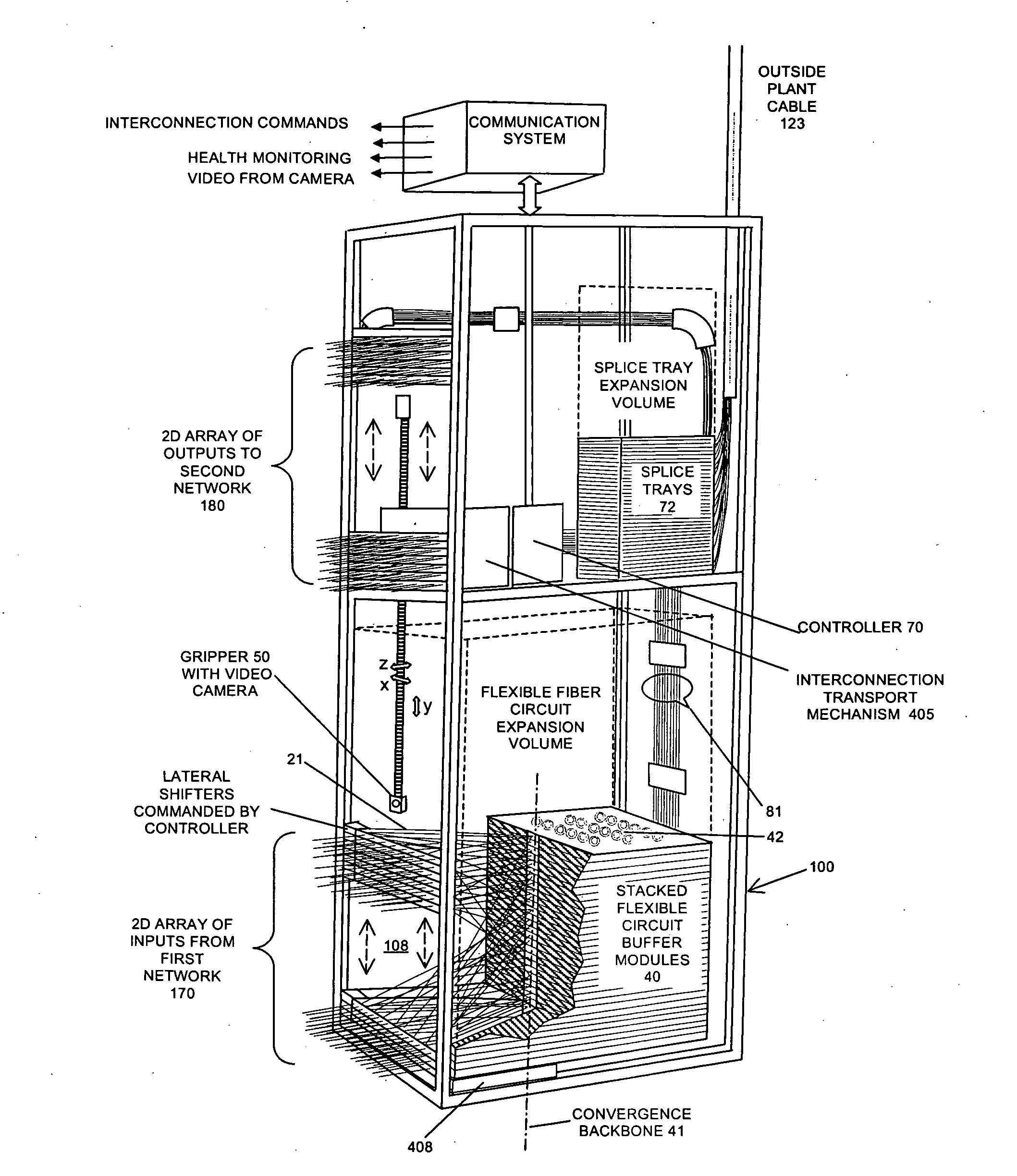

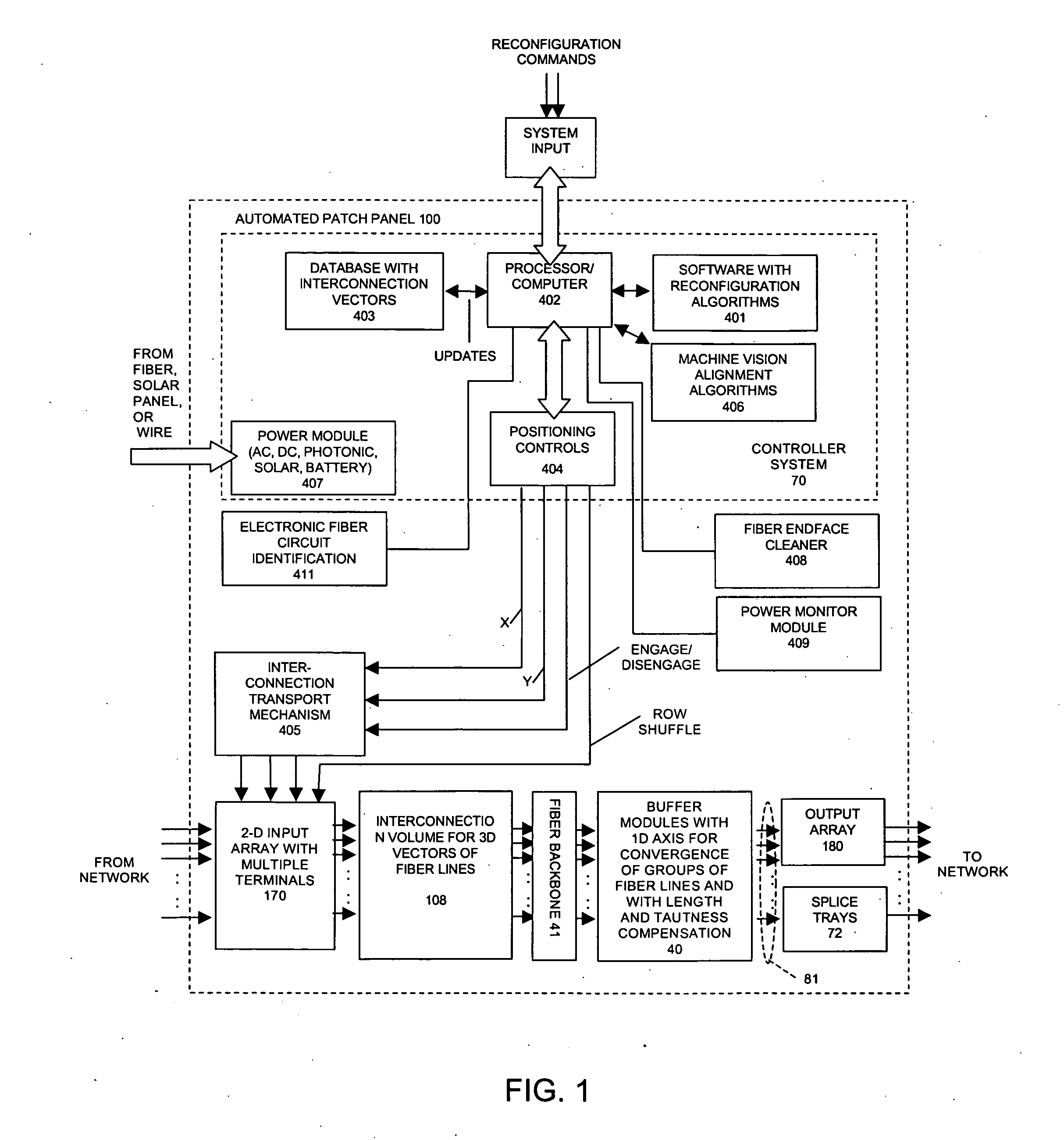

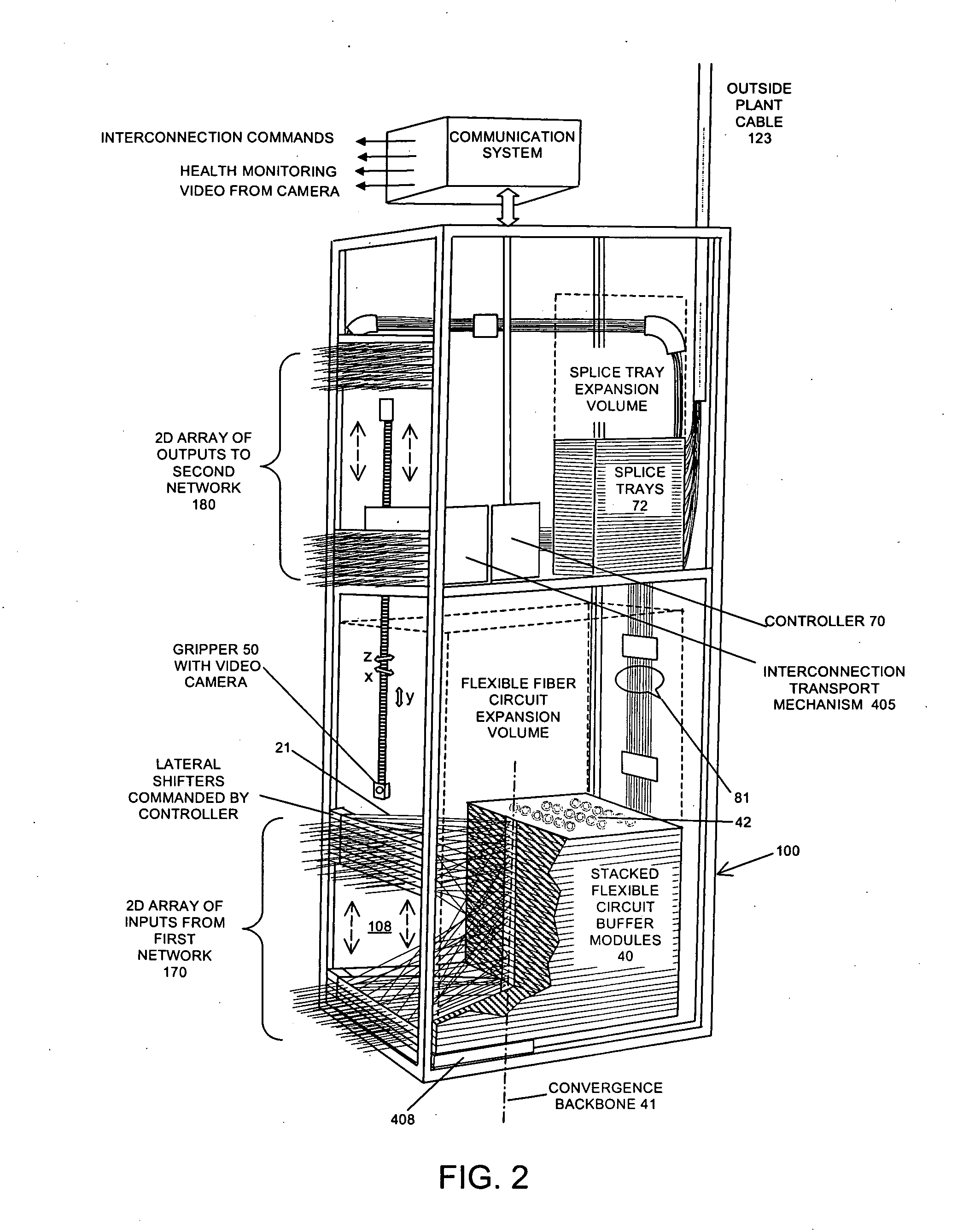

Scalable and modular automated fiber optic cross-connect systems

ActiveUS20100316334A1Improve reliabilitySmall sizeMultiplex system selection arrangementsProgramme controlComputer hardwareCross connection

This invention discloses highly scalable and modular automated optical cross connect switch devices which exhibit low loss and scalability to high port counts. In particular, a device for the programmable interconnection of large numbers of optical fibers (100's-1000's) is provided, whereby a two-dimensional array of fiber optic connections is mapped in an ordered and rule-based fashion into a one-dimensional array with tensioned fiber optic circuit elements tracing substantially straight lines there between. Fiber optic elements are terminated in a stacked arrangement of flexible fiber optic circuit elements with a capacity to retain excess fiber lengths while maintaining an adequate bend radius. The combination of these elements partitions the switch volume into multiple independent, non-interfering zones, which retain their independence for arbitrary and unlimited numbers of reconfigurations. The separation into spaced-apart zones provides clearance for one or more robotic actuators to enter the free volume substantially adjacent to the two-dimensional array of connectors and mechanically reconfigure connectors without interrupting other circuits.

Owner:TELESCENT

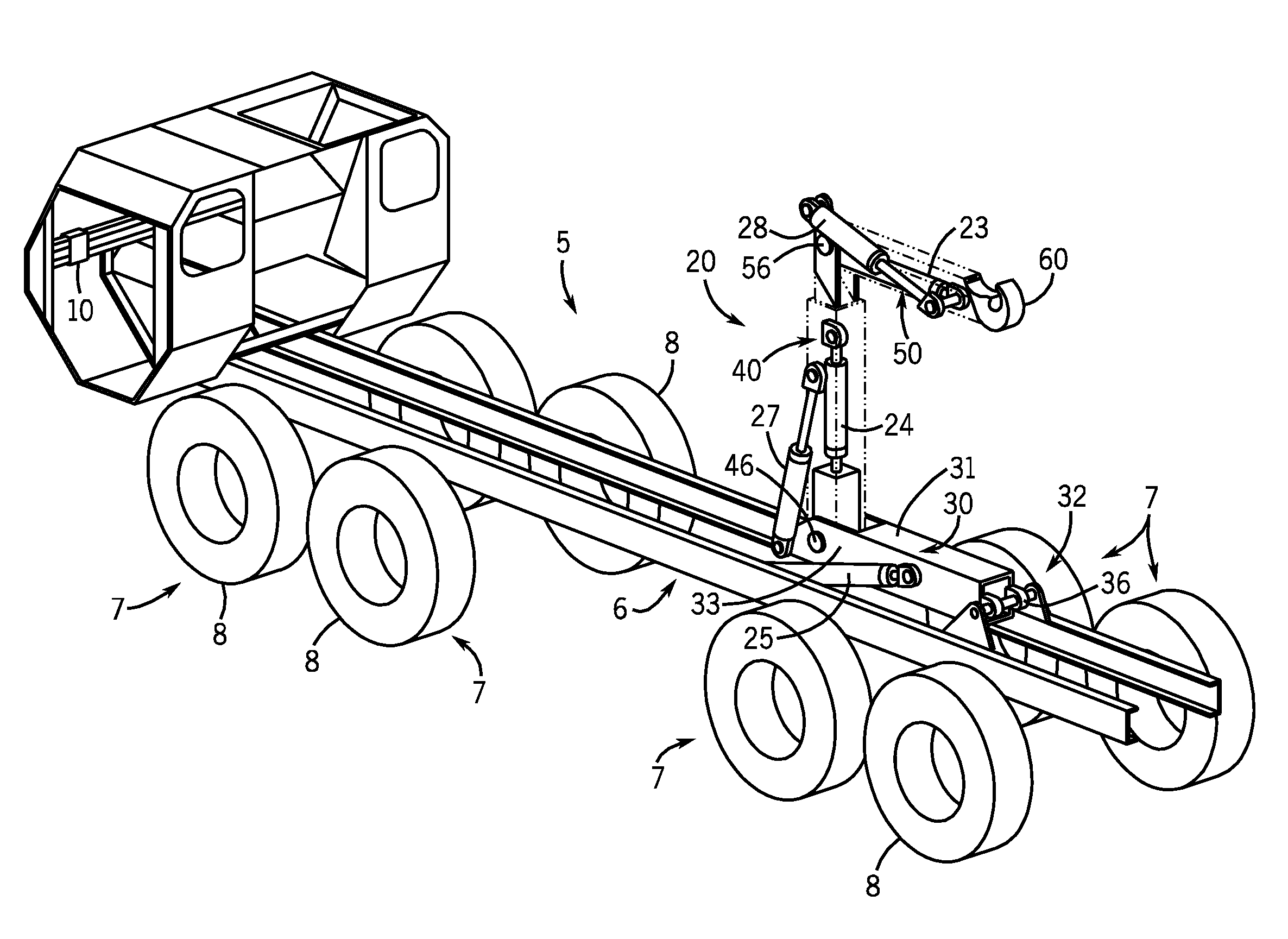

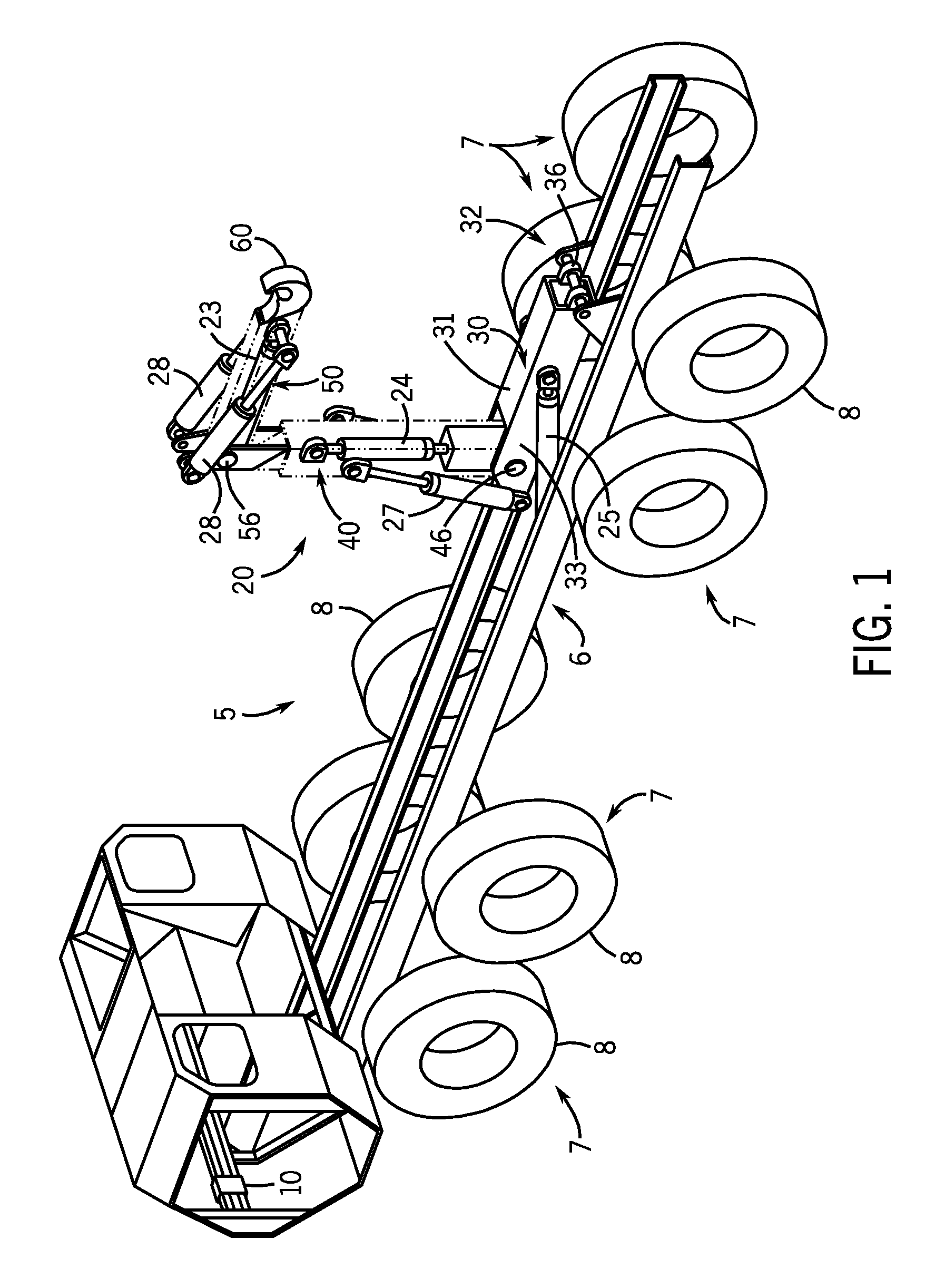

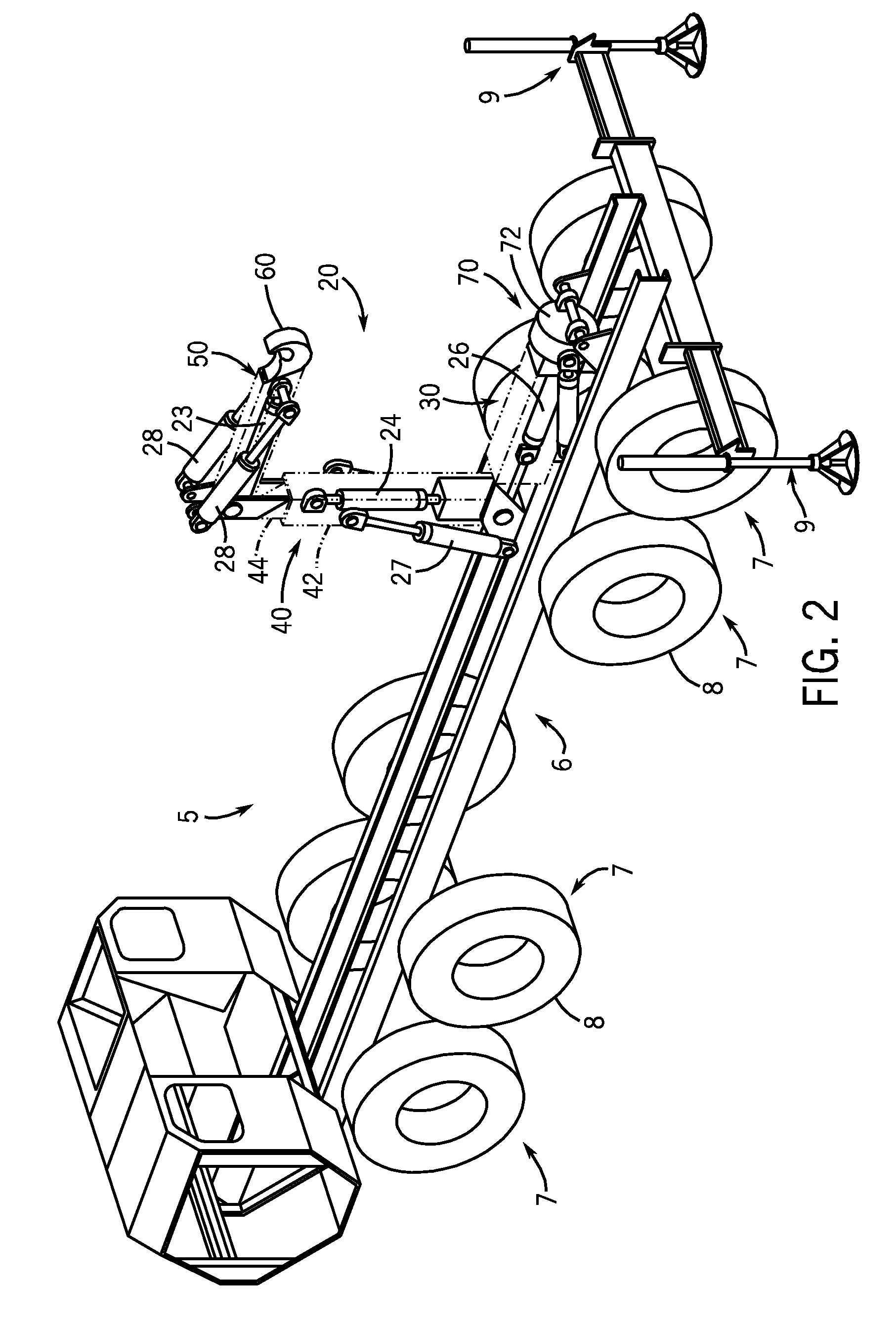

Rotatable and articulated material handling apparatus

A material handling apparatus for mounting on a support structure. The material handling apparatus comprises a telescopic riser portion coupled to the support structure. A telescopic boom portion is coupled to the riser portion. A telescopic jib portion is coupled to the riser portion. A hook is coupled to the jib portion. A control apparatus is coupled to each of the riser, boom, and jib portions. Wherein, each of the telescopic portions can be independently, selectively moved in a push-pull mode to manipulate material.

Owner:OSHKOSH CORPORATION

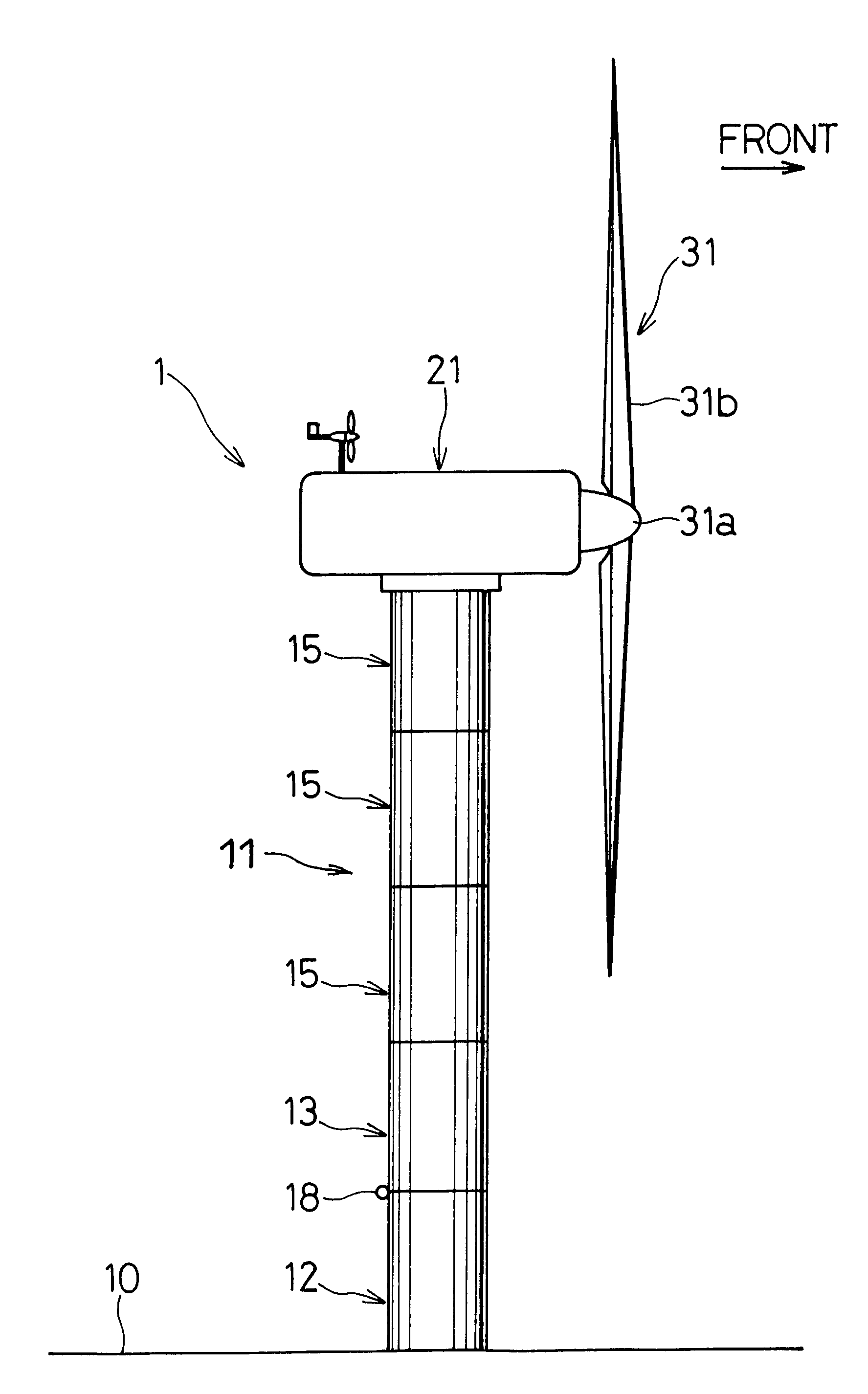

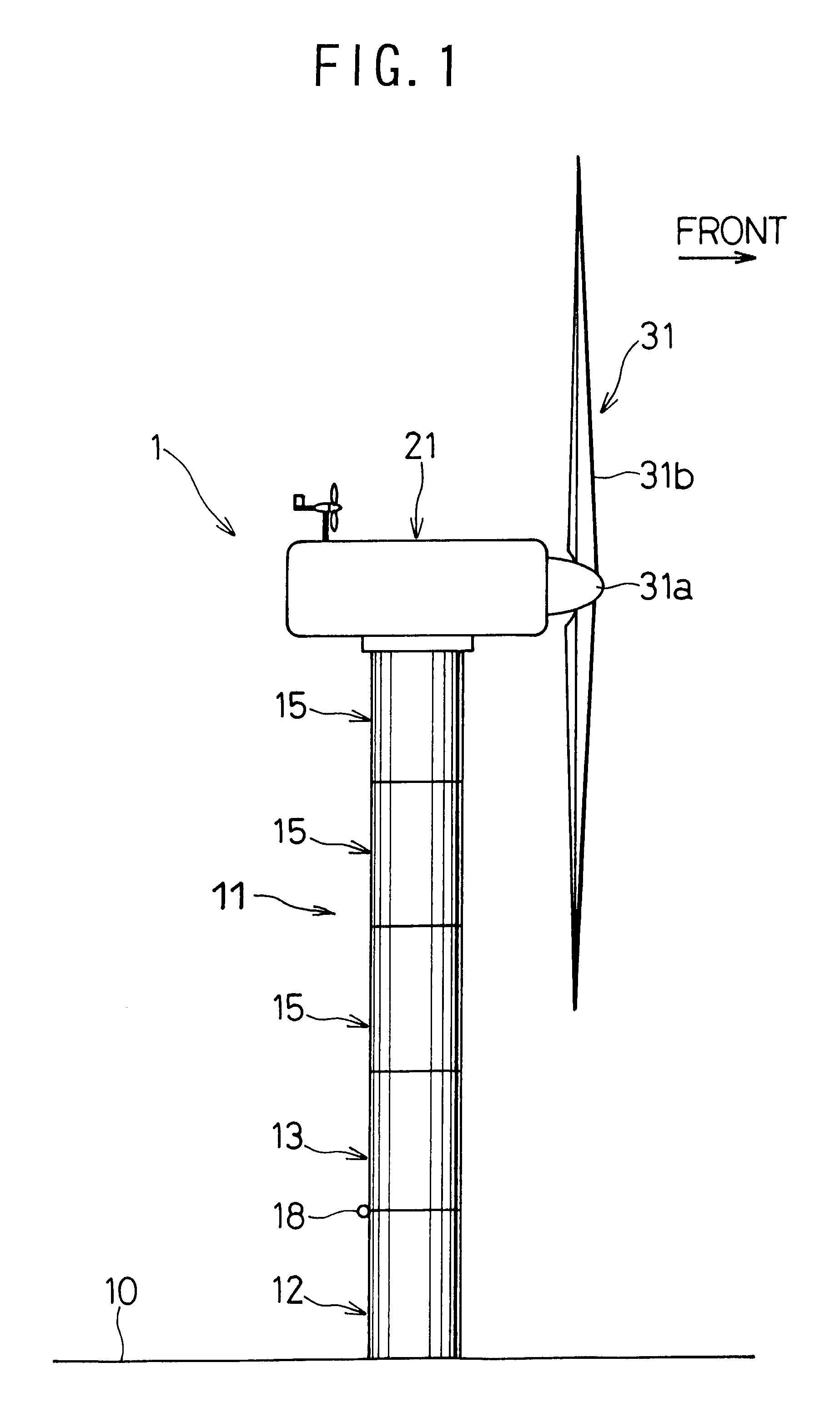

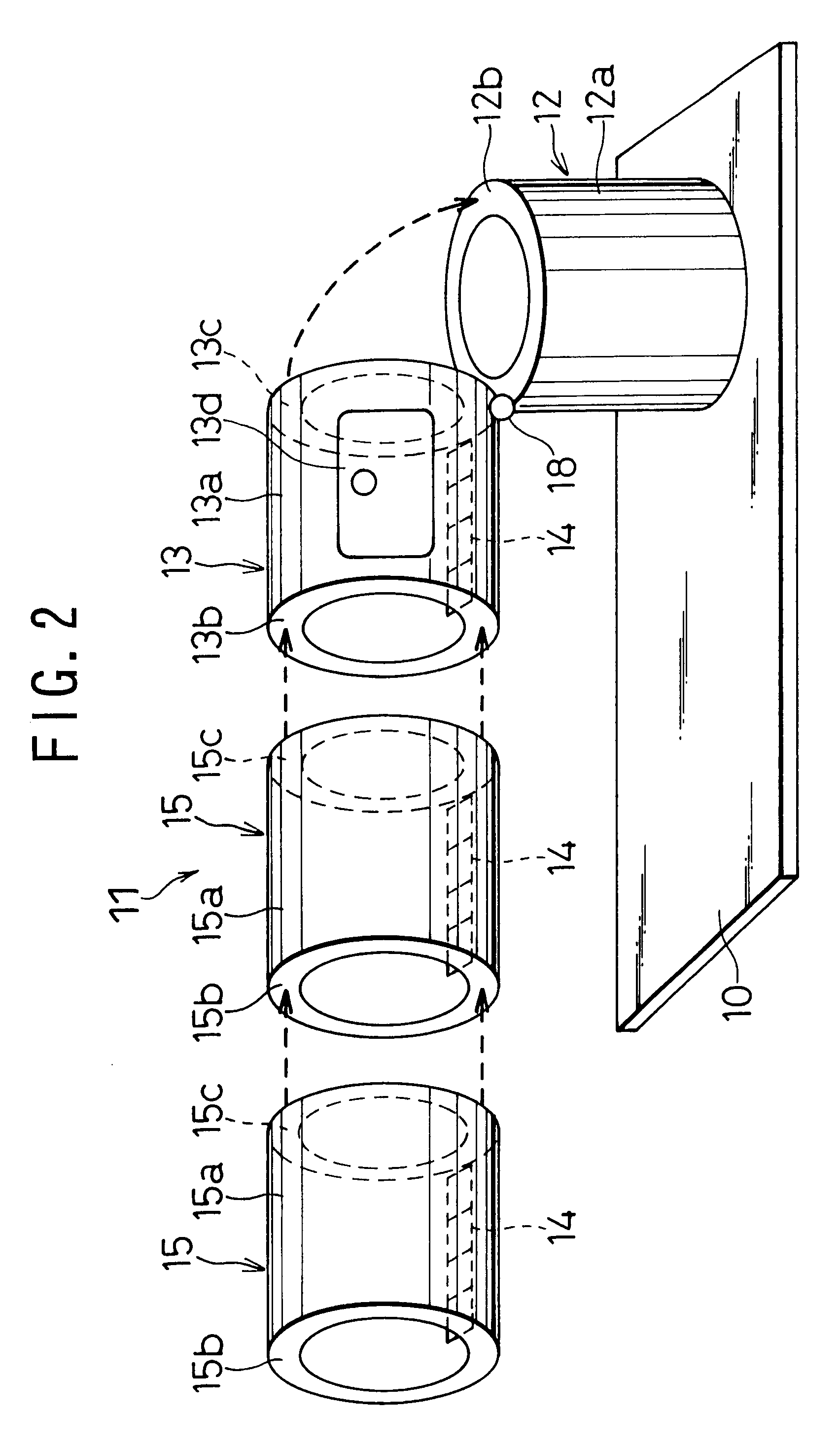

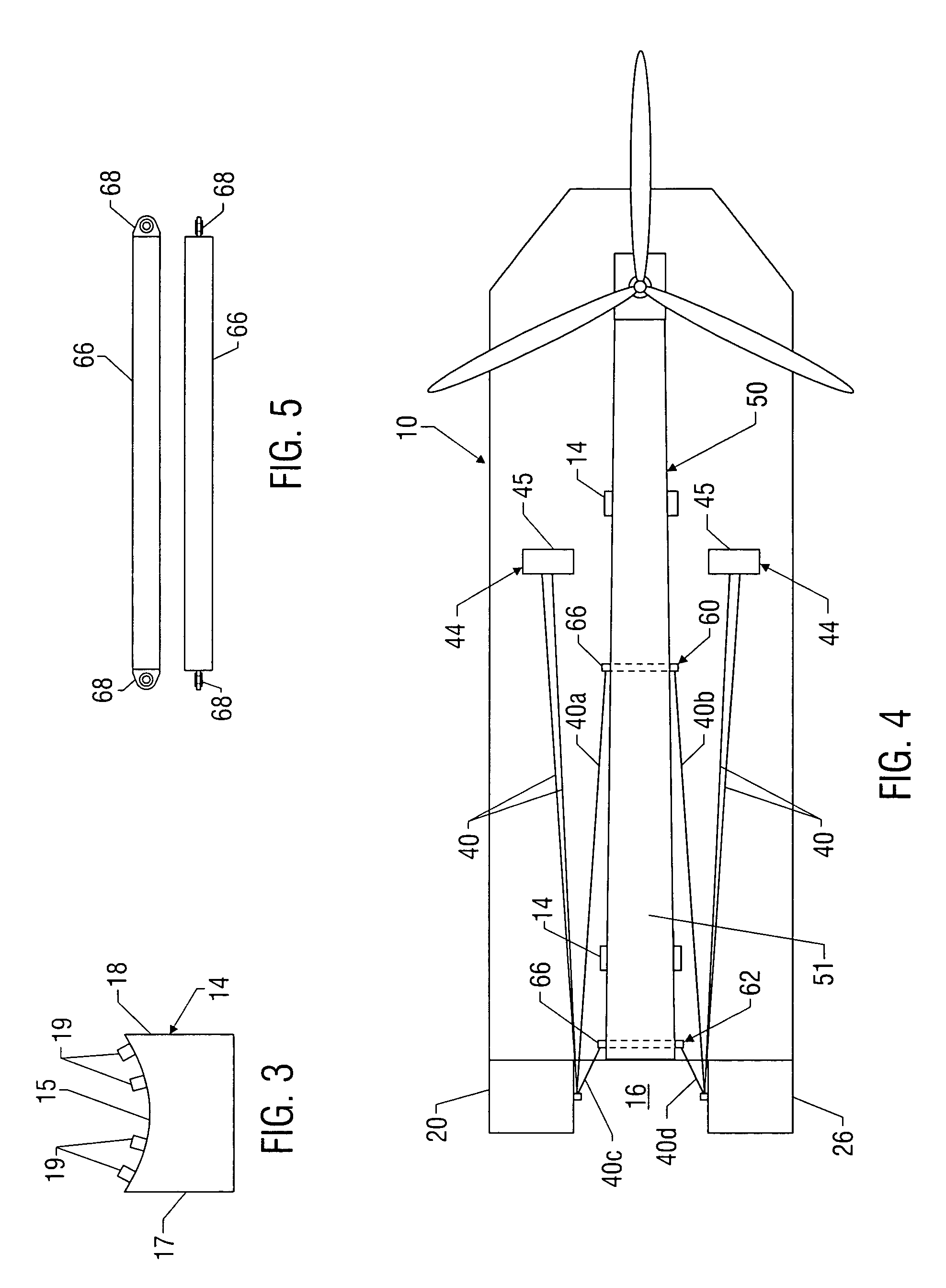

Horizontal axis type wind turbine and method of construction thereof

InactiveUS6408575B1Reduce construction costsEngine manufactureFinal product manufactureNacelleStanding Positions

A tower comprises a base tower member fixed on a base in the ground, a lower tower member hingedly connected at a lower end thereof with an upper end of the base tower member through a hinge and swinging between a lying position and a standing position, a first stage connecting tower member connected at a lower end thereof with an upper end of the lower tower member, a second stage connecting tower member connected at a lower end thereof with an upper end of the first stage connecting tower member, and a third stage connecting tower member connected at a lower end thereof with an upper end of the second stage connecting tower member. Thus formed tower is raised swingingly around the hinge from the lying position to the standing position. A nacelle includes a tower penetrating hole through which the tower vertically penetrates and is formed by a plurality of nacelle sections divisible around the tower penetrating hole. After the tower is built, a plurality of nacelle sections are collected around the tower and are connected with each other while the nacelle is penetrated by the tower. Then, the nacelle is lifted up along the tower in that state and fixed to the top end of the tower.

Owner:SUBARU CORP

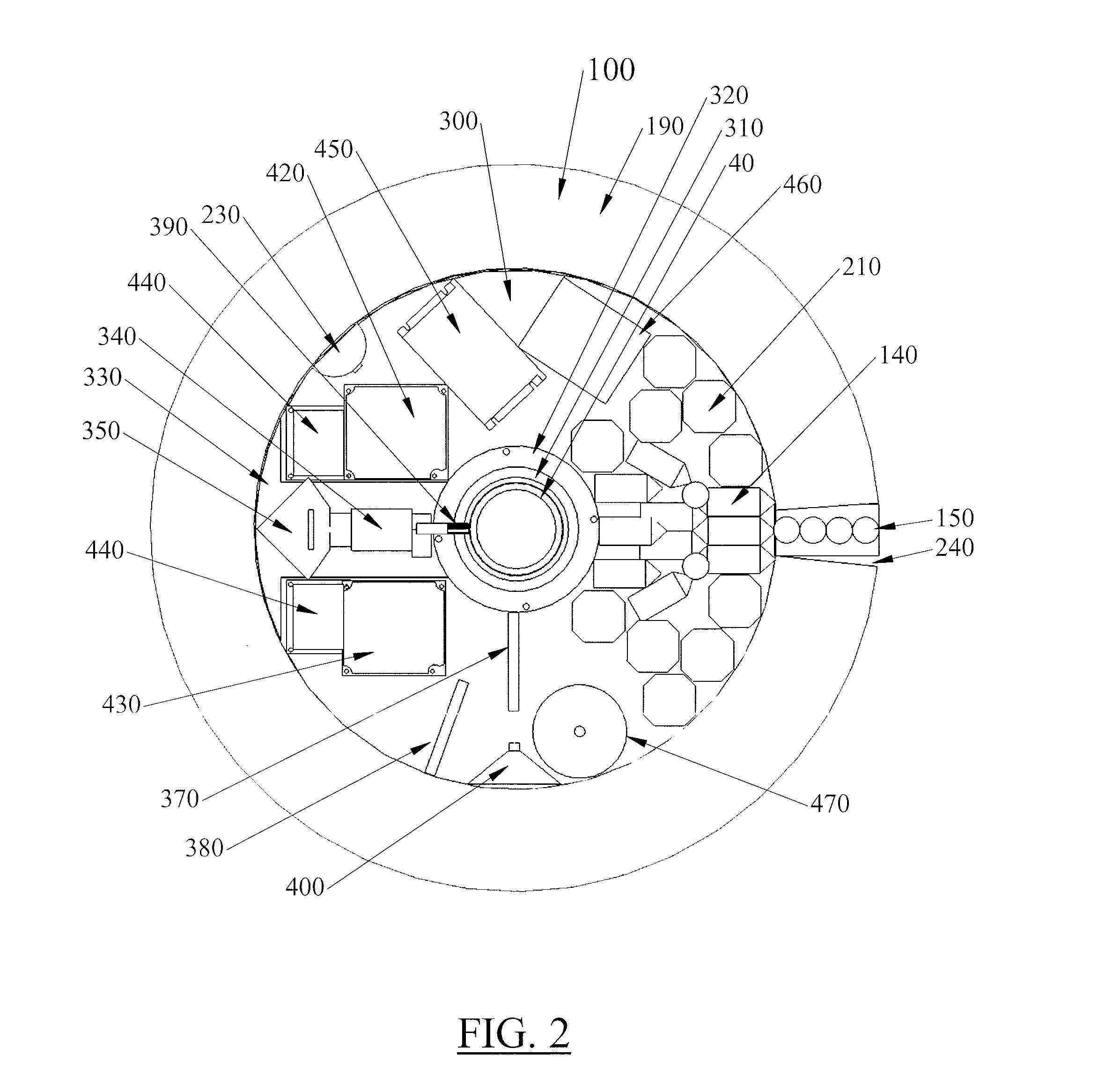

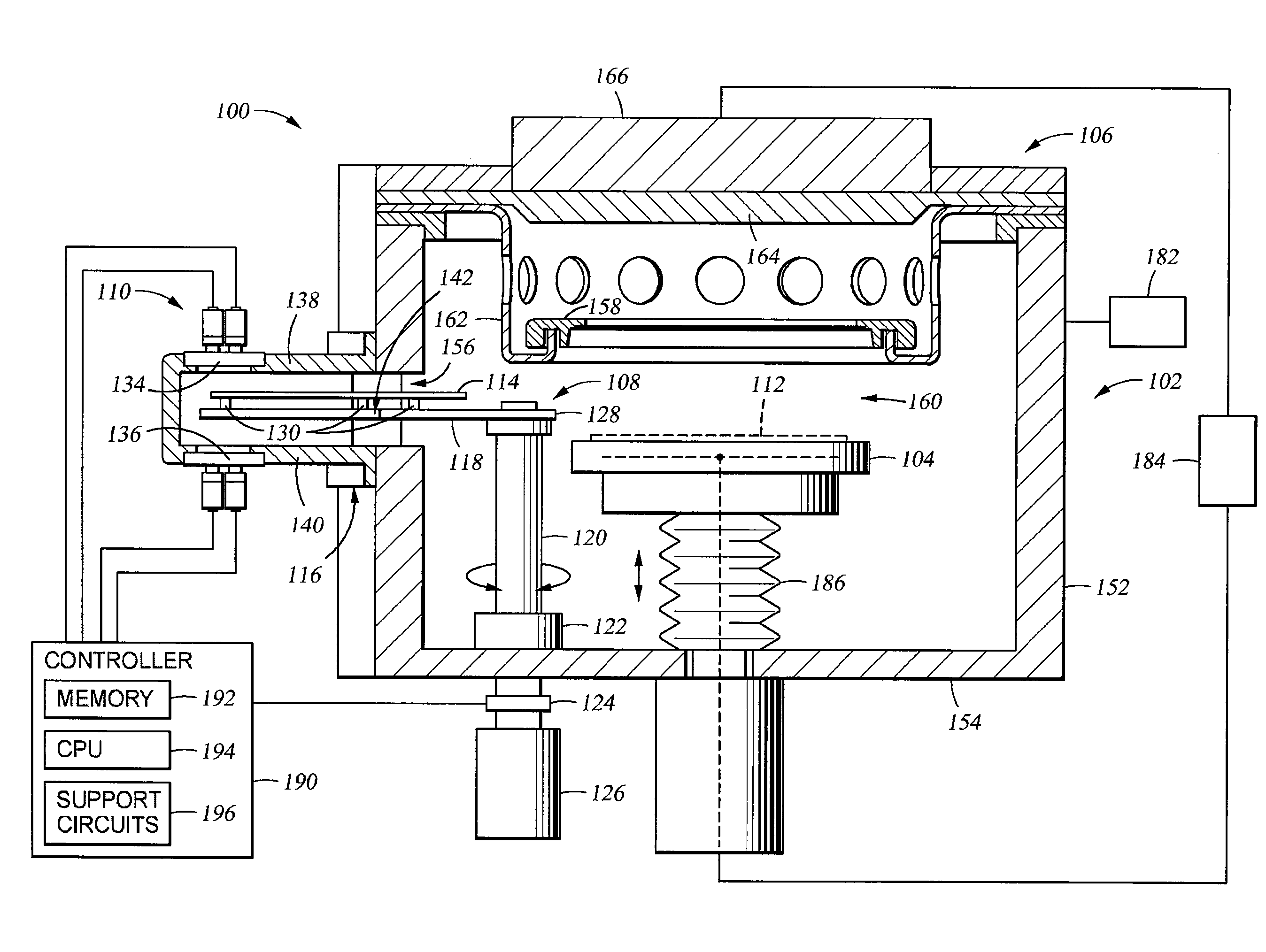

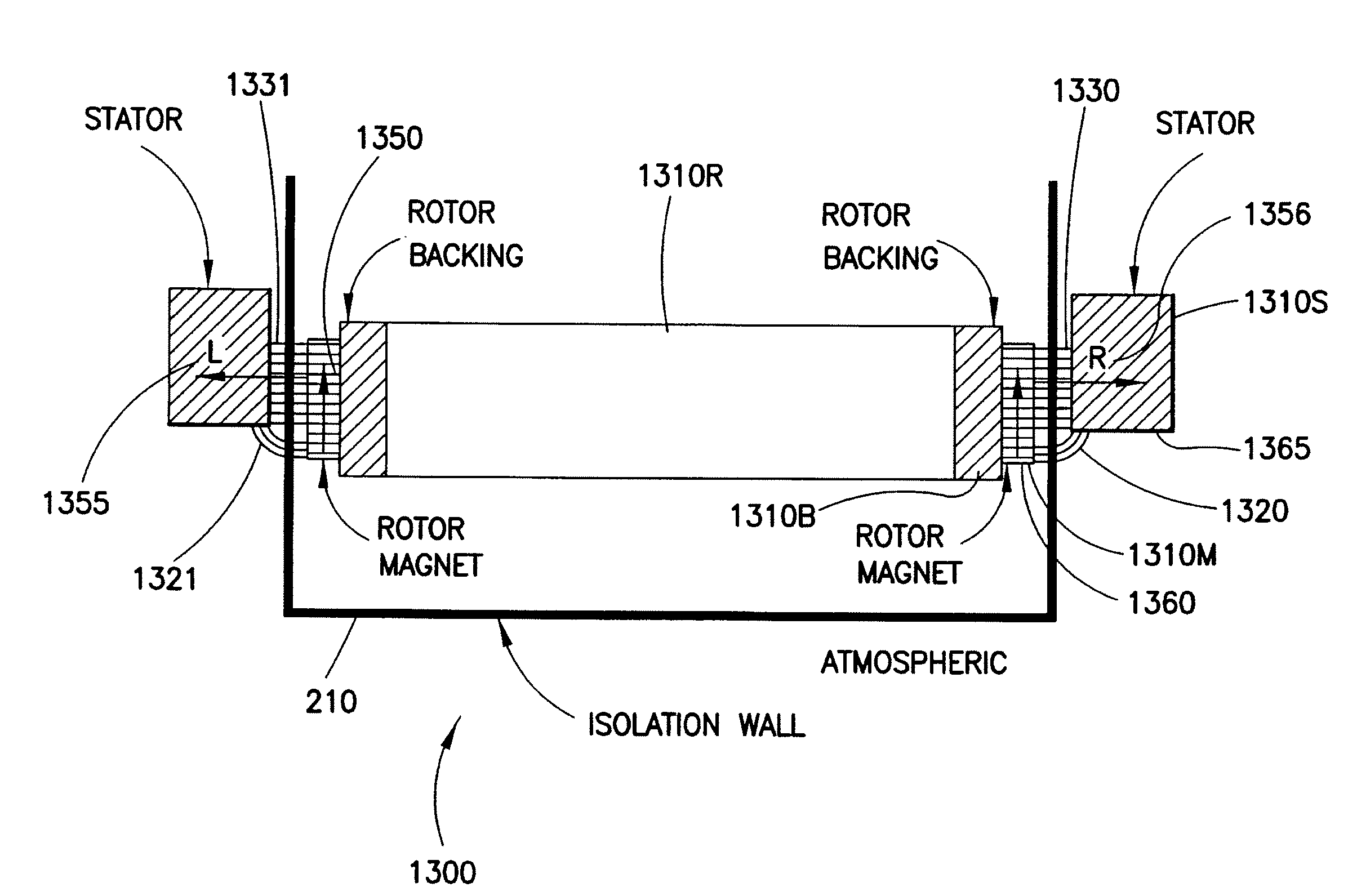

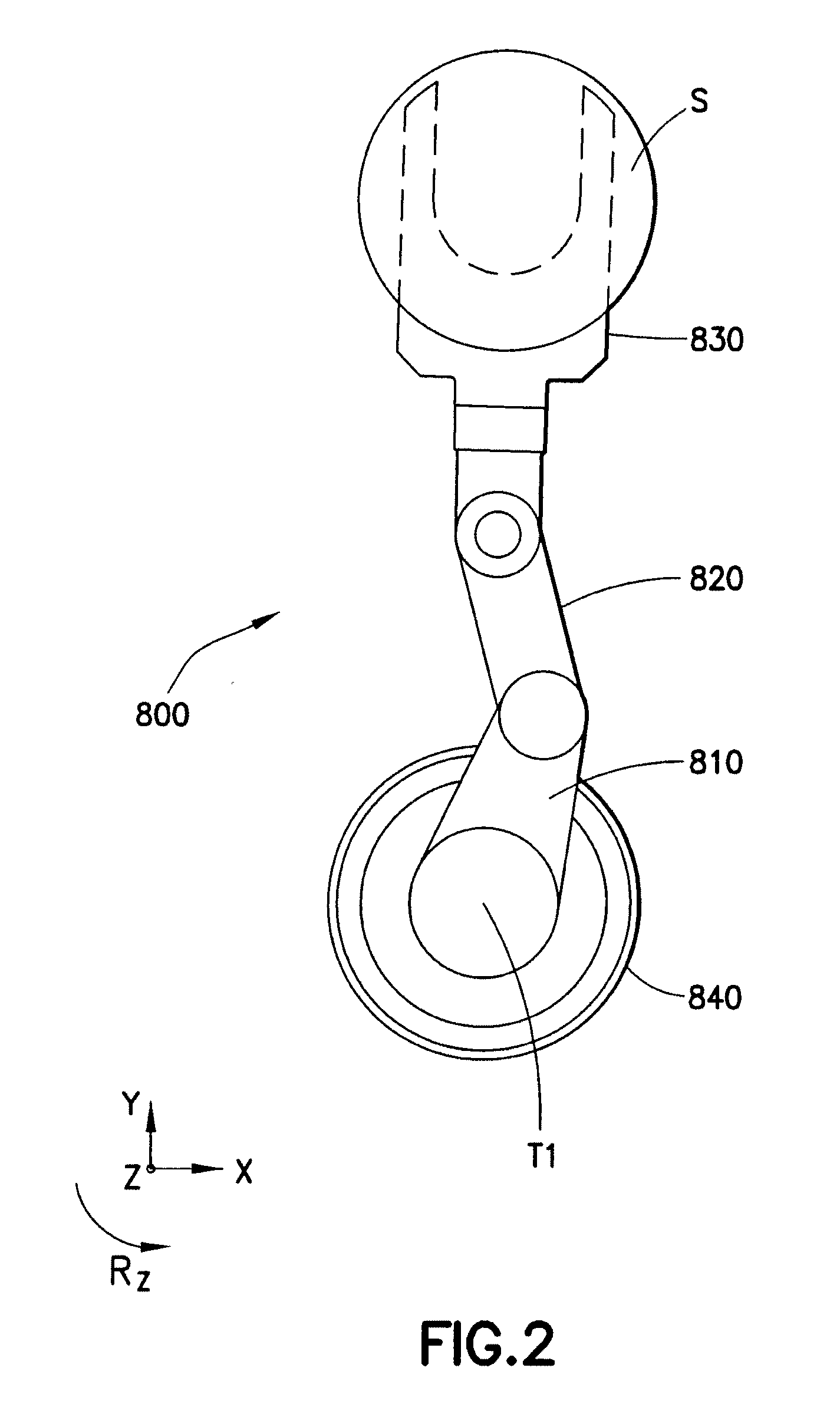

Robot drive with magnetic spindle bearings

A drive section for a substrate transport arm including a frame, at least one stator mounted within the frame, the stator including a first motor section and at least one stator bearing section and a coaxial spindle magnetically supported substantially without contact by the at least one stator bearing section, where each drive shaft of the coaxial spindle includes a rotor, the rotor including a second motor section and at least one rotor bearing section configured to interface with the at least one stator bearing section, wherein the first motor section is configured to interface with the second motor section to effect rotation of the spindle about a predetermined axis and the at least one stator bearing section is configured to effect at least leveling of a substrate transport arm end effector connected to the coaxial spindle through an interaction with the at least one rotor bearing section.

Owner:BOOKS AUTOMATION US LLC

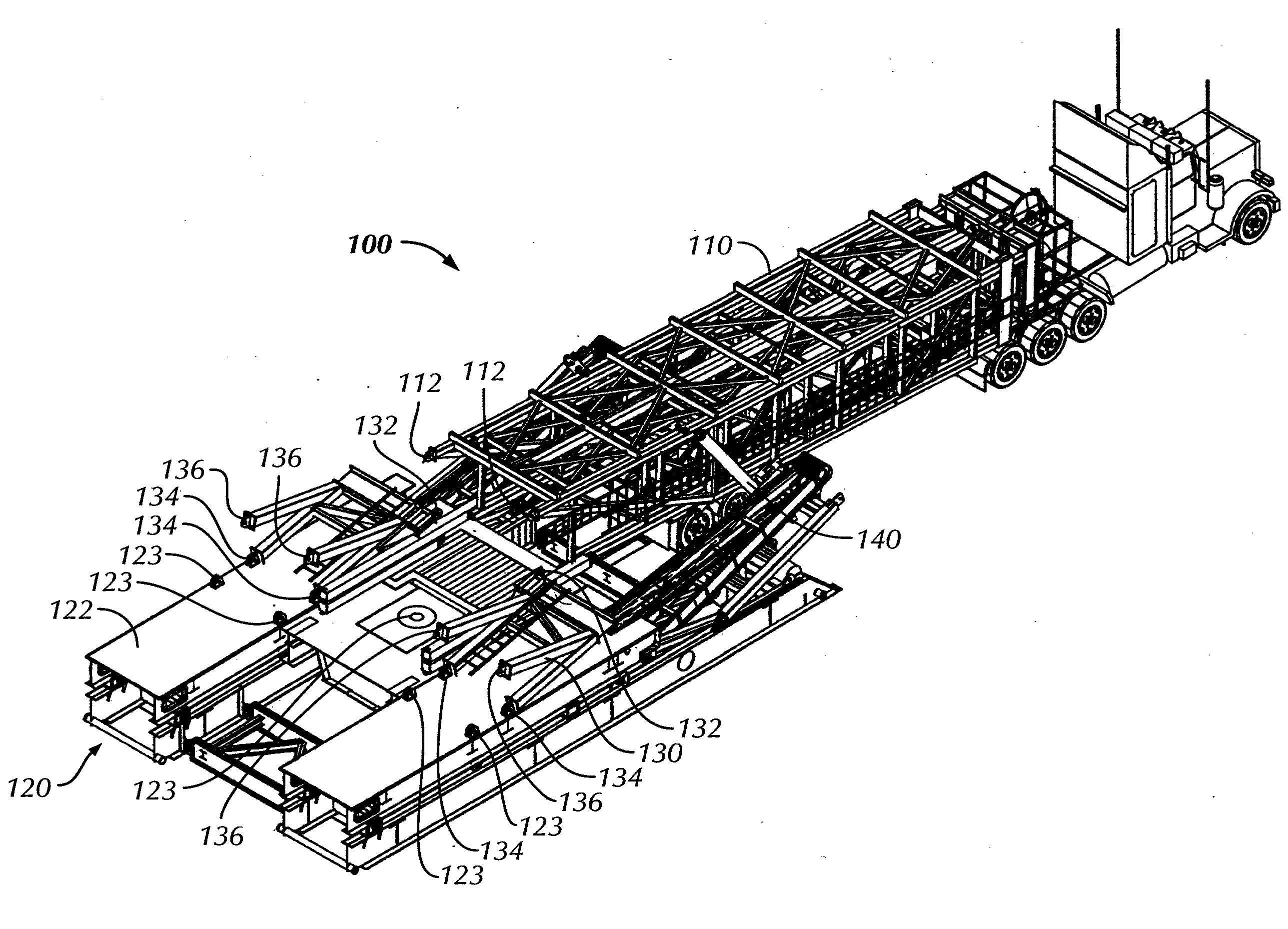

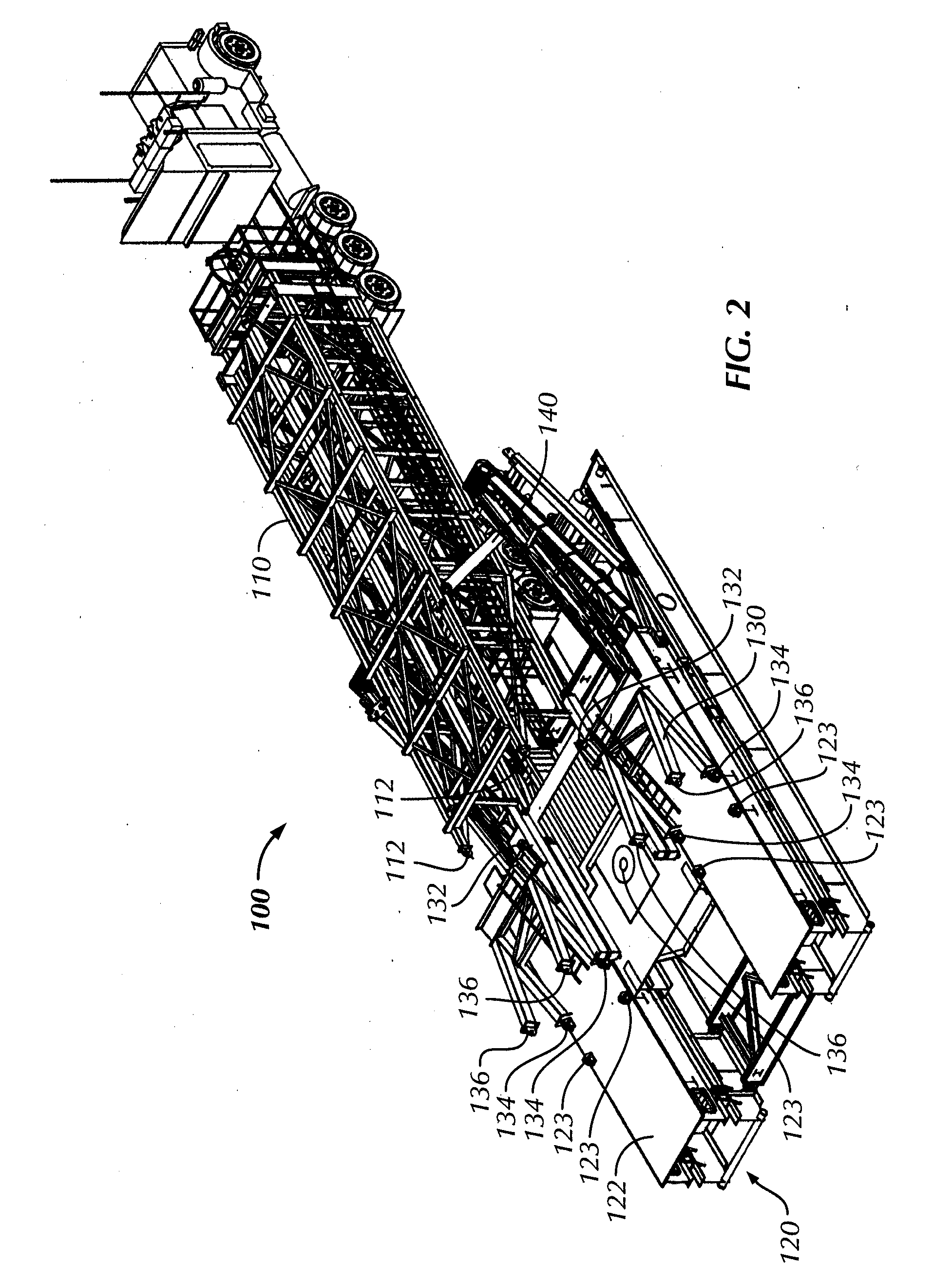

Portable drilling rig apparatus and assembly method

Owner:INTEGRATED DRILLING EQUIP

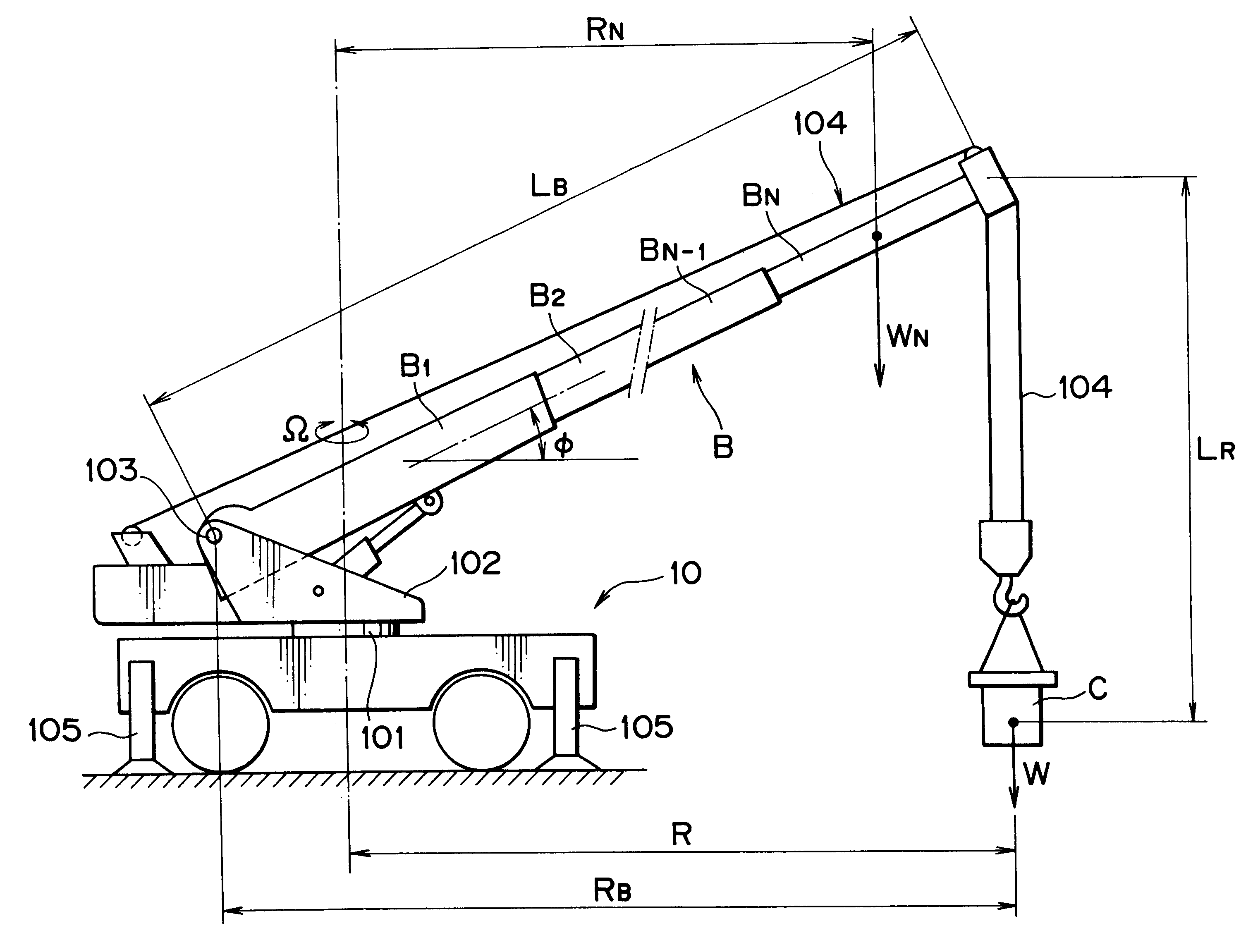

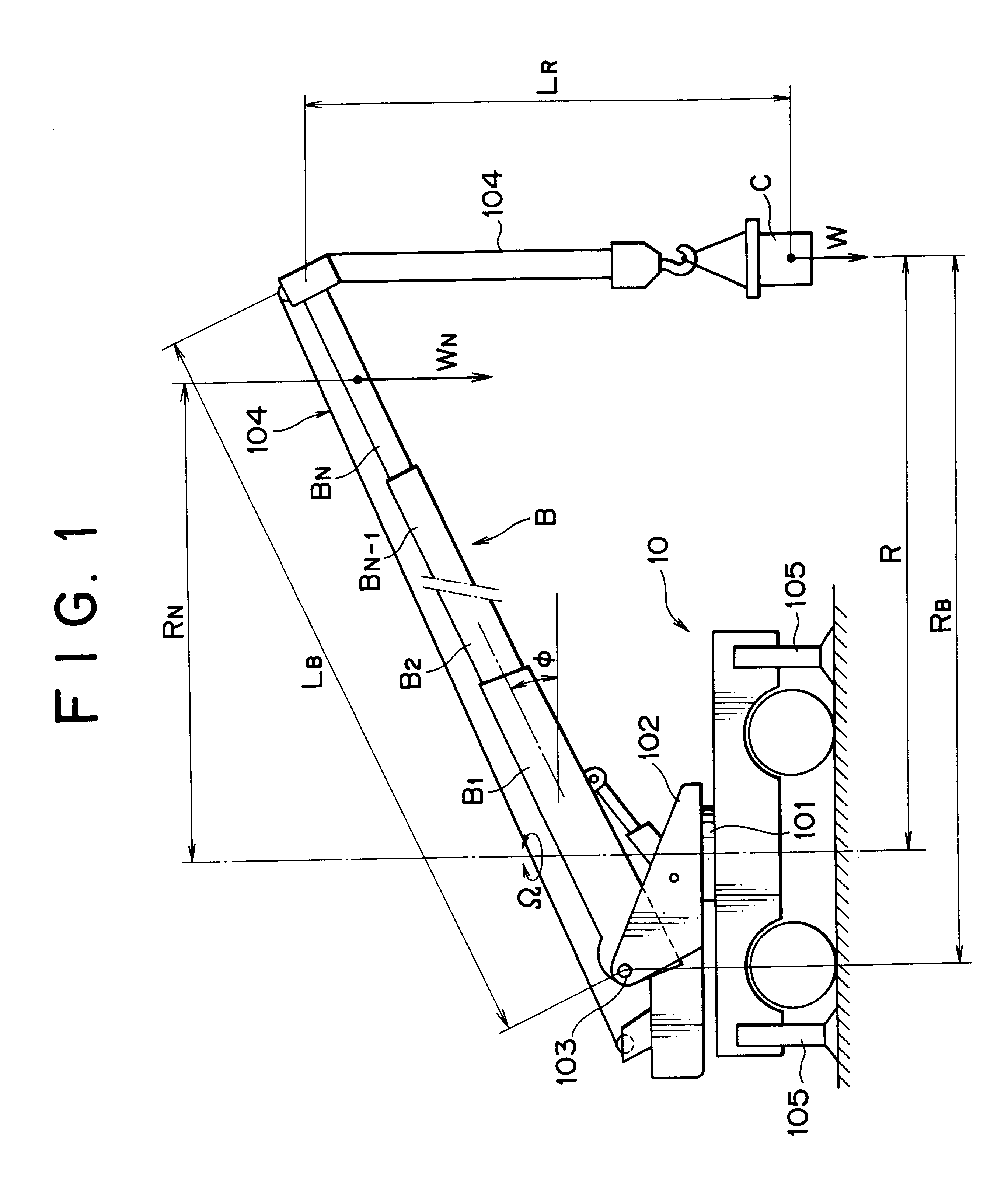

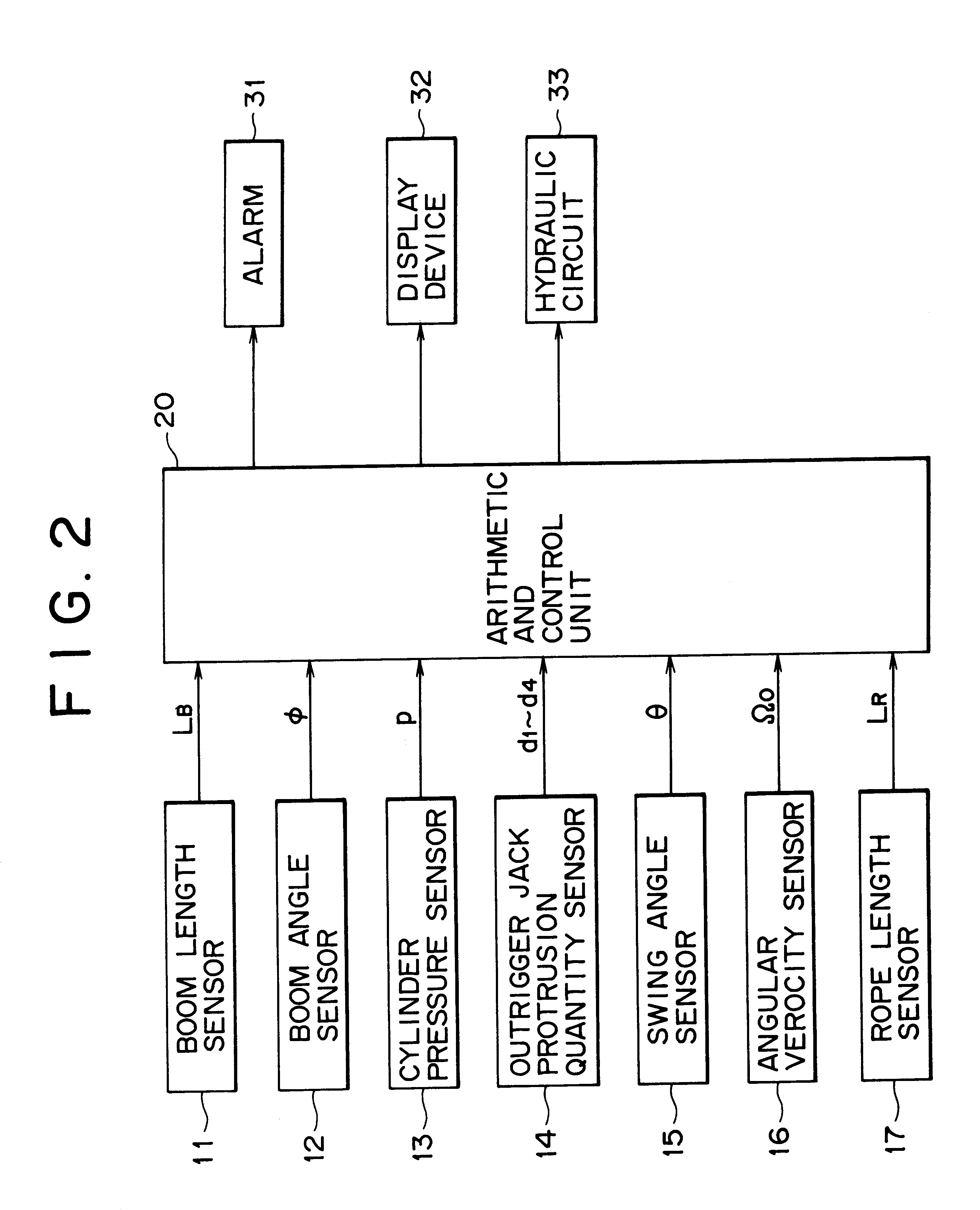

Swing type machine and method for setting a safe work area and a rated load in same

A method for setting a safe work area and a rated load in a swing type work machine, as well as a swing type work machine which utilizes the said method, are disclosed. An area where a strength-based safe work area which is established taking the strength of a swing member into account and a stability-based safe work area which is established taking the stability of the work machine into account overlap each other, is set as a safe work area to be used actually. Likewise, out of a strength-based rated load which is set taking the strength of the swing member into consideration and a stability-based rated load which is set taking the stability of the work machine into consideration, the lower one is set as a rated load to be used actually. Using the safe work area and rated load thus obtained, there are made a safety control and an appropriate display. According to this method, in a swing type work machine such as a crane, it is possible to establish a safe work area and a rated load both matching the actual hoisting capacity of the work machine.

Owner:KOBE STEEL LTD

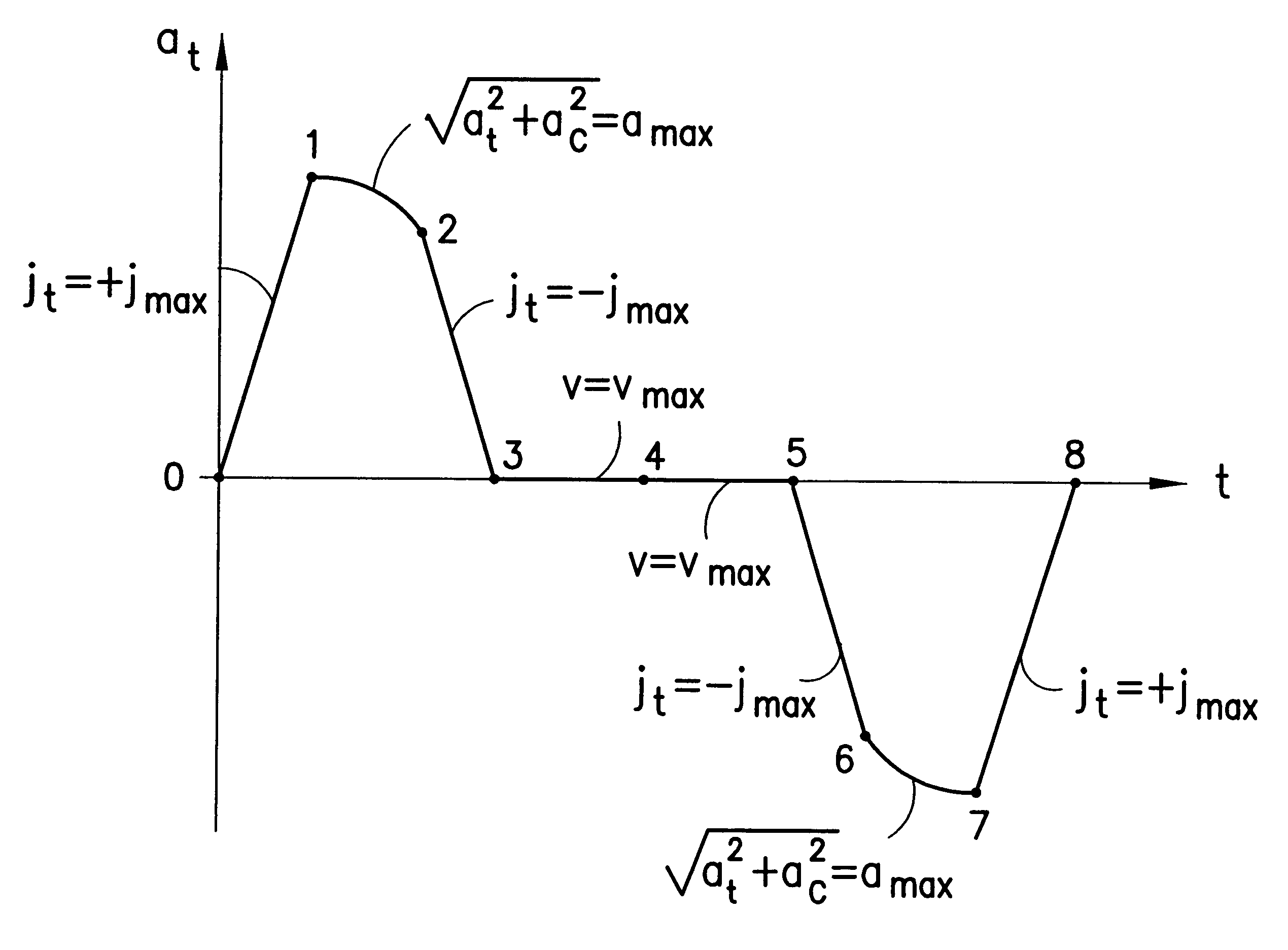

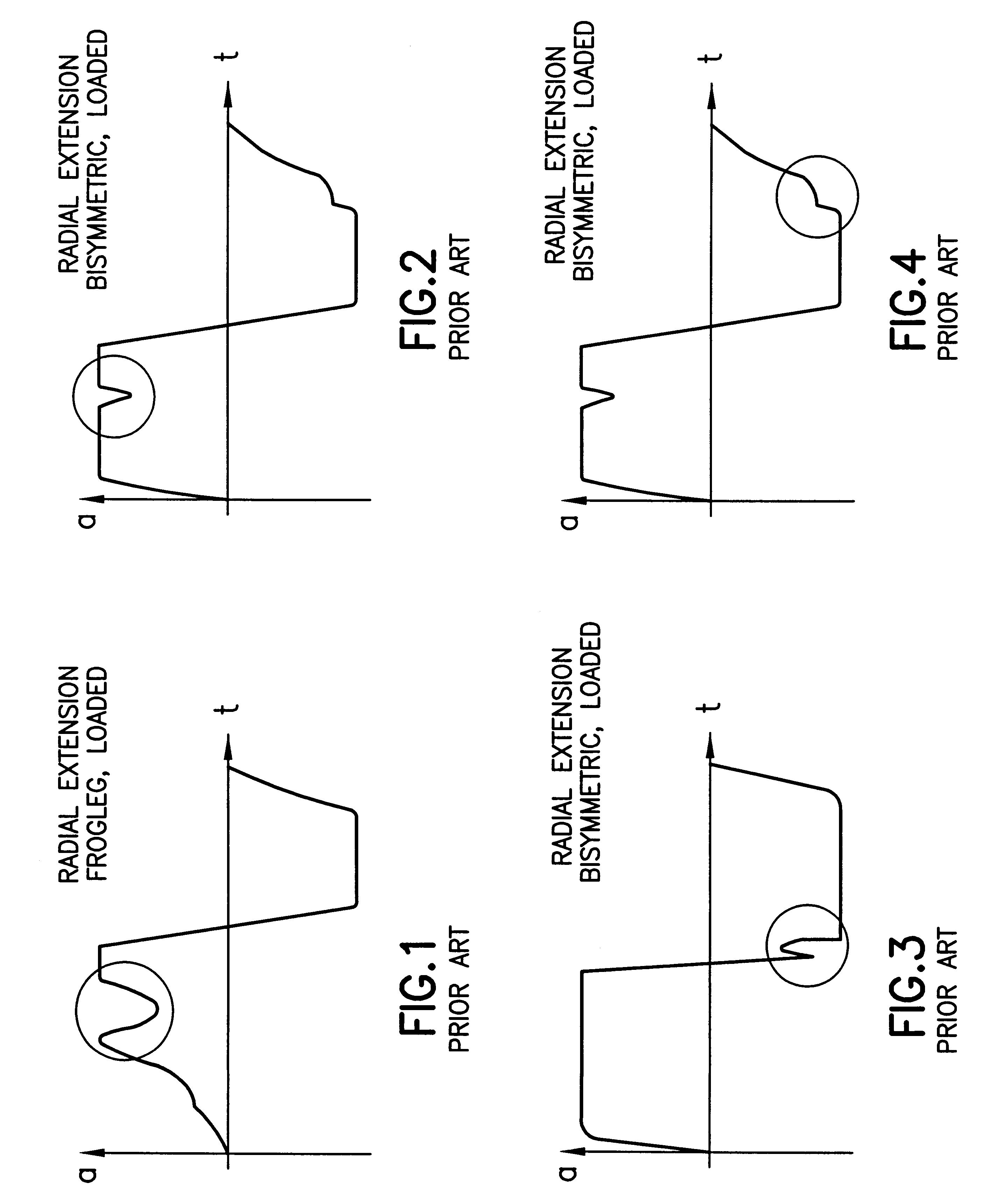

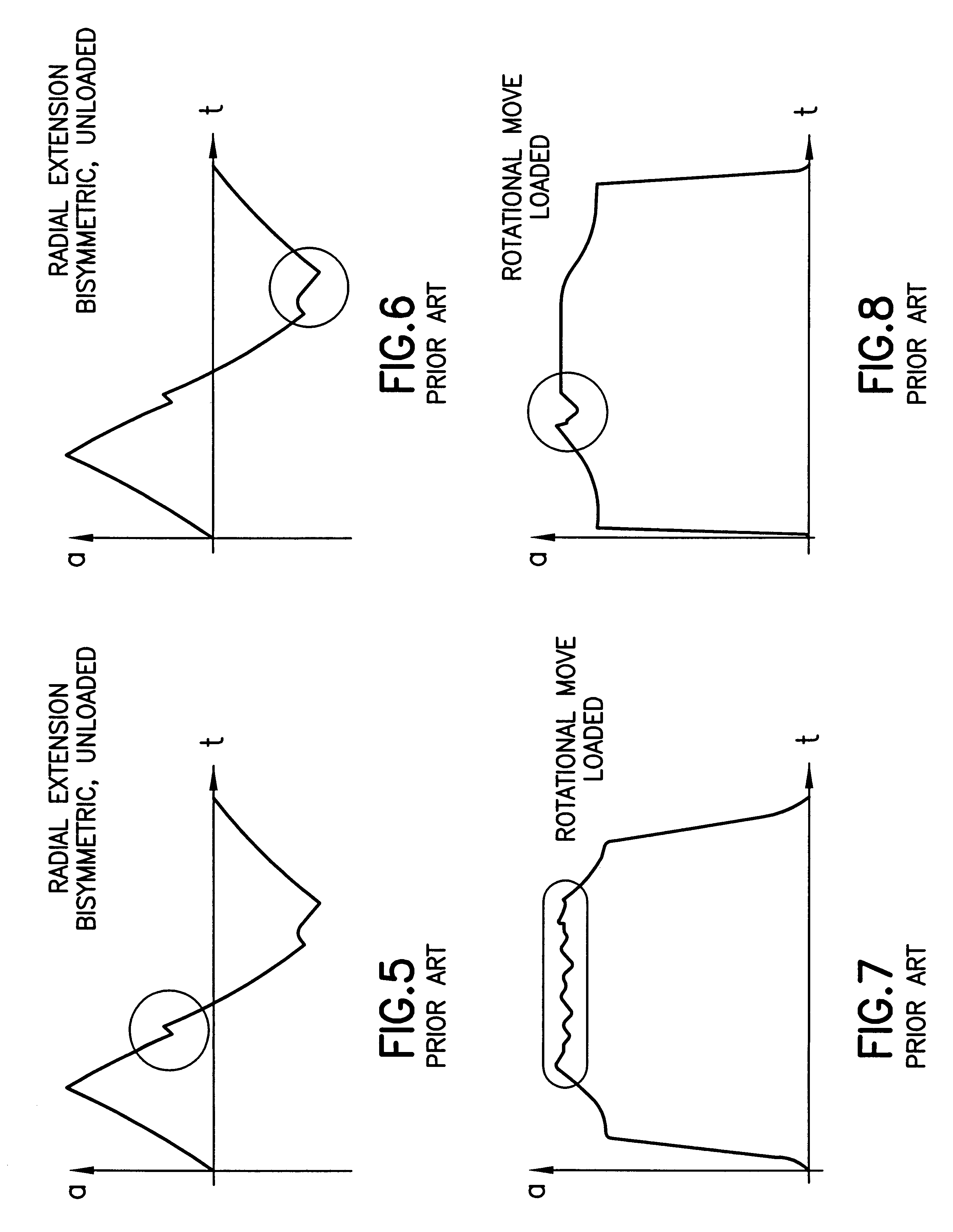

System of trajectory planning for robotic manipulators based on pre-defined time-optimum trajectory shapes

InactiveUS6216058B1Elimination of all typeShort travel timeProgramme-controlled manipulatorComputer controlEngineeringTrajectory planning

A system for providing the reliable and numerically efficient generation of time-optimum trajectories with easy-to-track or continuous acceleration profiles for simple and blended moves of single- and multi-arm robotic manipulators, such as an extension and retraction move along a straight line or a rotary move following a circular arc, with velocity, acceleration, jerk, and jerk rate constraints. A time-optimum trajectory is the set of the position, velocity, and acceleration profiles which describe the move of a selected end effector along a given path in the shortest time possible without violating given constraints, with a special case being an optimum abort trajectory, which brings the moving arm into complete rest in the shortest time. The invention involves firstly identifying the set of fundamental trajectory shapes which cover all possible combinations of constraints for a given category of moves, e.g., a move along a straight line or along a circular arc; next, decomposing the fundamental shapes into segments where a single constraint is active; and, then, determining the time optimum paths in the segments. As a result, a unique design of time-optimum trajectories is produced based on a set of pre-defined trajectory shapes. The invention also involves the blending of simple moves into a single trajectory by decomposing trajectories of the individual moves into their orthogonal components and overlapping them for a given time interval, which results in a non-stop move along a smooth transfer path.

Owner:BOOKS AUTOMATION US LLC

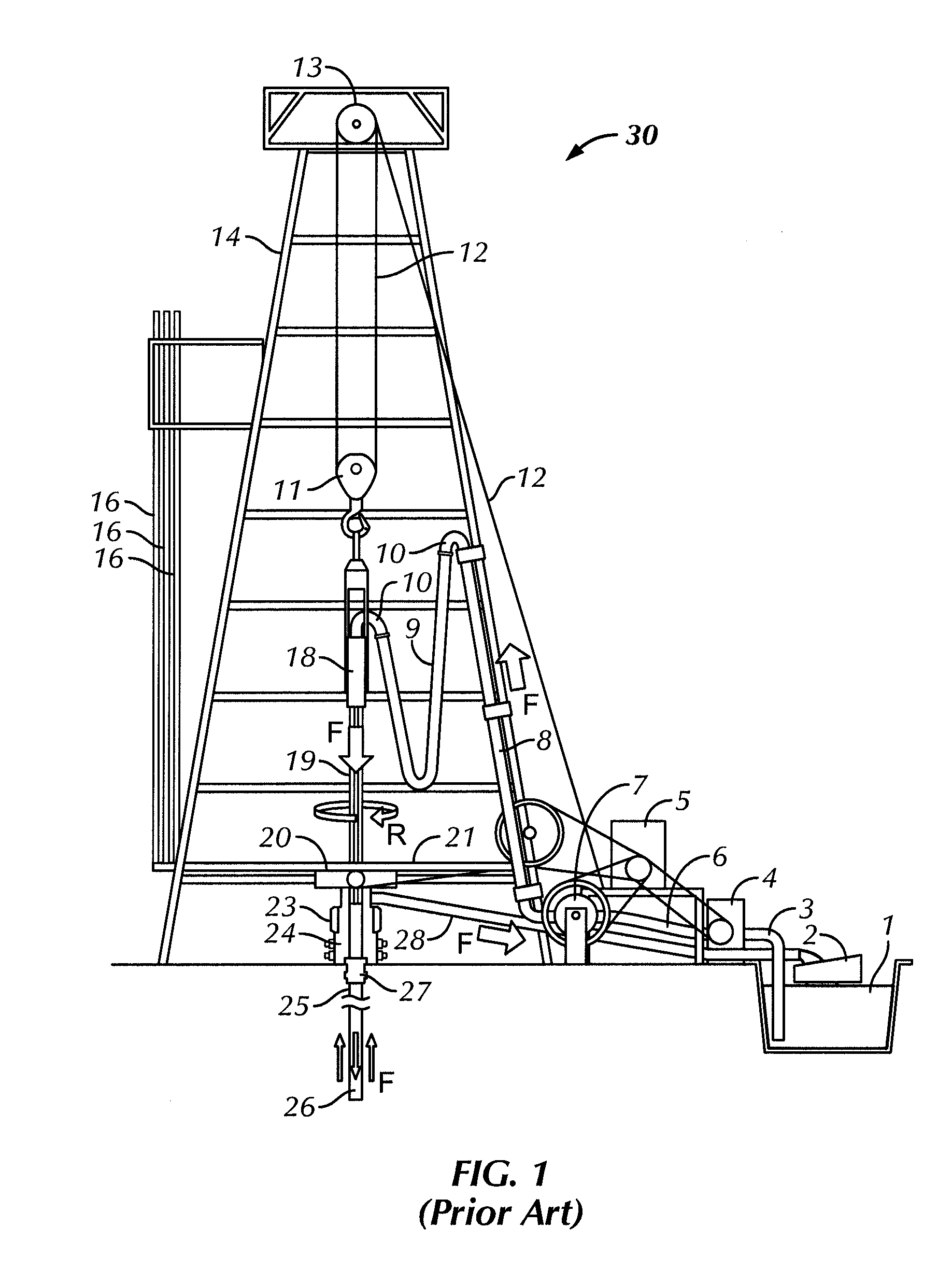

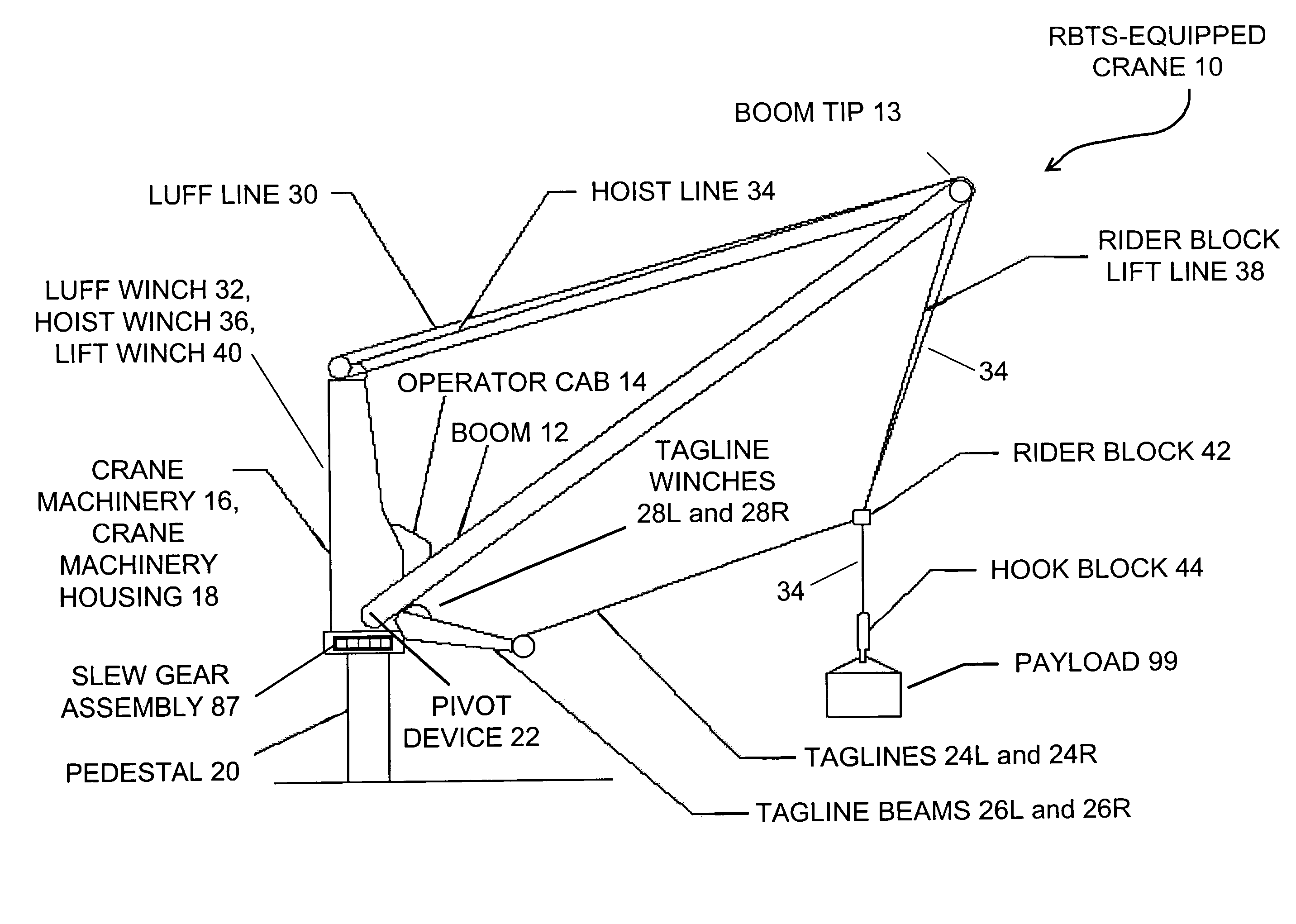

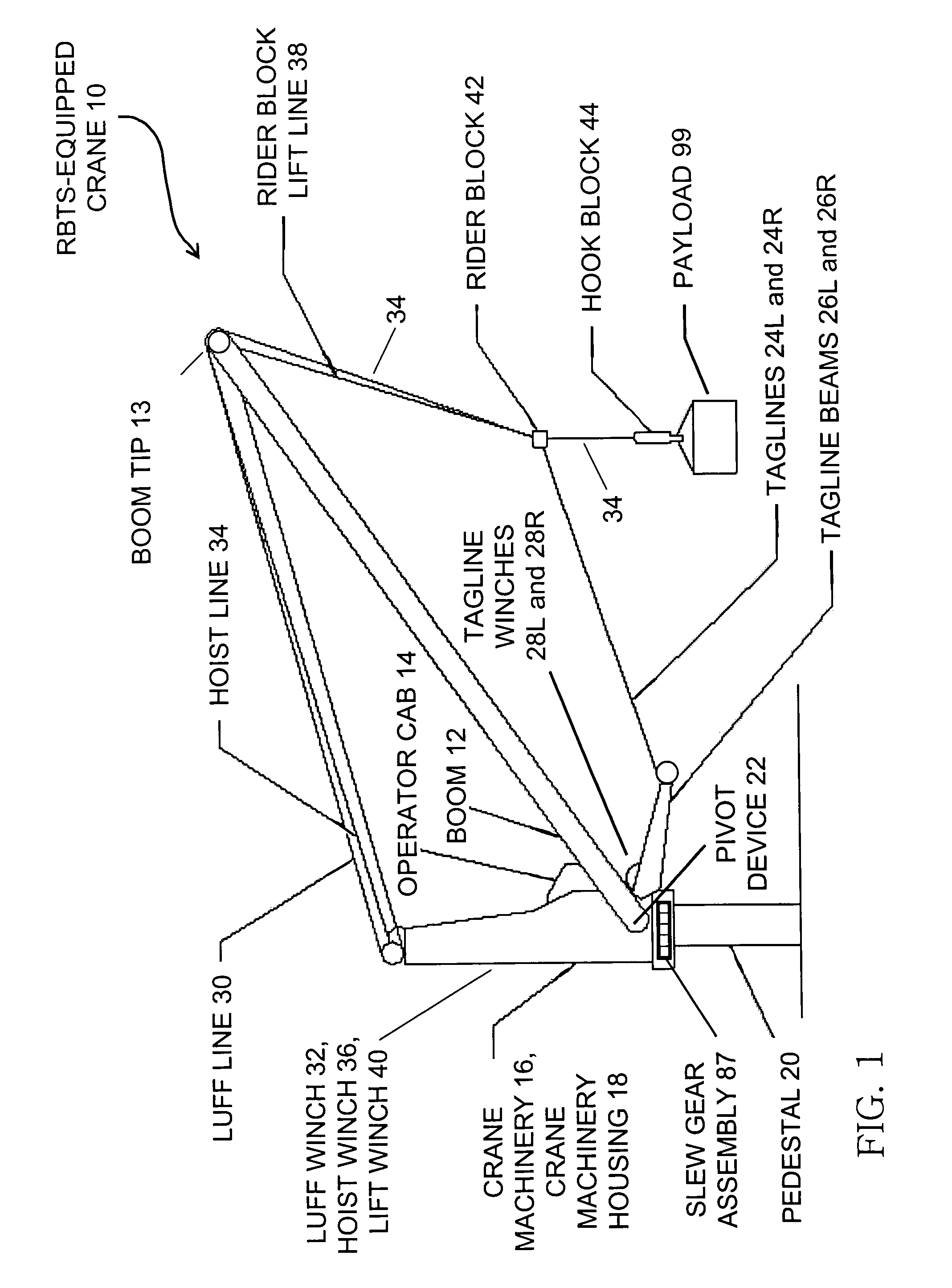

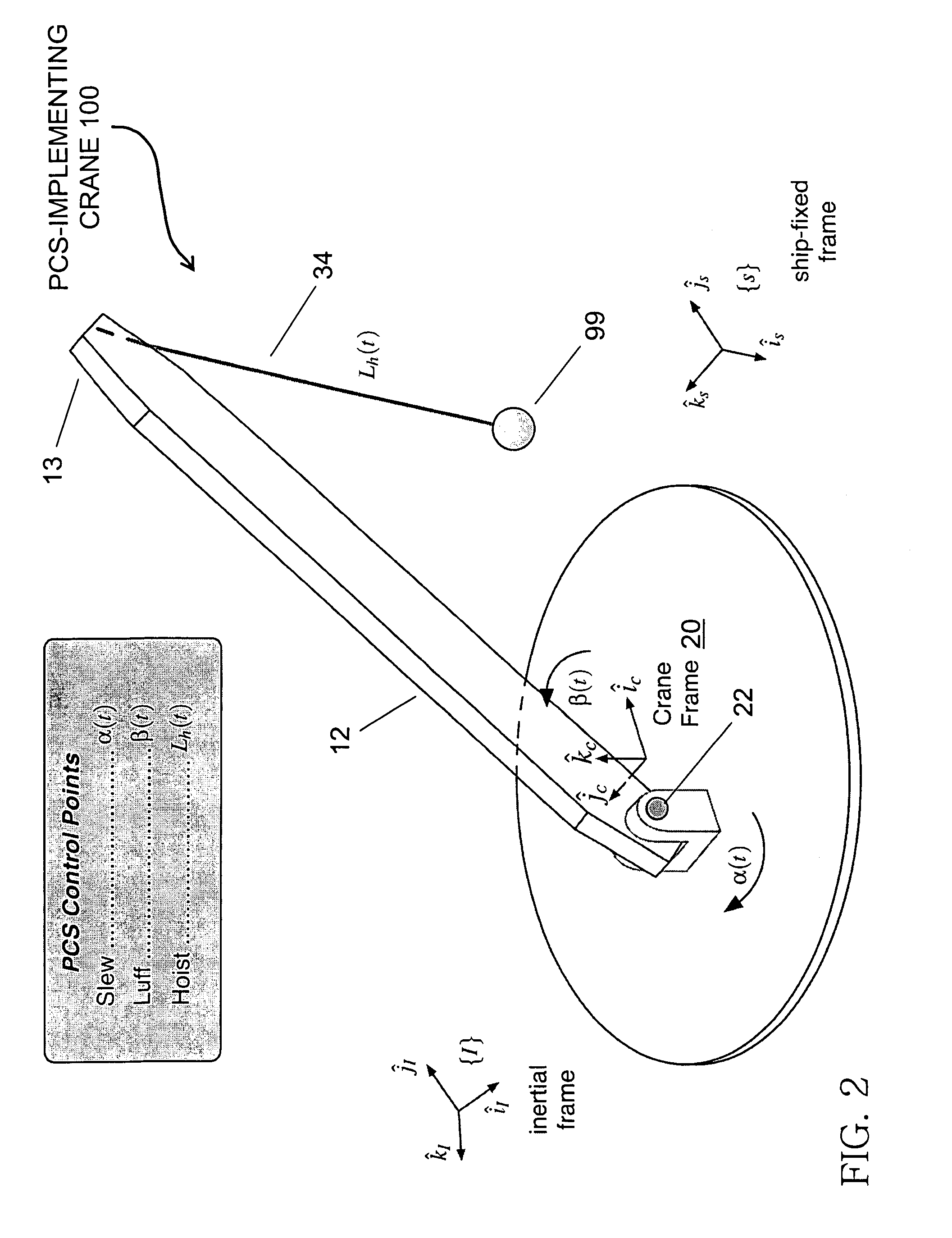

Pendulation control system with active rider block tagline system for shipboard cranes

ActiveUS7367464B1Good partitionOther workshop equipmentLoad-engaging elementsShip controlControl mode

The inventive control system, as typically embodied, includes sensing mechanisms, a computational processing unit, and an algorithm for processing inputs and generating outputs to control a rotating pedestal crane equipped with a Rider Block Tagline System (RBTS). Typical inventive embodiments uniquely feature a processing algorithm that distributes various control modes that operate not only through the crane's hoisting, luffing, and slewing mechanisms but also through the crane's RBTS; the inventive algorithm thereby effectuates motion compensation and pendulation damping with respect to the crane. This algorithmic allocation of control represents a more efficient crane anti-pendulation methodology than conventional methodologies; in particular, the inventive methodology exerts significantly greater control of the payload while exacting significantly less burden upon the hoisting, luffing, and slewing mechanisms of the crane.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

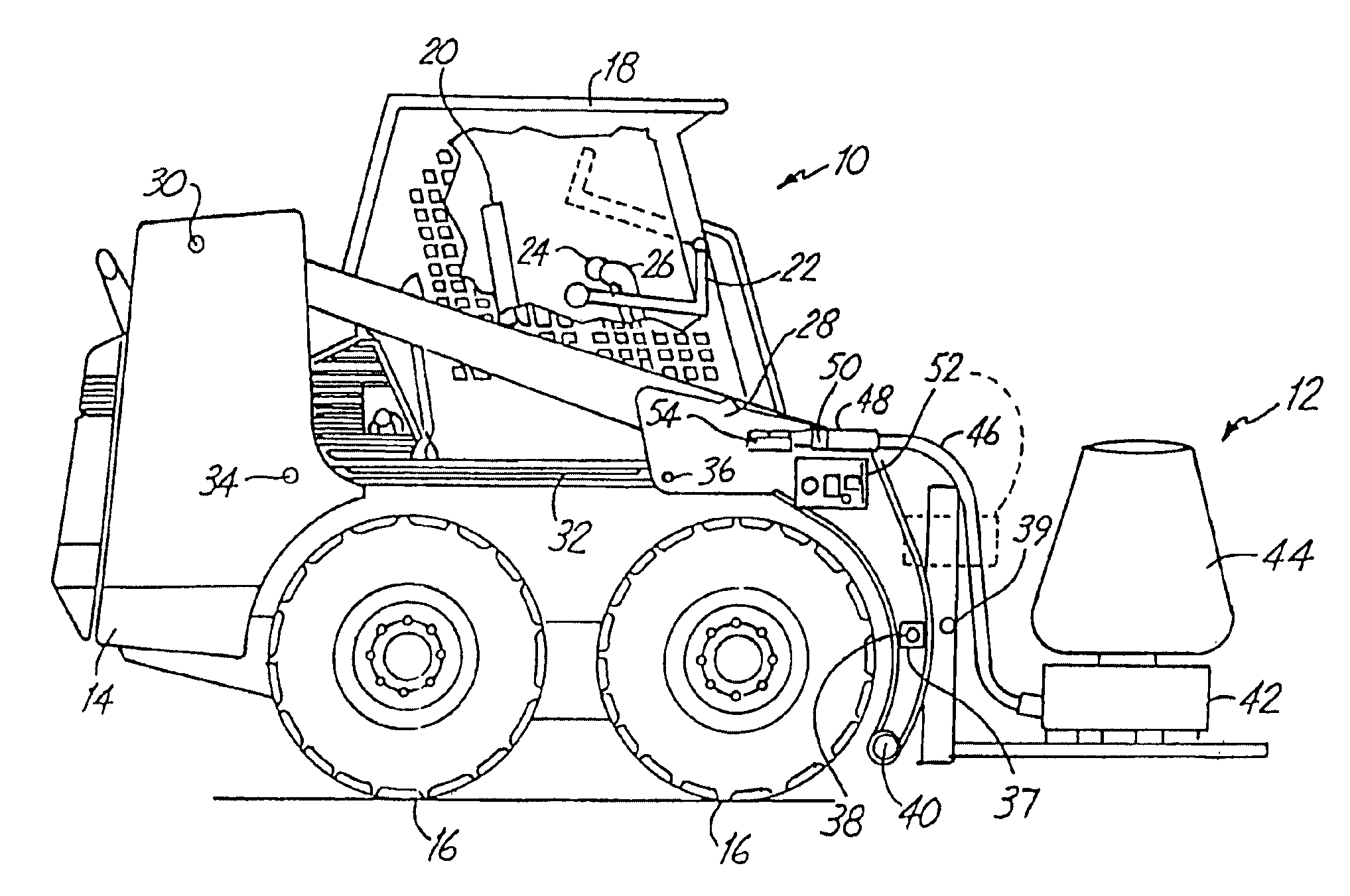

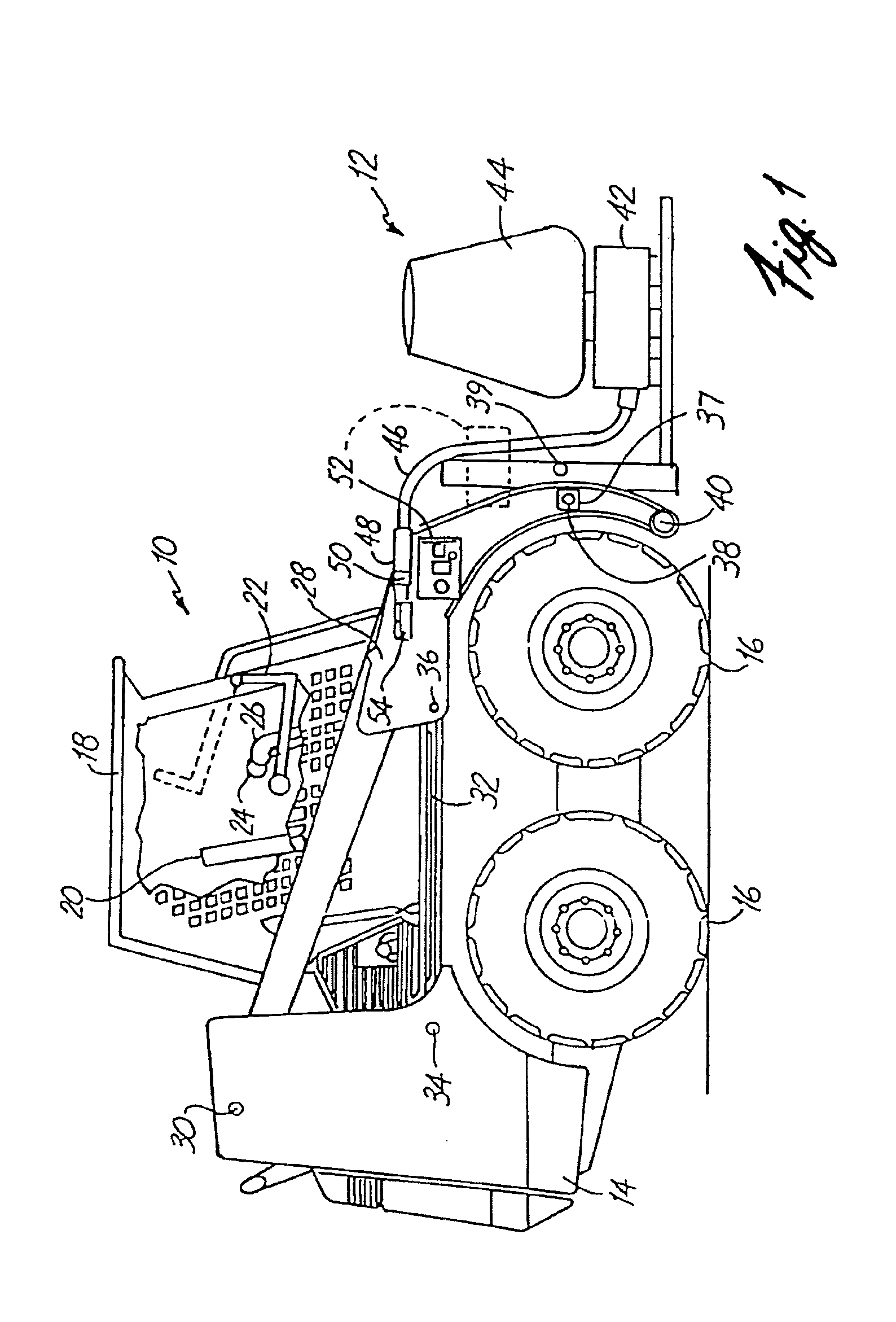

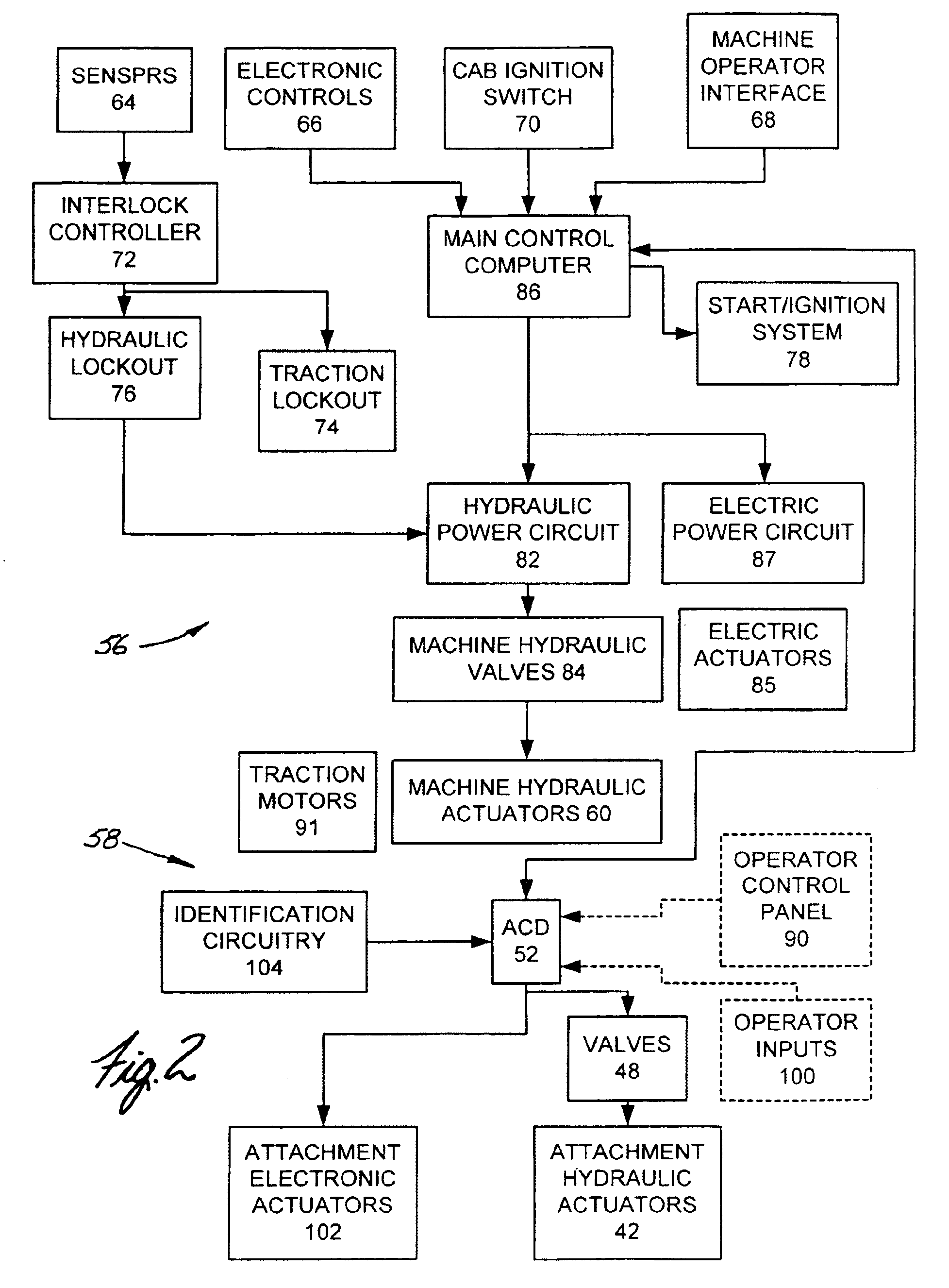

Attachment control device

The present invention provides an attachment for use with a power machine. An attachment control device includes a controller, such as a microprocessor, a microcontroller or other digital computer which senses the type of attachment and controls power to the attachment accordingly. In one embodiment, the attachment control device can be used for remotely controlling the attachment and includes an ignition switch and a stop switch and allows a user to operate the attachment from outside the operator compartment of the power machine, when the power machine is started from the attachment control device.

Owner:CLARK EQUIP CO INC

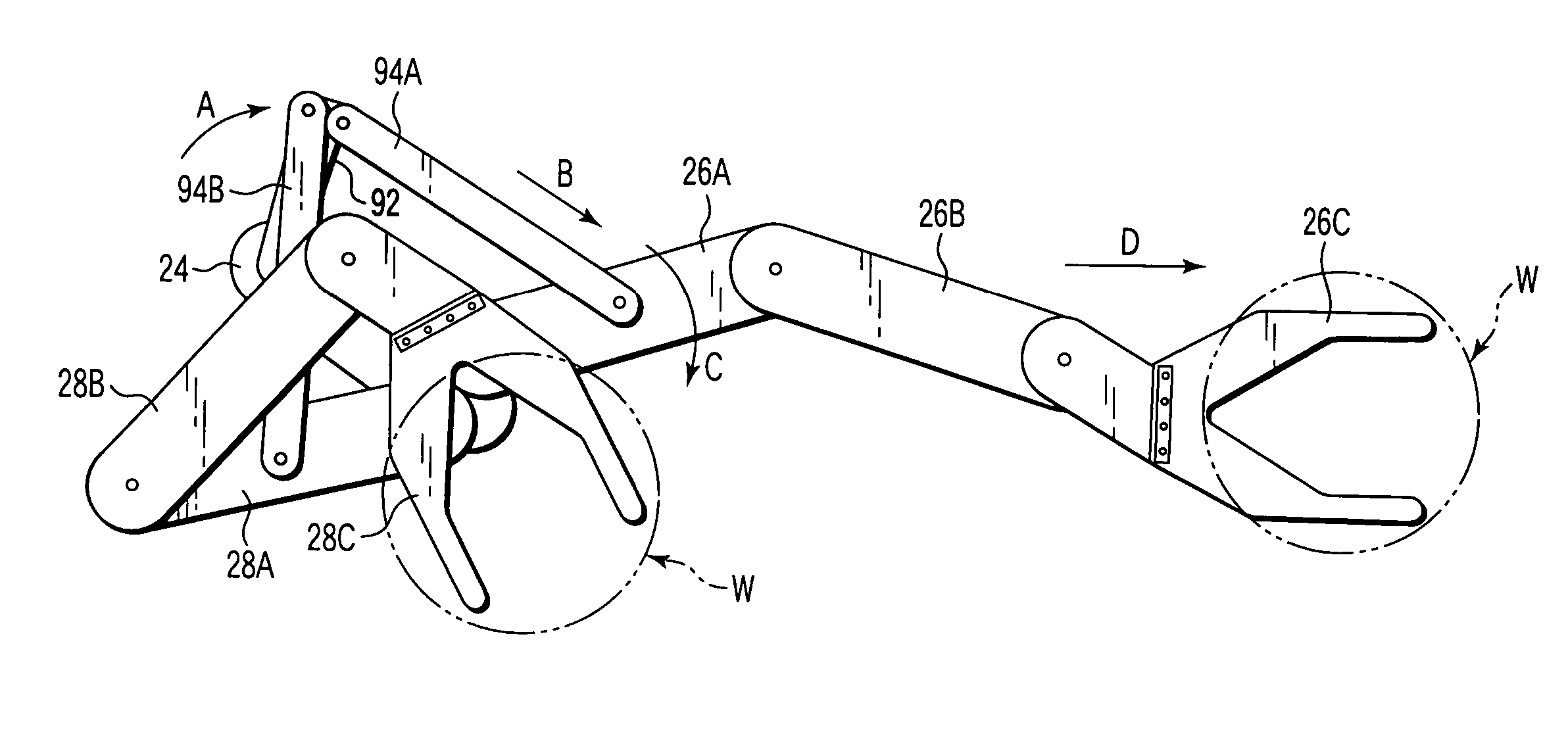

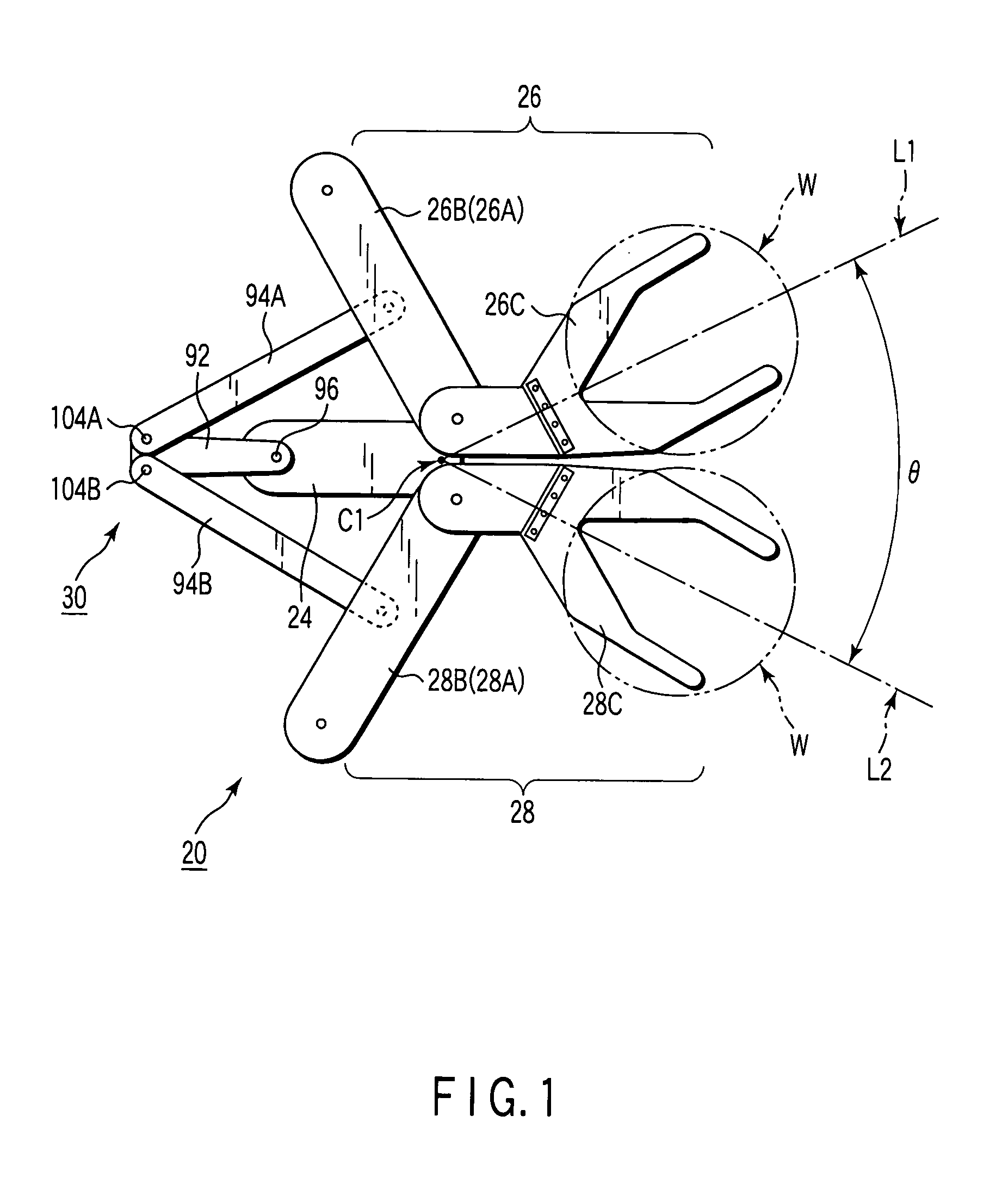

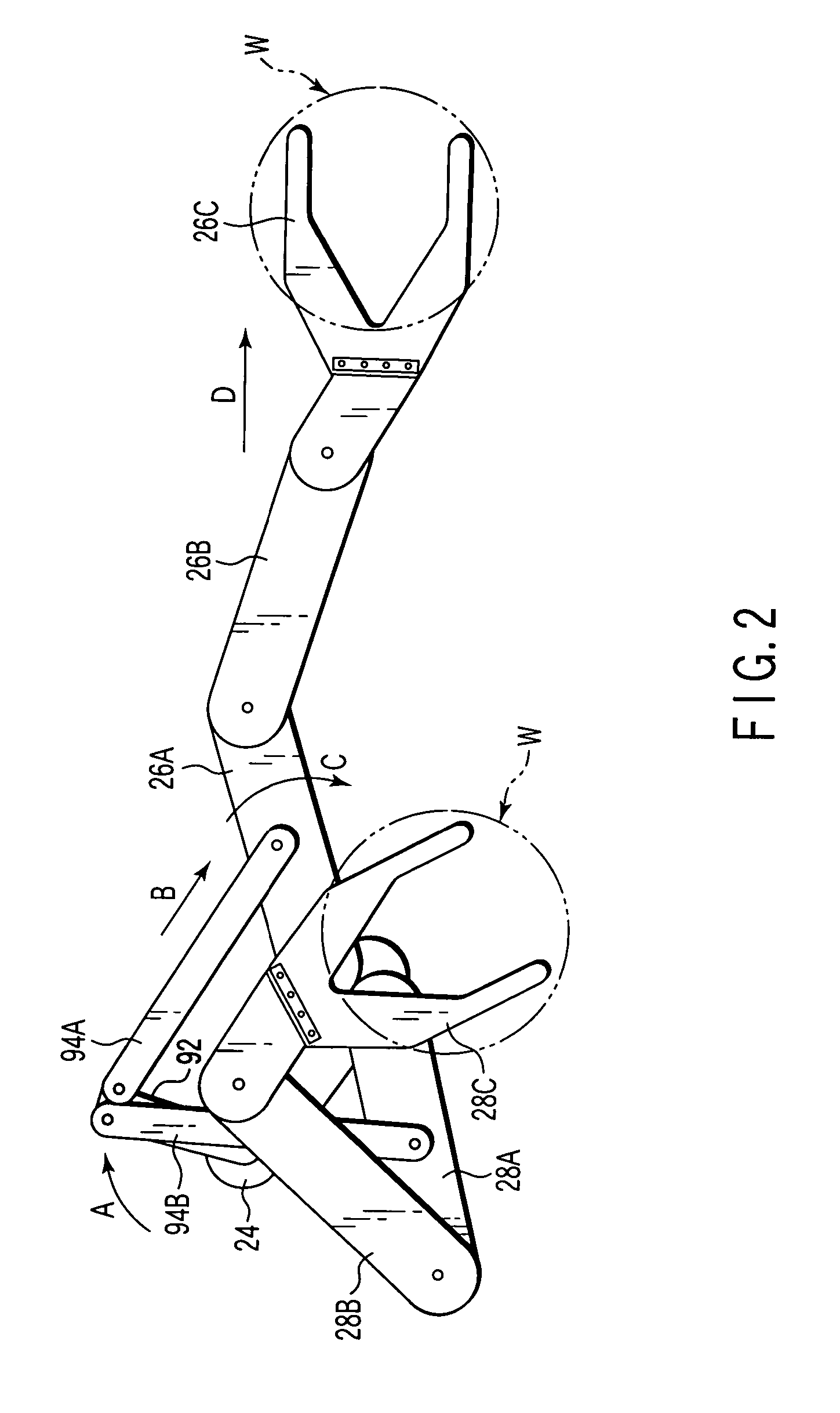

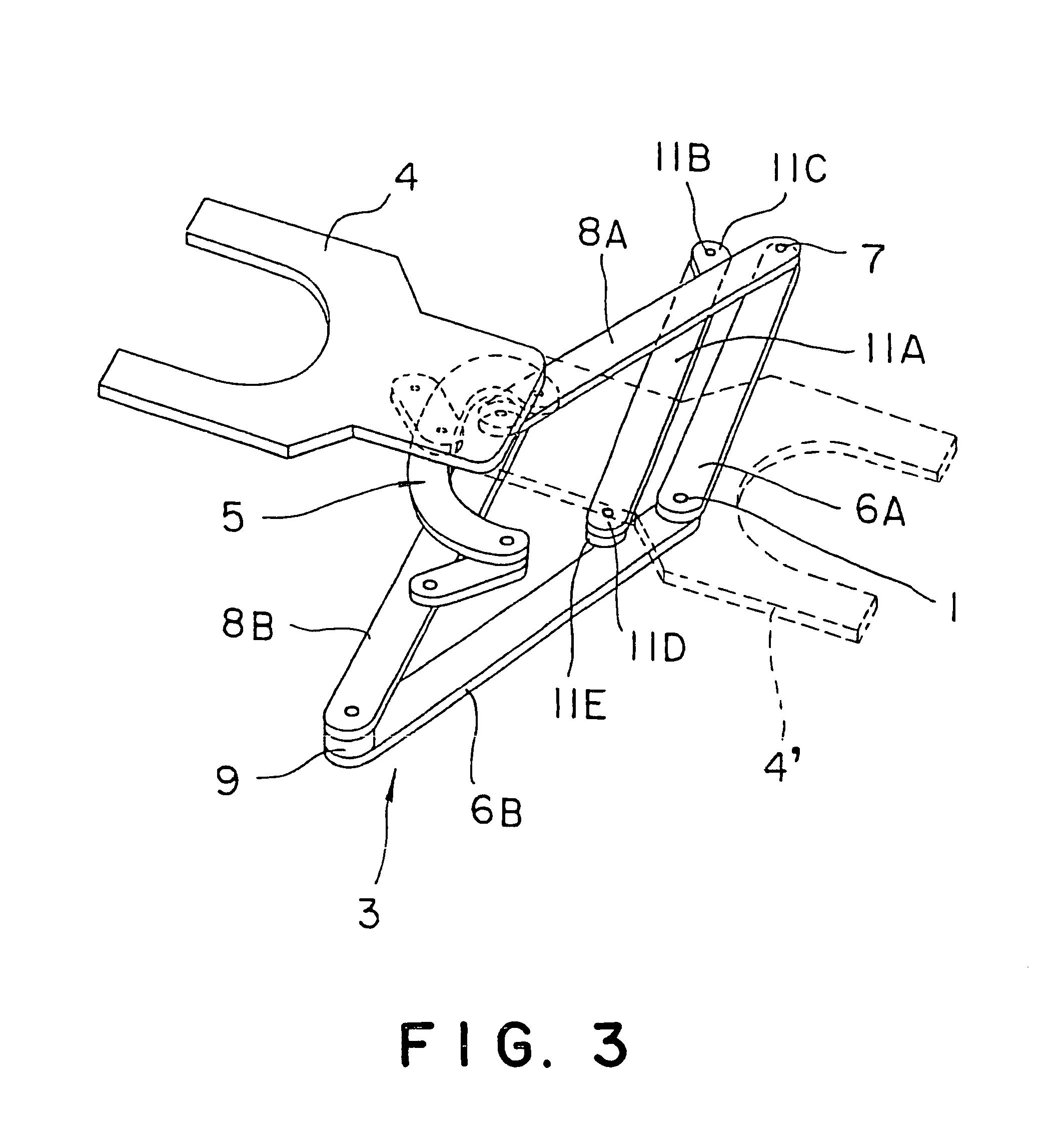

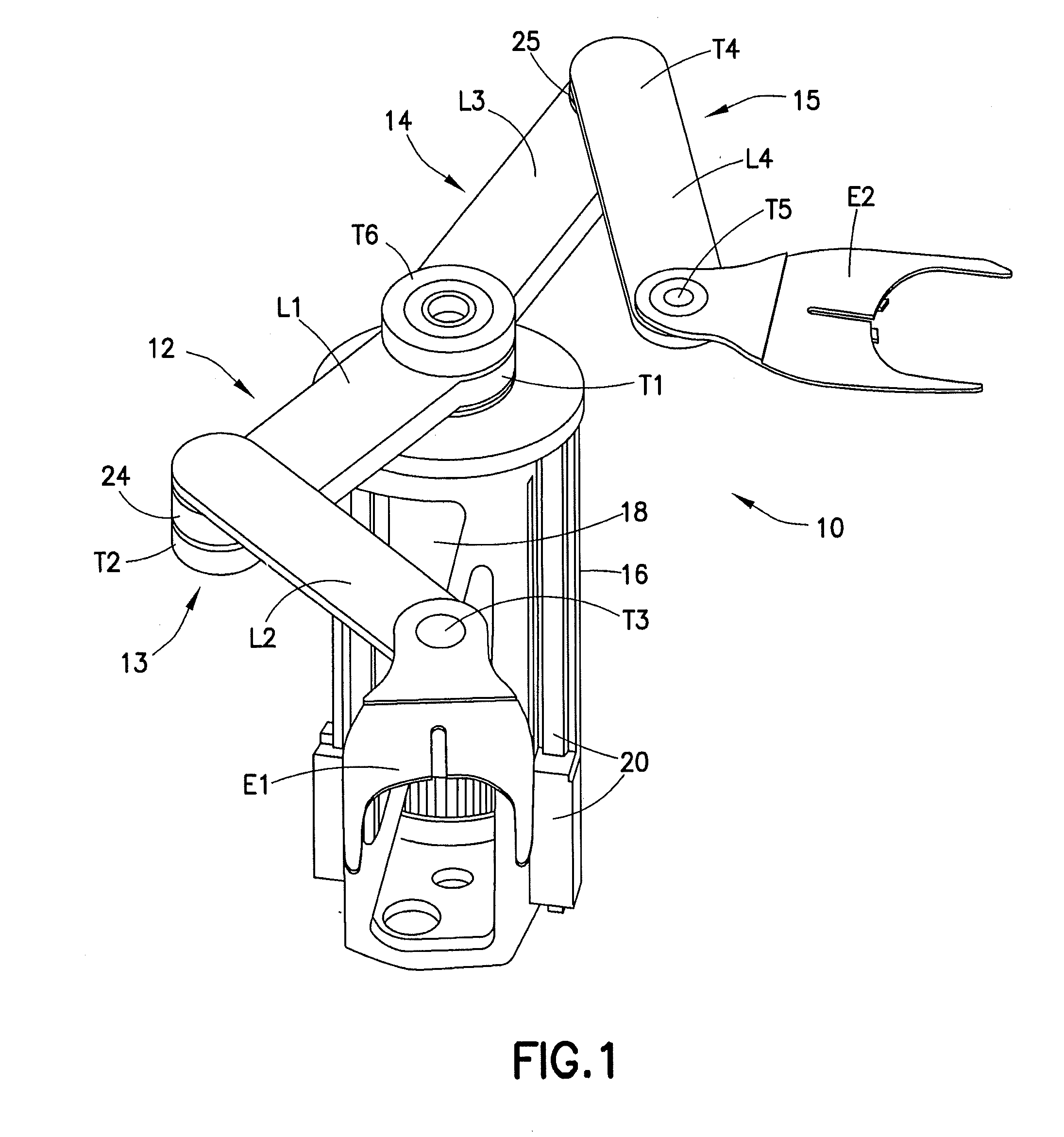

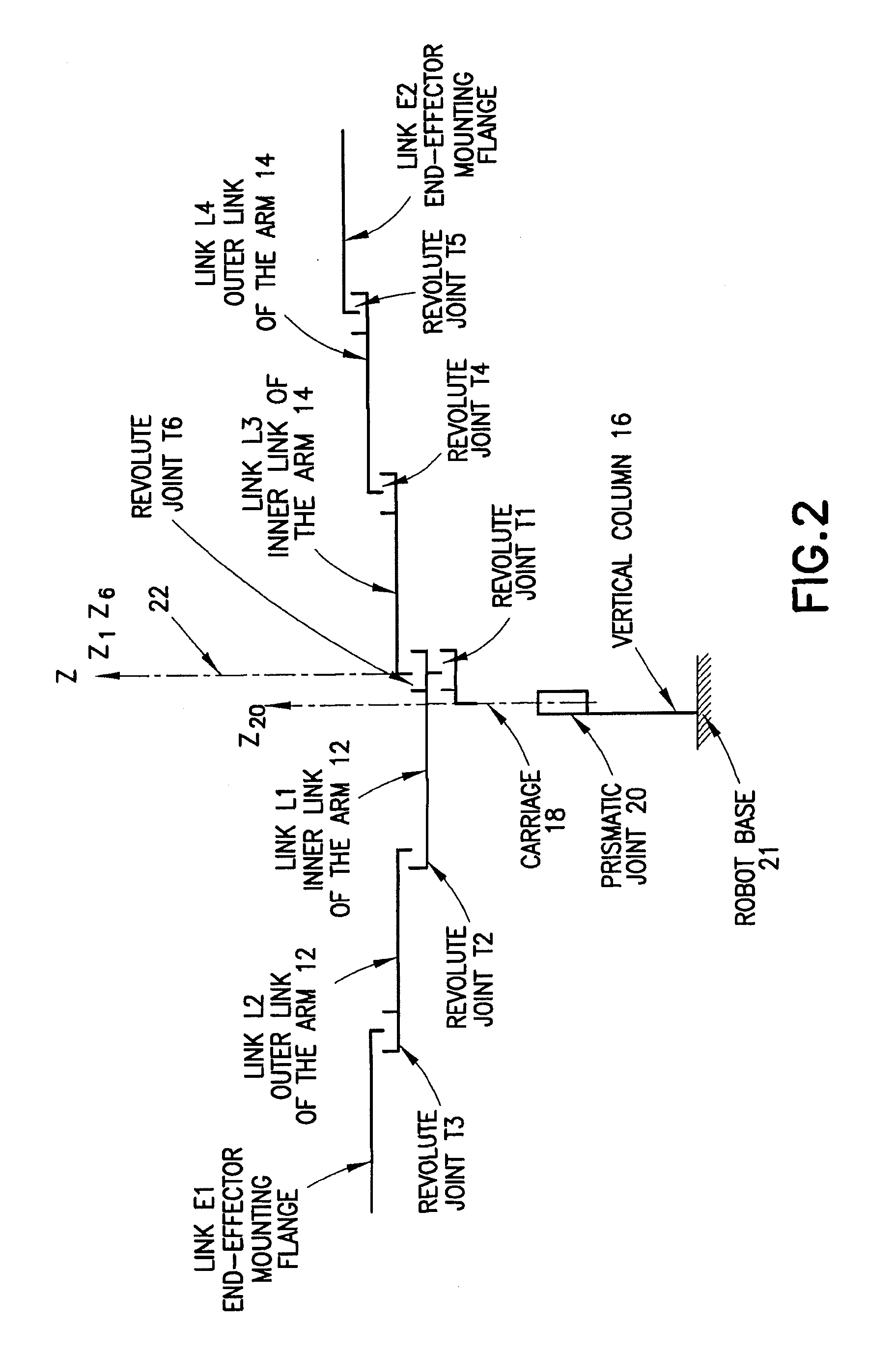

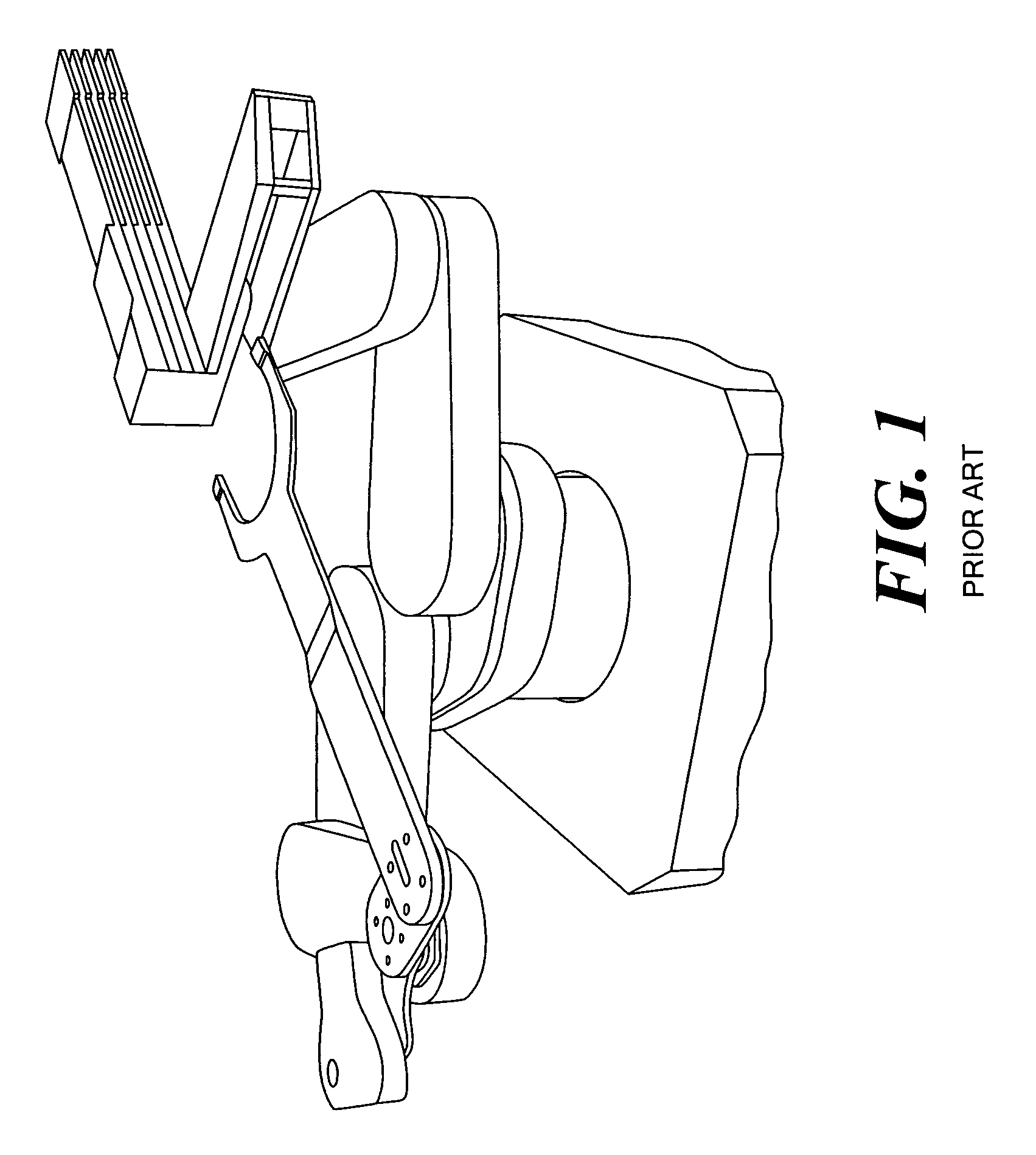

Dual scara arm

A substrate transport apparatus having a drive section and a scara arm operably connected to the drive section to move the scara arm. The scara arm has an upper arm and at least one forearm. The forearm is movably mounted to the upper arm and capable of holding a substrate thereon. The upper arm is substantially rigid and is adjustable for changing a predetermined dimension of the upper arm.

Owner:BOOKS AUTOMATION US LLC

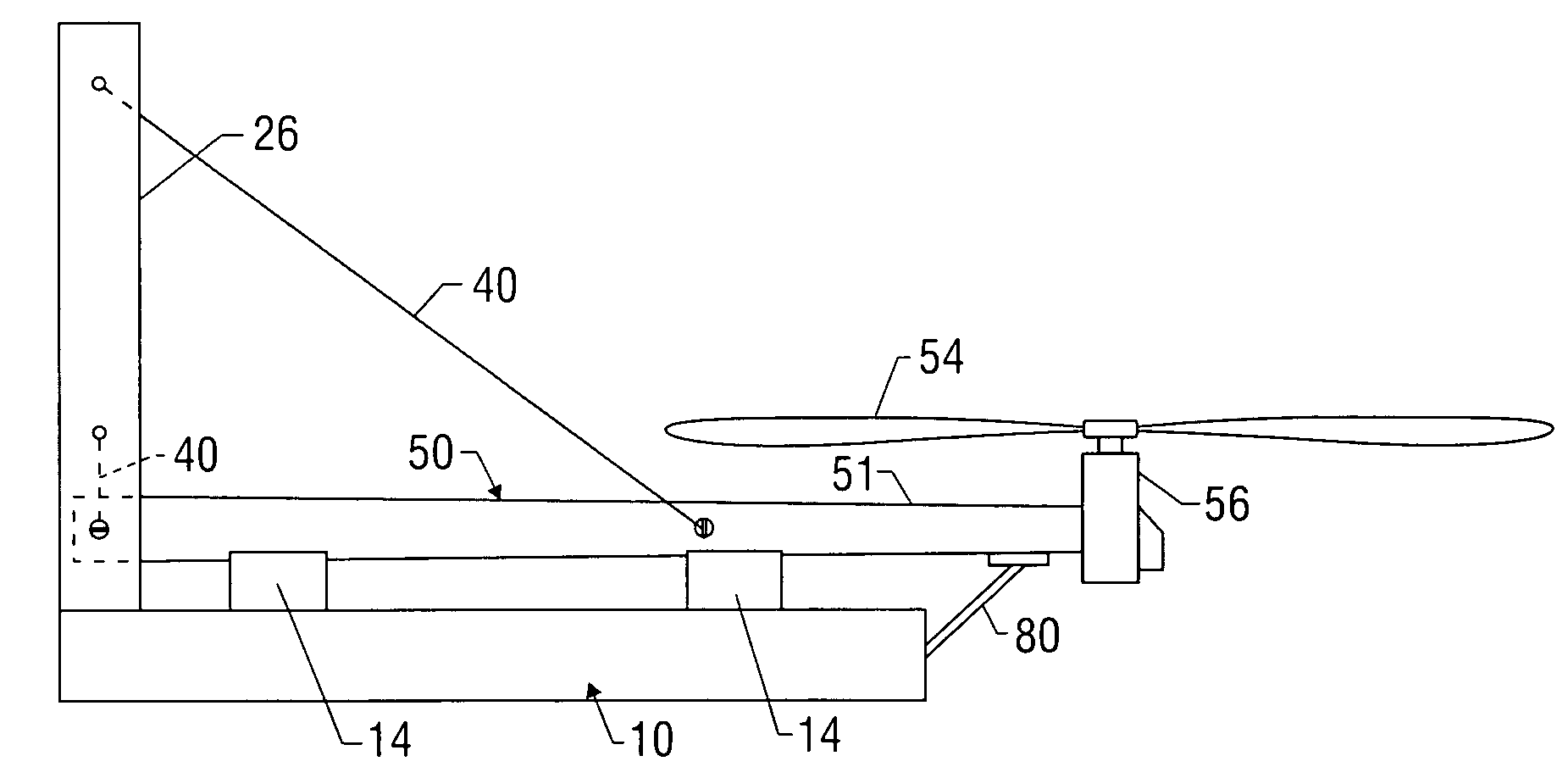

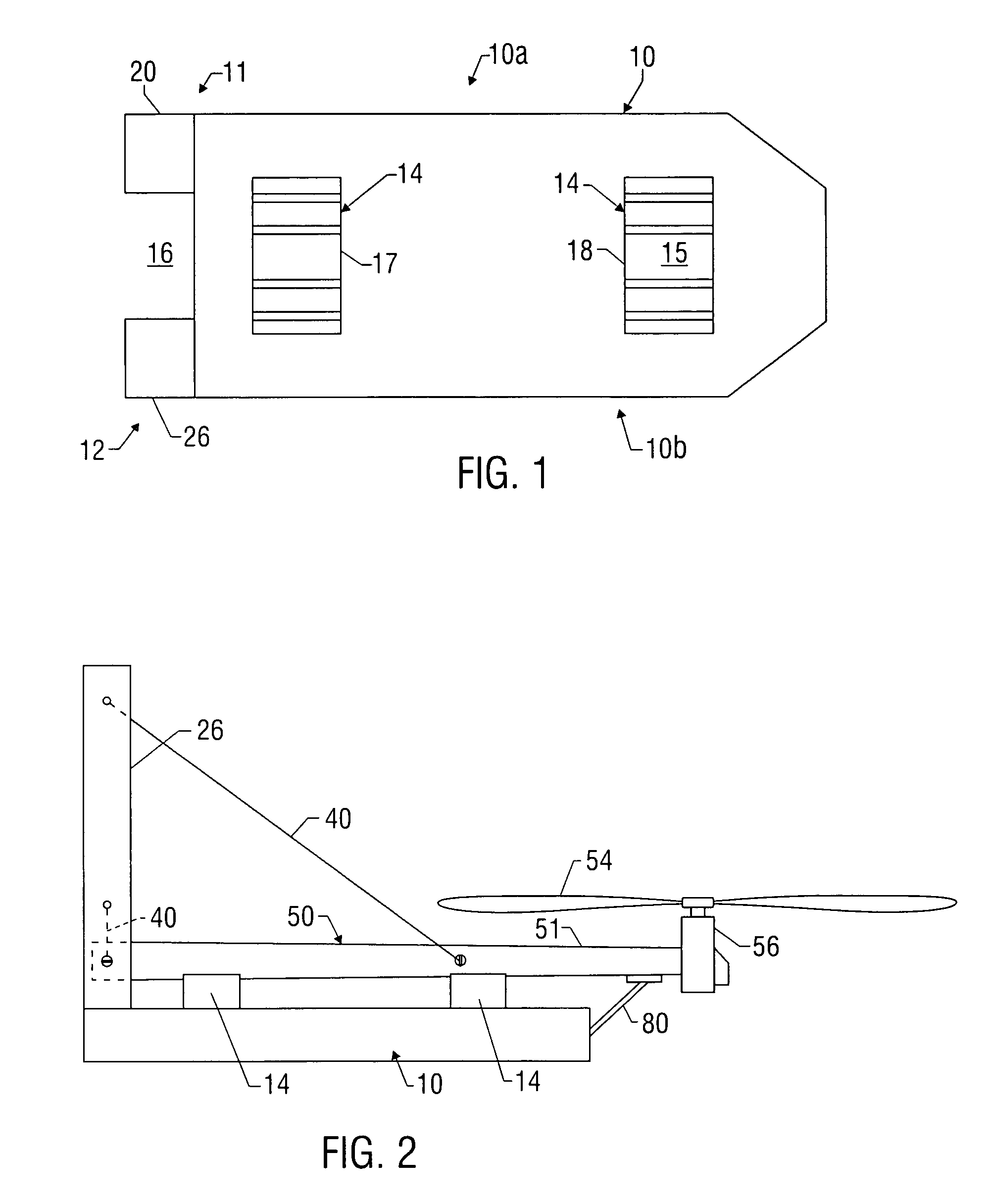

Apparatus, systems and methods for erecting an offshore wind turbine assembly

An embodiment of an apparatus useful for up-righting a wind turbine pillar at an offshore installation location includes a barge having first and second towers and an open area therebetween and which extends downwardly to the offshore installation location. At least two pulling lines extend from the towers to the pillar and are useful to assist in moving the pillar into a generally up-right orientation between the towers and lowering the pillar downwardly through the open area to the offshore installation location.

Owner:GEIGER WILLIAM CLYDE

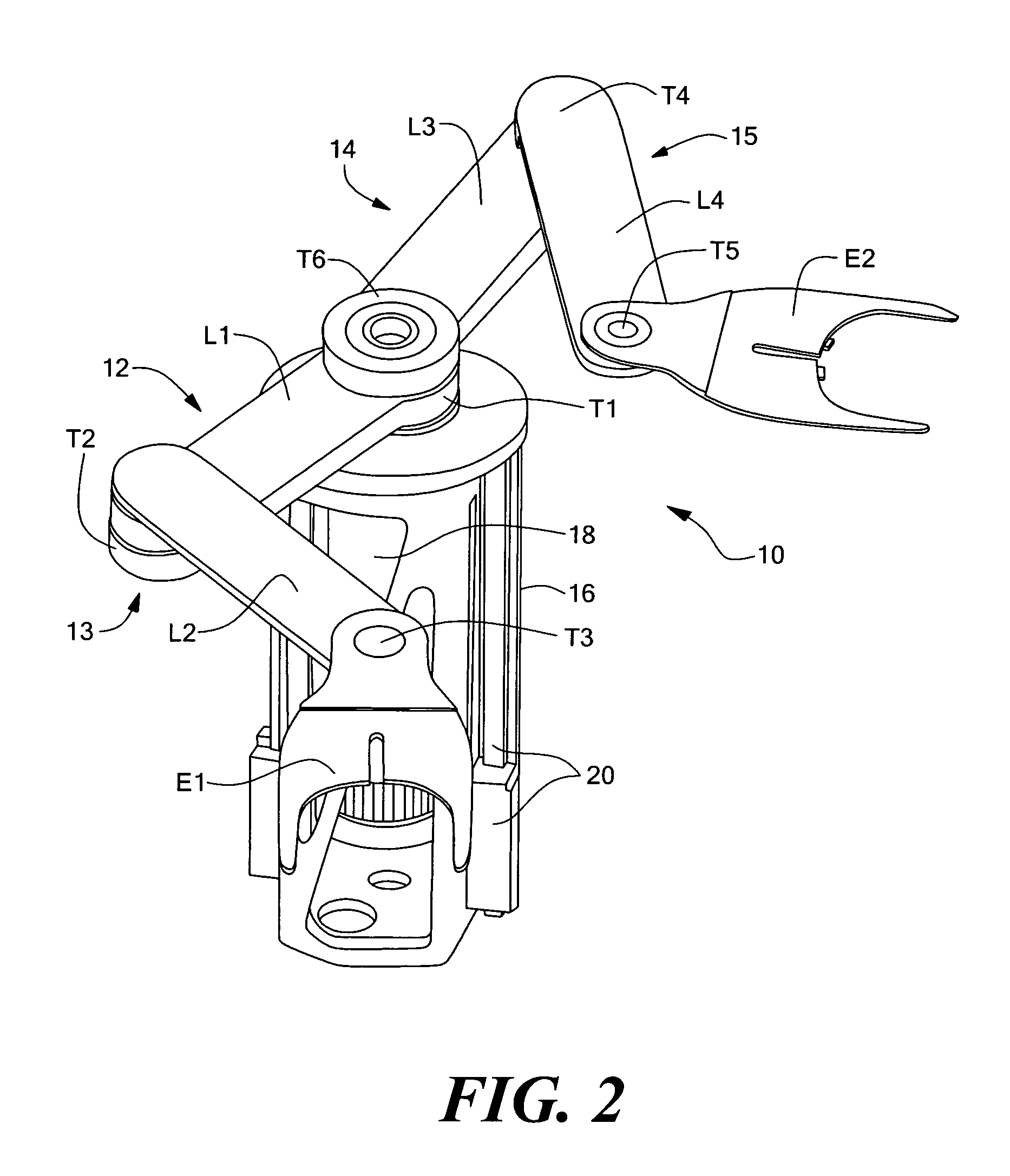

Dual arm robot

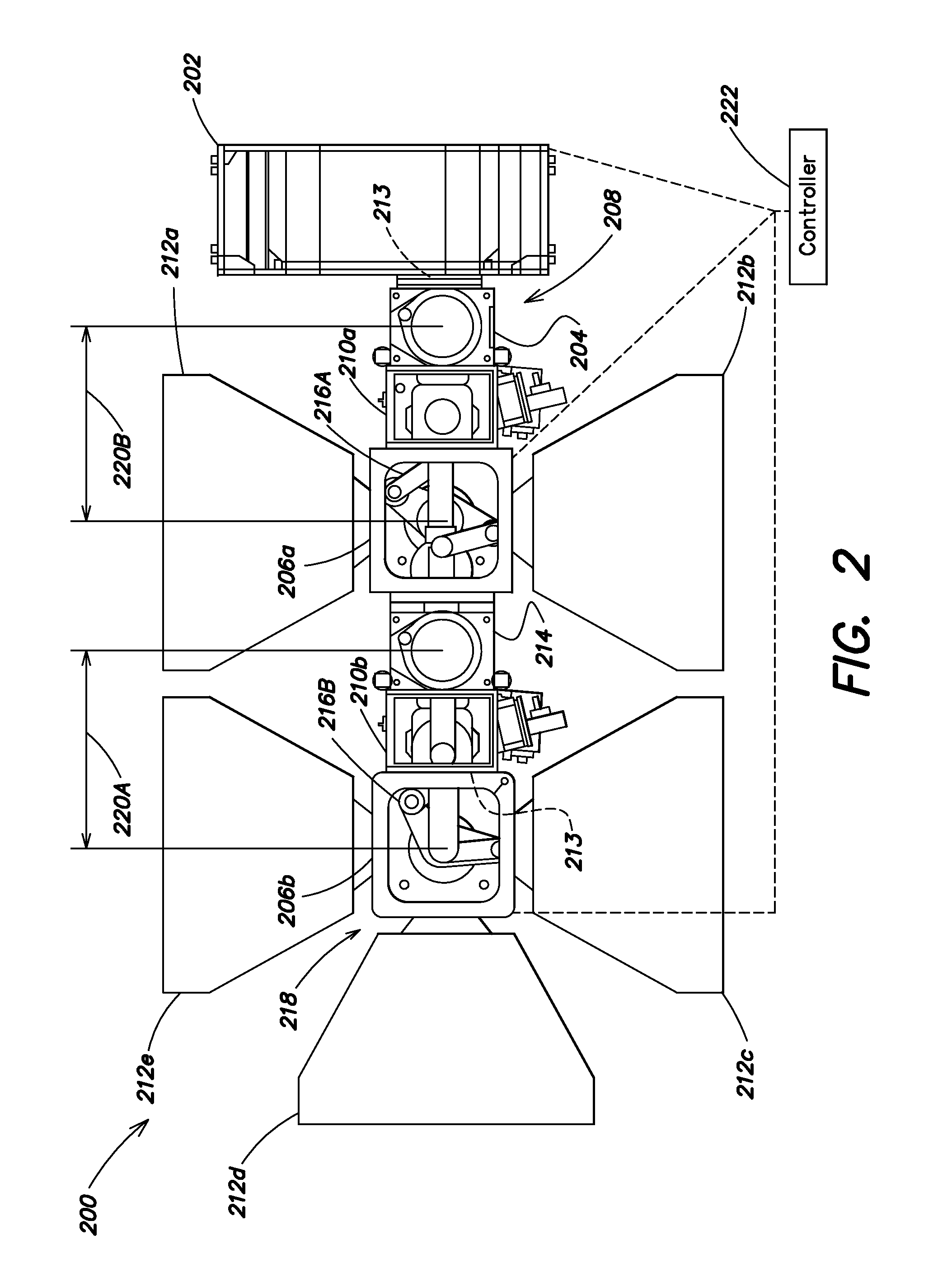

ActiveUS20120141235A1Programme-controlled manipulatorSemiconductor/solid-state device manufacturingEngineeringUpper Arms

A substrate processing apparatus including a frame, a first arm coupled to the frame at a shoulder axis having a first upper arm, a first forearm and at least one substrate holder serially and rotatably coupled to each other, a second arm coupled to the frame at the shoulder axis where shoulder axes of rotation of the arms are substantially coincident, the second arm having a second upper arm, a second forearm and at least one substrate holder serially and rotatably coupled to each other, and a drive section connected to the frame and coupled to the arms, the drive section being configured to independently extend and rotate each arm where an axis of extension of the first arm is angled relative to an axis of extension of the second arm substantially at each angular position of at least one of the first arm or the second arm.

Owner:BOOKS AUTOMATION US LLC

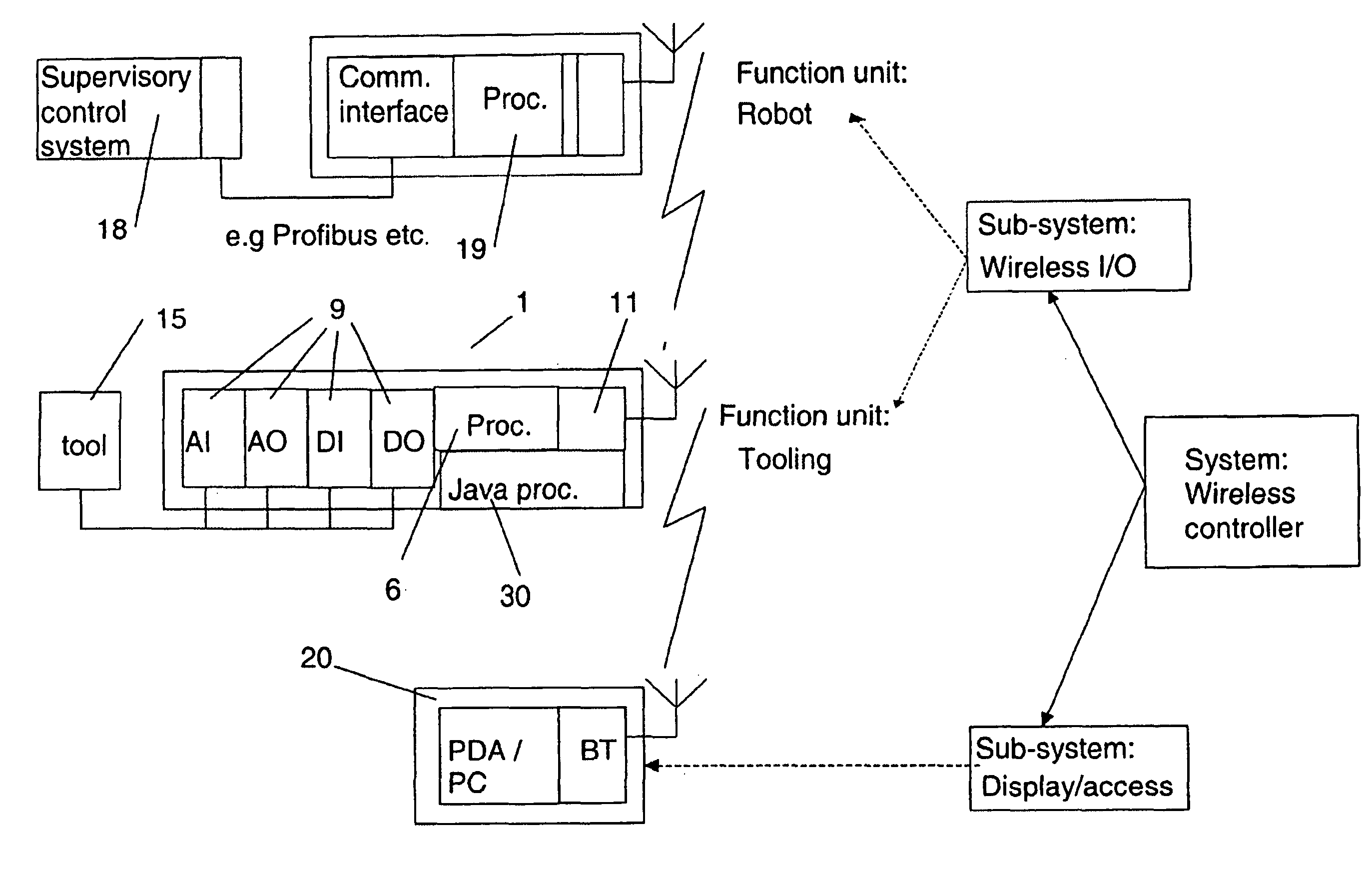

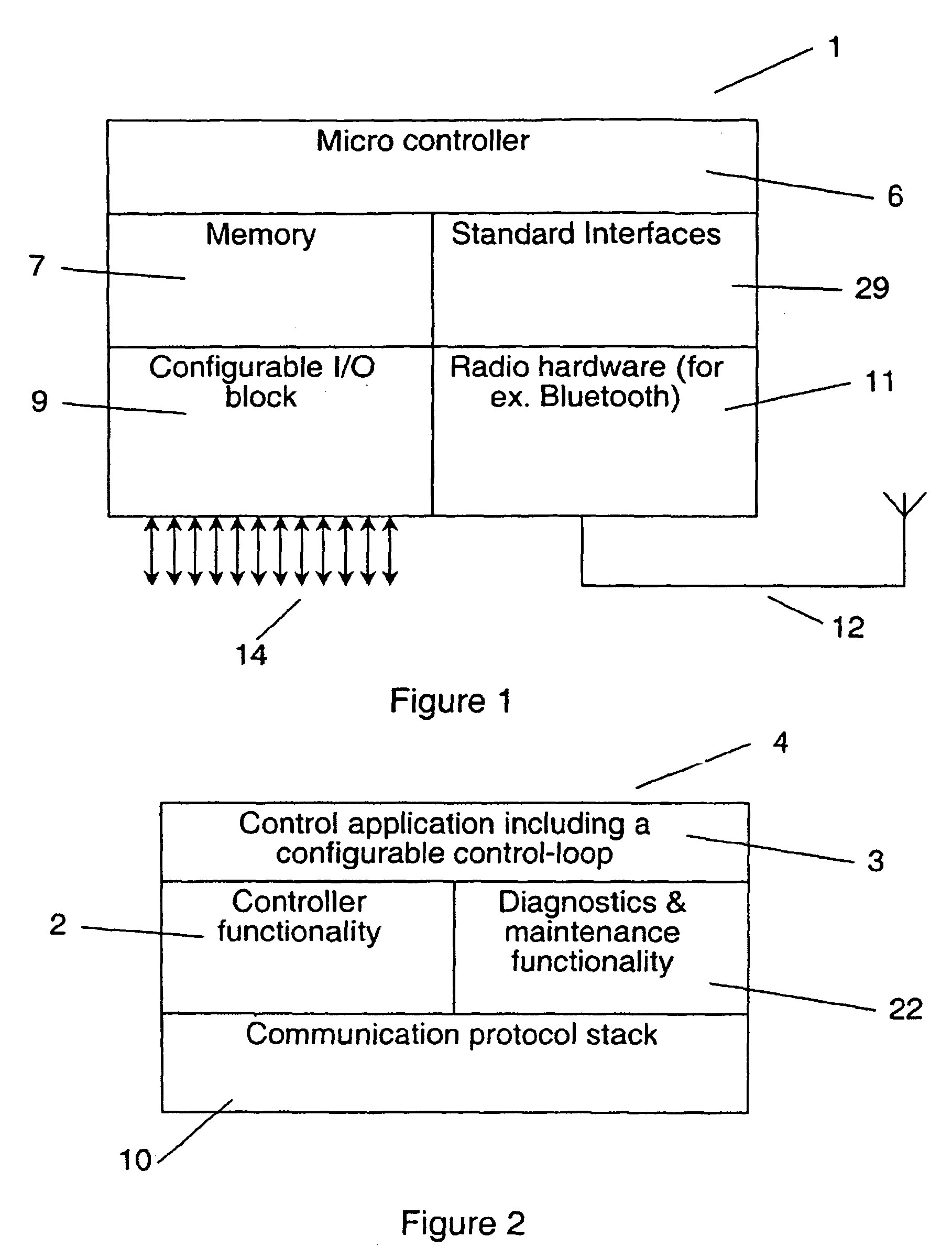

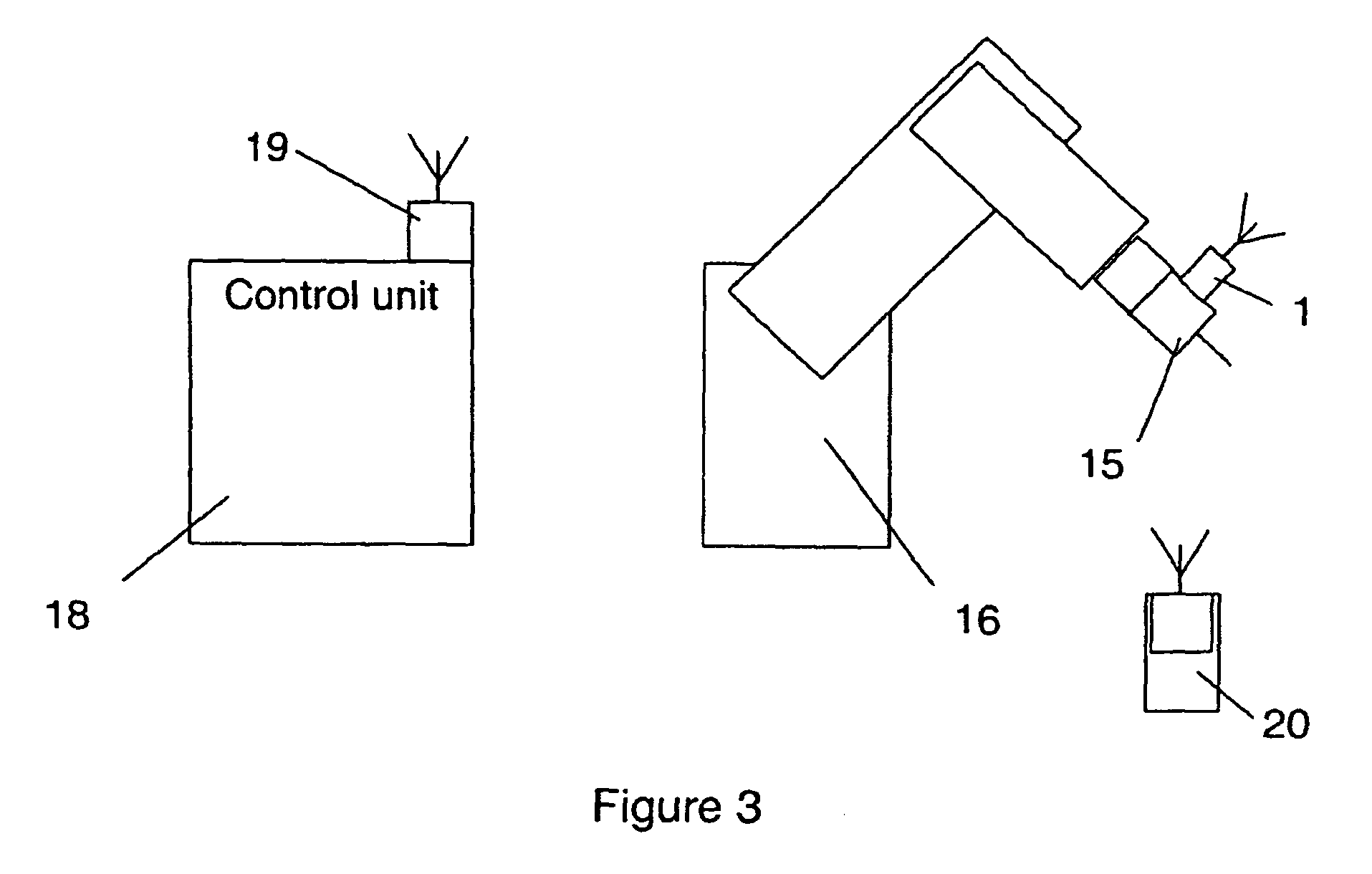

Wireless controller and a method for wireless control of a device mounted on a robot

InactiveUS7979162B2Reduce weightLow costProgramme-controlled manipulatorComputer controlWireless controlGraphical user interface

A wireless controller for controlling and / or monitoring a device arranged mounted on or relative to an industrial robot. A wireless communicator including a processor arranged with software means handles wireless communication to and from the device. A control carries out at least one control function for one or more actuators of the device. Also, a method, a computer program and a graphic user interface.

Owner:ABB RES LTD

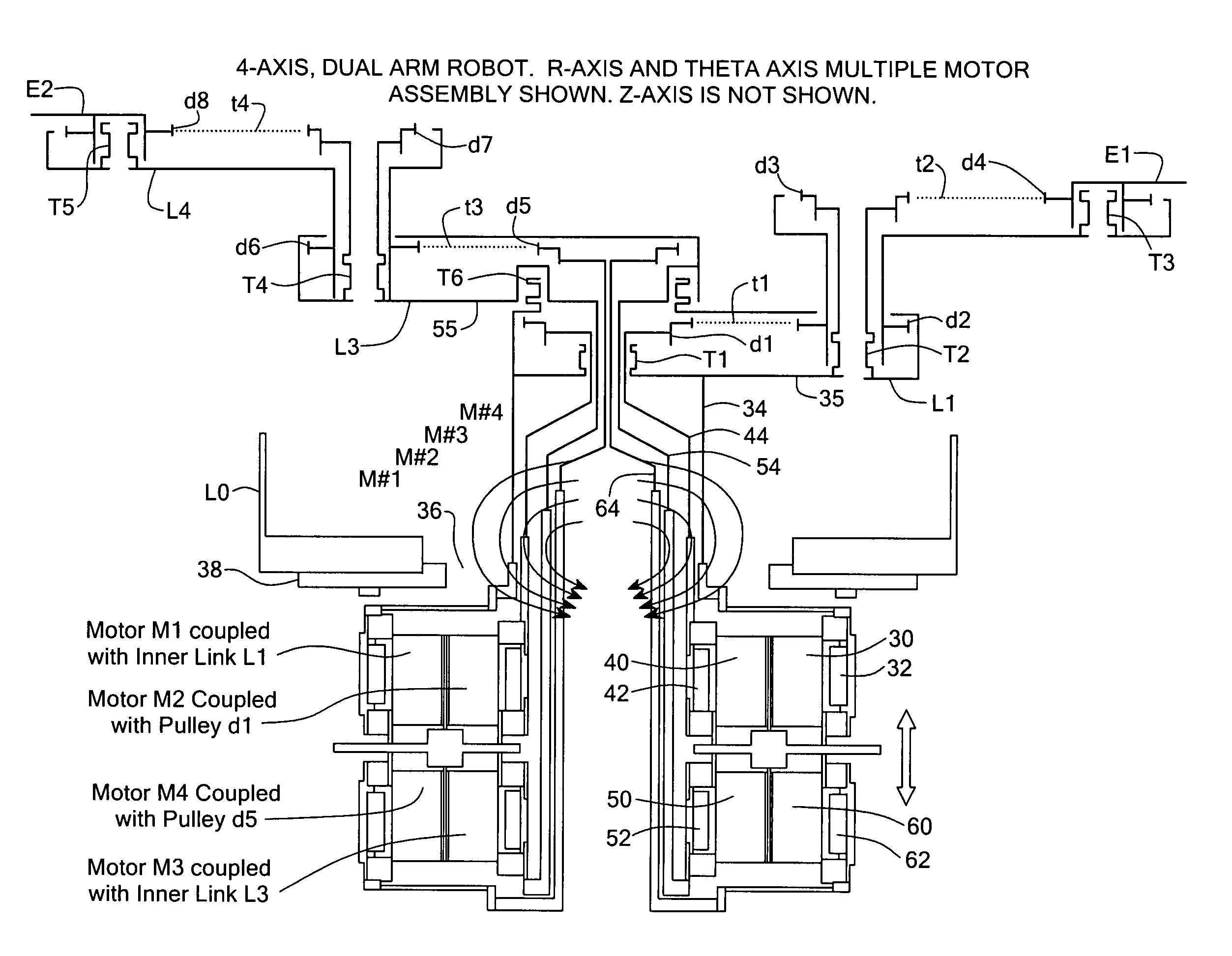

Dual arm robot

InactiveUS7891935B2Avoid collisionProgramme-controlled manipulatorMechanical apparatusThree degrees of freedomActuator

A dual arm robot assembly has two arms each having a set of joint / link pairs that, in conjunction with an actuator assembly, define at least three degrees of freedom to provide independent horizontal translation and rotation of a distalmost link. A vertical motion mechanism is also provided.

Owner:BOOKS AUTOMATION US LLC

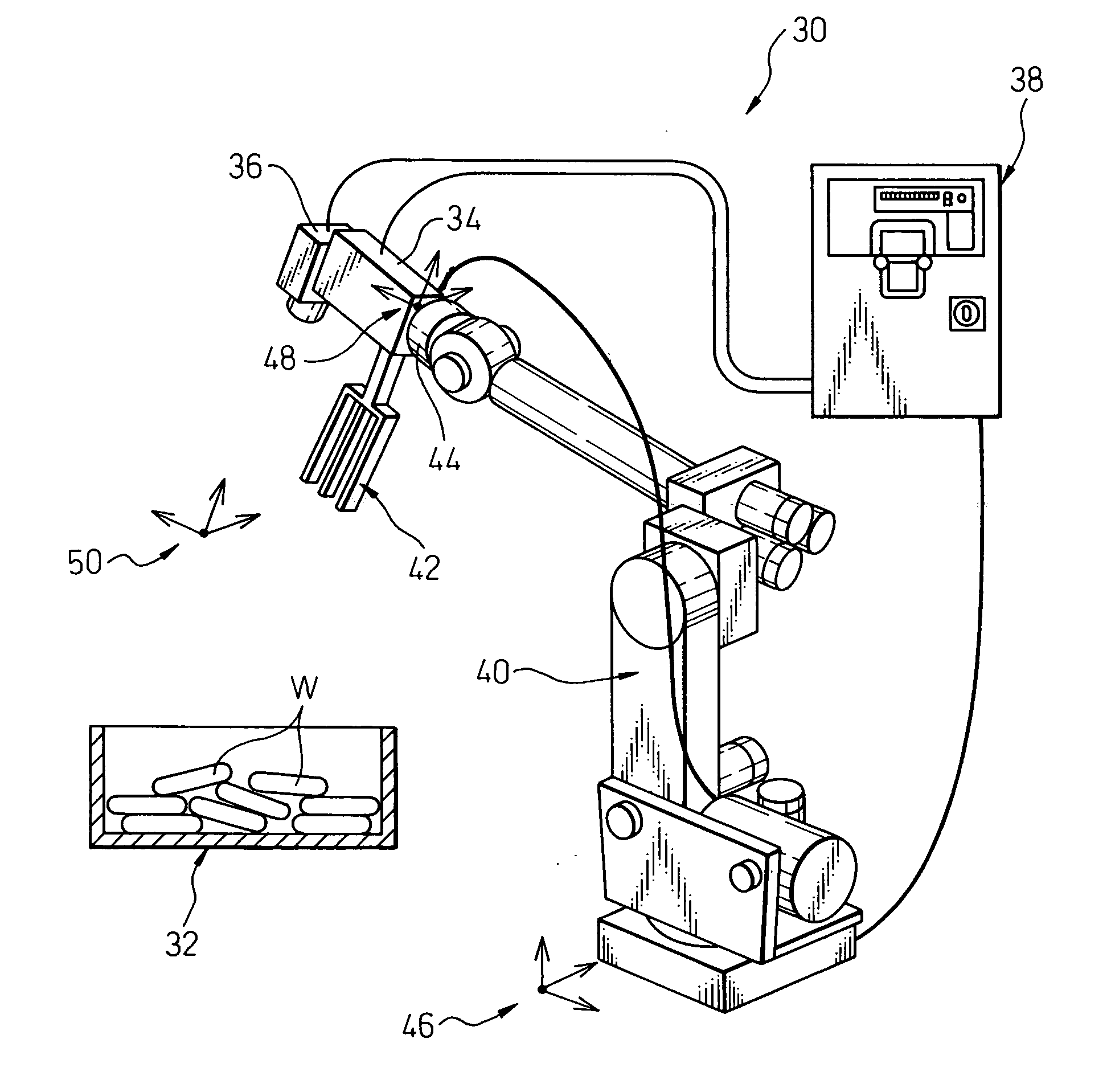

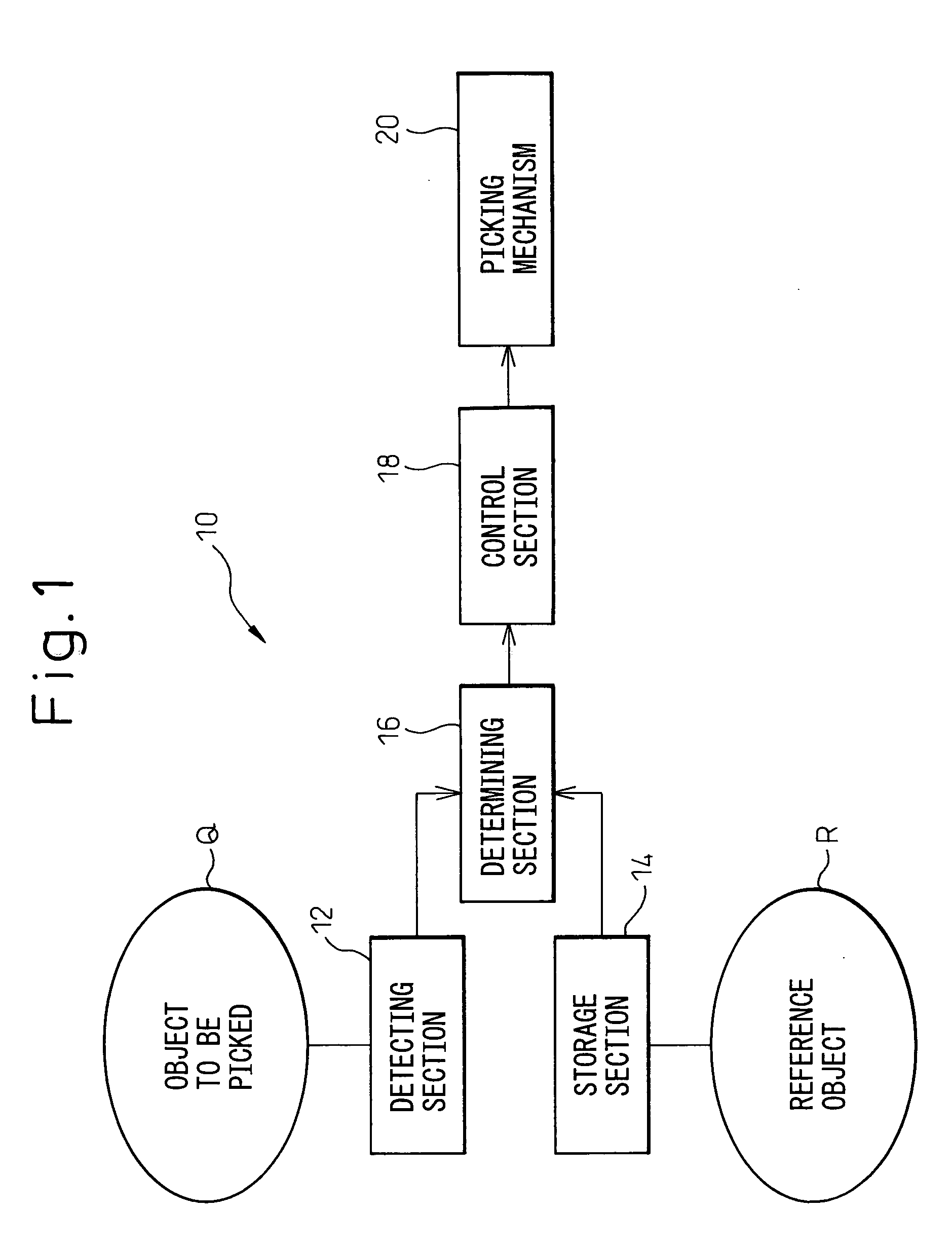

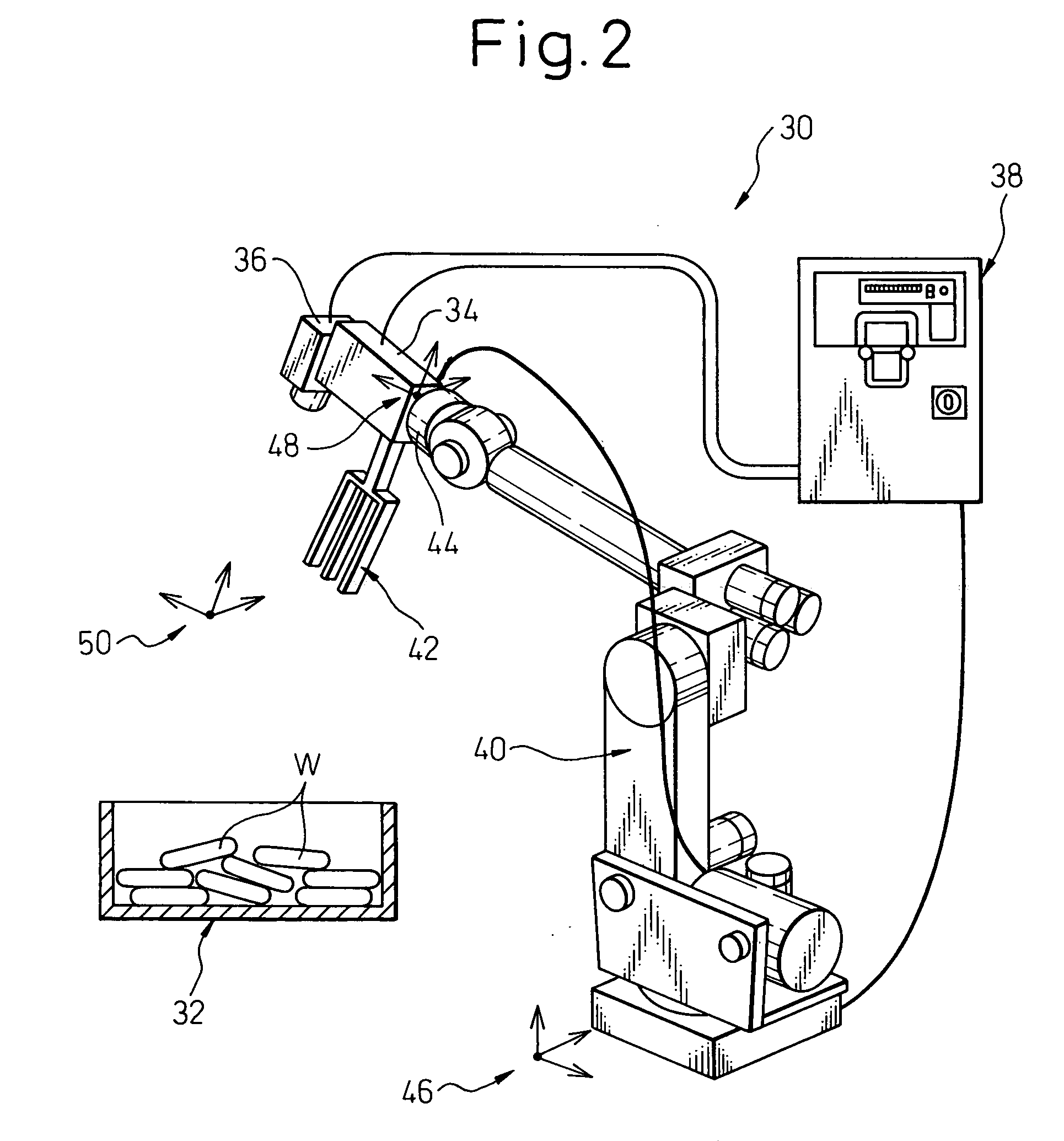

Object picking system

InactiveUS20060104788A1Increase productivityOperational securityImage enhancementProgramme-controlled manipulatorControl signalObject store

An object picking system for picking up, one by one, a plurality of objects. The system includes a detecting section detecting, as an image, an object to be picked, among a plurality of objects placed in a manner as to be at least partially superimposed on each other; a storage section storing appearance information of a predetermined portion of a reference object having an outward appearance identical to an outward appearance of the object to be picked; a determining section determining, in the image of the object to be picked detected by the detecting section, whether an inspected portion of the object to be picked, corresponding to the predetermined portion of the reference object, is concealed by another object, based on the appearance information of the reference object stored in the storage section; a control section deciding a picking motion for the object to be picked and outputting a control signal of the picking motion, based on a determination result of the determining section; and a picking mechanism performing the picking motion on the object to be picked in accordance with the control signal output from the control section.

Owner:FANUC LTD

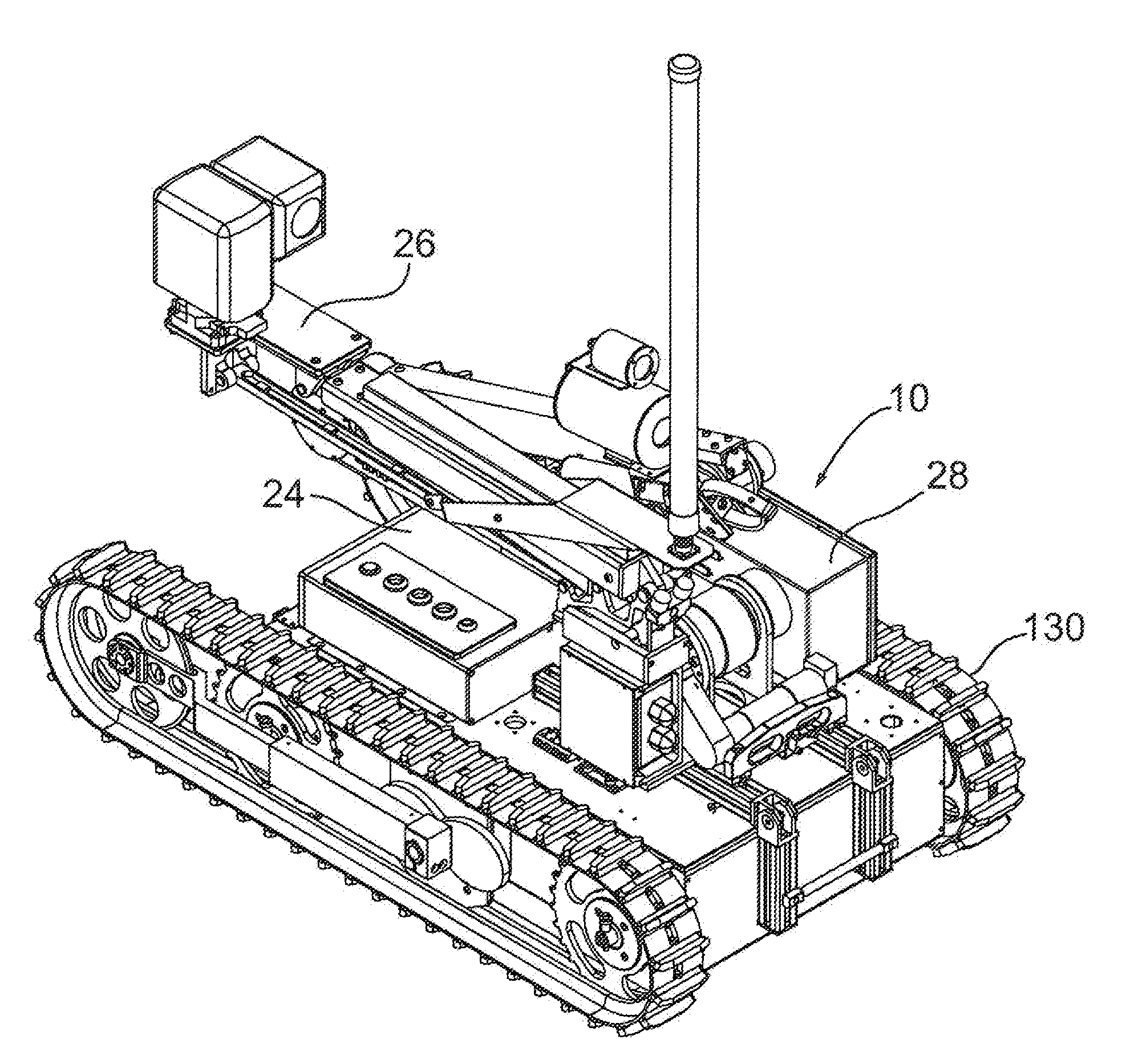

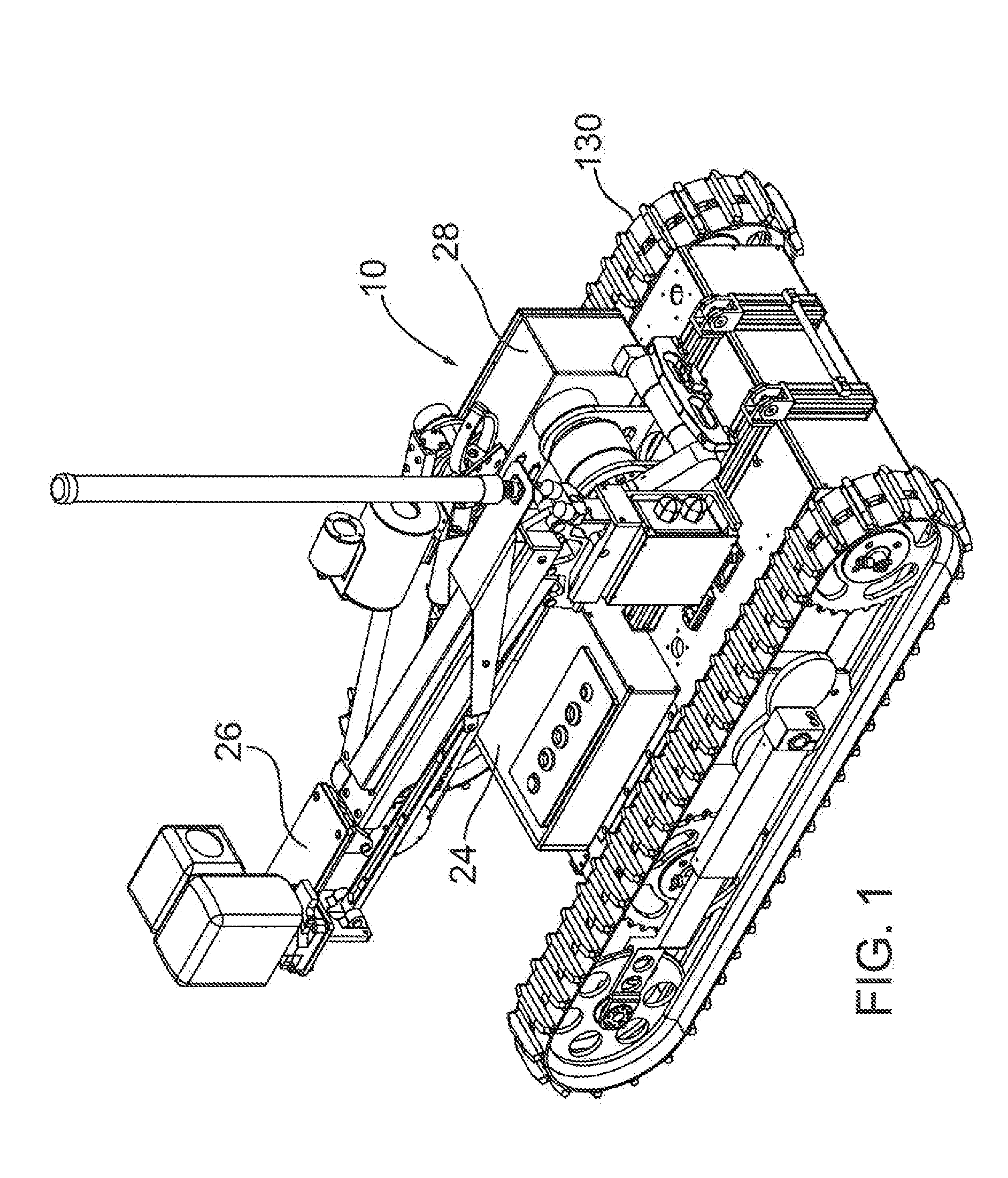

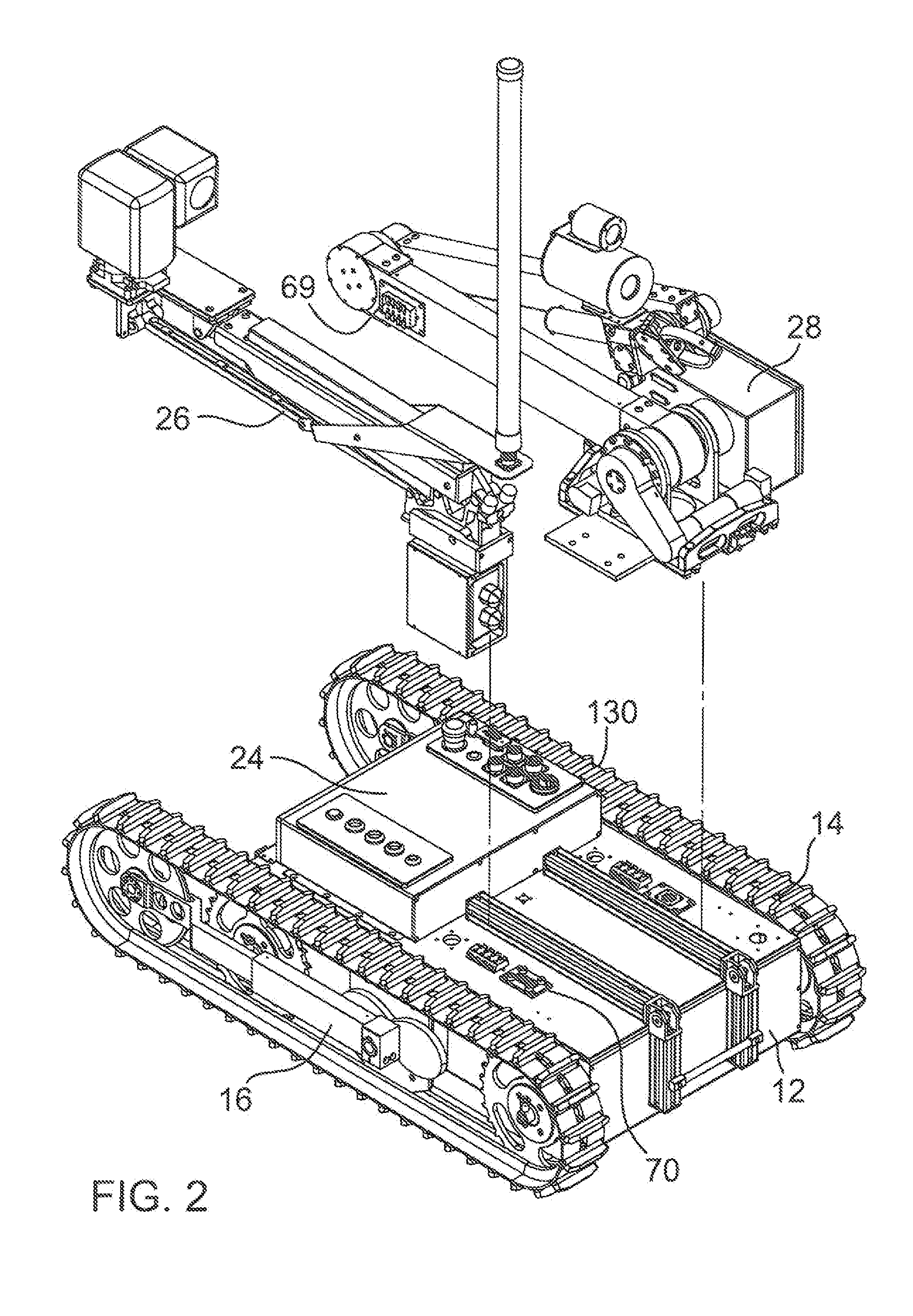

Modular mobile robot

InactiveUS20140031977A1Programme-controlled manipulatorMechanical machines/dredgersCommunications systemDistribution system

A mobile robot has a predetermined size of large, medium, small or back-packable. The mobile robot includes a chassis, drive system components, power components, a main processor, a communication system and a power and data distribution system. The chassis has a predetermined size of large, medium, small or back-packable. Drive system components are operably attached to the chassis and power components are operably connected to the drive system components and the power and data distribution system. Each drive system component has a predetermined size that is compatible with the chassis. The main processor, the communication system and the power and data distribution system are all operably connected together and operably connected to the traction components and the power components. The main processor, the communication system, and the power and data distribution system are all compatible with the predetermined size of the chassis and at least one other size.

Owner:ENG SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com