Patents

Literature

6316results about "Derricks/masts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

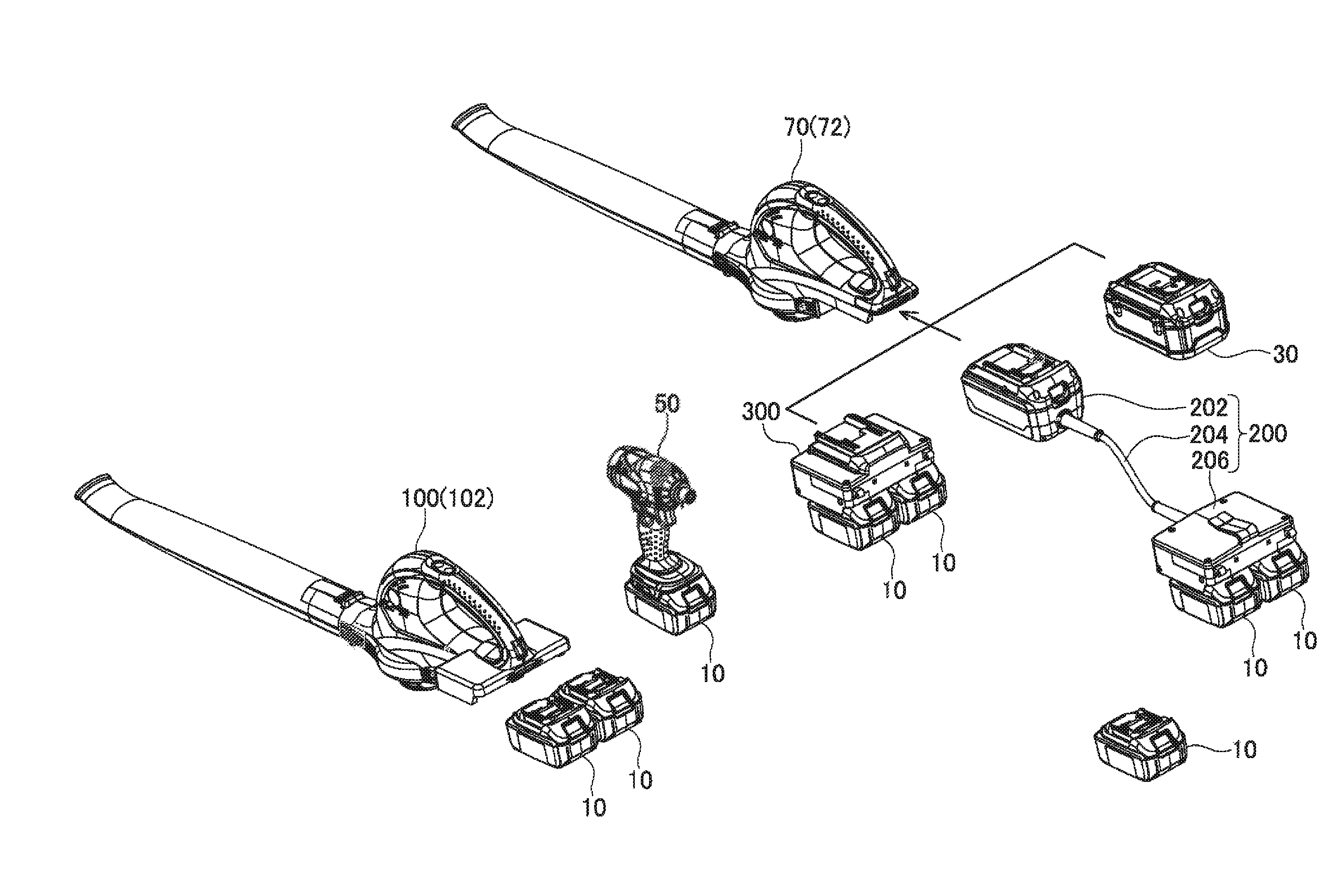

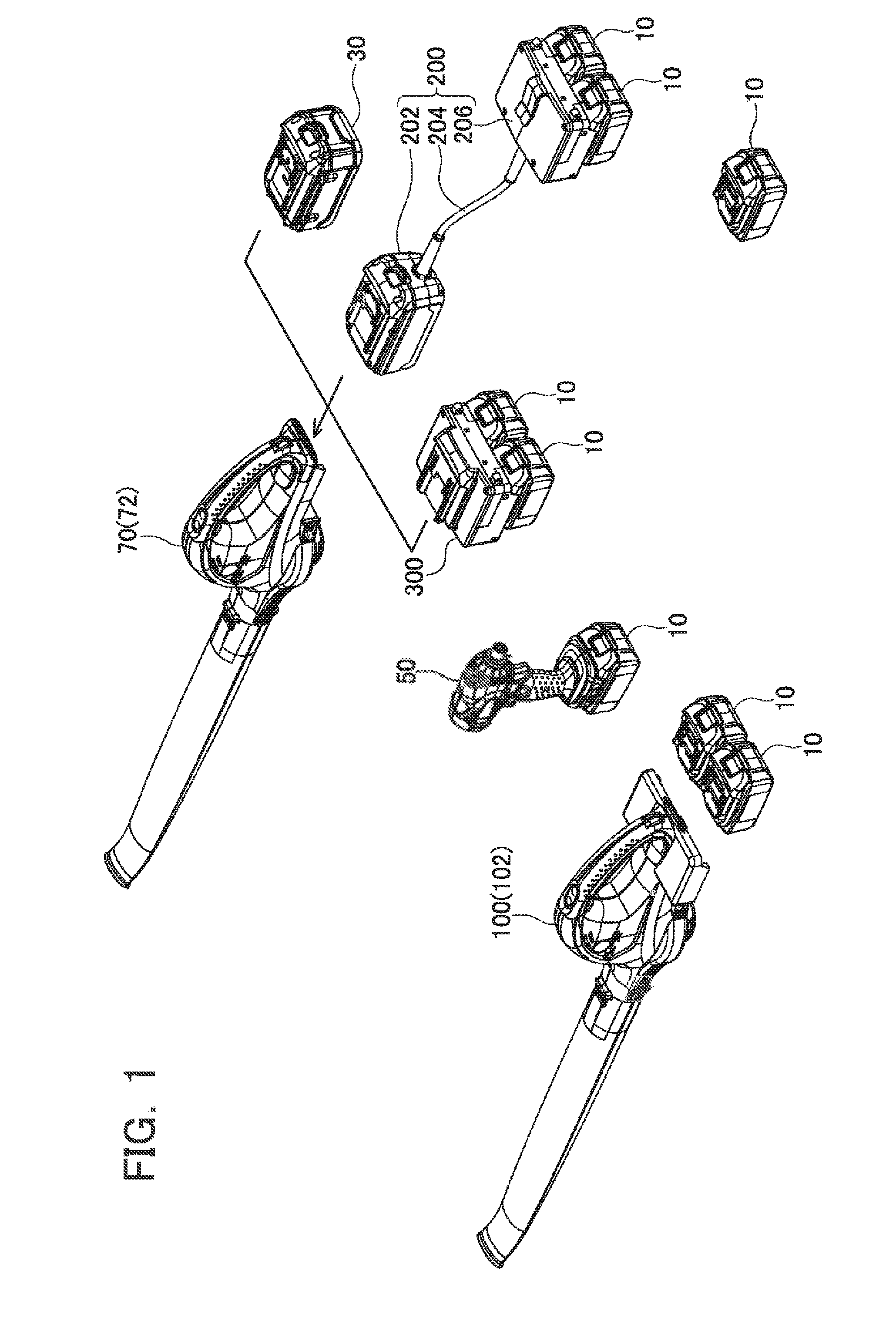

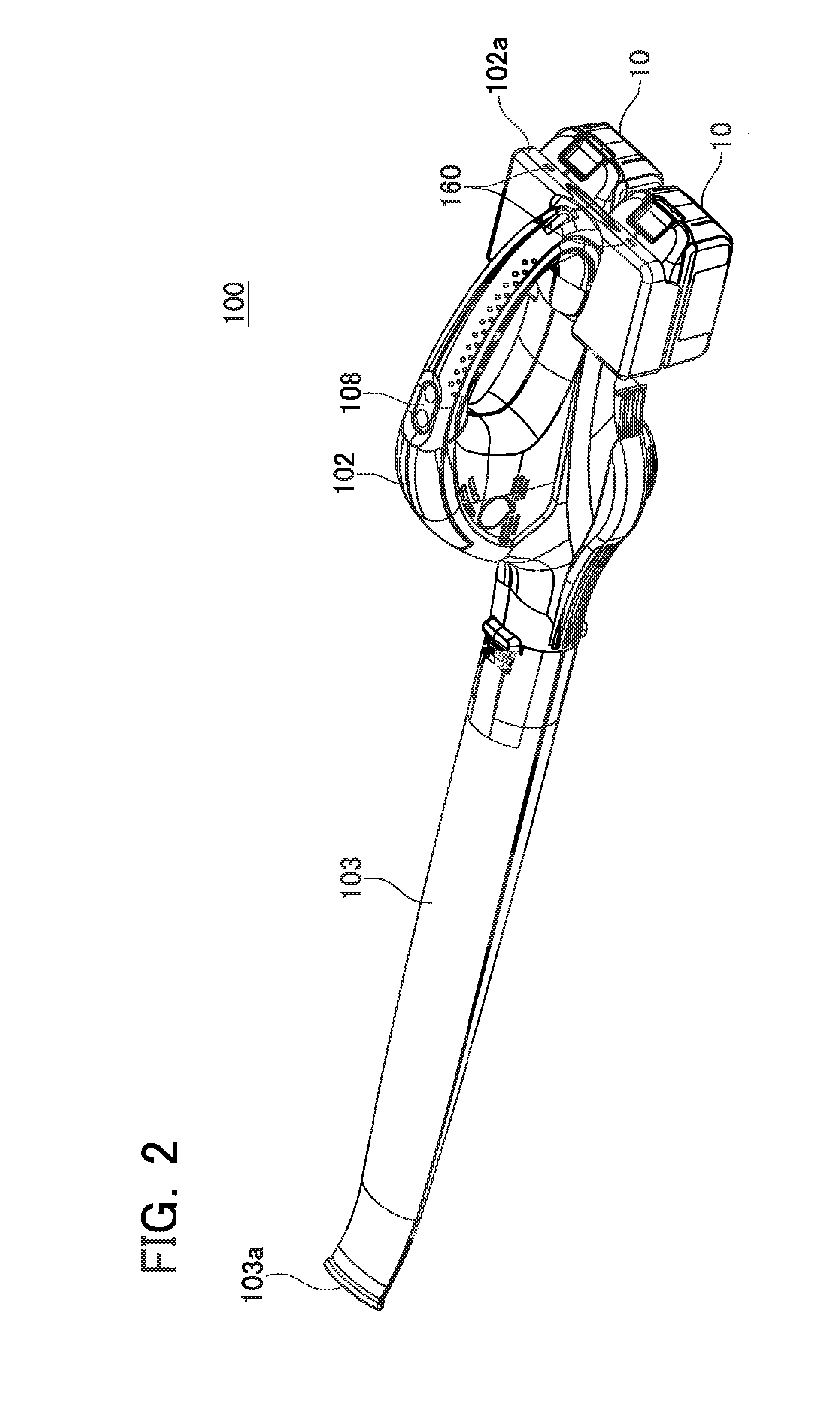

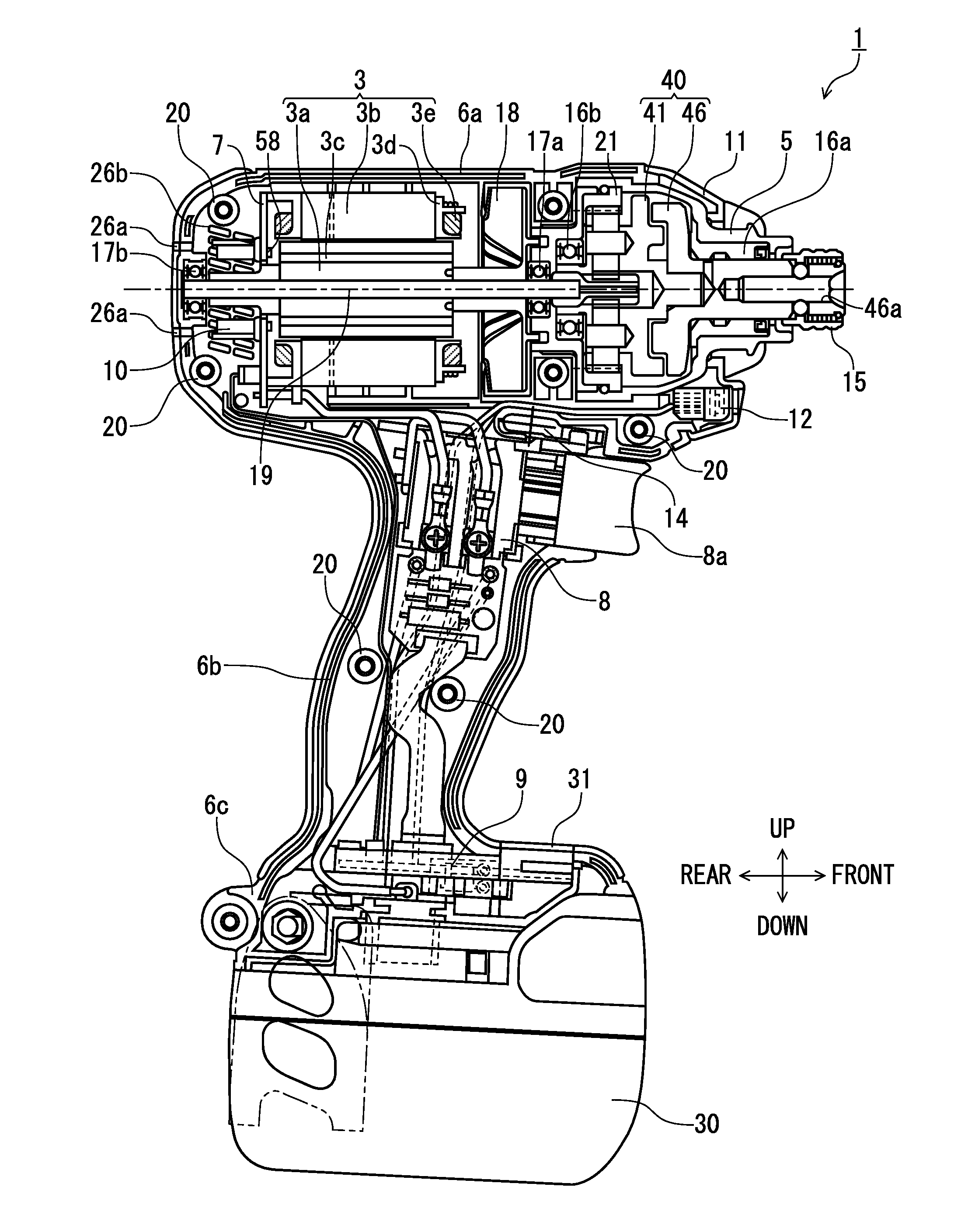

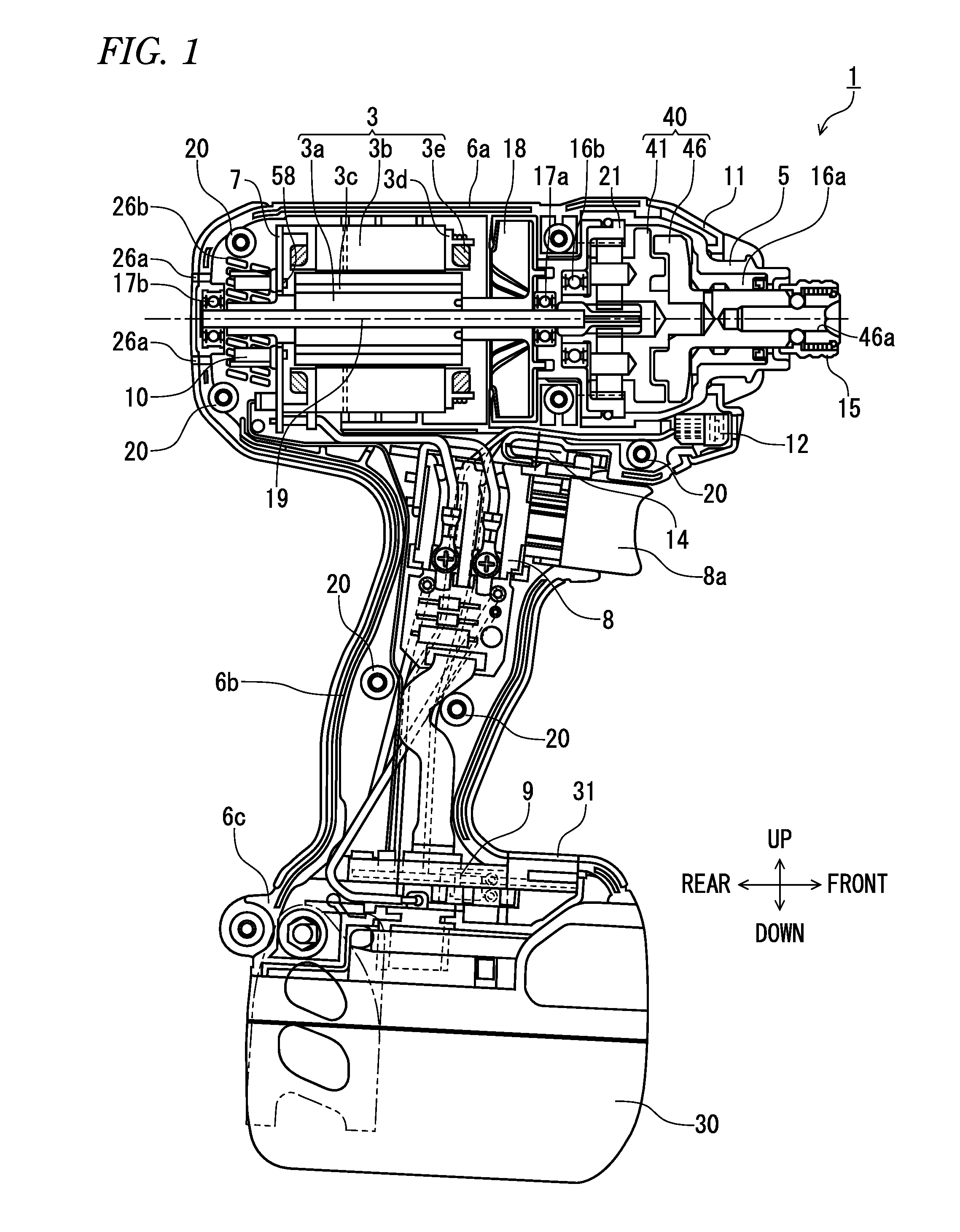

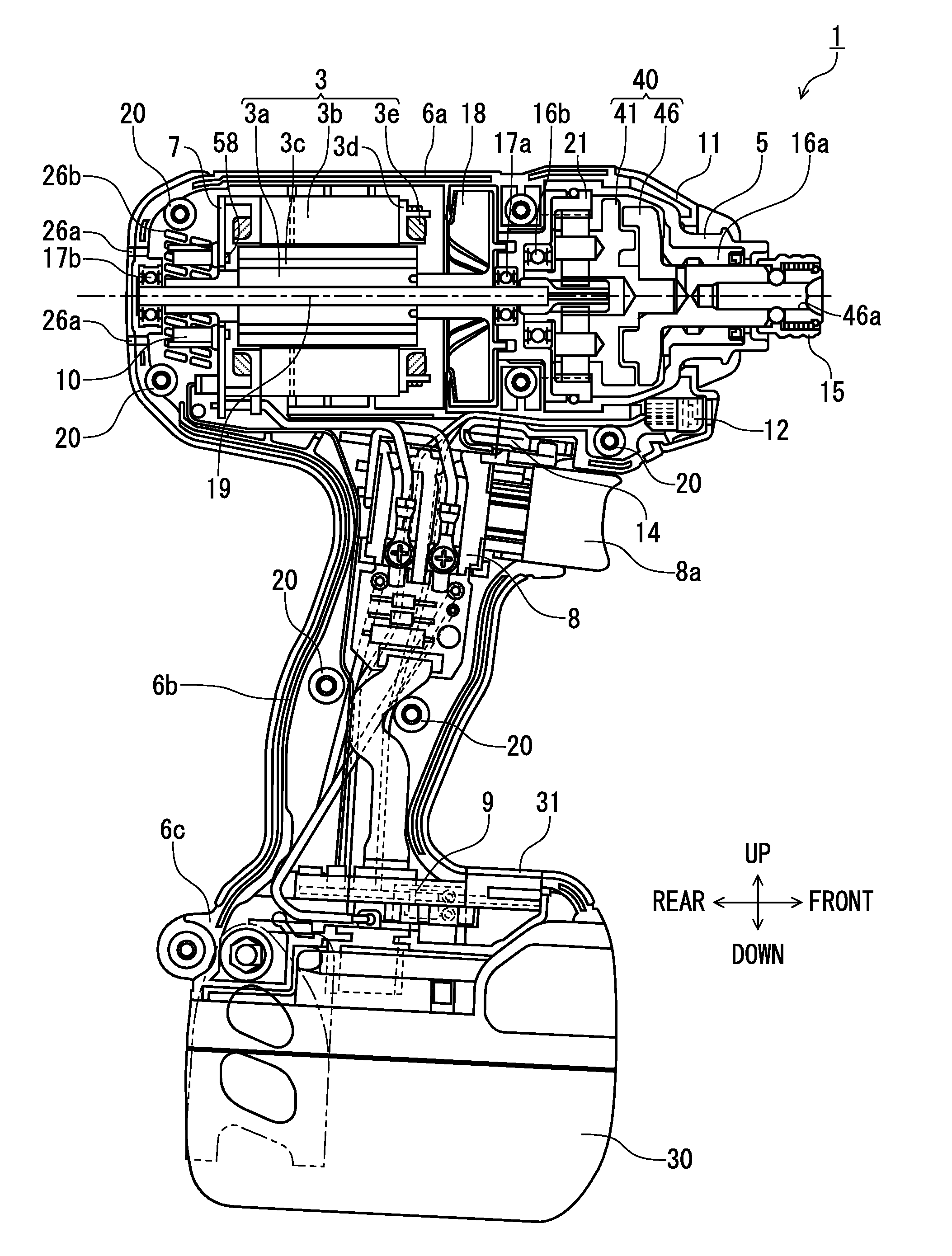

Electric tool powered by a plurality of battery packs and adapter therefor

ActiveUS8813866B2Avoid damageExtended service lifeCircuit monitoring/indicationIndicating/monitoring circuitsPower toolElectric power

Owner:MAKITA CORP

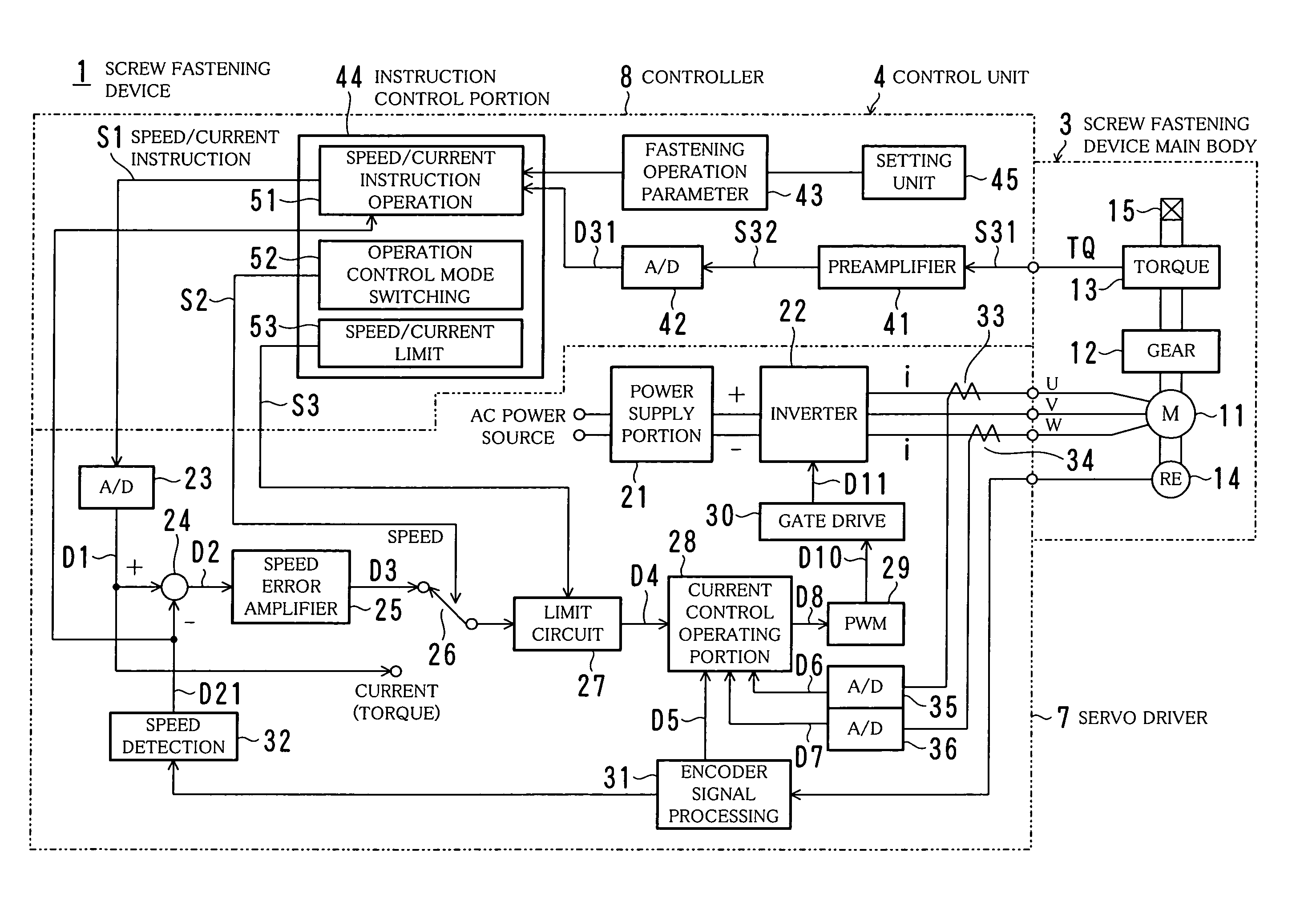

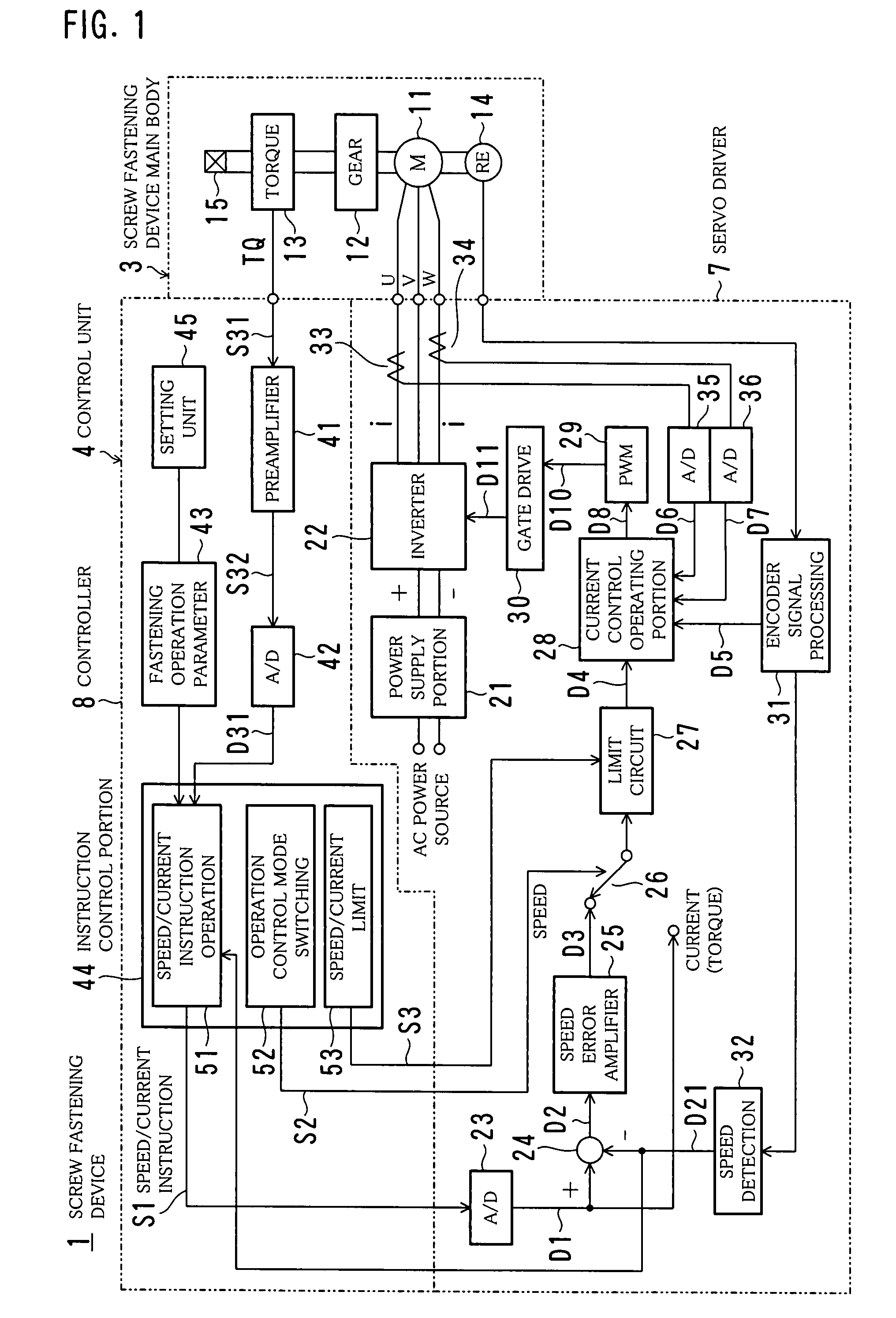

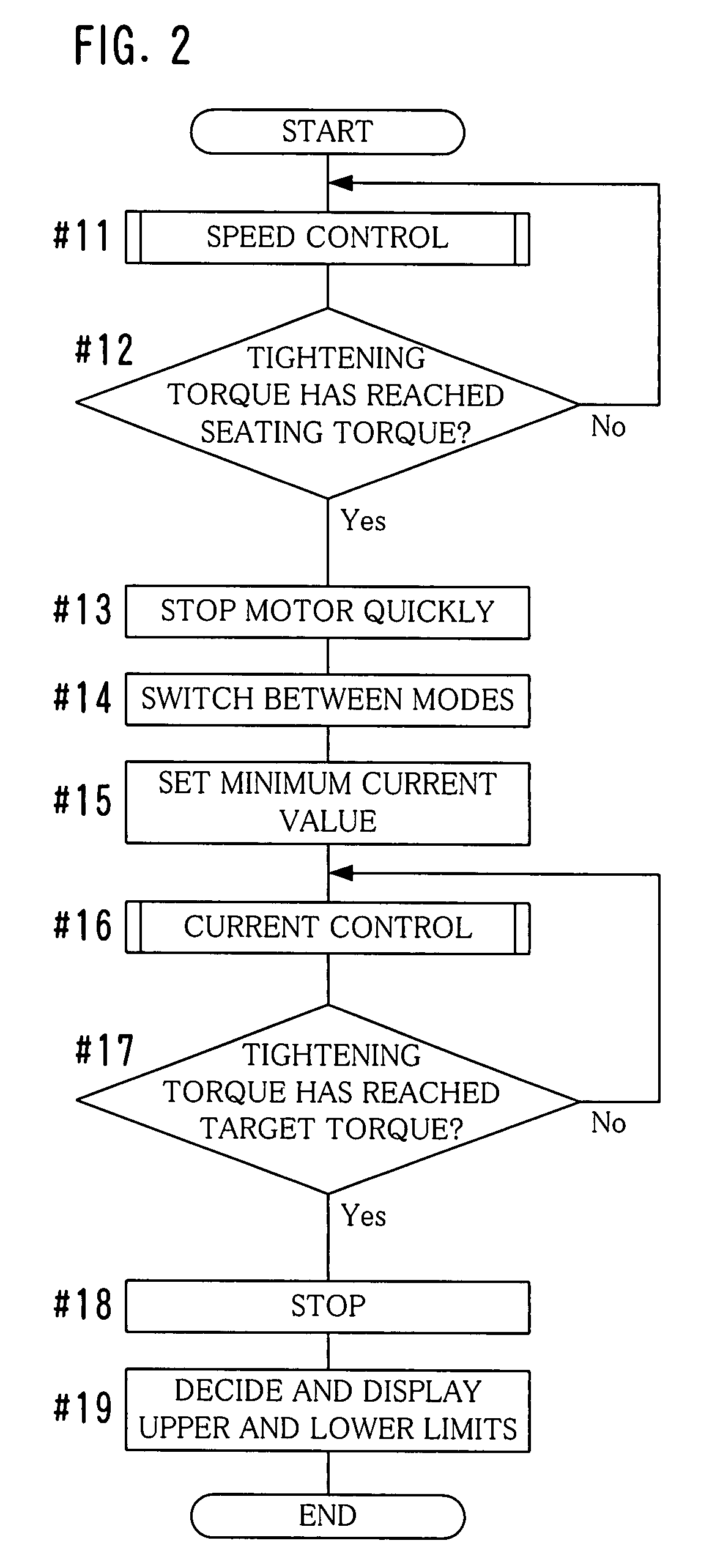

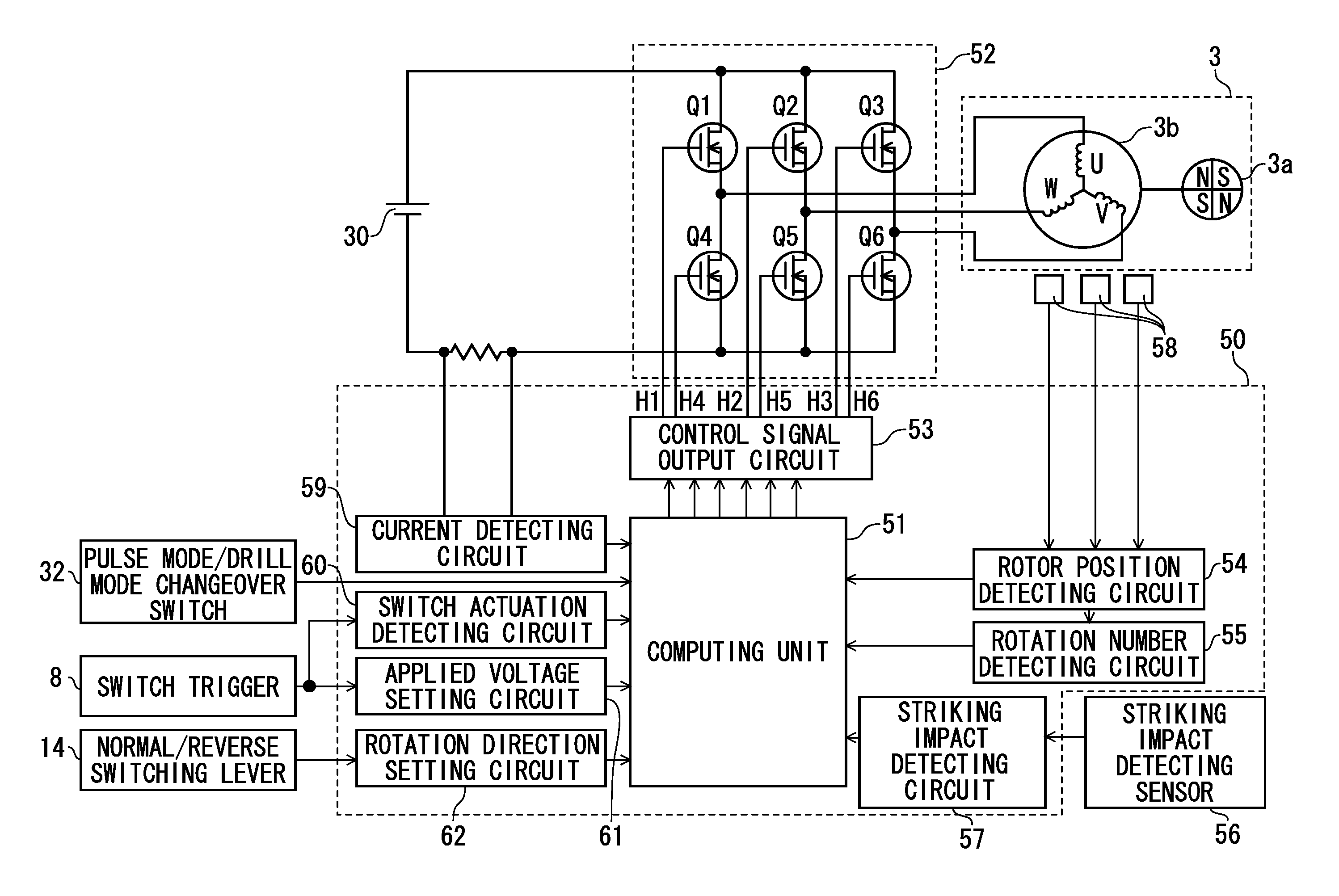

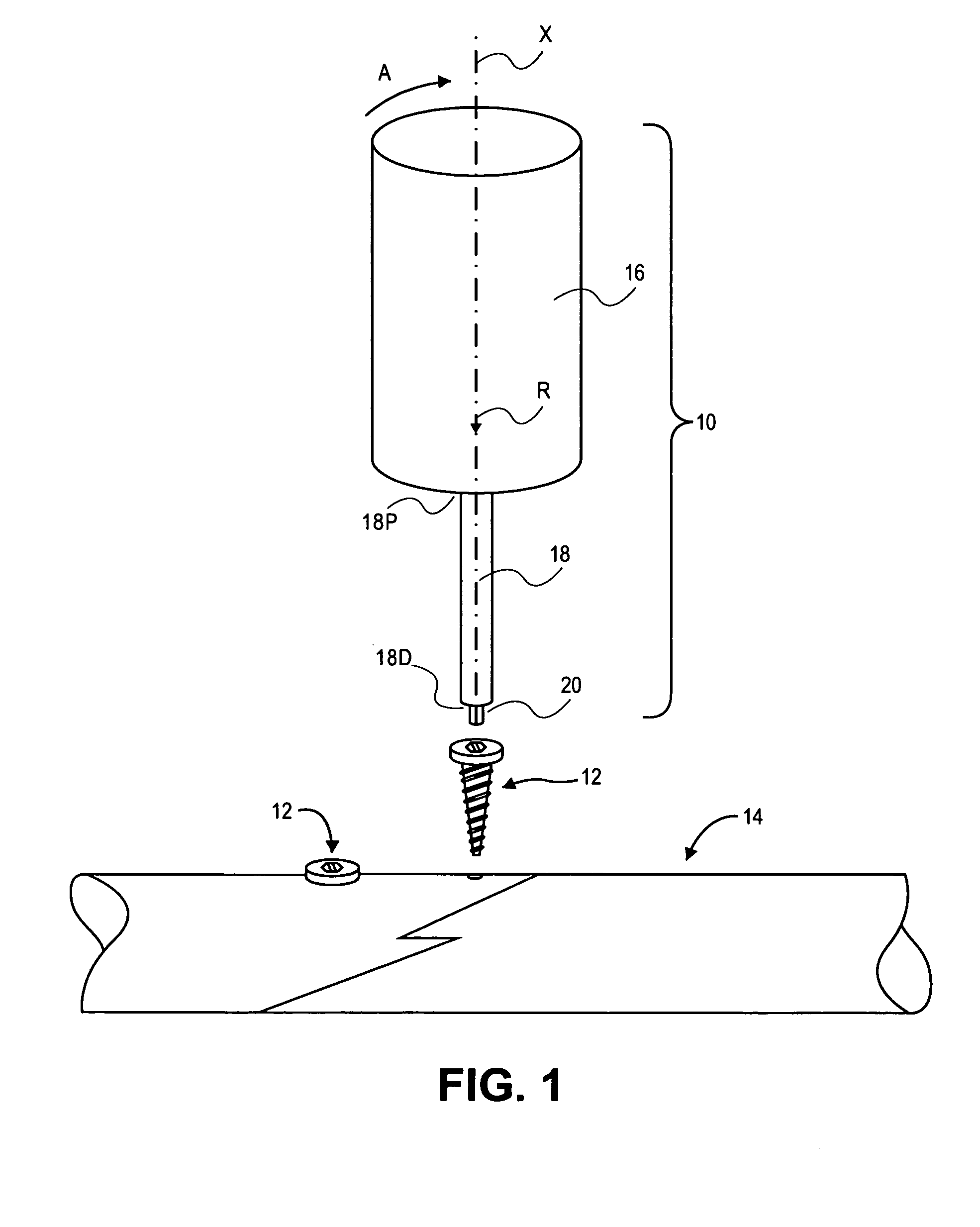

Control method and control unit for impact type screw fastening device

ActiveUS7770658B2Improve accuracyImprove fastening accuracyDrilling rodsConstructionsControl theoryElectrical current

An object is to improve accuracy of tightening torque and to shorten time necessary for fastening a screw in an impact type screw fastening device that uses an electric motor as a rotation driving source. A control method for the impact type screw fastening device that uses an electric motor as a rotation driving source includes the steps of driving the motor to rotate by supplying current to the motor intermittently so that torque exerted on a load by rotation of the motor becomes like pulses on the time axis, and controlling the current of every time of each pulse so that an increment of every time of each pulse of the torque after the torque reaches a target approach torque TQN that is a first set value becomes smaller than that before it reaches the target approach torque TQN.

Owner:ESTIC CORP

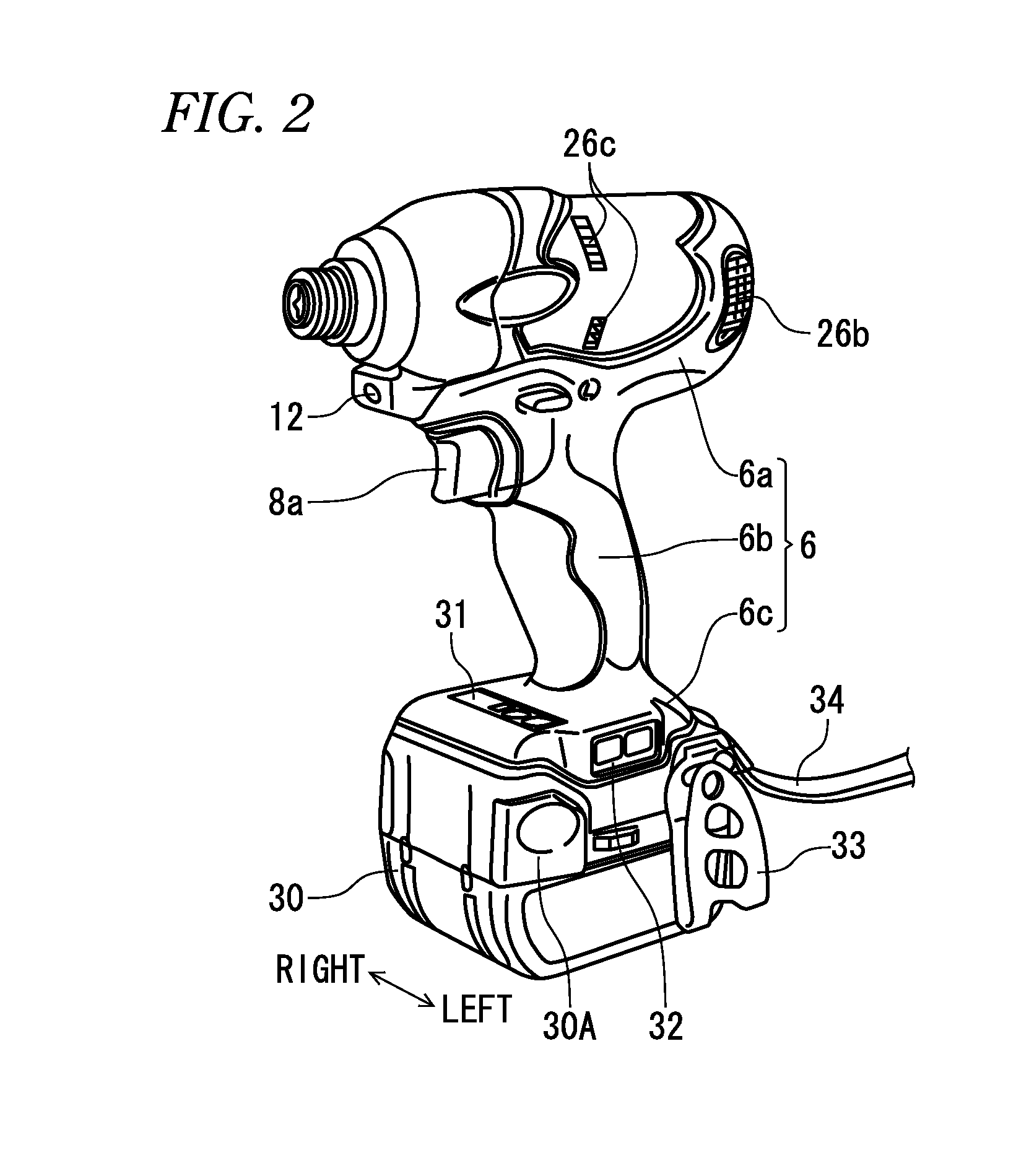

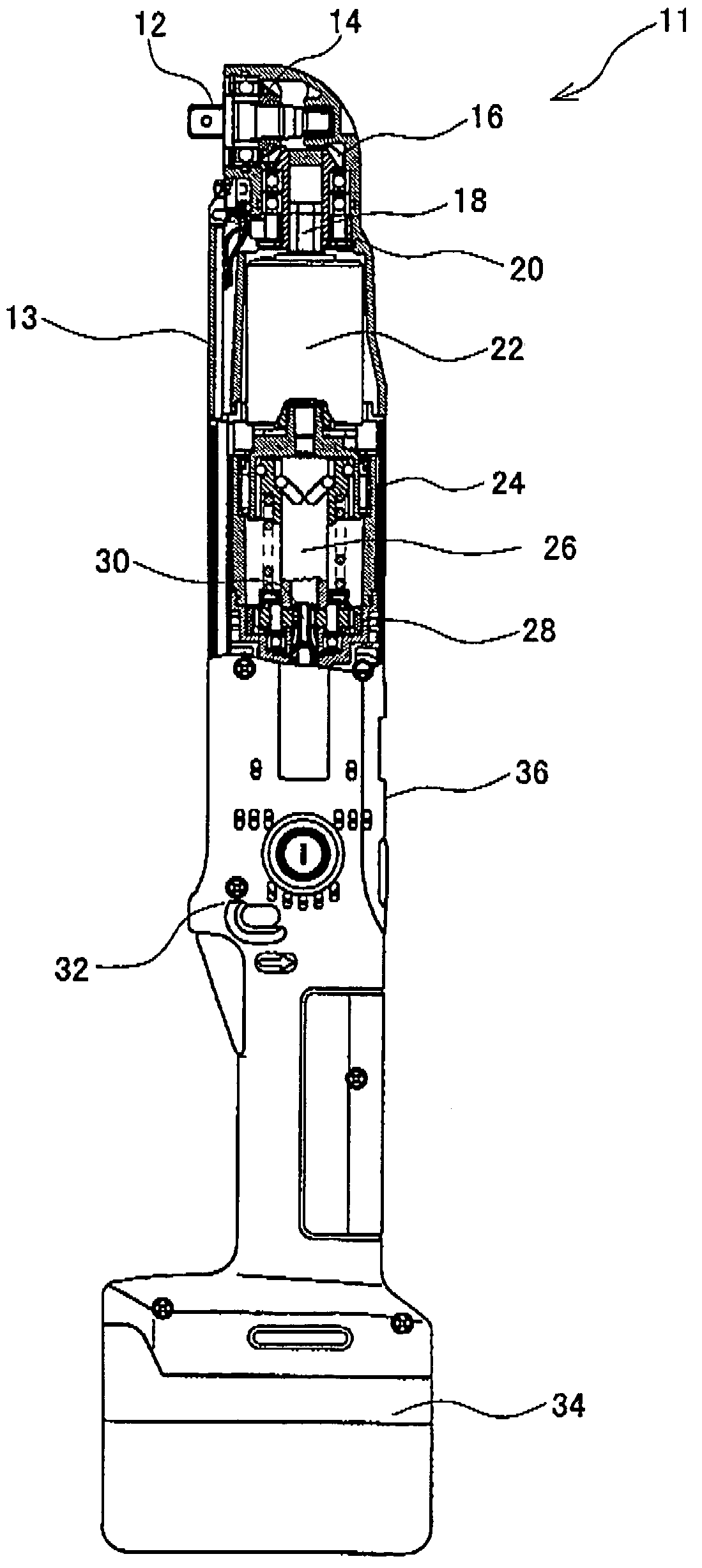

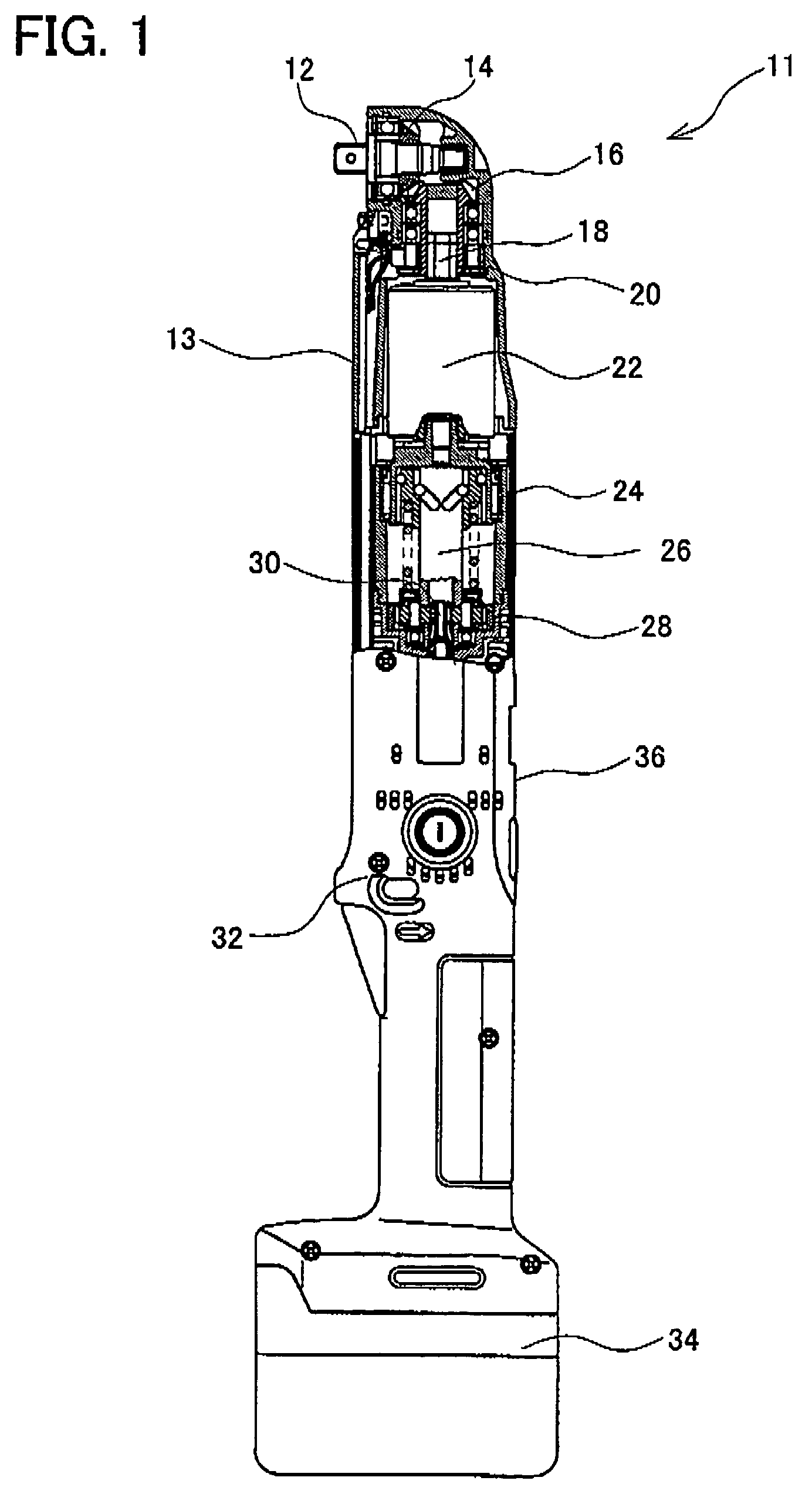

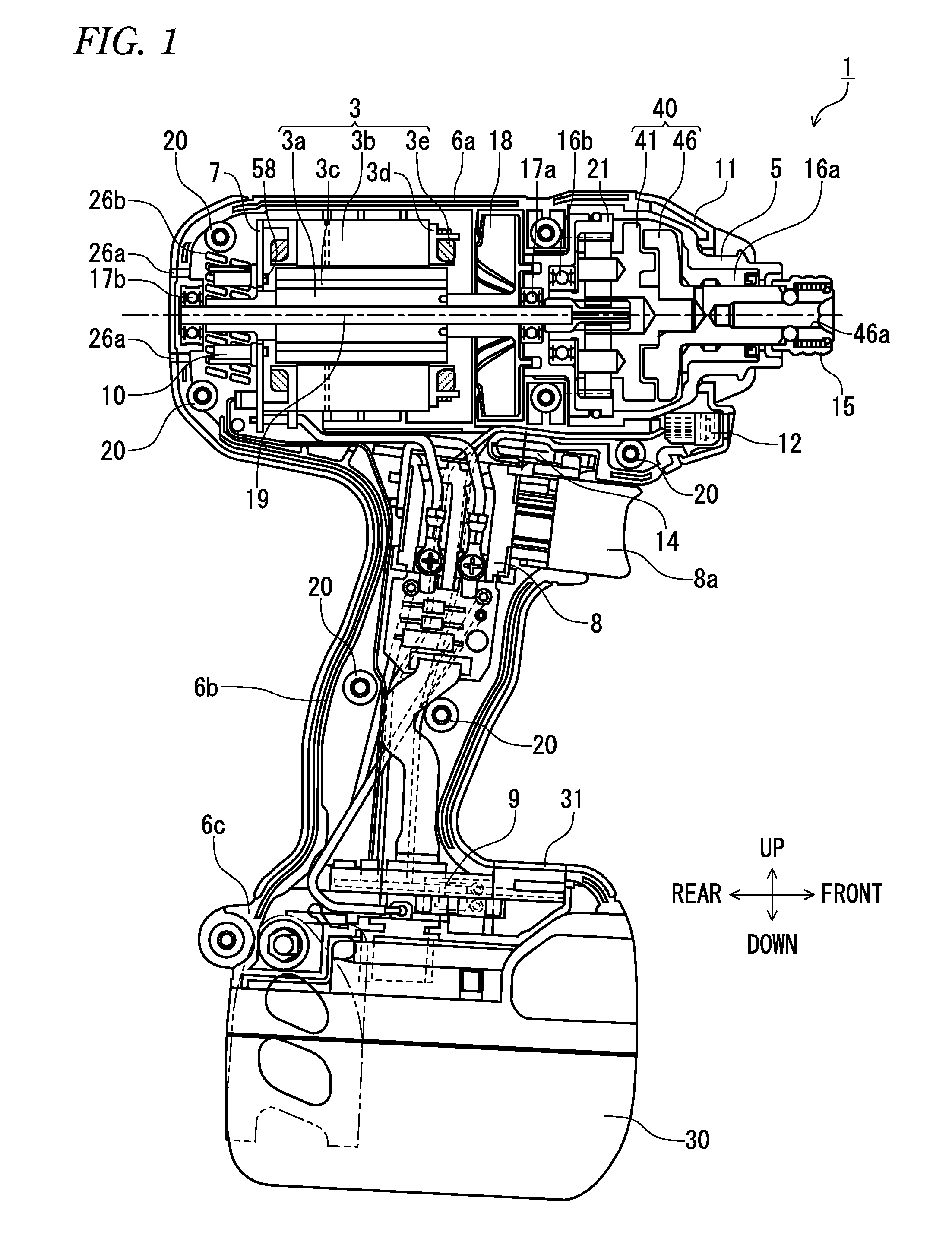

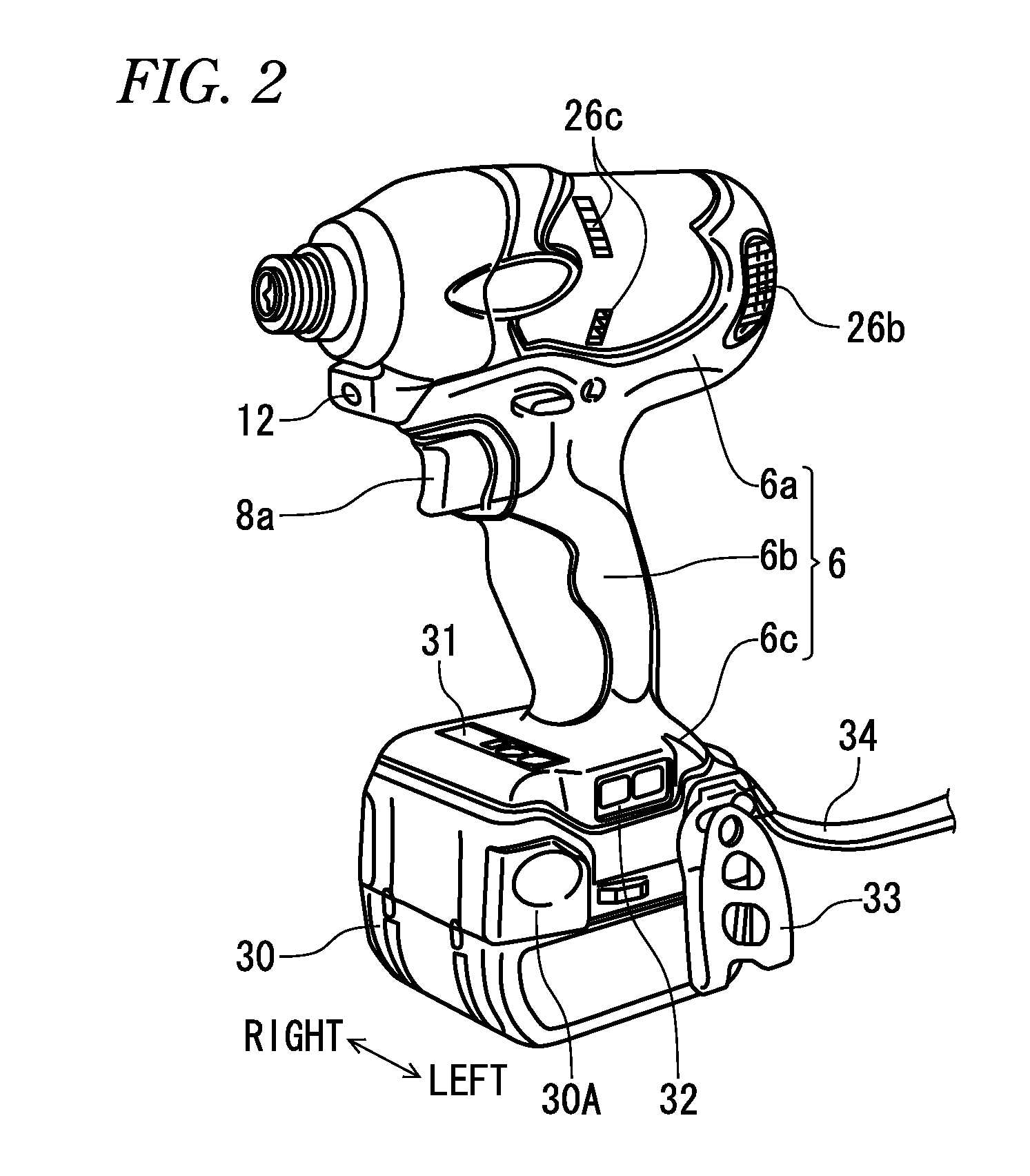

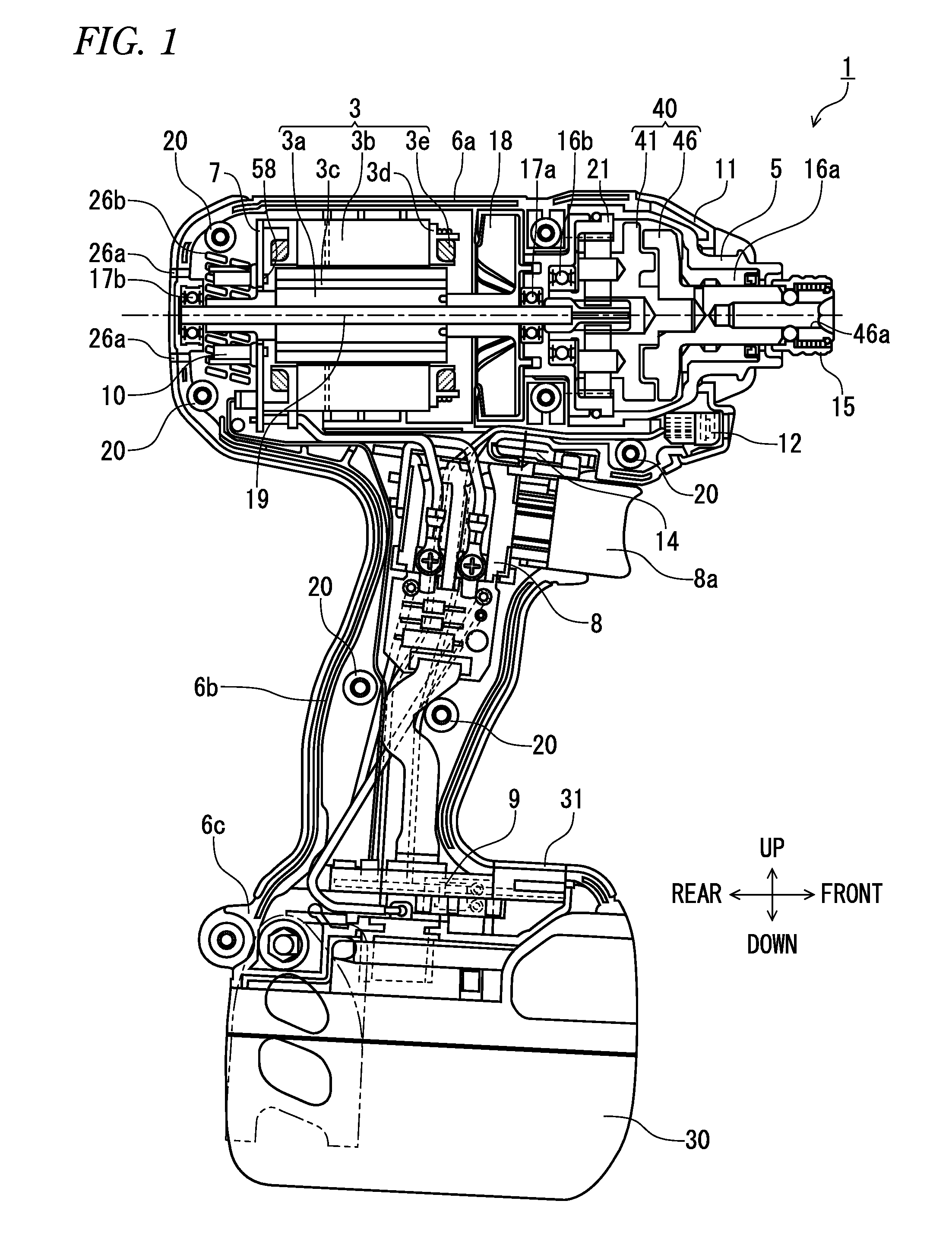

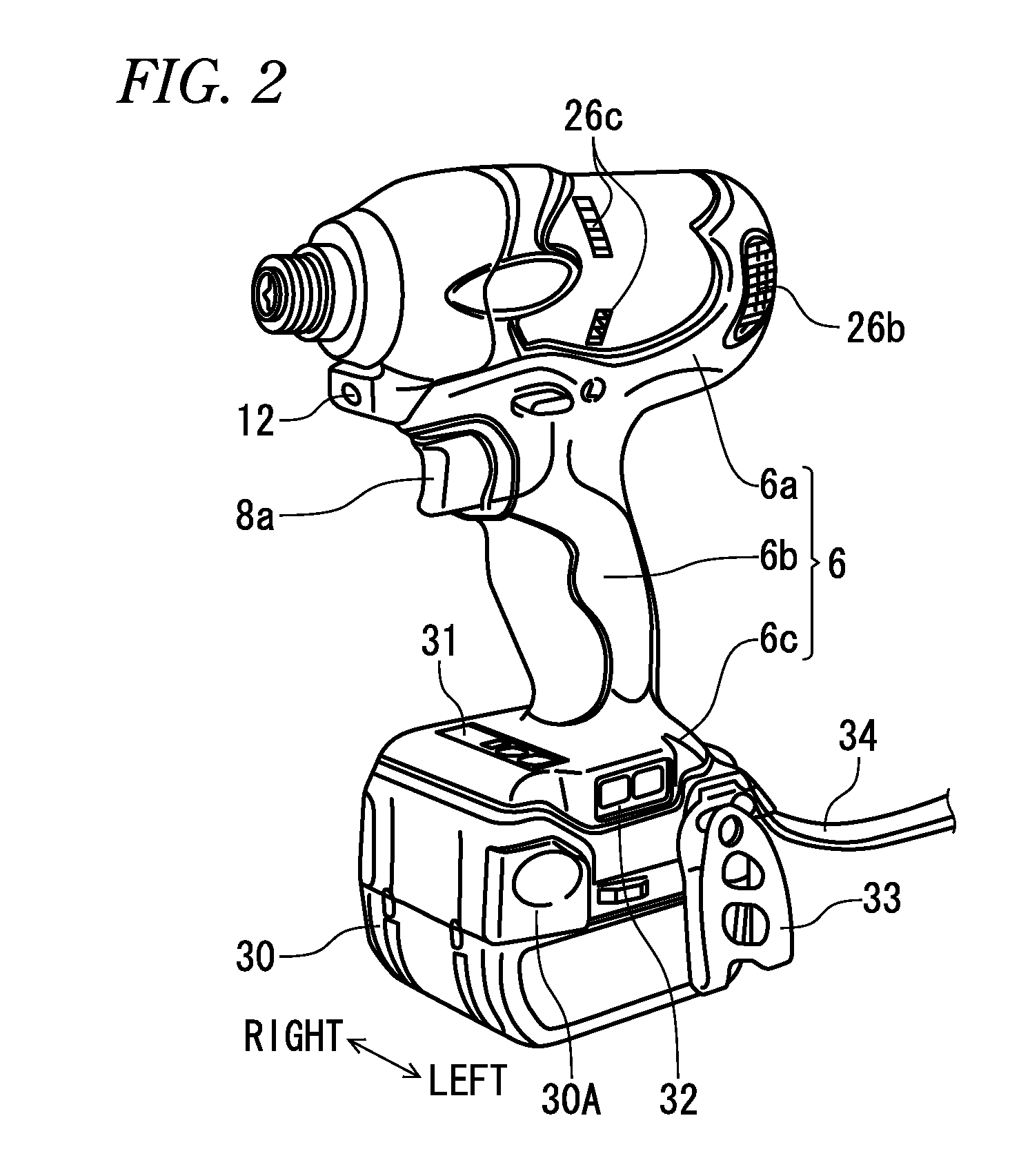

Impact tool

According to one embodiment, an impact tool includes: a motor; and a hammer that is connected to the motor and that has a striking-side surface; and an anvil that is journalled to be rotatable with respect to the hammer, that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor is drivable in: a first driving mode in which the motor is continuously driven in a normal rotation; a second driving mode in which the motor is intermittently driven only in the normal rotation; and a third driving mode in which the motor is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

Power tools

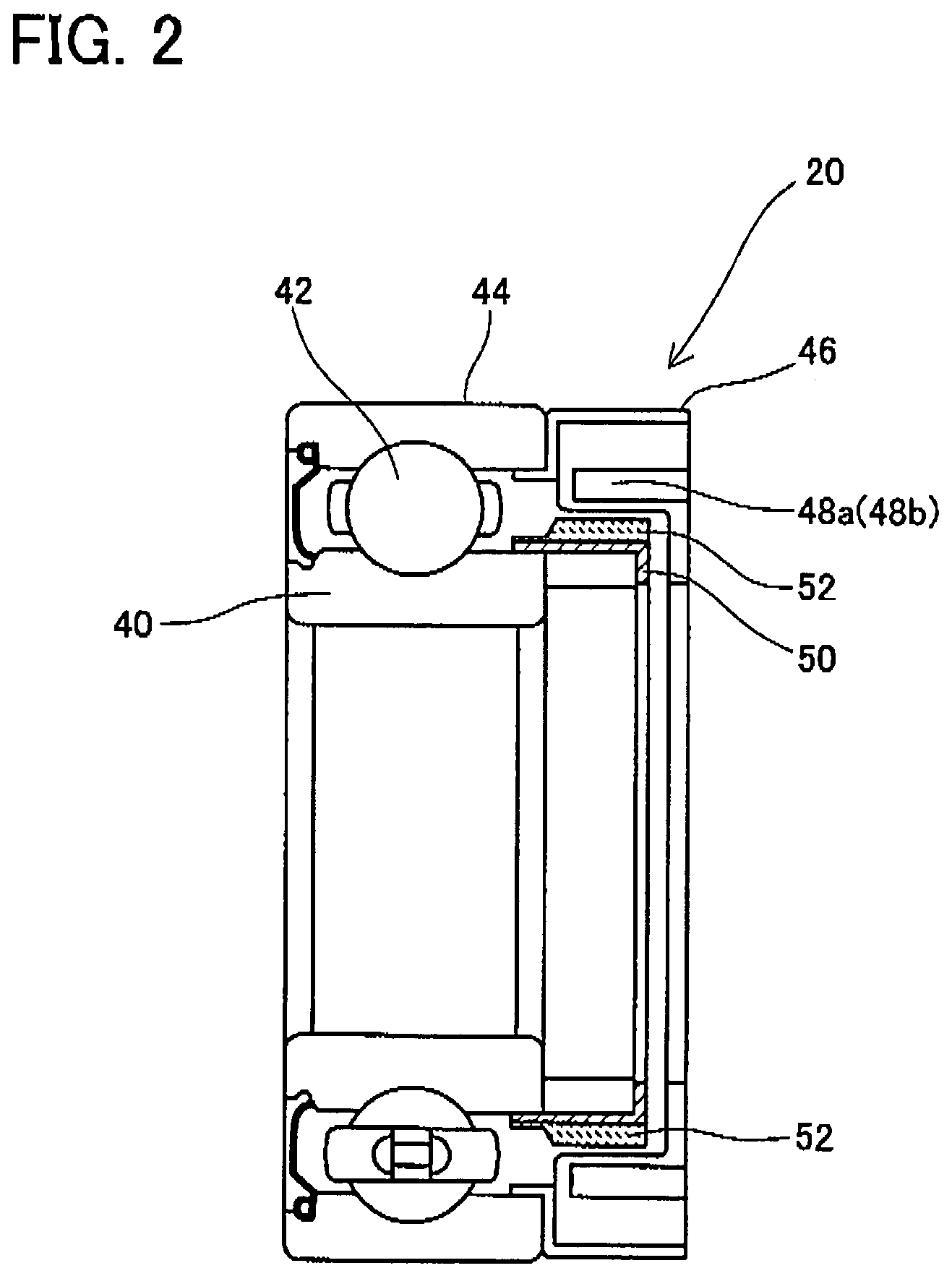

Power tool (11) may include a motor and oil pulse unit (22) that generates an elevated torque. Oil pulse unit (22) may be coupled to the motor and have output shaft (18). When load acting on output shaft (18) is less than a predetermined value, rotating torque generated by the motor is directly transmitted to output shaft (18). When the load acting on output shaft (22) exceeds the predetermined value, an elevated torque is generated by oil pulse unit (22) and applied to output shaft (18). Output shaft (18) may be connected to load shaft (12). A socket may be attached to the distal end of load shaft (12). Power tool (11) may further include detecting device (20) for detecting change in rotational angle of output shaft (18) and the direction of rotation thereof, and a control device. The detecting device (20) may output signals corresponding to a state of output shaft (18) to the control device. The control device may store the state of output shaft (18) at predetermined interval. Preferably, the control device may further determine a generating time, at which oil pulse unit (22) generates the elevated torque, based upon the state of output shaft (18).

Owner:MAKITA CORP

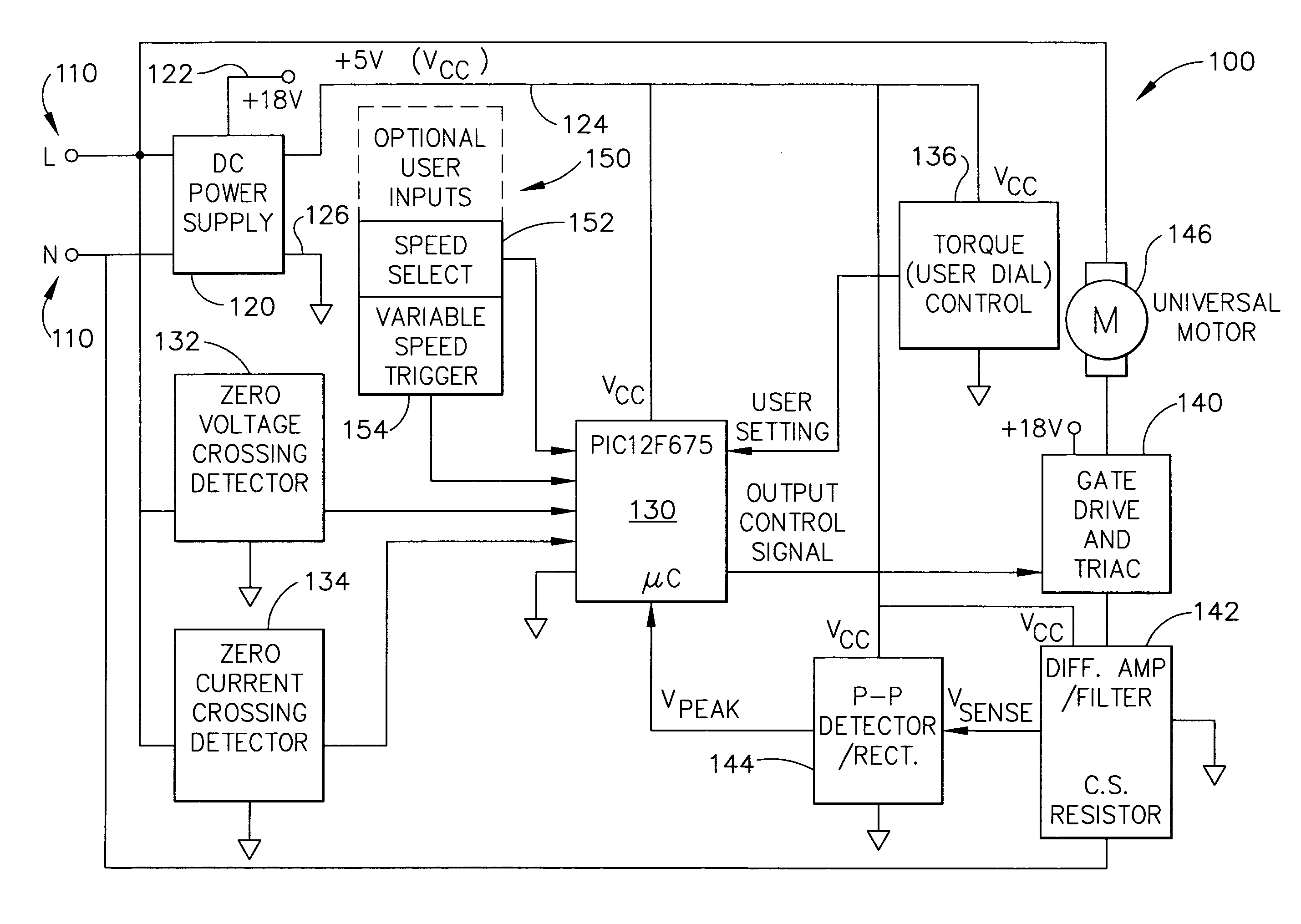

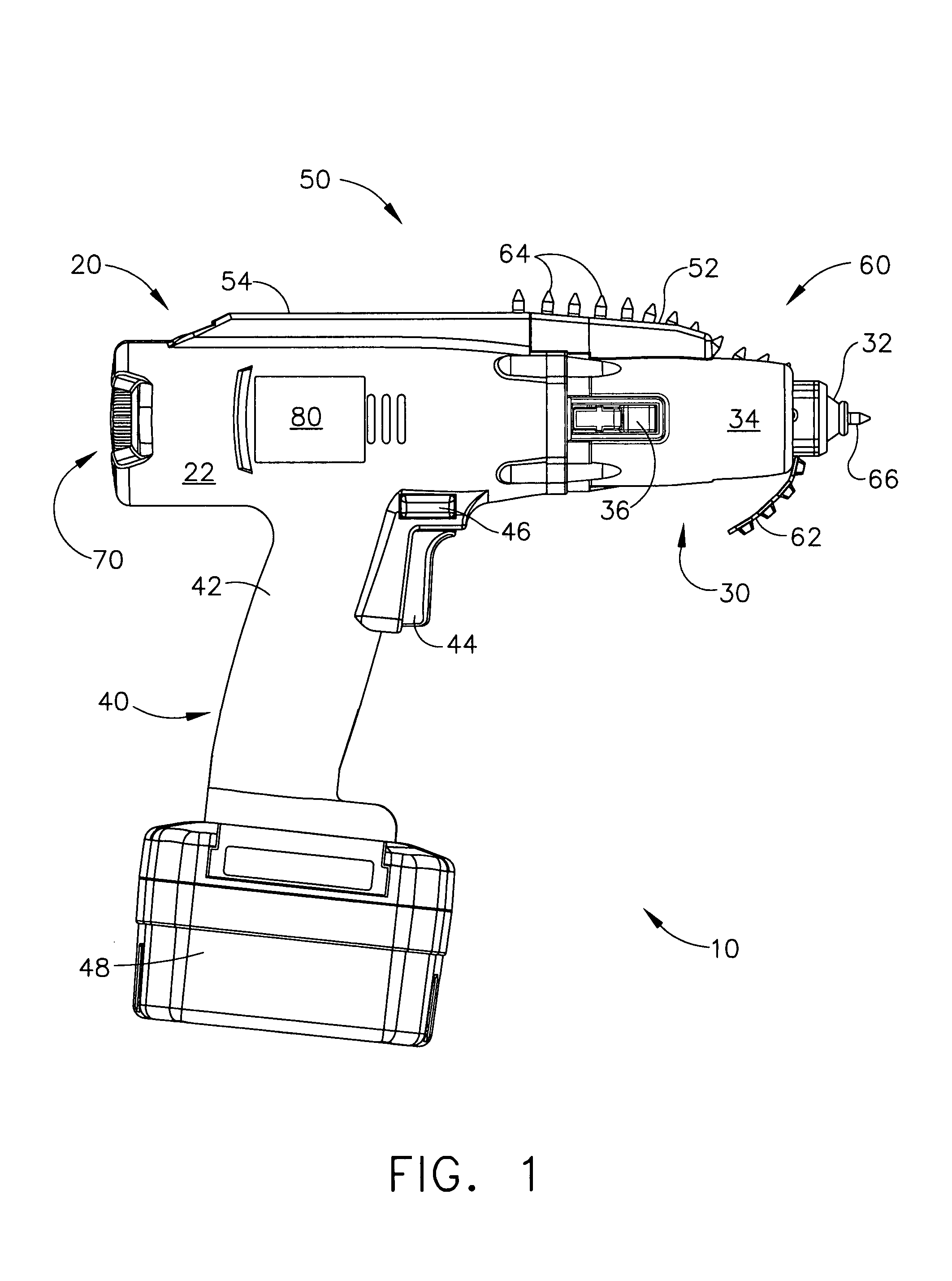

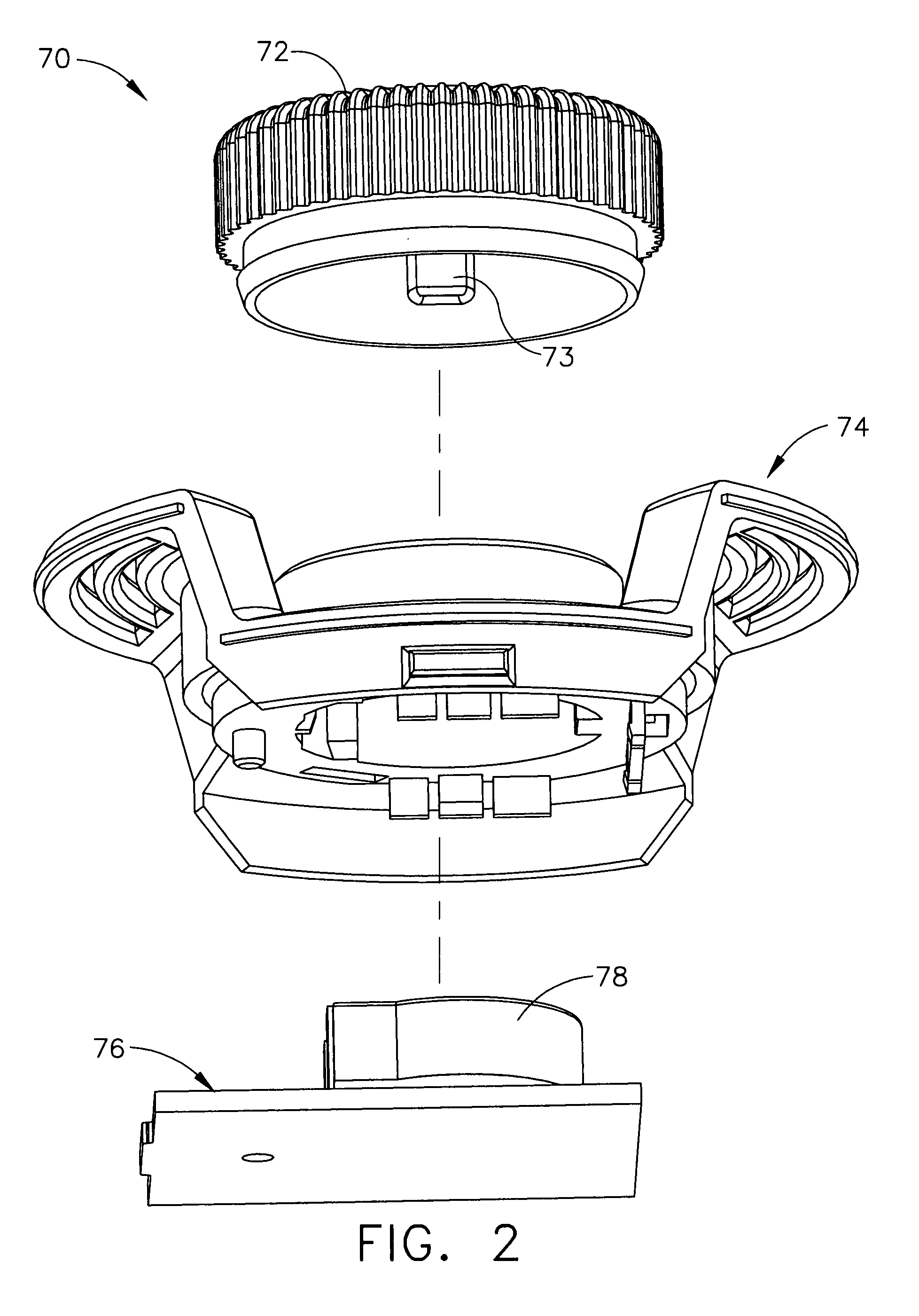

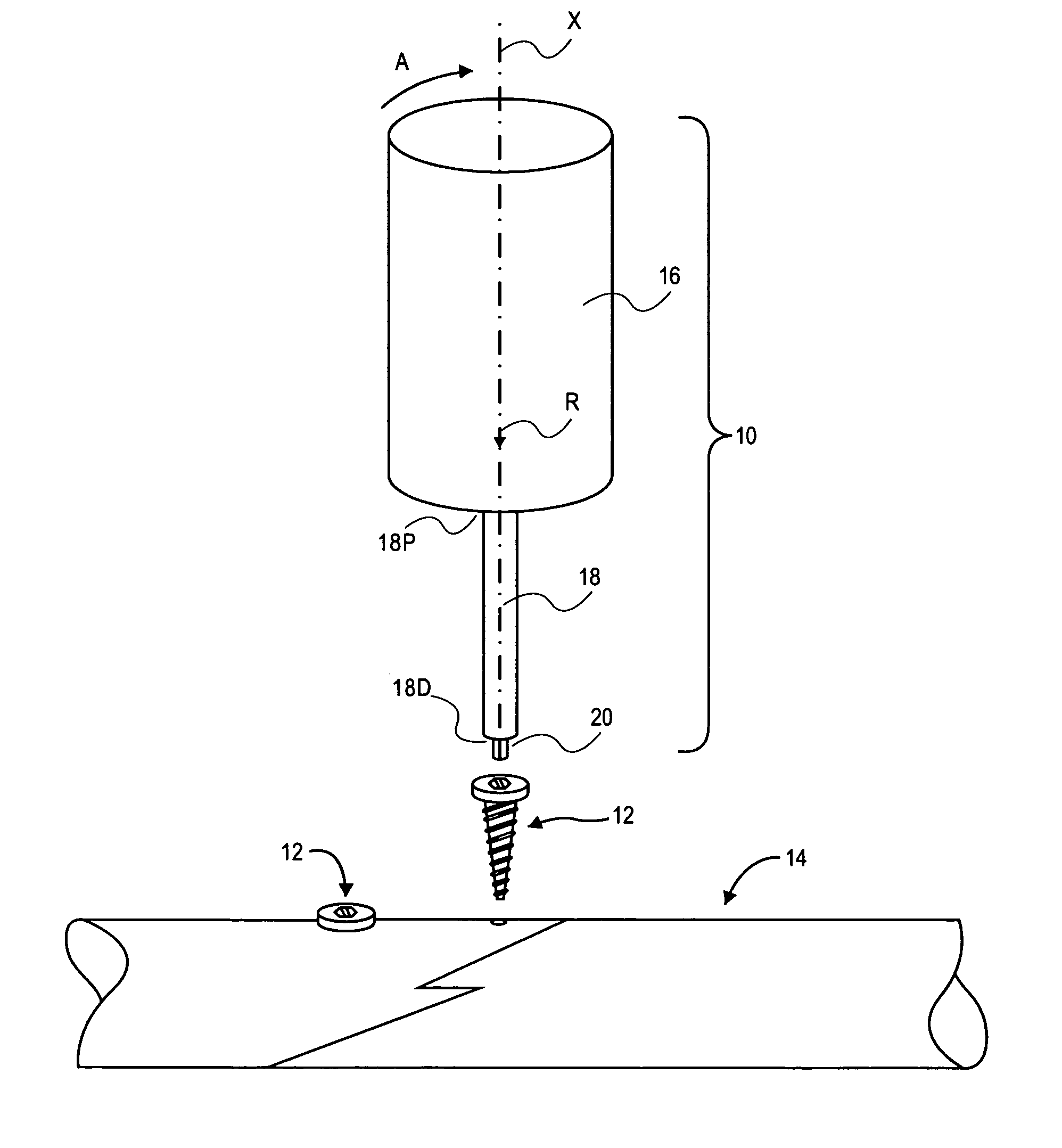

Apparatus for controlling a fastener driving tool, with user-adjustable torque limiting control

An improved hand-held fastener driving tool is provided with an adjustable torque limiting control. The tool is portable, and is electrically powered using either a battery pack or a power cord as a power source. The tool drives collated fasteners (e.g., screws) into solid objects. The motor current is measured to determine the amount of torque being applied to a screw by the motor and mechanical drive components. As the screw bottoms out, the motor torque increases to a point where it exceeds the user-adjusted torque limiting control. The motor is automatically turned off at that point, thereby preventing the screw from being stripped.

Owner:KYOCERA SENCO IND TOOLS INC

Impact tool

ActiveUS9314908B2Optimization mechanismConstructionsReciprocating drilling machinesEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:KOKI HLDG CO LTD

Method for controlling a power driver

A driving tool having a driver, a power source, a sensor and a controller. The power source selectively provides an input to the driver to cause the driver to translate along an axis. The sensor senses a condition in the power source that is indicative of a level of kinetic energy of an element in the power source and generates a sensor signal in response thereto. The controller is coupled to the power source and the sensor and is responsive to the sensor signal for deactivating the power source to inhibit the power source from providing the input to the driver when the level of kinetic energy of the element in the power source is below a predetermined threshold. A method for operating a driving tool is also provided.

Owner:BLACK & DECKER INC

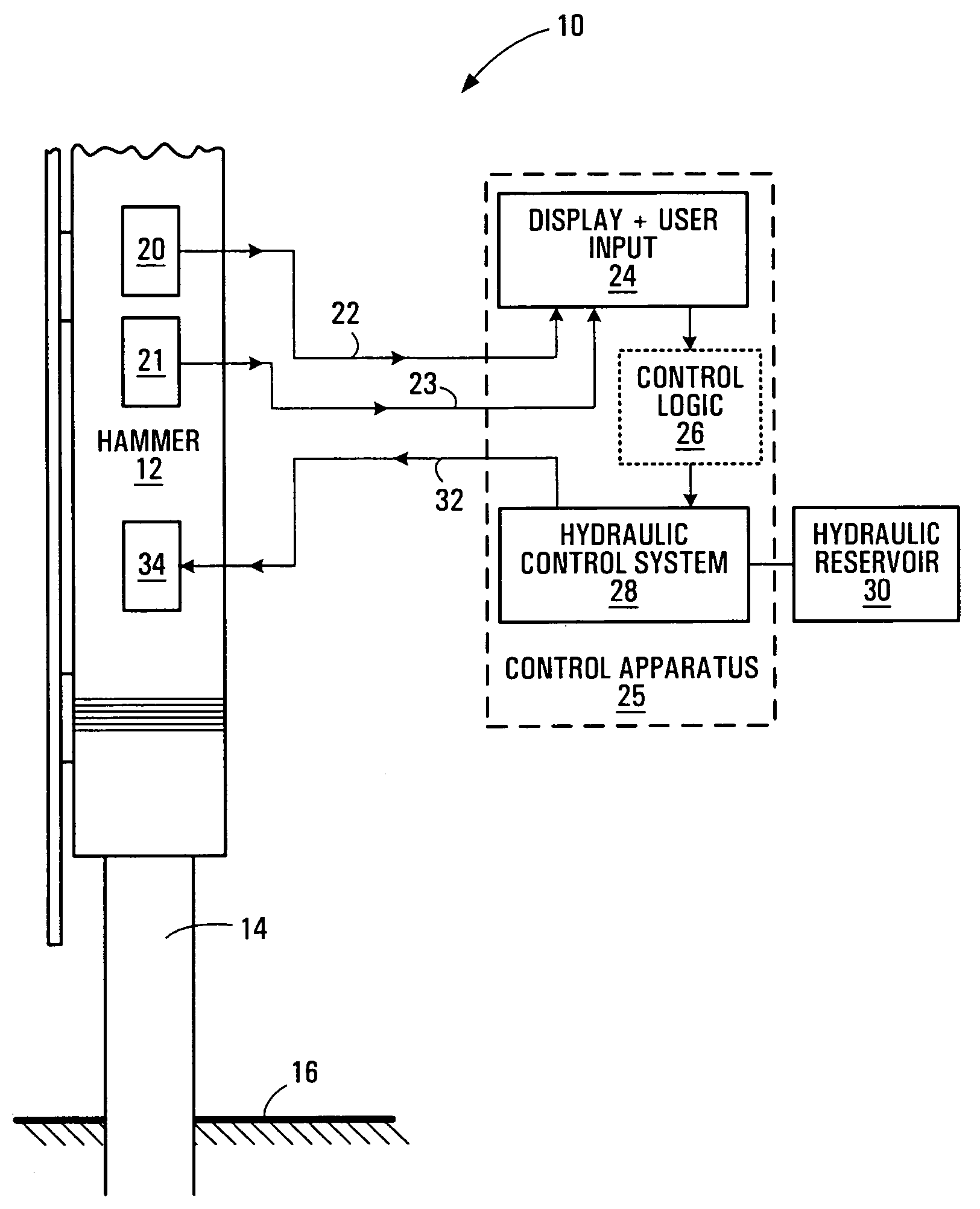

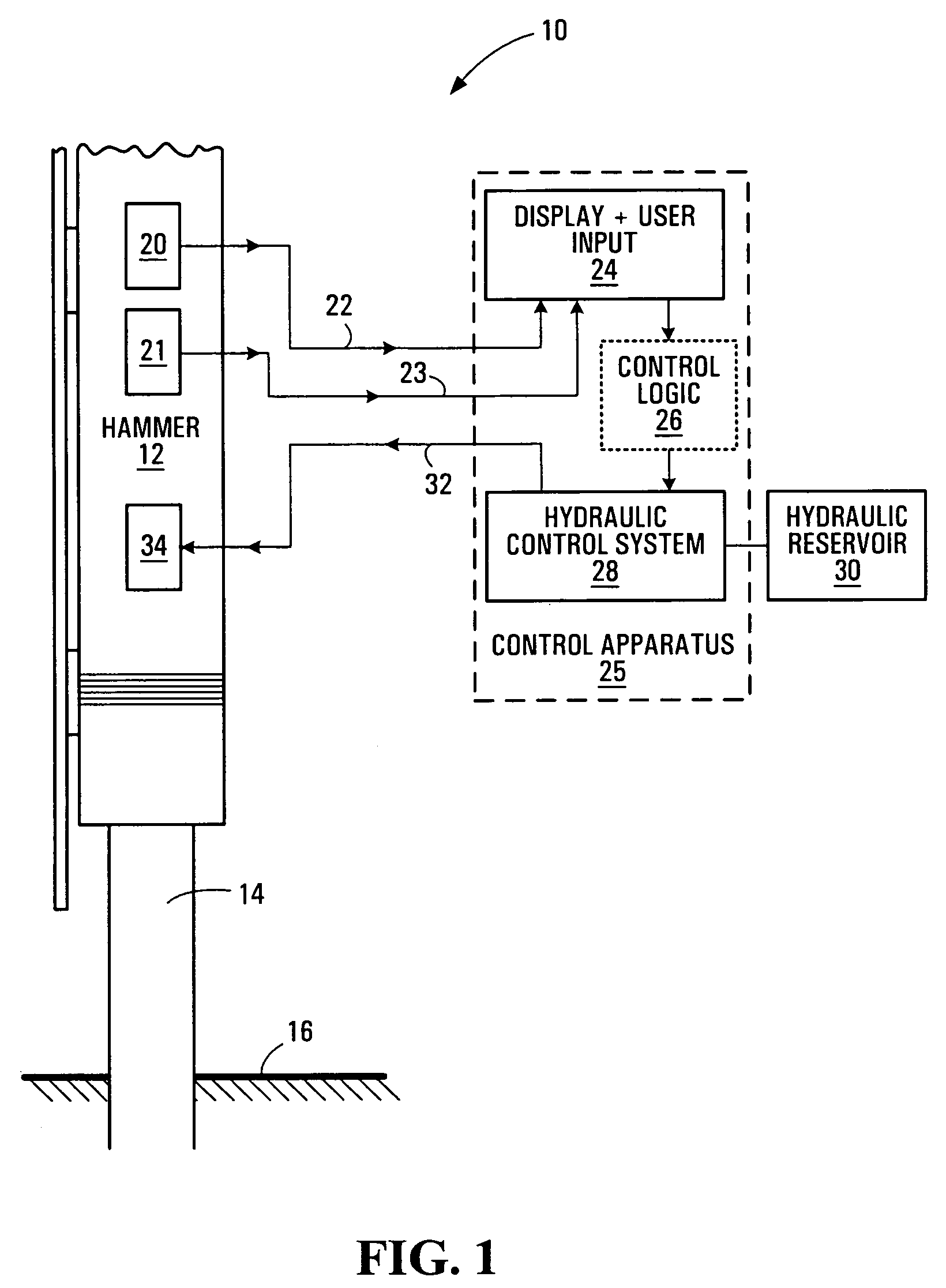

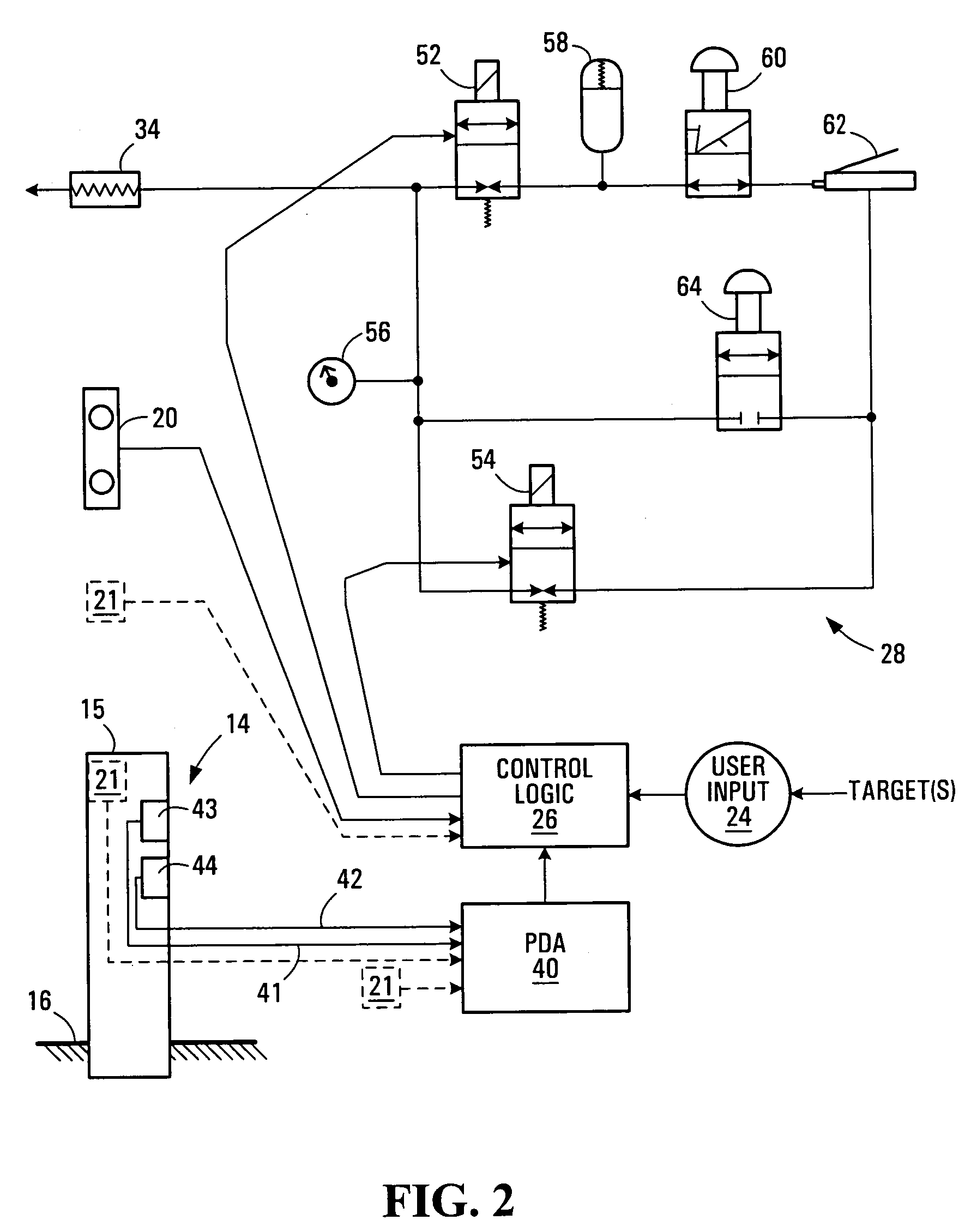

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

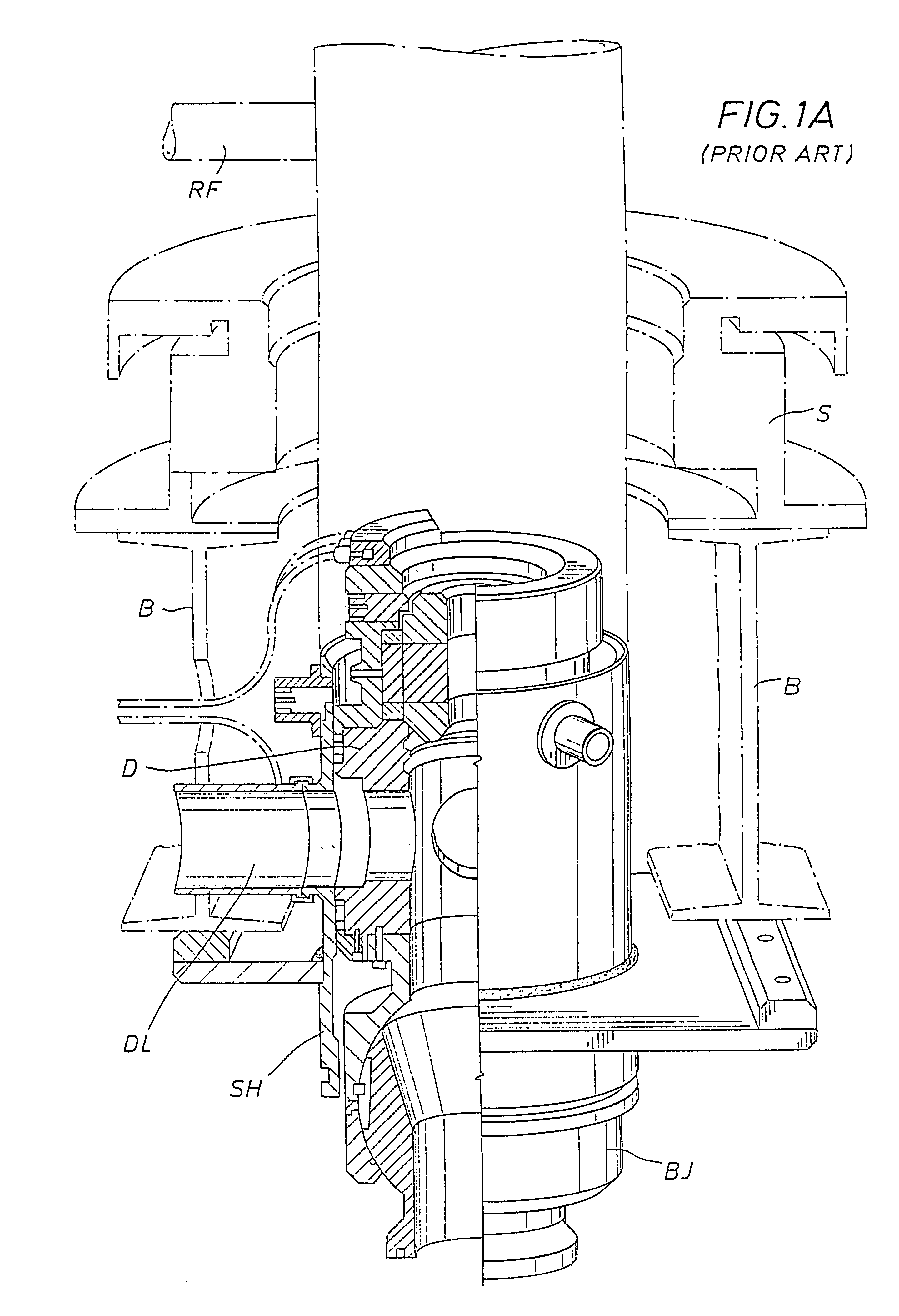

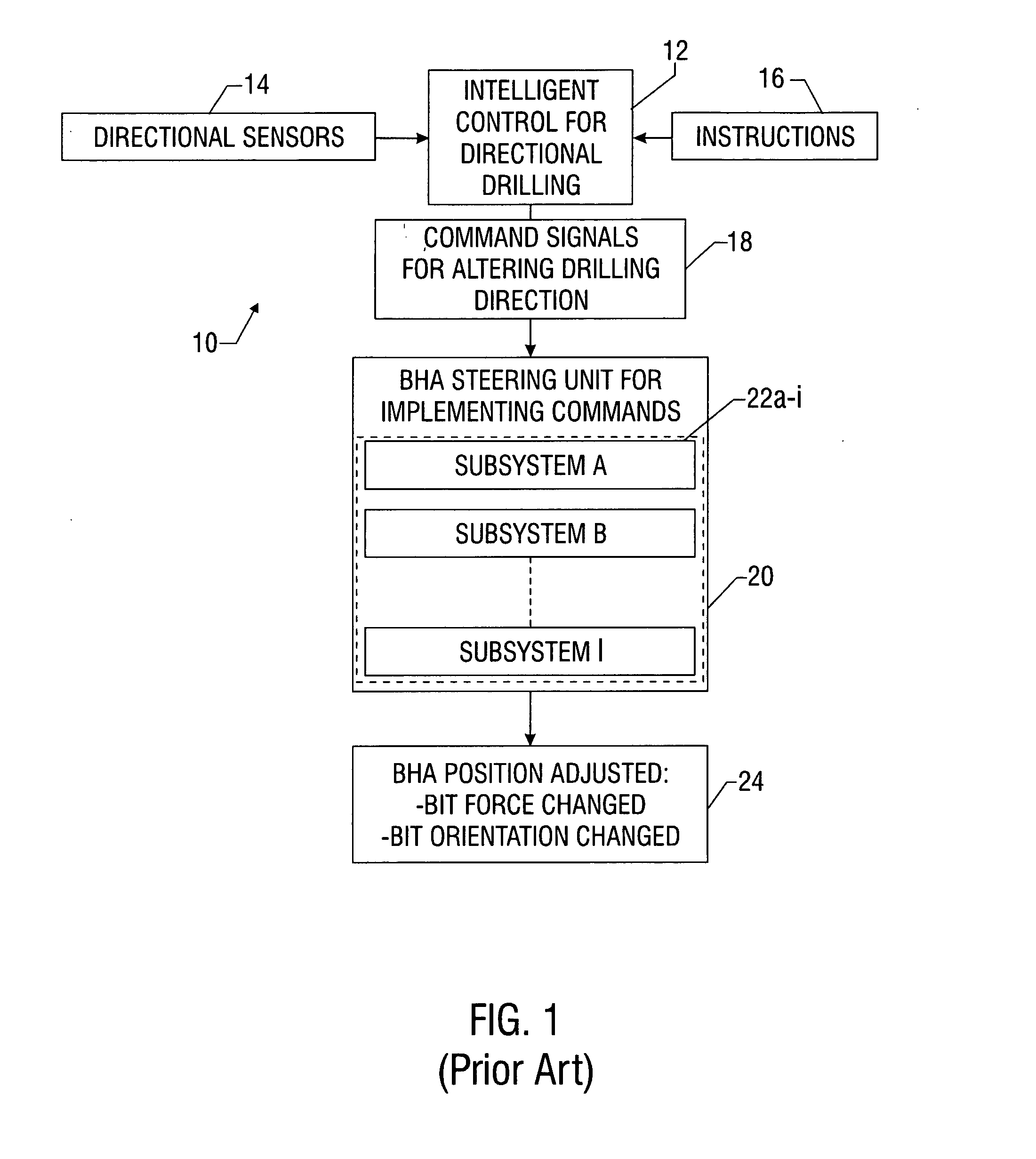

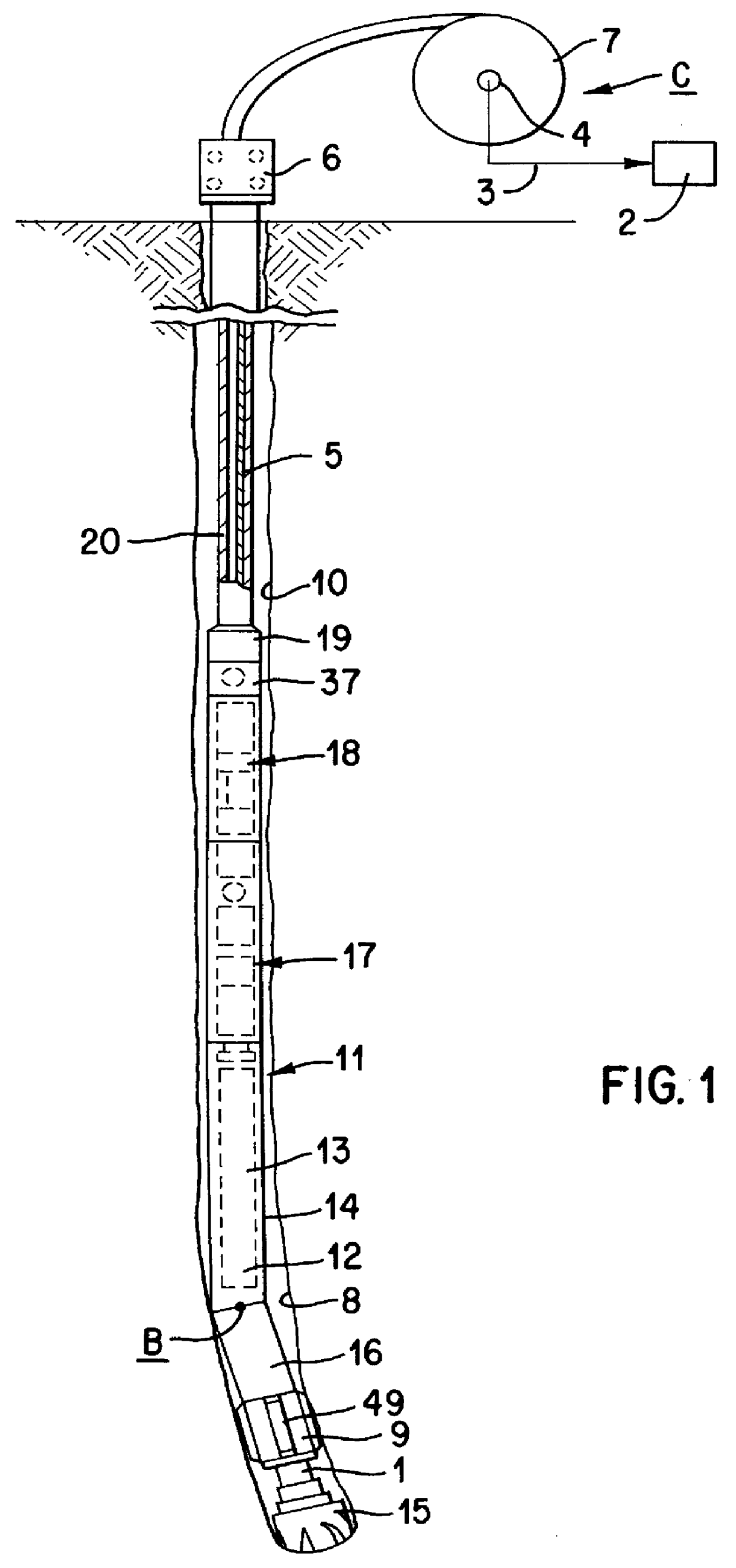

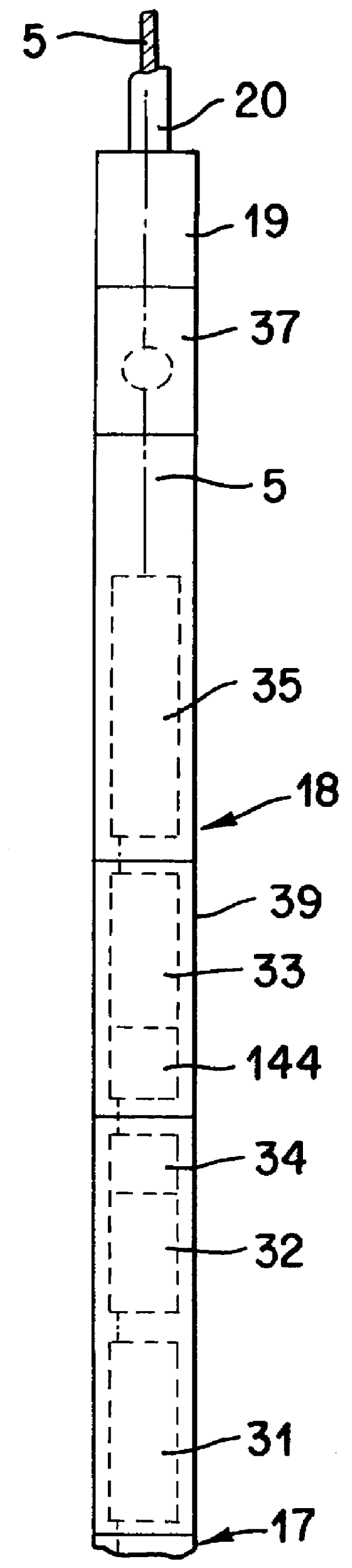

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

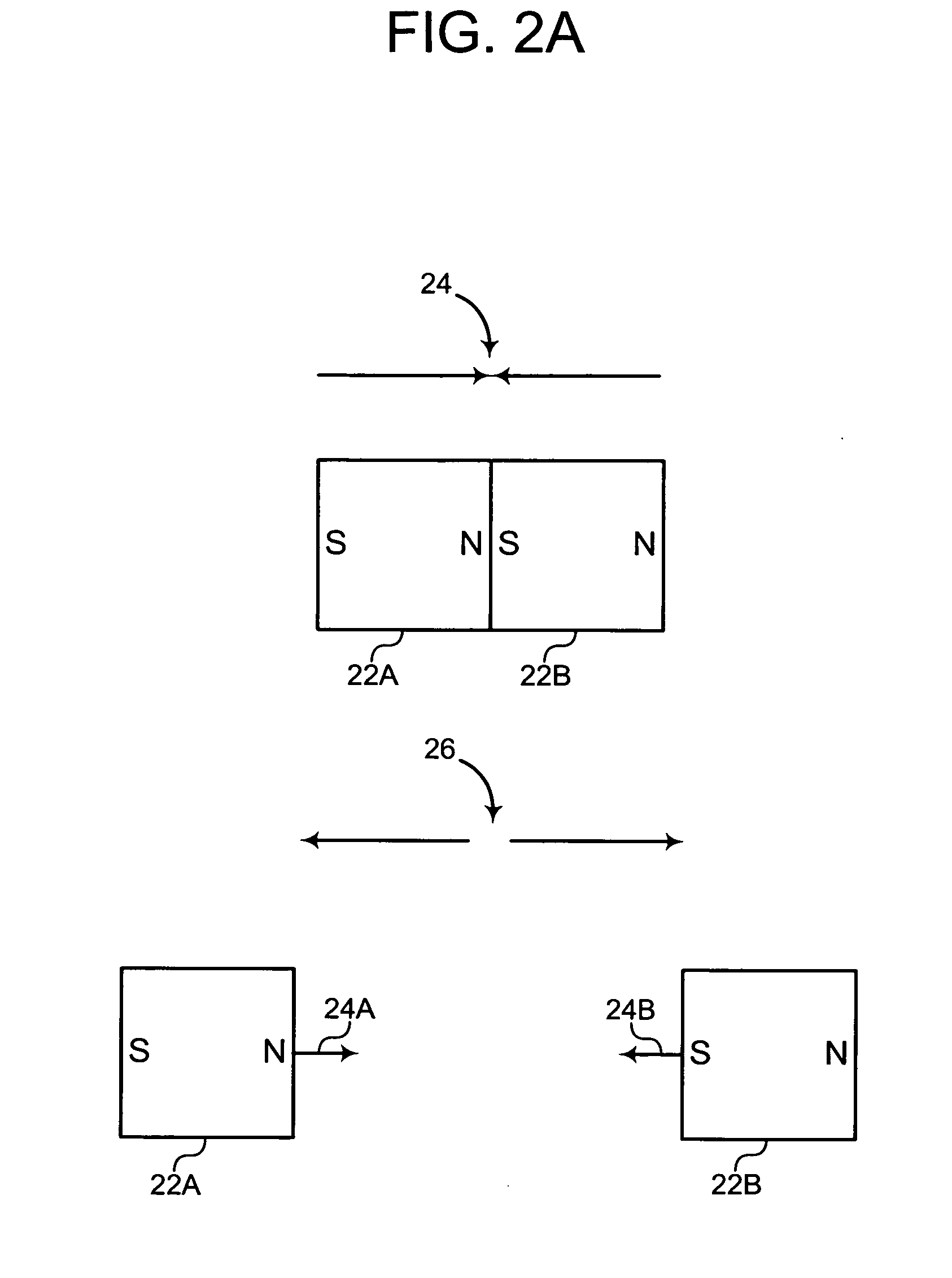

Magnetic torque-limiting device and method

In a torque-limiting device, a first end engages a fastener, a second end receives an applied torque, and a magnetic torque limiter transmits the applied torque from the second end to the first end to rotate the first end in conjunction with the second end when the applied torque is less than a predetermined limit.

Owner:PILLING WECK INC

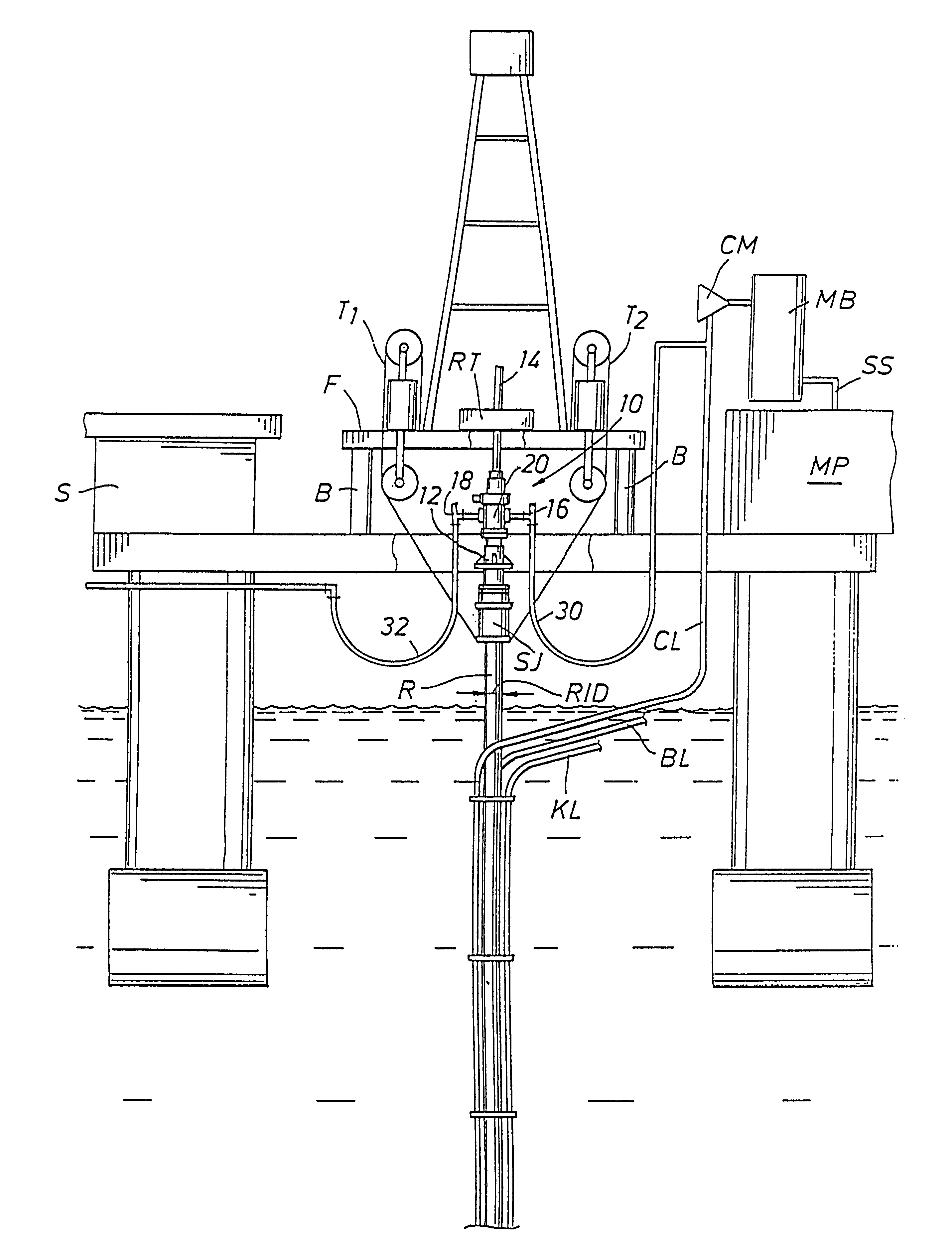

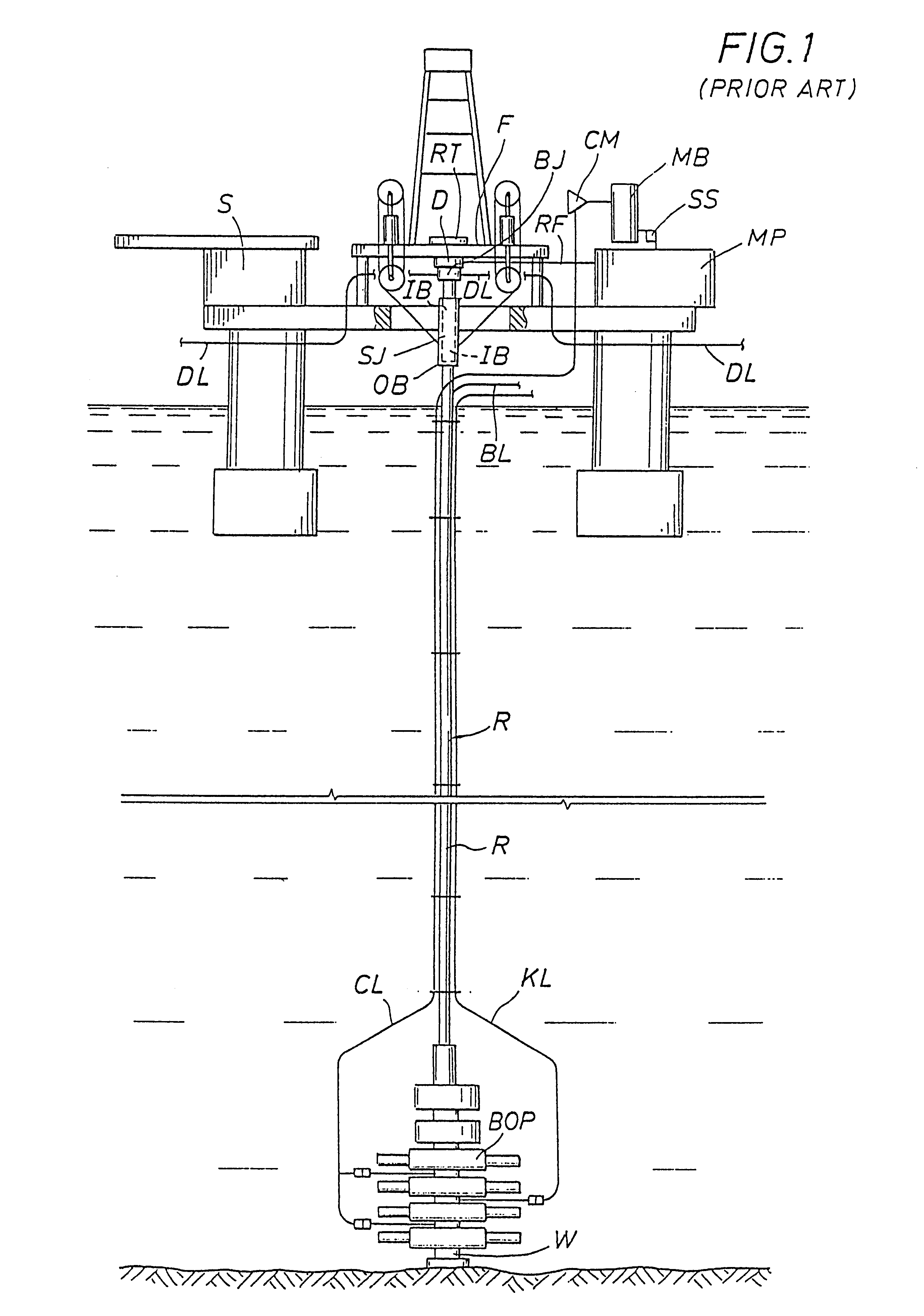

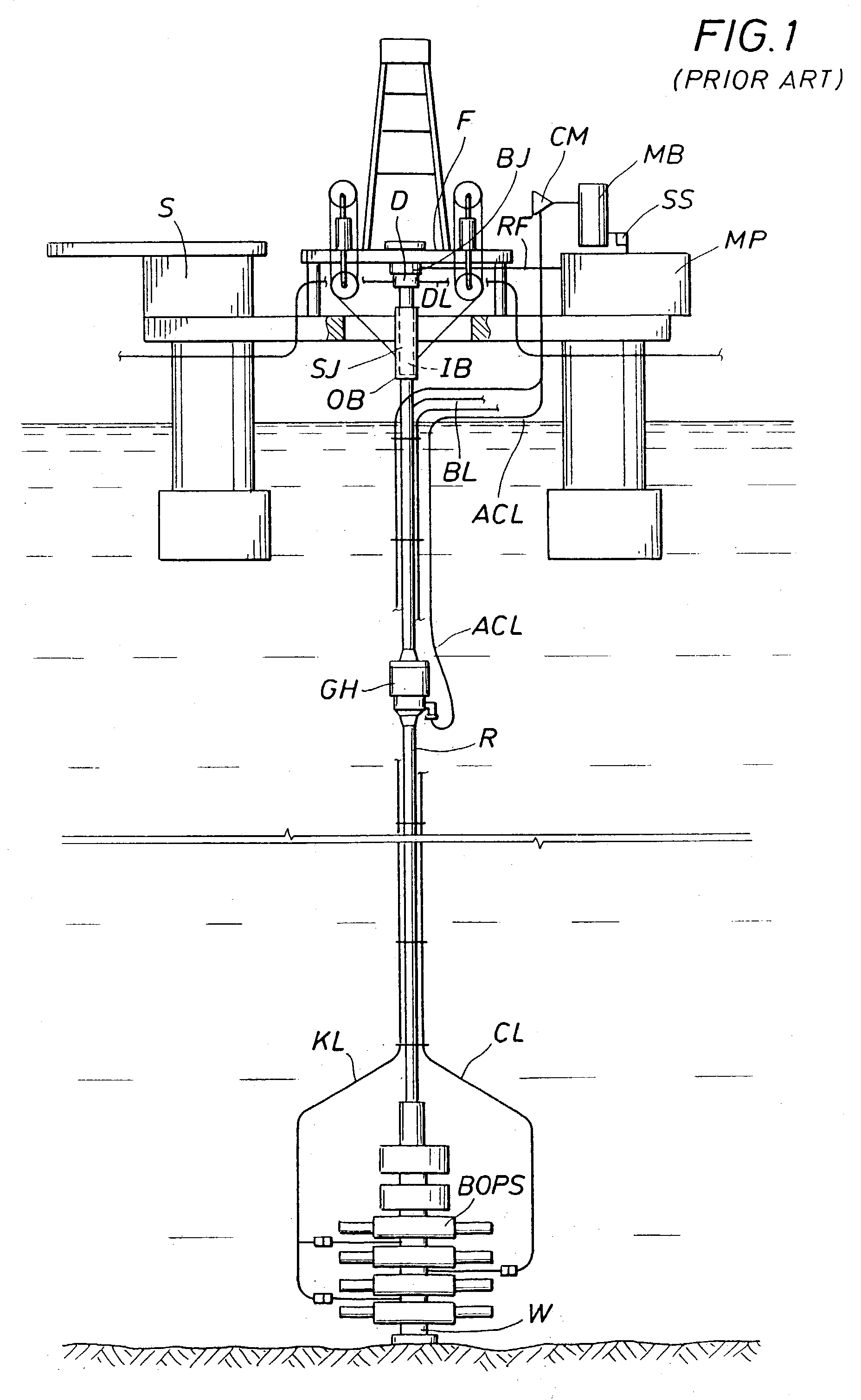

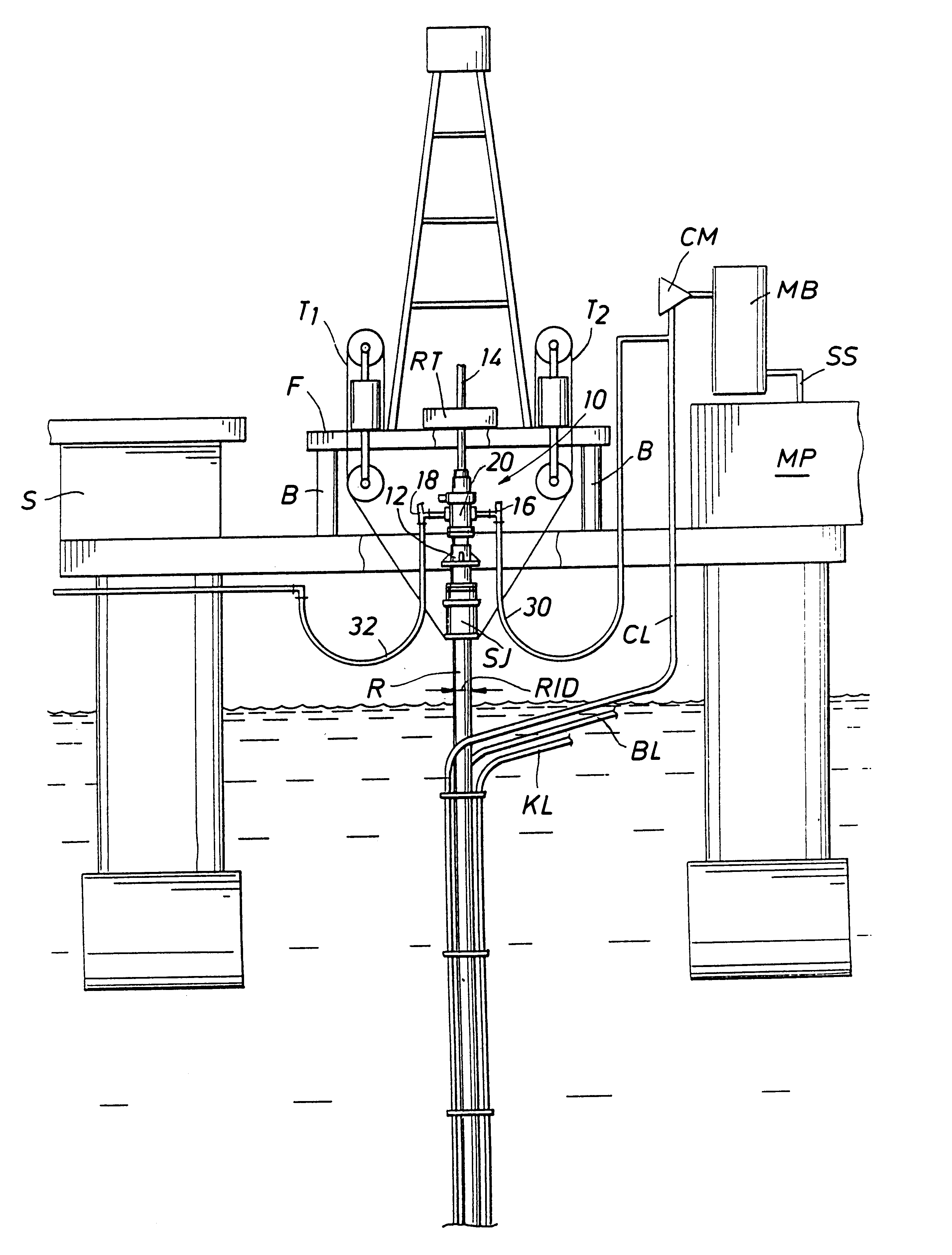

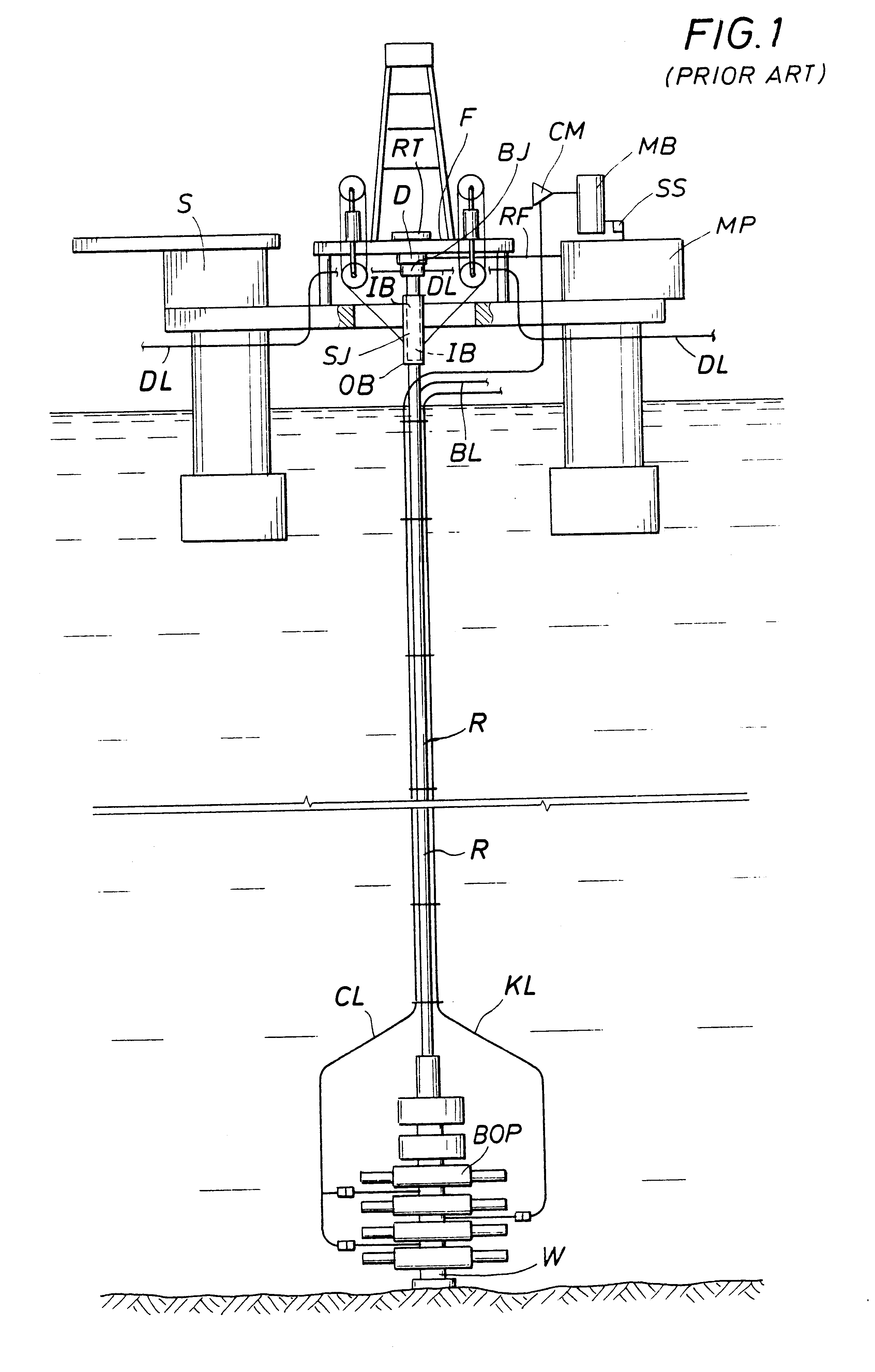

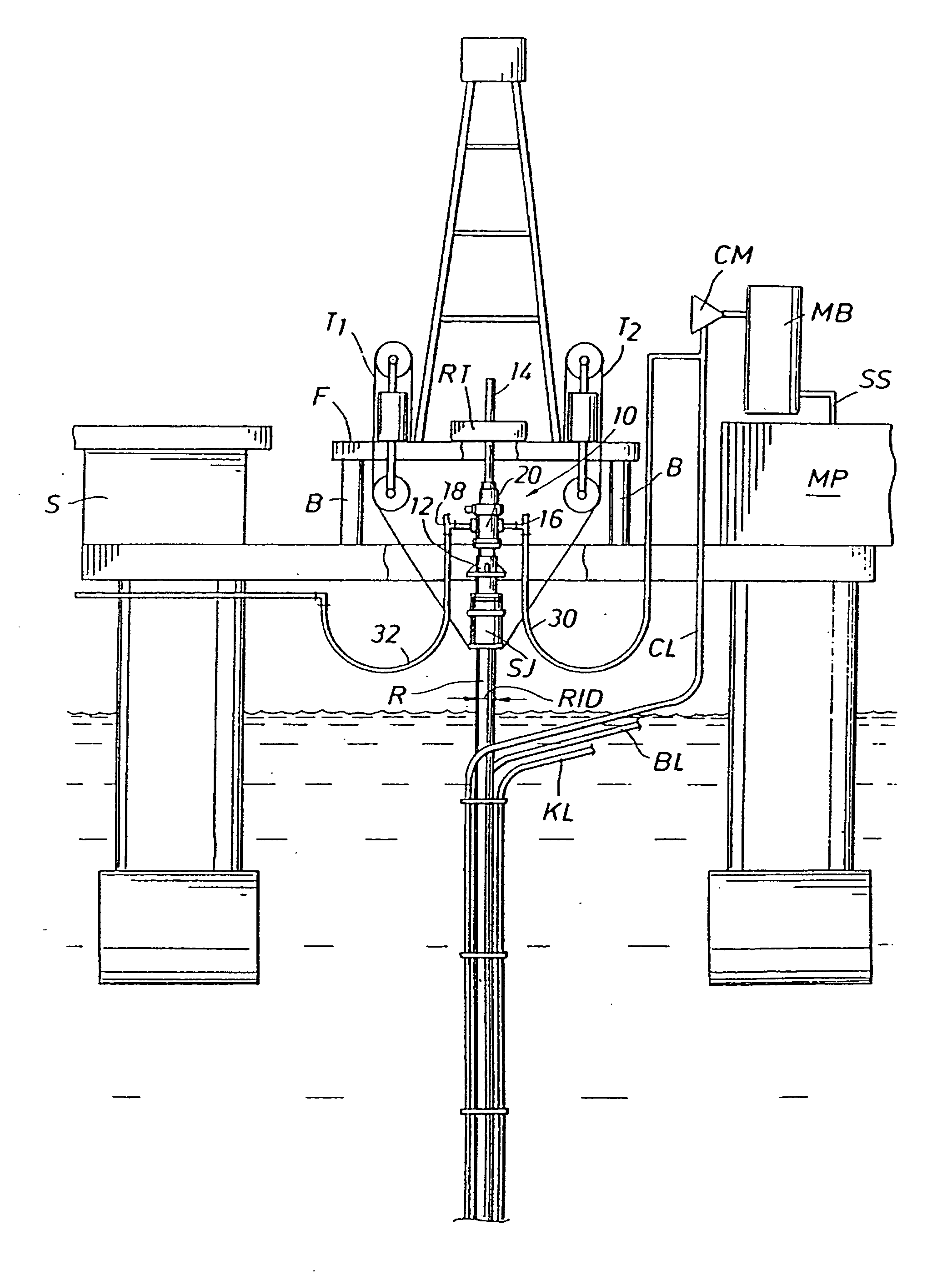

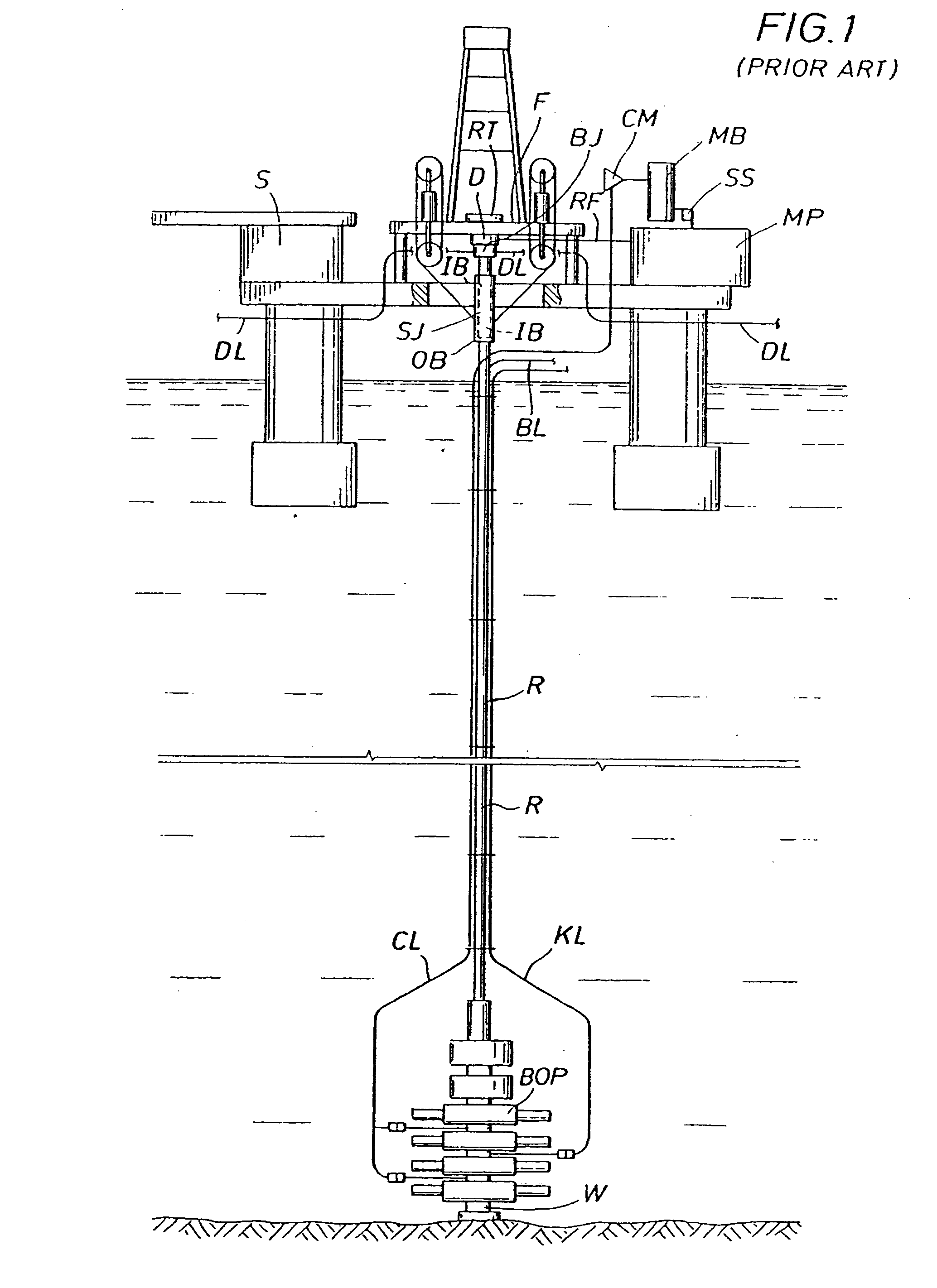

Method and system for return of drilling fluid from a sealed marine riser to a floating drilling rig while drilling

A floating rig or structure for drilling in the floor of an ocean using a rotatable tubular includes a seal housing having a rotatable seal connected above a marine riser fixed to the floor of the ocean. The seal rotating with the rotating tubular allows the riser and seal housing to maintain a predetermined pressure in the system that is desirable in underbalanced drilling, gas-liquid mud systems and pressurized mud handling systems. A flexible conduit or hose is used to compensate for the relative movement of the seal housing and the floating structure since the floating structure moves independent of the seal housing. A method for use of the system is also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

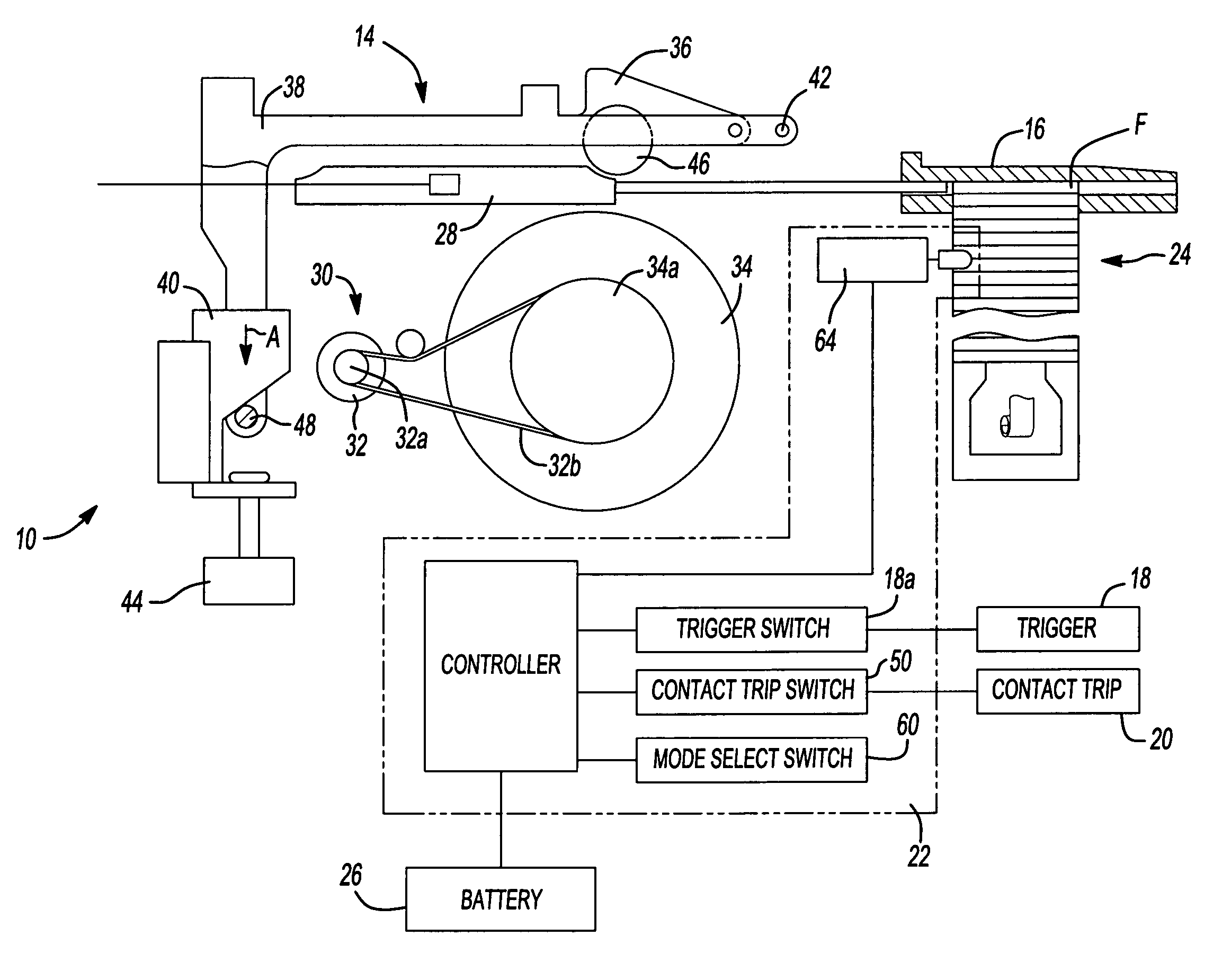

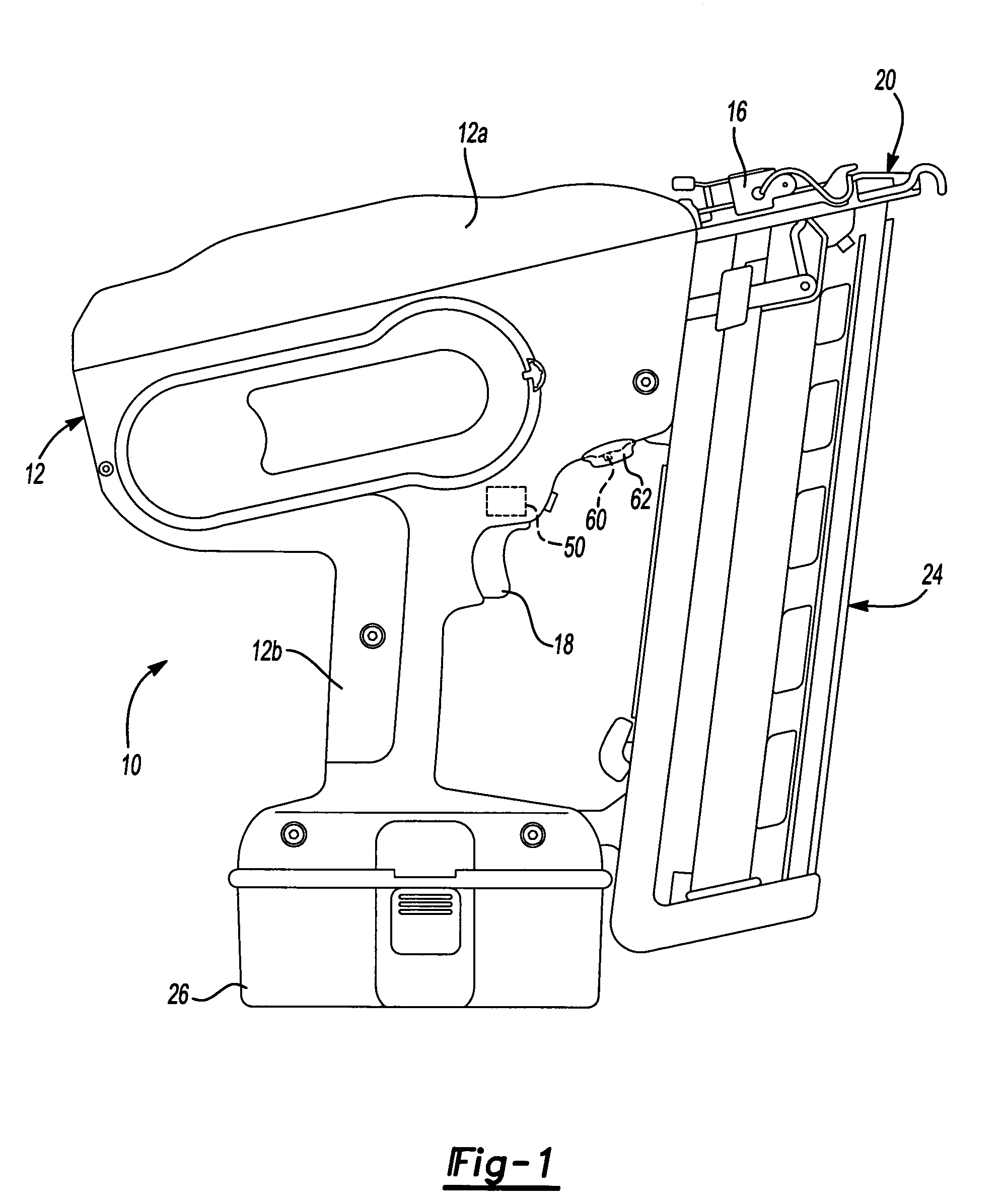

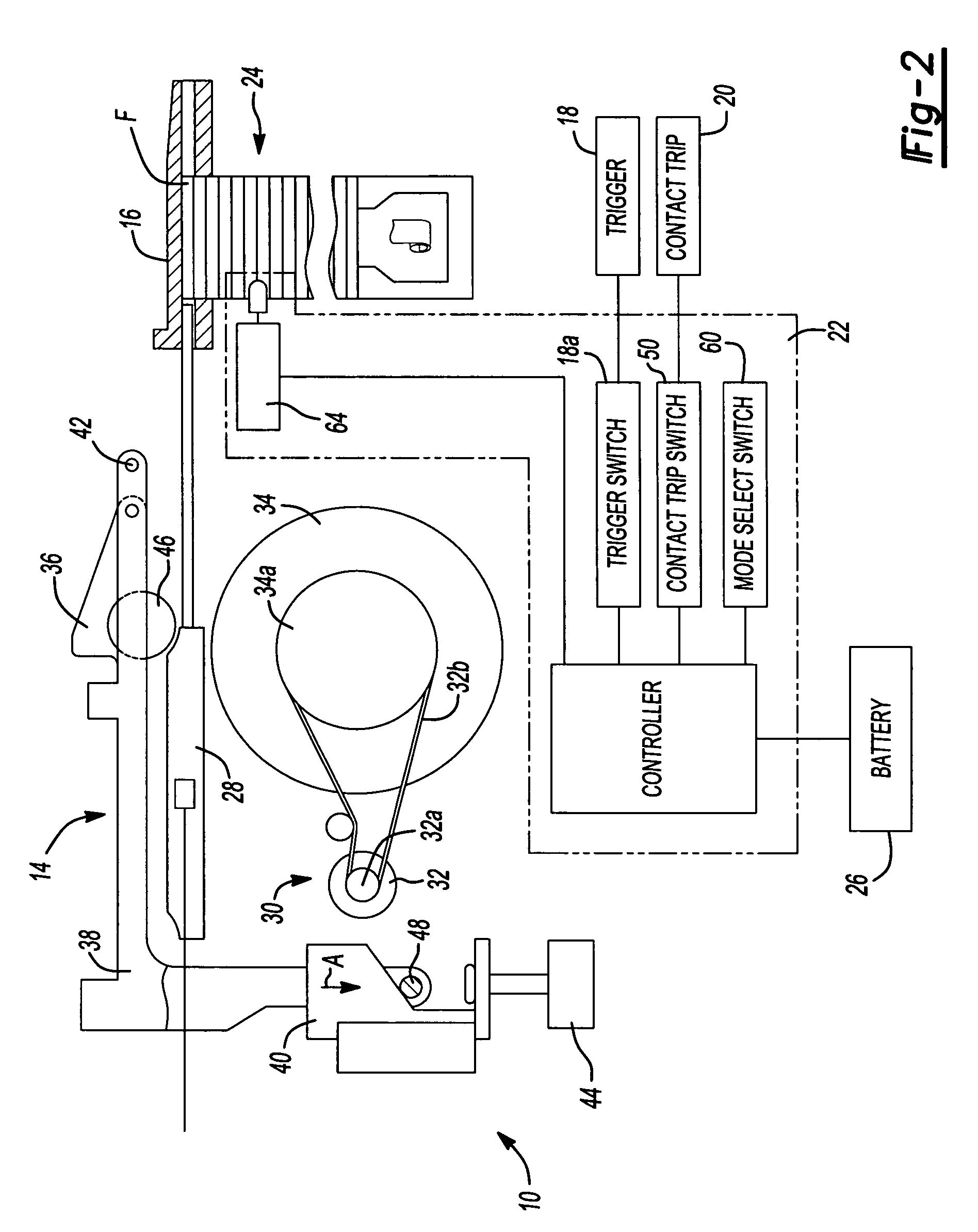

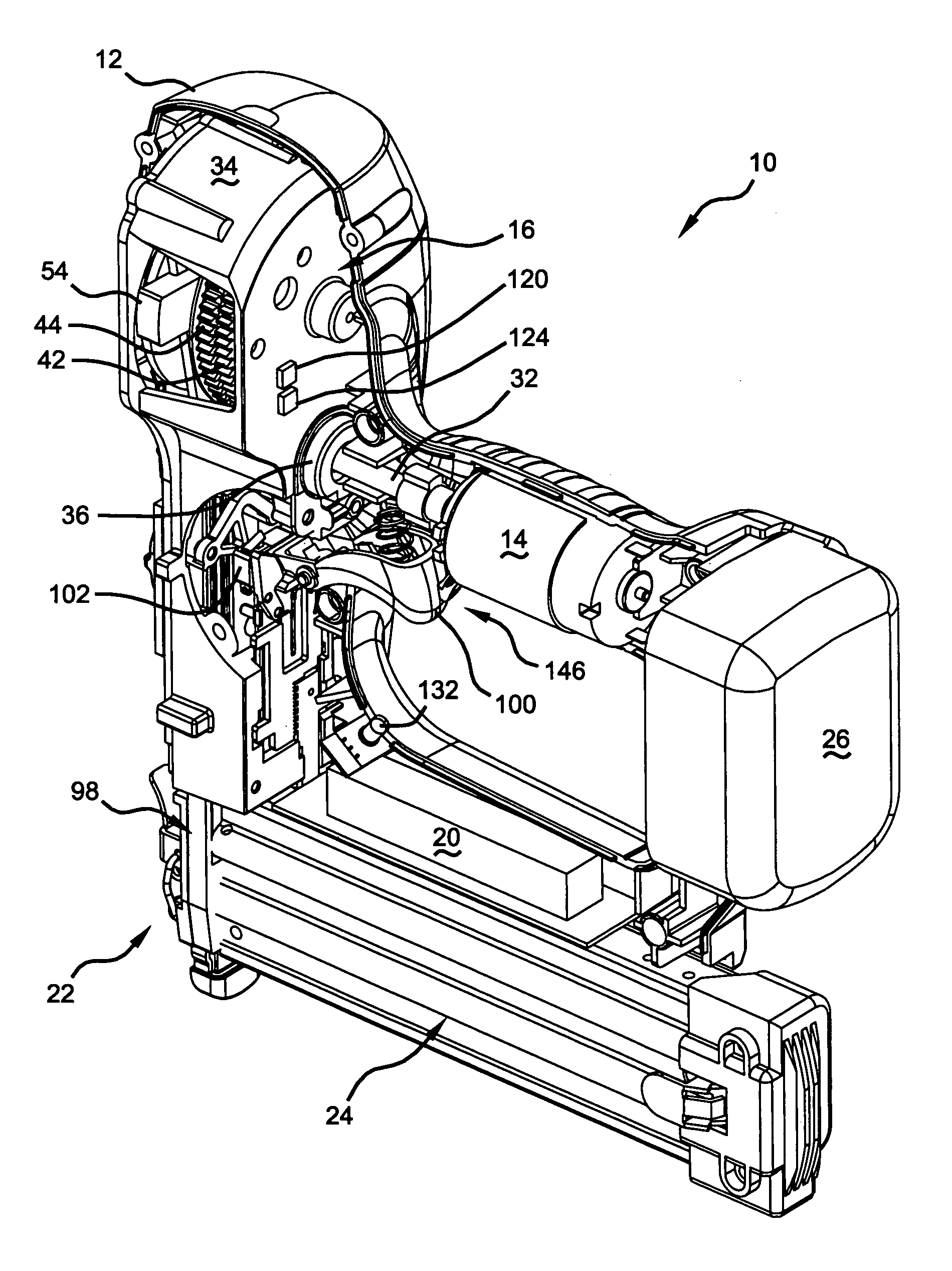

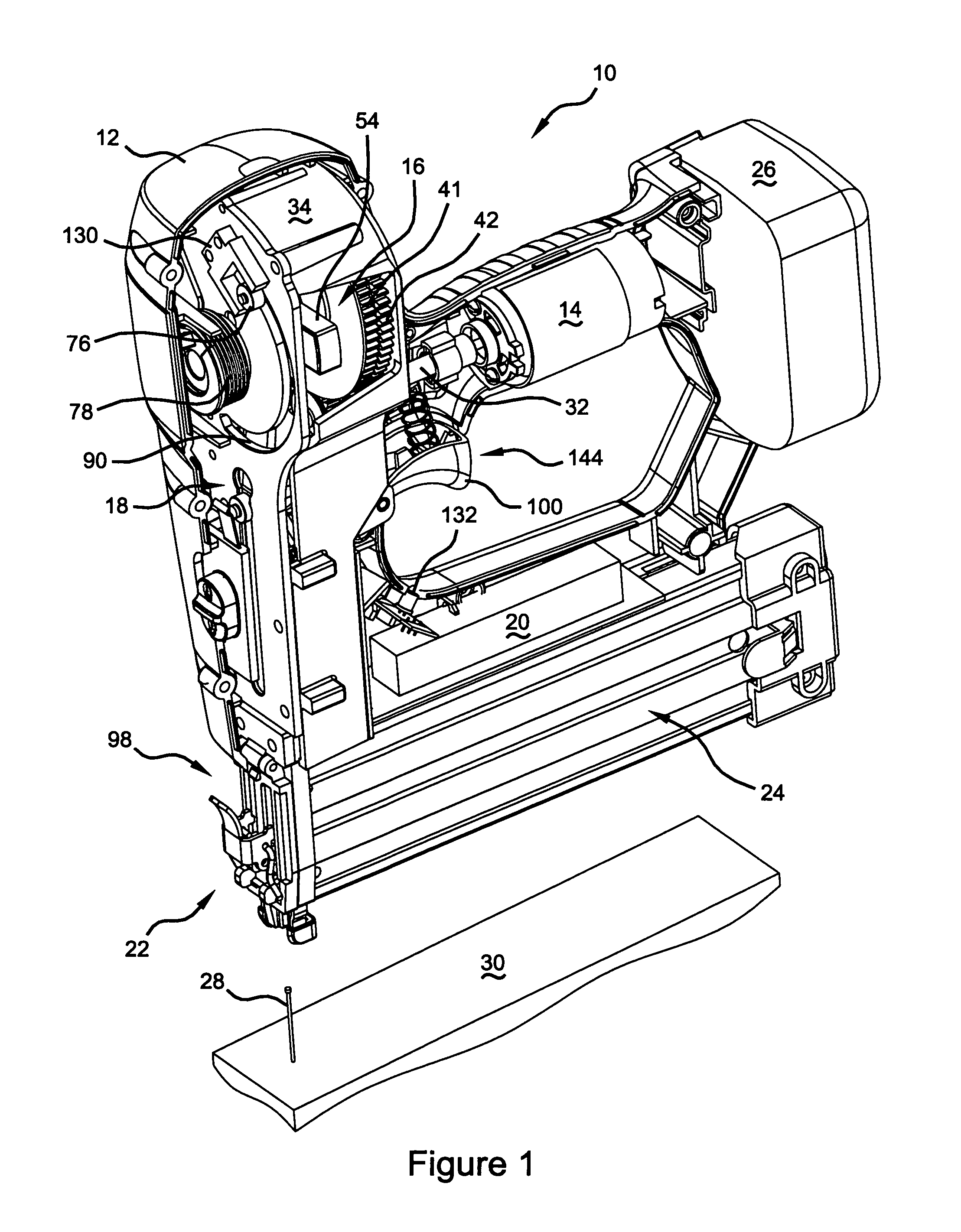

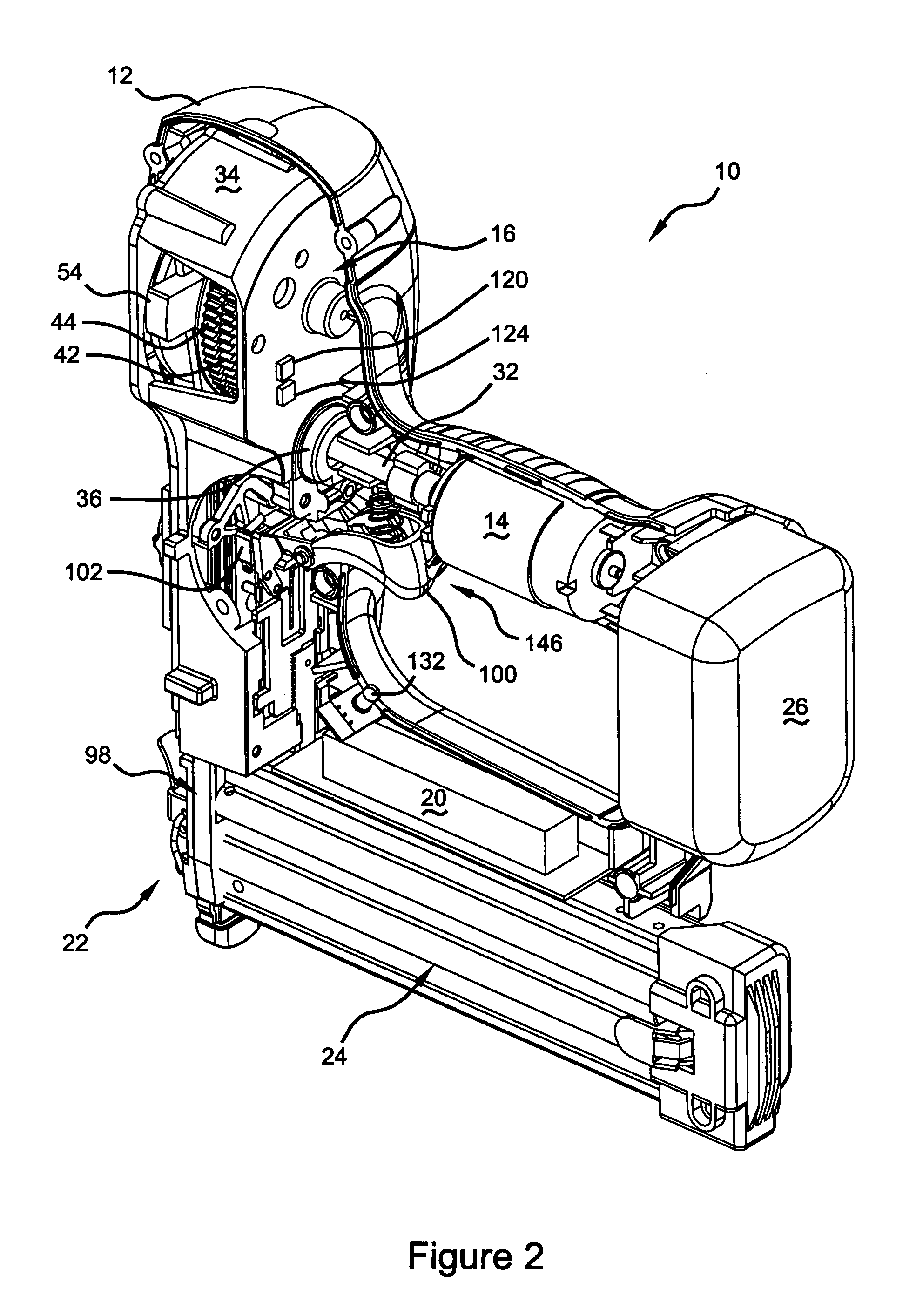

Electronic control of a cordless fastening tool

A fastening tool that drives a fastener into a work-piece. The tool includes a motor that is connected to a transmission. The transmission includes a flywheel. The tool also includes a driver mechanism that is adapted to drive the fastener into the work-piece. The flywheel is connected to the driver mechanism when the flywheel is in a flywheel firing position. The tool includes a control module that detects a flywheel position and compares the flywheel position to the flywheel firing position. The control module also adjusts the flywheel position based on the comparison. The control module ensures that the transmission has enough rotations to ensure that enough momentum can be generated to drive the fastener into the work-piece.

Owner:BLACK & DECKER INC

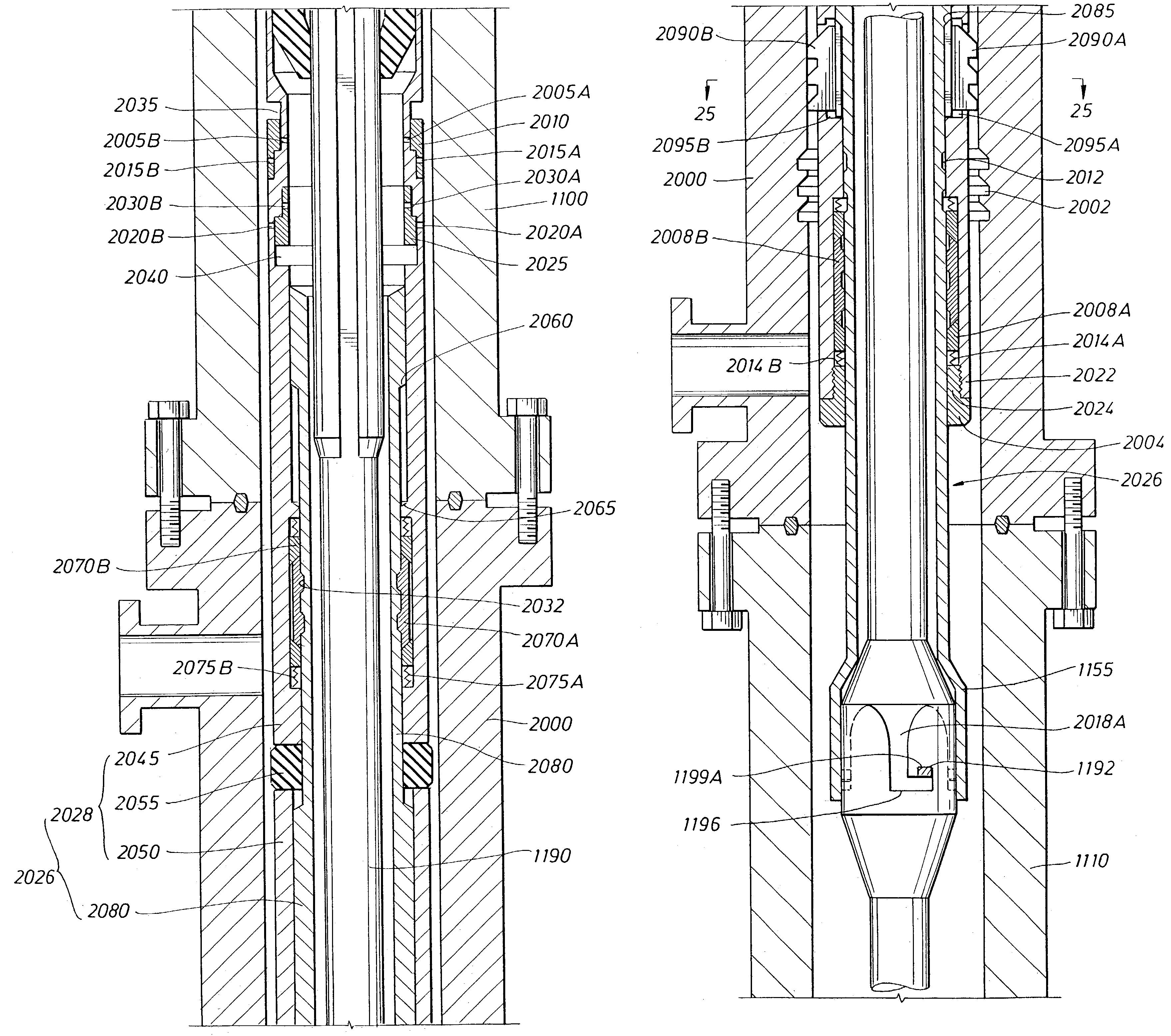

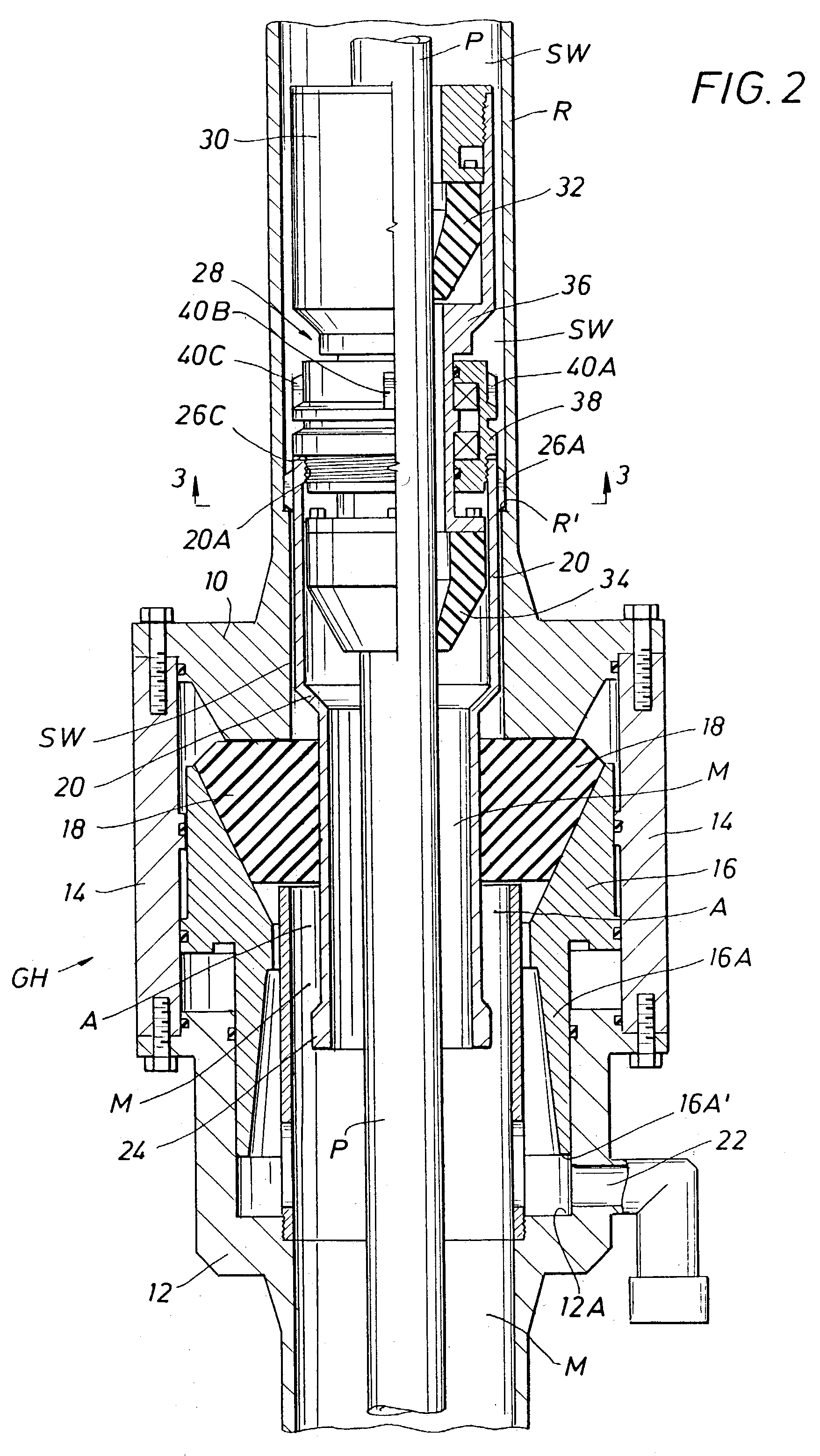

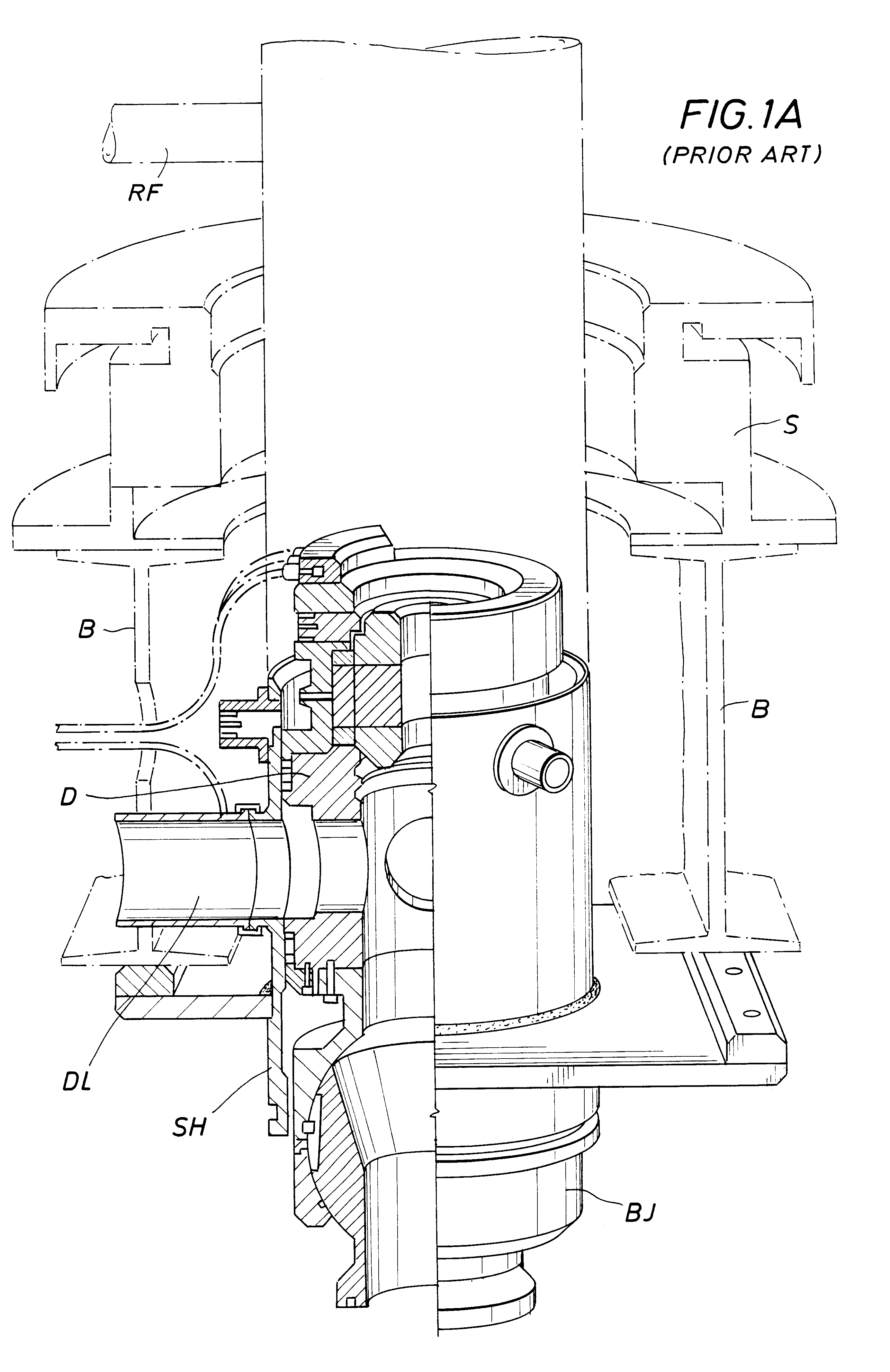

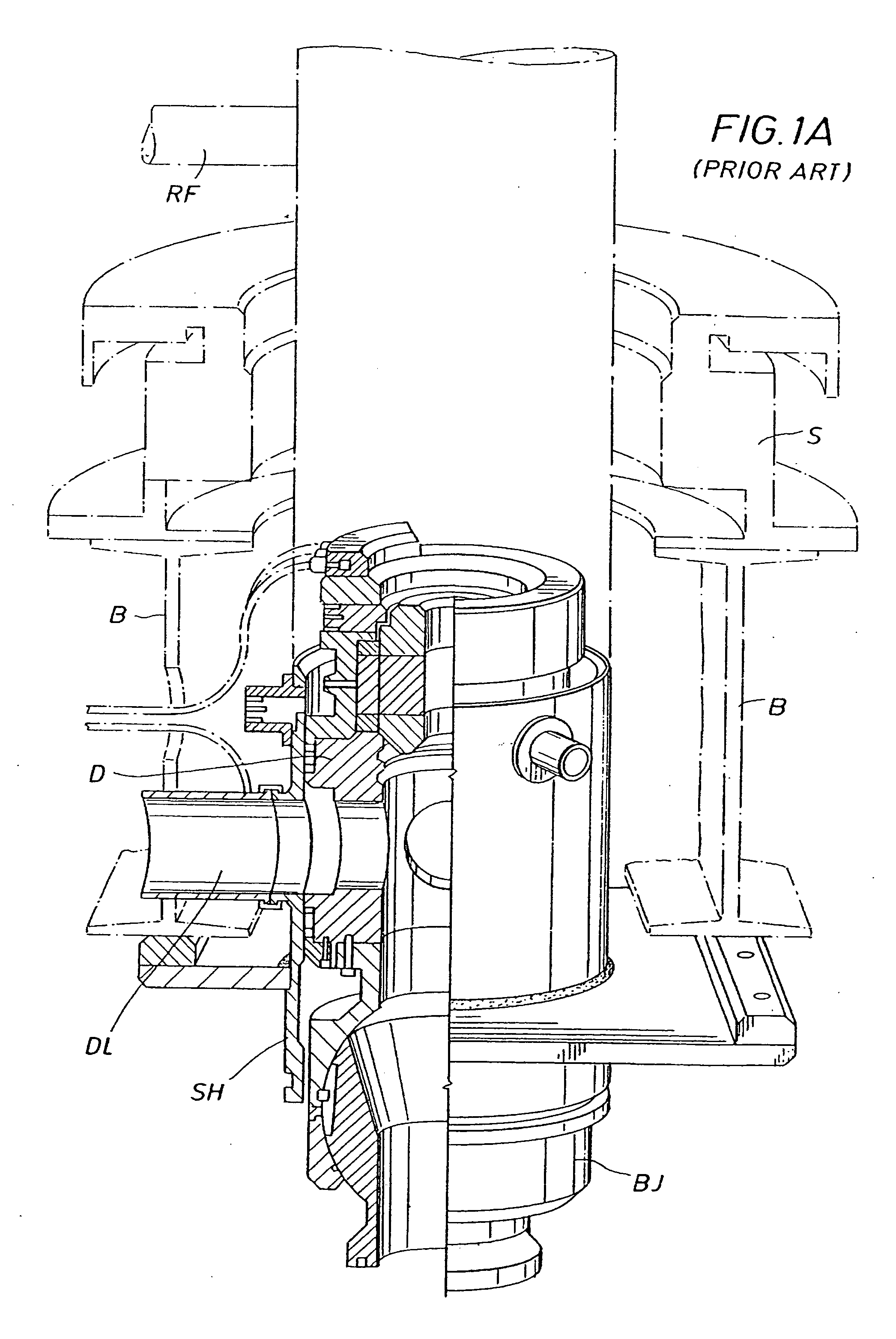

Internal riser rotating control head

A holding member provides for releasably positioning a rotating control head assembly in a subsea housing. The holding member engages an internal formation in the subsea housing to resist movement of the rotating control head assembly relative to the subsea housing. The rotating control head assembly is sealed with the subsea housing when the holding member engages the internal formation. An extendible portion of the holding member assembly extrudes an elastomer between an upper portion and a lower portion of the internal housing to seal the rotating control head assembly with the subsea housing. Pressure relief mechanisms release excess pressure in the subsea housing and a pressure compensation mechanism pressurize bearings in the bearing assembly at a predetermined pressure.

Owner:WEATHERFORD TECH HLDG LLC

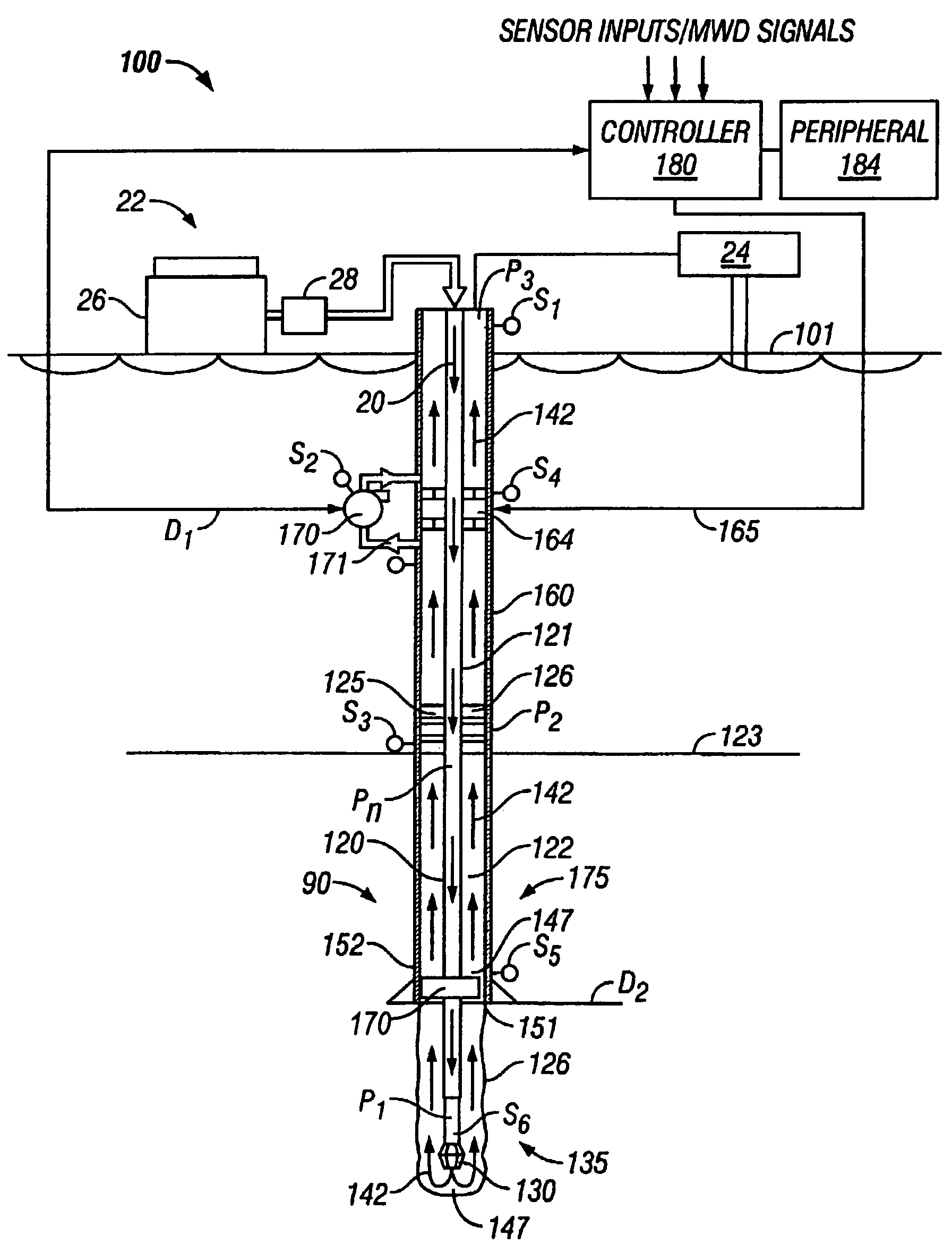

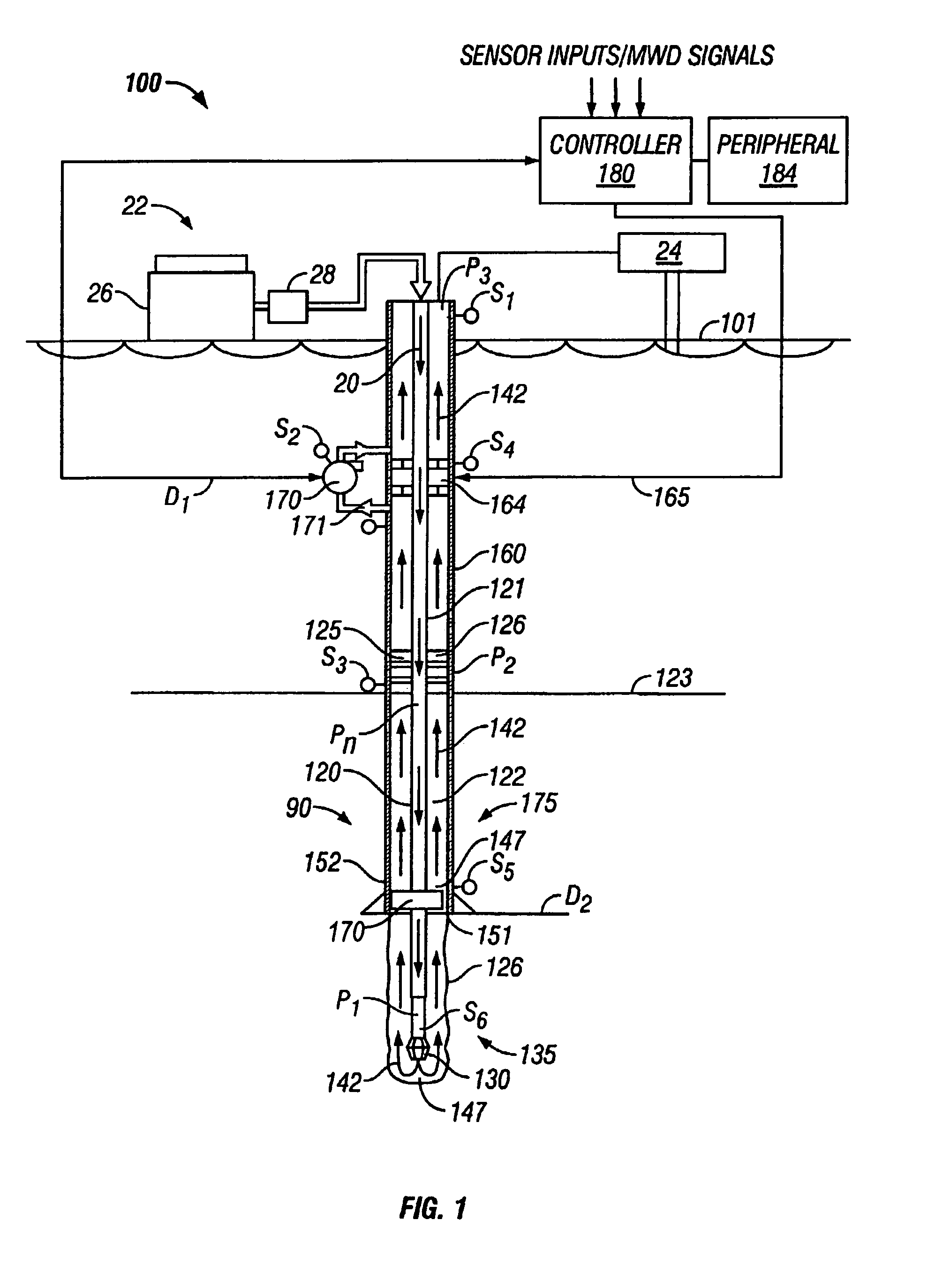

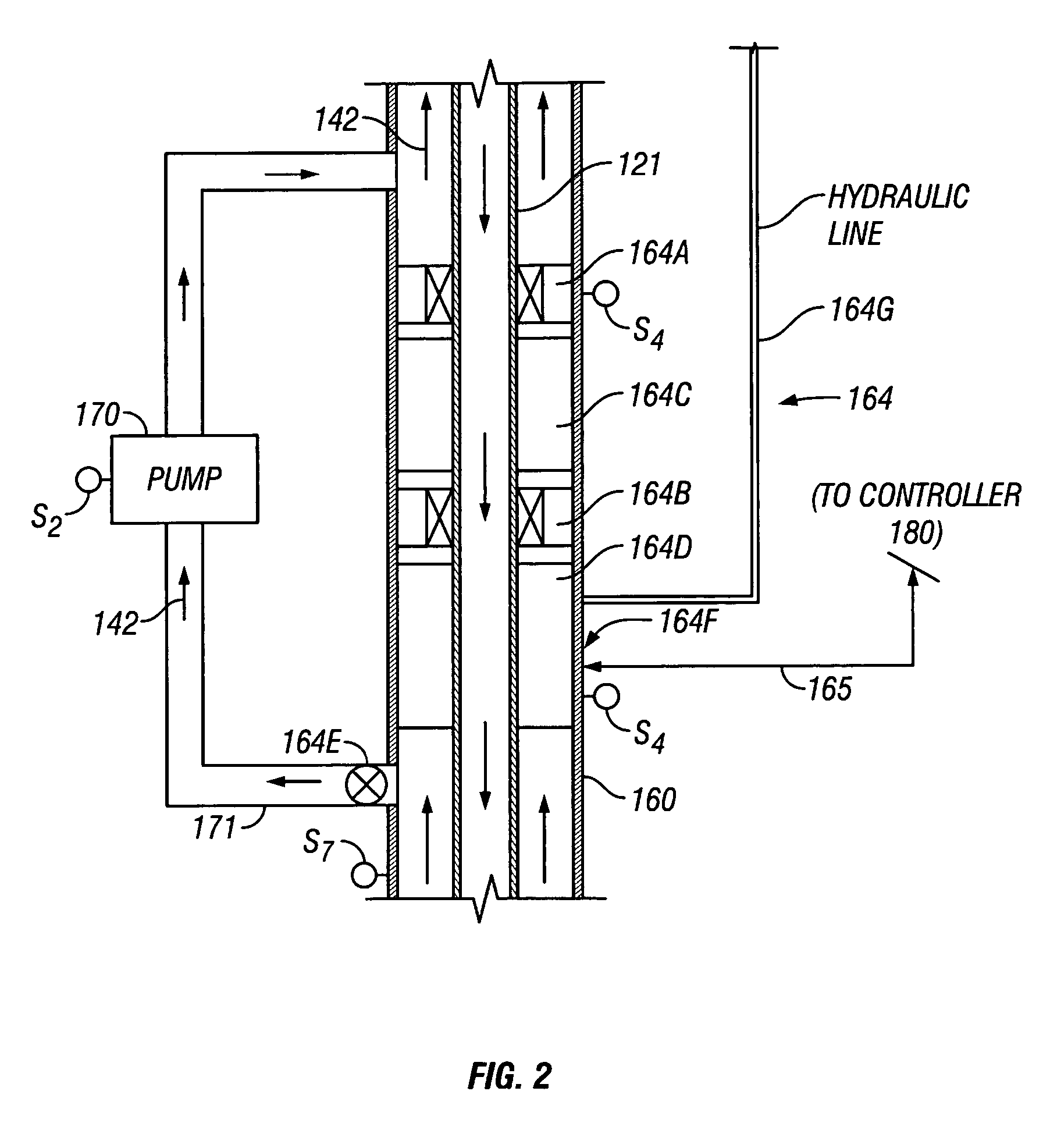

Drilling system and method for controlling equivalent circulating density during drilling of wellbores

A drilling system for drilling subsea wellbores includes a tubing-conveyed drill bit that passes through a subsea wellhead. Surface supplied drilling fluid flows through the tubing, discharges at the drill bit, returns to the wellhead through a wellbore annulus, and flows to the surface via a riser extending from the wellhead. A flow restriction device positioned in the riser restricts the flow of the returning fluid while an active fluid device controllably discharges fluid from a location below to just above the flow restriction device in the riser, thereby controlling bottomhole pressure and equivalent circulating density (“ECD”). Alternatively, the fluid is discharged into a separate return line thereby providing dual gradient drilling while controlling bottomhole pressure and ECD. A controller controls the energy and thus the speed of the pump in response to downhole measurement(s) to maintain the ECD at a predetermined value or within a predetermined range.

Owner:BAKER HUGHES INC

Well system

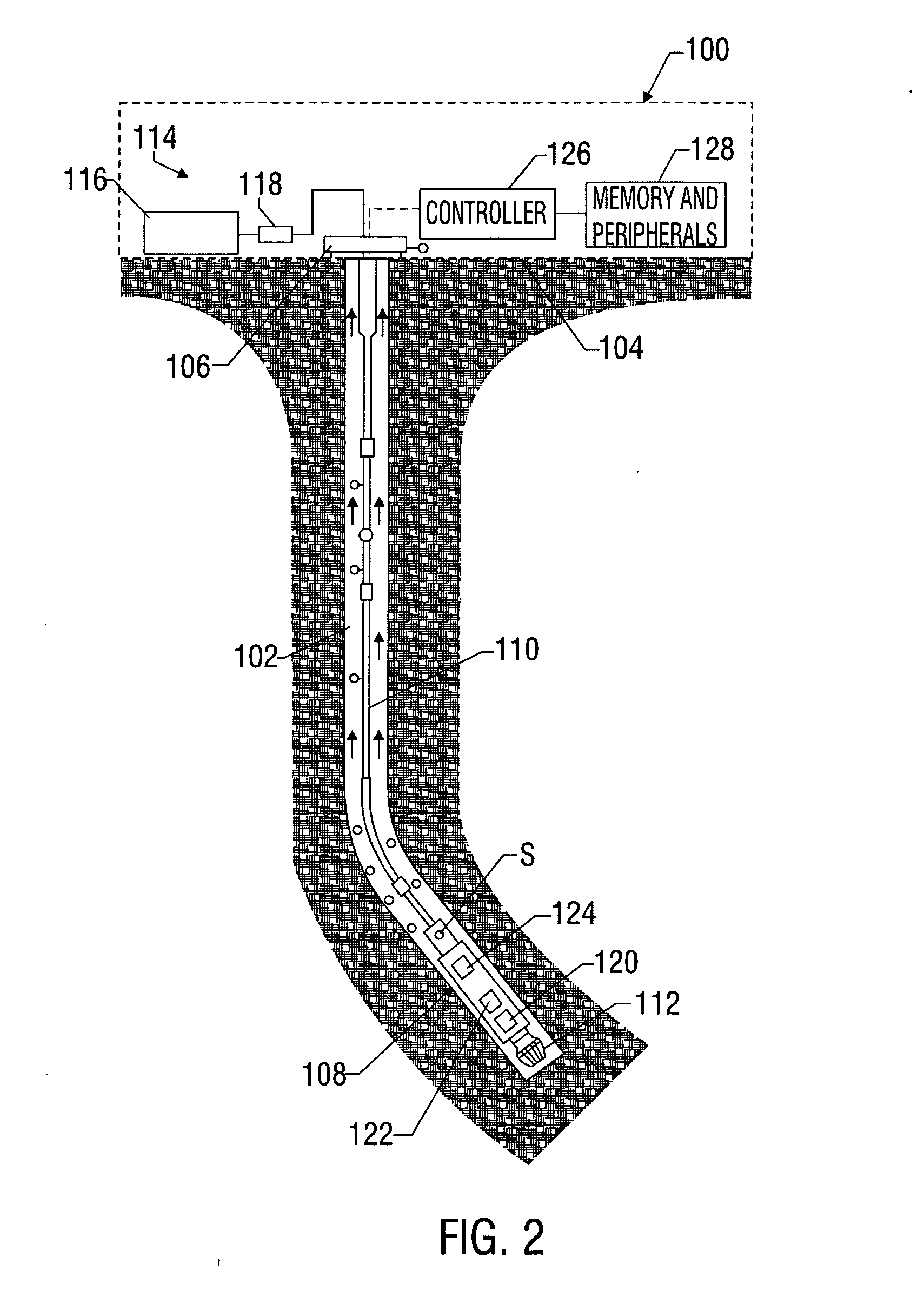

InactiveUS6923273B2Excessive vibrationLess expensiveElectric/magnetic detection for well-loggingDrilling rodsElectrical conductorEngineering

The drilling system includes a work string supporting a bottom hole assembly. The work string including lengths of pipe having a non-metallic portion. The work string preferably includes a composite coiled tubing having a fluid impermeable liner, multiple load carrying layers, and a wear layer. Multiple electrical conductors and data transmission conductors may be embedded in the load carrying layers for carrying current or transmitting data between the bottom hole assembly and the surface. The bottom hole assembly includes a bit, a gamma ray and inclinometer instrument package, a steerable assembly, an electronics section, a transmission, and a power section for rotating the bit. It may or may not include a propulsion system. The drilling system may be a gravity based drilling system that does include a propulsion system. Various motive means may be provided such as gravity, to apply weight on the bit.

Owner:HALLIBURTON ENERGY SERVICES INC

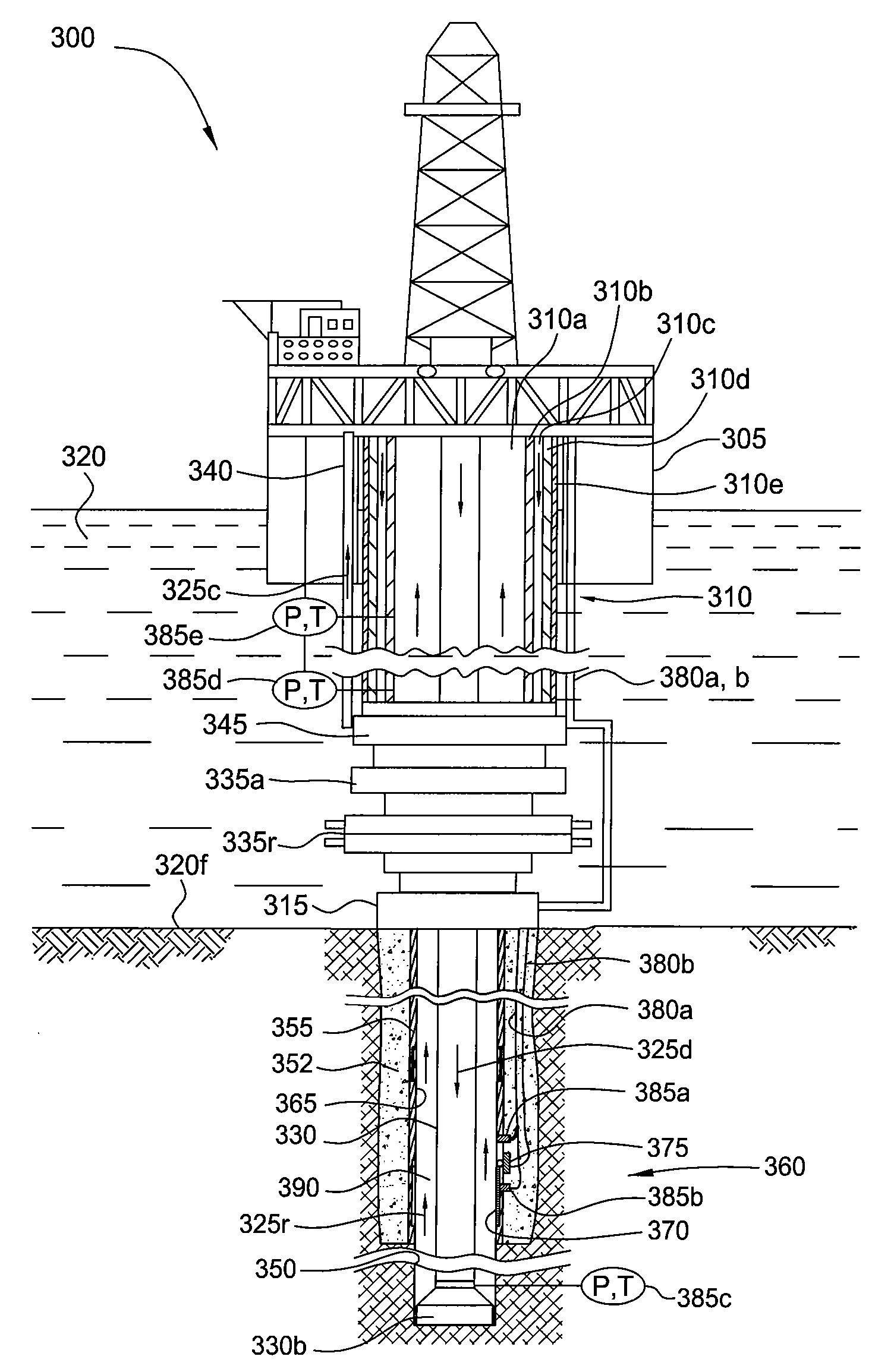

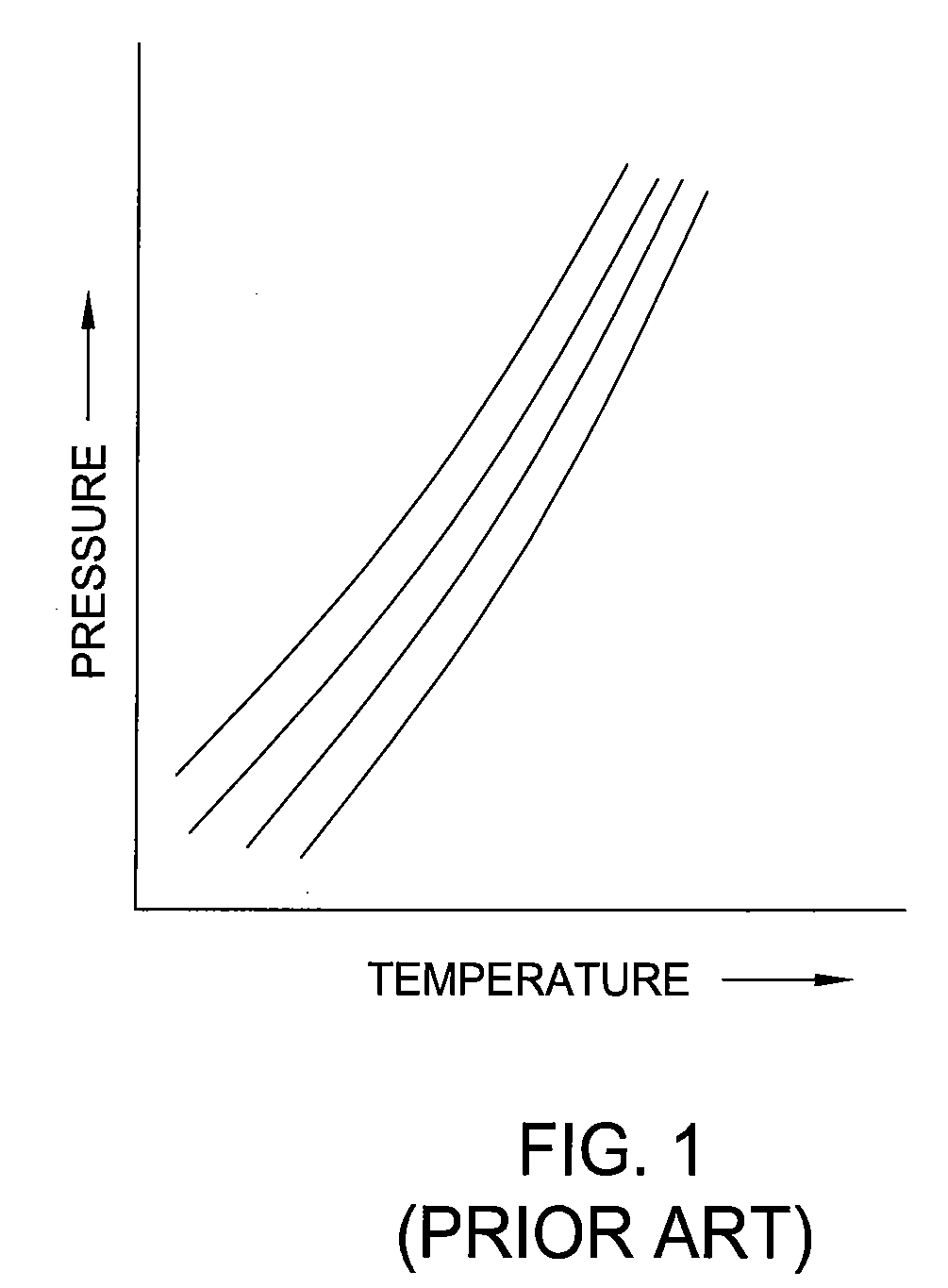

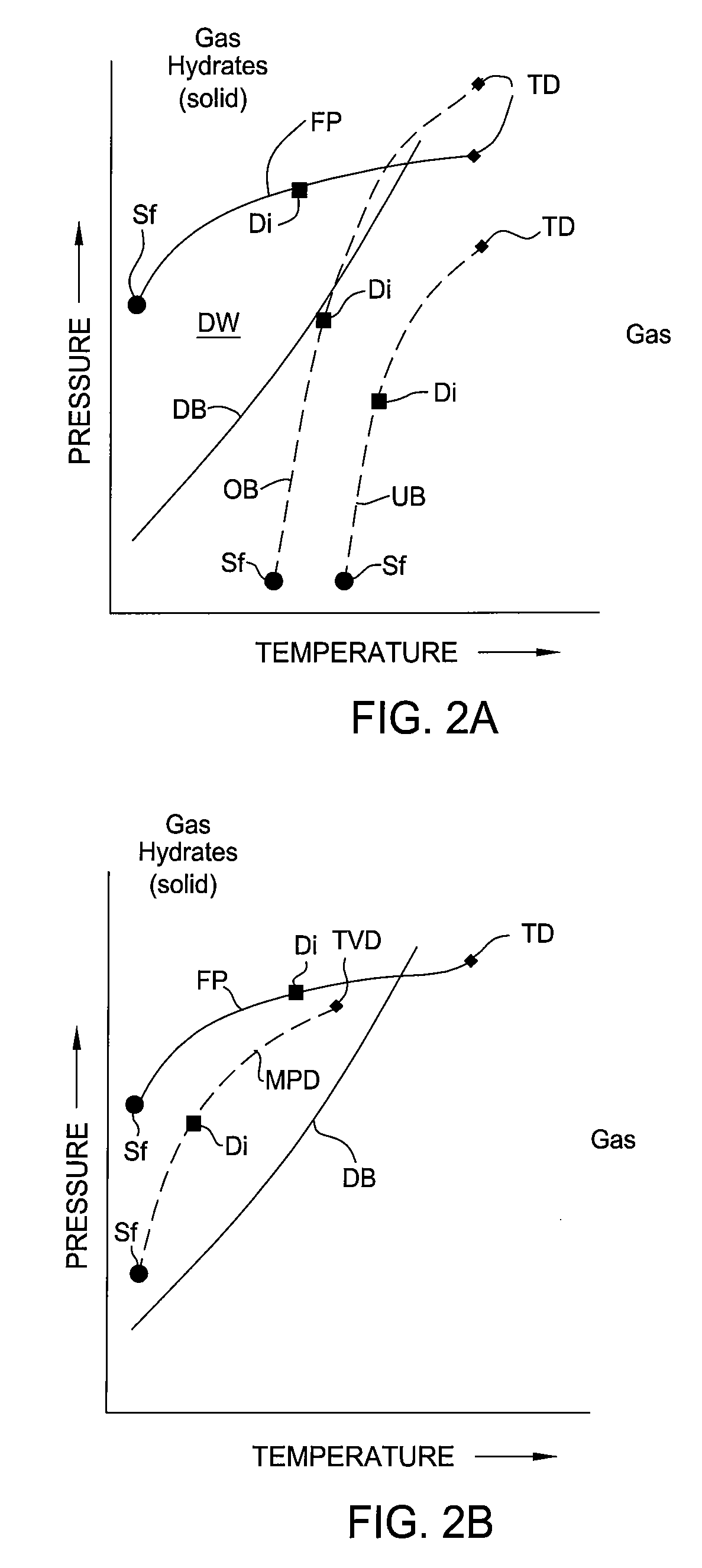

Managed pressure and/or temperature drilling system and method

The present invention relates to a managed pressure and / or temperature drilling system (300) and method. In one embodiment, a method for drilling a wellbore into a gas hydrates formation is disclosed. The method includes drilling the wellbore into the gas hydrates formation; returning gas hydrates cuttings to a surface of the wellbore and / or a drilling rig while controlling a temperature and / or a pressure of the cuttings to prevent or control disassociation of the hydrates cuttings.

Owner:WEATHERFORD TECH HLDG LLC

Zeolite-containing drilling fluids

Methods and compositions for wellbore treating fluids, especially drilling fluids, that comprise zeolite and a carrier fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Hand-held working tool

Owner:HILTI AG

Multi-activity offshore exploration and/or development drilling method and apparatus

Owner:TRANSOCEAN OFFSHORE DEEPWATER DRILLING

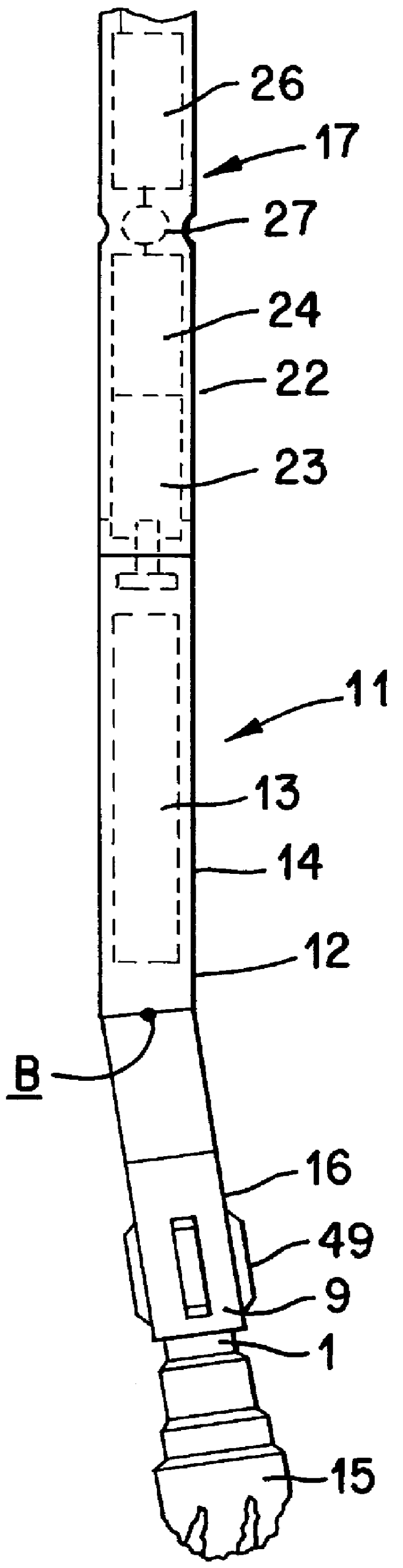

Steerable bit assembly and methods

ActiveUS20050056463A1Efficient and cost-effectiveFaster and less mechanically complexDrill bitsDrilling rodsShape changeExternal reference

A drilling system includes a steerable bottomhole assembly (BHA) having a steering unit and a control unit that provide dynamic control of drill bit orientation or tilt. Exemplary steering units can adjust bit orientation at a rate that approaches or exceeds the rotational speed of the drill string or drill bit, can include a dynamically adjustable articulated joint having a plurality of elements that deform in response to an excitation signal, can include adjustable independently rotatable rings for selectively tilting the bit, and / or can include a plurality of selectively extensible force pads. The force pads are actuated by a shape change material that deforms in response to an excitation signal. A method of directional drilling includes continuously cycling the position of the steering unit based upon the rotational speed of the drill string and / or drill bit and with reference to an external reference point.

Owner:BAKER HUGHES INC

Method and system for return of drilling fluid from a sealed marine riser to a floating drilling rig while drilling

A floating rig or structure for drilling in the floor of an ocean using a rotatable tubular includes a seal housing having a rotatable seal connected above a portion of a marine riser fixed to the floor of the ocean. The seal rotating with the rotating tubular allows the riser and seal housing to maintain a predetermined pressure in the system that is desirable in underbalanced drilling, gas-liquid mud systems and pressurized mud handling systems. The seal is contemplated to be either an active seal or a passive seal. A flexible conduit or hose is used to compensate for relative movement of the seal housing and the floating structure because the floating structure moves independent of the seal housing. A method for use of the system is also disclosed.

Owner:WEATHERFORD TECH HLDG LLC

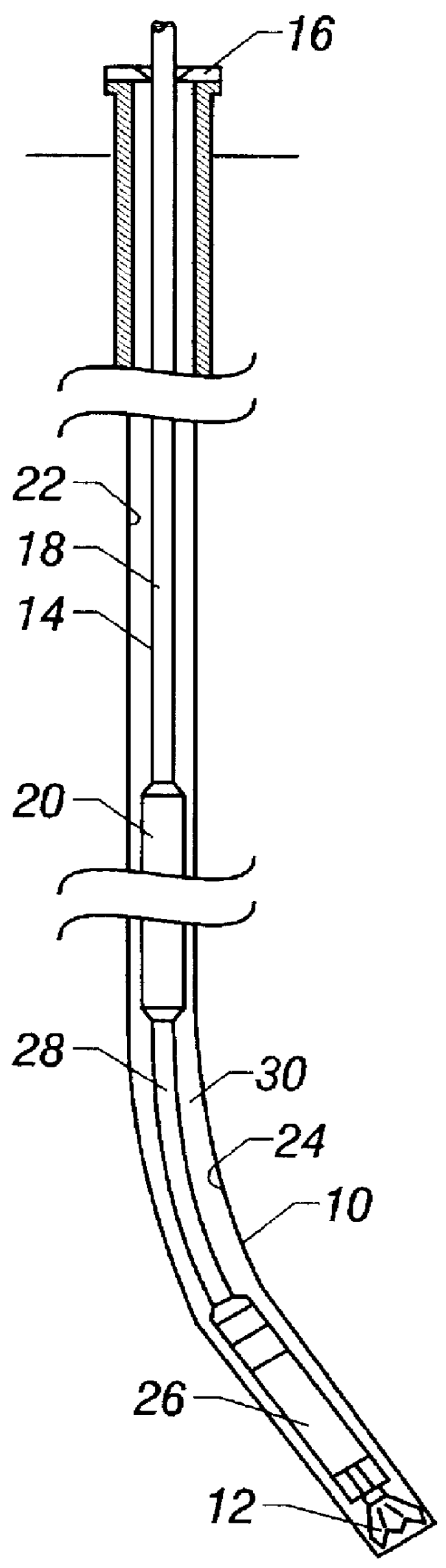

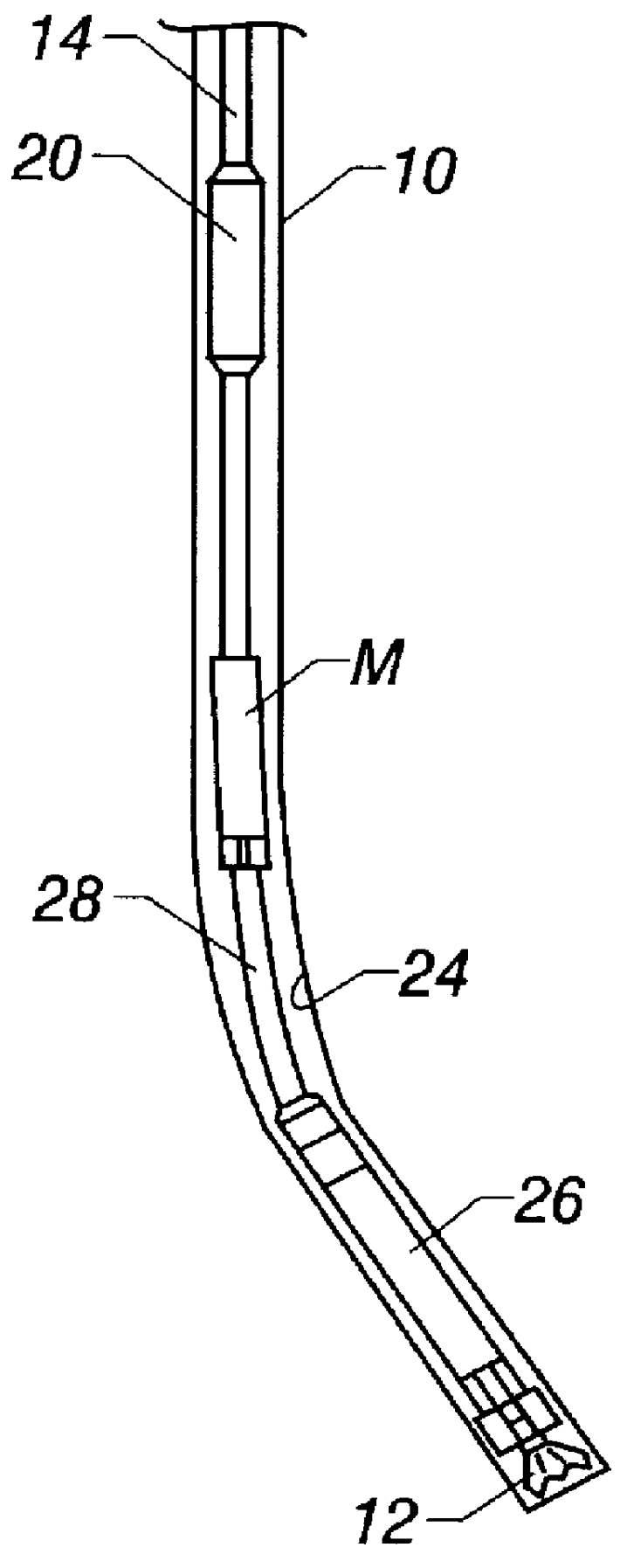

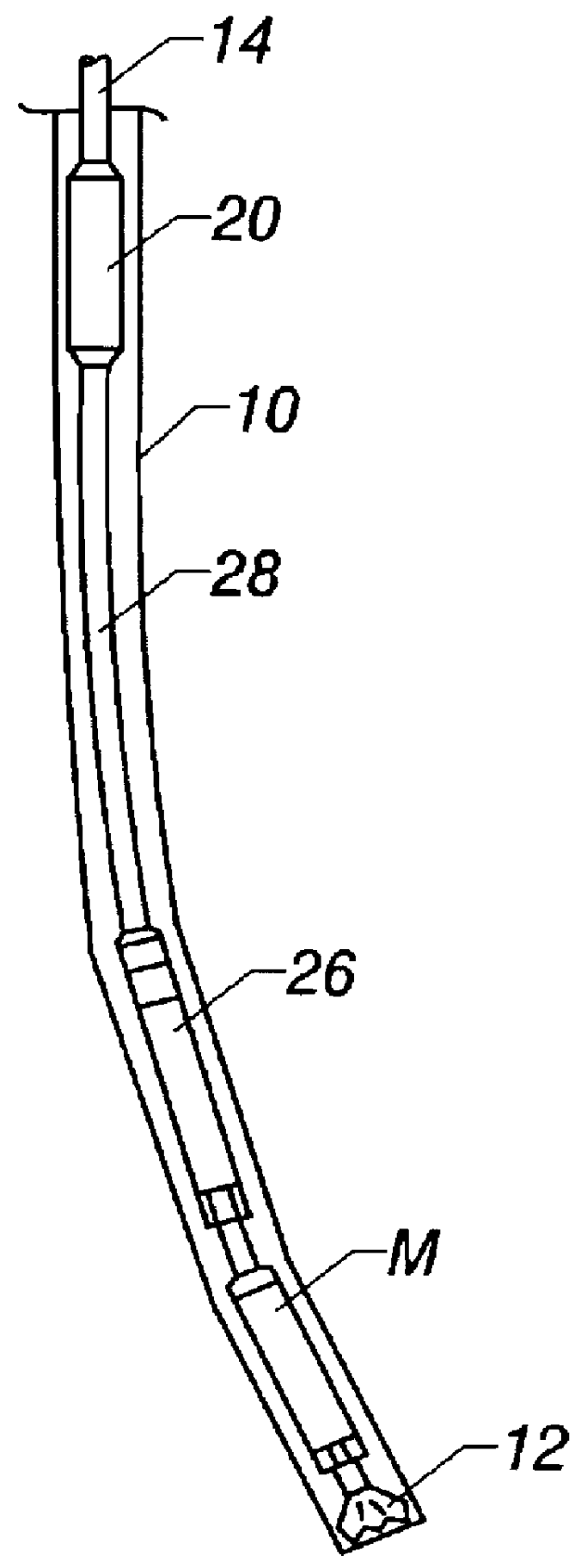

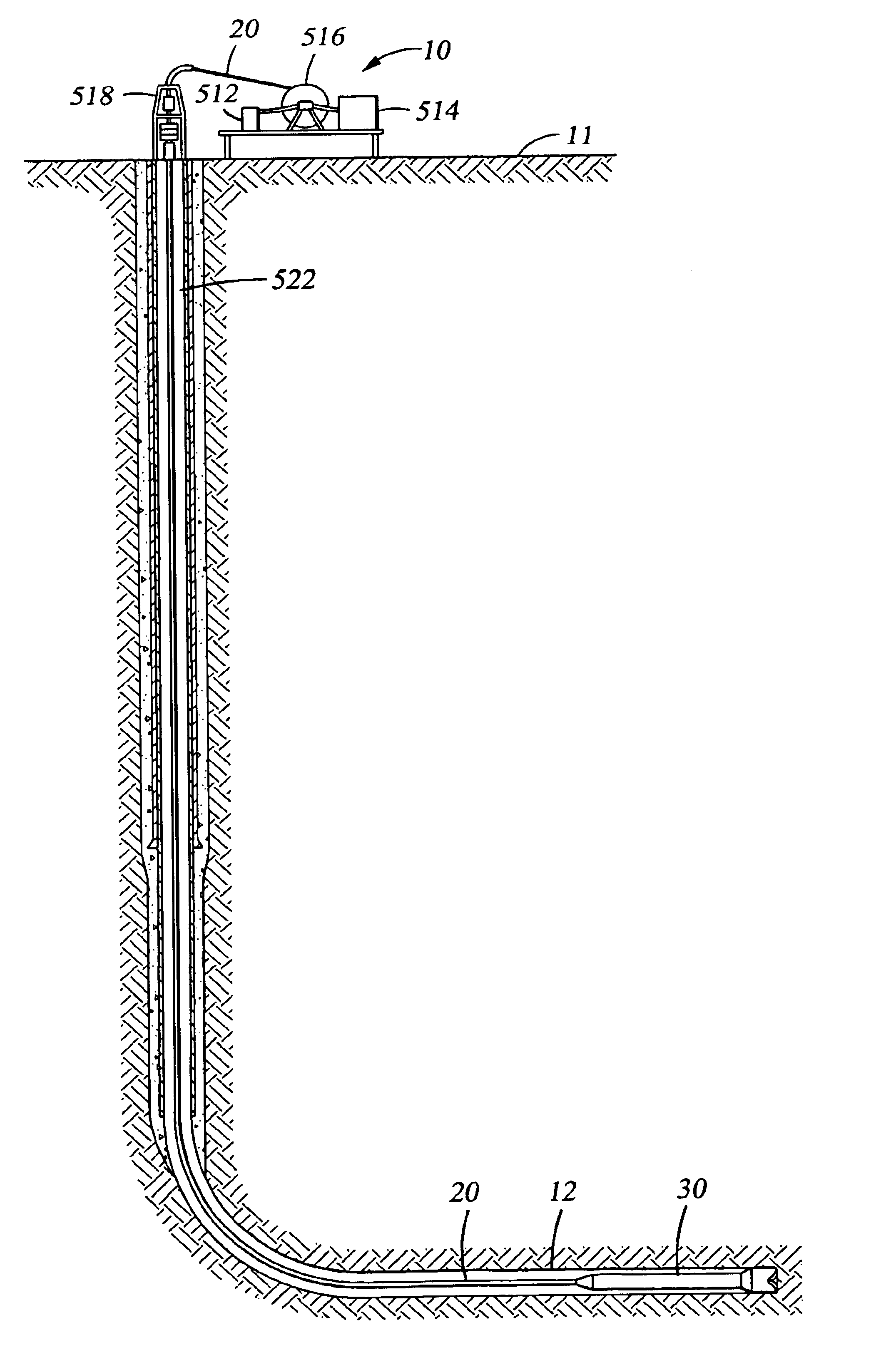

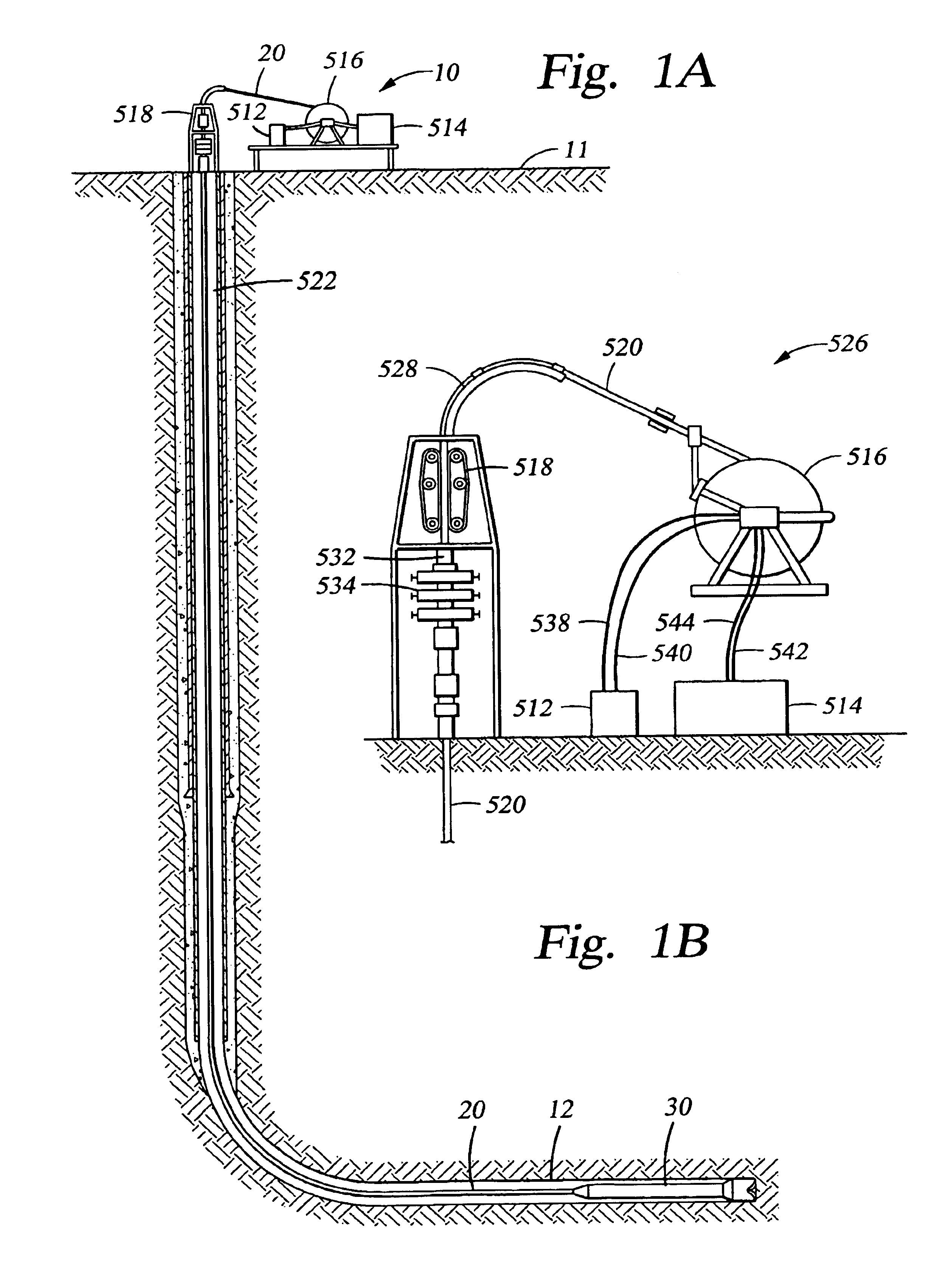

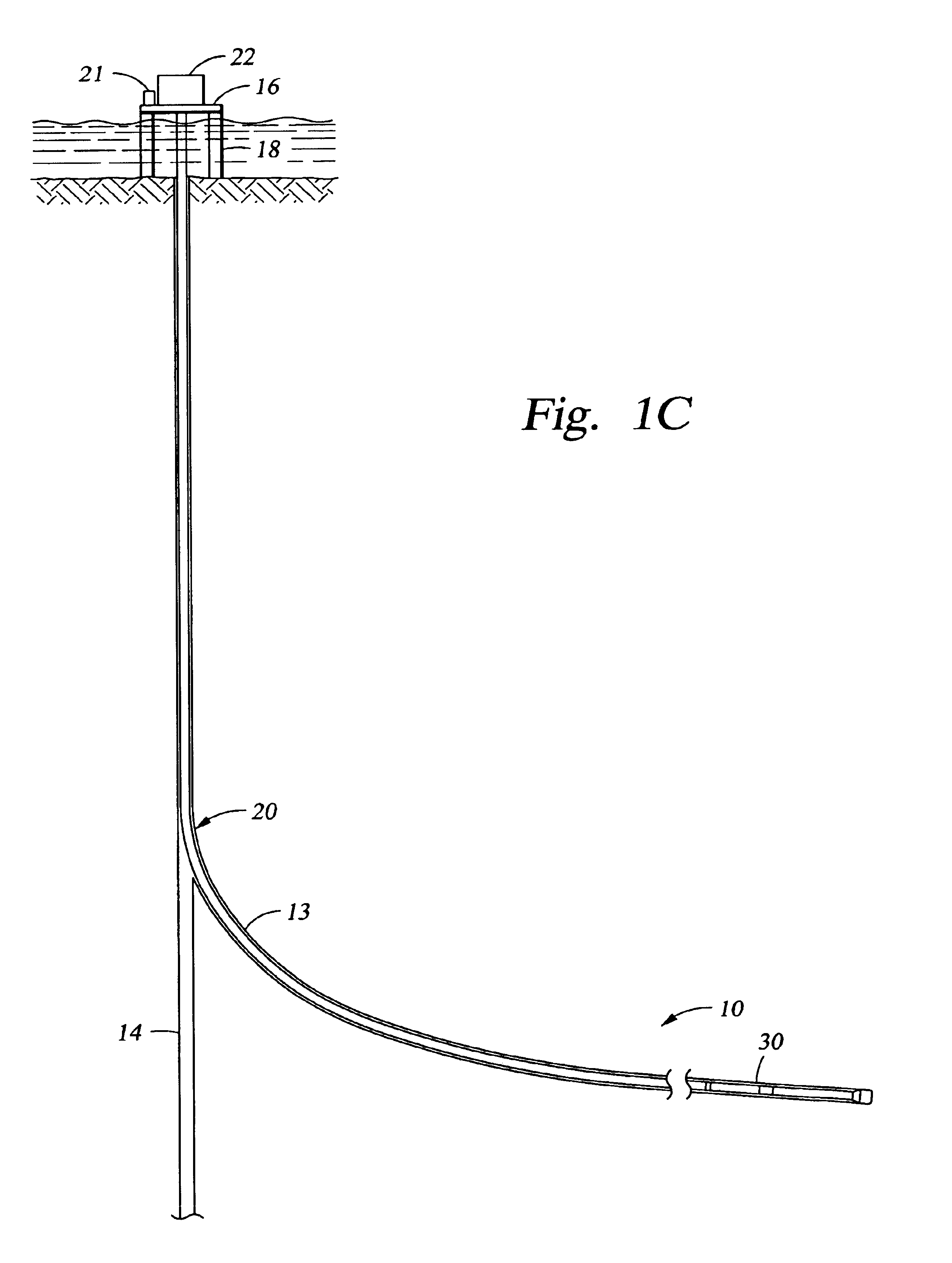

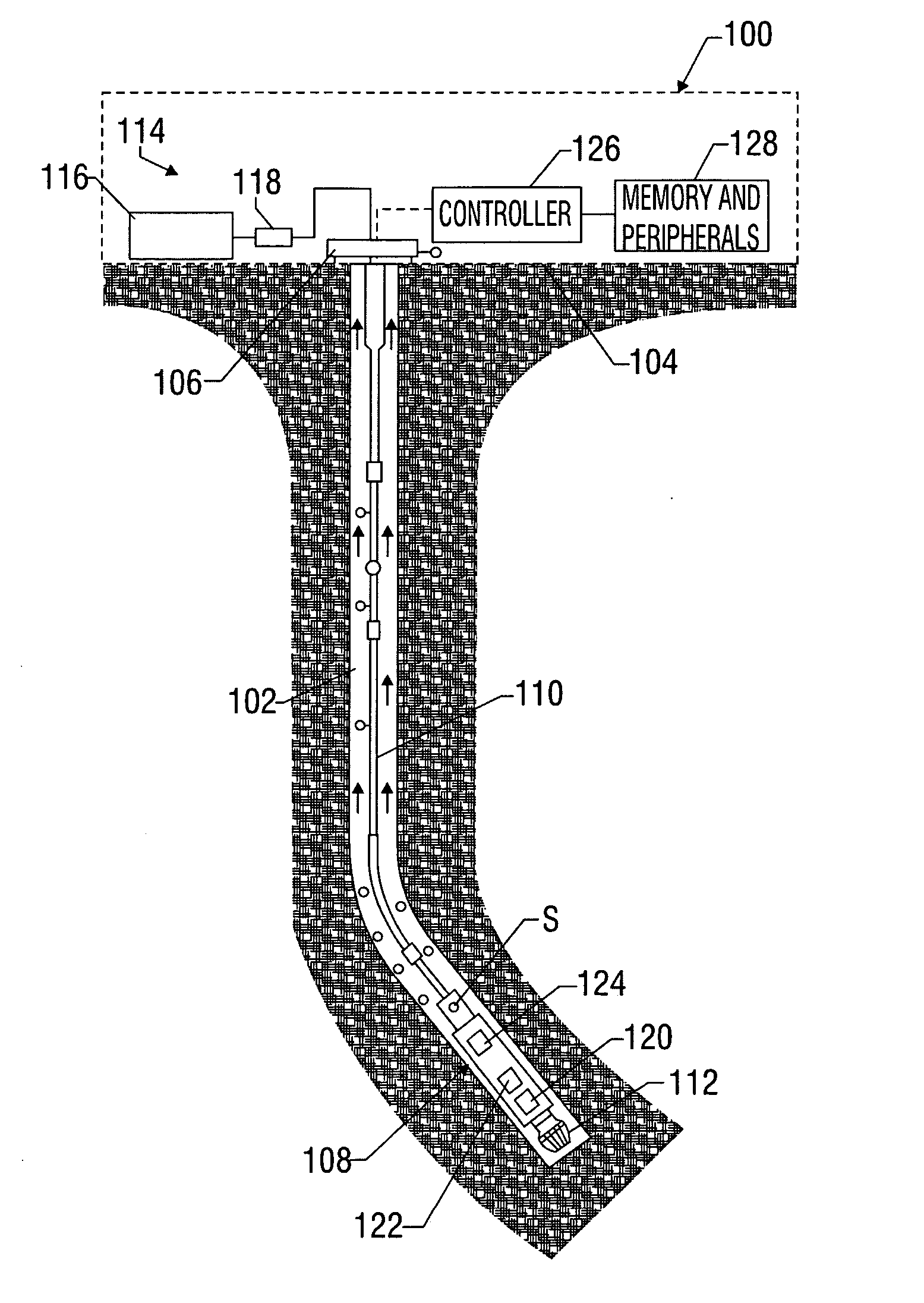

Apparatus and method for directional drilling using coiled tubing

A steerable directional drilling tool assembly includes a bent housing defining a bend angle and having a mud motor in its upper section and a drill bit below its lower section, an orienting tool rotatably coupled to such upper section and suspended on coiled tubing that extends upward to the surface, an electric motor in the orienting tool operable to rotate the bent housing in either hand direction to change or adjust the tool face angle of the bit, or continuously rotate the bent housing so that the bit drills straight-ahead, and an electric cable extending throughout the coiled tubing to furnish power from the surface to the electric motor and transmit electric signals to and from the surface. A logging tool can be included in the assembly for measuring characteristics of the formation, the borehole, and the tool assembly.

Owner:HEWLETT PACKARD CO +1

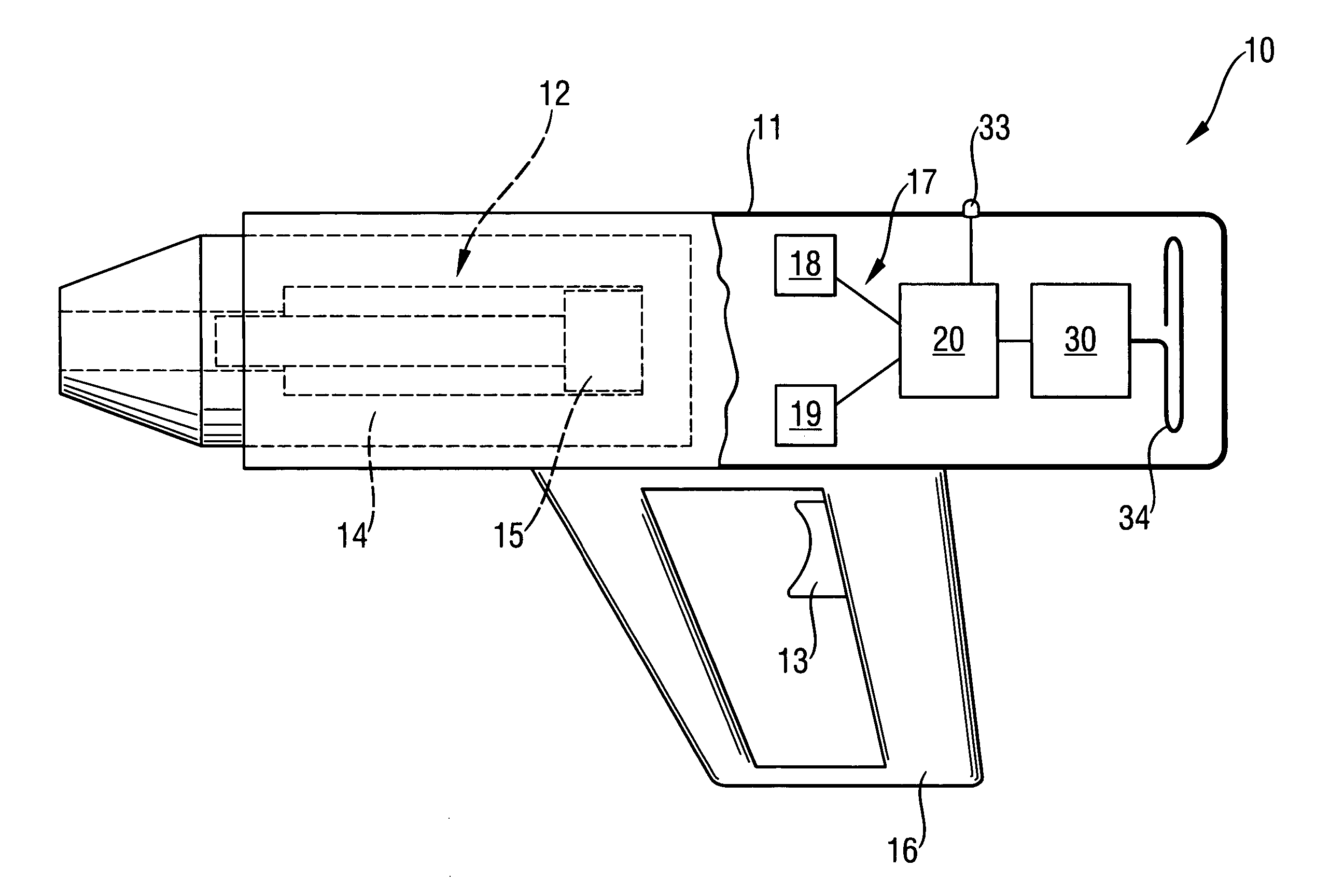

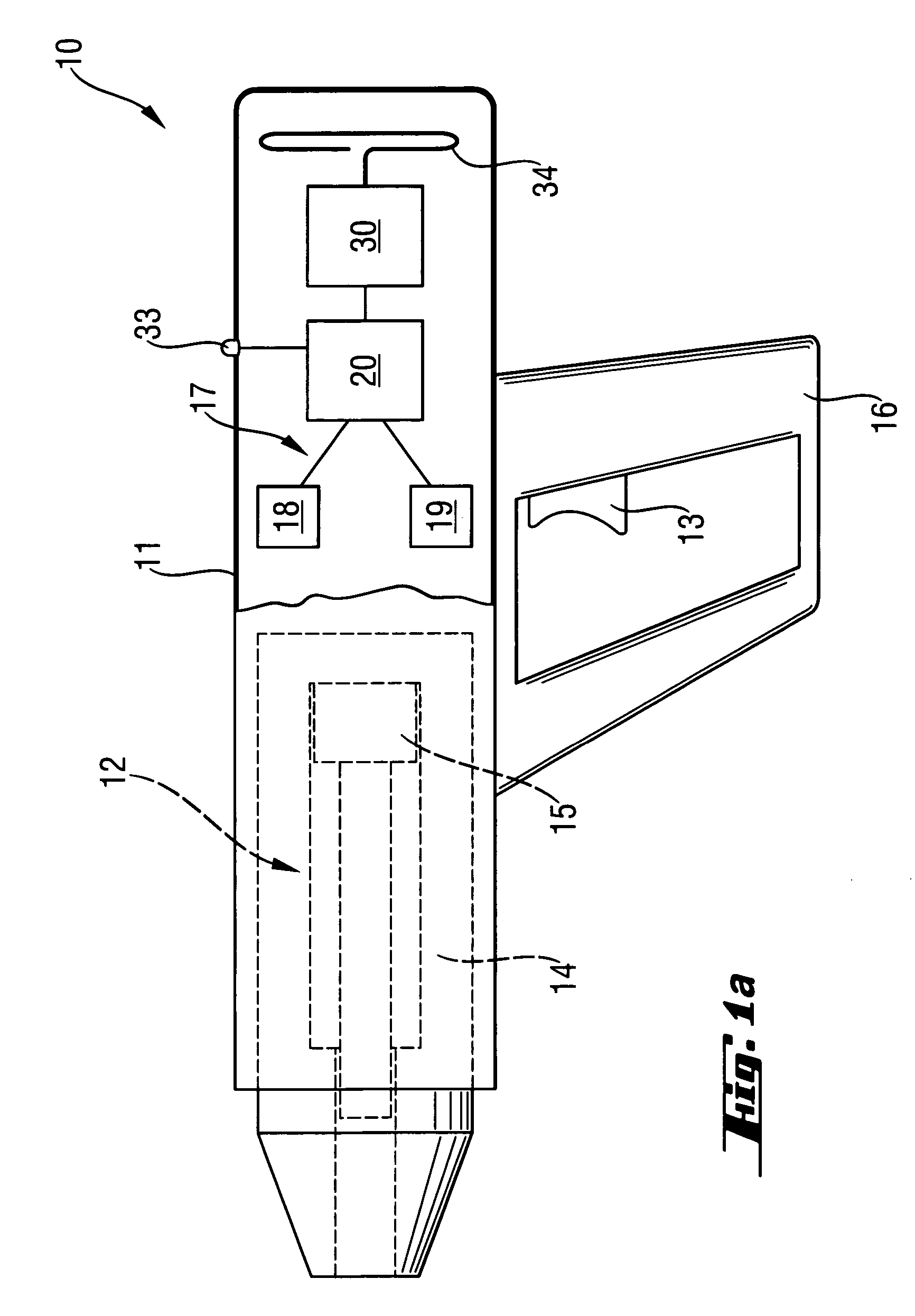

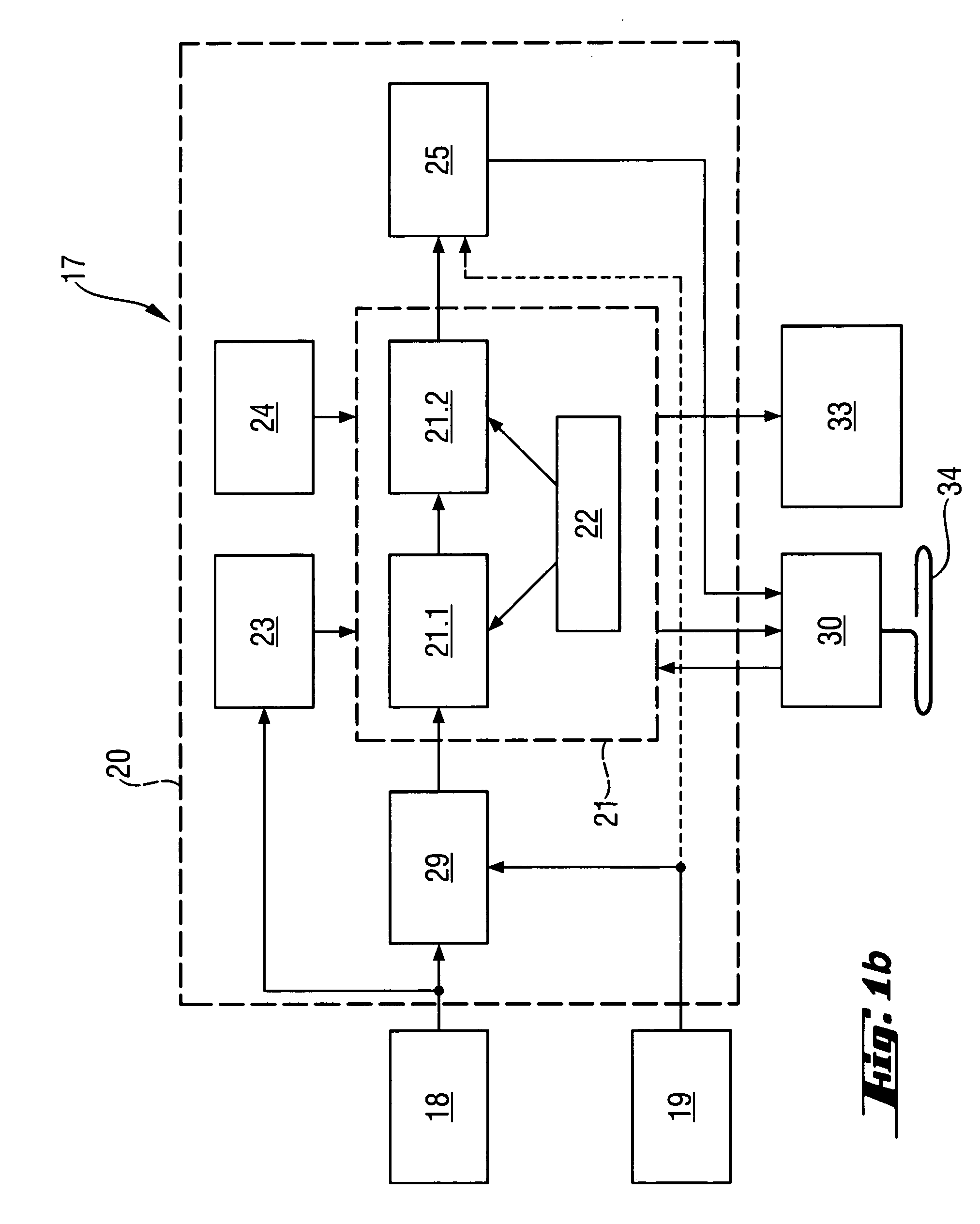

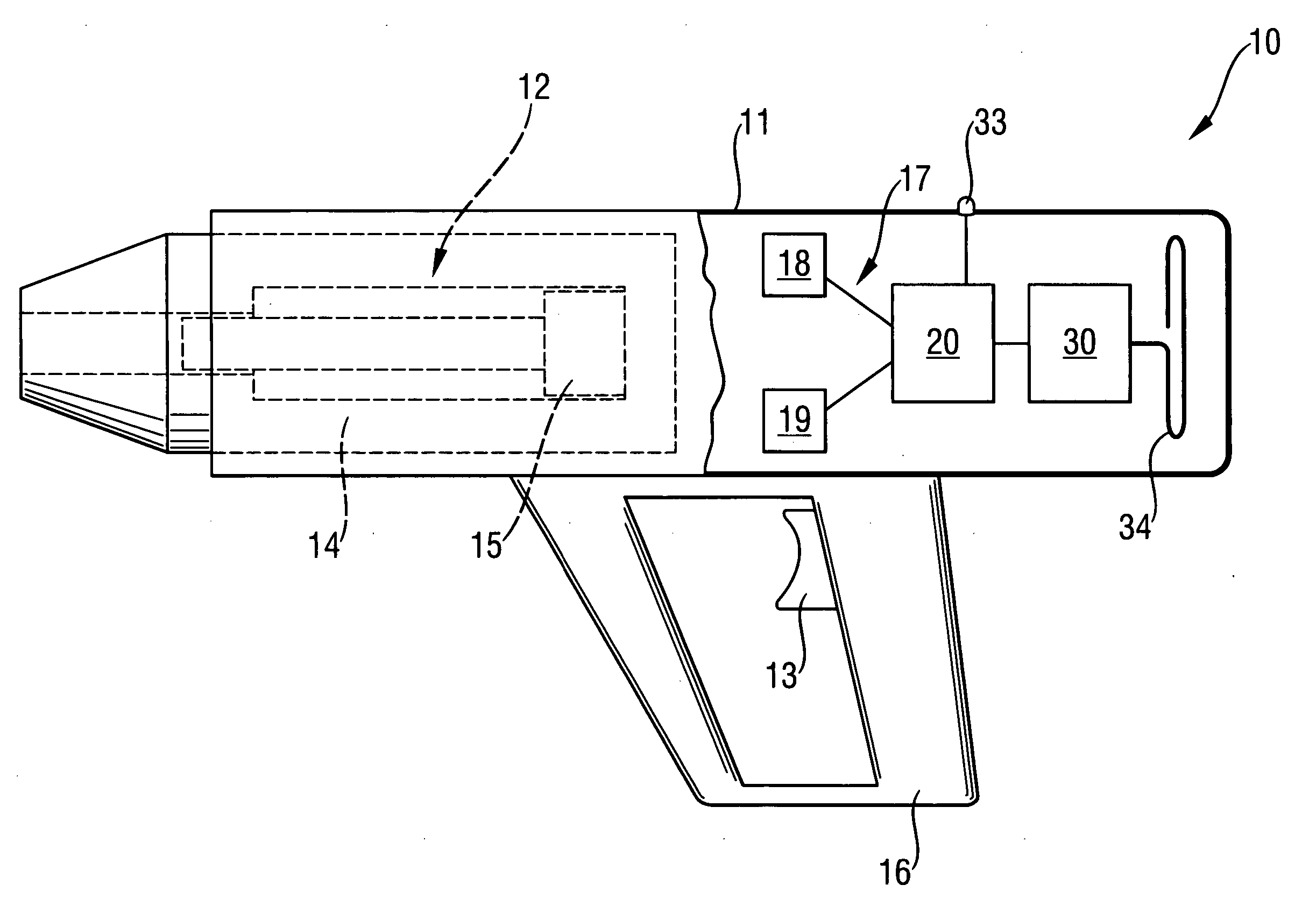

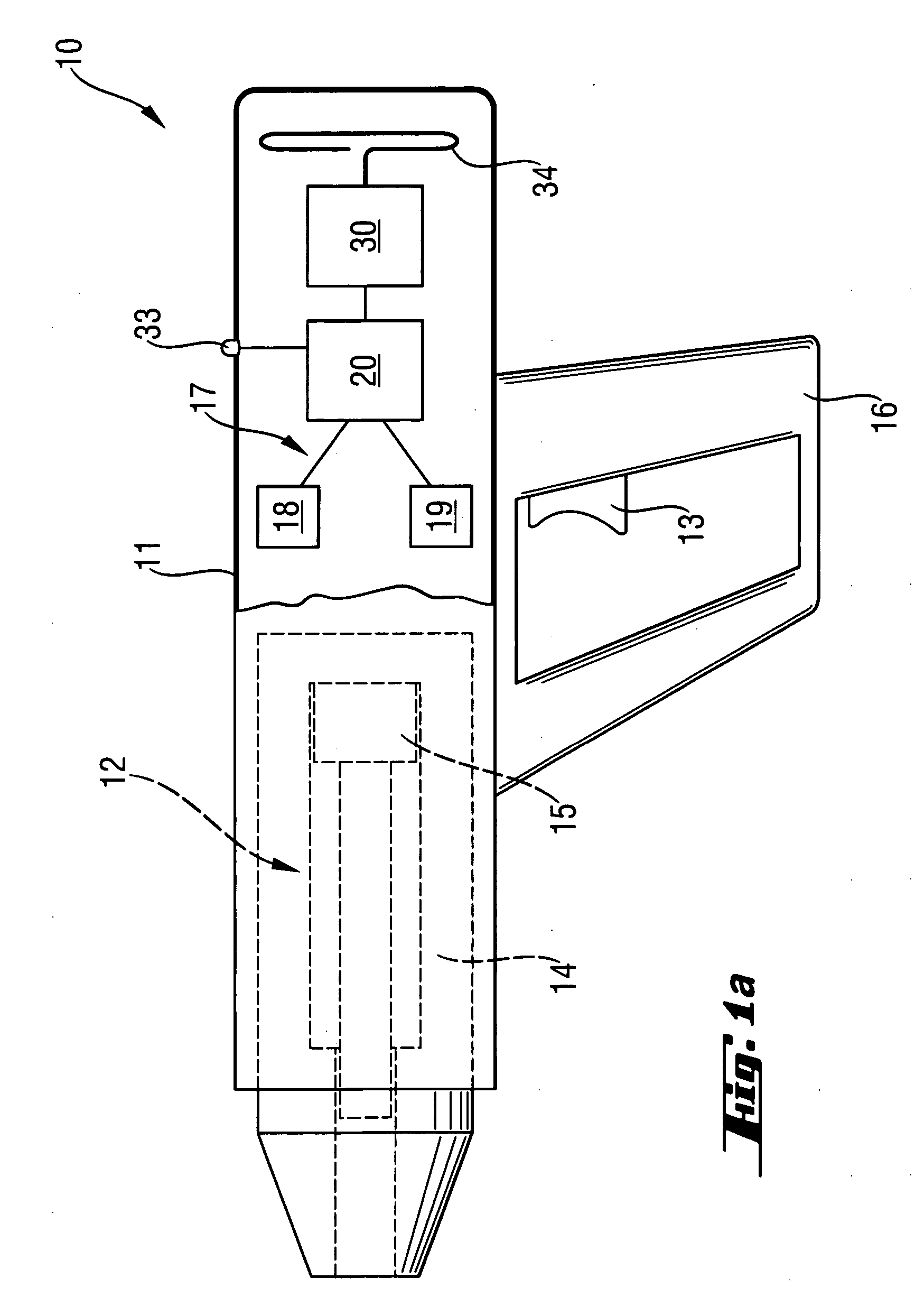

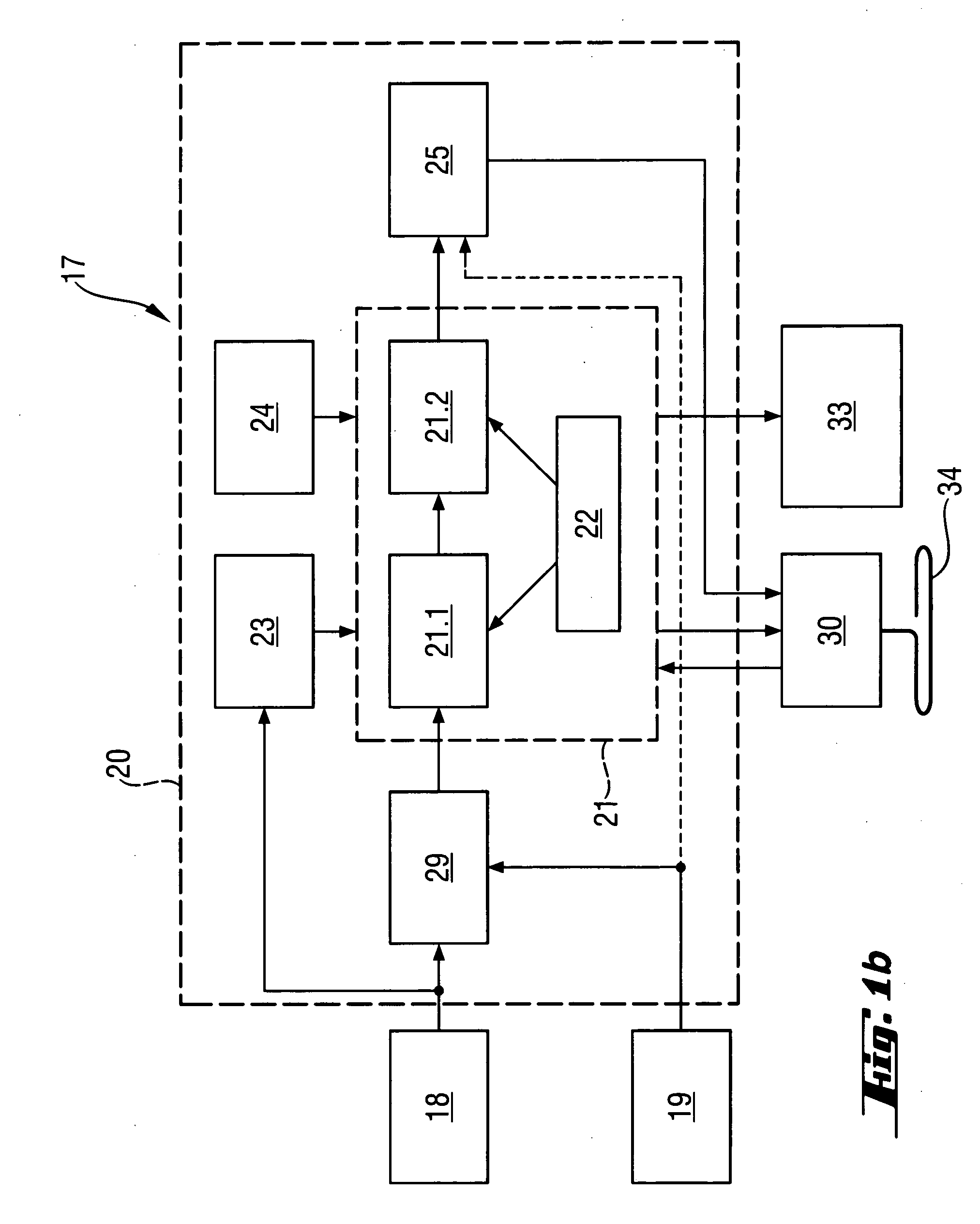

Hand-held working tool

The present invention relates to a hand-held working tool, such as a setting device used for driving fastening elements such as nails, bolts, pins and the like into a surface, or an at least partially percussive hand-held tool having a housing part (11) and a working mechanism such as a setting or striking mechanism arranged inside the housing of the device and having at least one sensing device (17) for sensing acceleration forces occurring during a setting or striking pulse as well as a handle. For improving this type of hand-held working tool (10) an interface (30) for data communication and data output is arranged on the hand-held working tool.

Owner:HILTI AG

Impact tool

ActiveUS20120279736A1Shorten the timeIncrease production capacityReciprocating drilling machinesConstructionsEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:HITACHI KOKI CO LTD

Drilling Fluid Additive for Reducing Lost Circulation in a Drilling Operation

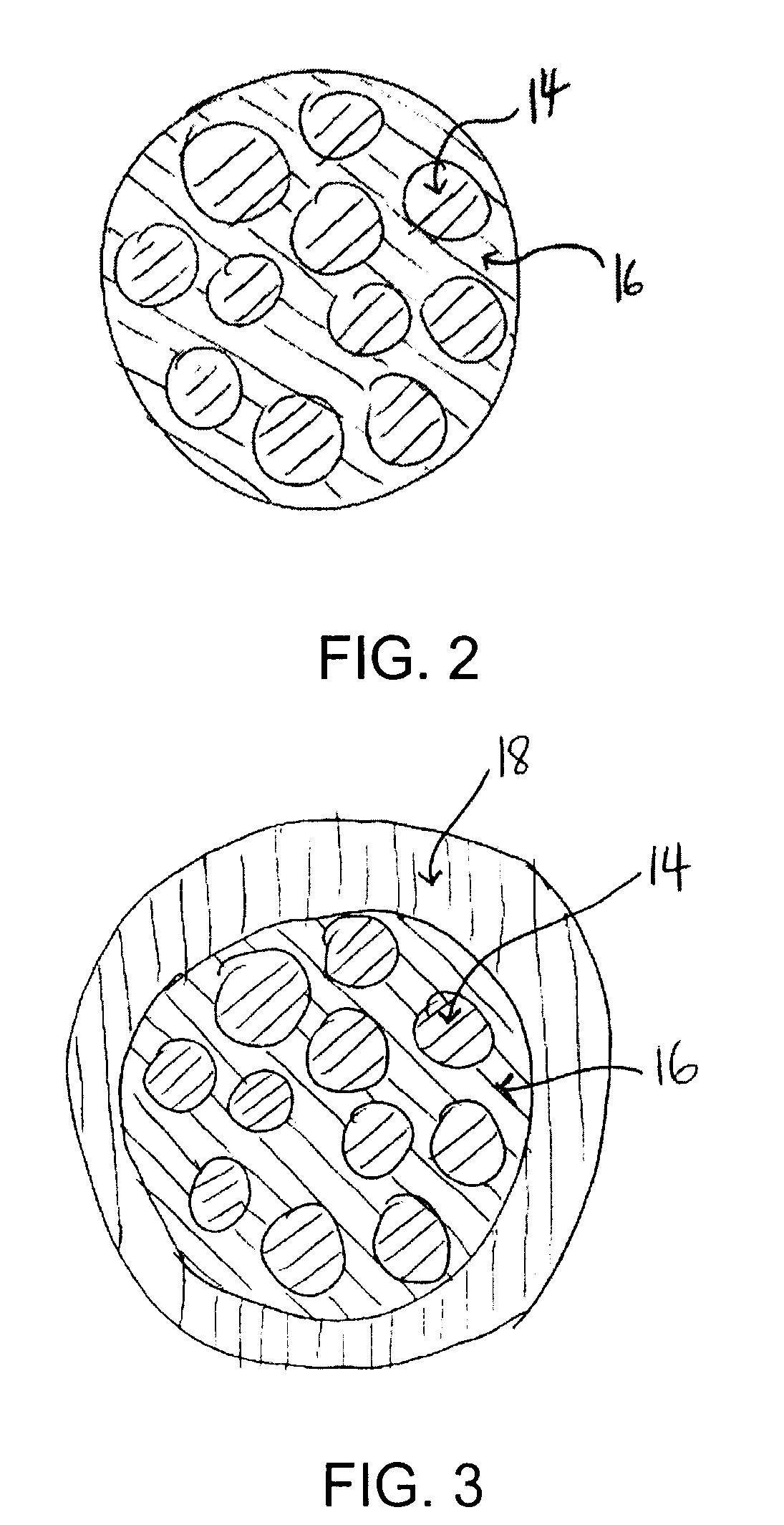

ActiveUS20100193244A1Improve performanceReducing and controlling lost circulationDrilling rodsDerricks/mastsWaxWell drilling

Generally, the present invention provides drilling fluid additives for reducing or controlling lost circulation in a drilling operation. The additives comprises particles. The particles comprise one or more solids in association a wax or waxy substance. A drilling fluid comprising a drilling fluid additive of the invention is also provided, as well as a method and use of the drilling fluid additive in a drilling operation to reduce or control lost circulation. Methods for manufacturing the drilling fluid additives are also described.

Owner:CANADIAN ENERGY SERVICES LP

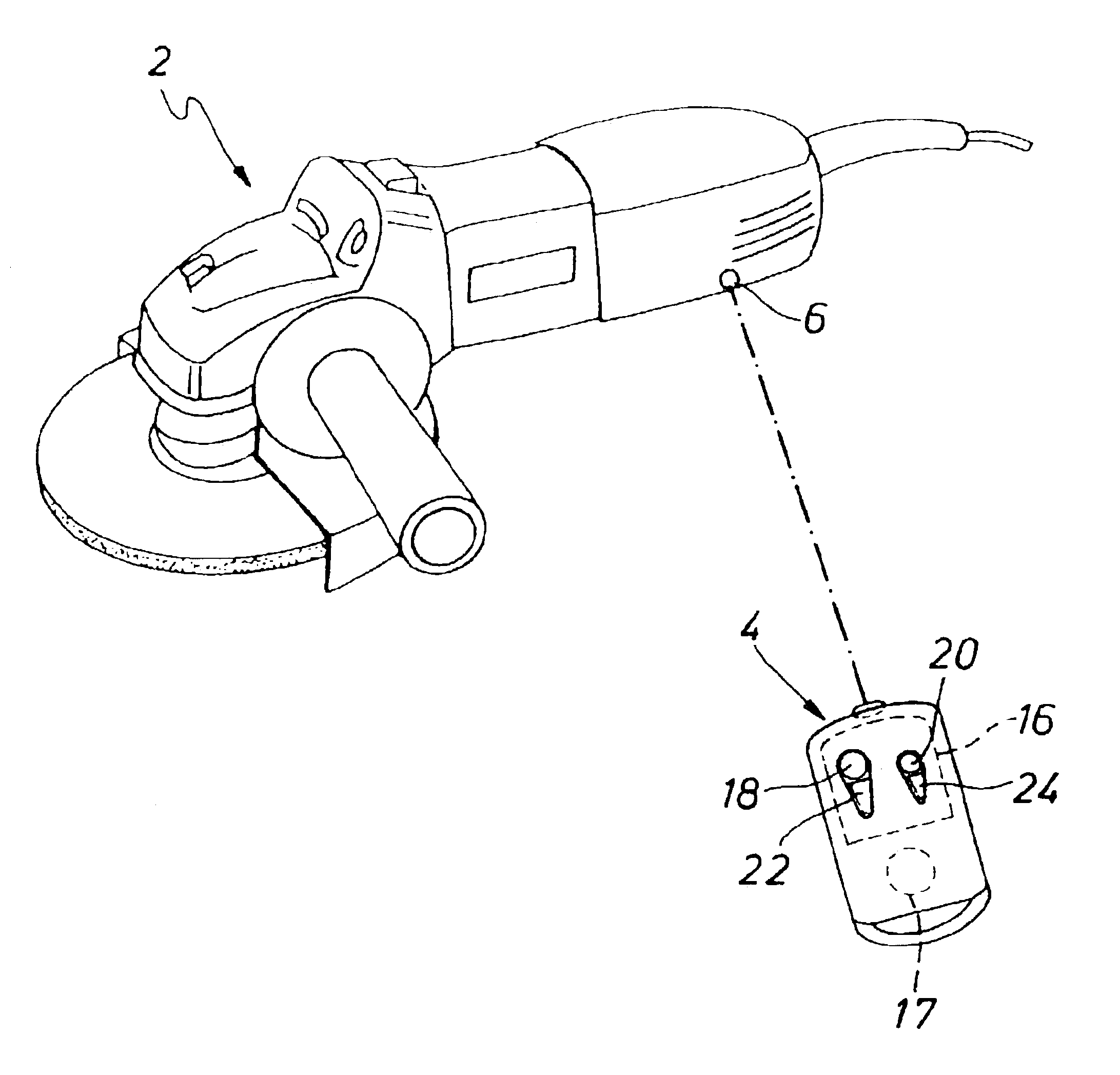

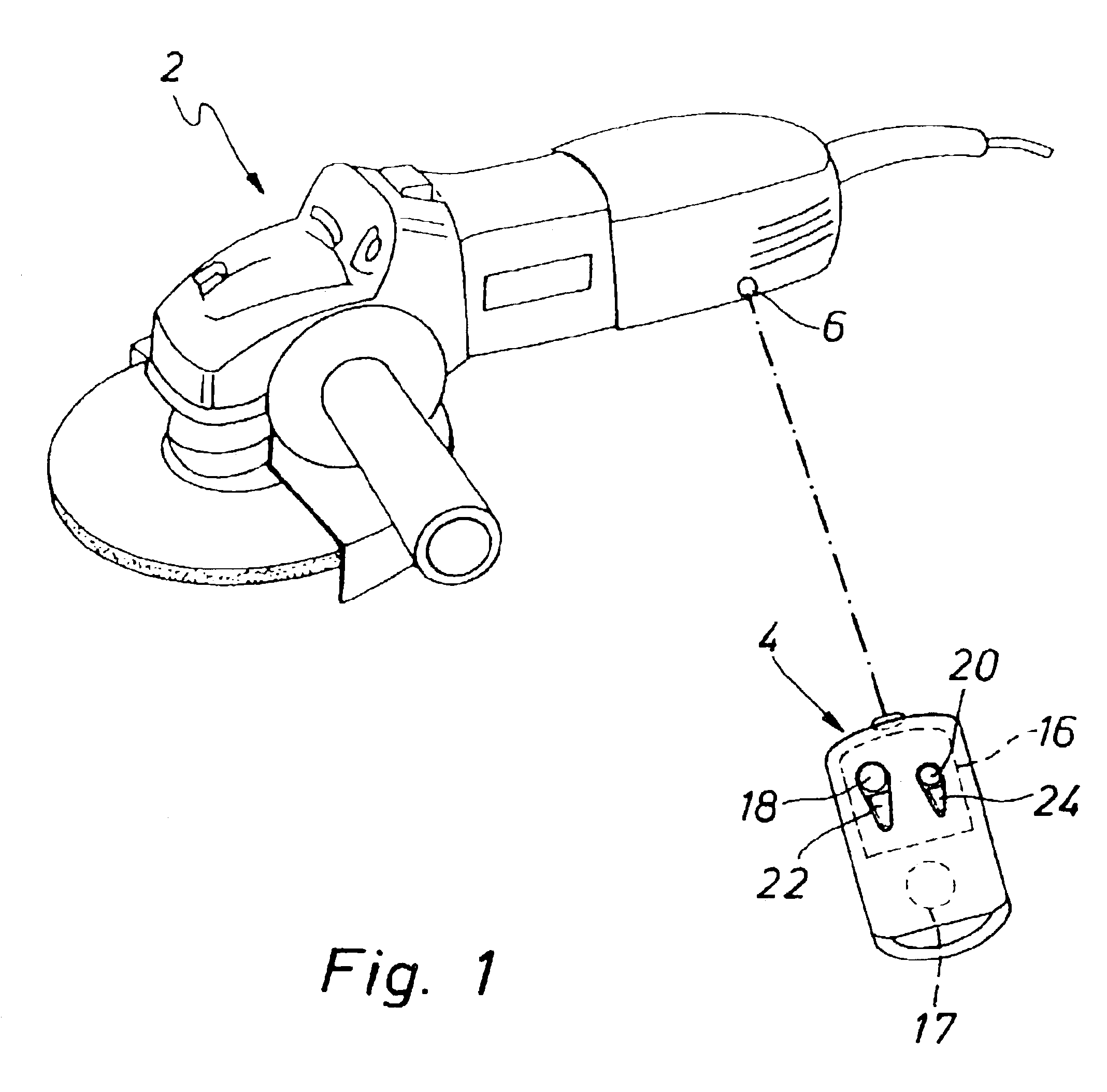

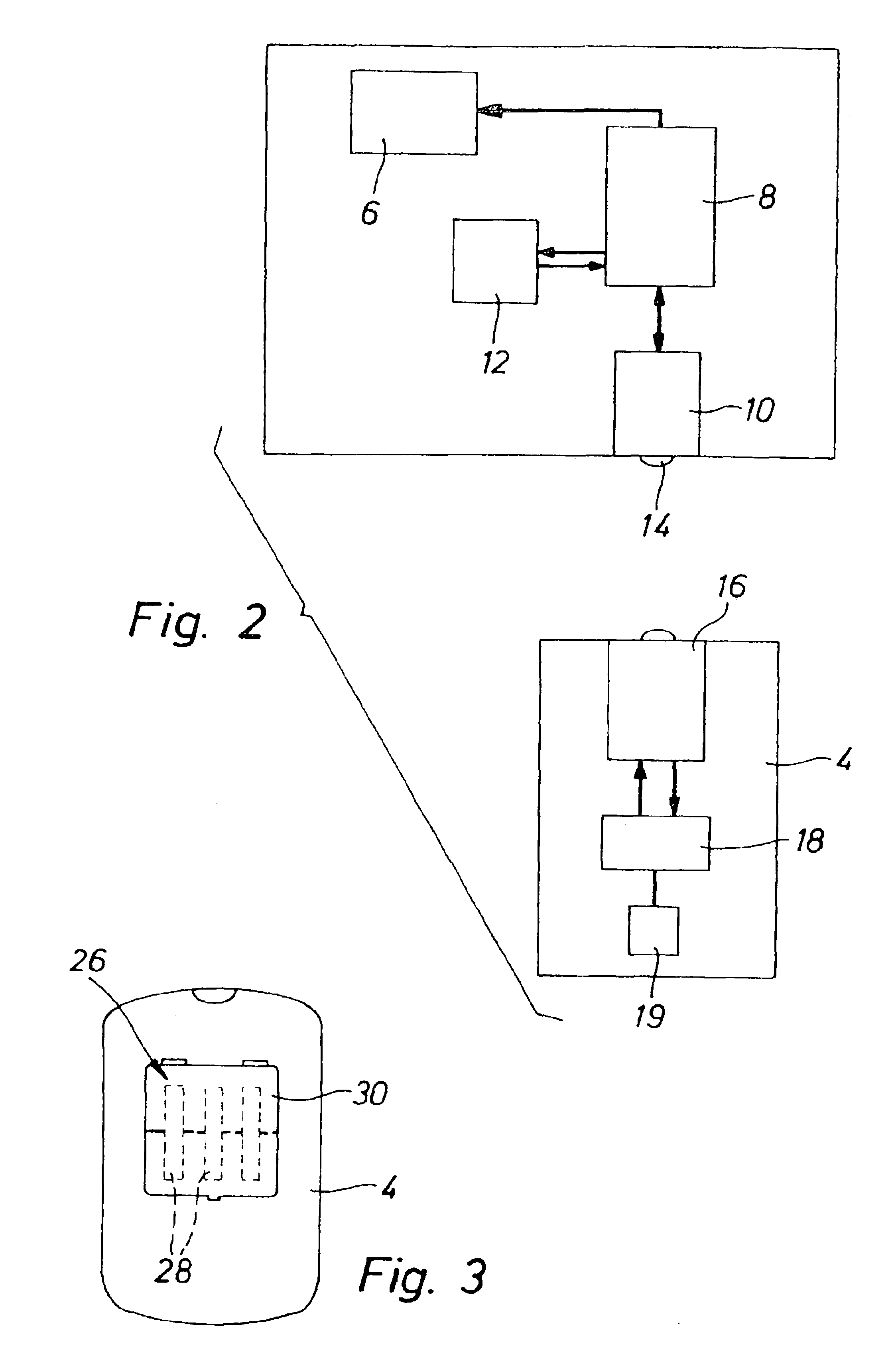

Electrical hand tool device

InactiveUS6872121B2Reduce sensitivityElectric signal transmission systemsDerricks/mastsContact freeControl electronics

An electrical hand tool device (2) comprises a control electronics (8) and a transmitter and receiver (10) which is responsive in a wireless and contact-free fashion, and with a storage medium (12) in which an authorization code is stored, wherein an operation locking state and an operation release state can be differentiated, and with an external transmitter and receiver means (16) which is accommodated in a separate portable device (4), wherein communication with the transmitter and receiver means (10) of the electrical hand tool device can be produced in a defined fashion through actuation of the external transmitter and receiver means (16) to change the operation state, and communication is provided only to change the operation state and optionally to change the authorization code.

Owner:METABOWERKE

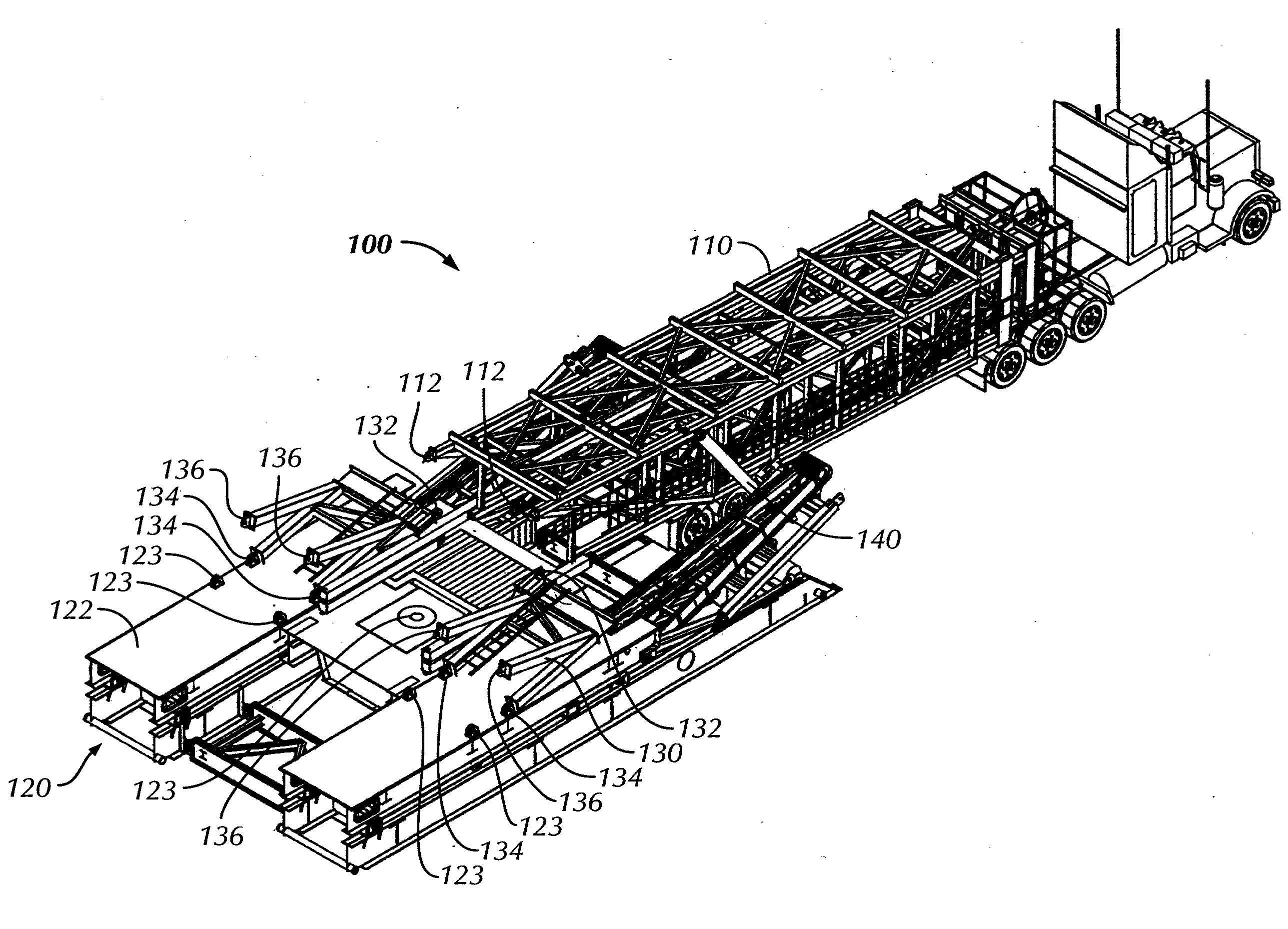

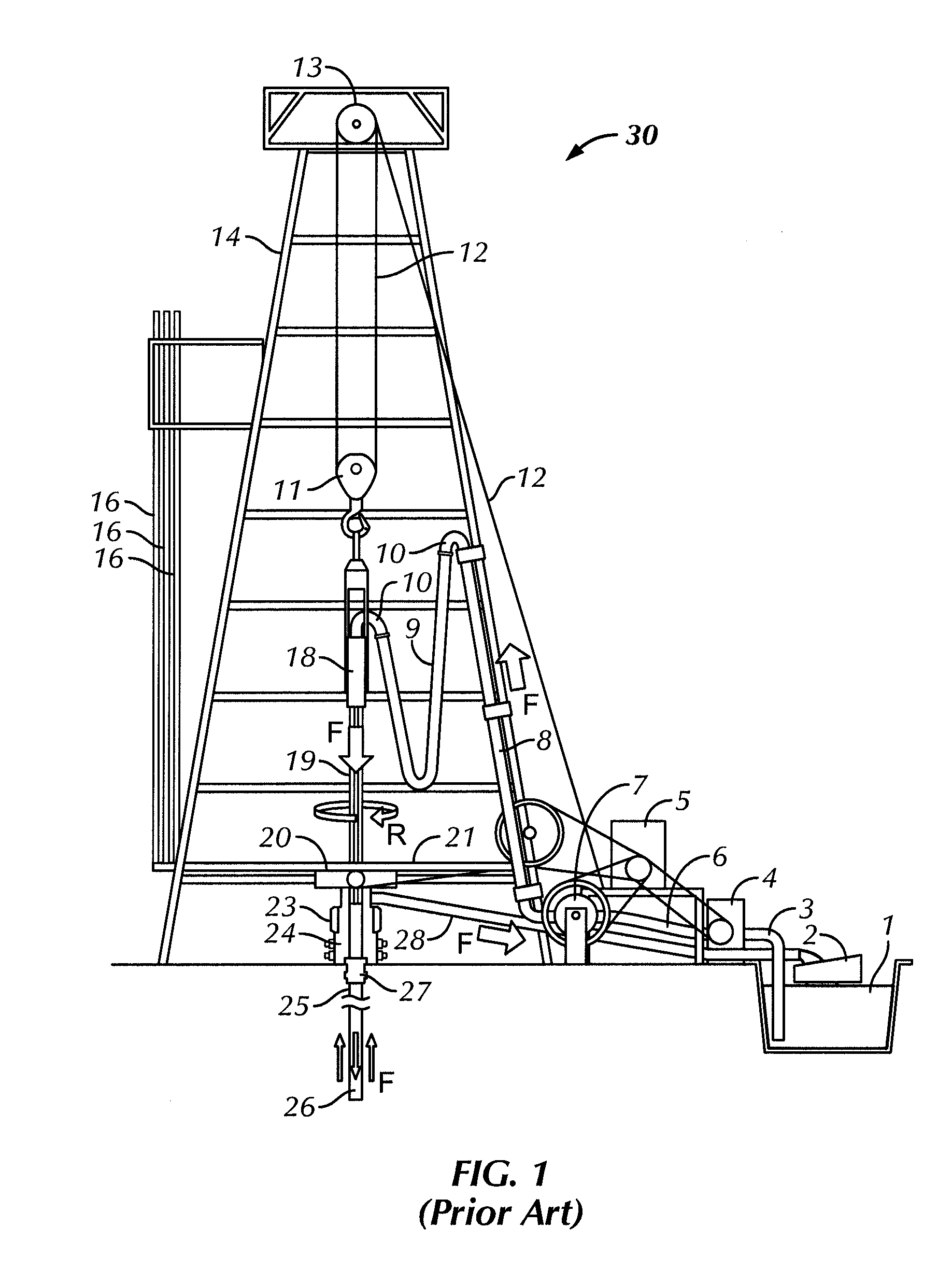

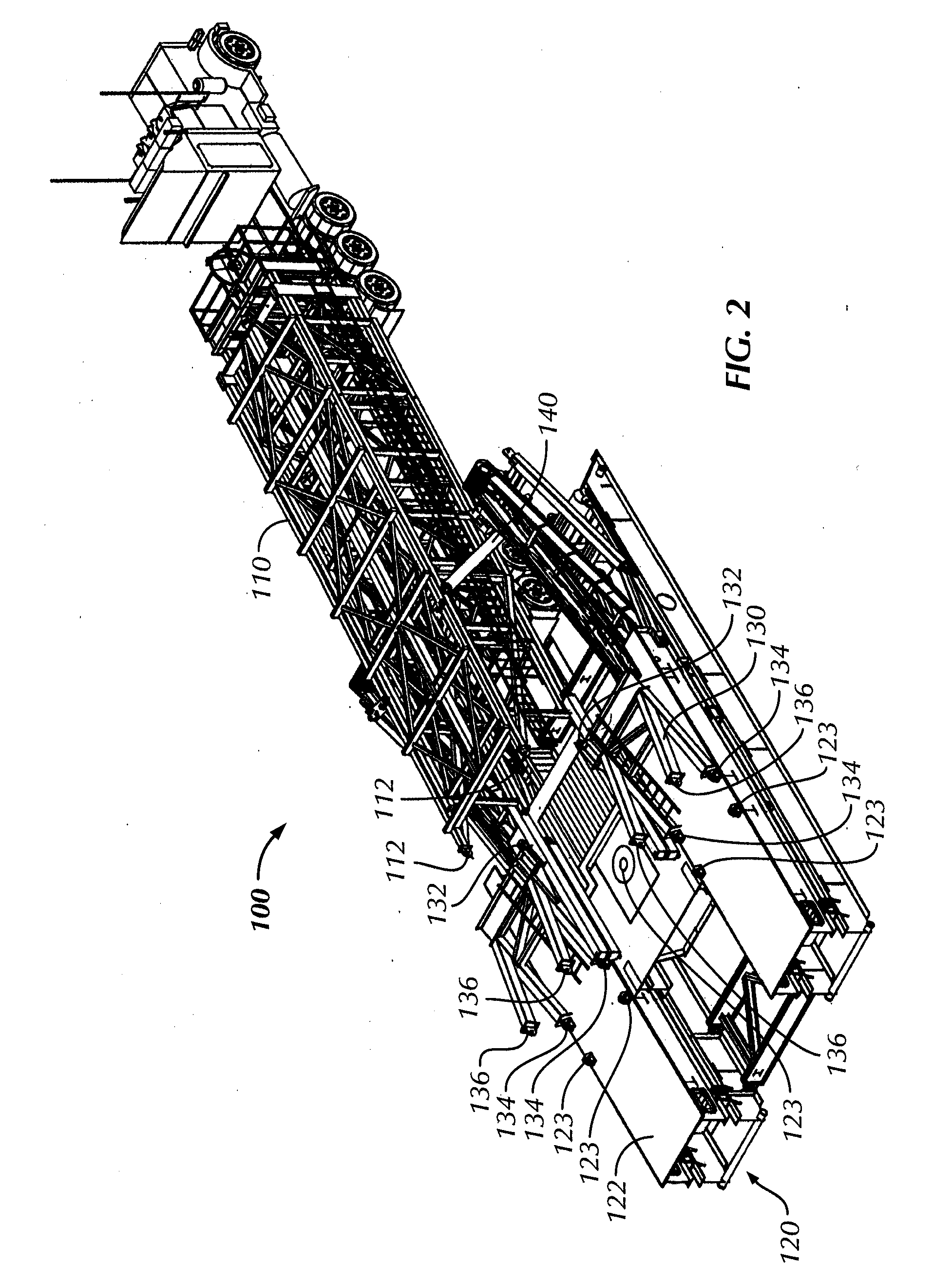

Portable drilling rig apparatus and assembly method

Owner:INTEGRATED DRILLING EQUIP

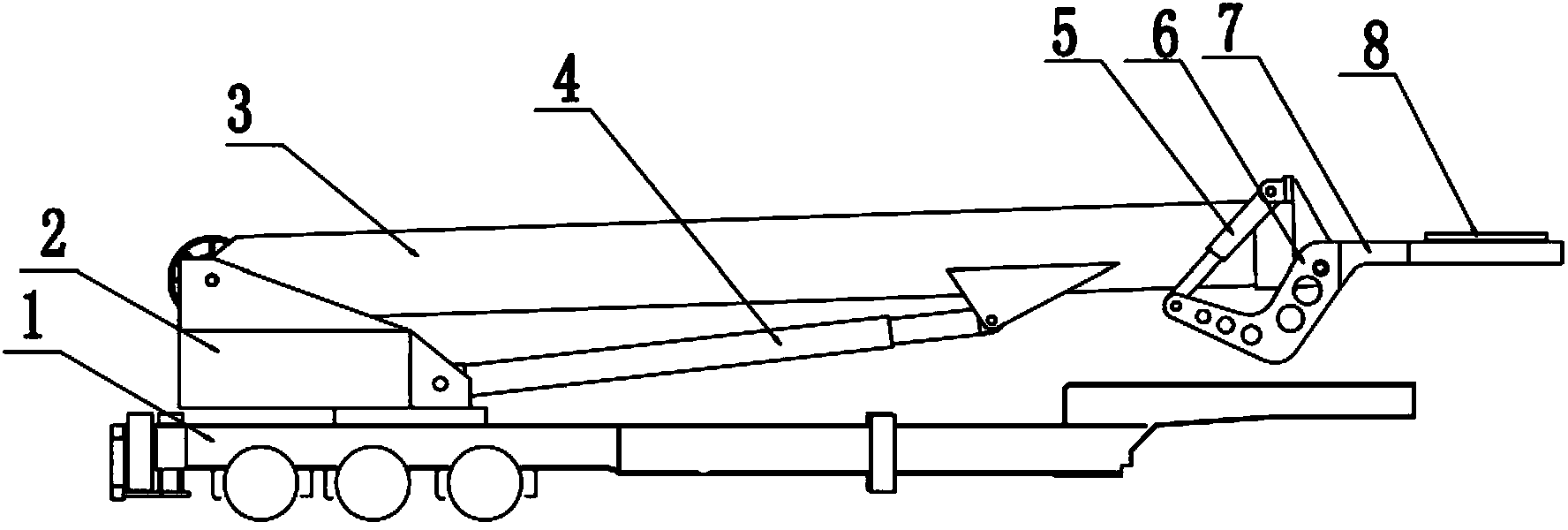

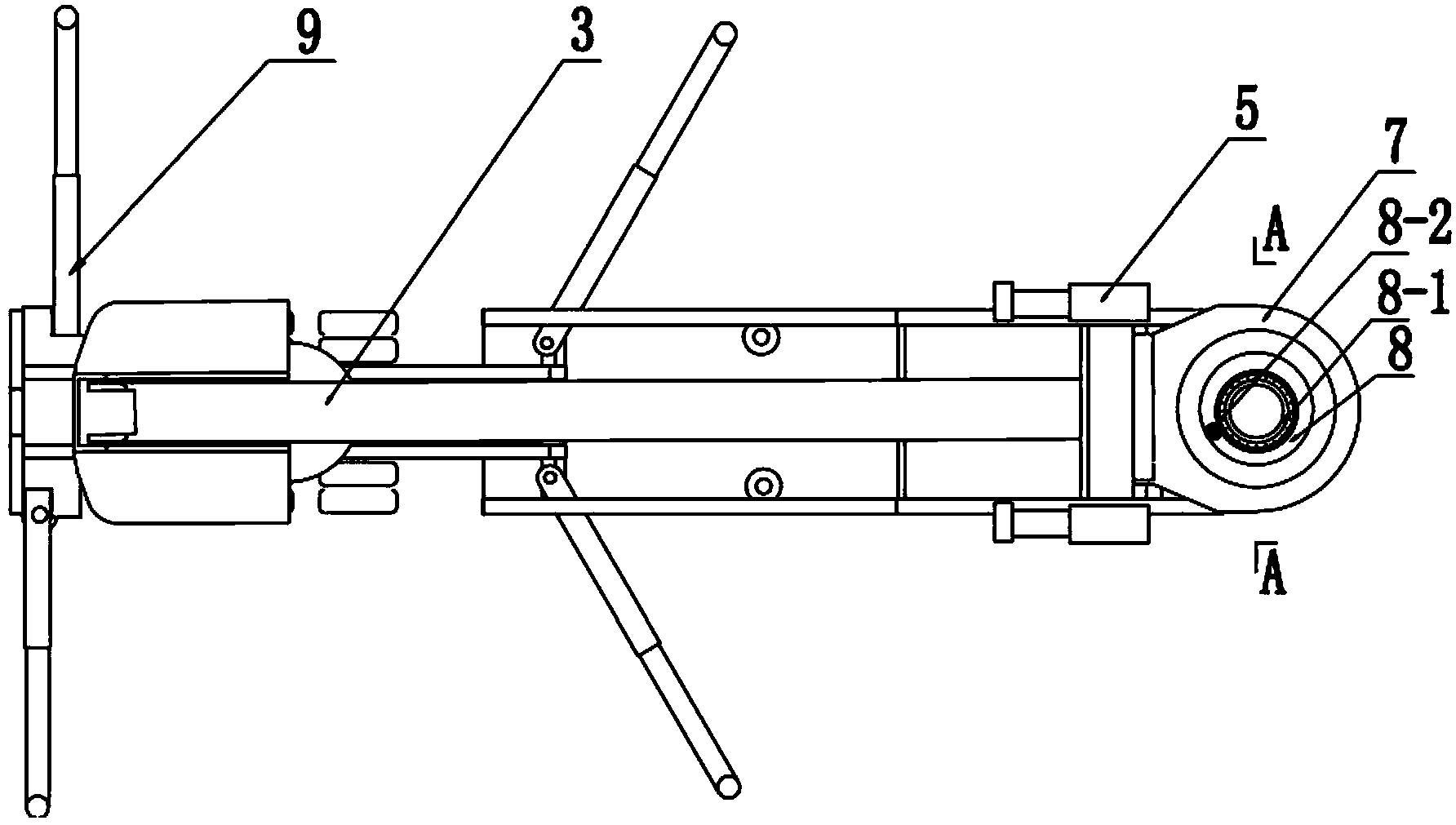

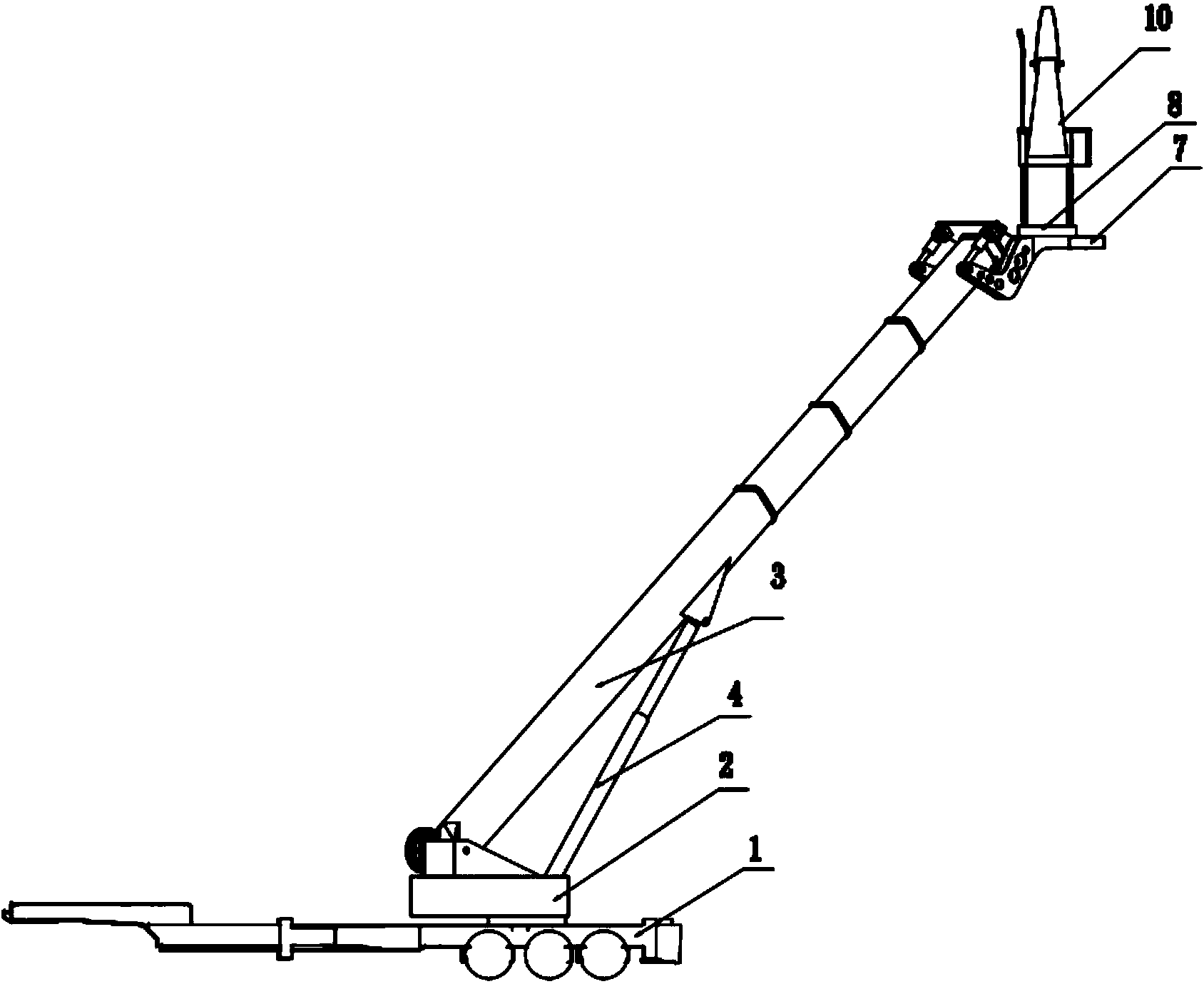

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

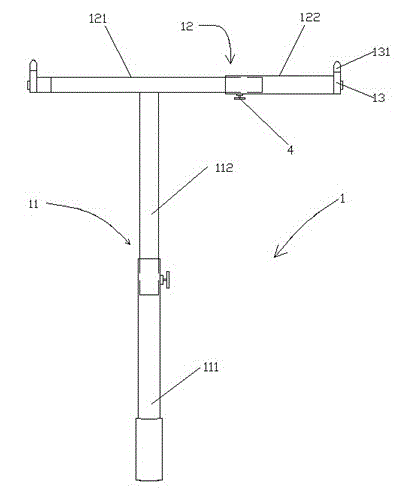

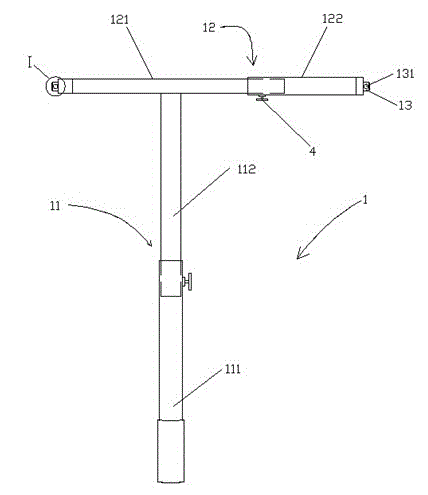

High-altitude drill positioning method of building

InactiveCN102979457AAvoid safety hazardsQuality assuranceDerricks/mastsDirectional drillingArchitectural engineeringDrill bit

The invention discloses a high-altitude drill positioning method of a building, which comprises a high-altitude marking device, a high-altitude drilling device and a high-altitude tightening device. The high-altitude drill positioning method comprises the following steps that when a plurality of fixing holes need to be drilled in the top surface of the building, the length of an adjustment rod of the high-altitude marking device is adjusted to be equal to the distance between any two fixing holes; a support rod of the high-altitude marking device is adjusted, so that the altitude from the top end of a marking rod to the ground is equal to the altitude from the fixing holes to the ground; the marking end head is pressed to the top surface, so as to draw marking points of the two fixing holes; the high-altitude drilling device is placed below the fixing holes, and a handle is pressed downward, so that a drill which is fixedly arranged on drilling equipment aligns with the marking points of the fixing holes; the drilling equipment is turned on to drill the holes which conform to a size; one end of an expansion bolt, which is provided with a nut, is inserted into the top end of the high-altitude tightening device; the expansion end of the bolt is inserted into a drilled fixing hole, and then a handle of the high-altitude tightening device is rotated to tighten the expansion bolt; and the steps are repeated, so as to complete the drill tightening operation of the remaining fixing holes. According to the high-altitude drill positioning method, the disadvantages of low construction quality and large difficulty because no reliable application point exists at high altitude are overcome, the construction quality is guaranteed, various potential safety hazards due to high-altitude construction of construction personnel are avoided, and the construction efficiency is greatly increased.

Owner:CHINA RAILWAY 19 BUREAU GRP ELECTRIC ENG

Method for pressurized mud cap and reverse circulation drilling from a floating drilling rig using a sealed marine riser

A method for drilling in the floor of an ocean from a floating structure using a rotatable tubular includes a seal housing having a rotatable seal connected above a portion of a marine riser fixed to the floor of the ocean. The seal rotating with the rotating tubular allows the riser and seal housing to maintain a predetermined pressure in the system that is desirable in pressurized mud cap and reverse circulation drilling. A flexible conduit or hose is used to compensate for relative movement of the seal housing and the floating structure because the floating structure moves independent of the seal housing. The drilling fluid is pumped from the floating structure into an annulus of the riser, allowing the formation of a mud cap downhole in the riser, or allowing reverse circulation of the drilling fluid down the riser, returning up the rotatable tubular to the floating structure.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com