Patents

Literature

12790 results about "Hydraulic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

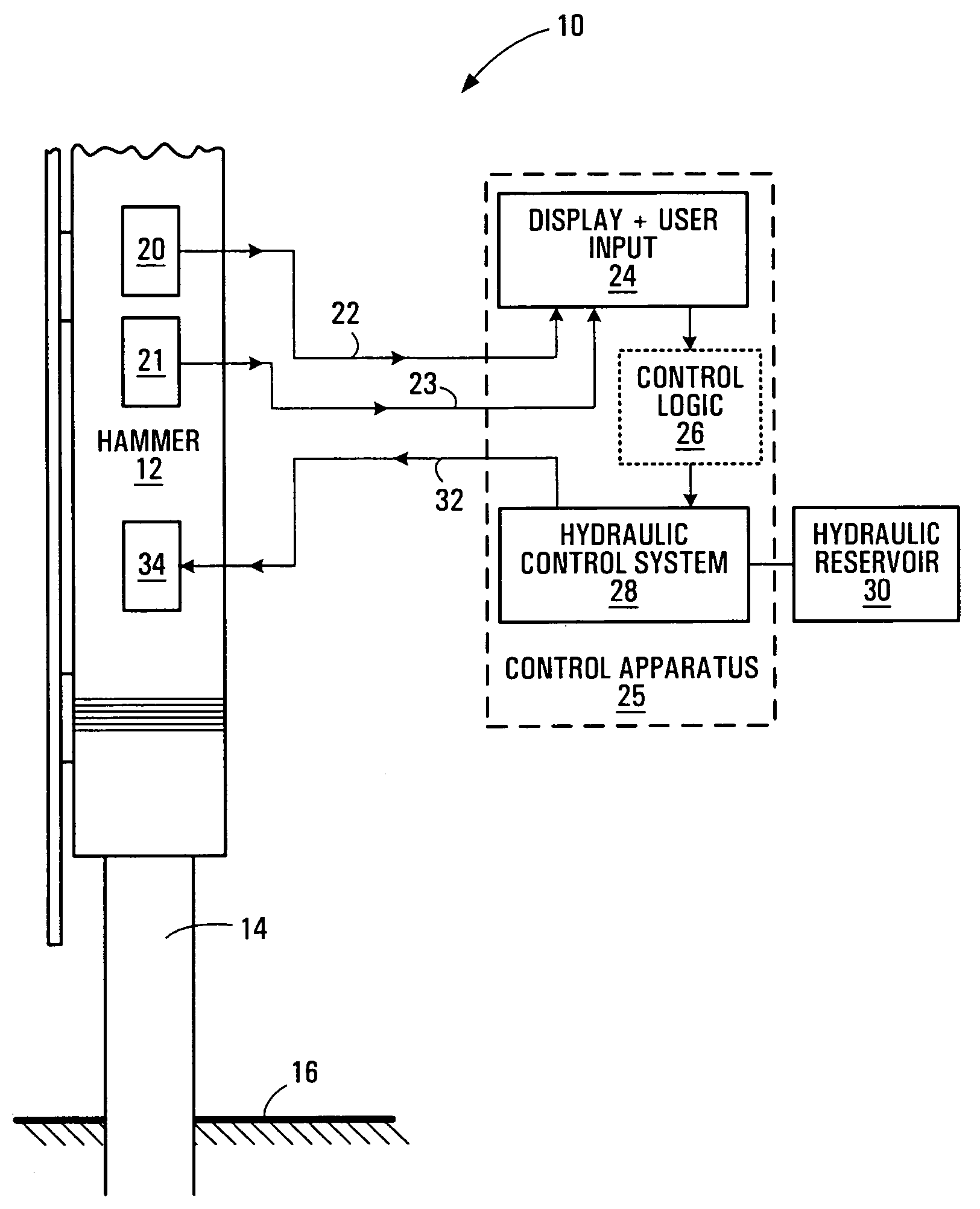

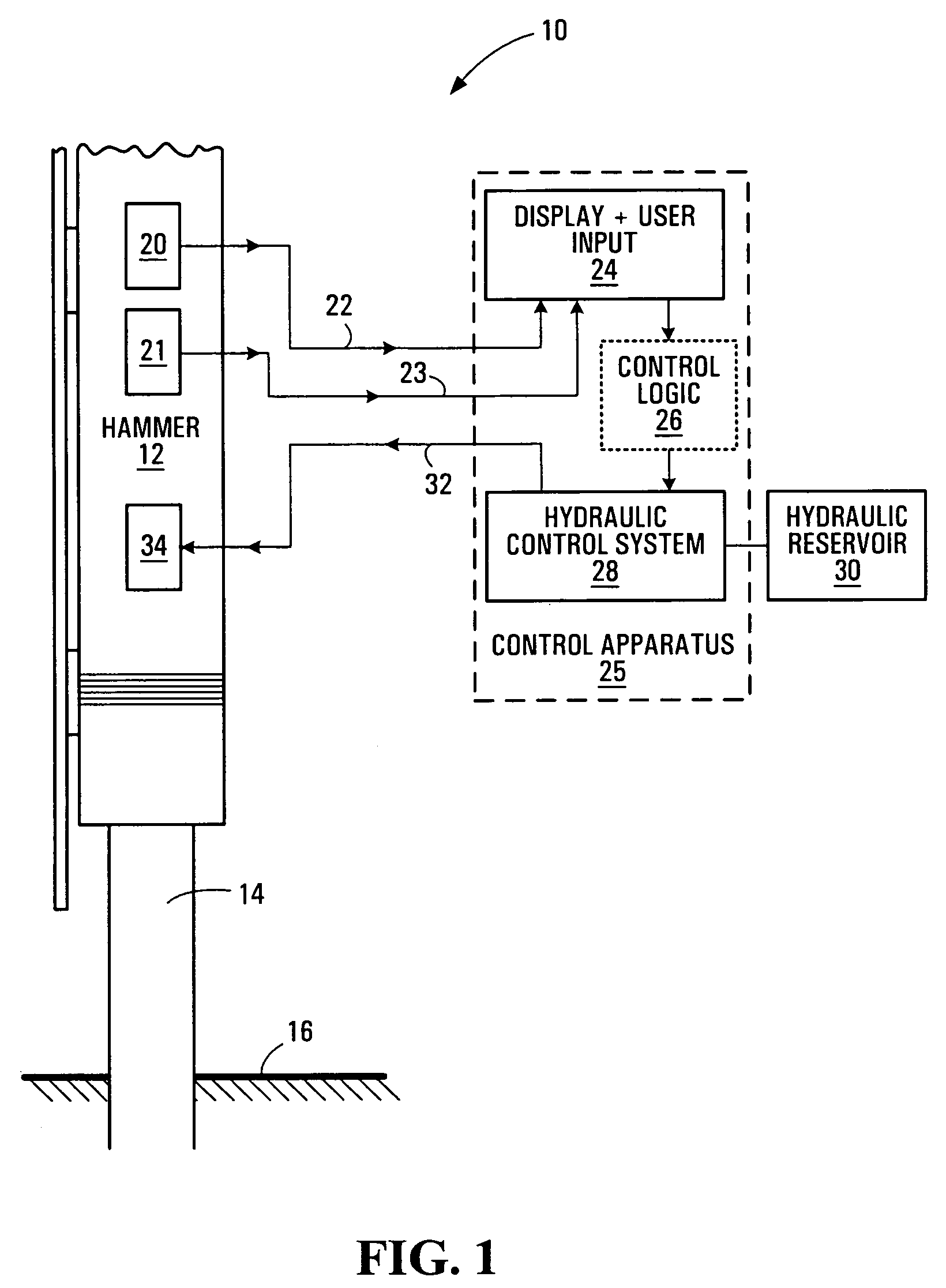

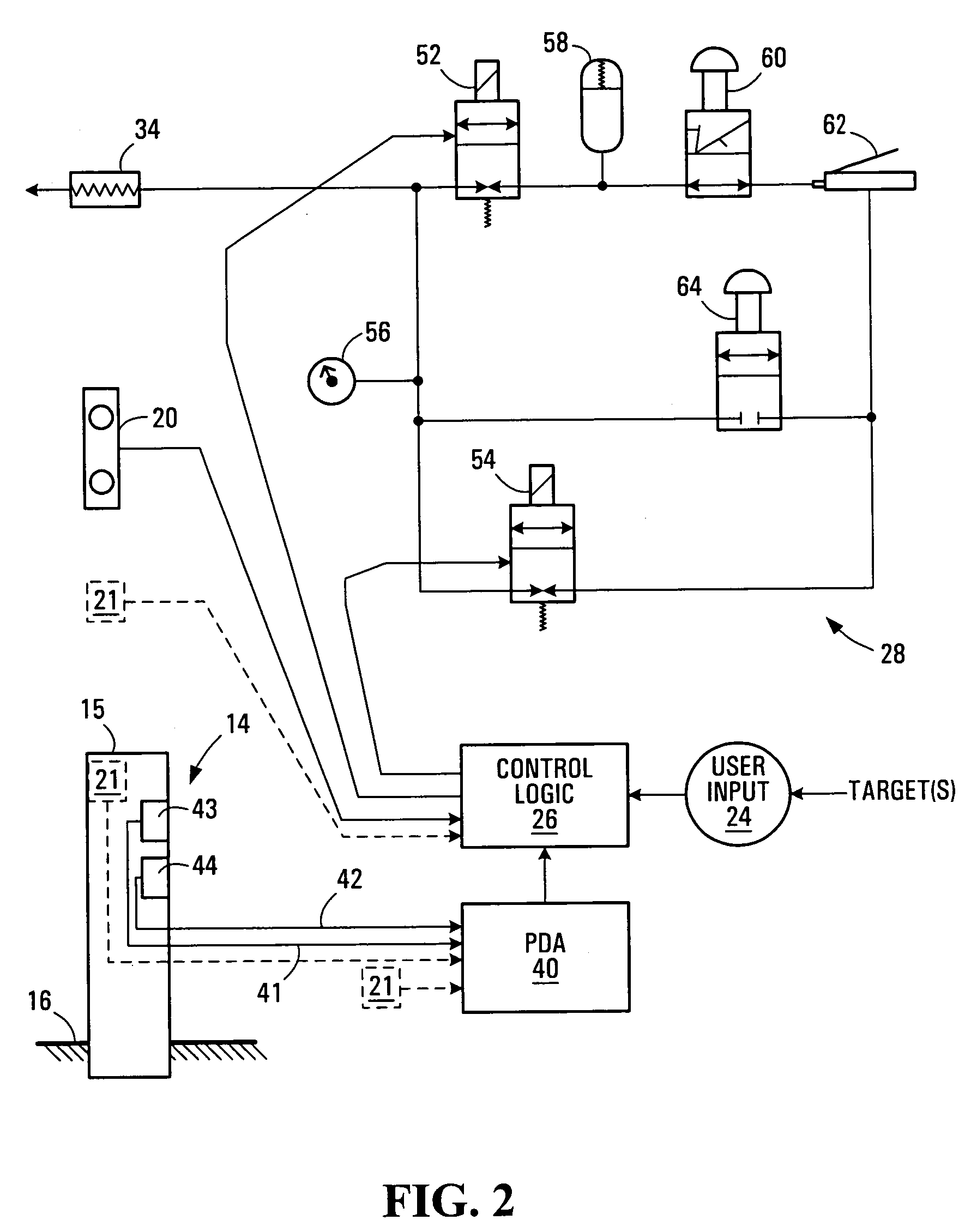

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

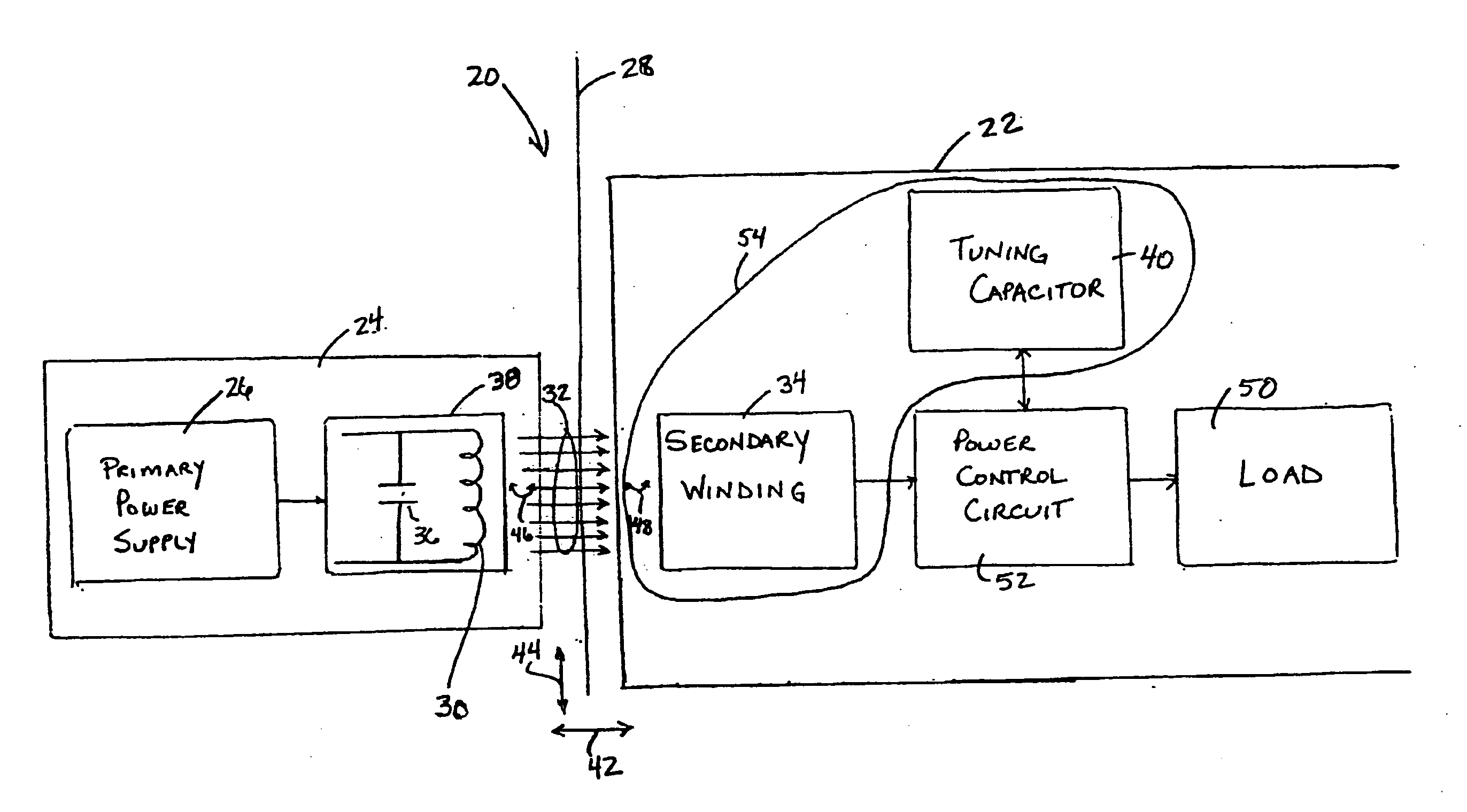

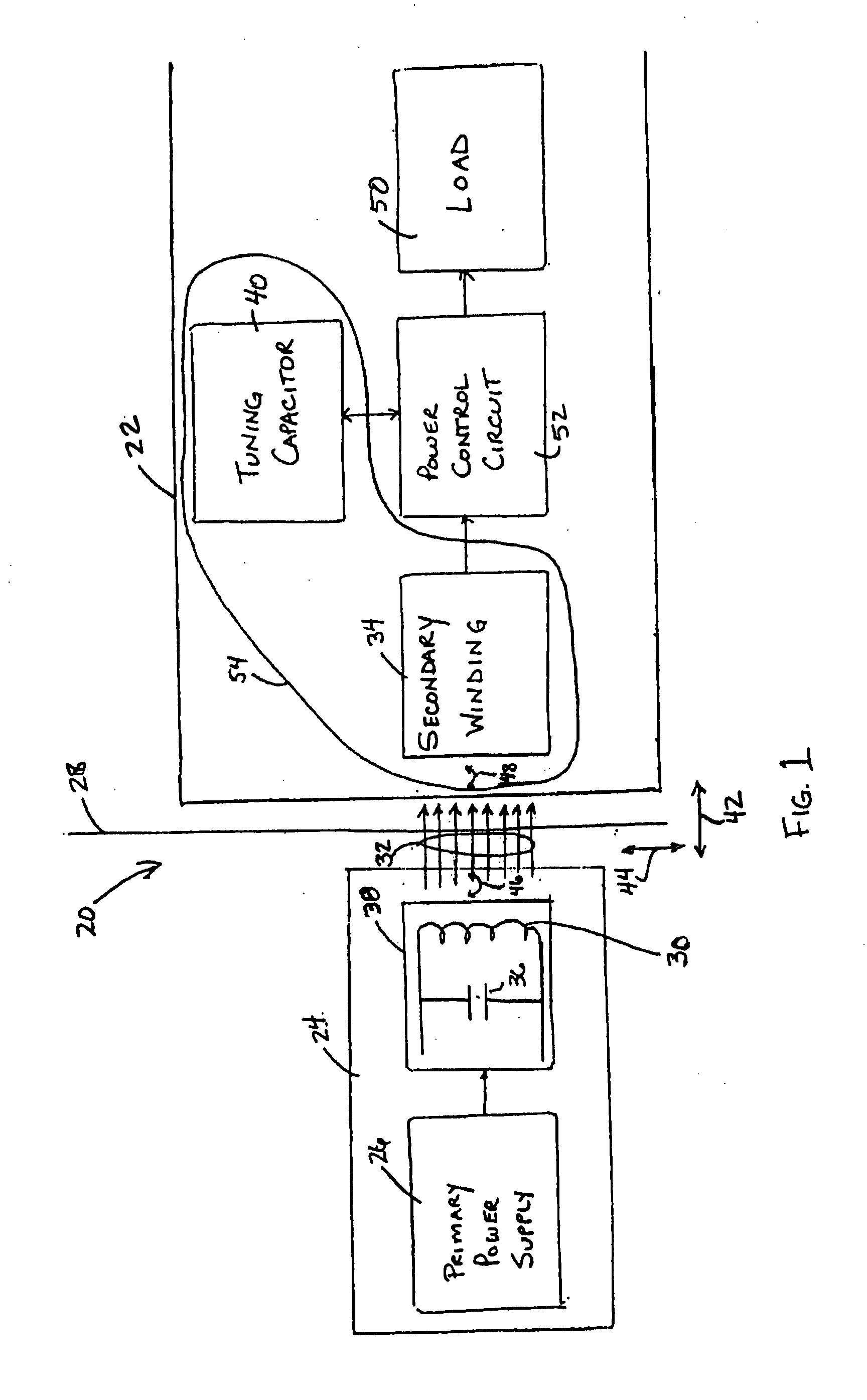

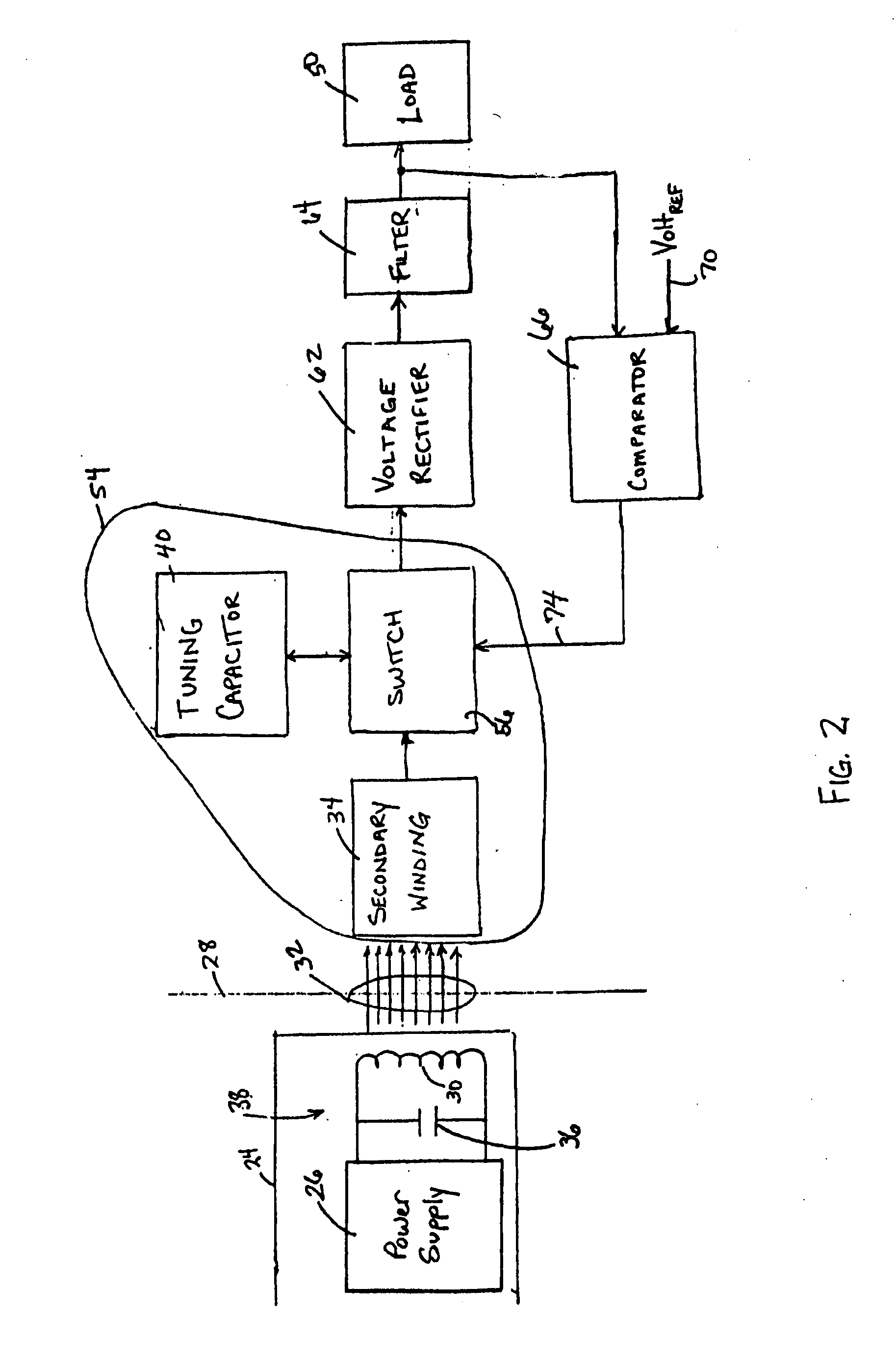

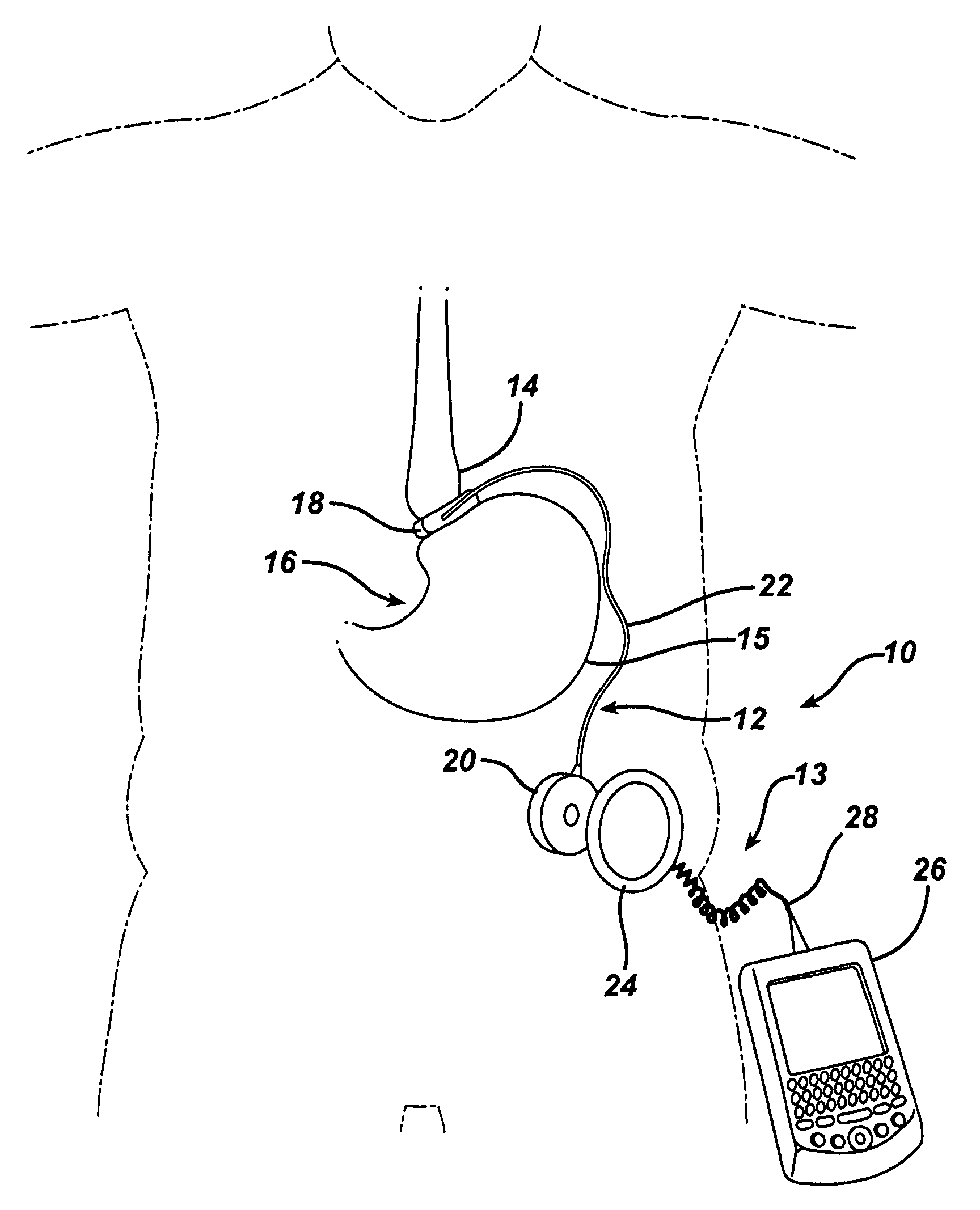

Medical implant having closed loop transcutaneous energy transfer (TET) power transfer regulation circuitry

InactiveUS20050288739A1Not easy to damageLess susceptible to inoperabilityElectrotherapyAnti-incontinence devicesElectrical batteryClosed loop

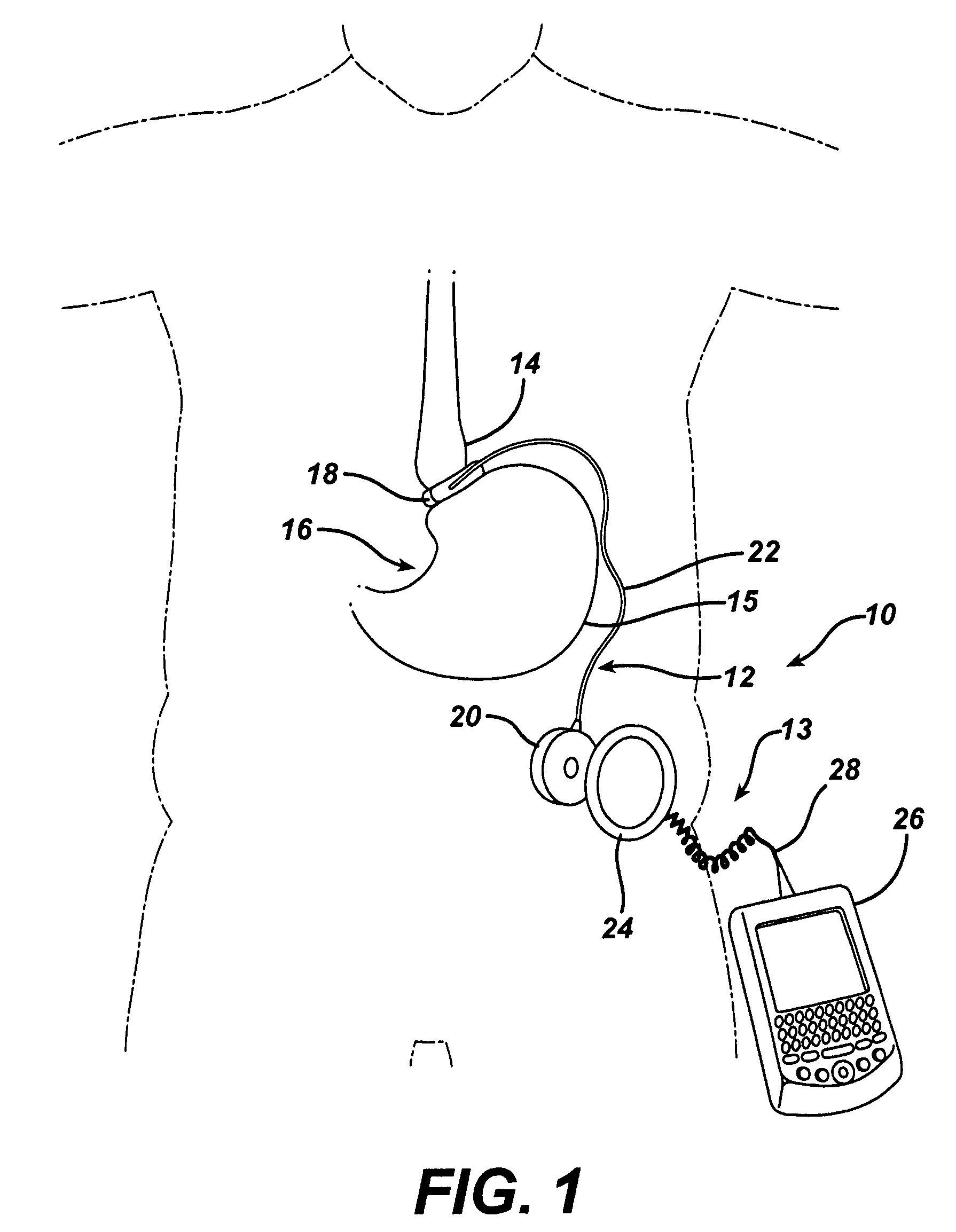

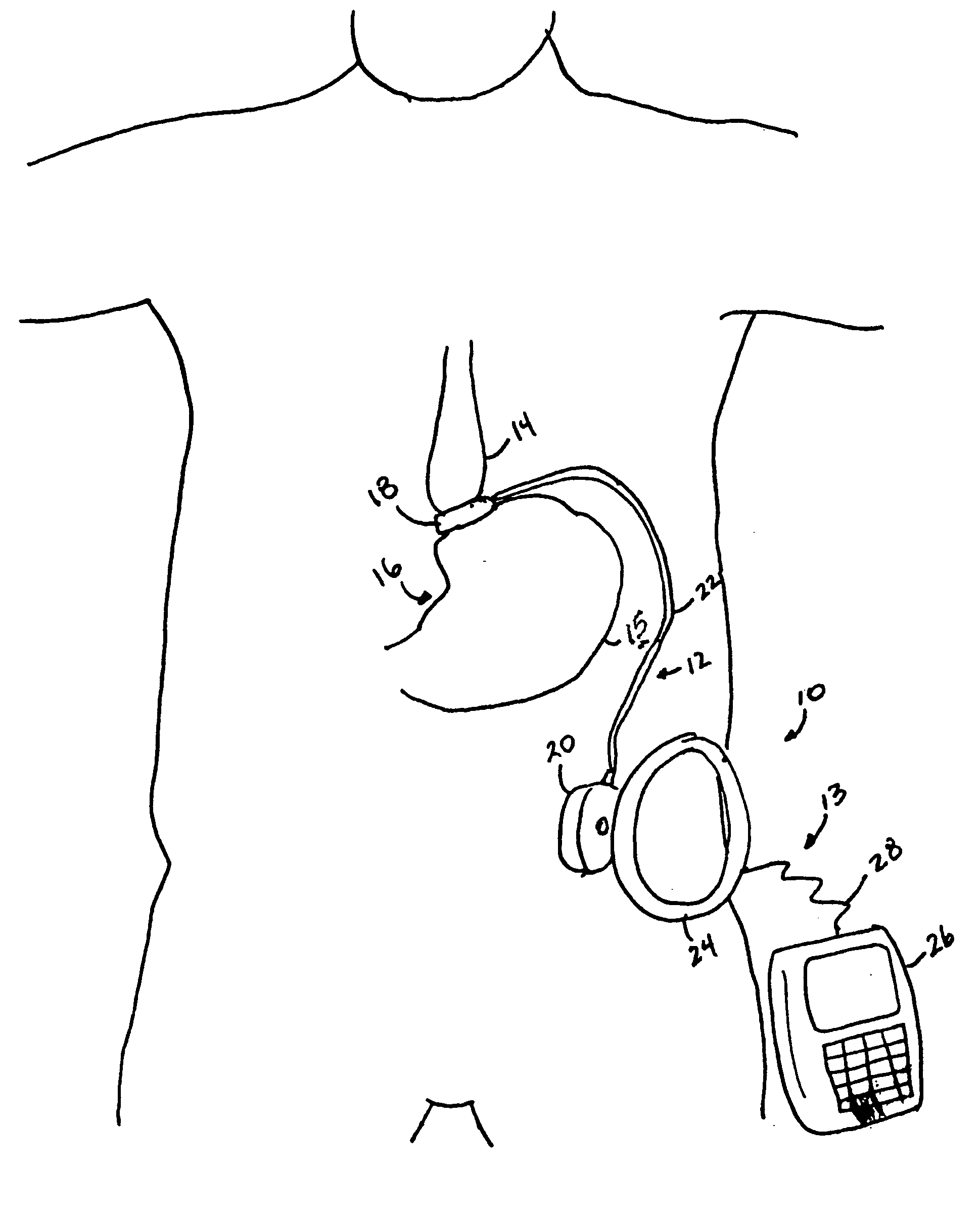

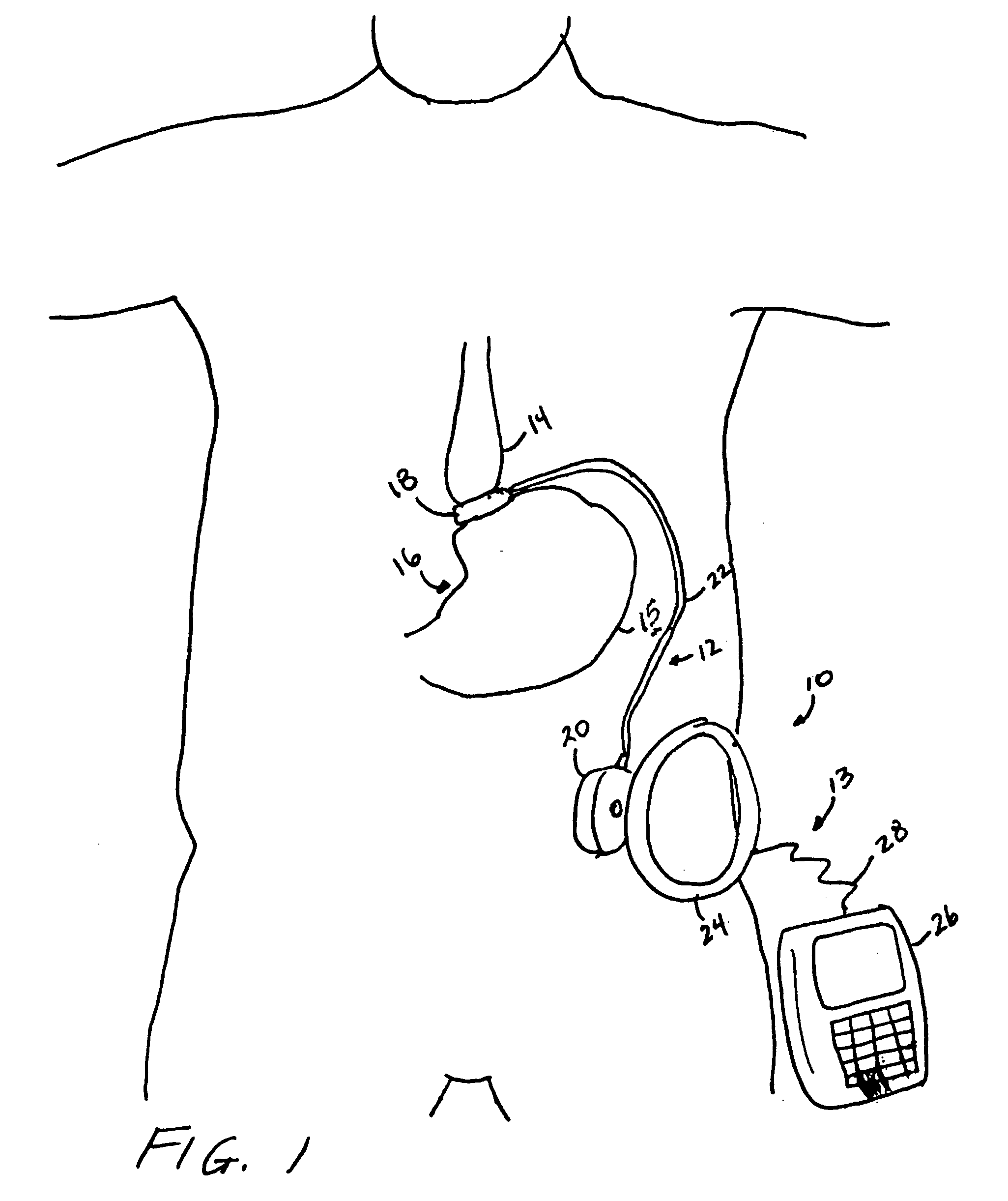

An implantable medical device, such as a bi-directional infuser device for hydraulically controlling an artificial sphincter (e.g., adjustable gastric band) benefits from being remotely powered by transcutaneous energy transfer (TET), obviating the need for batteries. In order for active components in the medical device to operate, a sinusoidal power signal received by a secondary coil is rectified and filtered. An amount of power transferred is modulated. In one version, a voltage comparison is made of a resulting power supply voltage as referenced to a threshold to control pulse width modulation (PWM) of the received sinusoidal power signal, achieving voltage regulation. Versions incorporate detuning or uncoupling of the secondary coil to achieve PWM control without causing excessive heating of the medical device.

Owner:ETHICON ENDO SURGERY INC

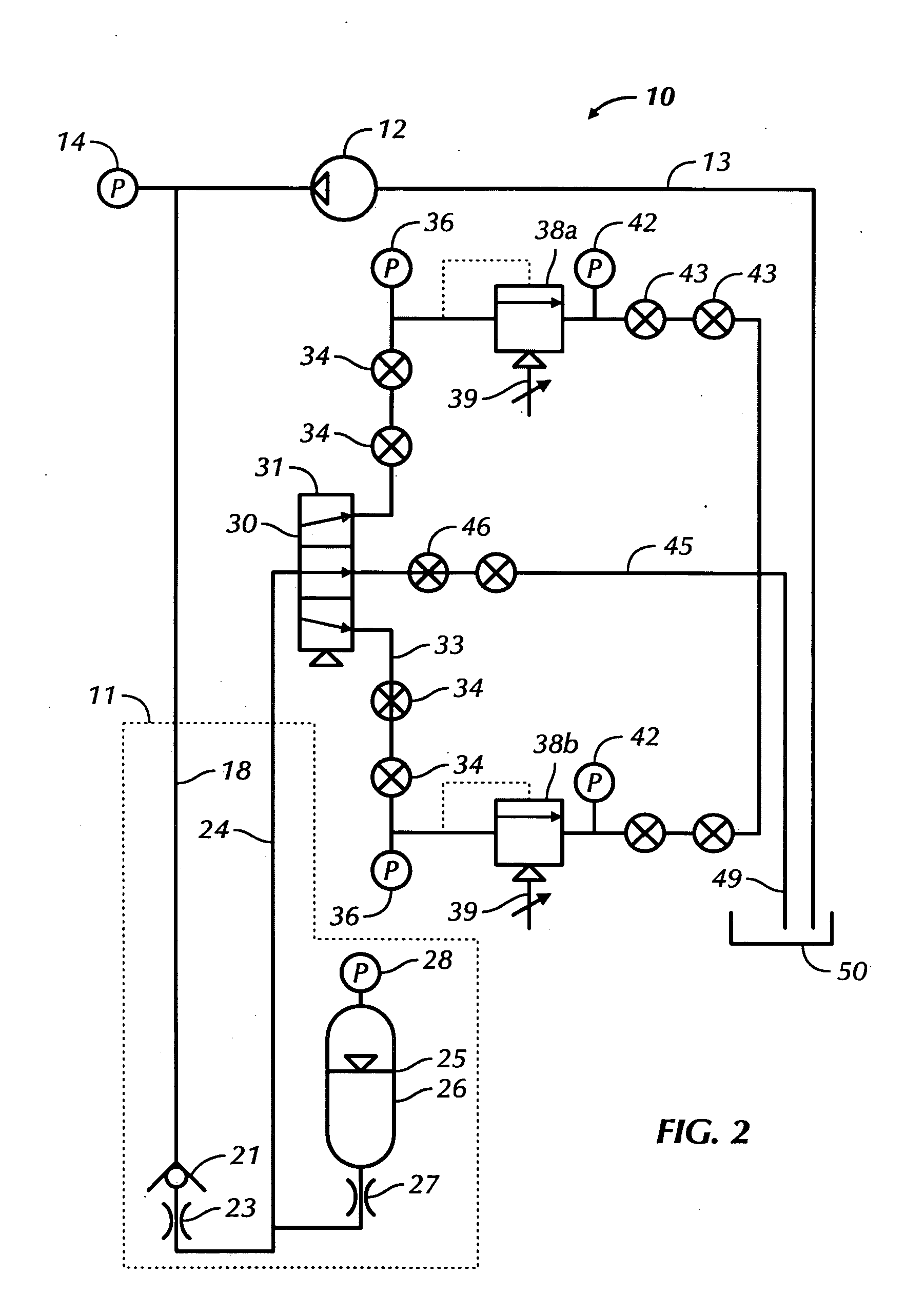

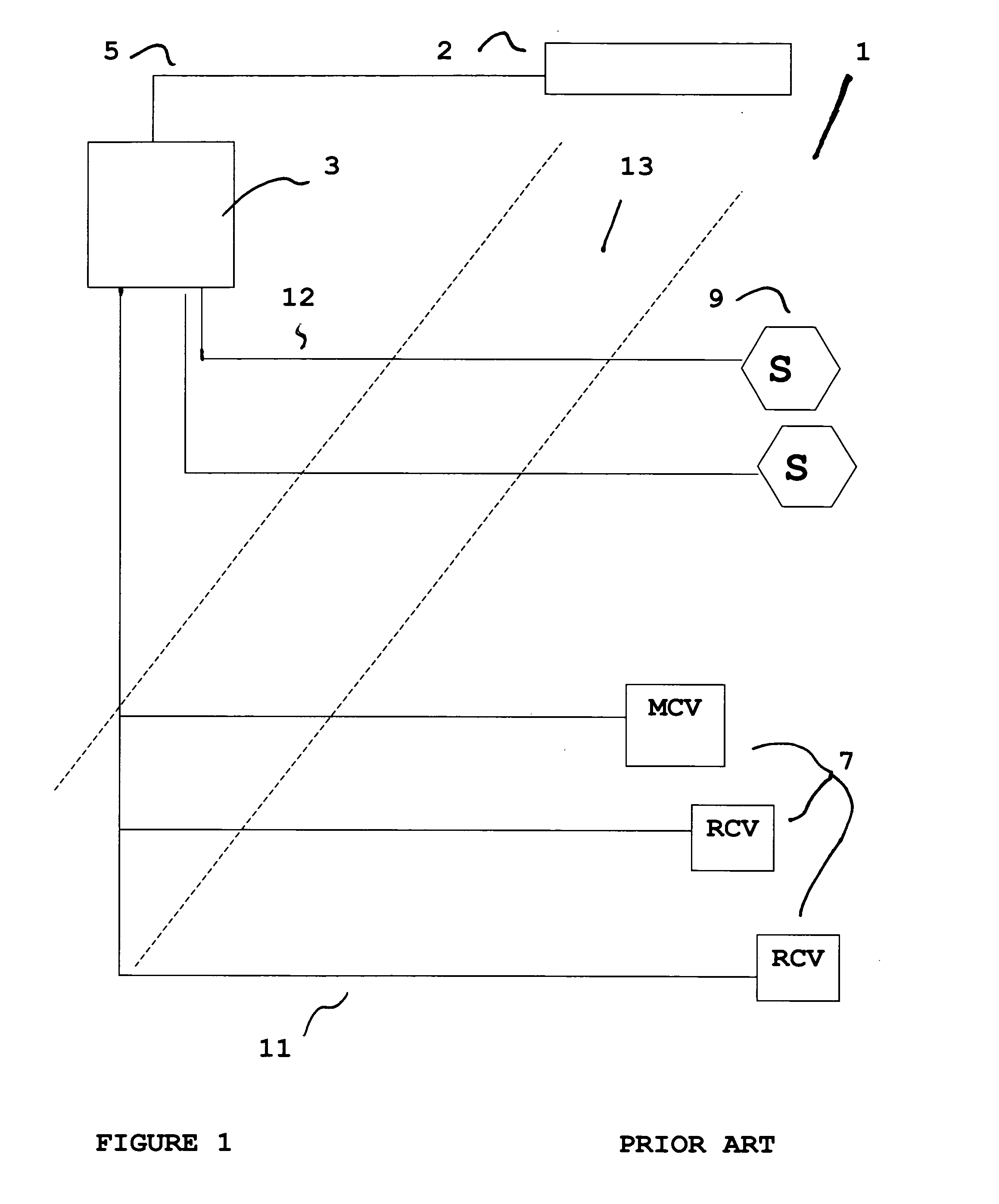

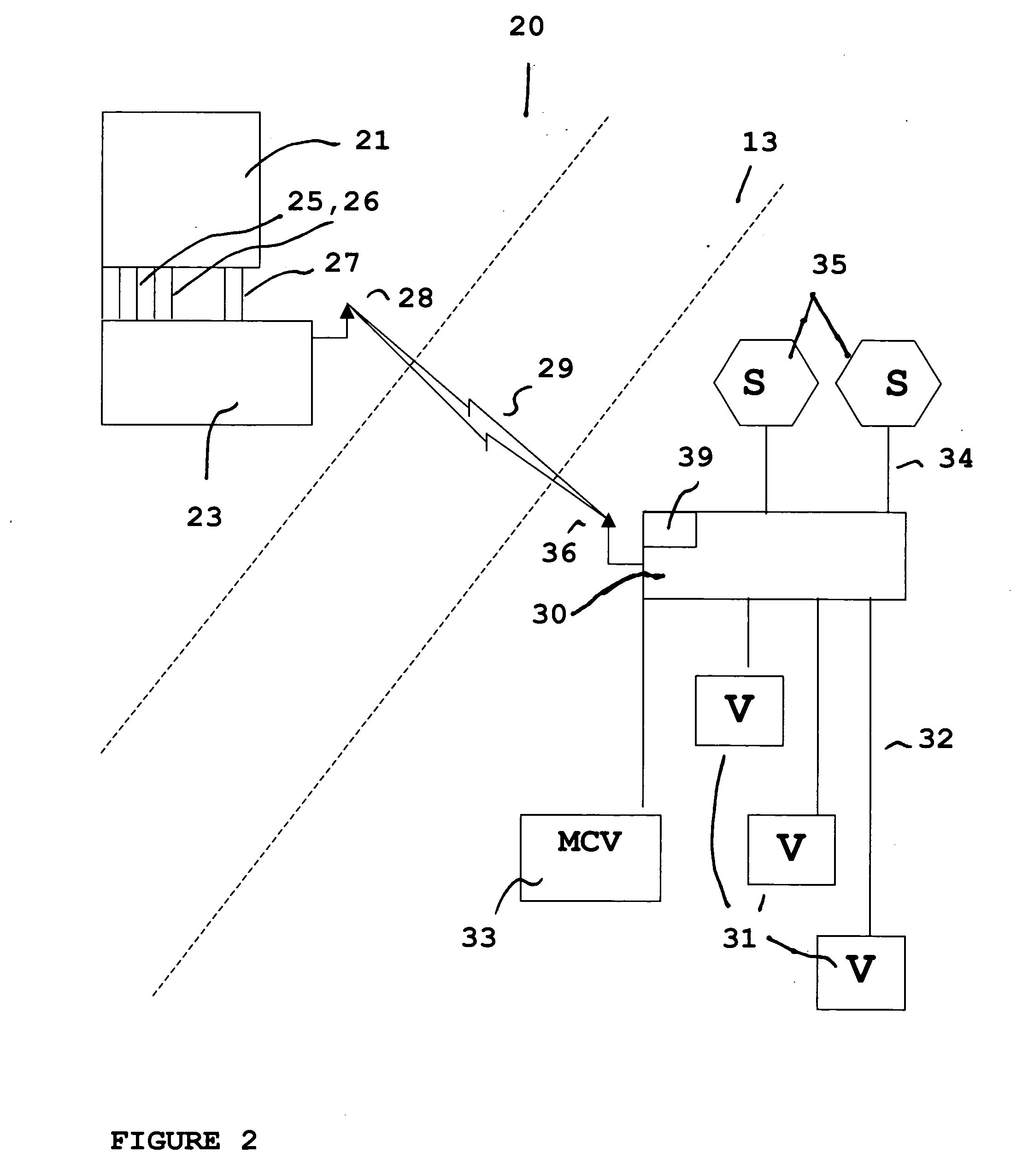

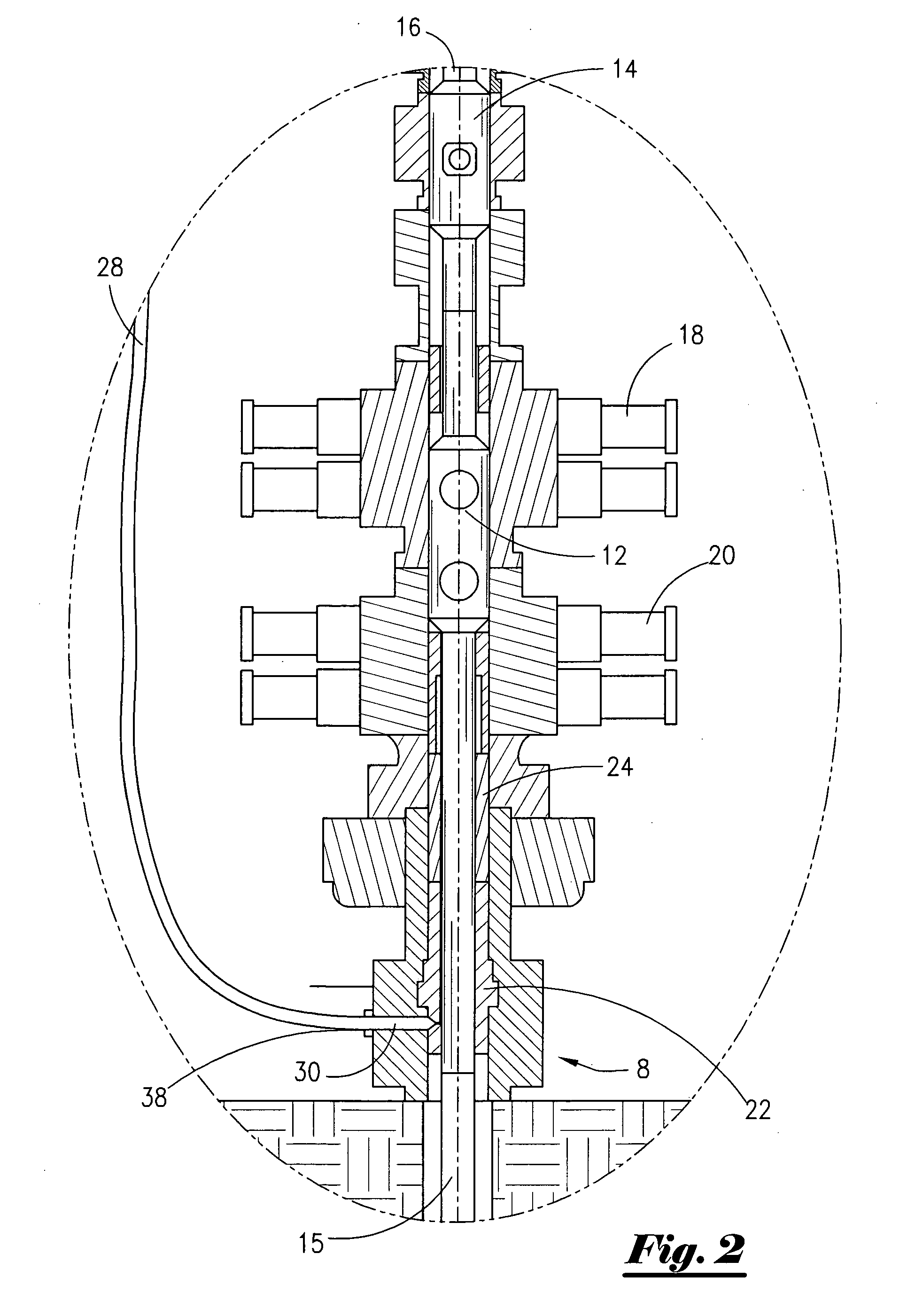

Well pressure control system

The present invention contemplates a choke control system that provides for local and off-site monitoring and control of the annulus flow pressure of a well. The choke control system includes a choke manifold connected to at least one choke and its associated actuator; a variety of instrumental drilling sensors, pump stroke counter switches, and choke position indicators; a local choke and hydraulic pressure control console; and a programmable controller in communication with the local choke and hydraulic pressure control console. The programmable controller handles the logical operations of the choke control system, including processing instrument measurements and operator input data to produce control signals for operating the choke, the choke actuator and the various valves associated with the choke manifold. The programmable controller is typically either an electronic digital computer and / or a programmable logic controller (PLC). The present invention further contemplates the two-way communication between the choke control system and the Internet via a satellite linkage.

Owner:EXPRO AMERICAS

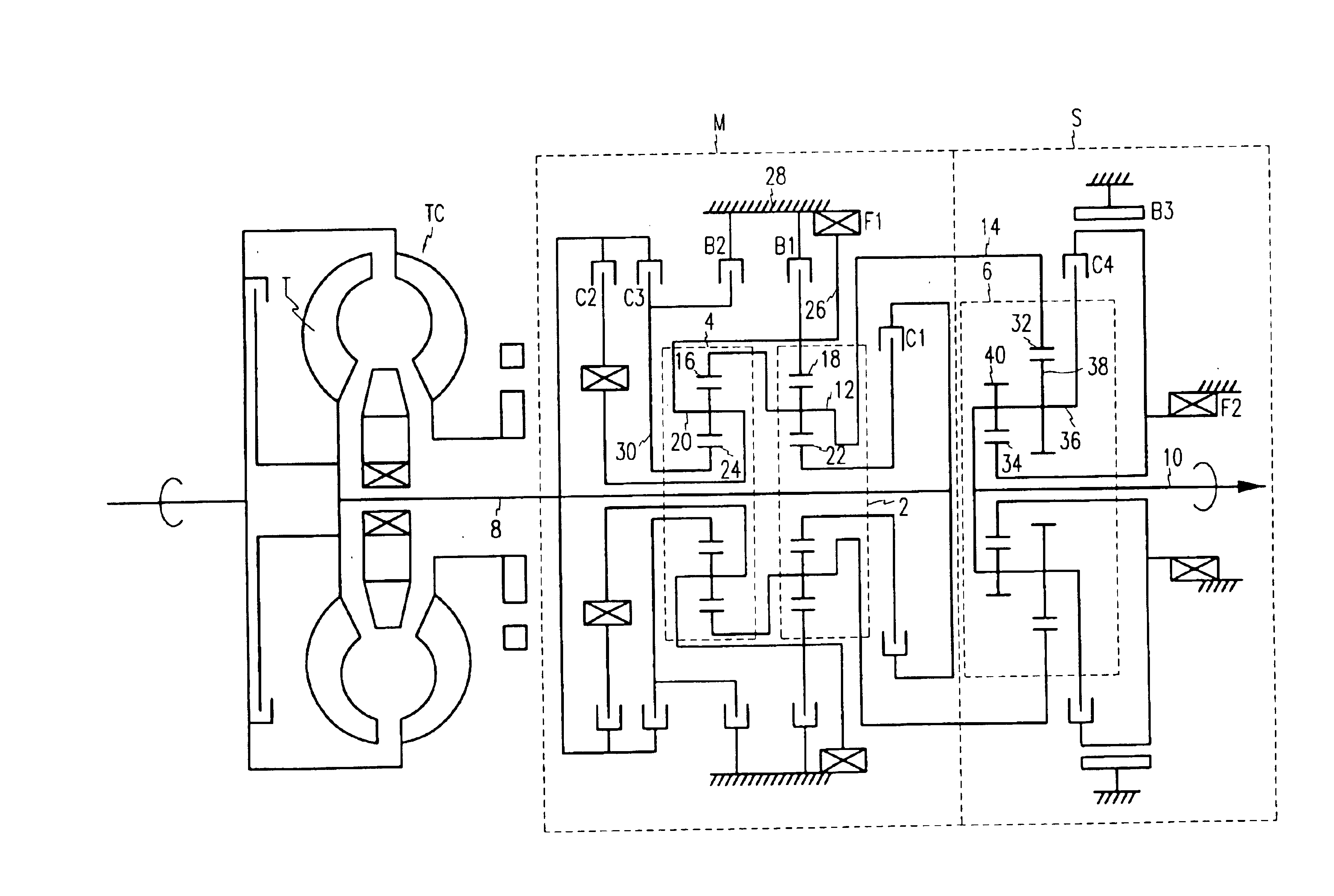

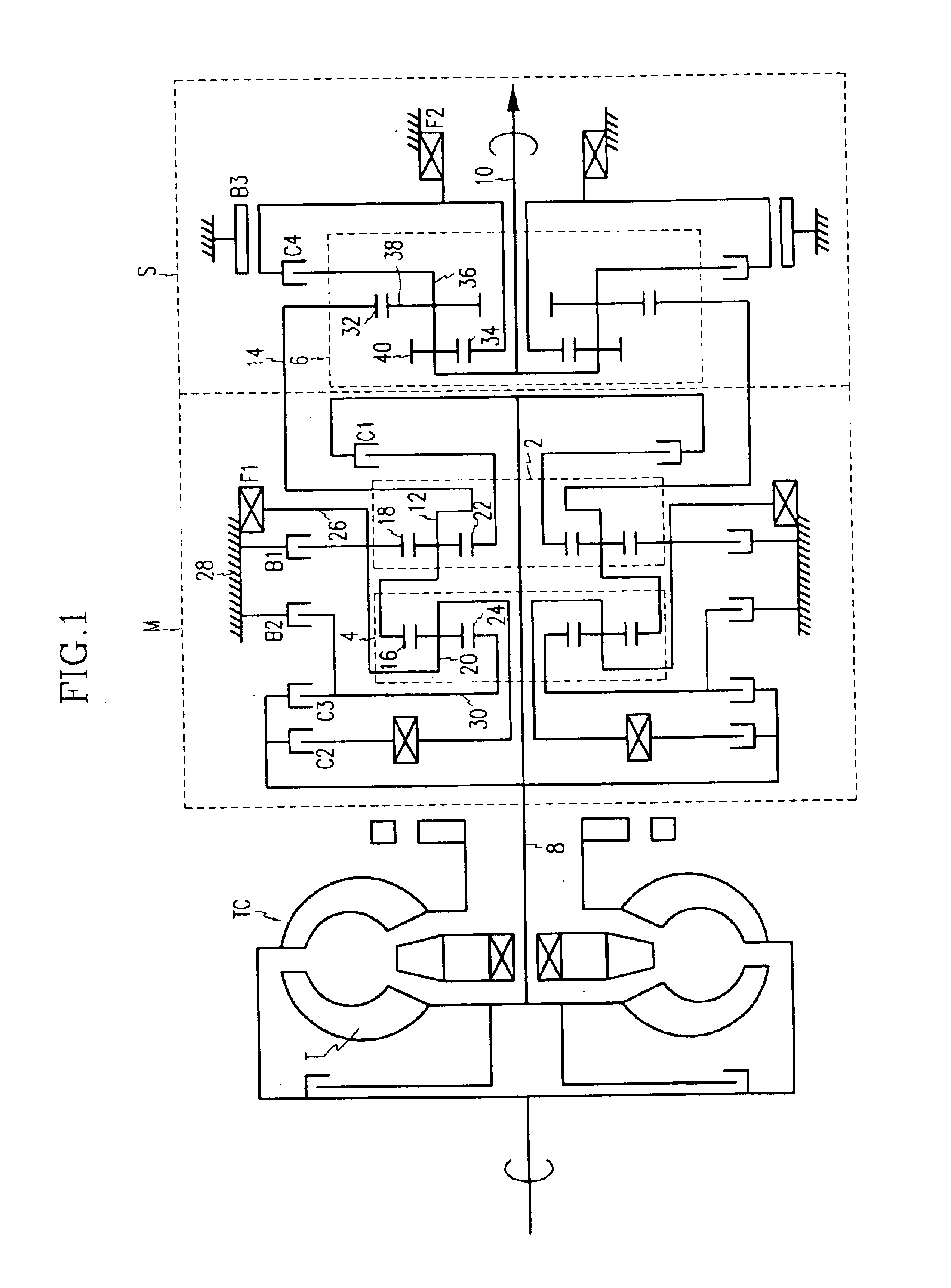

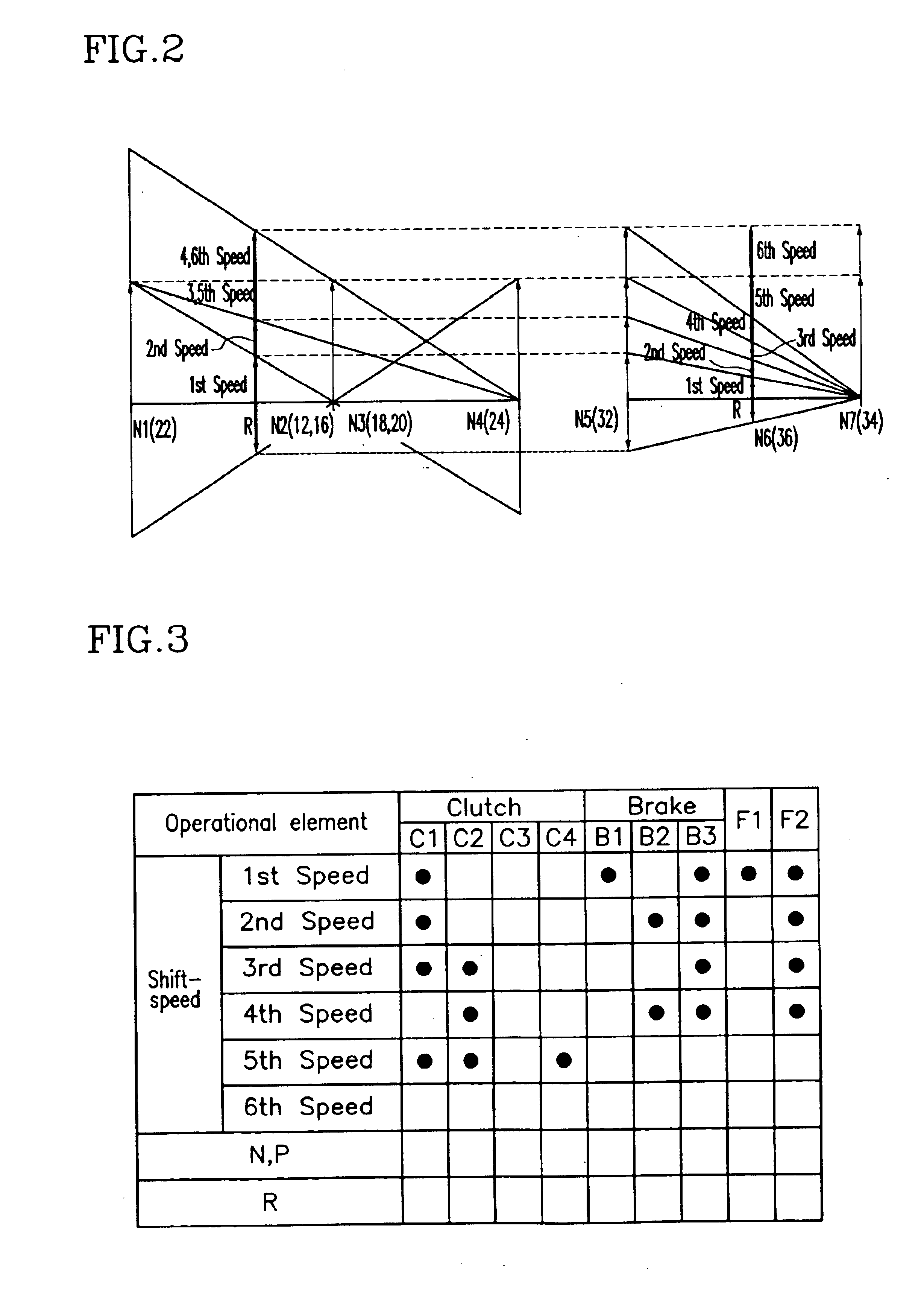

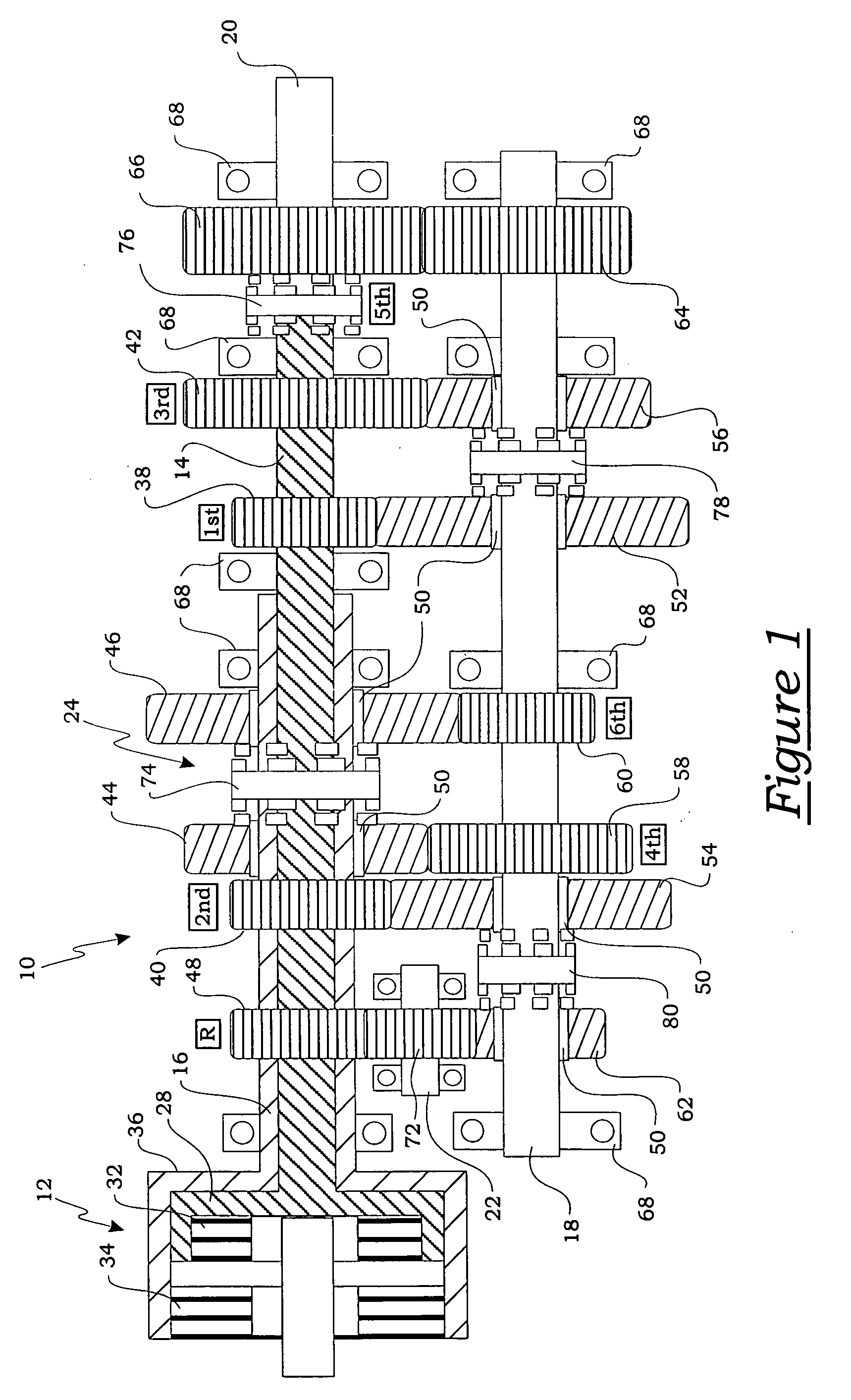

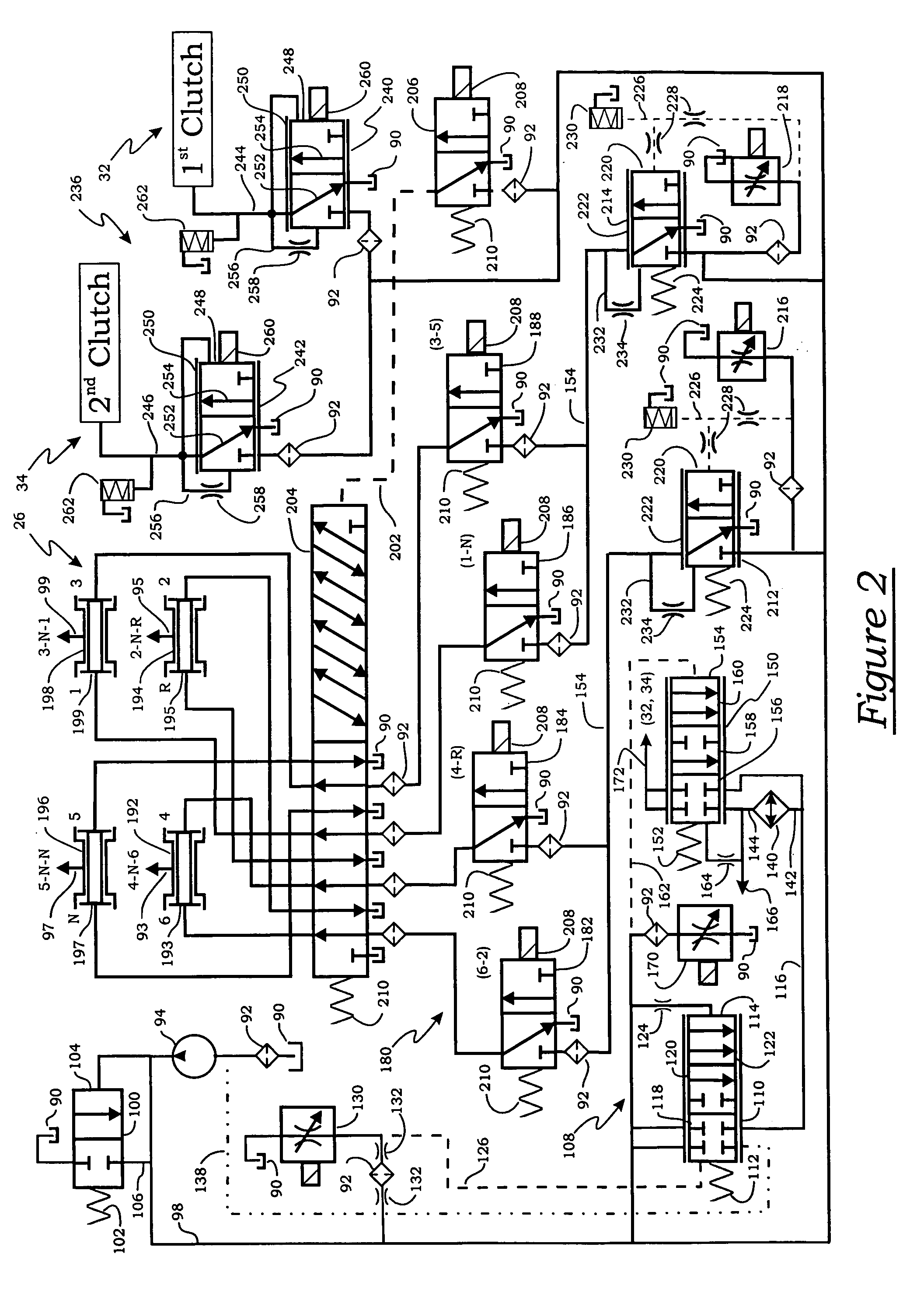

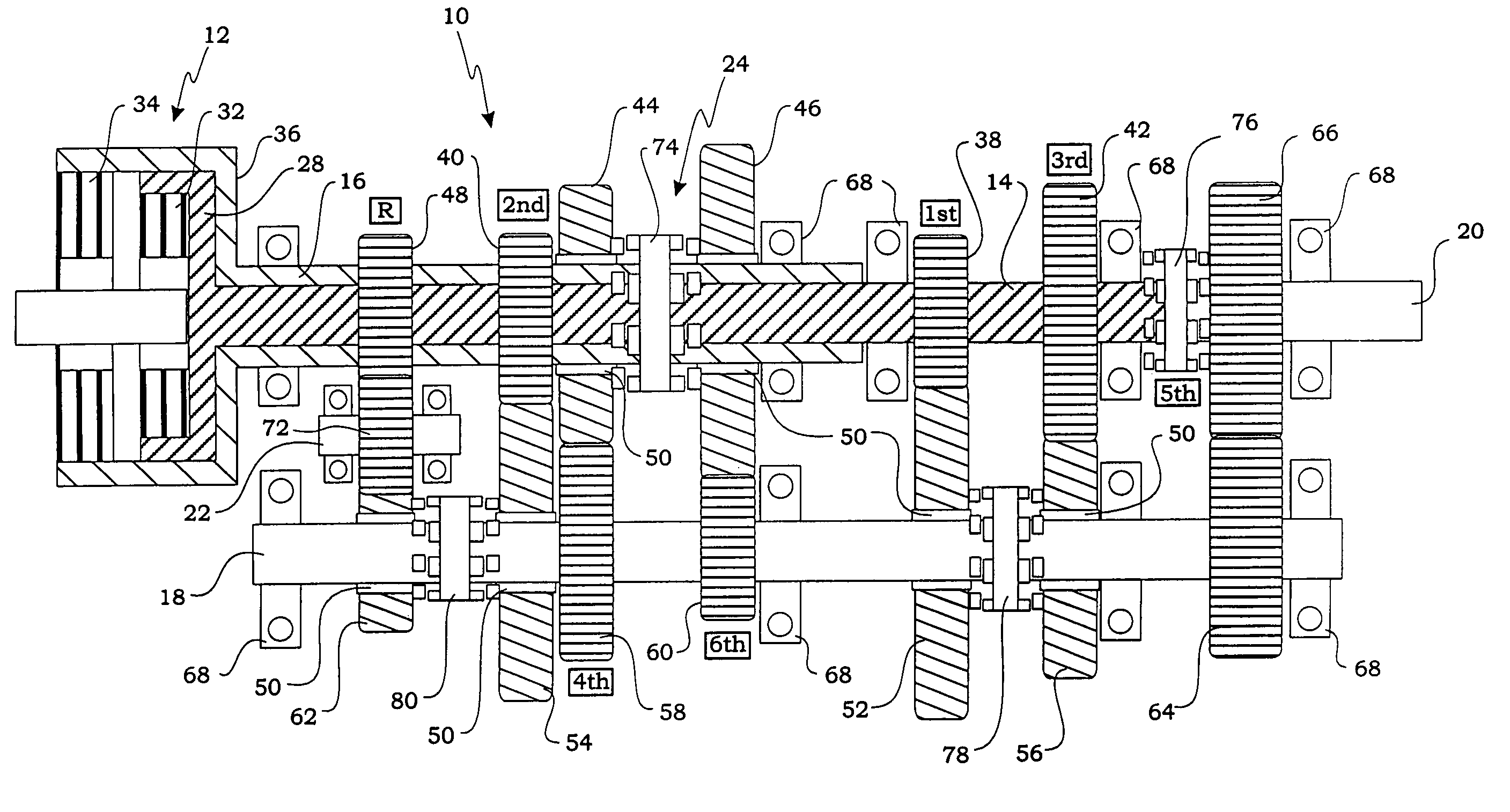

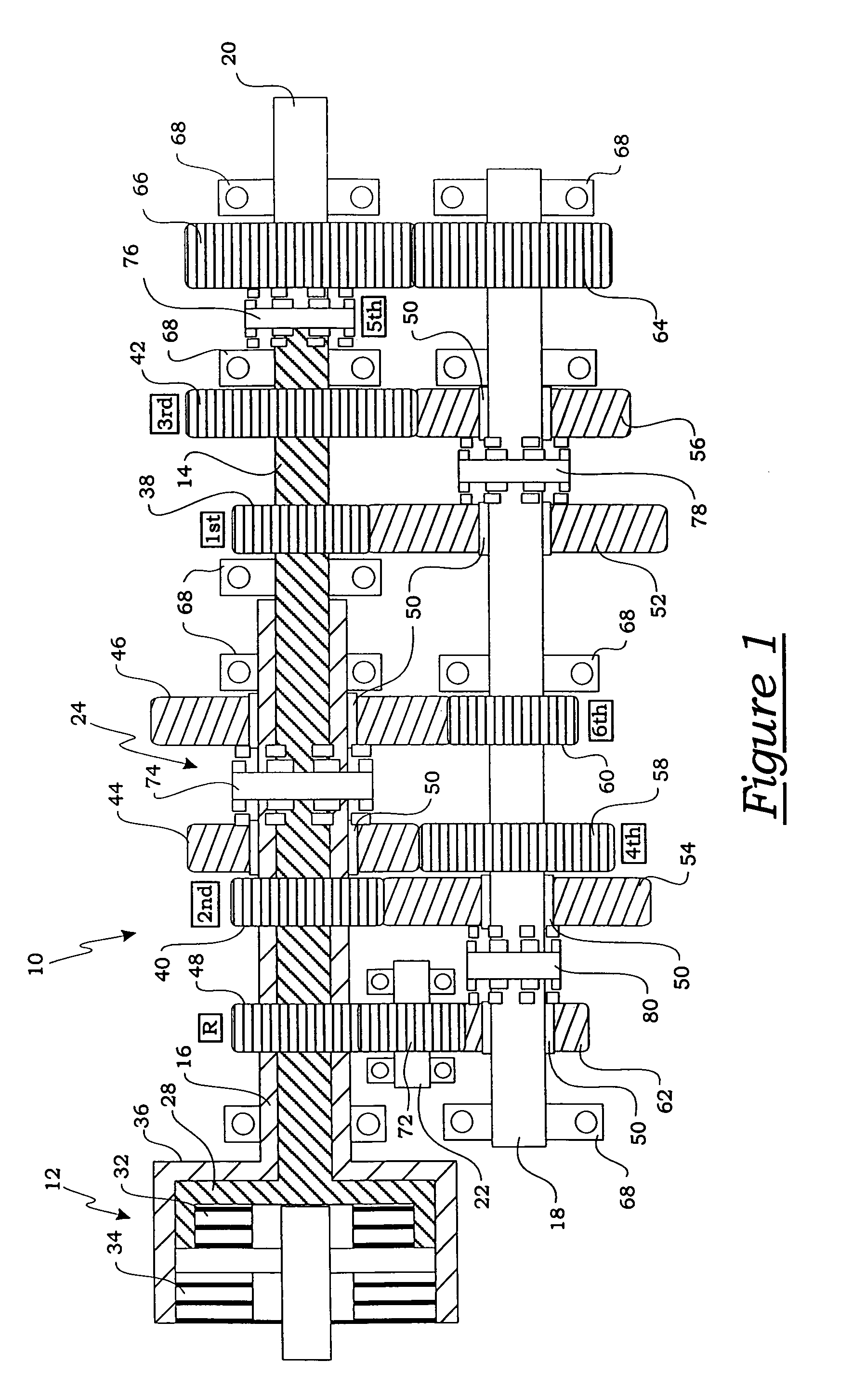

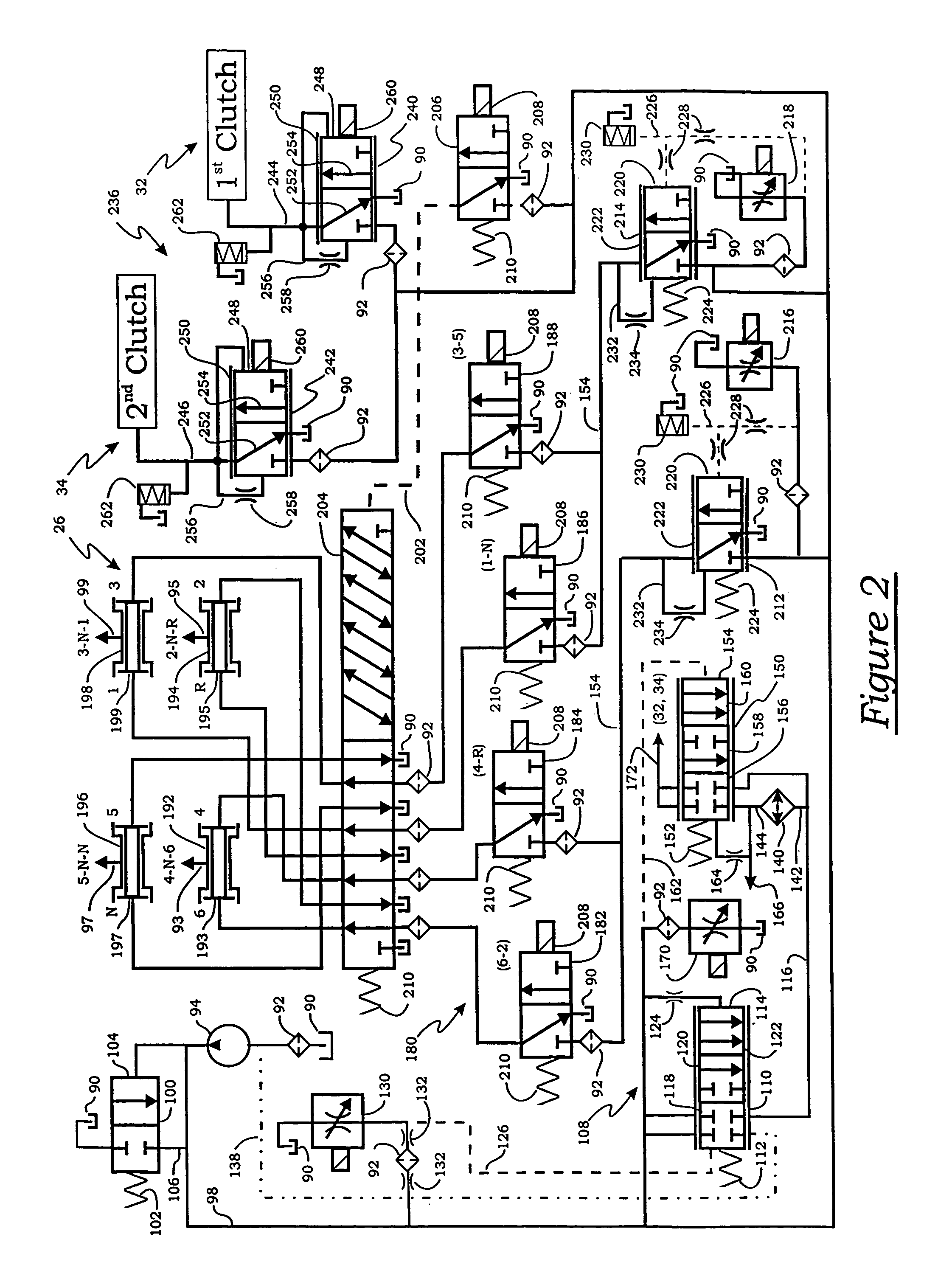

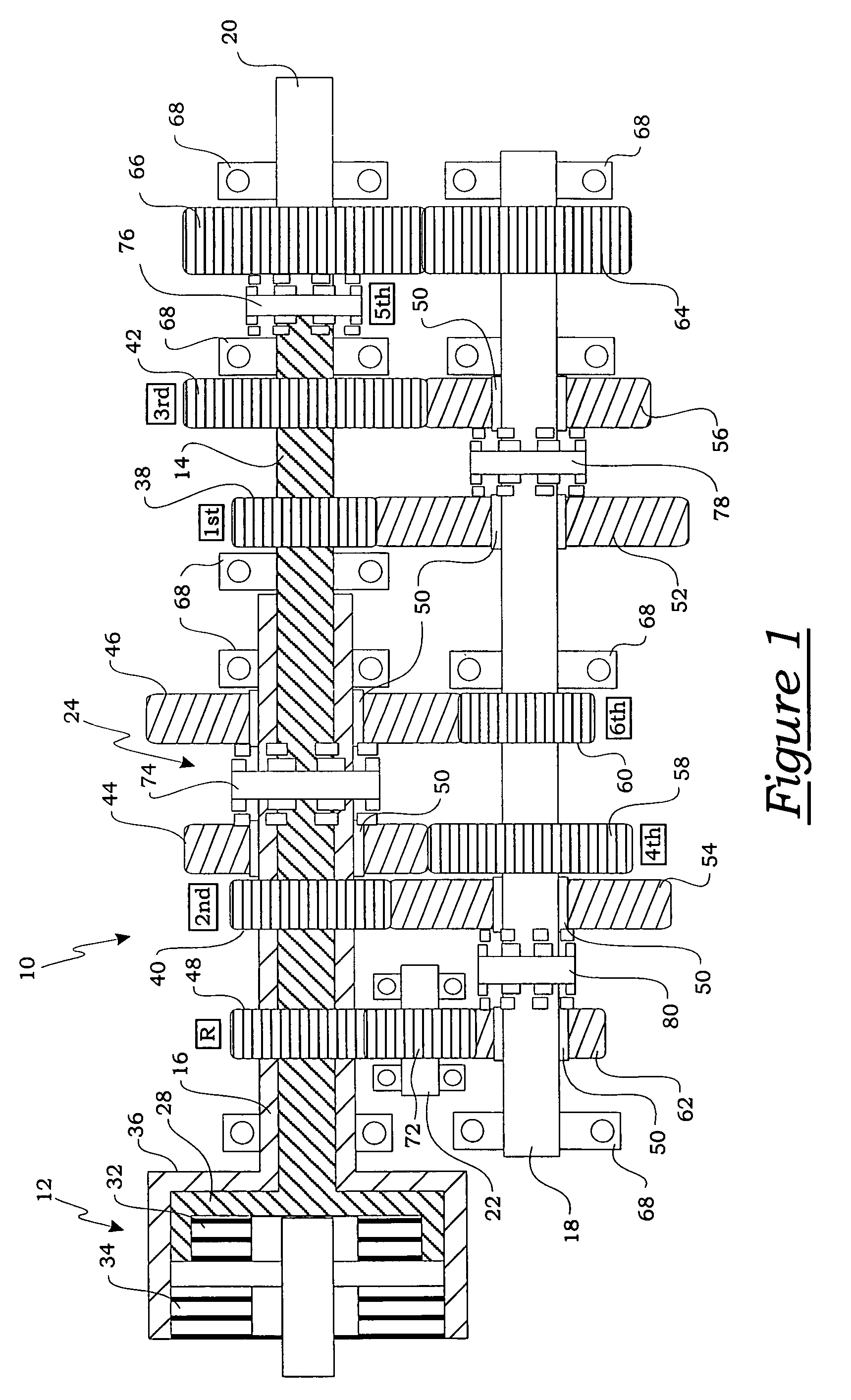

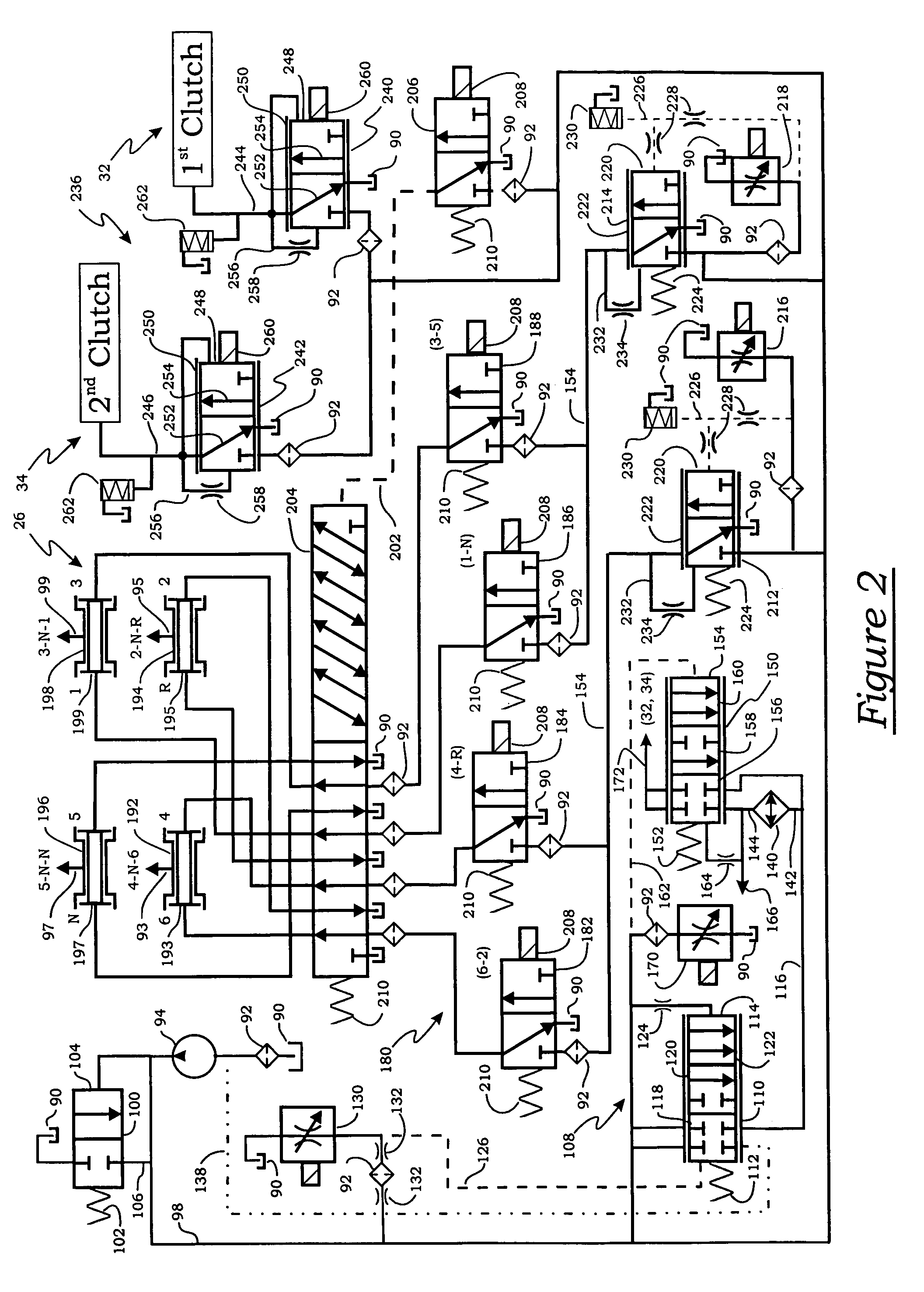

Six-speed powertrain and hydraulic control system for automatic transmission

InactiveUS6840885B2Improve power performanceImprove shift feelToothed gearingsGearing controlAutomatic transmissionControl system

The powertrain of a six-speed powertrain and a hydraulic control system includes a main shift section of first and second single pinion planetary gearsets, in which a first planet carrier is fixedly connected to a second ring gear. The powertrain also includes a first ring gear fixedly connected to a second planet carrier, and a first sun gear. The second planet carrier, and a second sun gear are variably connected to an input shaft through first, second, and third clutches, respectively. A connecting member connecting the first ring gear and the second planet carrier is variably connected to a housing through a first brake and a first one-way clutch. The second sun gear being variably connected to the housing by a second brake. The powertrain also includes a secondary shift section realized through a third single pinion planetary gearset, in which a third sun gear is connected to a third planet carrier via a fourth clutch, and is also connected to the housing through a third brake and a second one-way clutch.

Owner:HYUNDAI MOTOR CO LTD

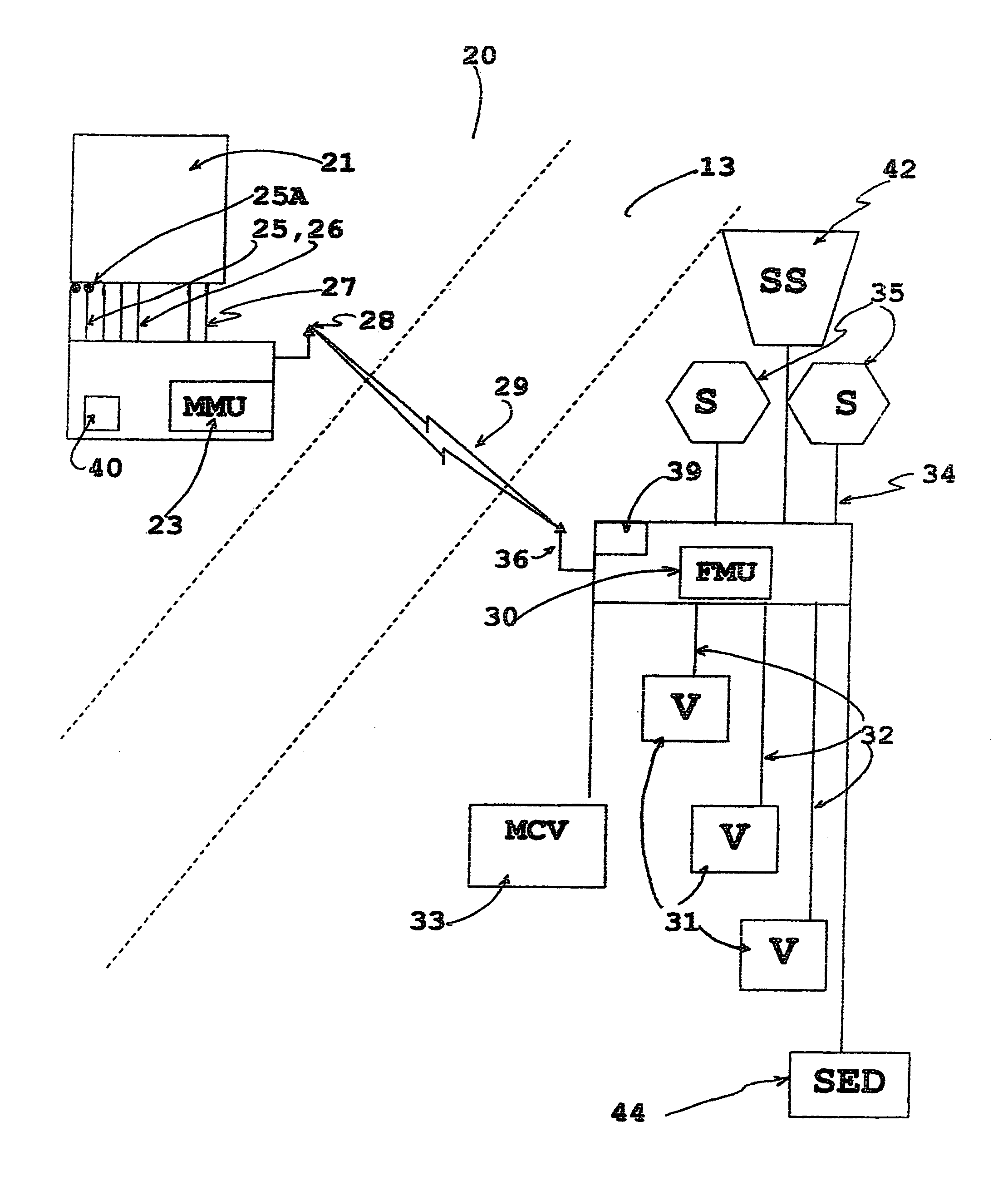

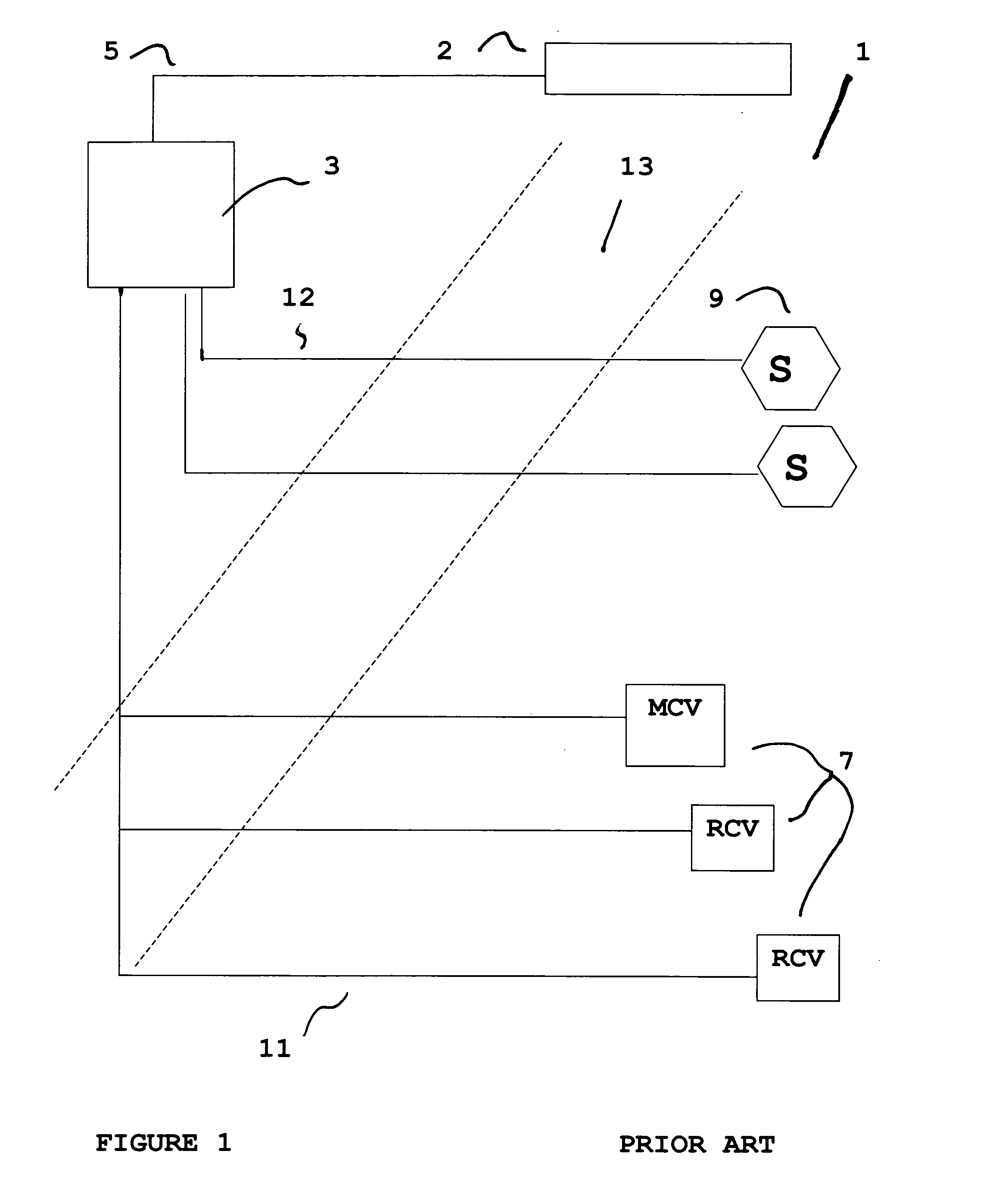

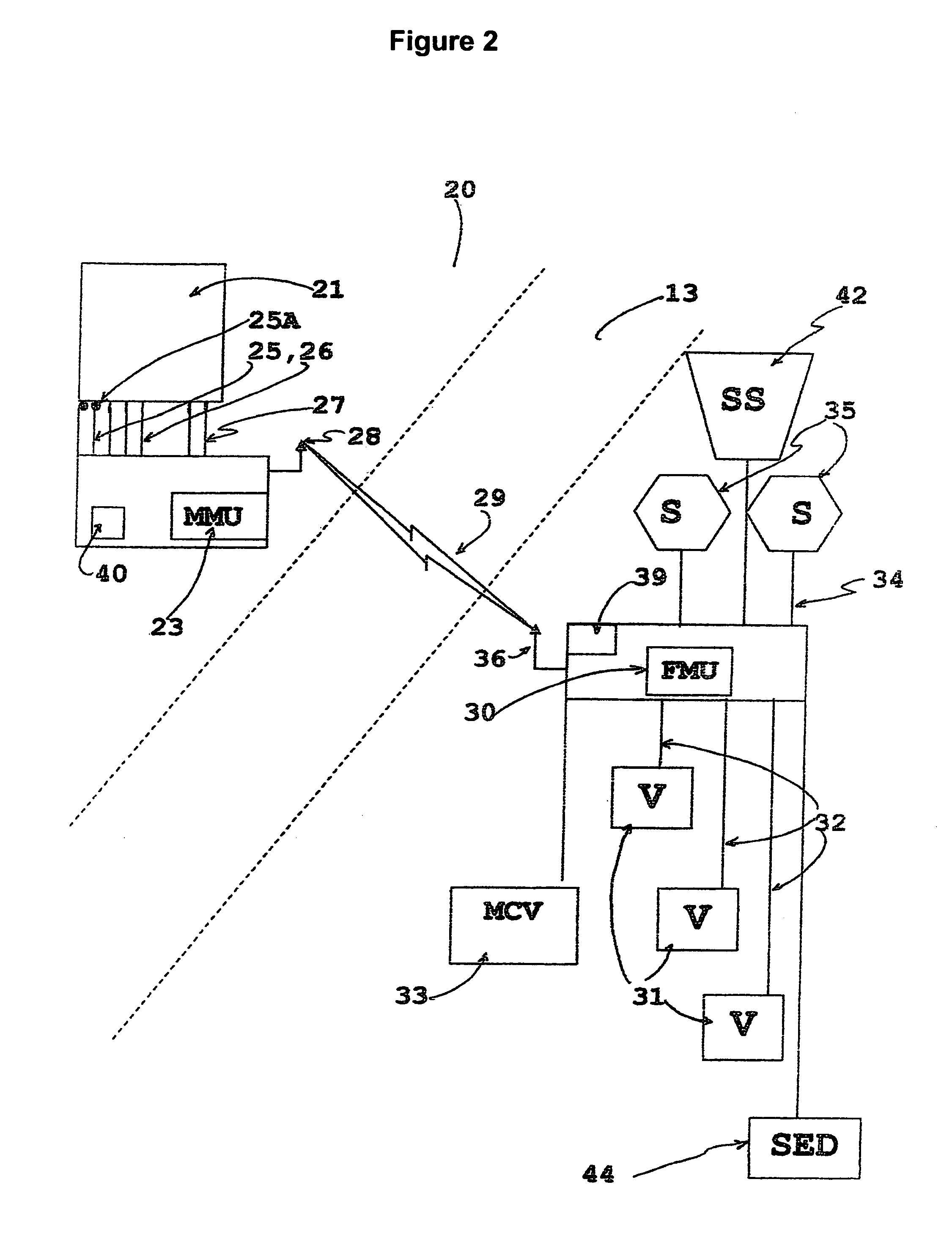

Wireless sensor and control transmitter system

InactiveUS7050887B2Cost effectiveEliminate needOperating means/releasing devices for valvesSelf-acting watering devicesData connectionLine sensor

Owner:TECHSTREAMS CONTROL SYST AN ARIZONA

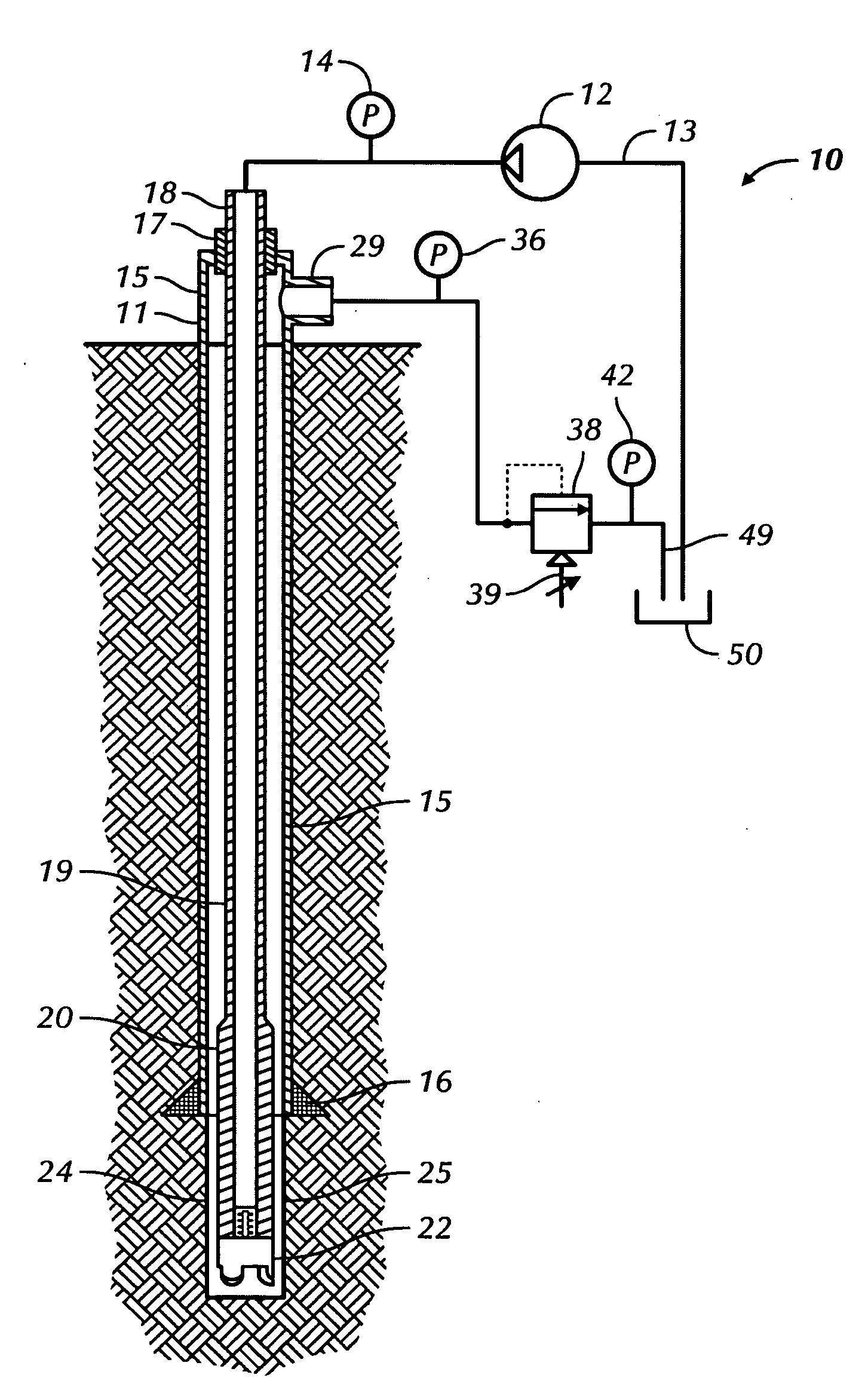

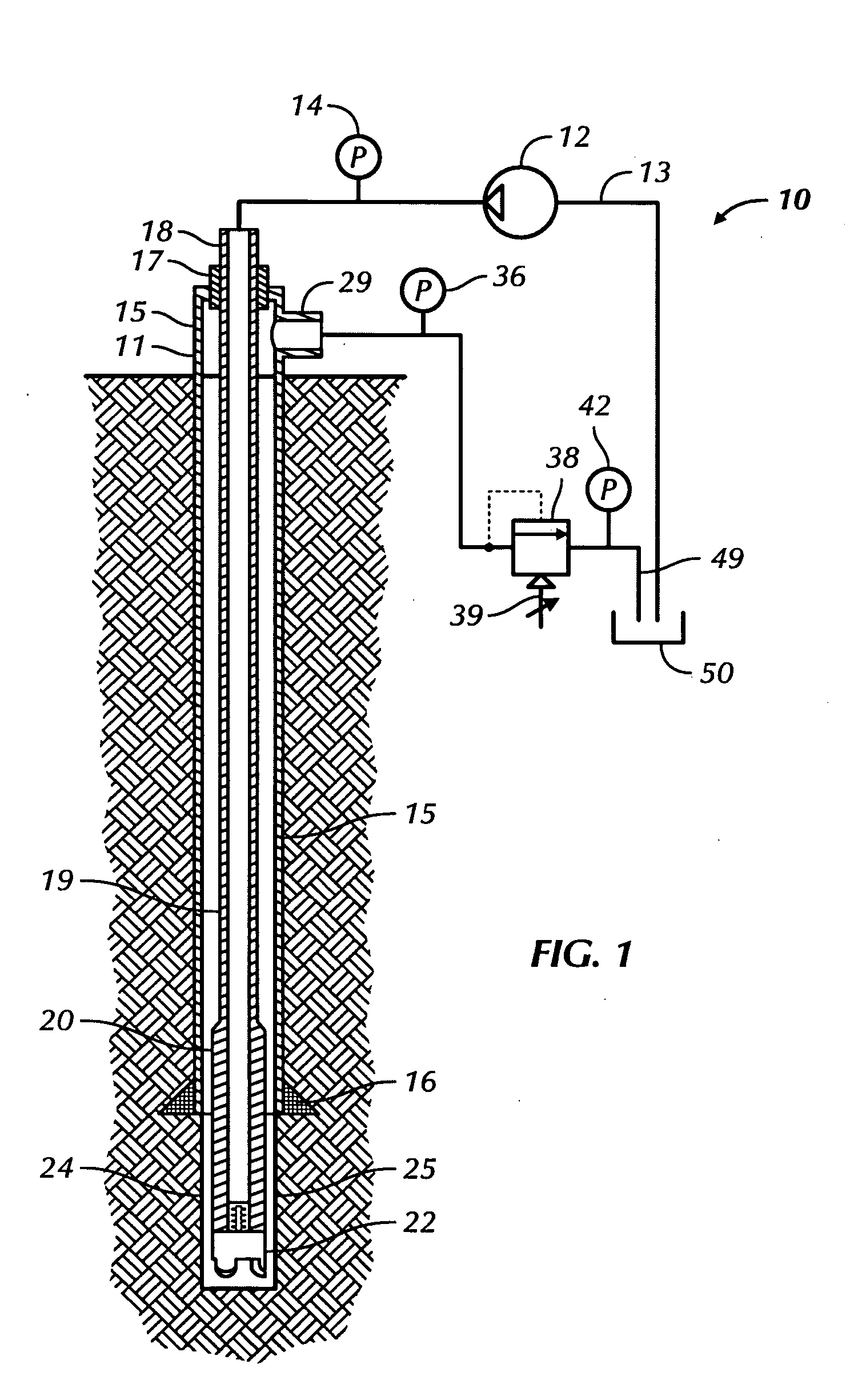

Metal bellows position feedback for hydraulic control of an adjustable gastric band

InactiveUS7481763B2Avoid the needNon-surgical orthopedic devicesObesity treatmentClosed loopEngineering

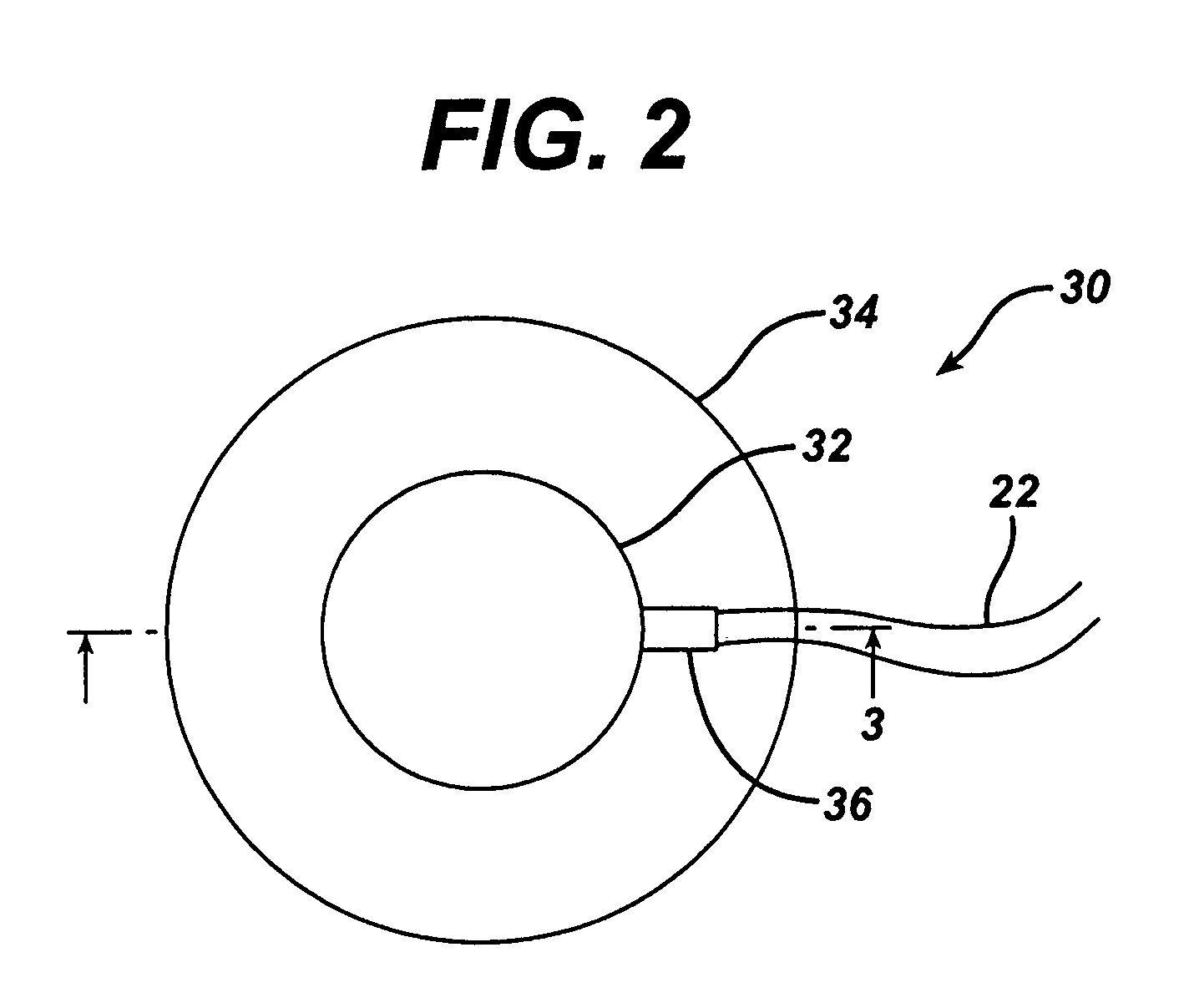

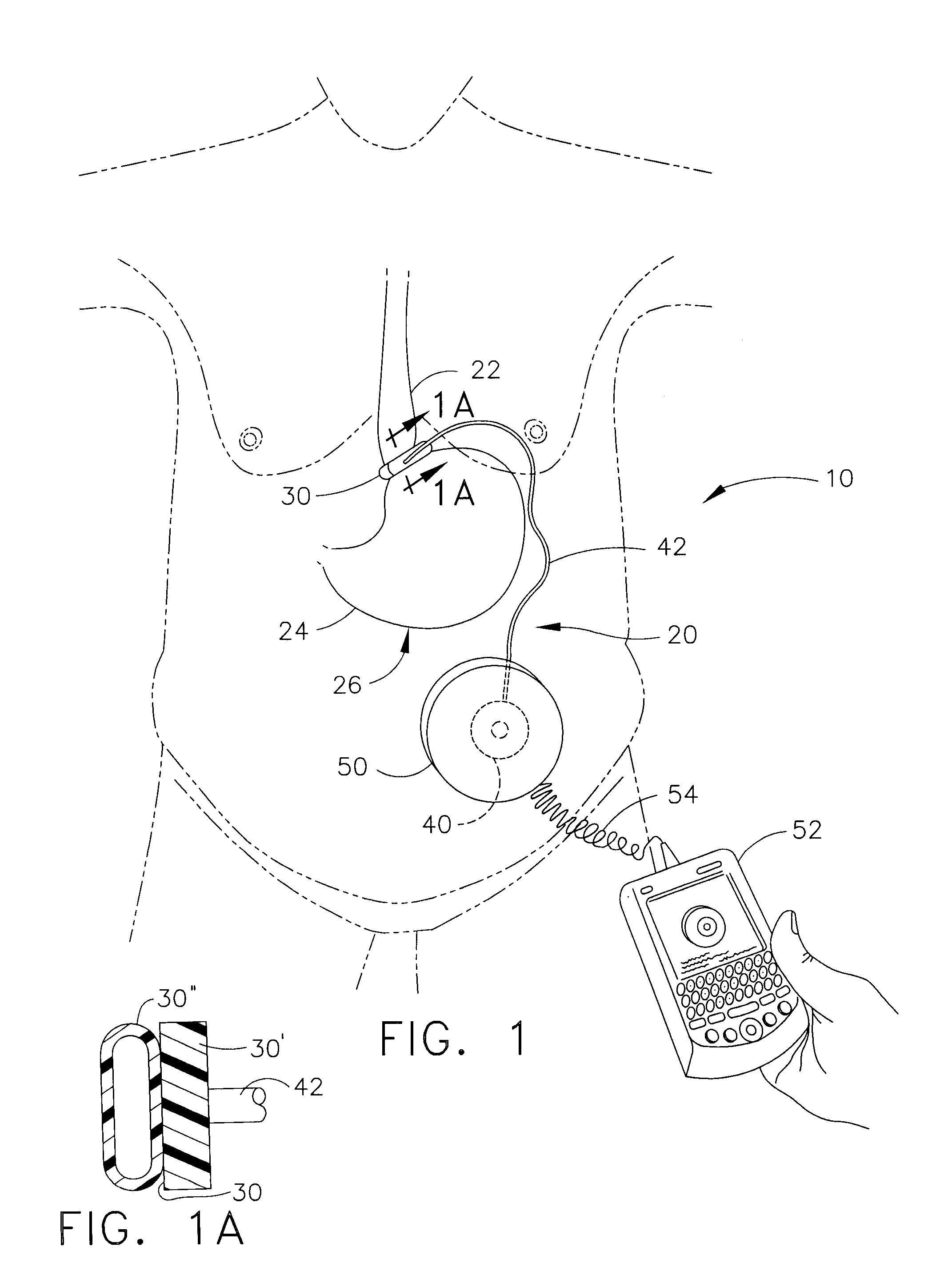

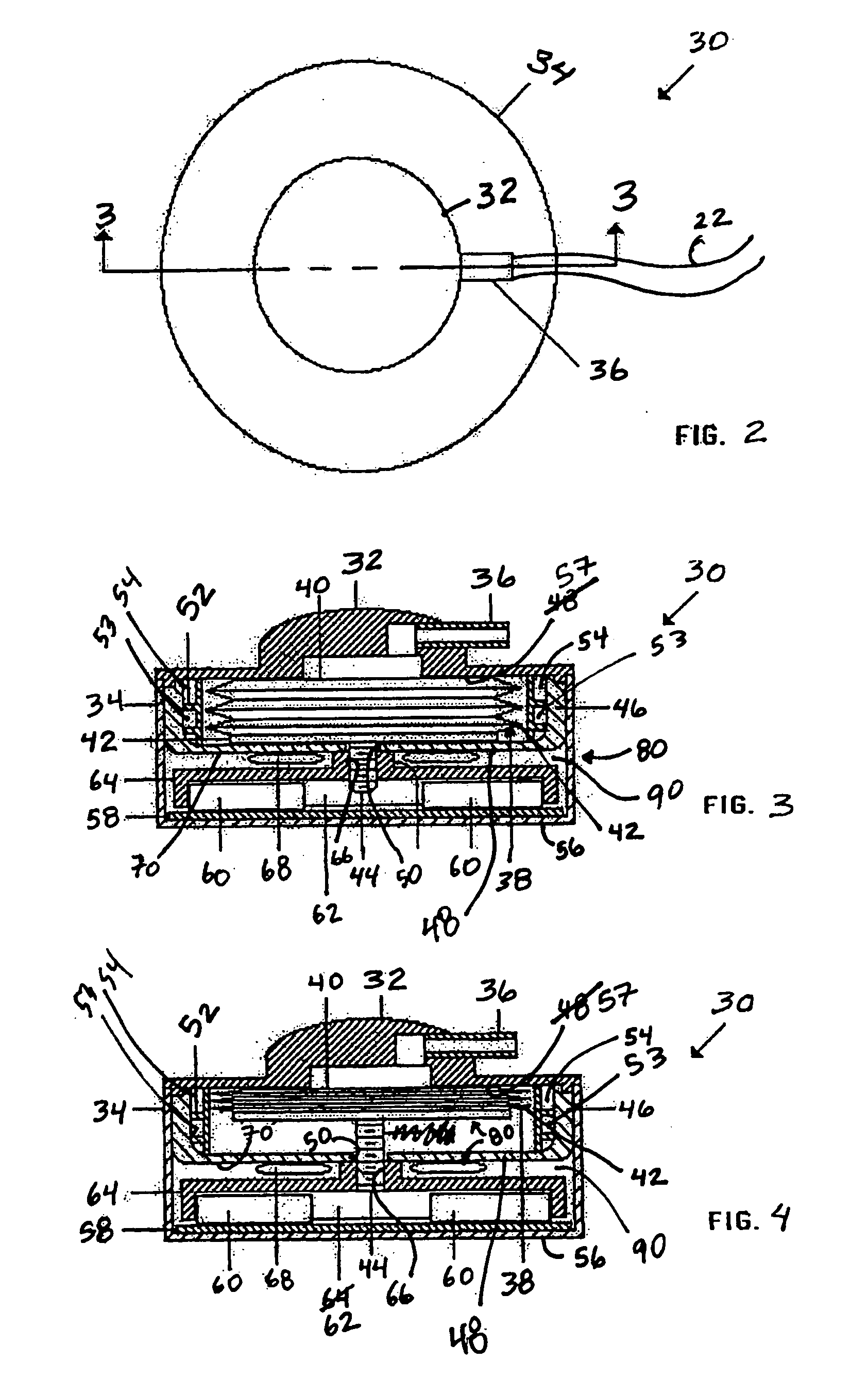

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume for hydraulic control of a gastric band. A piezoelectric driver (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic enclosure or case such as titanium. Directly sensing a position of the metal bellows yields an accurate reading of volume contained therein, allowing for closed-loop control of the gastric band.

Owner:ETHICON ENDO SURGERY INC

Bi-directional infuser pump with volume braking for hydraulically controlling an adjustable gastric band

InactiveUS7374565B2Increase varietyAvoid changeAnti-incontinence devicesPharmaceutical delivery mechanismPiezo electricEngineering

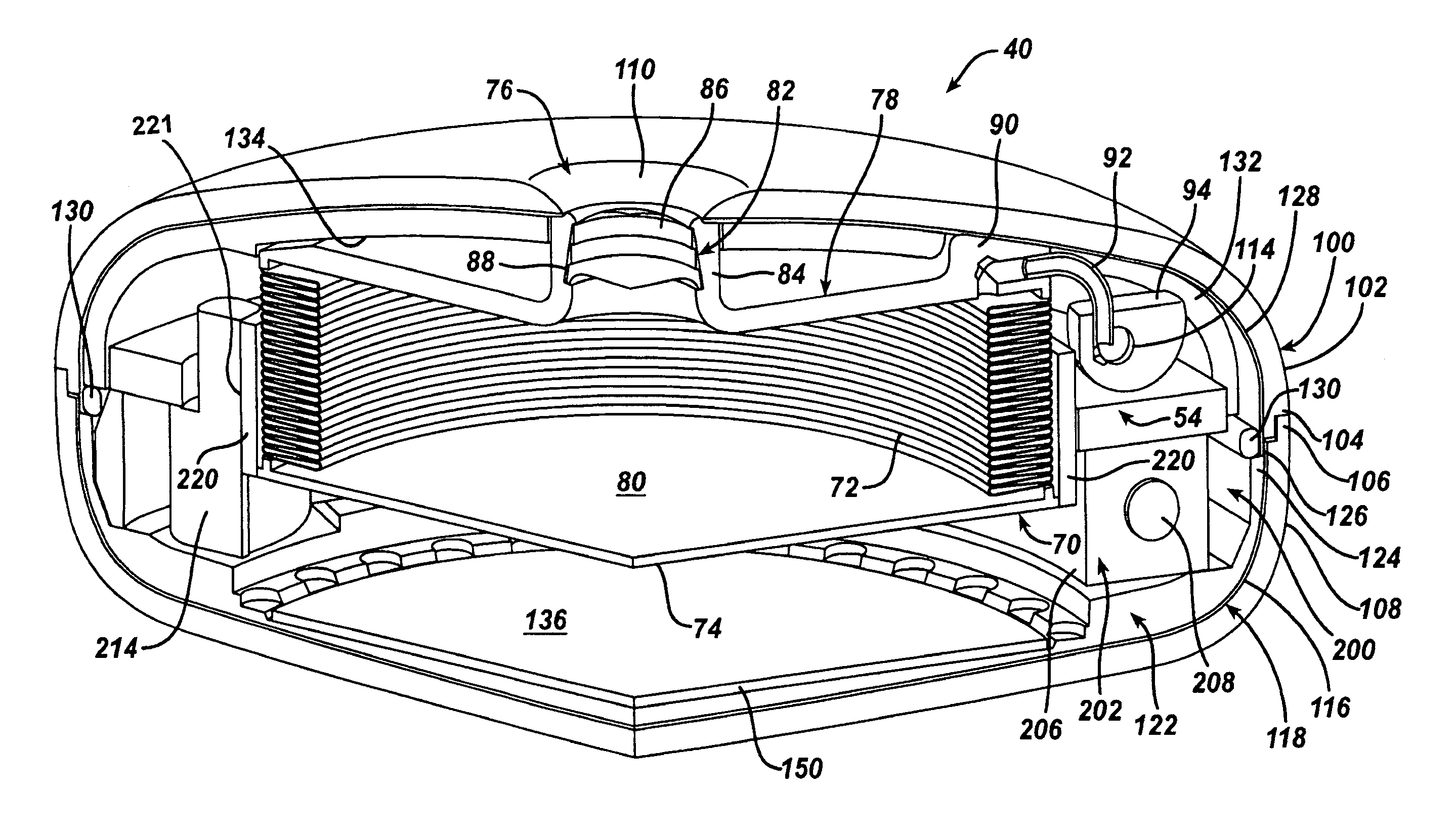

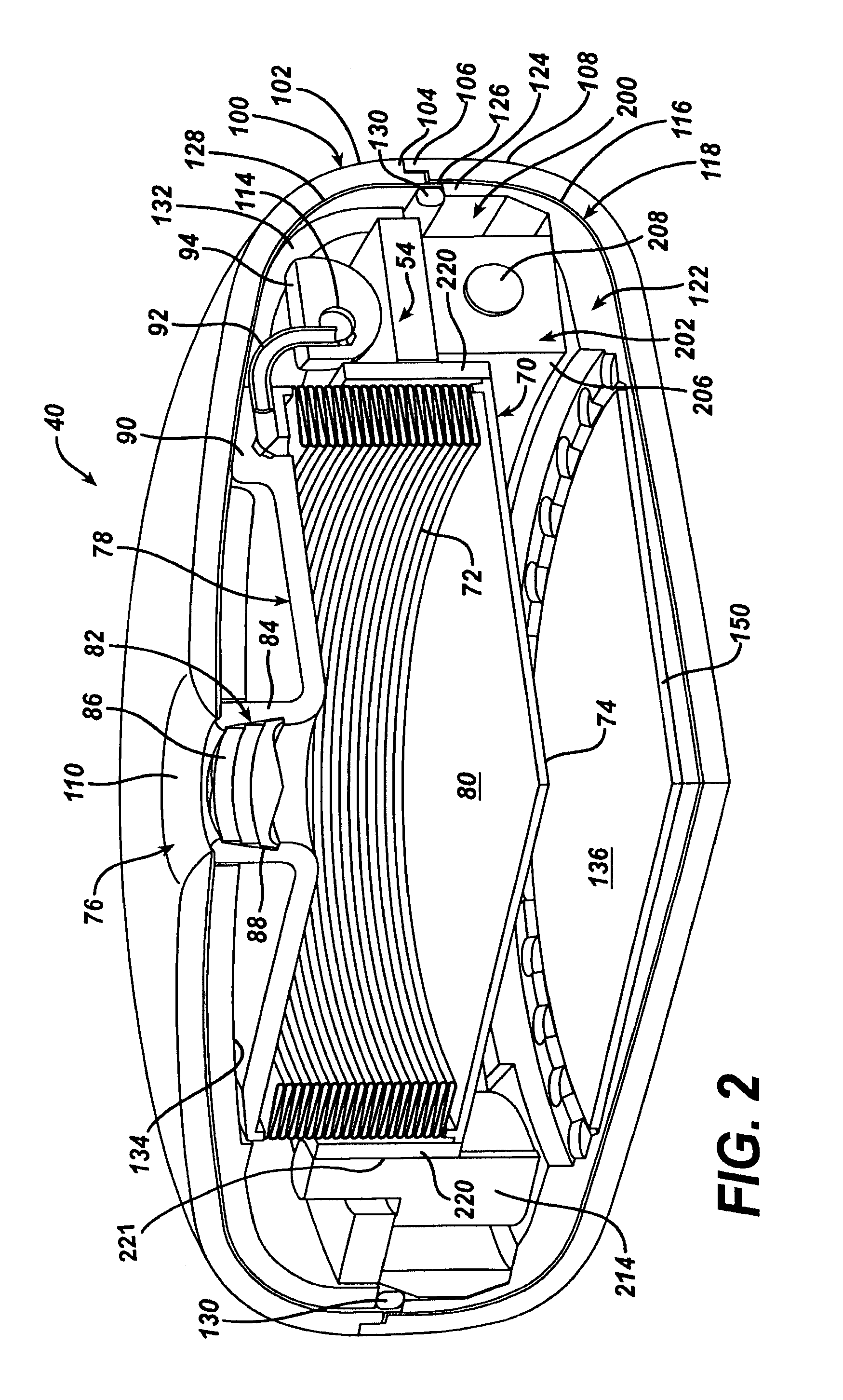

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Metal bellows position feedback for hydraulic control of an adjustable gastric band

InactiveUS20050267500A1Precise motion controlAvoid the needNon-surgical orthopedic devicesObesity treatmentClosed loopEngineering

A remotely controlled gastric band system that is practically immune to external magnetic fields, such as from a Magnetic Resonance Imaging (MRI) machine, incorporates a bi-directional pump and fluid reservoir to adjust fluid volume for hydraulic control of a gastric band. A piezoelectric driver (e.g., rotary actuator, linear actuator) selectively compresses and expands a metal bellows hermetically sealed within a biocompatible and nonferromagnetic enclosure or case such as titanium. Directly sensing a position of the metal bellows yields an accurate reading of volume contained therein, allowing for closed-loop control of the gastric band.

Owner:ETHICON ENDO SURGERY INC

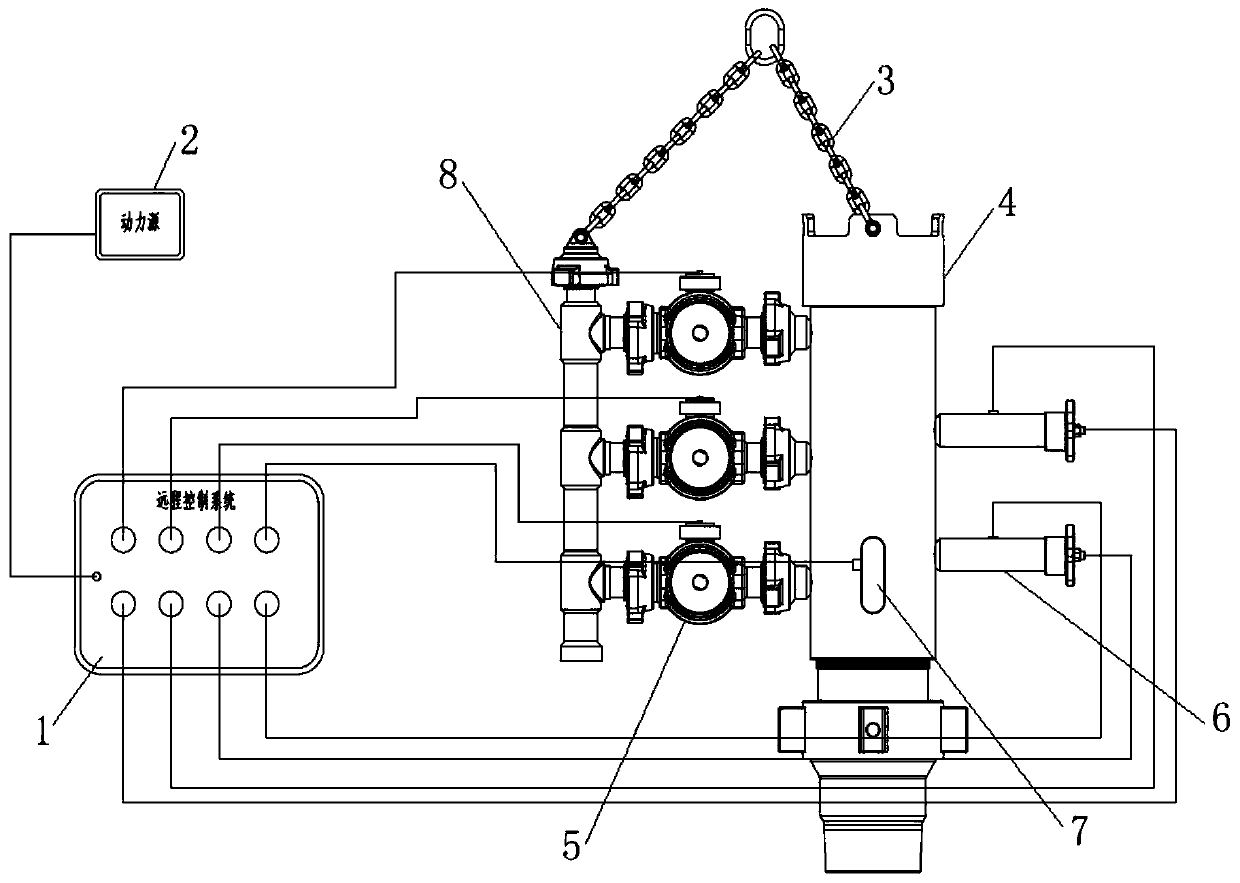

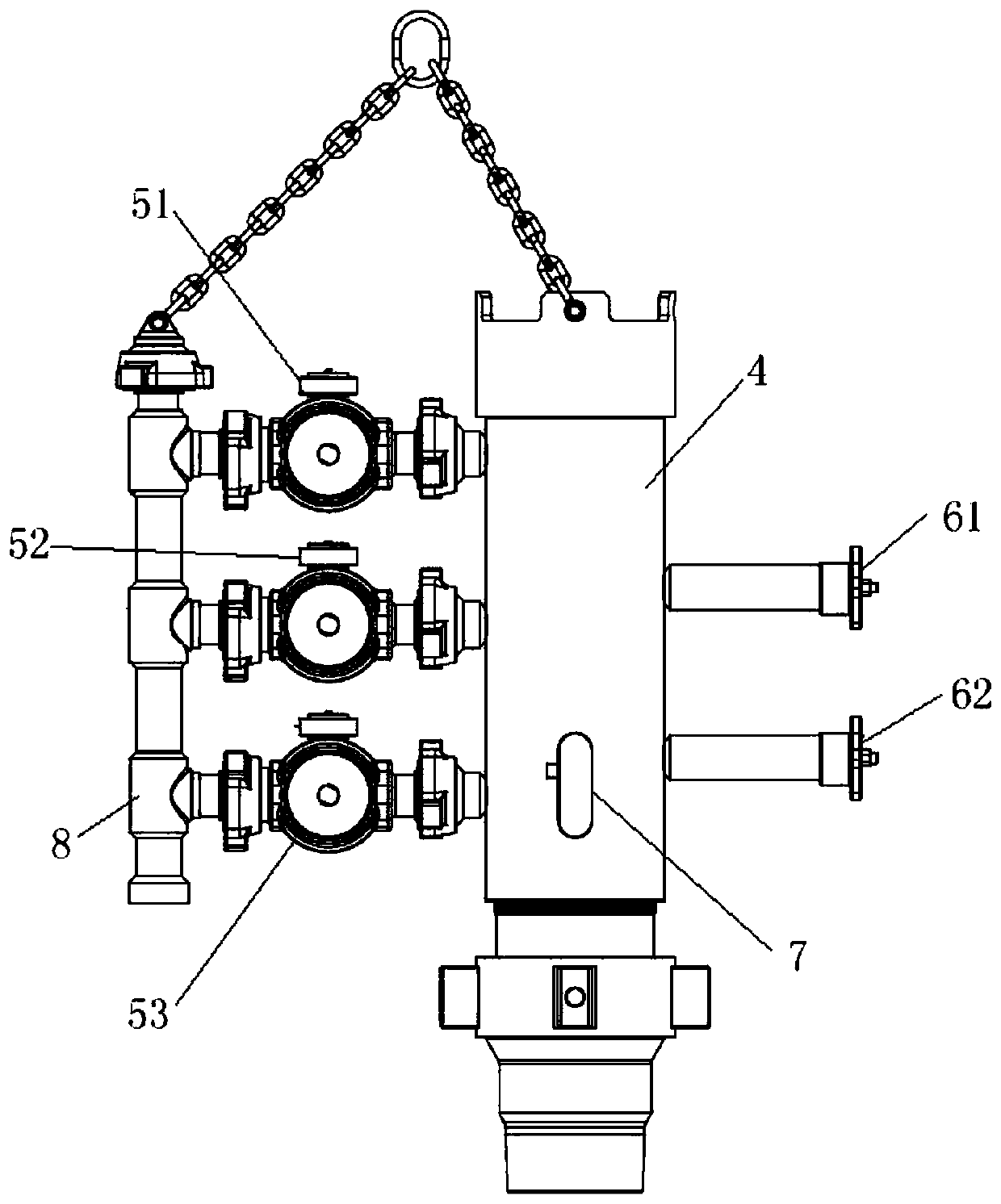

Remote control cement head

The invention discloses a remote control cement head, comprising a hydraulic control cement head, a remote control system and a power source, the power source is connected with the remote control system; the remote control system is connected with the hydraulic control cement head; the hydraulic control cement head is composed of a cement head main body, a hydraulic plug valve, a hydraulic stop pin, an indicator mechanism, and a circulating manifold, wherein the cement head main body and the circulating manifold are vertically arranged in parallel; one end of the hydraulic plug valve is connected with the circulating manifold; the other end of the hydraulic plug valve is connected with the cement head main body, the hydraulic stop pin is connected with the cement head main body and arranged on the opposite face of the hydraulic plug valve, the indicator mechanism is arranged on the cement head main body, and the indicator mechanism, the hydraulic stop pin and the hydraulic plug valve are not repeatedly arranged on the side face of the cement head body. The remote control cement head has the advantages that through remote operation of well cementation cement operation, safety of personnel is guaranteed, and operation risks are reduced.

Owner:JEREH ENERGY SERVICES

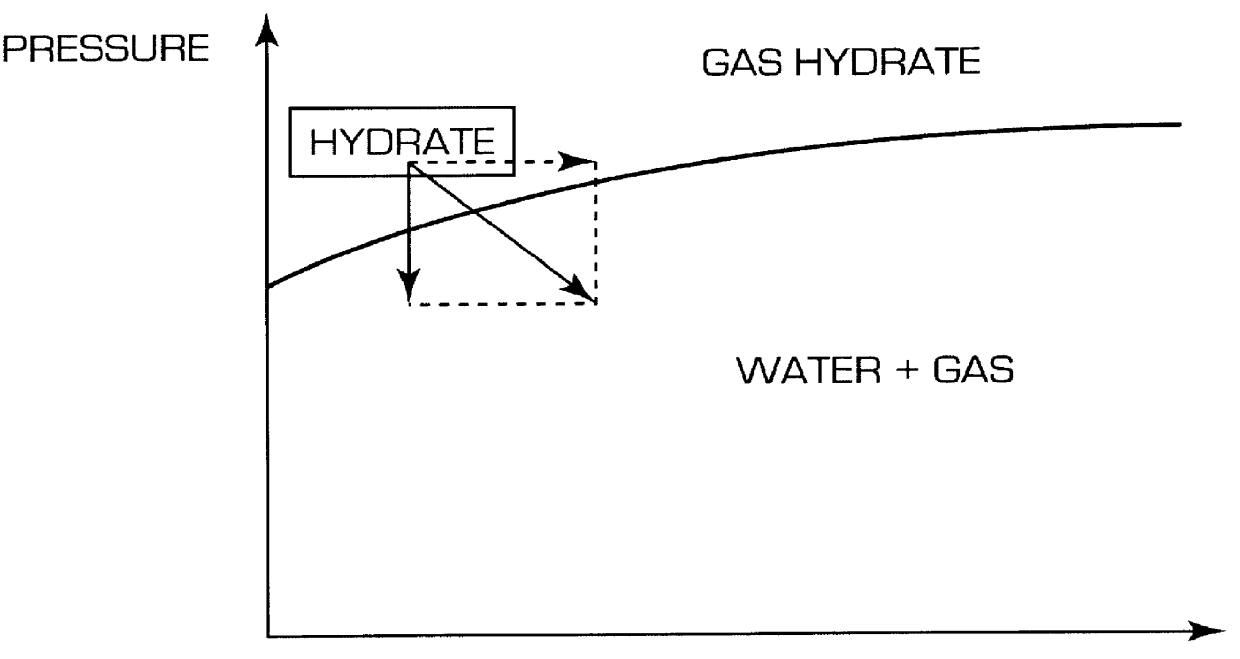

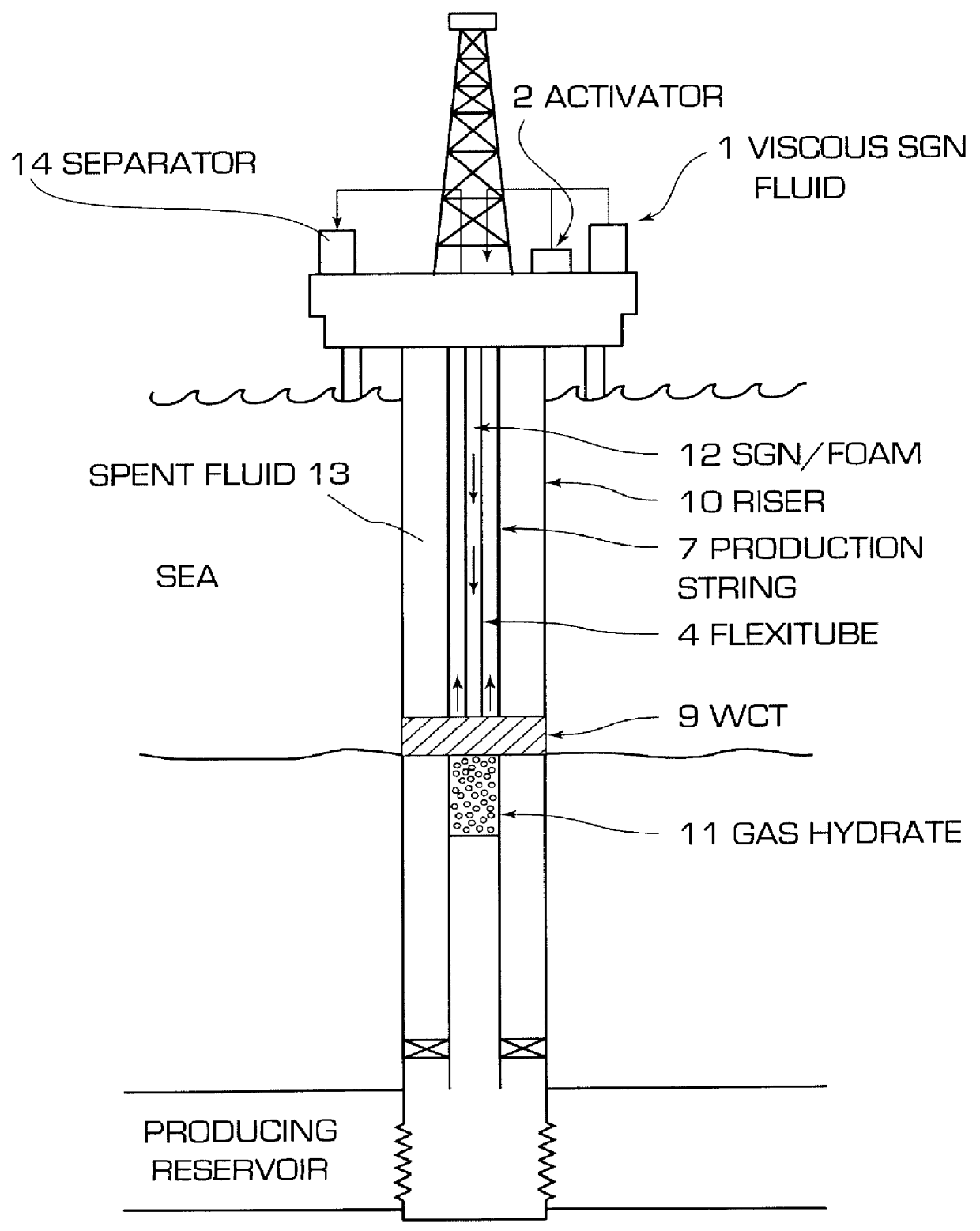

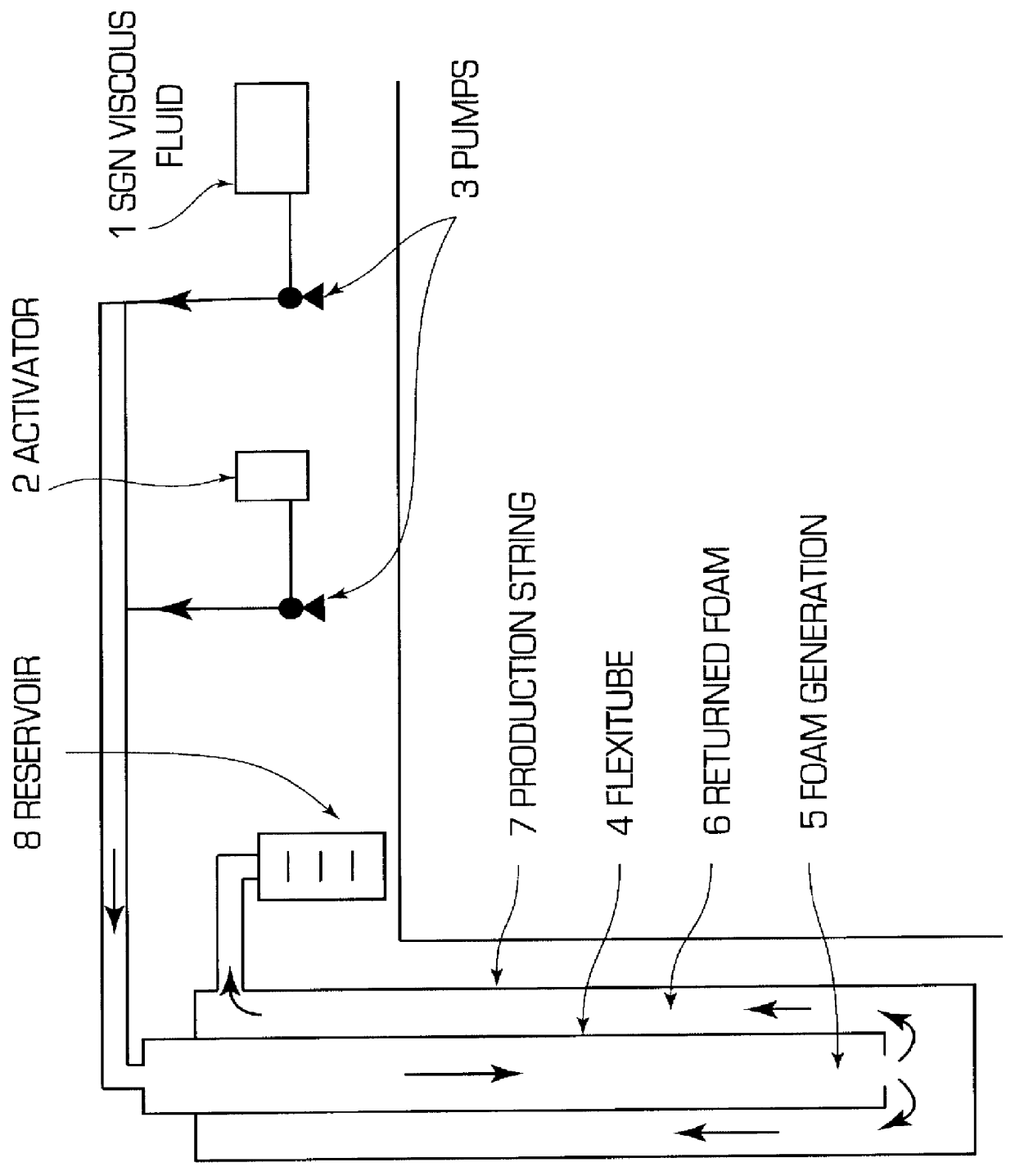

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

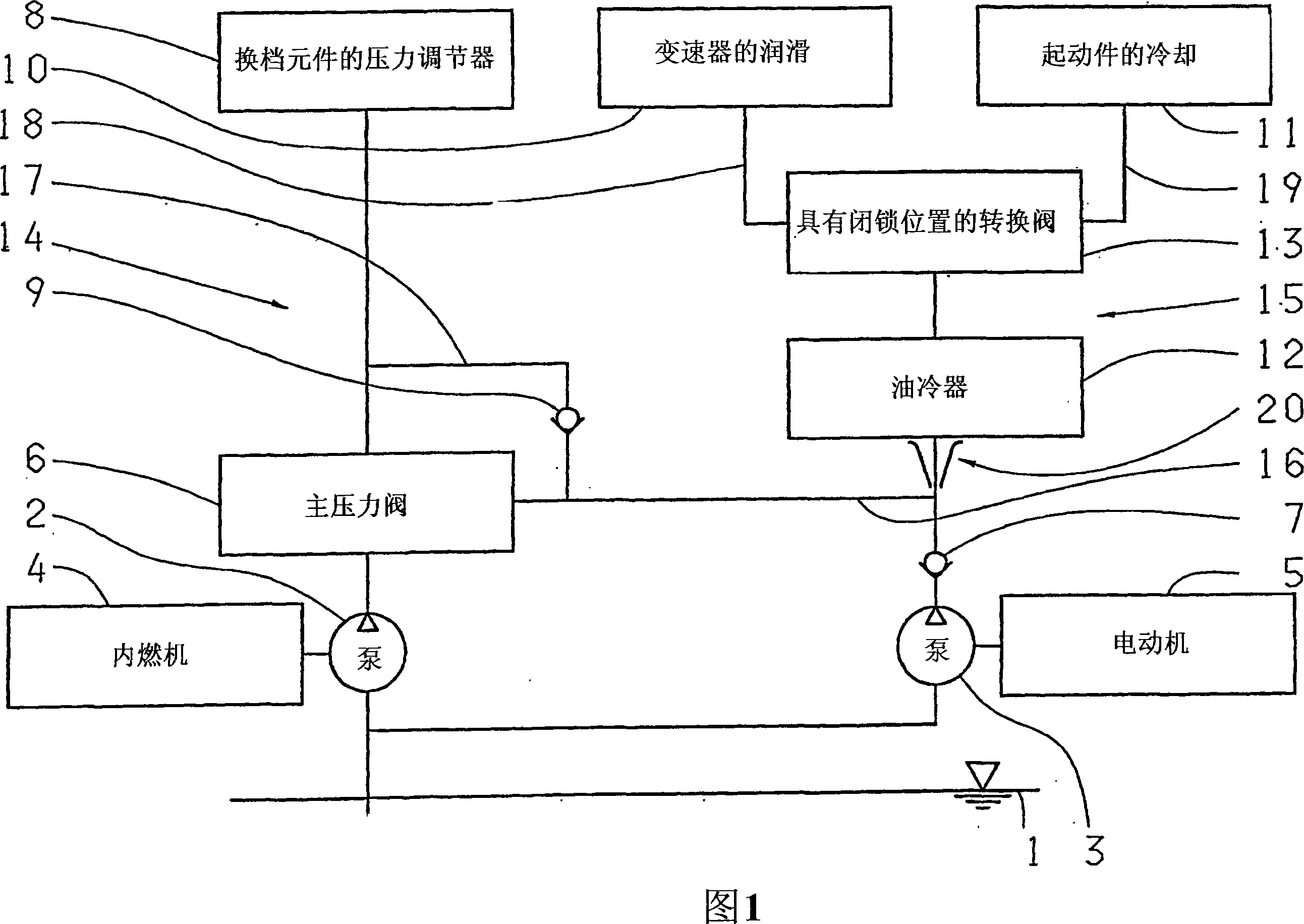

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveCN101147014AAvoid emissionsSave fuelGear lubrication/coolingGearing controlHydraulic control unitAutomatic transmission

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

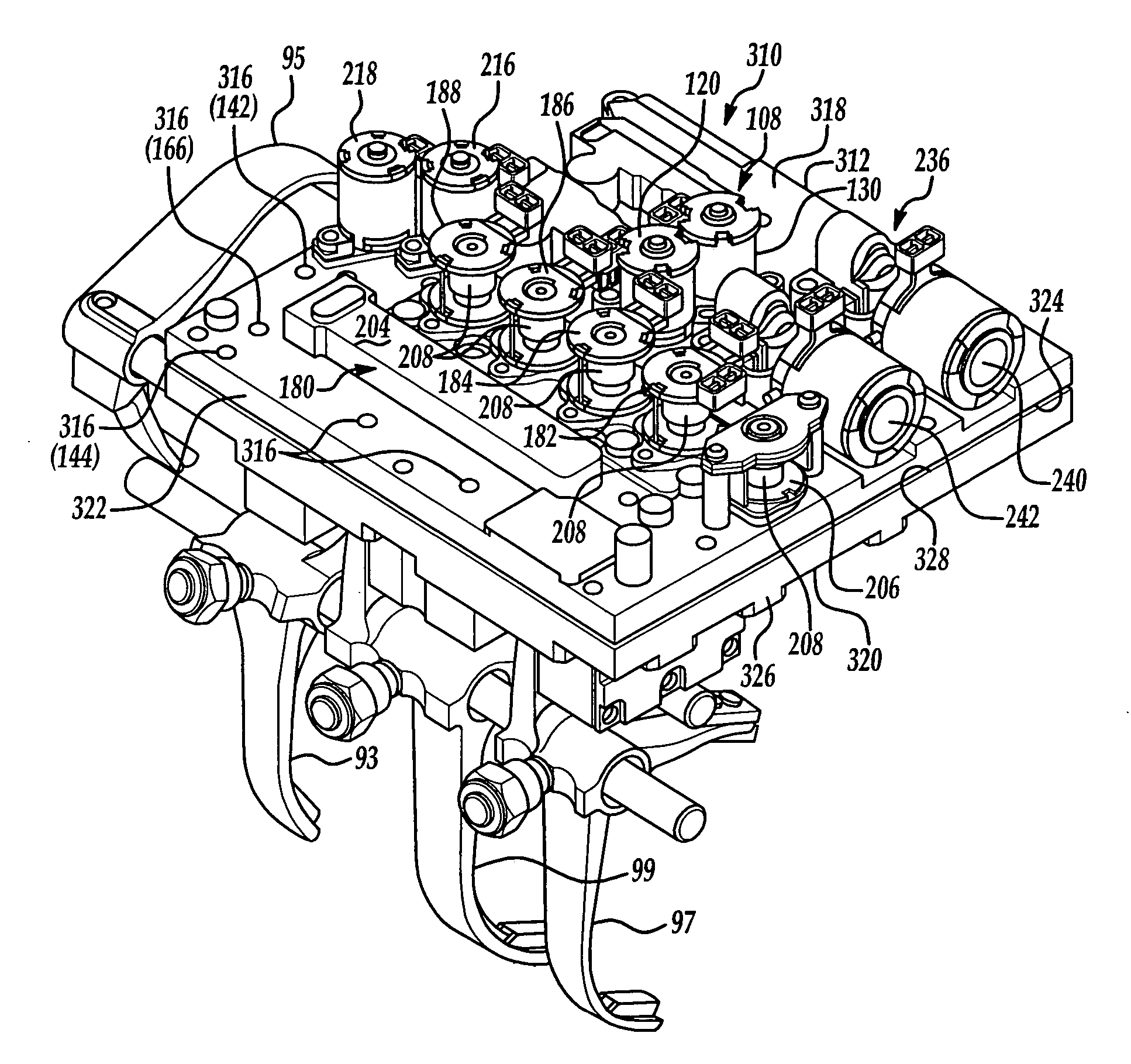

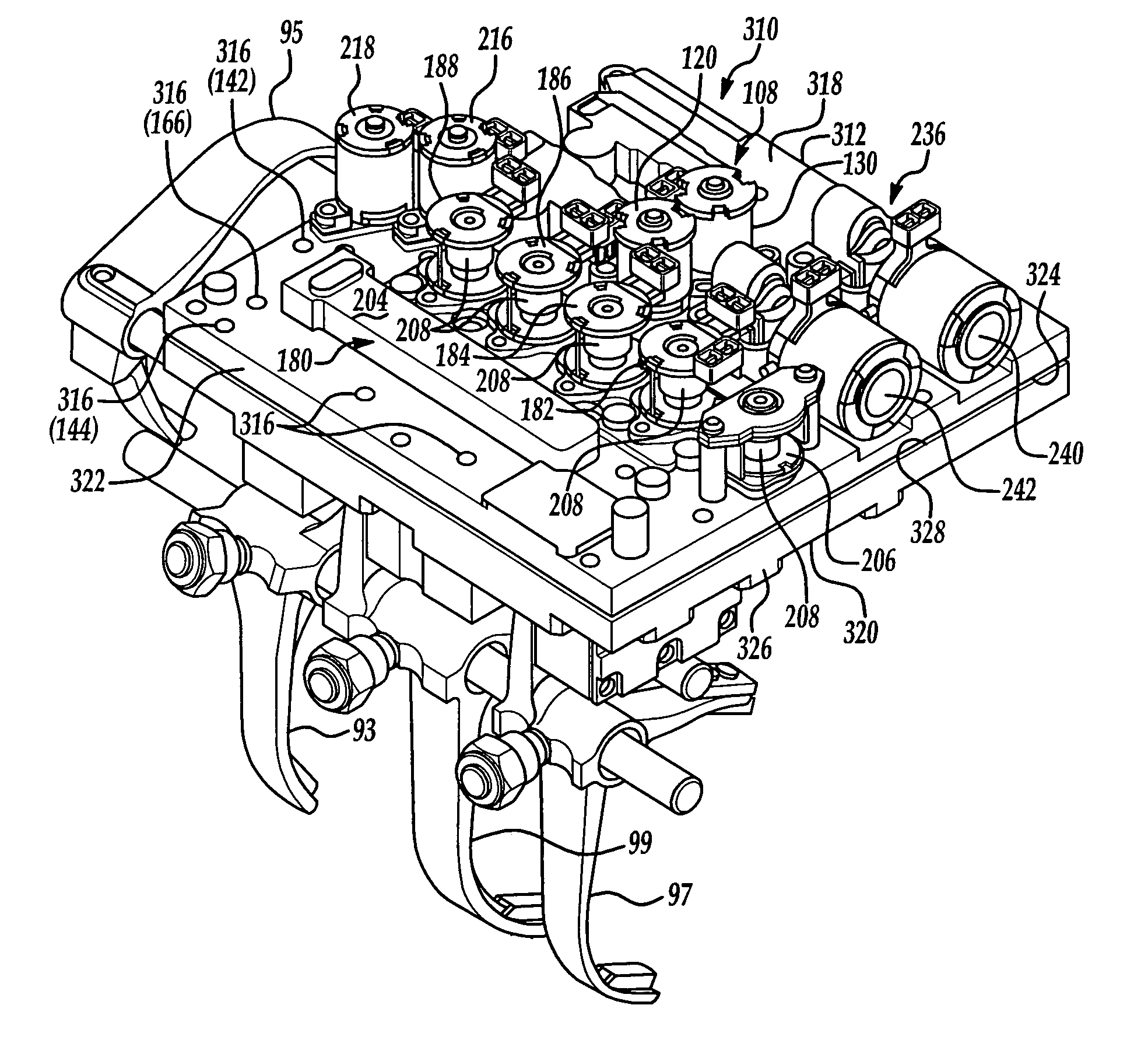

Integrated control module for a dual clutch transmission

ActiveUS20060005647A1Low costShorten assembly timeToothed gearingsGearing controlElectricityFluid control

An integrated control module for a dual clutch transmission that includes a valve body having an inlet, a plurality of outlets with a plurality of internal hydraulic passages disposed therebetween, and a hydraulic control assembly mounted to the valve body. The hydraulic control assembly is adapted to operatively control the pressurized hydraulic fluid from the inlet through the plurality of internal hydraulic passages to the plurality of outlets. The hydraulic control assembly includes at least one assembly from a group including, a shift actuation control assembly adapted to actuate the synchronizers of the transmission, a clutch actuation control assembly adapted to allow the selective and independent engagement and disengagement of each clutch, and a clutch cooling fluid control assembly adapted to control the cooling fluid provided to the clutches of the transmission. The module also includes a transmission control assembly that is mounted to the valve body in electrical communication with the hydraulic control assembly and operatively responsive to a higher level control system to provide the requisite control signals to control the operative functions of the dual clutch transmission.

Owner:BORGWARNER INC

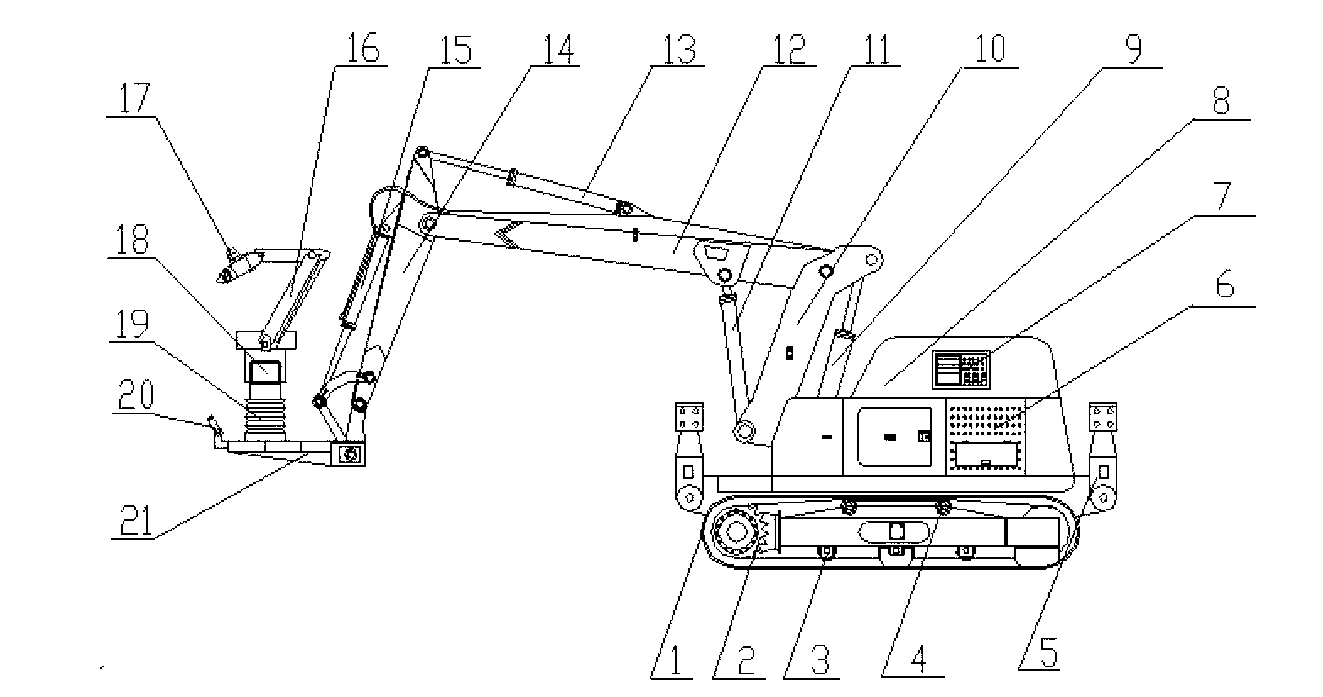

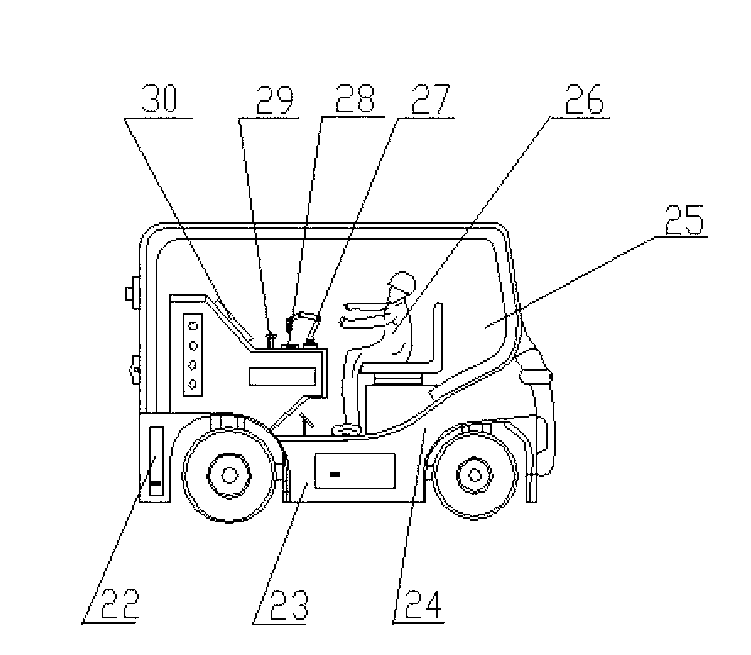

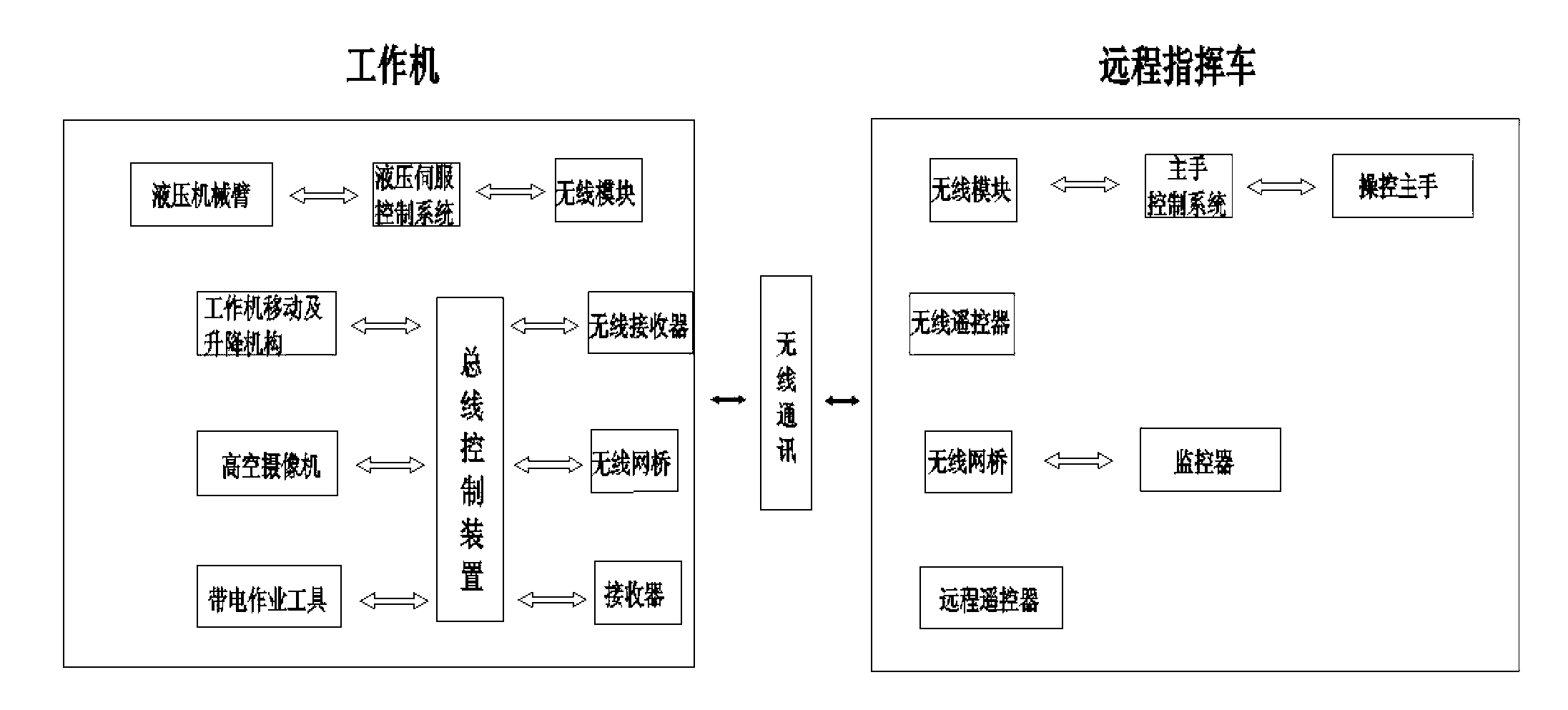

Live-working robot of transformer substation

ActiveCN103056866AGuaranteed isolationImprove the safety performance of live workingManipulatorTransformerHydraulic pump

The invention relates to a live-working robot of a transformer substation. All signals of a control system are wirelessly transmitted, so that the operational safety performance is improved for operation personnel. The live-working robot comprises a work machine and a remote-control command vehicle; the work machine mainly comprises a power system, an actuating mechanism, a hydraulic control system and an operating system, the actuating mechanism mainly comprises a traveling mechanism, a rotating platform, a lifting platform and a hydraulic mechanical arm with six degrees of freedom, the lifting platform comprises a plurality of insulating arms, the rotating platform is mounted on the traveling mechanism, the lifting platform is connected with the rotating platform, and the hydraulic mechanical arm with six degrees of freedom is connected with the lifting platform; and the hydraulic control system comprises a hydraulic pump and is connected with the power system, and the hydraulic pump is further connected with an oil tank on the traveling mechanism and is respectively connected with a lower electromagnetic reversing valve bank A, a central crossover coupling, an upper electromagnetic reversing valve bank B, a mechanical arm hydraulic servo valve bank C, driving cylinders of the various insulating arms and a rotating motor by a distributing valve.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

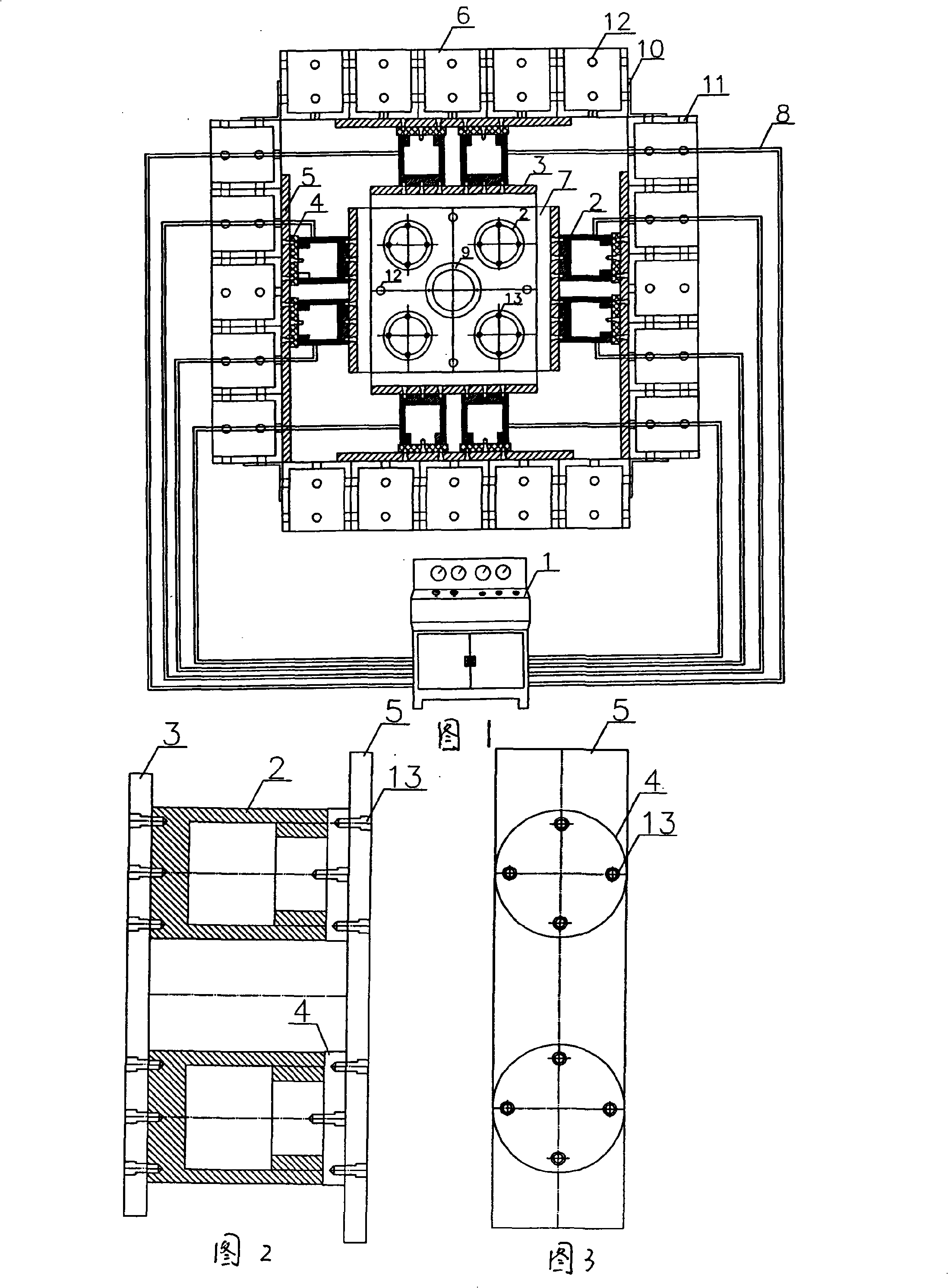

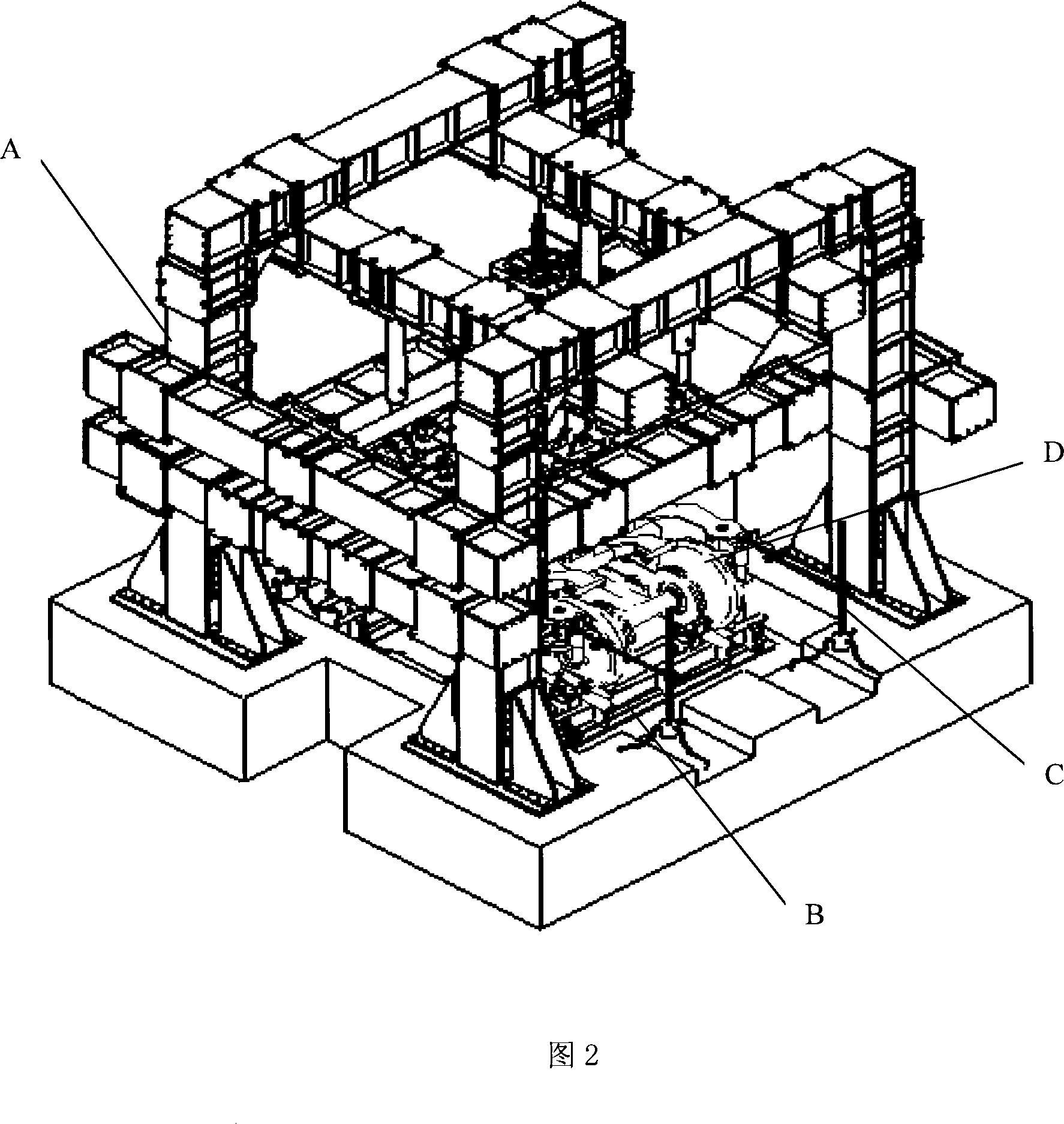

High crustal stress genuine three-dimensional load model trial system

The invention relates to a true three-dimensional loading model experiment system for highland stress, comprising an intelligent hydraulic control system, a high-pressure loading system and a counterforce device system, wherein, the high-pressure loading system is arranged in the counterforce device system; an intelligent hydraulic control test bed of the intelligent hydraulic control system is connected with the high-pressure loading system through a high-pressure oil pipe; the high-pressure loading system comprises a jack and loading plates; one end of the jack is connected with the loading plates; the other end of the jack is connected with the counterforce device system; and six loading plates connected with the jack respectively cling to front, rear, left, right, upper, lower side surfaces of a trial model. The system has the advantages of synchronous and independent highland stress loading, high loading automation degree and loading accuracy, more loading functions, the realization of the axial loading opening of a cavity, high rigidity of the loading system, good integral stability, simple and convenient operation and so on. The system can be widely used in deep underground cavity model experiment and research in engineering fields such as hydroelectric power, transportation, energy, mine, national defense and so on.

Owner:SHANDONG UNIV

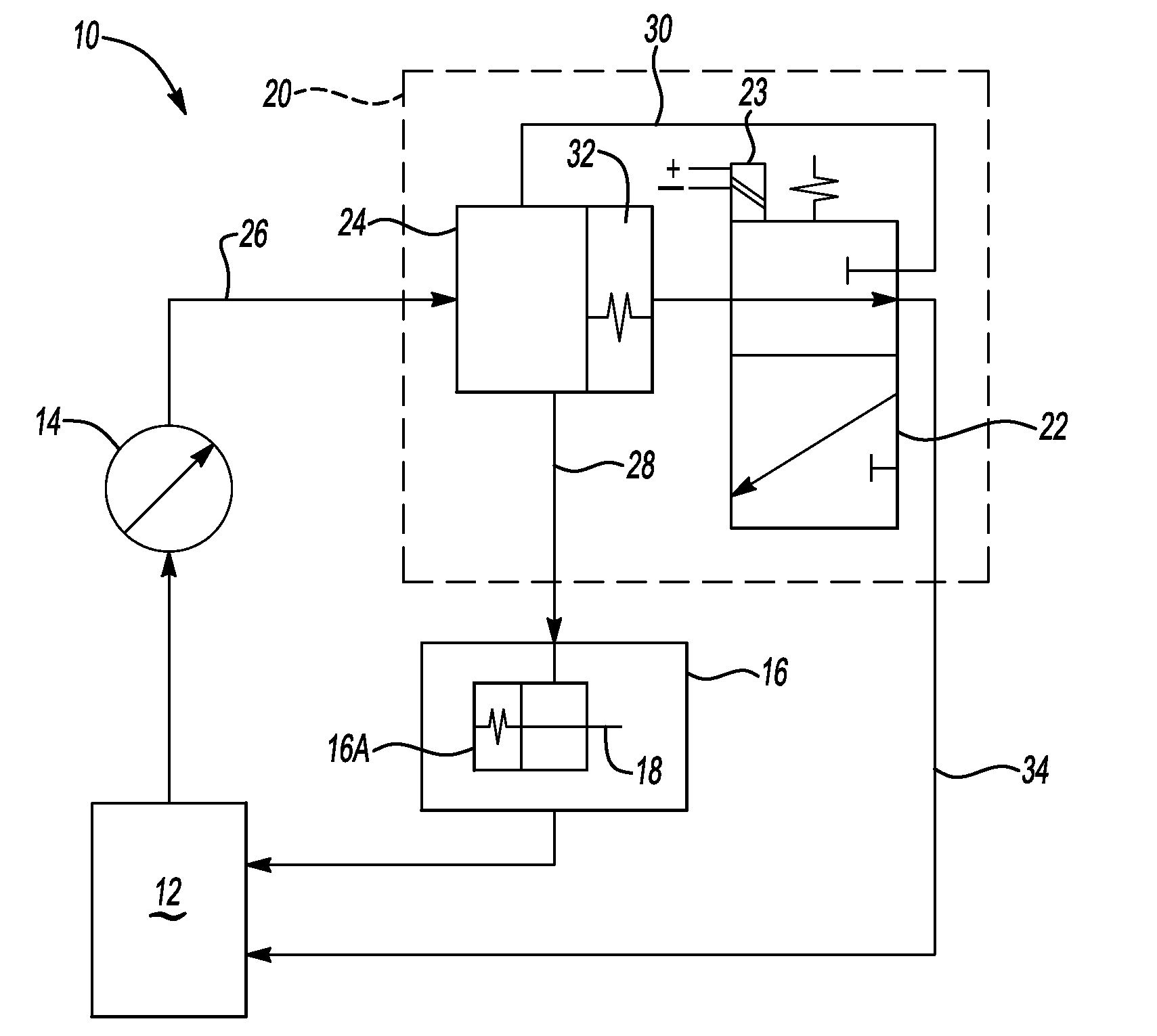

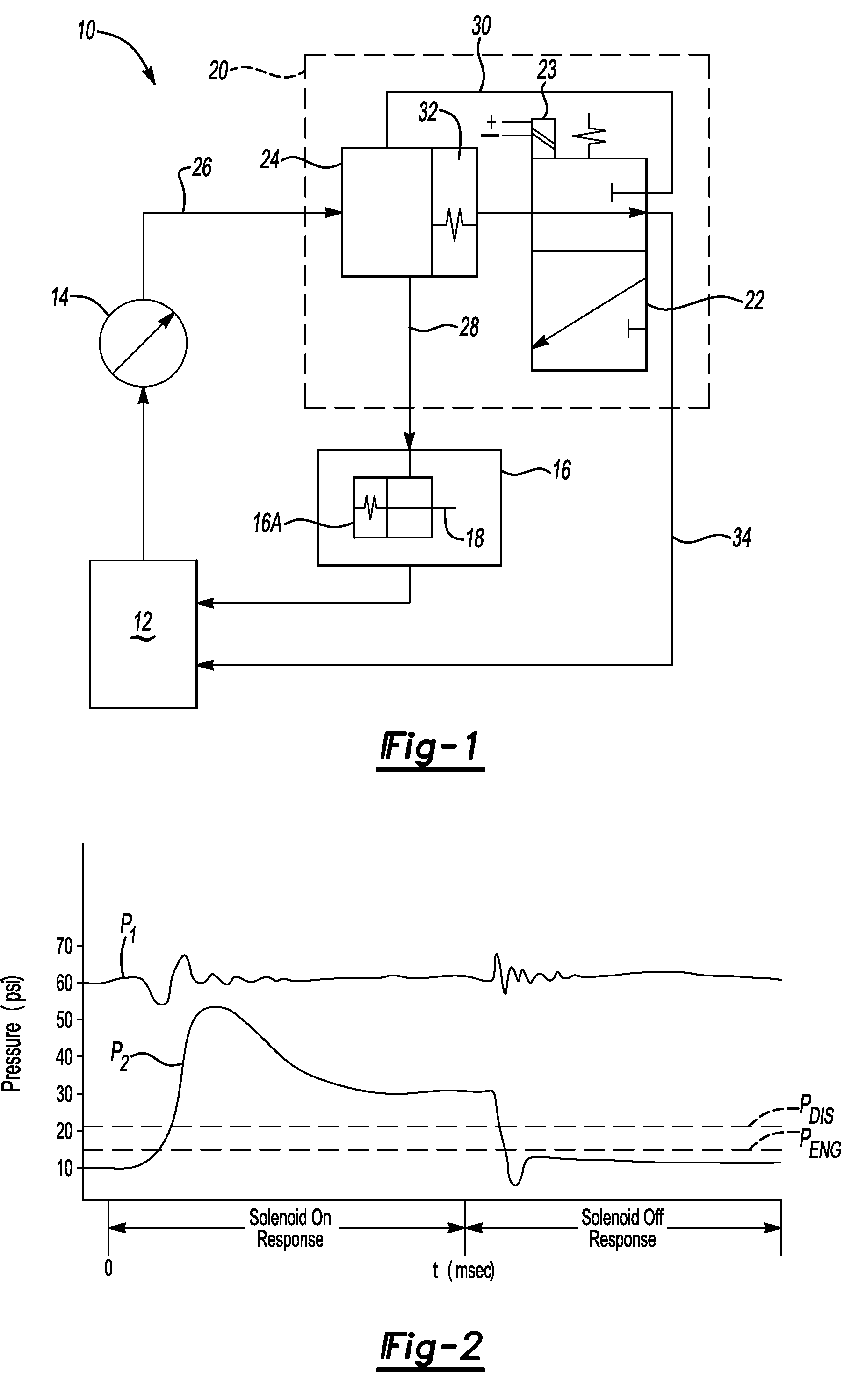

Valvetrain oil control system and oil control valve

InactiveUS20100018482A1Reduce fuel consumptionOperating means/releasing devices for valvesPipeline systemsControl systemEngineering

A hydraulic control system includes an oil control valve to control oil flow within a valvetrain. The control valve varies the flow rate to actuate an engine component from a first position to a second position based upon fluid pressure from the control valve. Varying the flow rate through the control valve includes increasing the flow rate through the control valve to increase the pressure to a first level to actuate the engine component to the first position. After the engine component is actuated, the flow rate through the control valve is maintained at a level sufficient to maintain the engine component in the first position. To actuate the engine component to the second position the flow rate through the control valve is then decreased. The fluid flow rate through the control valve is then maintained at a level sufficient to maintain the engine component in the second position.

Owner:EATON CORP

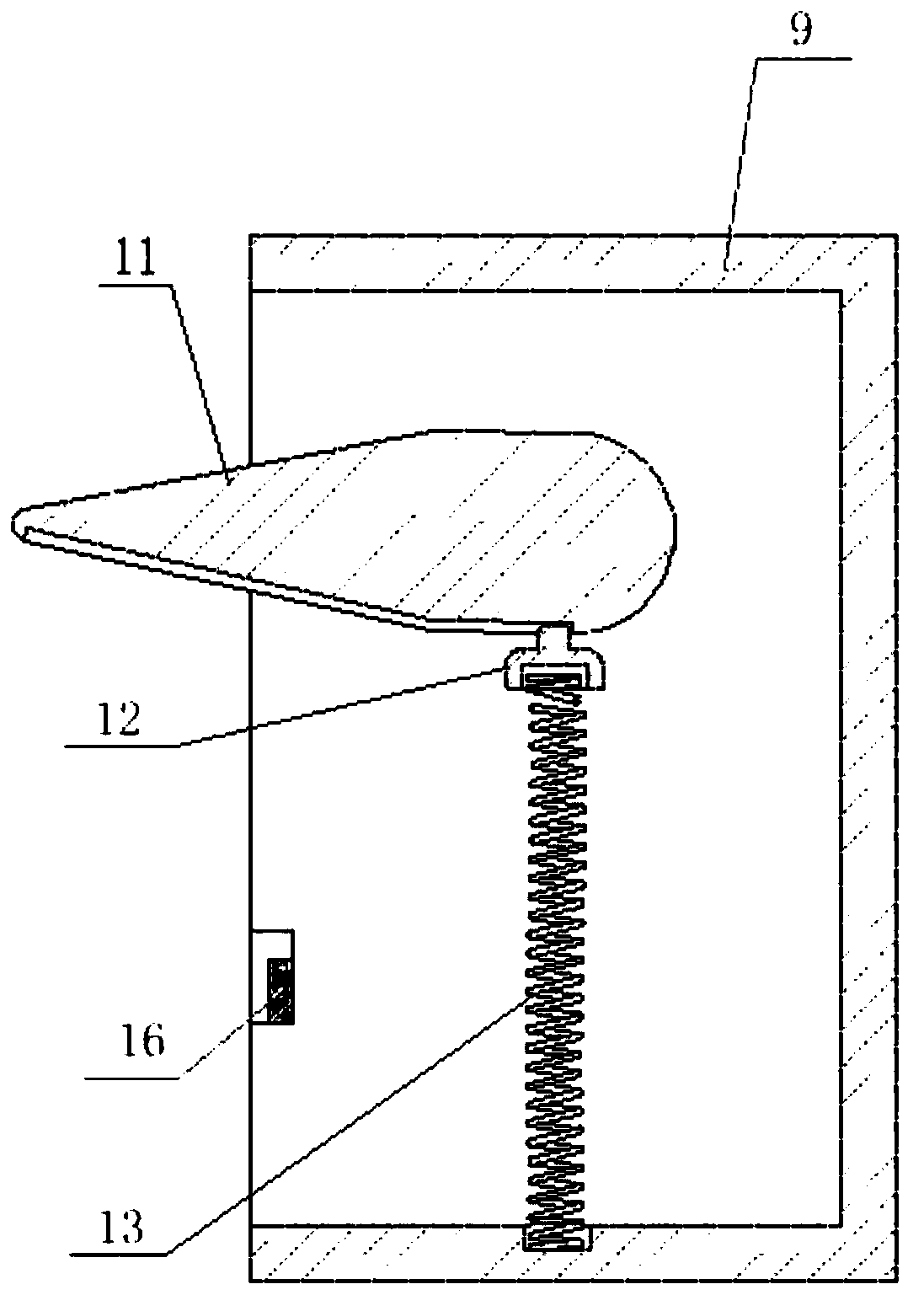

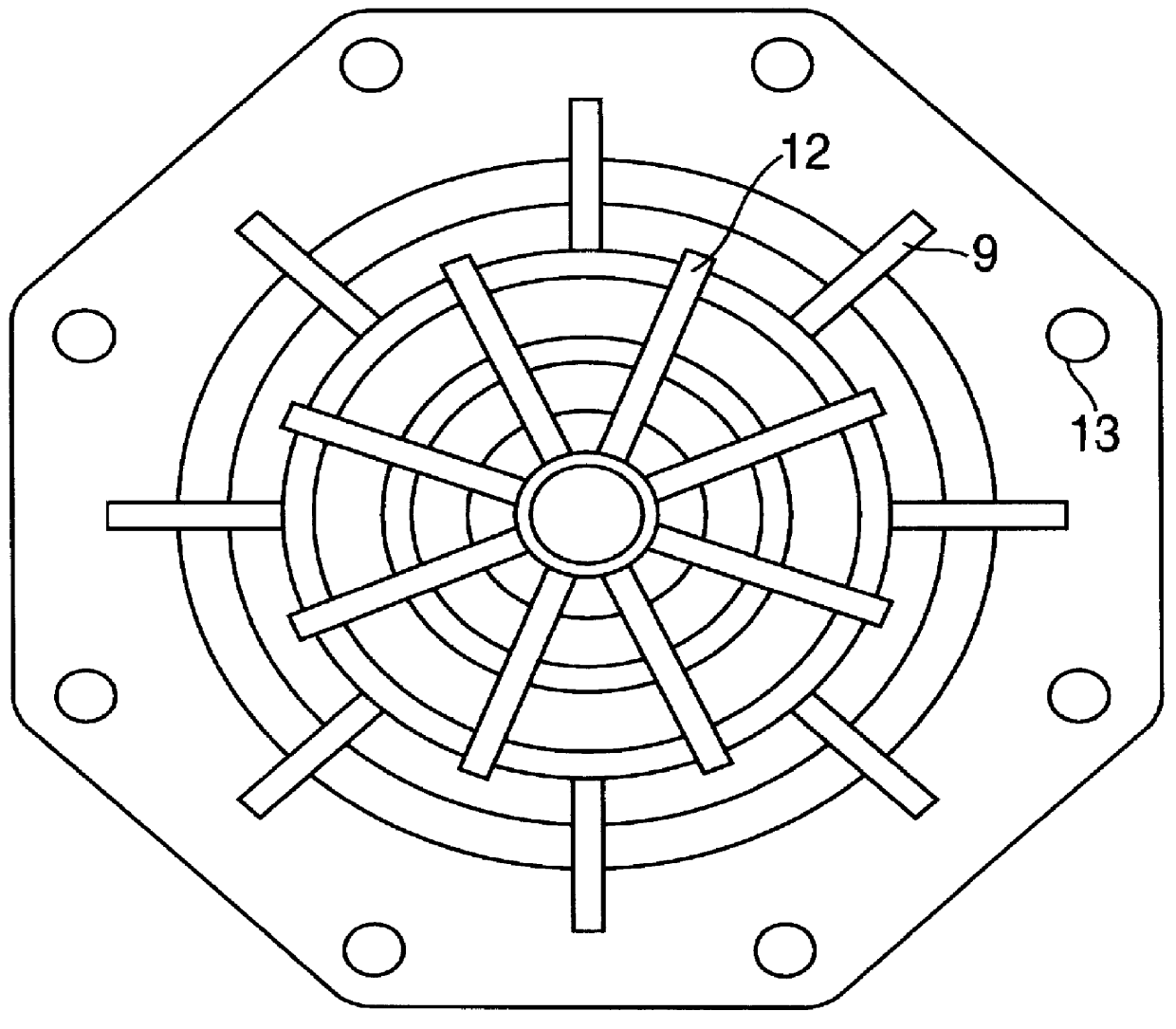

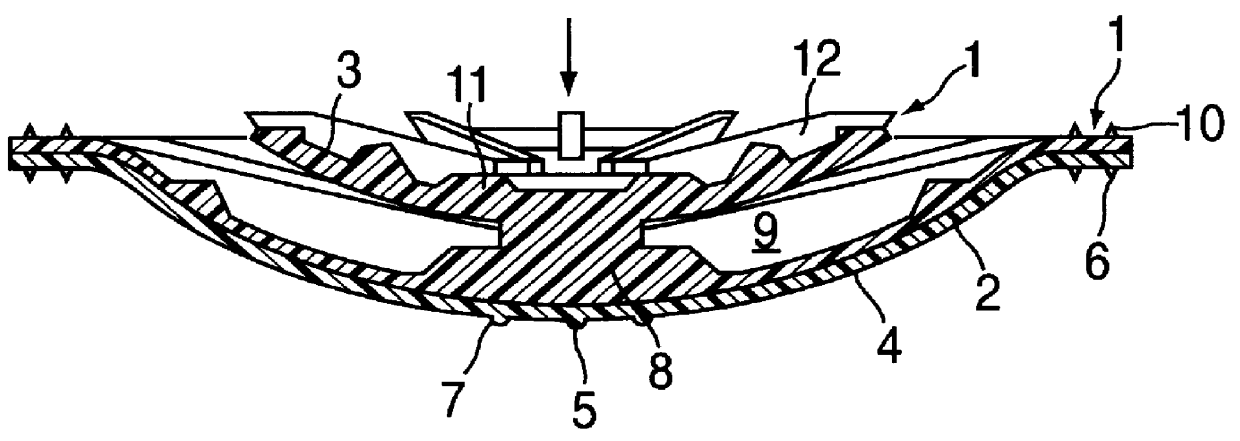

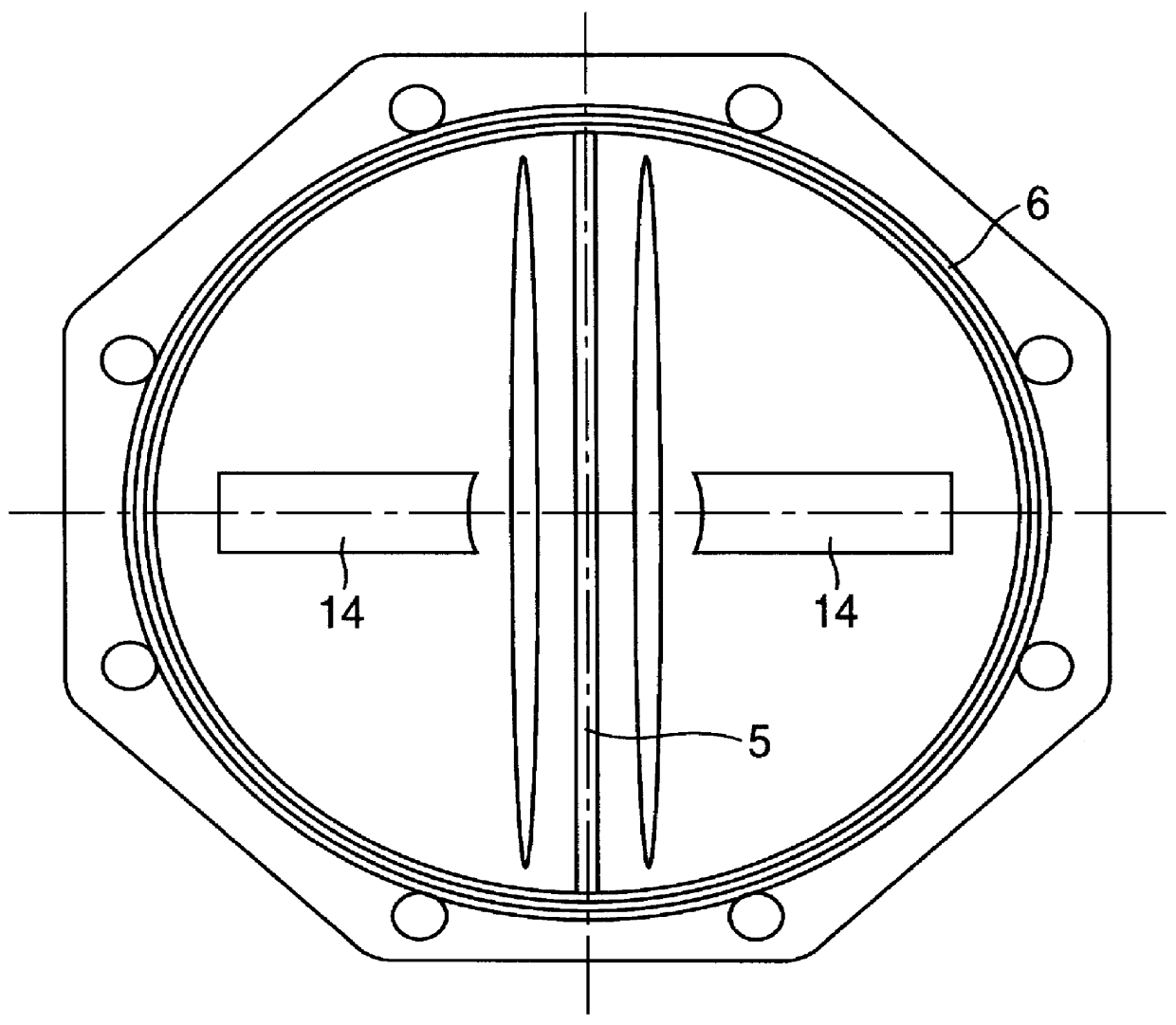

Spring diaphragm for shut-off valves and regulators

InactiveUS6095484AExtended service lifeDiaphragm valvesOperating means/releasing devices for valvesHermetic sealEngineering

A spring diaphragm for use in automatic hydraulic control valves of the type having a valve body having an inlet chamber, and an outlet chamber and a spring diaphragm interposed between the inlet and outlet chambers, which spring diaphragm, as a result of hydraulic pressure, is automatically moveable between an open and closed position, in which the diaphragm allows and prevents, respectively, communication between the inlet and outlet chambers, includes a two-part diaphragm element including a first lower part and second upper part generally spaced apart from one another, the first lower part being in the form of a flexible elastic disc which performs the function of a hermetic seal between the inlet and outlet chambers when the spring diaphragm is in the closed position and the second upper part being connected to the first part and being in the form of a resilient disc which performs the function of a spring to normally bias the spring diaphragm from the open to the closed position. The first and second parts each have resilient spring-like ribs on the first lower part serving to aid hermetic sealing when the diaphragm is in the closed position and the ribs on the second upper part serve to provide a main force to bias the diaphragm into the closed position.

Owner:RAPHAEL VALVES INDS 1975

Intelligent drilling expert system

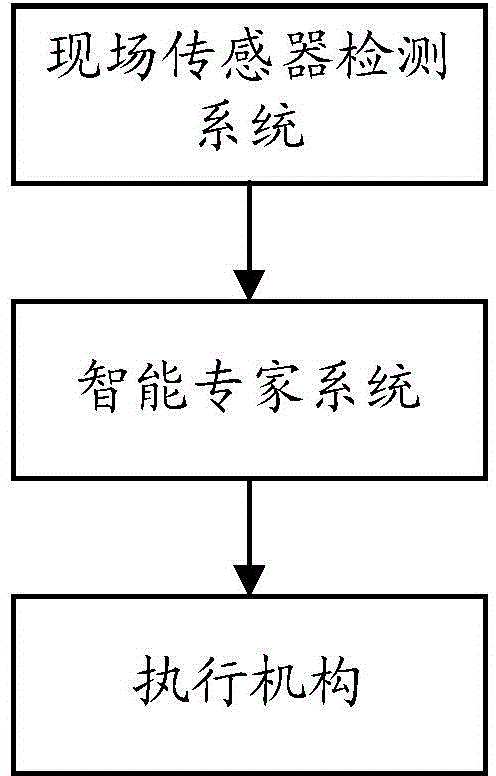

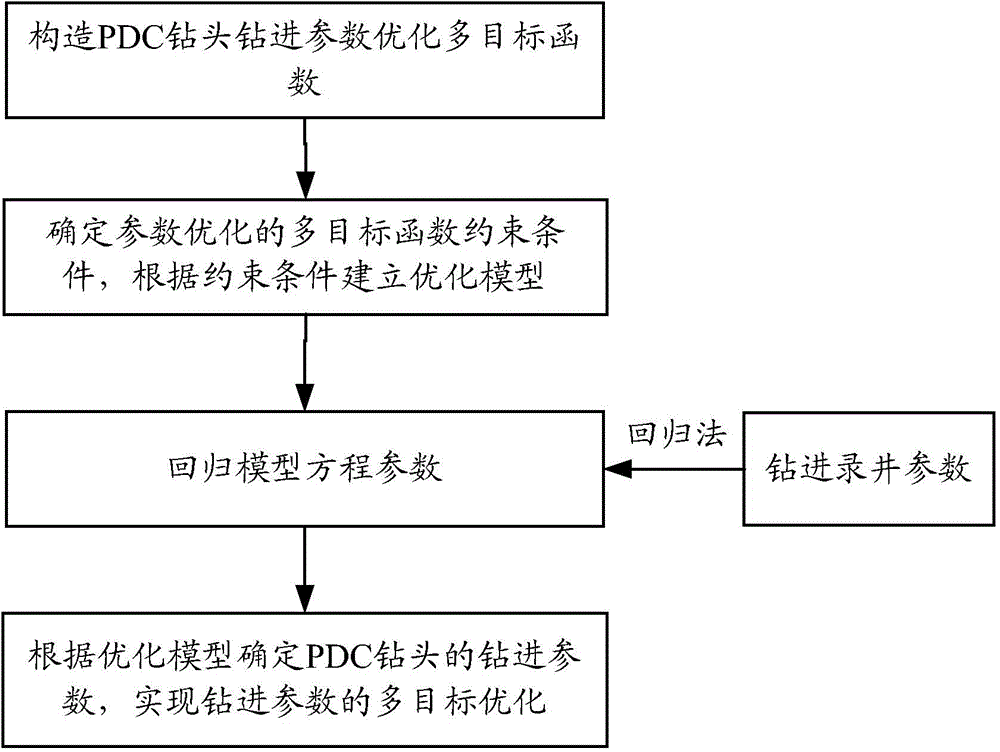

ActiveCN104806226AAccurate discoveryReal-timeAutomatic control for drillingEarly predictionAutomatic control

The invention provides an intelligent drilling expert system. The intelligent drilling expert system comprises a field sensor detection system, an intelligent expert system and an execution mechanism. An automatic closed-loop drilling regulation and control system is formed. Data in a whole drilling process are acquired through a field sensor; then, the acquired data are transmitted into a computer for processing, monitoring, prediction, analysis, explanation, control and the like. Most importantly, through the researched cross-specialty and cross-industry intelligent expert control models for drilling hydraulic control, well wall stability control, friction resistance and torque control, drilling speed and cost control, drilling complexity and accident control and the like, instantaneity, early discovery, early prediction, interpretation while drilling and an automatic control function can be realized, and accurate information is provided for drilling engineering; moreover, the intelligent drilling expert system has the advantages of reducing the drilling cost, increasing the drilling speed, avoiding sudden accidents and discovering oil and gas accurately.

Owner:北京四利通控制技术股份有限公司

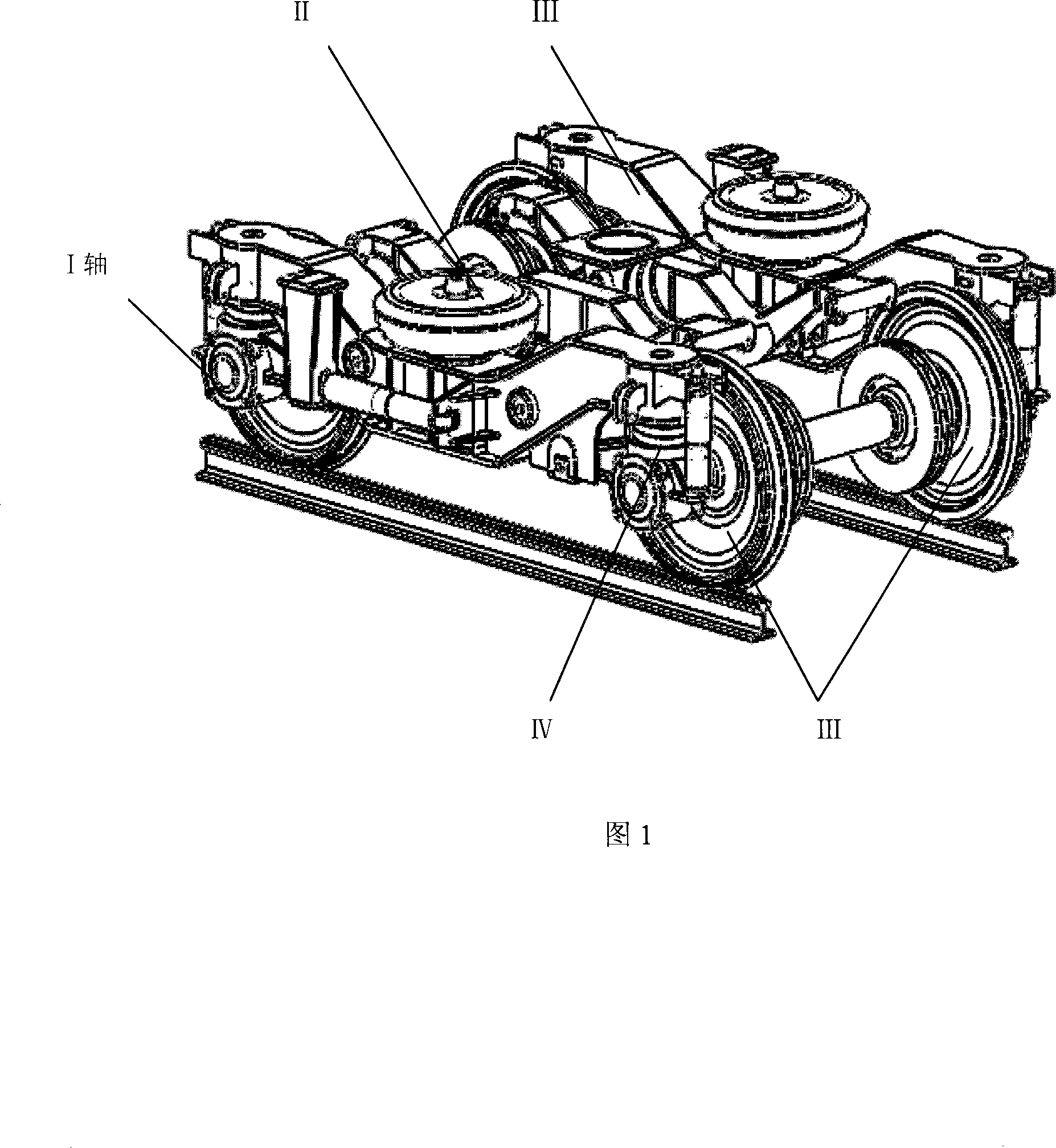

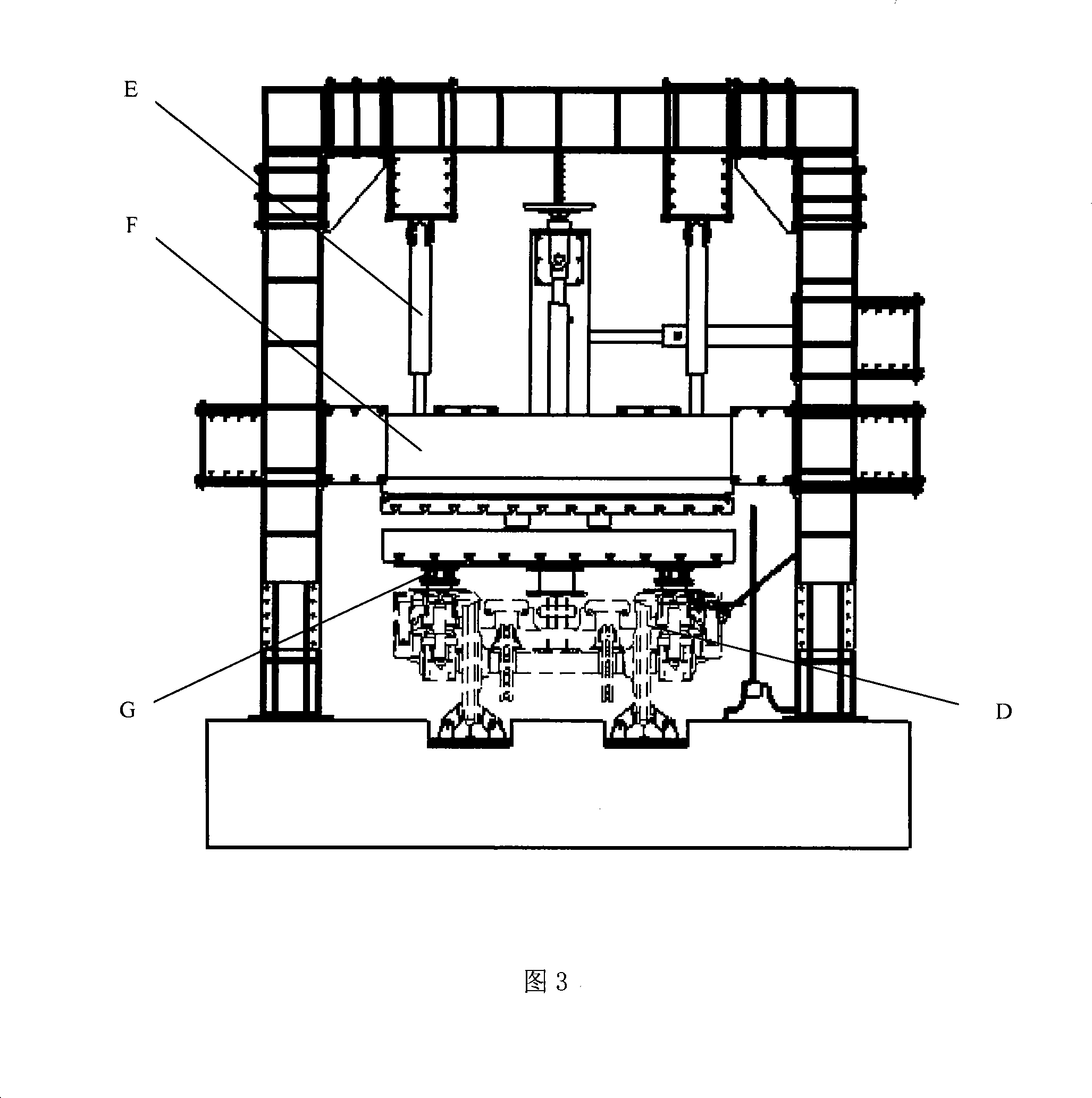

Four-column type rail vehicle bogie rigidity detection system

A rigidity detection system of four-column bogie of railway vehicles relates to railway vehicle performance detection equipment, which is designed for detecting the key kinetic parameters of bogie of railway vehicles under various motion states. The system comprises a mechanical system, a hydraulic system, a test system and a control system, wherein the mechanical system includes a gantry system (A) in frame structure composed of a crossbeam (1) and a vertical pillar (2), a five-degree-of-freedom force application system (F) composed of a simulated vehicle load pressure plate (5), a simulated vehicle load pressure column (4) and a simulated vehicle gravity center height adjusting mechanism (3), and a wheel pair positioning and clamping system (B) for clamping and positioning a rotation frame; the hydraulic system (E) includes a cylinder with vertical, longitudinal and transverse effects on the rotation frame; the test system includes a three-dimensional force detection system (G) and a rotation frame displacement detection system (C); and the control system is mainly composed of a hydraulic control system, an electric control system and a computer system.

Owner:JILIN UNIV

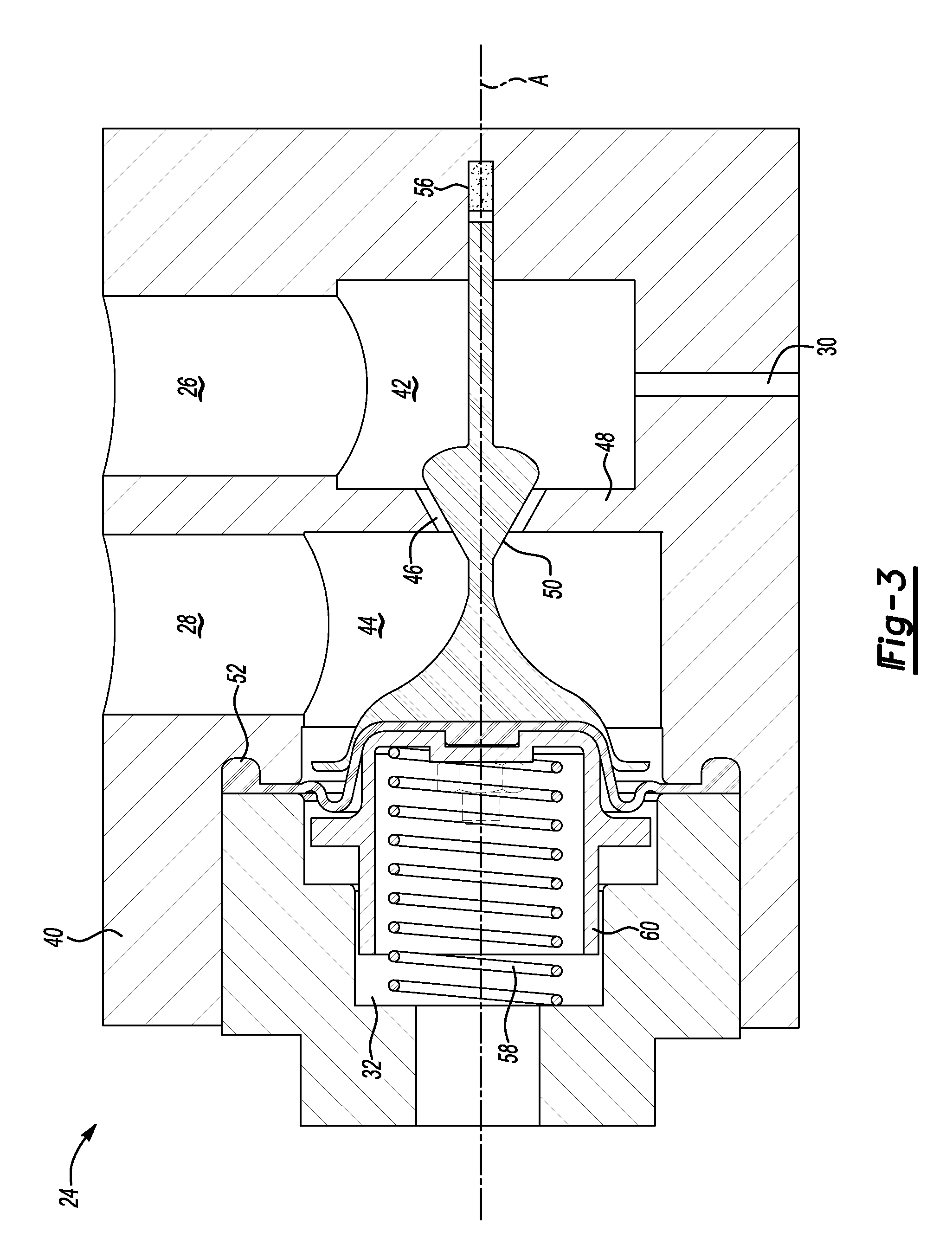

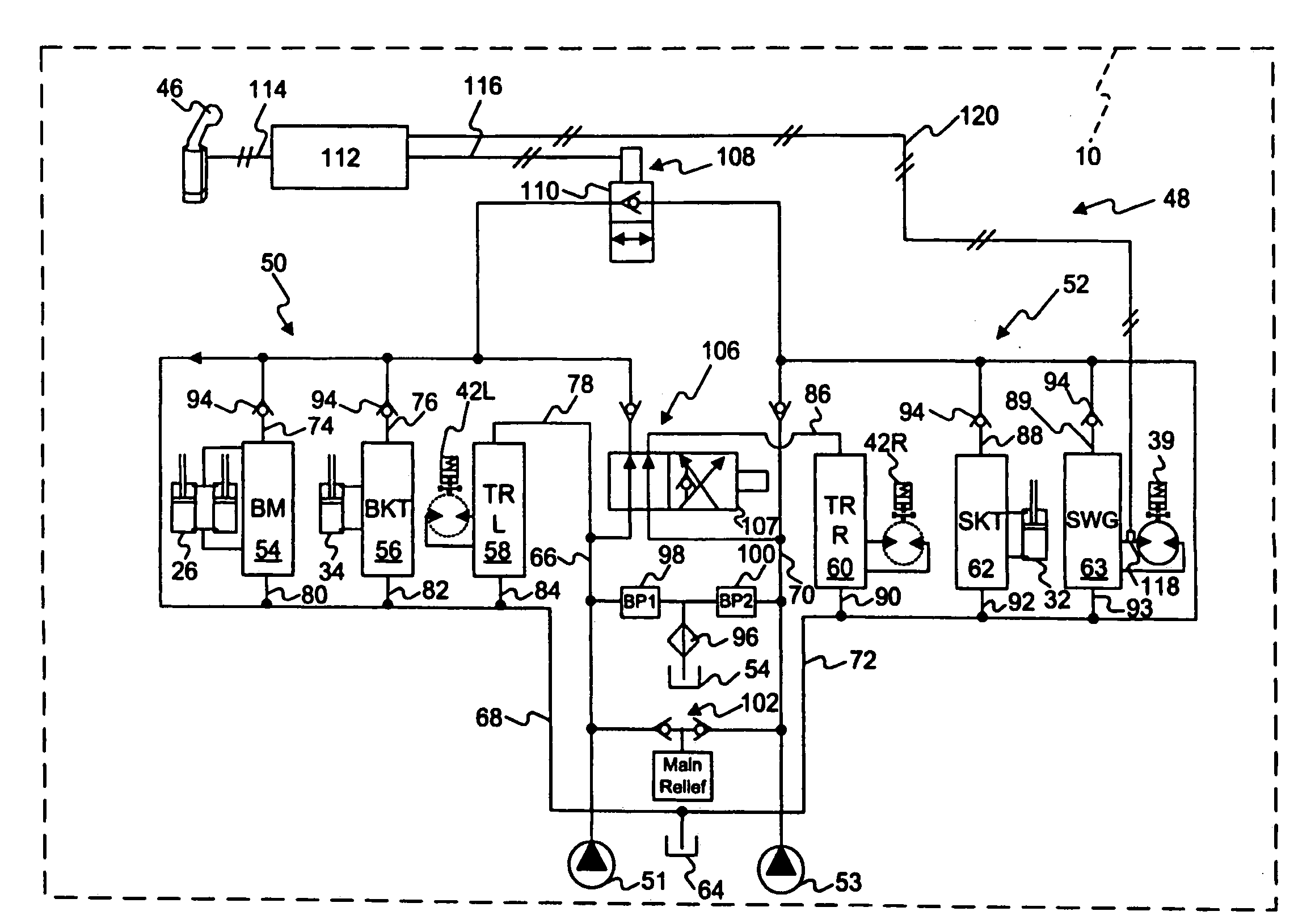

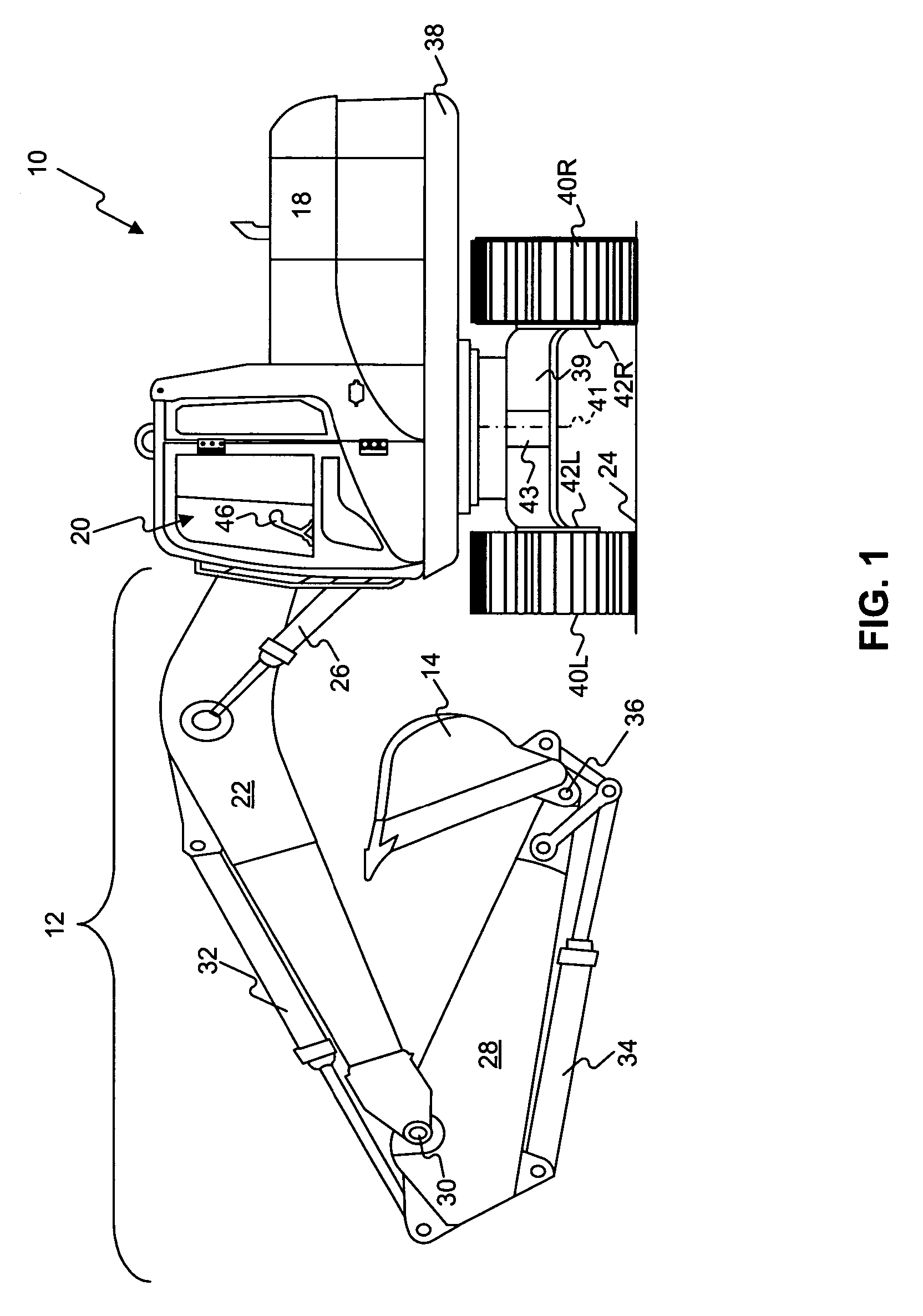

Multi-actuator pressure-based flow control system

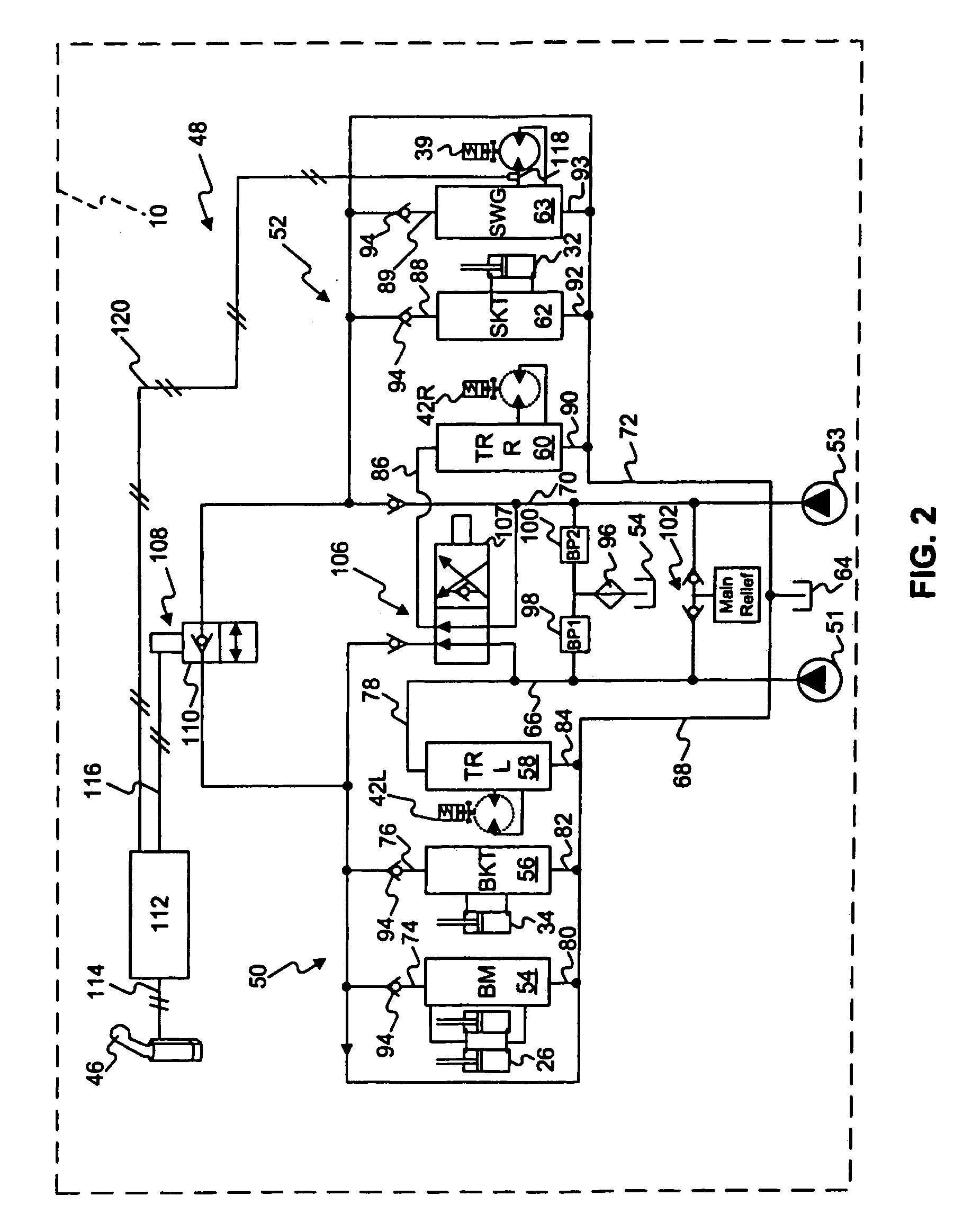

A hydraulic control system for a work machine is disclosed. The hydraulic control system has a fluid actuator, a supply of pressurized fluid, and a control valve movable to selectively pass pressurized fluid to the fluid actuator. The hydraulic control system also has a sensor configured to sense the pressure of the pressurized fluid passed to the fluid actuator and a controller in communication with the control valve and the sensor. The controller is configured to receive an input indicative of a desired velocity of the fluid actuator and to determine a fluid flow rate corresponding to the desired velocity. The controller is also configured to determine a ratio of the sensed pressure to a stall pressure of the supply and to scale down the determined flow rate an amount based on the determined ratio. The controller is further configured to move the control valve an amount corresponding to the scaled down flow rate.

Owner:CATEPILLAR SARL +2

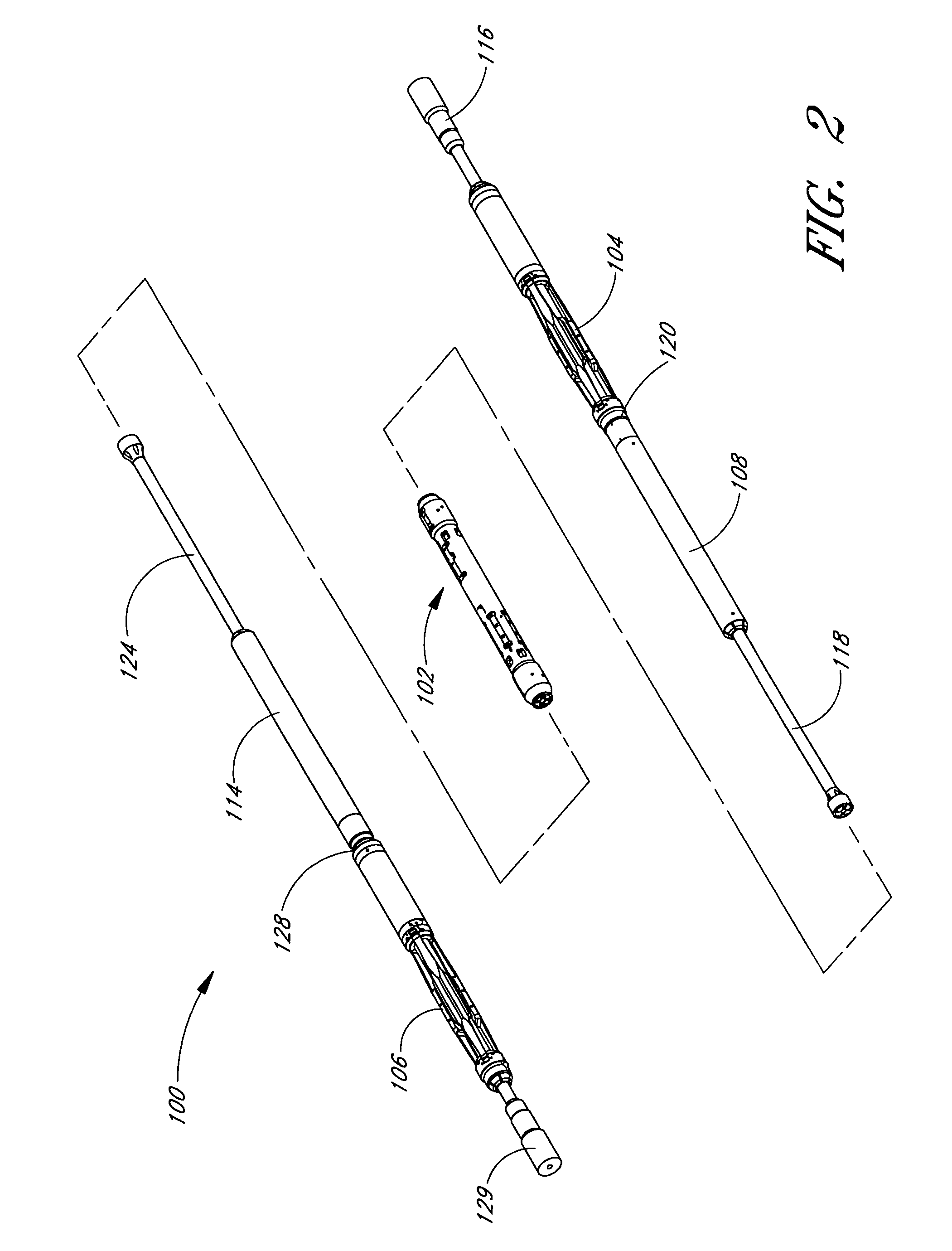

Tractor with improved valve system

InactiveUS7080700B2Long time lagBetter shiftingDrilling rodsReciprocating drilling machinesWorking fluidDetent

A hydraulically powered tractor includes an elongated body, two gripper assemblies, at least one pair of aft and forward propulsion cylinders and pistons, and a valve system. The valve system comprises an inlet control valve, a two-position propulsion control valve, a two-position gripper control valve, two cycle valves, and two pressure reduction valves. The inlet control valve spool includes a hydraulically controlled deactivation cam that locks the valve in a closed position, rendering the tractor non-operational. The propulsion control valve is piloted on both ends by fluid pressure in the gripper assemblies. The propulsion control valve controls the distribution of operating fluid to and from the propulsion cylinders, such that one cylinder performs a power stroke while the other cylinder performs a reset stroke. Each end of the gripper control valve is piloted by a source of high-pressure fluid selectively admitted by one of the cycle valves. The gripper control valve controls the distribution of operating fluid to and from the gripper assemblies. The cycle valves are spring-biased and piloted by fluid pressure in the propulsion cylinders, so that the gripper control valve shifts only after the cylinders complete their strokes. The pressure reduction valves limit the pressure within the gripper assemblies. These valves are spring-biased and piloted by the pressure of fluid flowing into the gripper assemblies. Some or all of the valves include centering grooves on the landings of the spools, which reduce leakage and produce more efficient operation. The propulsion control and gripper control valves include spring-assisted detents to prevent inadvertent shifting.

Owner:WWT NORTH AMERICA HLDG

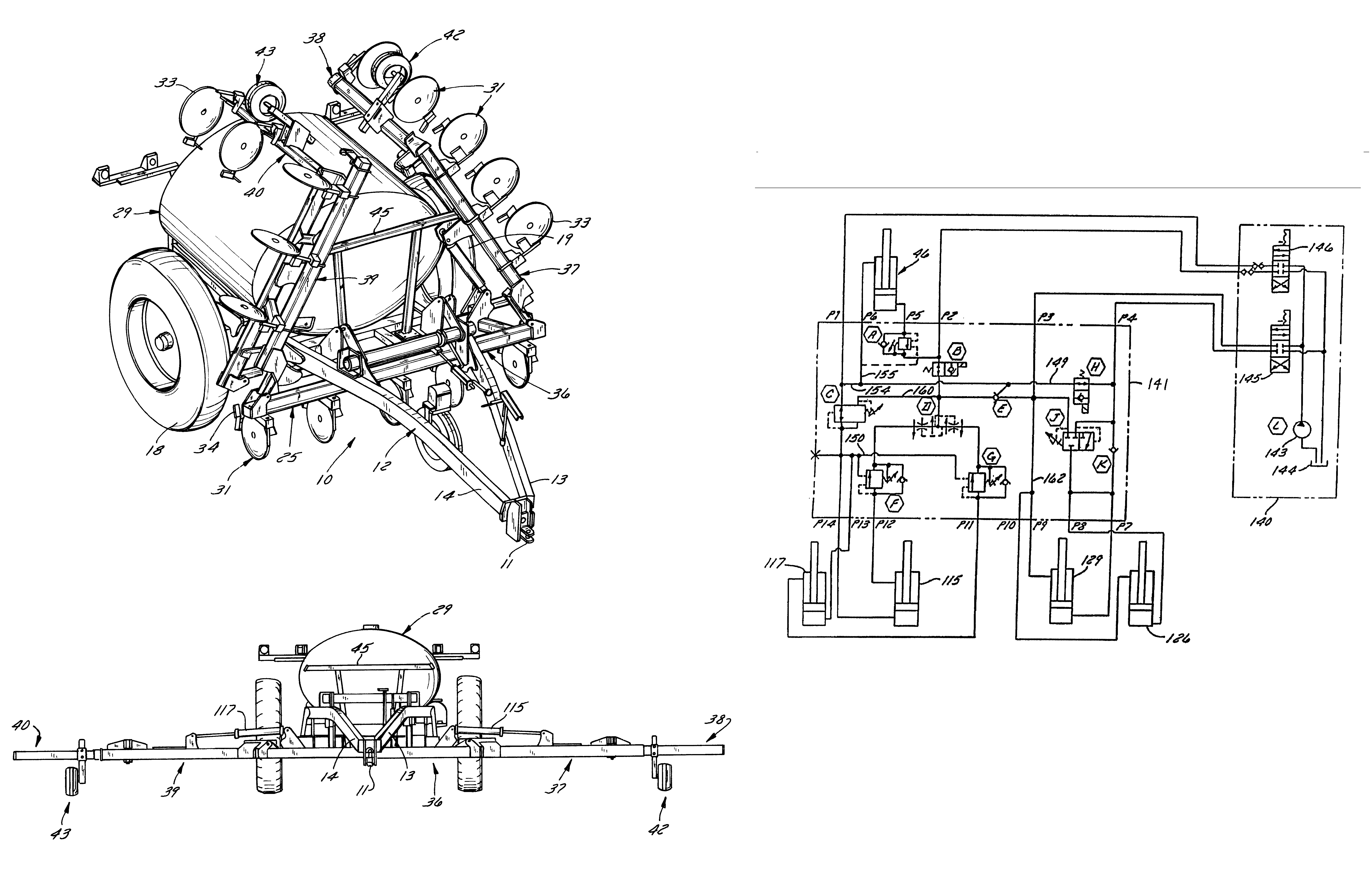

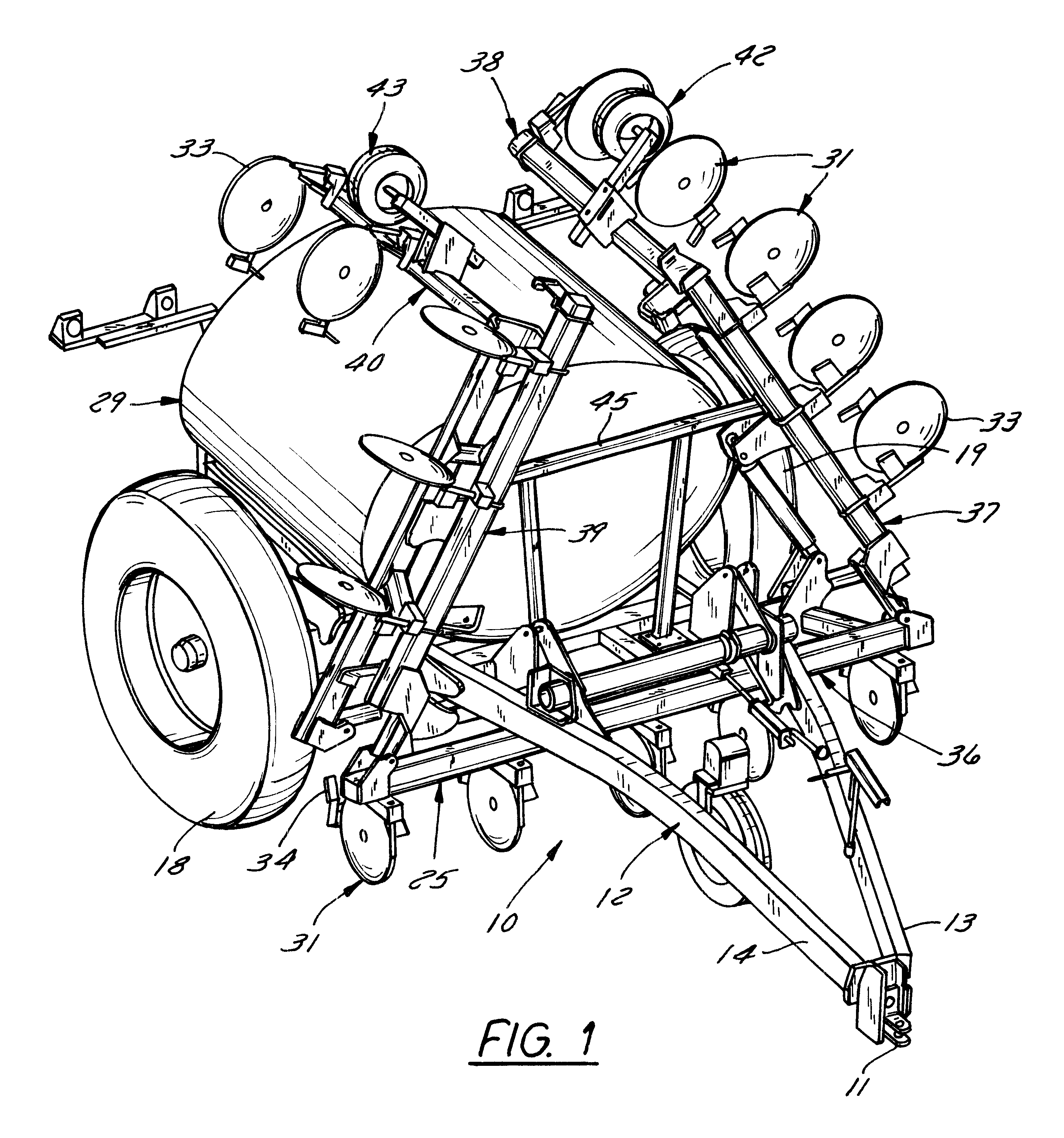

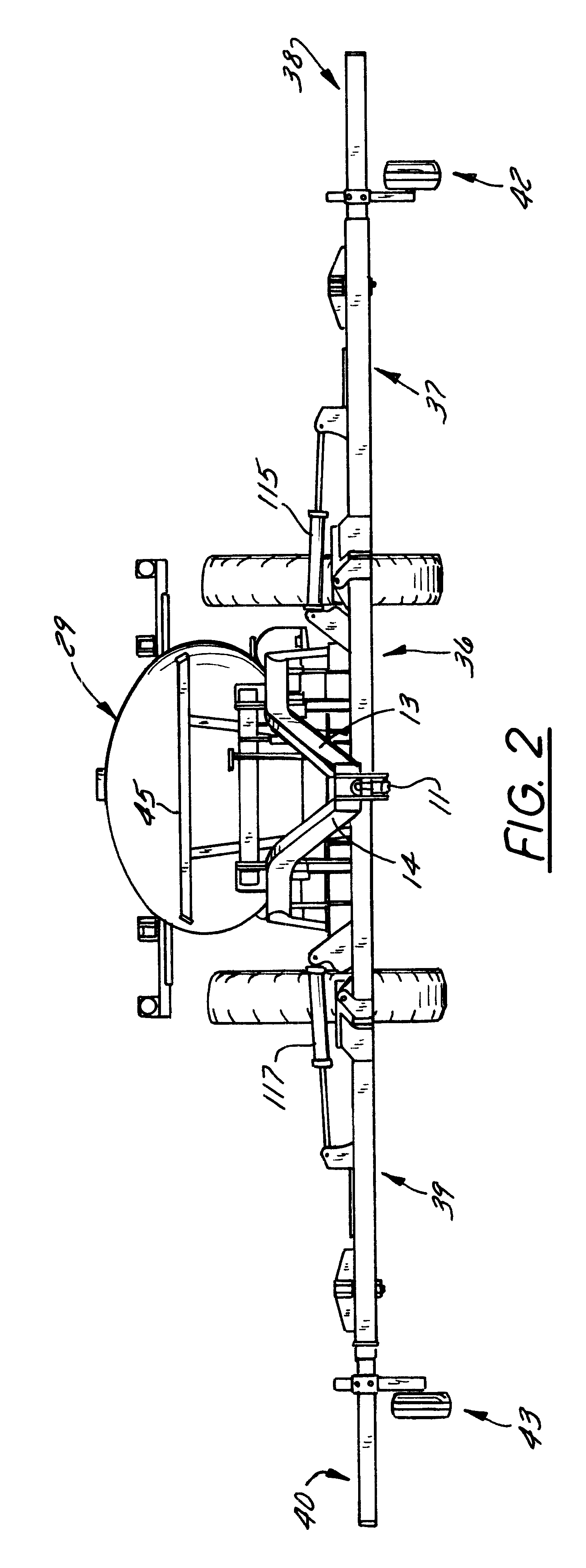

Flexible toolbar and operating hydraulic circuit

InactiveUS6675907B2Reduce the overall heightImprove securitySpadesAgricultural machinesHydraulic circuitEngineering

A winged implement includes an hydraulic control circuit having two operator-controlled valves, including a work valve and a transport valve. Using only these controls, and without leaving the tractor cab, the operator can (1) fold the implement for transport; (2) unfold the wings; (3) place the implement in the field use position with substantial constant down pressure on the wings; and (4) raise the wings and center section to an intermediate position with the wings inclined upwardly for end row turns.

Owner:CNH IND AMERICA LLC +1

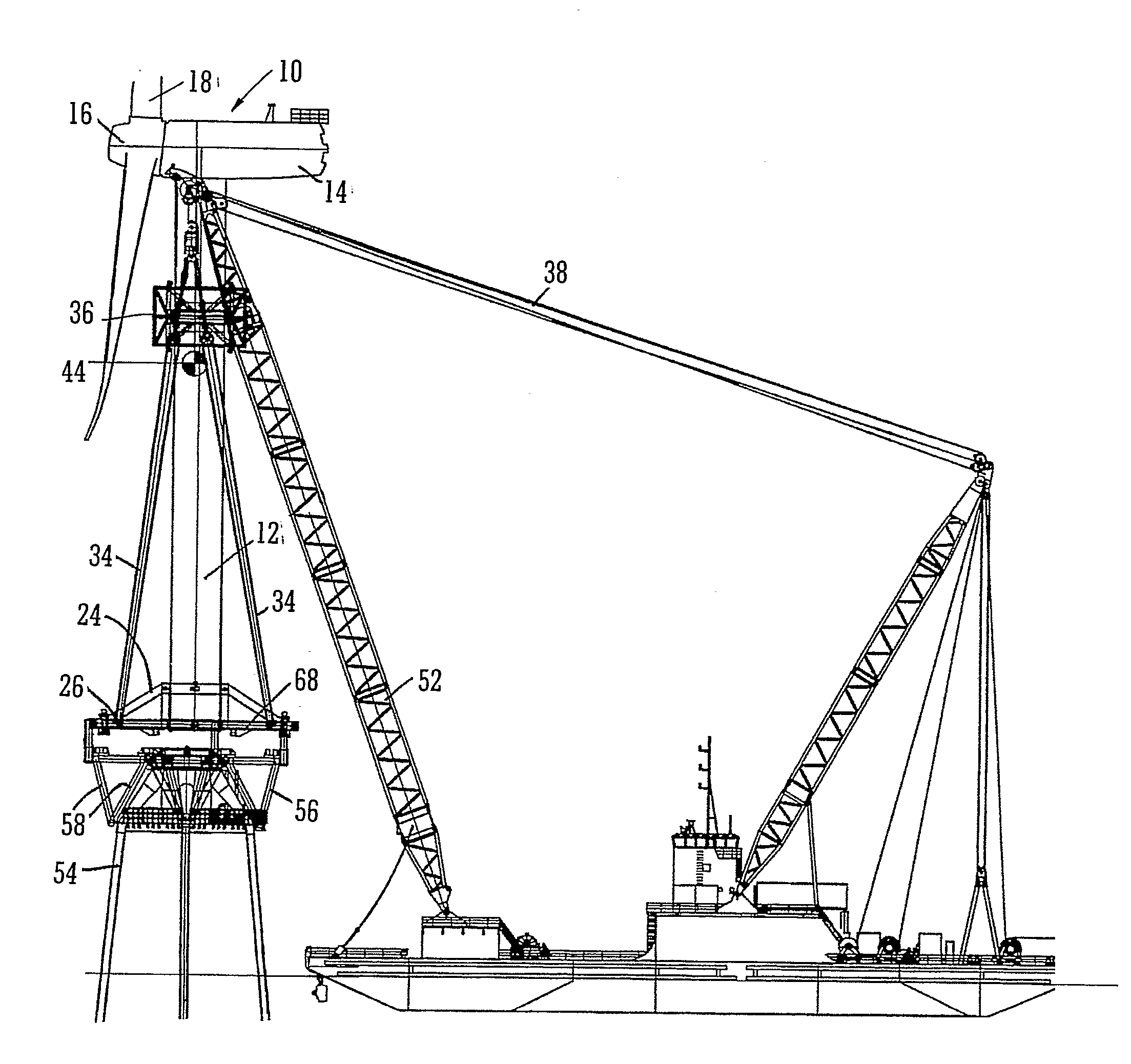

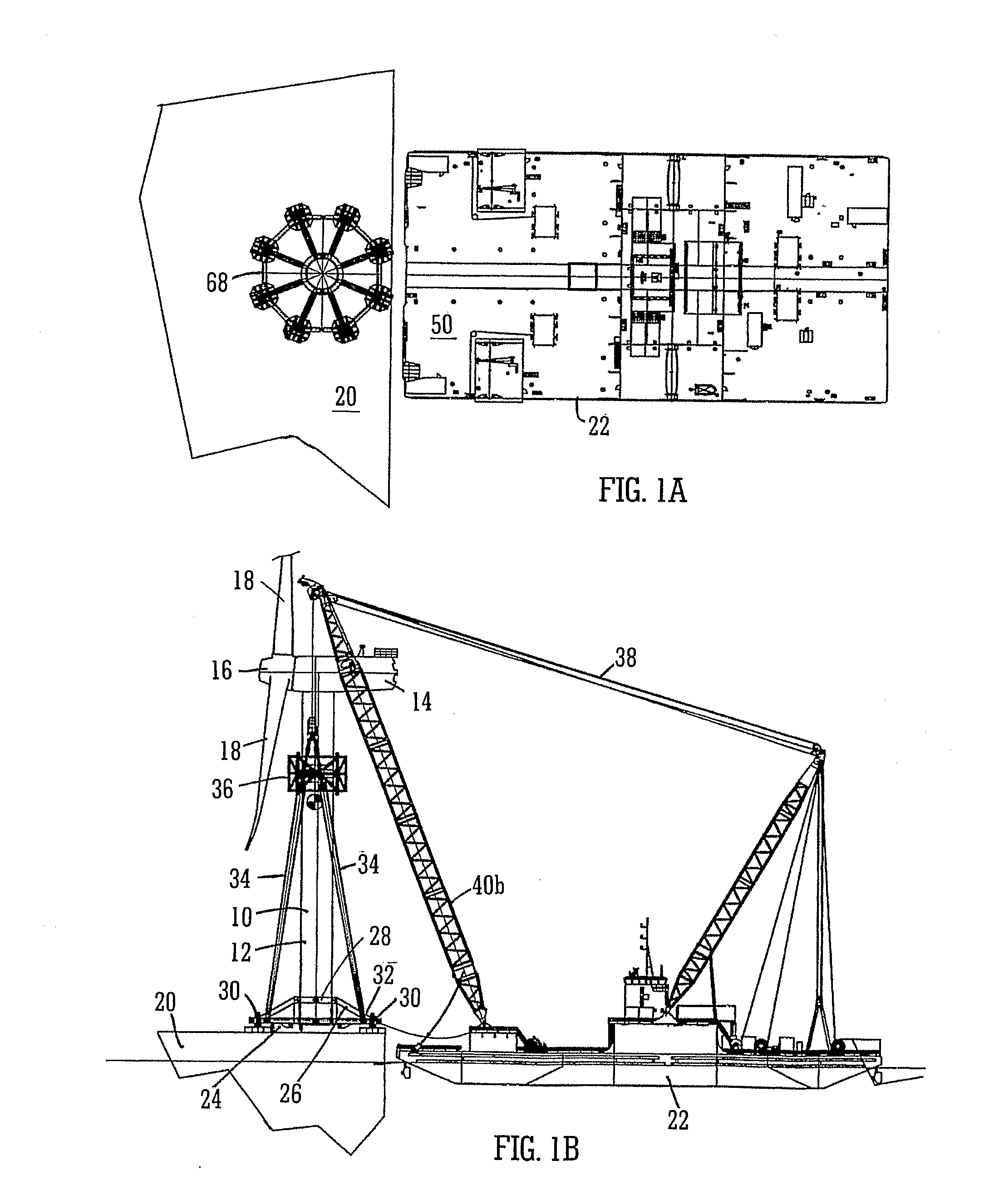

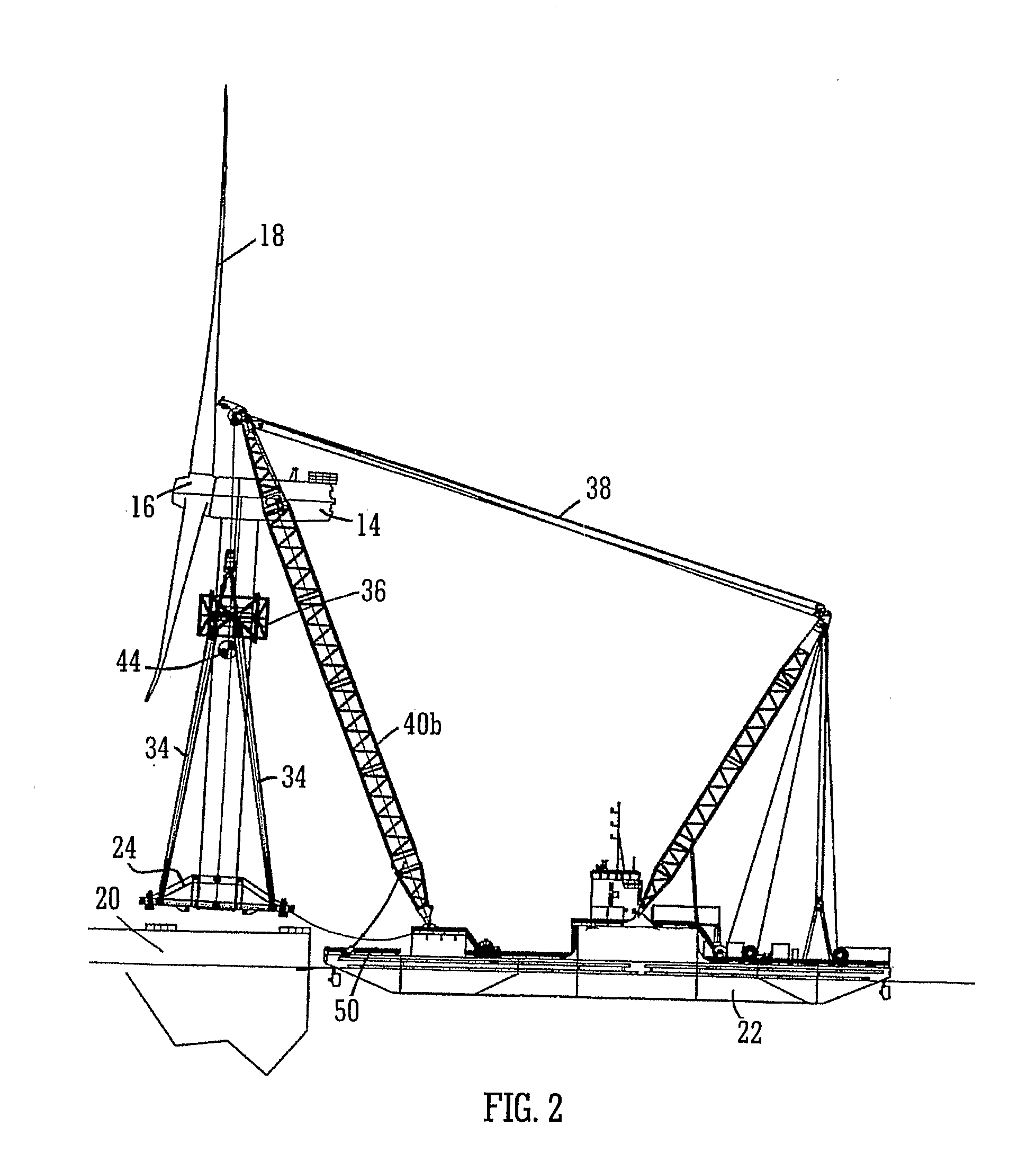

Installation Of Offshore Structures

A method and system for transporting an offshore structure such as a wind turbine generator includes a supporting frame in which the offshore structure is assembled on land in an upright configuration. The frame is used for lifting the structure onto a transport vessel, on which it is retained in the upright configuration. At its location of use, the offshore structure is transferred to a pre-prepared foundation. The foundation is provided with a frame which cooperates with the supporting frame. The supporting frame includes a plurality of legs having hydraulically controlled feet. The frame of the foundation includes an equal number of supporting formations on which the feet ultimately rest. The feet are moveable in response to the hydraulic control along a nominally vertical line of action and provide a damping arrangement for the mounting of the offshore structure.

Owner:IHC IQIP HLDG BV

Integrated control module for use in a dual clutch transmission having integrated shift actuator position sensors

ActiveUS7073407B2Low costReduce componentsGearboxesGear lubrication/coolingElectricityControl system

An integrated control module for a dual clutch transmission having an integrated shift actuator position sensor assembly that includes a valve body having a plurality of raised portions juxtaposed to each other with a plurality of shift actuator bores piston bores formed therein. A plurality of shift actuators are adapted to operatively move the synchronizers of said transmission to affect gear changes, and include a plurality of shift actuator pistons slidingly disposed within the shift actuator bores. A hydraulic control assembly is adapted to control the operative hydraulic functions of the transmission. A transmission control assembly in electrical communication with the hydraulic control assembly and with a higher level vehicle control system provides the requisite signals to control the hydraulic control assembly. A sensor assembly is also included that has a plurality of detecting elements fixedly mounted to the raised portions of the valve body and a plurality of reference elements fixedly mounted to each of the plurality of actuator pistons such that the detecting elements can sense the movement of the actuator pistons within the actuator piston bores to determine the positions of the transmission synchronizers.

Owner:BORGWARNER INC

Integrated control module for a dual clutch transmission

An integrated control module for a dual clutch transmission that includes a valve body having an inlet, a plurality of outlets with a plurality of internal hydraulic passages disposed therebetween, and a hydraulic control assembly mounted to the valve body. The hydraulic control assembly is adapted to operatively control the pressurized hydraulic fluid from the inlet through the plurality of internal hydraulic passages to the plurality of outlets. The hydraulic control assembly includes at least one assembly from a group including, a shift actuation control assembly adapted to actuate the synchronizers of the transmission, a clutch actuation control assembly adapted to allow the selective and independent engagement and disengagement of each clutch, and a clutch cooling fluid control assembly adapted to control the cooling fluid provided to the clutches of the transmission. The module also includes a transmission control assembly that is mounted to the valve body in electrical communication with the hydraulic control assembly and operatively responsive to a higher level control system to provide the requisite control signals to control the operative functions of the dual clutch transmission.

Owner:BORGWARNER INC

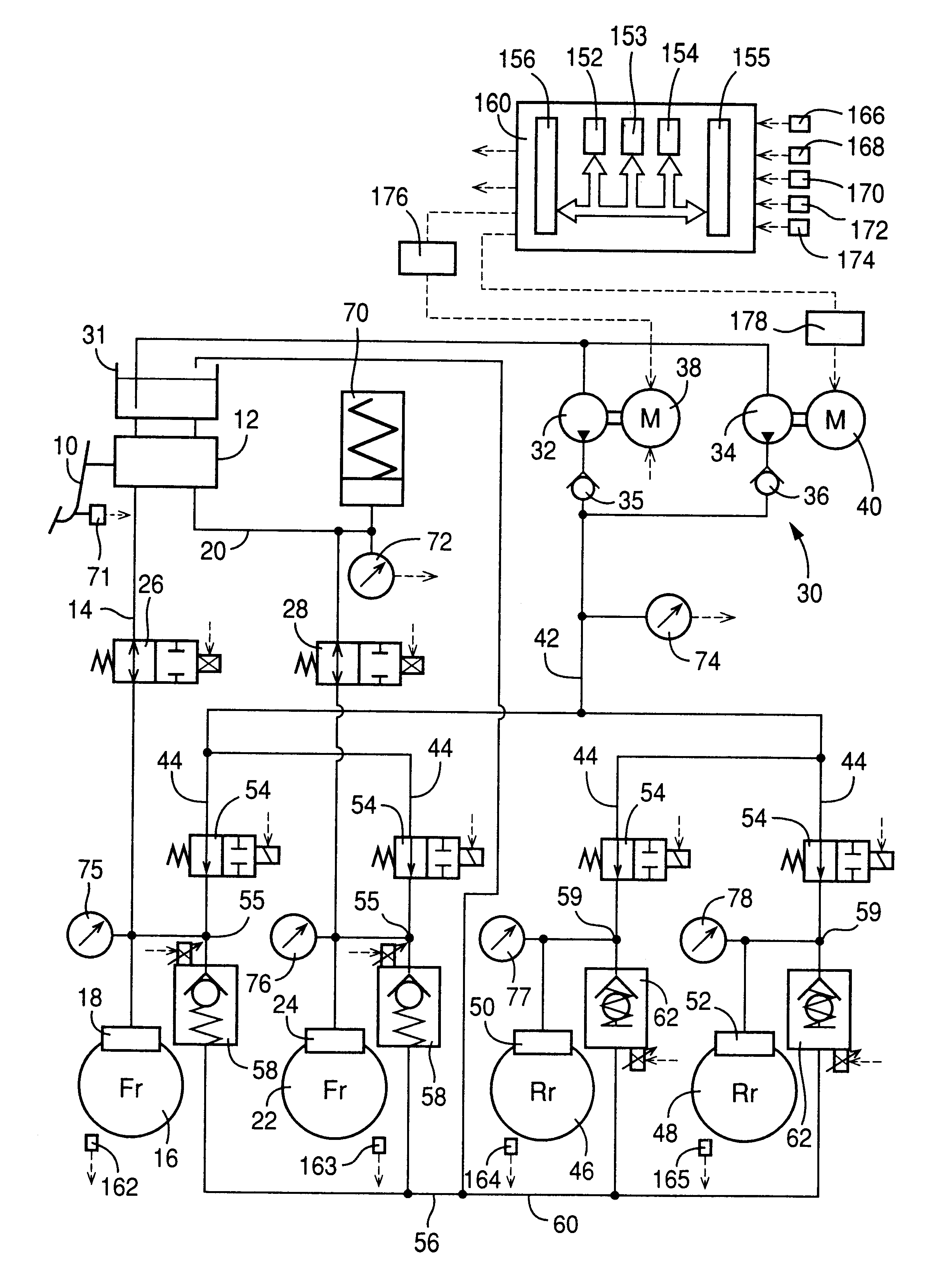

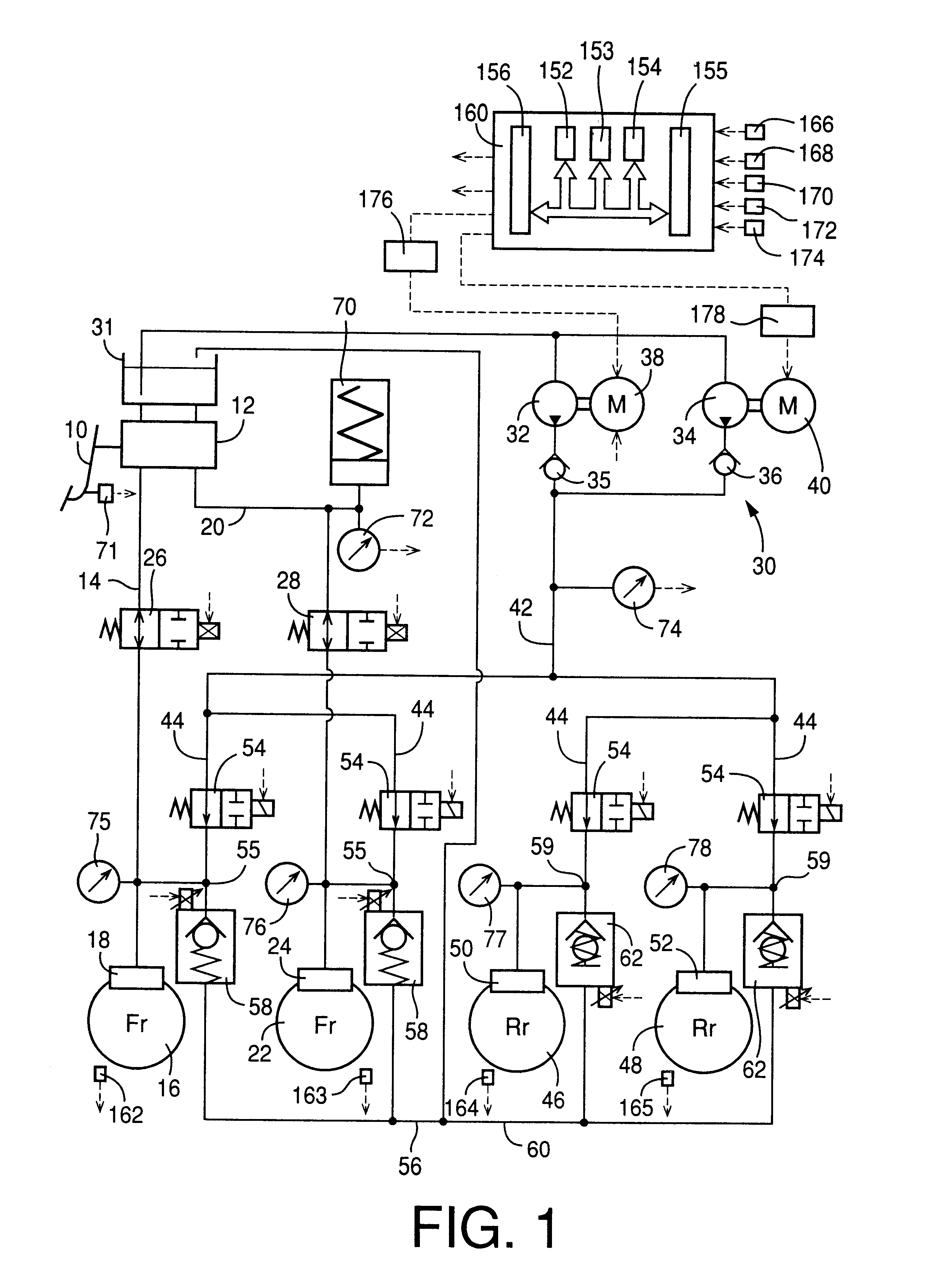

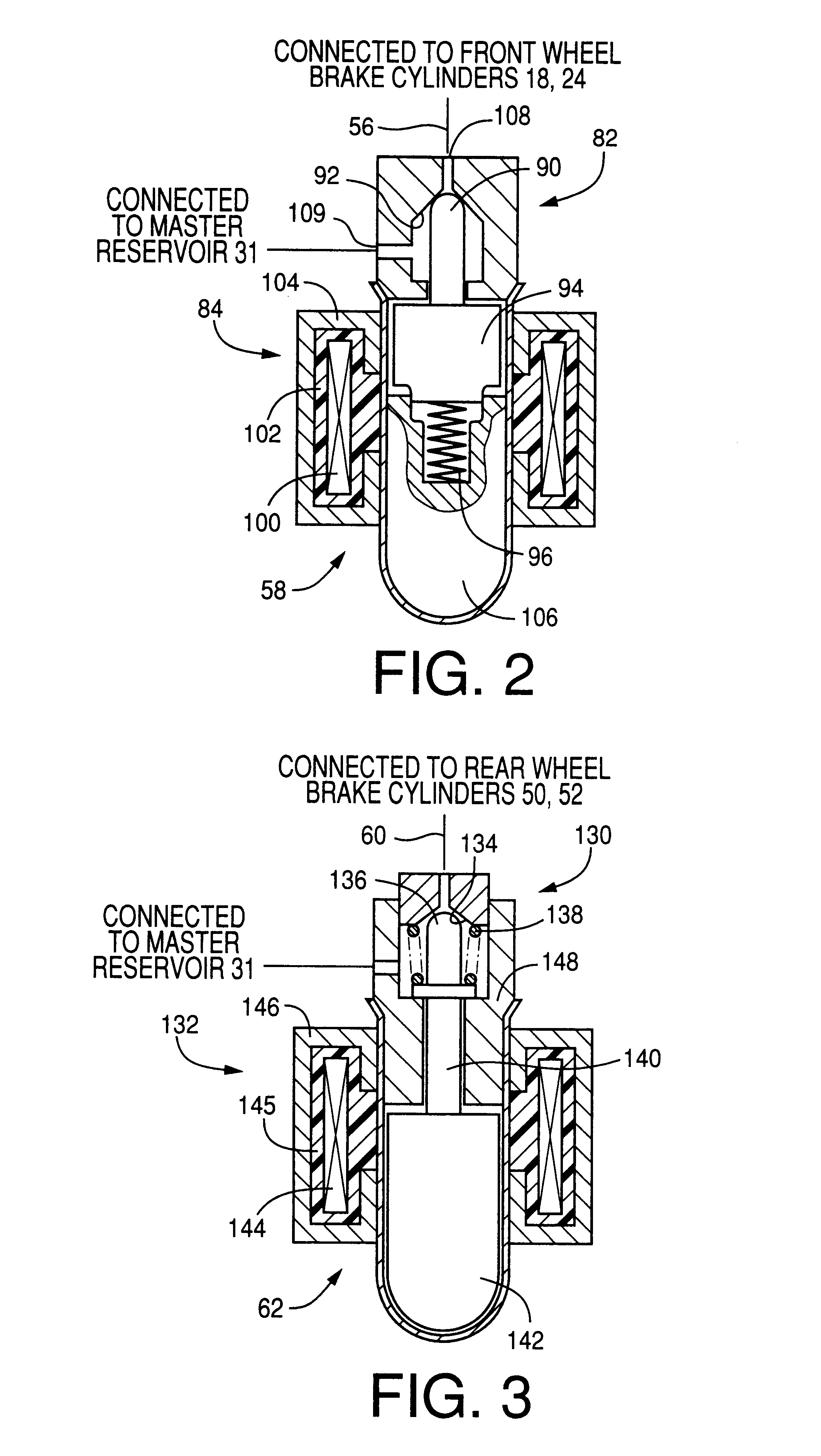

Apparatus for increasing brake cylinder pressure by controlling pump motor and reducing the pressure by controlling electric energy applied to control valve

Hydraulic pressure control apparatus for controlling a pressure of a brake cylinder pressure, including a pump device connected to the brake cylinder and including at least one set of a pump for delivering a pressurized fluid to the brake cylinder and a pump operating electric motor, a low-pressure source for storing the fluid discharged from the brake cylinder, a solenoid-operated pressure control valve disposed between the low-pressure source and the brake cylinder and operated with an electric energy applied thereto, for controlling the brake cylinder pressure depending upon the electric energy, and a controller including a pressure increase control device for increasing the brake cylinder pressure by controlling the electric motor, and a pressure reduction control device or reducing the brake cylinder pressure by controlling the electric energy applied to the control valve.

Owner:TOYOTA JIDOSHA KK

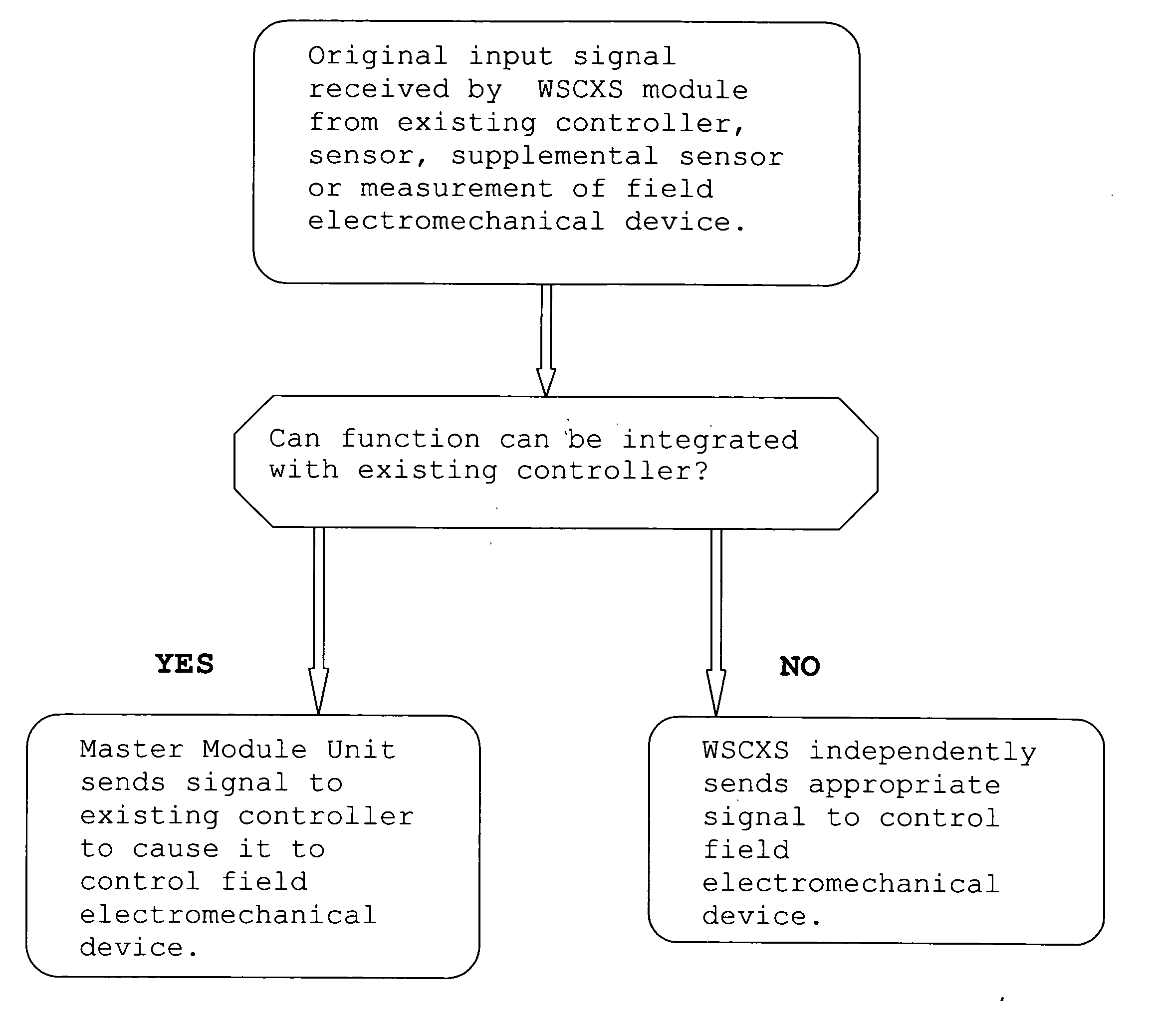

Wireless sensor and control transmitter system

InactiveUS20050137752A1Easy to implementImprove convenienceOperating means/releasing devices for valvesSelf-acting watering devicesLine sensorControl system

A wireless sensor and control transmitter system is provided for operating an irrigation or other hydraulic system. The system includes a master module unit hardwired to and in communication with the hydraulic system controller, and a field module unit that is hardwired to and in communication with field electromechanical control devices such as valves, solenoids and servo motors, and field sensors indicating, for example, atmospheric conditions. The master module unit and field module unit communicate with digital wireless communication and can act as a simple wireless bridge. The master module and field module units are capable of digitizing input signals from the devices to which they are hardwired and transmitting them to the opposite module; they are further capable of deciphering the digitized signals received to reproduce the original input signal and communicating it to the device to which it is hardwired. Supplemental functionality may be added to an existing hydraulic control system by including the WSCX and its system features of control and sensor functionality that may not otherwise be available in an existing controller system.

Owner:TECHSTREAMS CONTROL SYST AN ARIZONA

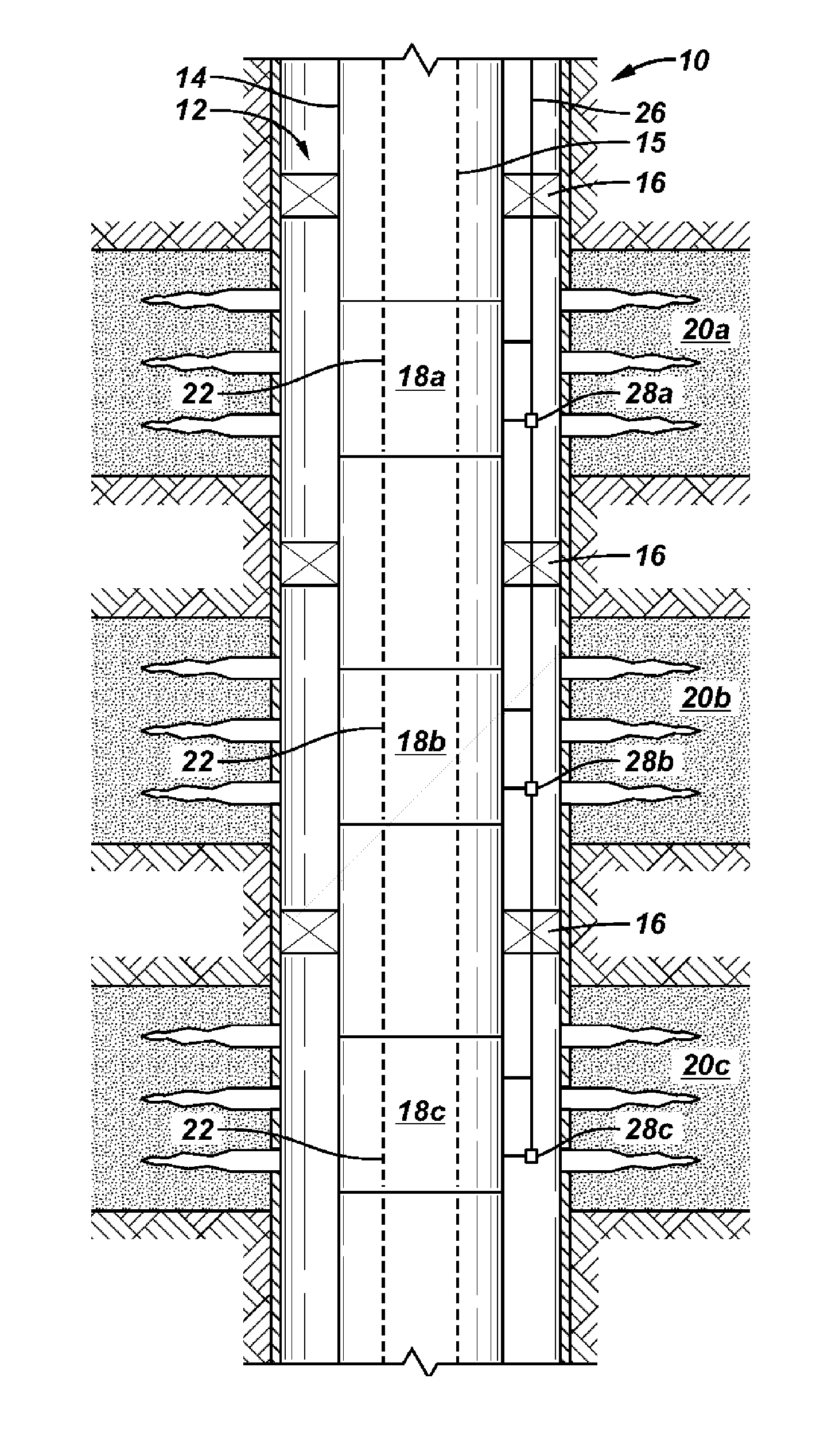

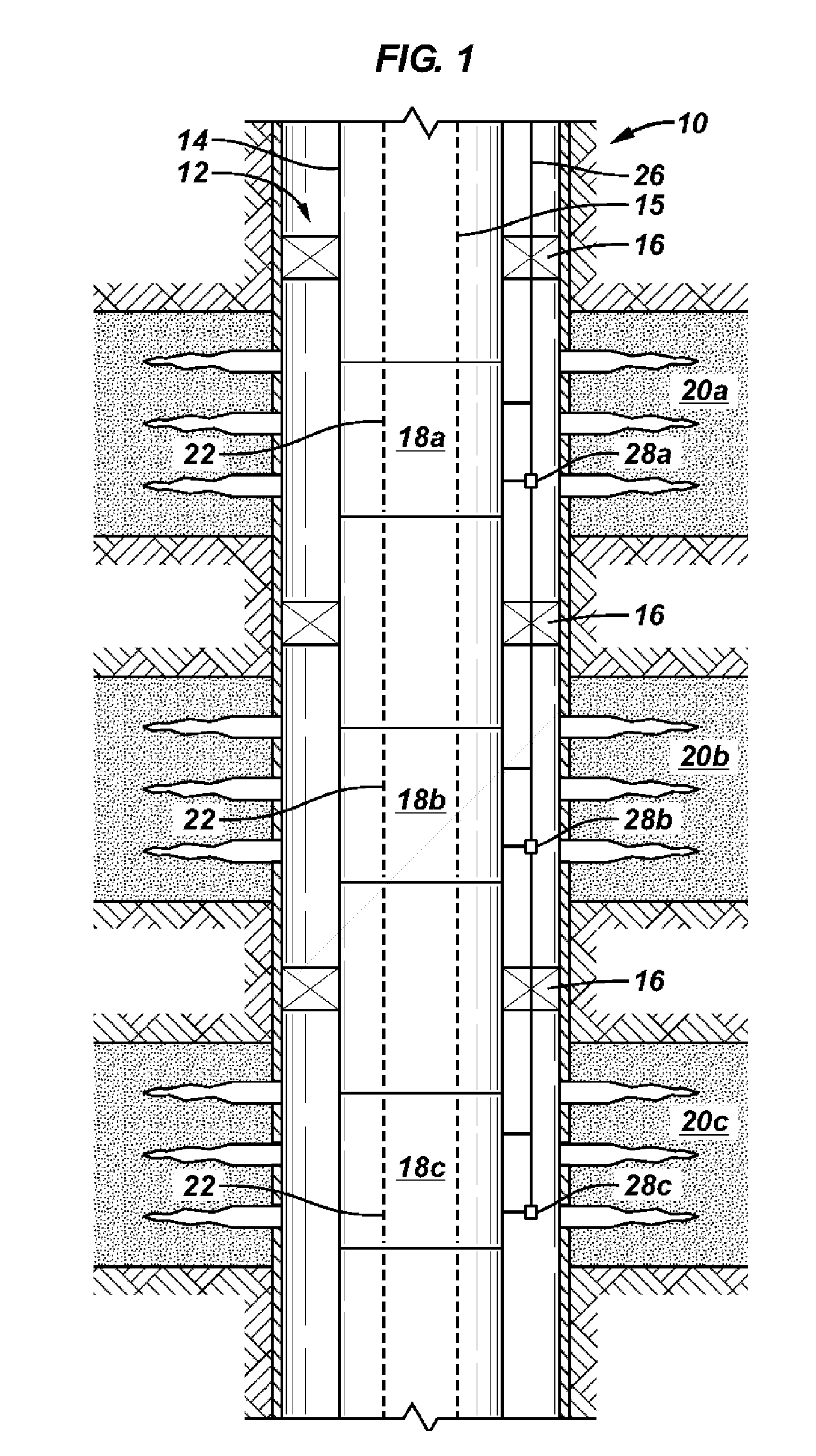

Multi-Drop Flow Control Valve System

A multi-drop flow control valve system having a plurality of hydraulically actuated flow control valve, each valve set in an initial operating position. The flow control valves are connected to a hydraulic control line in sequence, wherein the second flow control valve is below the first flow control valve and so on. Wherein a first hydraulic pressure in the control line will operate at least the first flow control valve to an actuated position and a second hydraulic pressure greater than the first hydraulic pressure will operate at least the first and second flow control valves to actuated positions. It may be desired for each of the control valves to be biased in the initial position when the hydraulic pressure is less than a base pressure.

Owner:SCHLUMBERGER TECH CORP

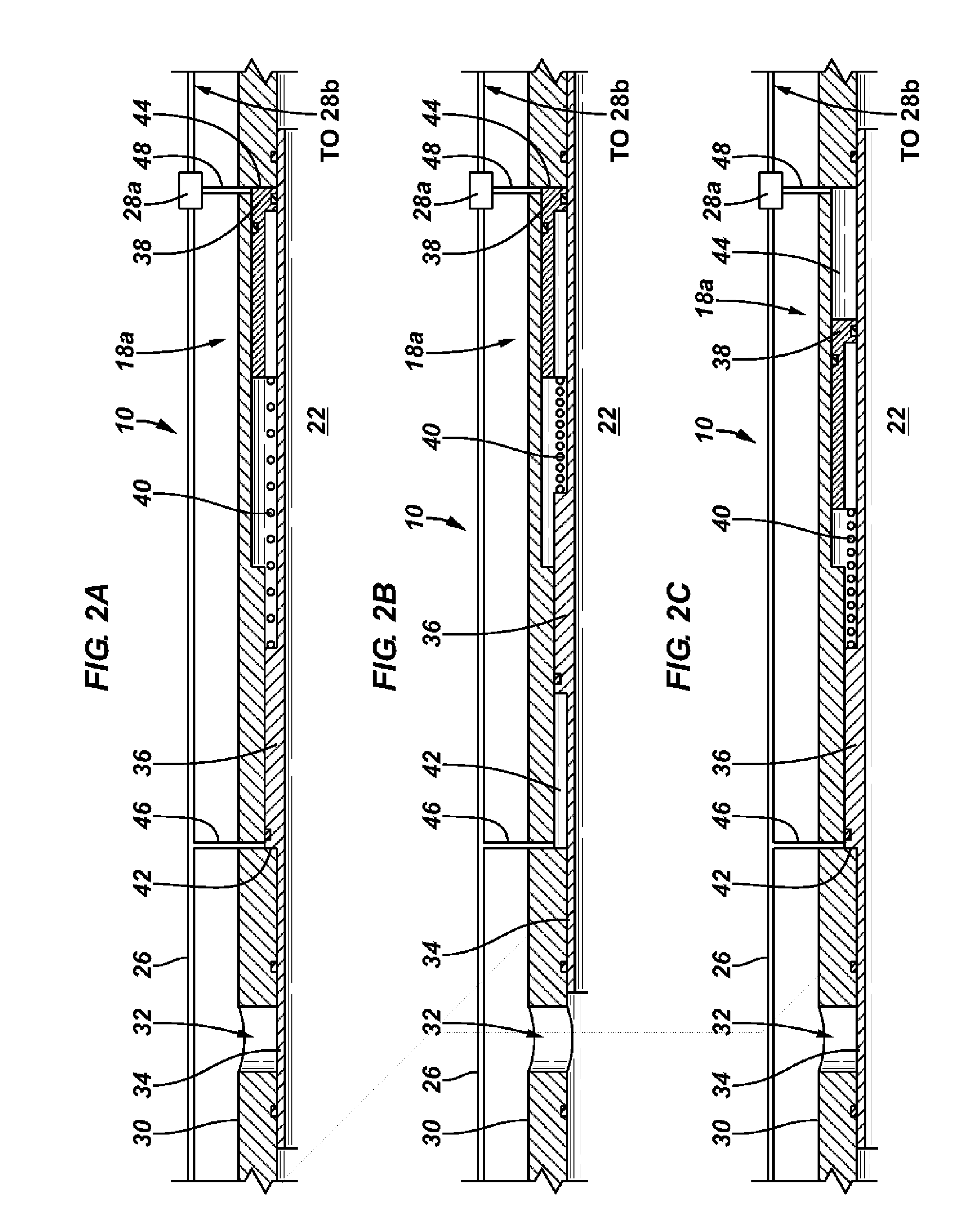

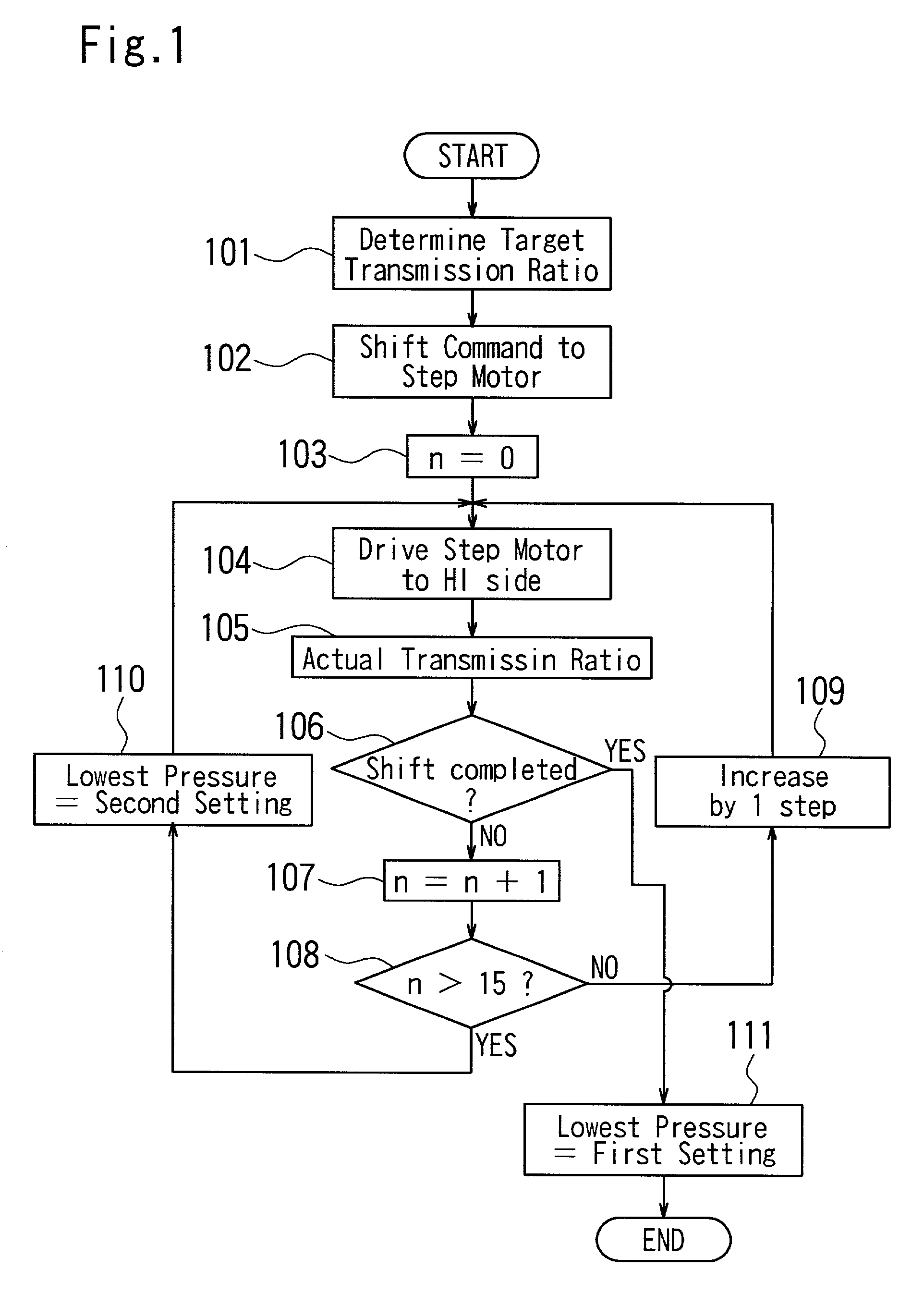

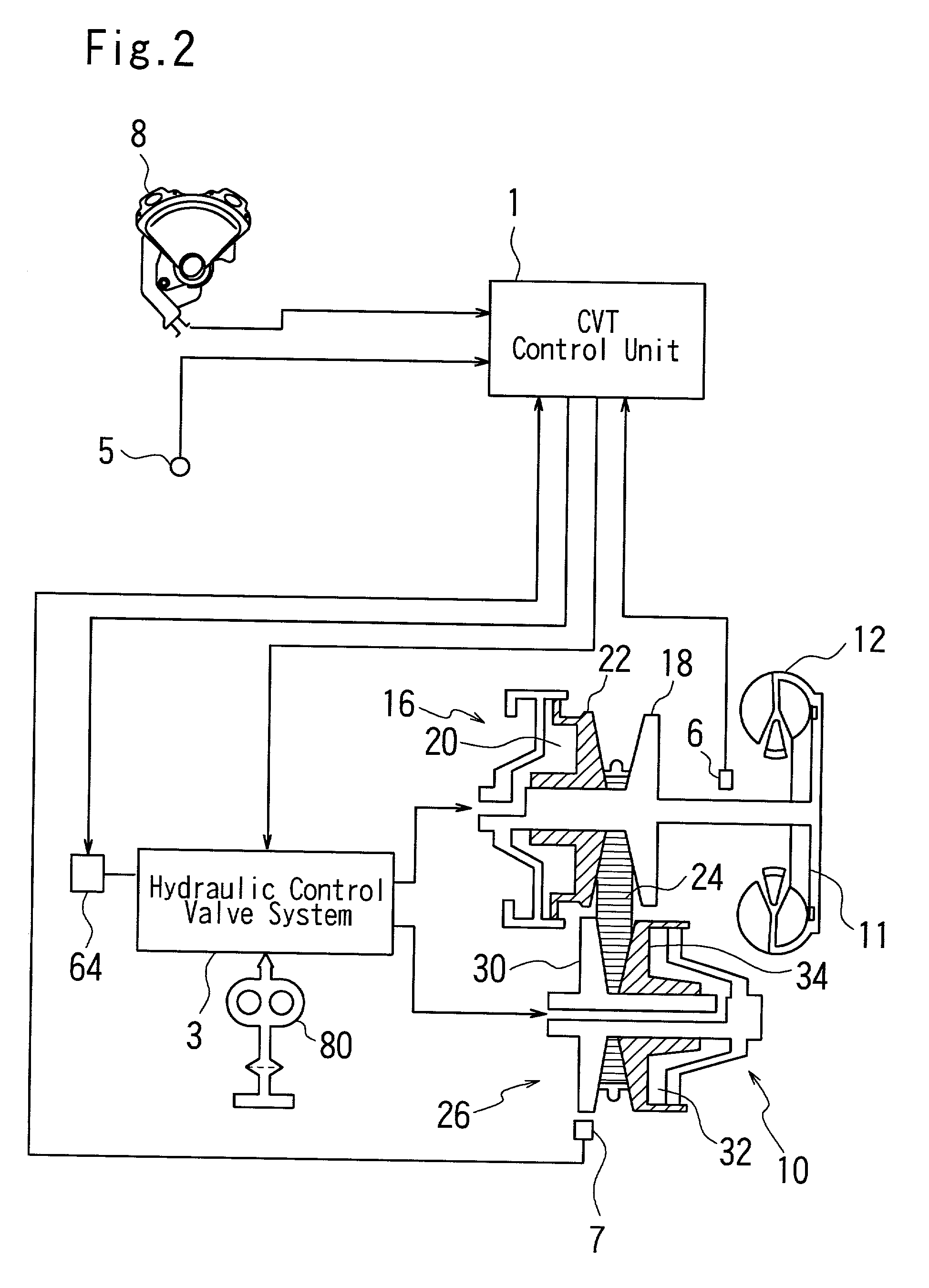

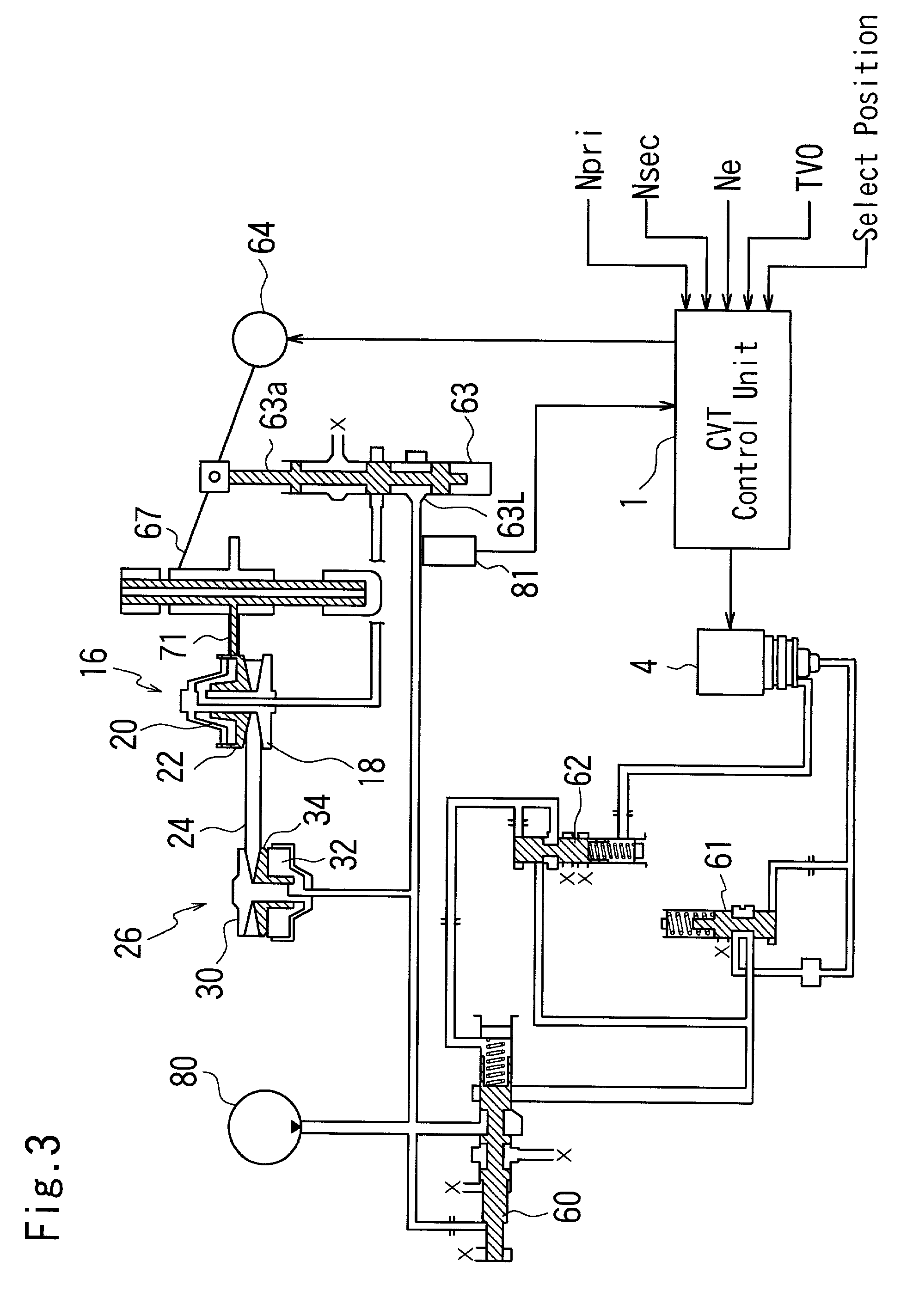

Hydraulic control system for a continuously variable transmission

InactiveUS20010023217A1Less frictional lossIncrease line pressureGearingRoad transportControl systemRotation velocity

A transmission mechanism of the continuously variable transmission comprises a set of primary and secondary pulleys between which a belt is provided. The CVT control unit is operable to supply line pressure directly to a secondary pulley and also to a primary pulley via a shift control valve associated with a step motor in such a manner as to control a transmission ratio. The CVT control unit calculates a standard step position of the step motor corresponding to the target transmission ratio and provides a command signal representative of a difference between the standard step position and the current position of the step motor. The shift control valve actuated by the step motor controls the pressure to be supplied to the primary pulley. The actual transmission ratio obtained on the basis of the rotation speeds of the pulleys is compared with the target transmission ratio. If the shift is not accomplished, the CVT control unit commands additional step number. Unless the shift to the HI side is accomplished at the time when the additional step number reaches the threshold value, the line pressure is increased so as to achieve the shift. Thus, the transmission normally operates with a low line pressure sufficiently to reduce a frictional loss at the contact areas of the belt and the pulleys, thereby resulting in an enhanced fuel economy.

Owner:JATCO LTD

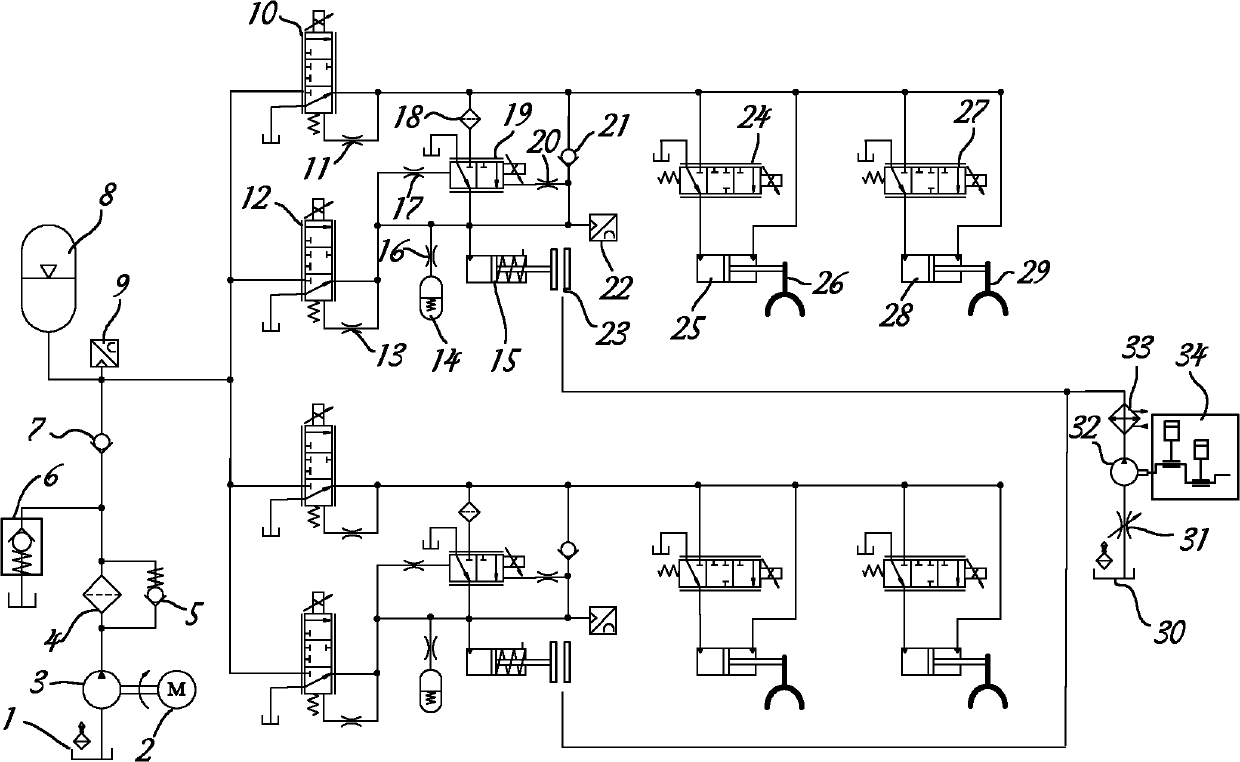

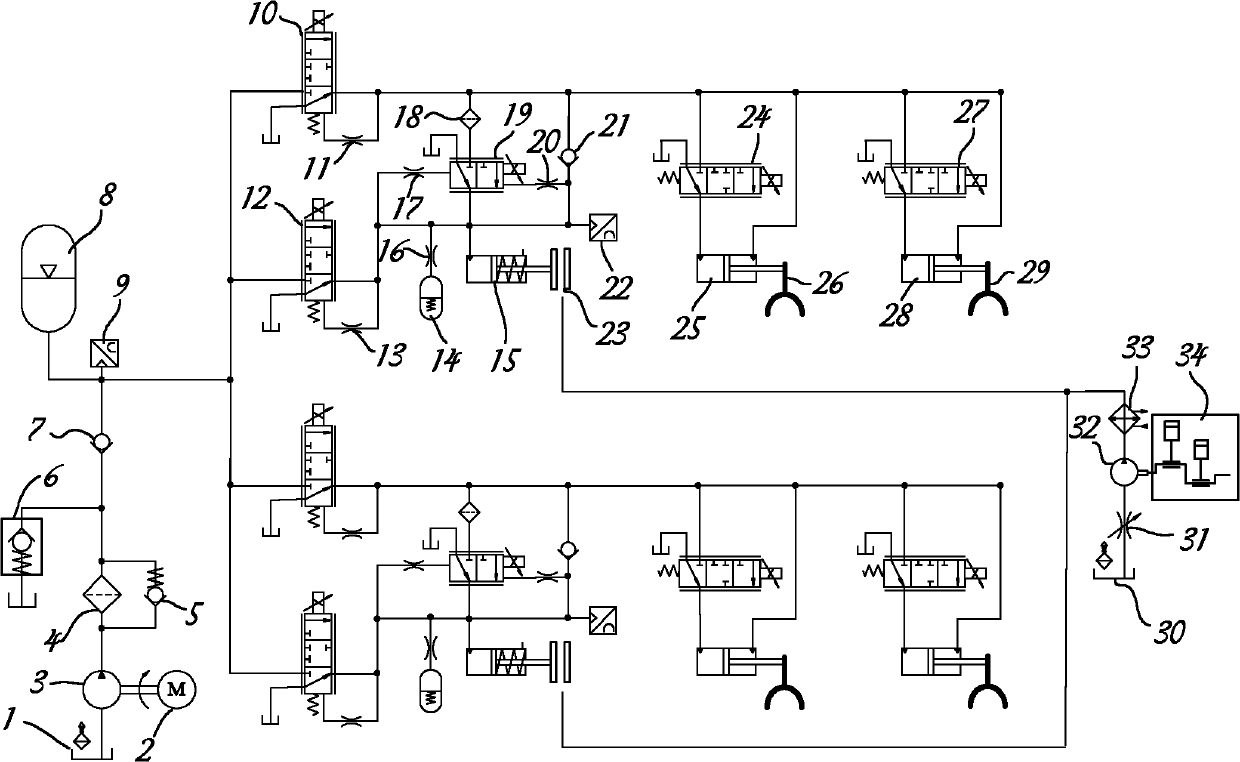

Hydraulic control system for wet-type double-clutch automatic transmission

ActiveCN102168754AReduce displacementLow powerClutchesGear lubrication/coolingAutomatic transmissionControl signal

The invention belongs to automobile transmissions, in particular to a hydraulic control system for a wet-type double-clutch automatic transmission. The hydraulic control system consists of two separate subsystems, wherein one subsystem is a clutch and gearshift mechanism hydraulic control subsystem which is mainly used for operating an odd number gear clutch and an even number gear clutch to separate and combine according to a control signal transmitted by an electronic control unit as well as operating a gear-shift mechanism control oil cylinder to finish switching of each gear synchronizer; and the other subsystem is a clutch cooling and lubricating subsystem. By adopting a more scientific and reasonable hydraulic control system, the efficiency of the hydraulic control system for the wet-type double-clutch automatic transmission is improved, the fuel consumption is reduced, the effects of saving energy and reducing emission are achieved, and the reliability of the system work and the compactness of the structure are enhanced.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

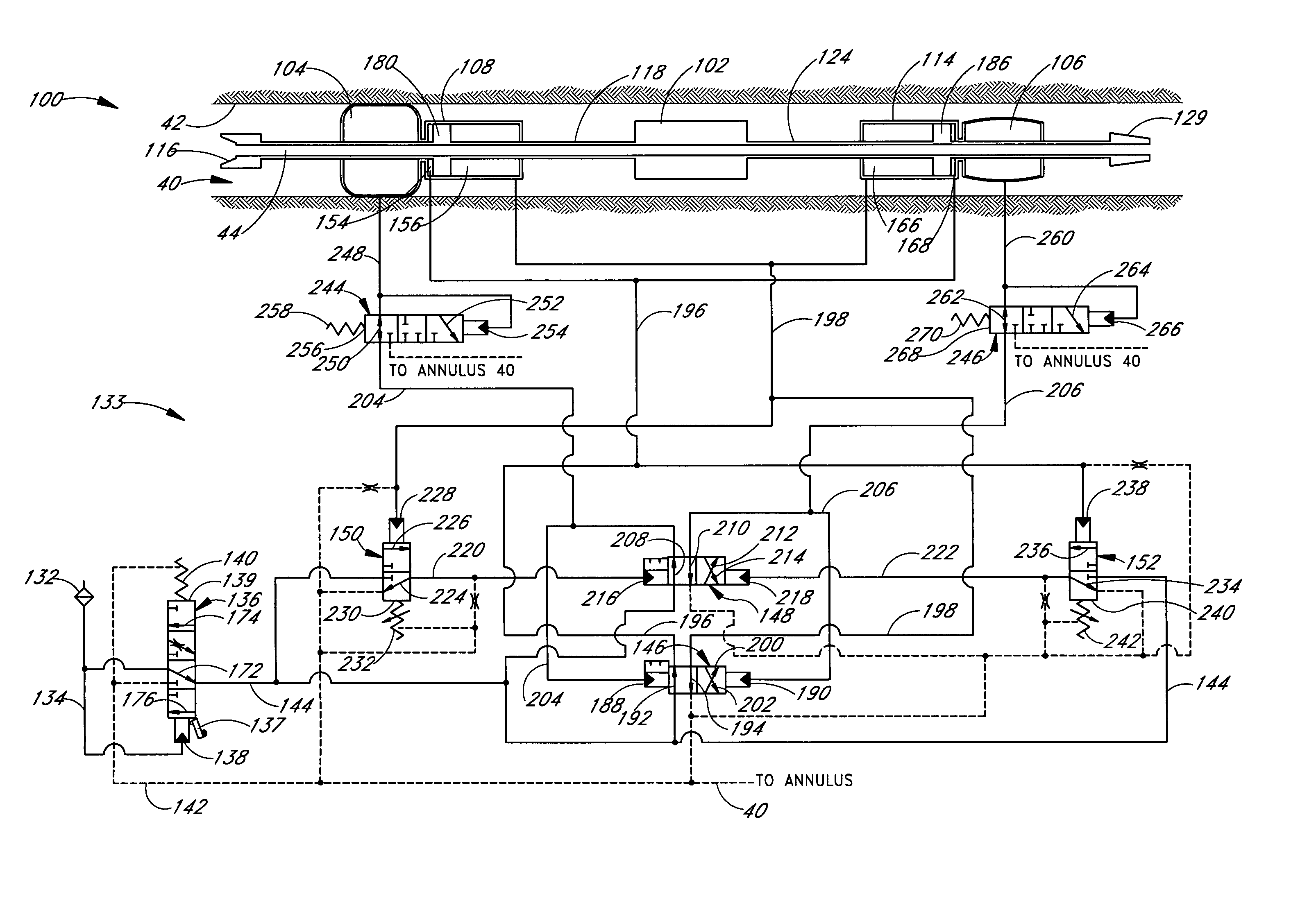

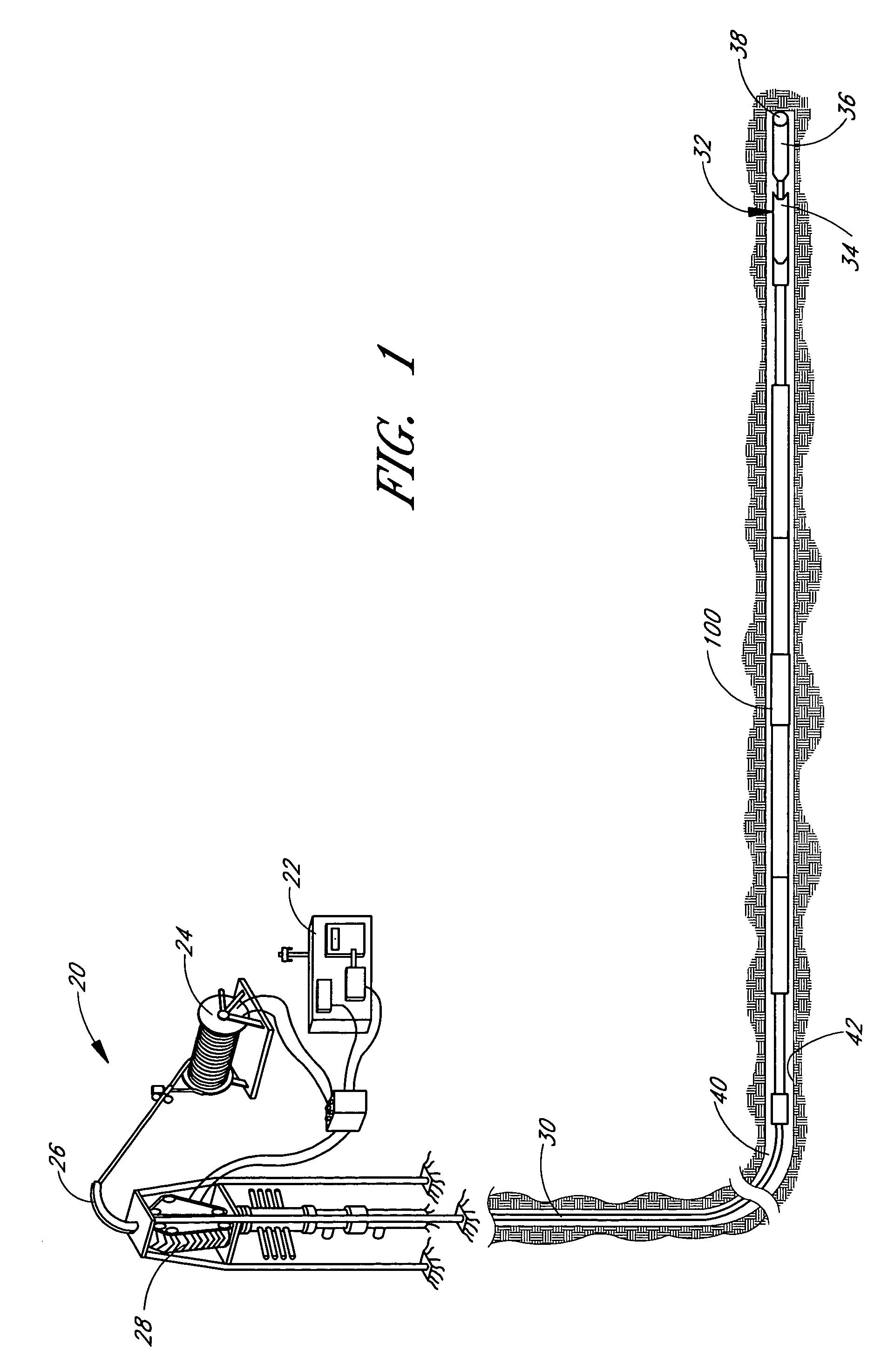

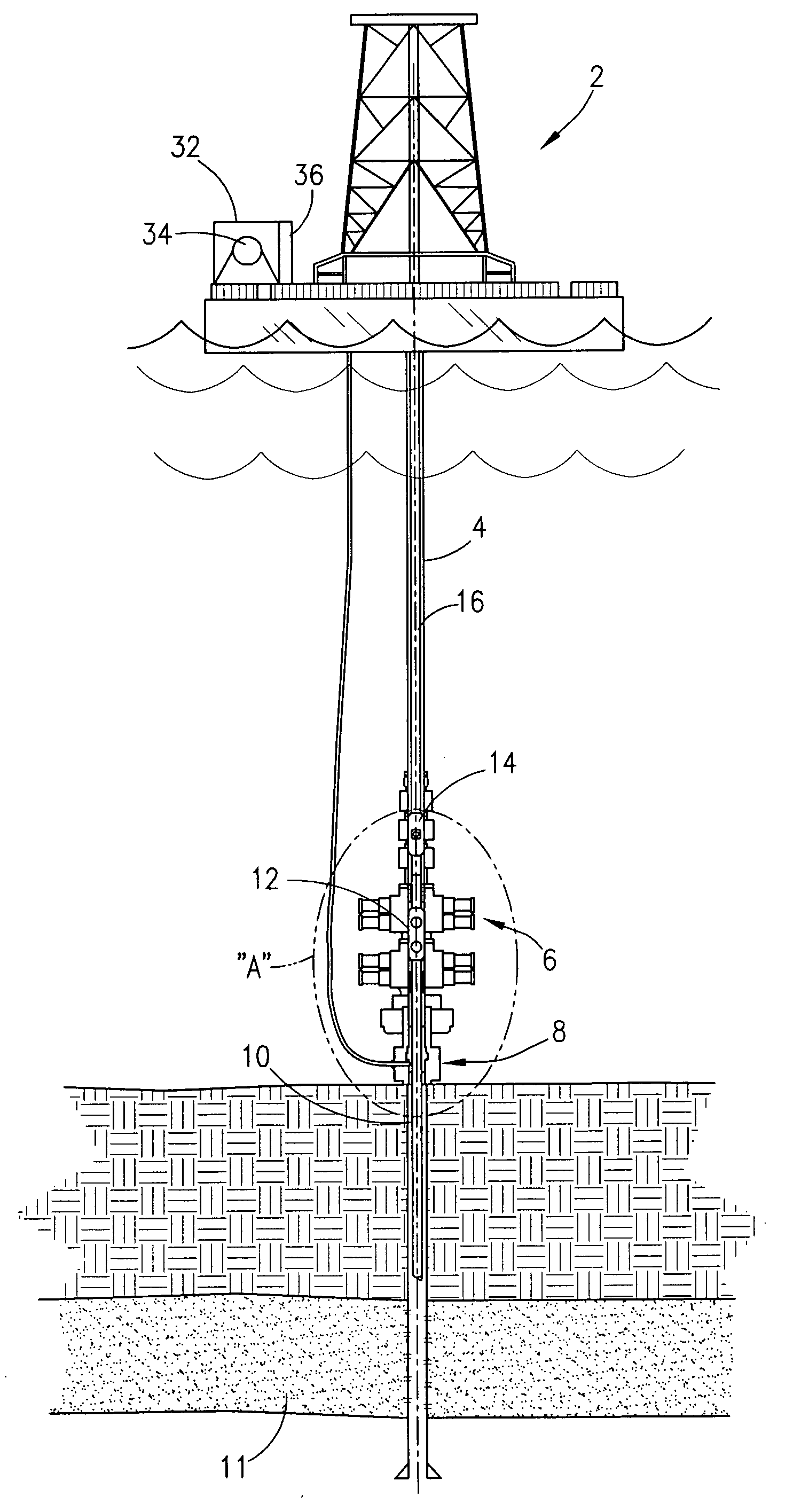

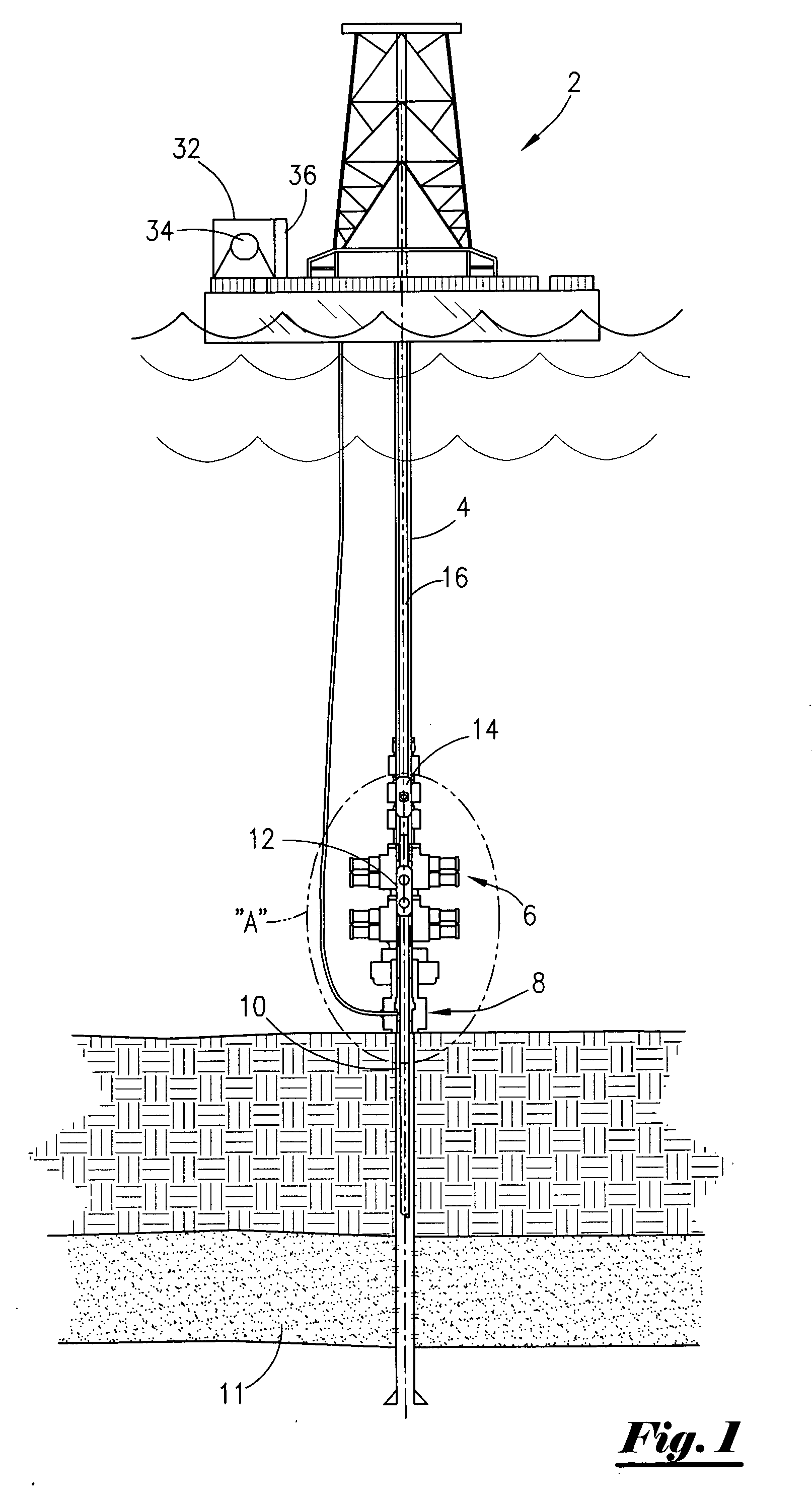

Method of controlling landing strings in offshore operations

InactiveUS20080110633A1Meet the regulationReduce riskFluid removalUnderwater drillingElectricityTubing hanger

A method and system of operating a landing string utilized on a floating platform. The landing string is disposed within a marine riser, with the marine riser being connected to a subsea production tree, and wherein the subsea production tree contains internal conduits communicating controls through a series of stab passageways. The method comprises providing a tubing hanger operatively connected to the landing string, delivering hydraulic or electrical controls from the floating platform through a control system umbilical to a junction plate operatively attached to the subsea production tree. The method further comprises landing the tubing hanger into the subsea production tree, establishing control of the tubing hanger by providing the hydraulic controls to the tubing hanger with the series of stab passageways through the subsea production tree, and establishing control of the completion bottom hole assembly with the stab passageways. In the preferred embodiment, the landing string has attached thereto a completion bottom hole assembly that will be placed in the well.

Owner:DEEPBLUE TECH L L C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com