Patents

Literature

5330 results about "Transmission ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The transmission ratio is defined as the ratio of the angular velocities or frequencies of rotation of the components. This usually refers to the ratio of the angular velocity of the driving component to the angular velocity of the driven component: u = ω 1 /ω 2. The concept of the transmission ratio is applicable both...

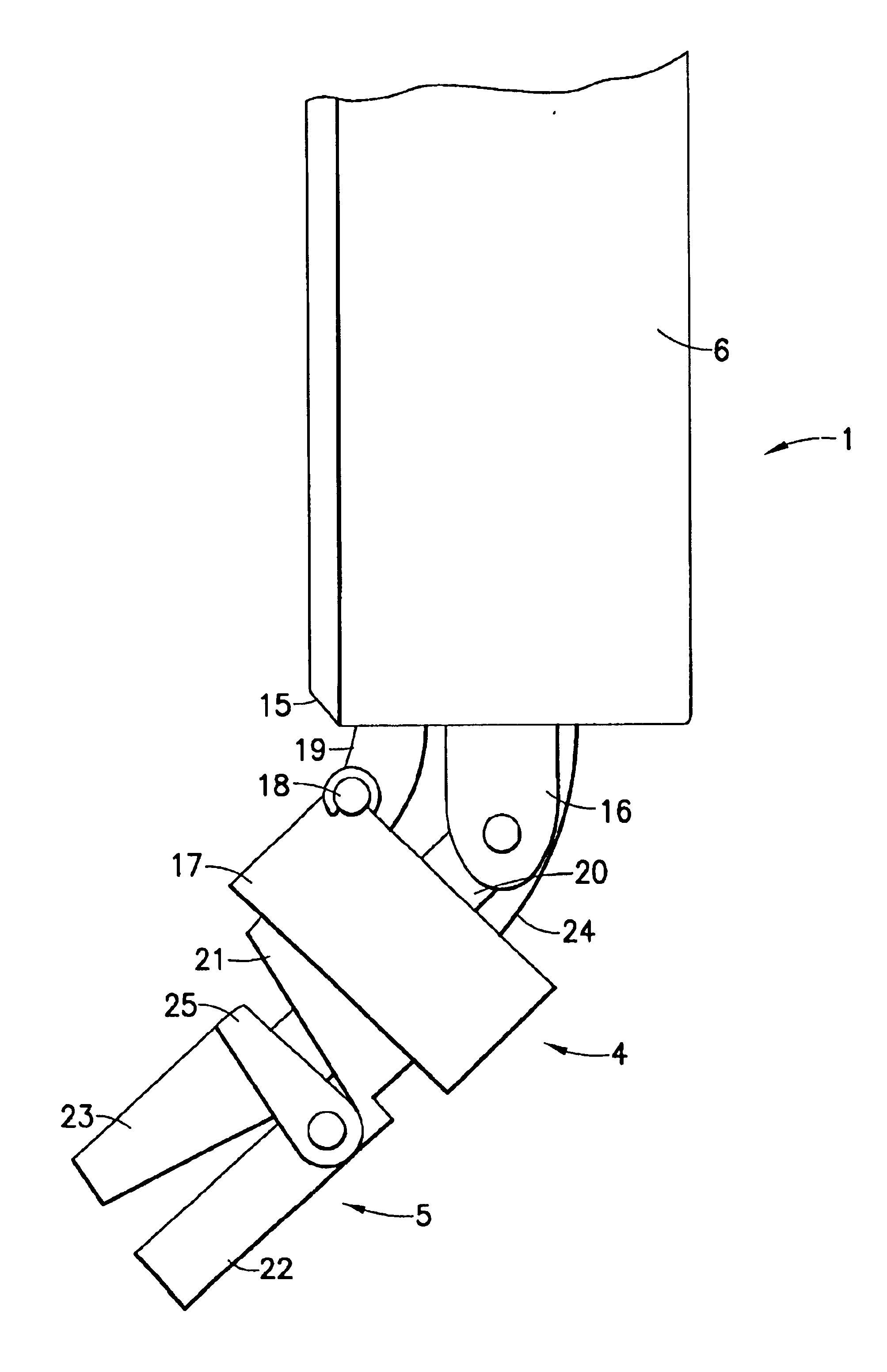

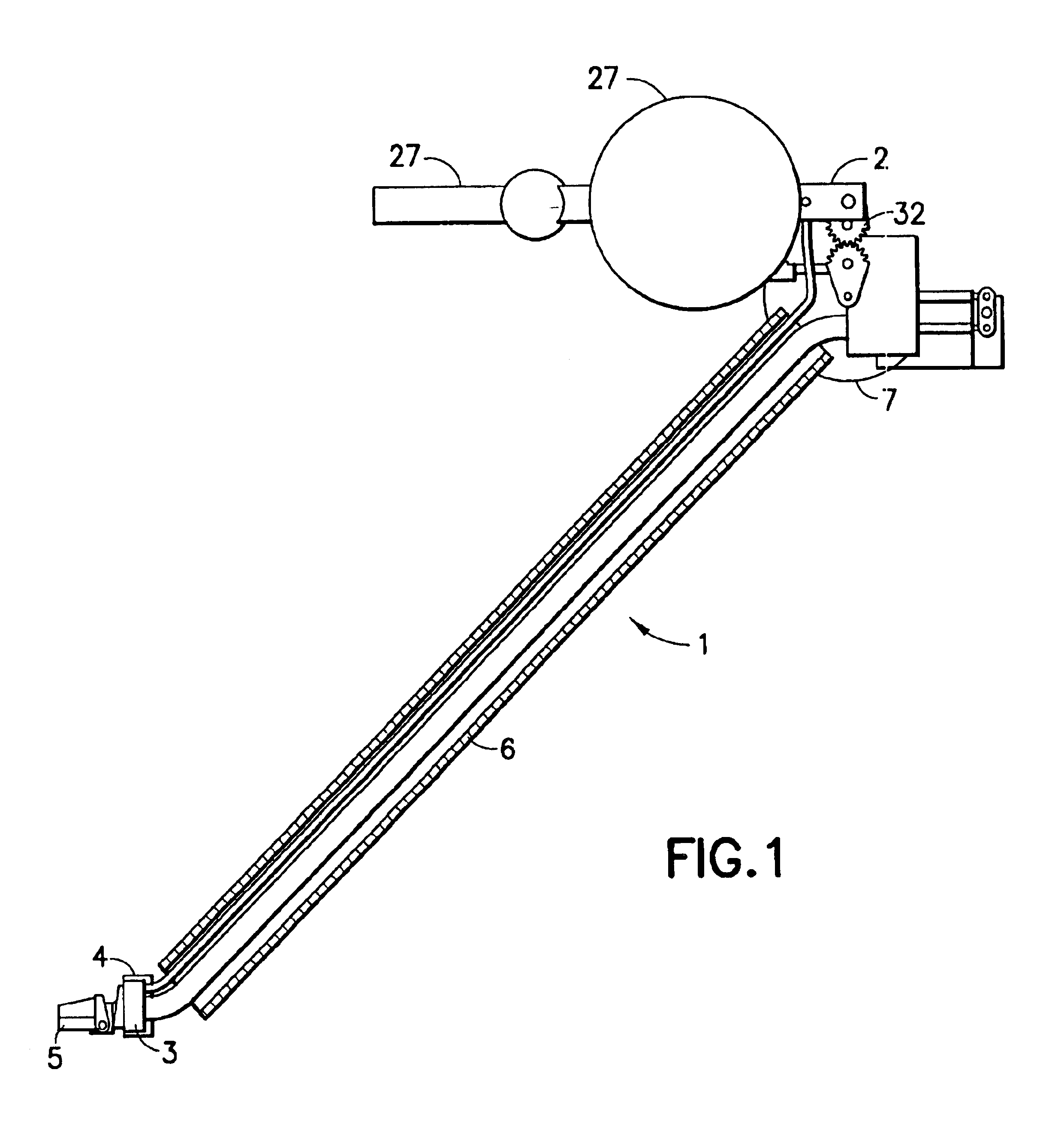

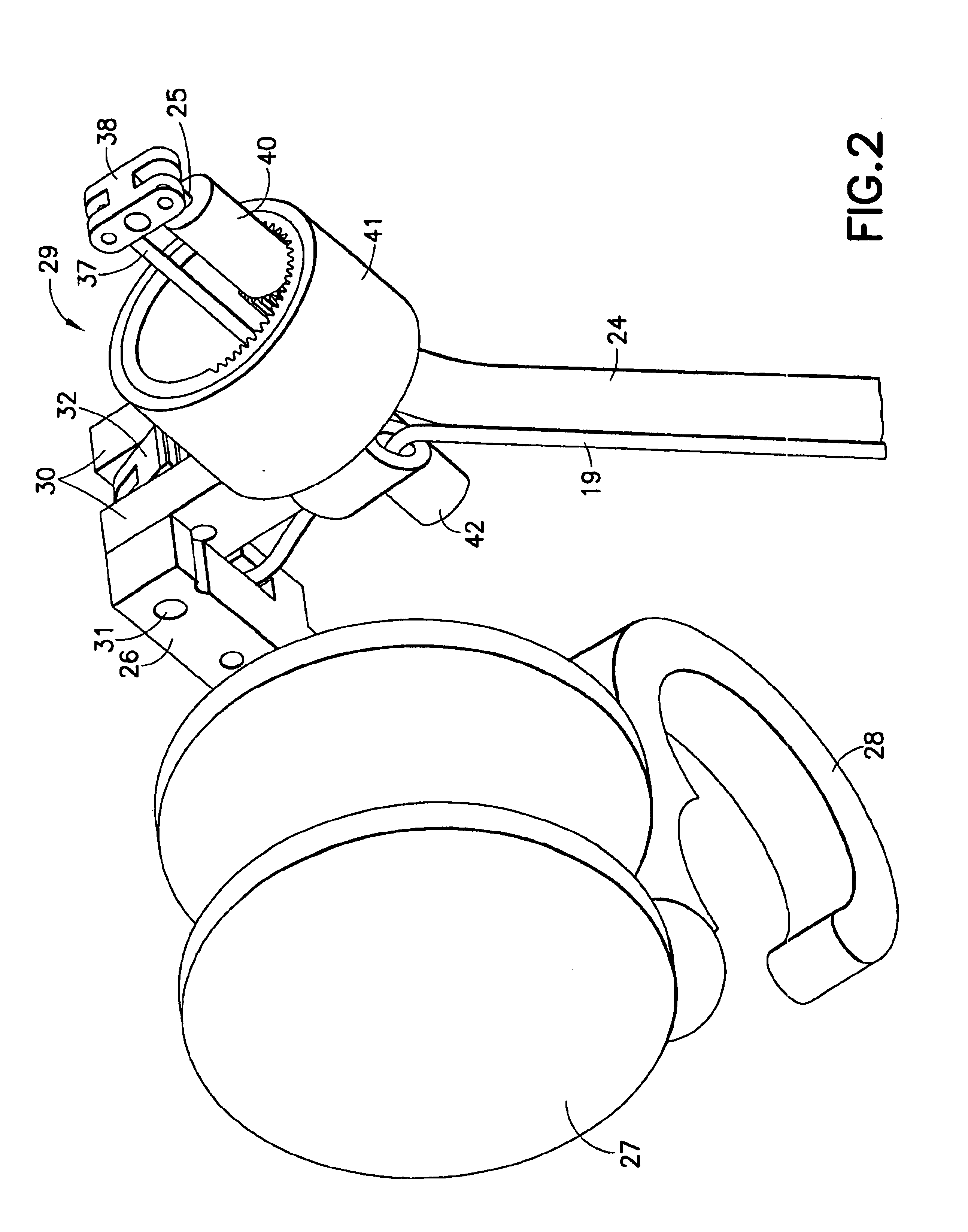

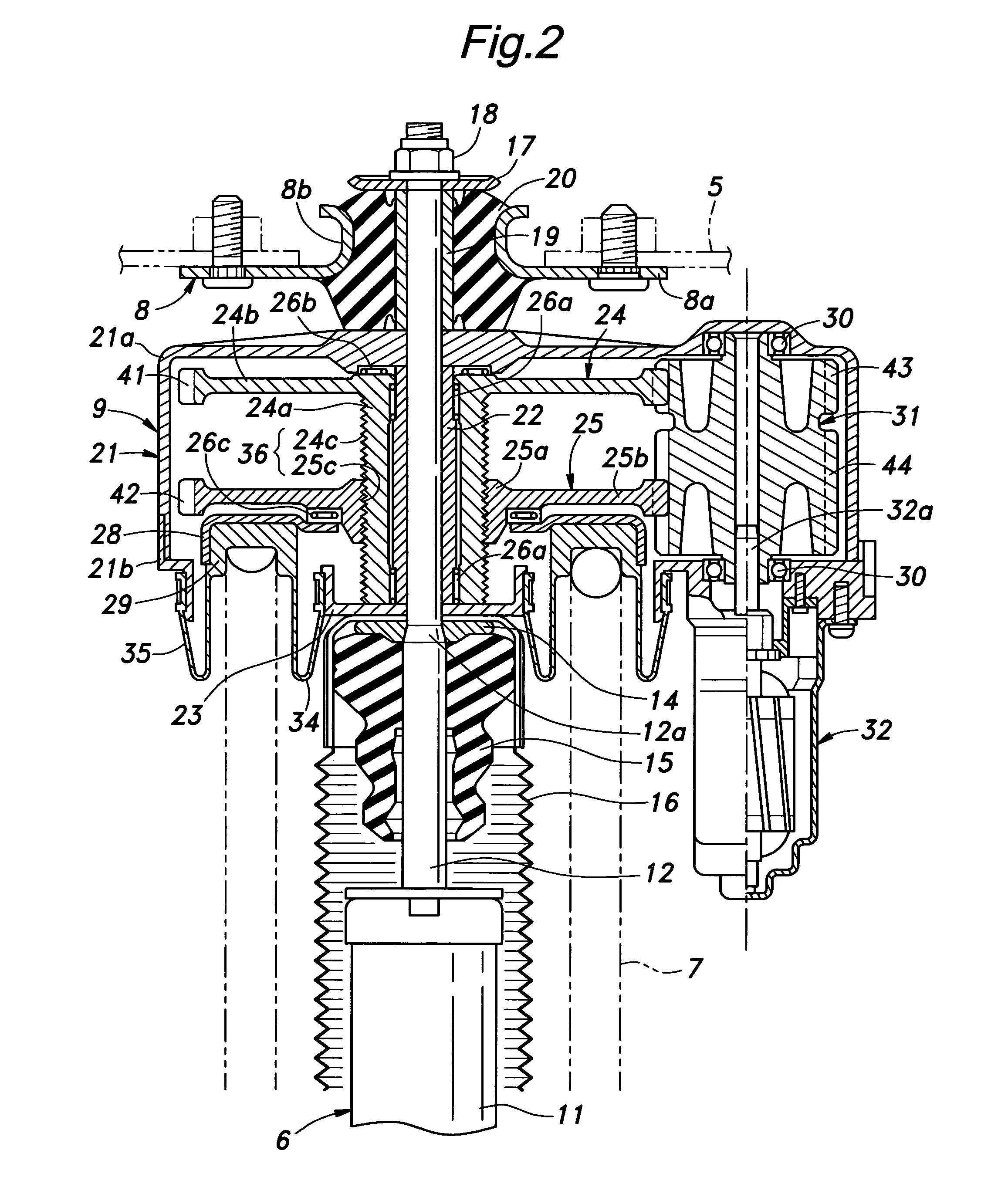

Surgical instrument for minimally invasive surgical interventions

InactiveUS6913613B2Function increaseEasy to implementSurgical forcepsLess invasive surgeryGear wheel

A surgical instrument for minimally invasive surgery includes a hollow shank with an actuating device arranged at the one end thereof and a bendable instrument tip arranged at the other end. The instrument tip is bendable toward the shank and carries a mouth part. The surgical instrument also includes a gear mechanism which transforms at least a movement of said actuating device by an operator into a rotation of said mouth part according to a predetermined transmission ratio in relation to the actuating movement.

Owner:TRANSENTERIX EURO SARL

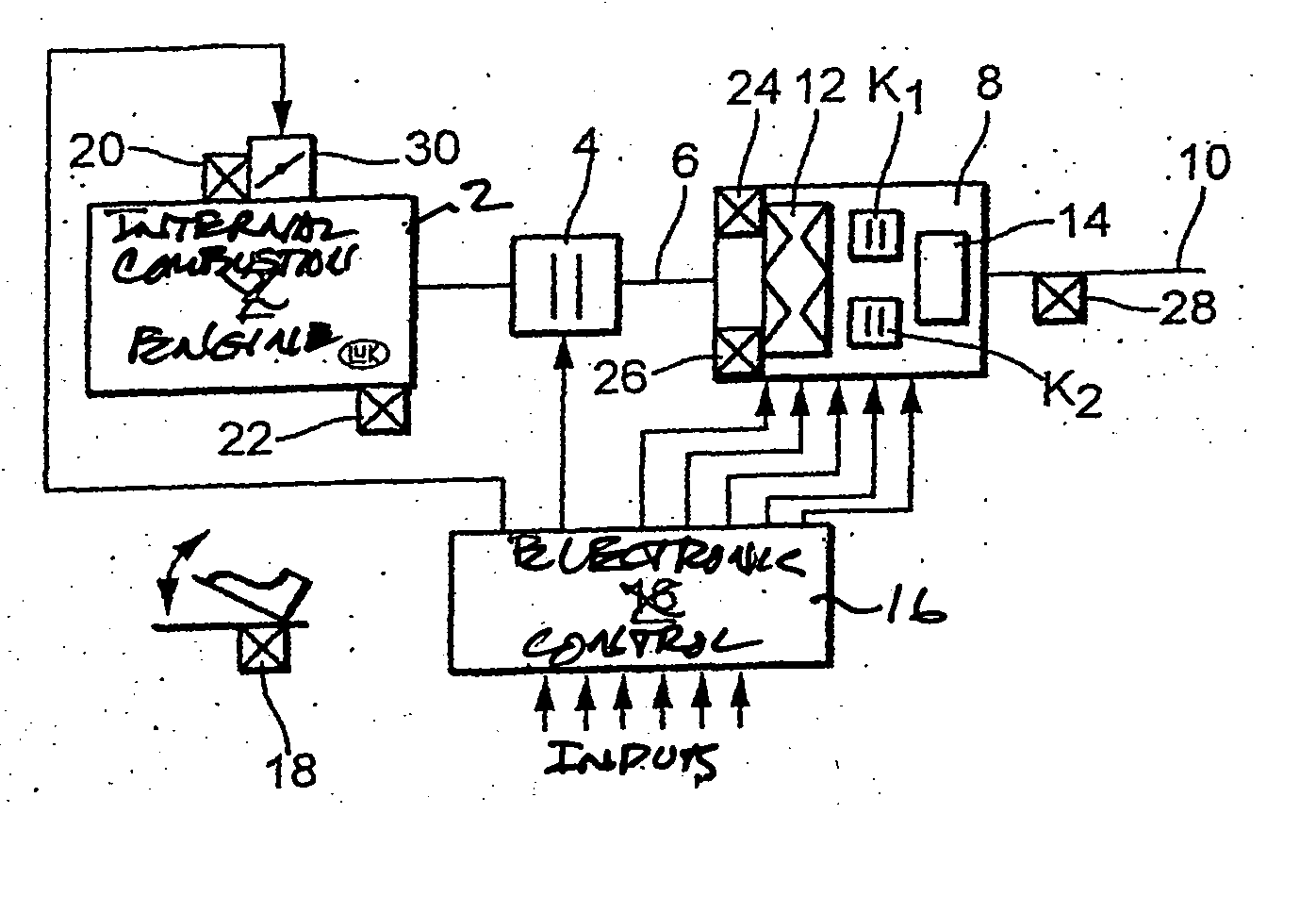

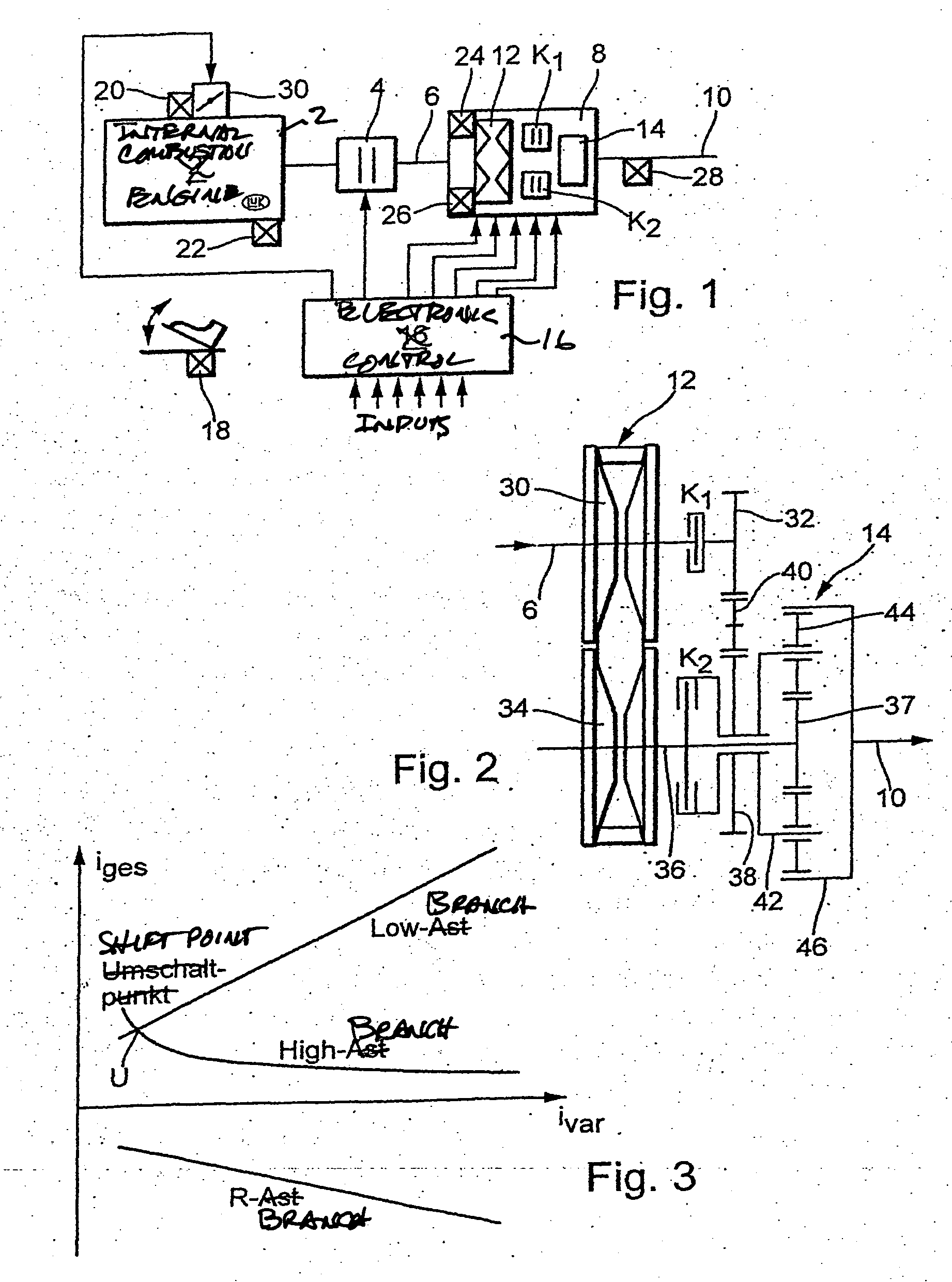

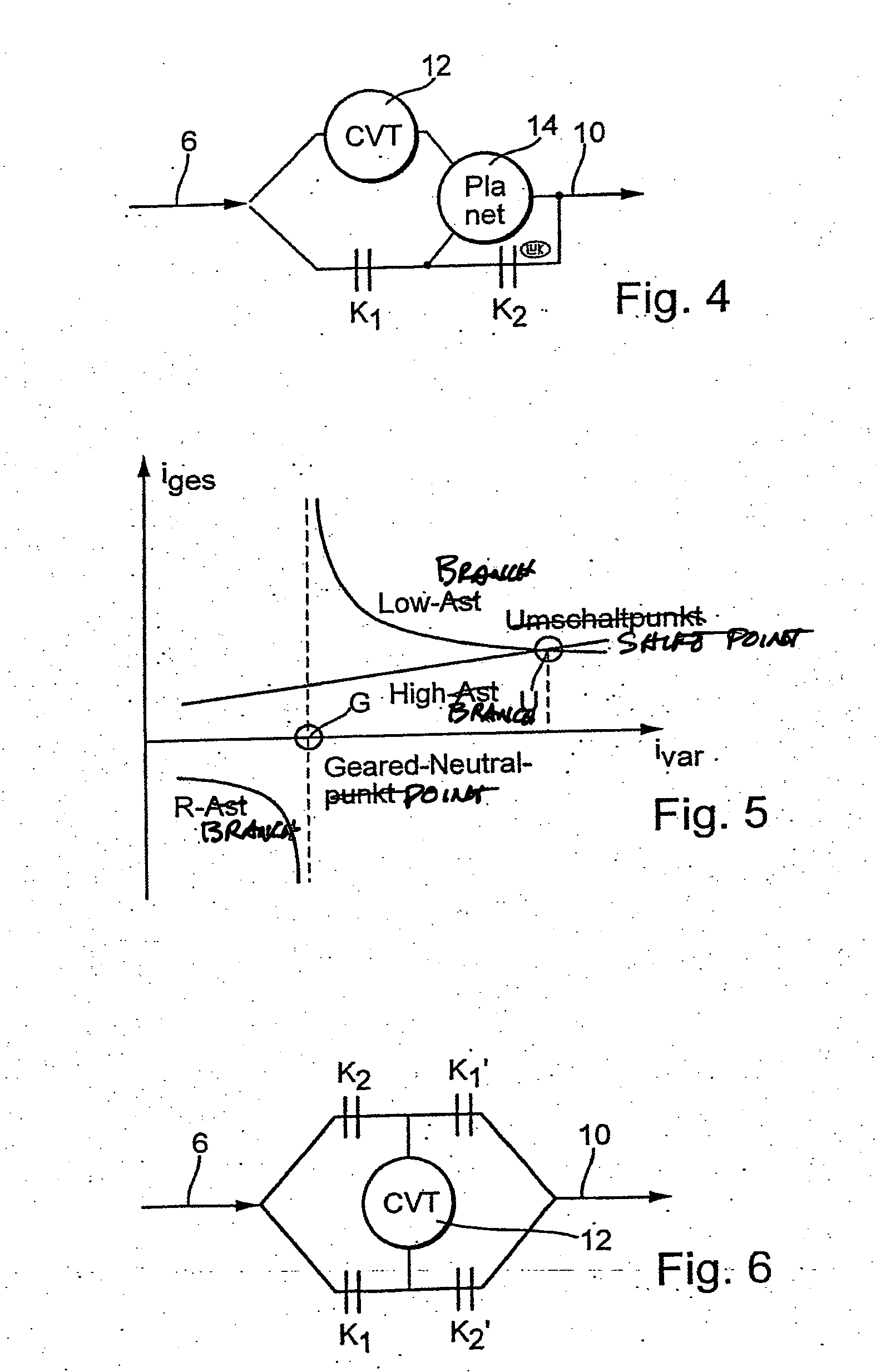

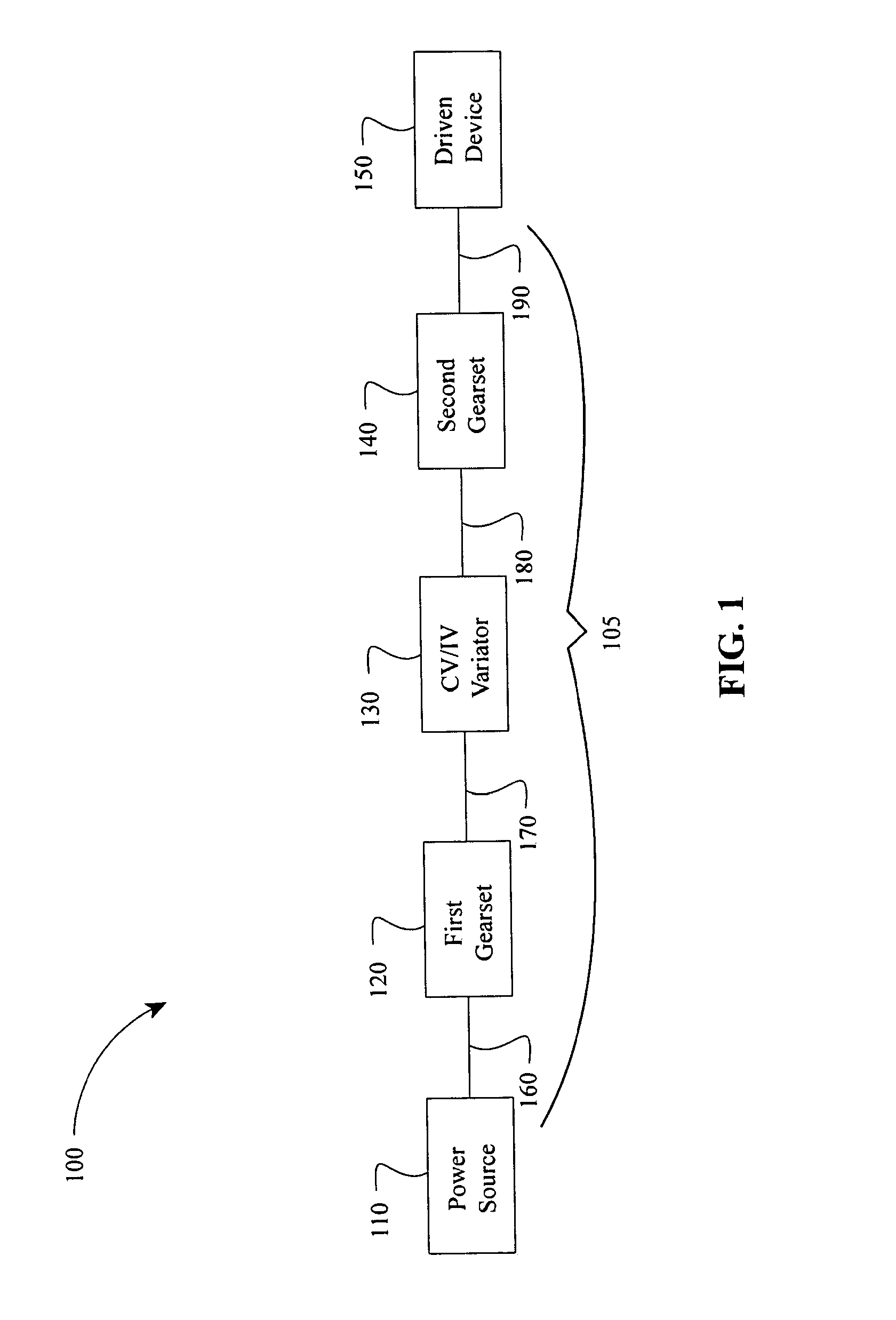

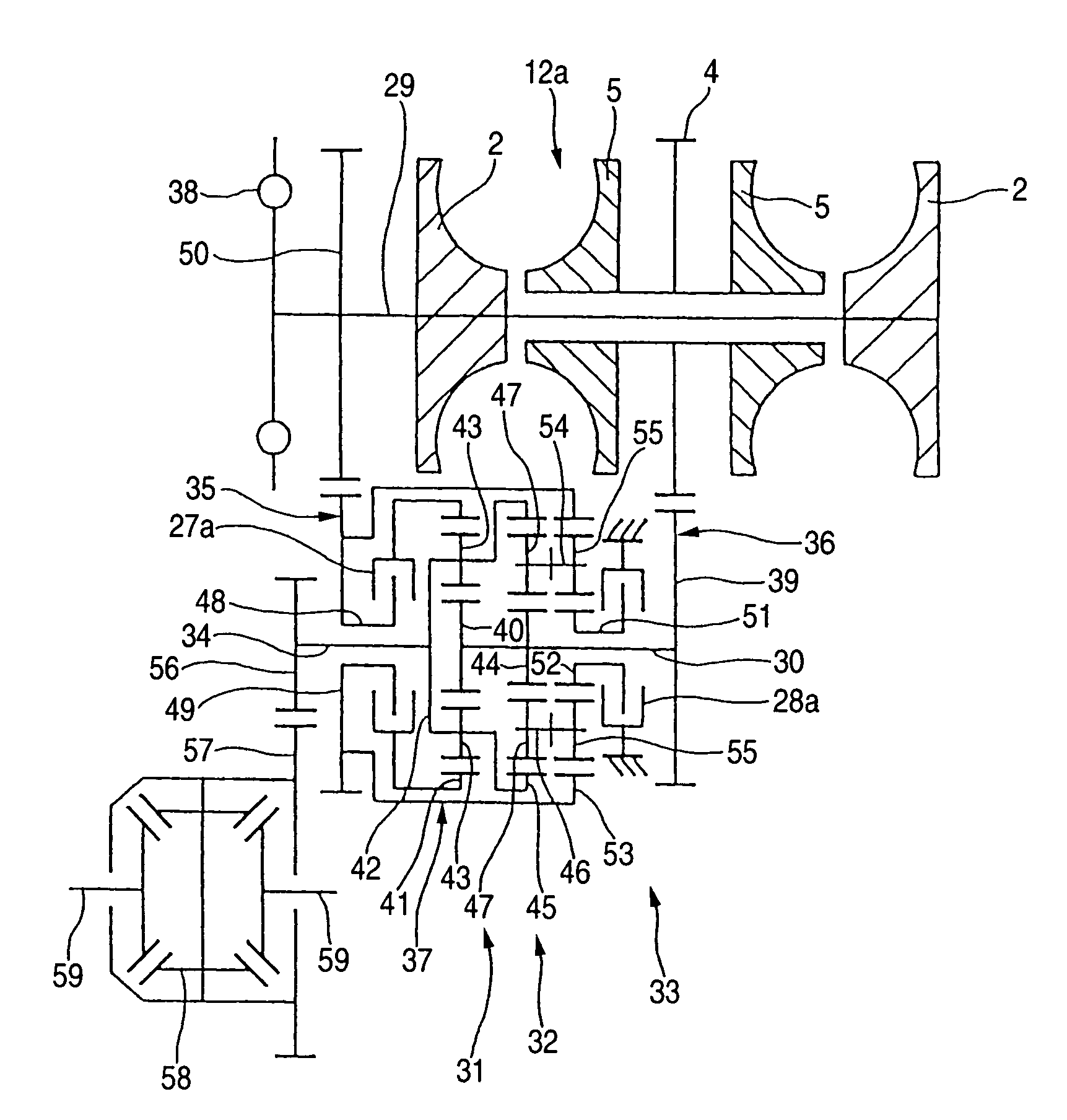

Methods for regulating the gear ratio of an automatic power-branched transmission, and automatic power-branched transmission

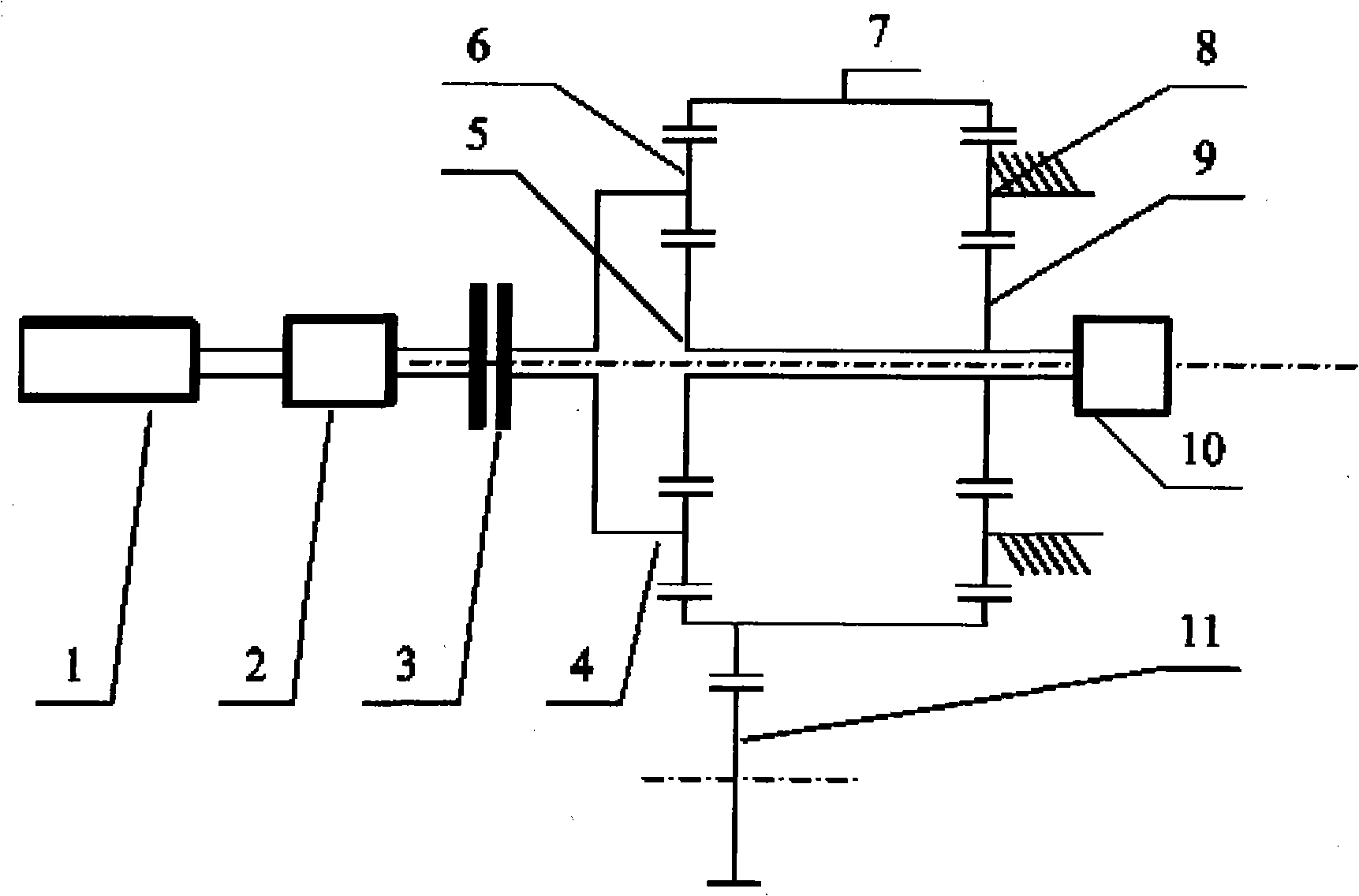

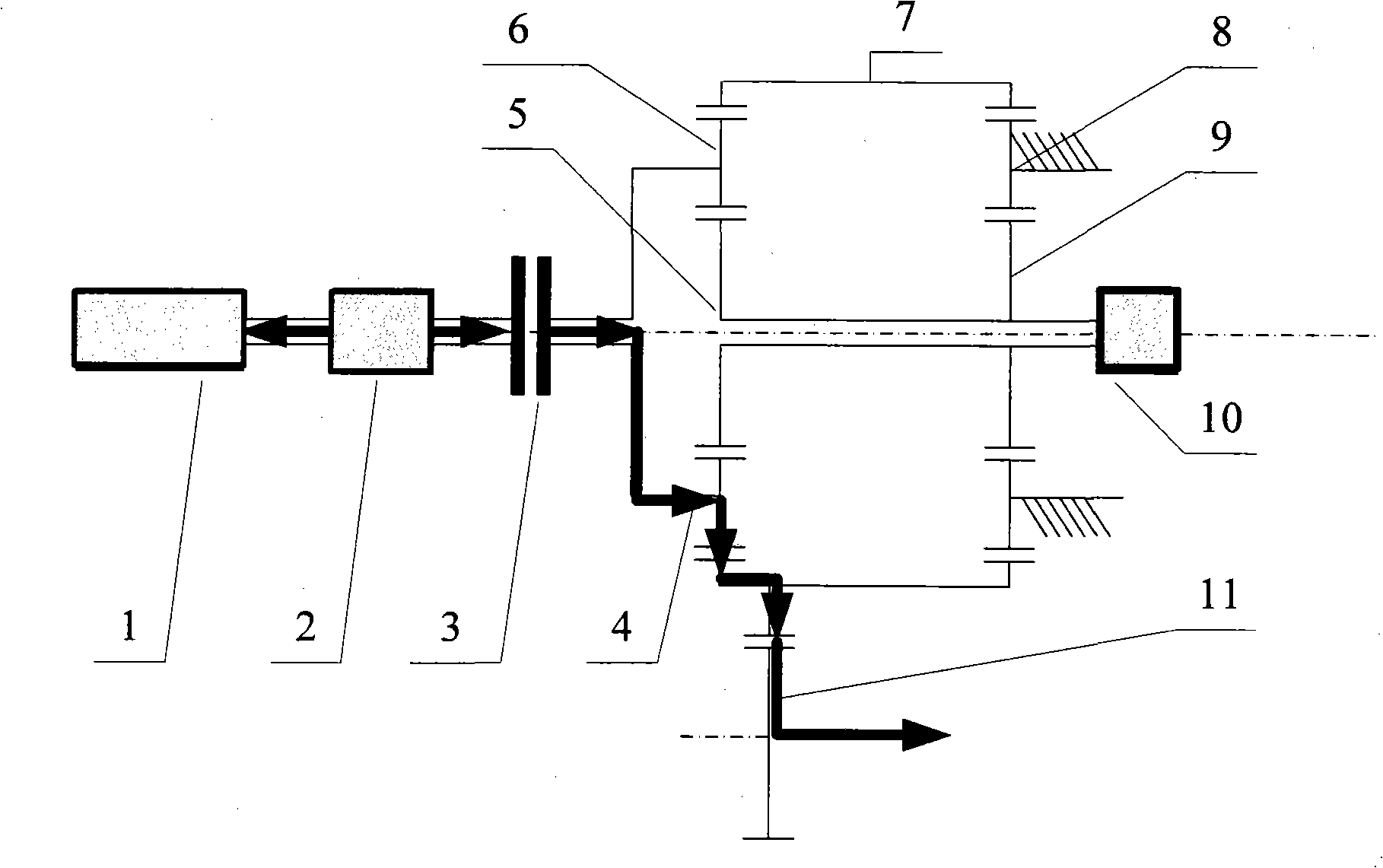

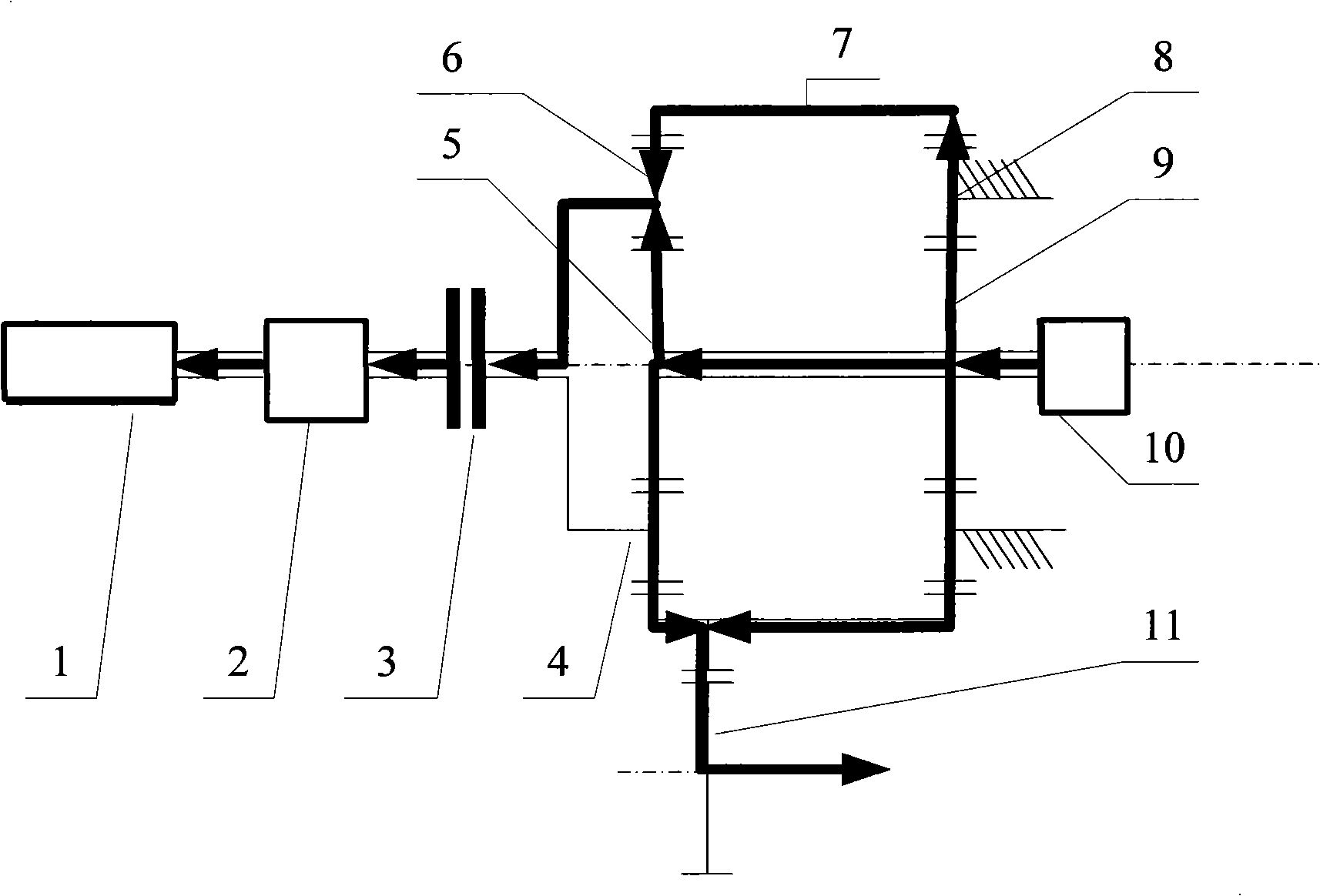

A method for regulating or controlling the transmission ratio of an automatic power-branched transmission. Power is transmitted through a shaft driven by an engine, a variable speed drive, a gear transmission, a driven shaft, and at least two control clutches. The variable speed drive and the gear transmission are connected to each other in such a way that the regulating range of the variable speed drive is traversed in one direction within a first range of transmission ratios, and is traversed in the opposite direction within a second range of transmission ratios during traversing of the entire range of transmission ratios. The shifting strategies result in reduced wear of the endless belt device and allow for comfortable changing between the transmission ratio ranges.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

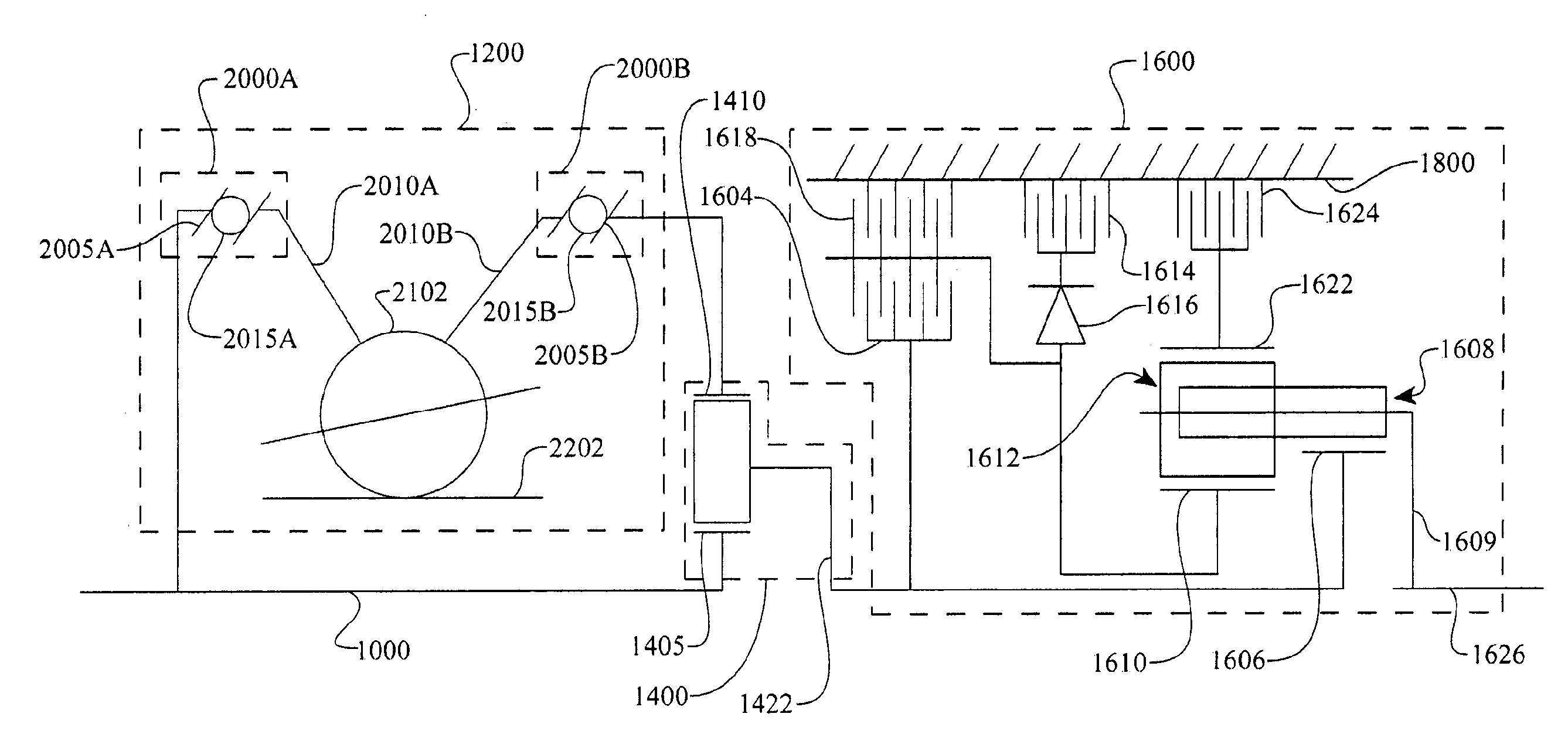

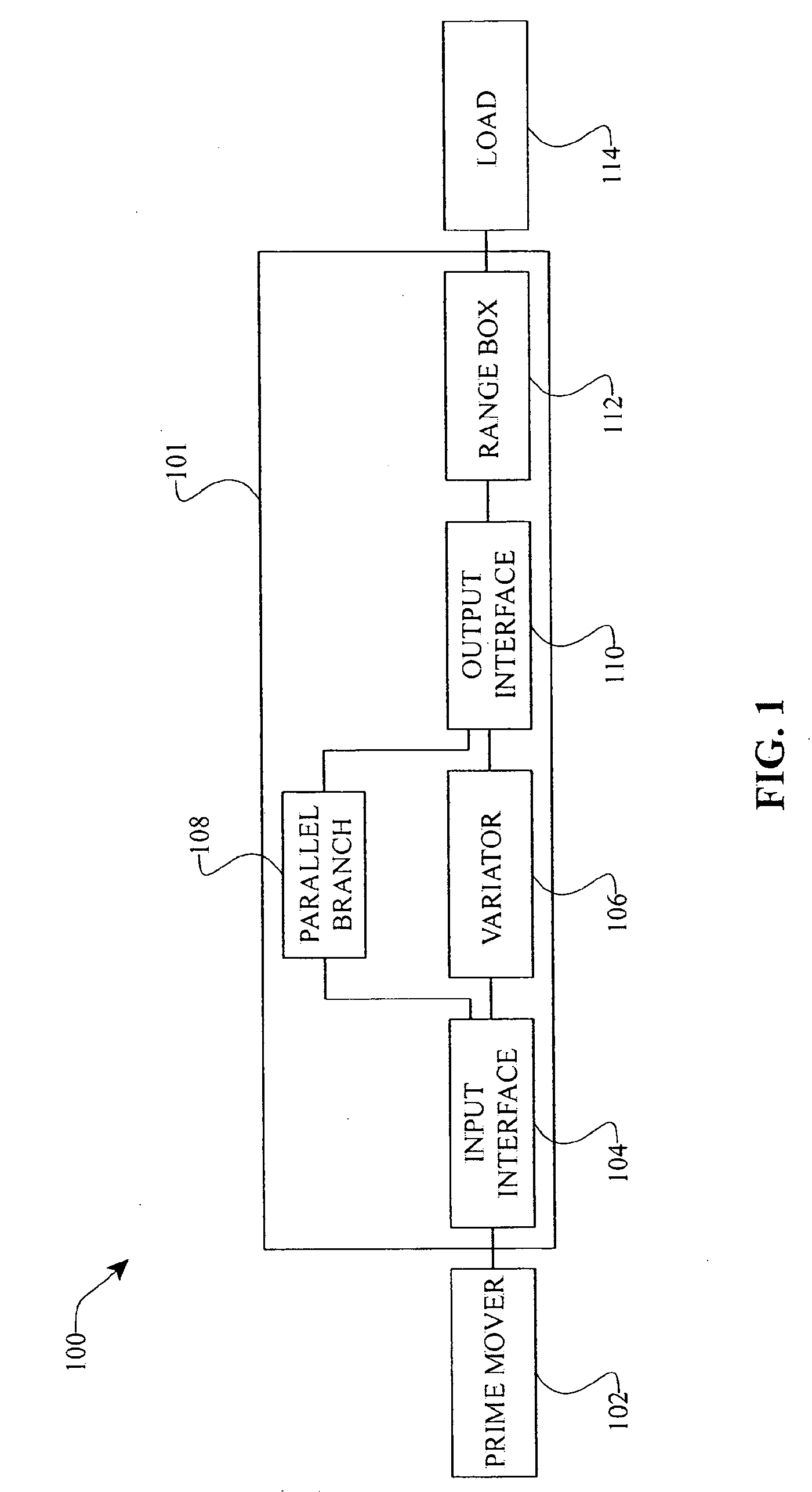

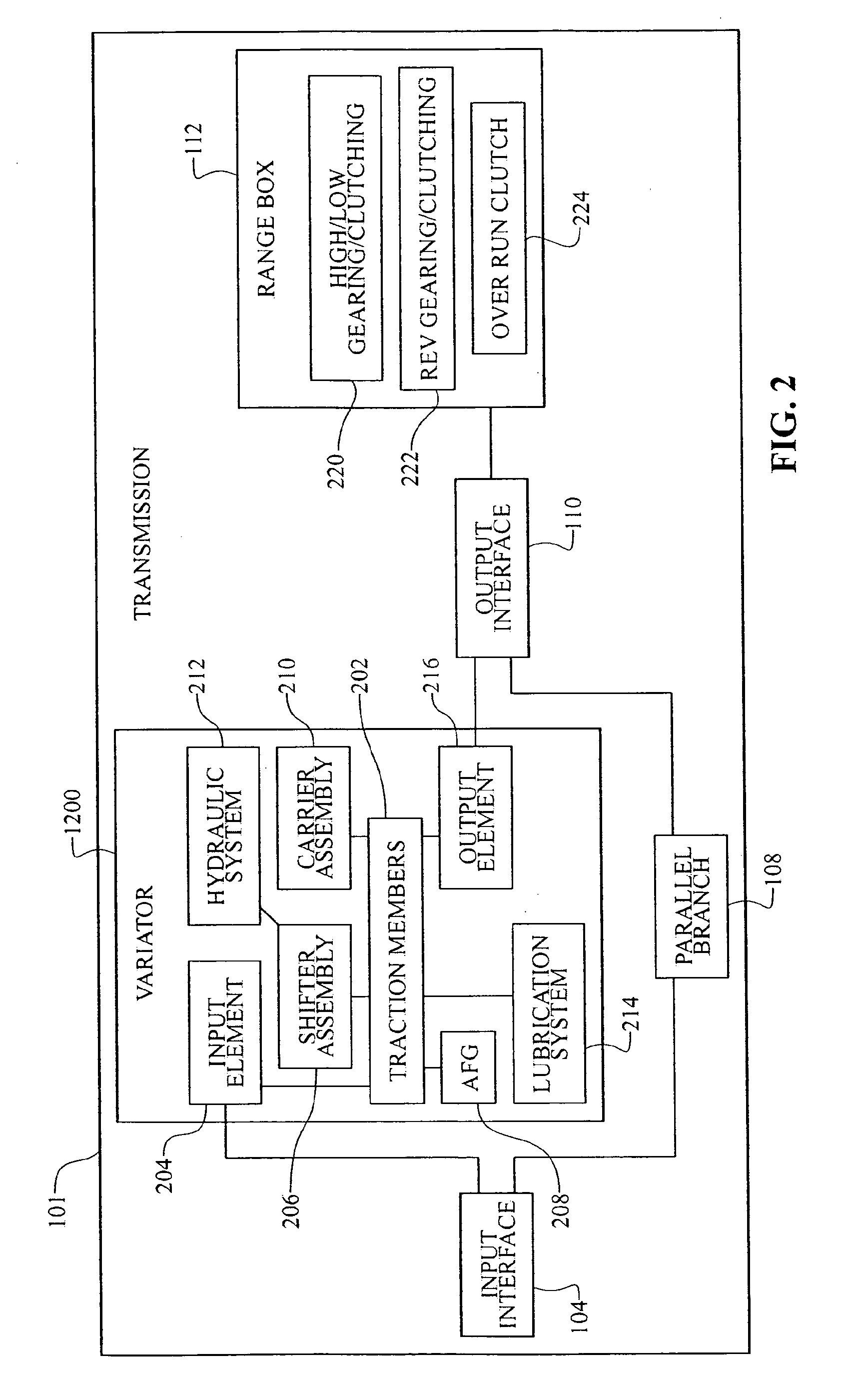

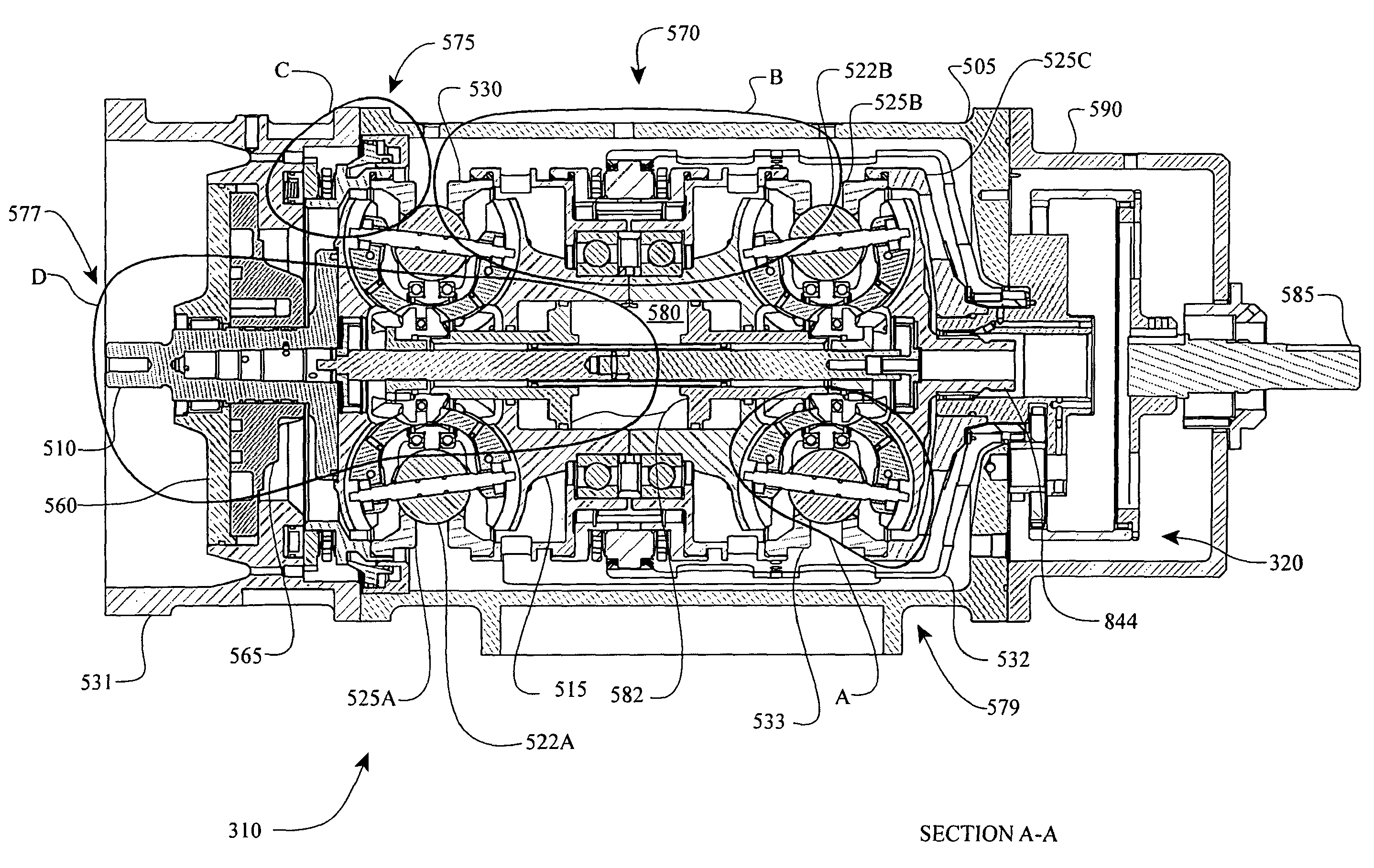

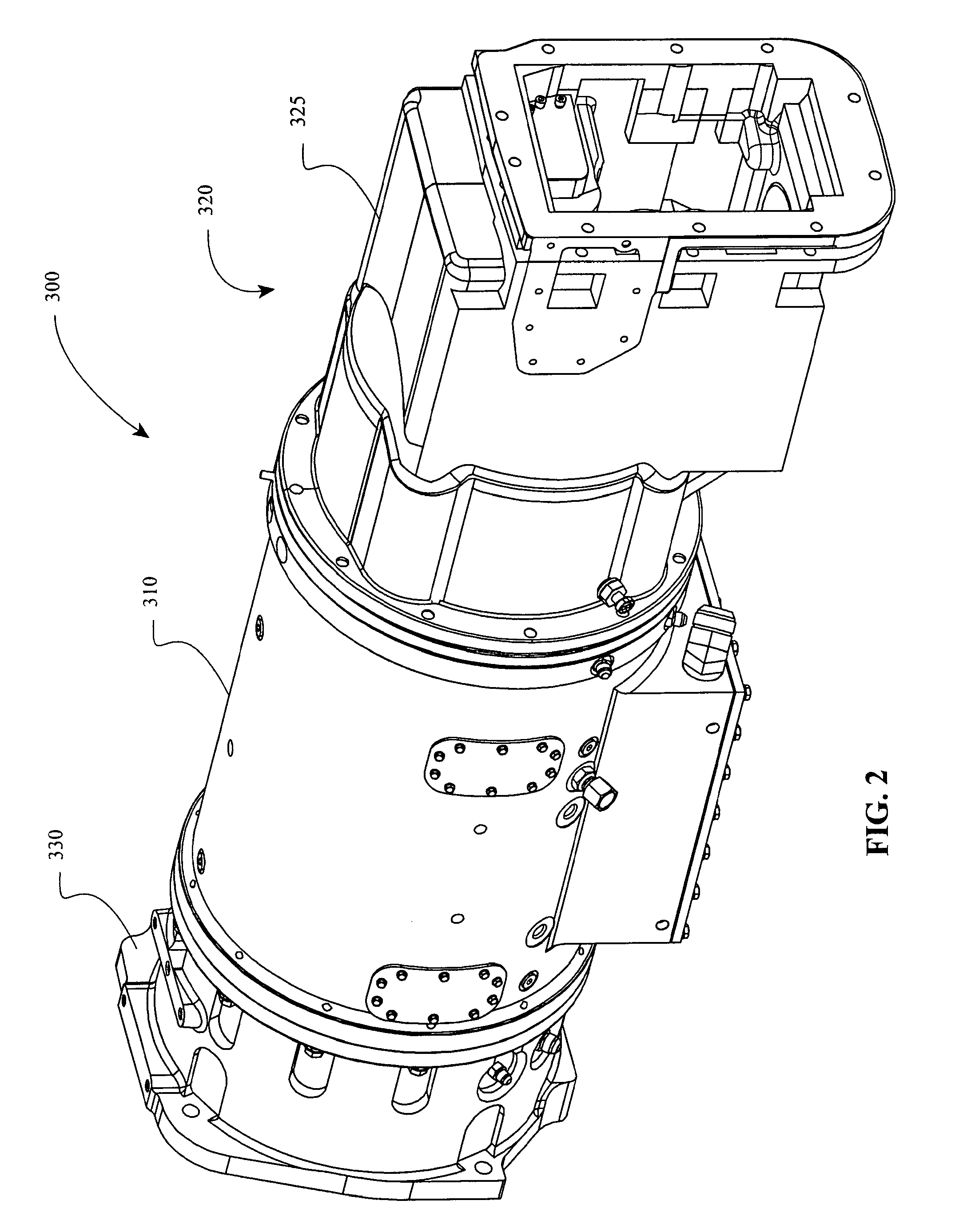

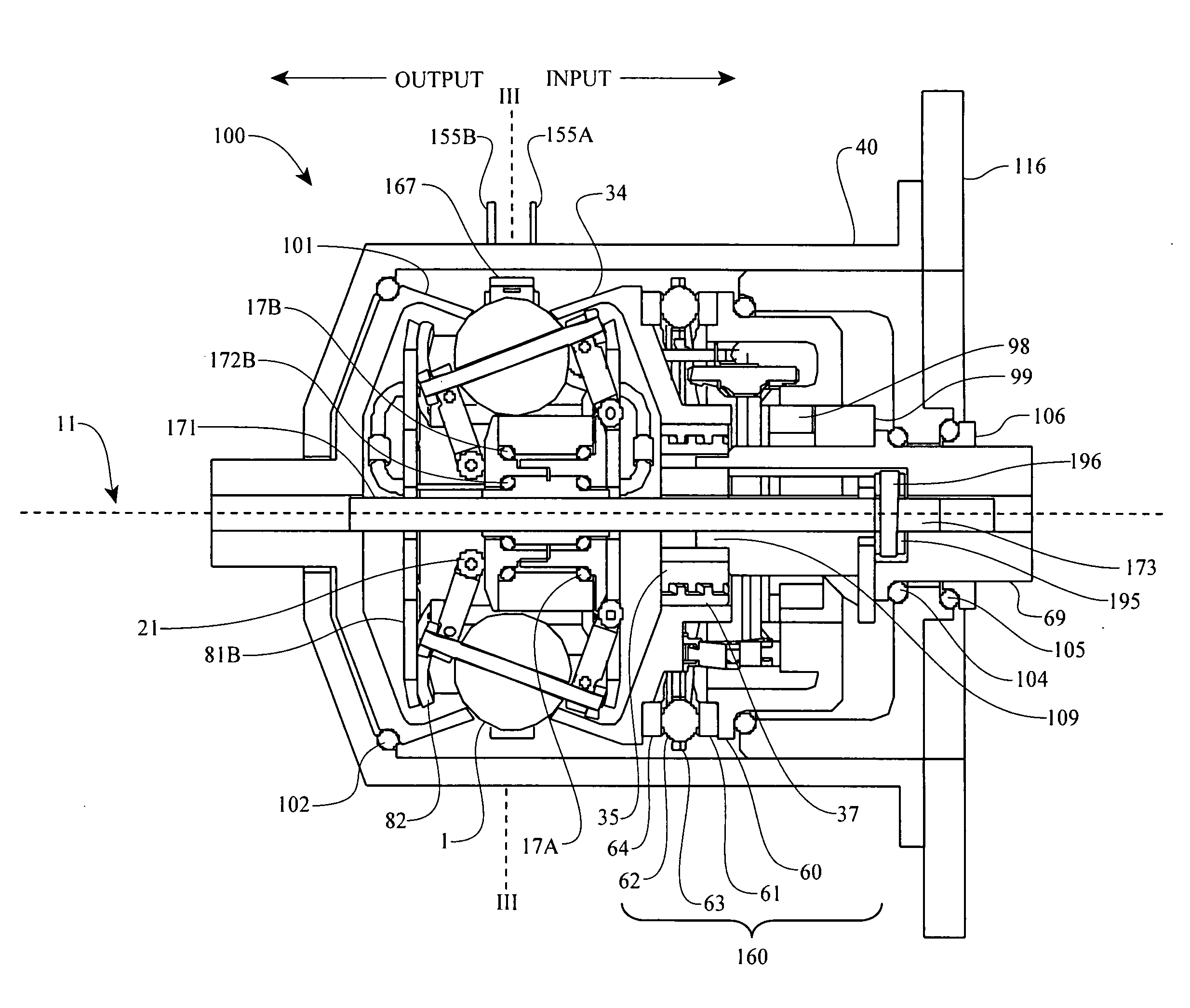

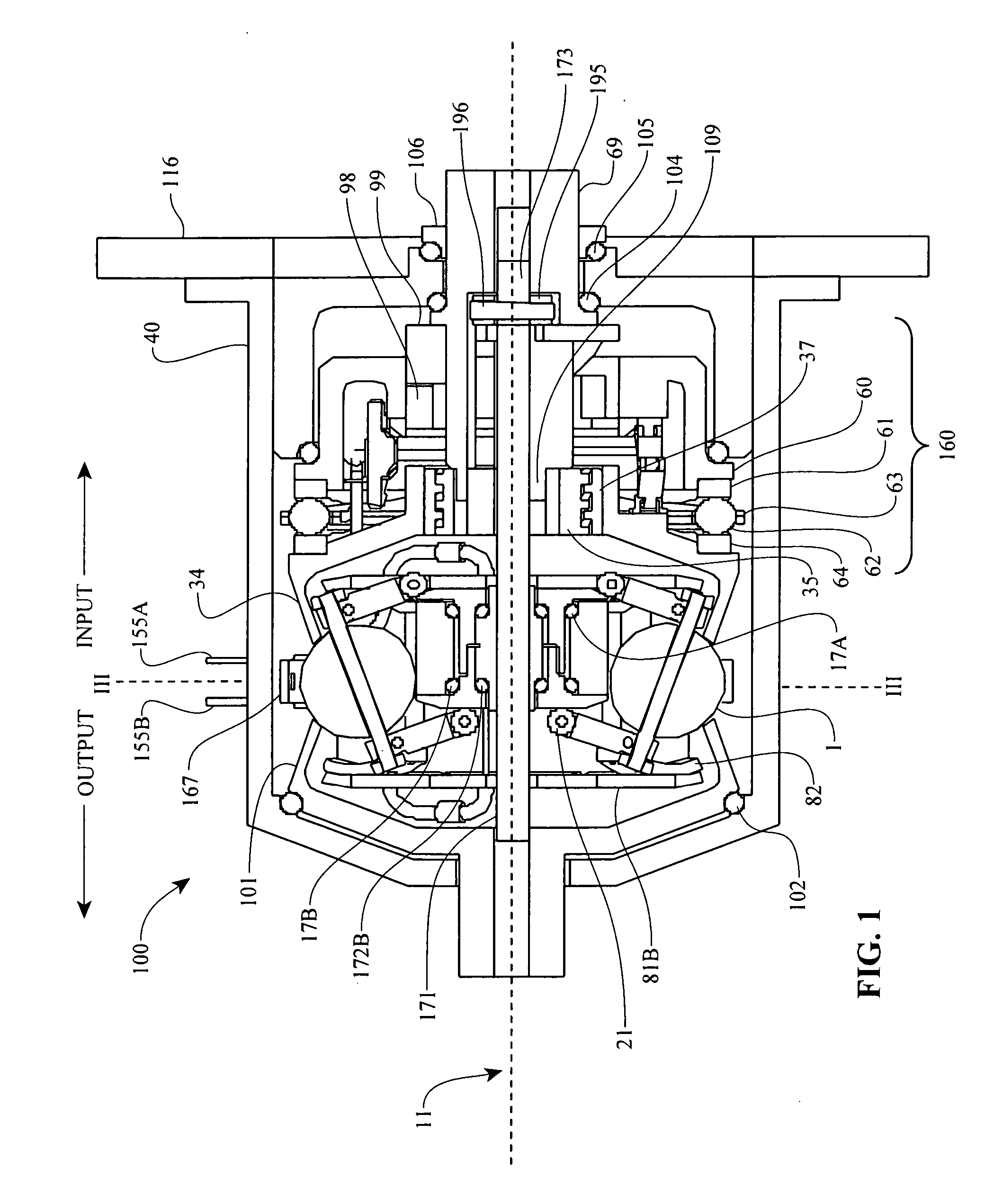

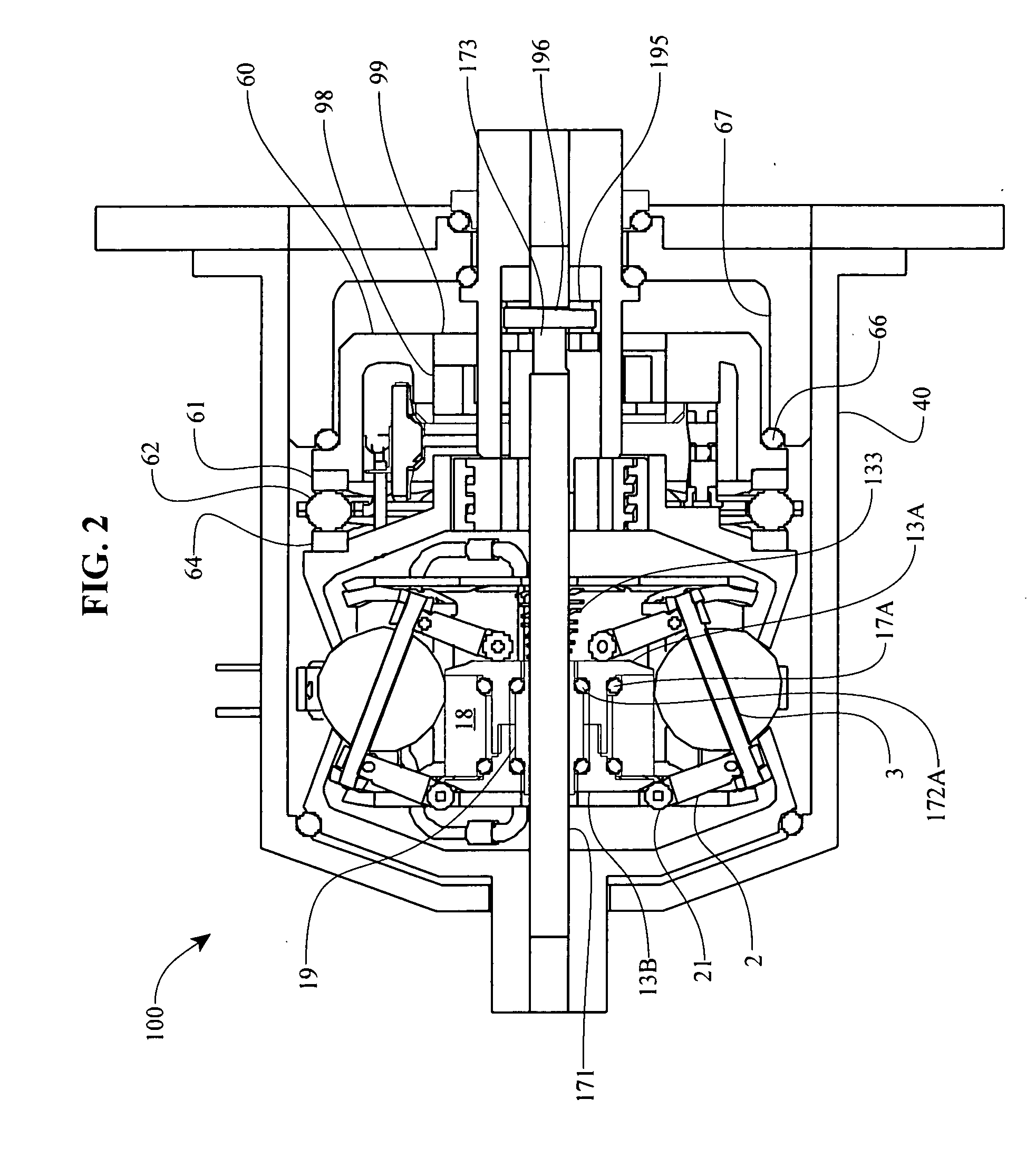

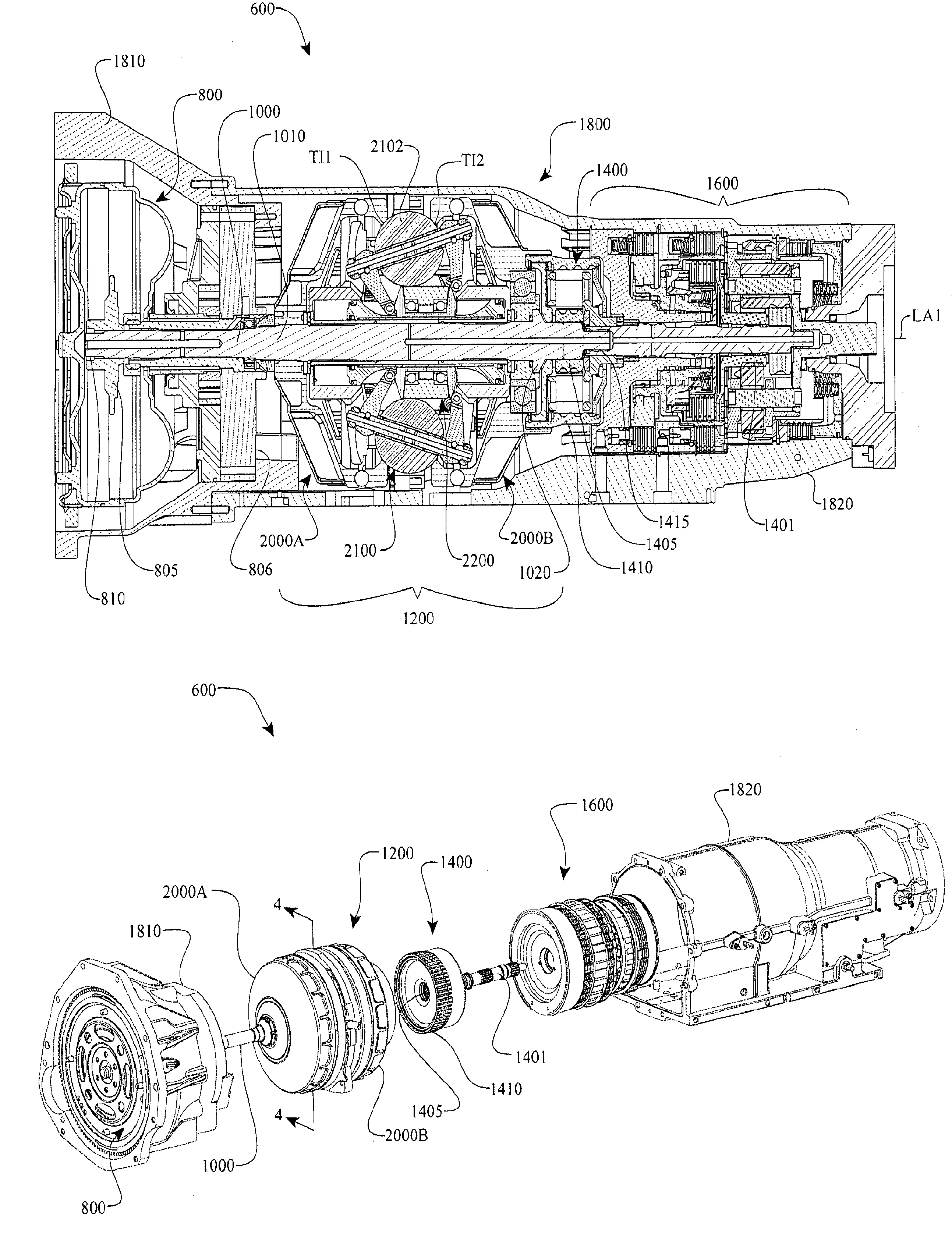

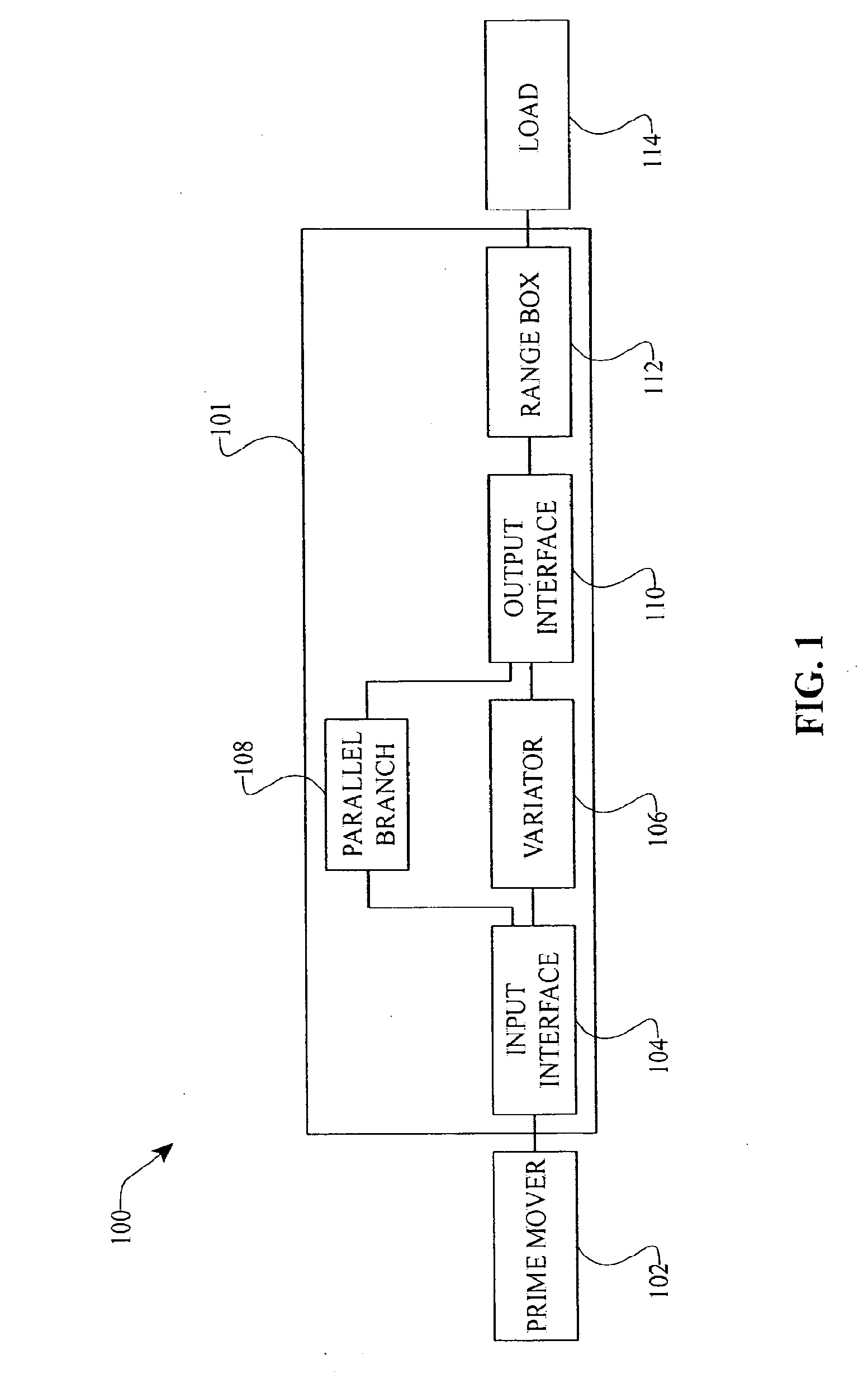

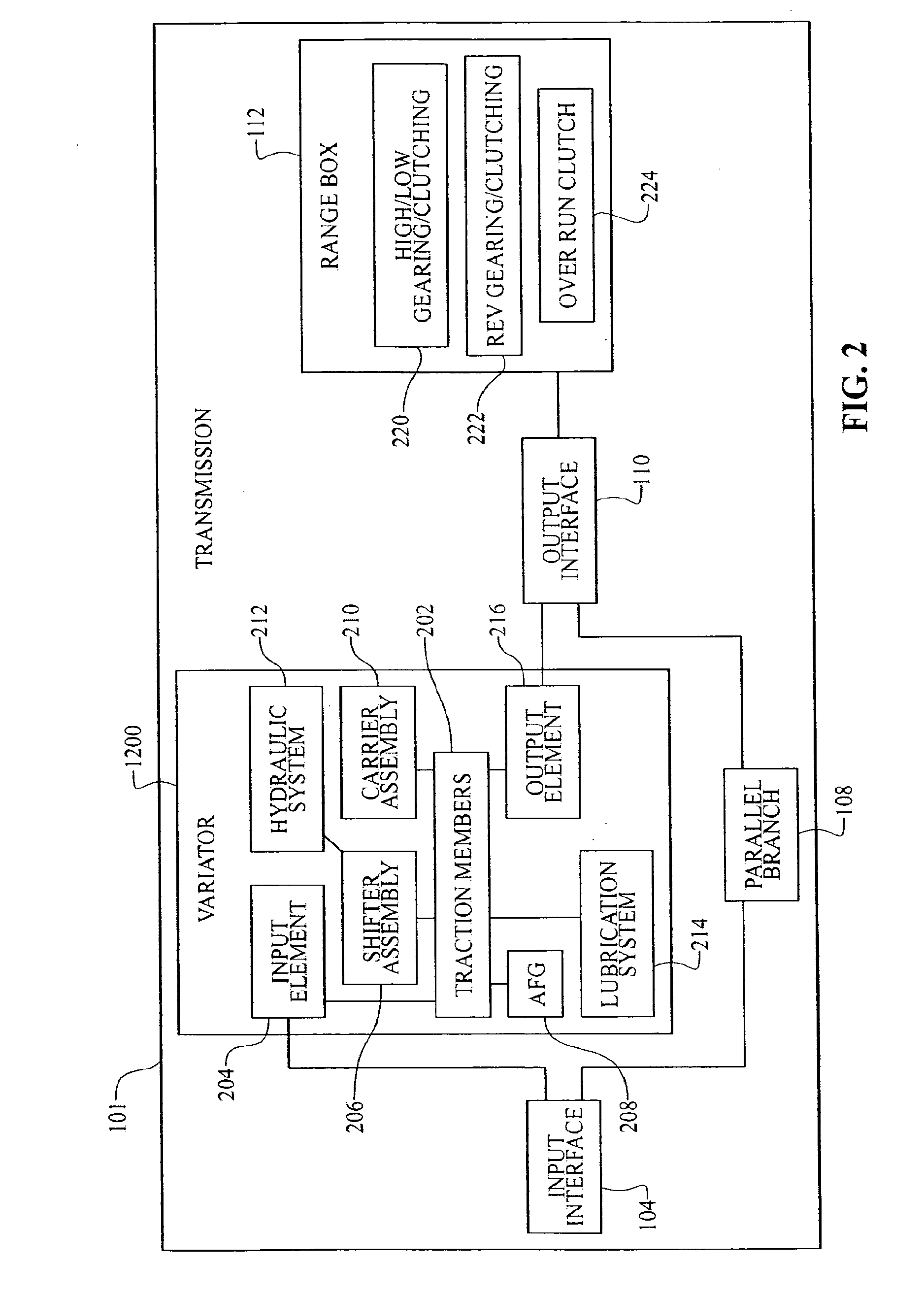

Continuously variable transmissions and methods therefor

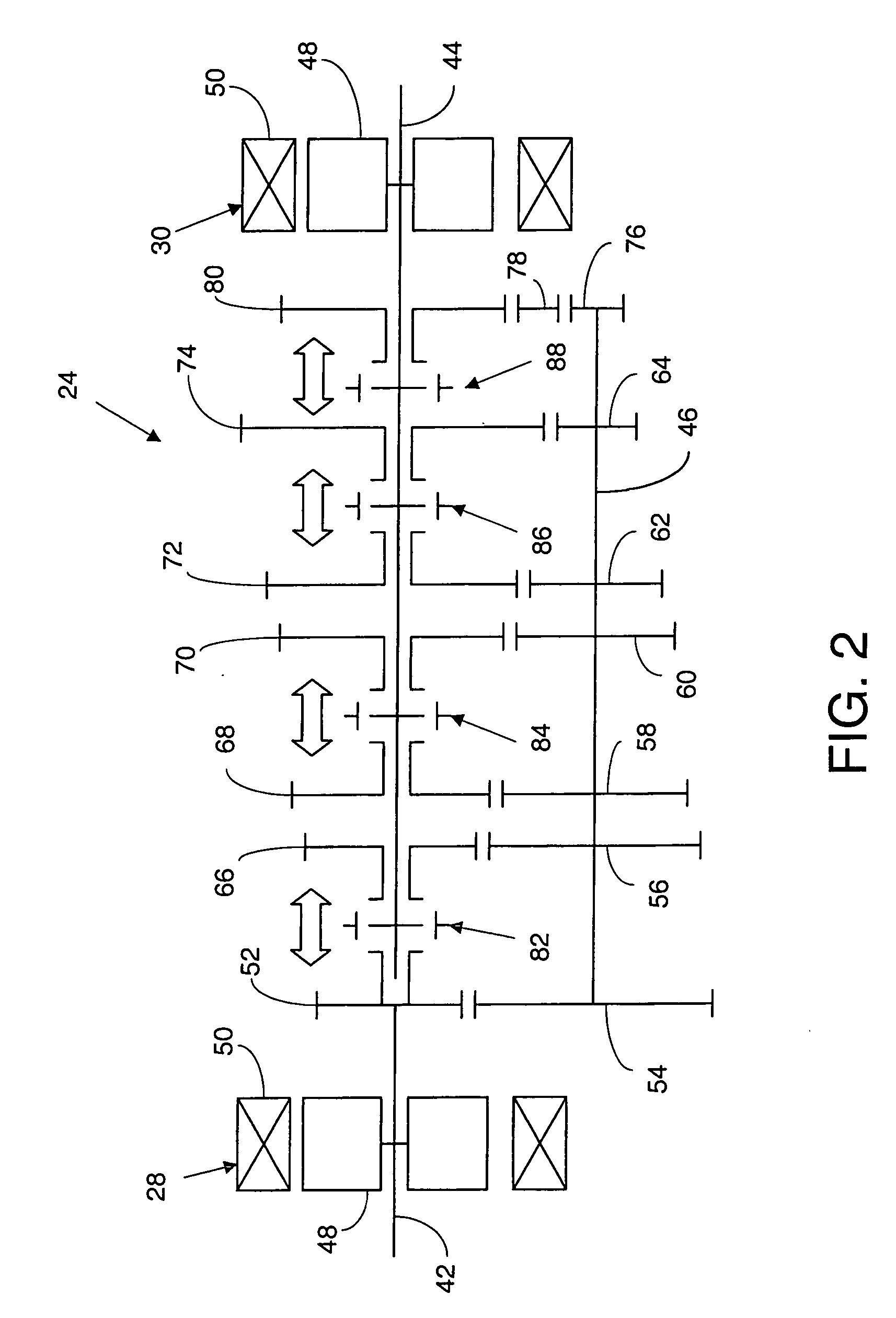

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

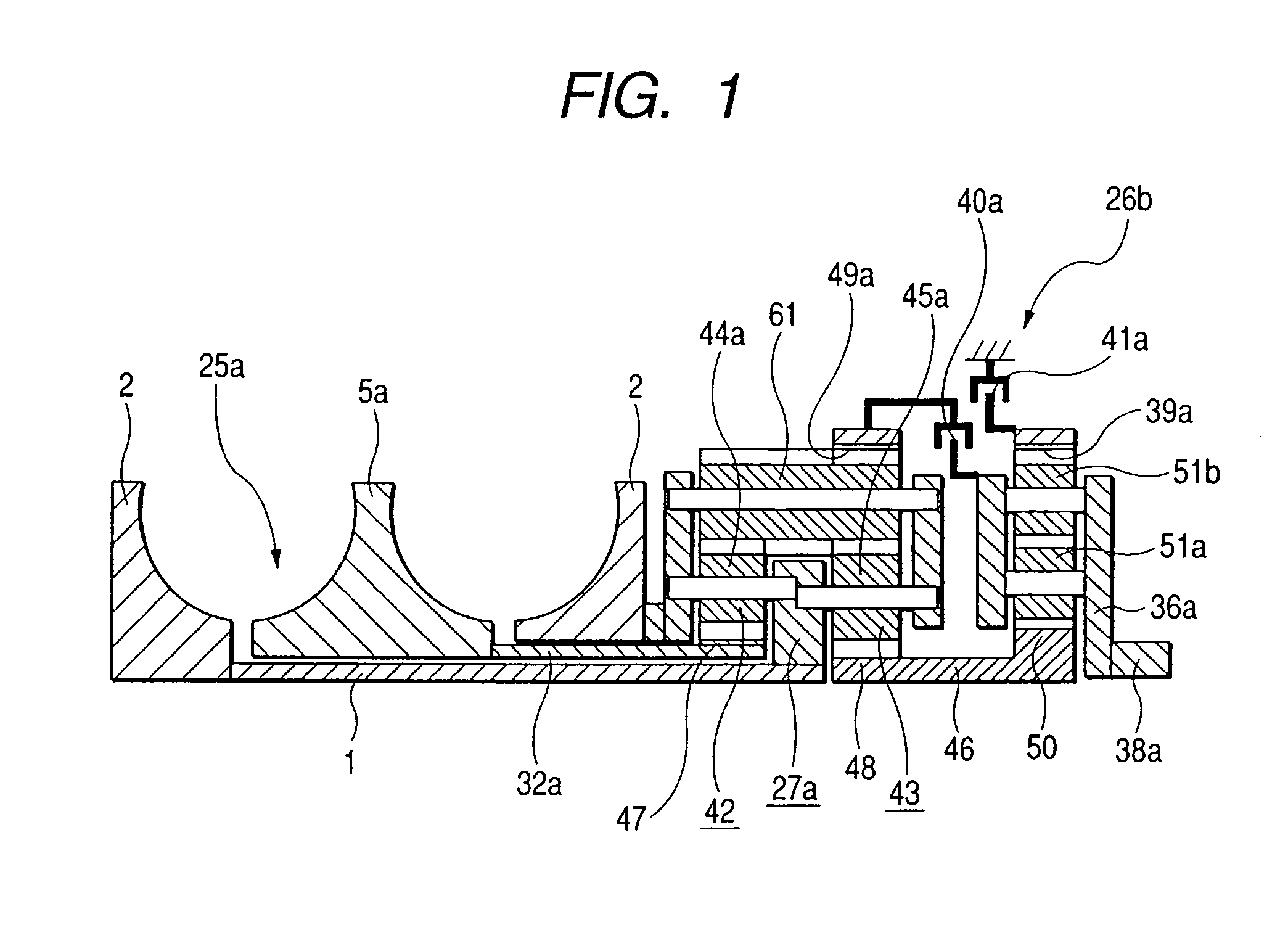

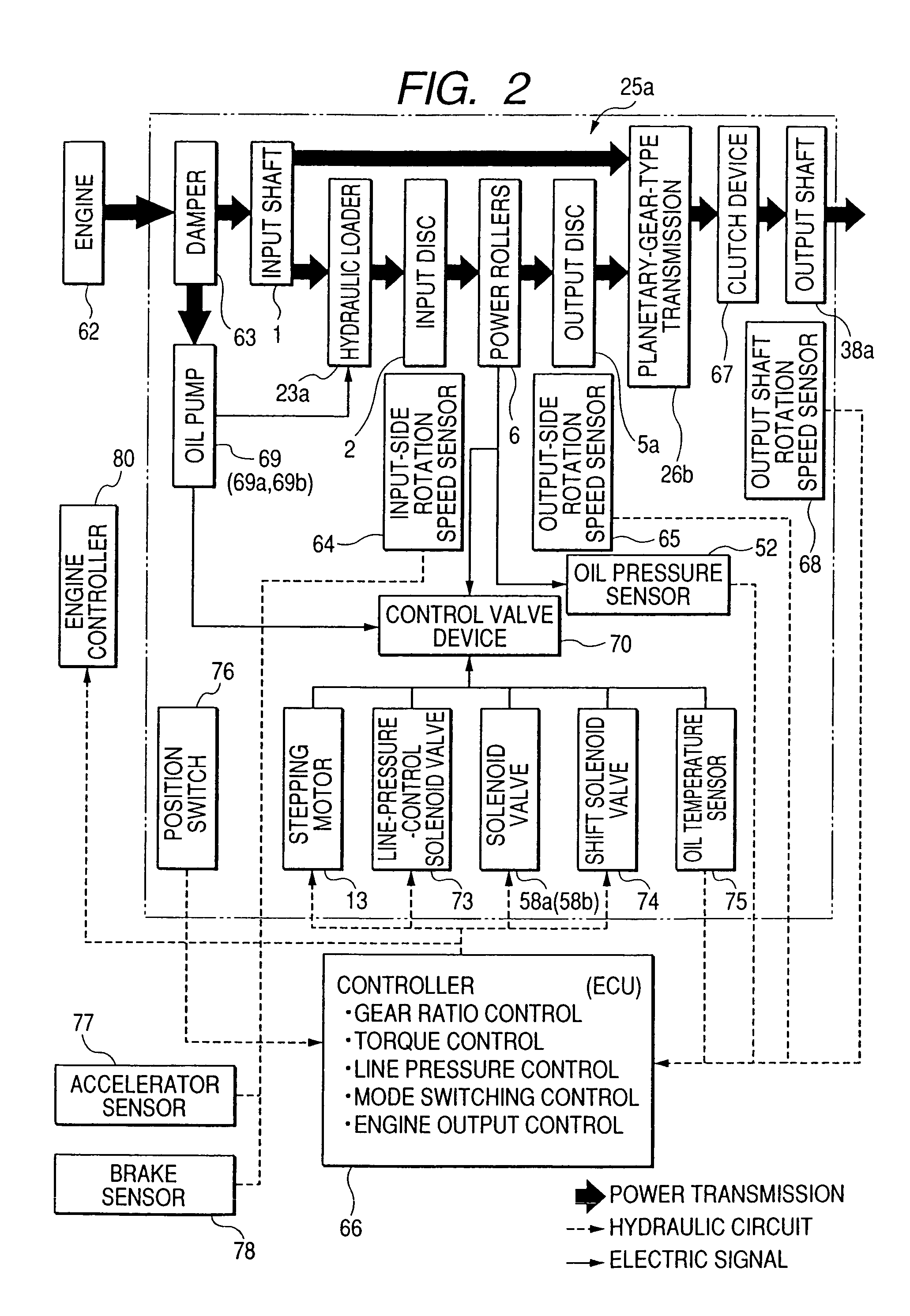

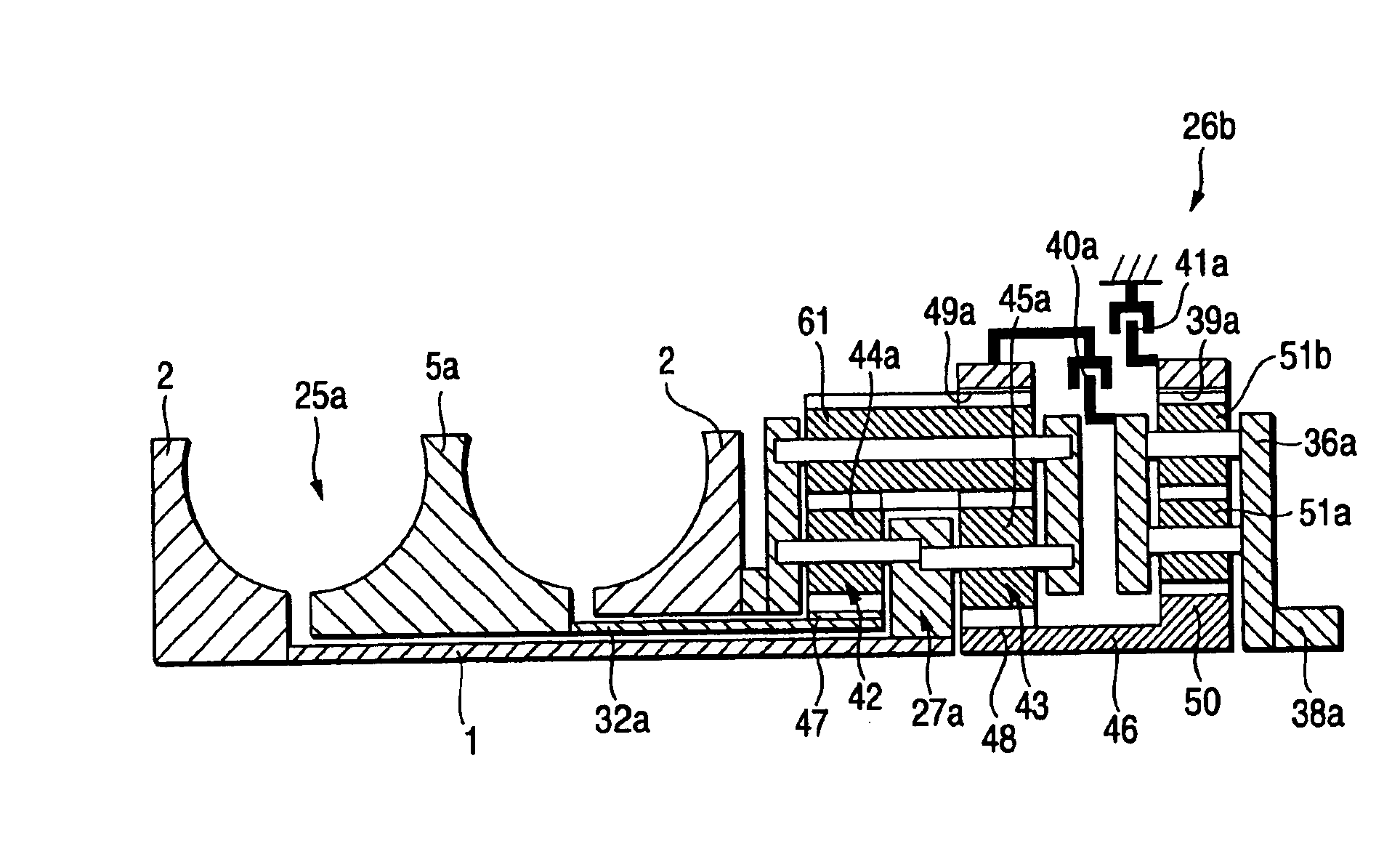

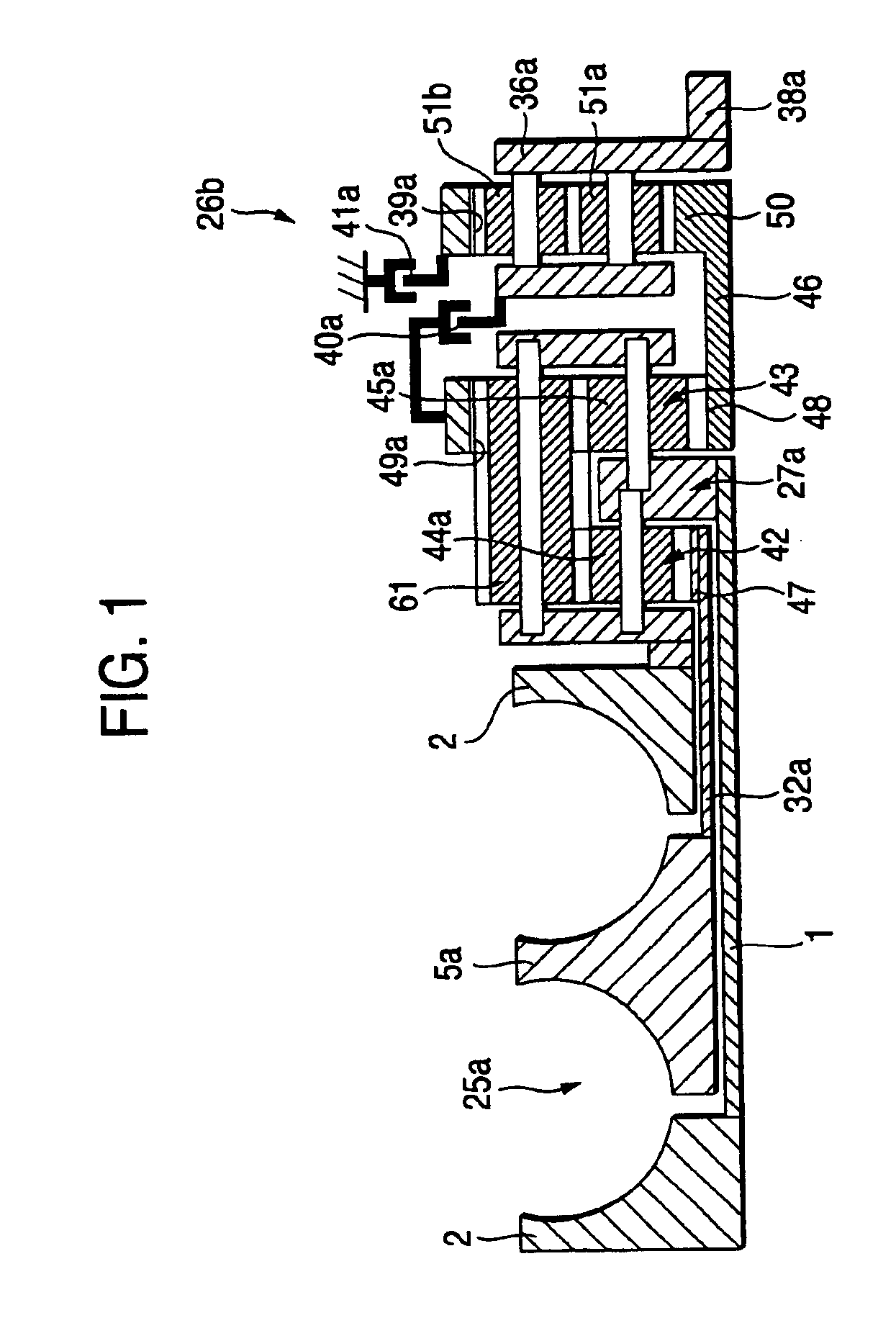

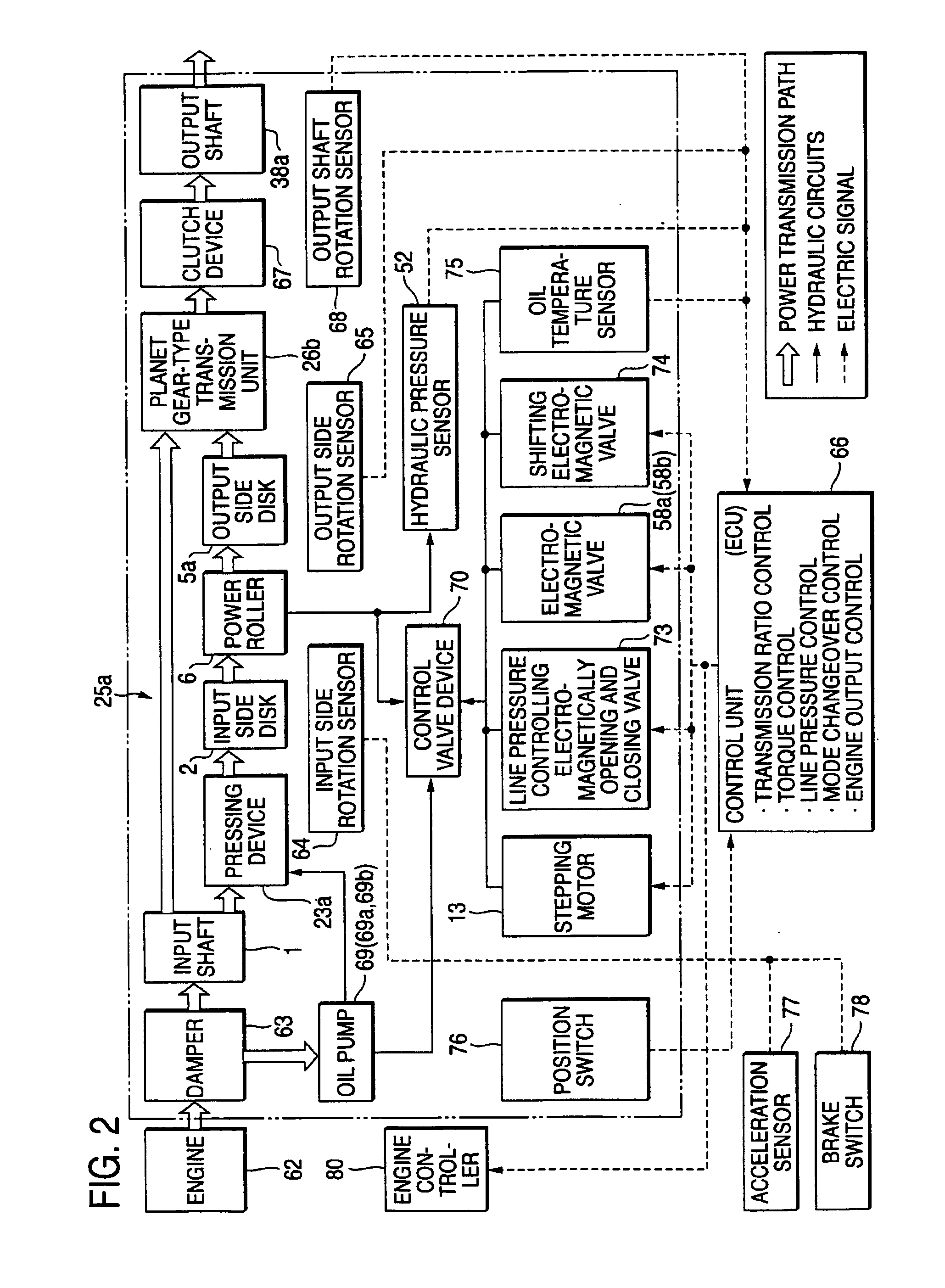

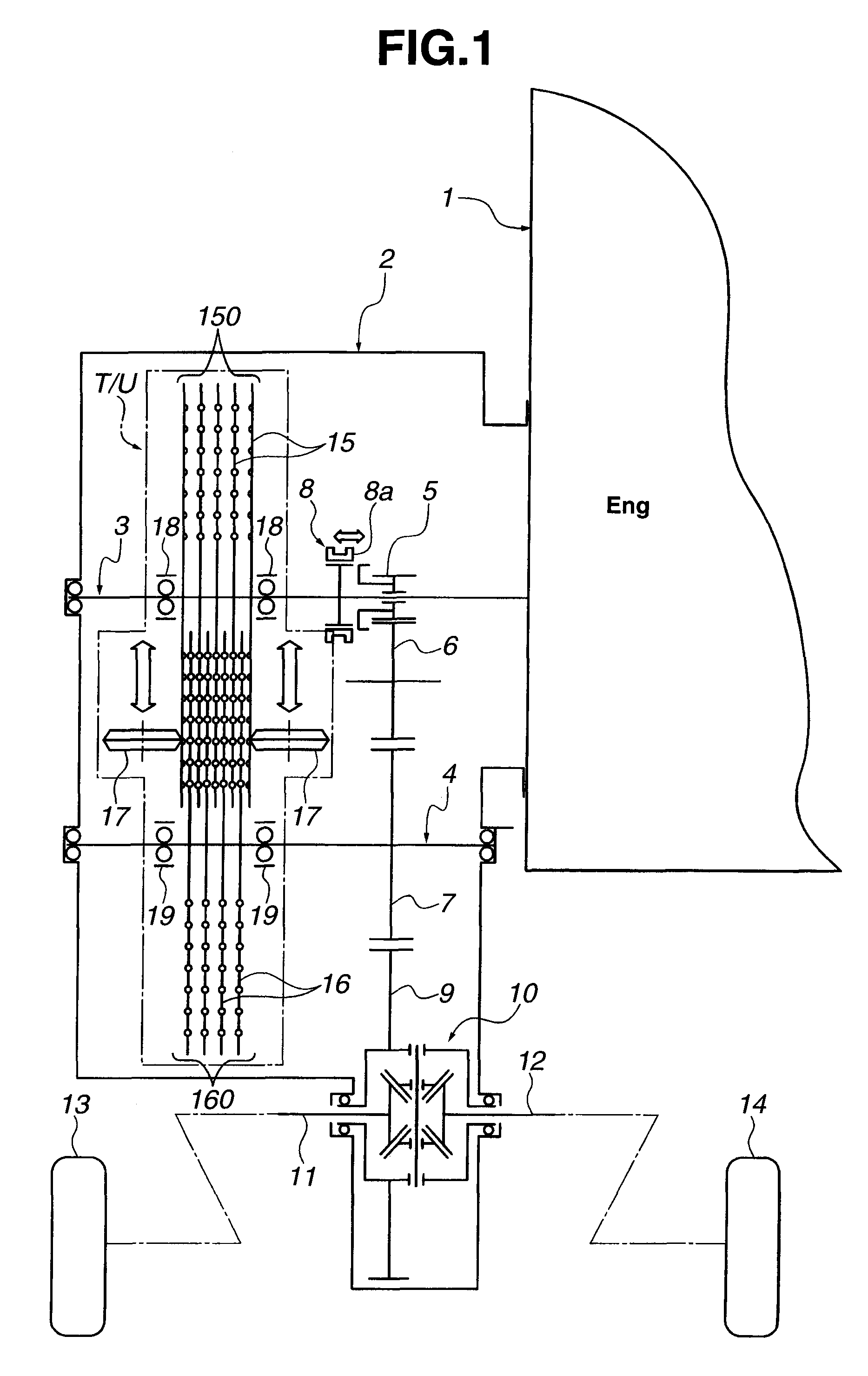

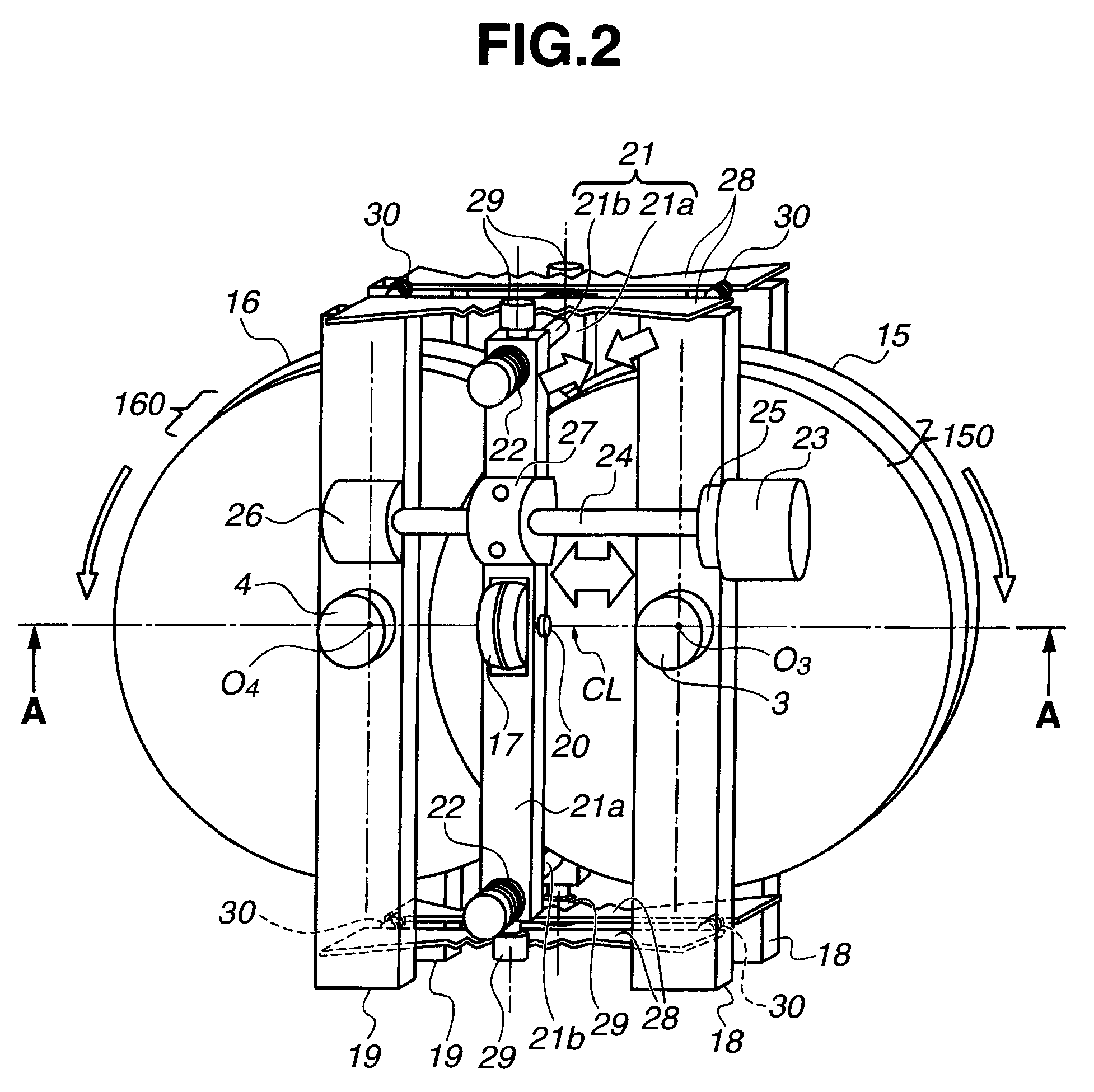

Continuously variable transmission apparatus

InactiveUS7160220B2Avoid feeling uncomfortableGearing controlEngine controllersControl theoryContinuously variable transmission

A continuously variable transmission apparatus includes: an input shaft, an output shaft, a toroidal continuously variable transmission, a gear-type differential unit including a plurality of gears, and a controller. The controller calculates a torque actually passing through the toroidal continuously variable transmission to obtain a deviation of the torque from a target value and adjusts a transmission ratio of the toroidal continuously variable transmission to eliminate the deviation. The controller stops the adjustment of the transmission ratio when the torque is not stable.

Owner:NSK LTD

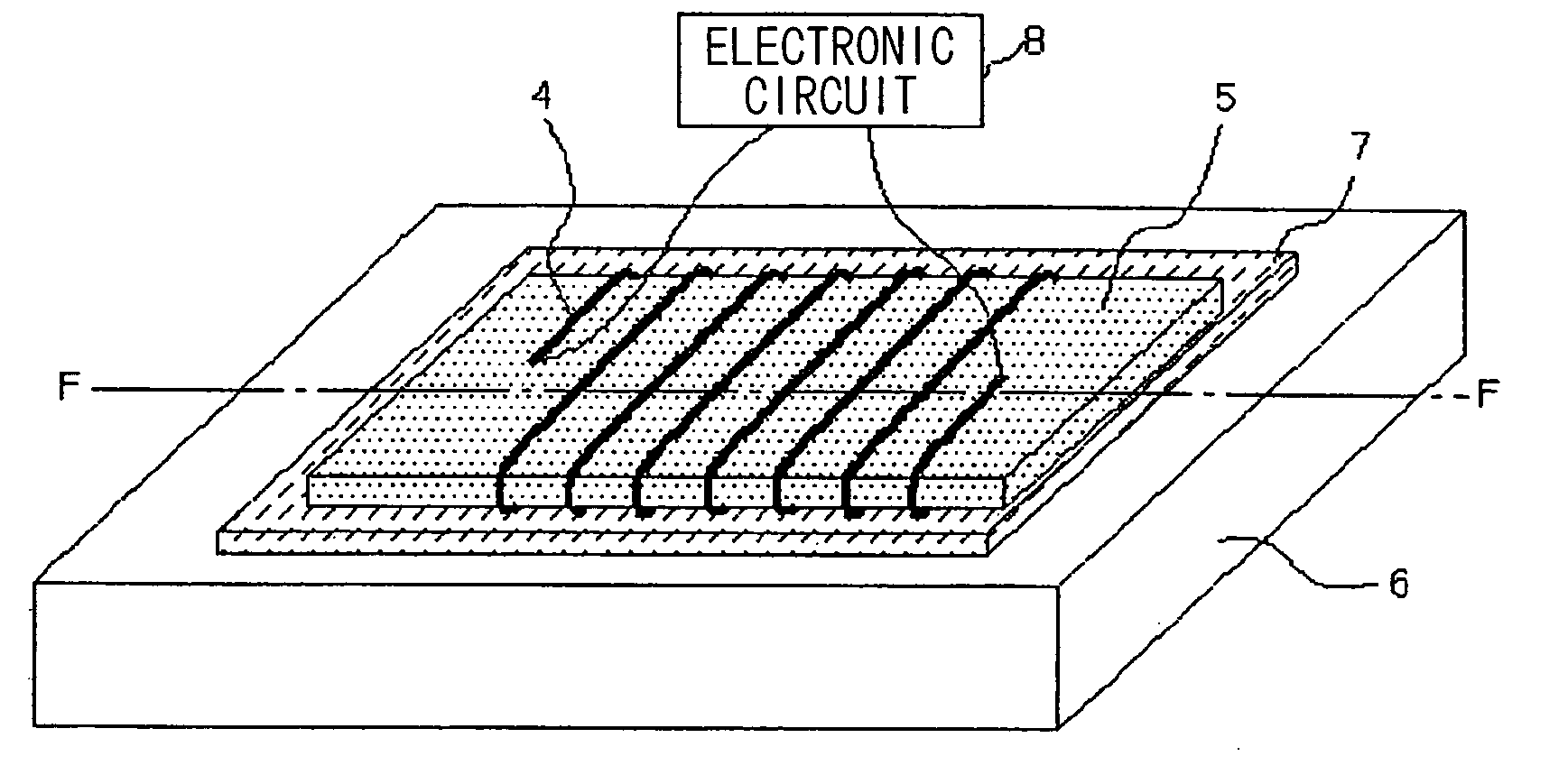

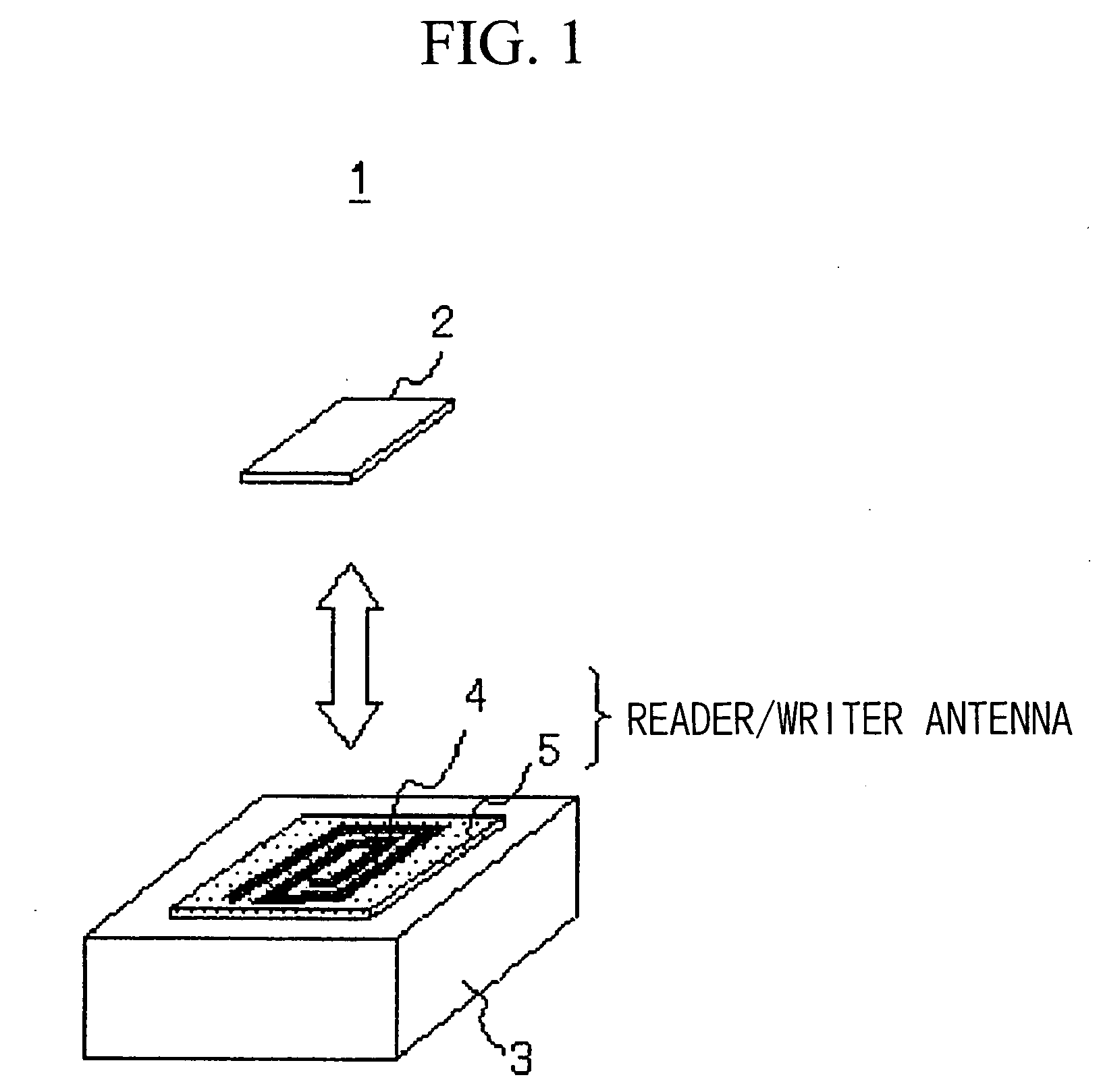

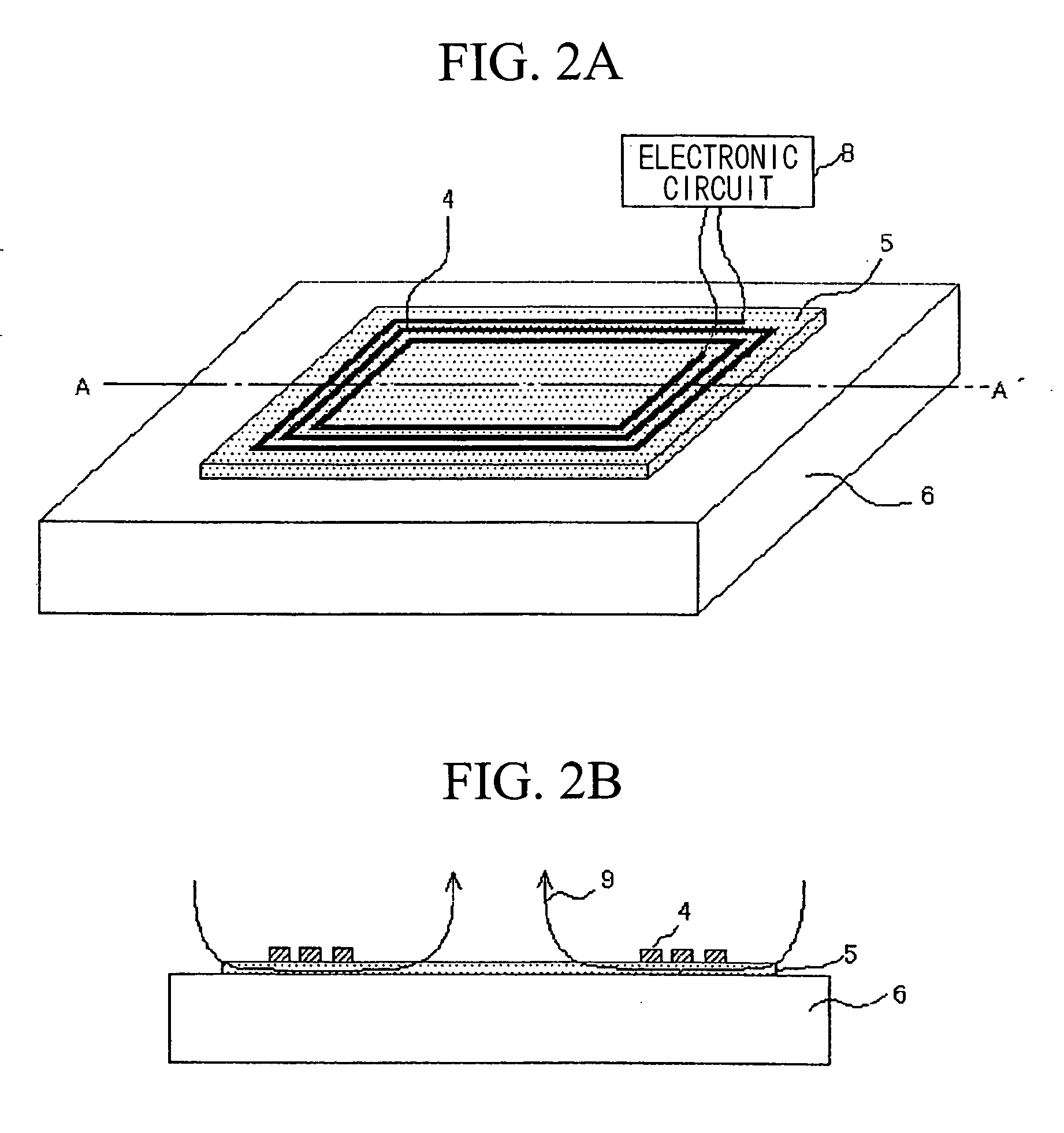

Antenna for reader/writer and reader/writer having the antenna

InactiveUS20050162331A1Limited varianceLoop antennas with ferromagnetic coreAntenna supports/mountingsMagnetic fluxMetal

A soft magnetic member (5) which is formed by a composite of an organic object such as a metal grain powder, a flake, a ferrite grain powder, a ferrite, an amorphous film or a layered member of the amorphous film with 10 mm or lower thickness so as to satisfy a predetermined relationship with an antenna area, a circumference length, and a magnetic transmission ratio and a conductive member (7) which has approximately 10×10−8 Ωm or lower, more preferably 0.005 Ω or lower initial resistance are provided between the an antenna coil which is formed at least one loop and a metal surface (6) of the conductive member such as a metal casing. The magnetic flux which invades into the conductive object is blocked by the soft magnetic member (5) and the conductive member (7) so as to restrict the influence thereof. By doing this, it is possible to provide a reader / writer antenna for an RFID system in which it is possible to restrict a variance of a resonating frequency and an increase in a loss even if it is disposed so as to contact the conductive object such as a metal casing.

Owner:MITSUBISHI MATERIALS CORP

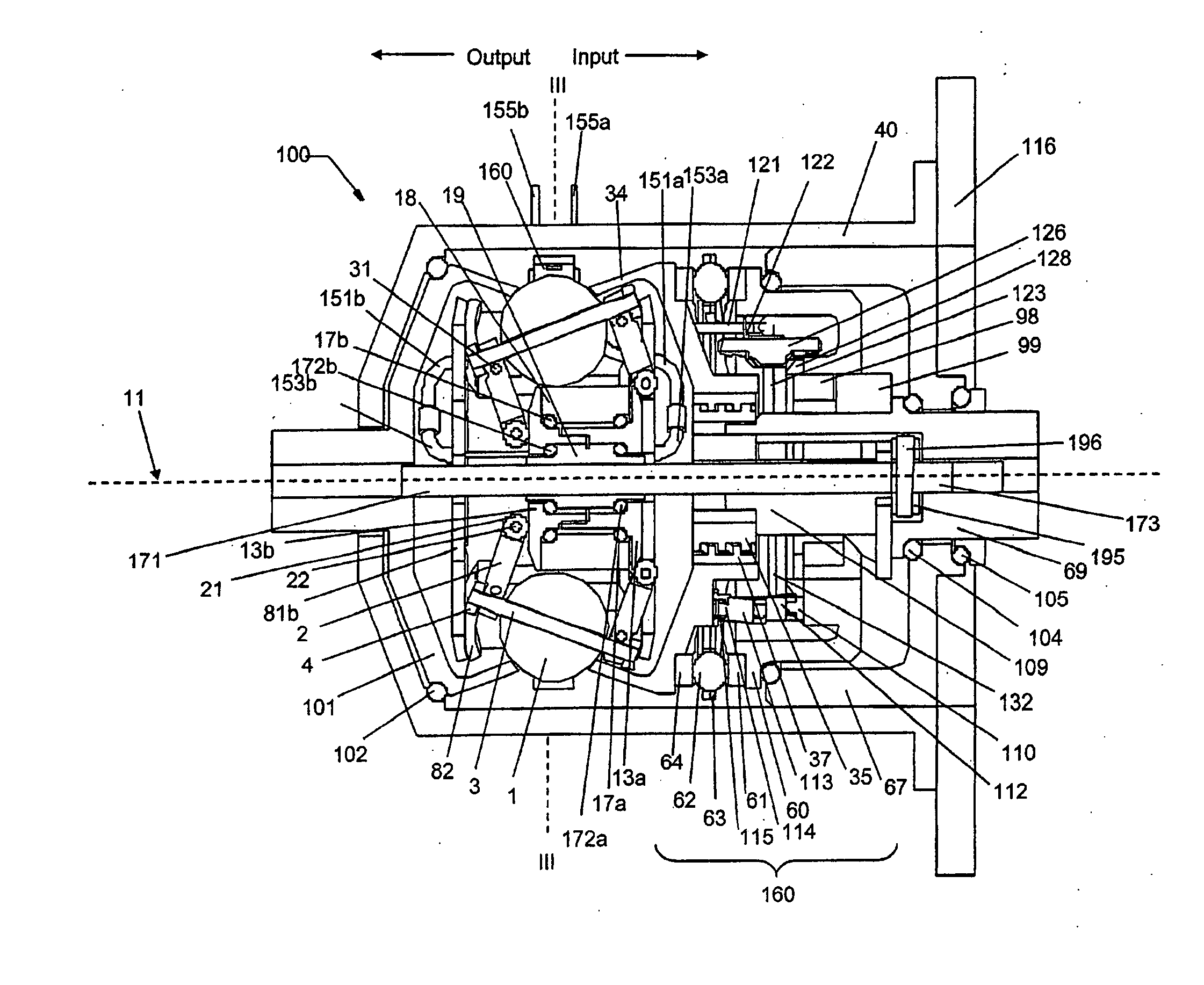

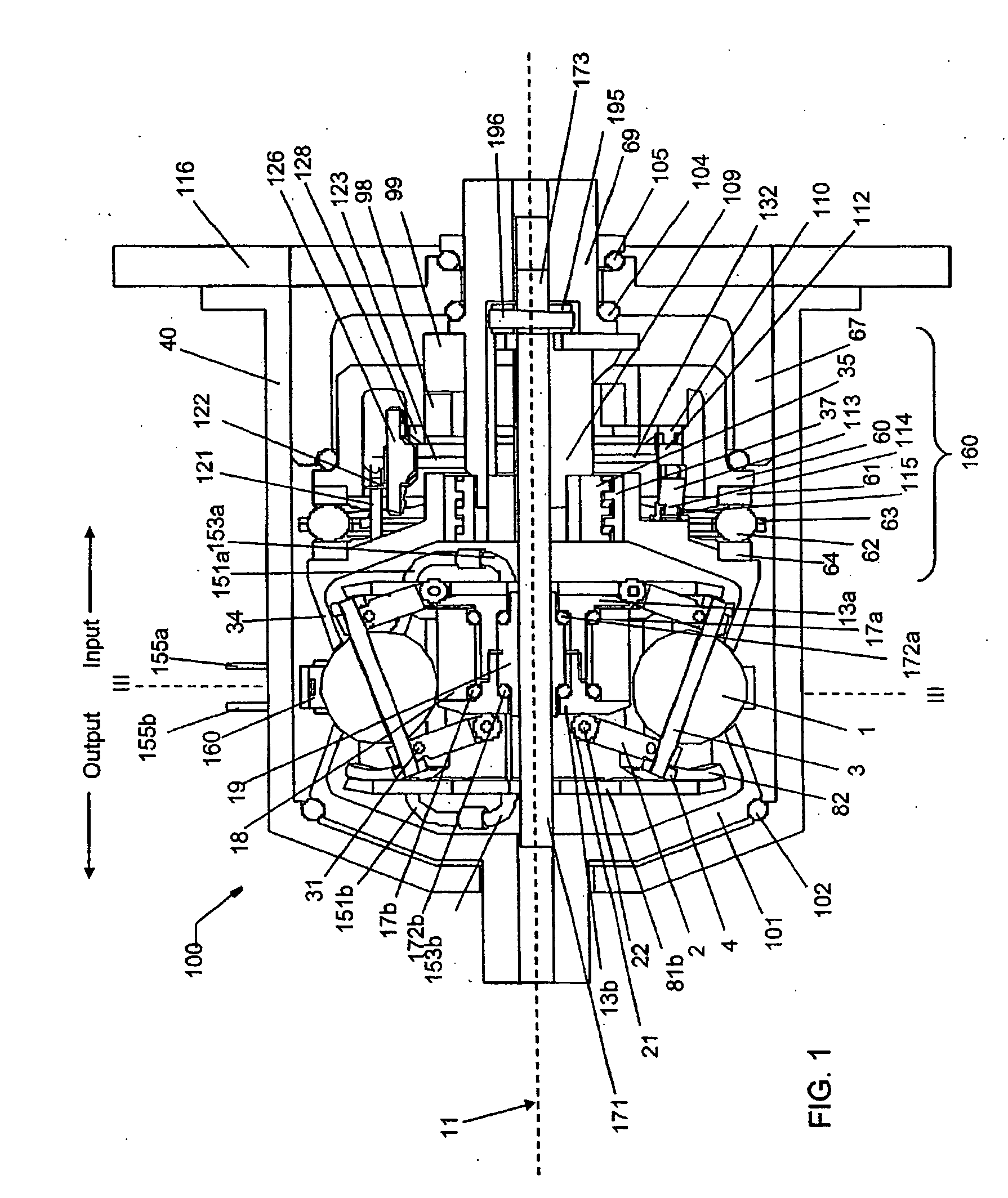

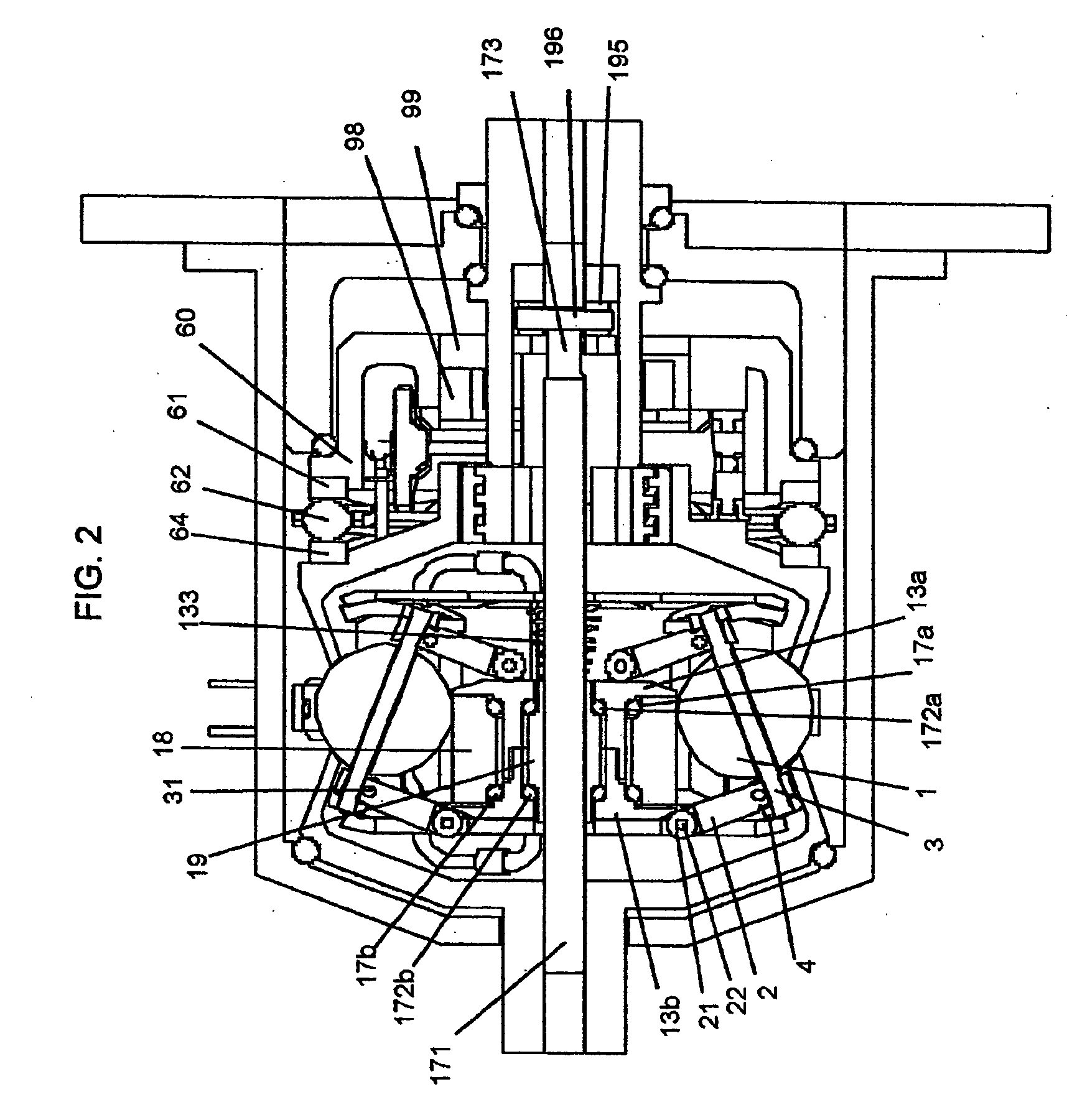

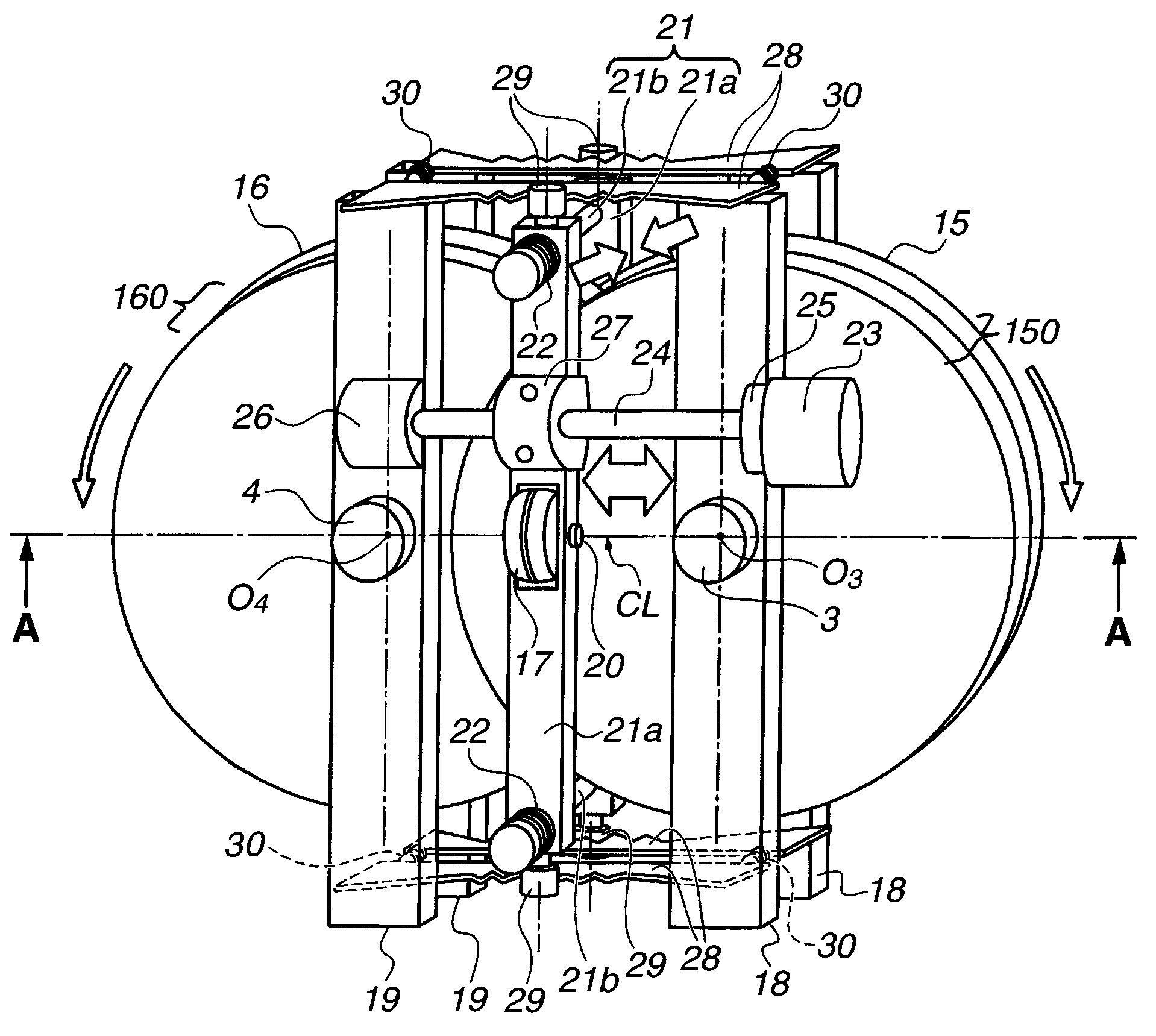

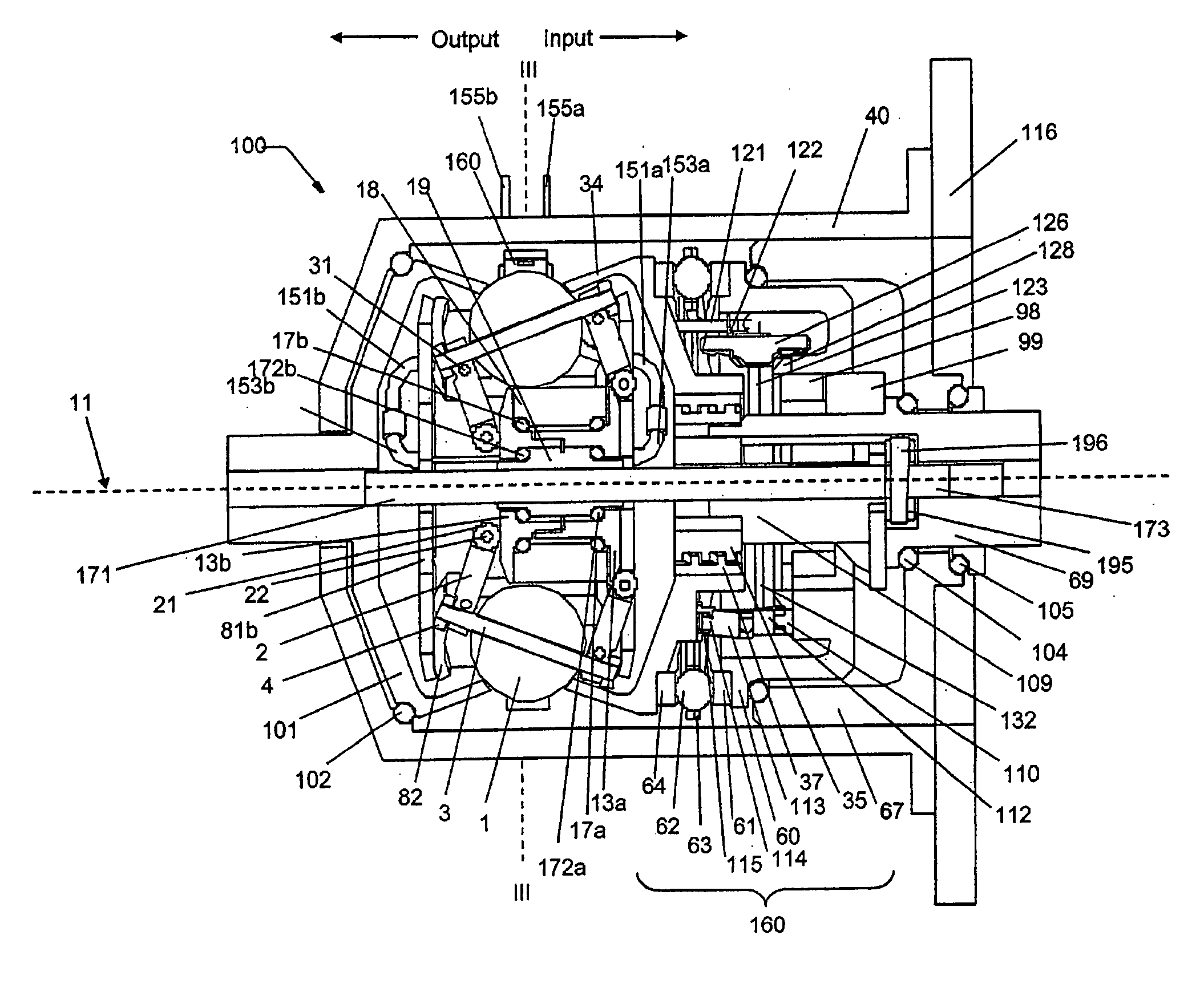

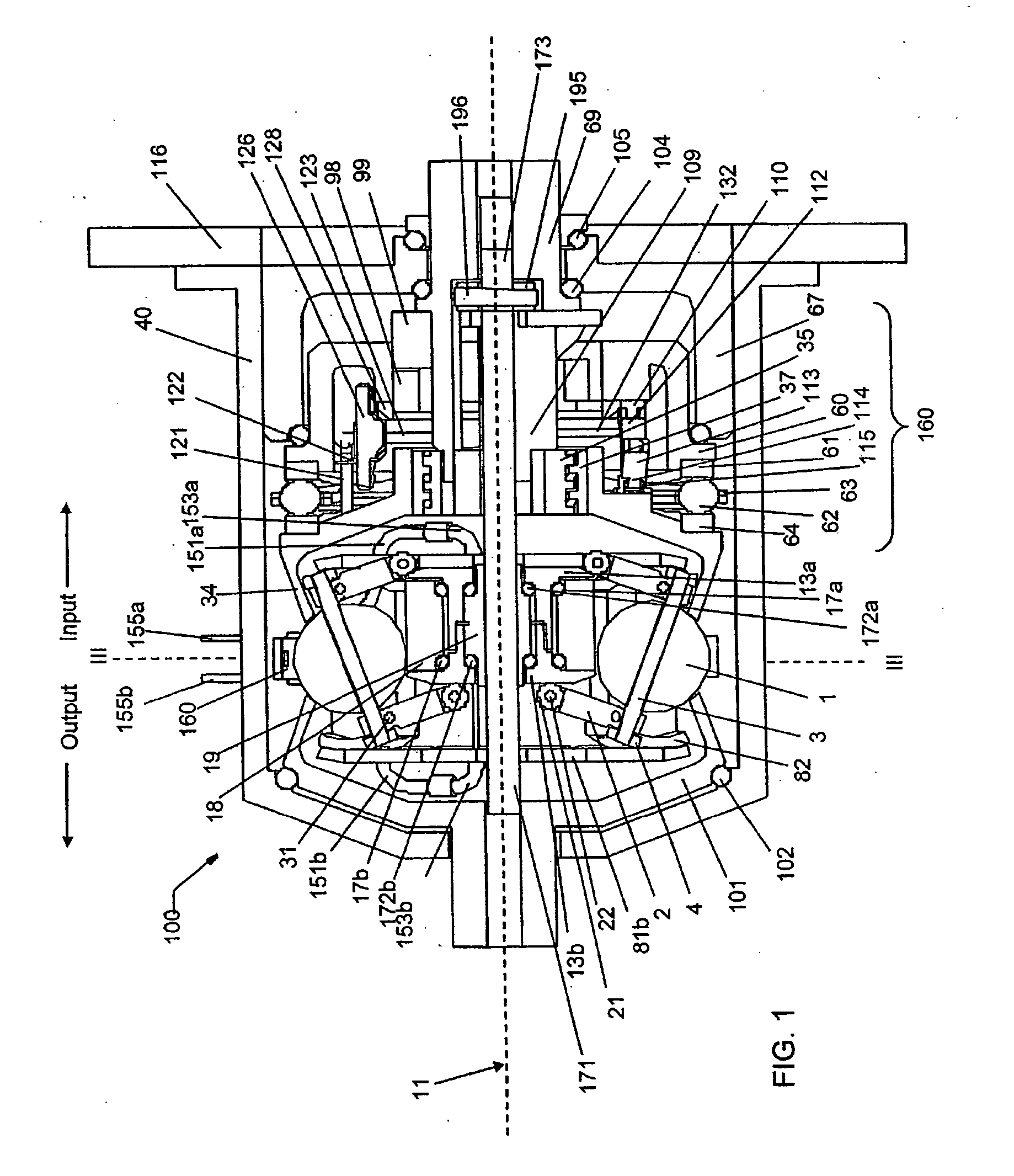

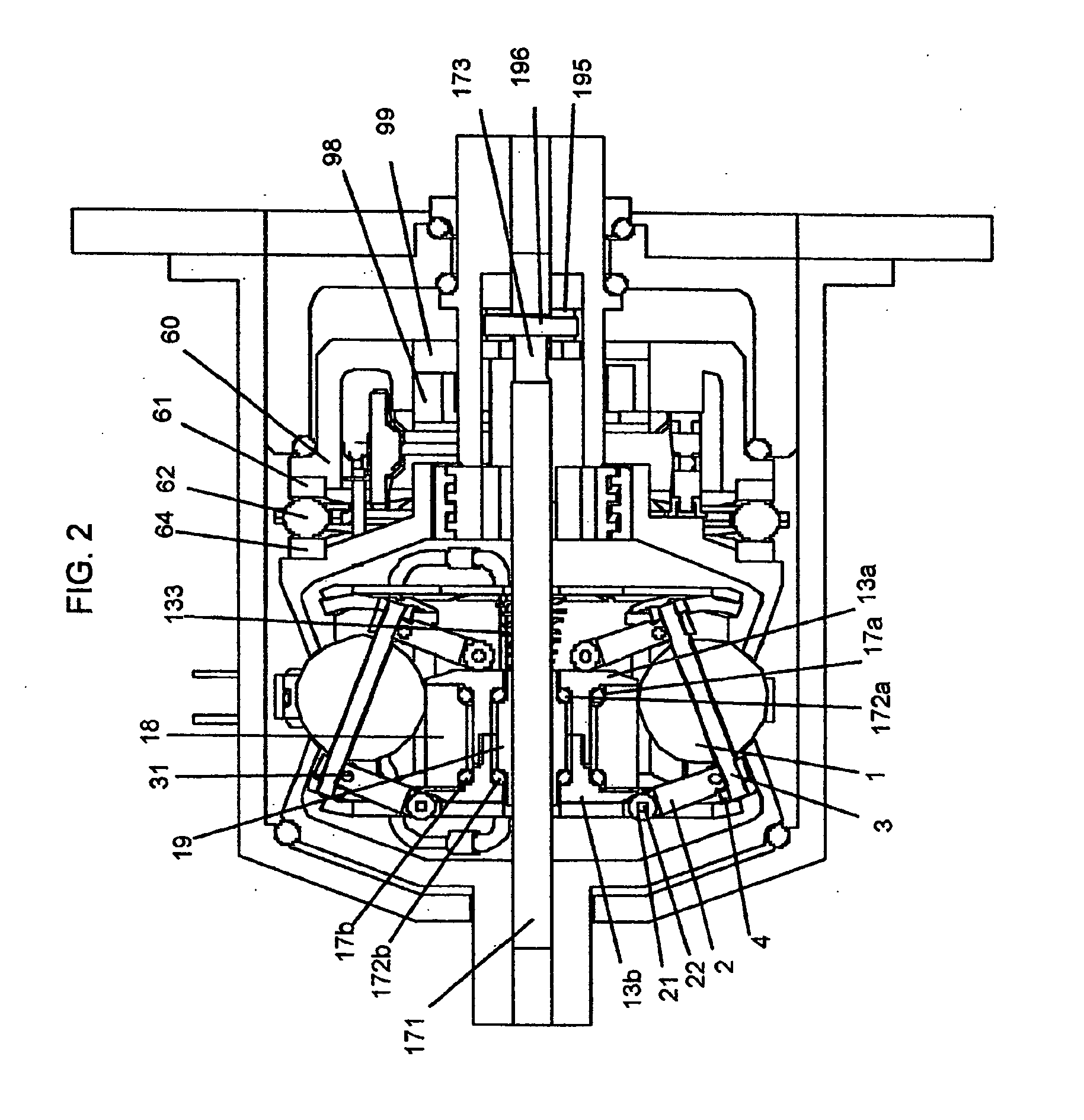

Infinitely variable transmissions, continuously variable transmissions, methods, assemblies, subassemblies, and components therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for infinitely variable transmissions (IVT) having a variator provided with a plurality of tilting spherical planets. In one embodiment, a variator is provided with multiple planet arrays. In another embodiment, a hydraulic system is configured to control the transmission ratio of the IVT. Various inventive idler assemblies and planet-pivot arm assemblies can be used to facilitate adjusting the transmission speed ratio of an IVT. Embodiments of a transmission housing and bell housing are adapted to house components of an IVT and, in some embodiments, to cooperate with other components of the IVT to support operation and / or functionality of the IVT. Various related devices include embodiments of, for example, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, and a rotatable carrier configured to support planet-pivot arm assemblies.

Owner:FALLBROOK INTPROP COMPANY

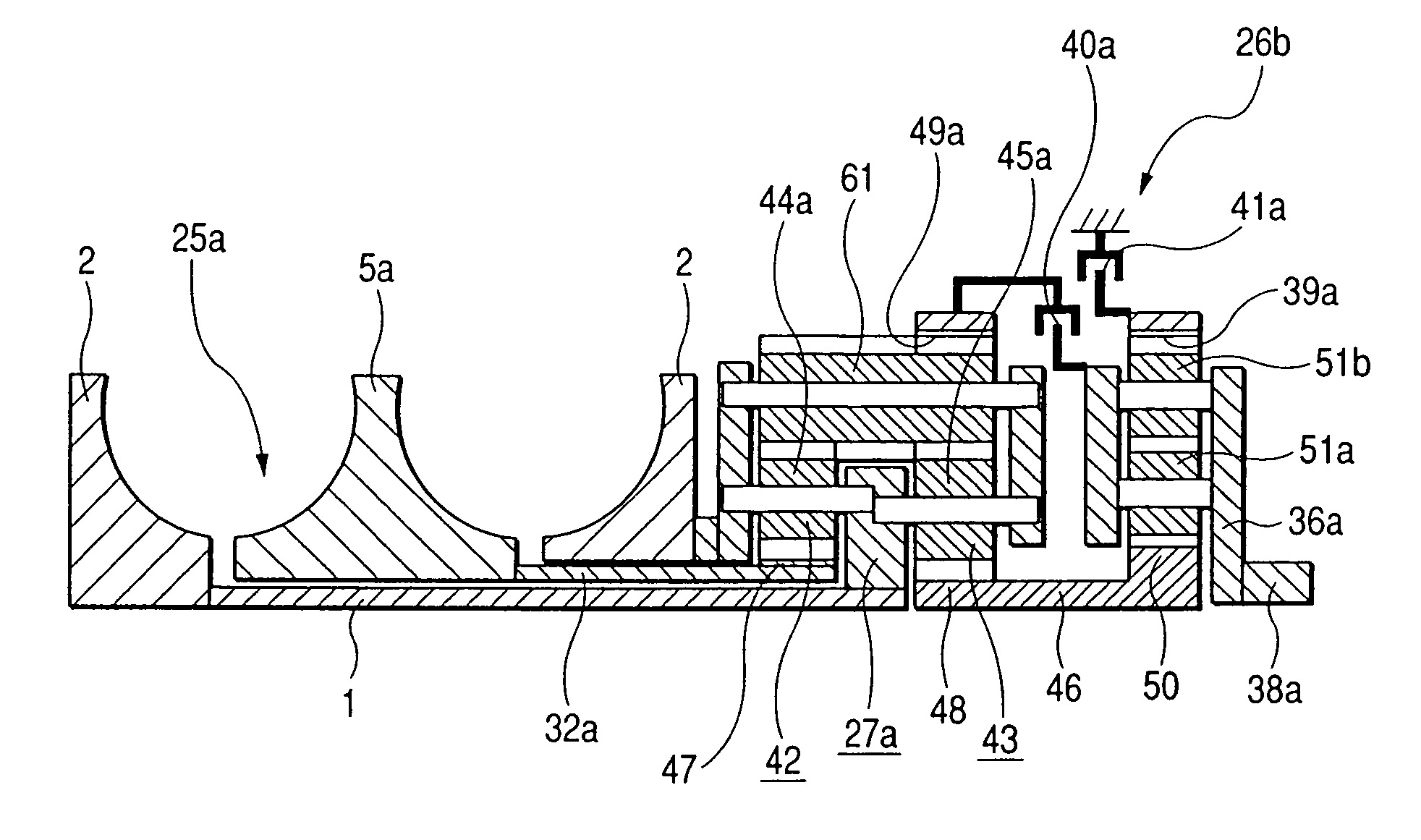

Continuously variable transmission apparatus

A continuously variable transmission apparatus having input and output shafts, a toroidal-type continuously variable transmission unit (CVT unit), a gear-type differential unit with gears, and a control unit, the CVT unit has; input and output side disks, power rollers, input and output side rotation sensors, wherein the differential unit has; a first input portion and a second input portion, and wherein the control unit regulates the transmission ratio of the CVT unit so as to change relative displacement speeds of the gears of the differential unit to thereby convert the rotational state of the output shaft to forward and backward rotations with a stationary state being interposed therebetween, with the input shaft being kept rotating in one direction, and to calculate a rotational speed of the output shaft based on rotational speeds of the input and output side disks and a gear ratio of the differential unit.

Owner:NSK LTD

Electromotive drives

A transmission having a plurality of tilting balls and opposing input and output discs provides an infinite number of speed combinations over its transmission ratio range. The transmission provides multiple powerpaths and can be combined with electrical components to provide motor / generator functionality, which reduces the overall size and complexity of the motor and transmission compared to when they are constructed separately. In one embodiment, rotatable components of a continuously variable transmission are coupled separately to an electrical rotor and to an electrical stator so that the rotor and stator rotate simultaneously in opposite directions relative to one another. In other embodiments, an electrical rotor is configured to transfer torque to or from a disc that is in contact with a plurality of speed adjusters, while an electrical stator is configured to transfer torque to a shaft that is operationally coupled to the speed adjusters via an idler.

Owner:FALLBROOK INTPROP COMPANY

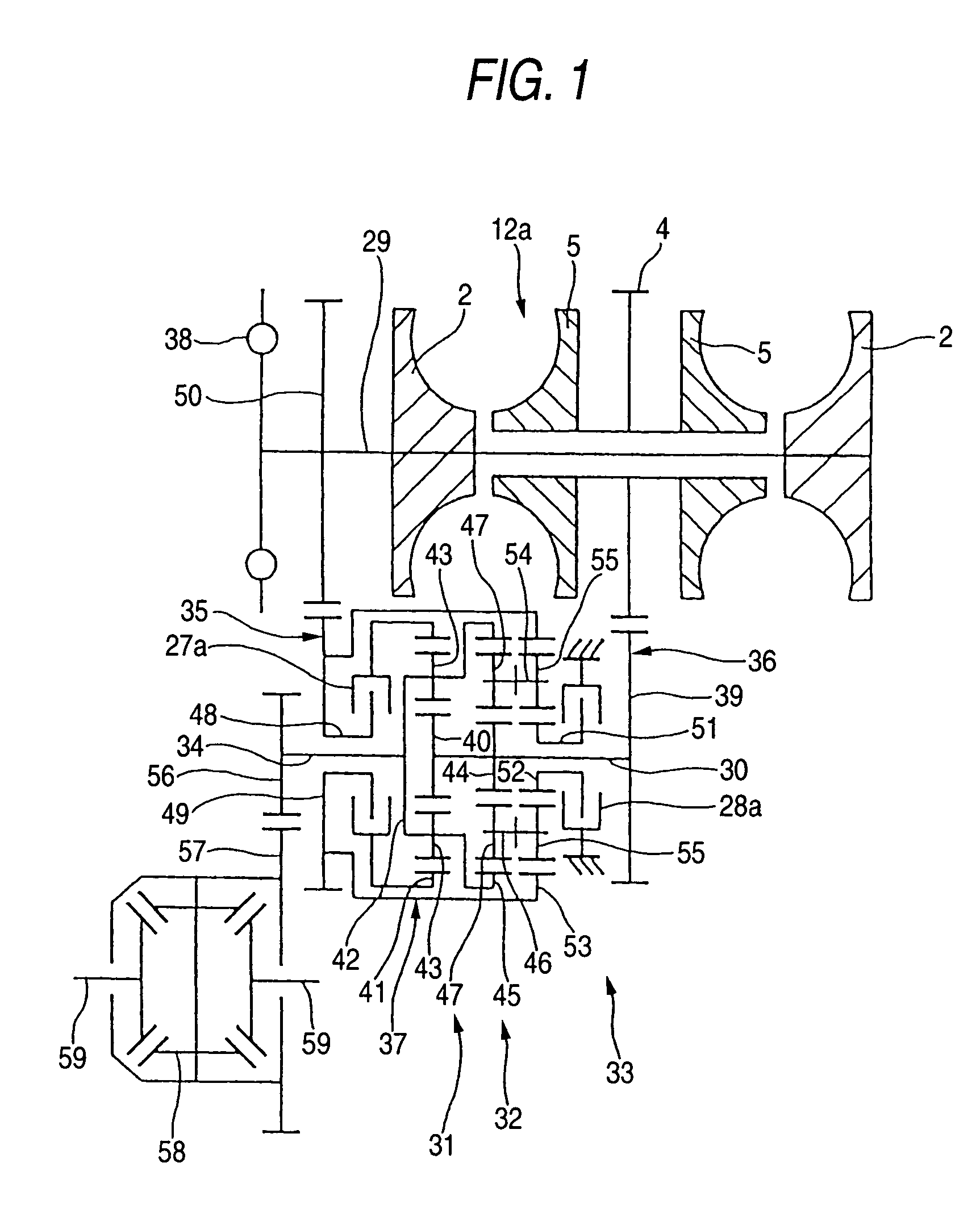

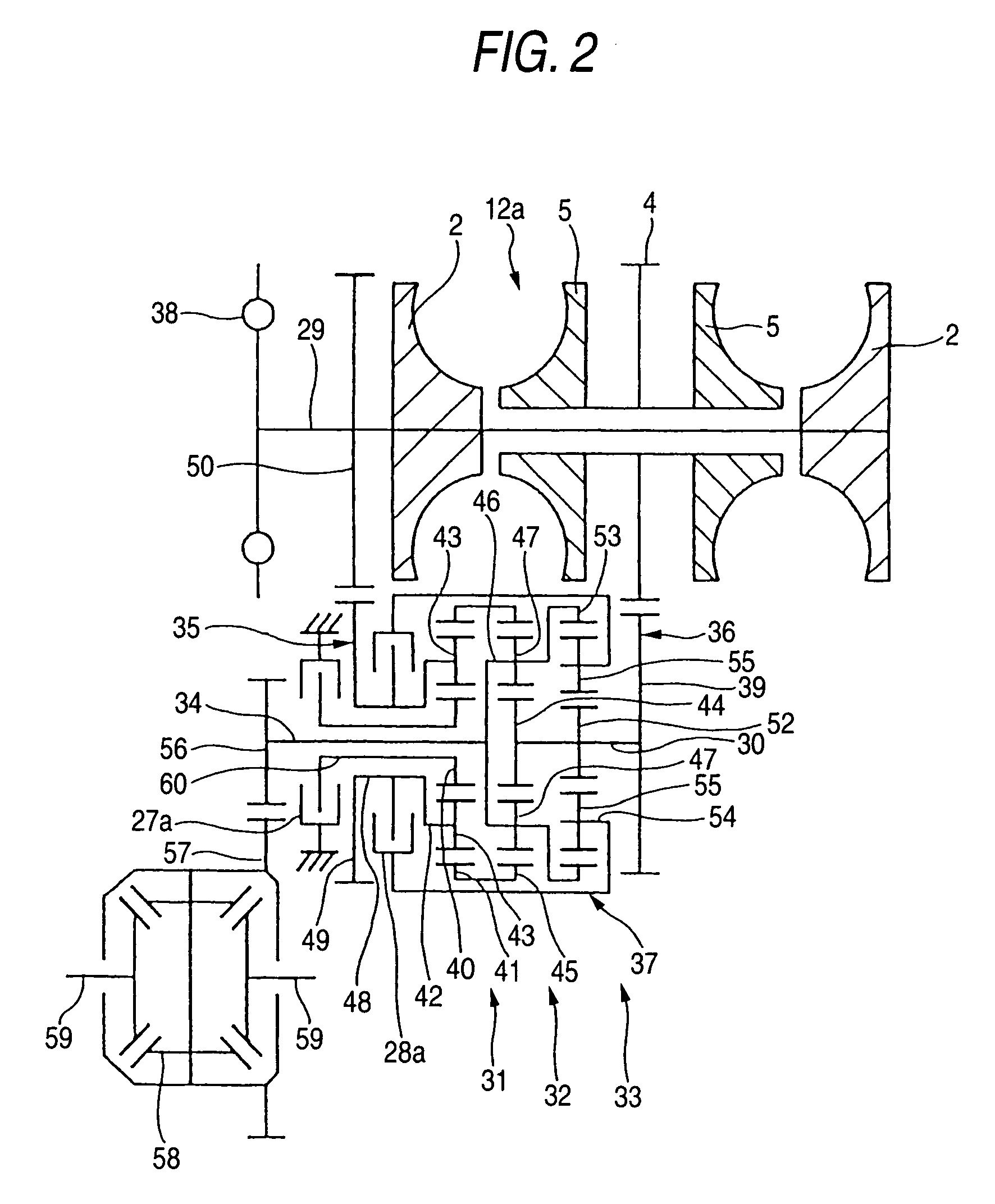

Continuously variable transmission apparatus

ActiveUS7094171B2Save spaceAxial-direction dimension can be reducedFriction gearingsGear wheelDrive shaft

A continuously variable transmission apparatus, has: an input shaft; a toroidal-type continuously variable transmission; a rotation transmission shaft; first, second and third planetary-gear-type transmissions; a first power transmission mechanism; a second power transmission mechanism; a third power transmission mechanism; and, a switching mechanism, wherein the second sun gear and one of the first and third sun gears are rotated together with the rotation transmission shaft to thereby execute the power transmission through the rotation transmission shaft and one of the first and second planetary-gear-type transmissions, and, in a state where the power transmission through the third planetary-gear-type transmission is cut off, in accordance with the control of the transmission ratio of the toroidal-type continuously variable transmission, the output shaft is stopped while the input shaft is rotating.

Owner:NSK LTD

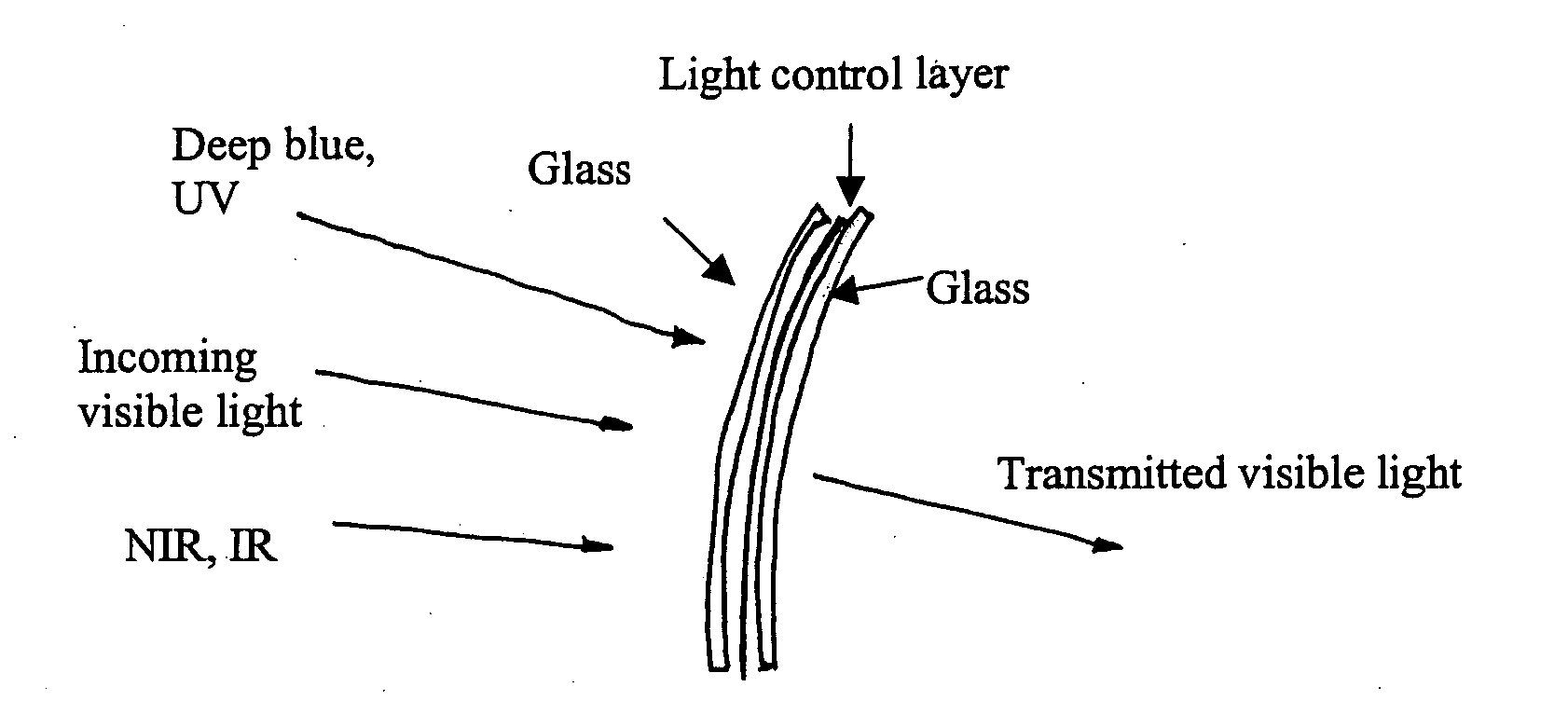

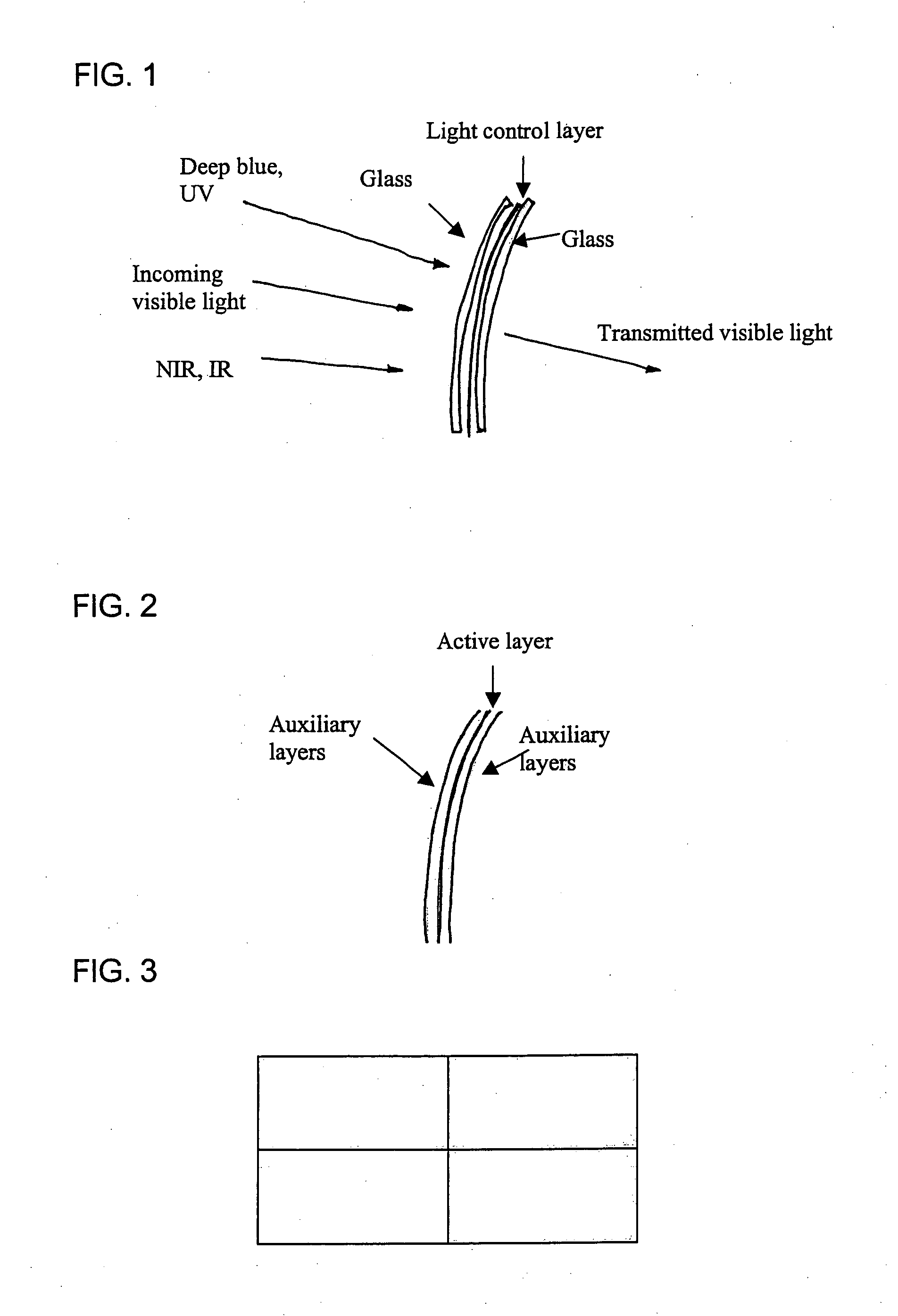

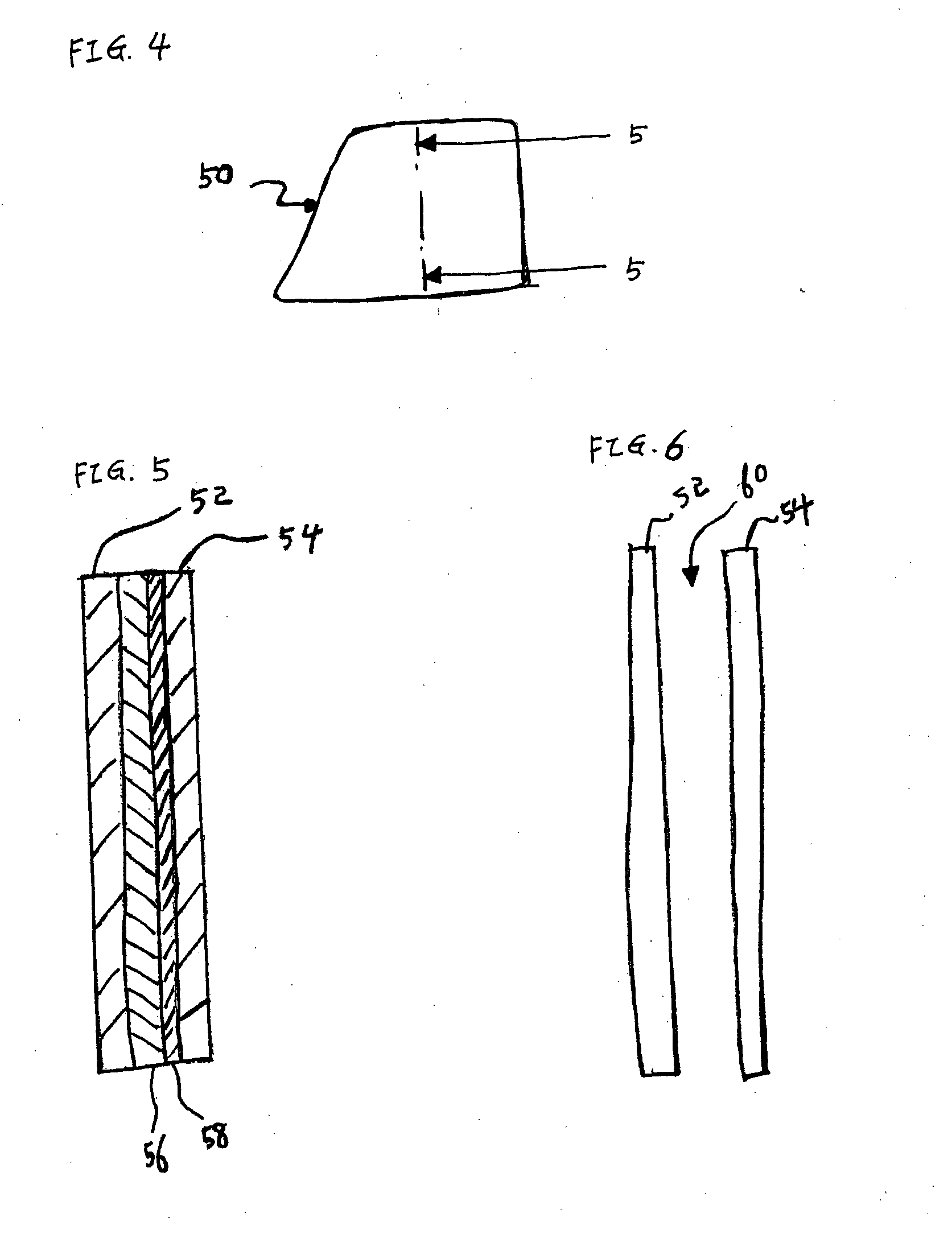

Adjustably opaque window

InactiveUS20050068629A1Reduce decreaseMinimized and eliminatedLight dependant control systemsAntiglare equipmentControl layerLight transmission

An adjustably opaque window including an external pane, an internal pane, a light transmission control layer and a shock-absorbing layer is provided. The external pane and the internal pane provide a cavity between them, and the light transmission control layer and the shock-absorbing layer are positioned in the cavity. The shock-absorbing layer is a flexible sheet that supports and protects the light transmission control layer. The light transmission layer consists of liquid crystal cells. The transmission ratio of the cells can be controlled variably.

Owner:LCT ENTERPRISES

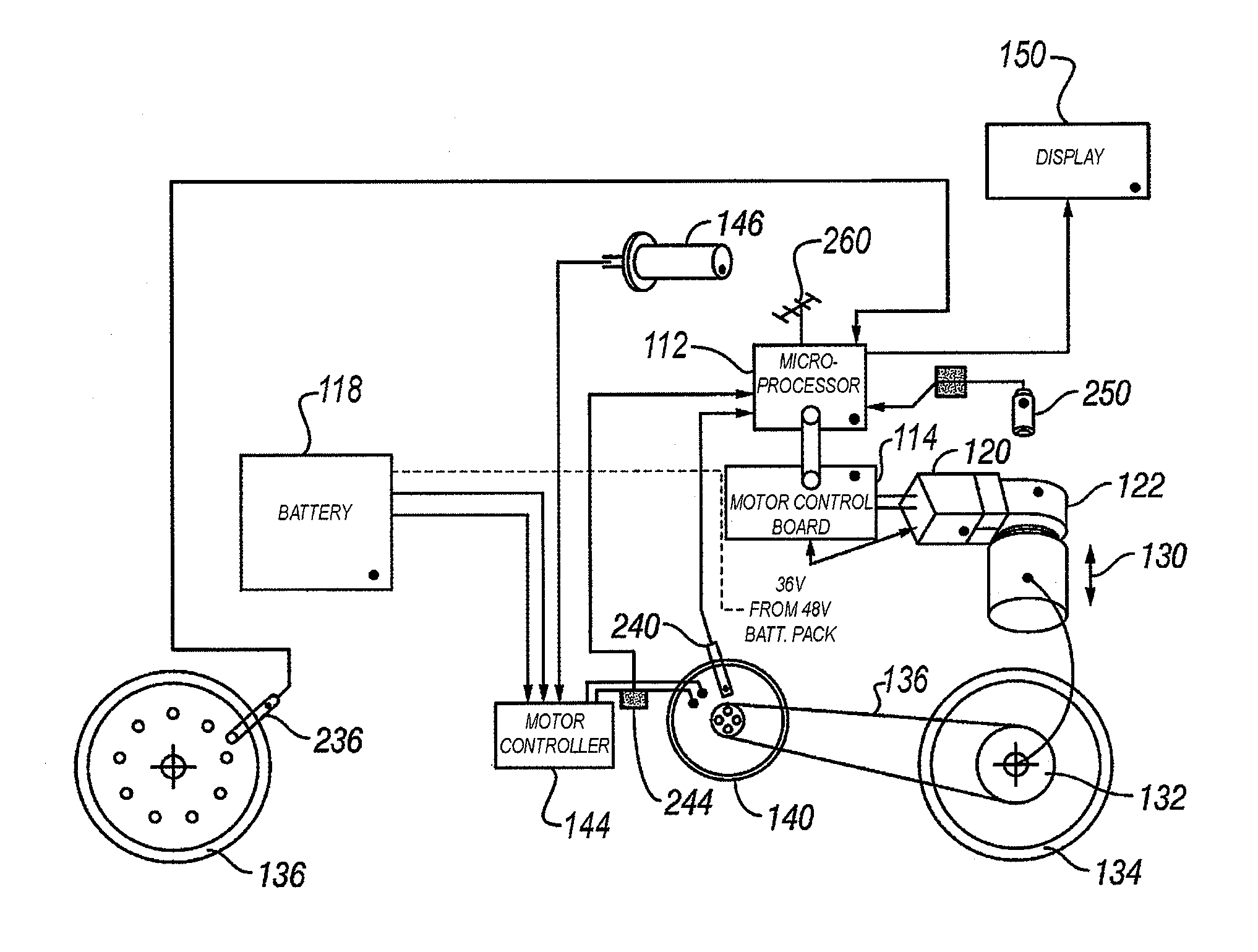

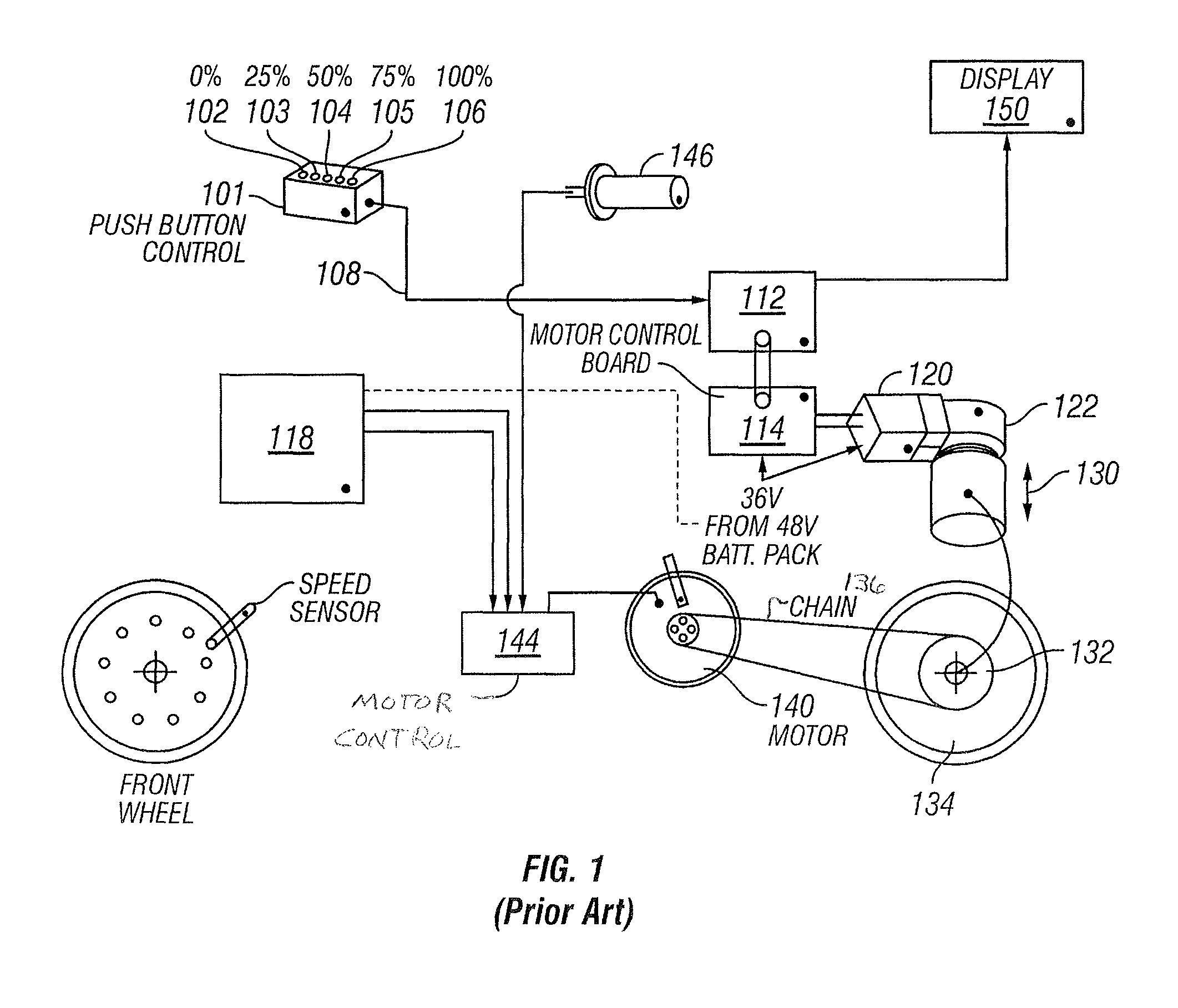

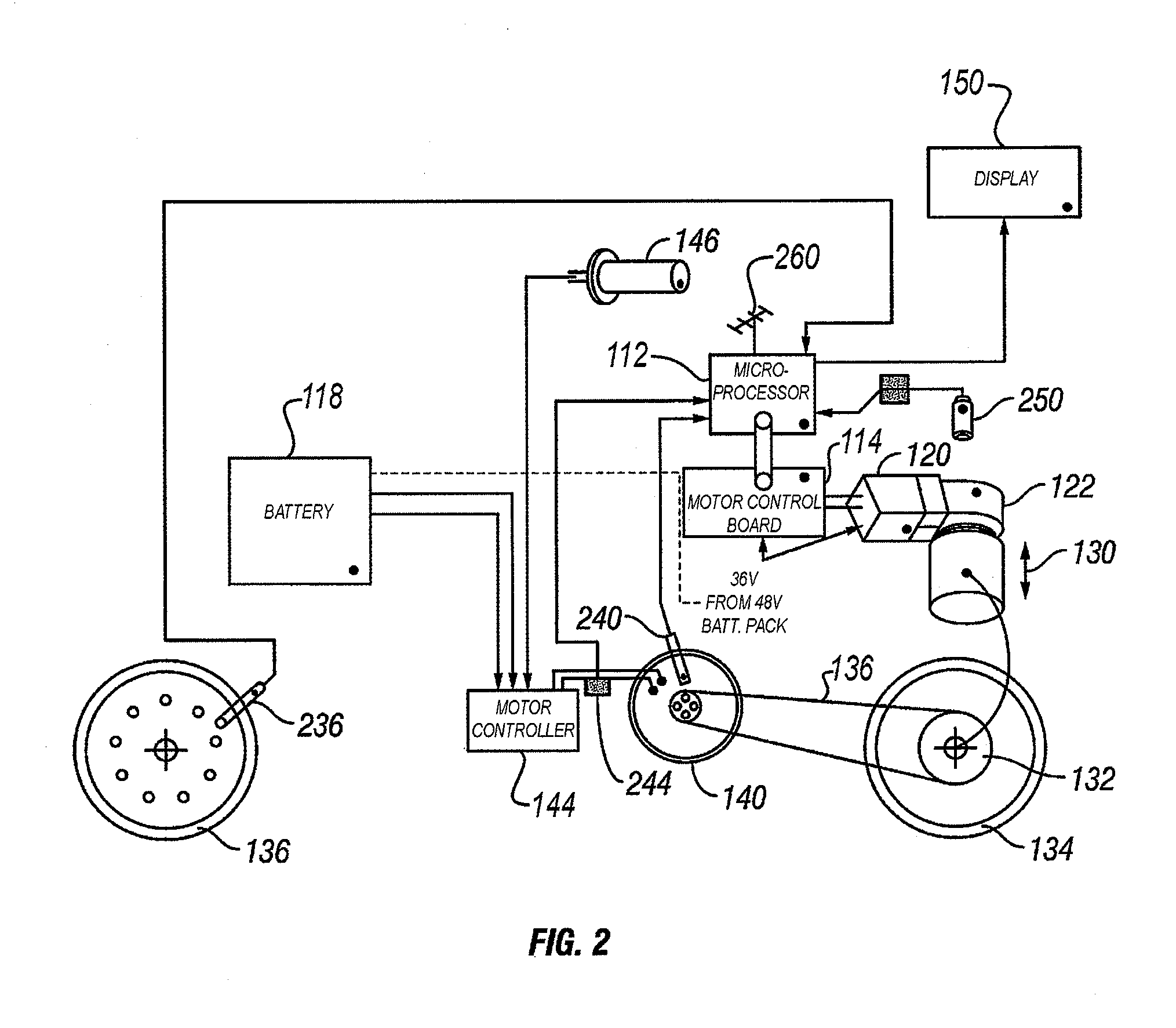

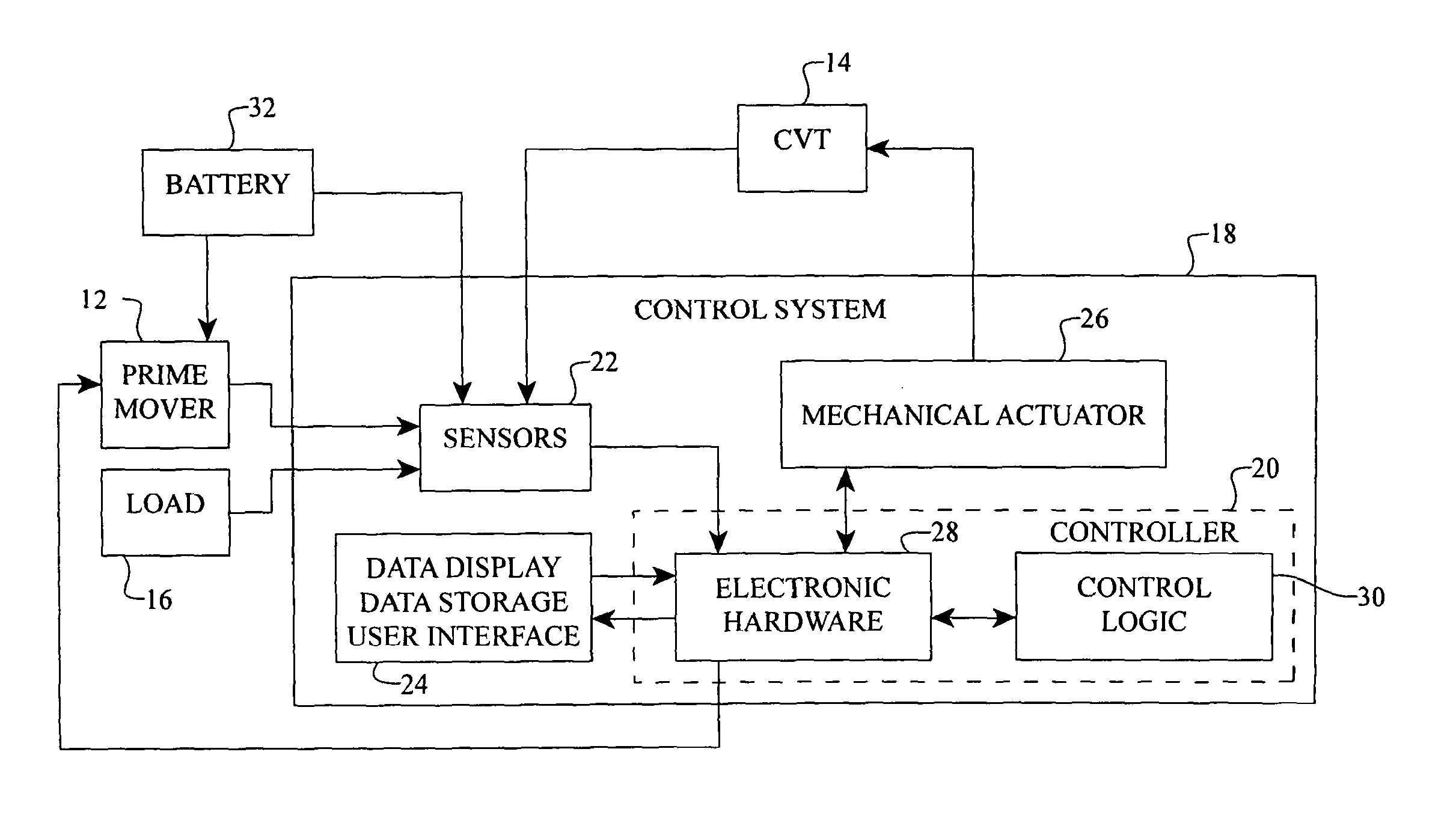

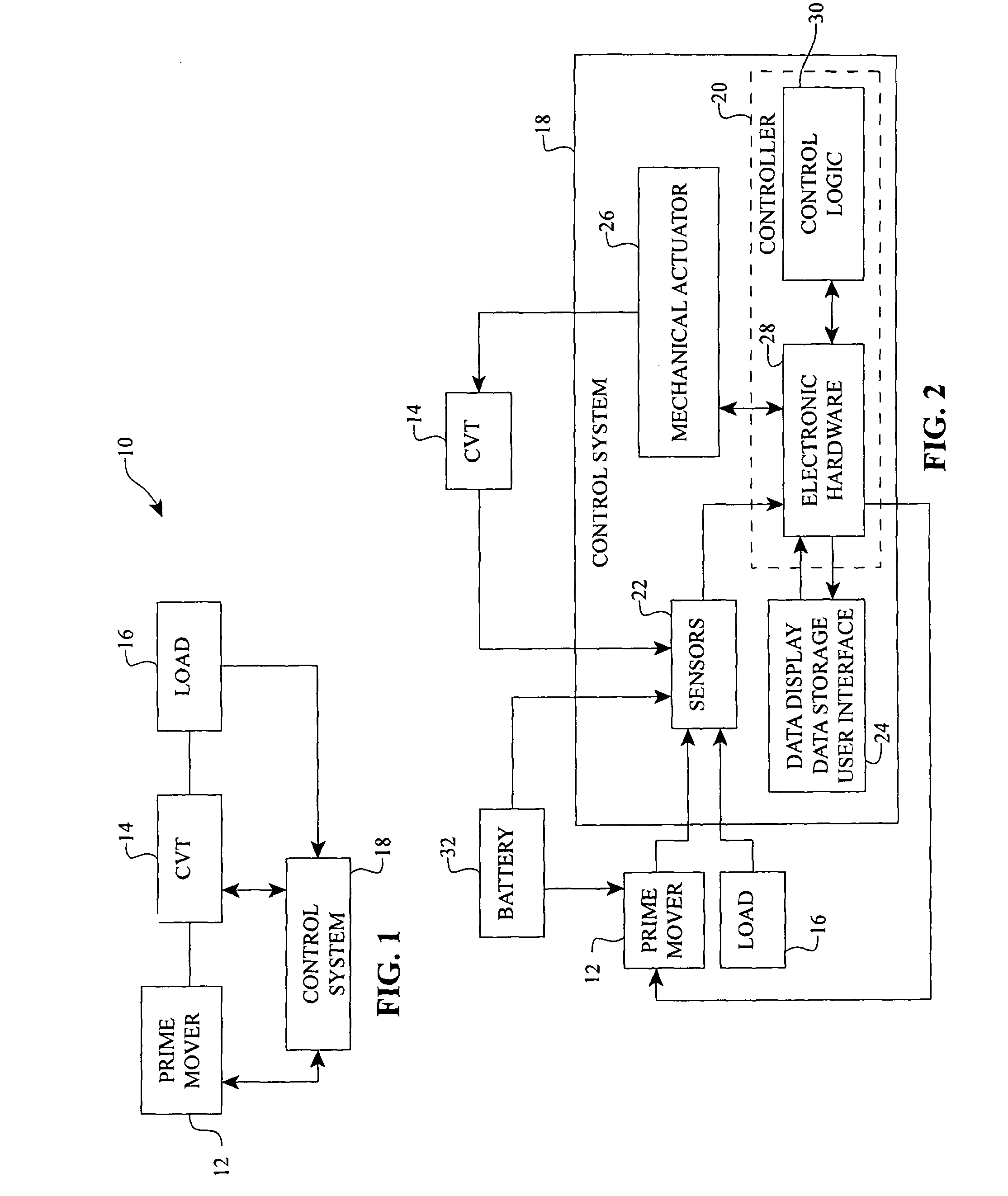

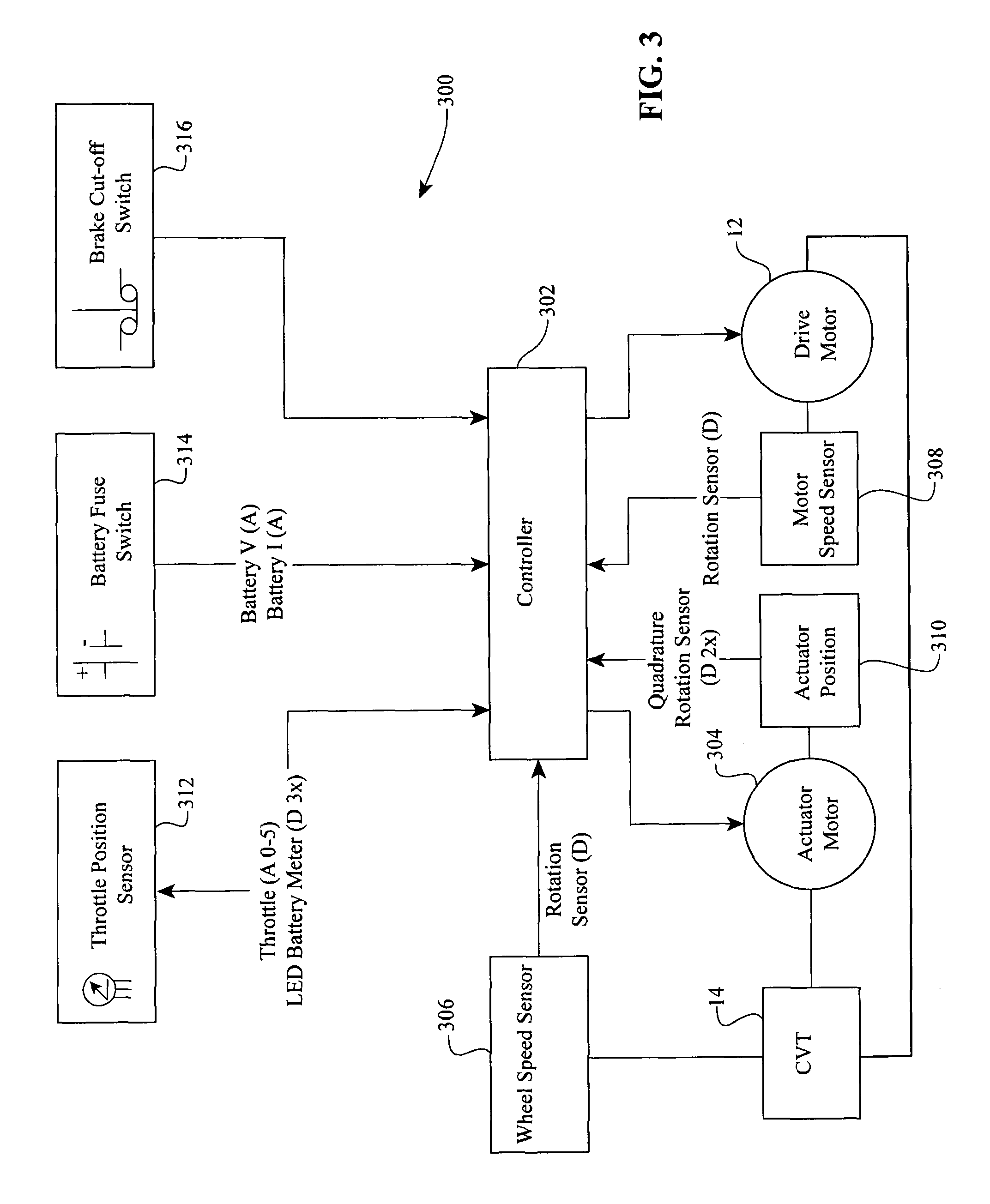

Scooter shifter

The present invention provides a system and method for automatically adjusting a continuously variable transmission (CVT) in a motorized vehicle. A microprocessor processor in the vehicle receives data about the operating status of the vehicle from a plurality. Examples of vehicle data include vehicle speed, motor speed, throttle position, current draw from a battery, and battery level. A servo motor is in mechanical communication with the CVT and provides an axial force to adjust the CVT. The microprocessor uses lookup tables of optimal set points for vehicle data to instruct the servo motor to adjust the transmission ratio of the CVT according to the vehicle data provided by the sensors.

Owner:FALLBROOK INTPROP COMPANY

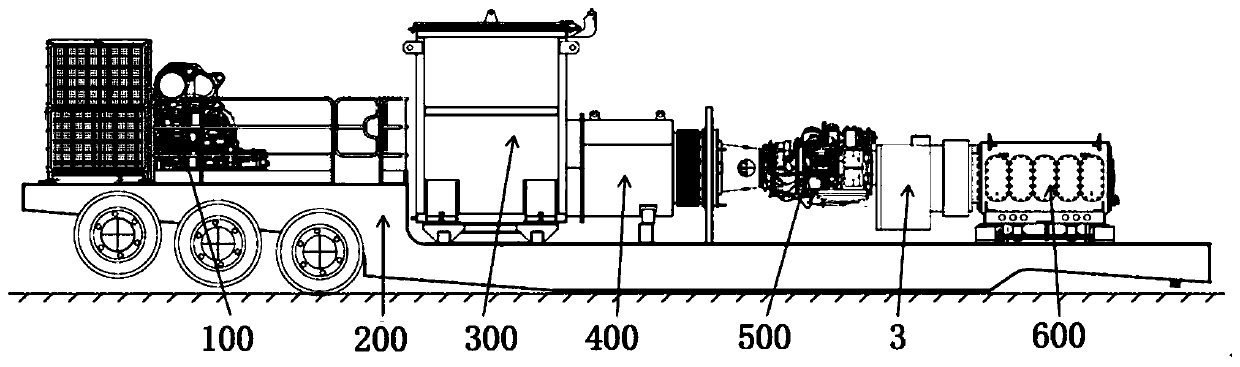

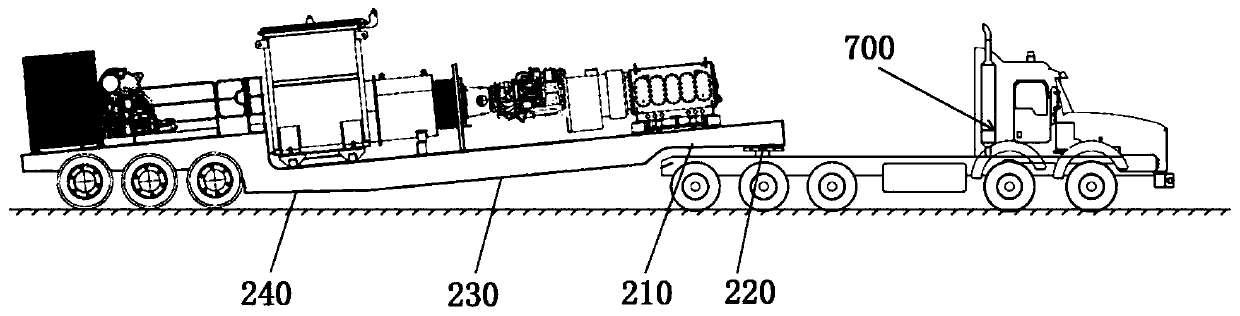

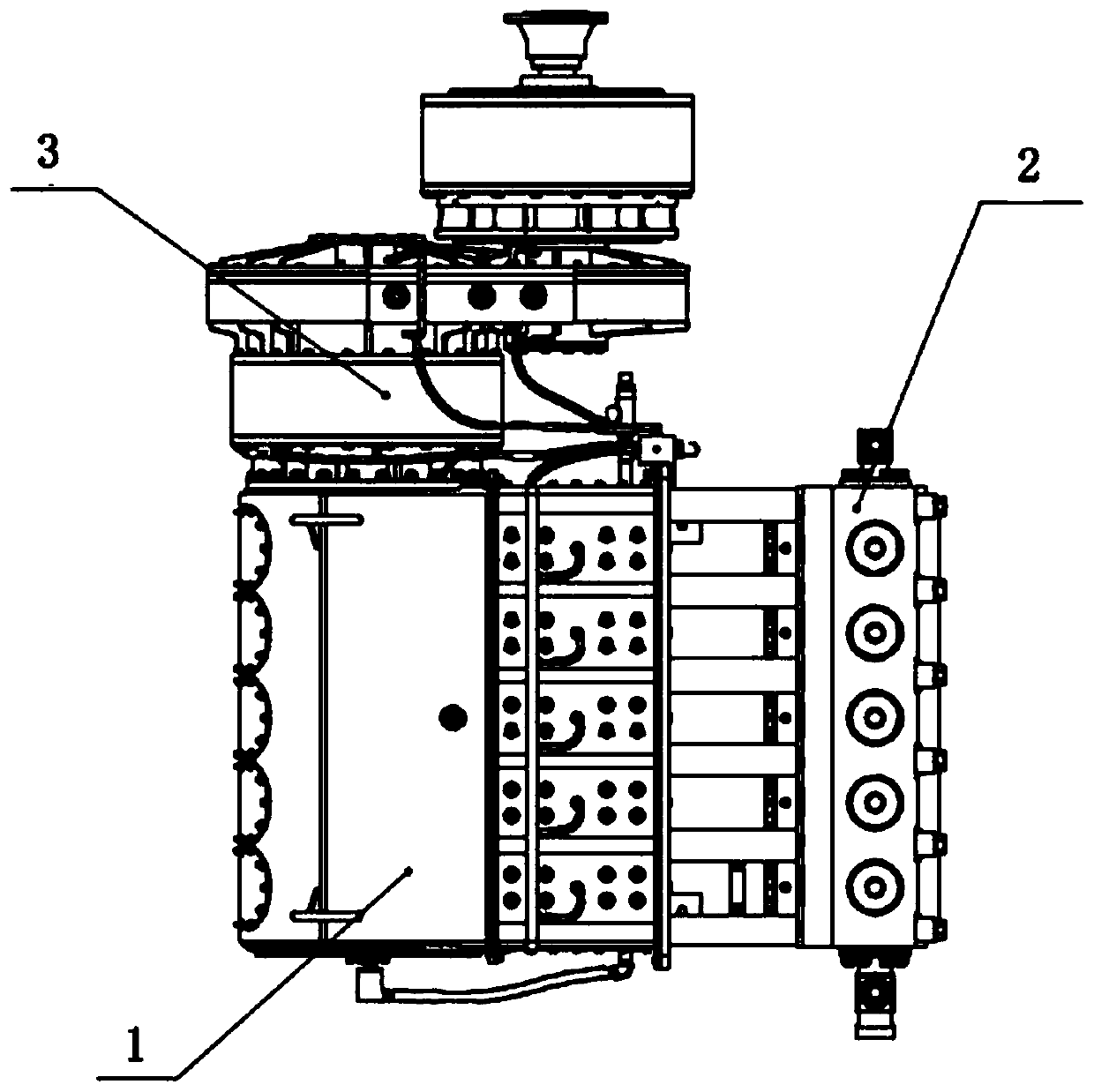

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

High-efficiency vehicular transmission

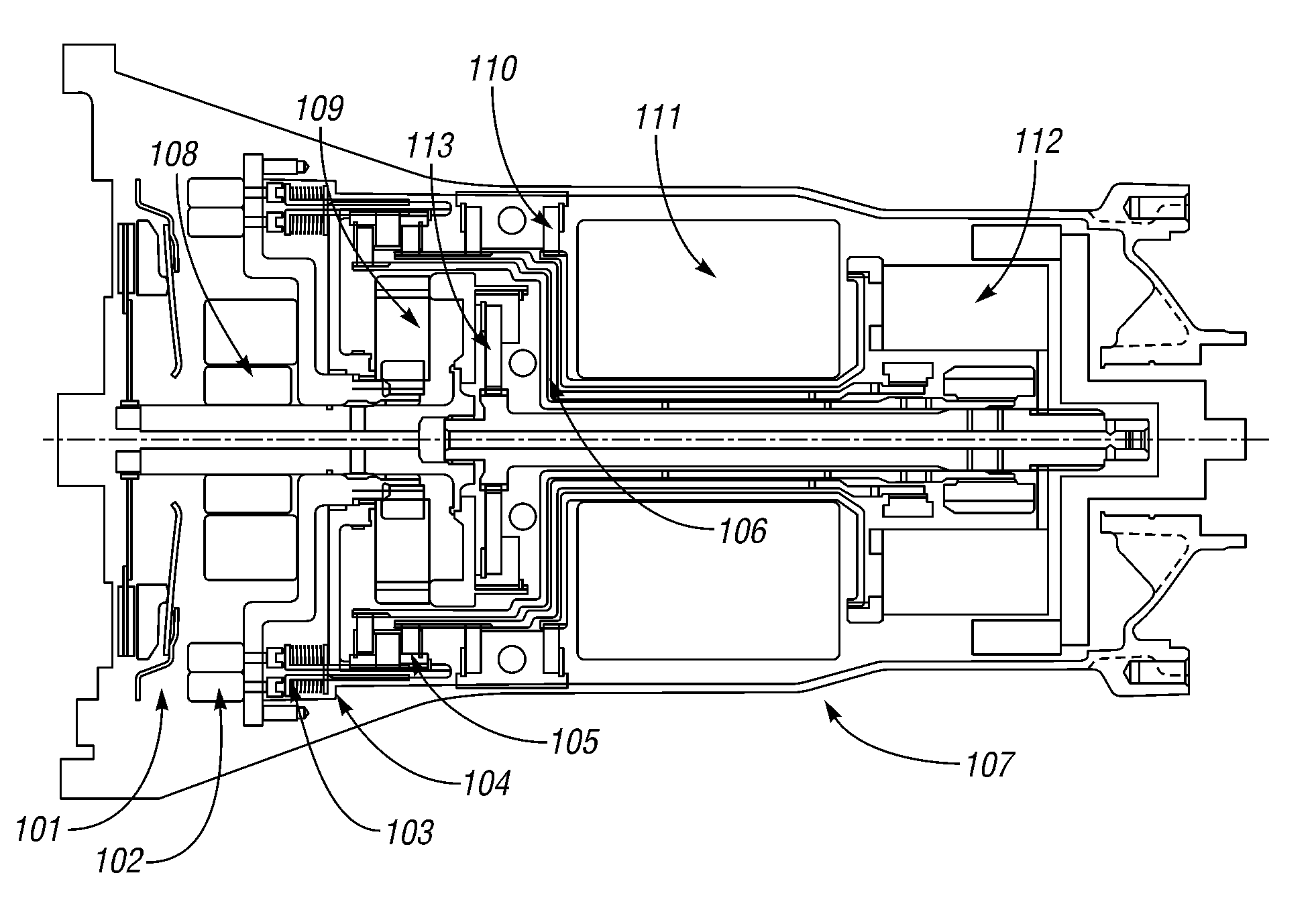

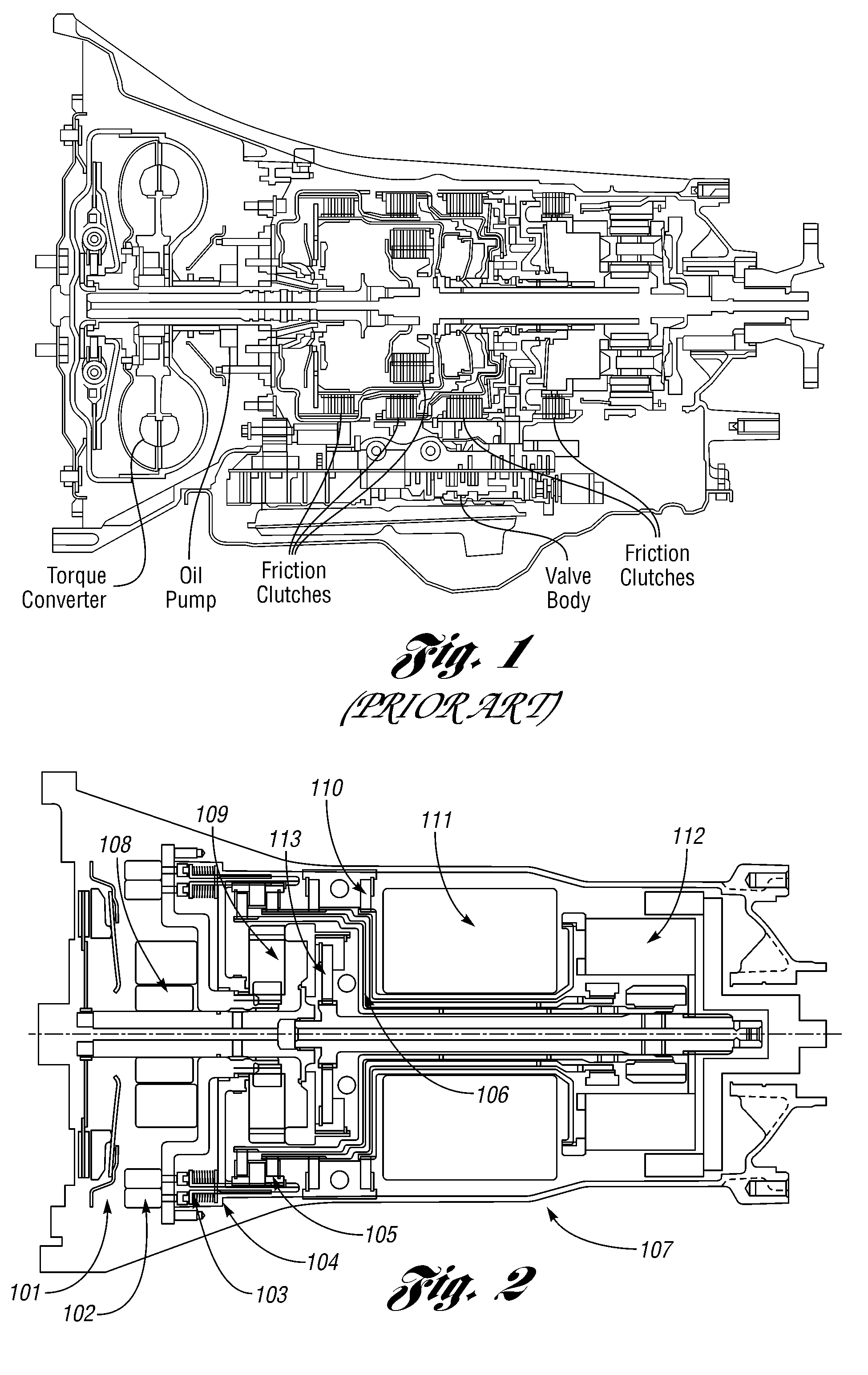

InactiveUS7942781B2Spread the wordSoften one-way clutch engagementsToothed gearingsElectric machinesCouplingAngular velocity

A high-efficiency vehicular transmission is provided. The transmission includes a transmission housing, a set of torque delivery elements which include first and second elements supported for rotation within the housing and an electric motor for changing angular velocity of at least one of the elements in response to an electrical signal during a shift to obtain a desired transmission ratio. At least one non-friction controllable coupling assembly has a coupling state for coupling the first element to either the second element or the housing and an uncoupling state for uncoupling the first element from either the second element or the housing, respectively. The at least one coupling assembly is non-hydraulically controlled to change state to maintain the desired transmission ratio.

Owner:MEANS IND INC

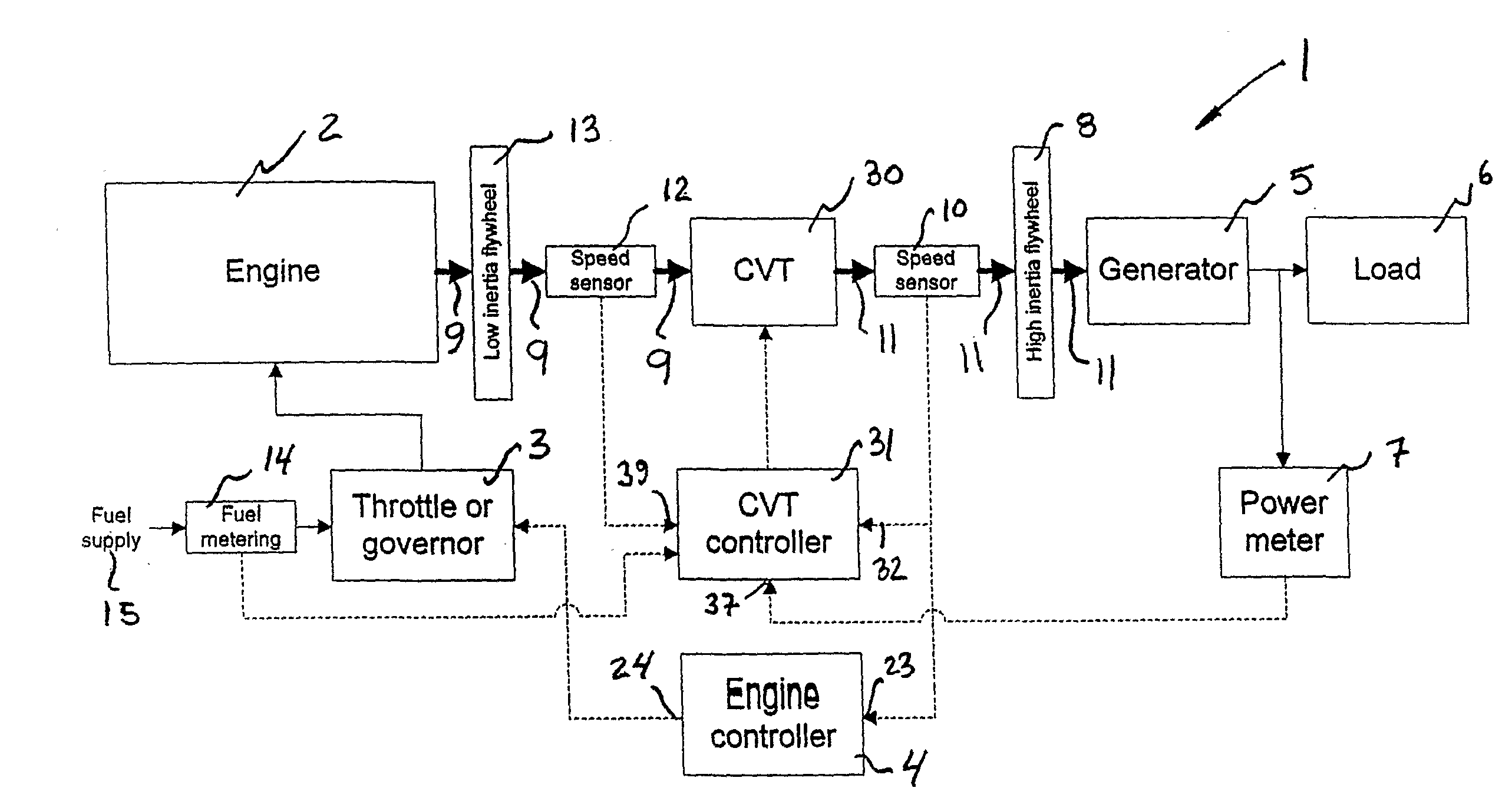

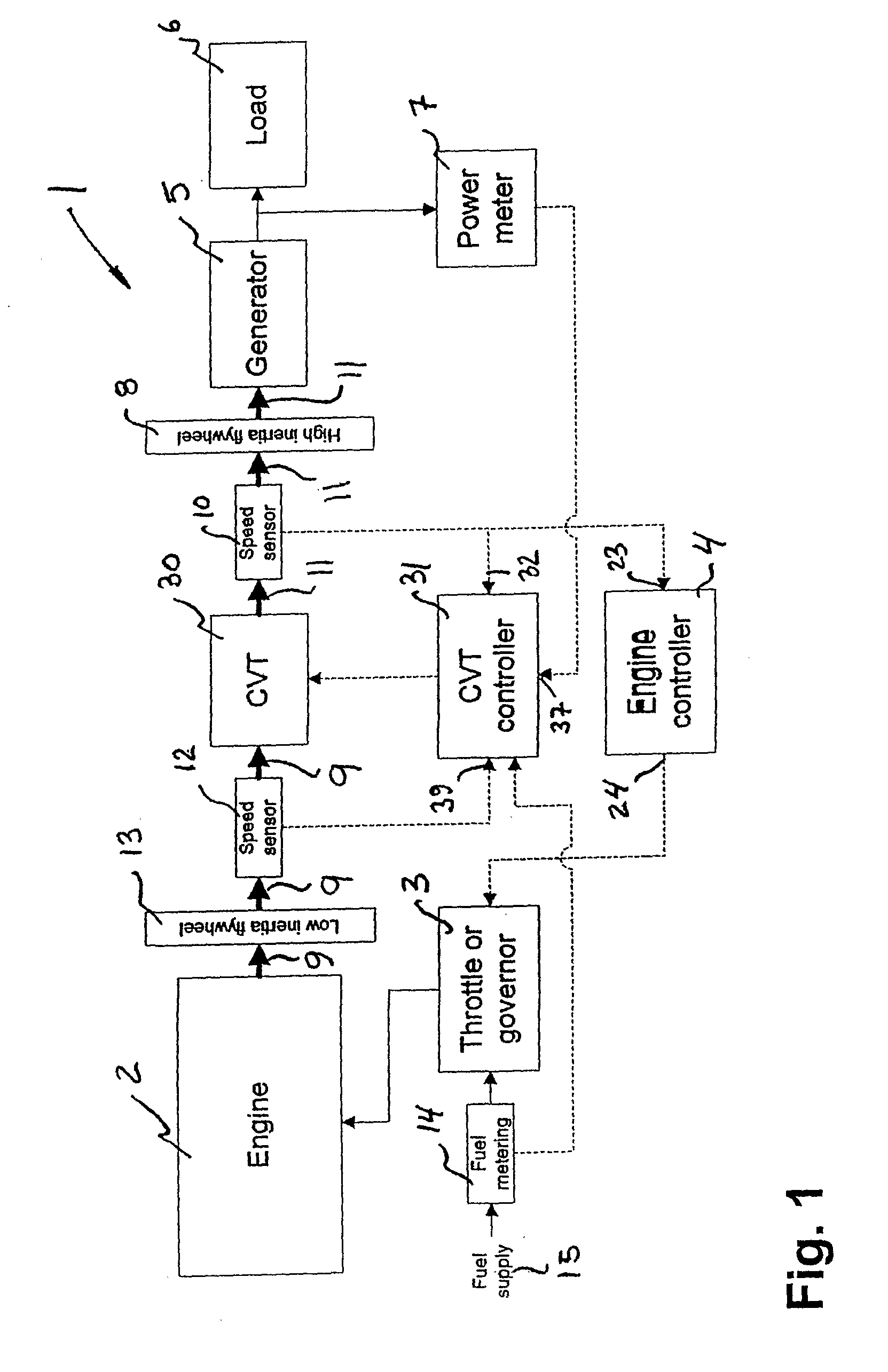

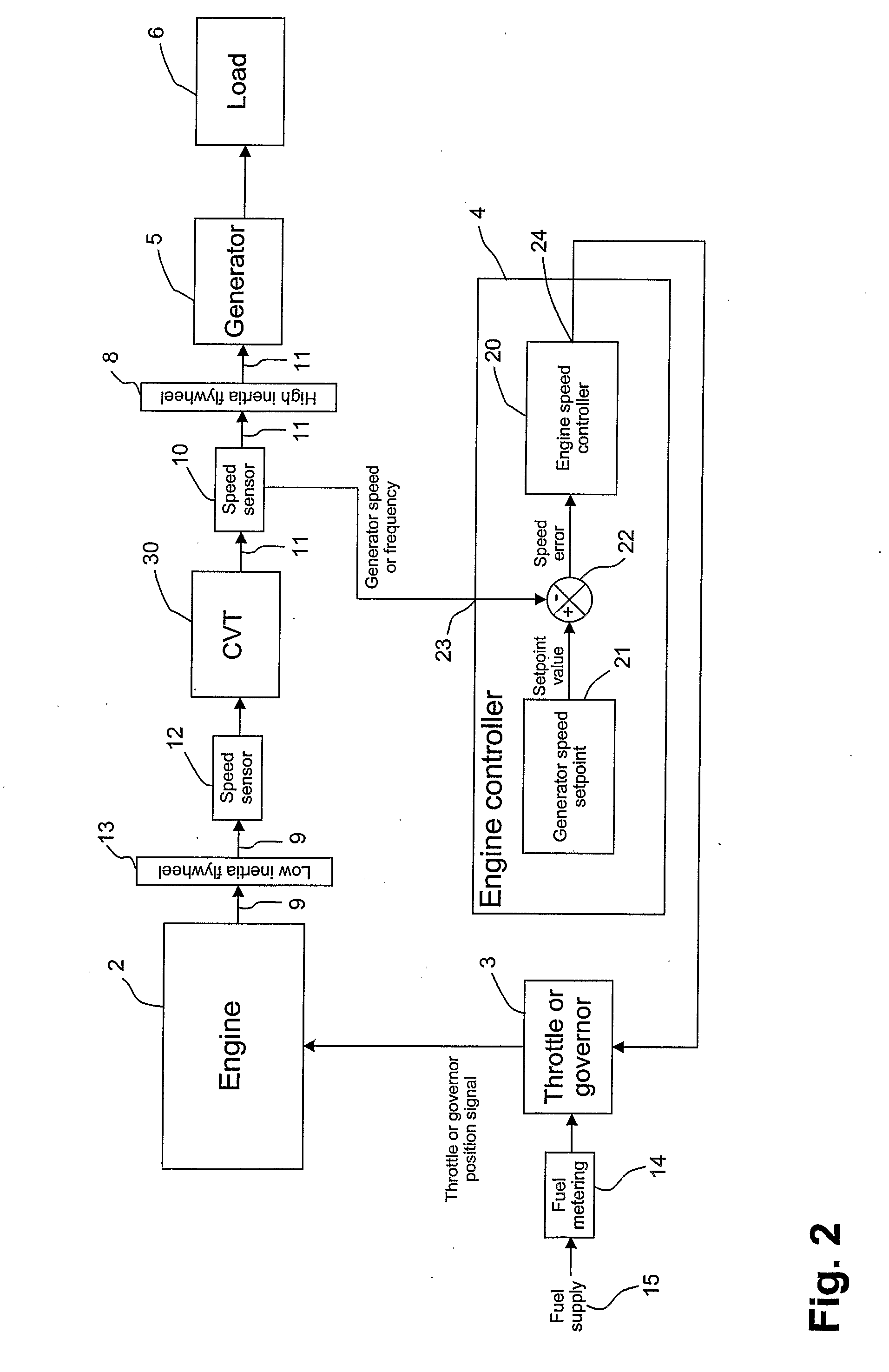

Steady-state and transitory control for transmission between engine and electrical power generator

InactiveUS20090023545A1Improve efficiencyDigital data processing detailsGearing controlSet pointElectric generator

A system (1) for transforming a variable output into an input having a desired speed value, including a transmission (30) receiving the output having a first speed (Ve) and producing the input having a second speed (Vgen), first, second and third sensors (12,10,7) producing data (39,32,37) corresponding to the first speed (Ve), second speed (Vgen) and a power demand (Pdem) for the input, a ratio set point controller (34), a ratio controller (36) and a speed controller (4). The ratio set point controller (34) receives the data (39,32,37) and calculates an available power (Pav), a stability level of the system (S,U1,U2), a desired value for the first speed (Ve), and a desired value and rate of change for the transmission ratio. The ratio controller (36) interfaces the ratio set point controller (34) and actuates the transmission (30) to change the transmission ratio to the desired value following the desired rate of change. The speed controller (4) changes the first speed (Ve) until the second speed (Vgen) corresponds to the desired speed value.

Owner:S O E TECH

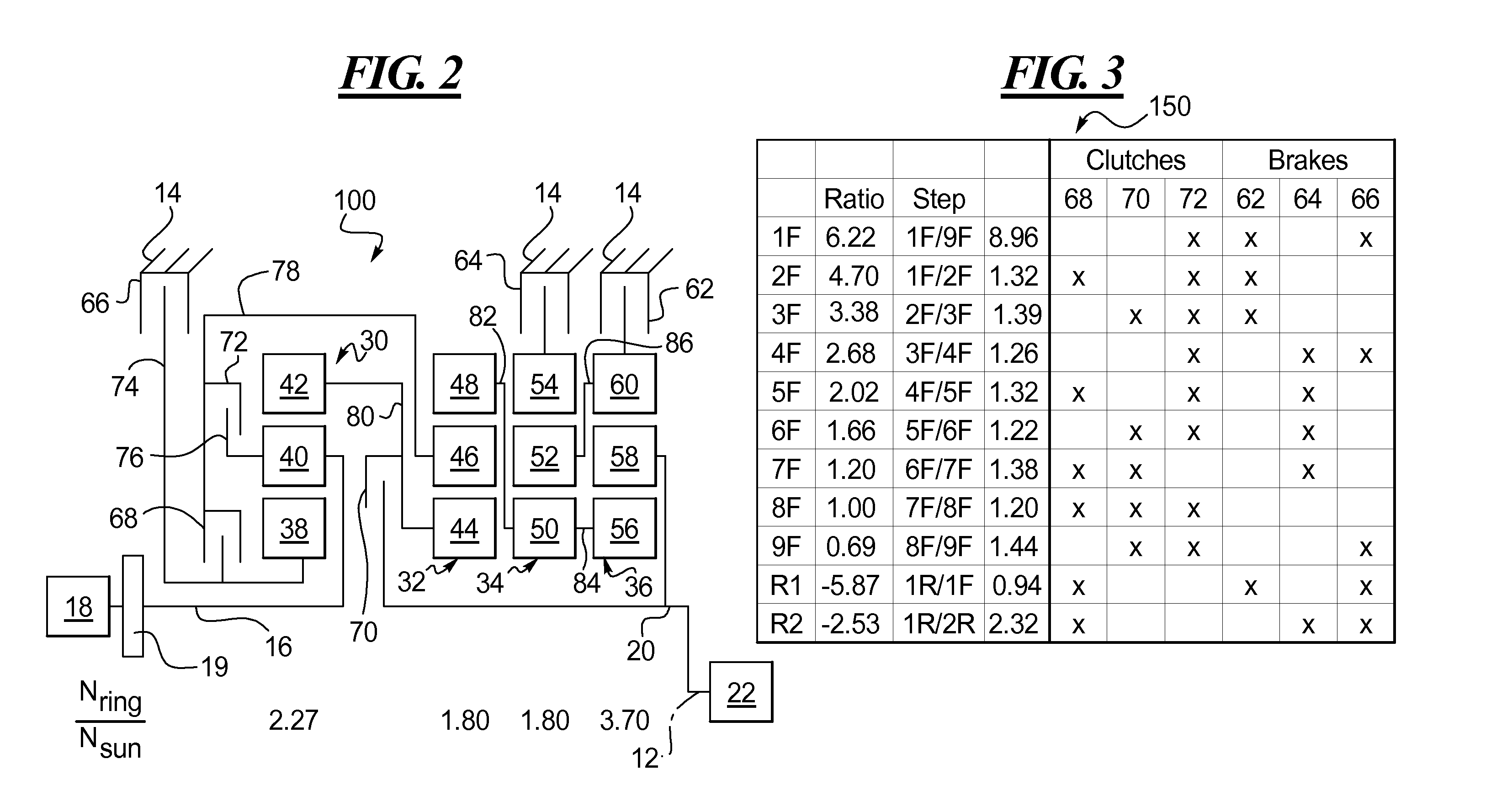

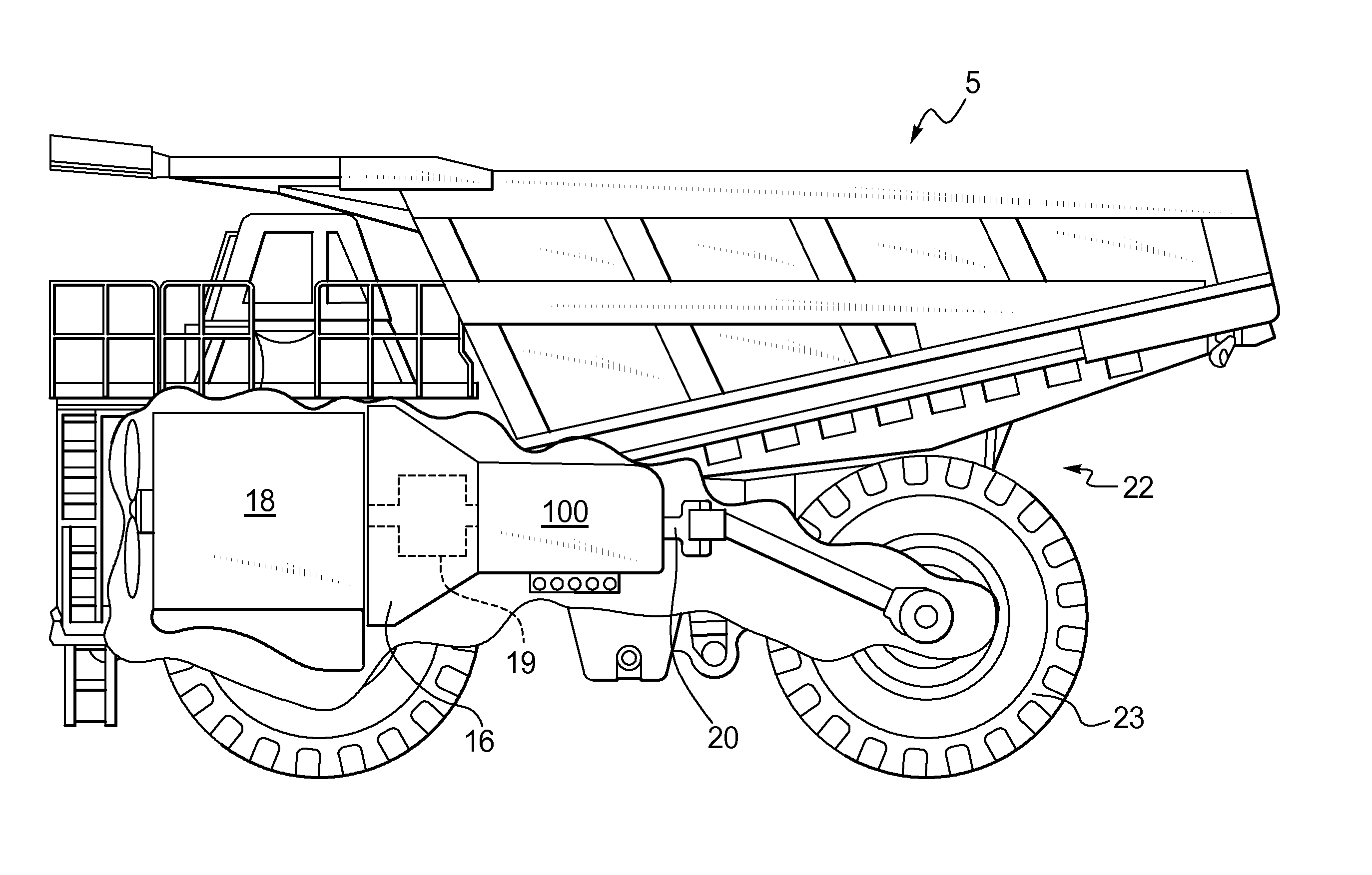

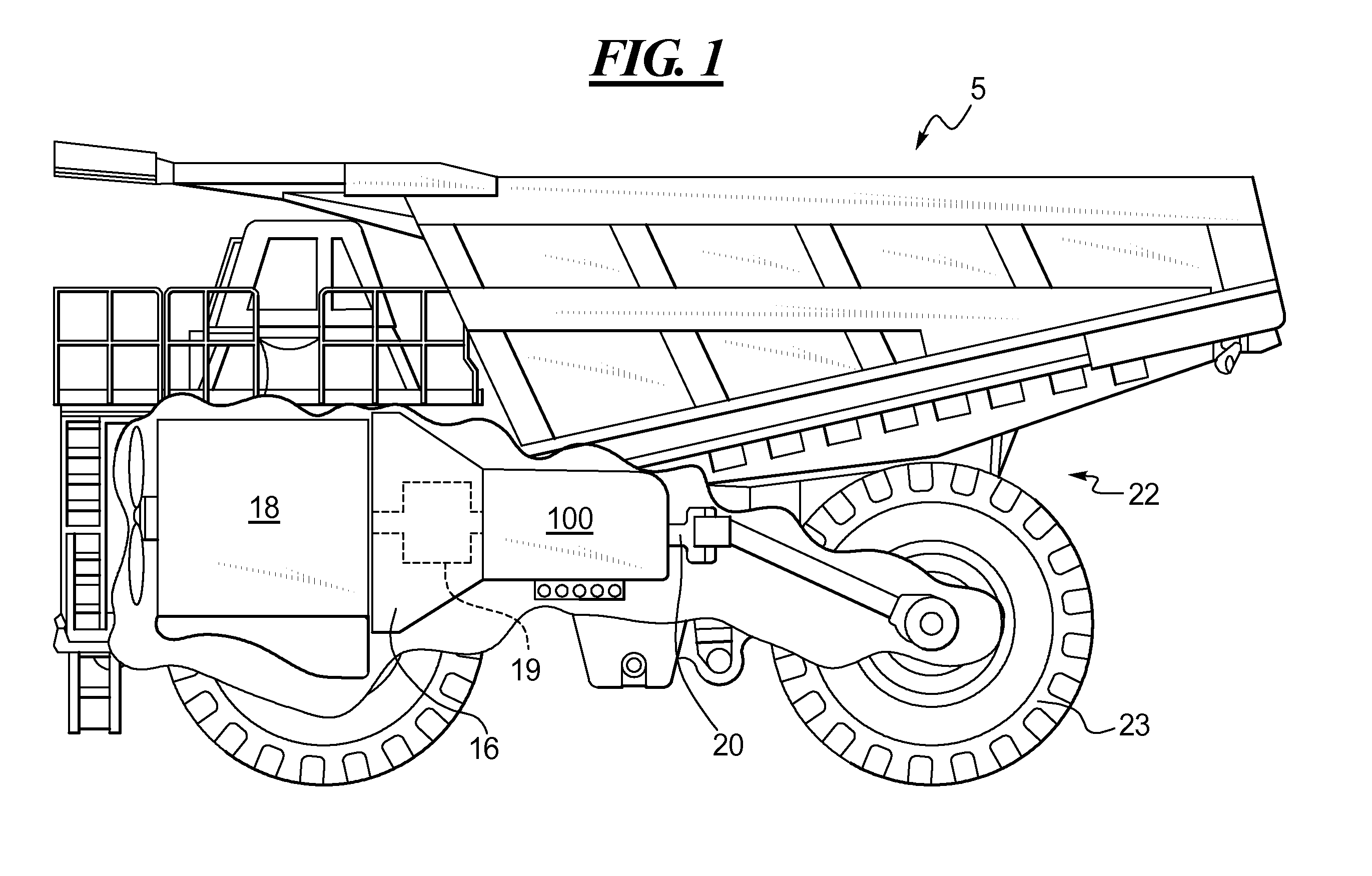

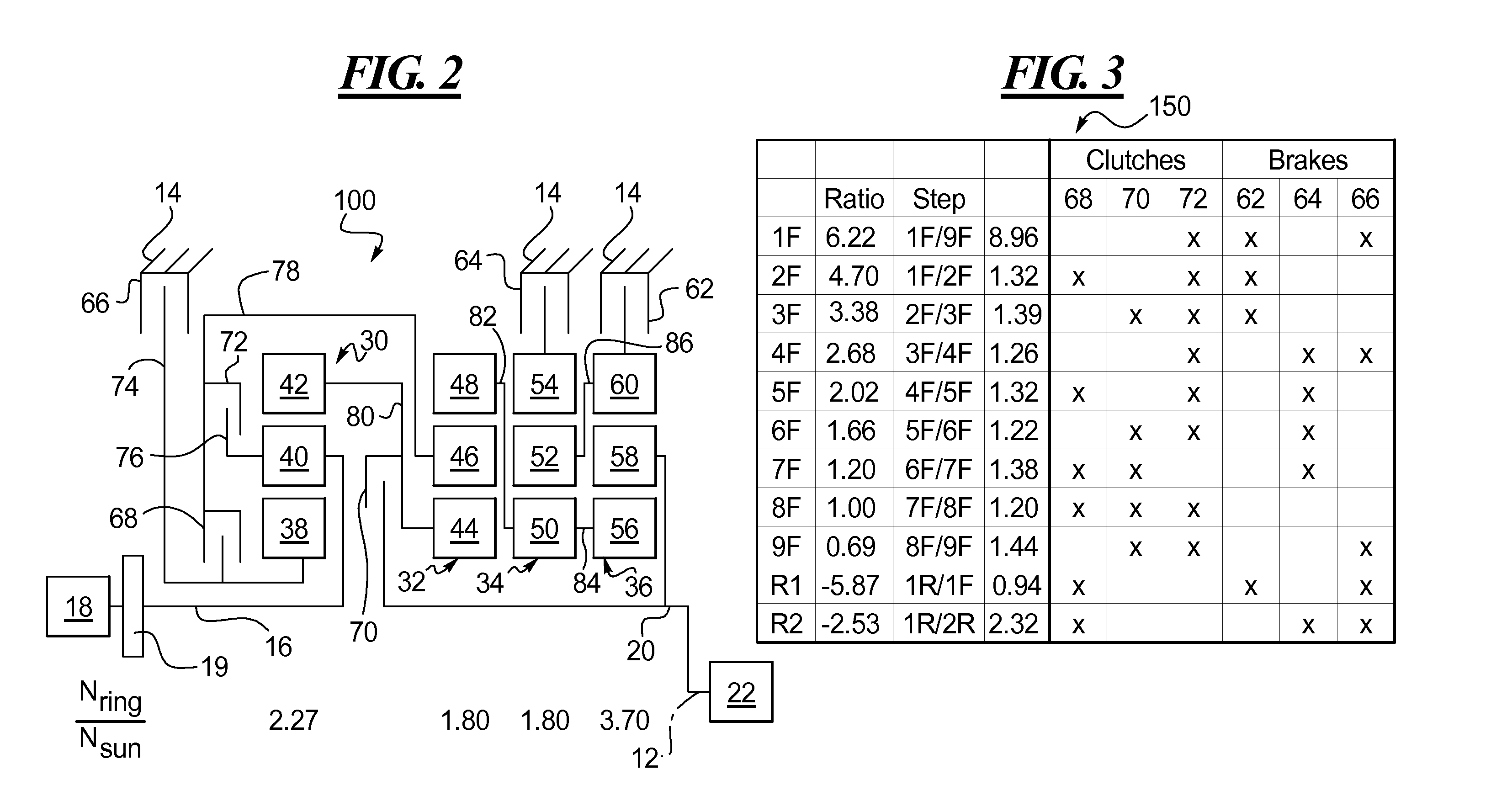

Multi-Speed Transmission

A multi-speed transmission may include an input member and an output member disposed in a housing. A first planetary gear set, a second planetary gear set, a third planetary gear set, and a fourth planetary gear set may also be disposed in the housing, each planetary gear set including a sun gear, a planet carrier, and a ring gear. Six control elements may be operably coupled to the planetary gear sets and selectively engageable to create a set of different gear ratios between the input member and the output member, the set of different gear ratios including at least nine forward gear ratios and at least two reverse gear ratios.

Owner:CATERPILLAR INC

Multi-speed transmission

Owner:CATERPILLAR INC

Continuously variable transmission

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

Transmission

Owner:JATCO LTD

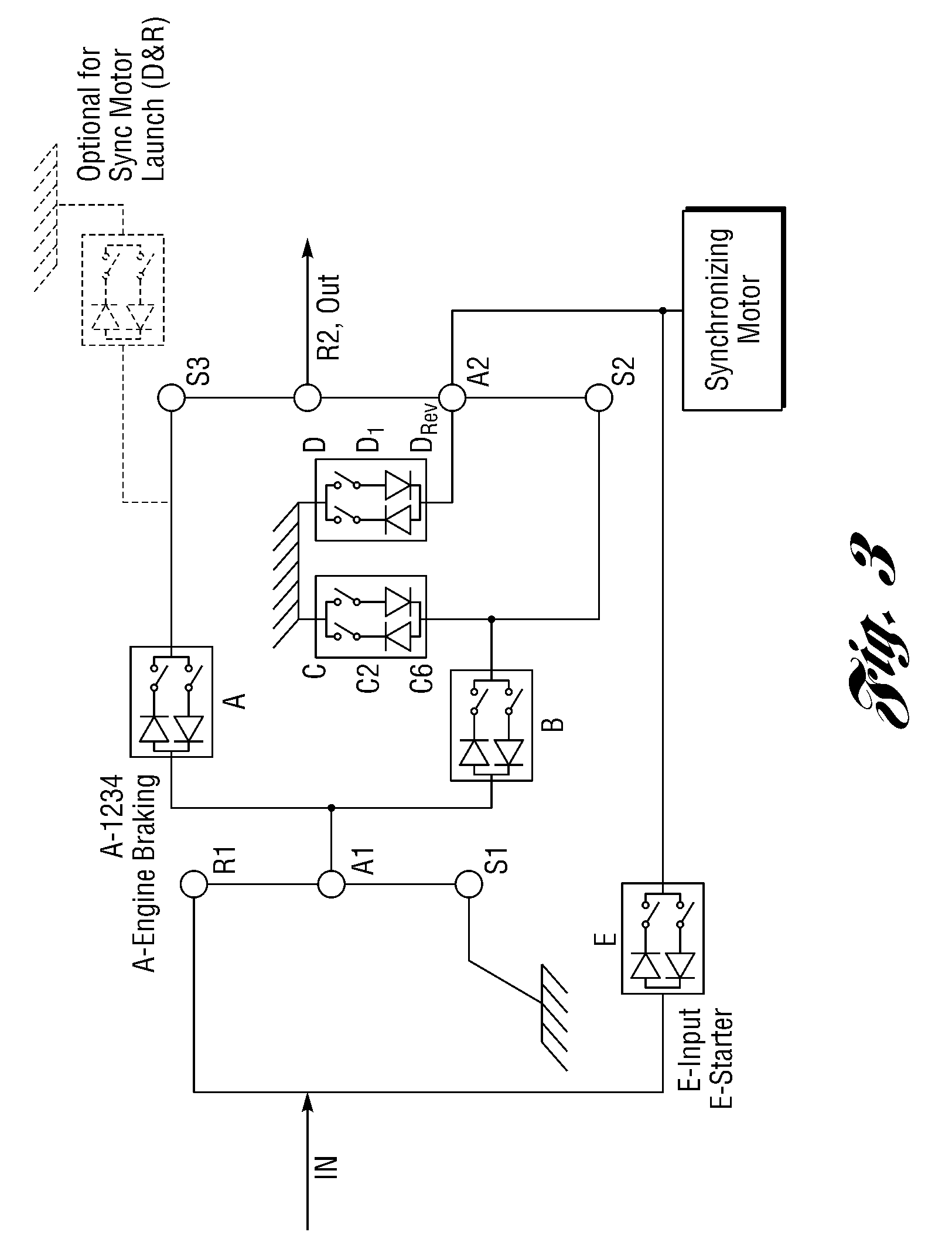

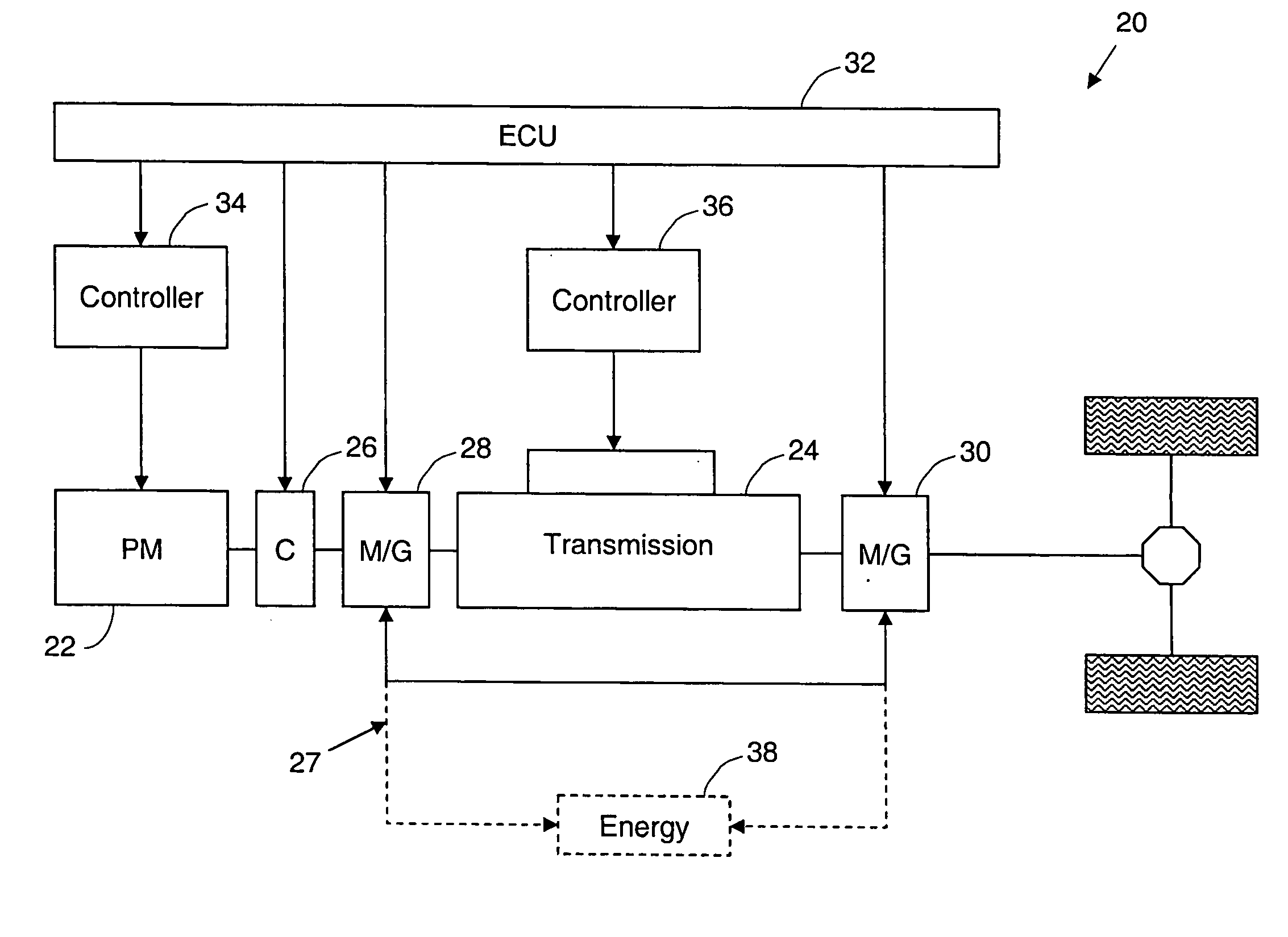

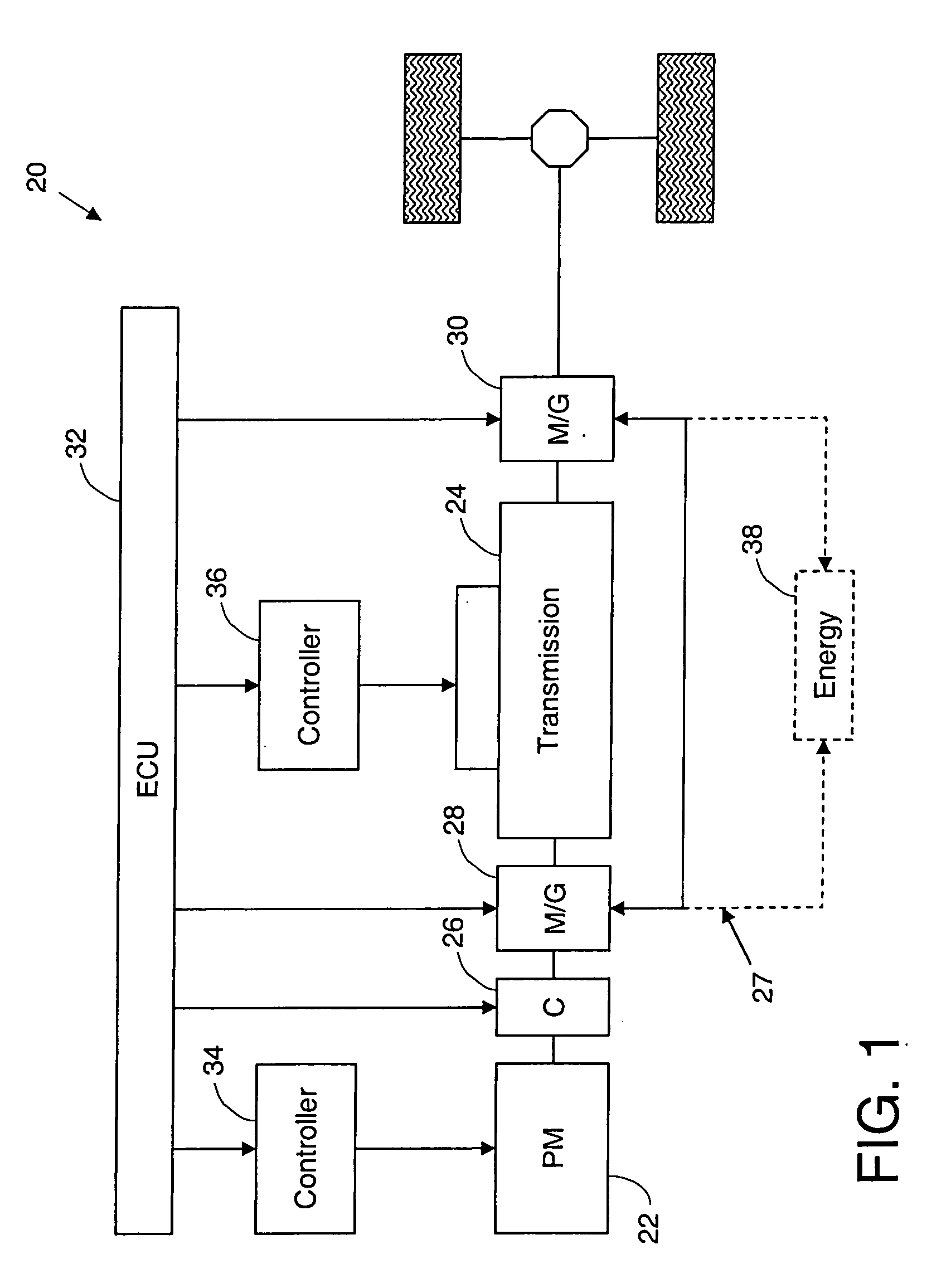

Hybrid powertrain system including smooth shifting automated transmission

InactiveUS20050164827A1Easy transferElectric propulsion mountingGas pressure propulsion mountingDrivetrainHybrid powertrain

A powertrain system is provided that includes a prime mover and a change-gear transmission having an input, at least two gear ratios, and an output. The powertrain system also includes a power shunt configured to route power applied to the transmission by one of the input and the output to the other one of the input and the output. A transmission system and a method for facilitating shifting of a transmission system are also provided.

Owner:EATON CORP

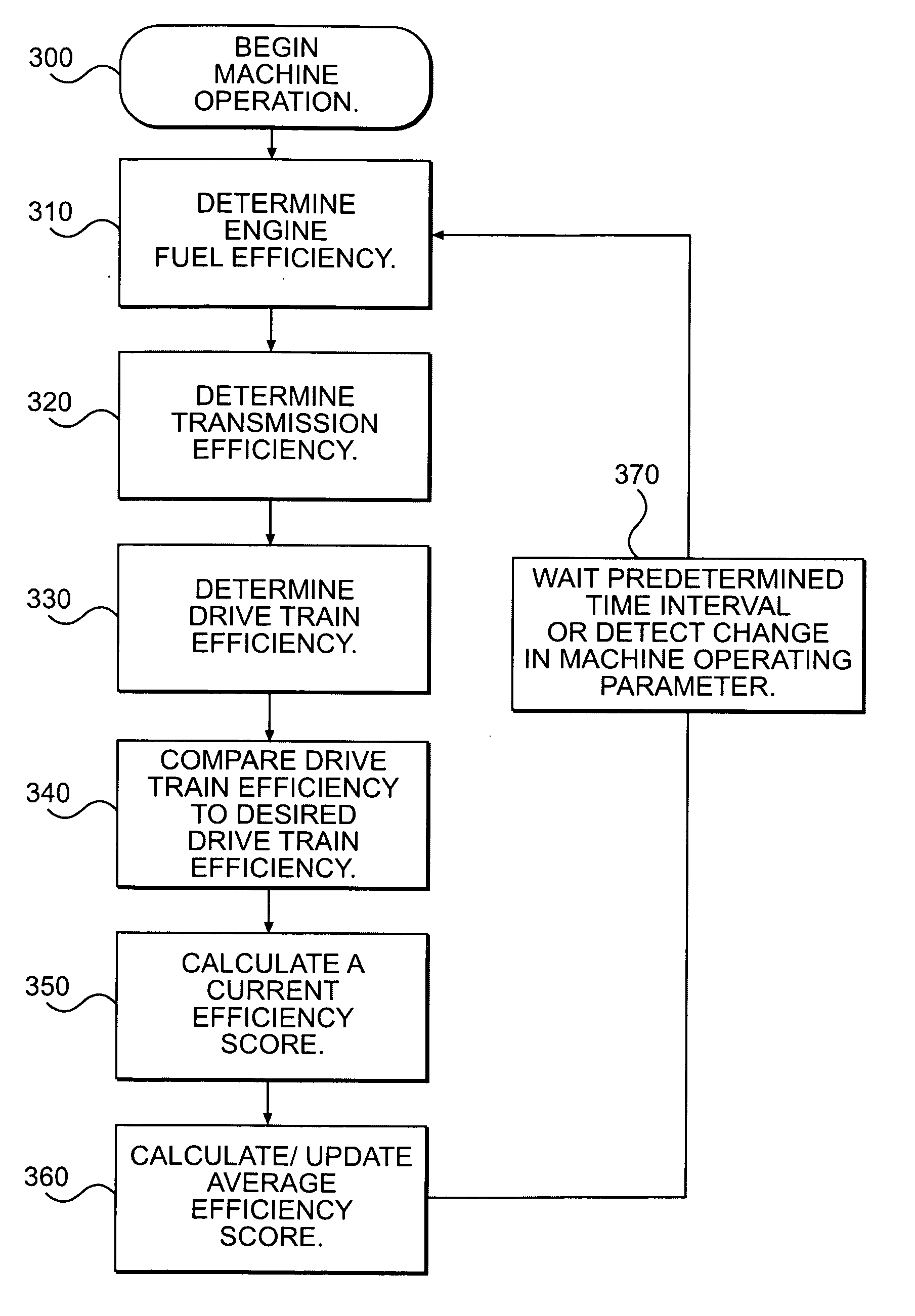

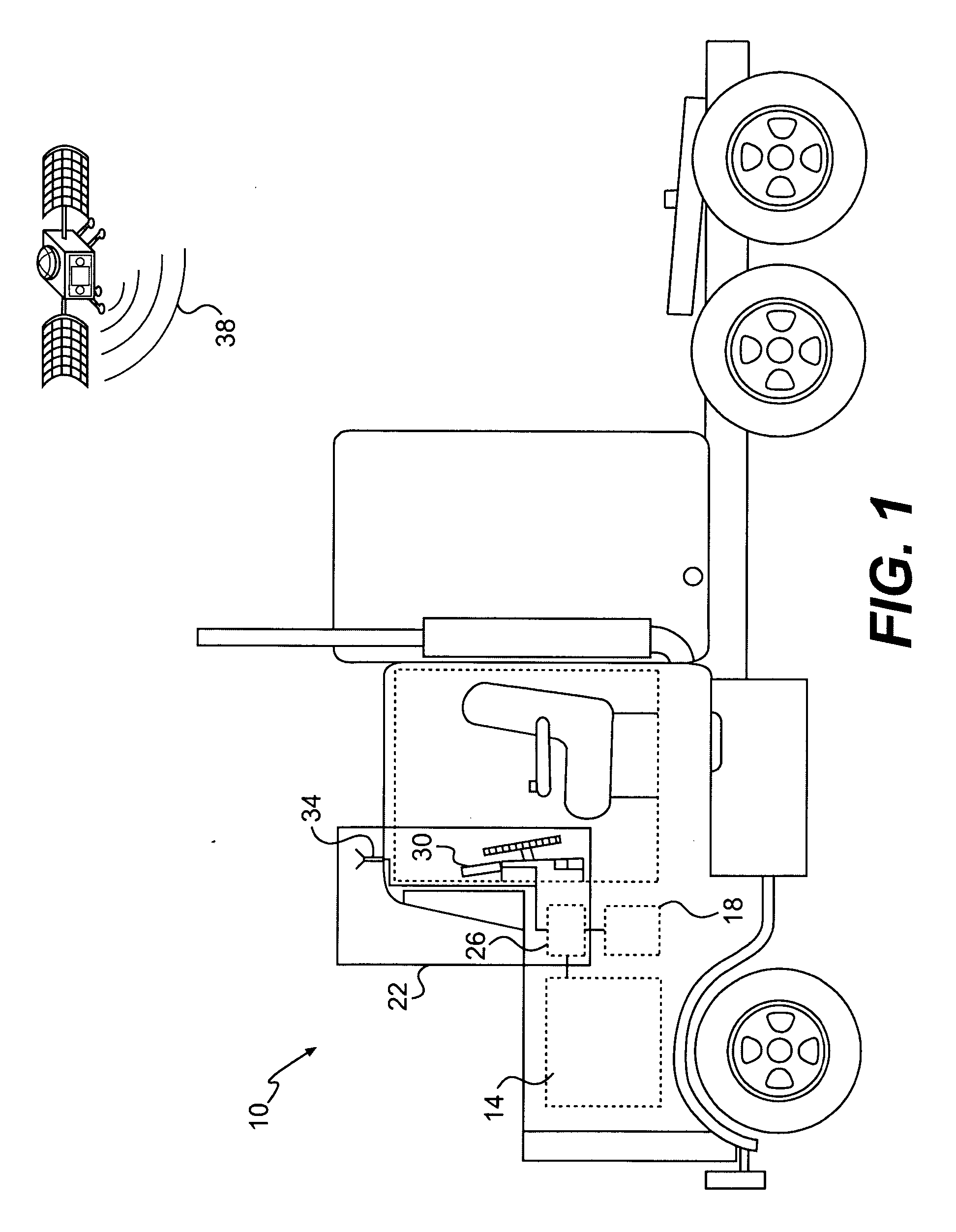

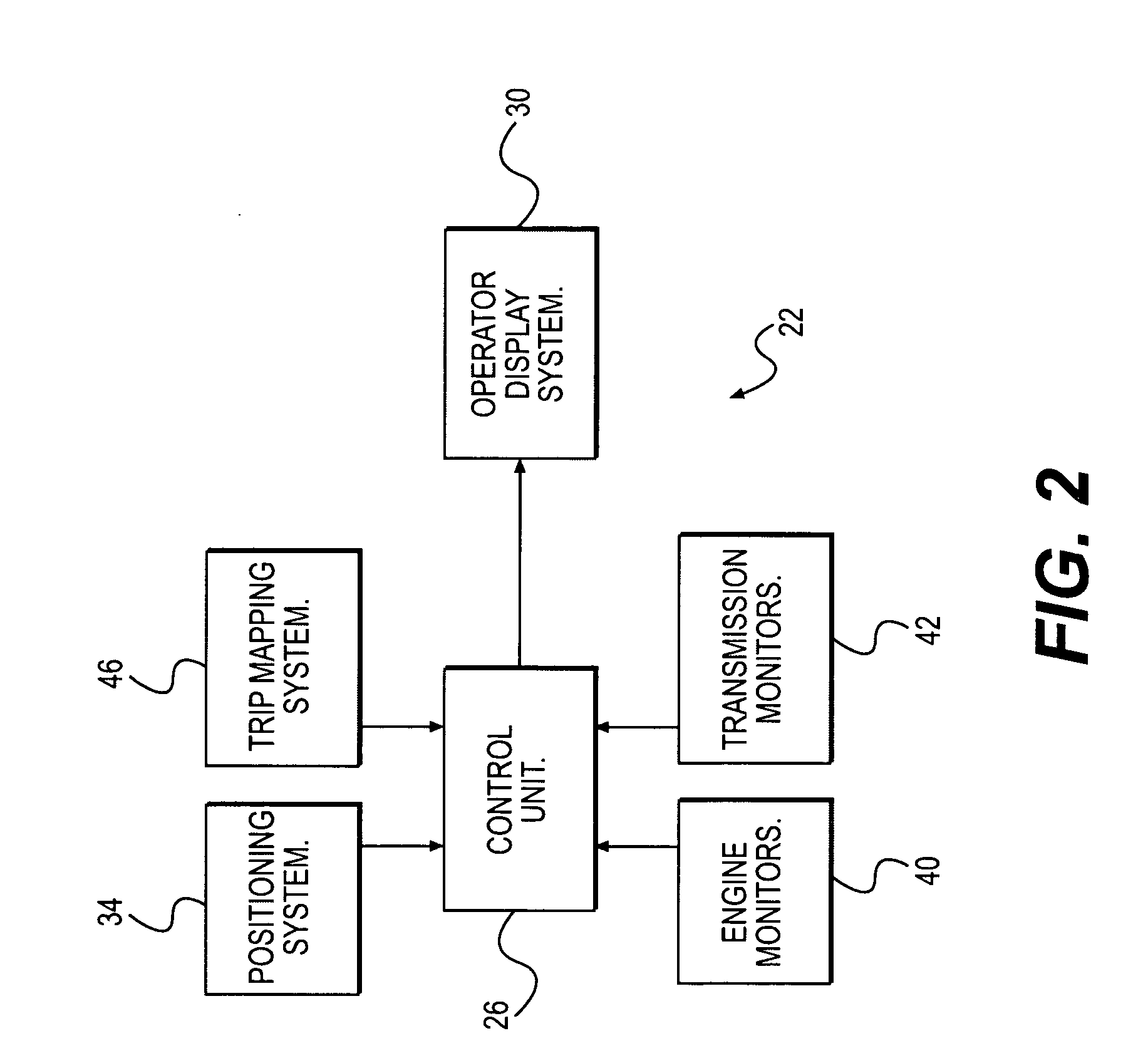

System for evaluating and improving driving performance and fuel efficiency

InactiveUS20070143002A1Analogue computers for vehiclesAnalogue computers for trafficFuel efficiencyMotor fuel

A method for monitoring driving performance is provided. The method may include determining an engine fuel efficiency based on an engine speed and power output and determining a transmission fuel efficiency based on a drive ratio. A drive-train fuel efficiency may be determined based on the engine fuel efficiency and transmission fuel efficiency, and the drive-train efficiency may be compared to a target drive-train efficiency.

Owner:CATERPILLAR INC

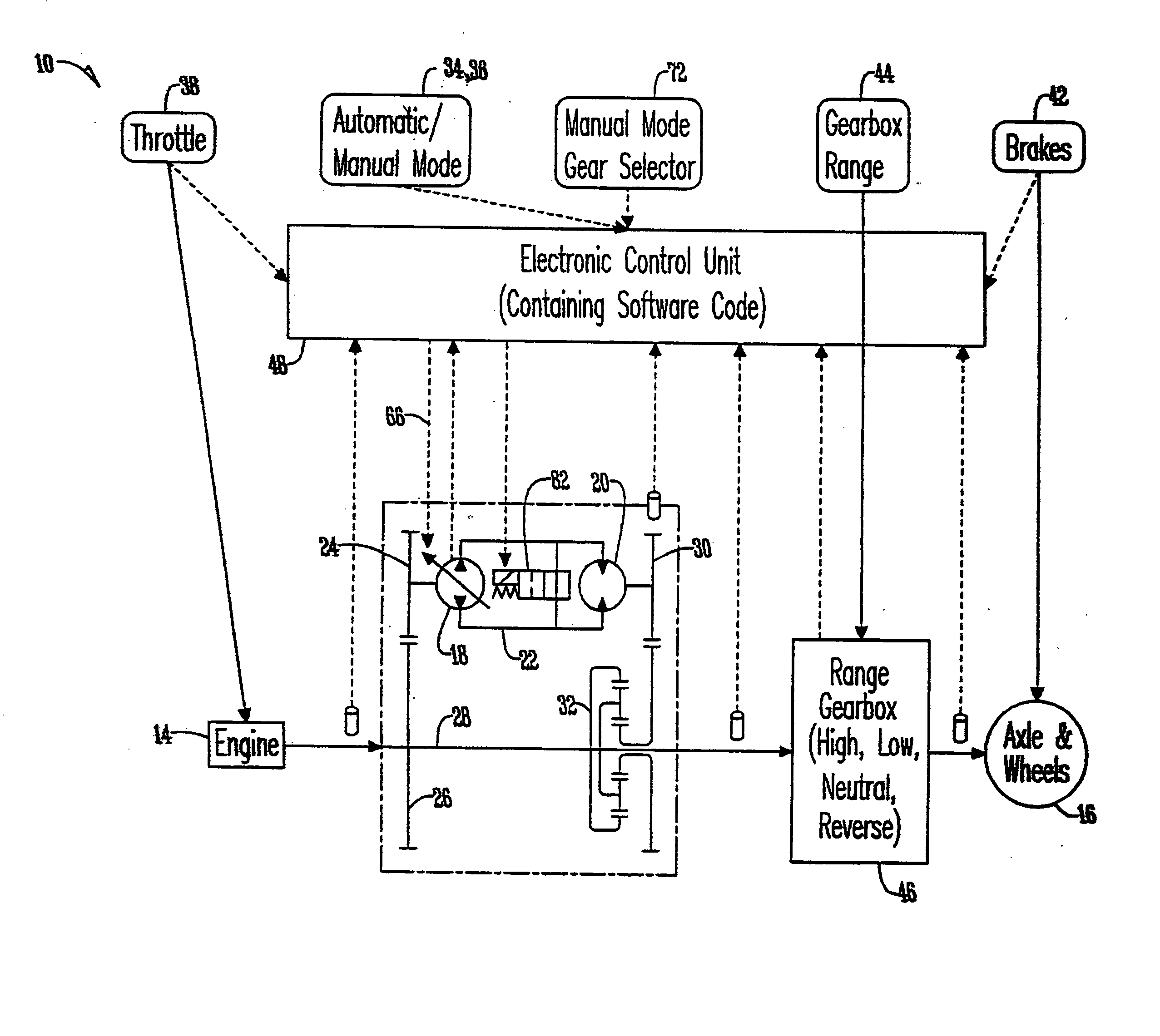

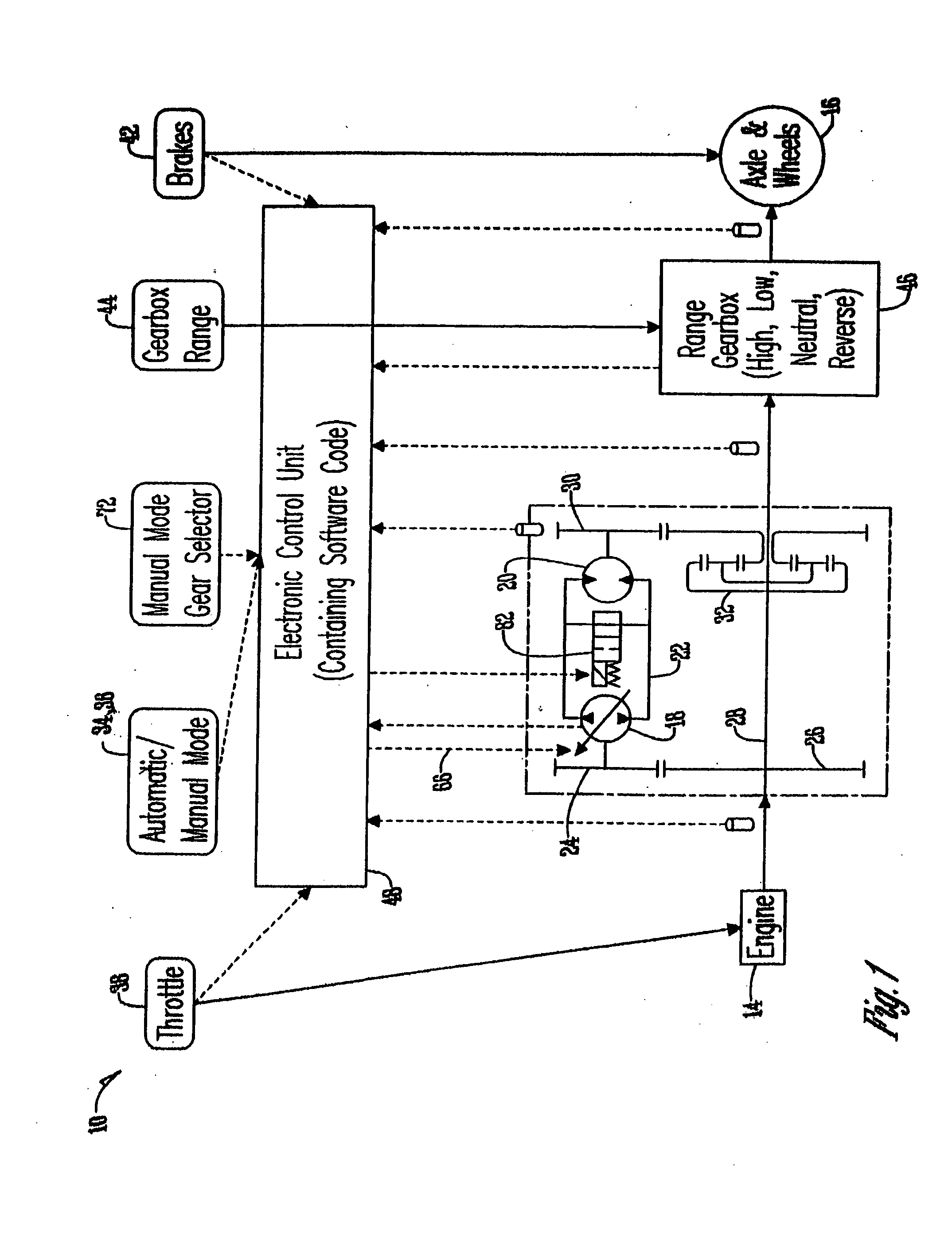

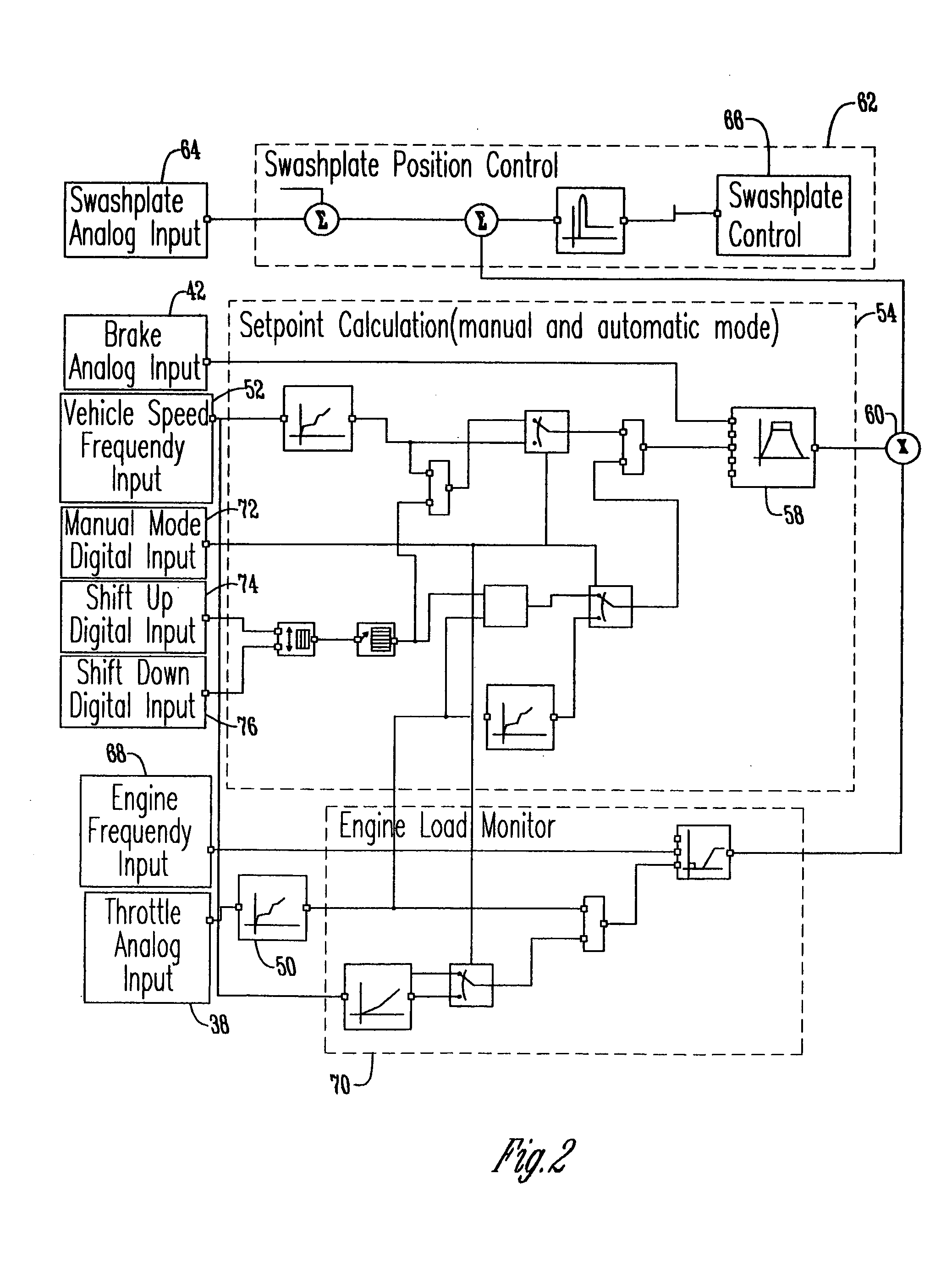

Hydromechanical transmission electronic control system for high speed vehicles

InactiveUS20050085979A1Quick changeSmooth conditionFluid couplingsVehicle fittingsElectronic transmissionElectronic control system

An electronic transmission control system is provided that can achieve a transmission ratio based on the operator inputs and the current vehicle operating conditions. The transmission constantly connects the engine to the load, and the transmission ratio is only varied by a change in command from the present invention. The transmission's mechanical function is solely to vary the ratio between its input and output. In using the present invention, an operator must select an operating mode, either automatic or manual, using a two-position switch. While in the automatic mode, the present invention determines the vehicle speed by considering the position of the throttle and the operator's use of brakes. In the manual mode, the present invention further considers the operator's selection of a gear condition.

Owner:DANFOSS POWER SOLUTIONS INC

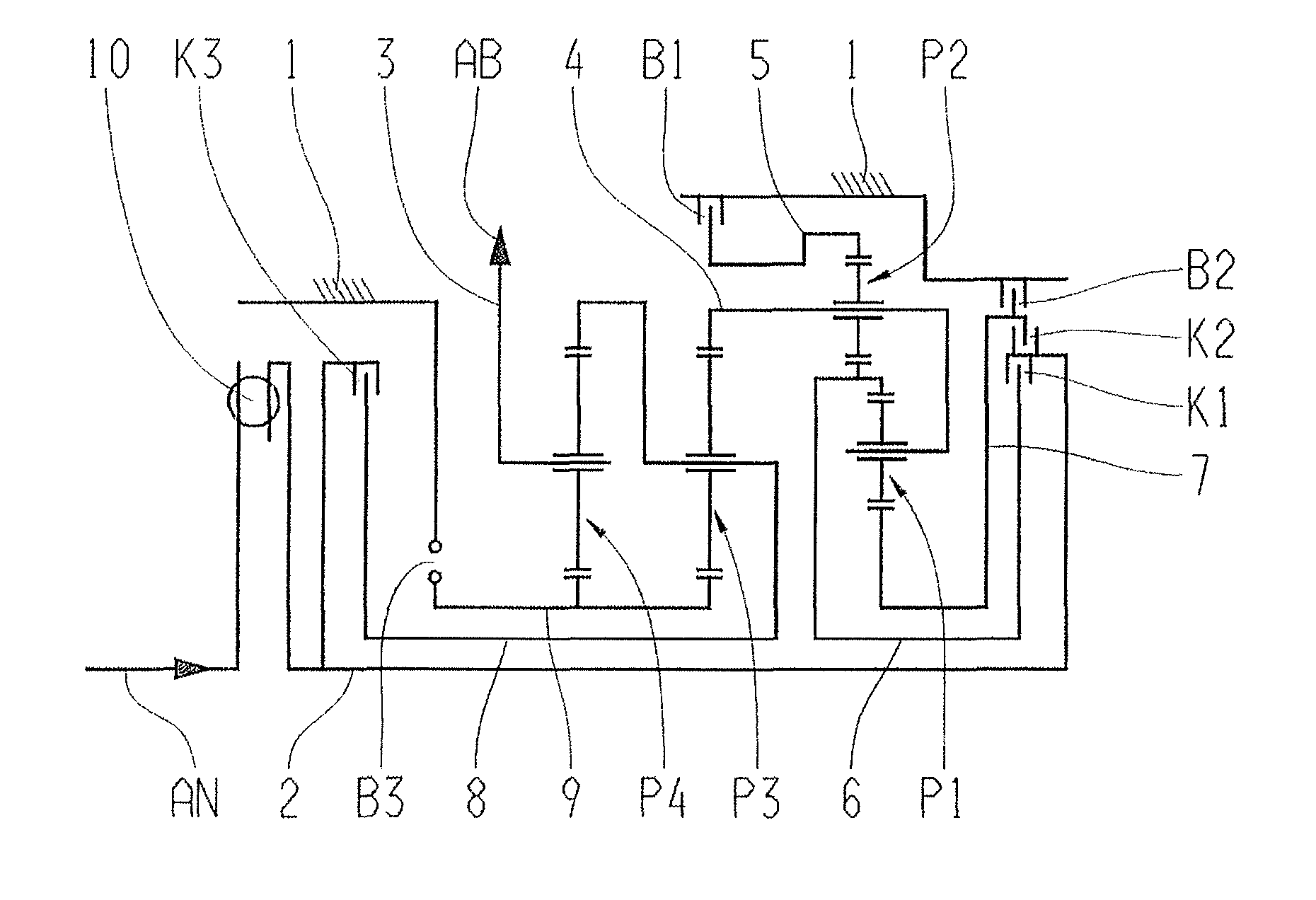

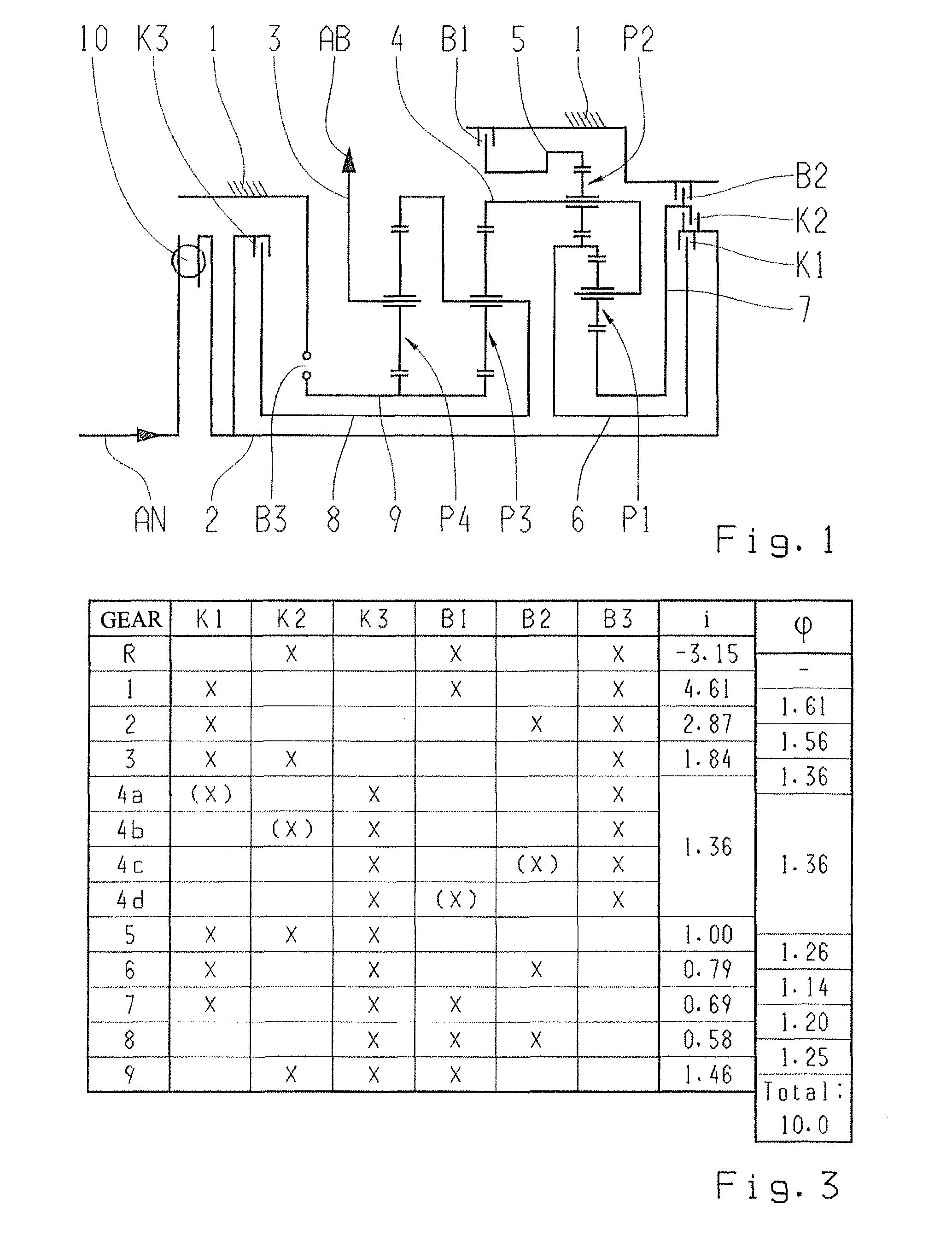

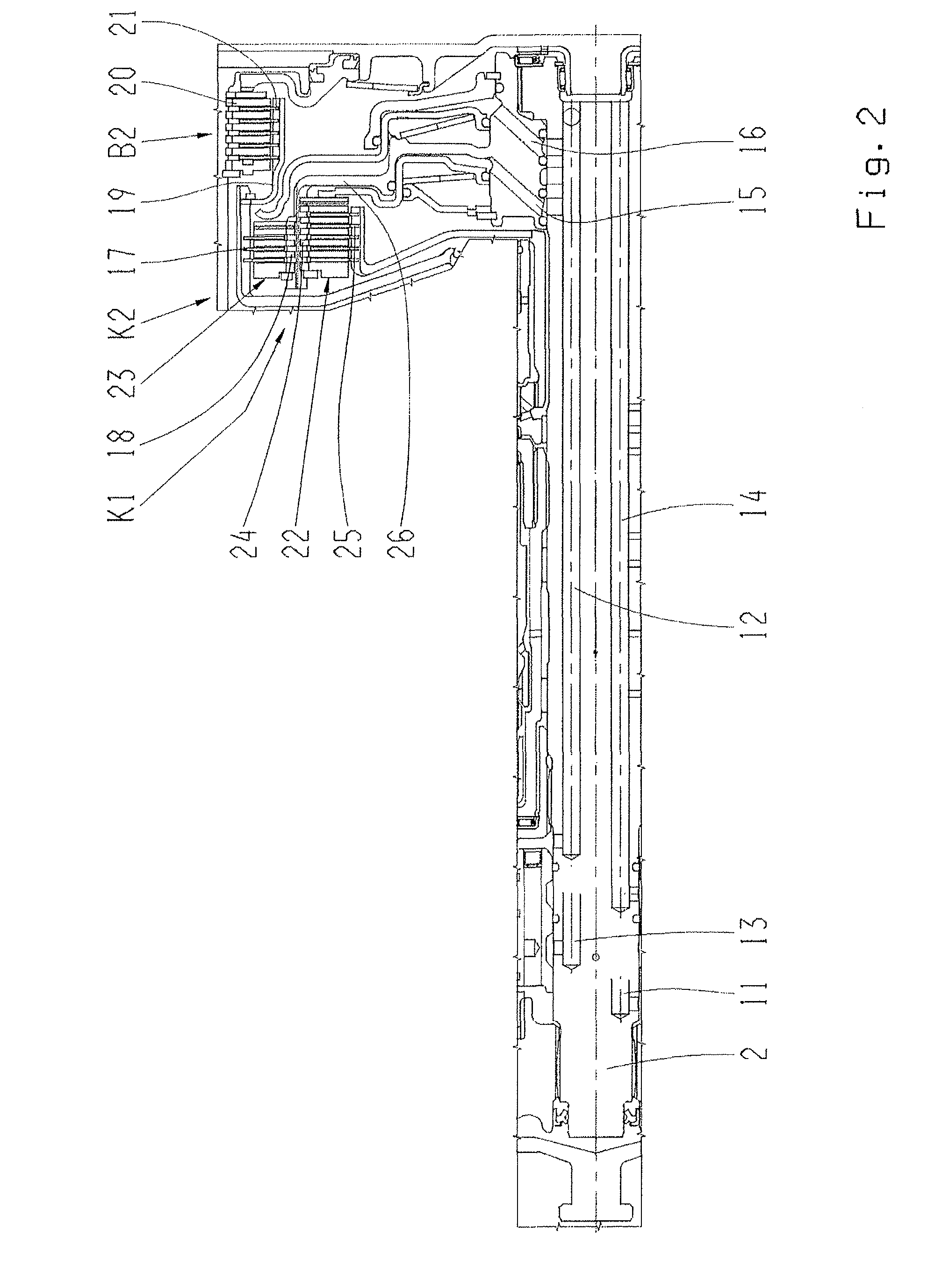

Planetary gear type multi-stage transmission

A motor vehicle multi-stage planetary transmission which has a housing that accommodates four planetary gear sets (P1, P2, P3, P4), shafts (2-9), three clutches (K1, K2, K3) and three brakes (B1, B2, B3) whose selective actuation implements various transmission ratios between drive and output shafts. The carriers of gear sets (P1, P2) are connected by shaft (4), the ring gear of gear set (P2) can be fixed to the housing, via shaft (5), by actuating brake (B1). A ring gear of gear set (P1) and a sun gear of gear set (P2) are coupled by shaft (6) which can be connected, via clutch (K1), to the drive shaft. A sun gear of gear set (P1) can be fixed, via brake (B2), to the housing and can be coupled, by clutch (K2), to drive shaft. The first and second clutches (K1, K2) are startup elements which initiate startup procedures.

Owner:ZF FRIEDRICHSHAFEN AG

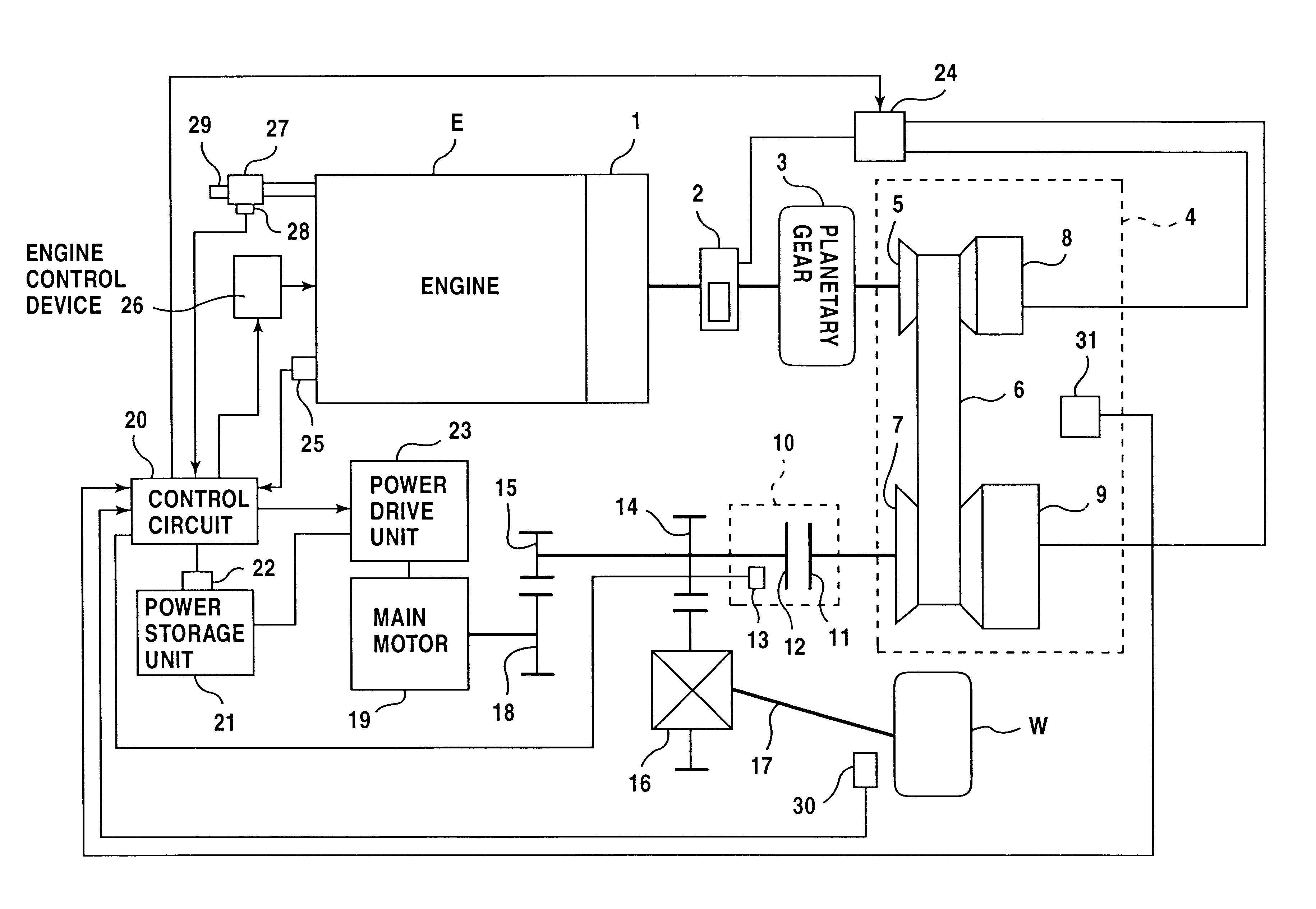

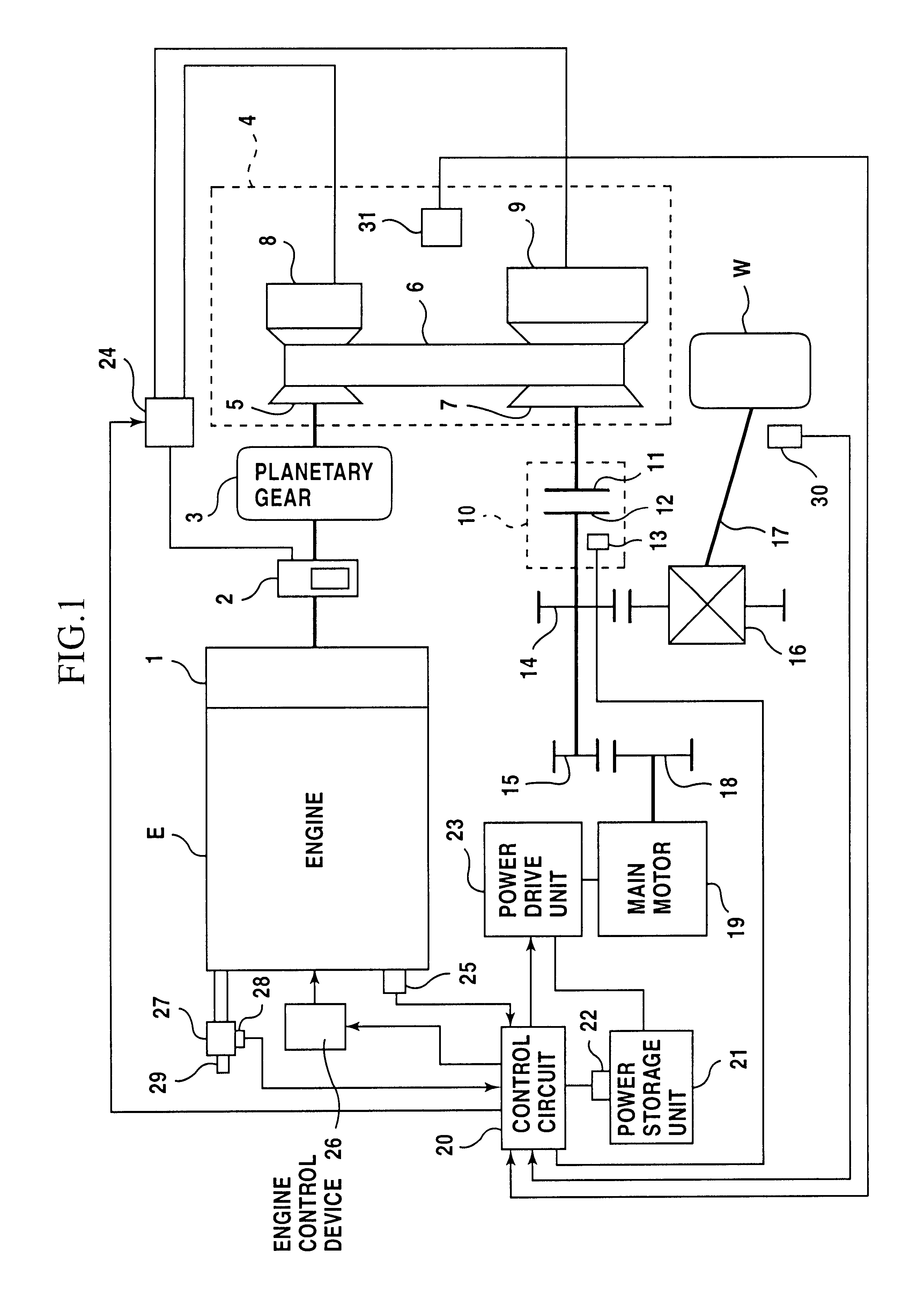

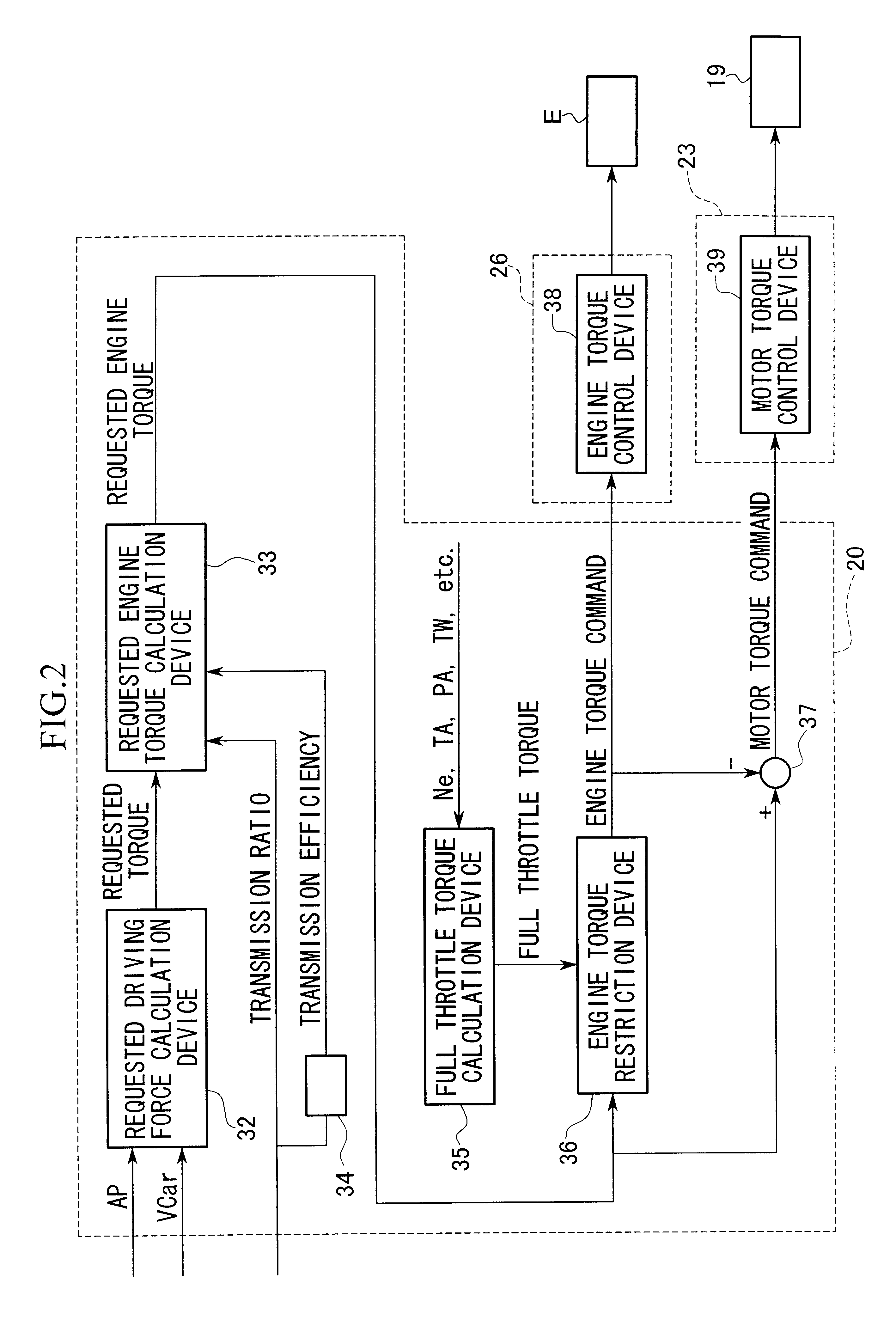

Control apparatus for hybrid vehicle

InactiveUS6359404B1Drive stabilityPoor responsivenessDC motor speed/torque controlDigital data processing detailsEngineeringHybrid vehicle

A control apparatus including a requestedtorque calculating device which calculates a torque requested for driving the hybrid vehicle; and a torque control device which controls a torque generated by an engine and a torque generated by an electric motor of the hybrid vehicle based on the requested torque calculated by the requested torque calculating device. The torque control device controls the electric motor so as to generate a torque obtained by subtracting a torque to be generated by the engine from the requested torque. Acoording to this control apparatus, if the responsiveness in changing the transmission ratio of the transmission is poor and the torque generated by the engine becomes lower than therequested torque, the electric motor is controlled to generate the deficient (supplementary) torque, and smooth acceleration of the vehicle can be performed.

Owner:HONDA MOTOR CO LTD

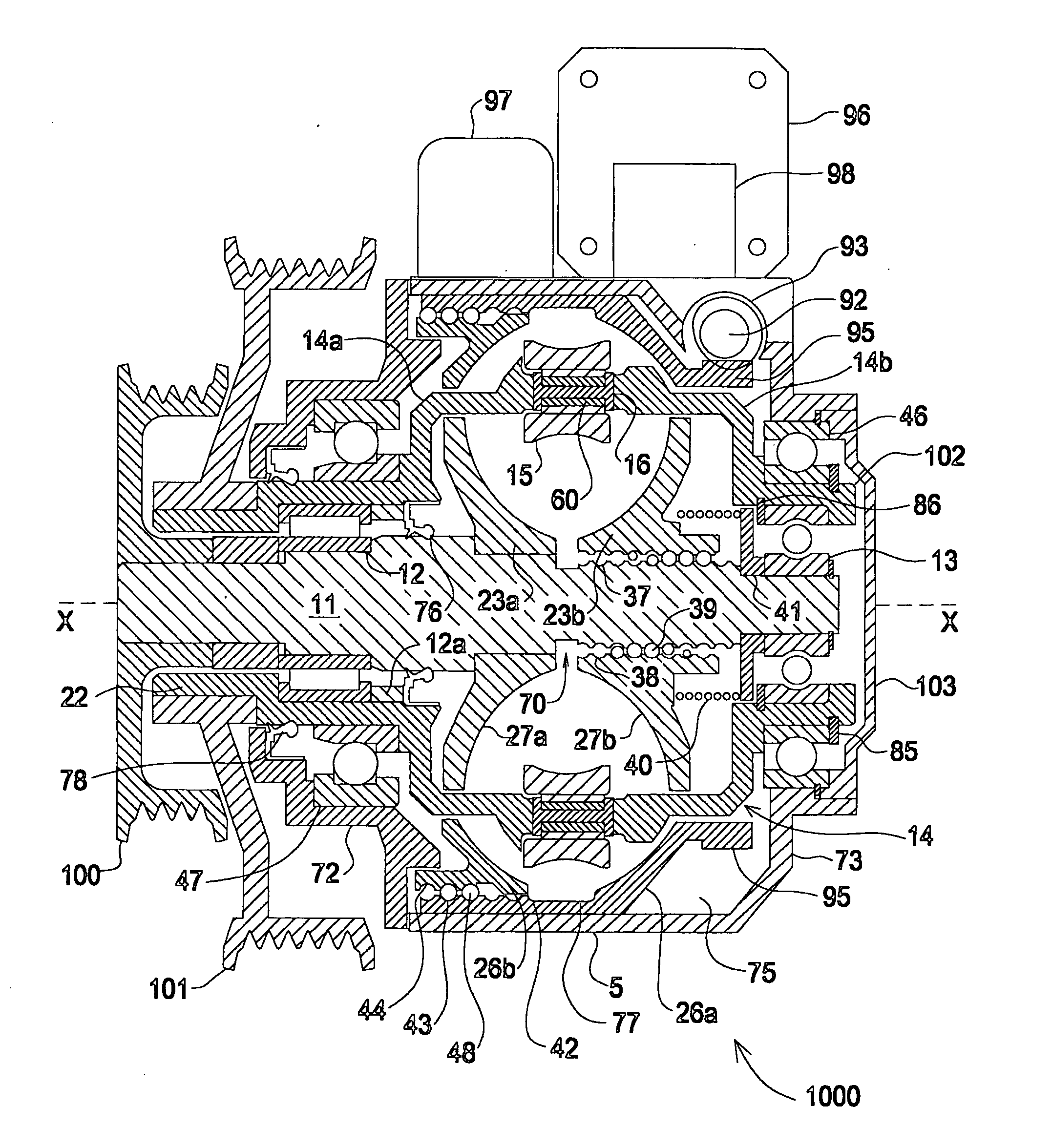

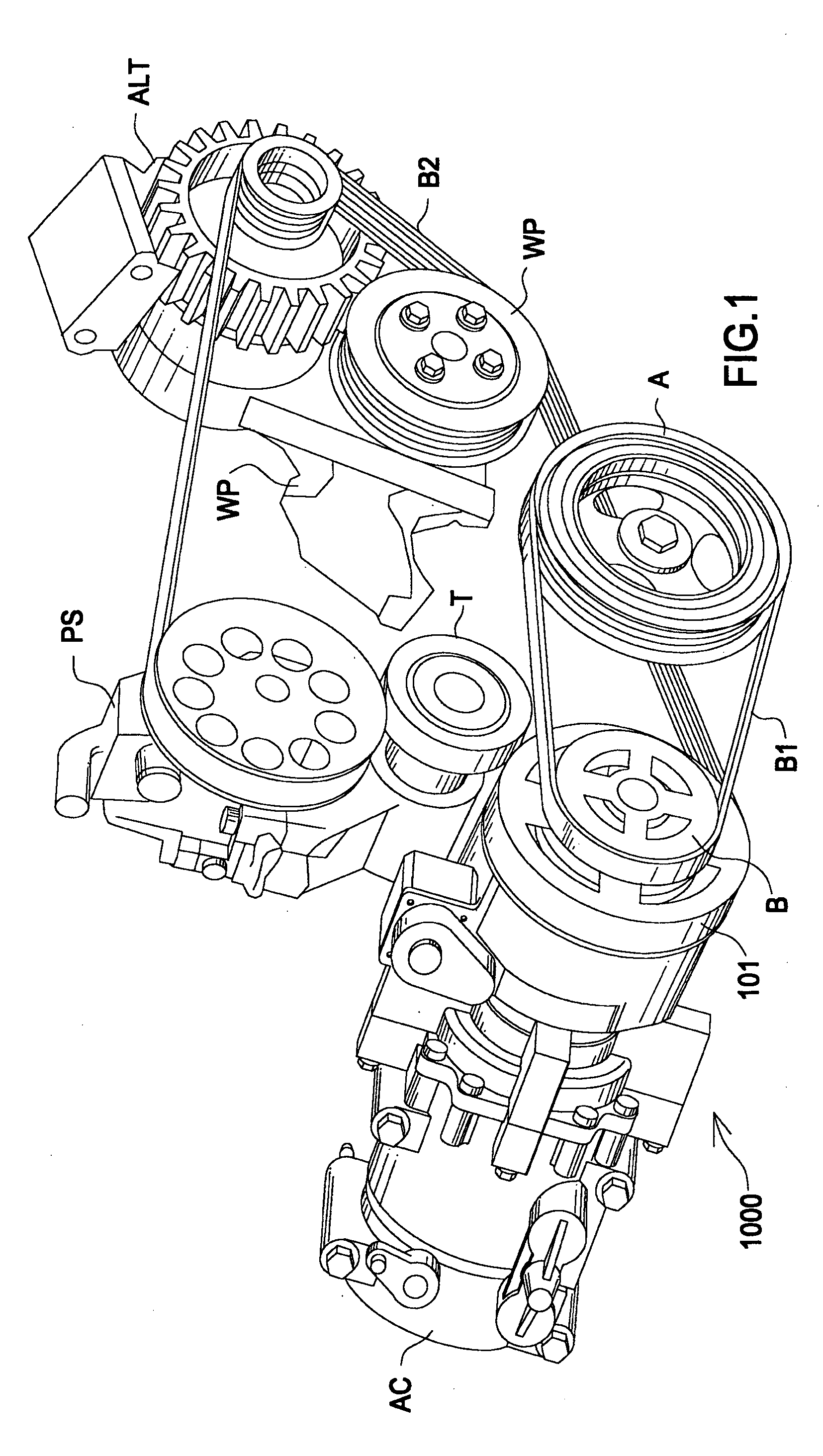

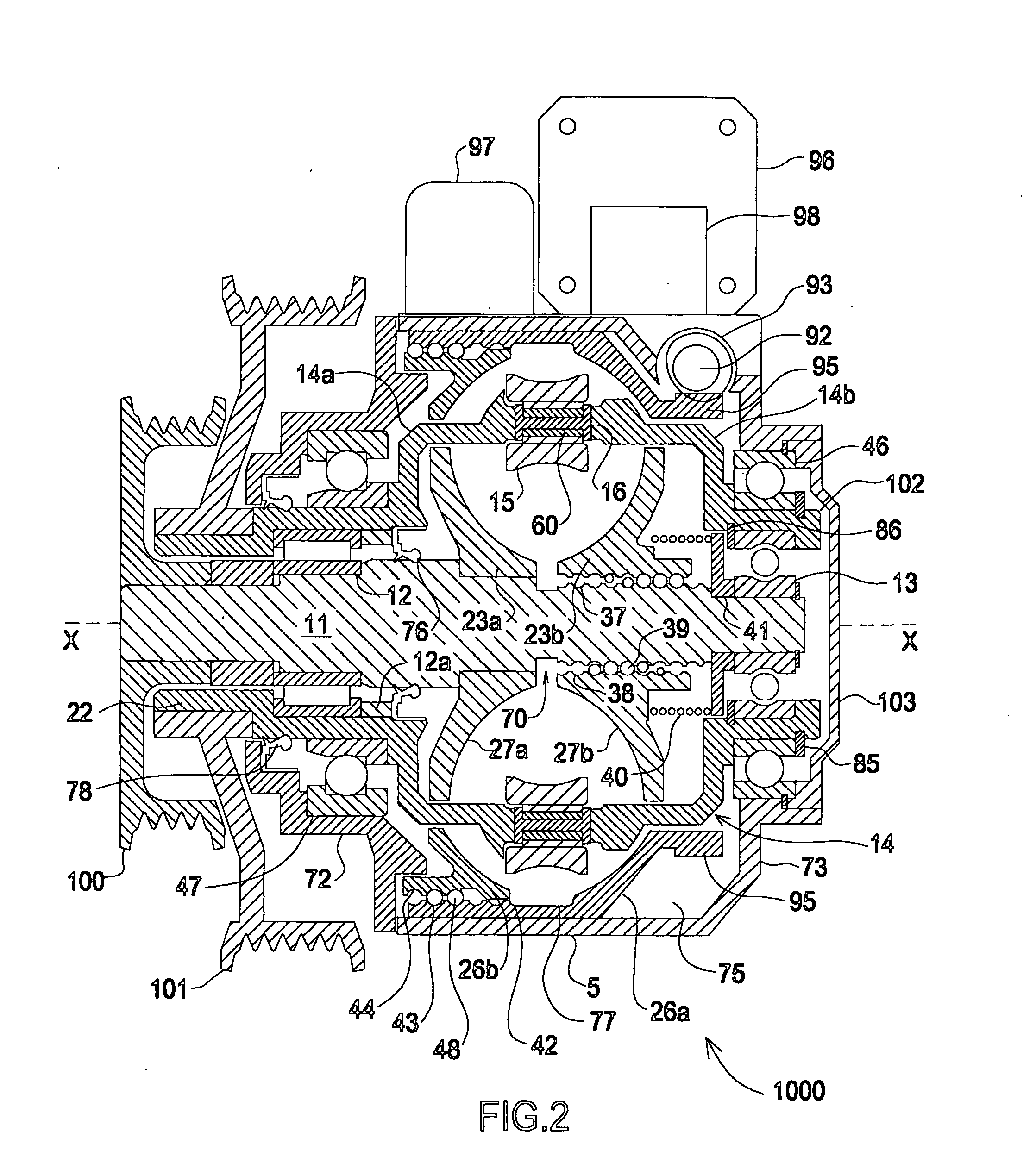

Transmission and constant speed accessory drive

InactiveUS20050181905A1Constant output speedGearing controlFriction clutchesControl systemDirect coupling

An infinitely variable speed ratio planetary ball transmission comprising planetary members in rolling contact with moveable inner and outer races and a constant speed accessory drive system utilizing the transmission. The transmission is infinitely variable between ratios of approximately 0.3 and 1.0. A transmission input shaft is connected to a prime mover such as a vehicle engine crankshaft by a drive belt. The transmission comprises at least one output shaft that is coaxial with the input shaft. An output pulley is attached to the output shaft. A belt is engaged between the output pulley and various engine accessories. A second end of the transmission output shaft may be directly coupled to an engine accessory mounted on the transmission. An included control system senses a crankshaft speed. A processor analyses the crankshaft speed and accordingly adjusts the transmission ratio using a stepper motor connected to a worm drive to maintain a constant output speed regardless of crankshaft speed.

Owner:THE GATES CORP

Continuously variable transmission

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmissions and methods therefor

Components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings are described. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. A transmission housing and bell housing can be adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Related devices include, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies.

Owner:FALLBROOK INTPROP COMPANY

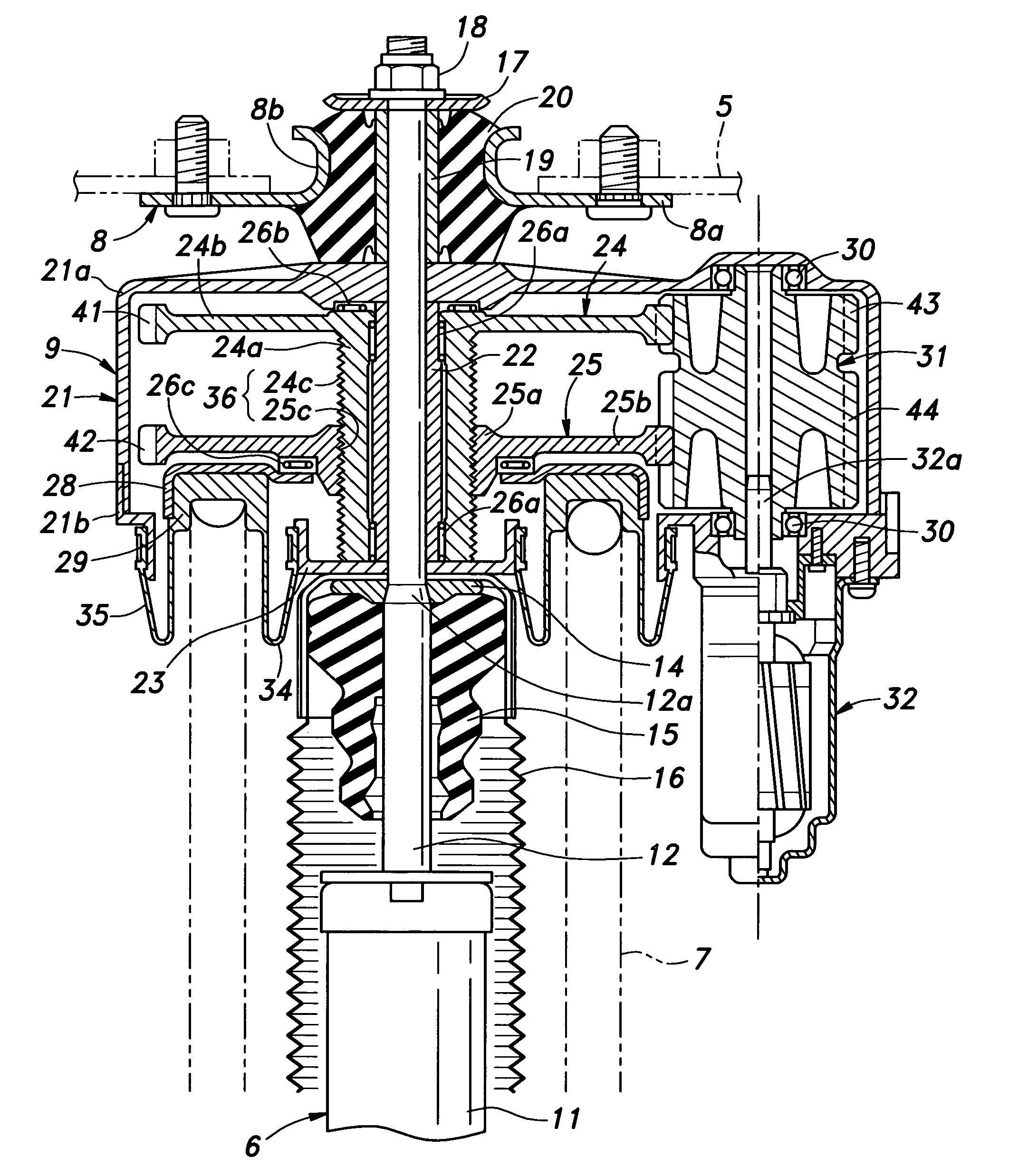

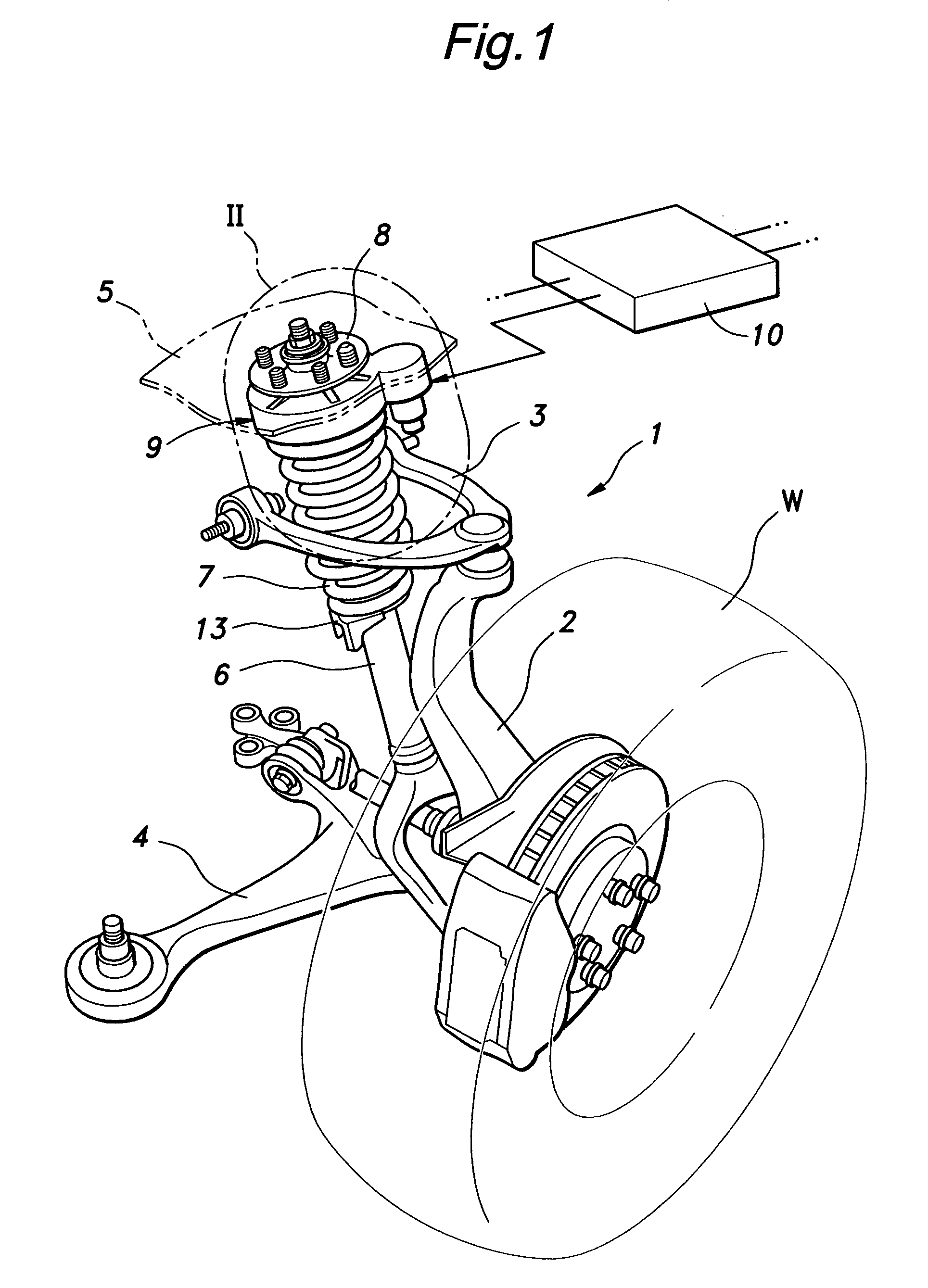

Vehicle height adjusting system

ActiveUS20070210539A1Stable supportCompact designVehicle cleaning apparatusToothed gearingsLinear motionDrive shaft

A first rotor (24; 124) and a second rotor (25; 125) are arranged in a coaxial and mutually rotatable relationship and are provided with a first driven gear (41; 141) and a second driven gear (42; 142), respectively. A drive shaft (31; 131) is also provided with a first drive gear (43; 143) and a second drive gear (44; 144) which are commonly connected to an output shaft of an electric motor (32; 132), and mesh with the first and second driven gears, respectively, at slightly different gear ratios. The first and second rotors are connected via a thread feed mechanism (36; 136) that converts a relative rotation between the first and second rotors into an axial linear movement between the first and second rotors that is used for changing a distance between a vehicle body part and a corresponding end of a suspension spring in a vehicle height adjusting system (9; 109). Owing to a differential rotation of a high gear ratio between the first and second rotors, a significant torque amplification is possible with a compact arrangement. The use of spur gears instead of a worm gear mechanism minimizes torque loss.

Owner:HONDA MOTOR CO LTD

Systems and methods for control of transmission and/or prime mover

Owner:FALLBROOK INTPROP COMPANY

Hybrid power vehicle double electric machine double row planetary gear single clutch drive apparatus

InactiveCN101323243ALower requirementIncrease profitHybrid vehiclesGas pressure propulsion mountingStarter generatorVehicle frame

The invention discloses a twin-motor two-planet-row and single clutch driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; the front planet row is provided with a front planet row planet wheel and a front planet row sun gear; the back planet row is provided with a back planet row planet wheel and a back planet row sun gear; the front planet row and the back planet row share a gear ring. The output shaft of an engine is connected with the input end of an integrated starter generator; the output end of the integrated starter generator is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the planet wheel of the front planet row through a planet carrier; the sun gear of the front planet row is connected with a drive motor; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is also connected with the drive motor; the outside gear of the gear ring is normally engaged with a power take-off gear. The twin-motor two-planet-row and single clutch driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

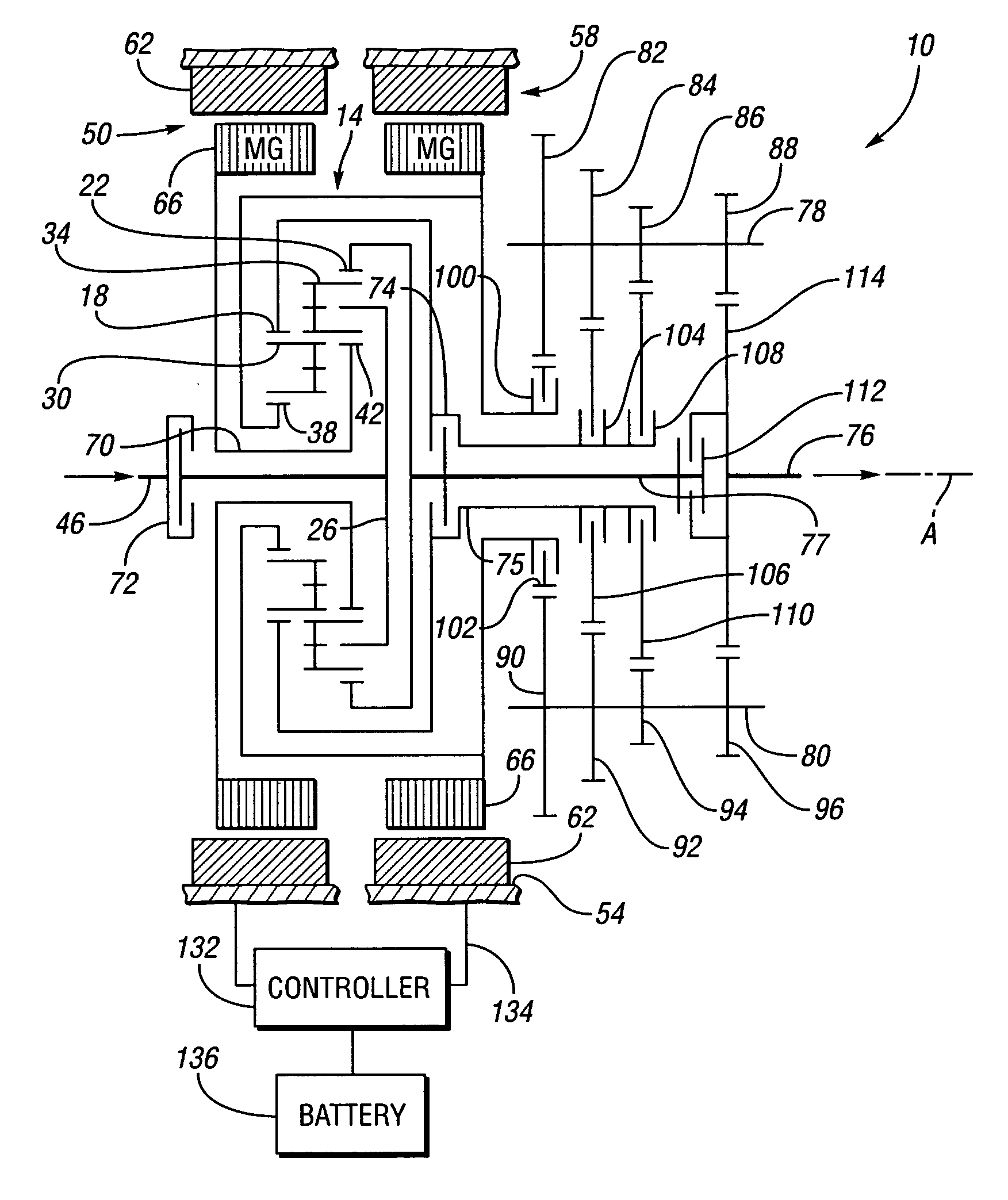

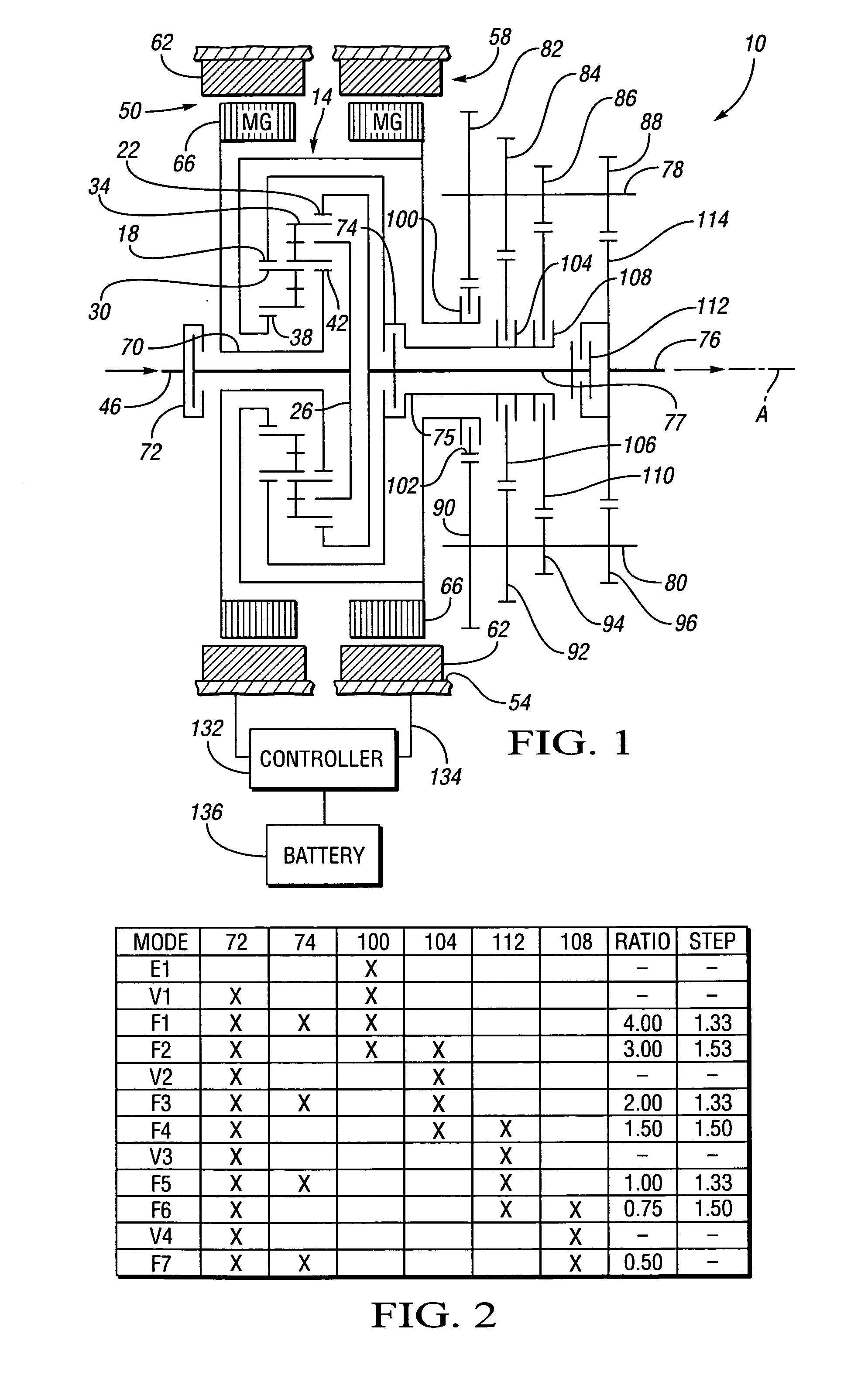

Electrically variable transmission with input split mode and compound split modes

ActiveUS20070099738A1Relax requirementsHybrid vehiclesElectric propulsion mountingElectricityGear wheel

A vehicle transmission includes a differential gear set having five coaxial gear elements and an output member. Two of the gear elements are controllable via torque transmitting mechanisms such as electric motors to establish a plurality of speed ratios between the input shaft and the output shaft. Two of the other gear elements are selectively operatively connectable to an output shaft via a gear arrangement that allows for a plurality of speed ratios between the gear elements and the output shaft. Additional torque transmitting mechanisms such as clutches are selectively engageable to provide continuously variable speed ranges between the input shaft and the output shaft, fixed gear ratios and an electric drive mode. The various speed ratios enable a plurality of compound split operating modes as well as an input split mode.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com