Patents

Literature

10186 results about "Planet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A planet is an astronomical body orbiting a star or stellar remnant that is massive enough to be rounded by its own gravity, is not massive enough to cause thermonuclear fusion, and has cleared its neighbouring region of planetesimals.

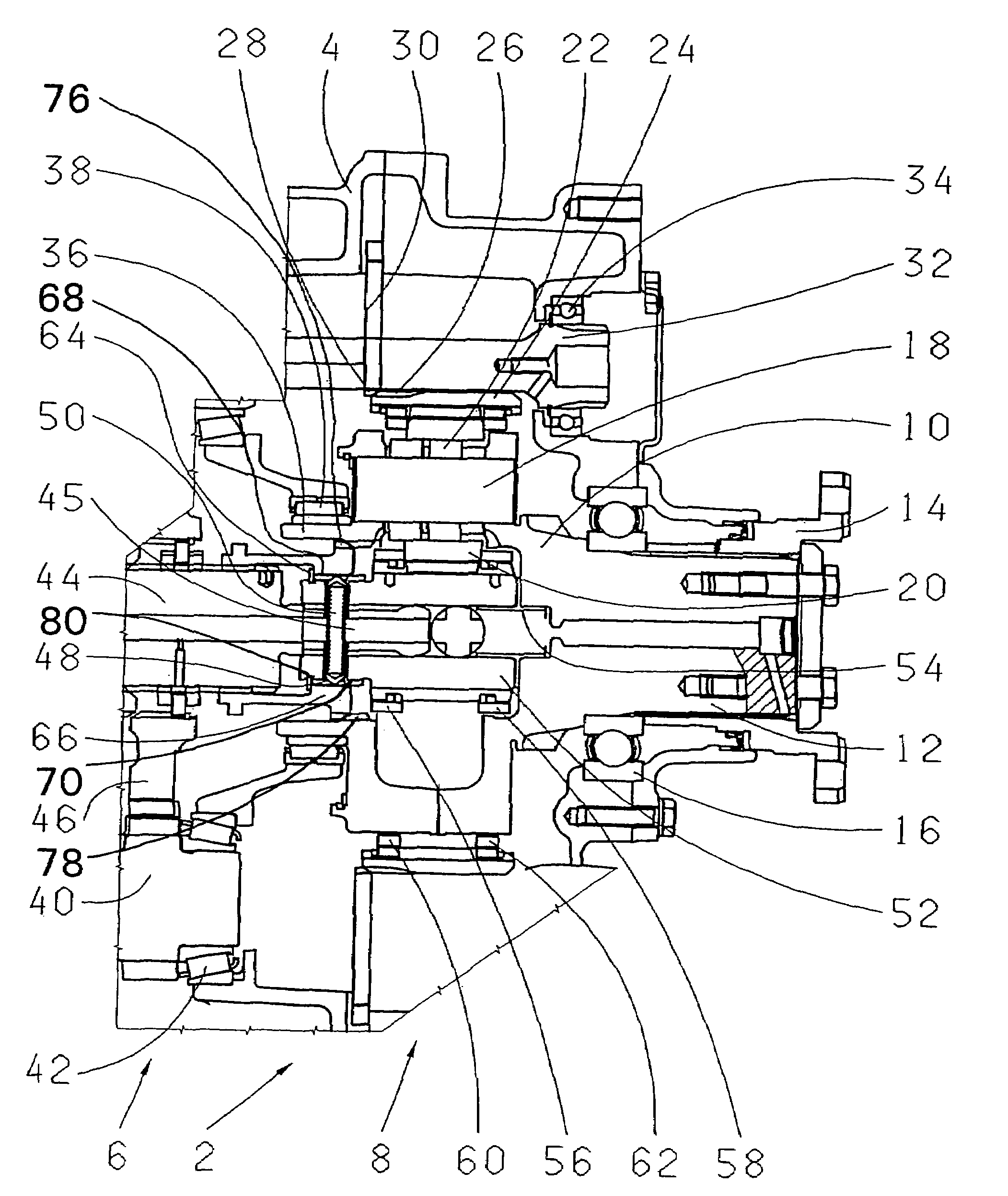

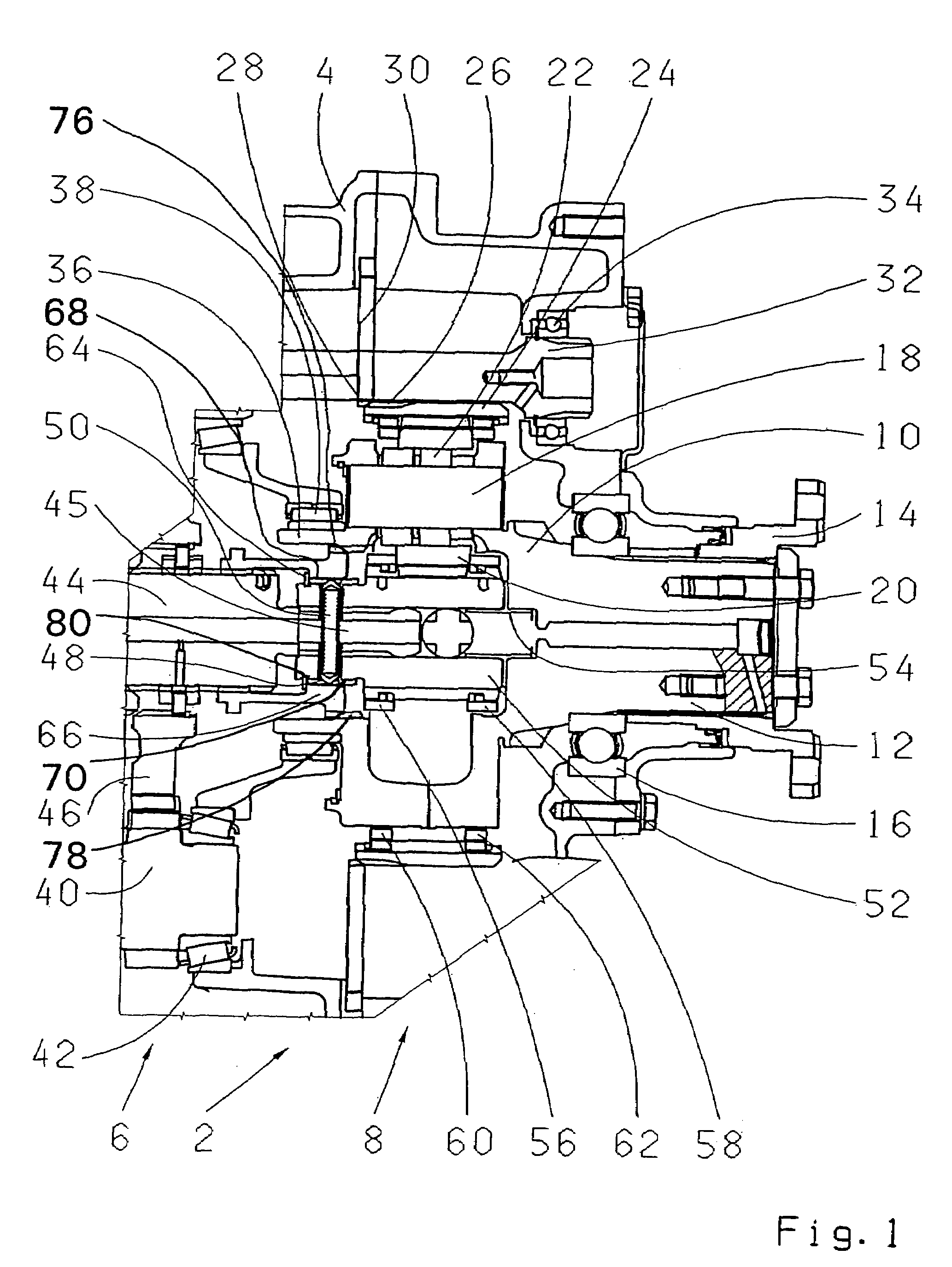

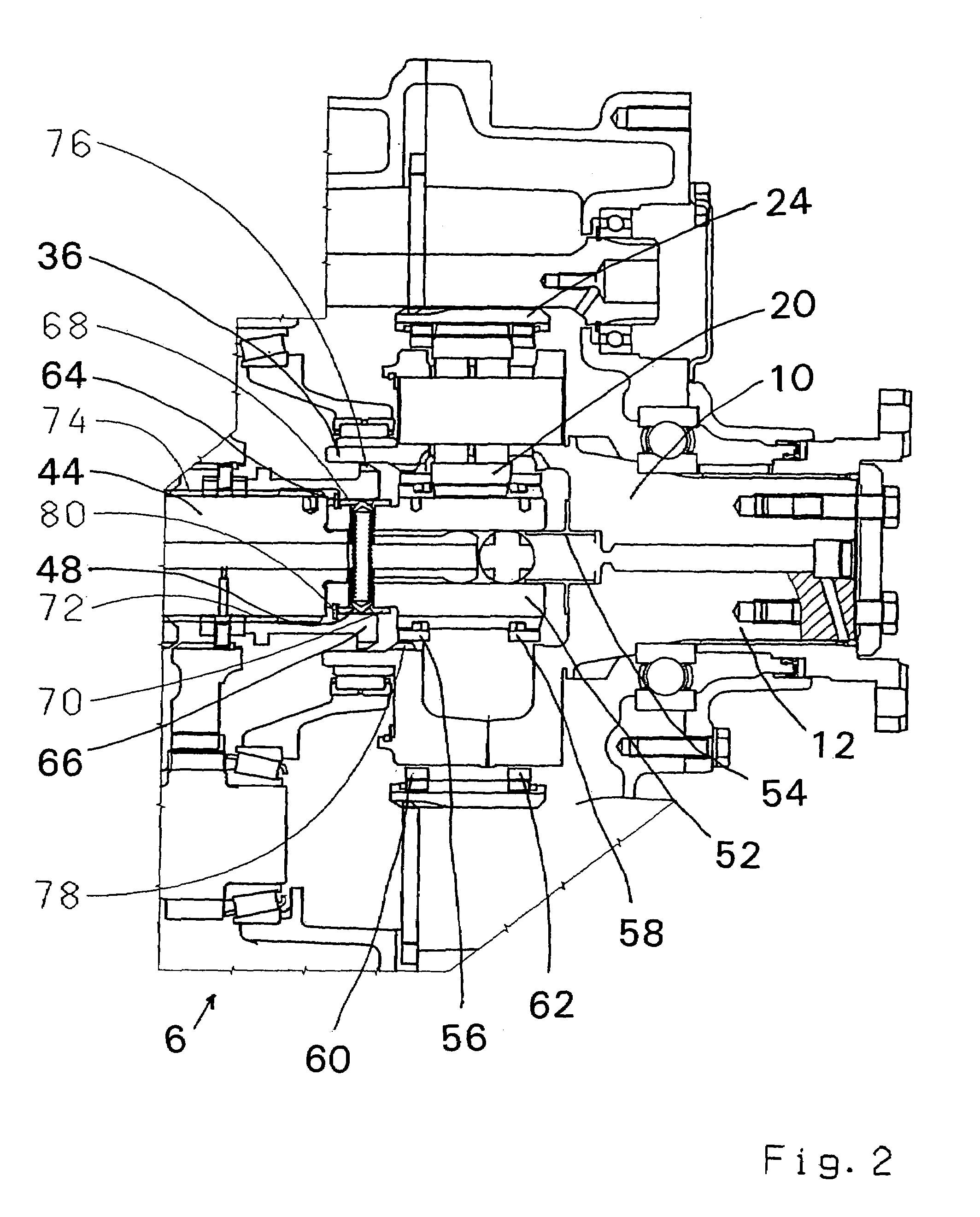

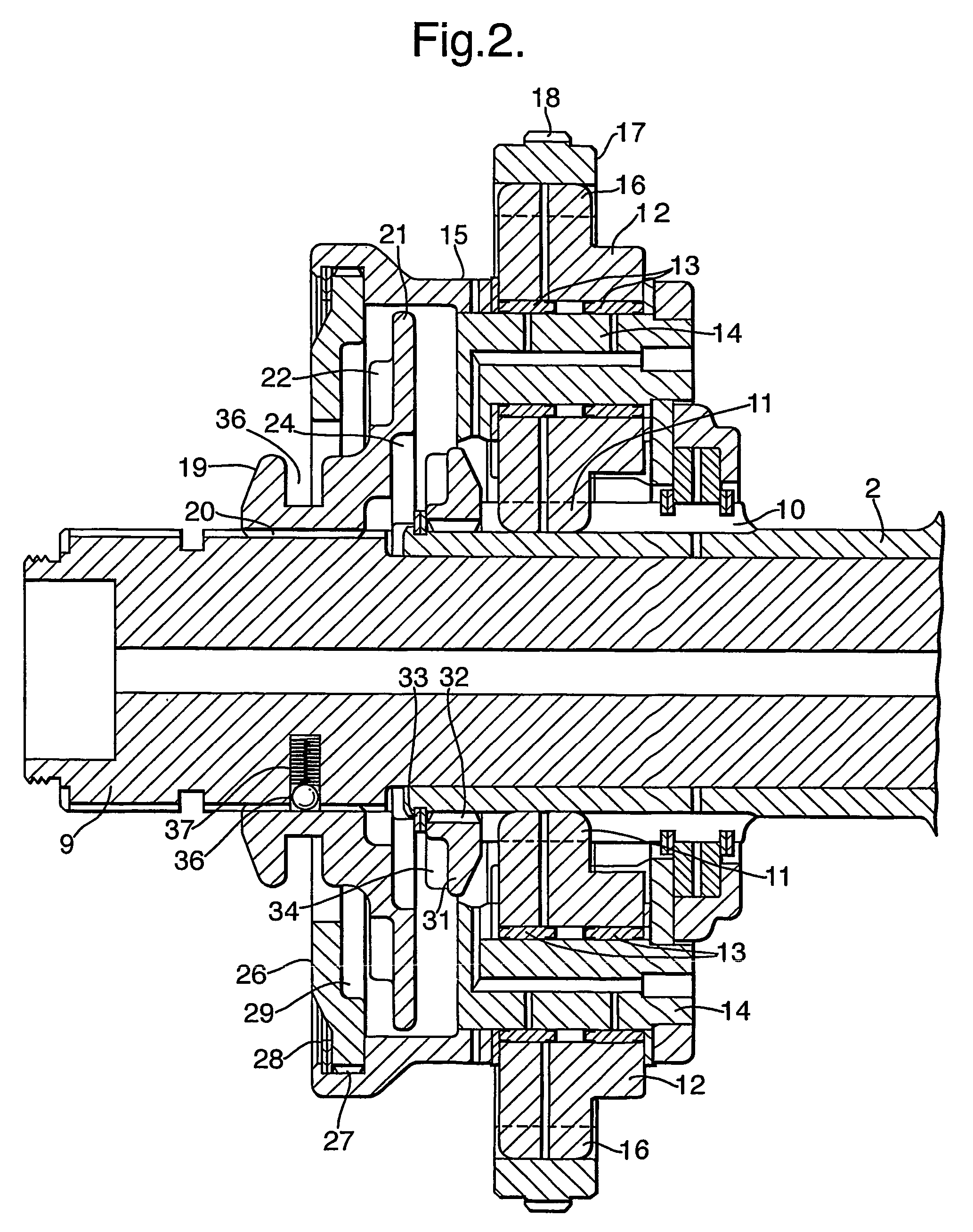

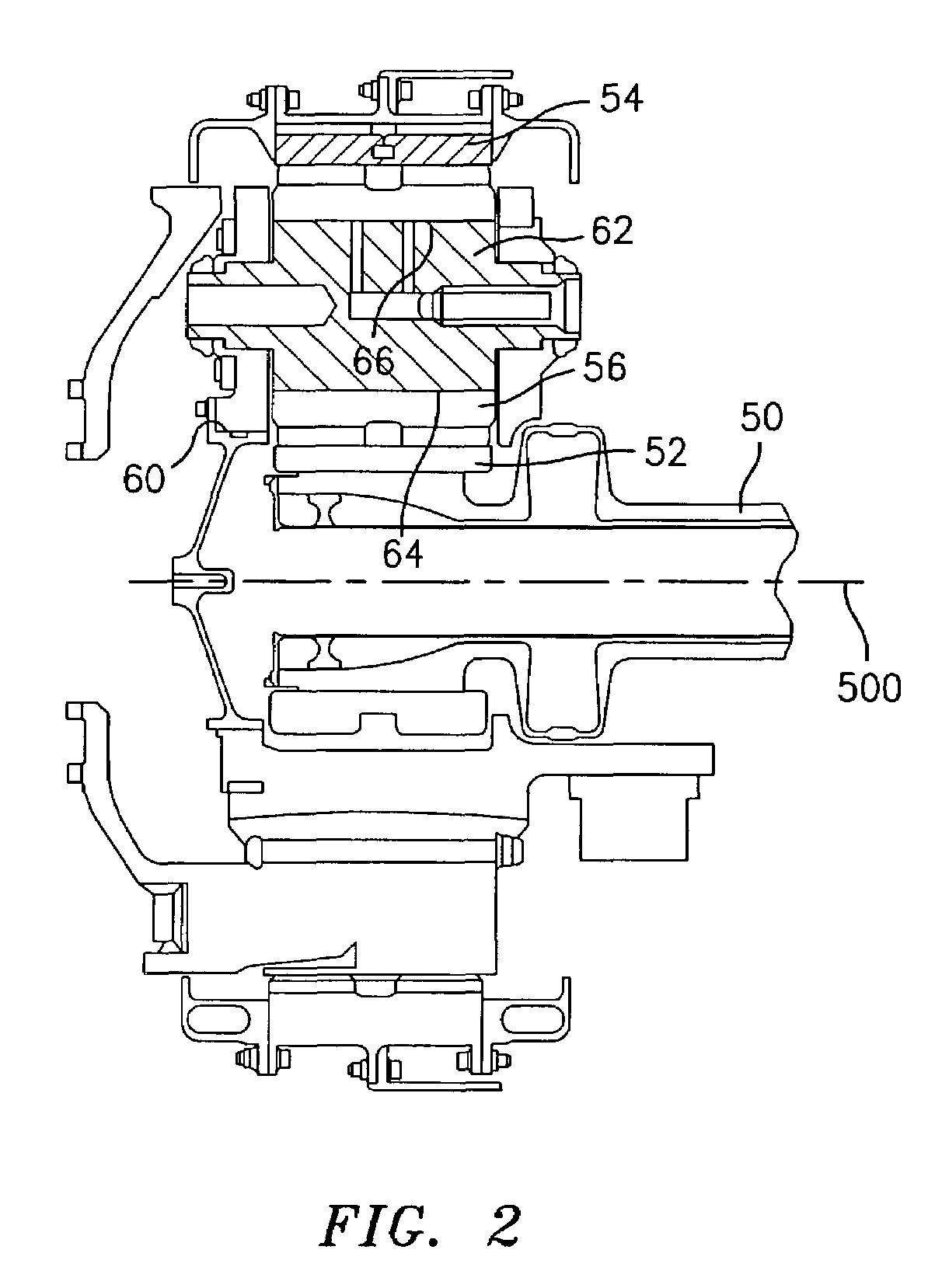

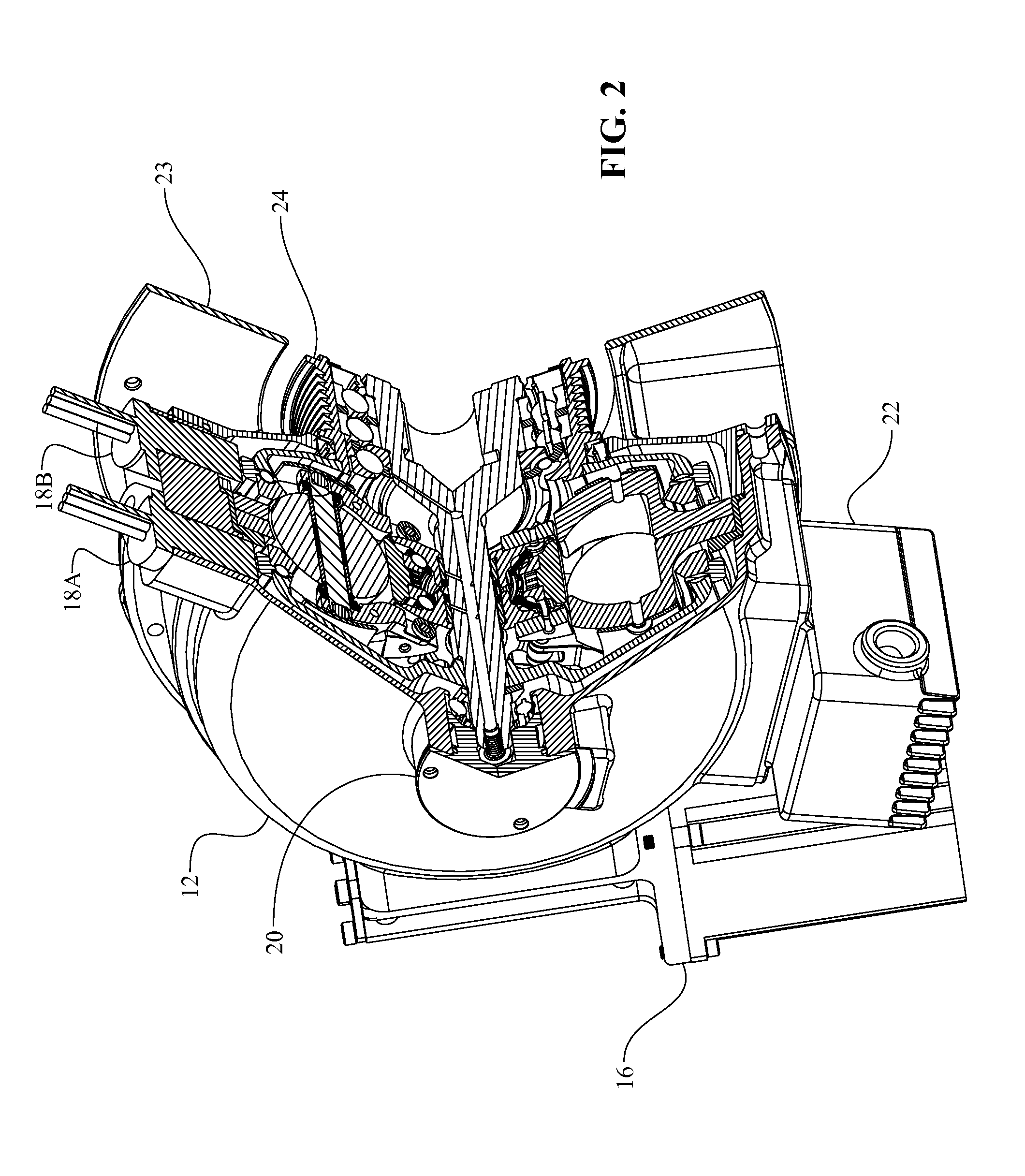

Planetary transmission

Proposed is a planetary transmission (8) comprising an internal gear (24), a sun gear (52) and a planet carrier (10), upon which at least one planet gear (20) is supported. The planetary transmission (8) possesses a clutch apparatus with a sliding sleeve (66), which in a first shift-position enables a direct connection between one of the shafts (44) driving the planetary transmission (8) and an output shaft (12) of the planetary transmission (8). In a second shift-position, the connection of the sliding sleeve (66) enables a change in the speed of rotation between the driving shaft (44) and the output shaft (12) of the planetary transmission (8). The planet gear (20) is so supported on the planet carrier (10), that in case of a shifting from a one shift-position into a respective other shift-position, the planet gear (20) on the planet carrier (20) becomes axially slidable.

Owner:ZF FRIEDRICHSHAFEN AG

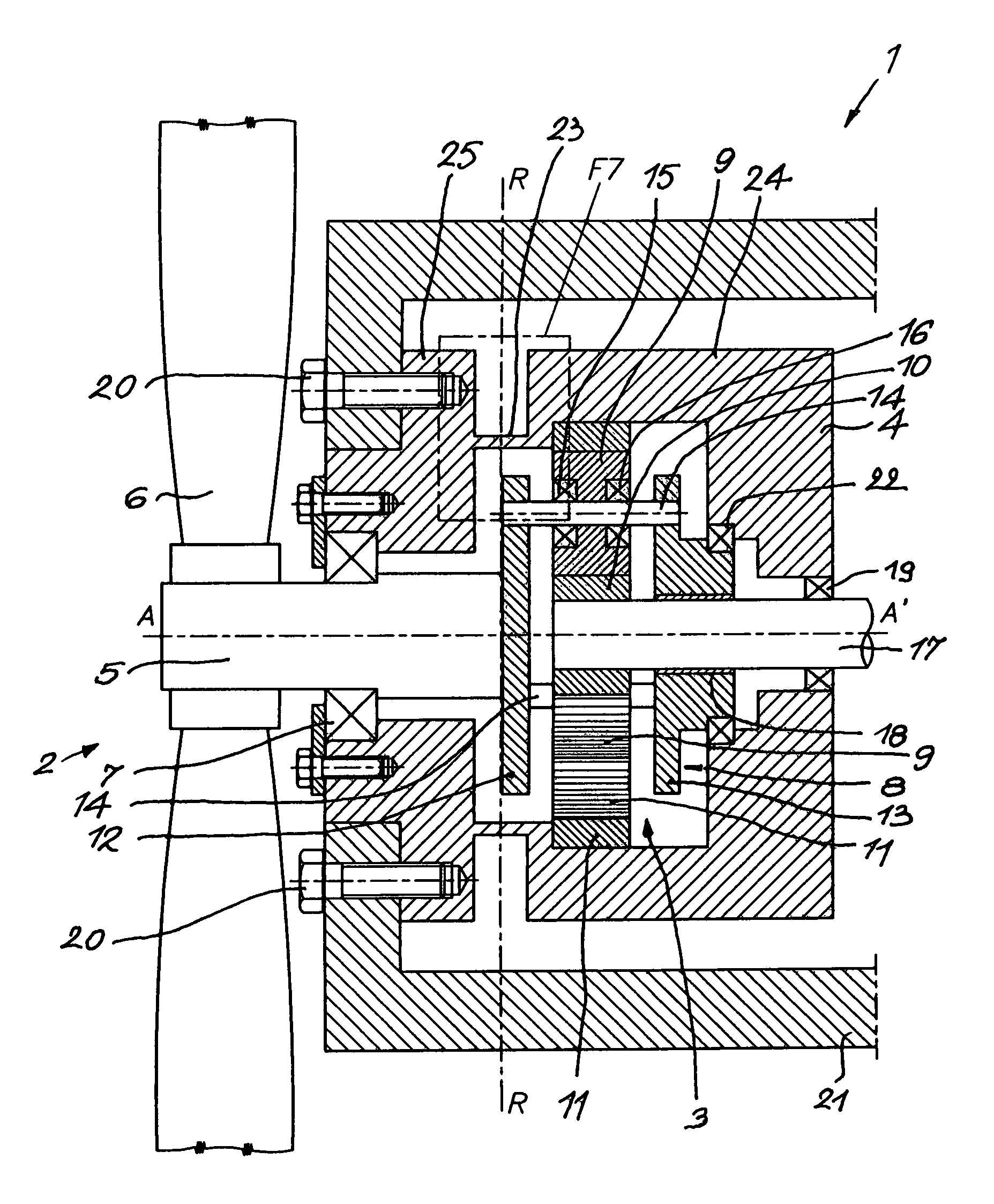

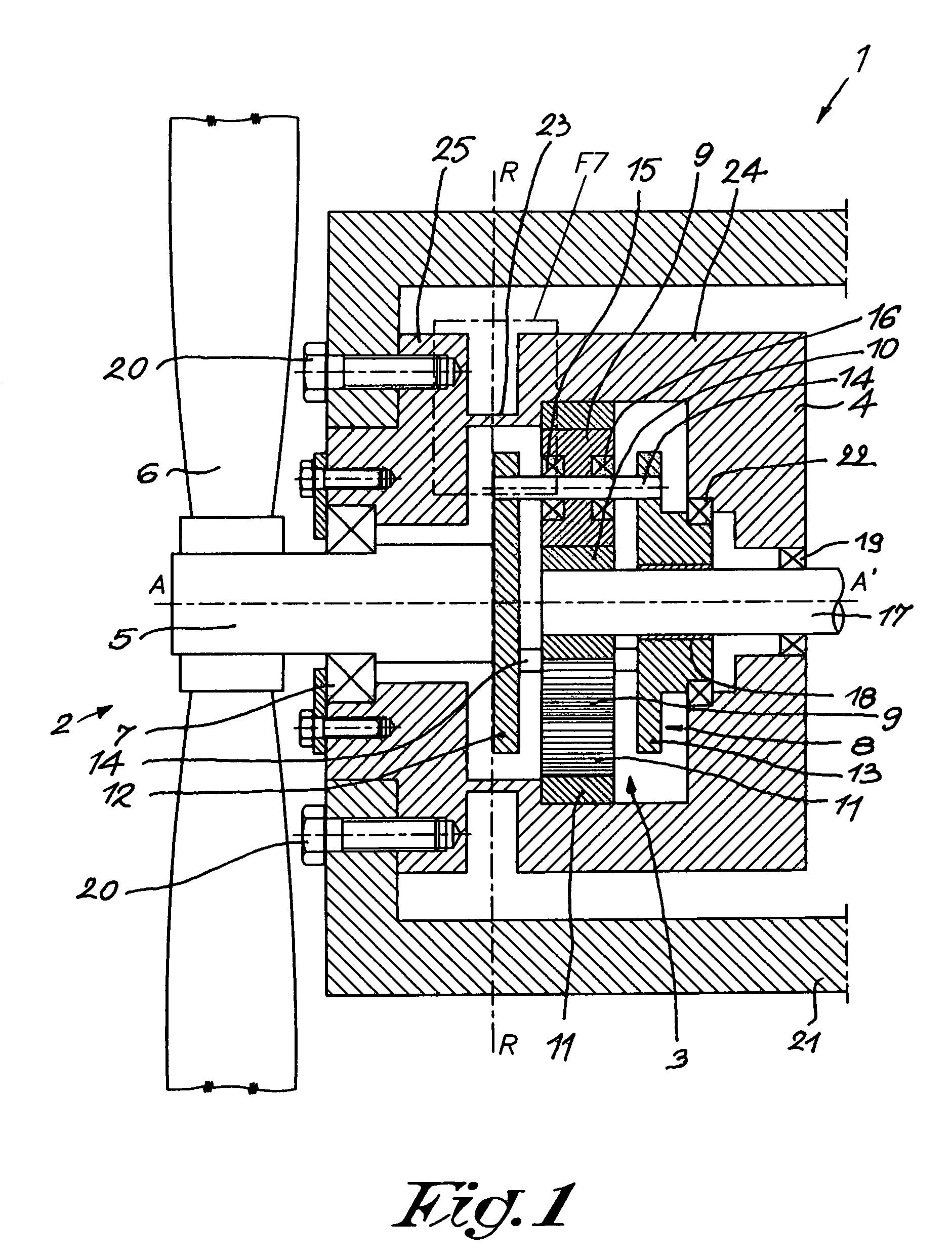

Gear change mechanism

ActiveUS7303502B2Easy to participateSpace minimizationToothed gearingsInterengaging clutchesEngineeringDog clutch

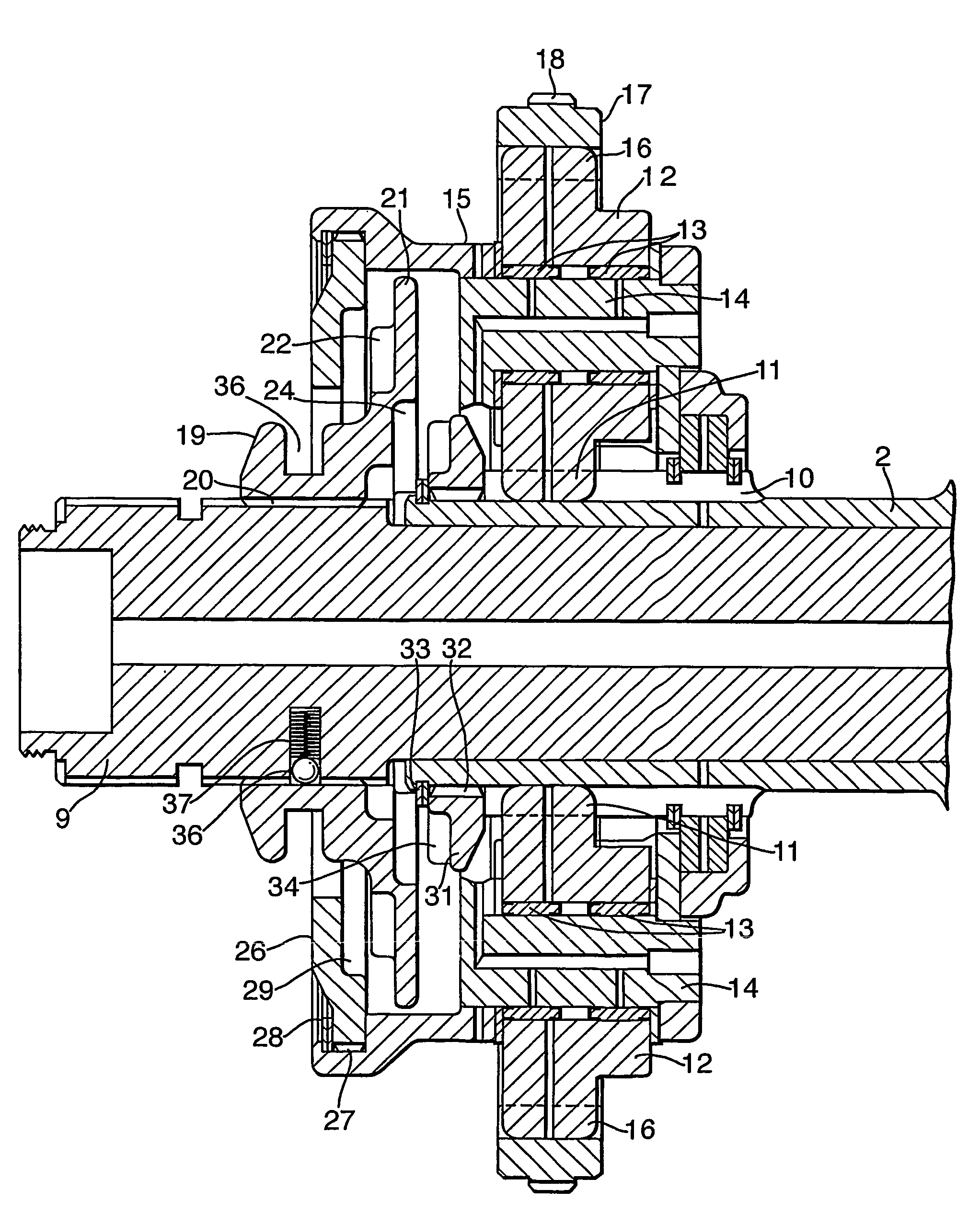

A gear change mechanism coupling a pair of shafts employs a planetary gear set comprising a sun gear fast with a first of the shafts, planet gears in a planet carrier, and an annulus or ring gear, the latter being fixed. A selector hub slidable on the other of the shafts has sets of radially spaced dogs to engage with corresponding dogs on the planet carrier and sun gear respectively, so as to couple the shafts at two different ratios depending on the axial position of the selector hub. This results in a more axially compact package than conventional dog clutch gear changers. In an alternative embodiment a reversing mechanism is provided by fixing the planet carrier and engaging the selector hub with the sun gear or annulus depending on its axial position.

Owner:QINETIQ LTD

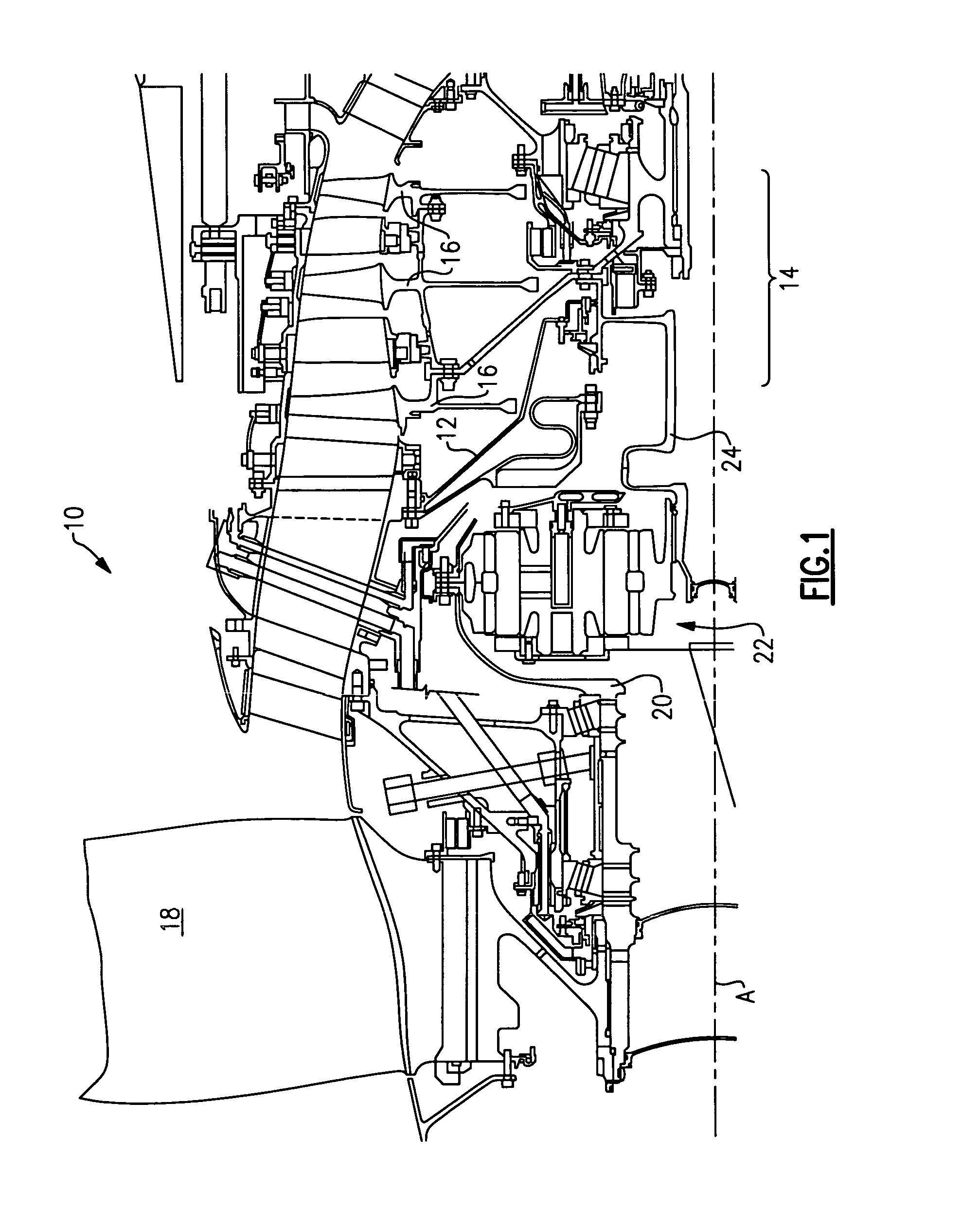

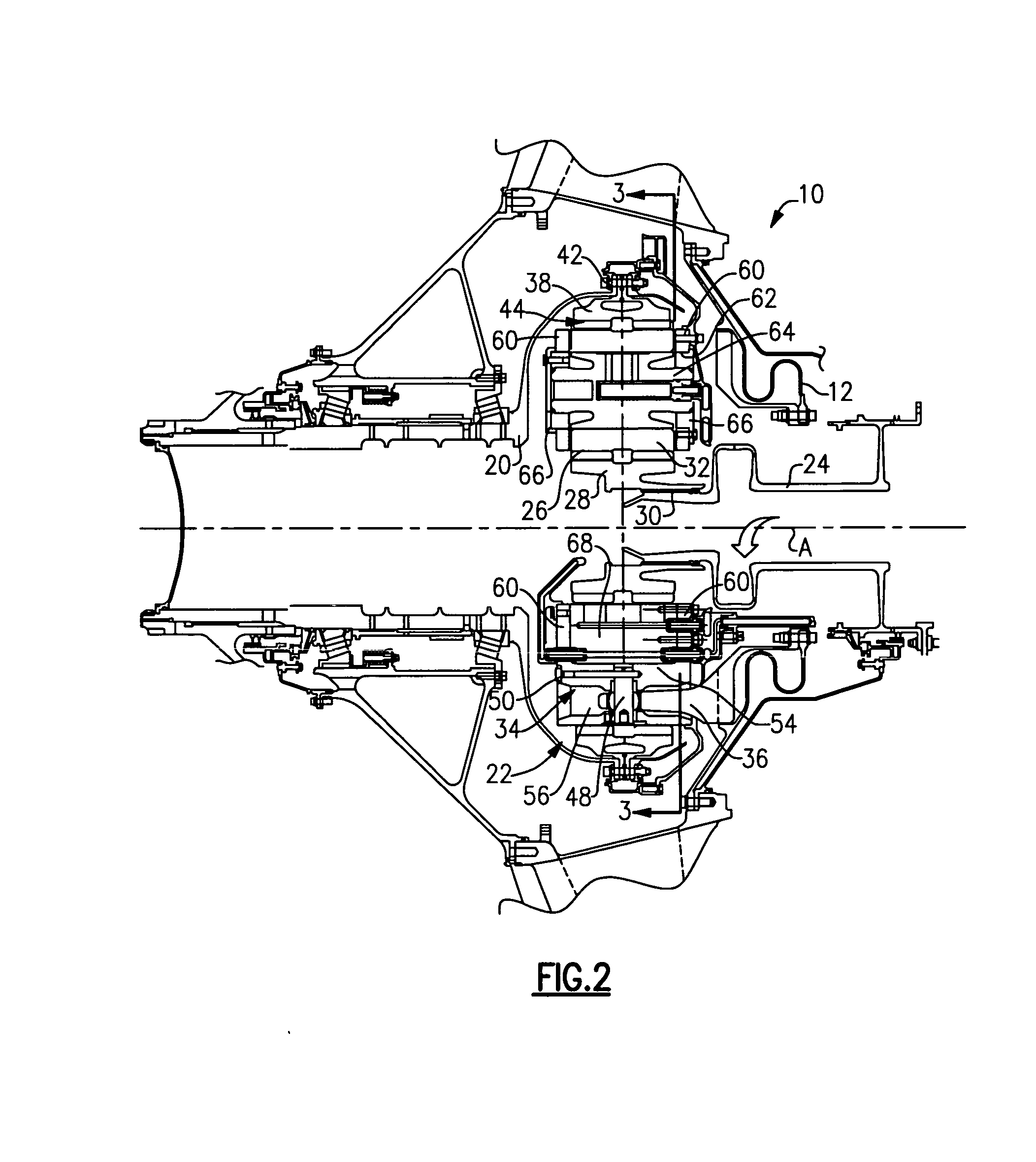

Geartrain coupling for a turbofan engine

Molybdenum disulfide (MoS2) is used as a journal coating for a gearing system. A particular application is the planetary gear system of a geared turbofan engine. Particularly advantageous coatings are deposited via physical vapor deposition (PVD) techniques.

Owner:RAYTHEON TECH CORP

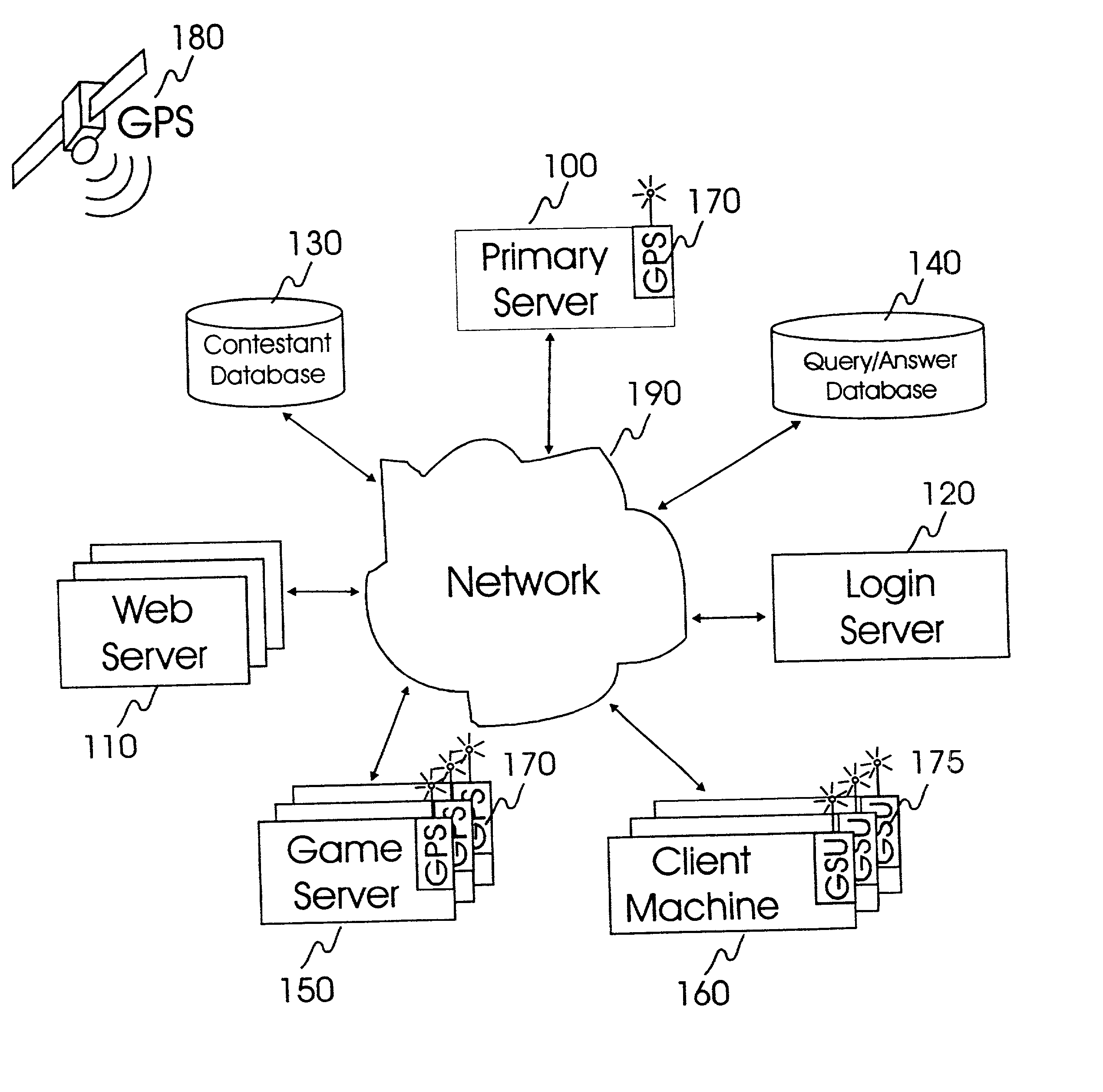

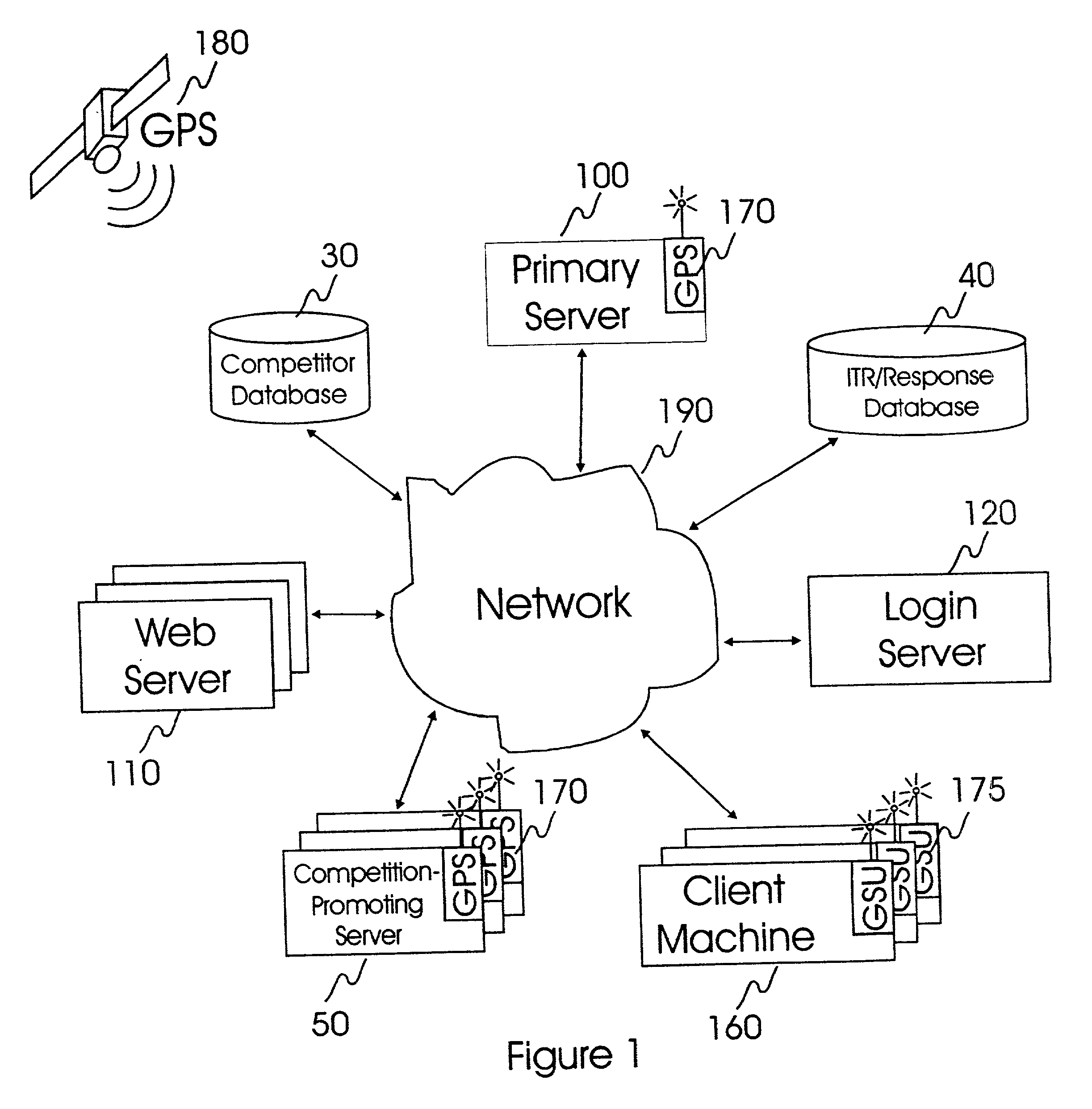

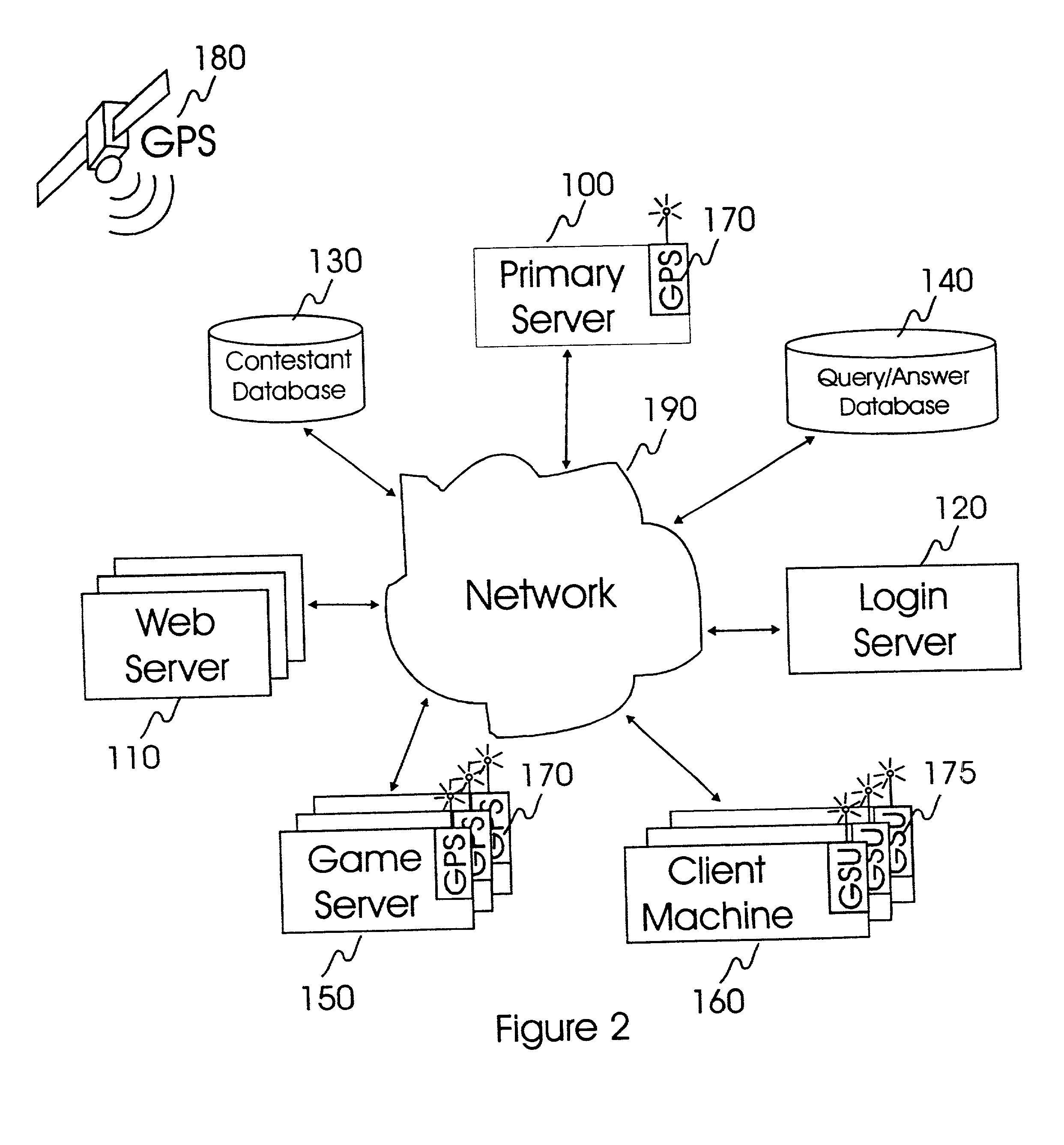

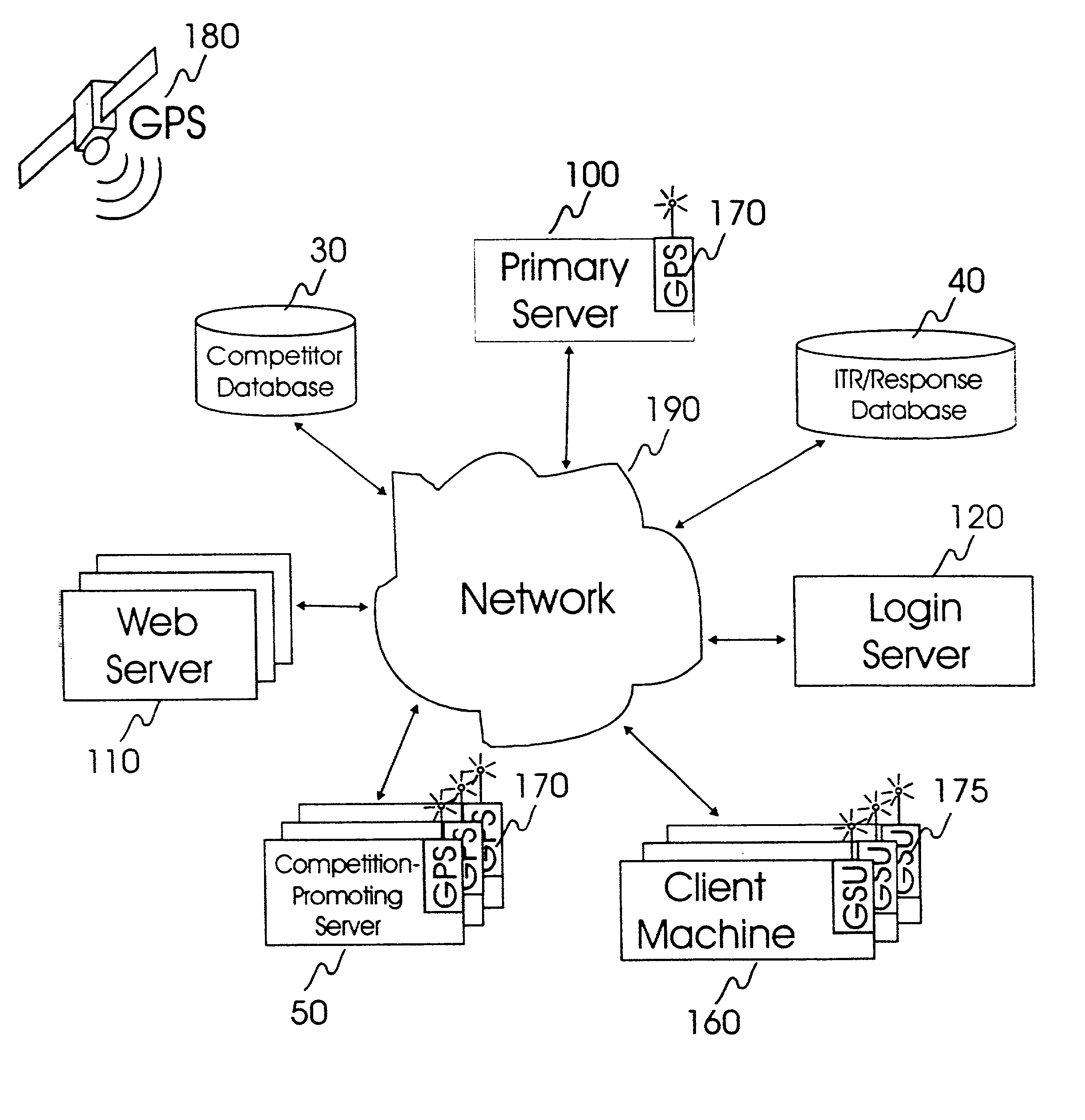

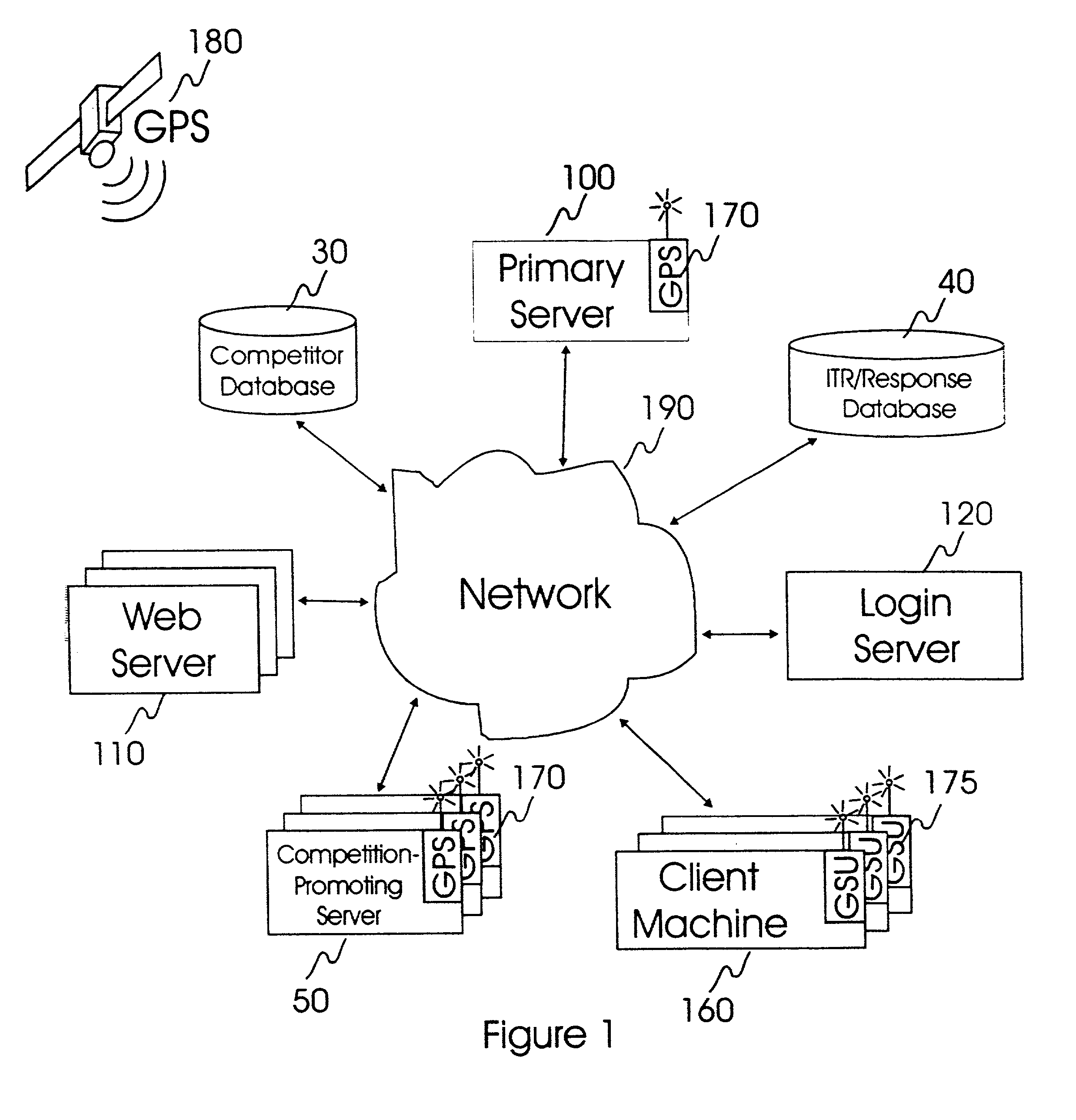

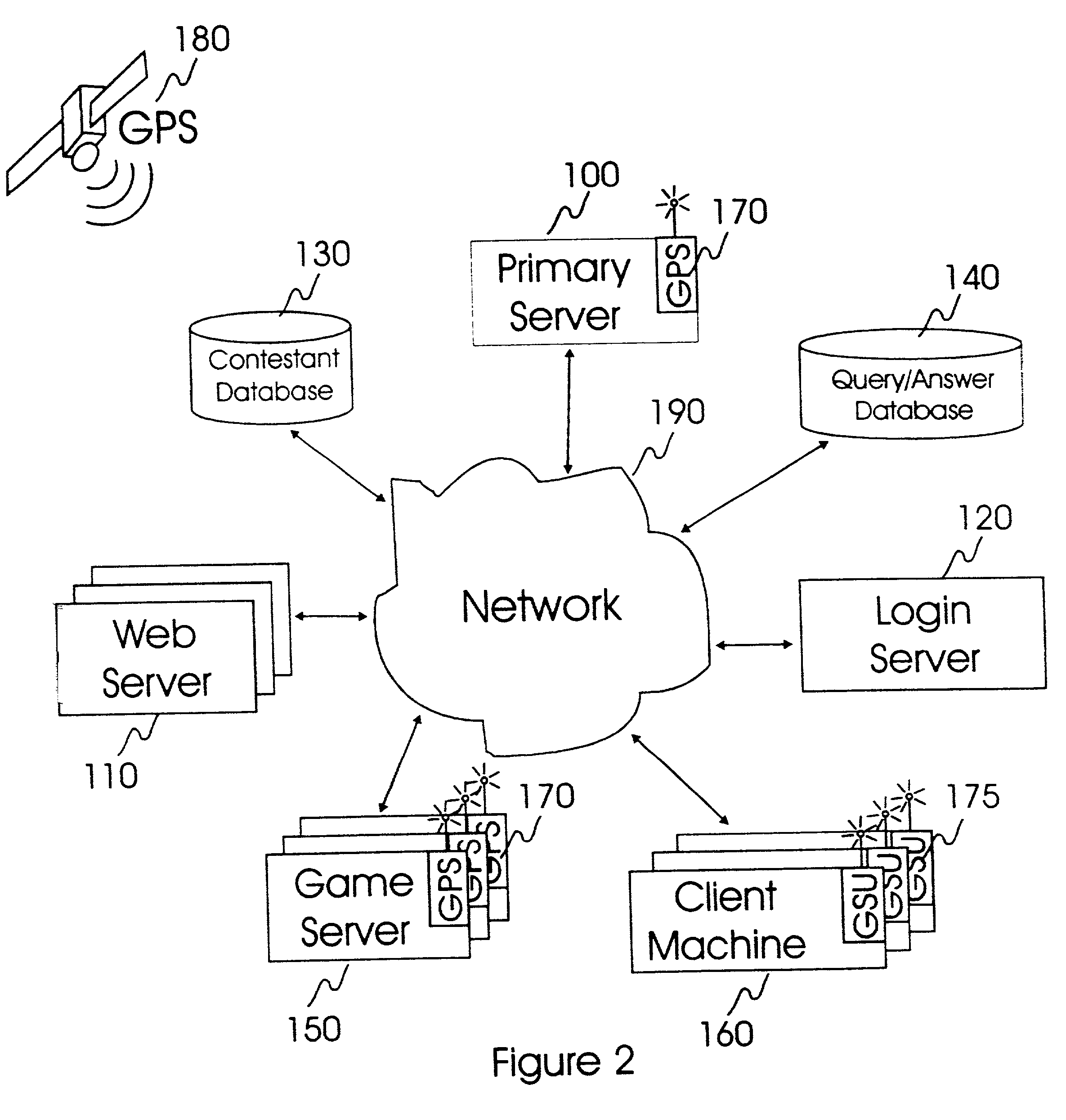

Internet-based system and method for fairly and securely enabling timed-constrained competition using globally time-sychronized client subsystems and information servers having microsecond client-event resolution

InactiveUS20020026321A1Avoiding shortcoming and drawbackBetterment of human societyBuying/selling/leasing transactionsVideo gamesTime responseTTEthernet

An improved system and method of fairly and securely enabling timed-constrained competitions over the Internet among millions of competitors while compensating for the variable network communication latencies experienced by client machines used by the competitors. The system employs globally time-synchronized Internet information servers and client machines in order to synchronize the initial display of each invitation to respond (e.g. stock price to buy or sell, query to answer, or problem to solve) on a client machine so each competitor can respond to the invitation at substantially the same time, regardless of his or her location on the planet, or the type of Internet-connection used by his or her client machine. Also, by using globally time-synchronized client machines, each competitor's response is securely time and space stamped at the client machine to ensure that competitor responses are resolved within microsecond accuracy.

Owner:REVEO

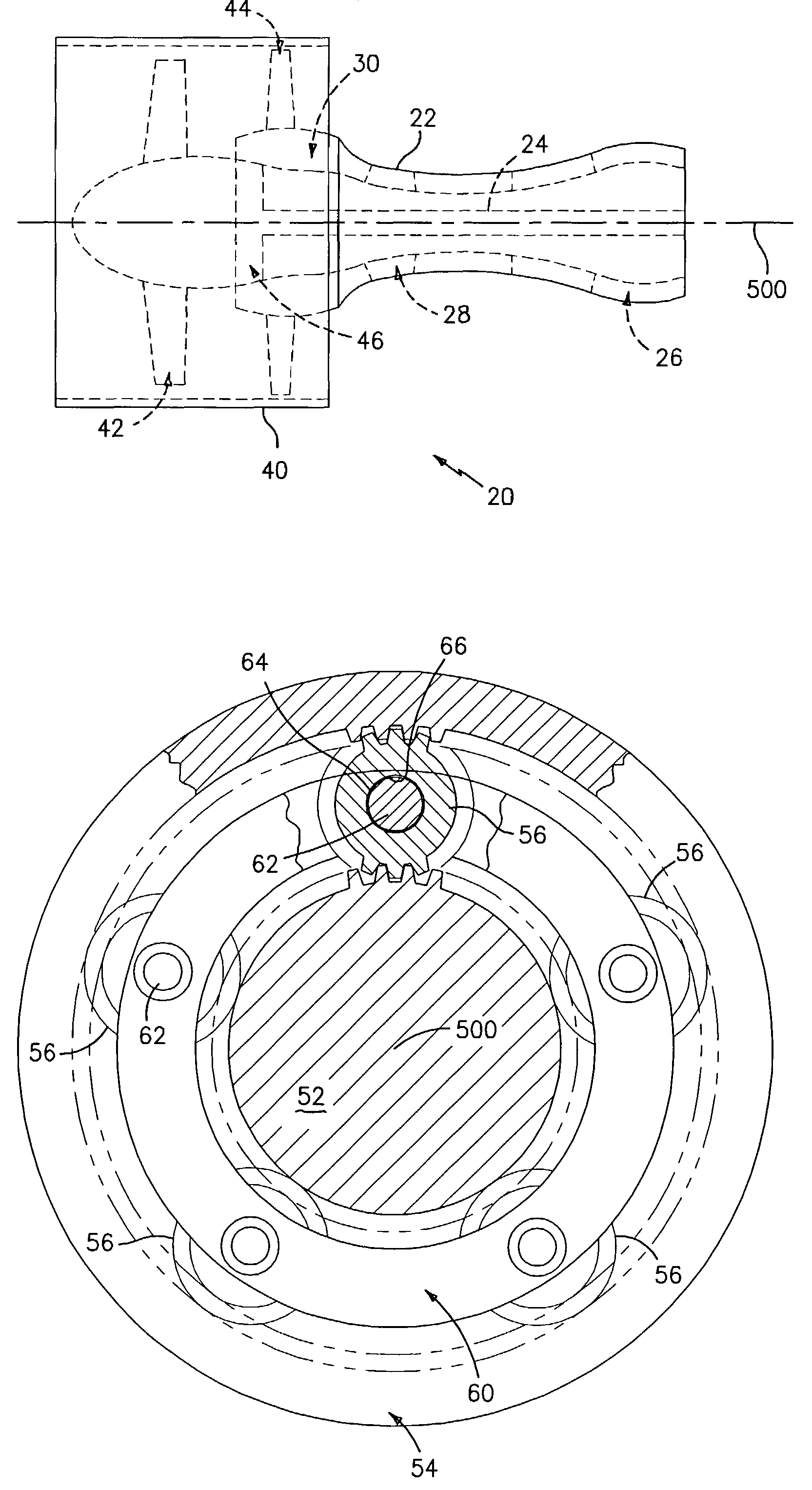

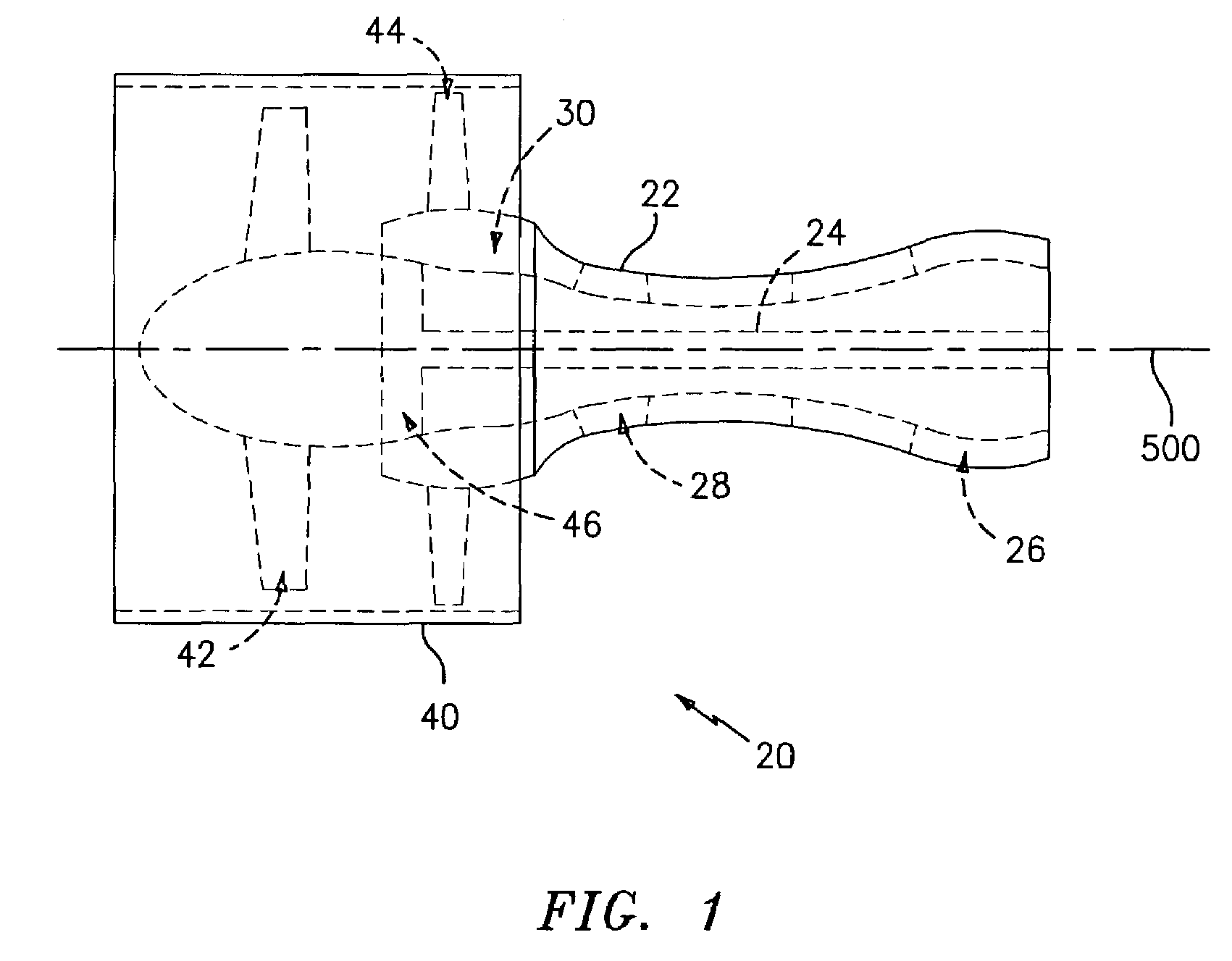

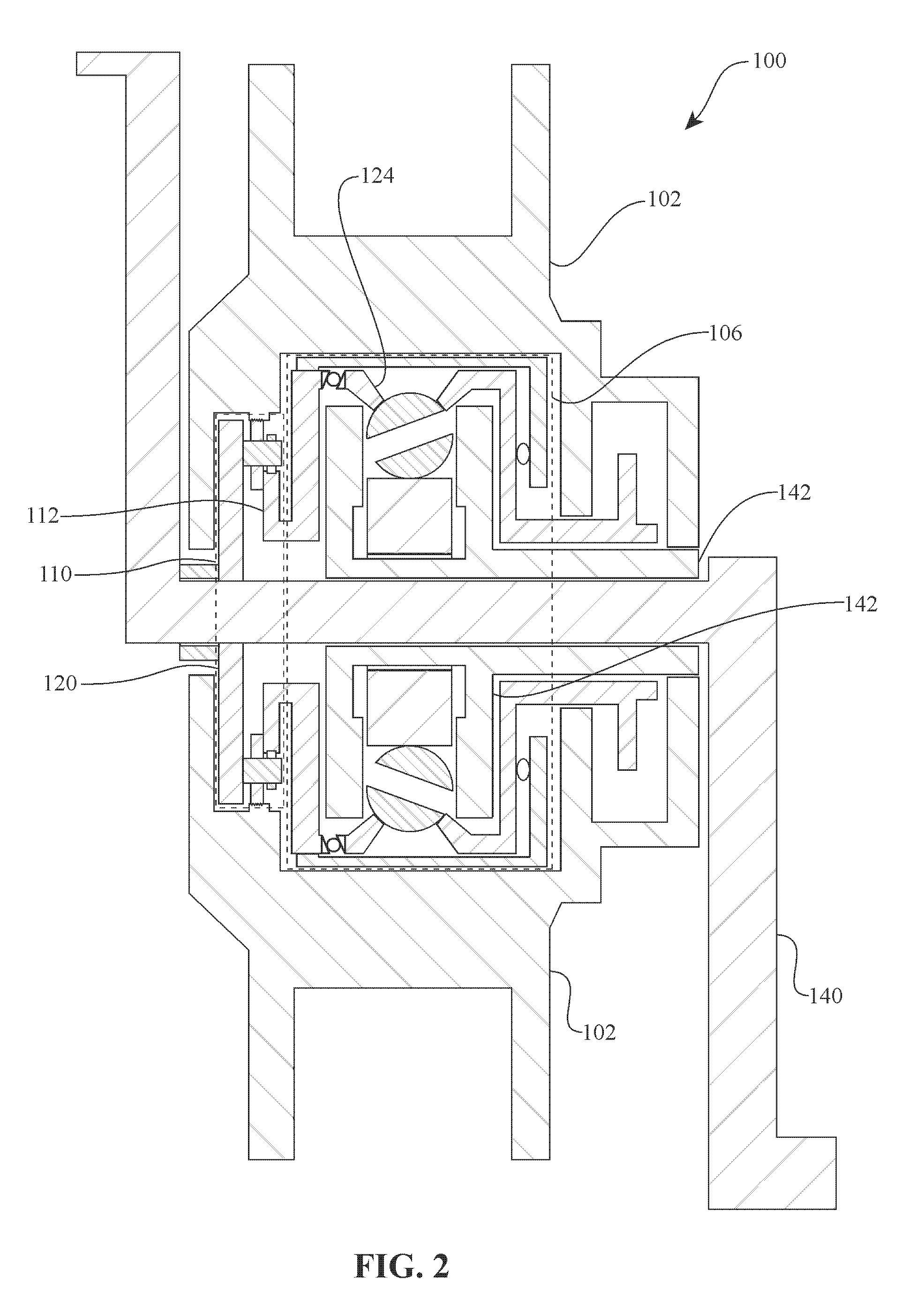

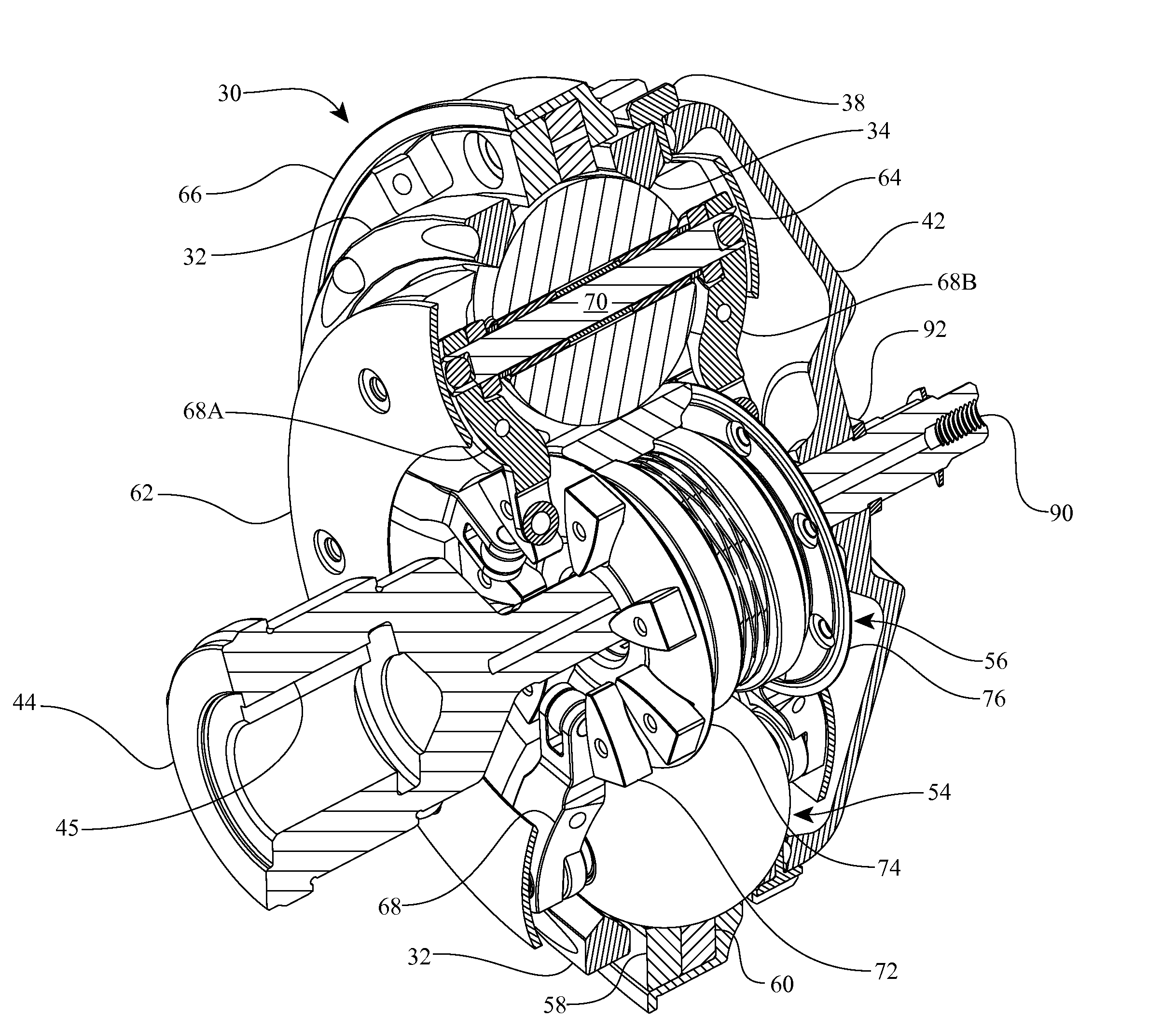

Epicyclic gear train integral sun gear coupling design

A coupling system for connecting a sun gear to a shaft within a planetary gear train, includes a sun gear coupling connecting the sun gear to the shaft. The sun gear coupling has at least one undulant flexible section joined to an inflexible spindle for accommodating misalignment between the sun gear and the shaft. The flexible section comprises a cylindrical ring having a diameter greater than the diameter of the spindle, and joined to the spindle by two longitudinally spaced apart diaphragms. The juncture between the diaphragms, the ring, and the spindle is curved in cross section on an outer side to improve flexibility and minimize stress concentrations, and the inner sides of the diaphragms are straight edges which result in a non-symmetric contour of the diaphragm walls.

Owner:RTX CORP

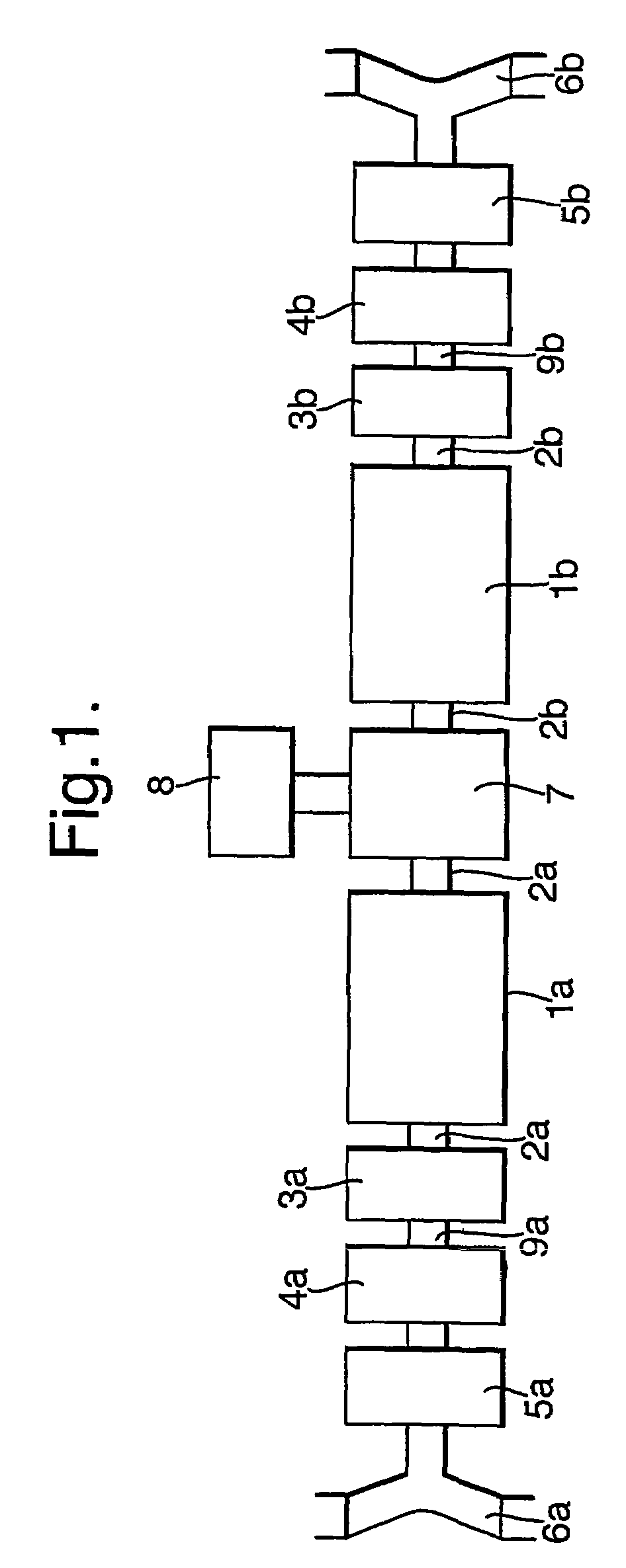

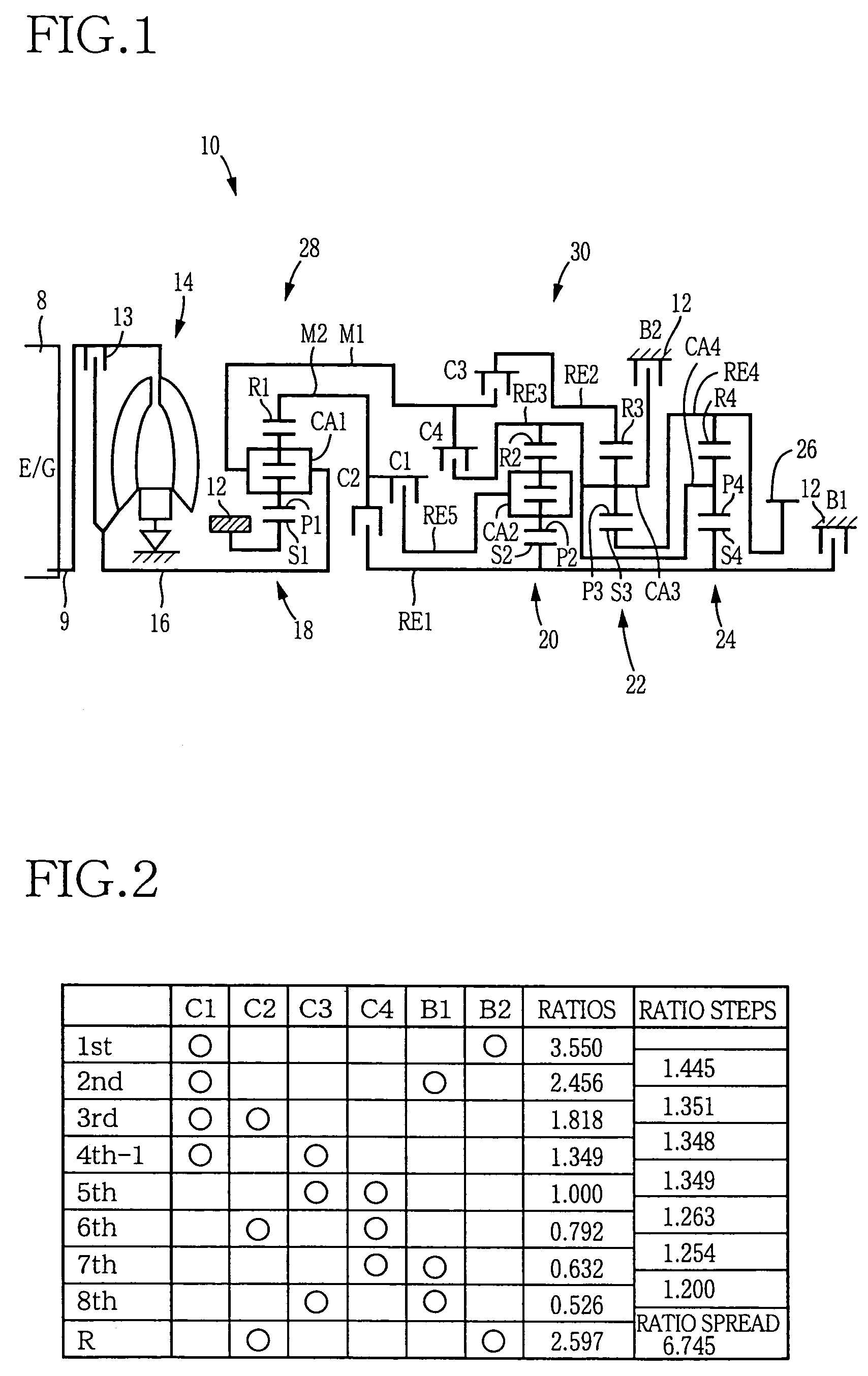

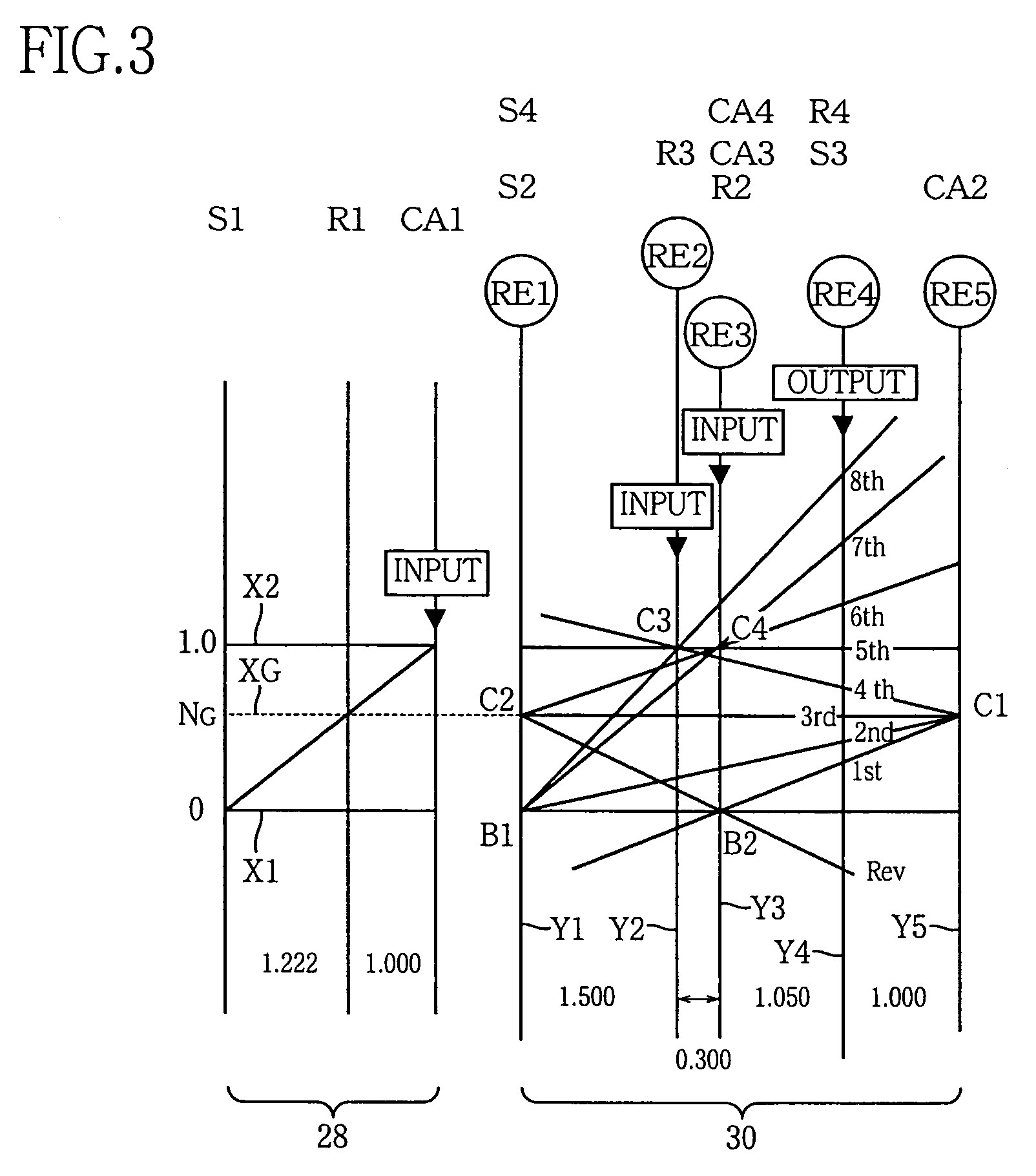

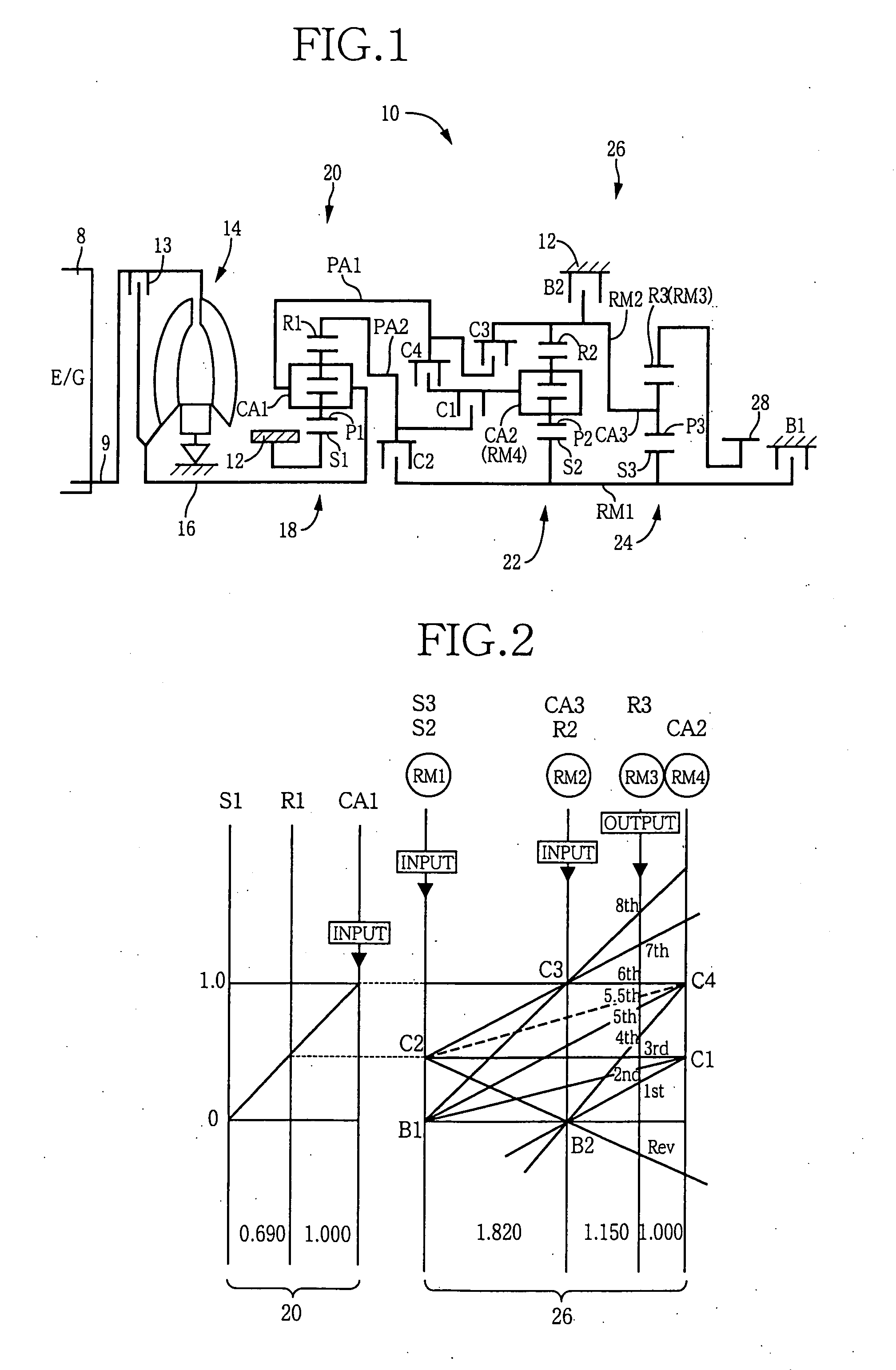

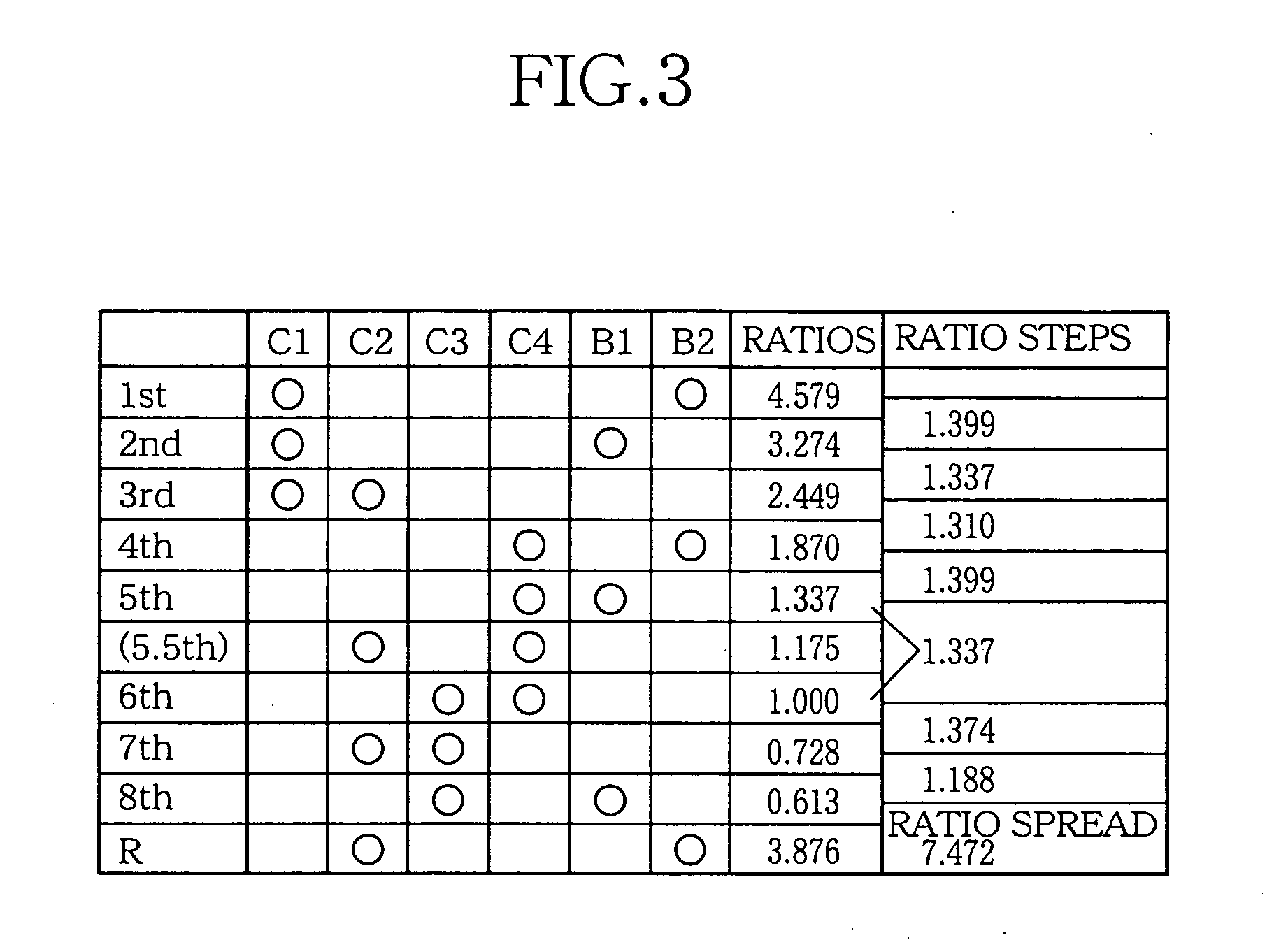

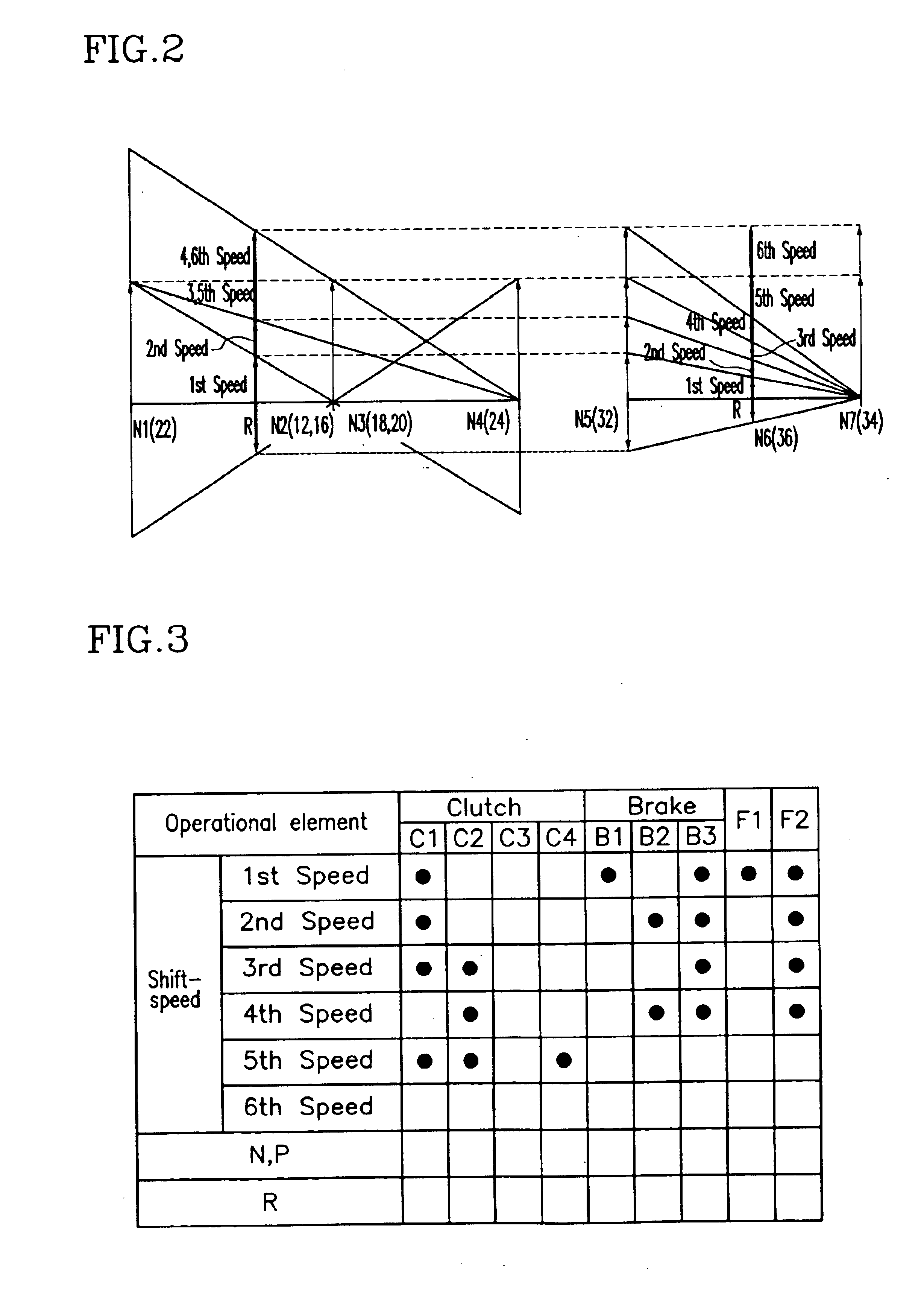

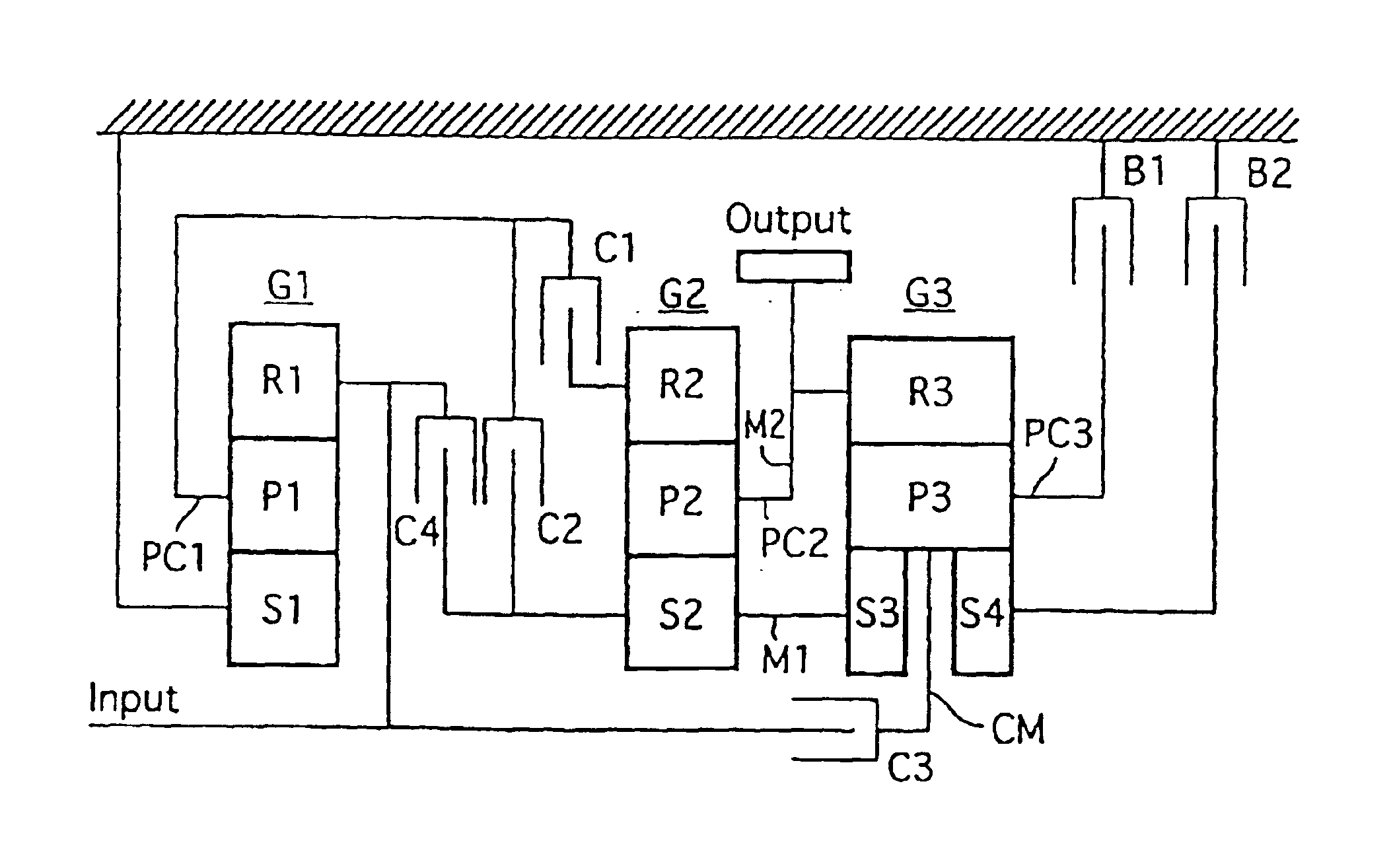

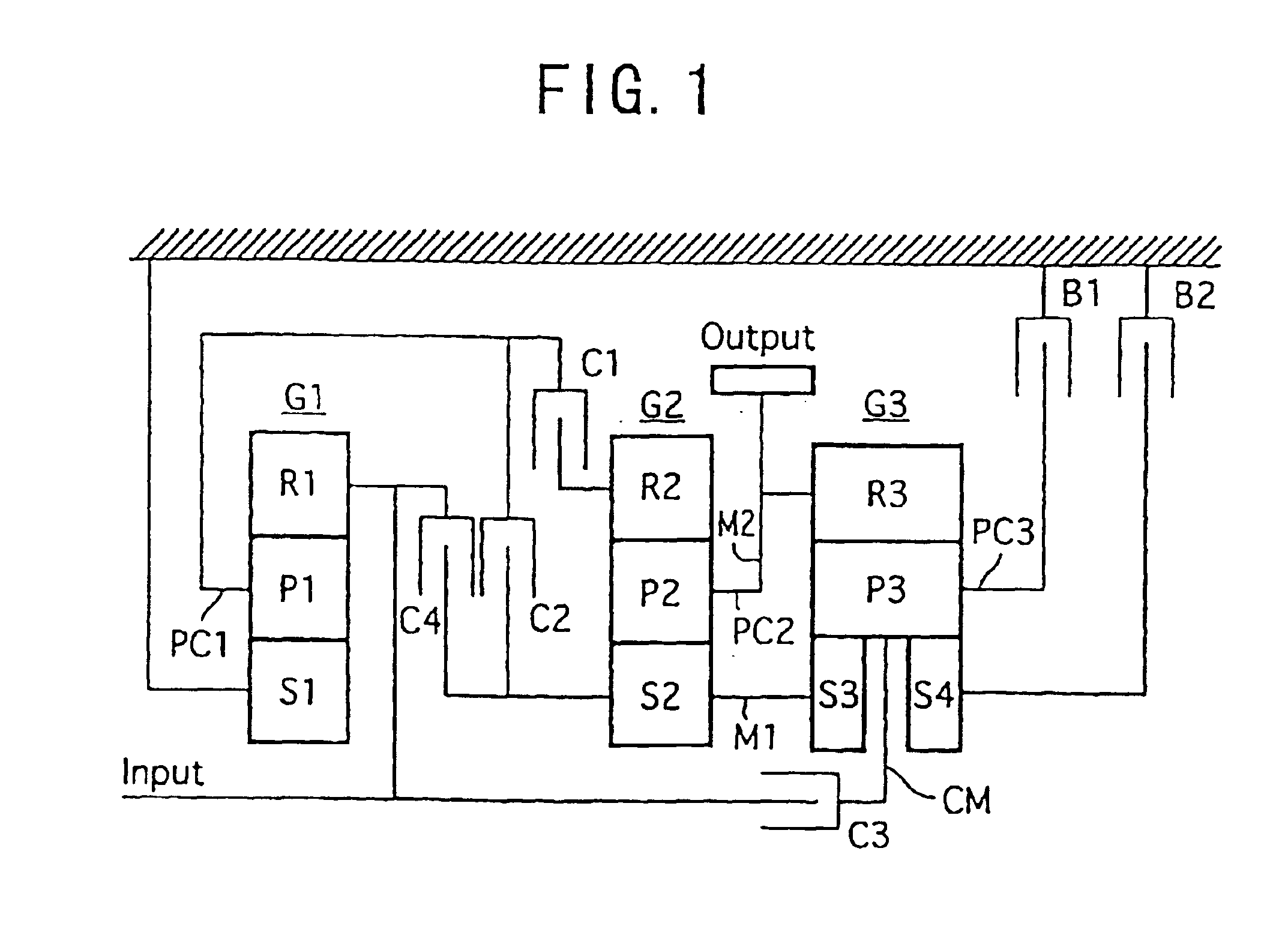

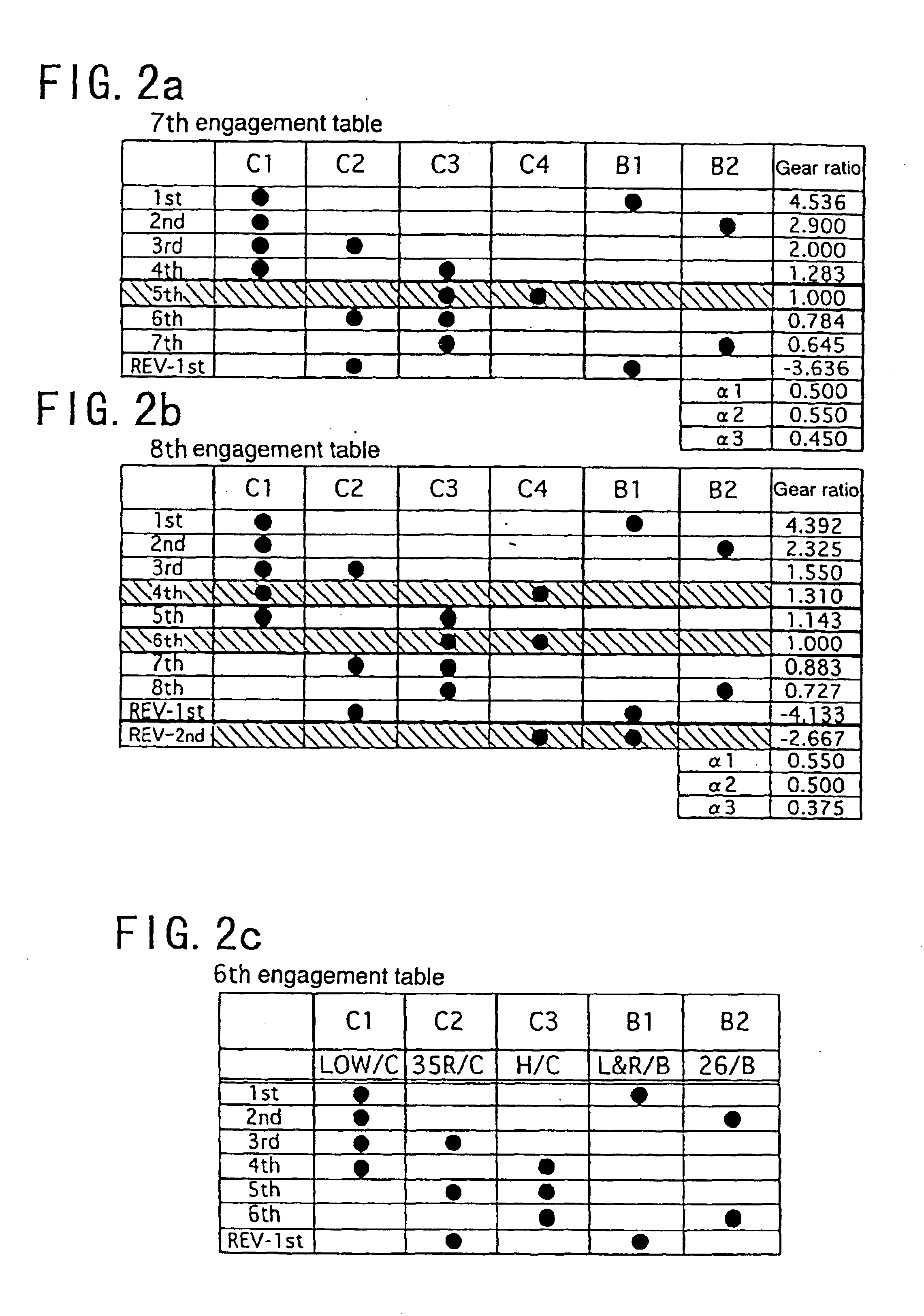

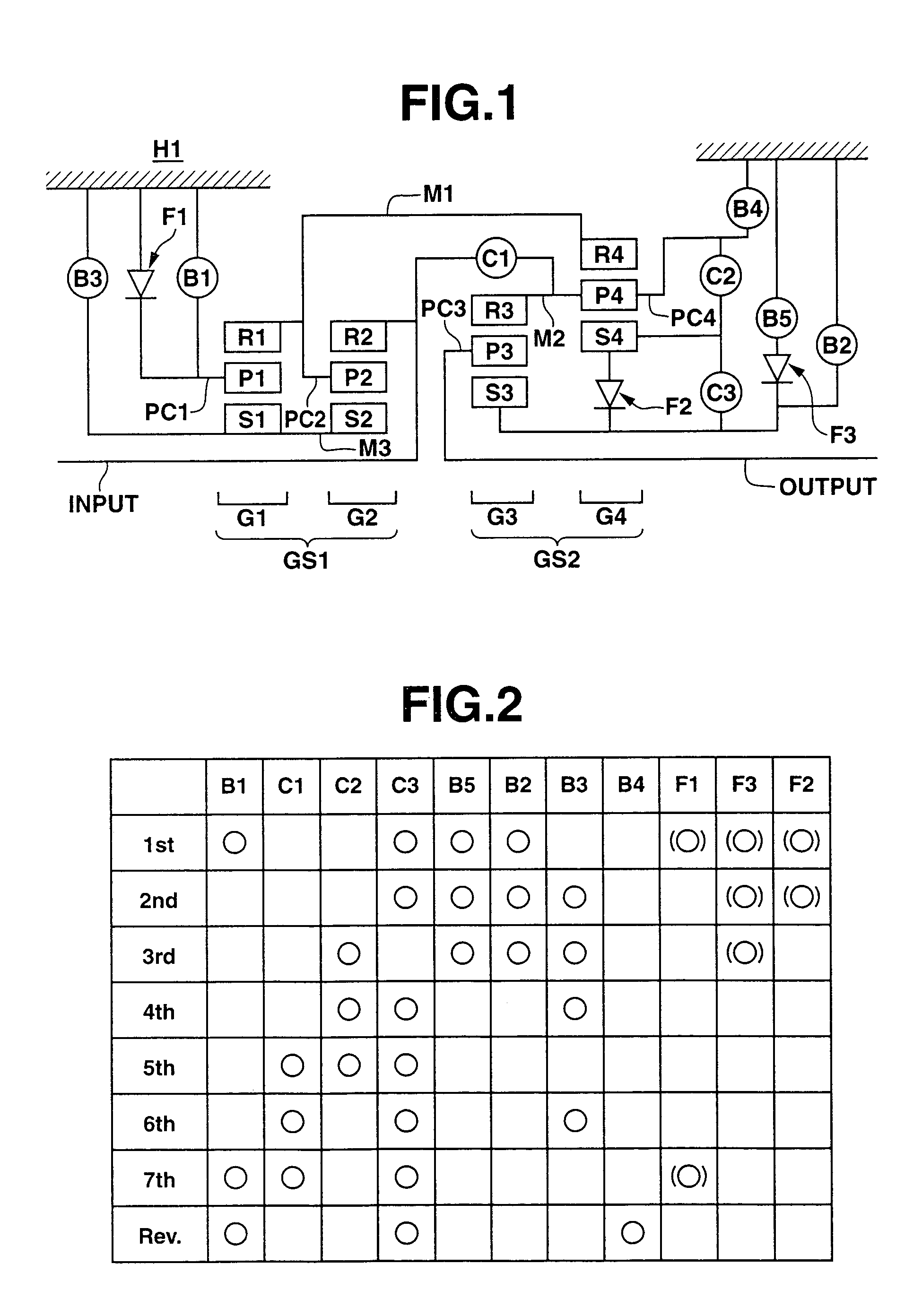

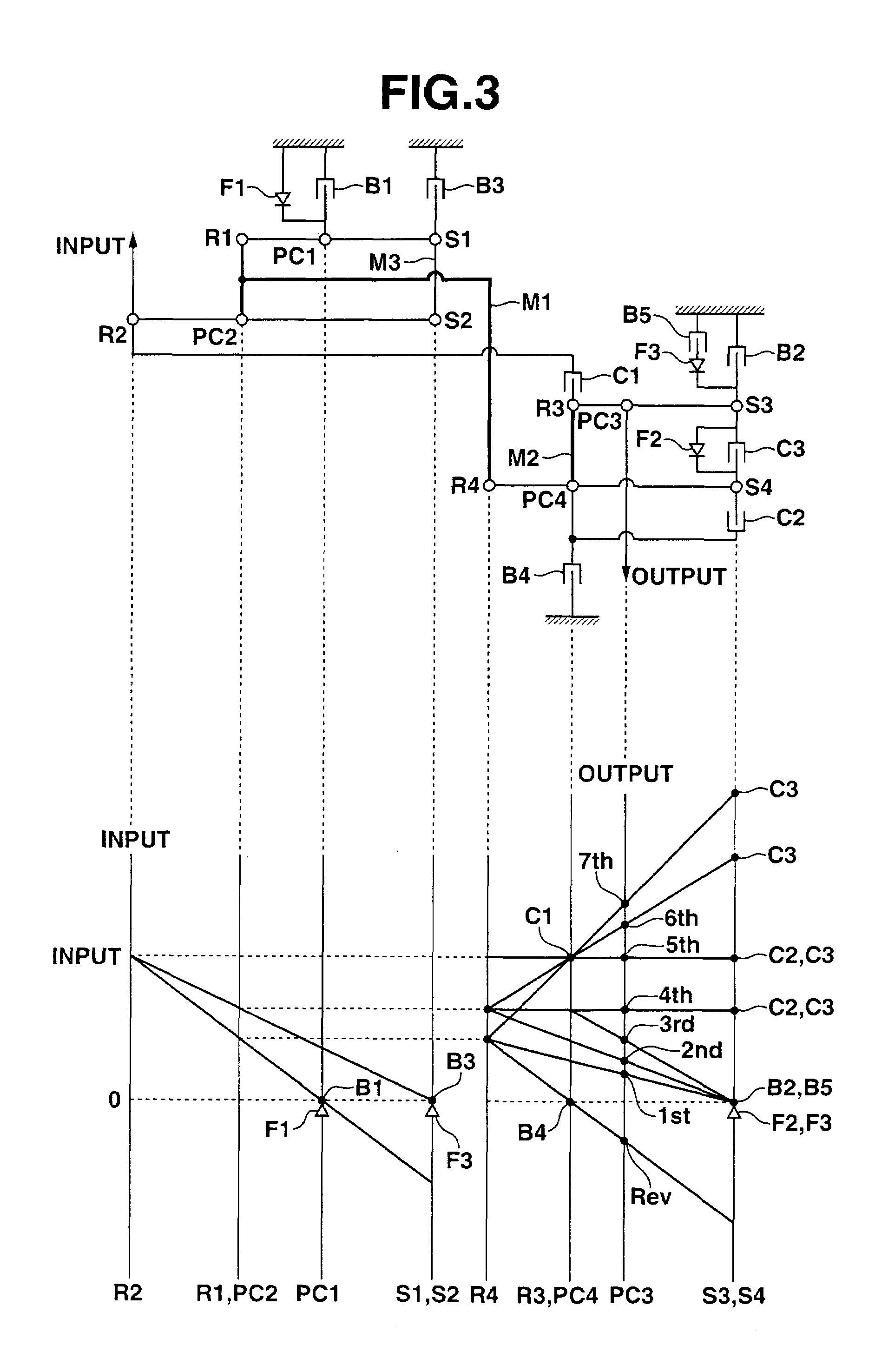

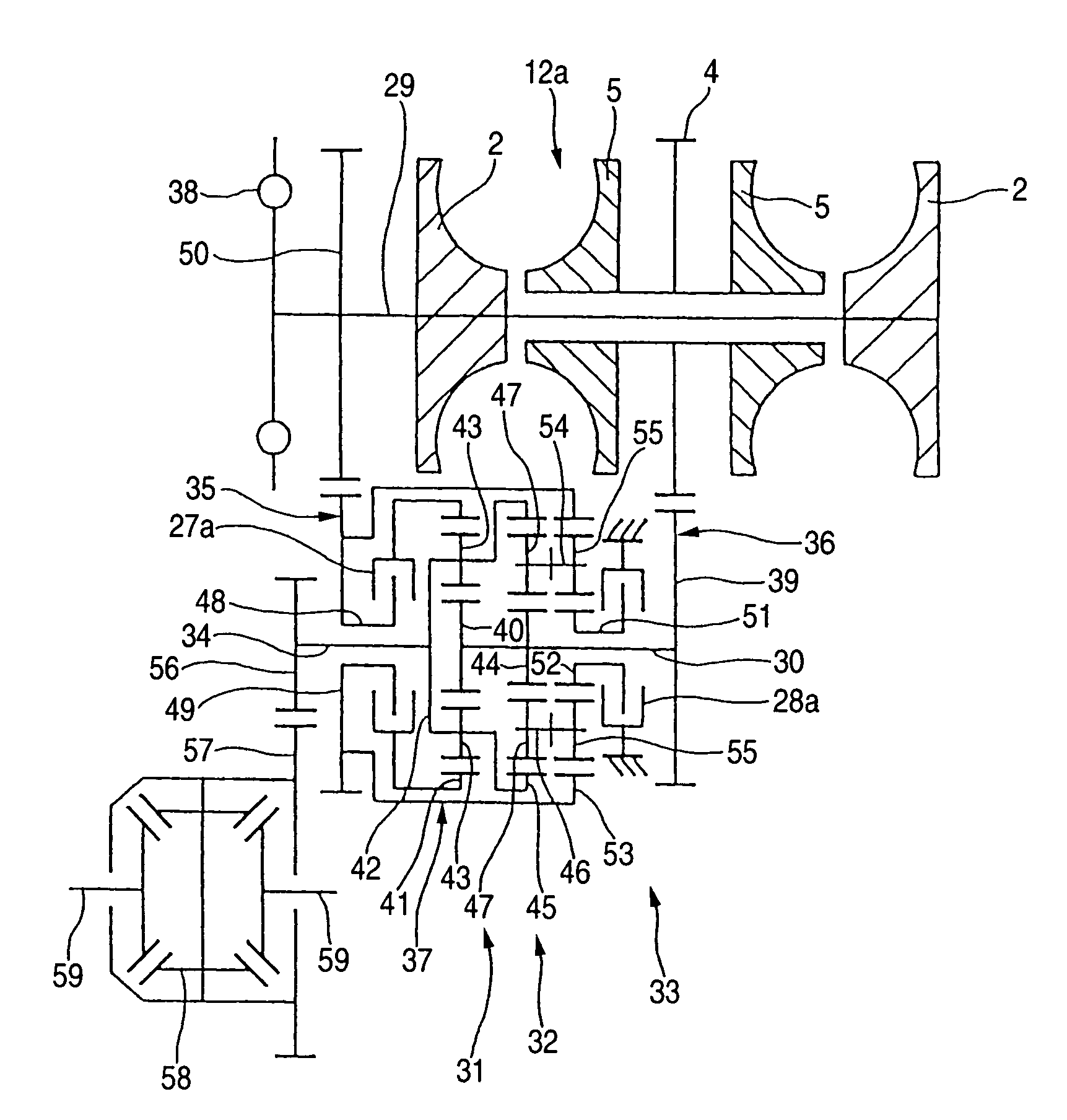

Planetary-gear-type multiple-step transmission for vehicle

InactiveUS7101305B2Small axial lengthShorten the axial lengthToothed gearingsTransmission elementsGear wheelEngineering

Owner:TOYOTA JIDOSHA KK

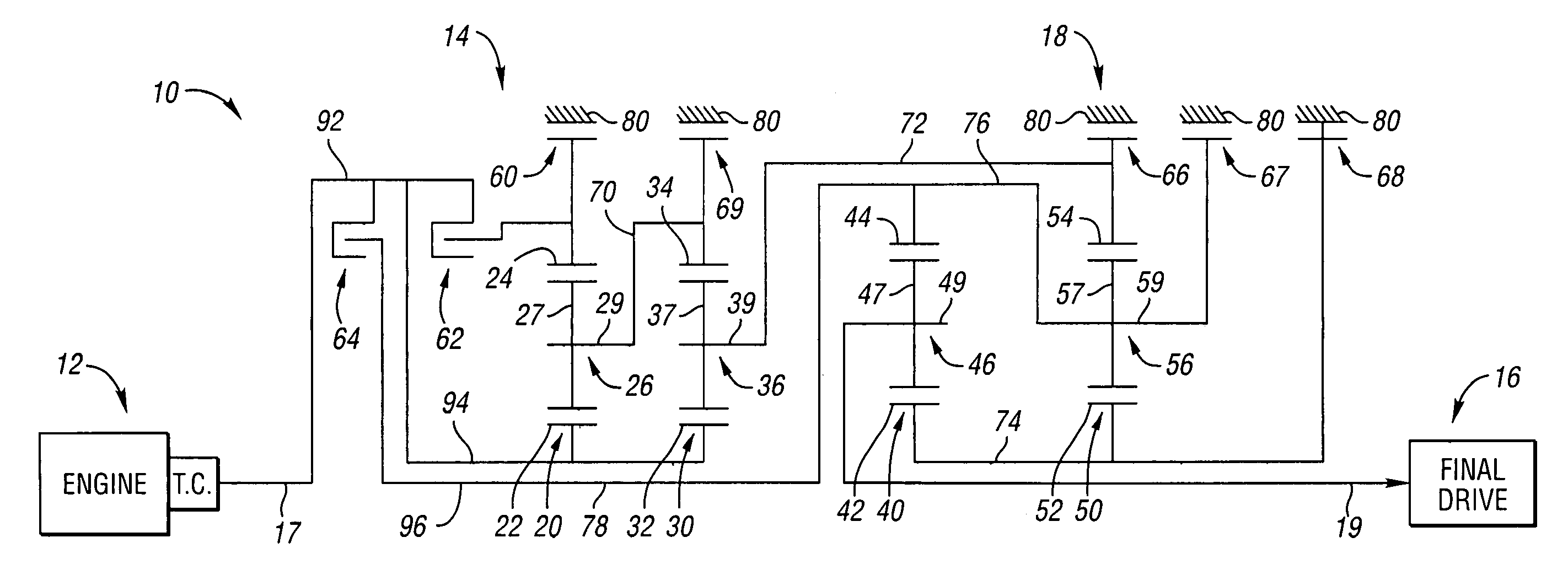

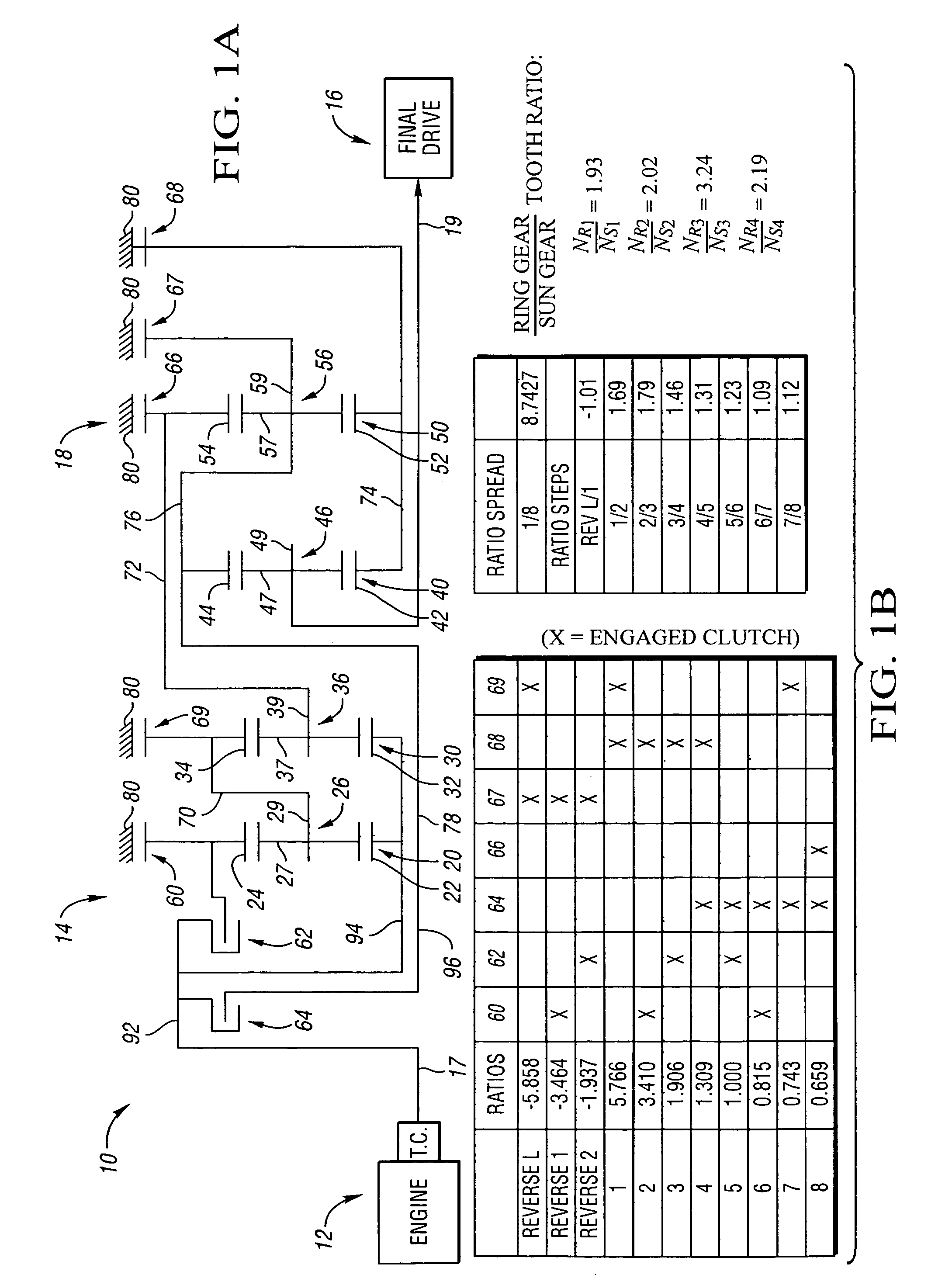

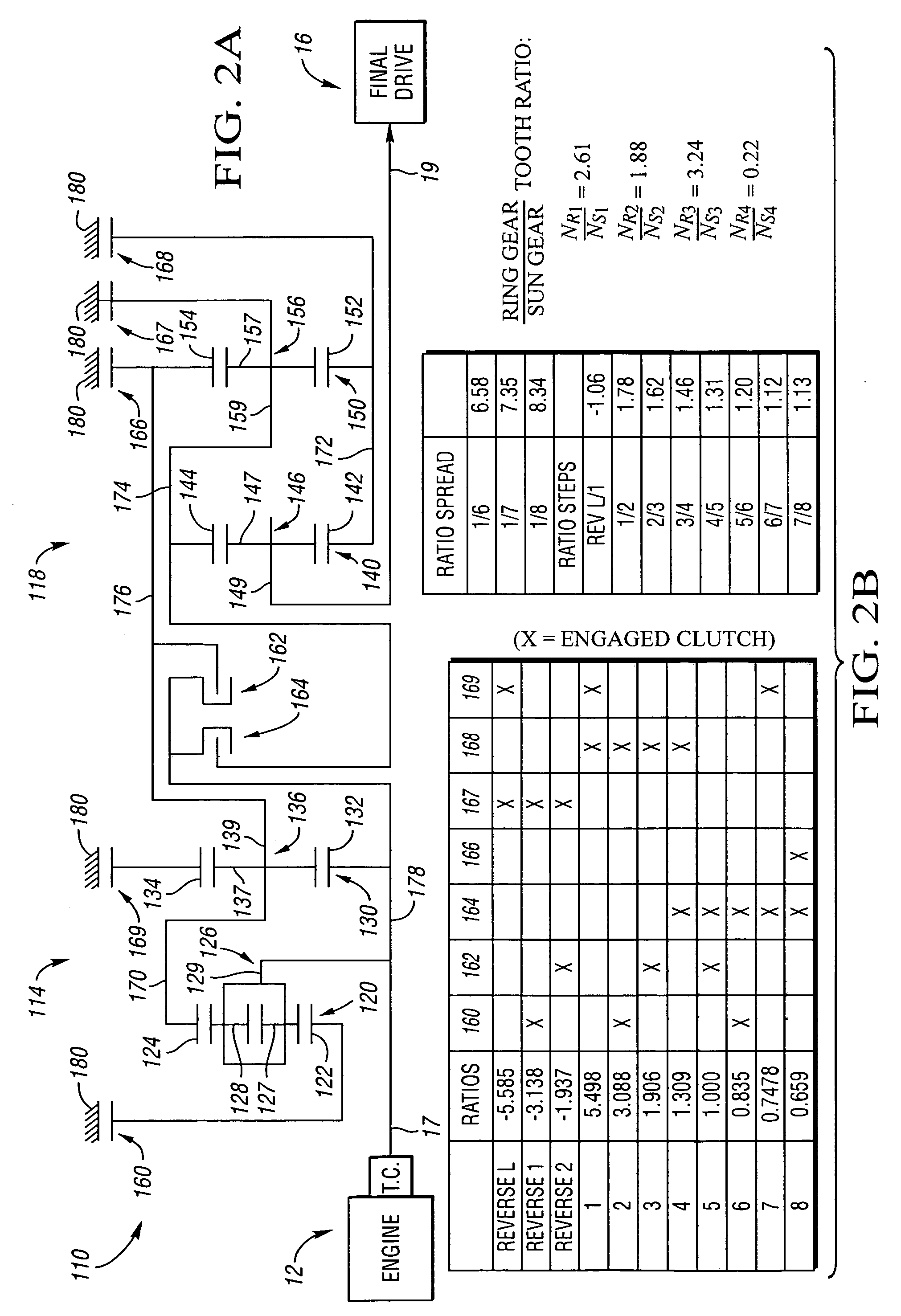

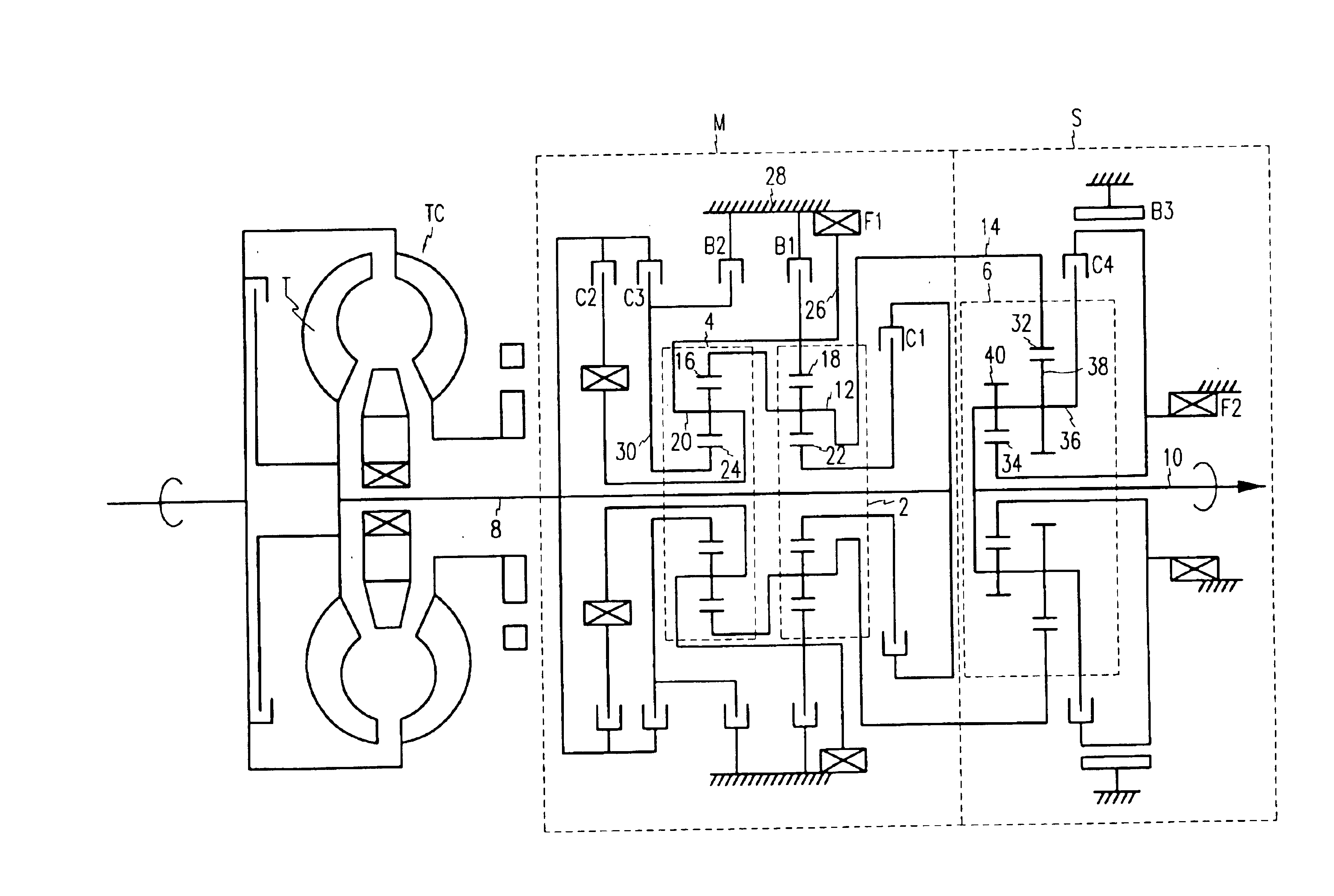

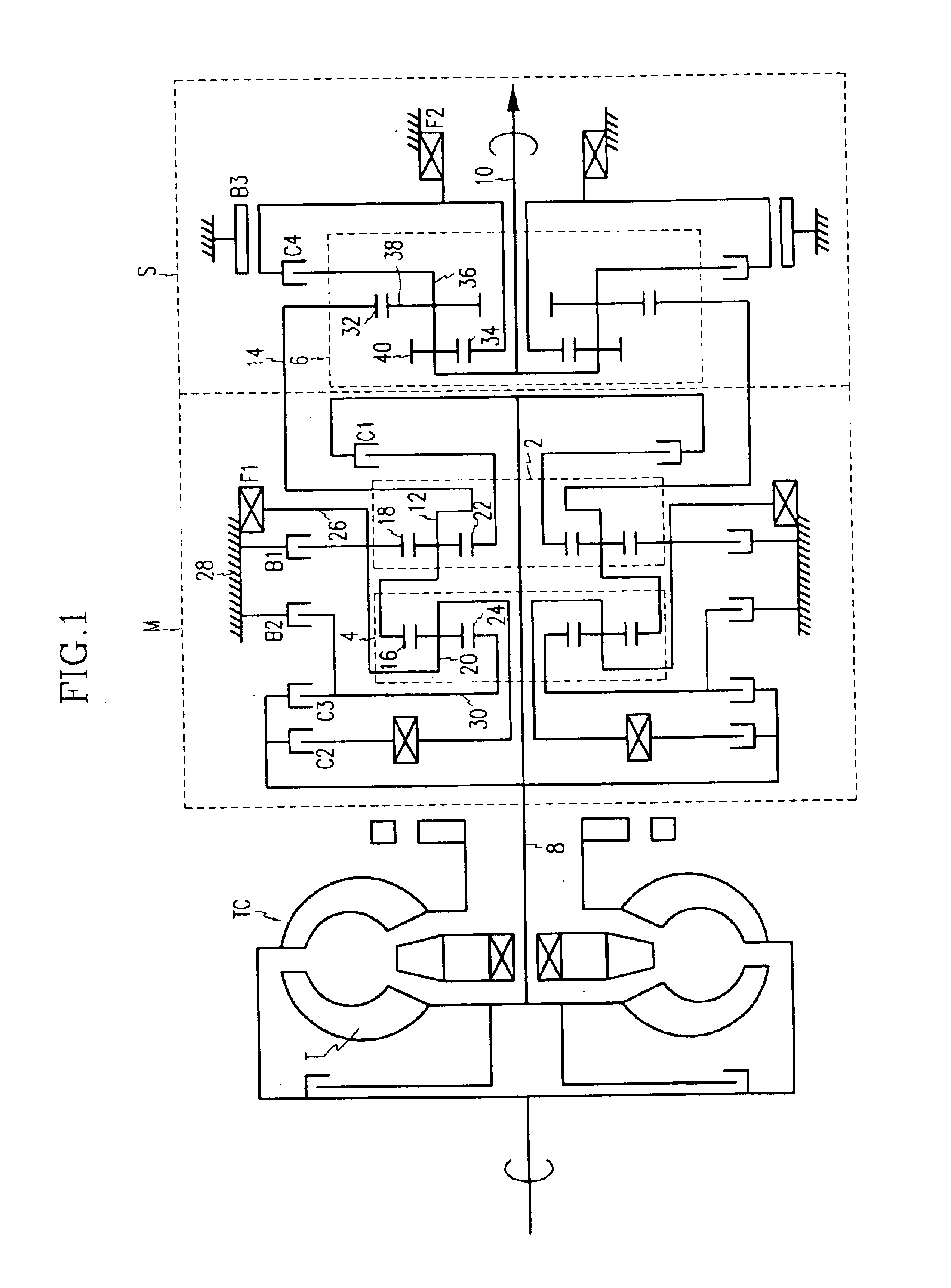

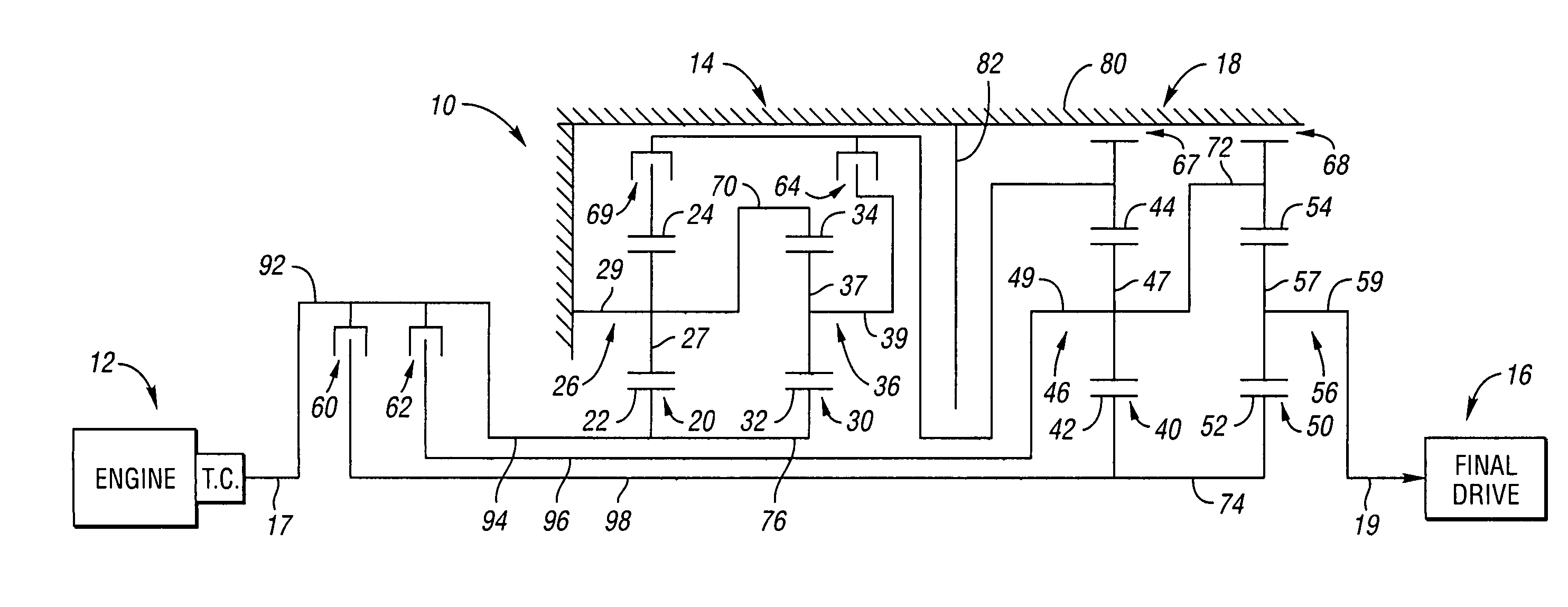

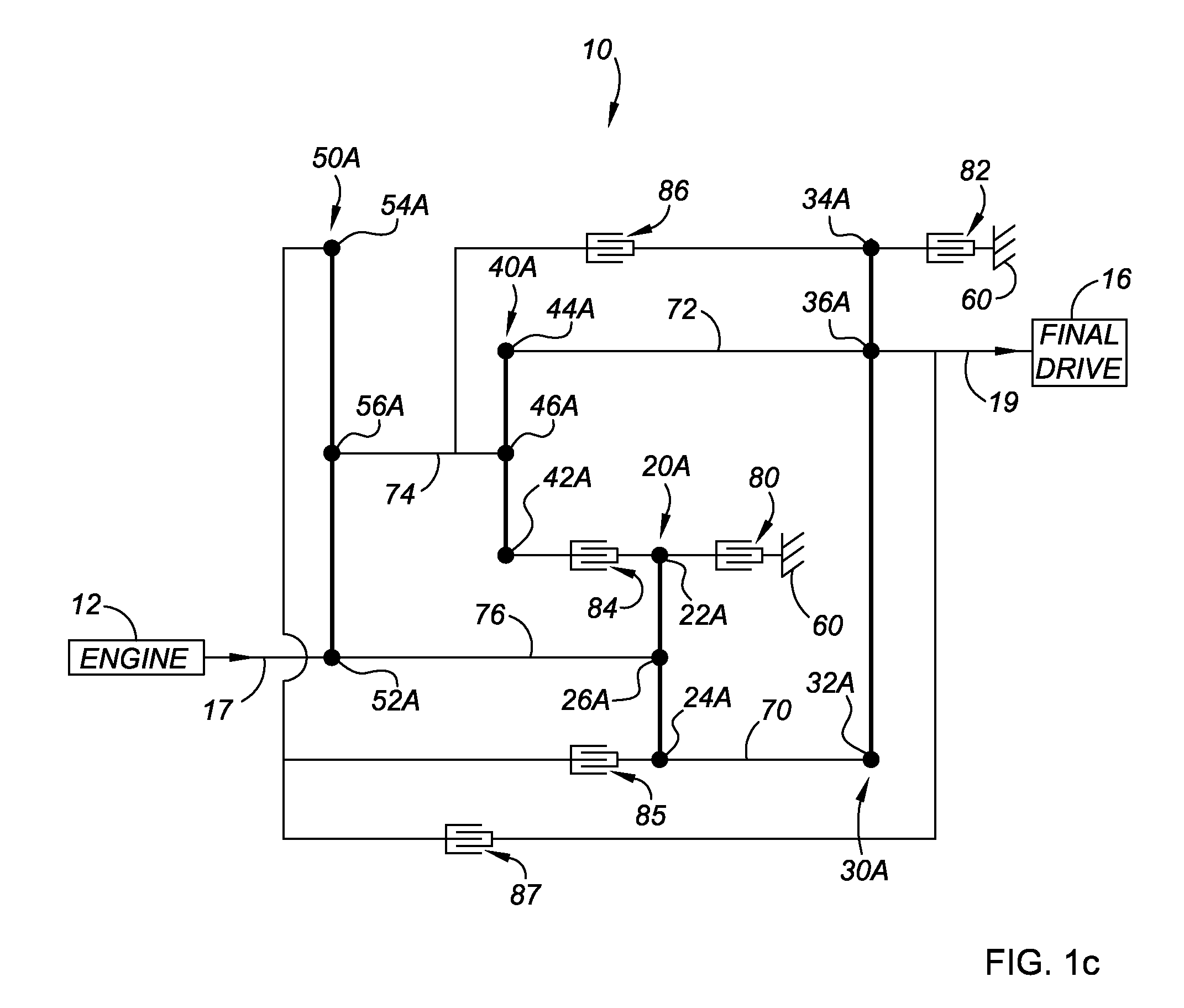

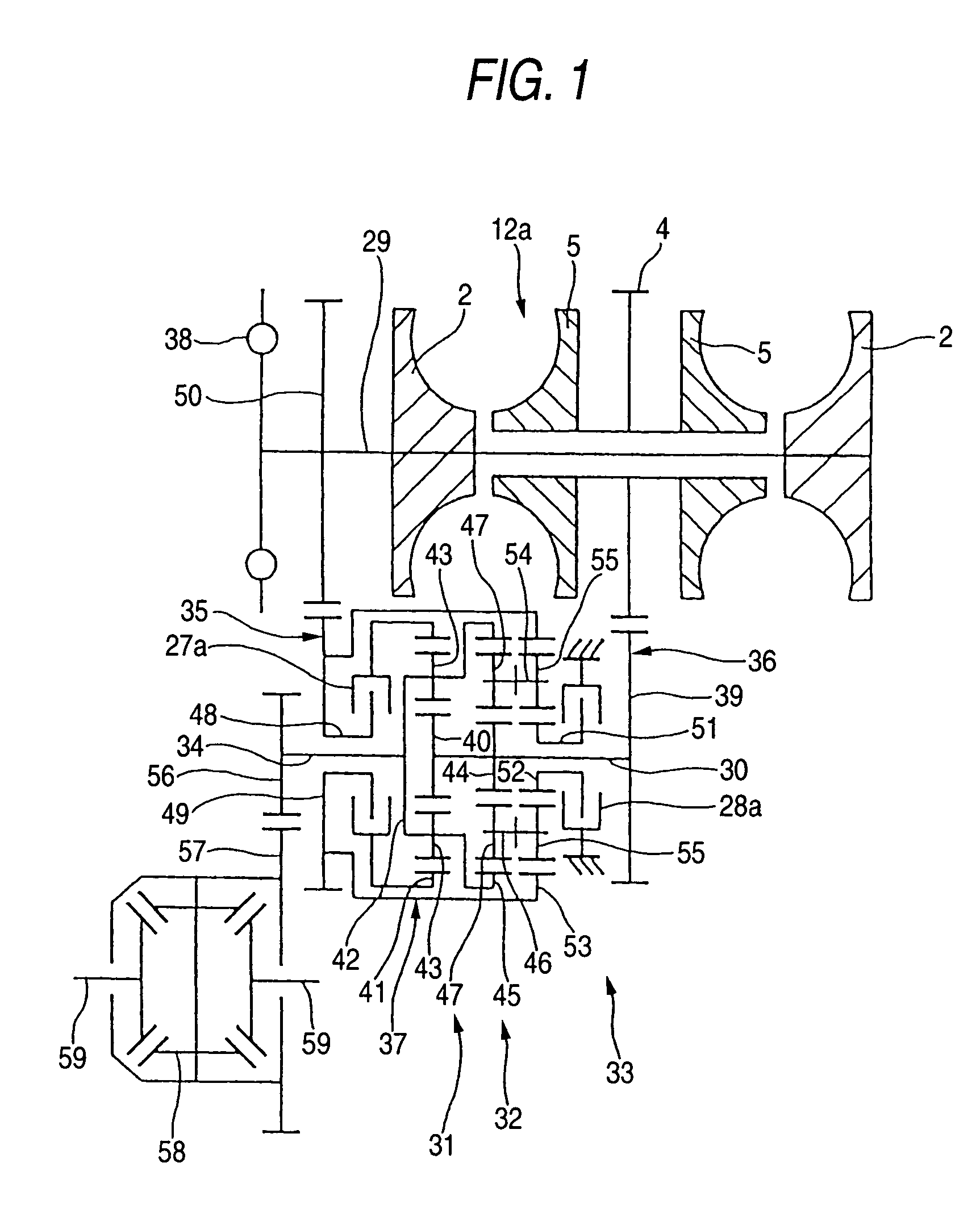

Eight-speed transmissions with four planetary gear sets

ActiveUS7163484B2Shorten speedLow sun gearToothed gearingsTransmission elementsGear wheelInterconnection

Owner:GM GLOBAL TECH OPERATIONS LLC

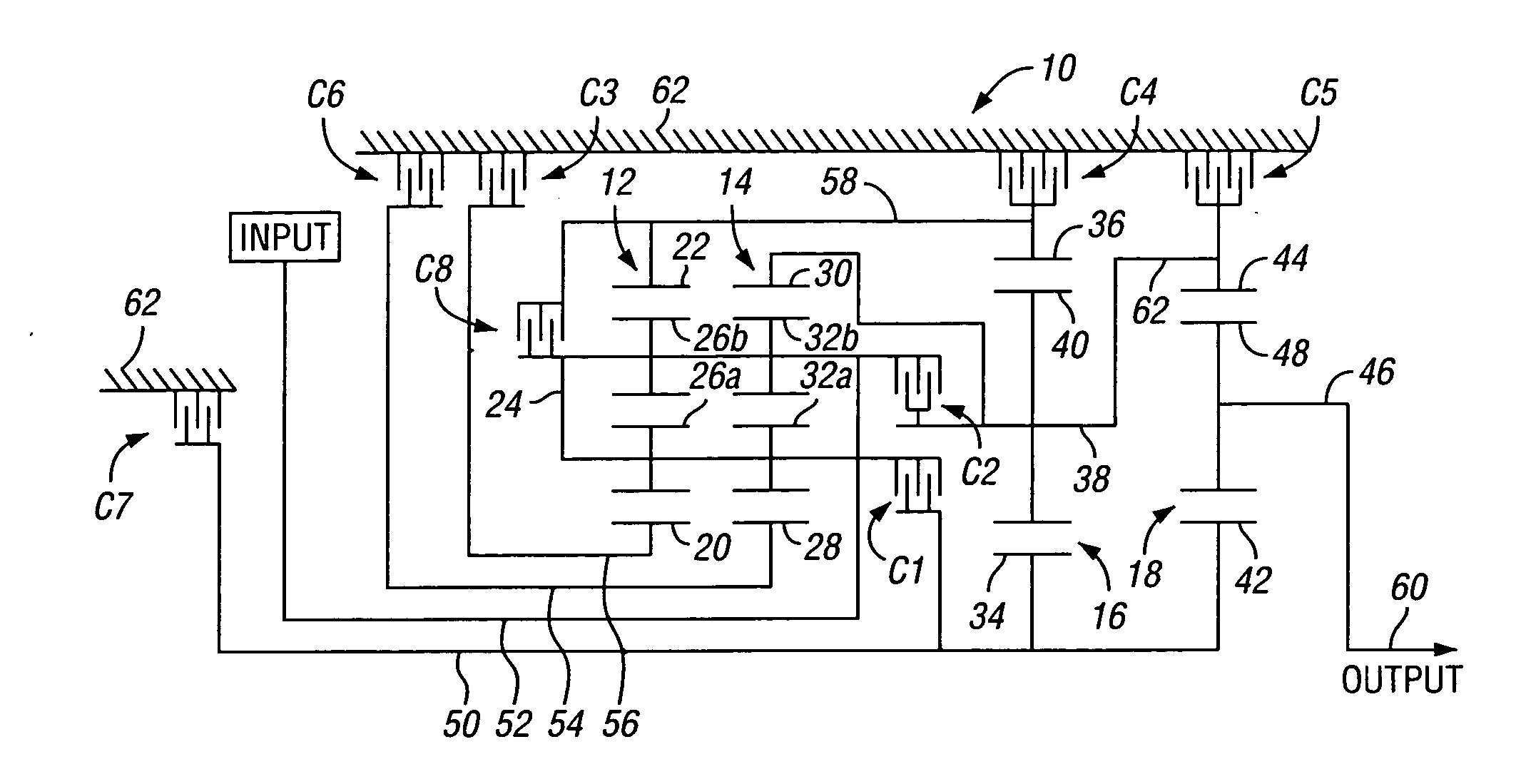

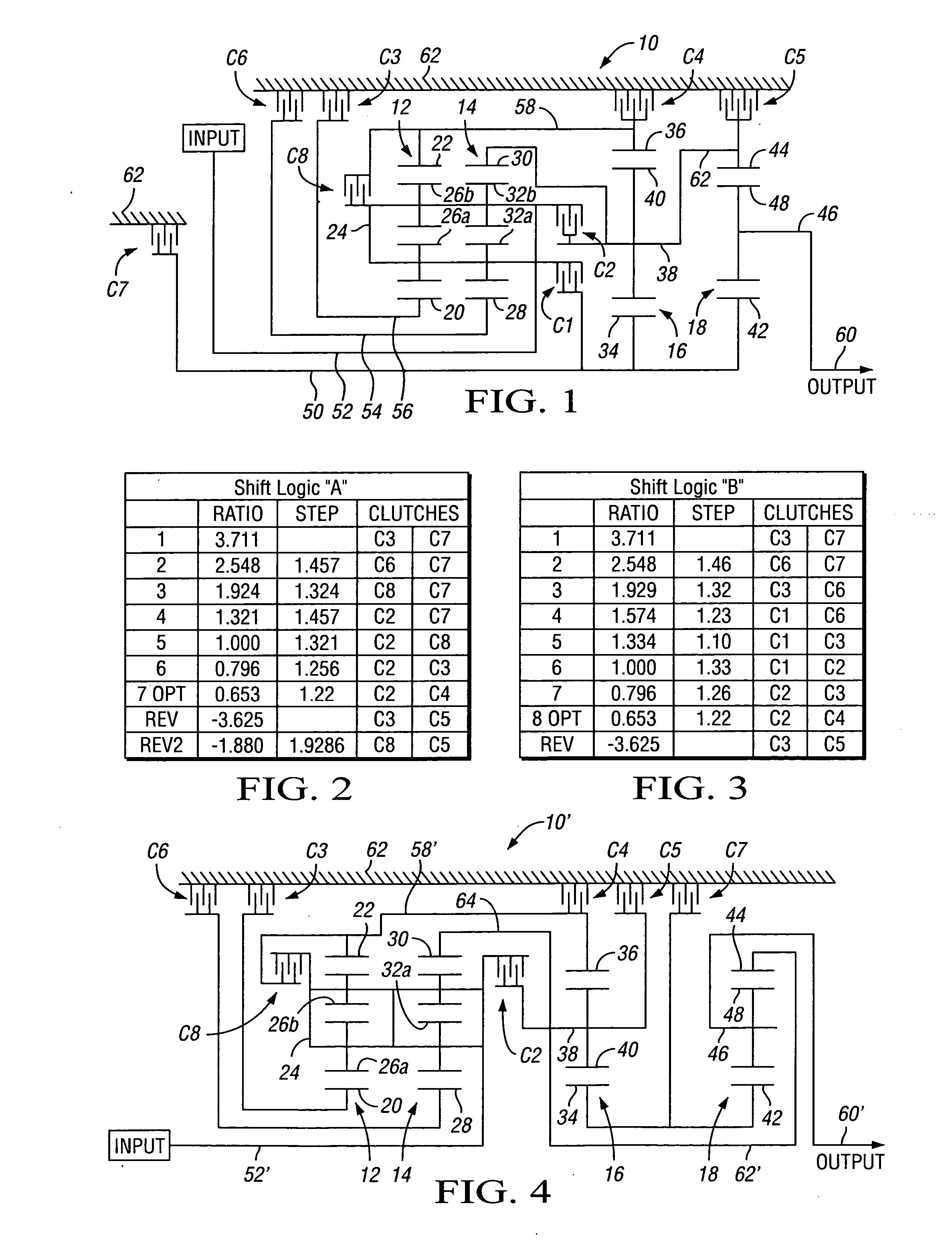

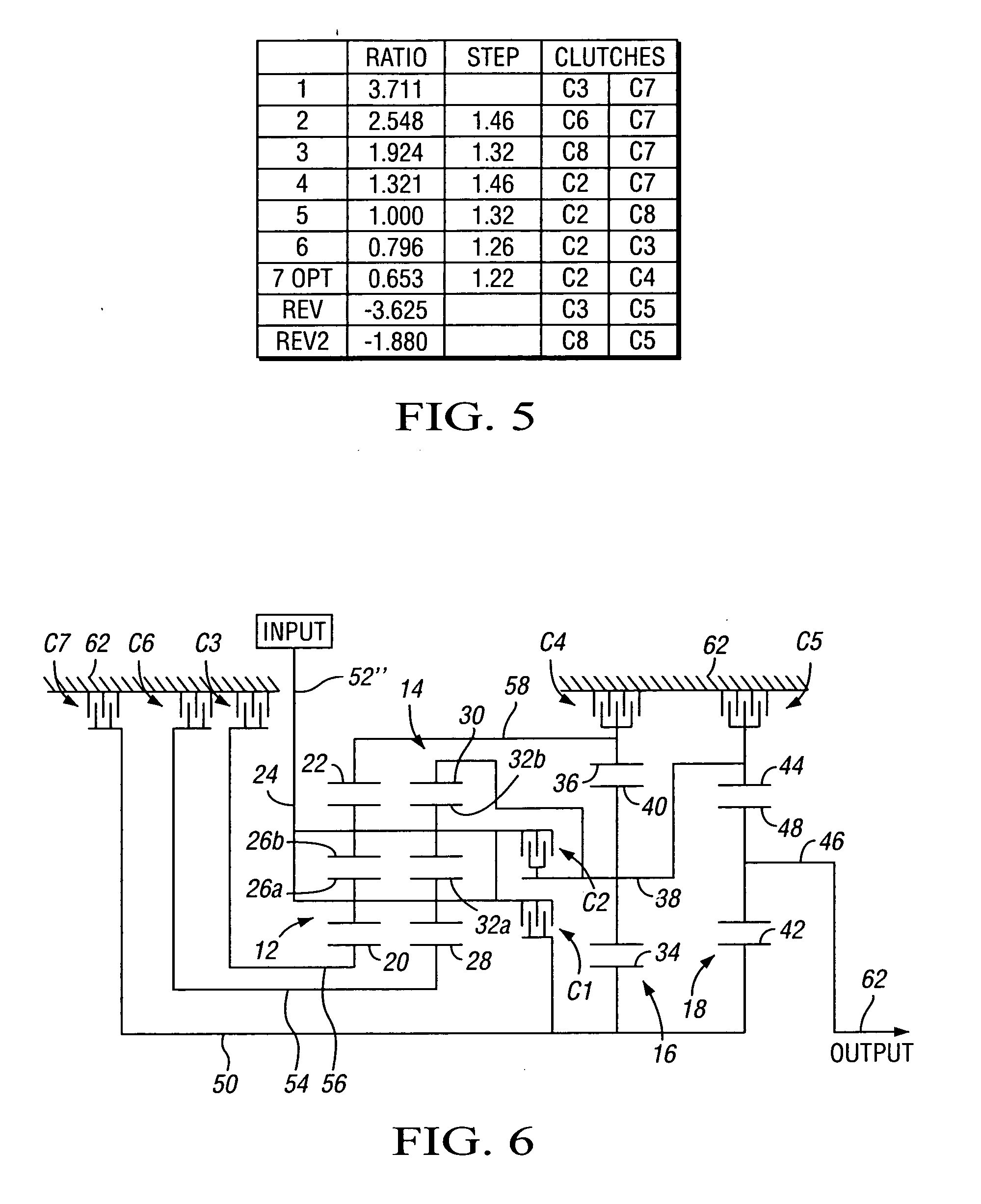

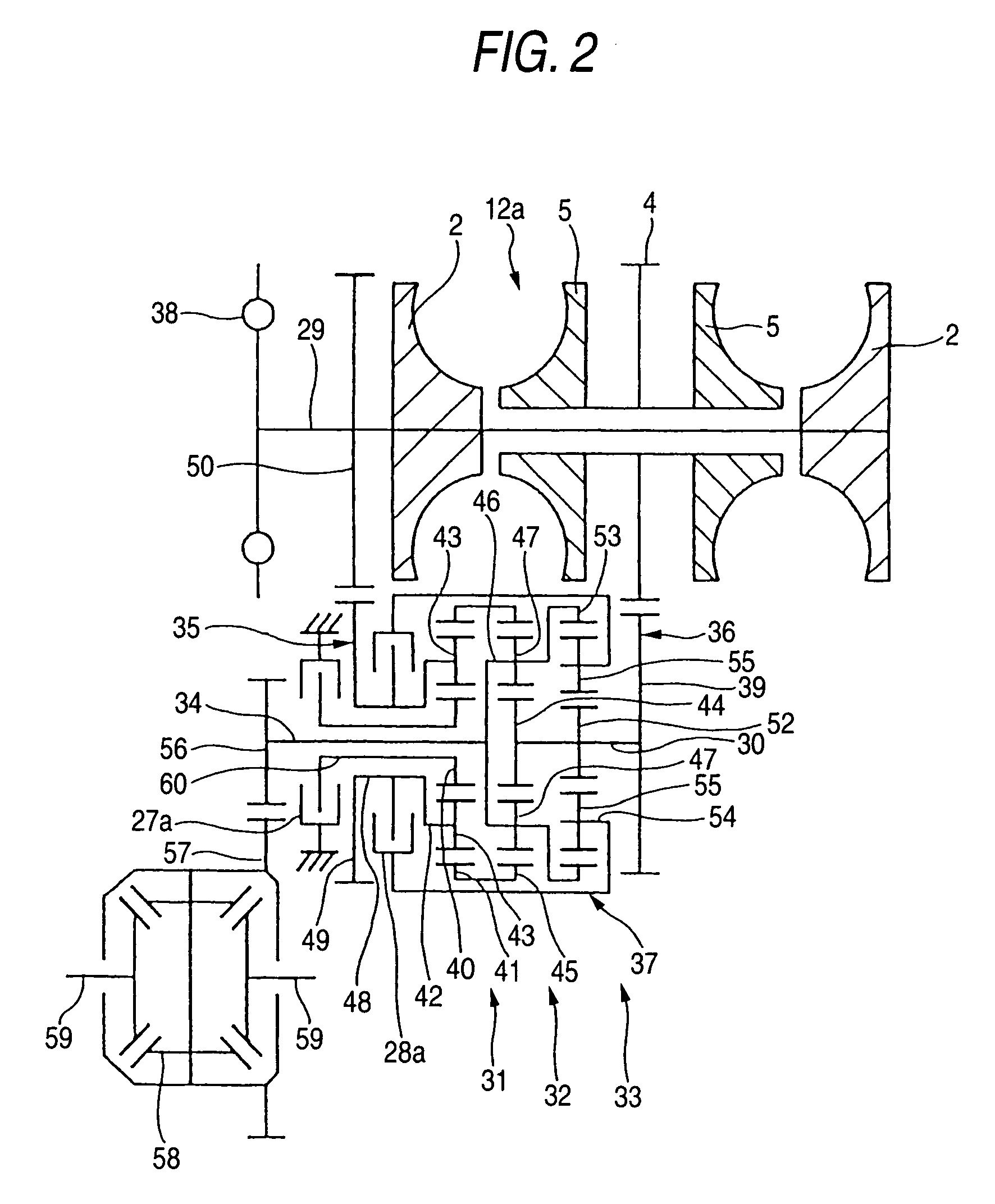

Multi speed transmission

ActiveUS20060270516A1Reduce internal loadSlow internal speedToothed gearingsTransmission elementsGear wheelEngineering

A transmission is provided having four planetary gearsets, each having respective first, second, and third members, and a plurality of selectively engageable torque transmitting devices configured to selectively interconnect selected members of the four planetary gearsets for unitary rotation thereby to provide a plurality of forward speed ratios and at least one reverse speed ratio between an input member and an output member.

Owner:ALLISON TRANSMISSION INC

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

Planetary-gear-type multiple-step transmission for vehicle

InactiveUS20050090362A1Easy constructionSmall sizeToothed gearingsTransmission elementsGear wheelEngineering

Owner:TOYOTA JIDOSHA KK

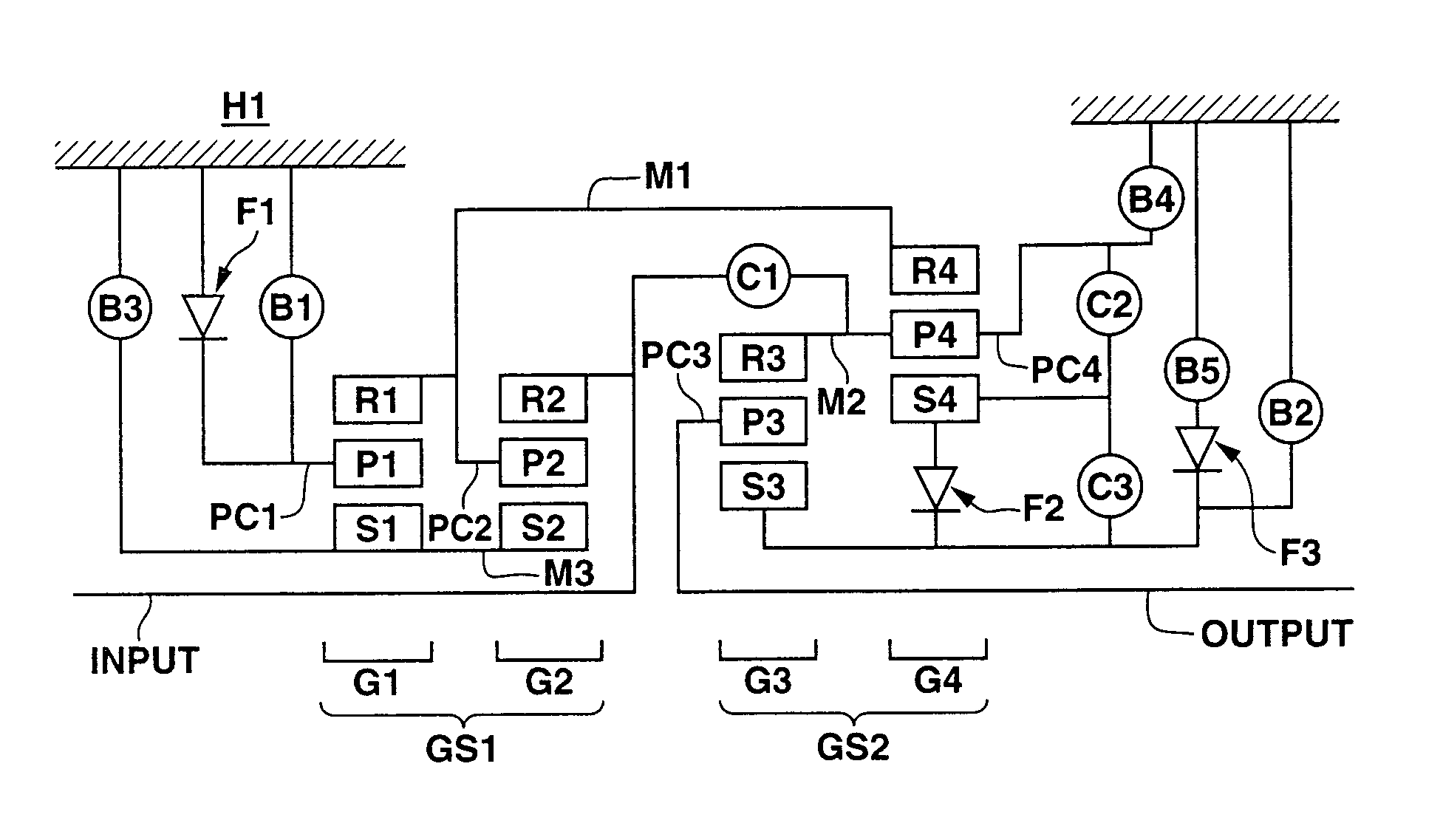

Six-speed powertrain and hydraulic control system for automatic transmission

InactiveUS6840885B2Improve power performanceImprove shift feelToothed gearingsGearing controlAutomatic transmissionControl system

The powertrain of a six-speed powertrain and a hydraulic control system includes a main shift section of first and second single pinion planetary gearsets, in which a first planet carrier is fixedly connected to a second ring gear. The powertrain also includes a first ring gear fixedly connected to a second planet carrier, and a first sun gear. The second planet carrier, and a second sun gear are variably connected to an input shaft through first, second, and third clutches, respectively. A connecting member connecting the first ring gear and the second planet carrier is variably connected to a housing through a first brake and a first one-way clutch. The second sun gear being variably connected to the housing by a second brake. The powertrain also includes a secondary shift section realized through a third single pinion planetary gearset, in which a third sun gear is connected to a third planet carrier via a fourth clutch, and is also connected to the housing through a third brake and a second one-way clutch.

Owner:HYUNDAI MOTOR CO LTD

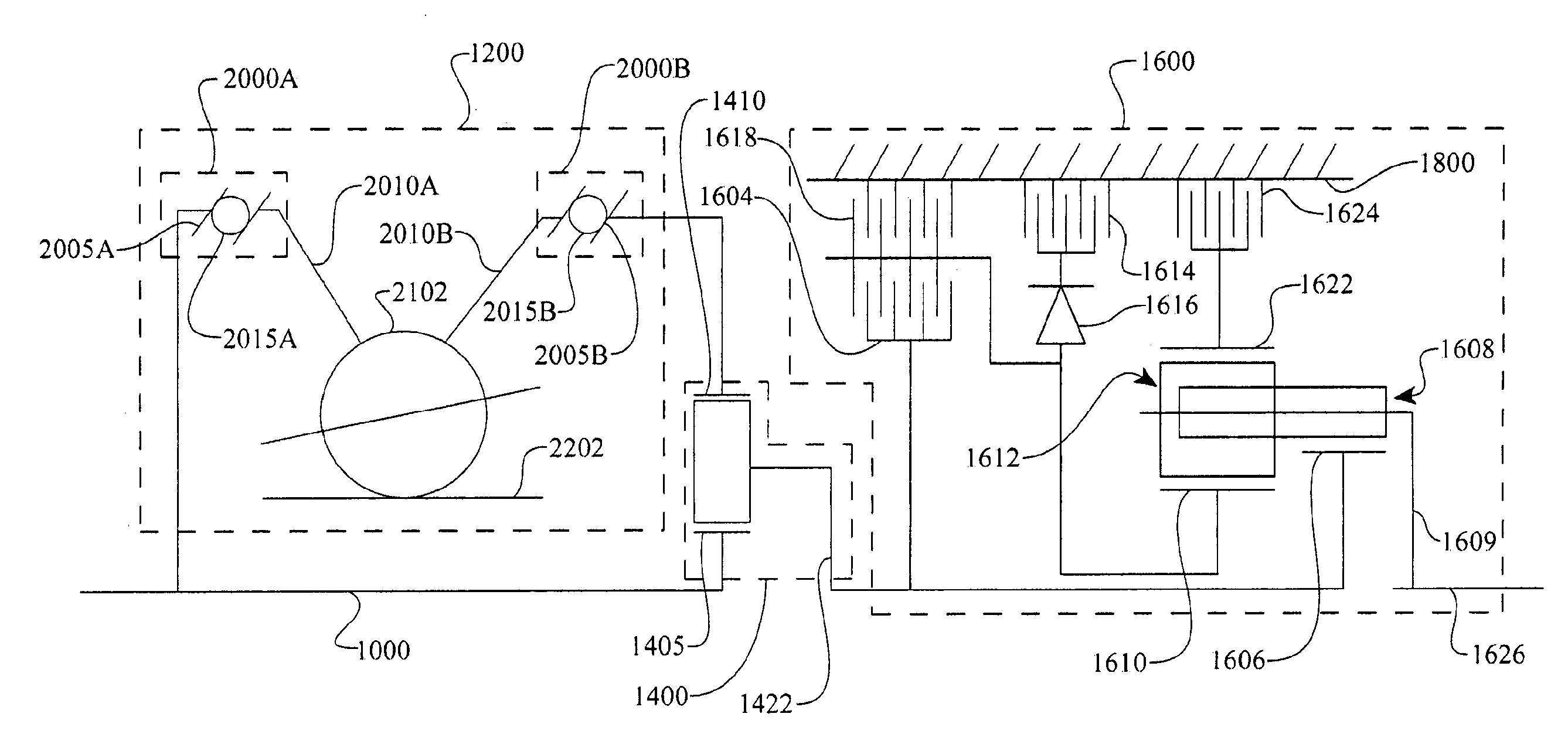

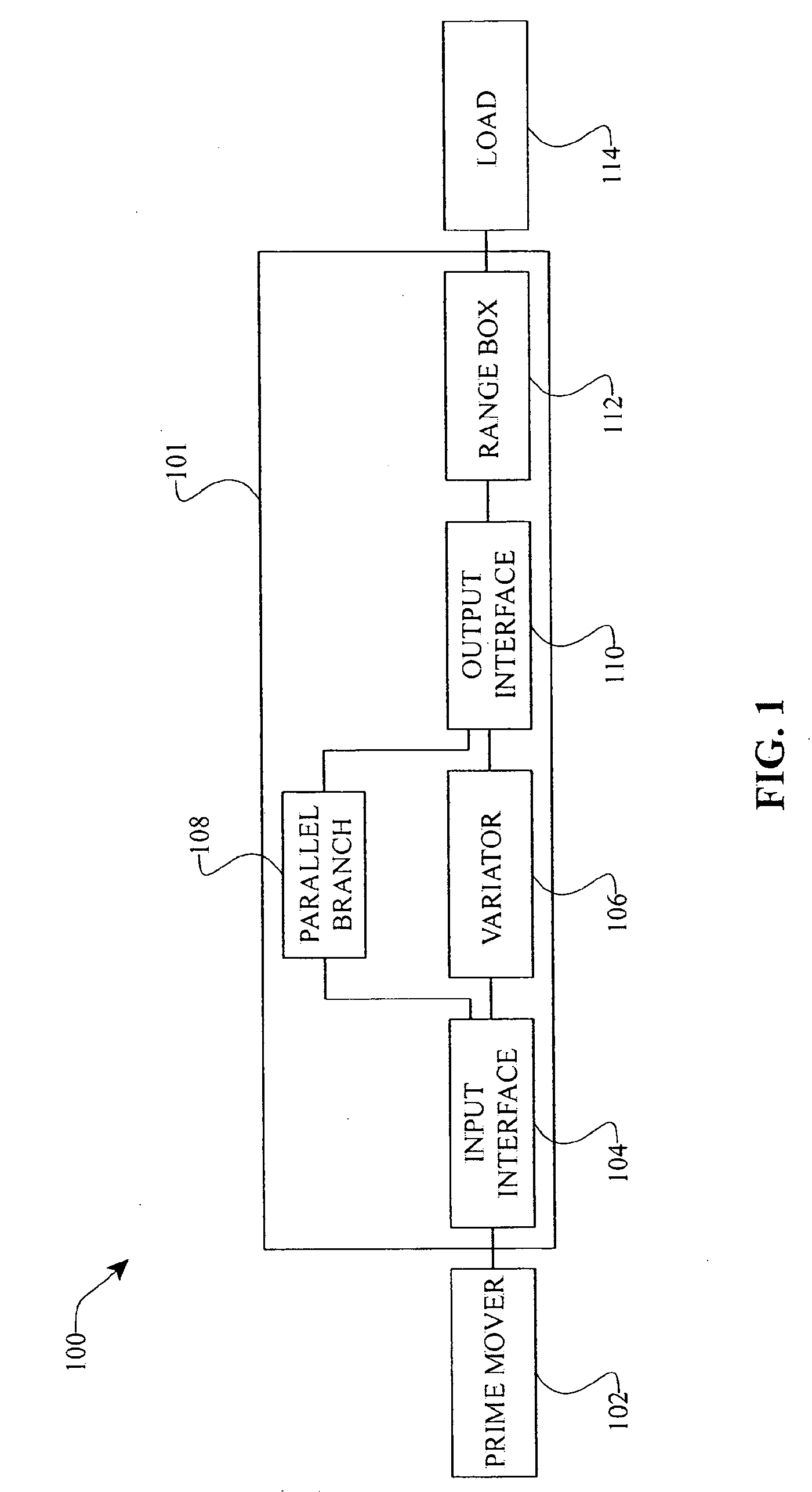

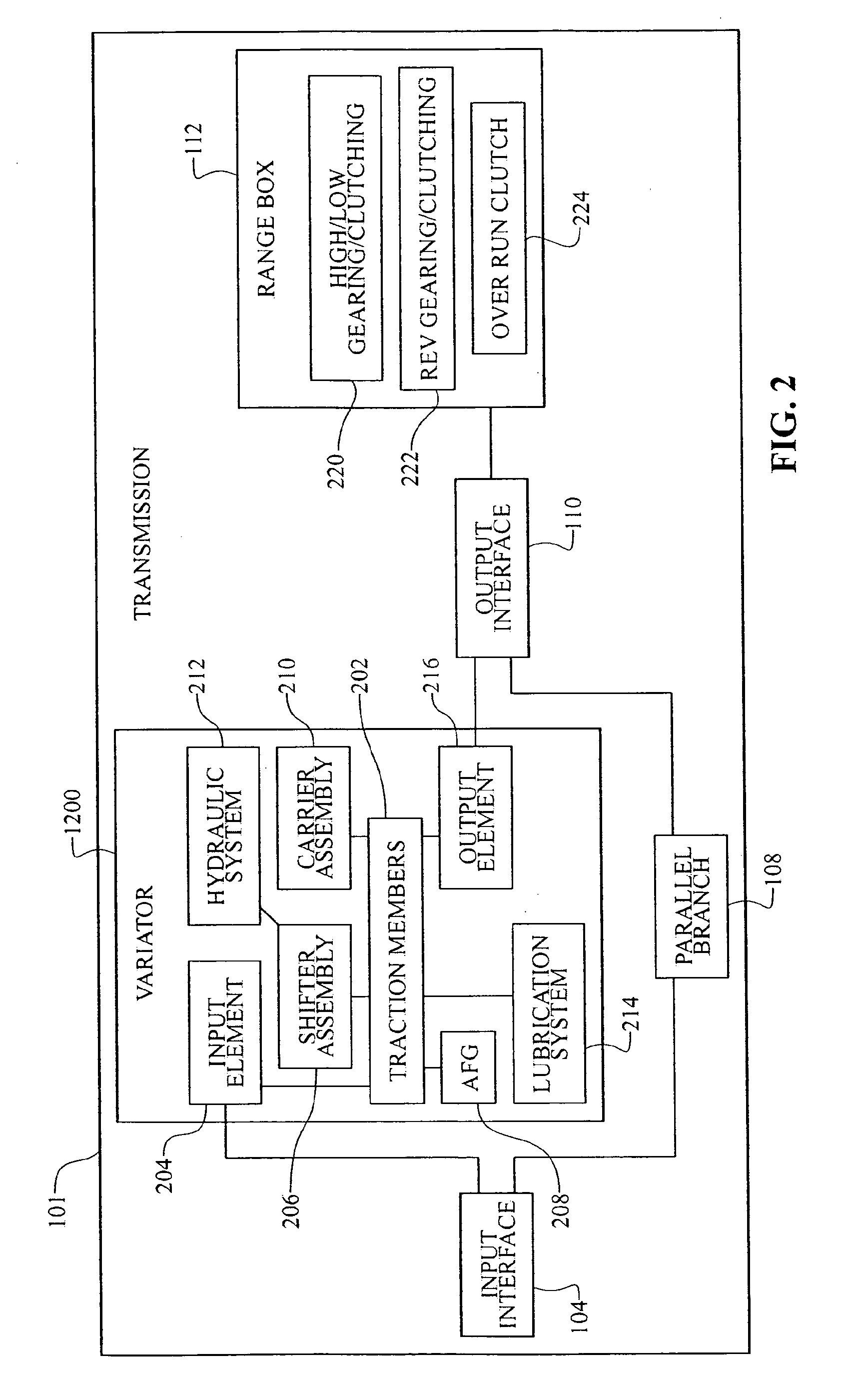

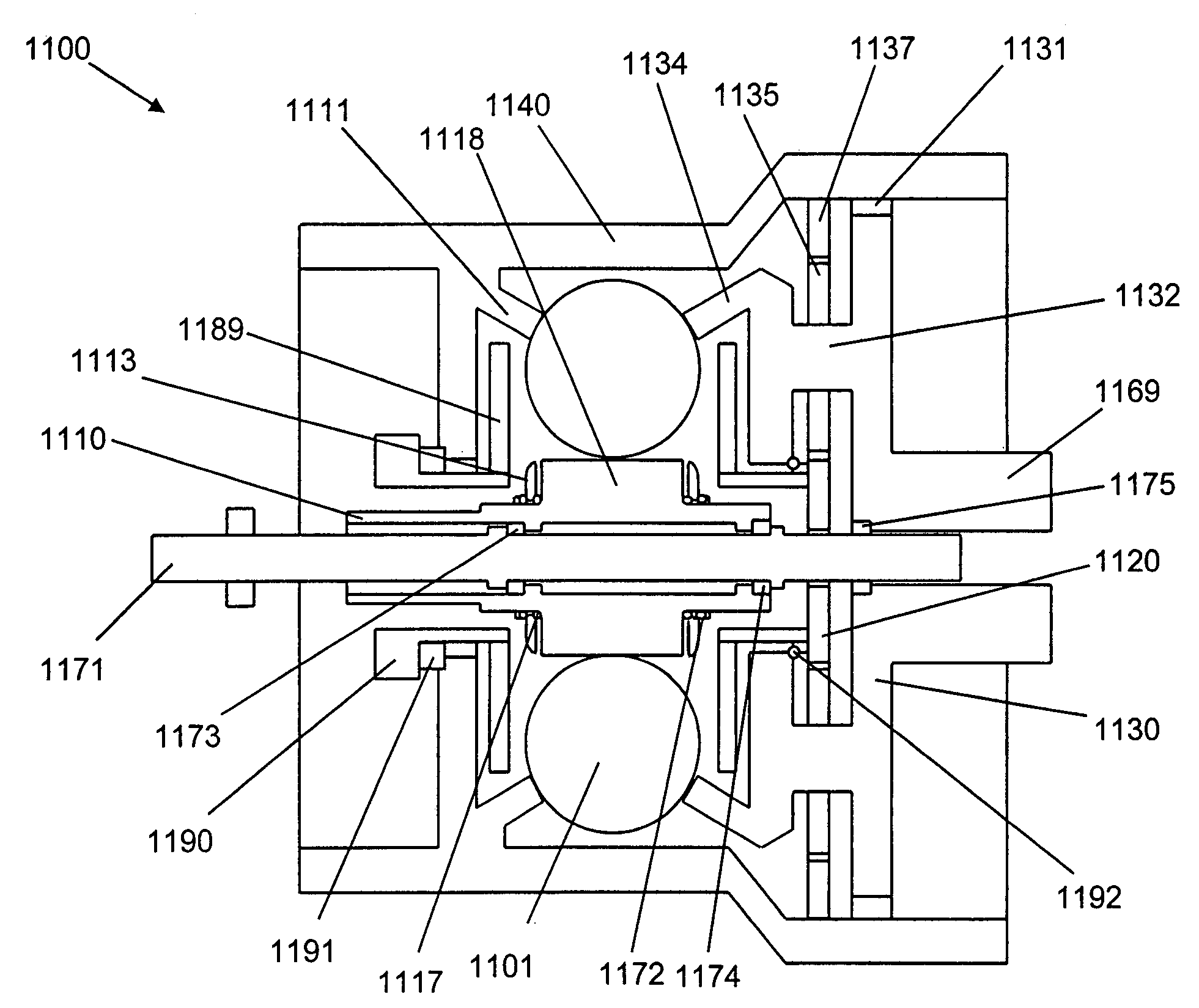

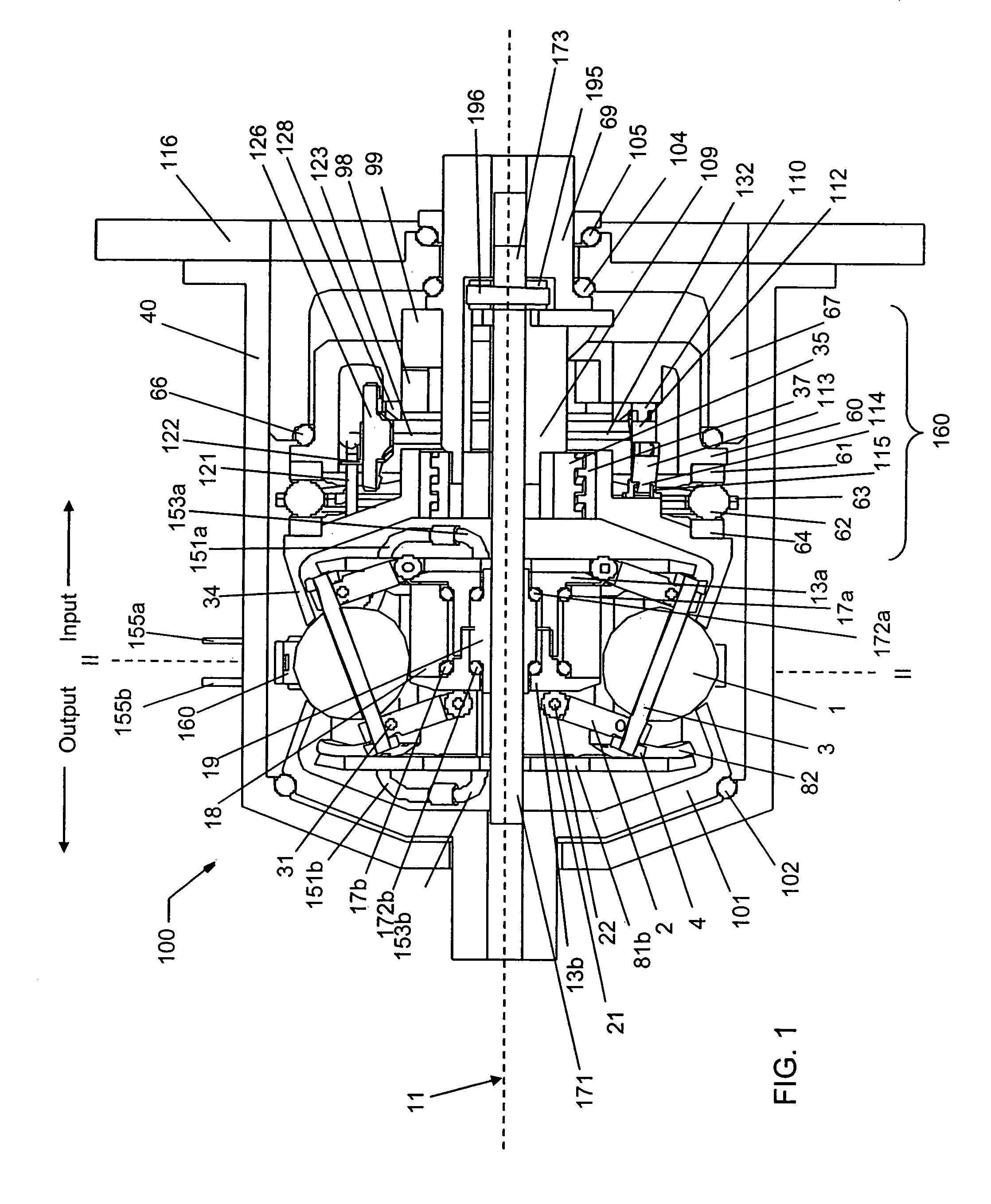

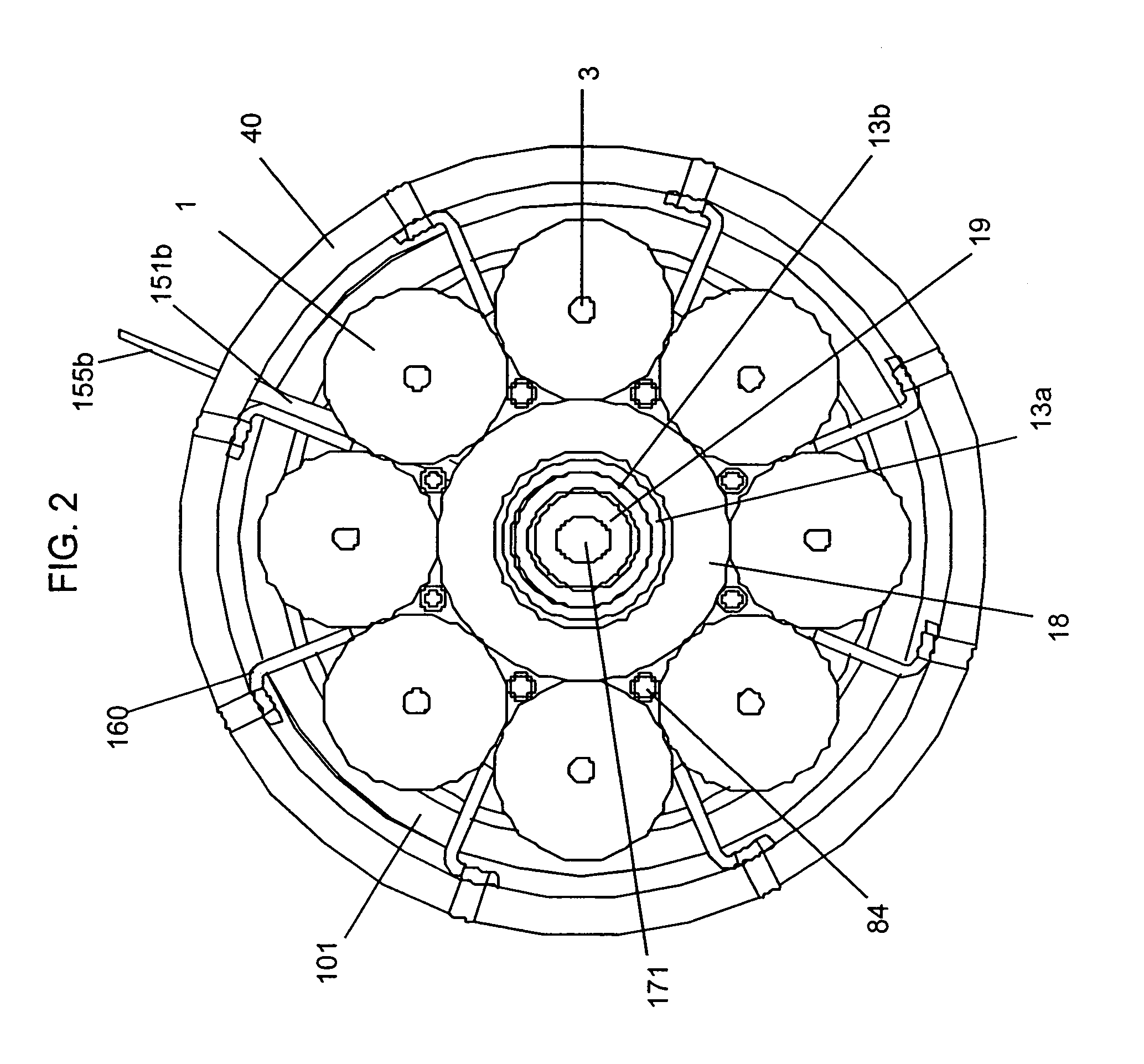

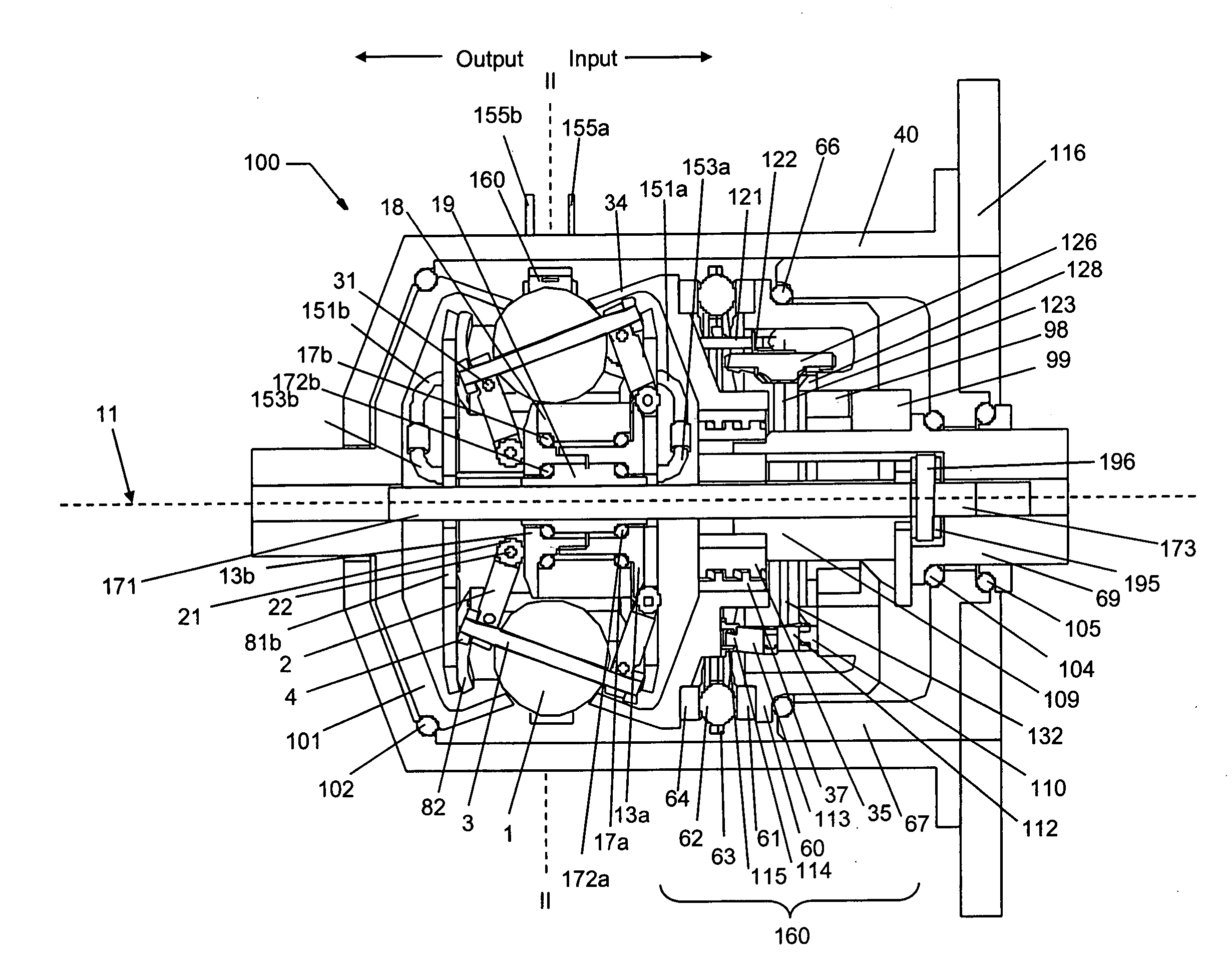

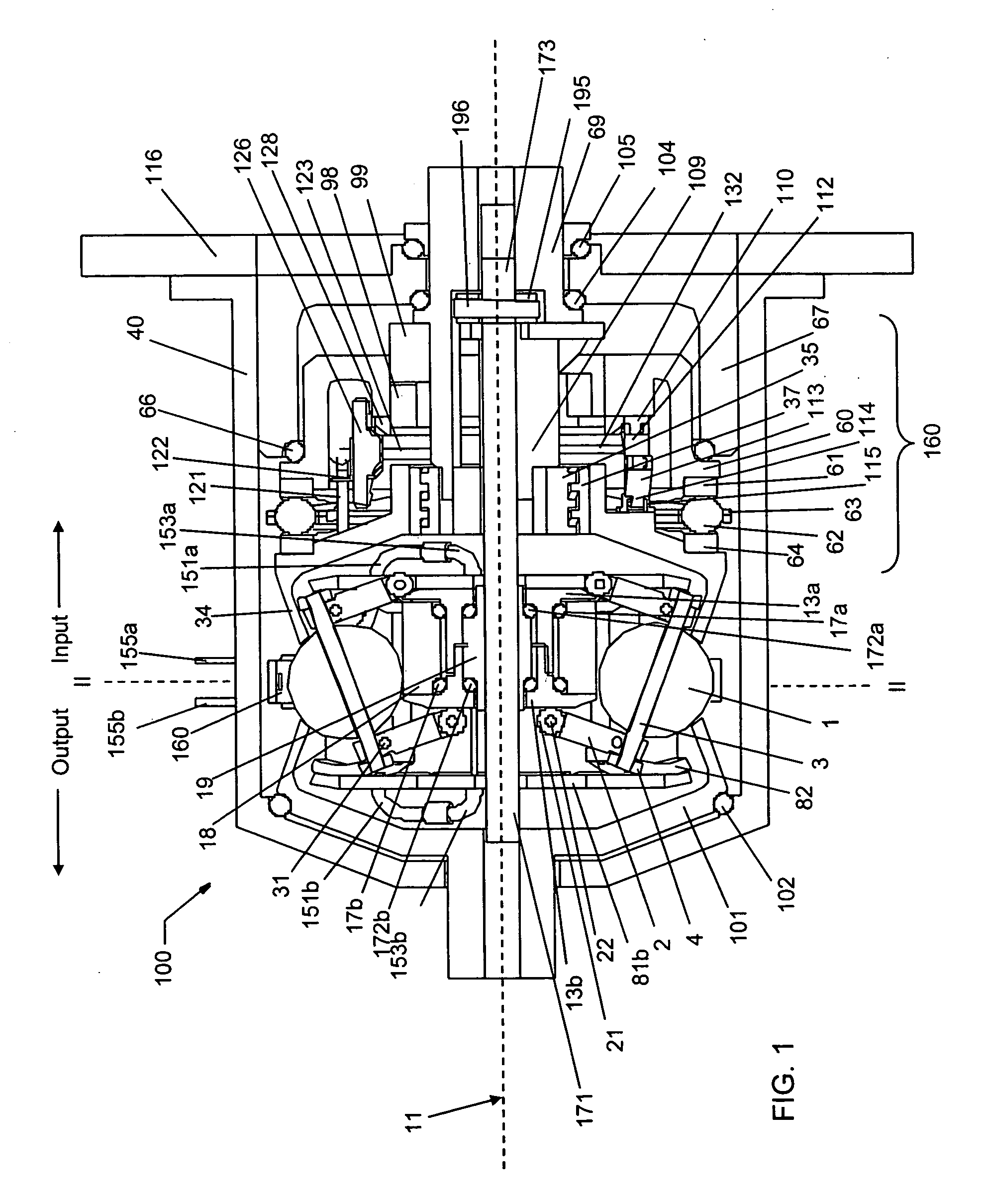

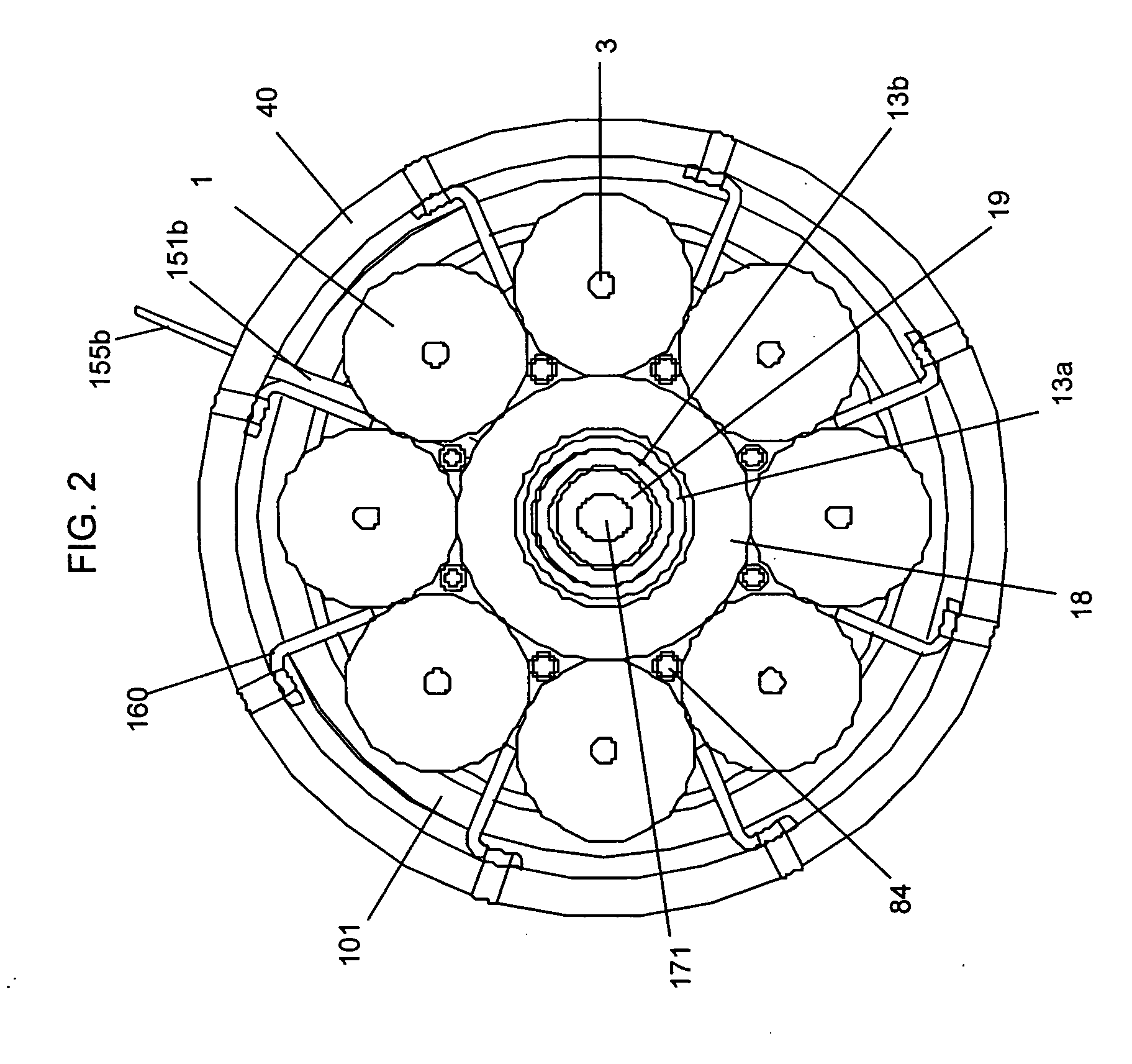

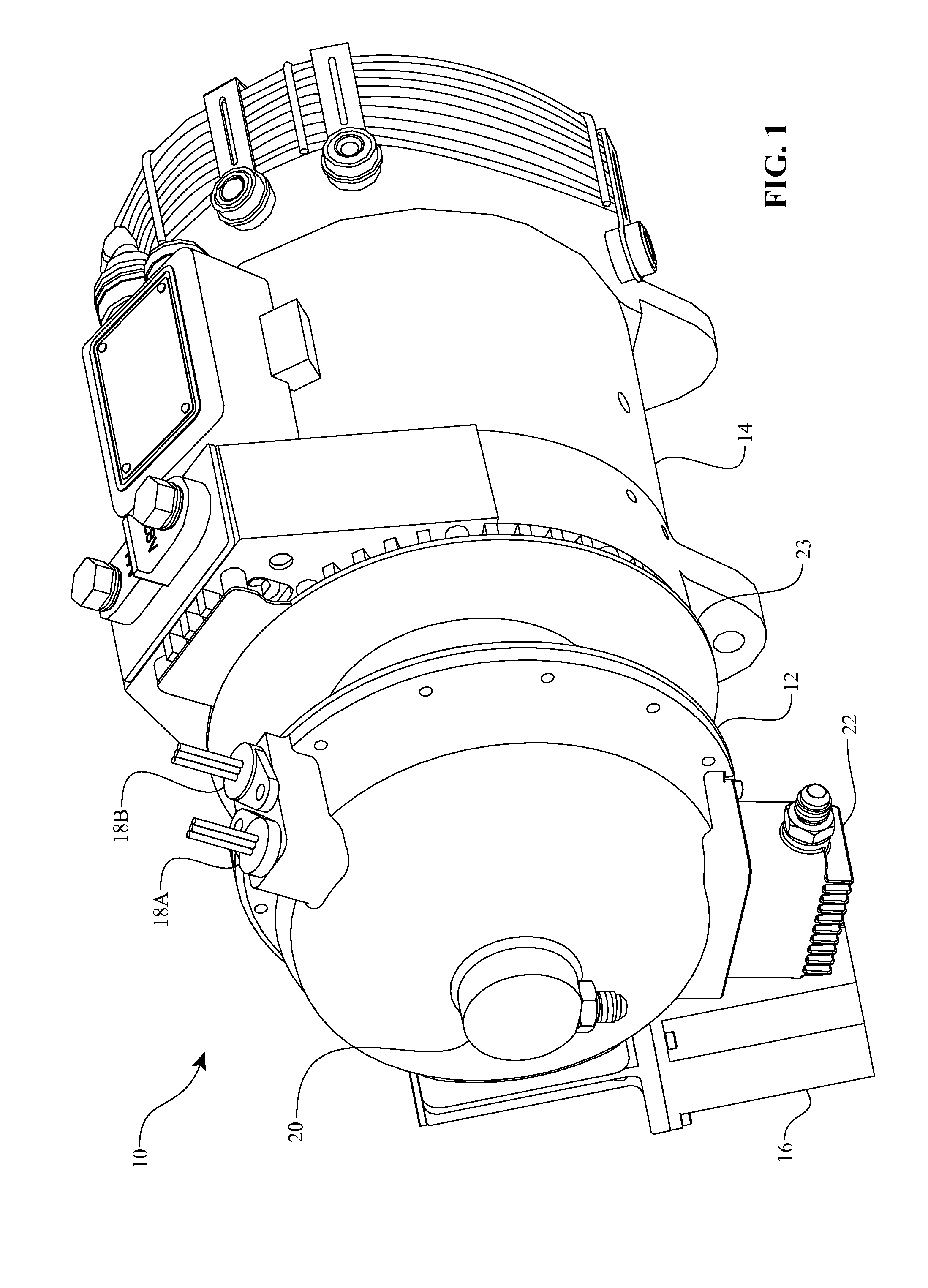

Continuously variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

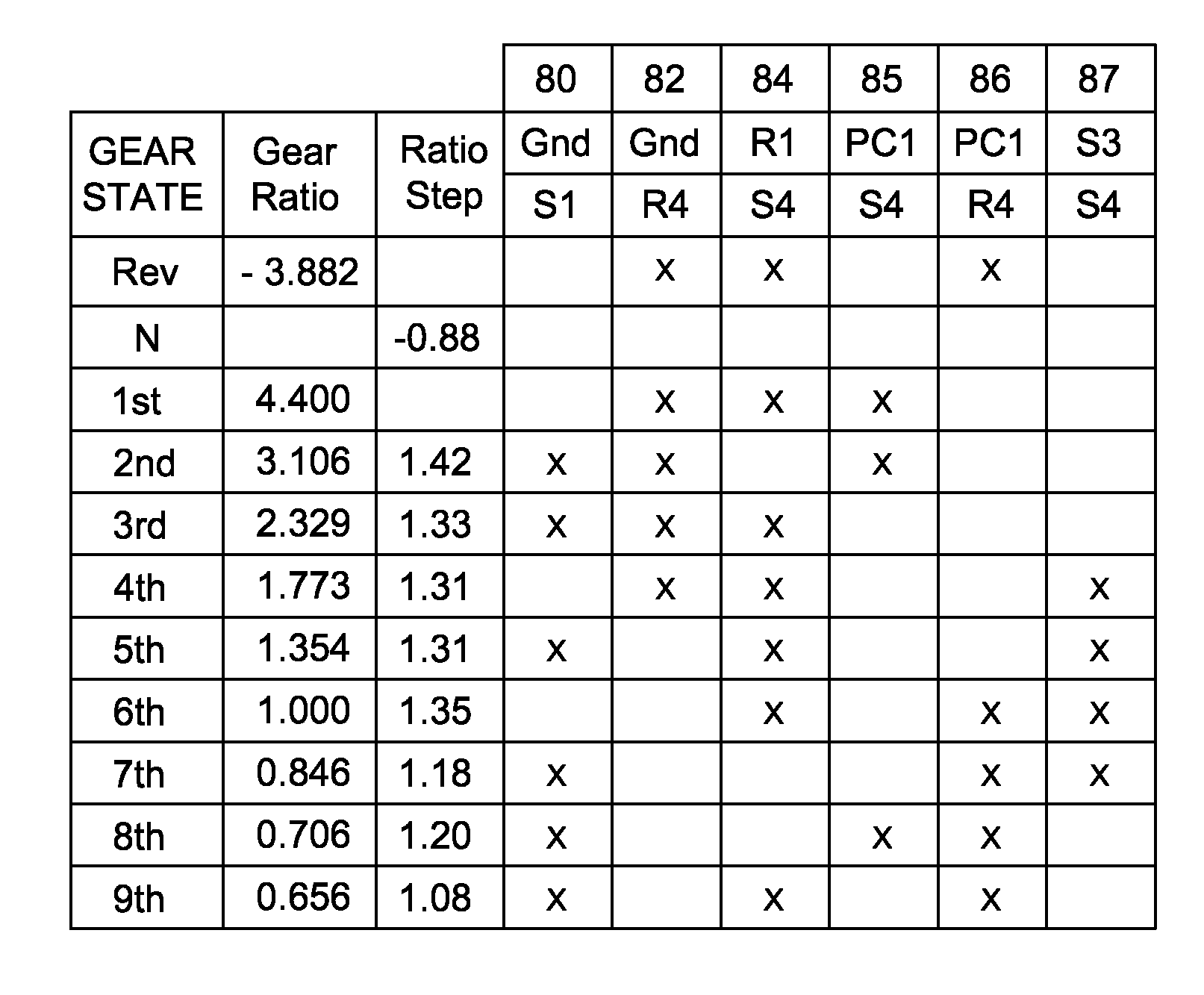

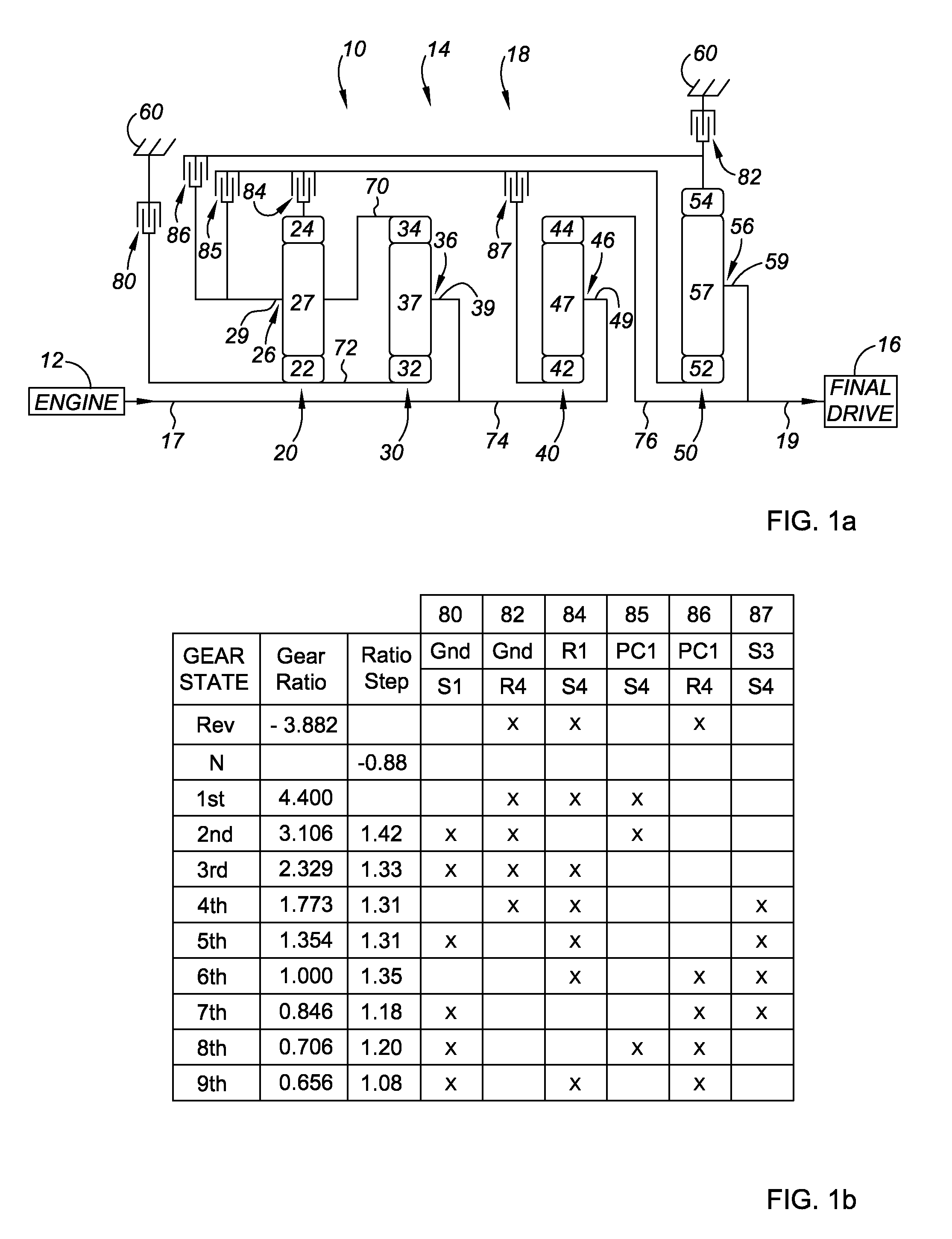

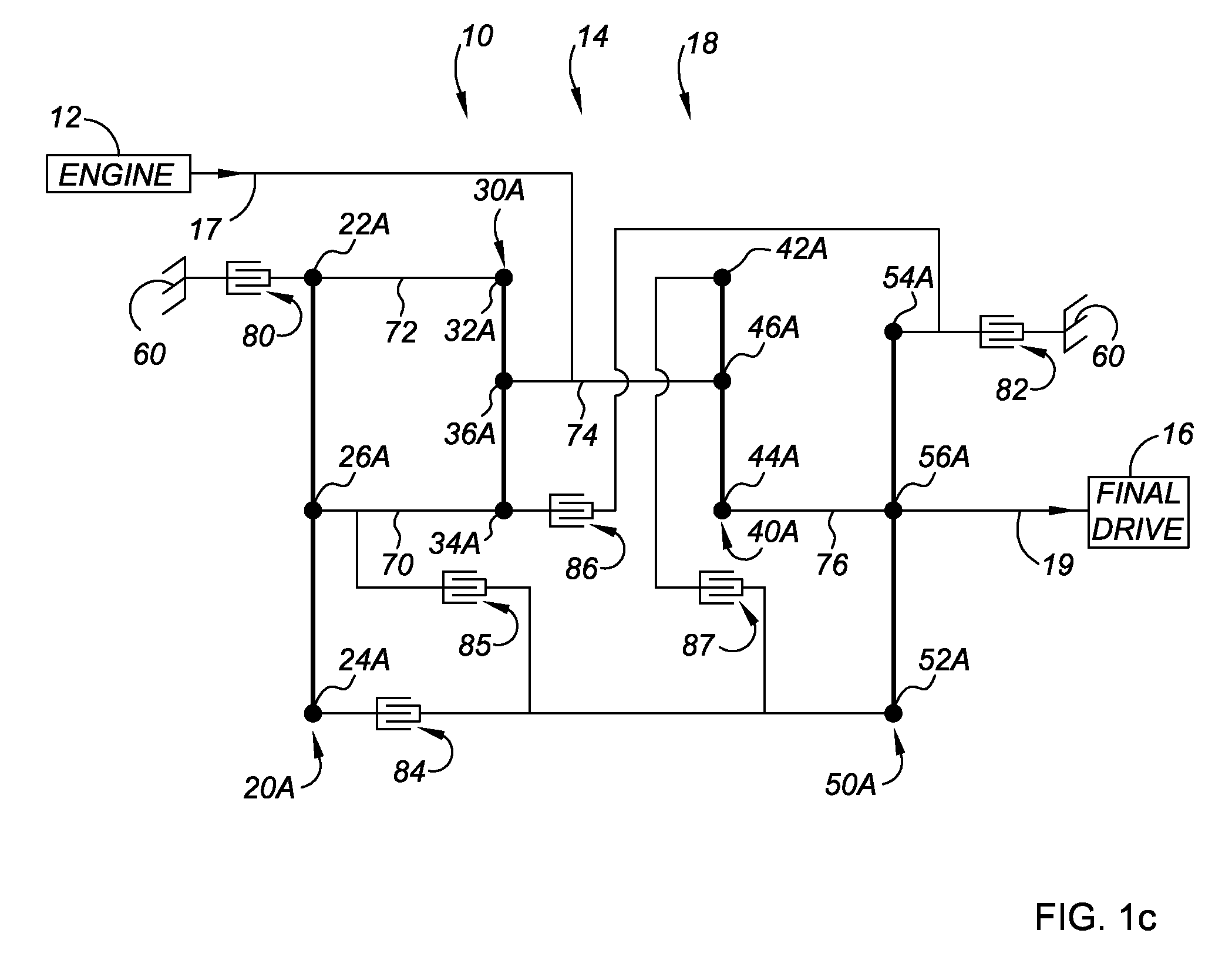

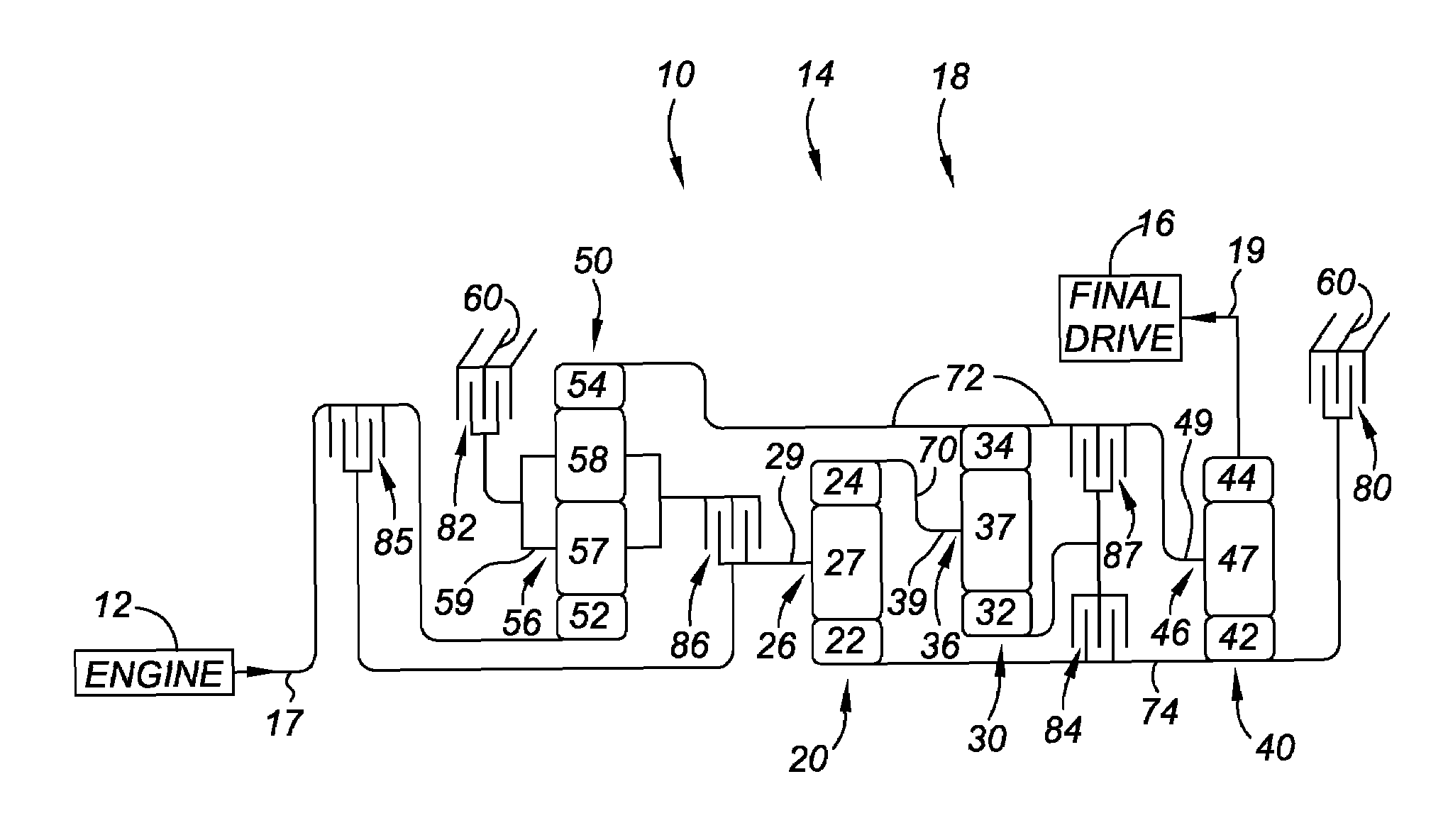

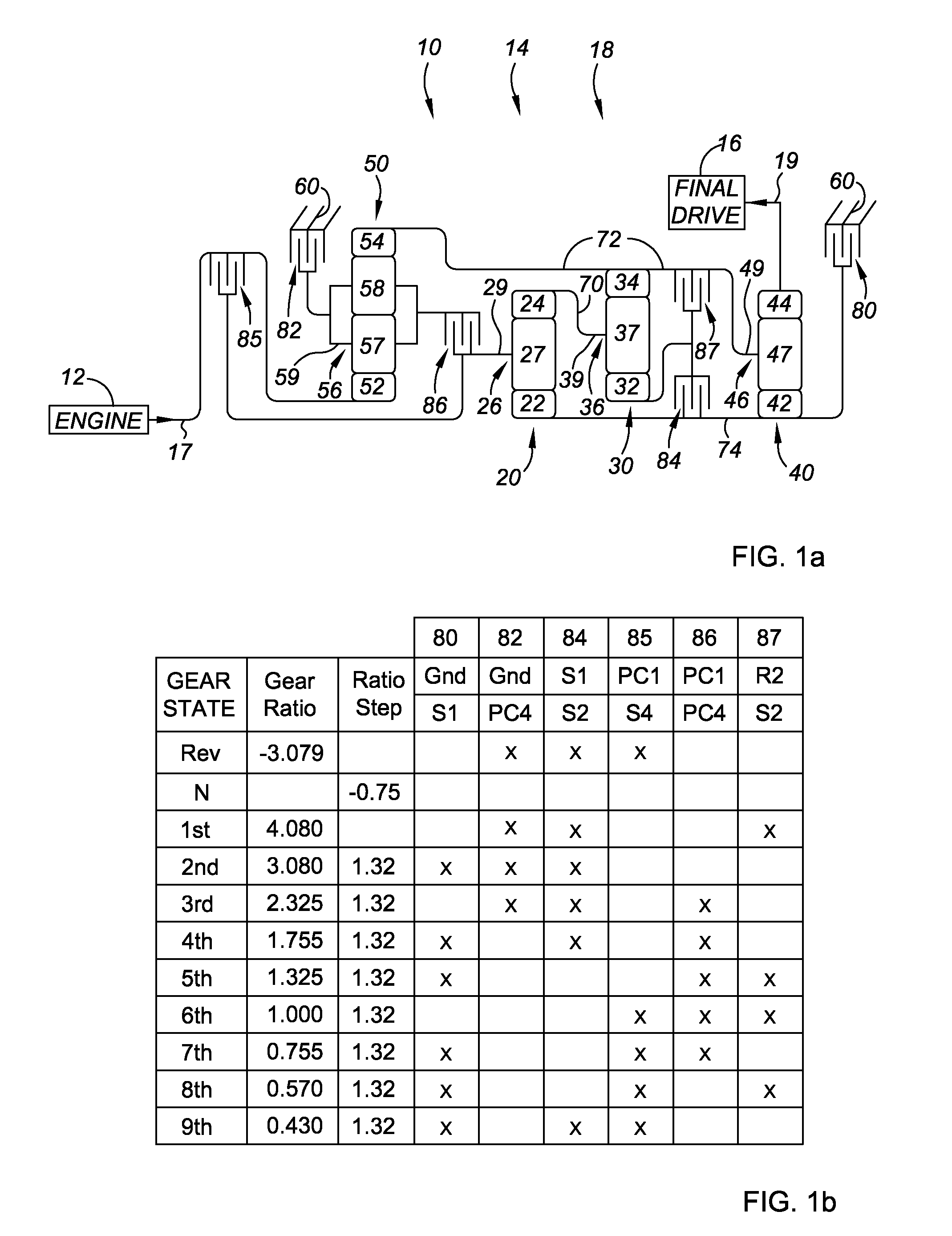

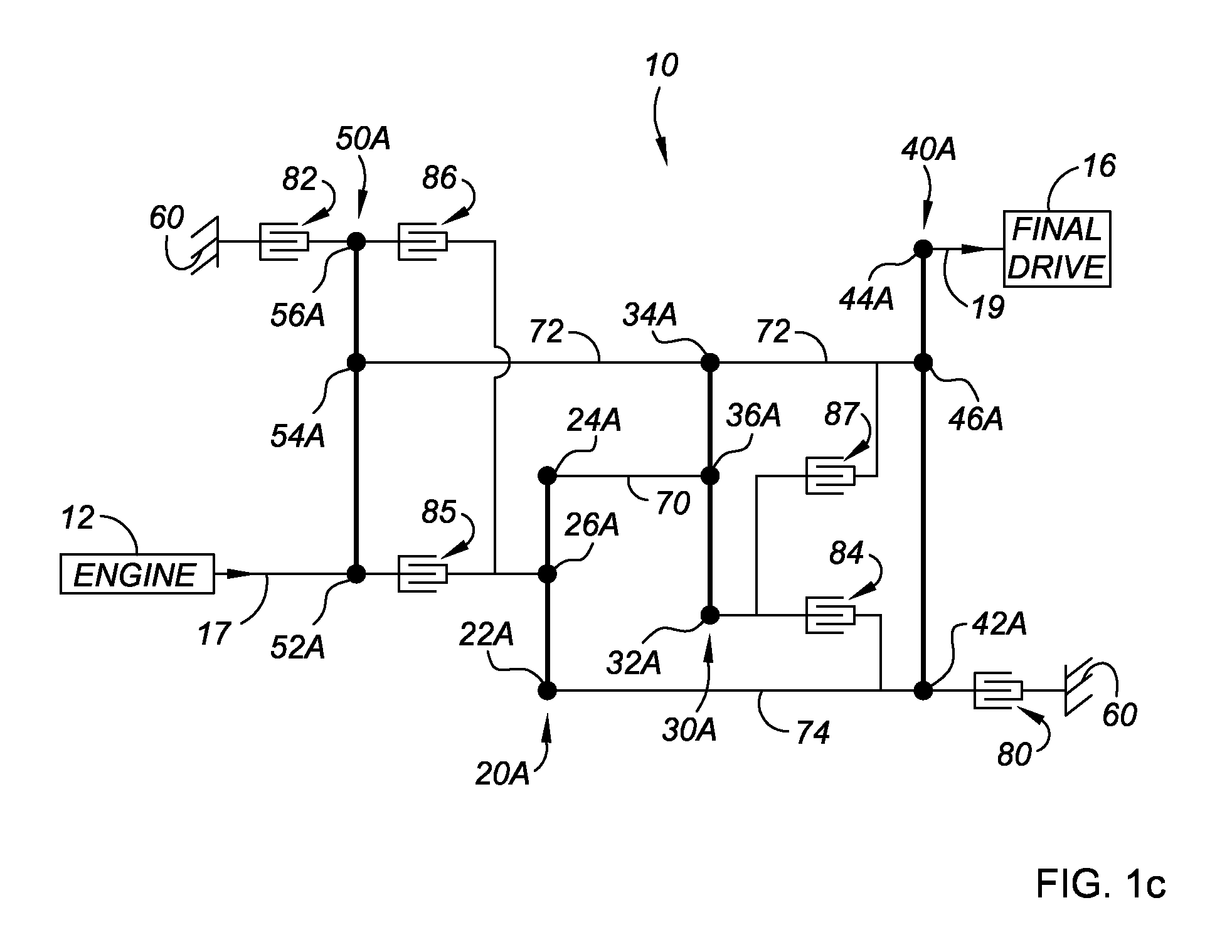

9-Speed Transmission

The transmission has a plurality of members that can be utilized in powertrains to provide nine forward speed ratios and one reverse speed ratio. The transmission includes four planetary gear sets, six torque-transmitting devices and four fixed interconnections. The powertrain includes an engine and torque converter that is continuously connected to one of the planetary gear members and an output member that is continuously connected with another one of the planetary gear members. The six torque-transmitting devices provide interconnections between various gear members, and the transmission housing, and are operated in combinations of three to establish nine forward speed ratios and one reverse speed ratio.

Owner:GM GLOBAL TECH OPERATIONS LLC

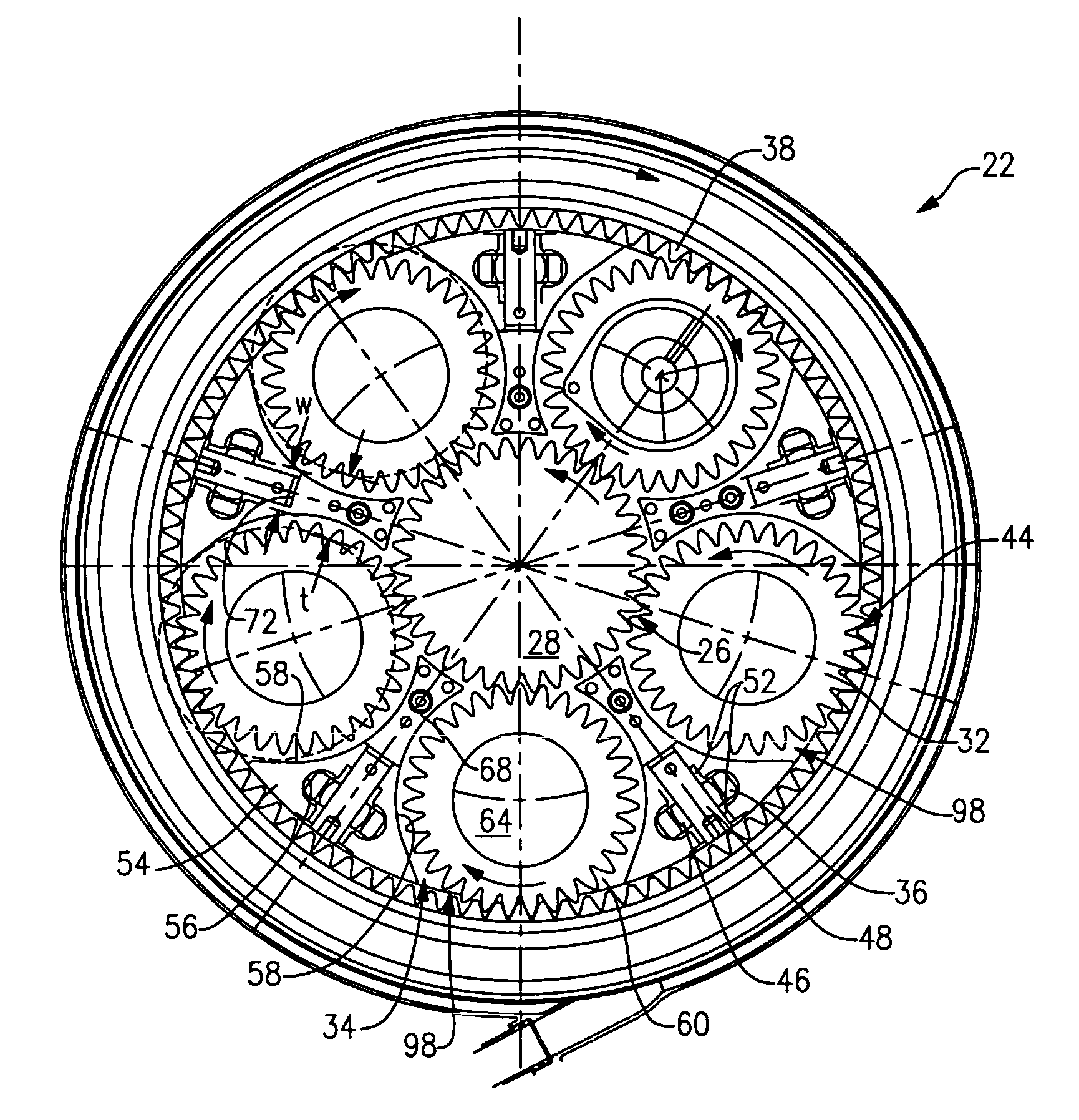

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

InactiveUS20070155567A1Easy to adjustImprove translationWheel based transmissionChain/belt transmissionEngineeringMechanical engineering

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

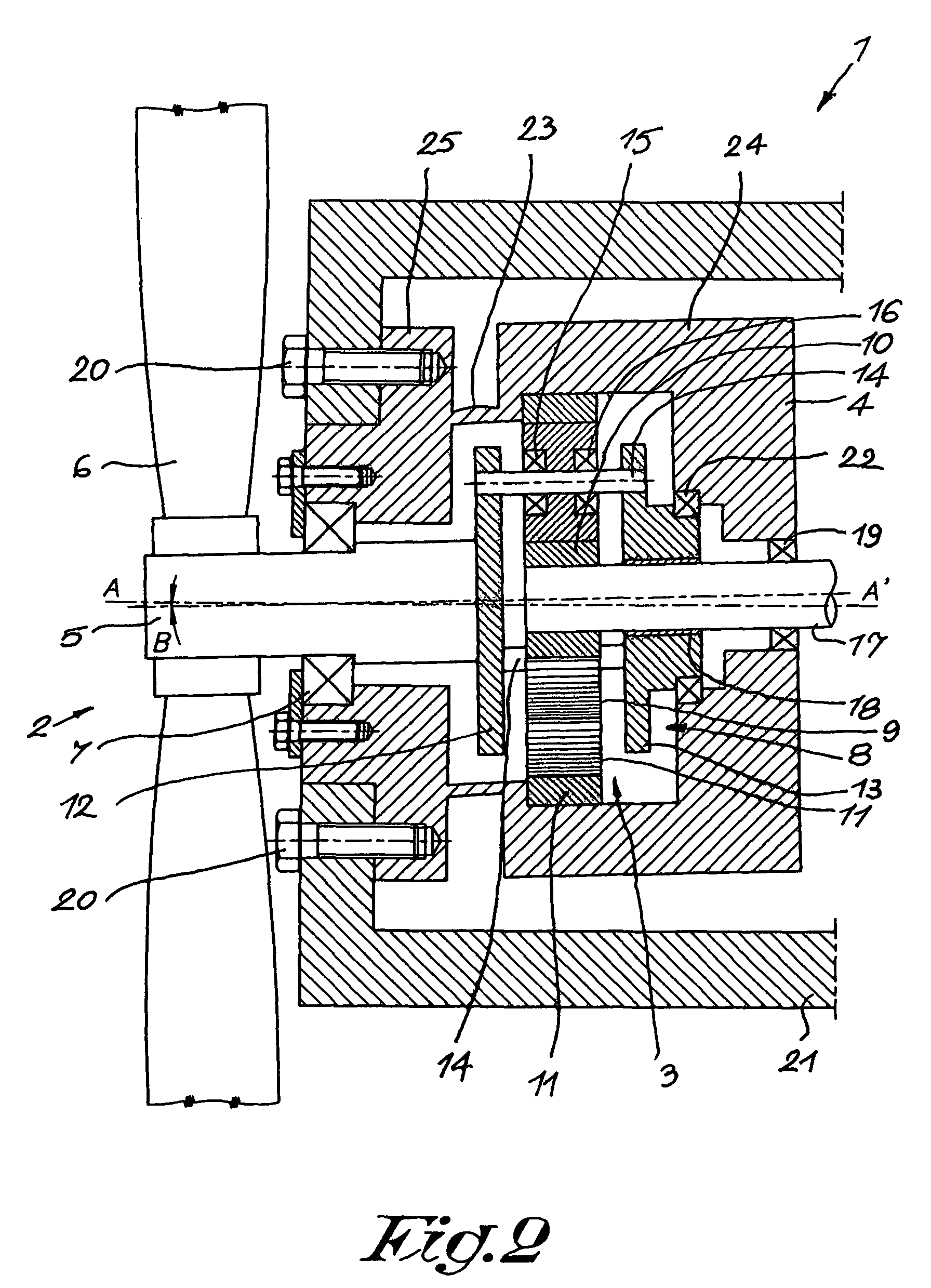

Gearbox for a wind turbine

A gearbox for a wind turbine includes a ring wheel unit provided in a housing; a driving shaft designed to be coupled to the rotor of the wind turbine and a single main bearing or a pair of main bearings which rotatably support the driving shaft in the housing. The ring wheel unit is formed of a sun wheel, a planet wheel, ring wheel which is fixed to the housing in a non-rotating manner and a planet carrier which is rigidly connected to the driving shaft. An additional bearing rotatably supports the planet carrier or the driving shaft relative to the housing. Between the part of the housing having the main bearing or the main bearings and the part of the housing with the additional bearing and the ring wheel, an elastic part is provided with relative torsional stiffness, yet relatively flexible to loads in the axial and / or radial direction.

Owner:HANSEN TRANSMISSIONS INT NV

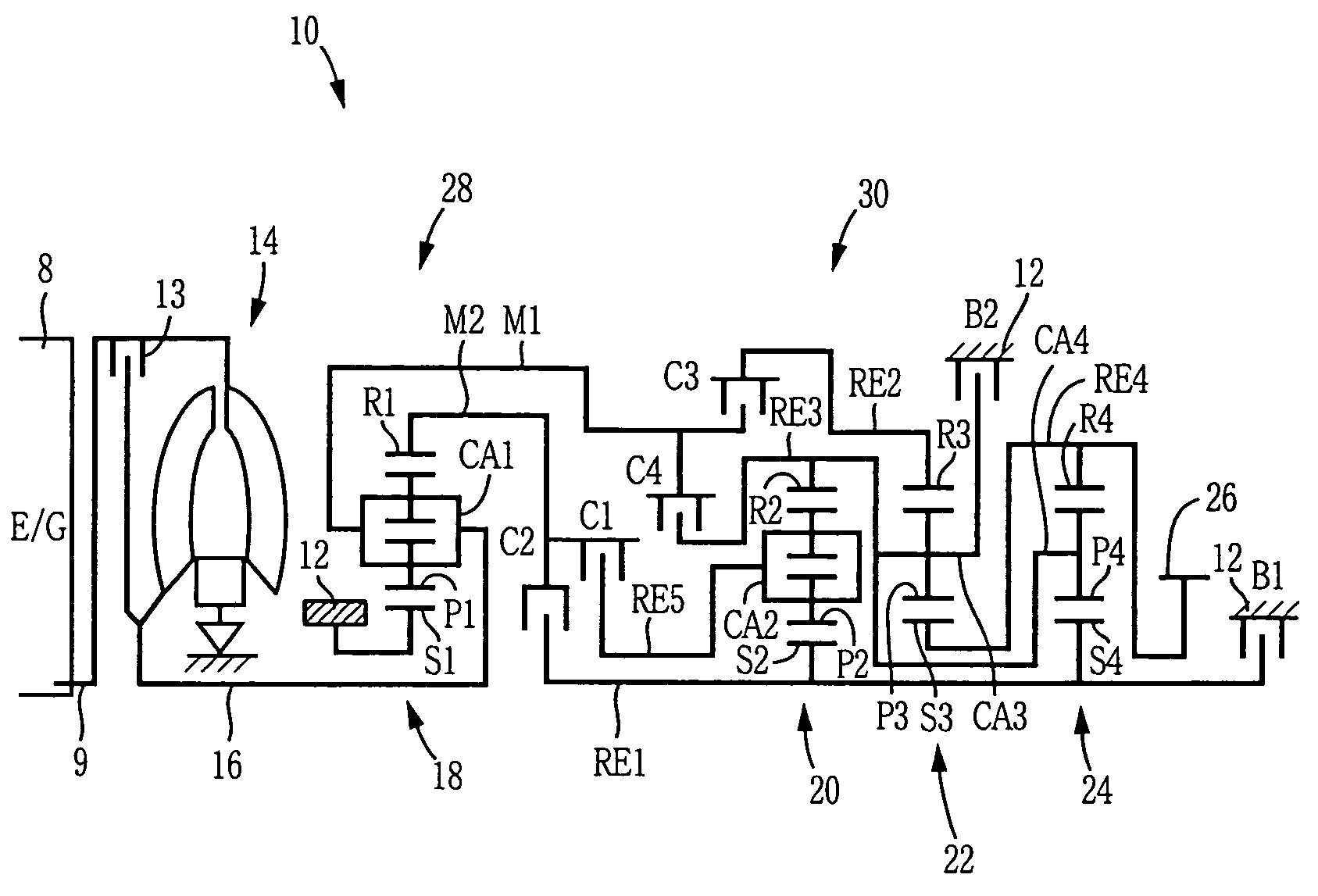

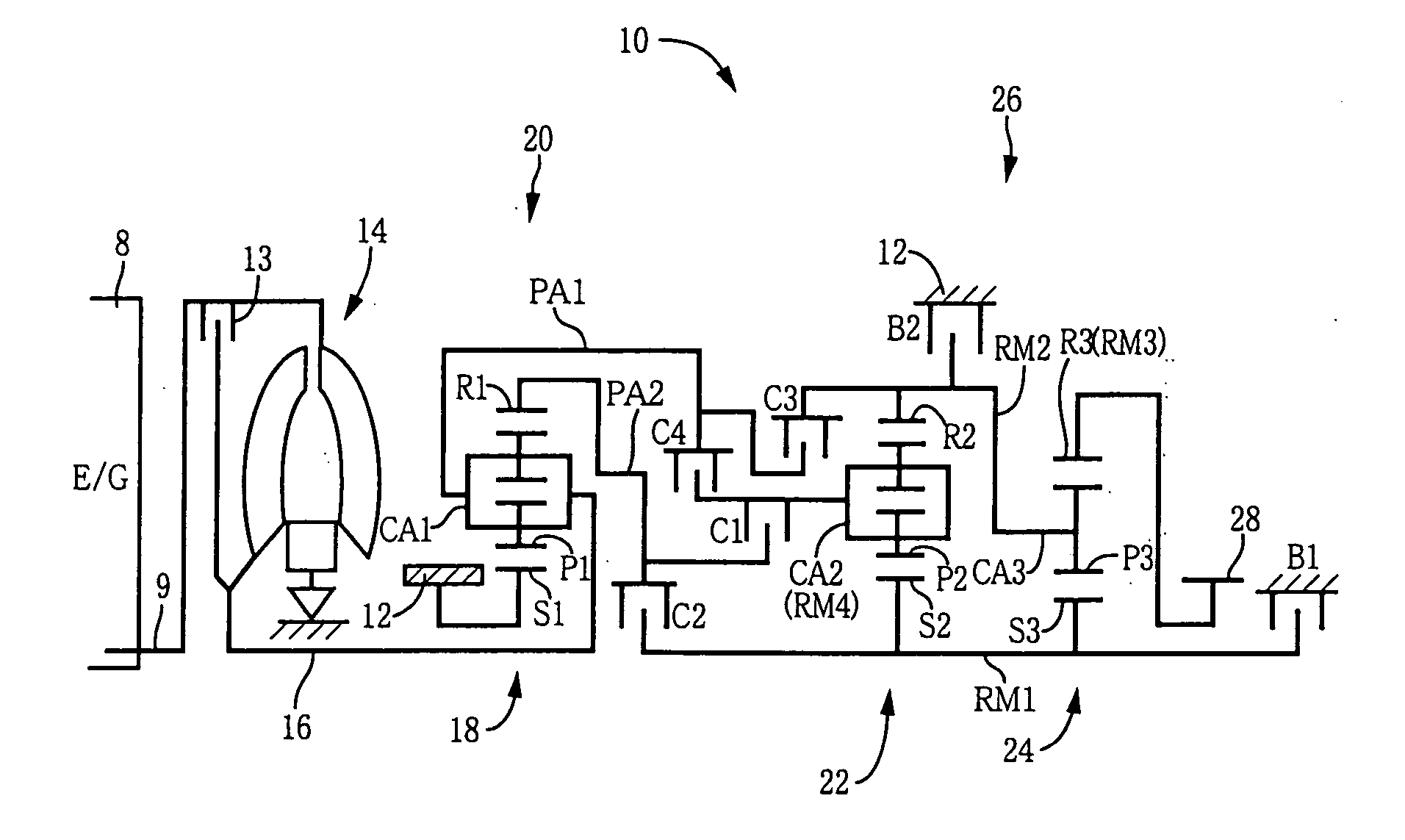

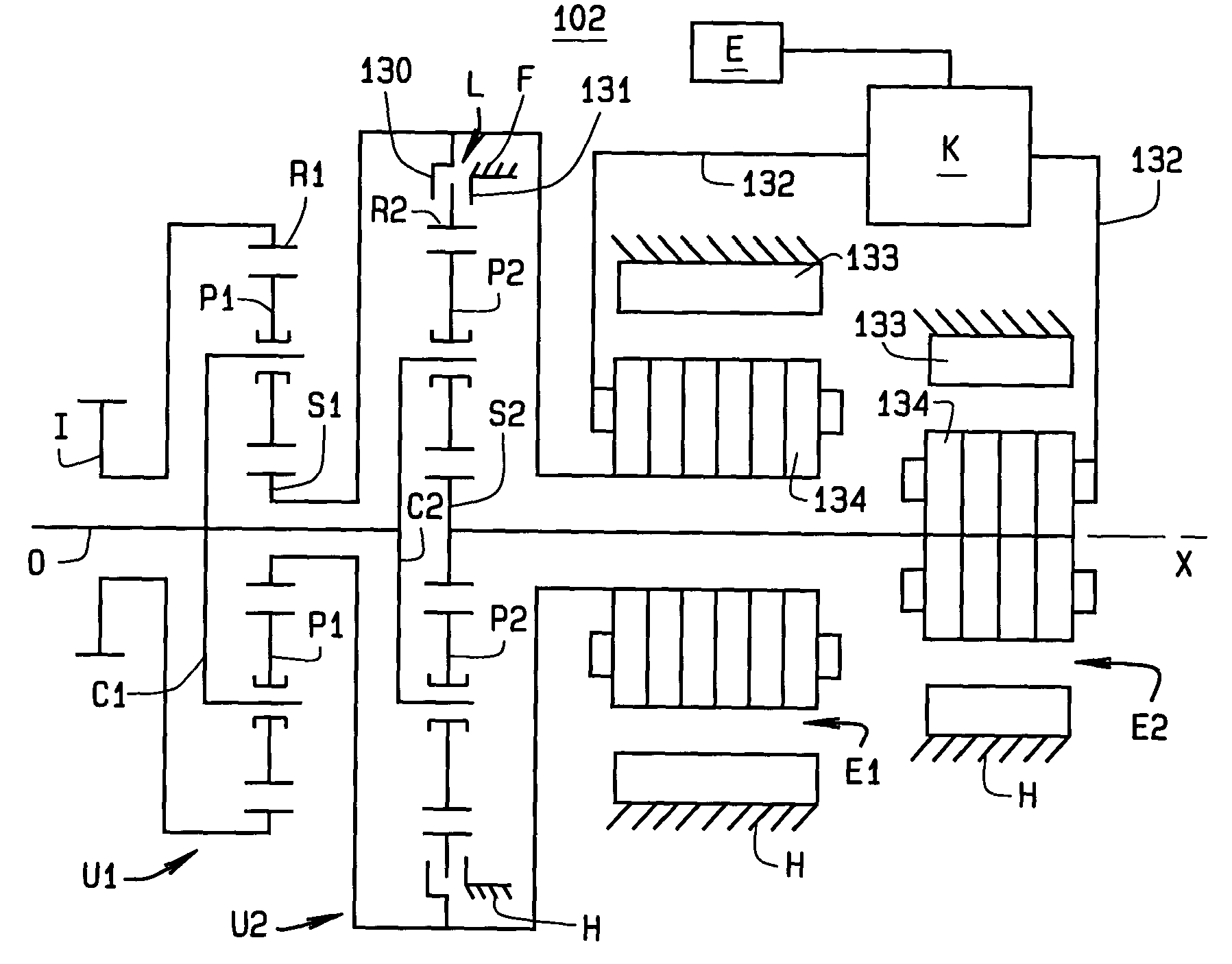

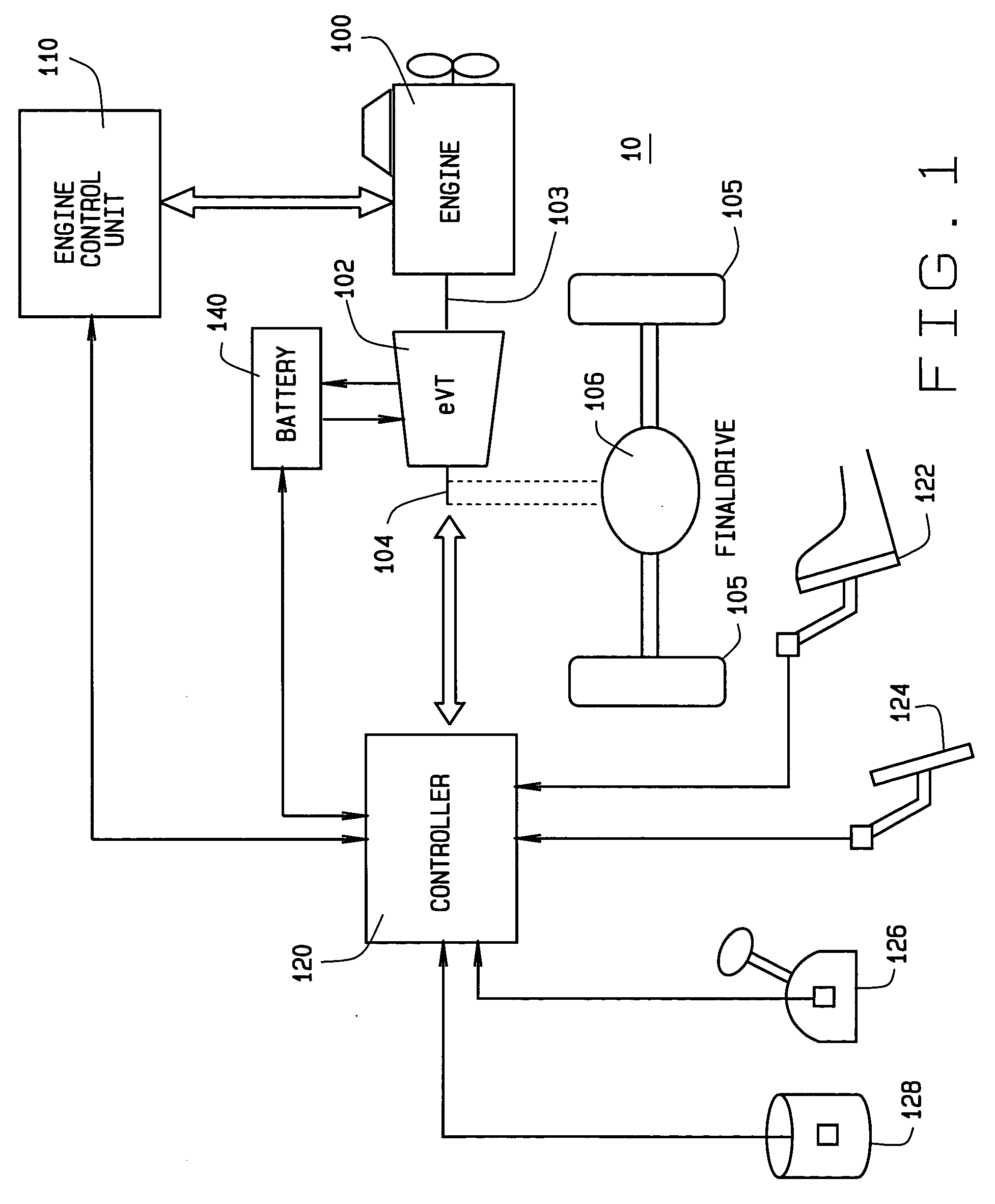

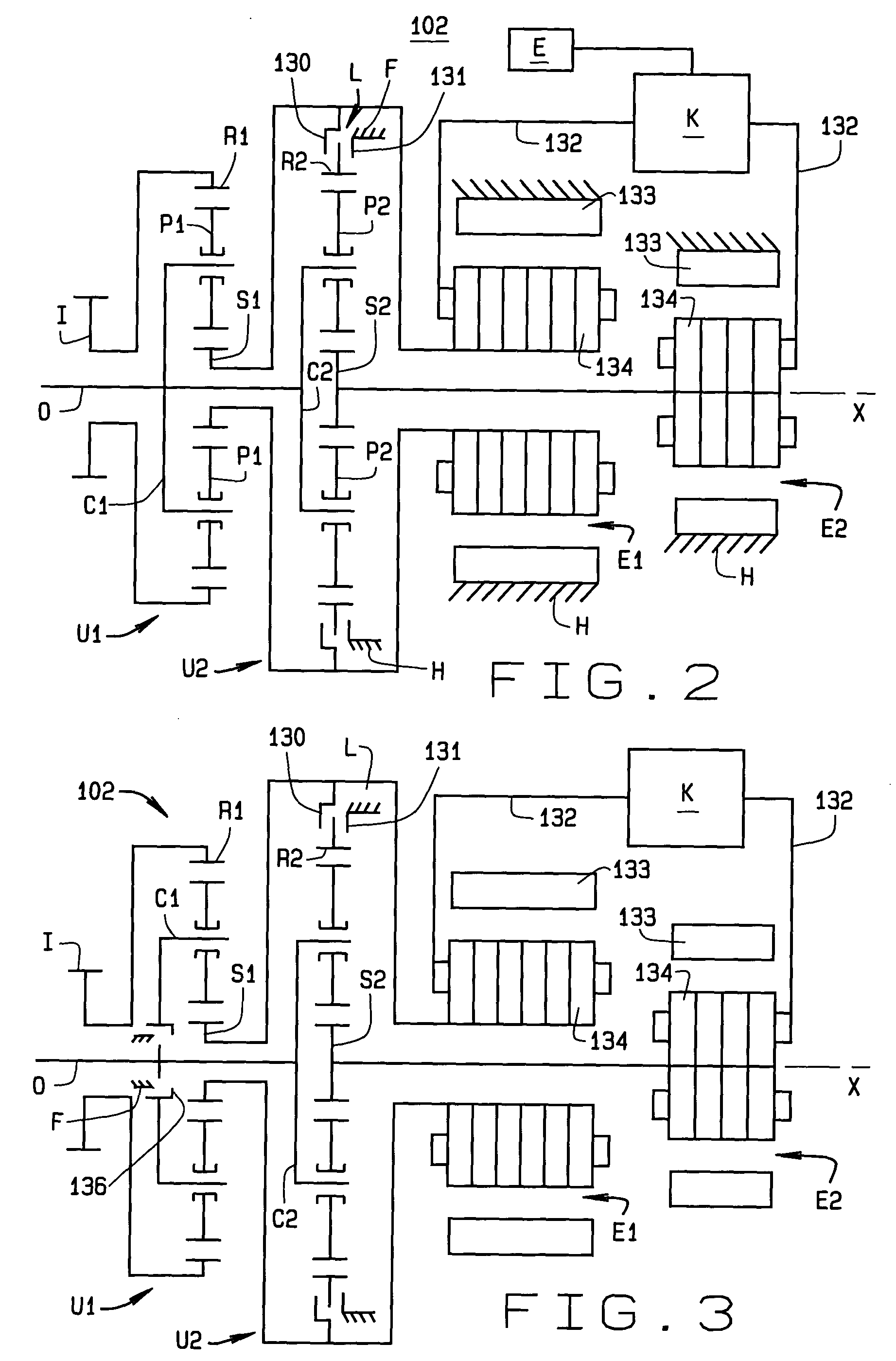

Method and apparatus for power flow management in electro-mechanical transmissions

A method for power management in an electro-mechanical power-split infinitely variable transmission (eVT) designed to operated within a designated speed ratio range for vehicular applications. The eVT is comprised of an input shaft coupled to the output shaft of a drive engine to receive power, a drive shaft, two electric machines, and a pair of planetary trains each having a sun member, a ring member, a set of planetary members, and a planet carrier. The eVT further contains one or more torque transfer devices to connect or disconnect members of the planetary trains for transferring torque. The drive shaft is coupled with a final drive of a vehicle for delivering or recapturing power to or from the vehicle drive wheels. The two electric machines are interconnected electronically via a power control unit and are coupled respectively with members of the planetary train. The method of power management in the eVT is selected based on the current speed and torque of the input and drive shafts, and upon the desired operating parameters.

Owner:THE TIMKEN CO

Continuously variable planetary gear set

A continuously variable planetary gear set is described having a generally tubular idler, a plurality of balls distributed radially about the idler, each ball having a tiltable axis about which it rotates, a rotatable input disc positioned adjacent to the balls and in contact with each of the balls, a rotatable output disc positioned adjacent to the balls opposite the input disc and in contact with each of the balls such that each of the balls makes three-point contact with the input disc, the output disc and the idler, and a rotatable cage adapted to maintain the axial and radial position of each of the balls, wherein the axes of the balls are oriented by the axial position of the idler.

Owner:FALLBROOK INTPROP COMPANY

Gear-operated speed change apparatus for automatic transmission

InactiveUS6910985B2Strength advantage of gearToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A gear-operated speed change apparatus for an automatic transmission, which can make the degree of freedom for selecting a gear ratio higher than that of the case using the Ravigneaux type composite planetary gear train, while achieving a strength advantage of the gear train, an improvement in the fuel economy, coaxial positioning of the input port and output portions and size reduction of the automatic transmission altogether. The apparatus can achieve at least seven forward speeds and one reverse speed by engaging / releasing four clutches and two brakes. One of the three planetary gear sets can reduce the speed of an input rotation always or increase the input rotation always. One of the remaining two planetary gear sets is a double sun gear type planetary gear set including a third carrier having a center member positioned between two sun gears for inputting or outputting a rotation.

Owner:JATCO LTD

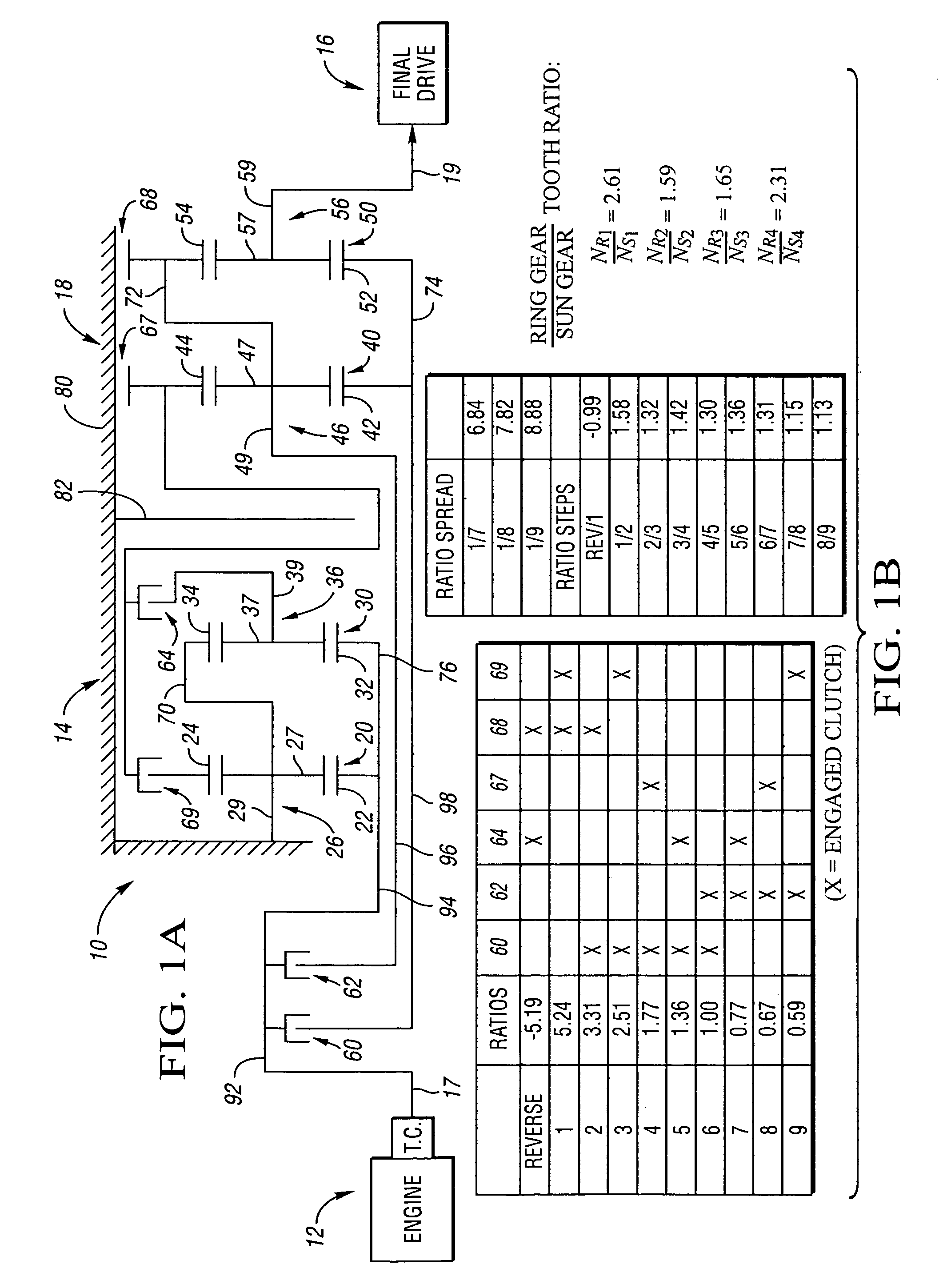

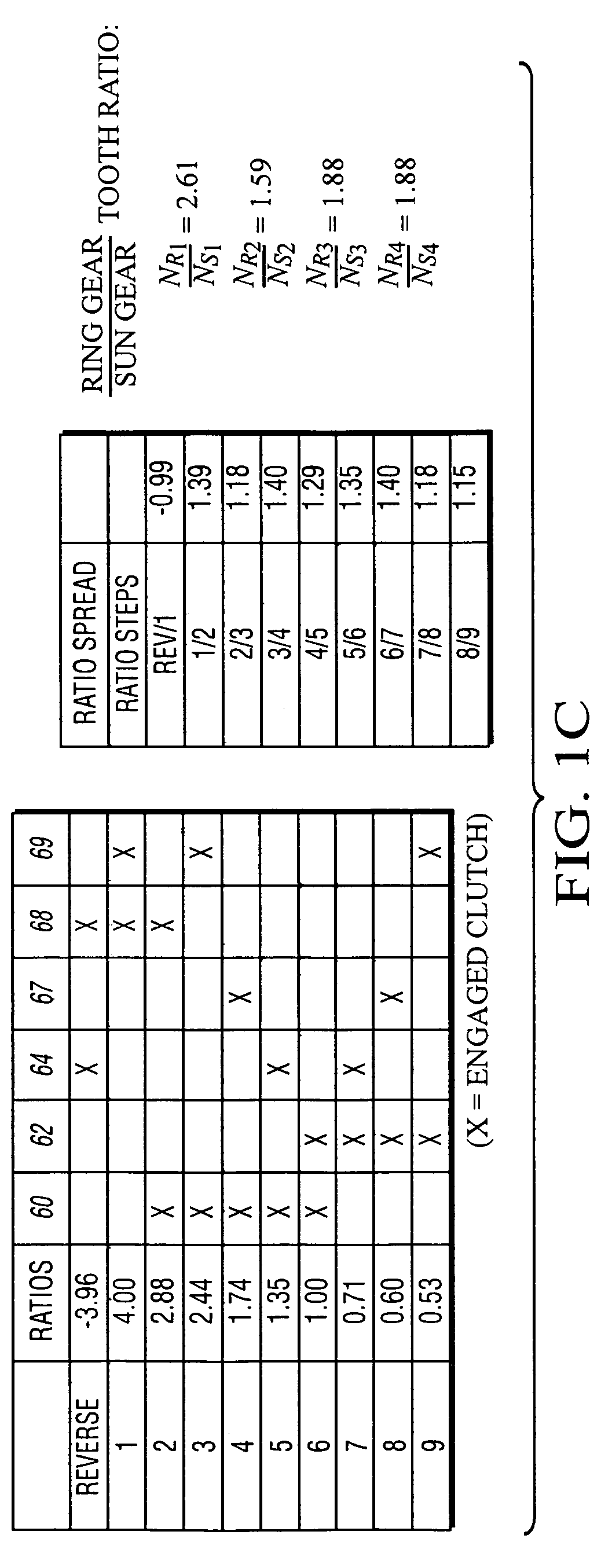

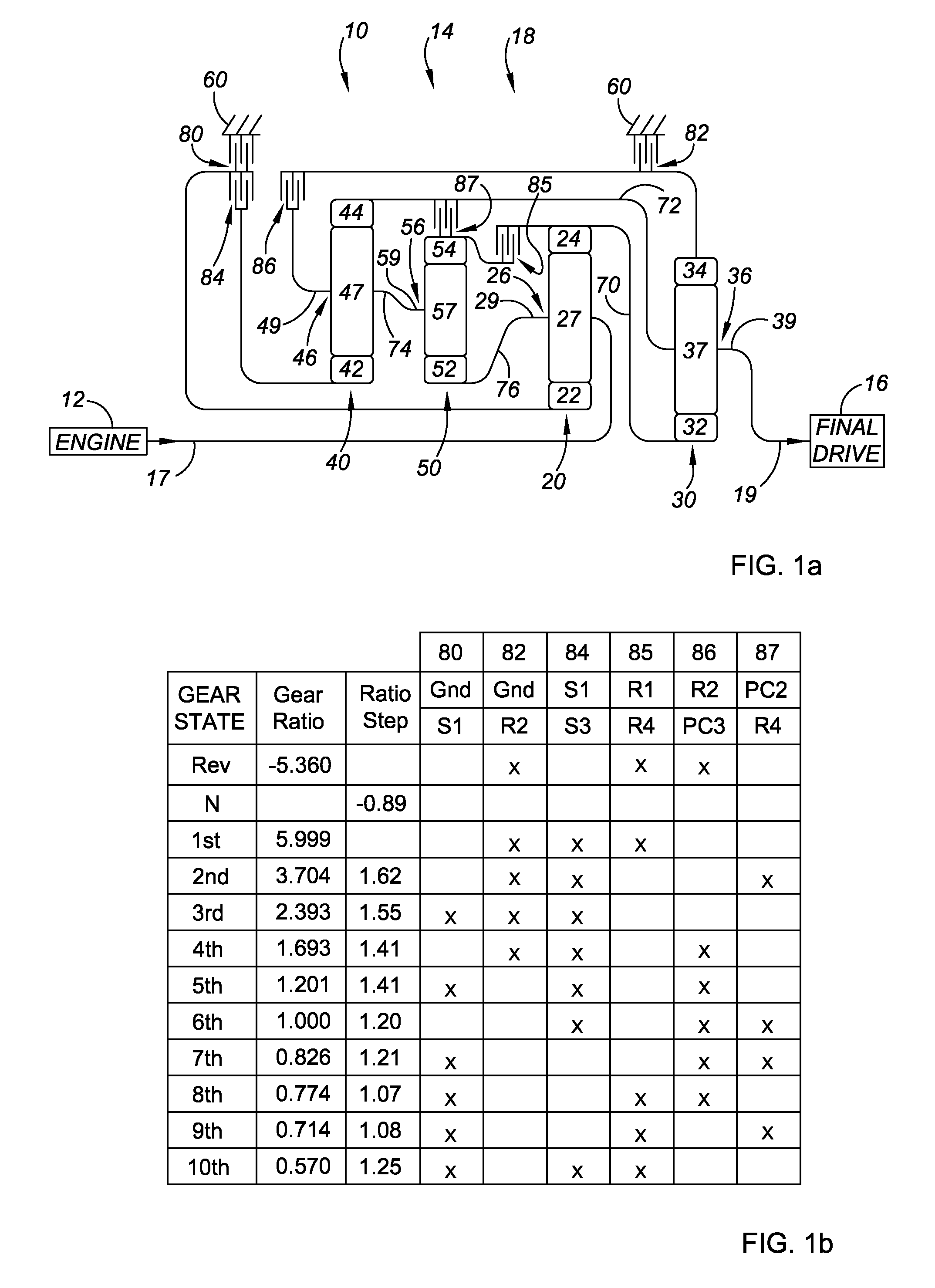

Nine-speed transmissions with four planetary gear sets

ActiveUS7226381B2Improve fuel economyImprove traction performanceToothed gearingsTransmission elementsGear wheelInterconnection

Nine-speed transmissions are provided that include four planetary gear sets having six torque-transmitting mechanisms and various fixed interconnections to provide nine forward speed ratios and a reverse speed ratio. The powertrain includes an engine and torque converter that is continuously connected to at least one of the planetary gear members and an output member that is continuously connected with another of the planetary gear members. The six torque-transmitting mechanisms are operated in combinations of two. Reduced component speeds and improved ratios are achieved.

Owner:GM GLOBAL TECH OPERATIONS LLC

Global synchronization unit (GSU) for time and space (TS) stamping of input data elements

InactiveUS20020069076A1Avoiding shortcoming and drawbackBetterment of human societySatellite radio beaconingBuying/selling/leasing transactionsTime responseTTEthernet

An improved system and method of fairly and securely enabling timed-constrained competitions over the Internet among millions of competitors while compensating for the variable network communication latencies experienced by client machines used by the competitors. The system employs globally time-synchronized Internet information servers and client machines in order to synchronize the initial display of each invitation to respond (e.g. stock price to buy or sell, query to answer, or problem to solve) on a client machine so each competitor can respond to the invitation at substantially the same time, regardless of his or her location on the planet, or the type of Internet-connection used by his or her client machine. Also, by using globally time-synchronized client machines, each competitor's response is securely time and space stamped at the client machine to ensure that competitor responses are resolved within microsecond accuracy.

Owner:REVEO

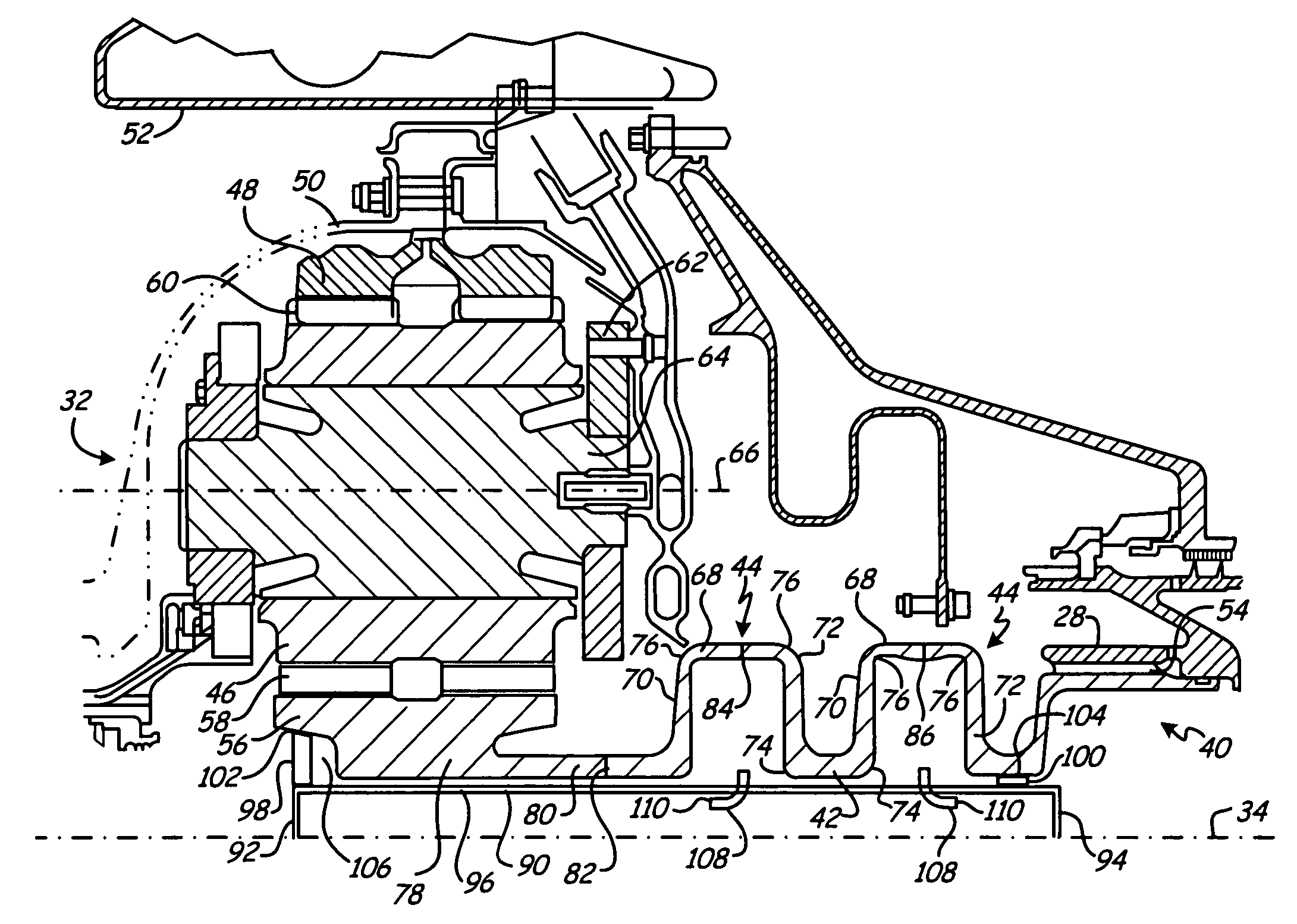

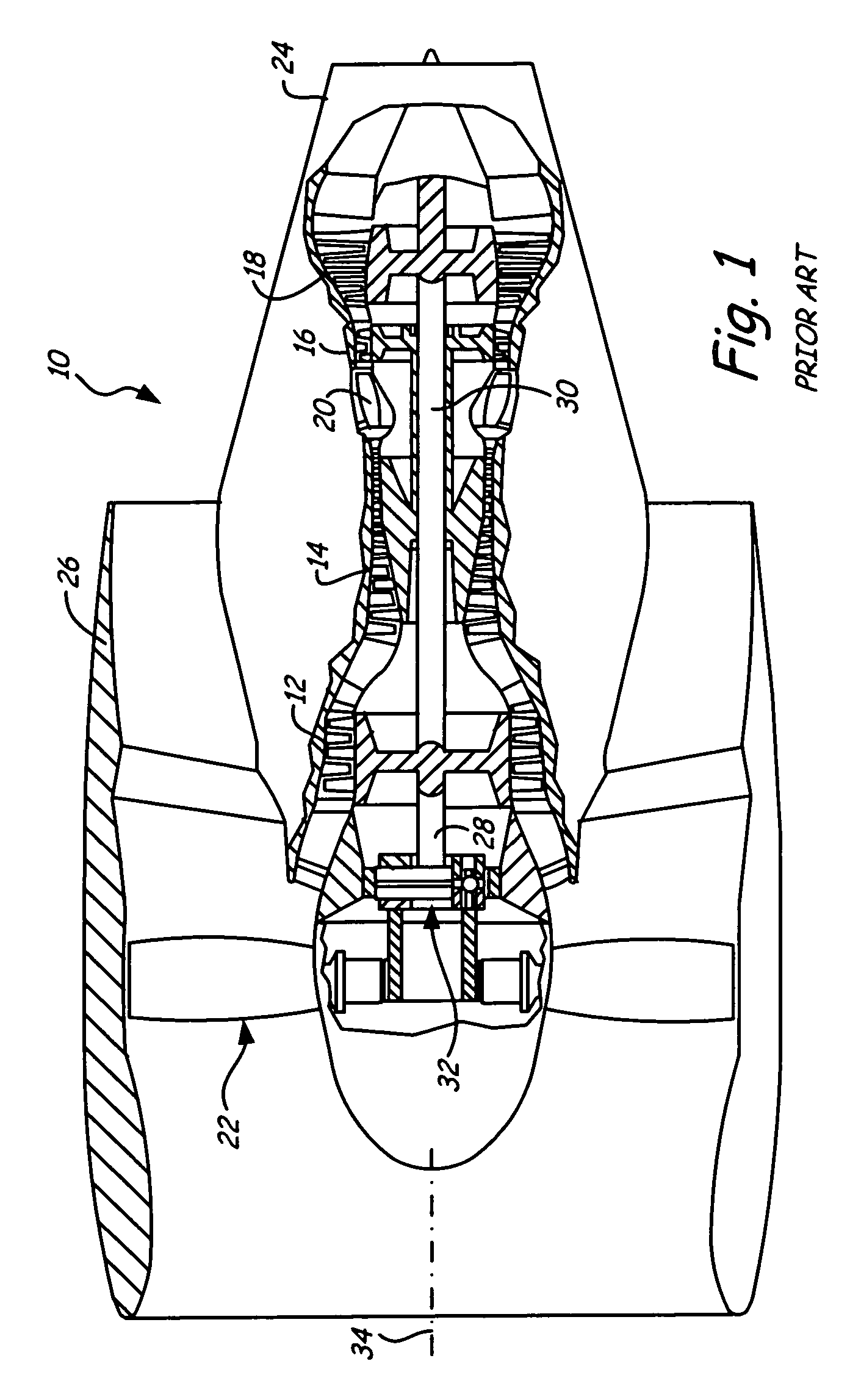

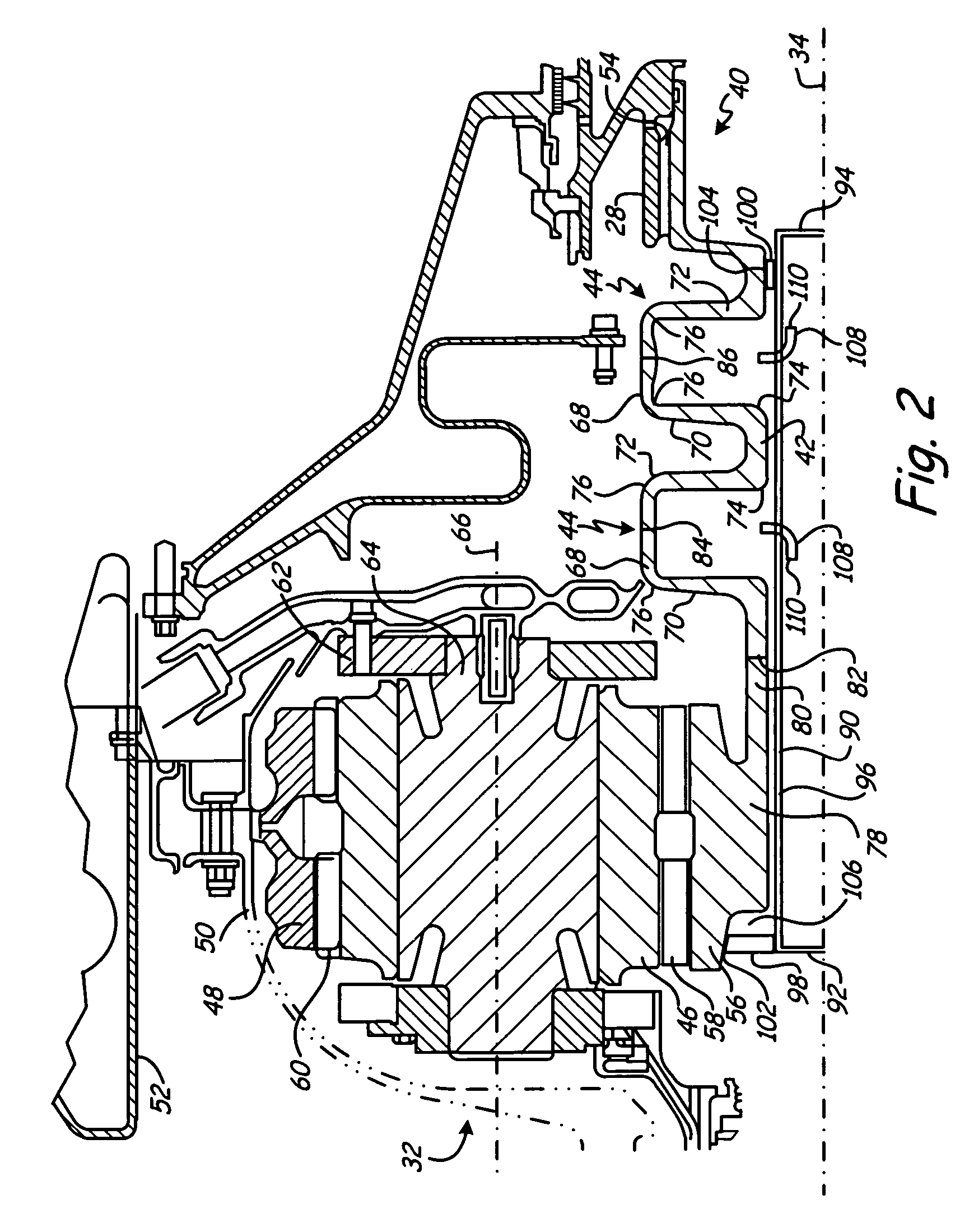

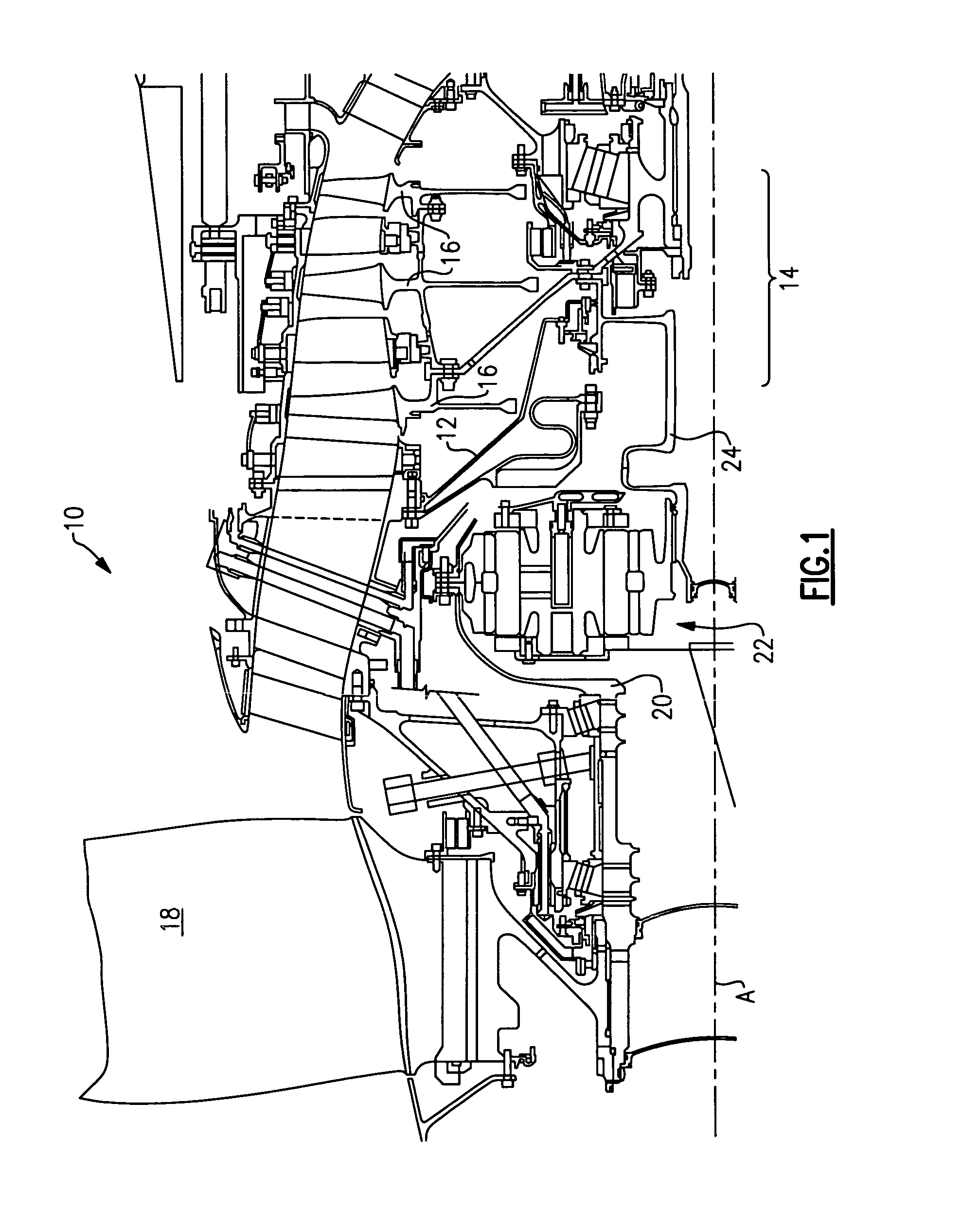

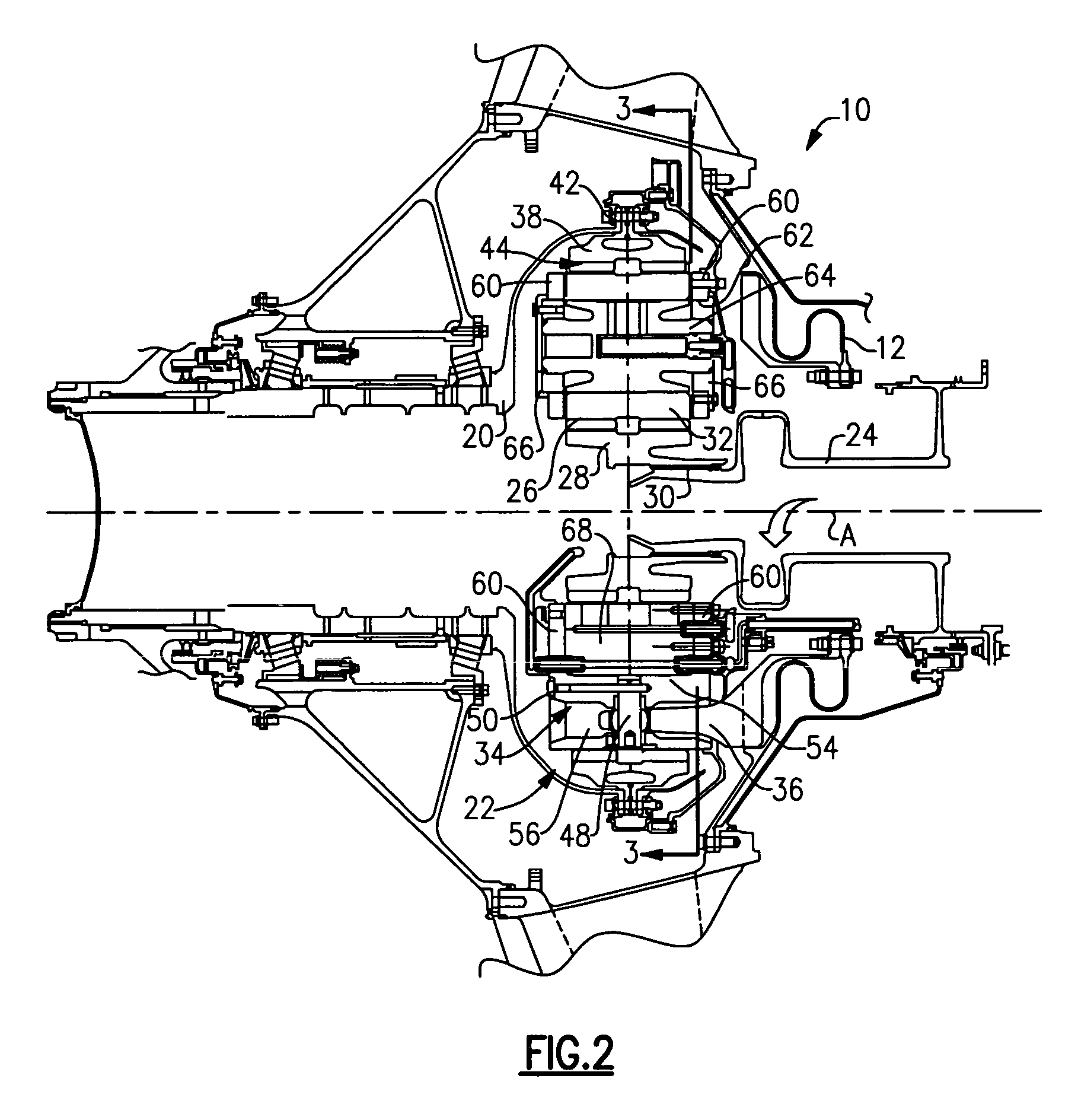

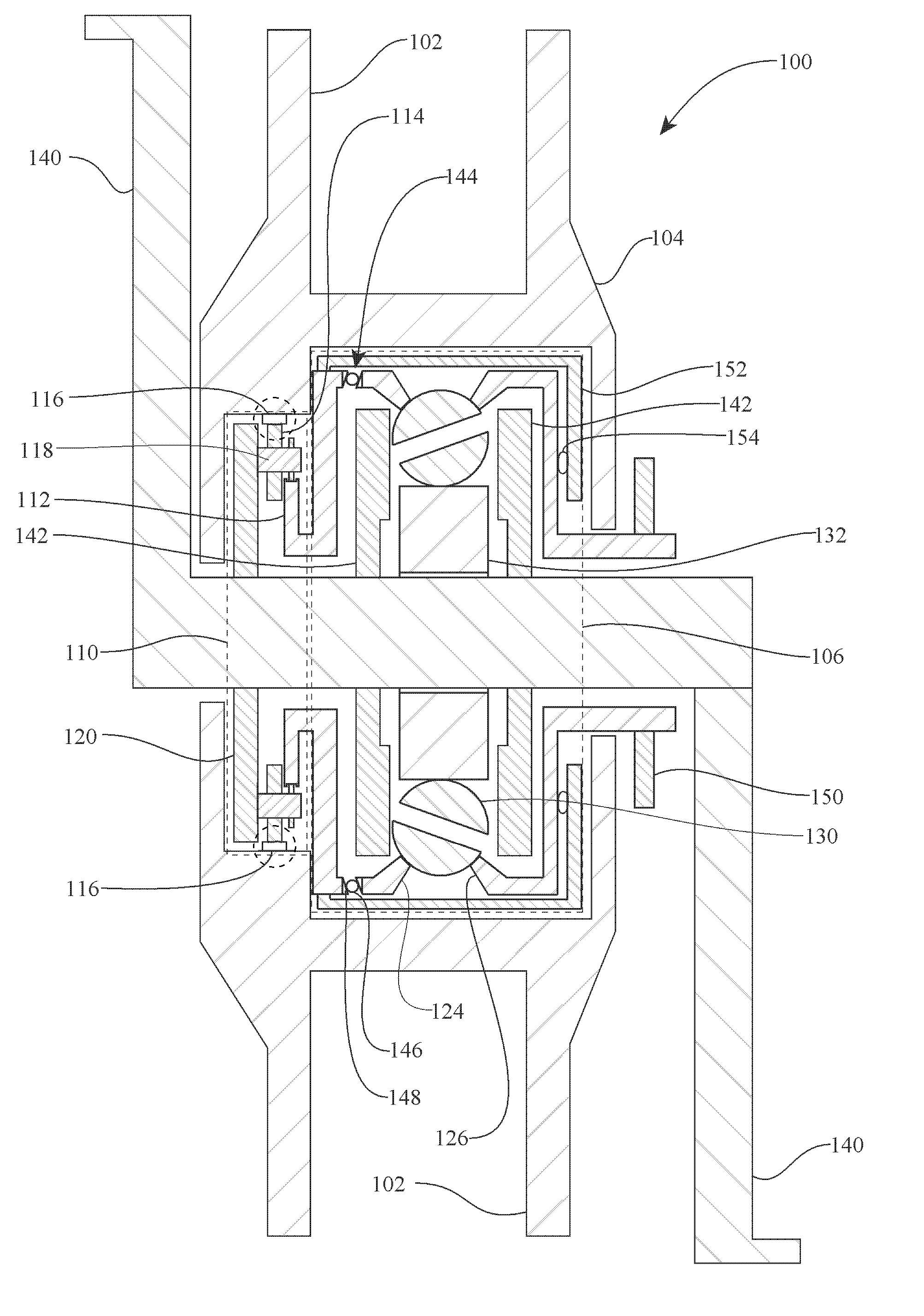

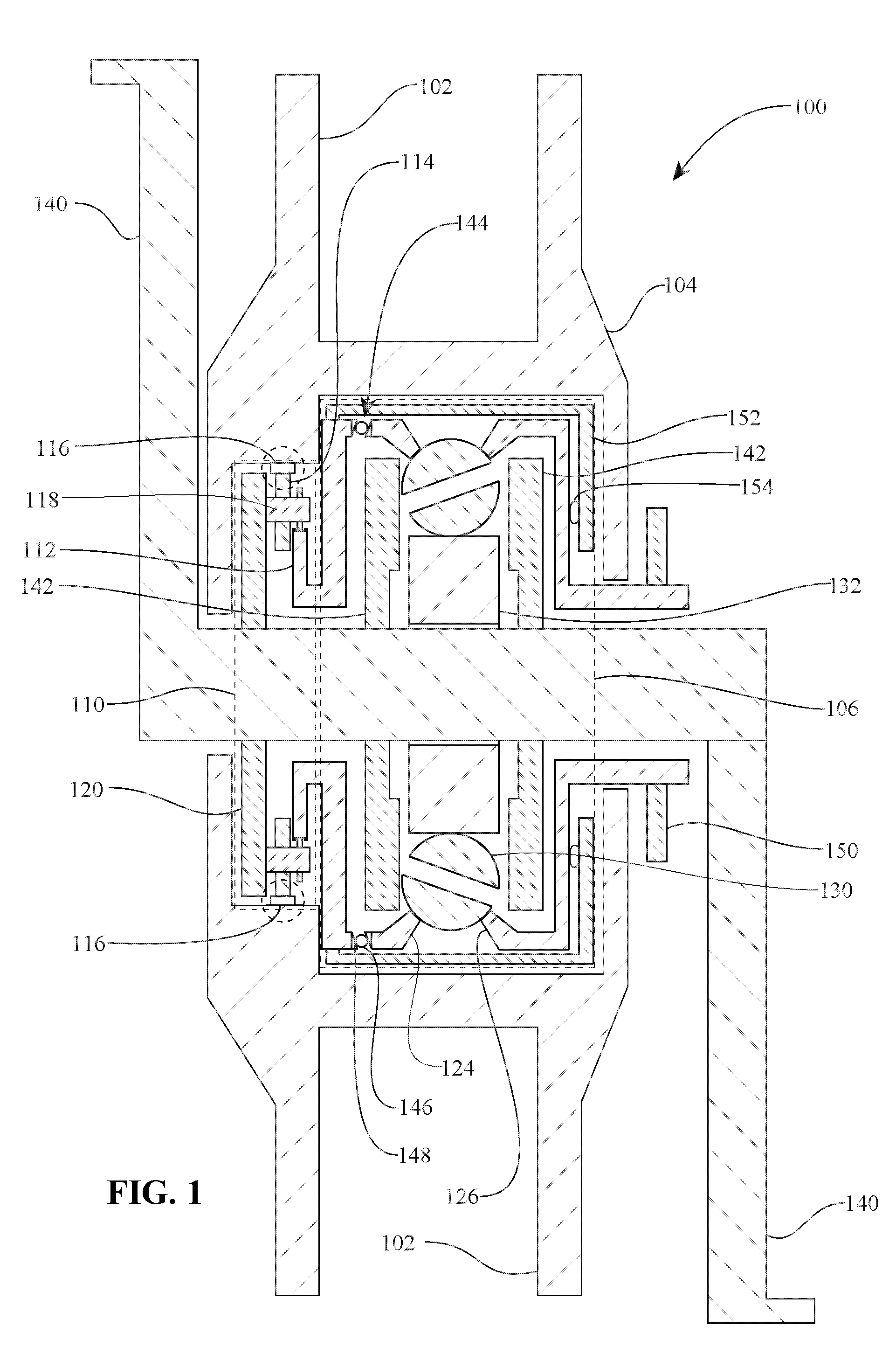

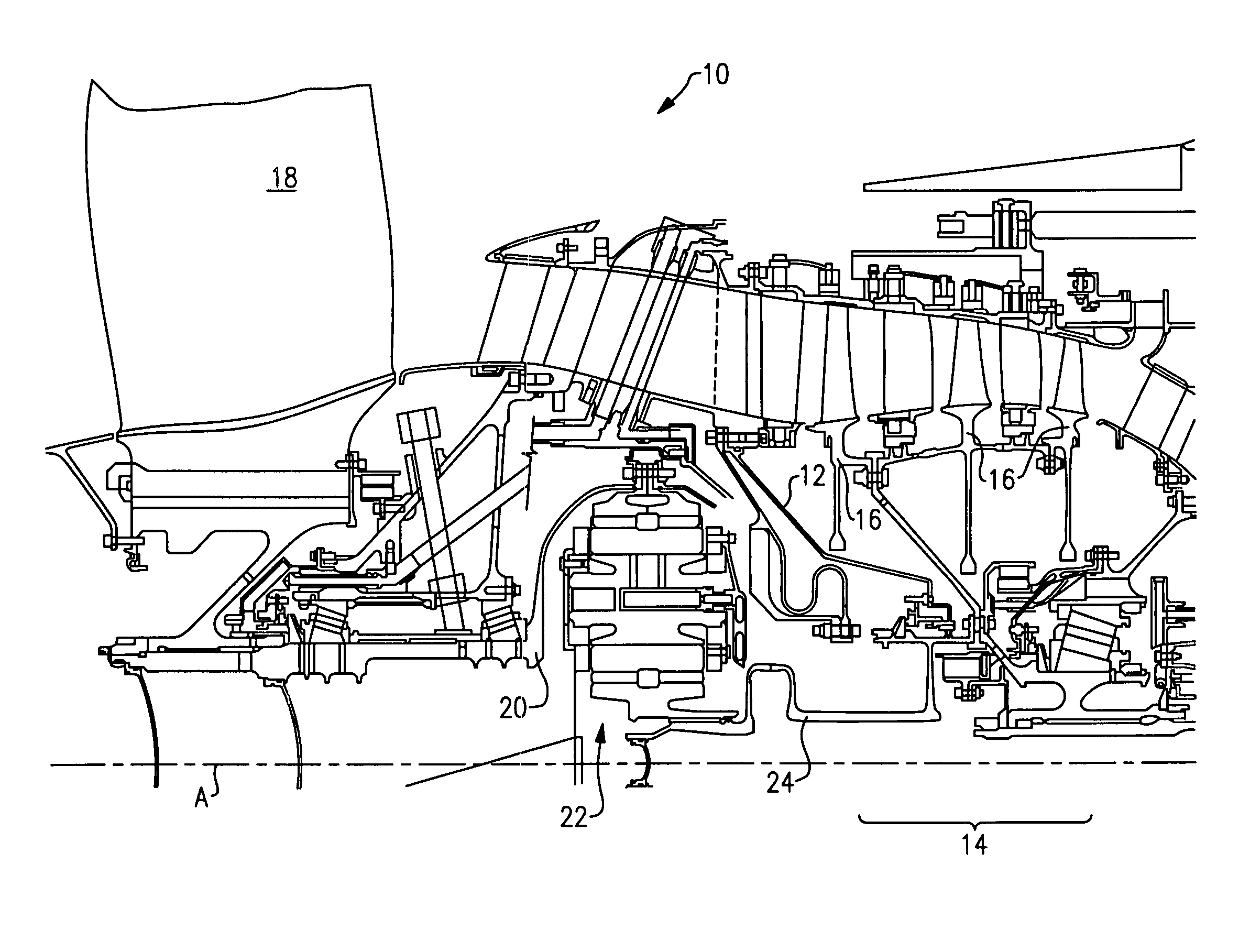

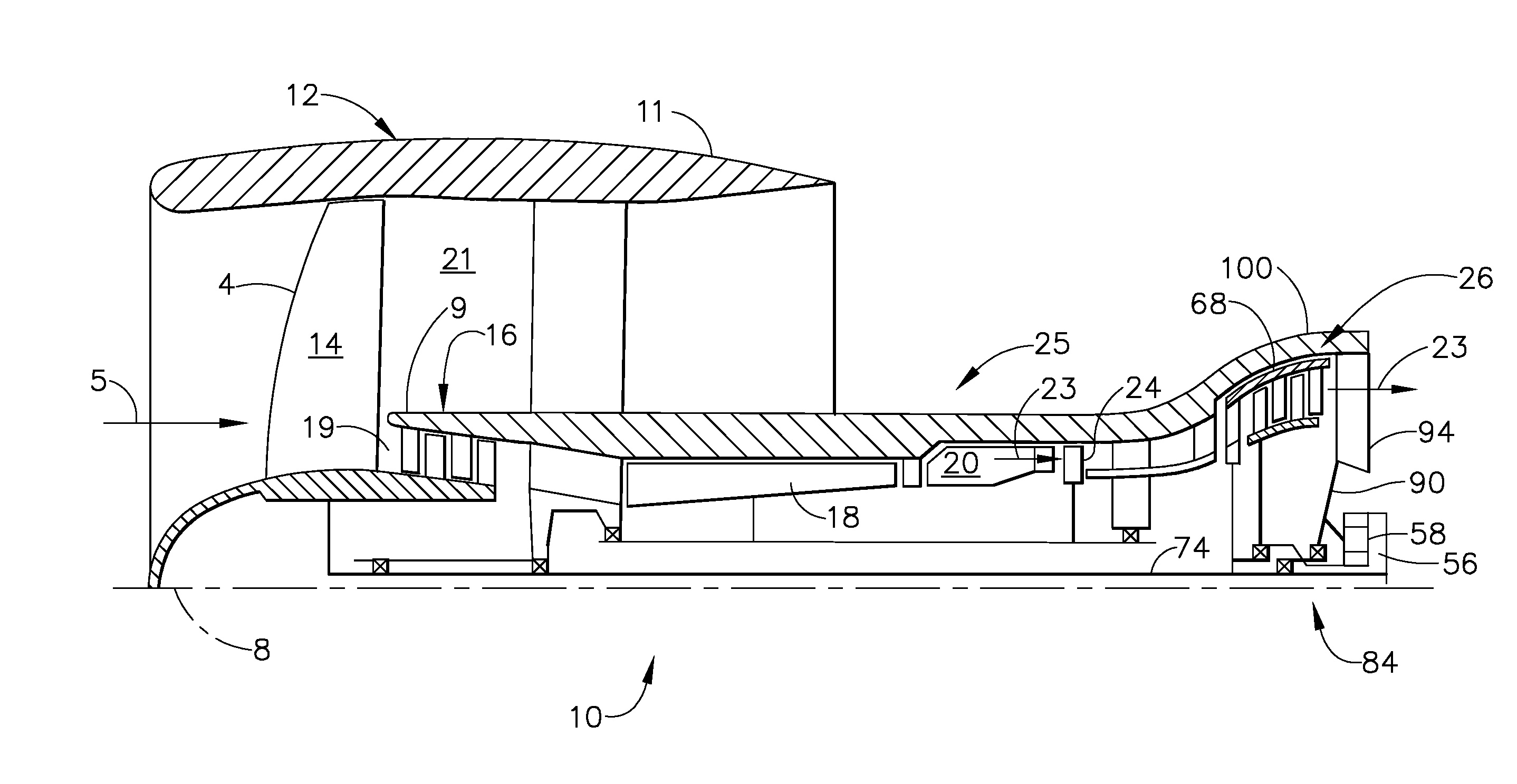

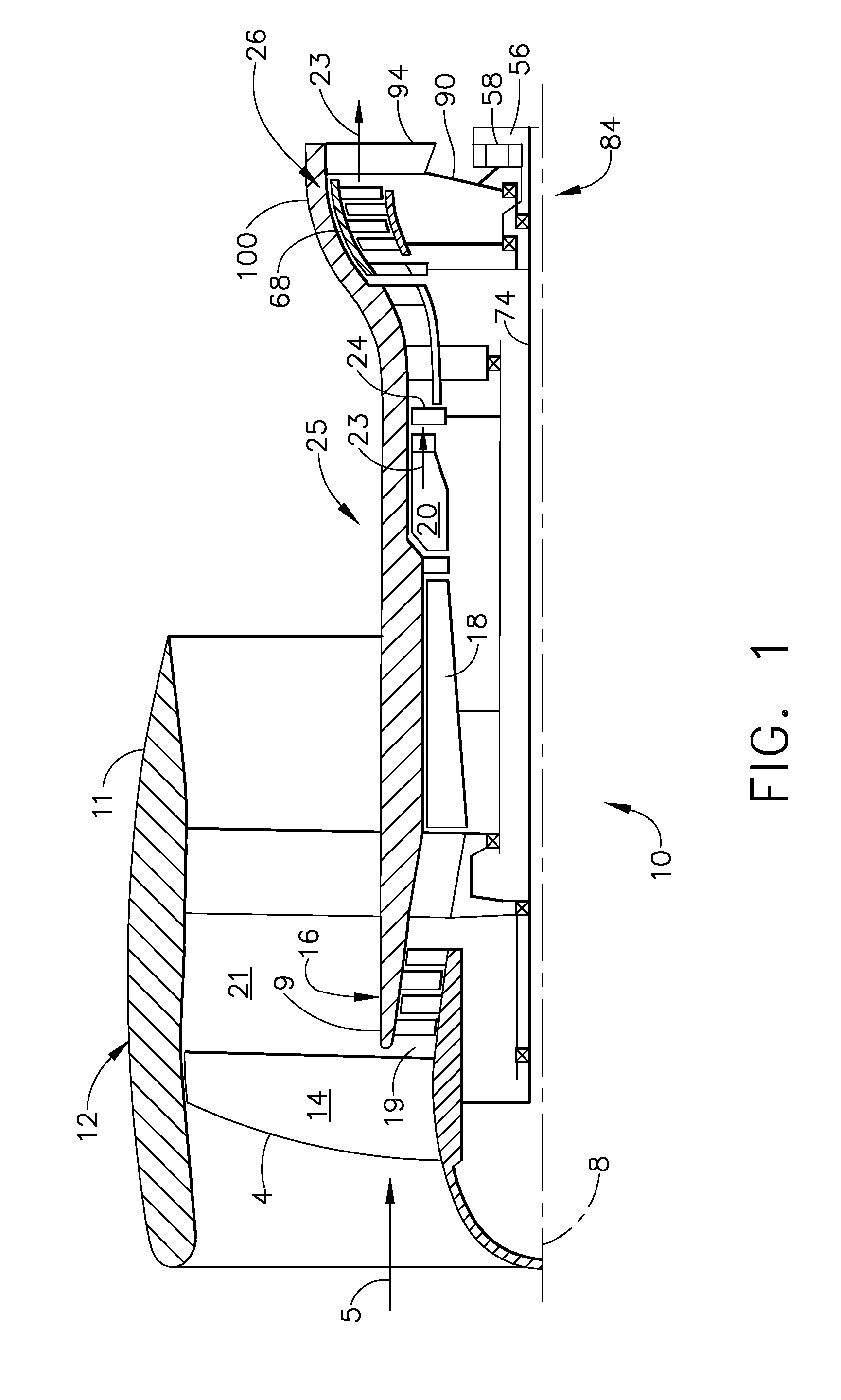

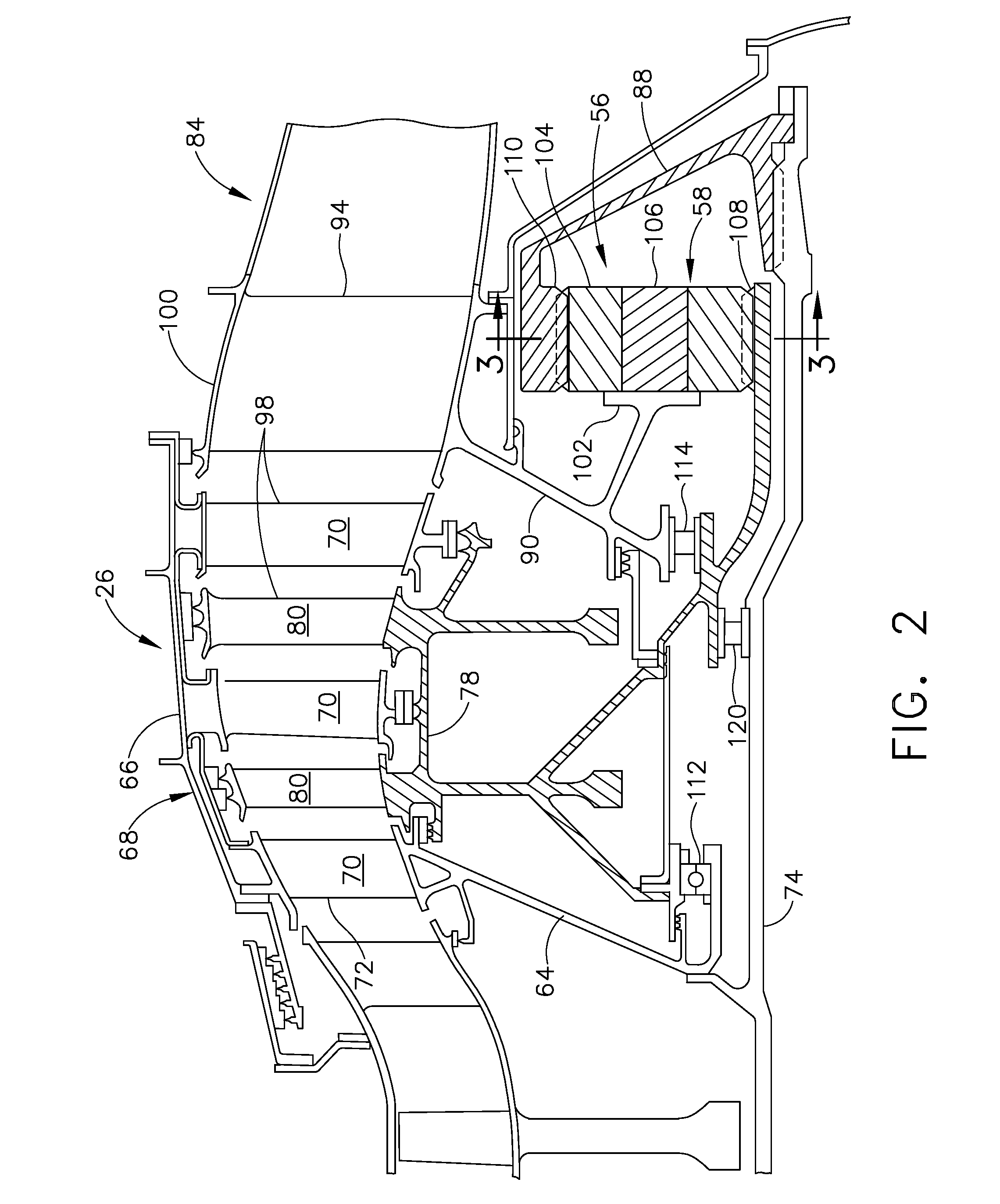

Oil baffle for gas turbine fan drive gear system

A gas turbine engine includes an epicyclic gear train that drives a turbo fan. The epicyclic gear train employs a one-piece carrier in which the spaced side walls are interconnected with circumferentially spaced apart mounts to form a unitary structure. Baffles are secured to the carrier near the mounts and provide lubrication passages that spray oil onto the sun gear and / or intermediate gears arranged between the baffles. The baffles can be constructed from a different material than the carrier since the baffles are not structural components in the gear train.

Owner:RAYTHEON TECH CORP

Continuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

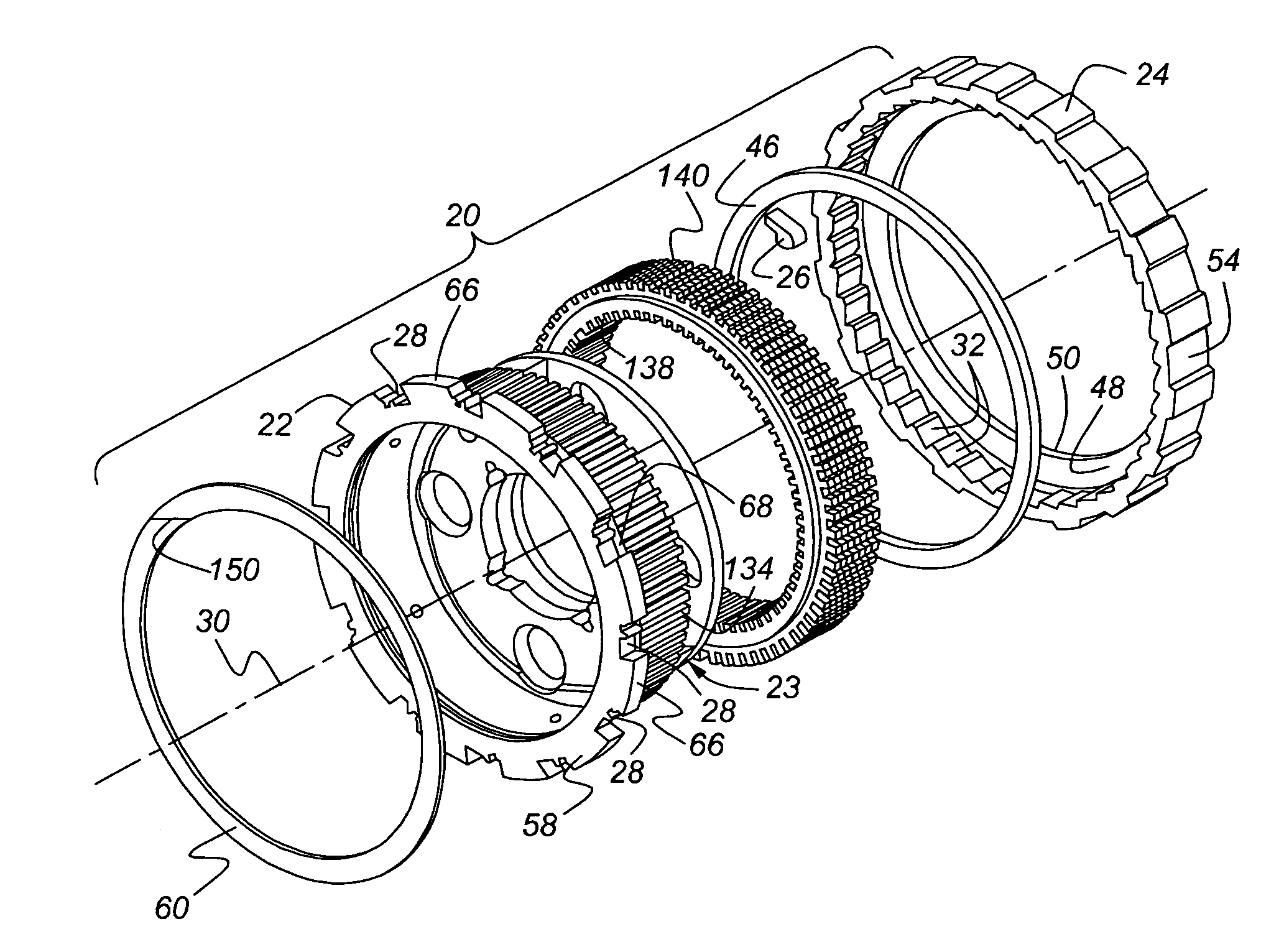

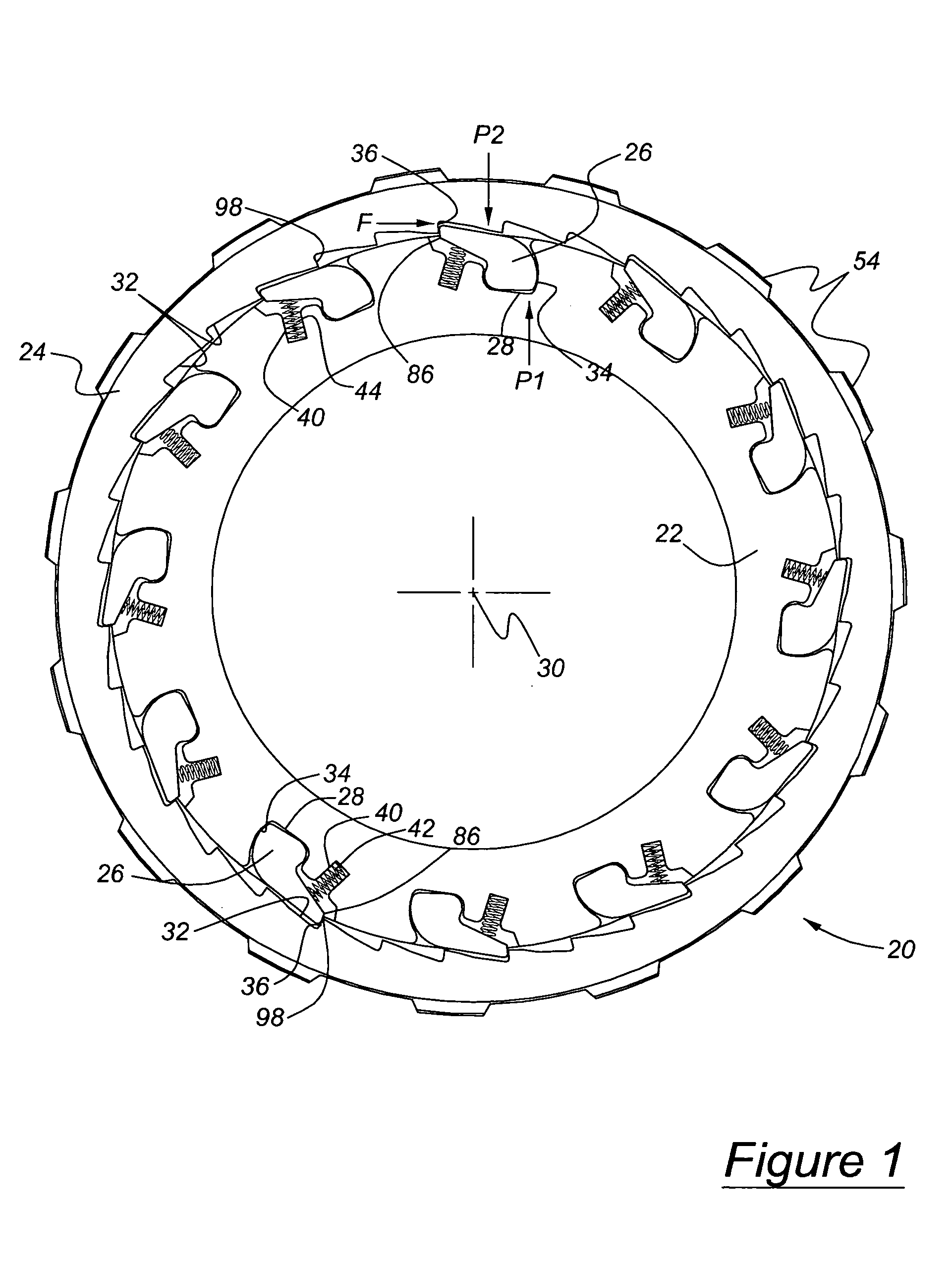

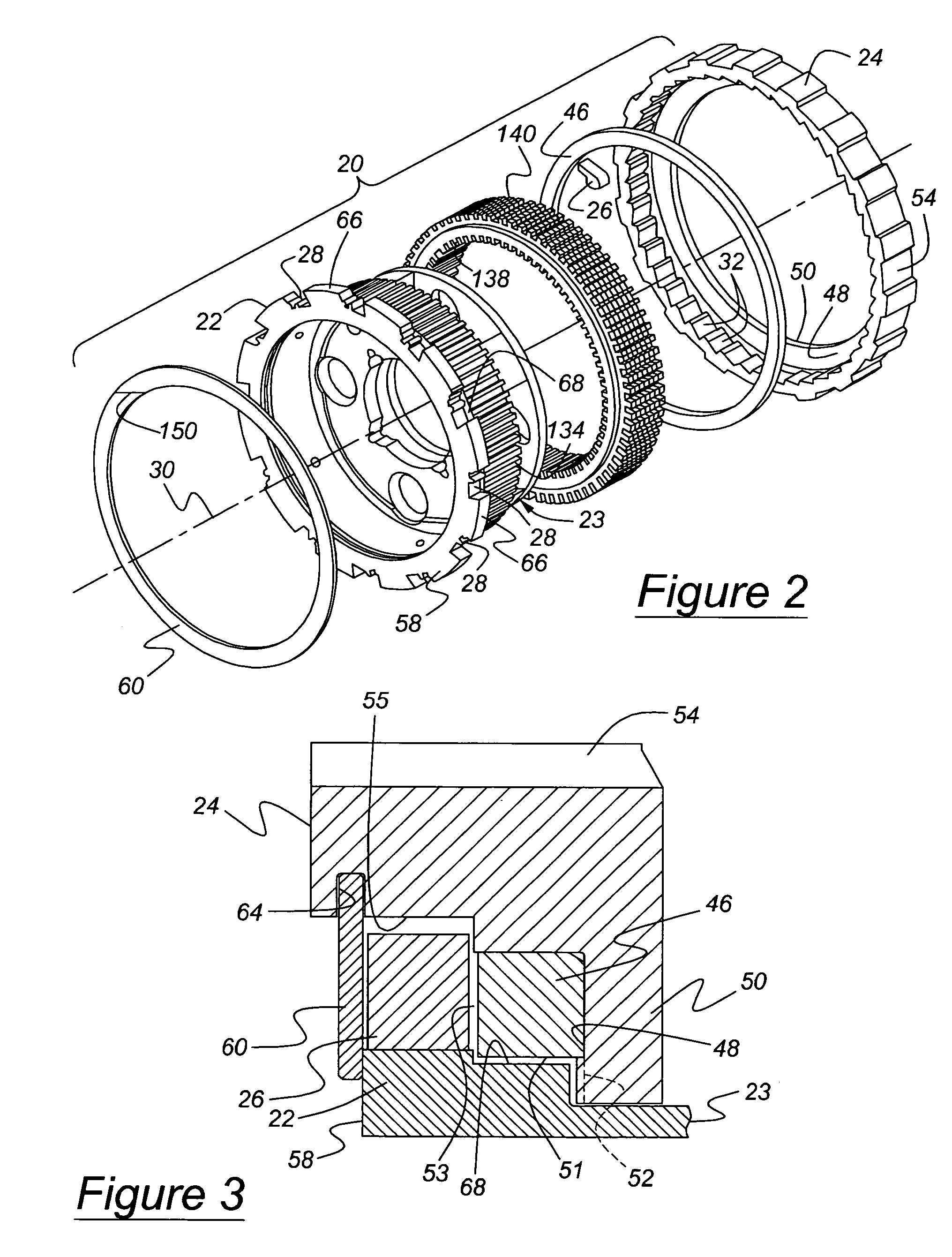

Automatic transmission carrier assembly including an overrunning brake

ActiveUS7223198B2Well formedEliminate needToothed gearingsGearing detailsAutomatic transmissionEngineering

A carrier assembly for a planetary gearset of a transmission includes a pinion carrier, a one-way brake having a rocker ring integral with the carrier and having multiple pockets mutually spaced about an axis and located on an outer radial surface of the carrier. A cam ring includes multiple notches angularly spaced about the axis and facing the rocker ring. A rocker, located in each pocket, pivots about a pivot center to engage the cam ring, and a spring urges each rocker to pivot toward engagement with the cam ring. A hydraulically actuated friction brake secured to the carrier alternately holds the carrier against rotation relative to a housing and permits the carrier to rotate.

Owner:FORD GLOBAL TECH LLC

9-speed transmission

The transmission has a plurality of members that can be utilized in powertrains to provide nine forward speed ratios and one reverse speed ratio. The transmission includes four planetary gear sets, six torque-transmitting devices, and three fixed interconnections. The powertrain includes an engine and torque converter that is continuously connected to one of the planetary gear members and an output member that is continuously connected with another one of the planetary gear members. The six torque-transmitting devices provide interconnections between various gear members, and the transmission housing, and are operated in combinations of three to establish nine forward speed ratios and one reverse speed ratio.

Owner:GM GLOBAL TECH OPERATIONS LLC

Power transmission mechanism

Owner:JATCO LTD

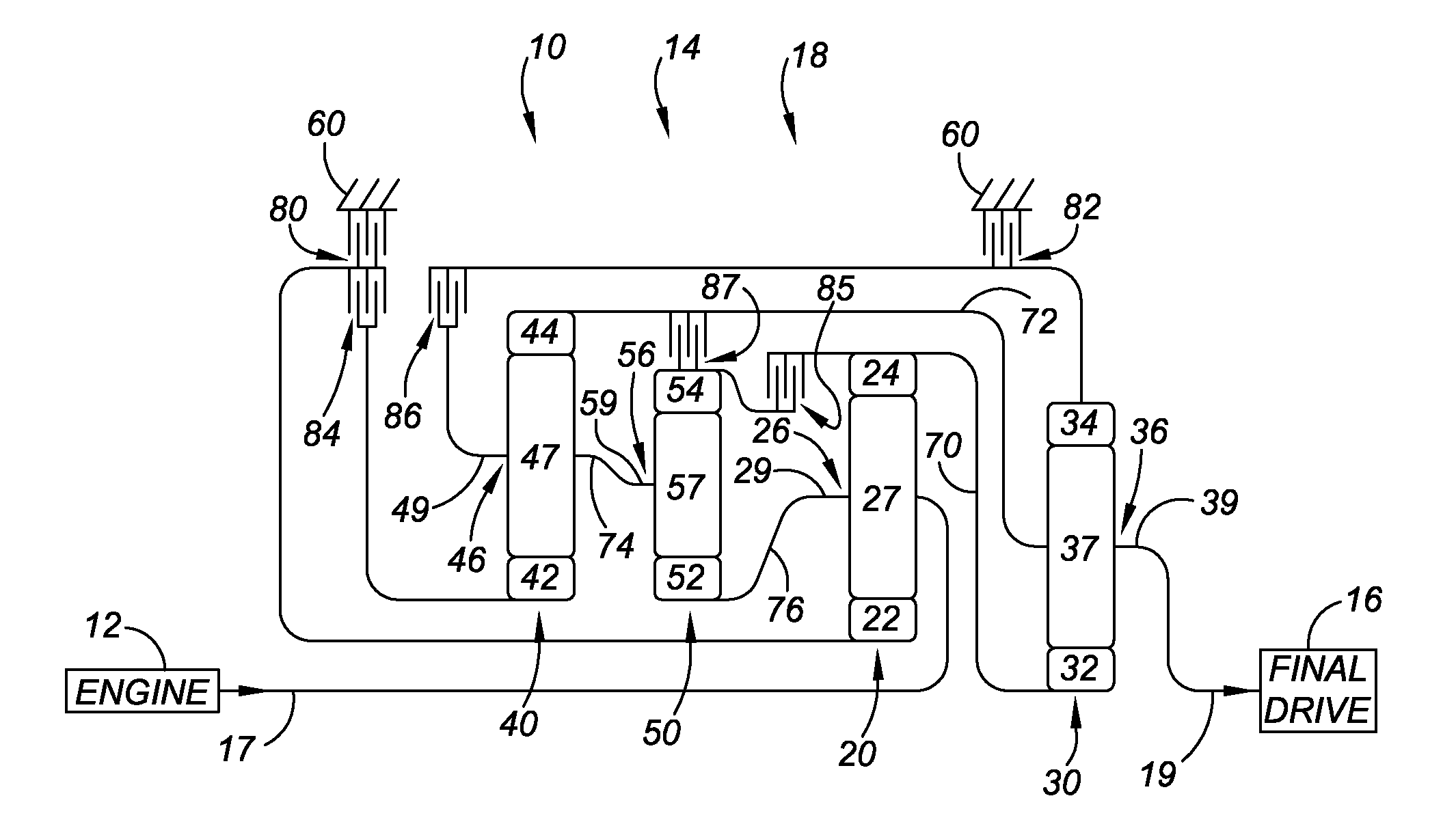

10-speed transmission

The transmission has a plurality of members that can be utilized in powertrains to provide ten forward speed ratios and one reverse speed ratio. The transmission includes four planetary gear sets, six torque-transmitting devices, and four fixed interconnections. The powertrain includes an engine and torque converter that is continuously connected to one of the planetary gear members and an output member that is continuously connected with another one of the planetary gear members. The six torque-transmitting devices provide interconnections between various gear members, and the transmission housing, and are operated in combinations of three to establish ten forward speed ratios and one reverse speed ratio.

Owner:GM GLOBAL TECH OPERATIONS LLC

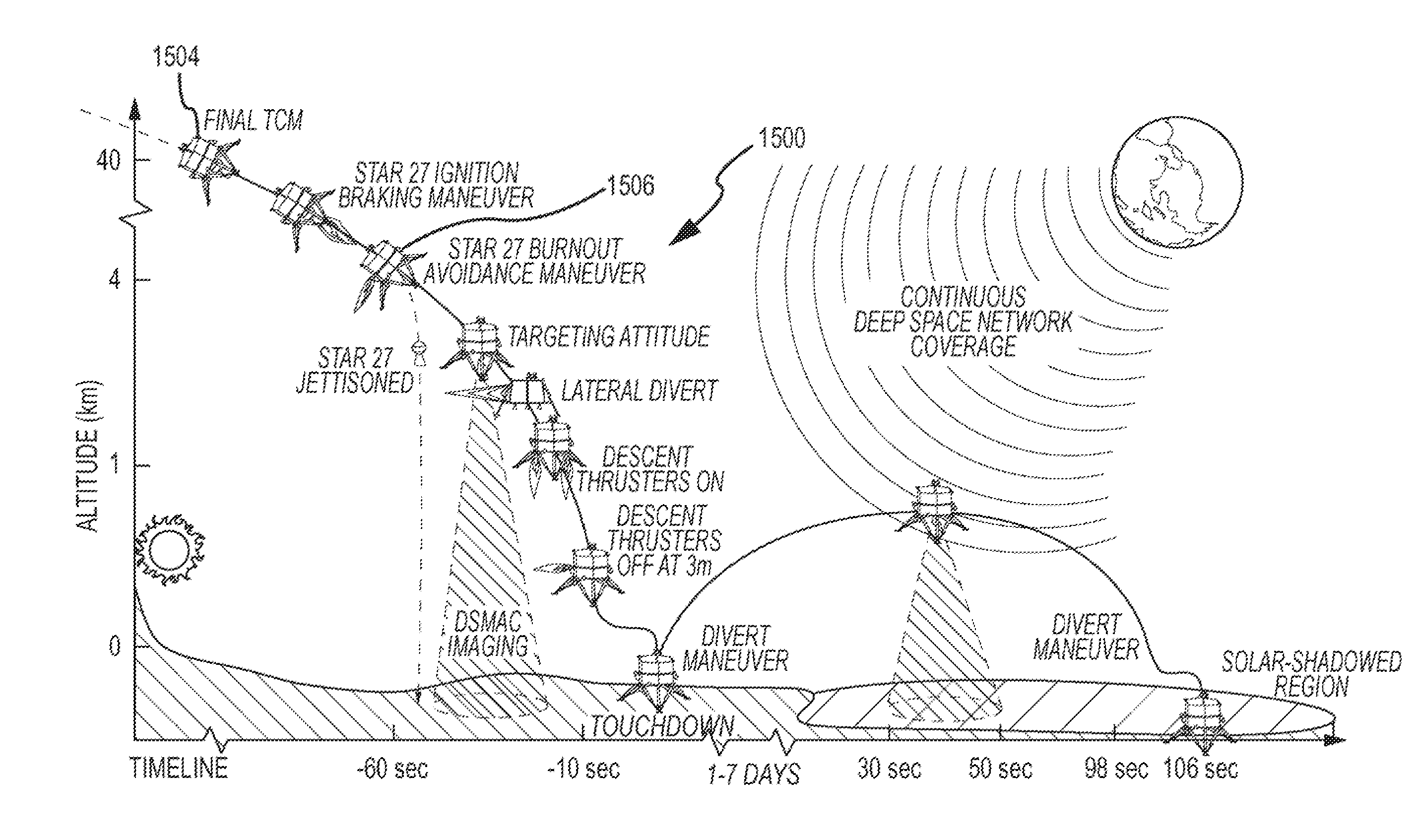

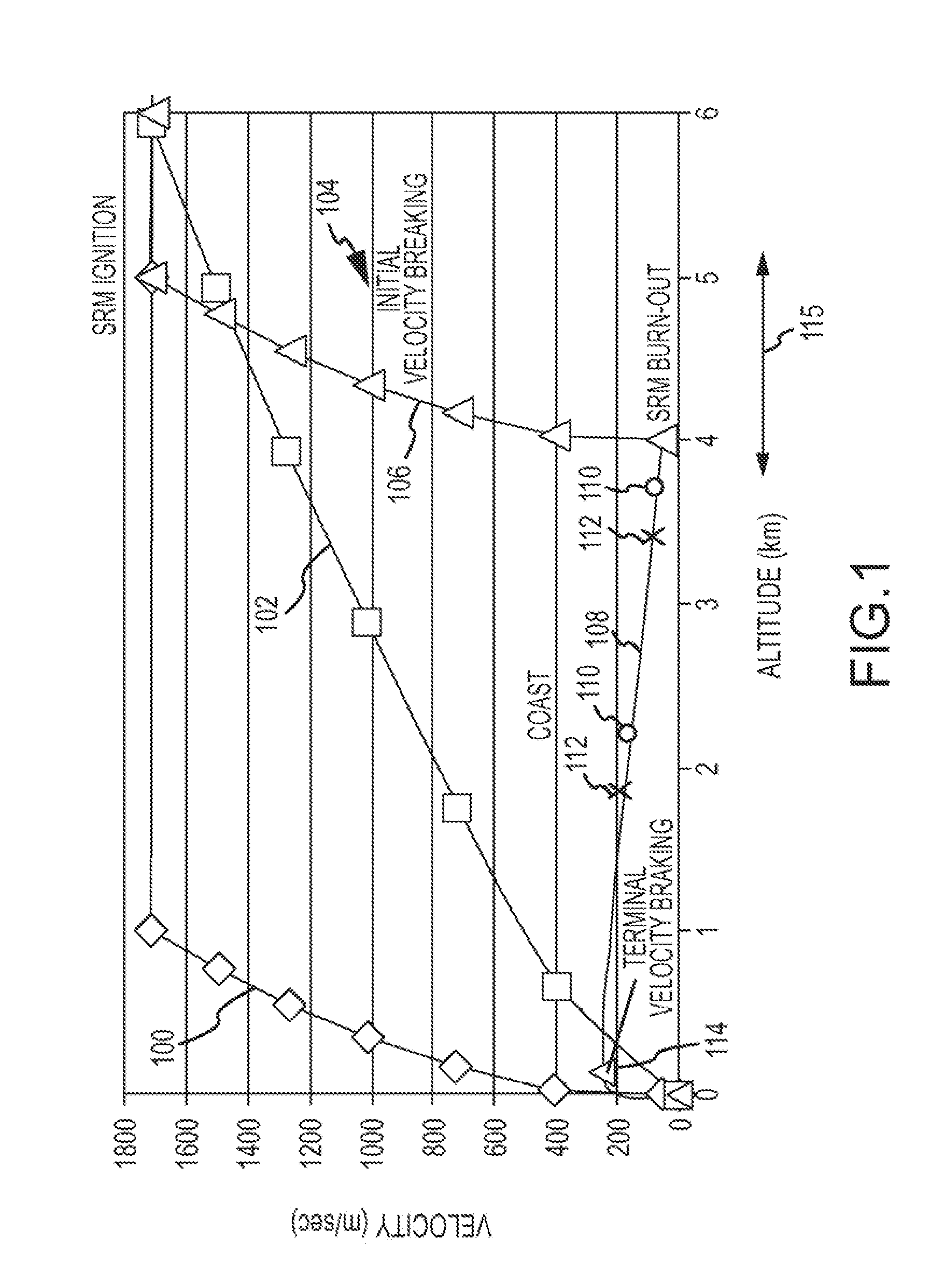

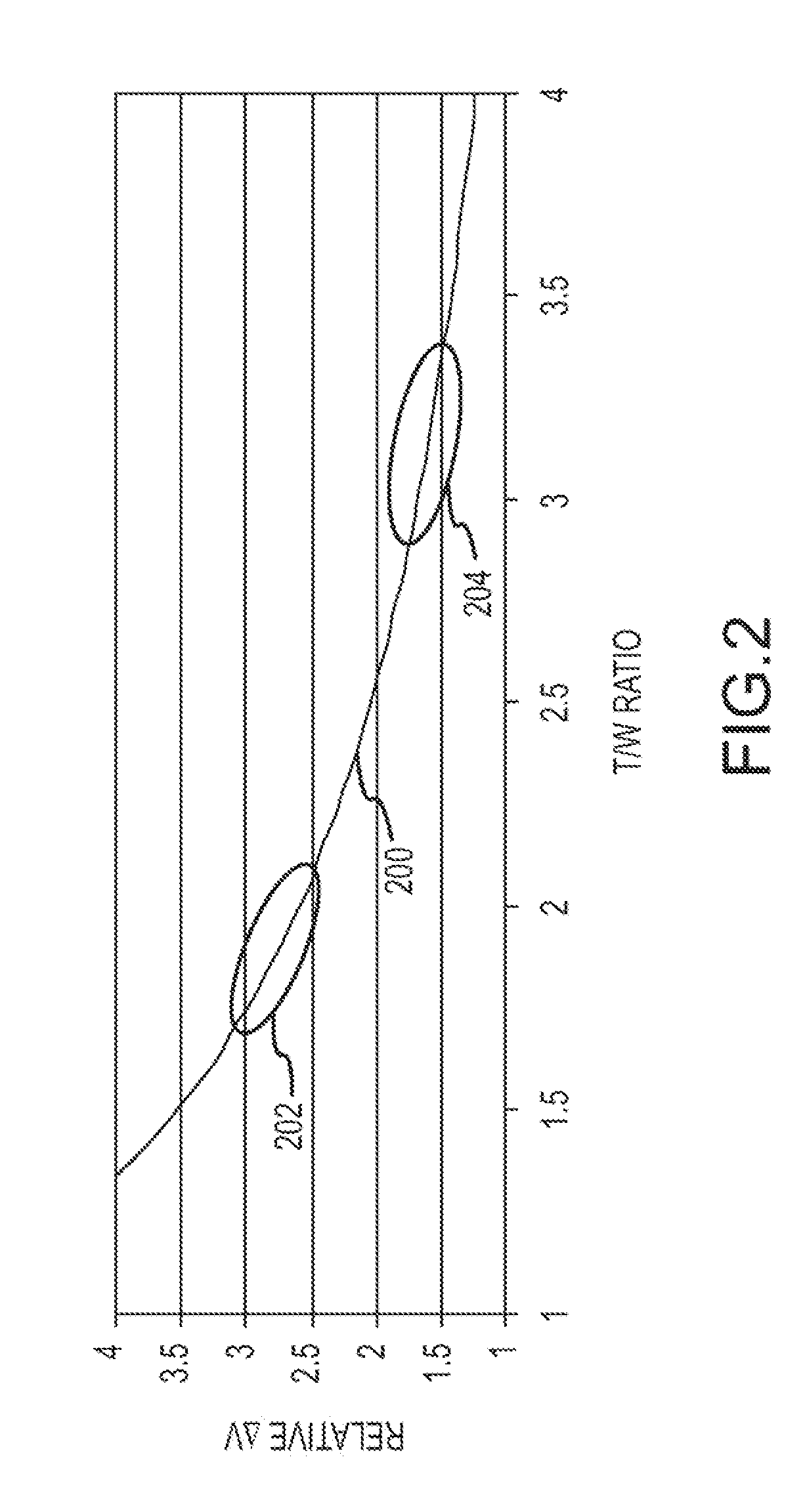

Autonomous Space Flight System and Planetary Lander for Executing a Discrete Landing Sequence to Remove Unknown Navigation Error, Perform Hazard Avoidance and Relocate the Lander and Method

ActiveUS20080023587A1Detect and avoid hazardIncreased payload capacityCosmonautic propulsion system apparatusInstruments for comonautical navigationReference mapImage resolution

An autonomous unmanned space flight system and planetary lander executes a discrete landing sequence including performing an initial velocity braking maneuver to remove velocity at altitude, coasting during which the planet surface is imaged and correlated to reference maps to estimate cross-track and along-track navigation errors and one or more lateral braking maneuvers are performed to reduce cross-track navigation error, and performing a terminal velocity braking maneuver(s) to reduce the along-track braking maneuver and remove the remainder of the velocity just prior to landing. A bi-propellant propulsion system provides a very high T / M ratio, at least 15:1 per nozzle. Short, high T / M divert maneuvers provide the capability to remove cross-track navigation error efficiently up to the maximum resolution of the reference maps. Short, high T / M terminal velocity braking maneuver(s) provide the capability to remove along-track navigation error to a similar resolution and remove the remaining velocity in a very short time window, approximately 3-15 seconds prior to touchdown. The propulsive efficiency frees up mass which can be allocated to a fuel to remove the unknown navigation errors, perform hazard avoidance and / or relocate the lander by flying it to another site or be allocated to additional payload.

Owner:RAYTHEON CO

Continuously variable transmission apparatus

ActiveUS7094171B2Save spaceAxial-direction dimension can be reducedFriction gearingsGear wheelDrive shaft

A continuously variable transmission apparatus, has: an input shaft; a toroidal-type continuously variable transmission; a rotation transmission shaft; first, second and third planetary-gear-type transmissions; a first power transmission mechanism; a second power transmission mechanism; a third power transmission mechanism; and, a switching mechanism, wherein the second sun gear and one of the first and third sun gears are rotated together with the rotation transmission shaft to thereby execute the power transmission through the rotation transmission shaft and one of the first and second planetary-gear-type transmissions, and, in a state where the power transmission through the third planetary-gear-type transmission is cut off, in accordance with the control of the transmission ratio of the toroidal-type continuously variable transmission, the output shaft is stopped while the input shaft is rotating.

Owner:NSK LTD

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com