Patents

Literature

1105results about "Road transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

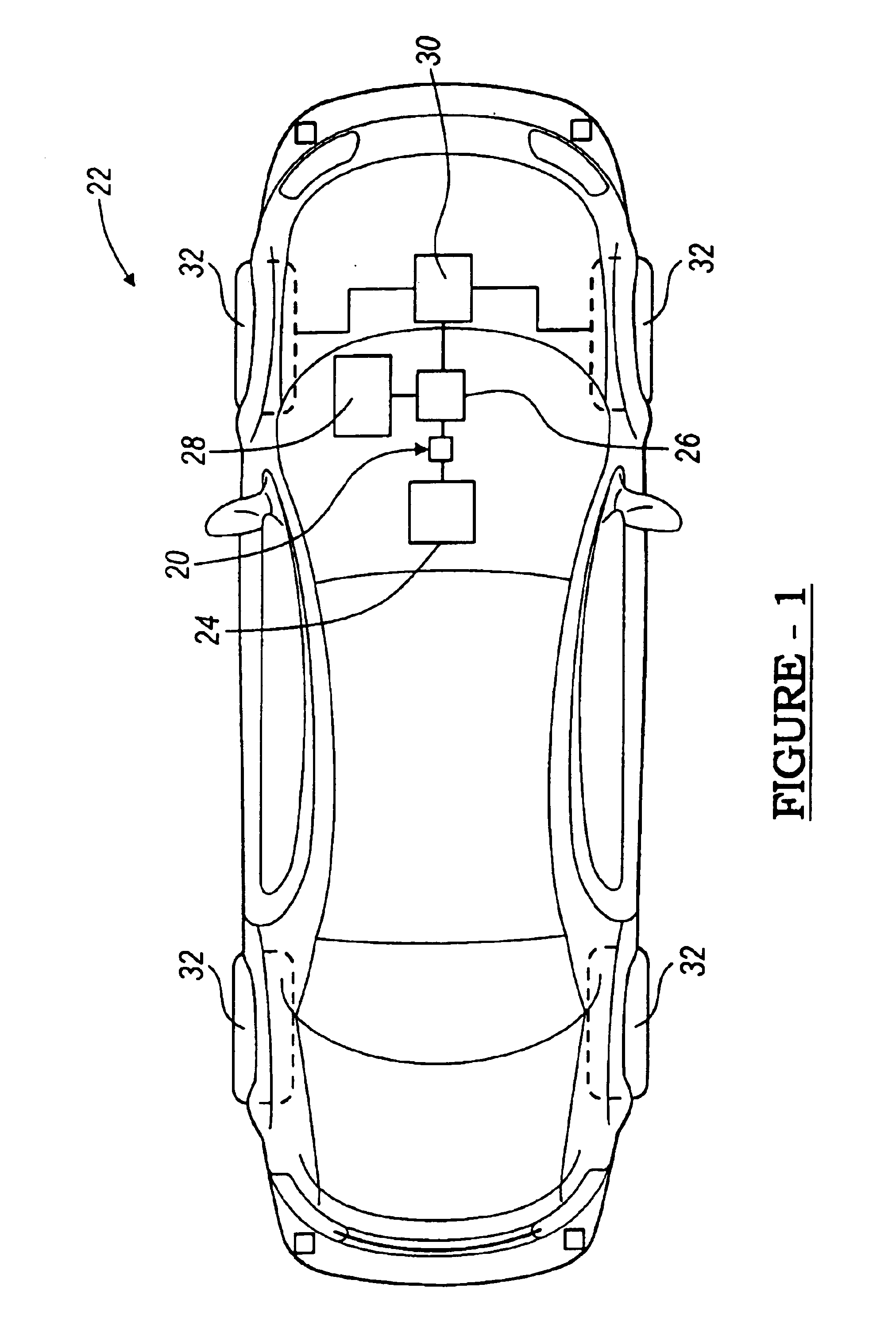

Hybrid electric drive and control method therefor

InactiveUS6376927B1Increase fuel consumptionImprove drivabilityInternal combustion piston enginesGearing controlHysteresisEngineering

A fuel management control method for a hybrid electric vehicle drive having an internal combustion engine and an electric motor arranged in parallel such that both can propel the vehicle; the system including an electric motor driven fuel pump and a programmable microprocessor; and wherein the method further includes monitoring vehicle speed and sensing braking pressure and directing signals of both vehicle speed and braking to the microprocessor and processing such inputs in accordance with an aggressive fuel management program including shut-off of fuel flow to the gas engine in response to vehicle braking at vehicle speeds above a predetermined maximum hysteresis speed and maintaining the fuel shut off during vehicle coasting above a predetermined speed while controlling the electric motor to provide regenerative braking or vehicle start during such fuel shut off modes of operation.

Owner:SATURN CORPORATION

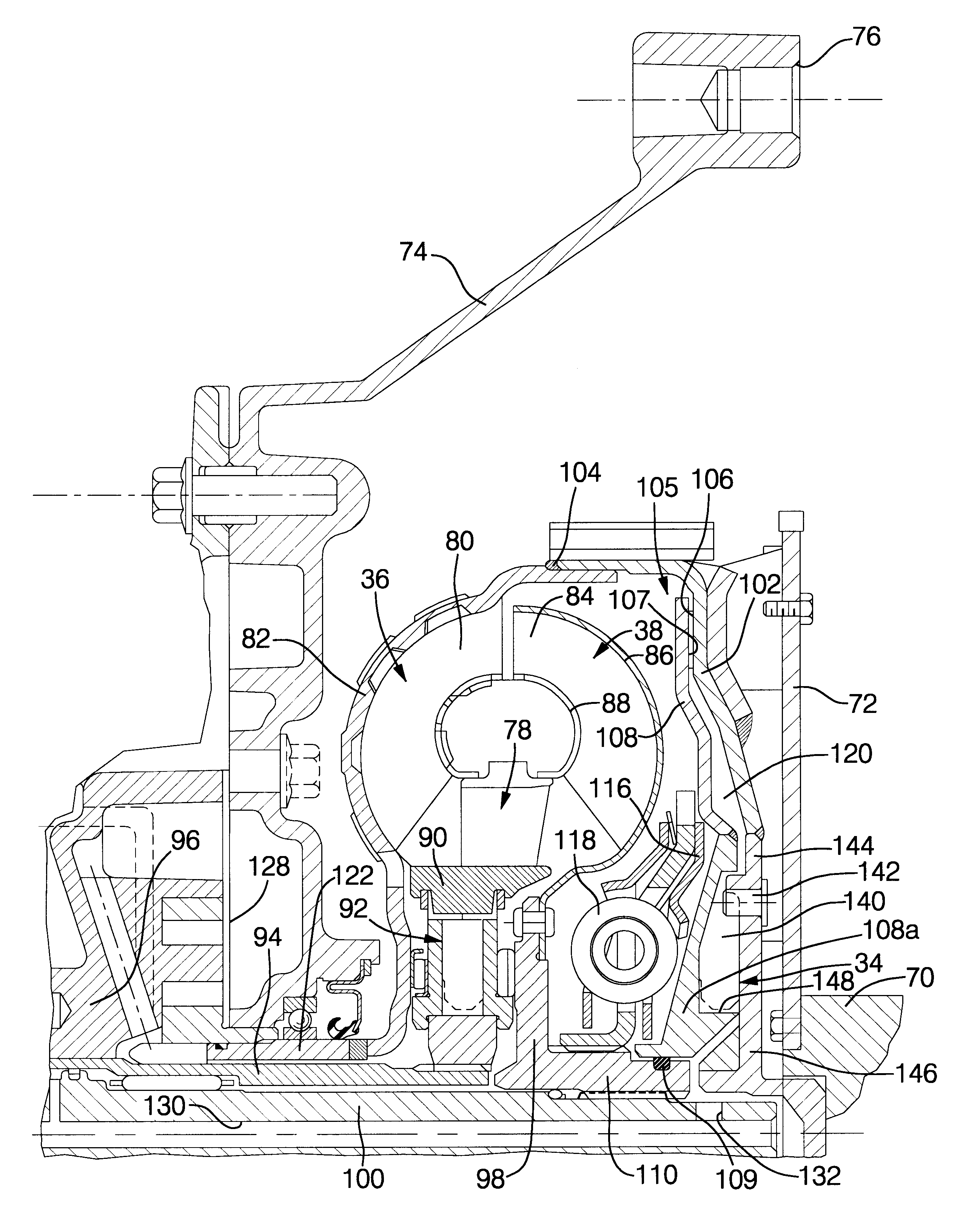

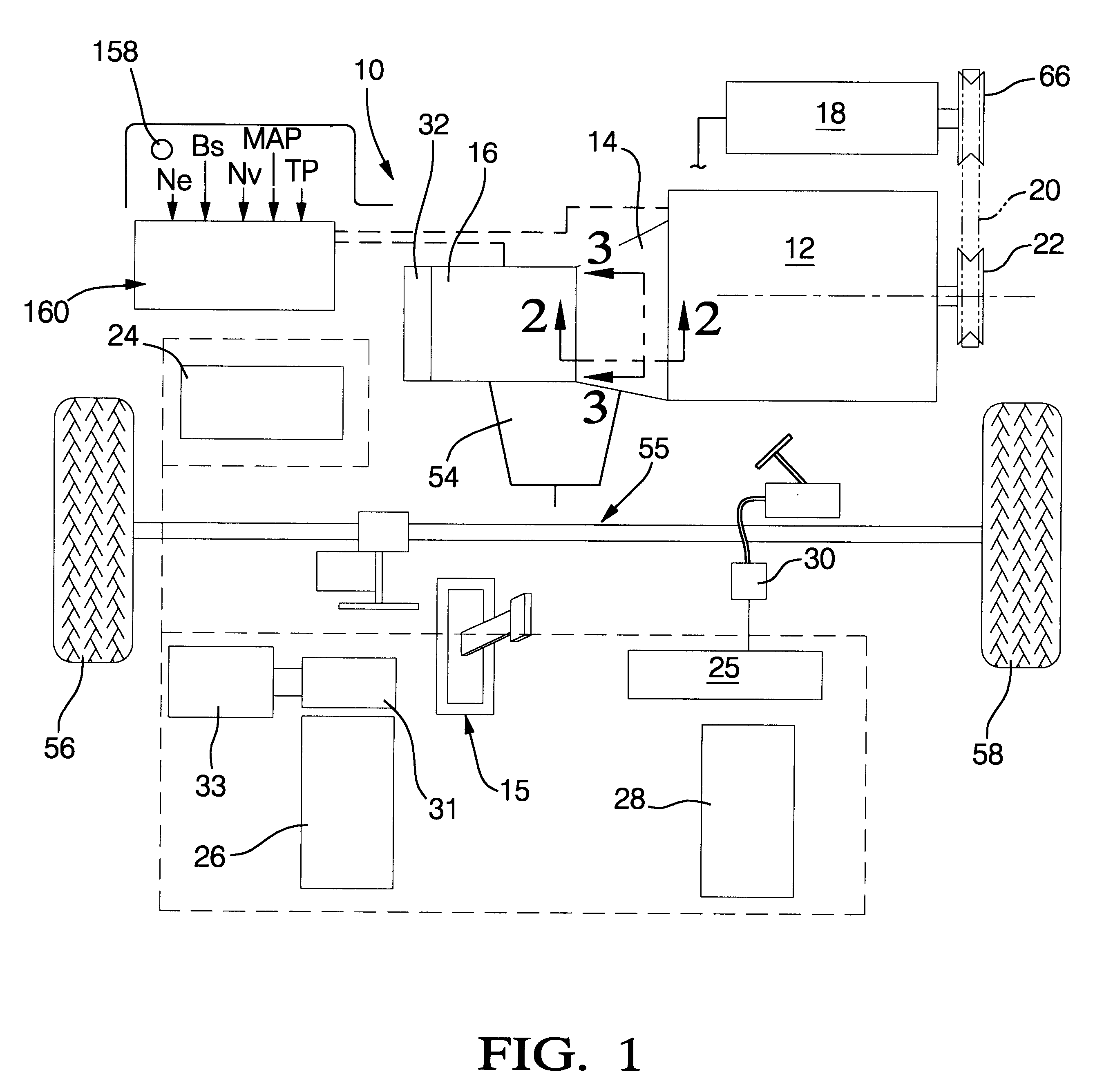

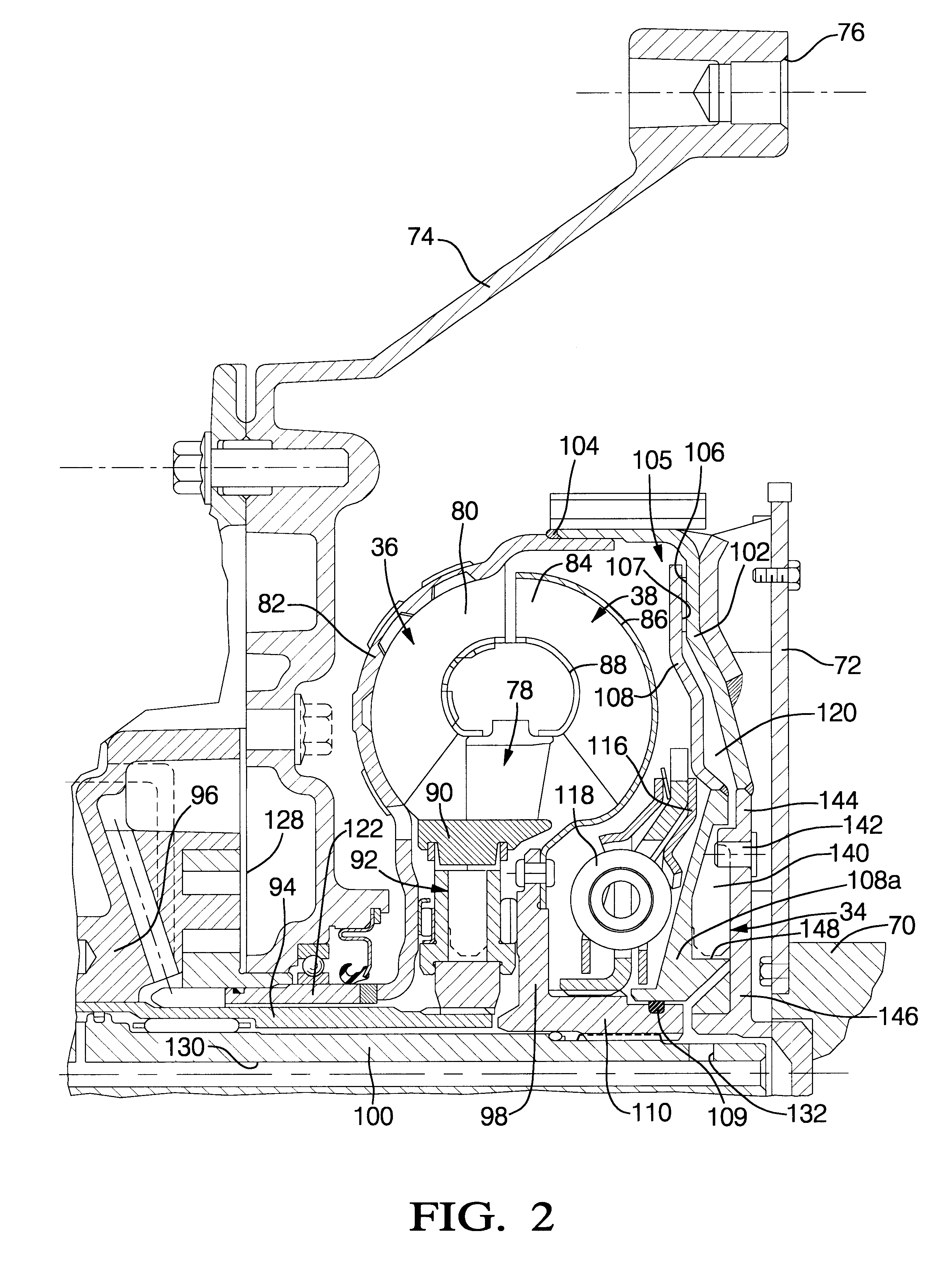

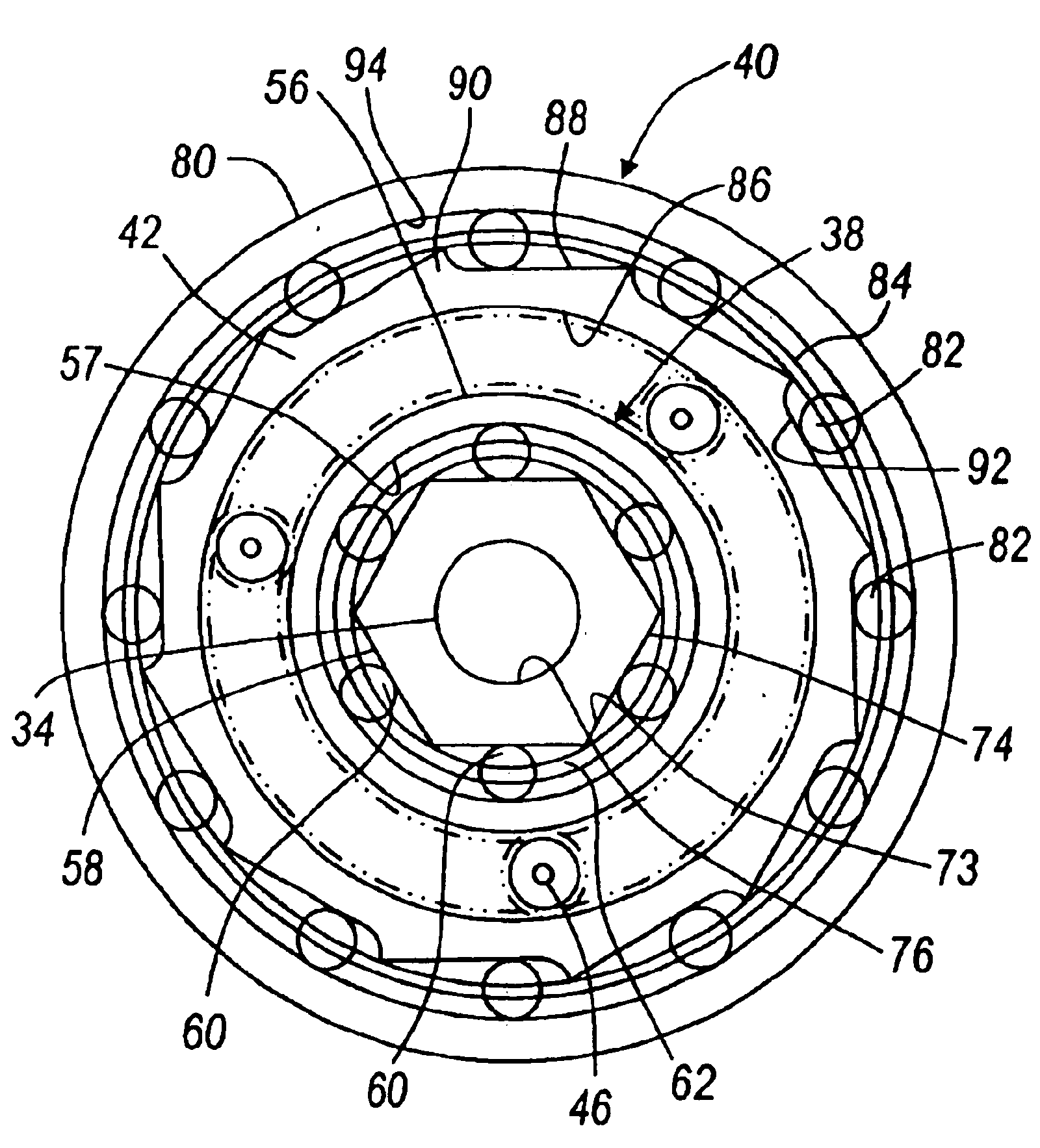

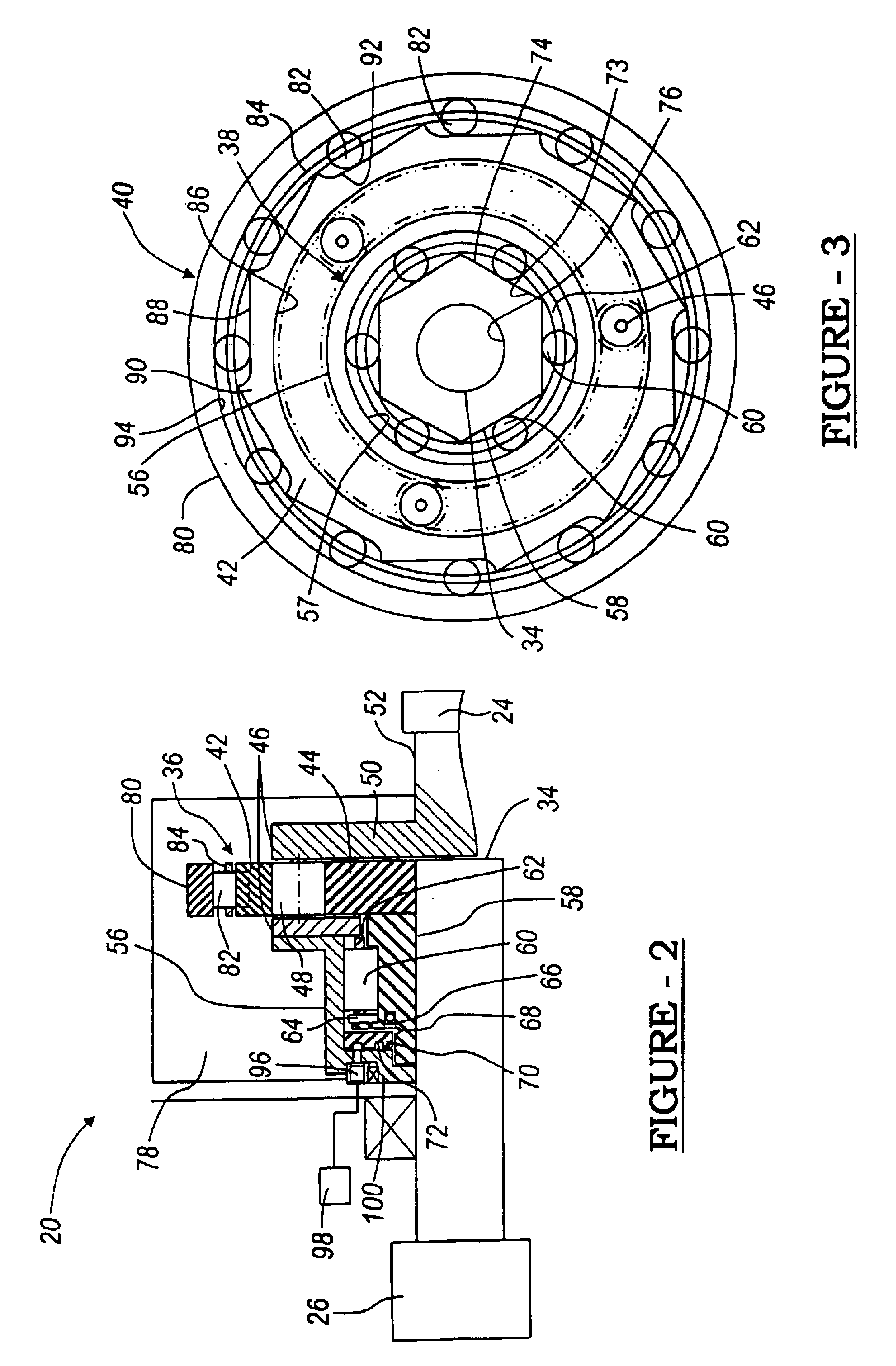

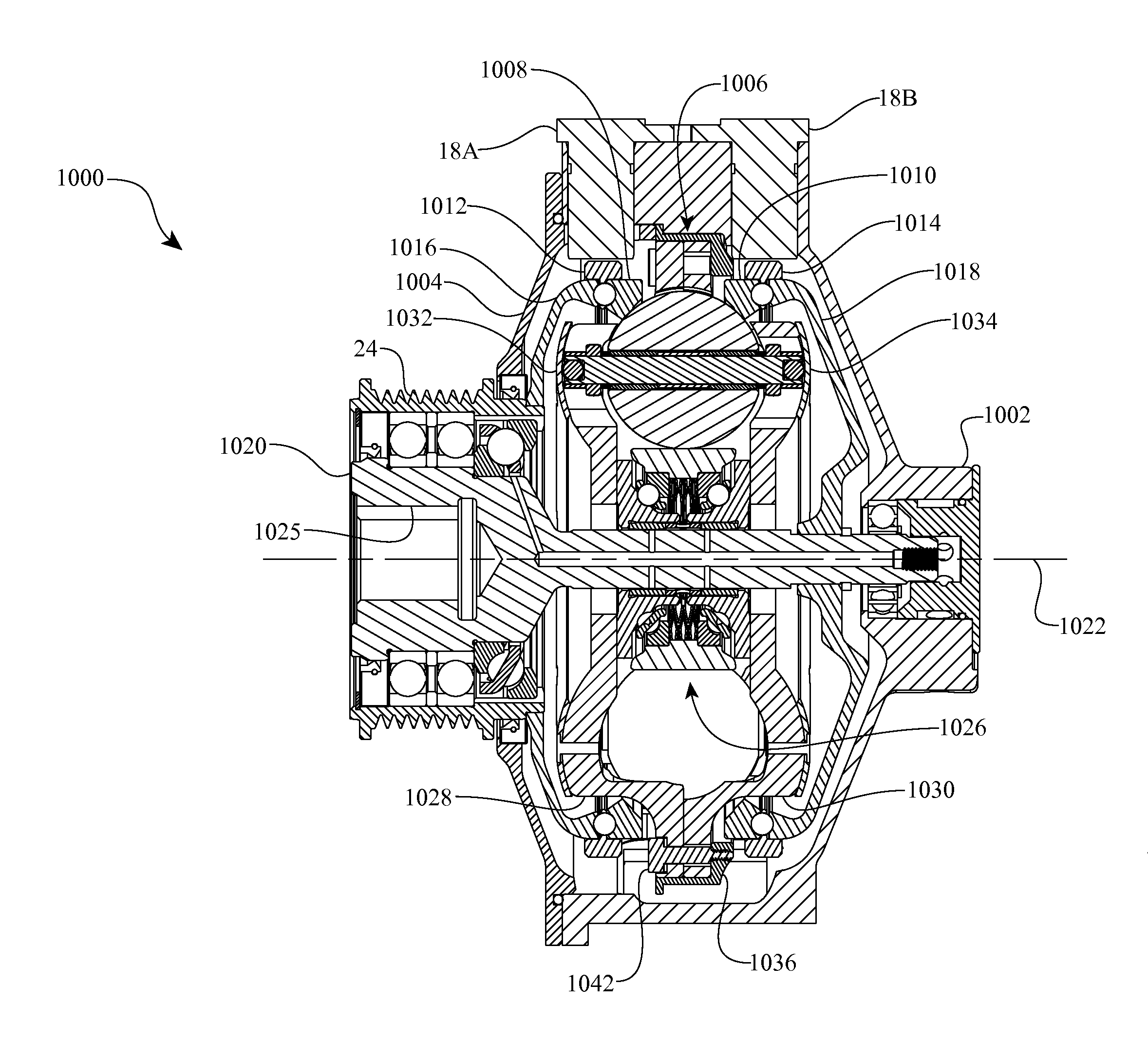

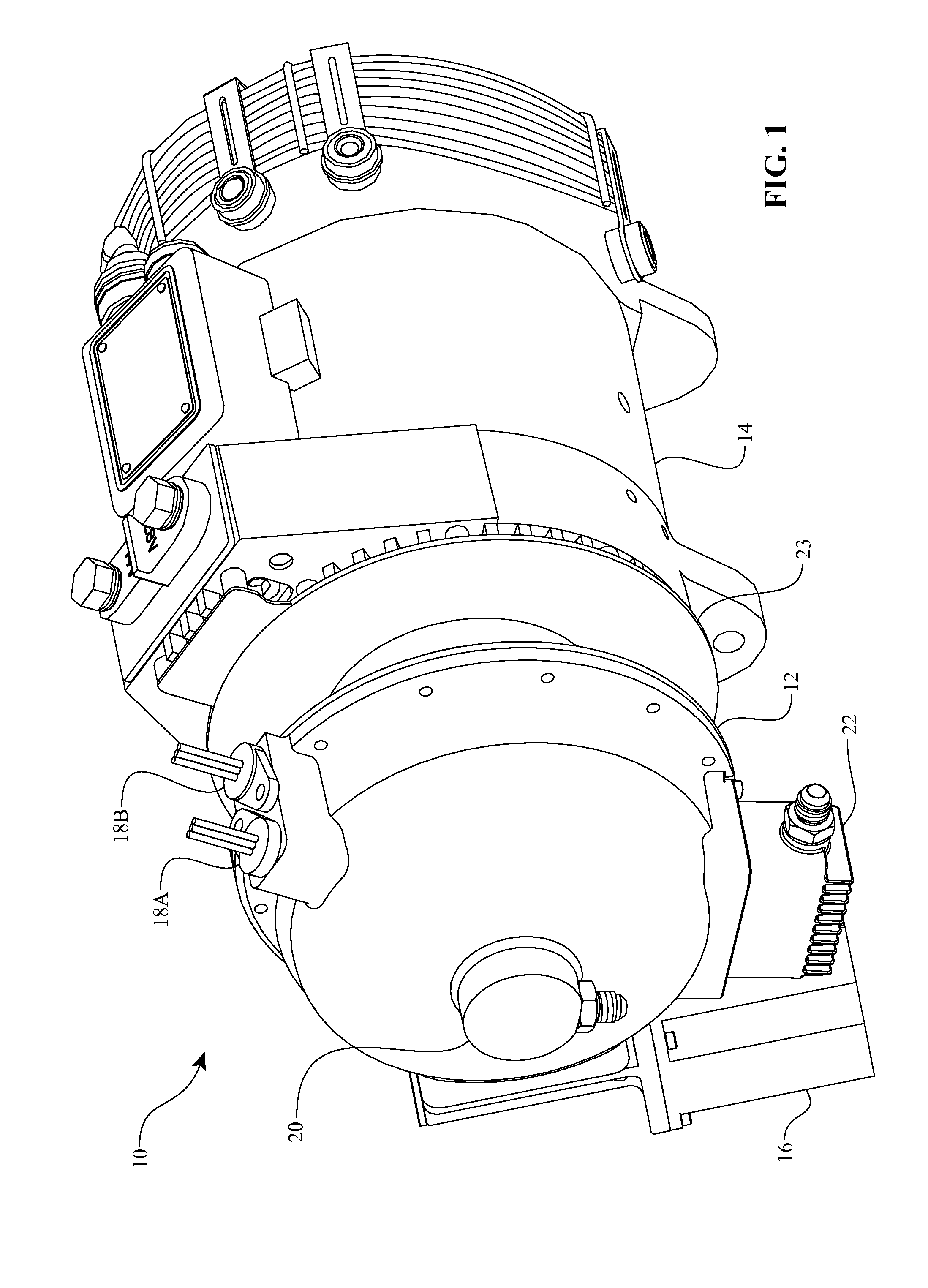

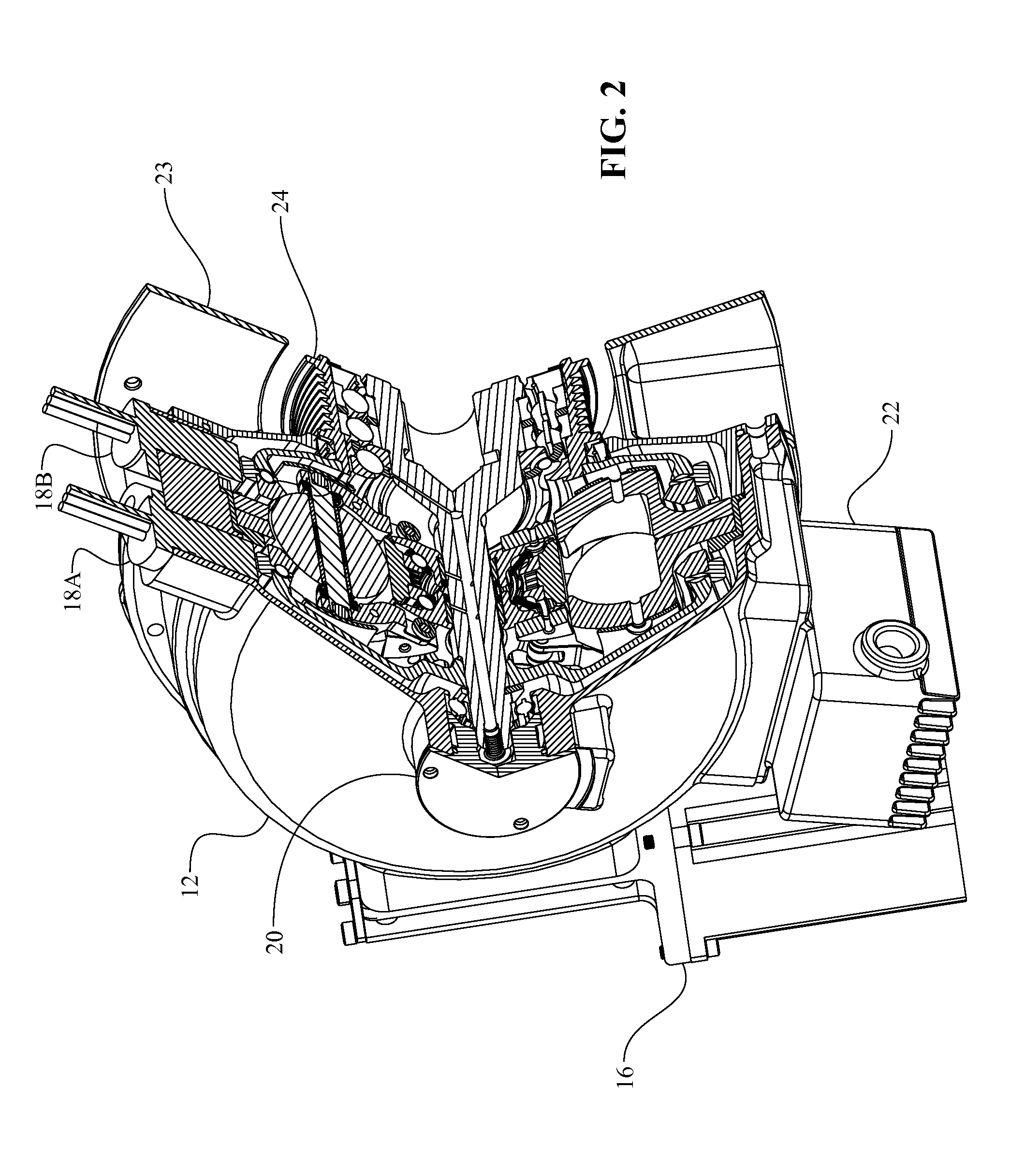

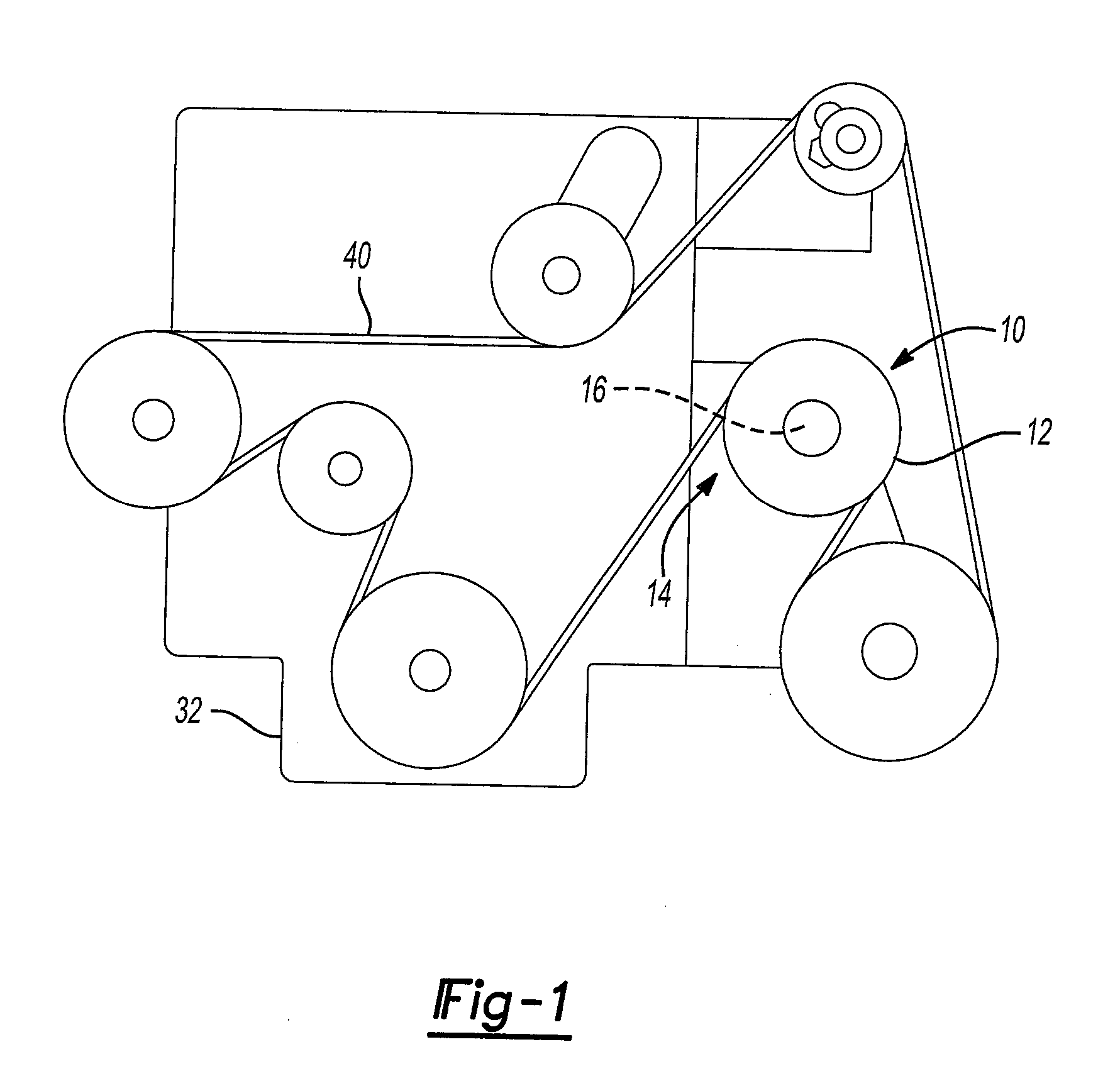

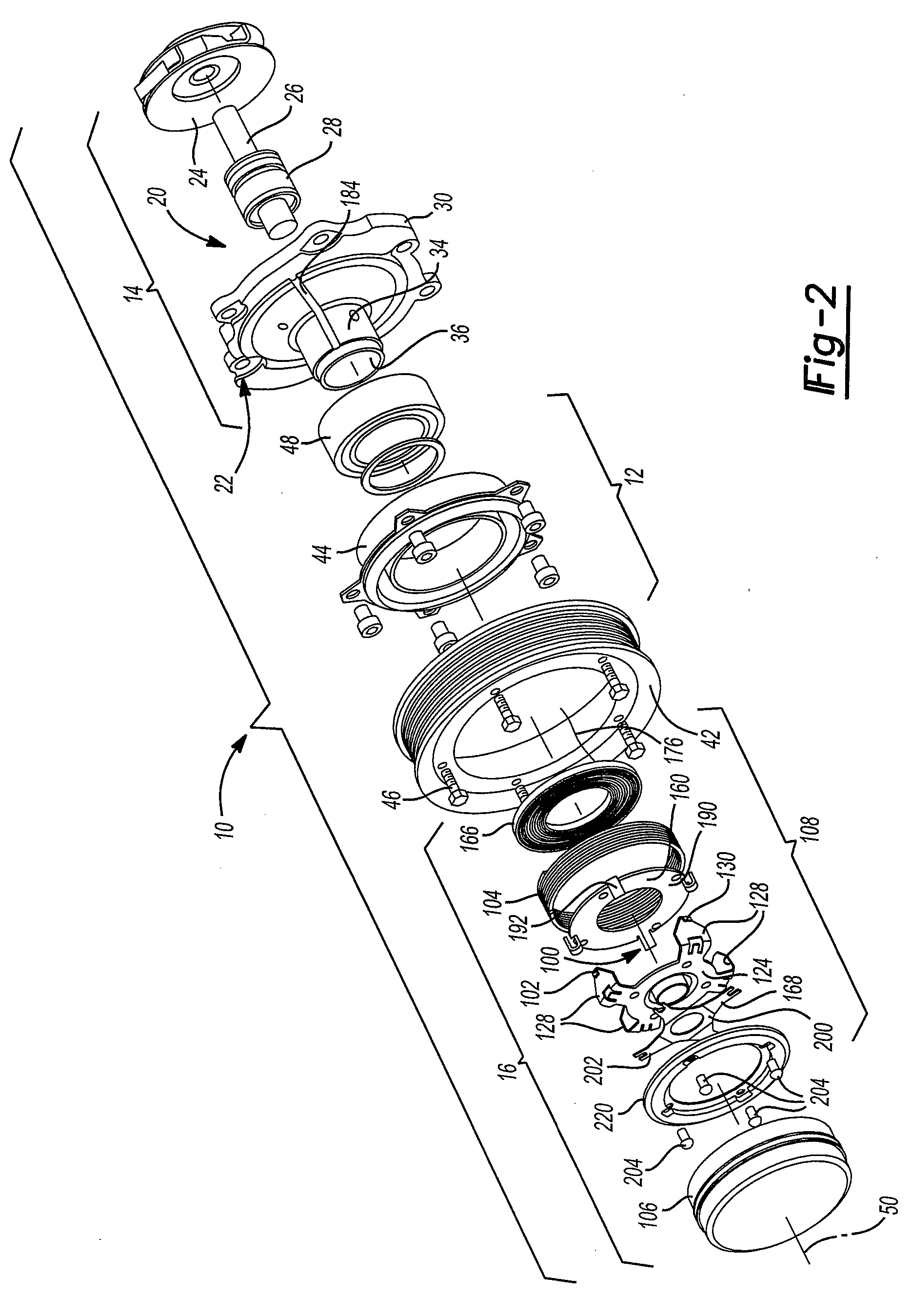

Series drive clutch

InactiveUS6846257B2Prevent rotationPlural diverse prime-mover propulsion mountingFluid clutchesCombustionEngineering

A clutch mechanism is disclosed for use with a hybrid electric vehicle wherein the electric motor-generator and engine are arranged in a series configuration. The clutch mechanism is positioned between and in communication with the electric motor-generator and engine to allow for either direct drive or a predetermined gear ratio between the electric motor-generator and engine. The electric motor-generator is preferably an integrated electric motor and generator. The engine is preferably a combustion engine.

Owner:NTN CORP

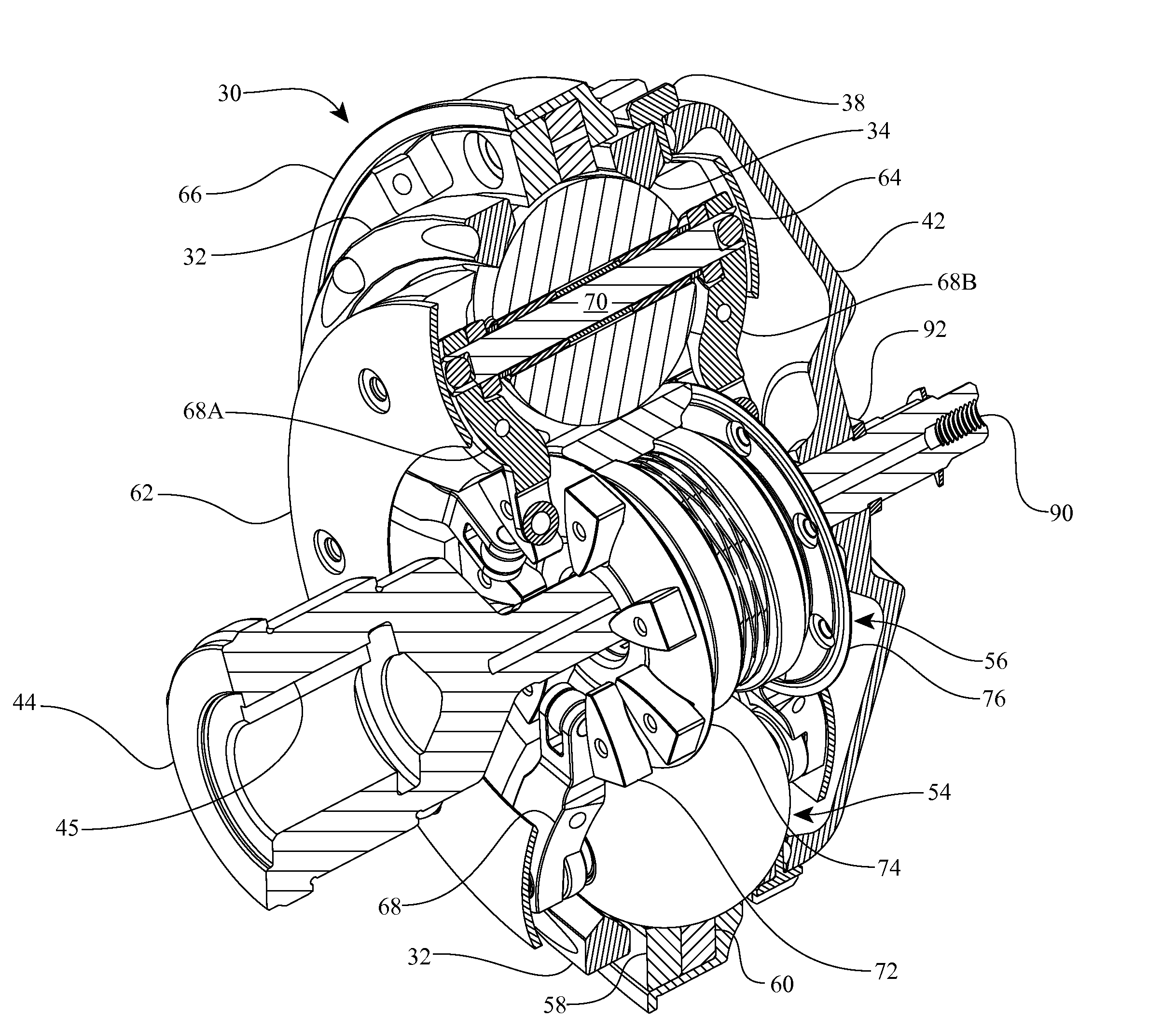

Continuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

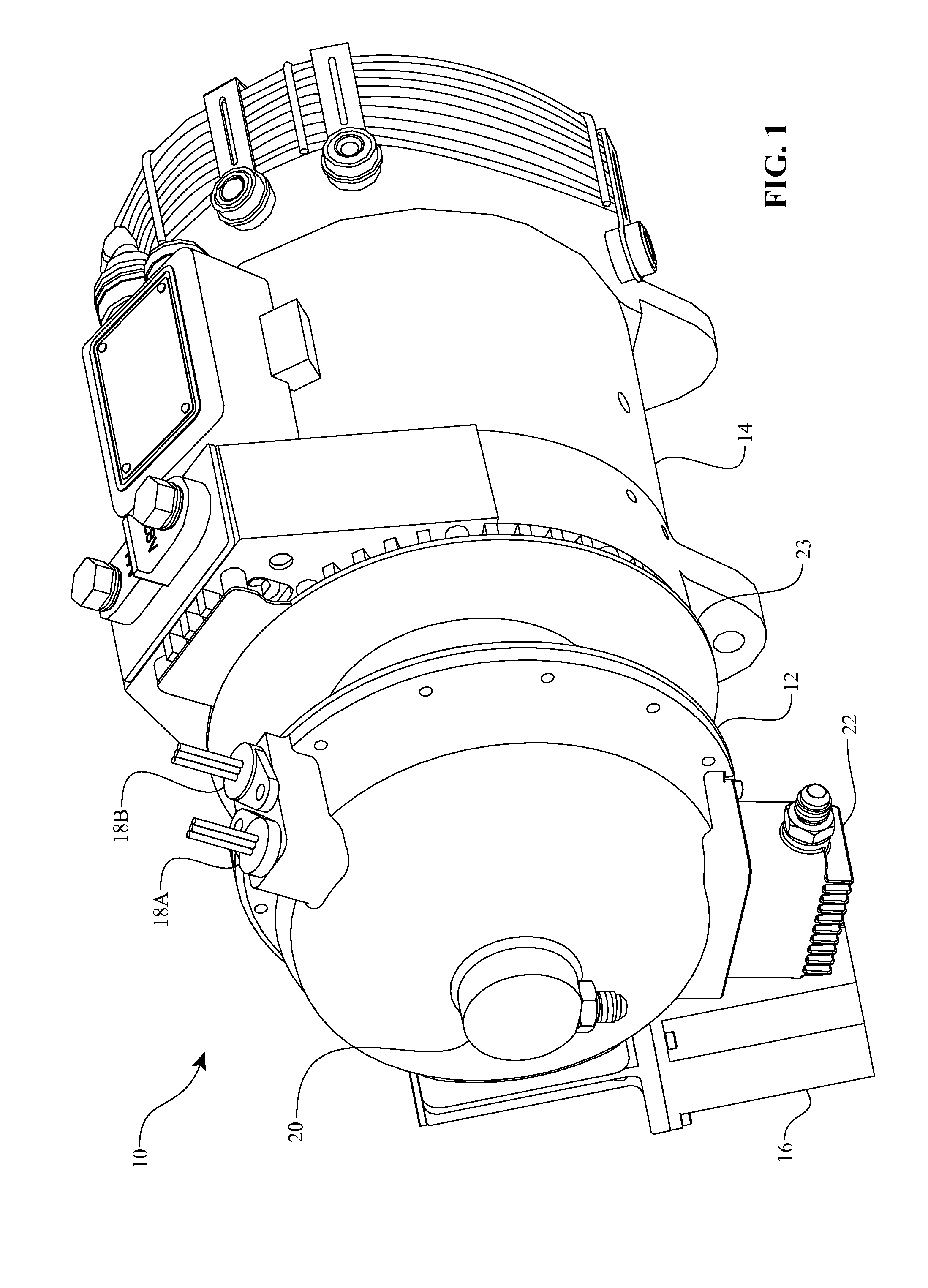

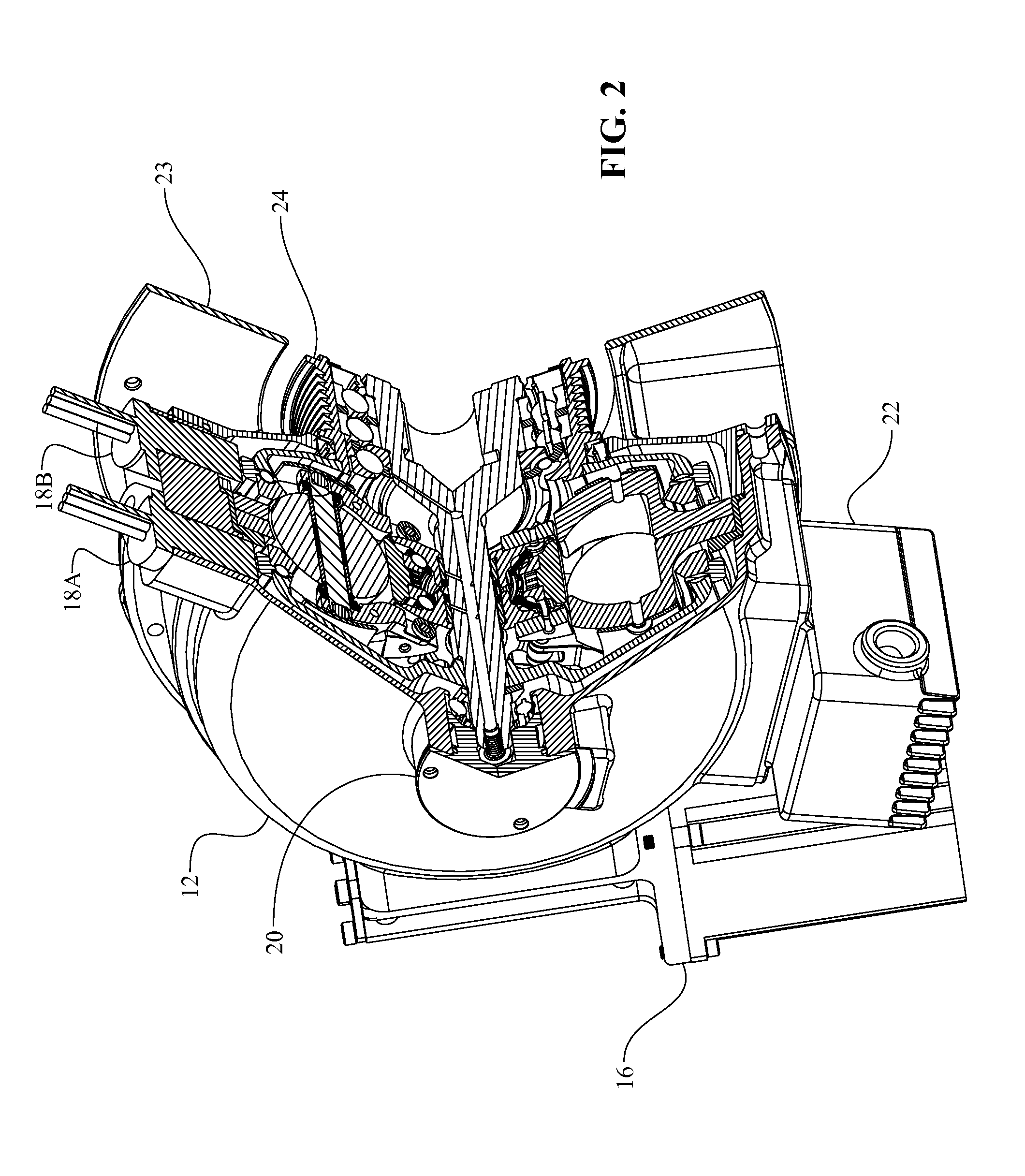

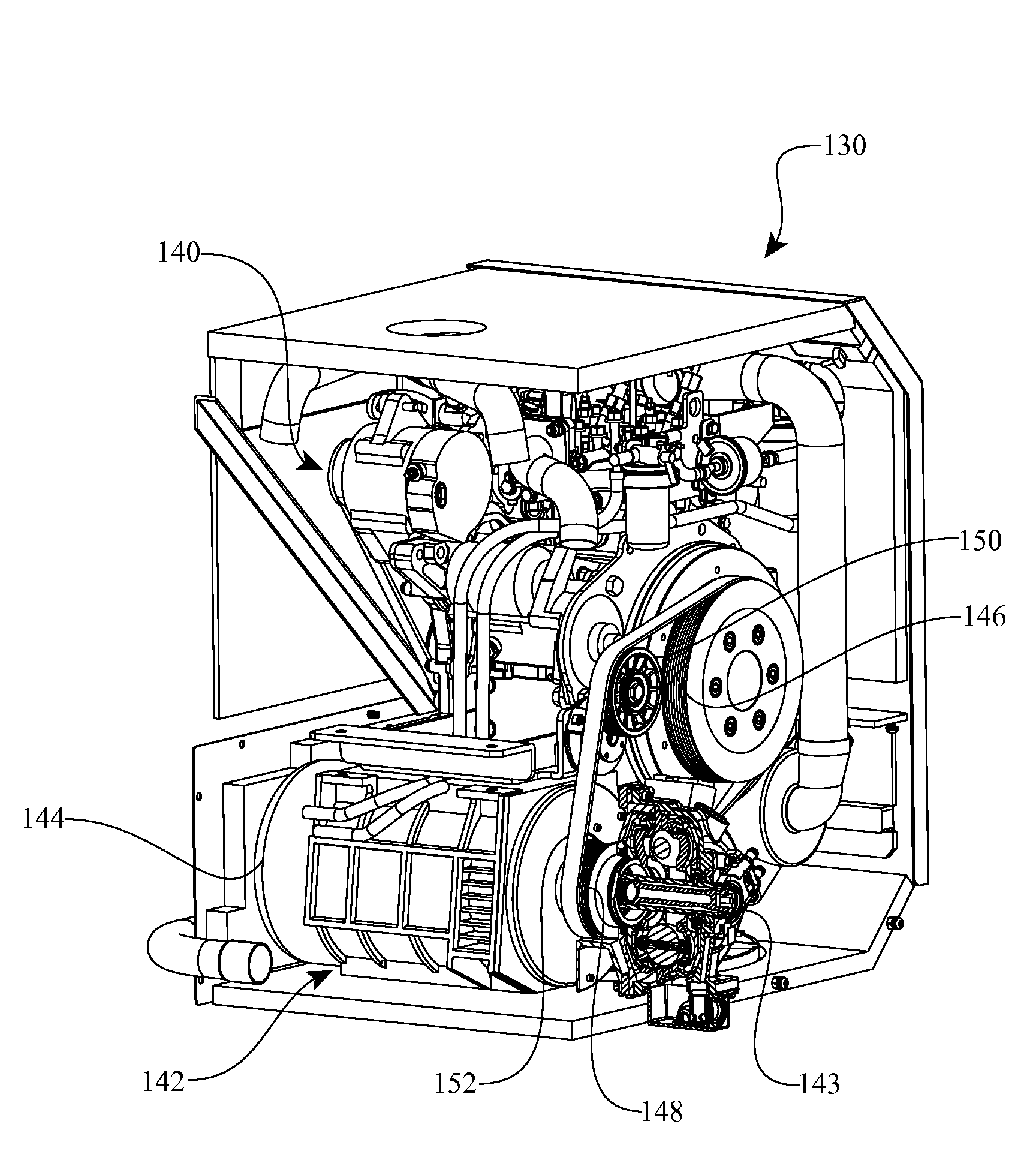

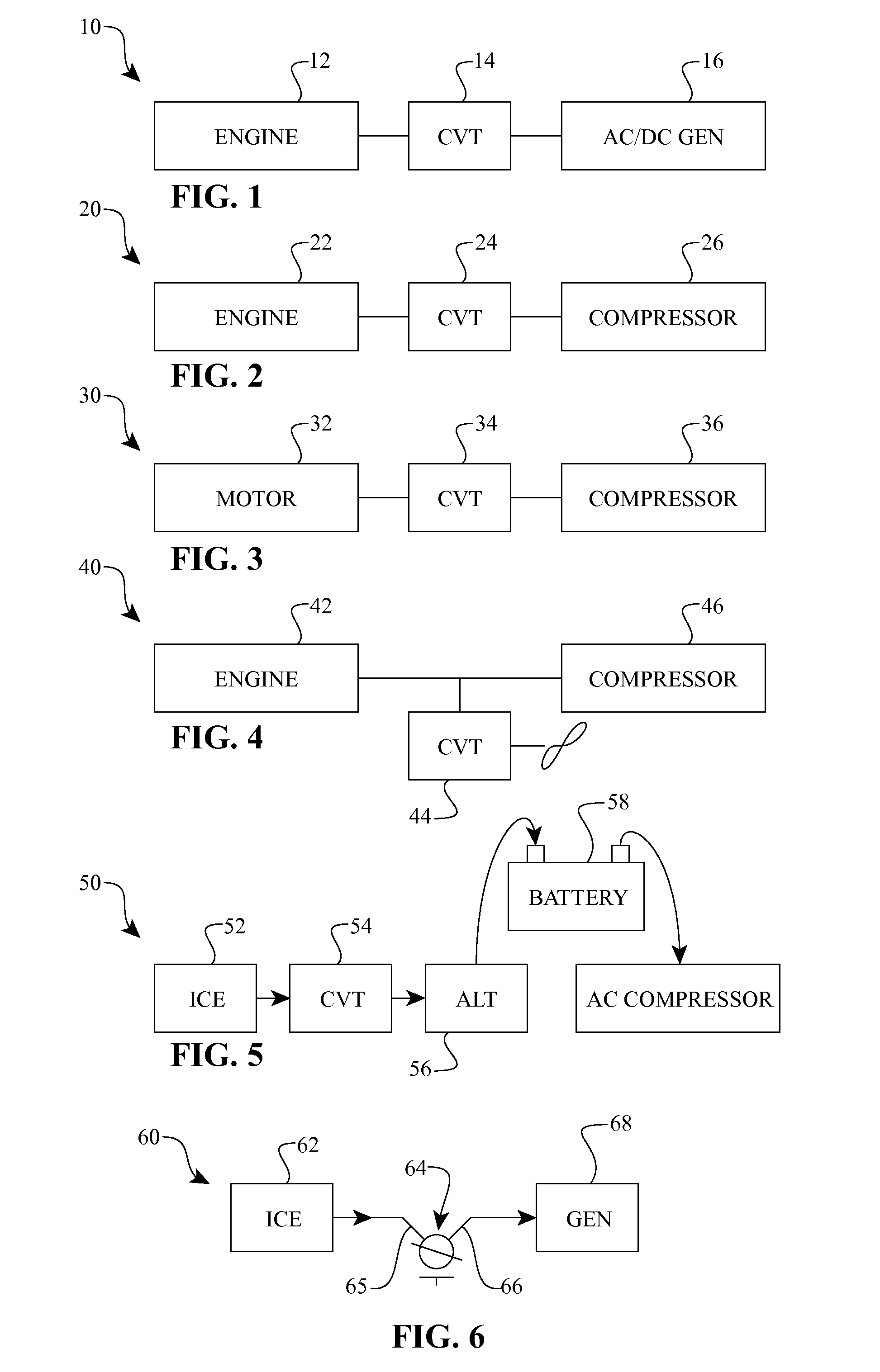

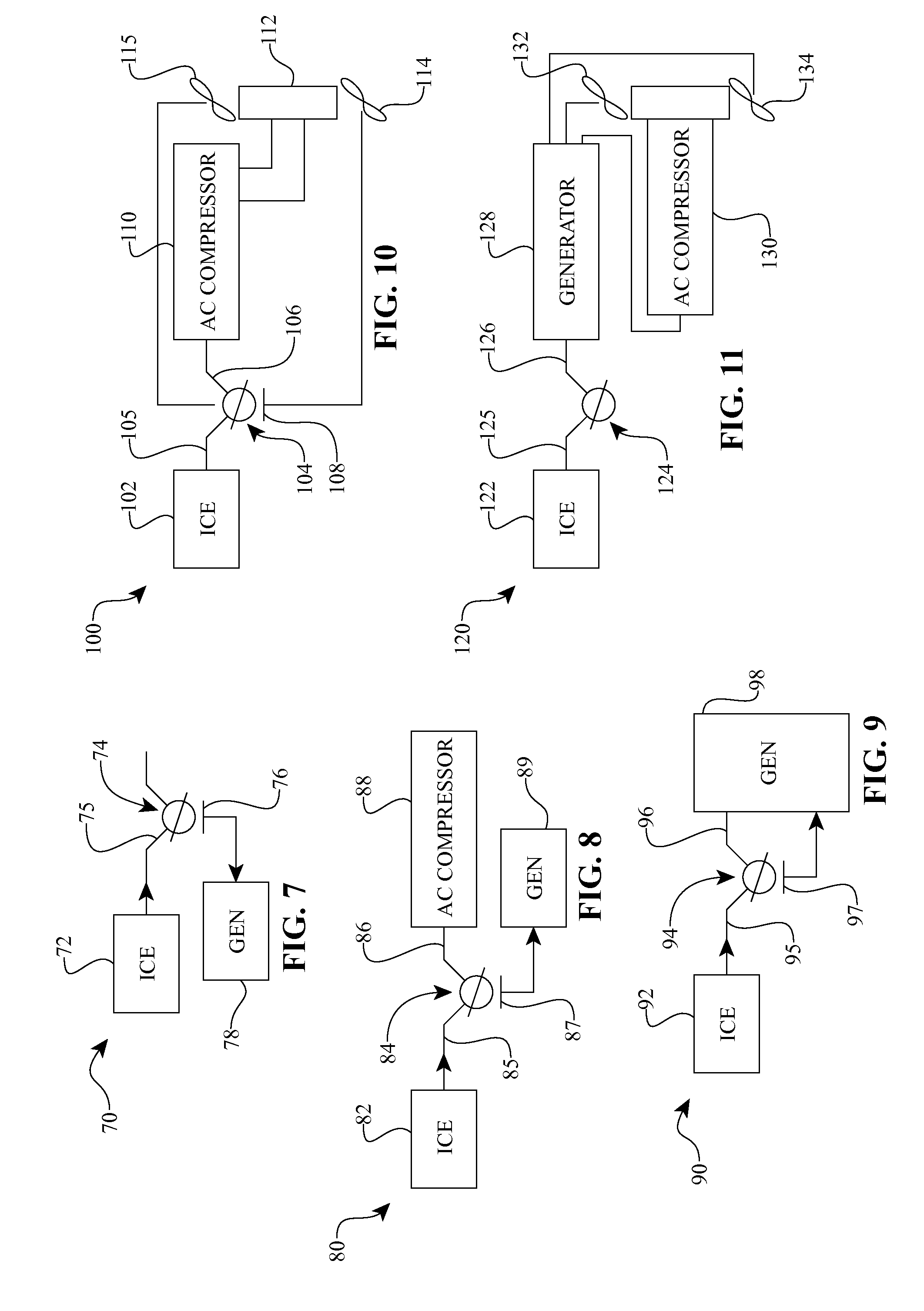

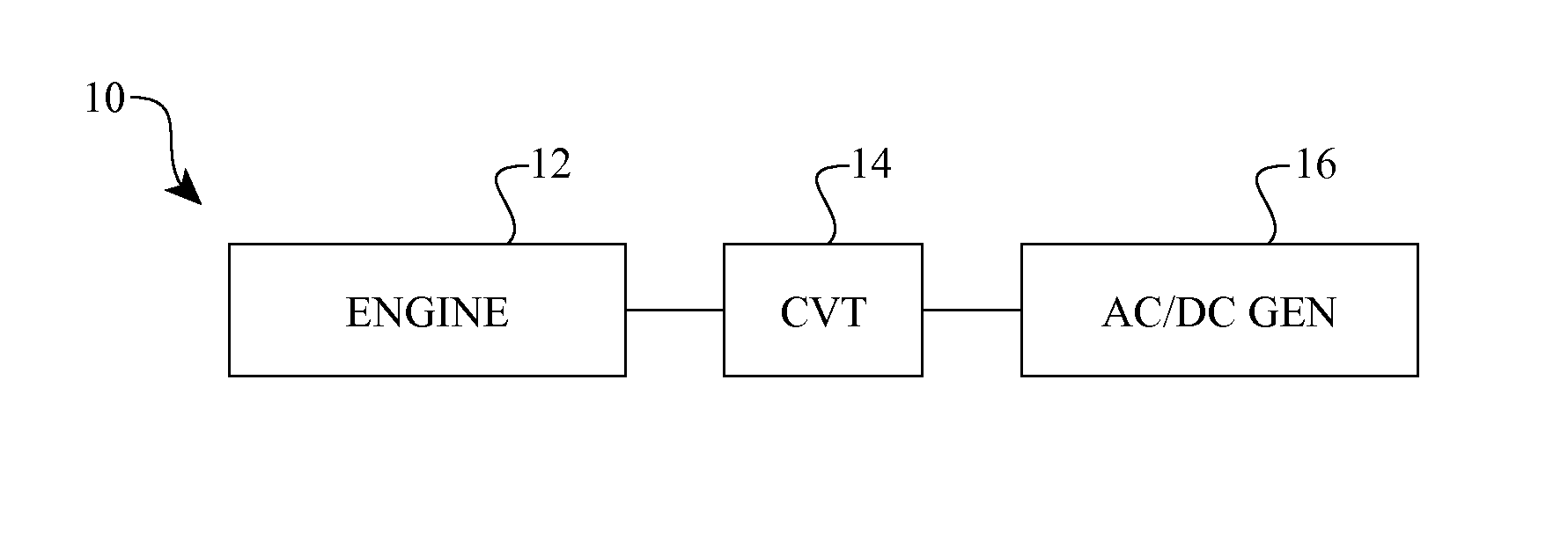

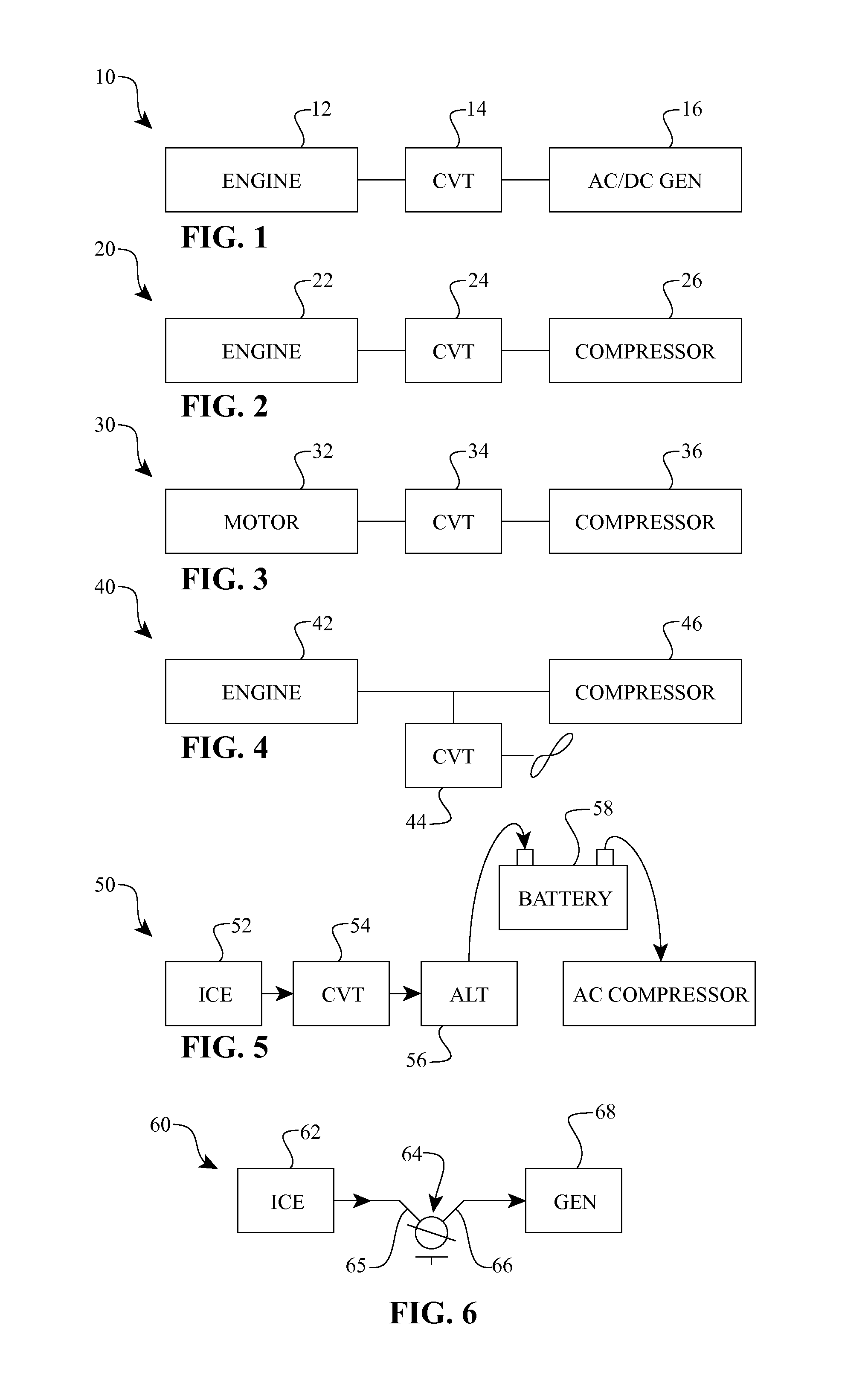

Auxiliary power unit having a continuously variable transmission

InactiveUS20120258839A1Fuel consumption is minimizedIncreased power demandAuxillary drivesVehicle fittingsCombustionControl system

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

Continuously variable transmission

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable accessory drives (CVAD). In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD. In another embodiment, a skew-based control system includes a skew actuator coupled to a carrier member. In some embodiments, the skew actuator is configured to rotate a carrier member of a CVT. Various inventive traction planet assemblies can be used to facilitate shifting the ratio of a CVT. In some embodiments, the traction planet assemblies include legs configured to cooperate with the carrier members. In some embodiments, a traction planet assembly is operably coupled to the carrier members. Embodiments of a shift cam and a traction sun are adapted to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Among other things, shift control interfaces for a CVT are disclosed.

Owner:FALLBROOK INTPROP COMPANY

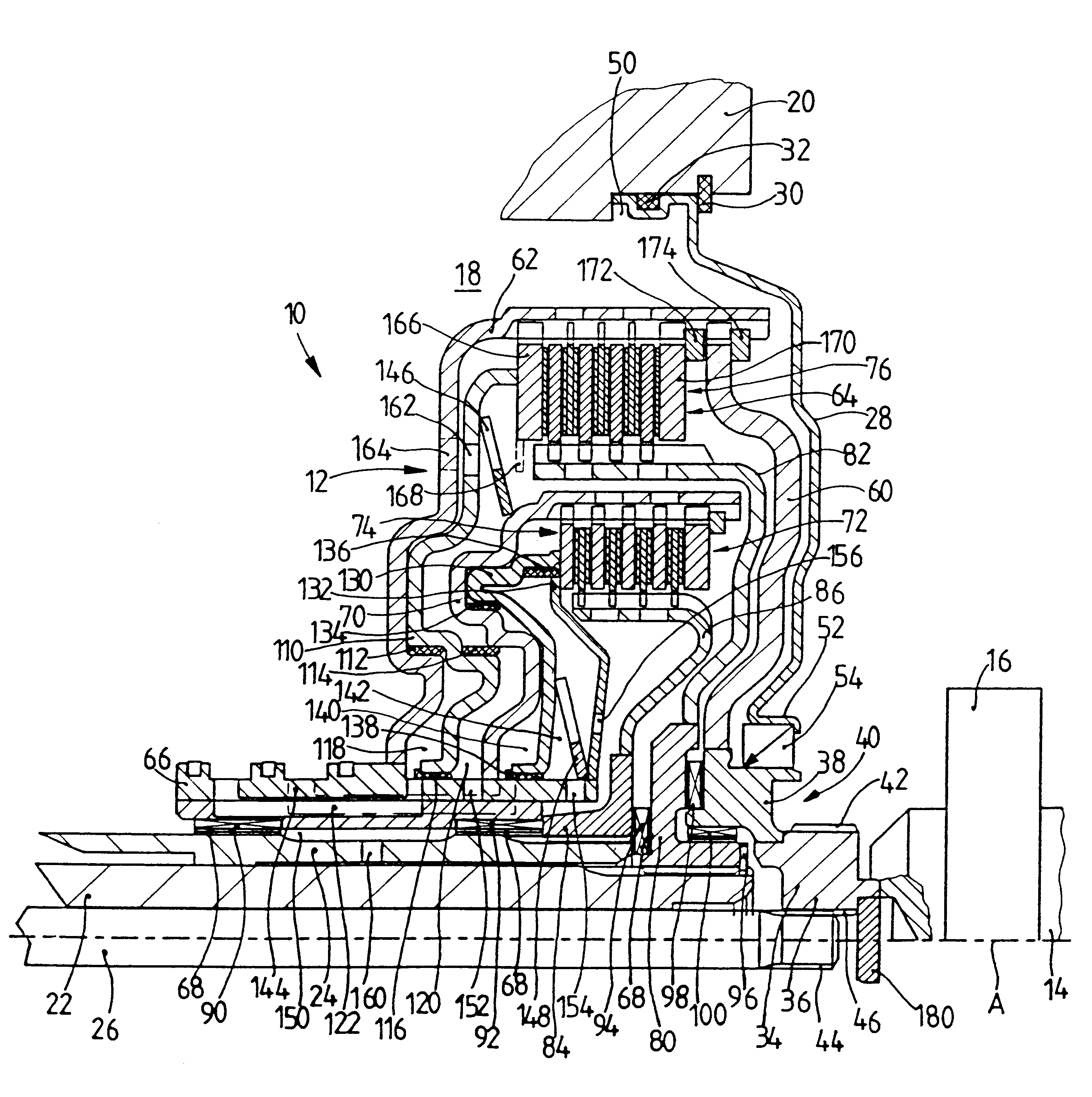

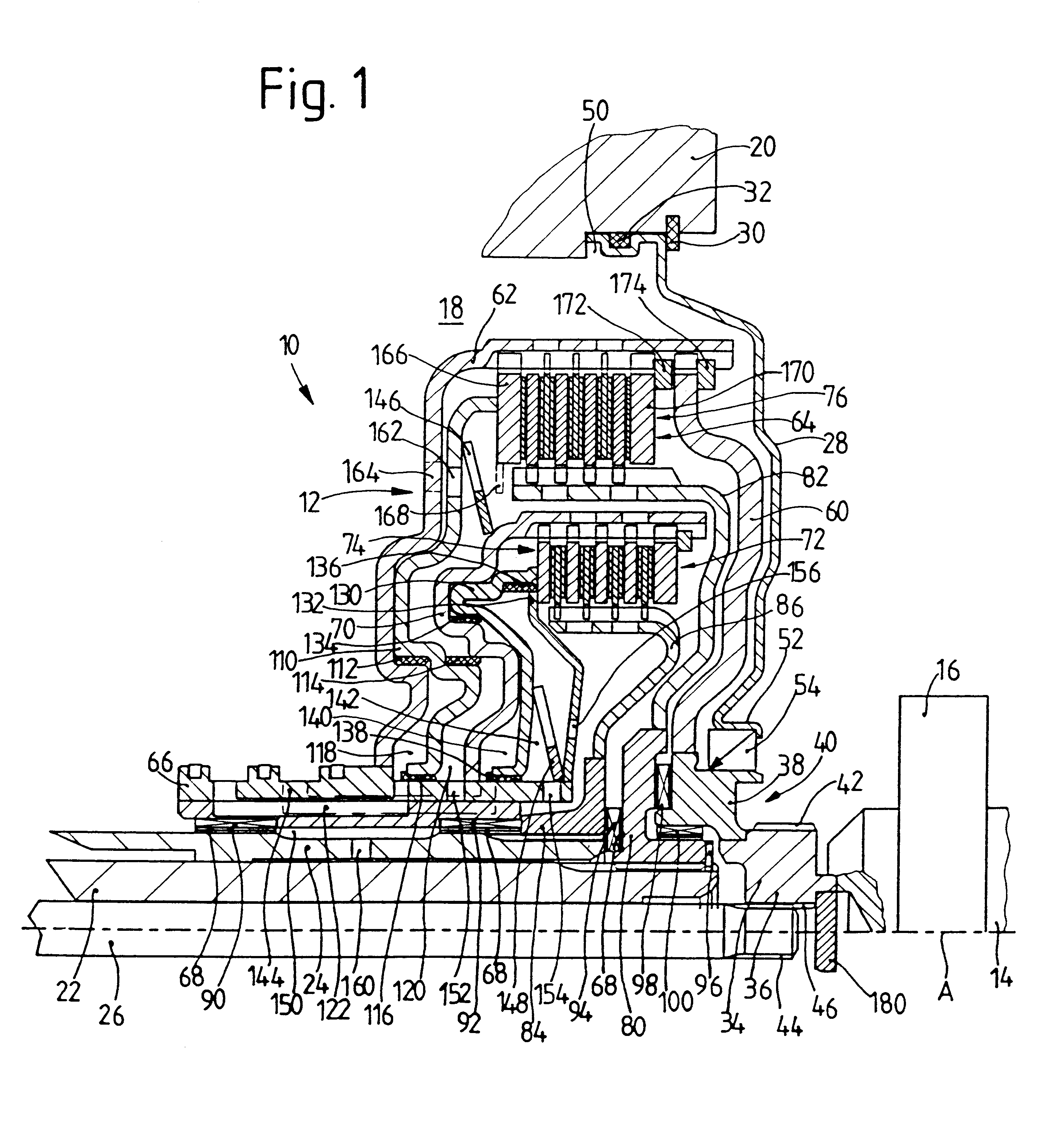

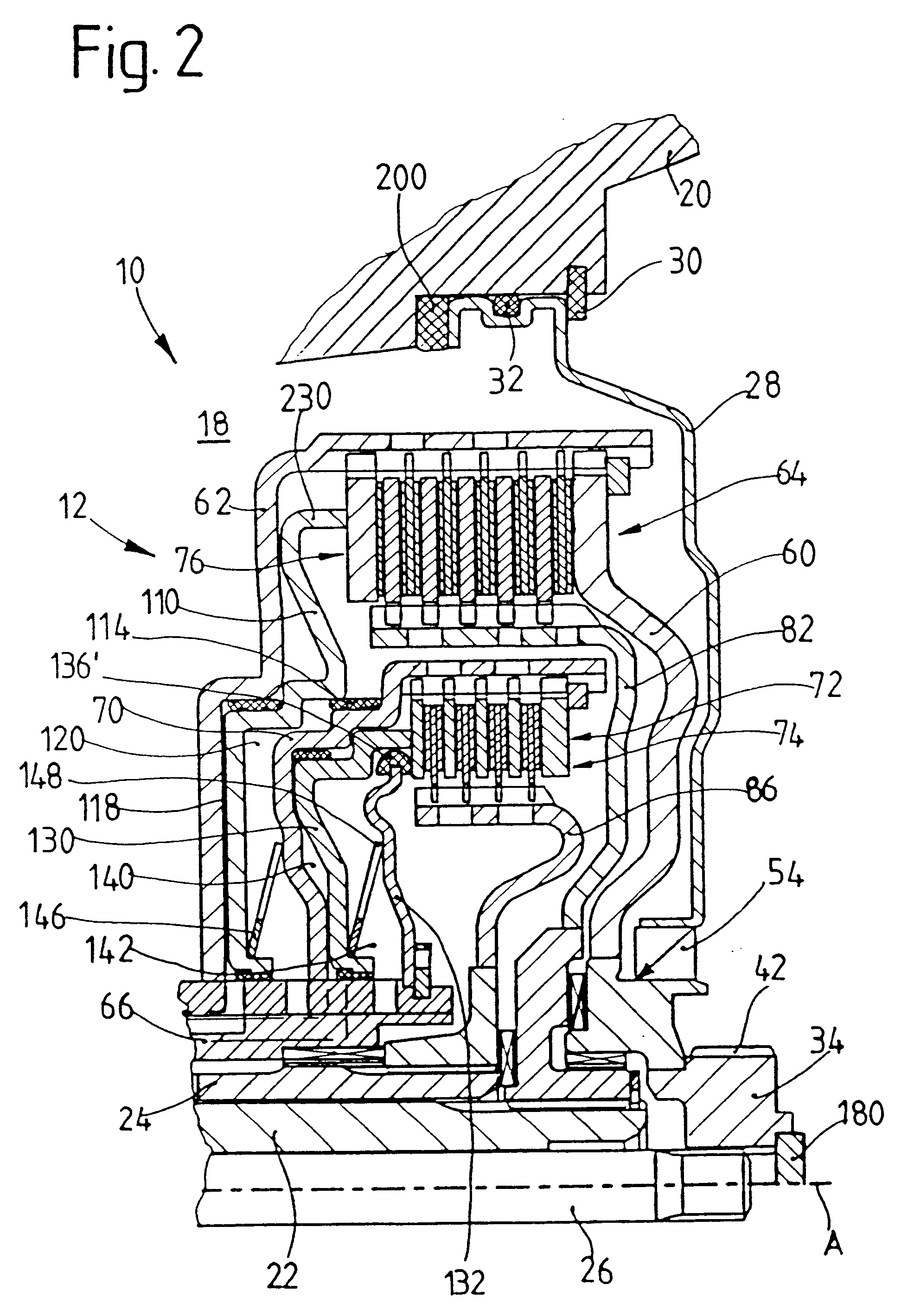

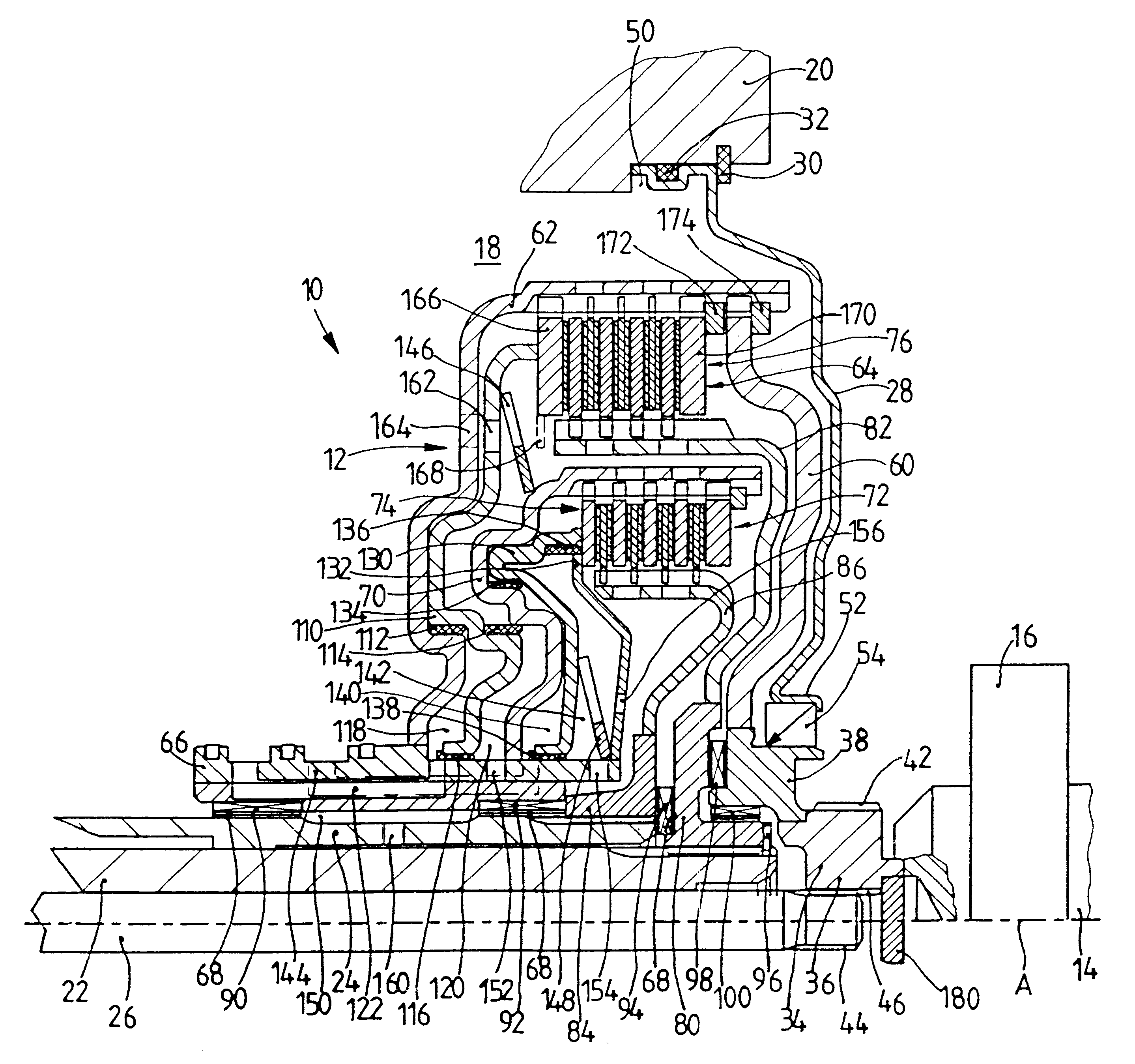

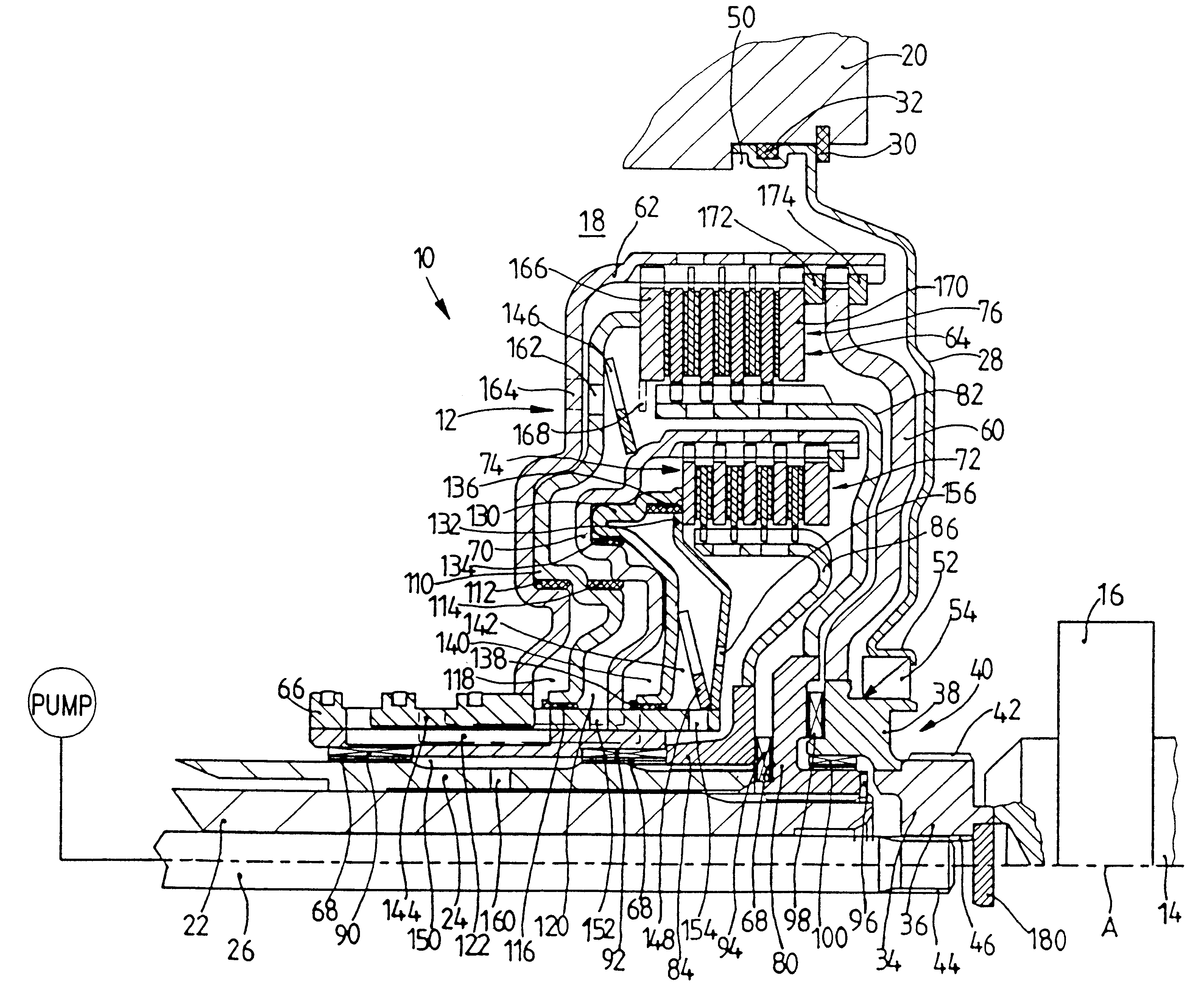

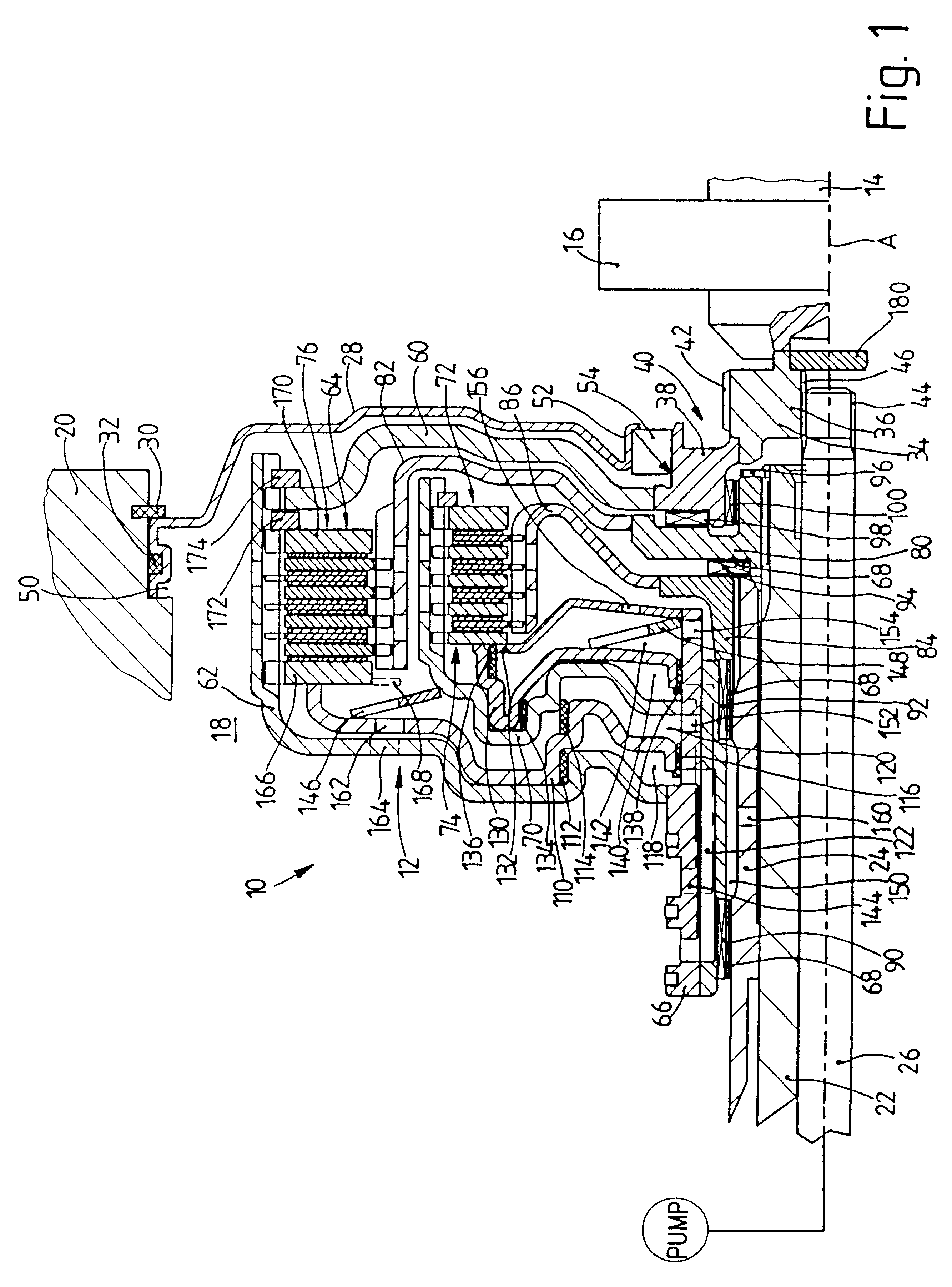

Multiple-clutch device

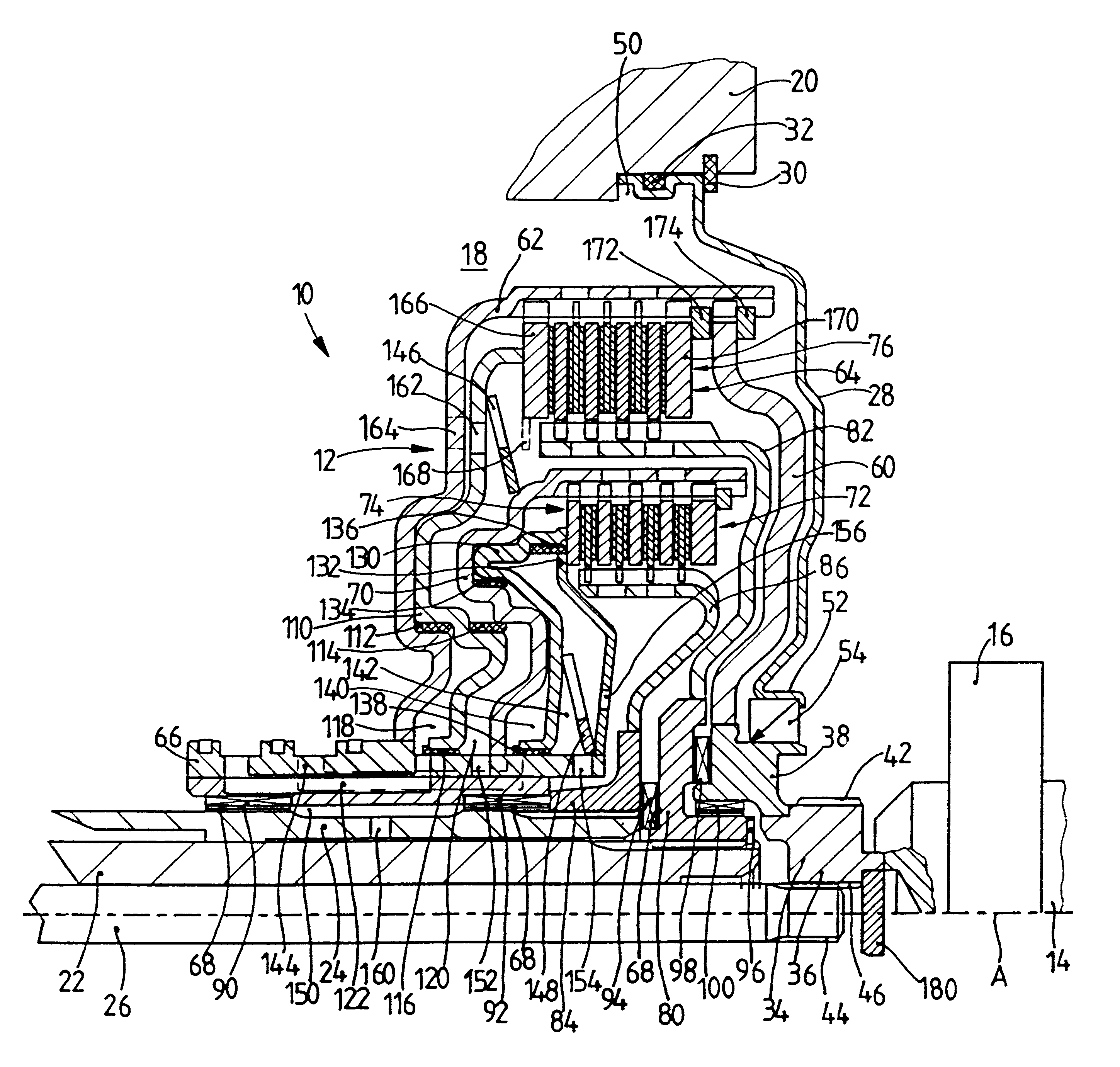

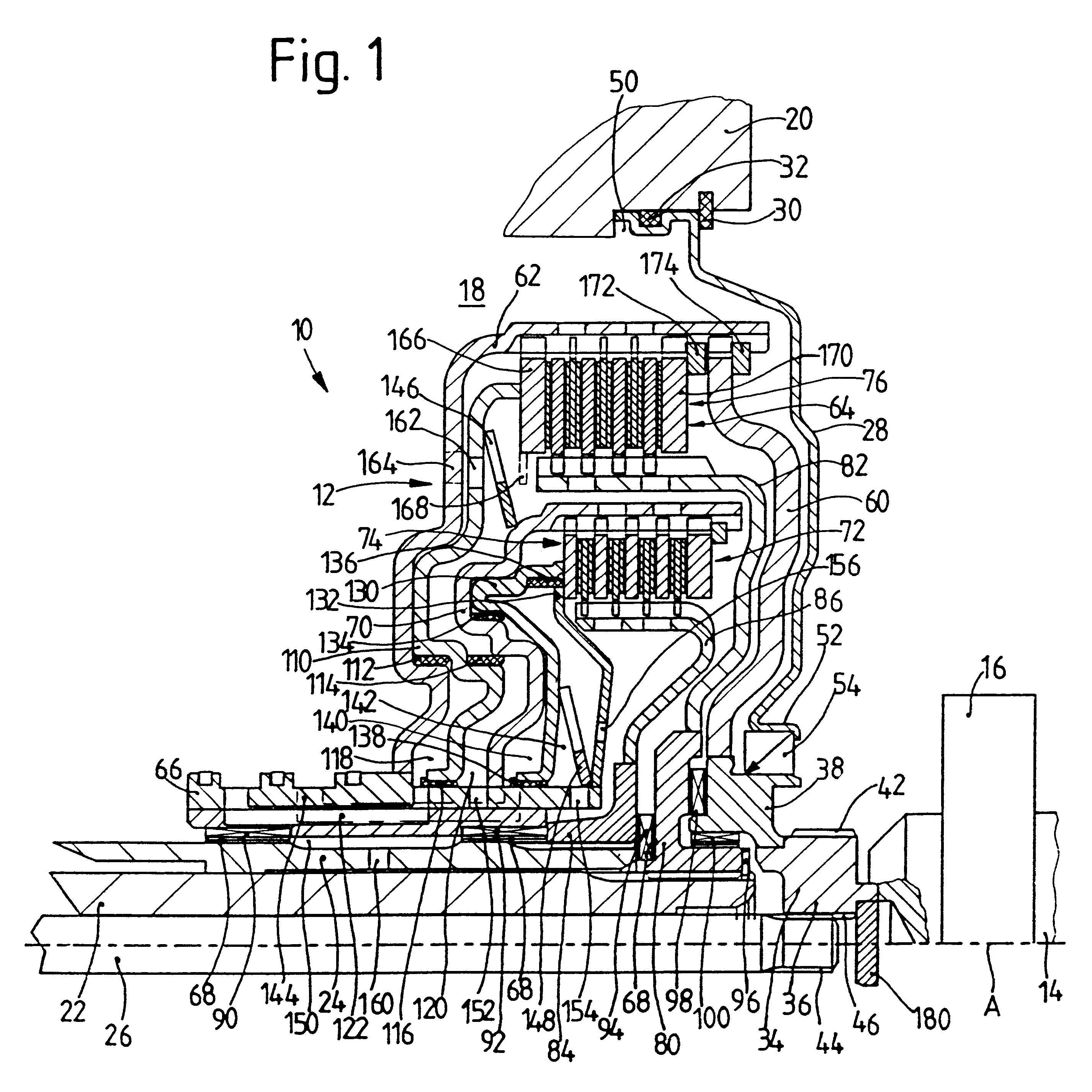

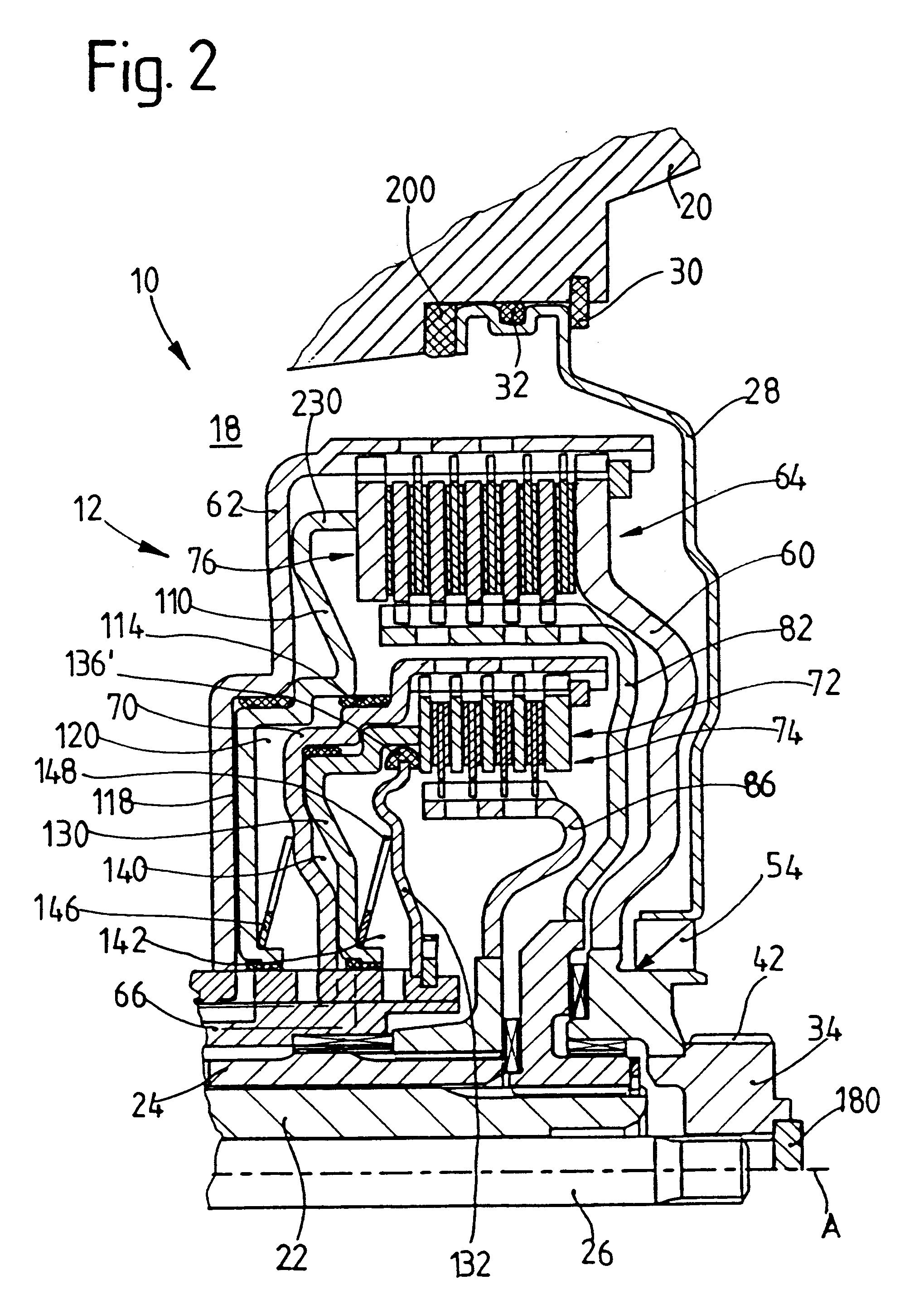

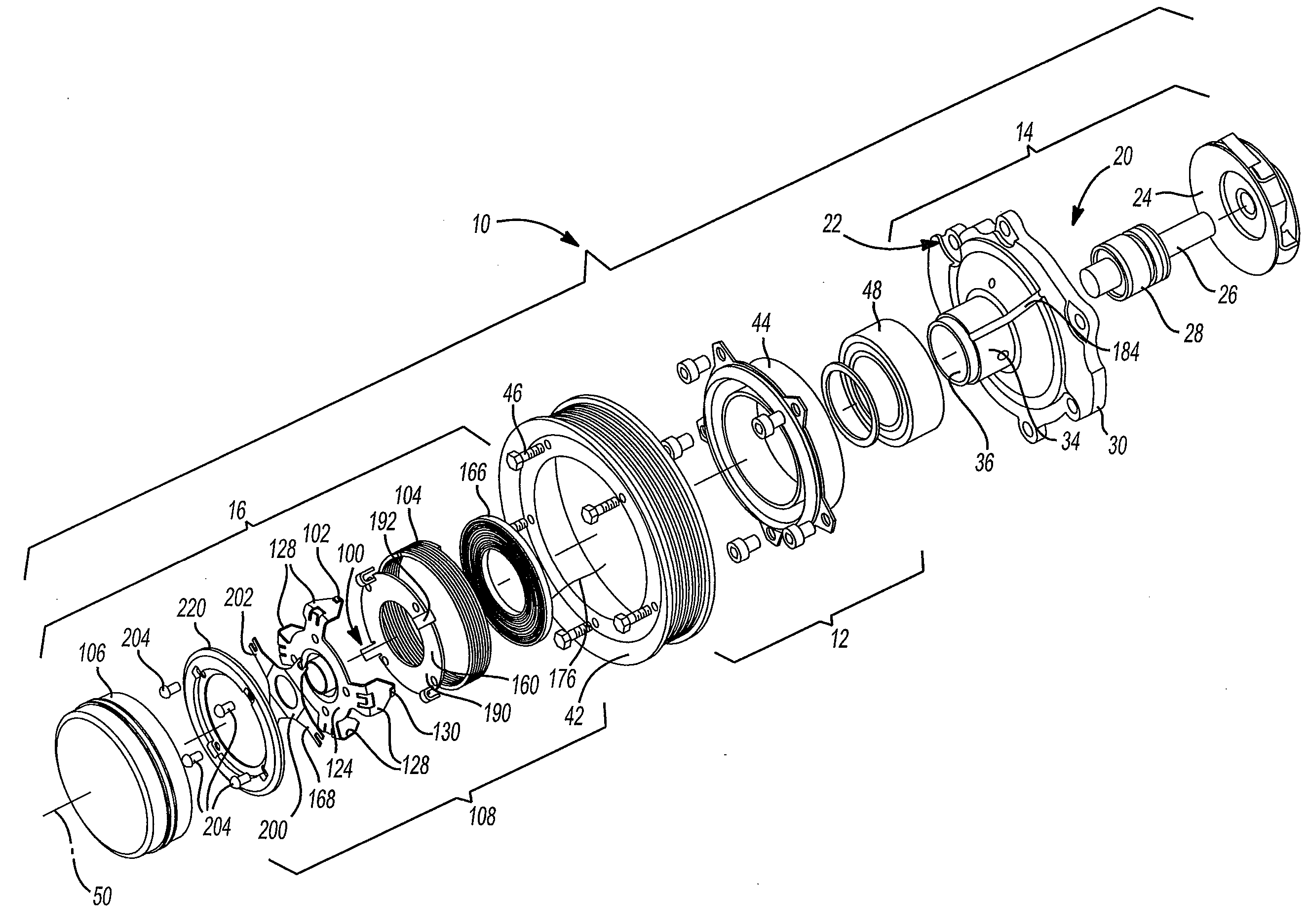

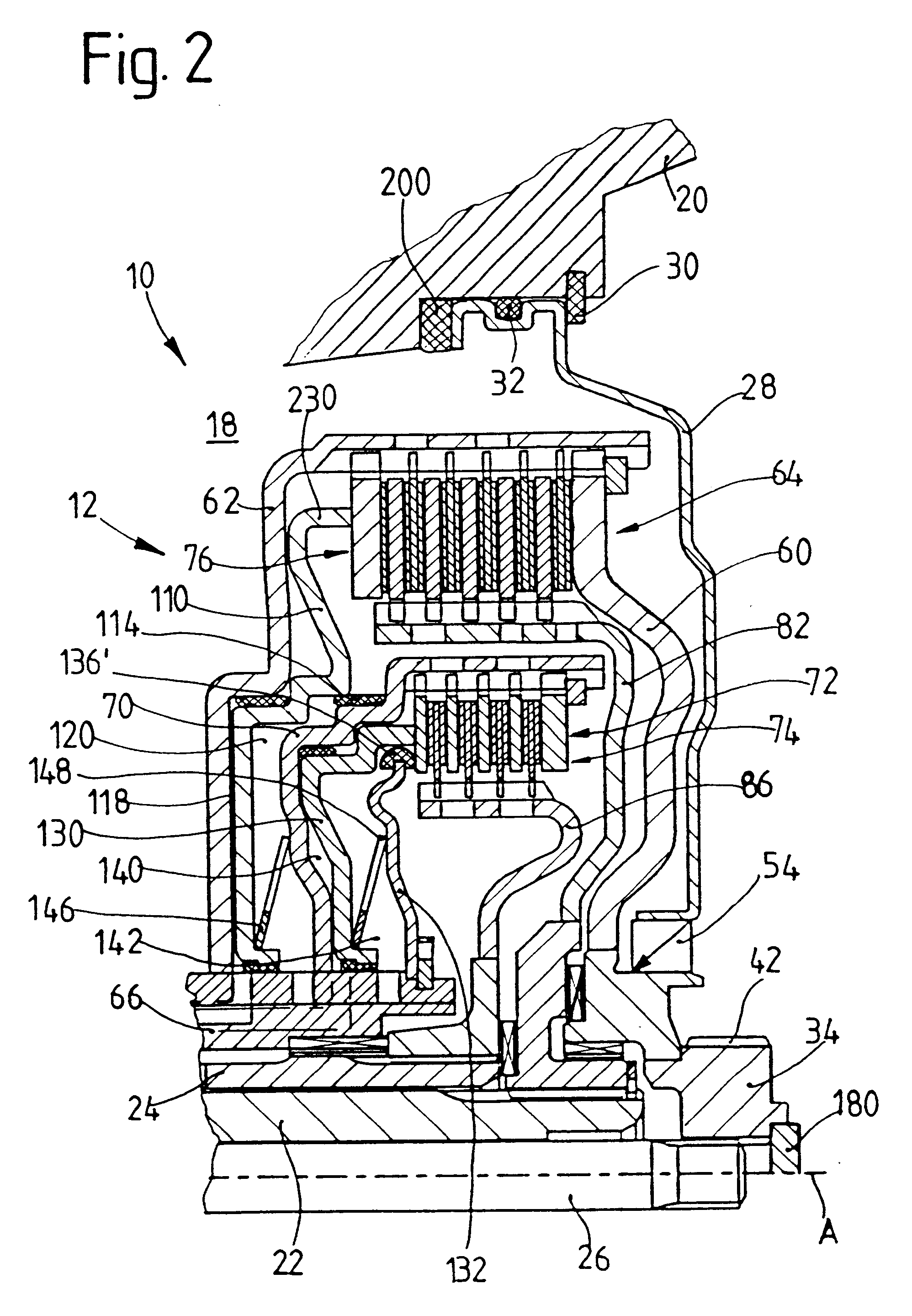

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

Electro-mechanical automatic transmission having dual input shafts

InactiveUS6044719APrevent rollbackImprove efficiencyRoad transportGear lubrication/coolingAutomatic transmissionEngineering

An electro-mechanical automatic transmission is provided including a first input shaft and a second input shaft concentric with the first input shaft. A plurality of drive gears are rotatably mounted to each input shaft and are provided with synchronizer devices for selectively engaging the drive gears to the input shafts. A driver shaft is provided with a plurality of driven gears in meshing engagement with the drive gears. The electro-mechanical automatic transmission is provided with a pair of electro-mechanical clutch actuators for selectively disengaging dual clutches which transmit engine torque to the input shafts, as well as an electro-mechanical shift actuator system which operatively engage the synchronizer devices for selectively engaging the drive gears.

Owner:FCA US

Multiple-clutch device

InactiveUS6464059B1Reduced Tolerance RequirementsReduce dependenceRotary clutchesFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. It is suggested that a bearing arrangement is associated with at least one of the clutch arrangements, wherein the latter is supported or can be supported so as to be relatively rotatable by means of the bearing arrangement on at least one of the transmission input shafts, at least one of which is constructed as a hollow shaft and a shaft constructed as a hollow shaft encloses the other shaft, preferably at least at the radial outer transmission input shaft which is constructed as a hollow shaft.

Owner:VOLKSWAGEN AG +1

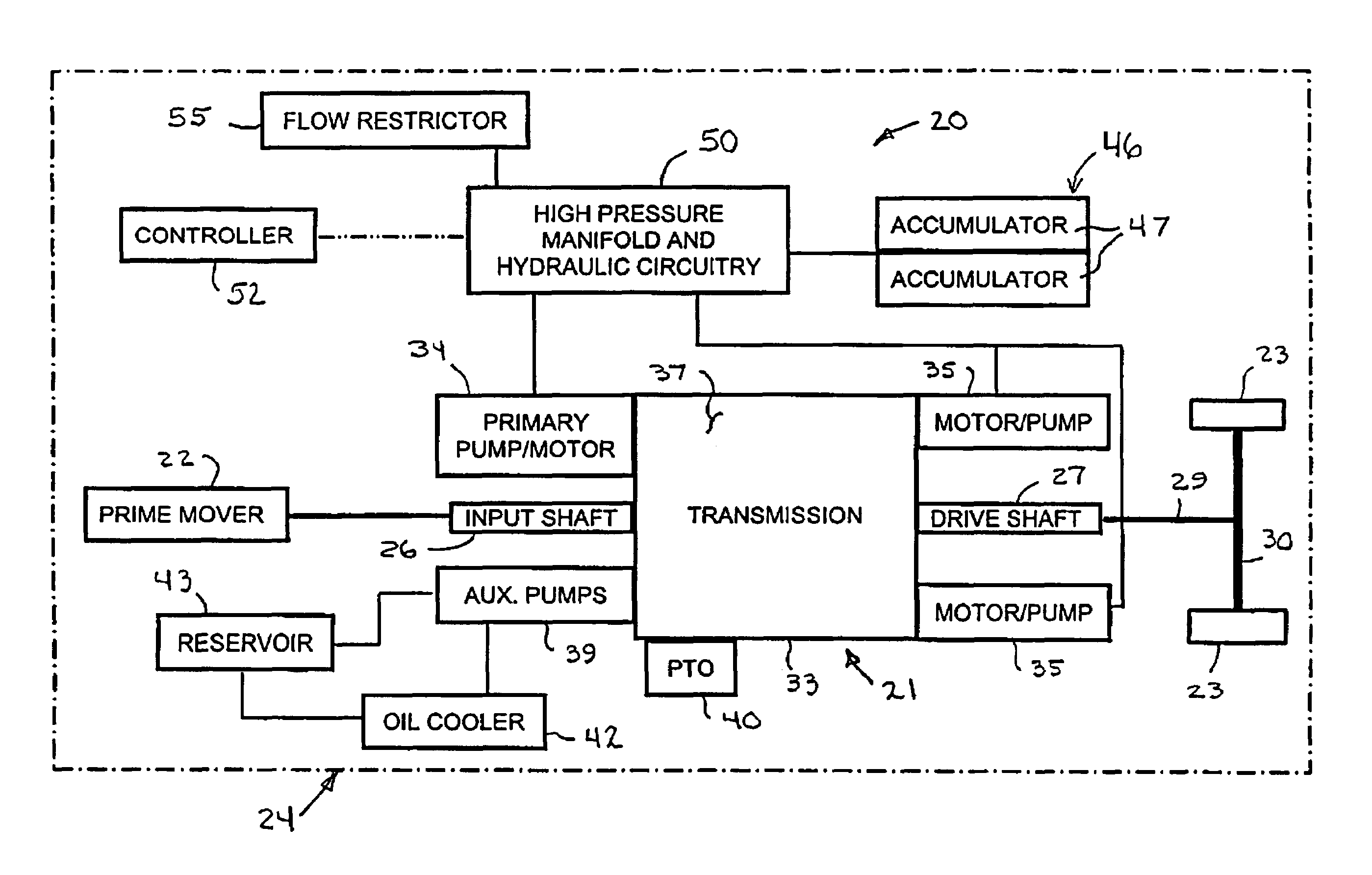

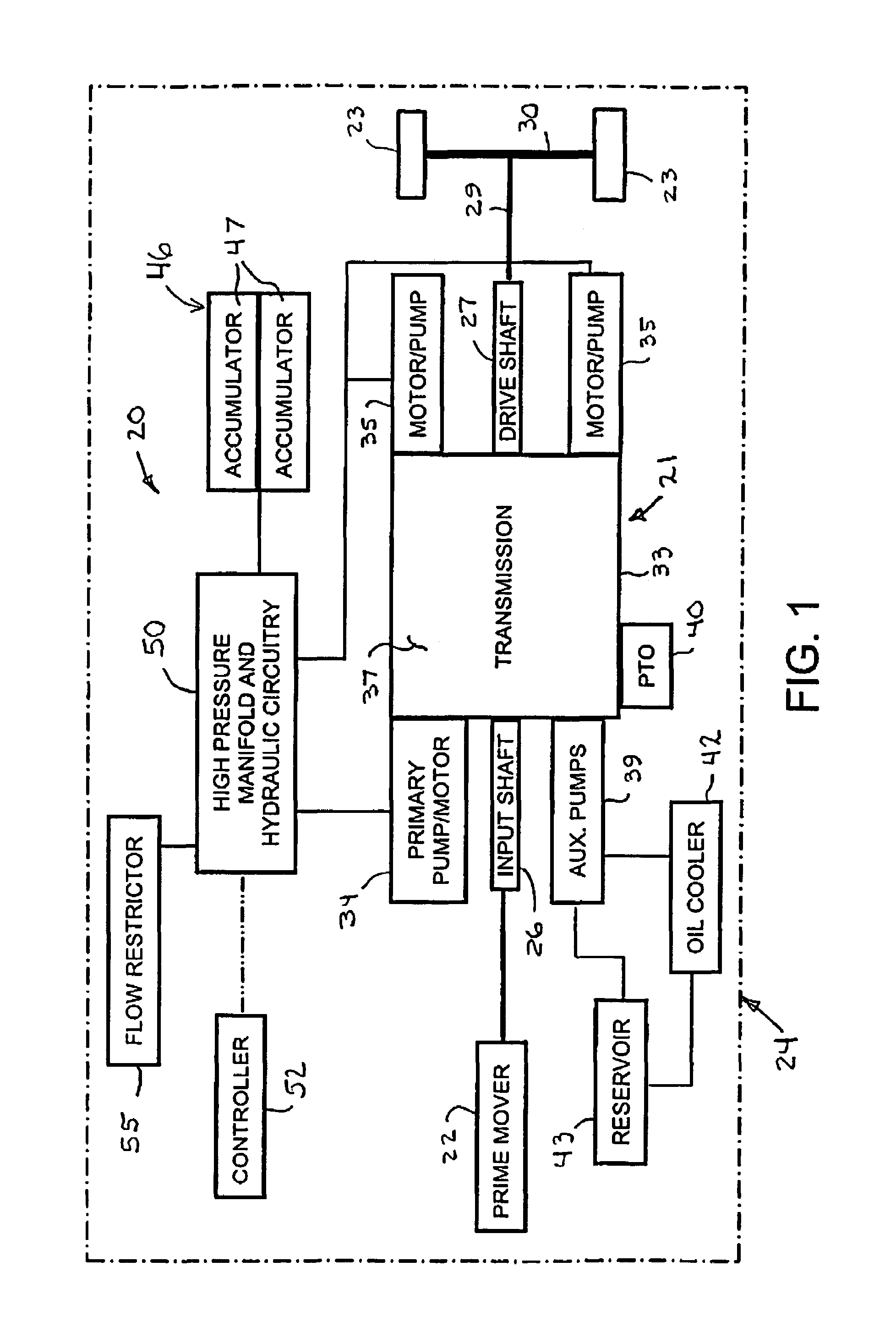

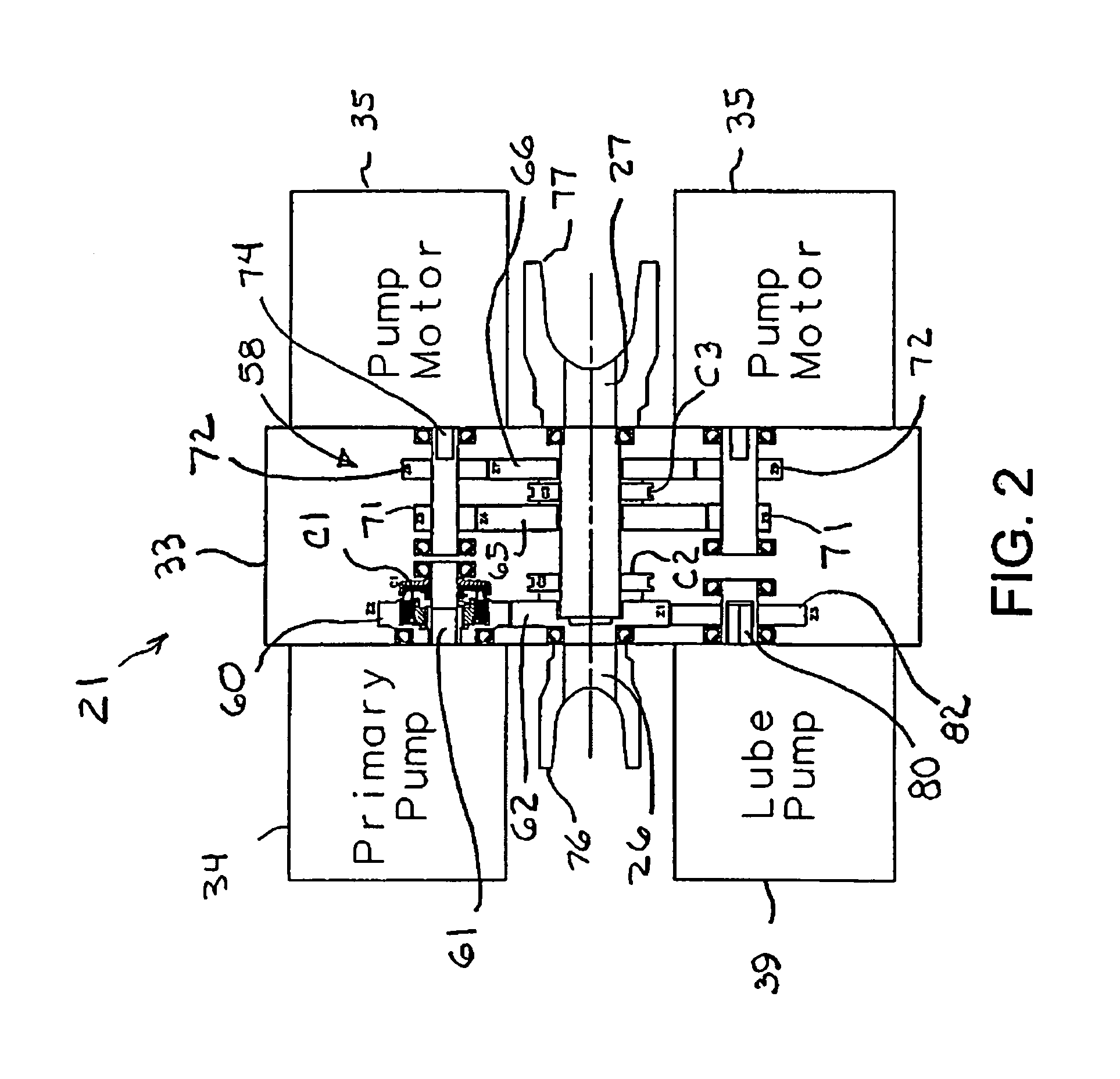

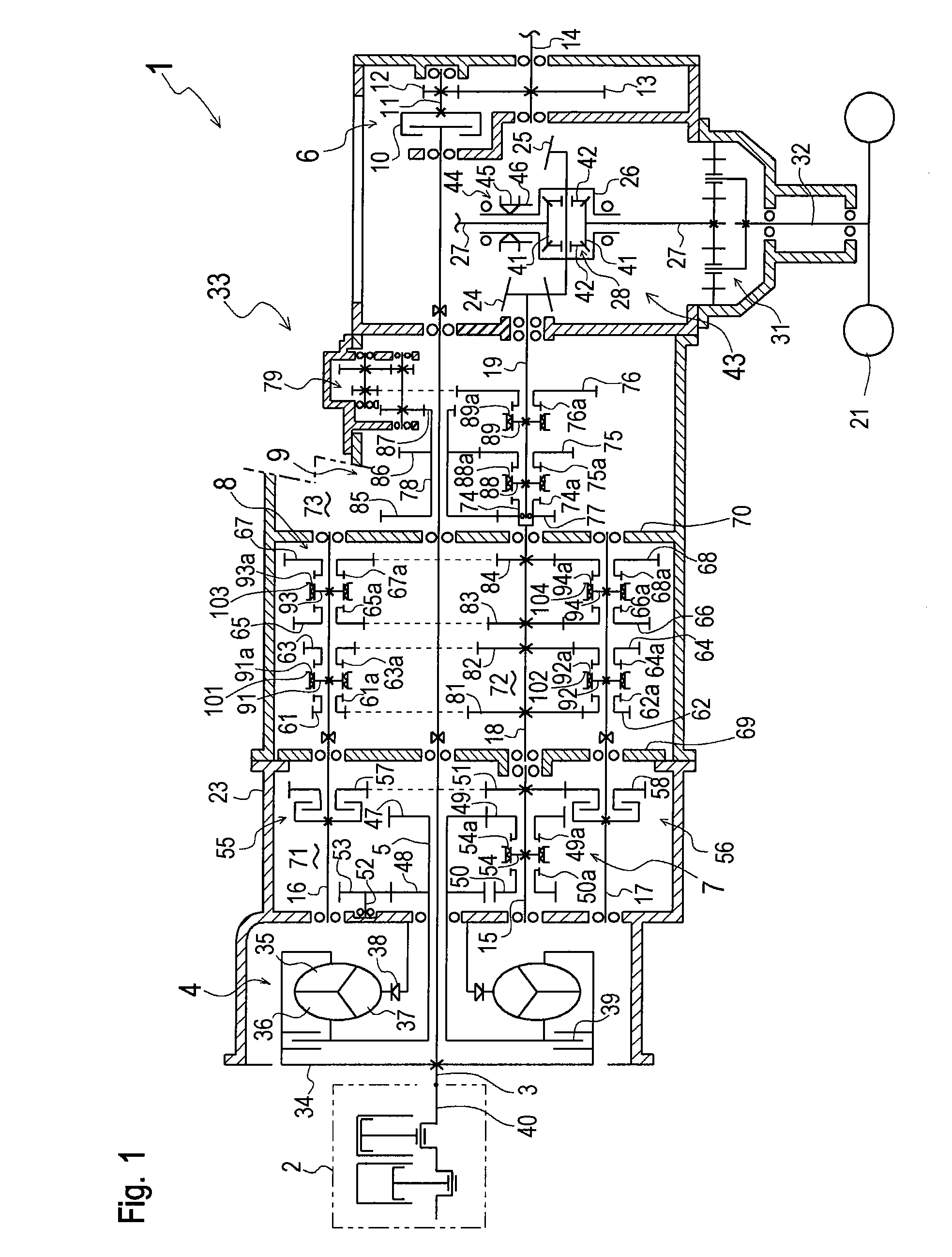

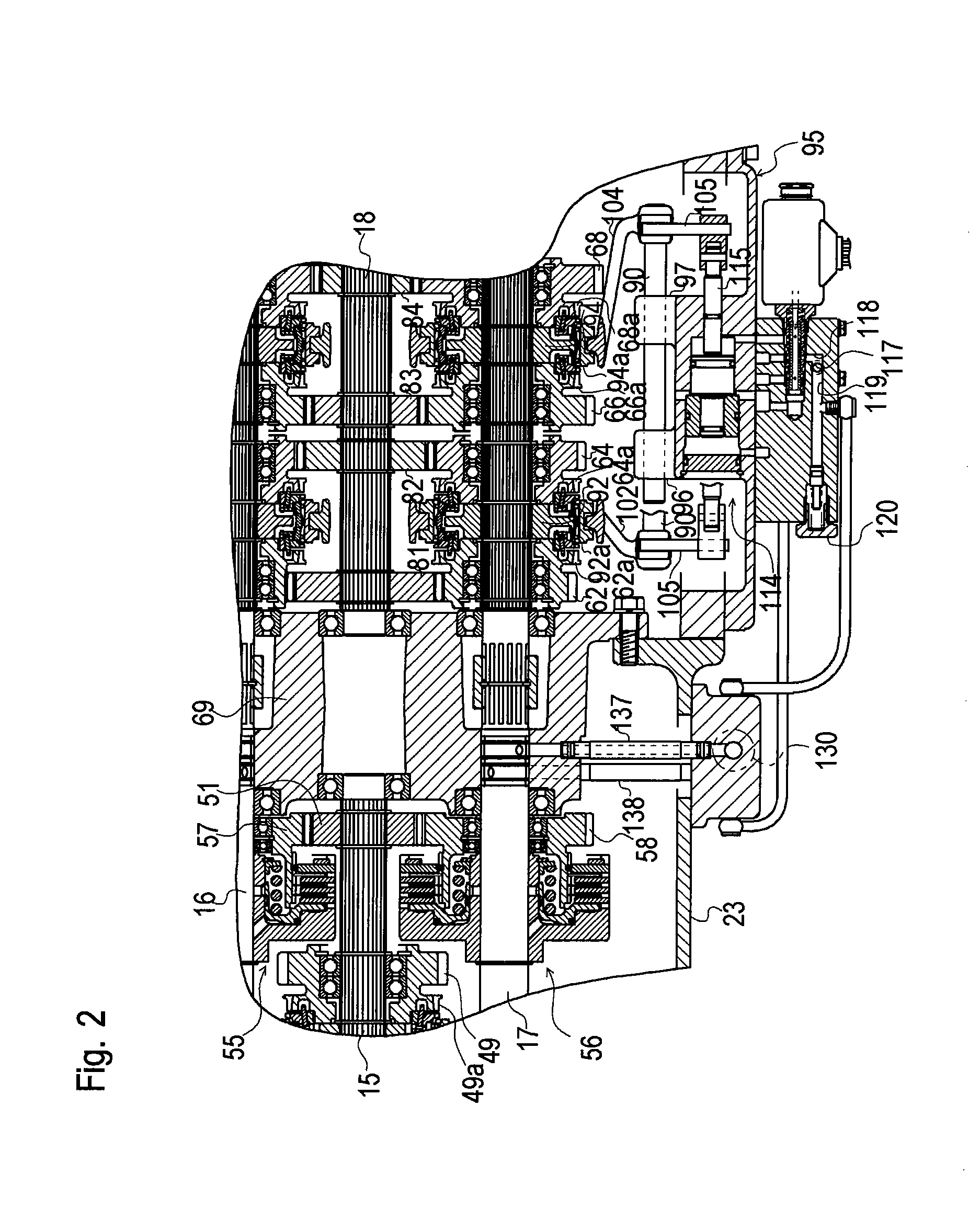

Gear box for hydraulic energy recovery

A hydraulic energy recovery and a mechanical drive system in one unit that also provides integral mounting of hydraulic pump / motors for primary drive, secondary drive, and pumps for cooling, lubrication, and low pressure systems along with a mounting position for a power take-off device.

Owner:PARKER HANNIFIN CORP

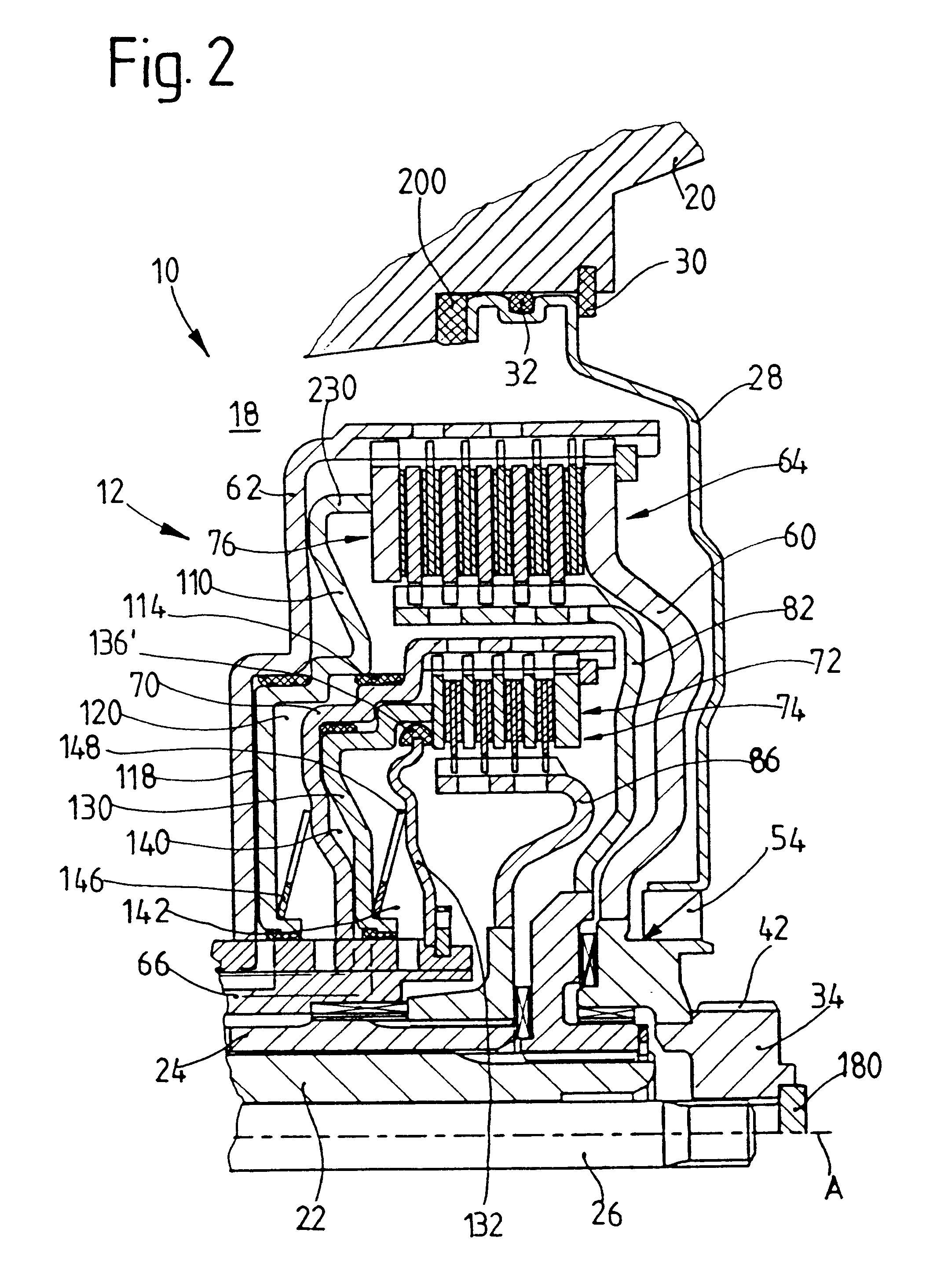

Multiple-clutch device

InactiveUS6454074B1Guaranteed uptimeEasy to assembleMechanical actuated clutchesFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that at least one of the clutch arrangements has an actuating piston defining a pressure chamber for actuation, preferably for engagement of the clutch arrangement by means of a pressure medium, preferably a hydraulic medium, wherein the actuating piston divides the pressure chamber from an associated centrifugal force pressure compensation chamber which receives a pressure compensation medium.

Owner:VOLKSWAGEN AG +1

Driven accessory with low-power clutch for activating or de-activating same

ActiveUS20100122882A1Reduce and eliminate residual magnetismRoad transportMagnetically actuated clutchesEngineeringMoment of inertia

A driven accessory having a clutch that permits selective operation of an accessory portion. The clutch employs rotational inertia to control driving engagement of a wrap spring to an interior clutch surface on a drive member and / or driving disengagement of the wrap spring from the interior clutch surface.

Owner:LITENS AUTOMOTIVE INC

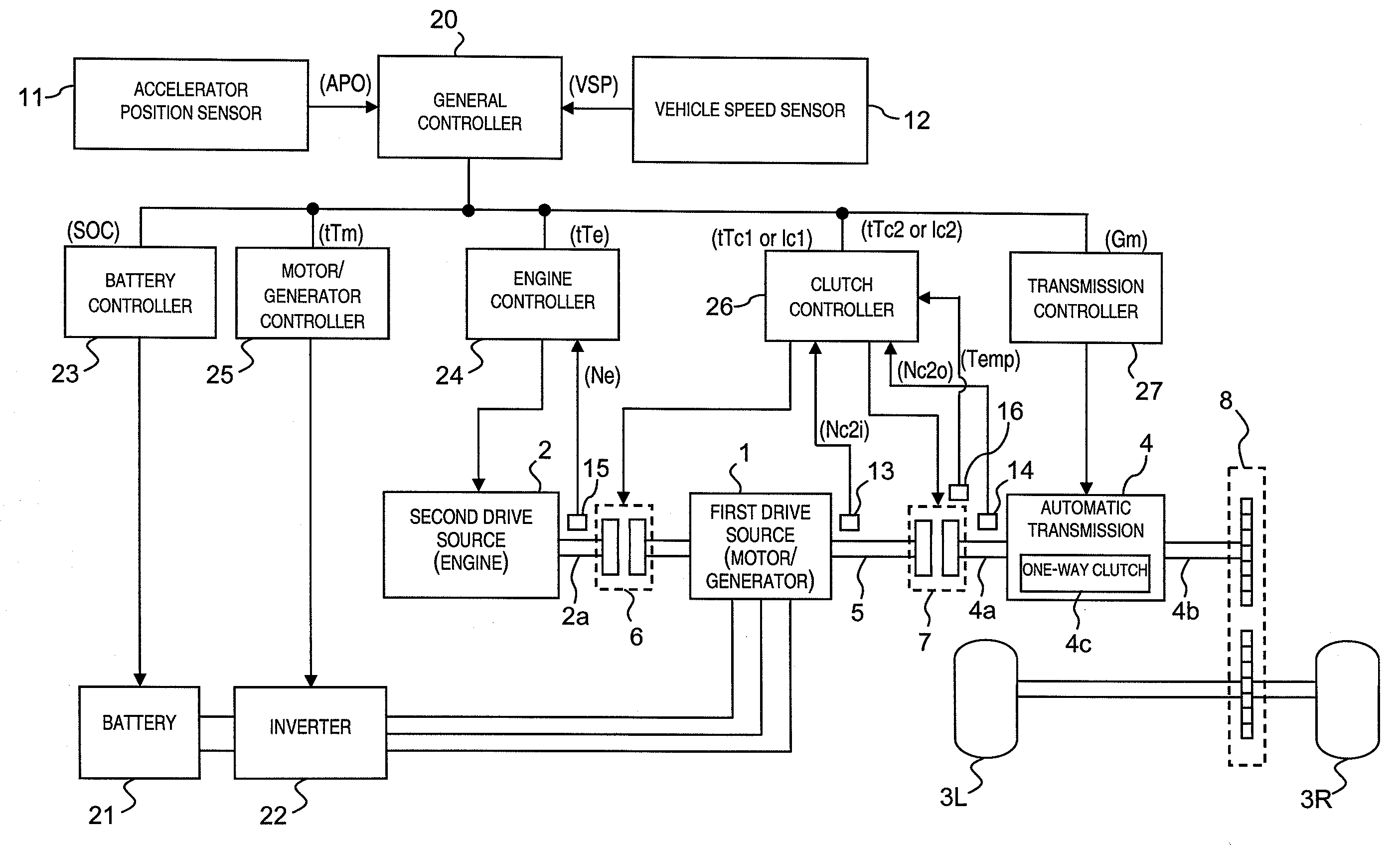

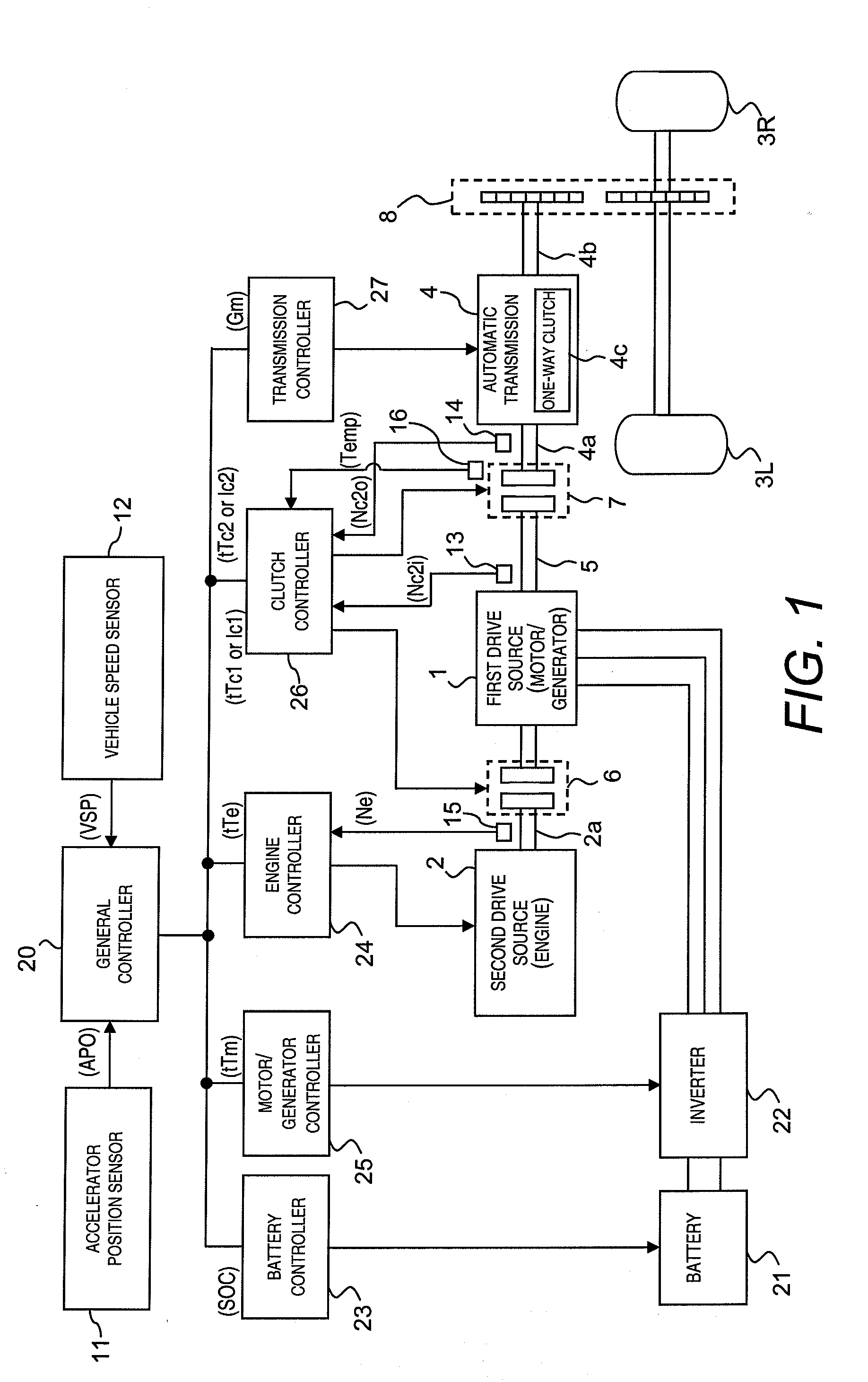

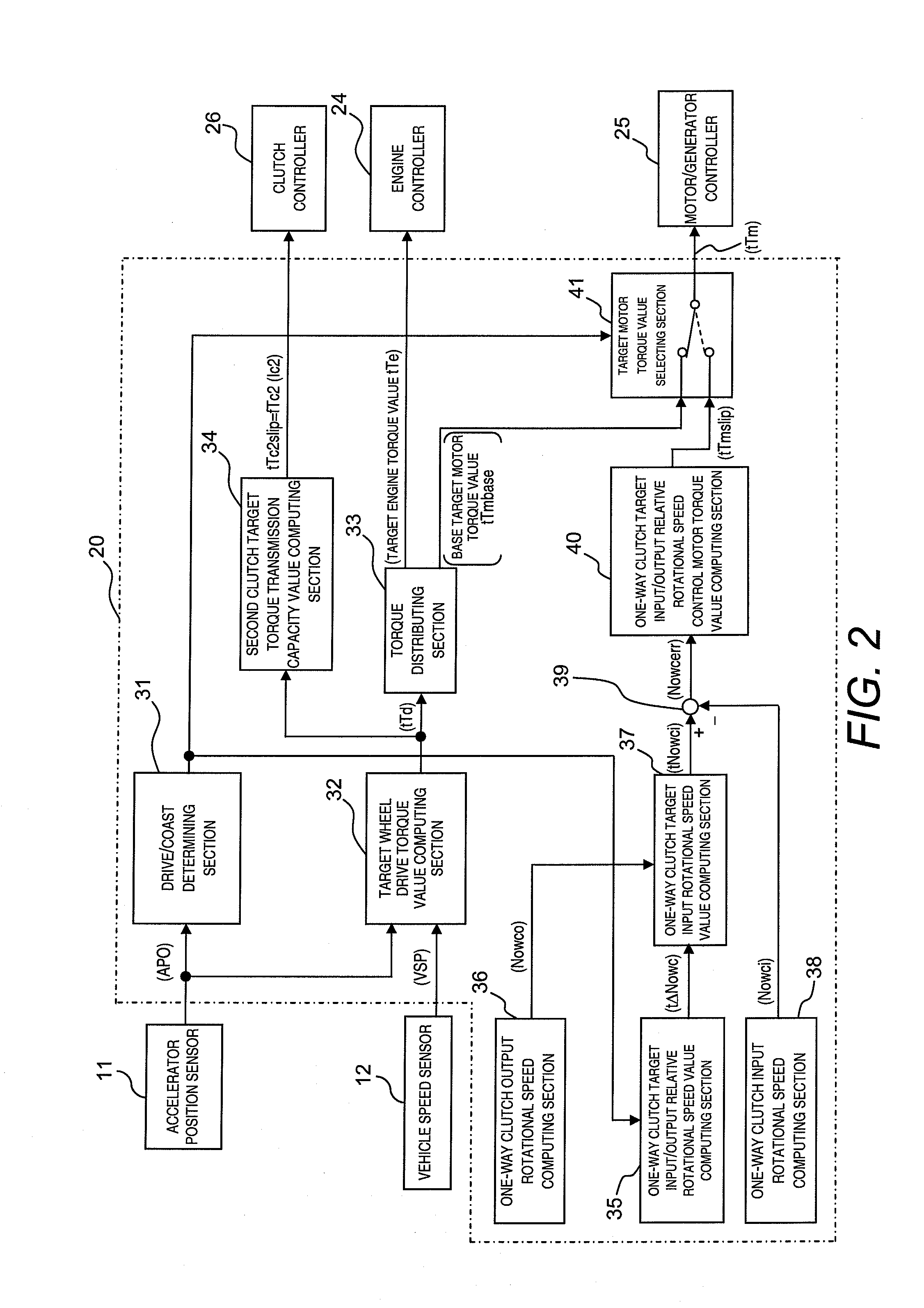

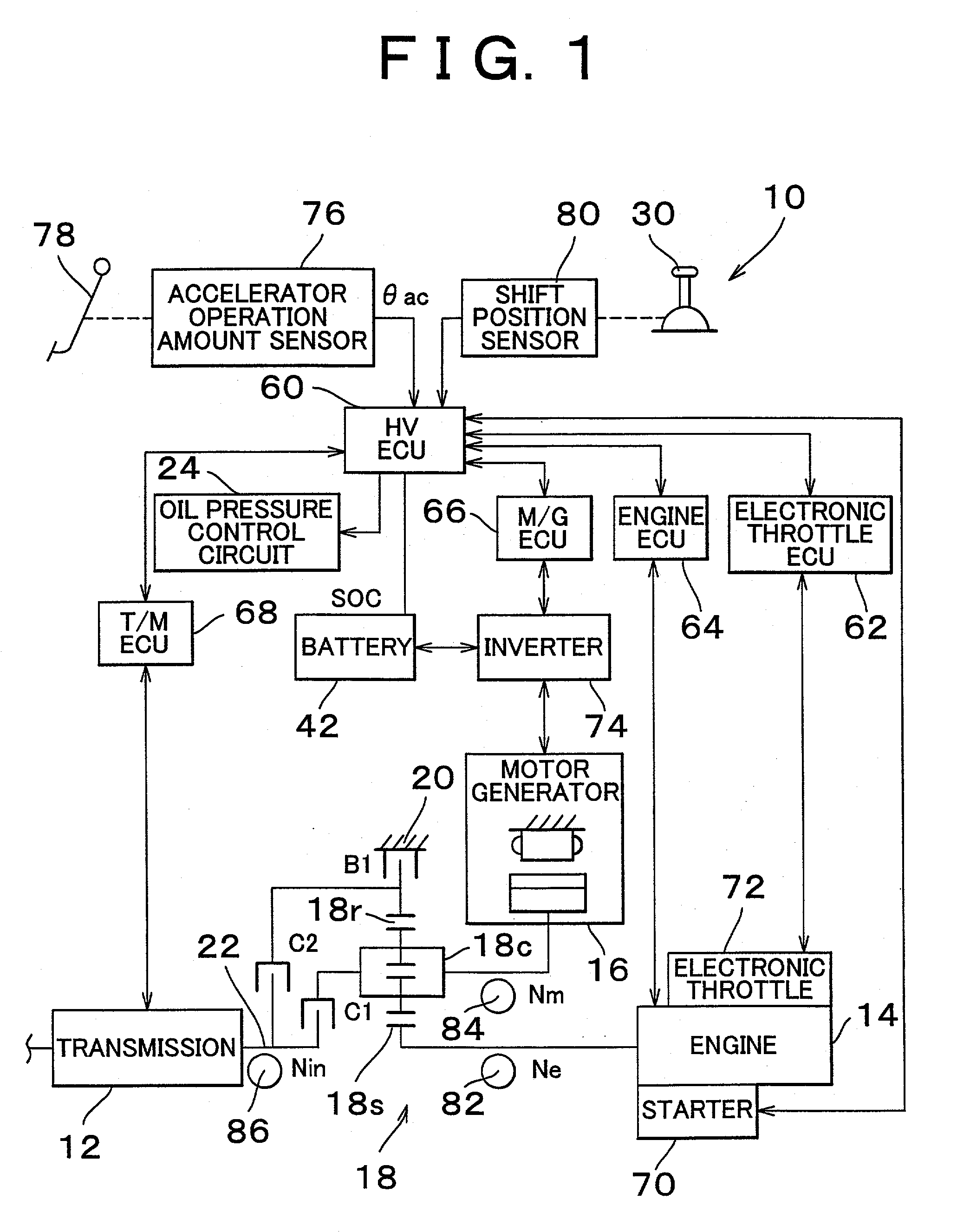

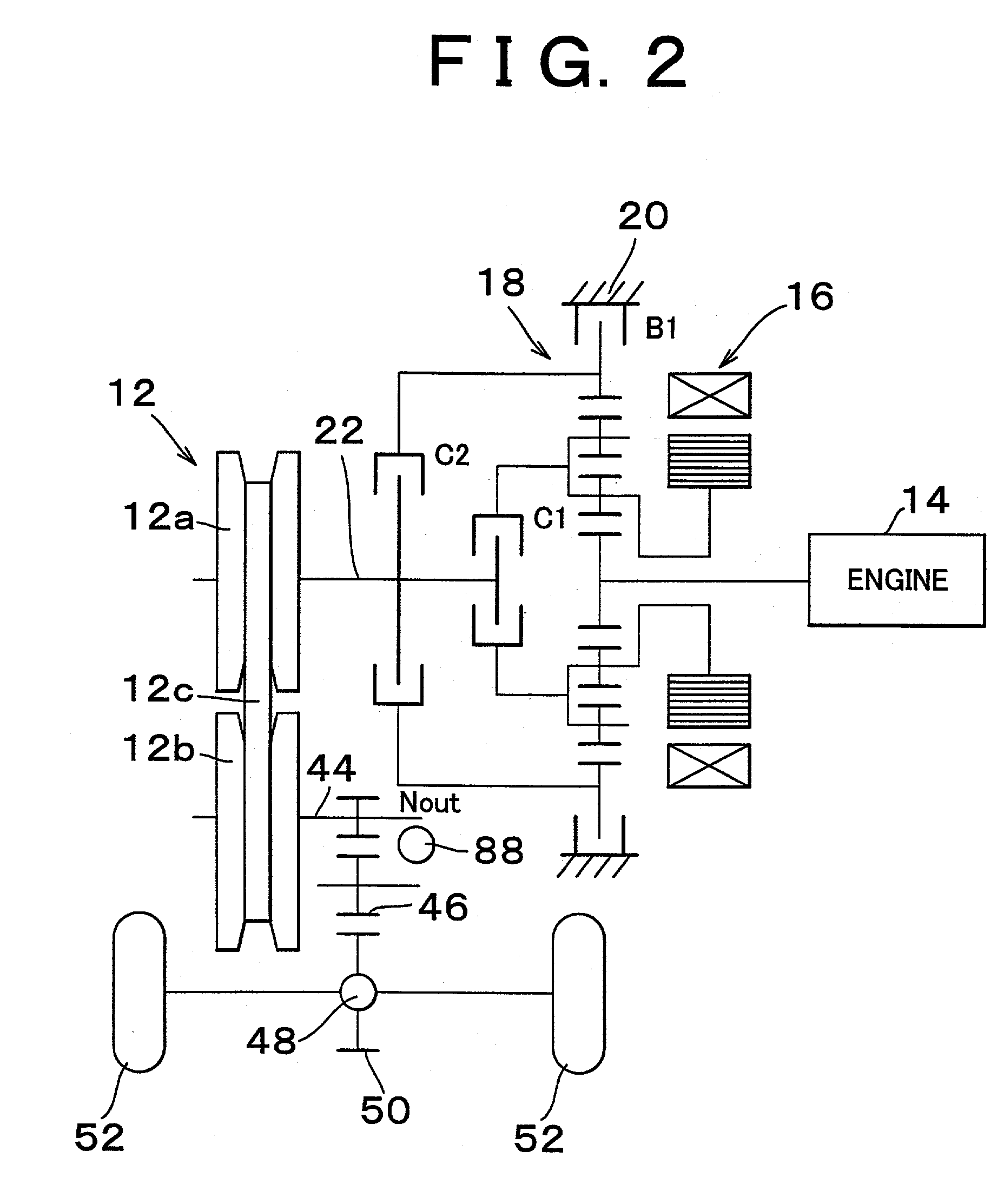

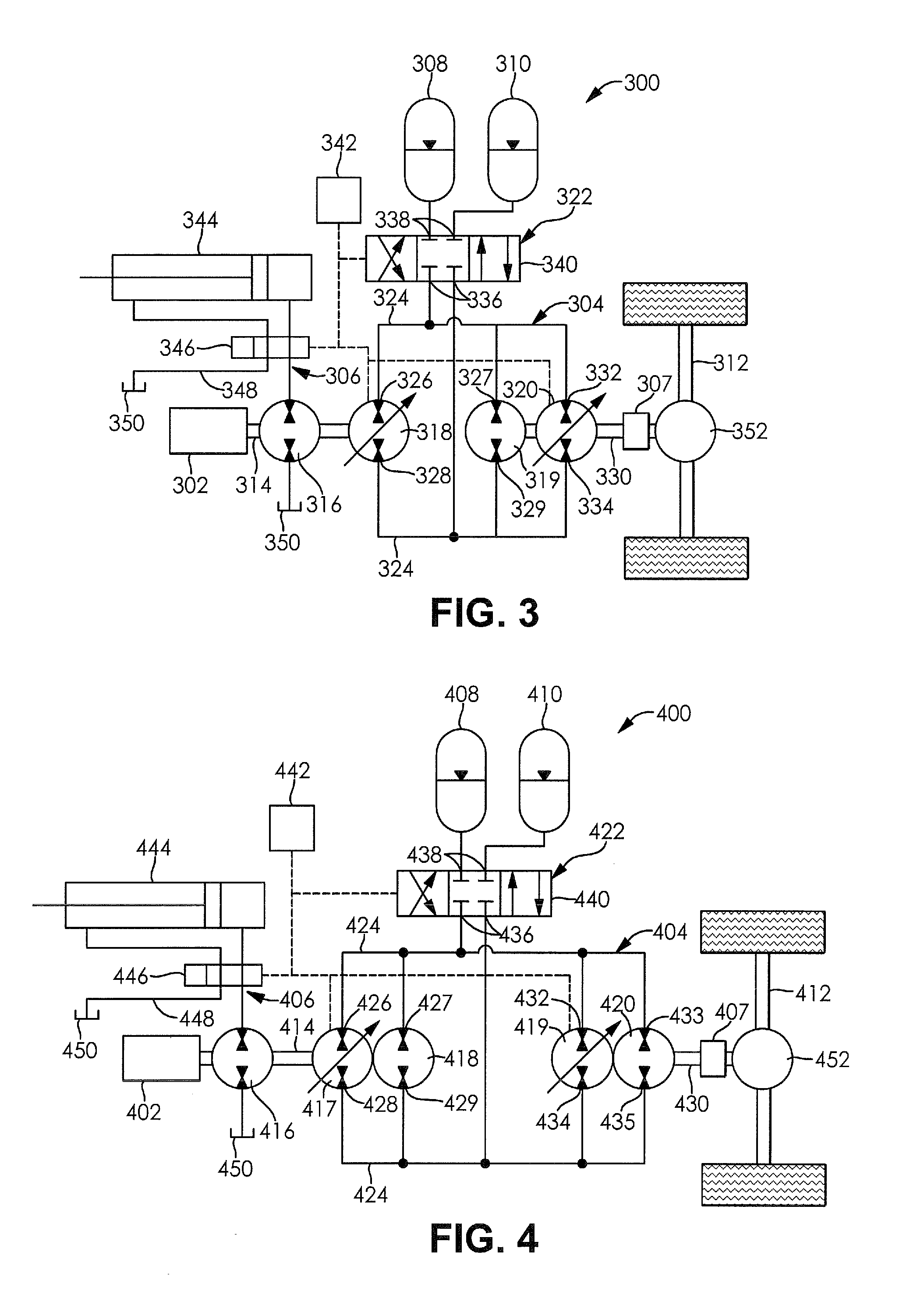

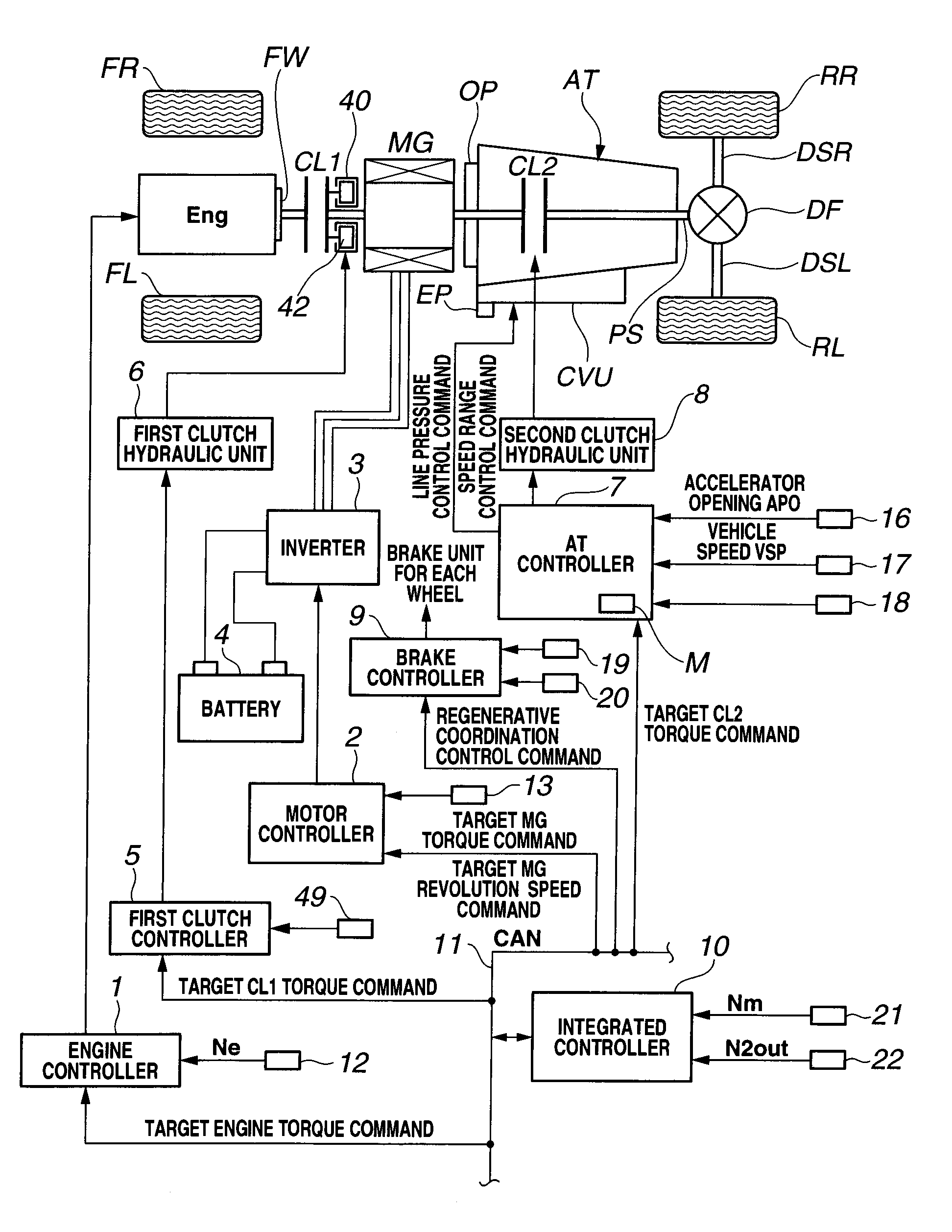

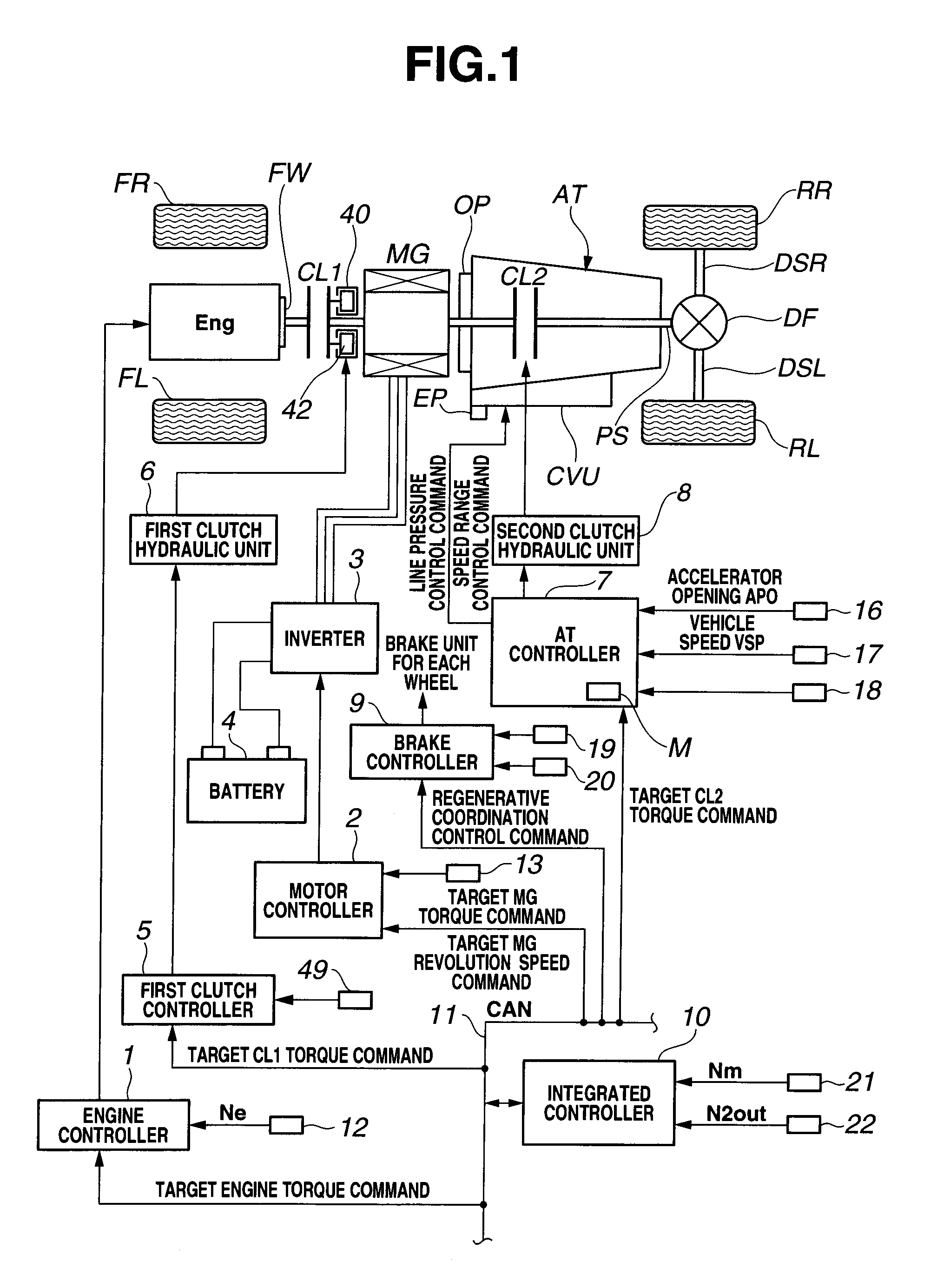

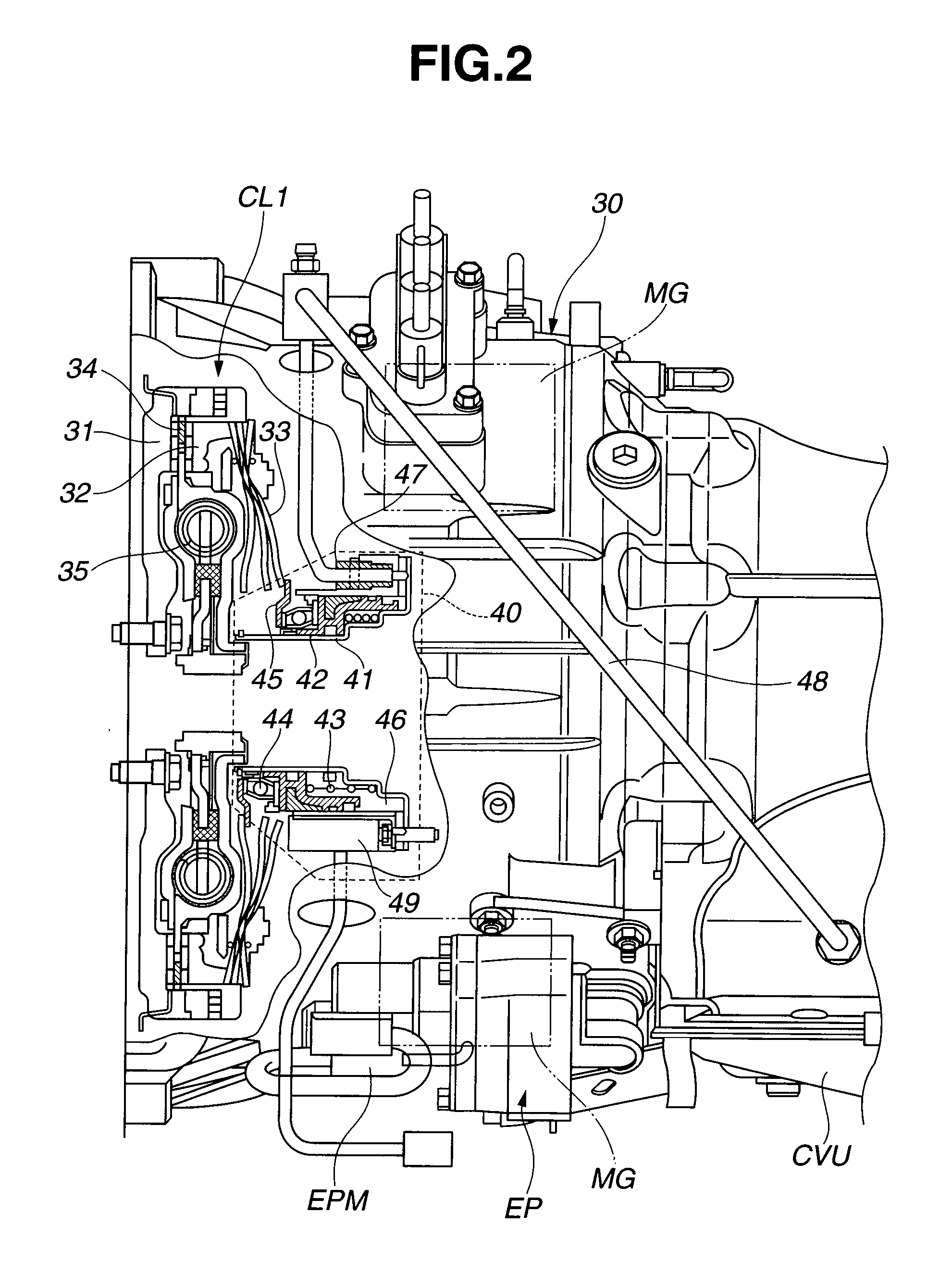

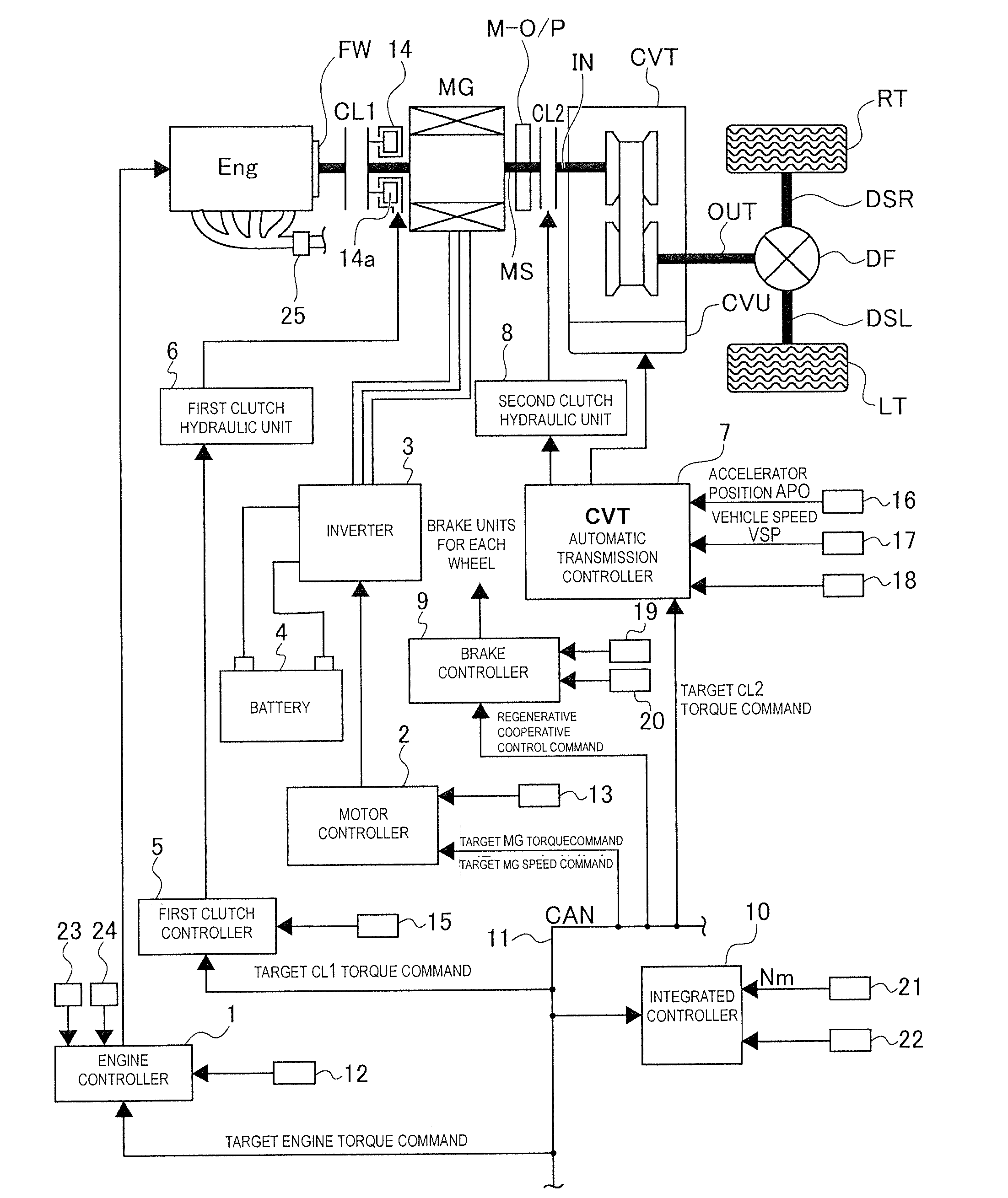

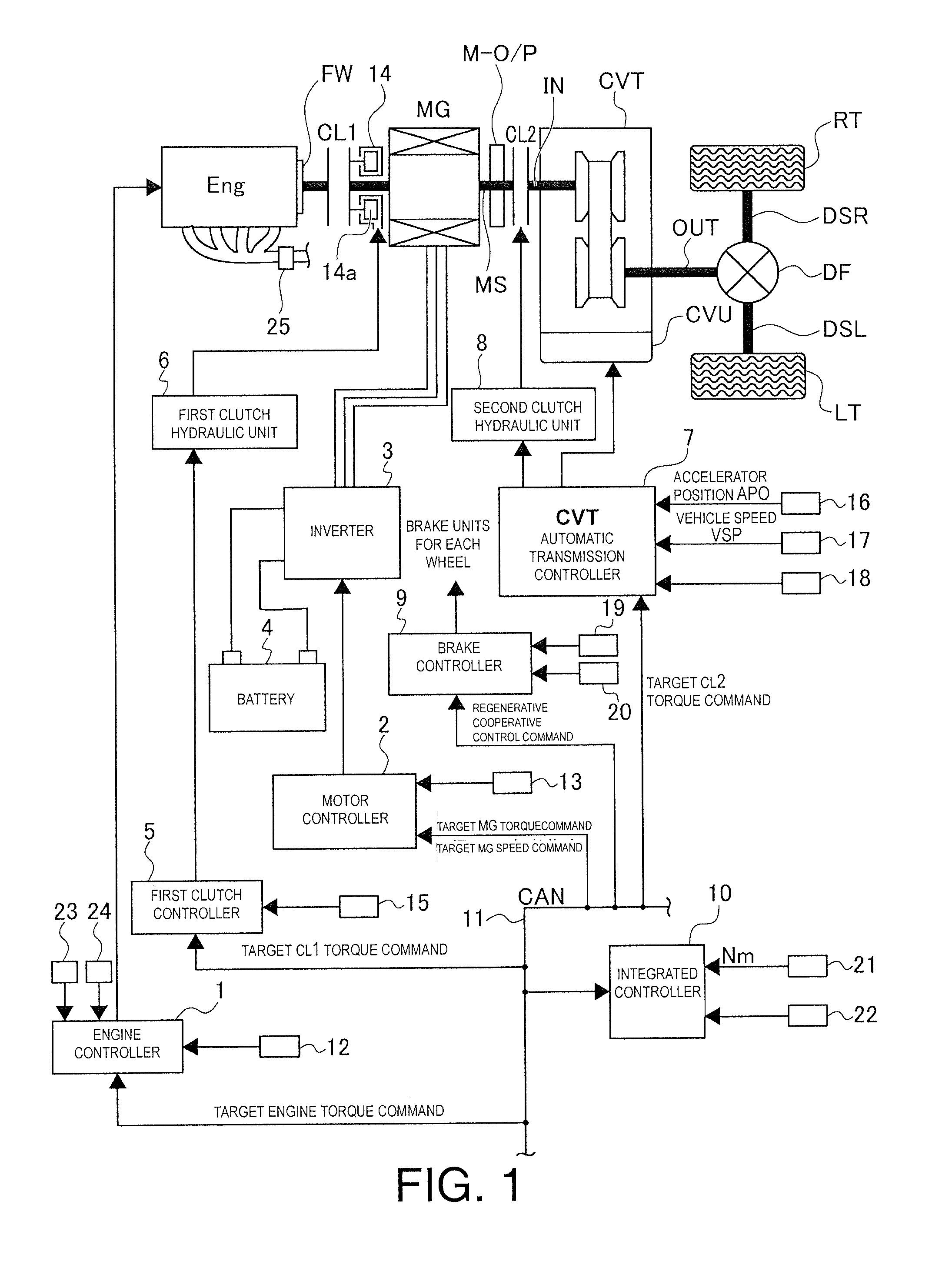

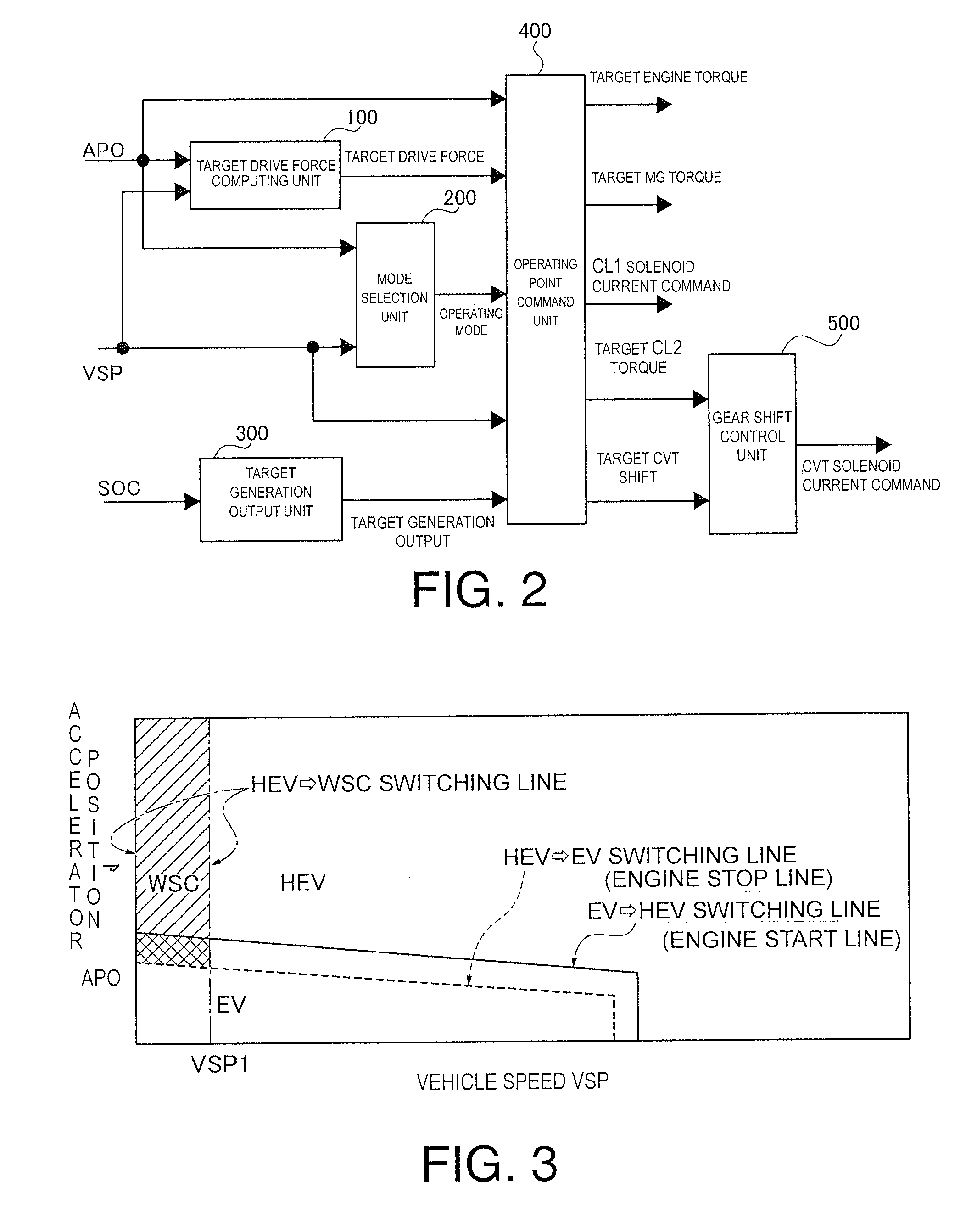

Hybrid vehicle control apparatus

ActiveUS20080058154A1Physical shock resulting from gear shifting can be eliminatedEasy to controlRoad transportGas pressure propulsion mountingElectricityDrive wheel

A hybrid vehicle control apparatus is provided with a motor / generator arranged between an engine and a transmission, a first clutch disposed between the engine and the motor / generator, a second clutch disposed in a power train spanning from the motor / generator to a drive wheel, and a controller. The controller controls the engagement of the first and second clutches to select either an electric drive mode or a hybrid drive mode. The controller executes a rotational speed control of the motor / generator while in a coasting state with torque being transmitted through a one-way clutch of the transmission such that the rotational speed control increases an input rotational speed of the one-way clutch to a value closer to an output rotational speed of the one-way clutch with a difference between the input and output rotational speeds of the one-way clutch becoming equal to a target value.

Owner:NISSAN MOTOR CO LTD

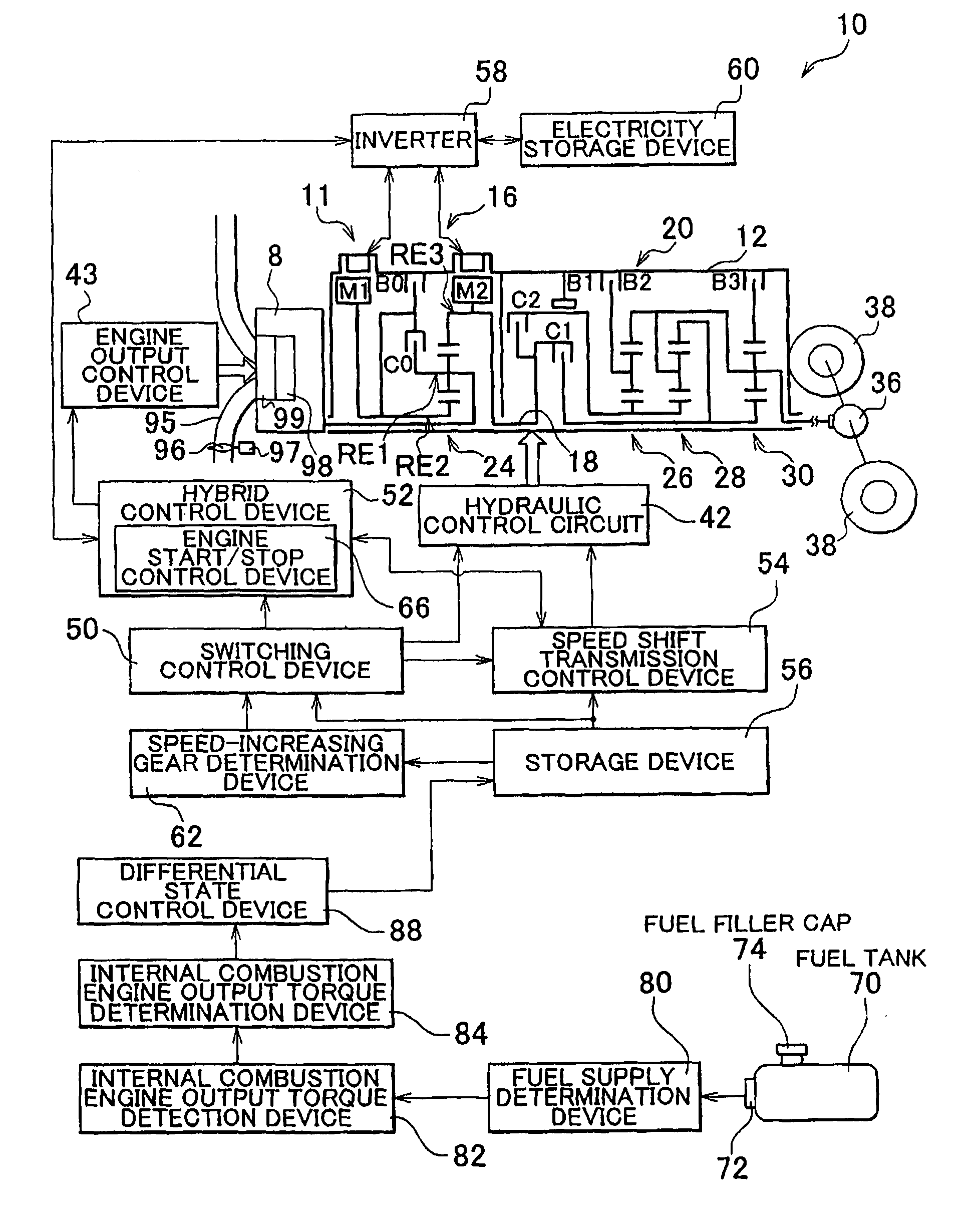

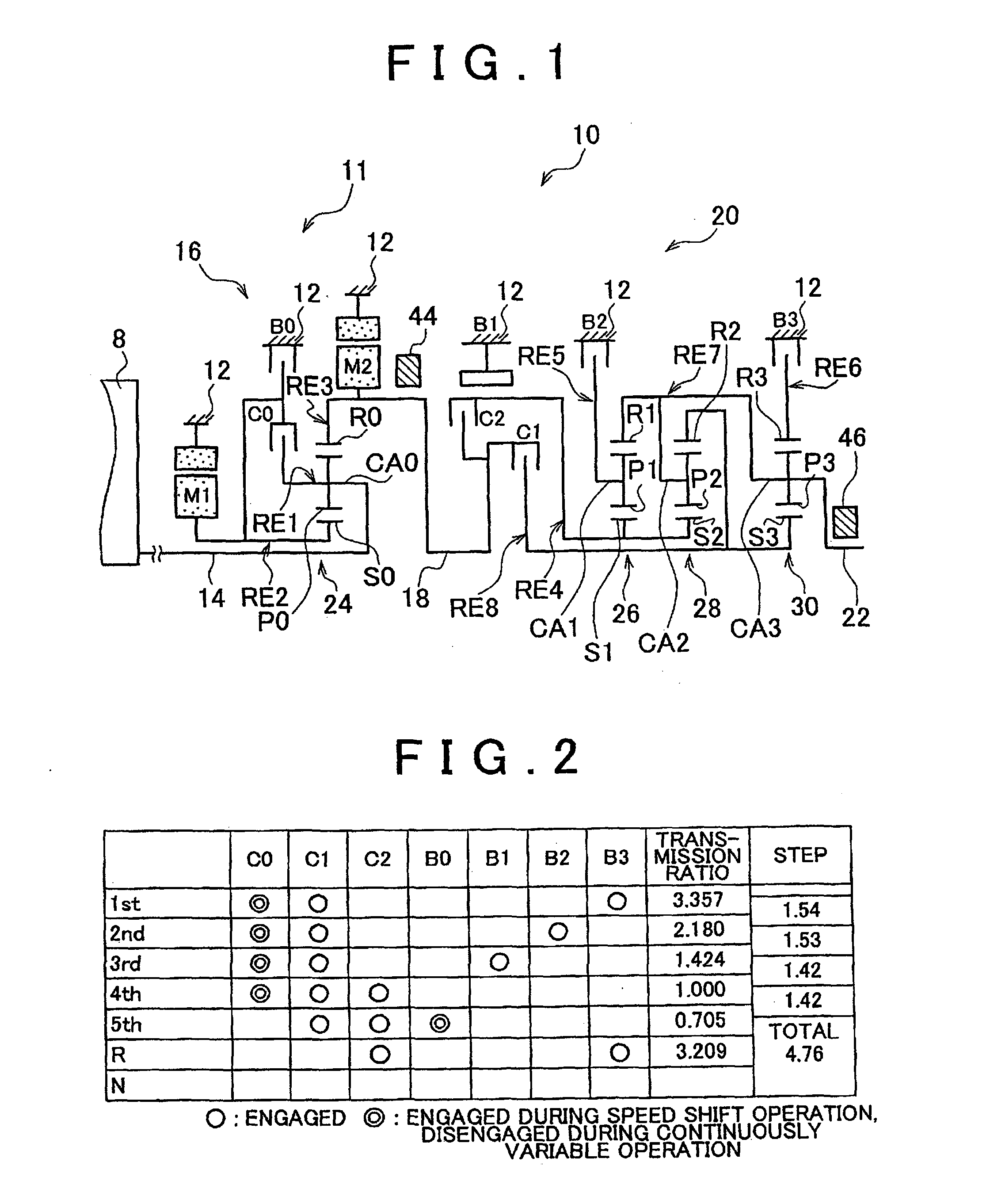

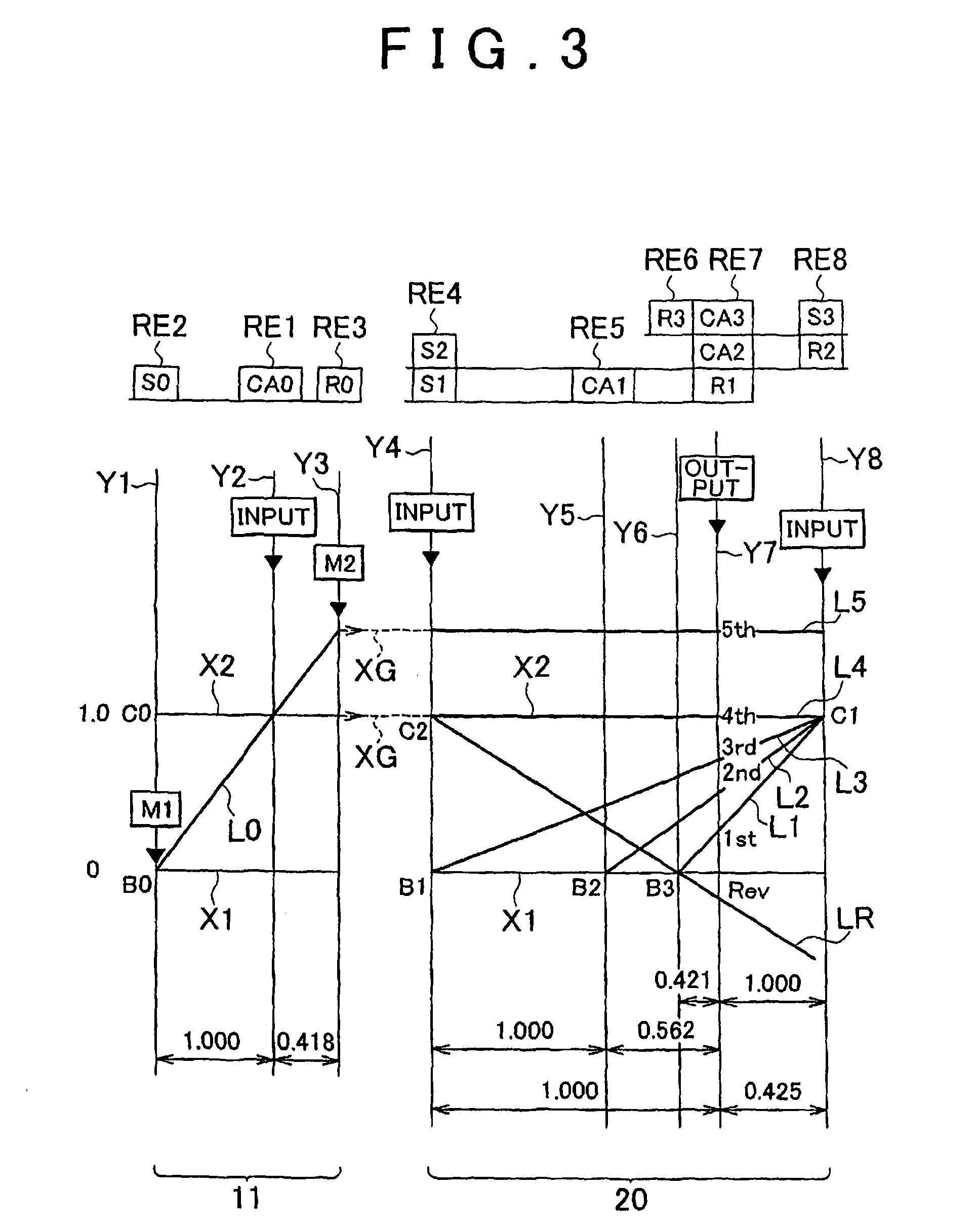

Control device for power transmission device for vehicle

When an engine is driven on a different type of fuel (for example, ethanol-containing fuel) from a reference fuel (for example, gasoline) and the engine torque is thus greater than that produced when the engine is driven on the reference fuel, a differential state control device expands a non-differential range compared to that at the time when the reference fuel is used. Thus, in the case where a plurality of types of fuel including the reference fuel are supplied to the engine, the advantage of switching a power distribution mechanism between a differential enabled state and a non-differential state can be fully utilized in correspondence with engine torque characteristics which may vary in accordance with the type of fuel for the engine. As a result, the fuel consumption rate can be reduced in correspondence with the plurality of types of fuel supplied to the engine, for example.

Owner:TOYOTA JIDOSHA KK

Auxiliary power unit having a continuously variable transmission

InactiveUS8845485B2Minimize consumptionMinimum fuel consumption valueAuxillary drivesAir-treating devicesCombustionControl system

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for auxiliary power units (APU). In one embodiment, the APU includes a source of rotational power such as a combustion engine operably coupled to a continuously variable transmission (CVT). The CVT can be coupled to a load. In some embodiments, the load is provided by a generator. In one embodiment, the APU has a control system configured to control the operation of the engine and the operation of the CVT. The control system can facilitate substantially constant speed operation of the generator in the presence of variable operation of the engine. In another embodiment, the APU includes a continuously variable accessory drive (CVAD) operably coupled to an engine. The CVAD can include a continuously variable transmission operably coupled to a generator. In one embodiment, a skew-based control system is adapted to facilitate a change in the ratio of a CVAD.

Owner:FALLBROOK INTPROP COMPANY

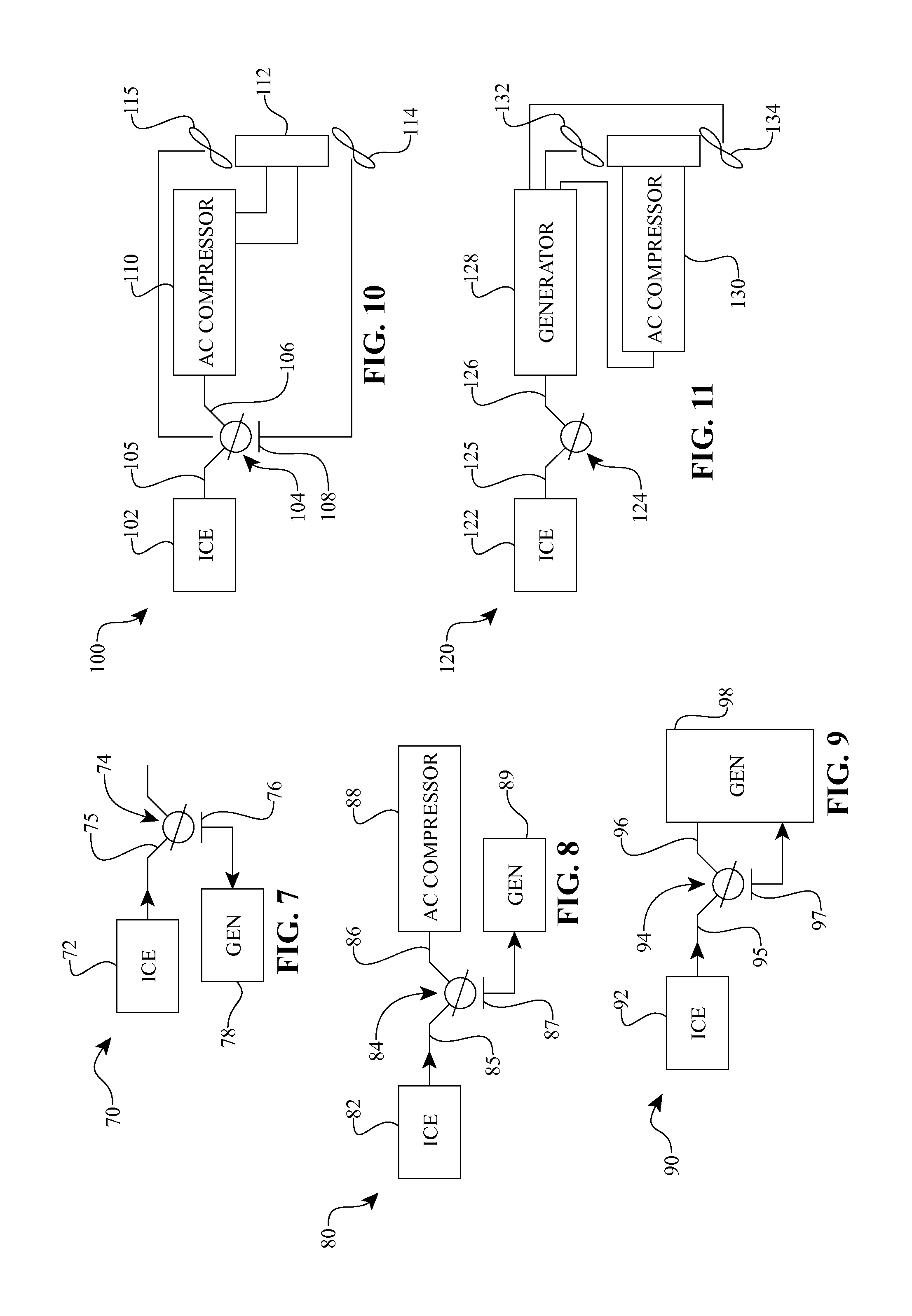

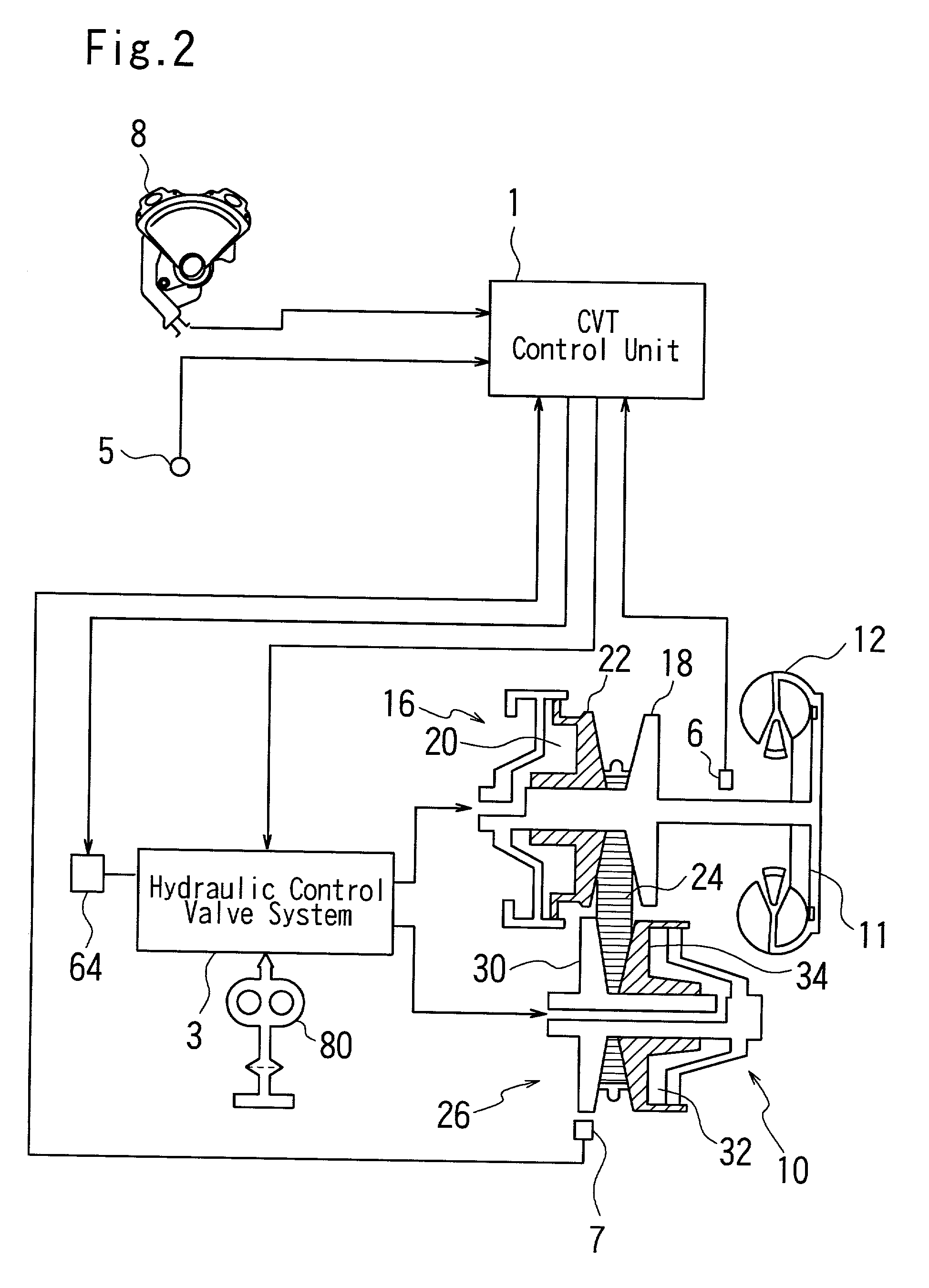

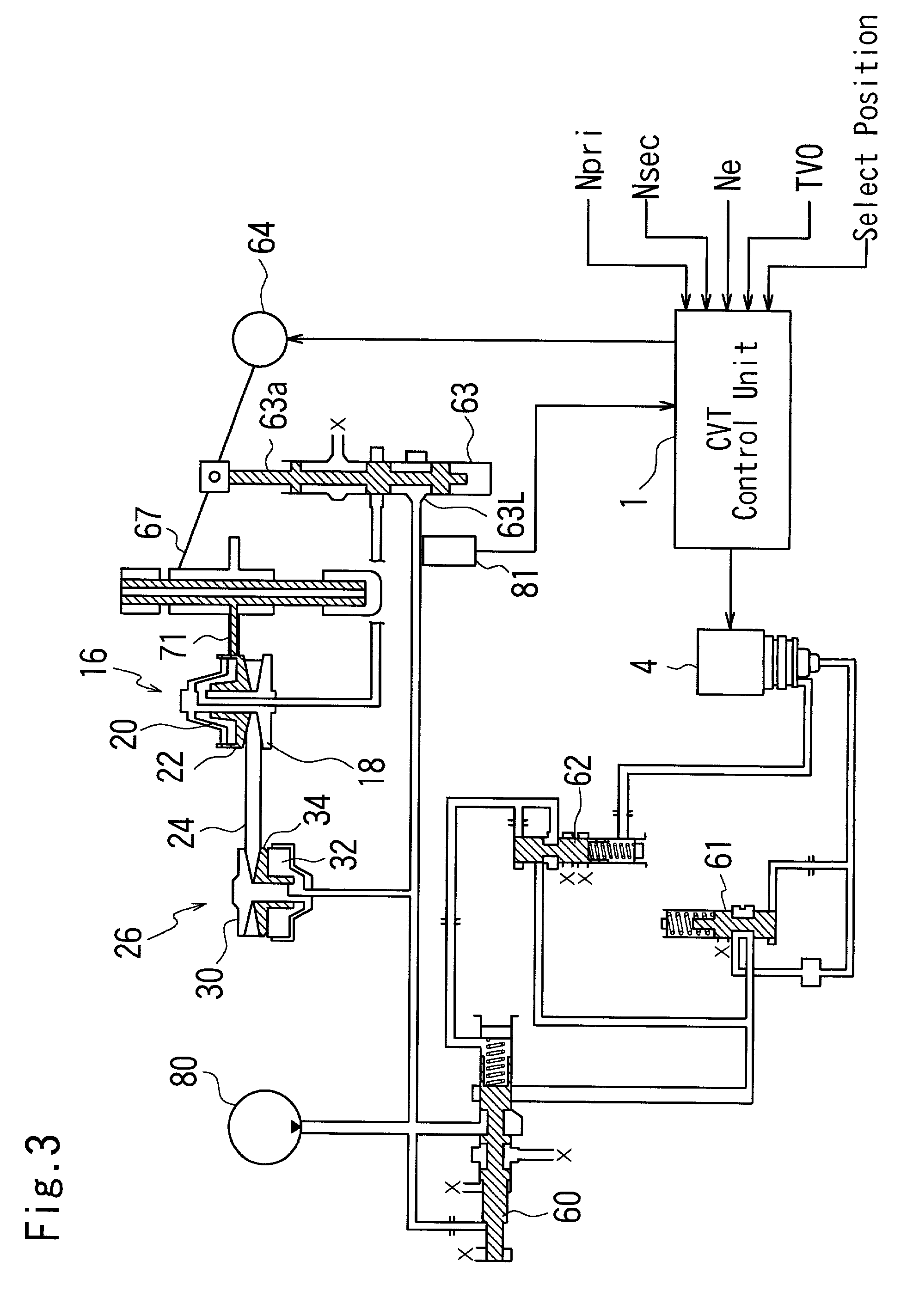

Hydraulic control system for a continuously variable transmission

InactiveUS20010023217A1Less frictional lossIncrease line pressureGearingRoad transportControl systemRotation velocity

A transmission mechanism of the continuously variable transmission comprises a set of primary and secondary pulleys between which a belt is provided. The CVT control unit is operable to supply line pressure directly to a secondary pulley and also to a primary pulley via a shift control valve associated with a step motor in such a manner as to control a transmission ratio. The CVT control unit calculates a standard step position of the step motor corresponding to the target transmission ratio and provides a command signal representative of a difference between the standard step position and the current position of the step motor. The shift control valve actuated by the step motor controls the pressure to be supplied to the primary pulley. The actual transmission ratio obtained on the basis of the rotation speeds of the pulleys is compared with the target transmission ratio. If the shift is not accomplished, the CVT control unit commands additional step number. Unless the shift to the HI side is accomplished at the time when the additional step number reaches the threshold value, the line pressure is increased so as to achieve the shift. Thus, the transmission normally operates with a low line pressure sufficiently to reduce a frictional loss at the contact areas of the belt and the pulleys, thereby resulting in an enhanced fuel economy.

Owner:JATCO LTD

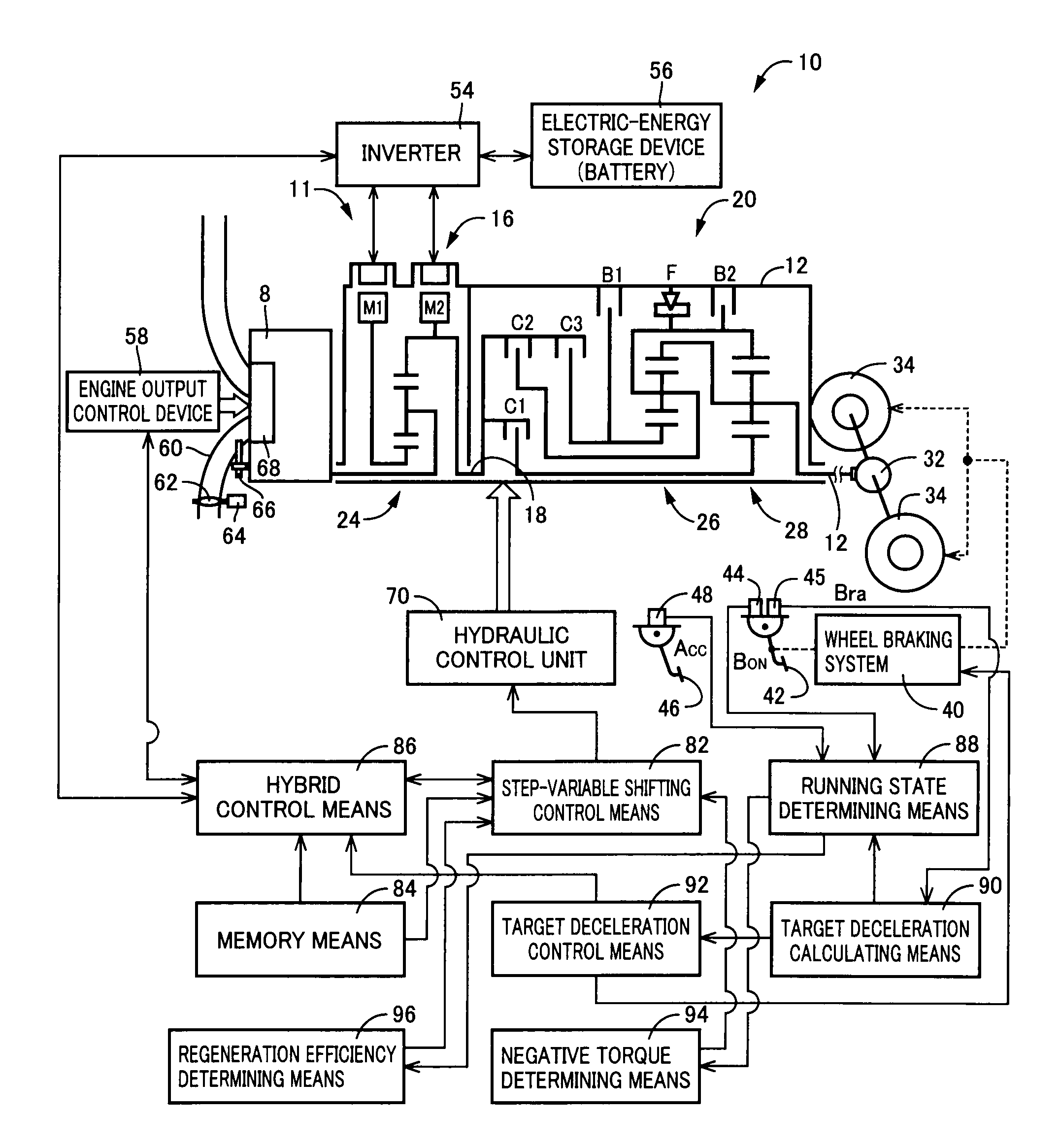

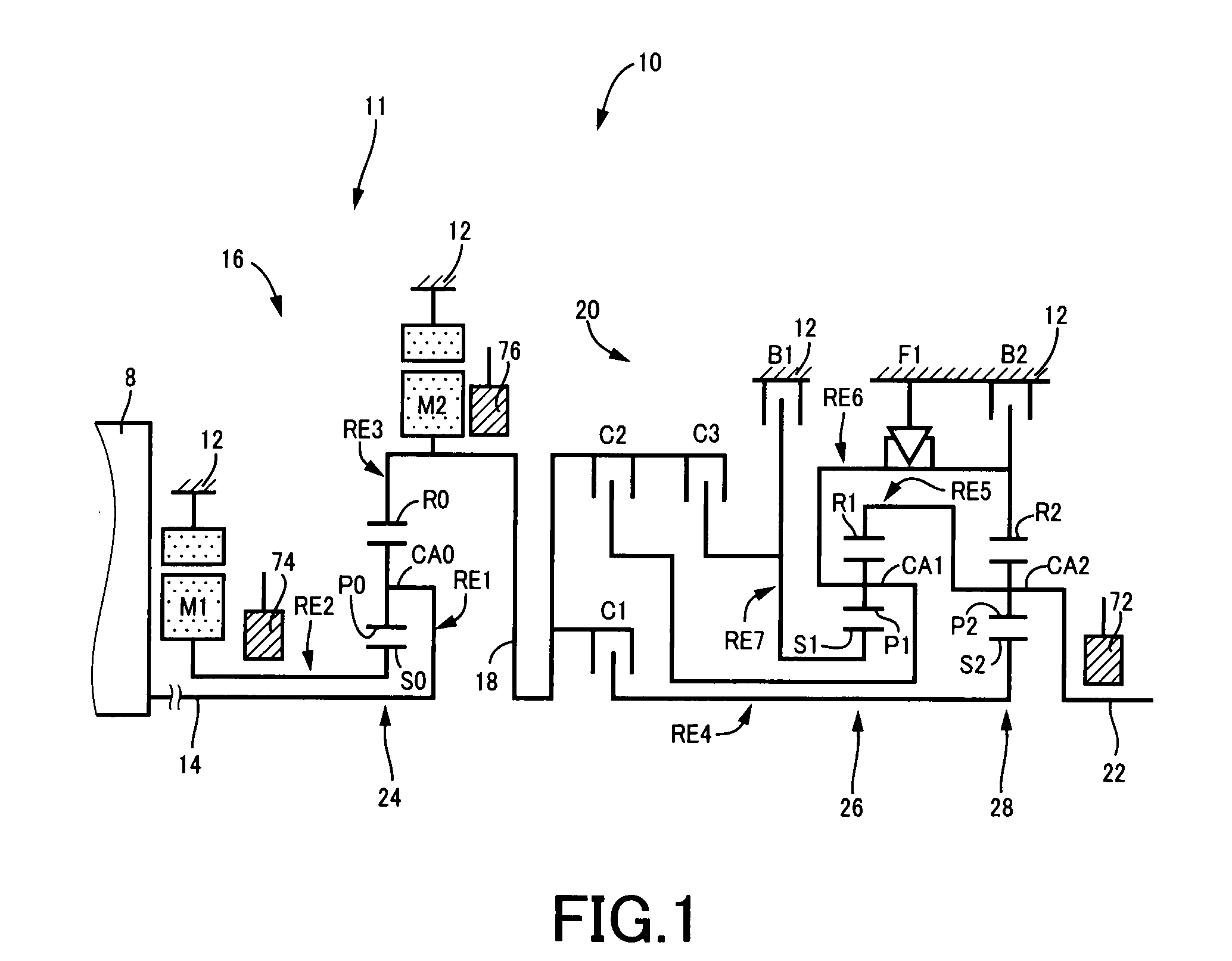

Control apparatus for vehicular power transmitting system

ActiveUS20120072065A1Reduce transmissionDigital data processing detailsGearingControl equipmentVariator

A control apparatus for a power transmitting system of a vehicle provided with a transmission portion having a plurality of speed ratios to be established in steps, and an electric motor operatively connected to an input-side rotary member of said transmission portion and controlled to generate a regenerative torque in a decelerating state of the vehicle, the control apparatus is configured: to implement a shifting control to perform a shifting operation of said transmission portion under the condition of a determination in the decelerating state of the vehicle that an input torque of said transmission portion including said regenerative torque is substantially zero; and to implement the shifting control to perform the shifting operation of said transmission portion under the condition of an improvement of a fuel economy rather than the determination that the input torque of said transmission portion is substantially zero, when a target deceleration value of the vehicle is larger than a predetermined threshold value.

Owner:TOYOTA JIDOSHA KK

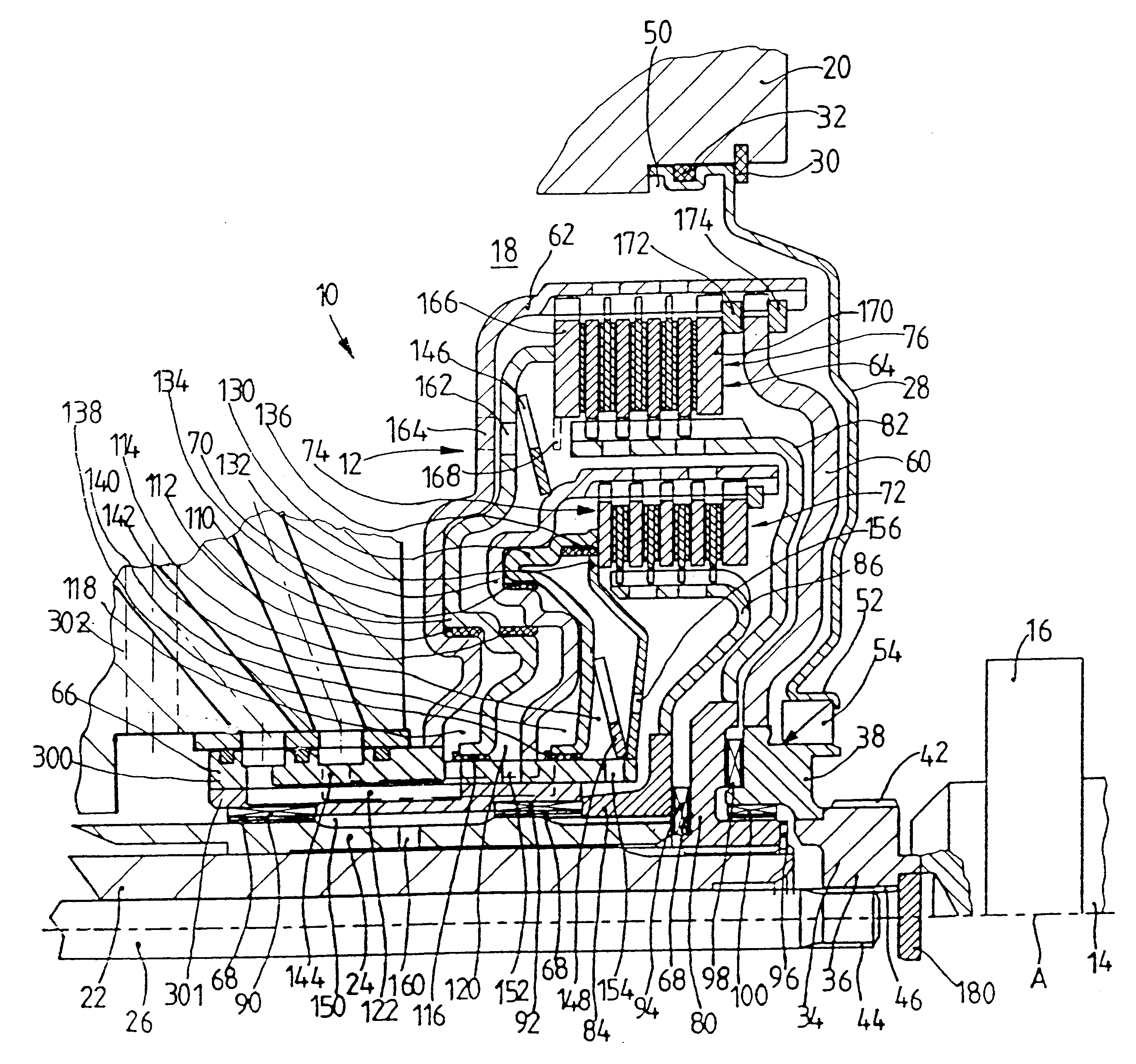

Multiple-clutch device

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that at least one of the clutch arrangements is constructed as a plate clutch arrangement and has an actuating piston defining a pressure chamber for actuation, preferably for engagement, of the plate clutch arrangement by means of a pressure medium, preferably hydraulic medium, wherein cooling fluid, possibly cooling oil, can be supplied to the plate clutch arrangement from a cooling fluid supply, possibly a cooling oil supply, wherein the actuating piston, and also, if desired, a plate carrier, possibly an outer plate carrier, has at least one pressure compensation opening and / or cooling fluid outlet opening in a radial outer and / or central area.

Owner:ZF FRIEDRICHSHAFEN AG +1

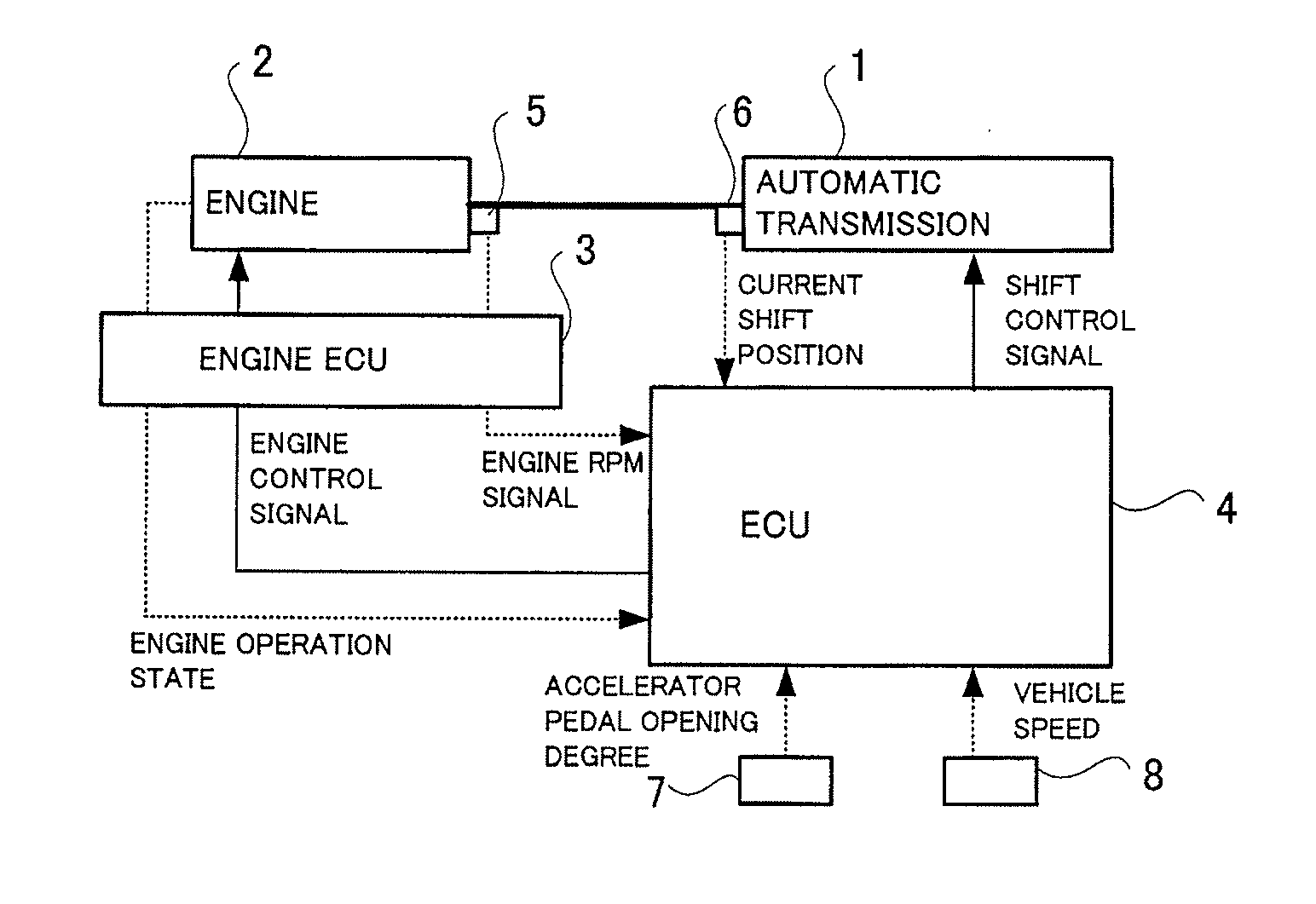

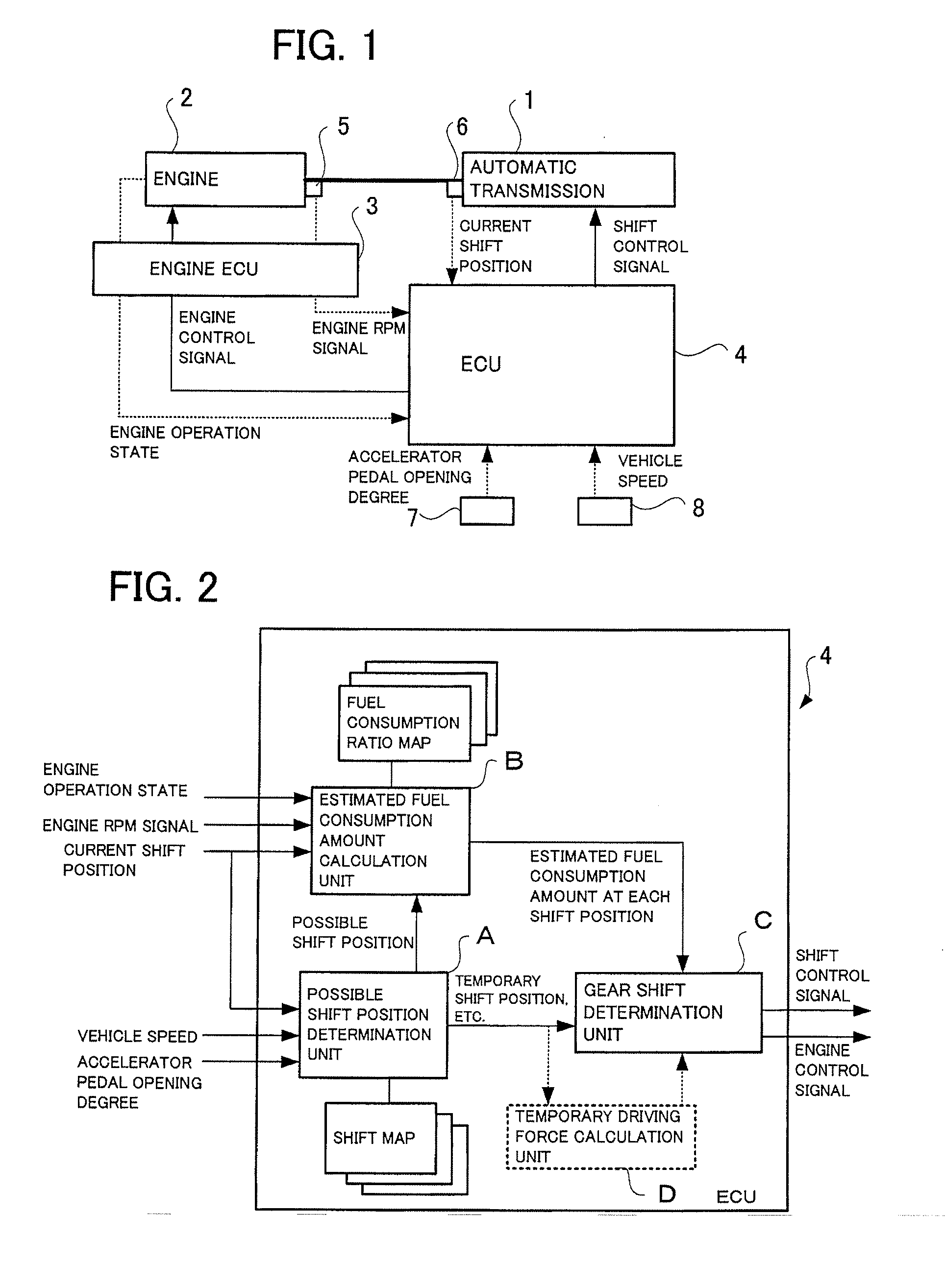

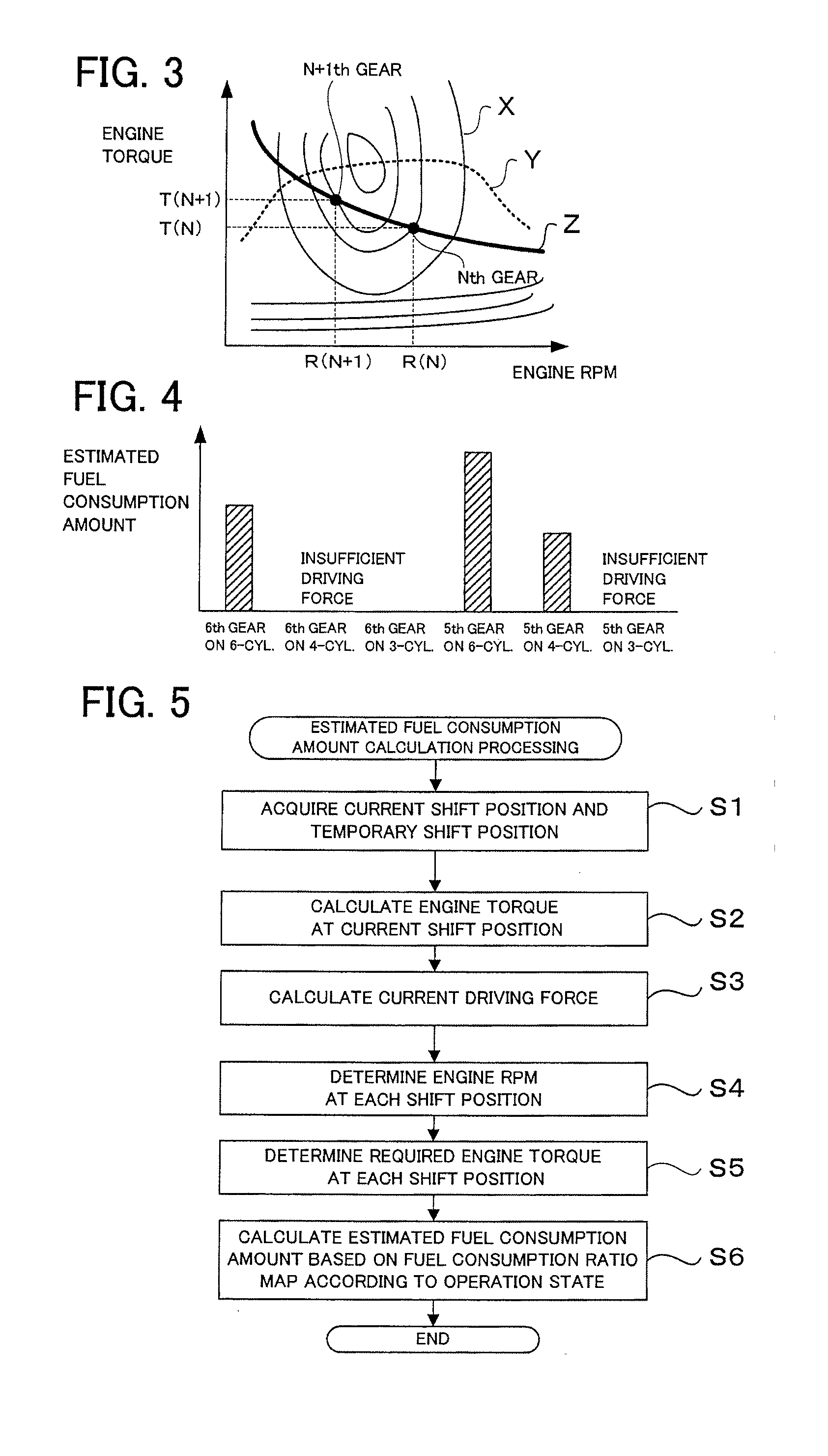

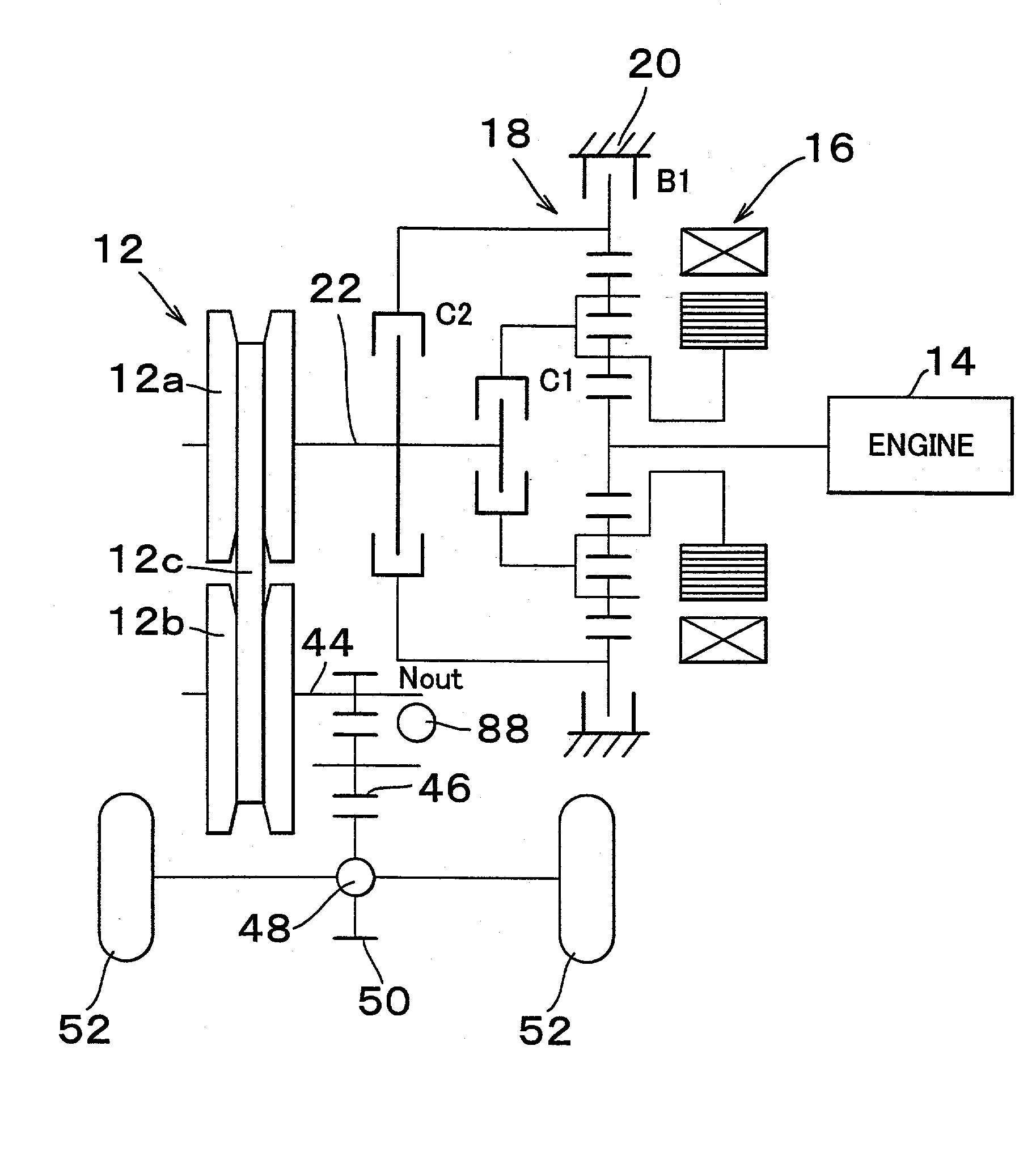

Control device for automatic transmission

ActiveUS20130184949A1Reduce fuel consumptionSmall fuel consumption amountDigital data processing detailsRoad transportAutomatic train controlAutomatic control

For each engine operation state to which a variable cylinder engine can be switched, a fuel consumption amount to be consumed to generate a driving force required to maintain a current traveling state of a vehicle for each of a current gear and a new gear after a possible shift-up is calculated. An automatic shift control of shifting up to the new gear is performed in a condition that a calculated fuel consumption amount of the new gear after the possible shift-up is smaller than a calculated fuel consumption amount of the current gear. In this way, the fuel consumption amount can be optimally reduced and the shift control can be performed without degrading the traveling performance, even in the vehicle equipped with the variable cylinder engine.

Owner:HONDA MOTOR CO LTD

Vehicle drive control apparatus and method

InactiveUS20020173391A1Solve insufficient capacityReduce power transmission lossesElectric propulsion mountingGearingDevice WheelControl theory

Methods and apparatus for a vehicle drive control apparatus changes in the transfer torque capacity of a power transfer device according to various states of operation with respect to at least one drive power source. The vehicle drive control apparatus includes a power transfer device that has a variable transfer torque capacity and the drive power sources that rotate a device wheel via the power transfer device. A controller is included that causes a vehicle to selectively run in a variety of run modes that differ in states of operation with respect to at least one of the drive power sources. The controller changes the transfer torque capacity of the power transfer device in accordance with the various run modes. According to the vehicle device control apparatus, a target oil pressure is raised by a predetermined amount when the mode of run is change, or when the vehicle descends in a direction opposite to a vehicle starting direction at the time of a hill climb start.

Owner:TOYOTA JIDOSHA KK

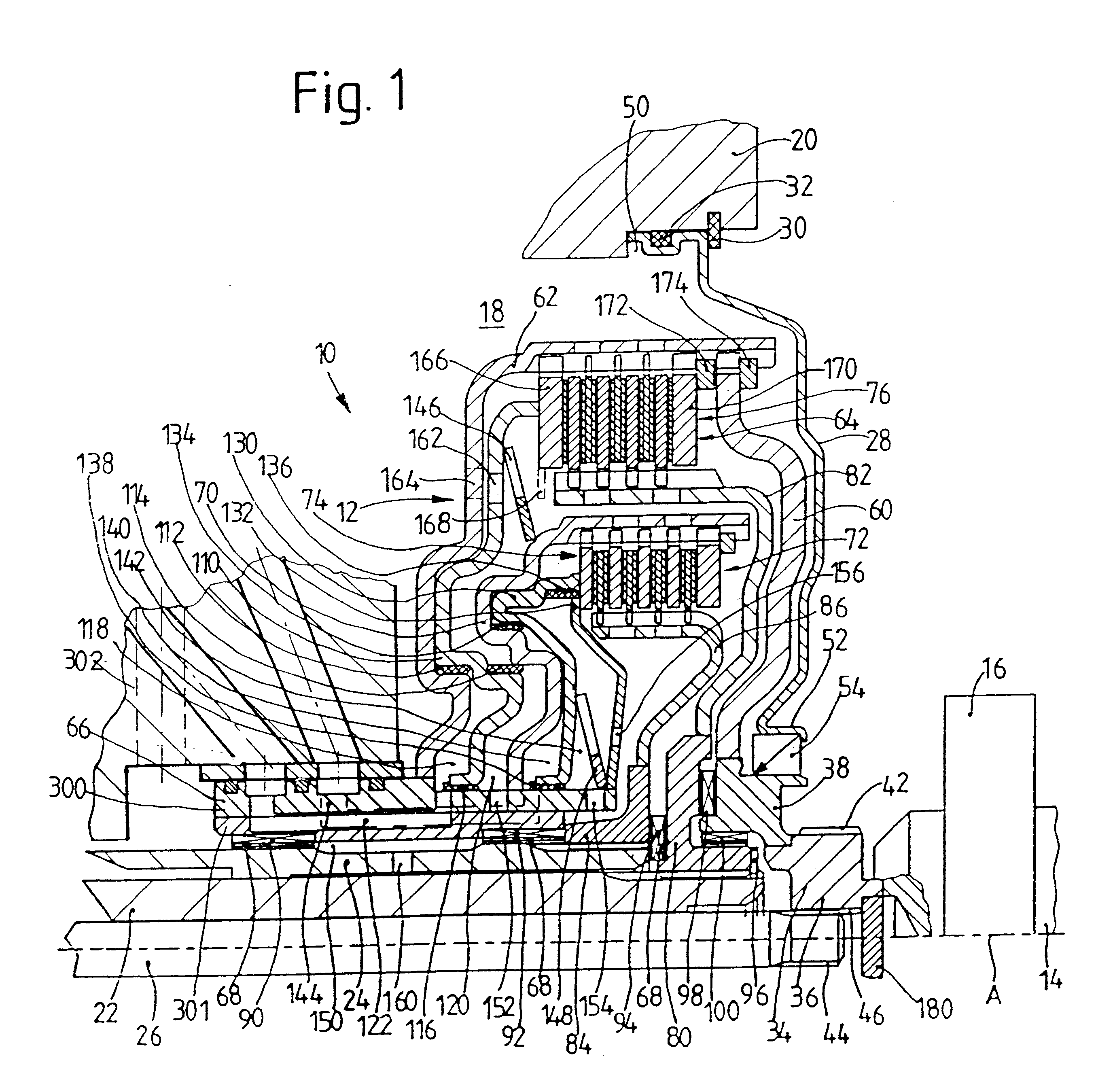

Multiple-clutch device

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that a bearing arrangement is associated with at least one of the clutch arrangements, wherein the latter is supported or can be supported so as to be relatively rotatable by means of the bearing arrangement on at least one of the transmission input shafts, at least one of which is constructed as a hollow shaft and a shaft constructed as a hollow shaft encloses the other shaft, preferably at least at the radial outer transmission input shaft which is constructed as a hollow shaft.

Owner:VOLKSWAGEN AG +1

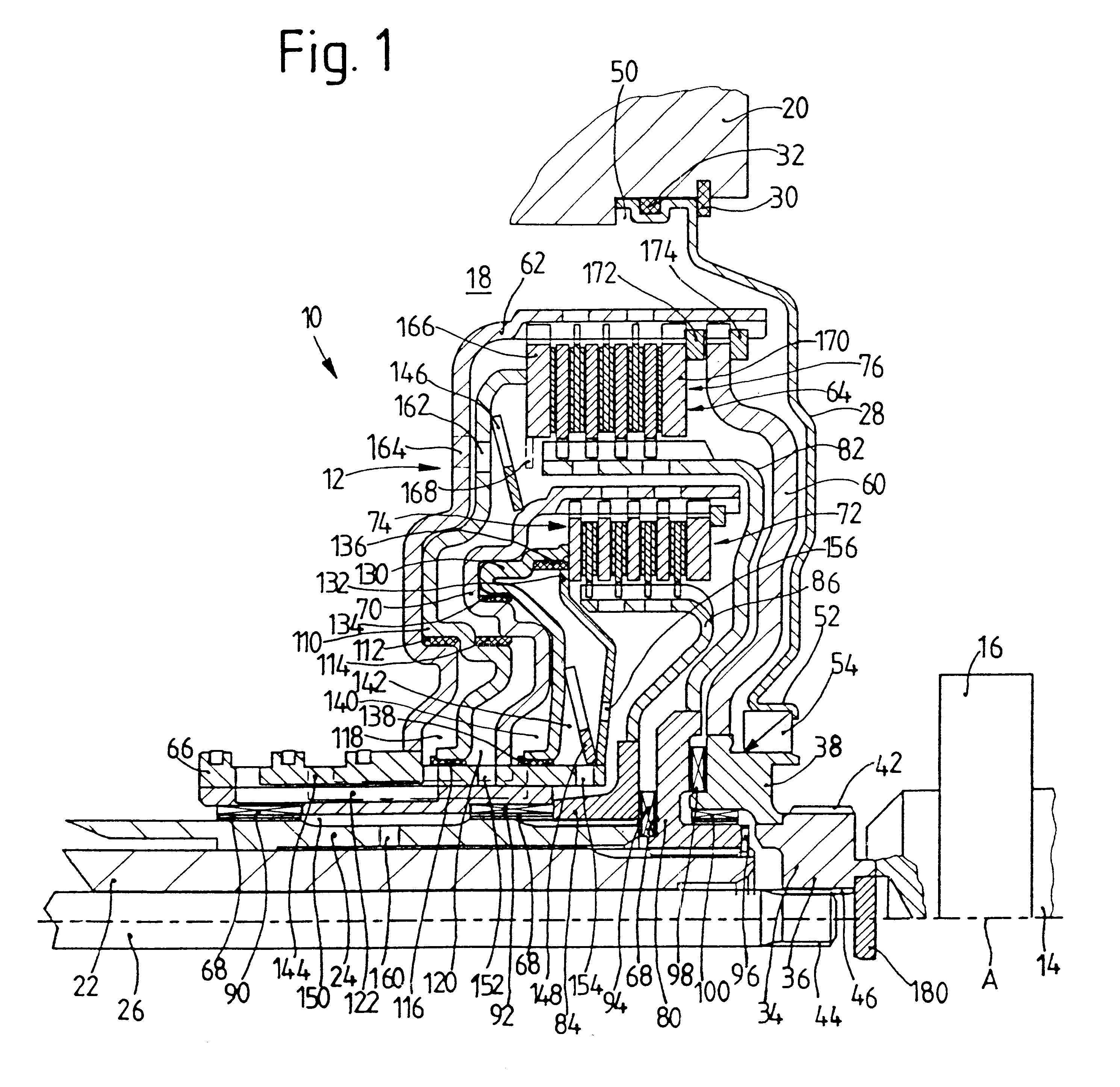

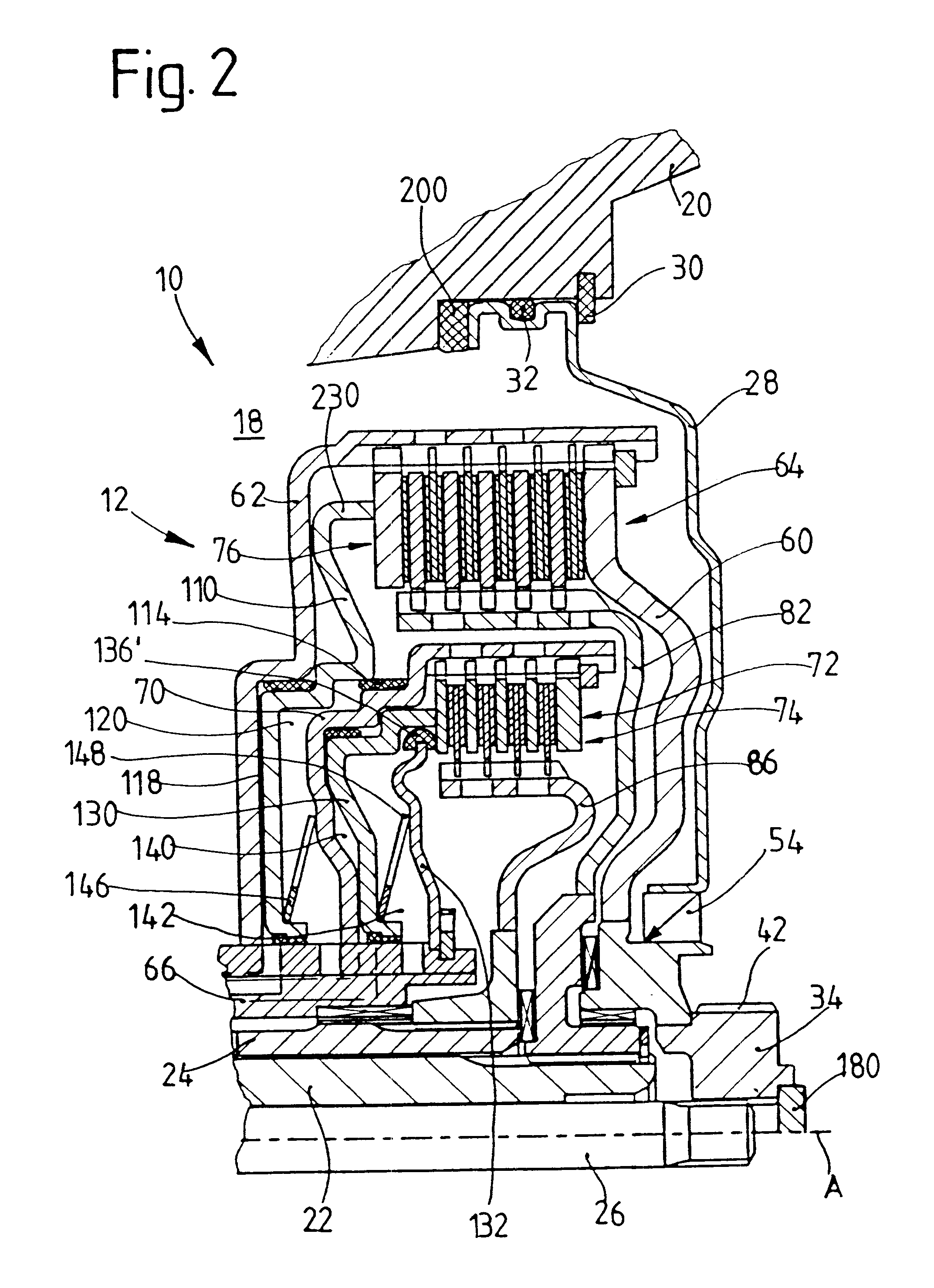

Dual clutch for a transmission with two input shafts

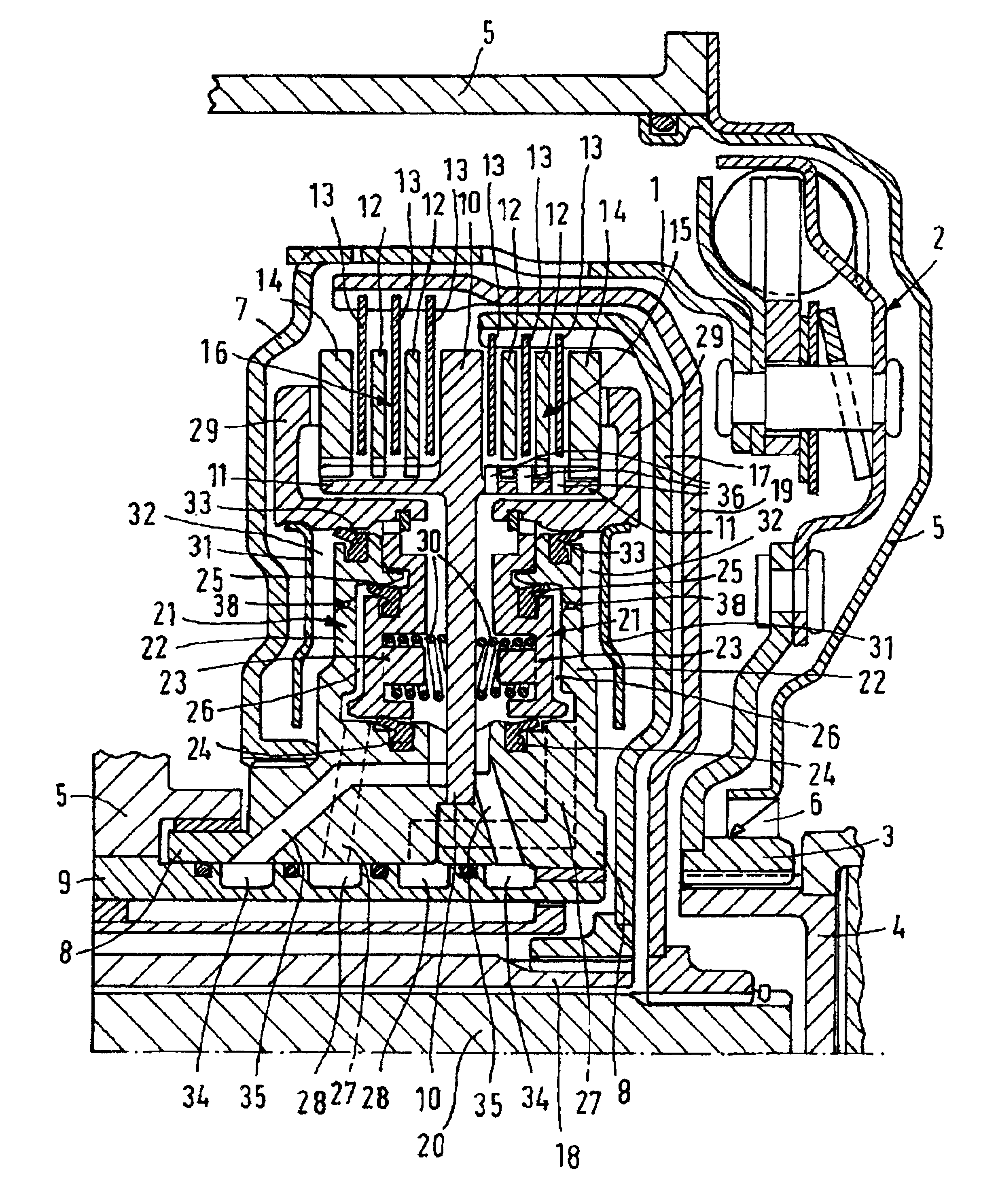

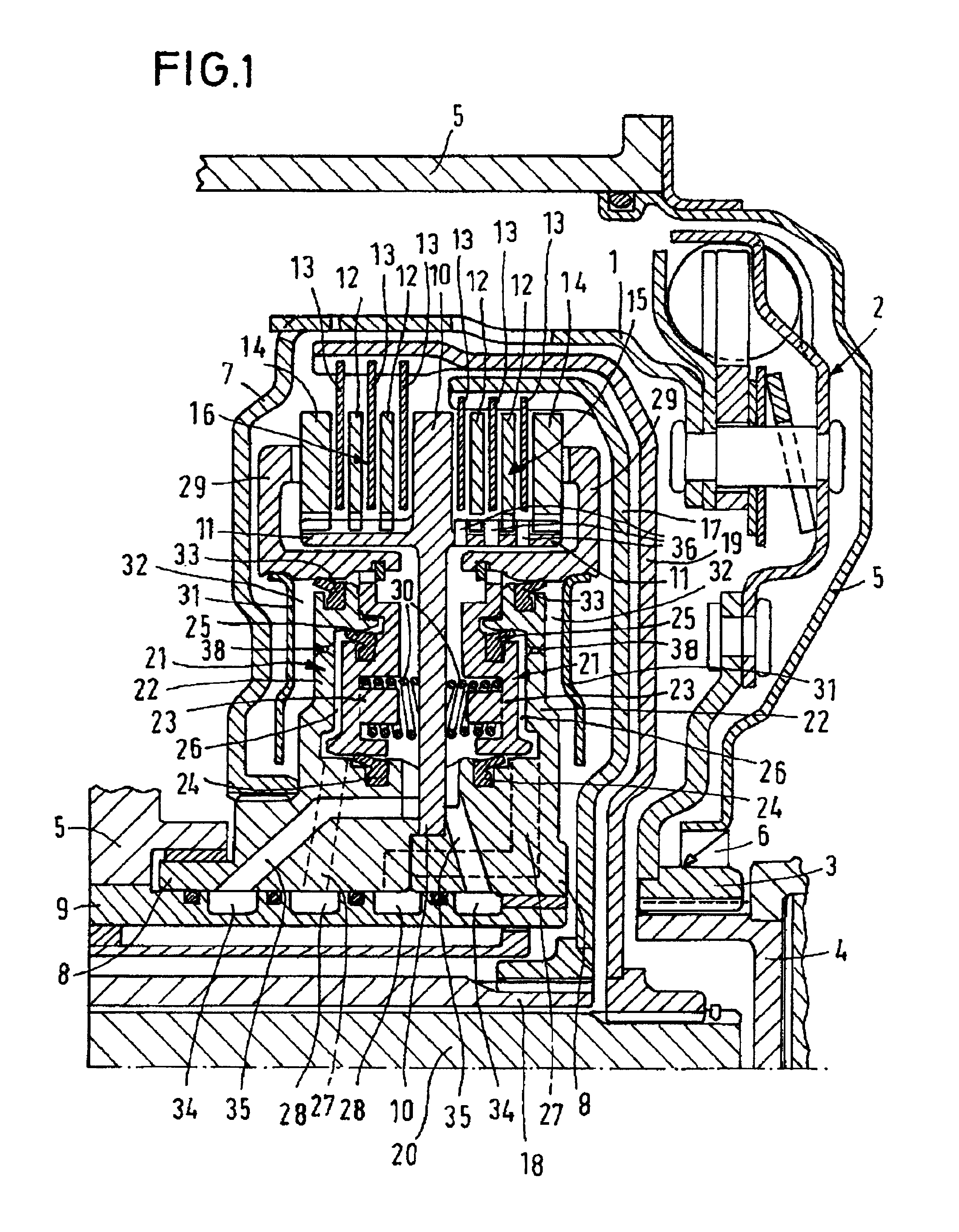

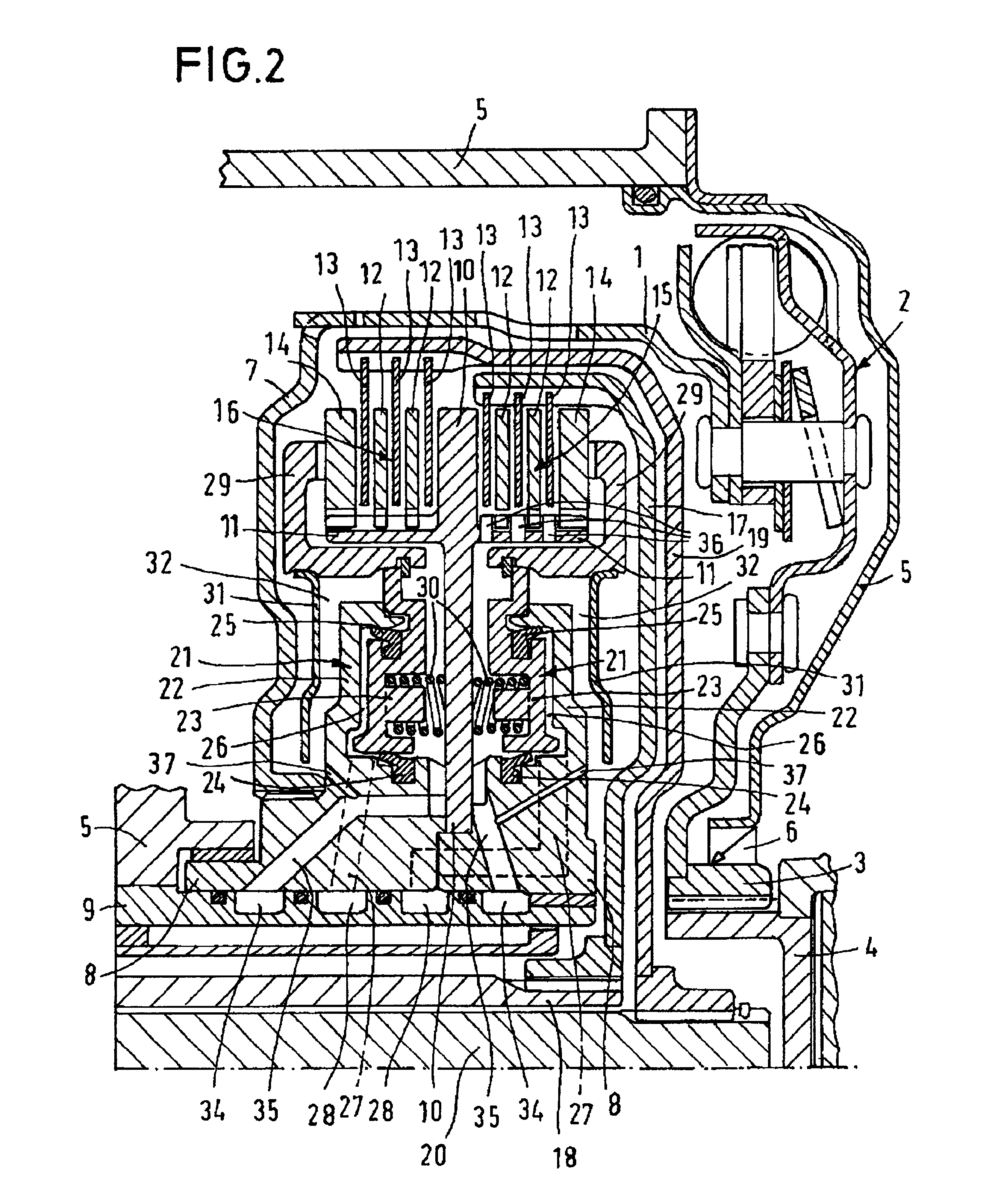

InactiveUS6929107B2Increased torque capacityCompact structureMechanical actuated clutchesFluid actuated clutchesMobile vehicleEngineering

The invention relates to a hydraulic twin clutch for a transmission with two transmission input shafts, preferably for a power-shift transmission in motor vehicles, with concentric arrangement of the two transmission input shafts, a driven clutch housing, two hydraulically actuated clutches with friction disks and annular piston-cylinder units, the first clutch connecting the clutch housing selectably to the first transmission input shaft and the second clutch connecting the clutch housing selectably to the second transmission input shaft. It is distinguished by the fact that the two clutches are arranged adjacent one another, separated by a clutch web firmly connected to the clutch housing, and the two piston-cylinder units provided for the actuation of the clutch are likewise arranged adjacent one another and separated by the clutch web, between the clutches and the transmission input shafts, on a smaller diameter than the clutches. The essential advantages are compact construction combined with high torque capacity and the possibility of achieving complete compensation of the centrifugal-force-dependent pressures in the working chambers through the provision of a compensating chamber.

Owner:FORD GLOBAL TECH LLC

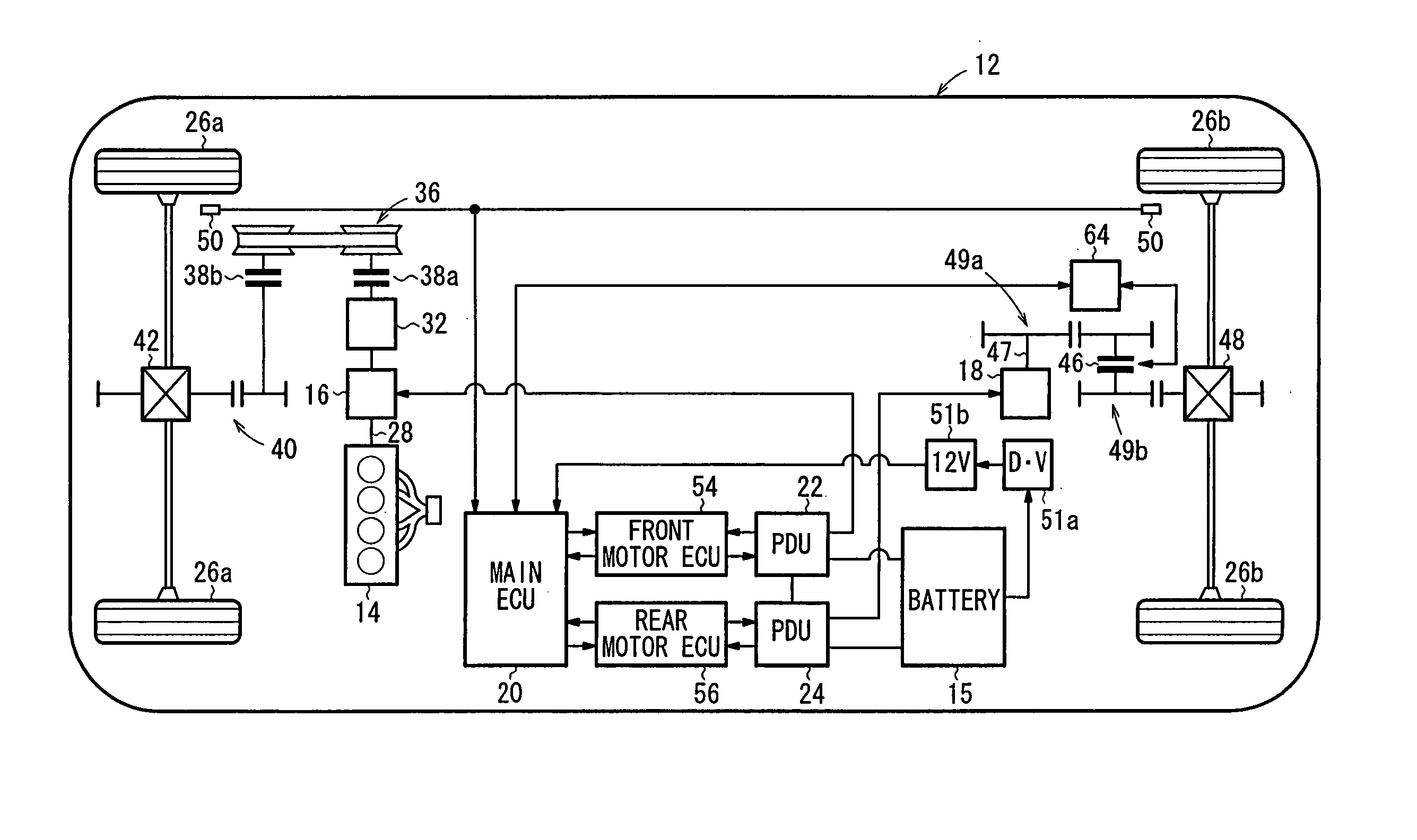

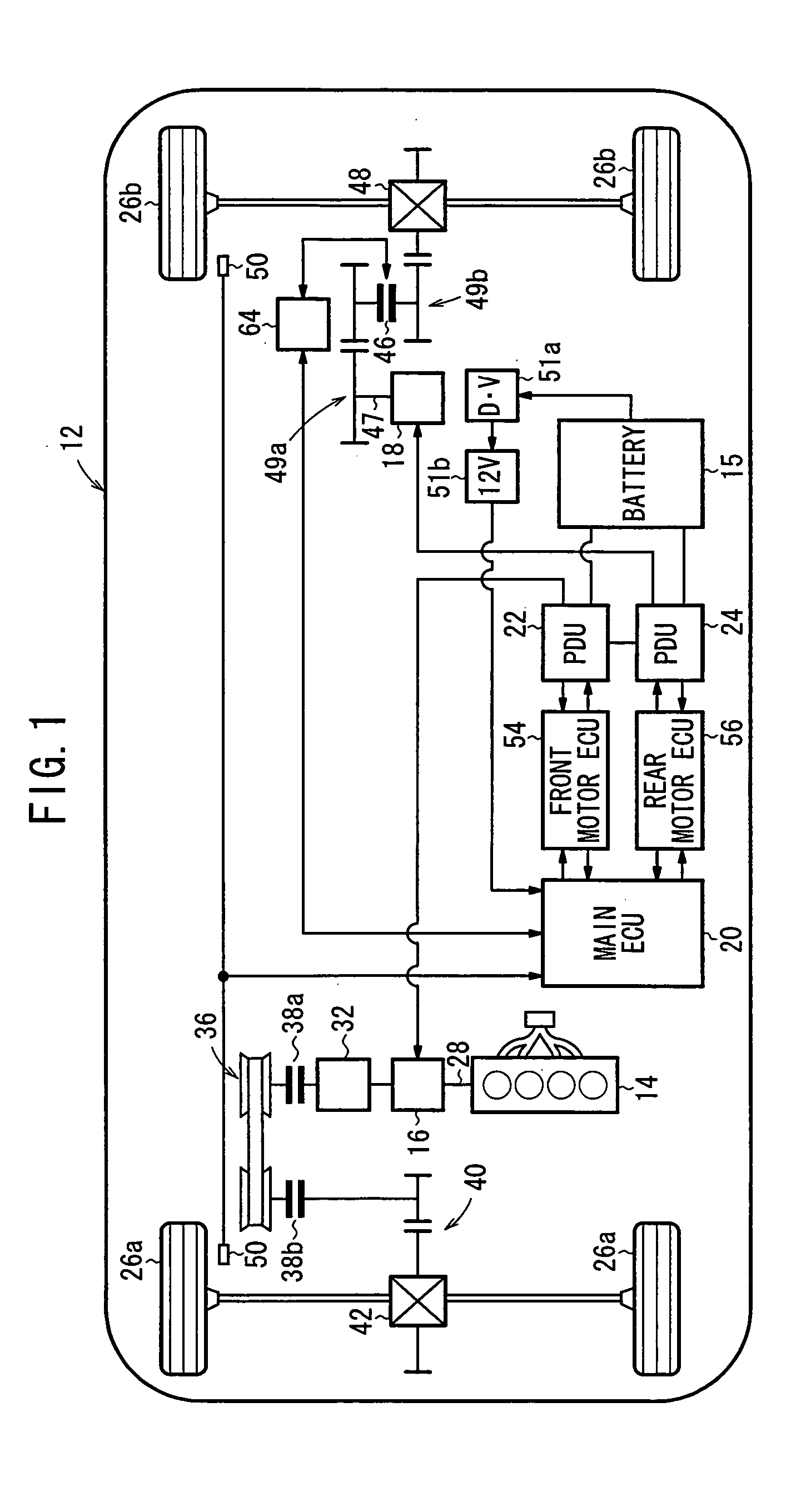

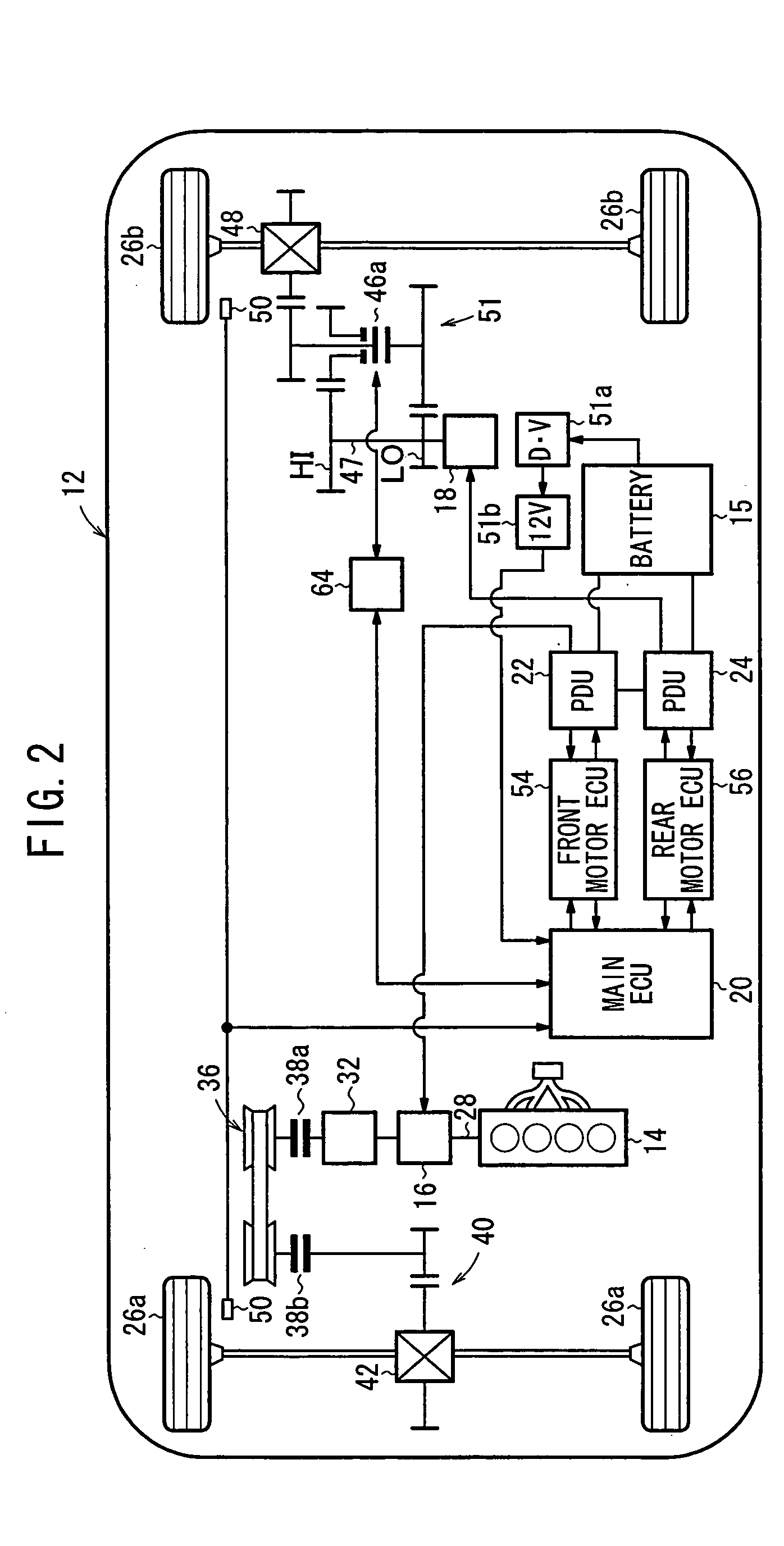

Drive control apparatus for hybrid vehicle

ActiveUS7040433B2Increase rangeReduce fuel consumptionElectrical controlRoad transportMotor driveElectric vehicle

A rotational shaft receives drive power from an engine and a first motor, and drives front wheels through front clutches. A second motor drives rear wheels. The first motor and the second motor are supplied with electric power from a battery. A main ECU controls an electric vehicle mode in which the first clutches are disengaged, the supply of fuel to the engine is stopped, and the second motor drives the rear wheels to propel a hybrid vehicle, by dividing the electric vehicle mode into a first propulsion mode and a second propulsion mode. In the first propulsion mode, the first motor is de-energized. In the second propulsion mode, a load imposed on the second motor is greater than that of the first propulsion mode, and the first motor is supplied with electric power to rotate the rotational shaft at a predetermined speed.

Owner:HONDA MOTOR CO LTD

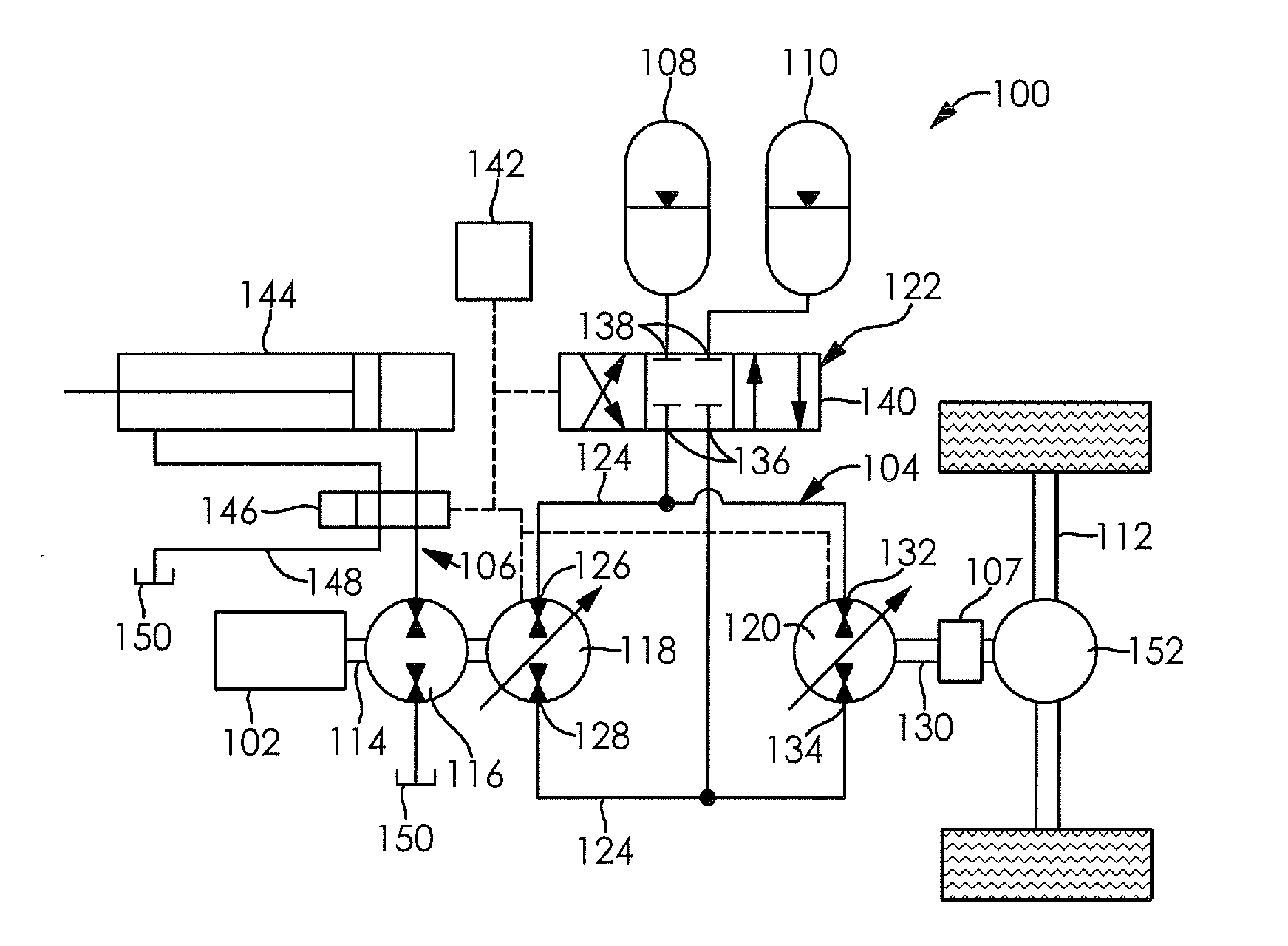

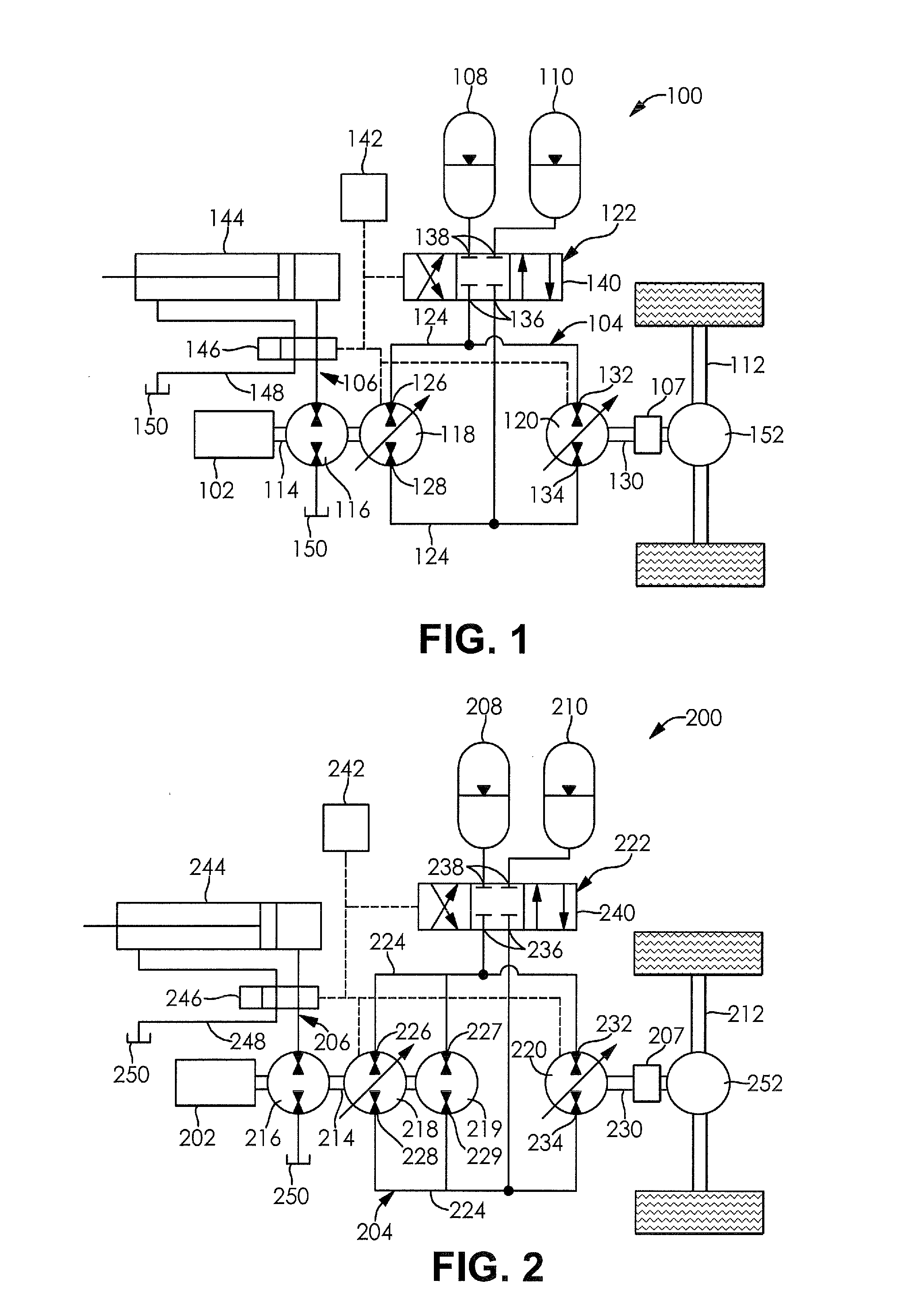

Accumulator assisted hydrostatic driveline and optimization method thereof

InactiveUS20120240564A1Easily procuredEasily servicedRotary clutchesAccumulator installationsState of chargeEngineering

A hydrostatic driveline for a vehicle, a method for minimizing a fuel consumption rate of the vehicle, and a method for tracking an optimal state of charge function for a hydrostatic accumulator are provided. The driveline includes a power source, a drive axle, a first fluid accumulator, a second fluid accumulator, an auxiliary circuit including a first pump drivingly engaged with the power source, and a drive circuit including a second pump drivingly engaged with the power source, a motor drivingly engaged with the drive axle, and a directional valve. The second pump is in fluid communication with the directional valve and the directional valve in fluid communication with the first fluid accumulator and the second fluid accumulator. The directional valve may be selectively controlled to direct fluid from the second pump and the motor to the first fluid accumulator and the second fluid accumulator.

Owner:DANA BELGIUM

Control apparatus for hybrid vehicle

ActiveUS20100075798A1Easy to getImprove fuel economyClutchesInternal combustion piston enginesSeparated stateMode control

A control apparatus of hybrid vehicle having a first clutch which is in a disengaged state by being supplied with hydraulic fluid and a second clutch which is in an engaged state by being supplied with the hydraulic fluid, has a line pressure controller controlling a line pressure of the hydraulic fluid, and a drive mode controller changing a drive mode between HEV mode in which the first clutch is engaged and the vehicle travels with the engine and the motor / generator being a power source and EV mode in which the first clutch is disengaged and the vehicle travels with only the motor / generator being the power source. The line pressure controller sets the line pressure in HEV mode to a pressure level required for the engagement of the second clutch, and sets the line pressure in EV mode to a higher line pressure than the line pressure in HEV mode.

Owner:JATCO LTD +1

Hybrid vehicle control device

ActiveUS20110021312A1Maintain efficiencyReduce speedElectrical controlInternal combustion piston enginesDrive wheelEngineering

A hybrid vehicle control device is provided with an engine stop control section and a fuel injection control section. The engine stop control section is configured to issue an engine speed reduction command to reduce an engine speed of an engine during an engine stopping operation occurring in response to establishment of an engine stop condition by using an electric motor and slip engaging a drive-wheel side clutch disposed between the electric motor and a drive wheel such that the drive-wheel side clutch transmits rotational torque between the electric motor and the drive wheel. The fuel injection control section is configured to issue a fuel injection command to continue fuel injection during the engine stopping operation until the engine speed decreases below a prescribed engine speed whereupon the fuel injection is stopped.

Owner:NISSAN MOTOR CO LTD

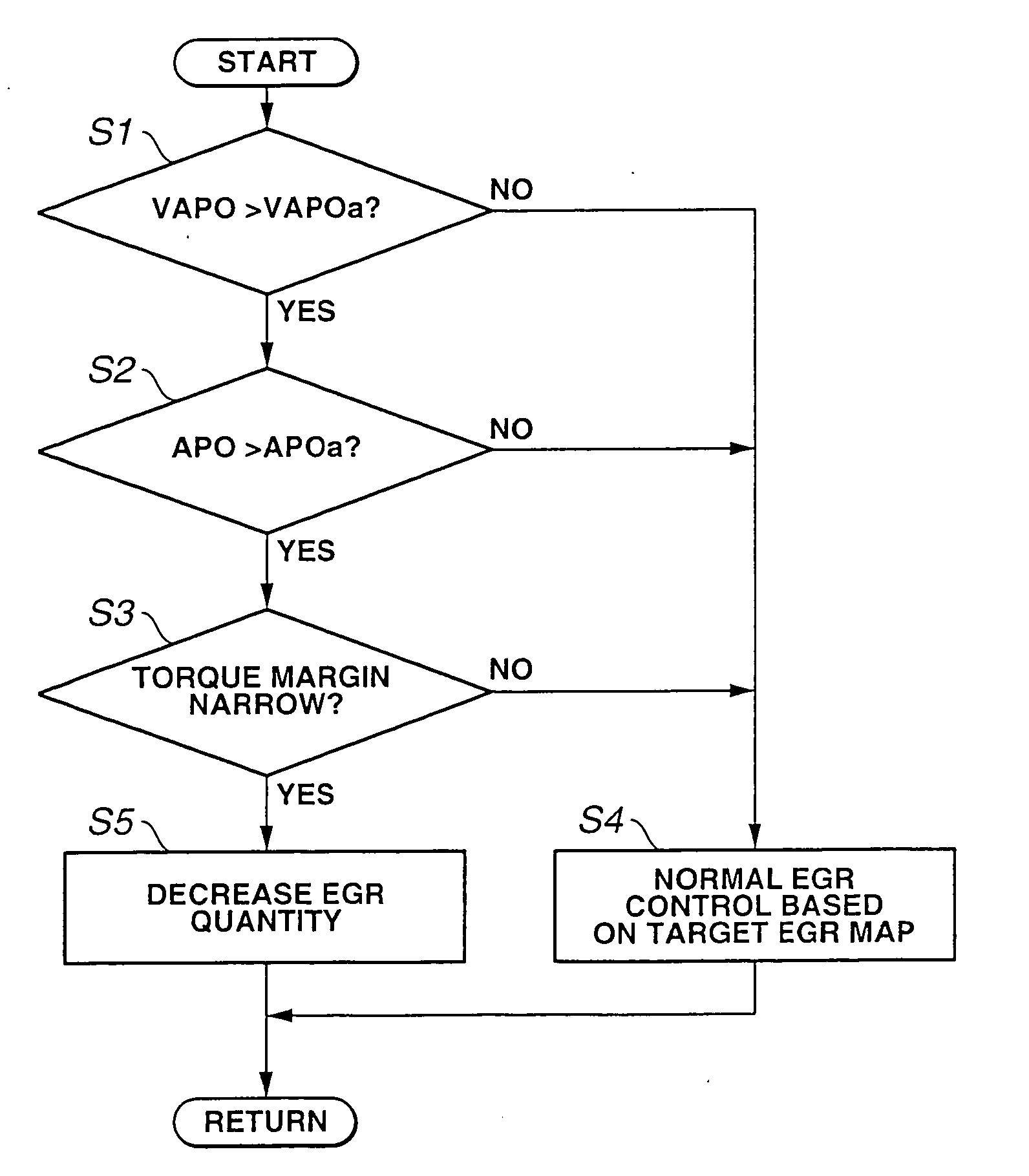

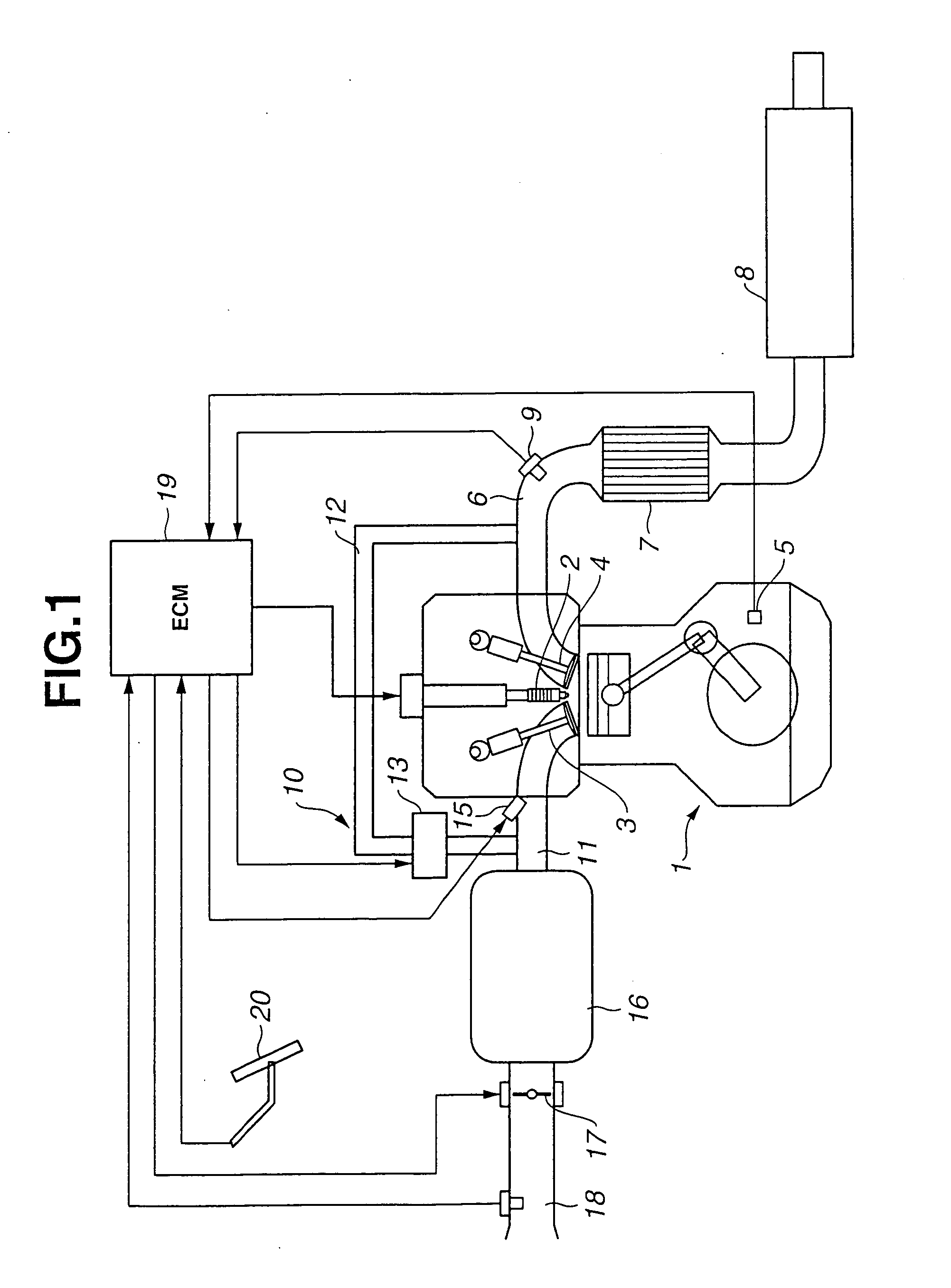

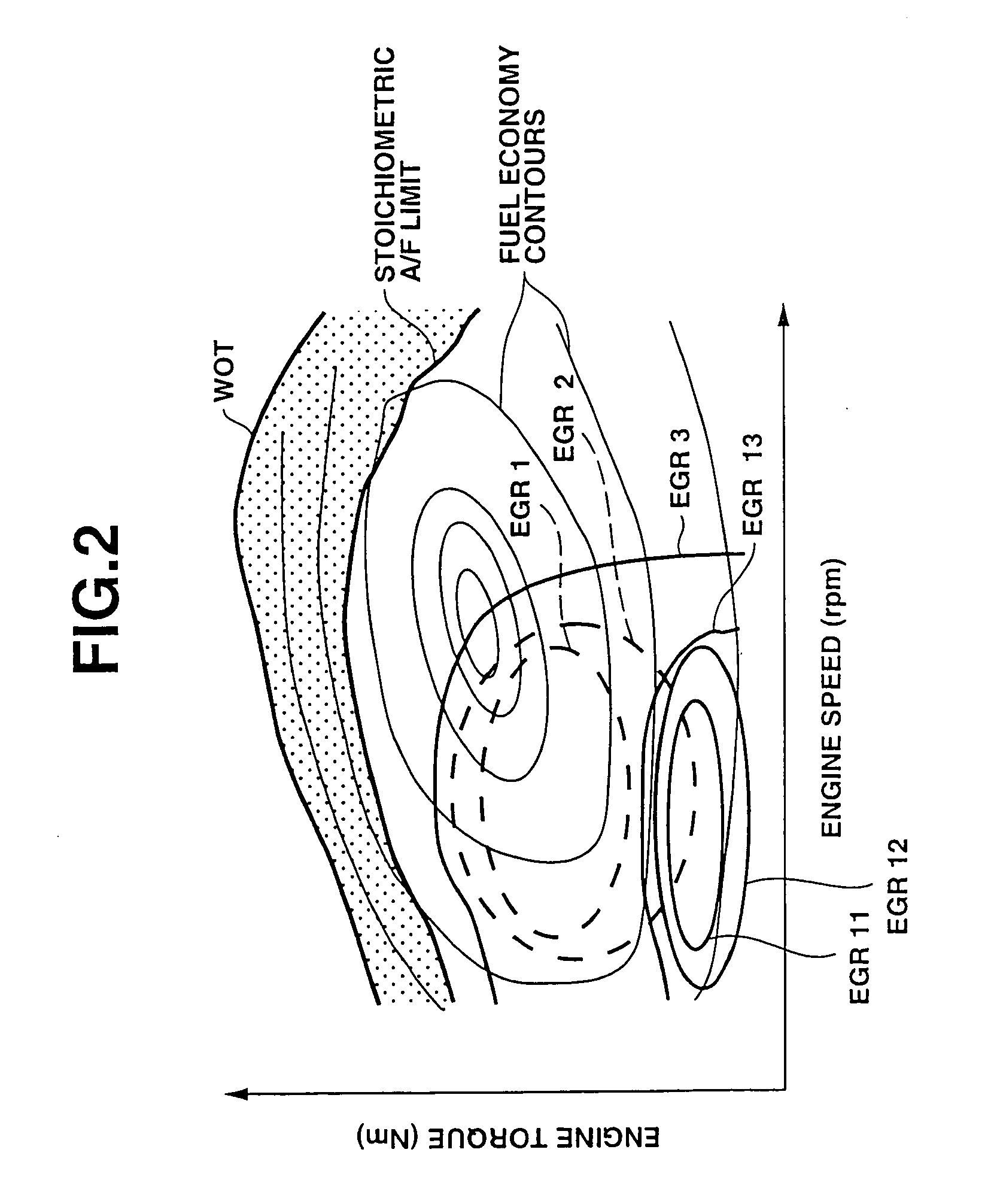

Control apparatus and process for internal combustion engine

ActiveUS20050171670A1Reduce impactIncrease fuel consumptionElectrical controlInternal combustion piston enginesExhaust gas recirculationAcceleration Unit

A control apparatus for an internal combustion engine with an exhaust recirculation system includes an acceleration request sensing section to sense a driver's acceleration request; and an engine operating condition sensing section to sense a current engine operation condition at the time of detection of the driver's acceleration request, to determine a margin from the engine operating condition at the time of detection of the driver's acceleration request, to a fuel economy deterioration region on a higher load side. A controlling section controls the EGR quantity, such as EGR rate, of the exhaust recirculation system in accordance with the margin.

Owner:NISSAN MOTOR CO LTD

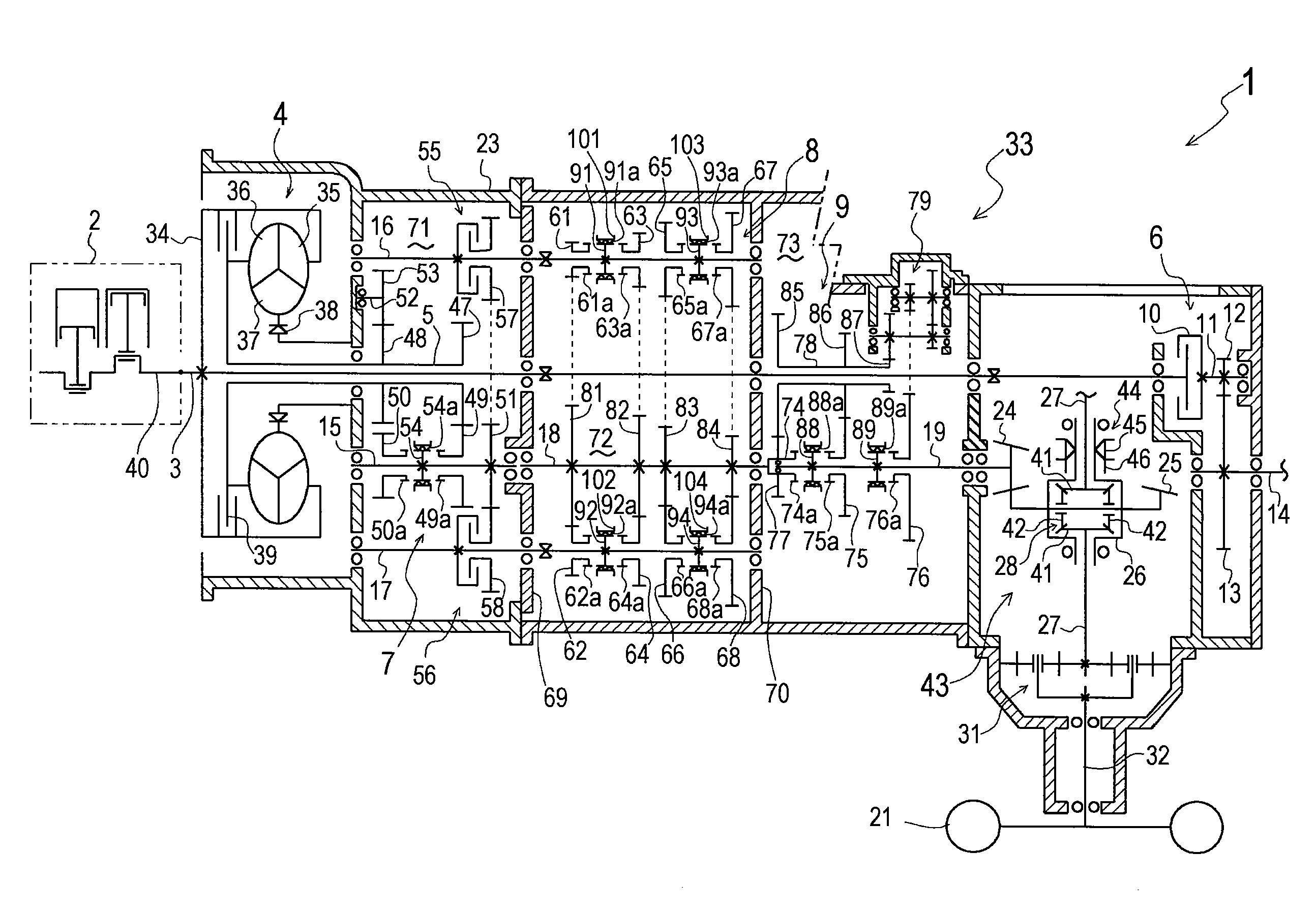

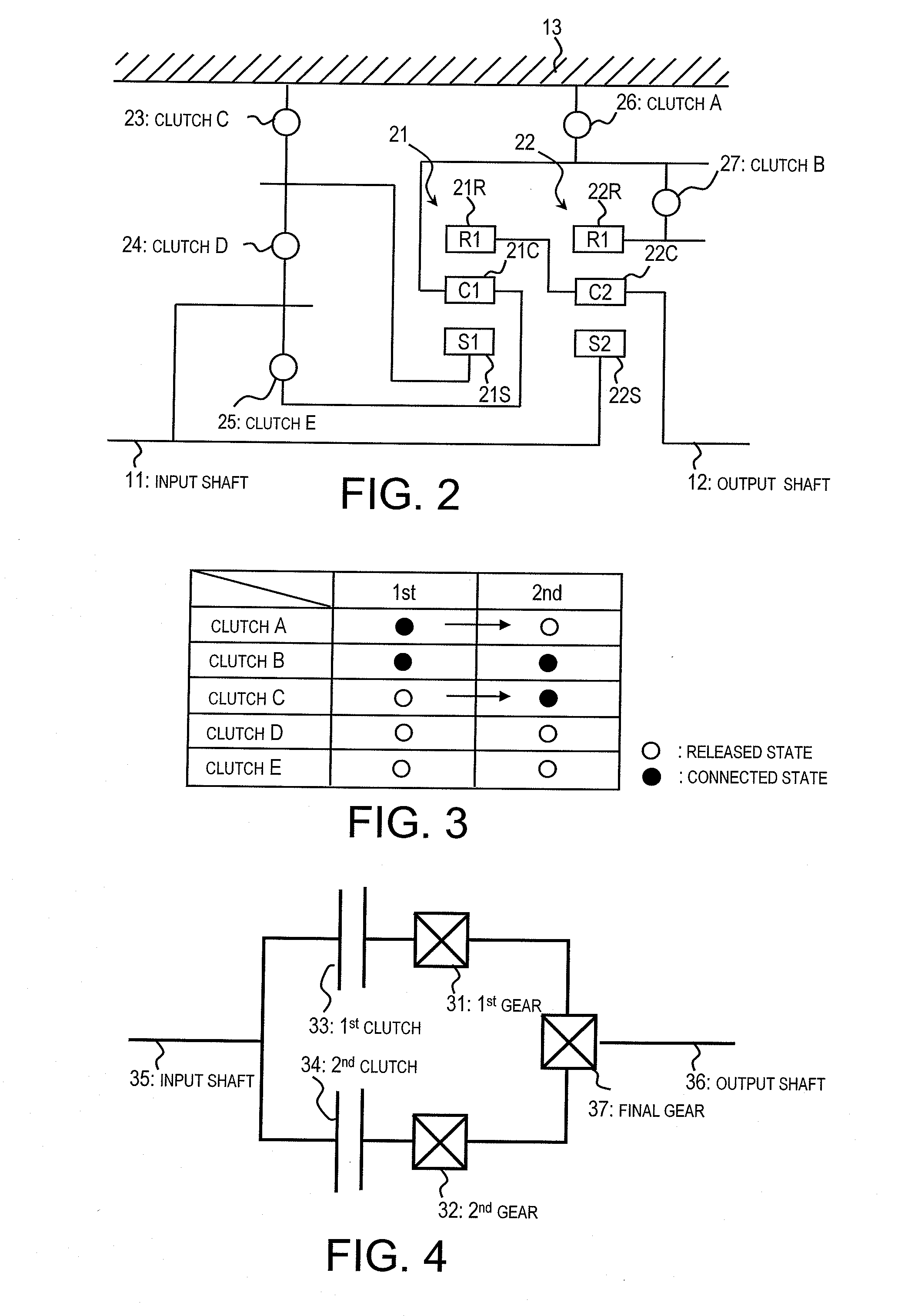

Working Vehicle Transmission System

InactiveUS20080214348A1Efficiency in workabilityEfficient power transmissionRoad transportToothed gearingsTransmitted powerEngineering

A working vehicle transmission system comprises a PTO device for driving an external working device by power of a prime mover, and a multistage transmission for transmitting power from the prime mover to an axle. The multistage transmission includes a main speed-change mechanism and a sub speed-change mechanism. The main speed-change mechanism has plural drive trains for setting respective different speed stages. The sub speed-change mechanism is disposed downstream of the main speed-change mechanism and has plural drive trains for setting respective different speed stages. The main speed-change mechanism includes a first clutch and a second clutch. The main speed-change mechanism drive trains used for setting odd-numbered speed stages are activated by engaging the first clutch. On the other hand, the main speed-change mechanism drive trains used for setting even-numbered speed stages are activated by engaging the second clutch. During a speed-change operation of the main speed-change mechanism, an engagement action of one of the first and second clutches and a disengagement action of the other of the first and second clutches overlap each other. A reverser is disposed upstream of the first and second clutches of the main speed-change mechanism so as to enable switching the direction of output rotation transmitted to the first and second clutches from one direction to the opposite direction.

Owner:KANZAKI KOKYUKOKI MFG

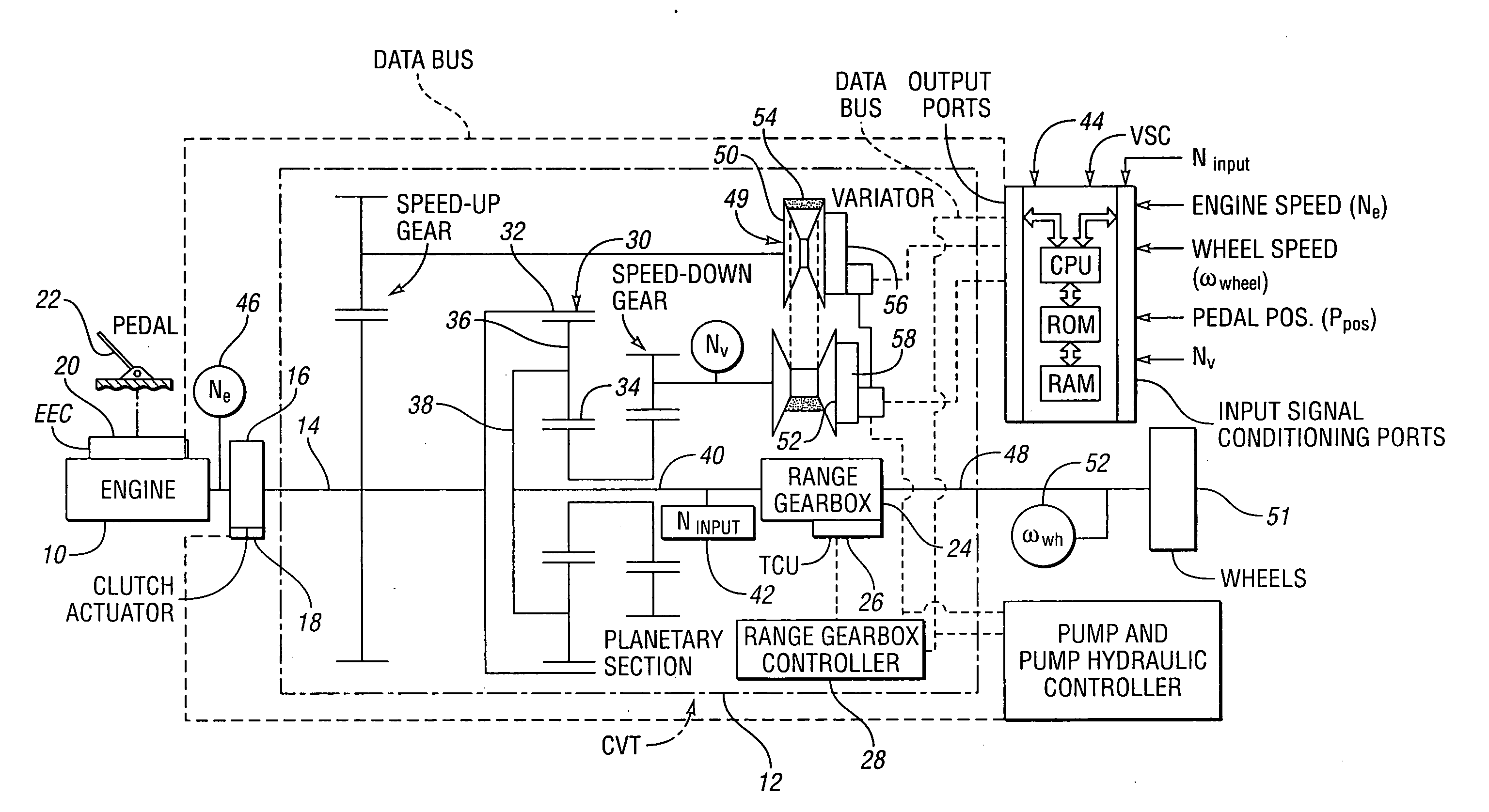

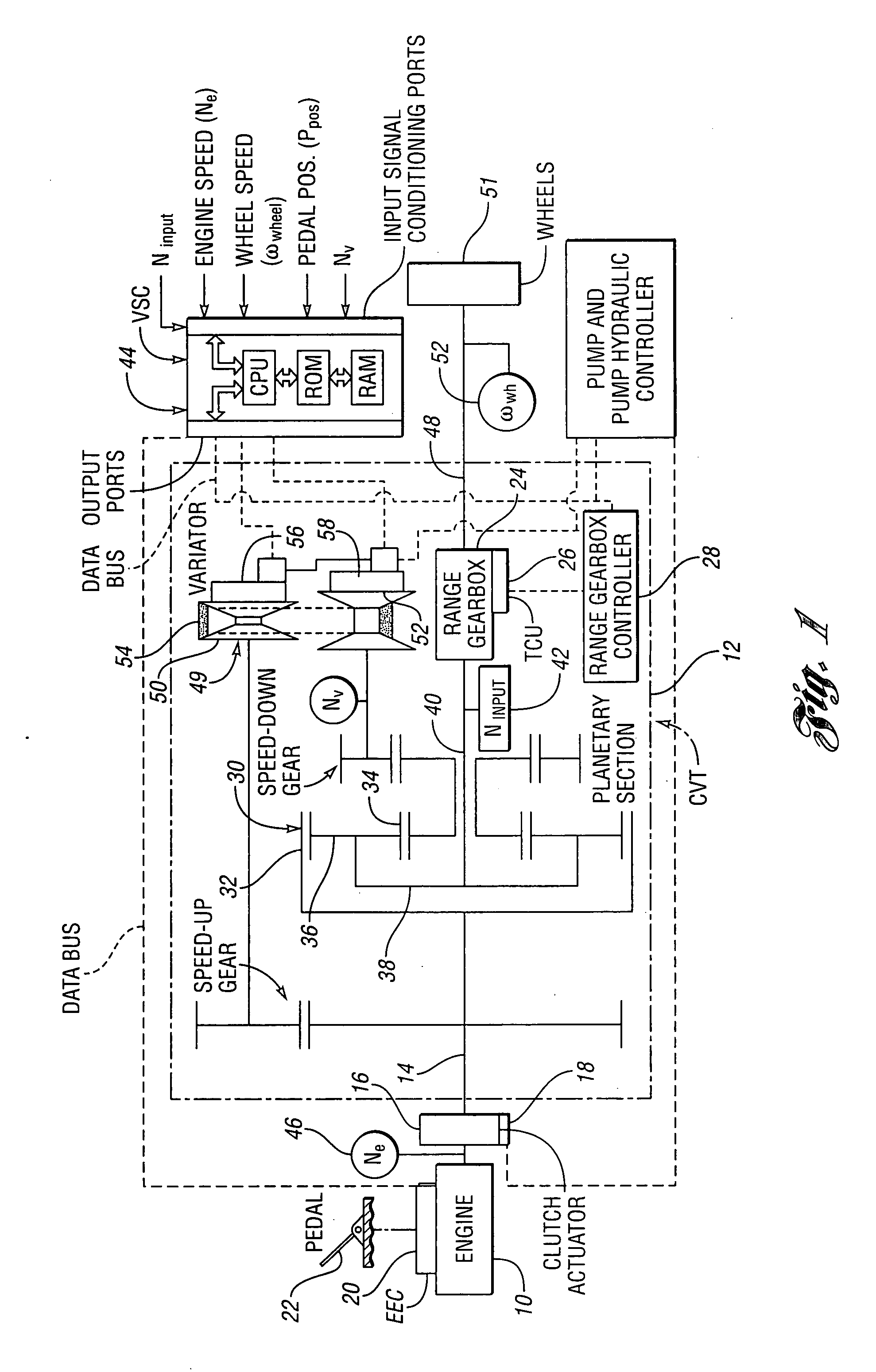

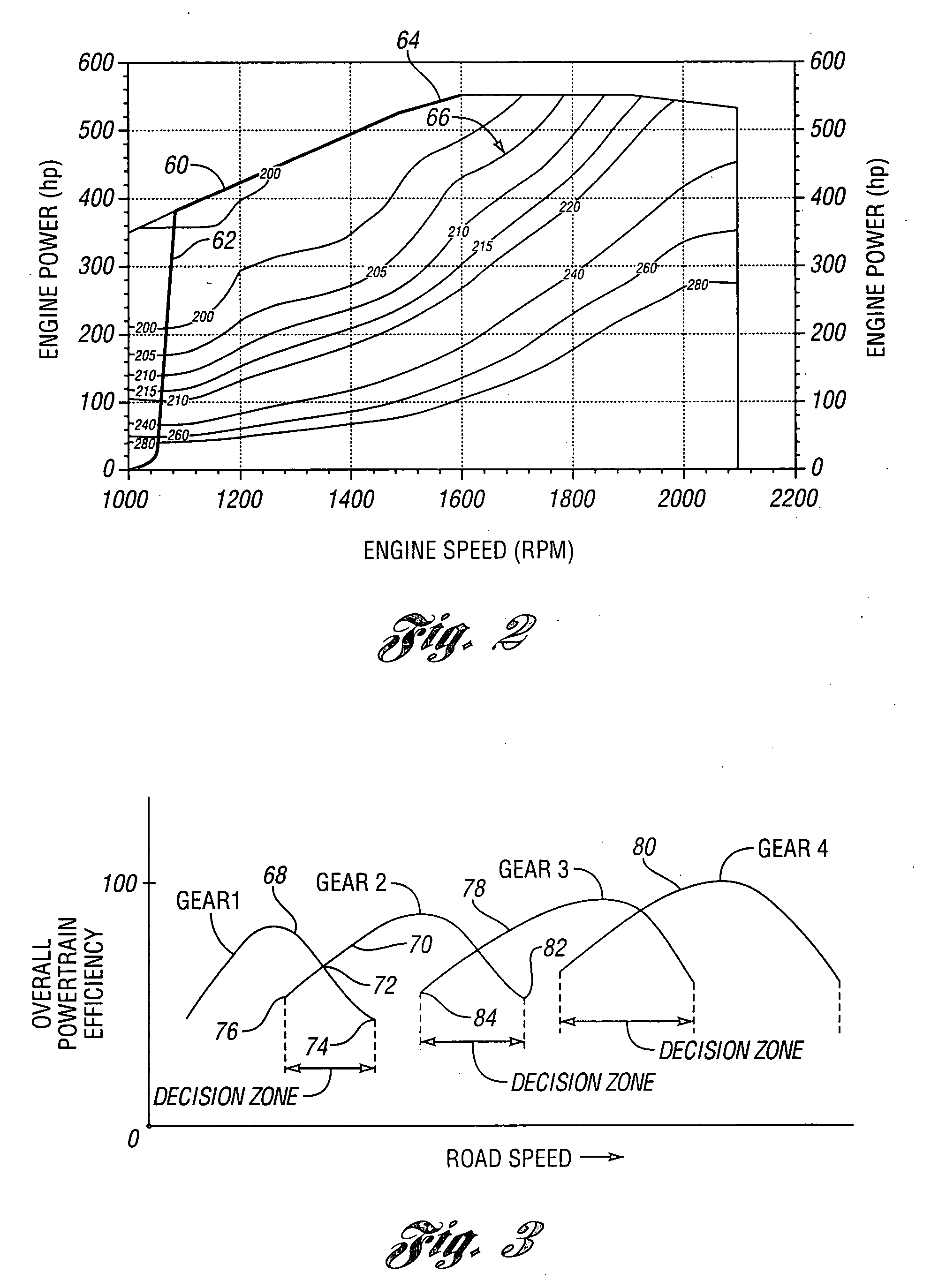

Method for controlling a vehicle powertrain having step ratio gearing and a continuously variable transmission to achieve optimum engine fuel economy

InactiveUS20090105041A1Ignores effectGuaranteed normal transmissionGearingRoad transportPowertrainMotor fuel

A method is disclosed for controlling overall transmission ratios in a vehicle powertrain with an engine, fixed multiple-ratio gearing and infinitely variable ratio components. For a given vehicle speed and for a given vehicle traction wheel horsepower, the fixed multiple-ratio gearing and the infinitely variable ratio components are controlled to operate with an overall ratio that will permit the engine to operate with optimum efficiency.

Owner:EATON INTELLIGENT POWER LIMITED

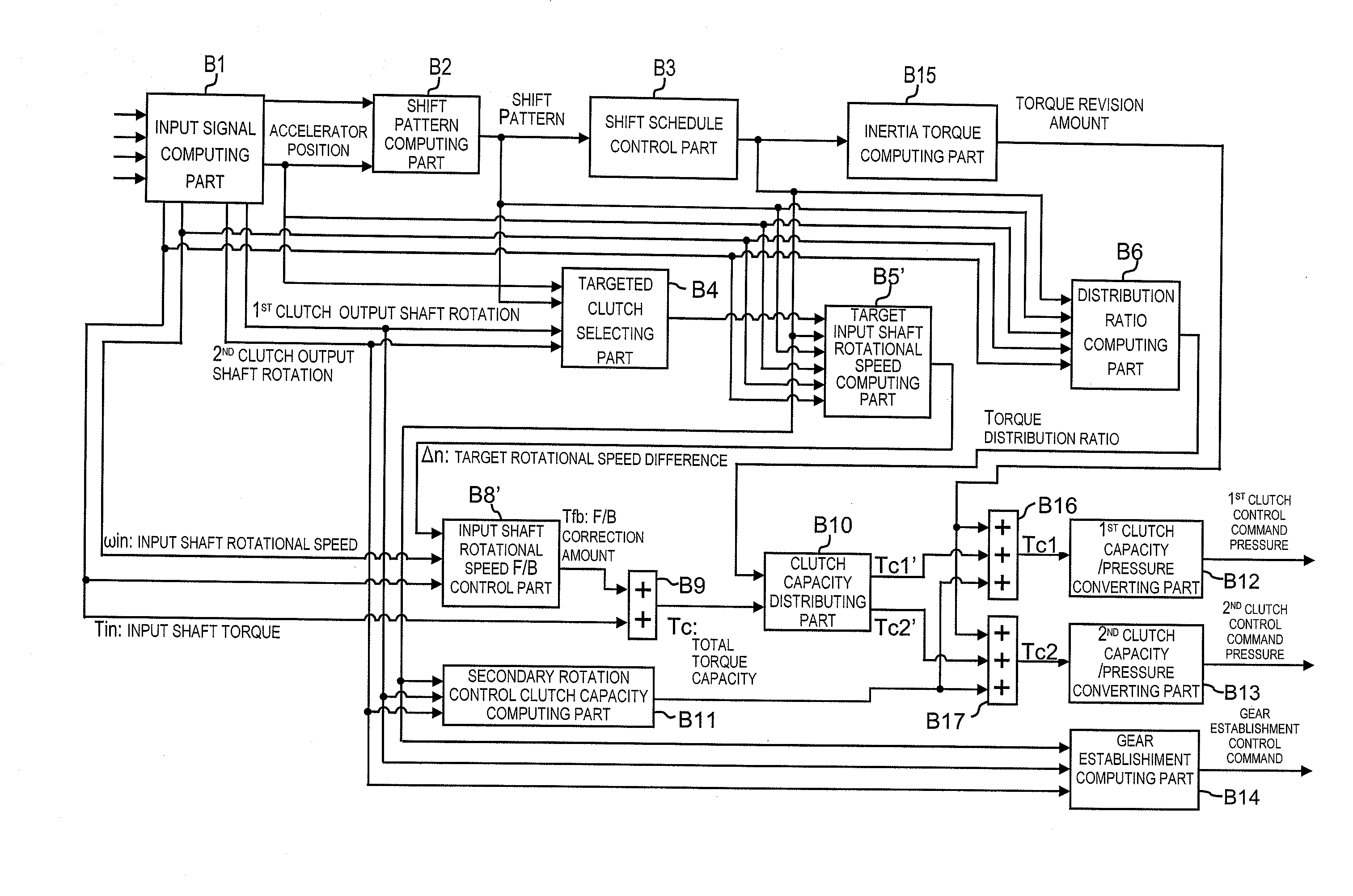

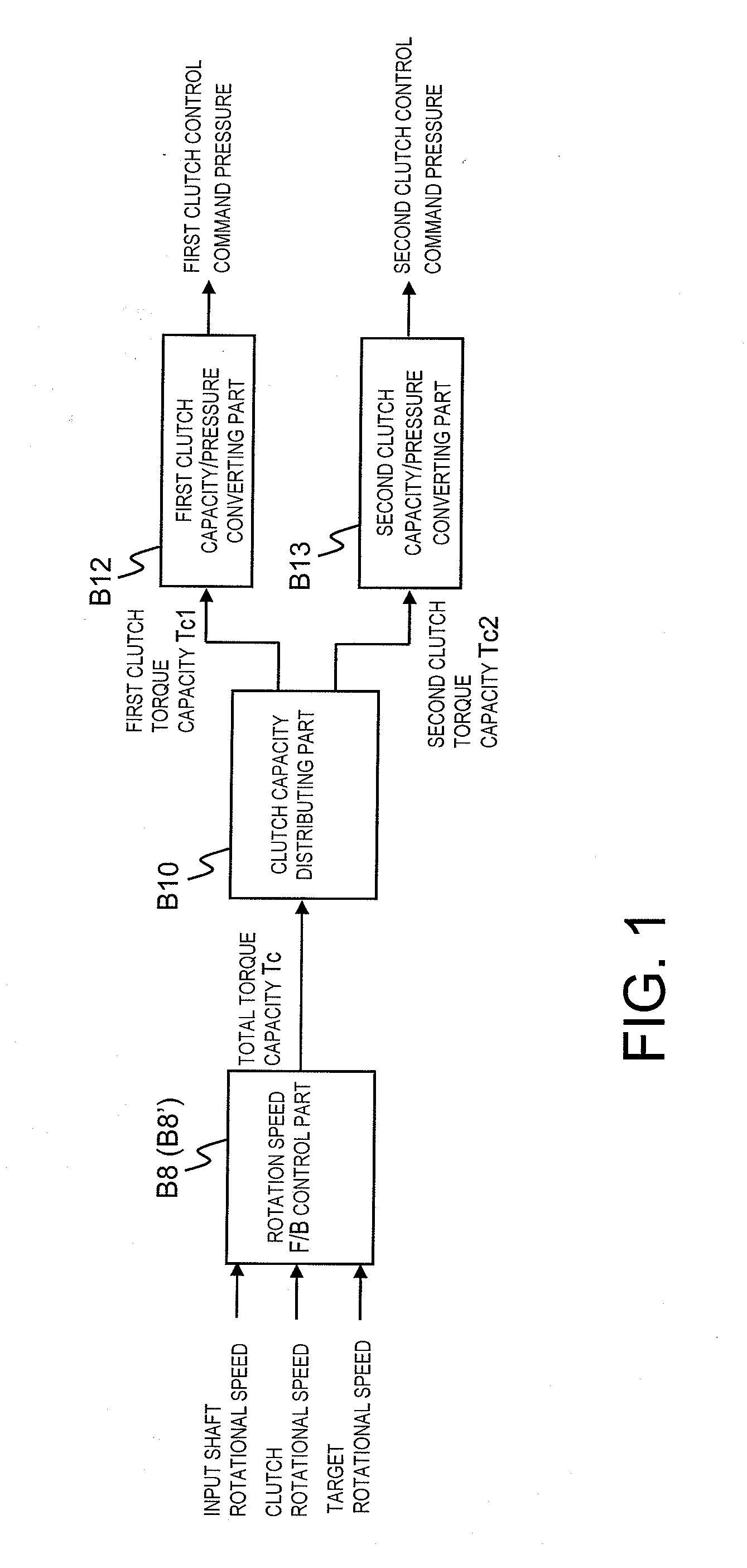

Automatic transmission control apparatus

InactiveUS20080096721A1Shock is smallEfficient use ofDigital data processing detailsRoad transportAutomatic transmissionControl theory

An automatic transmission control apparatus is provided with a control scheme that focuses on the rotational speed differences of the frictional engaging elements and the distribution of torque transferred by the frictional engaging elements. When the automatic transmission is upshifted while in a power-off state, the individual torque capacity of a frictional engaging element being released and the individual torque capacity of a frictional engaging element being connected are corrected by adding a prescribed torque capacity amount to each of the individual torque capacities during an inertia phase of the shift control in which a compensation is executed for inertia related to changing the gear ratio. In this way, frictional losses are induced in the frictional engaging elements so as to absorb the inertia torque and lower the input rotational speed more quickly.

Owner:JATCO LTD

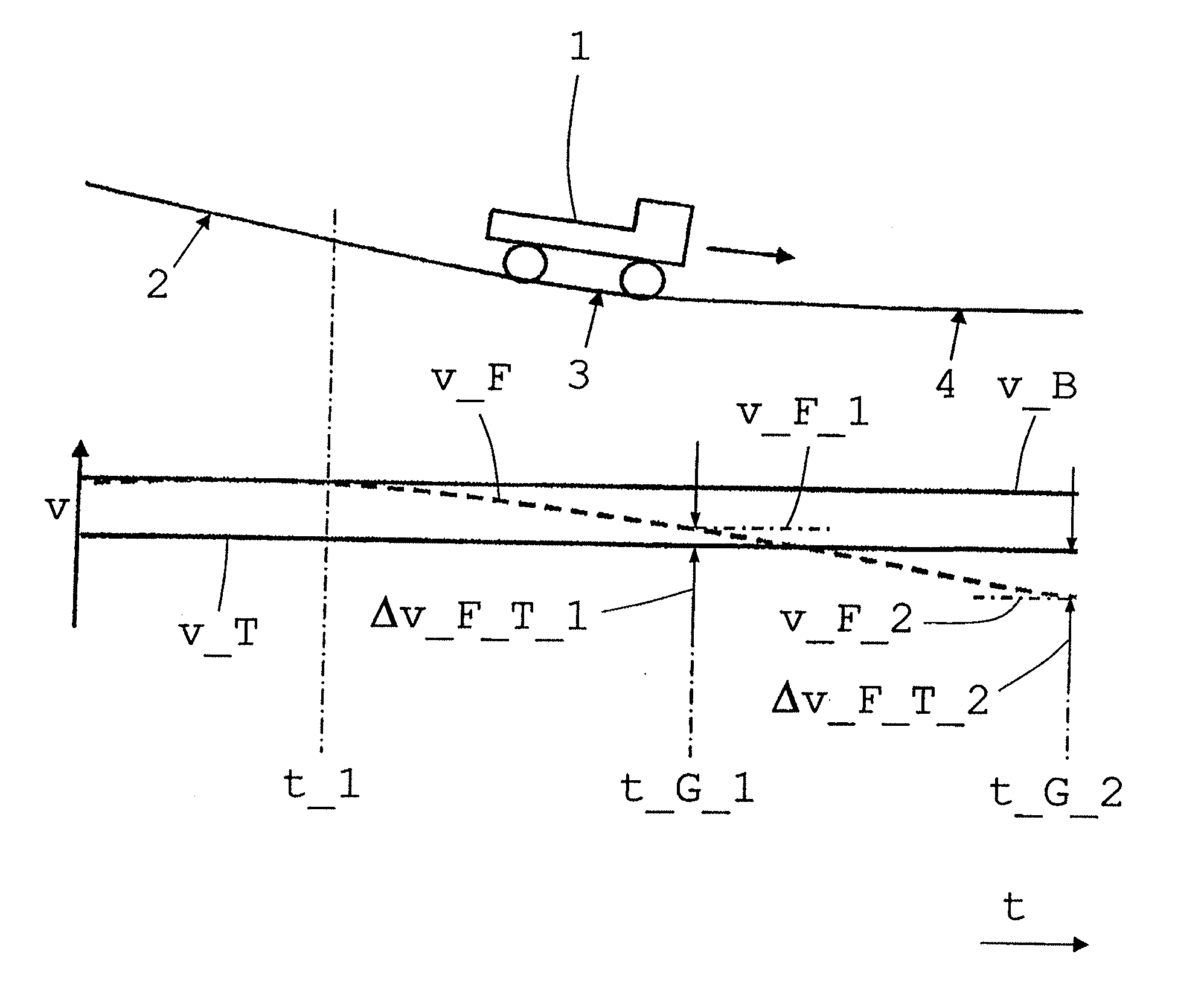

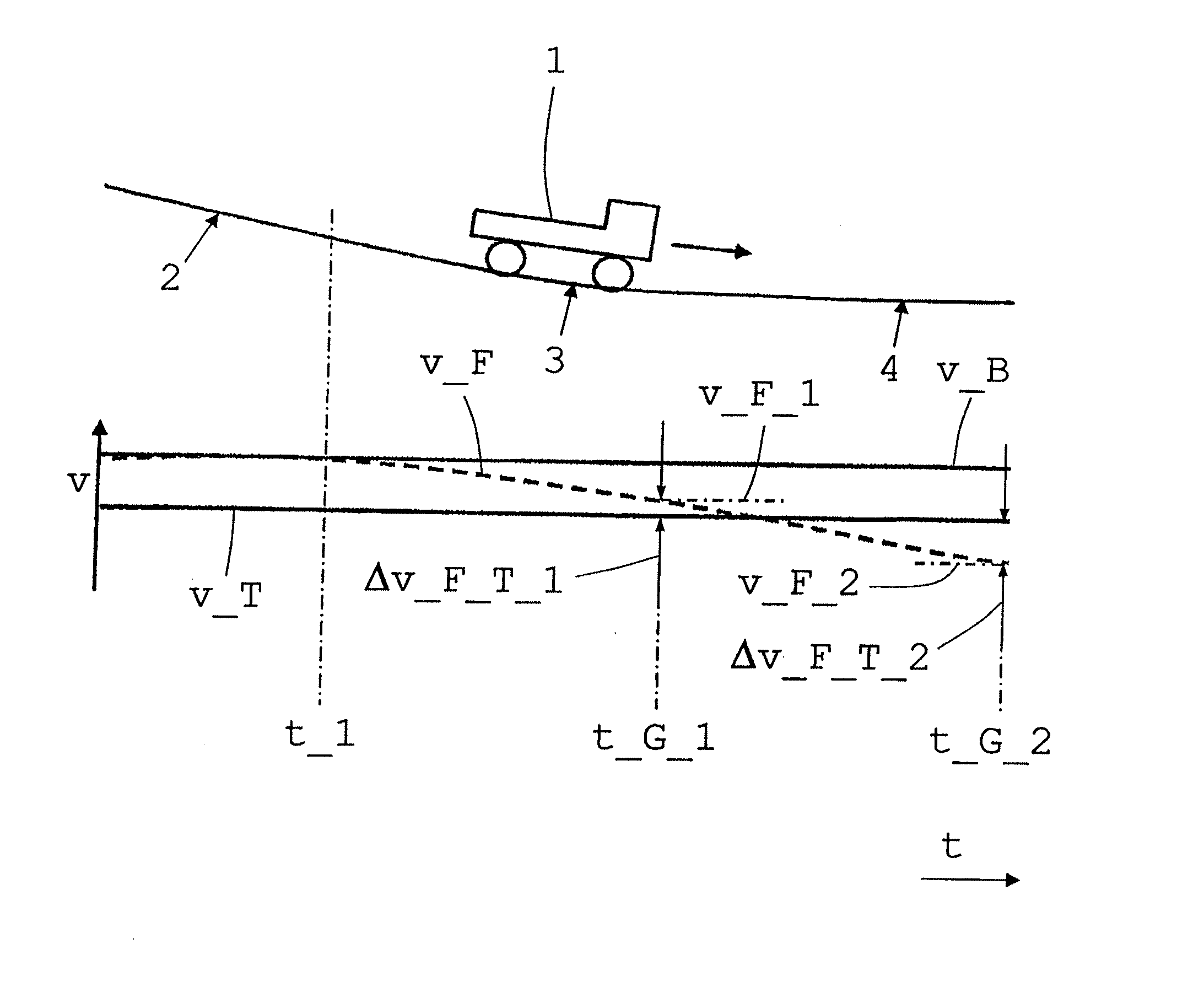

Method for controlling a rolling or coasting function of a vehicle

InactiveUS20120220424A1Save fuelEffective and comfortable drivingRoad transportEngine controllersAutomatic transmissionDrive motor

A method of controlling a rolling or a coasting function of a vehicle, such as a commercial vehicle, having a drive train including a drive motor, an automatic or automated transmission that is controllable by transmission controls, a controllable shifting mechanism for interrupting the flow of power in the drive train, and a driving speed control device. The flow of power in the drive train is interrupted in a suitable driving situation. In order for the rolling or the coasting function to be exploited as efficiently as possible, and still be terminated safely and comfortably, the flow of power in the drive train is restored depending on a selectable difference in speed (Δv_F_T) between the current vehicle speed (v_F) and a speed limit (v_T) set by the driving speed control device.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com