Patents

Literature

10264 results about "Oil pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil pressure is an important factor in the longevity of most internal combustion engines. With a forced lubrication system (invented by Frederick Lanchester), oil is picked up by a positive displacement oil pump and forced through oil galleries (passageways) into bearings, such as the main bearings, big end bearings and camshaft bearings or balance shaft bearings. Other components such as cam lobes and cylinder walls are lubricated by oil jets.

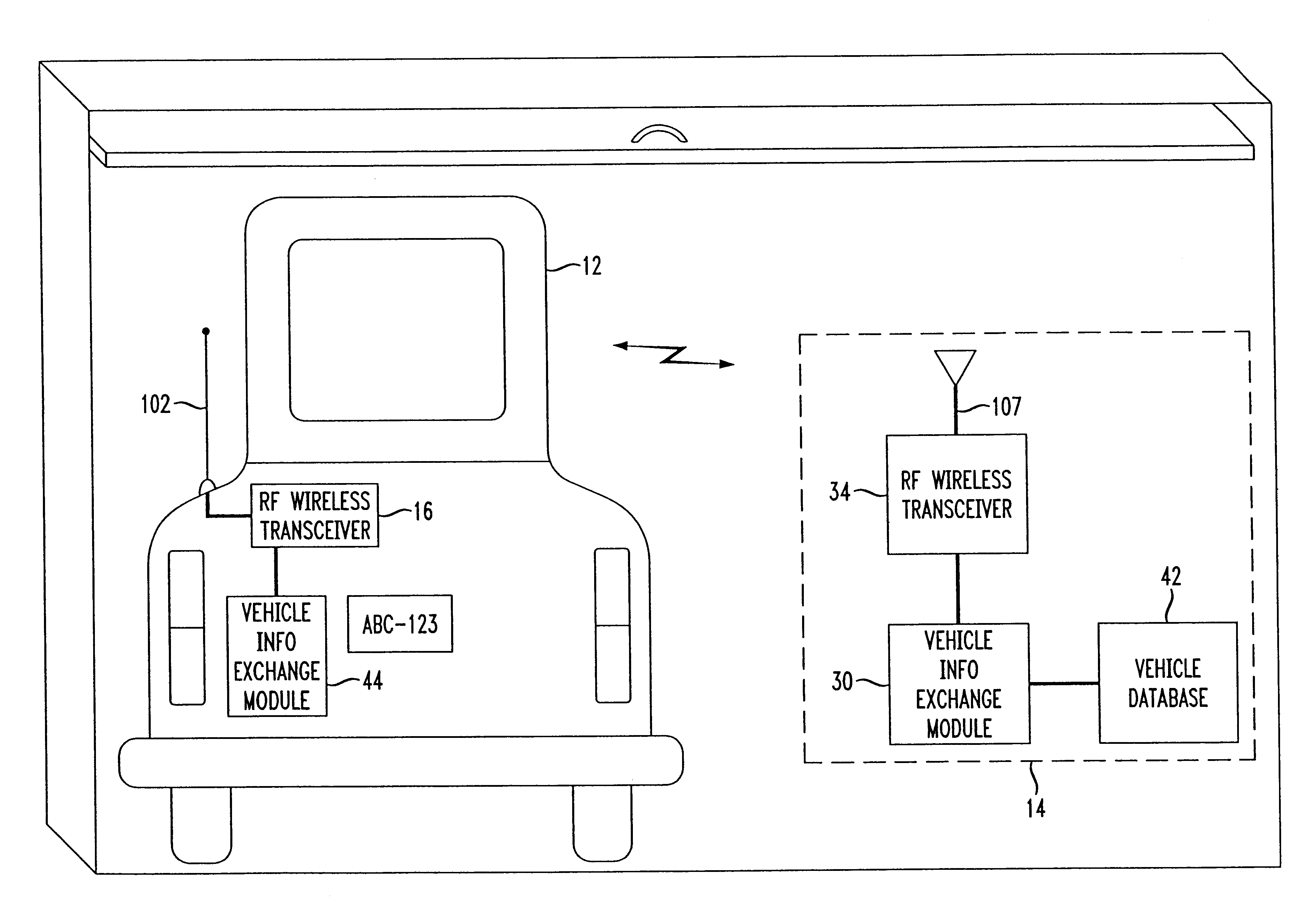

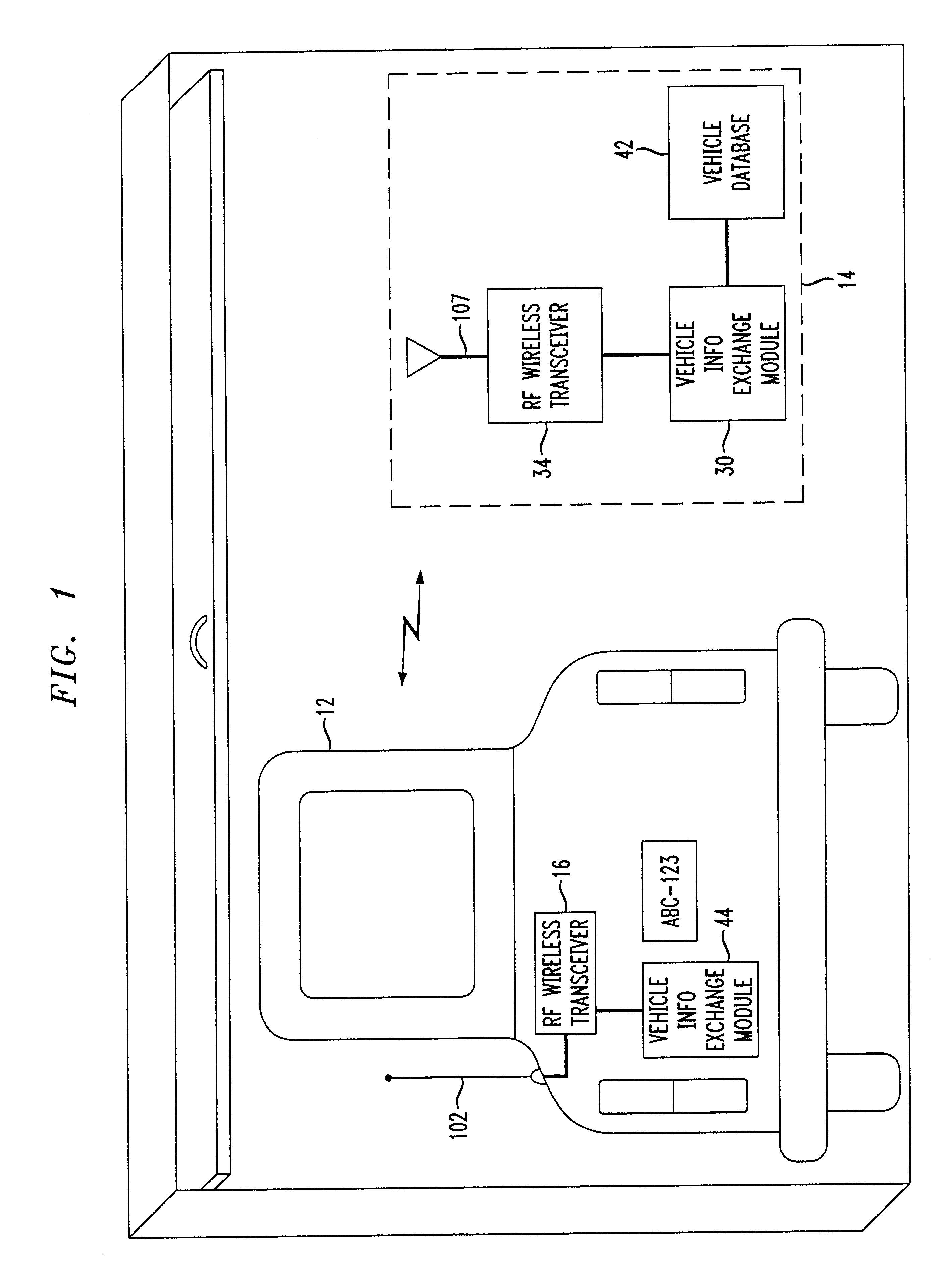

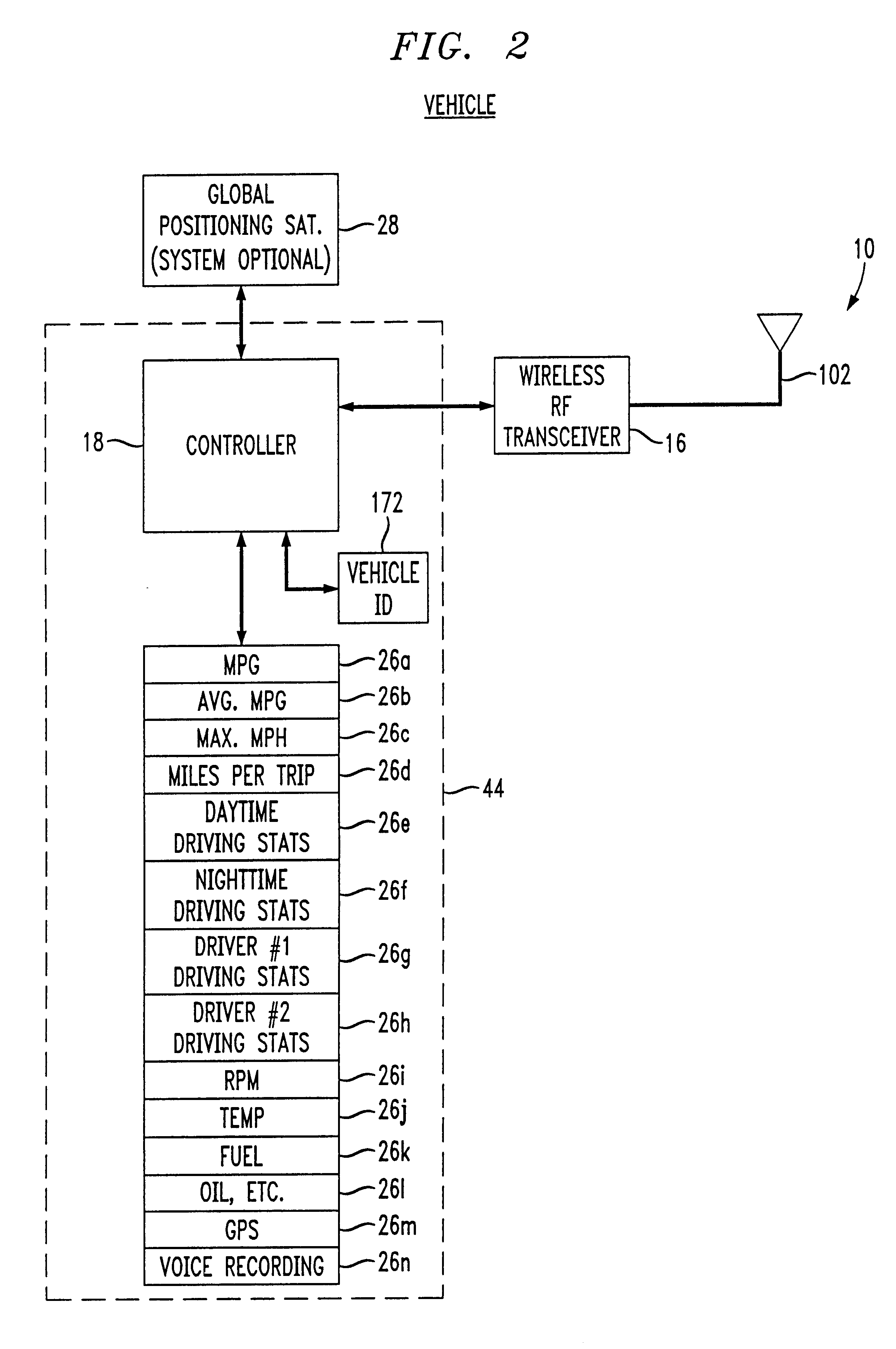

Wireless piconet access to vehicle operational statistics

InactiveUS6408232B1Vehicle testingArrangements for variable traffic instructionsTransceiverDriver/operator

A wireless piconet transceiver is mounted in a vehicle, and a complementary fixed wireless piconet transceiver is mounted in a garage, service station, police squad car, etc., for communication with the vehicle when parked adjacent thereto. The vehicle establishes a temporary piconet network with the user's home piconet. Vehicle operational statistics are tracked and maintained in a centralized vehicle computer database. This database can be manipulated to store the data desired by the vehicle owner. Via a wireless piconet connection, this database can transmitted to another piconet device such as the owner's computer. This computer system can be part of a wireless piconet, such as Bluetooth, This provides the computer with the ability to communicate with external wireless devices such as a cell phone, PDA, computer, or a cordless telephone. This invention allows for the configuration, or selection of desired vehicle data to be tracked. This configuration can take place on the owner's home computer (or laptop) and consequently transmitted to the vehicle computer using a wireless piconet protocol, e.g., the Bluetooth protocol. Additionally, this configuration can be manipulated by a direct interface to the vehicle provided by the manufacturer. Exemplary vehicle statistics which may be tracked include, but are not limited to, miles per gallon, average miles per hour, maximum MPH, miles driven per trip, driving statistics based on time of day and / or on identified driver, rotations of the engine per minute (RPM), temperature of engine, fuel gauge level, oil pressure, tires, brakes, engine coolant, wiper fluid, global positioning satellite (GPS) system, and / or even compressed voice from inside car cockpit during operation of vehicle.

Owner:CARRUM TECH LLC

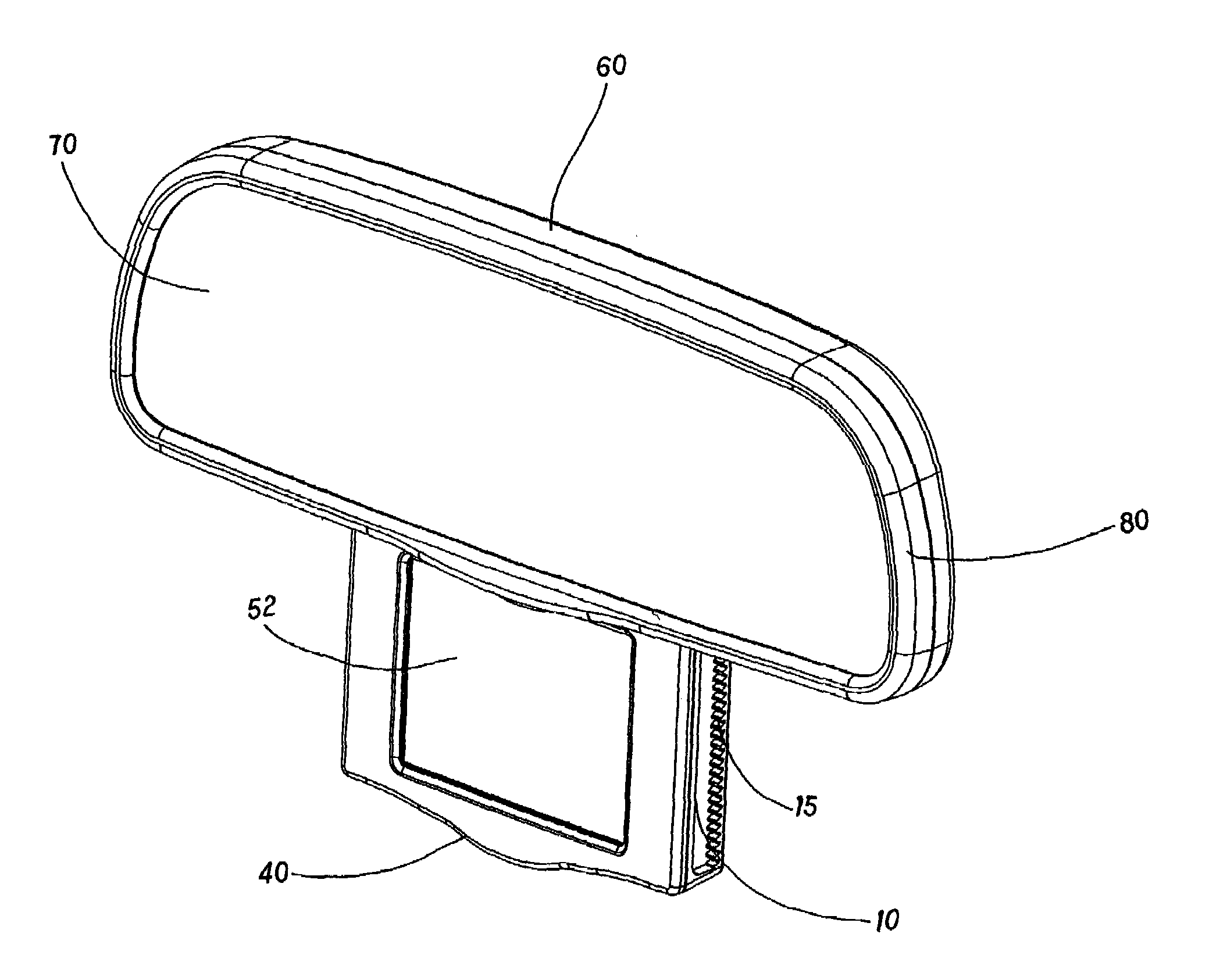

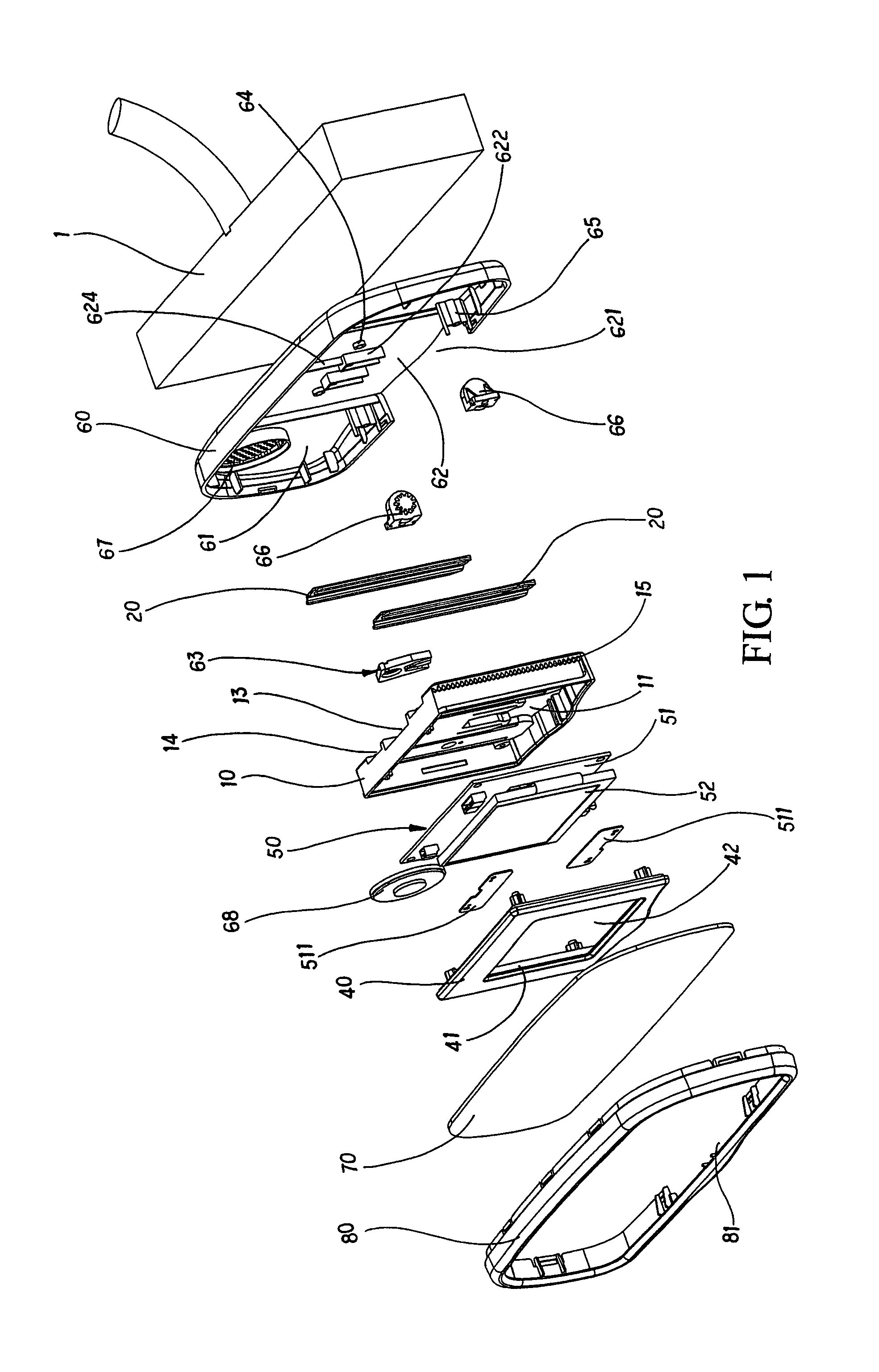

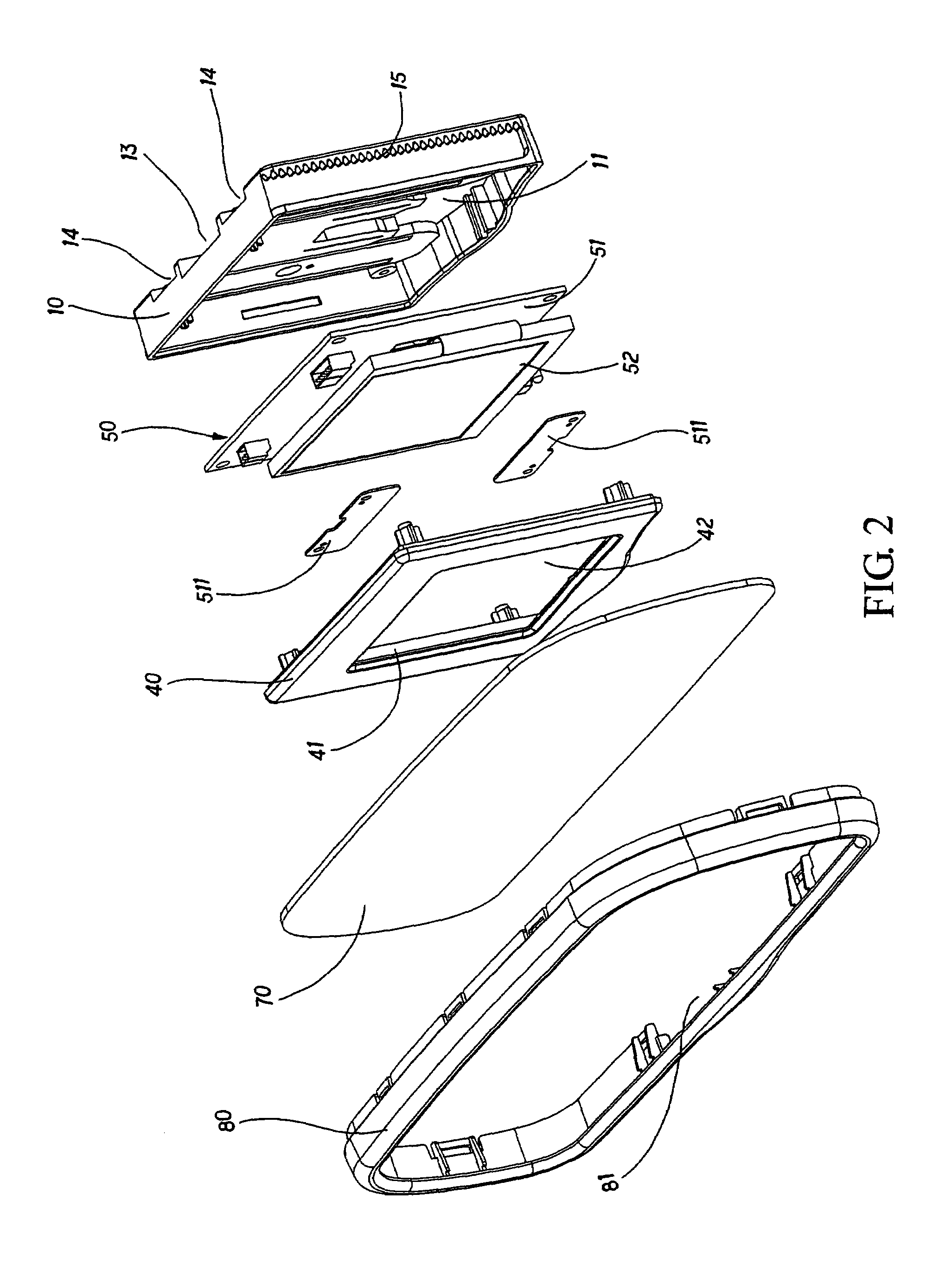

Automobile rearview mirror with LCD display

An automobile rearview mirror with an LCD display comprises a front panel, a mount, a display unit housed between the front panel and the mount, a front frame, a rear shell, and a mirror. The display unit, the front panel, the mount and the mirror are contained between the rear shell and the mirror. The automobile rearview mirror thereby assembled can be installed at the location of a rearview mirror in an automobile. There are two springs disposed between the mount and the rear shell that provide the force needed to pull down the front panel and the display monitor. The slide motion is further assisted by rail sectors, corresponding slide elements, gear sectors and oil-pressure gear wheels. The automobile rearview mirror is further provided with locking pieces and releases for properly retained the position of the display unit.

Owner:LI SHIN NAN

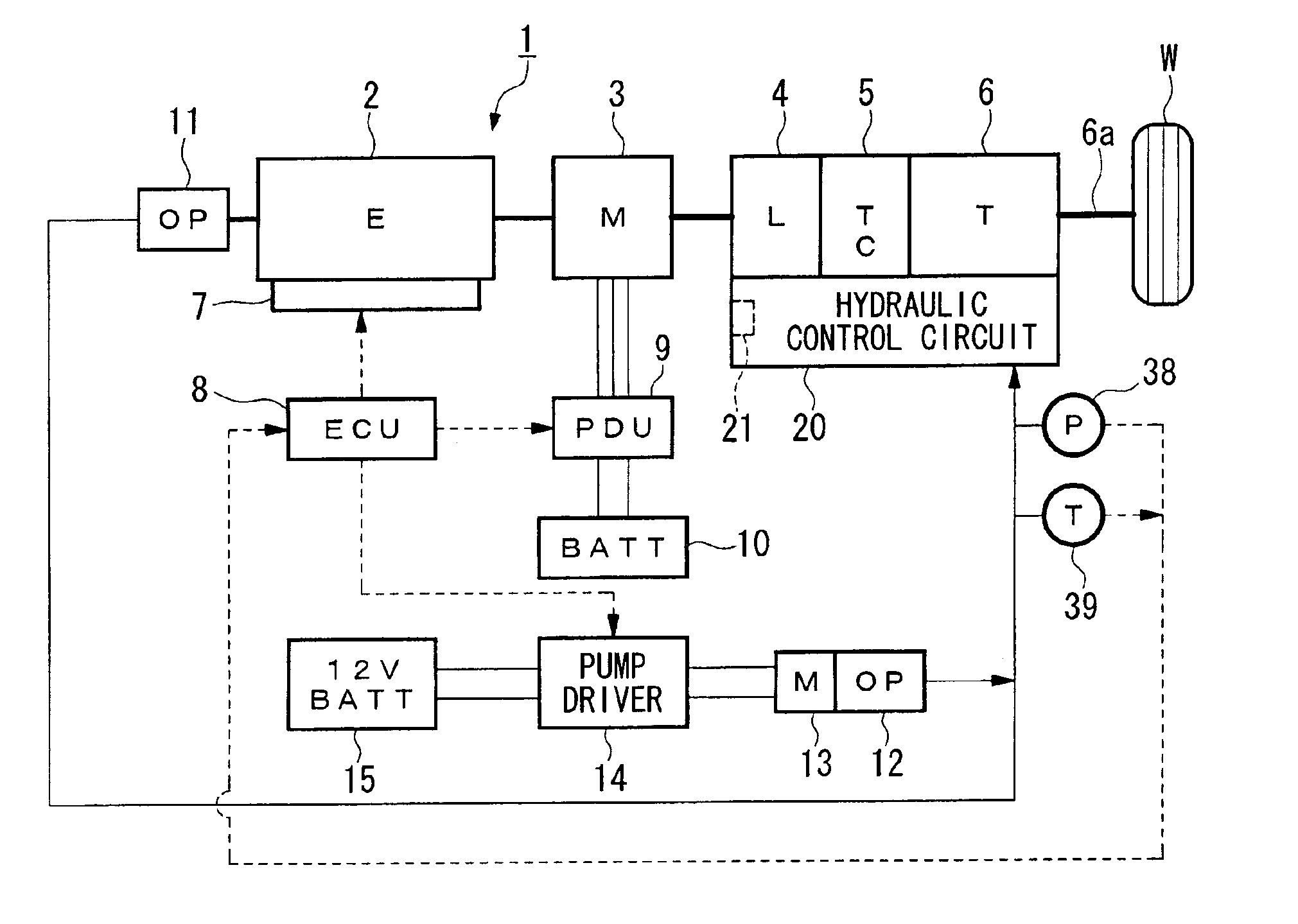

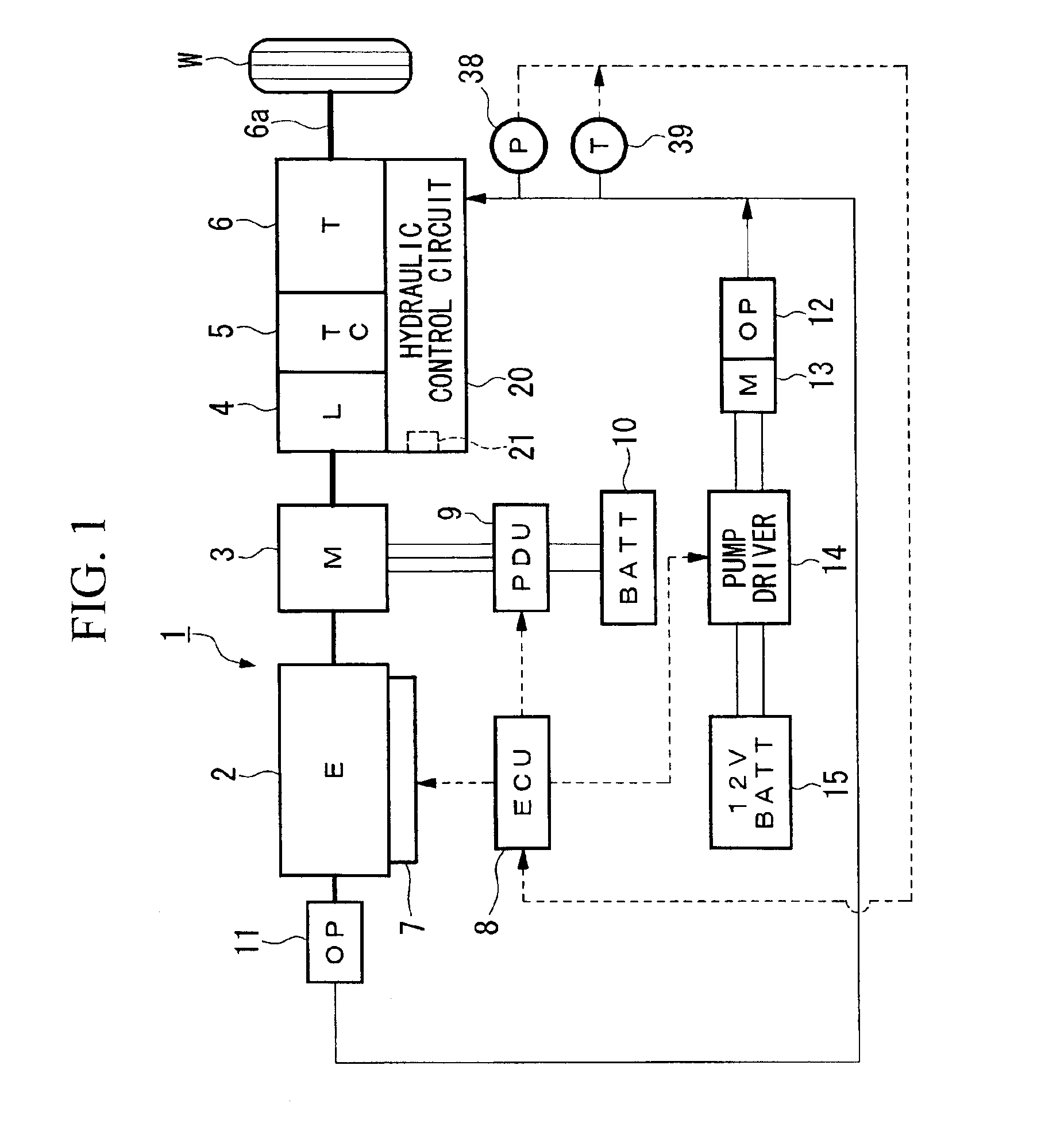

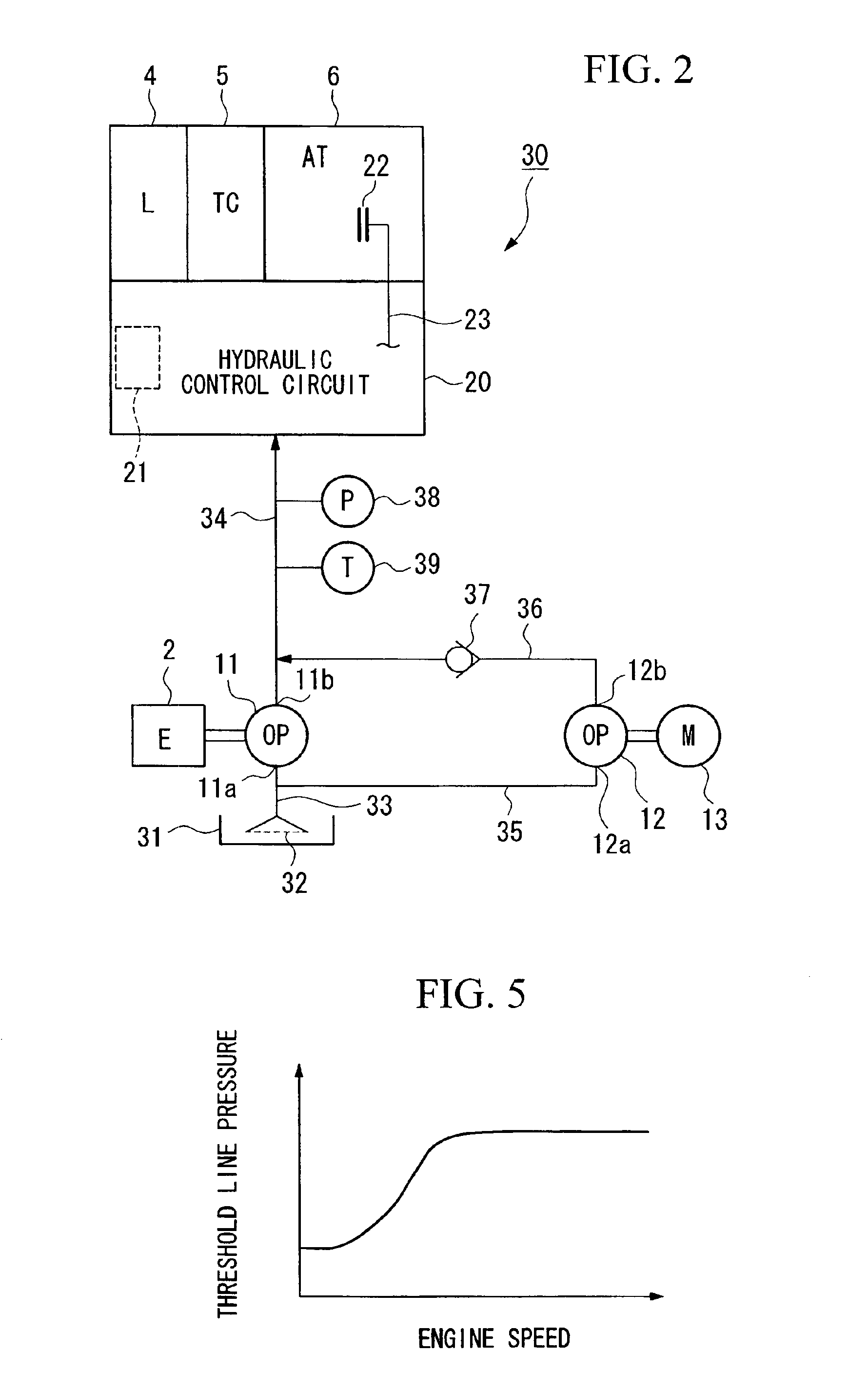

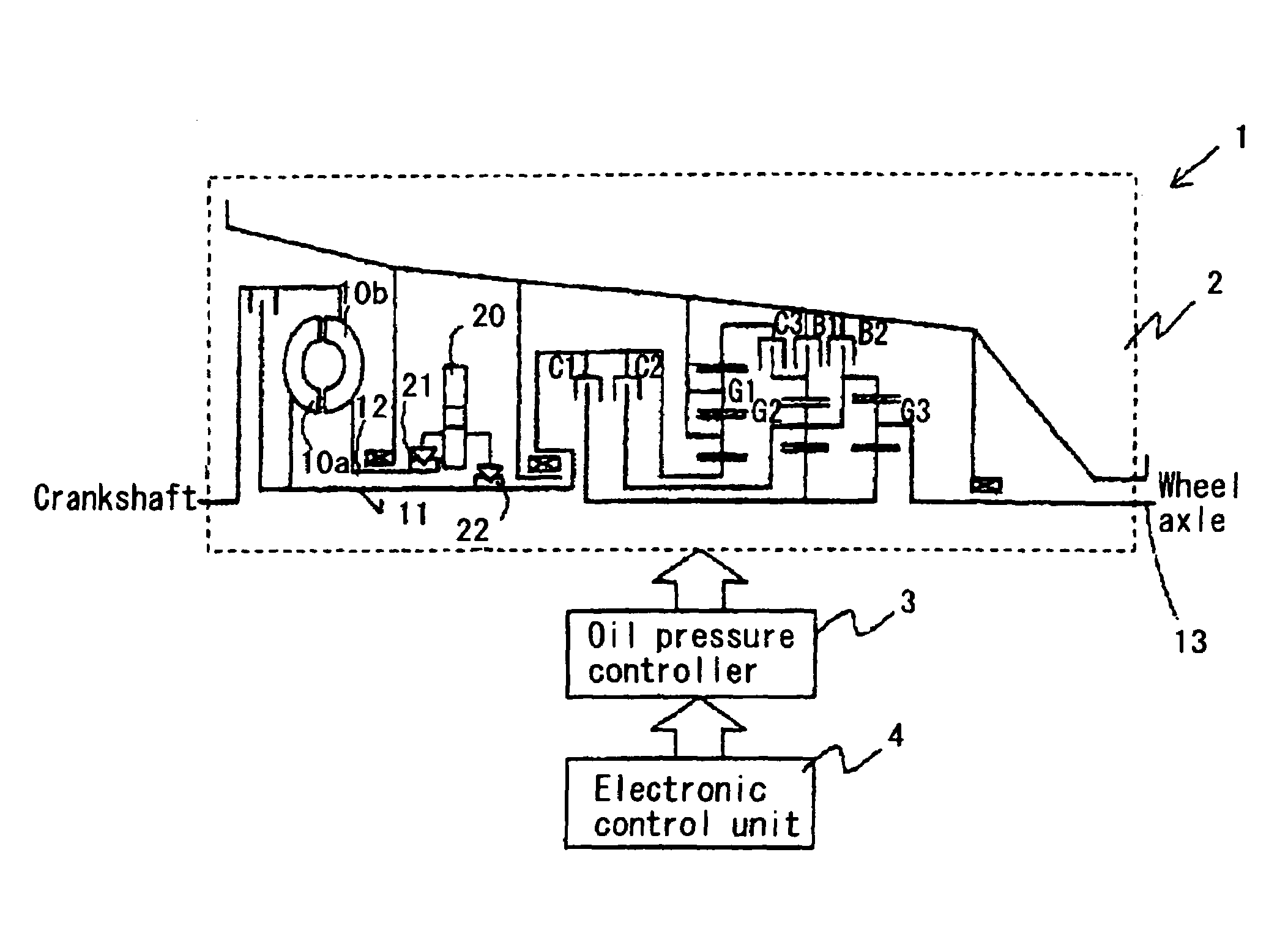

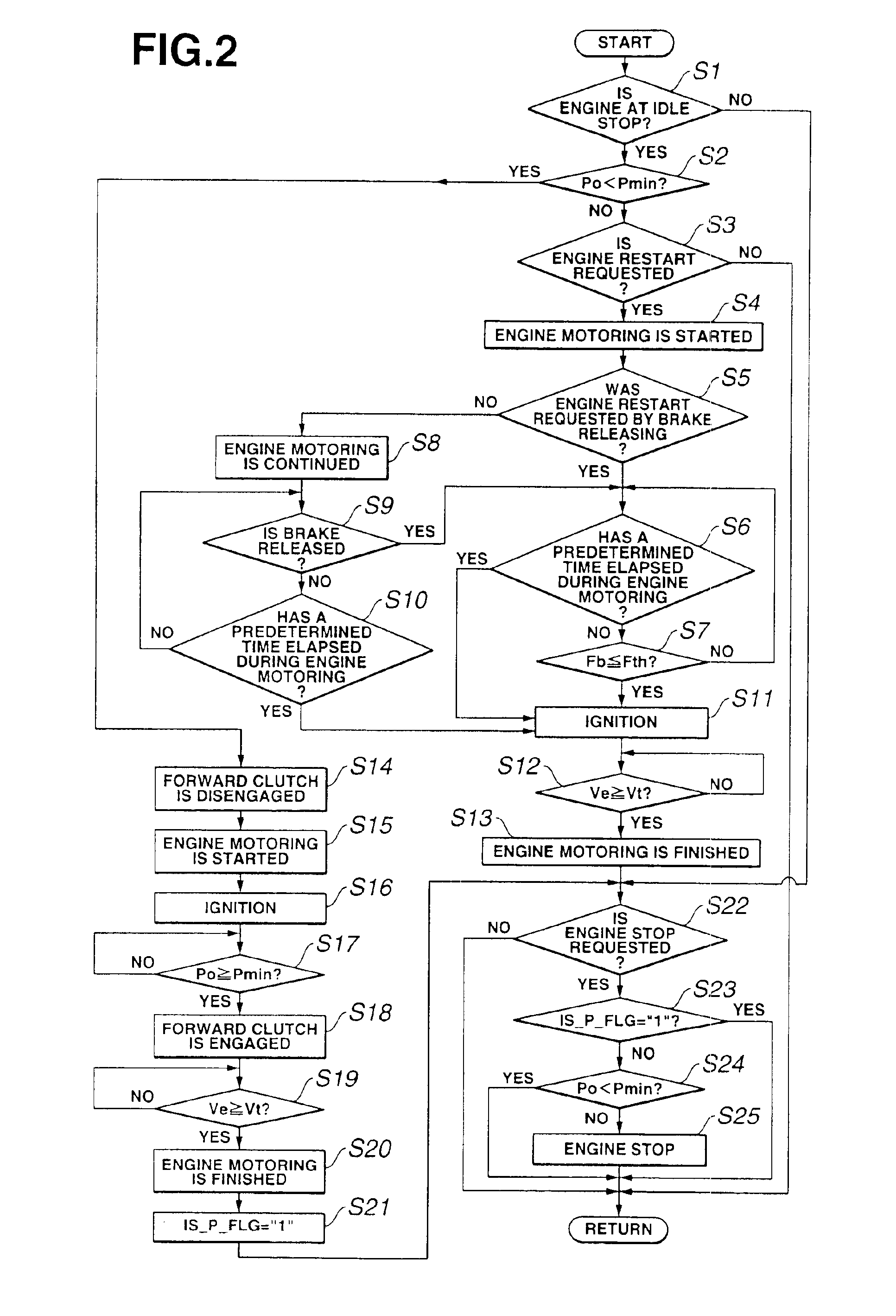

Control system for stopping and starting vehicle engine

ActiveUS6913558B2Degradation can be preventedEngagement can be preventedAnalogue computers for vehiclesElectrical controlAutomotive engineeringOil pressure

An engine stop and start control system for securing a normal line pressure in a hydraulic circuit of the transmission. The system has an engine as a power source for driving the vehicle; a transmission; a mechanical oil pump, operated by the power produced by the engine, for supplying oil pressure to the transmission; an automatic engine stopping and starting section for automatically stopping the engine under predetermined stopping conditions and automatically starting the engine under predetermined starting conditions; and an electric oil pump operated when the predetermined stopping conditions are satisfied, so as to supply the oil pressure to the transmission. The automatic engine stopping and starting section has a control section for prohibiting the automatic engine stop when the line pressure in a hydraulic circuit for supplying oil pressure to the transmission is equal to or lower than a predetermined value while the engine is operated.

Owner:HONDA MOTOR CO LTD

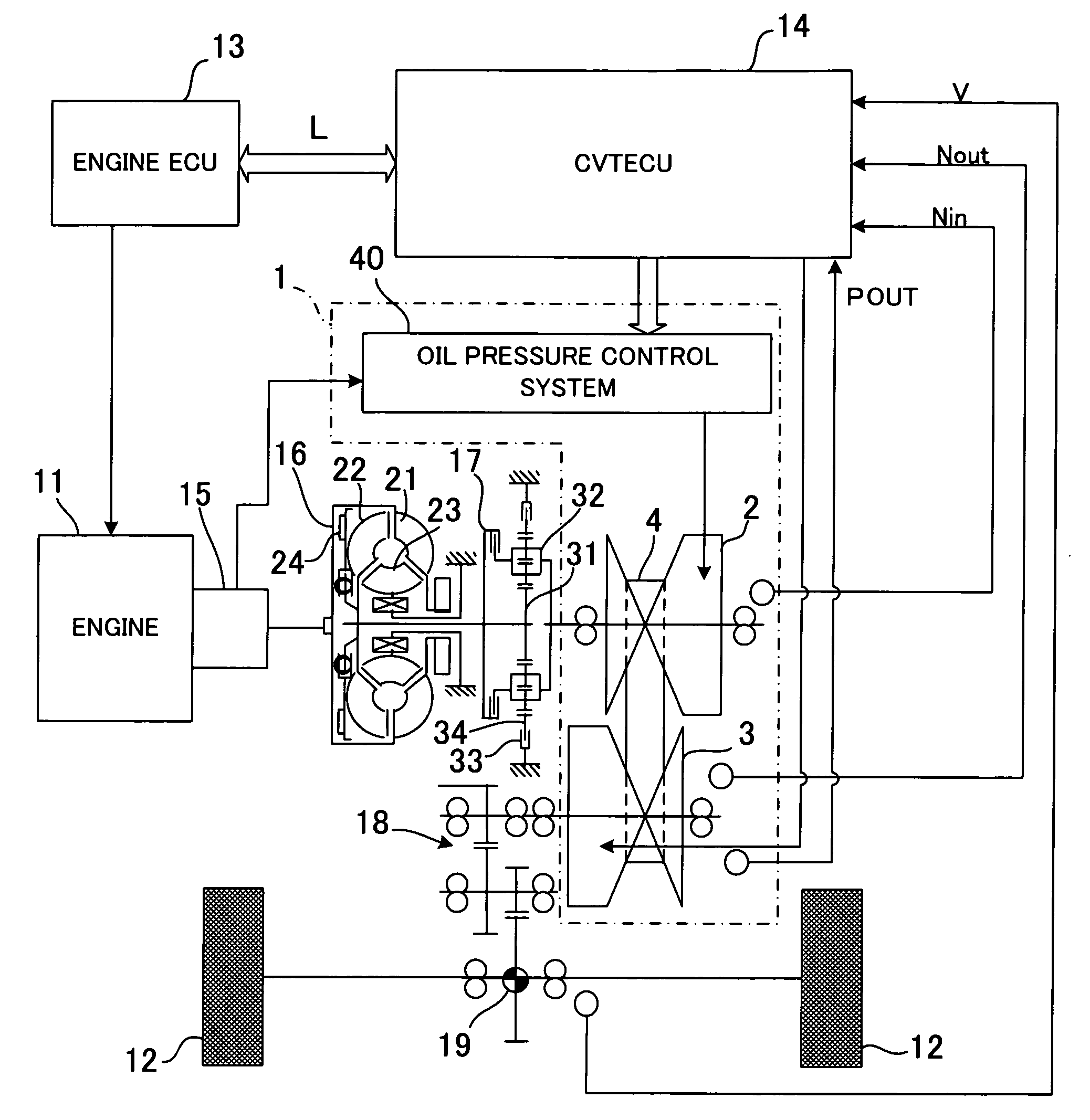

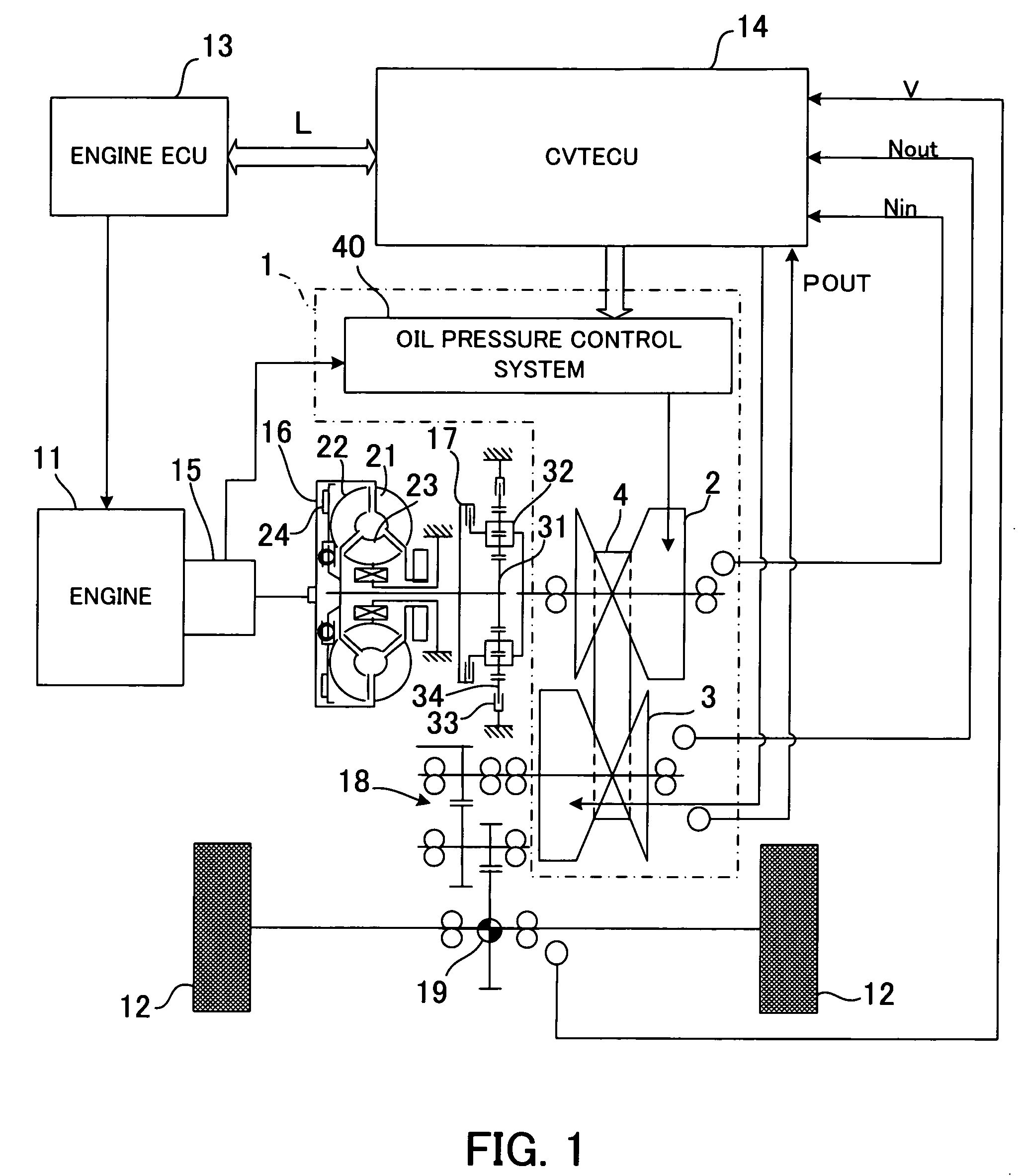

Method of controlling continuously variable transmission and control system

An oil pressure-learning method which enables an oil pressure control system that controls line pressure and belt clamping pressure by oil pressure actuators independently of each other, to accurately control both the line pressure and the belt clamping pressure. The oil pressure-learning method is applied to an oil pressure control system provided with a line pressure control solenoid for controlling a line pressure control valve, and a belt clamping pressure control solenoid for controlling a belt clamping pressure control valve. A belt clamping pressure command value that is outputted to the belt clamping pressure control solenoid as a control command value of belt clamping pressure, and a line pressure command value that is outputted to the line pressure control solenoid as a control command value of line pressure are learned in advance. This enables the oil pressure control system to control both the line pressure and the belt clamping pressure with accuracy.

Owner:FUJITSU GENERAL LTD

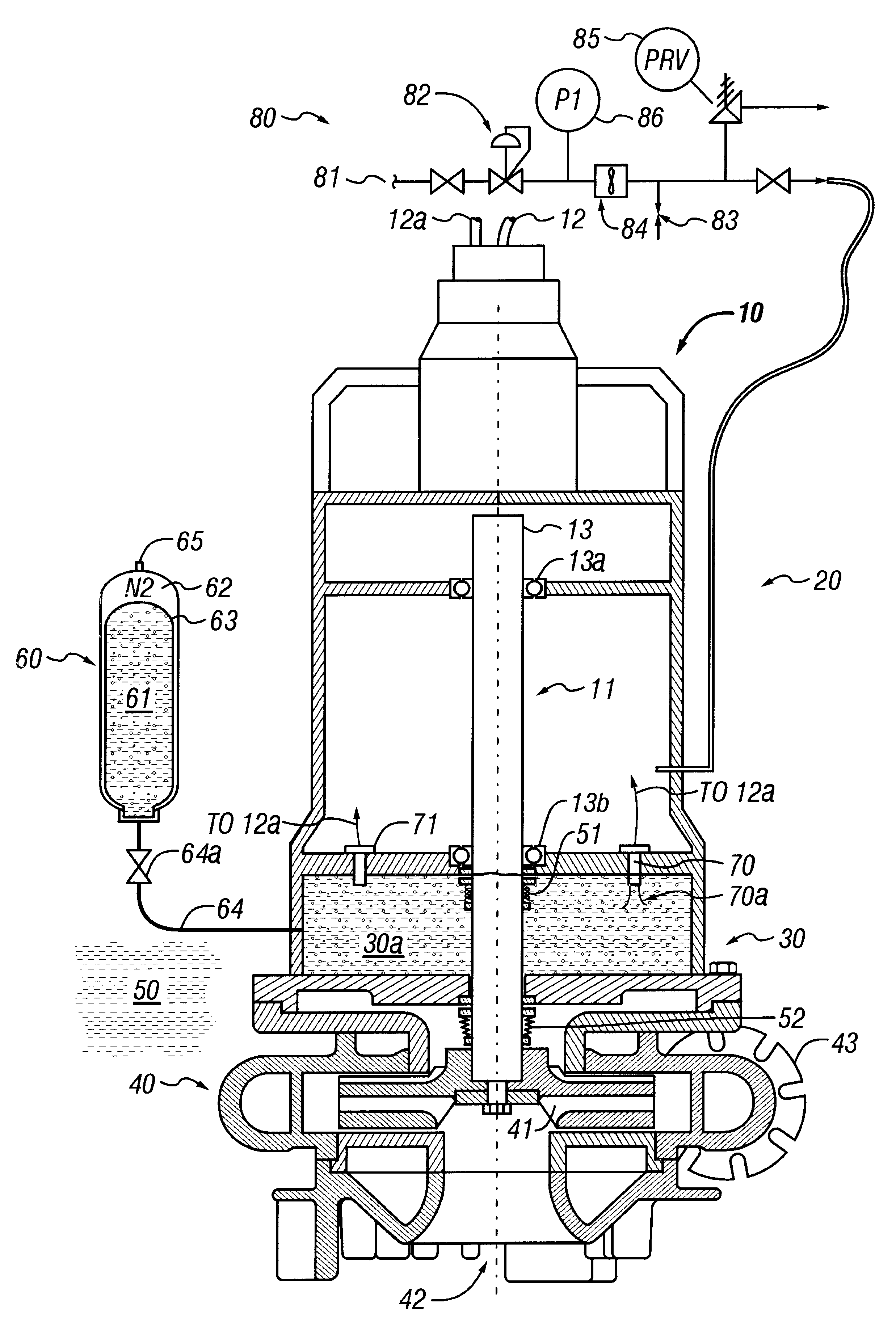

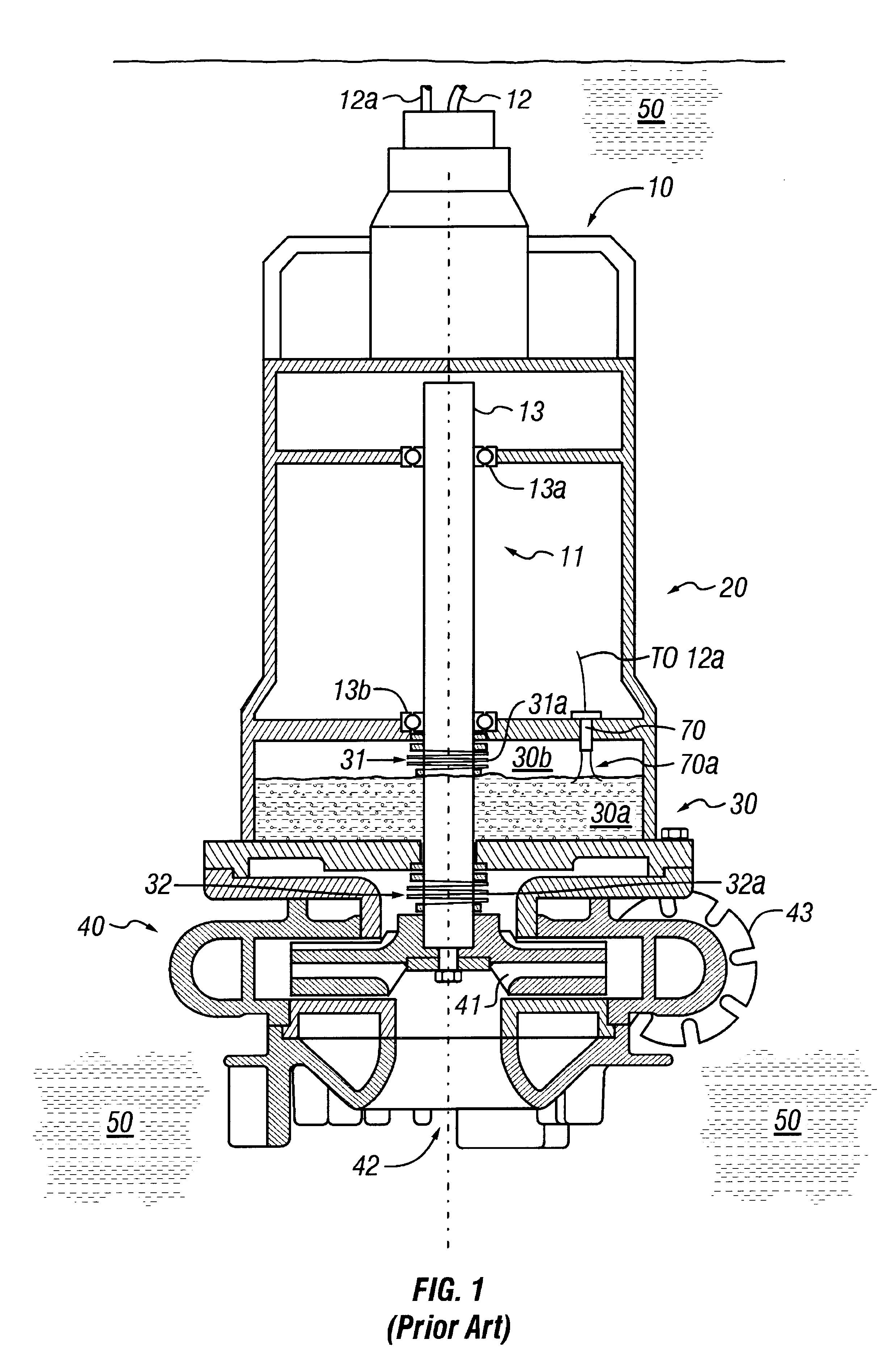

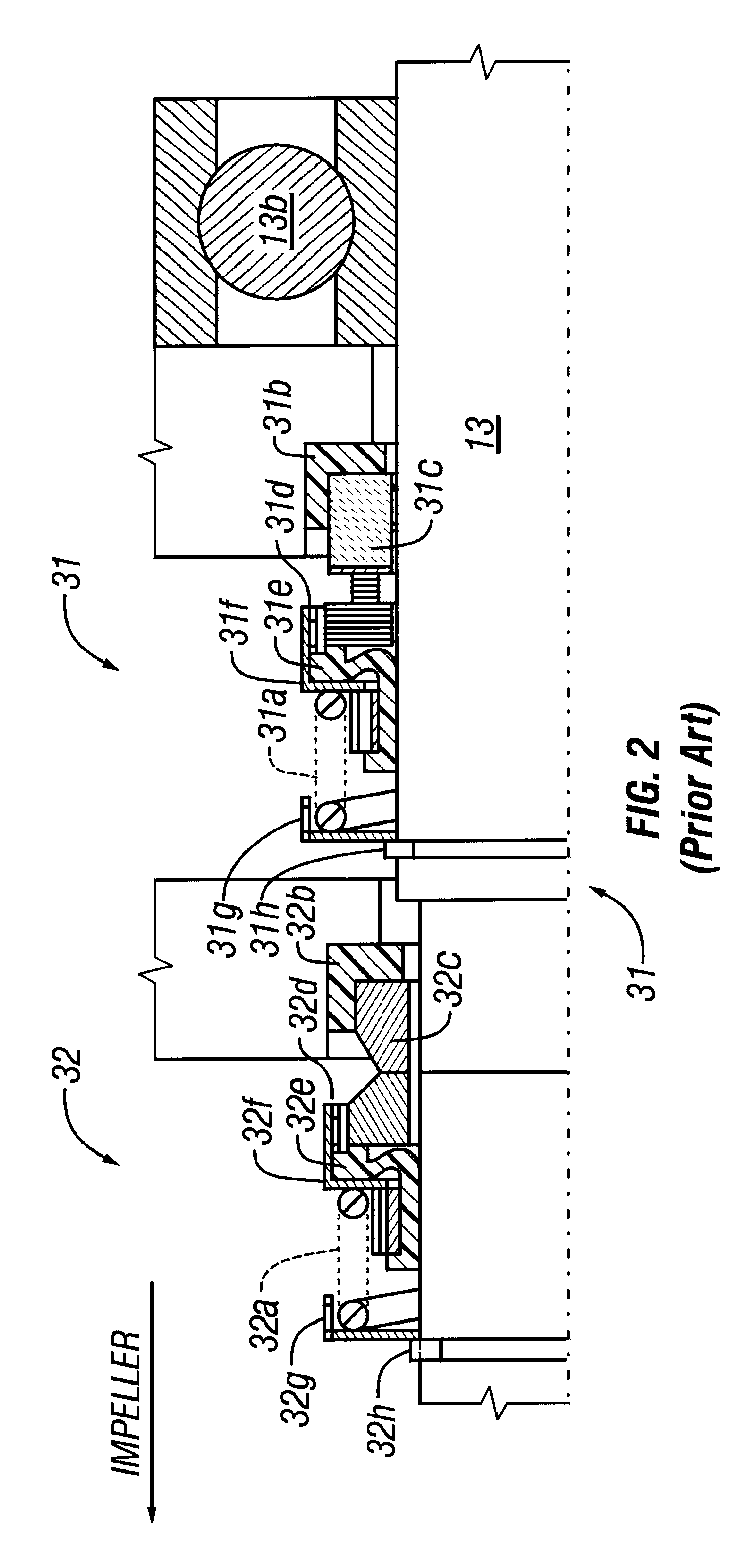

Pressurized seal for submersible pumps

A submersible pump employs a sealed, oil-filled chamber with a moisture-sensing probe to detect the presence of any pumpage, such as water, which has leaked into the chamber. If contamination is detected, the pump may be shut down for repairs before it fails. Two mechanical seals are installed the lower seal is located between the pump and the oil chamber and an upper seal is located between the oil chamber and the motor. The improvement disclosed herein combines a pressurized oil accumulator with the pump oil chamber described above. The accumulator is divided into two compartments separated by a bladder, one compartment being connected to the reservoir of the pump and filled with oil for providing make-up oil to the reservoir and for accepting surplus (expansion) oil from the reservoir. The second compartment is pressurized and applies pressure to the bladder that, in turn, transfers the pressure to the oil in the first compartment and to the oil-filled chamber. The purpose is to pressurize the pump oil chamber in order to equalize pressure across the seals and thereby prevent failure of the seals or, at least, extend their life. The invention also includes apparatus for purging the motor casing with air and a pressure transducer for detecting a decrease in reservoir oil pressure.

Owner:SHELL OIL CO

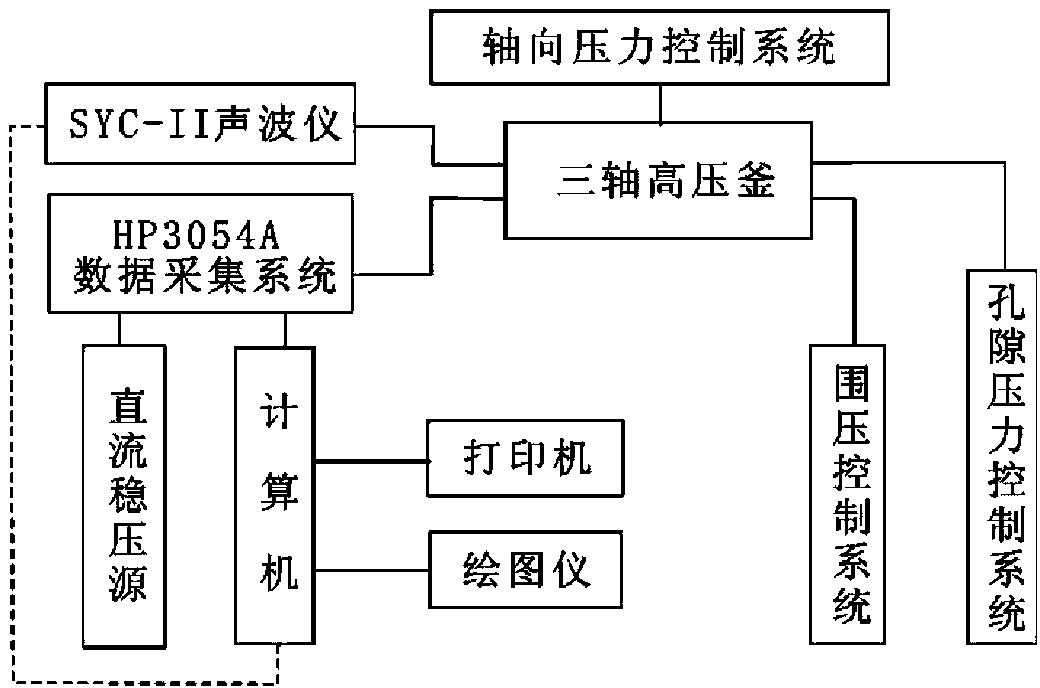

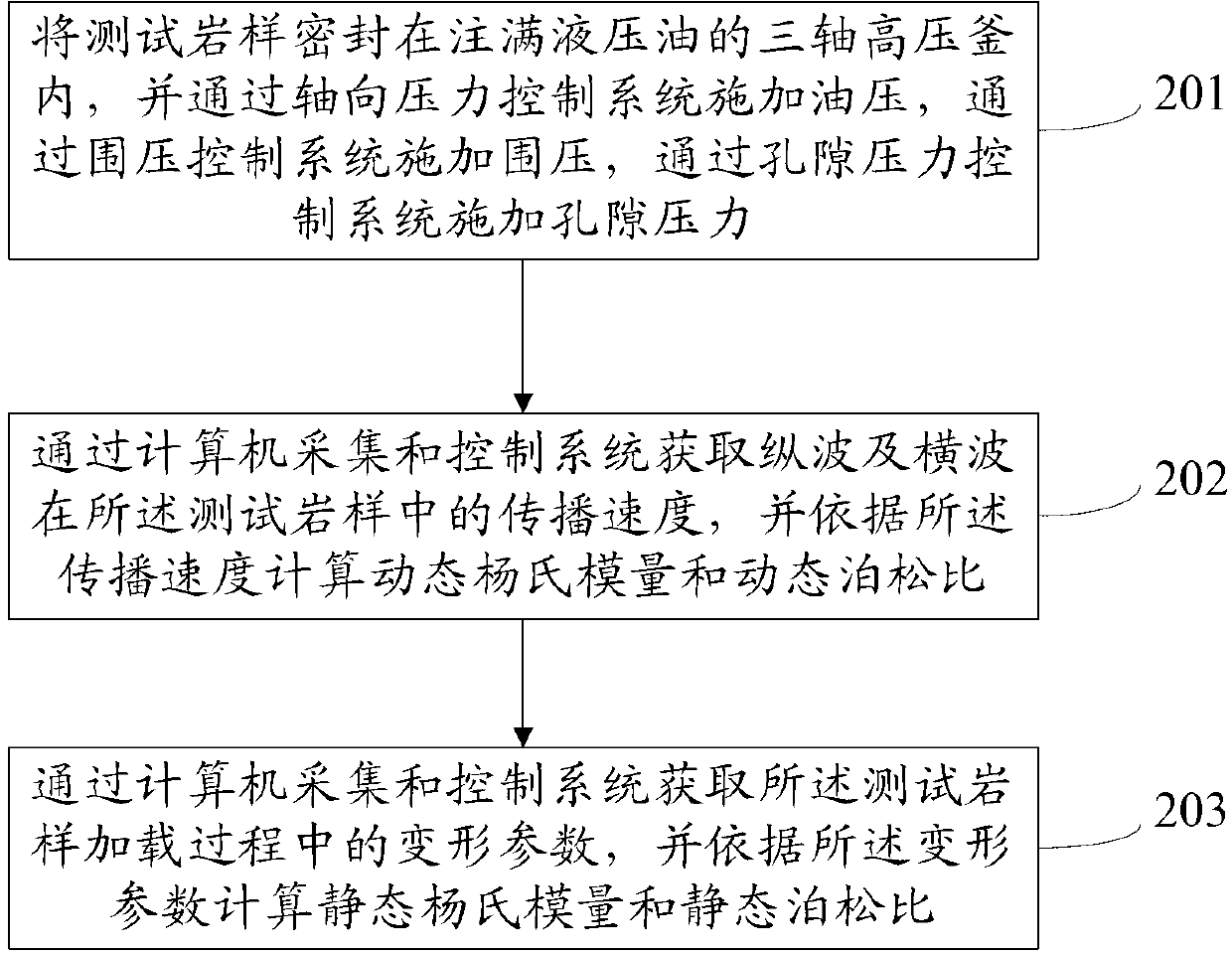

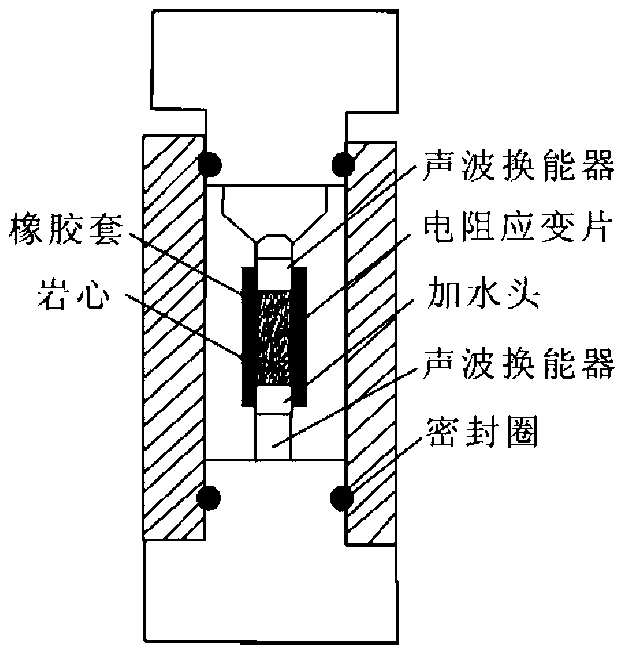

Method for synchronous measurements on dynamic and static elastic parameters of rocks

InactiveCN103278389AGuaranteed validityGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesControl systemAxial pressure

The invention provides a method and a device for synchronous measurements on dynamic and static elastic parameters of rocks by using a rock triaxial anti-compression testing device. The method comprises: sealing a test rock sample in a triaxial autoclave filled with hydraulic oil, applying an oil pressure by an axial pressure control system, applying a confining pressure by a confining pressure control system, and applying a pore pressure by a pore pressure control system; acquiring propagation speeds of longitudinal waves and transverse waves in the test rock sample by a computer acquisition and control system, and calculating the dynamic Young modulus and the dynamic Poisson ratio according to the propagation speeds; and acquiring deformation parameters of the test rock sample during a loading process by the computer acquisition and control system, and calculating the static Young modulus and the static Poisson ratio according to the deformation parameters. The method and the device can ensure validity and accuracy of hydrocarbon reservoir rock mechanical parameter measurements in thousands of meters deep underground and under the conditions of complex confining pressure, high temperature, high pore pressure and polyphase fluid.

Owner:PEKING UNIV

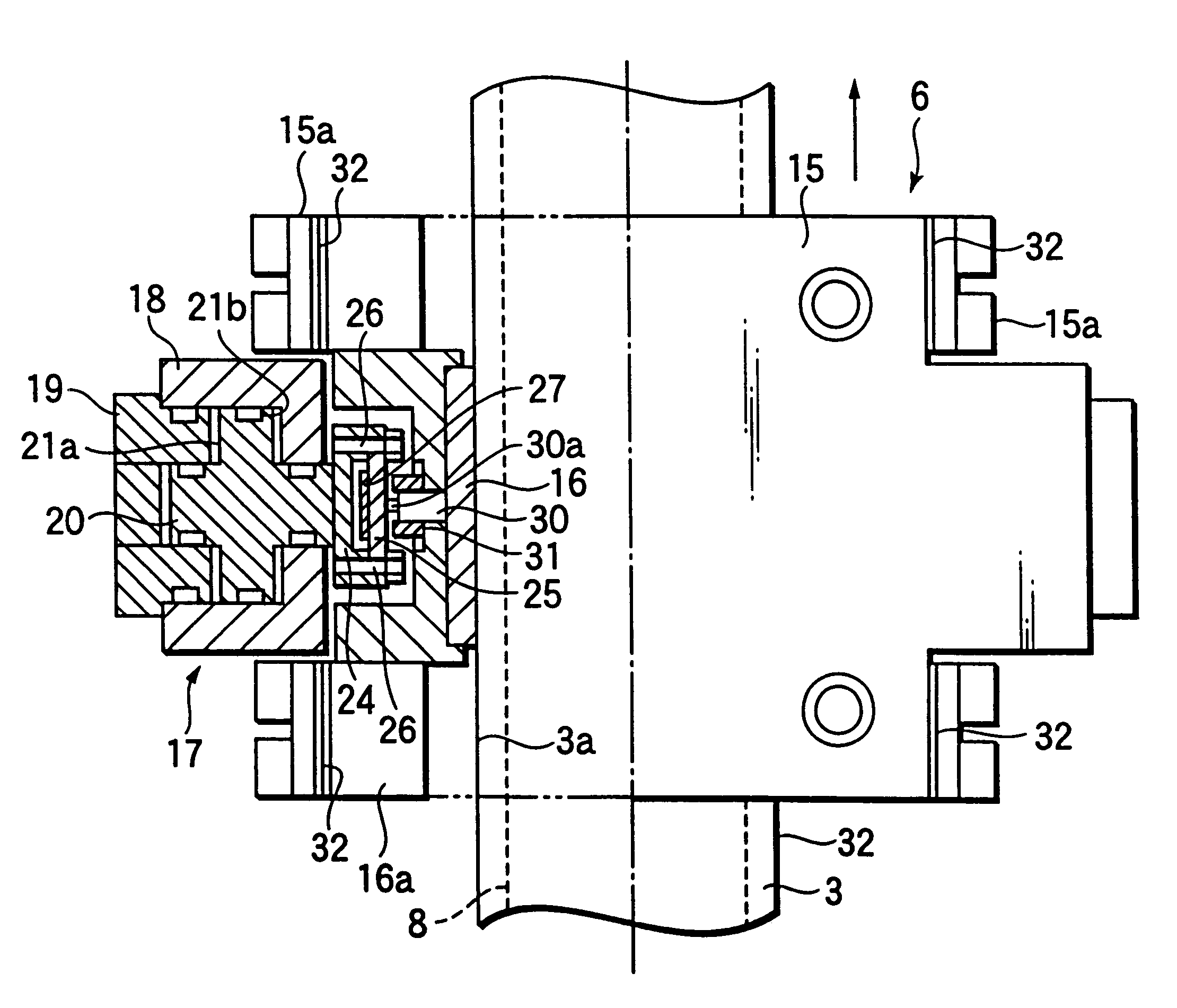

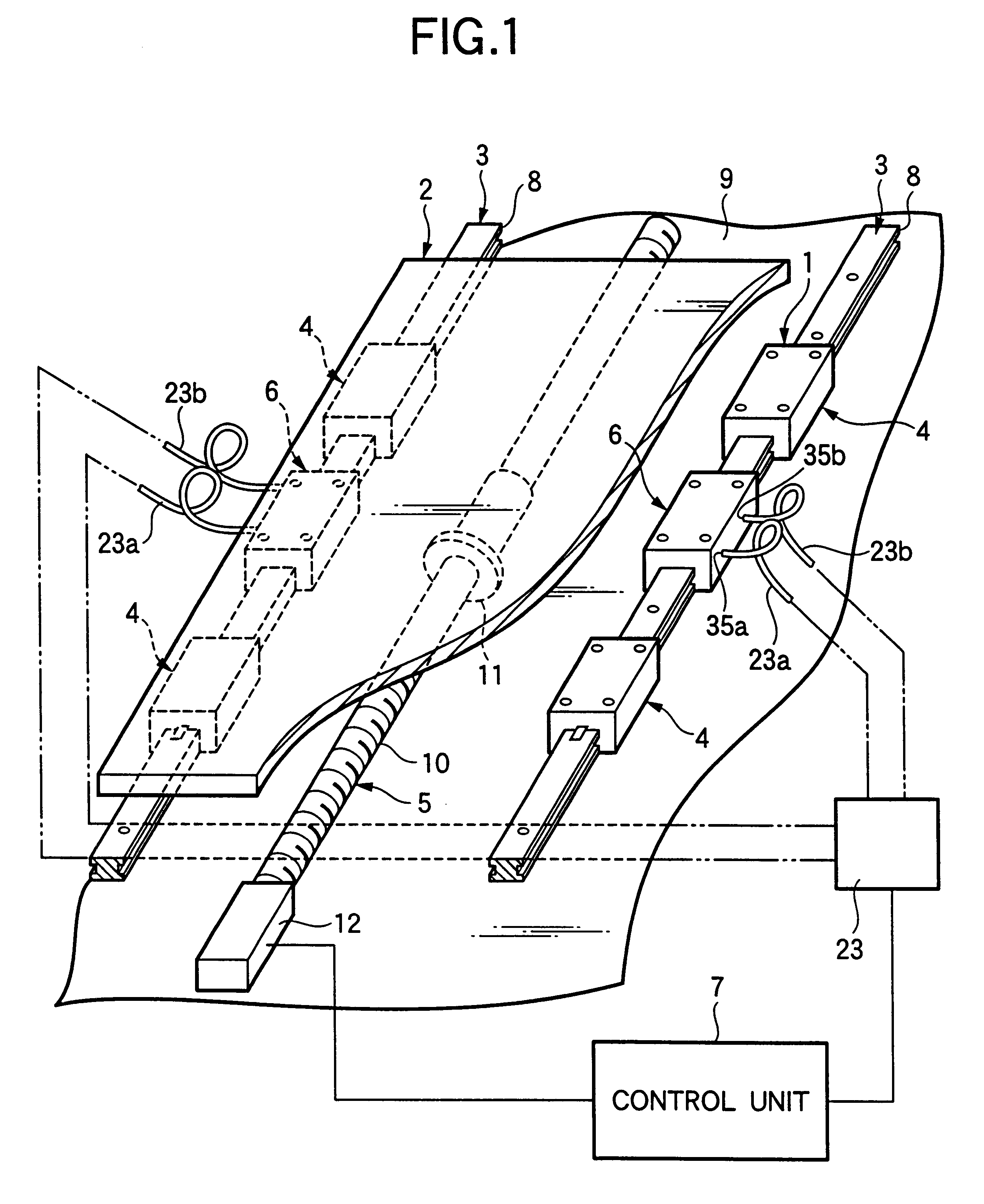

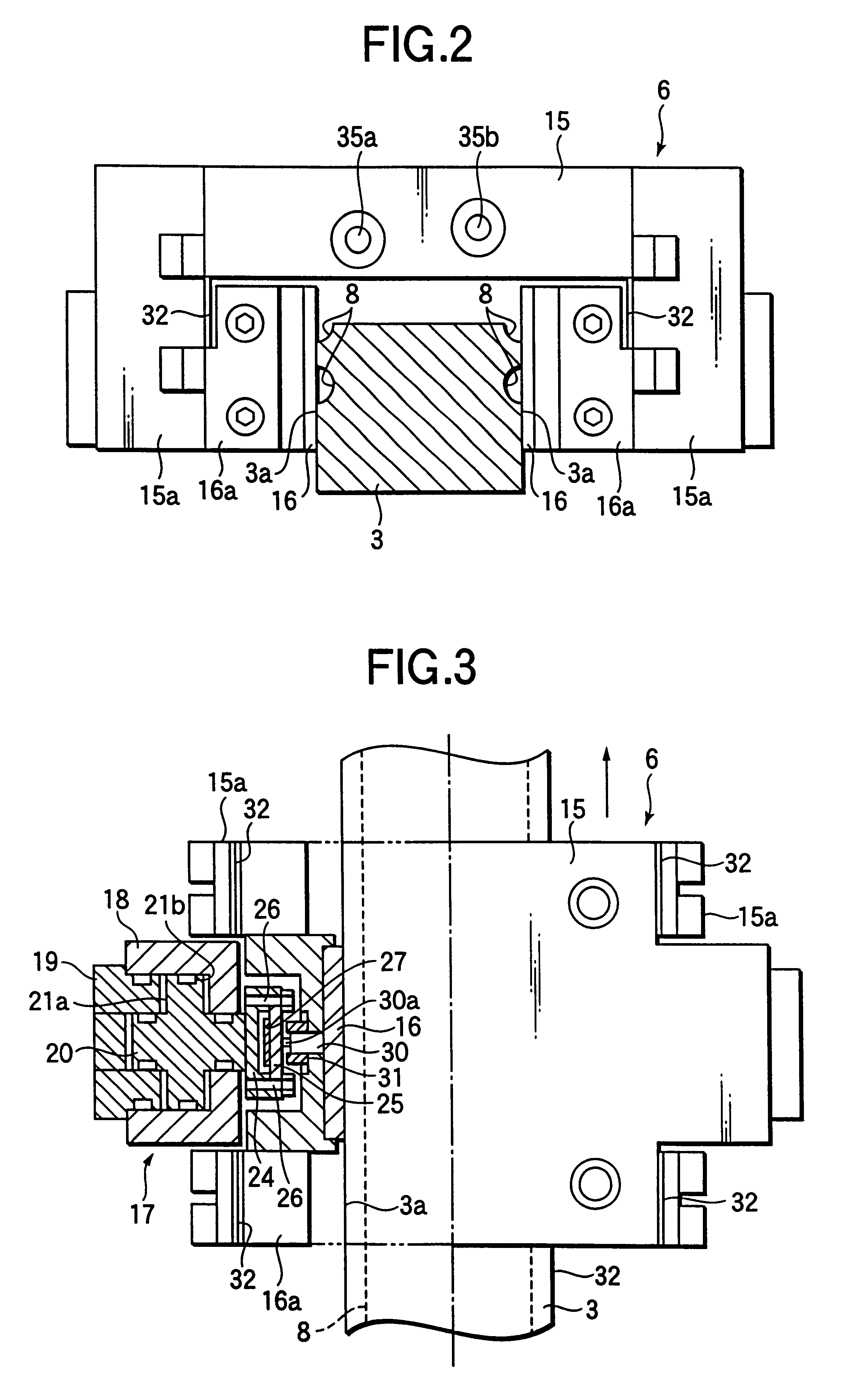

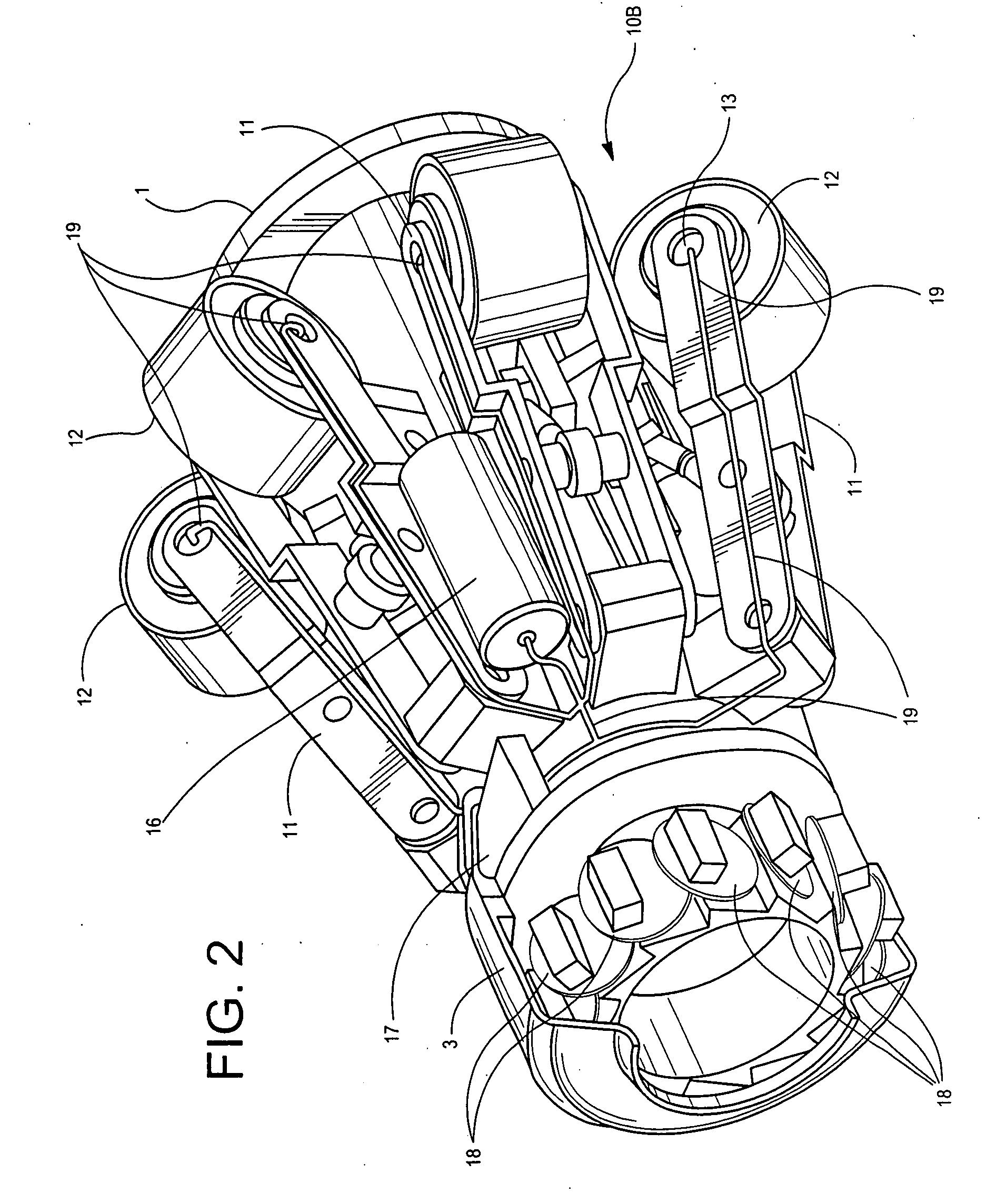

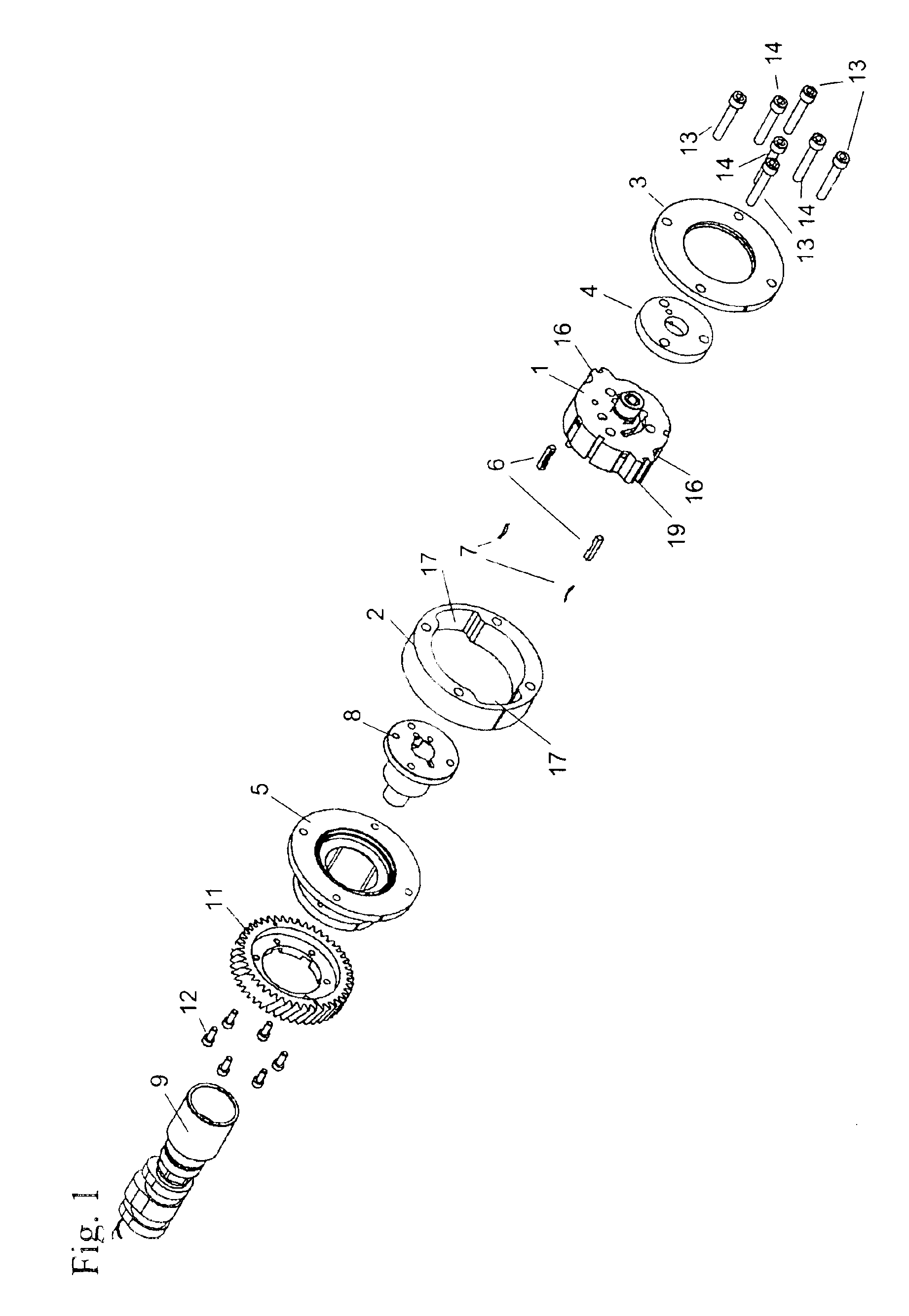

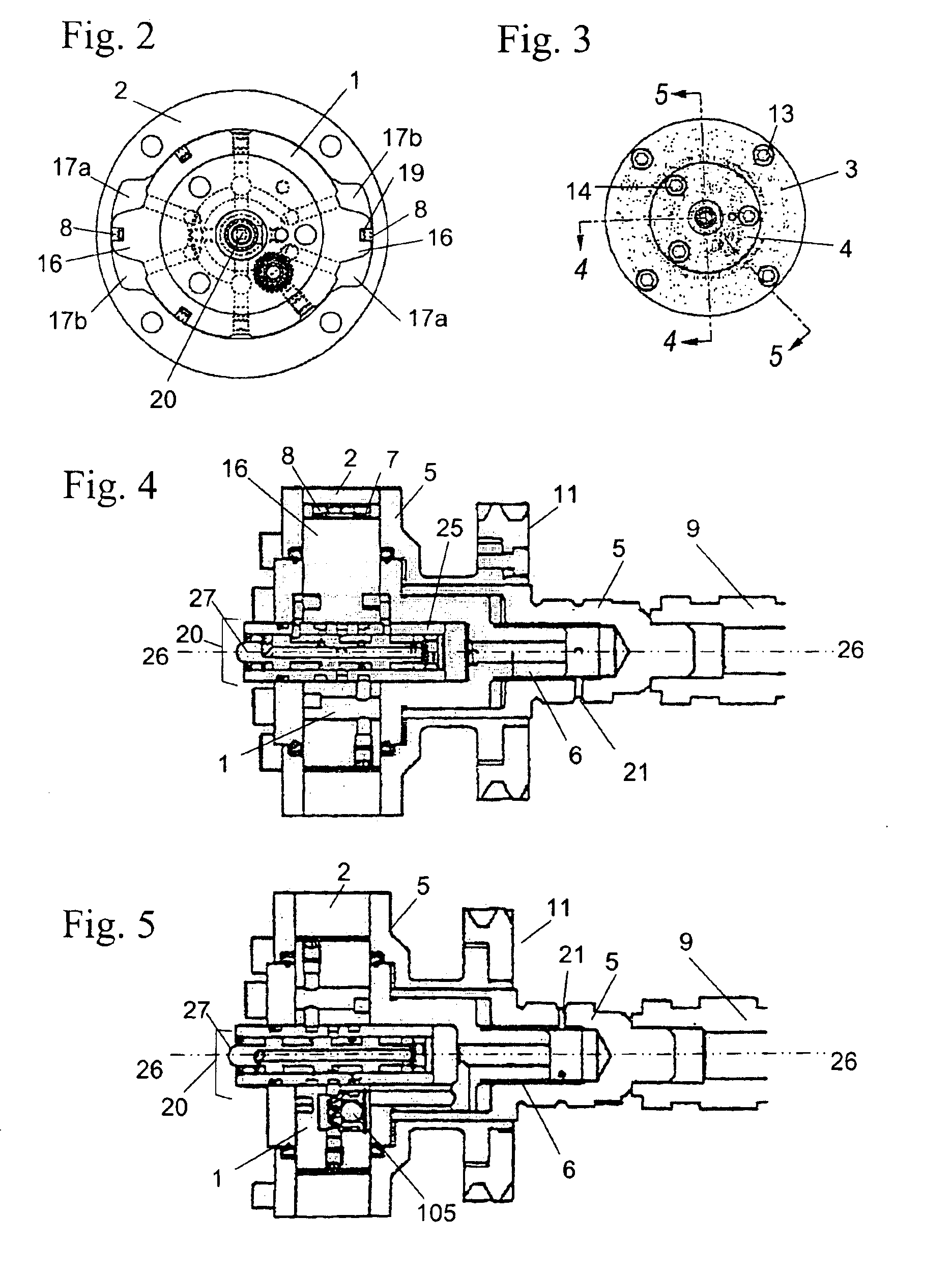

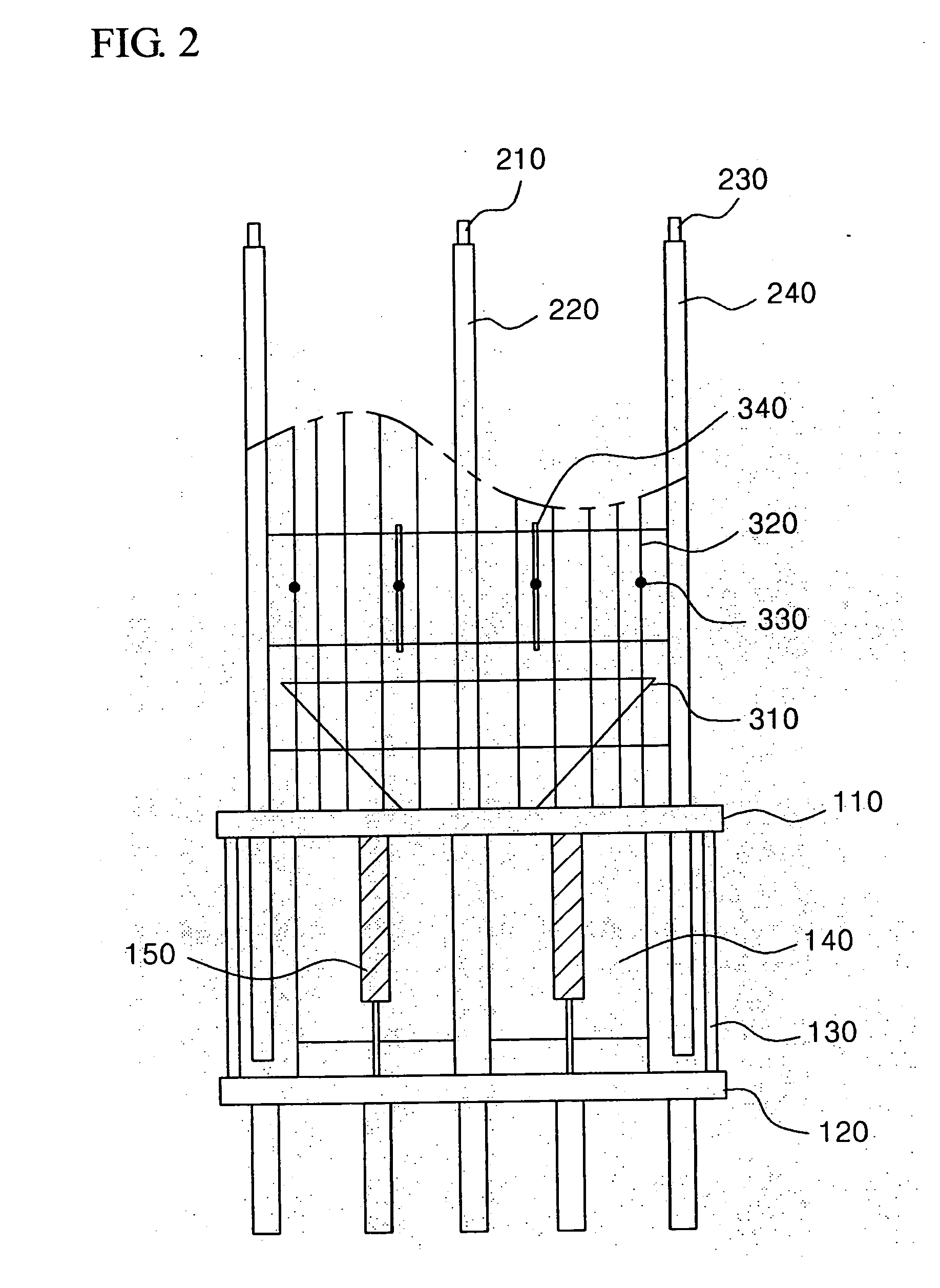

Linear guide apparatus

The linear guide apparatus includes a guide rail 3 including a rolling body rolling groove 8 and a friction apply unit 6 assembled to the guide rail 3. The friction apply unit 6 includes a unit main body 15, a brake member 16, an oil pressure cylinder 17 and a plate spring 32. The brake member 16 is disposed so as to face the side surface 3a of the guide rail 3 and can be contacted with the other portions of the side surface 3a than the rolling body rolling groove 8 thereof. The oil pressure cylinder 17 includes a piston member 20 which is structured to be driven in a positive direction to thereby press the brake member 16 against the side surface 3a of the guide rail 3 and also the piston member 20 can be driven in the opposite direction to thereby remove the pressure of the brake member 16 from the side surface 3a.

Owner:NSK LTD

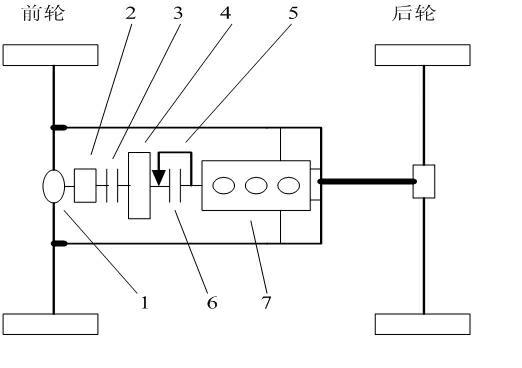

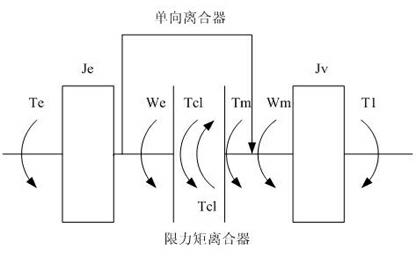

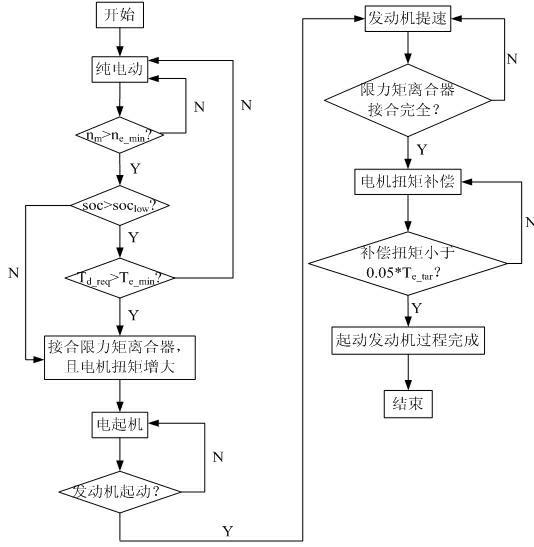

Control method utilizing motor to start engine for double-clutch type hybrid electric vehicle

InactiveCN102490718AIncrease or decrease torqueReduce torqueHybrid vehiclesMotor speedHydraulic cylinder

The invention enables a novel single-motor and double-clutch type hybrid electric vehicle to be a study object and provides a control method of the process of utilizing a motor to start an engine during vehicle running. First a structure and a working mode of the hybrid electric vehicle are analyzed, a system dynamics model is established, a working range of the hybrid electric vehicle is divided, corresponding torque management strategies are formulated; then in the practical application process, whether the conditions for utilizing the motor to start the engine are achieved is judged by calculating demand torque, value of state of charge (SOC) of a battery, a rotating speed of the motor; and when the conditions for utilizing the motor to start the engine are achieved, model switch is performed, a moment-limiting clutch jointing instruction is sent out, and the processing of utilizing the motor to start the engine is achieved by controlling oil pressure of a moment-limiting clutch hydraulic cylinder and utilizing the formulated torque coordination-control strategies to perform coordination control of motor torque, engine torque and transmission torque of a moment-limiting clutch. By utilizing the advantage that the motor responds fast and timely increasing or reducing the motor torque according to the control strategies, the control method provides the demand torque for starting the engine during the vehicle running or compensates the insufficiency of the engine torque, reduces impact degree in the switching process and improves ride comfort of the hybrid electric vehicle.

Owner:CHONGQING UNIV

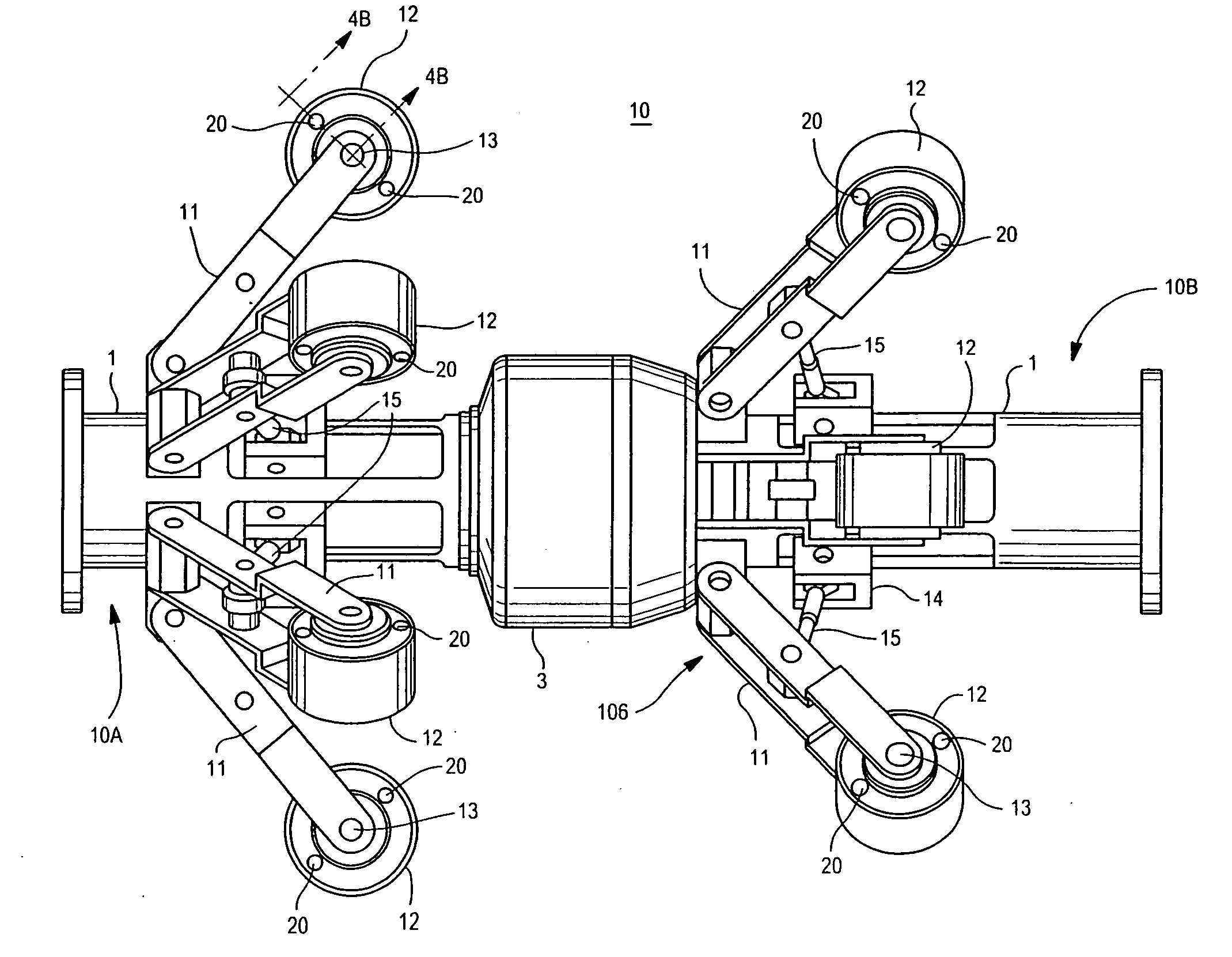

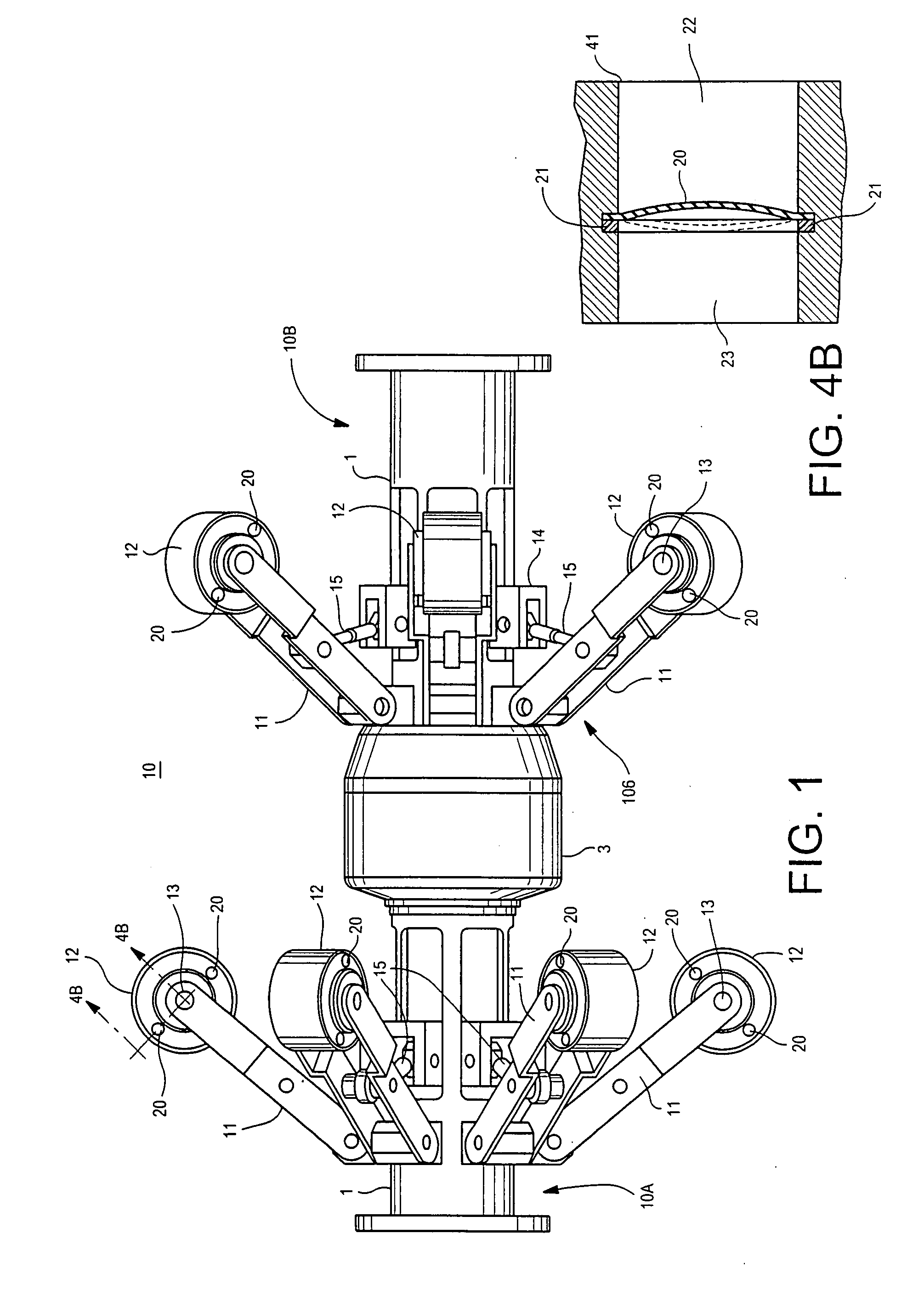

Pressure-balanced electric motor wheel drive for a pipeline tractor

InactiveUS20080245258A1Avoid lostReduce sensitivityRailway tunnelsRailway componentsMotor driveAmbient pressure

A self-propelled crawler / tractor apparatus is disclosed for traveling through a tubular pipeline while conducting pipeline wall inspection operations and / or towing gear for cleaning, maintenance and the like. The crawler / tractor apparatus is propelled by a plurality of radially positioned motorized traction wheels. Each motorized traction wheel includes a brushless DC electric motor along with clutch, gearbox and other mechanical drive components integrated into a compact self-contained motorized wheel assembly which is sealed and filled with an electrically non-conductive lubricating / cooling oil. The seal integrity at each wheel assembly is maintained against oil leakage and debris ingress by a pressure-balancing mechanism which matches internal oil pressure to the exterior ambient pressure present in the pipeline. The electric motor drive for each traction wheel is individually controlled via an onboard computer to provide a wide range of torque and wheel speeds.

Owner:GENERAL ELECTRIC CO

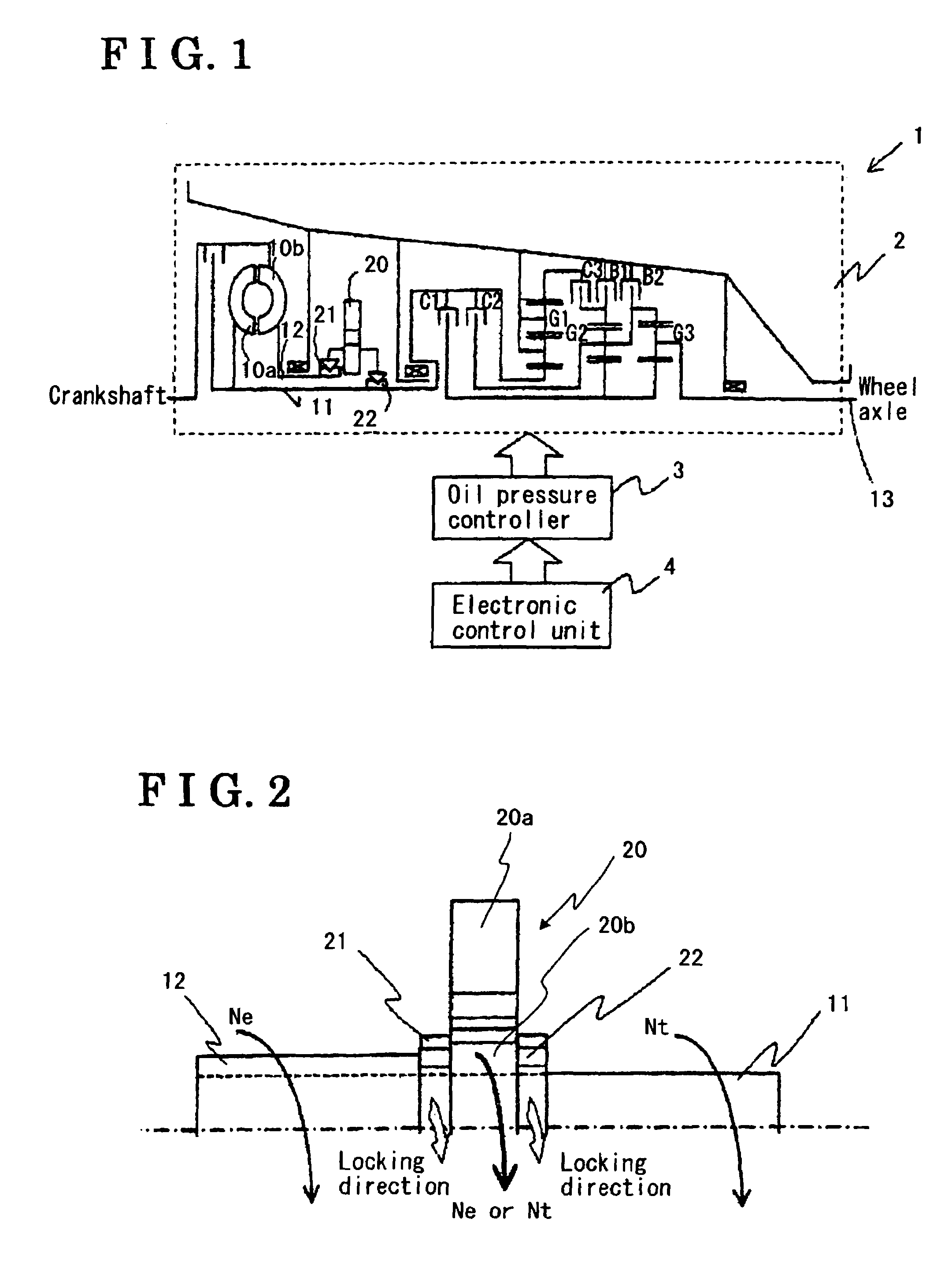

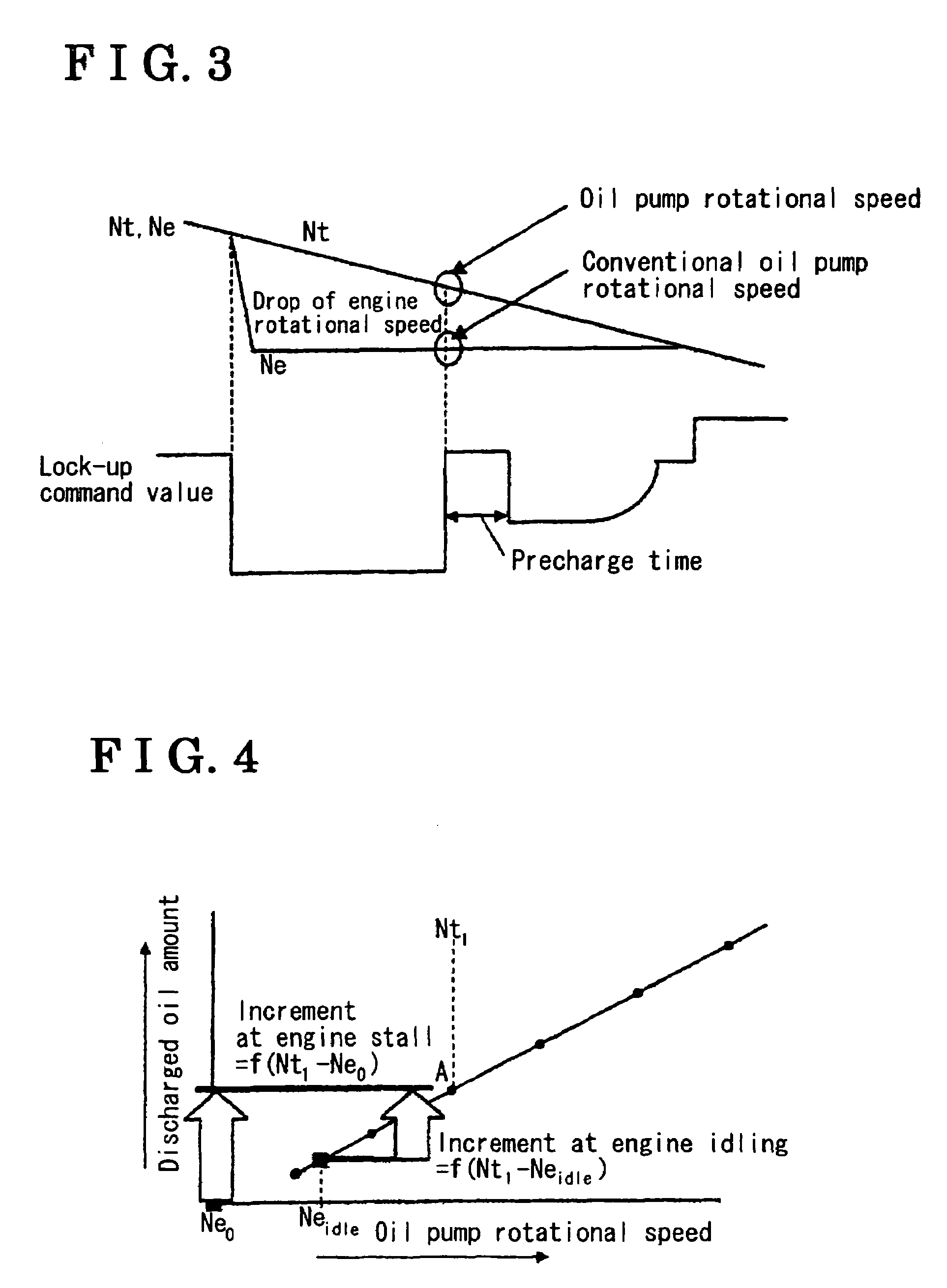

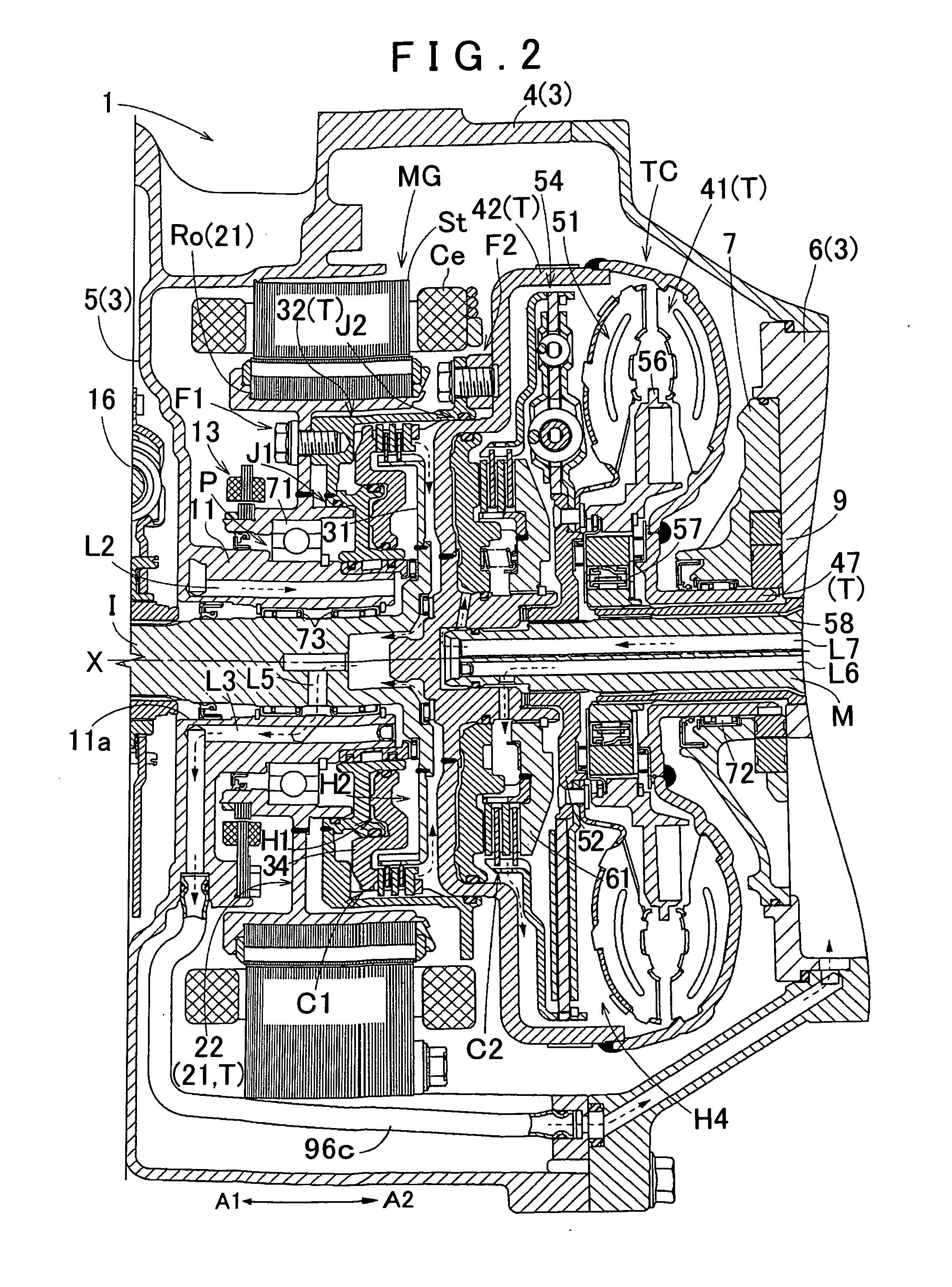

Automatic transmission apparatus

Owner:AISIN SEIKI KK

Vehicle with automatic engine stop/restart function and automatic engine stop/restart system and method for vehicle

InactiveUS6881170B2Deteriorating durabilityElectrical controlInternal combustion piston enginesAutomatic transmissionControl system

A vehicle with an automatic engine stop / restart function comprises an engine, an automatic transmission having an oil pump driven in synchronism with the engine to supply an oil pressure to the automatic transmission, an oil pressure controller to hold the oil pressure in the automatic transmission during an automatic stop of the engine, and a control system. The control system is configured to: determine whether the oil pressure in the automatic transmission becomes lower than a predetermined value during the engine automatic stop; shift the automatic transmission into a neutral state when the oil pressure in the automatic transmission becomes lower than a predetermined value during the engine automatic stop; restarts the engine; and then, shift the automatic transmission into a drive state after the oil pressure in the automatic transmission is increased to the predetermined value by the oil pump driven in synchronism with the engine.

Owner:NISSAN MOTOR CO LTD

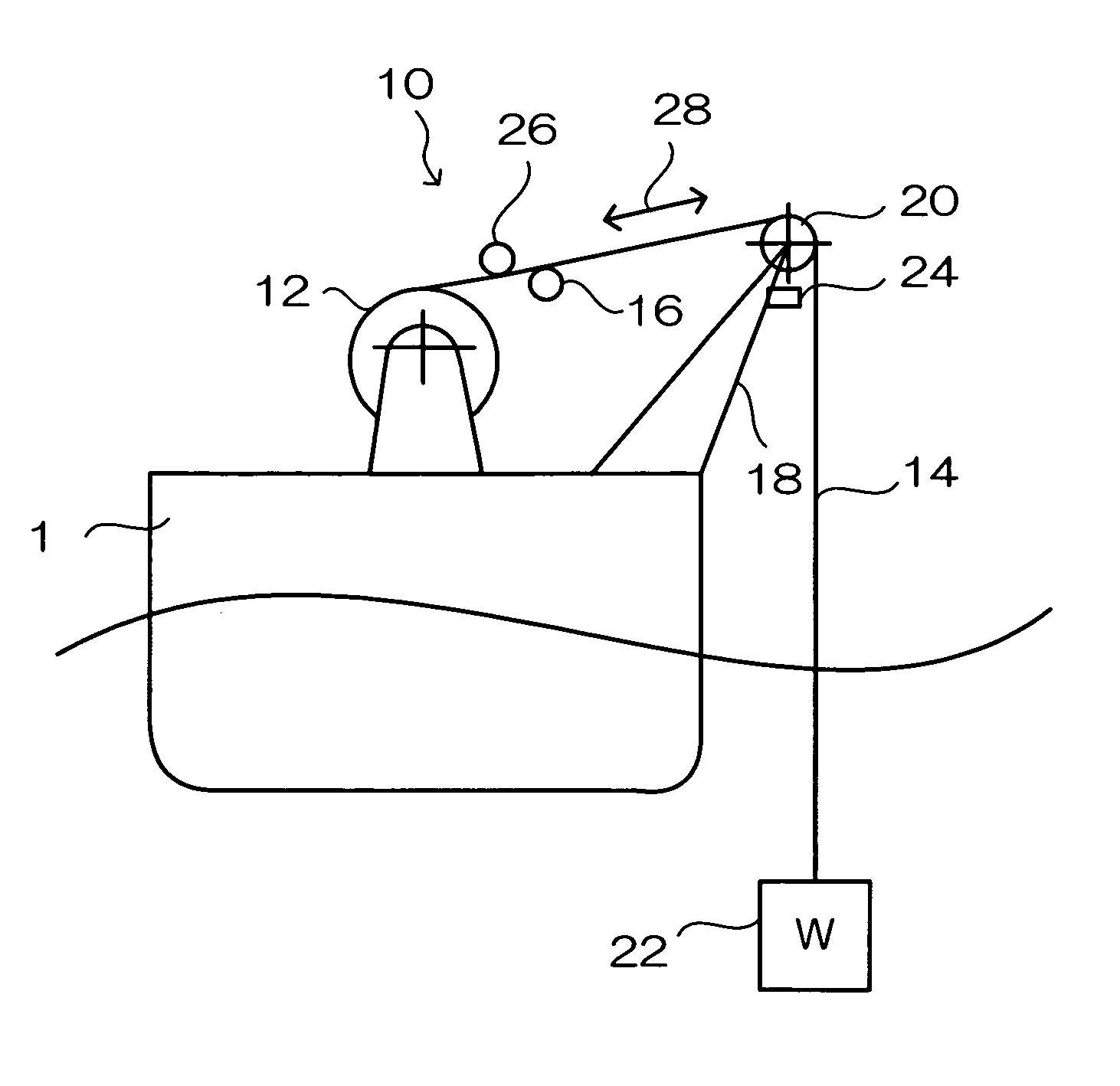

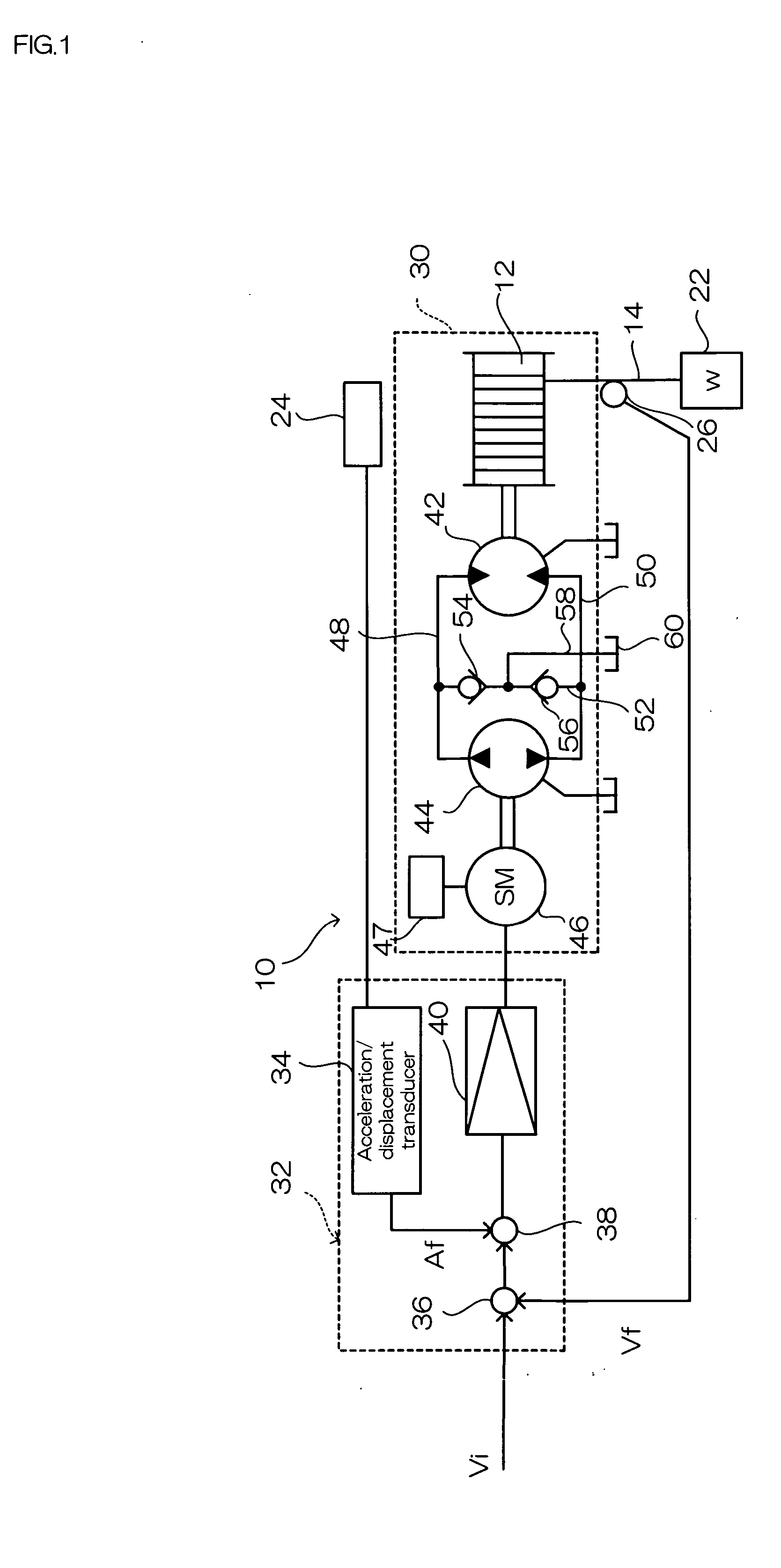

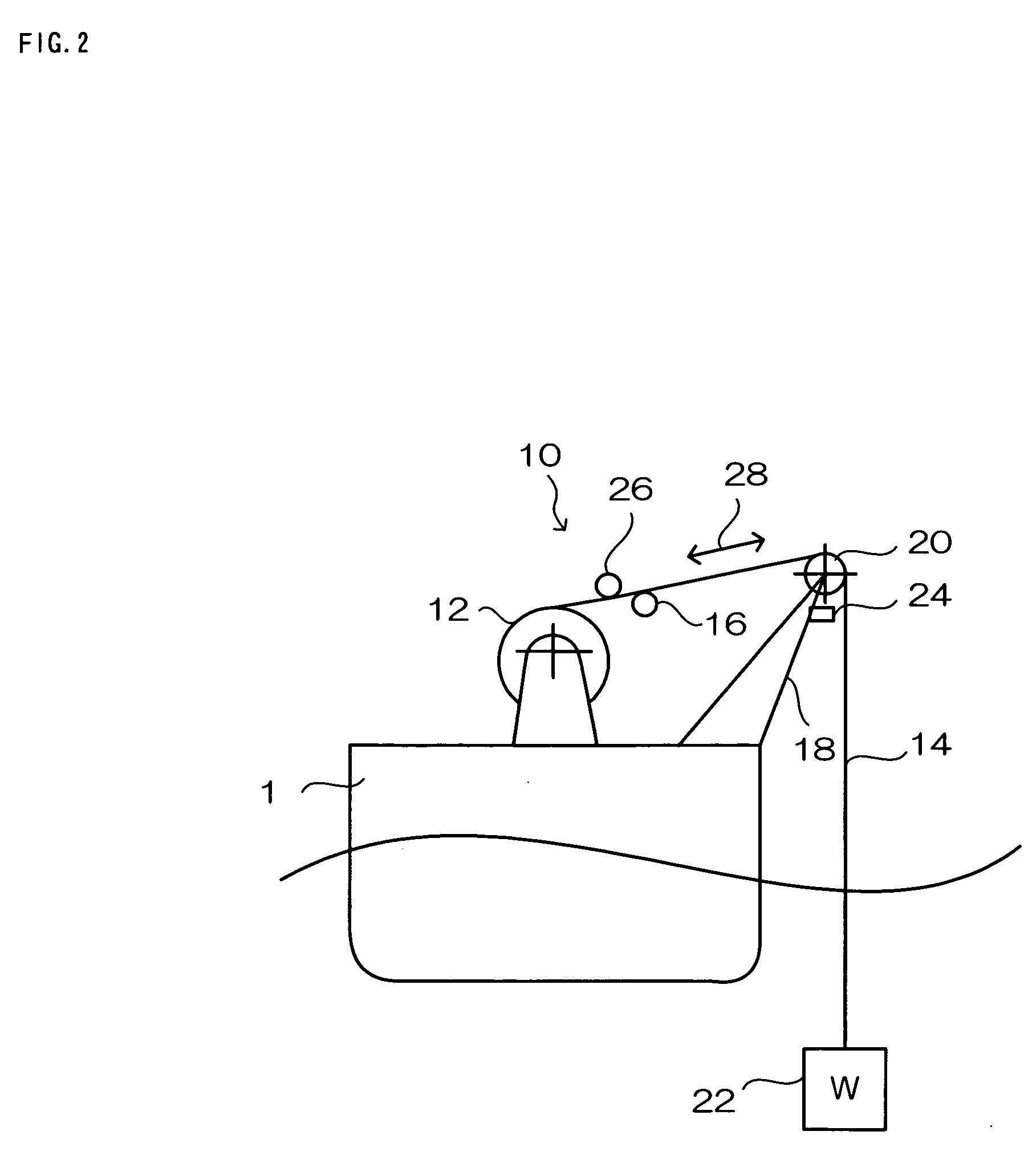

Hoisting device with vertical motion compensation function

InactiveUS20050242332A1High precisionConsumption energy can be savedCargo handling apparatusServomotorsControl signalTransducer

A hoisting device can be small-sized and energy can be saved. A hoisting device 10 according to the present invention has a hoist 30 and a control unit 32. The hoist 30 rotates a drum 12 having a wire 14 wound thereon by an oil pressure motor 42 rotatable in normal and reverse directions. To the oil pressure motor 42, operating oil is supplied from an oil pressure pump 44. The oil pressure pump 44 is a two-way discharge fixed capacity type, and rotated by a servomotor 46. An acceleration / displacement transducer 34 in the control unit 32 finds a moving direction and a moving speed of a wire hanging point in the vertical direction from an output signal of an acceleration sensor 24. The control unit 32 outputs a drive control signal of the servomotor 46 according to a paying-out speed or a rolling-up speed of the wire 14 offsetting the vertical motion of the wire hanging point caused by the heaving of a hull based on a speed instruction Vi of the paying-out or rolling-up speed of the wire, a detected signal of the acceleration sensor 24 and a detected signal of a wire speed sensor 26.

Owner:MITSUI ENG & SHIPBUILD CO LTD +2

Hydraulic tensioner lifter

To provide an adequate biasing load to an endless transmission belt by biasing forces of a plurality of springs with different biasing forces and oil pressure biasing force to permit an easy adjustment. In a structure which includes an almost cylindrical plunger, a tensioner body into which the plunger is fitted, high pressure oil chambers are formed by the tensioner body and the plunger and supplied with oil pressure. Two tensioner springs, a rigid spring and a soft spring are supported by the tensioner body and are arranged in series for biasing the plunger. The plunger in its fully stretched state is supported by the serially arranged rigid and soft tensioner springs. In a condition when the plunger is pushed back from this fully stretched state by a prescribed amount or further, the plunger is supported by the rigid tensioner spring.

Owner:HONDA MOTOR CO LTD

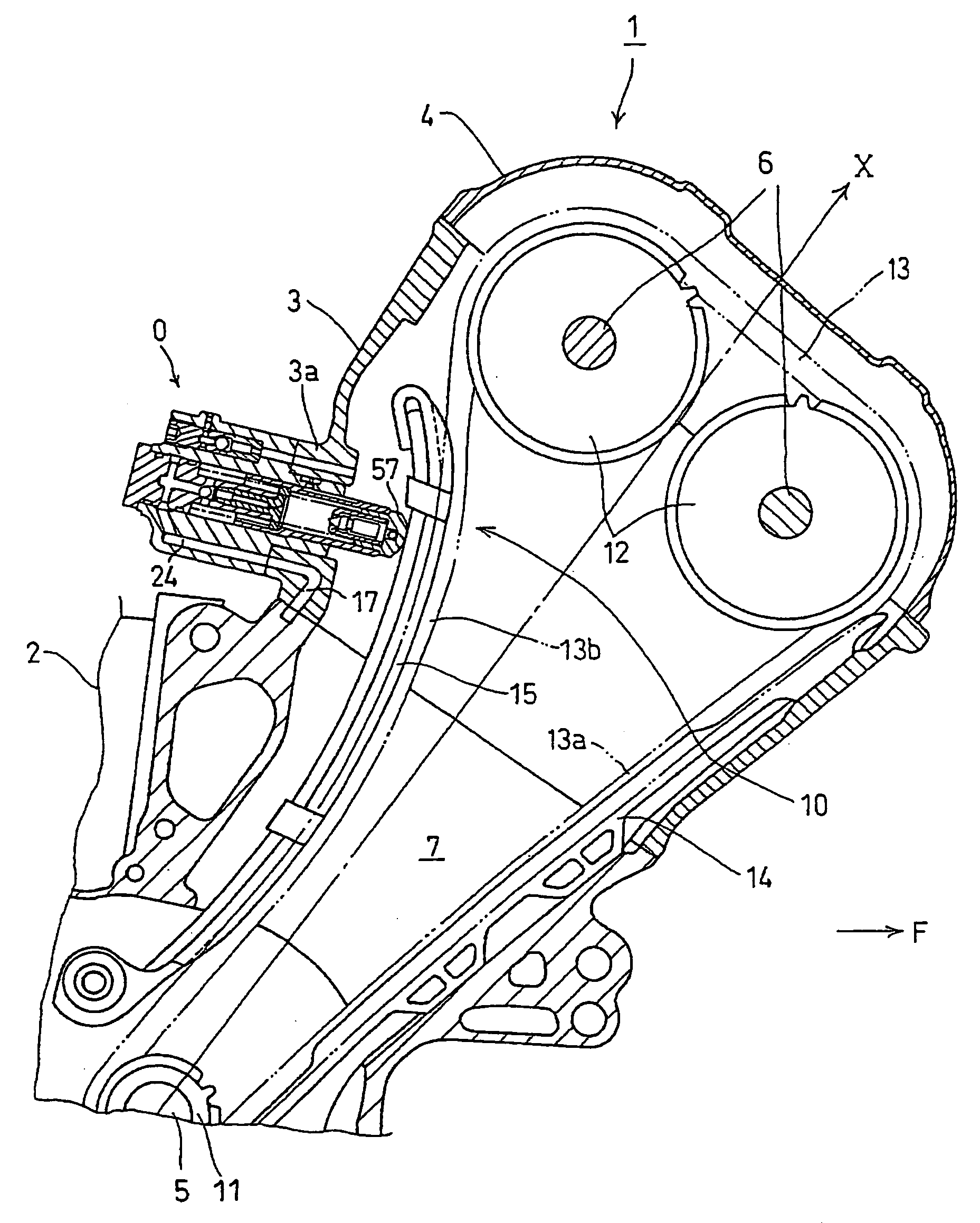

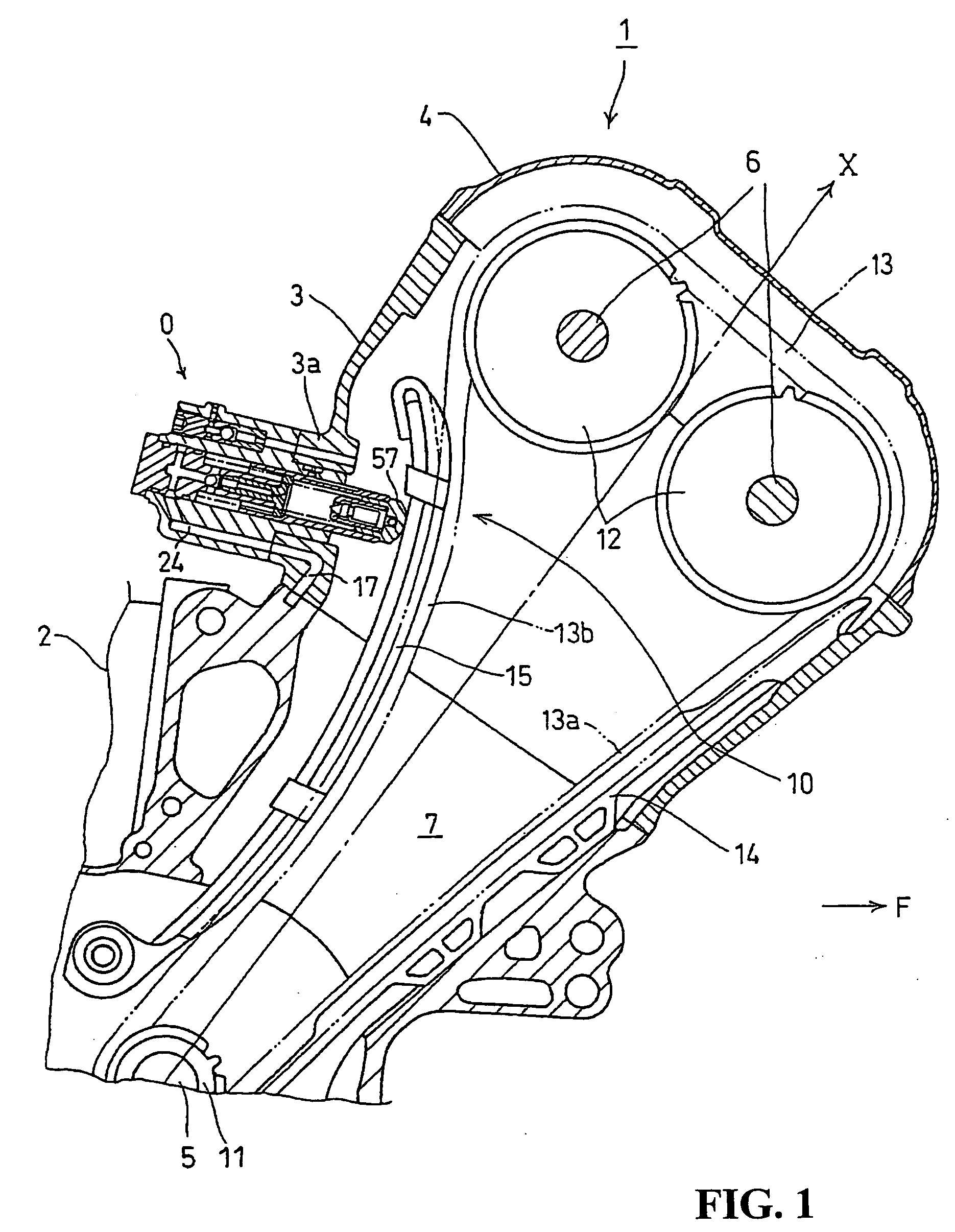

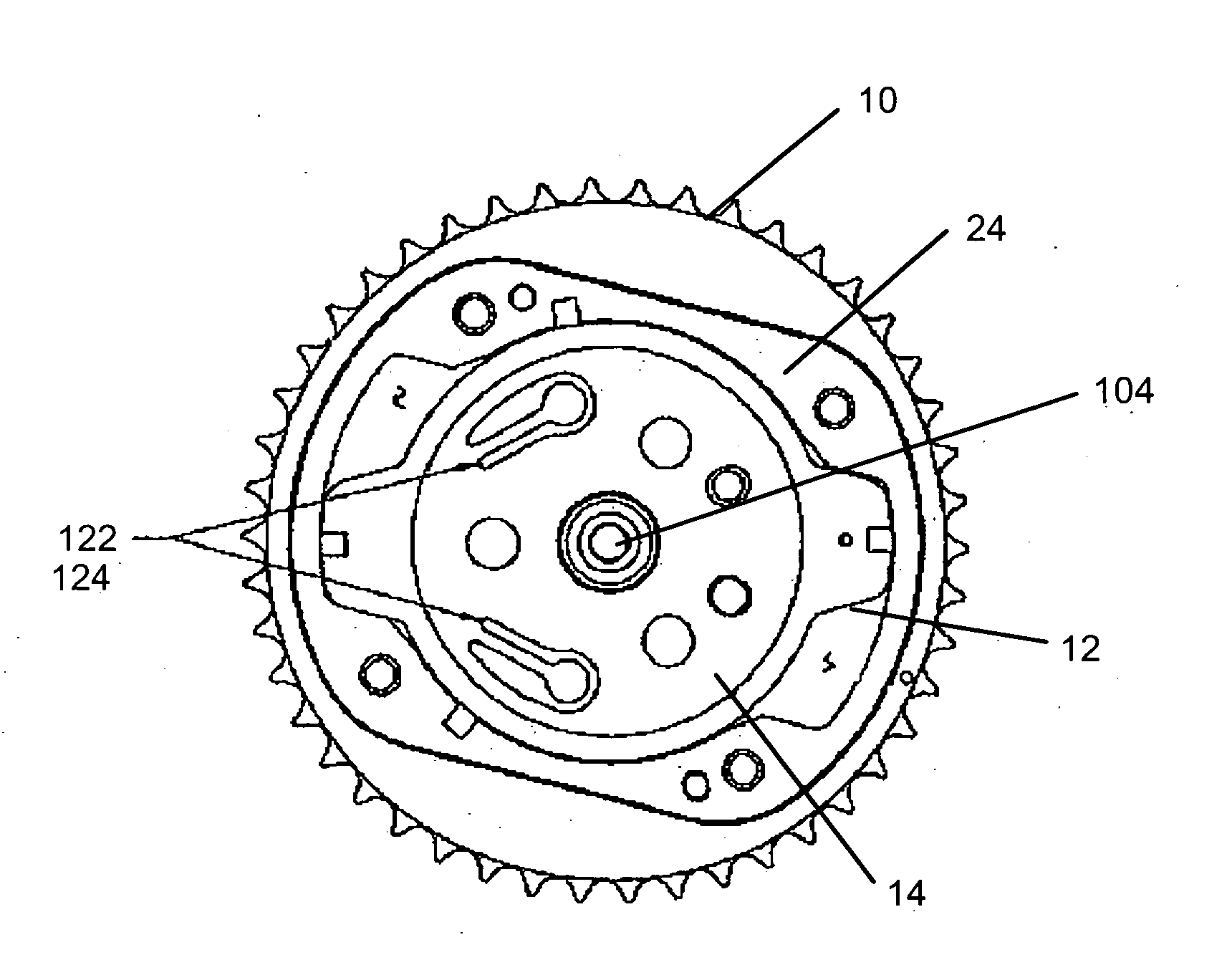

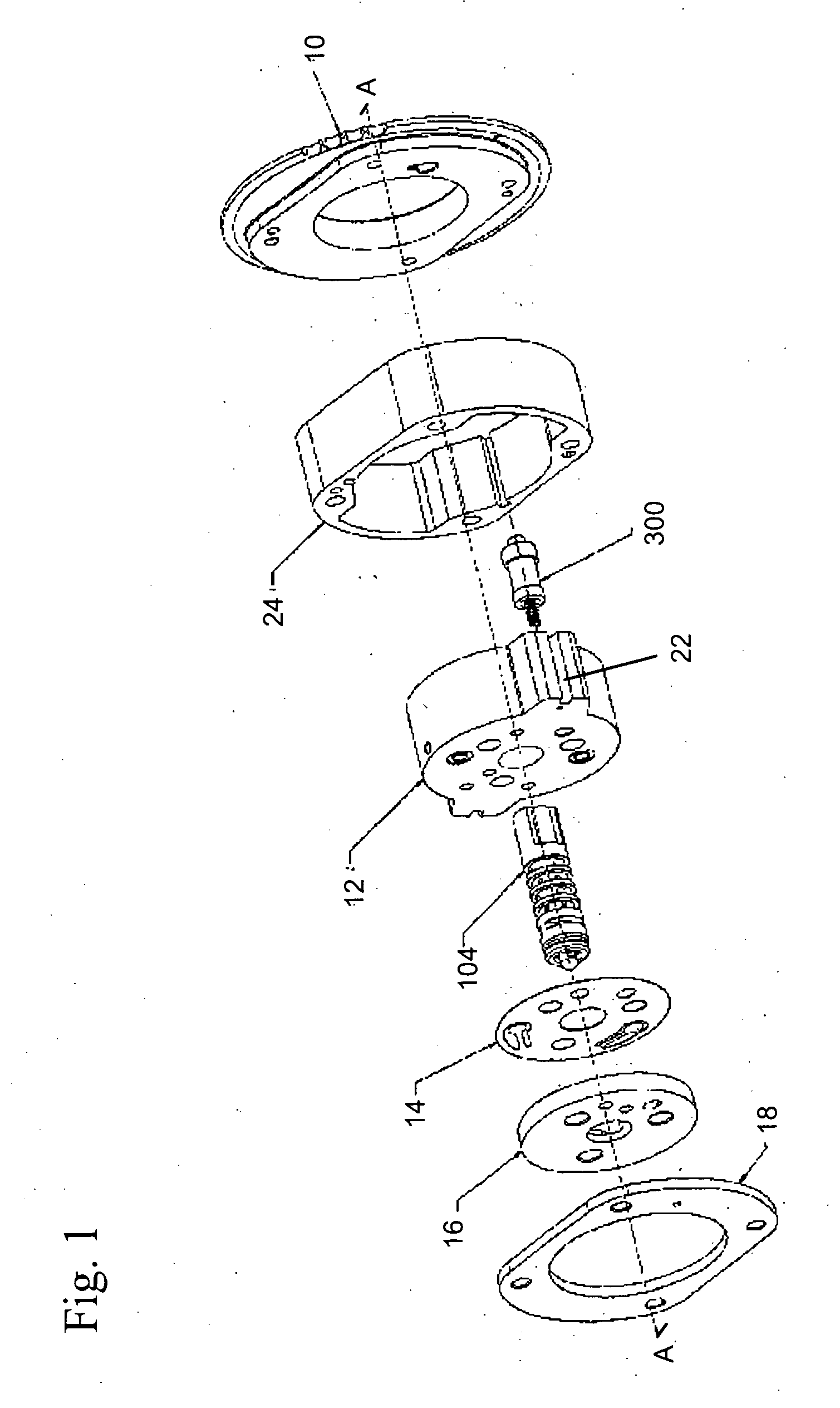

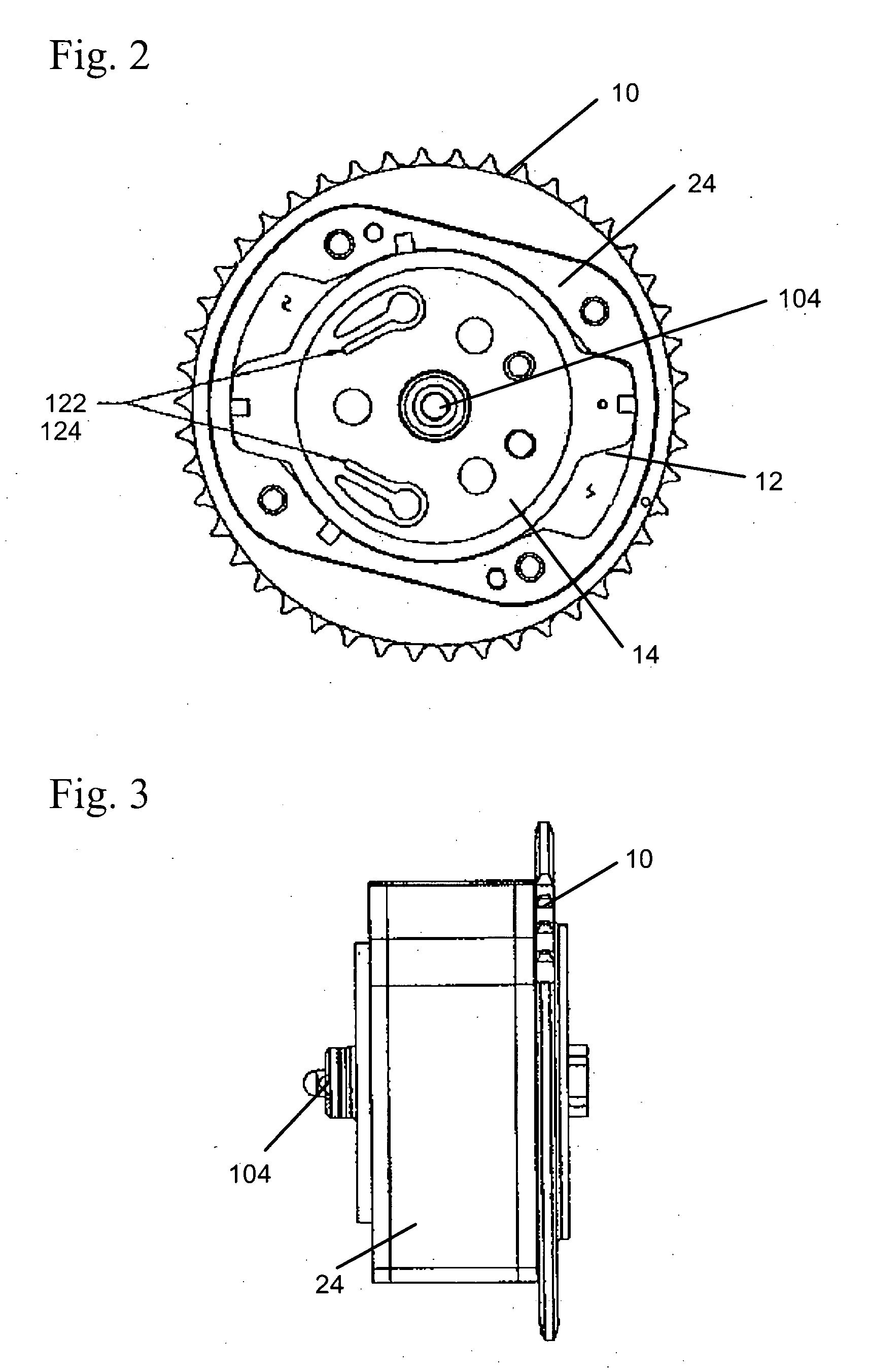

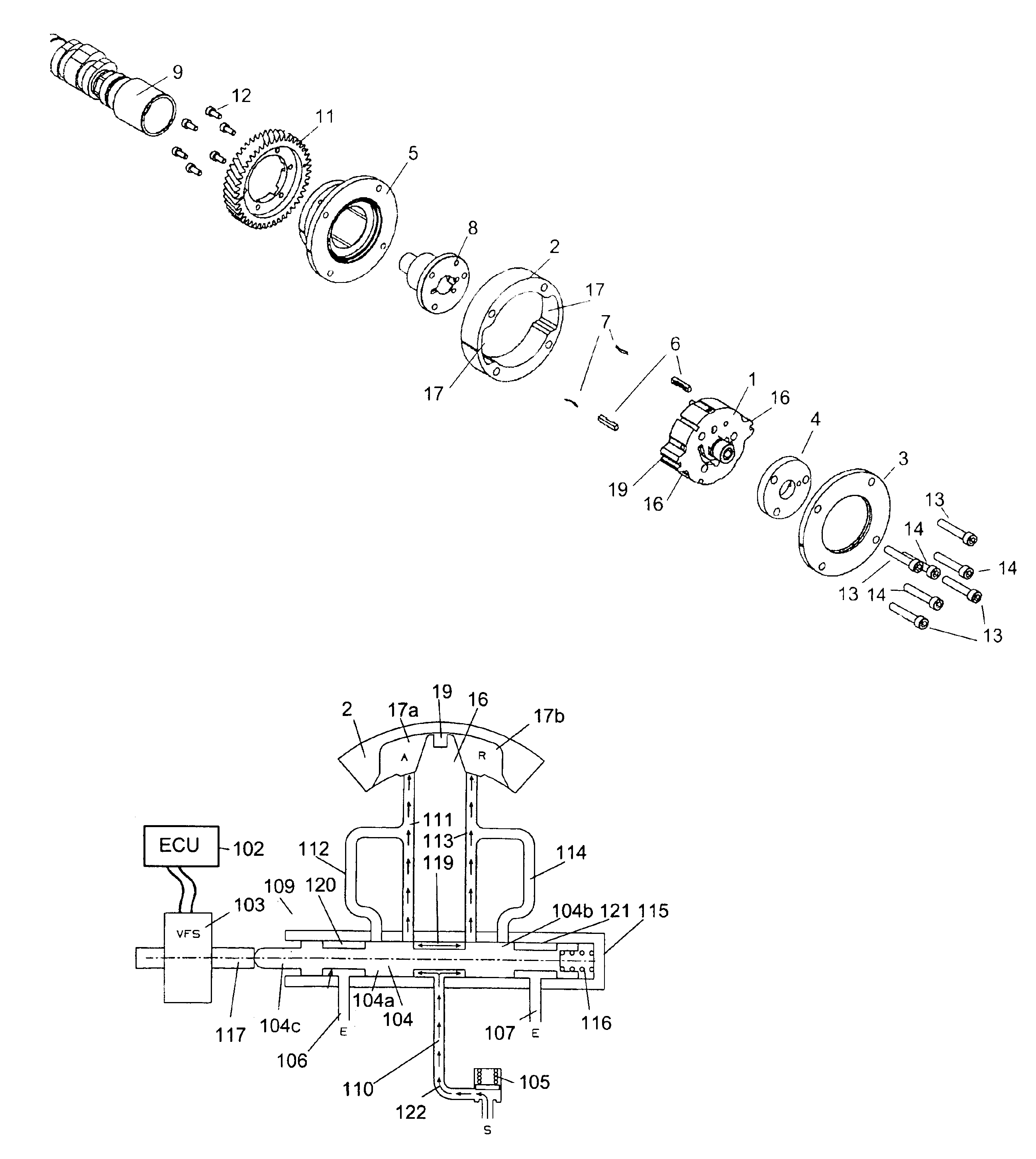

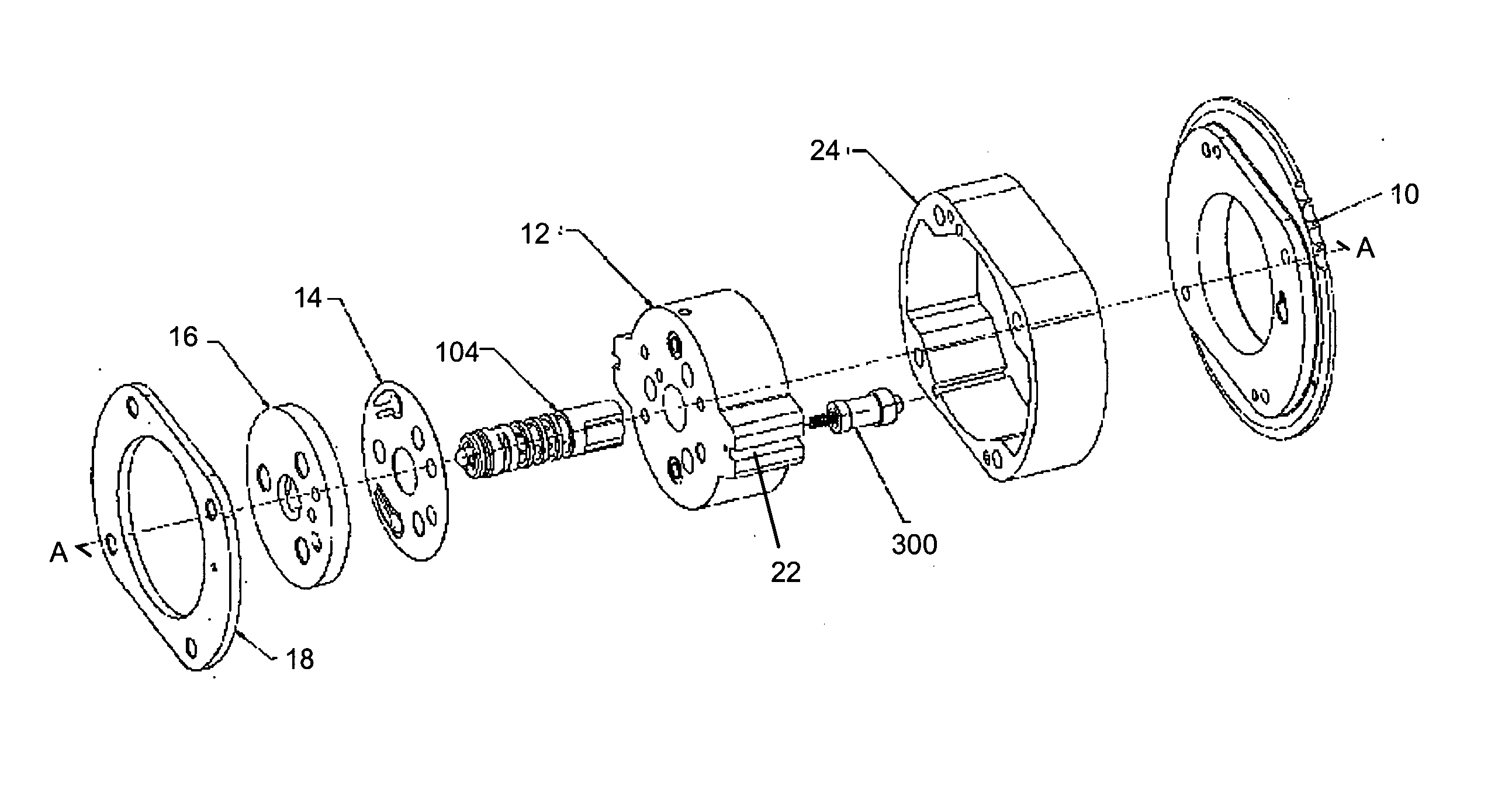

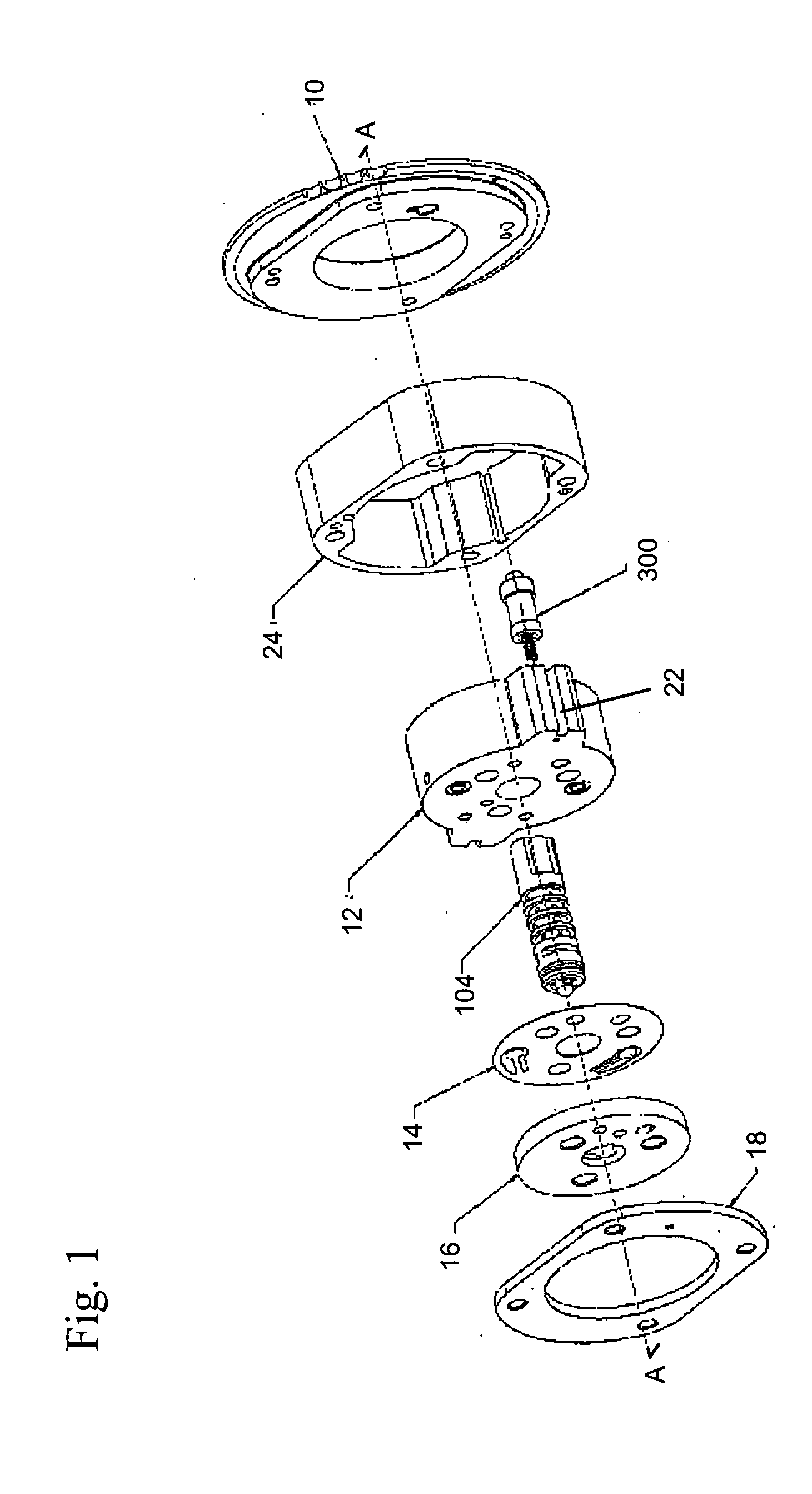

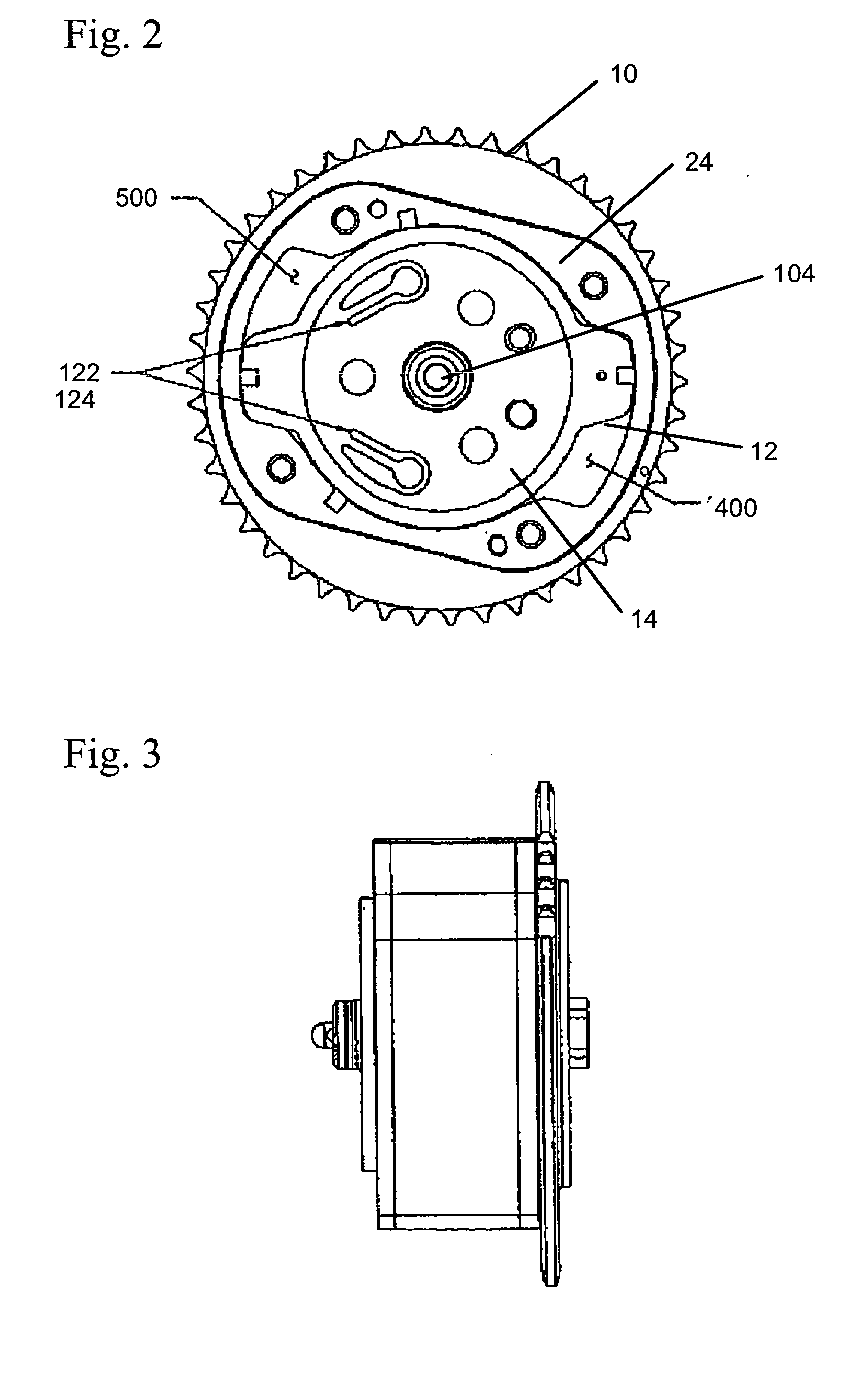

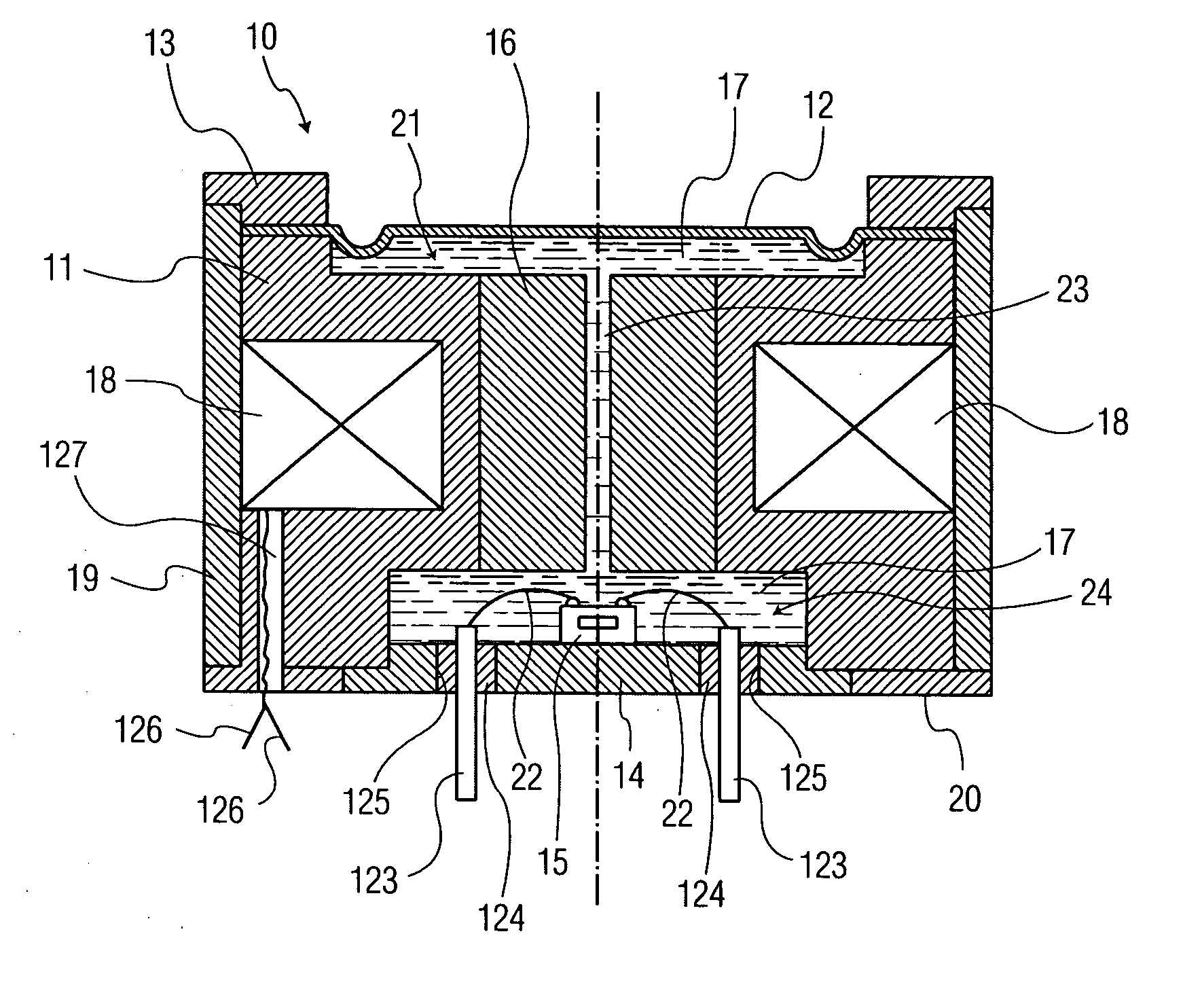

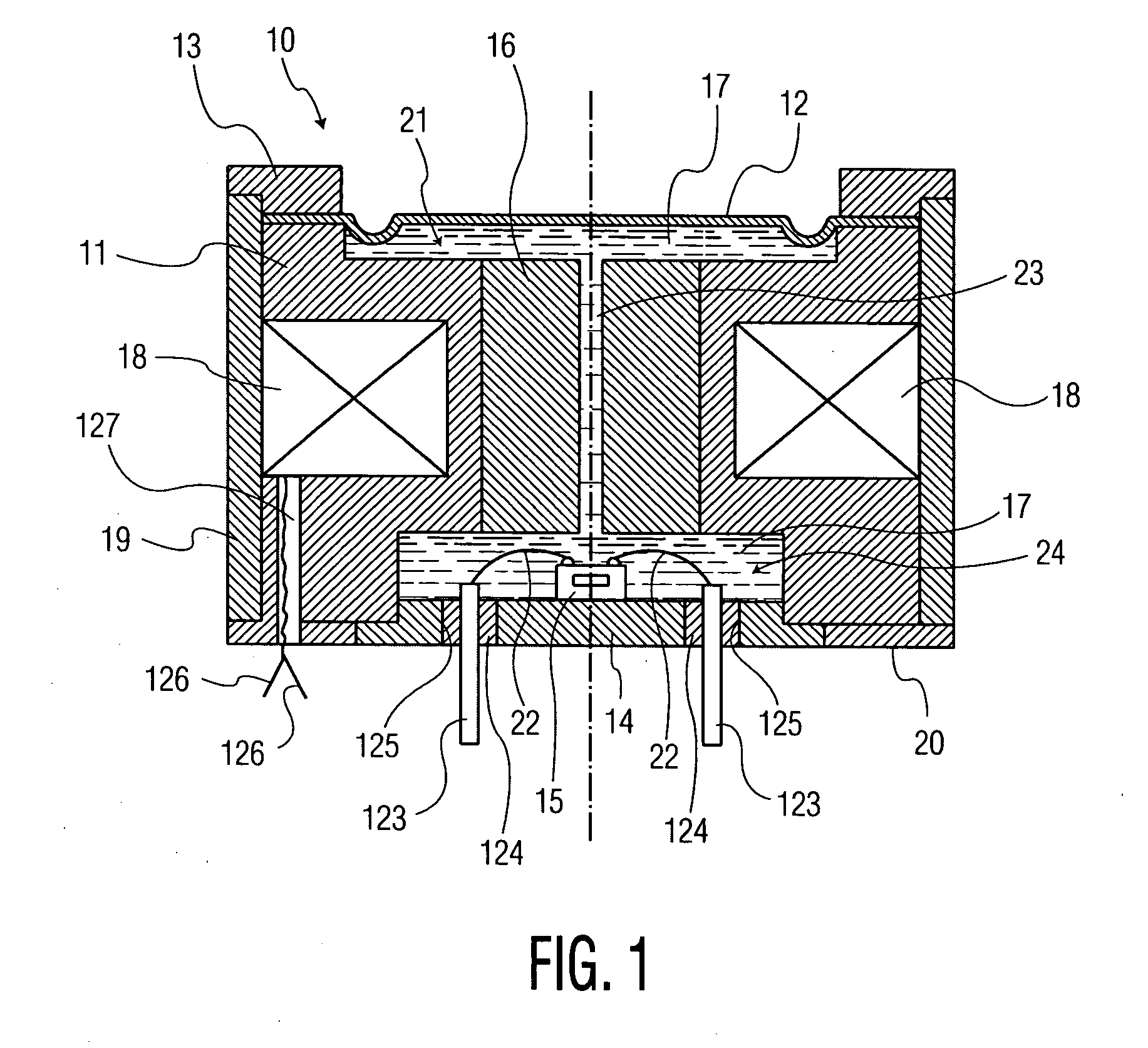

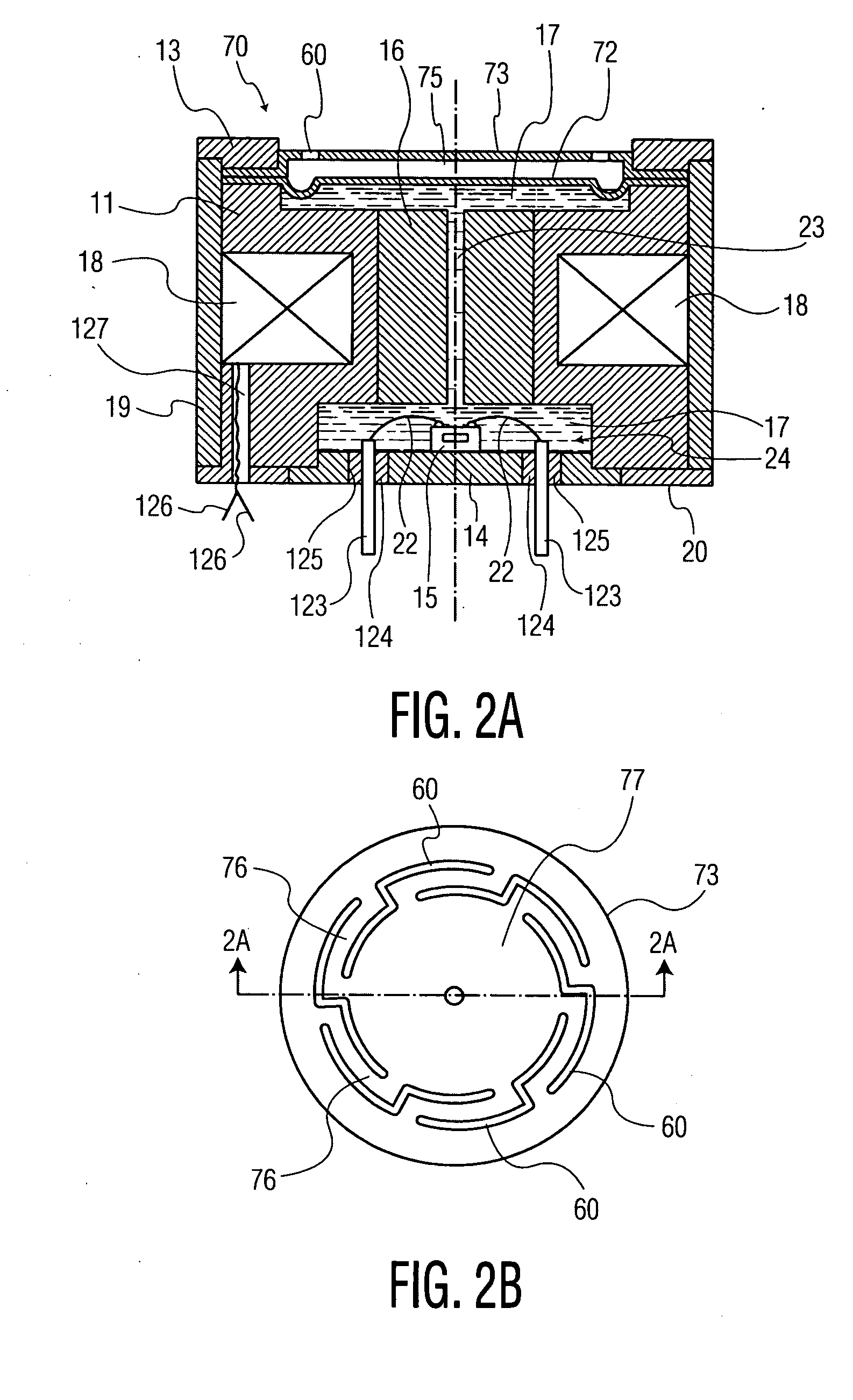

CTA phaser with proportional oil pressure for actuation at engine condition with low cam torsionals

A variable camshaft timing phaser for an internal combustion engine having at least one camshaft comprising a plurality of vanes in chambers defined by a housing and a spool valve. The vanes define an advance and a retard chamber. At least one of the vanes is cam torque actuated (CTA) and at least one of the other vanes is oil pressure actuated (OPA). The spool valve is coupled to the advance and retard chamber defined by the CTA vane and the advance chamber defined by the OPA vane. When the phaser is in the advance position, fluid is routed from the retard chamber defined by the OPA vane to the retard chamber defined the CTA vane. When the phaser is in the retard position, fluid is routed from the retard chamber defined by the CTA vane to the advance chamber defined by the CTA vane.

Owner:BORGWARNER INC

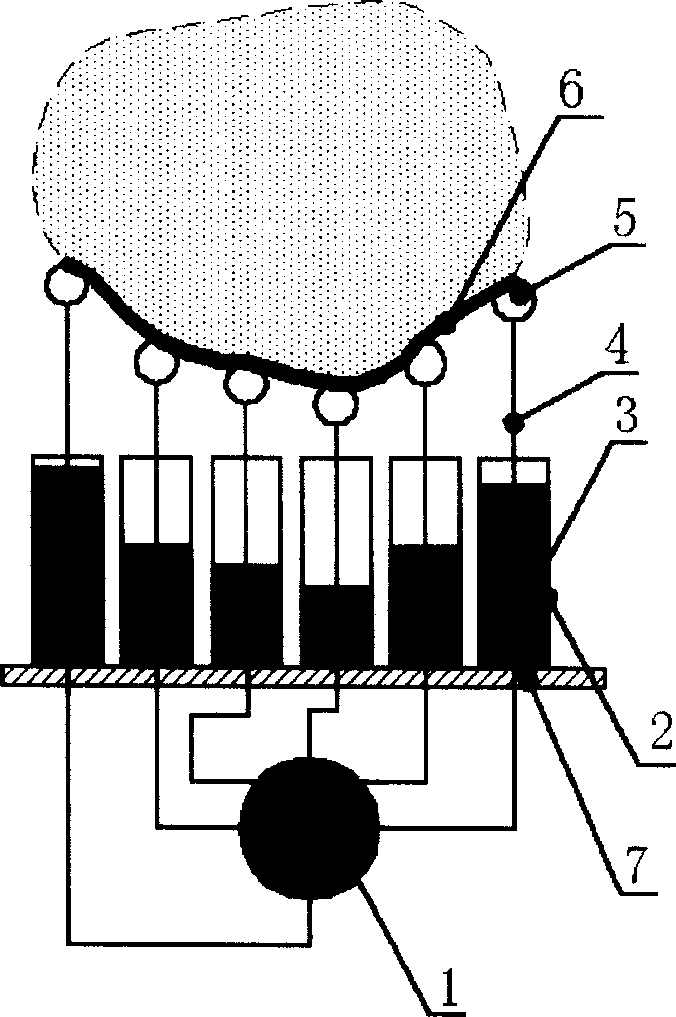

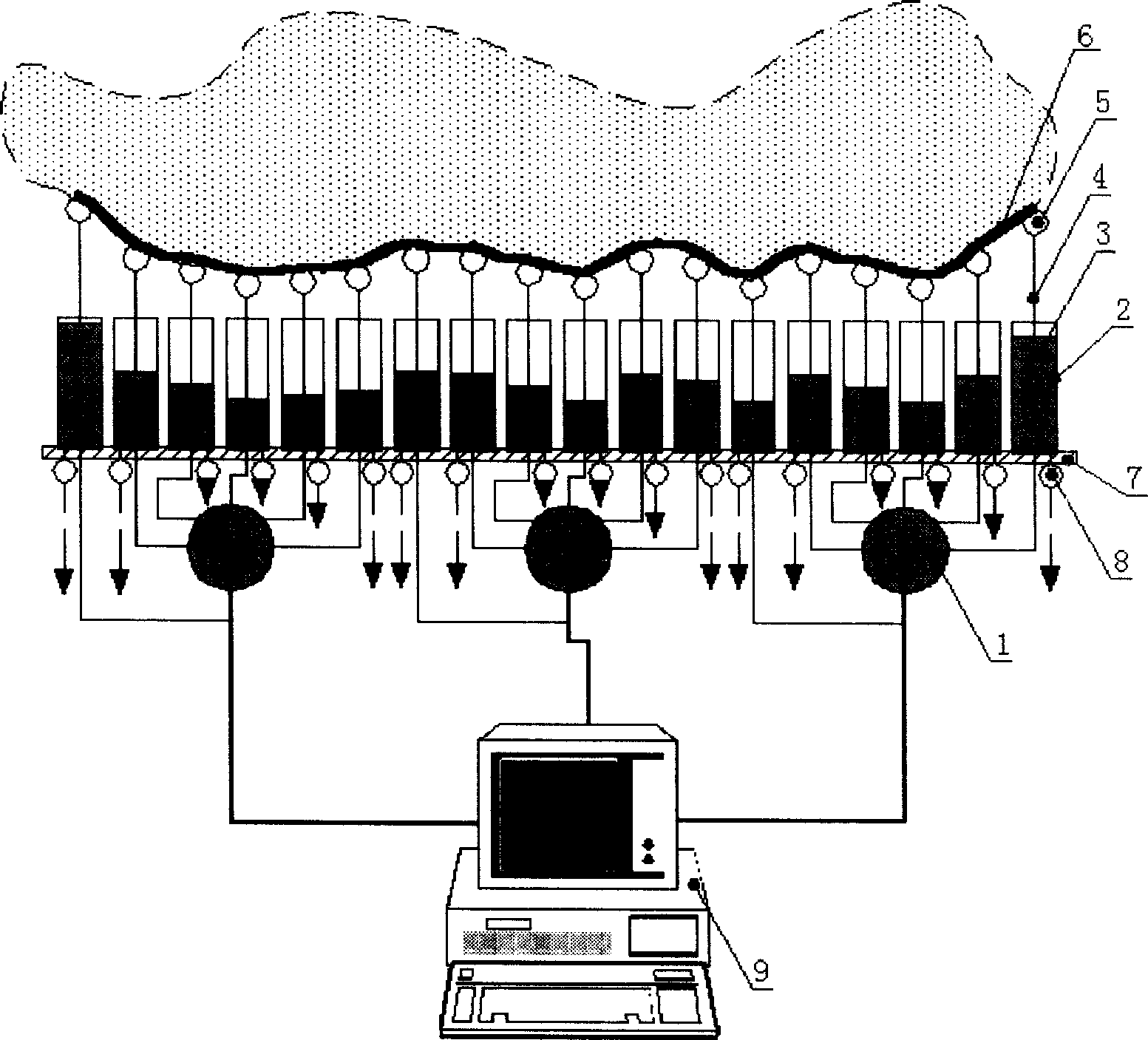

Clamping holder with rigidity changeable flexible surface

InactiveCN1799784AWith variable stiffnessWith flexible surfaceProgramme-controlled manipulatorPower flowManipulator

The invention relates to a method for producing robot, mechanical arm or mechanical clamp, belonging to the electromagnetic flowing deformation application technique. It comprises a flexible film and a support element, wherein, the support element is formed by hydraulic pistons in array and a multi-path magnetic flowing deformation valve; the hydraulic piston comprises a cylinder body and a piston with straight movement in said cylinder; the surface of flexible film is connected with piston end; the valve of multi-path magnetic flowing deformation has two or more connectors while each connector is through to the cylinder to form a sealed chamber to contain the magnetic flowing deformation liquid; two magnetic electrodes made from soft magnetic material are arranged inside the valve while their distance is at least 0.5mm; the magnetic deformation liquid can be replaced by electric flowing deformation liquid while the magnetic flowing deformation valve can be replaced by electric flowing deformation valve. Said invention can non-stepped adjust the rigidity of every position of flexible film via adjusting the voltage of multi-path flowing deformation valve or the magnetic field of multi-path flowing deformation valve, to apply the clamped matters in different rigidities and shapes.

Owner:UNIV OF SCI & TECH OF CHINA

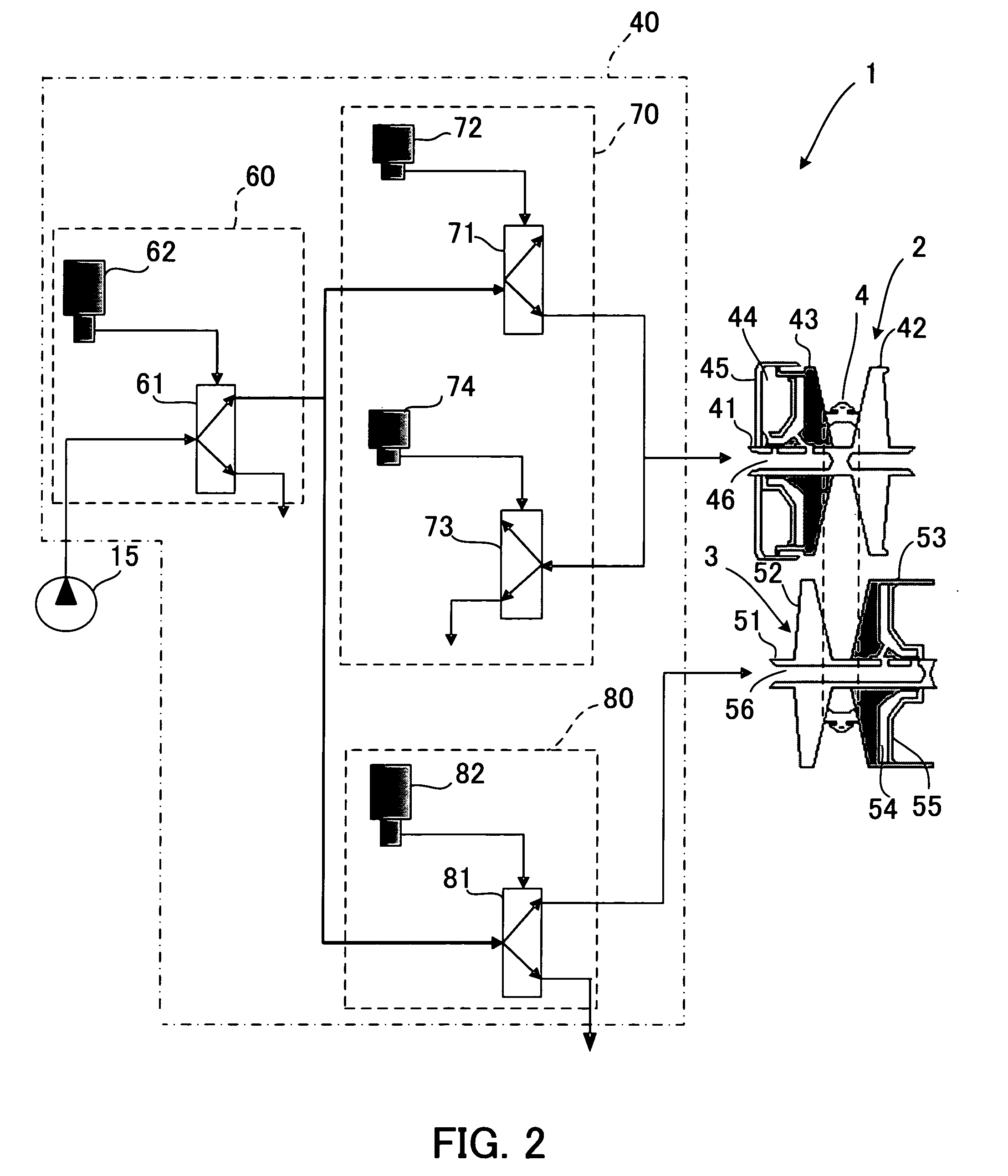

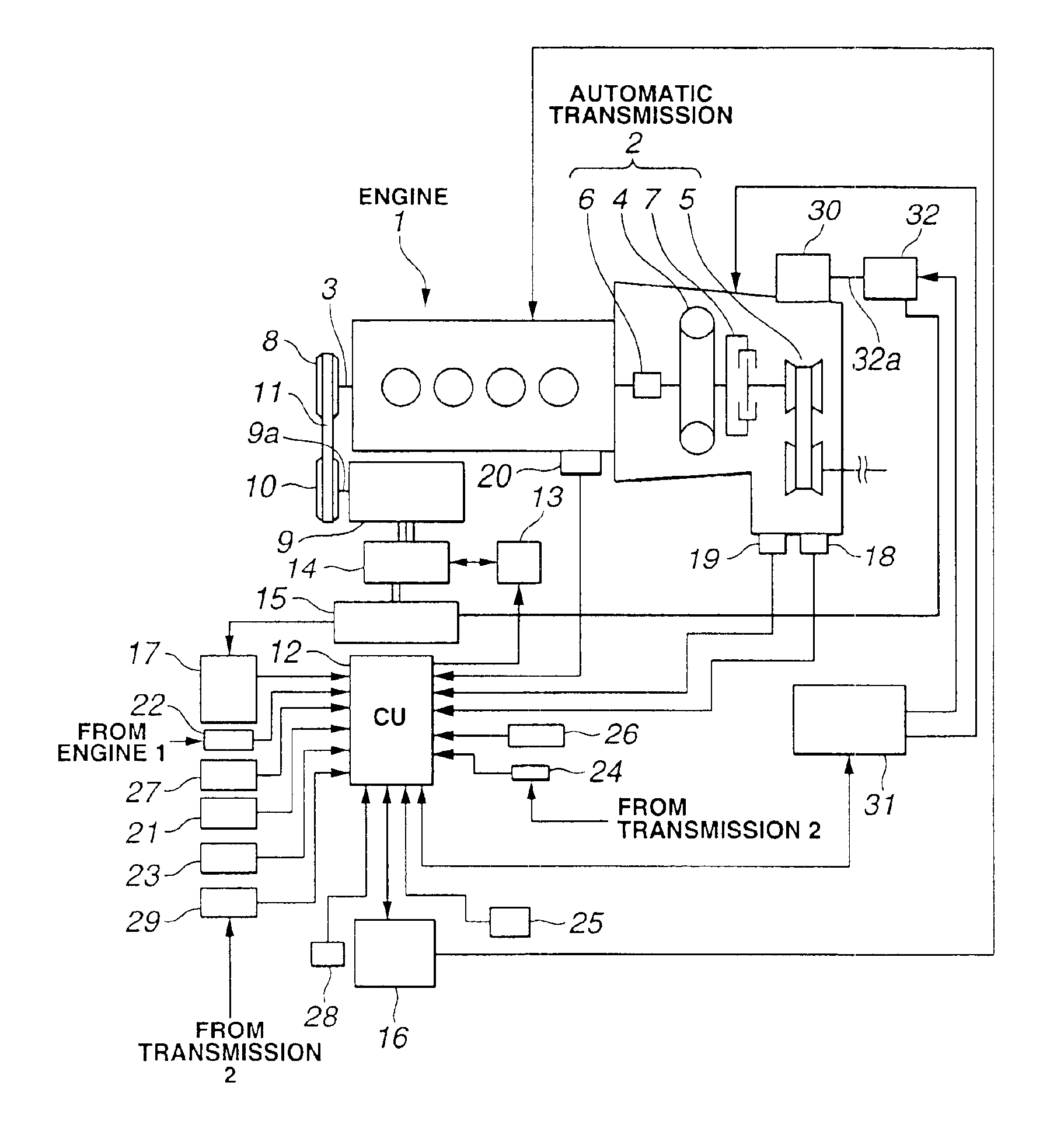

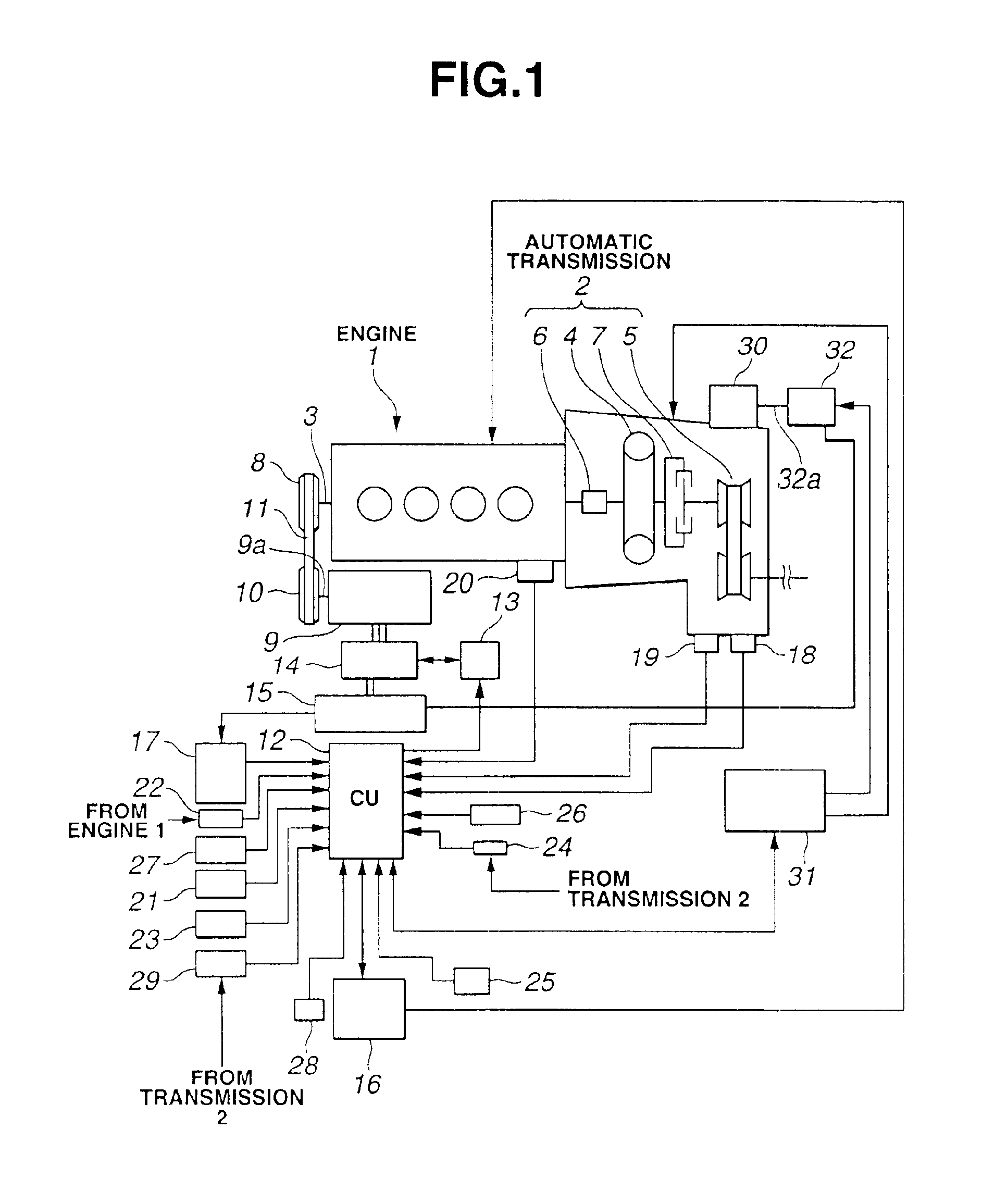

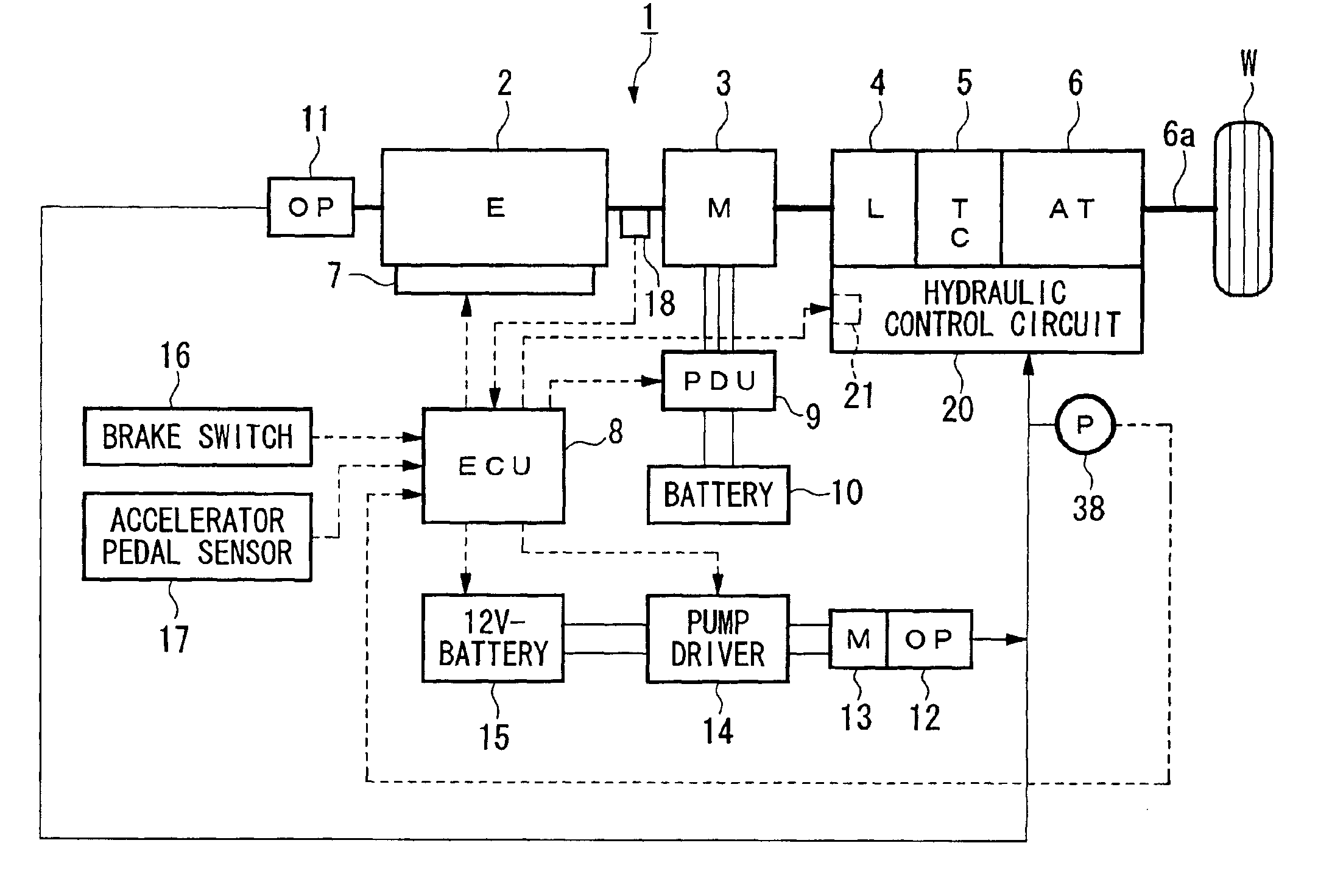

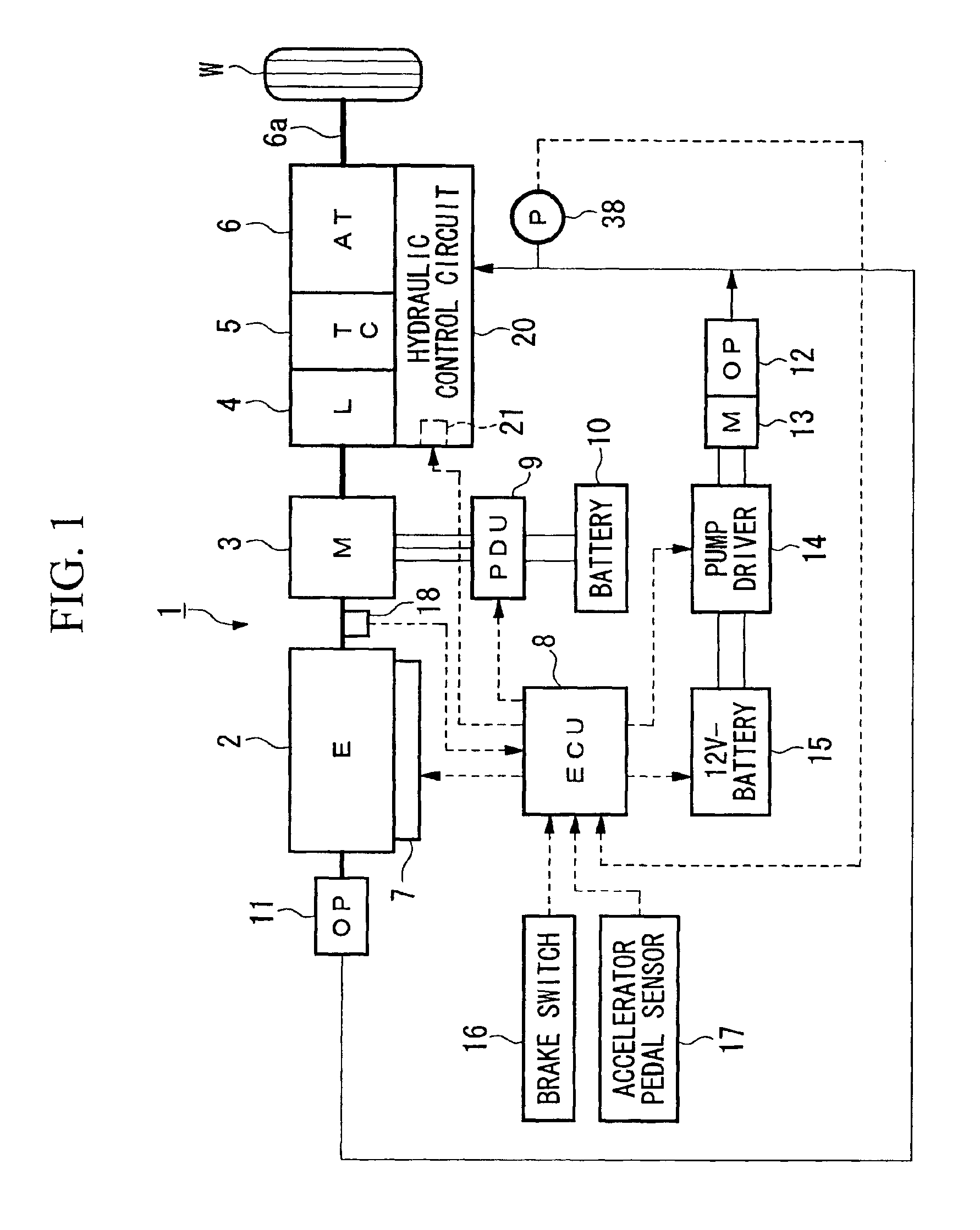

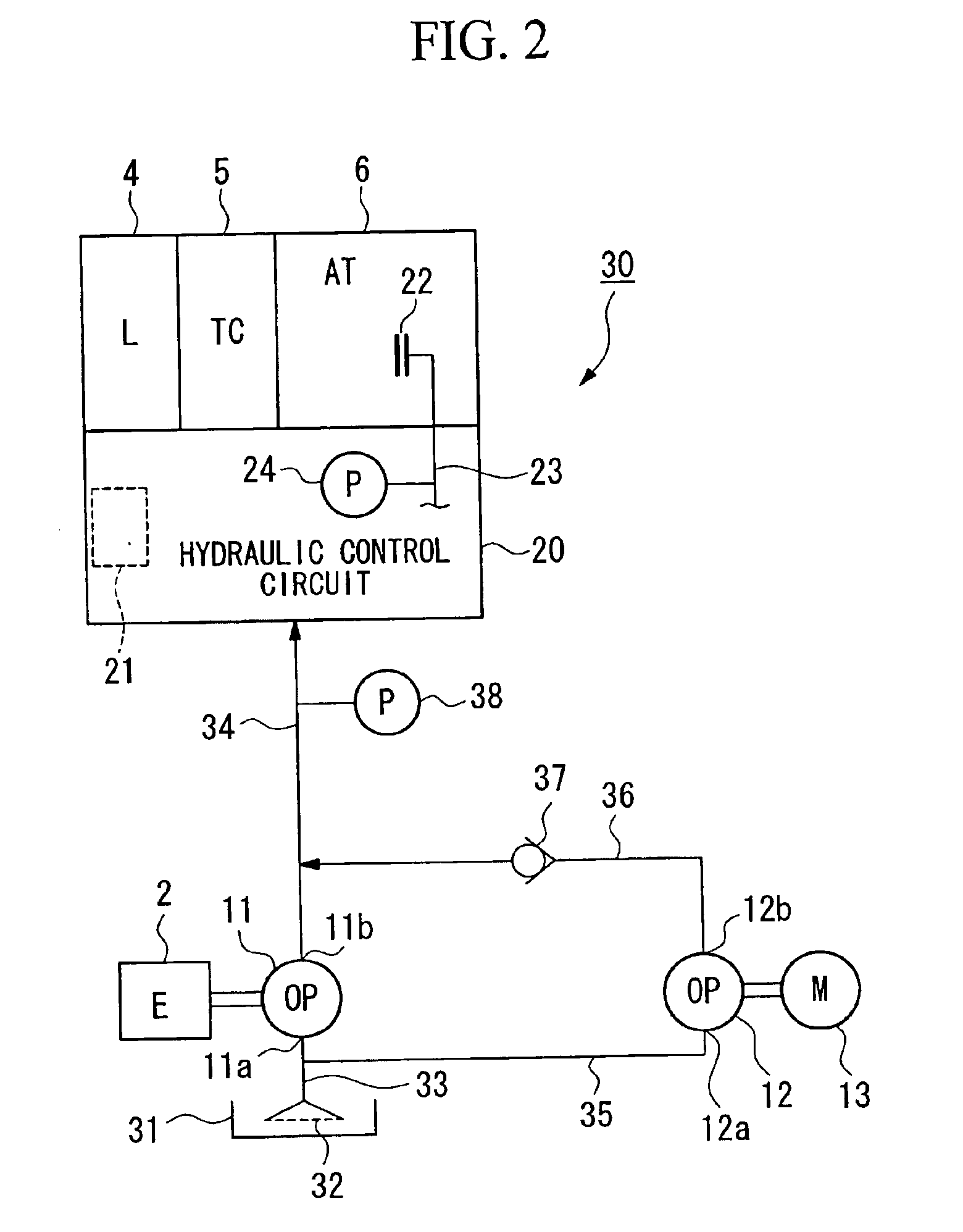

Hydraulic control apparatus for hybrid vehicle

InactiveUS7041030B2Smooth transmissionClutchesInternal combustion piston enginesMotor driveTorque transmission

A hydraulic control apparatus for a hybrid vehicle, which enables a smooth torque transmission when an engine of the vehicle is started from an idling stop state. The hydraulic control apparatus includes an engine and a motor as power sources, a transmission having a torque converter, a clutch for a starting gear, an engine automatic stop and start device which is associated with the engine, a motor-driven oil pump for supplying oil pressure to the transmission, a brake pedal sensor, an accelerator pedal sensor, an engine revolution rate sensor. The oil pressure applied to the clutch is controlled to a level corresponding to a creeping torque when the engine is automatically stopped. When the brake pedal is released, the engine is automatically started, the accelerator pedal is not depressed, and the engine revolution rate is less than an idling revolution rate, the oil pressure applied to the clutch is maintained to the level corresponding to the creeping torque.

Owner:HONDA MOTOR CO LTD +1

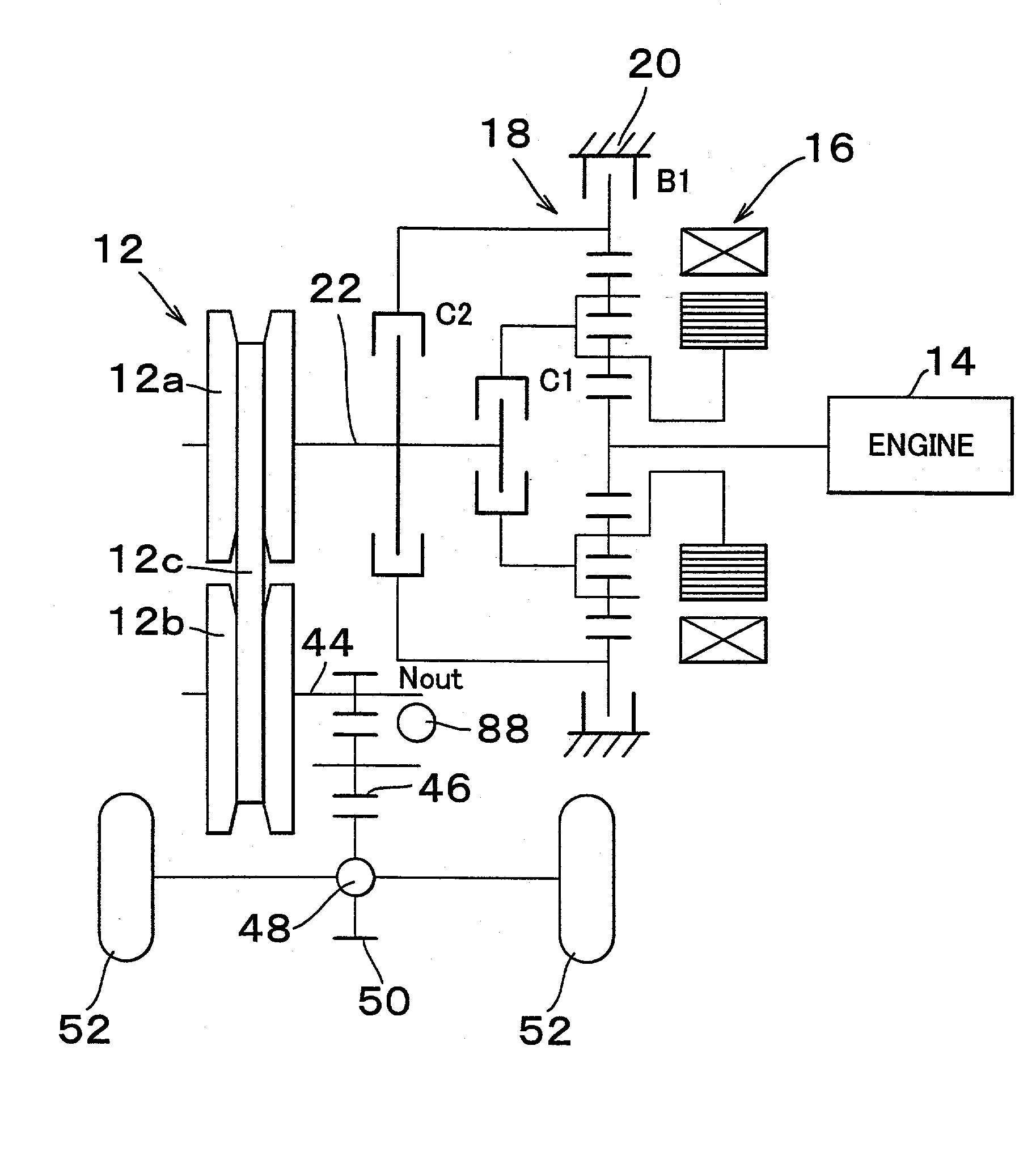

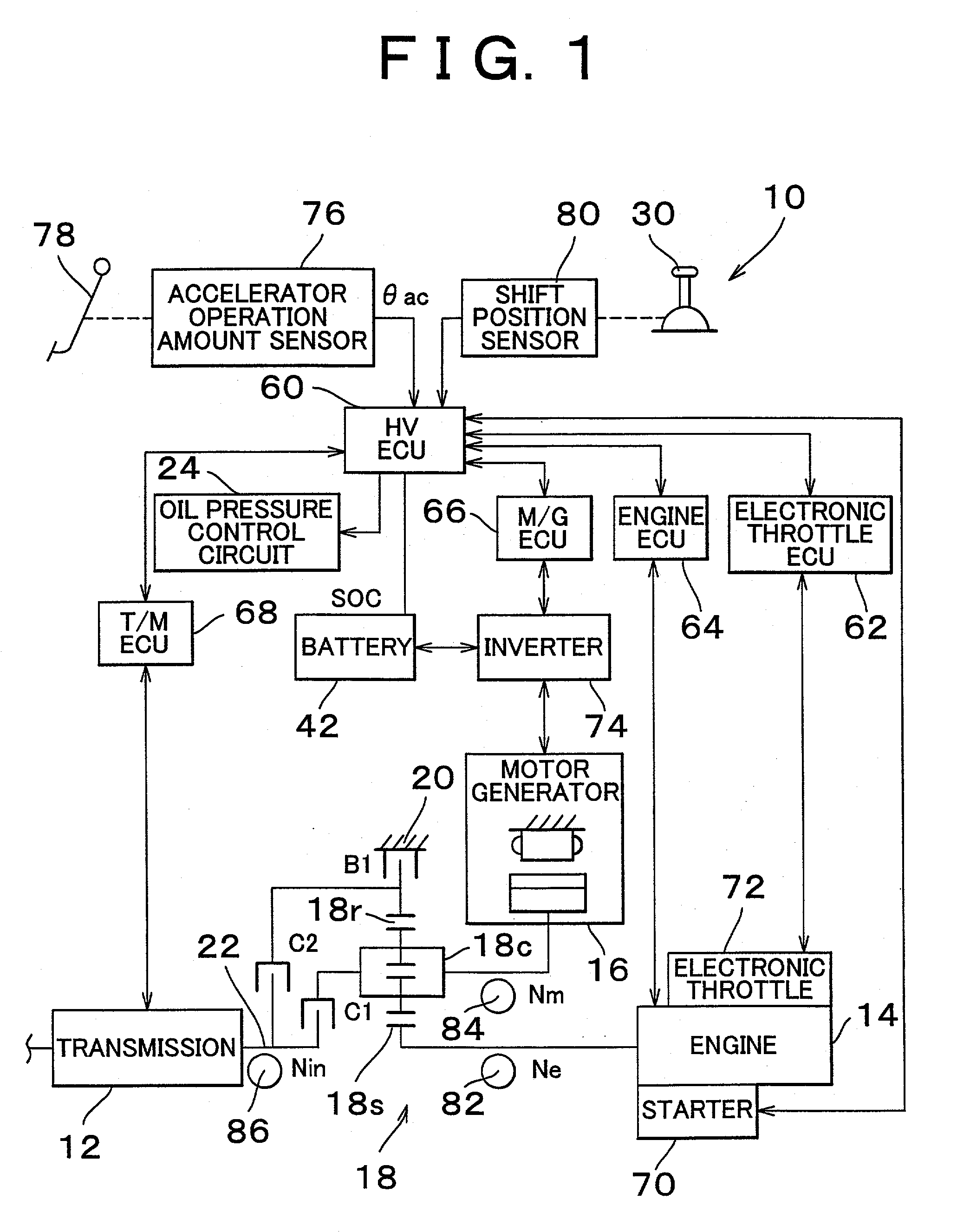

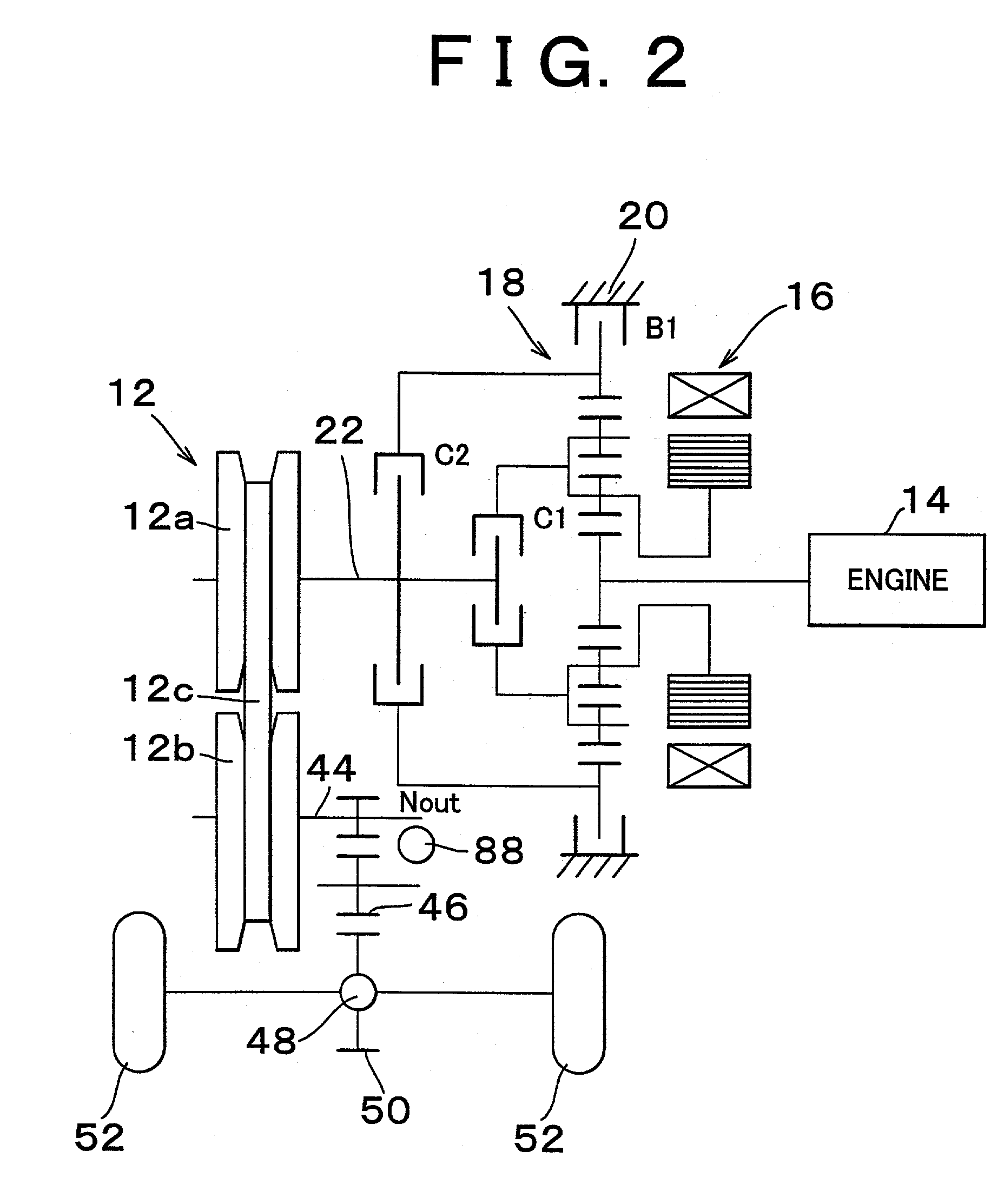

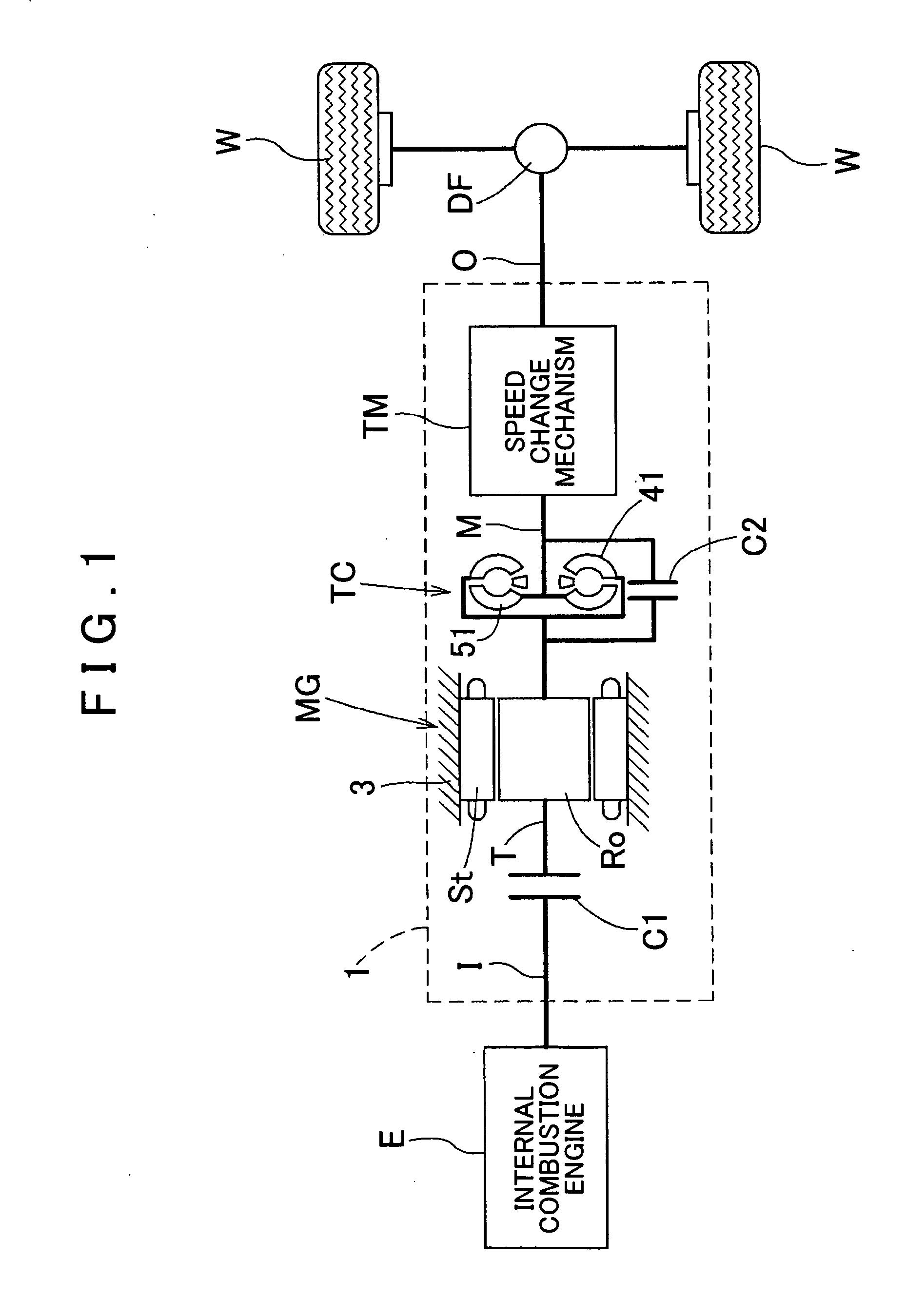

Vehicle drive control apparatus and method

InactiveUS20020173391A1Solve insufficient capacityReduce power transmission lossesElectric propulsion mountingGearingDevice WheelControl theory

Methods and apparatus for a vehicle drive control apparatus changes in the transfer torque capacity of a power transfer device according to various states of operation with respect to at least one drive power source. The vehicle drive control apparatus includes a power transfer device that has a variable transfer torque capacity and the drive power sources that rotate a device wheel via the power transfer device. A controller is included that causes a vehicle to selectively run in a variety of run modes that differ in states of operation with respect to at least one of the drive power sources. The controller changes the transfer torque capacity of the power transfer device in accordance with the various run modes. According to the vehicle device control apparatus, a target oil pressure is raised by a predetermined amount when the mode of run is change, or when the vehicle descends in a direction opposite to a vehicle starting direction at the time of a hill climb start.

Owner:TOYOTA JIDOSHA KK

Torsional assisted multi-position cam indexer having controls located in rotor

InactiveUS6883481B2Reduce leakageImprove responseYielding couplingValve drivesControl systemEngineering

An infinitely variable cam indexer utilizes engine oil pressure to actuate a cam and preferably uses an inlet check valve in the oil source to minimize back flow during a torque reversal. The control system is in the center of the rotor and uses an electromechanical actuator, preferably a variable force solenoid, acting directly on the spool to control oil flow. This design reduces leakage and improves the response of the phaser. There are shorter oil passages as compared to a control system mounted at the cam bearing.

Owner:BORGWARNER INC

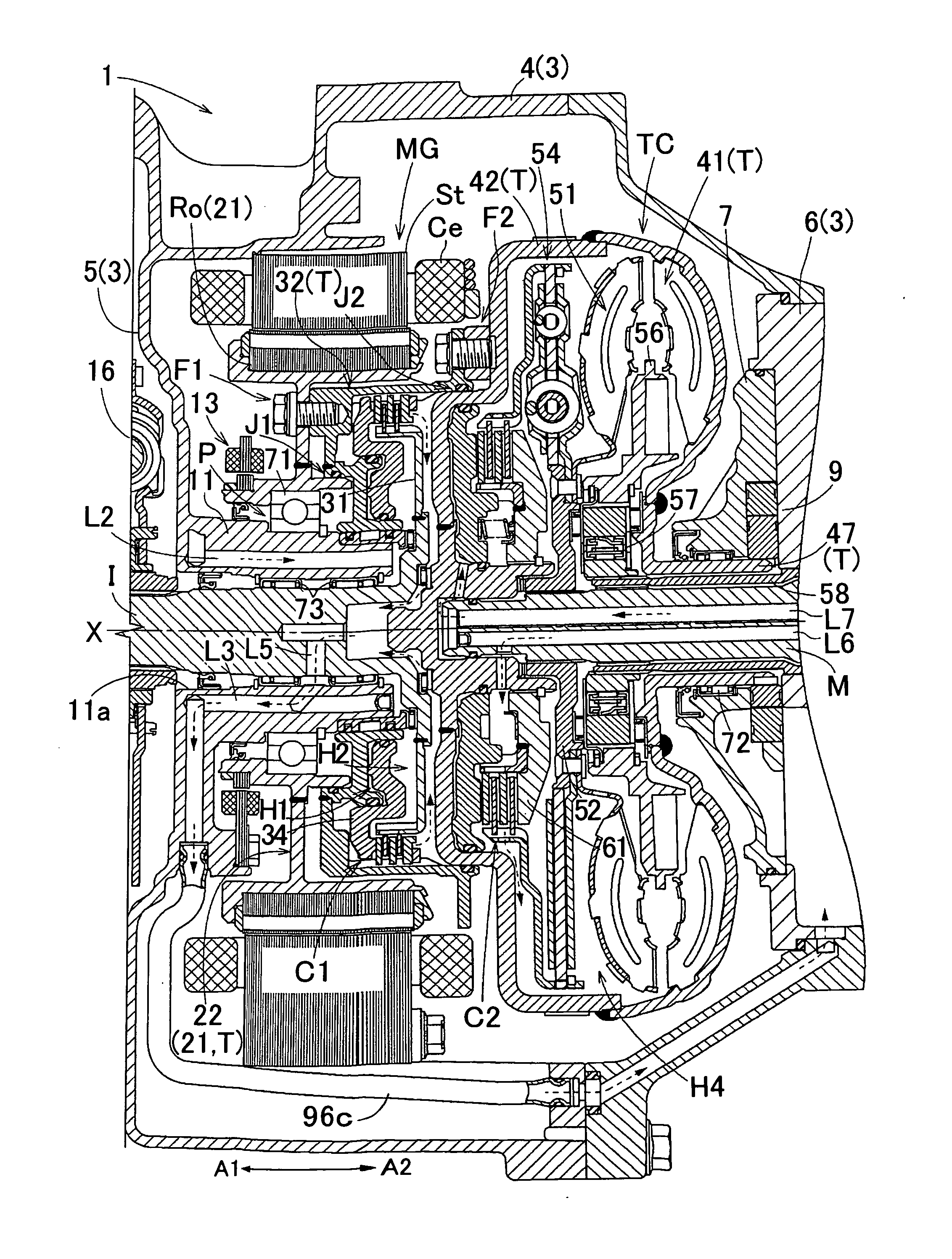

Vehicle drive device

ActiveUS20110240430A1Improve cooling effectImprove manufacturabilityRotary clutchesGear lubrication/coolingFluid couplingElectric machine

A drive device for a vehicle configured between an internal combustion engine and a wheel. The drive device includes a rotary electric machine, and an engagement device connecting the drive device to the engine by a fluid coupling using hydraulic pressure. A case houses at least a portion of the drive device and includes a support wall extending radially, and a cylindrical projecting portion projecting from the support wall toward a side in an axial second direction that is in a direction opposite to the axial first direction. The engagement device includes an operating oil pressure chamber supplied with the hydraulic pressure. A rotor member of the rotary electric machine is radially supported by the cylindrical projecting portion in a rotatable state via a support bearing. The cylindrical projecting portion is formed with an operating oil supply passage supplying oil to the operating oil pressure chamber.

Owner:AISIN AW CO LTD +1

CTA phaser with proportional oil pressure for actuation at engine condition with low cam torsionals

ActiveUS20050103297A1Yielding couplingOscillating piston enginesSpool valveInternal combustion engine

A variable camshaft timing phaser for an internal combustion engine having at least one camshaft comprising a plurality of vanes in chambers defined by a housing and a spool valve. The vanes define an advance and retard chamber. At least one of the vanes is cam torque actuated (CTA) and at least one of the other vanes is oil pressure actuated (OPA). The spool valve is coupled to the advance and retard chamber defined by the CTA vane and the advance chamber defined by the OPA vane. When the phaser is in the advance position, fluid is routed from the retard chamber defined by the OPA vane to the retard chamber defined the CTA vane. When the phaser is in the retard position fluid is routed from the retard chamber defined by the CTA vane to the advance chamber defined by the CTA vane.

Owner:BORGWARNER INC

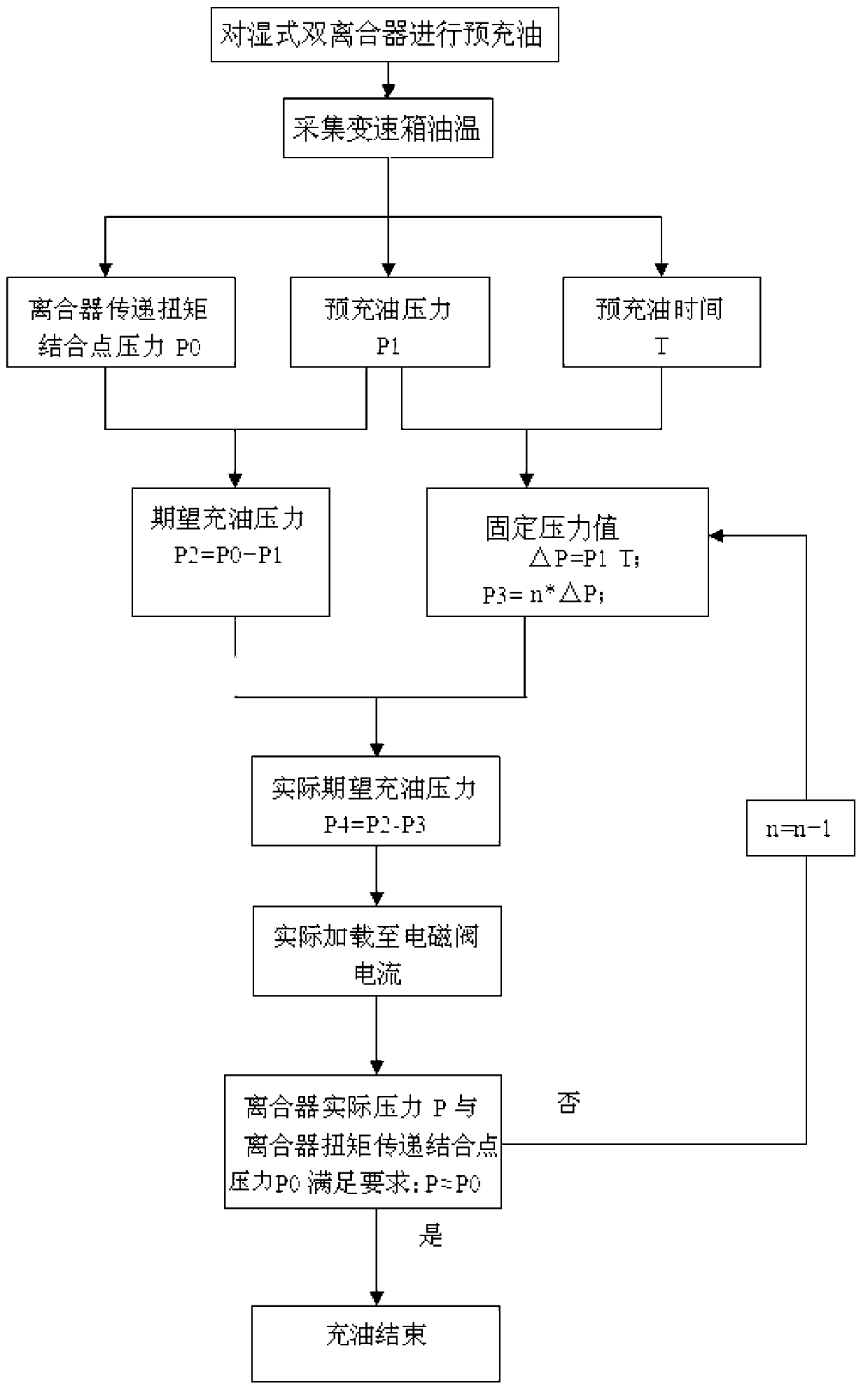

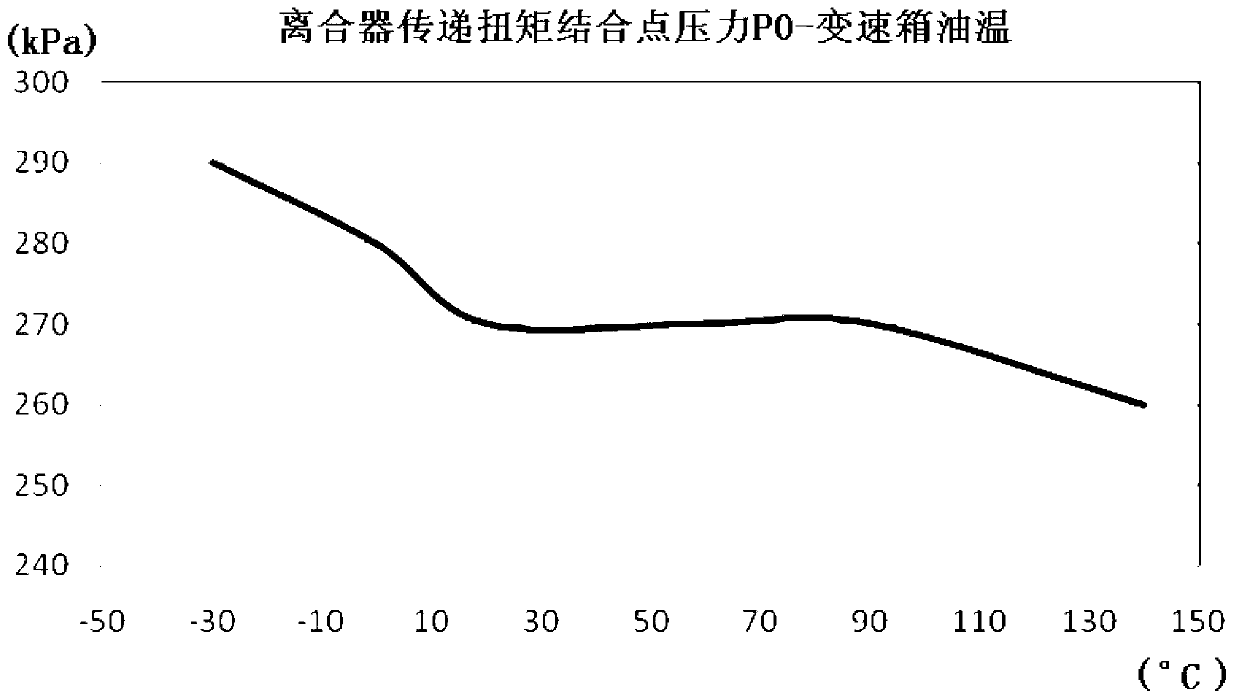

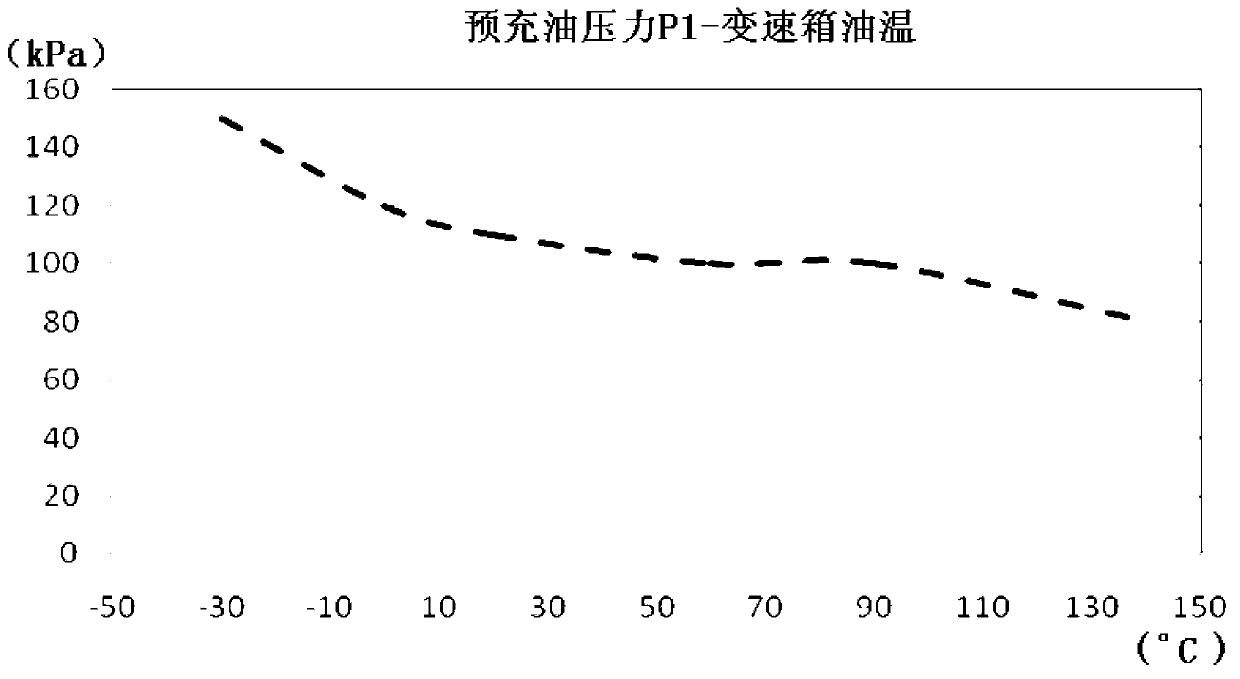

Wet dual-clutch automatic transmission and precharging pressure control method thereof

The invention discloses a wet dual-clutch automatic transmission and a precharging pressure control method thereof. The control method includes the steps: 1, performing oil precharging on duel wet clutches; 2, acquiring clutch torque transmission combination point pressure P0 and oil precharging pressure P1 according to acquired transmission oil temperature; 3, acquiring actual expected oil charging pressure P4 according to the formula that P4=P0+P1; 4, loading electromagnetic valve current corresponding to the P4 to an electromagnetic valve of the clutches according to the actual expected oil charging pressure P4; 5, measuring actual pressure P of the clutches, judging difference between the actual pressure P of the clutches and the clutch torque transmission combination point pressure P0 is within a preset error range or not, if so, executing a step 6, and otherwise, subtracting a fixed pressure value delta P from the actual expected oil charging pressure P4, and then executing the step 4; and 6, finishing oil charging. During oil precharging of the clutches, oil can be charged into a hydraulic oil chamber of each clutch quickly, oil pressure is established, conditions for torque transmission are satisfied, and response is rapid.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

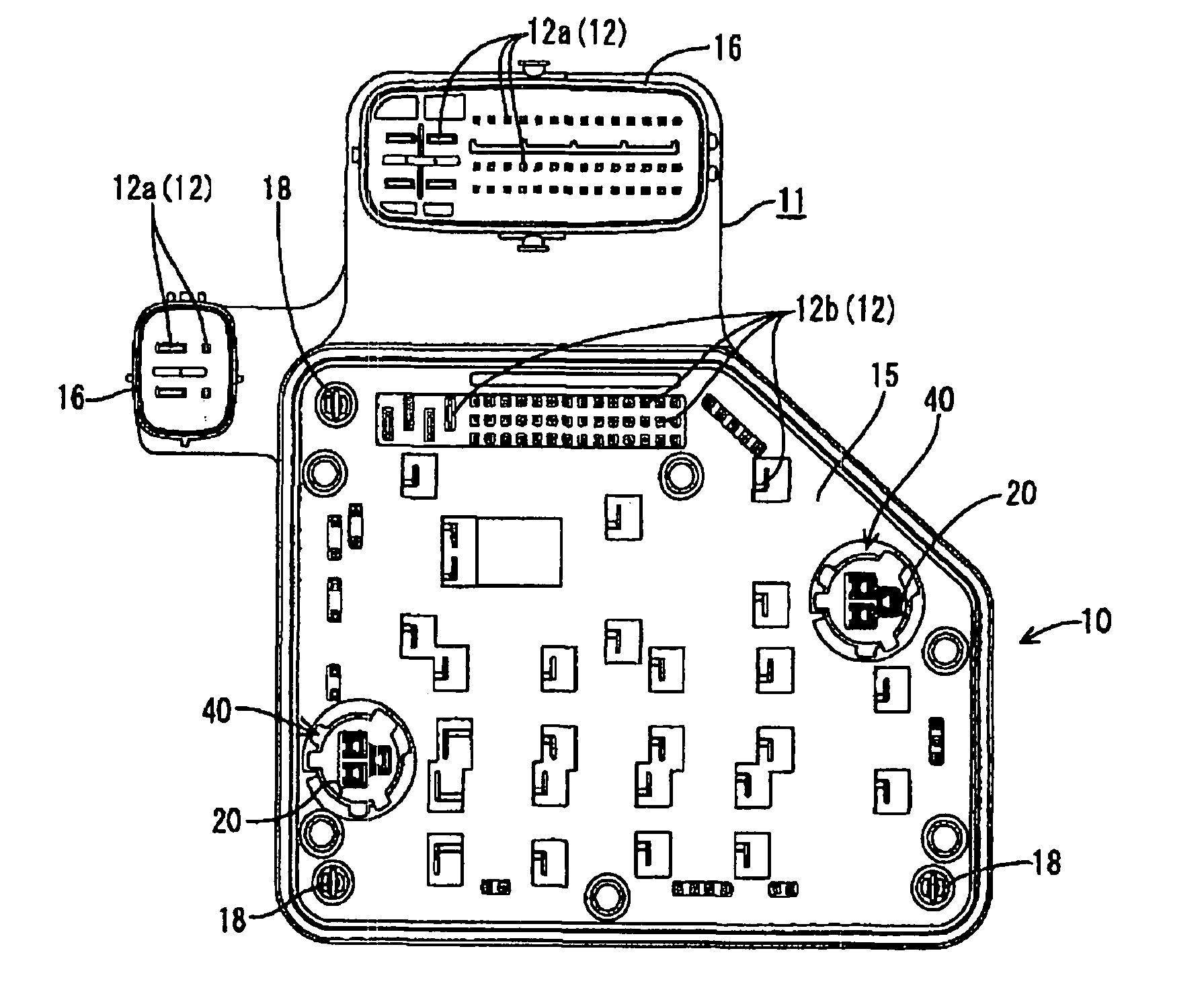

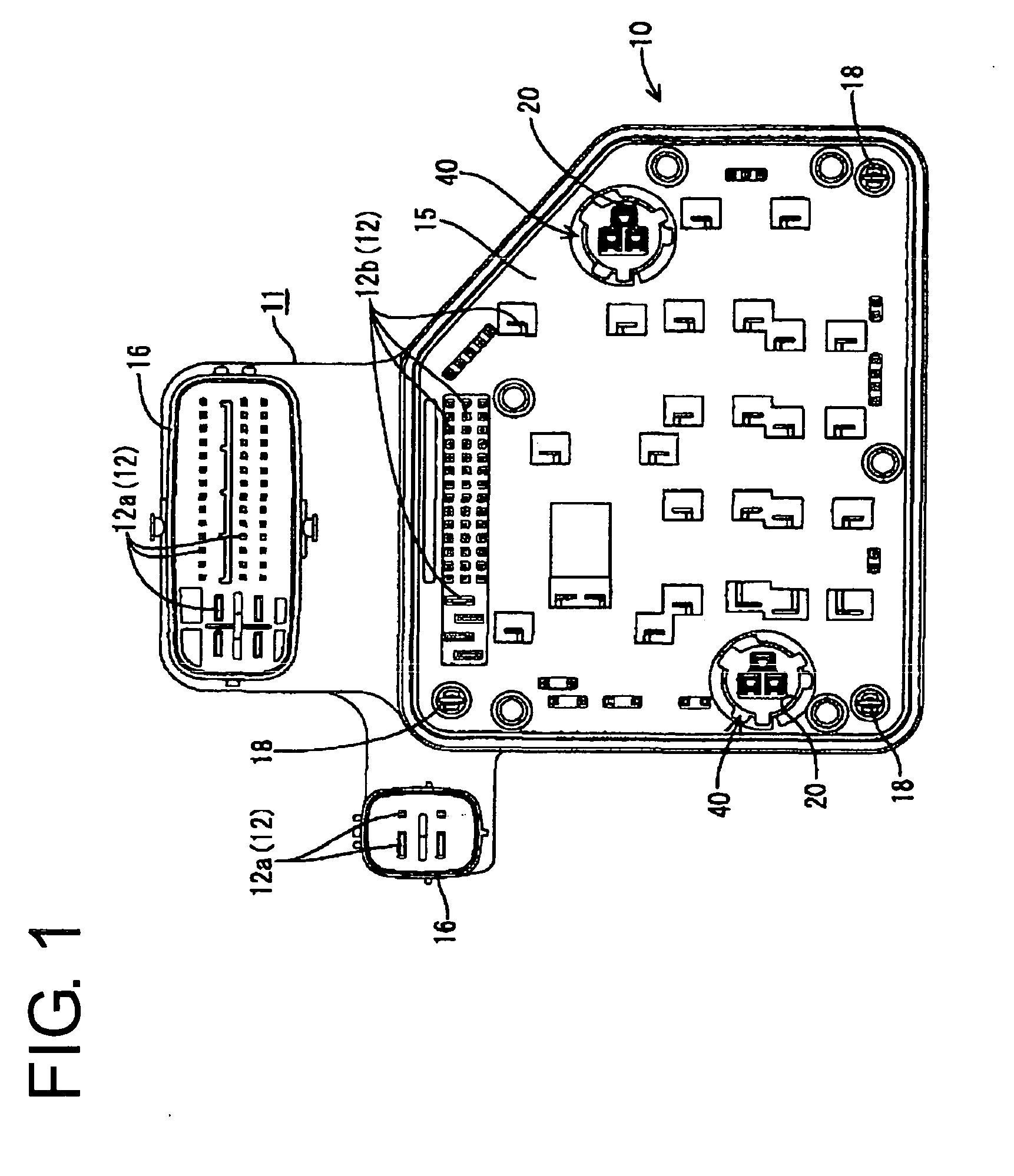

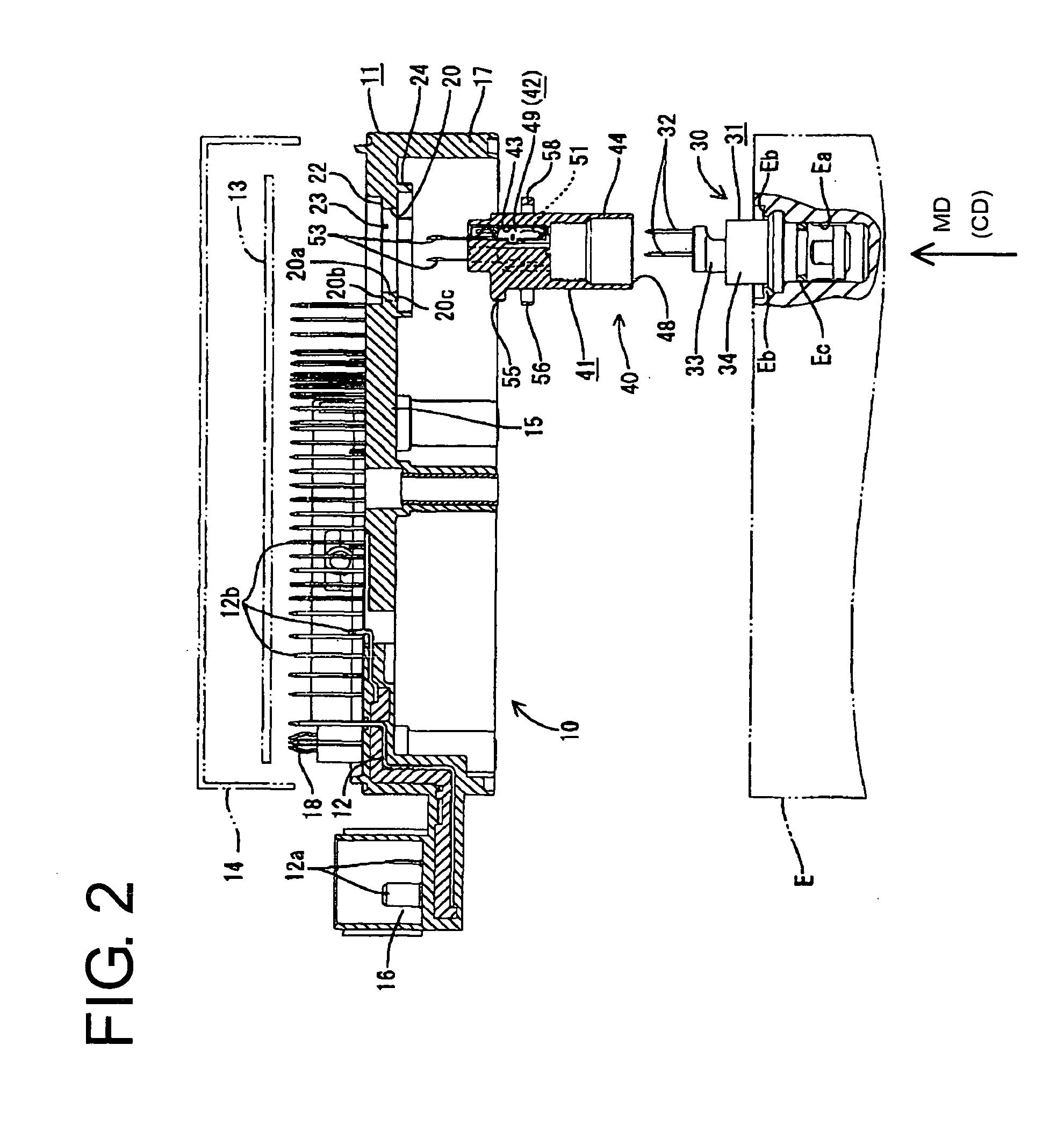

Construction for connecting a circuit board and an electrical part, a brake oil pressure control unit

ActiveUS20050032402A1Easy to separateSmooth connectionVehicle connectorsSubstation/switching arrangement detailsEngineeringPrinted circuit board

A first electronic control unit (10) provided with a printed circuit board (13) and a second electronic control unit (E) having pressure sensors (30) mounted therein can be assembled with each other. Intermediate connectors (40) are mounted in the first electronic control unit (10), and terminal fittings (42) are accommodated therein. Each terminal fitting (42) is provided with a board-side connecting portion (53) to be soldered to the printed circuit board (13) and a resilient contact piece (51) to be resiliently brought into contact with a terminal portion (32) of the pressure sensor (30).

Owner:SUMITOMO WIRING SYST LTD

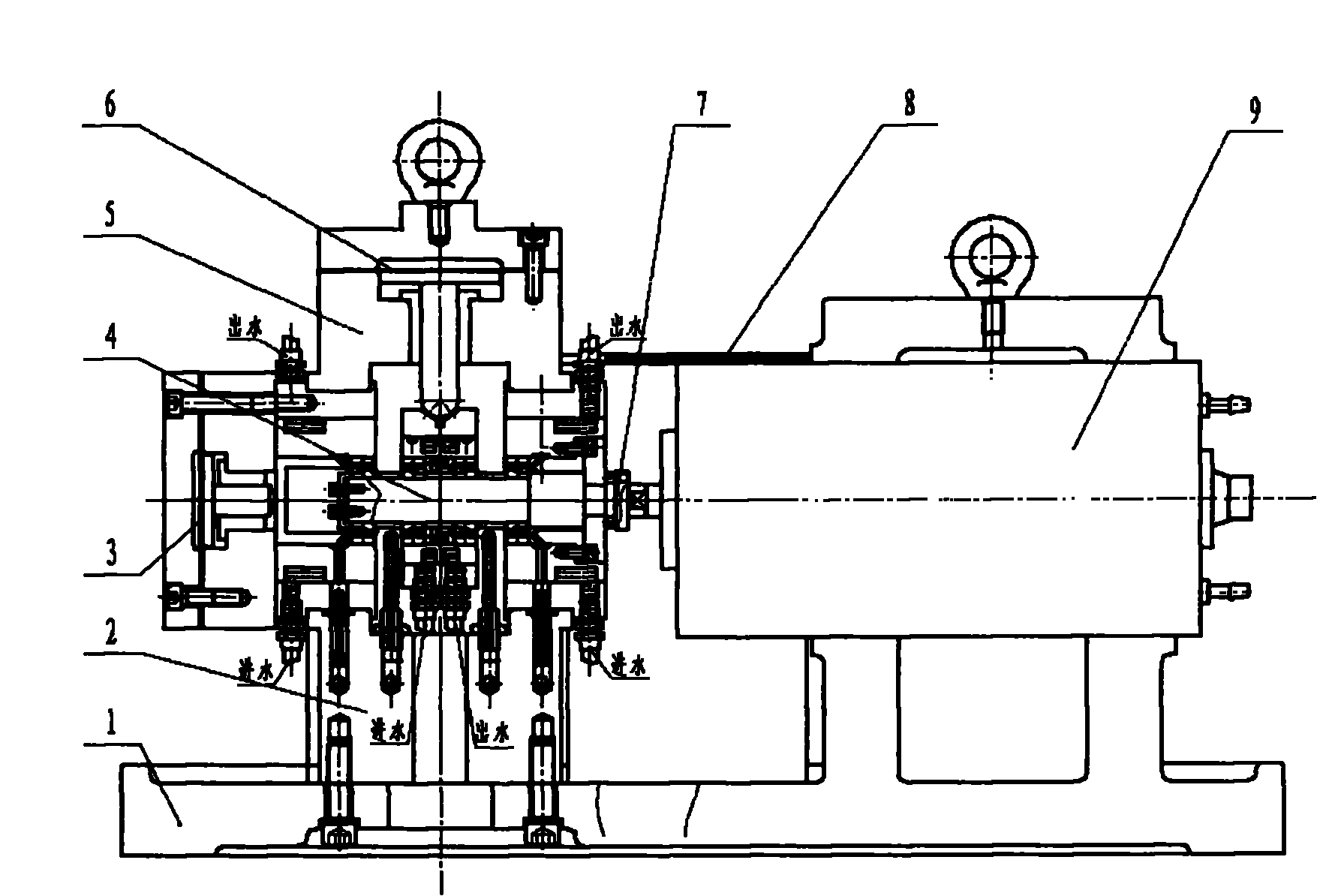

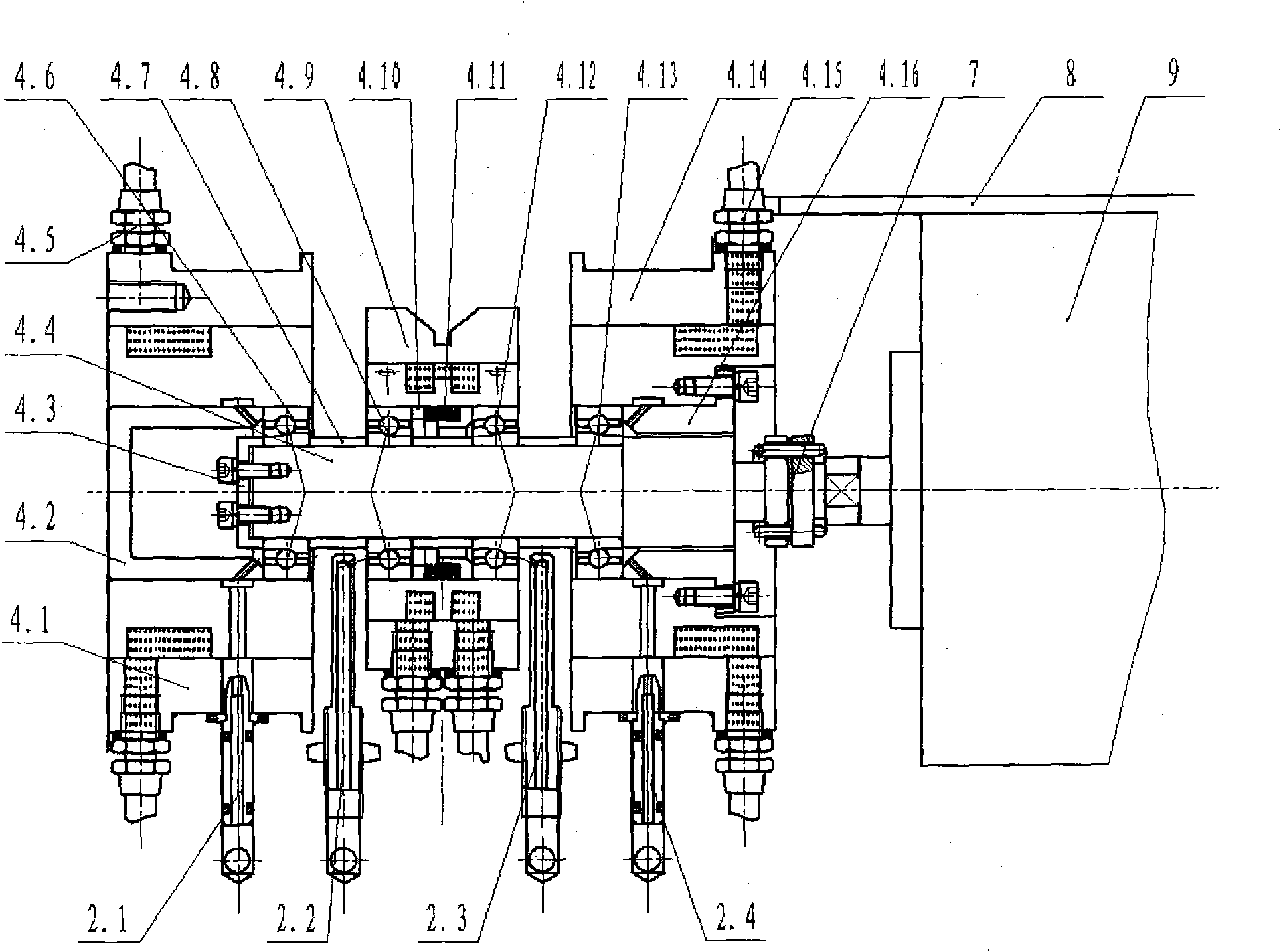

High-speed dynamic simulation test method for electric mainshaft bearing

ActiveCN101975659AEasy to achieve high speedRealize stepless speed regulationMachine bearings testingComputer databasePetroleum engineering

The invention relates to a high-speed dynamic simulation test method used for an electric mainshaft bearing. The electric mainshaft bearing comprises a frame, a main body pedestal, an axial loading cylinder, a test head assembly, a main body gland, a radial loading cylinder, a shaft coupling, a protecting hood, an electric mainshaft, a lubricating oil pipe, an axial loading oil pipe, a vibration sensor, a radial loading oil pipe and a temperature sensor and also a final assembly of all the parts. A hydraulic loading system is started to provide pressure oil to the axial loading cylinder and the radial loading cylinder, the electric mainshaft drives a test mainshaft to rotate, the radial loading cylinder exerts radial force on a first test accompanying bearing and a second test accompanying bearing through a radial loading sleeve, and the radial loading cylinder exerts axial force on a first test bearing and a second test bearing through an axial loading sleeve. The entire test is controlled by a computer to display parameters of the rotating speed, the axial load and the radial load, the oil pressure, the cooling water temperature, the bearing temperature, the bearing vibration, the power current of the electric mainshaft and the test time, and the parameters are saved in a computer database and analyzed.

Owner:国创(洛阳)轴承产业技术研究院有限公司

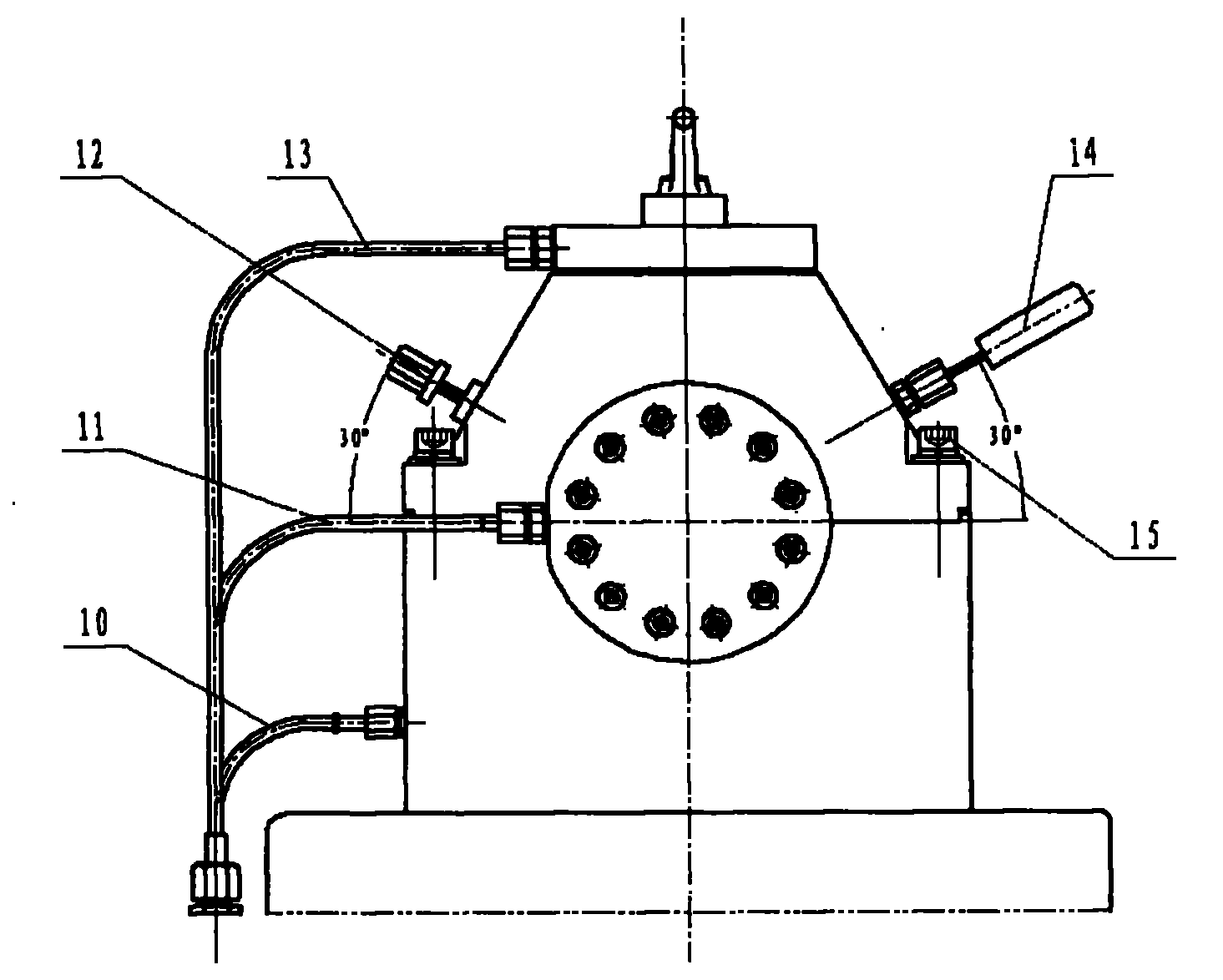

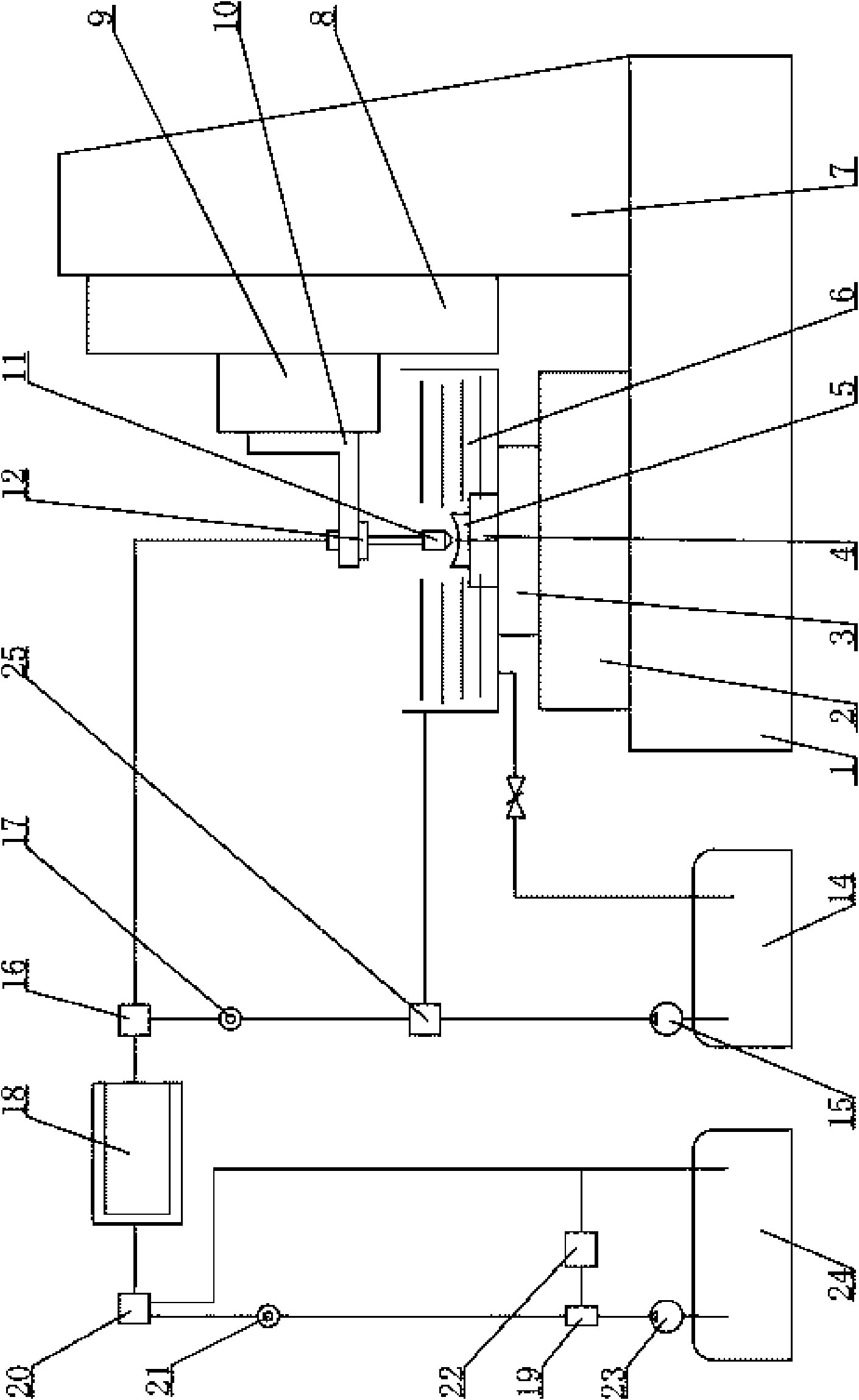

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

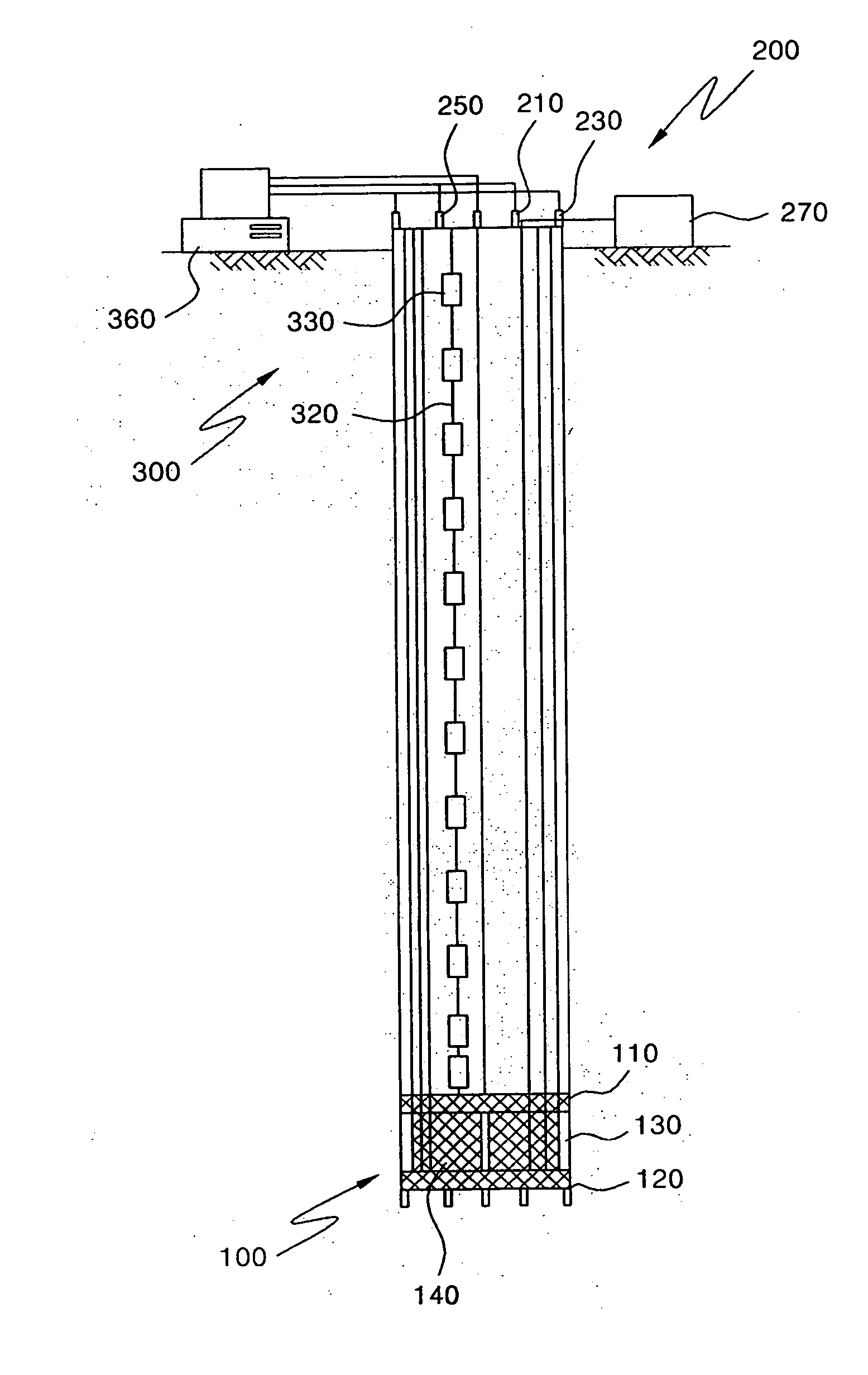

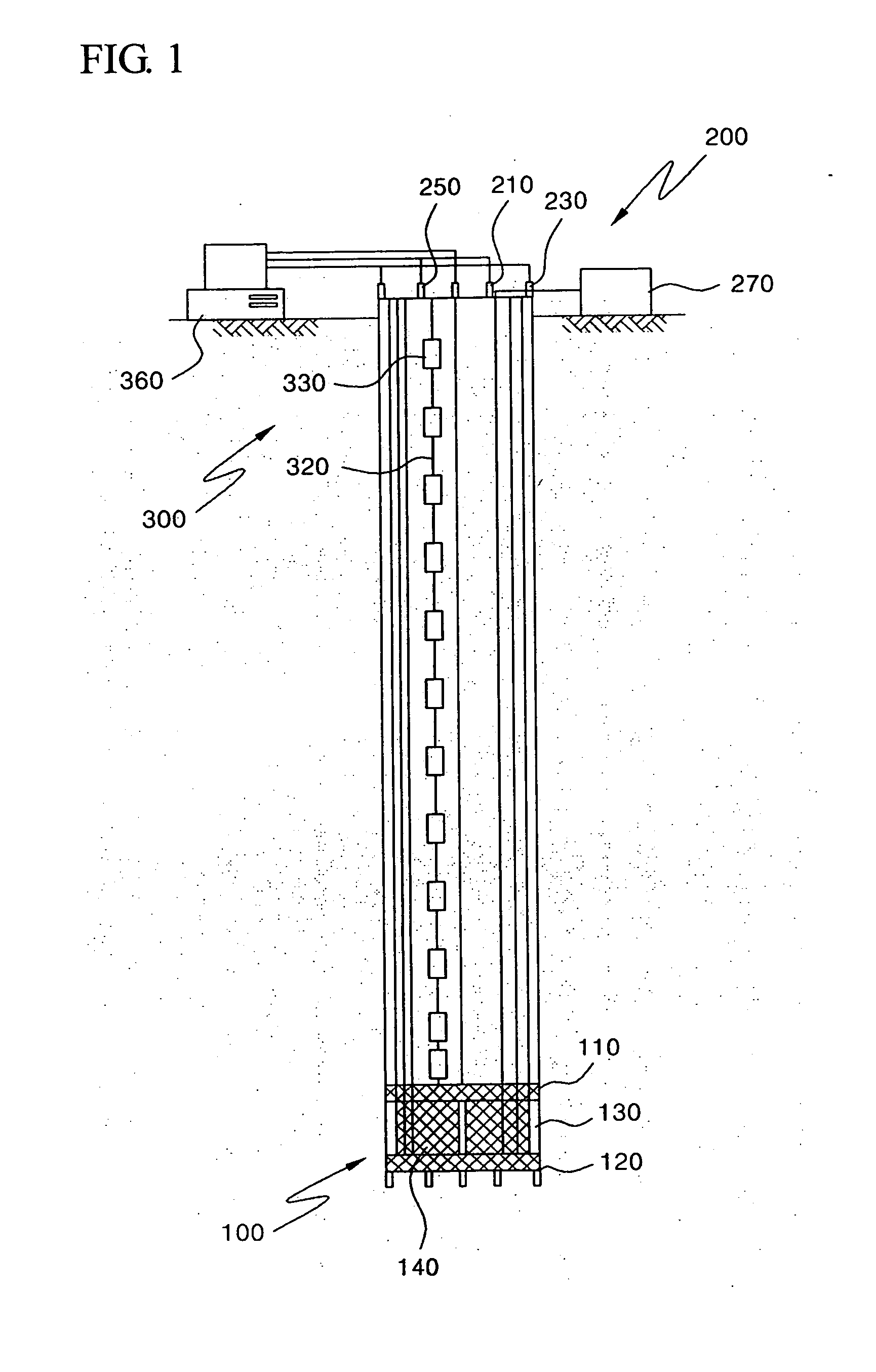

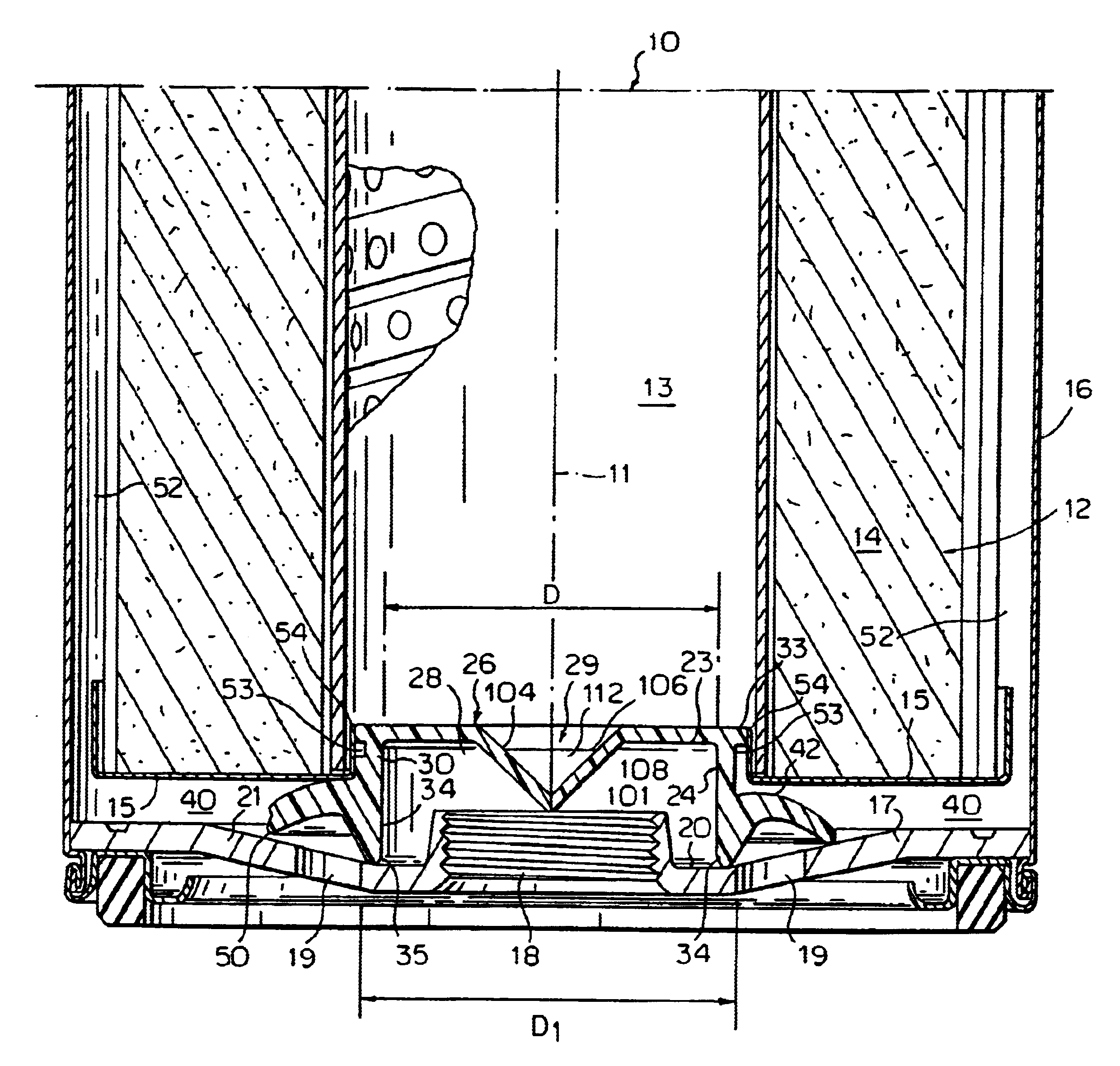

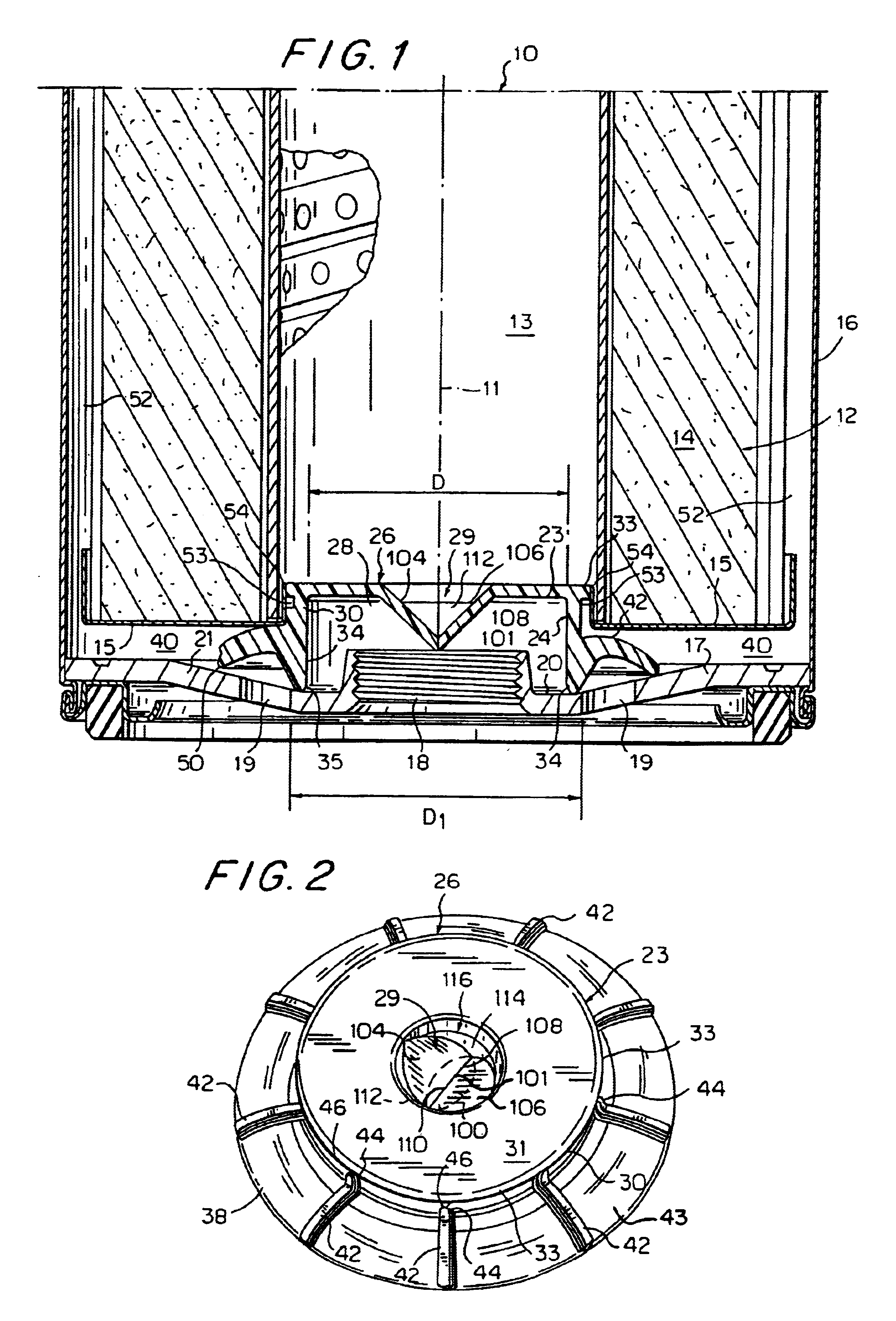

Apparatus and method for measuring supporting force of large diameter ferroconcrete piles

ActiveUS20060213279A1Reduce in quantityIncrease load capacityFlow propertiesFoundation testingReinforced concreteMeasuring instrument

An apparatus measures a supporting force of ferroconcrete piles by means of a bi-directional front end oil pressure loading apparatus using a high pressure loading system capable of measuring a supporting force, a sinking amount and an axis load distribution on the ferroconcrete piles. The apparatus comprises: a steel plate having a predetermined thickness and diameter and including upper and lower discs having penetration holes through which concrete passes; a fixing member for separating the discs from each other by a predetermined distance; a high oil pressure cylinder for producing an oil pressure force; an oil cylinder inflation displacement measuring sensor for measuring a displacement; an upper displacement measuring rod coupled to the upper disc for measuring a displacement of the upper disc; a lower displacement measuring rod coupled to the upper disc for measuring a displacement of the lower disc; an axis load transition measuring instrument including a tremie induction tube coupled to the upper disc for guiding concrete to the penetration holes; iron elements coupled to the upper disc; a load sensor for measuring ground abrasion; and a sensor line for transferring a signal and current to the load sensor. A corresponding method is disclosed.

Owner:G TECH CO LTD A ORGANIZED UNDER THE LAWS OF THE REPUBLIC OF KOREA +2

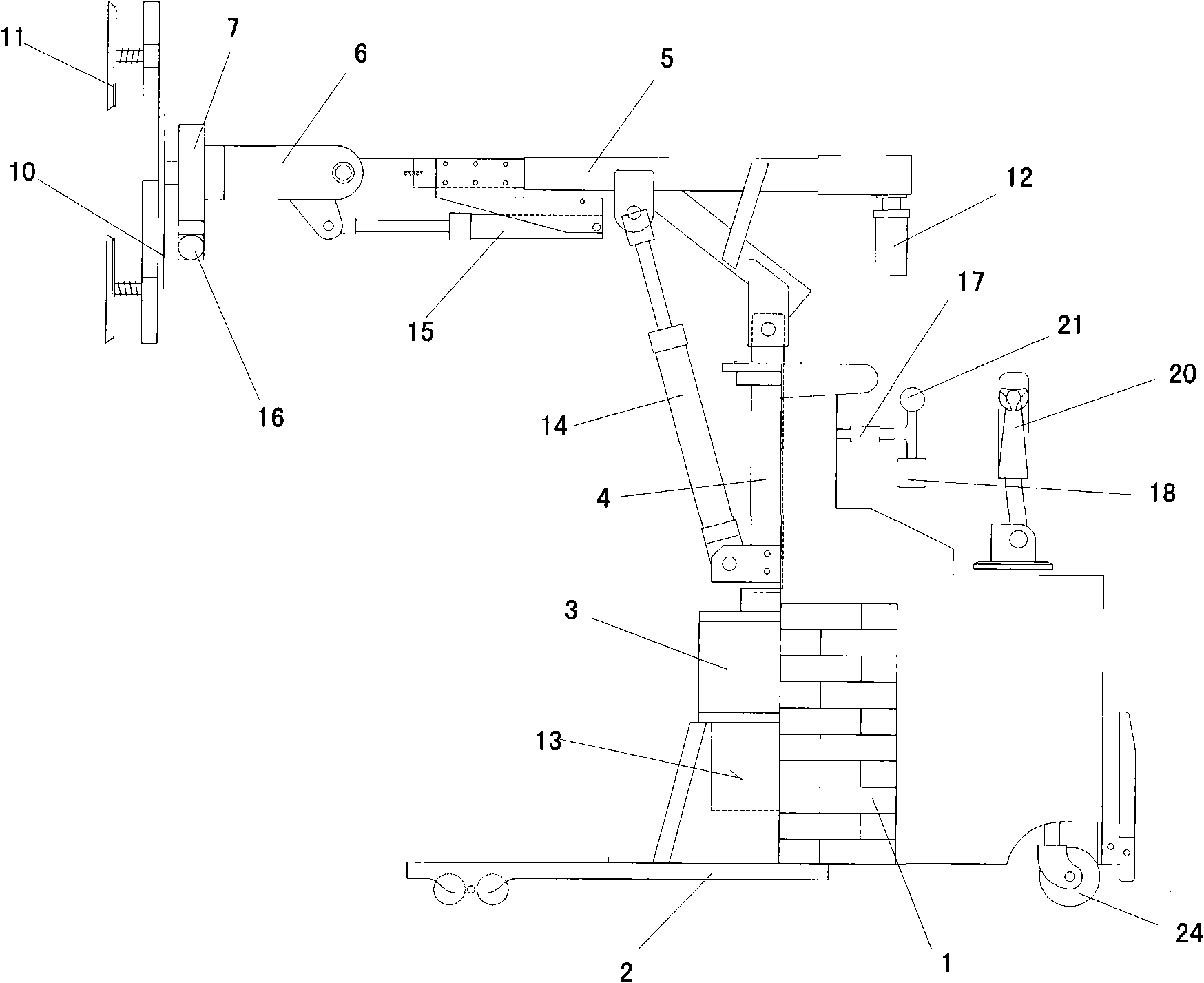

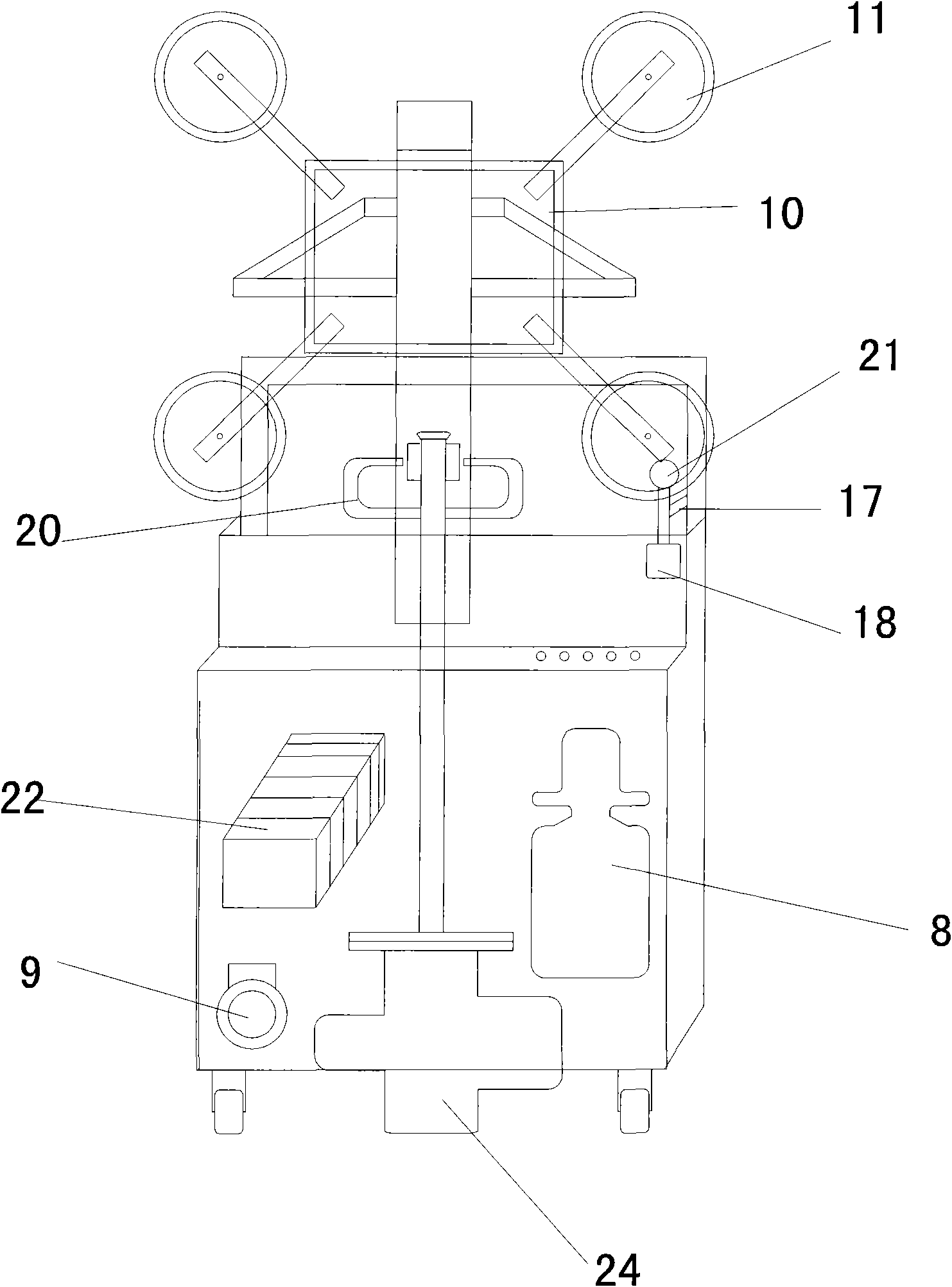

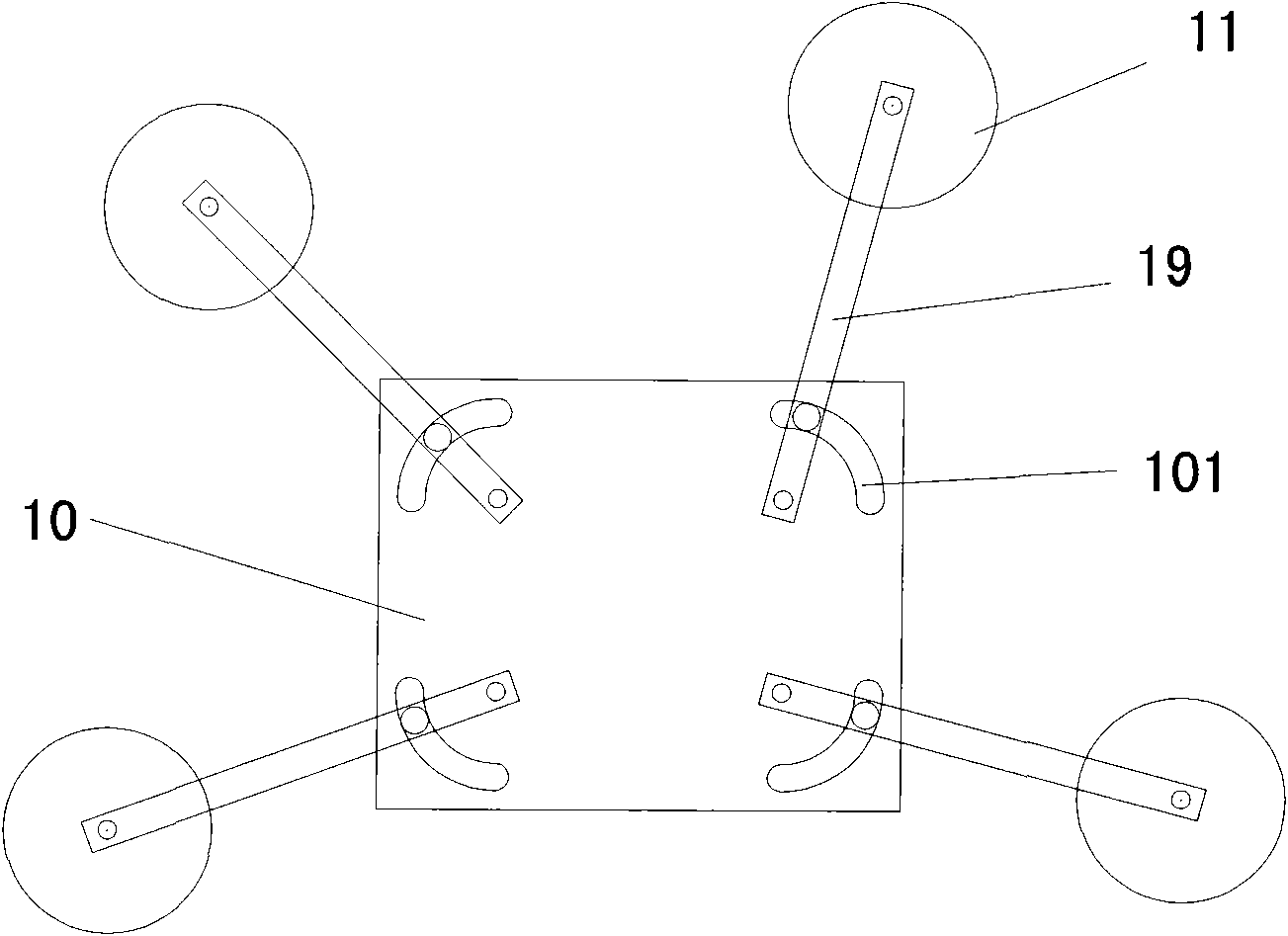

Rotary type vacuum loading hoisting machine

The invention relates to a rotary type vacuum loading hoisting machine, which comprises an electric vehicle driven by a storage battery power supply, a bracket arranged on the electric vehicle, a plurality of action arms arranged on the bracket, a set of oil pressure hoisting mechanism and a set of vacuum loading mechanism. The set of the oil pressure hoisting mechanism comprises an oil pump driven by the storage battery power supply and a plurality of oil cylinders connected with oil passages of the oil pump, and the plurality of the oil cylinders are in driving connection with plurality of the action arms respectively. The set of the vacuum loading mechanism comprises a vacuum pump driven by the storage battery power supply, a sucking disc bracket connected with the front end of the oil pressure hoisting mechanism and a plurality of vacuum sucking discs connected with the sucking disc bracket, and the plurality of the vacuum sucking discs are connected with gas passages of the vacuum pump respectively. The rotary type vacuum loading hoisting machine is used for conveying glass, has the advantages of safety, convenience and quickness, and can be used as a machine for conveying and mounting glass curtain walls.

Owner:上海力进铝质工程有限公司

Internal pressure simulator for pressure sensors

InactiveUS20070095146A1Simple and cost-effectiveSimple and cost-effective to and implementFluid pressure measurement using inductance variationFluid pressure measurement using ohmic-resistance variationInternal pressurePressure sense

In oil-filled pressure sensors, the measured pressure is applied to a compliant isolation diaphragm, which causes the pressure of the internal oil to increase until it equals the external pressure. The pressure is sensed by a pressure sensing capsule, such as a MEMS piezoresistive pressure sensor. The invention incorporates an electromagnetic force generator, such as a coil and a magnetic core, within the pressure sensor in order to generate simulated pressure. When the coil is energized, the electromagnetic field creates a uniform distributed force, which moves the isolation diaphragm directly, or via an external flexure, in a manner to cause the pressure of the internal oil to increase, which is sensed by the pressure sensing capsule, which responds by producing an output signal proportional to the electromagnetic force. The simulated pressure is employed in order to perform sensor operation monitoring and self-calibration via measurement of the output signal.

Owner:BROSH AMNON

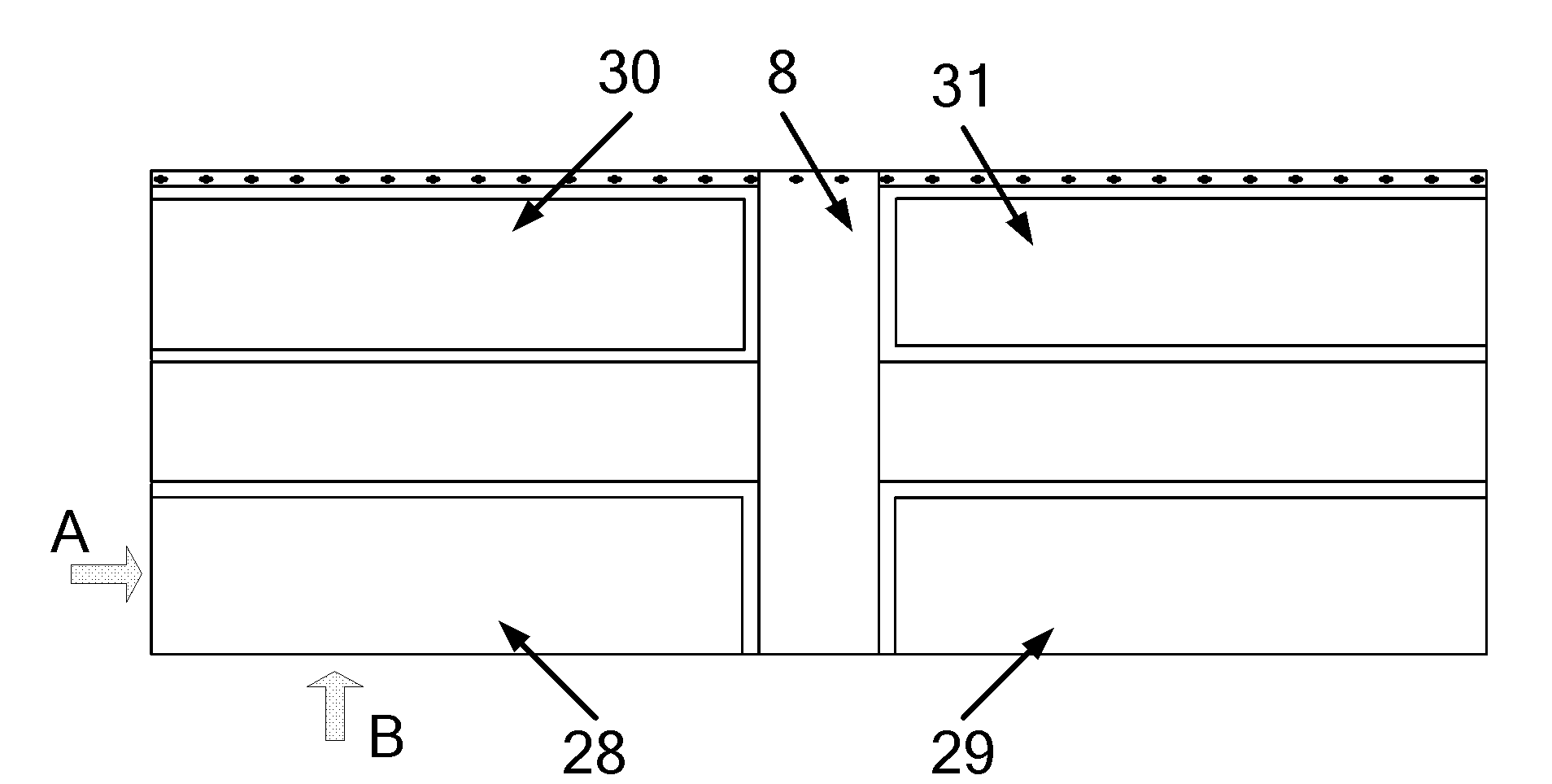

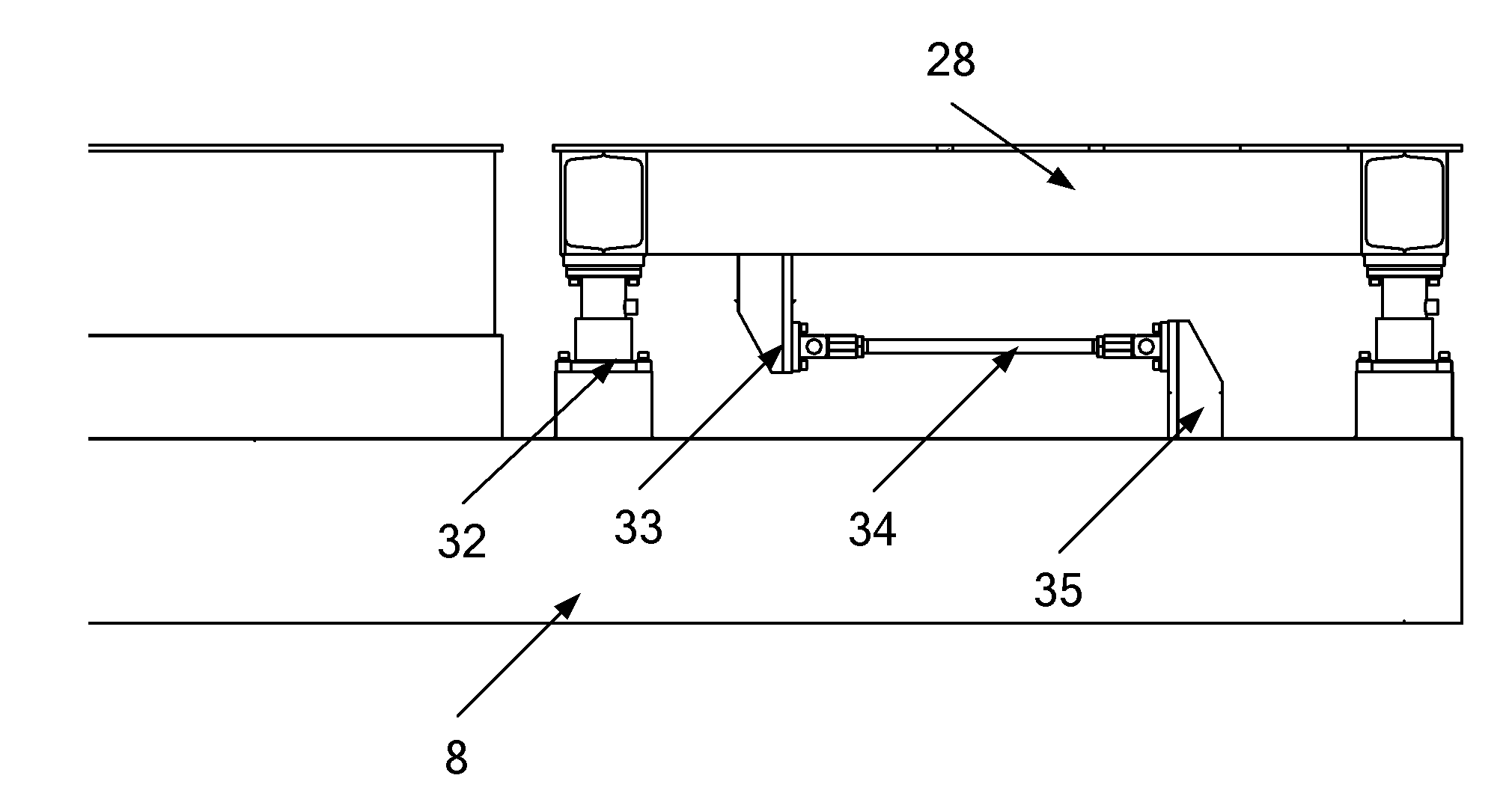

Automobile stability parameter test bench and test method using same

InactiveCN101893517ARealize measurementReduce testing workloadVehicle testingStatic/dynamic balance measurementStability parameterMeasurement device

The invention relates to an automobile stability parameter test bench and a test method using the same, which are used for integrally testing automobile mass parameters, centroid position parameters and anti-tipping angle parameters. The automobile stability parameter test bench of the invention comprises a measuring platform, four platform balances, platform supporting columns, a foundation, three hydraulic cylinders, an inclination angle measuring device, hydraulic sensors, a pump station and a computer, wherein the four platform balances are installed on the measuring platform and are supported by a weighting sensor; the supporting points of the platform supporting columns are distributed in rectangular peaks; the foundation is used for bearing the supporting columns and the platform; the three hydraulic cylinders are arranged between the platform and the foundation and can enable the platform to incline longitudinally or laterally; the inclination angle measuring device is fixed on the platform; the hydraulic sensors are installed in the positions of the upper cavity and the lower cavity of the two hydraulic cylinders which enable the platform to incline longitudinally; the pump station is connected with the hydraulic cylinders; and the computer is used for acquiring and calculating the data of the weighing sensor, the oil pressure of the hydraulic cylinders and the inclination angle data of the platform. Compared with the existing test equipment, the invention can finish tests of automobile total mass, axle loads, wheel loads, centroid positions, anti-tipping angles and the like, so that the test workload and the test cost of the parameter tests are greatly reduced.

Owner:JILIN UNIV

Three valve filter element support for filter cartridge

InactiveUS6936162B1Avoid cleaningPreventing pre-filling of the filter cartridgeCheck valvesEqualizing valvesReflux valveFilter media

A unitary three valve filter element support is used in a filter cartridge in which the filter cartridge includes an annular filter element within a housing closed by an end plate having a central opening surrounded by an array of radial openings spaced a fixed radial distance from one another. The unitary support has an annular sealing lip for sealing with the end cap of the filter element, which sealing lip deflects under oil pressure providing a first valve to allow oil to bypass the filter element if the filter media of the filter element is clogged. A second valve is a dirty side anti-drainback valve that is provided by a radial flange projecting from the unitary body. A third valve is a clean side valve aligned with the hollow core of the annular filter element to prevent drainback of clean oil and to prevent refilling of the filter cartridge with used or unfiltered oil.

Owner:WIX FILTRATION

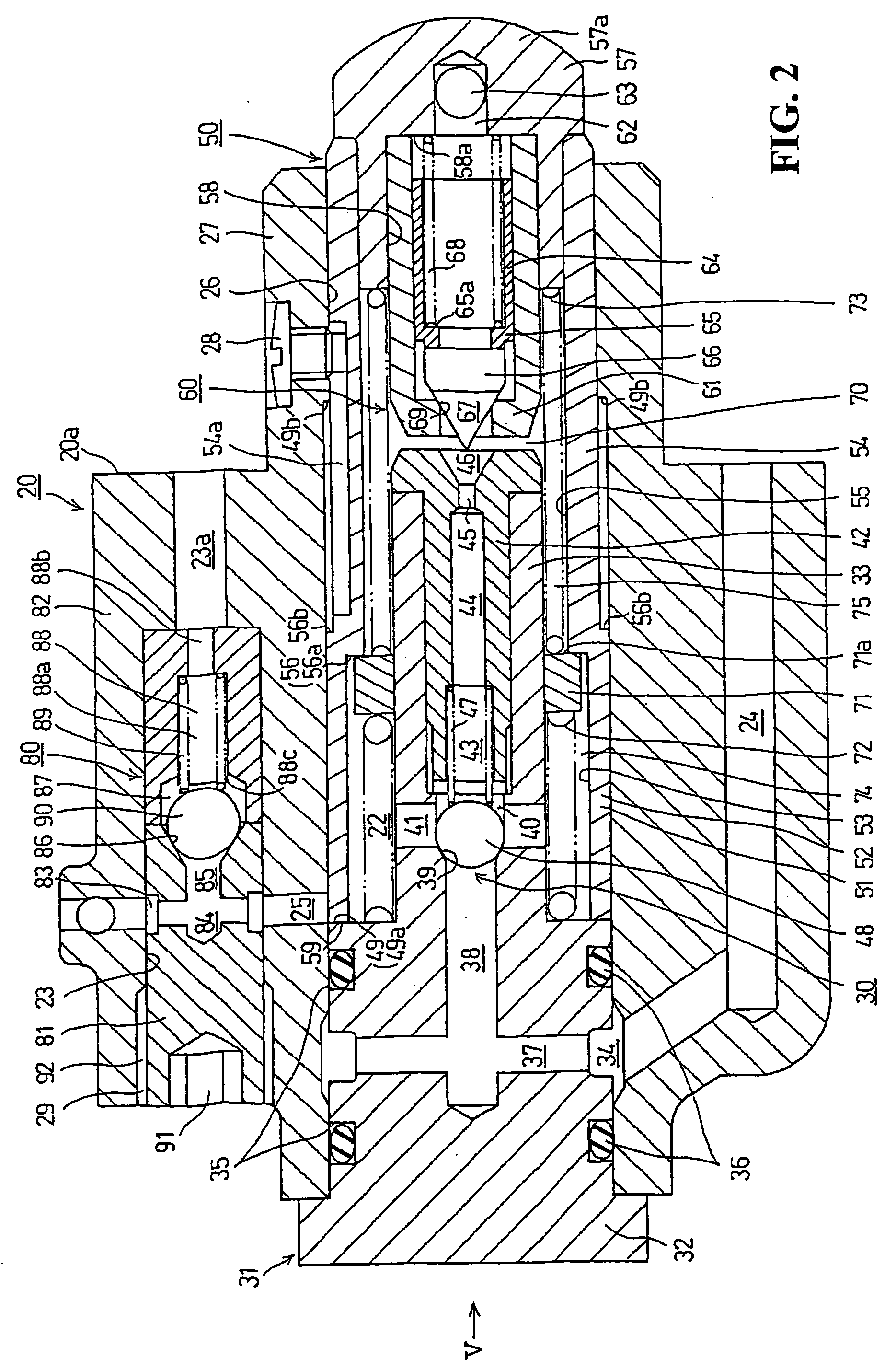

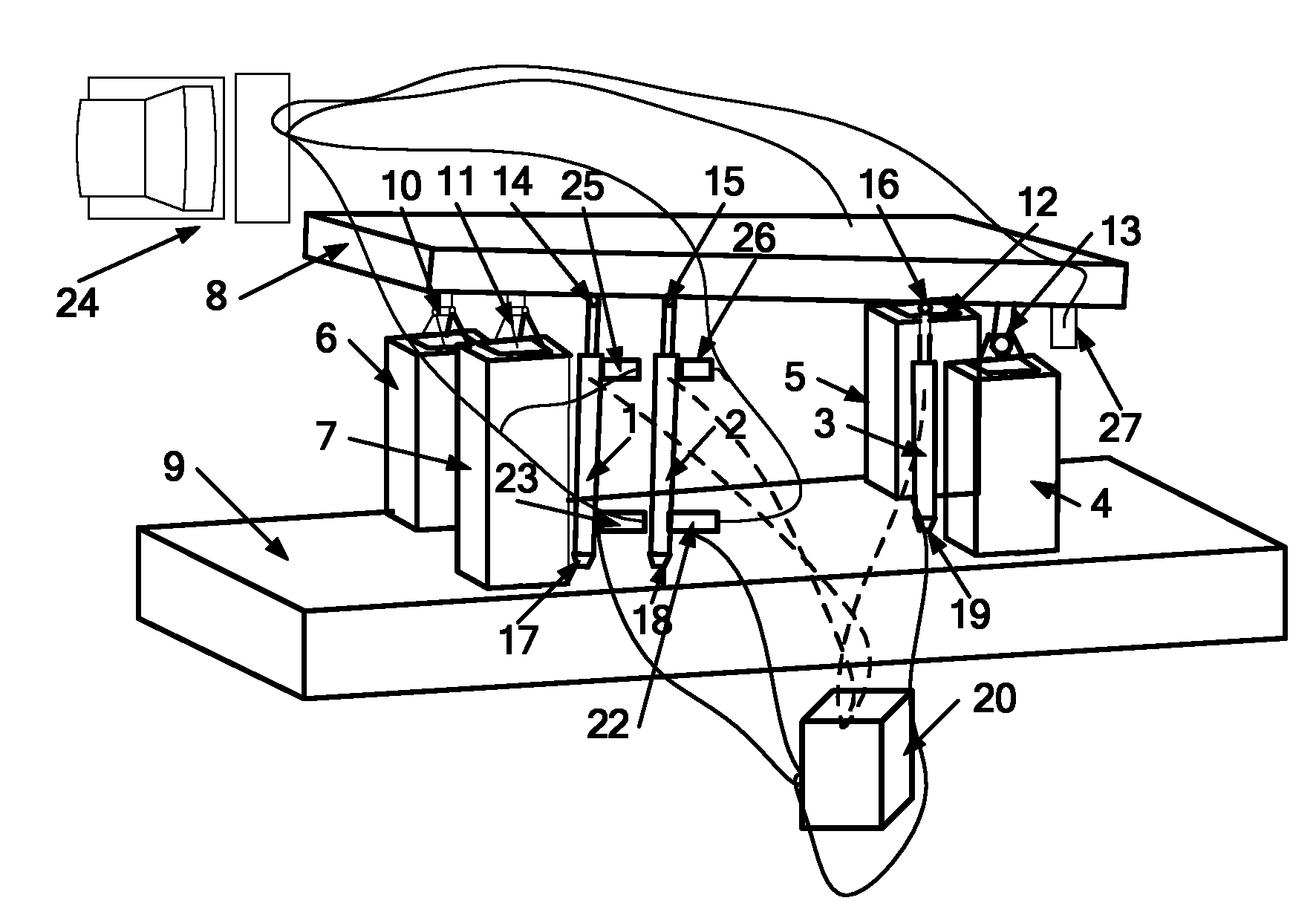

Motor pump unit

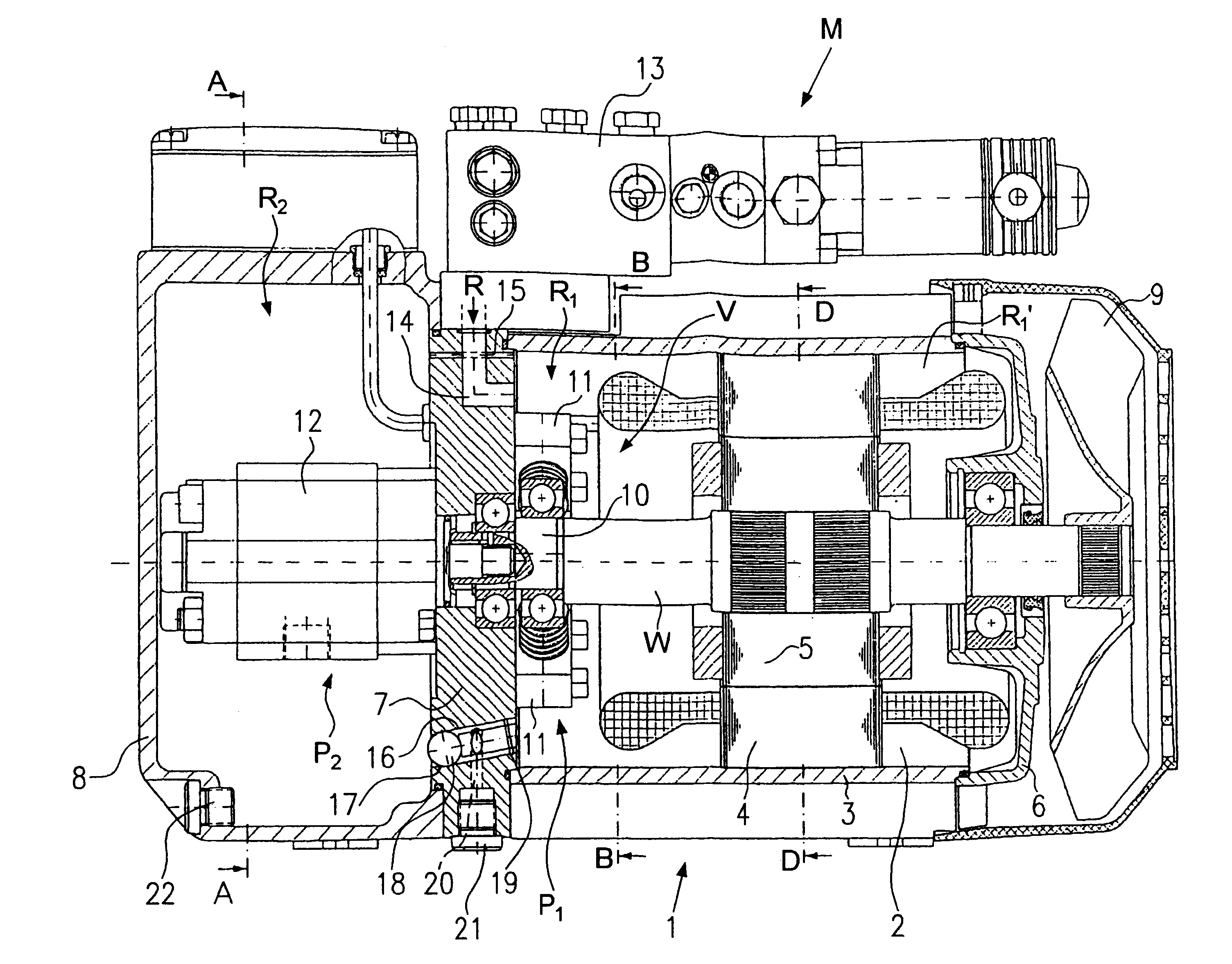

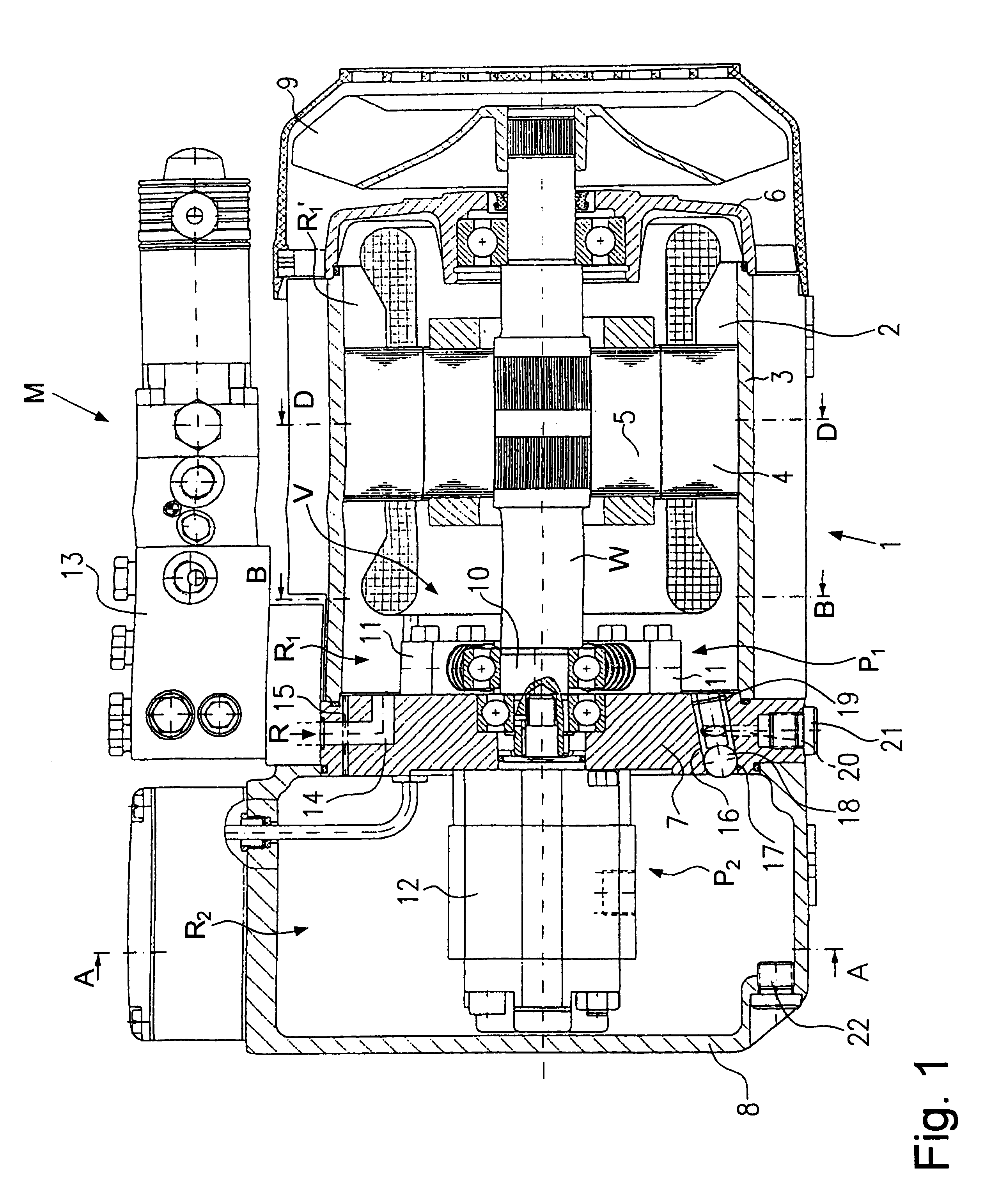

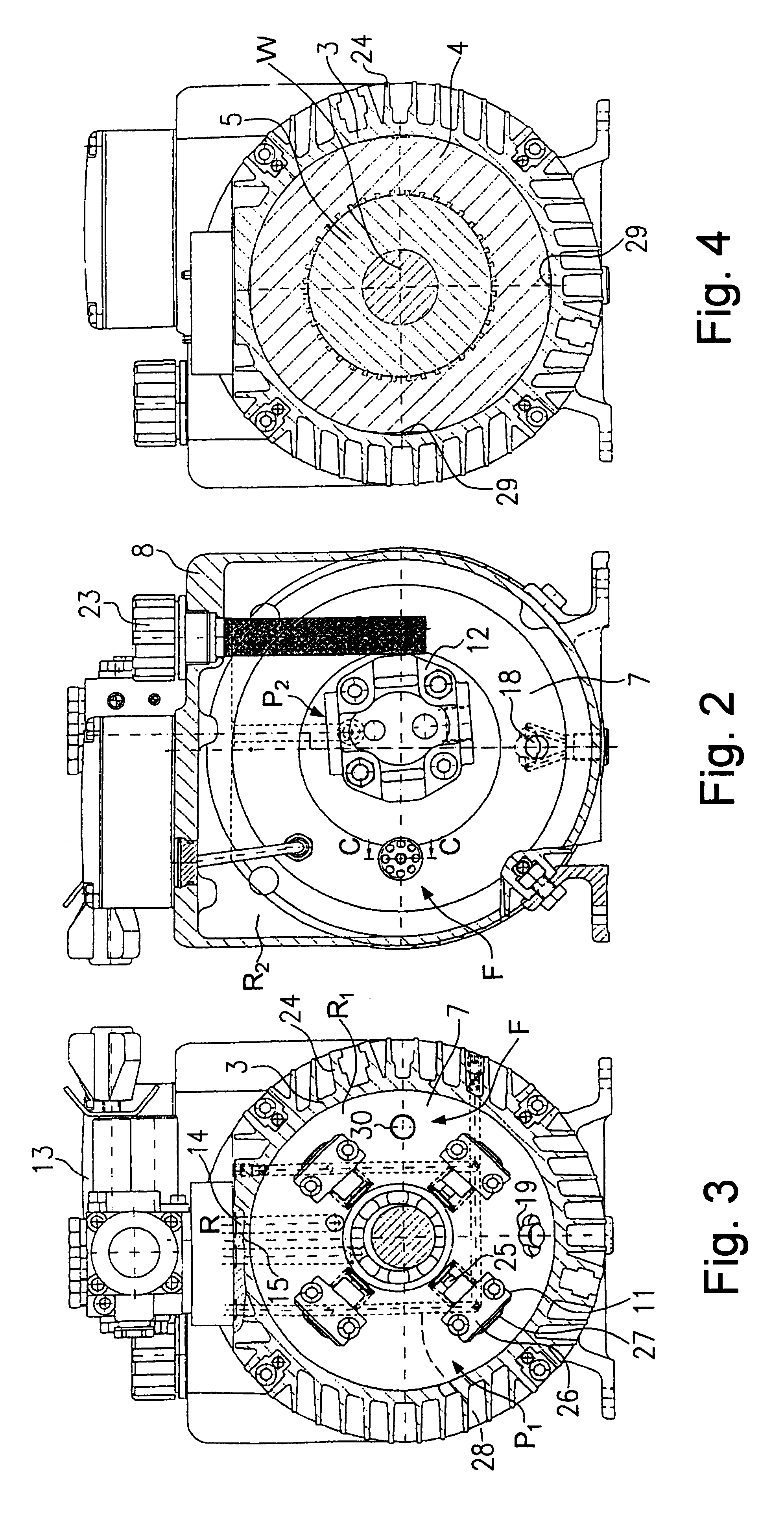

InactiveUS6524084B2Improve supply efficiencyAvoids getting trappedPositive displacement pump componentsPiston pumpsRadial piston pumpEngineering

A motor pump aggregate M has a housing 1 defining an oil reservoir with first and second chambers R1, R2. An electromotor 2 is driving via its motor shaft W at least one radial piston pump arrangement P1 provided within said first chamber R2. Both chambers R1, R2 are separated by a separation wall 7. A filling and pressure biasing system V is provided for said first chamber R1 in order to adjust within said first chamber R1 a predetermined oil filling level and a pre-selected oil pressure pre-biasing for said radial piston pump arrangement P1.

Owner:HEILMEIER & WEINLEIN FAB FUR OEL HYDRAULIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com