Patents

Literature

46126 results about "Printed circuit board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A printed circuit board (PCB) mechanically supports and electrically connects electronic components or electrical components using conductive tracks, pads and other features etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Components are generally soldered onto the PCB to both electrically connect and mechanically fasten them to it.

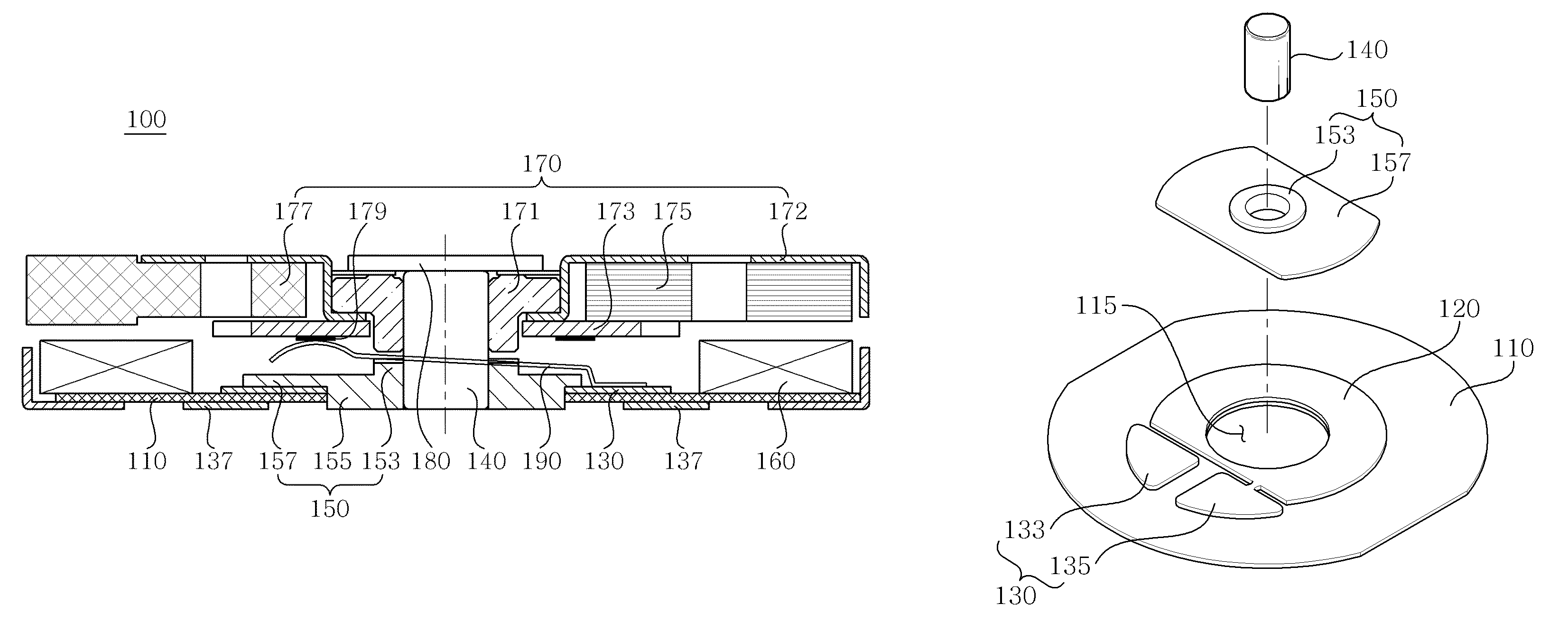

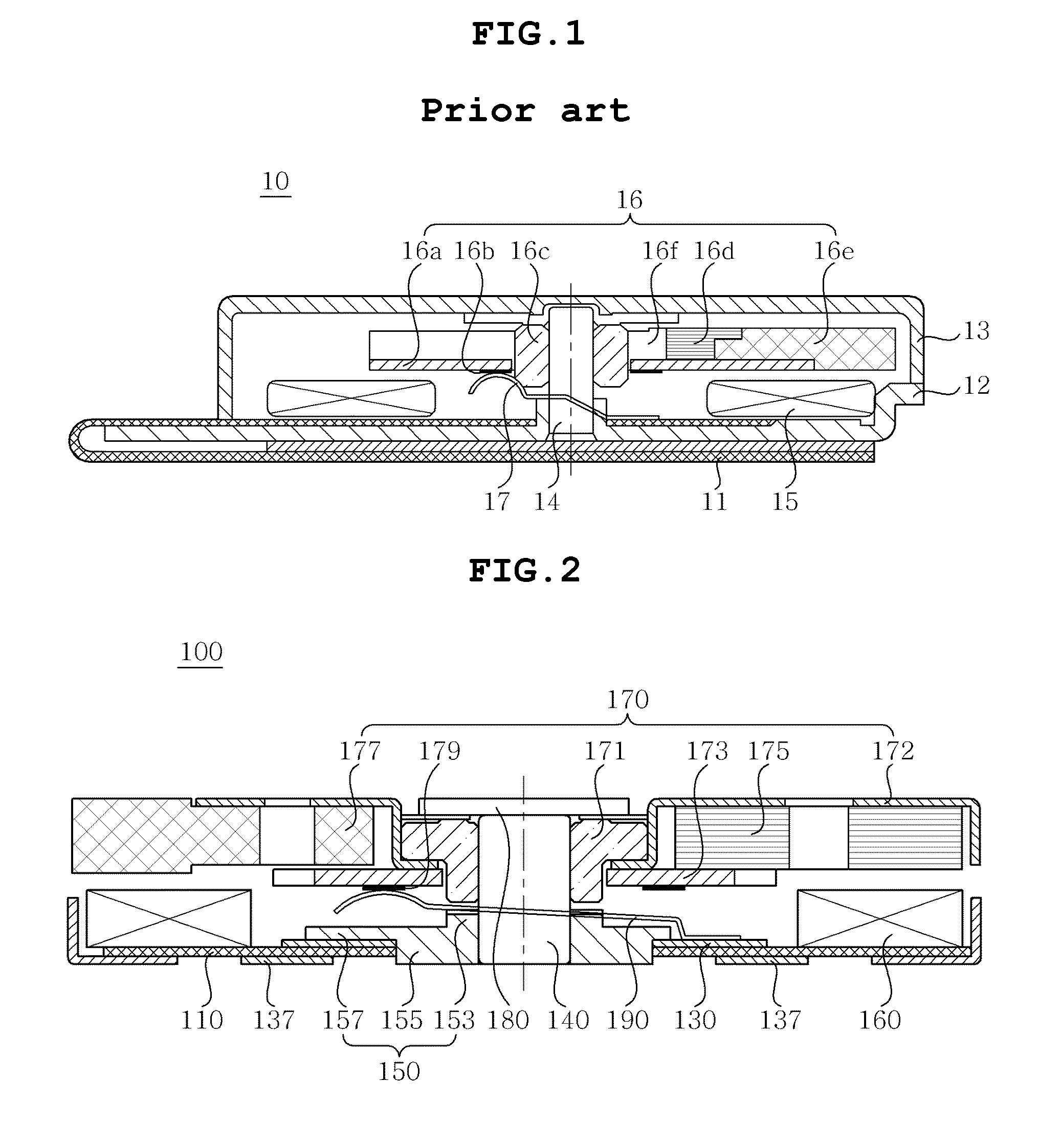

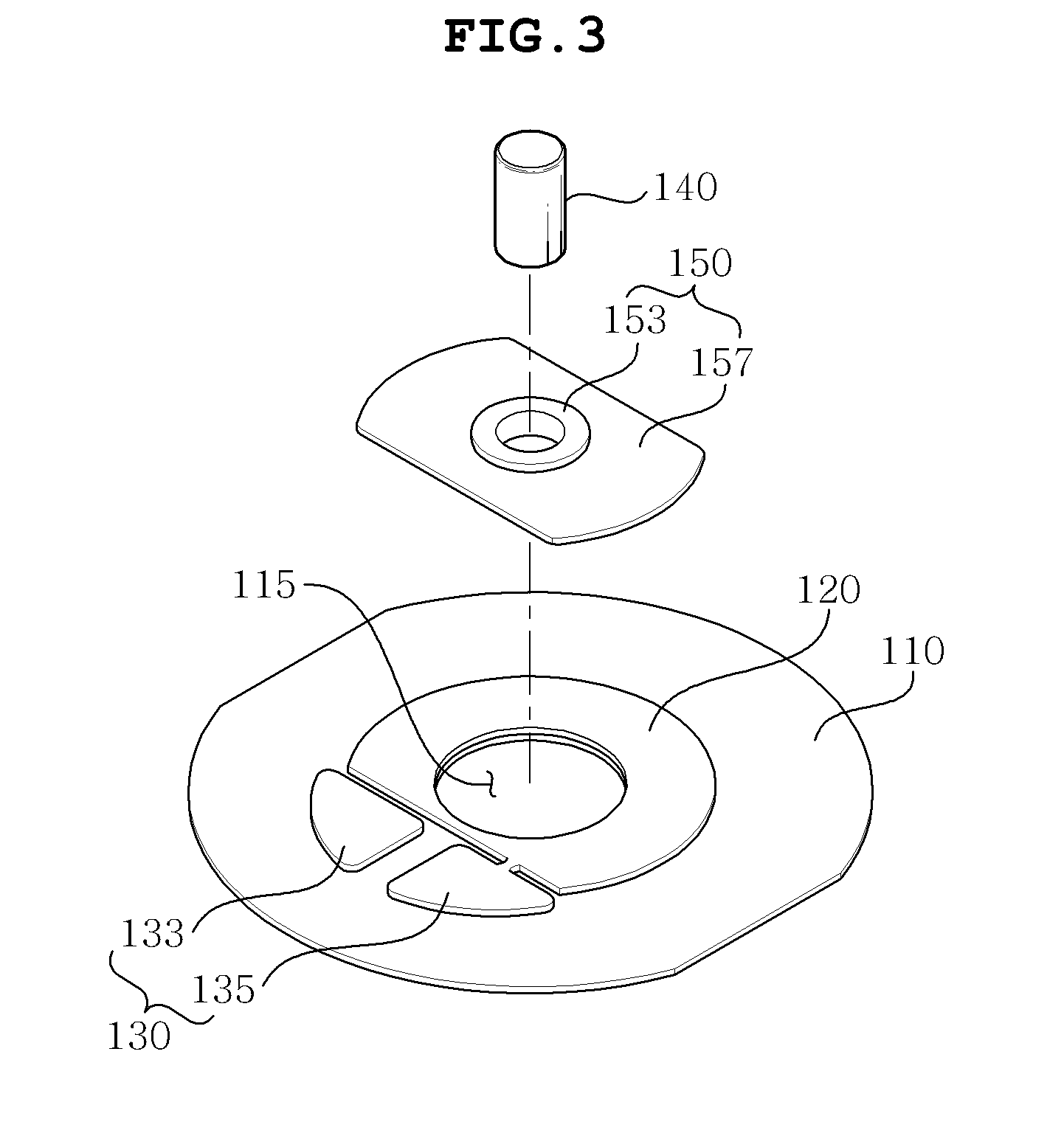

Flat type vibration motor

InactiveUS8227946B2Increase connection forceReduce noiseMechanical energy handlingSupports/enclosures/casingsElectricityEngineering

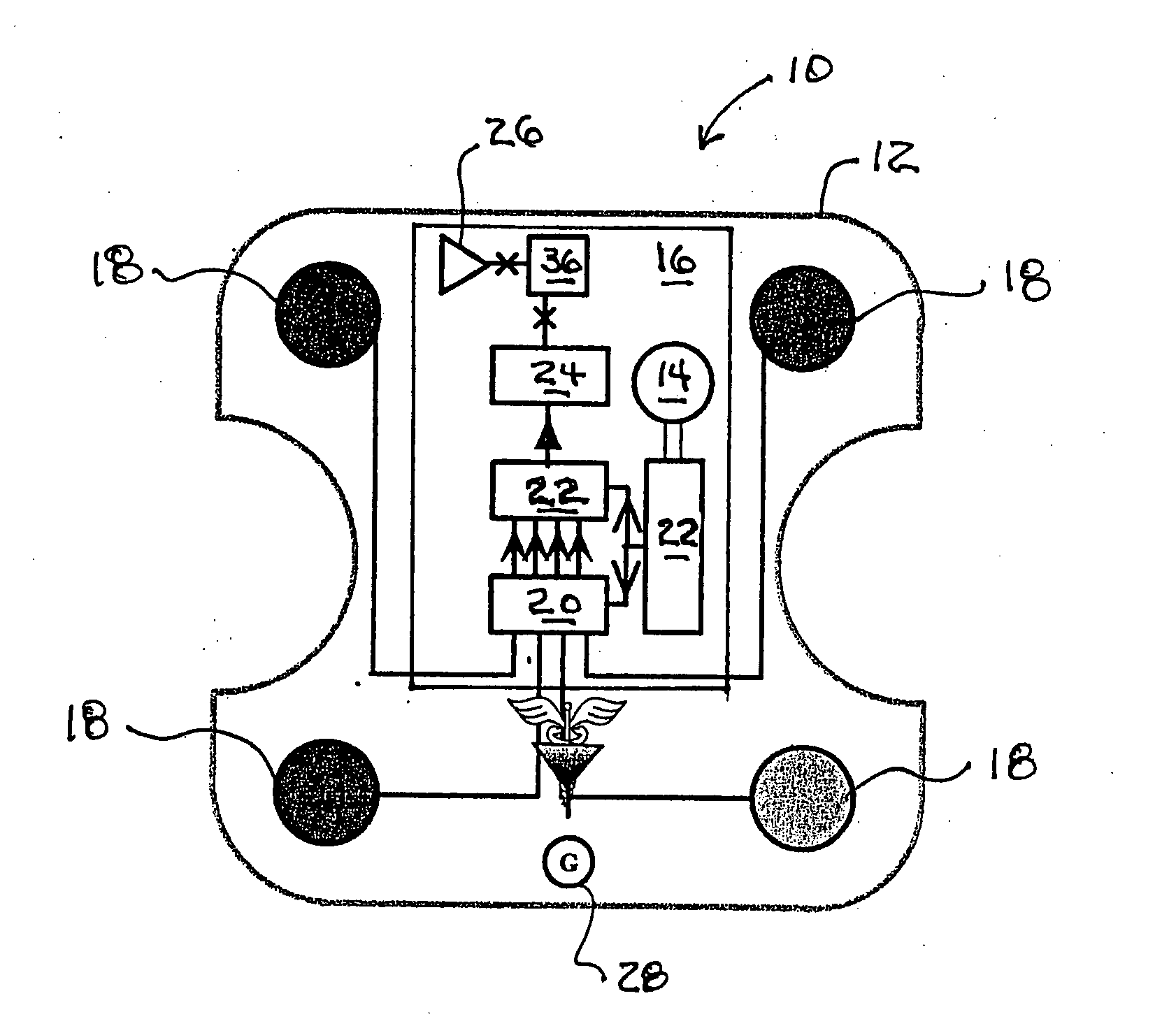

There is provided a flat type vibration motor 100 that includes a bracket 150 with a shaft 140 of which one end is inserted into and fixed to the center thereof, a printed circuit board 110 having a terminal portion 130 receiving external electricity and disposed on the side of the bracket 150, a stator disposed on the top of the printed circuit board 110, a rotor 170 rotatably installed in the shaft 140 and generating vibration while rotating by interaction with the stator 160, and a stopper 180 installed at the other end of the shaft 140. The bracket 150 and the shaft 140 are electrically connected with the terminal portion 130. Further, it is possible to use the bracket or a shaft as an external power connection terminal by electrically connecting a negative terminal to the bracket and the shaft through the contact portion.

Owner:MPLUS

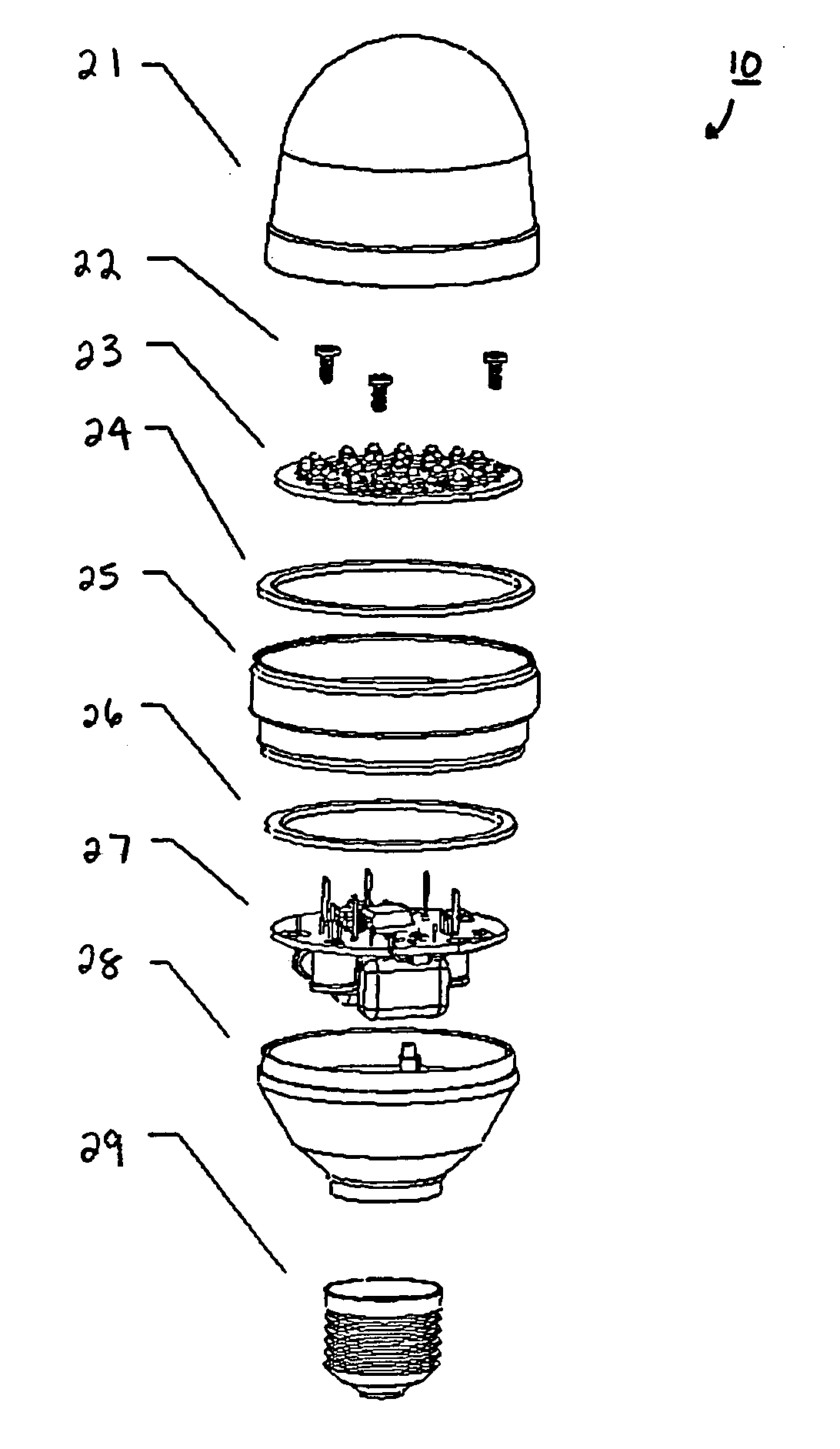

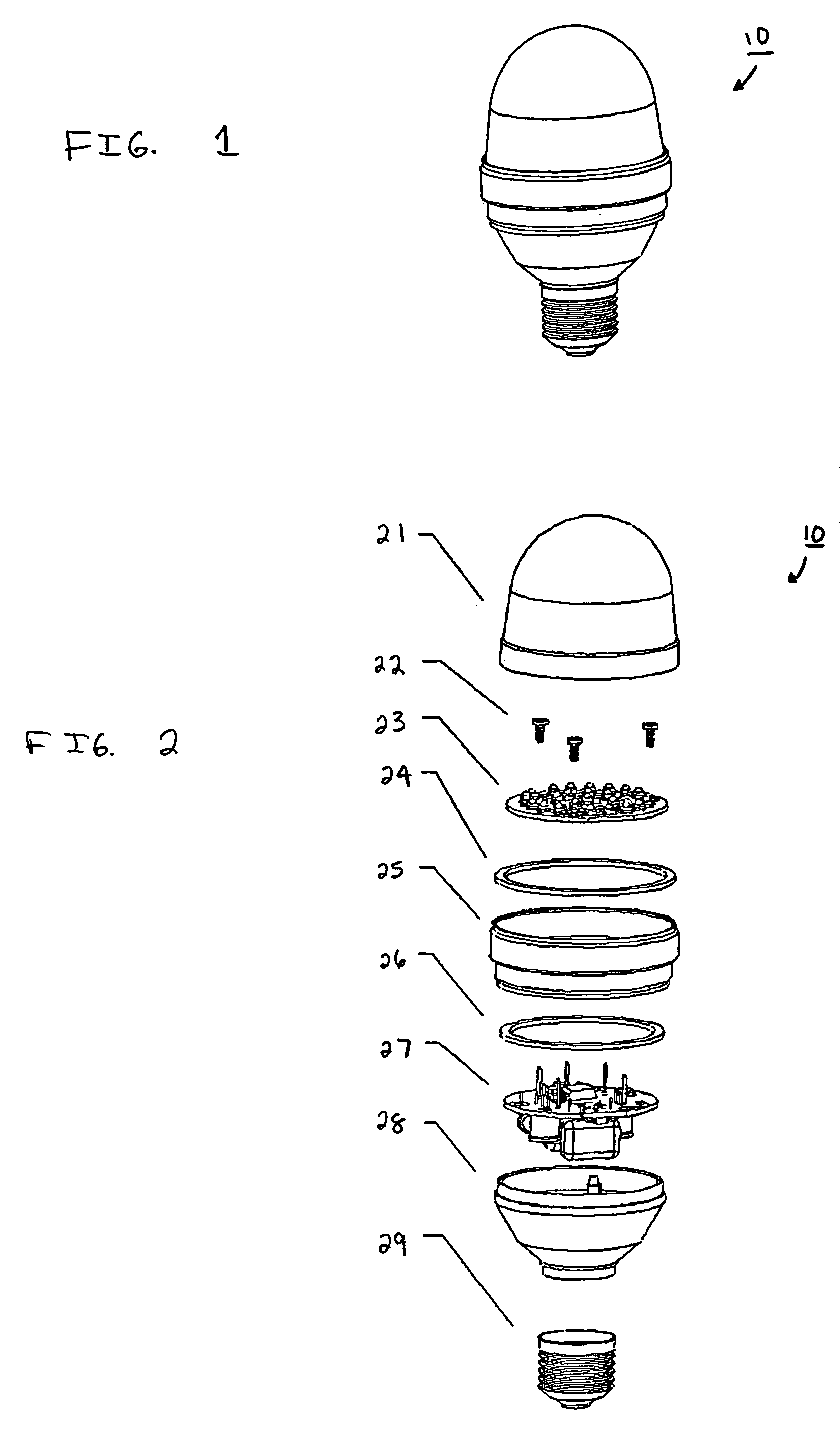

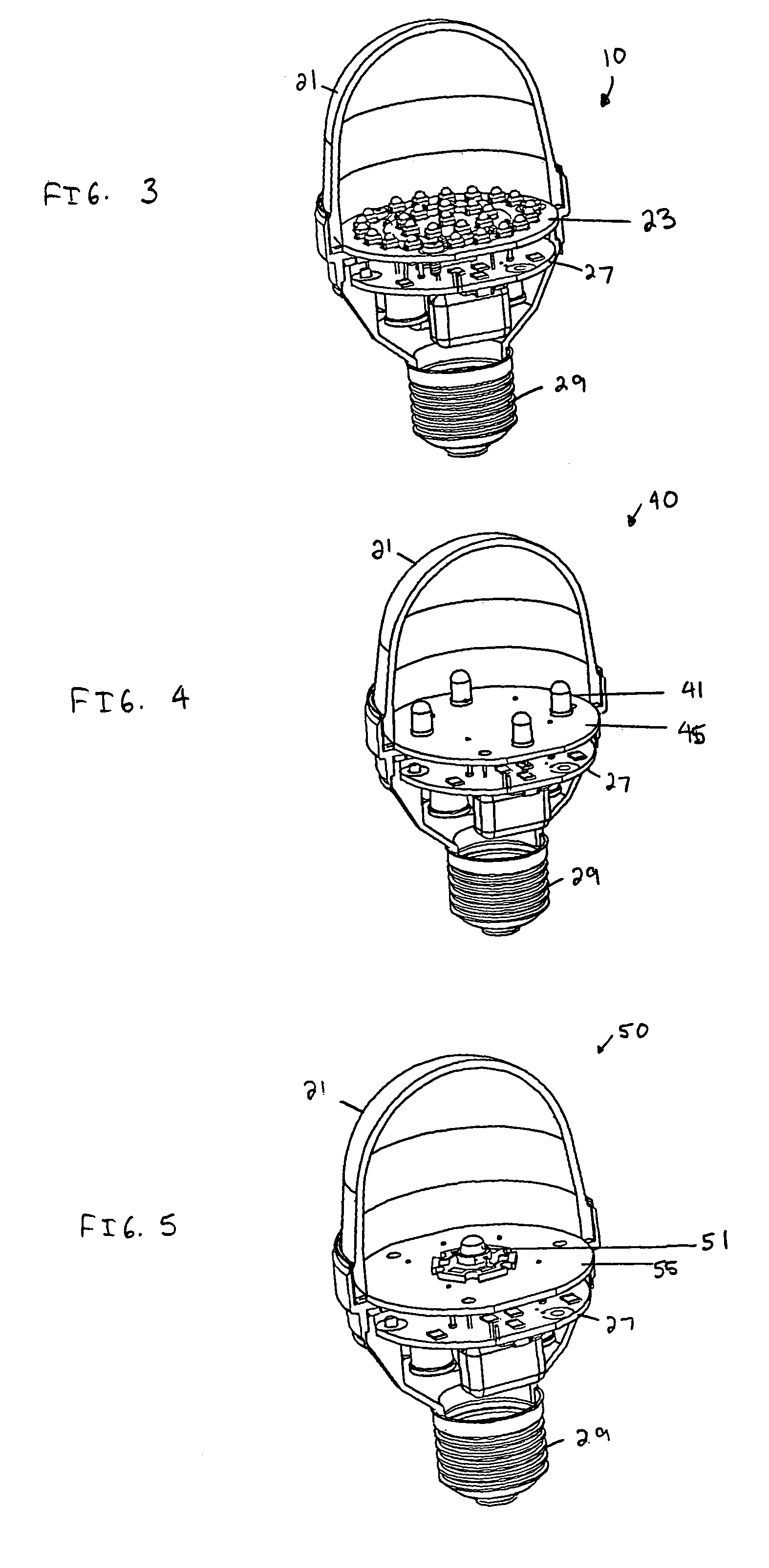

Light emitting diode (LED) light bulbs

ActiveUS6948829B2Improve performanceEasy to manufactureFurnace componentsPoint-like light sourceEngineeringPrinted circuit board

A light emitting diode (LED) light bulb that includes plural individual elements as sub-assembly elements of the overall light bulb. Different sub-assembly elements of a lens, a LED printed circuit board, a housing also functioning as a heat sink, a lower housing, and other individual sub-assembly components are utilized. The LED printed circuit board sub-assembly containing the LEDs can also be provided relatively close to a base.

Owner:DIALIGHT CORP

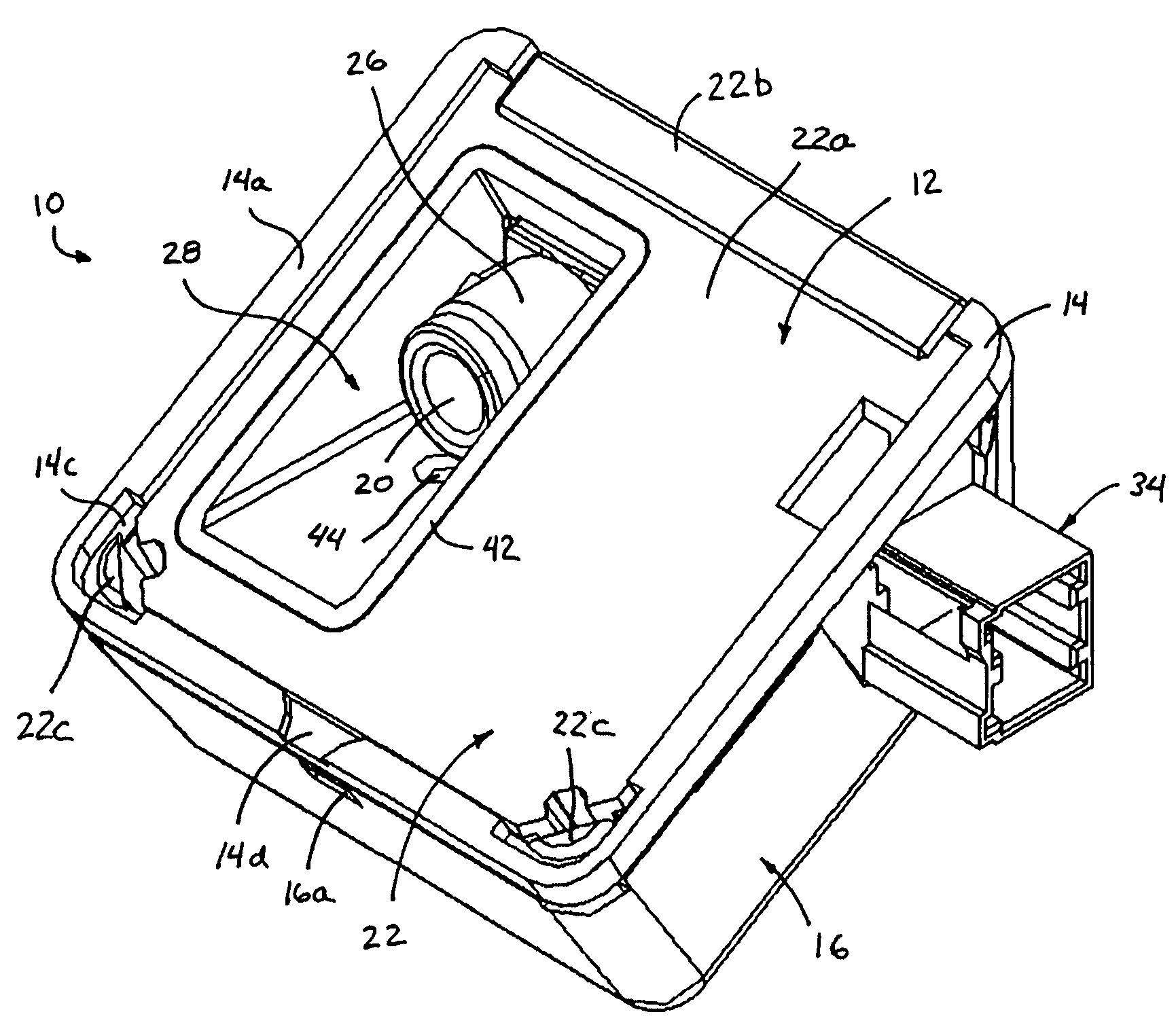

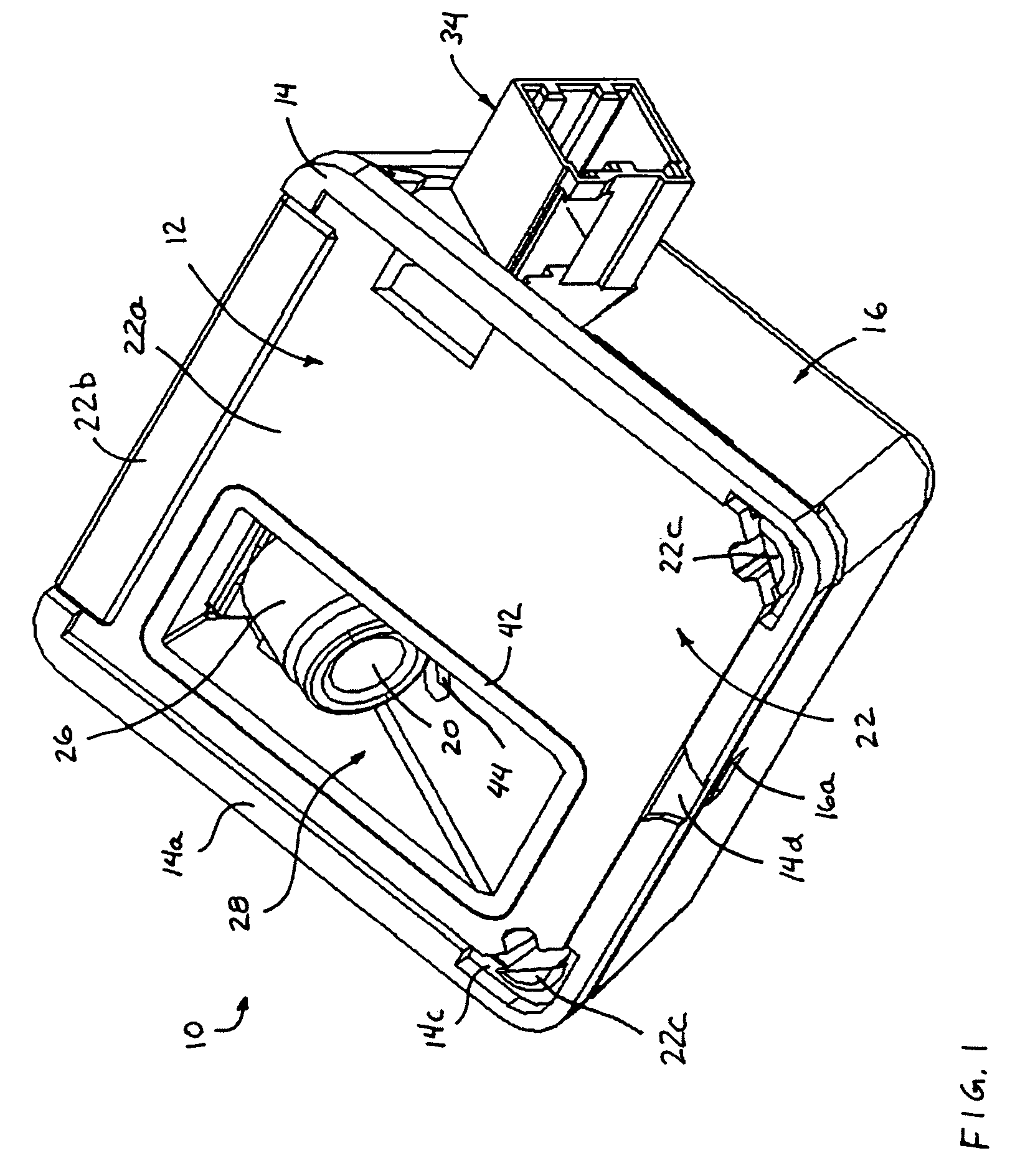

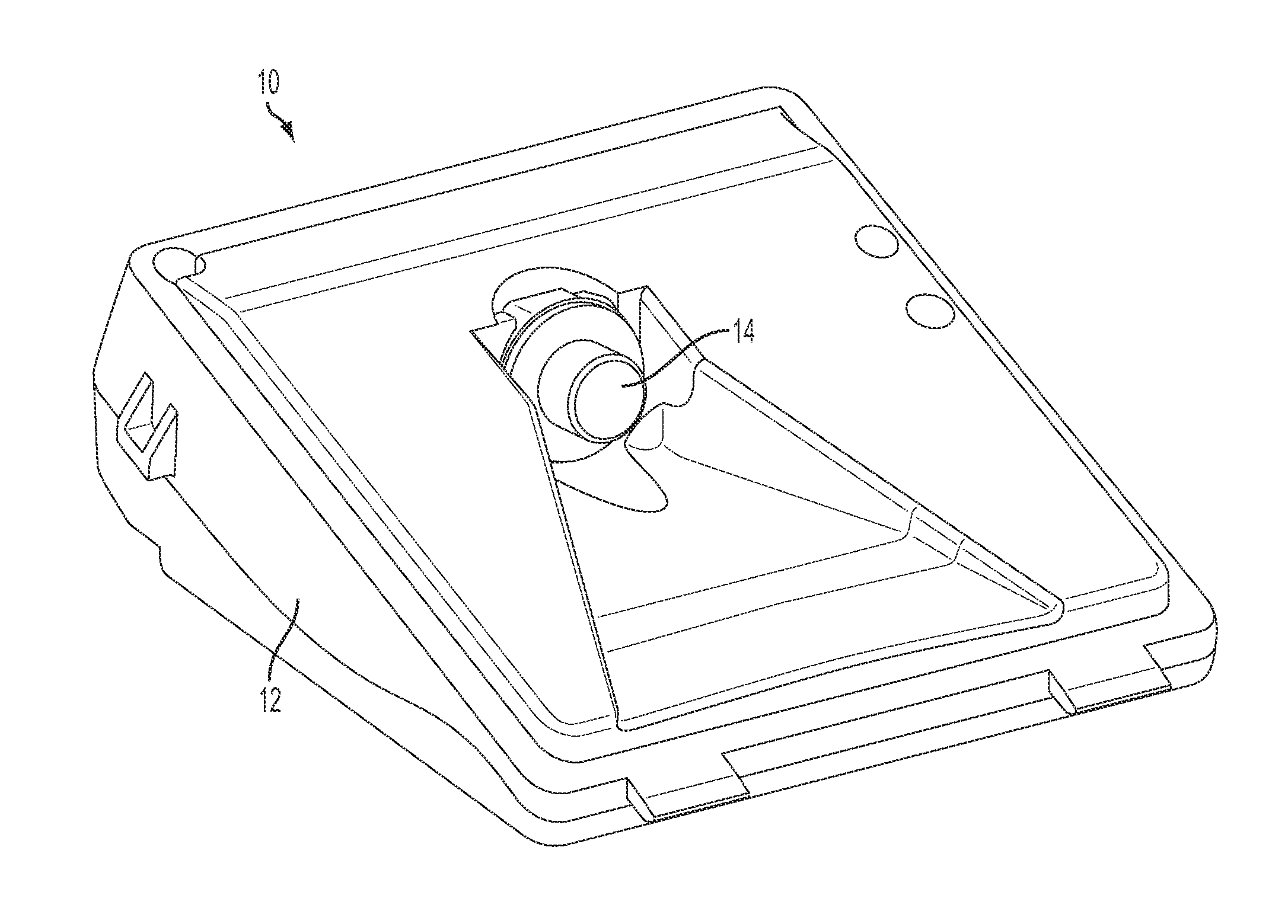

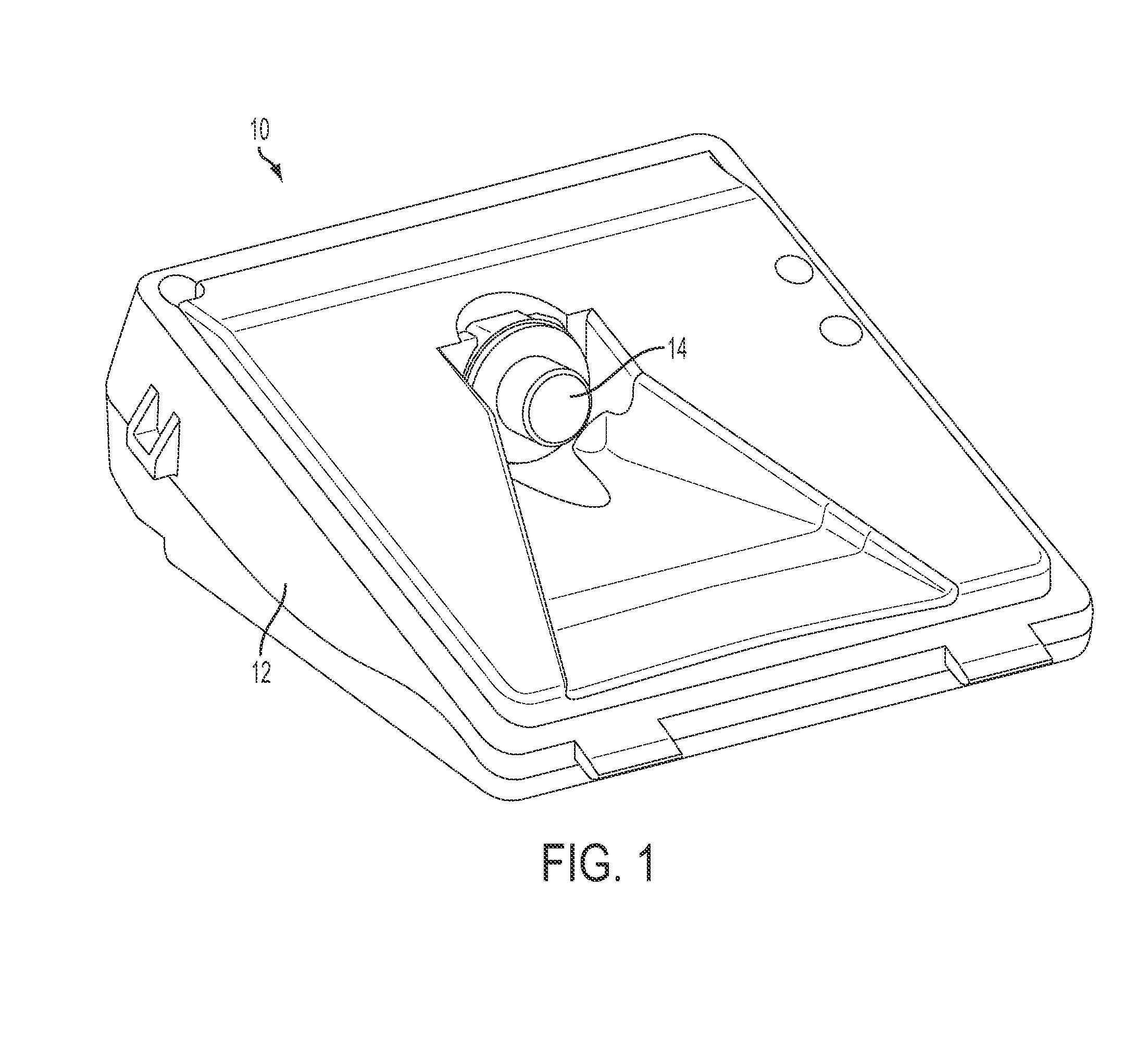

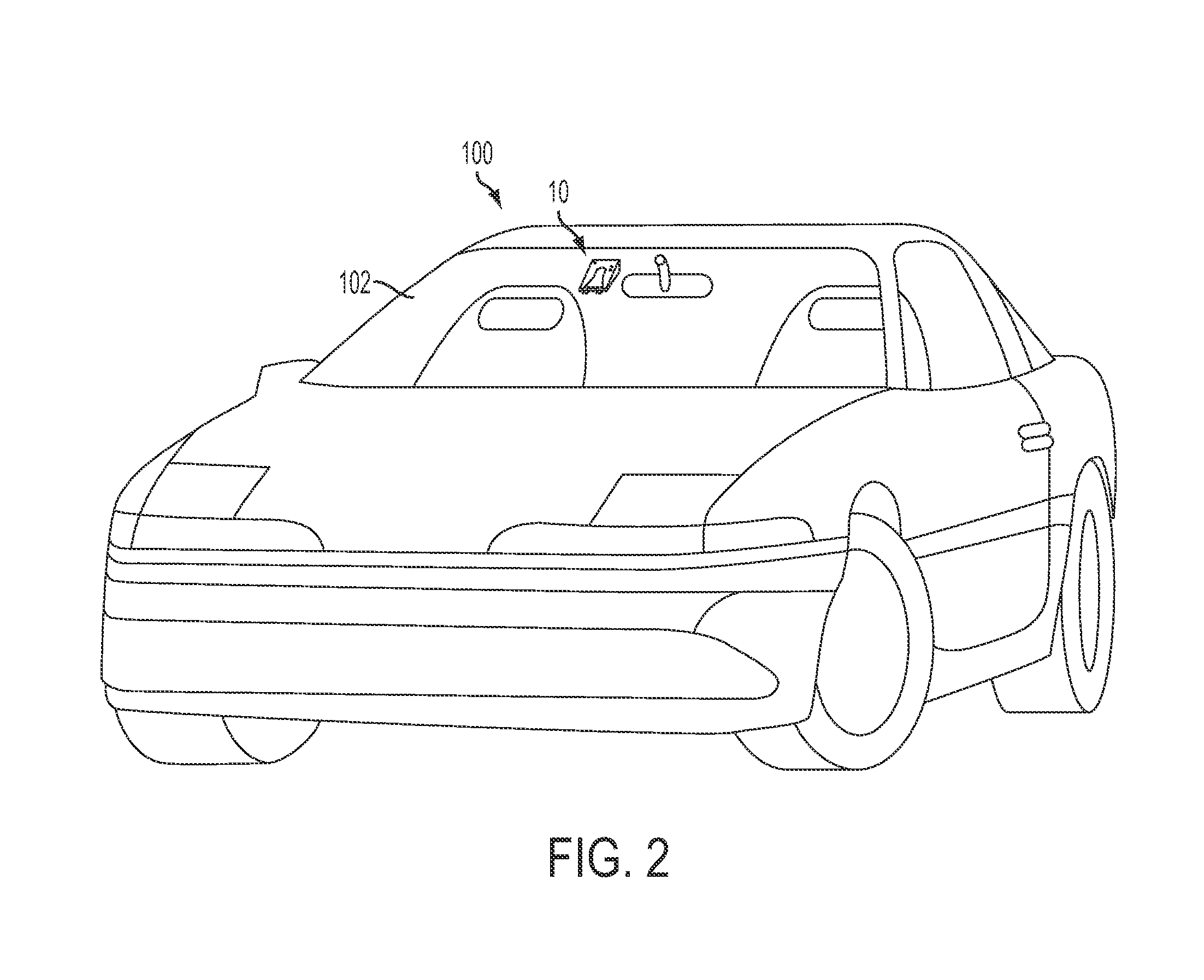

Accessory module for vehicle

ActiveUS7480149B2Good adhesionEasy to assembleCharacter and pattern recognitionOptical signallingEngineeringElectrical connector

An accessory module is mountable to an interior surface of a vehicle windshield and includes a mounting element securable to an interior surface of a windshield of a vehicle, and an accessory support having a base portion attachable to the mounting element. The accessory support includes an accessory holding element configured to hold an accessory, at least one circuitry holding element configured to hold a printed circuit board at the accessory support, and an electrical connector for electrically connecting the printed circuit board and the accessory to an electrical source of the vehicle. The base portion, the accessory holding element and the circuitry holding element are integrally molded together so that the accessory support comprises a unitarily molded accessory support. The accessory module includes a cover portion attachable to the accessory support to substantially encompass the accessory and the printed circuit board within the accessory module.

Owner:MAGNA ELECTRONICS INC

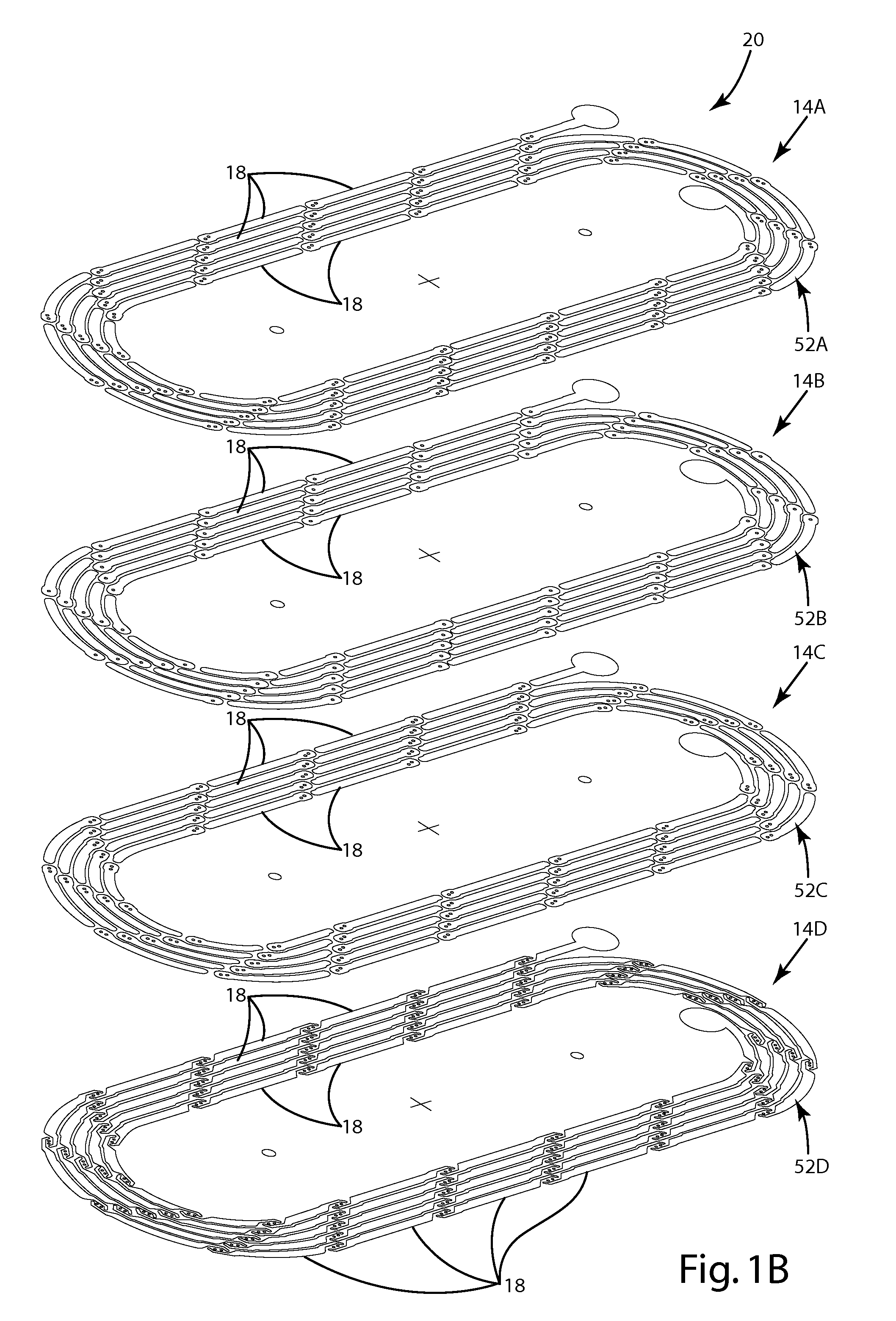

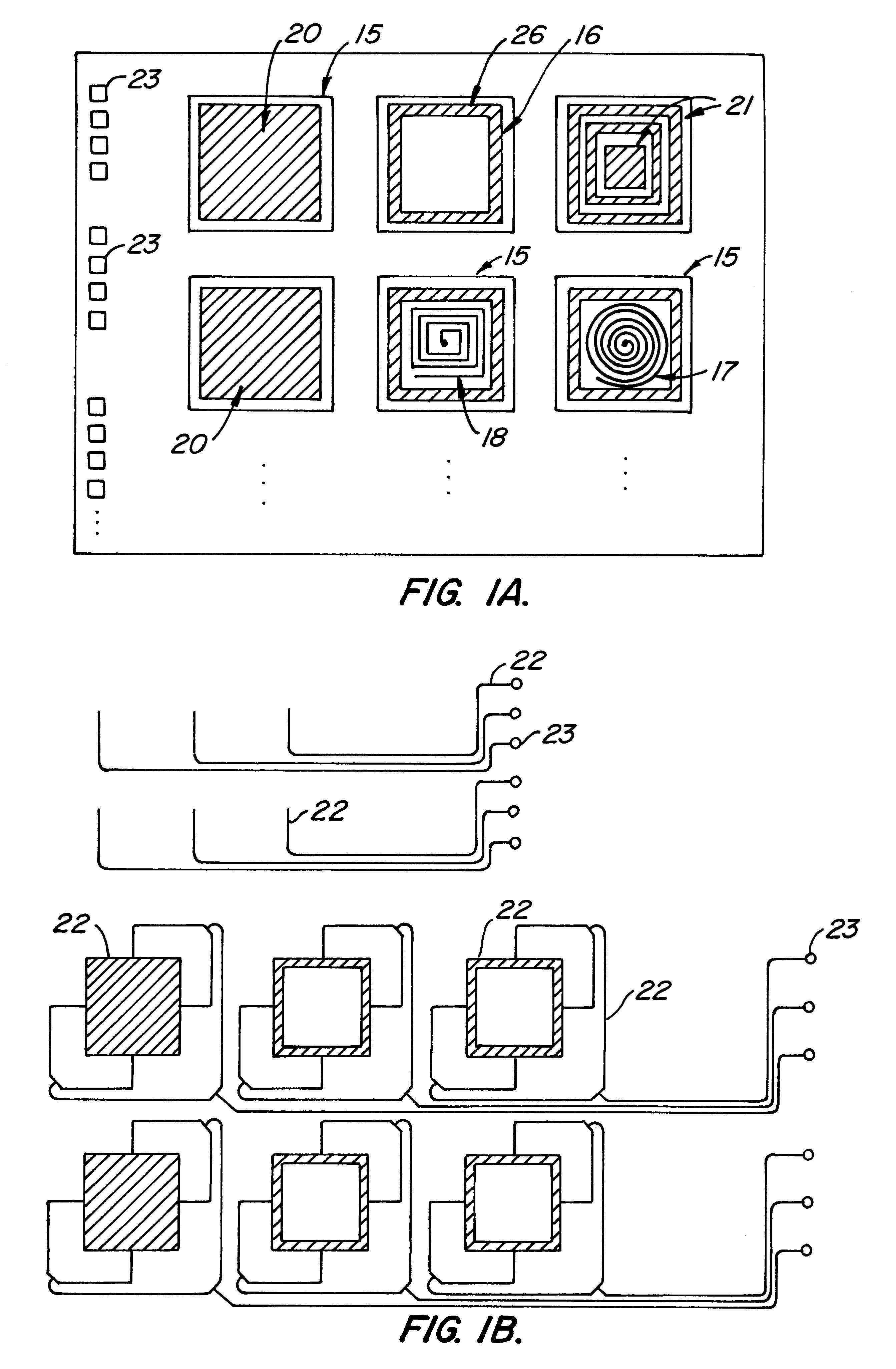

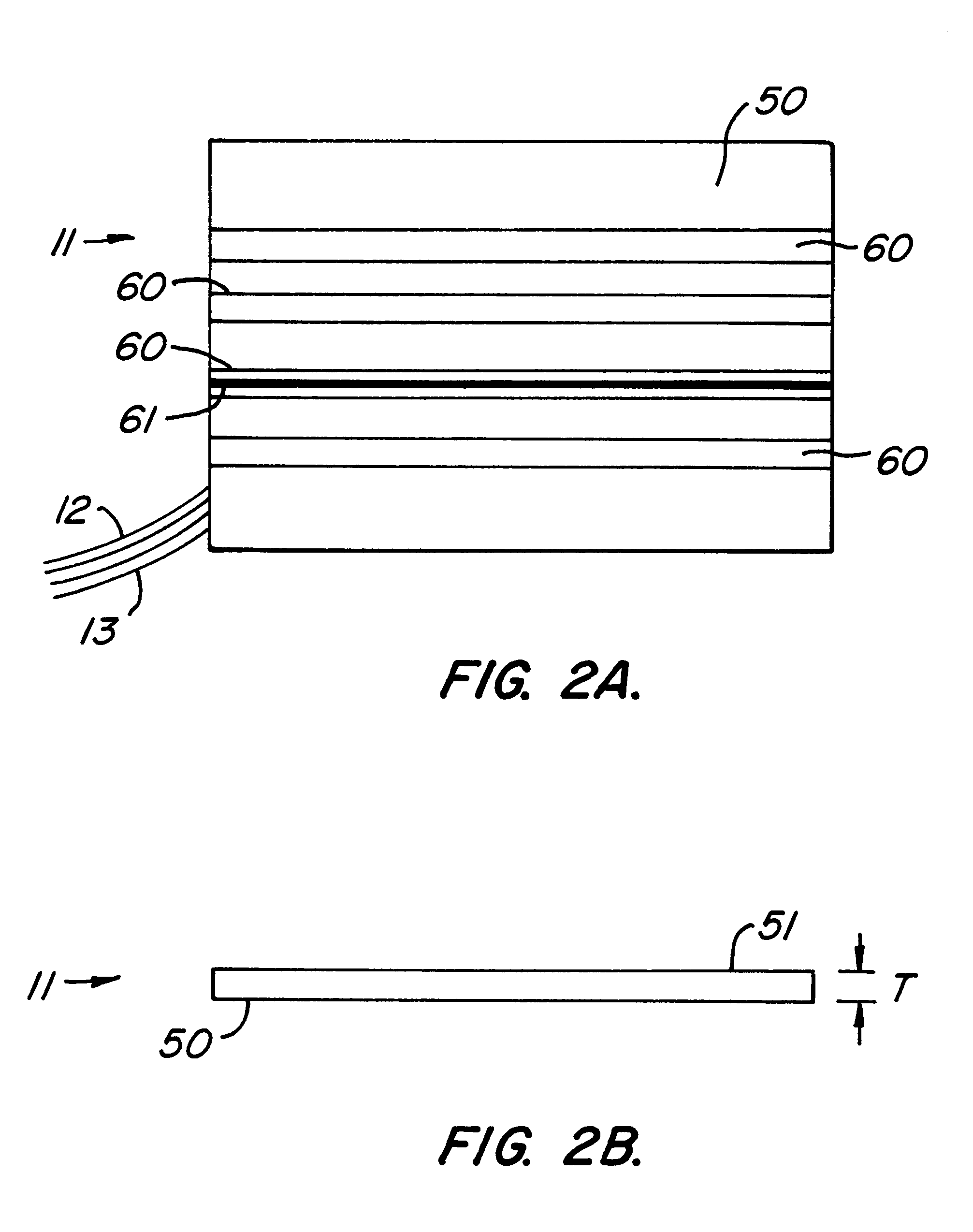

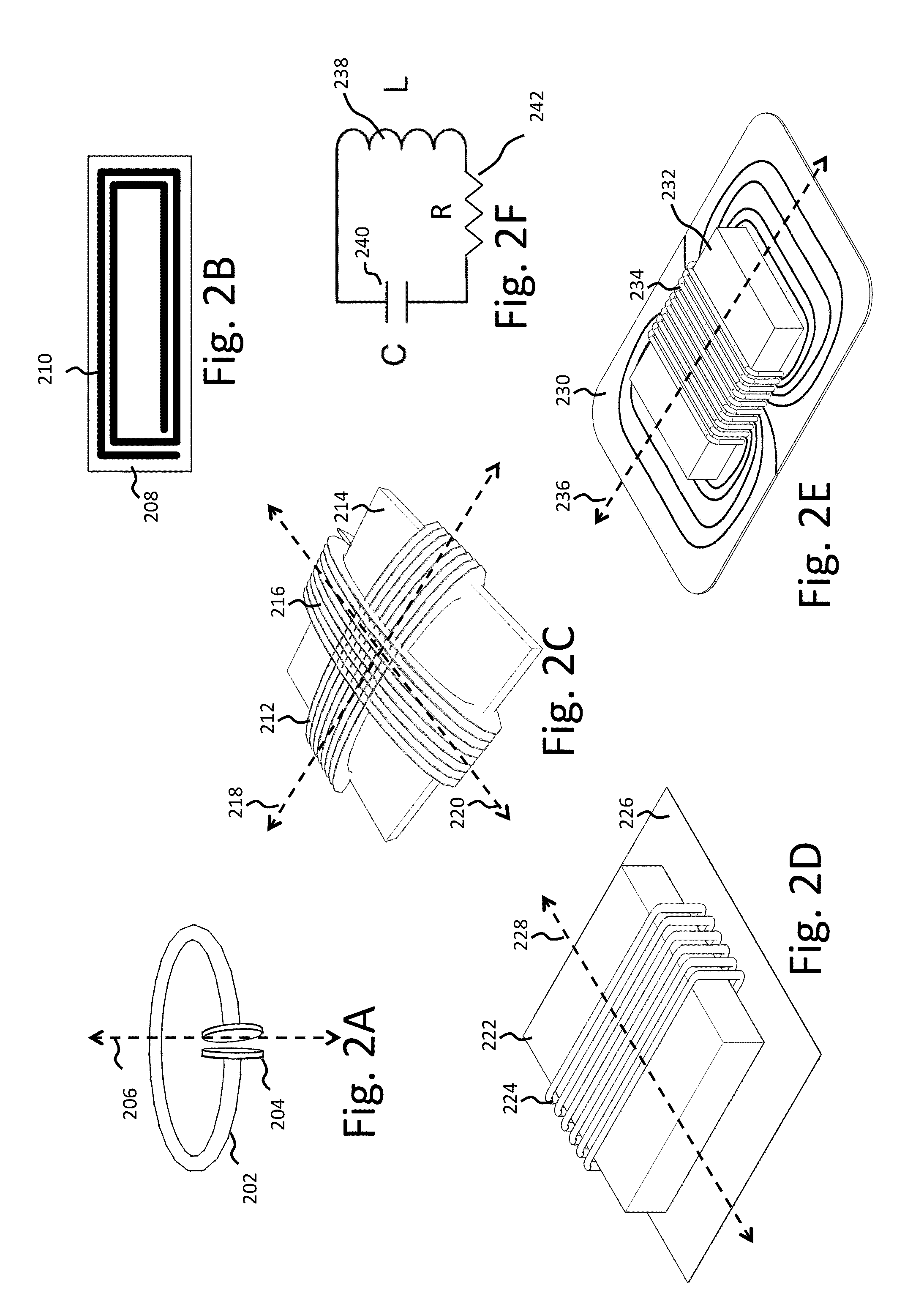

Printed circuit board coil

ActiveUS20090085706A1Reduce skin effectReduce lossTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

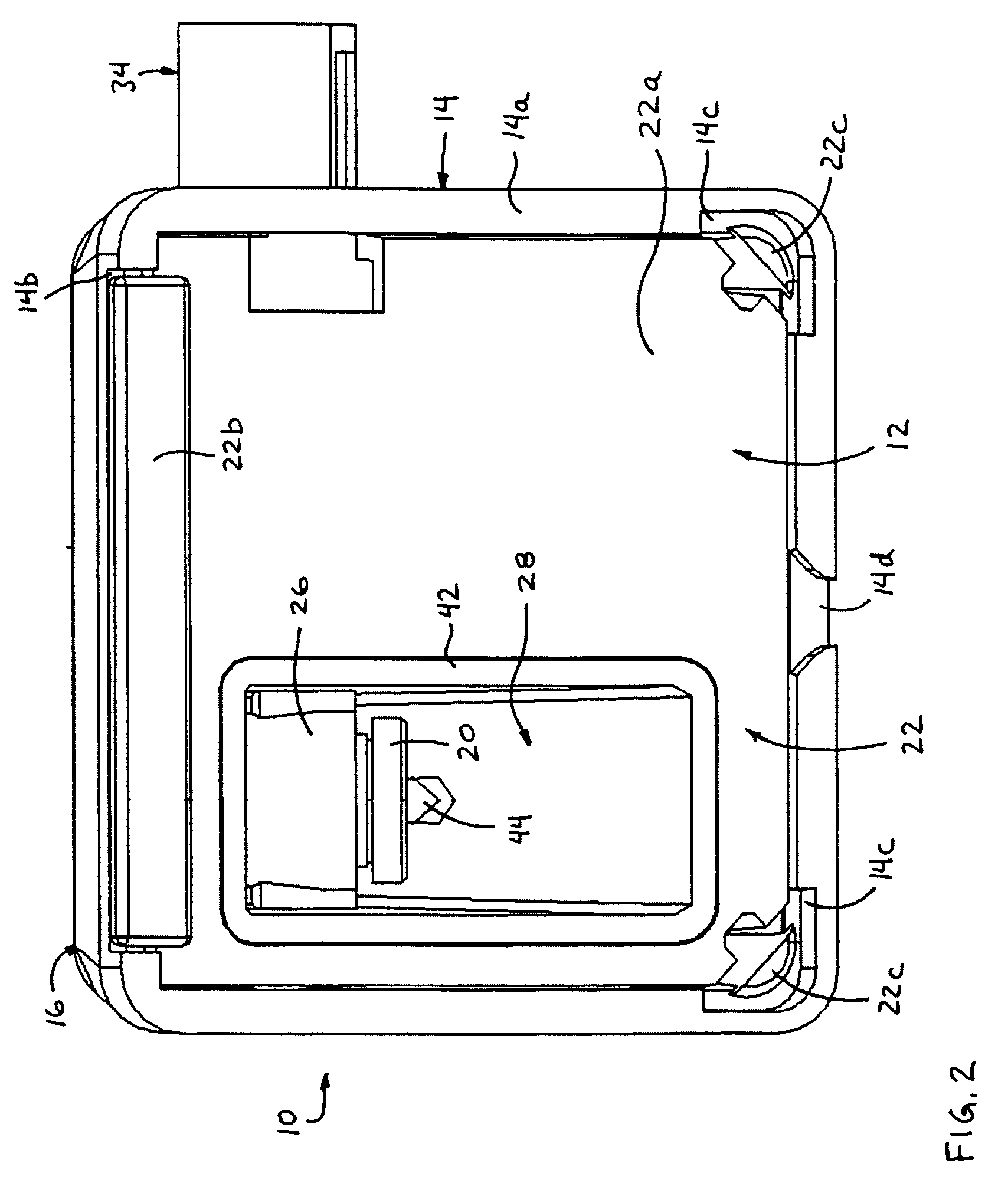

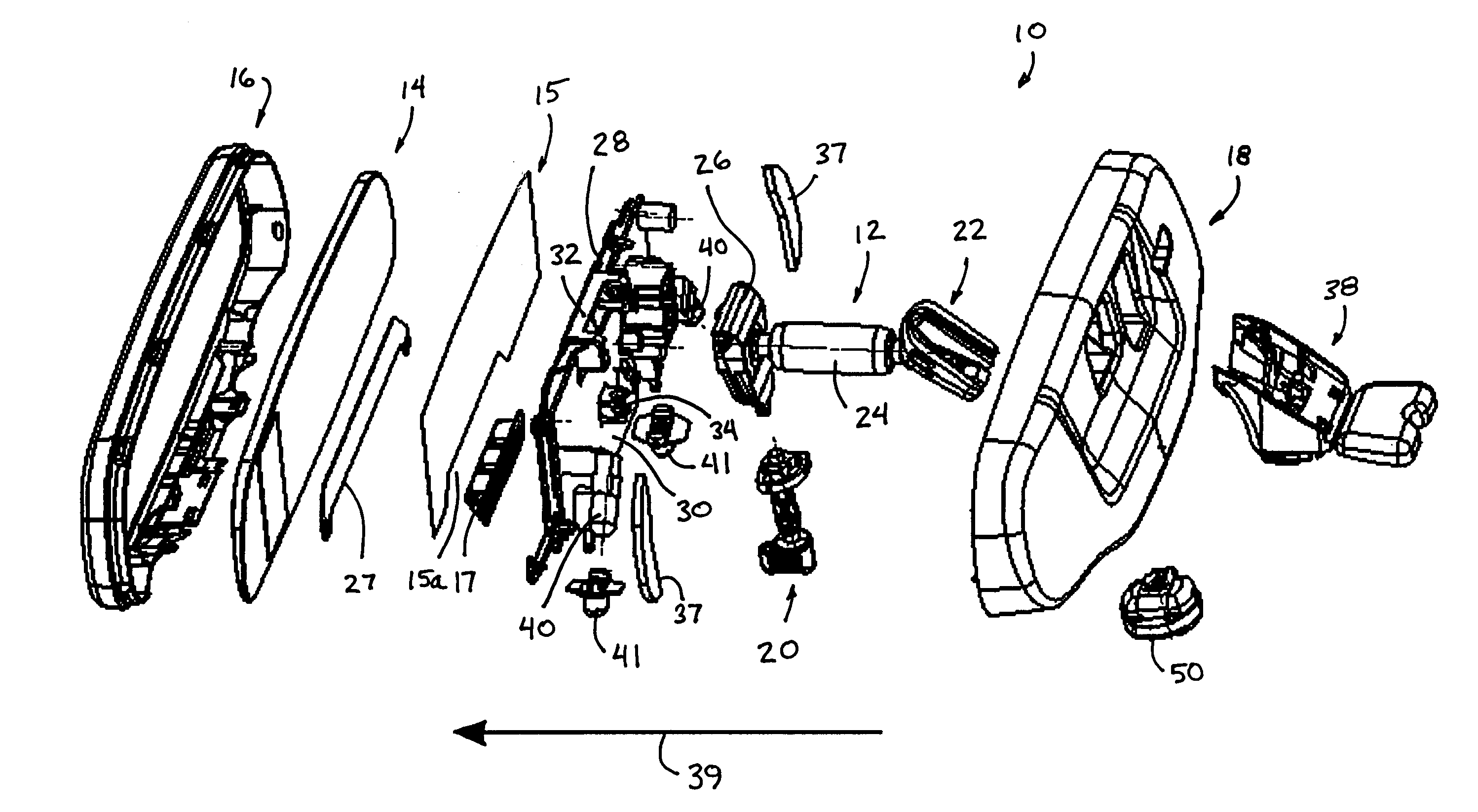

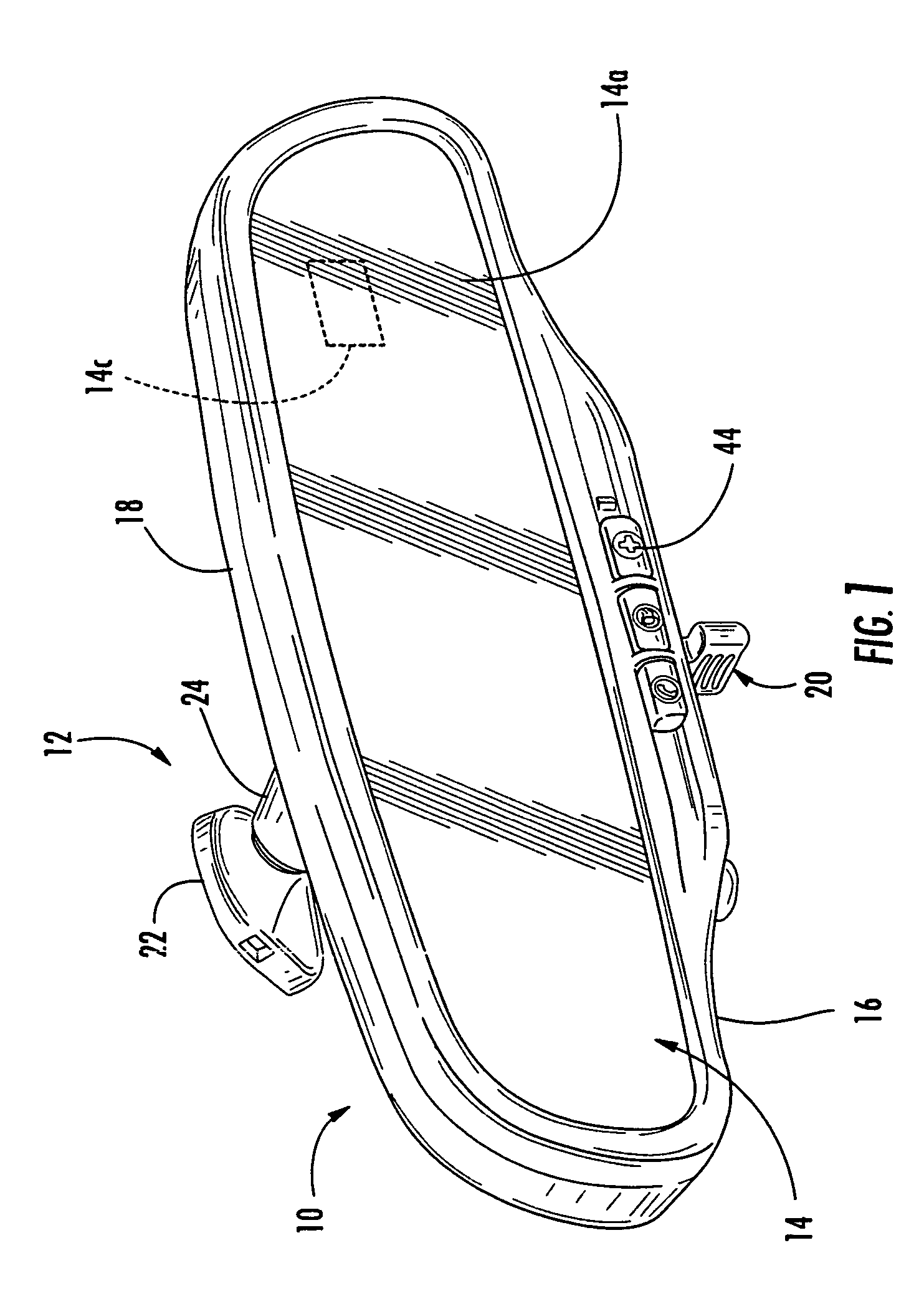

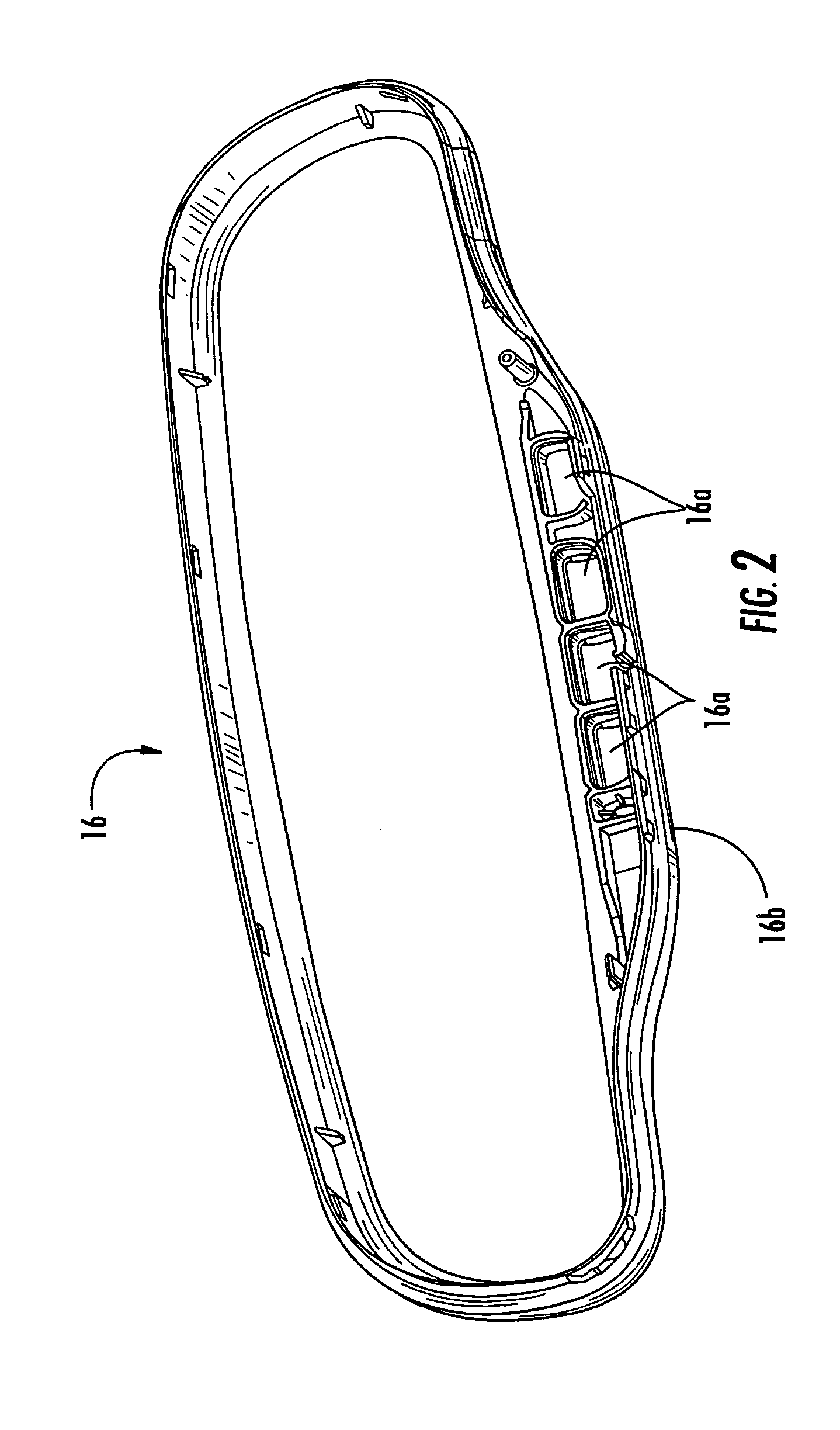

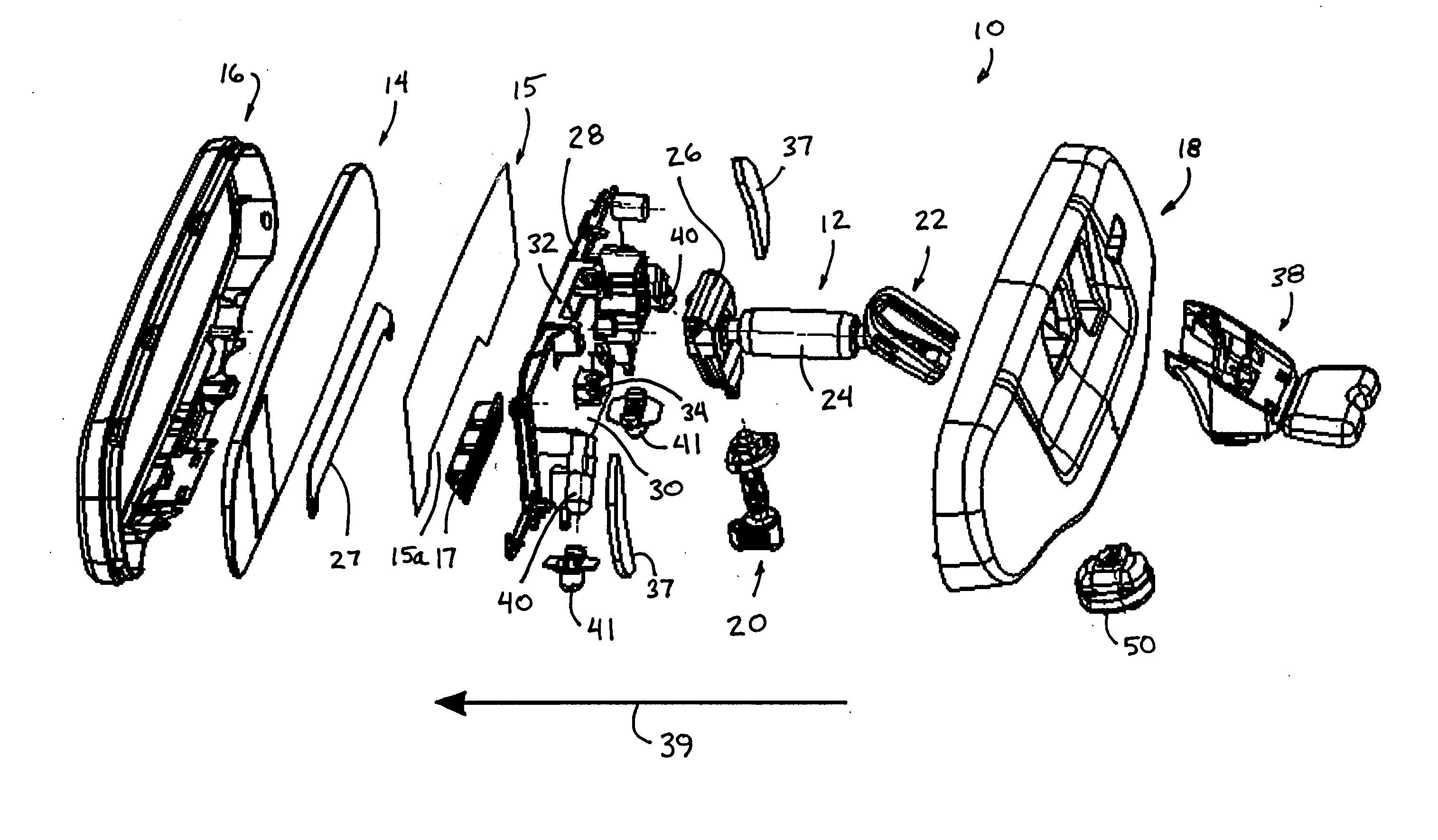

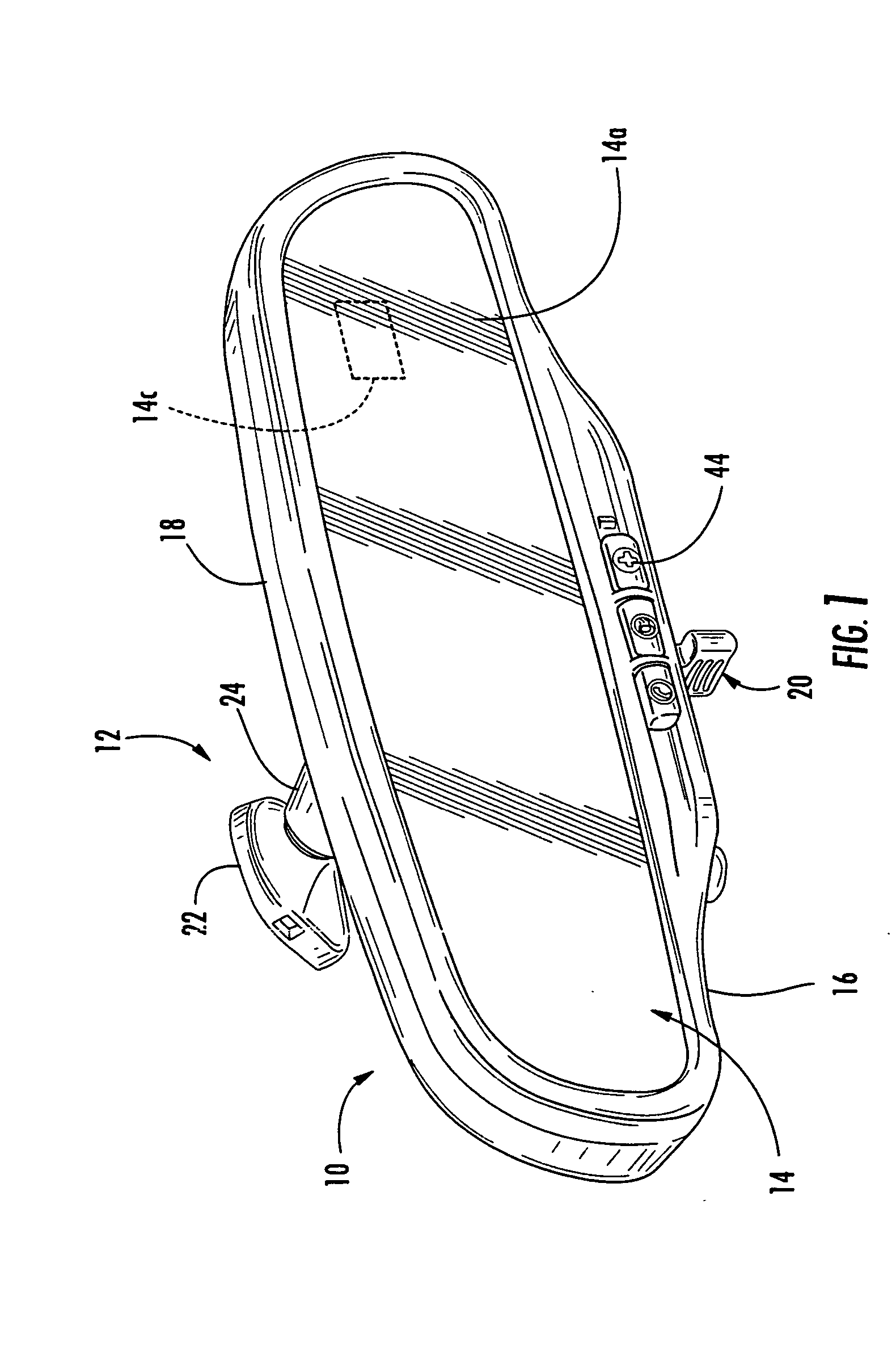

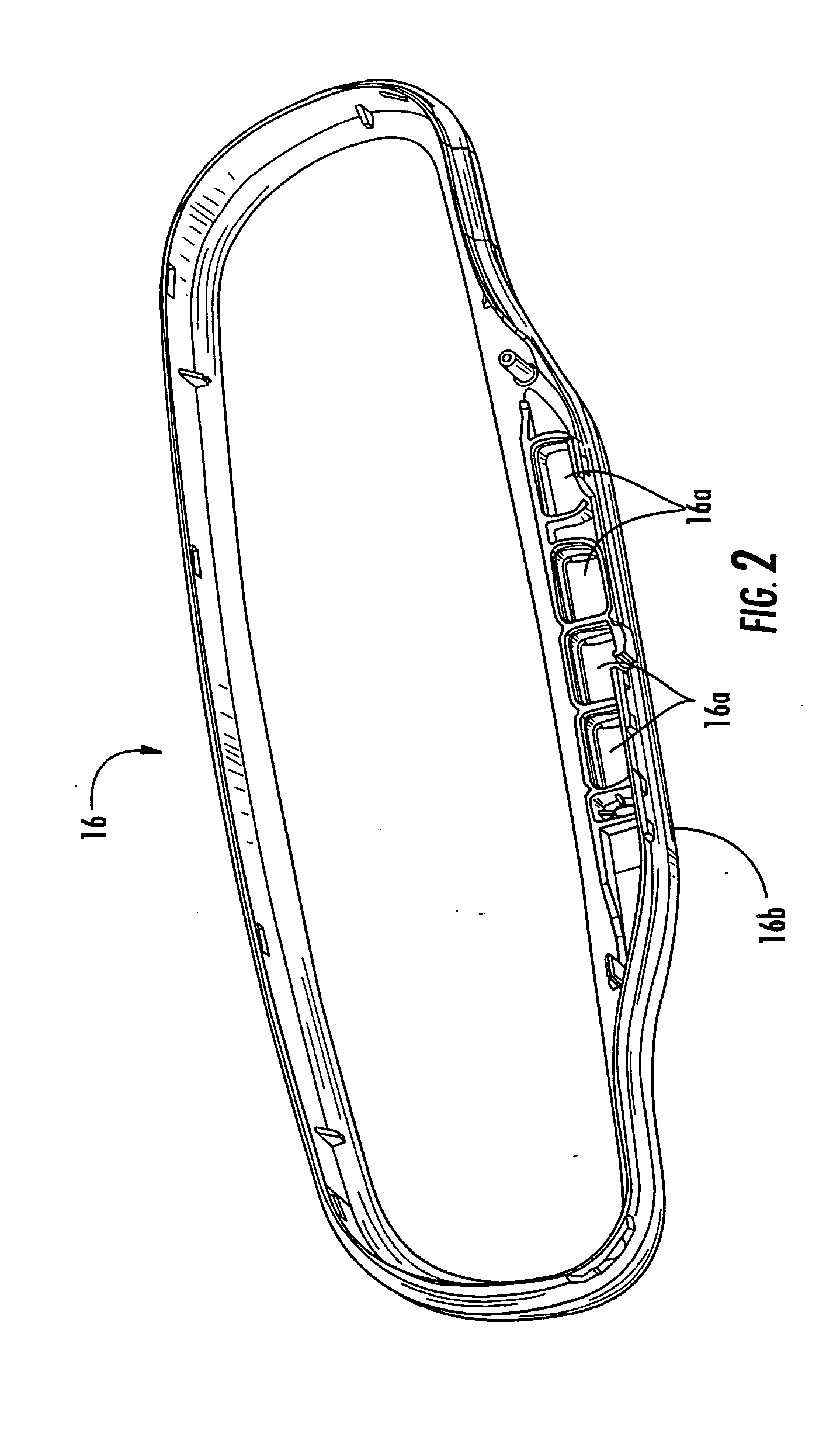

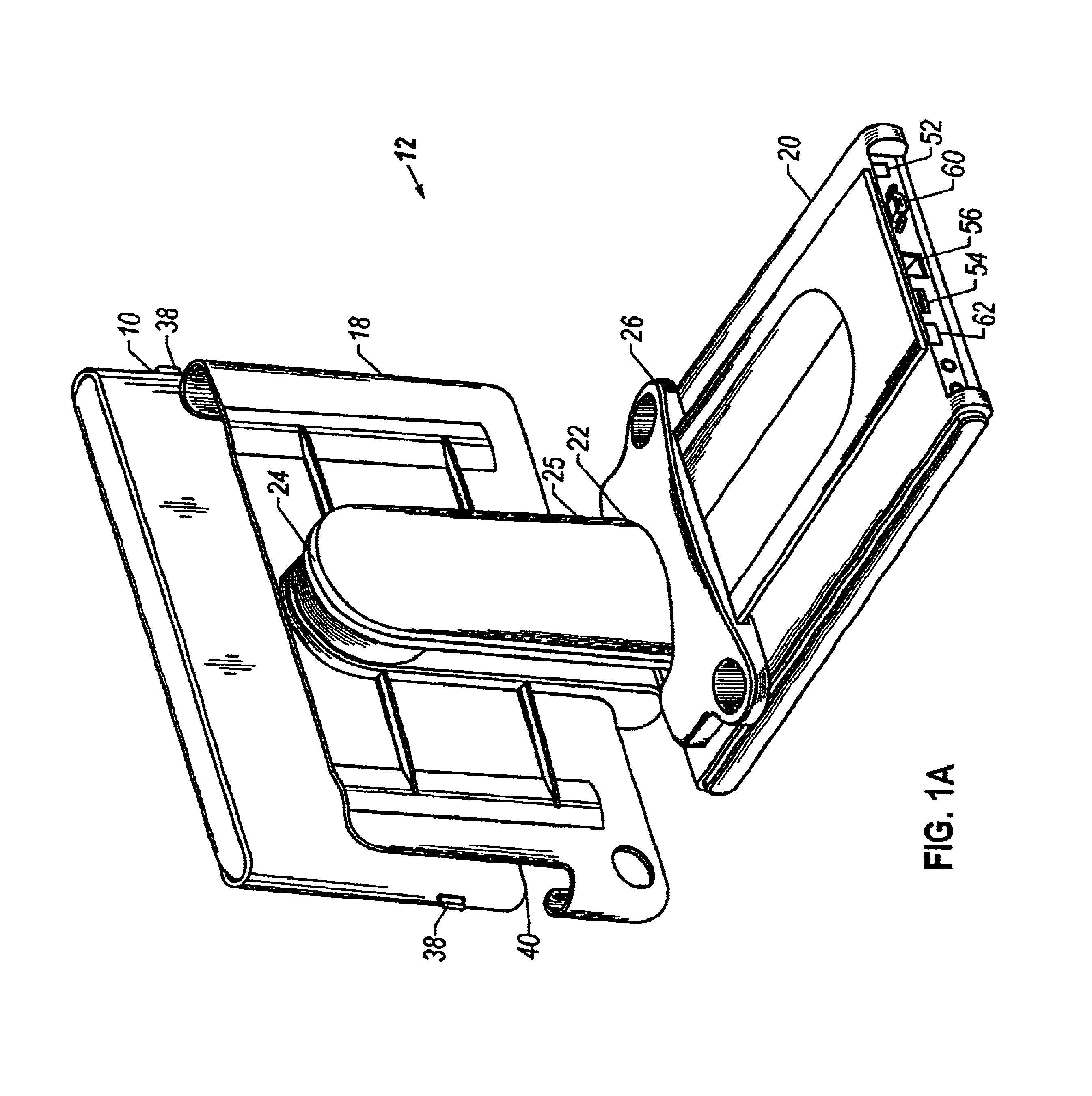

Interior rearview mirror assembly

InactiveUS7249860B2Facilitate efficient assembly of assemblyEasy to assembleMirrorsMountingsPrismEngineering

An interior rearview mirror assembly for a vehicle includes a reflective element and a casing. An attachment plate is secured to the reflective element and an electronic circuitry element, such as a printed circuit board, is attached to the attachment plate. The attachment plate includes at least one mounting member protruding through the circuit board for engaging a mounting assembly that mounts the mirror assembly to an interior portion of the vehicle and directly supports the attachment plate, along with the printed circuit board and the reflective element at an end of the mounting assembly. The mounting assembly may comprise a toggle assembly for a prismatic reflective element.

Owner:DONNELLY CORP

Interior rearview mirror assembly

InactiveUS20050078389A1Facilitate efficient assembly of assemblyEasy to assembleMirrorsMountingsPrismPrinted circuit board

An interior rearview mirror assembly for a vehicle includes a reflective element and a casing. An attachment plate is secured to the reflective element and an electronic circuitry element, such as a printed circuit board, is attached to the attachment plate. The attachment plate includes at least one mounting member protruding through the circuit board for engaging a mounting assembly that mounts the mirror assembly to an interior portion of the vehicle and directly supports the attachment plate, along with the printed circuit board and the reflective element at an end of the mounting assembly. The mounting assembly may comprise a toggle assembly for a prismatic reflective element.

Owner:DONNELLY CORP

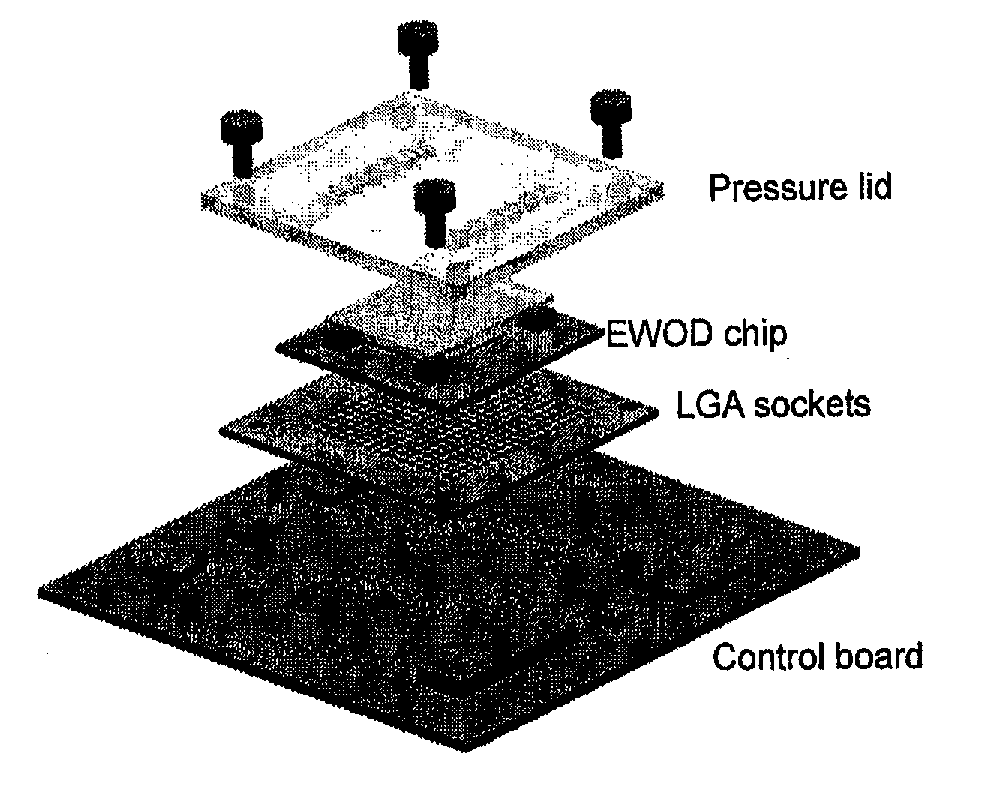

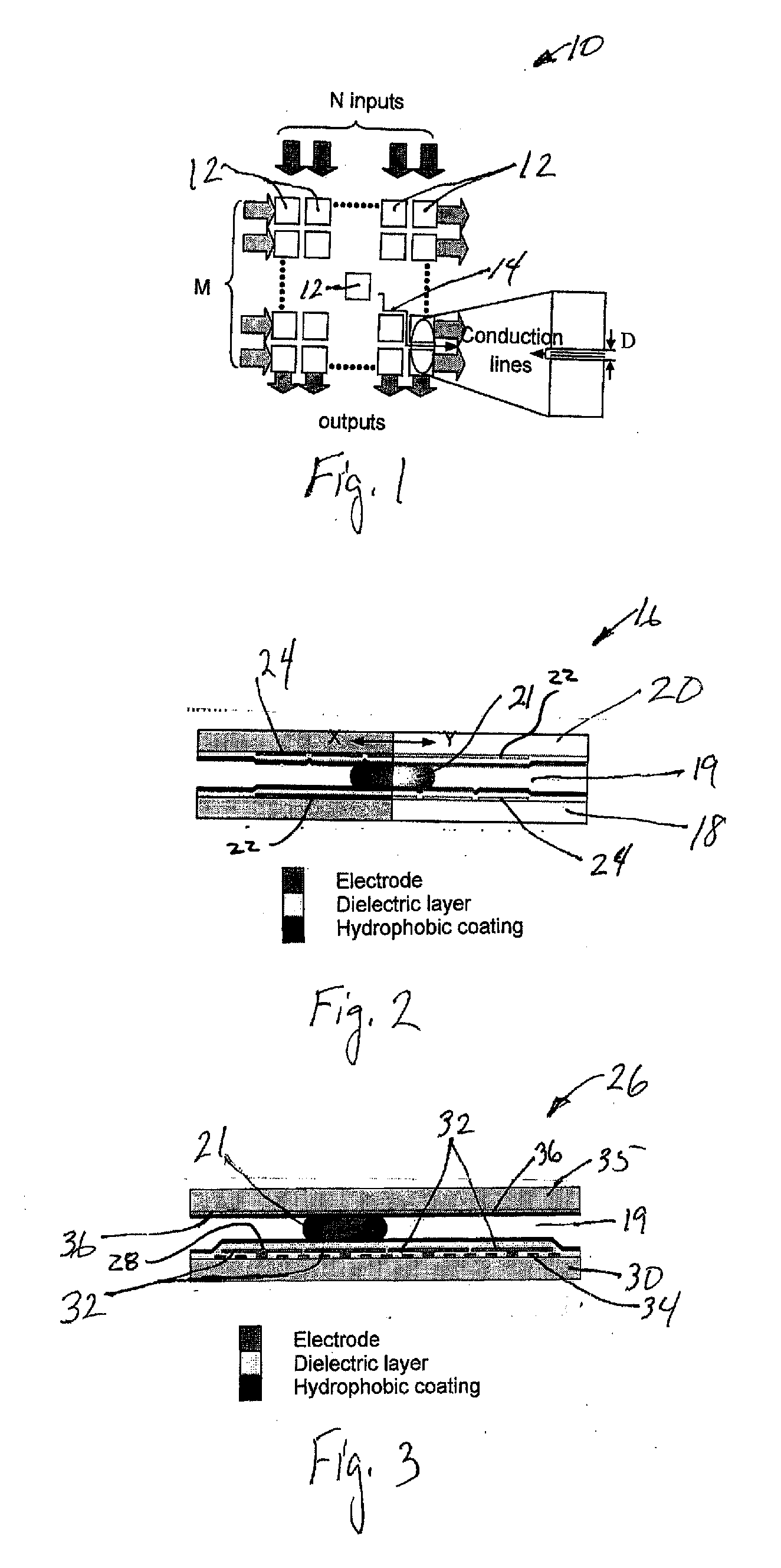

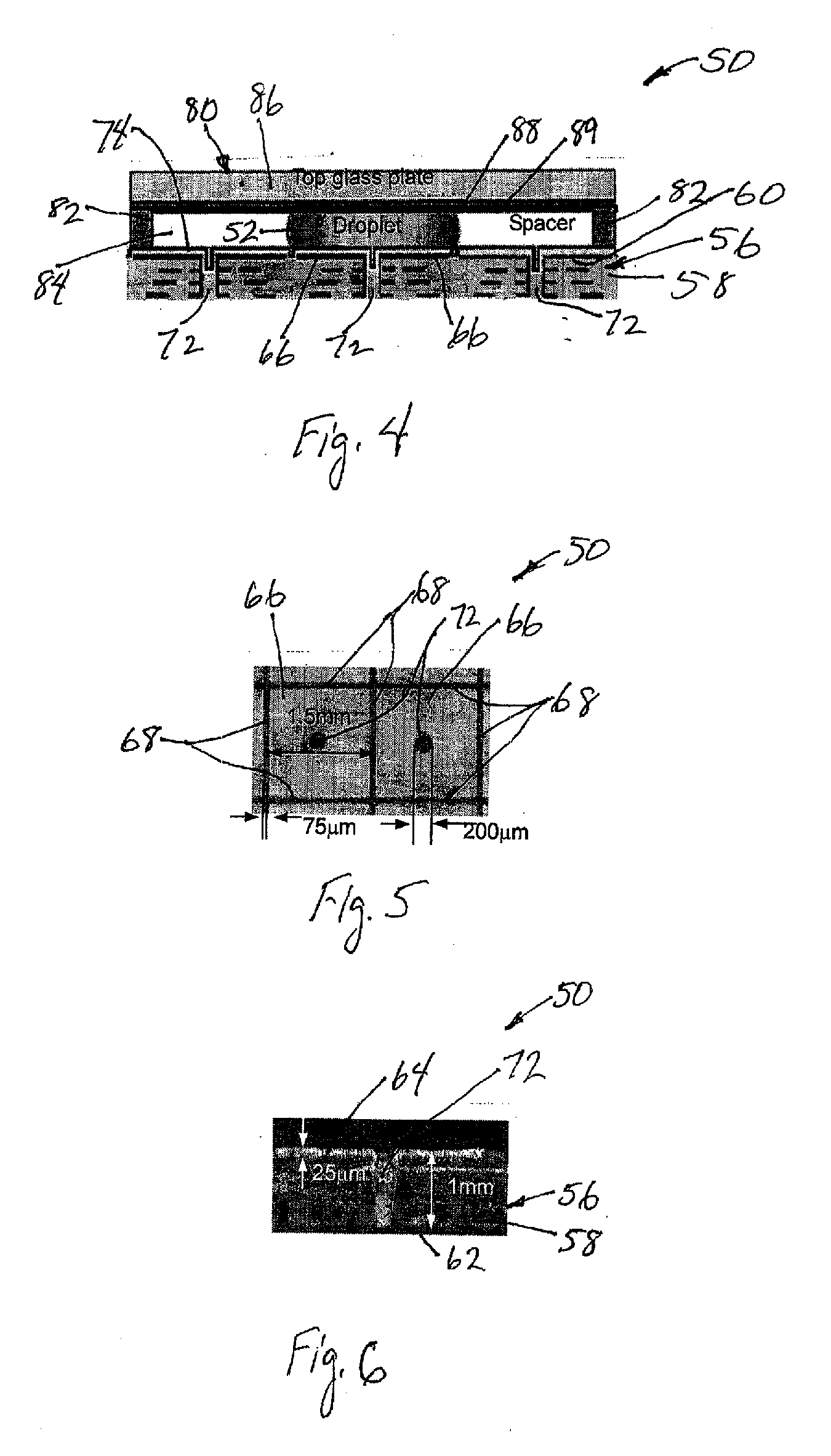

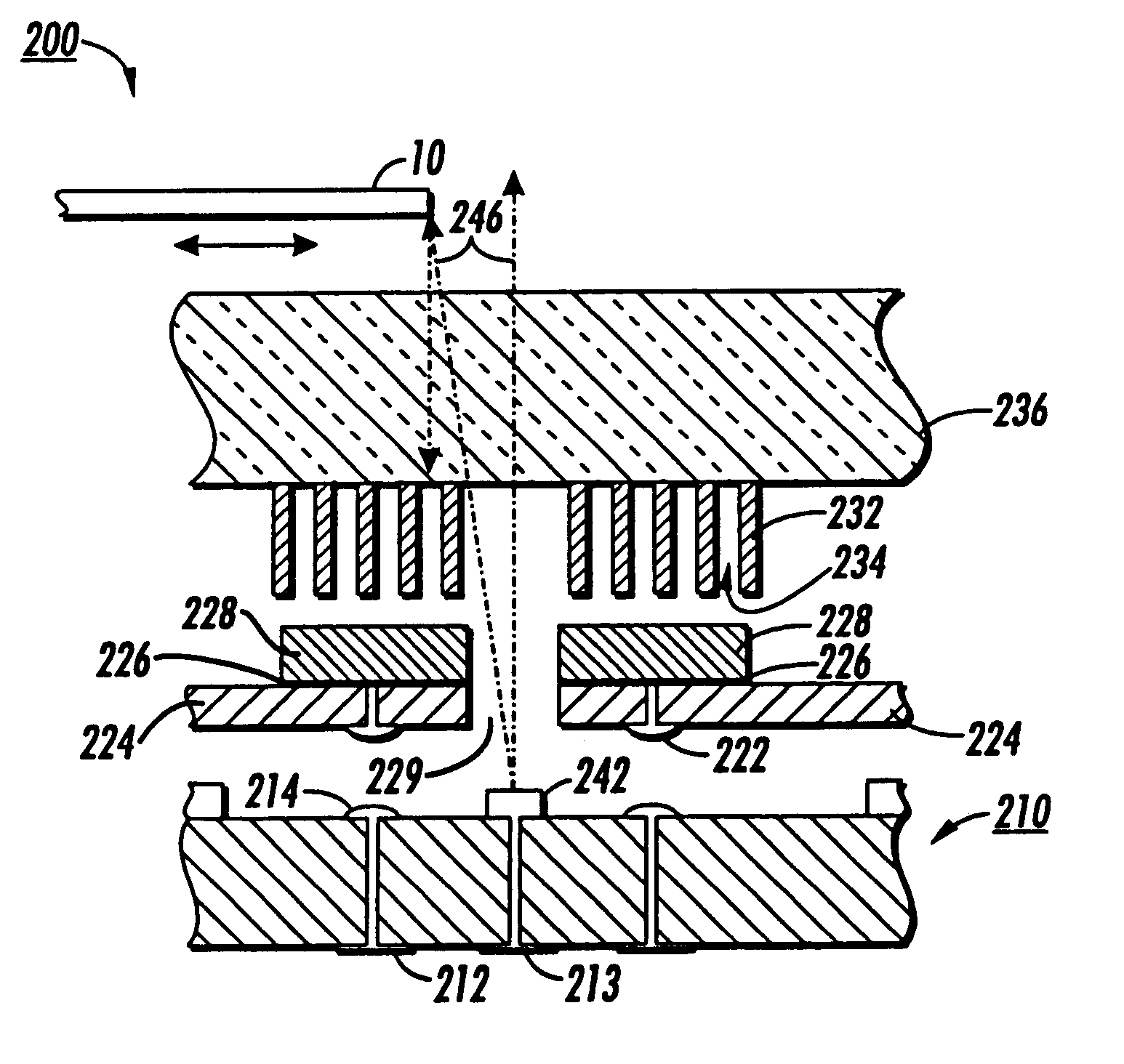

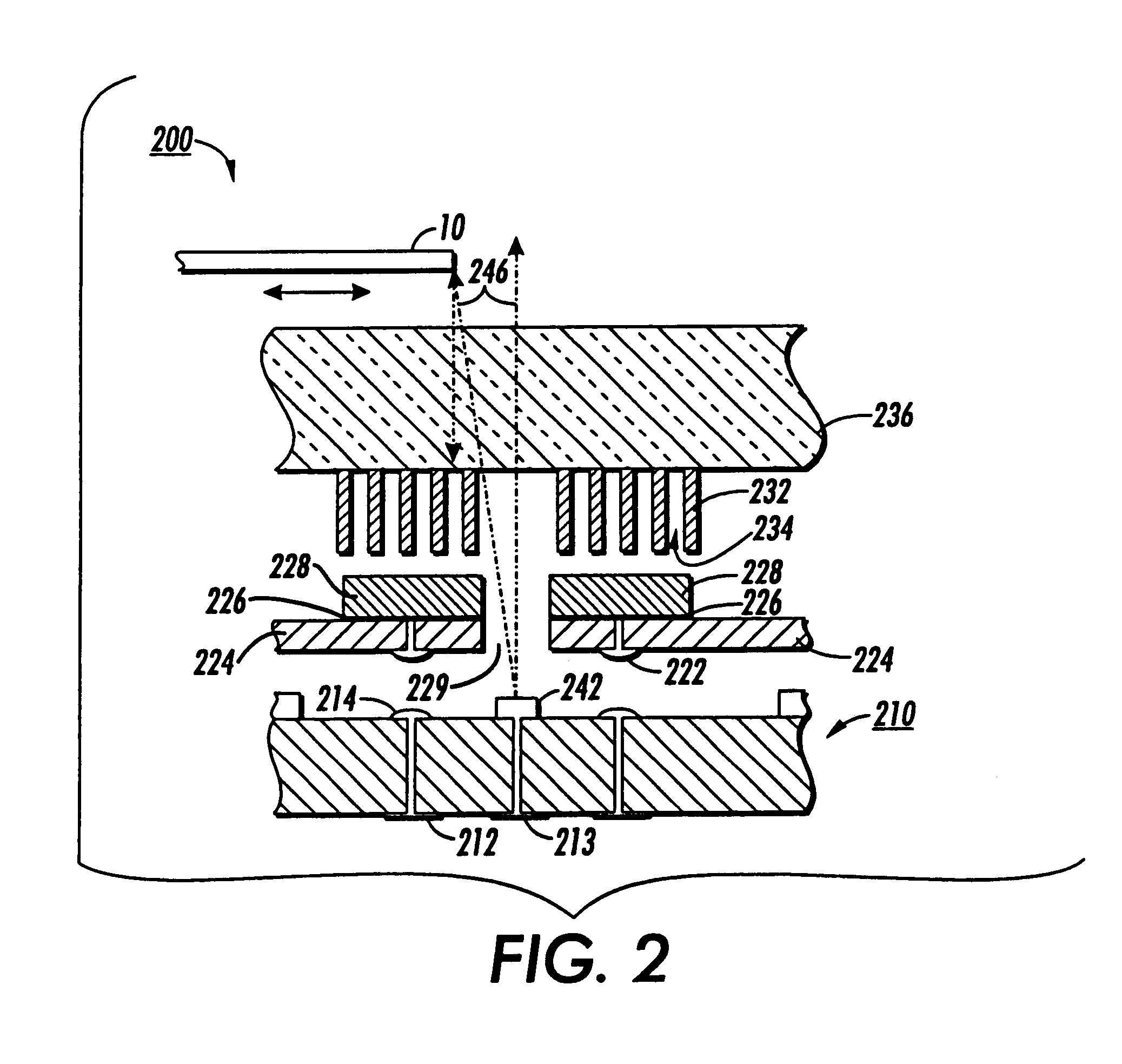

Small object moving on printed circuit board

A printed circuit board based digital or droplet microfluidic system and method for producing such microfluidic system are disclosed. The digital microfluidic device comprises a printed circuit board having a substrate and a plurality of electrode pads disposed on the top surface of the substrate in a rectangular array. A via extends from each electrode pad through the substrate to other locations on the substrate . A dielectric layer is disposed on the electrode pads. Droplets may be manipulated using electrowetting principles and others by applying a voltage to the desired electrodes. Each electrode pad can be controlled directly and independently from the other electrode pads to modify the surface wettability of the dielectric layer in the vicinity of the electrode pad by applying a voltage to the desired electrode pad(s). In this way, droplets may be formed, moved, mixed, and / or divided or other small objects manipulated while in air or immersed in a liquid on the dielectric surface.

Owner:RGT UNIV OF CALIFORNIA

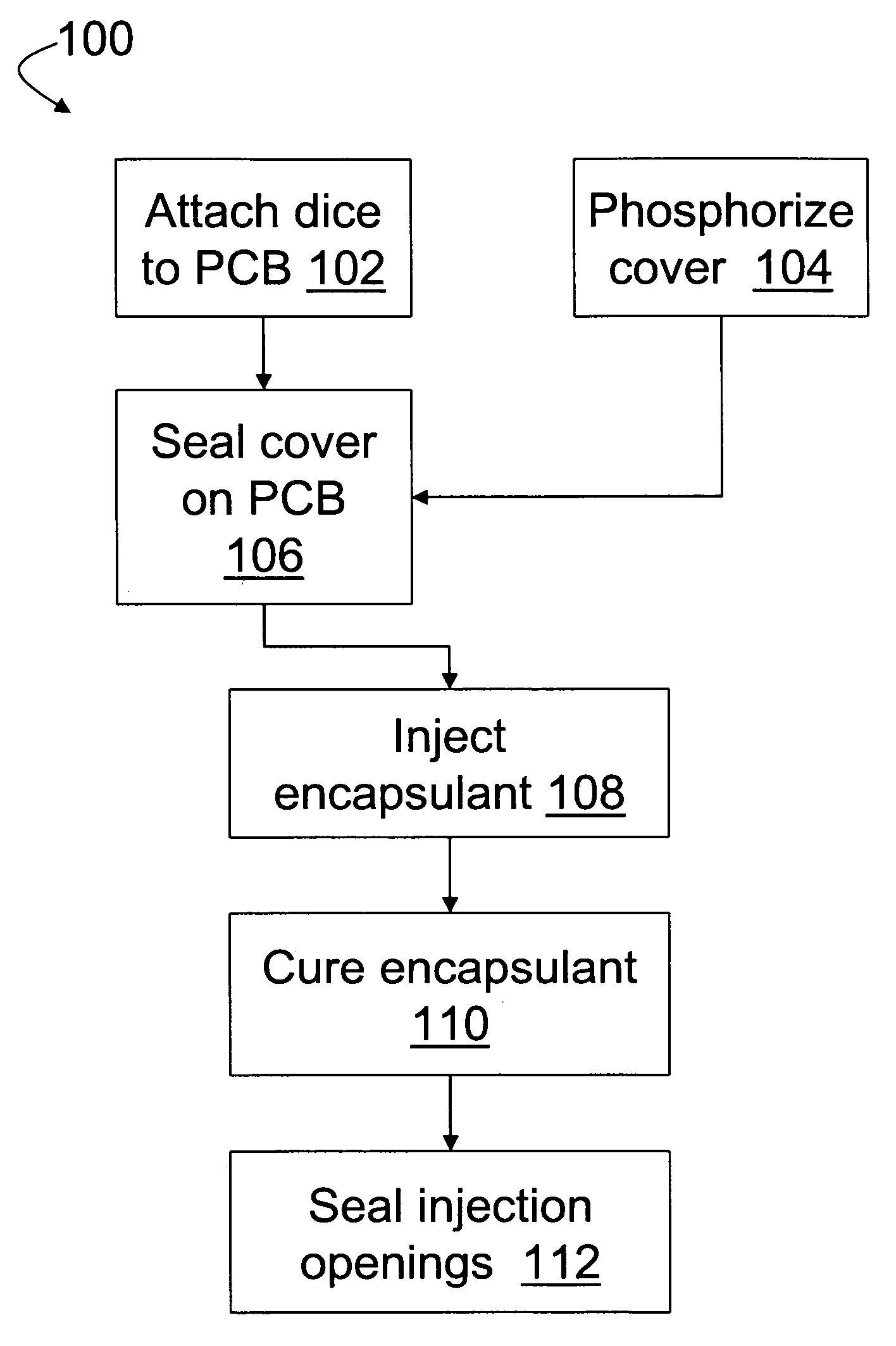

LED lighting assemblies with thermal overmolding

ActiveUS20070121326A1Thermal conductivityPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

One or more light emitting diode diodes (LEDs) are attached to a printed circuit board. The attached LEDs are connectable with a power source via circuitry of the printed circuit board. An overmolding material is insert molded an over at least portions of the printed circuit board proximate to the LEDs to form a free standing high thermal conductivity material overmolding that covers at least portions of the printed circuit board proximate to the LEDs. The free standing high thermal conductivity material has a melting temperature greater than about 100° C. and has a thermal conductivity greater than or about 1 W / m·K. In some embodiments, the free standing high thermal conductivity material is a thermoplastic material.

Owner:GE LIGHTING SOLUTIONS LLC

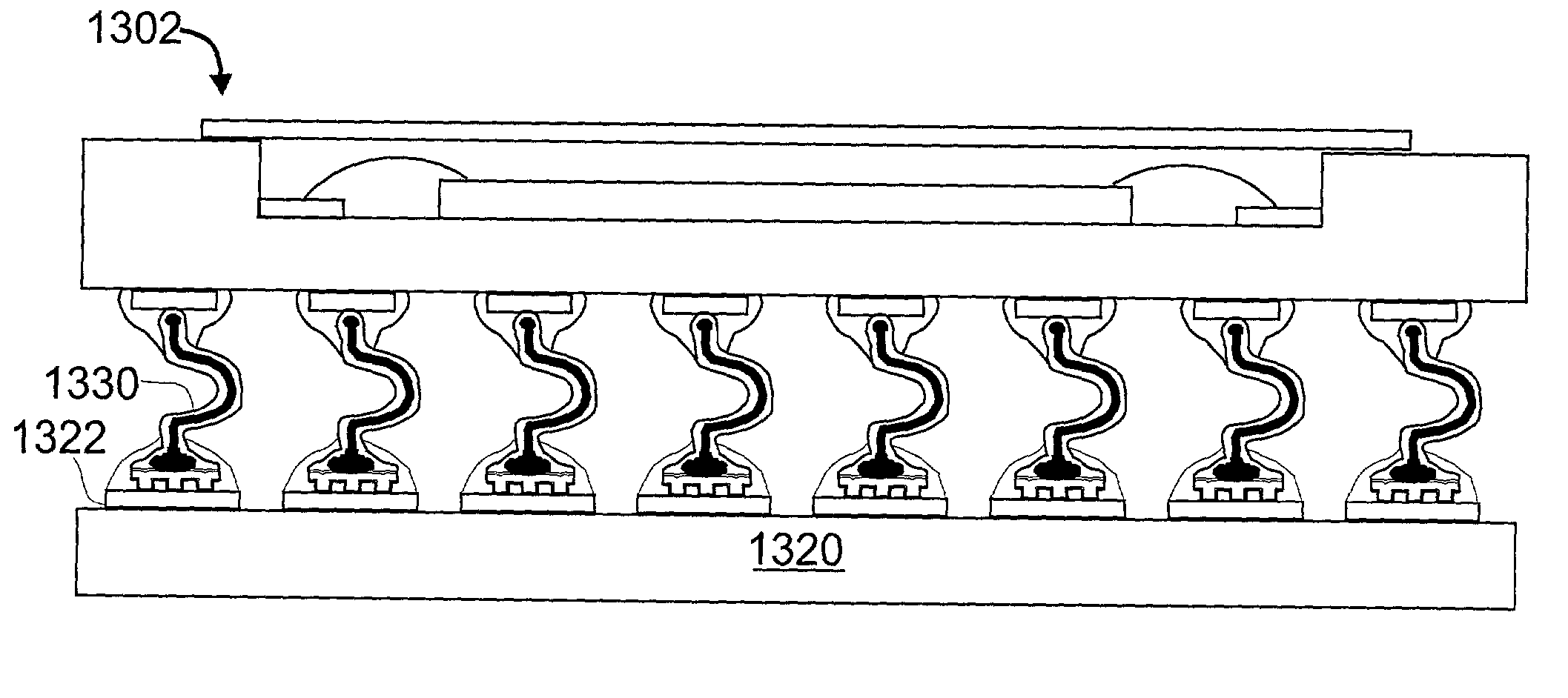

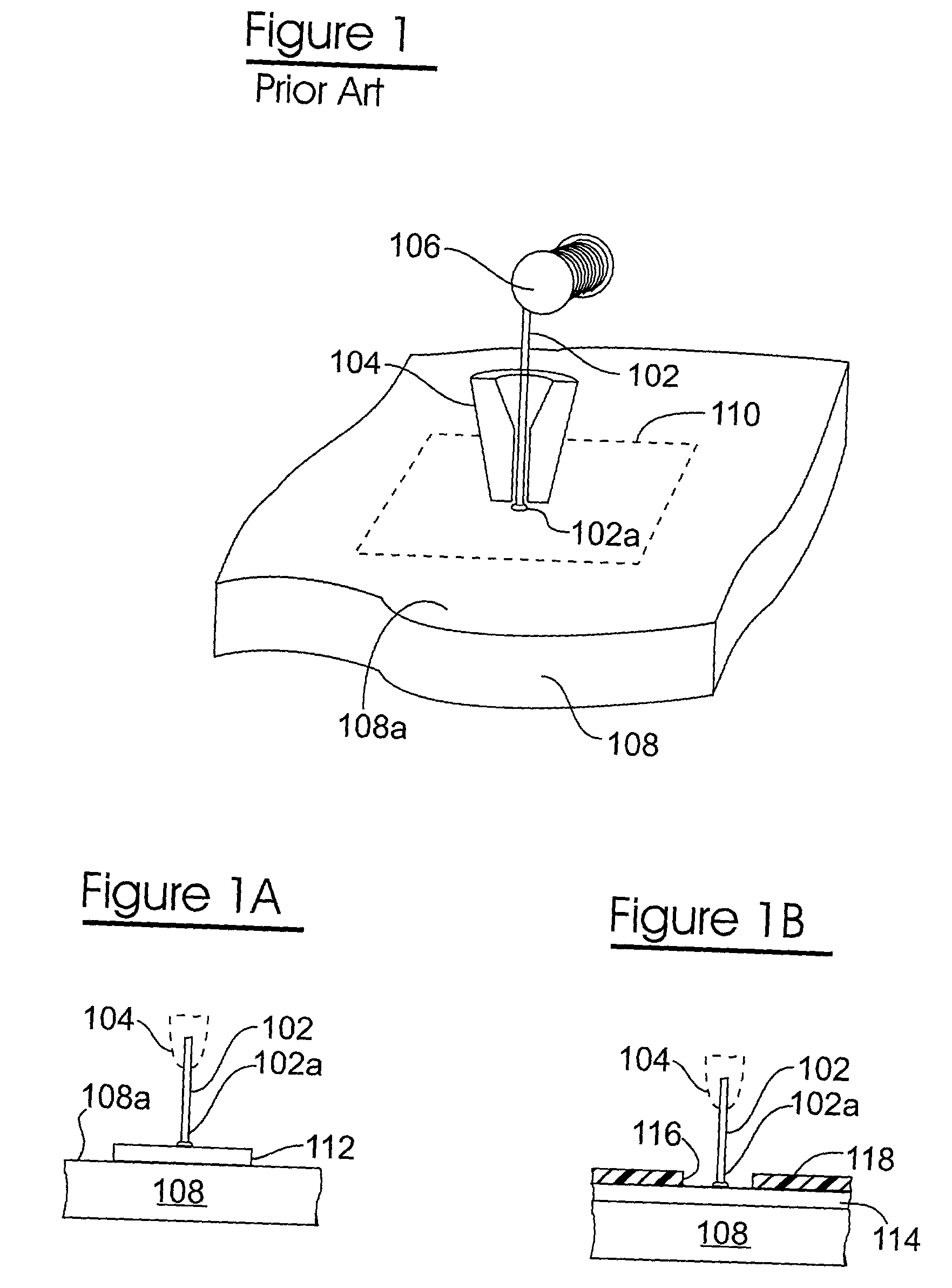

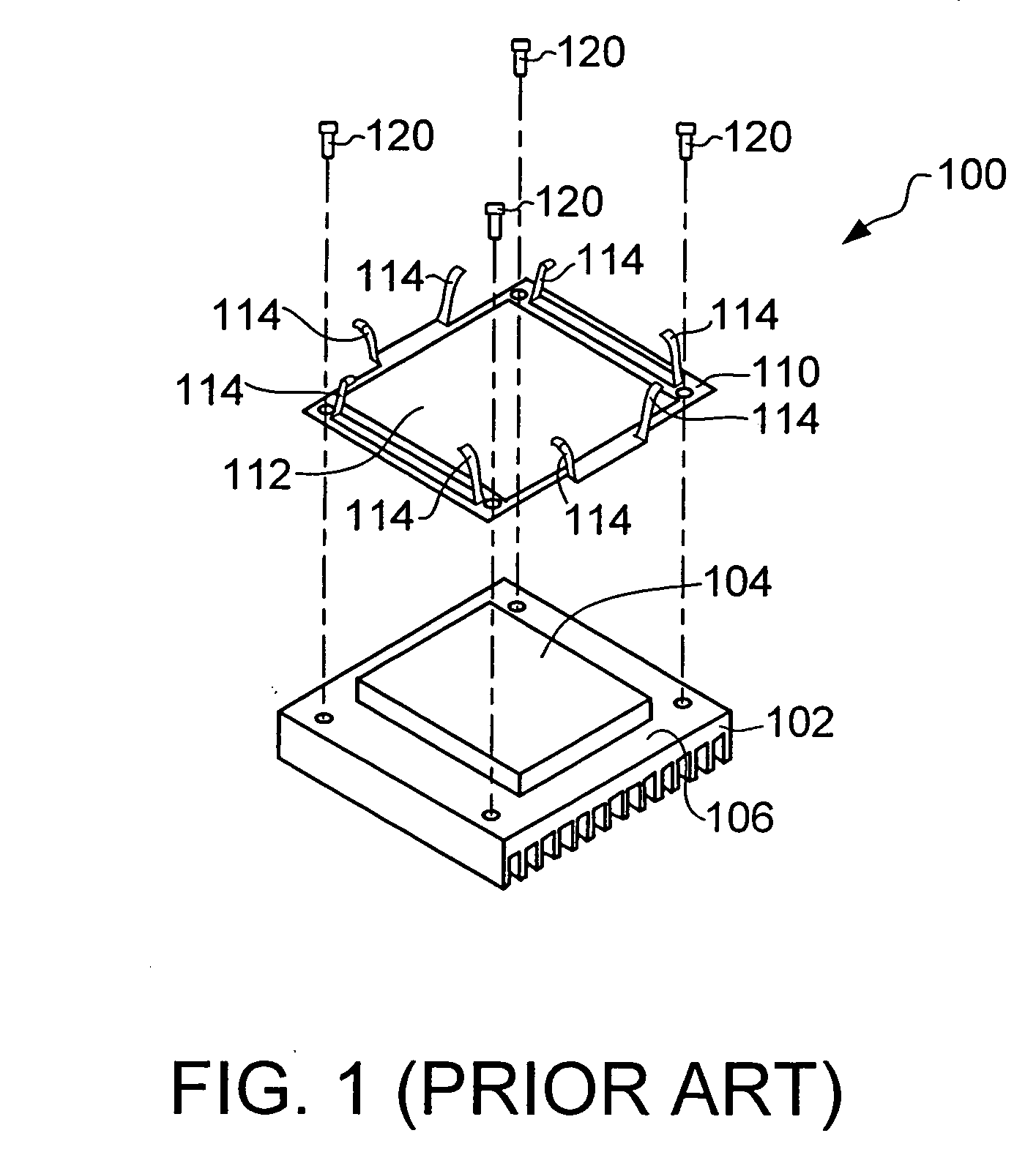

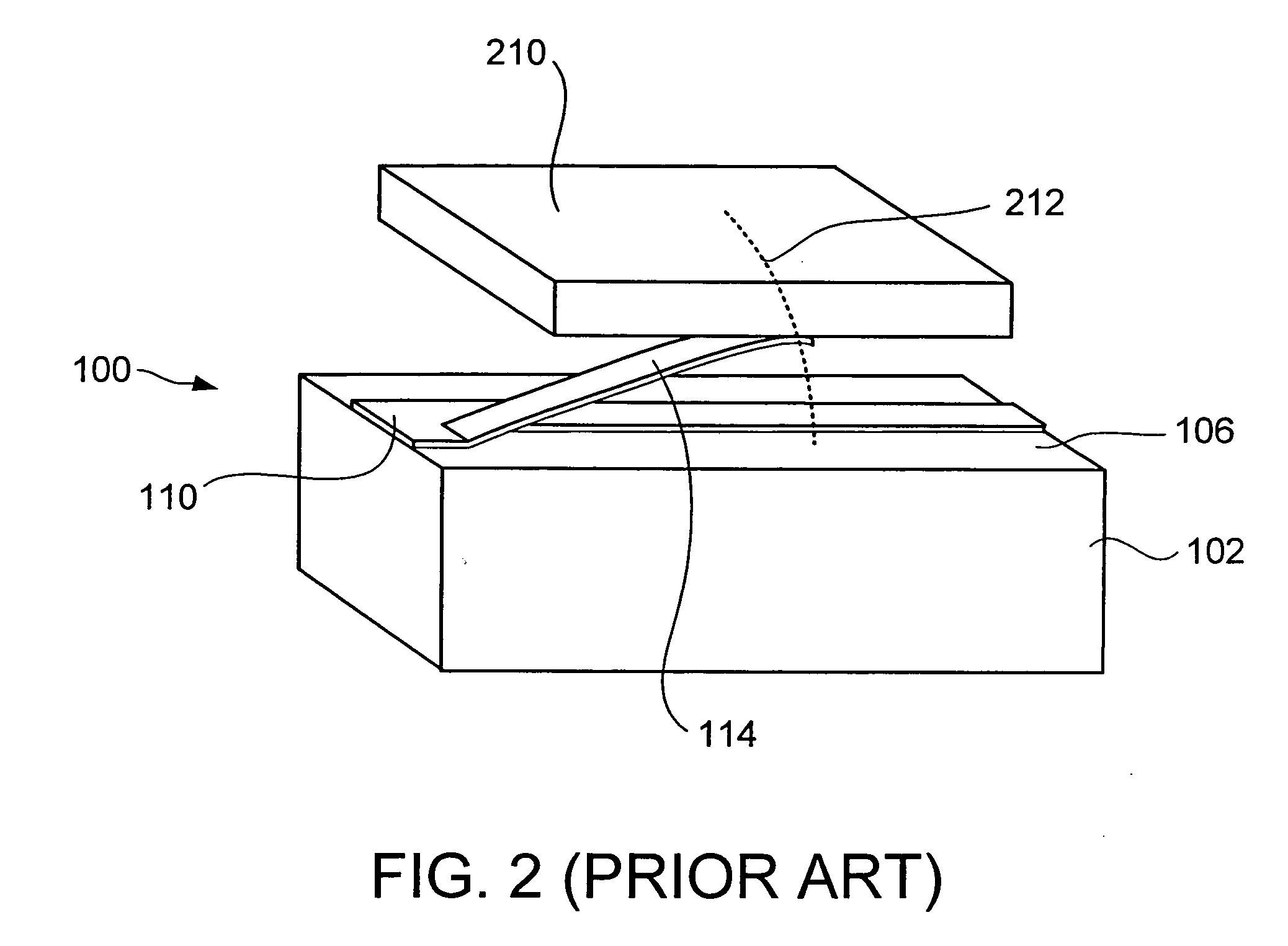

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

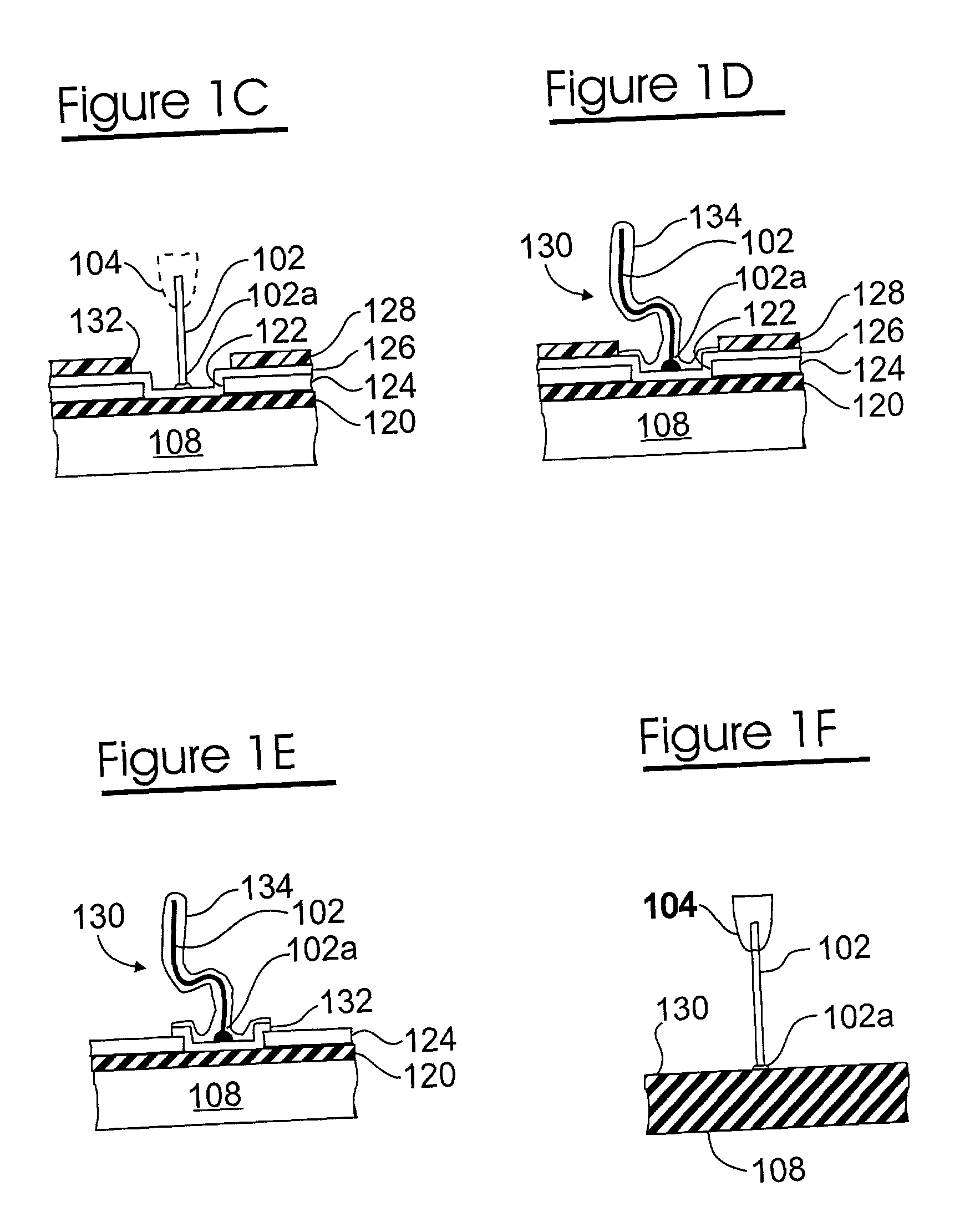

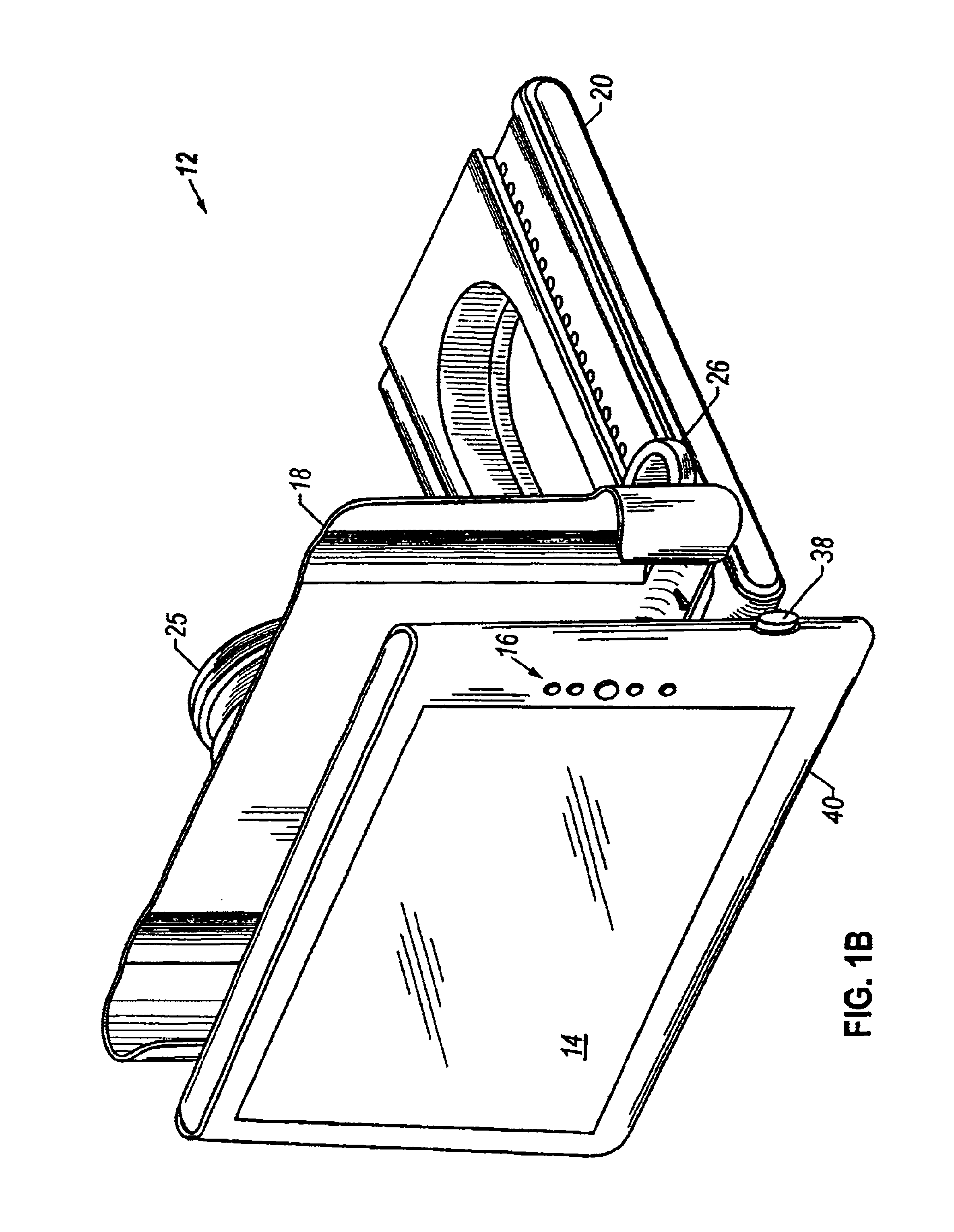

Tablet computing device with three-dimensional docking support

InactiveUS6856506B2Improved expansion baseImproved docking stationInput/output for user-computer interactionCoupling device connectionsTablet computerData connection

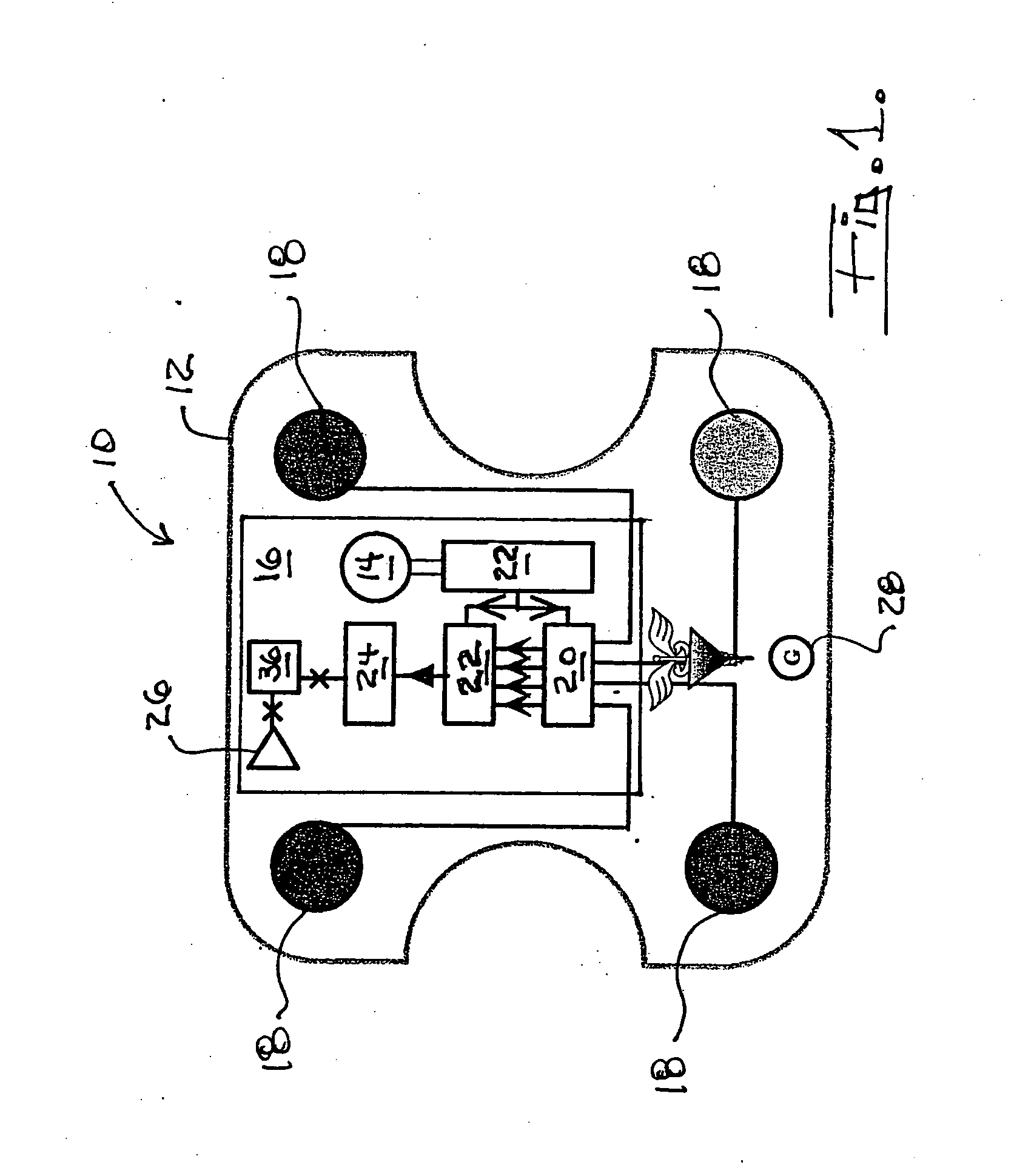

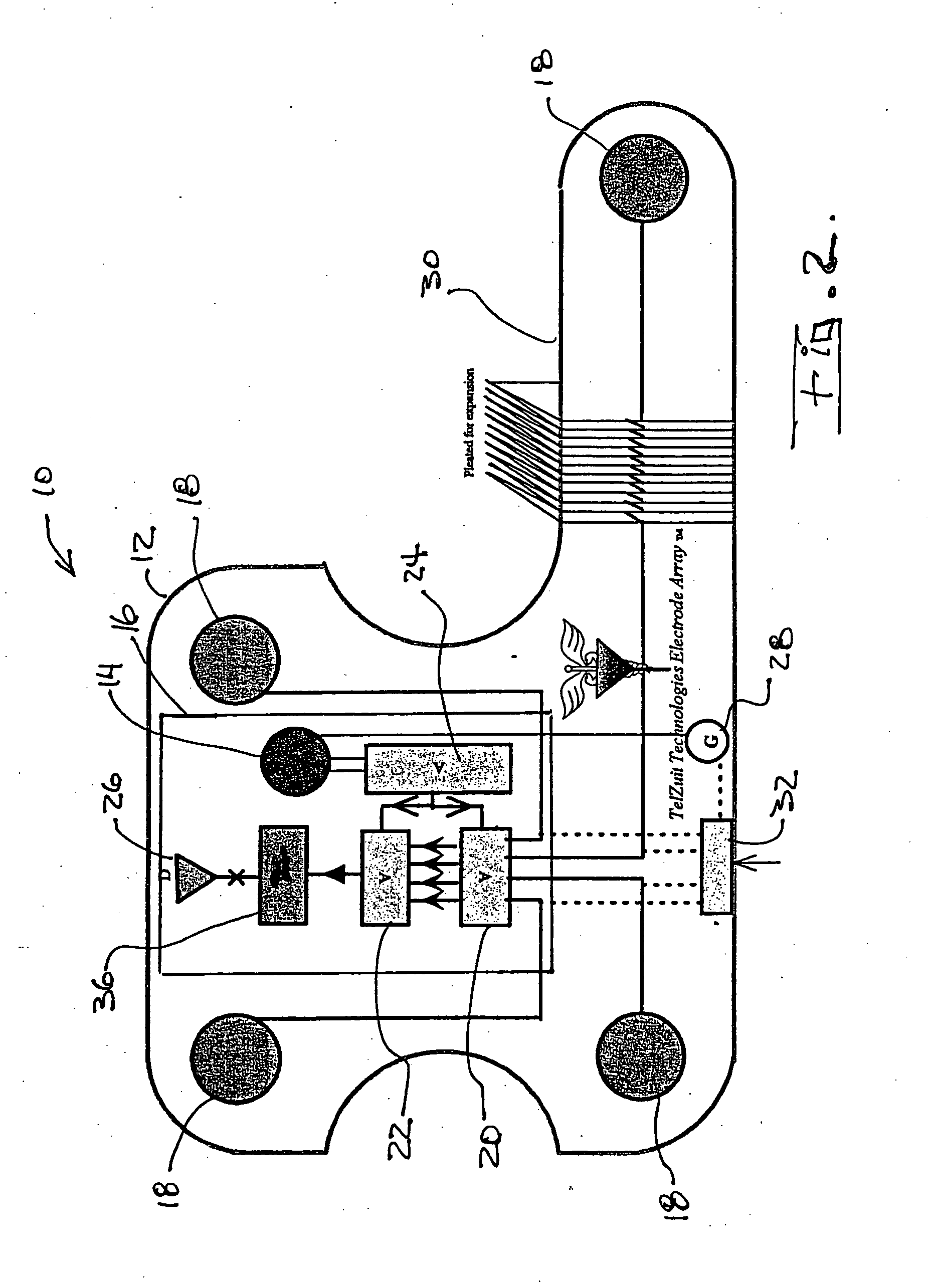

The present invention provides a tablet computer and a docking station assembly. This docking station comprises a docking assembly for positioning with three degrees of freedom and having a data connector for mechanically supporting and interfacing with the tablet computer. A support member couples the docking assembly to an expansion base. The base includes a number of ports for interfacing with a variety of peripheral devices or power supplies. These varieties of ports mount to a printed circuit board contained within the expansion base. A flexible printed circuit (FPC) combines the signal pathways for the variety of ports, allowing the signal pathways to travel from the printed circuit board and to the data connector. The tablet computing device has a plurality of contact or touch points positioned on the right and left edges of the tablet to facilitate aligning the tablet to the docking assembly in either a landscape or portrait mode.

Owner:ZEBRA TECH CORP

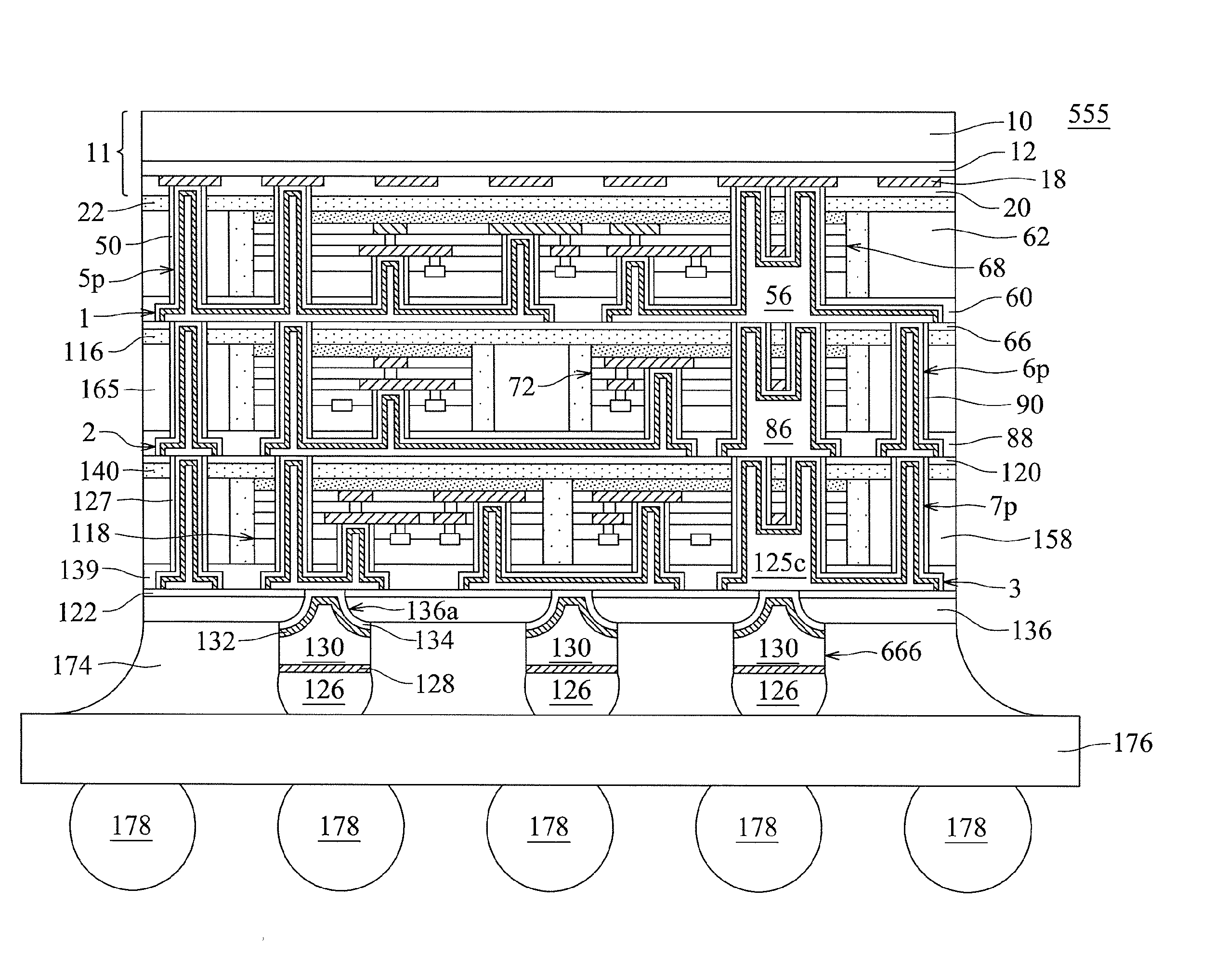

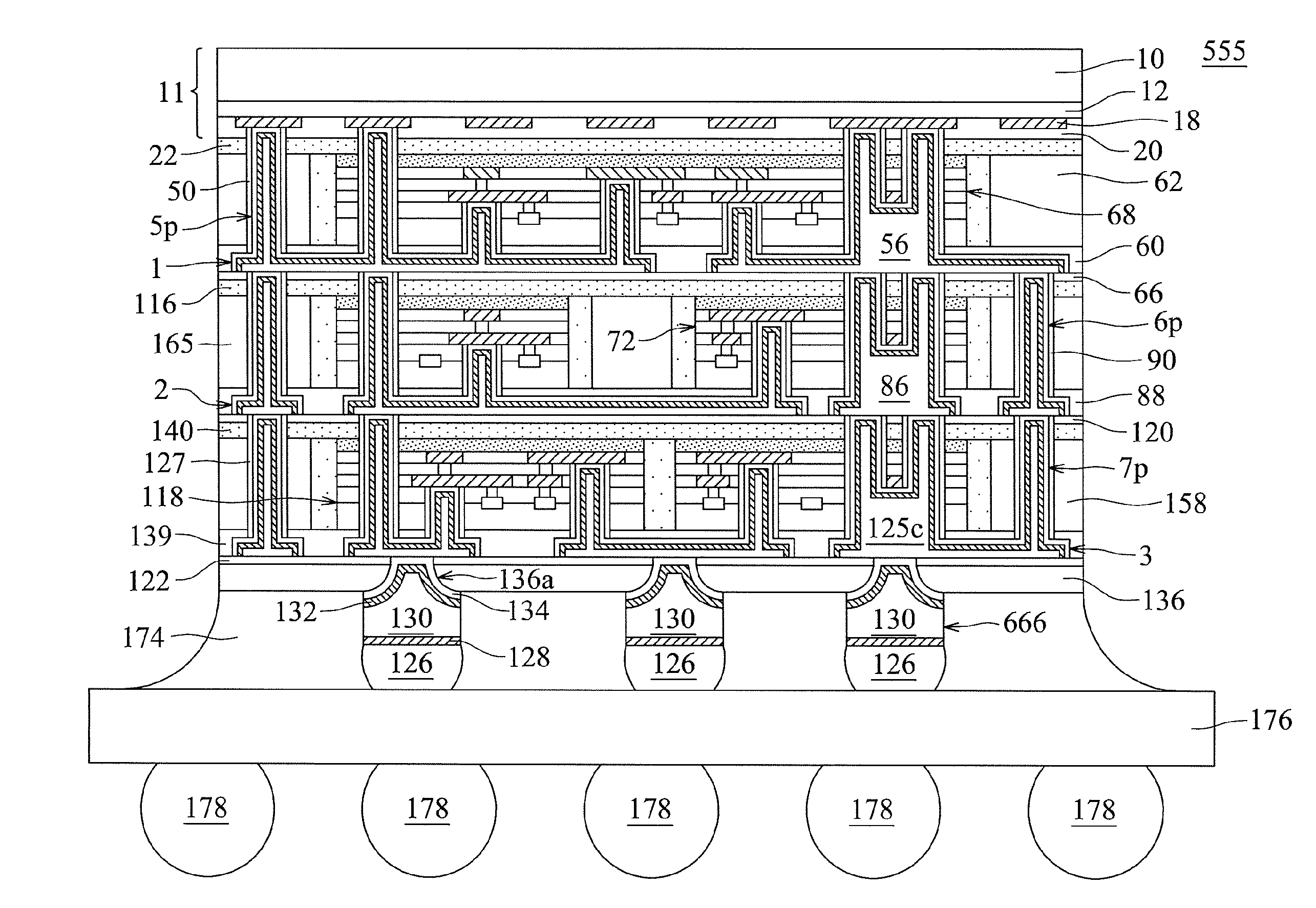

System-in packages

ActiveUS20110026232A1Improve uniformitySemiconductor/solid-state device detailsCircuit arrangements on support structuresMetal interconnectSystem in package

System-in packages, or multichip modules, are described which can include multi-layer chips and multi-layer dummy substrates over a carrier, multiple through vias blindly or completely through the multi-layer chips and completely through the multi-layer dummy substrates, multiple metal plugs in the through vias, and multiple metal interconnects, connected to the metal plugs, between the multi-layer chips. The multi-layer chips can be connected to each other or to an external circuit or structure, such as mother board, ball grid array (BGA) substrate, printed circuit board, metal substrate, glass substrate, or ceramic substrate, through the metal plugs and the metal interconnects.

Owner:QUALCOMM INC

Wireless medical monitoring apparatus and system

An apparatus for monitoring an electrical signal from a patient's body includes a disposable electrode patch having a thin flexible housing with an adhesive exterior, a power source, a printed circuit board, a plurality of electrodes, a converter for converting a detected electrical signal from the patient's body to a digital signal, a processor for processing the digital signal, and a transmitter connected for transmitting the processed digital signal as a wireless signal. A monitoring unit communicating with the electrode patch includes a power source, a transceiver, a global positioning receiver, a processor, at least one communication port for external communications, and a display. A system of the invention includes a plurality of patients having medical monitors wirelessly communicating biometric information to a central processor for archiving and accessing.

Owner:HALTHION MEDICAL TECH INC

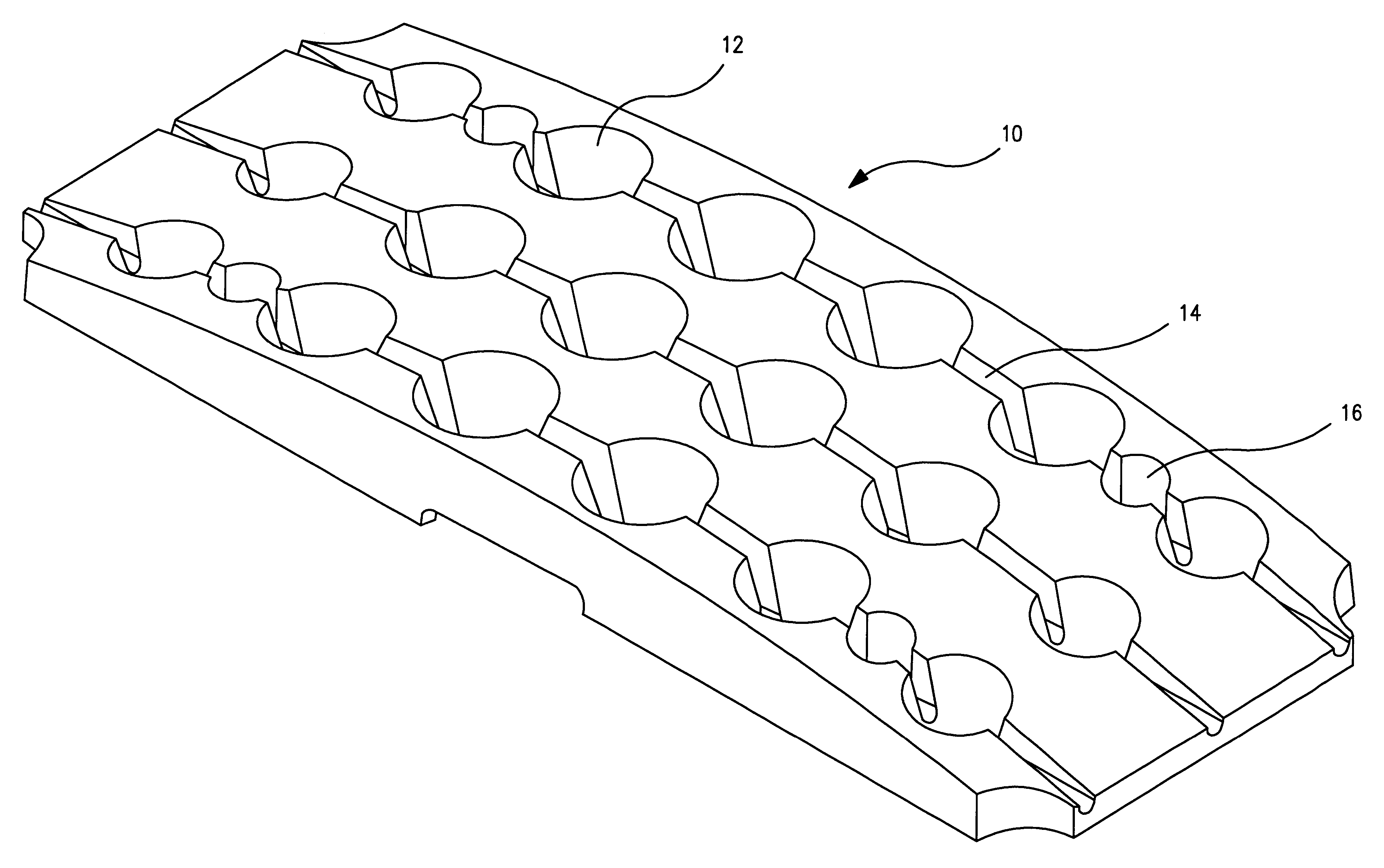

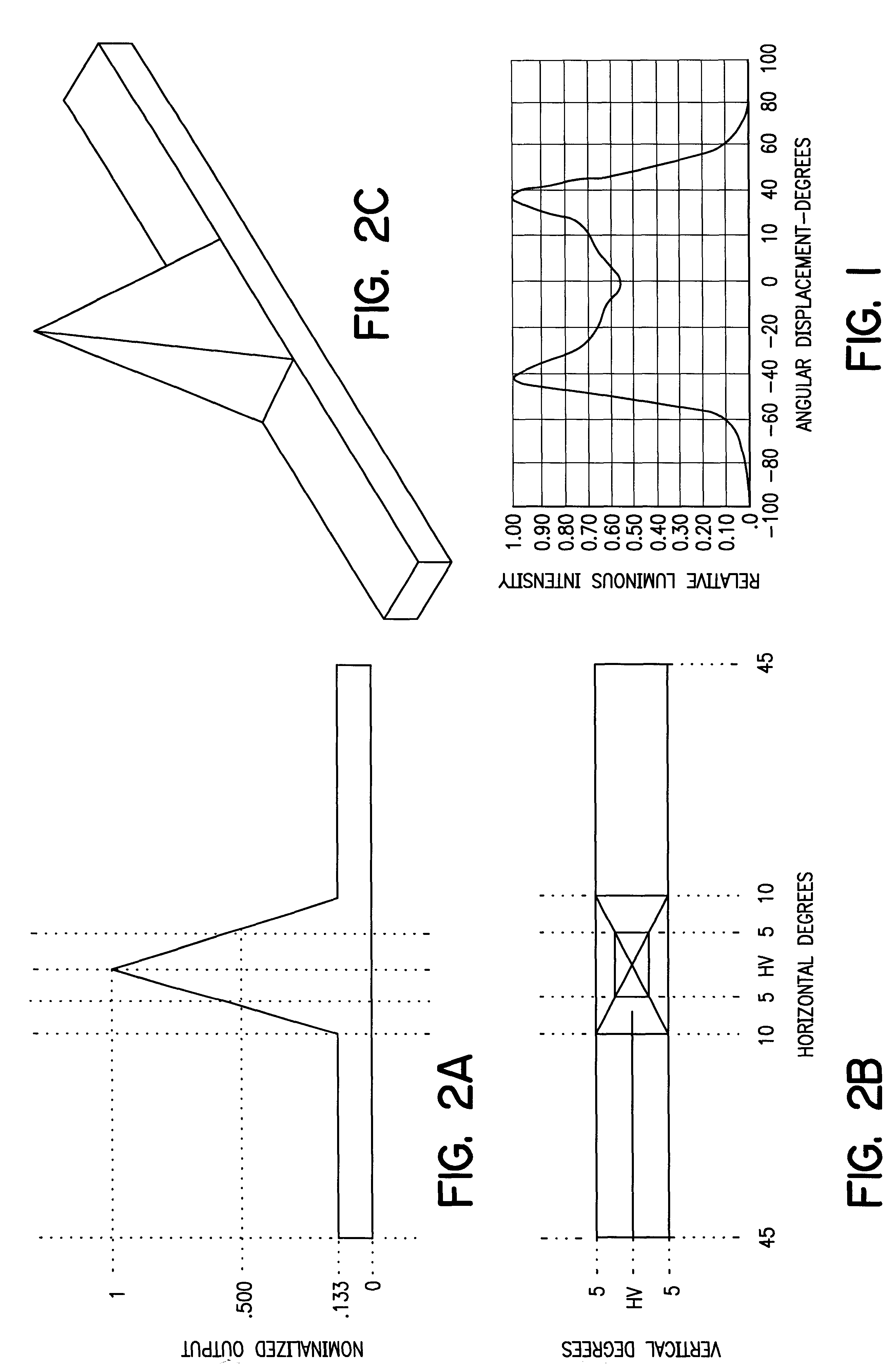

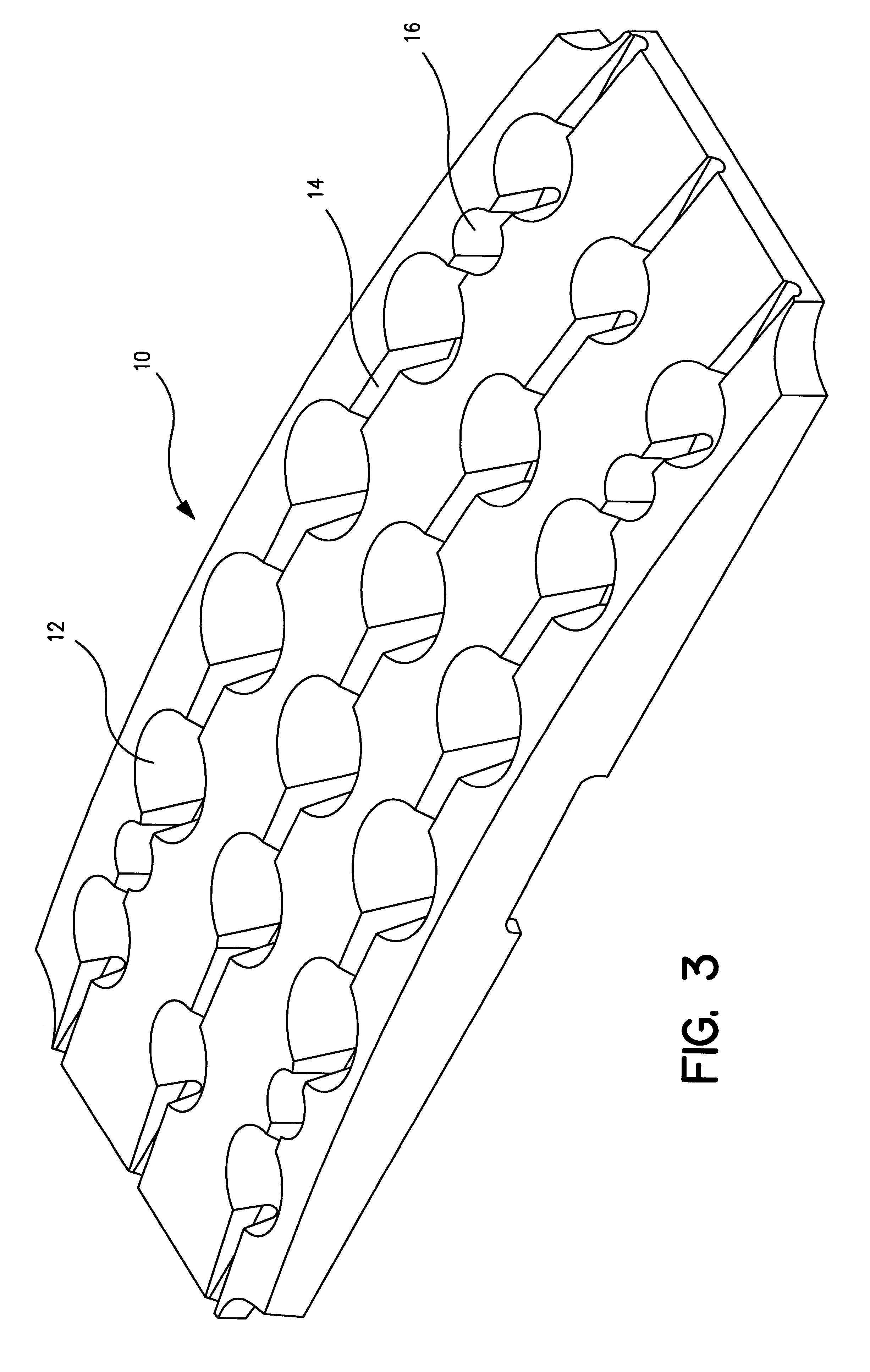

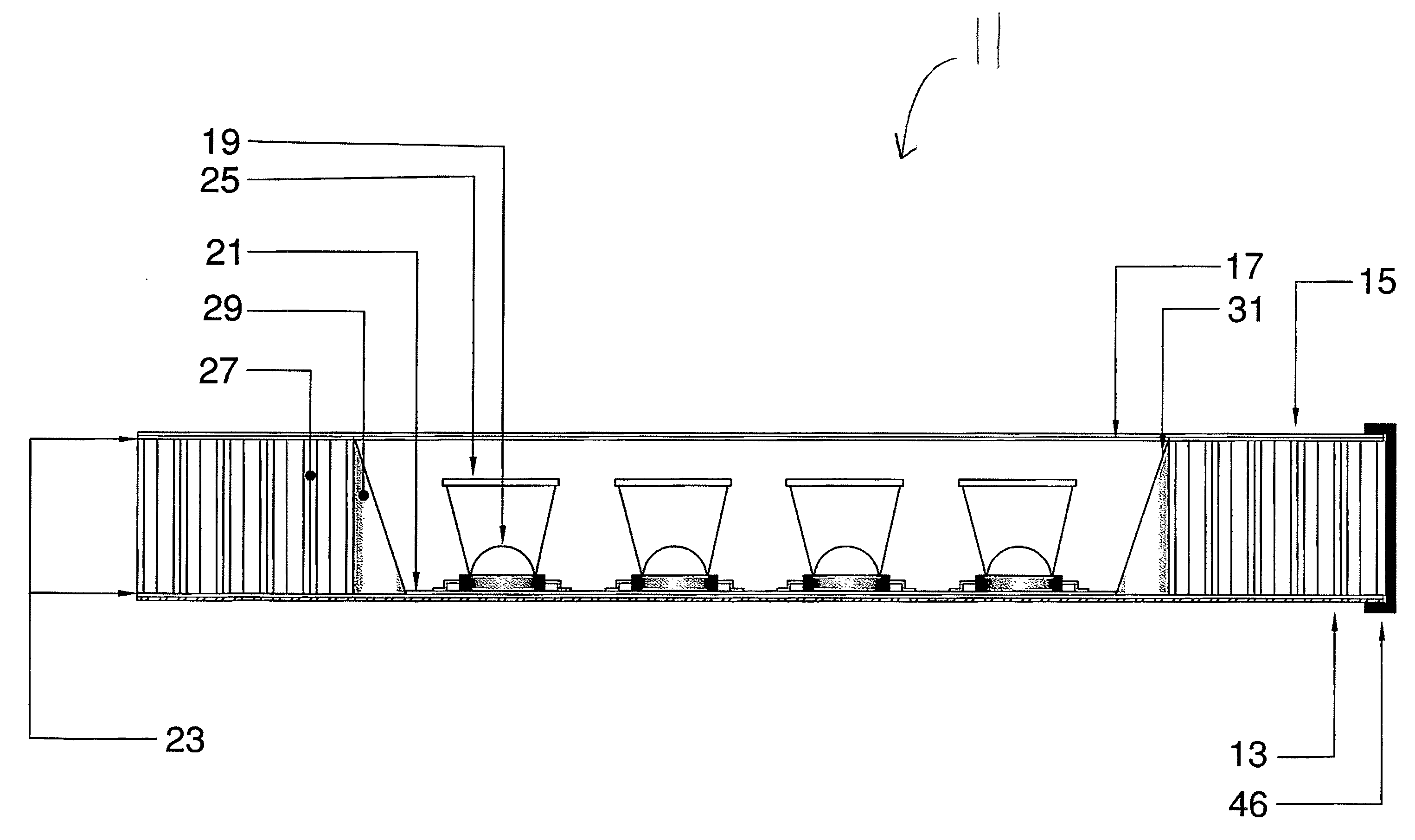

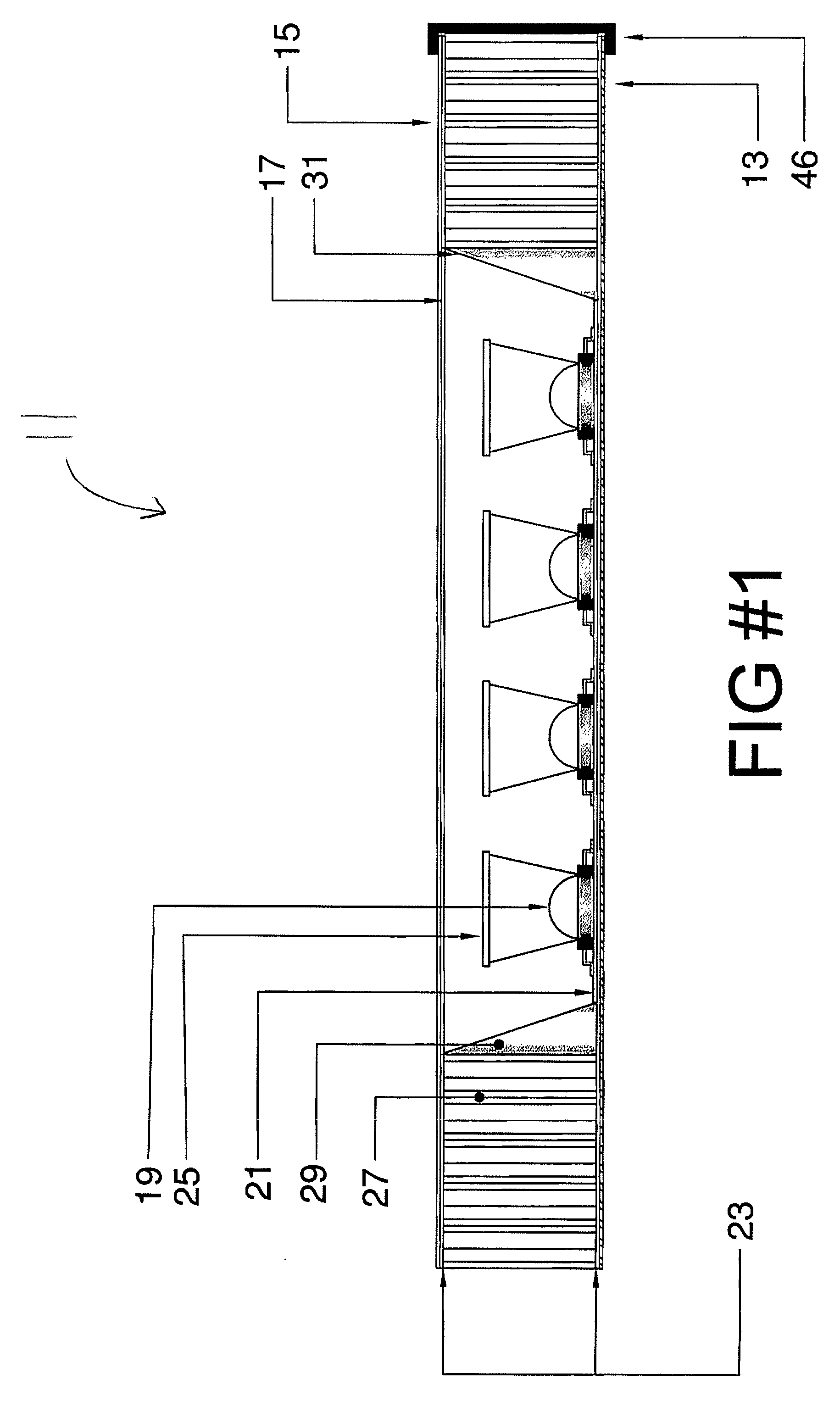

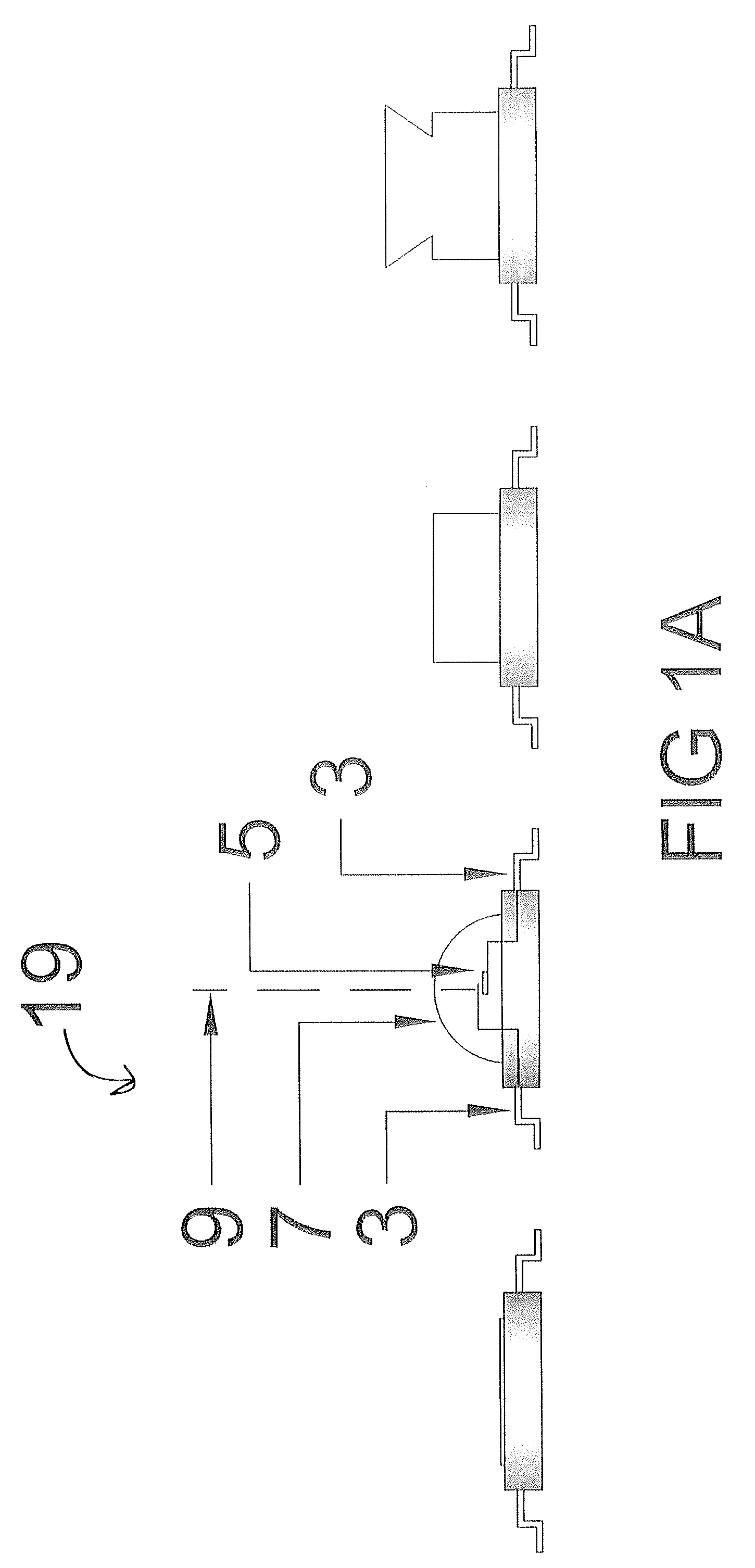

High flux led assembly

InactiveUS6318886B1Point-like light sourceLighting heating/cooling arrangementsHigh fluxHigh intensity

A high intensity light source employs a plurality of light emitting diodes associated with a unitary reflector subassembly. The reflector subassembly defines an array of frustoconical reflectors arranged in rows and columns with the adjacent reflectors of each row being connected by a diverging slot with reflective wall surfaces. The light emitting diodes are mounted on a printed circuit board which forms a component of heat sink subassembly.

Owner:WHELEN ENGINEERING COMPANY

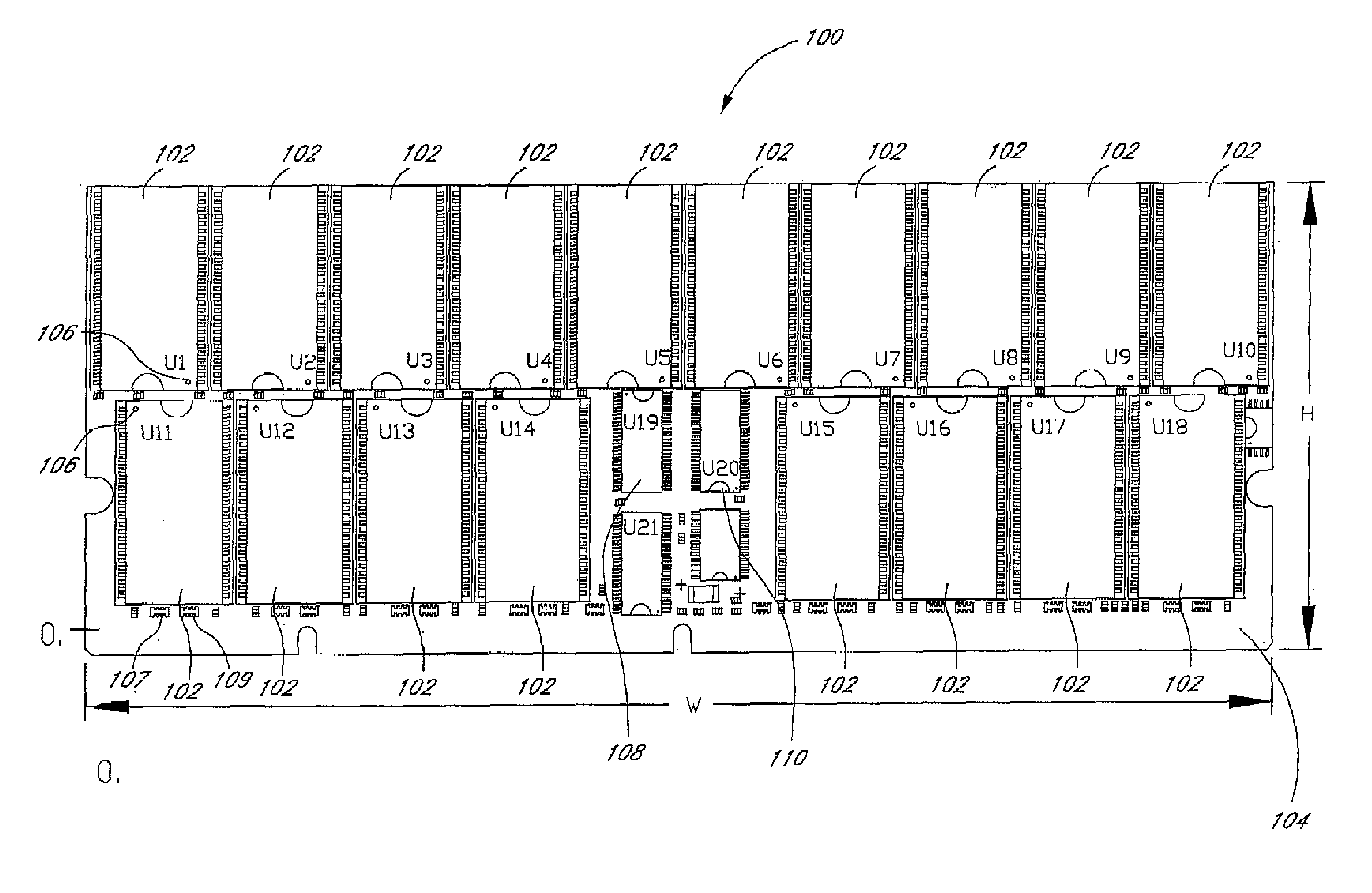

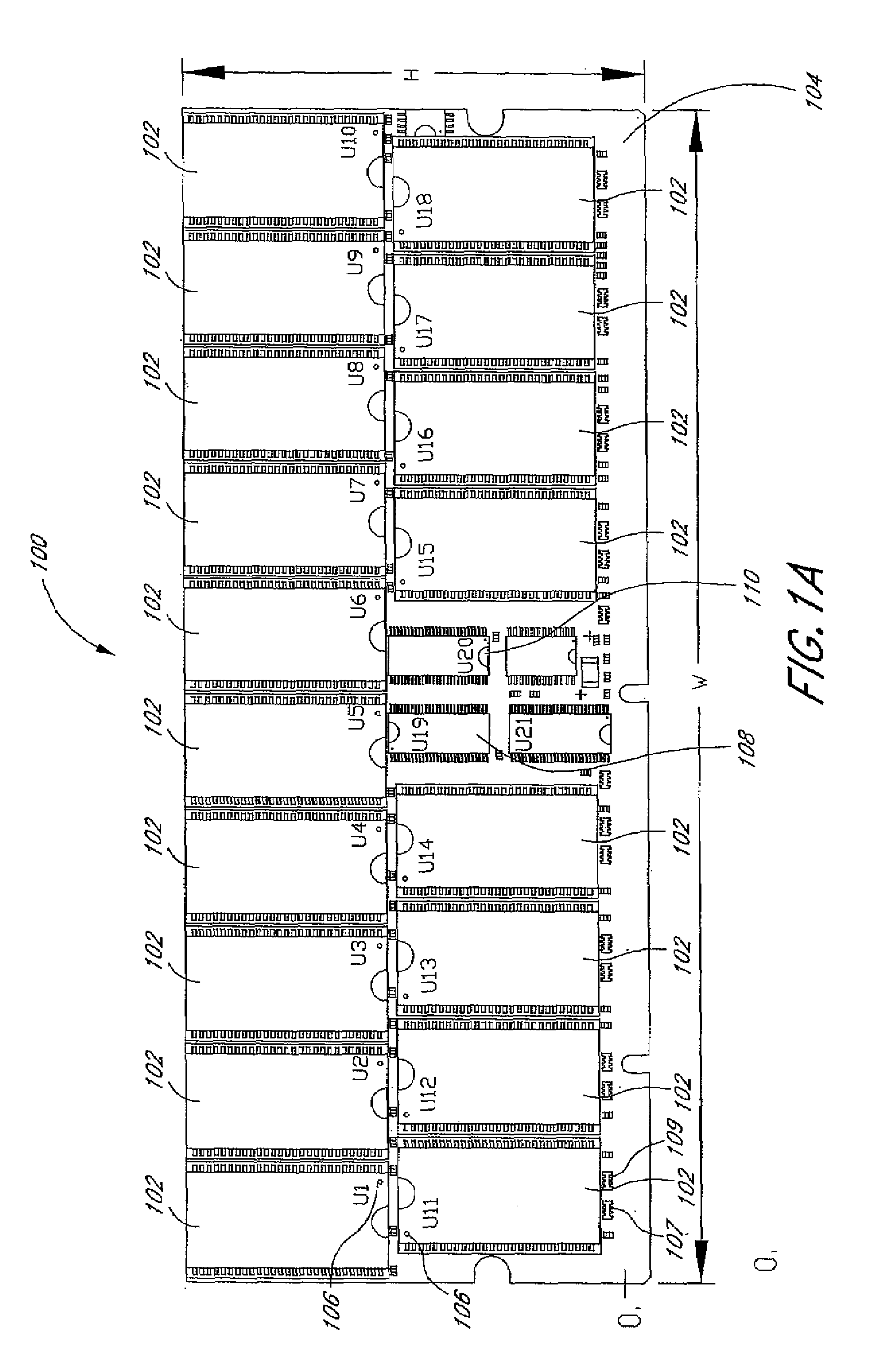

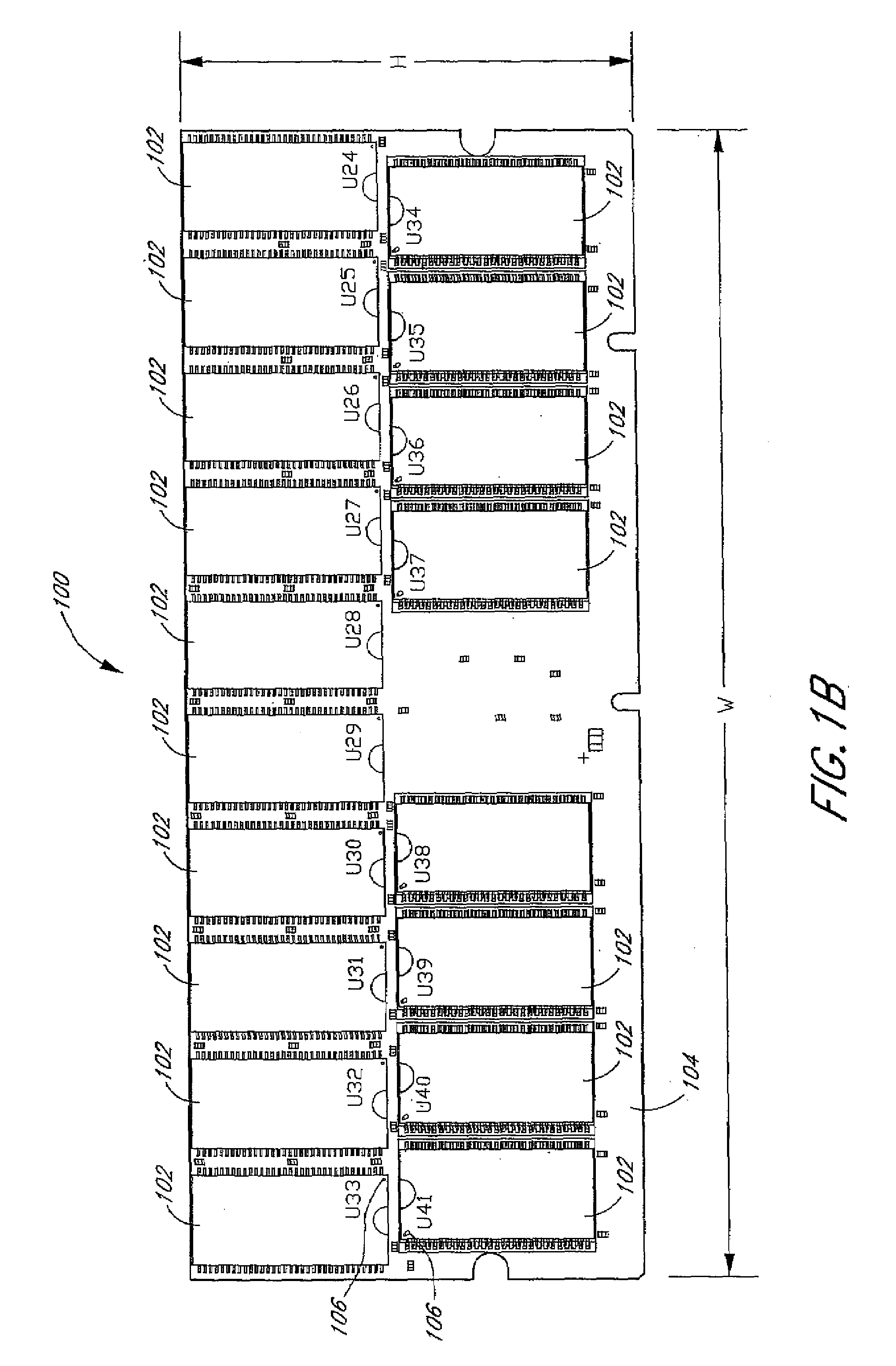

Arrangement of integrated circuits in a memory module

InactiveUS20050018495A1Final product manufactureCross-talk/noise/interference reductionGigabyteProcessor register

Abstract of the Disclosure Integrated circuits utilizing standard commercial packaging are arranged on a printed circuit board to allow the production of one-Gigabyte, two-Gigabyte, and four-Gigabyte capacity memory modules. A first row of integrated circuits is oriented in an opposite orientation to a second row of integrated circuits. The integrated circuits in the first row on a first lateral portion of the printed circuit board and in the second row on the first lateral portion are connected to a first addressing register with two register integrated circuits. The integrated circuits in the first row on the second lateral portion and in the second row on the second lateral portion are connected to a second addressing register with two register integrated circuits. Each addressing register processes a non-contiguous subset of the bits in each data word.

Owner:NETLIST INC

Two dimensional object position sensor

InactiveUS6476376B1Inexpensive to fabricateReduce the amount requiredInvestigating moving sheetsCounting objects on conveyorsSensor arrayLight energy

Apparatus and method for sensing the position, size, shape and location orientation of one or more objects in two dimensions. The position sensor uses arrays of light sensors mounted on a substrate. When an object passes in proximity to the light sensors light energy from a plurality of light sources is either reflected from the object to the light sensors, or is emitted directly to the light sensors. The light energy is then converted to individual signals and transmitted through circuit traces in a printed circuit board to a local controller. The information may then be processed to determine the size, position, shape and location orientation of an object.

Owner:XEROX CORP

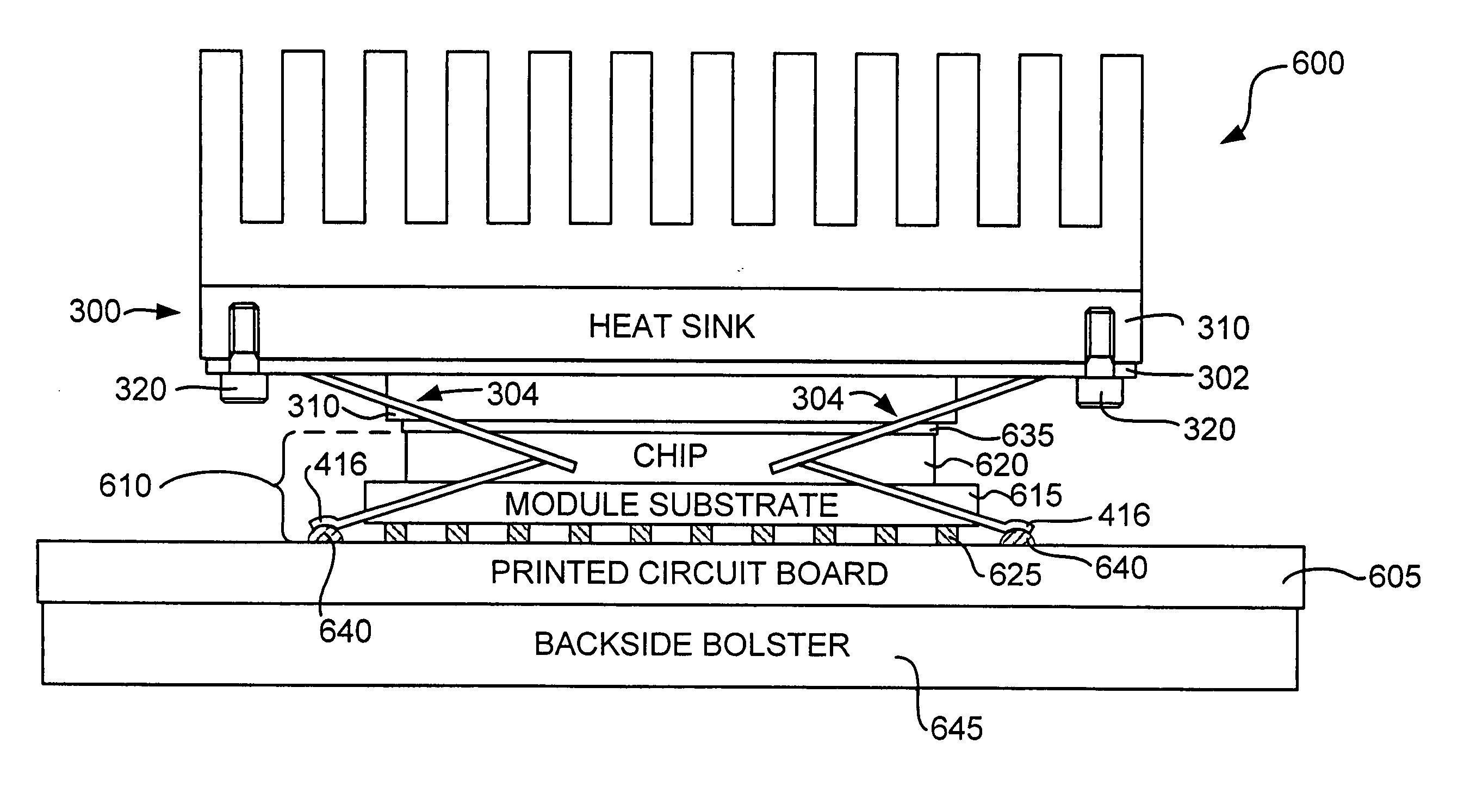

Method and apparatus for grounding a heat sink in thermal contact with an electronic component using a grounding spring having multiple-jointed spring fingers

InactiveUS20070097653A1Not easy to slipRestrict movementSemiconductor/solid-state device detailsSolid-state devicesElectricityElectromagnetic interference

A grounding spring for electromagnetic interference (EMI) suppression is interposed between a heat sink and a printed circuit board (PCB). The grounding spring comprises a conductive material having an opening formed at its base through which the heat sink makes thermal contact with an electronic module mounted on the PCB. The base makes electrical contact with a peripheral surface of the heat sink, and multiple-jointed spring fingers extend from the base to make electrical contact with conductive pads on the PCB. During compression, the movement of each spring finger's tip is substantially limited to the z-axis. Accordingly, the final installed location of the tip can be precisely controlled even when the grounding spring must accommodate a wide variety of installed heights of the heat sink relative to the PCB. Preferably, the spring fingers terminate with a concave tip that is less susceptible to sliding off the conductive pads.

Owner:IBM CORP

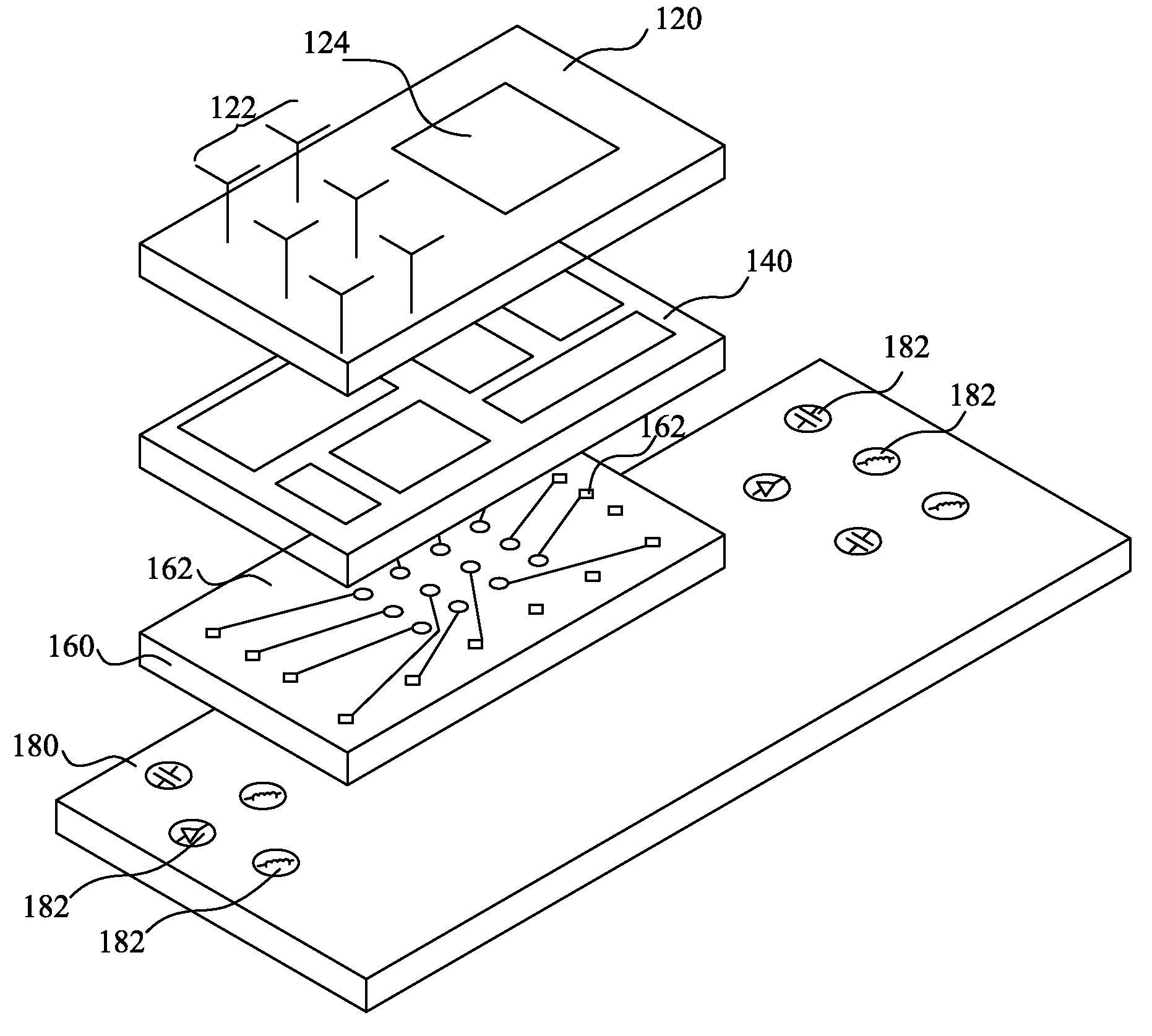

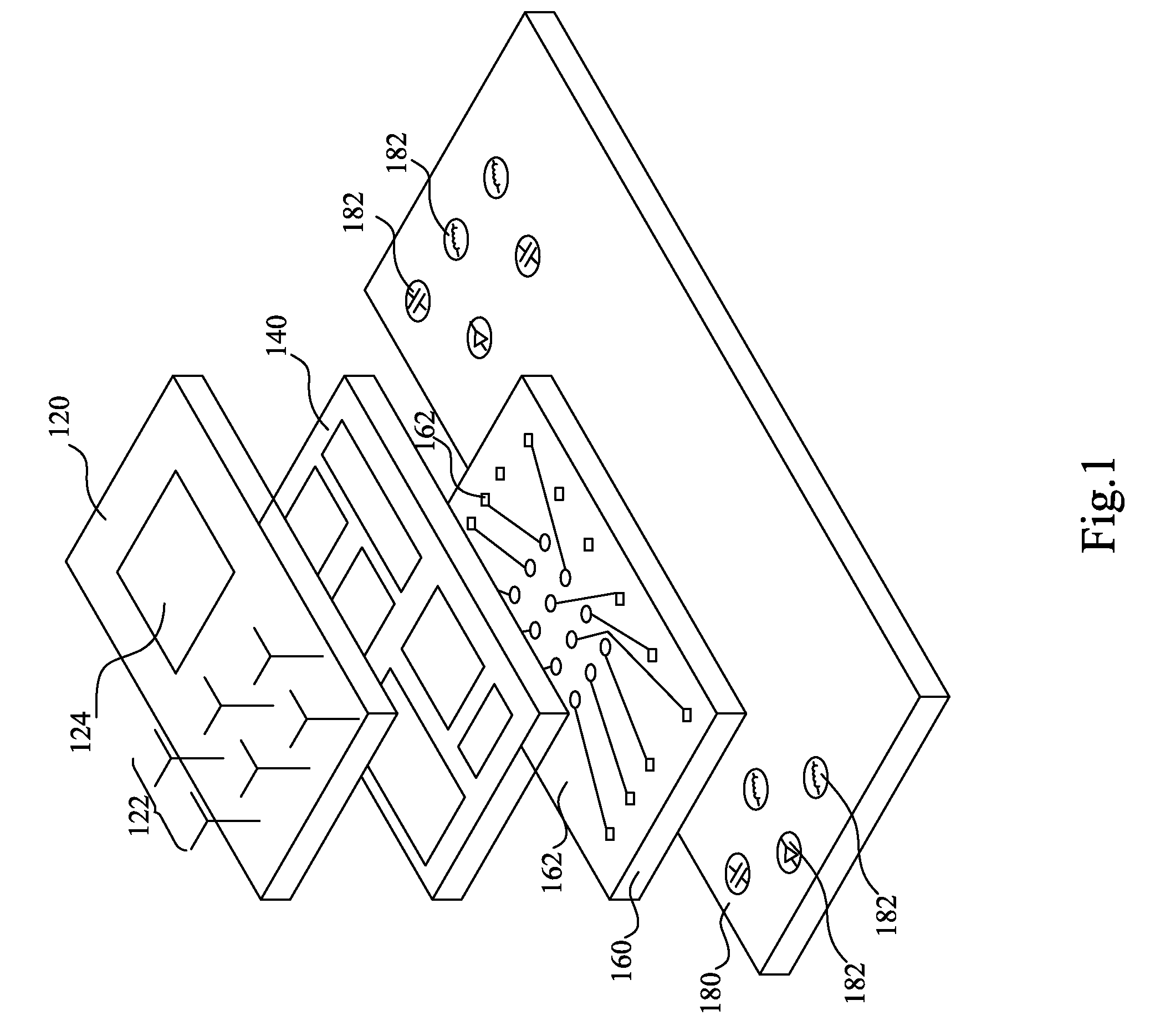

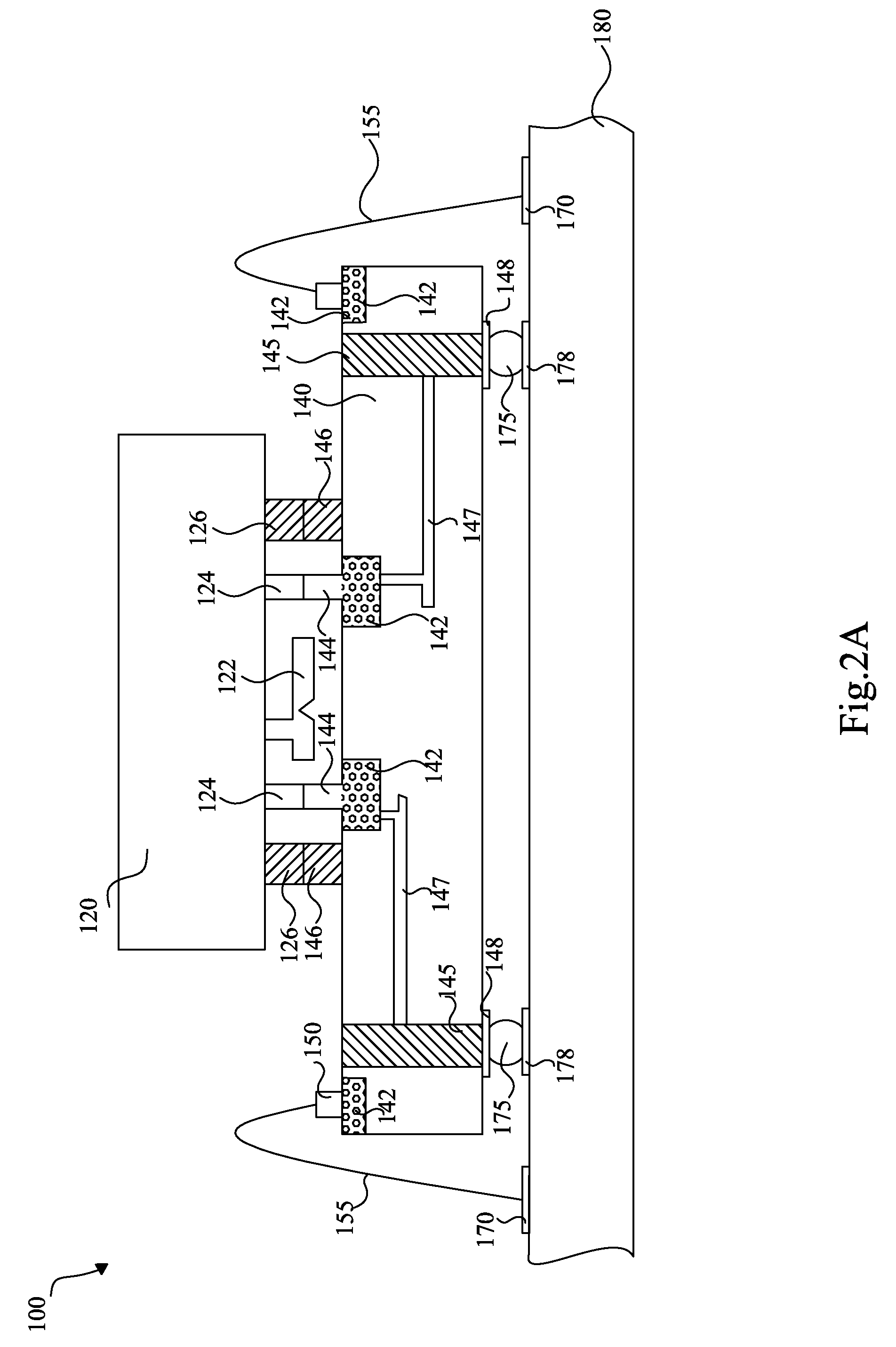

MEMS Packaging Including Integrated Circuit Dies

InactiveUS20090194829A1Highly integratedReduced package footprintSemiconductor/solid-state device detailsSolid-state devicesOn boardElectrical connection

MEMS packaging schemes having a system-on-package (SOP) configuration and a system-on-board (SOB) configuration are provided. The MEMS package comprises one or more MEMS dies, a cap section having one or more integrated circuit (IC) dies, and a packaging substrate or a printed circuit board (PCB) arranged in a stacking manner. Vertical connectors, such as through-silicon-vias (TSVs), are formed to provide short electrical connections between the various components. The MEMS packaging schemes enable higher integration density, reduced MEMS package footprints, reduced RC delays and power consumption.

Owner:TAIWAN SEMICON MFG CO LTD

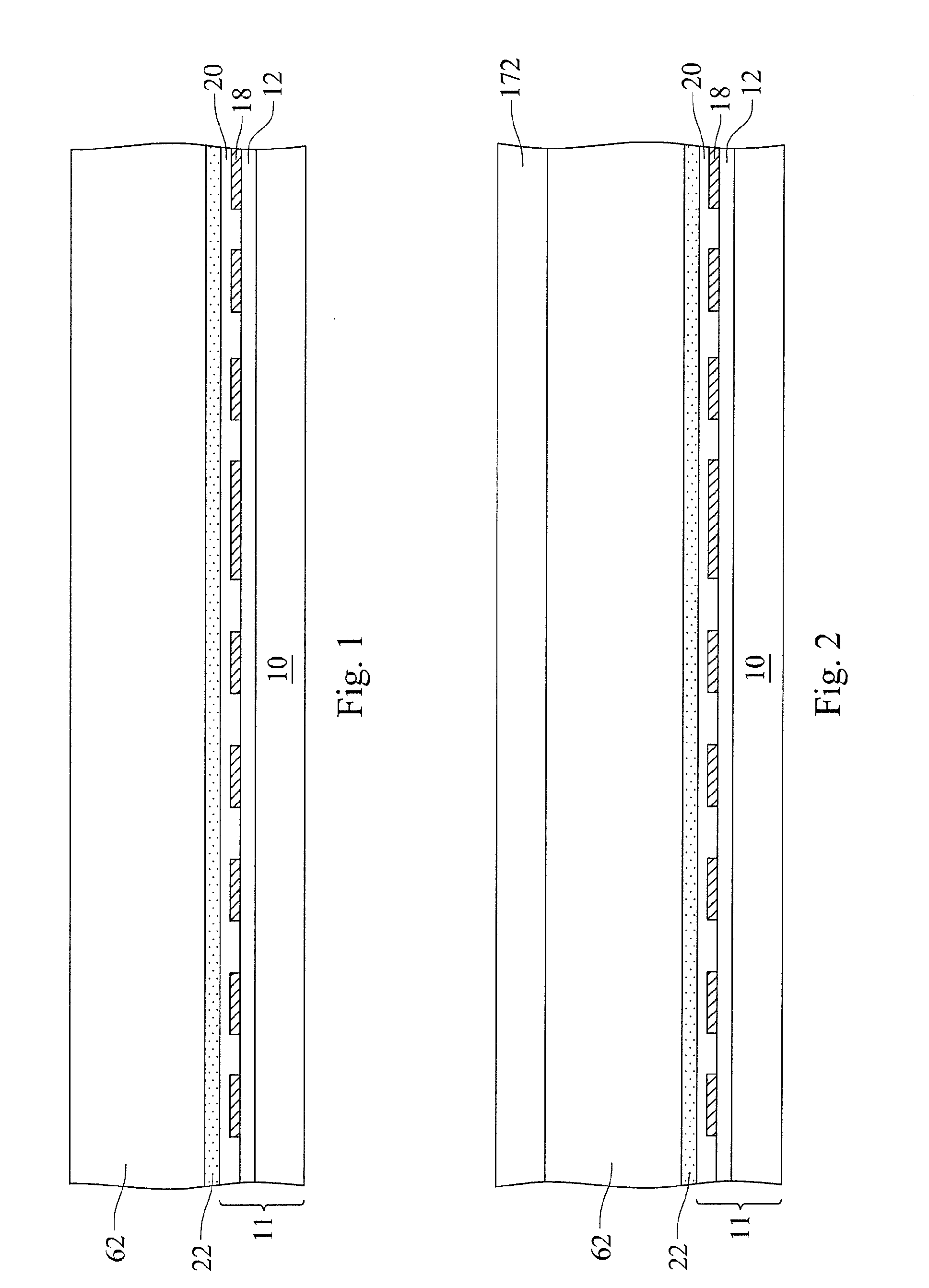

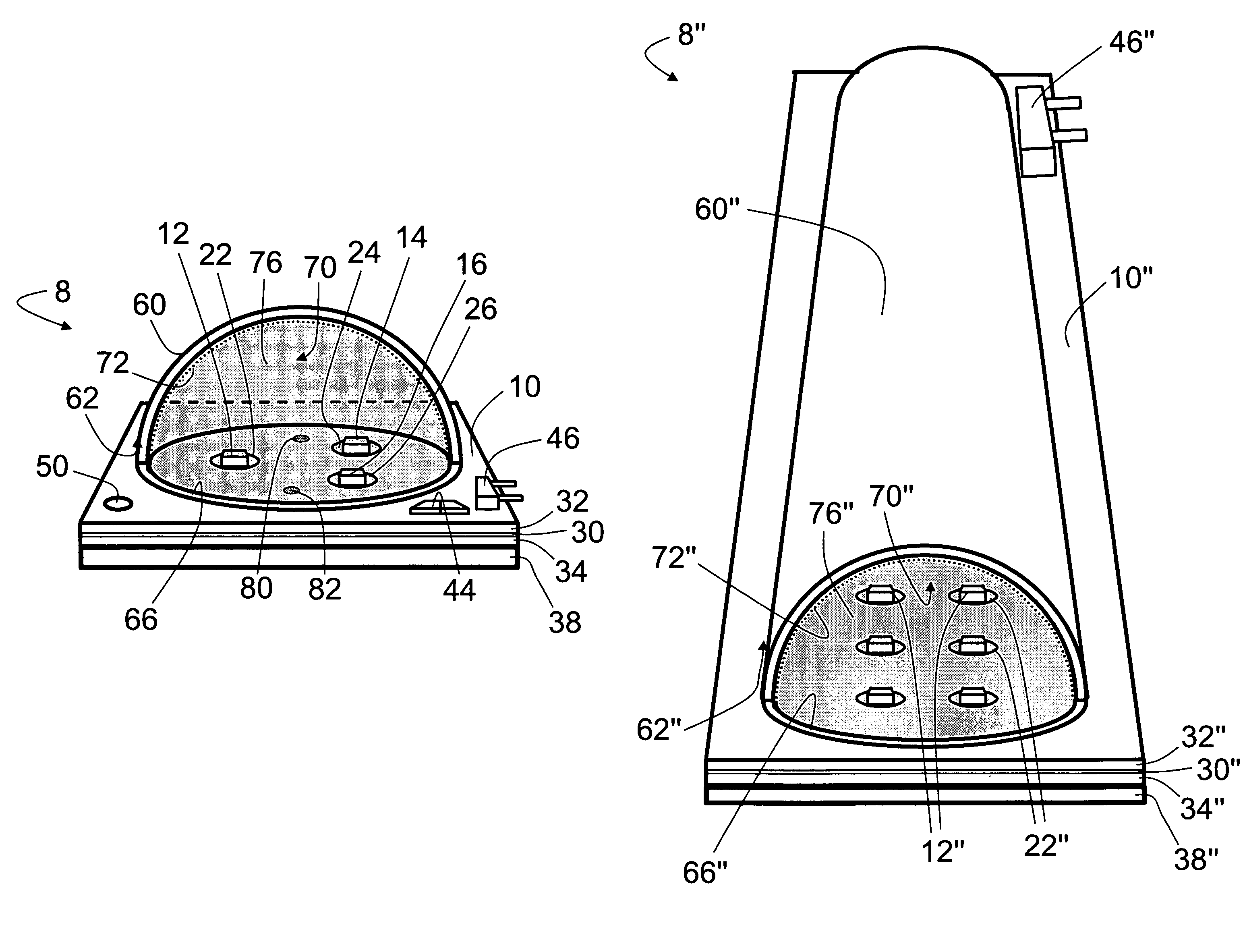

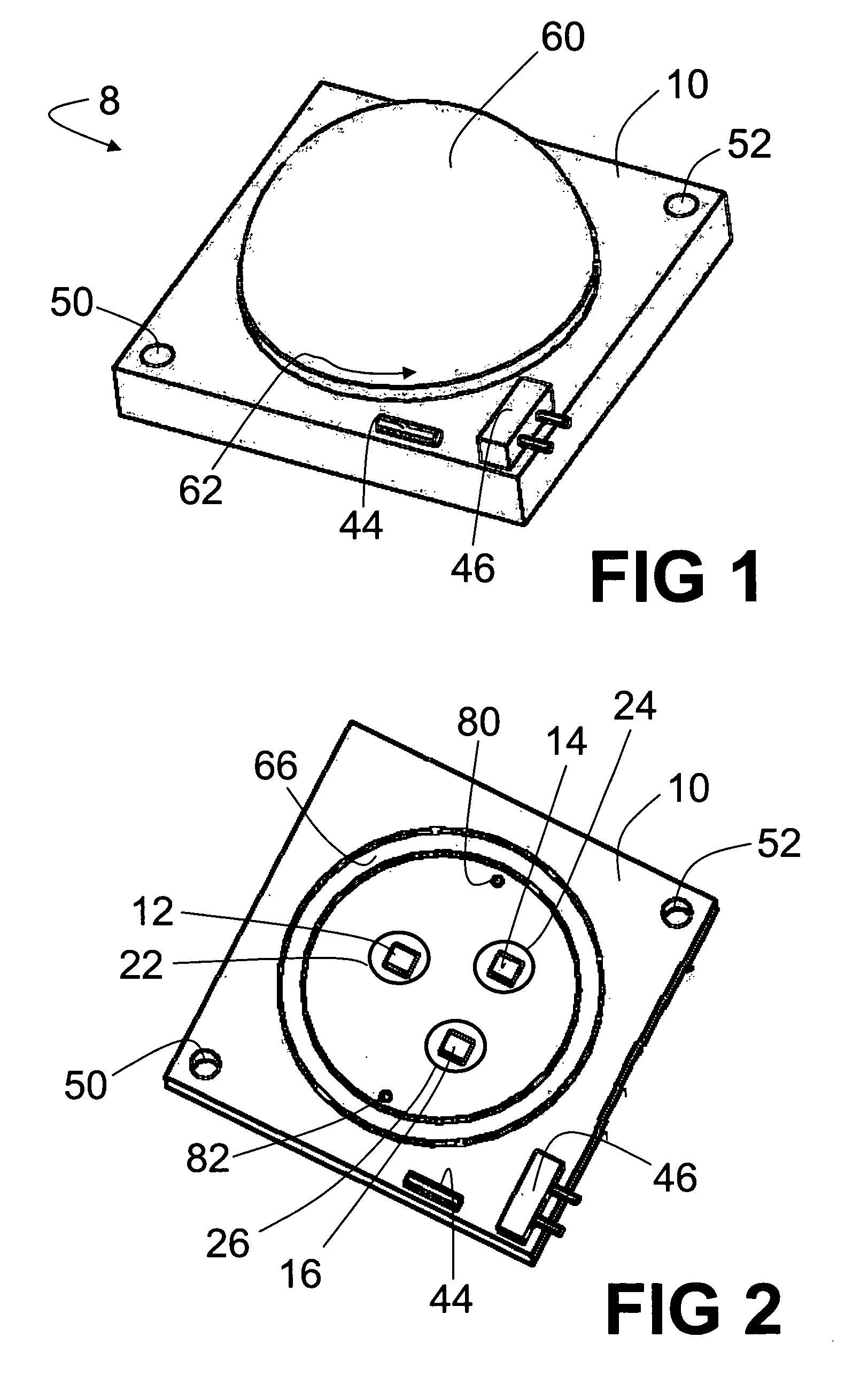

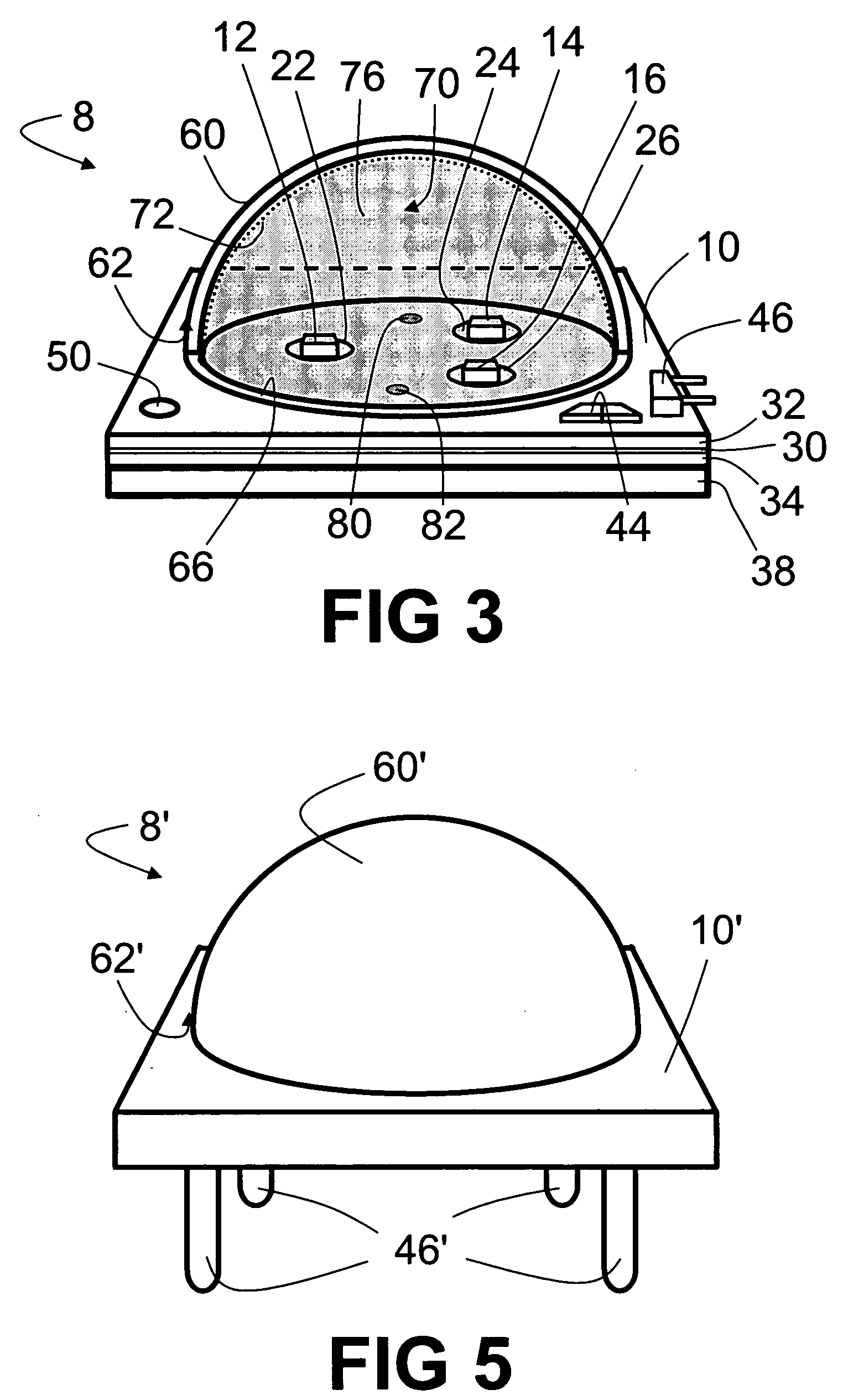

Light emitting diode component

InactiveUS7224000B2Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

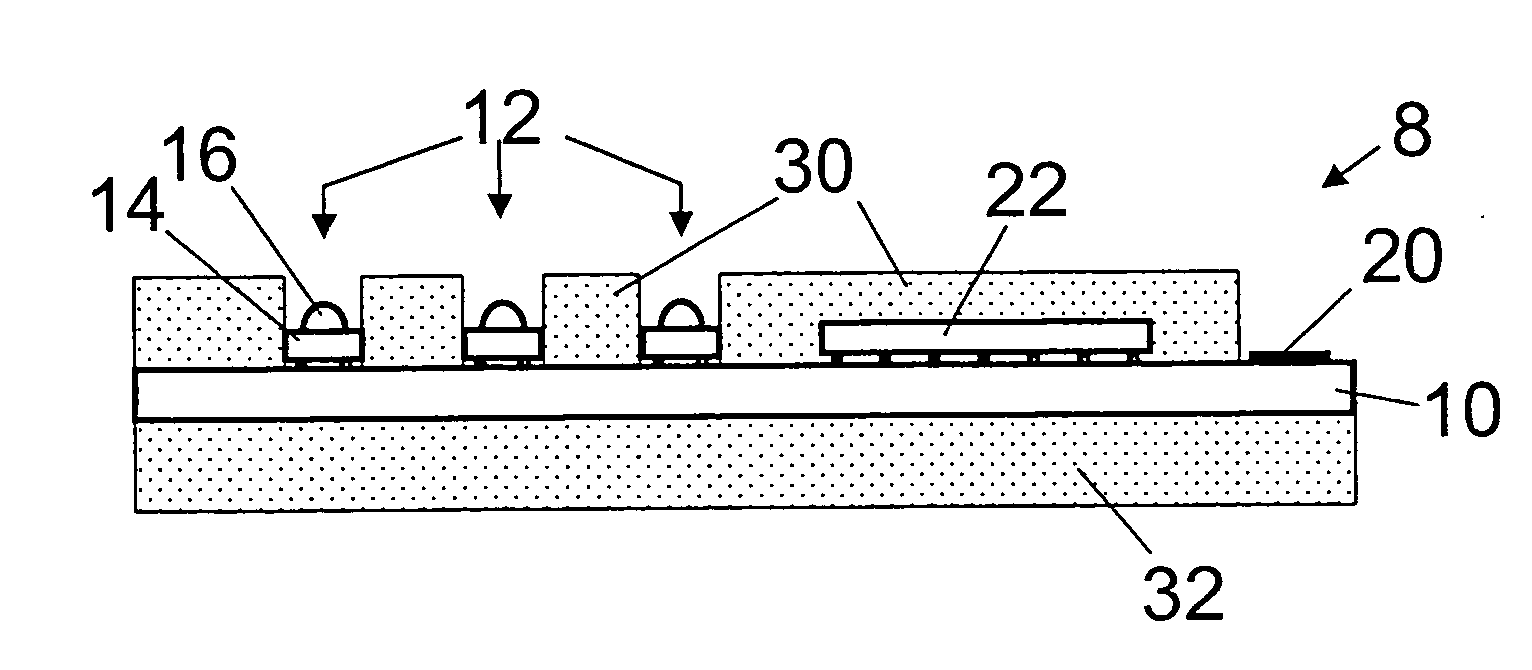

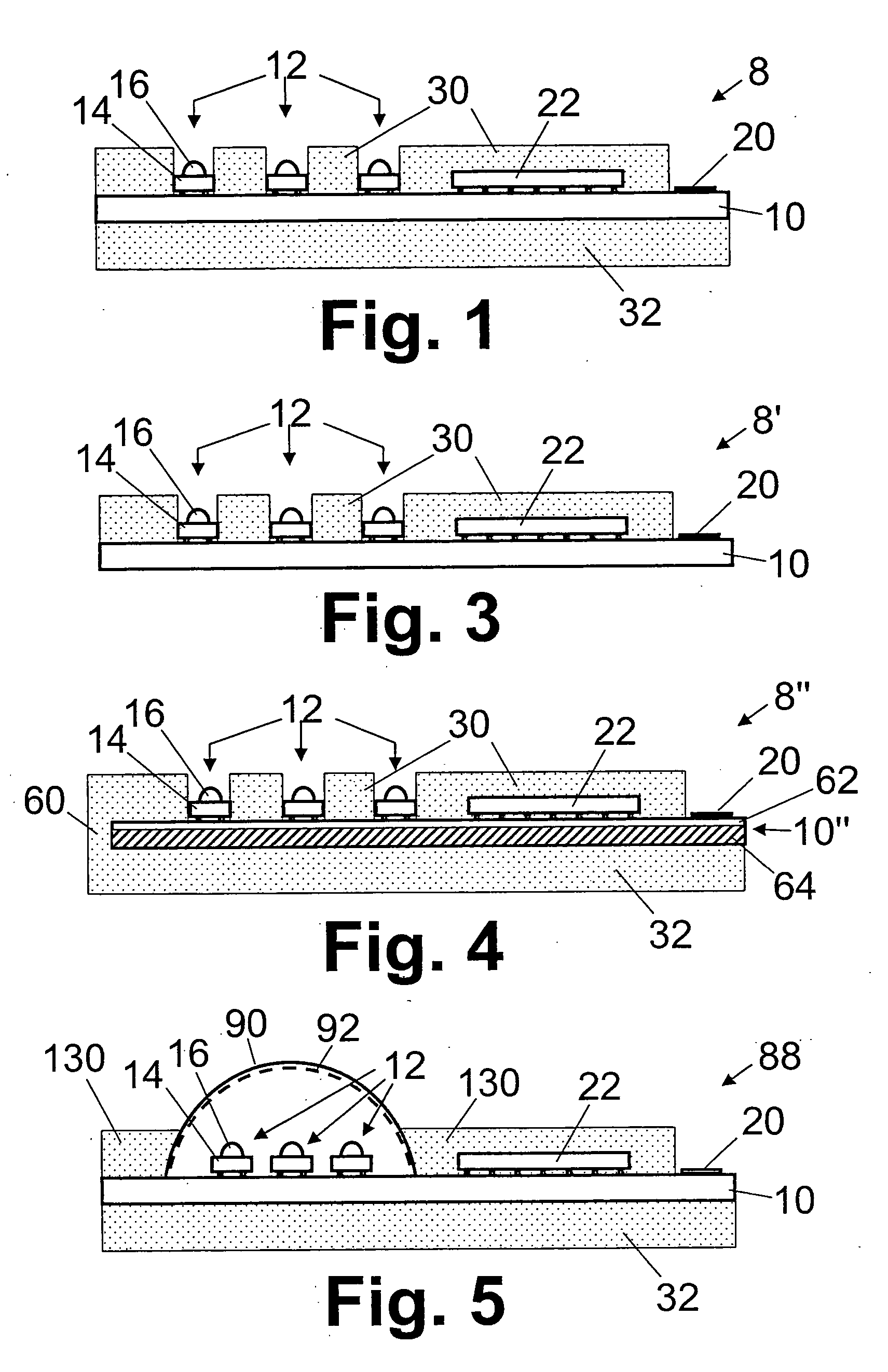

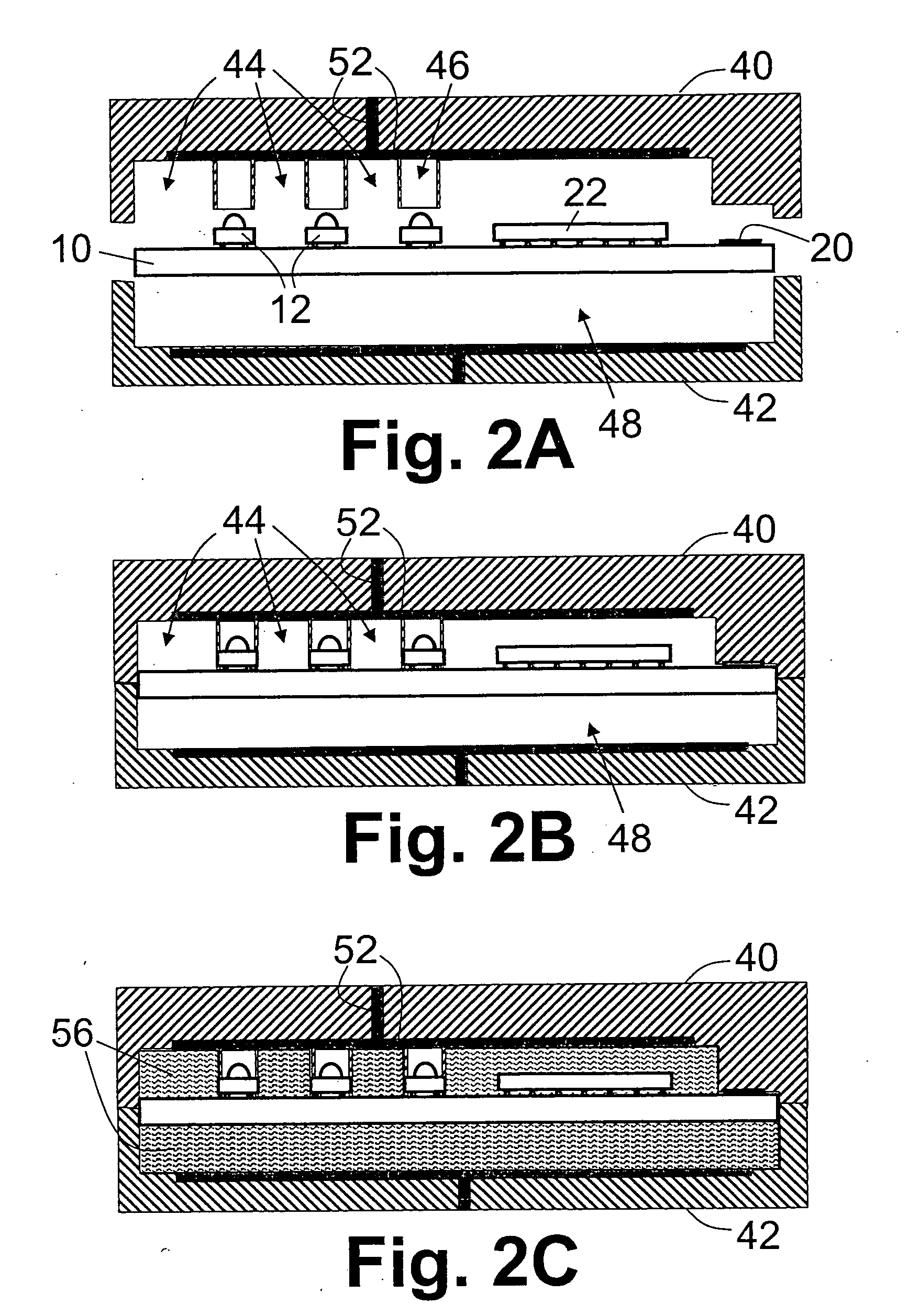

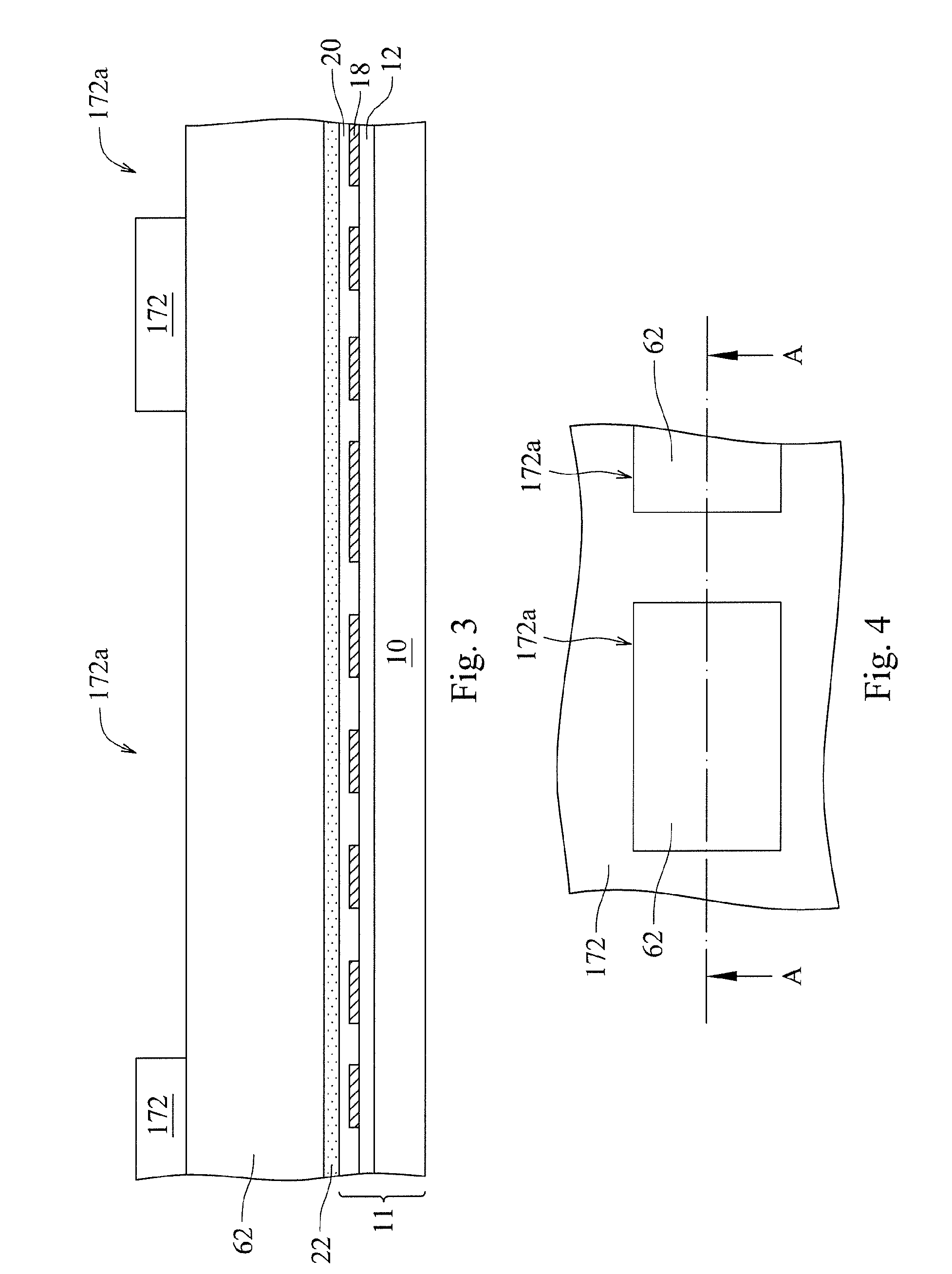

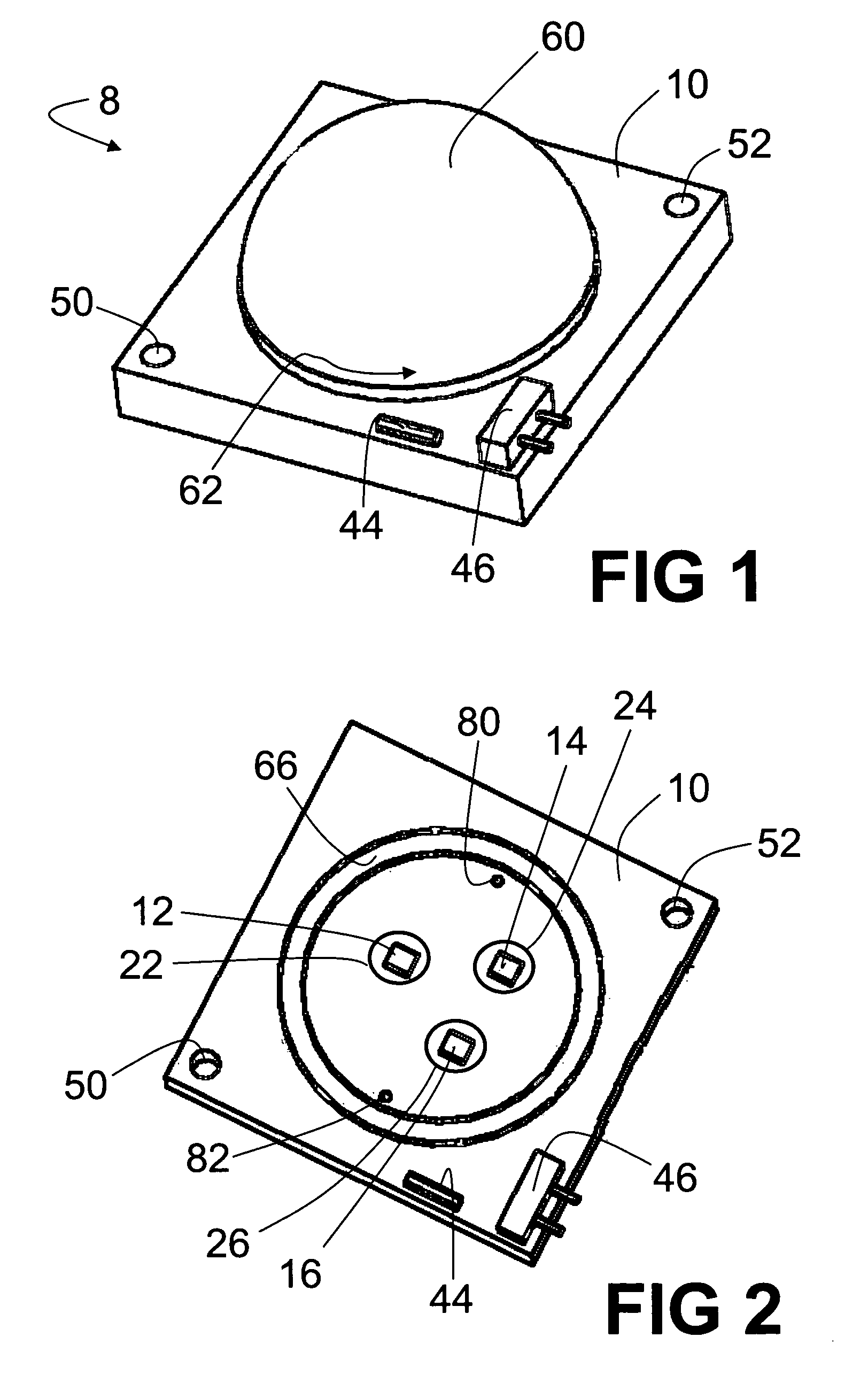

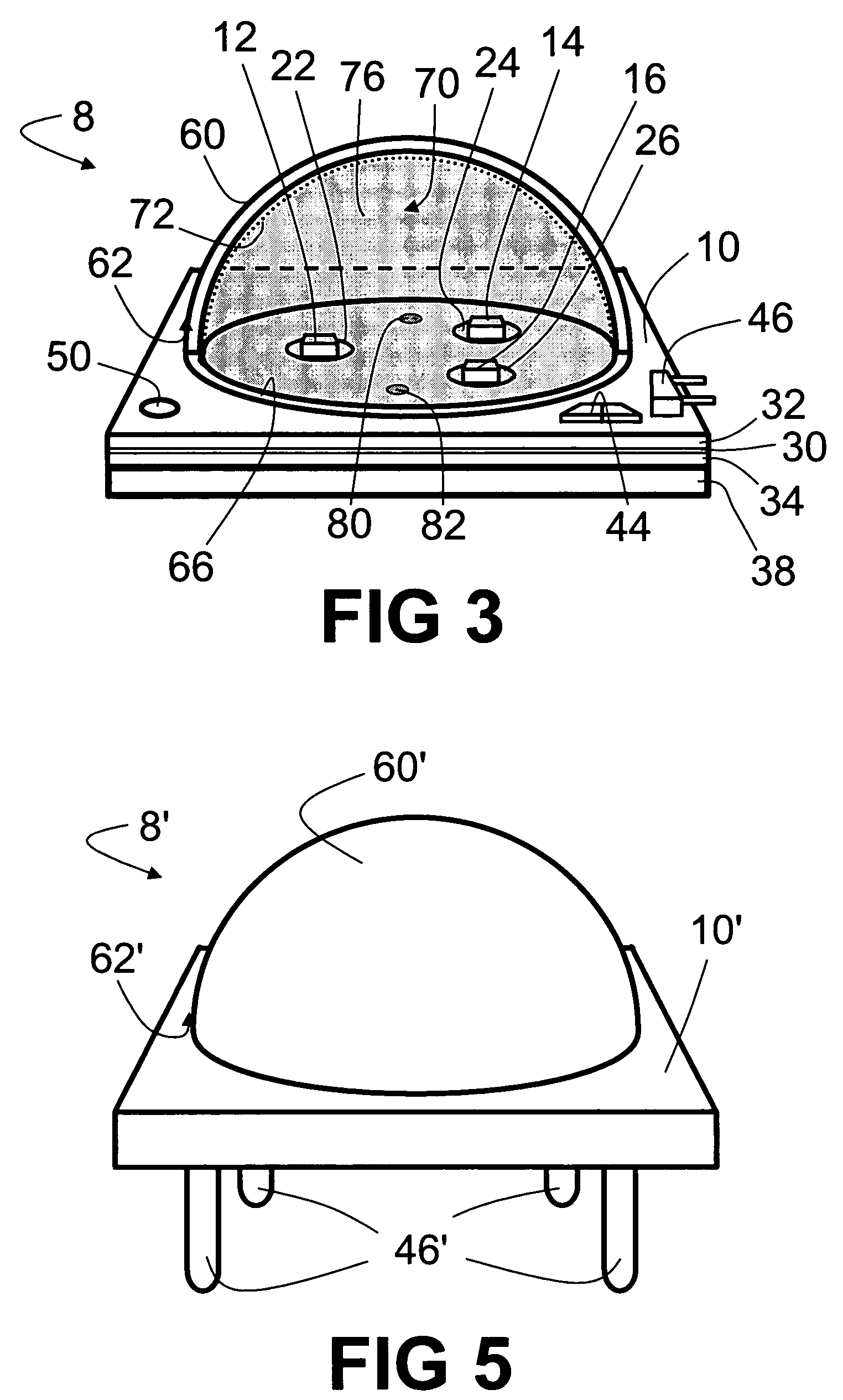

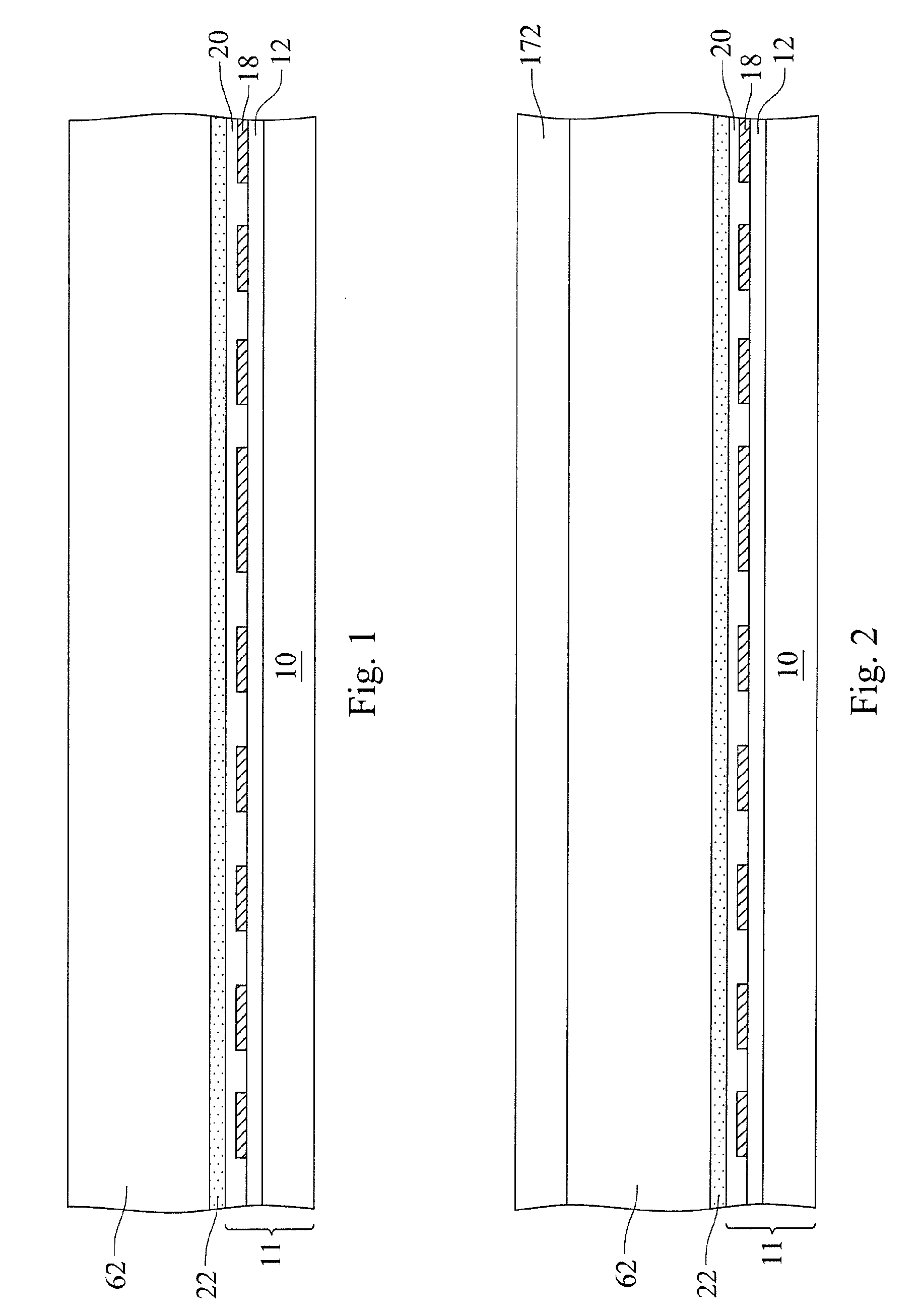

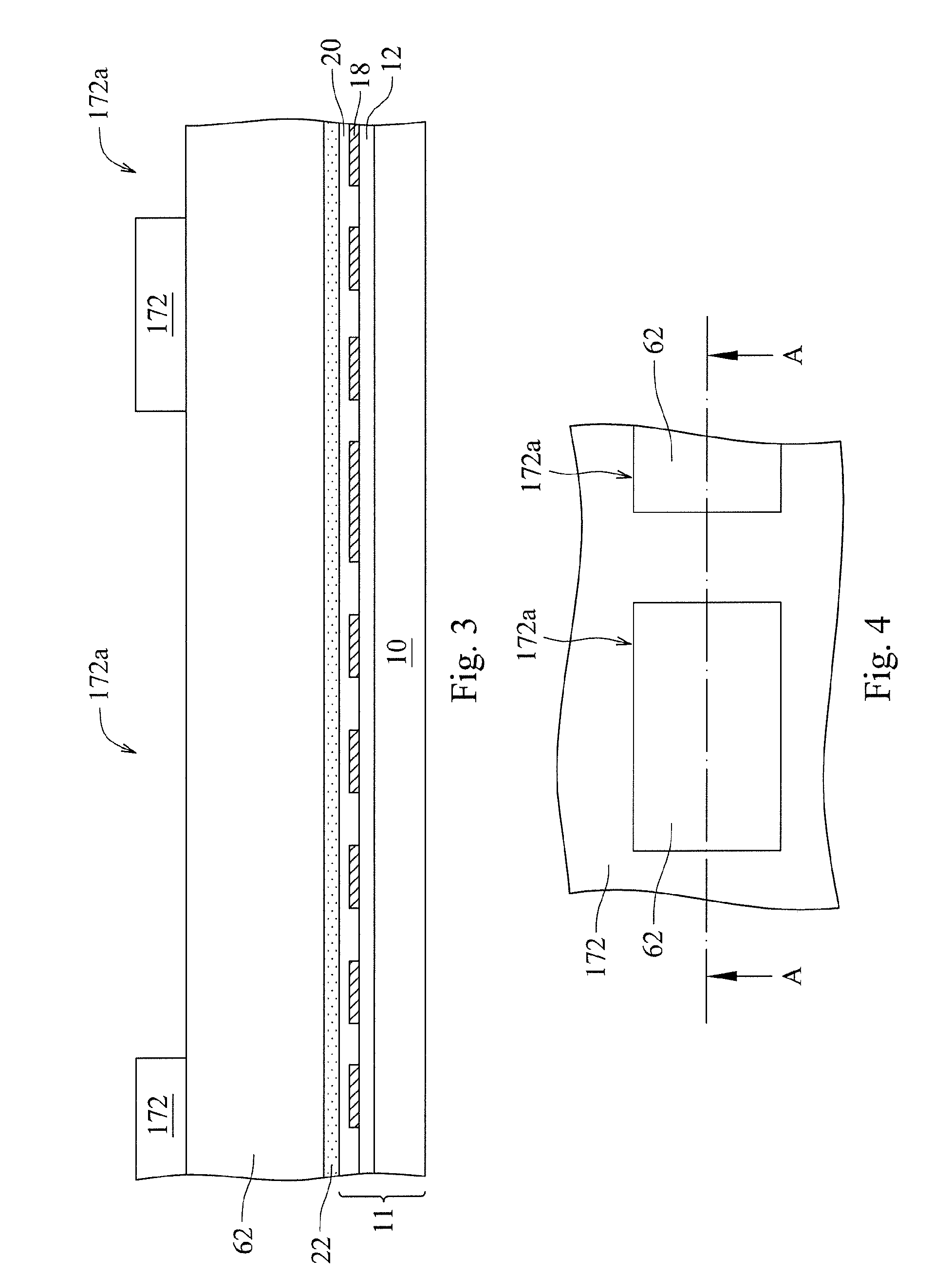

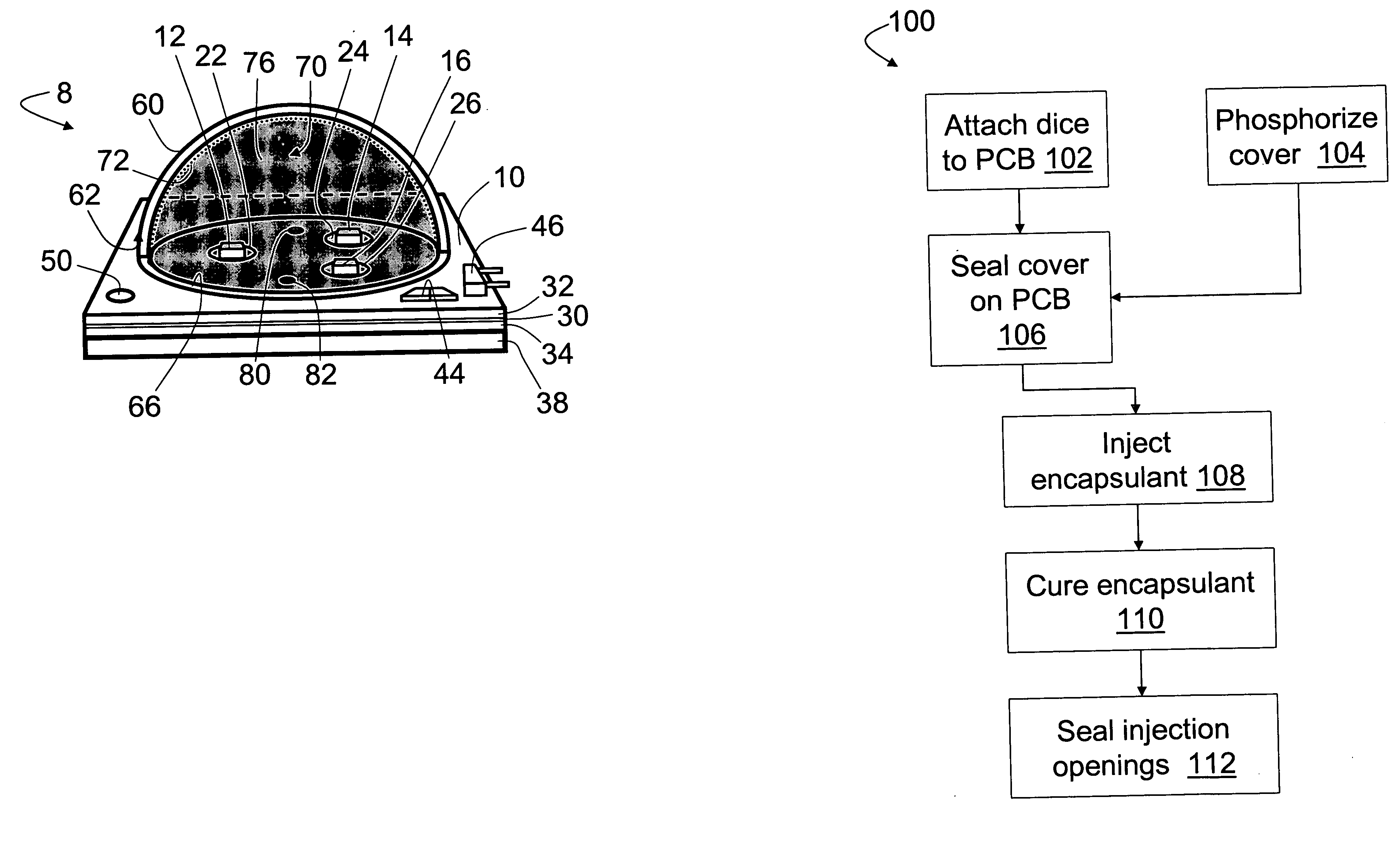

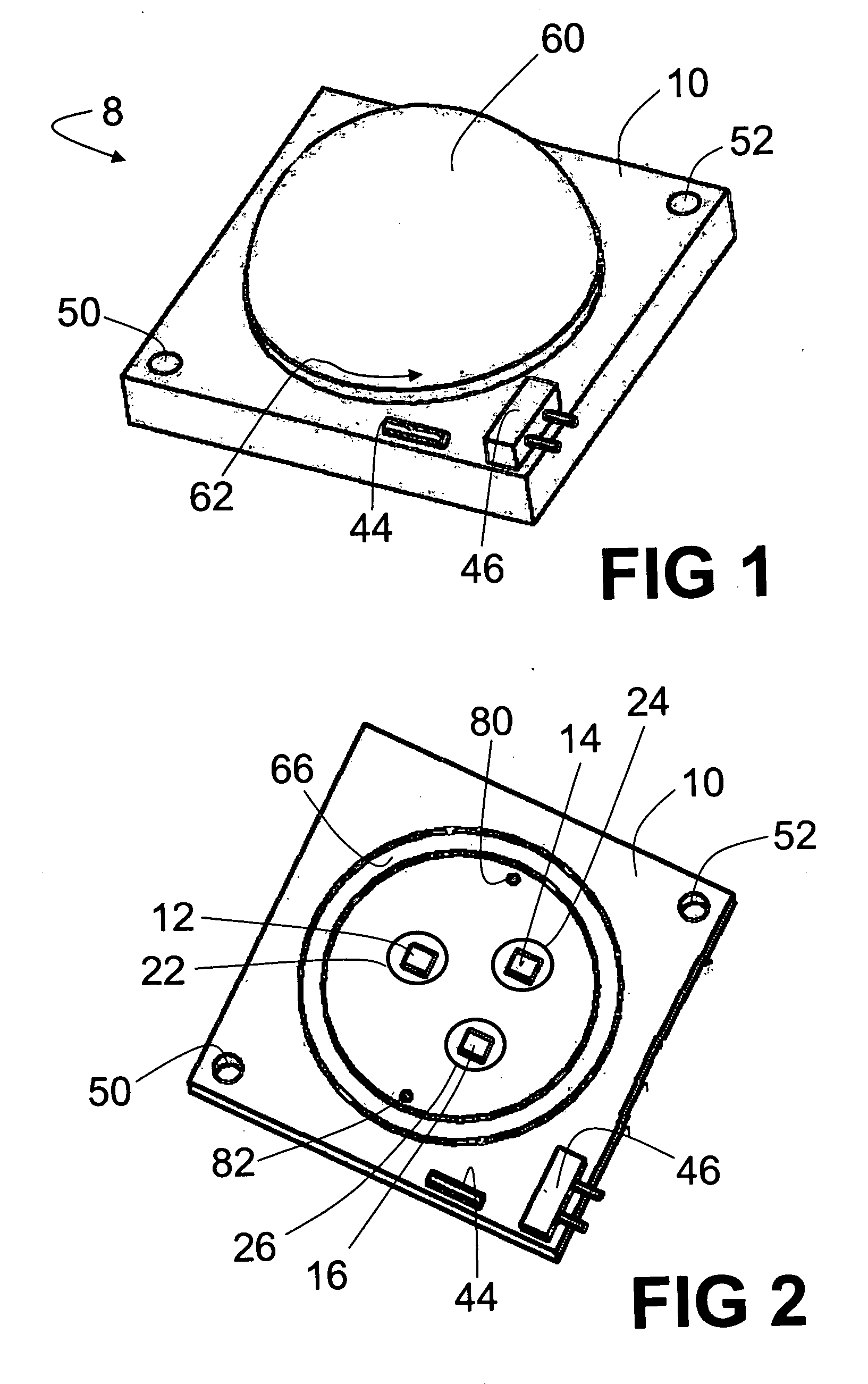

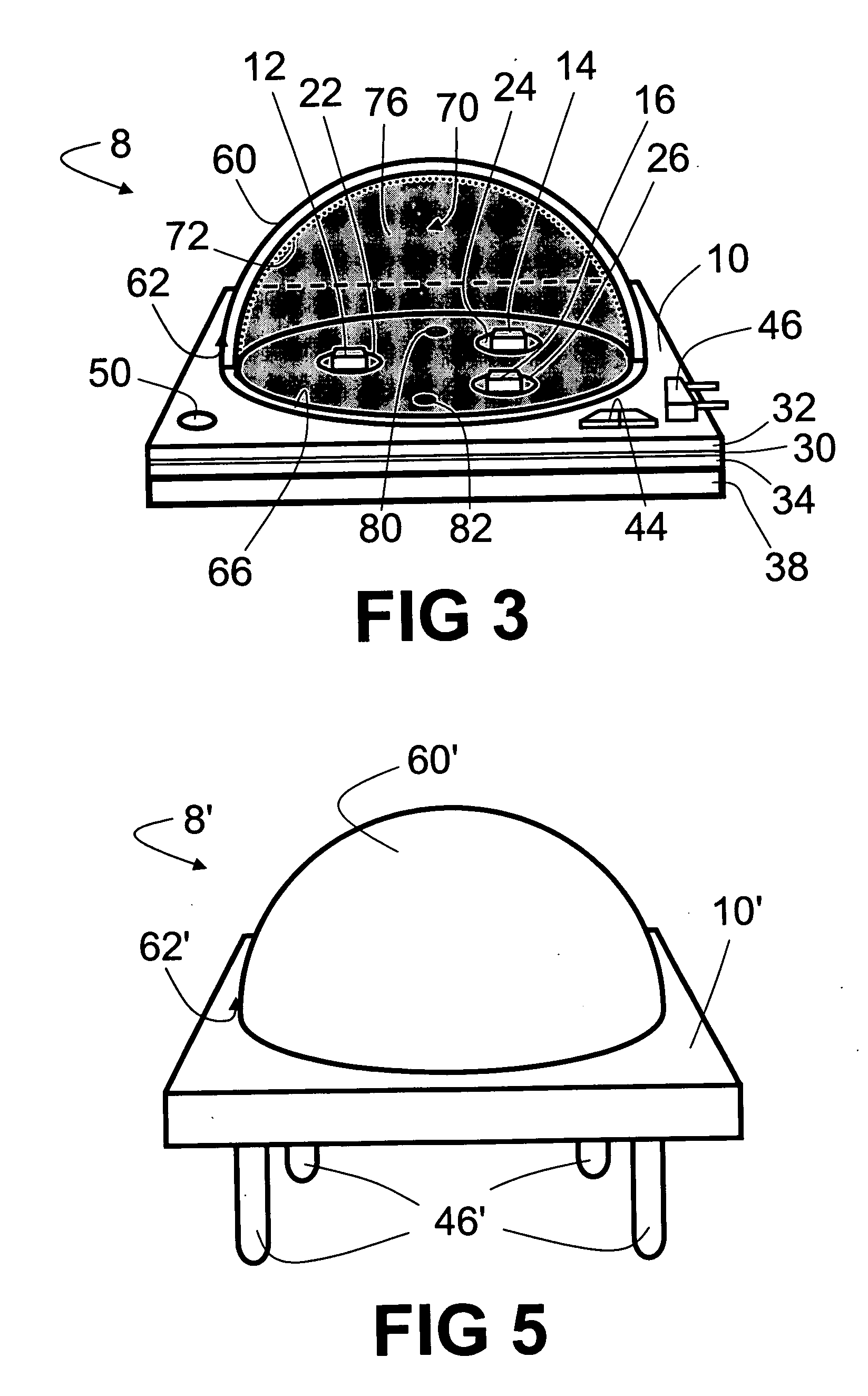

A light emitting package (8, 8′, 8″, 208, 408) includes a printed circuit board (10, 10′, 10″, 210, 410) supporting at least one light emitting die (12, 12″, 14, 16, 212, 412). A light transmissive cover (60, 60′, 60″, 260, 460) is disposed over the at least one light emitting die. The cover has an open end defining a cover perimeter (62, 62′, 62″, 262, 462) connected with the printed circuit board. An inside surface of the cover together with the printed circuit board defines an interior volume (70, 70″, 270, 470) containing the at least one light emitting die. An encapsulant (76, 76″, 276, 278, 476) is disposed in the interior volume and covers at least the light emitting die.

Owner:GENERAL ELECTRIC CO +1

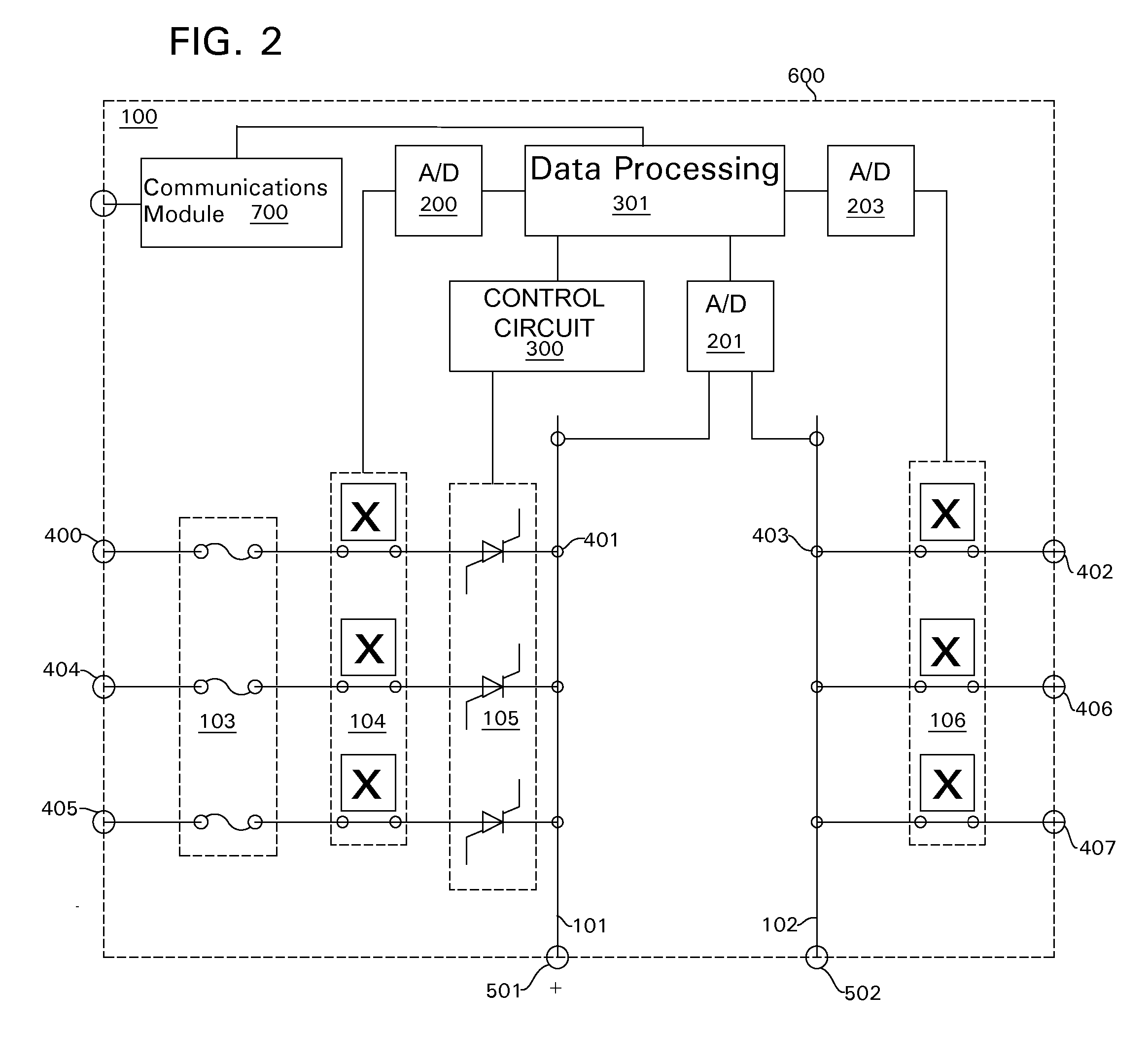

Direct current combiner box with power monitoring, ground fault detection and communications interface

InactiveUS20060237058A1Save a lot of timeShorten the timeBatteries circuit arrangementsPV power plantsCommunication interfaceDc current

A combiner box is used to collect direct current from solar panels or other energy sources. The combiner box integrates all means necessary for ground fault detection, current monitoring, voltage monitoring, and power monitoring. The combiner box may include a communication interface suitable for Web enabled monitoring, electronic notifications of system status, and / or remote control of system functions. In one embodiment, the combiner box uses integrated circuits and printed circuit board technology to achieve new efficiencies in manufacturing, installation and system analysis at the string level. A separate hand piece may be used by installers to test the performance of the combiner box, installation of the solar panels, performance of the solar panels and connections between the solar panels and the combiner box.

Owner:ENERGY RECOMMERCE

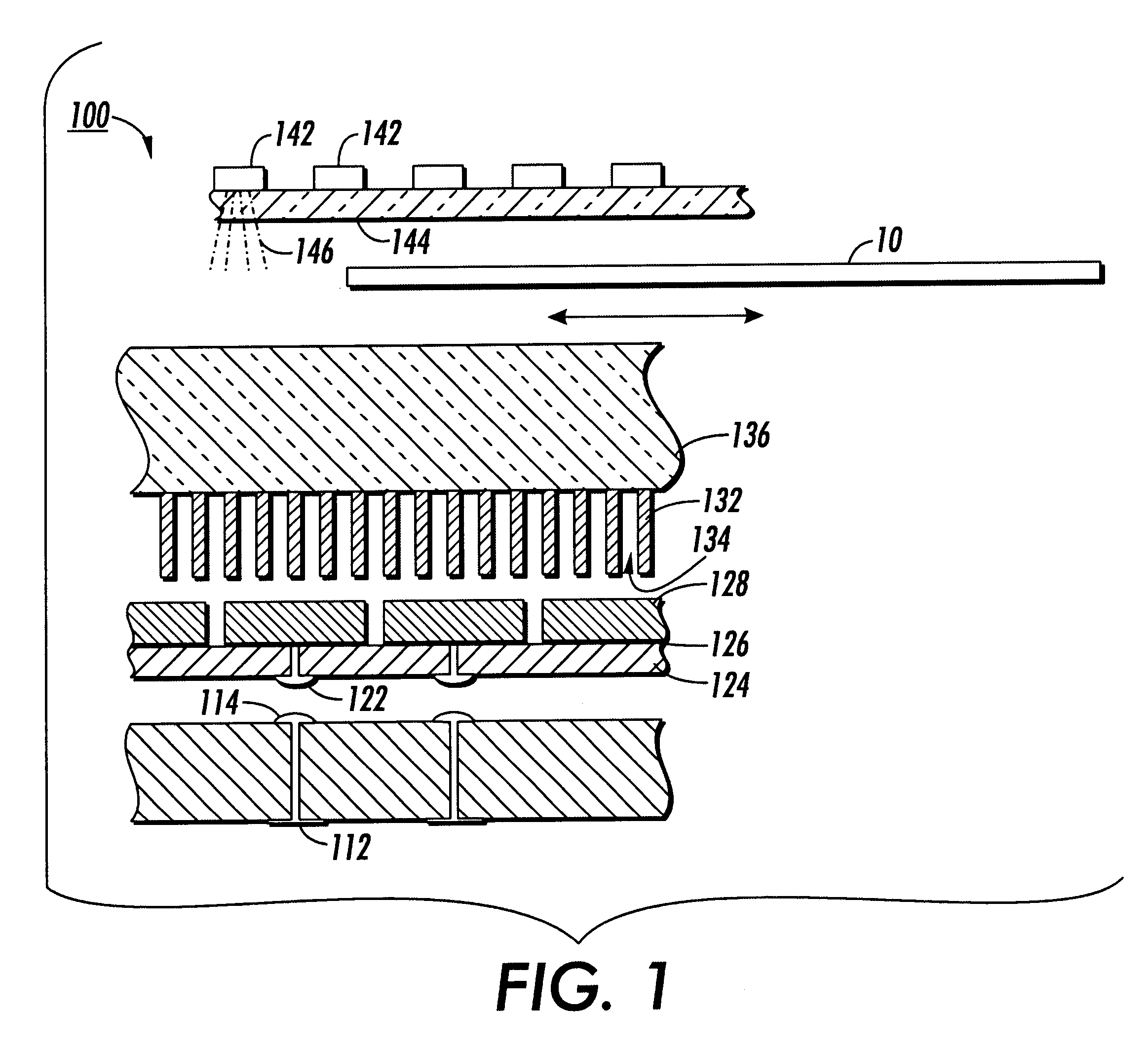

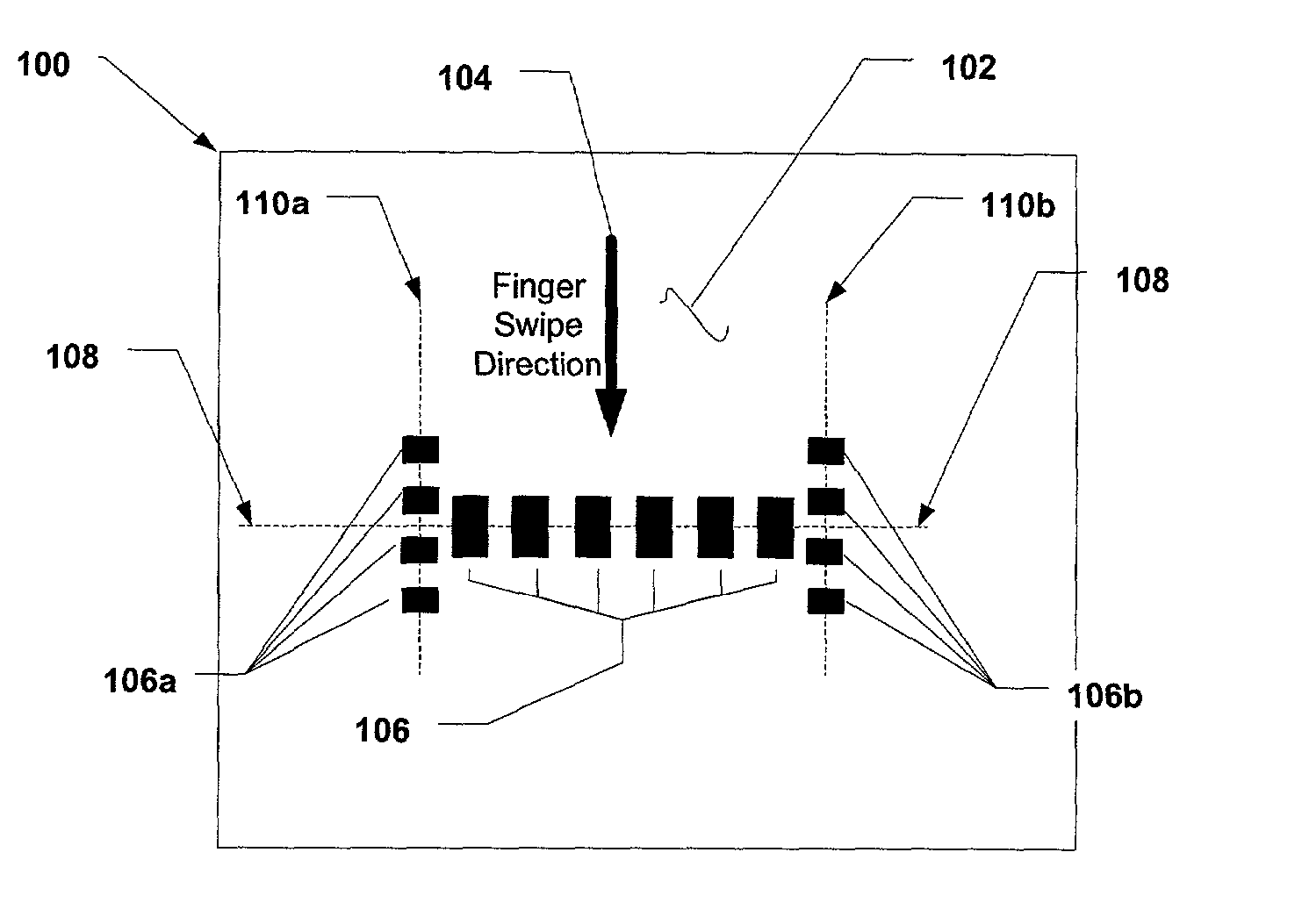

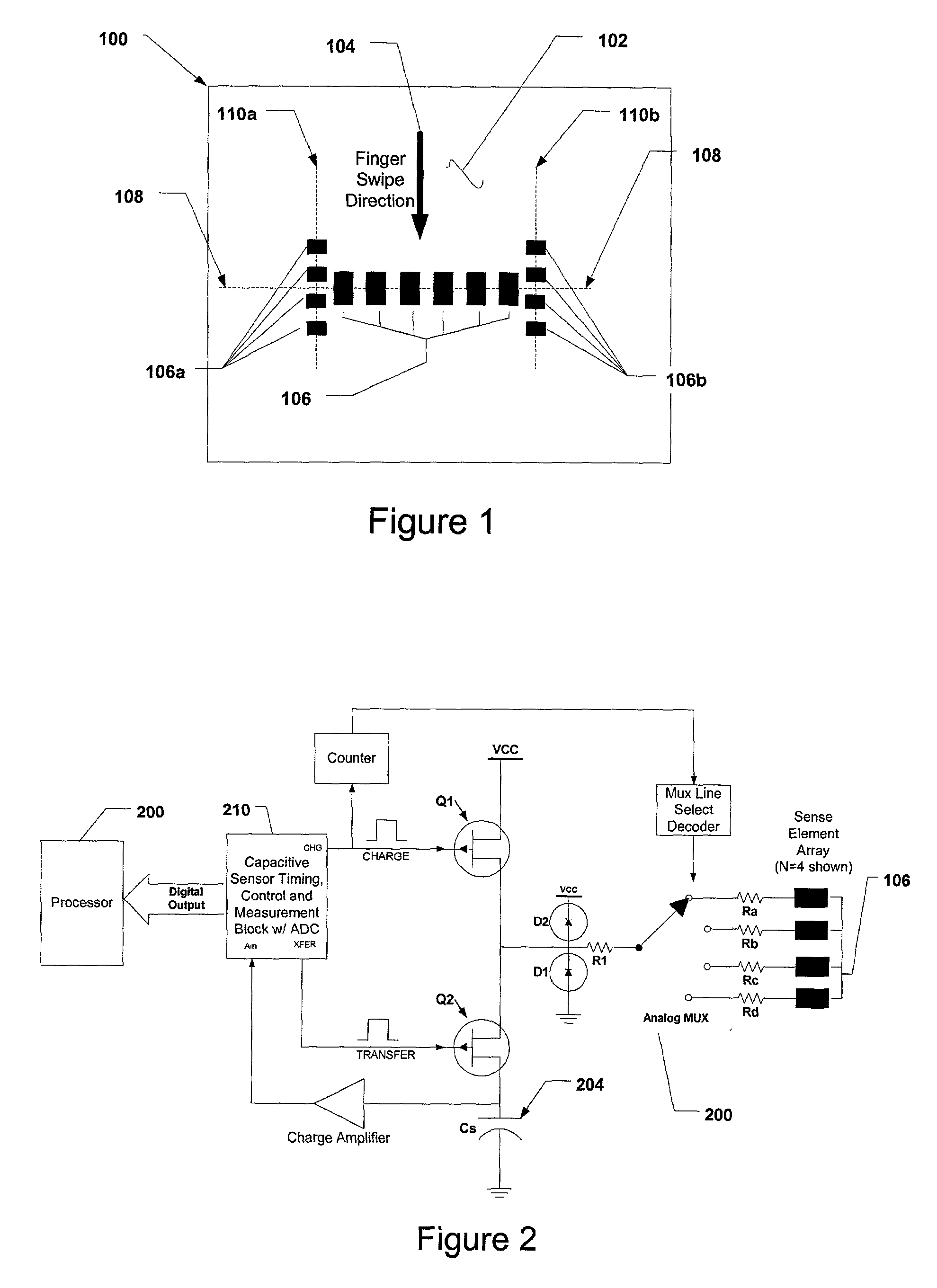

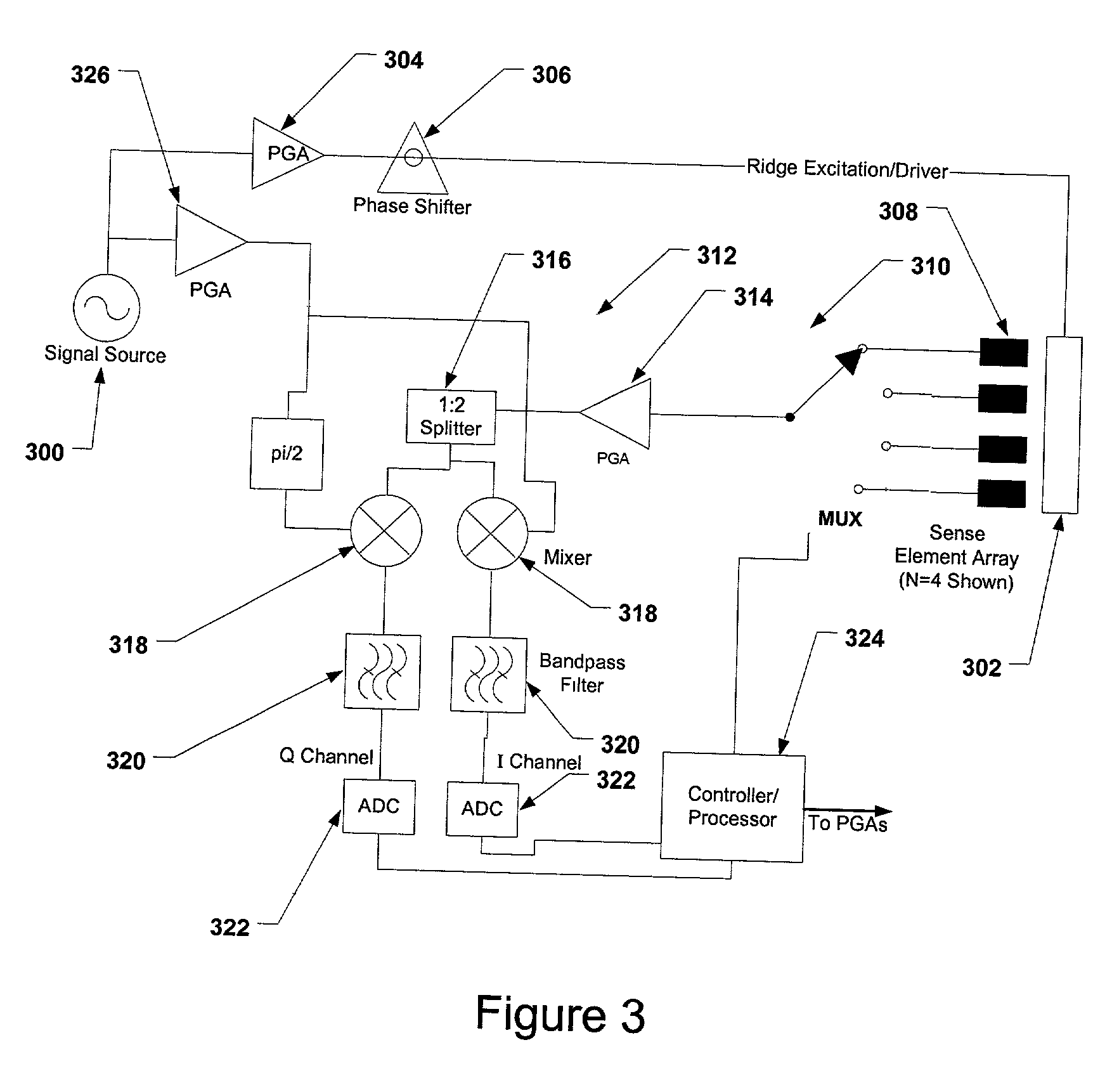

Sensor apparatus and method for use in imaging features of an object

A sensing device and method for use in imaging surface features of an object is provided. A surface along which an object can slide in a predetermined direction includes an array of contact sense elements configured to form a single array oriented transverse to the predetermined direction and at least one additional contact sense element located in spaced relation to the single array in a manner that enables a velocity measurement of the object in the predetermined direction. A scanning device is configured to provide a periodic scan of the array of contact sense elements, and a processor in circuit communication with the scanning device is configured to receive data from the scanning device and to produce image and velocity data related to the object. Preferably, the contact sense elements are electrically conductive elements disposed on a ceramic or polymeric substrate, using printed circuit board construction. A technique is described that enables the reconstruction of an object from such a device

Owner:ARETE ASSOCIATES INC

LED light fixture

InactiveUS20070247842A1Low thermal conductivityLower resistancePlanar light sourcesCeilingsInfraredElectricity

A light fixture using LEDs includes a lower skin layer possessing heat transfer properties. A circuit board is affixed to the lower skin layer, and a single LED, or a plurality of LEDs, is electrically connected to the circuit board. The single LED, or plurality of LEDs, when electrically activated, emits light through substantially around a vertical axis. The light fixture also includes a core possessing heat transfer properties that is in thermal contact with the LED and has an interior cavity for the LED. The core is affixed to the lower skin layer, and an upper skin layer, containing a window or windows over the LED or LEDs, is affixed to the core. The LEDs may be white, infrared, ultraviolet, and / or colored and may be mounted on a printed circuit board or individually.

Owner:INTEGRATED ILLUMINATION SYST

System-in packages

ActiveUS8503186B2Improve uniformityCircuit arrangements on support structuresSemiconductor/solid-state device detailsMetal interconnectSystem in package

Owner:QUALCOMM INC

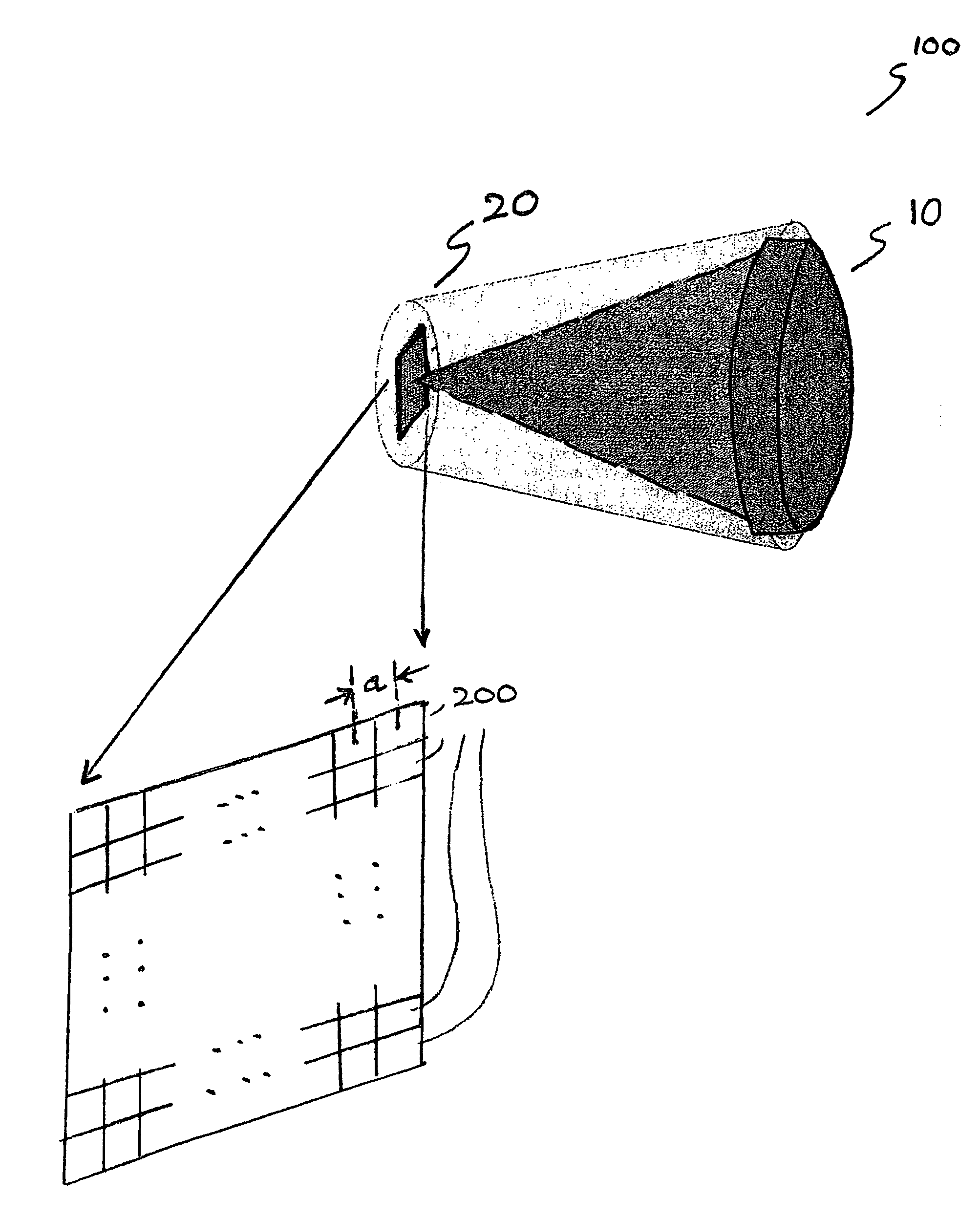

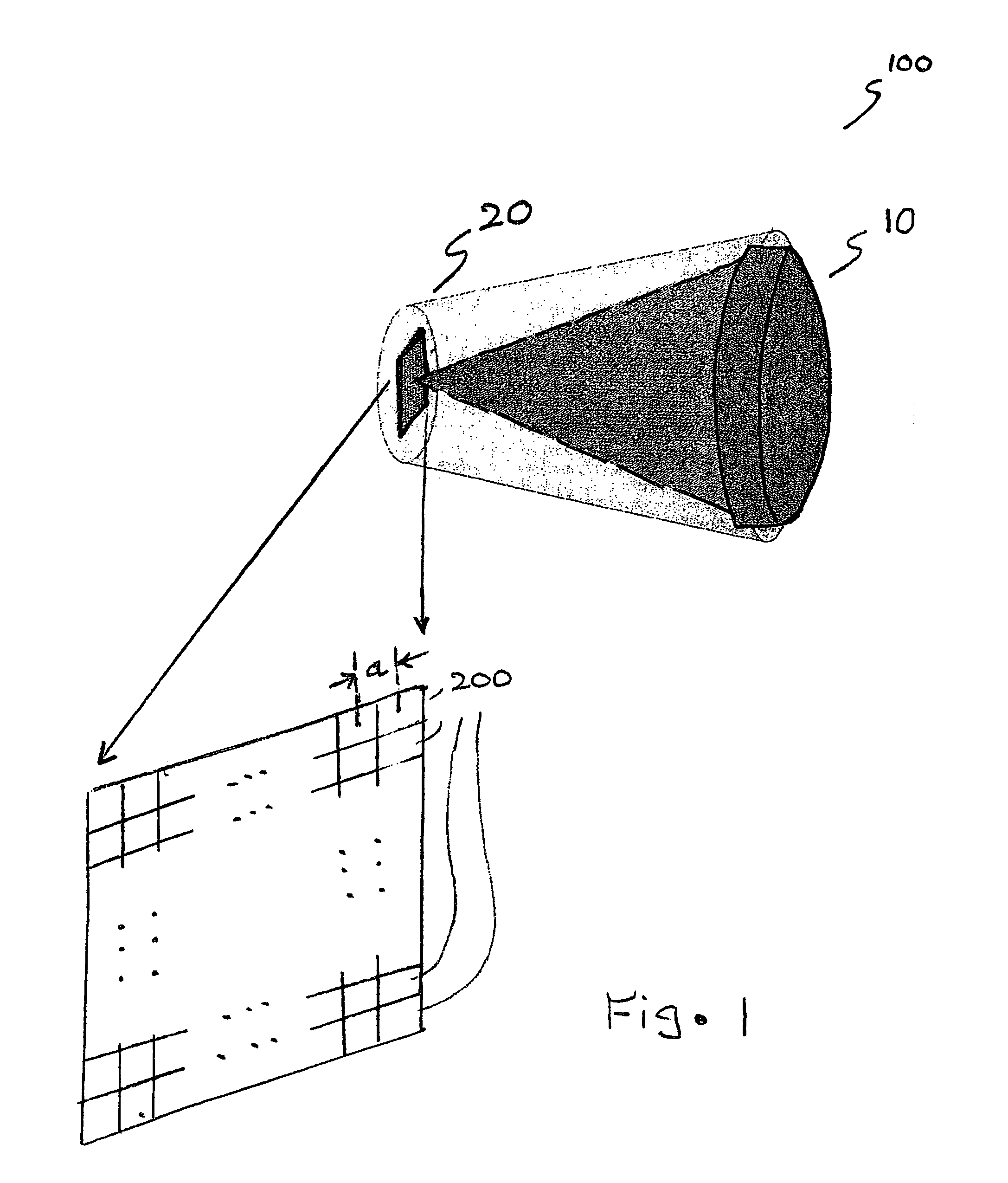

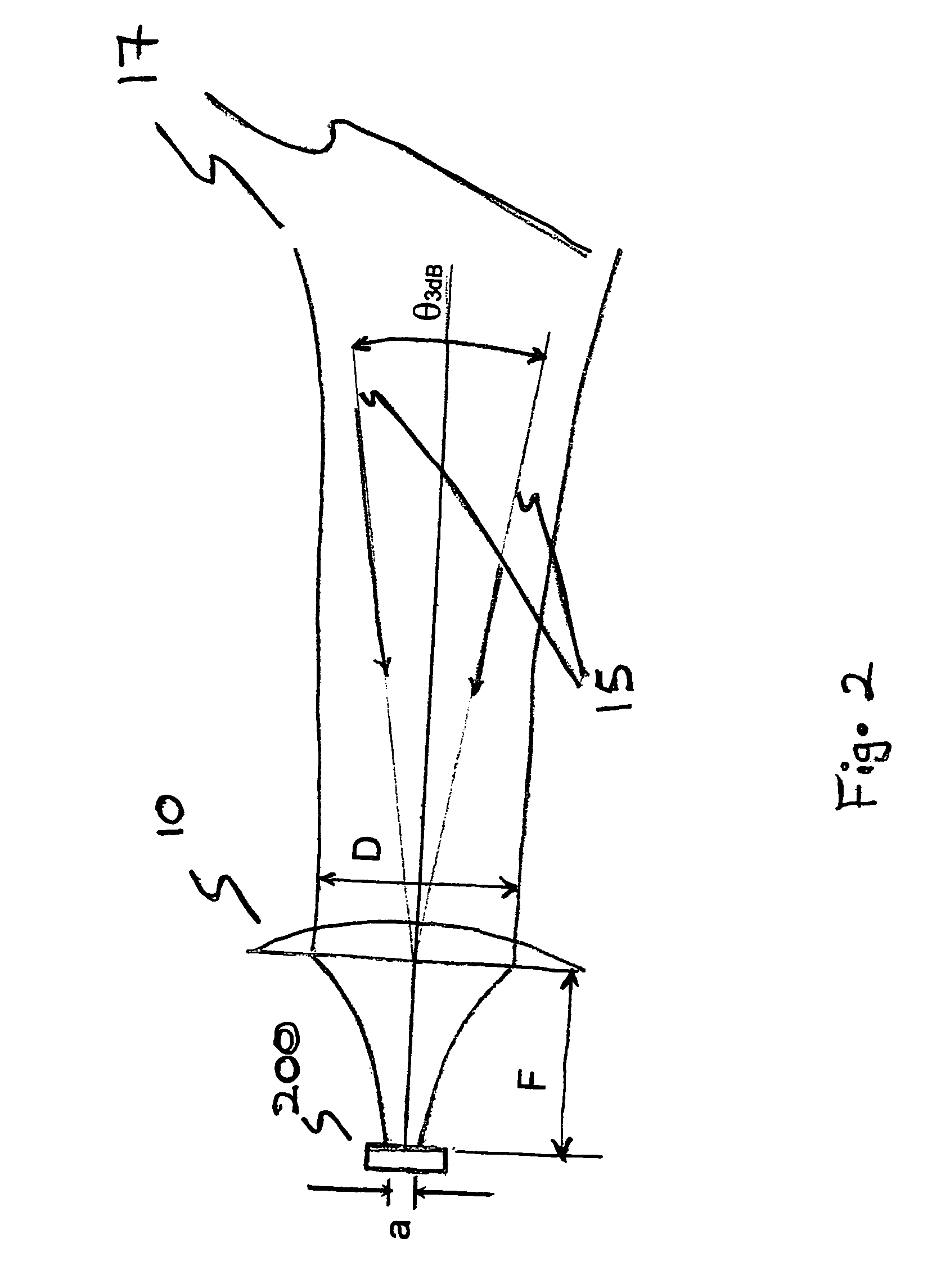

Low cost millimeter wave imager

InactiveUS7583074B1Low costUseful sensitivity levelMeasurement using dc-ac conversionMeasurement using ac-dc conversionLow noiseTunnel diode

Low cost millimeter wave imagers using two-dimensional focal plane arrays based on backward tunneling diode (BTD) detectors. Two-dimensional focal arrays of BTD detectors are used as focal plane arrays in imagers. High responsivity of BTD detectors near zero bias results in low noise detectors that alleviate the need for expensive and heat generating low noise amplifiers or Dicke switches in the imager. BTD detectors are installed on a printed circuit board using flip chip packaging technology and horn antennas direct the waves toward the flip chip including the BTD detectors. The assembly of the horn antennas, flip chips, printed circuit board substrate, and interconnects together work as an imaging sensor. Corrugated surfaces of the components prevent re-radiation of the incident waves.

Owner:HRL LAB

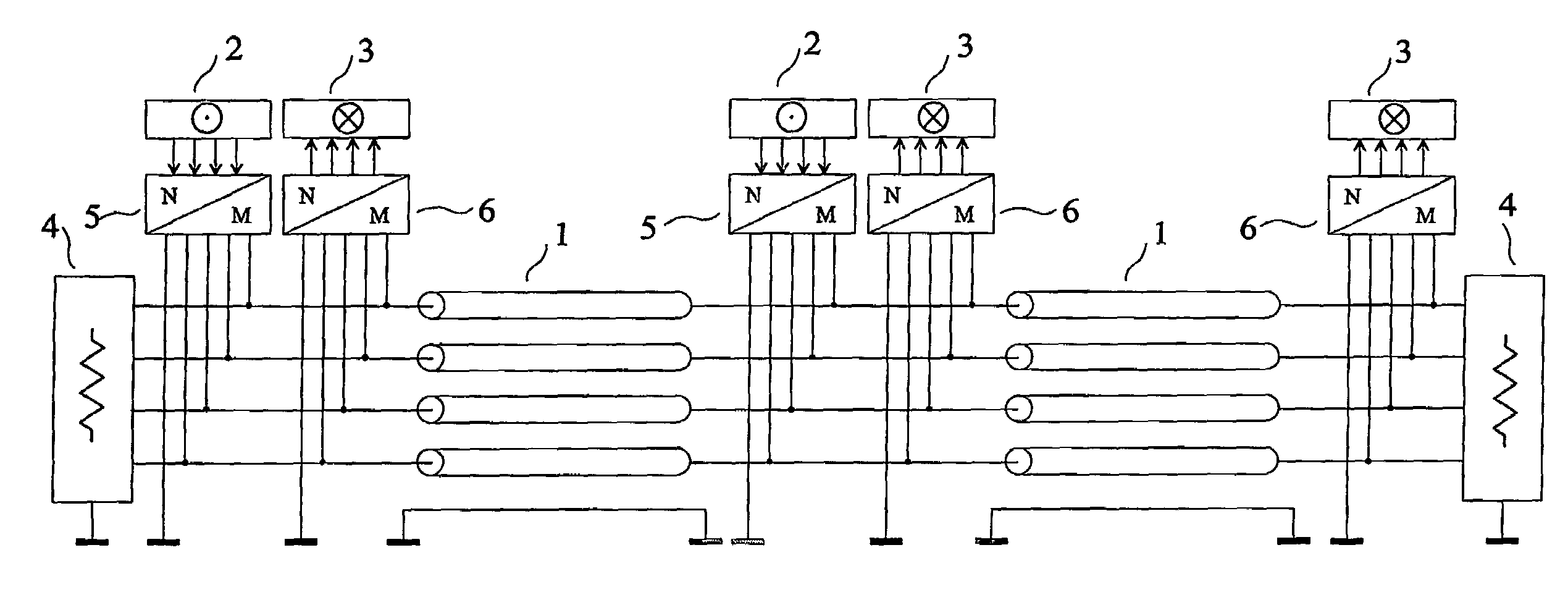

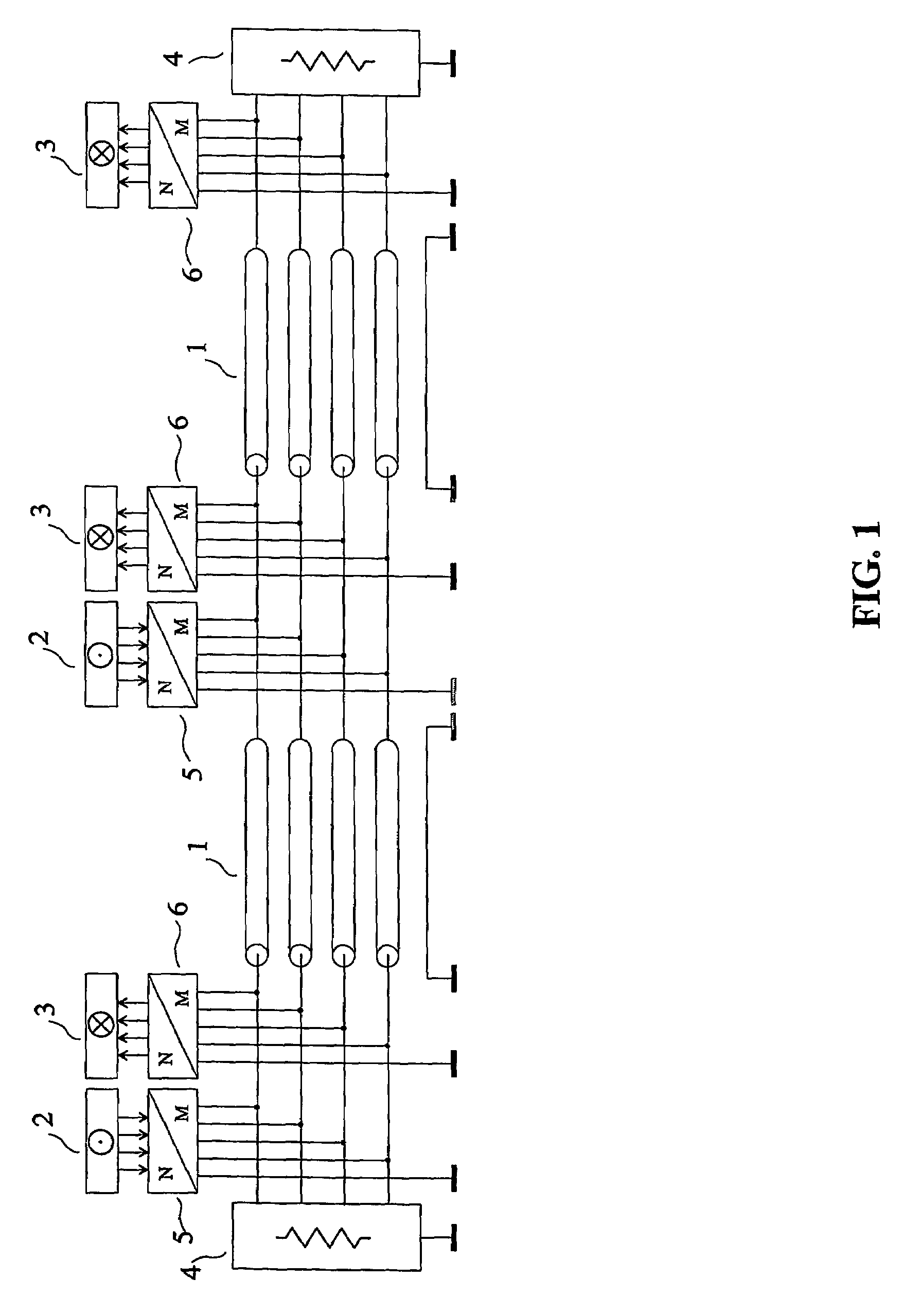

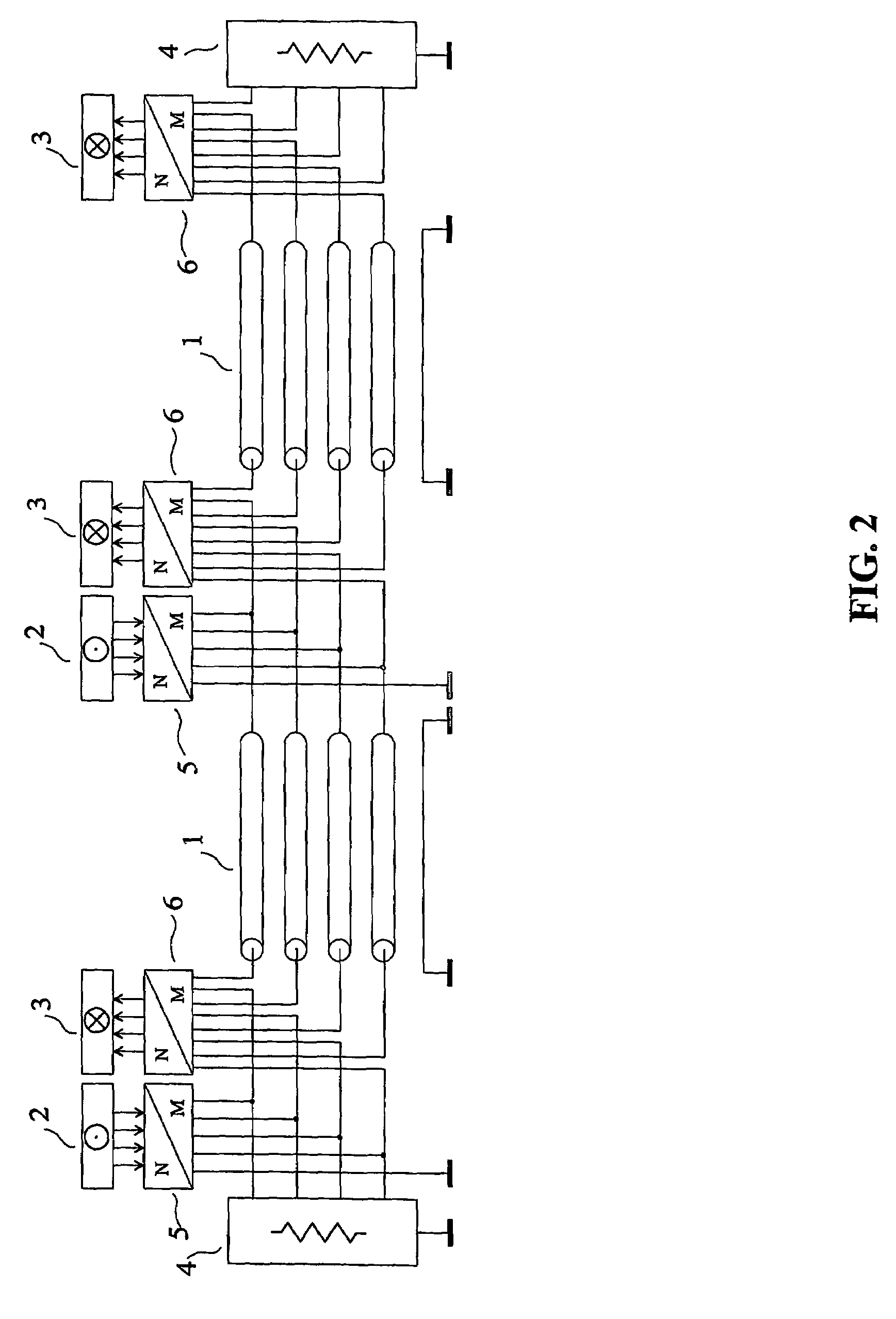

Method and device for transmission without crosstalk

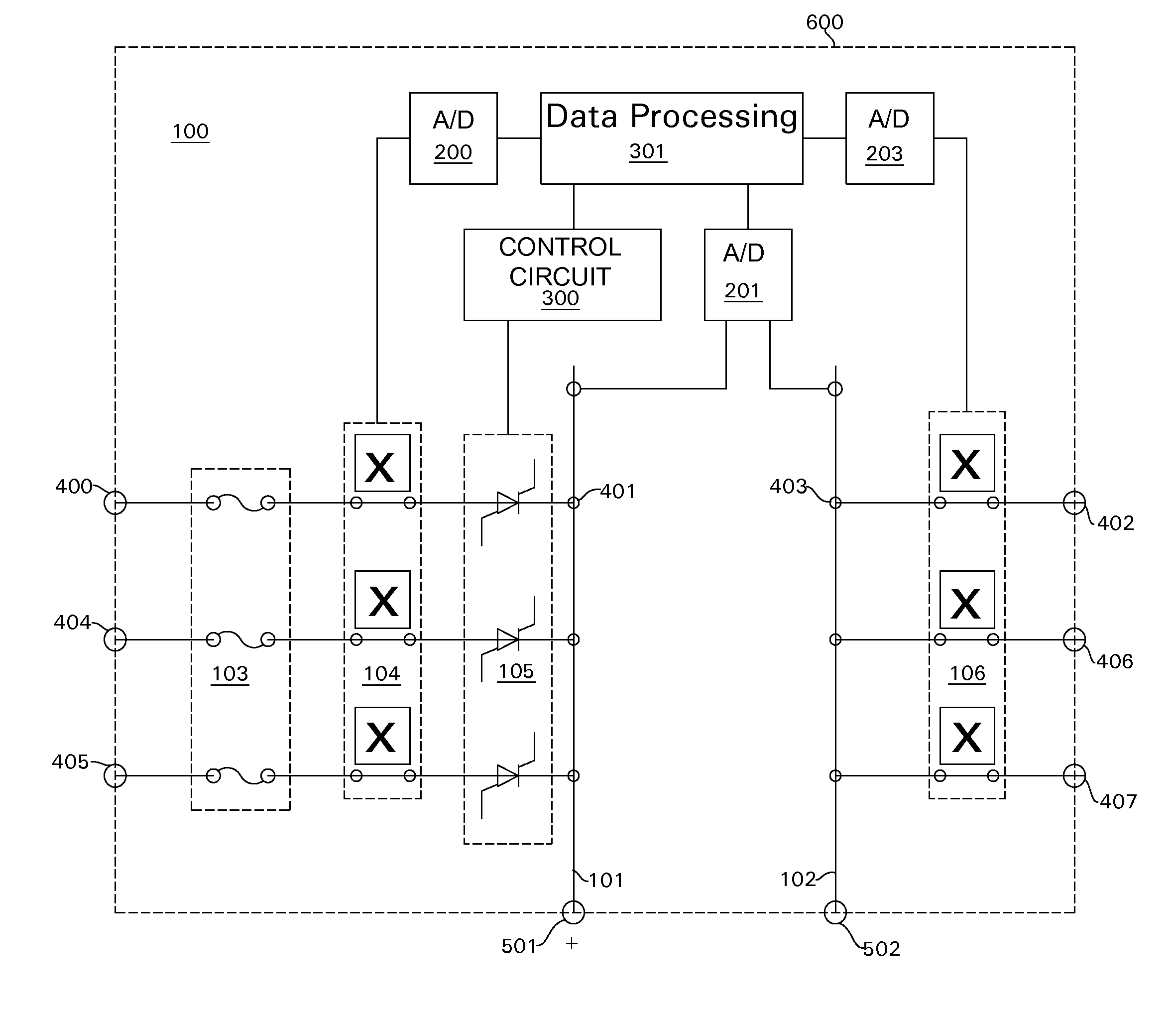

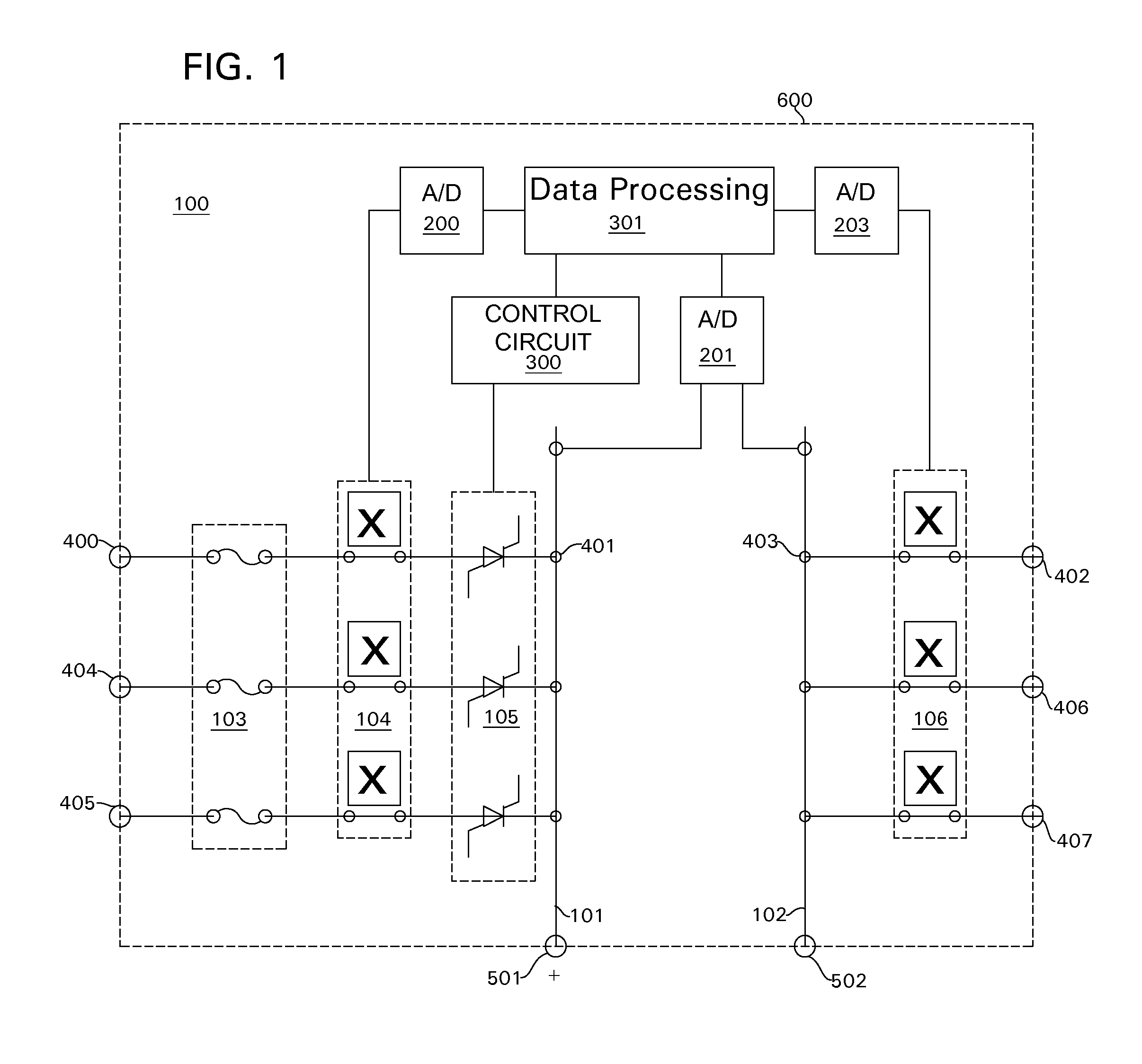

ActiveUS7408426B2Simplifying the transmitting circuits and/or the receiving circuitsSimplification of the transmitting circuits and/or the receiving circuitsReliability increasing modificationsDc network circuit arrangementsElectrical conductorInterconnection

The invention relates to a method and a device for transmission without crosstalk in interconnections used for sending a plurality of signals, such as the interconnections made with flat multiconductor cables, or with the tracks of a printed circuit board, or inside an integrated circuit. An interconnection with four parallel transmission conductors plus a reference conductor has each of its ends connected to a termination circuit. The transmitting circuit receives at its input the signals of the four channels of the source and its output terminals are connected to the conductors of the interconnection. The receiving circuit(s) input terminals are connected to the conductors of the interconnection, and its four output channels are connected to the destination. The signals of the four channels of an active source are sent to the four channels of the destination, without noticeable crosstalk.

Owner:S AQUA SEMICONDUCTOR LLC

Vehicular camera system

ActiveUS20140160284A1Television system detailsLine/current collector detailsEngineeringPrinted circuit board

A vehicular camera system includes an imager assembly that can include an imager disposed on an imager circuit board and a lens positioned to direct light to the imager. A main circuit board is operatively connected to the imager circuit board. The main circuit board can include at least one processor for processing images captured by the imager. The main circuit board has an opening, and at least a portion of the imager assembly extends through the opening.

Owner:MAGNA ELECTRONICS

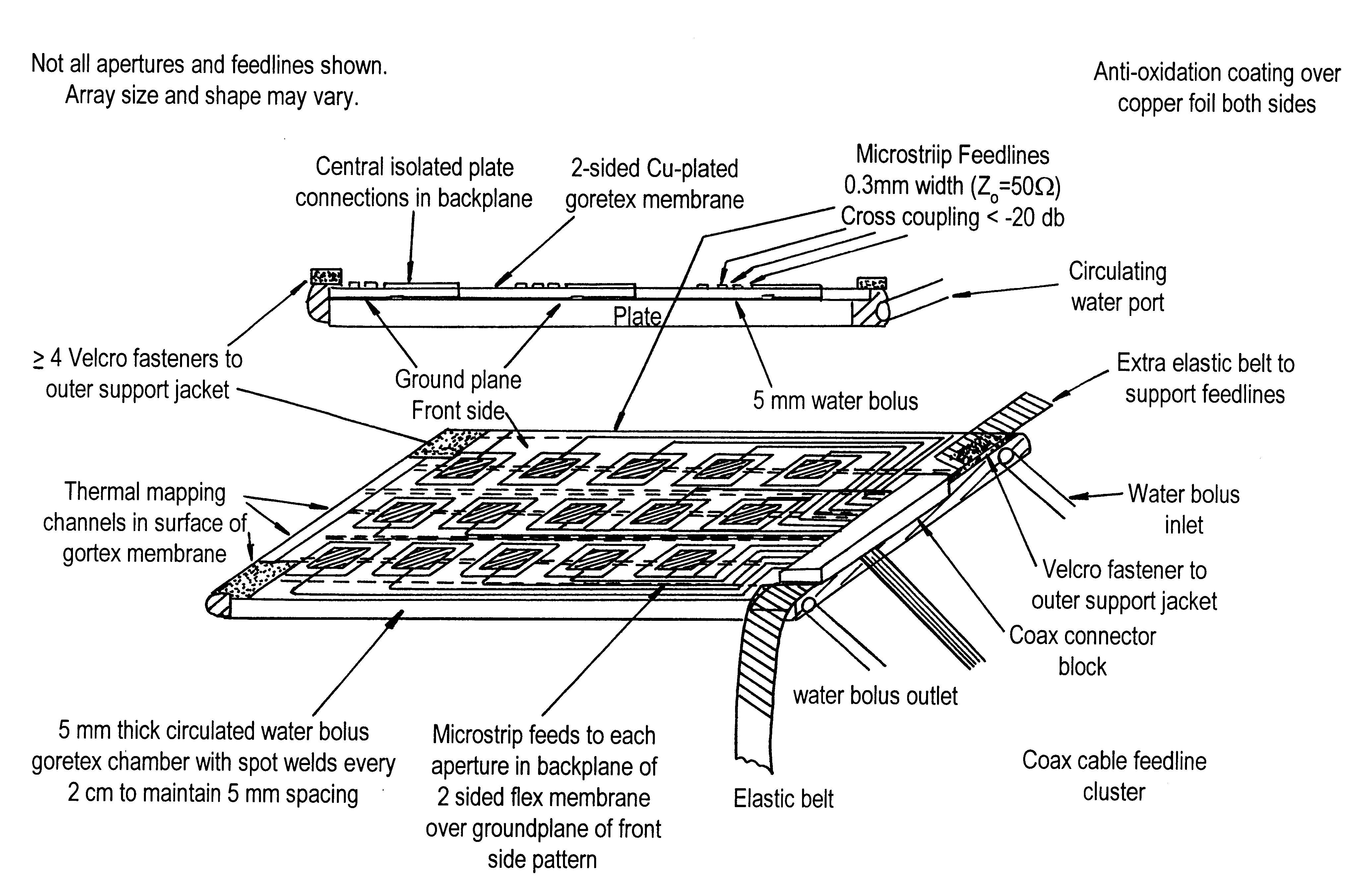

Microwave garment for heating and/or monitoring tissue

InactiveUS6330479B1Reduce manufacturing costImproved patient comfortElectrotherapyMicrowave therapyDielectric substrateEngineering

A flexible microwave applicator and method of use thereof. The applicator includes a flexible, dielectric-containing compartment (e.g. temperature regulated water or oil) having a variable contour, tissue-engaging surface and an opposite non-tissue-engaging surface and an antenna array adjacent to a non-tissue-engaging surface. The antenna array includes at least one flexible printed circuit board having a front metal surface, a dielectric substrate, a back metal surface, a connection structure for connecting the antenna array to at least one external microwave device, at least one dual concentric conductor aperture on the front surface, and at least one microstrip feedline in communication with the dual concentric conductor aperture and the connection structure. The microwave applicator also includes flexible attachment material for placement over the antenna array and dielectric compartment to allow the microwave applicator to be attached to a subject like a garment which closely conforms to the anatomy portion to be heated. The flexible attachment material may be configured such that the microwave applicator is configured as an appropriately-shaped type of garment, for example, a vest, jacket, cap, hood, blanket, custom shaped conformal wrap, sleeve, or as a pair of shorts.

Owner:RGT UNIV OF CALIFORNIA

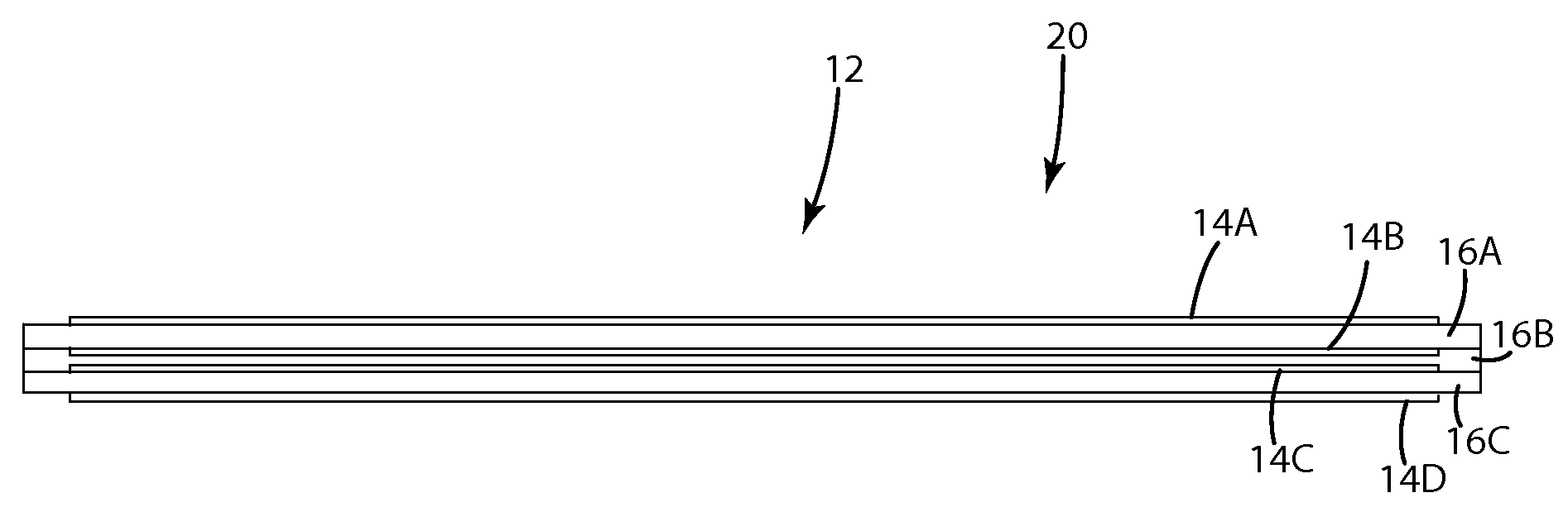

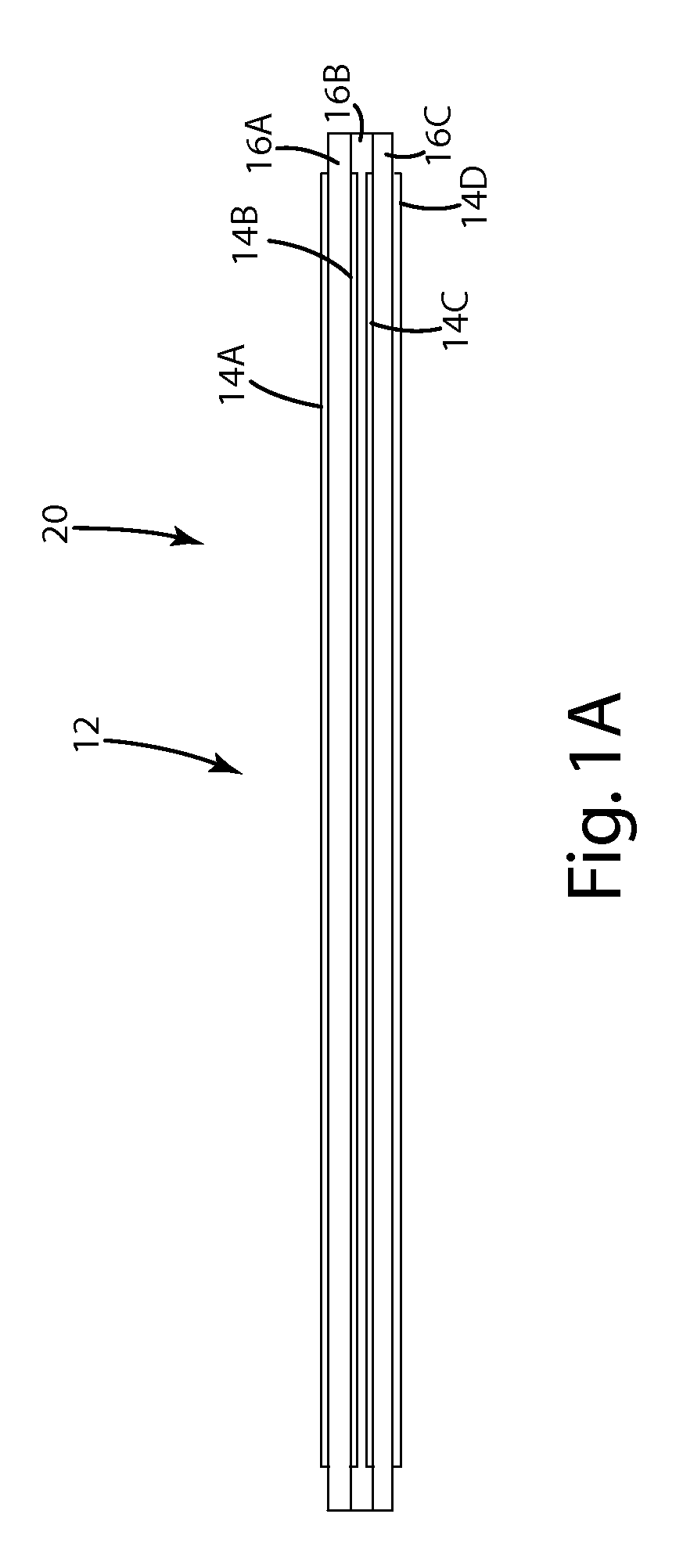

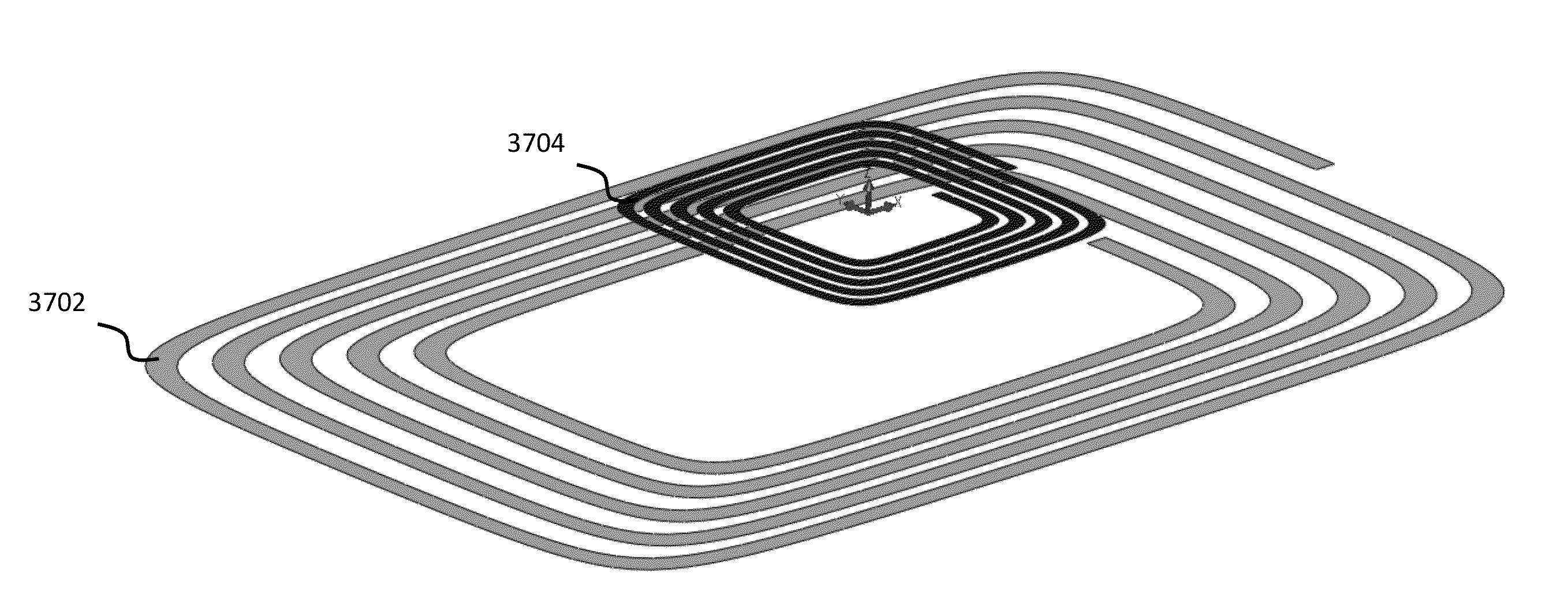

High frequency PCB coils

Described herein designs for high frequency printed circuit board (PCB) resonator coils. The resonator coils are printed or etched on a thin substrate. The number of loops of the resonator coil, the width of each trace, the spacing between the traces, and the like are adjusted to increase the quality factor Q of the resonator coils.

Owner:WITRICITY CORP

Light emitting diode component

ActiveUS20050239227A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringPrinted circuit board

A light emitting package (8, 8′, 8″, 208, 408) includes a printed circuit board (10, 10′, 10″, 210, 410) supporting at least one light emitting die (12, 12″, 14, 16, 212, 412). A light transmissive cover (60, 60′, 60″, 260, 460) is disposed over the at least one light emitting die. The cover has an open end defining a cover perimeter (62, 62′, 62″, 262, 462) connected with the printed circuit board. An inside surface of the cover together with the printed circuit board defines an interior volume (70, 70″, 270, 470) containing the at least one light emitting die. An encapsulant (76, 76″, 276, 278, 476) is disposed in the interior volume and covers at least the light emitting die.

Owner:GENERAL ELECTRIC CO +1

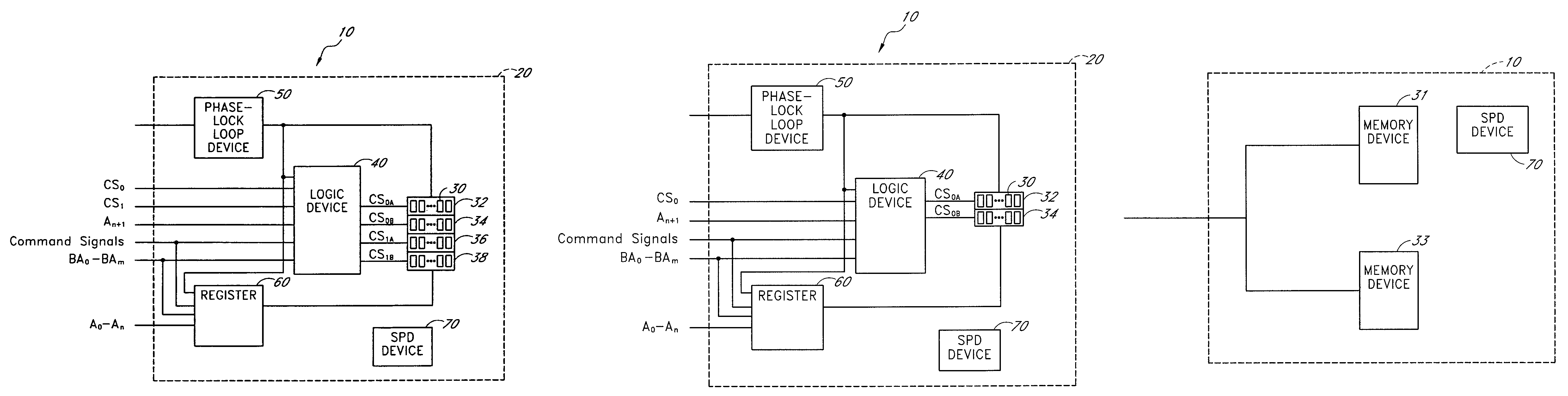

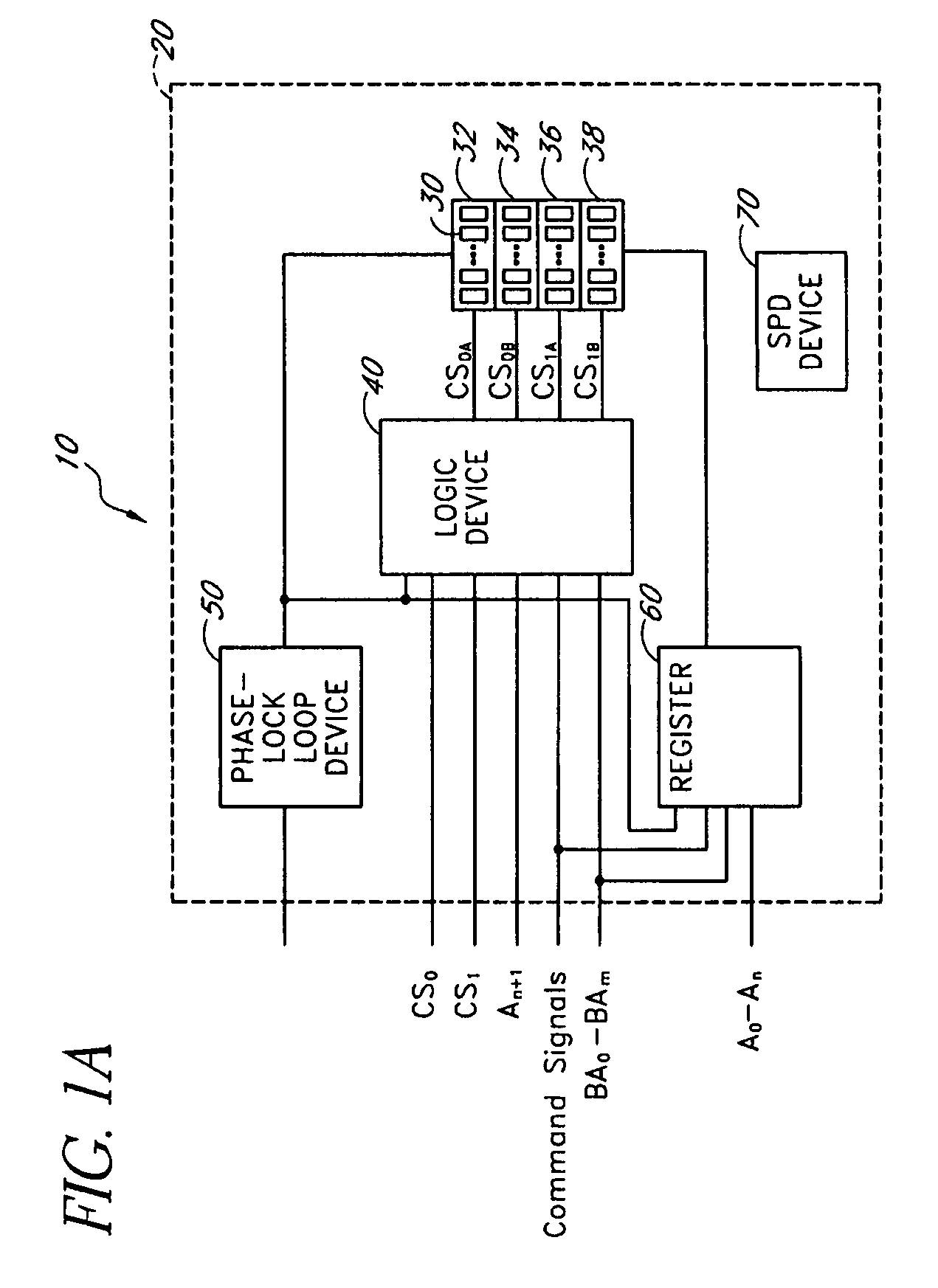

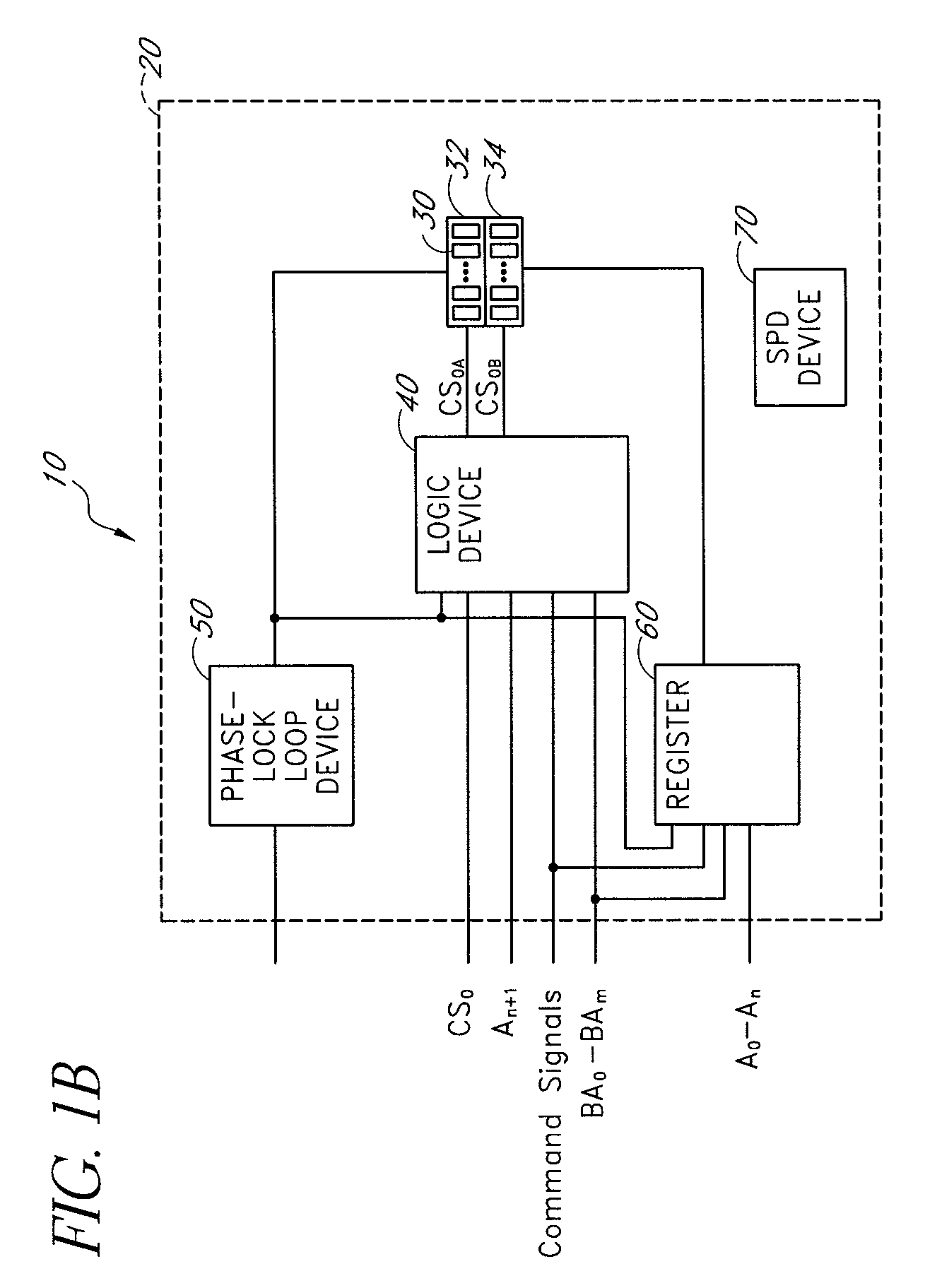

Memory module decoder

A memory module connectable to a computer system includes a printed circuit board, a plurality of memory devices coupled to the printed circuit board, and a logic element coupled to the printed circuit board. The plurality of memory devices has a first number of memory devices. The logic element receives a set of input control signals from the computer system. The set of input control signals corresponds to a second number of memory devices smaller than the first number of memory devices. The logic element generates a set of output control signals in response to the set of input control signals. The set of output control signals corresponds to the first number of memory devices.

Owner:NETLIST INC

Light emitting diode component

ActiveUS20060097245A1Semiconductor/solid-state device detailsElectric circuit arrangementsPhosphorEffect light

In a lighting package, a printed circuit board supports at least one light emitting die. A light transmissive cover is disposed over the at least one light emitting die. A phosphor is disposed on or inside of the light transmissive dome-shaped cover. The phosphor outputs converted light responsive to irradiation by the at least one light emitting die. An encapsulant substantially fills an interior volume defined by the light-transmissive cover and the printed circuit board.

Owner:GENERAL ELECTRIC CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com