Patents

Literature

426 results about "Repeat pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

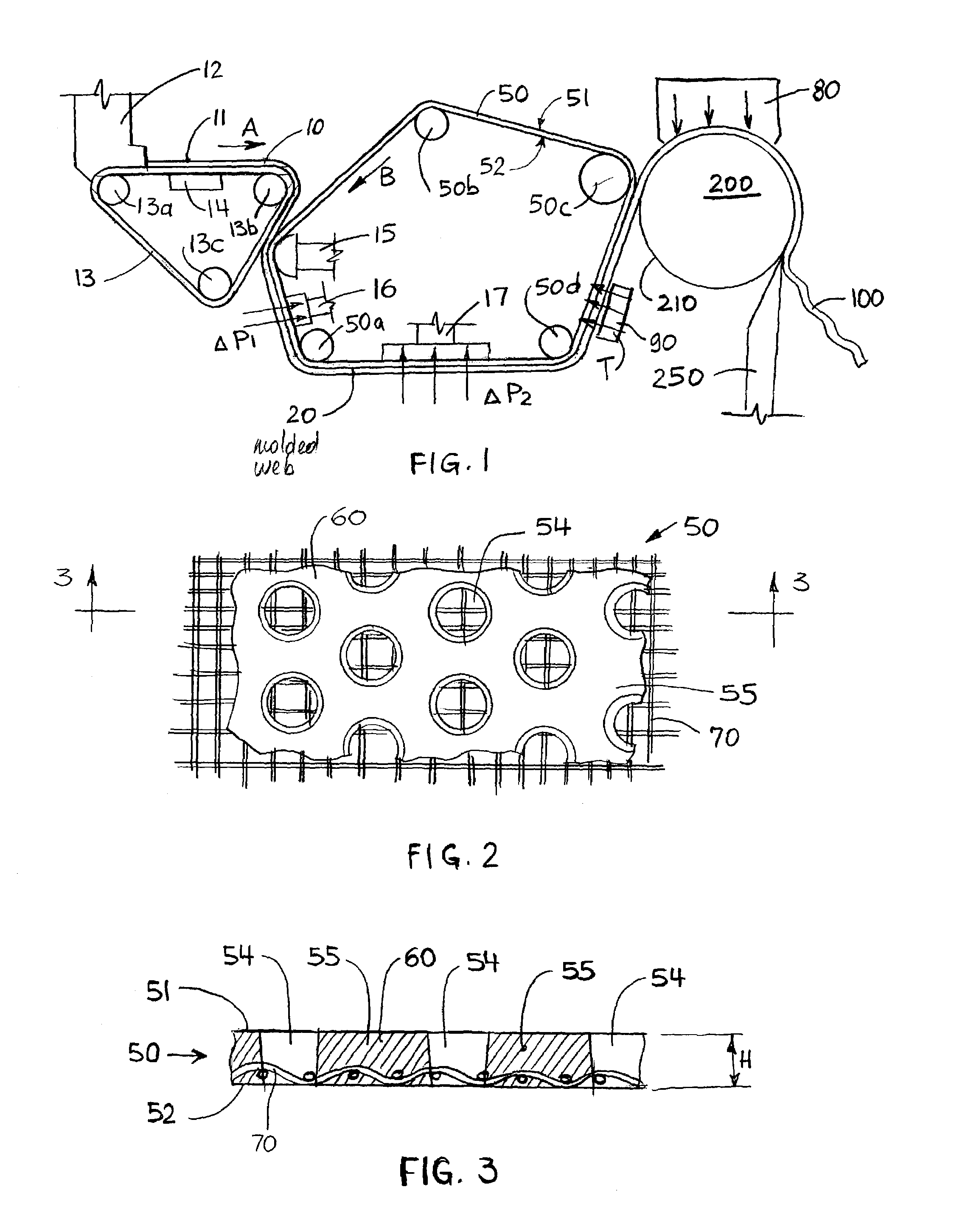

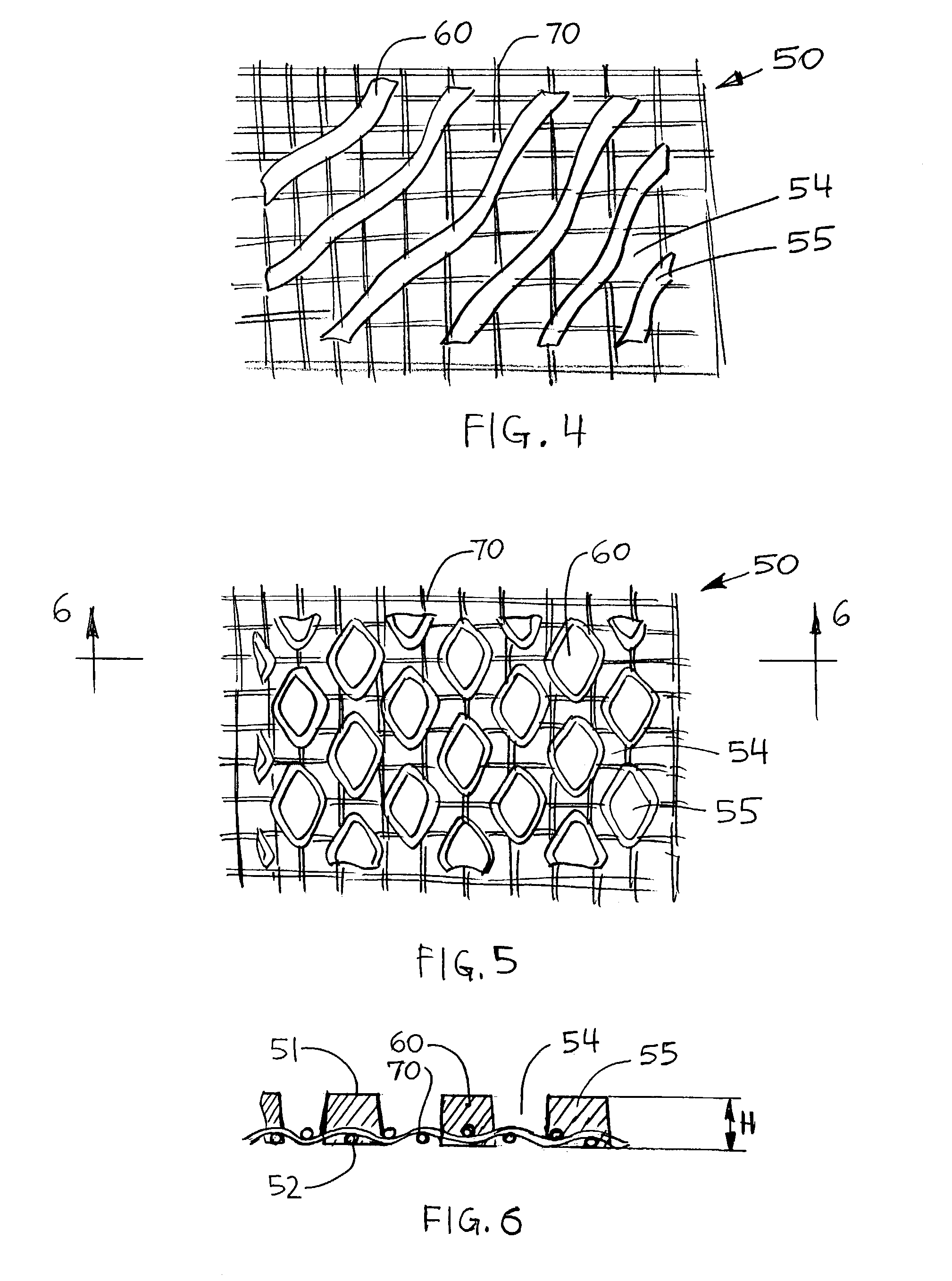

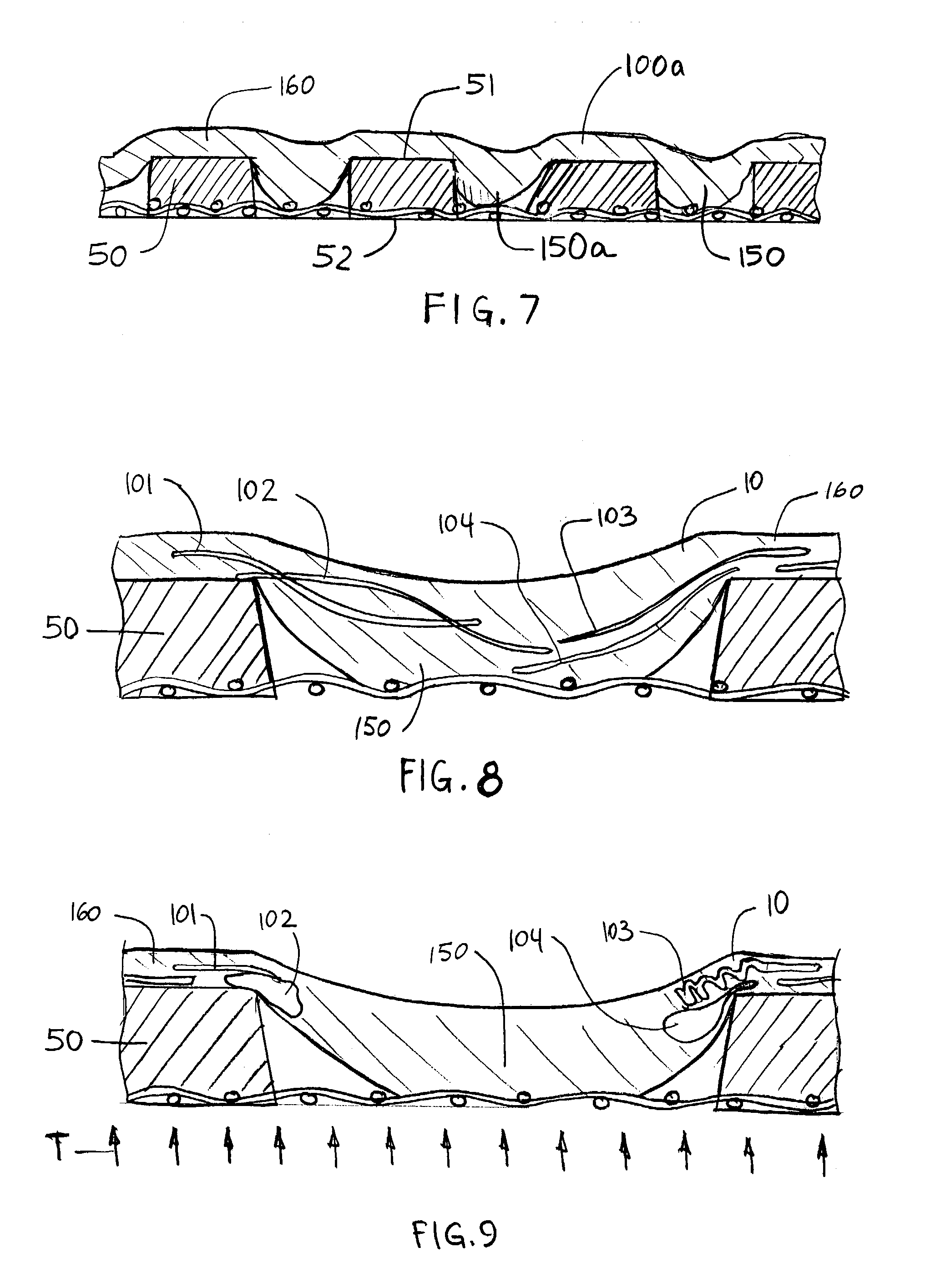

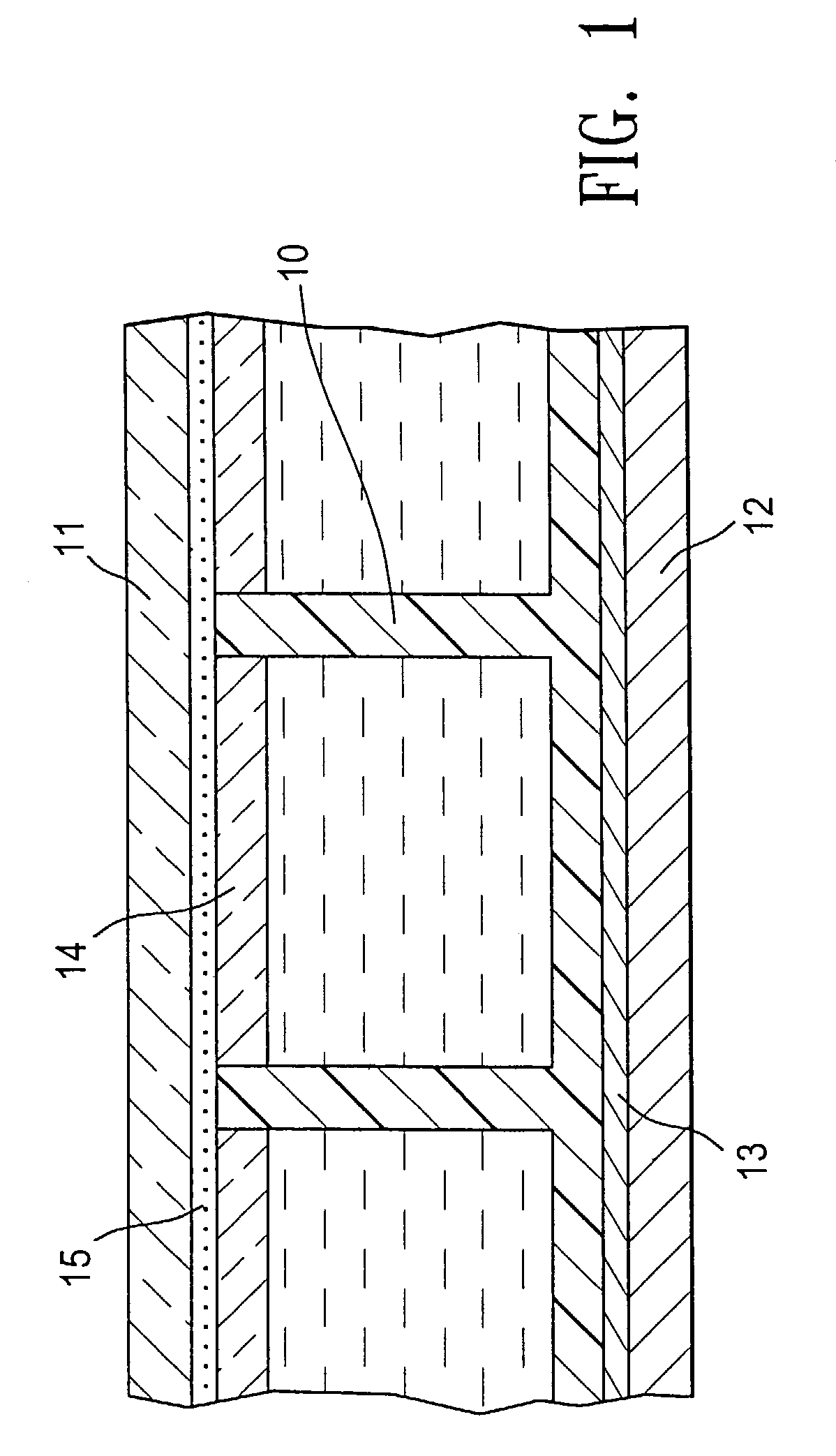

Process for making unitary fibrous structure comprising randomly distributed cellulosic fibers and non-randomly distributed synthetic fibers

InactiveUS7067038B2High densityNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceRepeat pattern

Owner:THE PROCTER & GAMBLE COMPANY

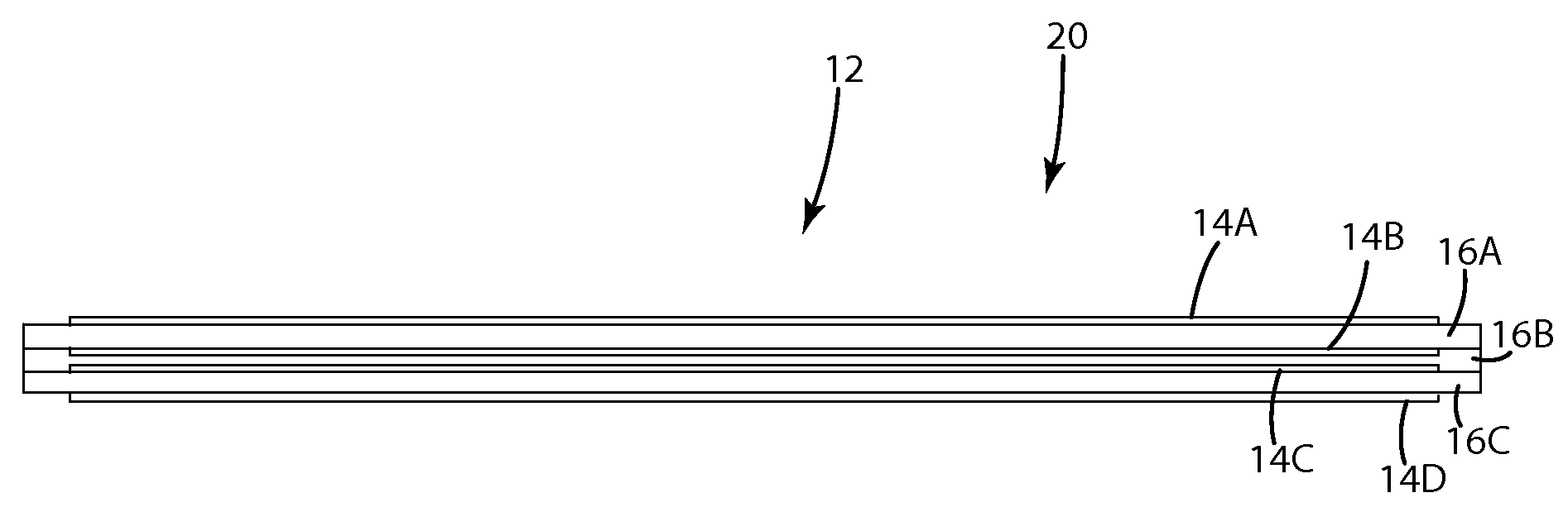

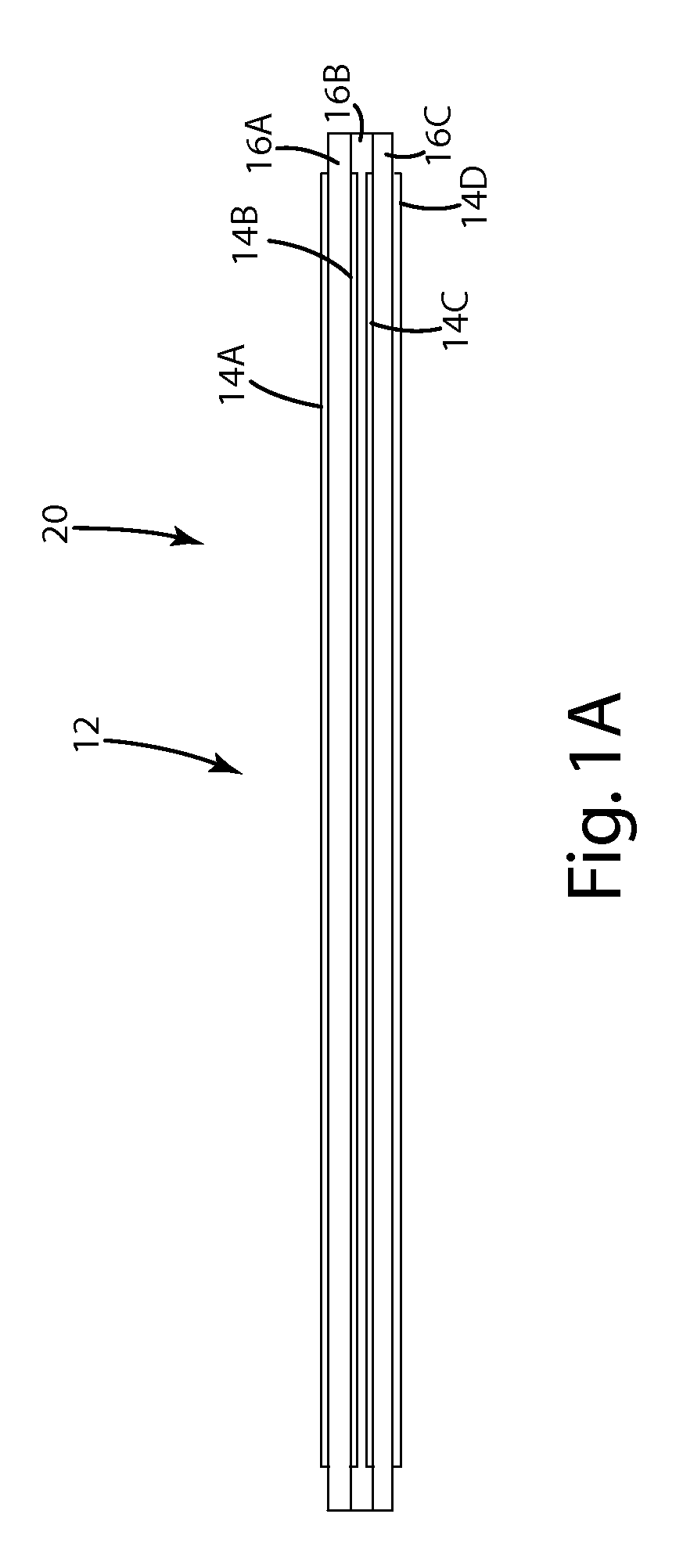

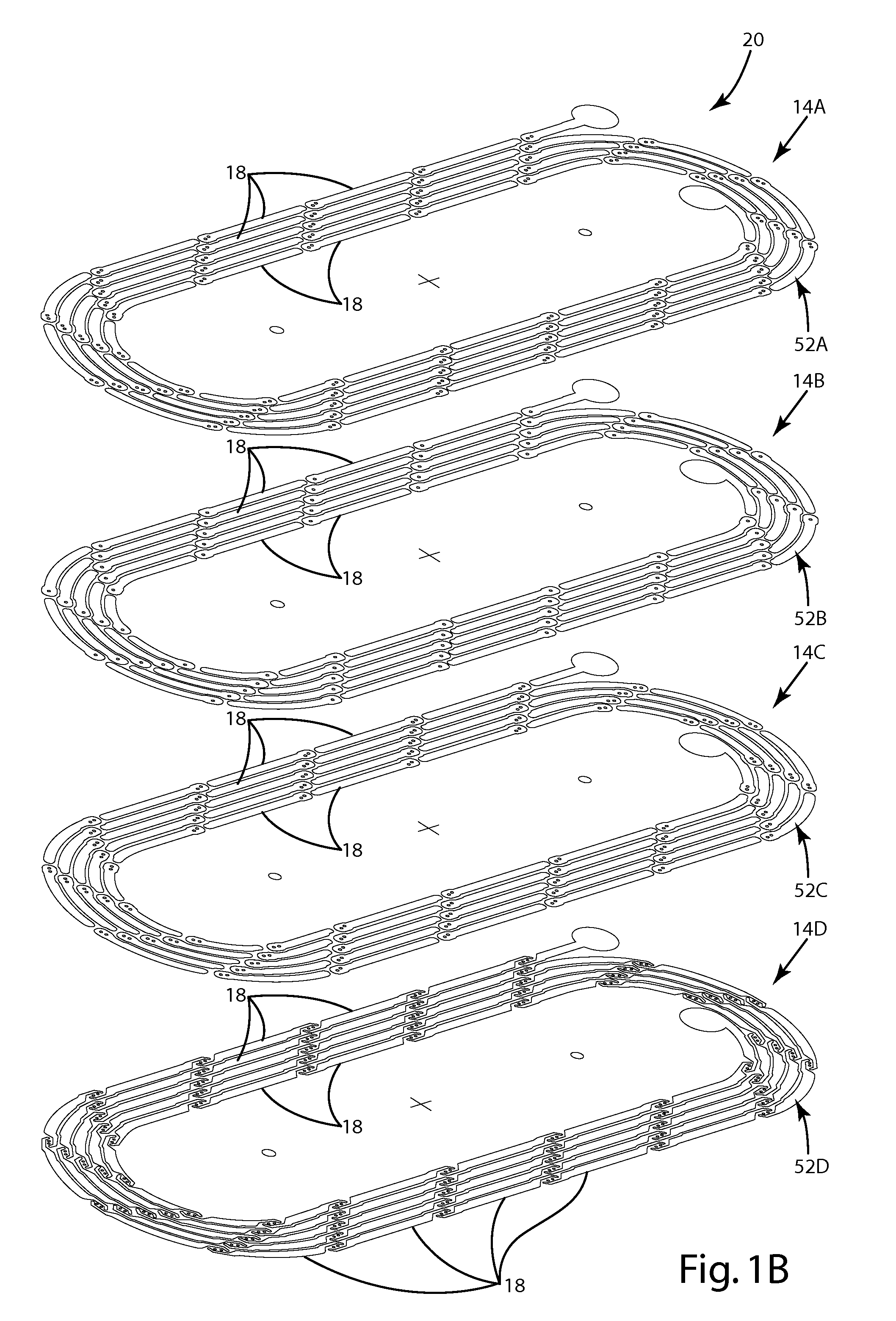

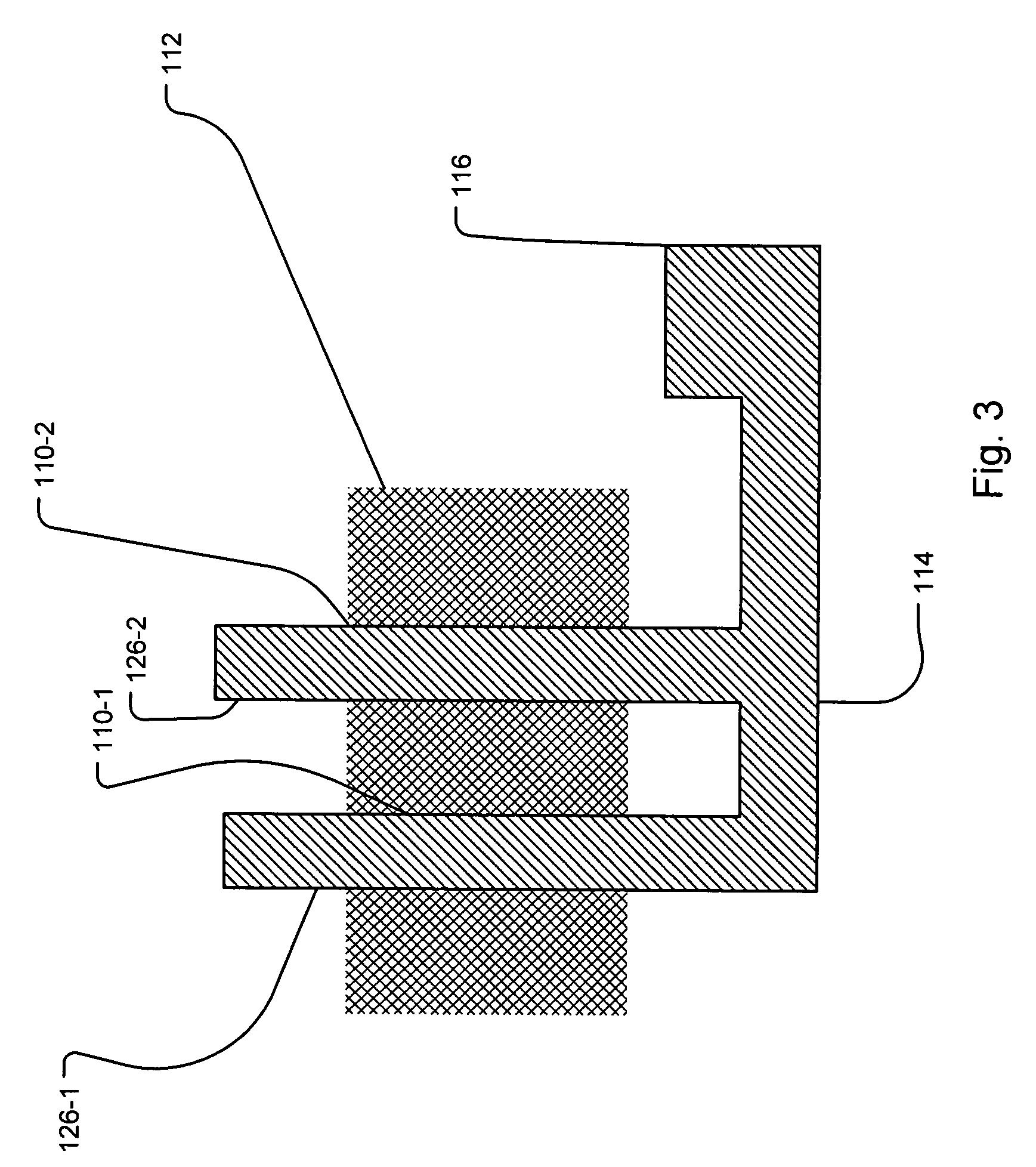

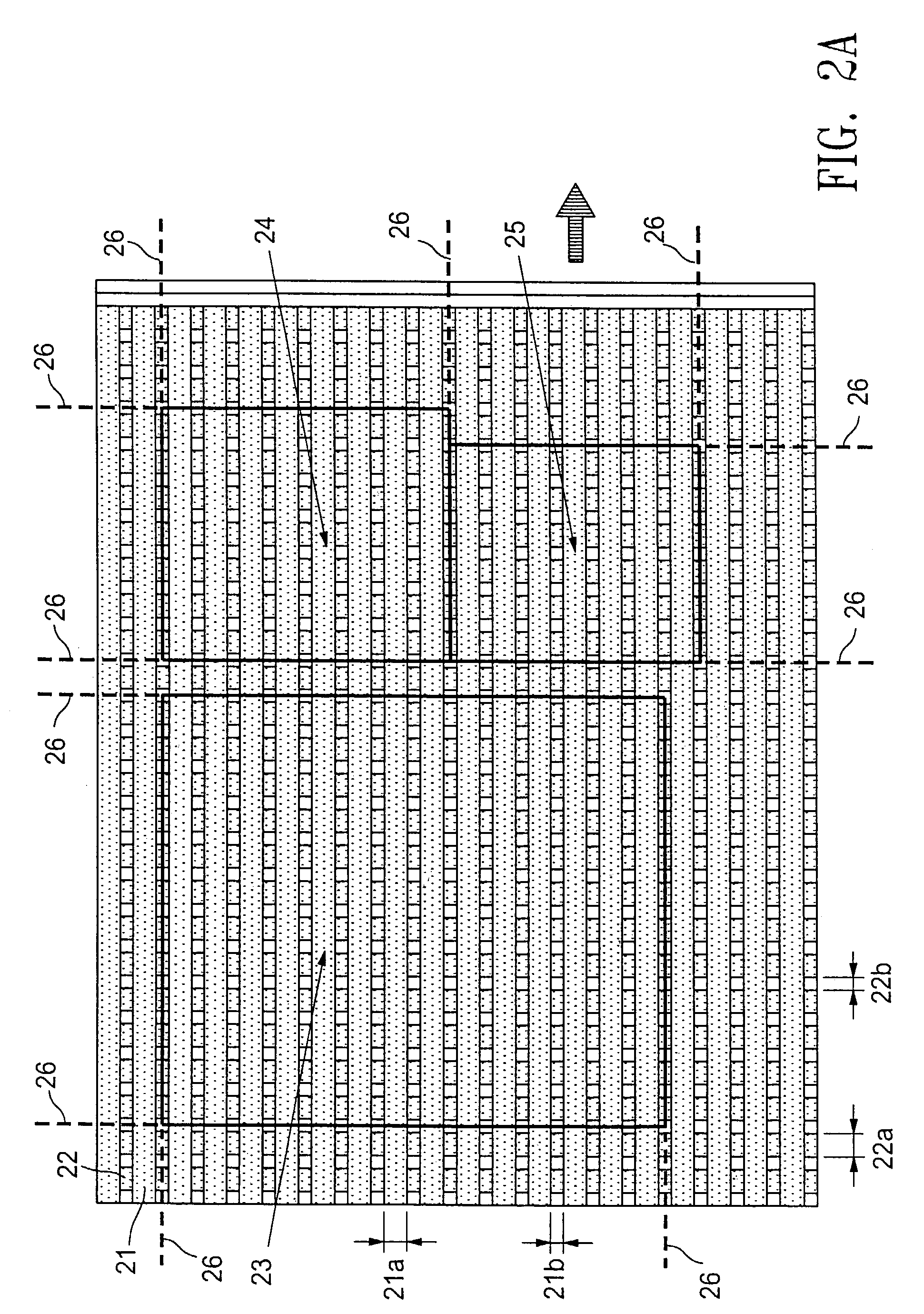

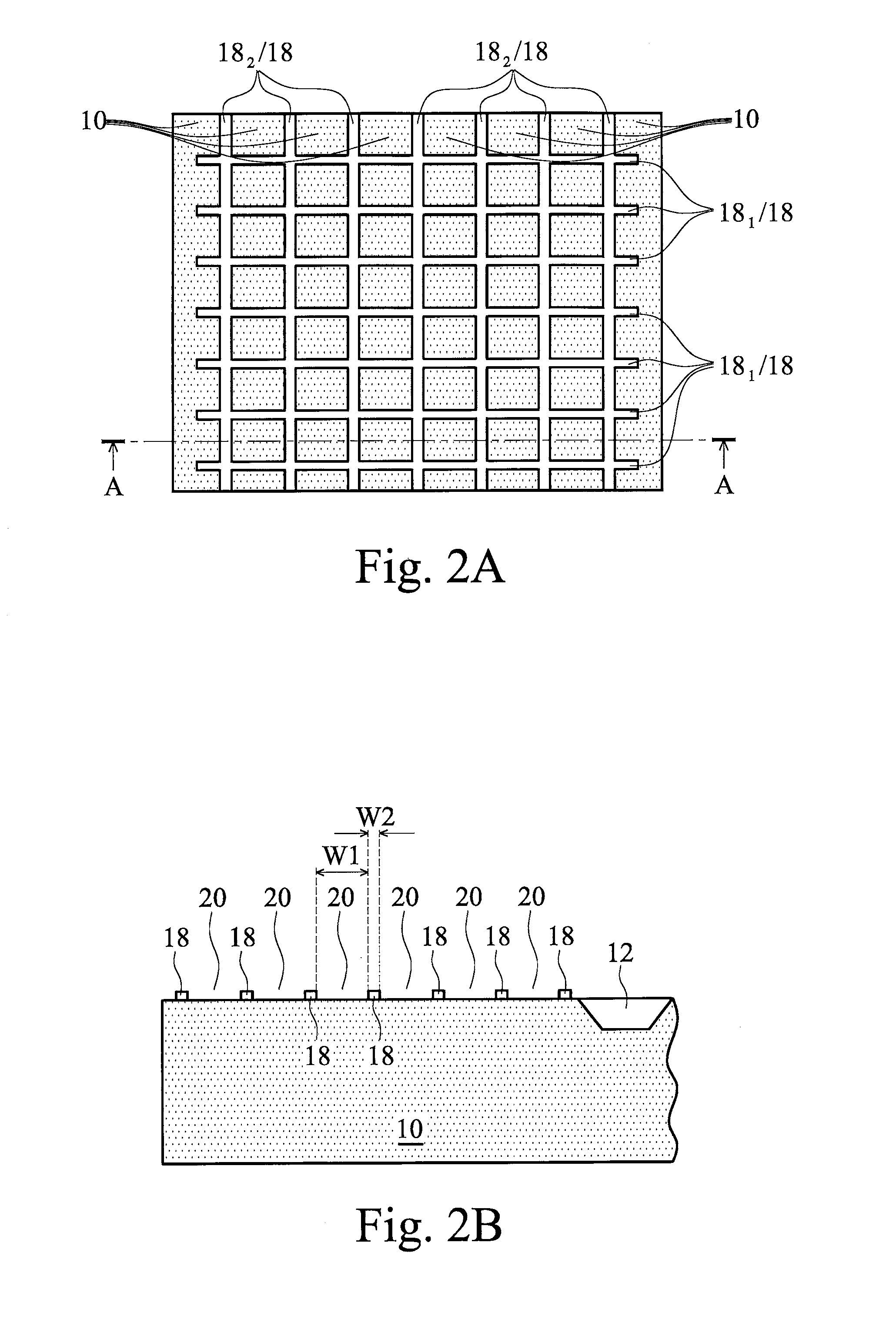

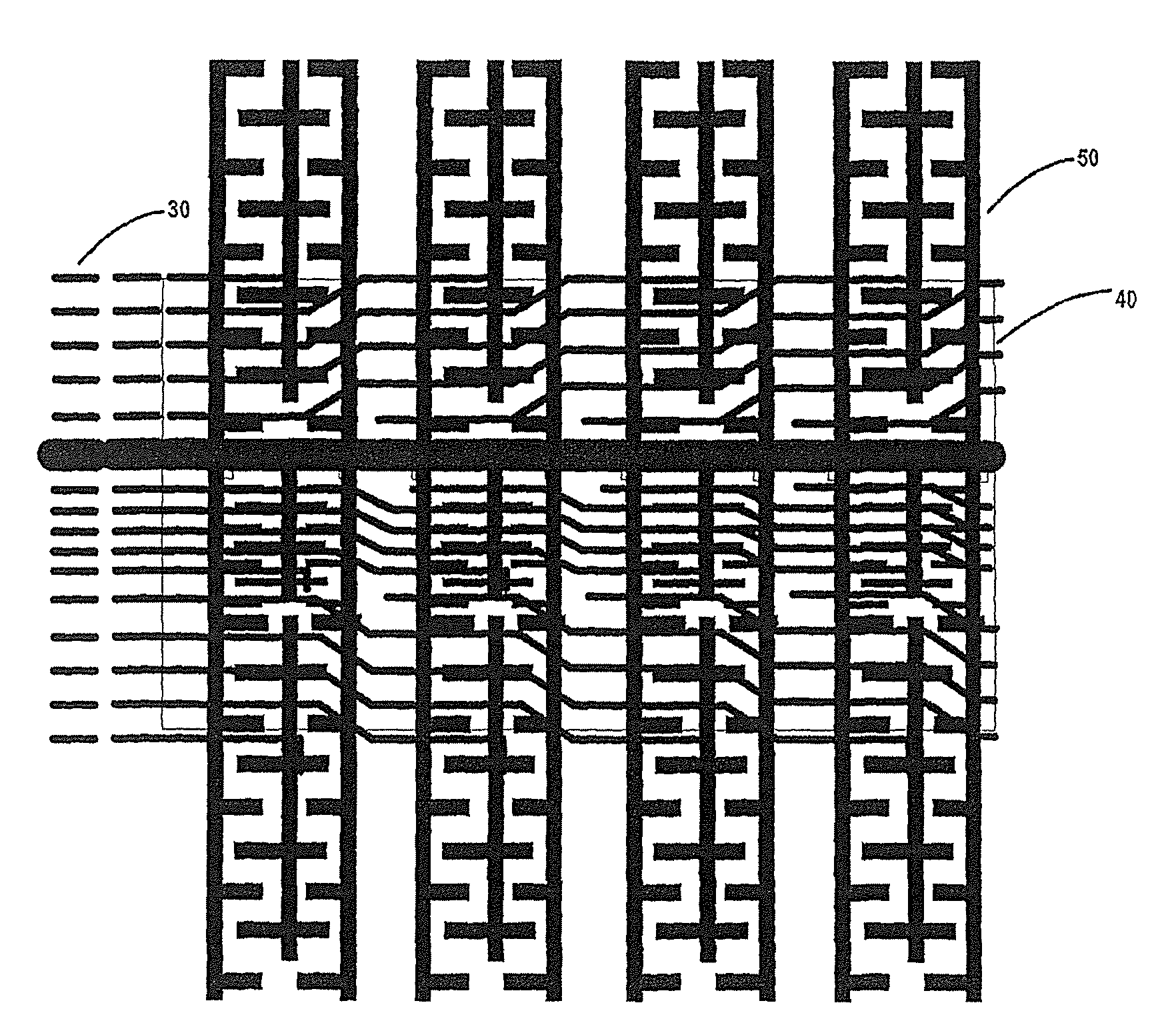

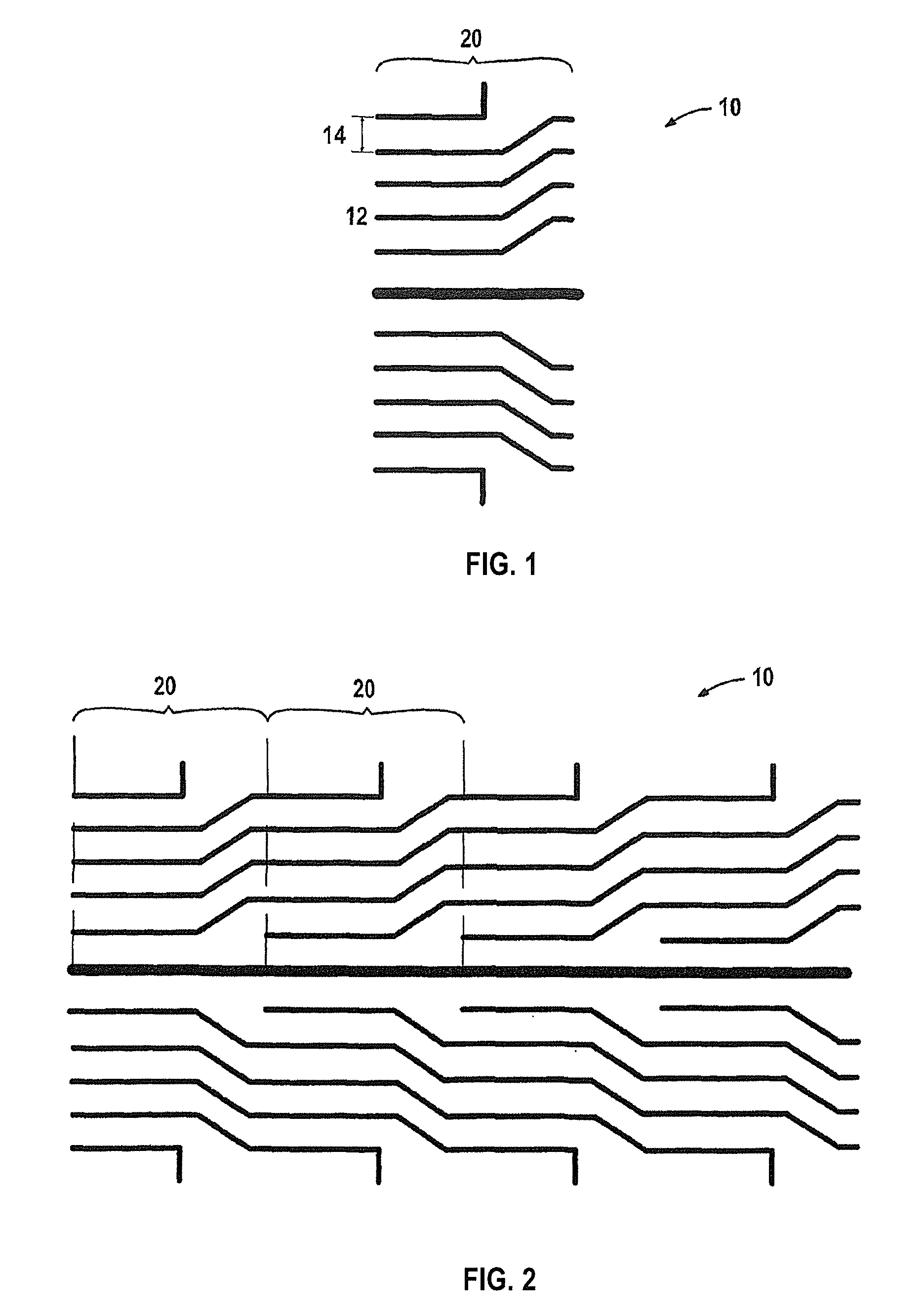

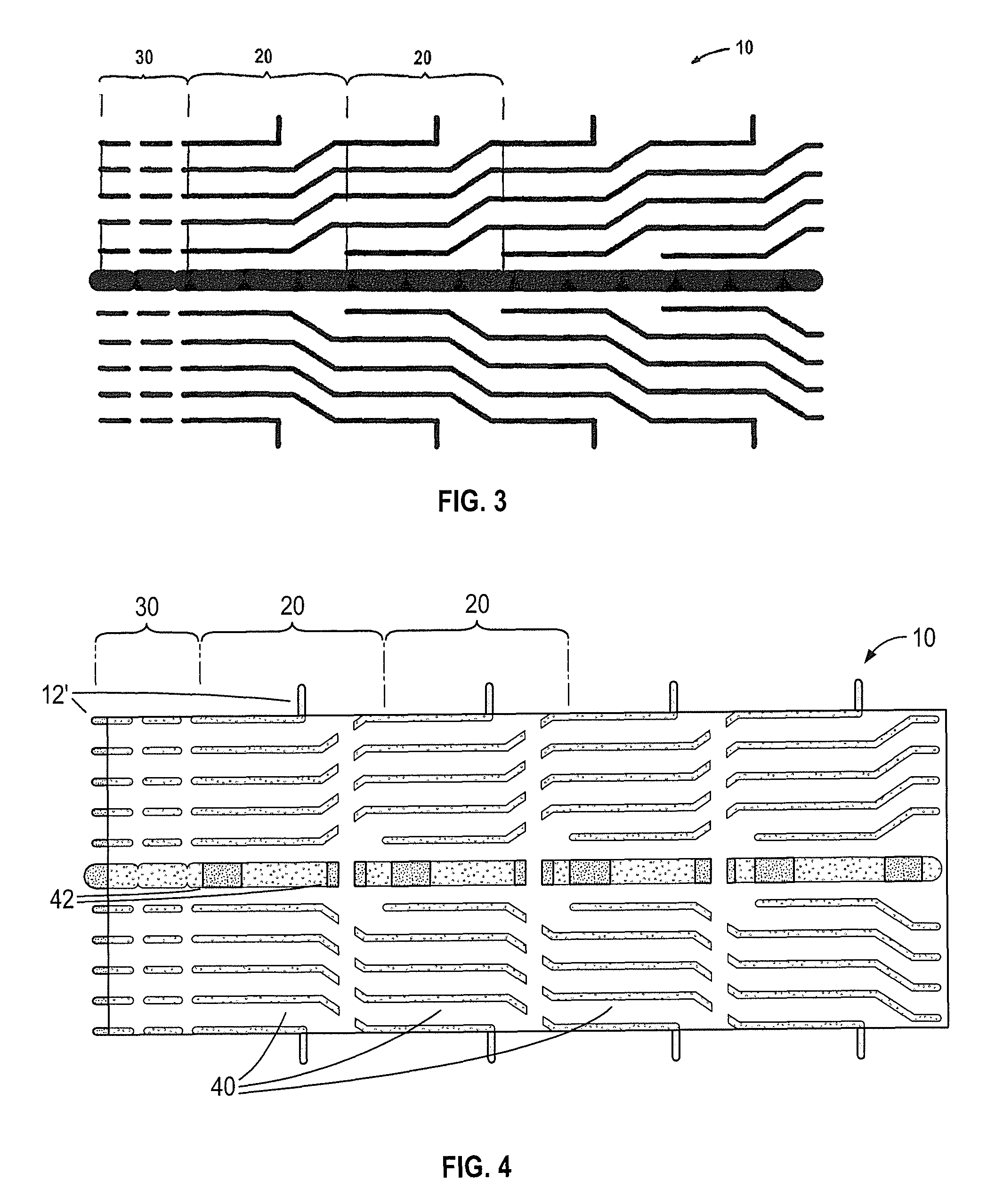

Printed circuit board coil

ActiveUS20090085706A1Reduce skin effectReduce lossTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

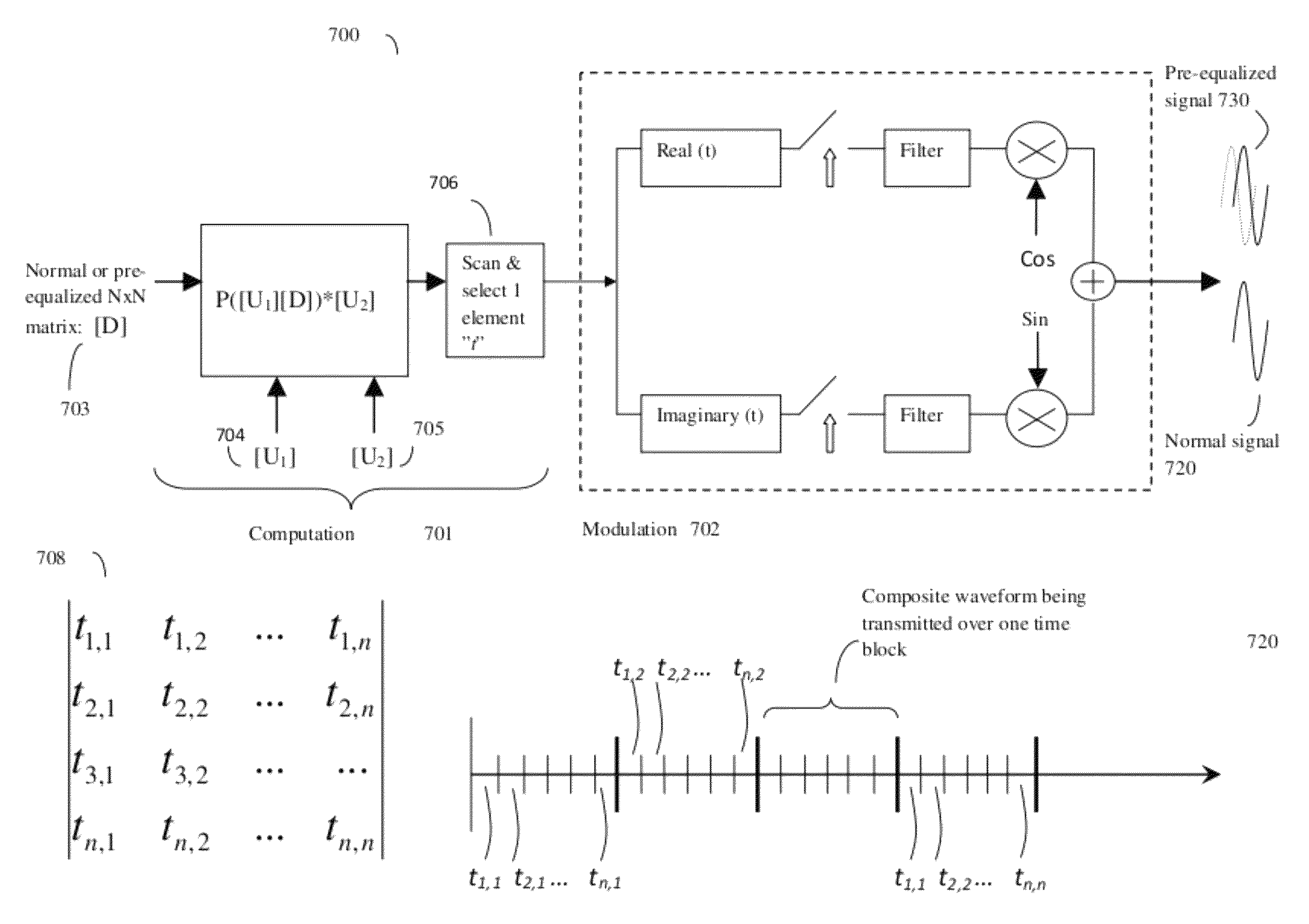

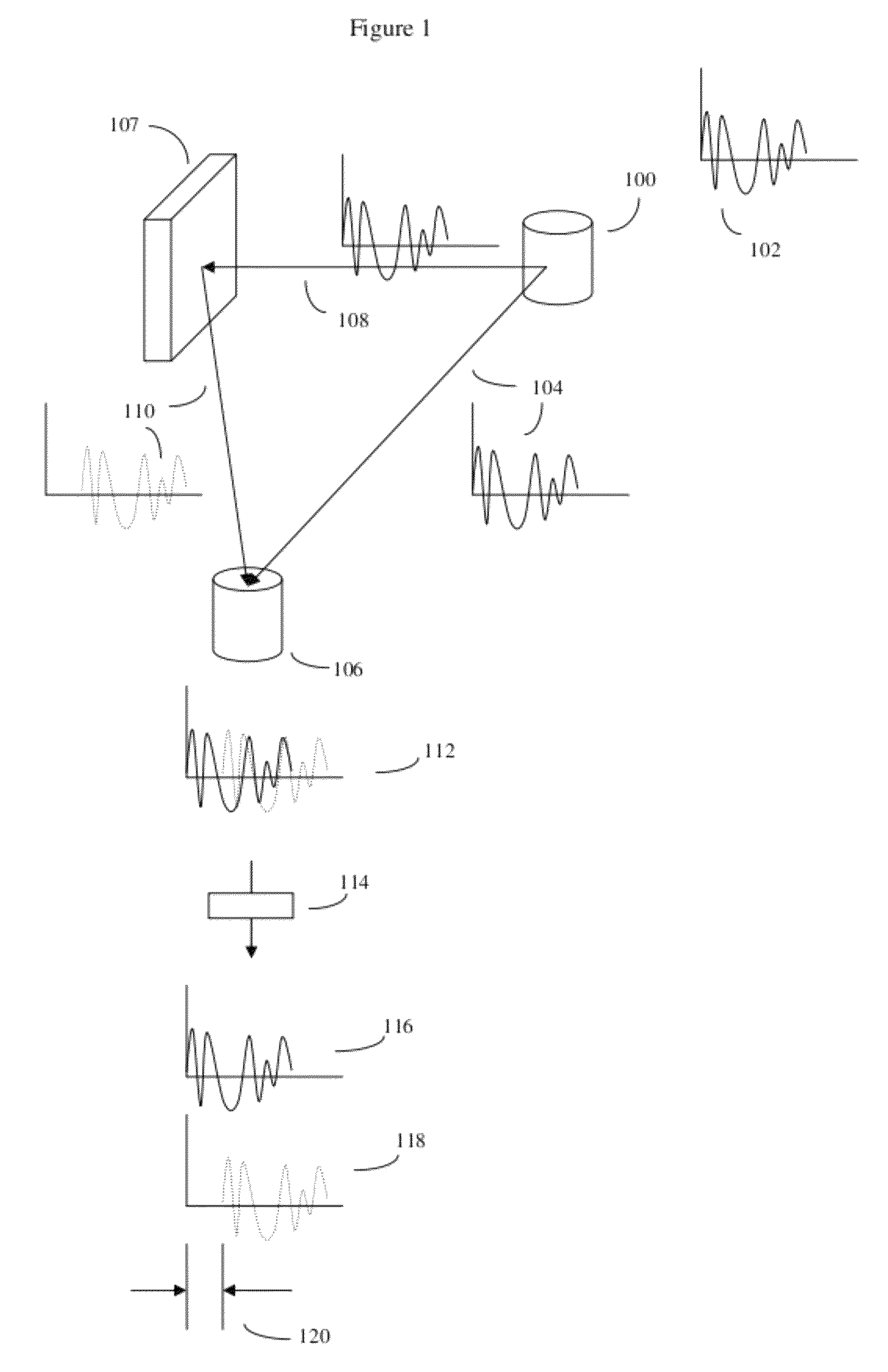

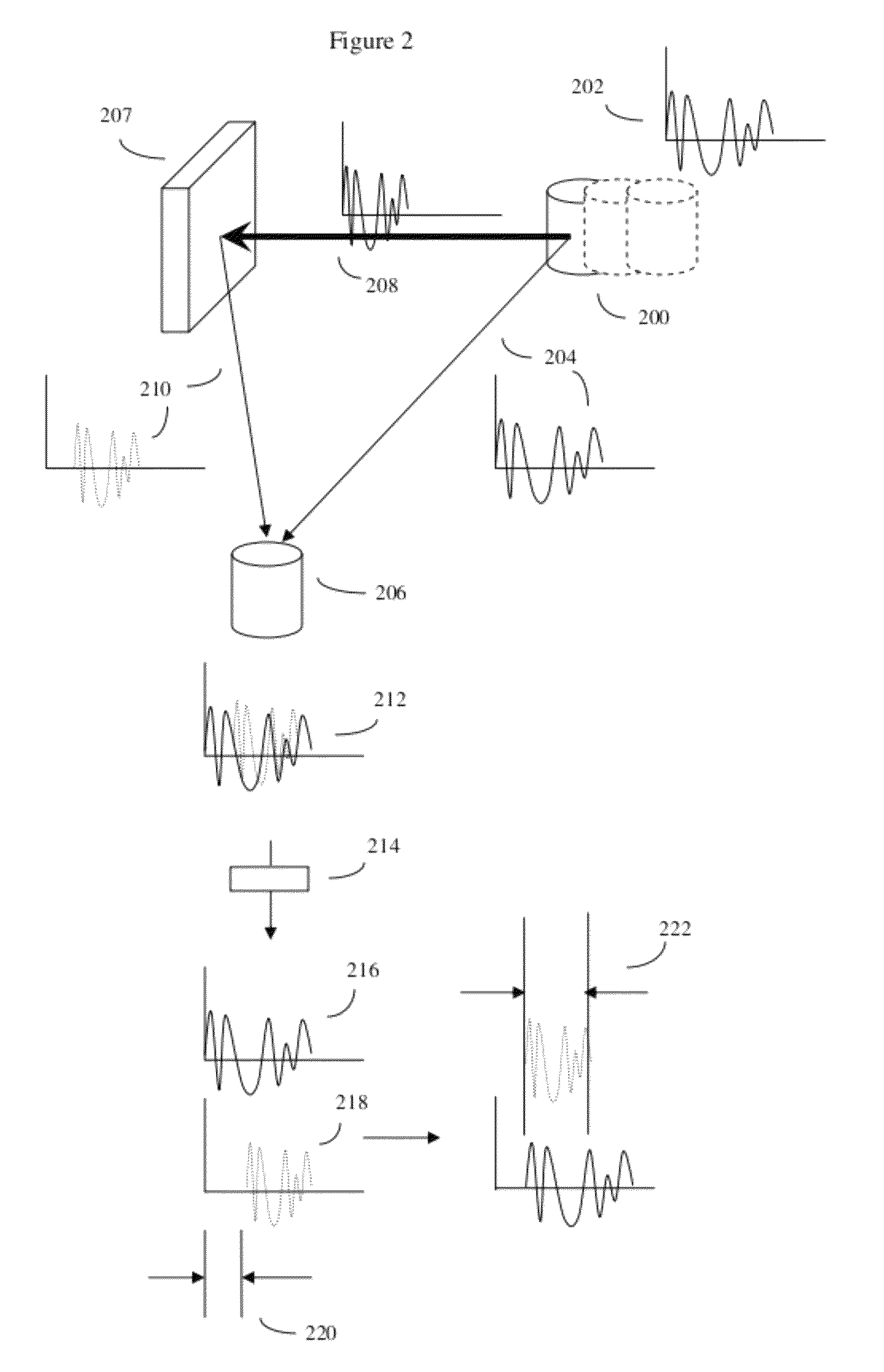

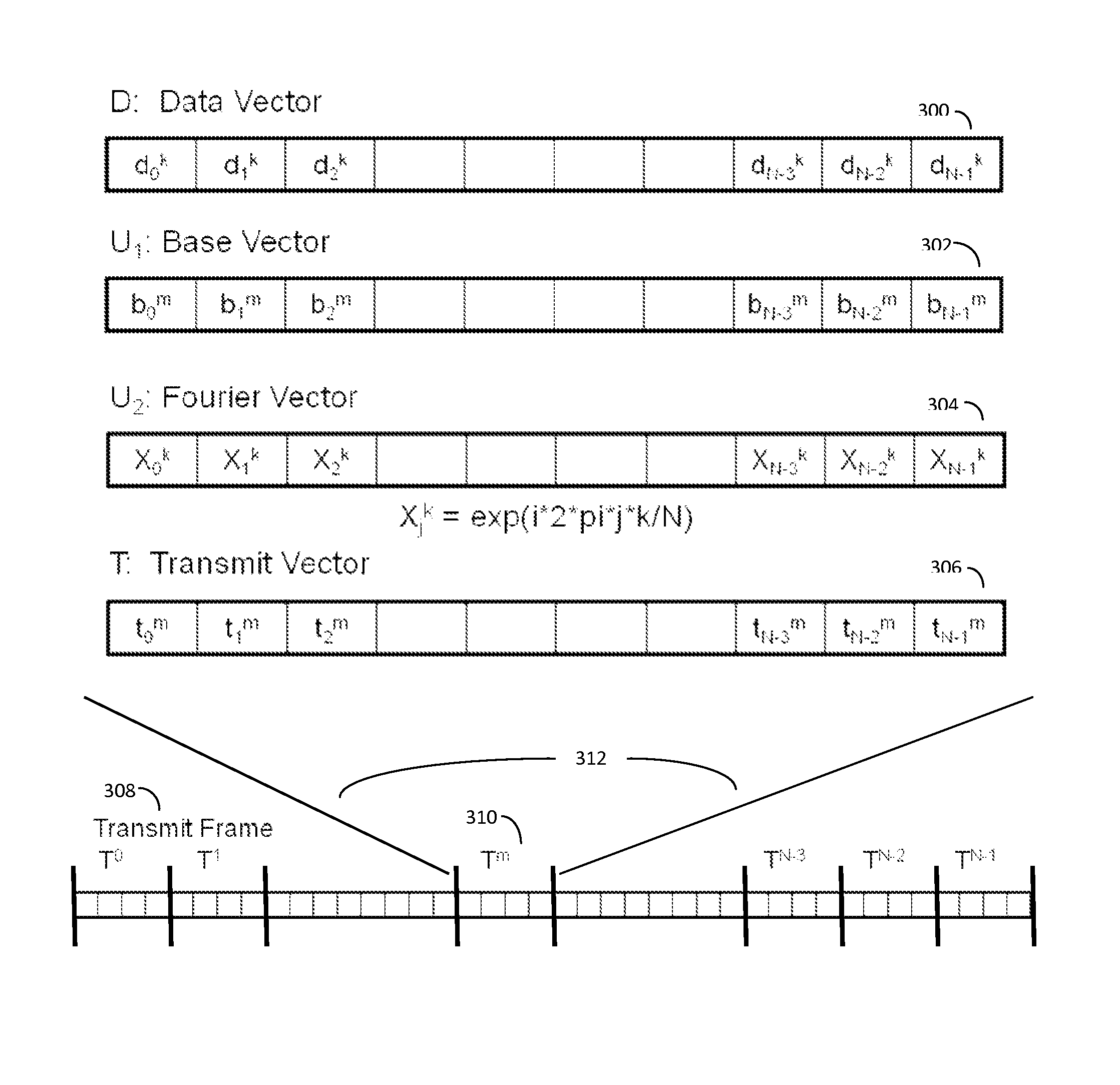

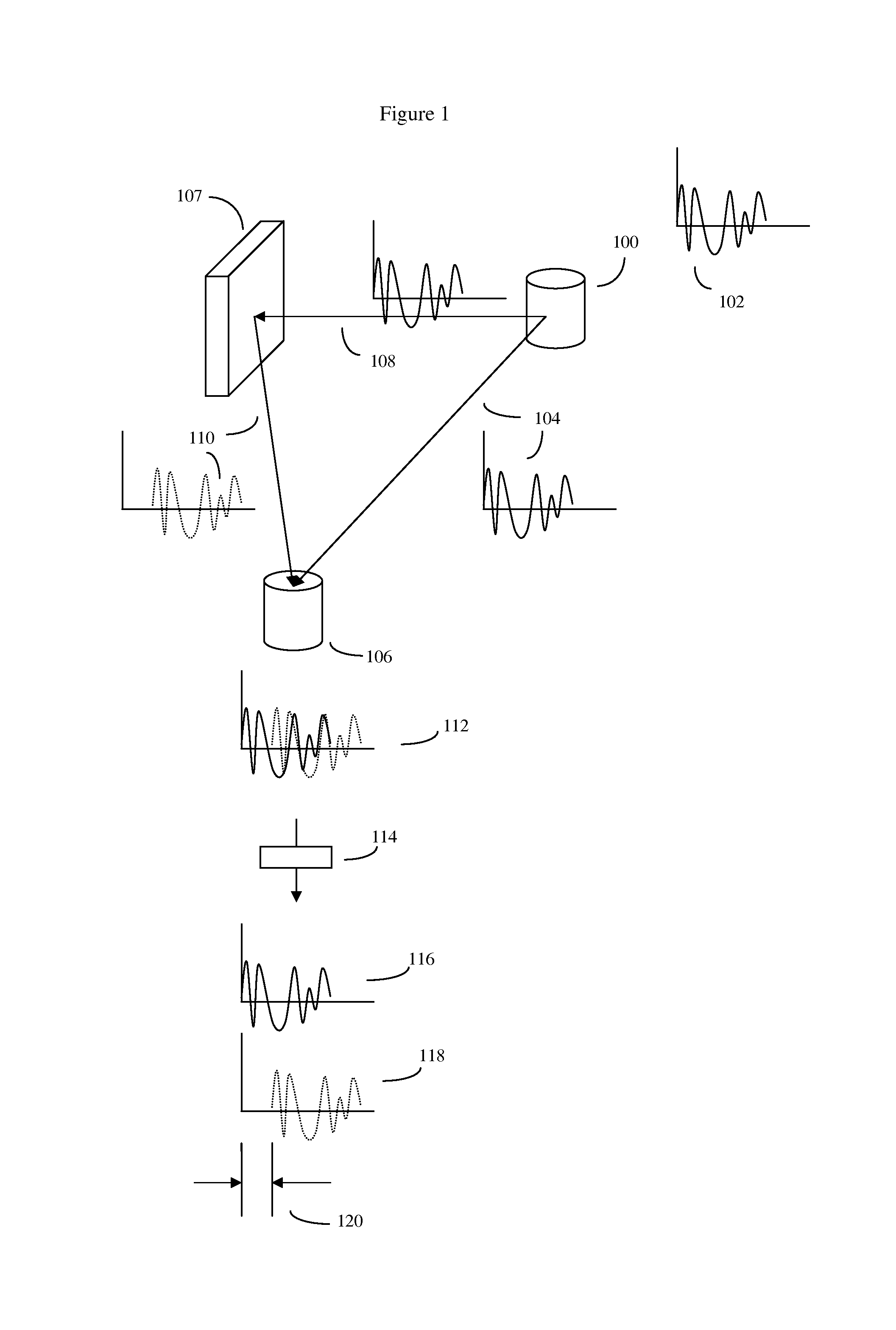

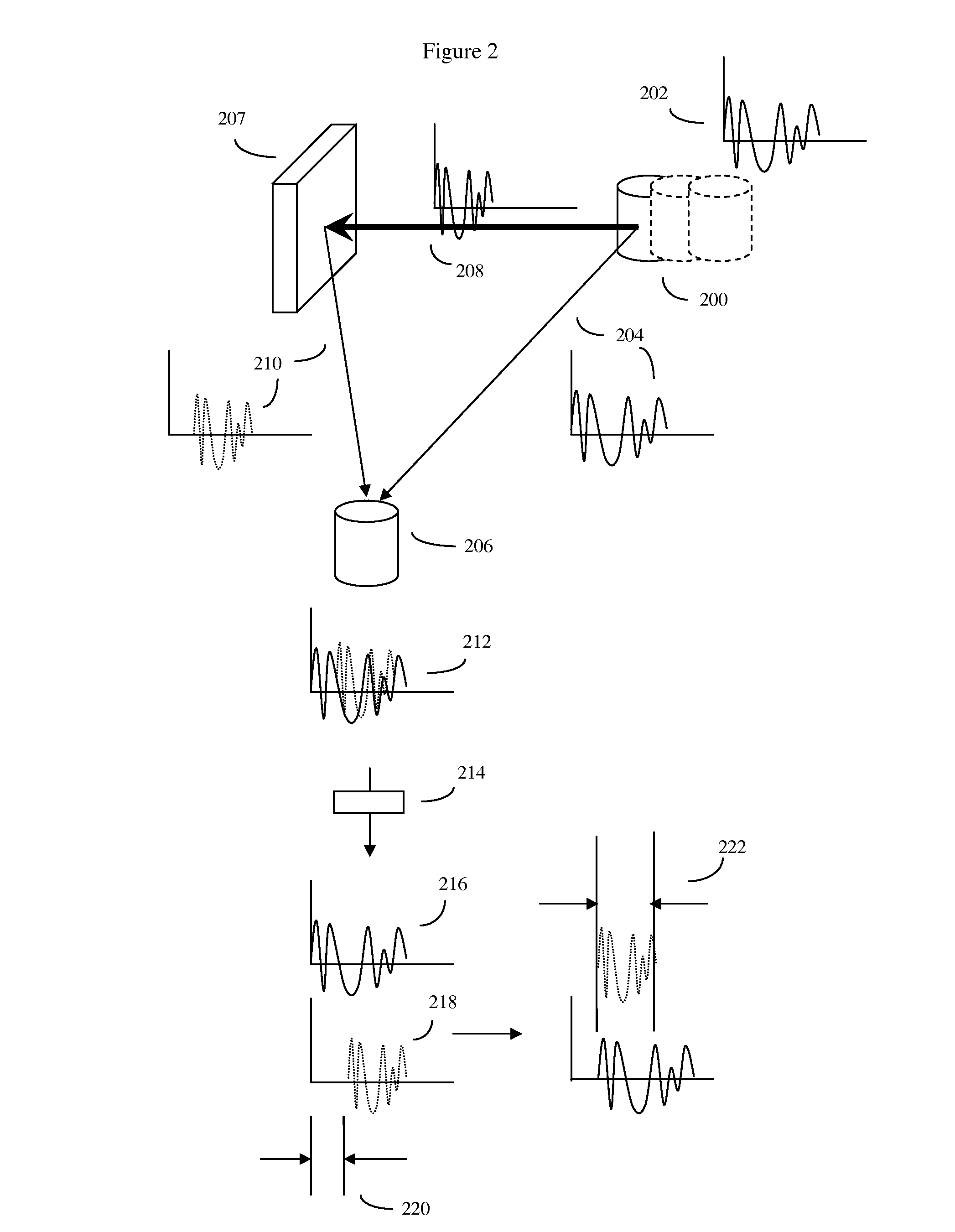

Signal modulation method resistant to echo reflections and frequency offsets

ActiveUS9083595B2Improve performancePromote decompositionNetwork traffic/resource managementMulti-frequency code systemsHigh rateEngineering

A method of modulating communications signals, such as optical fiber, wired electronic, or wireless signals in a manner that facilitates automatic correction for the signal distortion effects of echoes and frequency shifts, while still allowing high rates of data transmission. Data symbols intended for transmission are distributed into N×N matrices, and used to weigh or modulate a family of cyclically time shifted and cyclically frequency shifted waveforms. Although these waveforms may then be distorted during transmission, their basic cyclic time and frequency repeating structure facilitates use of improved receivers with deconvolution devices that can utilize the repeating patterns to correct for these distortions. The various waveforms may be sent in N time blocks at various time spacing and frequency spacing combinations in a manner that can allow interleaving of blocks from different transmitters. Applications to channel sounding / characterization, system optimization, and also radar are also discussed.

Owner:COHERE TECH

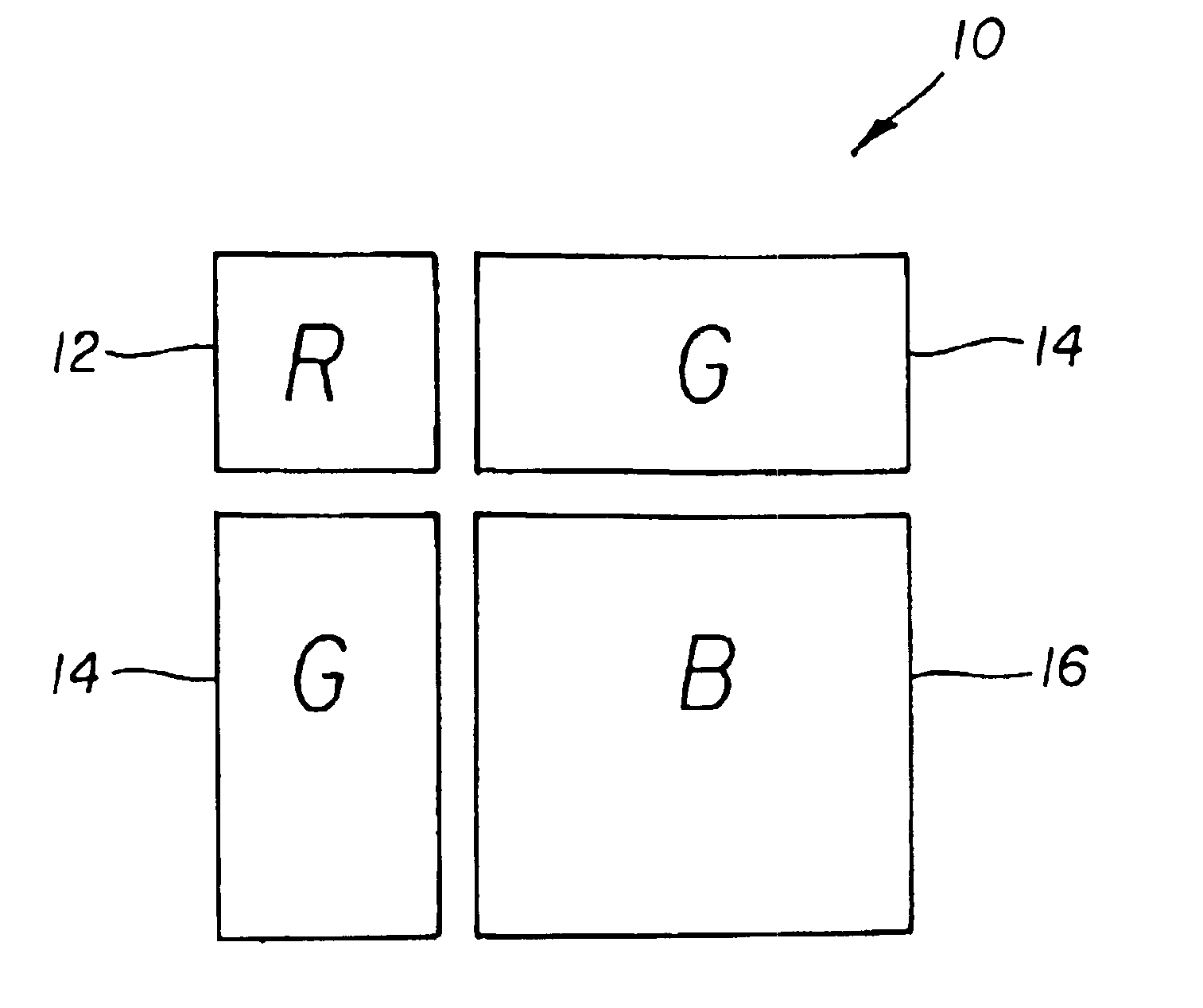

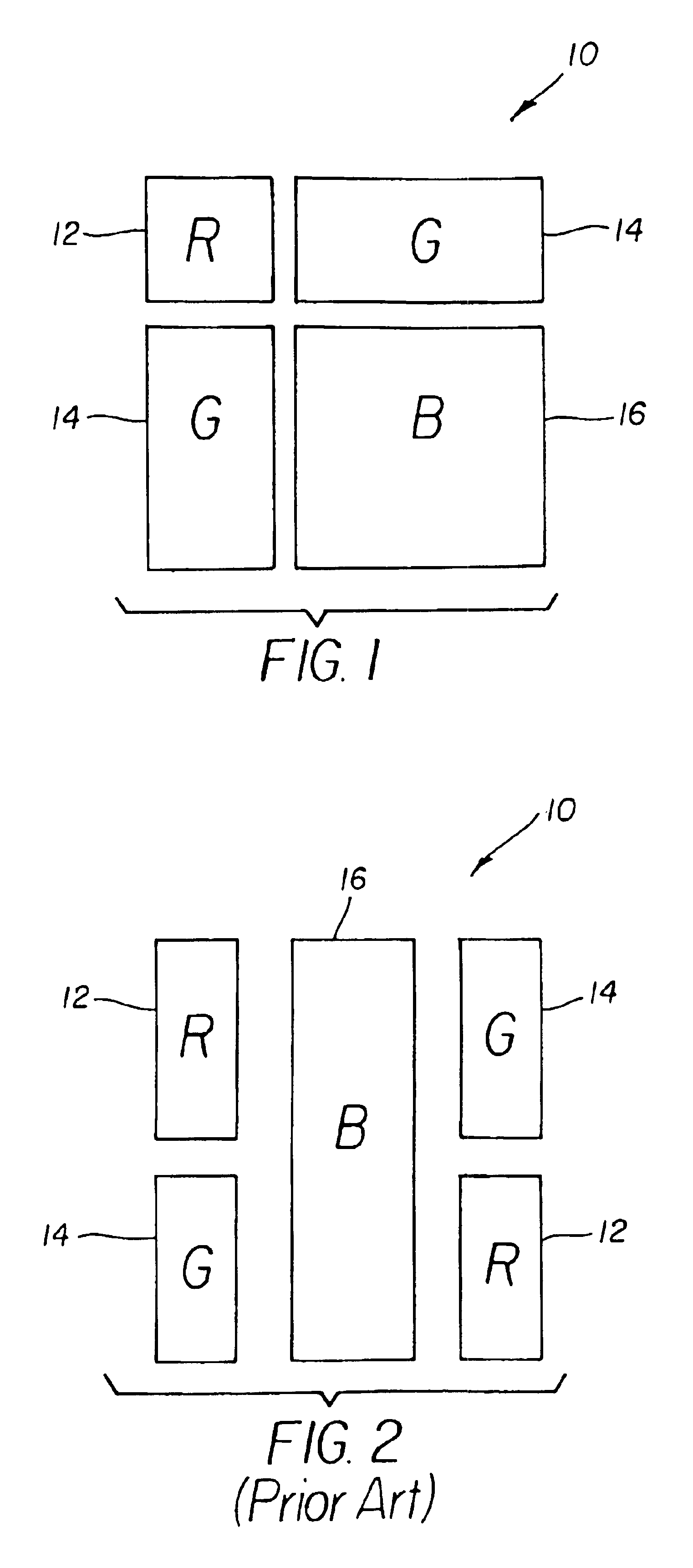

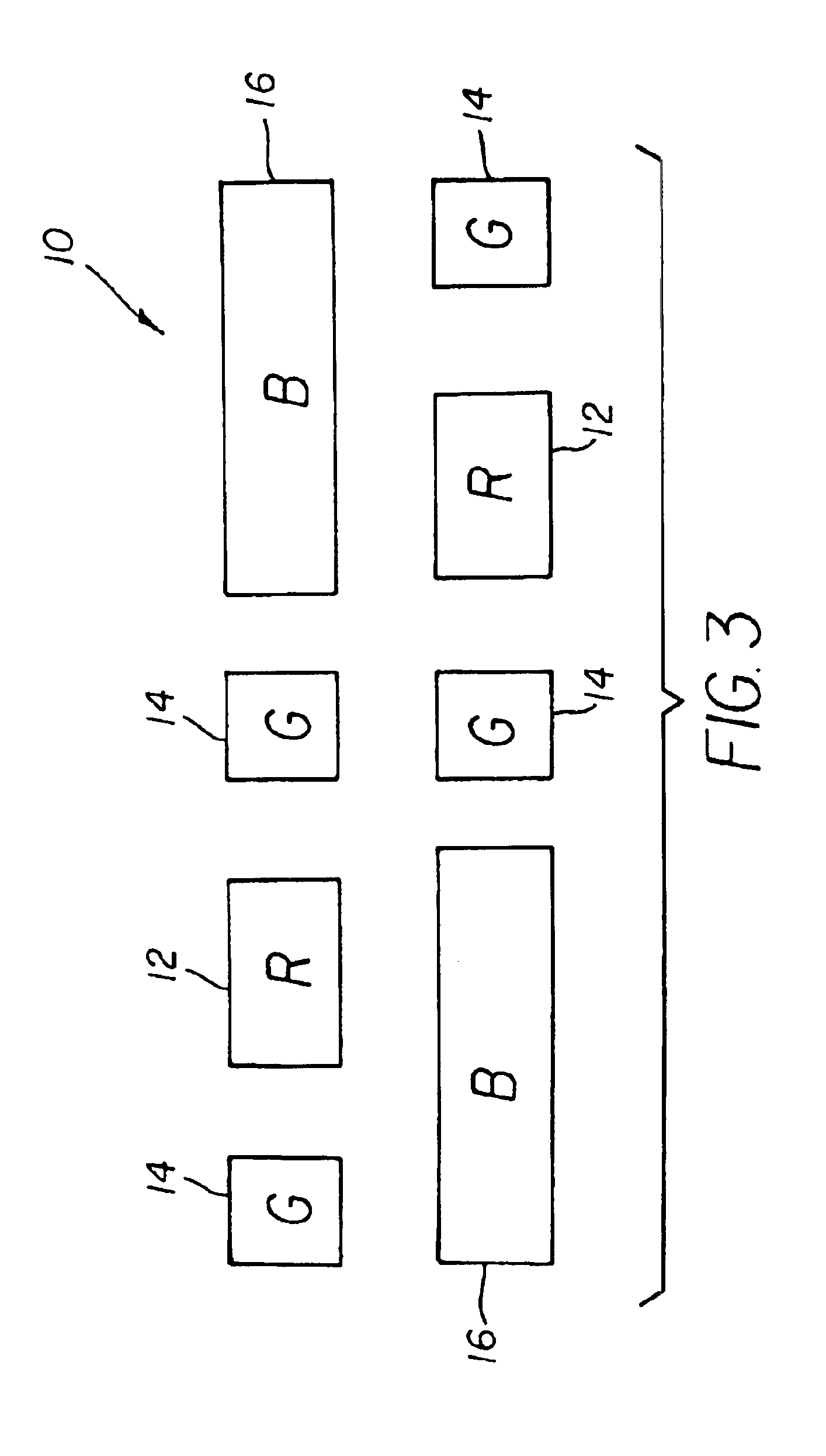

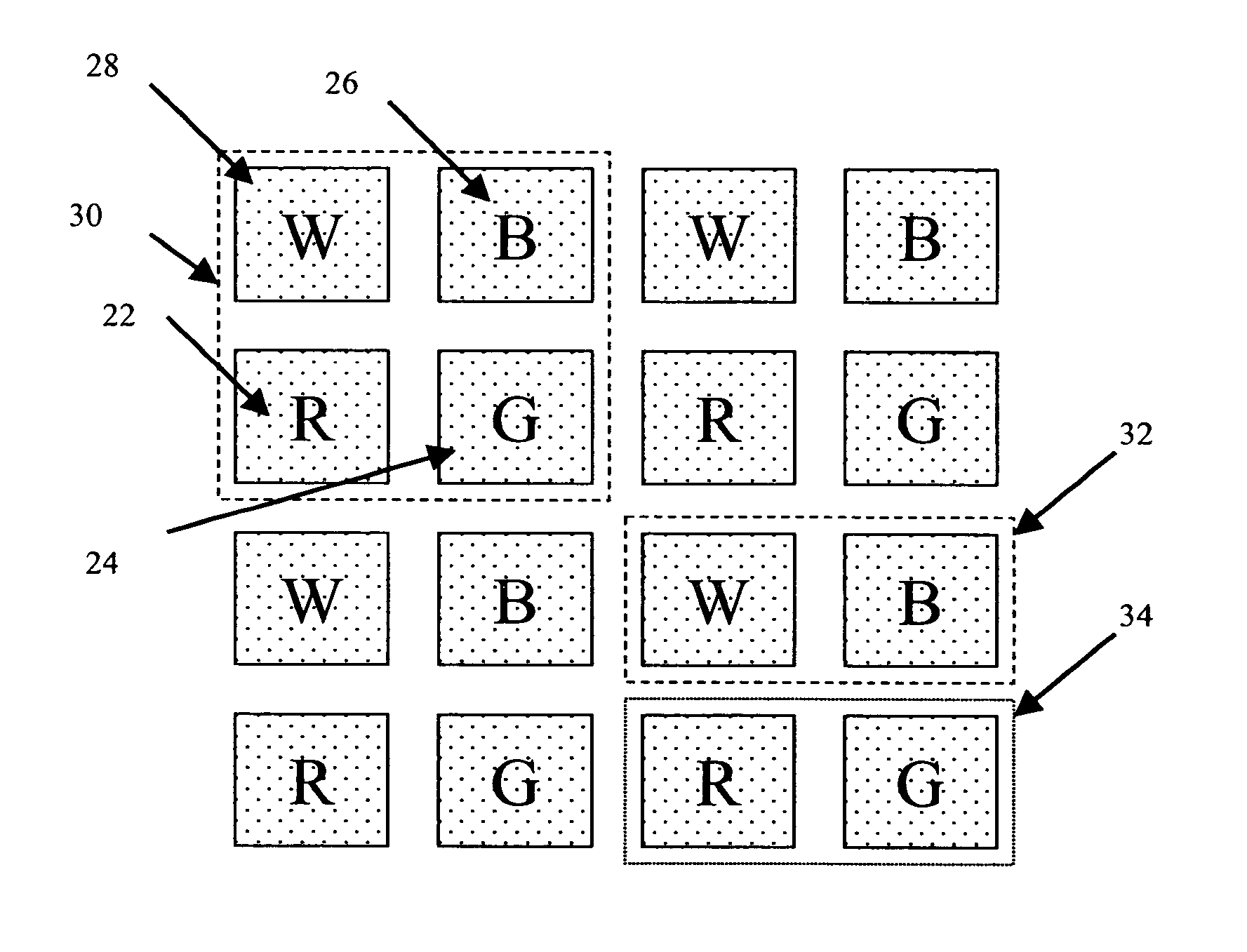

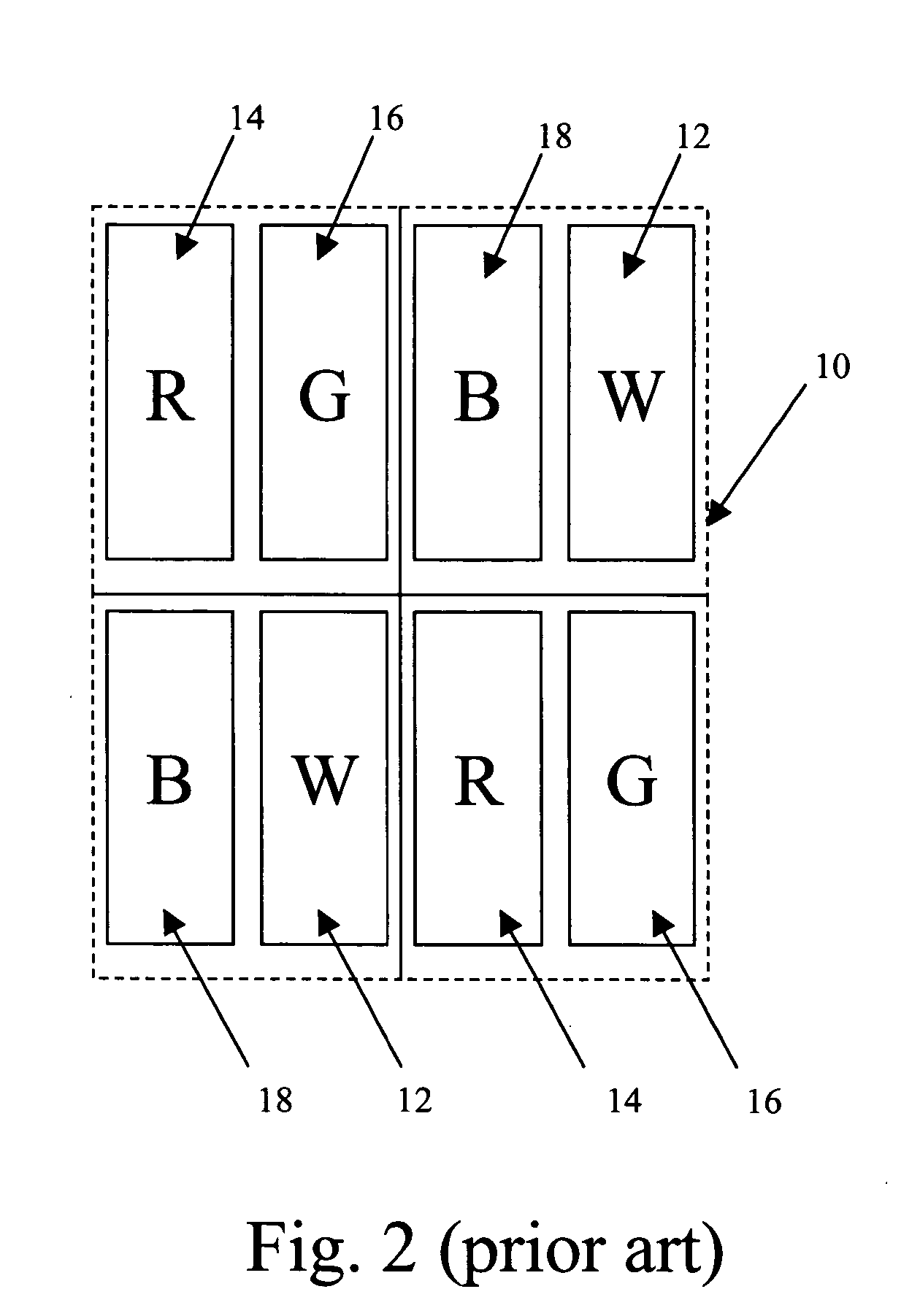

Color OLED display having repeated patterns of colored light emitting elements

InactiveUS6867549B2Improve power efficiencyImprove resolutionElectroluminescent light sourcesSolid-state devicesColor imageRepeat pattern

An OLED display device for displaying a color image includes an array of different colored independently controllable light emitting elements arranged in repeated patterns, a number of light emitting elements of at least one color in each pattern being different than a number of light emitting elements of a different color and the different number of light emitting elements of the different colors being a function of a relative human visual frequency response to the colors, and a relative size of light emitting elements of different colors being a function of a lifetime of the light emitting elements, an efficiency of the light emitting elements, and the number of light emitting elements of the different colors in the pattern, wherein at least one of the lifetime, and the efficiency is different for different colors.

Owner:GLOBAL OLED TECH

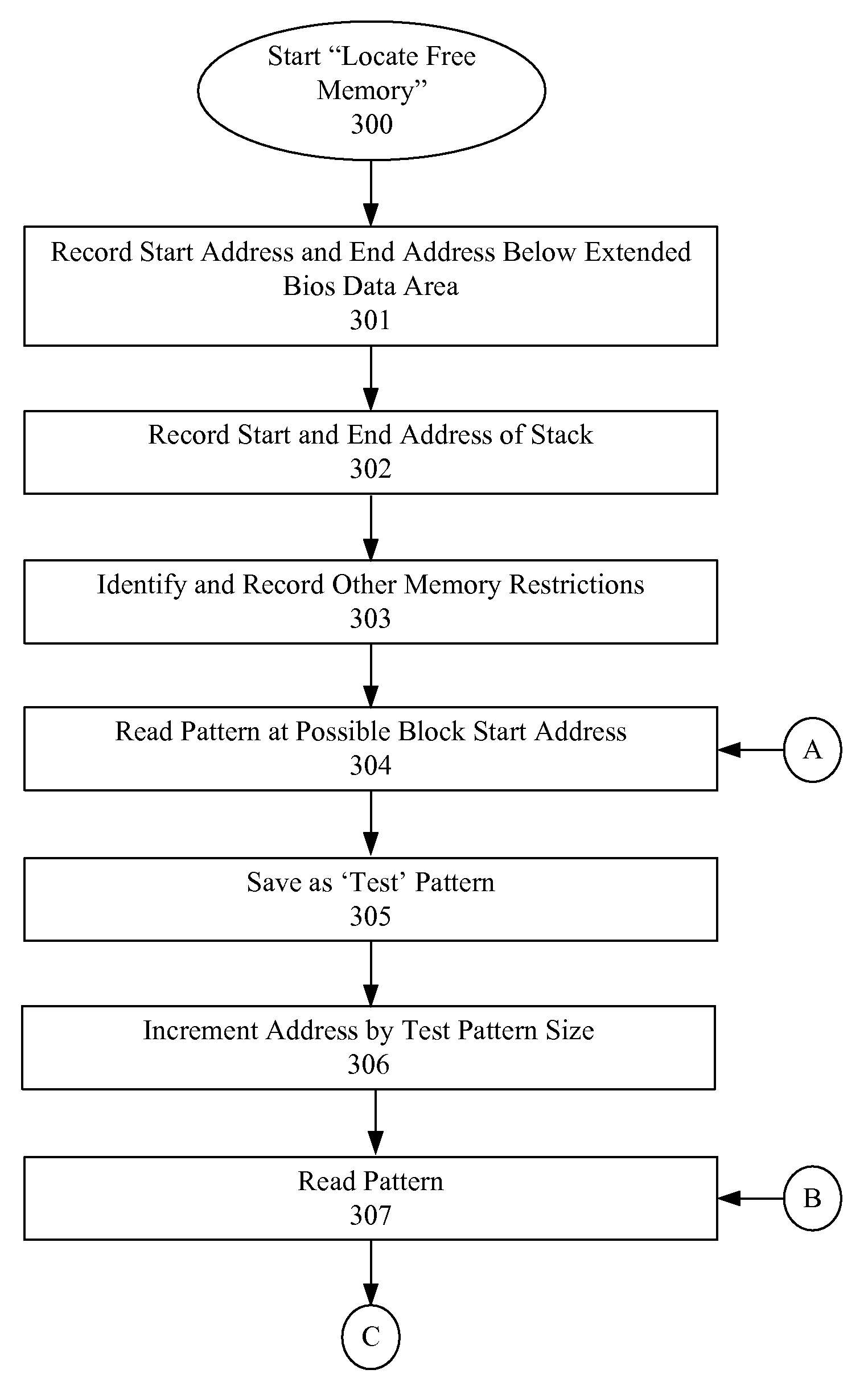

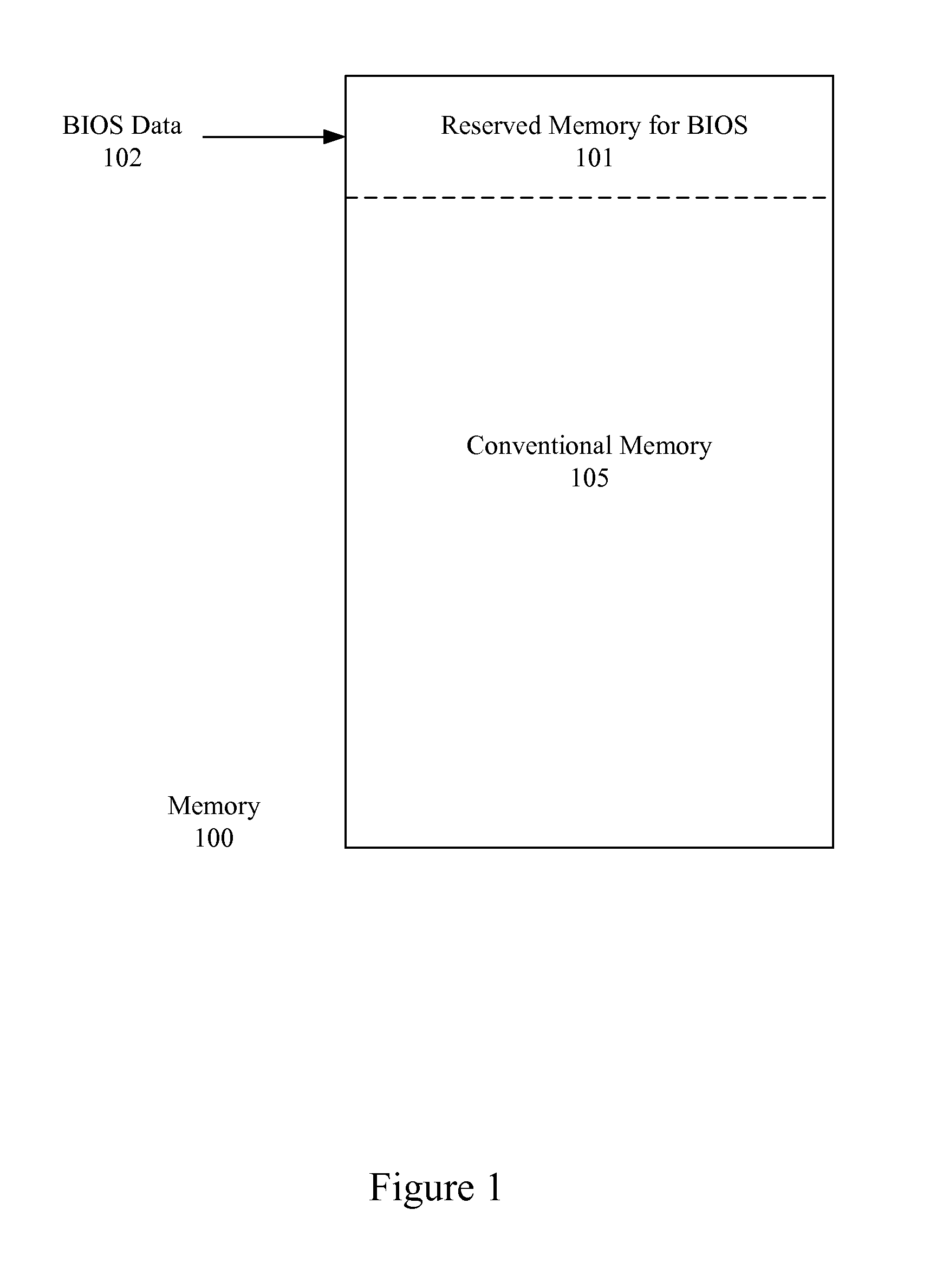

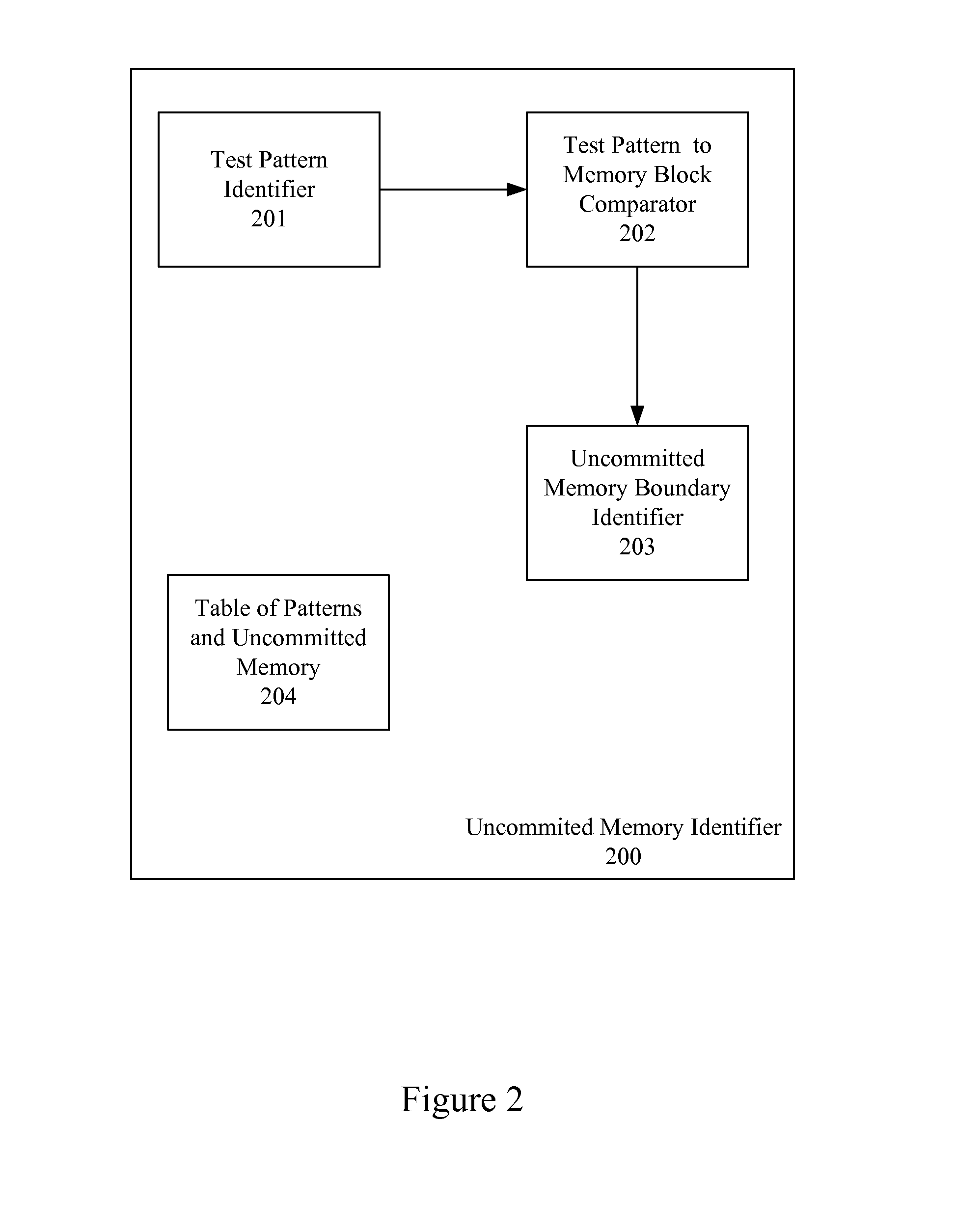

Identification of Uncommitted Memory Blocks During an Initialization Procedure

InactiveUS20080065852A1Easy to useDigital computer detailsProgram controlConventional memoryOption ROM

An apparatus and method are described for identifying uncommitted memory in a system RAM during an initialization process of a computer system, such as a boot procedure or power-on self test, during which memory management is uncontrolled. In various embodiments of the invention, repeating patterns that are indicative of uncommitted memory blocks are identified within a conventional memory area of the system RAM. At least some of the uncommitted memory blocks are allocated for use by an option ROM or other BIOS data and a table is created identifying these uncommitted memory blocks. After the BIOS code exits the system RAM, the table is used to restore the uncommitted memory blocks into their previous data states.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

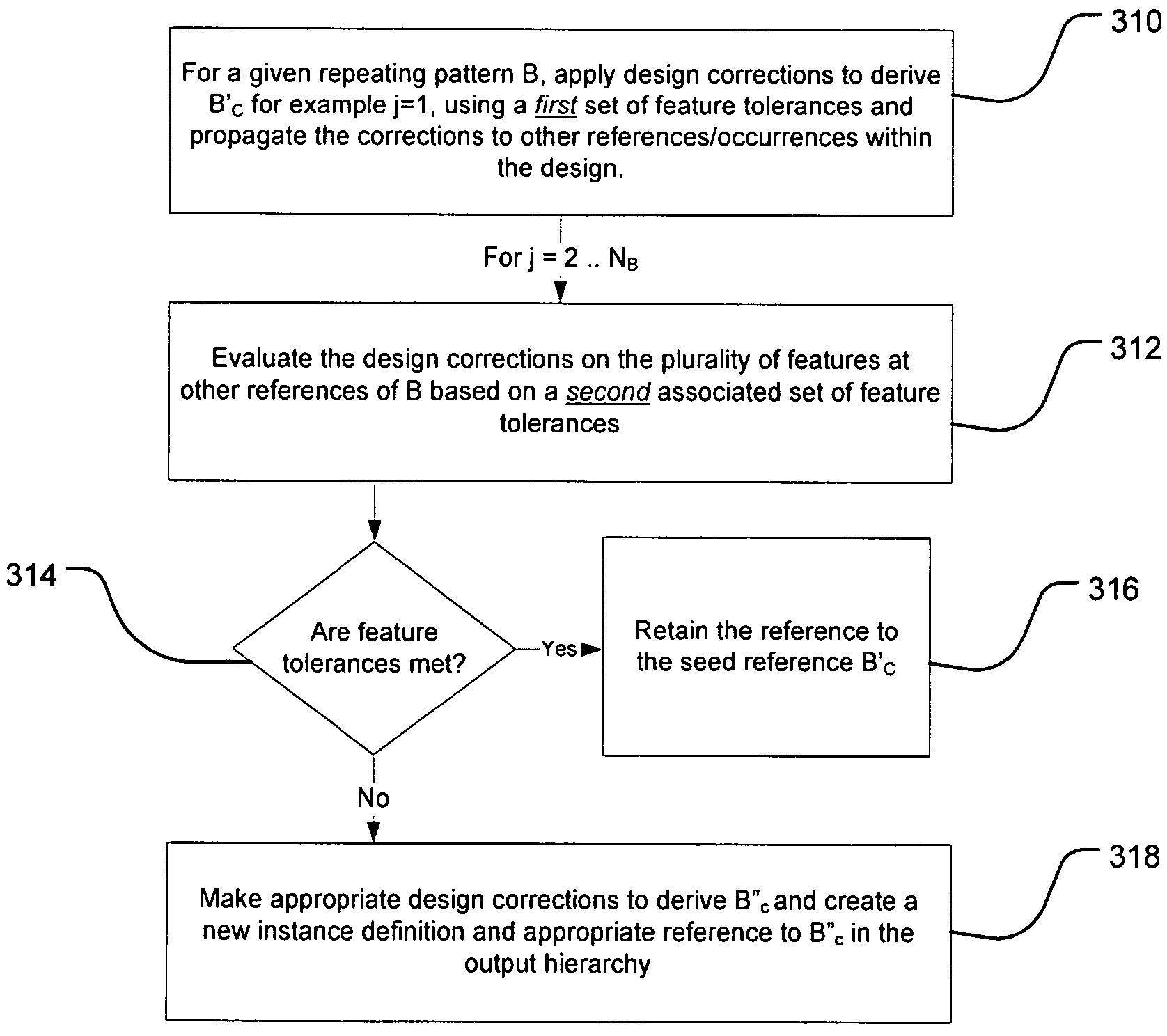

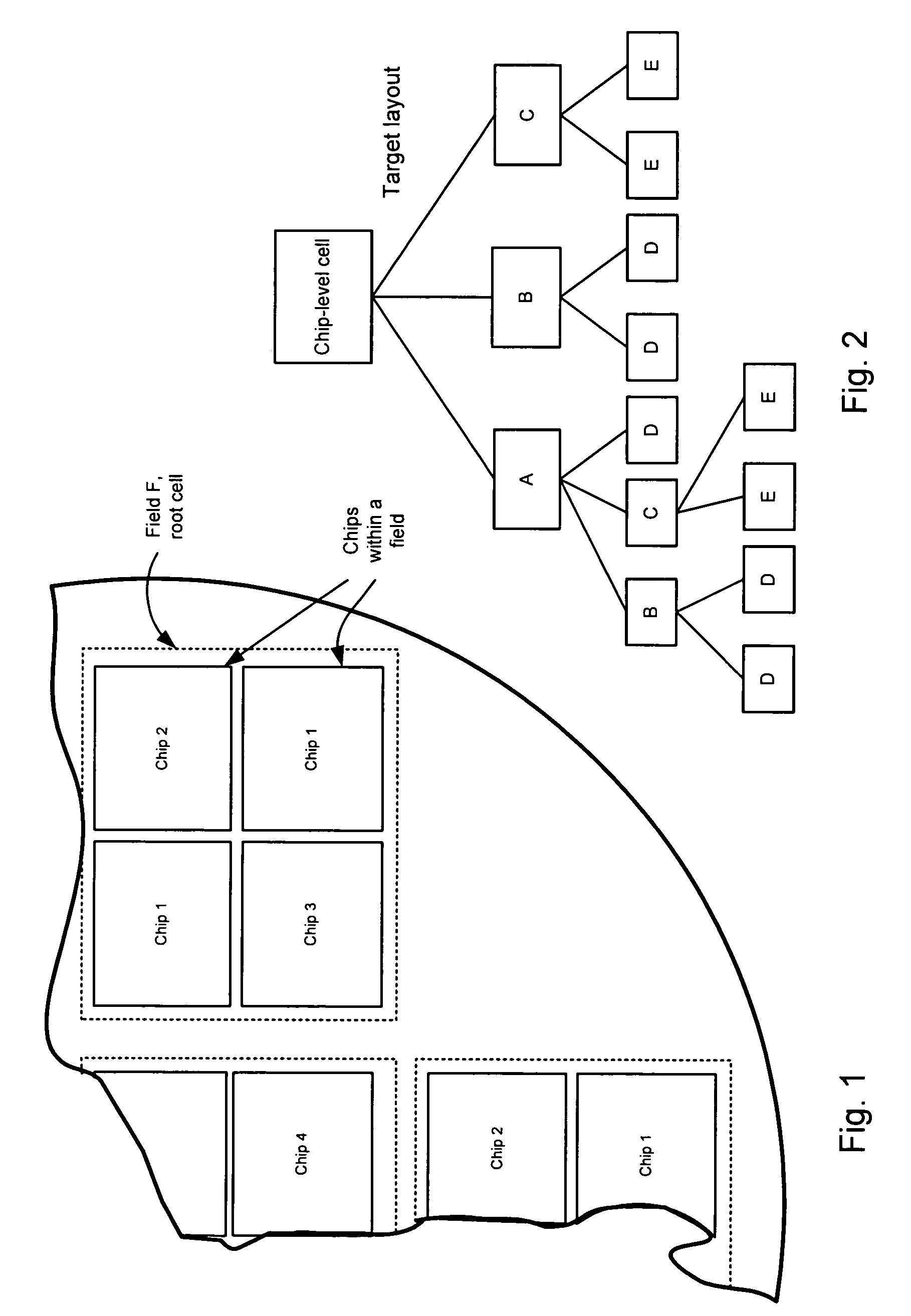

Method and system for managing design corrections for optical and process effects based on feature tolerances

ActiveUS7337421B2CAD circuit designSpecial data processing applicationsApplying knowledgeLithographic artist

Owner:CADENCE DESIGN SYST INC

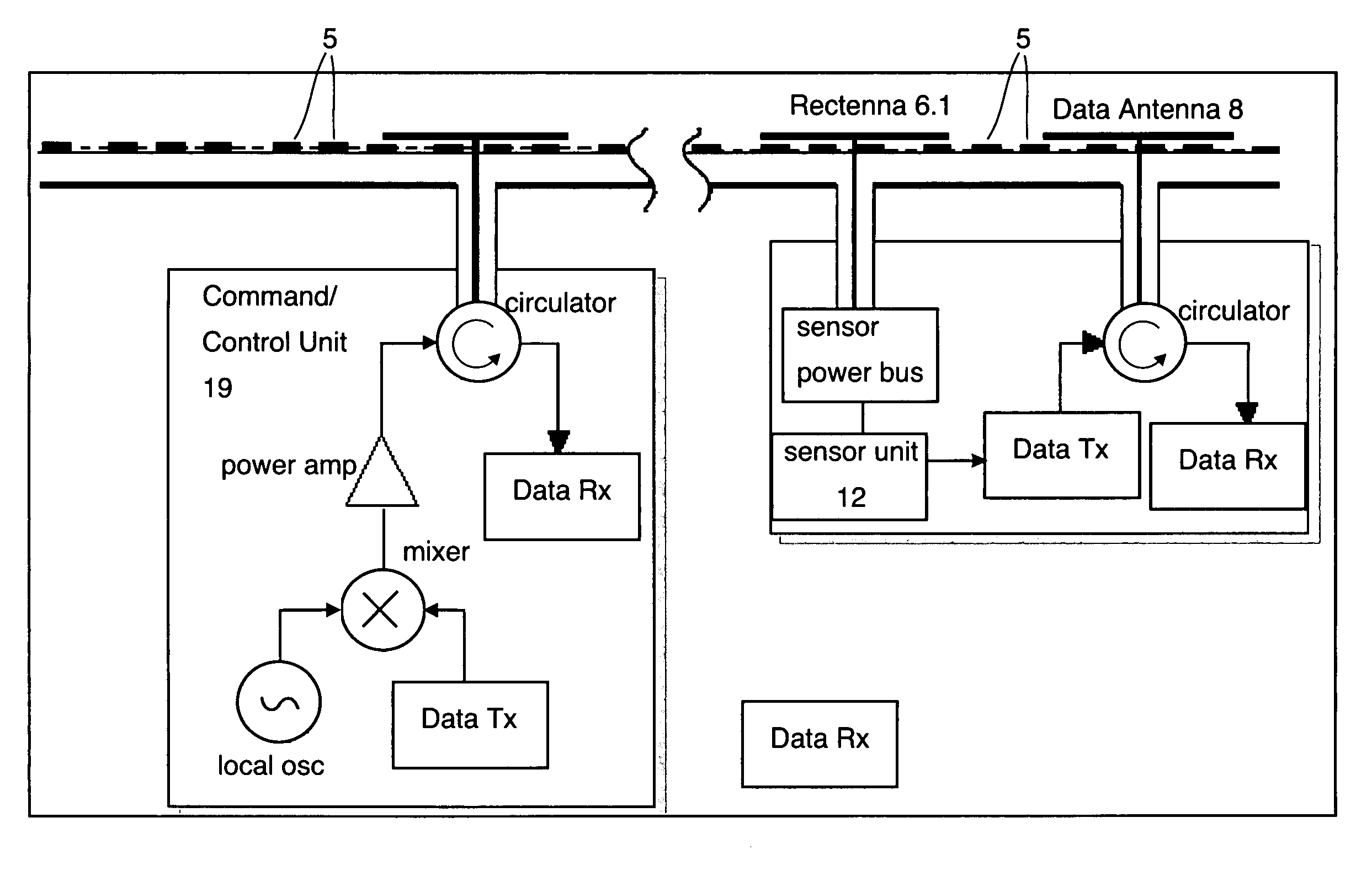

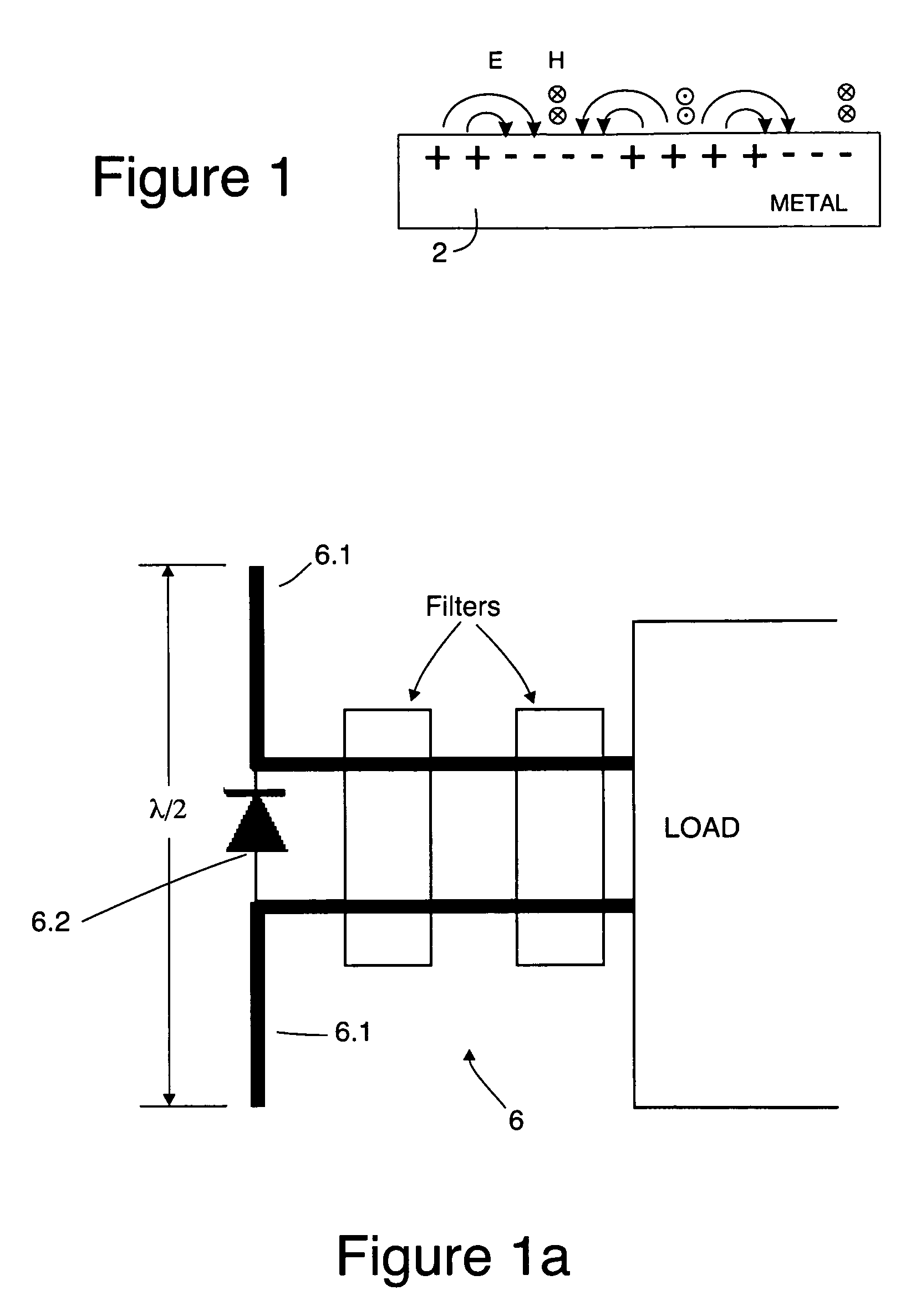

Large-scale adaptive surface sensor arrays

An adaptive surface has a dielectric surface with a repeating pattern of electrically conductive structures disposed thereon or therein, the dielectric surface in combination with repeating pattern of electrically conductive structures forming a metasurface for binding surface waves thereto. A plurality of actuators on the dielectric surface alter the shape of the metasurface in response to control signals. A plurality of sensors on the dielectric surface for measuring a desired parameter and converting it to data. A plurality of rectennae disposed on the dielectric surface for providing electrical power to said actuators and to said sensors. A plurality of data antennas are disposed on or in the dielectric surface, the data antennas being coupled with data receivers and data transmitters for receiving data from an external source for controlling the actuators and for transmitting data from said sensors to an external receiver.

Owner:HRL LAB

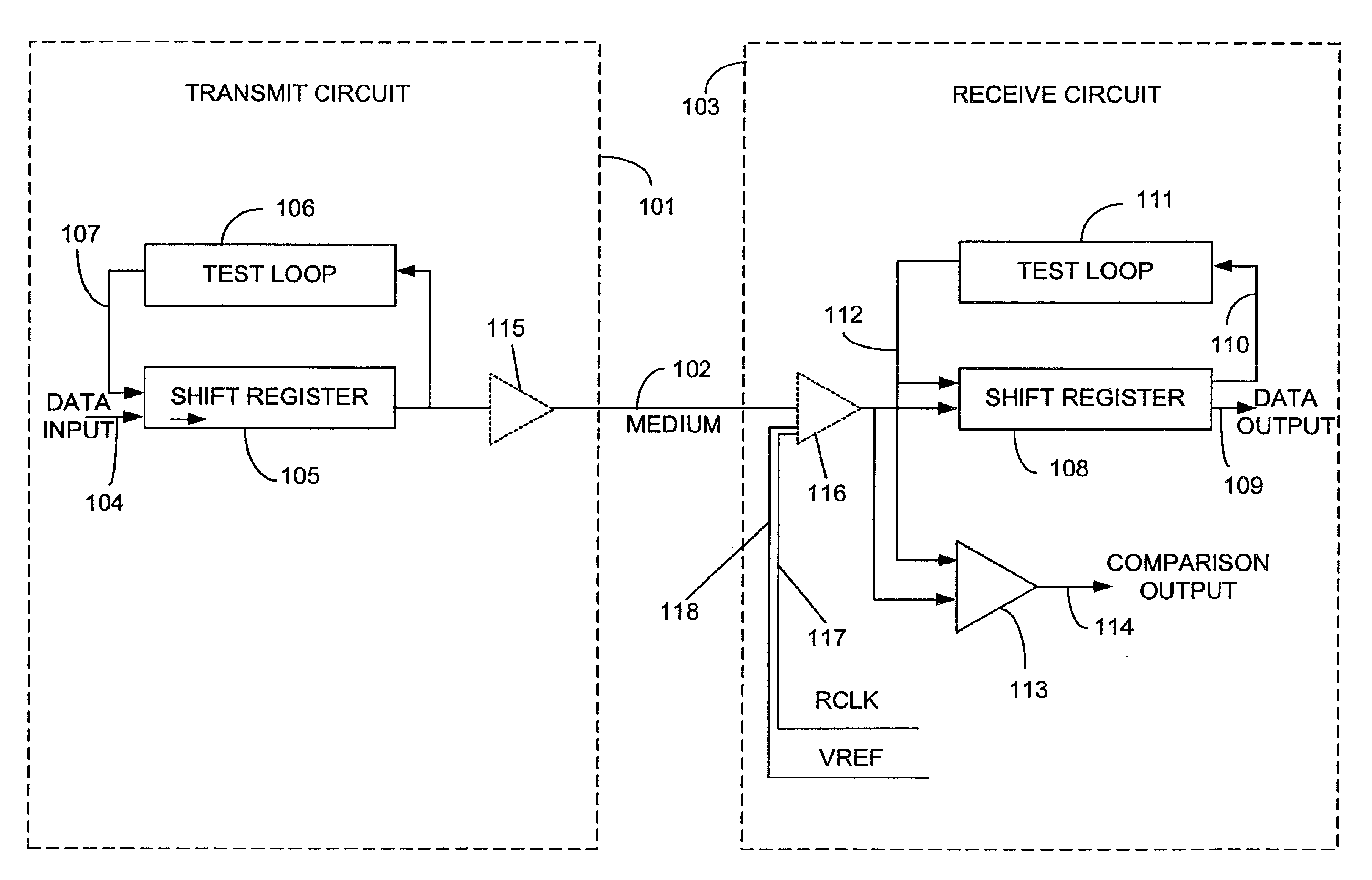

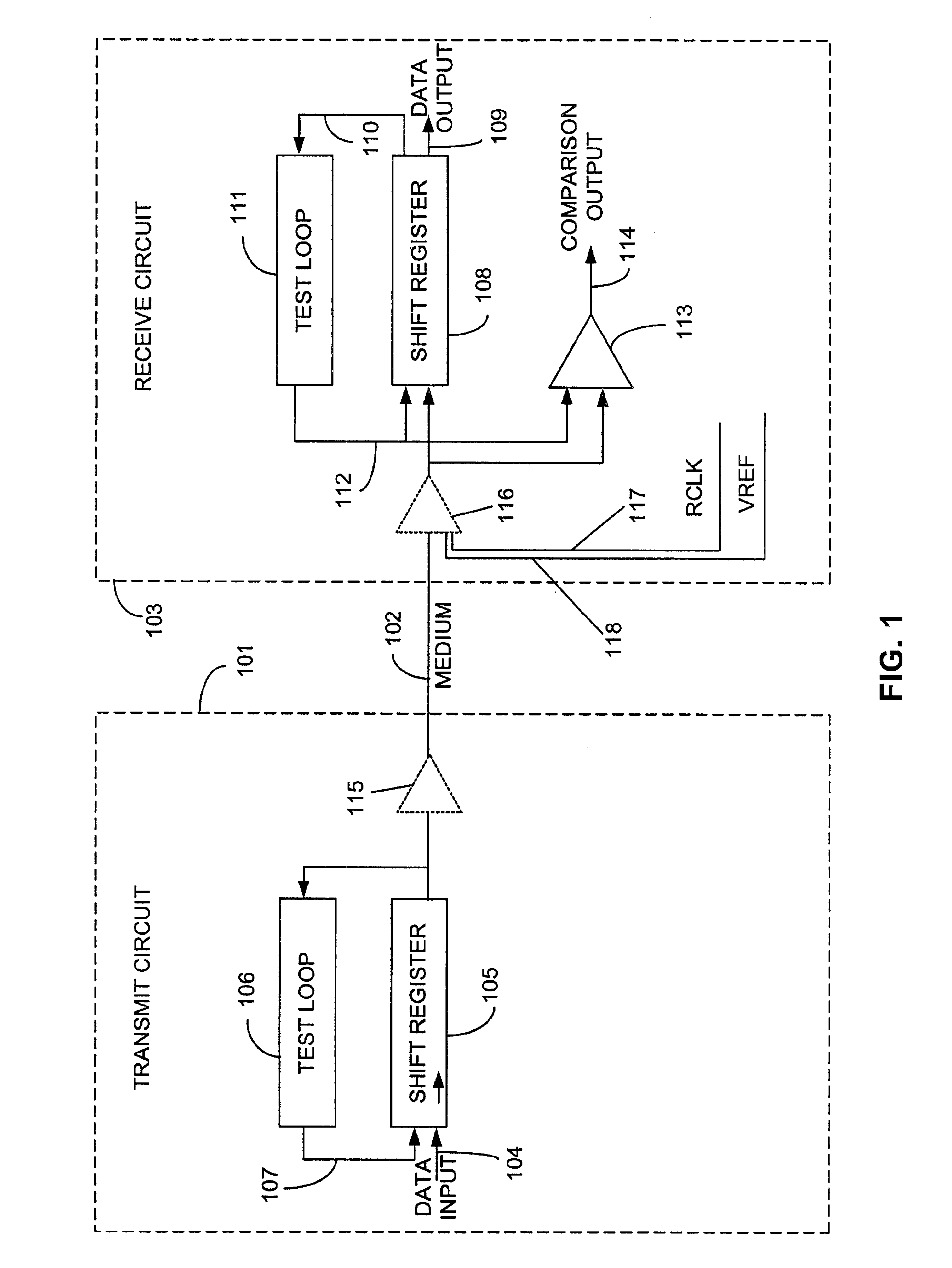

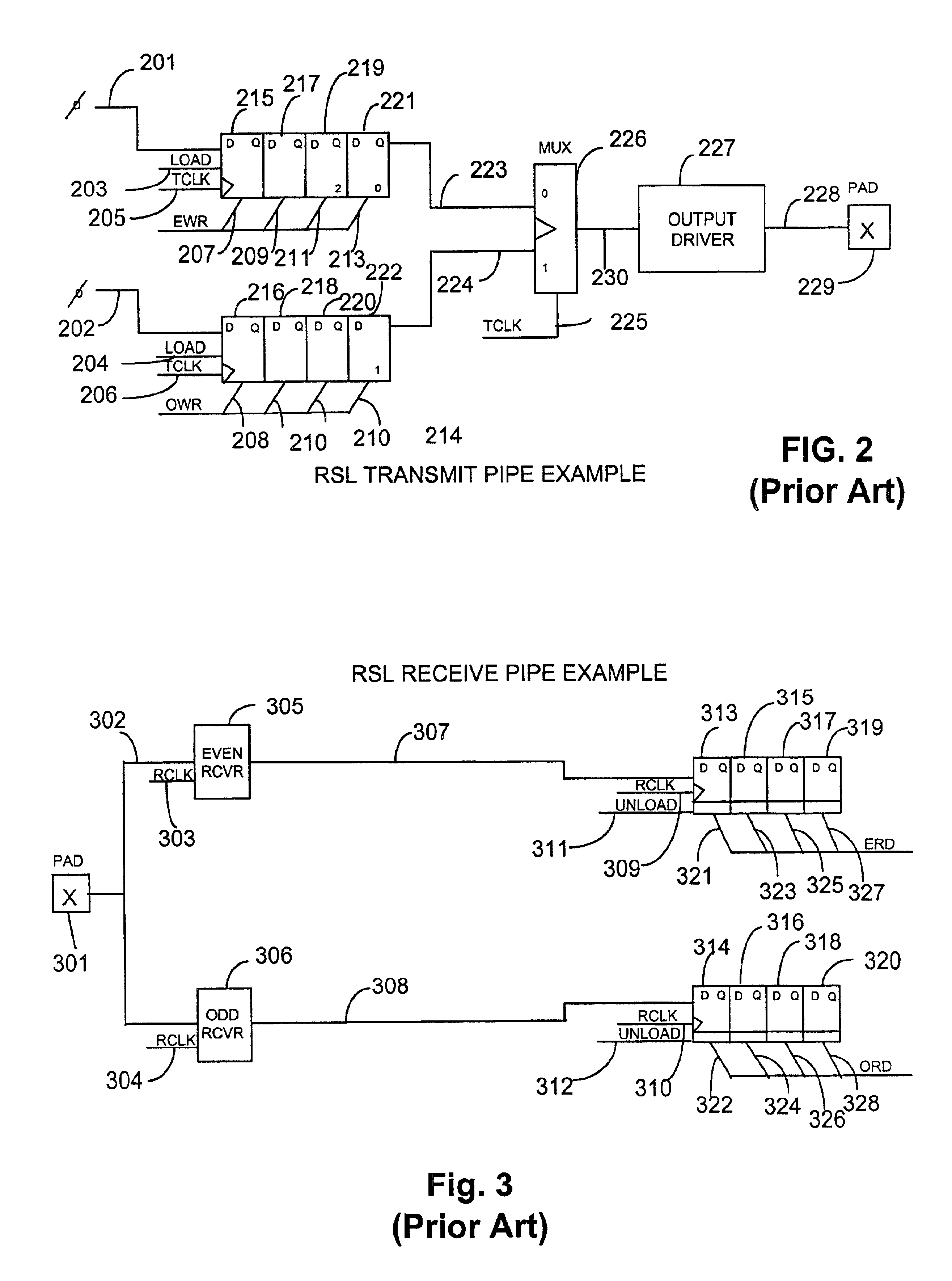

Method and apparatus for evaluating and calibrating a signaling system

InactiveUS6873939B1Amplifier modifications to reduce noise influenceElectronic circuit testingCrosstalk cancellationElectrical conductor

A method and apparatus for evaluating and calibrating a signaling system is described. Evaluation is accomplished using the same circuits actually involved in normal operation of the signaling system. Capability for in-situ testing of a signaling system is provided, and information may be obtained from the actual perspective of a receive circuit in the system. A pattern of test information is generated in a transmit circuit of the system and is transmitted to a receive circuit. A similar pattern of information is generated in the receive circuit and used as a reference. The receive circuit compares the patterns. Any differences between the patterns are observable. Preferably, the patterns are repeating patterns that allow many iterations of testing to be performed. In one embodiment, a linear feedback shift register (LFSR) is implemented to produce patterns. Information obtained from testing may be used to assess the effects of various system parameters, including but not limited to output current, crosstalk cancellation coefficients, and self-equalization coefficients, and system parameters may be adjusted to optimize system performance. An embodiment of the invention may be practiced with various types of signaling systems, including those with single-ended signals and those with differential signals. An embodiment of the invention may be applied to systems communicating a single bit of information on a single conductor at a given time and to systems communicating multiple bits of information on a single conductor simultaneously.

Owner:RAMPART ASSET MANAGEMENT LLC

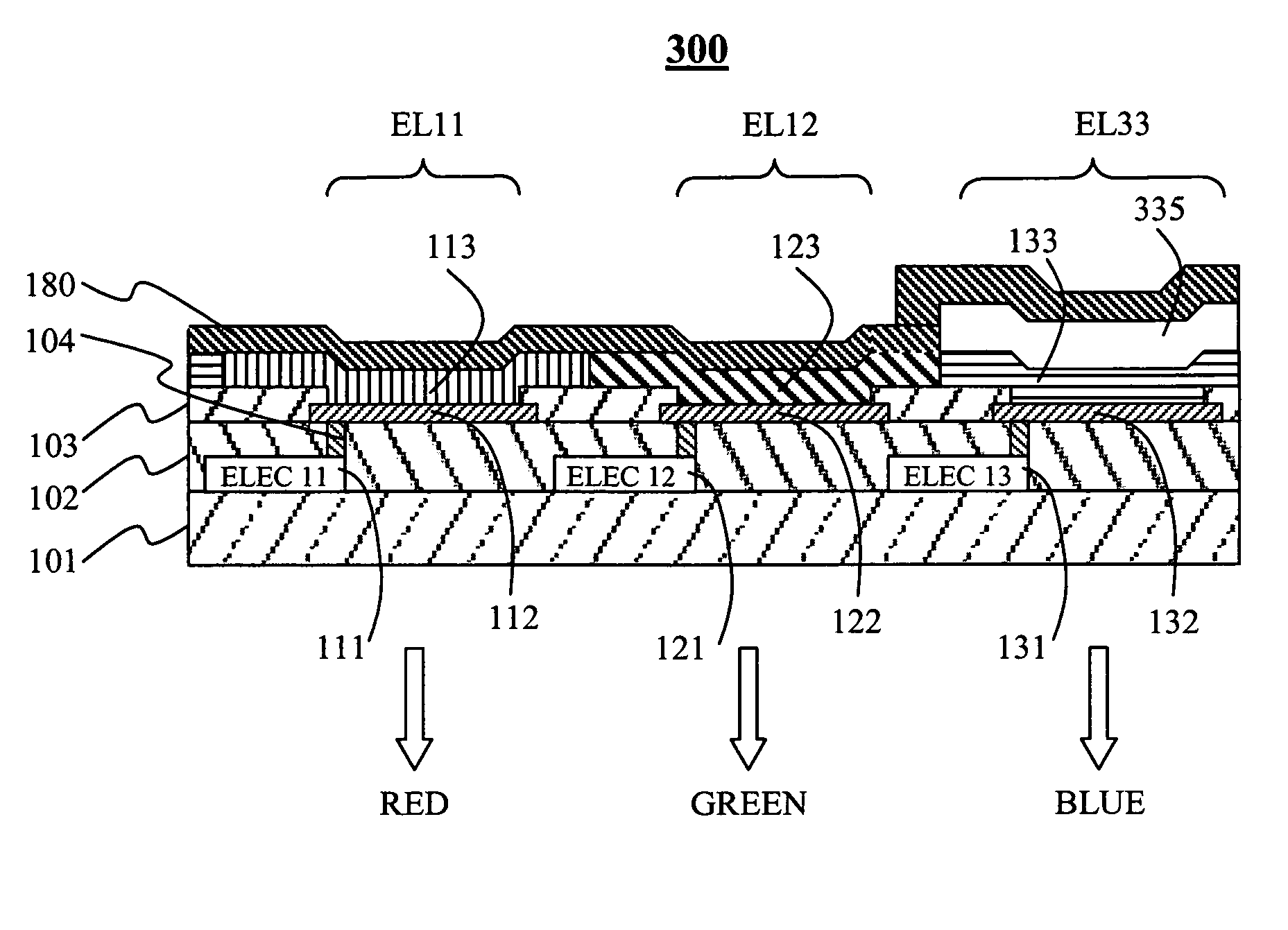

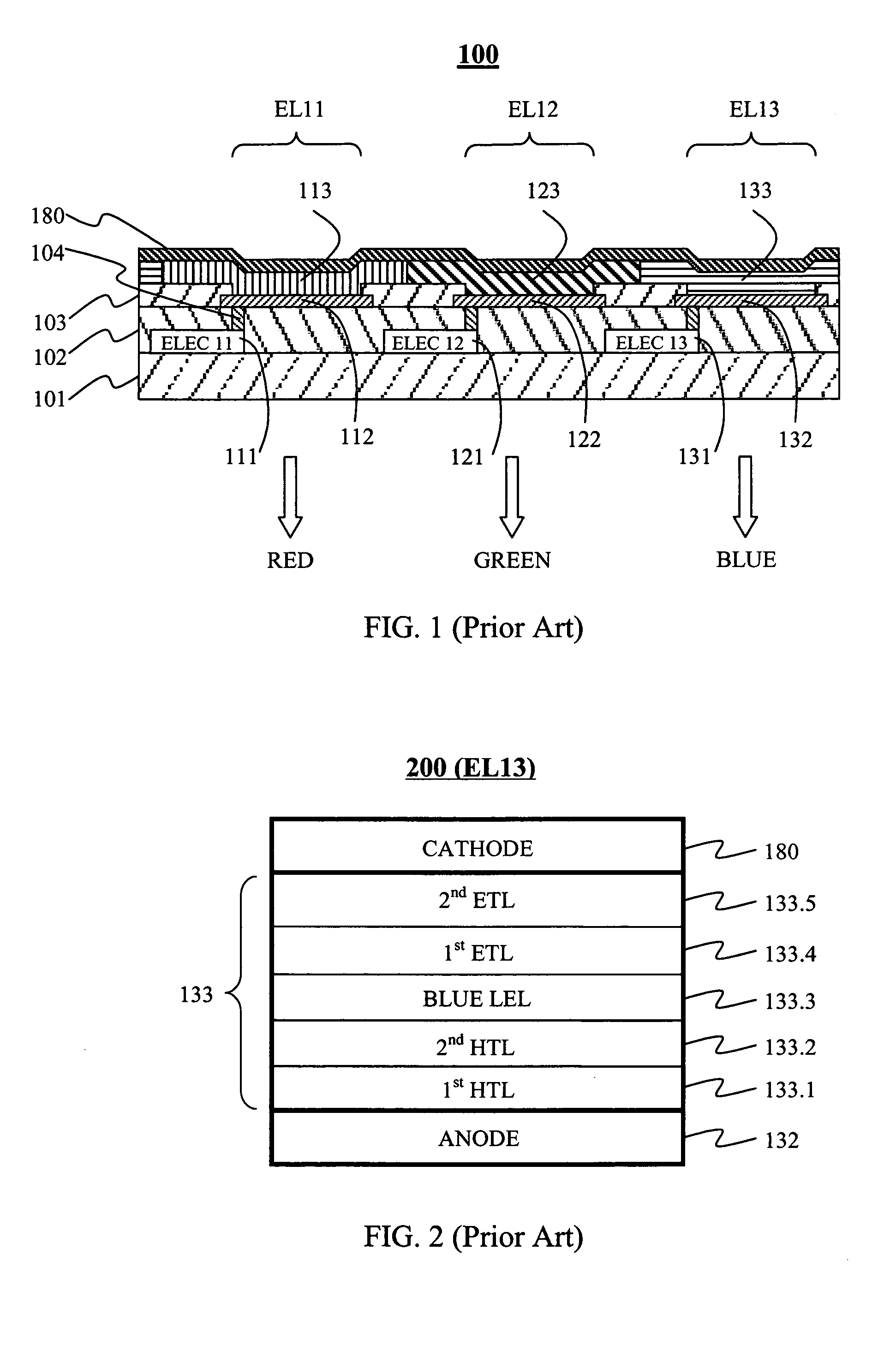

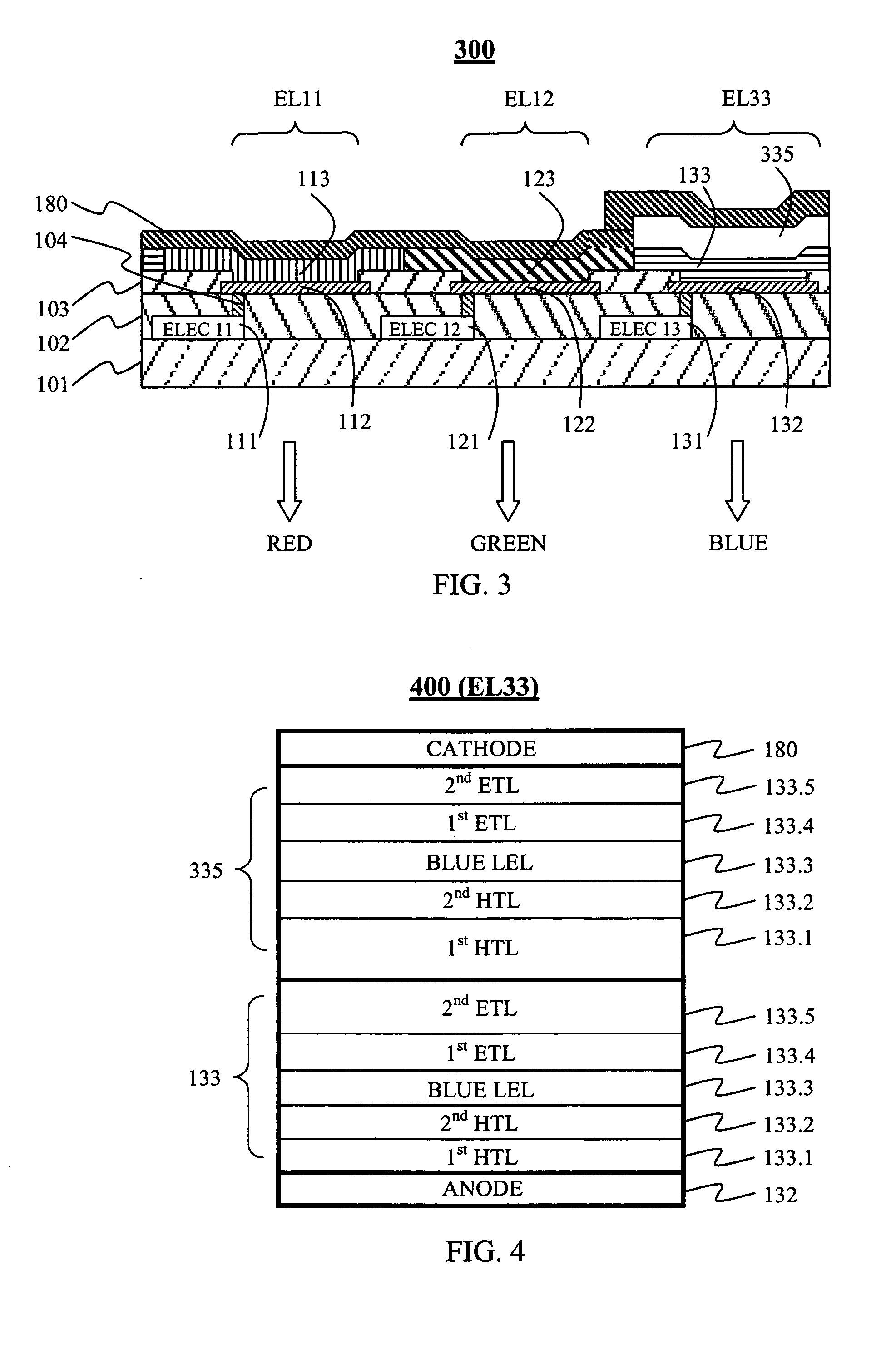

Full-color organic display having improved blue emission

ActiveUS20050173700A1Improve luminous efficiencyDecreasing surface emitting areaDischarge tube luminescnet screensStatic indicating devicesColor imageBlue emission

A full-color organic display for displaying a color image, including an array of pixels arranged in repeating patterns, wherein each pixel has red, green, and blue light-emitting subpixels, and wherein each red and green light-emitting subpixel contains only one EL unit, while each blue light-emitting subpixel contains more than one vertically stacked EL unit.

Owner:GLOBAL OLED TECH

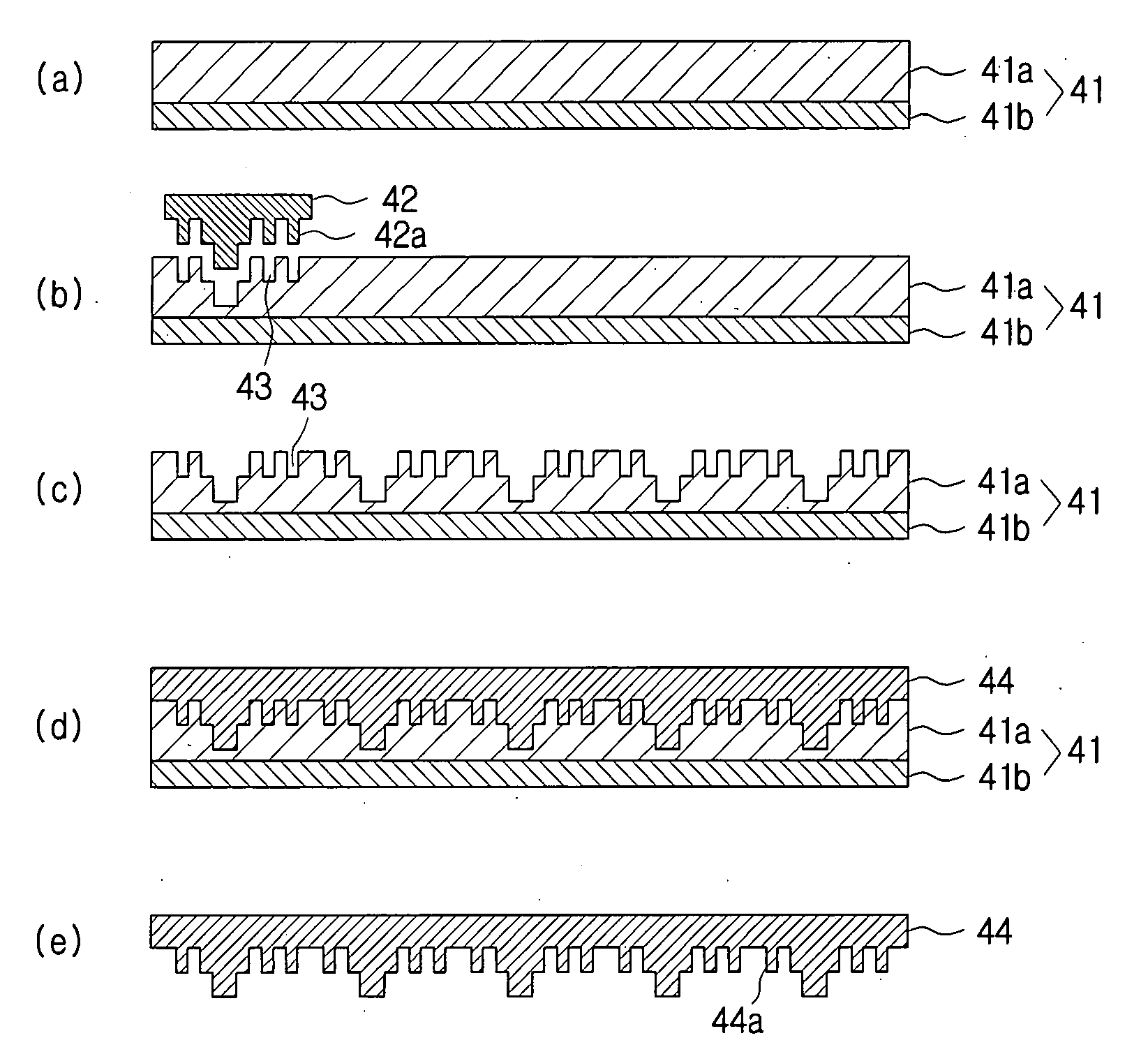

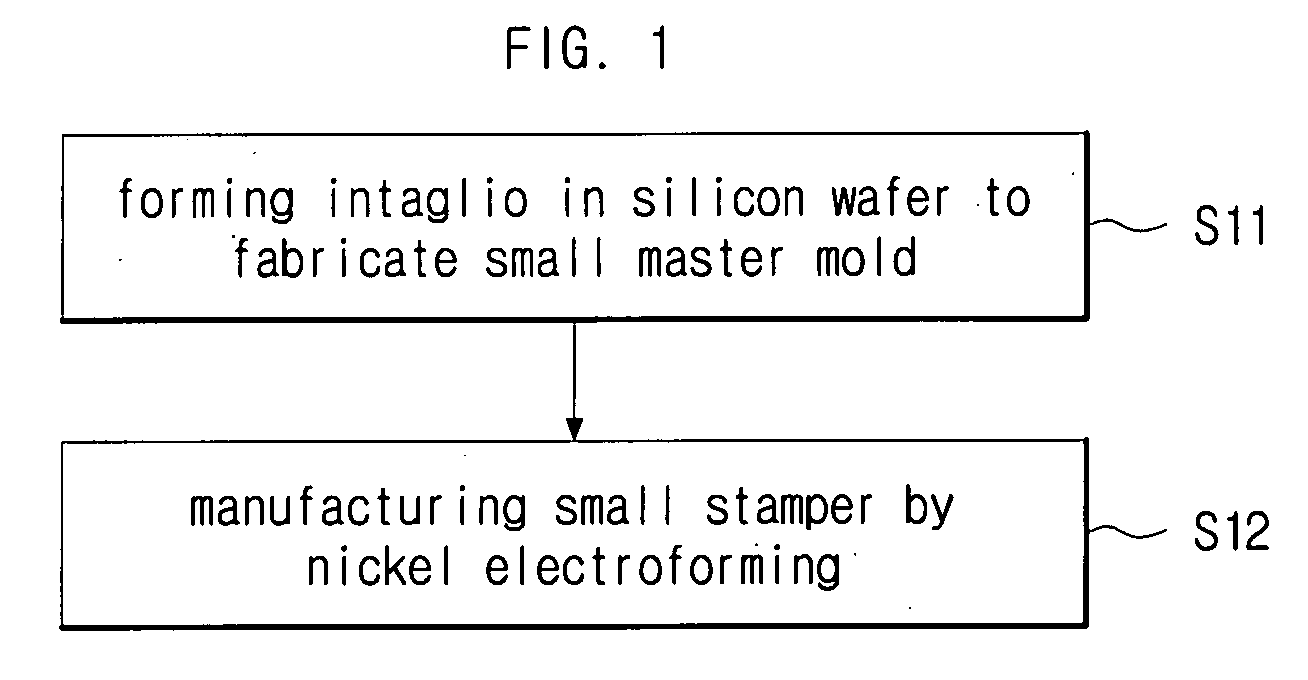

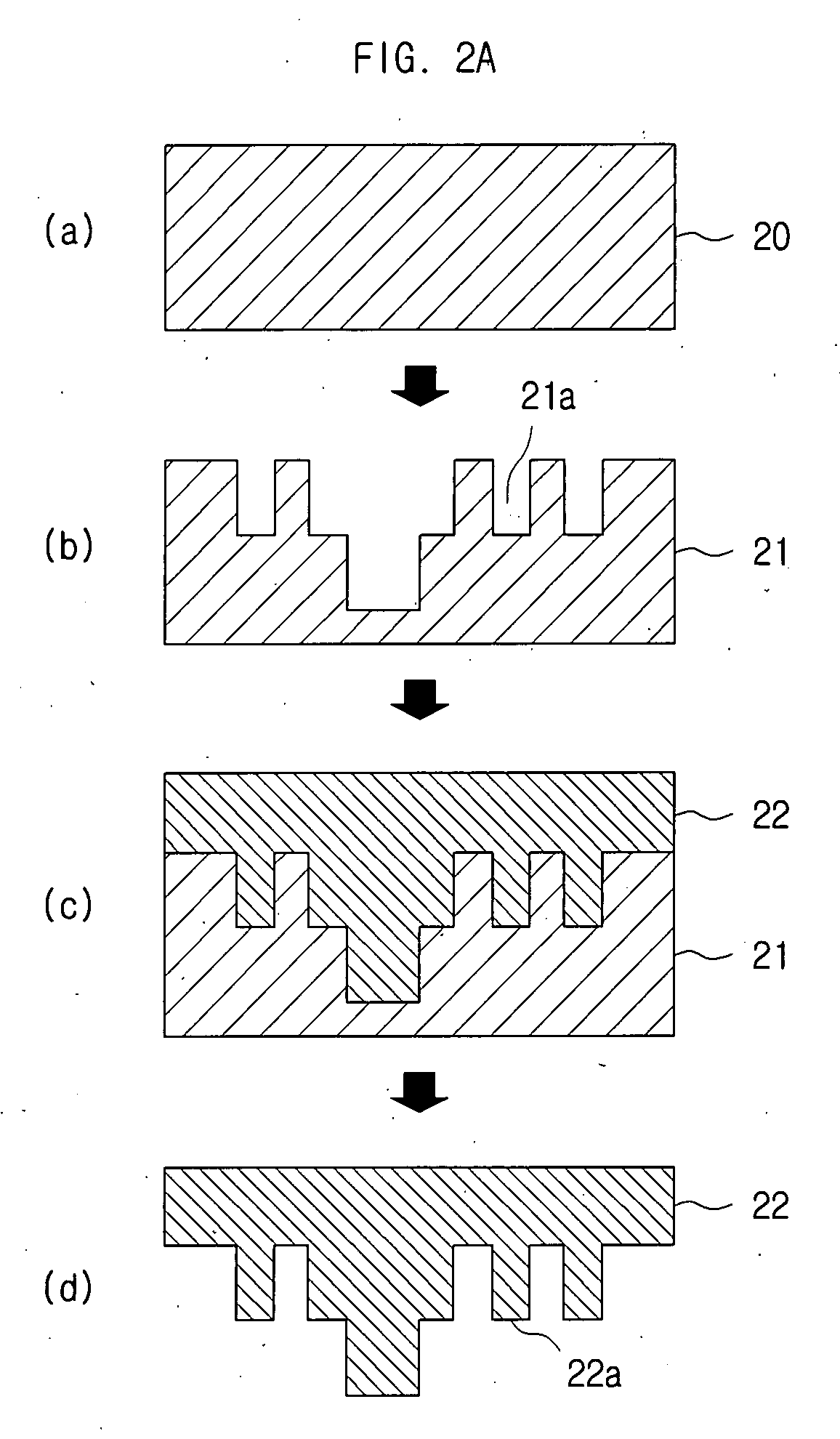

Method of manufacturing a stamper

InactiveUS20080054518A1Photomechanical apparatusPrinted circuit manufactureRepeat patternManufacturing engineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Signal modulation method resistant to echo reflections and frequency offsets

ActiveUS20120201322A1Improve performancePromote decompositionModulated-carrier systemsNetwork traffic/resource managementHigh rateFrequency shift

A method of modulating communications signals, such as optical fiber, wired electronic, or wireless signals in a manner that facilitates automatic correction for the signal distortion effects of echoes and frequency shifts, while still allowing high rates of data transmission. Data symbols intended for transmission are distributed into N×N matrices, and used to weigh or modulate a family of cyclically time shifted and cyclically frequency shifted waveforms. Although these waveforms may then be distorted during transmission, their basic cyclic time and frequency repeating structure facilitates use of improved receivers with deconvolution devices that can utilize the repeating patterns to correct for these distortions. The various waveforms may be sent in N time blocks at various time spacing and frequency spacing combinations in a manner that can allow interleaving of blocks from different transmitters. Applications to channel sounding / characterization, system optimization, and also radar are also discussed.

Owner:COHERE TECH

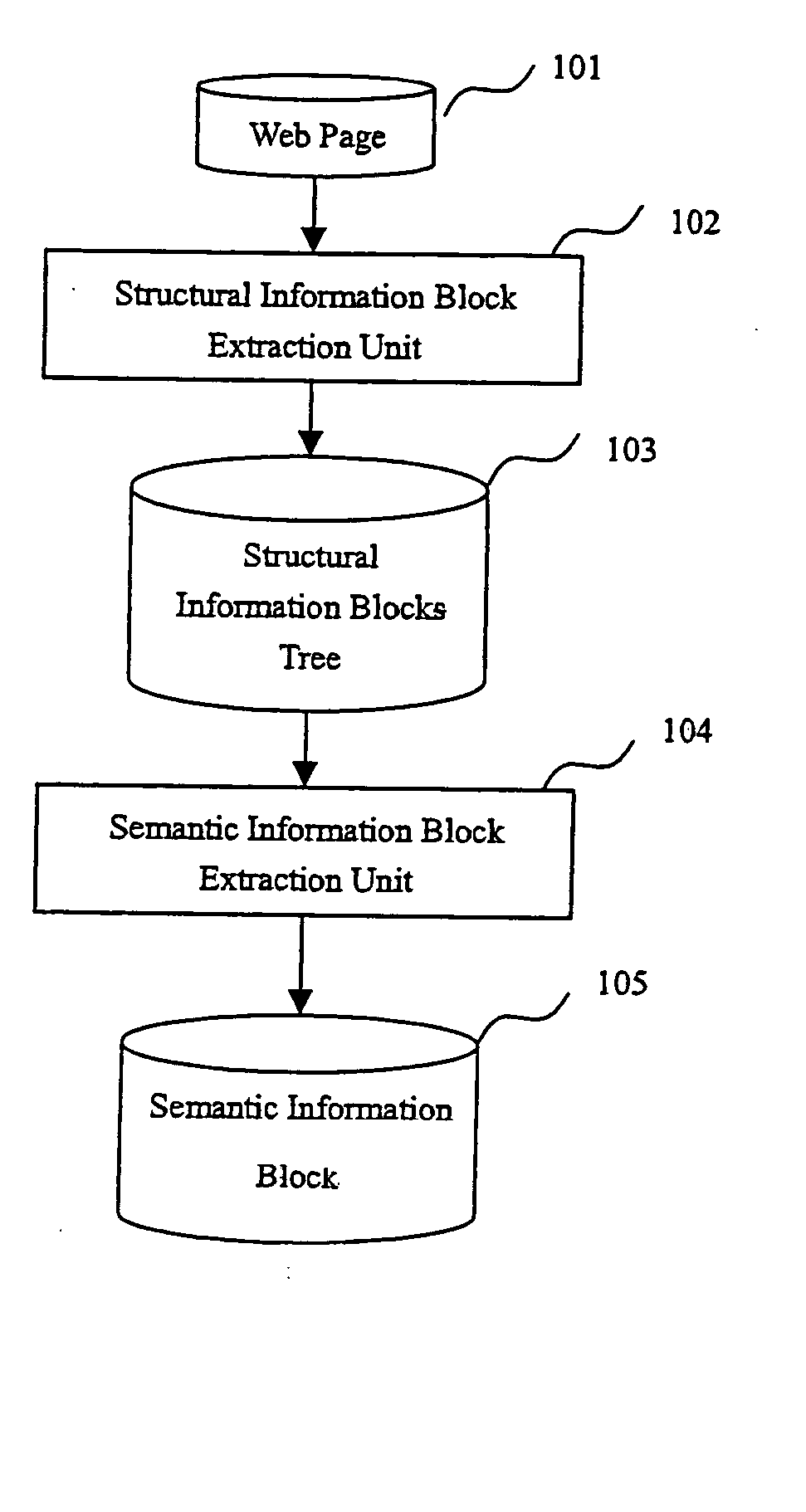

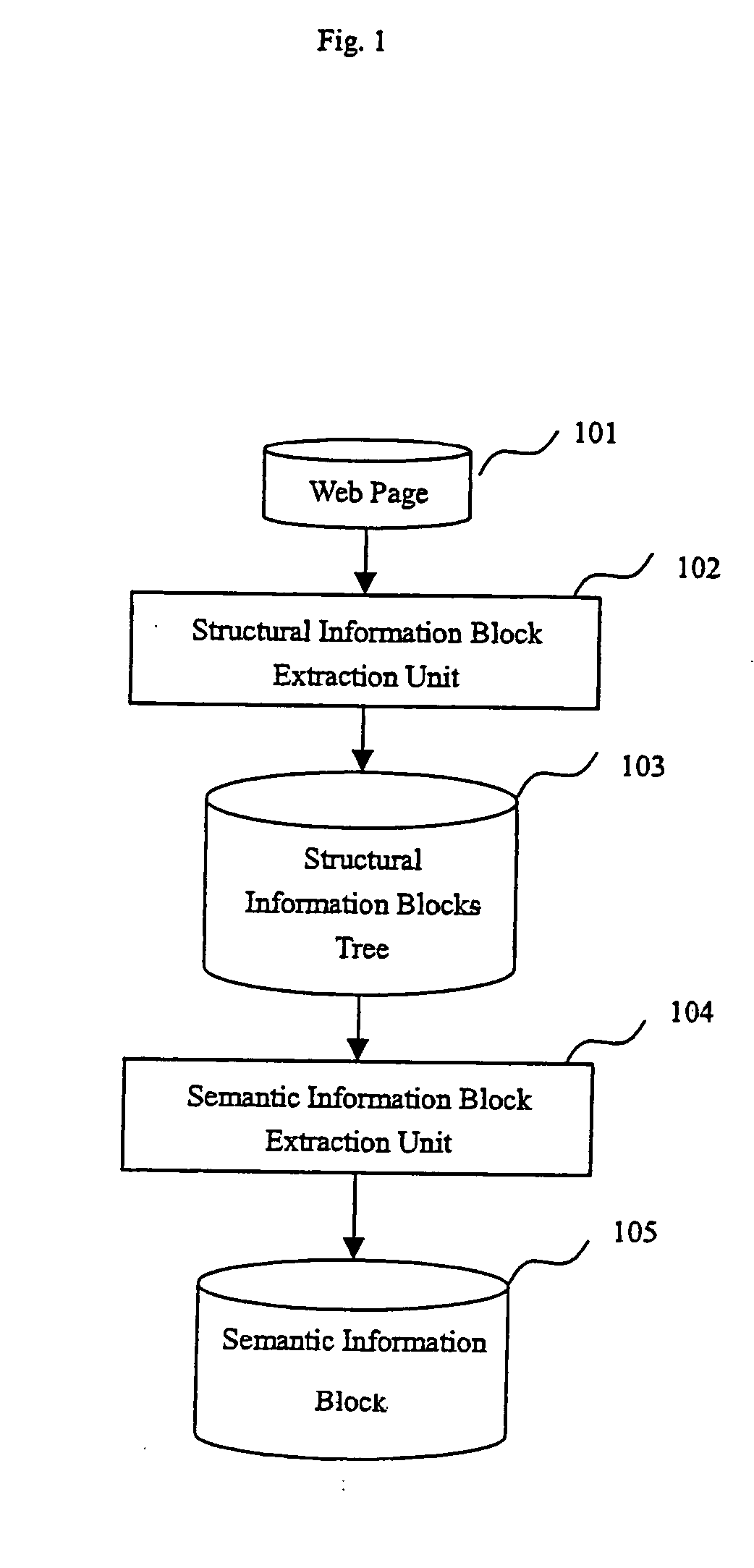

Information block extraction apparatus and method for Web pages

InactiveUS20050066269A1Improve performanceGuaranteed successDigital data information retrievalSemantic analysisRepeat patternSemantic information

A method and apparatus for identifying coherent areas within a Web page. First, a Web page is parsed into an HTML DOM tree and an HTML tag token stream. Next, repeated-patterns are induced from the Web page. After filtering out improper repeated-patterns and generating corresponding instances of the repeated-patterns, the repeated-patterns are mapped back to corresponding regions in the Web page. Based on the mappings, a hierarchical RST tree containing information blocks is generated. Information items within the information blocks are detected then used to generate a hierarchical structural information block tree. Information blocks from the structural information block tree are then classified into text information blocks and link information blocks. Based on the classification and block semantic similarity, the bocks are clustered then grouped into semantic information blocks. The semantic information blocks contain main text information blocks and related link blocks which, if necessary, can be labeled.

Owner:FUJITSU LTD +1

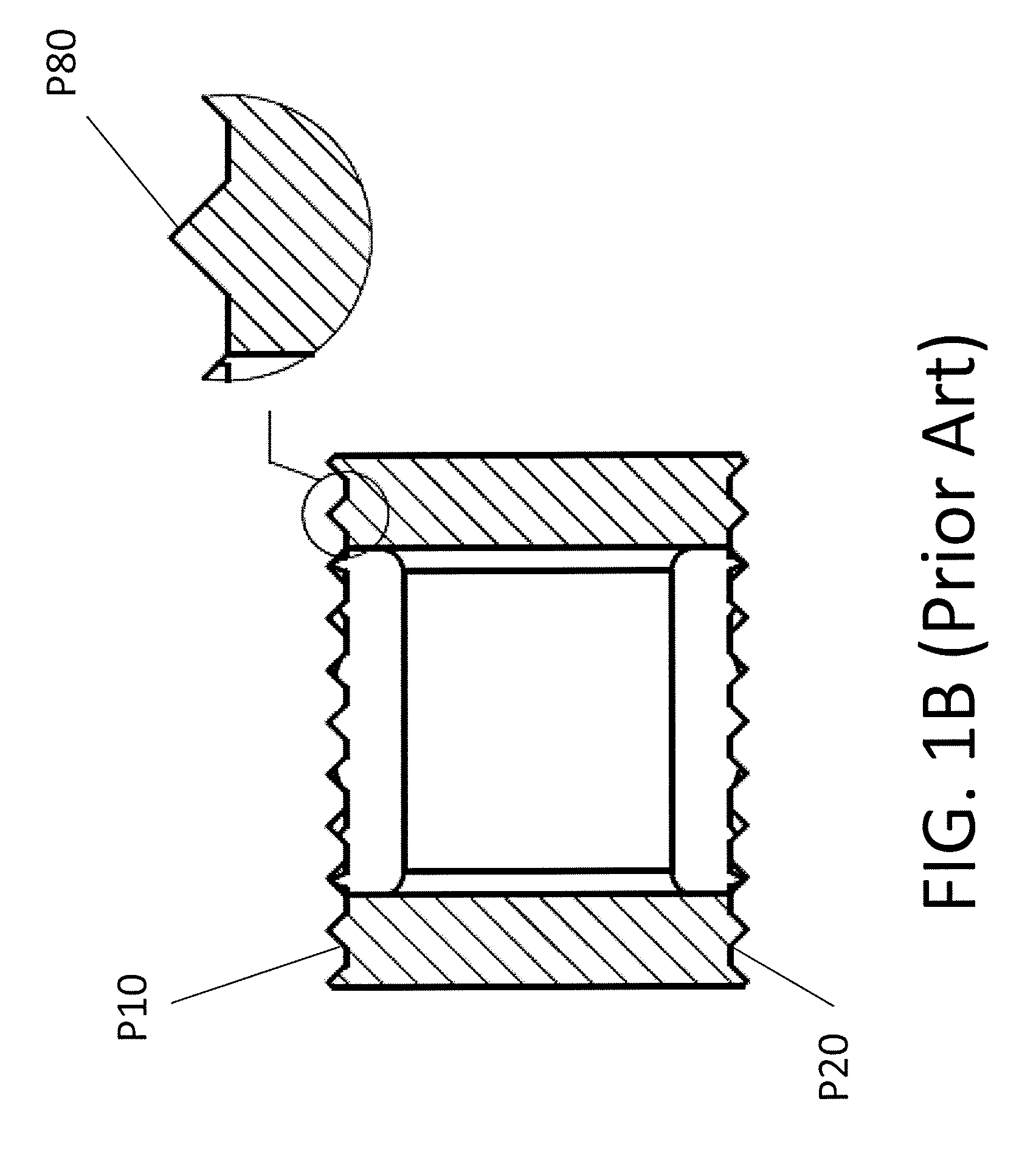

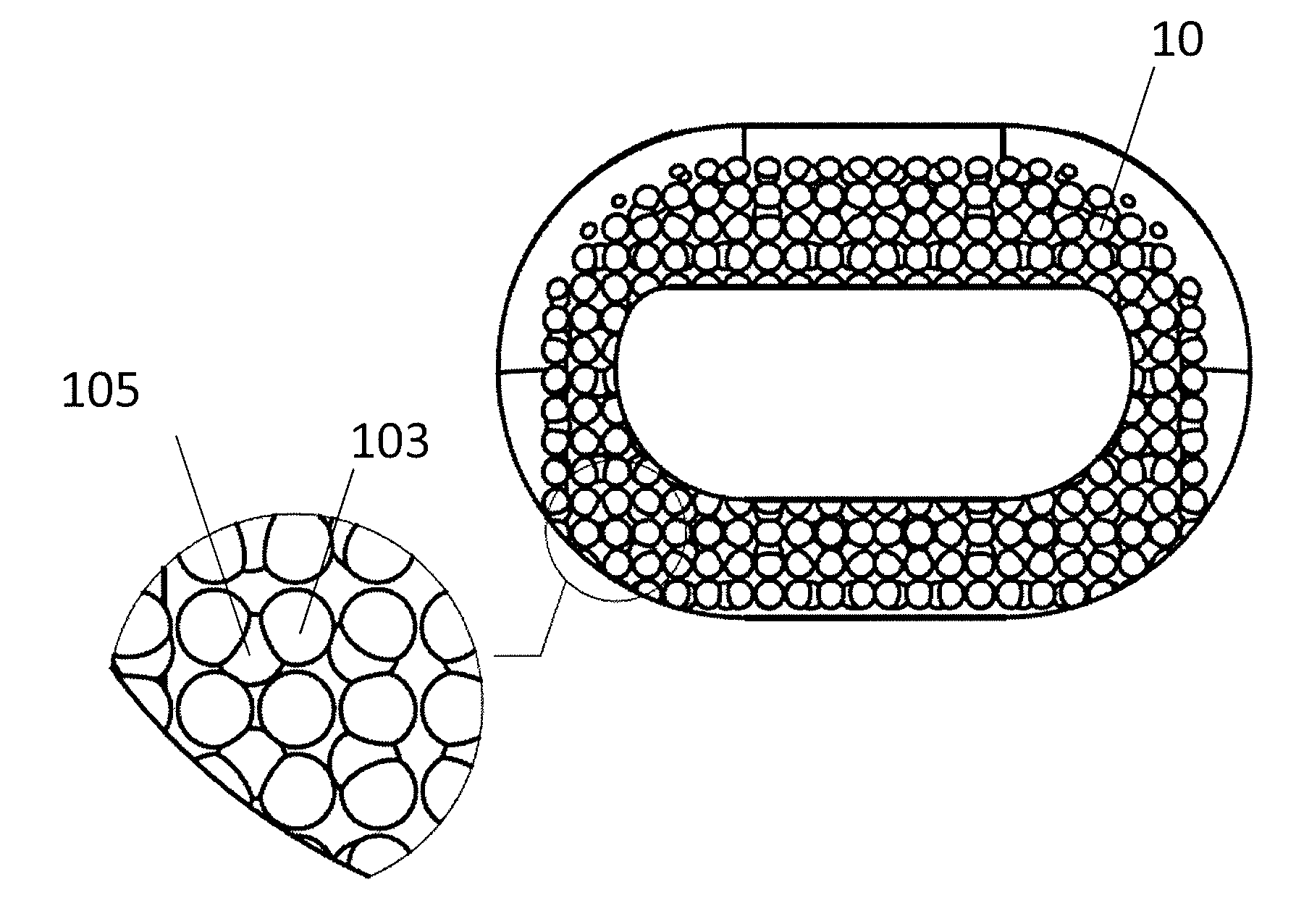

Processes for producing regular repeating patterns on surfaces of interbody devices

ActiveUS20120312778A1Sufficient bioactivityHigh positioning accuracyDecorative surface effectsVacuum evaporation coatingRough surfaceMedicine

Processes for producing interbody spinal implants having a body with a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture; and optionally, one or two integration plates affixed to the body. The processes include applying an additive process, a subtractive process, or both processes to at least one surface of the interbody spinal implant to form a roughened surface topography having a regular repeating pattern. The roughened surface topography is specifically designed to provide certain frictional characteristics, load dispersion, and to influence the biological responses that occur during bone healing and fusion.

Owner:TITAN SPINE

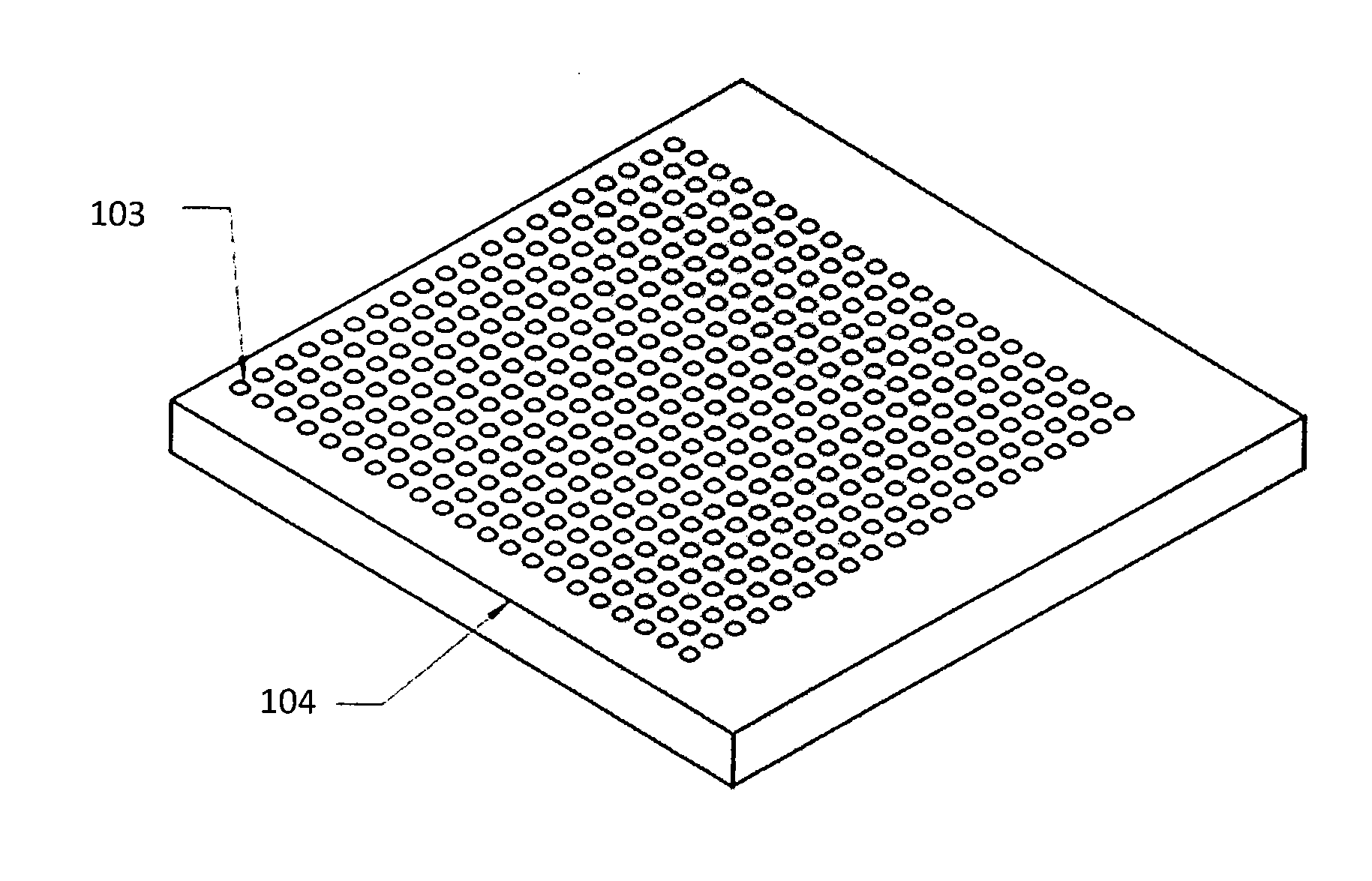

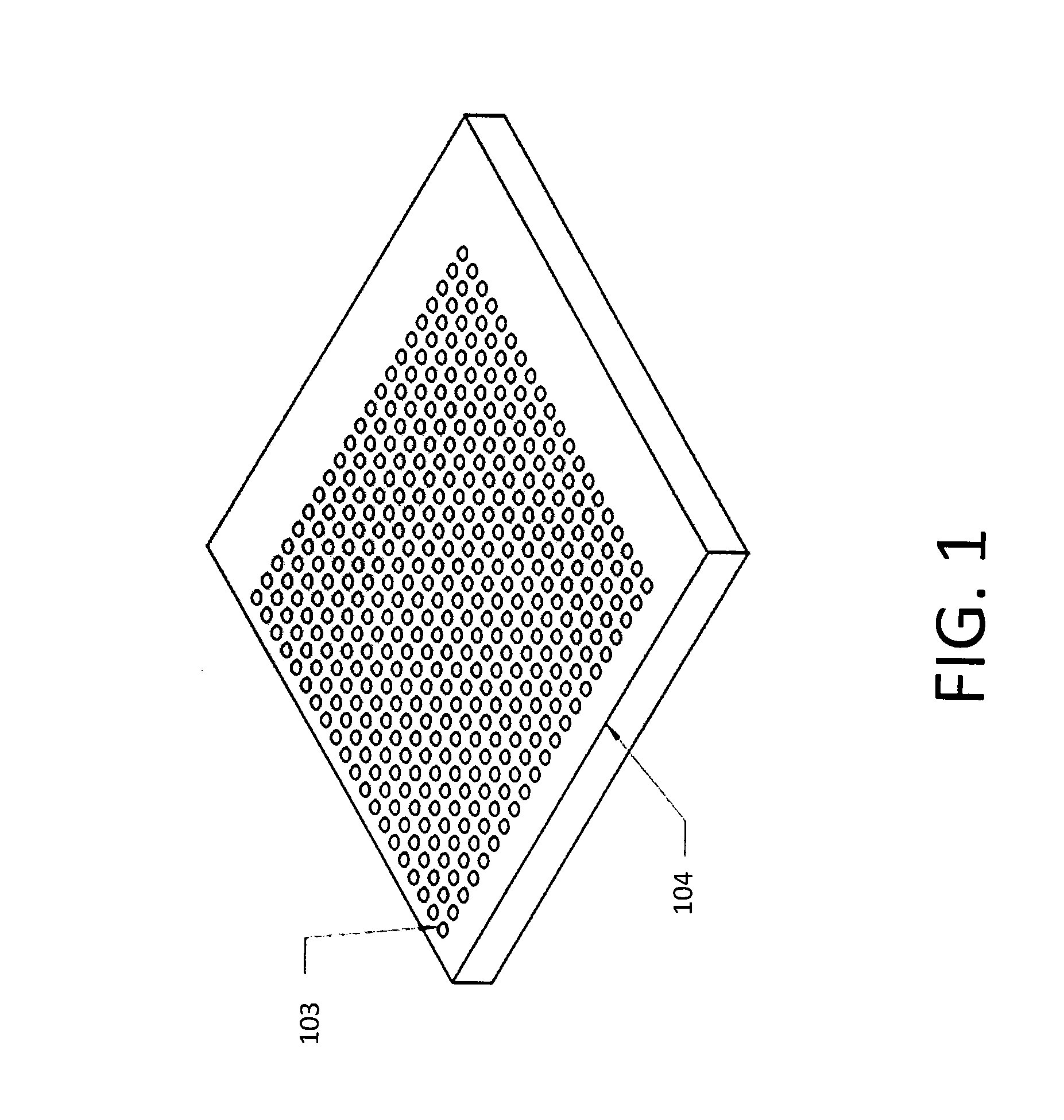

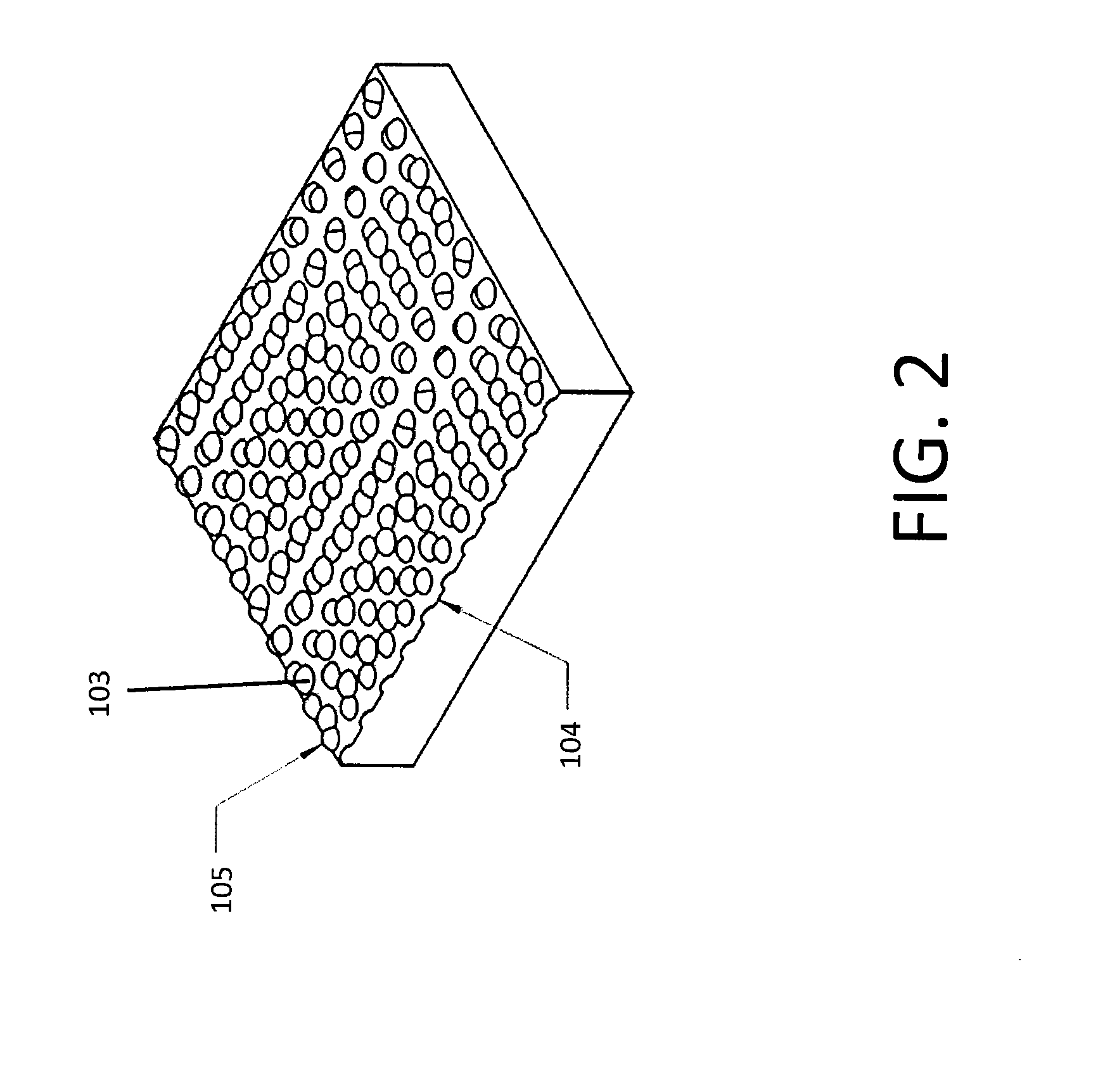

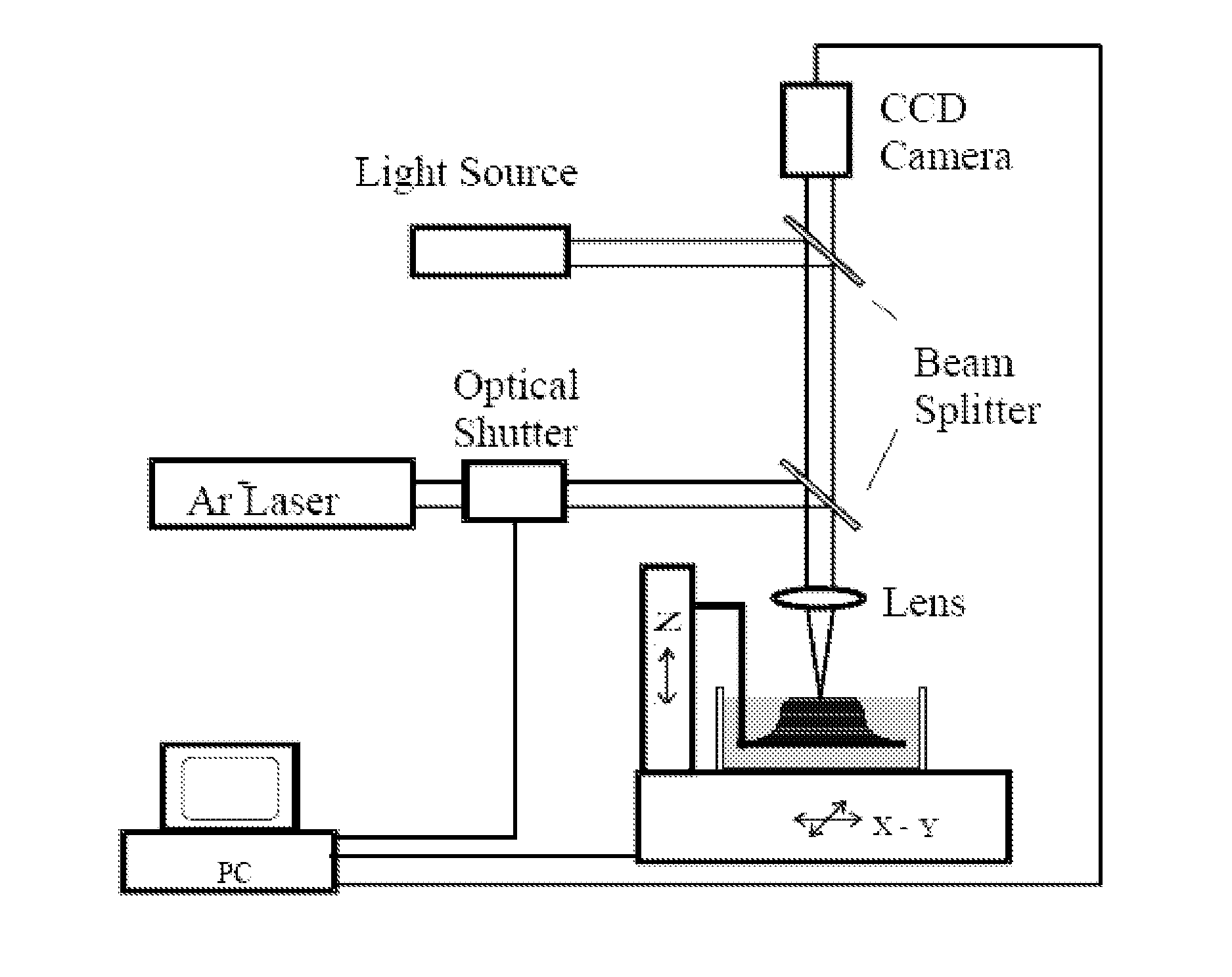

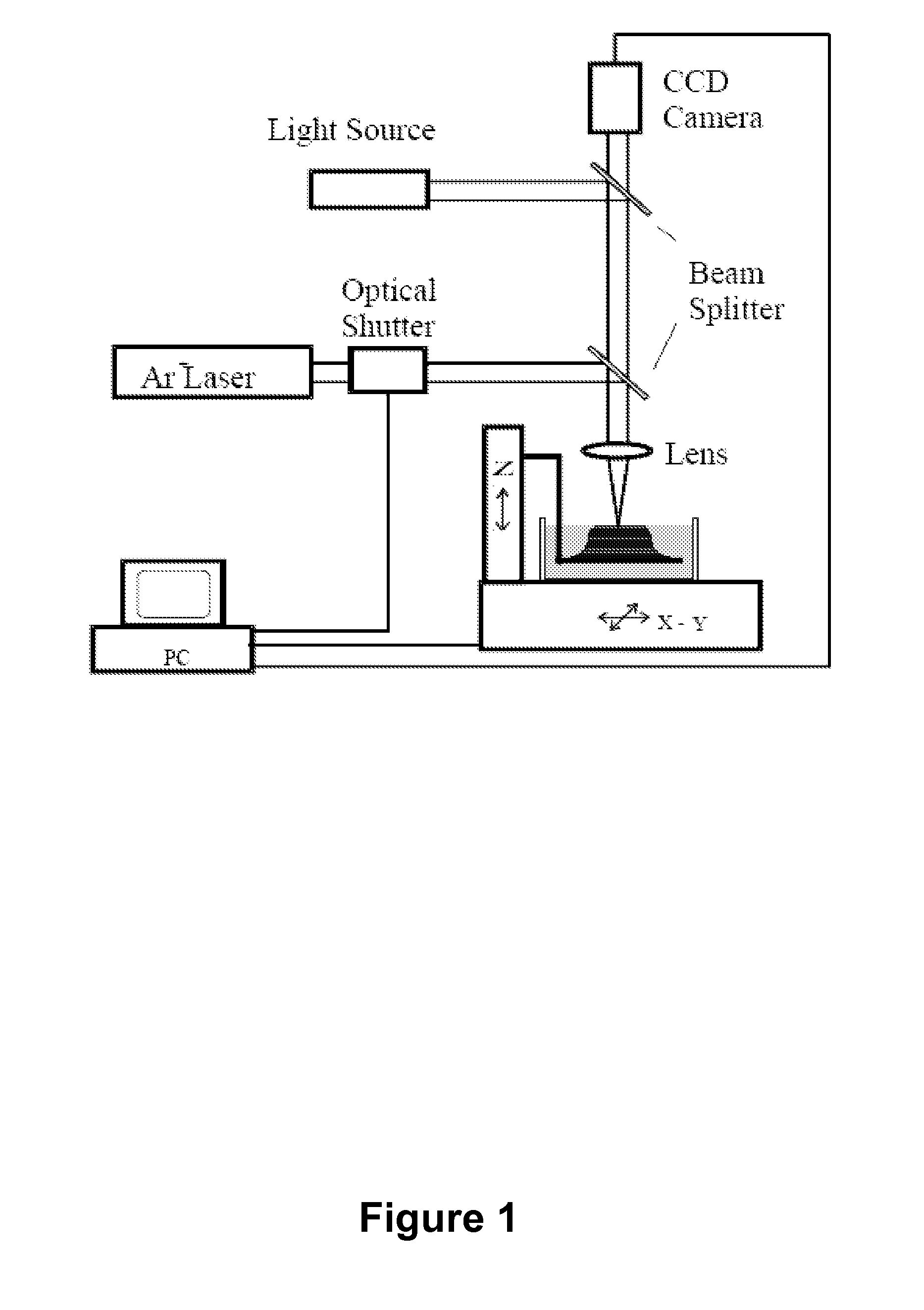

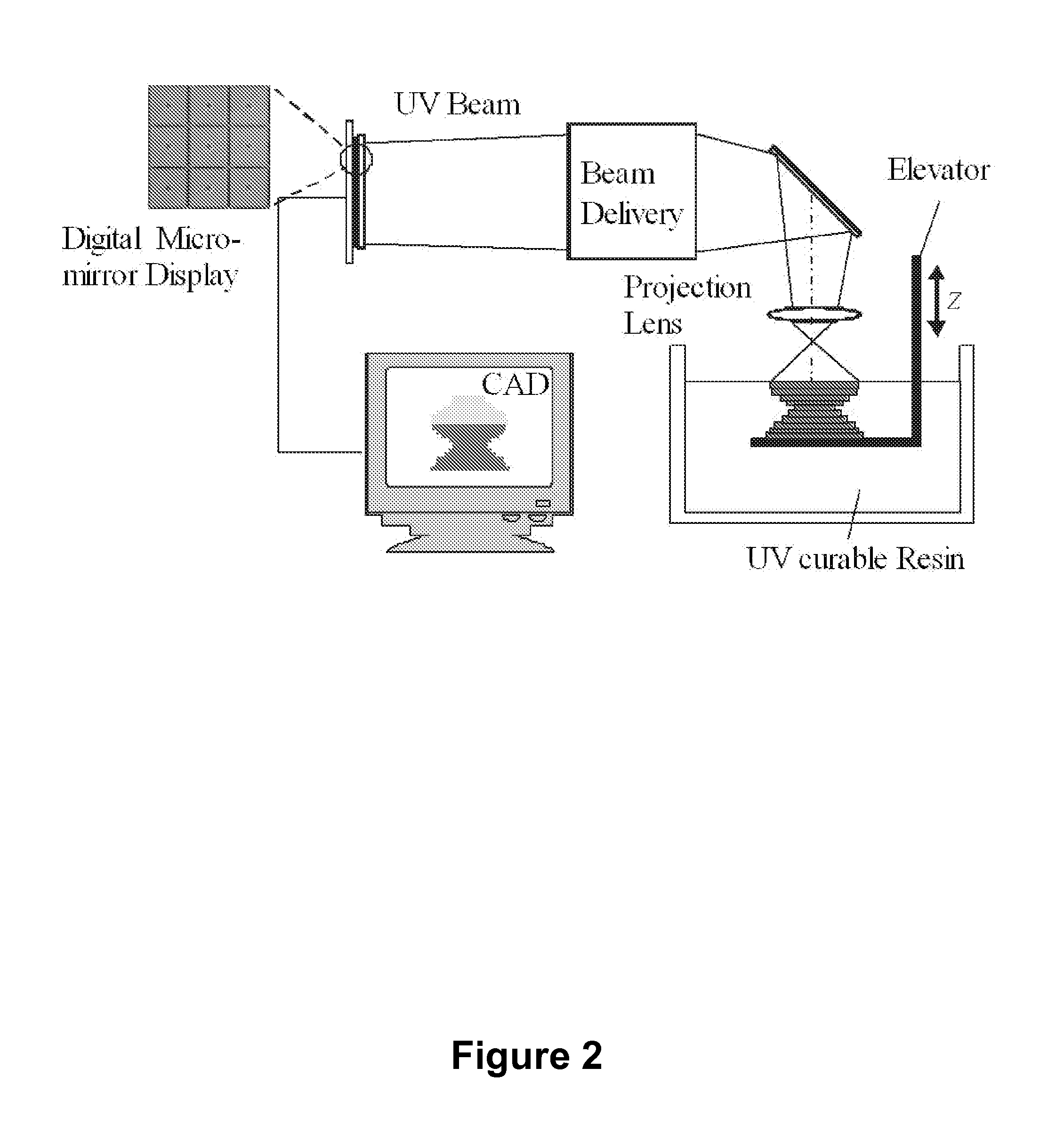

Three-Dimensional Microfabricated Bioreactors with Embedded Capillary Network

InactiveUS20110033887A1Promote growthFacilitating growth and expansionBioreactor/fermenter combinationsBiological substance pretreatmentsCapillary networkEngineering

In an aspect, the present invention uses projection micro stereolithography to generate three-dimensional microvessel networks that are capable of supporting and fostering growth of a cell population. For example, provided is a method of making a microvascularized bioreactor via layer-by-layer polymerization of a photocurable liquid composition with repeated patterns of illumination, wherein each layer corresponds to a layer of the desired microvessel network. The plurality of layers are assembled to make a microvascular network. Support structures having different etch rates than the structures that make up the network provides access to manufacturing arbitrary geometries that cannot be made by conventional methods. A cell population is introduced to the external wall of the network to obtain a microvascularized bioreactor. Provided are various methods and related bioreactors, wherein the network wall has a permeability to a biological material that varies within and along the network.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

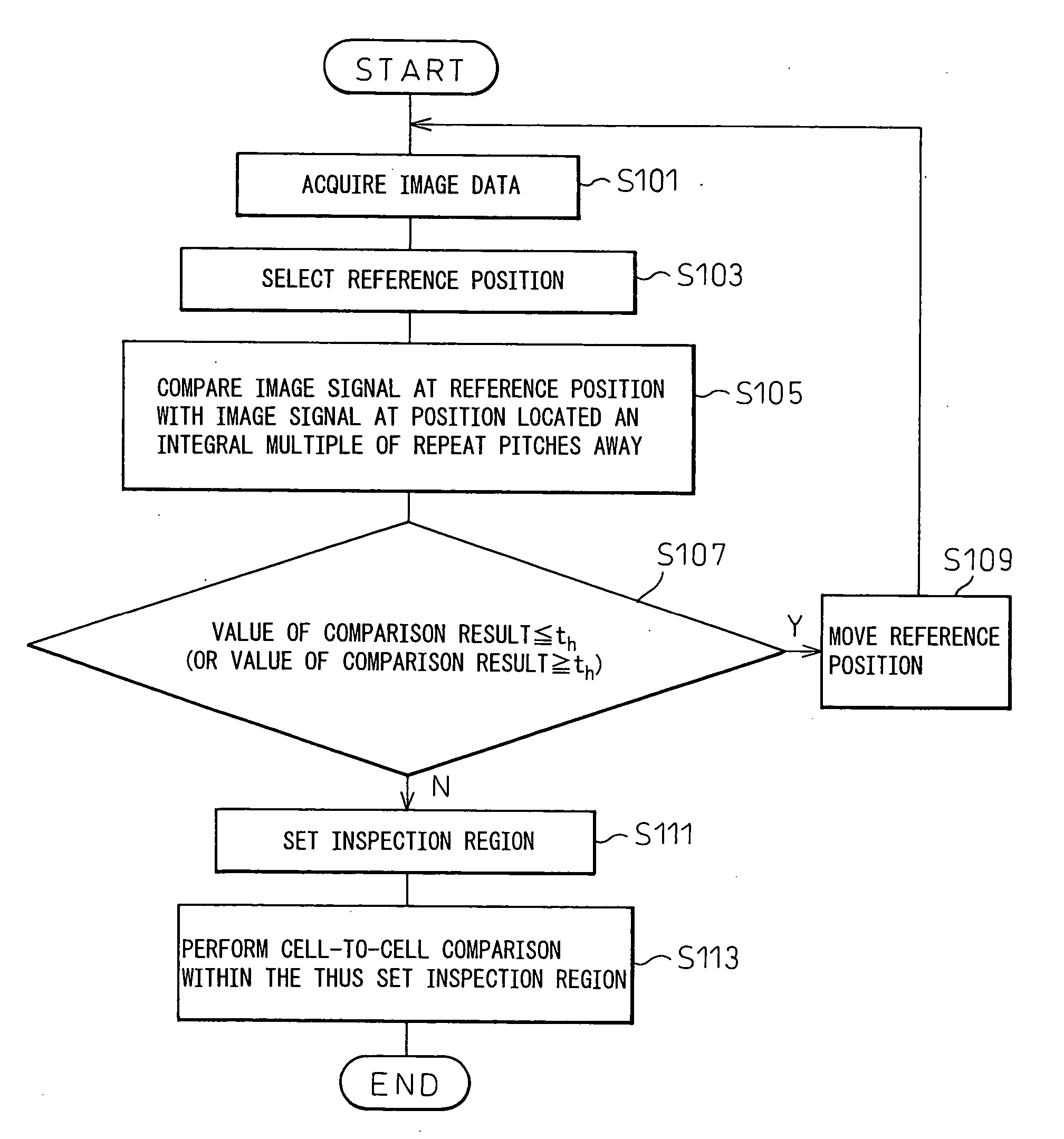

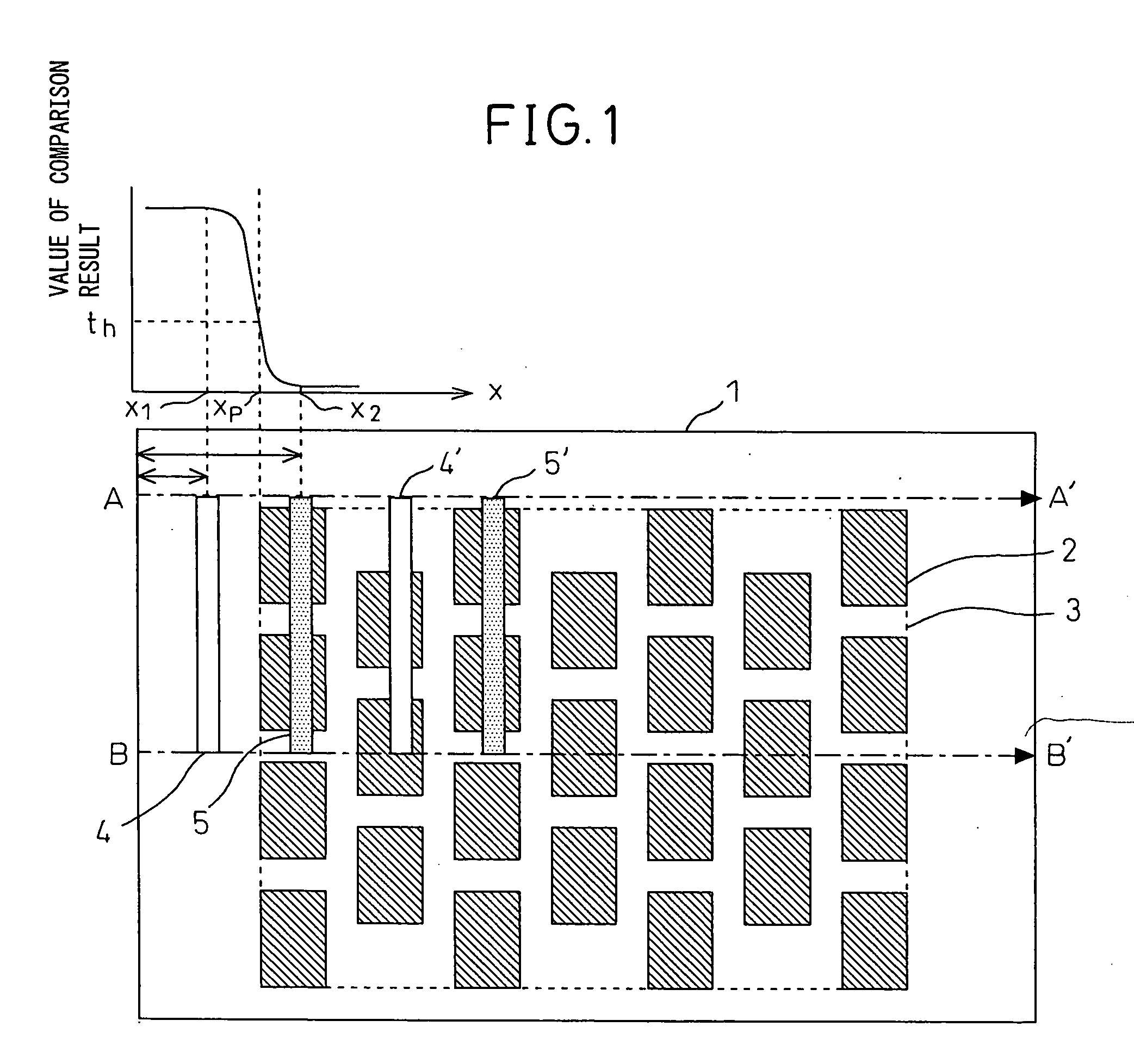

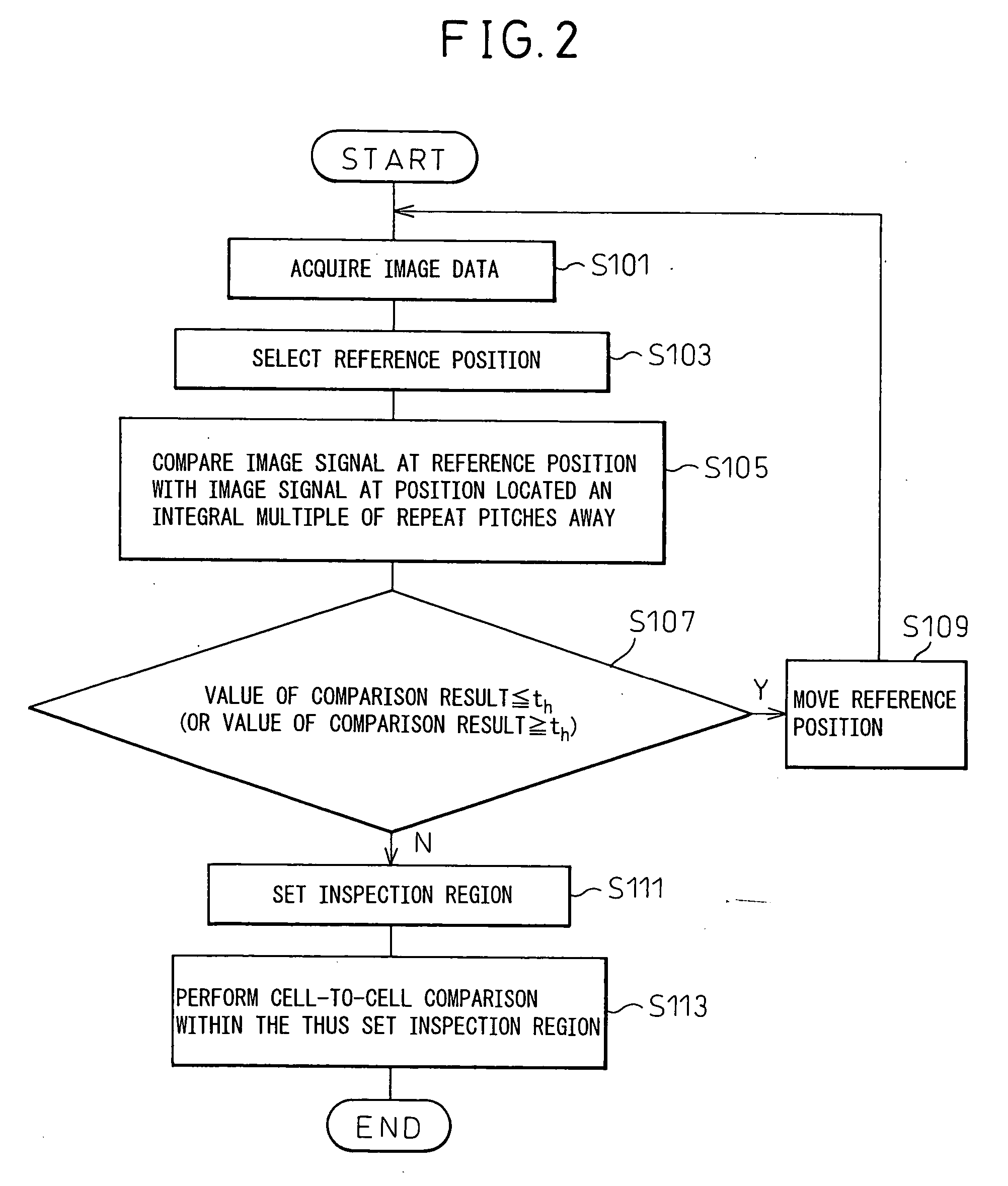

Pattern comparison inspection method and pattern comparison inspection device

InactiveUS20060280358A1Inspection speed is fastImage enhancementImage analysisRepeat patternImage signal

A pattern comparison inspection apparatus comprises: a reference position selecting portion (41) which selects from among positions on an inspection target pattern a reference position which is judged whether it should be contained in an inspection region; an image comparing portion (42) which compares an image signal at the reference position with an image signal at a position located an integral multiple of a repeat pitch away from the reference position; and an inspection region setting portion (43) which sets the inspection region by containing therein the reference position when a comparison result from the image comparing portion shows a value not greater than a prescribed threshold value. Thus, in the pattern comparison inspection apparatus which performs inspection for a pattern defect by comparing repeated patterns with each other in the inspection target pattern having a repeated pattern region, the inspection region can be enlarged within the bounds of the repeated pattern region.

Owner:TOKYO SEIMITSU

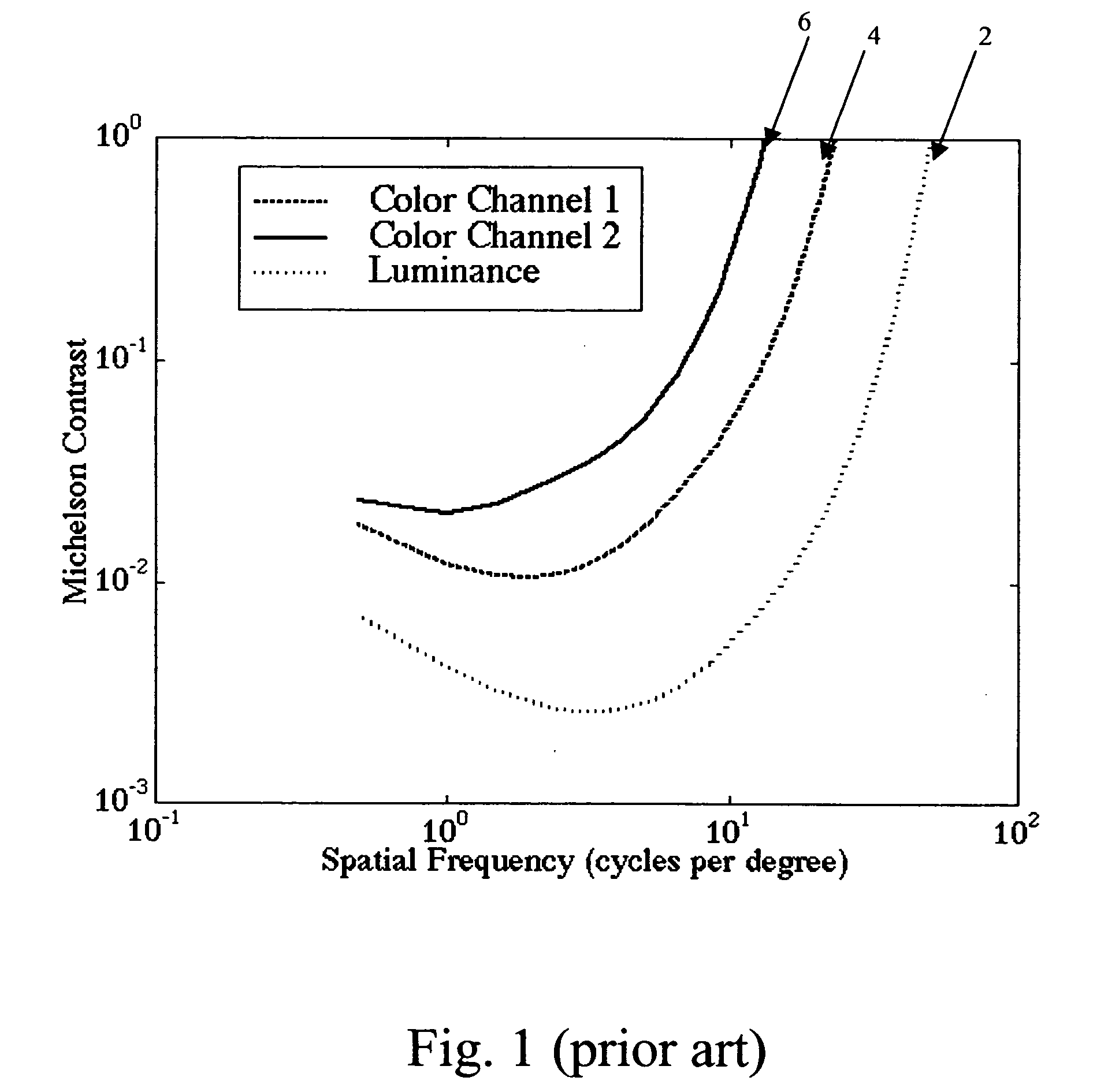

Color display system with improved apparent resolution

ActiveUS20070257944A1Improved apparent resolutionReduced image processing complexityCathode-ray tube indicatorsInput/output processes for data processingColor imageDisplay device

Owner:GLOBAL OLED TECH

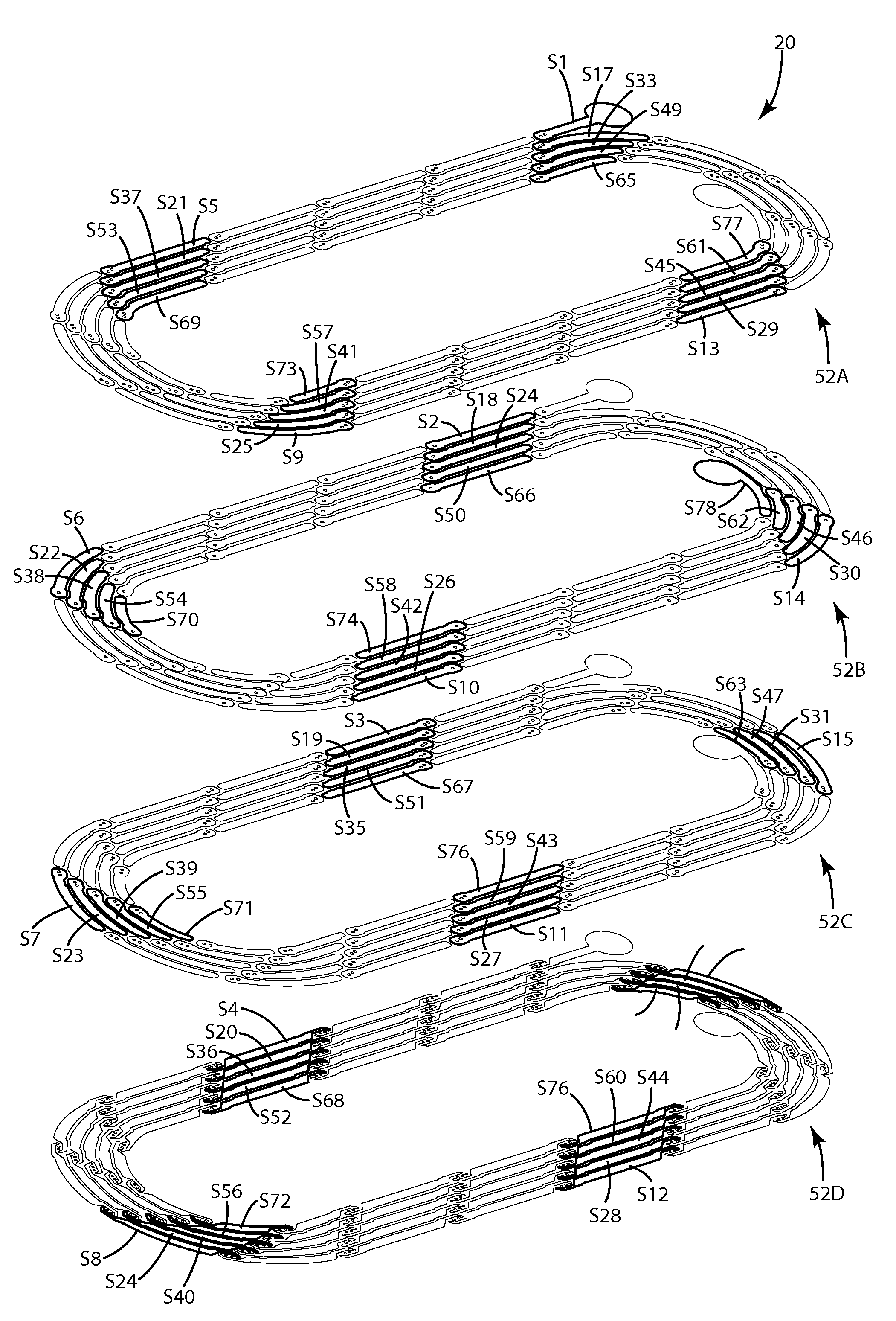

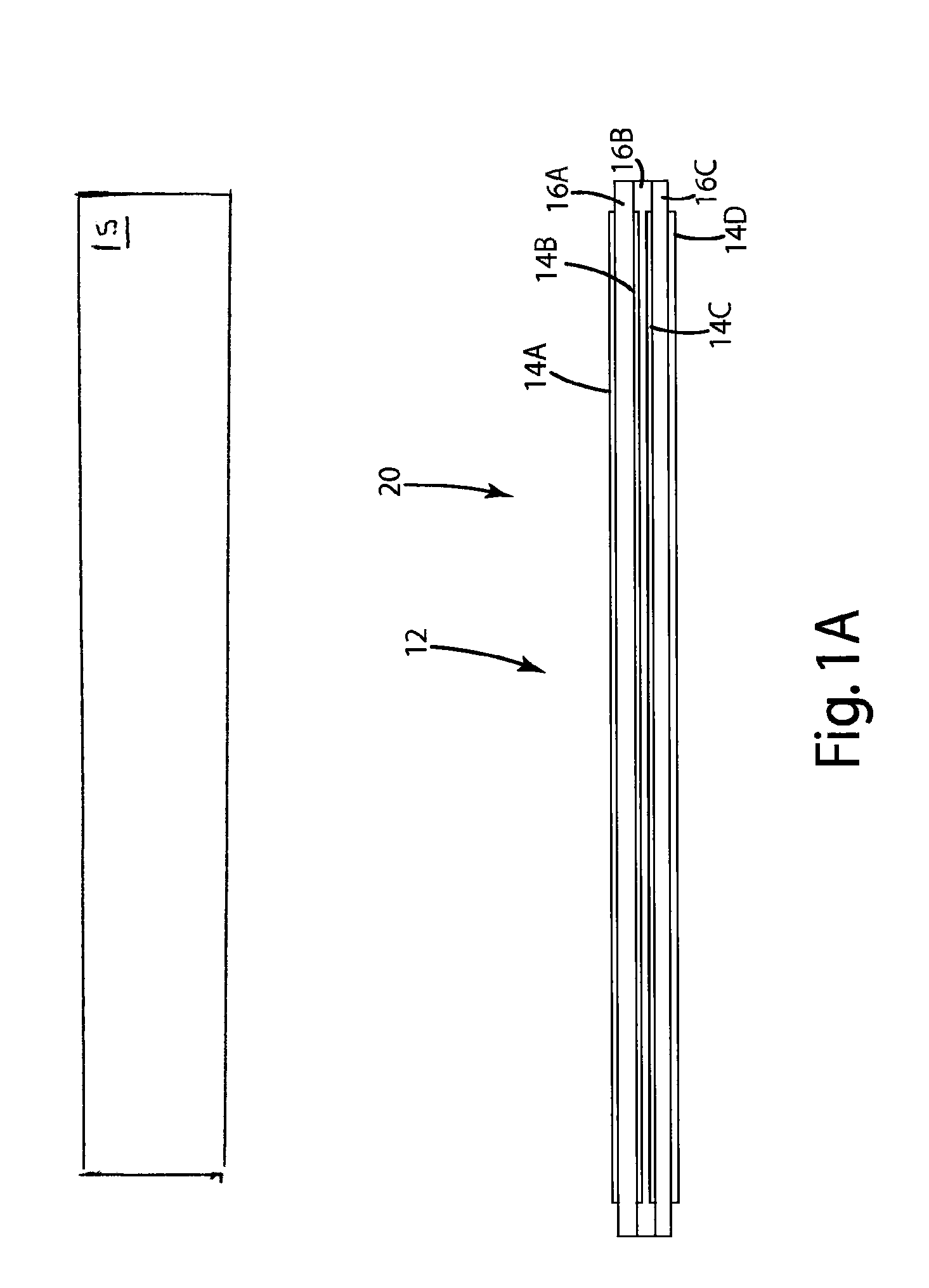

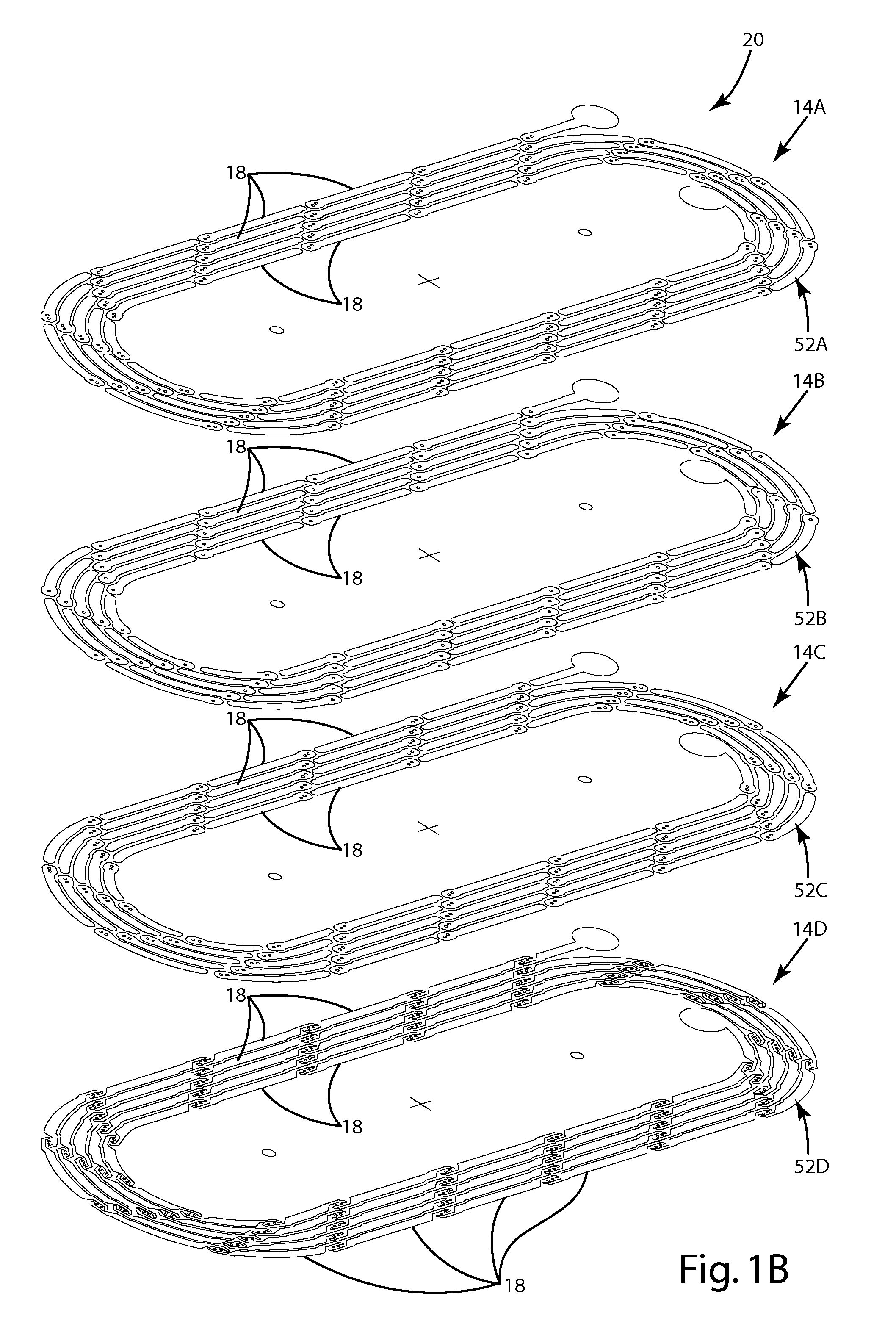

Printed circuit board coil

ActiveUS7973635B2Reliable and easily implementedImprove coiling efficiencyTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

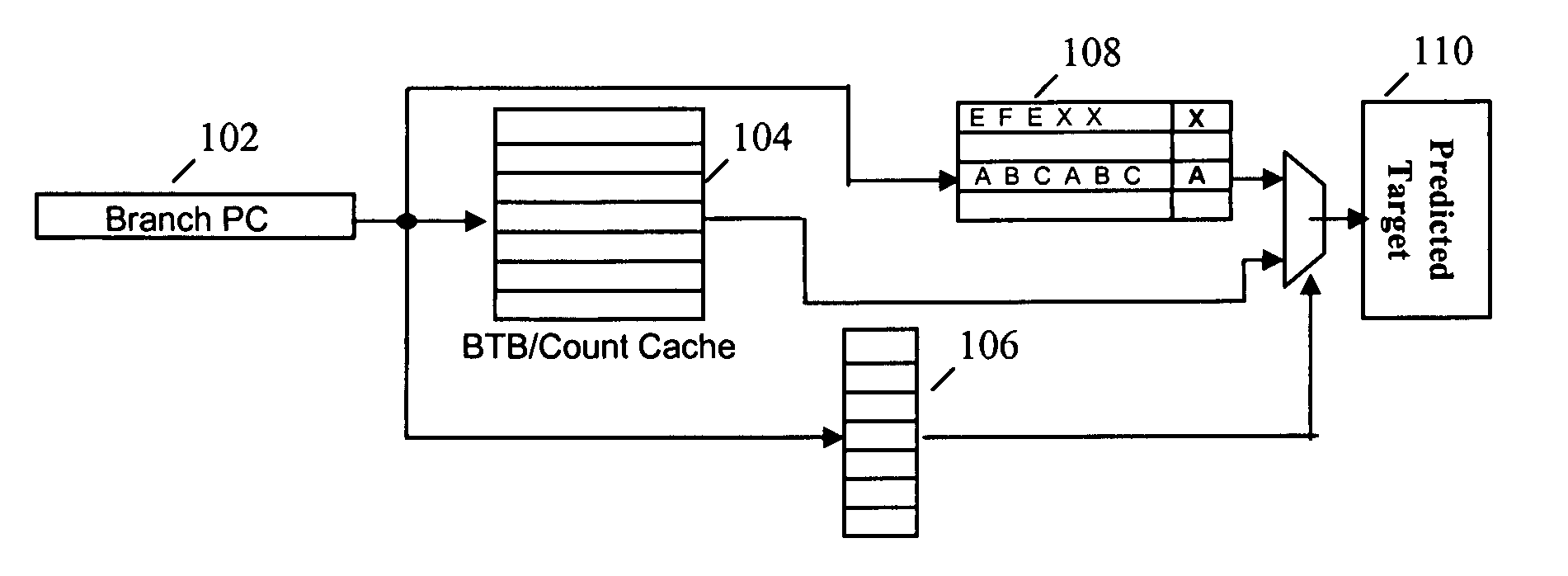

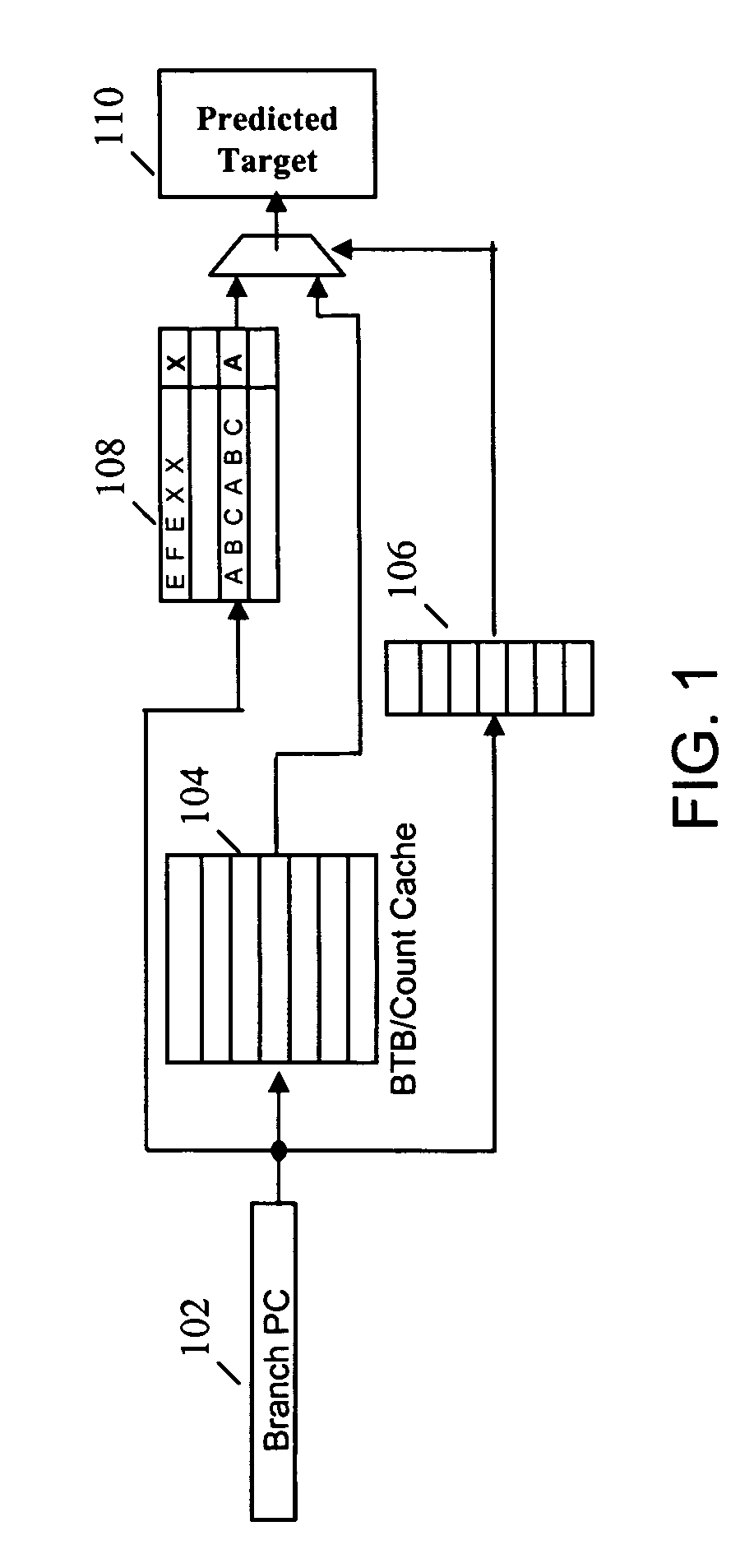

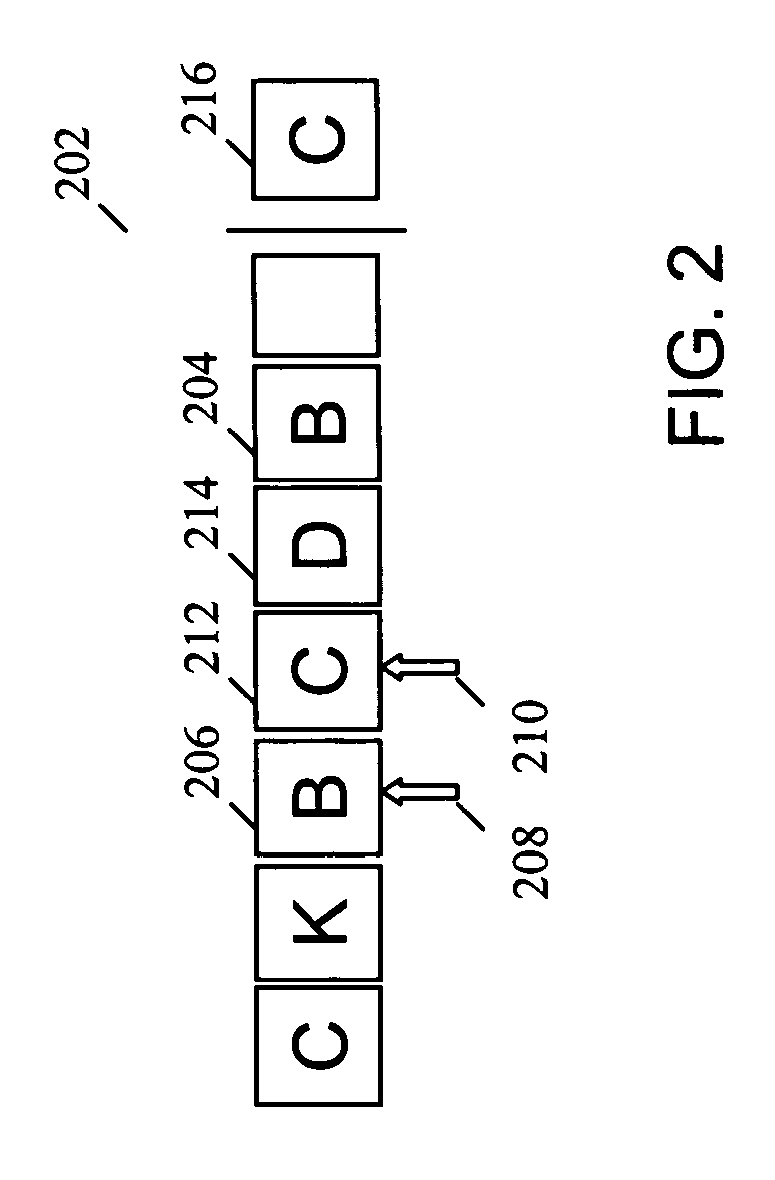

Branch target prediction for multi-target branches

InactiveUS20060242393A1Digital computer detailsSpecific program execution arrangementsInformation processingParallel computing

An information processing system for branch target prediction is disclosed. The information processing system includes a memory for storing entries, wherein each entry includes a plurality of target addresses representing a history of target addresses for a multi-target branch and logic for reading the memory and identifying a repeated pattern in a plurality of target addresses for a multi-target branch. The information processing system further includes logic for predicting a next target address for the multi-target branch based on the repeated pattern that was identified.

Owner:IBM CORP

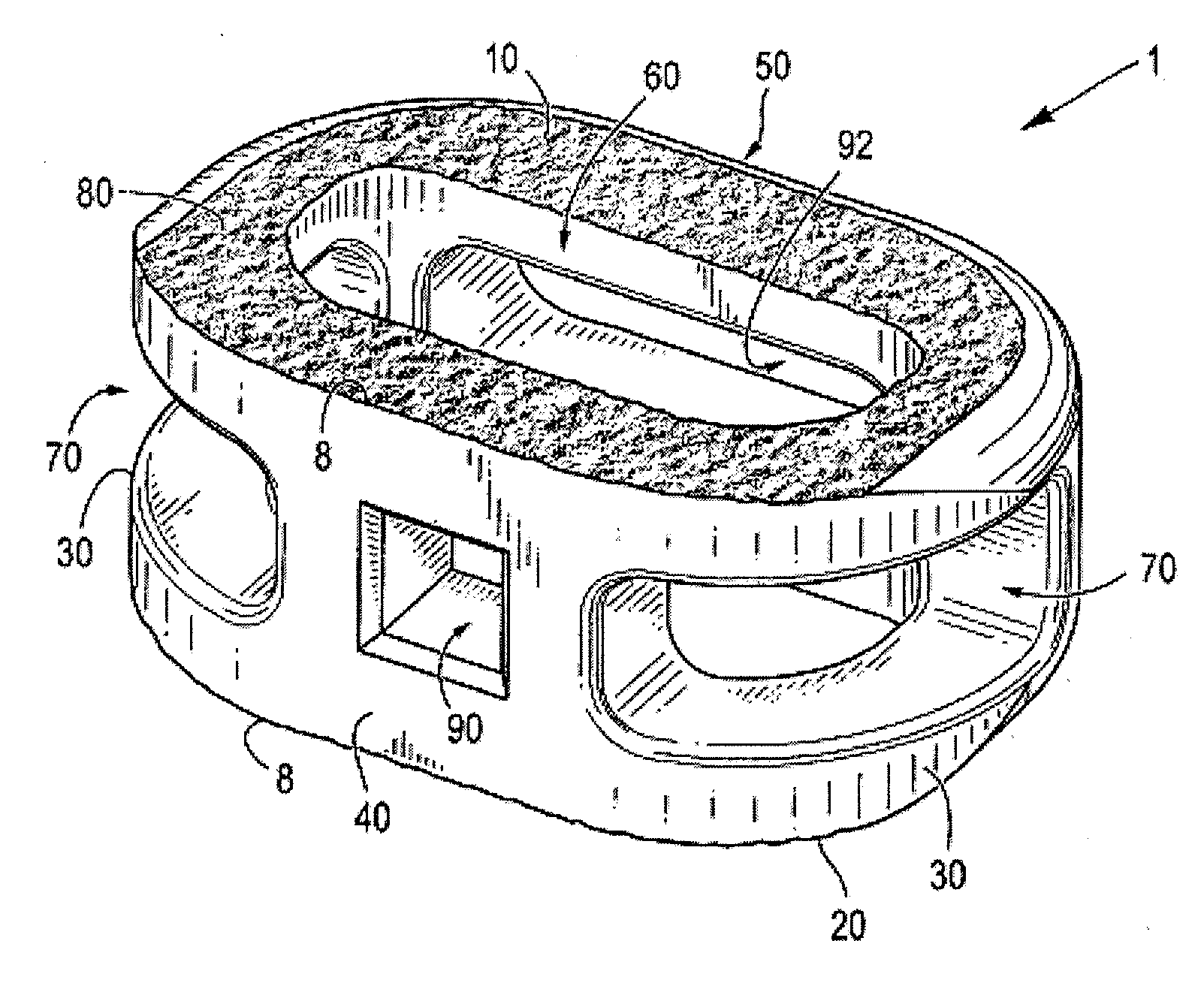

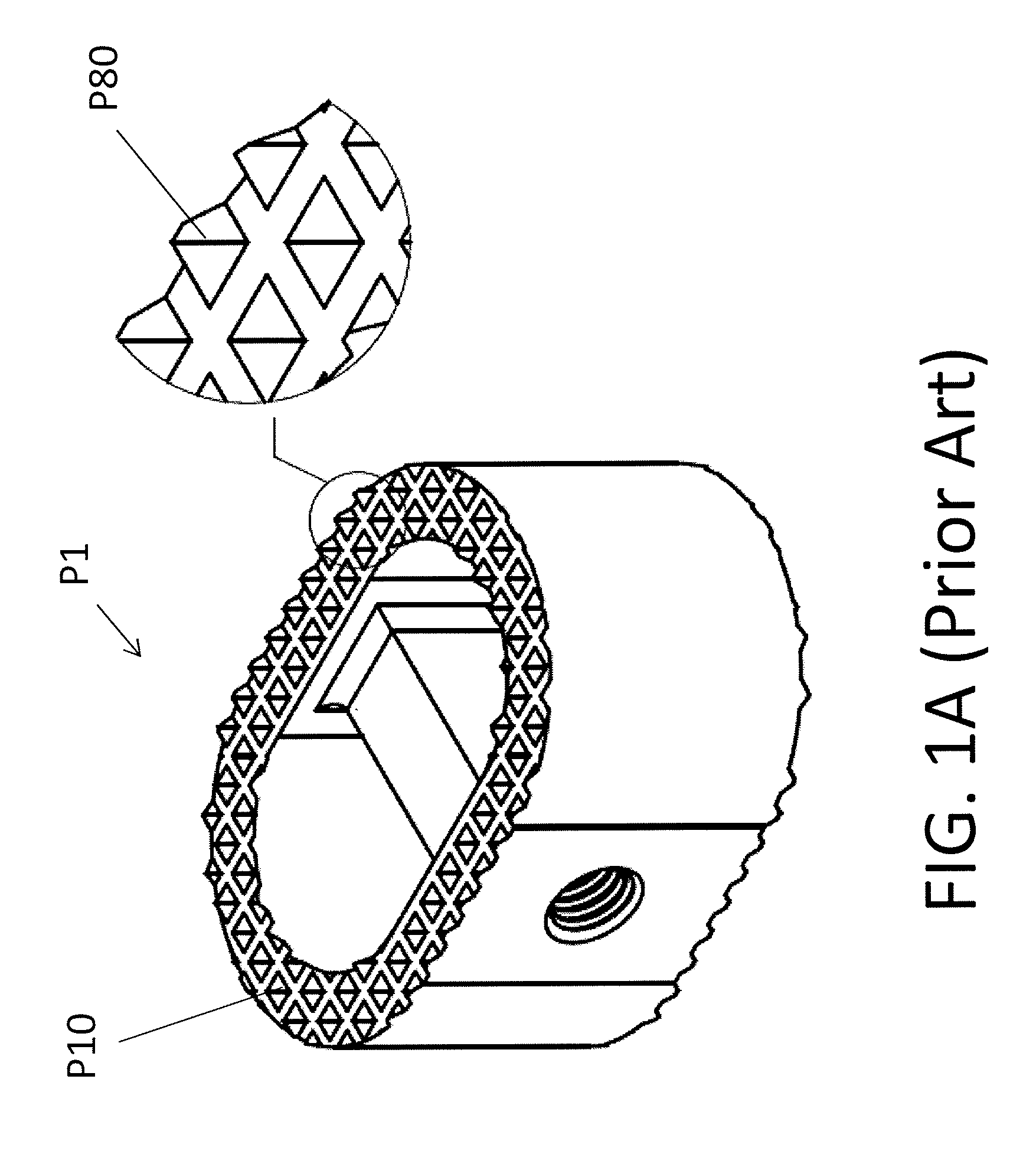

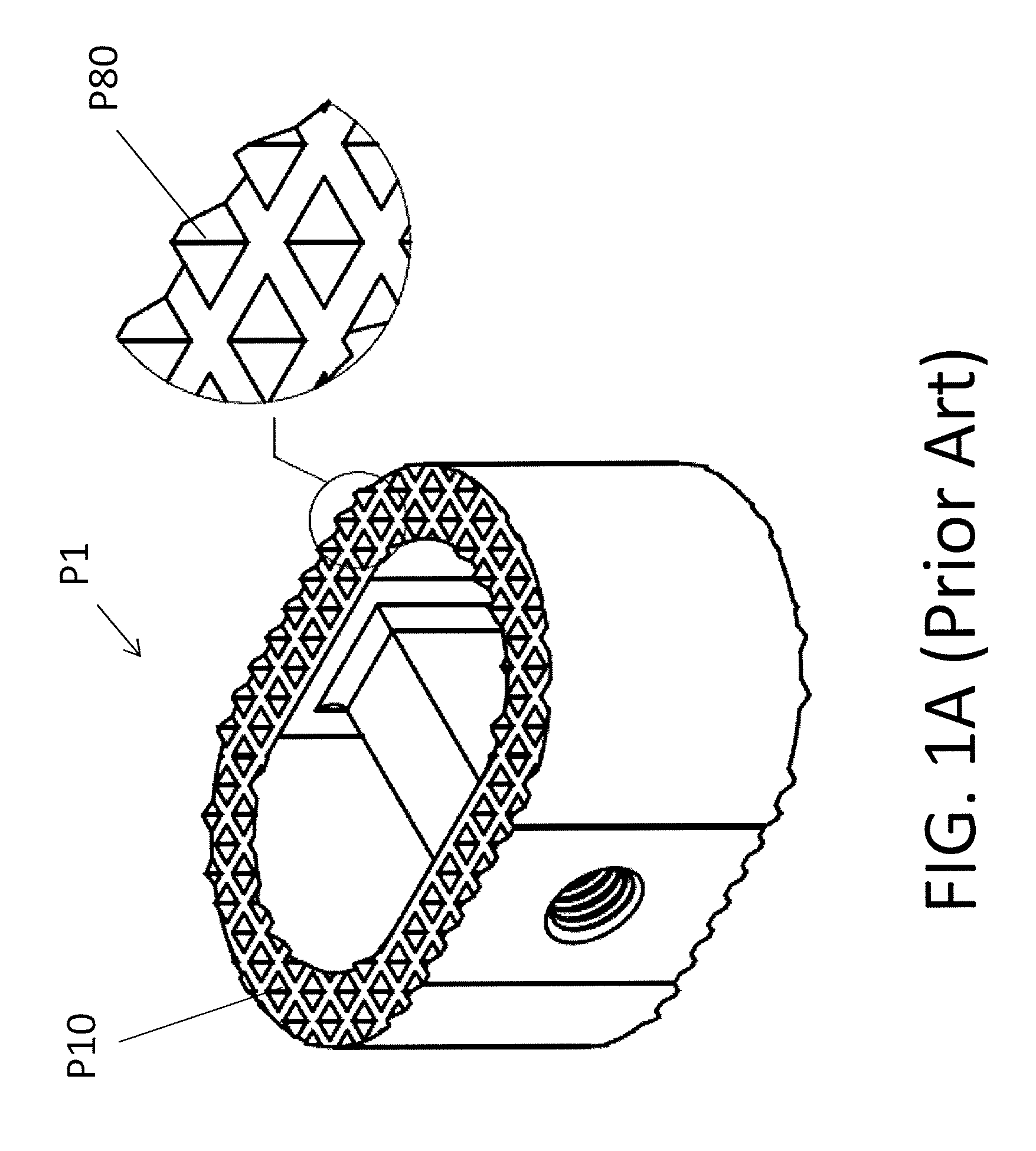

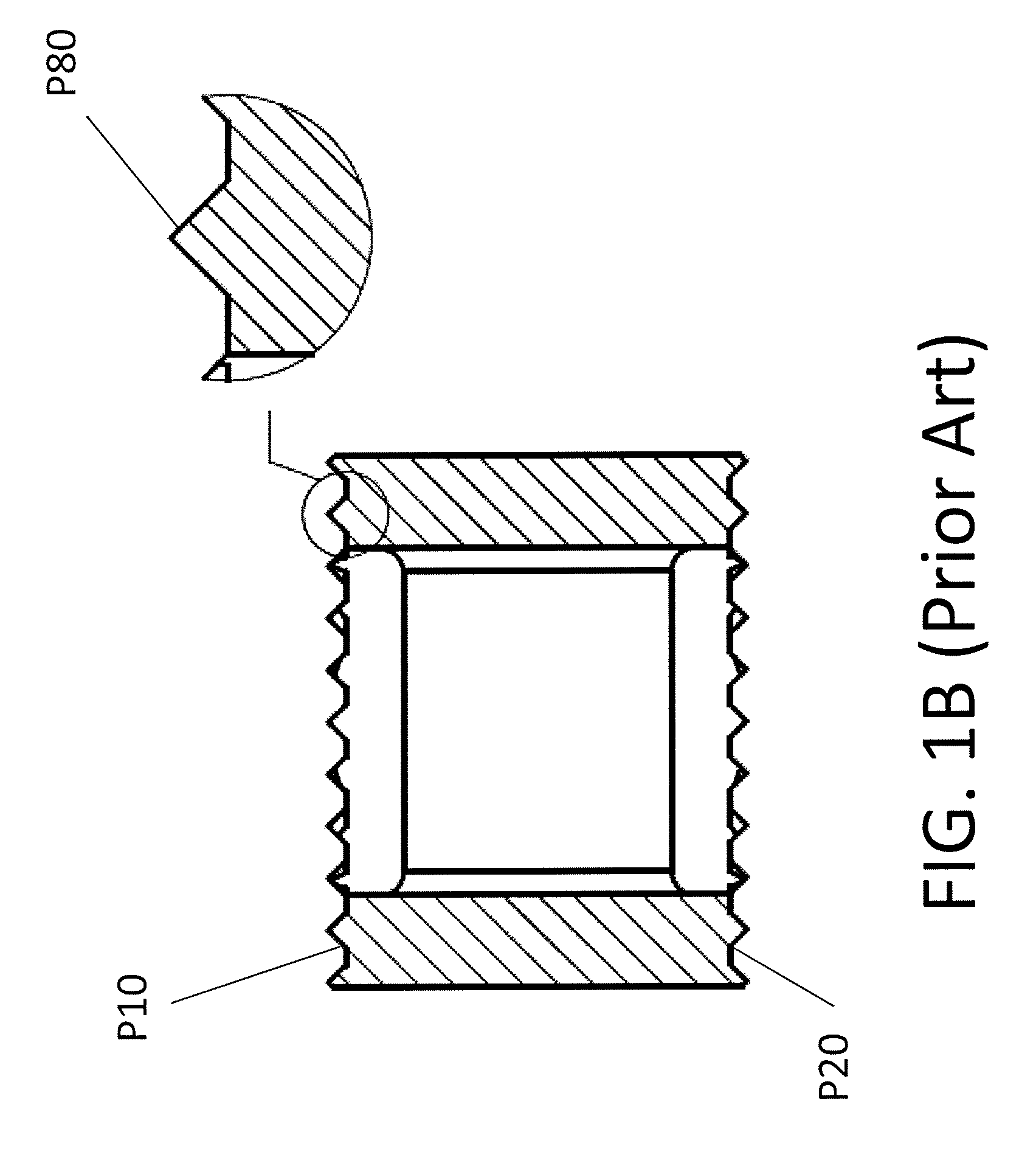

Implants with integration surfaces having regular repeating surface patterns

ActiveUS20130006363A1Increase frictionImplant stabilityBone implantSpinal implantsSurface patternBone structure

An interbody spinal implant, such as a solid-body or composite implant. The implant has at least one integration surface with a roughened surface topography including a repeating pattern, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebral endplates and to inhibit migration of the implant. The repeating pattern is formed of at least three at least partially overlapping repeating patterns. The repeating patterns may radiate at a fixed distance from at least one point and may include recesses having a slope of thirty degrees or less relative to the integration surface. Also disclosed are processes of fabricating the integration surfaces.

Owner:TITAN SPINE

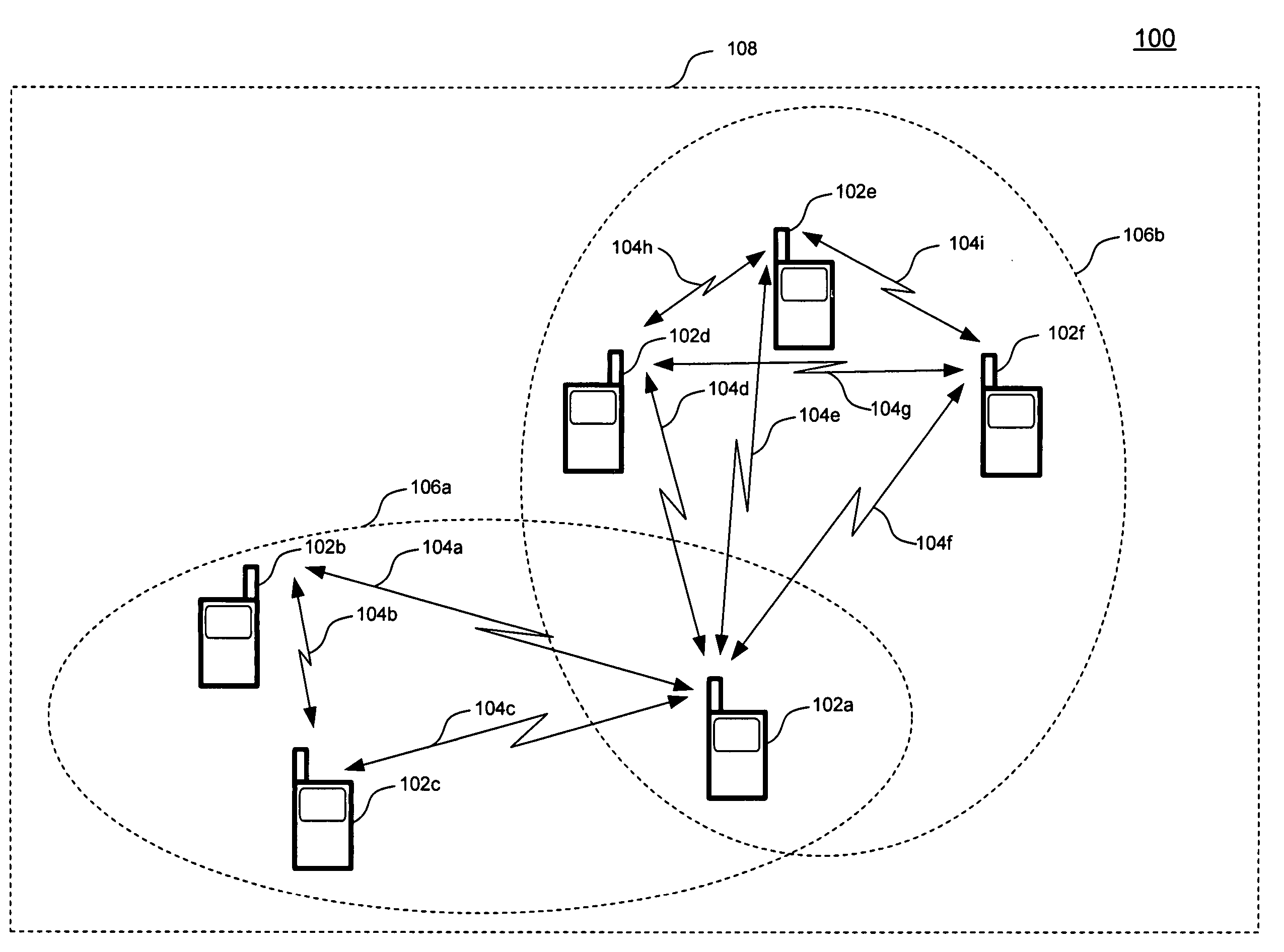

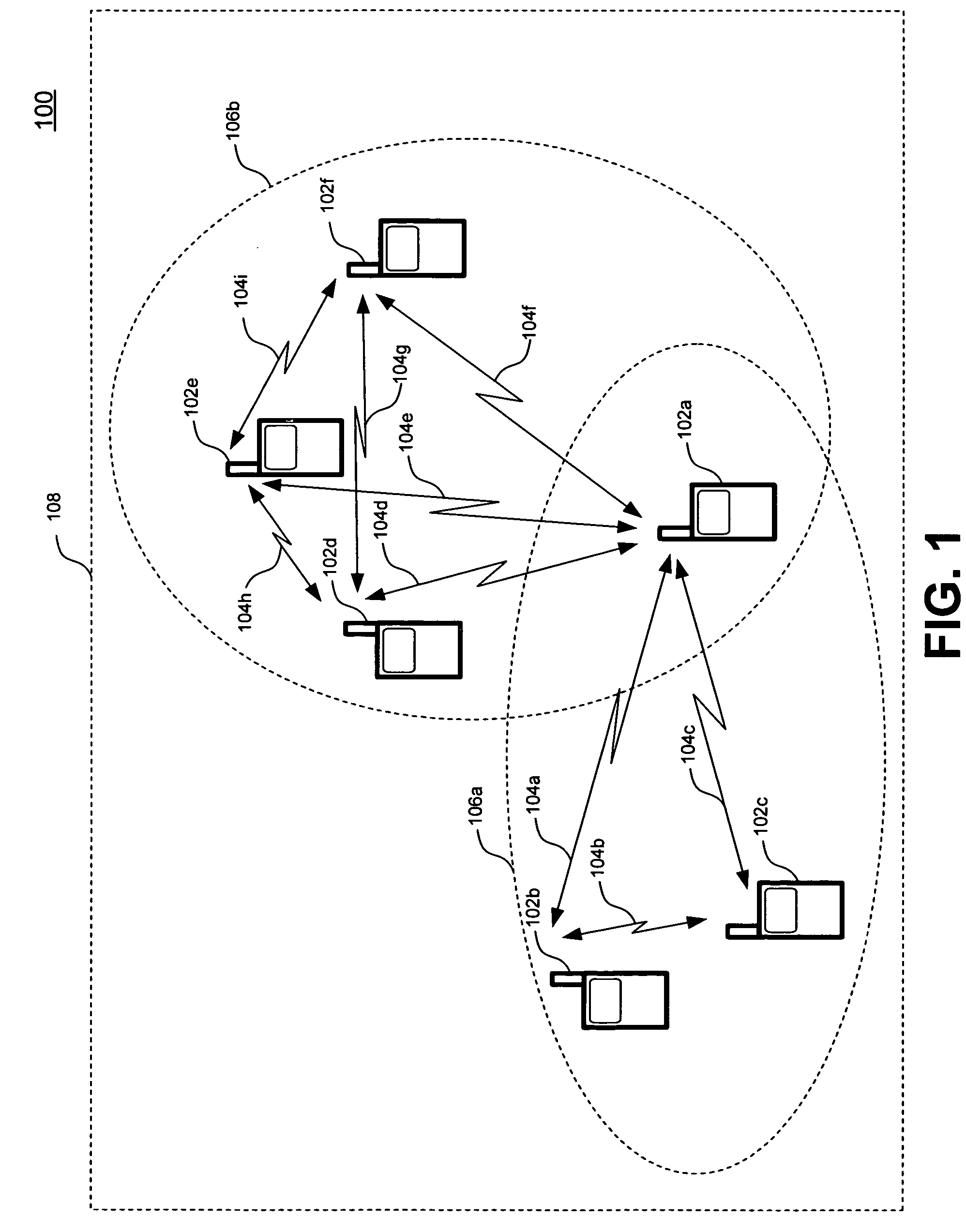

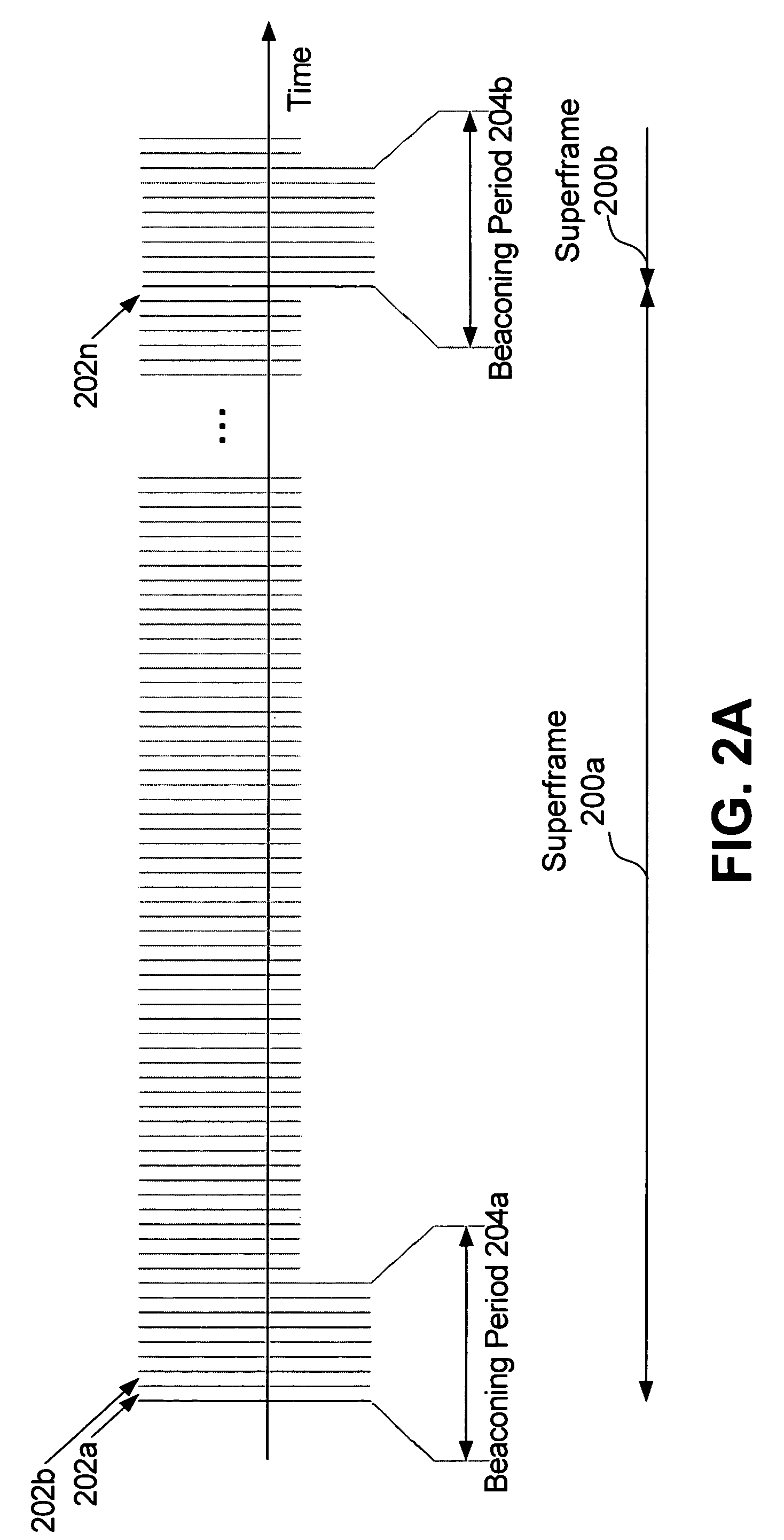

Adaptive beacon period in a distributed network

InactiveUS20050249173A1Reduce power consumptionEfficient of communication resourceAssess restrictionNetwork topologiesRepeat patternSelf adaptive

Multiple nodes communicate using repeating patterns of superframes, where each of the superframes includes a beacon period. A beacon slot in a first Media Access Slot (MAS) is reserved by the plurality of nodes. This reserved slot occurs in the beginning of the beacon period and is used for communicating information relating to the superframe configuration. This information may involve adjustments to the number of MASs reserved for beaconing.

Owner:PROVENANCE ASSET GRP LLC

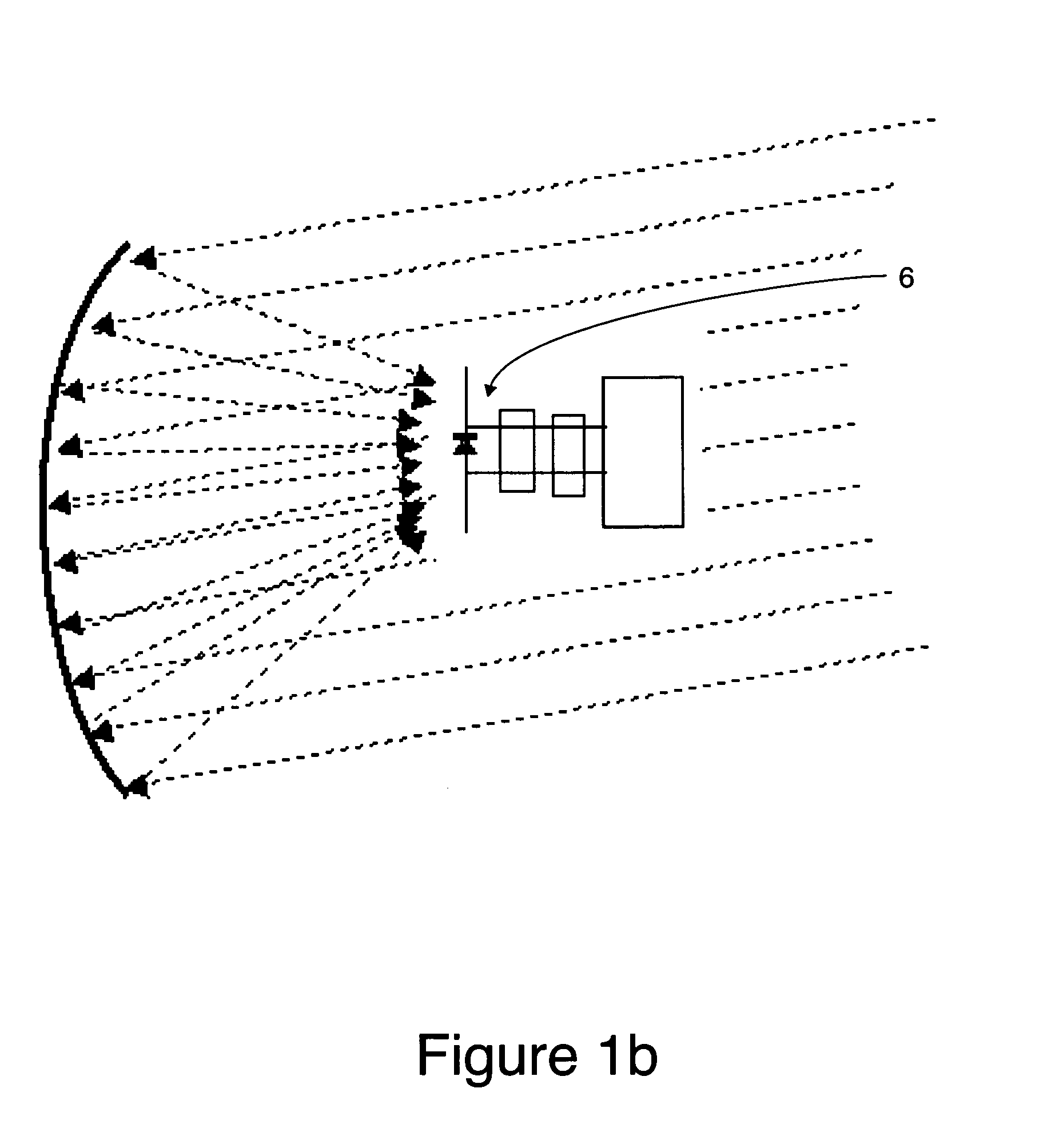

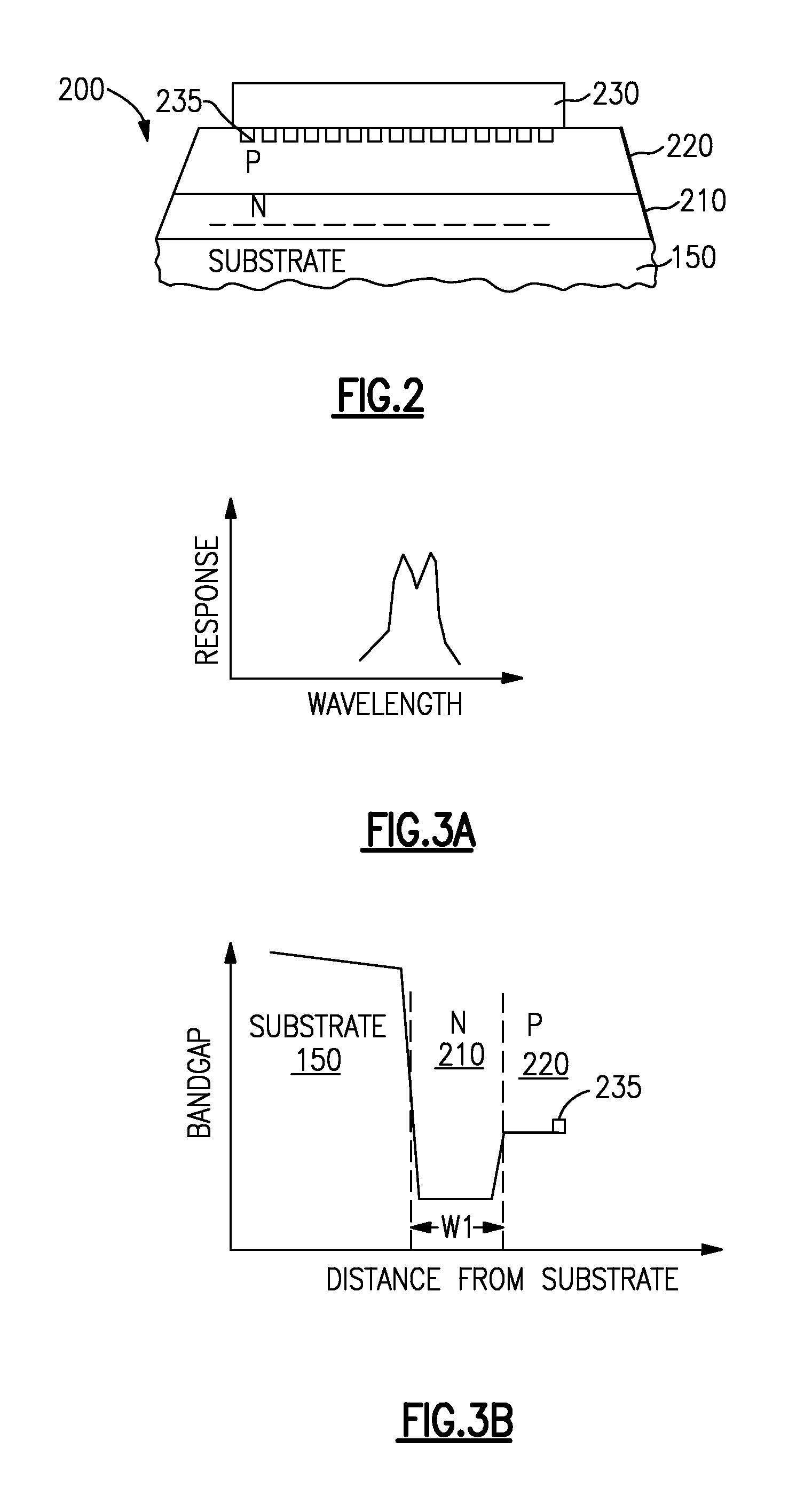

Photodetector with surface plasmon resonance

ActiveUS20130228887A1Reduce thicknessEasy to solveSolid-state devicesDiodePhotovoltaic detectorsPhotodetector

Methods and structures for providing single-color or multi-color photo-detectors leveraging plasmon resonance for performance benefits. In one example, a radiation detector includes a semiconductor absorber layer having a first electrical conductivity type and an energy bandgap responsive to radiation in a first spectral region, a semiconductor collector layer coupled to the absorber layer and having a second electrical conductivity type, and a plasmonic resonator coupled to the collector layer and having a periodic structure including a plurality of features arranged in a regularly repeating pattern.

Owner:RAYTHEON CO

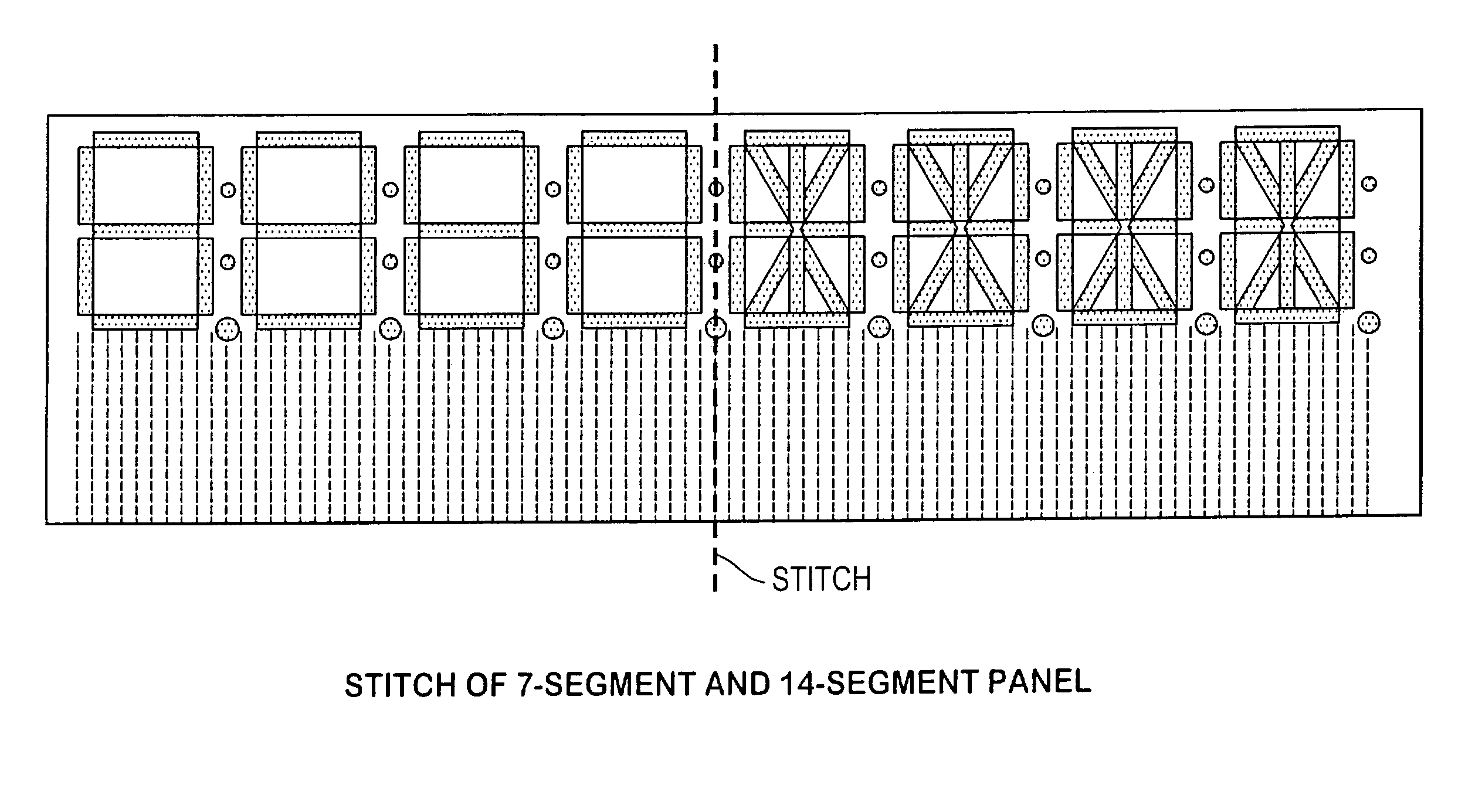

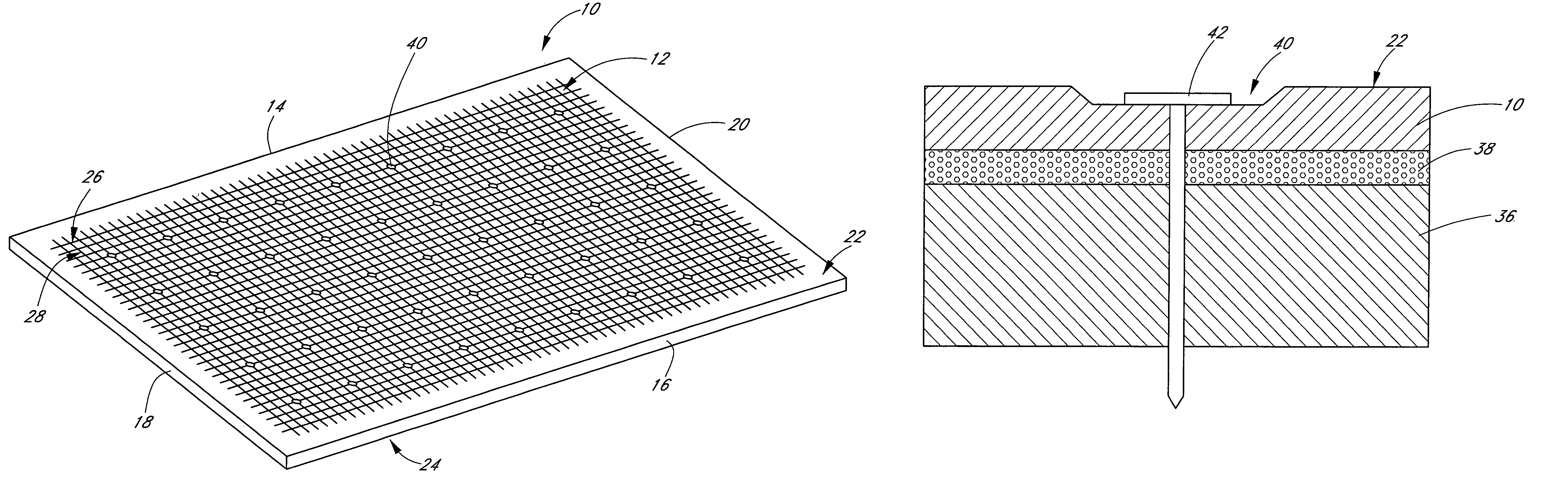

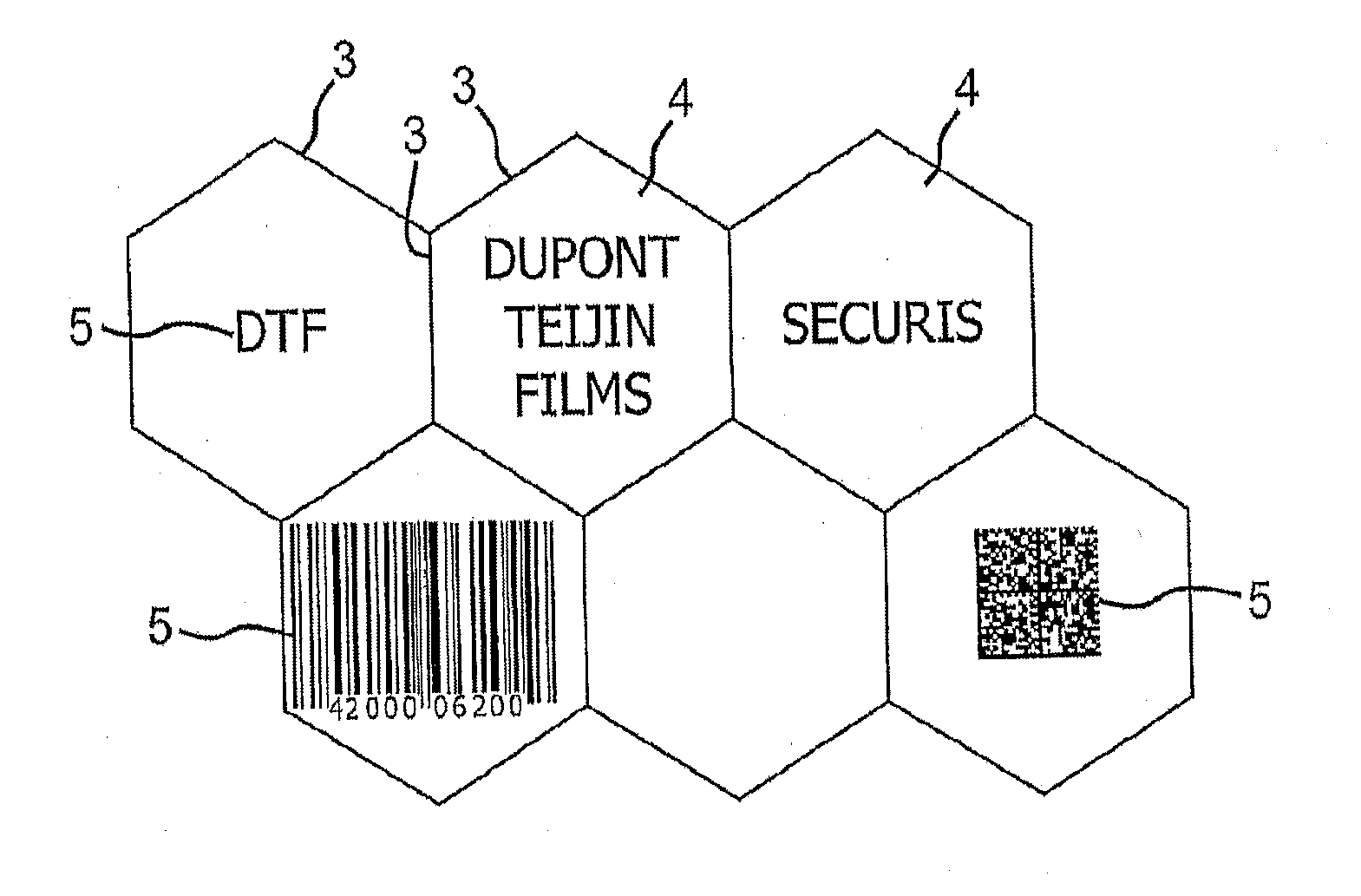

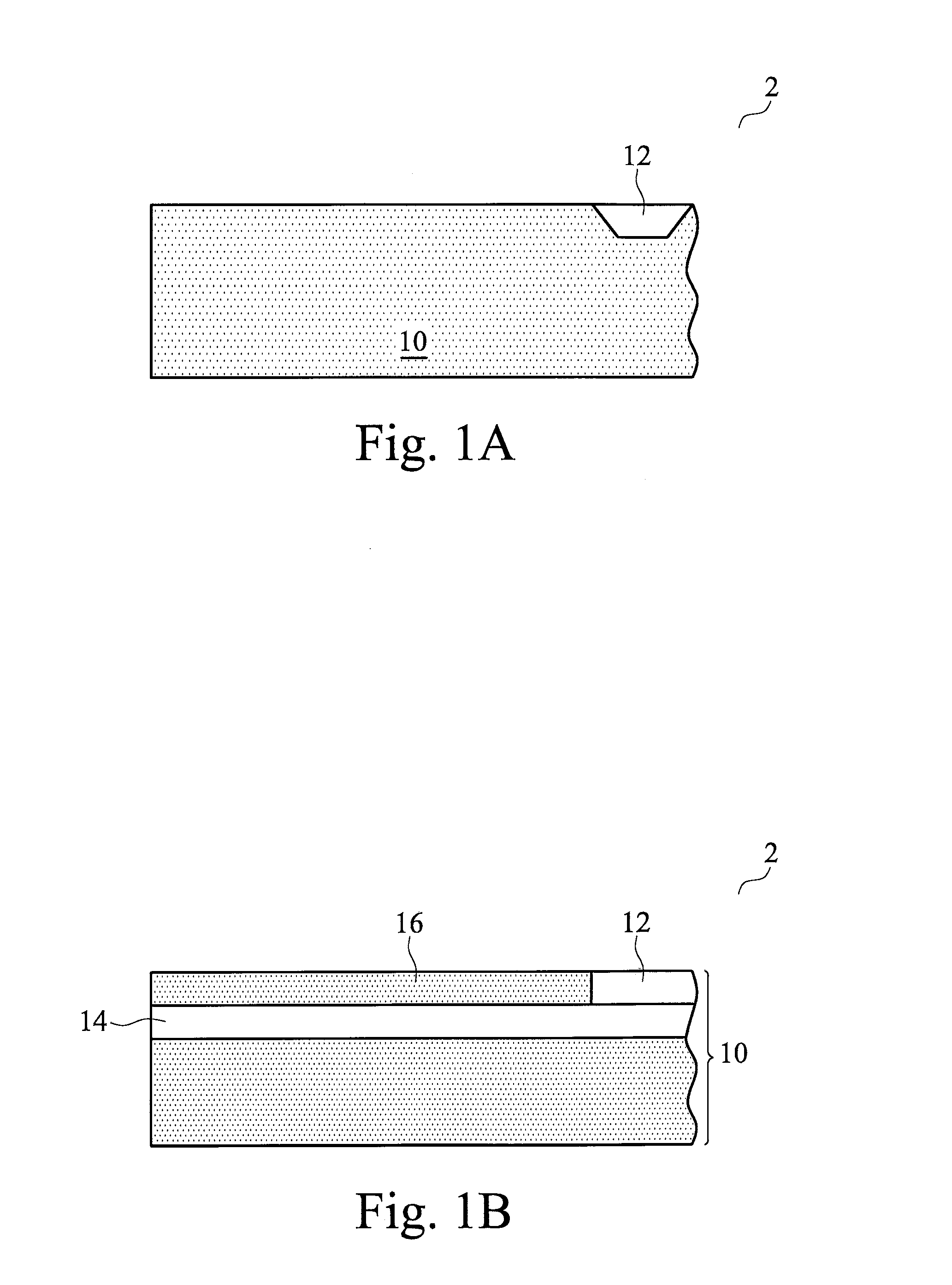

Electrode and connecting designs for roll-to-roll format flexible display manufacturing

InactiveUS7327346B2Easy to installEasy maintenanceStatic indicating devicesNon-linear opticsRepeat patternPulp and paper industry

The present invention generally is directed to electrode designs suitable for roll-to-roll format flexible manufacturing of an EPD. It is also directed to an EPD having a segment design in a repeated pattern across an entire roll of the display. The EPD preferably is microcup-based. The EPD manufactured according to the present invention has the appearance of a roll of wall paper and it can be cut into any desired sizes or formats. The EPD has electrode or trace lines which may be exposed by asymmetrical cutting and stripping without the need of precision registration.

Owner:E INK CALIFORNIA

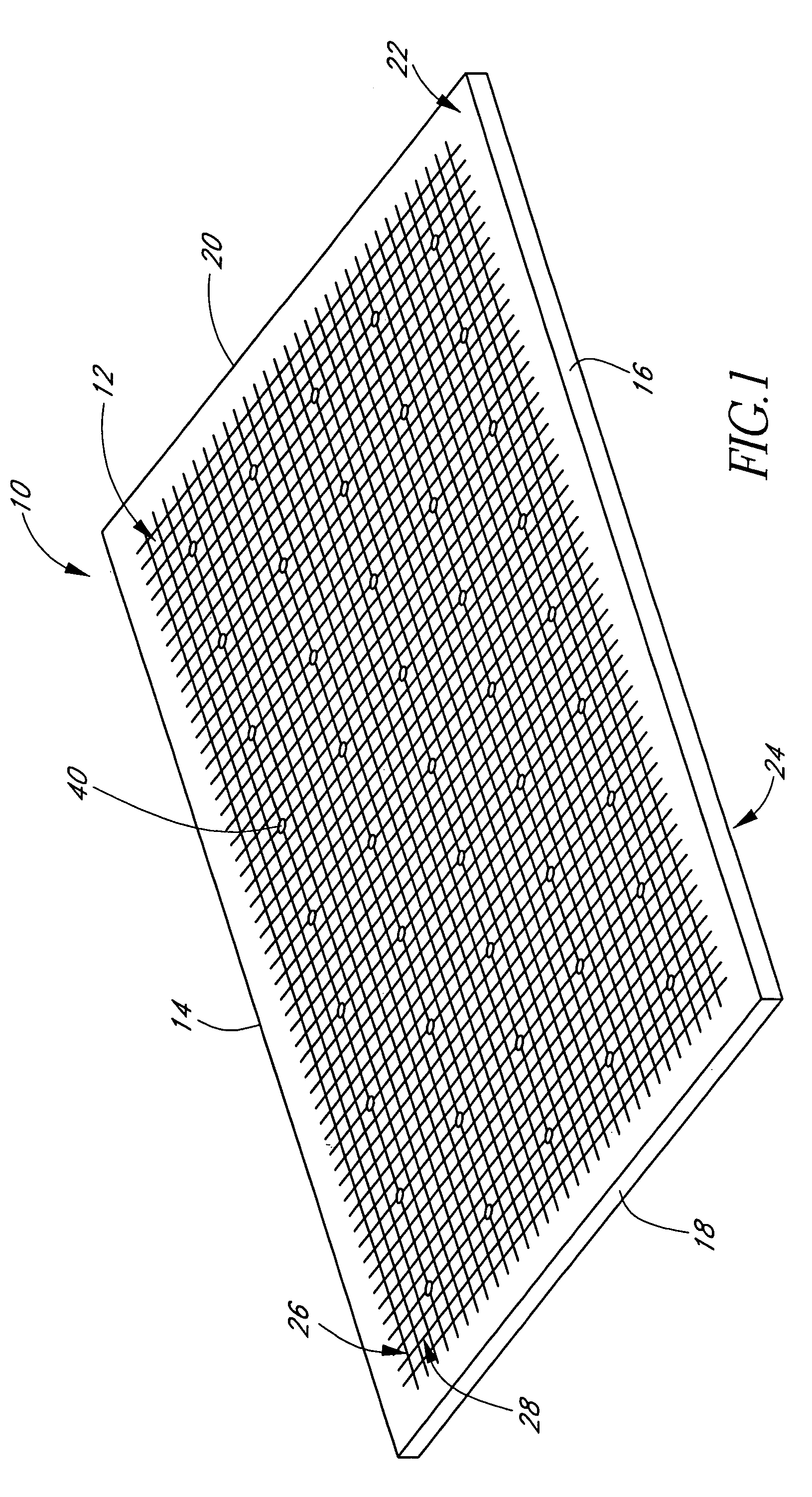

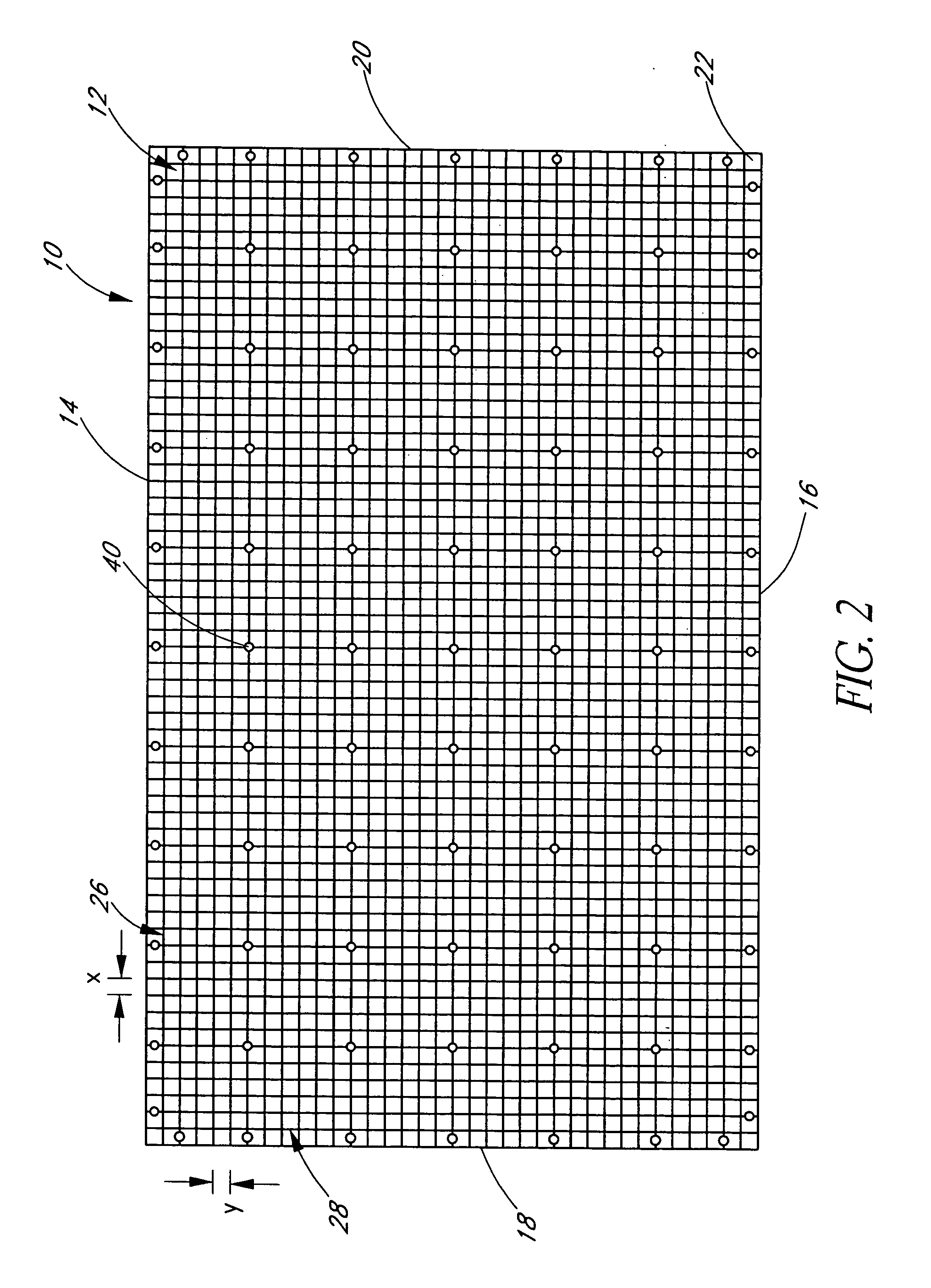

Surface groove system for building sheets

InactiveUS7325325B2Small sizeReduce strength of sheetConstruction materialMechanical measuring arrangementsWood veneerRepeat pattern

The present invention involves building sheets with a plurality of grooves indented into a surface of the building sheet to provide a guide for cutting the building sheet along the grooves. Preferably, the grooves are arranged in a regularly repeating pattern and are spaced apart by a standard unit of measurement in order for a cutter to accurately size the building sheet to a precise dimension. A simple scoring knife is preferably used to score the sheet along the grooves, without the need for a straight edge, and the sheet is broken by simply bending the sheet of along the score mark. The grooves are preferably provided at a depth into the surface the sheet such that they do not substantially decrease the strength of the sheet or affect off-groove scoring. Thus, a score mark can be made between or across grooves without deflection of the mark into a groove and without breakage of the sheet along a groove when the sheet is bent.

Owner:JAMES HARDIE TECH LTD

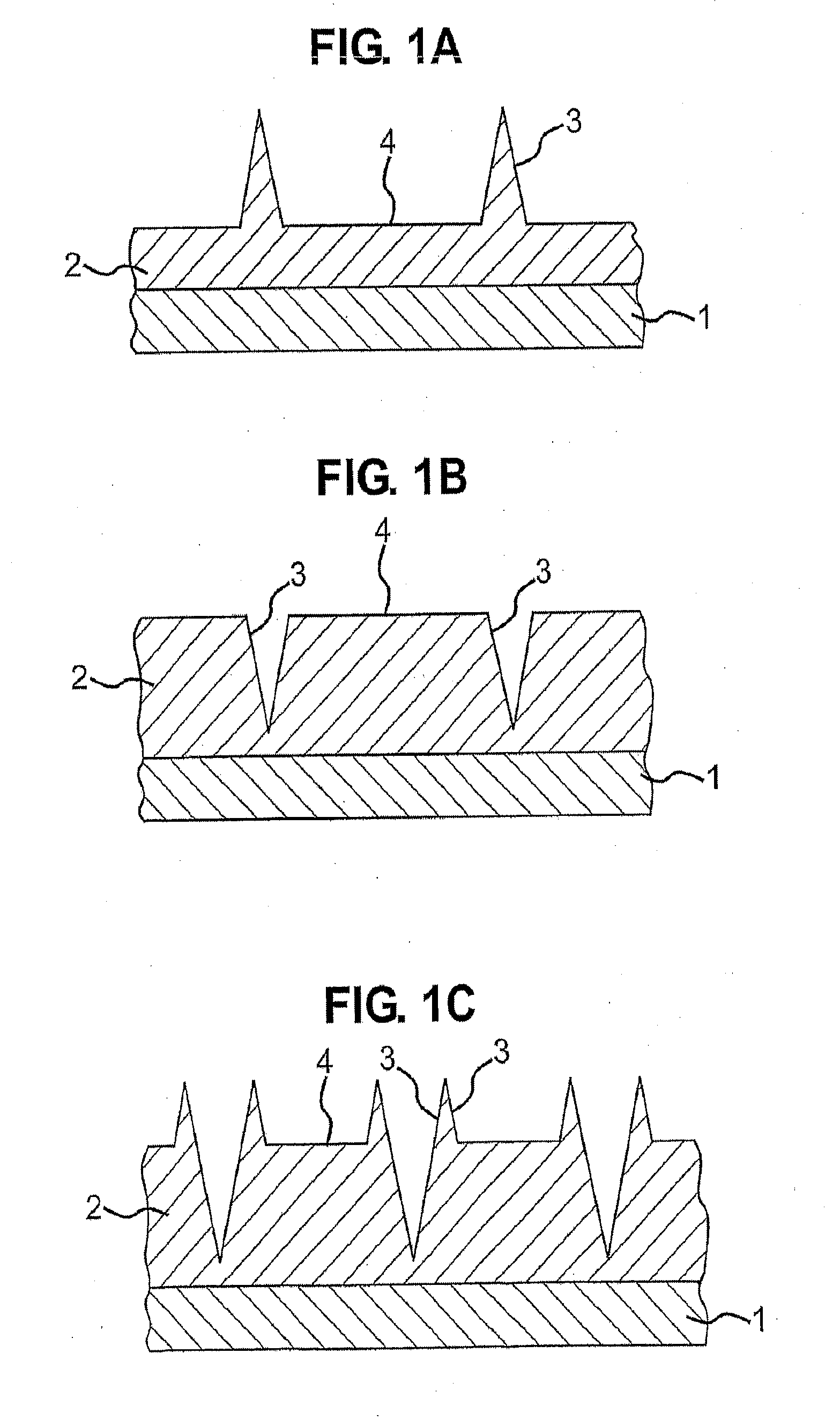

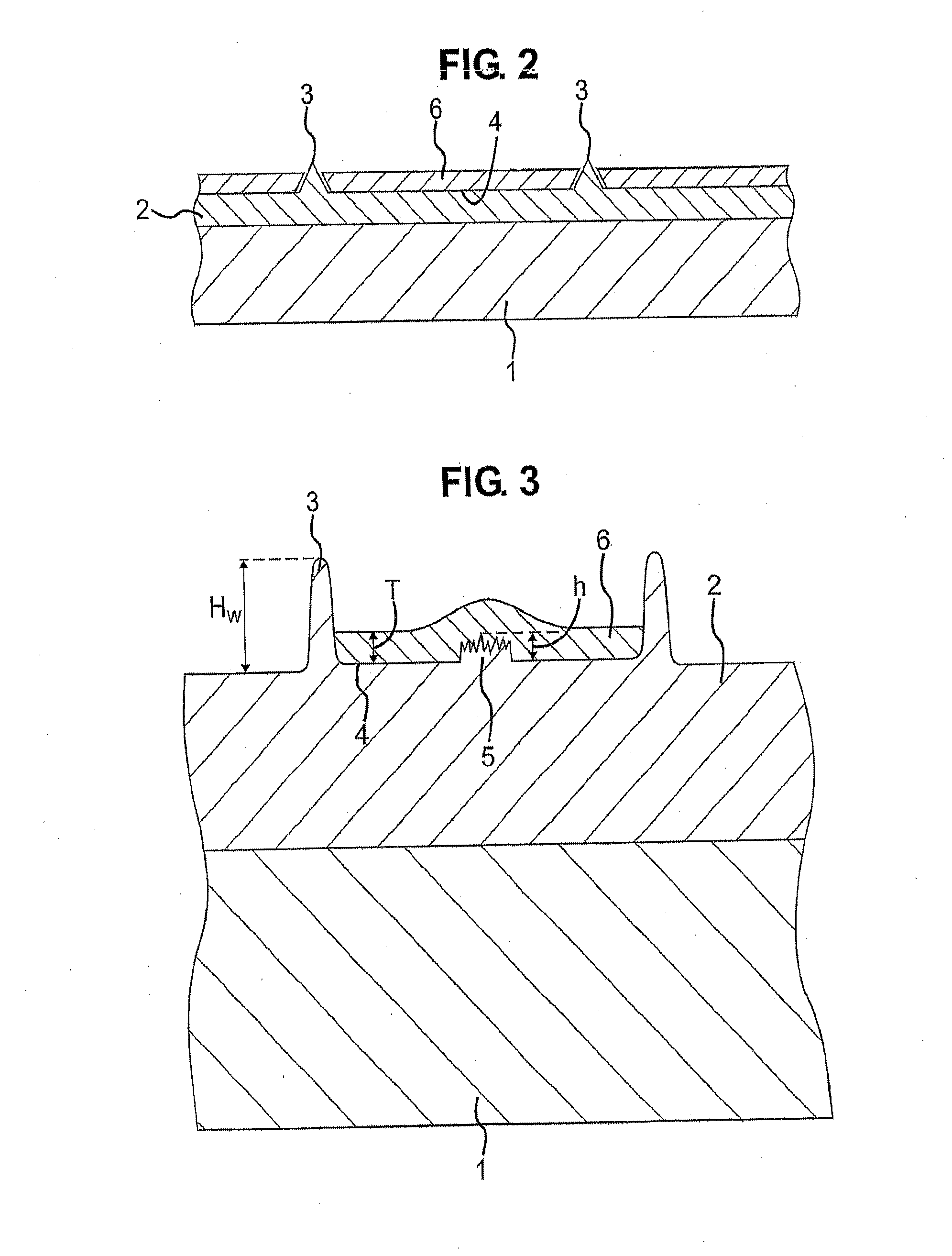

Method of manufacture of particles with controlled dimensions

ActiveUS20150337137A1Reduce risk of damageEfficient conversionPigmenting treatmentPig casting plantsRepeat patternMaterials science

A process for the preparation of particles with controlled dimensions comprising the steps of: (i) providing a laminar substrate having a patterned surface comprising a micro-relief repeat pattern comprising one or more discrete cells, each cell consisting of a floor portion and walls having a height (HW); (ii) depositing organic or inorganic material onto the patterned surface and into the cells to provide a thickness (T) of the deposited material wherein T≦HW (iii) stripping the deposited organic or inorganic material from the surface of the substrate; and (iv) collecting the particles formed from said organic or inorganic material; and a composition obtainable from said process comprising a plurality of particles (P), wherein the number (n) of particles in said composition is at least 10, wherein said particles (P) are platelets exhibiting a planar geometry which is circular or which is made up of a number (x) of planar (y)-sided polygon(s), wherein x is from 1 to 20 and y is at least 3 wherein if x is greater than 1 then said planar (y)-sided polygons are fused along one or more sides thereof, wherein the width (WP) of the platelets (P) at their widest point is no more than about 250 pm and the thickness of the platelets (P) is in the range of 10 nm to 50 nm.

Owner:SZUSCIK MACHNICKI ANDREW HENRY

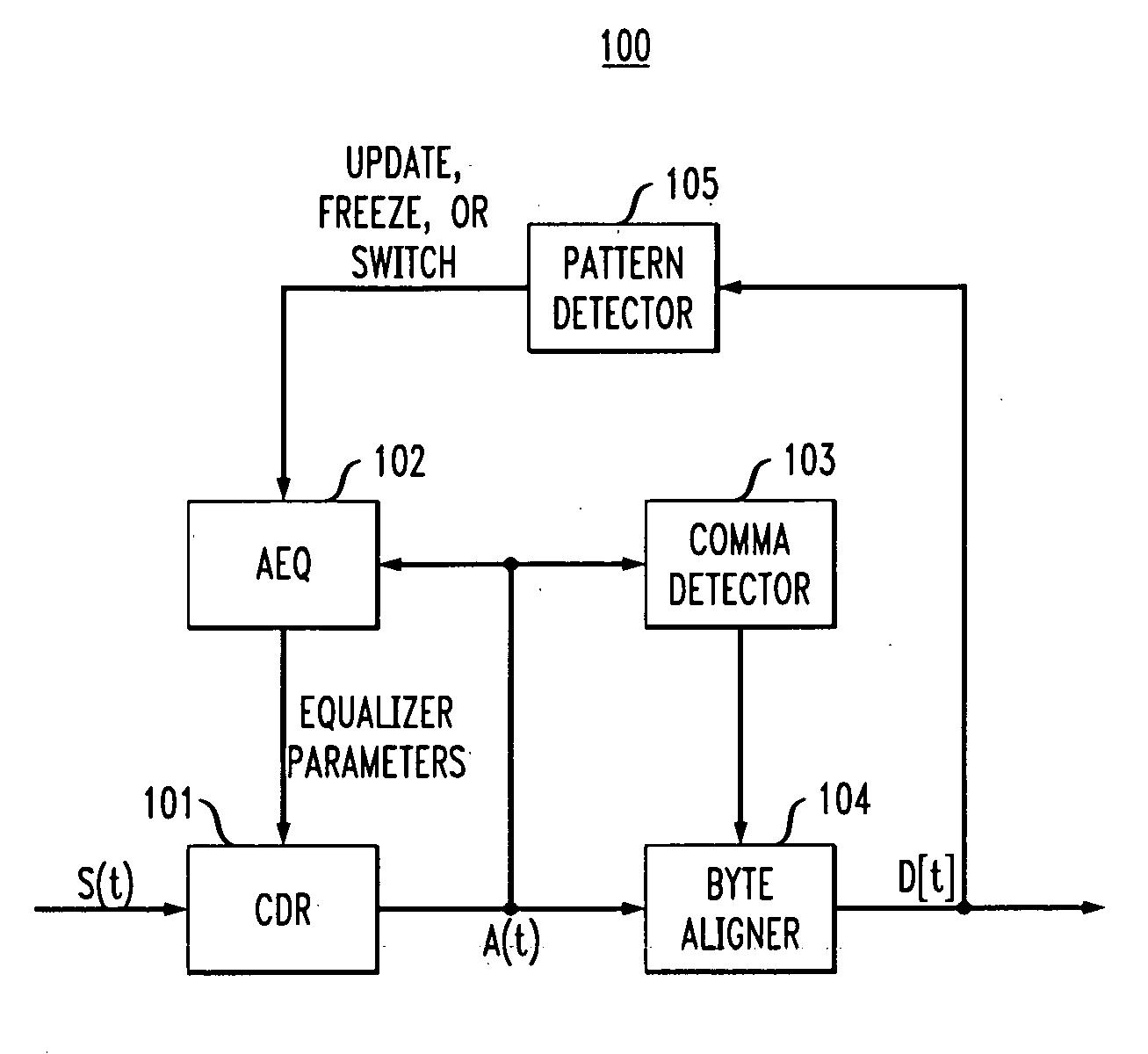

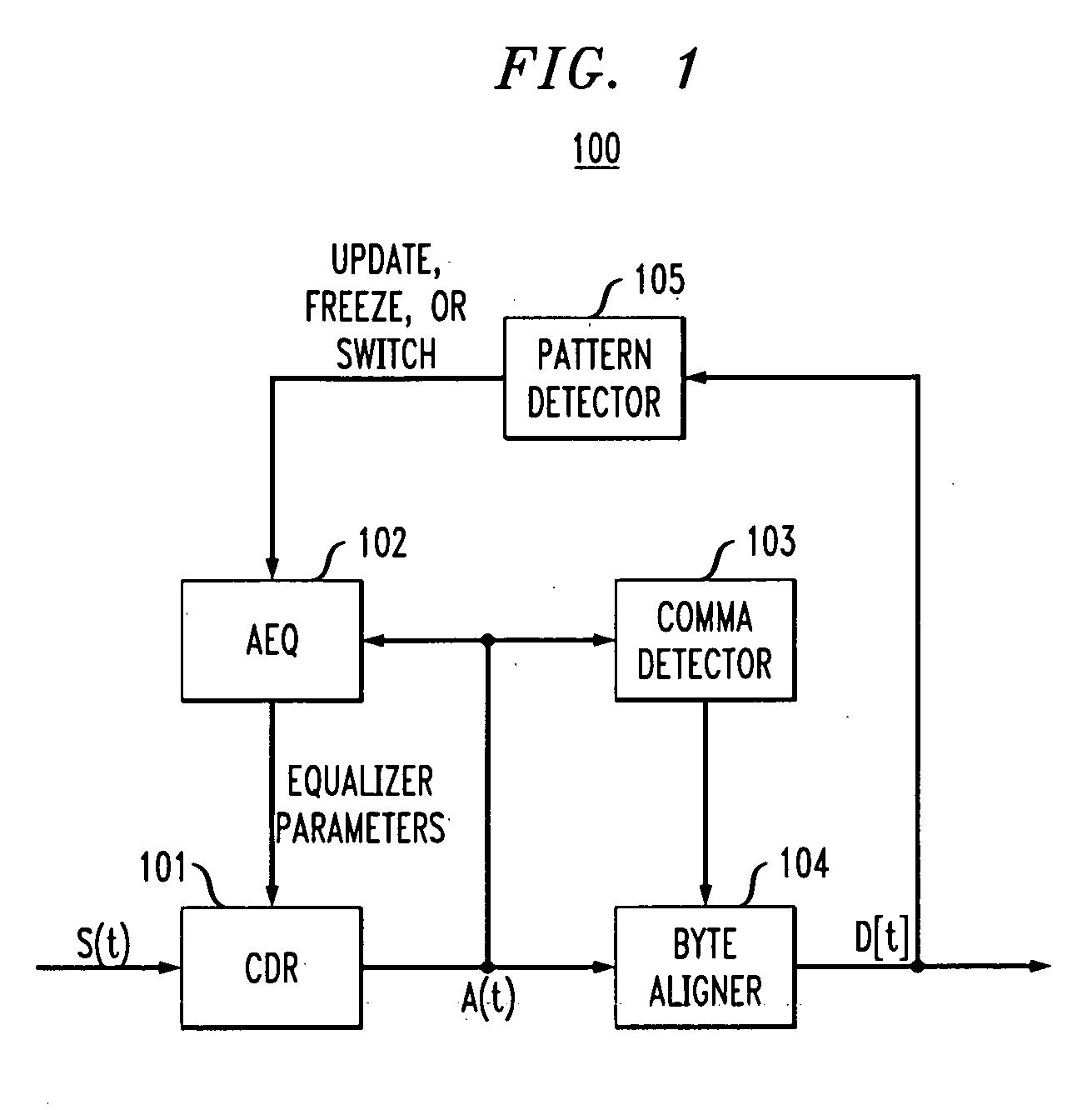

Adaptive equalization employing pattern recognition

In described embodiments, an adaptive equalizer employed by a receiver in a communication channel, such as Fibre Channel, employs pattern recognition. When a repeating pattern, such as an IDLE or ARBFF pattern, is employed by a standard to, for example, maintain a communication link, an equalizer of the receiver might adaptively set its equalizer parameters based on characteristics of the signal energy of the repeating pattern rather than adaptively set its equalizer parameters based on characteristics of the signal energy of generally random user data carried on the link. Pattern recognition by the receiver allows for maintaining adaptive equalizer parameters at settings preferred for data detection of the typical random data, improving data detection performance of the receiver when the channel transitions from a preset or synchronization repeating pattern to a user random data pattern.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

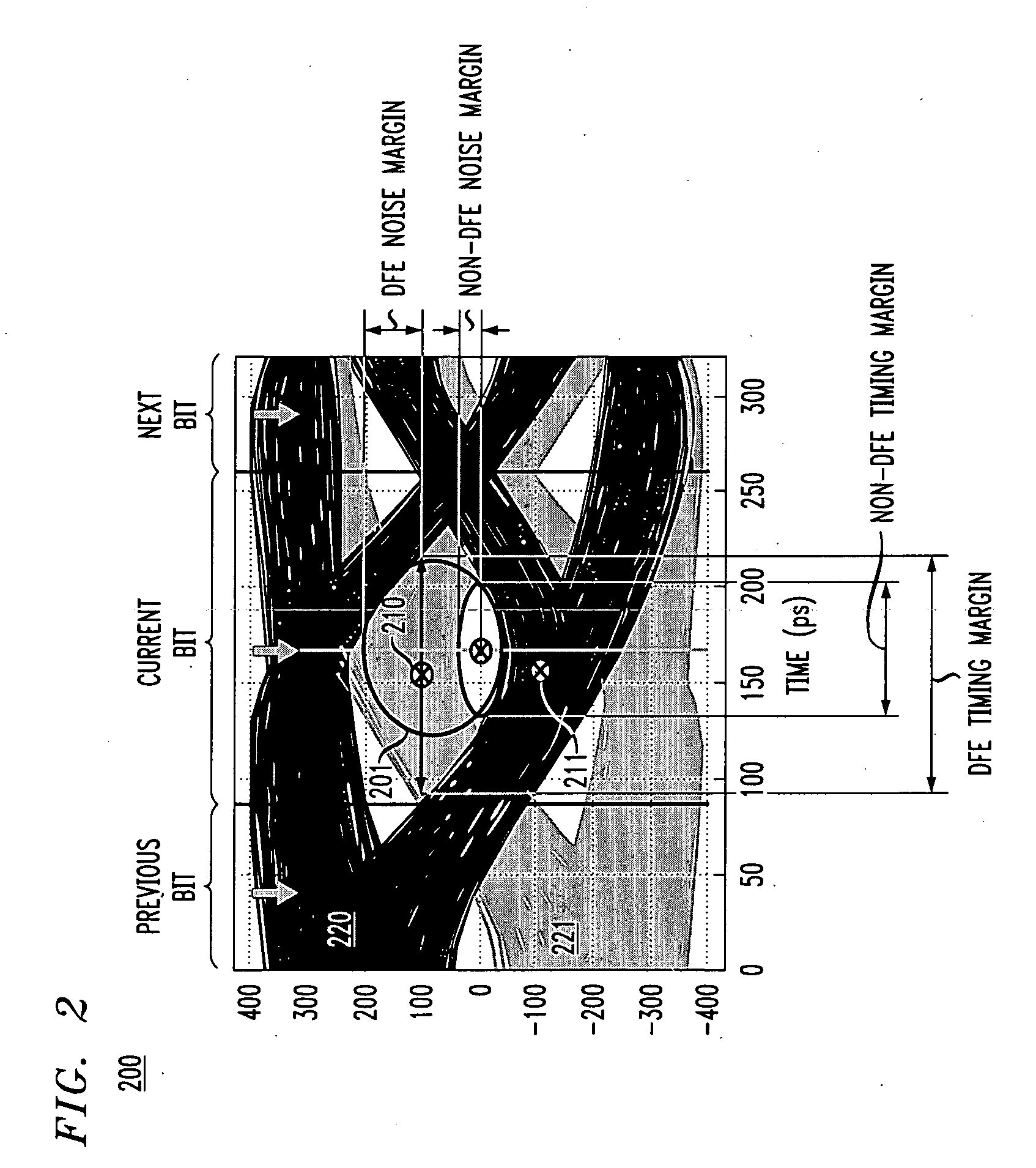

Group-III Nitride Epitaxial Layer on Silicon Substrate

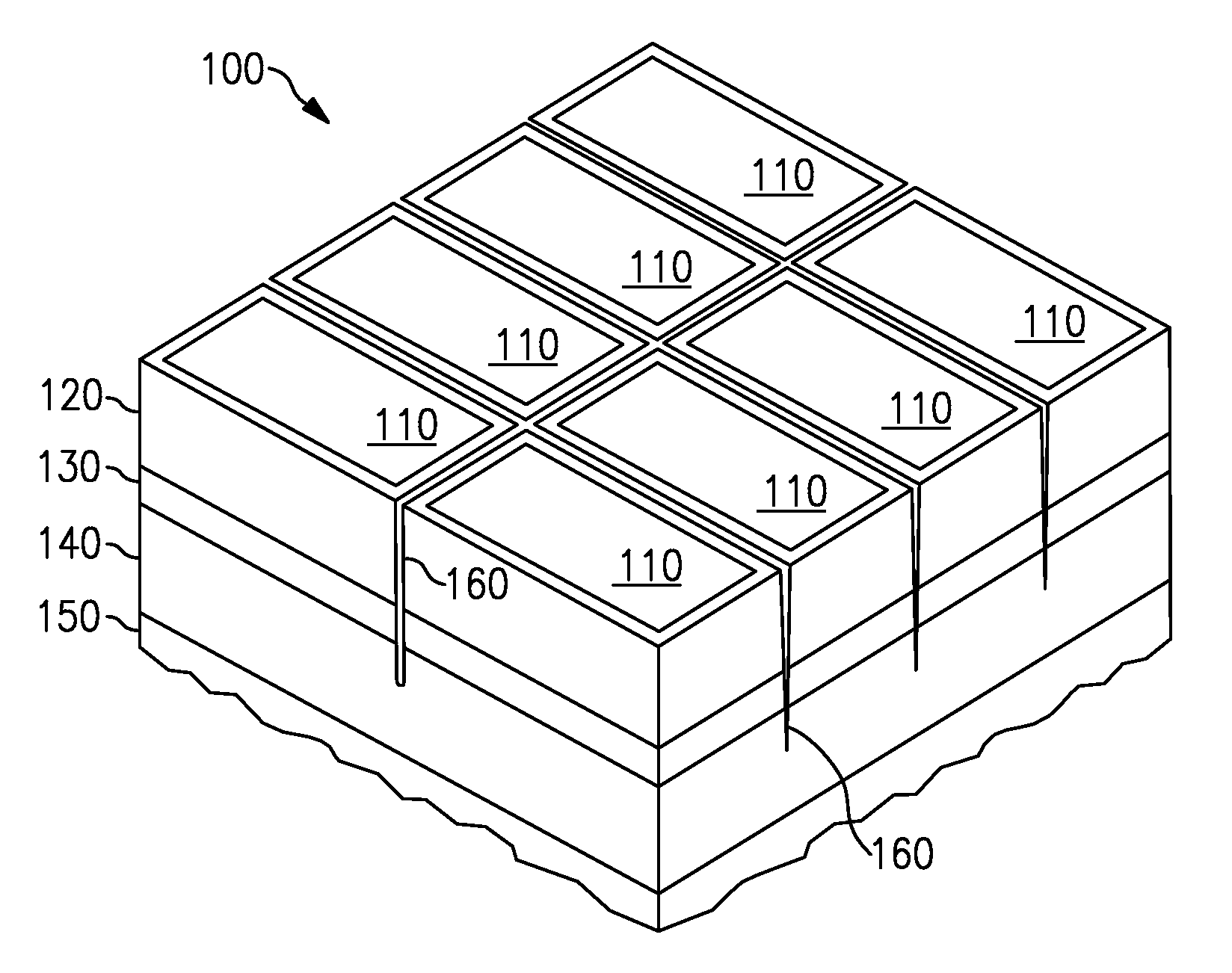

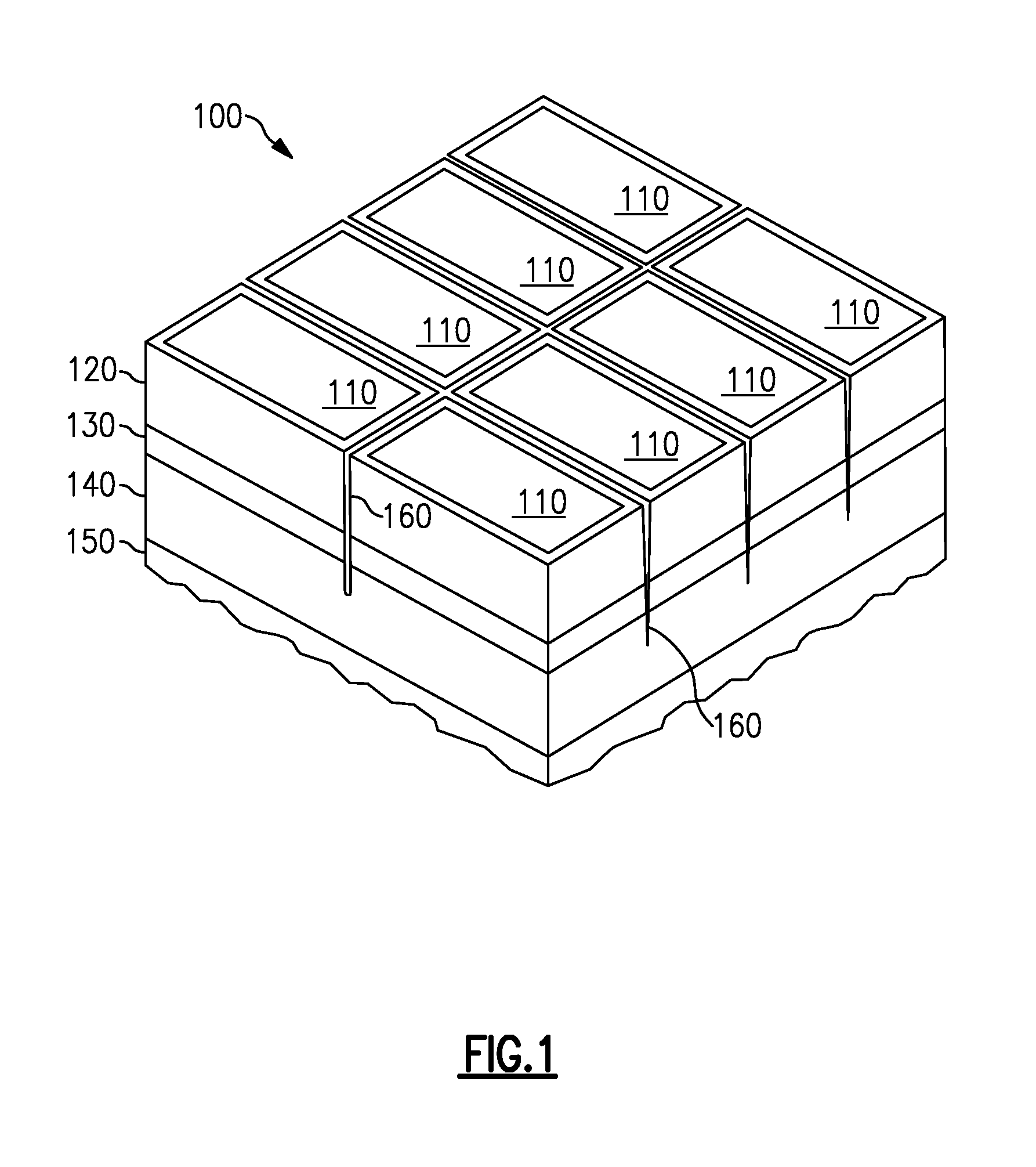

ActiveUS20090261363A1Solid-state devicesSemiconductor/solid-state device manufacturingRepeat patternFaceting

A semiconductor device includes a silicon substrate; silicon faceted structures formed on a top surface of the silicon substrate; and a group-III nitride layer over the silicon faceted structures. The silicon faceted structures are separated from each other, and have a repeated pattern.

Owner:TAIWAN SEMICON MFG CO LTD

Implants with integration surfaces having regular repeating surface patterns

ActiveUS8758443B2Prevent and minimize damageIncrease frictionBone implantSpinal implantsSpinal columnBone structure

An interbody spinal implant, such as a solid-body or composite implant. The implant has at least one integration surface with a roughened surface topography including a repeating pattern, without sharp teeth that risk damage to bone structures, adapted to grip bone through friction generated when the implant is placed between two vertebral endplates and to inhibit migration of the implant. The repeating pattern is formed of at least three at least partially overlapping repeating patterns. The repeating patterns may radiate at a fixed distance from at least one point and may include recesses having a slope of thirty degrees or less relative to the integration surface. Also disclosed are processes of fabricating the integration surfaces.

Owner:TITAN SPINE

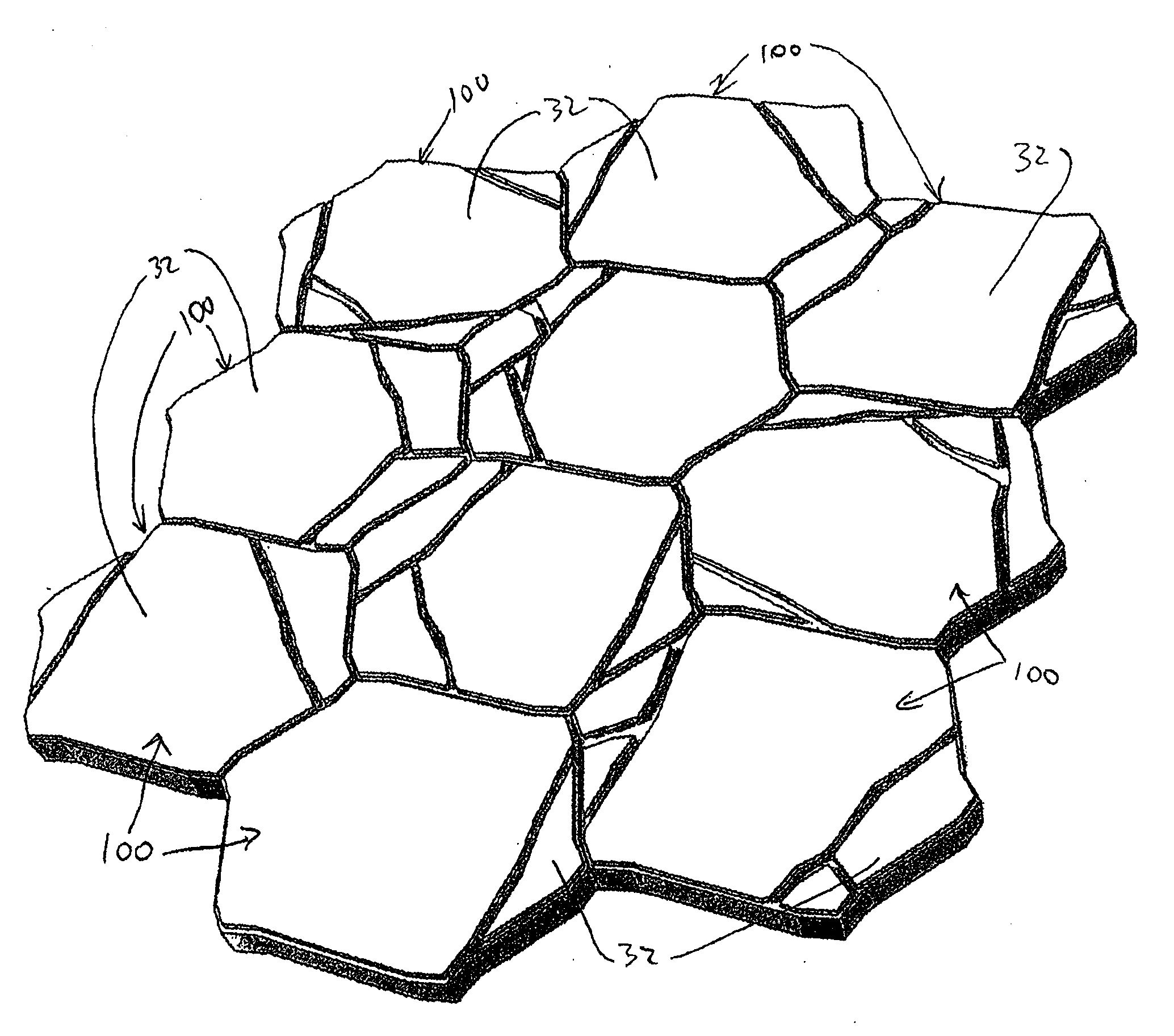

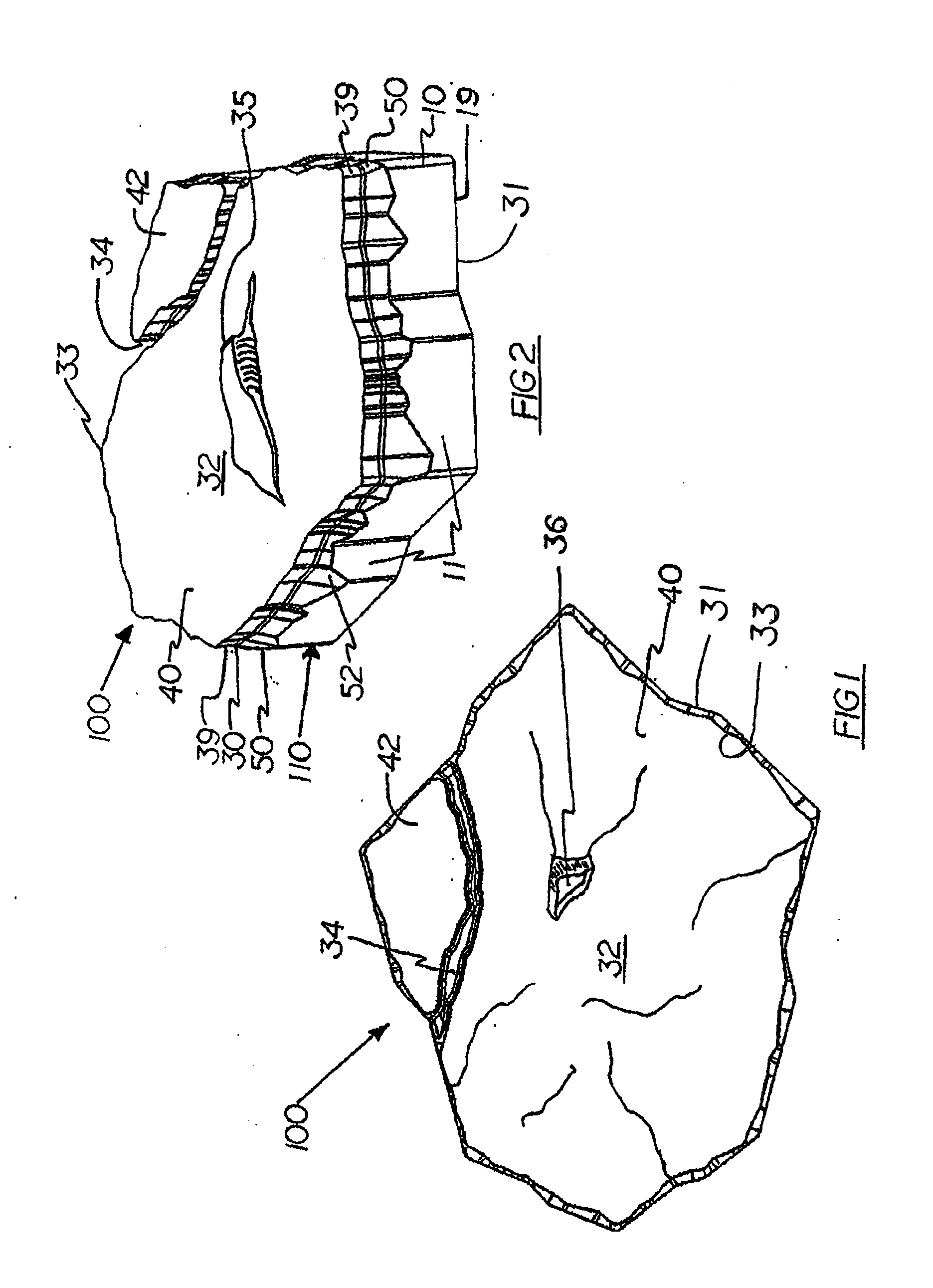

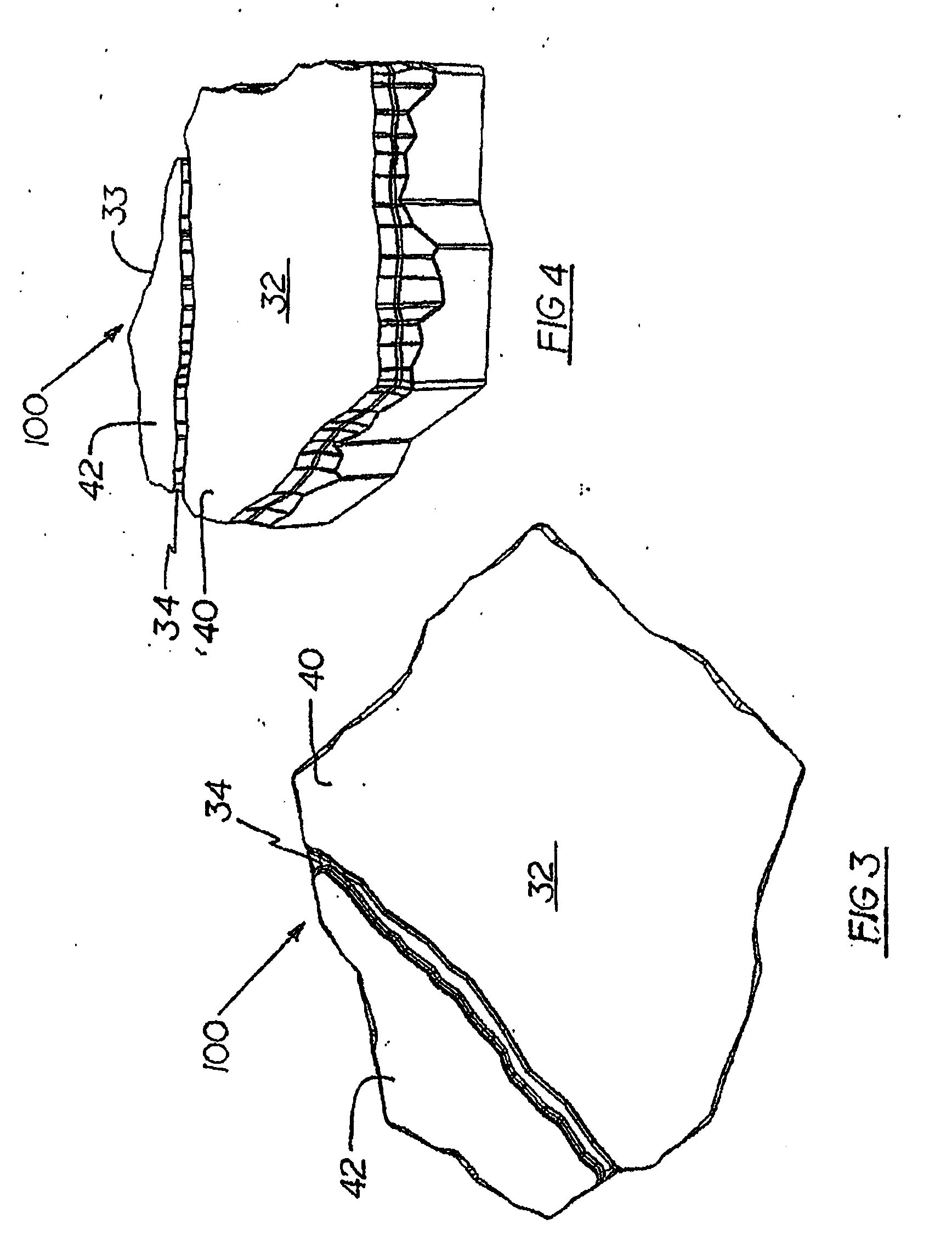

Artificial stone

ActiveUS20110067333A1Enhance natural appearanceLarge widthCovering/liningsNatural patternsRepeat patternEngineering

An artificial stone is disclosed for use in creating a covering for a supporting surface. The artificial stone includes a body for placement on the supporting surface, which is shaped for mating engagement with like stones with intermediate perimeter joints to produce a continuous surface covering. The stone has a facing surface on the body, which facing surface has a contour defining a surface area and is subdivided by at least one simulated joint into a major surface portion and at least one minor surface portion. The major surface portion is free of simulated joints and extends over at least about 60% of the total surface of the facing surface. The stone further includes at least one perimeter recess in the body for generating a gap between the stone and another like stone in mating engagement therewith, which gap is wider than adjacent the adjoining perimeter joint. Stones of this construction can easily be arranged in a regular, repeated pattern to generate a continuous covering for the supporting surface with the surface of the resulting covering having an irregular, natural appearance. The irregular top contours of the stones, the uneven division of the facing surface and the perimeter recesses and the resulting gaps between mating stones simulate the appearance of a natural stone surface covering for walkways, roadways, pavements or walls.

Owner:OLDCASTLE BUILDING PROD CANADA INC

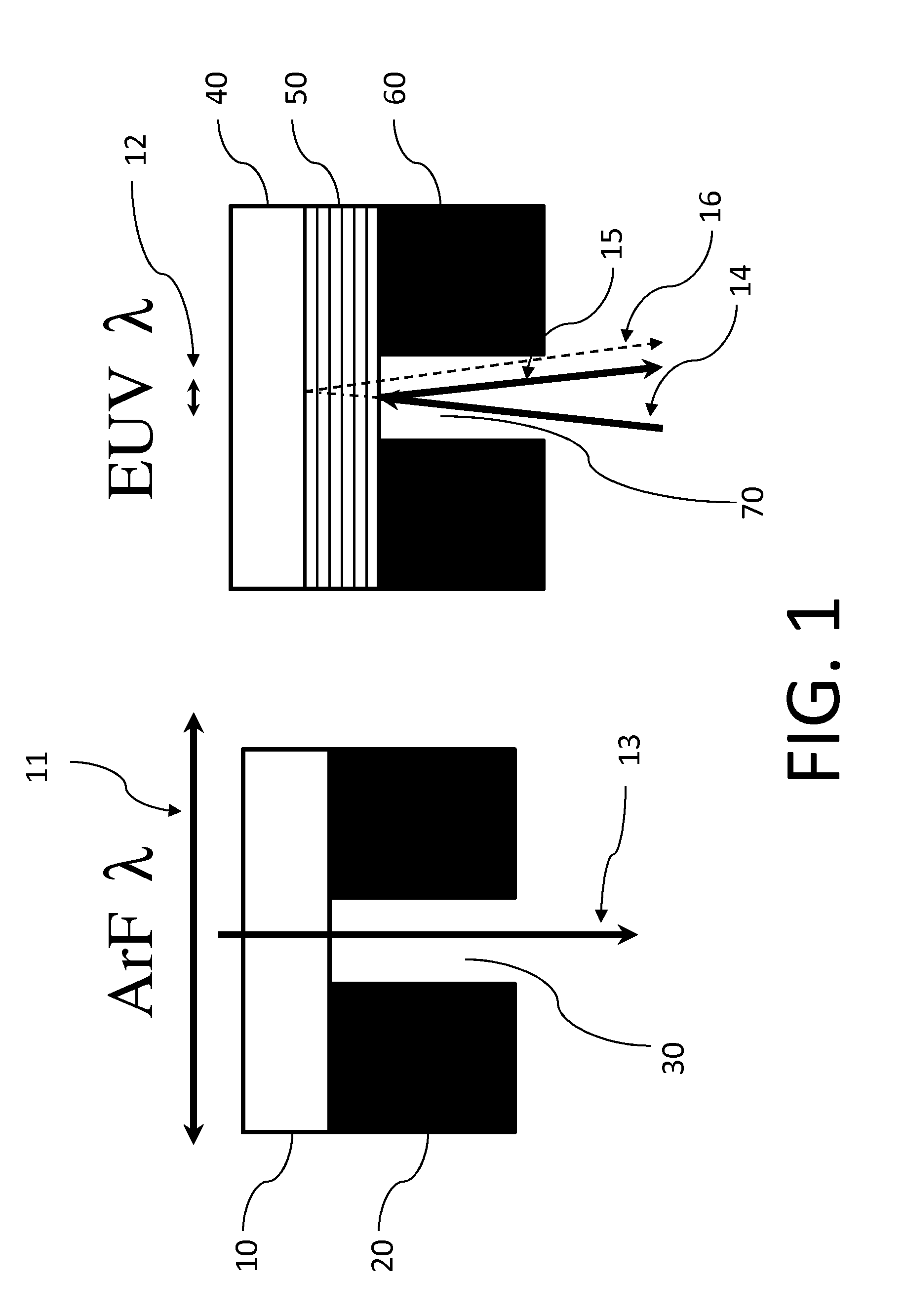

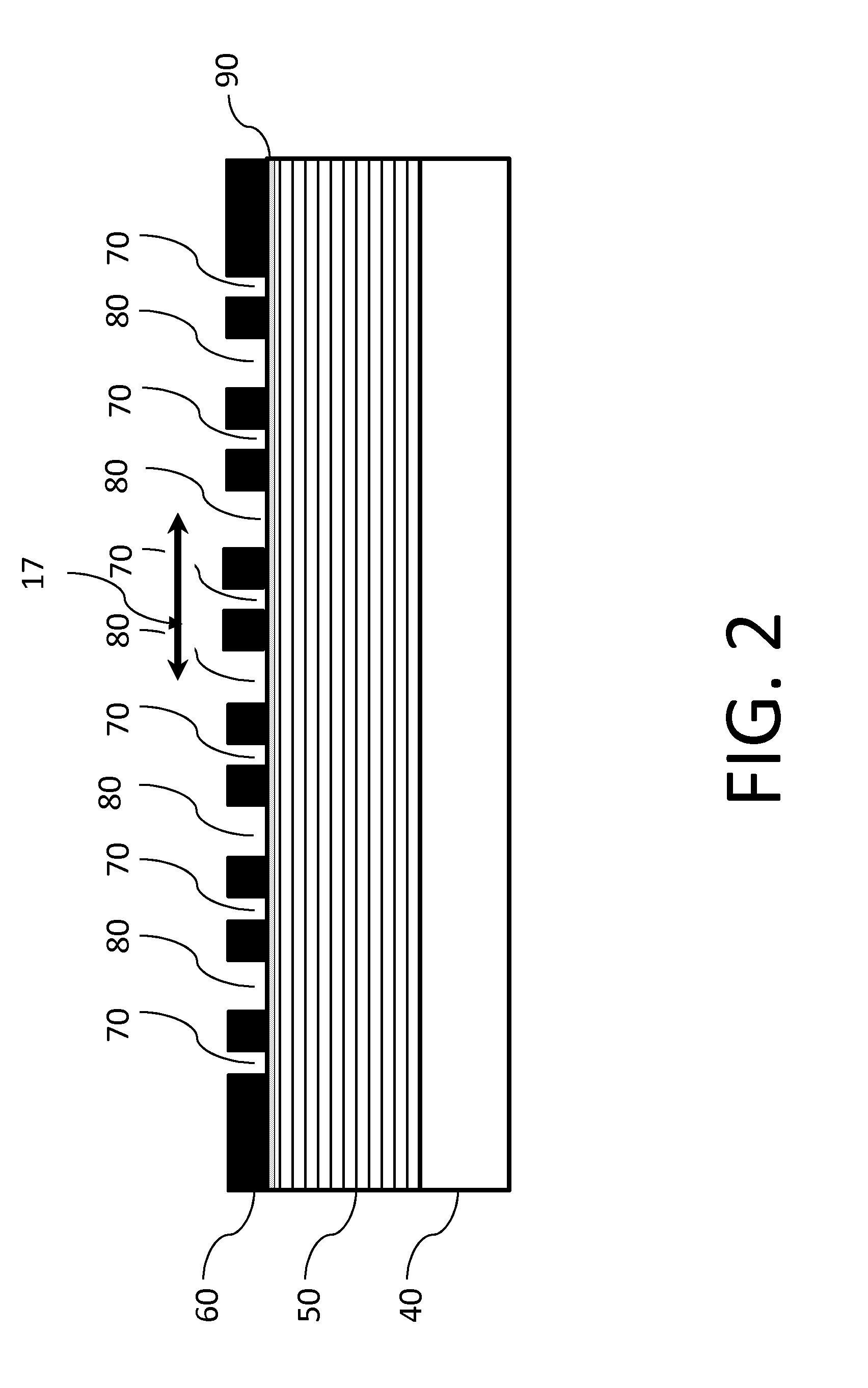

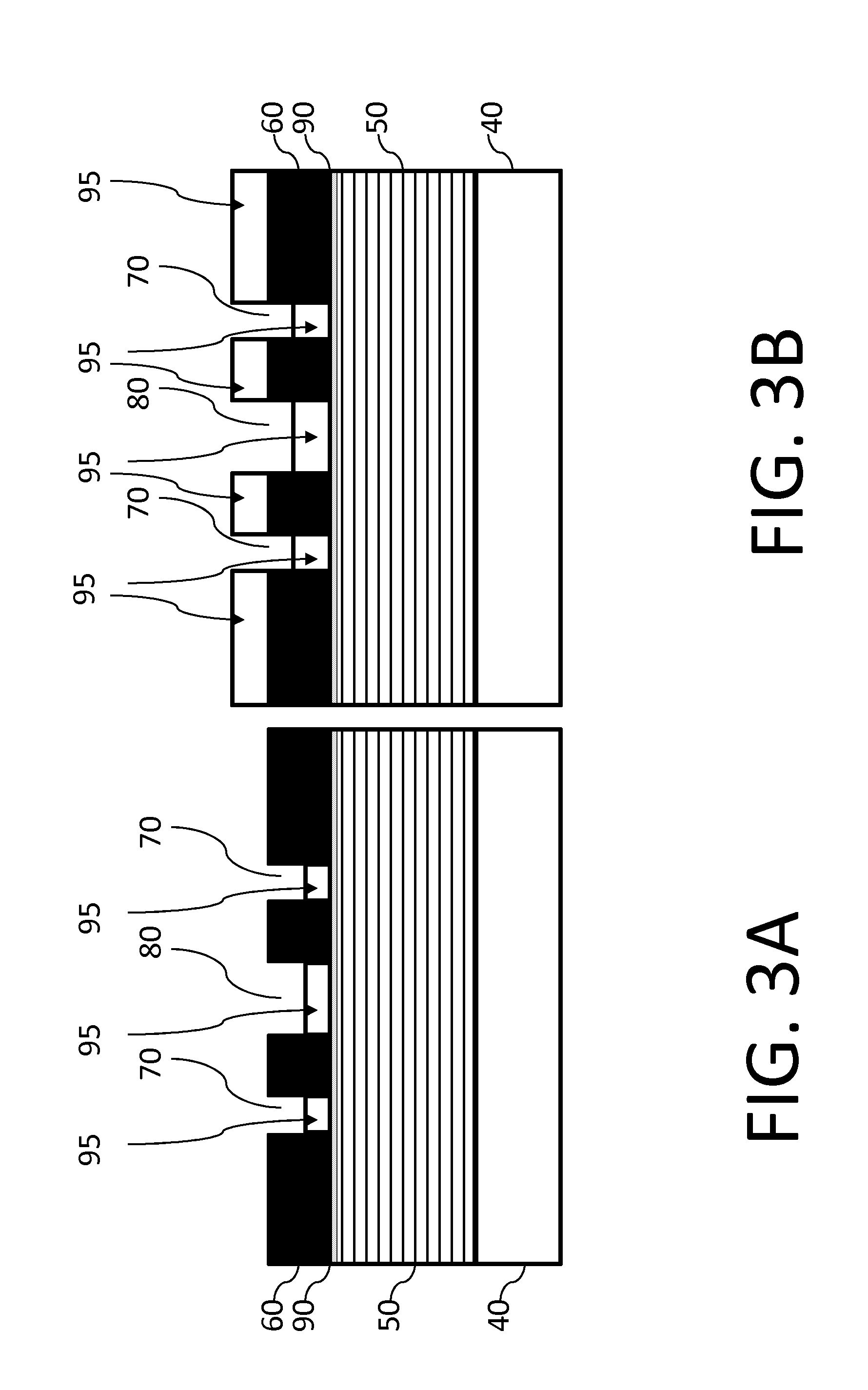

Structure and method for fixing phase effects on EUV mask

ActiveUS20160238924A1The effect is accurateOriginals for photomechanical treatmentRepeat patternRefractive index

This invention relates to a structure for fixing phase effects on EUV mask which contains a repeating pattern with an assist feature, or a pattern with two different sized features in close proximity. The EUV mask with the repeating pattern is capable of printing a group of trenches on a photoresist layer. The invention also relates to a method of fabricating an EUV mask for fixing phase effects. The EUV mask contains an absorber layer over the multilayer reflector, and the absorber layer is patterned to form a mask pattern which contains absorptive regions and reflective regions. The absorber is in the absorptive regions, and a phase shifter is deposited at least in the whole reflective regions of the mask pattern to a thickness capable of correcting phase effects. The phase shifter has an index of refraction value is about equal to or less than that of the absorber. The thickness of the phase shifter is determined by simulation.

Owner:IBM CORP

Method for manufacturing long force sensors using screen printing technology

InactiveUS7984544B2Avoid bubblingAvoid separationPrinted circuit assemblingManufacture of electrical instrumentsScreen printingElectrical conductor

A force or pressure sensor and appertaining method for manufacturing are provided in which the sensor comprises a repeating conductive trace pattern that can be replicated to produce a consistent conductive trace across more than one adjacent pattern section forming an electrical bus, wherein more than one section of a series of conductive traces are printed on a thin and flexible dielectric backing using the pattern. The thin and flexible dielectric backing has a repeated pattern of conductive traces printed above the dielectric backing and one or more dielectric layers provided above the conductive traces, the dielectric layers having access regions permitting contact of conductors above the one or more dielectric layers, and a sensor conductor layer printed above the one or more dielectric layers that contacts the conductive traces via at least one of the access regions or regions not covered by the one or more dielectric layers.

Owner:ROSENBERG ILYA D +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com