Patents

Literature

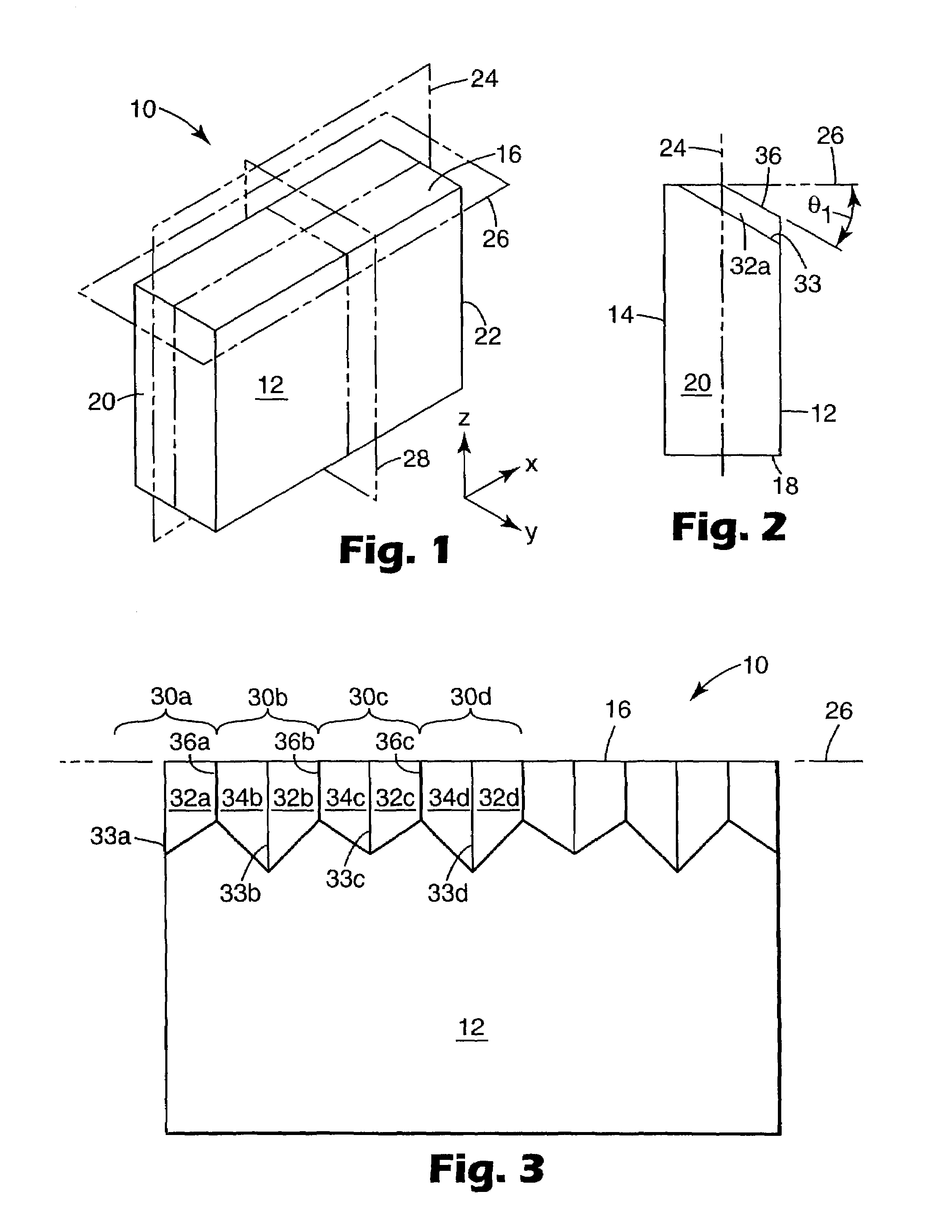

1579 results about "Wood veneer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm (1/8 inch), that typically are glued onto core panels (typically, wood, particle board or medium-density fiberboard) to produce flat panels such as doors, tops and panels for cabinets, parquet floors and parts of furniture. They are also used in marquetry. Plywood consists of three or more layers of veneer. Normally, each is glued with its grain at right angles to adjacent layers for strength. Veneer beading is a thin layer of decorative edging placed around objects, such as jewelry boxes. Veneer is also used to replace decorative papers in Wood Veneer HPL. Veneer is also a type of manufactured board.

Method of making fabric-creped sheet for dispensers

ActiveUS7585389B2More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationWood veneerBiomedical engineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Resilient flooring compositions

InactiveUS20120276348A1Improve wear resistanceReduce the possibilityCovering/liningsSpecial ornamental structuresWood veneerNatural fiber

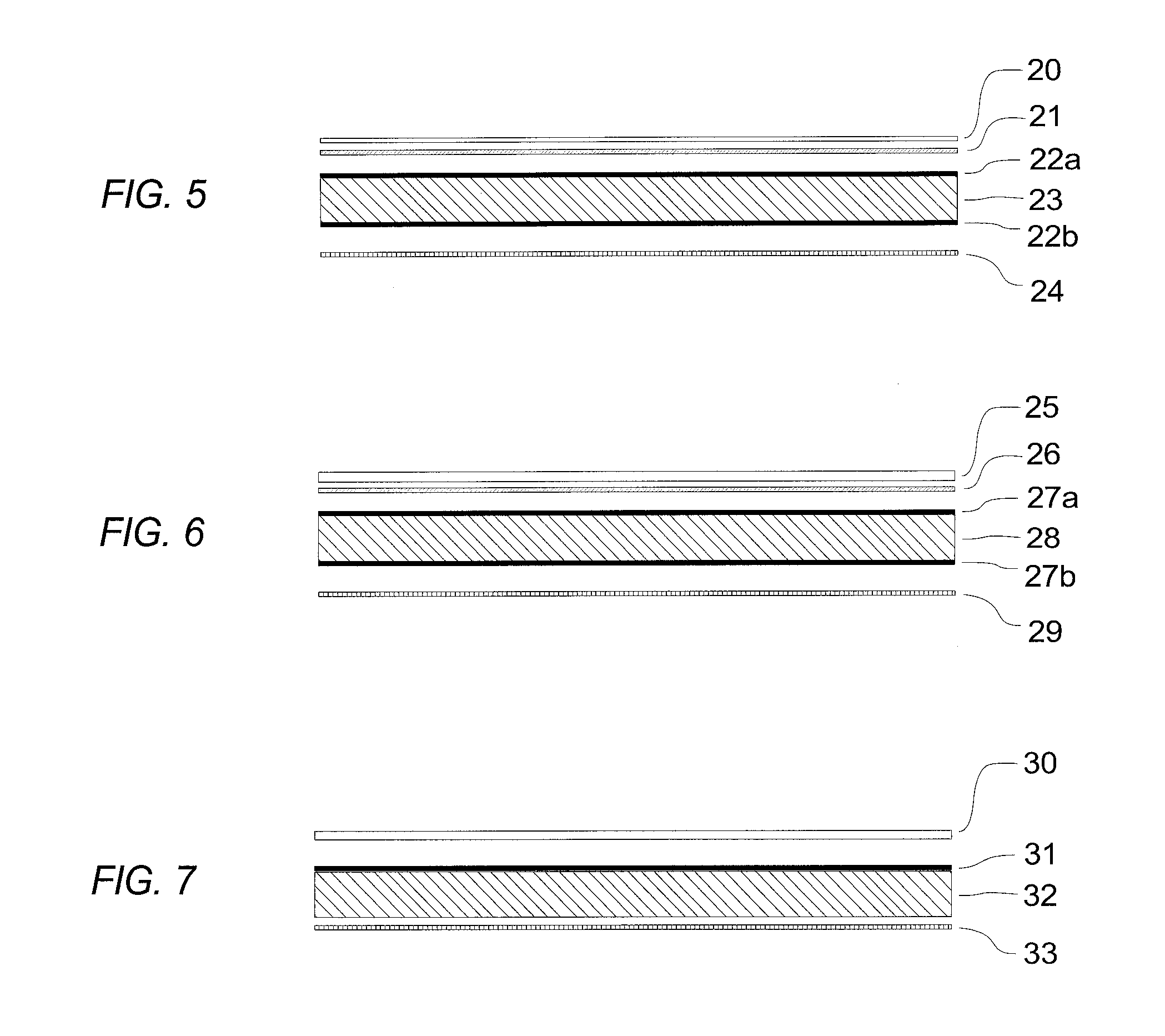

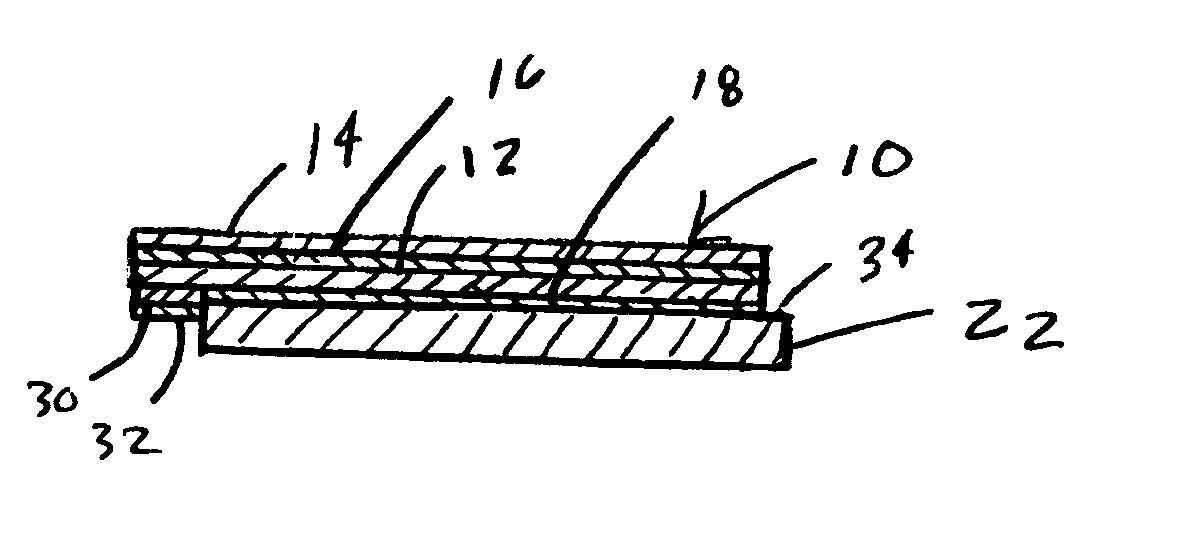

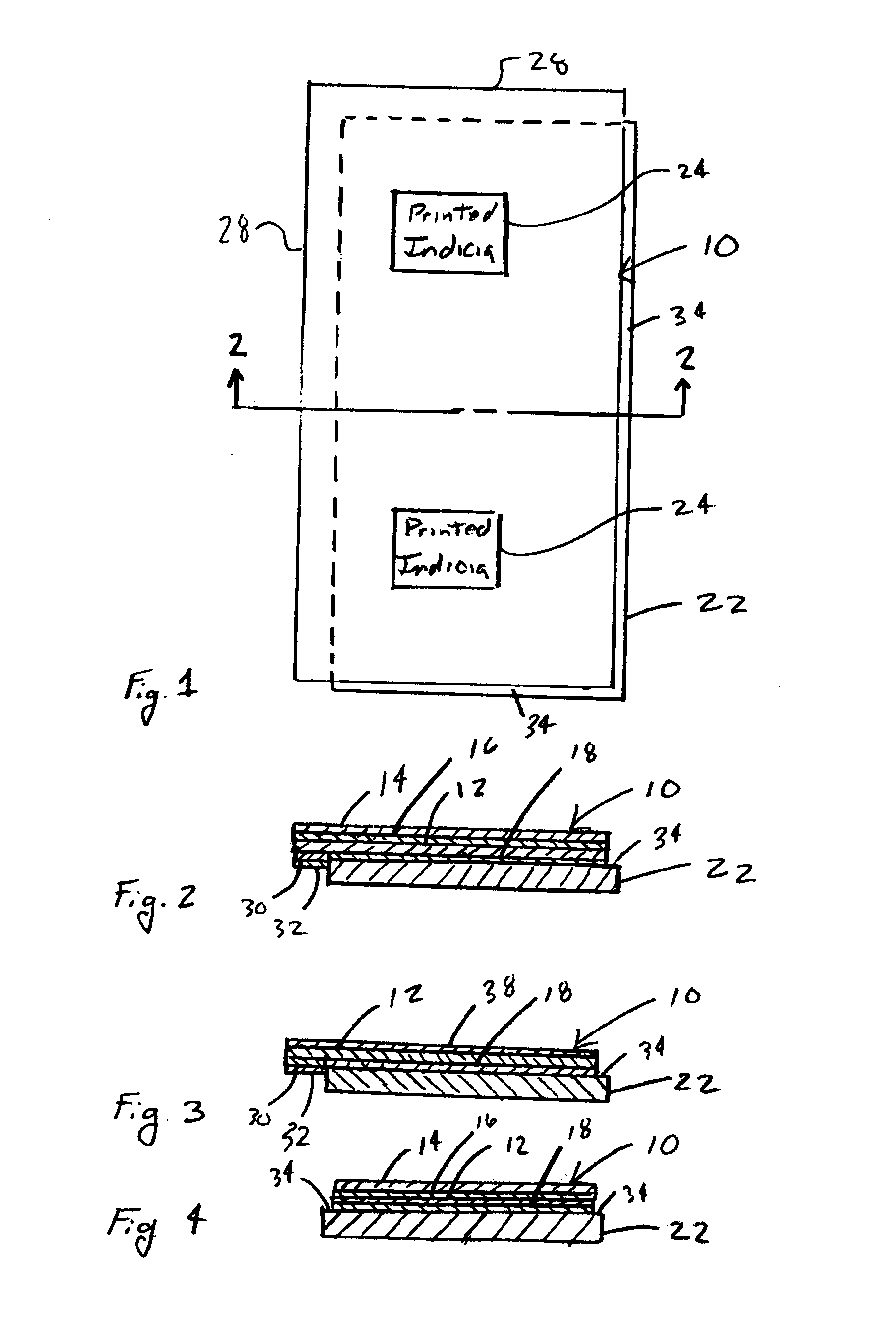

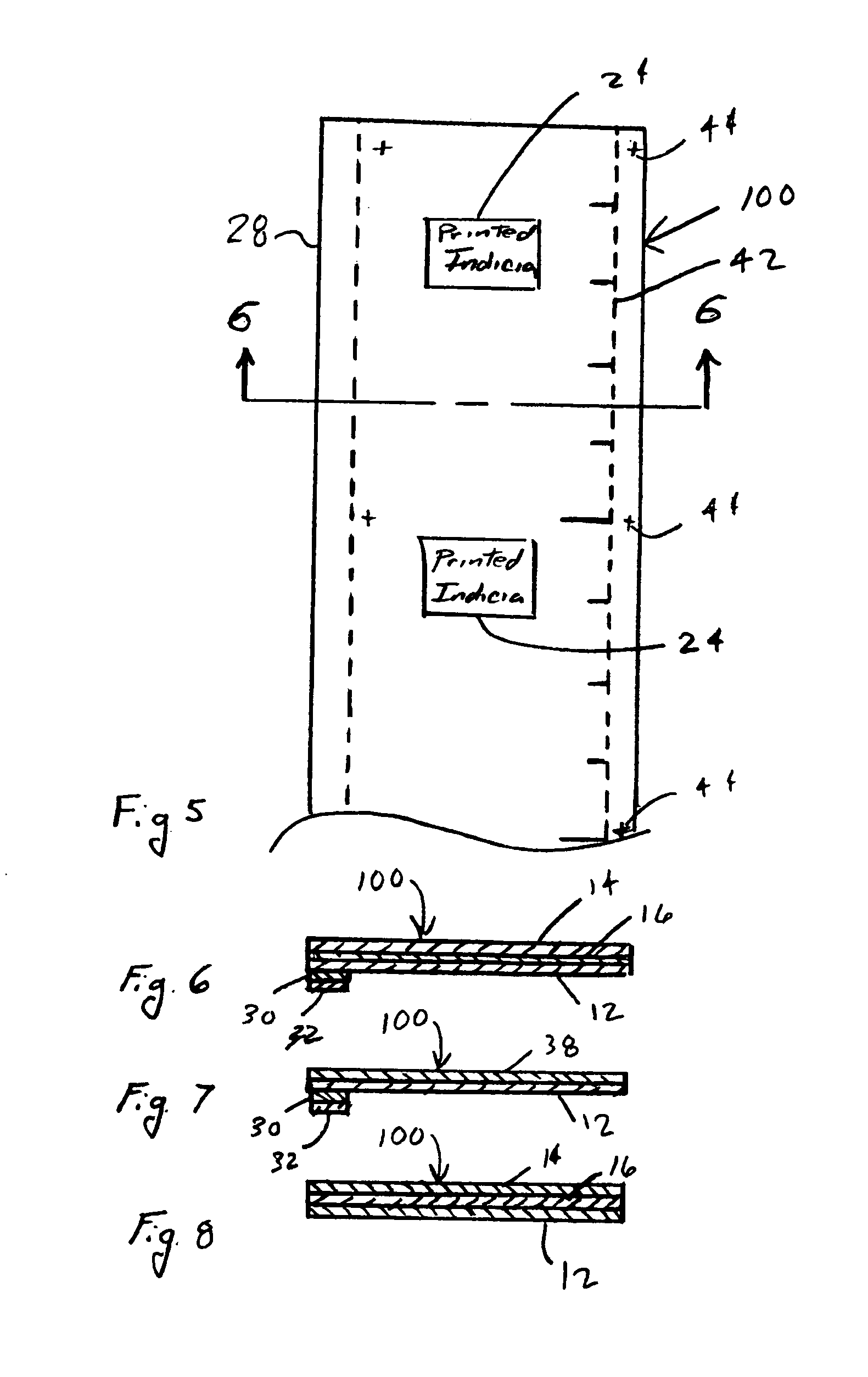

Resilient flooring materials made from impregnated papers or foils and core materials are provided. As well, the methods for producing such products are provided. In particular, panels, with a layered structure, created by forming an assembly which consists of laminating a heat-activated resin impregnated decorative layer with printed graphics or a wood veneer decorative layer, a core material made up of one or more heat-activated resin-impregnated papers or other materials including linoleum, natural or synthetic rubber, cork, flexible natural fiber composites or other core materials, and a heat-activated resin impregnated paper backing layer. The heat-activated resin also acts to waterproof each of the layers and abrasion particles may be incorporated to improve wear properties. The panels may also be formed into three-dimensional products.

Owner:CLAUSI ROBERT N +1

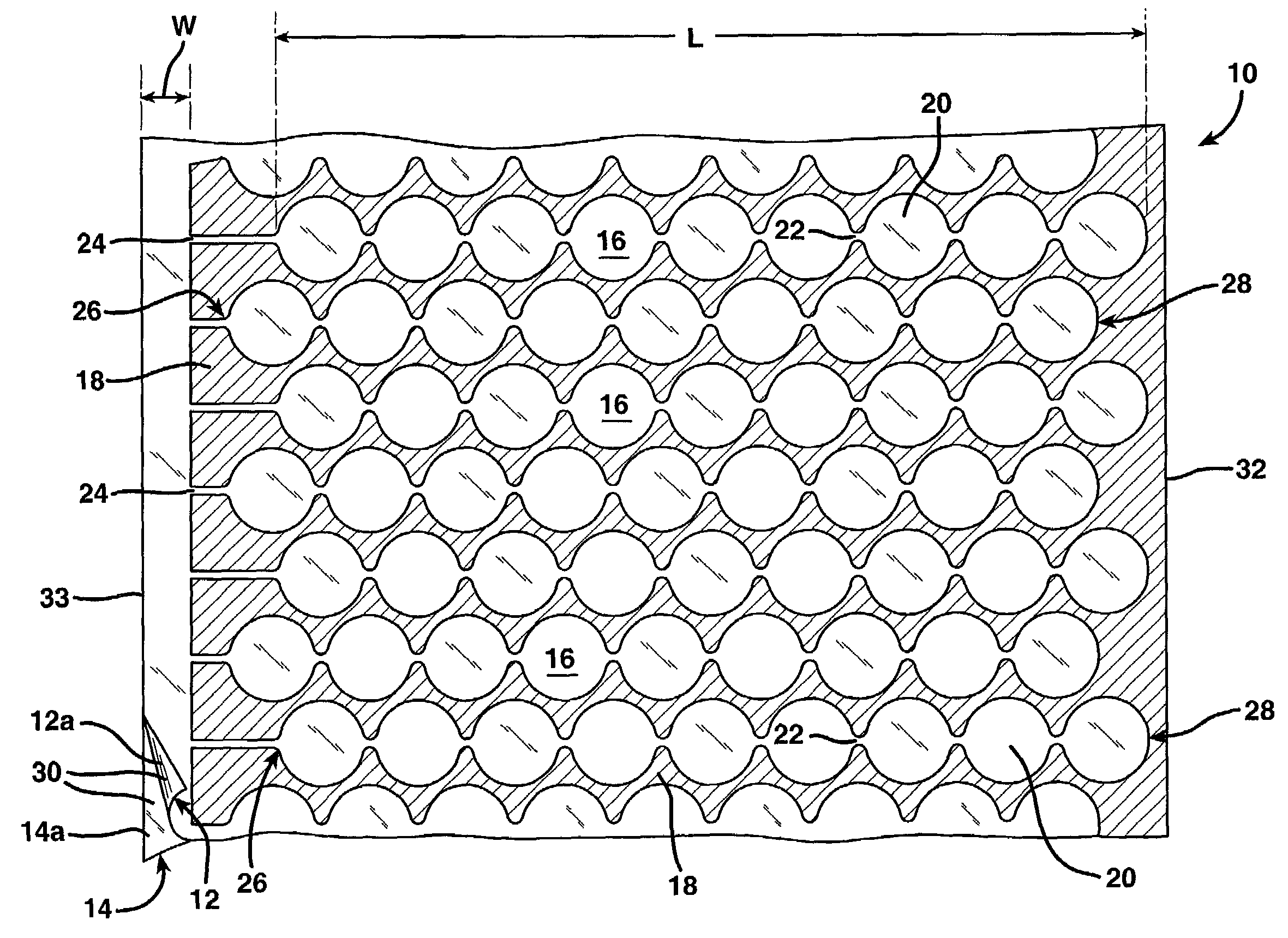

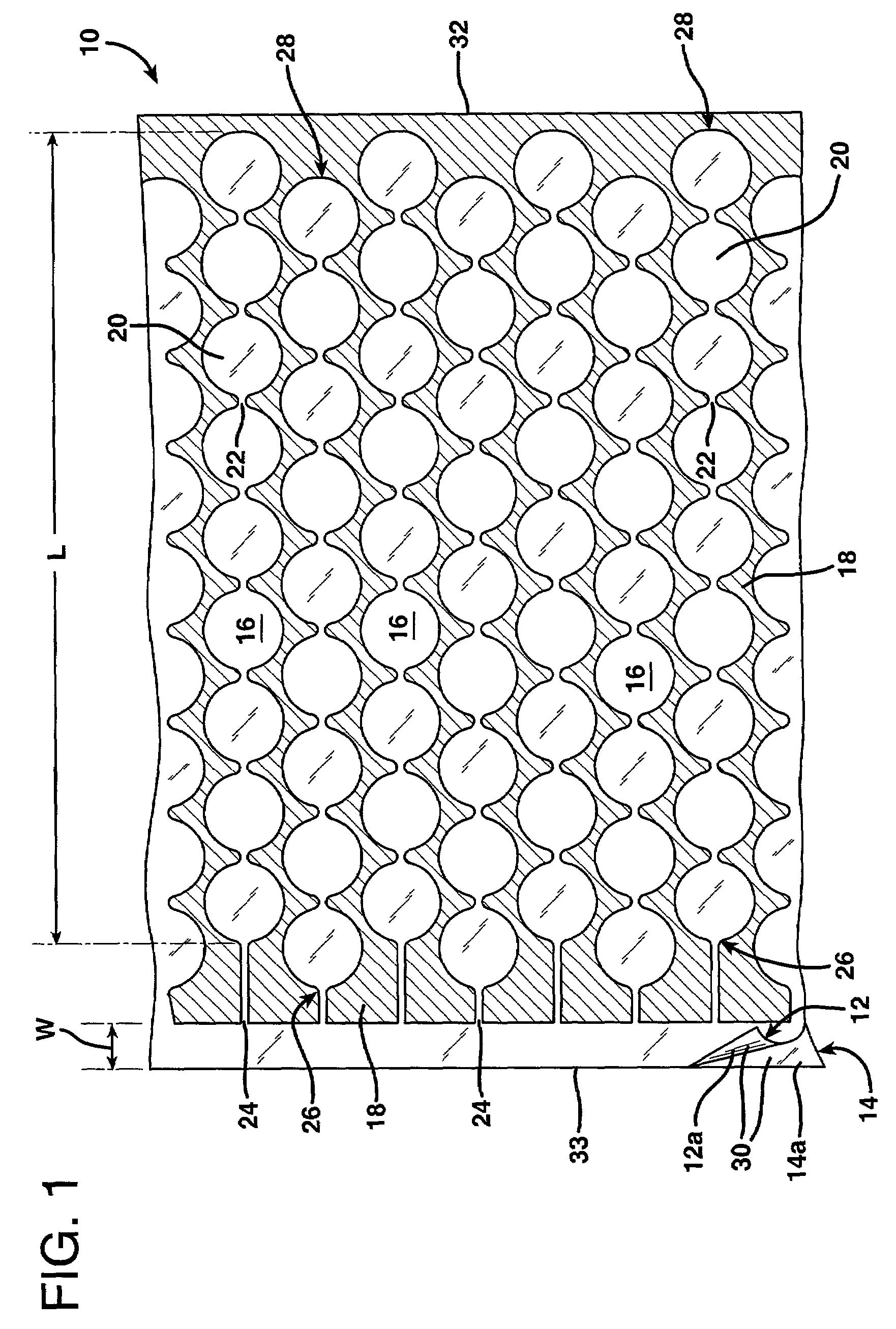

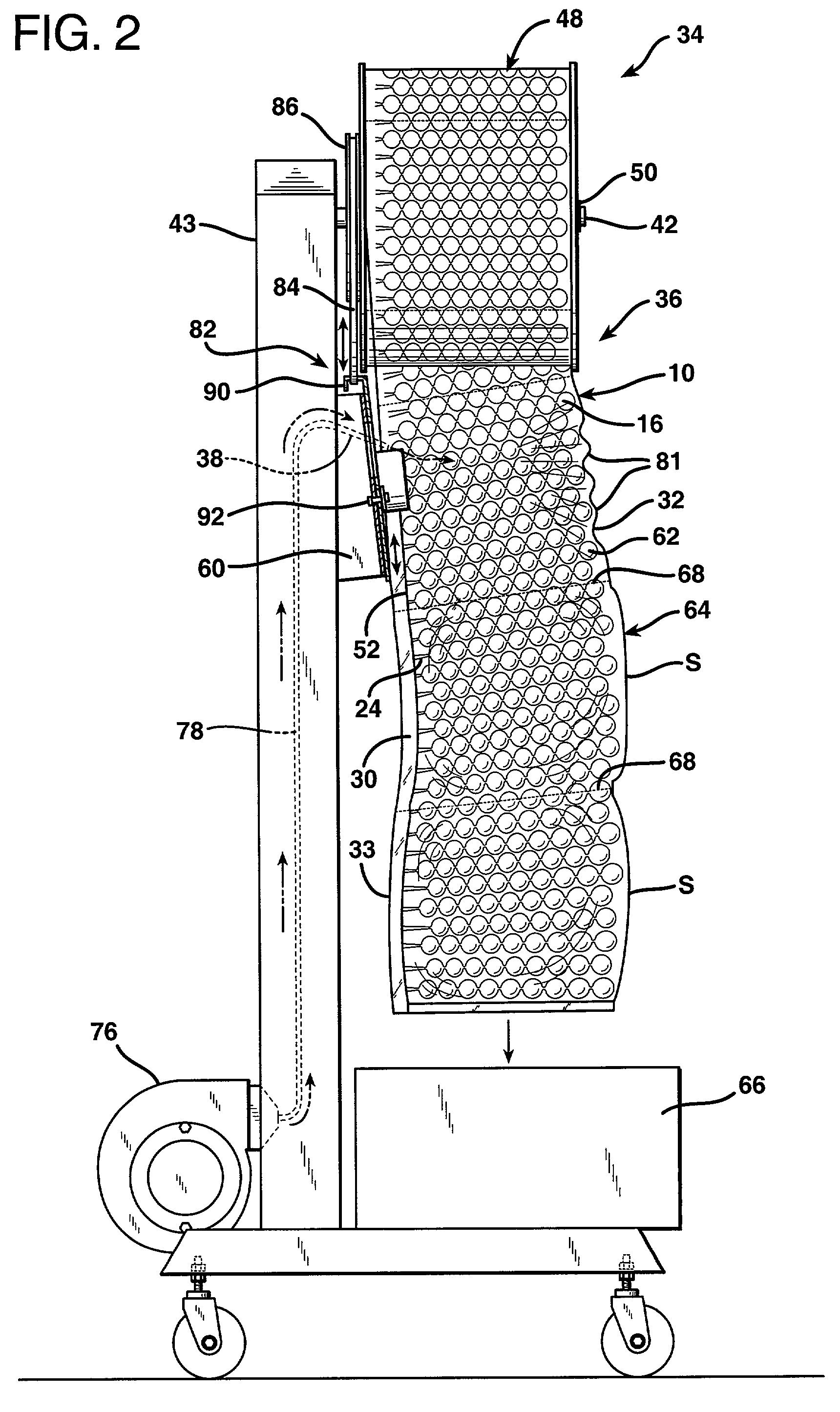

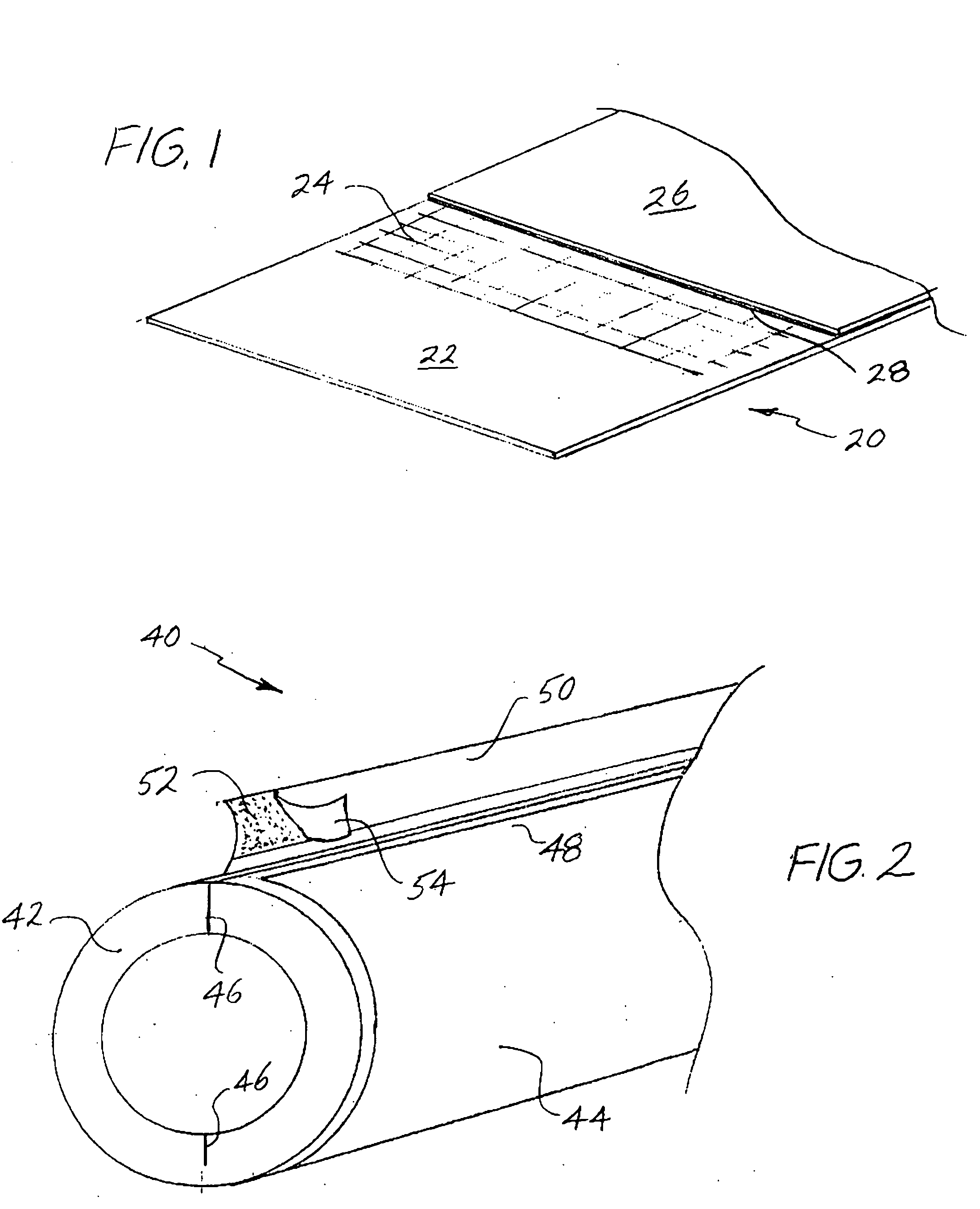

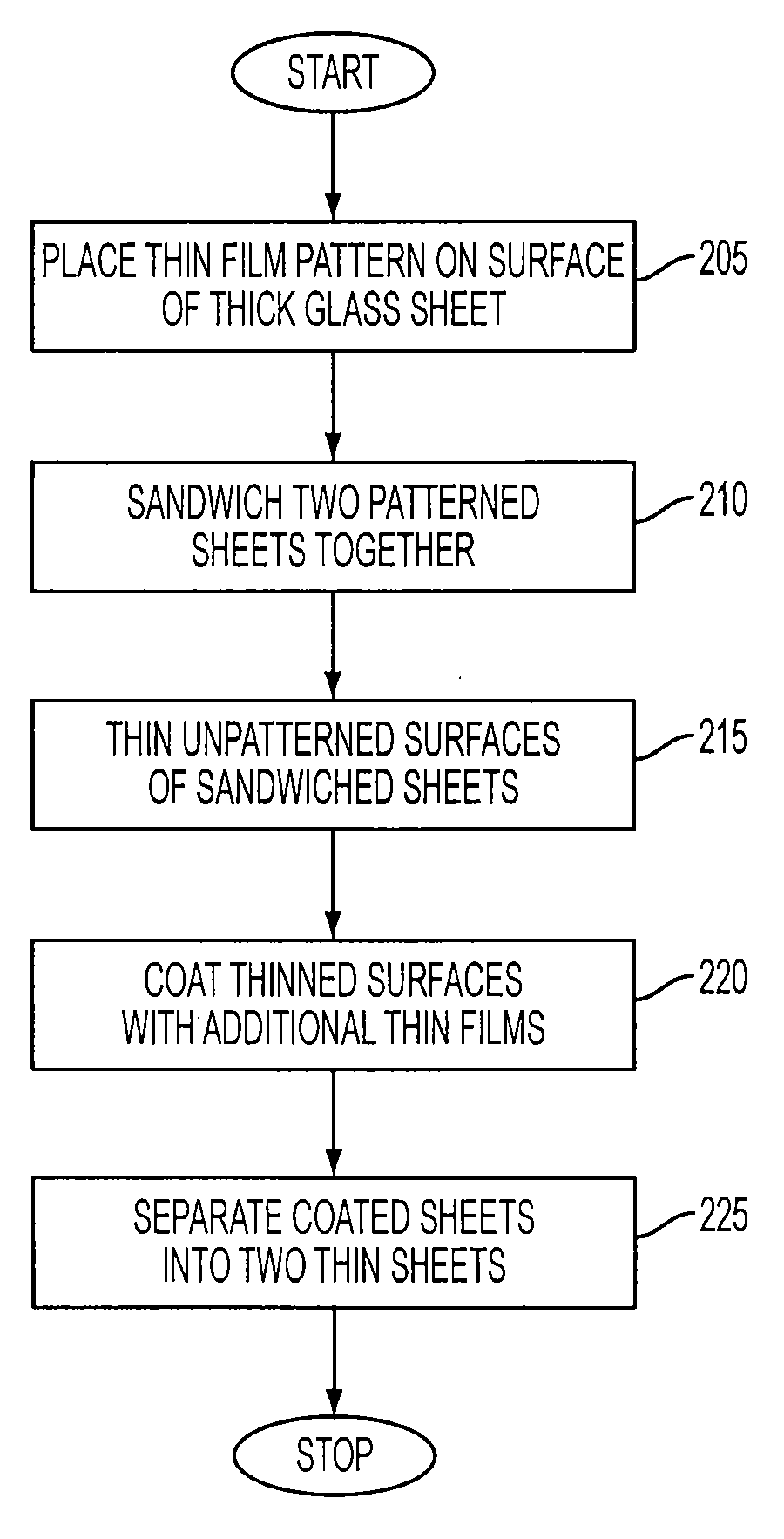

Apparatus and method for forming inflated chambers

An inflatable web, and method and apparatus for inflating the web, which generally includes two sheets having inner surfaces sealed to each other in a pattern defining a series of inflatable chambers of predetermined length, each of the chambers having at least one change in width over their length; an inflation port located at a proximal end of each chamber, the inflation ports being formed by intermittent seals between the sheets; and longitudinal flanges formed by a portion of each of the sheets that extend beyond the inflation ports and intermittent seals.

Owner:SEALED AIR U S

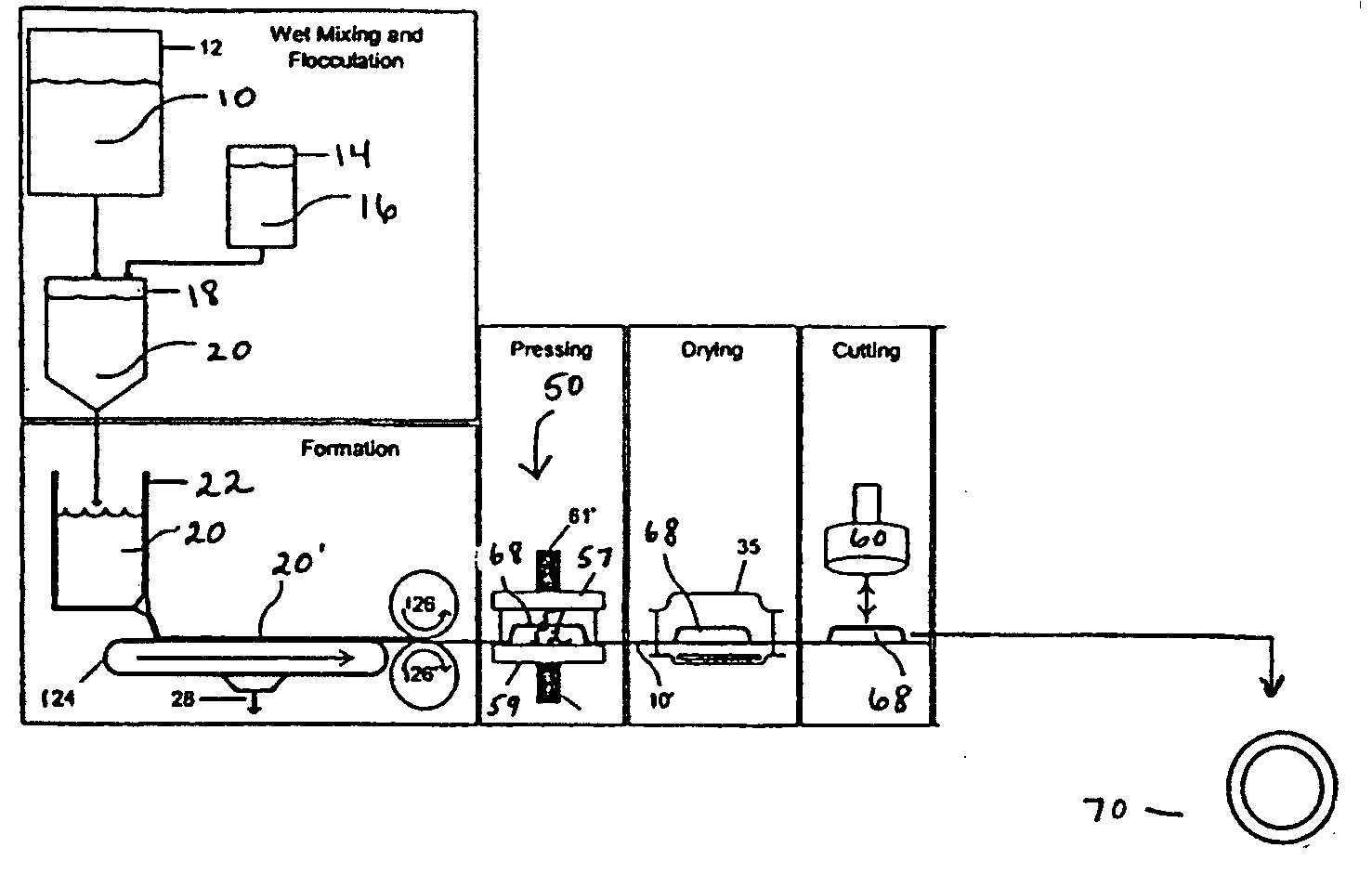

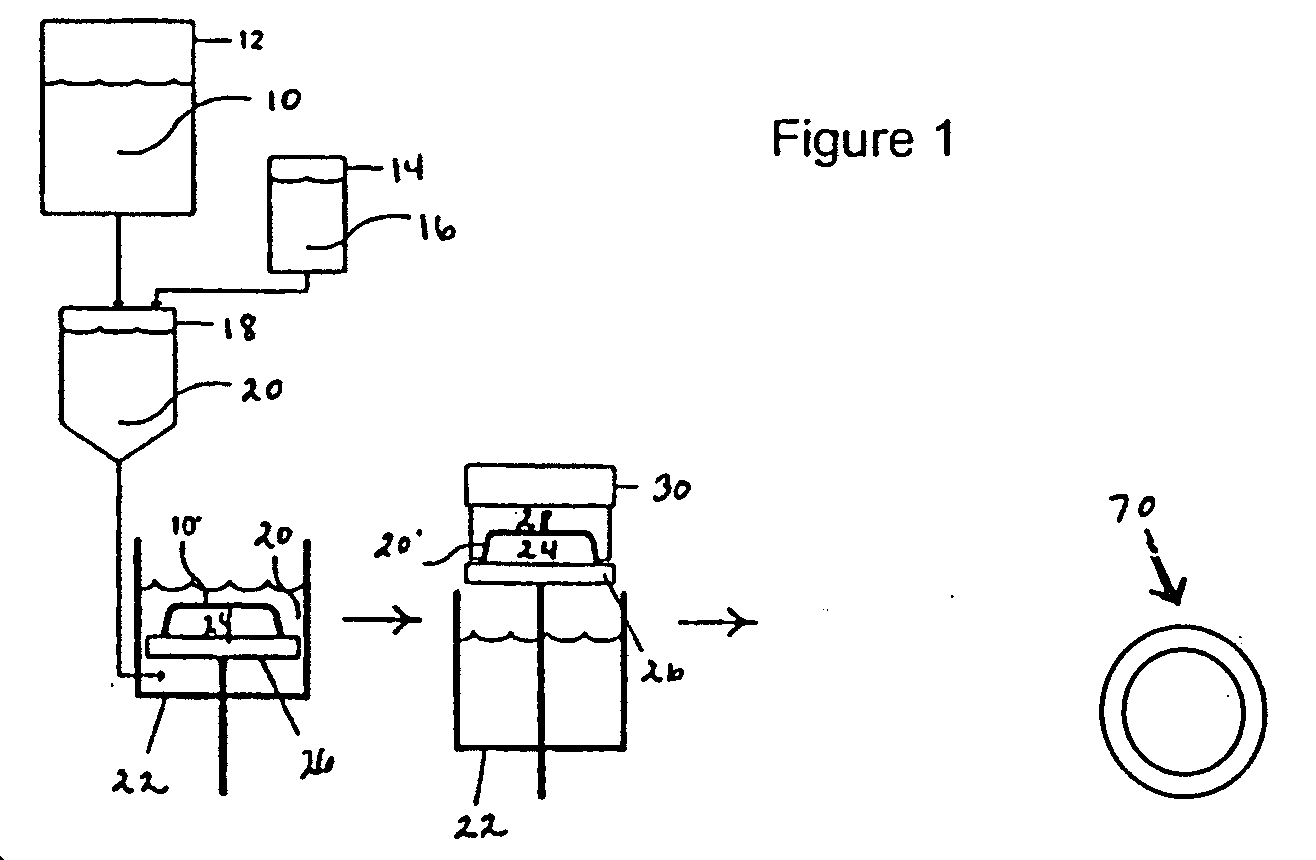

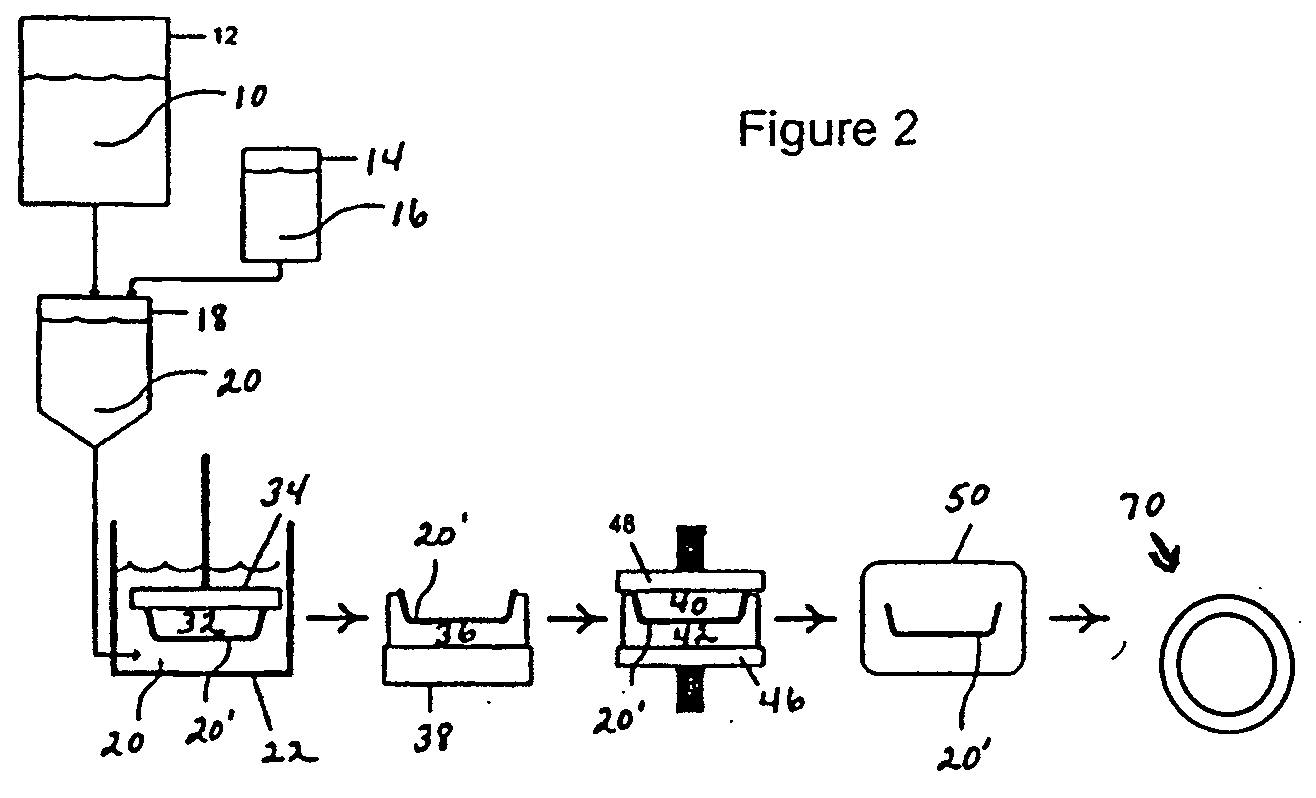

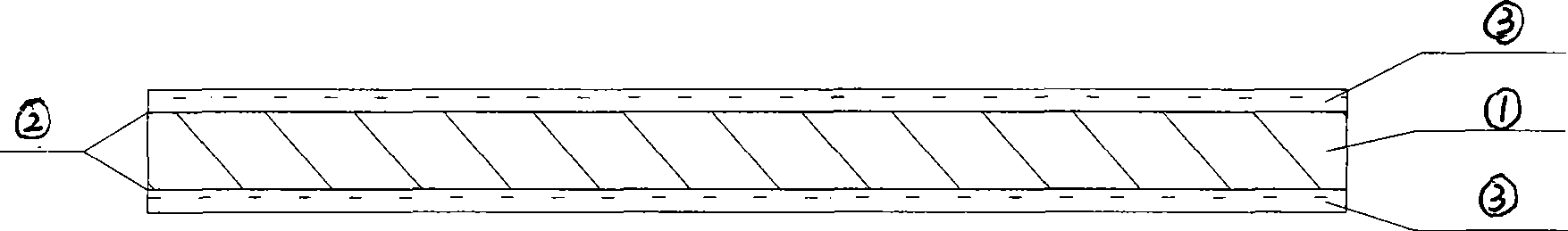

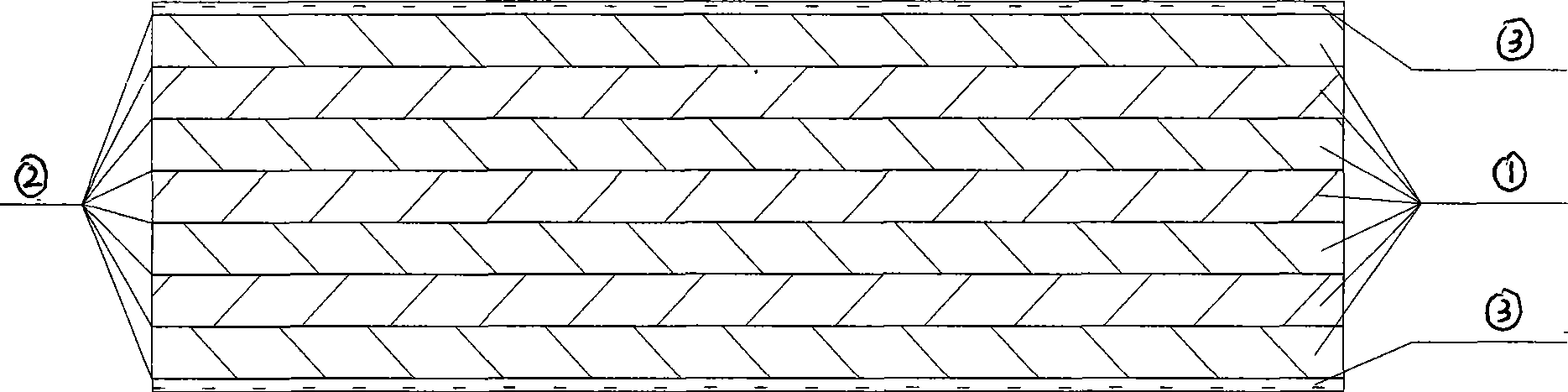

Engineered wood product

InactiveUS20100310893A1Lamination ancillary operationsSynthetic resin layered productsWood veneerCellulose fiber

Engineered wood products, methods of making the products, laminates including the products, and articles of manufacture which include the engineered products or composites, are disclosed. The products include wood and / or other cellulosic fibers, and can include non-cellulosic fibers, all or part of which can be derived from post-industrial and / or post-consumer materials. The products also include a binding agent, such as a latex dispersion, as well as hydrophobic materials, processing aids, colorants, and the like. The product can be in the form of a sheet, a three dimensional article or a plurality of laminated sheets, and can include one or more additional layers, such as top coat layers, reinforcing layers, cushioning layers, wood veneer layers, and / or additional product layers. The products can be used as flooring, and in construction, cabinetry, and the like.

Owner:SSI HOLDCO INC A DELAWARE +1

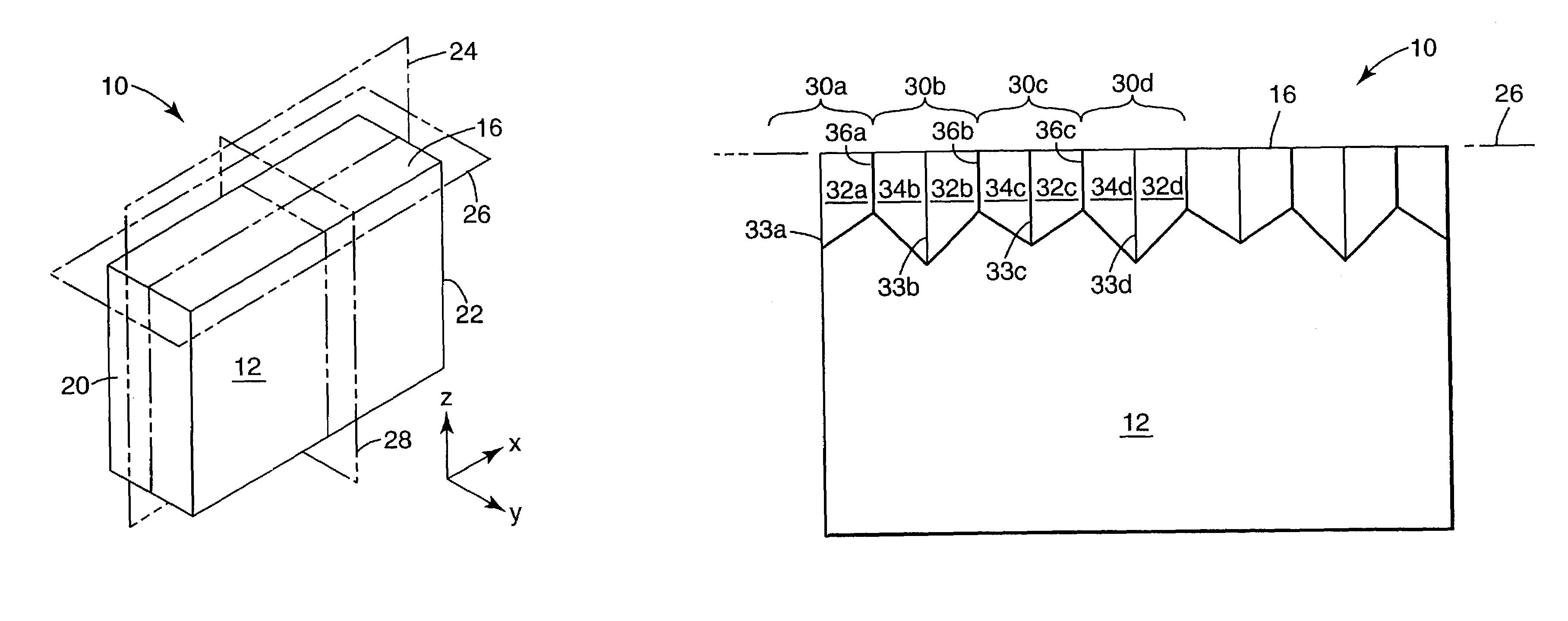

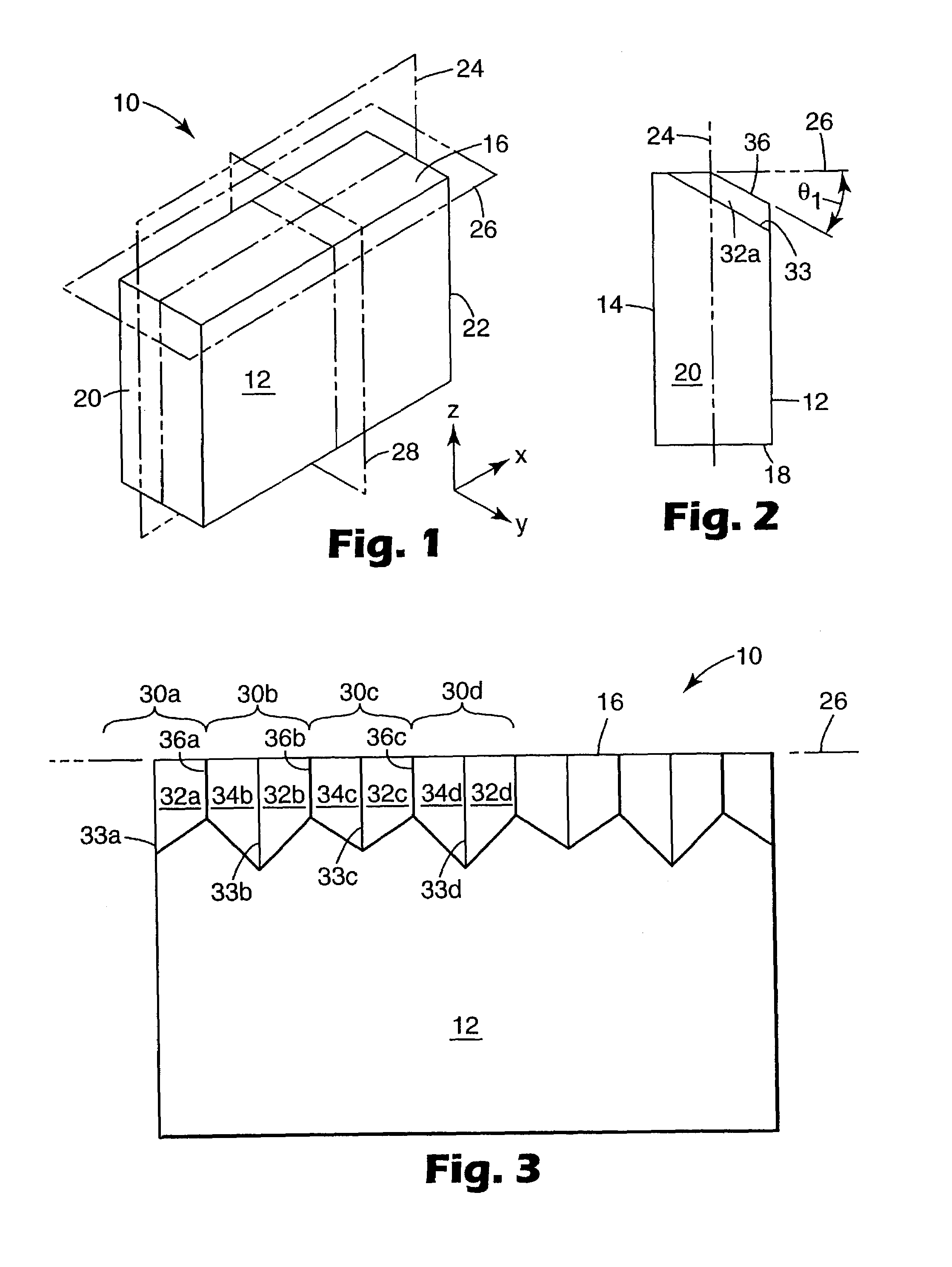

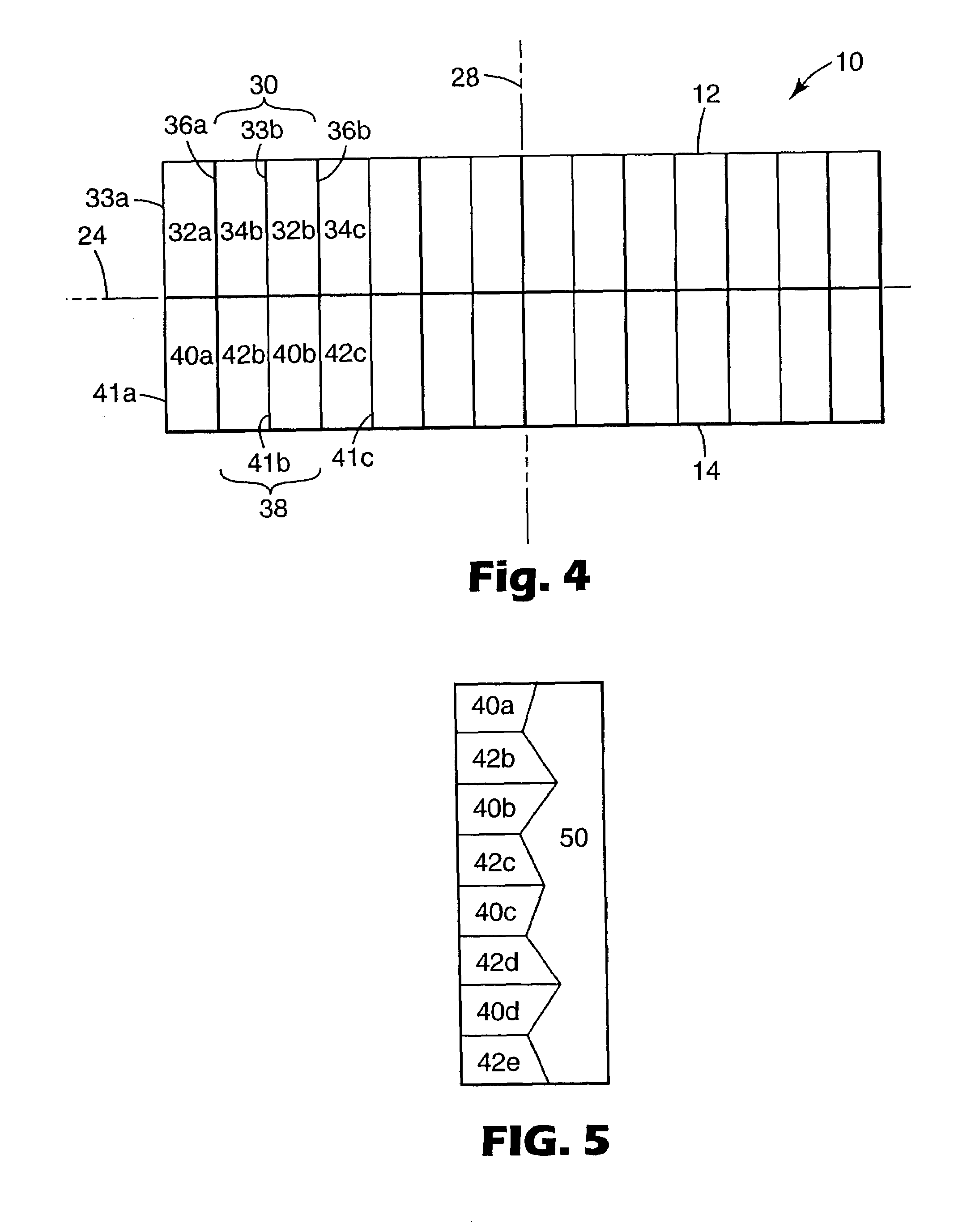

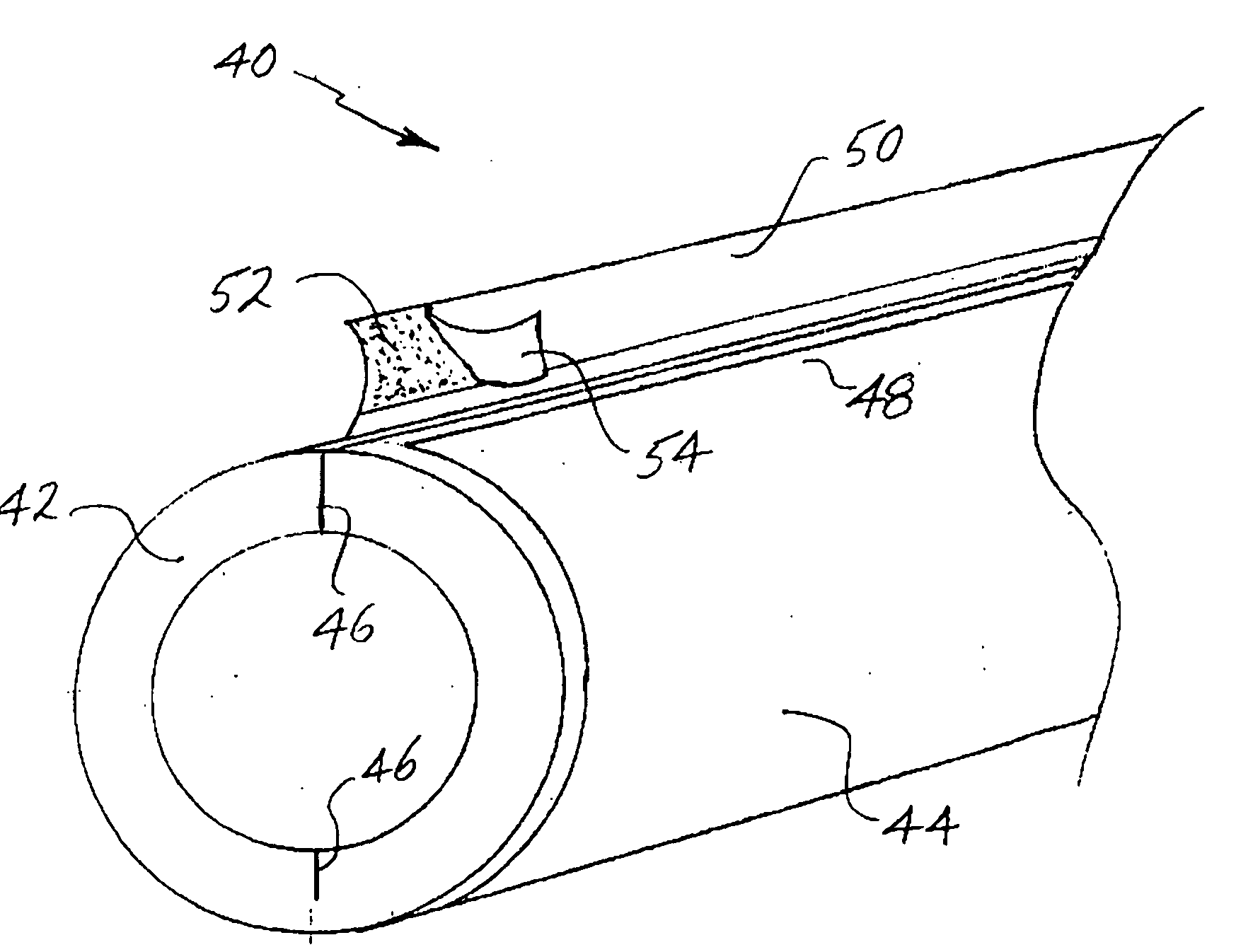

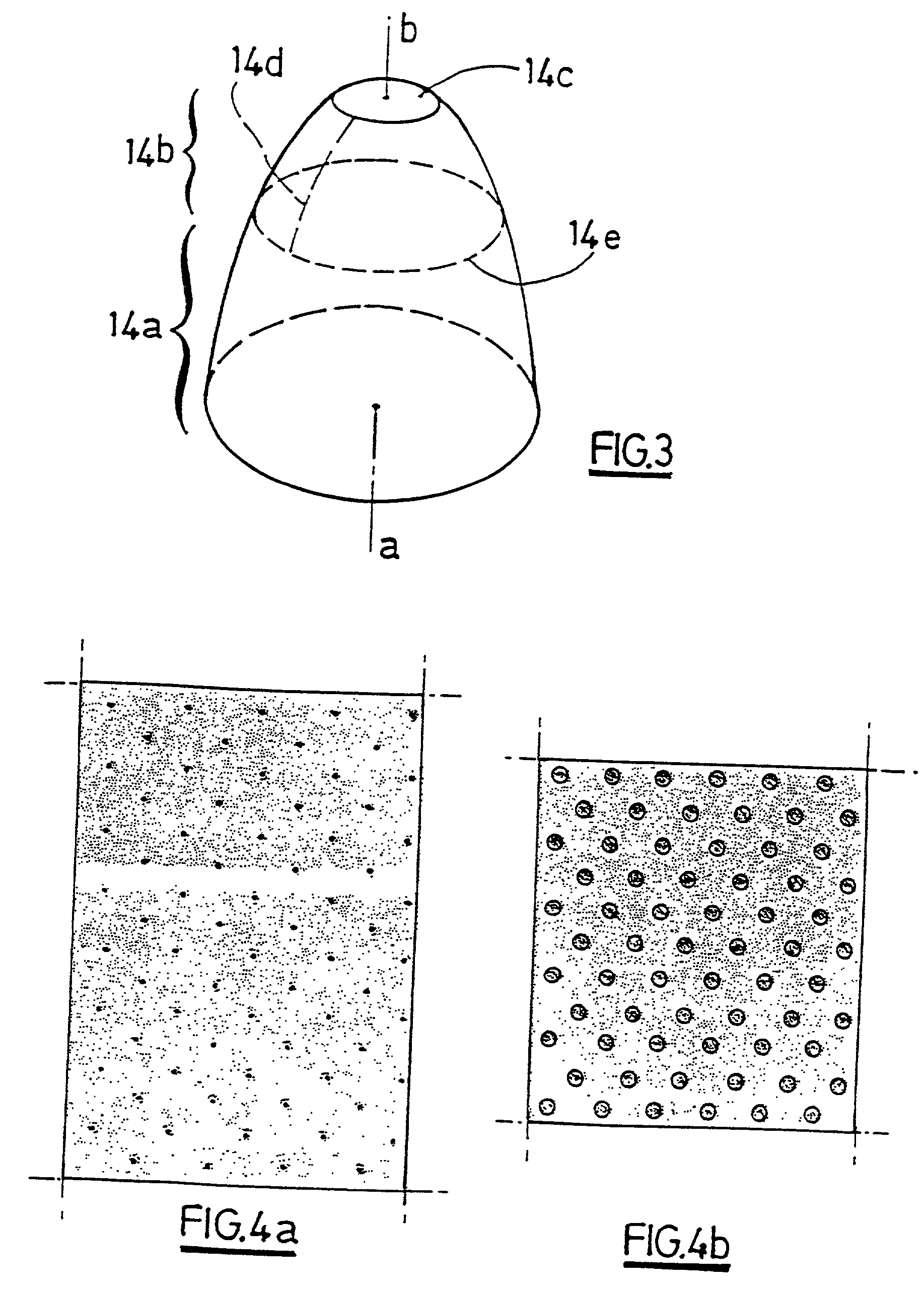

Lamina comprising cube corner elements and retroreflective sheeting

ActiveUS7156527B2Increase brightnessImprove propertiesLamination ancillary operationsLaminationWood veneerEngineering

The present invention is directed to lamina(e) comprising cube corner elements, a tool comprising an assembly of laminae and replicas thereof. The invention further relates to retroreflective sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

Facing and faced insulation products

ActiveUS20080081138A1Less moistureLess expansionPipe protection by thermal insulationGlass/slag layered productsWood veneerFiber

A facing laminate for insulation products includes: a foil or metallized polymeric film sheet layer forming an inner layer of the laminate that is adapted be bonded directly to a surface of an insulation product; a paper composite sheet layer, which may include synthetic and / or inorganic fibers, forming an outer exposed layer of the laminate; and a scrim intermediate and bonded to the foil or metallized polymeric film sheet and paper composite sheet layers. The facing laminate may include a humectant and / or a water, oil, and / or grease repellant component. The paper composite sheet layer of the laminate exhibits greater dimensional stability and reduced wrinkling when the laminate is exposed to conditions of high humidity. Insulation products to be faced with this facing laminate include pipe insulation, duct board, duct wrap insulation, metal building insulation, and other building insulation products.

Owner:JOHNS MANVILLE CORP

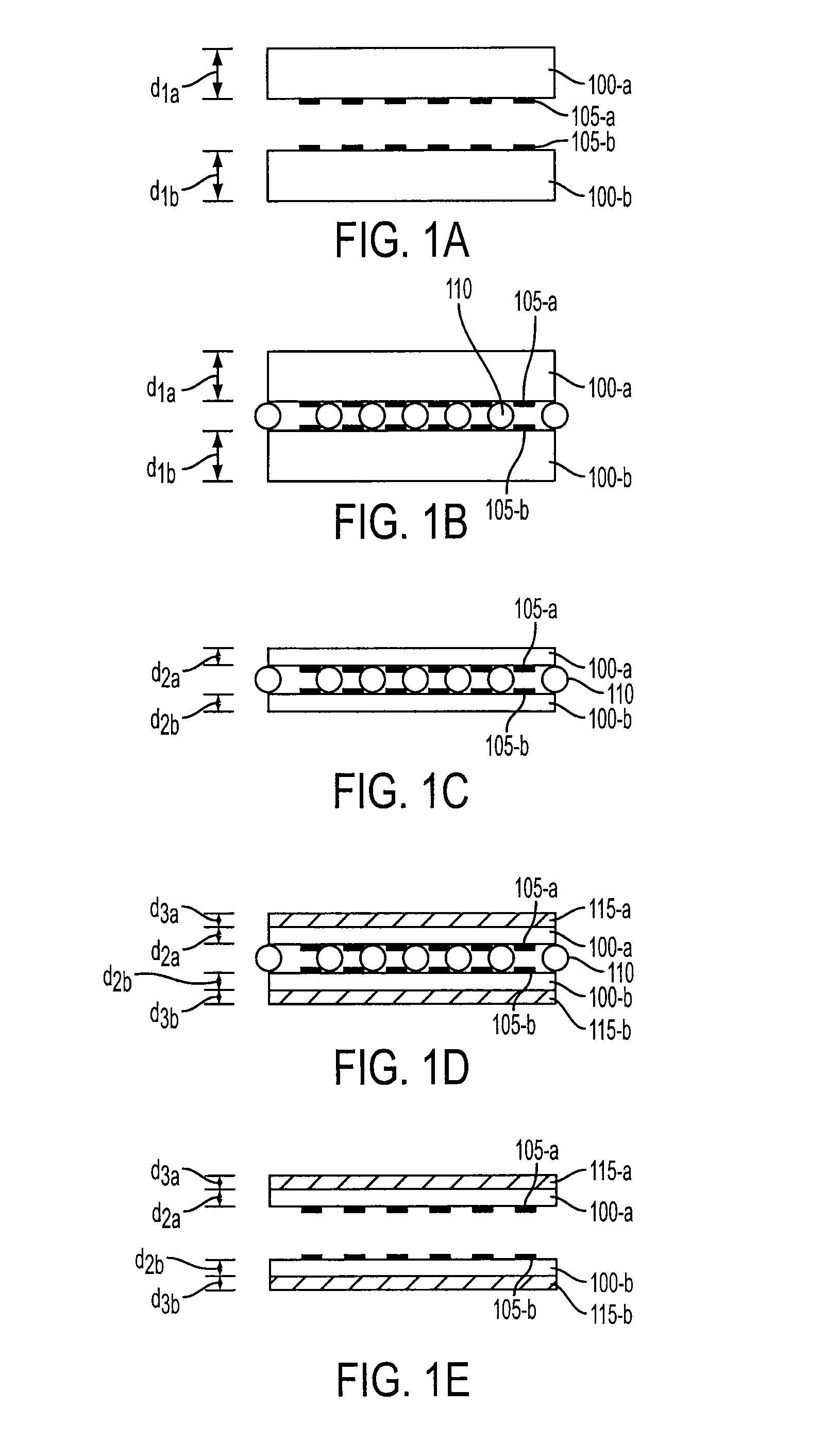

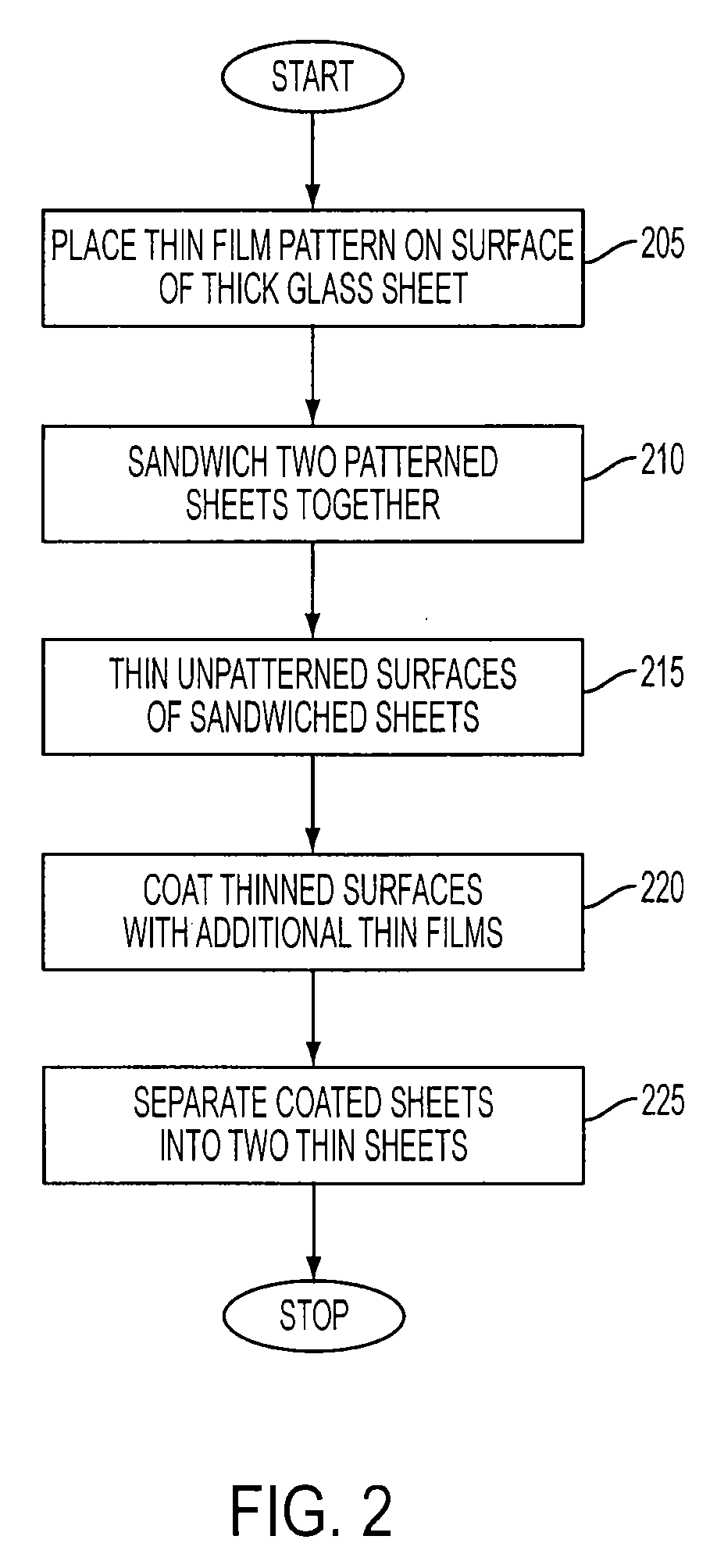

Method for Fabricating Thin Sheets of Glass

Fabrication of thin sheets of glass or other substrate material for use in devices such as touch sensor panels is disclosed. A pair of thick glass sheets, typically with thicknesses of 0.5 mm or greater each, may each be patterned with thin film on a surface, sealed together to form a sandwich with the patterned surfaces facing each other and spaced apart by removable spacers, either or both thinned on their outside surfaces to thicknesses of less than 0.5 mm each, and separated into two thin glass sheets. A single thick glass sheet, typically with a thickness of 0.5 mm or greater, may be patterned, covered with a protective layer over the pattern, thinned on its outside surface to a thickness of less than 0.5 mm, and the protective layer removed. This thinness of less than 0.5 mm may be accomplished using standard LCD equipment, despite the equipment having a sheet minimum thickness requirement of 0.5 mm.

Owner:APPLE INC

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

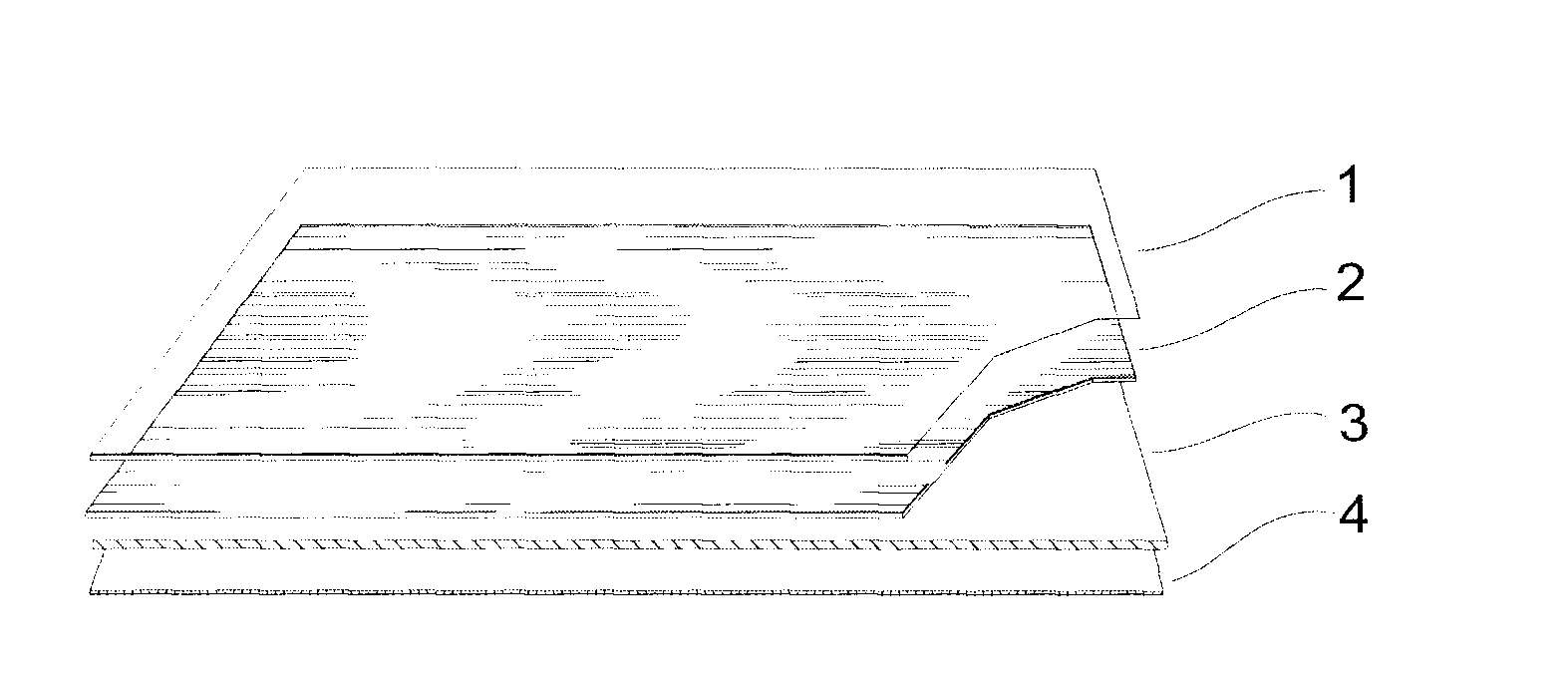

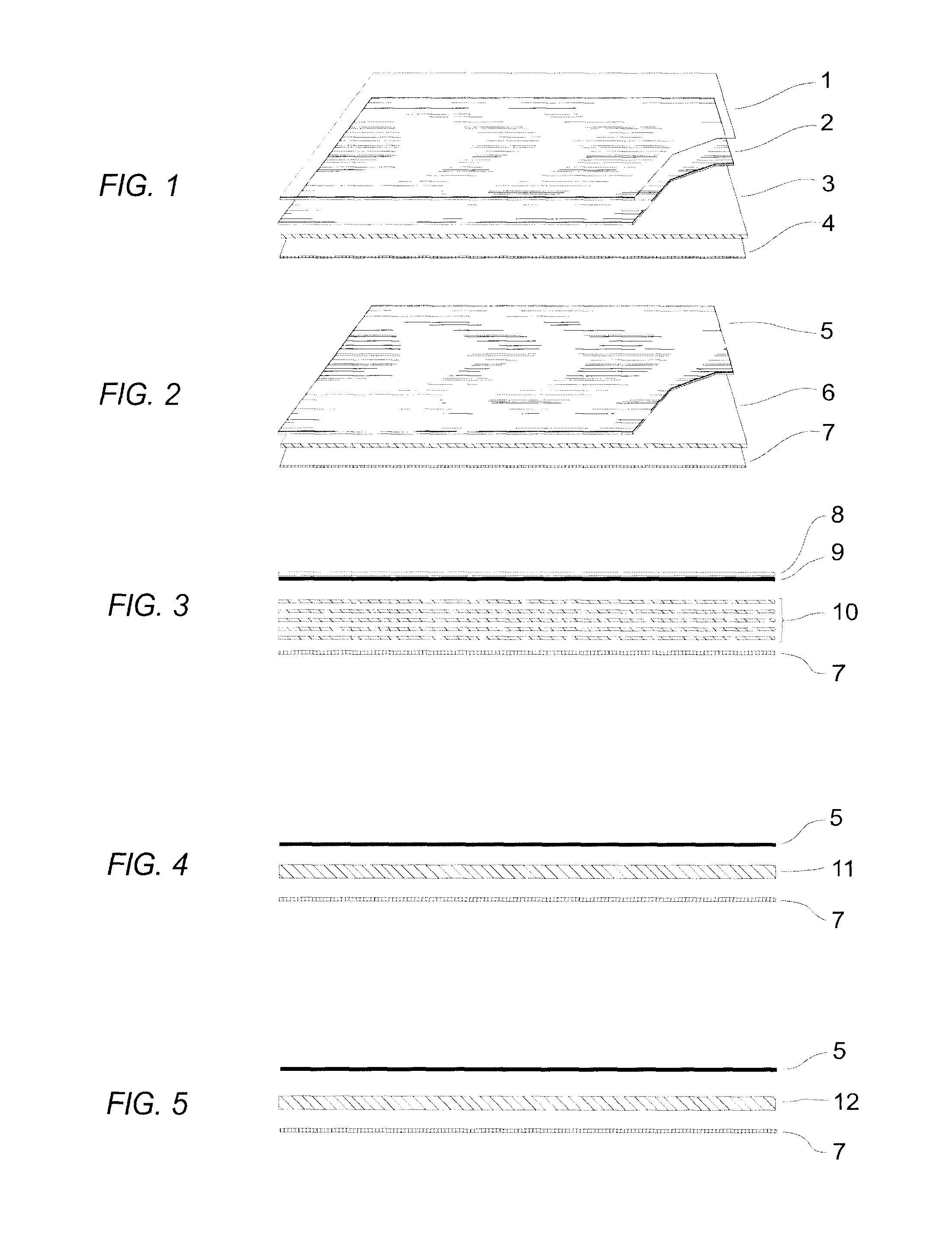

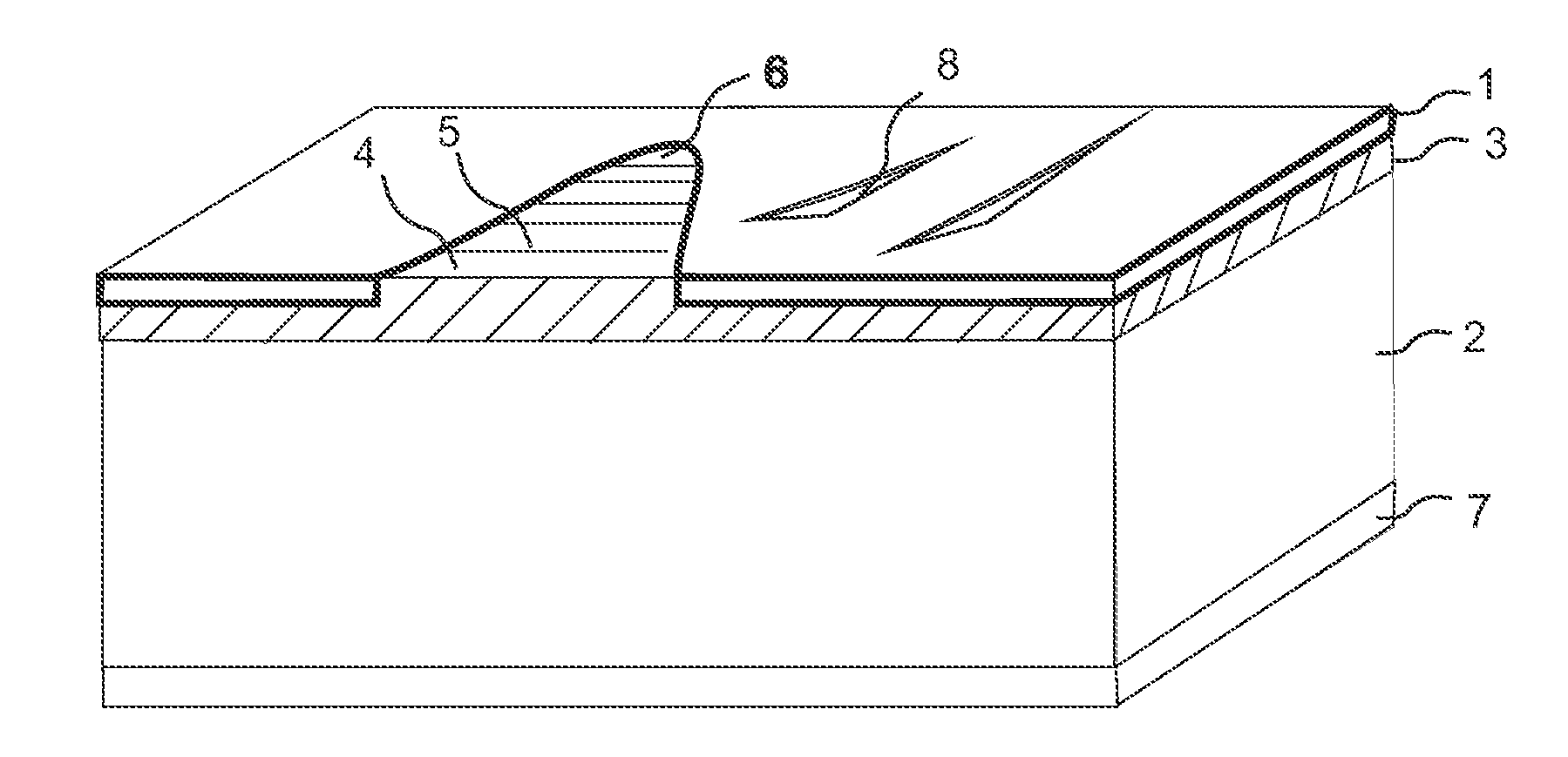

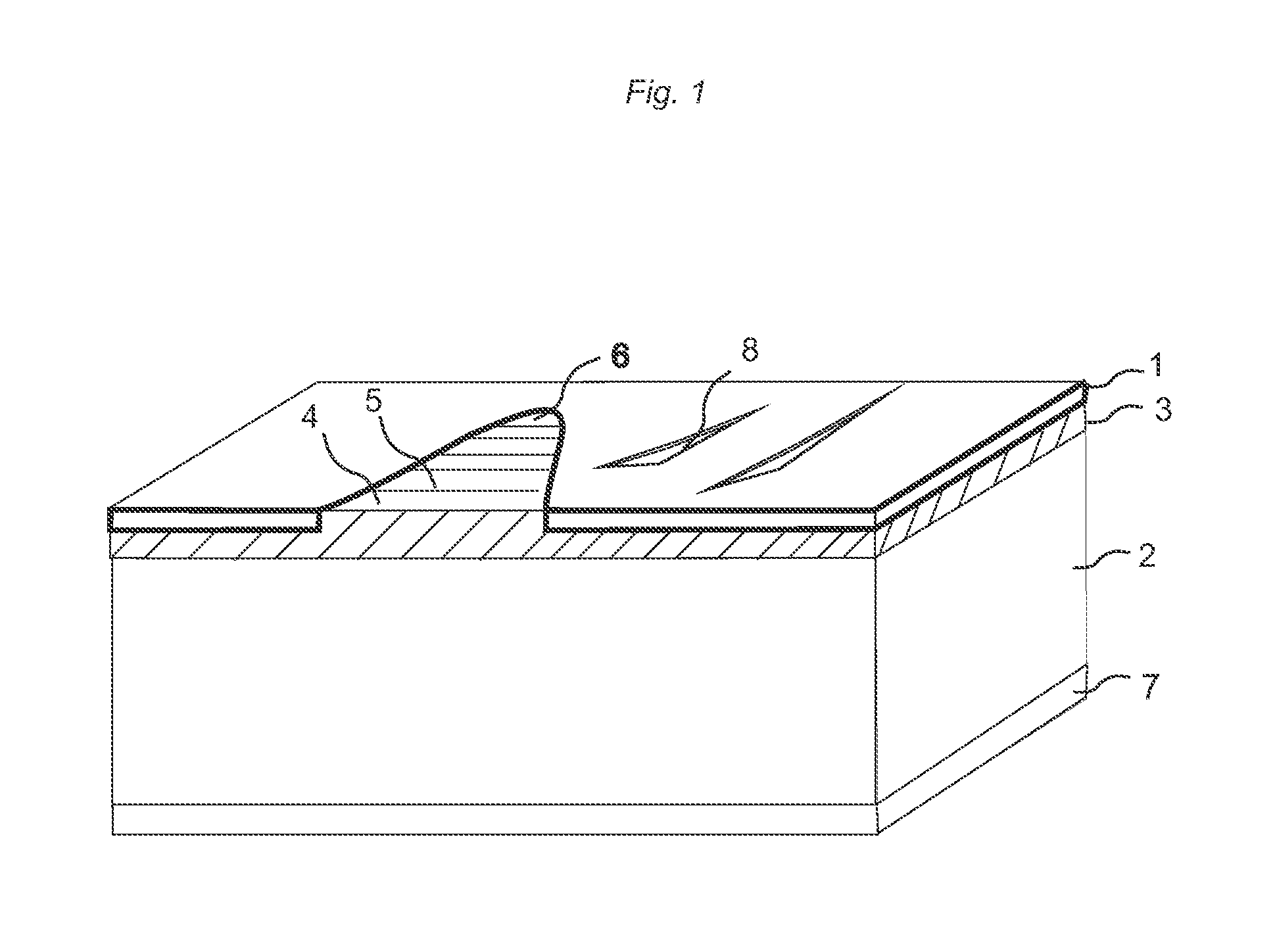

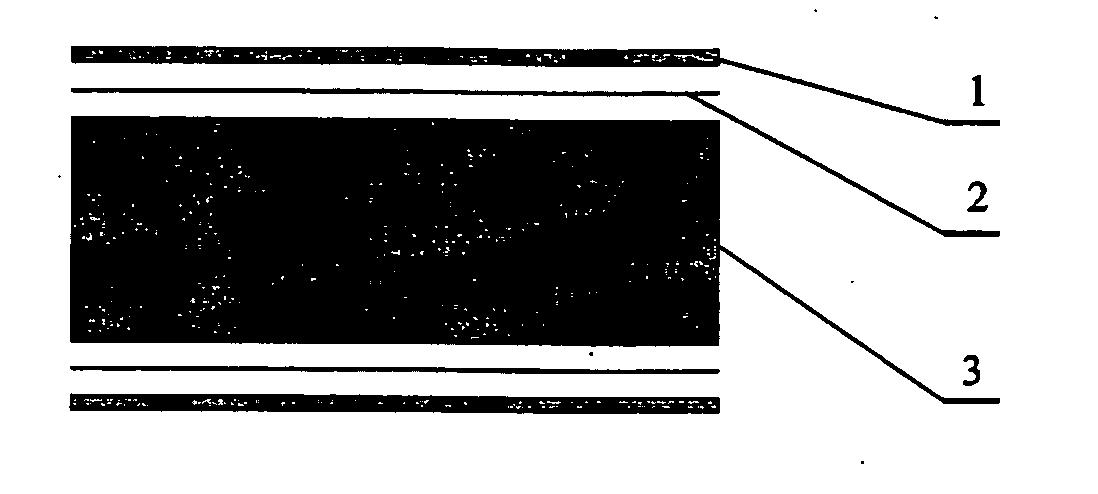

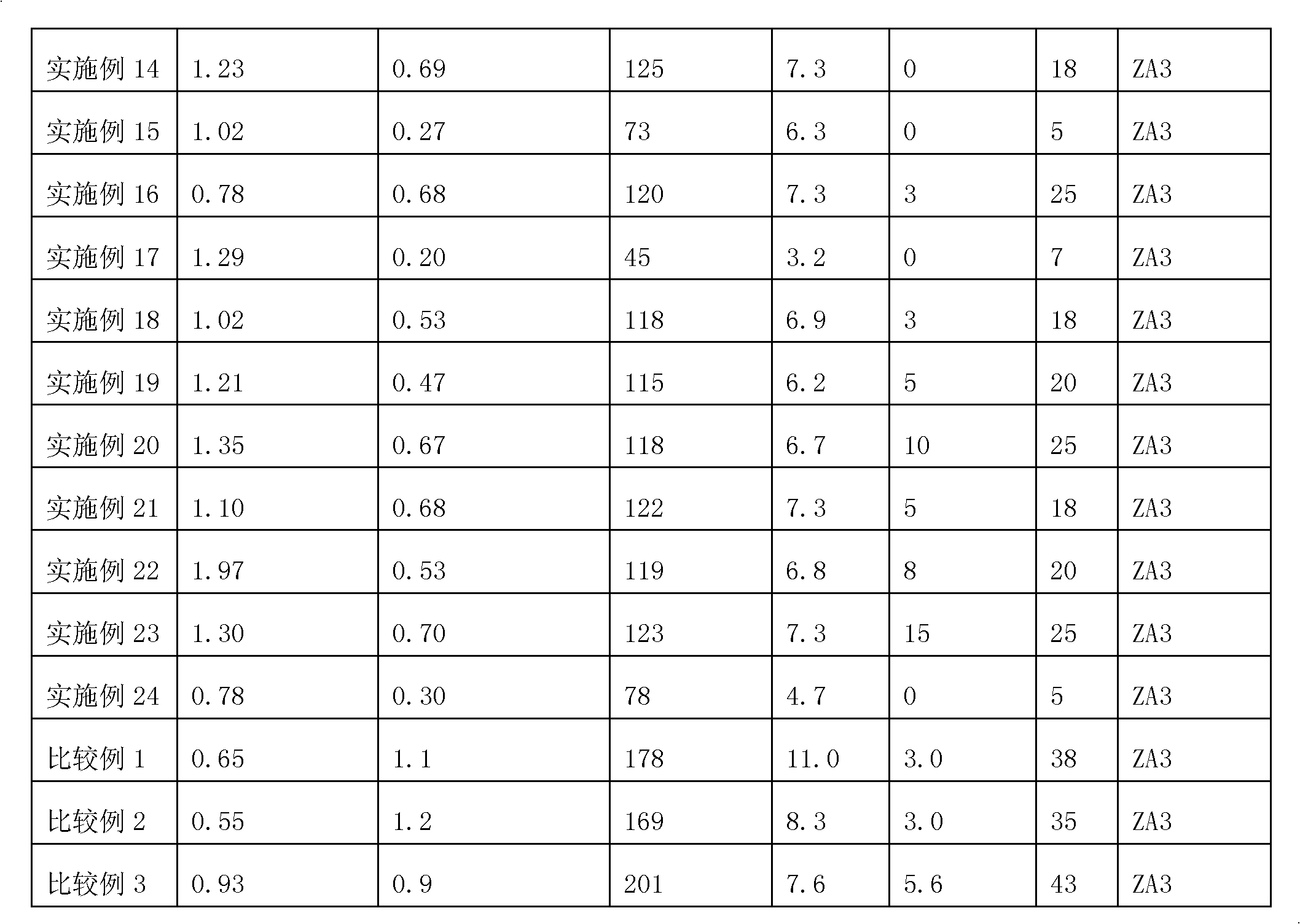

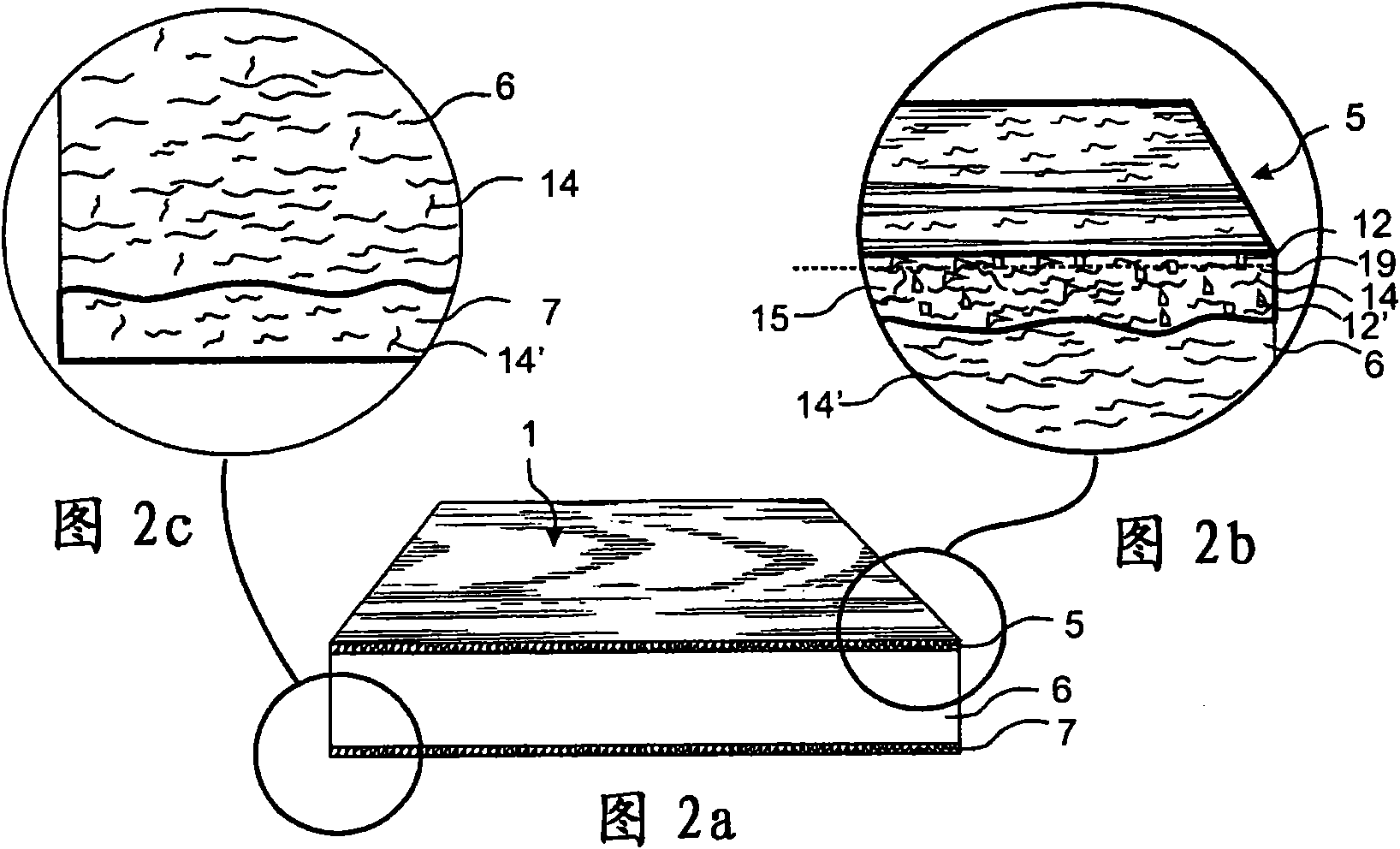

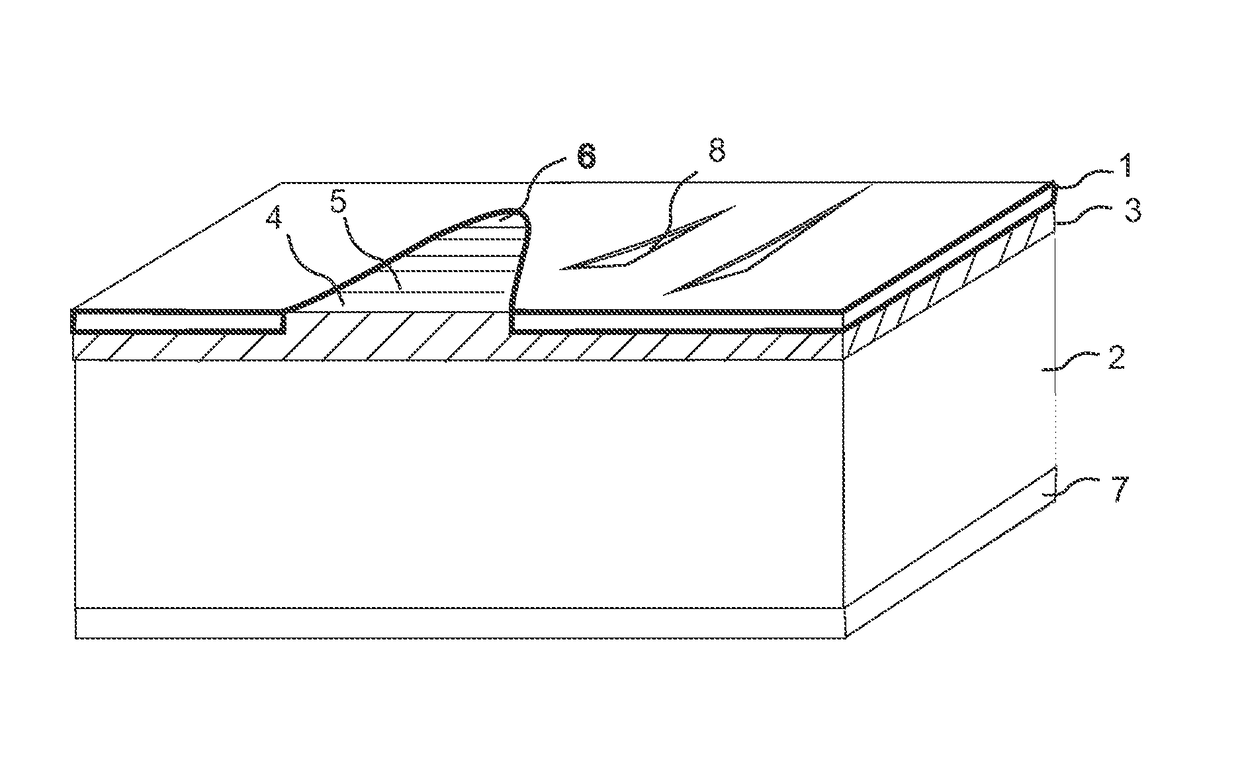

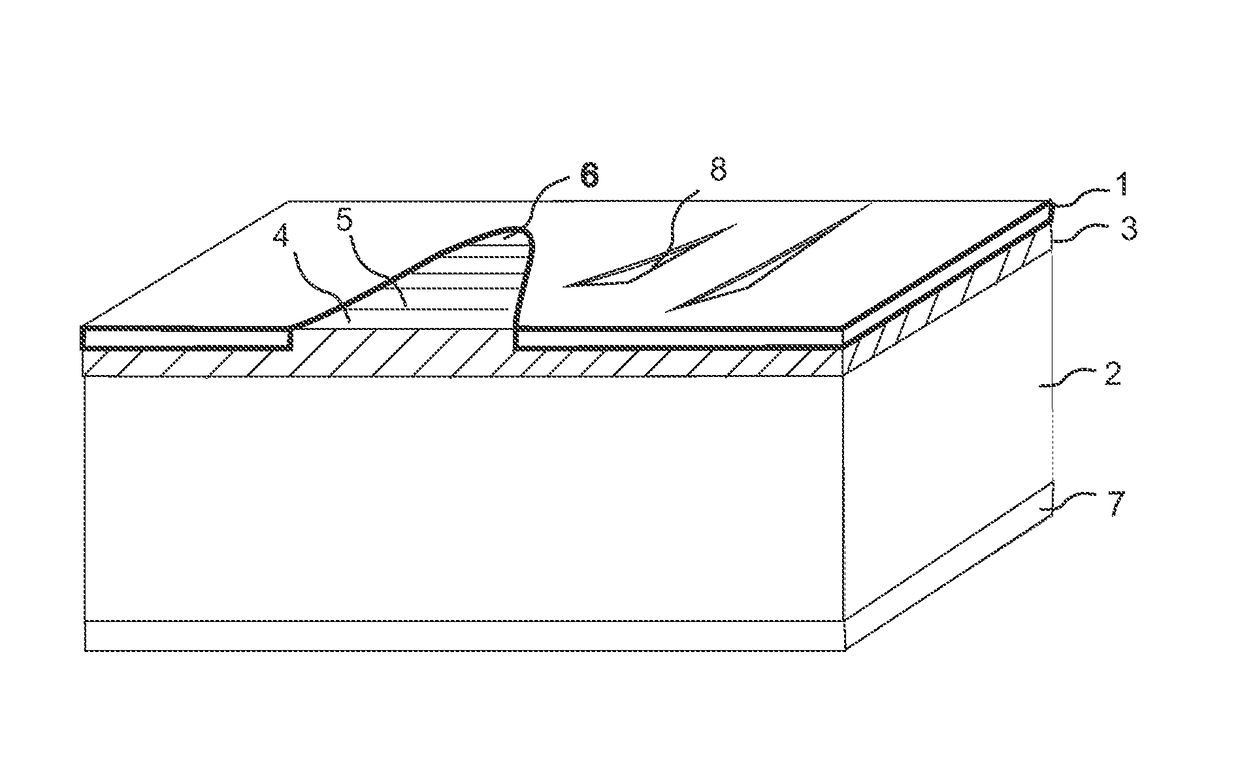

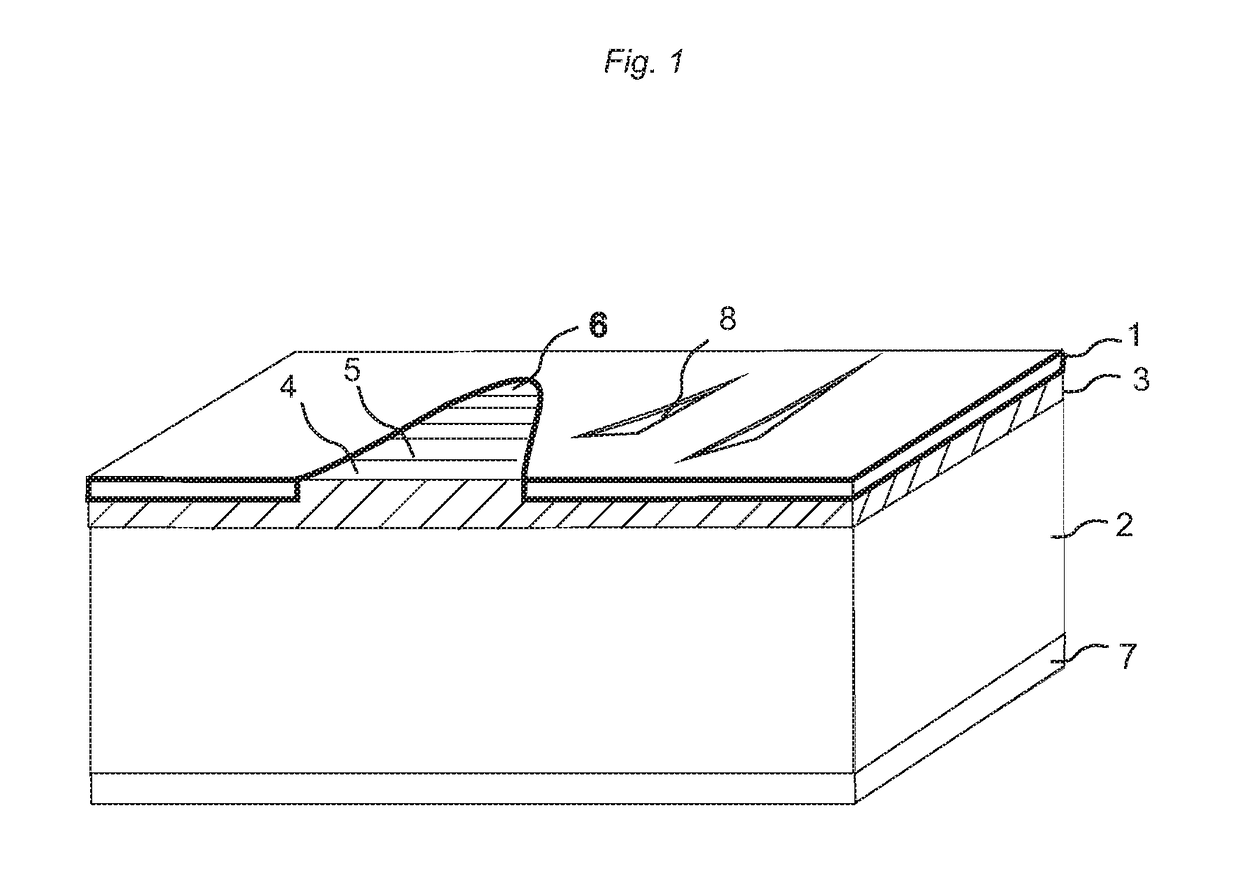

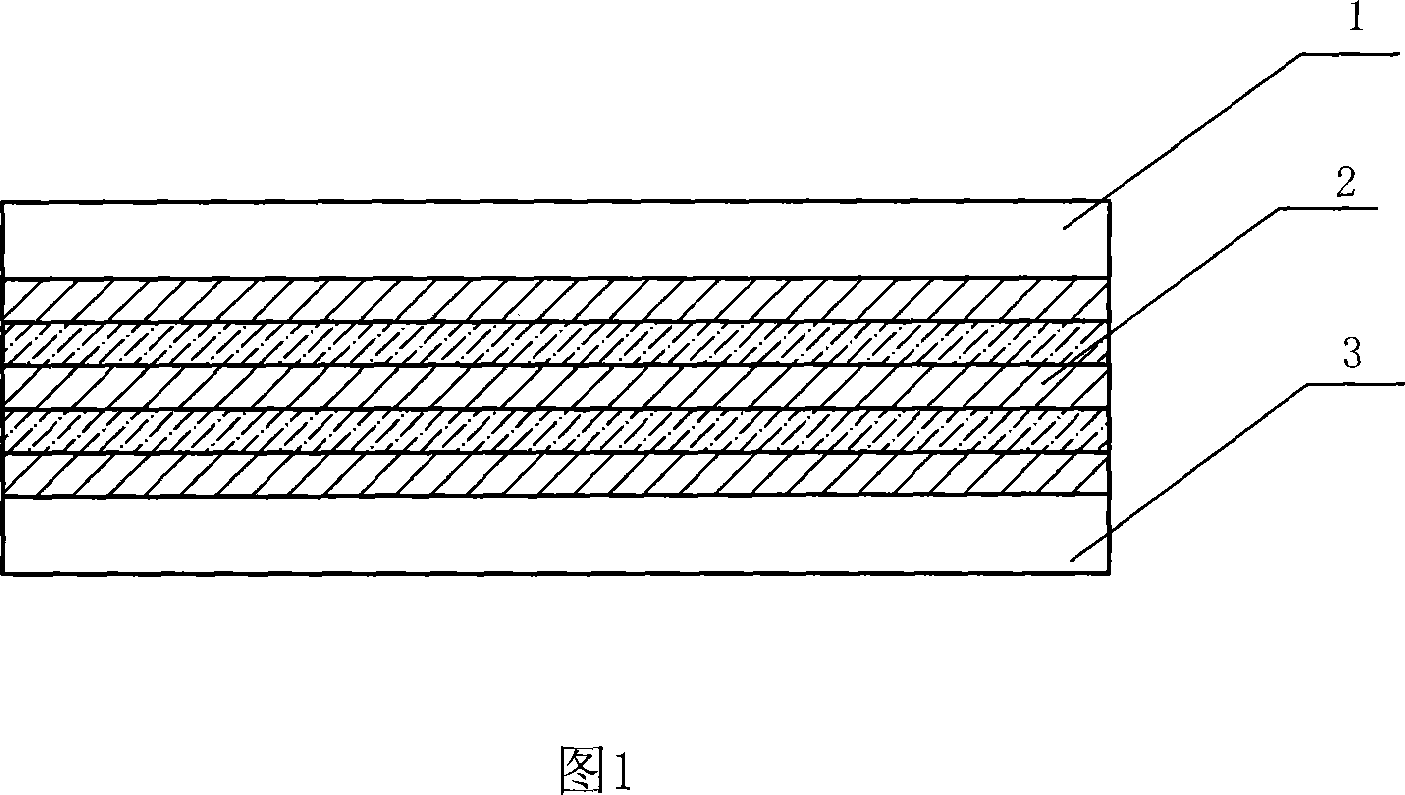

Wood fibre based panel with a surface layer

ActiveUS20150197942A1Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

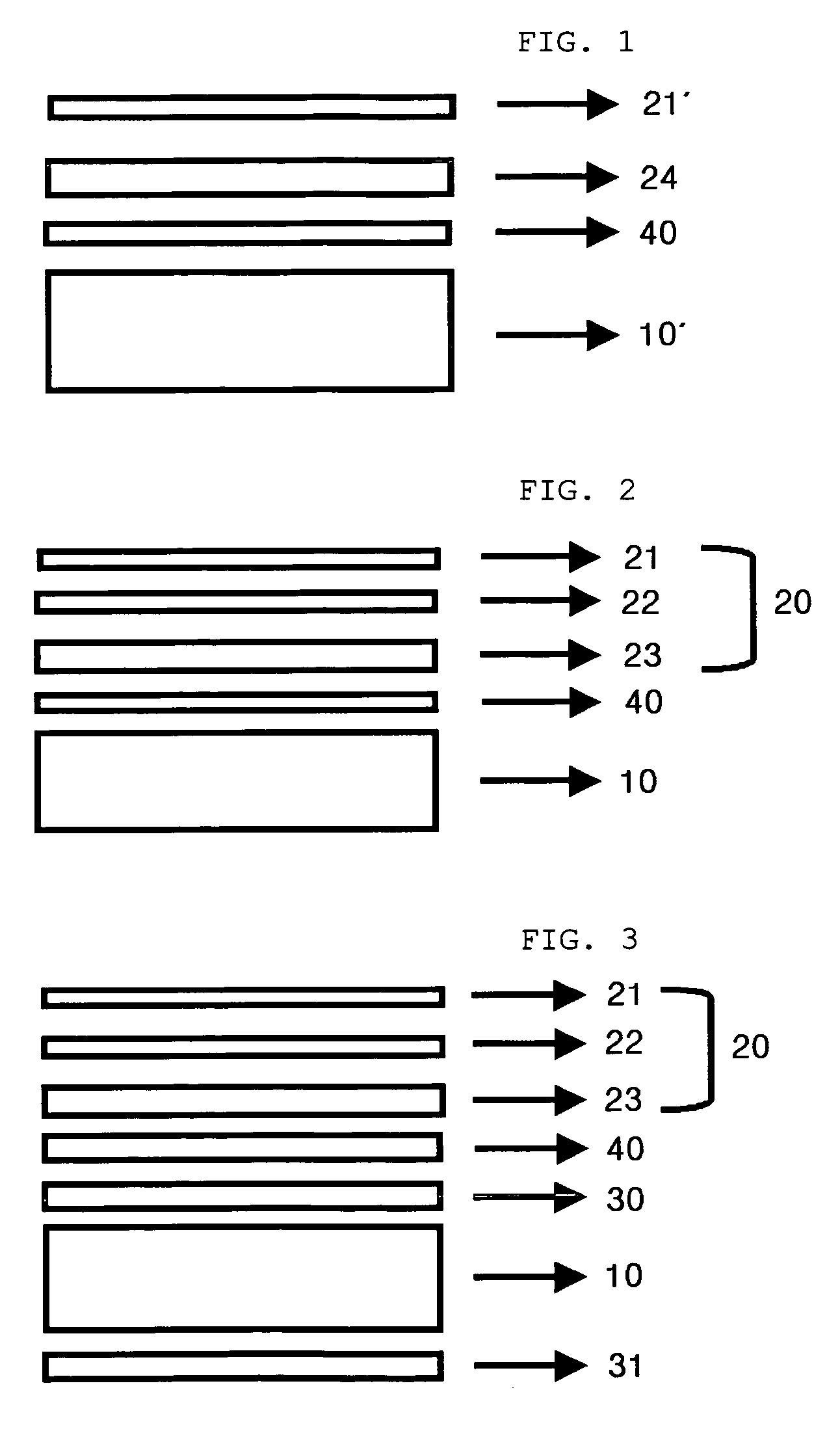

A building panel with a surface layer (1) including a wood veneer, a wood fibre based core (2) and a sub-layer (3) between the surface layer (1) and the core (2). The sub-layer (3) includes wood fibres (4) and a binder (5). The surface layer (1) has surface portions (6) including material from the sub-layer (3). The surface portions (6) including material from the sub-layer (3) extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

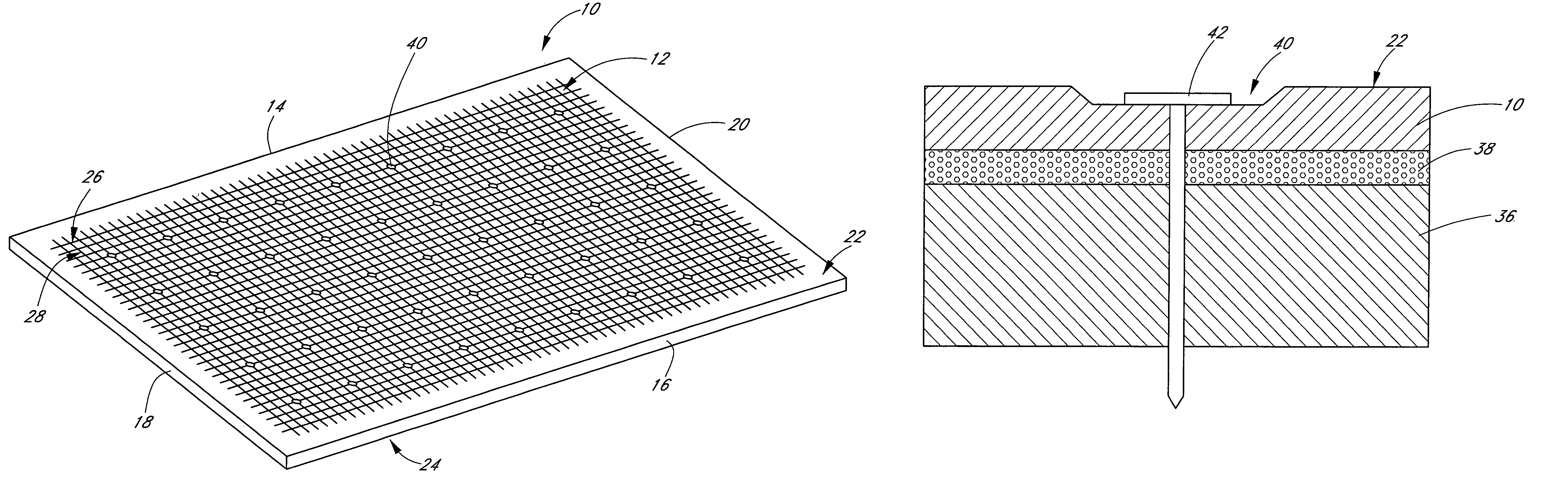

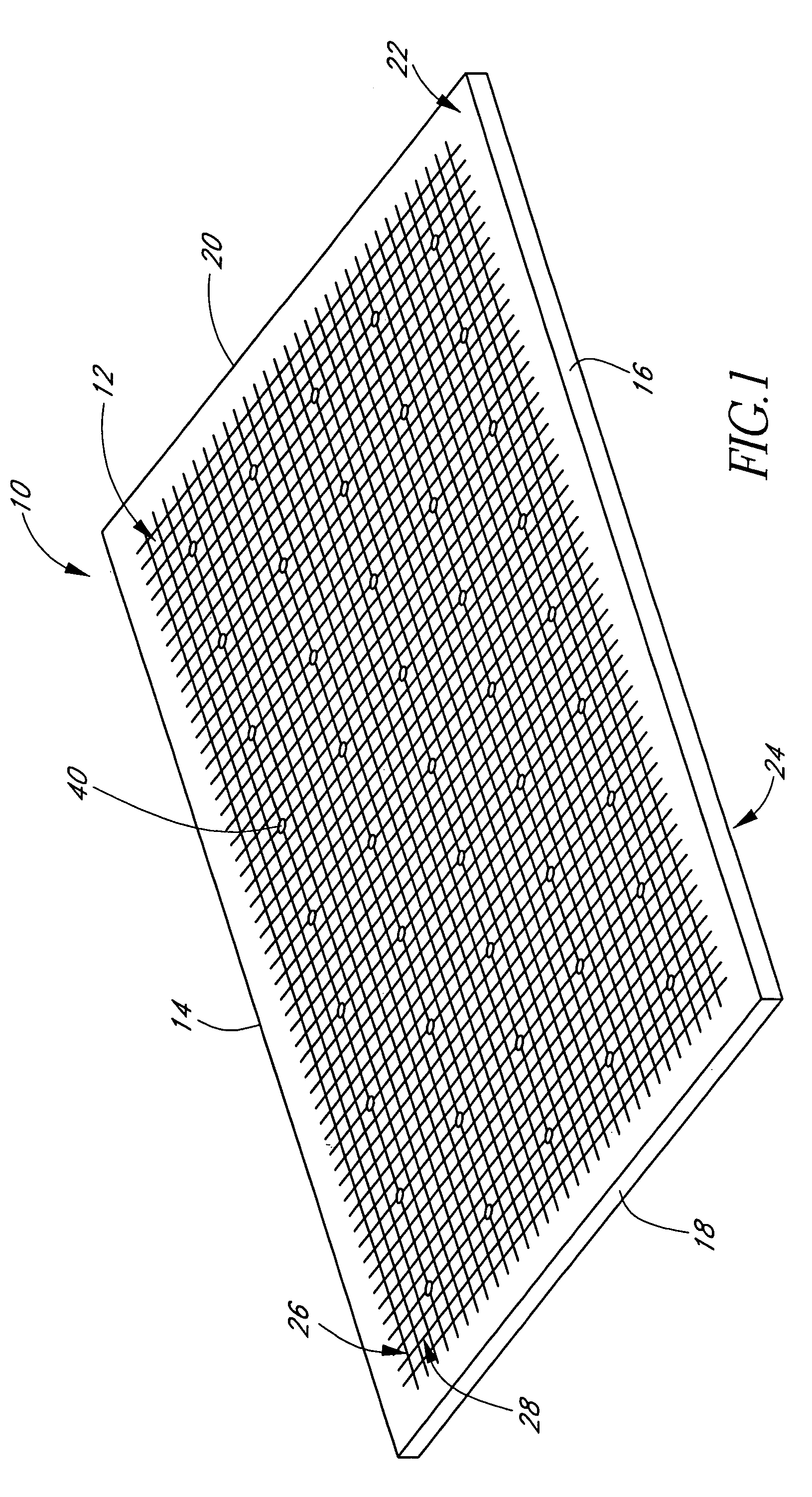

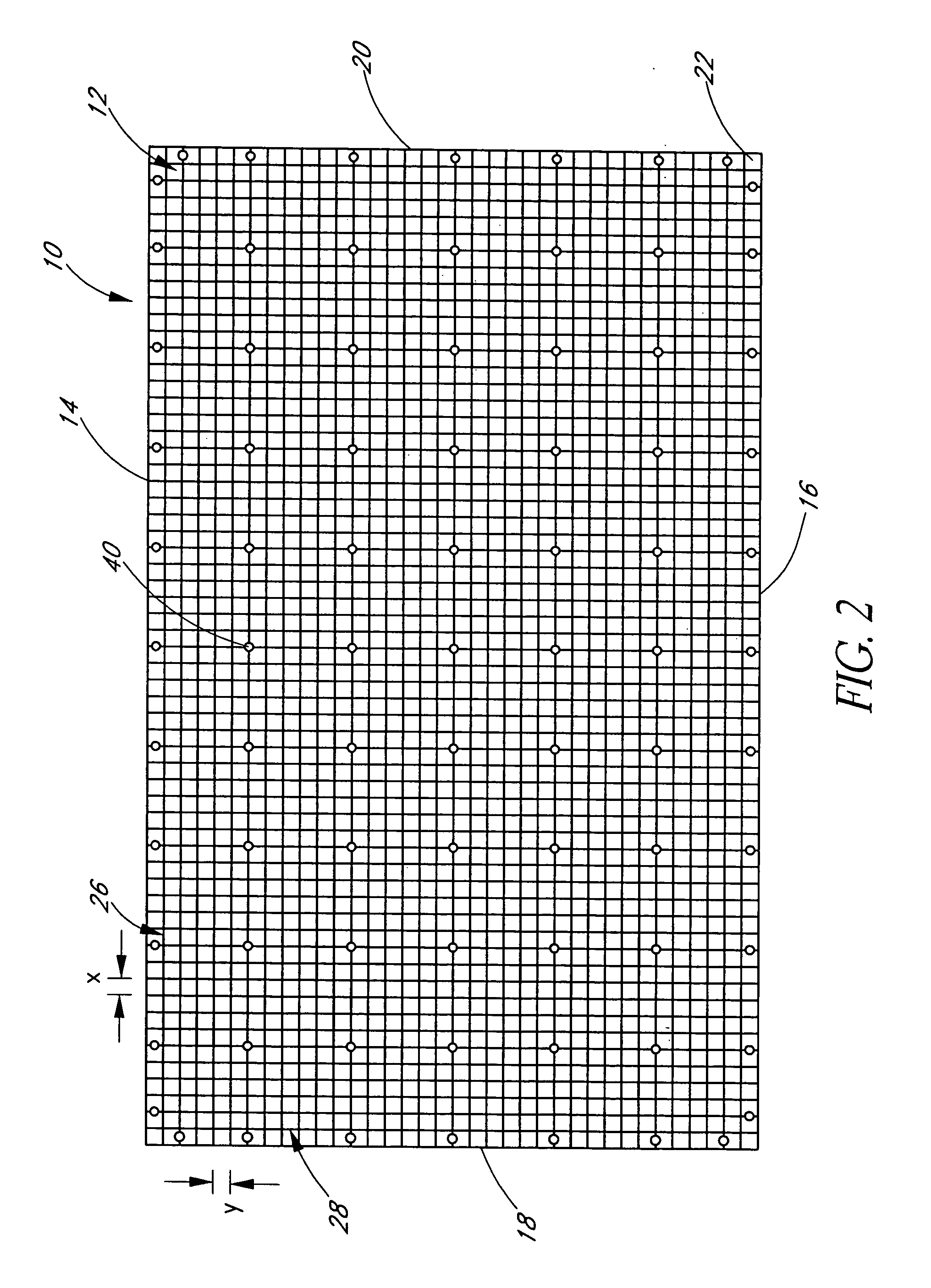

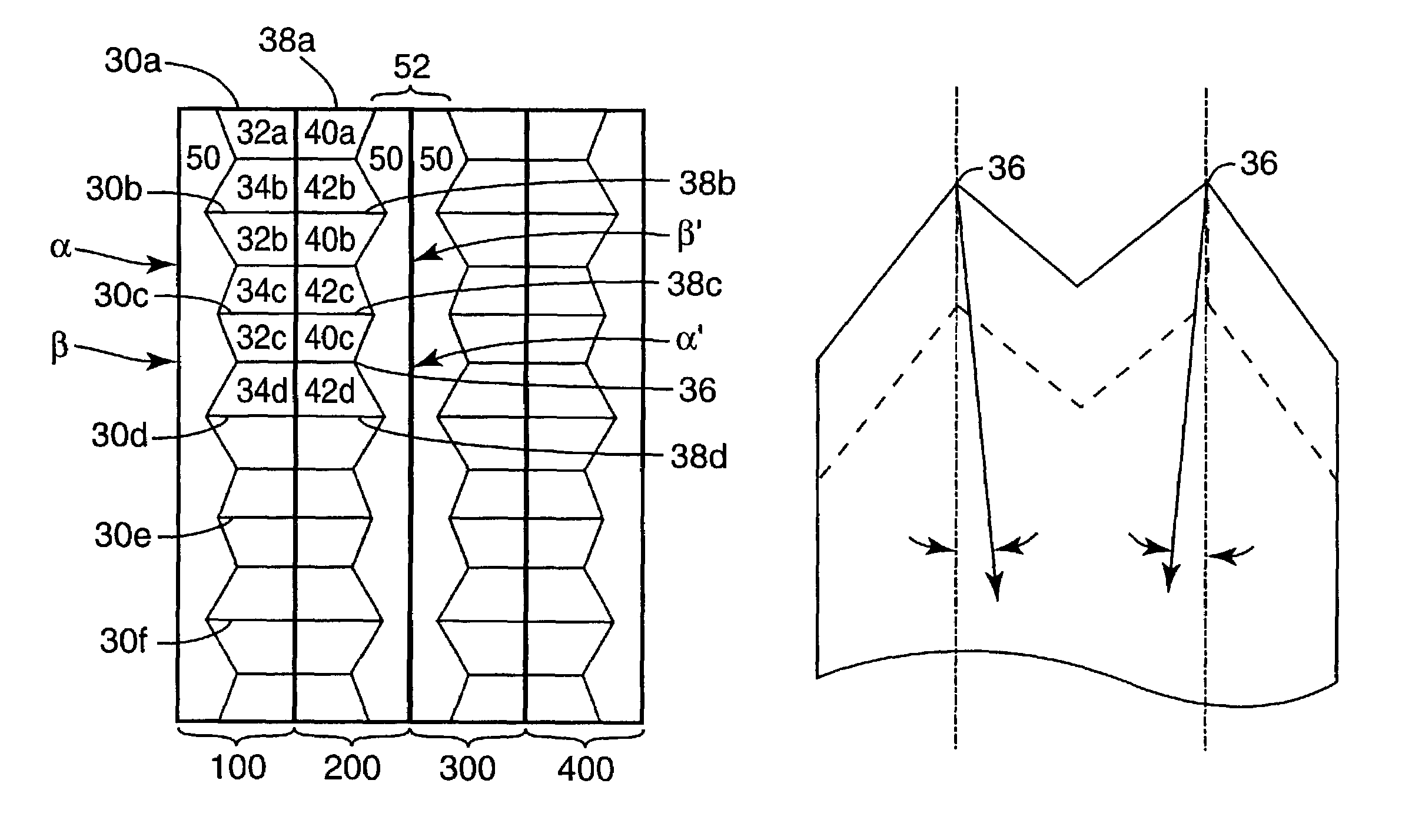

Surface groove system for building sheets

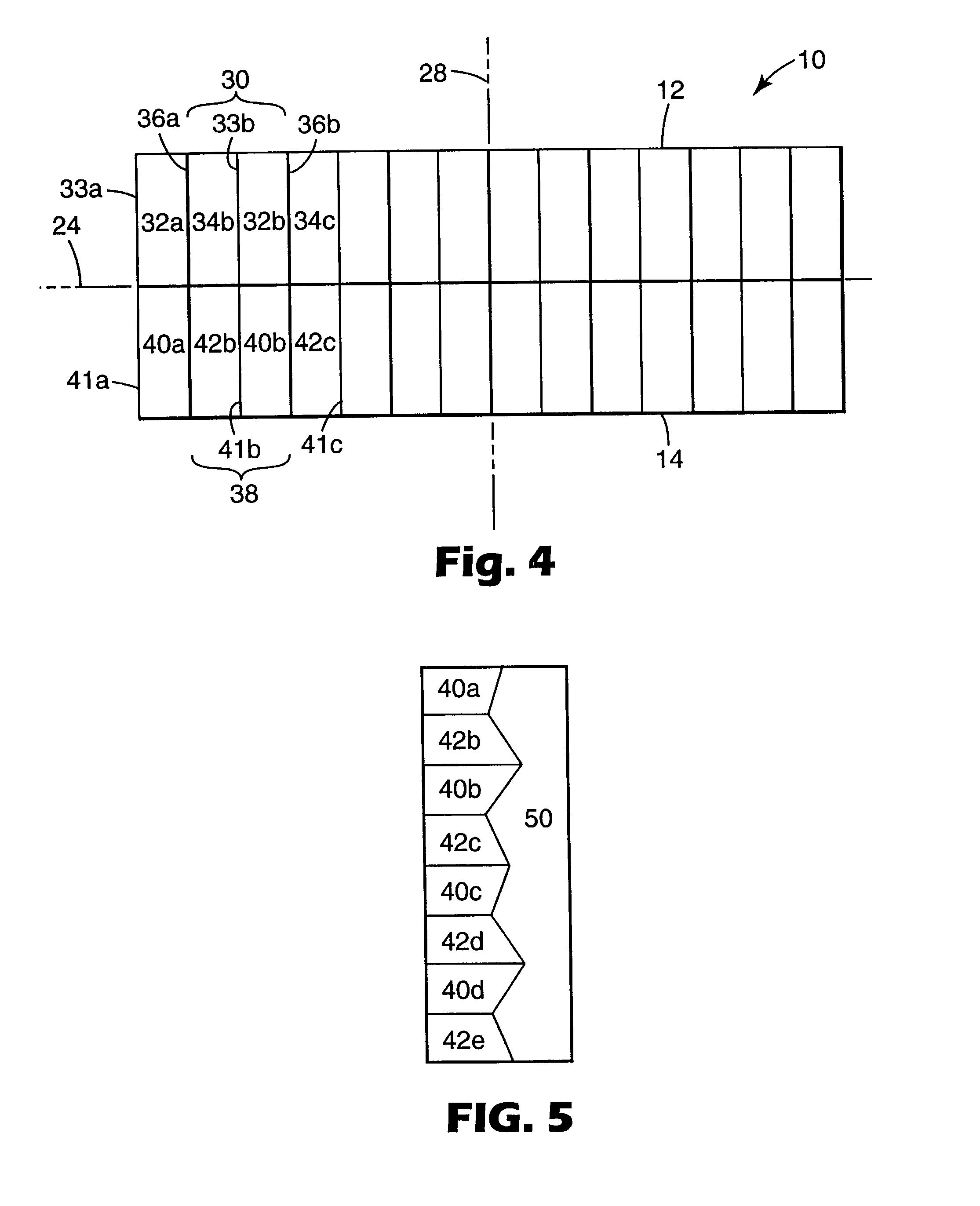

InactiveUS7325325B2Small sizeReduce strength of sheetConstruction materialMechanical measuring arrangementsWood veneerRepeat pattern

The present invention involves building sheets with a plurality of grooves indented into a surface of the building sheet to provide a guide for cutting the building sheet along the grooves. Preferably, the grooves are arranged in a regularly repeating pattern and are spaced apart by a standard unit of measurement in order for a cutter to accurately size the building sheet to a precise dimension. A simple scoring knife is preferably used to score the sheet along the grooves, without the need for a straight edge, and the sheet is broken by simply bending the sheet of along the score mark. The grooves are preferably provided at a depth into the surface the sheet such that they do not substantially decrease the strength of the sheet or affect off-groove scoring. Thus, a score mark can be made between or across grooves without deflection of the mark into a groove and without breakage of the sheet along a groove when the sheet is bent.

Owner:JAMES HARDIE TECH LTD

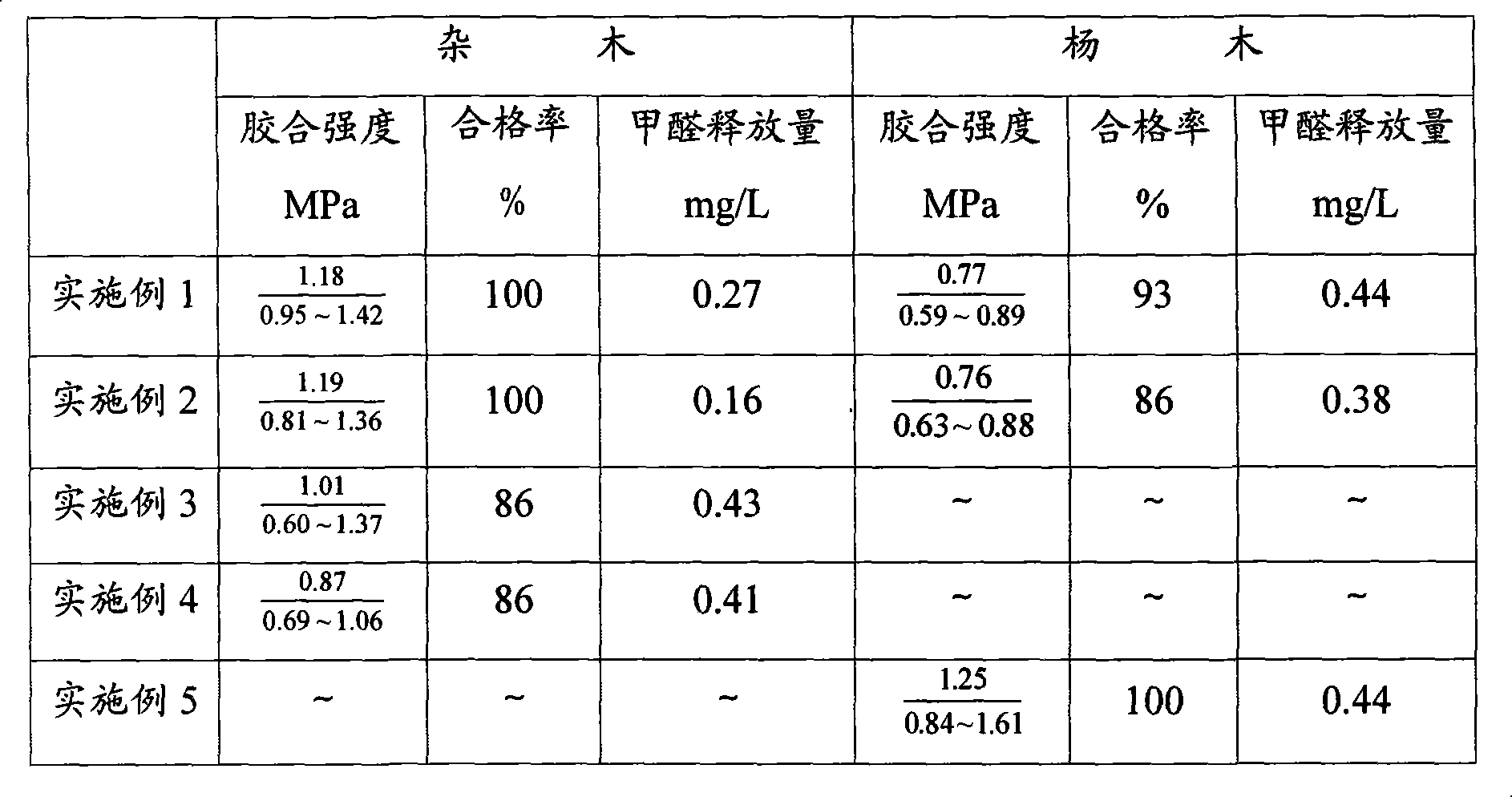

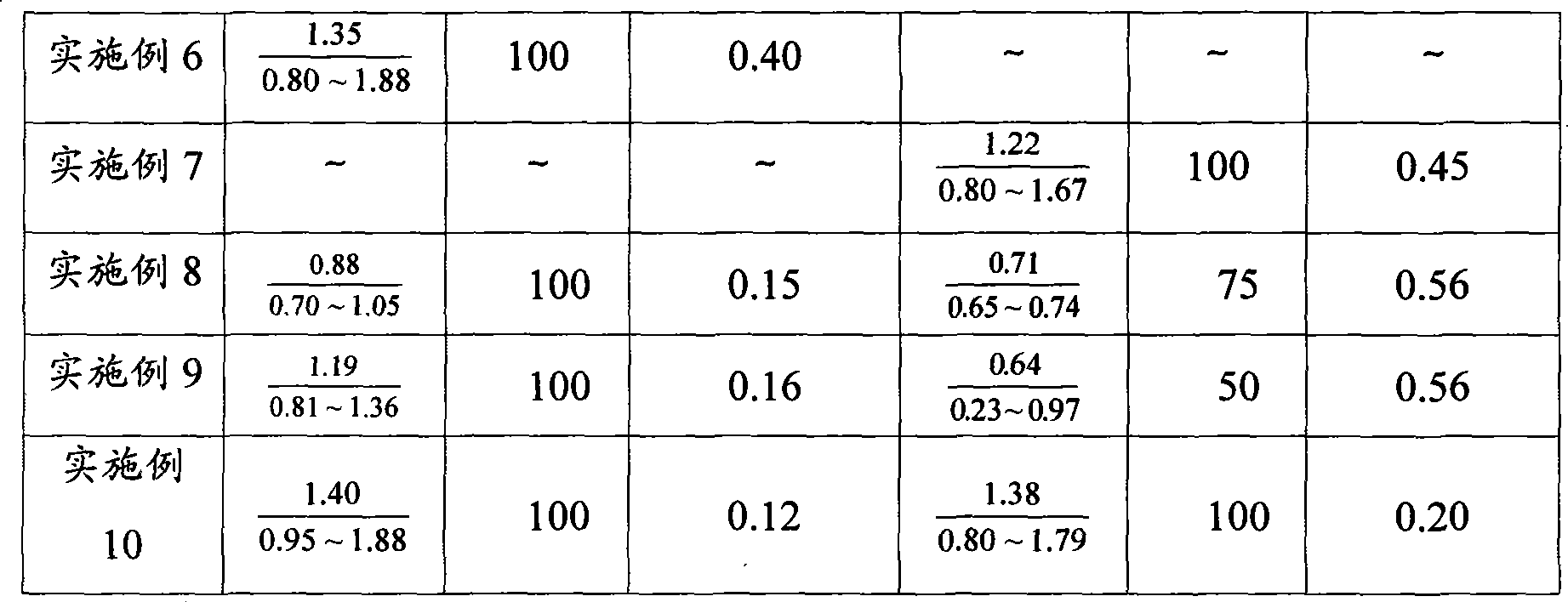

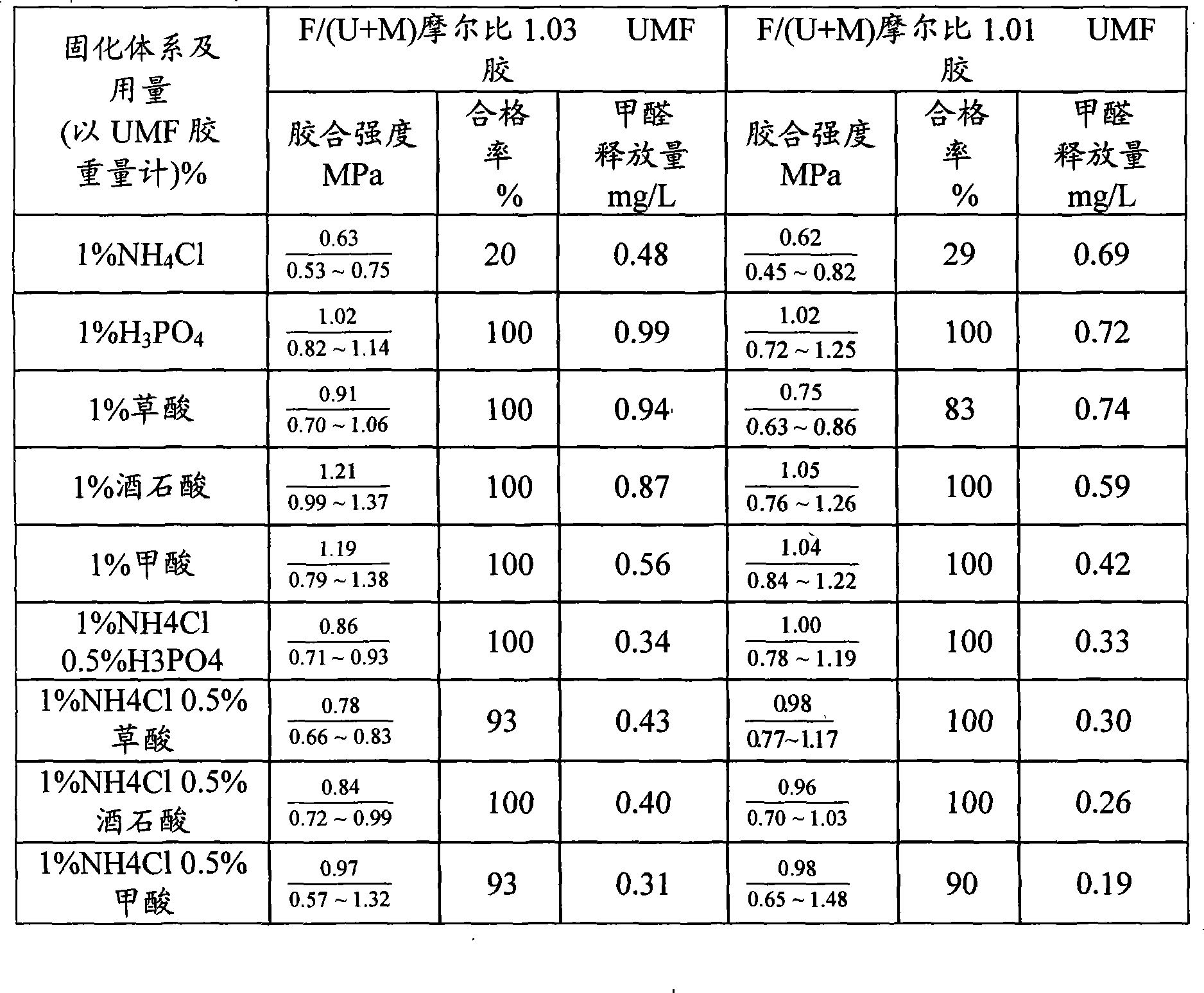

Method for manufacturing E0 level wood veneer

InactiveCN101244571AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesWood veneer joiningWood veneerEther

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Container flooring material and method of manufacture

A board suitable for use as container flooring uses bamboo and fast-growth low-density wood. Thin layers of high-density bamboo composites are used to overlay on surfaces of a core layer which can be the composite of wood veneer and wood strand-based composite, or wood veneer and bamboo stripe sheet composite. This invention combines the benefits of bamboo and wood materials to produce a bamboo-wood composite board having sufficient mechanical and physical strength and durability for use as container flooring.

Owner:ALBERTA INNOVATES TECH FUTURES

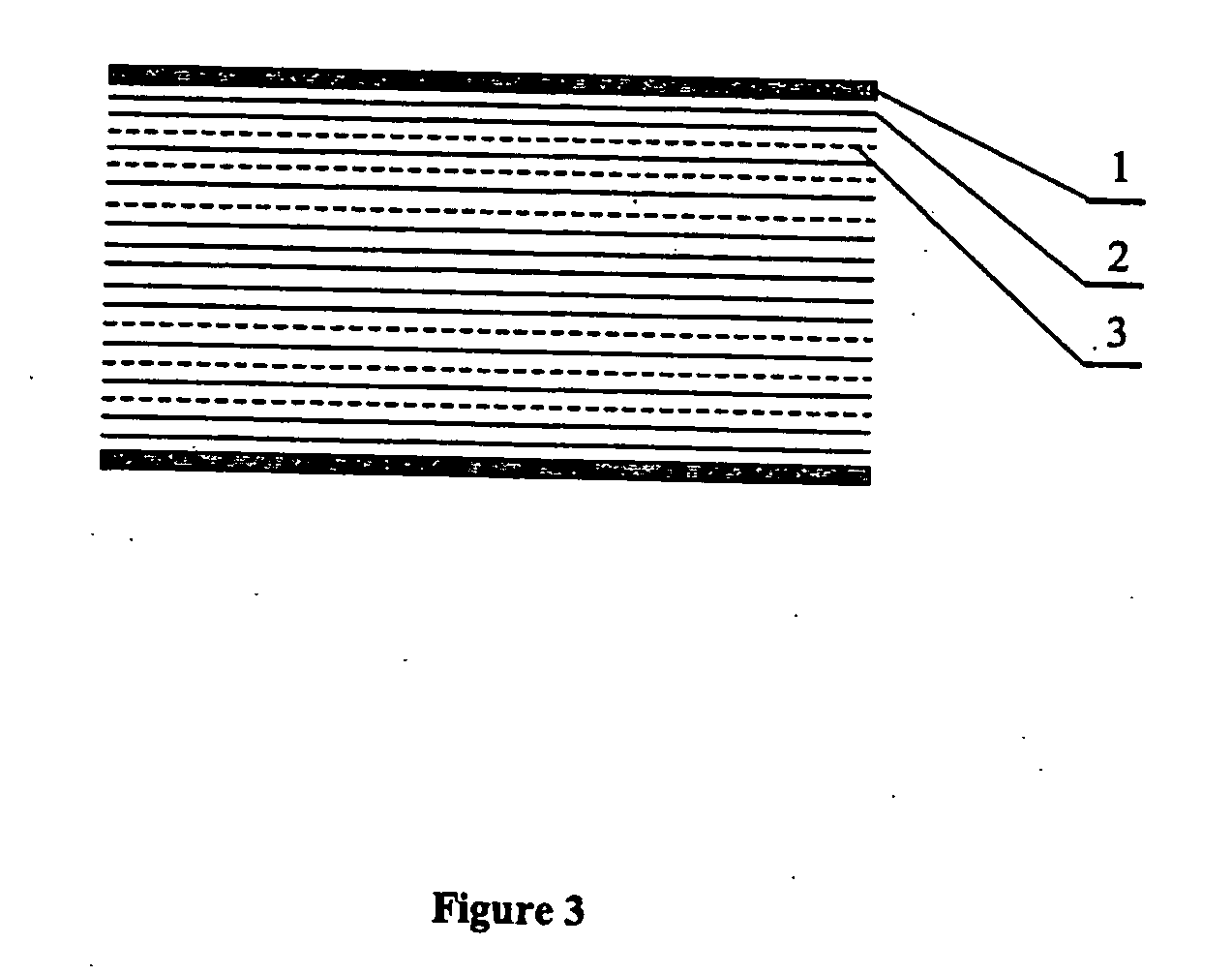

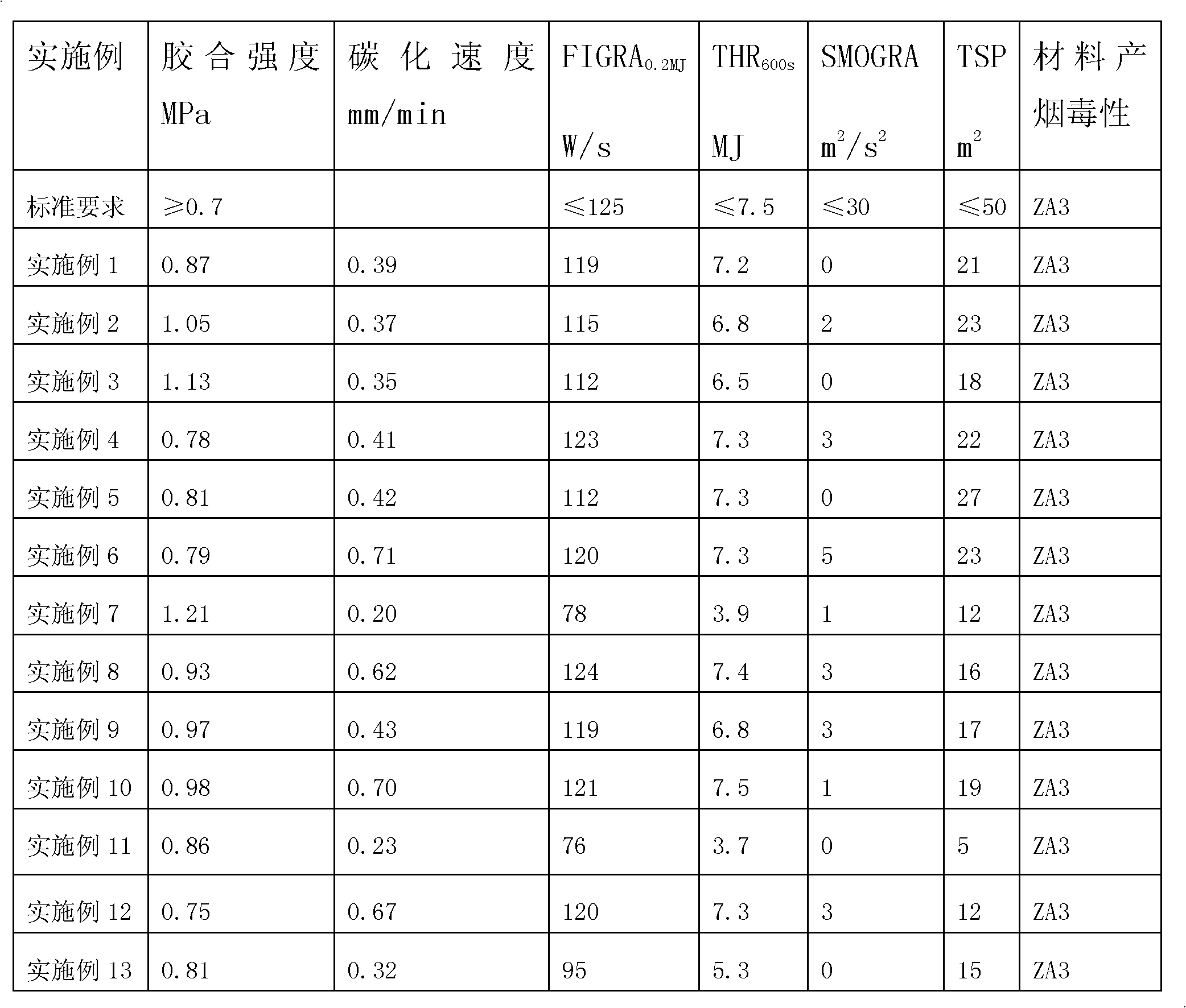

Antiflaming plywood or veneer lamination and manufacturing method thereof

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

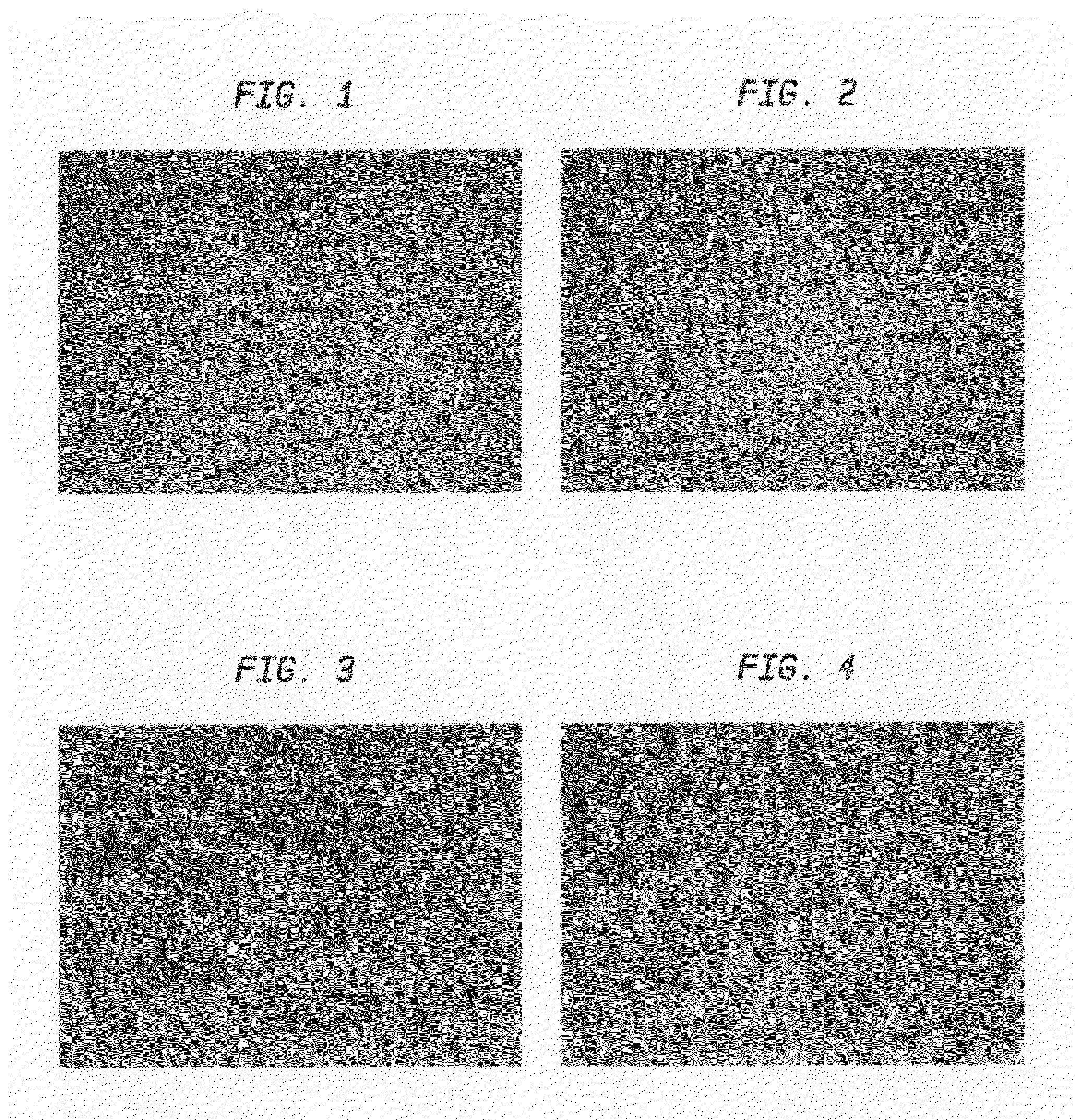

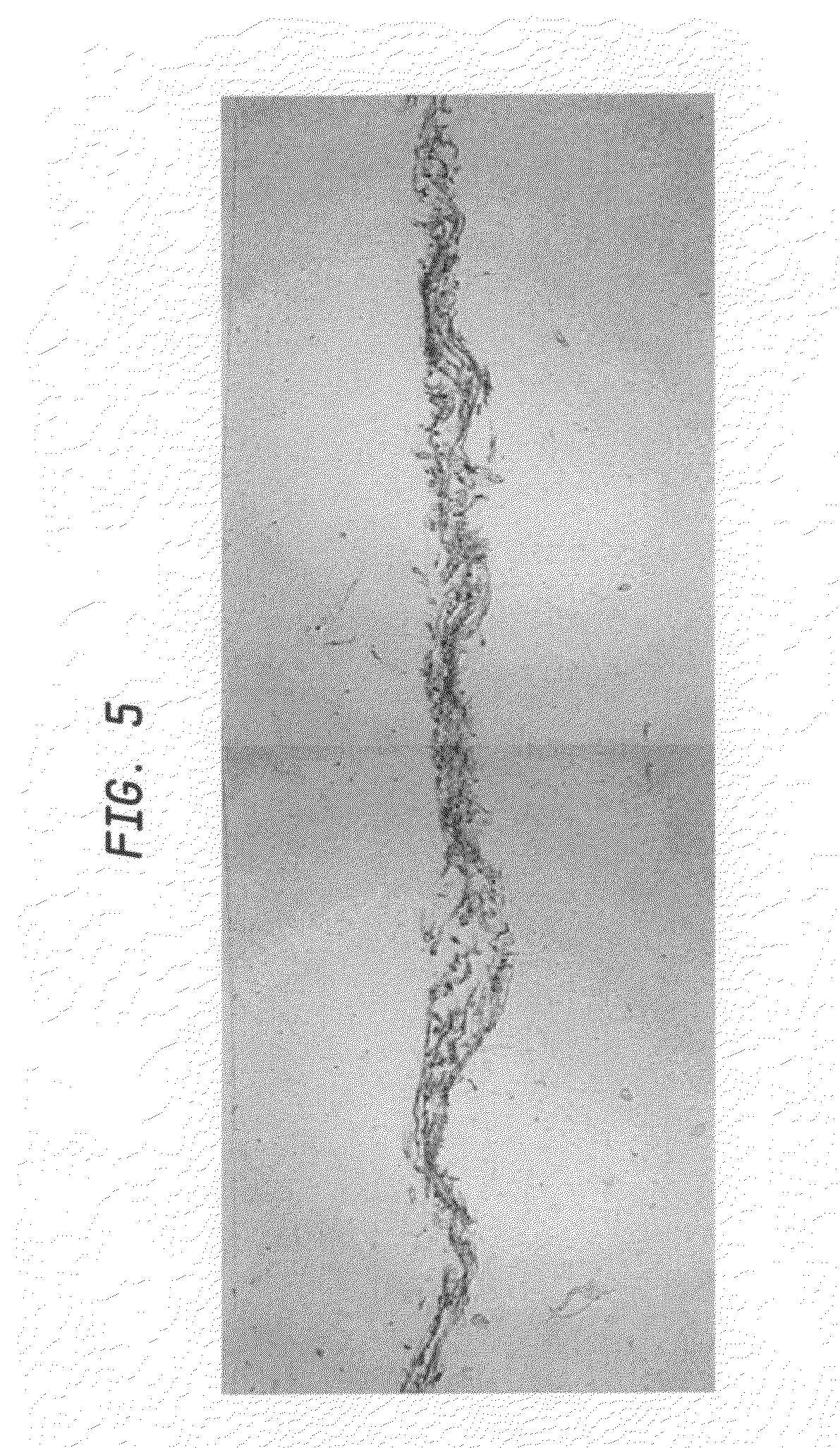

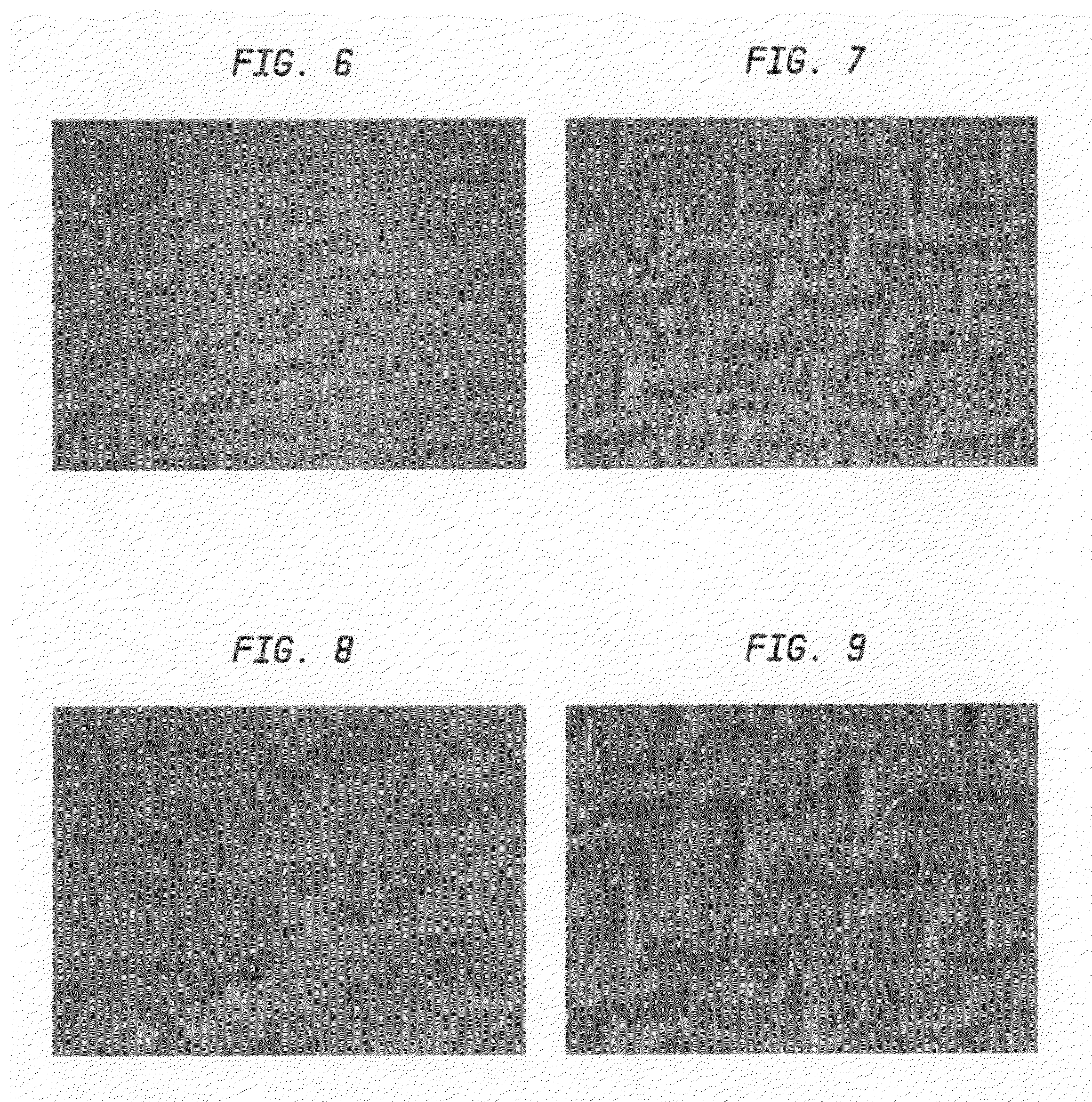

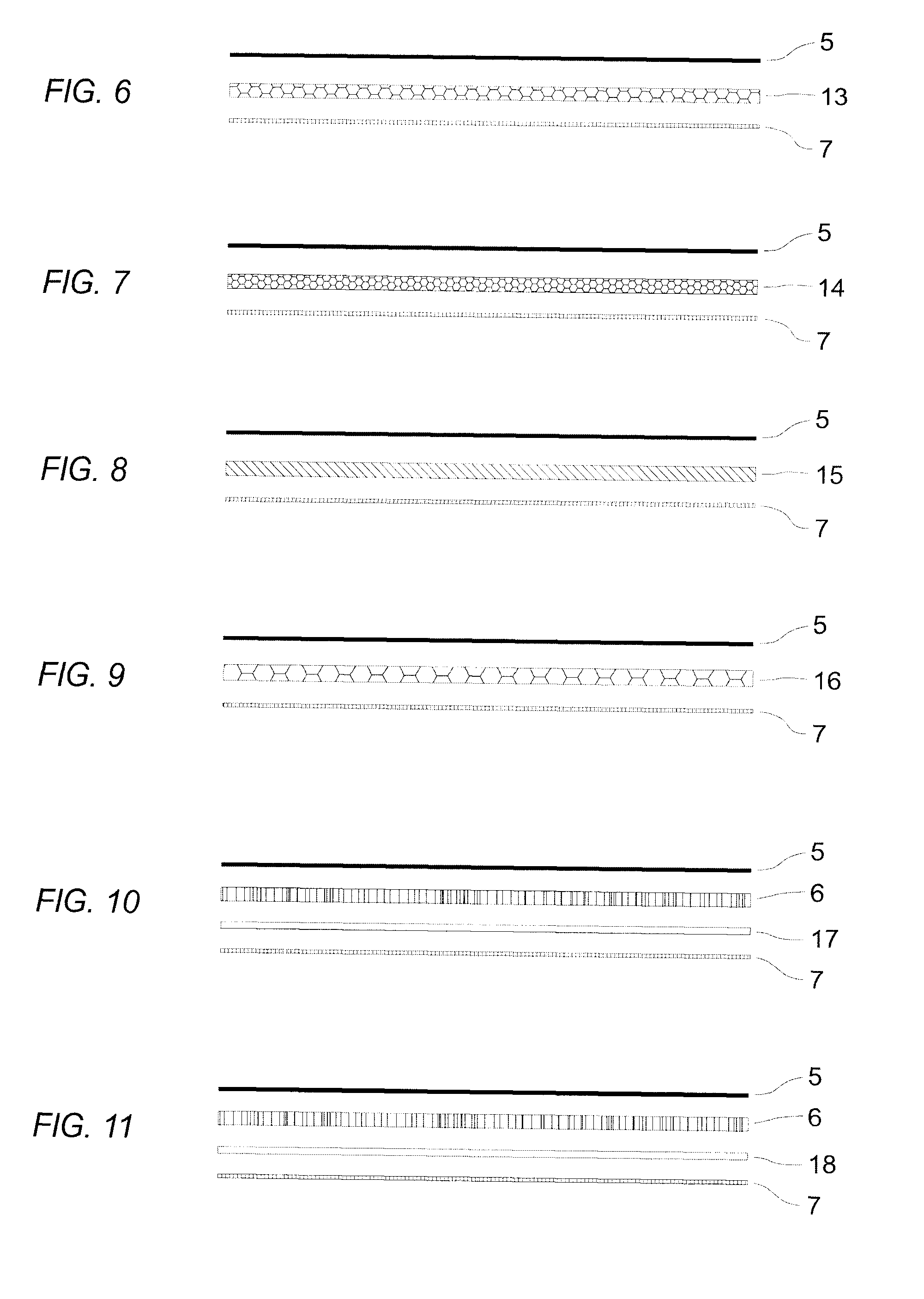

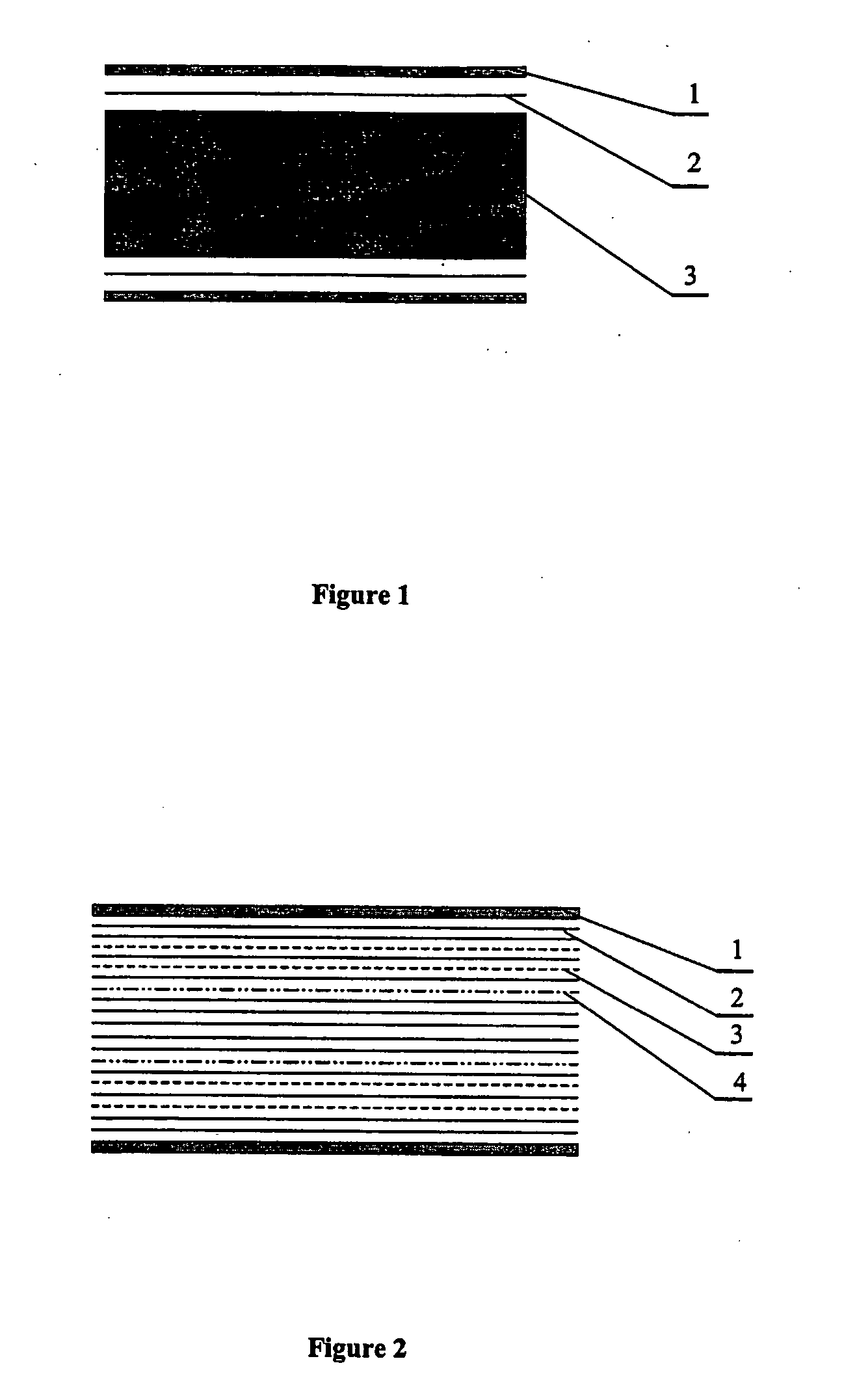

Fibre based panels with a wear resistance surface

ActiveCN101998896AImprove impact resistanceEasy to moveLiquid surface applicatorsLamination ancillary operationsWood veneerSurface layer

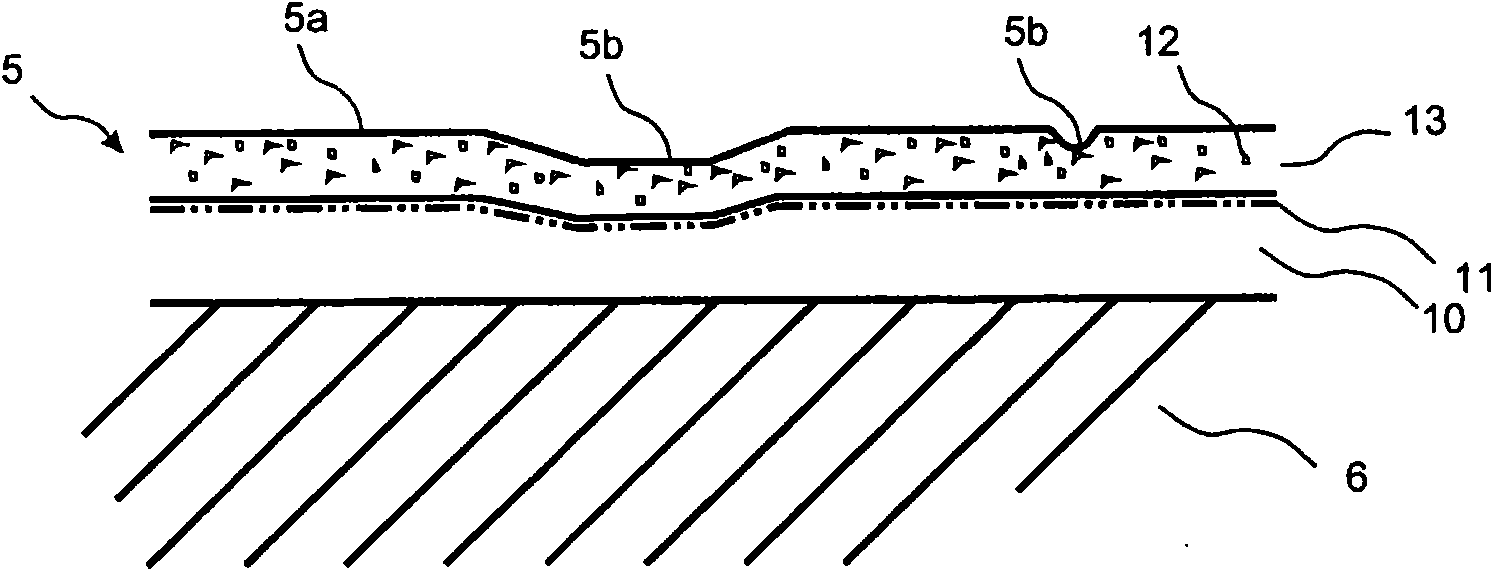

Floor board (1) comprising a wood fibre based core (6) such as HDF, a thin surface layer (5) such as wood veneer, and a sub layer (6a) between the surface layer (5) and the core (6). The sub layer (6a) comprises wood fibres (14) and an uncured binder (19) and is applied on the core (6) as a powder. The layers (5, 6a) are connected to the core (6) and embossed in register by heating and pressing, the uncured sub layer (6a) behaving similar to a paste or a liquid substance and creating a uniform counter pressure under the thin surface layer (5), thus providing an easier forming of deep and sharp embossing without damaging the surface layer (5).

Owner:VÄLINGE INNOVATION AB

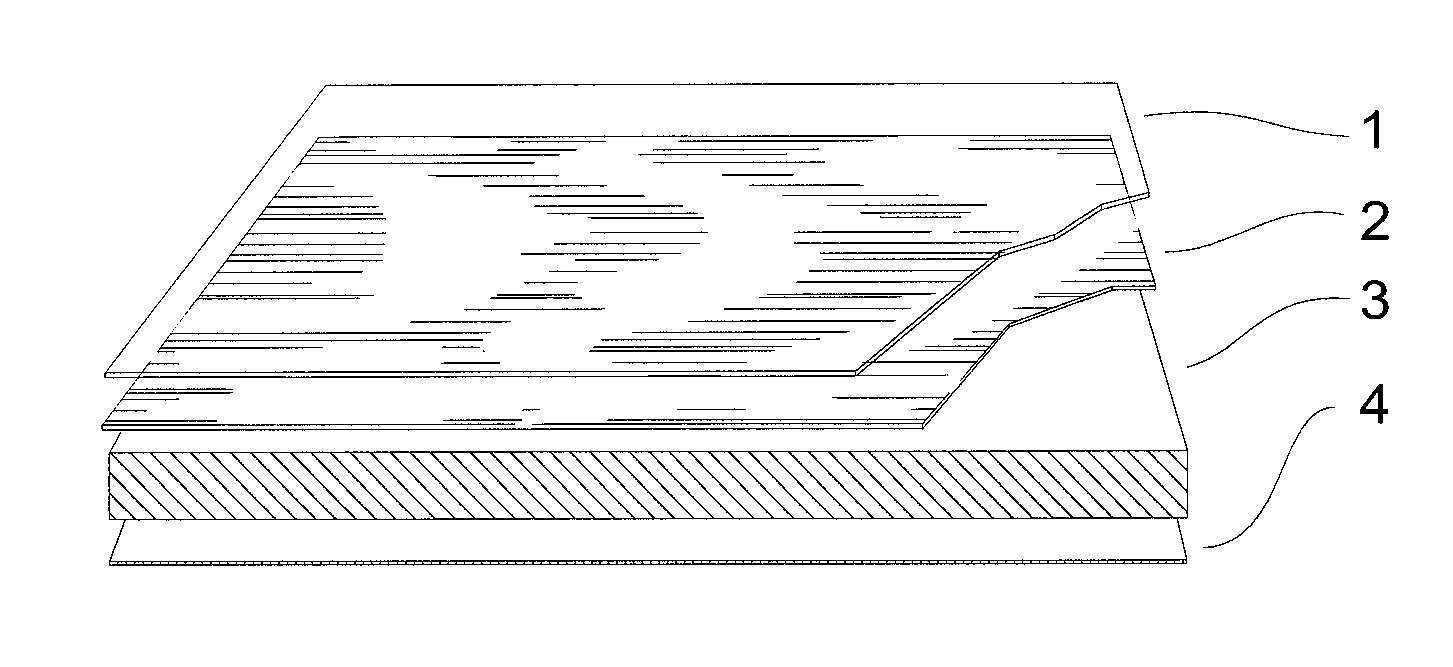

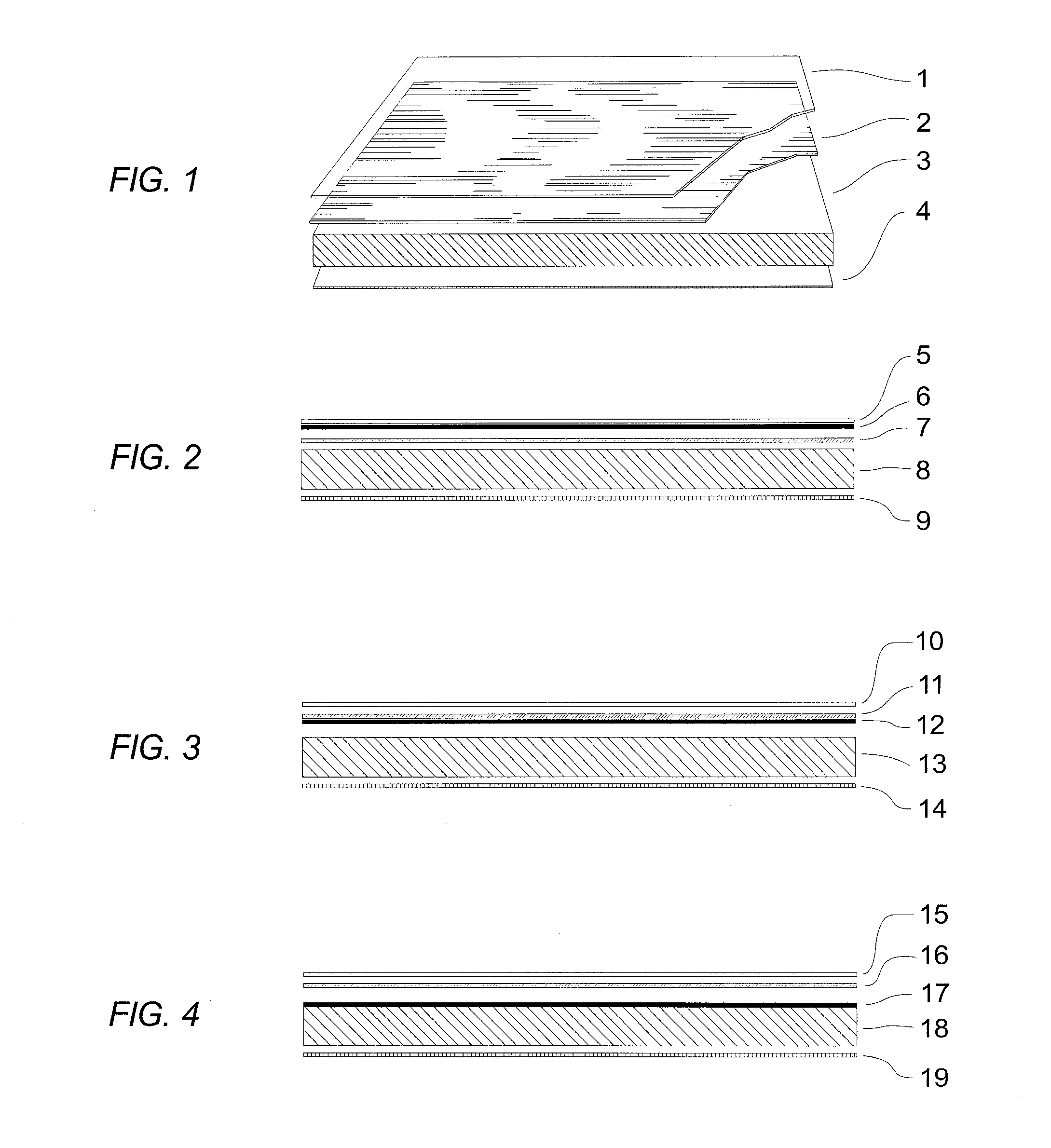

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

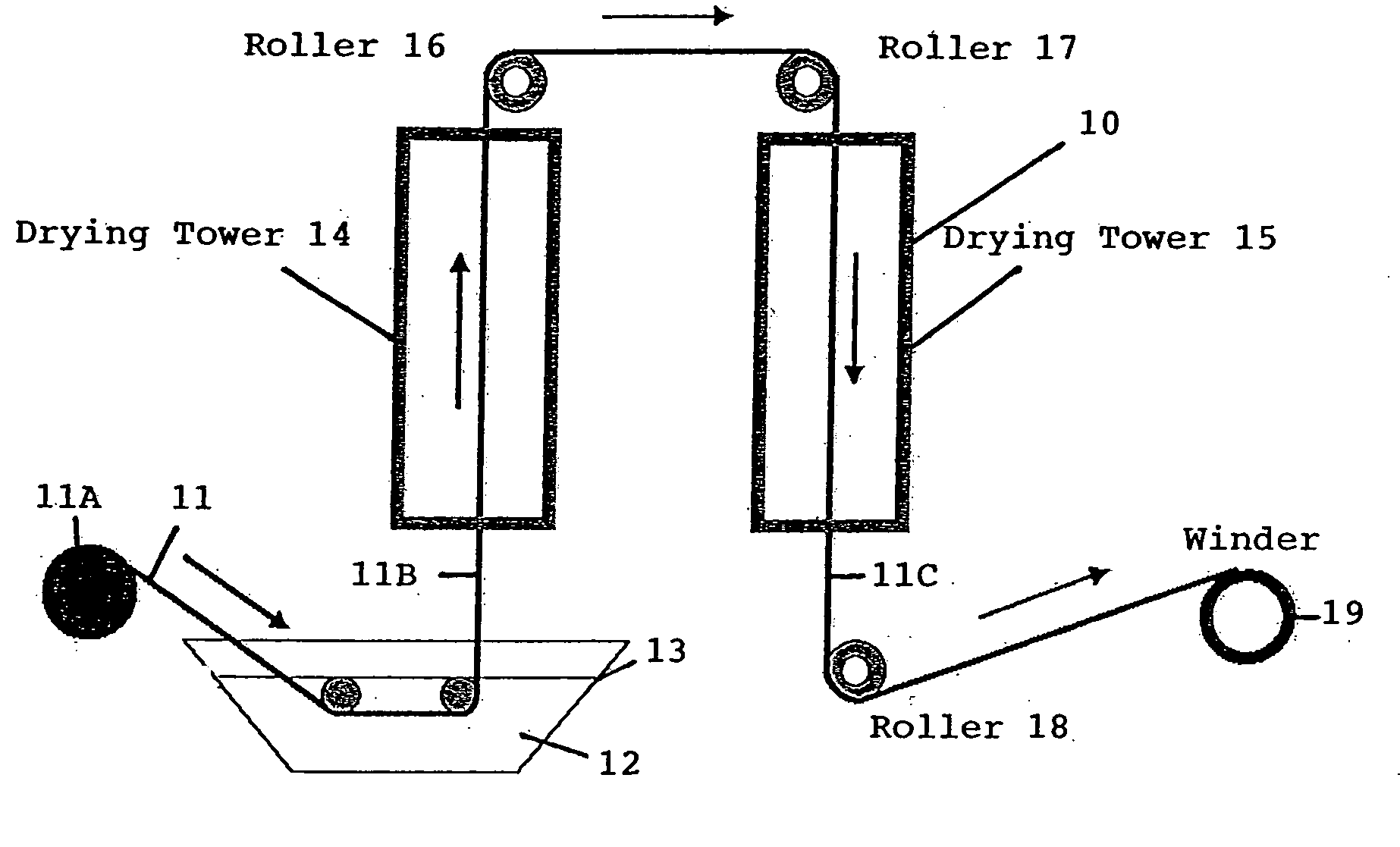

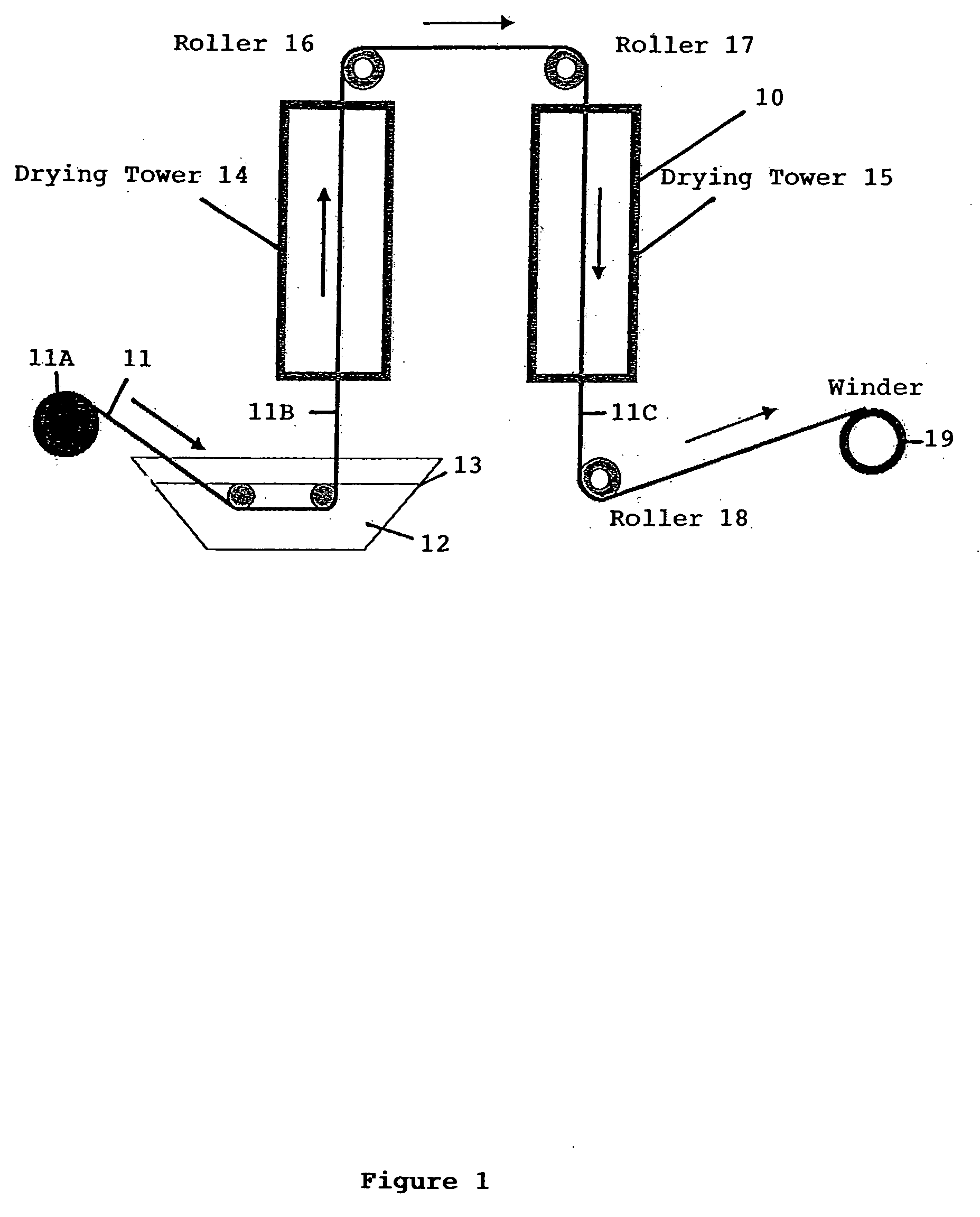

Reinforced composite with a tow of fibers and process for the preparation thereof

A graphite coated tow of fibers having exfoliated and pulverized graphite platelets coated on an outer surface of the fibers are provided. A process is provided for surface coating of the graphite platelets onto the fibers. The graphite coated tow of fibers are used to produce a reinforced composite material. Reinforced composite materials incorporating the graphite coated fibers can be electrostatically painted without using a conductive primer on a surface to be painted.

Owner:MICHIGAN STATE UNIVESITY BOARD OF TRUSTEES OF

Protective barrier

InactiveUS20030170418A1Per unit area is lowReduce weightNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberAviation

A protection product has thermal and acoustic barrier characteristics such that it satisfies the requirements of the standard 14 CFR, part 25 issued by the Federal Aviation Administration. The product is designed to be applied along metallic and composite structures, such as aircraft cockpits, boat hulls or the outside structures of trains or of other means of transport. The product is essentially in the form of a "mat" consisting of one or several fibre layers, preferably glass fibres, enclosed in a sheath. The sheath generally comprises at least one first support, preferably made of an organic material having sealing and anti-condensation properties, and an impregnated mica paper. The mica paper preferably has a weight per unit area of less than 50 g / m2 and comprises flakes of mica with a form factor greater than 1000.

Owner:COGEBRI SA

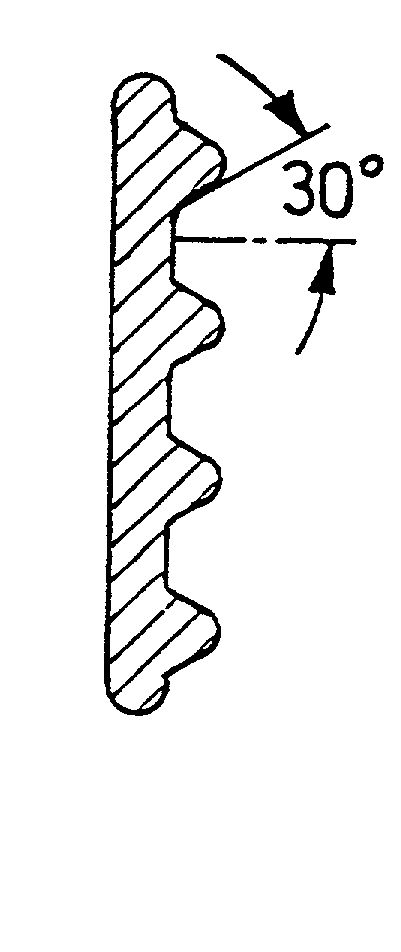

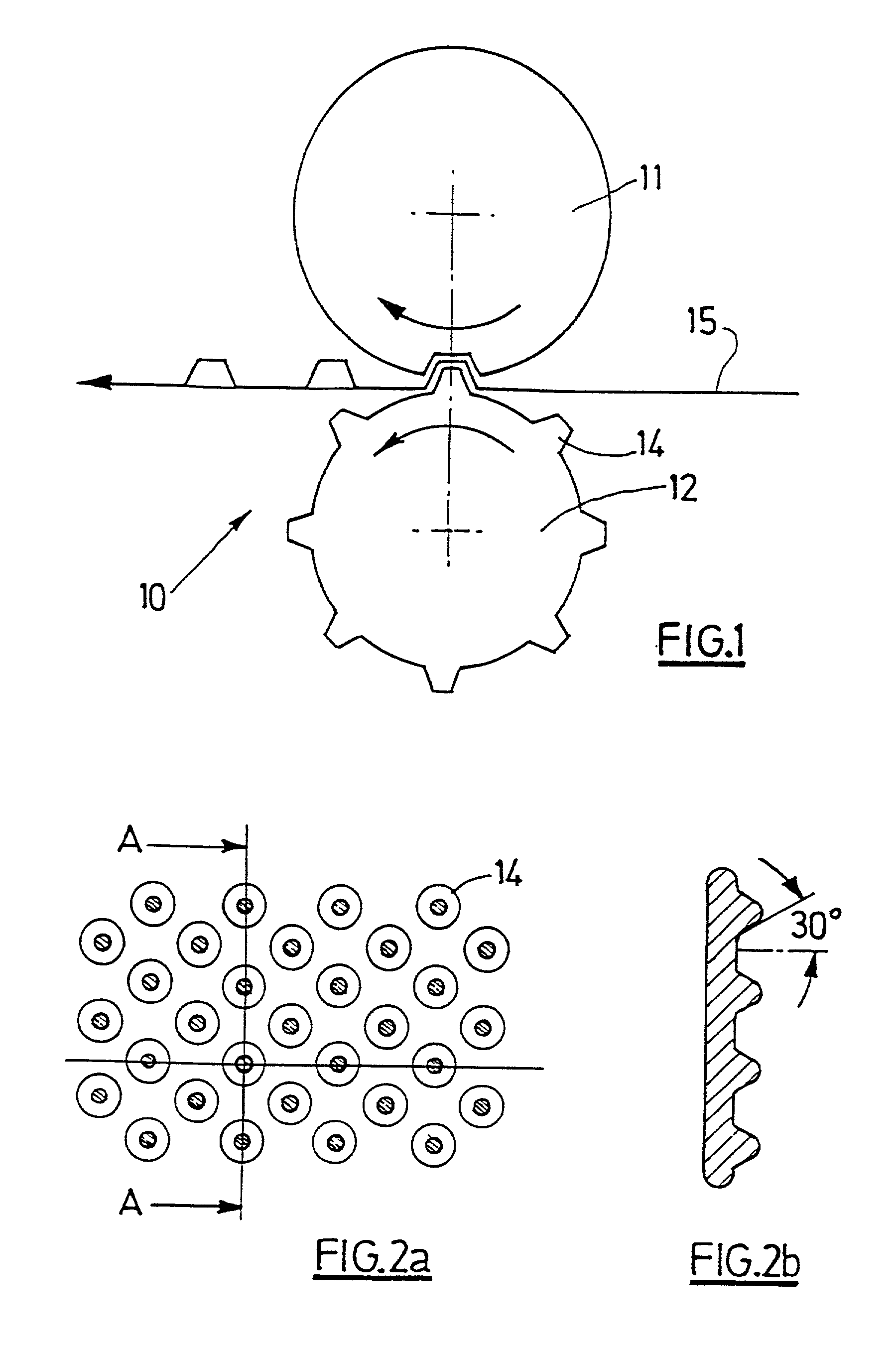

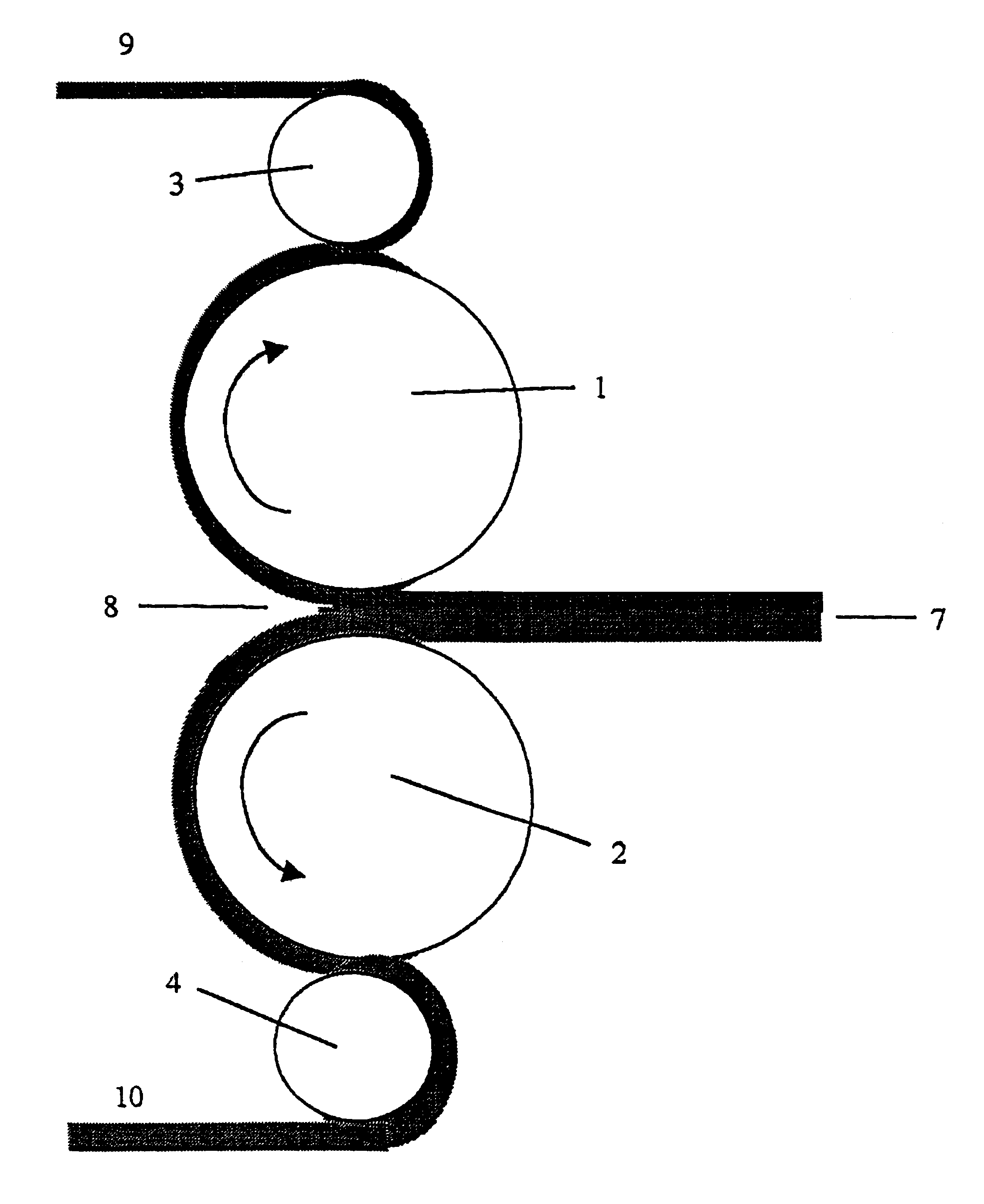

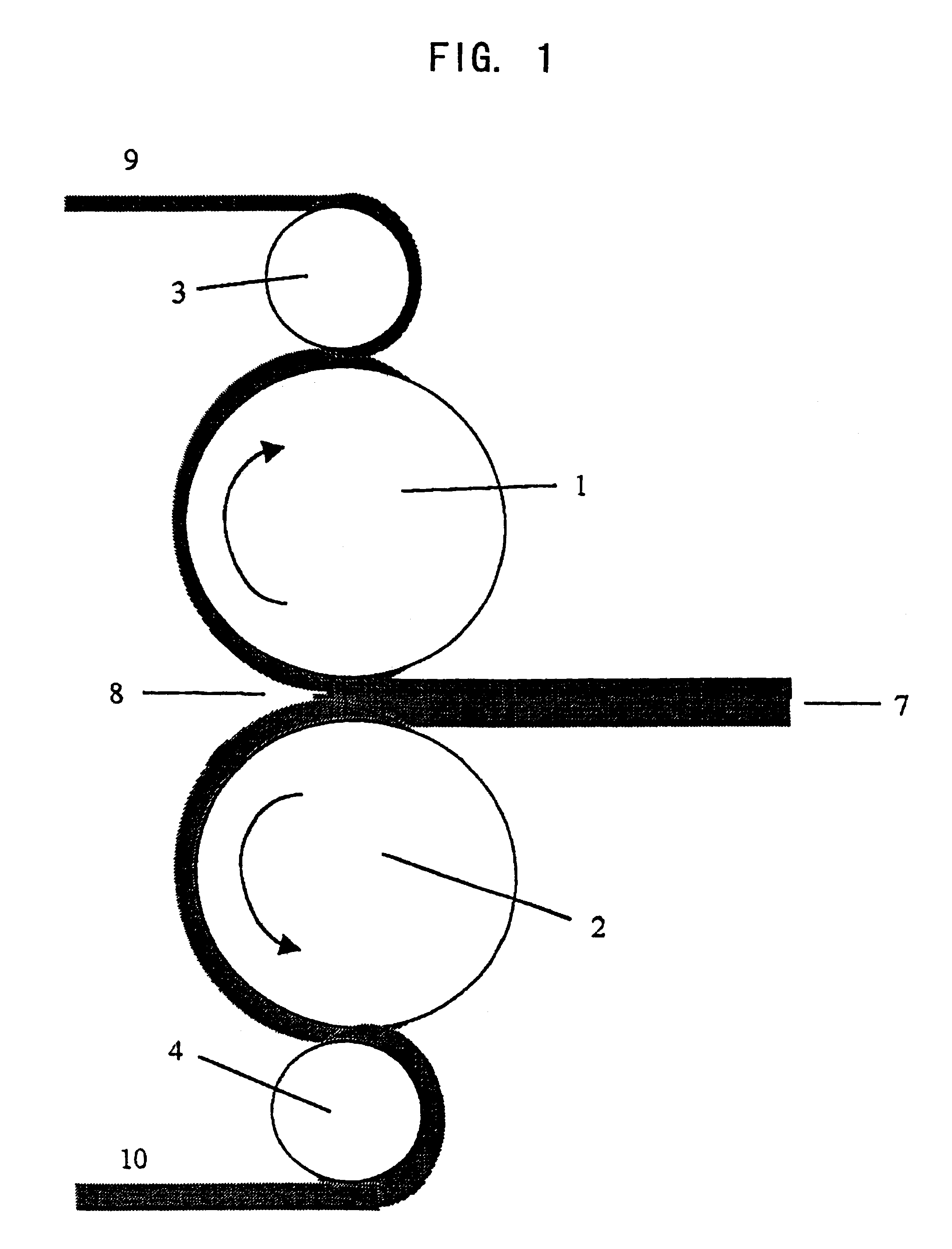

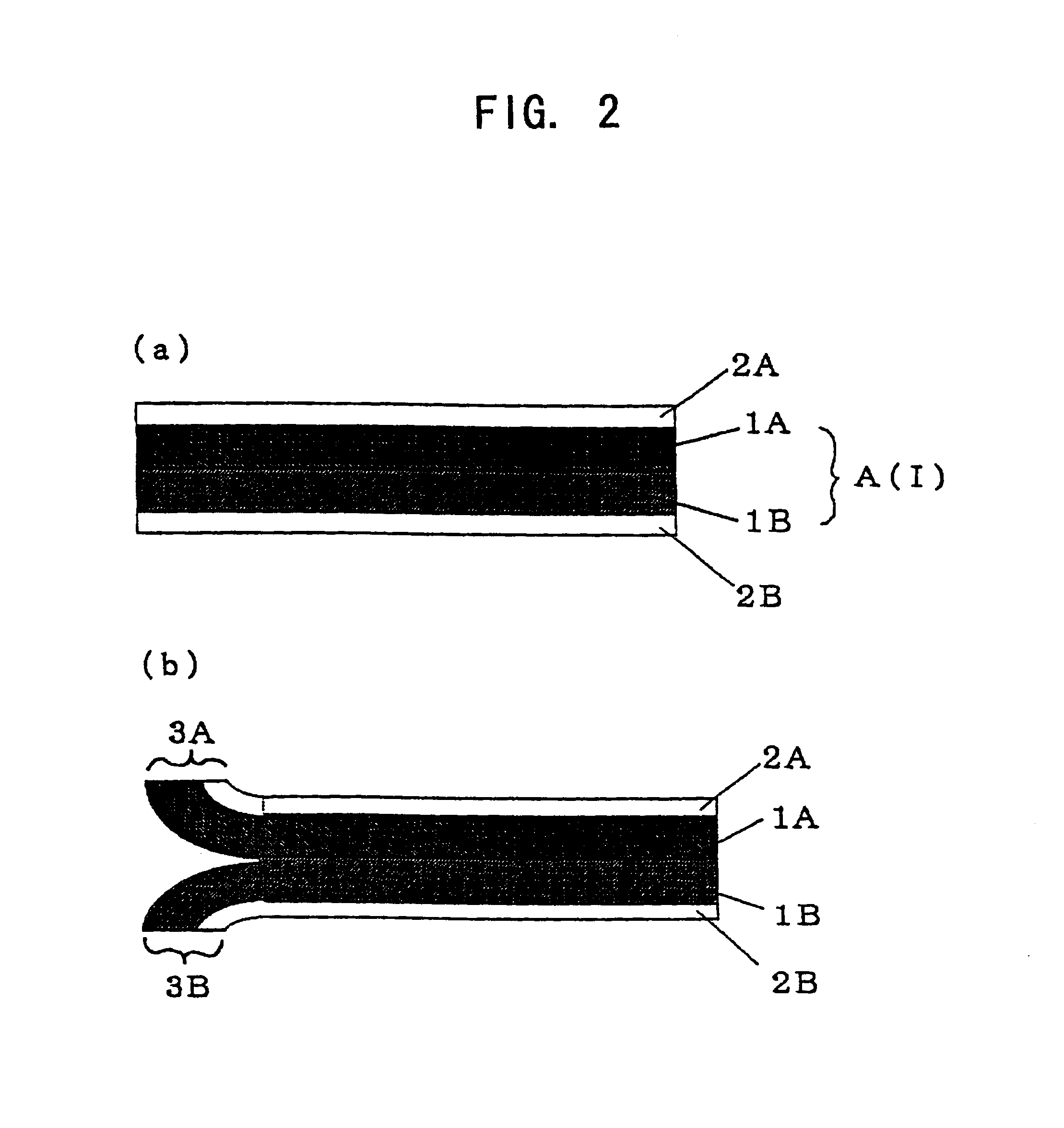

Method for fabricating an embossed sheet of cellulose tissue, a product so made and an embossing cylinder

InactiveUS20030008109A1Increasing the thicknessLow tear strengthNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseWood veneer

The invention relates to a method for manufacturing a sheet of paper tissue which is embossed by an embossing cylinder of which the surface is fitted at least in part with embossing elements. The elements include a frustoconical base portion and a tip portion. The method is characterized in that the tip segment includes a flat of which the area is less than 75% of the smaller cross-sectional area of the base. Preferably the area of the flat is less than 20% of the base cross-sectional area. The invention furthermore concerns a sheet thusly manufactured and to sheets made of several plies of which at least one is a ply of the invention.

Owner:ESSITY OPERATIONS FRANCE

Lamina comprising cube corner elements and retroreflective sheeting

InactiveUS7152983B2Improve propertiesIncrease brightnessLamination ancillary operationsLaminationWood veneerEngineering

The present invention is directed to lamina(e) comprising cube corner elements, a tool comprising an assembly of laminae and replicas thereof. The invention further relates to retroreflective sheeting.

Owner:3M INNOVATIVE PROPERTIES CO

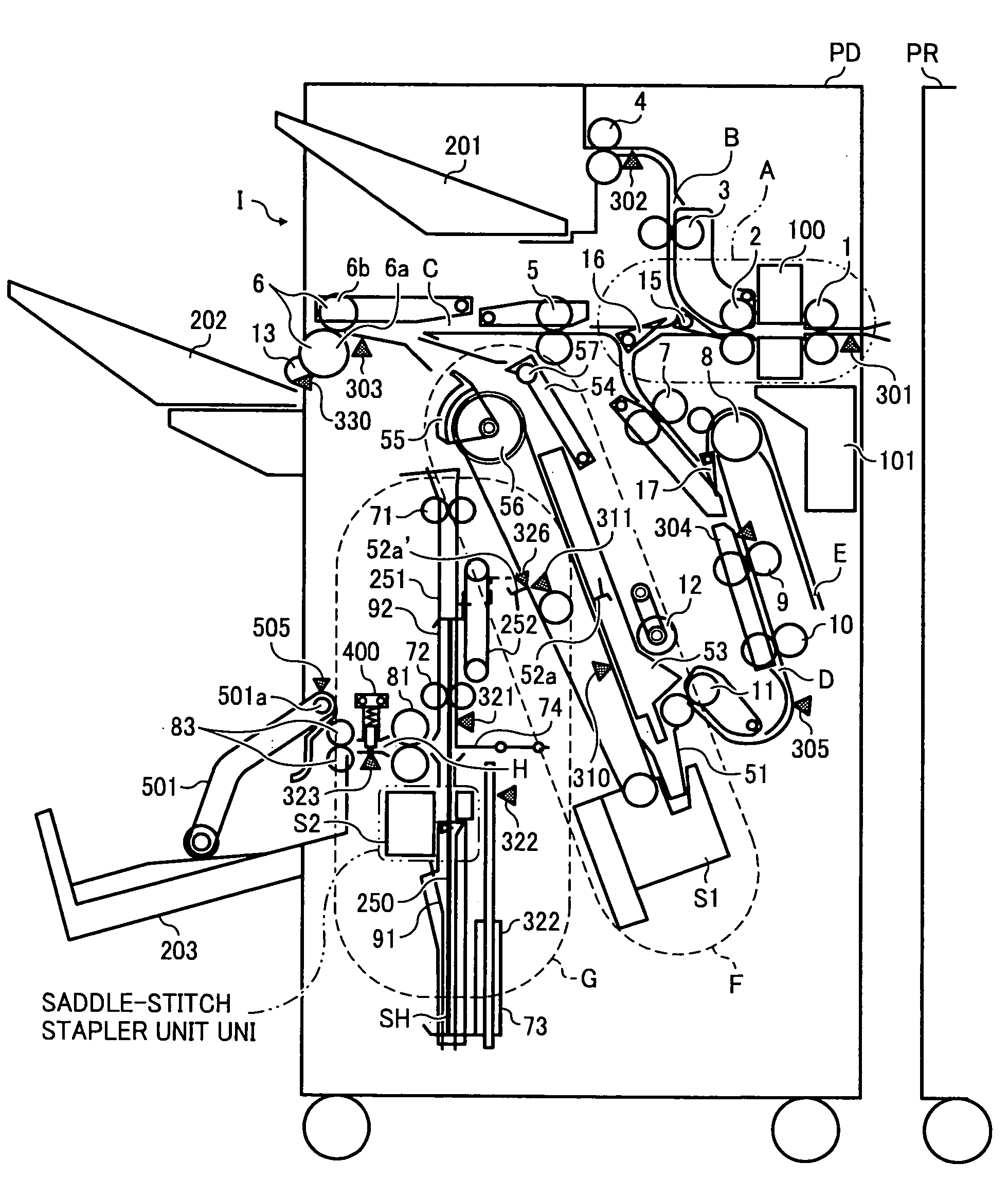

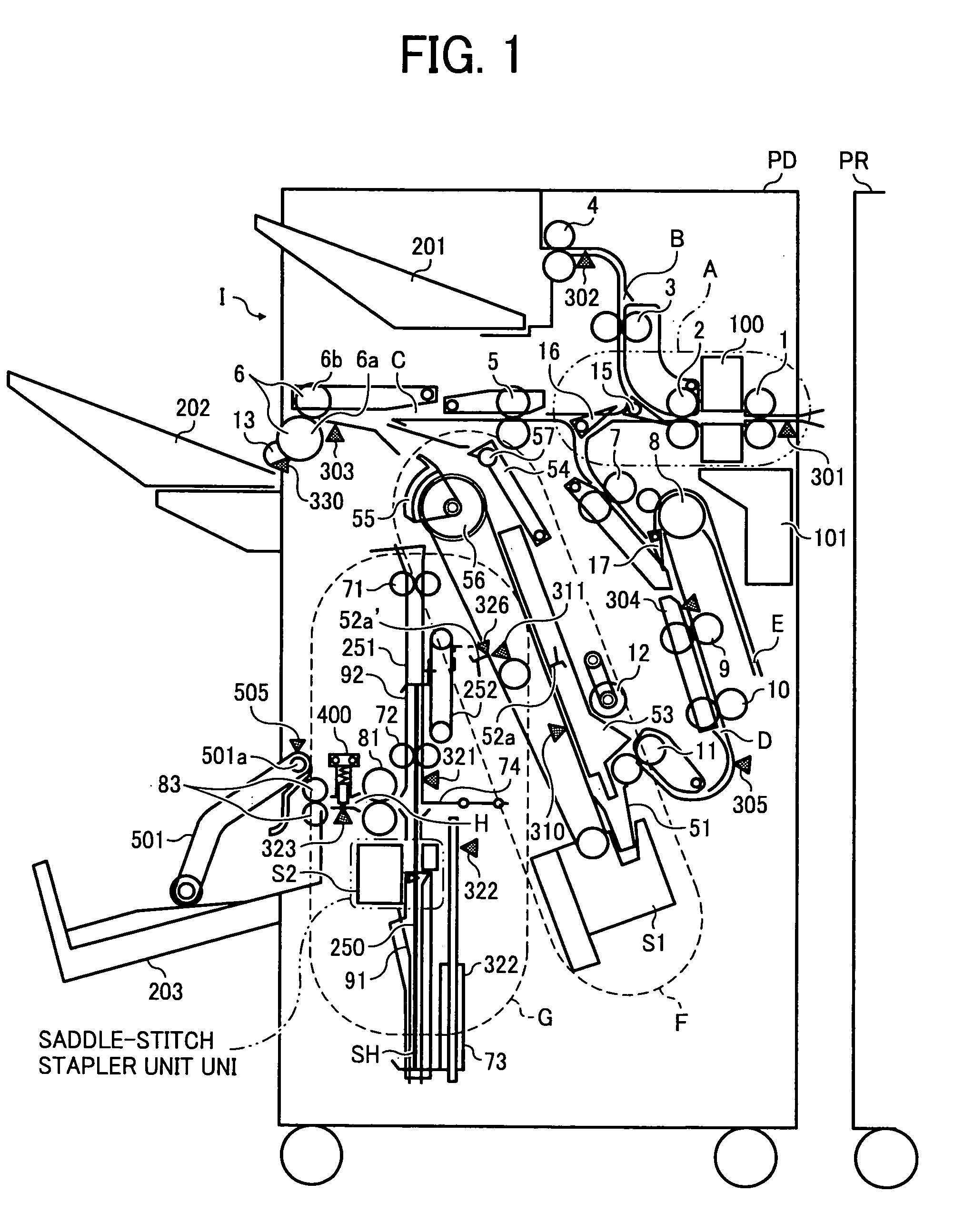

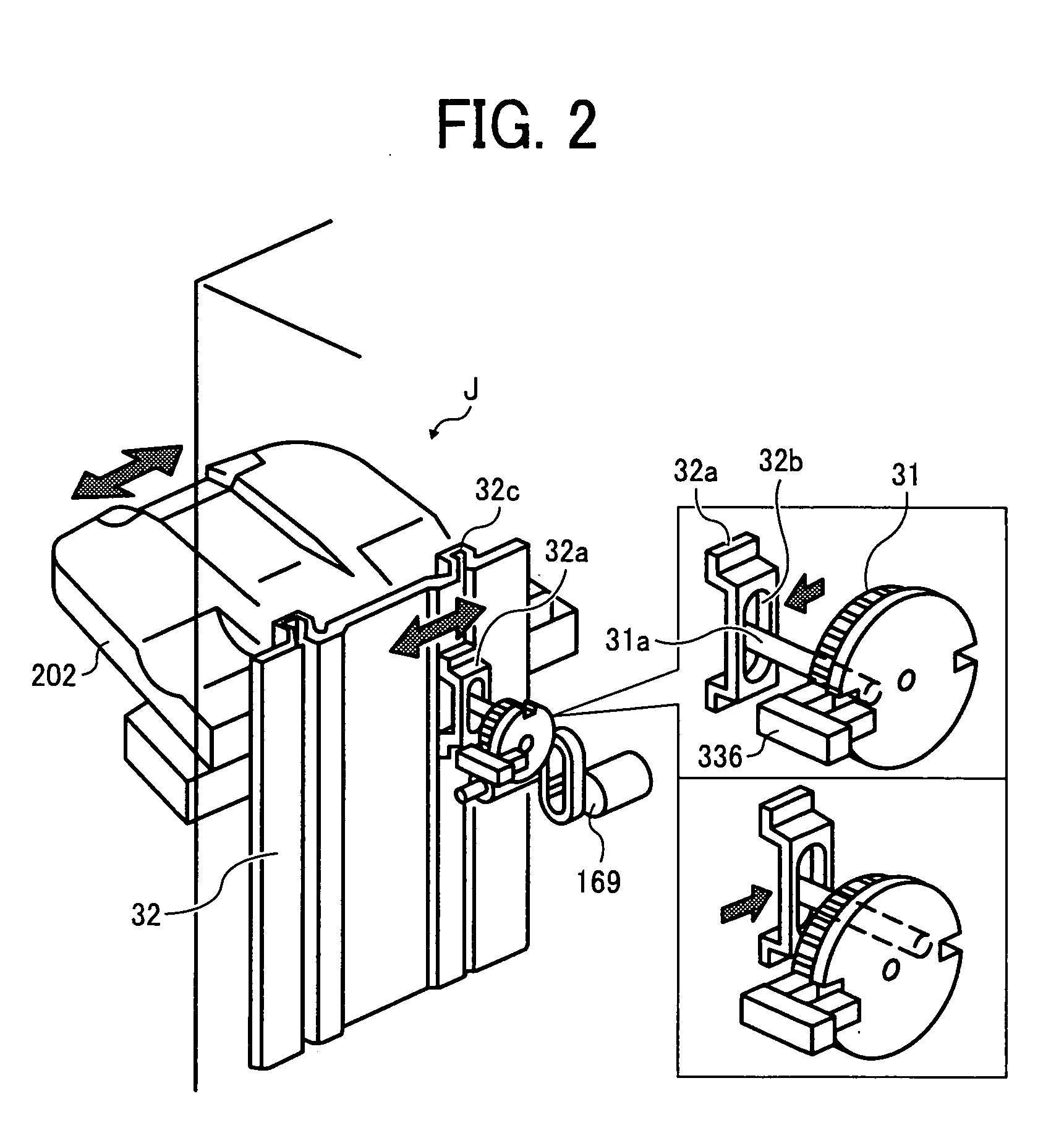

Sheet creaser, sheet finisher, image forming apparatus, sheet folding method, and computer program product

Owner:RICOH KK

Multi-layer paper peelable into at least two thin sheets

InactiveUS6977111B2Low densityLose weightNon-fibrous pulp additionSpecial paperWood veneerStencil printing

Disclosed is a multi-layer paper suitable as a material for preparing heat-sensitive stencil printing masters. The multi-layer paper is produced by combining a plurality of thin paper layers by paper making. The multi-layer paper has a peel strength of 10 N / m or less and may be delaminated into at least two tissue sheets.

Owner:RICOH KK +1

Wood fibre based panel with a surface layer

ActiveUS10100535B2Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

A building panel with a surface layer (1) including a wood veneer, a wood fibre based core (2) and a sub-layer (3) between the surface layer (1) and the core (2). The sub-layer (3) includes wood fibres (4) and a binder (5). The surface layer (1) has surface portions (6) including material from the sub-layer (3). The surface portions (6) including material from the sub-layer (3) extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

Wood fibre based panel with a surface layer

ActiveUS20190010711A1Attractive surface designSurface property and cost structureDecorative surface effectsSpecial ornamental structuresWood veneerSurface layer

A building panel with a surface layer including a wood veneer, a wood fibre based core and a sub-layer between the surface layer and the core. The sub-layer includes wood fibres and a binder. The surface layer has surface portions including material from the sub-layer. The surface portions including material from the sub-layer extend into the wood veneer.

Owner:VÄLINGE INNOVATION AB

Sound Attenuating Laminate Materials

ActiveUS20120103722A1Reduce and eliminate sound transmissionReduce noiseCovering/liningsSpecial ornamental structuresElastomerWood veneer

Sound absorbing or attenuating laminate flooring materials are provided, which are directed to be used in the production of floor covering, floor panels, furniture panels, cabinets, counter-tops and wall panels. As well, the methods for producing such products are provided. In particular, abrasion resistant panels, with a laminated structure, created by forming an assembly which consists of laminating a heat-activated resin impregnated paper wear layer, a decorative layer with printed graphics or a wood veneer decorative layer, a medium density (MDF) or high-density (HDF) natural fiber-based core and a resin impregnated paper balancing layer. To achieve sound absorbing and / or attenuating properties, any or all paper layers may be pre coated with an additional flexible elastomeric coating, film or material prior to assembly of the panel, or the natural fiber core panel may be coated with a flexible elastomeric coating, film or material prior to assembly with the papers. The flexible elastomeric coating, film or material acts to absorb, reduce, and / or ameliorate the sound transmissions inherent in laminated panels.

Owner:CLAUSI ROBERT N +1

Disposable protective sheeting for decks and floors

Disposable protective sheeting for covering decks and floors during construction and the like. The protective sheeting includes a first layer of a barrier material impervious to liquid and pervious to vapor and a second layer of an overlay material providing a slip-resistant upper surface that is bonded to the first layer. Alternatively, the sheeting can be a single layer of barrier material treated to be slip resistant. The sheeting can be provided in rolls and temporarily secured to the decks and floors at the construction site or pre-installed onto decking materials off-site. When construction is complete, the disposable protective sheeting is removed to expose a contamination and damage free surface.

Owner:KADLEC GARY F

Container and platform floor with bamboo oriented structure shaving board as sandwich layer and manufacturing method thereof

InactiveCN101214669AMeet performance requirementsImprove pressure resistanceWood veneer joiningFlat articlesSandwich likeWood veneer

Belonging to the field of composite boards and production methods thereof, the present invention relates to a oriented structural bamboo flakeboard as the sandwich layer of a container and a carriage bottom board and a production method thereof, in particular to a container and a carriage bottom board, which are produced with the oriented structural bamboo flakeboard as the sandwich layer substrate, and a production method thereof. The oriented structural bamboo flakeboard is composed of a surfacial layer, a sandwich layer and a bottom layer which are bonded together, and is characterized in that the sandwich layer is of a structural flakeboard which is formed by more than five layers of crisscross bamboo flakes which are directionally paved and bonded, and the surfacial layer and the bottom layer are of more than one layer of single wood veneer or impregnated paper or phenolic impregnated paper, or the surfacial layer and the bottom layer are the composite layers of the wood veneer and the impregnated paper or the phenolic impregnated paper. The production method includes the production and bonding of the sandwich layer, the surfacial layer and the bottom layer. The present invention resolves the problems of the scarcity and ecological destruction of the materials of the traditional containers and carriage bottom boards, and not only is the cost reduced, but also the mass production of the novel bottom boards which meet the technical requirements of the international container and carriage bottom board industry is satisfied.

Owner:邱天祥

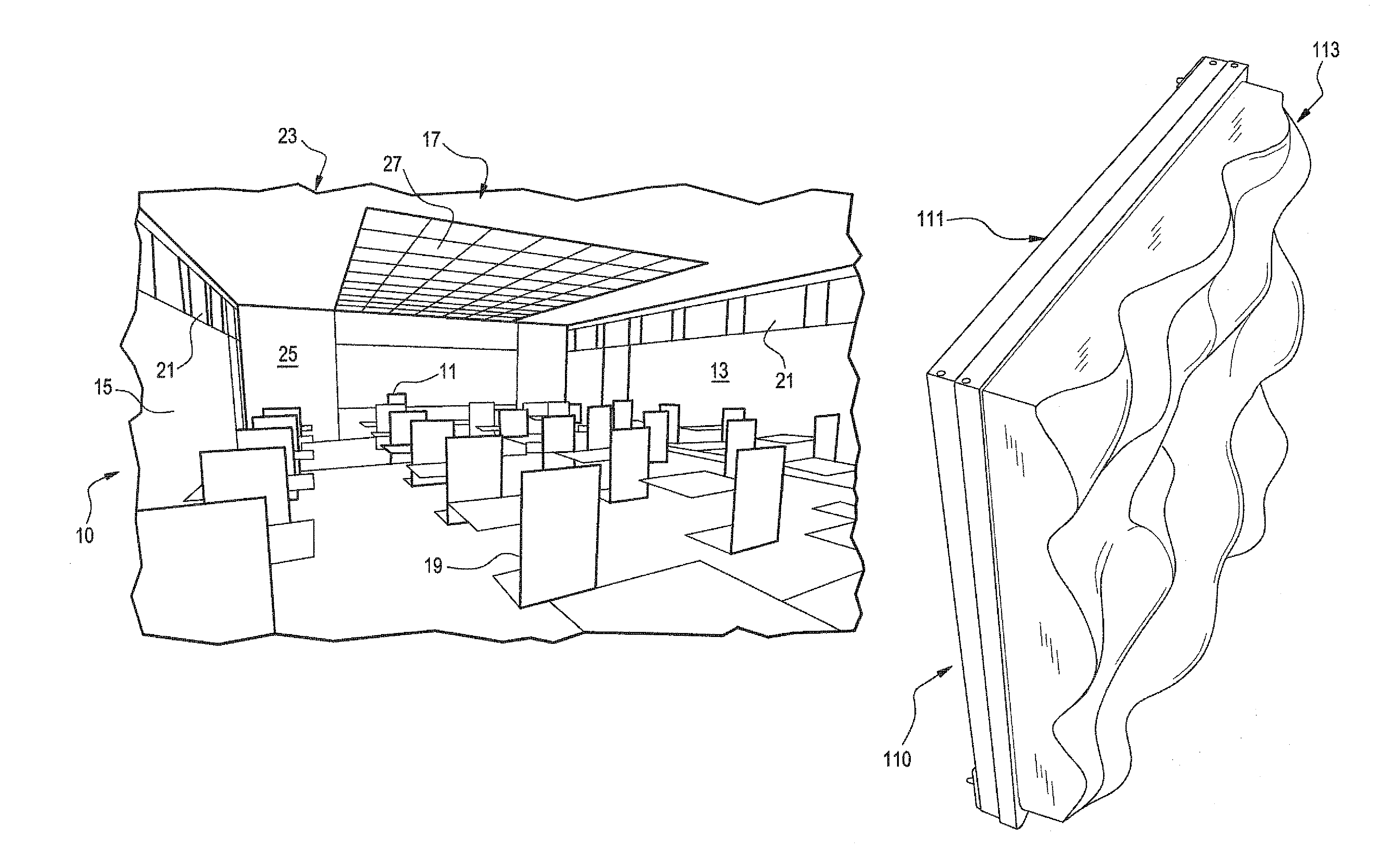

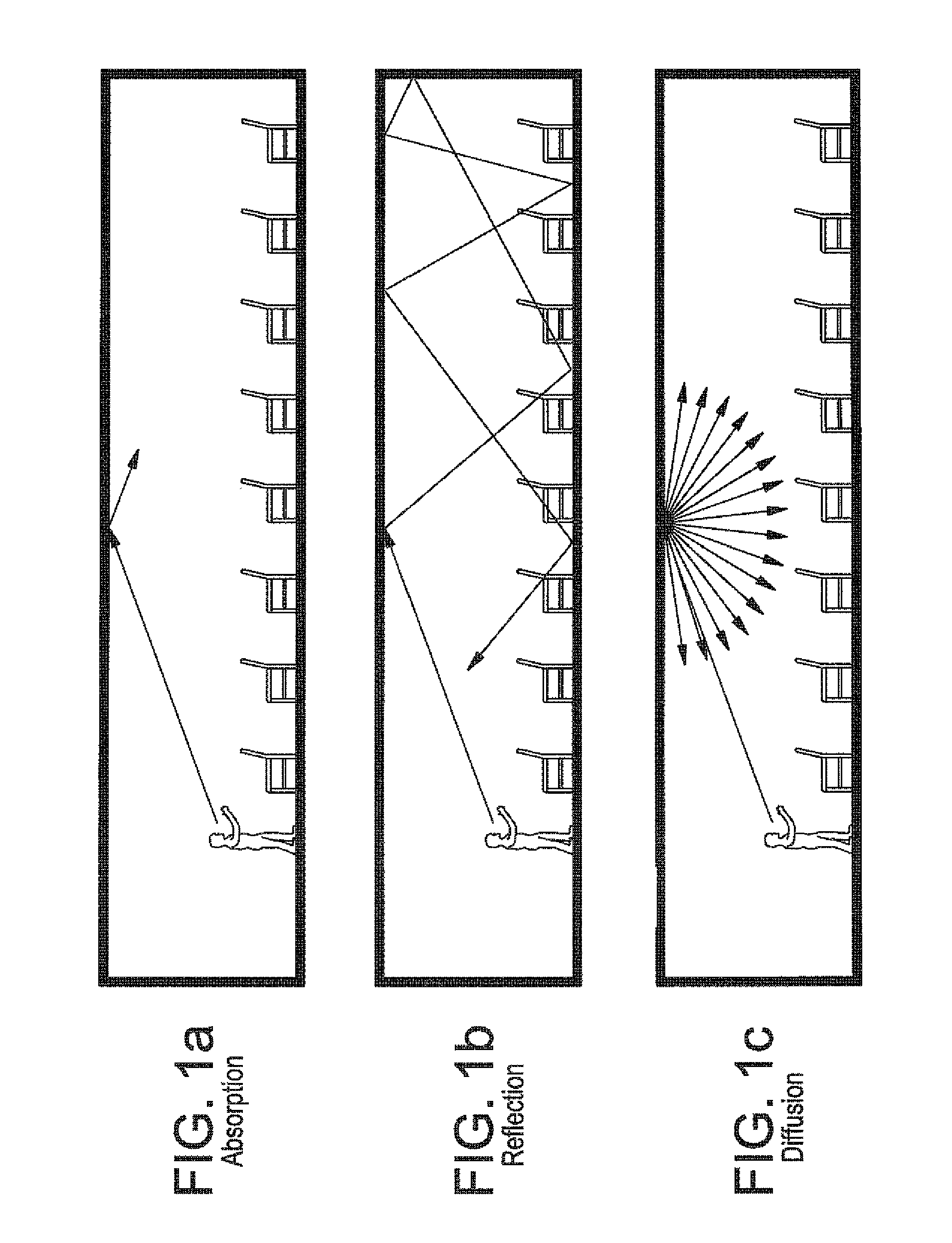

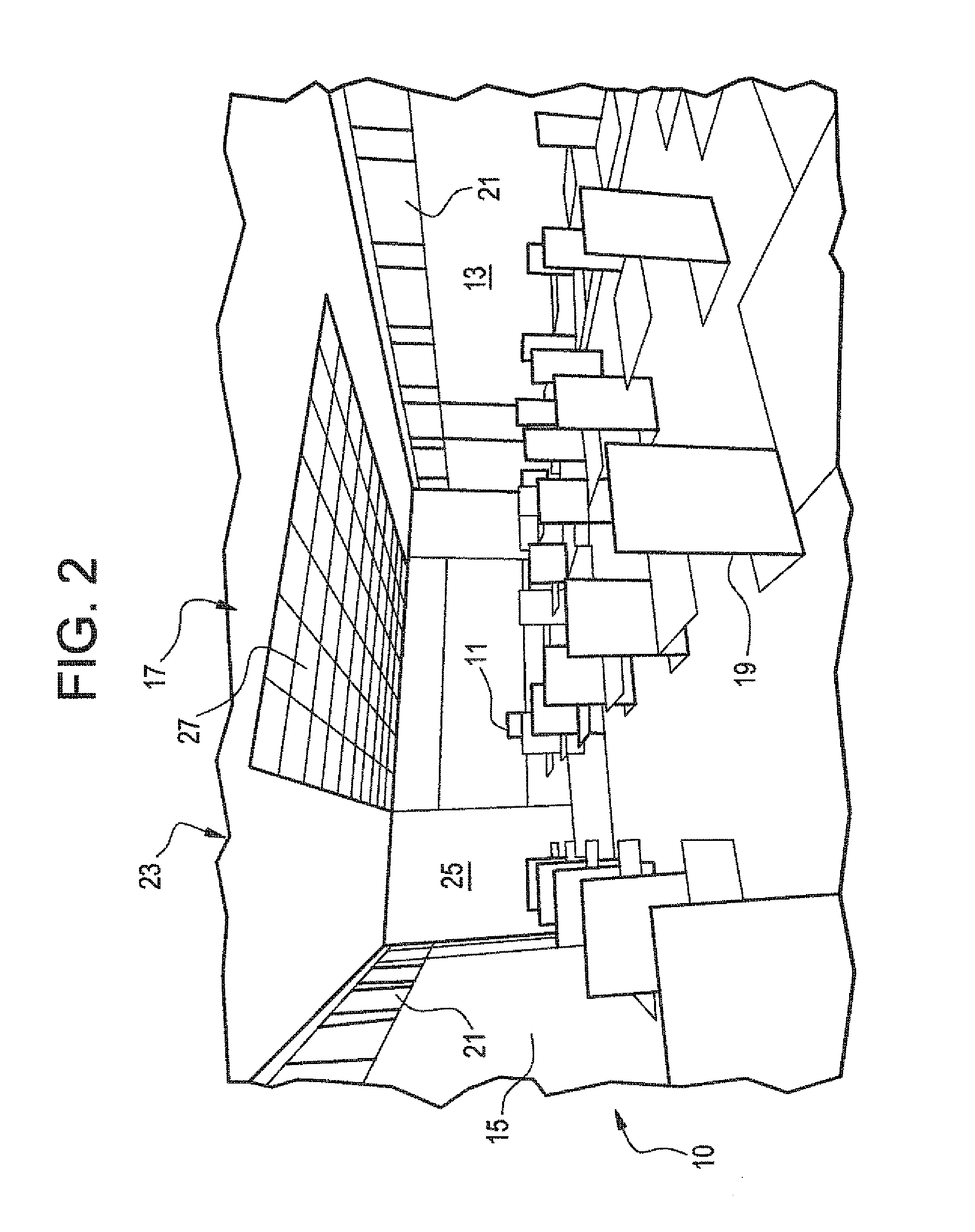

Combination light diffuser and acoustical treatment and listening room including such fixtures

Combination light diffusion with either sound diffusion or absorption is provided in a single lighting fixture, to provide uniform luminosity and sound control. The traditional flat light diffuser is replaced with a translucent acoustical element which either diffuses sound or absorbs the sound. The sound diffuser topology includes random surfaces, geometrical shapes, number theoretic diffusers or optimized rectilinear or curvilinear surfaces. The translucent sound absorber includes microperforated or microslit panels, as well as translucent fabrics and microperforated, translucent wood veneers.

Owner:DANTONIO PETER

Wood flooring laminated with high pressure veneer and impregnated low weight printing paper

InactiveUS20060062966A1Improves poor realityImprove surface strengthCovering/liningsSpecial ornamental structuresThermoplasticWood veneer

Disclosed herein is a UV surface-coated laminate wood flooring for an under-floor heating system comprising a back-grooved base, an adhesive layer and a printed wood veneer layer wherein the printed wood veneer layer is produced by impregnating and coating a low-basis weight printed paper with a thermoplastic or thermosetting resin, integrally forming the paper layer with a low-price reinforcing layer by pressing under high pressure, treating the surface of the paper layer with an acryl based primer, and coating the primer-treated paper layer with a solvent-free type UV coating paint, and wherein the back-grooved base and the printed wood veneer layer are adhered to each other by the adhesive layer.

Owner:LG CHEM LTD

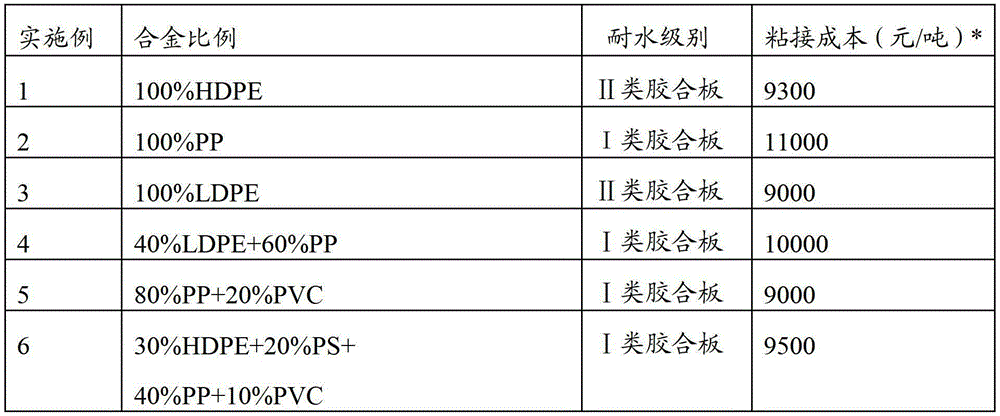

Formaldehyde-free plywood and fabrication method thereof

ActiveCN103144152ASolve the hazardImprove physical and mechanical propertiesLayered product treatmentPlastic recyclingEnvironmental resistanceWood veneer

A method for fabricating a formaldehyde-free plywood with waste plastic alloy is used for fabricating the novel plywood without free formaldehyde being released by fabricating a plastic alloy film with different waste plastics and taking the plastic alloy film as a bonding material. The method comprises the steps of smashing and cleaning the different waste plastics, allowing the waste plastics to be independent or mixing the waste plastics to a scale, adding relevant packing and assistant, conducting film blowing and calendering to prepare the plastic alloy adhesive film in certain breadth and thickness, conducting crossed assembly with a wood veneer, conducting hot pressing and cold pressing, and obtaining the formaldehyde-free plywood. The fabrication method for the nontoxic and environment-friendly formaldehyde-free plywood with the waste plastics solves the problem that the free formaldehyde released by the ordinary plywood has a toxic action on an environment and a human body, and a recycling approach for the waste plastics is provided.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

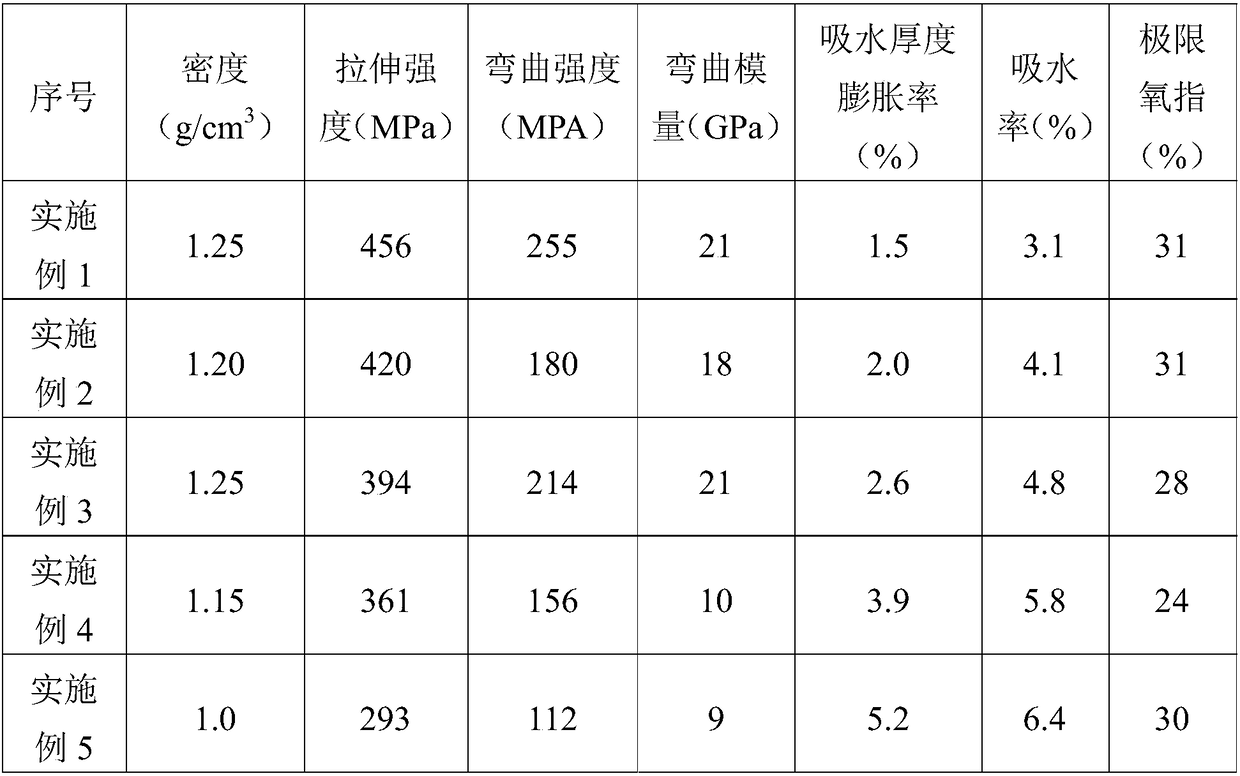

Preparation method for wood-bamboo reinforced resin composite material based on high-pressure densification

ActiveCN108772922AIncrease productivityPromote greenWood treatment detailsReed/straw treatmentStress concentrationHigh pressure

The invention relates to a preparation method for a wood-bamboo reinforced resin composite material based on high-pressure densification, and belongs to the field of composite materials and artificialboards. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification comprises the steps that lignin and hemicellulose are partially removedfrom wood veneers, wood boards or bamboo sheets by a chemical reagent, the chemical reagent is removed by water, and the water is replaced by ethanol or acetone; the wood veneers, the wood boards orthe bamboo sheets with lignin and hemicelluloses removal are put into a mixed solution of a resin system or a resin solution and a flame retardant, a diluent and / or a toughening agent additive, or sequentially put into the resin system or the resin solution and the mixed solution of the additive, so that the resin and additive penetrate into cells and cell pores of the wood or the bamboo; and semi-finished products are assembled into blanks, and high-pressure densification and high-temperature curing are carried out to prepare the high-strength composite material. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification overcomes the stress concentration problem caused by the pores and the like in an existing artificial board,and the prepared novel structural composite material has good mechanical properties and flame retardancy, so that the application of wood in the structural fields of airplanes, high-speed trains, buildings and the like are greatly promoted.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com