Fibre based panels with a wear resistance surface

A wood fiber, surface layer technology, applied in the device, lamination, coating and other directions of coating liquid on the surface, can solve the problems of low impact resistance locking system, etc., to achieve high impact resistance, easy to form and compress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

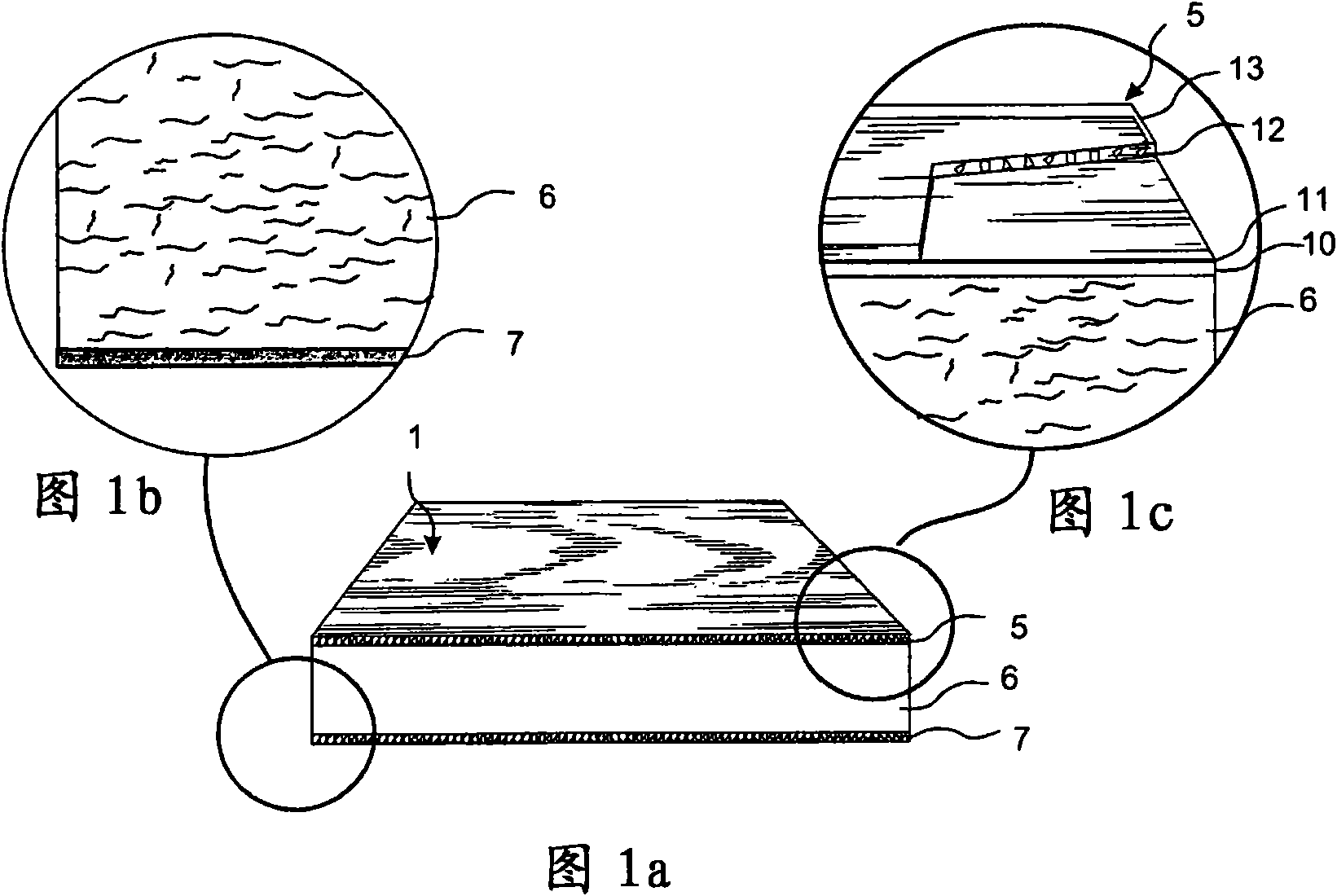

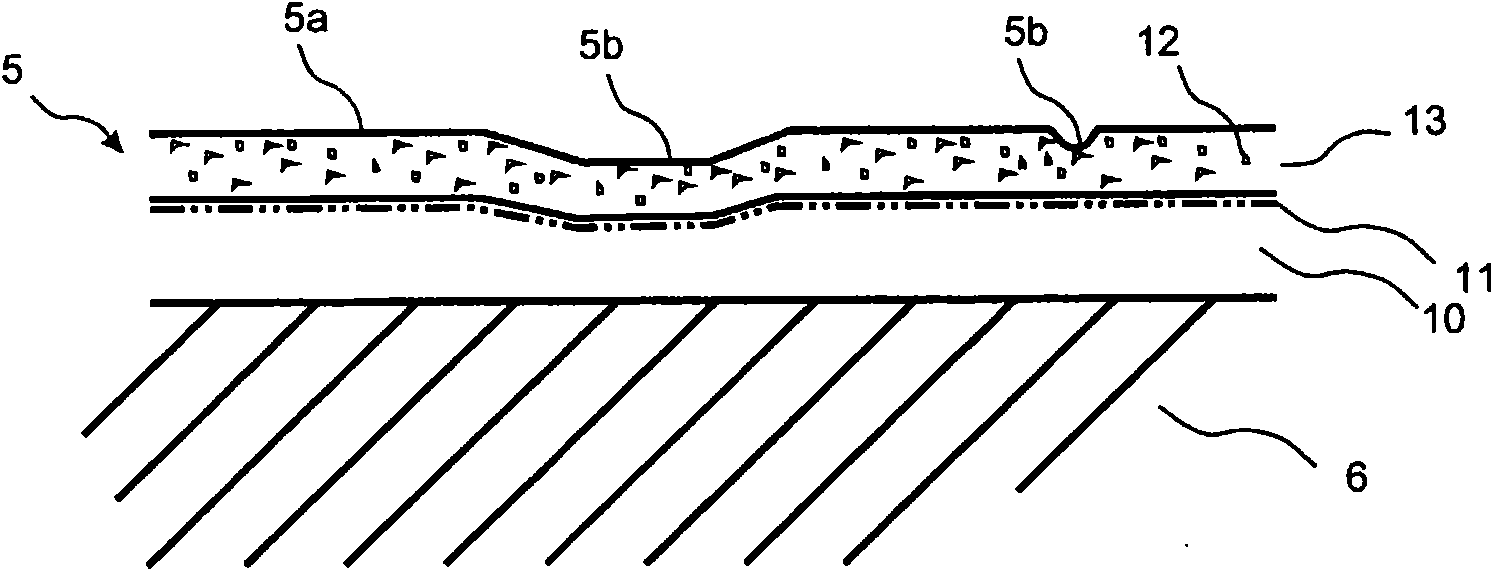

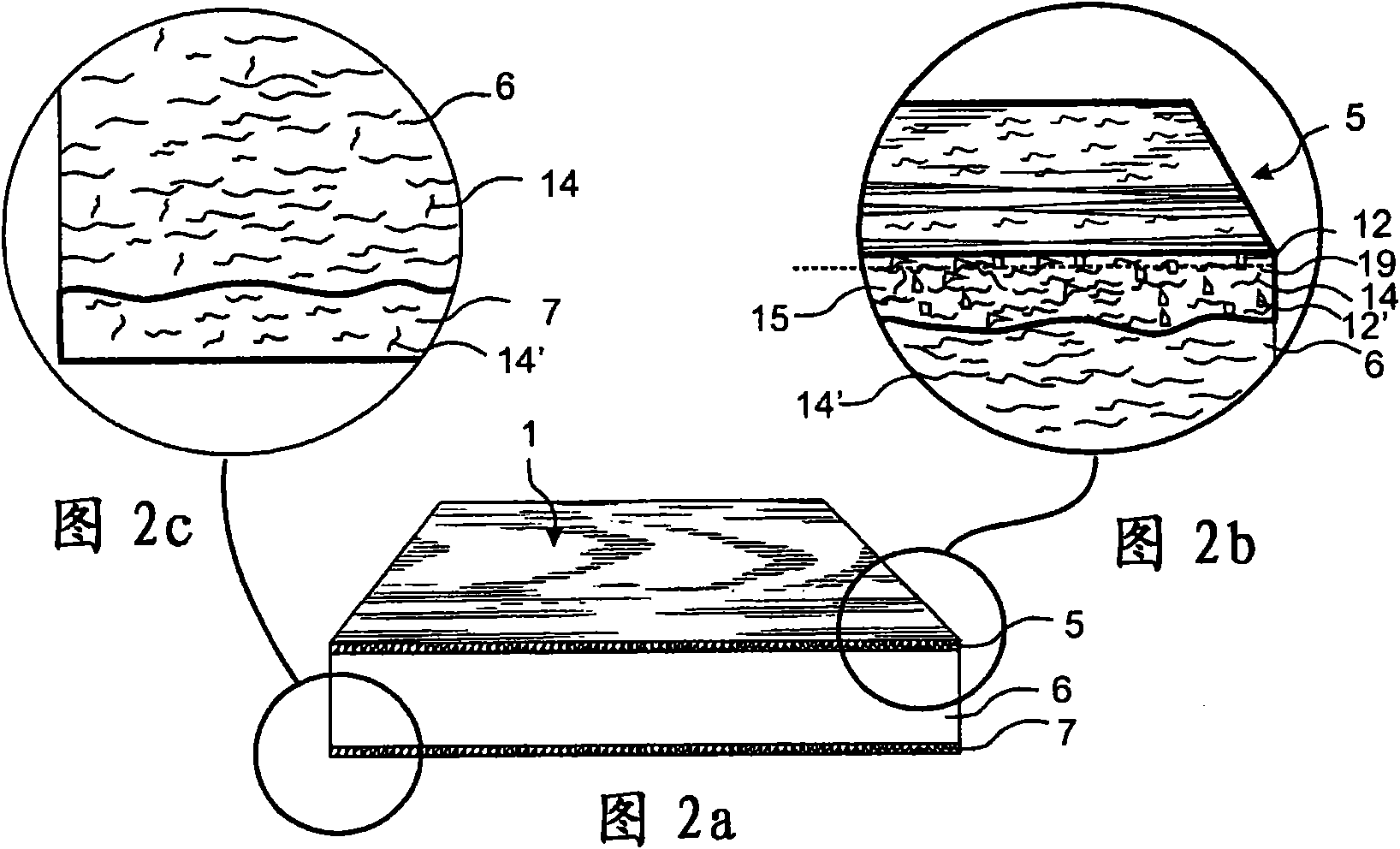

[0063] Figure 1a A laminate floor panel 1 according to known technology is shown, comprising a surface layer 5 , a core 6 and a balancing layer 7 . Figure 1c A surface layer 5 is shown. This surface layer 5 has an upper wear-resistant layer 13 made of a transparent material with excellent wear resistance. This wear layer generally consists of a transparent paper impregnated with melamine resin to which particles 12 of aluminum oxide have been added. A decorative layer 10 comprising paper with a printed pattern 11 is impregnated with melamine resin and placed under this transparent wear-resistant layer 13 . The wear layer 13 and the decorative layer 10 are laminated under pressure and heat to a core, typically a fiber based core (eg HDF), forming thereon a surface layer 5 about 0.2 mm thick. Figure 1b A balancing layer 7 is shown, which is also typically melamine impregnated paper. This balancing layer keeps the floor panels flat as humidity changes over time. The trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com