Patents

Literature

9812 results about "Bobbin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bobbin is a spindle or cylinder, with or without flanges, on which wire, yarn, thread or film is wound. Bobbins are typically found in sewing machines, cameras, and within electronic equipment. In non-electrical applications the bobbin is used for tidy storage without tangles.

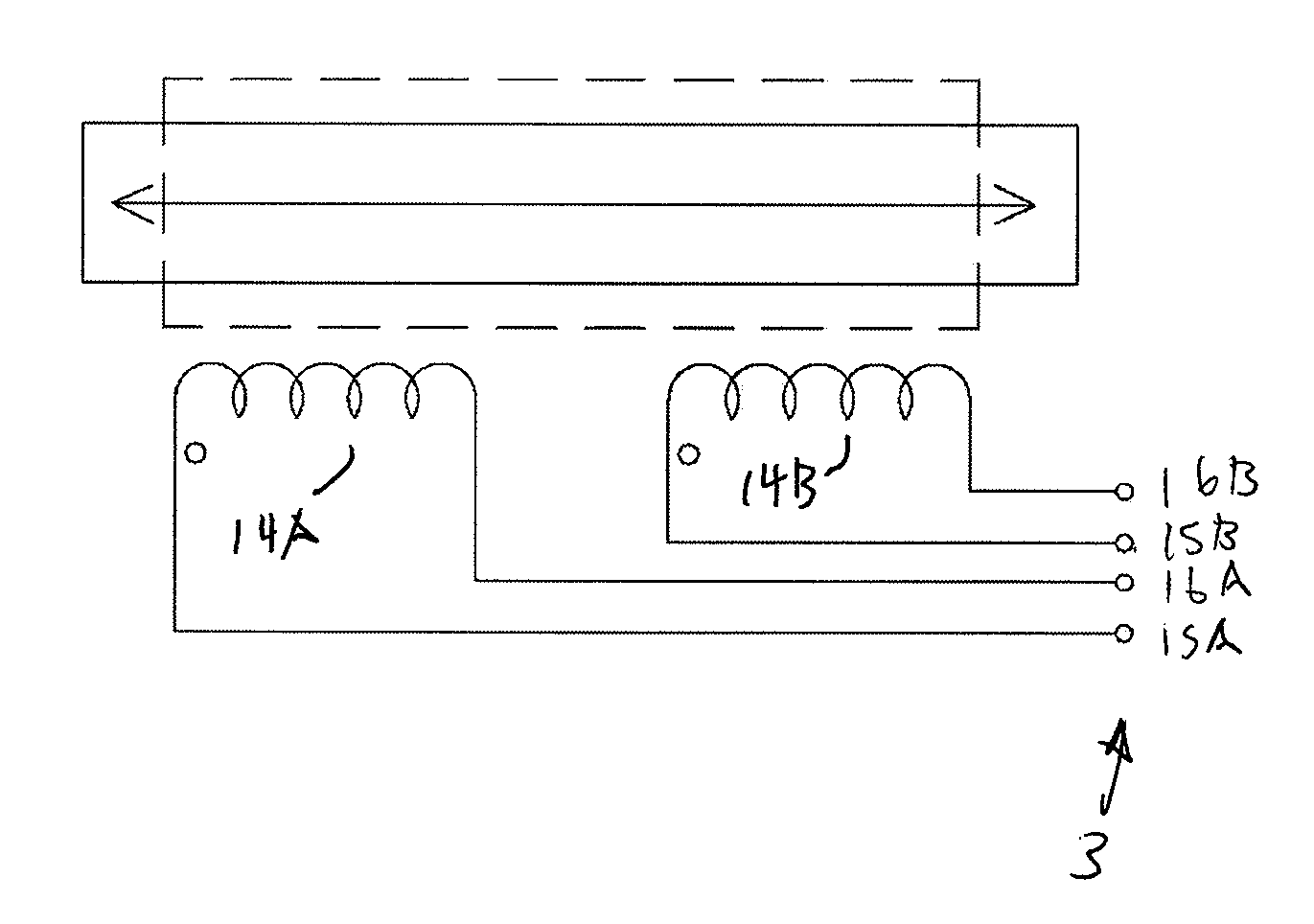

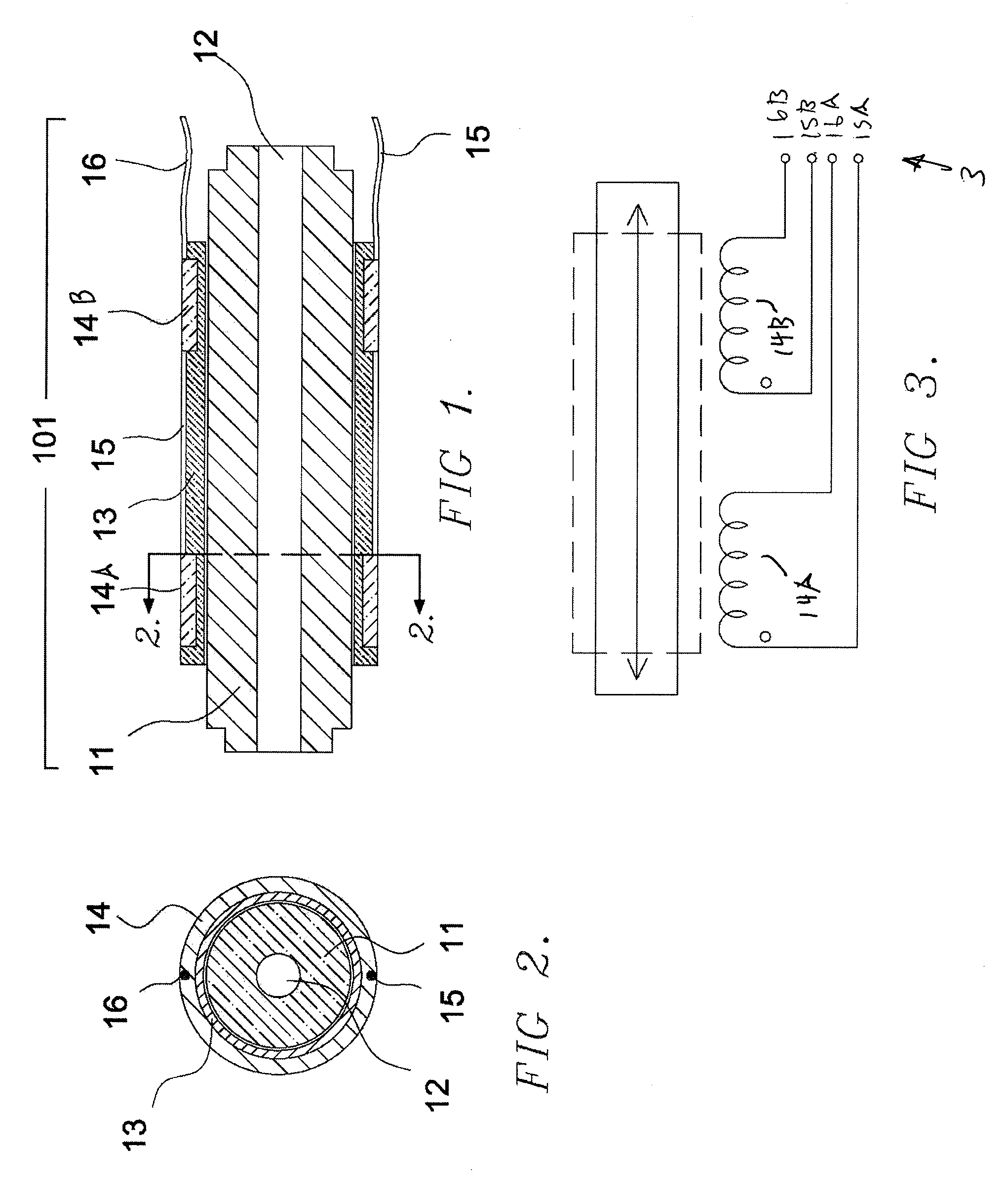

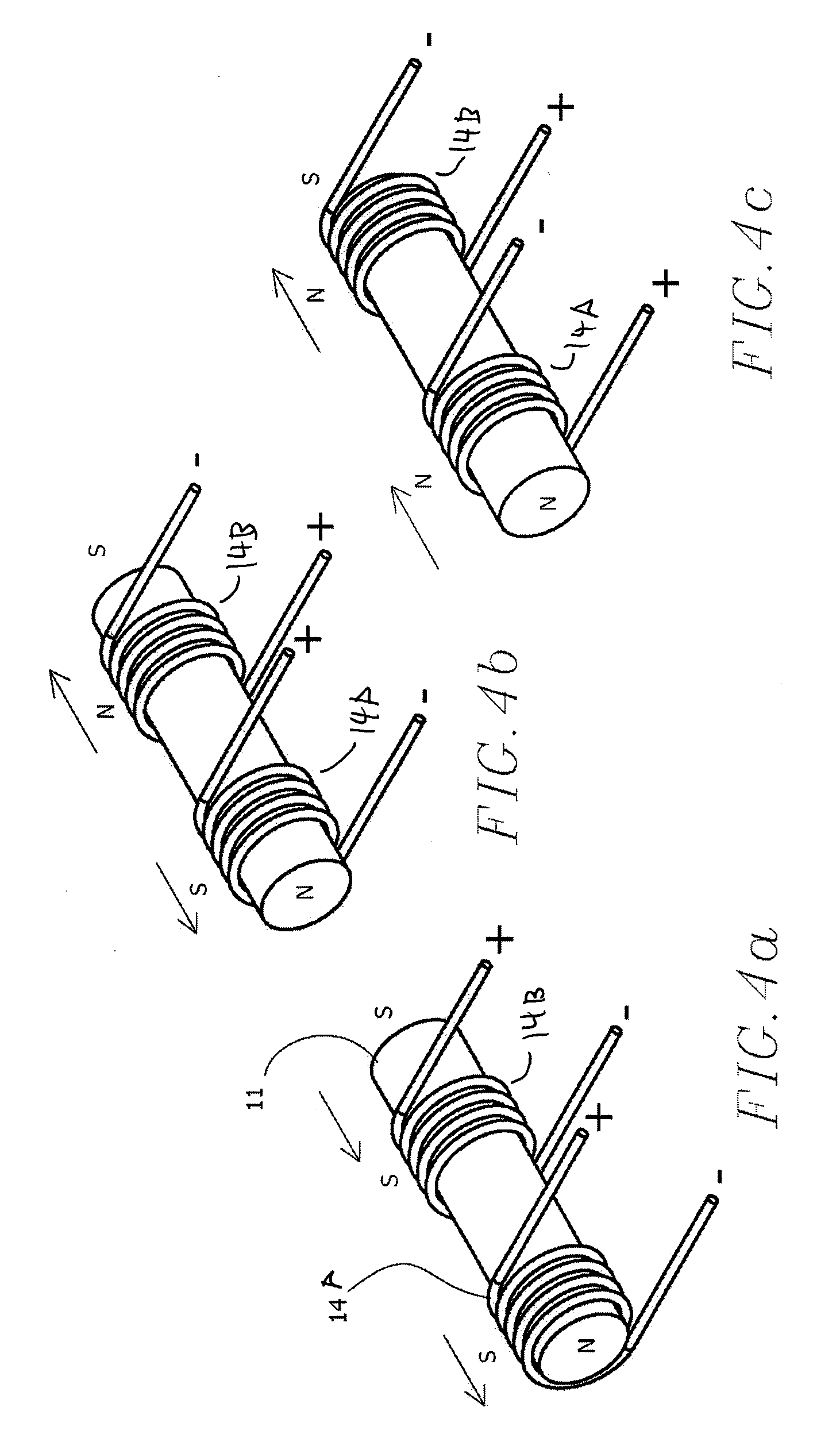

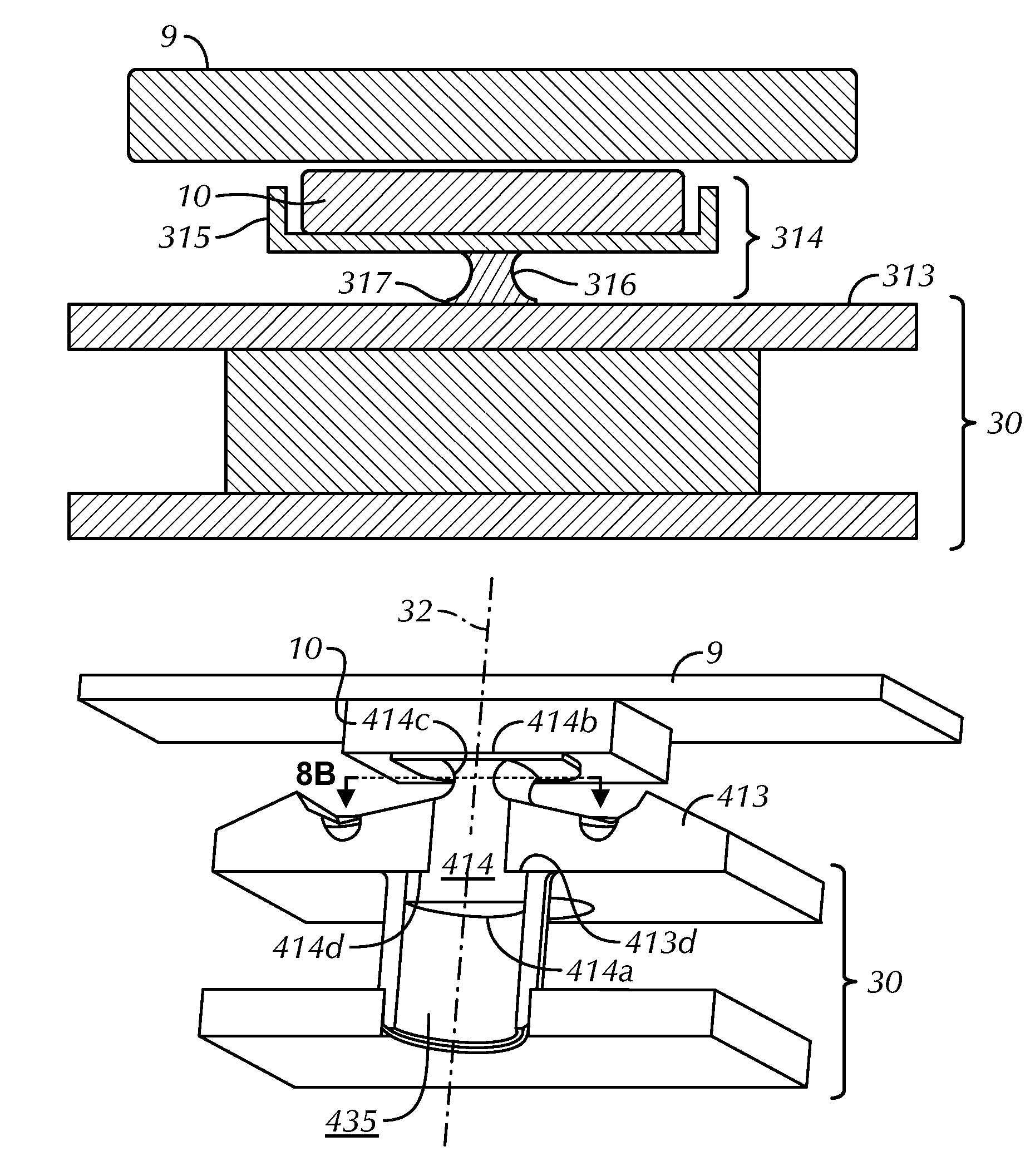

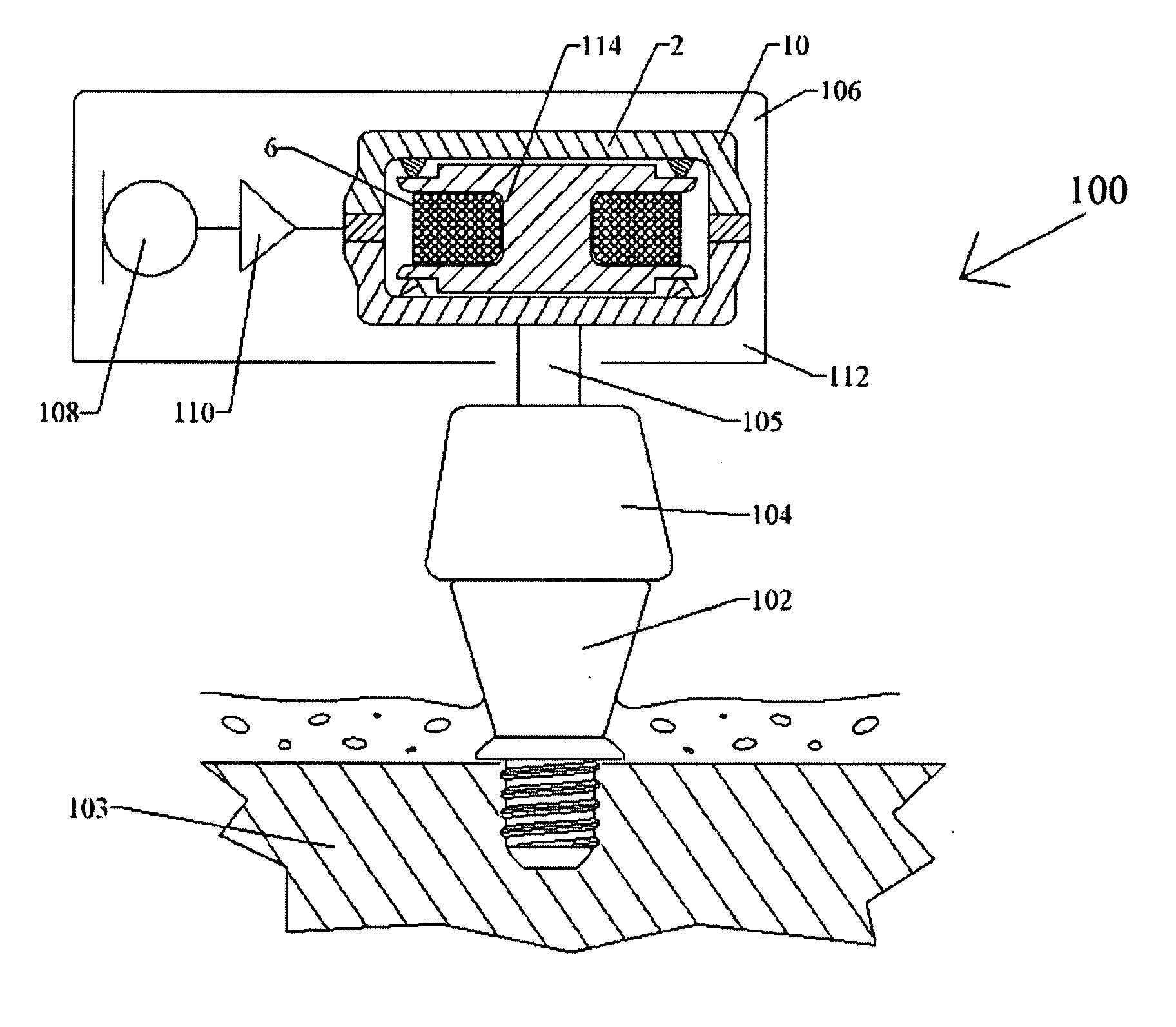

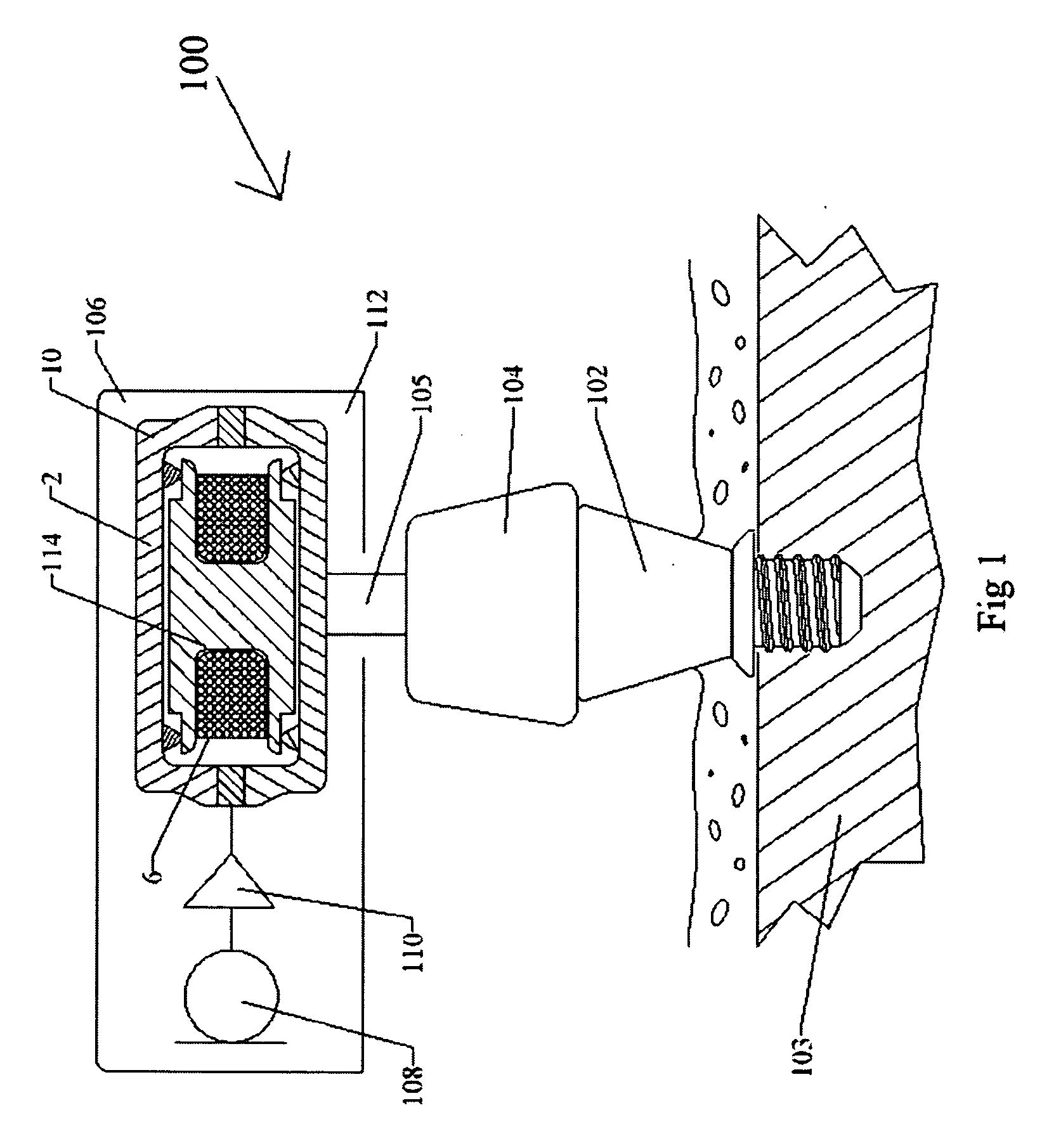

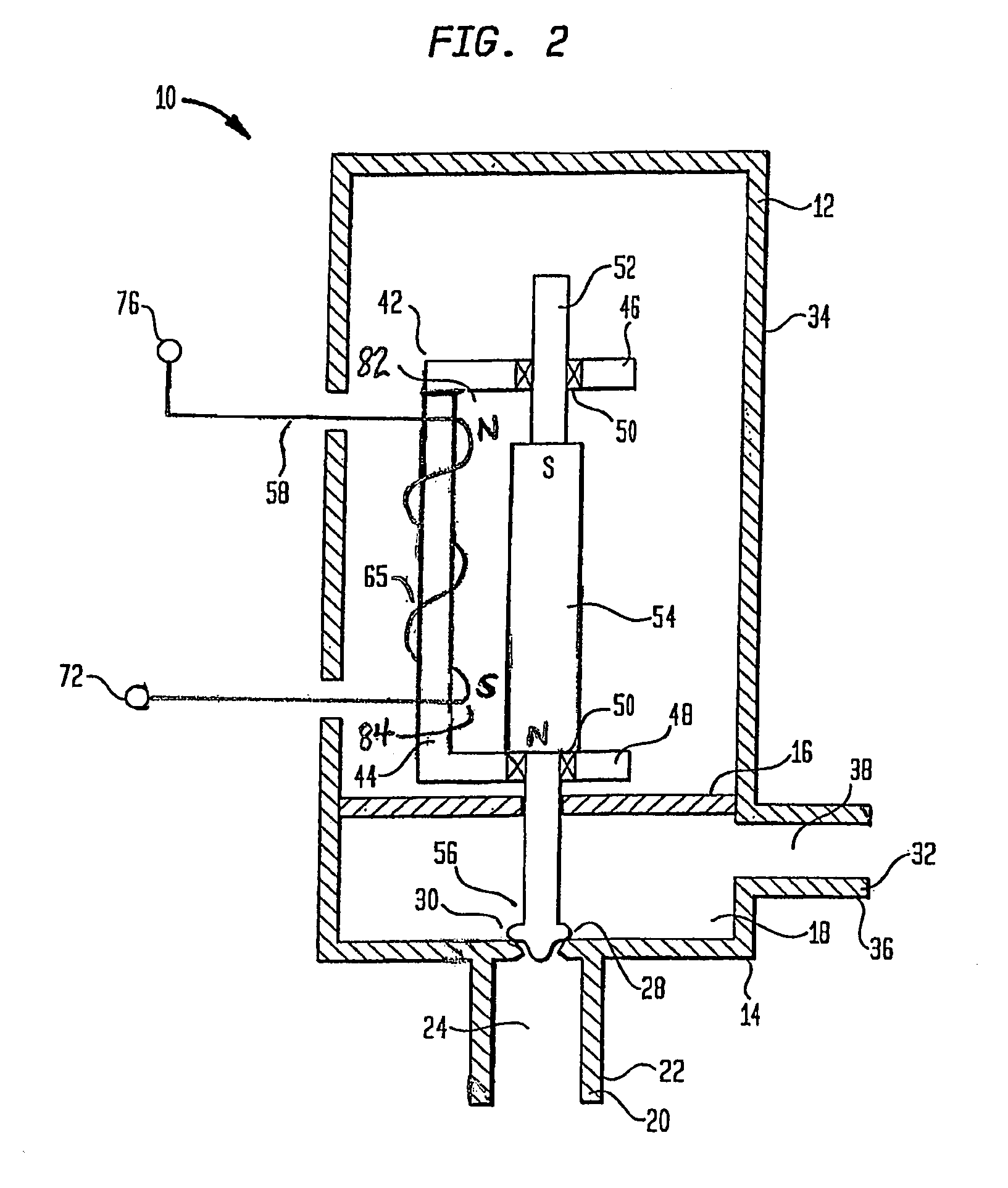

Magnetic linear actuator for deployable catheter tools

InactiveUS20080297287A1Easy to controlGood precisionDiagnostic recording/measuringSensorsDiagnostic Radiology ModalityLinear motion

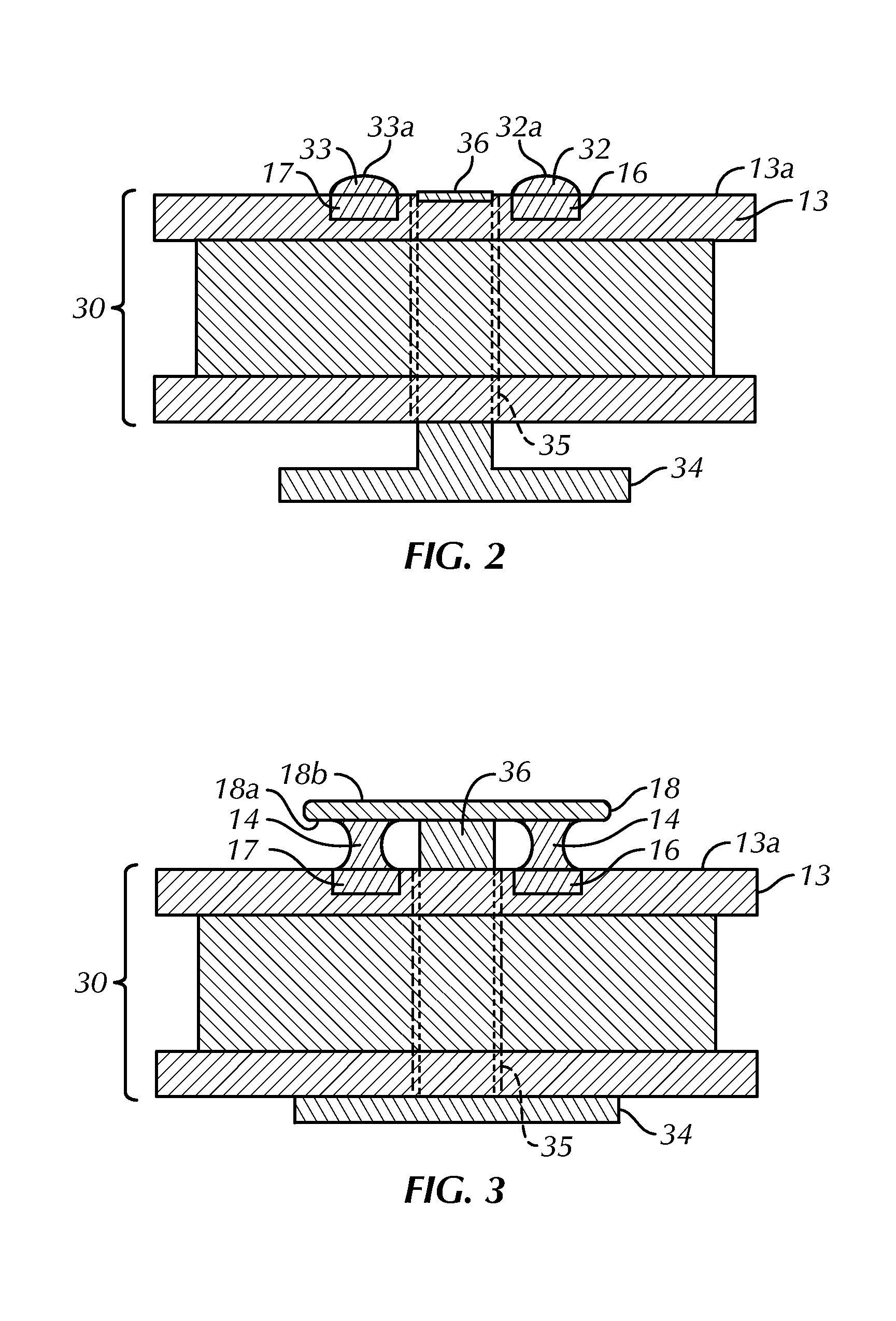

Using the linear forces that are provided by an electromagnetic solenoid applied near the distal end of a medical catheter, various surgical instruments can be actuated or deployed for use in interventional medicine. The linear actuator uses the principles of magnetic repulsion and attraction as a means for moving a bobbin that can be attached to various types of moving components that translate linear movements into the actuation of a tool that is attached to the linear actuator. Using independent solenoid coils, movement modality is increased from two possible positions to three.

Owner:NEURO KINESIS CORP

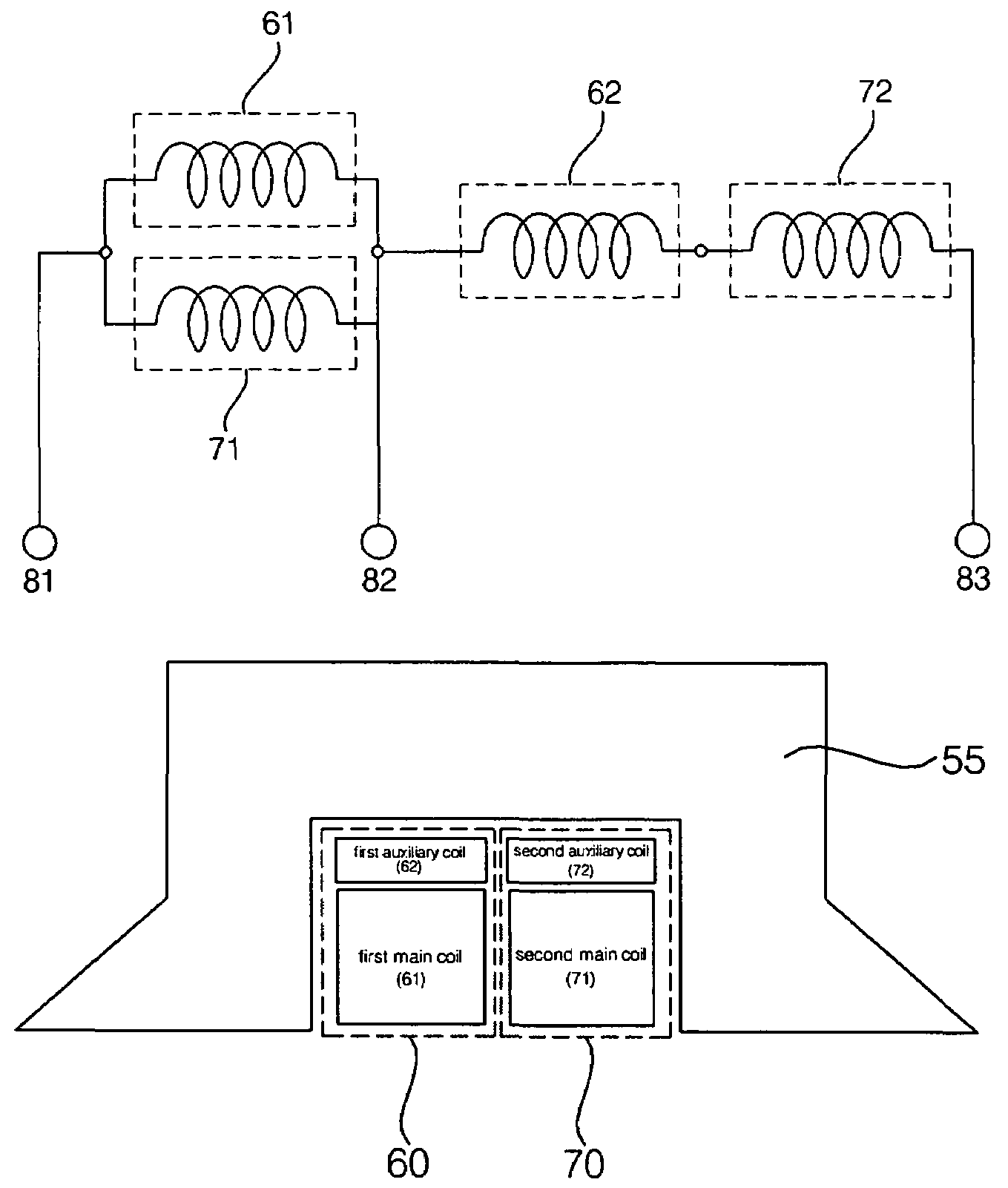

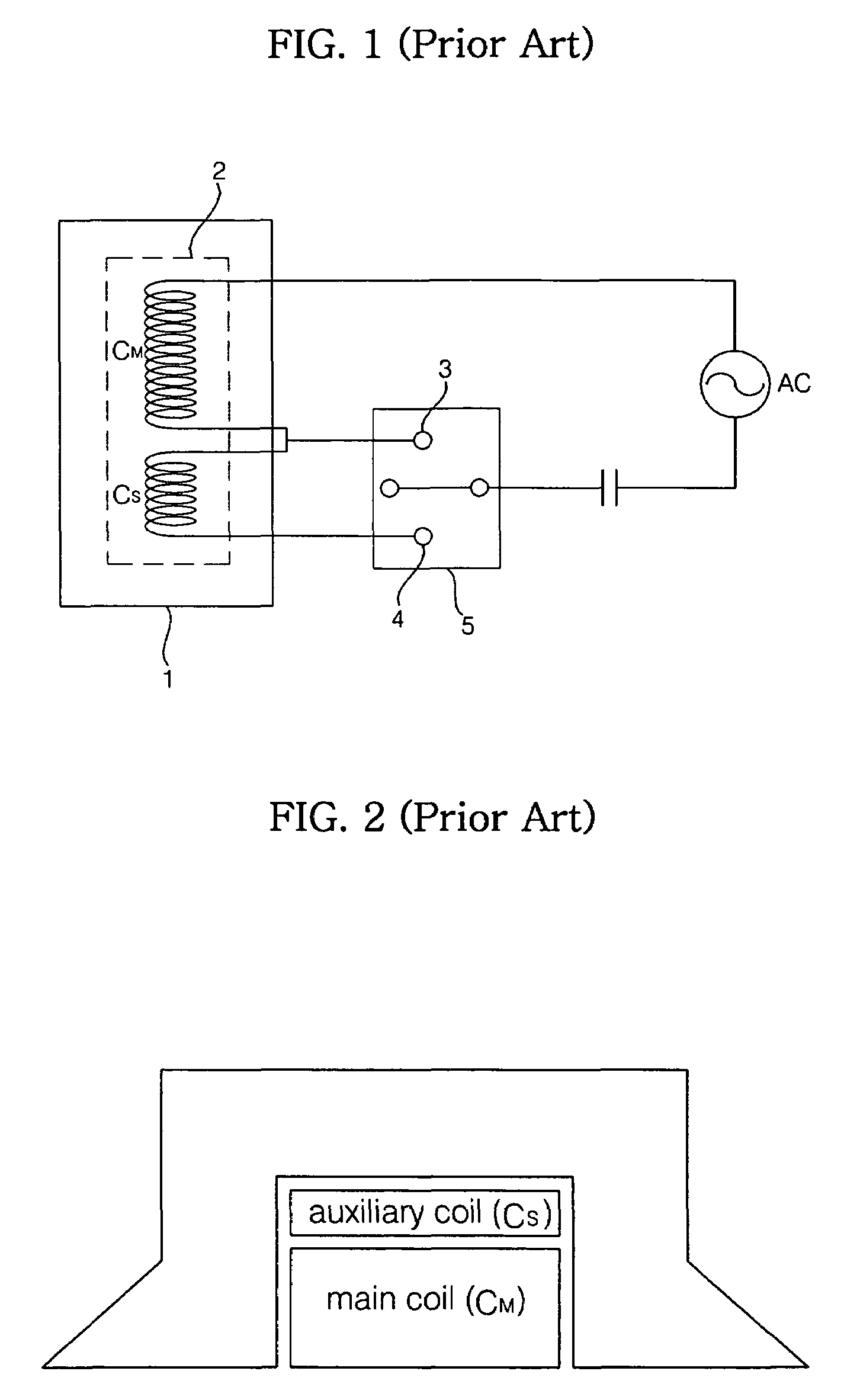

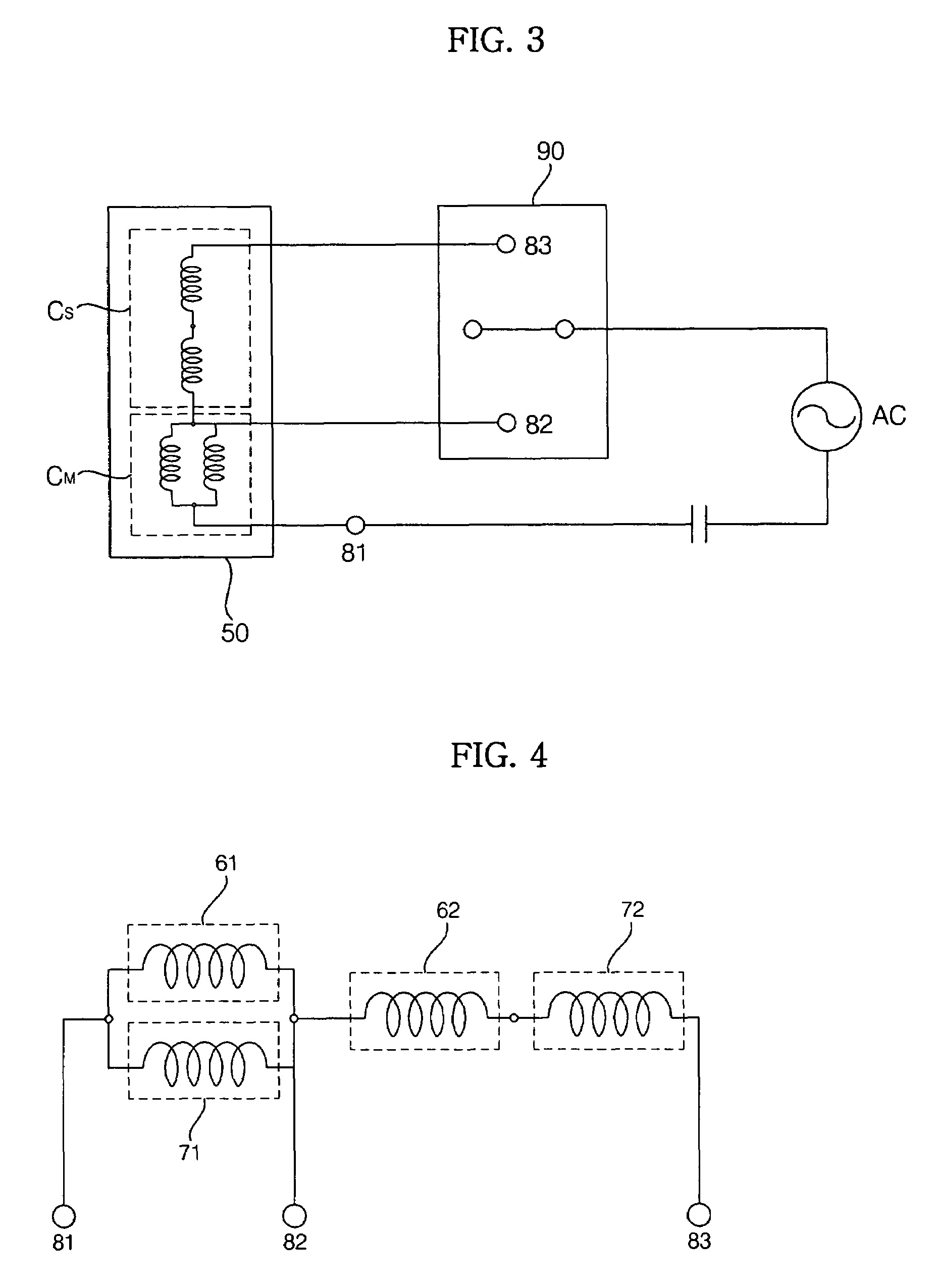

Linear motor and linear compressor using the same

ActiveUS7489055B2Improve efficiencySmall sizeAC motor controlDC motor speed/torque controlBobbinElectrical conductor

Disclosed herein is a linear motor in which a plurality of coil groups are connected in series or in parallel and driving power is applied to part or all of the coil groups according to load applied to the linear motor, thereby achieving improved motor efficiency with a reduced motor size. The linear motor includes a bobbin, the plurality of coil groups wound on the bobbin, the plurality of coil groups being connected in series or in parallel to allow the driving power to be applied to part or all of the coil groups, and a magnet adapted to be linearly reciprocated by a magnetic field produced by the coil groups depending on load current flowing through the coil groups. As a result of connecting the plurality of coil groups, which are formed of a plurality of coil conductors, in series or in parallel, the capacity of the coil groups is variable depending on the load of the motor, resulting in improved motor efficiency. Also, using the coil conductors having a small cross sectional area enables reduction in the size of the motor.

Owner:LG ELECTRONICS INC

Scan element for use in scanning light and method of making the same

A scan element includes a bobbin having a central axis about which is wound an electromagnetic wire coil and having a flange oriented generally transverse to the central axis. At least one elastomeric support has a first end coupled to the flange. A permanent magnet has first and second surfaces, a central axis, and a magnetization direction oriented generally transverse to the central axis of the permanent magnet. The magnet is supported by a second end of the elastomeric support. A mirror has a central axis and is mounted on the second surface of the magnet. The central axes of the mirror and magnet are coaxial with the central axis of the bobbin. The elastomeric support provides a return force when the magnet and the mirror are rotated at an angle from the central axis during energization of the electromagnetic wire coil.

Owner:METROLOGIC INSTR

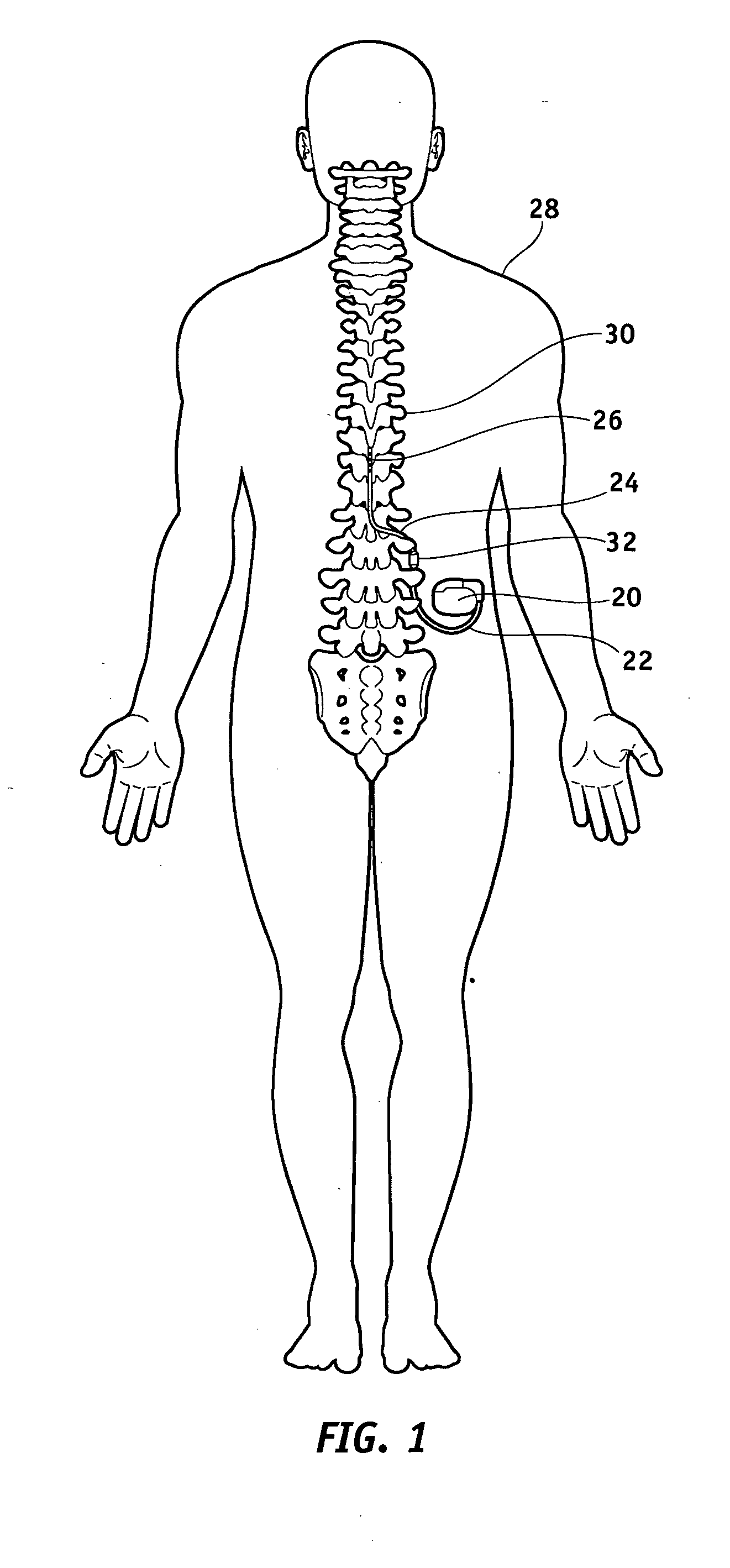

Lead electrode for use in an MRI-safe implantable medical device

A lead configured to be implanted into a patient's body comprises a lead body and a conductive filer positioned within the lead body and having a distal portion. An electrode is electrically coupled to the lead body and comprises a stimulation portion, a bobbin, and at least one coil of wire wound on the bobbin and electrically coupled between the stimulation portion and the distal end region to form an inductor between the distal end region and the stimulation portion.

Owner:MEDTRONIC INC

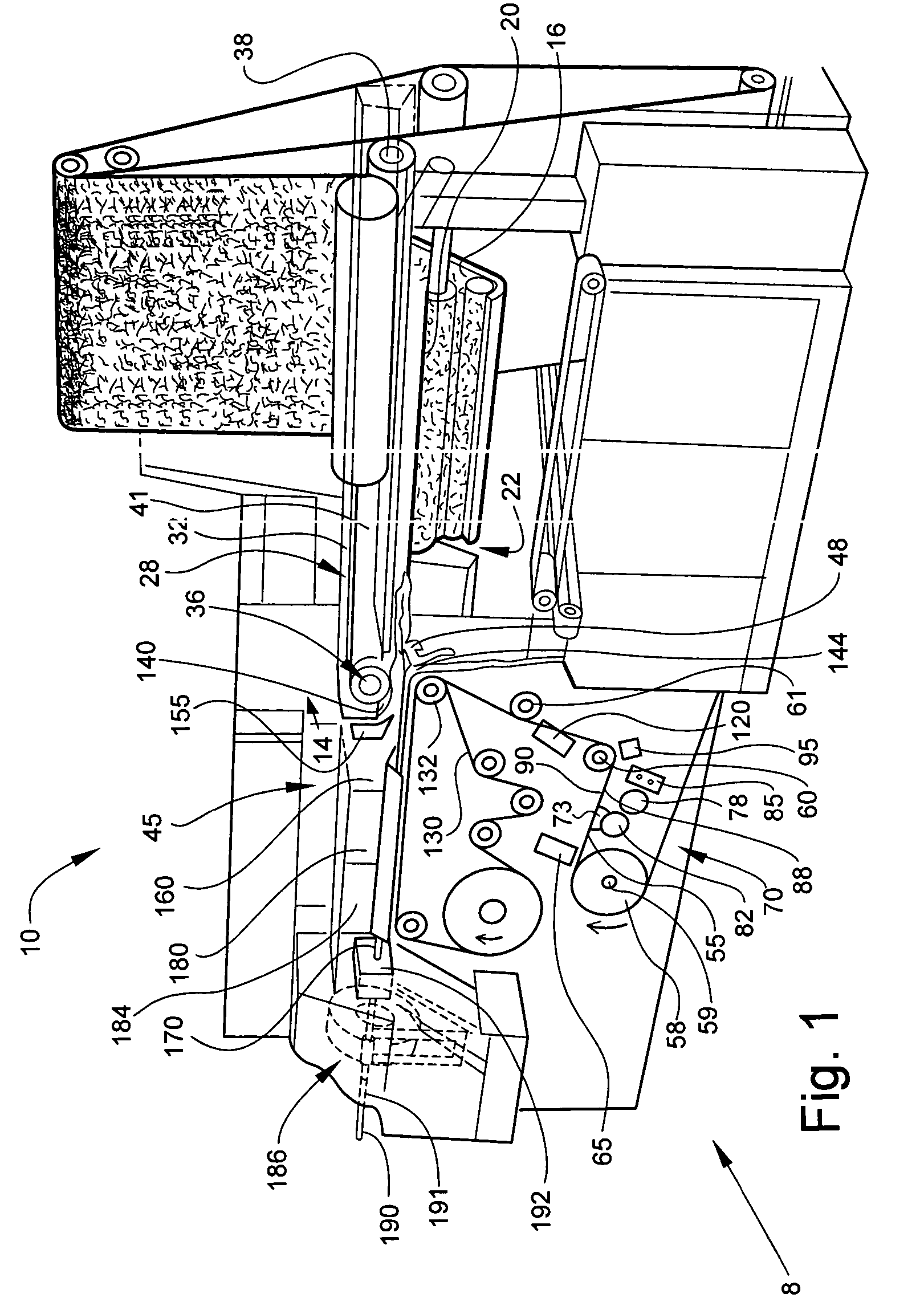

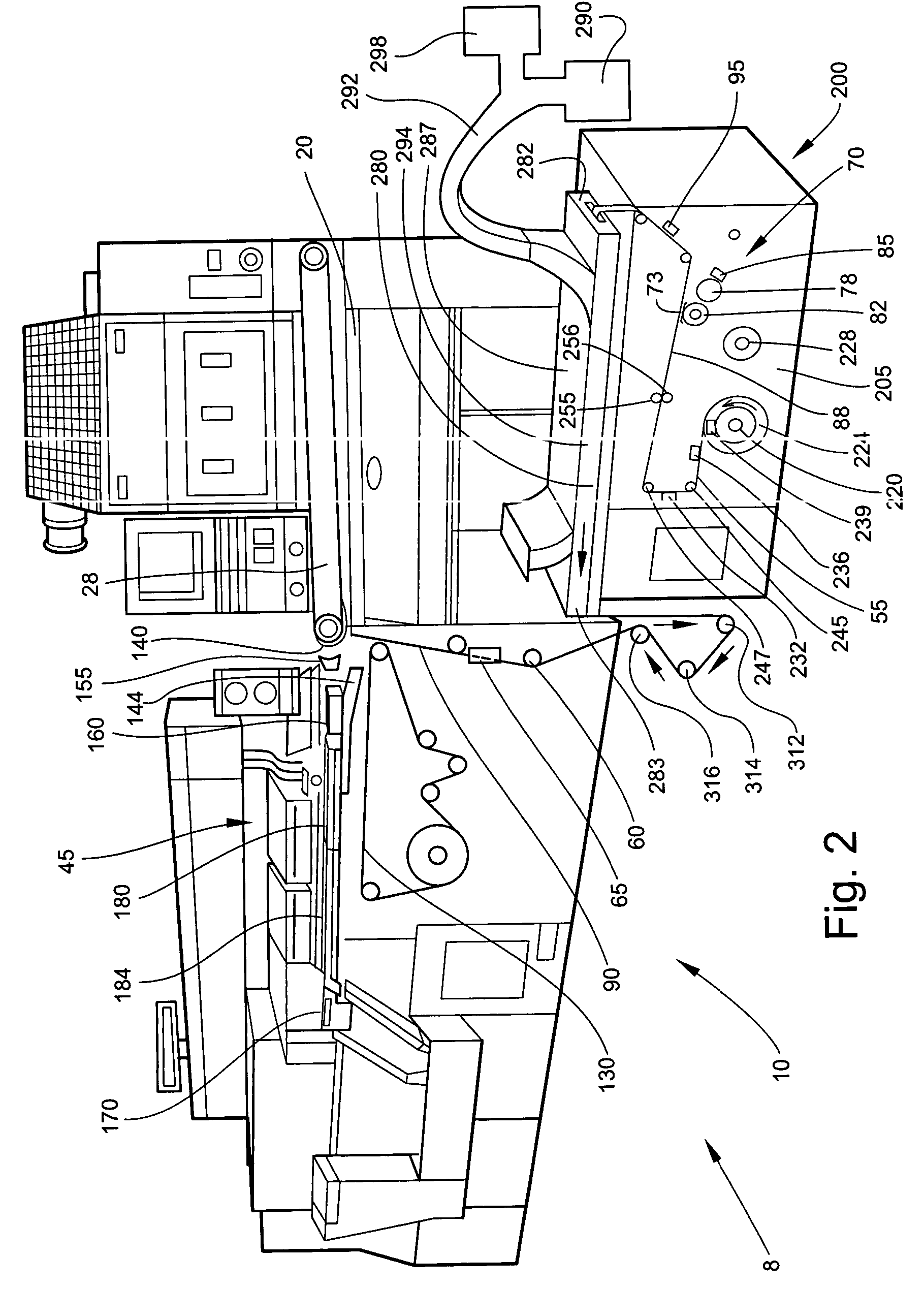

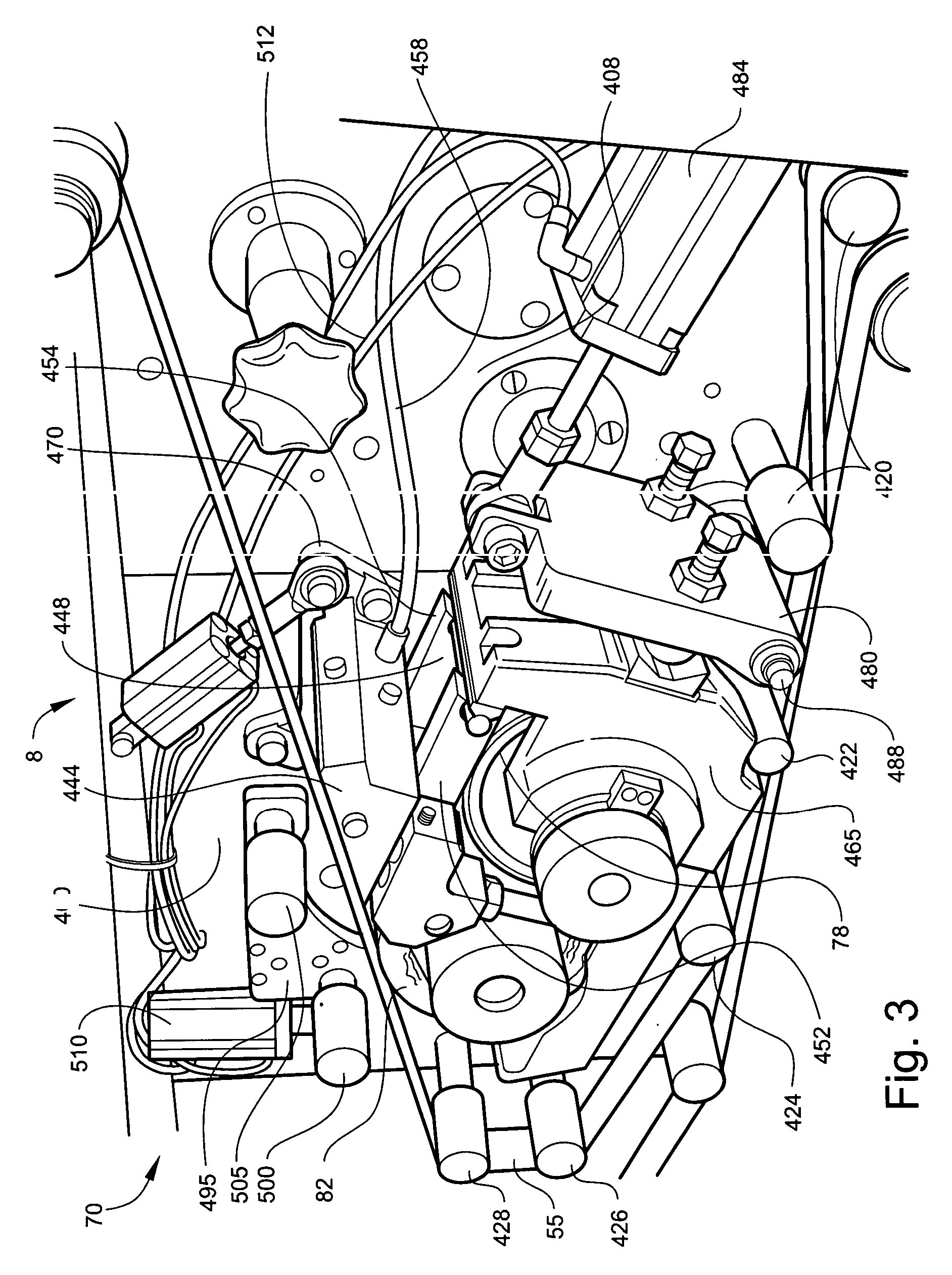

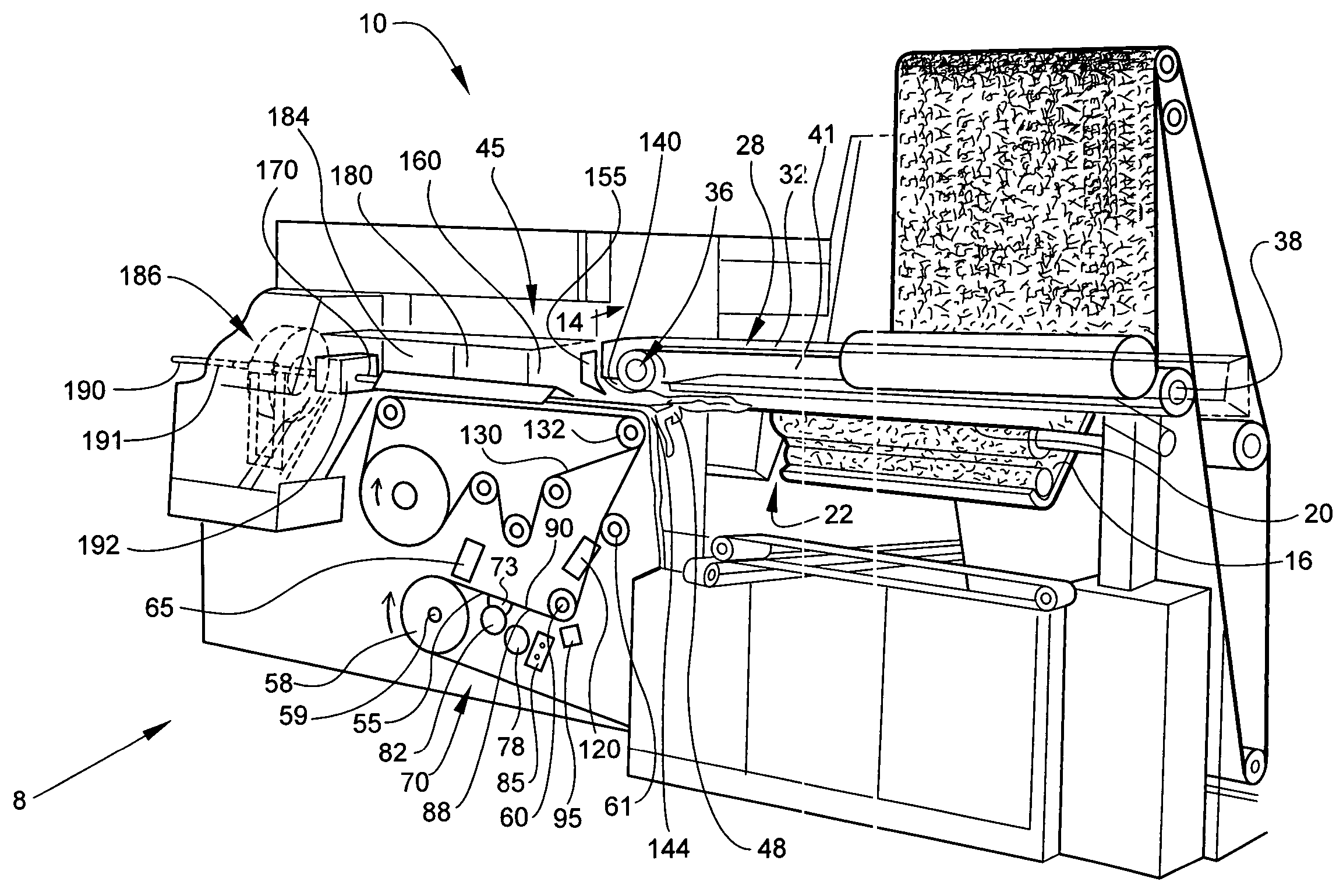

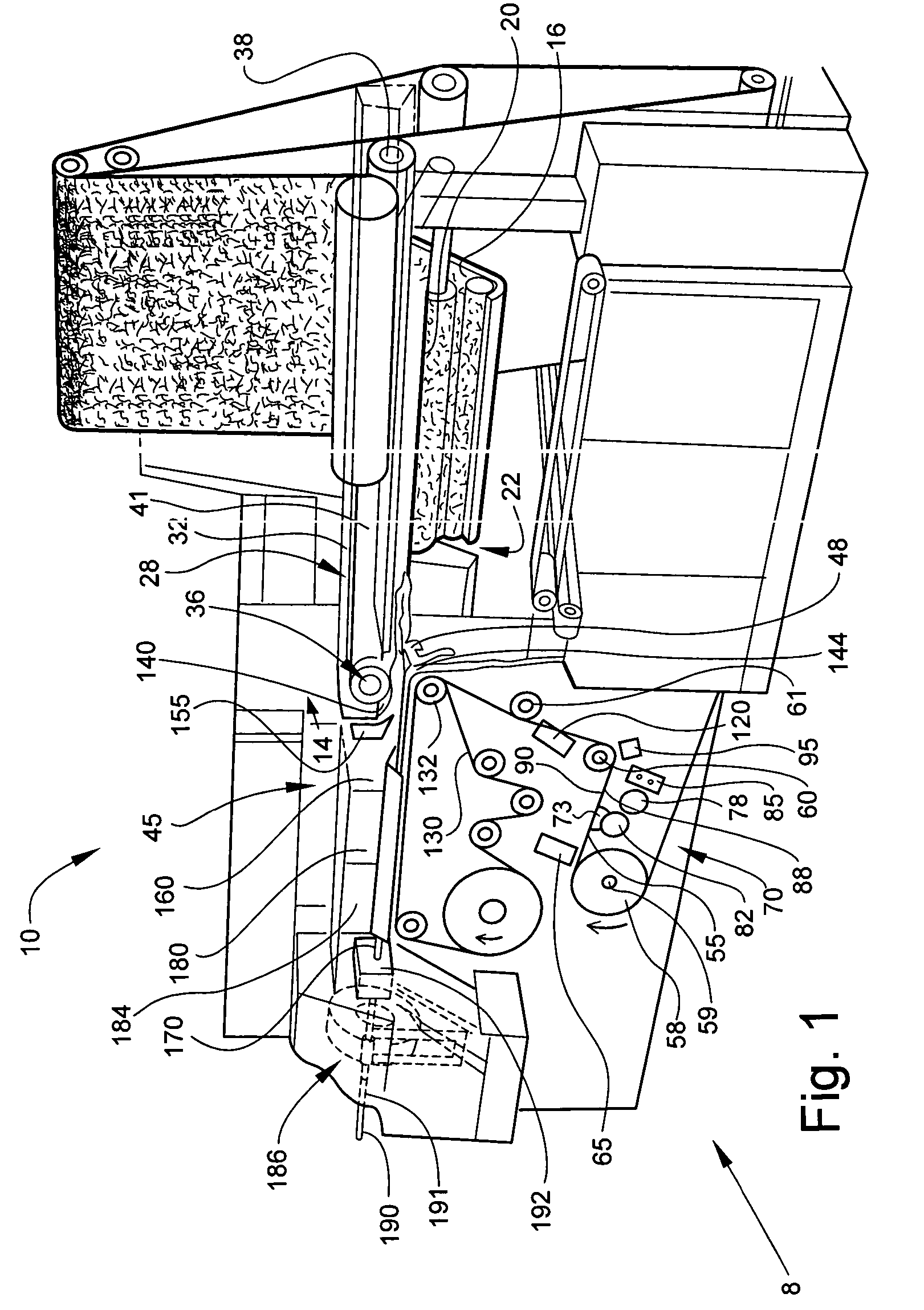

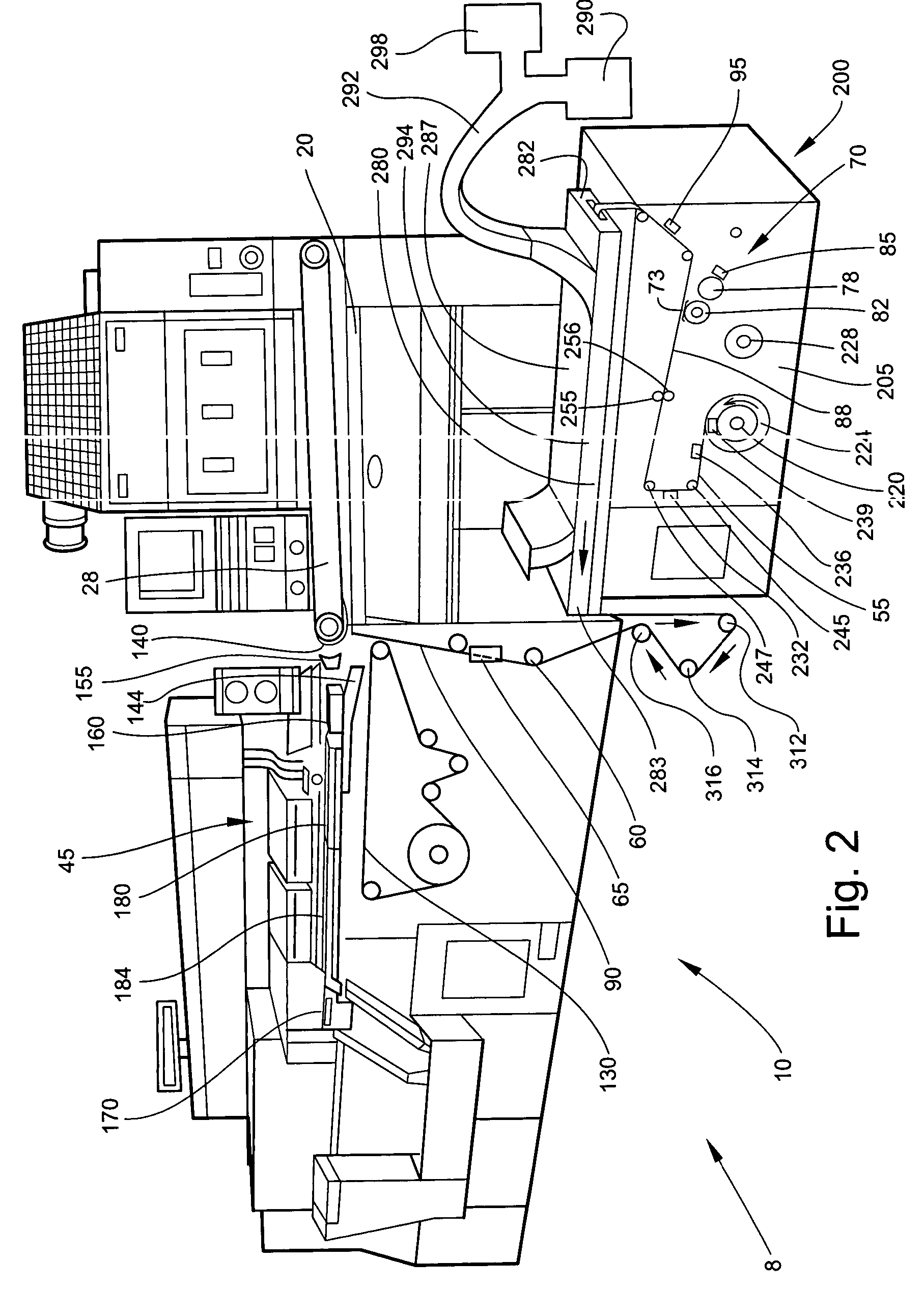

Materials, equipment and methods for manufacturing cigarettes

ActiveUS20050076929A1Minimize and avoid and prevent transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinAssembly systems

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers a series of roller. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. An alternate assembly system provides a source of paper web, applies additive material to that web in a pattern, dries the paper web, and winds the treated paper web on to a bobbin; and that bobbin is later used to provide a source of paper web on a cigarette making machine unrolls that bobbin, receives the treated paper web from that bobbin, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

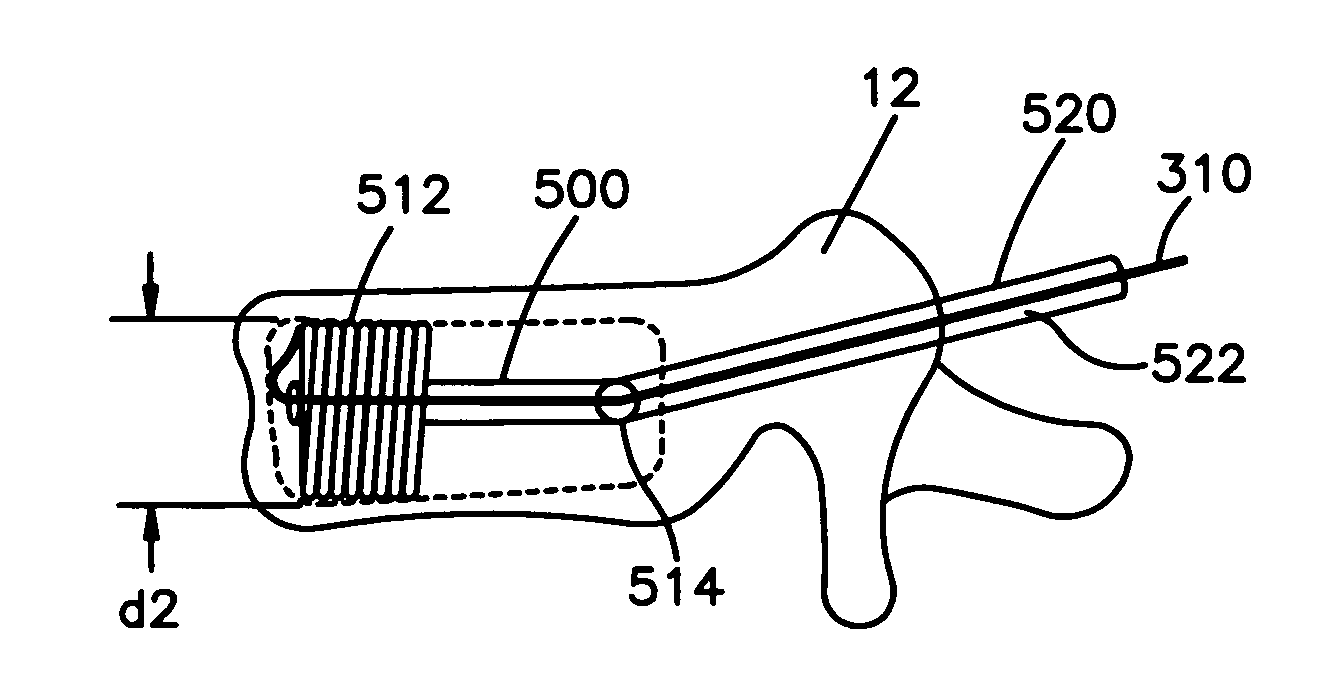

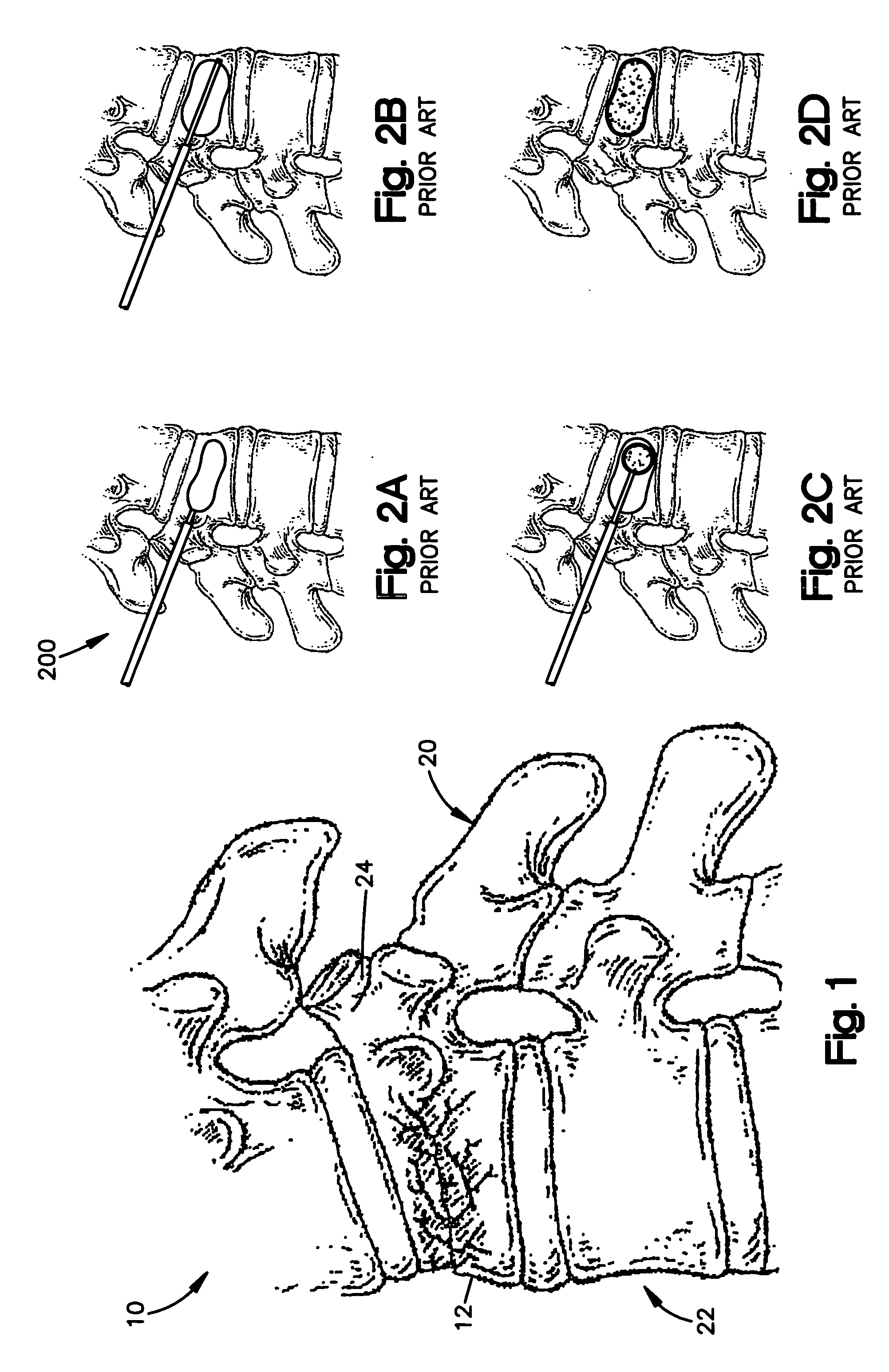

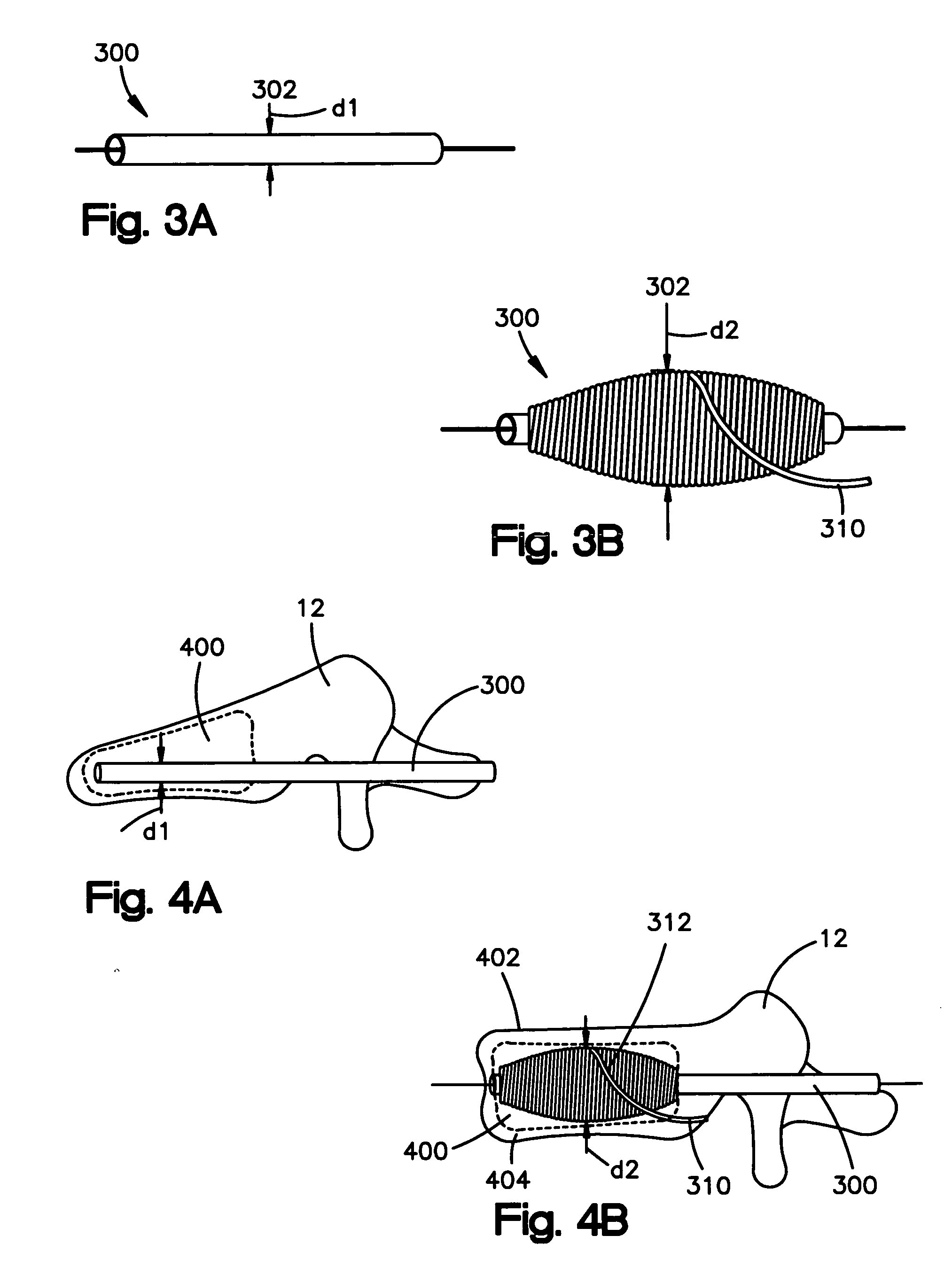

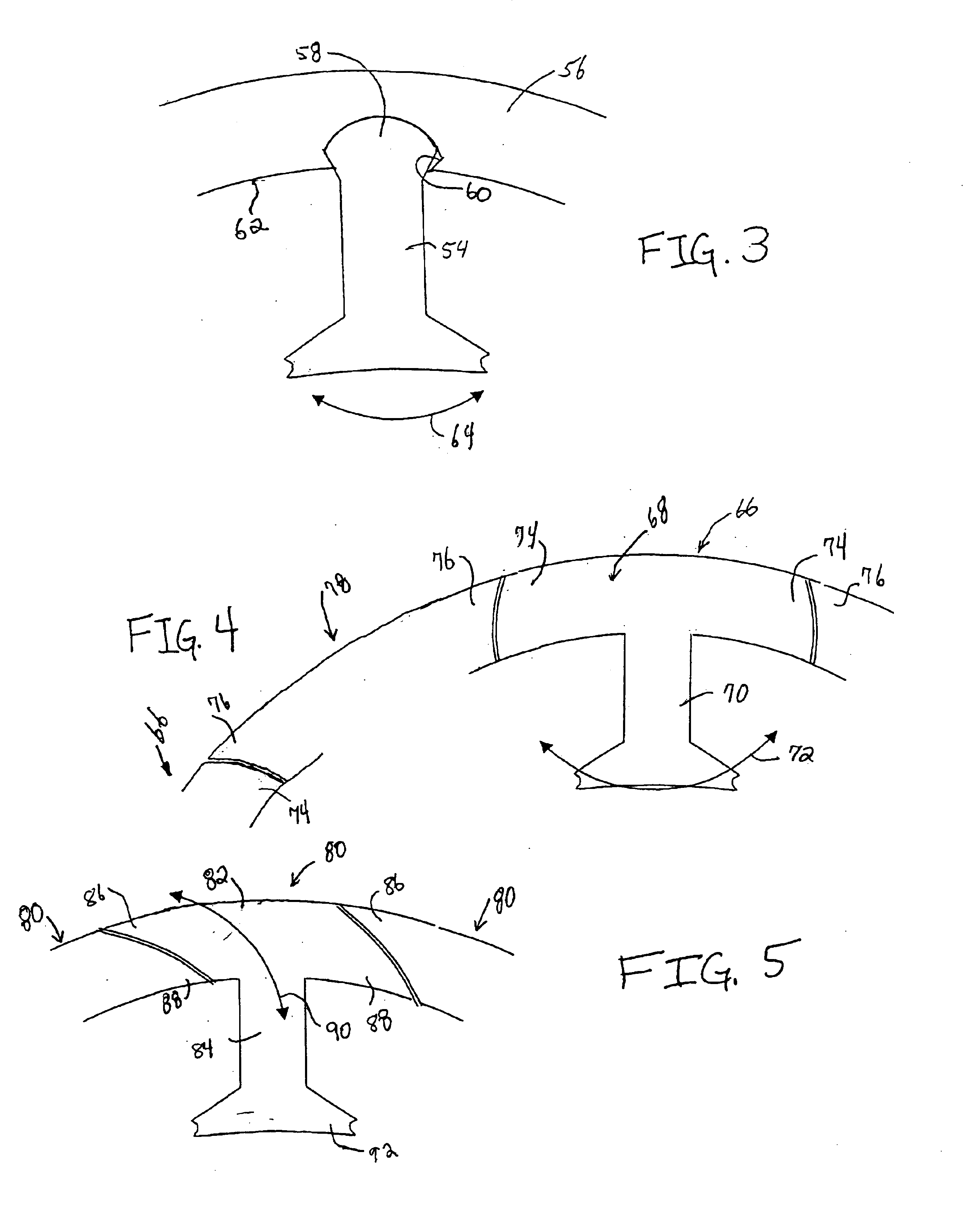

Apparatus and methods for treating bone

ActiveUS20070055274A1Increased radialIncreasing diameter of coilInternal osteosythesisSpinal implantsFiberBobbin

Implants and methods for bone treatment, preferably minimally invasive treatment, including repositioning of vertebrae may comprise insertion of a bobbin having a wire, string, thread or band, coiled around the bobbin. During coiling, the diameter of the bobbing / band complex may increase. Such increase in diameter can push against the inner side of the endplates of the vertebral body, and augment the vertebral body to its original height. The implant may also take the form of a coiled sleeve which when inserted into the vertebral body is uncoiled. The force of the uncoiling sleeve pushes against the inner side o the endplates of the vertebral body, restoring the vertebral body to its original height. The implant may also take the form of fibrous masses comprised of a thread or other relatively thin structure, for example a fiber or strand, of any biocompatible material having desired characteristics, for example a shape memory alloy, titanium, stainless steel, another metal or metal alloy, a ceramic, a composite or any combination thereof. The, strand, thread or other fiber may be coiled, woven, matted, tangled or otherwise formed into a wool-like mass or body having a desired configuration. Expansion of the expandable member within the vertebral body or other bone may reposition the fractured bone to a desired height and augment the bone to maintain the desired height. A bone cement or other filler can be added to further treat and stabilize the vertebral body or other bone.

Owner:SYNTHES USA

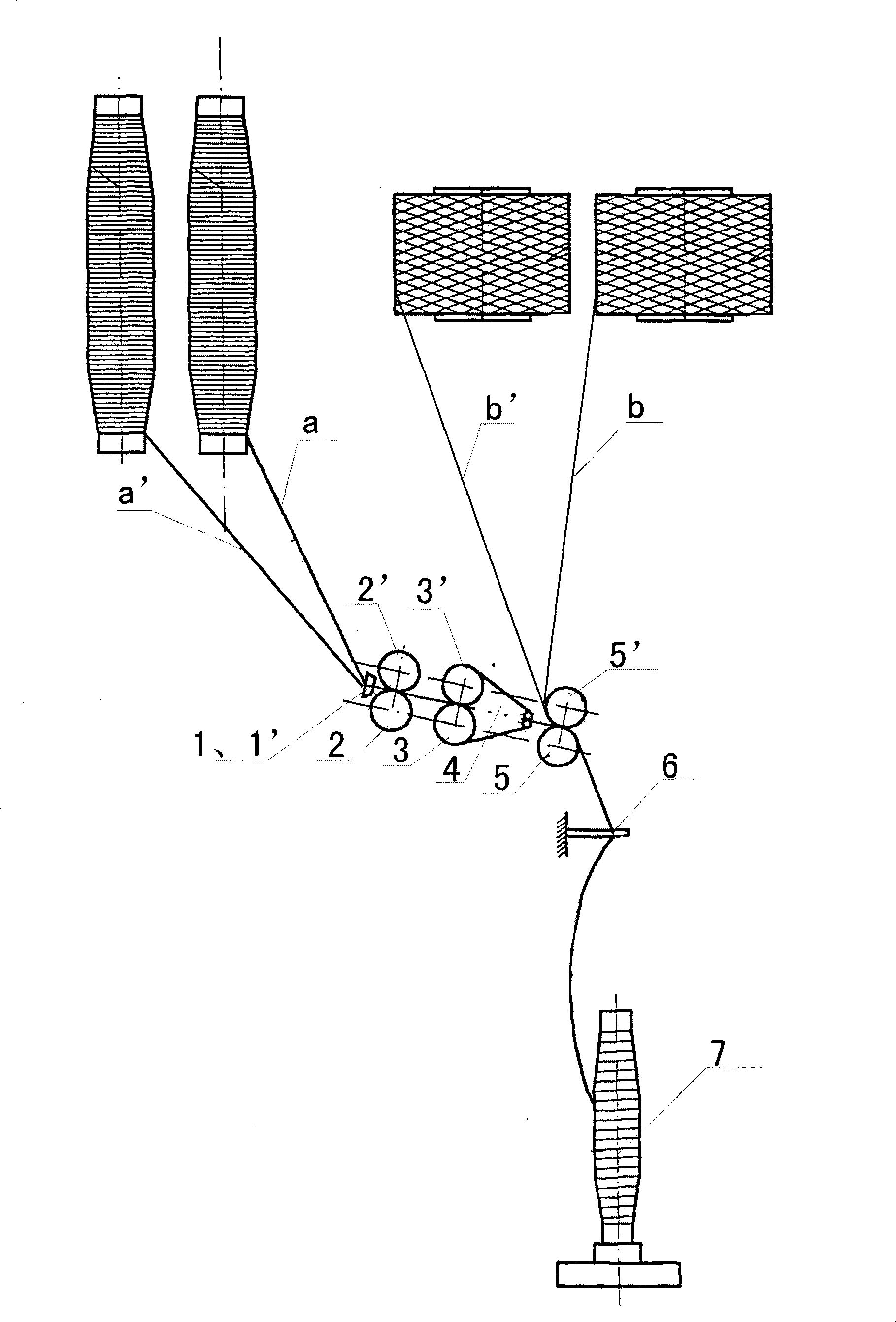

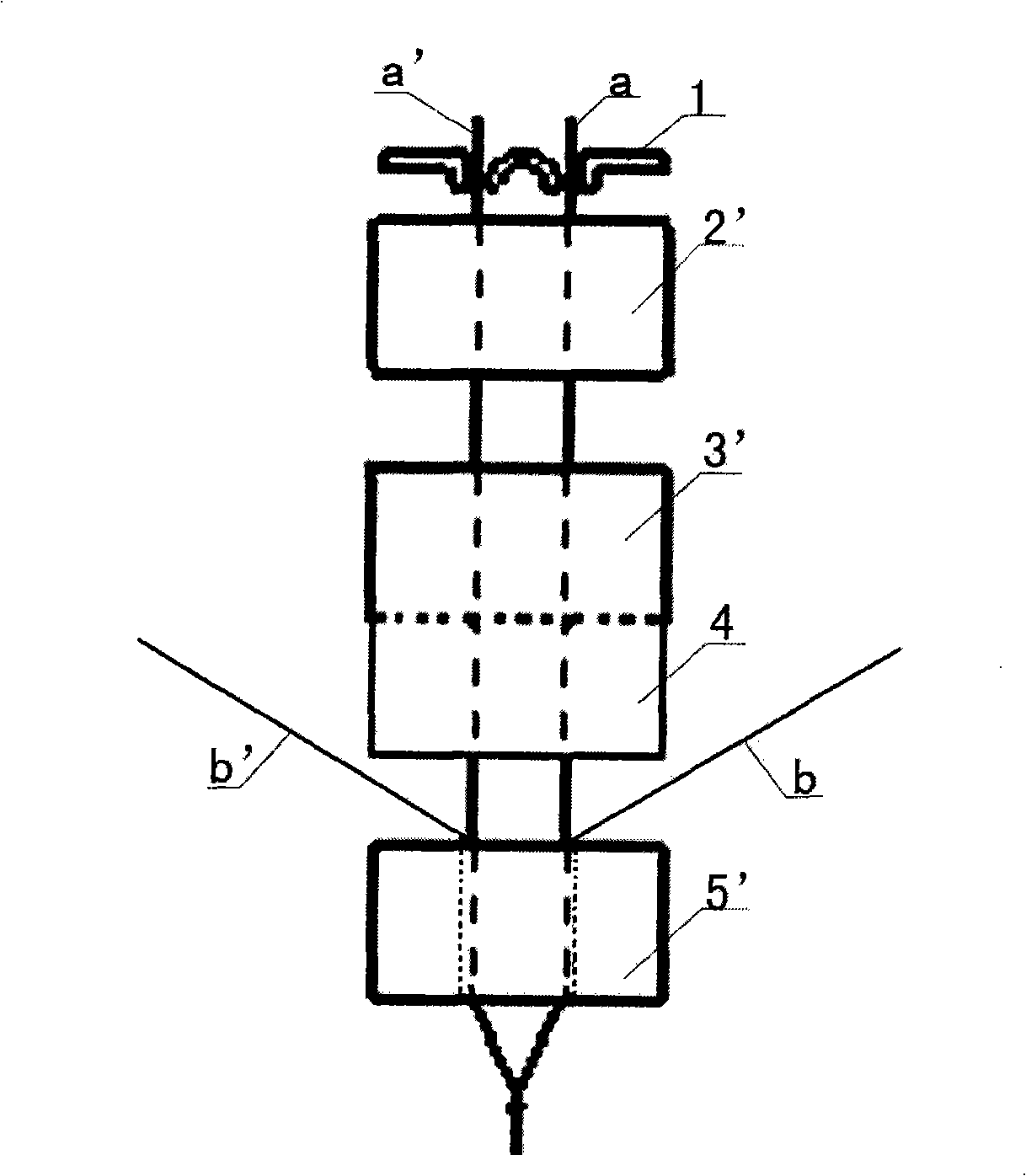

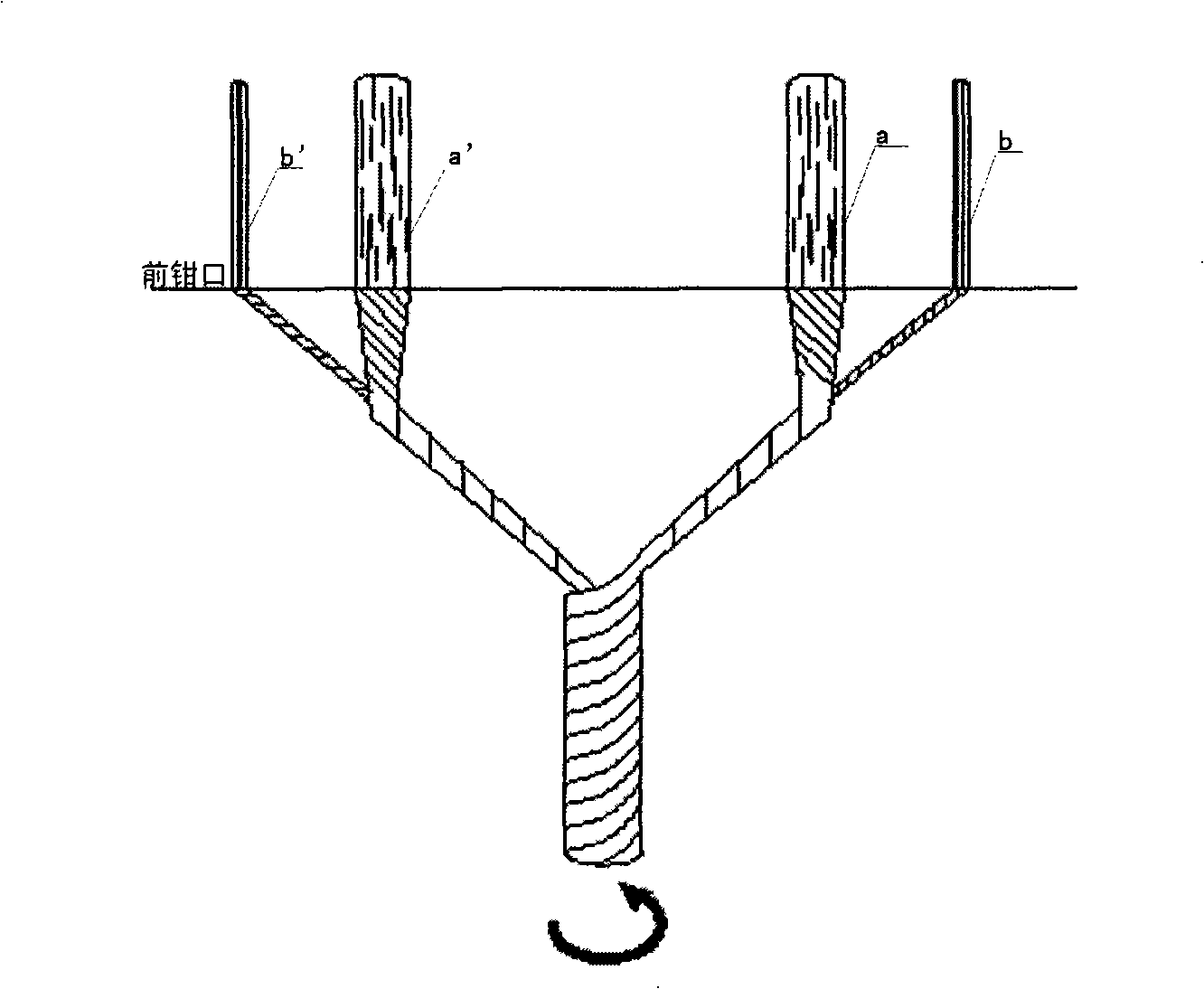

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

Cigarette and wrapping materials therefor

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

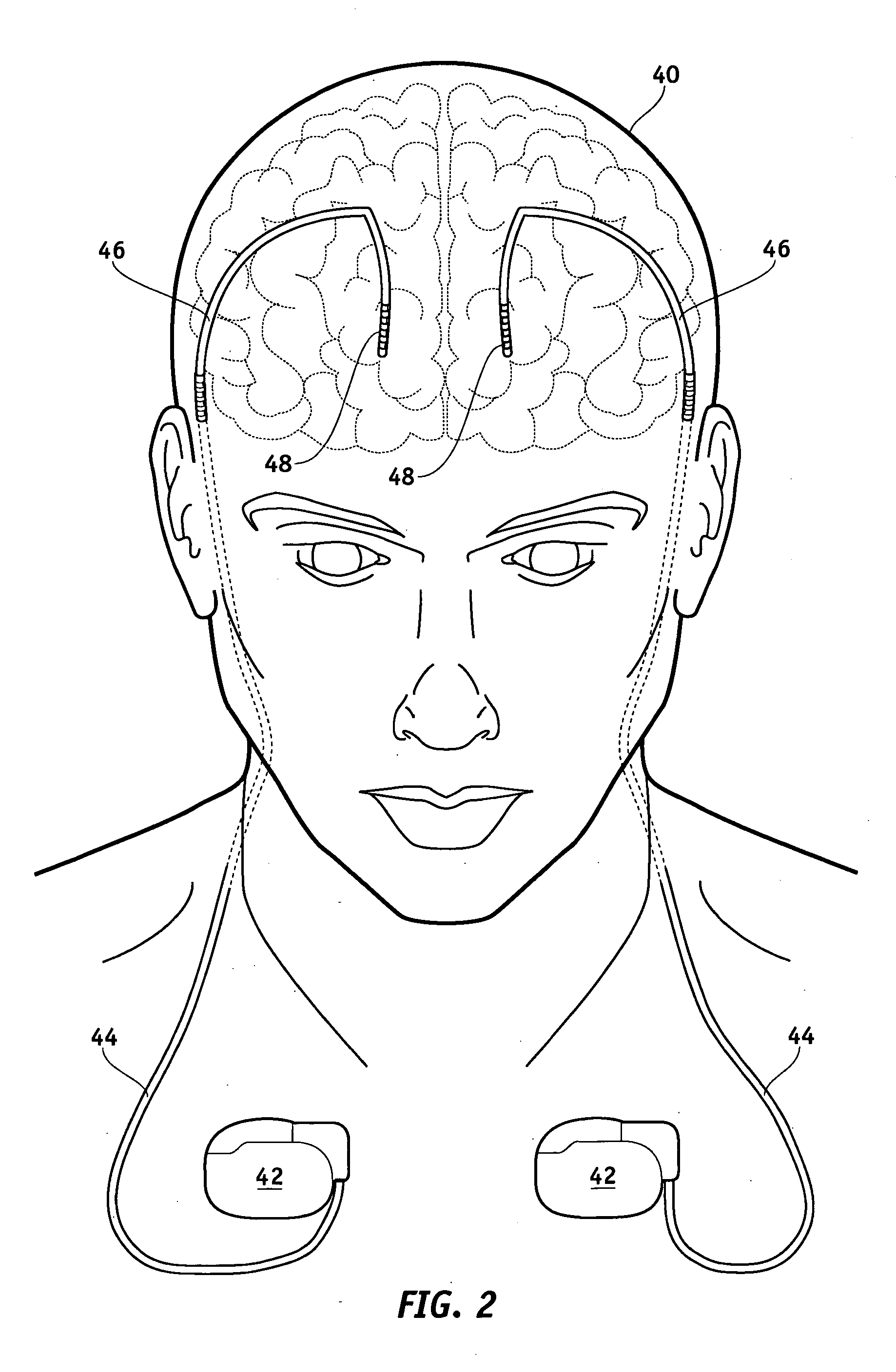

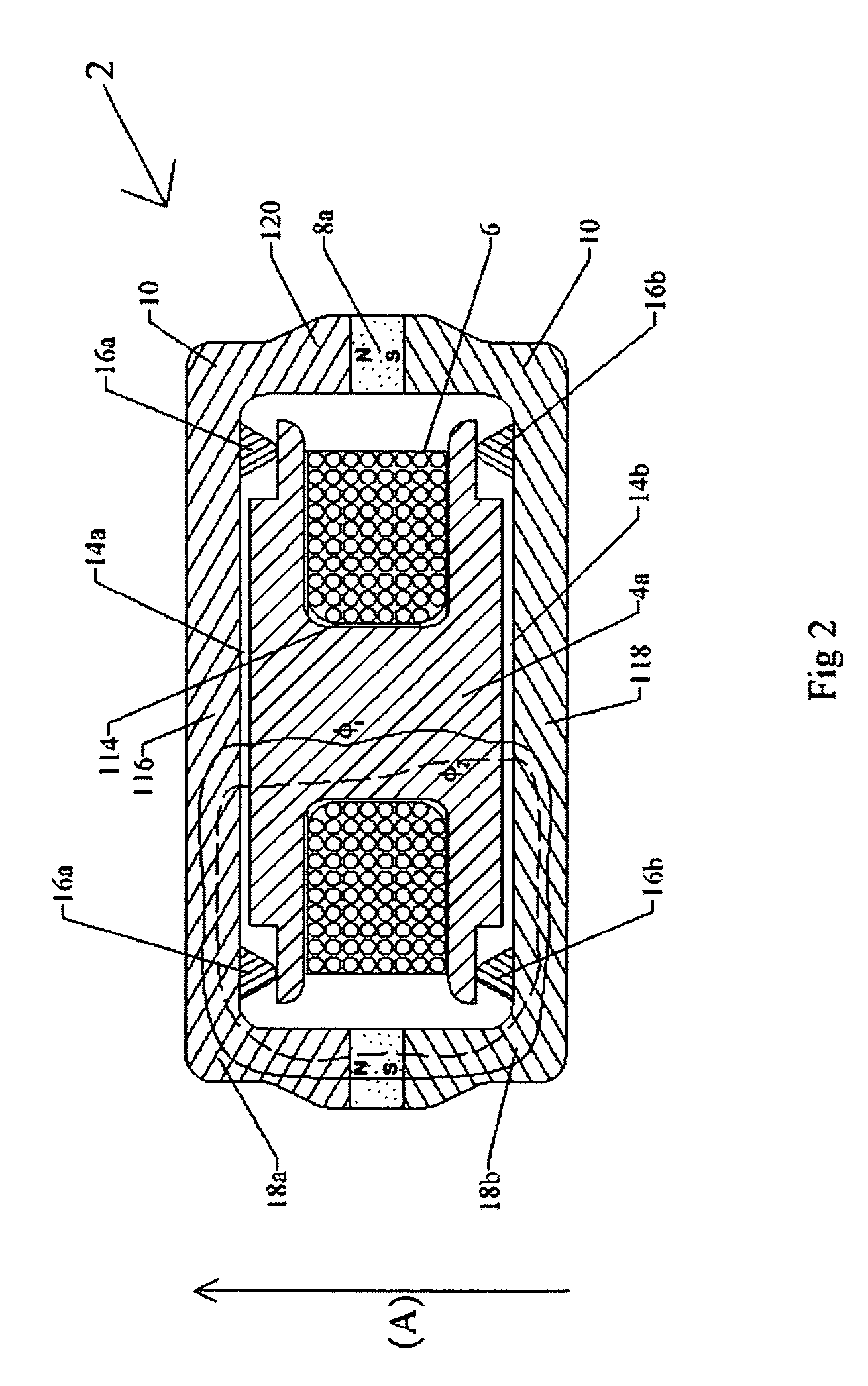

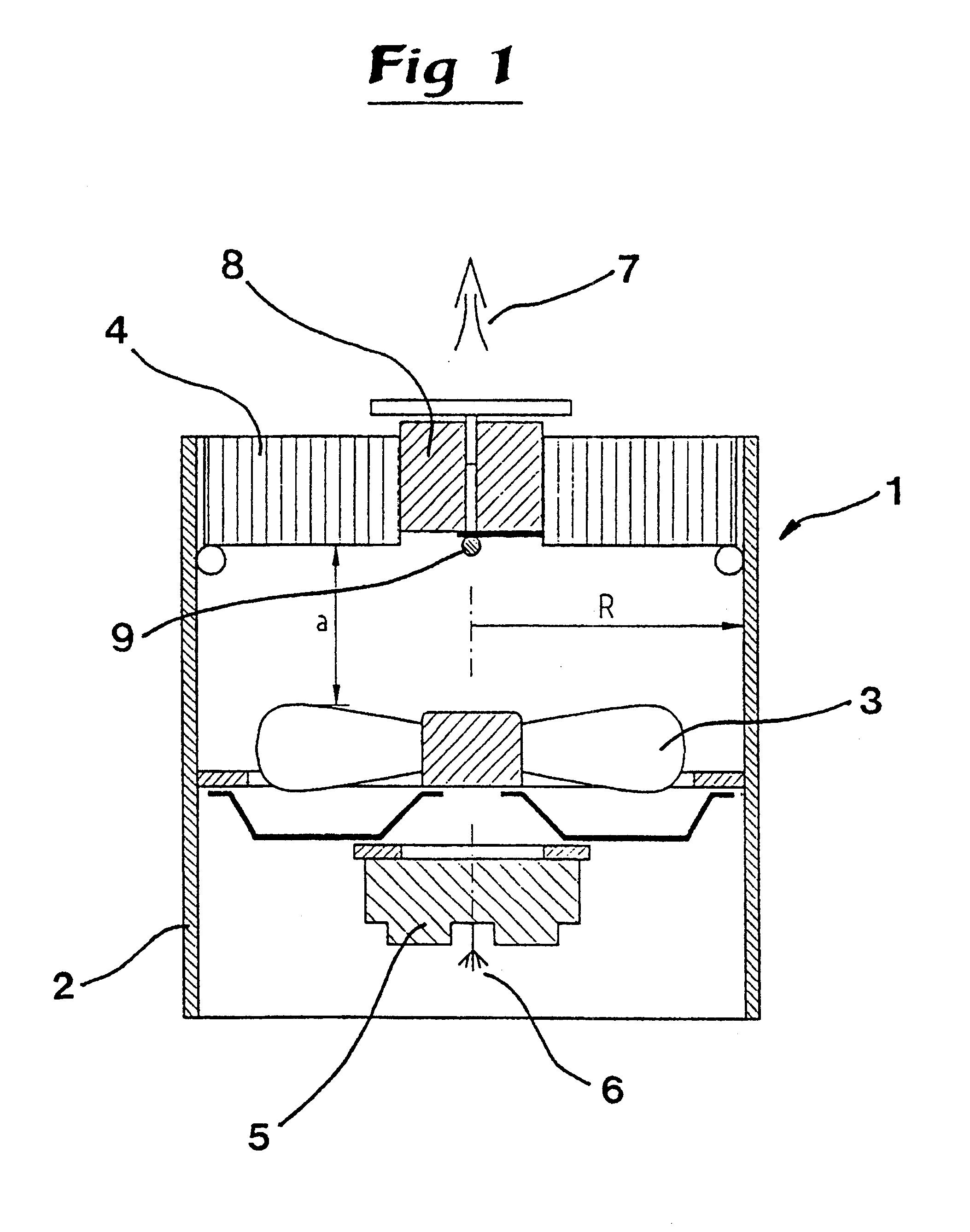

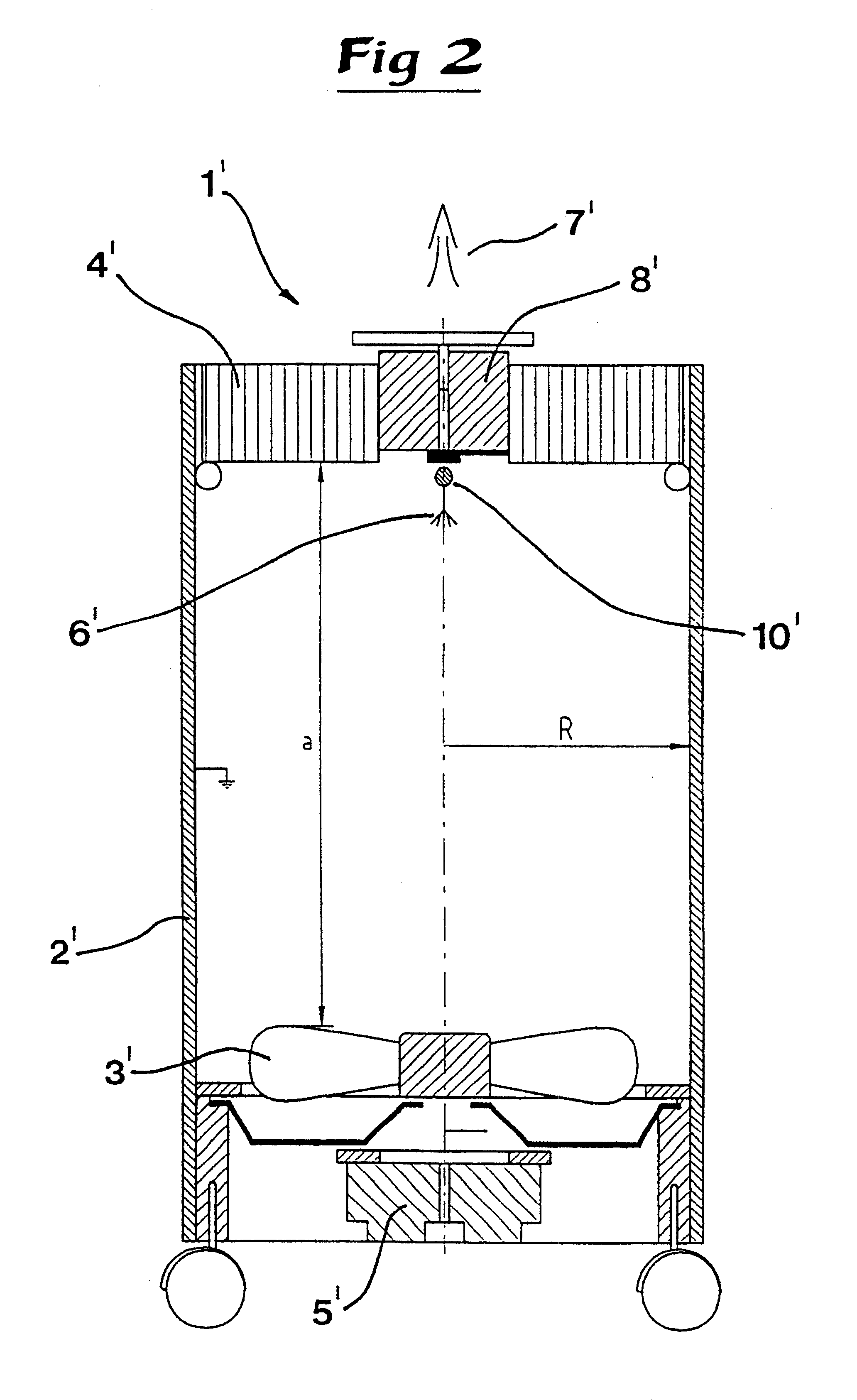

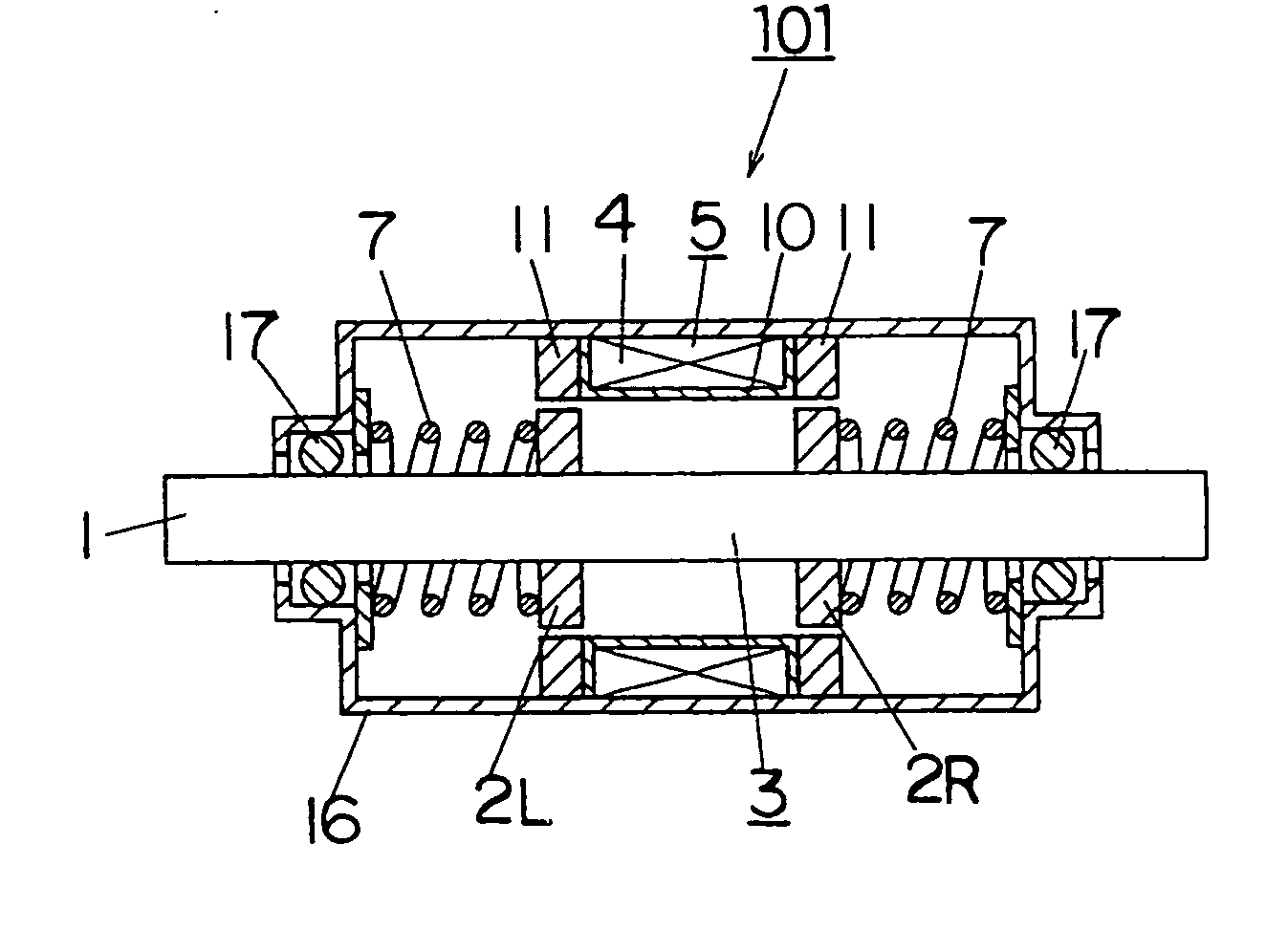

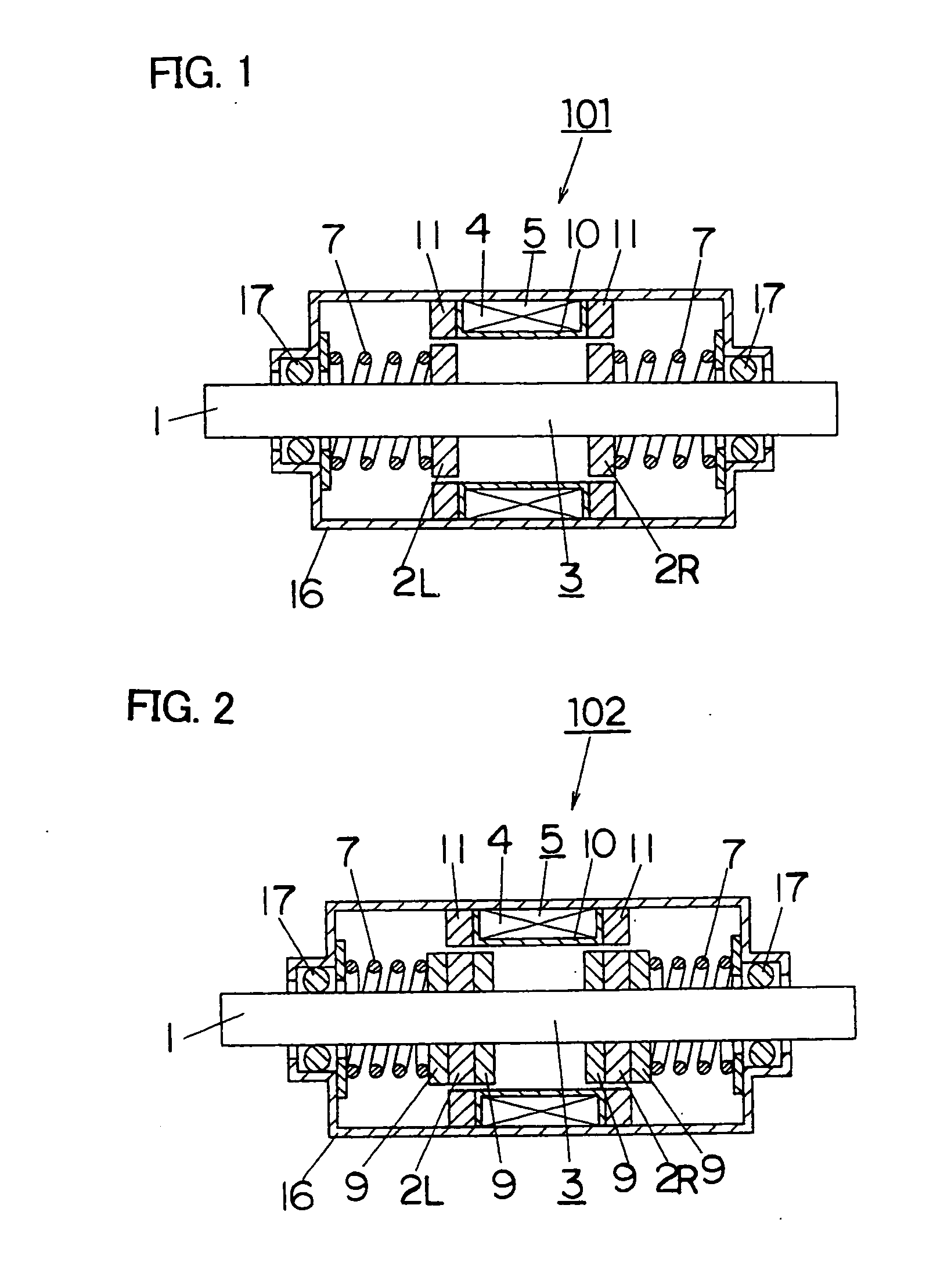

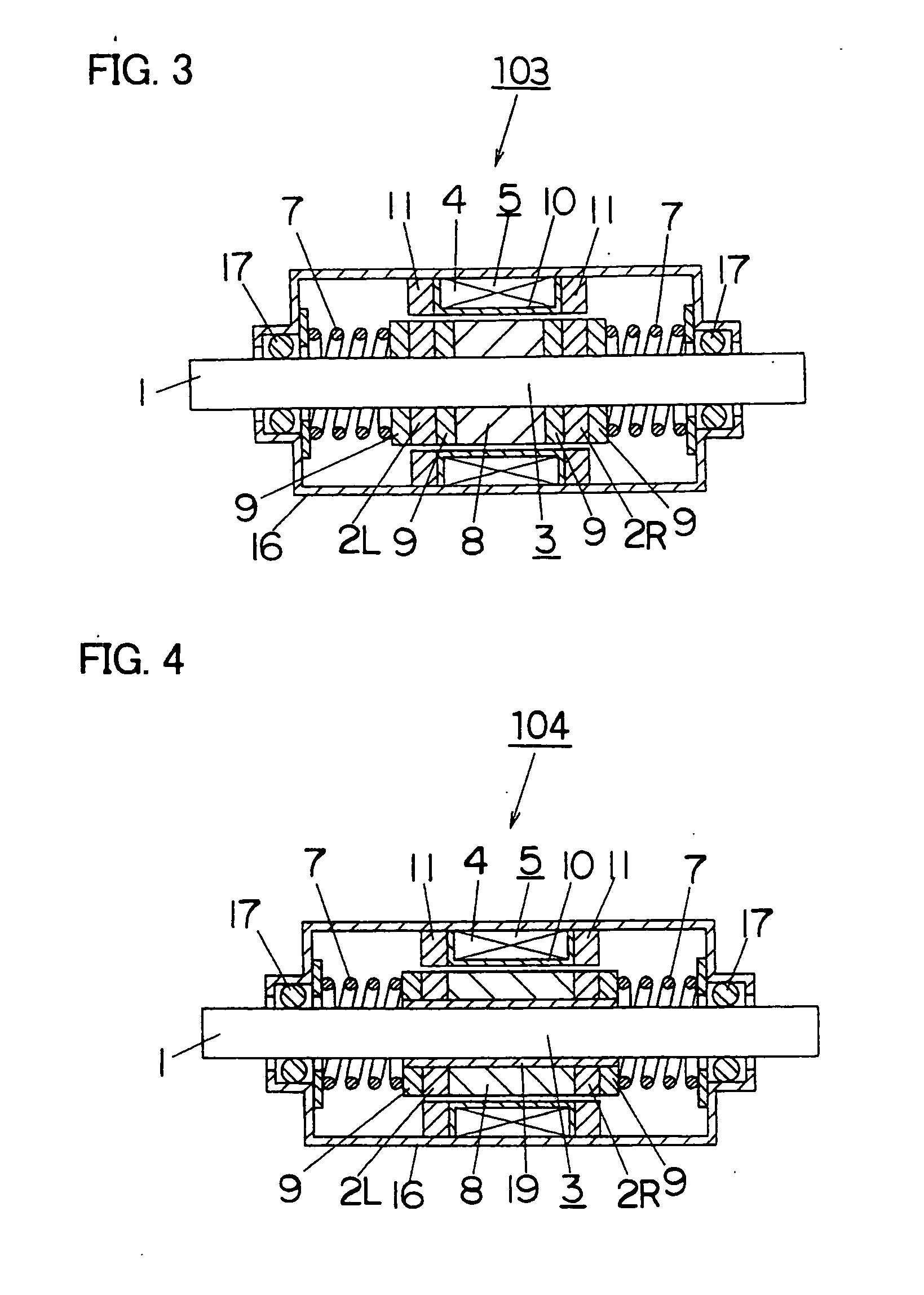

Vibrator for bone-conduction hearing

ActiveUS20060045298A1Lower resonance frequencyIncreased durabilityBone conduction transducer hearing devicesMechanical energy handlingBobbinEngineering

The vibrator system is for generating bone conduction vibrations. A magnet (8a) provides a static magnetic flux (φ1) that follows a first path. A bobbin (4a) is disposed at a center a vibrator (2). A housing (10) encloses the bobbin and has a coil surrounding a center of the bobbin. The coil is powered by an alternating current for providing an alternating dynamic magnetic flux (φ2) following the first path through a magnetic circuit. The housing has an upper end (116). The upper end and the bobbin have a first gap (14a) formed therebetween. The housing has a lower end (118) opposite the upper end. The lower end and the bobbin have a second gap (14b) formed therebetween. The magnet is positioned so that the static magnetic flux (φ1) is passing through the first and second gaps in a direction substantially parallel with an axial direction (A) of the vibrator. Suspension means (16a, 16b) are provided for suspending the bobbin in a center of the housing.

Owner:OTICON

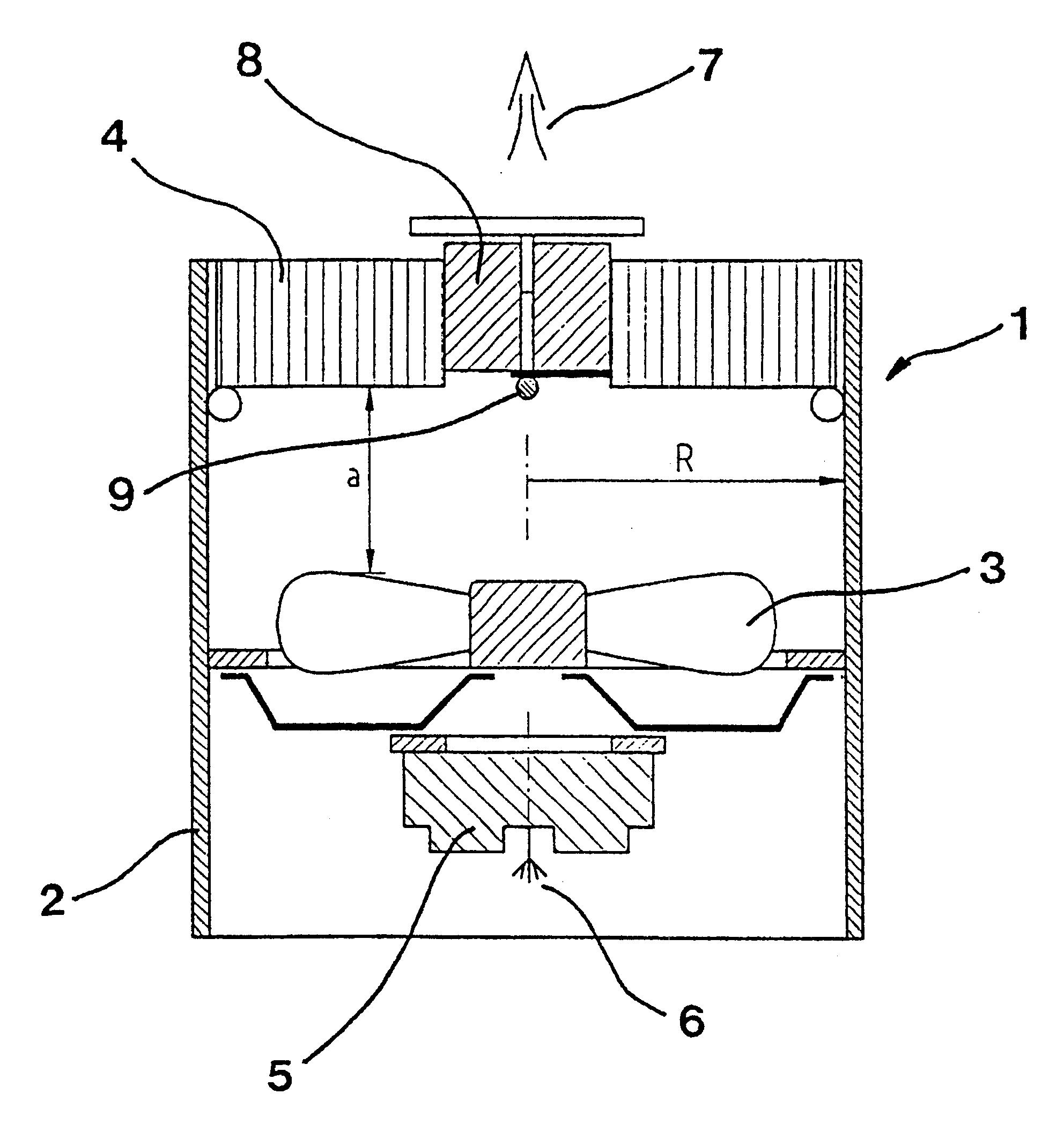

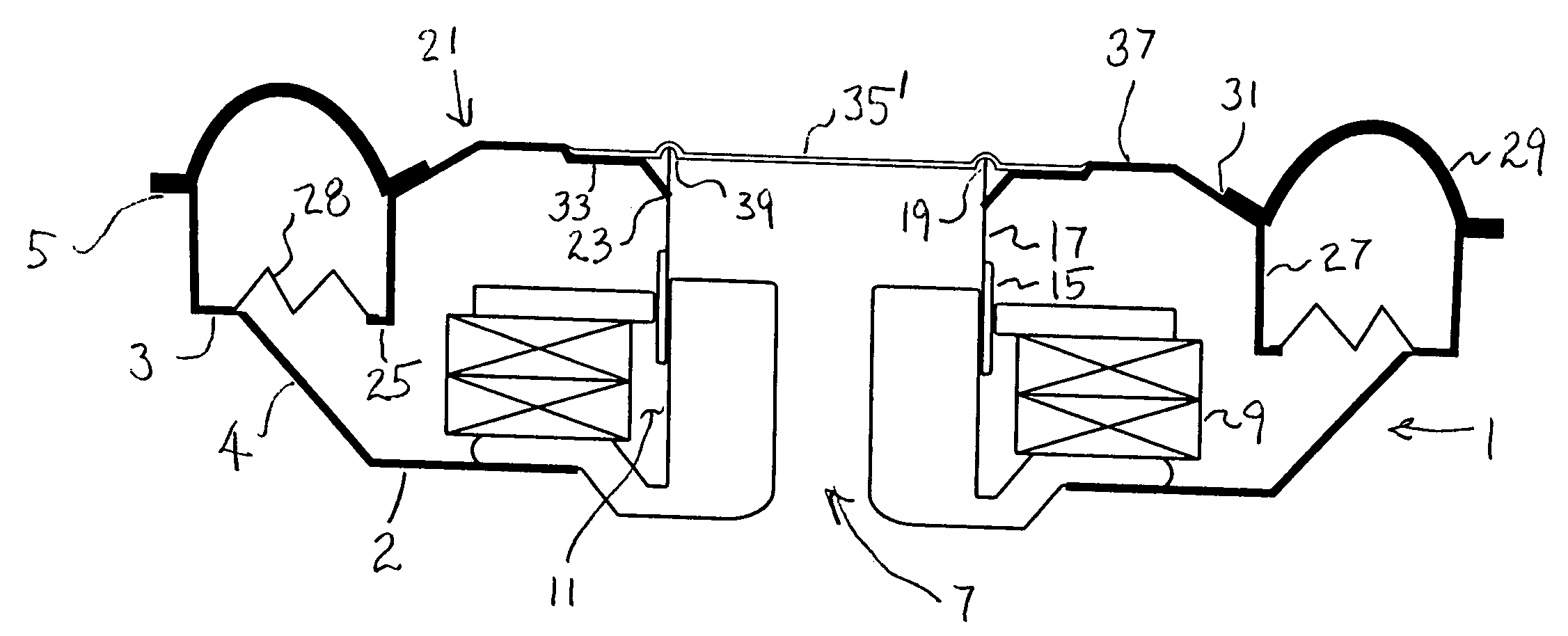

Device for air cleaning

The present invention is directed to a device (1;1';1''; 1'''; 1''''; 1''''') for air cleaning, especially from electrically charged particles, the device (1;1';1''; 1'''; 1''''; 1''''') including an air flow channel (2;2';2''; 2'''; 2''''; 2'''''), an air transporting mechanical fan (3;3';3''; 3'''; 3''''; 3'''''), a precipitator (4;4';4''; 4'''; 4''''; 4'''''), a high voltage source (5;5';5''; 5'''; 5''''; 5'''''), the precipitator (4;4';4''; 4'''; 4''''; 4''''') including two band-like electrode elements that are wound several times around an axis or bobbin body (7;7';7''; 7'''; 7''''; 7'''''), a gap distance being present between adjacent electrode elements, respective electrode elements being electrically connected with each terminal of the high voltage source (5;5';5''; 5'''; 5''''; 5'''''), characterized in that the precipitator (4;4';4''; 4'''; 4''''; 4''''') is arranged downstream of the fan (3;3';3''; 3'''; 3''''; 3''''').

Owner:EURUS AIRTECH

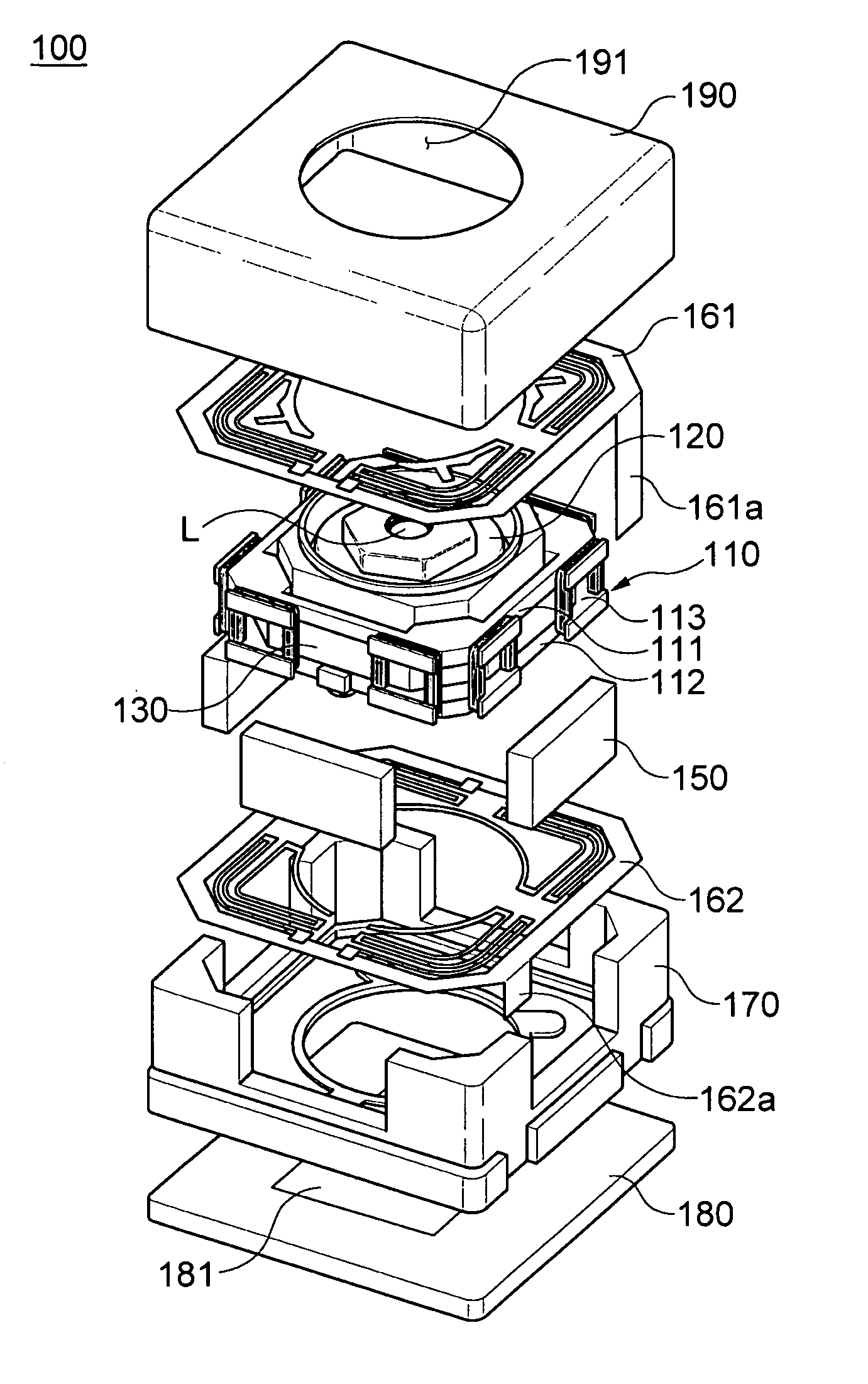

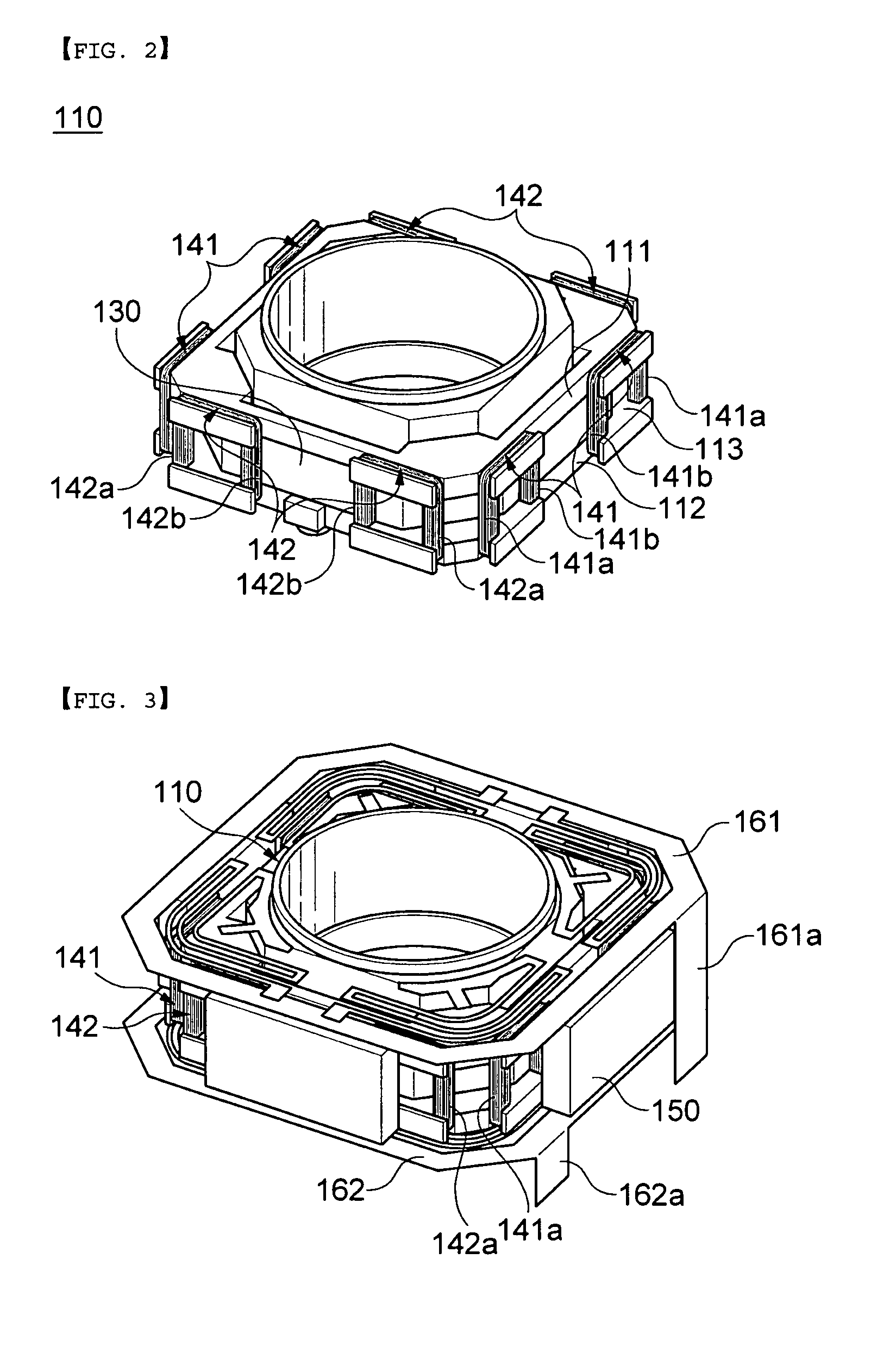

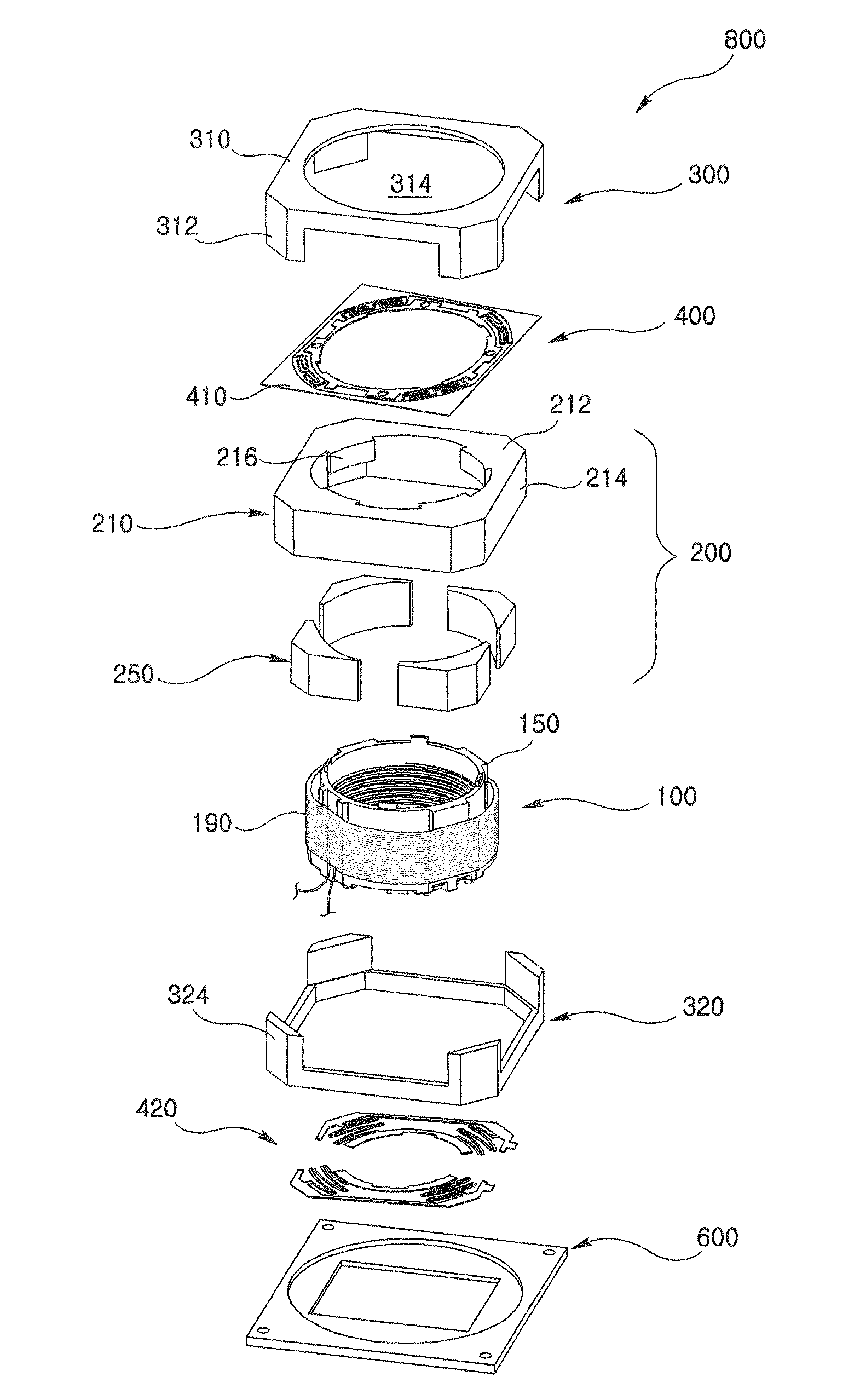

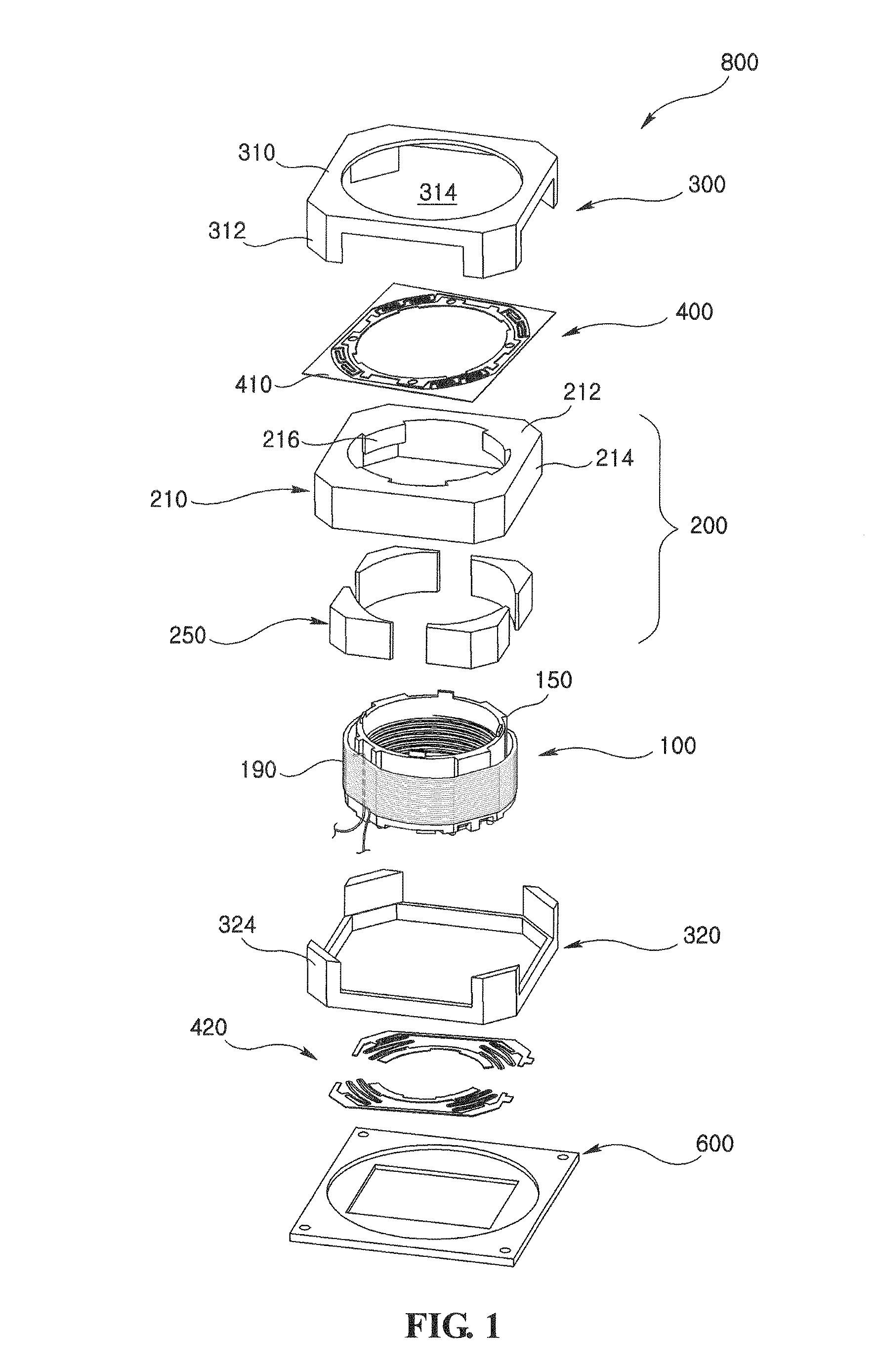

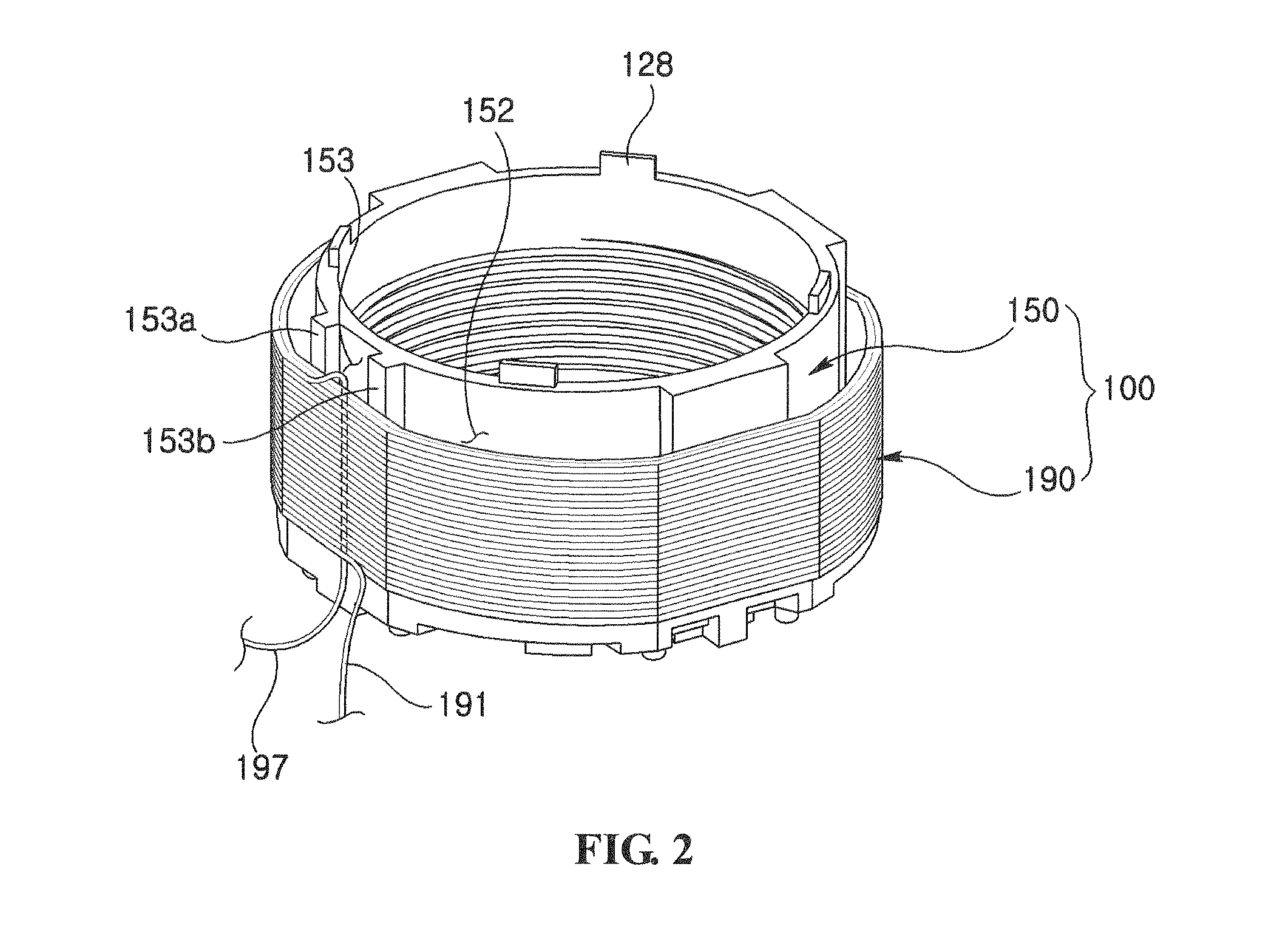

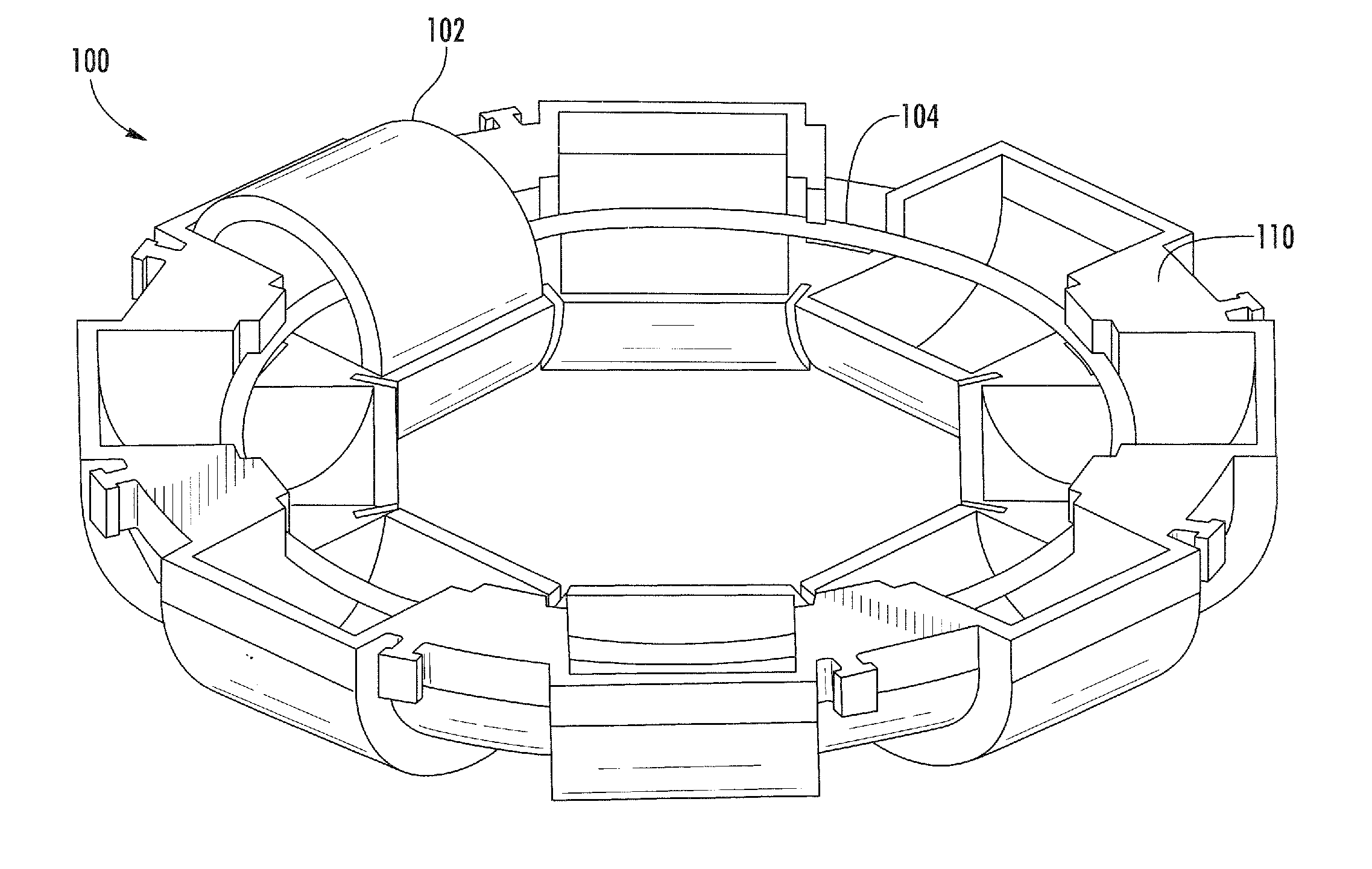

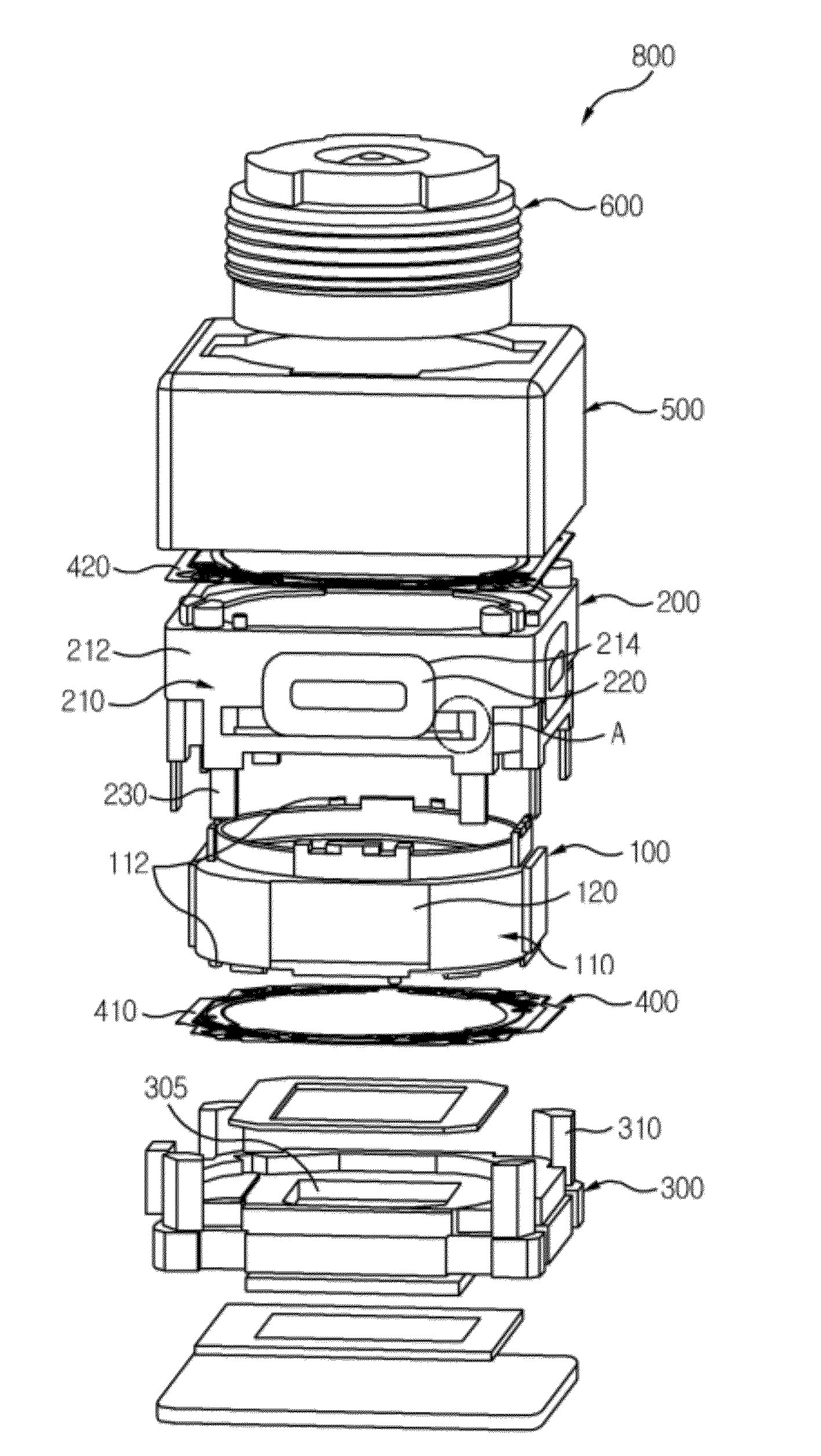

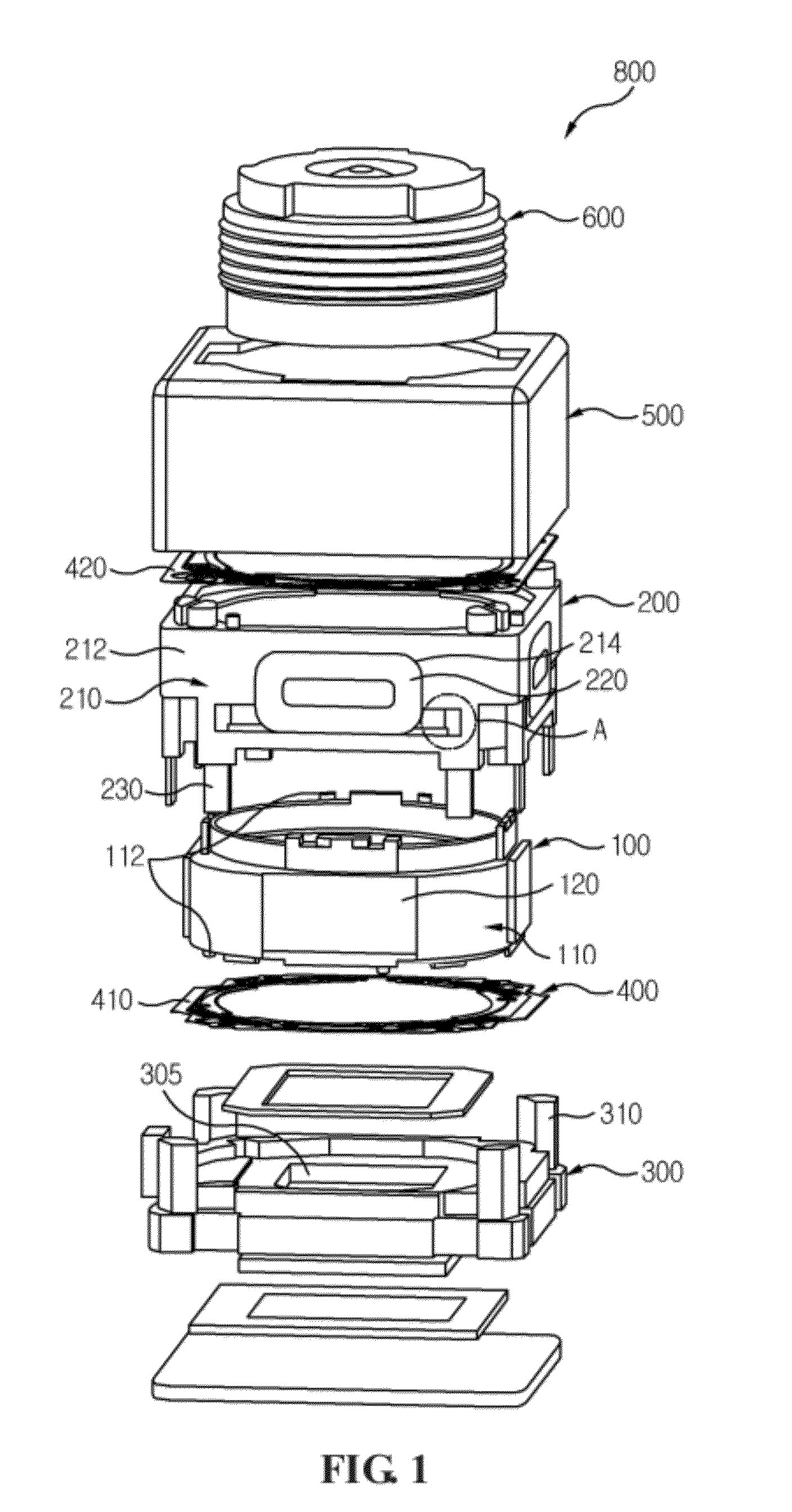

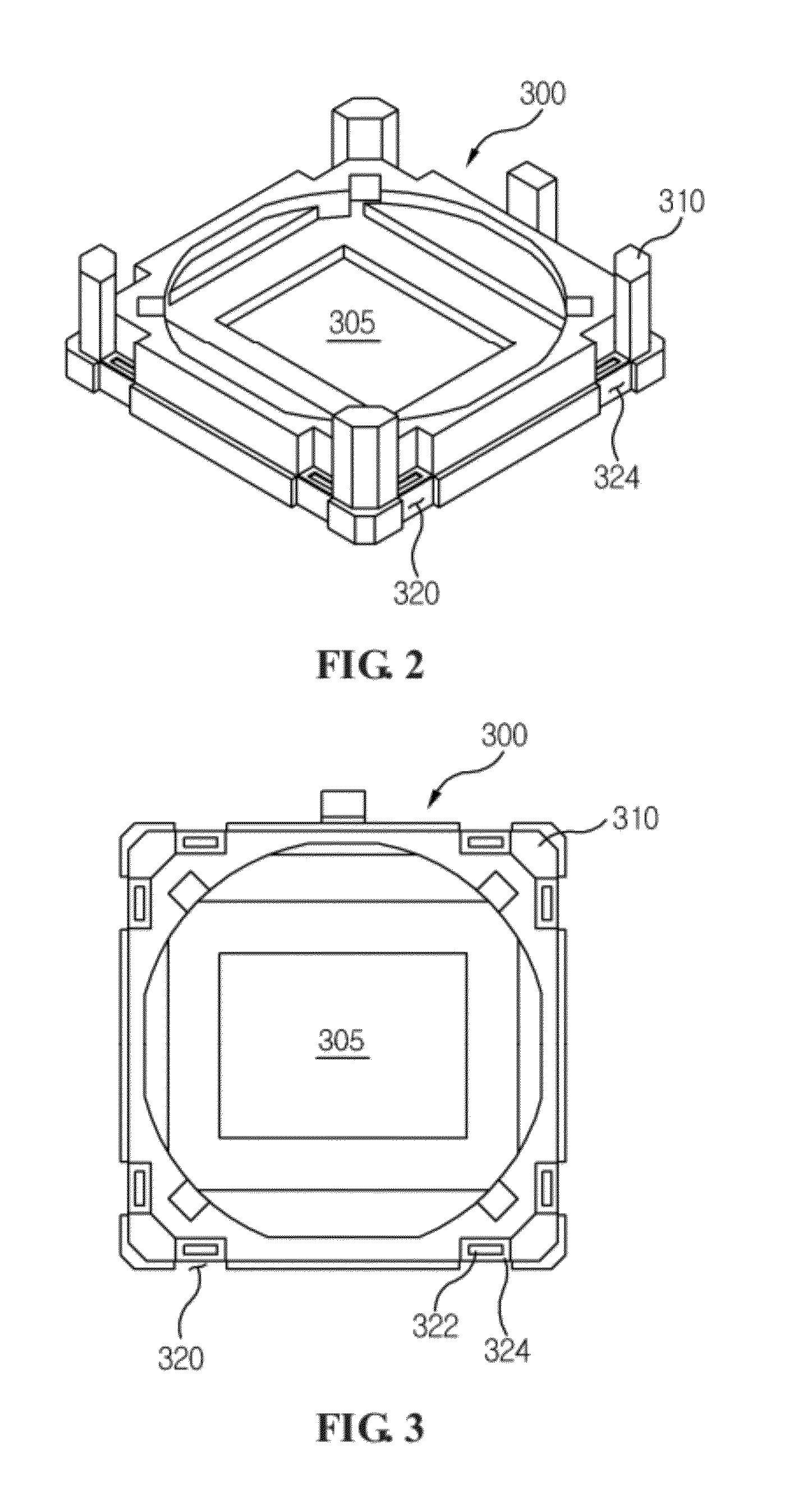

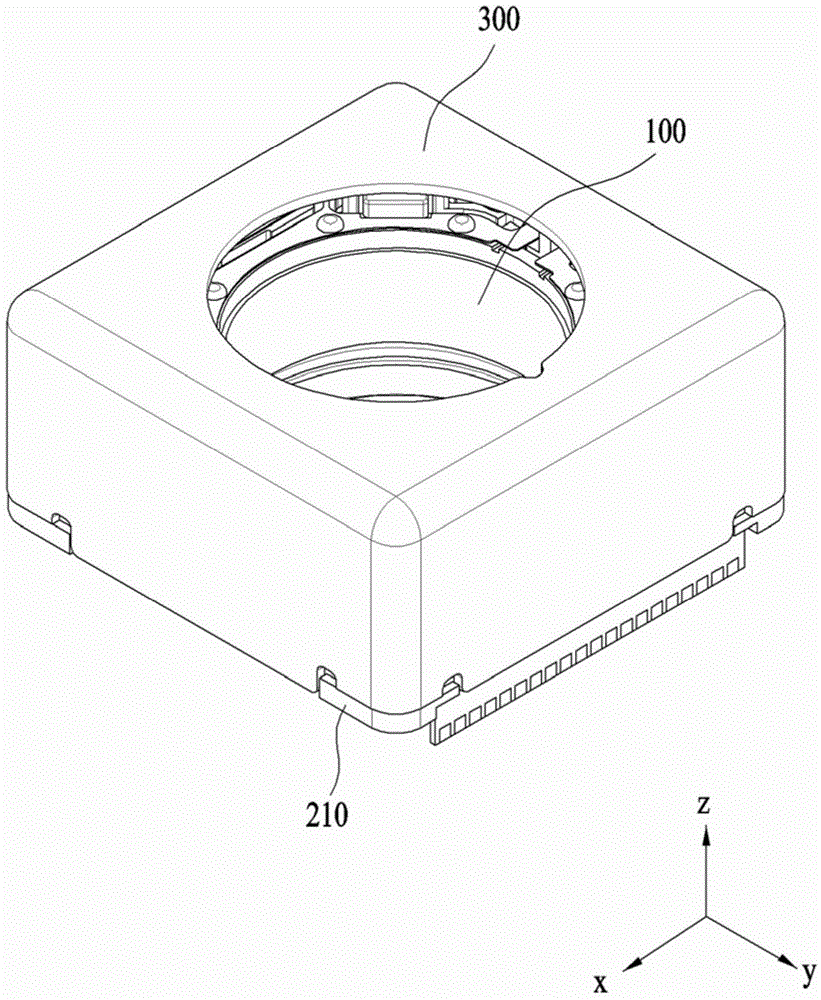

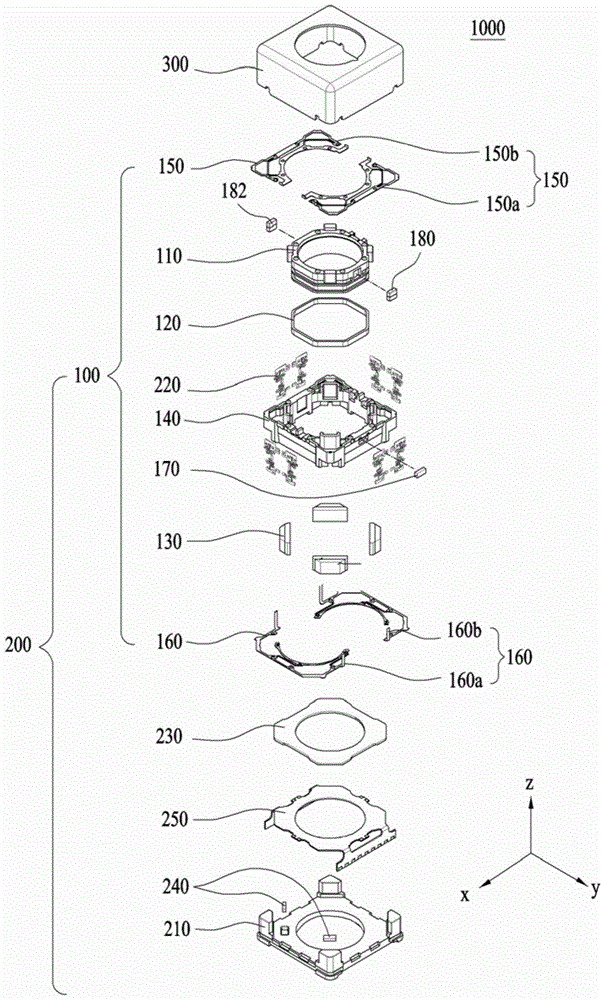

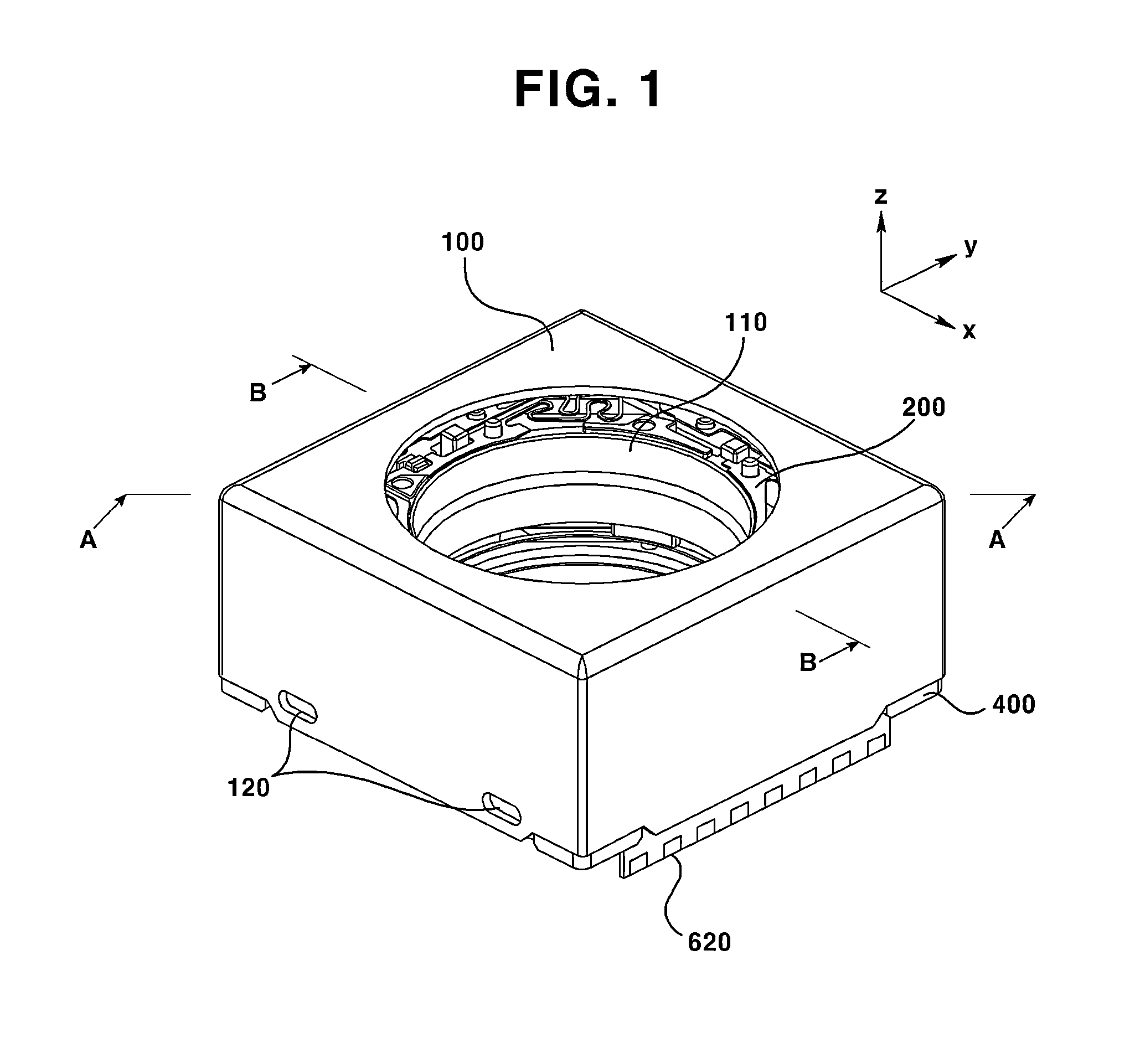

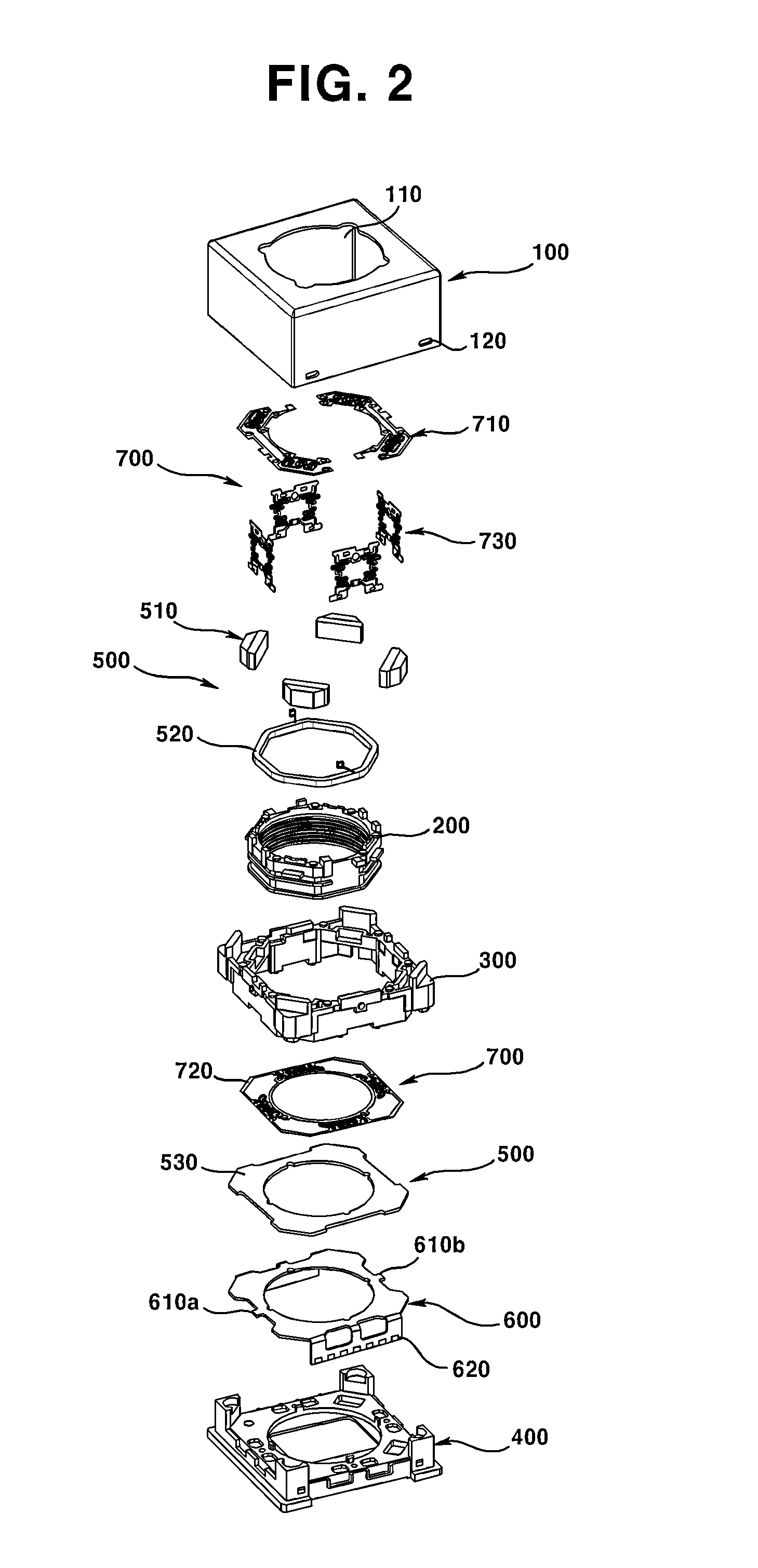

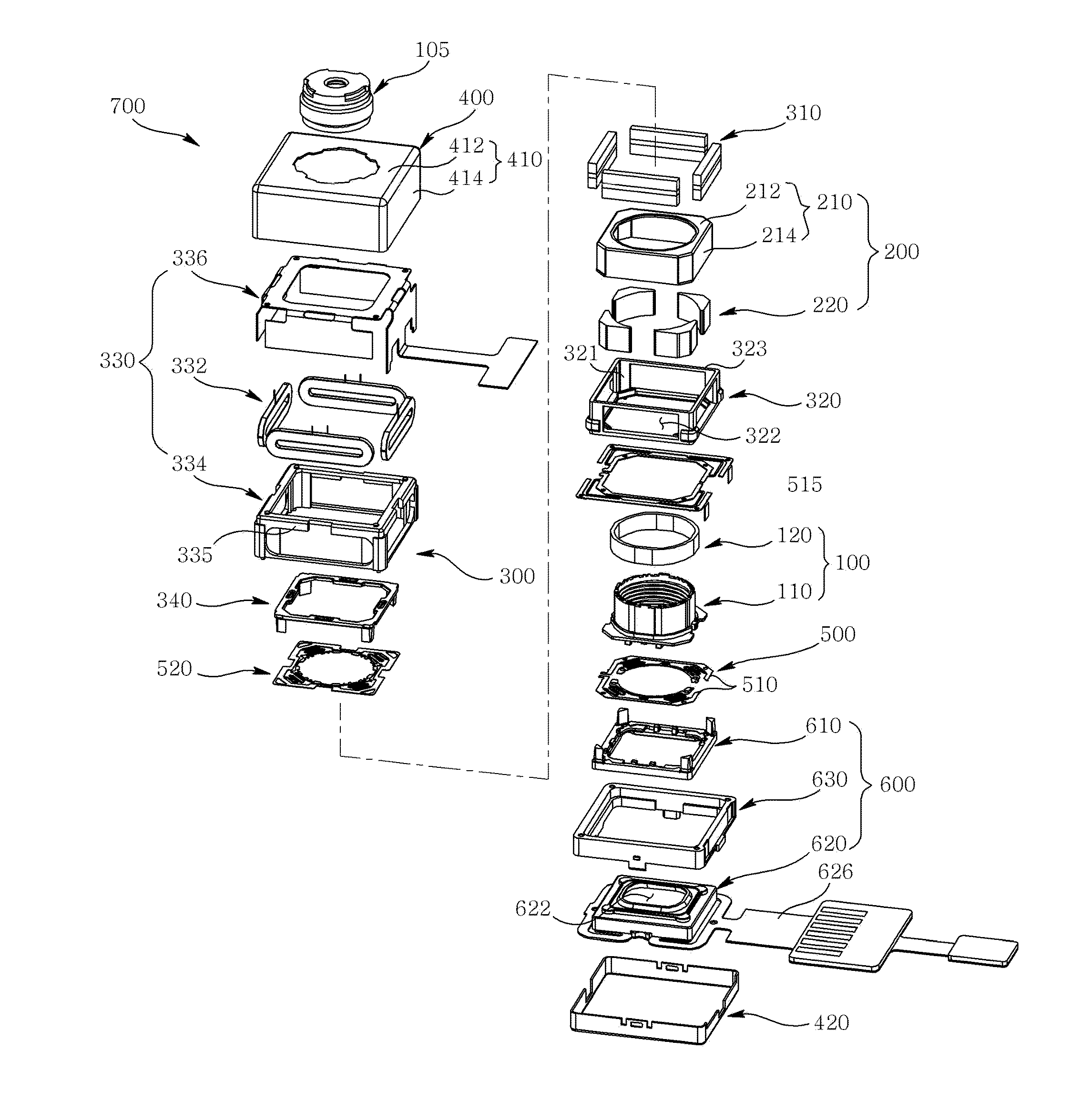

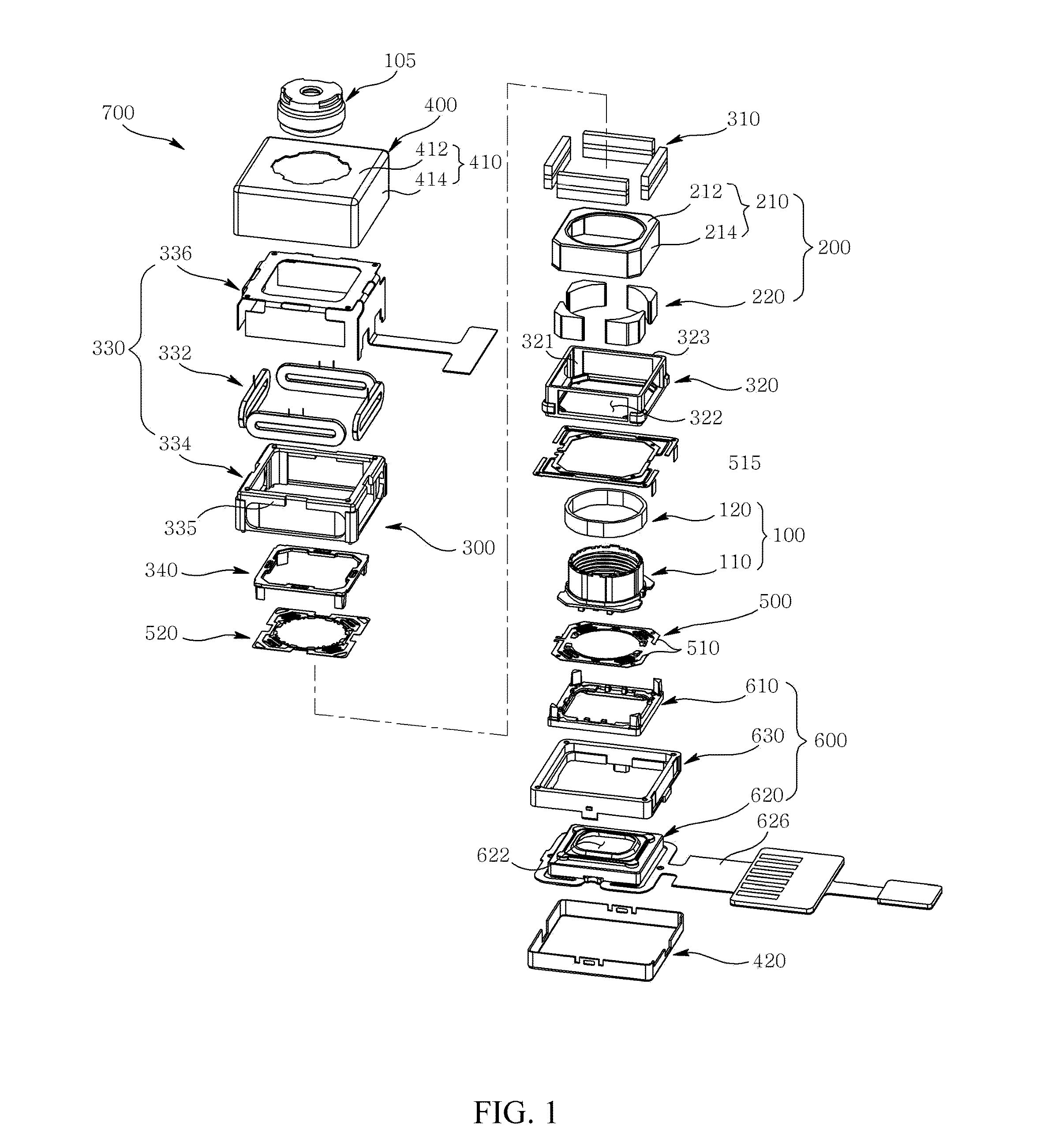

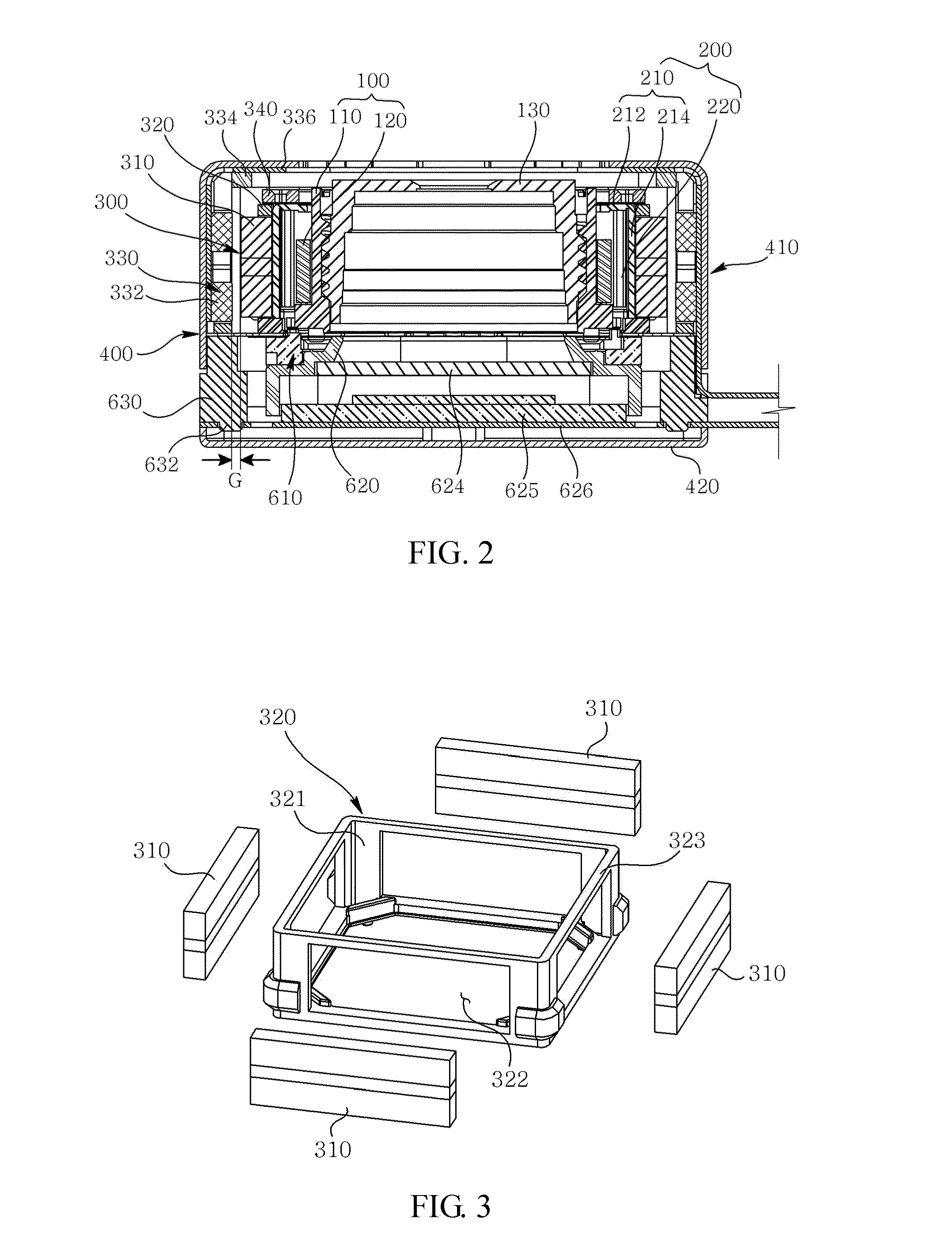

Image photographing device having function for compensating for hand vibration

Disclosed herein is an image photographing device having a function for compensating hand vibration to simultaneously perform auto focusing and hand vibration compensation. The image photographing device having a function for compensating hand vibration includes: a bobbin having a lens unit mounted therein, a driving coil in a Z axis direction wound on an outer peripheral surface thereof, and a driving coil in an X axis direction and a driving coil in a Y axis direction mounted outside the driving coil in a Z direction; a plurality of magnets mounted outside the driving coil in an X axis direction and the driving coil in a Y axis direction; an elastic member elastically combined with an upper portion and a lower portion of the bobbin; a housing into which the bobbin combined with the magnet and the elastic member is inserted; and a shield case combined with an upper portion of the housing.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Voice coil motor

ActiveUS20120008221A1Easy to adjustImprove reliabilityProjector focusing arrangementCamera focusing arrangementBobbinCoupling

A VCM (voice coil motor) is disclosed, the VCM including: a rotor including a cylindrical bobbin for accommodating a lens and protruded at a bottom end with a boss, and a coil block arranged at a periphery of the bobbin; a stator including a magnet facing the coil block and a yoke fixing the magnet; and an elastic member including a first elastic member formed with a through hole coupled to the boss of the bobbin and a second elastic member coupled to an upper end facing the bottom end of the bobbin; wherein the boss is formed with a disengagement prevention unit preventing the first elastic member from being disengaged from the boss, and the first elastic member is formed with a coupling unit contacting a joint where the disengagement prevention unit and the coupling unit meet.

Owner:LG INNOTEK CO LTD

Voice coil motor, coil block for voice coil motor, method of manufacturing the coil block, and voice coil motor having the coil block

ActiveUS20120008220A1Easily identifiableSimple structureProjector focusing arrangementFilament handlingBobbinEngineering

A VCM (voice coil motor) is disclosed, the VCM including: a rotor including a lens-fixing hollow holed bobbin including a coil discharge unit formed from a peripheral upper end to a peripheral bottom end facing the peripheral upper end, and a coil block arranged at a periphery of the bobbin and including a cylindrically wound coil; a stator including a magnet facing the coil block and a yoke fixing the magnet; a case including a bottom case arrange with the bobbin and an upper case coupled to the bottom case and having an opening at a portion corresponding the bobbin; and an elastic member elastically supporting an upper end of the bobbin and a bottom end facing the upper end of the bobbin, wherein a distal end of the coil arranged at an upper end of the coil block employs the coil discharge unit to be discharged to a bottom end of the bobbin.

Owner:LG INNOTEK CO LTD

Current sensing devices and methods

ActiveUS20110148561A1Improve performanceIncrease manufacturing costTransformers/inductances coils/windings/connectionsCurrent measurements onlyBobbinEngineering

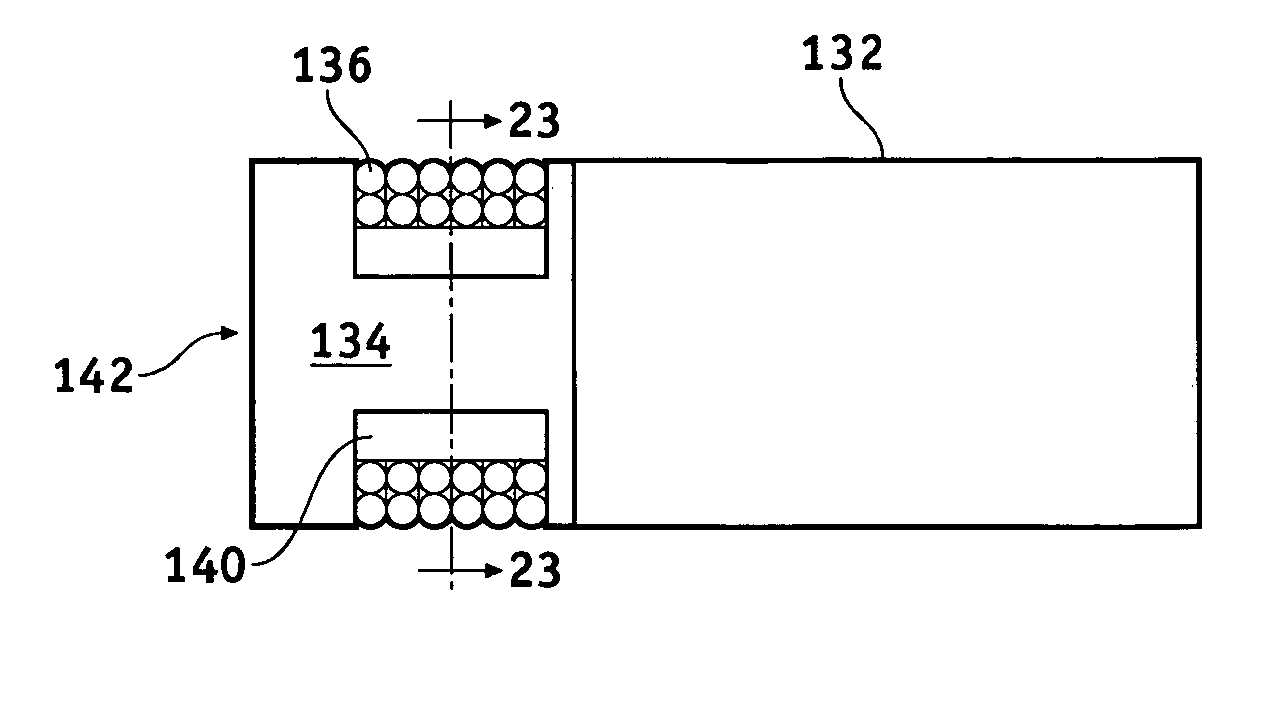

A low-cost and high-precision current sensing device and methods for use and manufacturing. In one embodiment, the current sensing apparatus comprises a Rogowski-type coil which is manufactured in segments so as to facilitate the manufacturing process. In an exemplary embodiment, the current sensing apparatus segments comprise a number of bobbin elements that are wound and subsequently formed into complex geometric shapes such as torus-like shapes. In an alternative embodiment, bonded windings are utilized which allow the segments to be formed without a bobbin or former. In yet another alternative embodiment, the aforementioned current sensing devices are stacked in groups of two or more. Methods of manufacturing and using the aforementioned current sensing apparatus are also disclosed.

Owner:PULSE ELECTRONICS

Multifunctional Voice Coil Motor

ActiveUS20120200176A1Prevent deviationEasy to adjustProjector focusing arrangementCamera focusing arrangementBobbinEngineering

A multifunctional voice coil motor is disclosed, the motor including a rotor including a bobbin and a plurality of magnets arranged at a periphery of the bobbin, a stator including a housing wrapping each magnet and a plurality of coil blocks each arranged at a position corresponding to that of each magnet, a base coupled to the housing, and an elastic member elastically supporting the rotor.

Owner:LG INNOTEK CO LTD

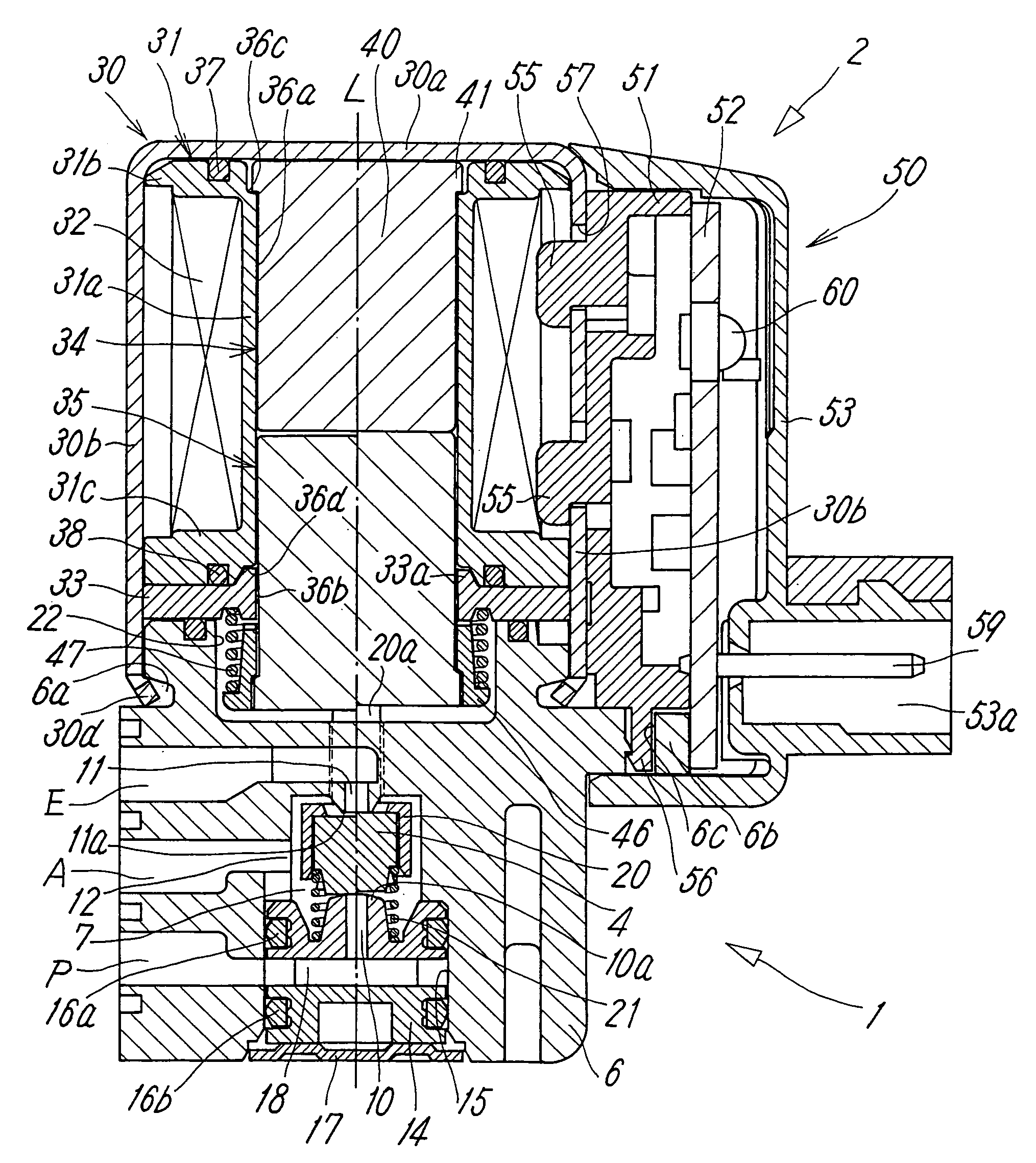

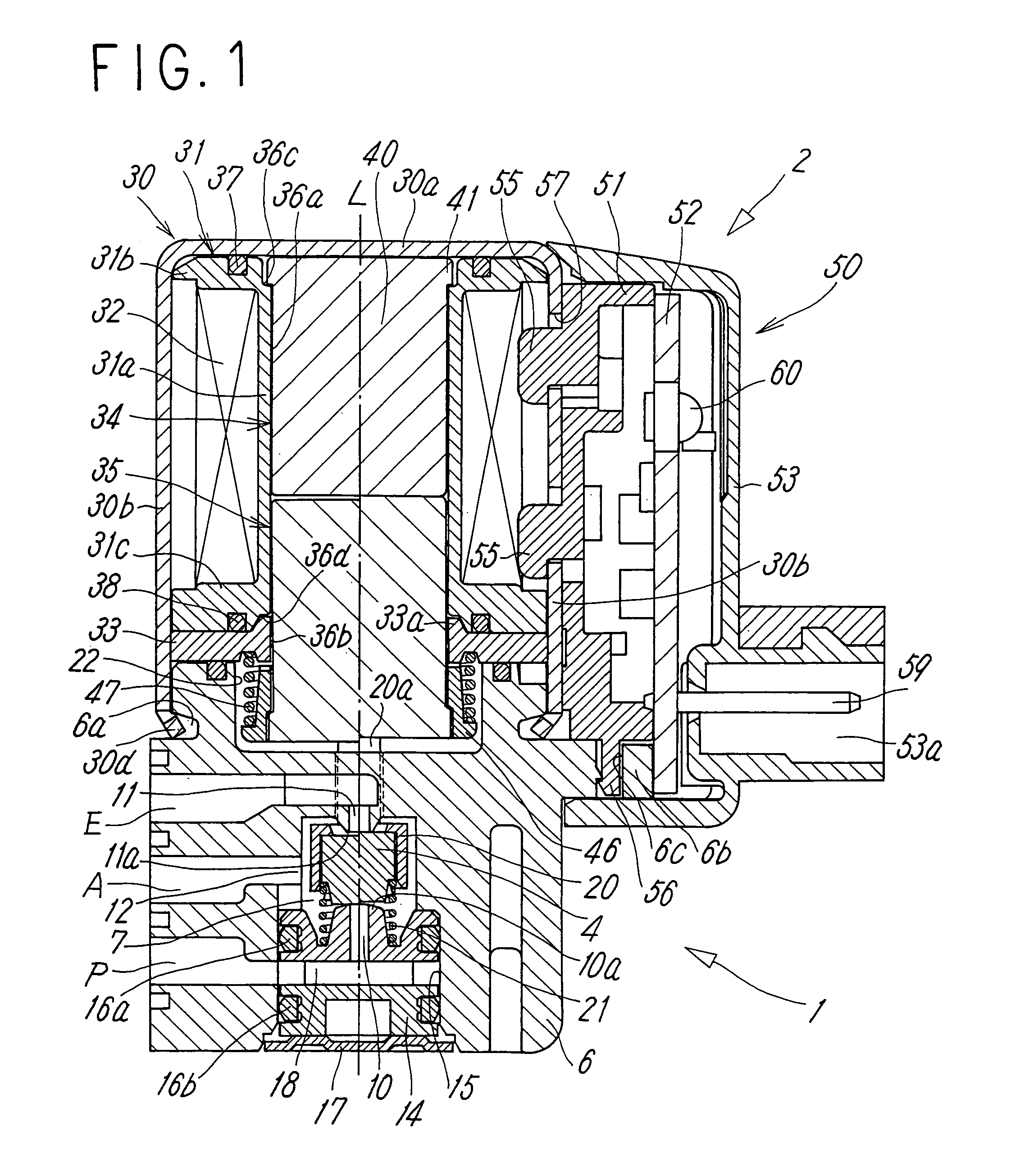

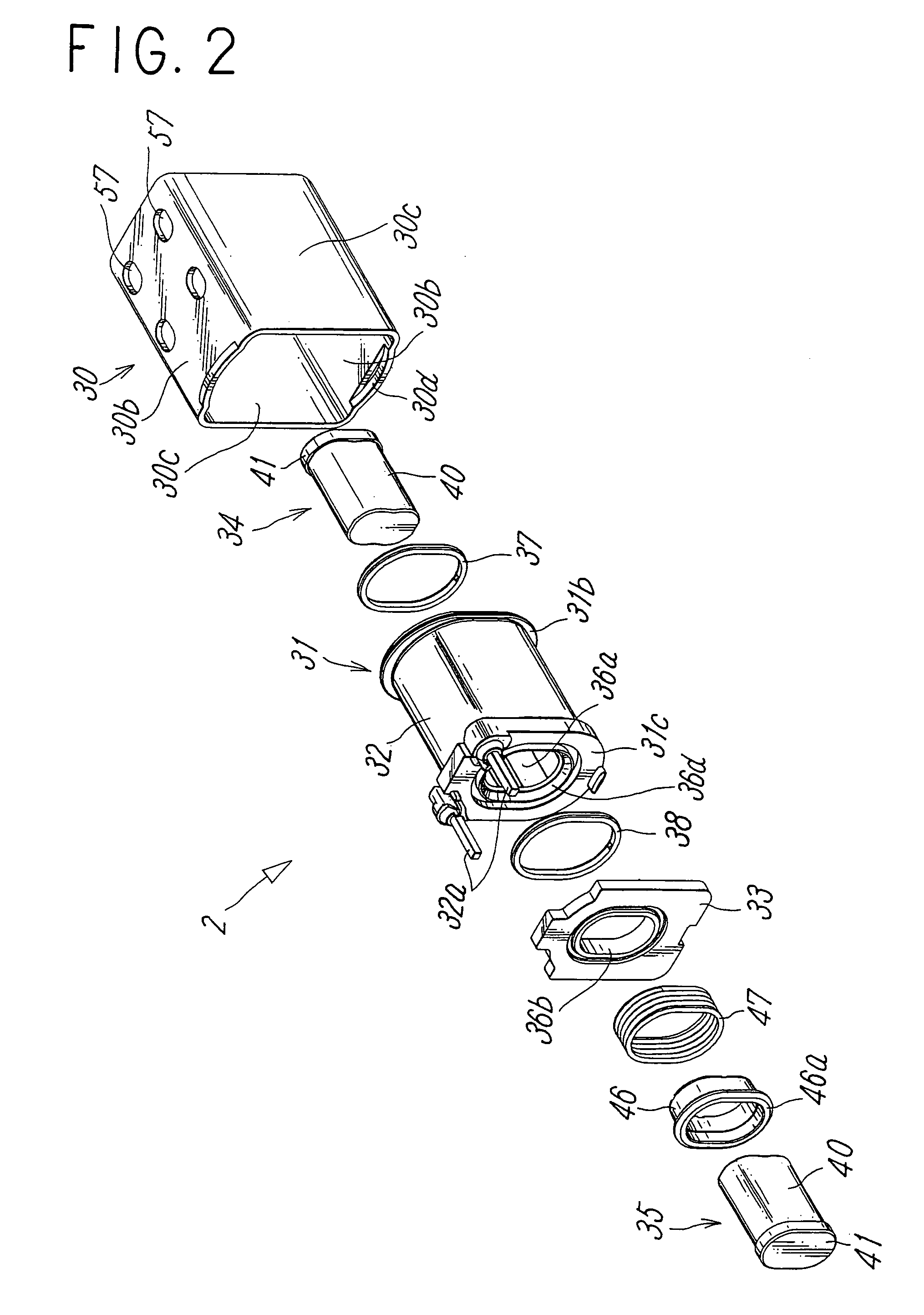

Electromagnetic valve

ActiveUS7273206B2Simple structureReduce manufacturing costOperating means/releasing devices for valvesMultiple way valvesBobbinNuclear engineering

An electromagnetic manipulating portion of an electromagnetic valve includes a fixed iron core fixedly disposed in the inside hole of a bobbin and a movable iron core movably disposed in the inside hole and attracted to the fixed iron core by a magnetic attraction force. The fixed iron core and the movable iron core are composed of the same normally magnetic material in the same shape and in the same size and have compatibility each other.

Owner:SMC CORP

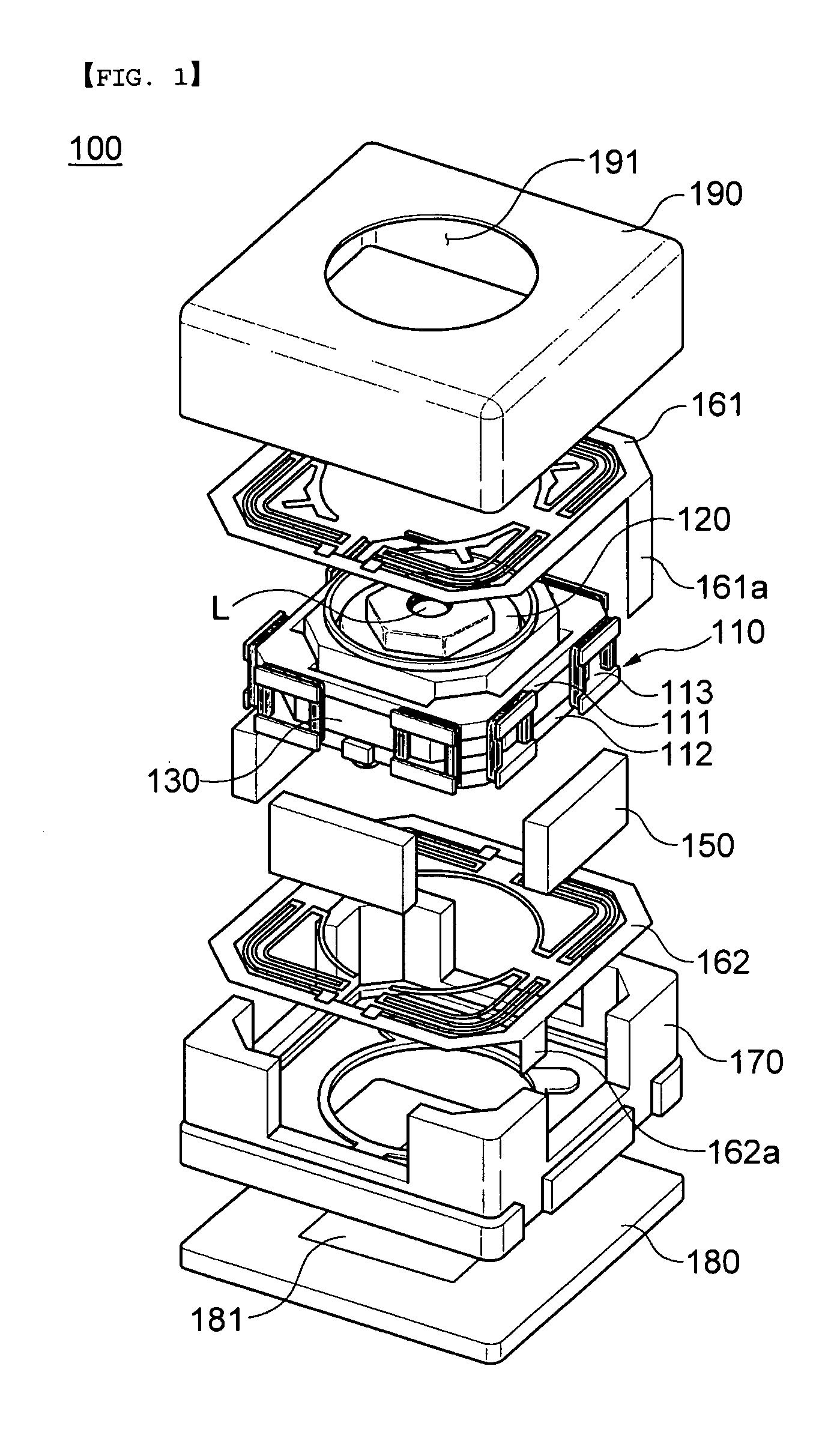

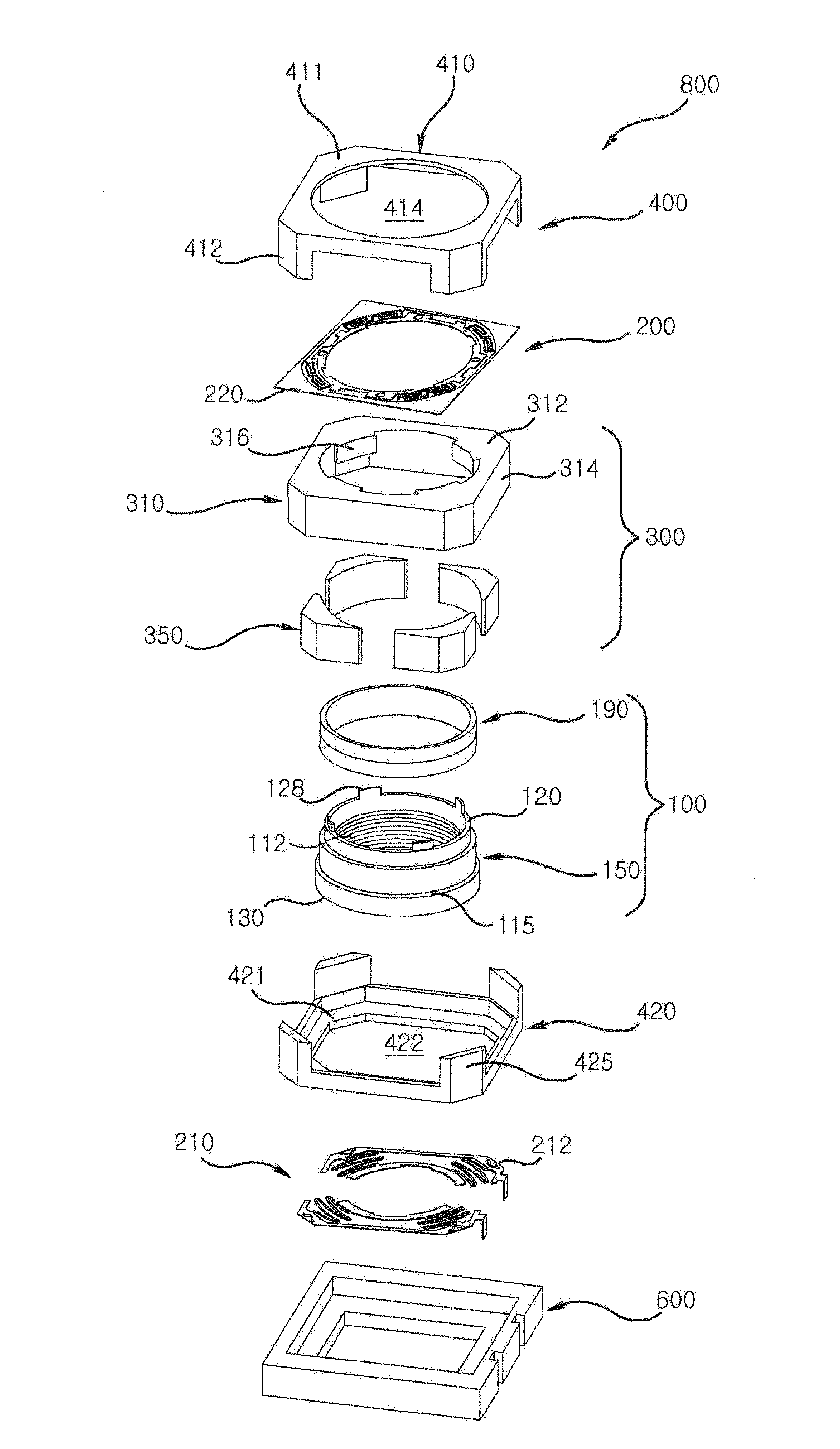

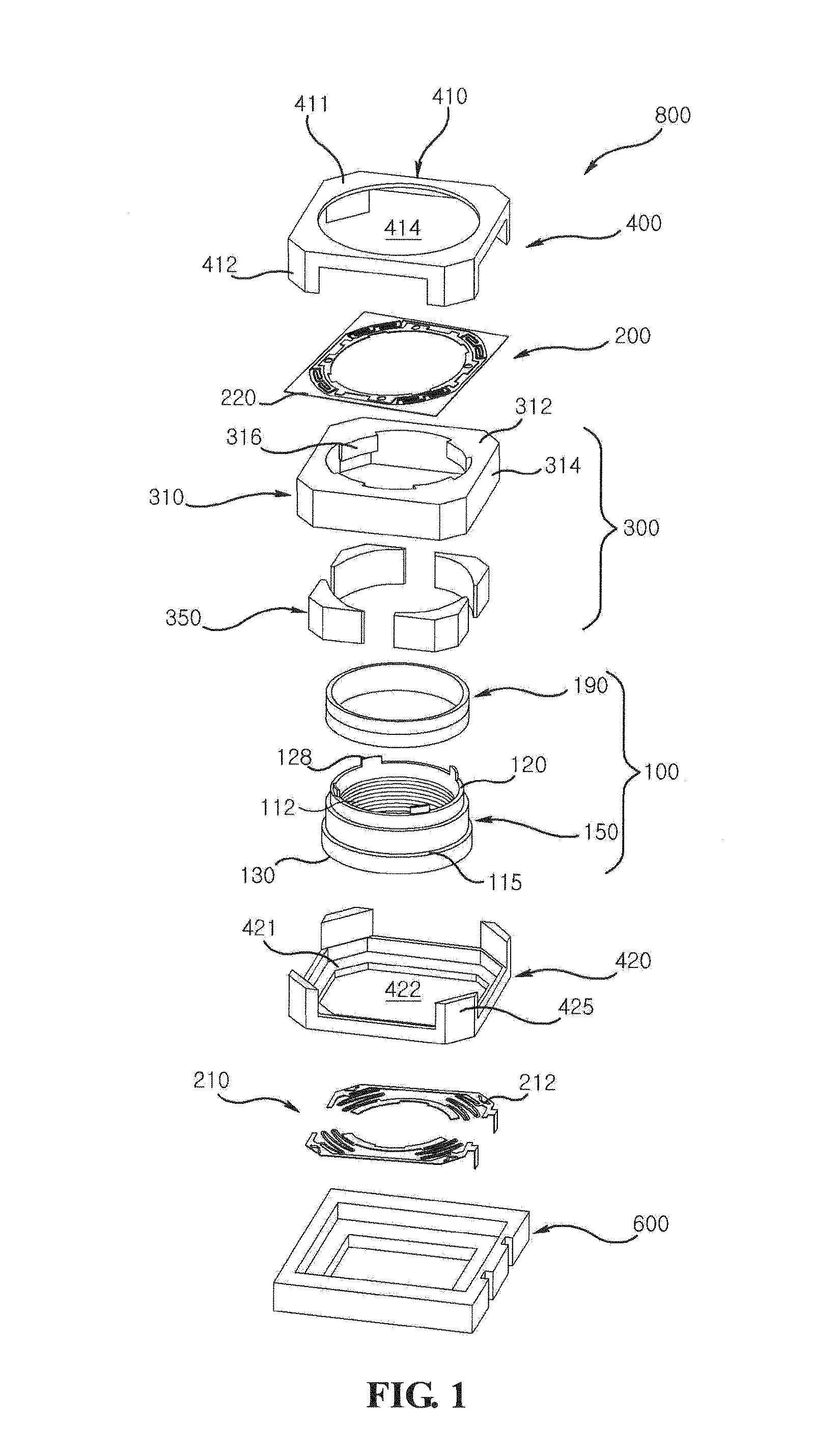

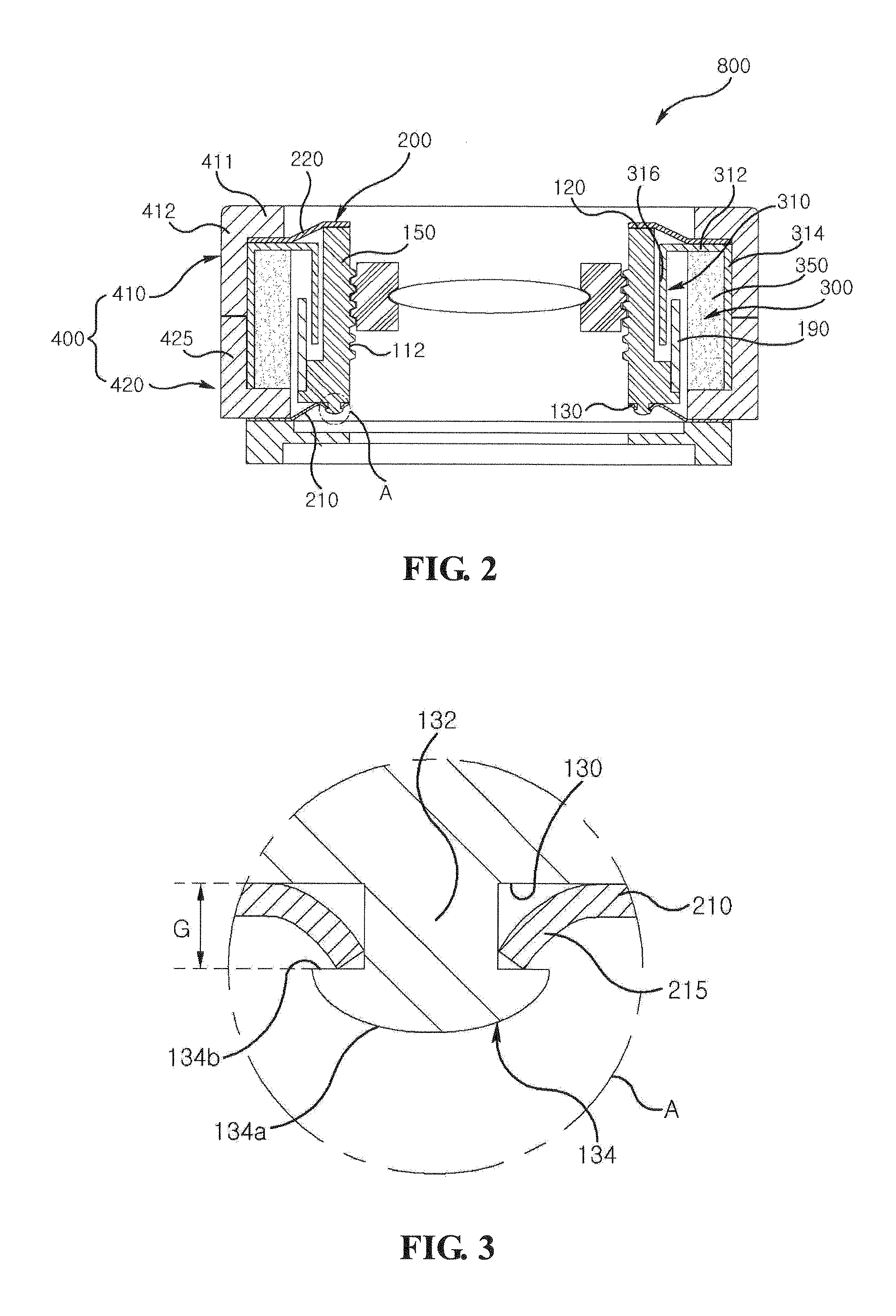

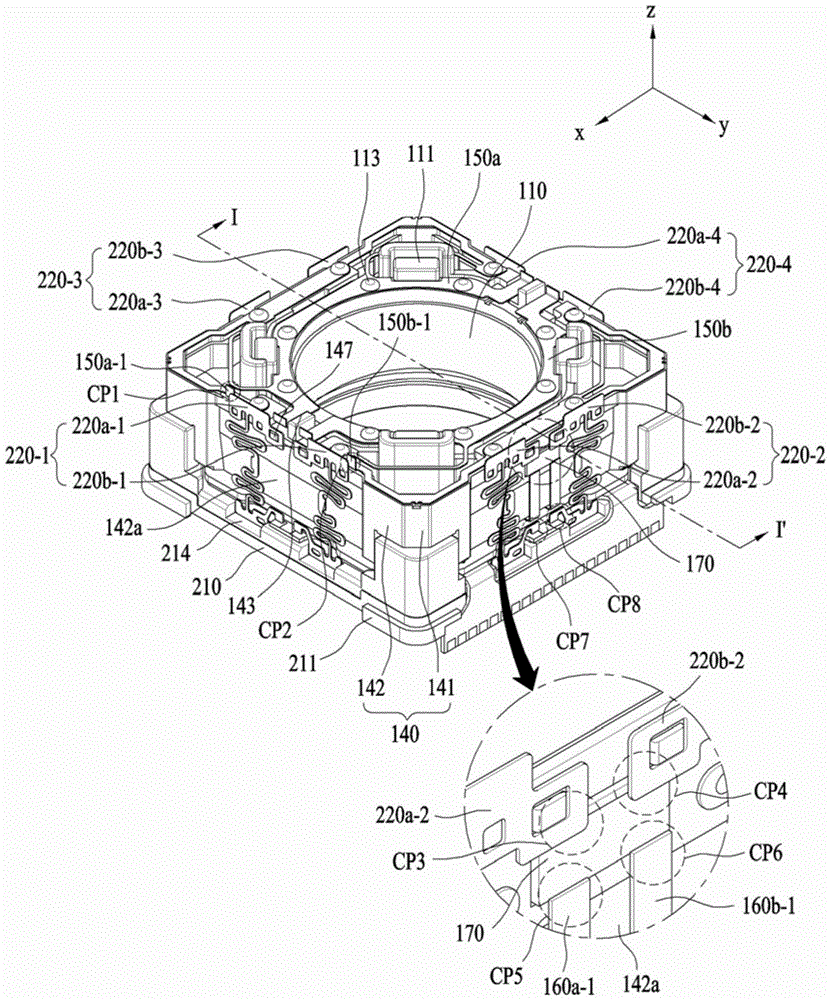

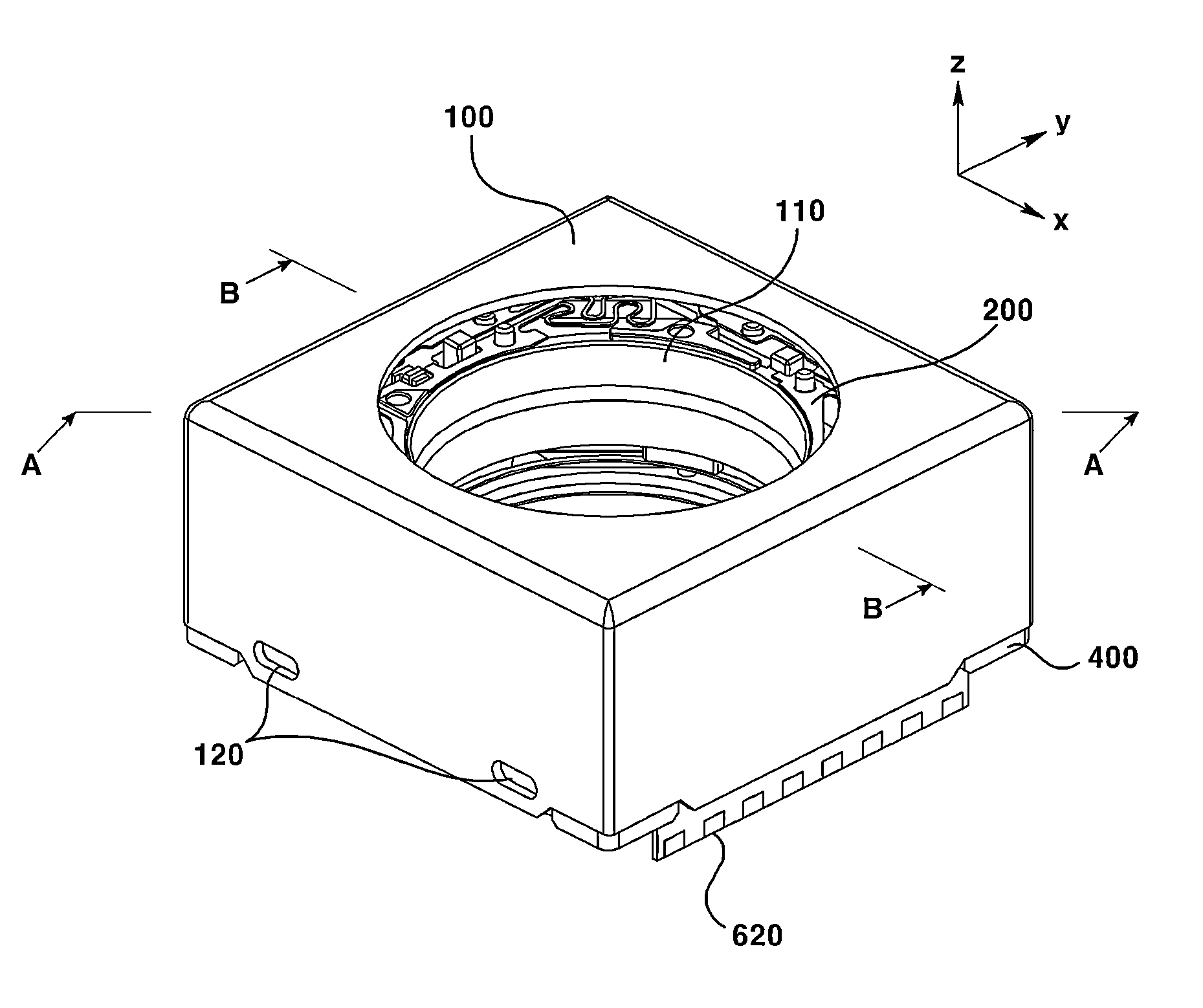

Lens moving unit and camera module having the same

ActiveCN104902149AReciprocating/oscillating/vibrating magnetic circuit partsTelevision system detailsBobbinEngineering

A lens moving apparatus includes a first lens moving unit including a bobbin having a first coil mounted at an outer circumference thereof, a first magnet being opposite to the first coil, and a housing for supporting the first magnet, and a second lens moving unit including a base, a plurality of support member pairs for supporting the housing such that the housing is movable relative to the base, and a second coil opposite to the first magnet, wherein each of the support member pairs includes first and second support members separated from each other, the first and second support members being disposed at the same side of the housing in a state in which the first and second support members are adjacent to each other, and power is supplied to the first coil through a first support member pair, which is one of the support member pairs.

Owner:LG INNOTEK CO LTD

Lens Driving Device

ActiveUS20140355120A1Rapid responseGuaranteed uptimeProjector focusing arrangementCamera focusing arrangementBobbinOptical axis

A lens driving device is proposed, including a cover can whose upper side surface includes an opening formed to expose a lens and whose side surface extends from the upper side surface to a base, a base that is secured to the cover can; a housing that is arranged on top of the base and moves in first and second directions that are perpendicular to an optical axis, a bobbin that is housed in the housing and moves in an optical axis direction, an actuator that includes a magnet unit arranged in the housing, a first coil unit arranged in an outer side surface of the bobbin, and a second coil unit that is arranged on top of the base, and a substrate that is disposed between the second coil unit and the base so as to control the first coil unit and the second coil unit.

Owner:LG INNOTEK CO LTD

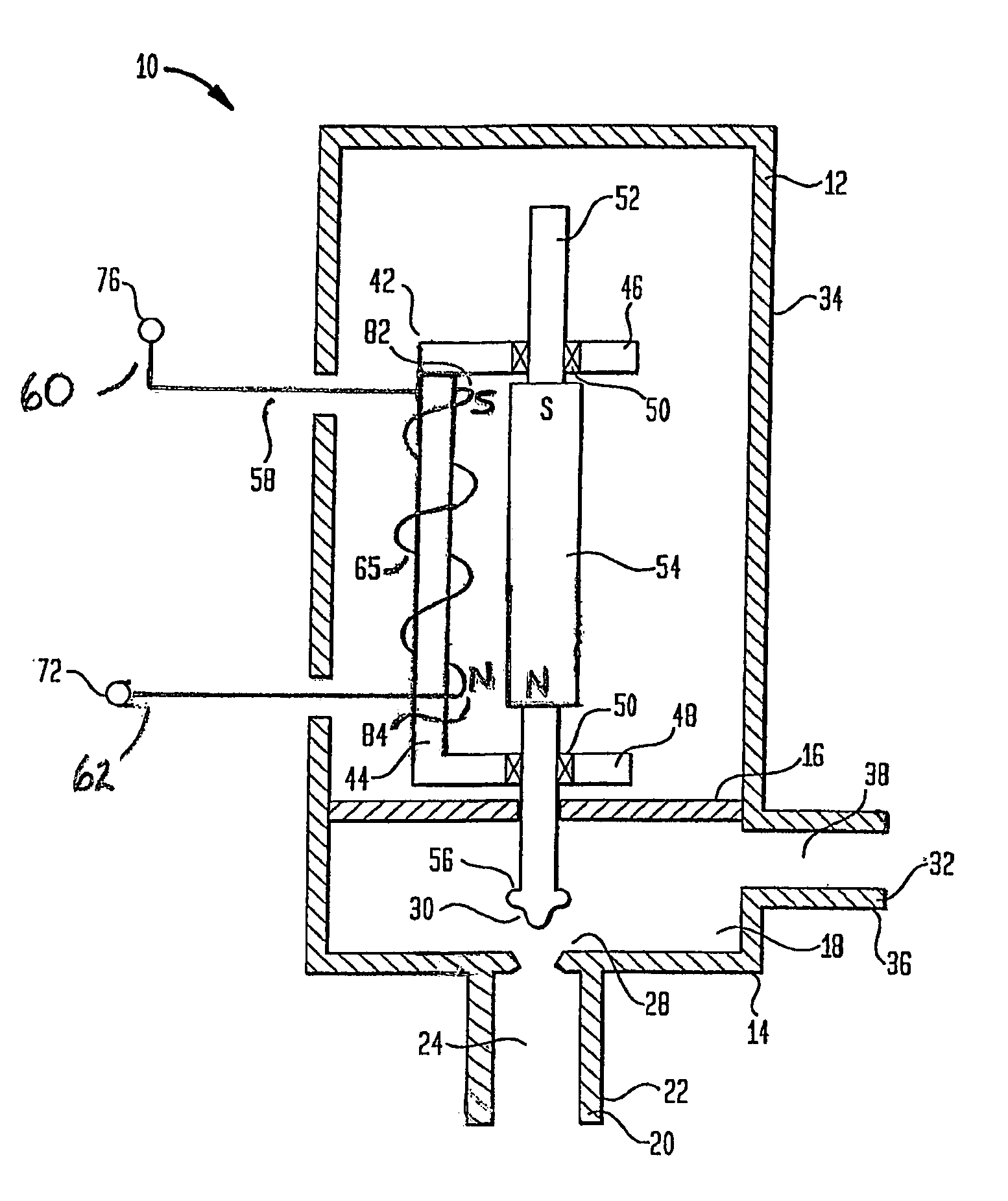

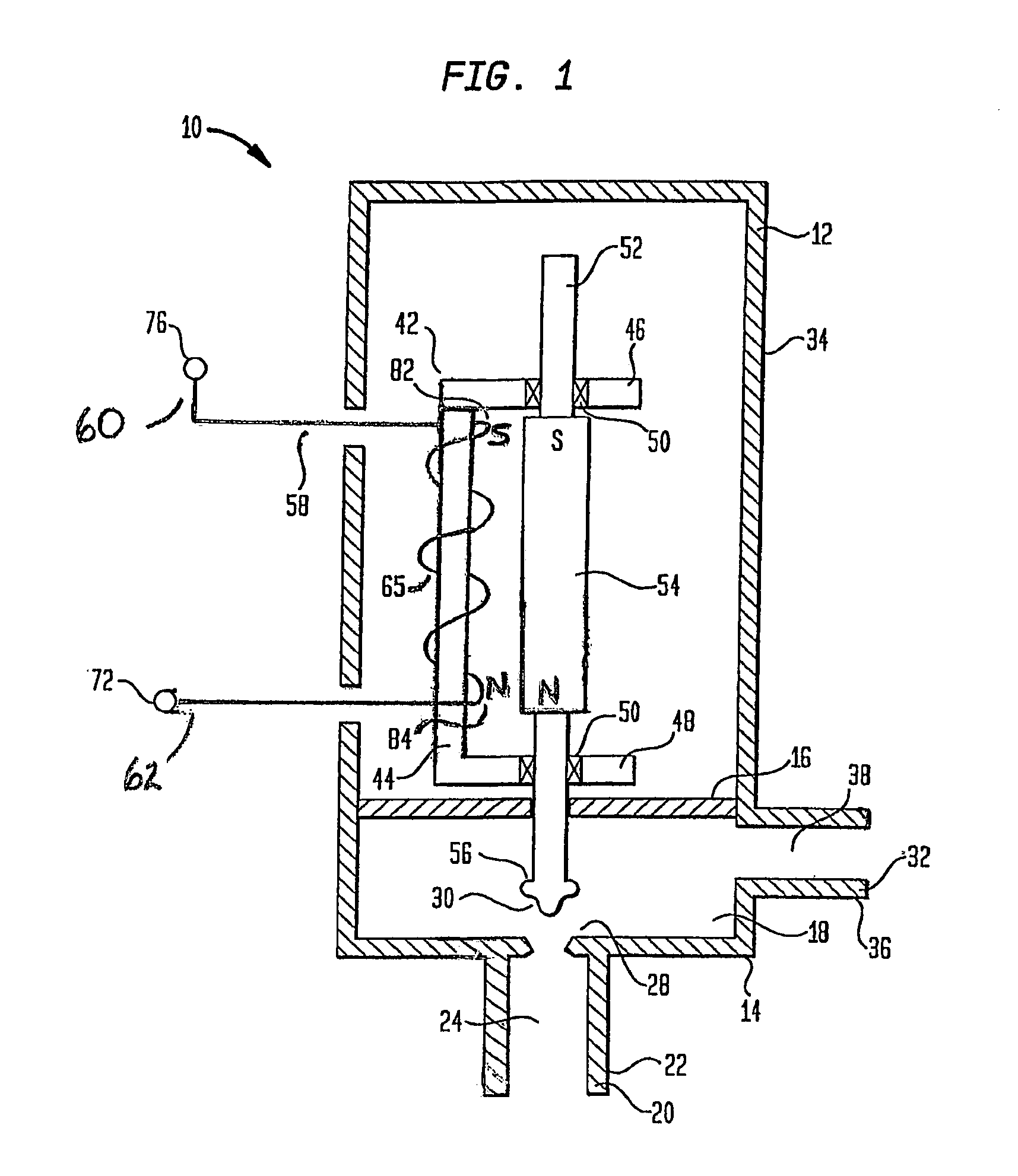

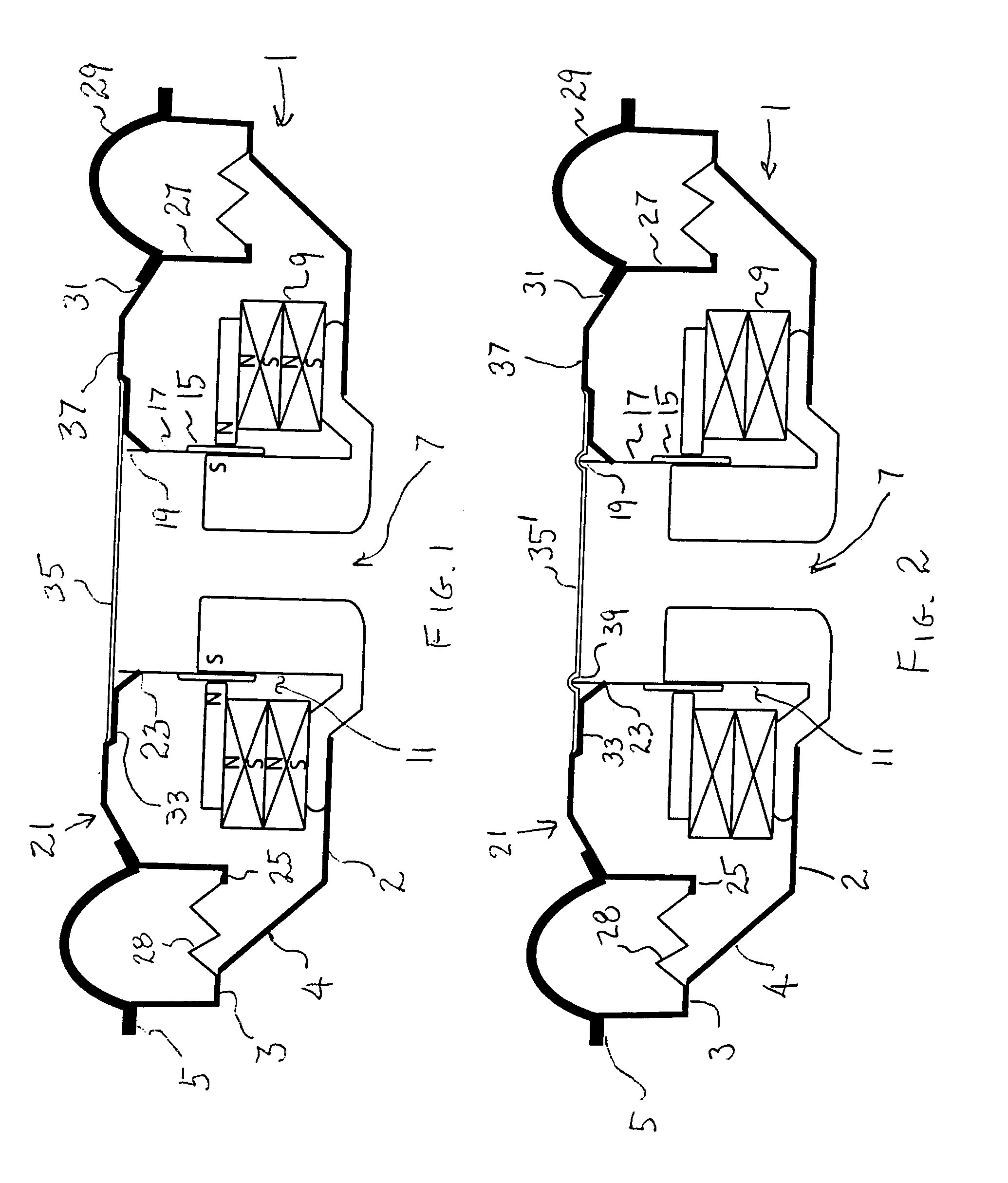

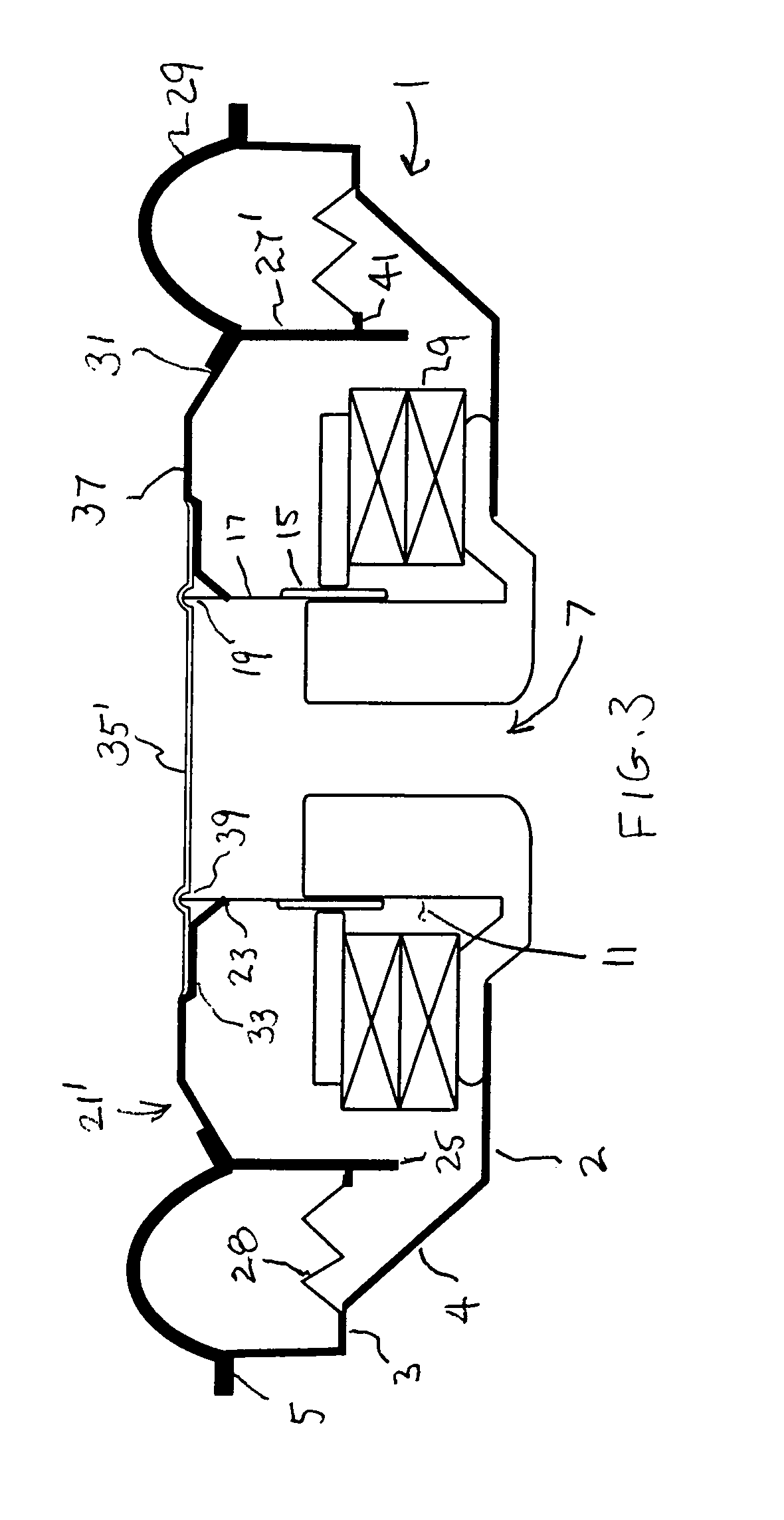

Bipolar valve having permanent magnet

ActiveUS7011076B1Operating means/releasing devices for valvesNon-fuel substance addition to fuelBobbinSolenoid valve

A solenoid for use in valves used in evaporative emission control systems, such as canister purge valves or vent solenoid valves. The solenoid includes a housing having an inlet port and an outlet port. The housing further includes a guide element having a bobbin section. A valve shaft is slidably mounted to the guide element, wherein the valve shaft includes a permanent magnet and a valve element. The valve element is movable between a closed position wherein the inlet port is closed and an open position wherein the inlet port is opened. A coil is formed on the bobbin adjacent the magnet. In use, the coil generates directional magnetic fields oriented to cause the magnet to be repelled to move the valve element to the open position and oriented to cause a magnetic attraction with the magnet to move the valve element to the closed position.

Owner:SIEMENS VDO AUTOMOTIVE CORP

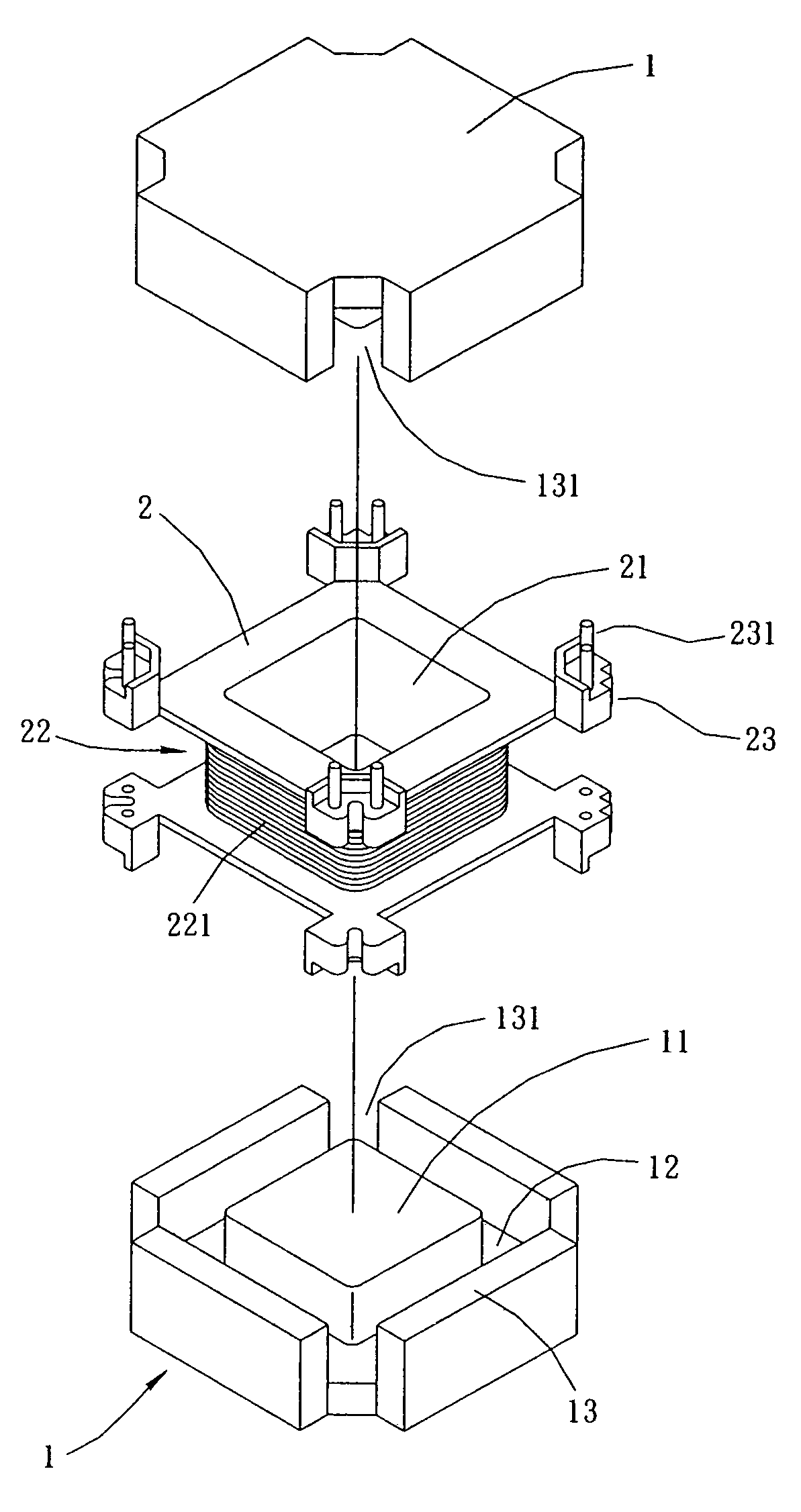

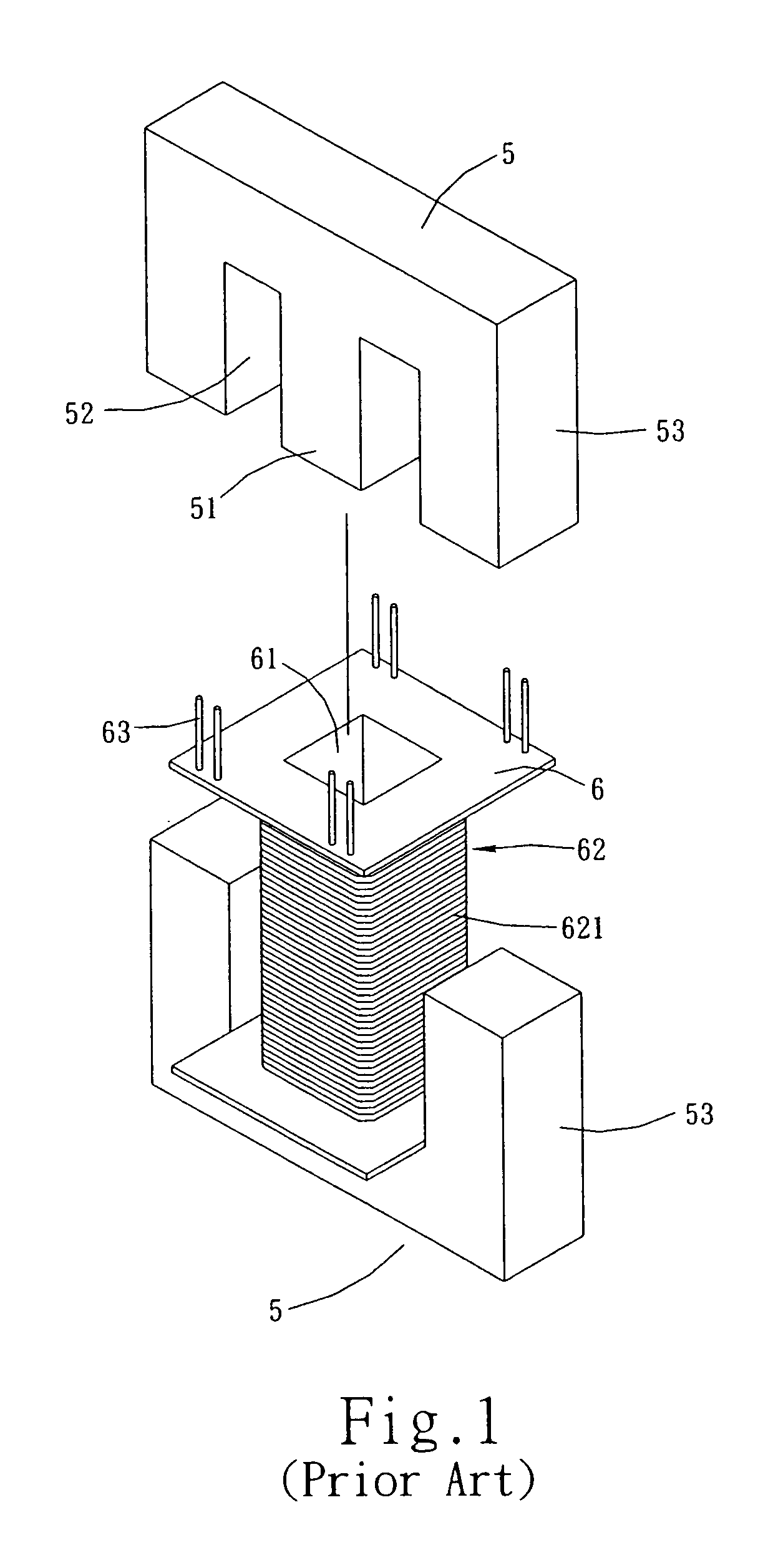

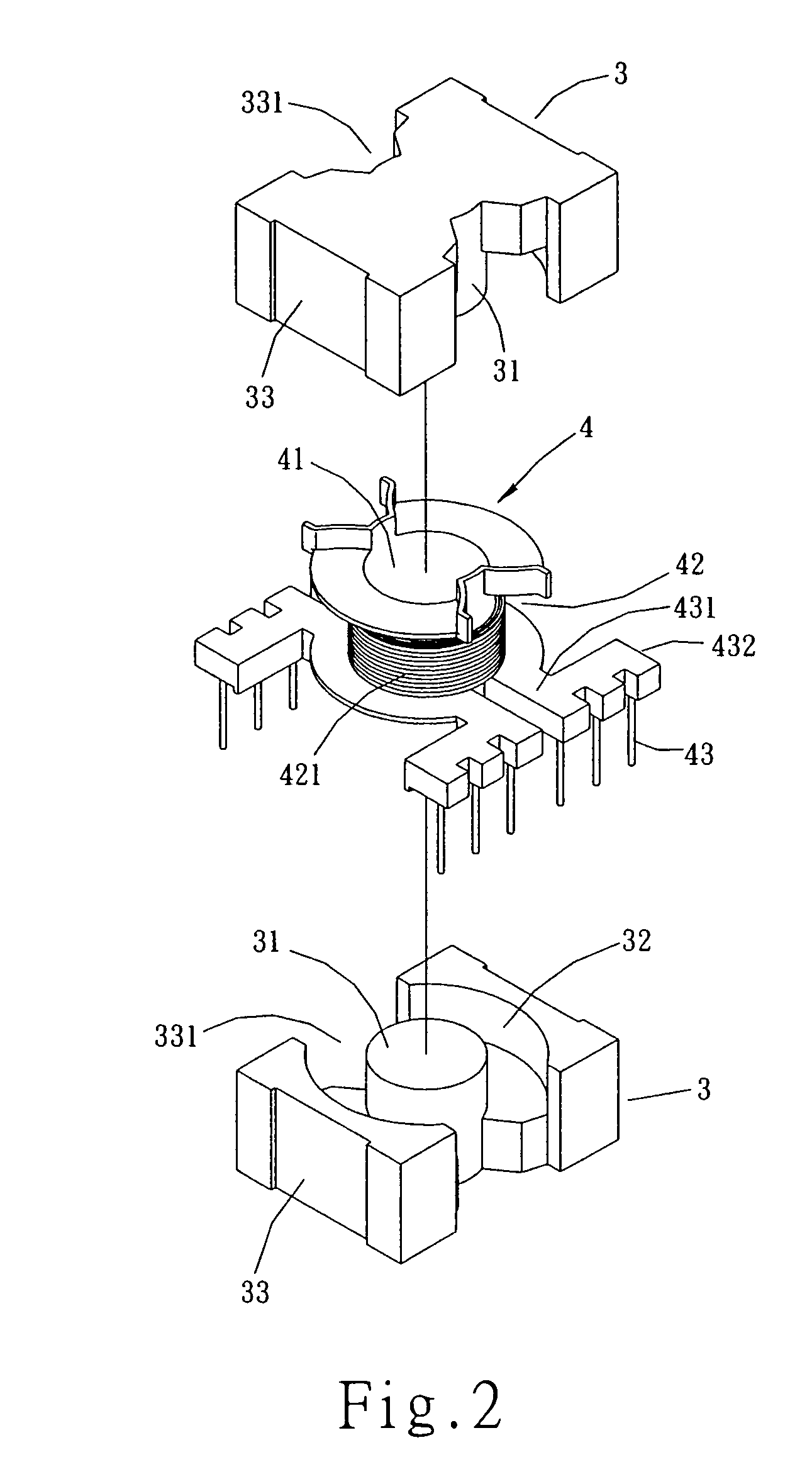

Structure of inductance core and wire frame

ActiveUS7061358B1Increase coverageLessen inductance leakageTransformers/inductances coils/windings/connectionsCoilsBobbinEngineering

An improved structure of inductance core and wire frame mainly provides a center post at the center portion of the core. A containing circumferential channel is also provided at the periphery of the center post to make the outer circumference of the containing circumferential channel form a surrounded circumferential side wall that has small area of indentation openings at the end corners only. A center hole is also provided at the center portion of the wire frame that accommodates the center post, and a bobbin for the winding of the coil is further provided at the outer circumference of the center hole. A salient lead-out seat is provided at the end corner of the wire frame, and brazing posts are also provided on the same side at the upper edge of each of the lead-out seat to connect to the drawing head of the coil. By the use of the center post of the core embedding into the center hole of the wire frame, as well as making use of the containing circumferential channel to contain the wire frame, each of the lead-out seat of the wire frame can stretch out through the openings of the core. The magnetic leakage can be lessened and the inductance efficiency can be improved by making use of the circumferential side wall to form an integral surrounded covering.

Owner:YANG SEN TAI

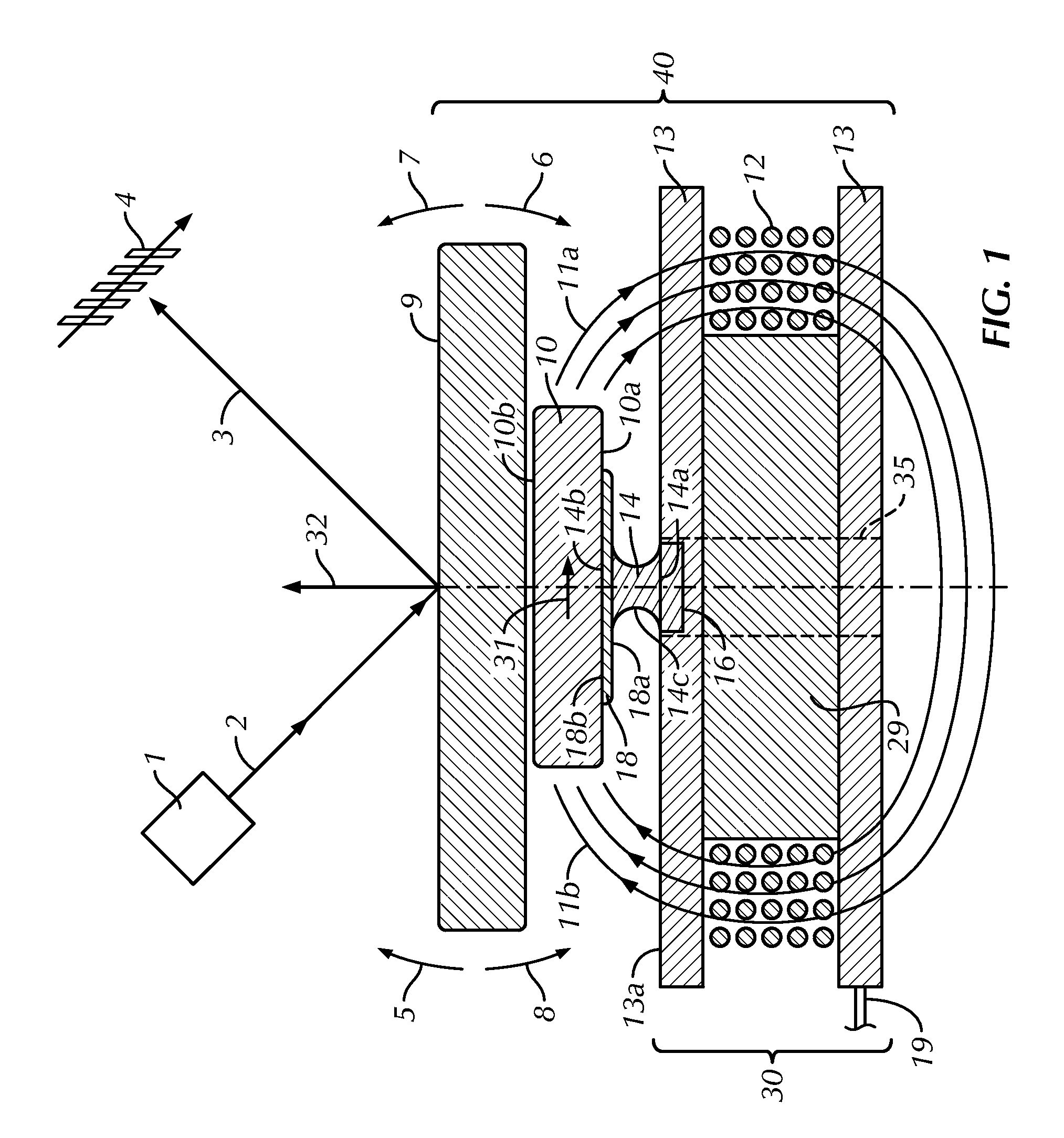

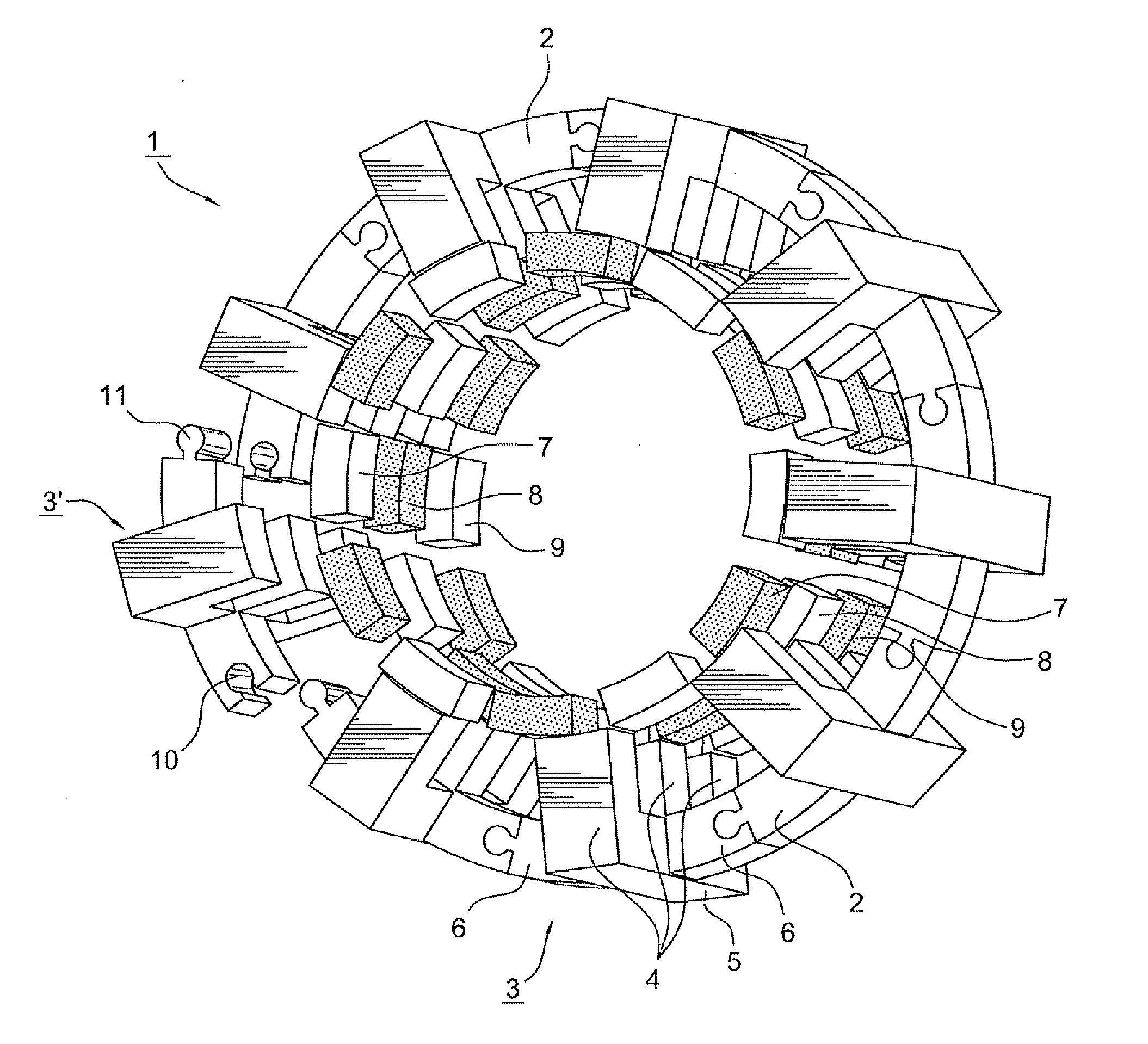

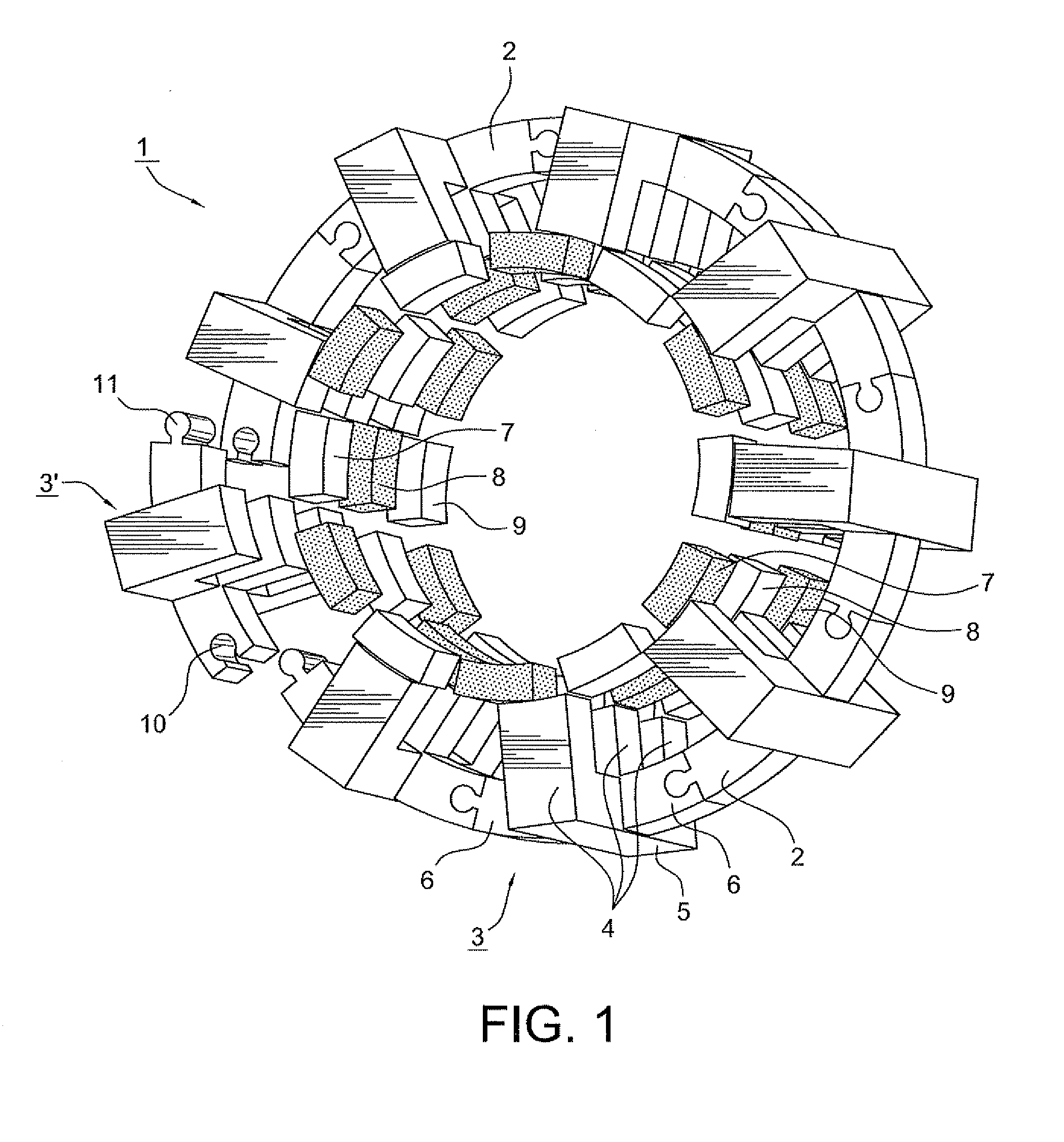

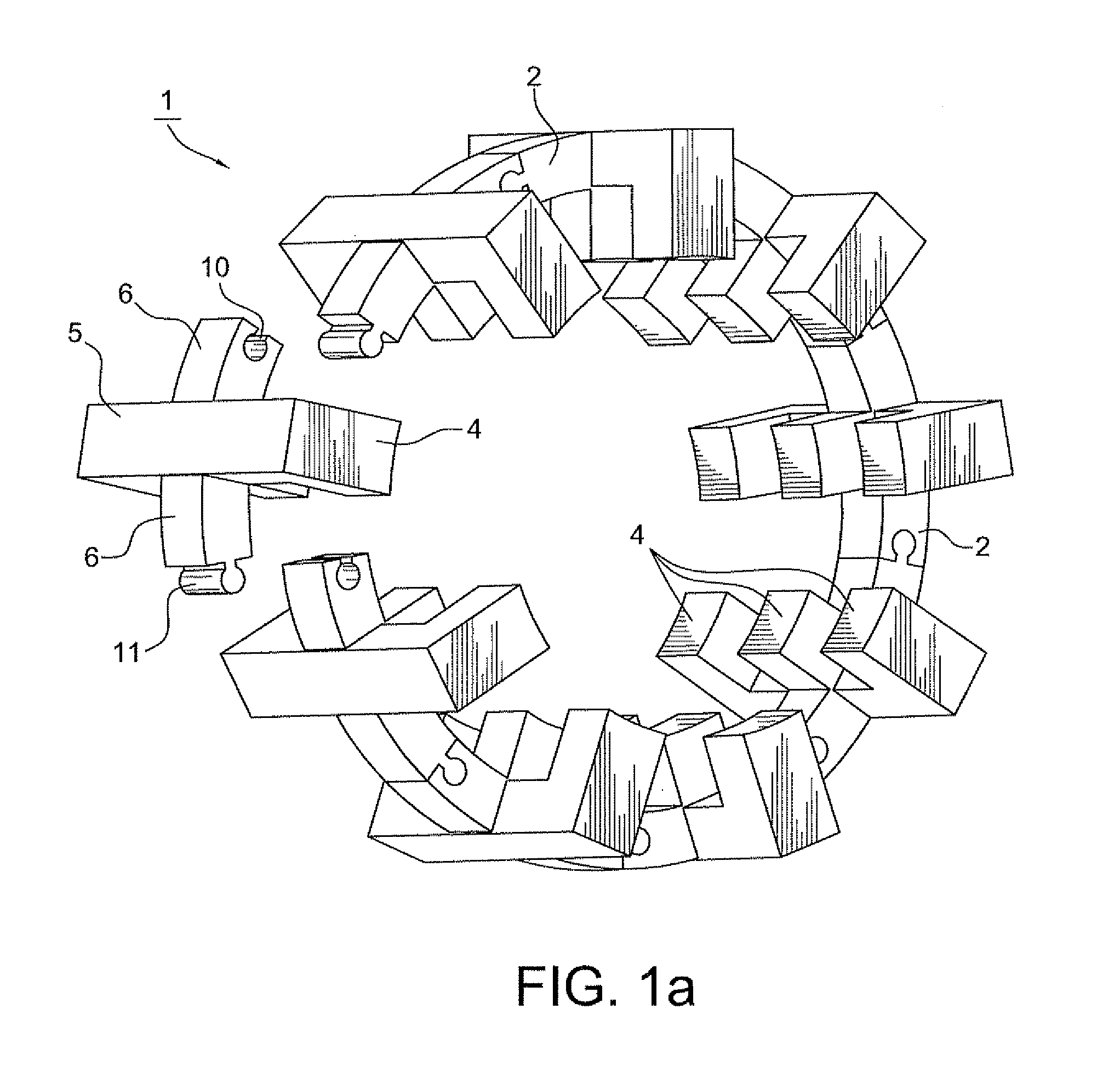

High efficiency magnetic core electrical machines

InactiveUS20130154397A1Increase powerImprove utilizationWindingsMagnetic circuit rotating partsBobbinElectric machine

A high efficiency magnetic core electrical machine includes magnet and coil assemblies that may be axially stacked to form modules. The magnet sub-assemblies include magnet locators on which multiple permanent magnets are arranged, and the coil sub-assembly includes a pair of bobbin holders supporting multiple bobbins and magnetic cores that extend through the bobbins and through openings in the bobbin holders to form magnetic poles that face the permanent magnets. The permanent magnets and magnetic poles may be arranged in various zero-cogging configurations, including one in which the permanent magnets on opposite sides of the coil assembly are skewed relative to each other to cause cogging force cancellation. In addition, a power matching circuit may be used to optimize the output power of the electrical machine to rotor speed when the electrical machine is used as a generator.

Owner:SULLIVAN JOHN T

Low profile audio speaker with minimization of voice coil wobble, protection and cooling

A low profile speaker that is designed to substantially eliminate wobble of the bobbin and voice coil during operation with two different electromagnetic motor designs. In each design there is an added feature to of a downward extension of the outer edge of the cone that bottoms out on the bottom surface of the frame before the bottom edge of the bobbin strikes the bottom of the air gap thus preventing damage to the bobbin and voice coil when the voice coil is overdriven downward. Additionally, there are two different bobbin and voice coil cooling feature for use with electromagnetic motors that utilize a Tyoke construction.

Owner:SAHYOUN JOSEPH Y

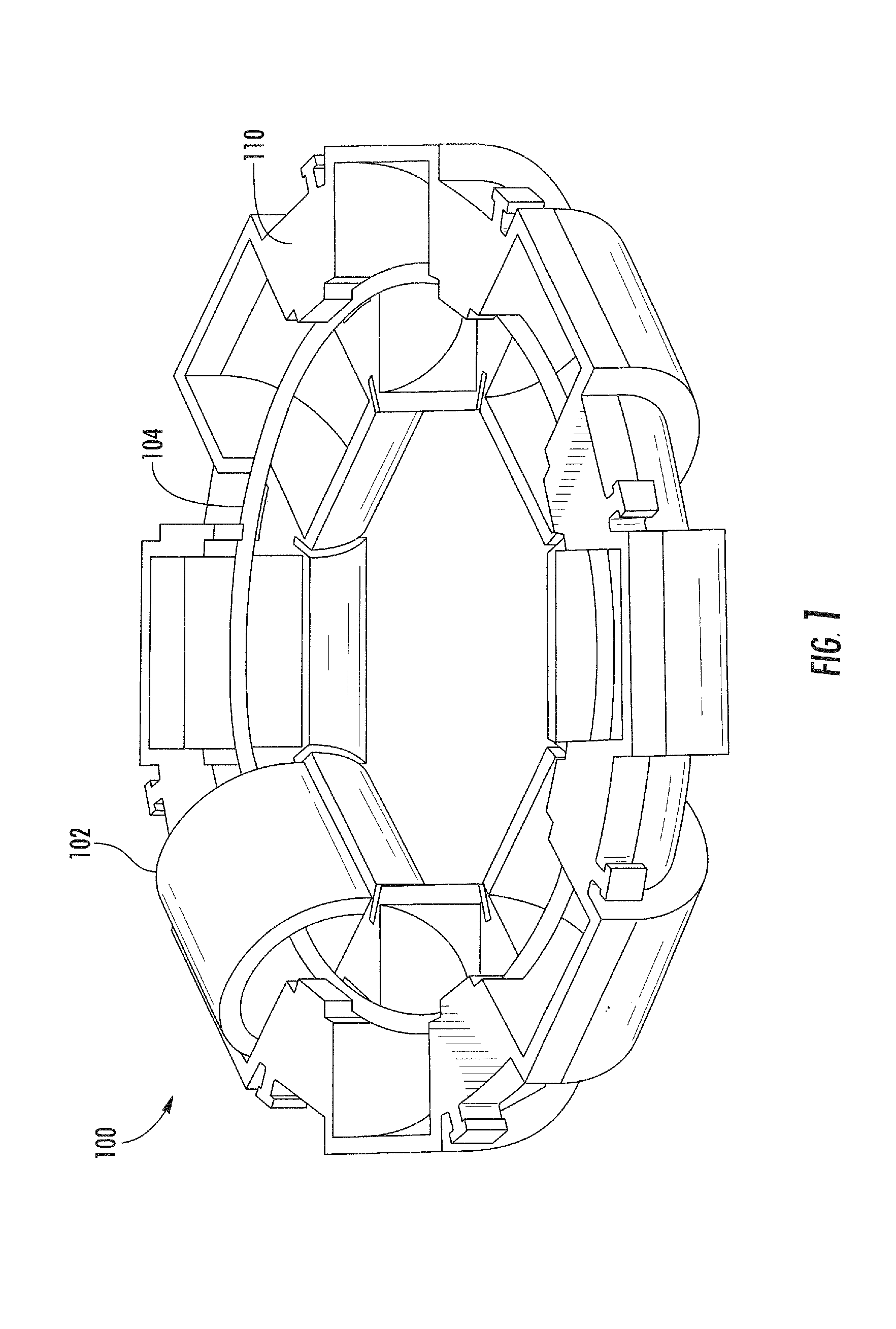

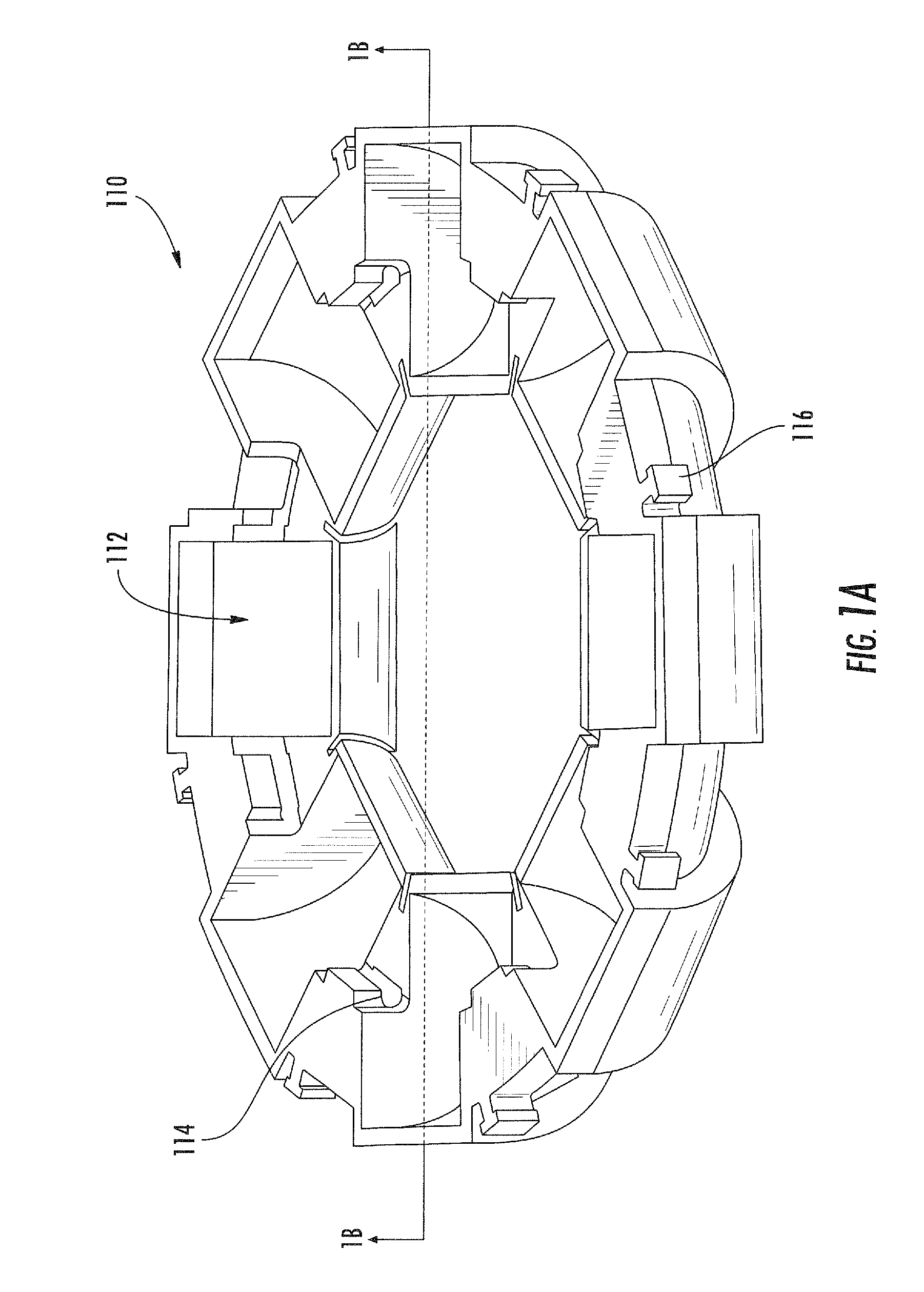

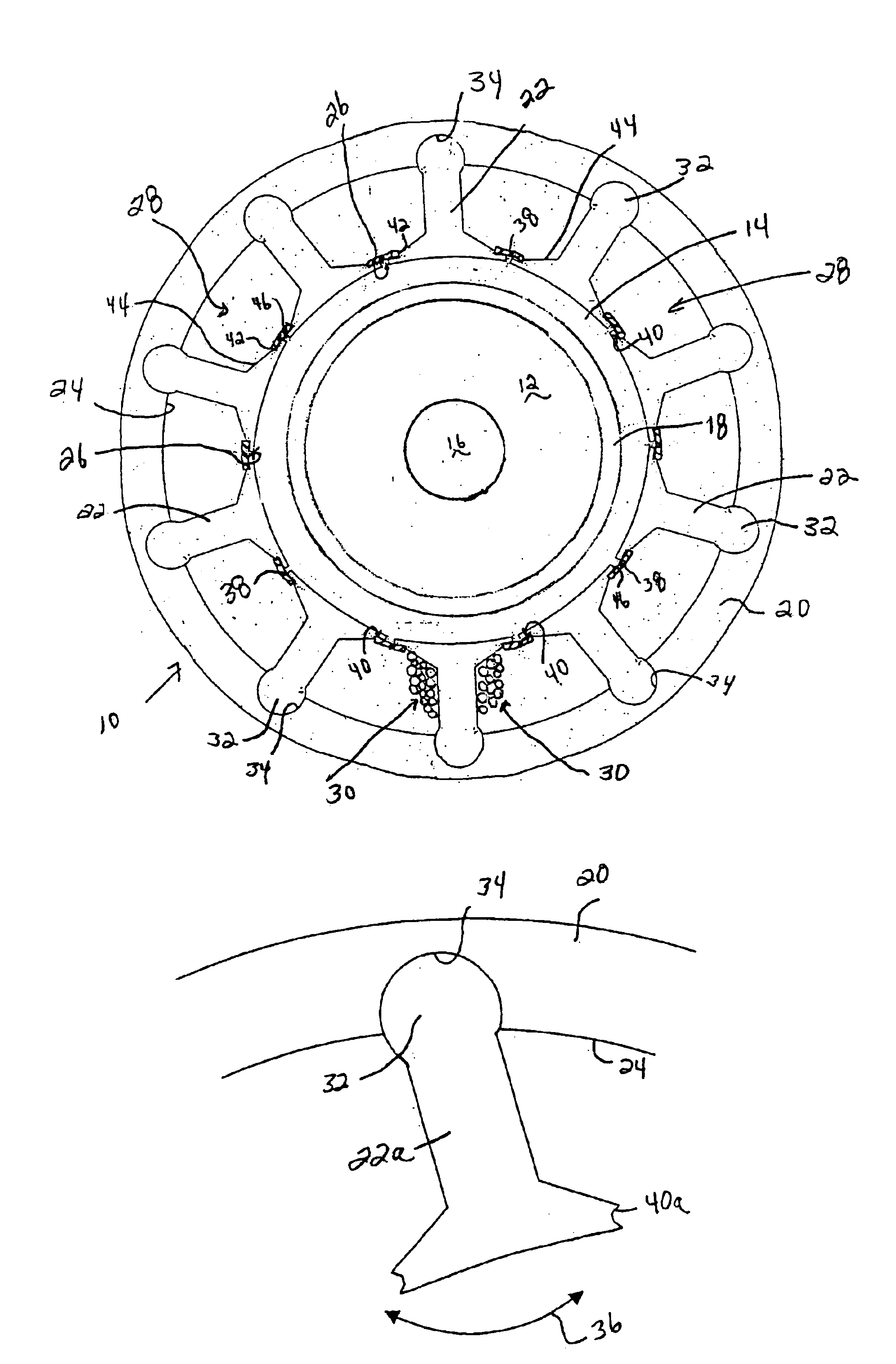

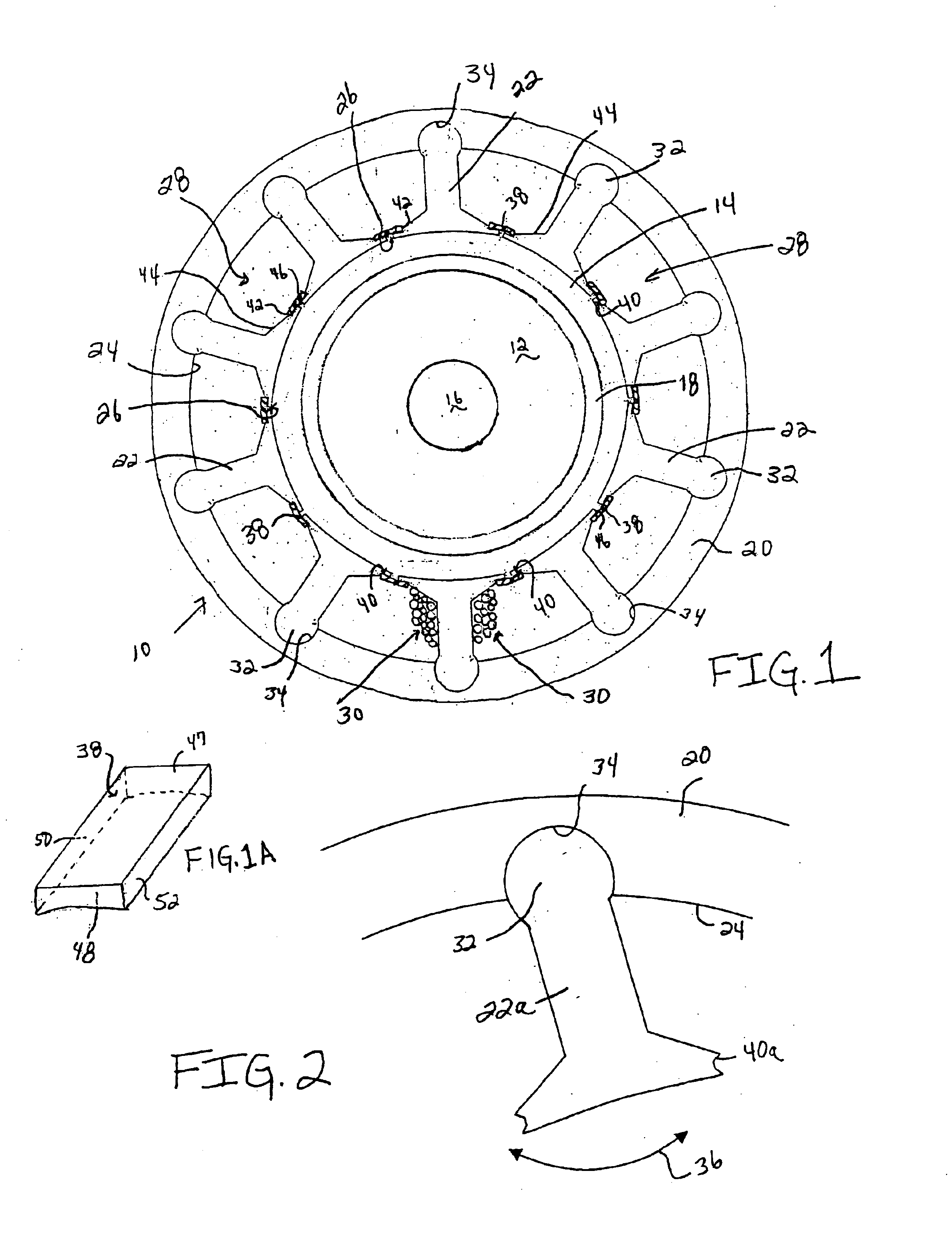

Stator design for permanent magnet motor with combination slot wedge and tooth locator

InactiveUS6844653B2Minimizing cogging torqueImprove power densityWindings insulation shape/form/constructionSynchronous motorsLoose toothBobbin

A segmented stator for a permanent magnet motor. The stator includes a plurality of stator segments forming an annular stator yoke and a plurality of stator teeth extending from an edge of the stator yoke. At least one coupling is between adjacent stator segments and shaped to allow movement of adjacent teeth in a so-called loose tooth design. Slot wedges are located between adjacent teeth to prevent the conductive windings from moving out of the slots through the slot openings. The slot wedges also prevent movement of adjacent teeth with respect to one another. The segmented stator can comprise an annular yoke with a plurality of discrete teeth or a plurality of assemblies including a rim section and a tooth section. The slot wedges can be keyed wedges that maintain their position through interlocking and / or can be integrated with a stator bobbin.

Owner:VALEO ELECTRICAL SYST

Voice coil motor

A VCM is disclosed, the VCM including a rotor including a bobbin arranged at an upper surface of a base formed with an opening, and a driving coil wound on the bobbin, a stator including a driving magnet opposite to the driving coil, and a yoke secured by the driving magnet at an inner surface of a lateral plate, and a tilting unit including a tilt magnet arranged at an outer surface of the lateral plate, a housing fixing the tilt magnet, and a tilt coil unit opposite to the tilt magnet.

Owner:LG INNOTEK CO LTD

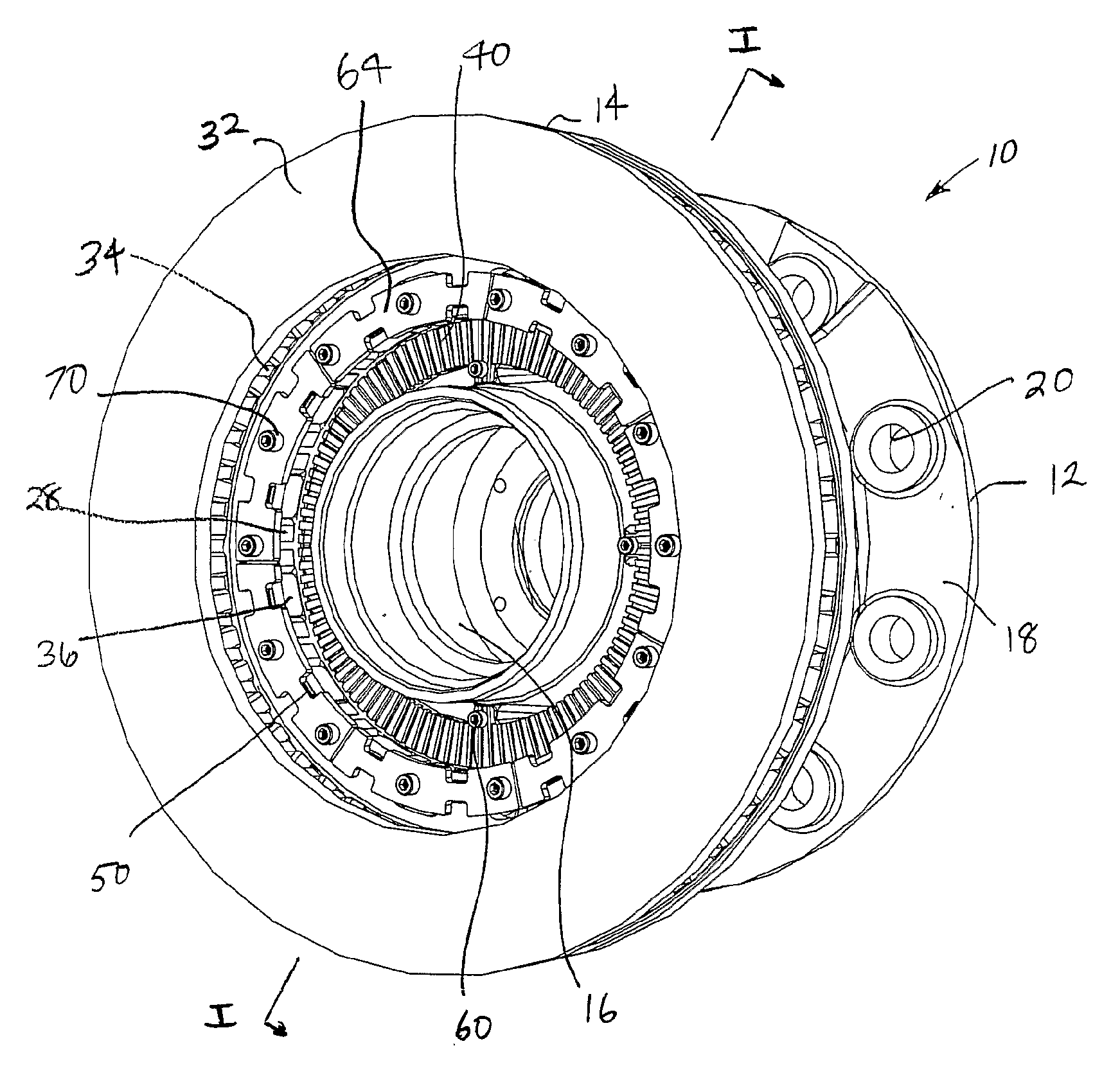

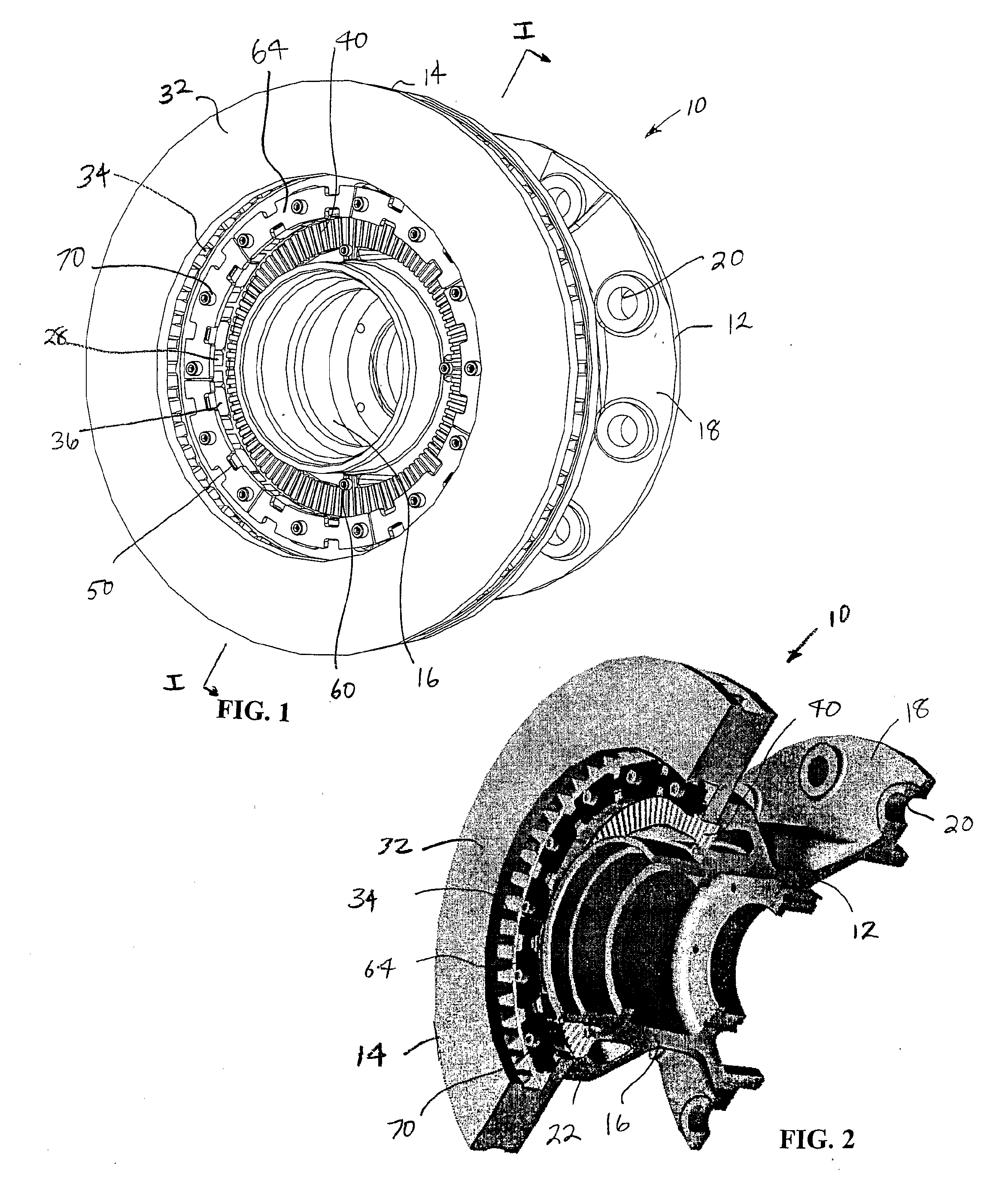

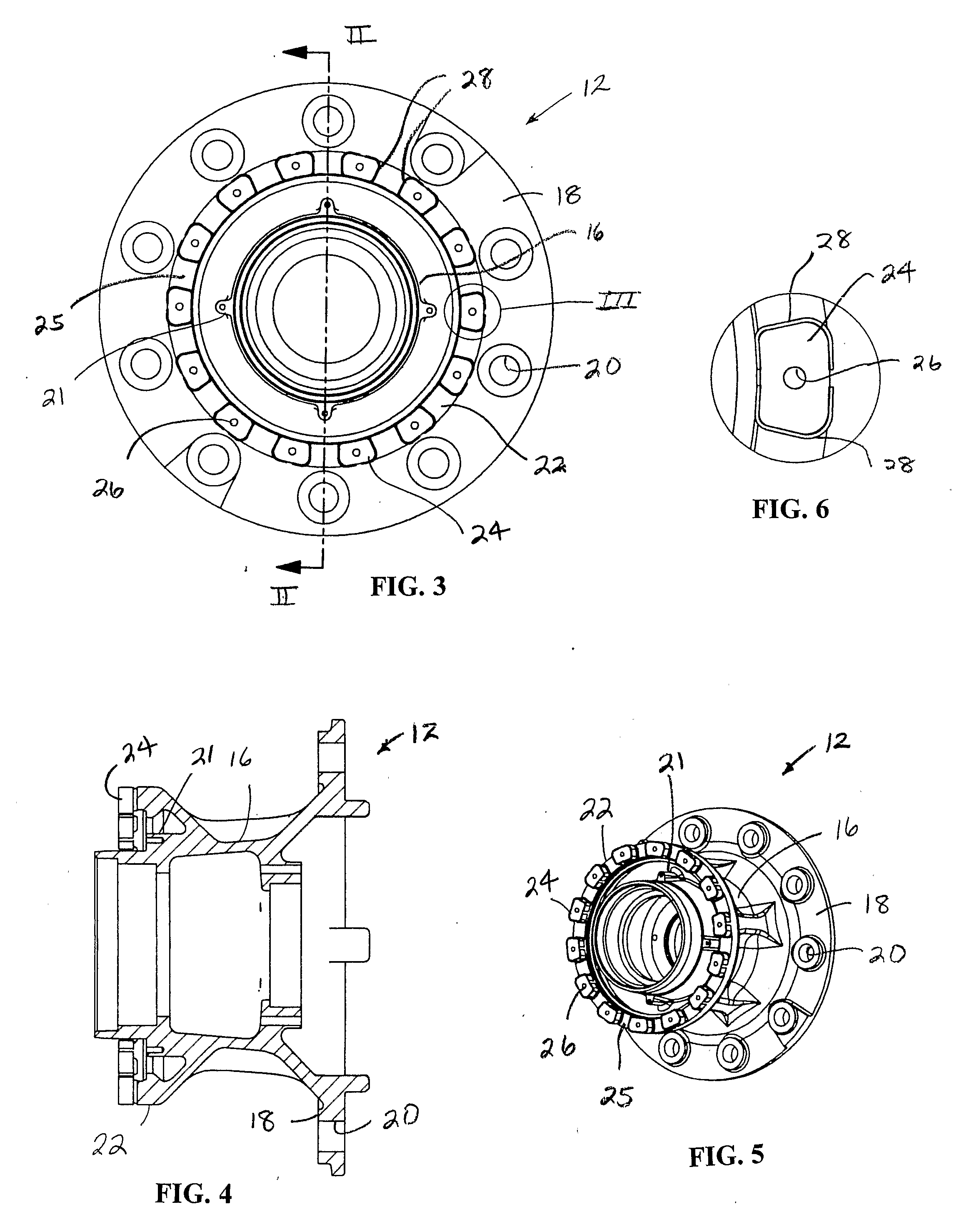

Brake rotor and abs tone ring attachment assembly that promotes in plane uniform torque transfer distribution

A brake assembly for use on vehicles includes a rotor having connection tabs and a hub having bobbins, integrally formed or separate, with the rotor connection tabs being positioned between the hub bobbins and clamped together with a top plate. An ABS tone ring is fastened to the hub and is circumscribed by the rotor. Alternatively, an ABS tone ring can be formed as part of the top plate. A spring clip can be used with the top plate to accommodate thermal expansion of the rotor and eliminate rotor rattling. Torque is transferred from the brake rotor to the hub in a common plane to prevent twisting in the fastener connection.

Owner:PERFORMANCE FRICTION

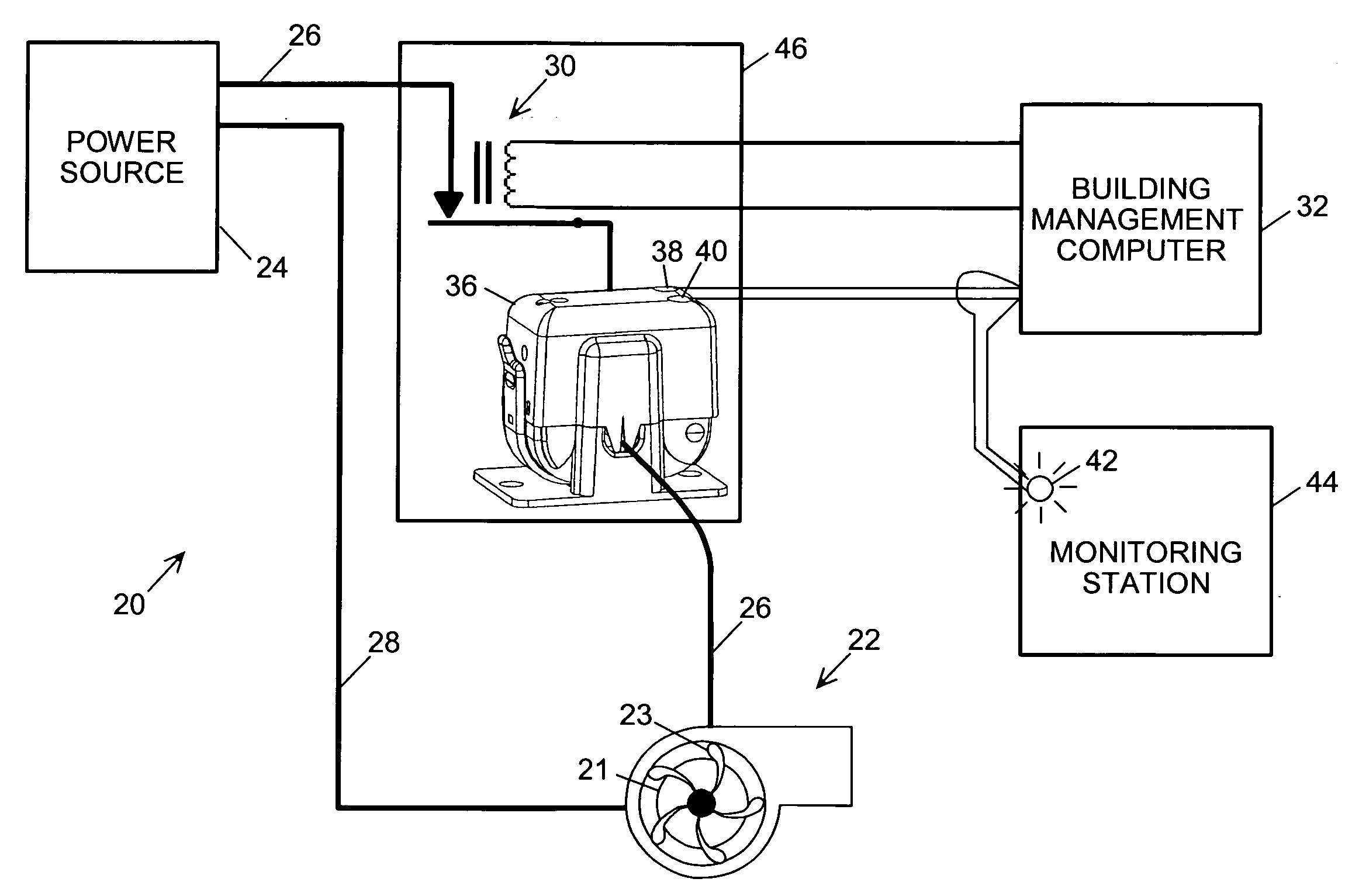

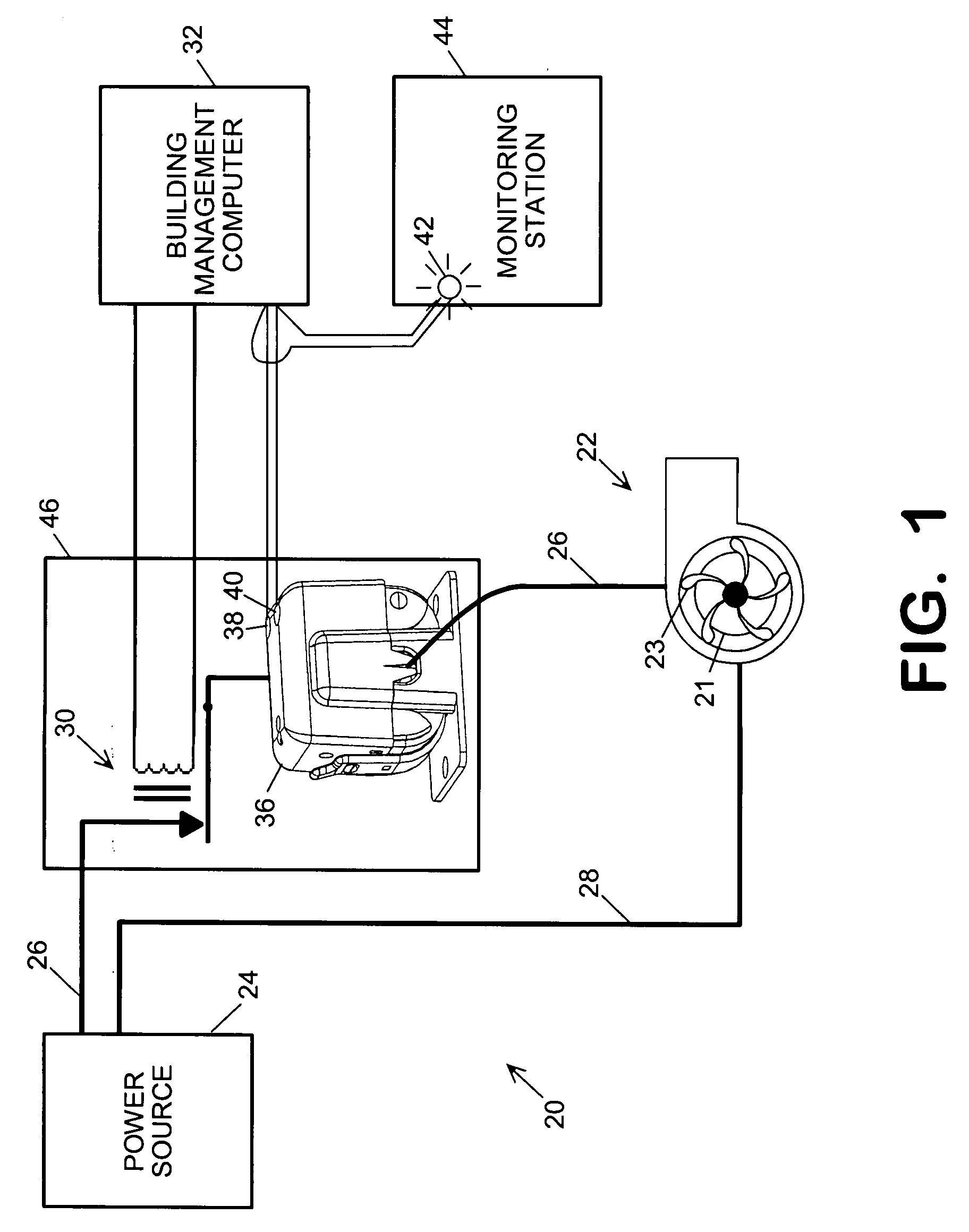

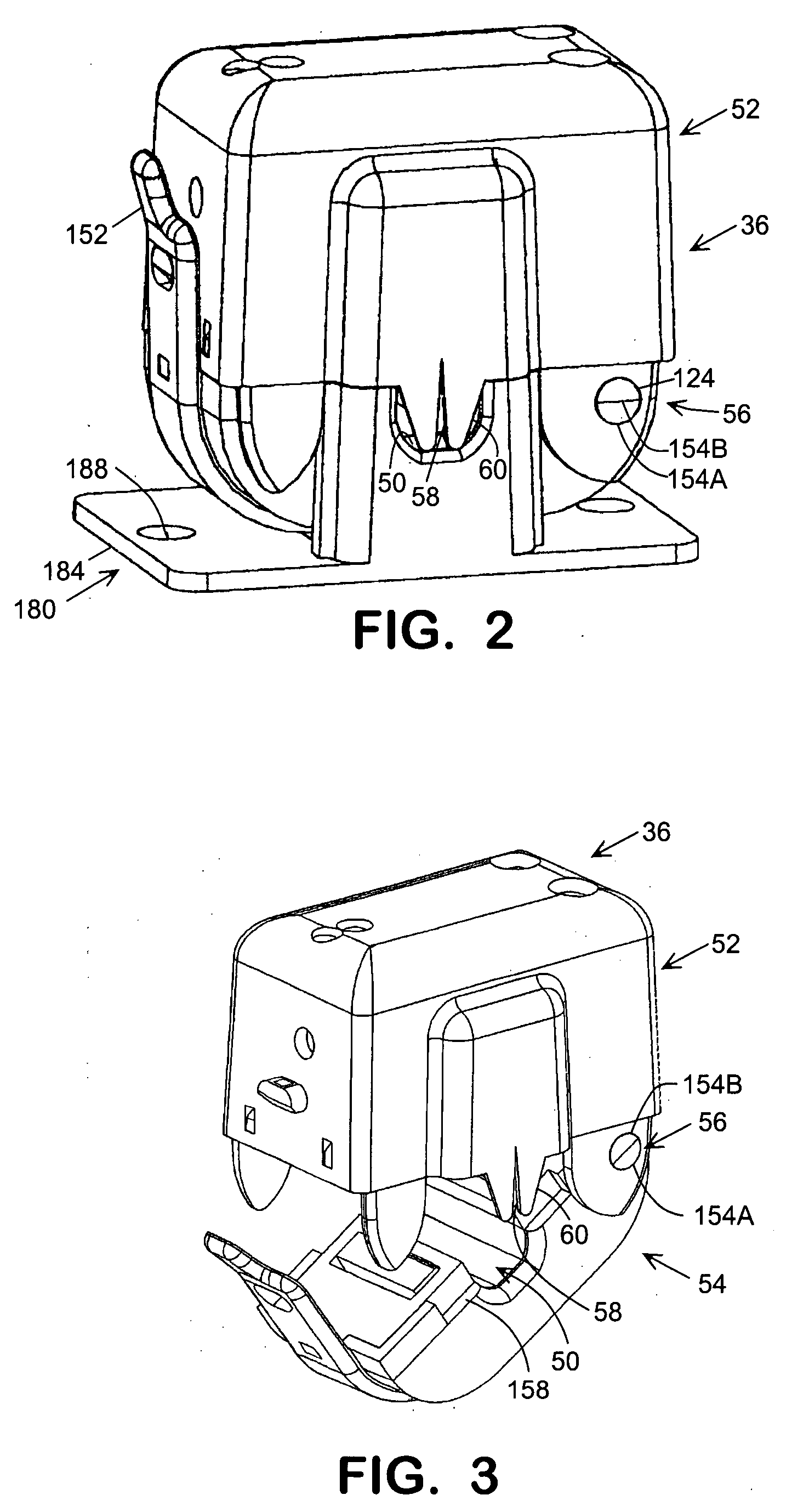

Split core status indicator

The size of a status indicator for monitoring a current in a power cable is reduced by integrating a bobbin for the secondary winding with a current transformer core and integrating a circuit board including output terminals with a current transformer assembly.

Owner:VERIS INDS

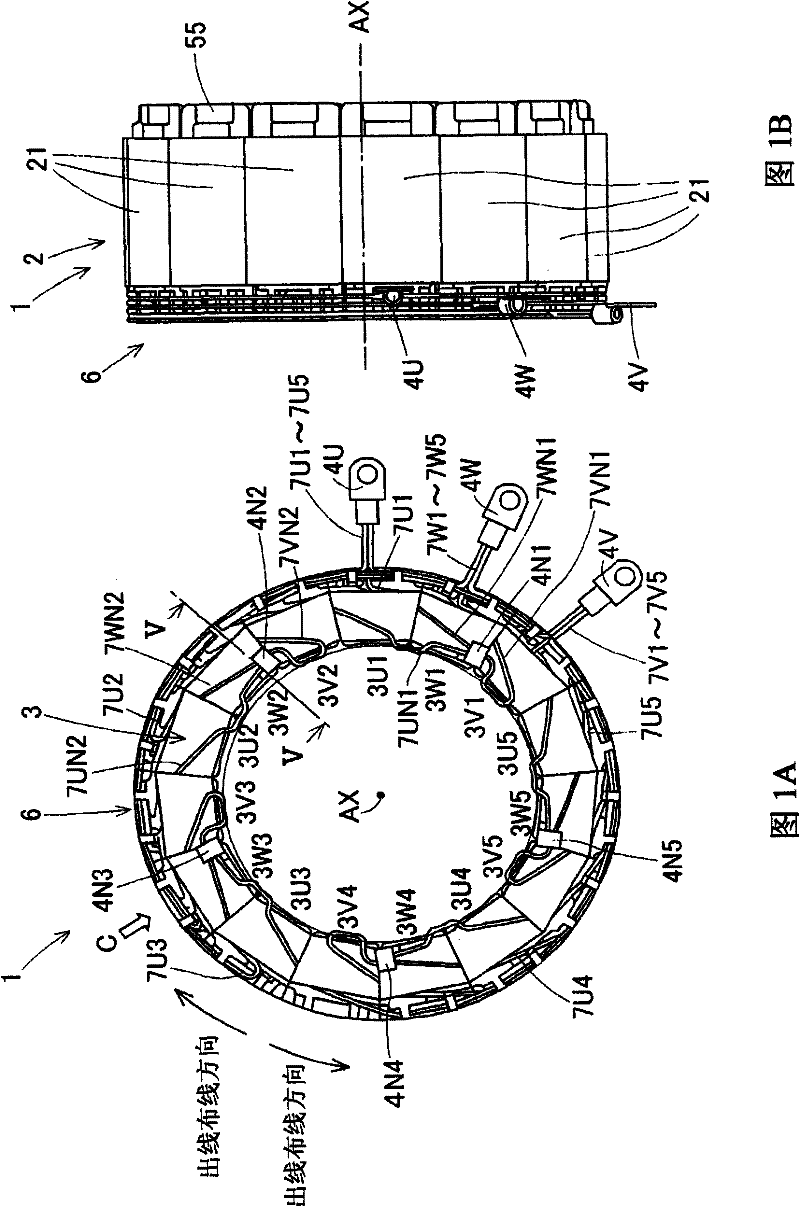

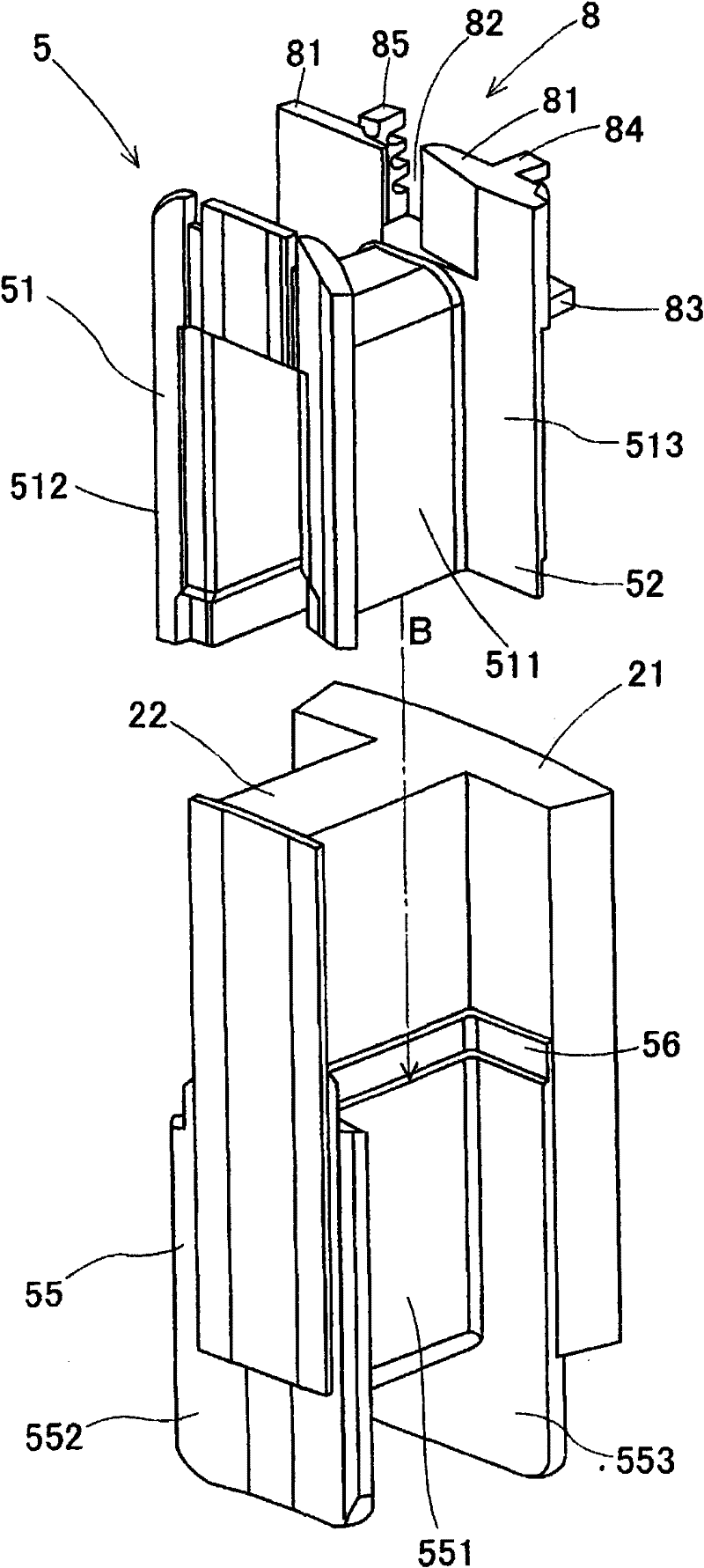

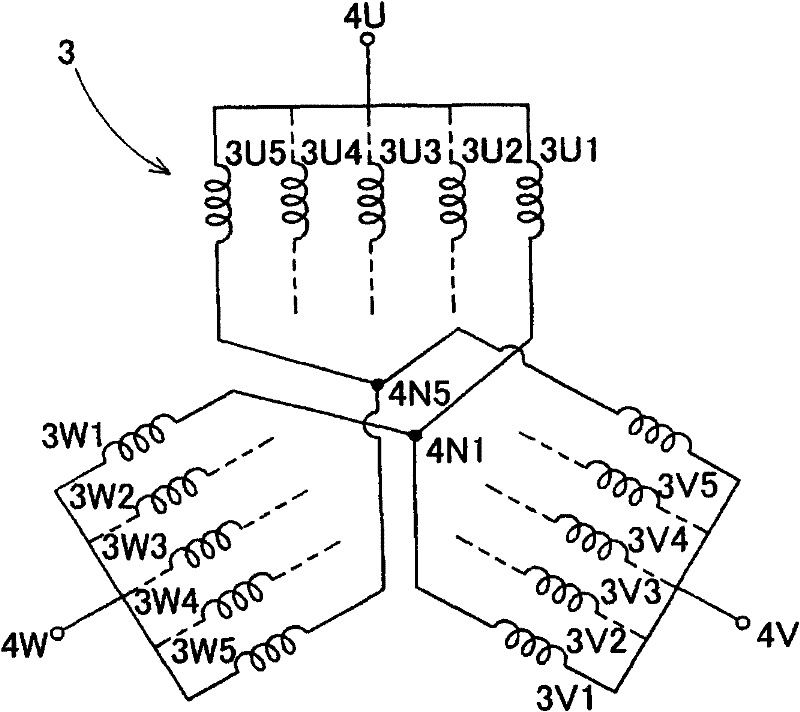

Stator for rotary electrical machine

InactiveCN102201708AReduce in quantityLow costWindings insulation shape/form/constructionMagnetic circuit stationary partsBobbinElectric machine

A stator (1, 10) for a rotary electrical machine, includes a stator core (2) in a cylinder shape and having plural magnetic pole teeth (22), which are arranged in a circumferential direction of the stator while keeping a distance therebetween and each of which protrudes in a radial direction of the stator core, a coil (3) configured with a conductive wire wound around each of the magnetic pole teeth, an insulating bobbin (5) provided between the coil and the corresponding magnetic pole tooth, and an electric power supply portion (6, 60) arranged axially outwardly of the stator core, electrically connecting the coil with an outside of the stator, and including an outgoing wire (7U1, 7U2, 7U3, 7U4, 7U5, 7V1, 7V2, 7V3, 7V4, 7V5, 7W1, 7W2, 7W3, 7W4, 7W5), which corresponds to a portion of at least one of a winding start and a winding end of the conductive wire being extended by a predetermined length, and an isolating member (8, 80) having a groove portion (86U, 86V, 86W, 96U, 96V, 96W) for accommodating and guiding the corresponding outgoing wire.

Owner:AISIN SEIKI KK

Reciprocation type linear driving actuator and power toothbrush using the same

InactiveUS20070040457A1Easy to manufactureSmall volumeBrush bodiesMechanical energy handlingBobbinActuator

In a reciprocal linear driving actuator used as a drive source of a power toothbrush, two permanent magnets are formed substantially disc shape or substantially tubular shape, and fitted to and fixed on a shaft directly or via a spacer with a predetermined distance in axial direction of the shaft, so that a moving object is constituted by the shaft and the permanent magnets. On the other hand, a tubular shaped stator, which is constituted by a coil wound around a bobbin and stationary yokes and so on, is provided to face side faces of the permanent magnets of the moving object via a predetermined clearance so that a center axis thereof becomes coaxial with the center axis of the shaft. By supplying alternating current to the coil, the moving object is driven reciprocally and linearly in the axial direction of the shaft.

Owner:MATSUSHITA ELECTRIC WORKS LTD

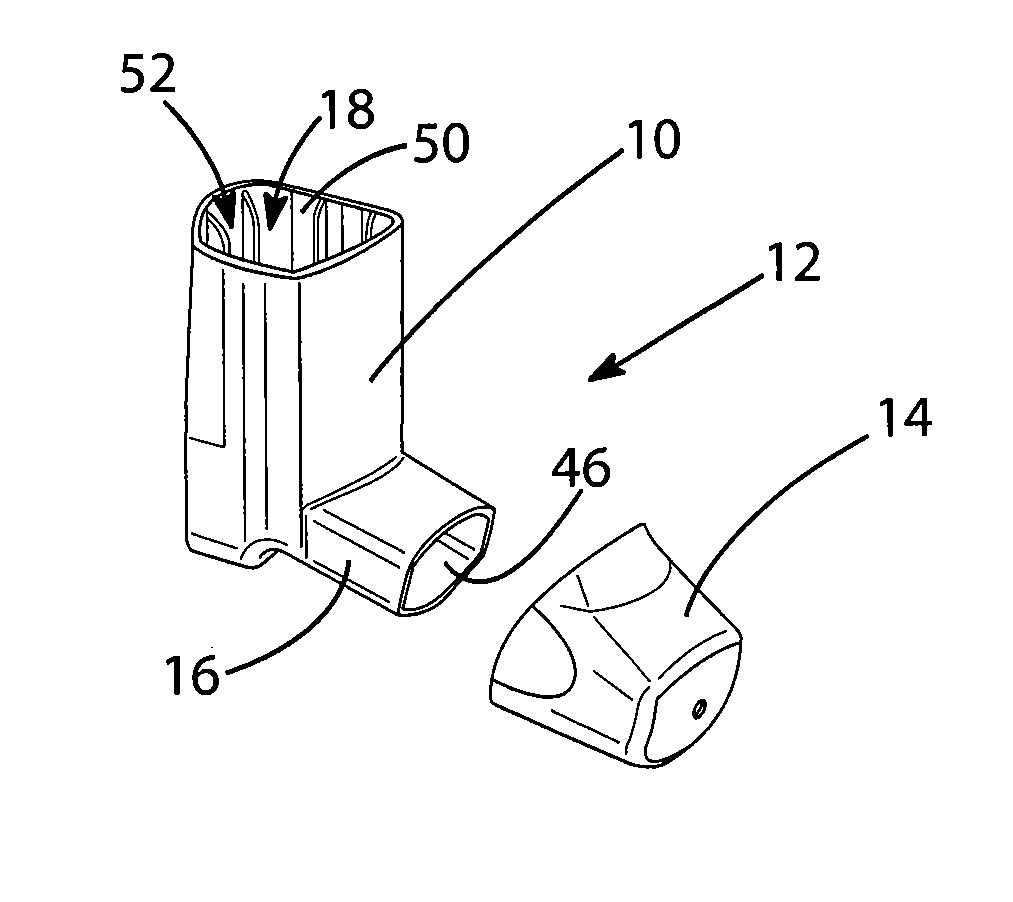

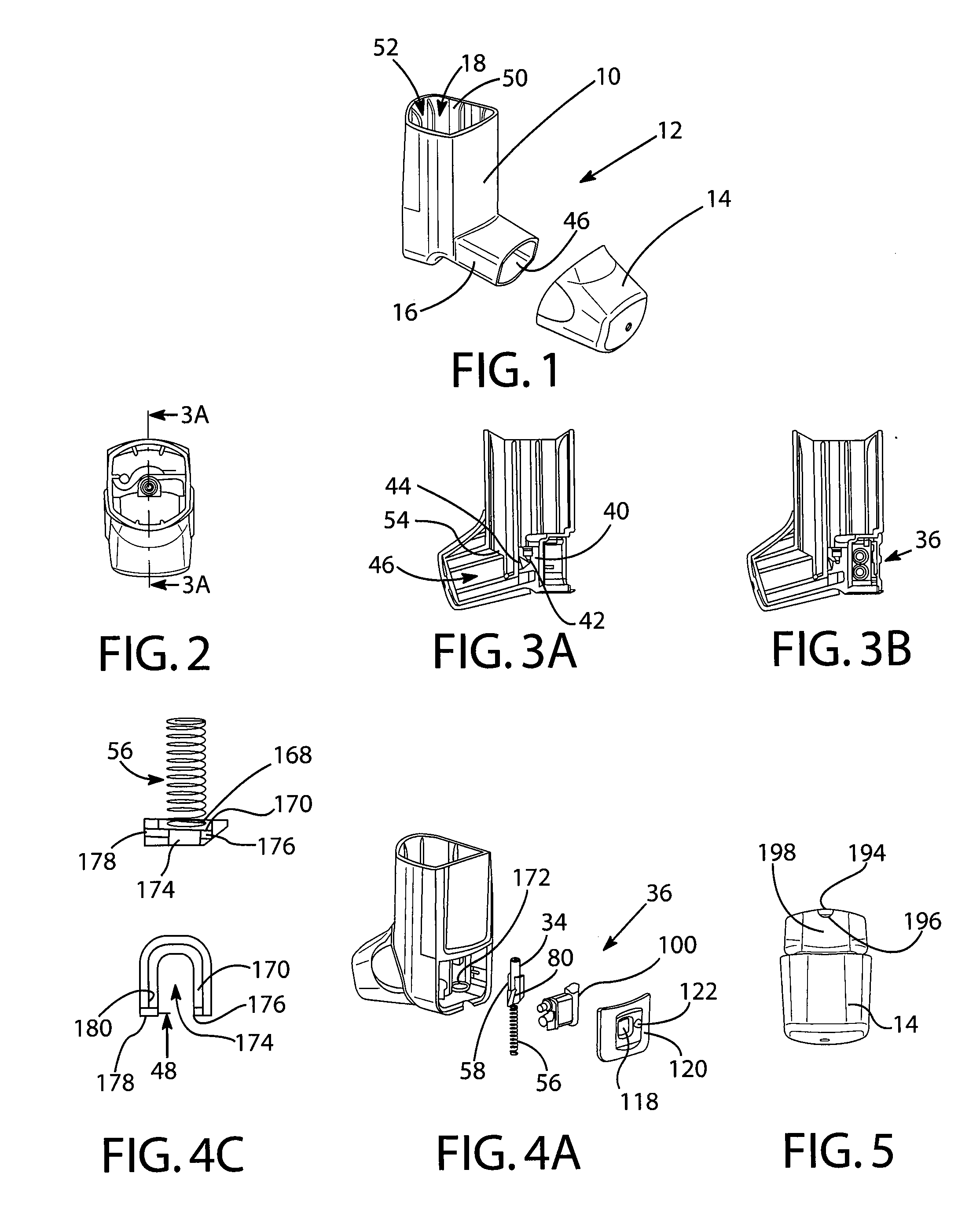

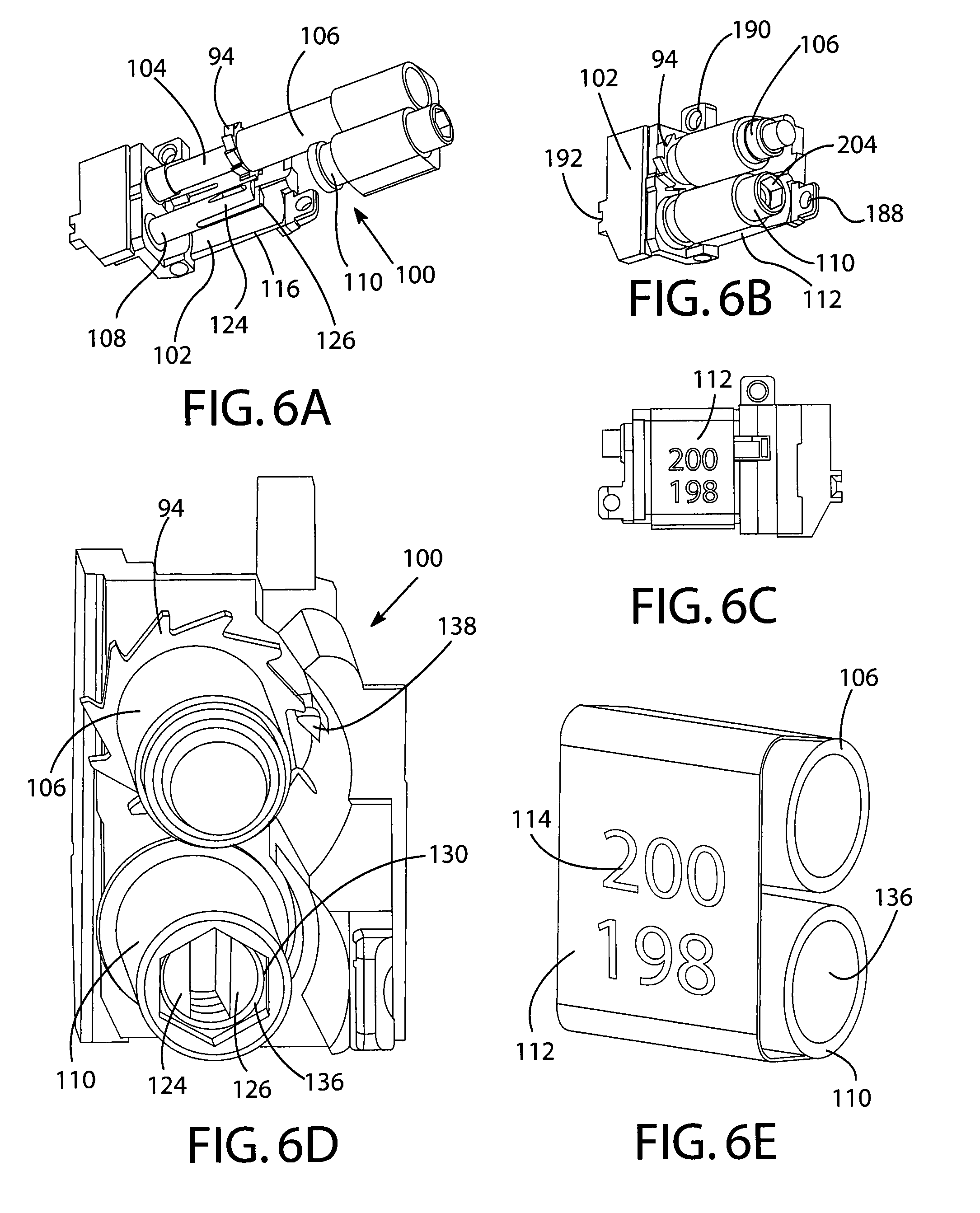

Dose counters for inhalers, inhalers and methods of assembly thereof

ActiveUS20110283997A1Prevent unwanted motionReliable countingMedical devicesLiquid transferring devicesBobbinEngineering

A manually operated metered dose inhaler includes a dose counter chamber including a dose display tape driven by a ratchet wheel which is driven in turn by an actuator pawl actuated by movement of a canister, the tape unwinding from a stock bobbin during use of the inhaler, a rotation regulator being provided for the stock bobbin and including a wavelike engagement surface with concavities which engage against control elements in the form of protrusions on resilient forks of a split pin thereby permitting incremental unwinding of the stock bobbin yet resisting excessive rotation if the inhaler is dropped onto a hard surface.

Owner:TEVA PHARMA IRELAND +2

Stator cooling

The present invention is an energy storage apparatus having a rotor and a stator. The stator includes a bobbin having a cylindrical shape and open at each end. The bobbin includes at least one fin extending longitudinally on an exterior surface of the bobbin. The bobbin also includes a phase winding longitudinally and circumferentially encircling said bobbin. The winding is separated by at least one fin. The bobbin also includes at least one cooling passage for transporting a cooling medium.

Owner:FCA US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com