Patents

Literature

3188 results about "Assembly systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

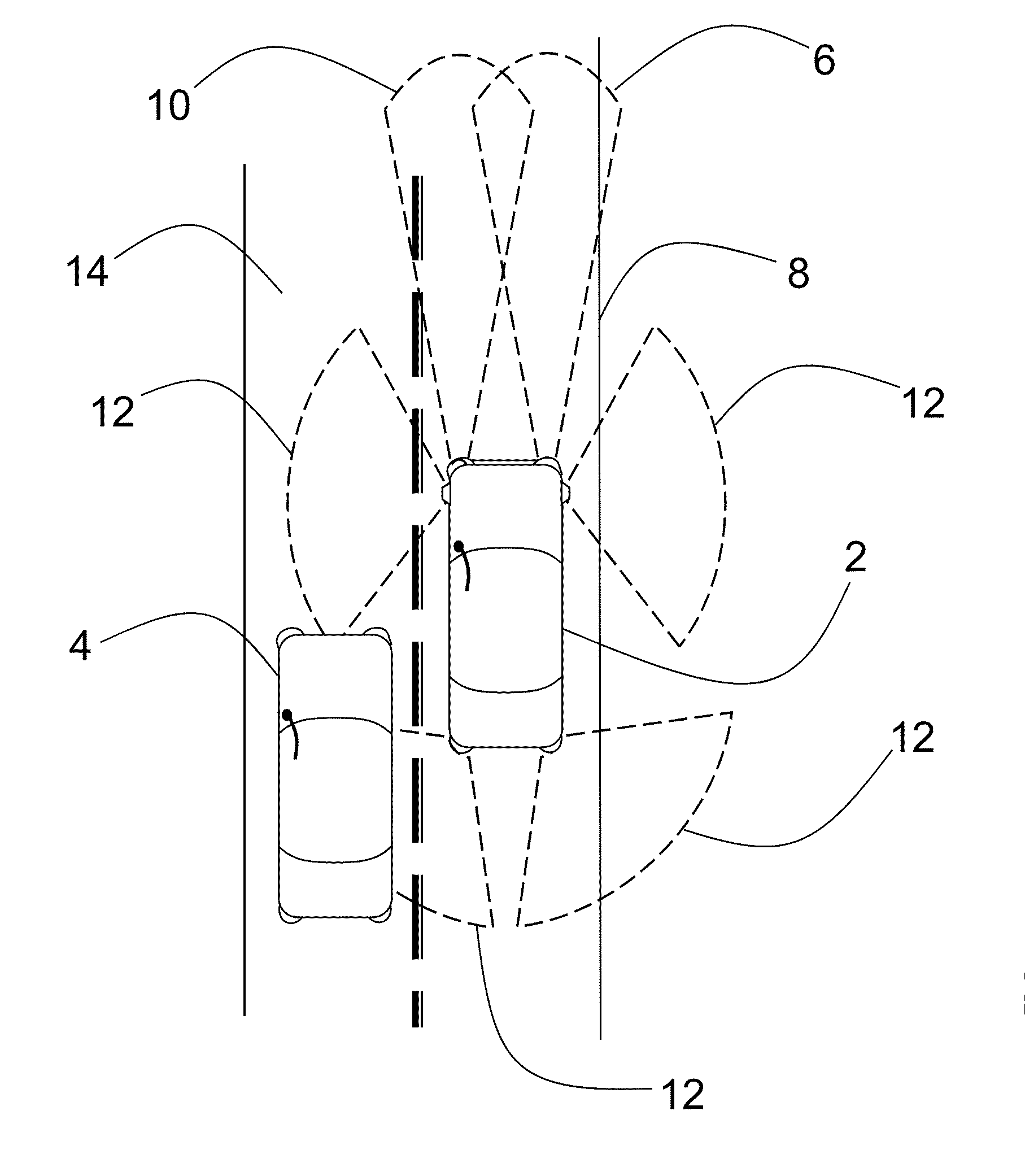

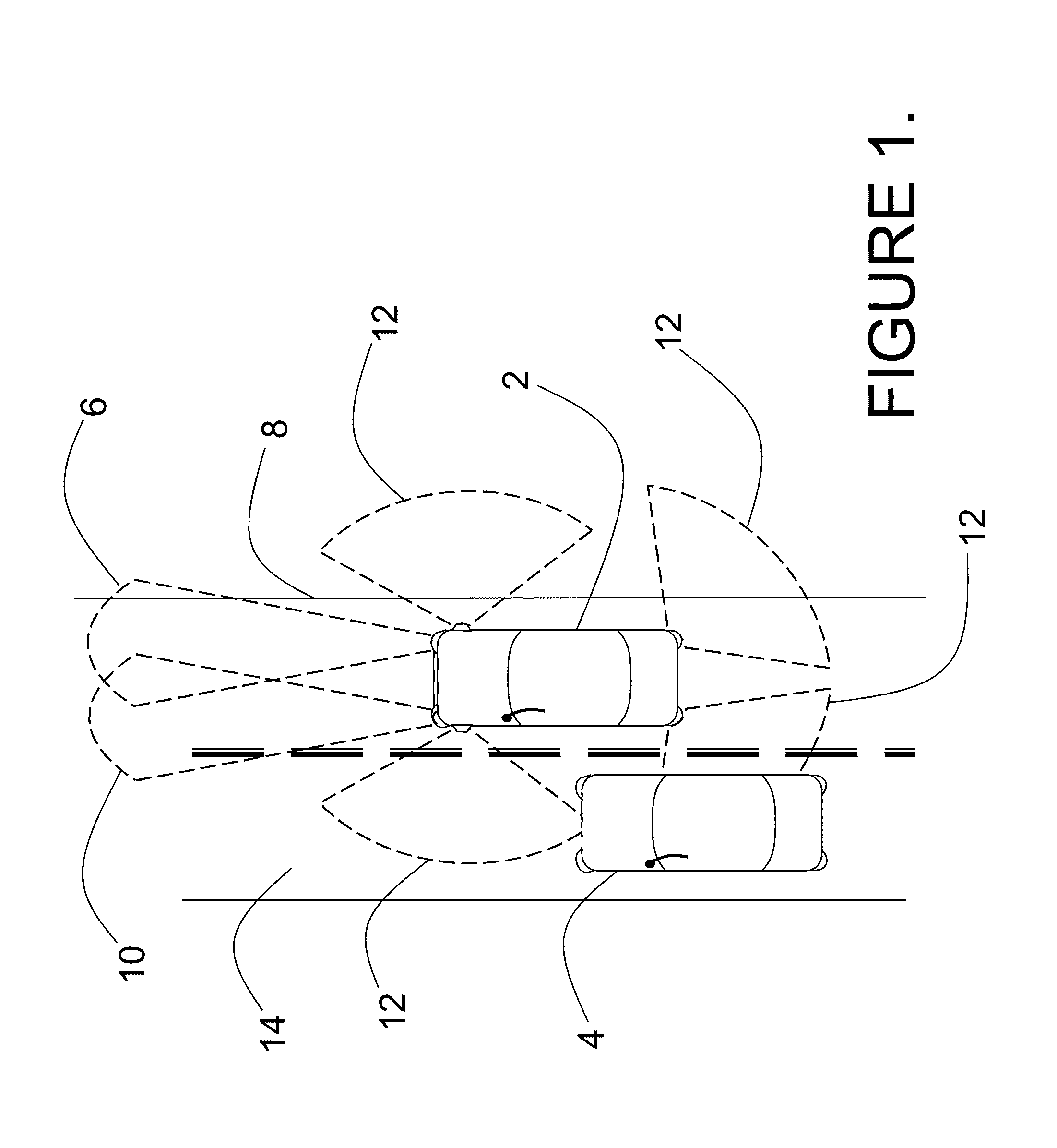

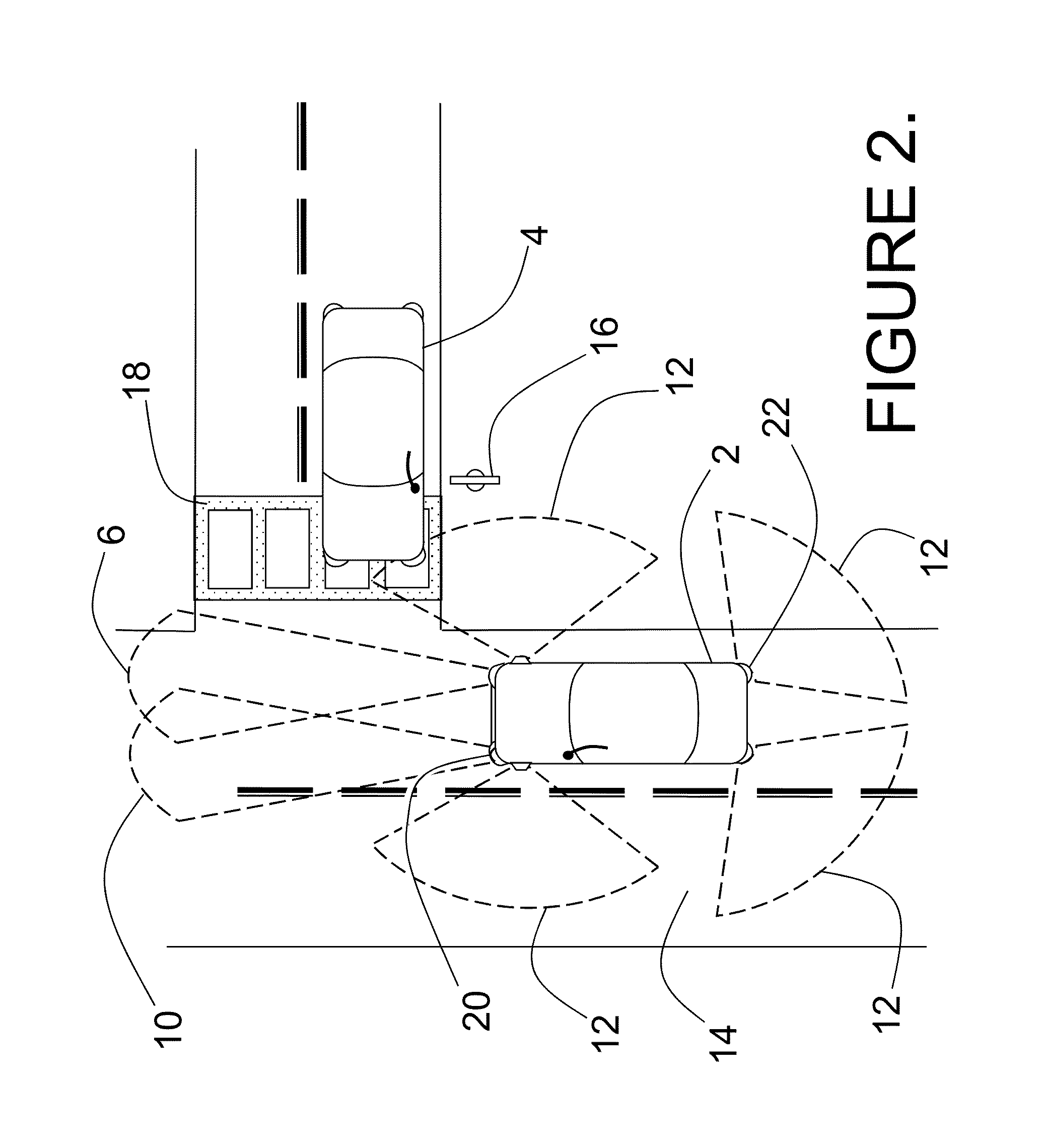

Automotive auxiliary ladar sensor

A vehicle and ladar sensor assembly system is proposed which makes use of forward mounted long range ladar sensors and short range ladar sensors mounted in auxiliary lamps to identify obstacles and to identify potential collisions with the vehicle. A low cost assembly is developed which can be easily mounted within a body panel cutout of a vehicle, and which connects to the vehicle electrical and computer systems through the vehicle wiring harness. The vehicle has a digital processor which interprets 3D data received from the ladar sensor assembly, and which is in control of the vehicle subsystems for steering, braking, acceleration, and suspension. The digital processor onboard the vehicle makes use of the 3D data and the vehicle control subsystems to avoid collisions and steer a best path.

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

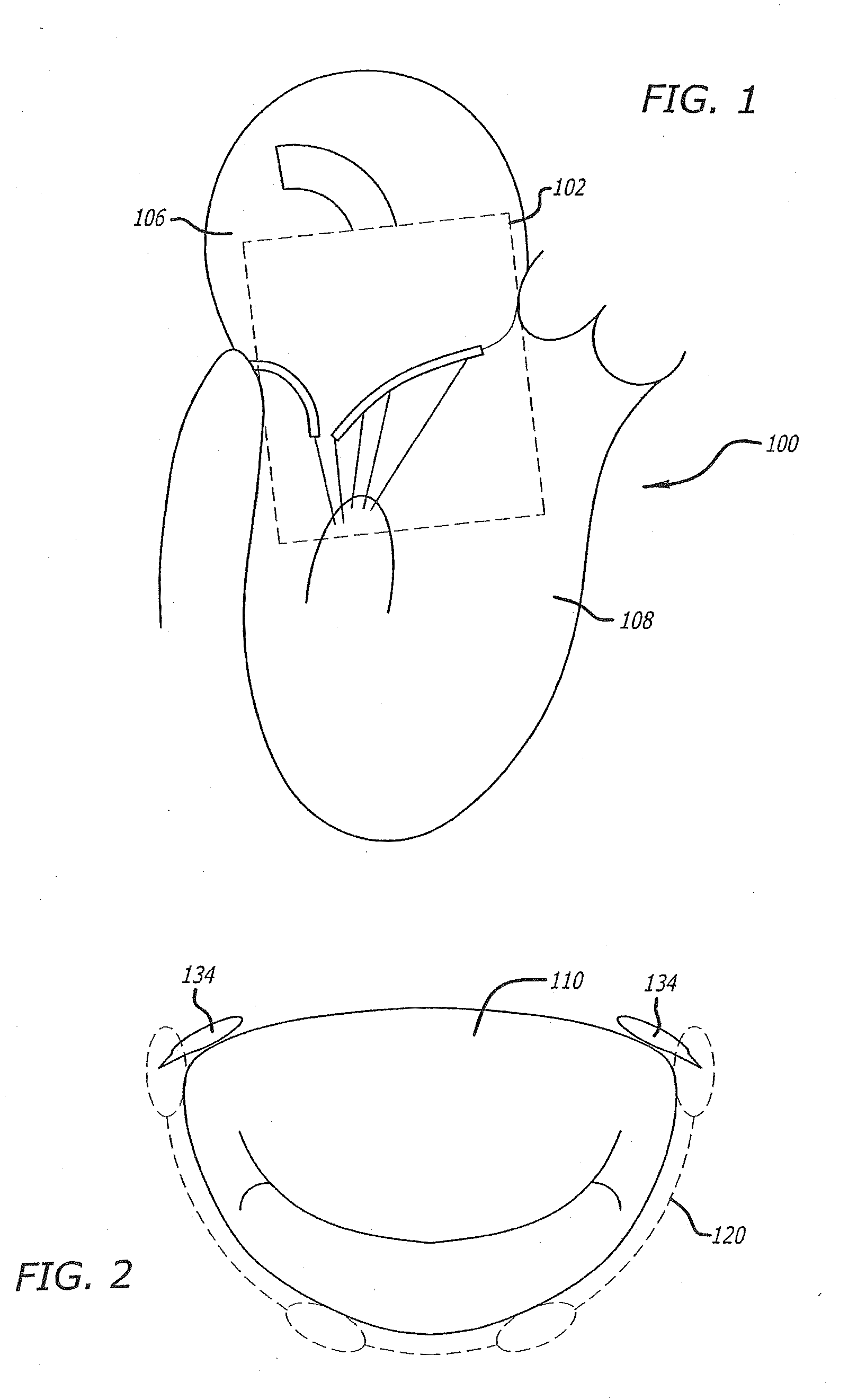

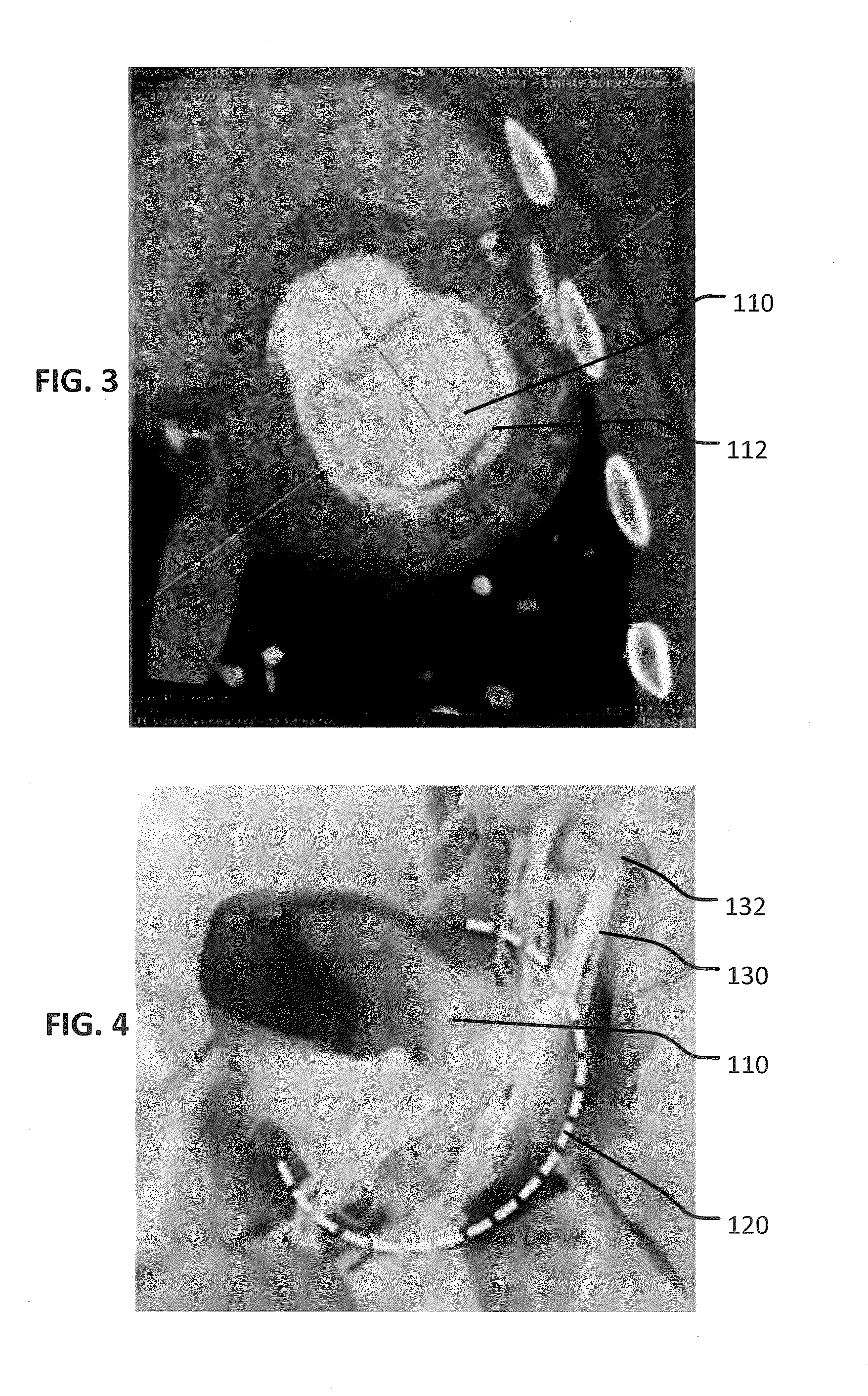

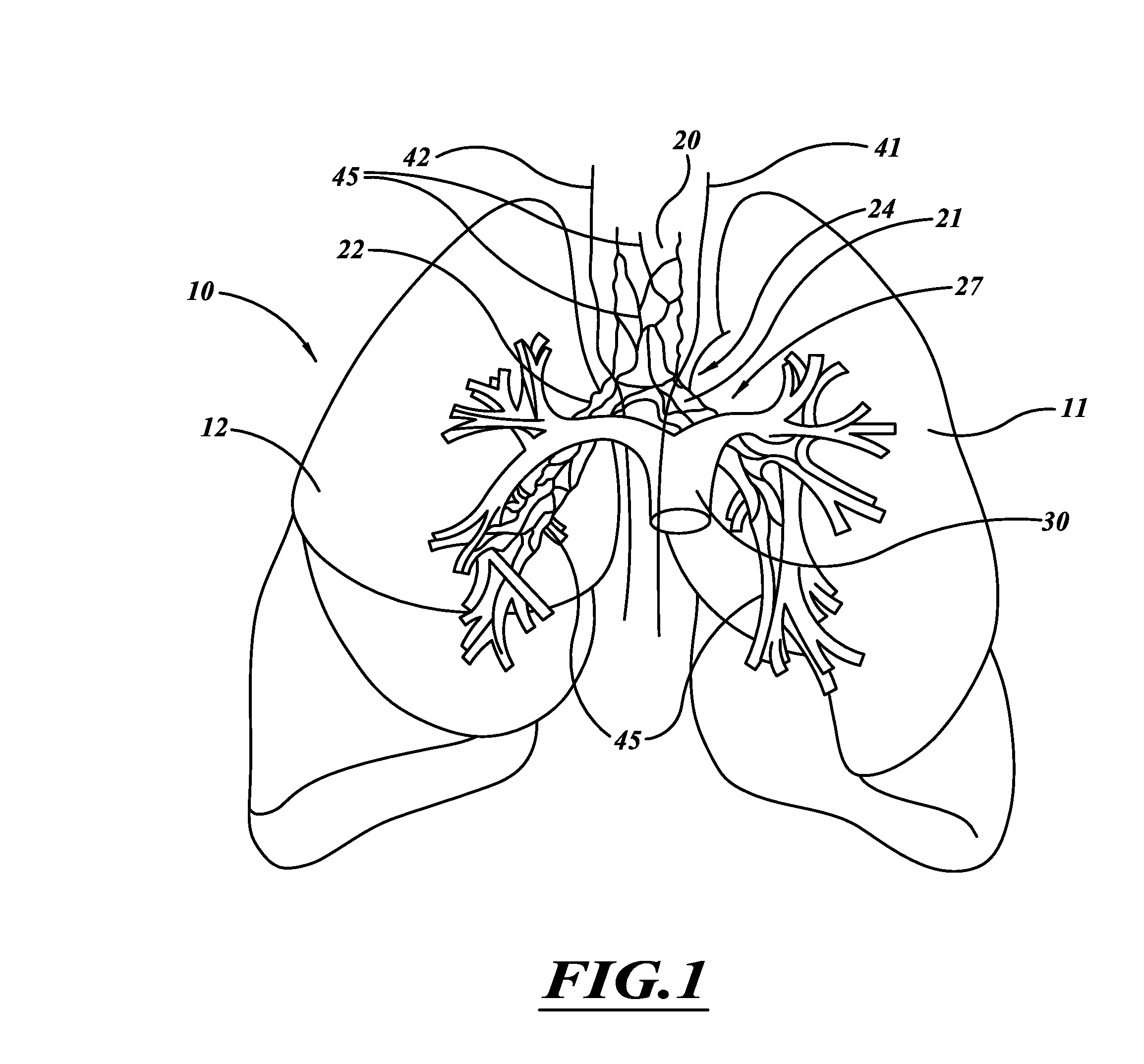

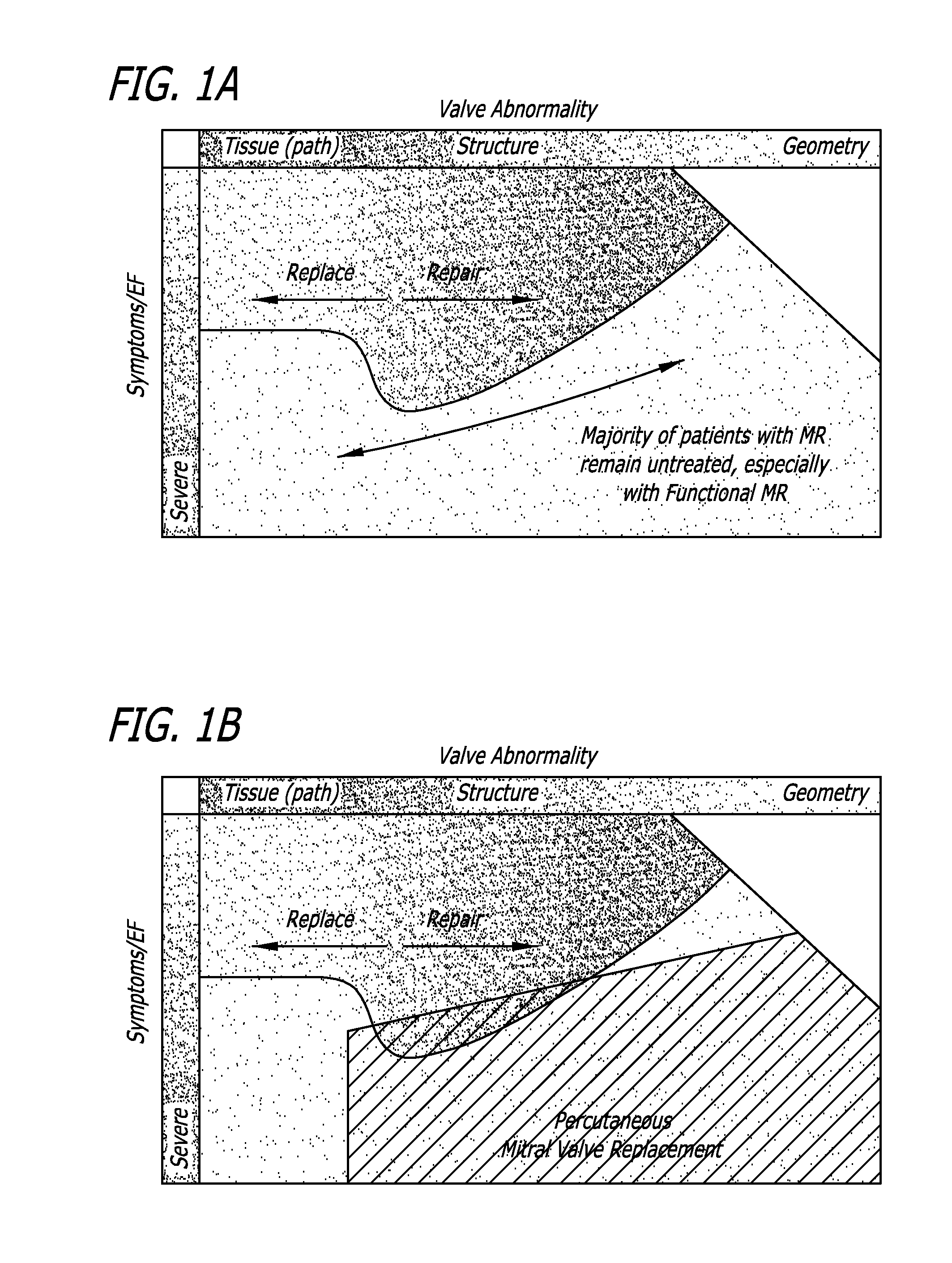

Two stage anchor and mitral valve assembly

ActiveUS20150359629A1Improves LV geometryEasy to implementHeart valvesMitral valve leafletMedical treatment

Systems and methods for medical interventional procedures, including approaches to valve implantation. In one aspect, the methods and systems involve a modular approach to mitral valve therapy.

Owner:CAISSON INT LLC

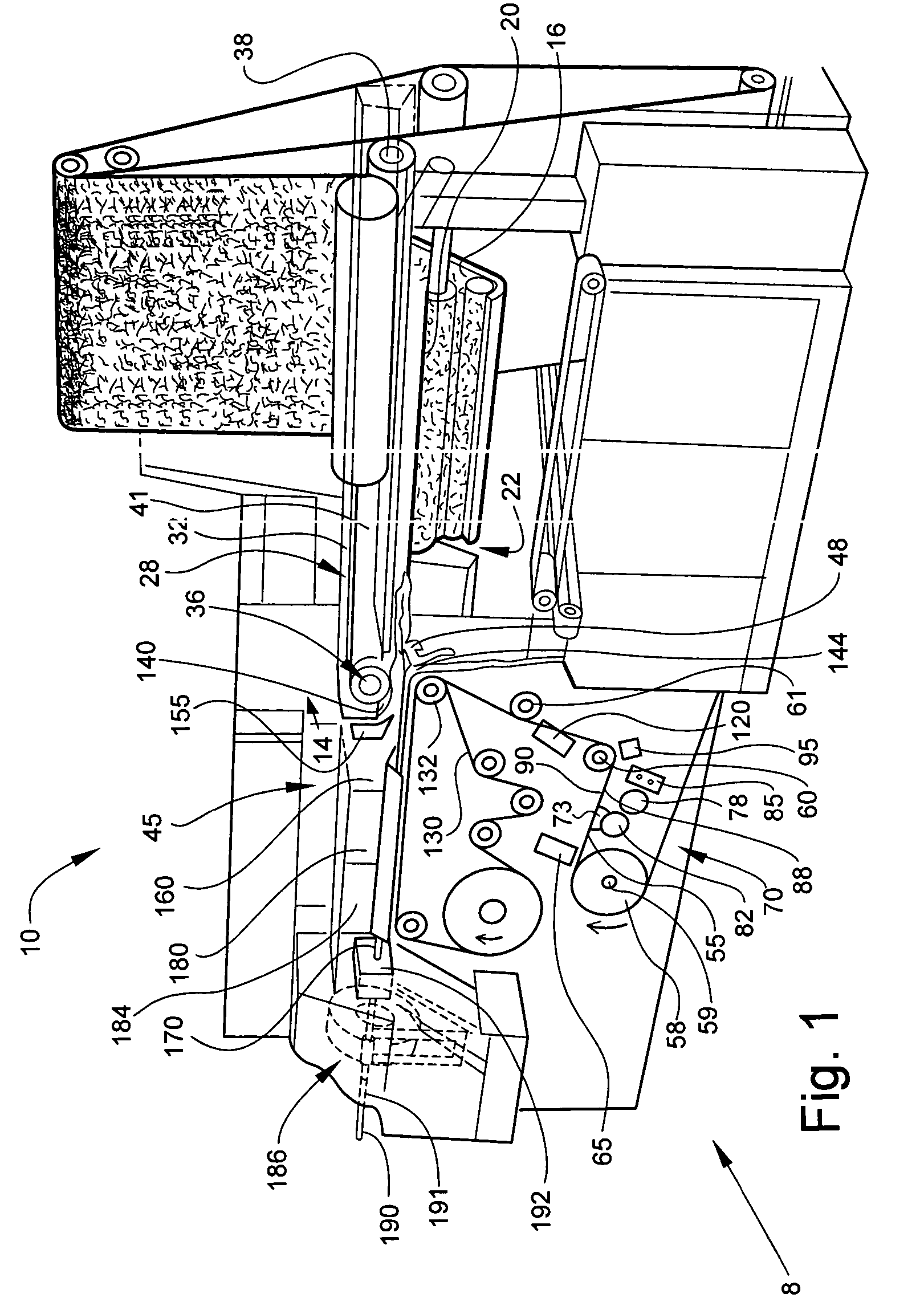

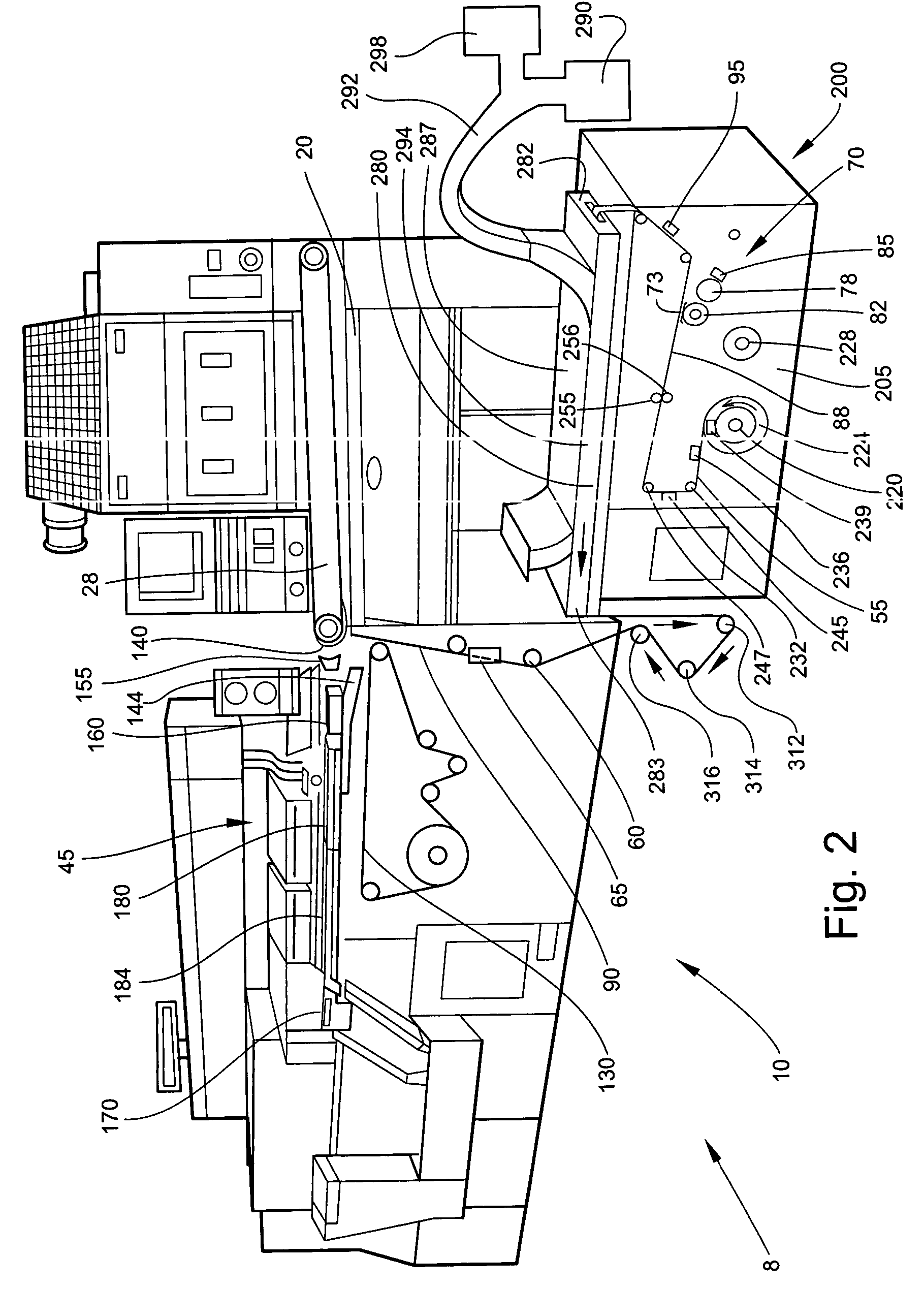

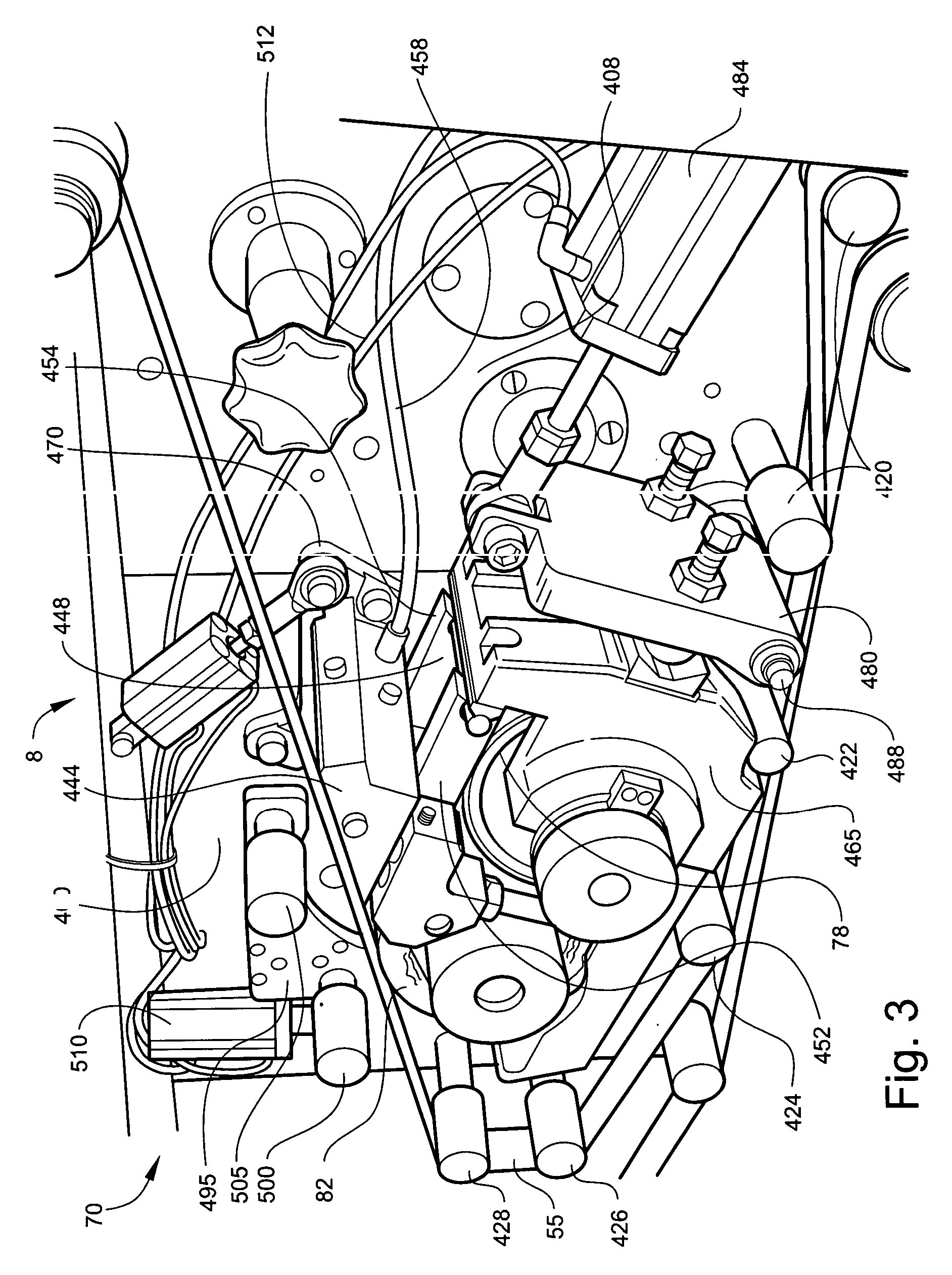

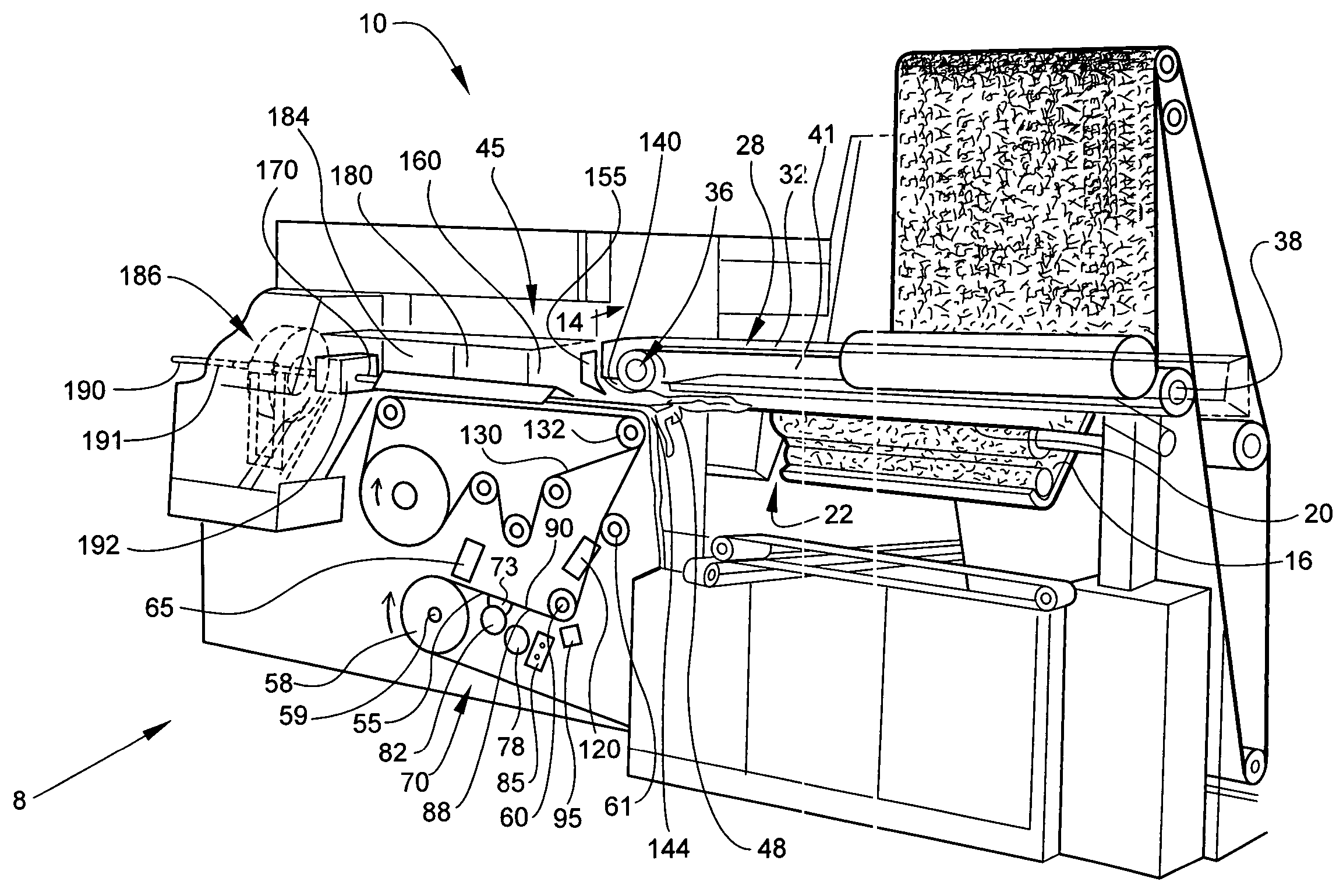

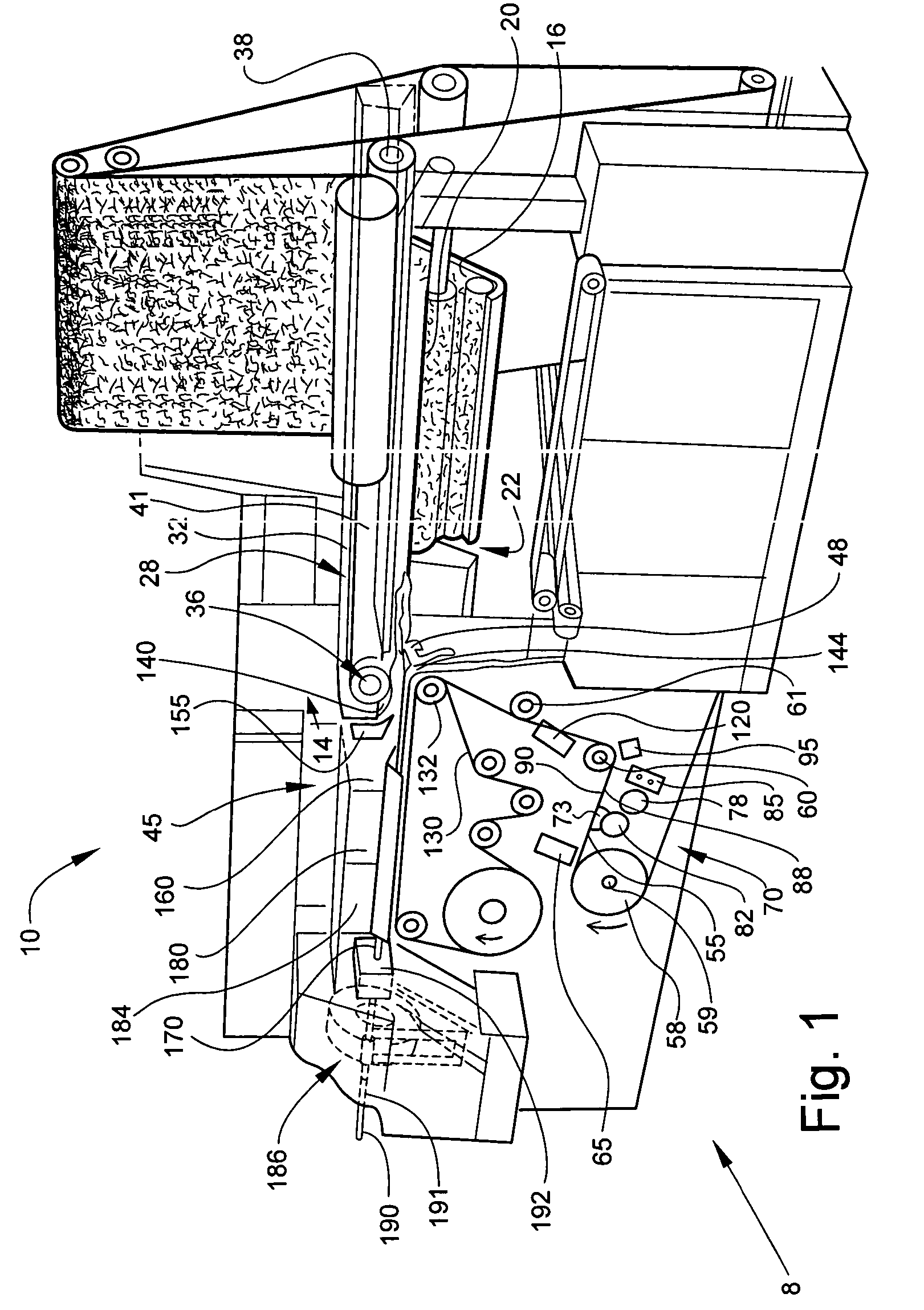

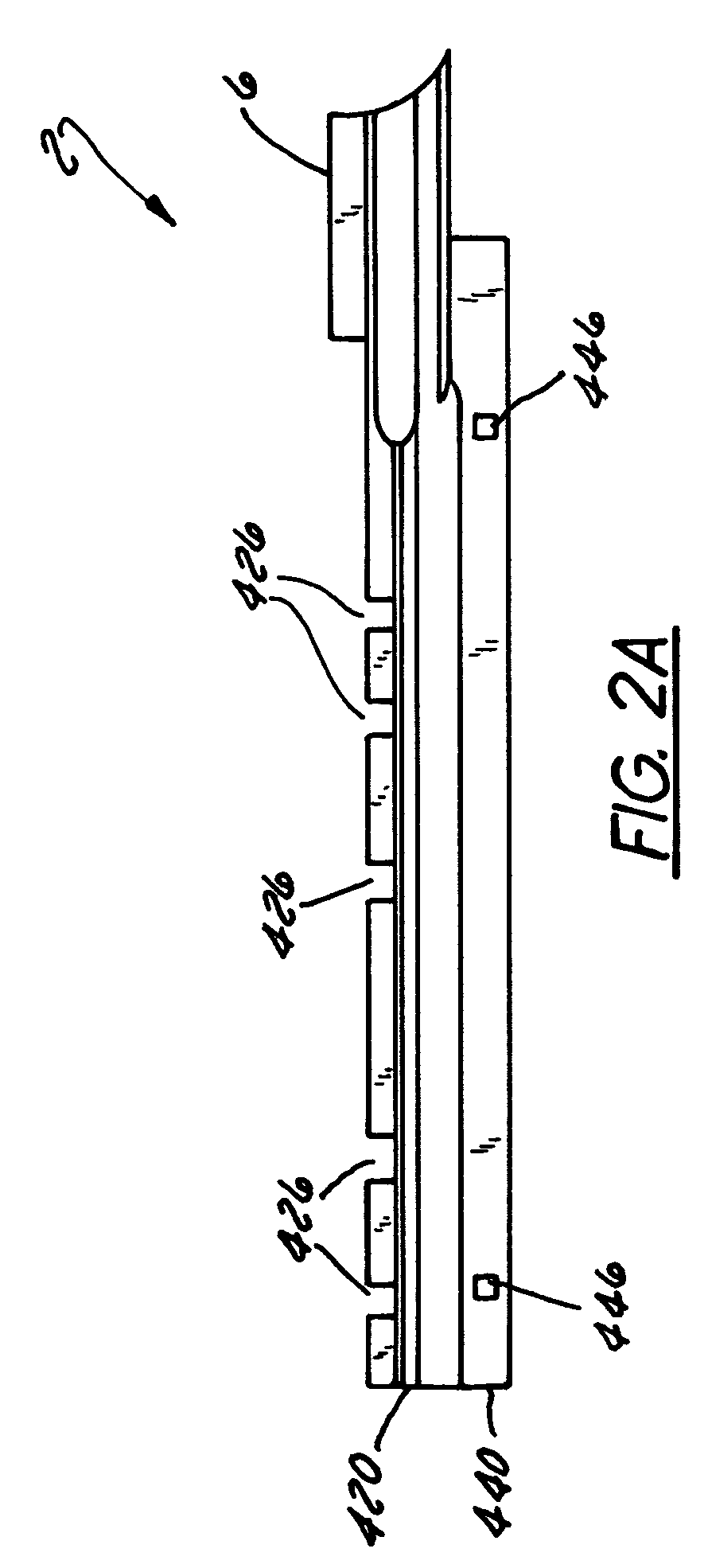

Materials, equipment and methods for manufacturing cigarettes

ActiveUS20050076929A1Minimize and avoid and prevent transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinAssembly systems

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers a series of roller. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. An alternate assembly system provides a source of paper web, applies additive material to that web in a pattern, dries the paper web, and winds the treated paper web on to a bobbin; and that bobbin is later used to provide a source of paper web on a cigarette making machine unrolls that bobbin, receives the treated paper web from that bobbin, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

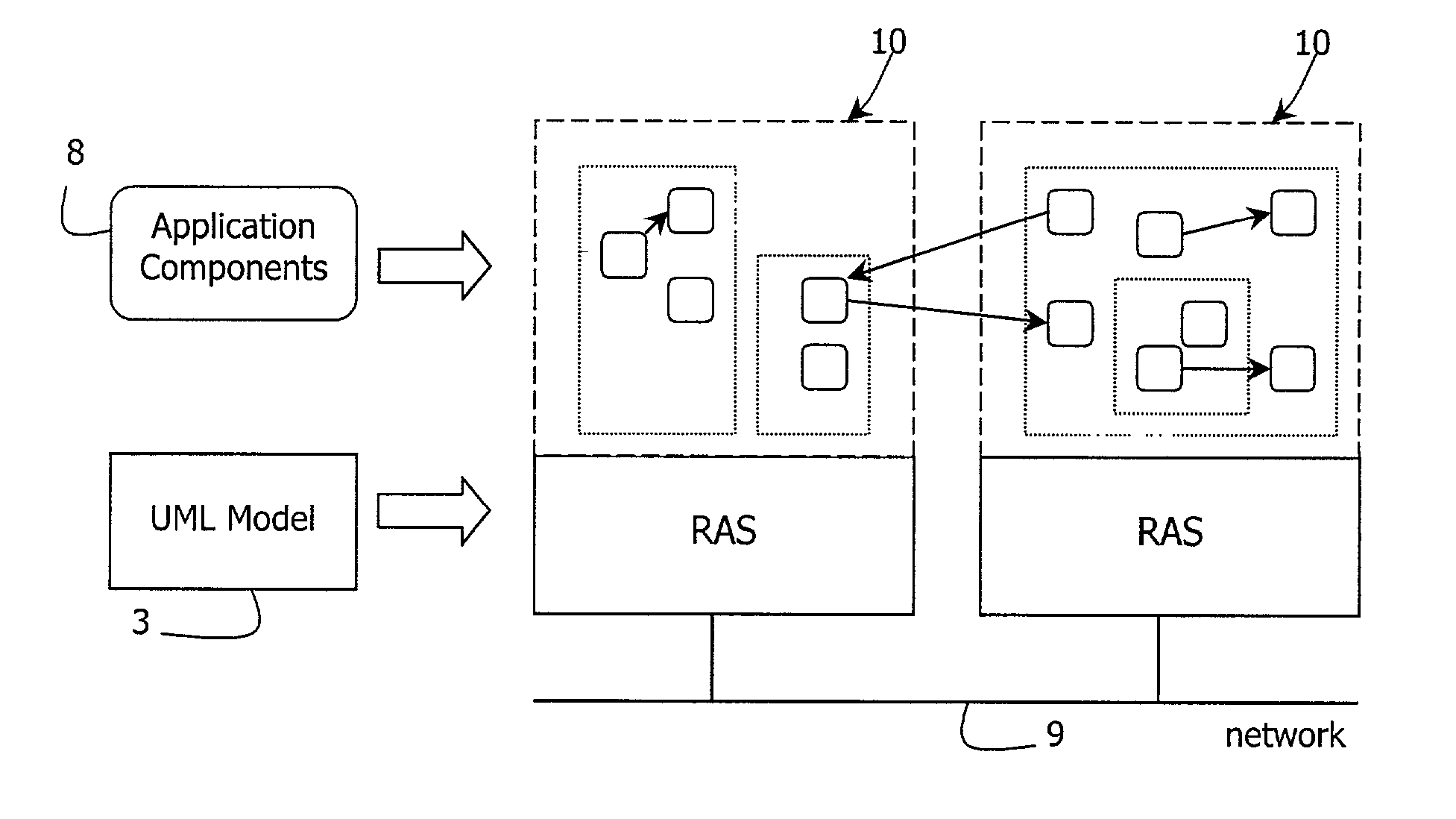

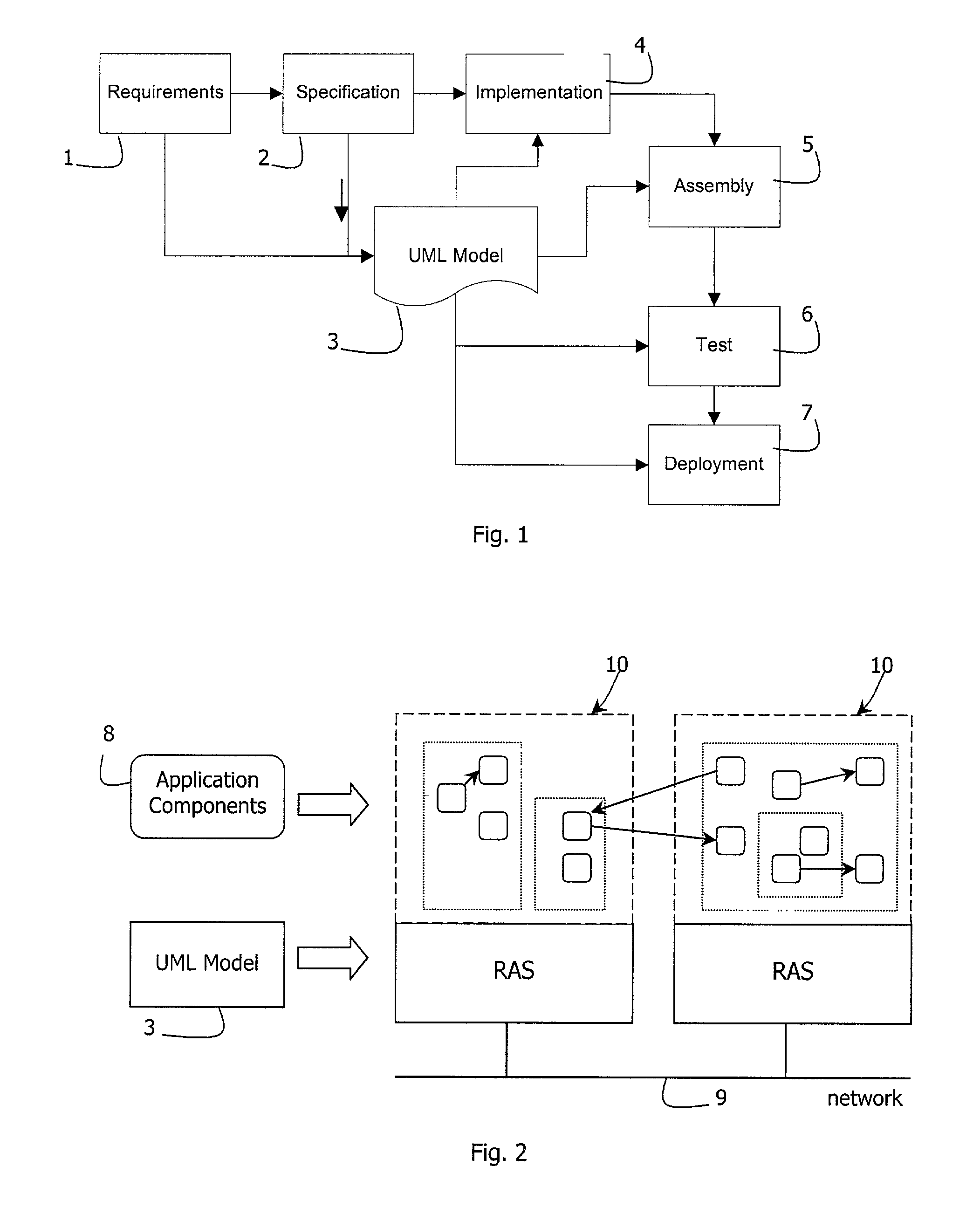

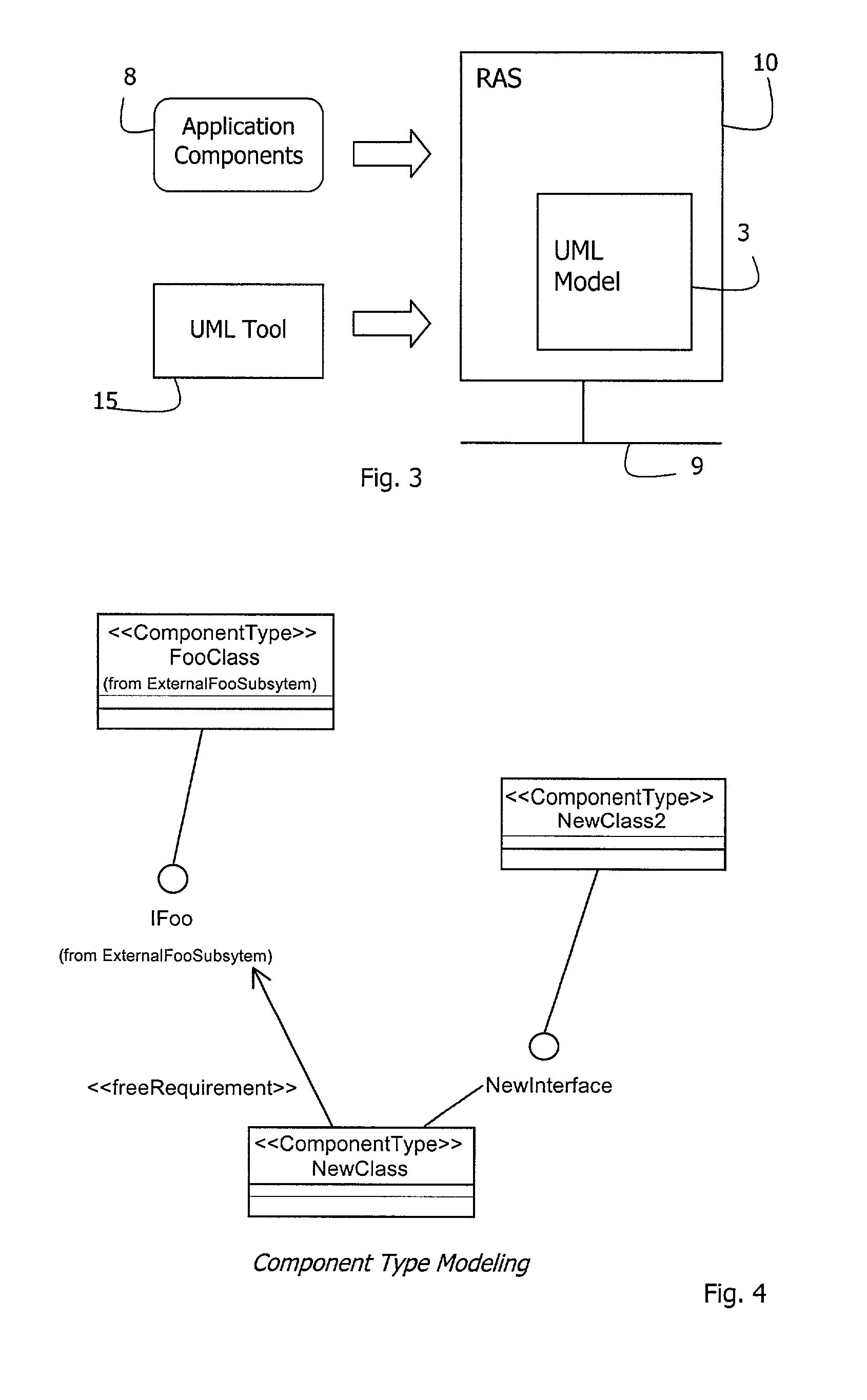

Software development process

InactiveUS20020104068A1Increase flexibilitySoftware designSpecific program execution arrangementsSoftware development processSoftware system

A flexible component-based software system is developed by generating a UML model (3) in a specification phase (4). Components are generated in an implementation phase (4). The UML model (3) is transformed to a meta model. A runtime architecture service (RAS, 10) dynamically assembles a system in runtime according to the meta model. A modelling tool (15) modifies the meta model via an API (34) and a meta modeller (31). This allows dynamic re-configuration of the system.

Owner:WILDE TECH

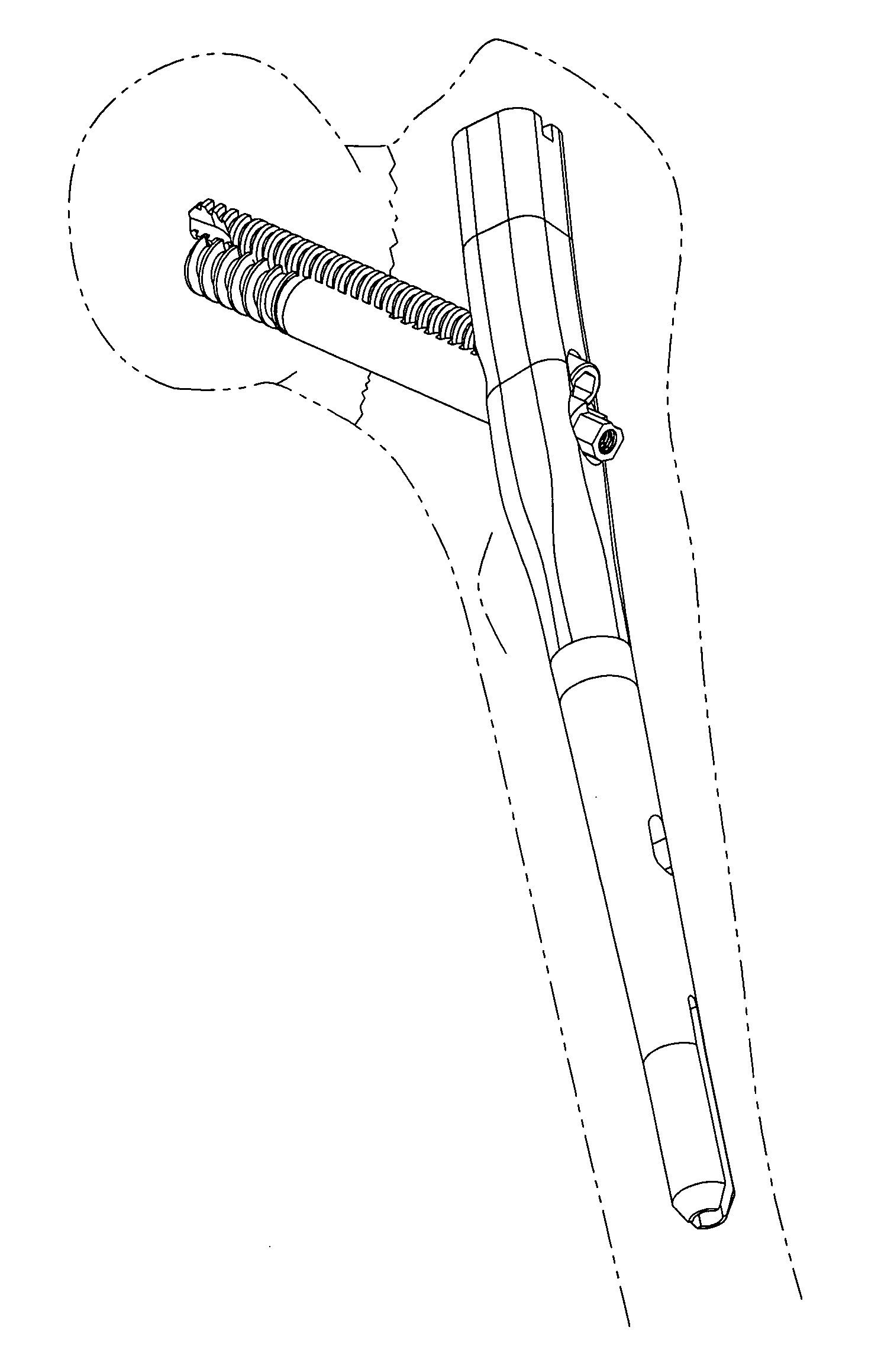

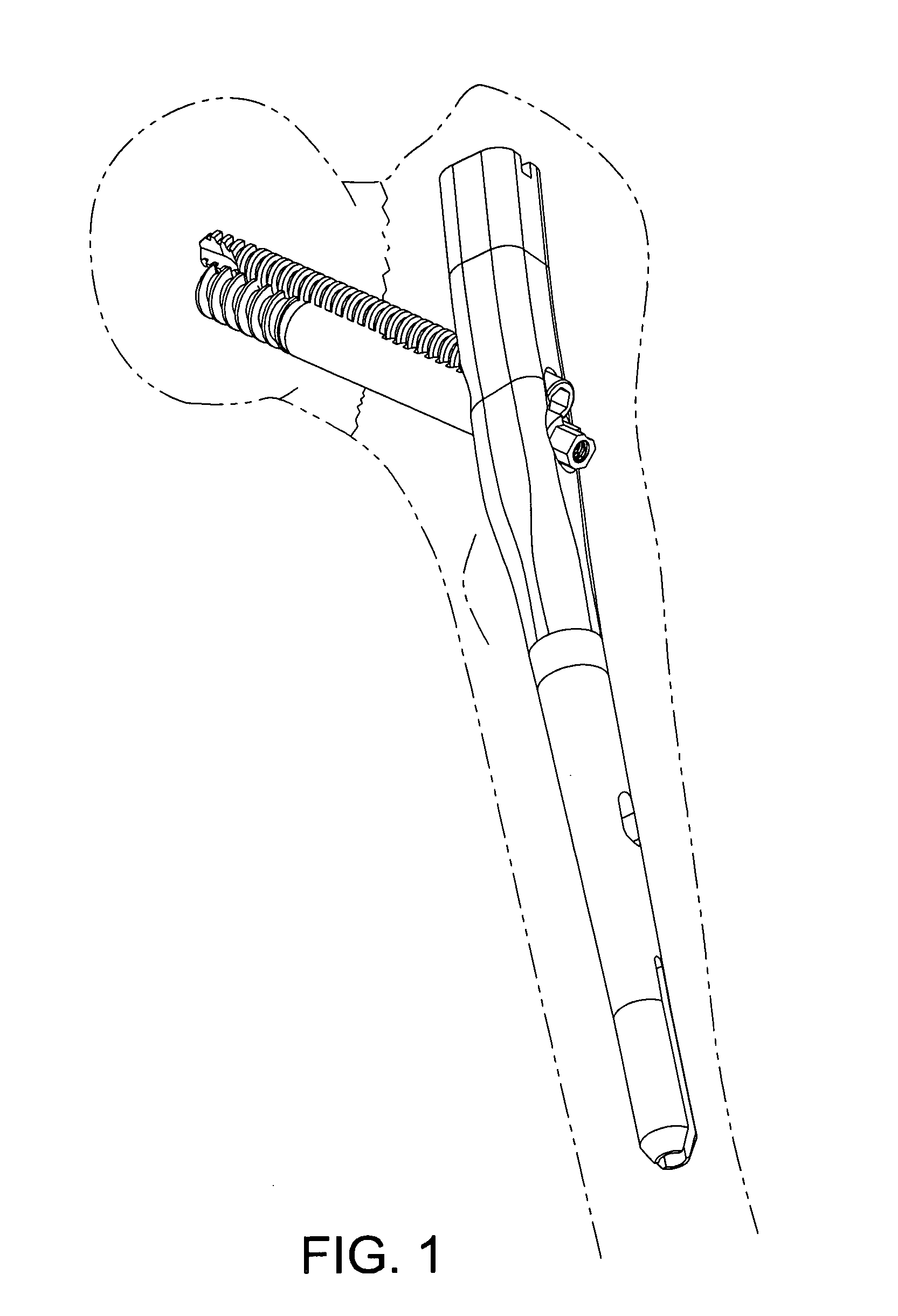

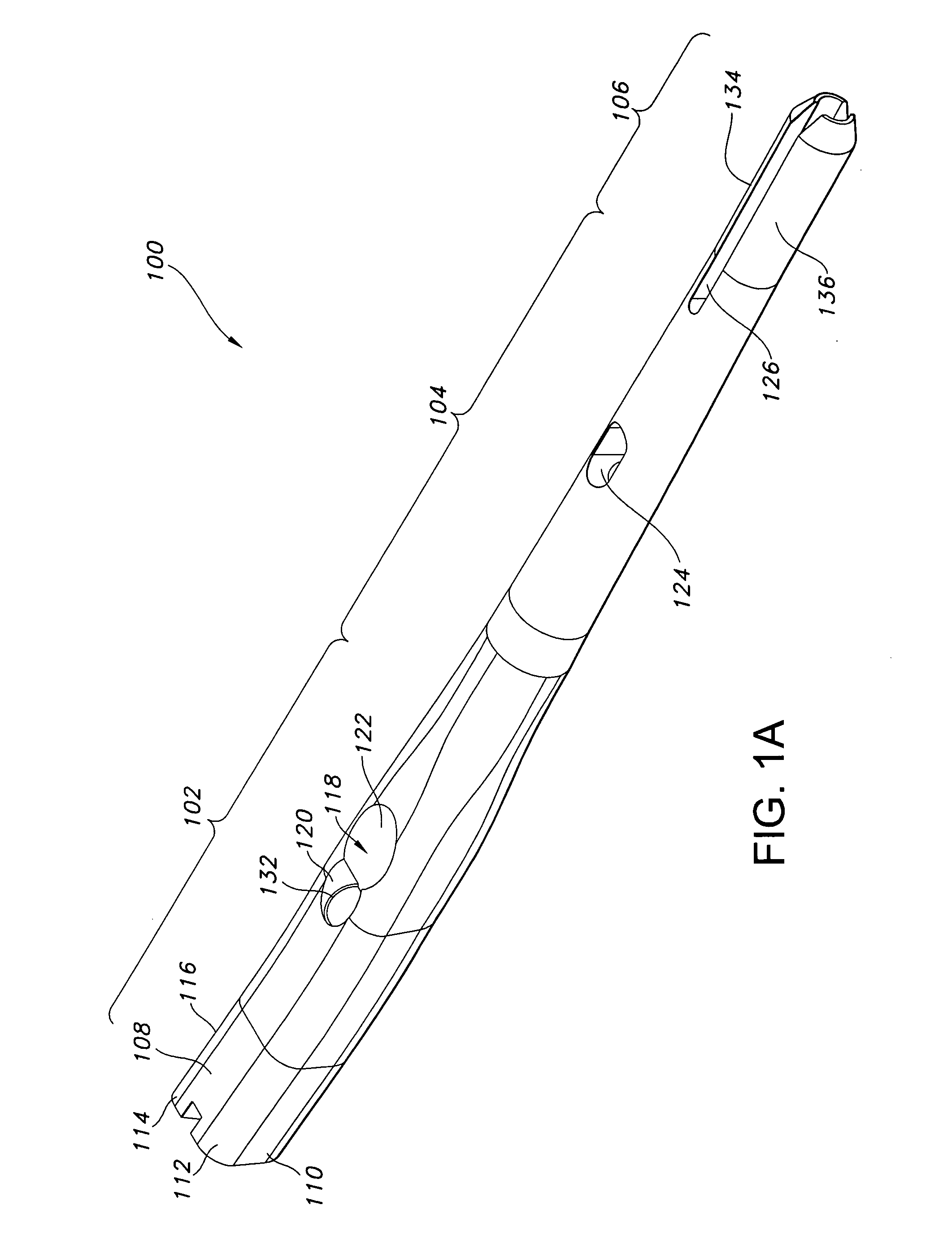

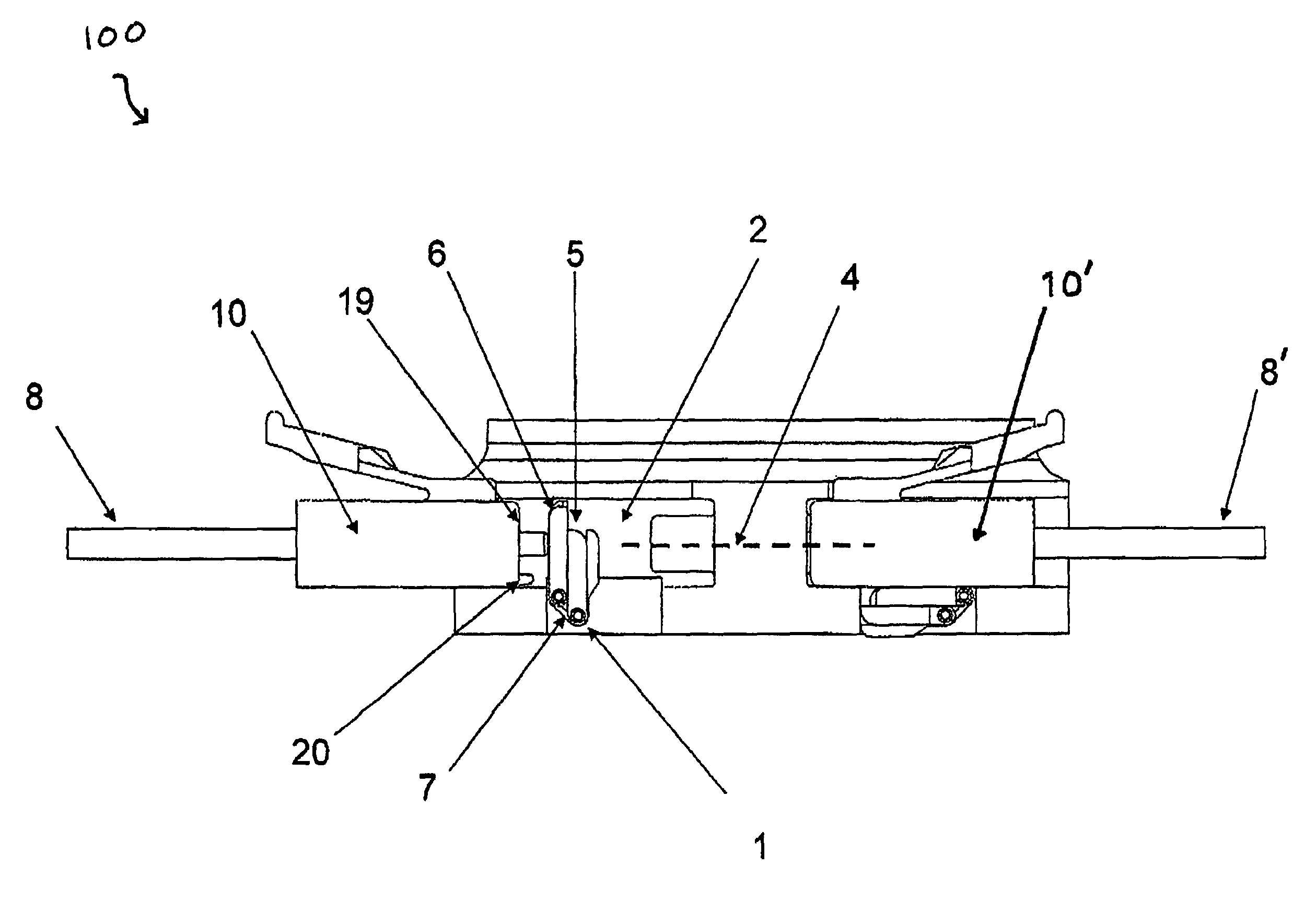

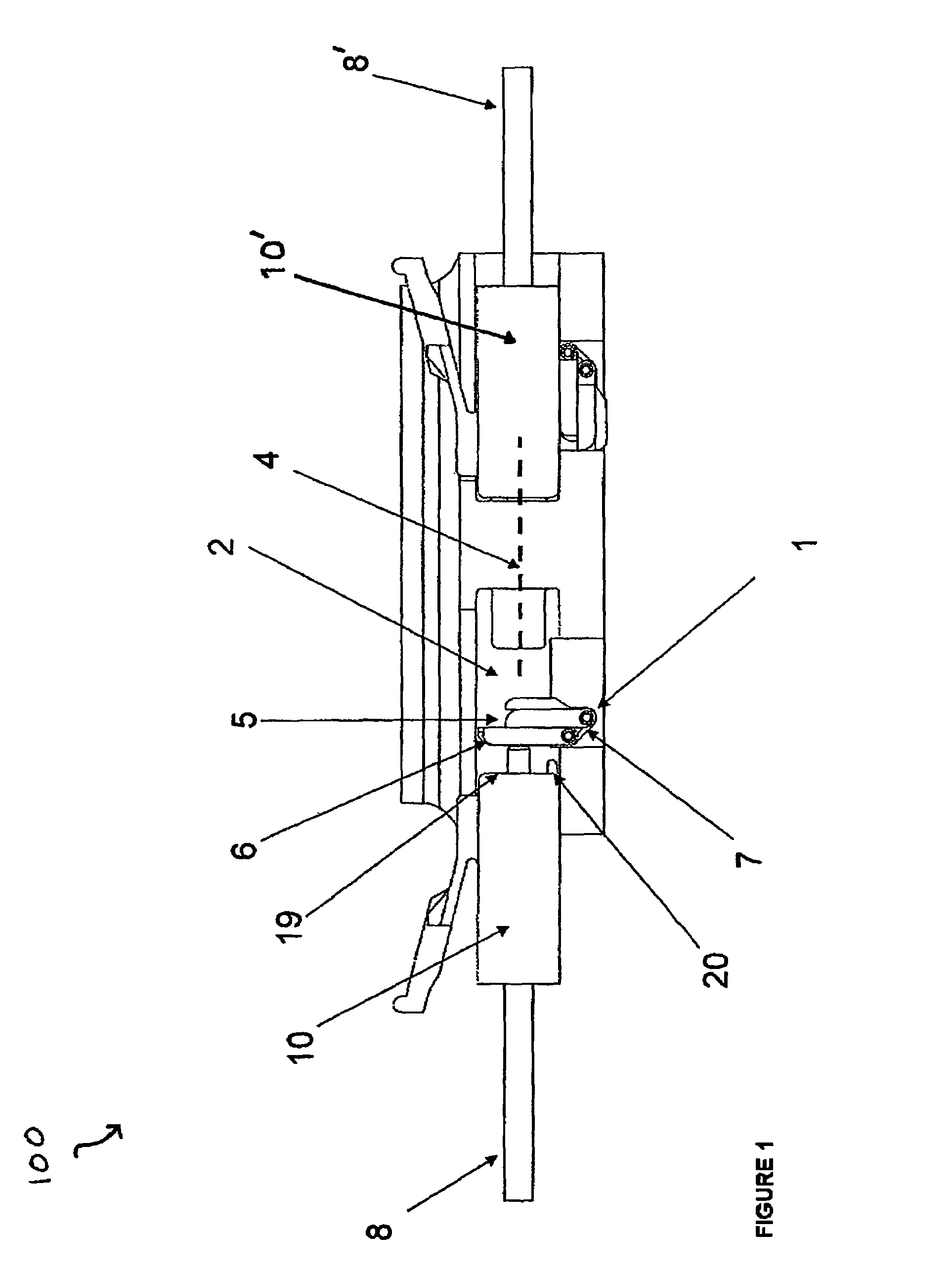

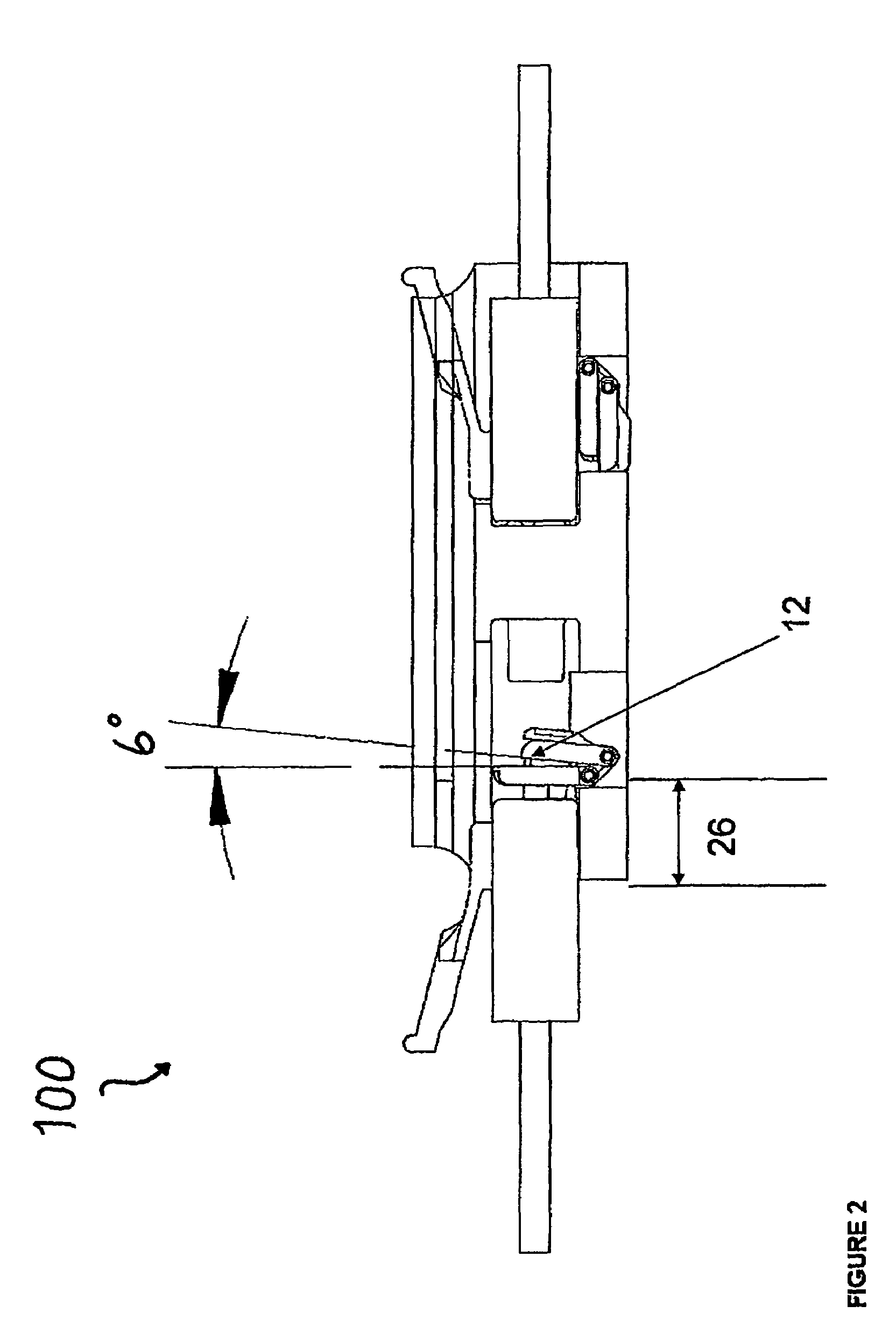

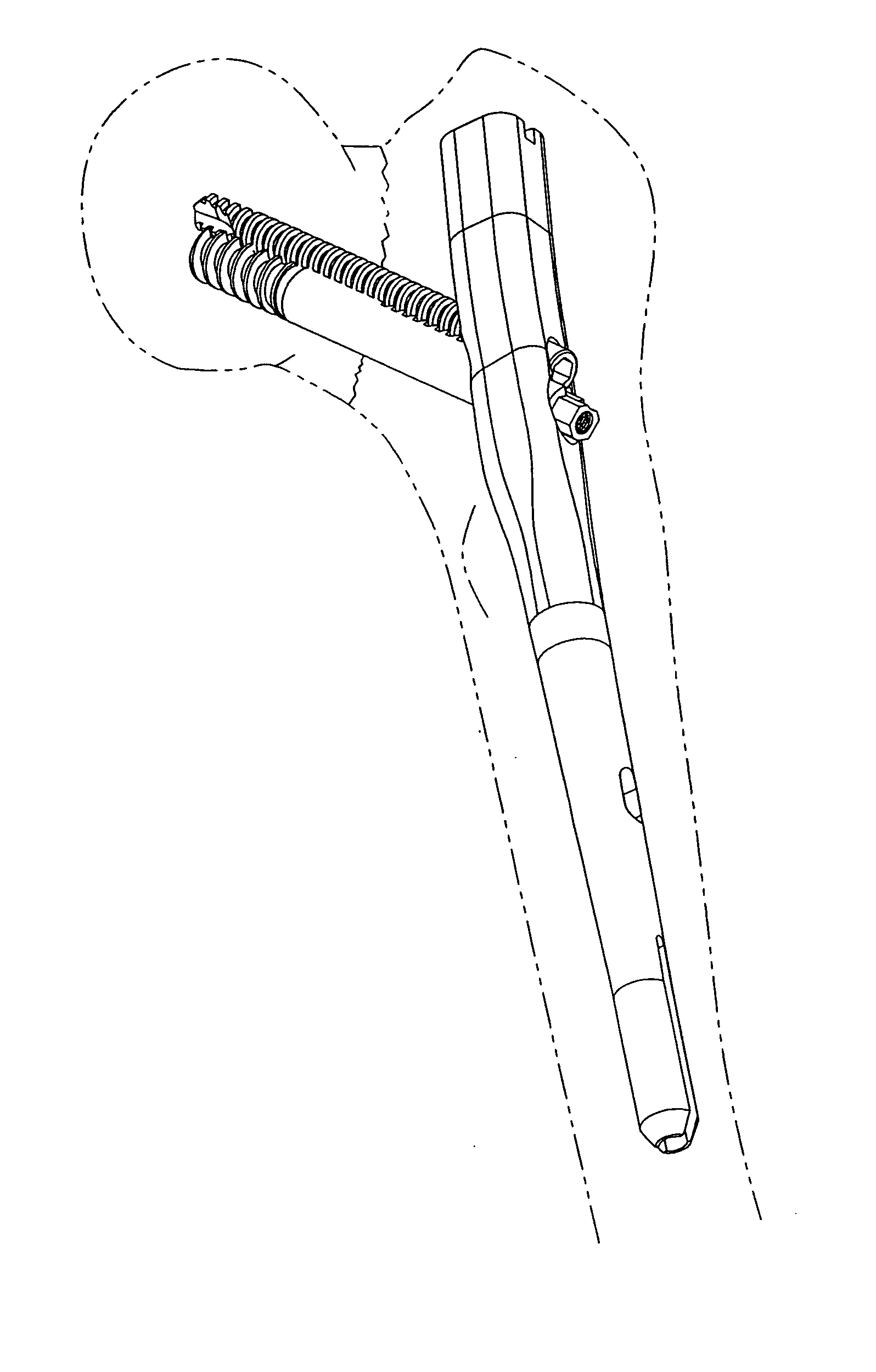

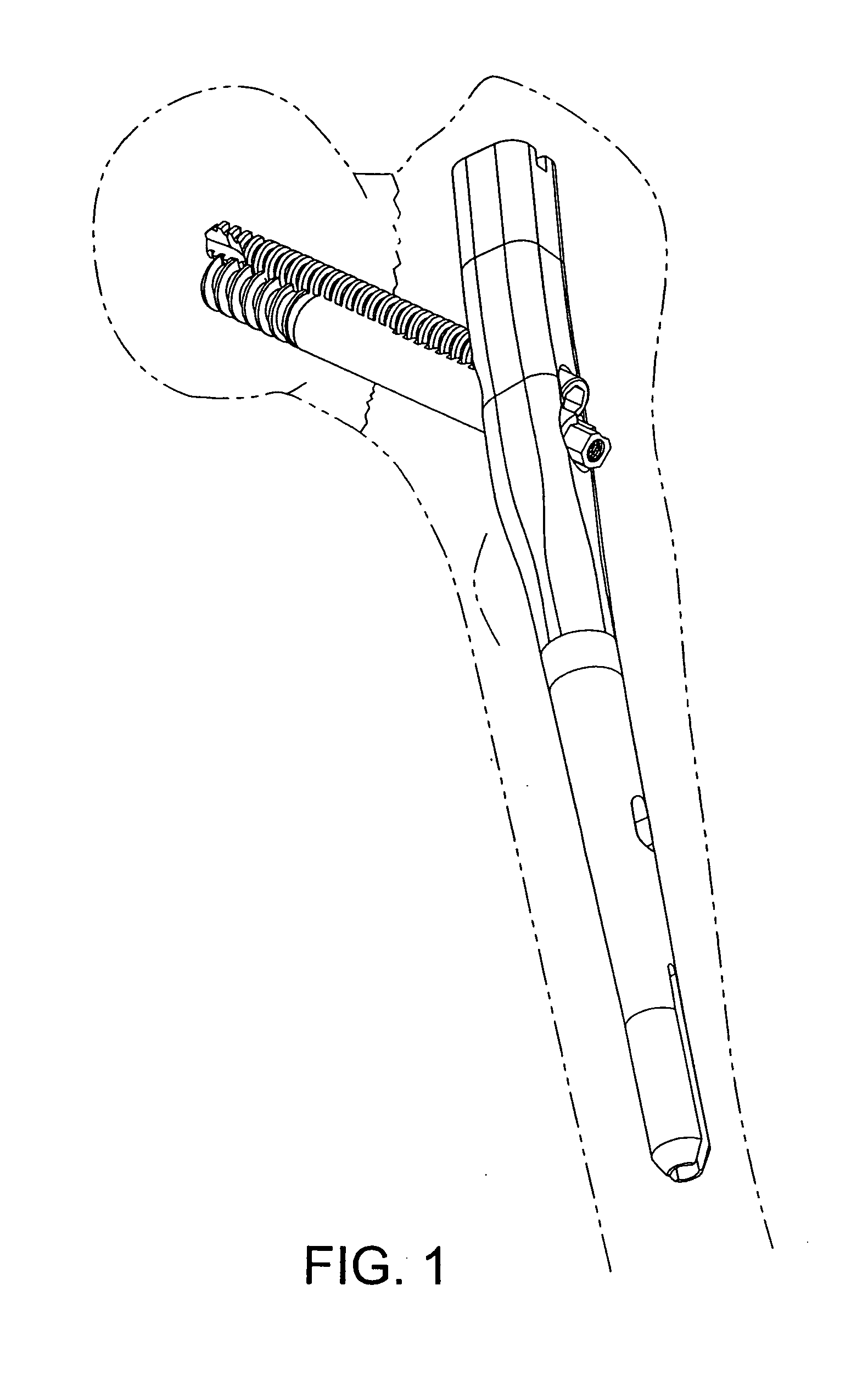

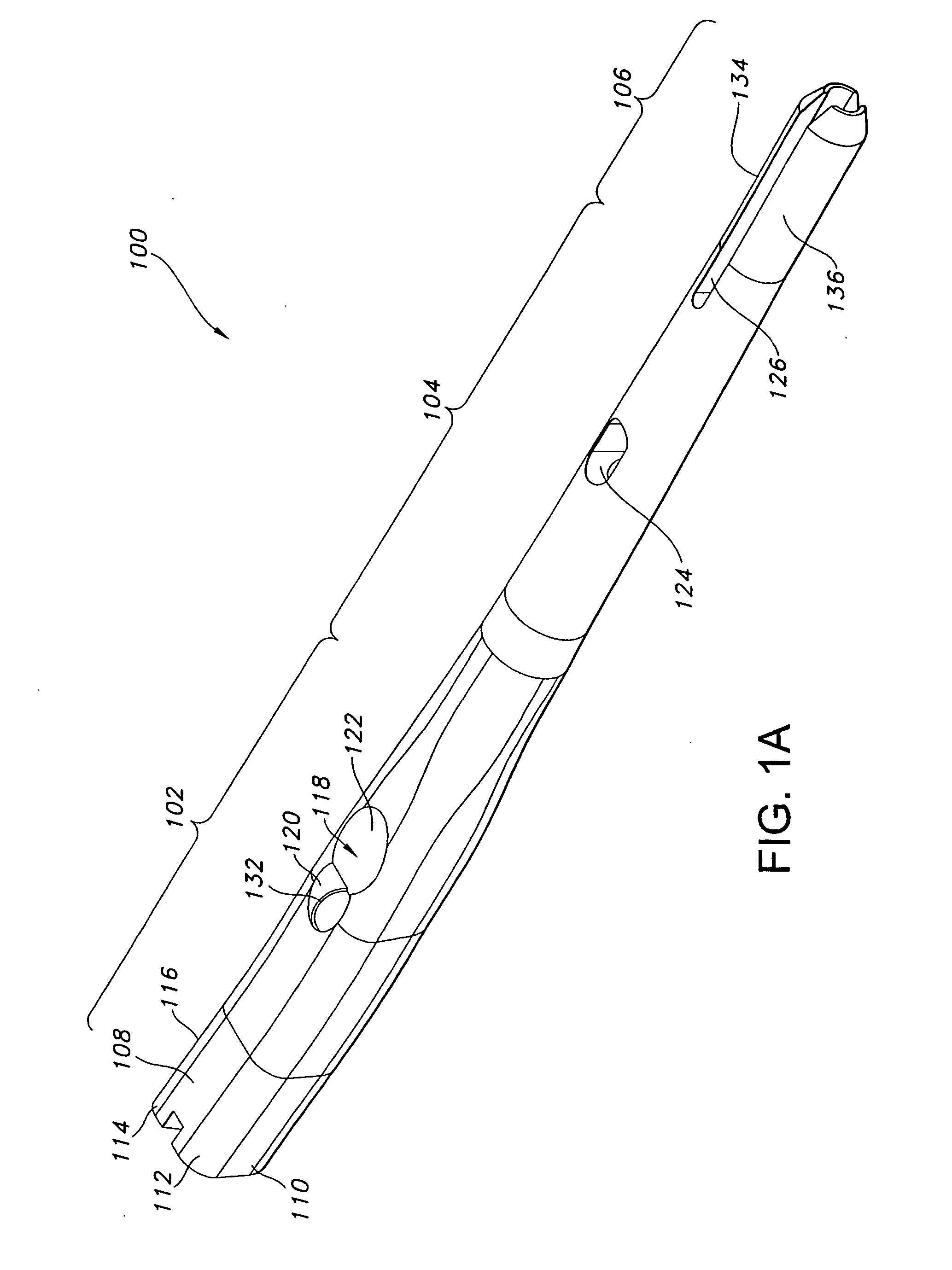

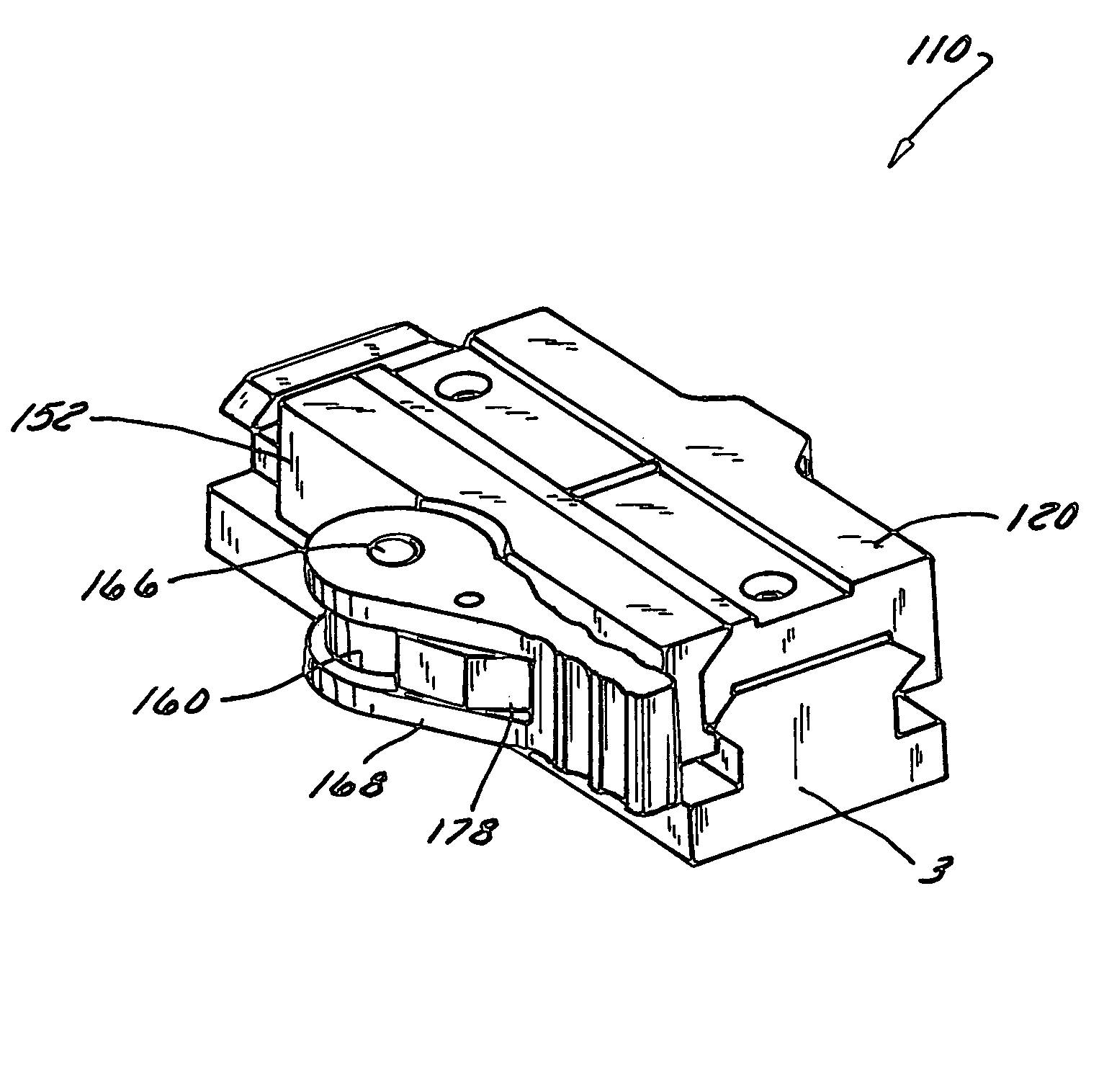

Orthopaedic implant and screw assembly

InactiveUS20050055024A1High strengthIncrease resistanceInternal osteosythesisJoint implantsCompression deviceEngineering

Systems, devices and methods are disclosed for treating fractures. The systems, devices and methods may include one or both of an implant, such as an intramedullary nail, and a fastening assembly, such as a lag screw and compression screw assembly. The implant in some embodiments has a proximal section with a transverse aperture and a cross-section that may be shaped to more accurately conform to the anatomical shape of cortical bone and to provide additional strength and robustness in its lateral portions, preferably without requiring significant additional material. The fastening assembly may be received to slide, in a controlled way, in the transverse aperture of the implant. In some embodiments, the engaging member and the compression device are configured so that the compression device interacts with a portion of the implant and a portion of the engaging member to enable controlled movement between the first and second bone fragments. This configuration is useful for, among other things, compressing a fracture.

Owner:SMITH & NEPHEW INC

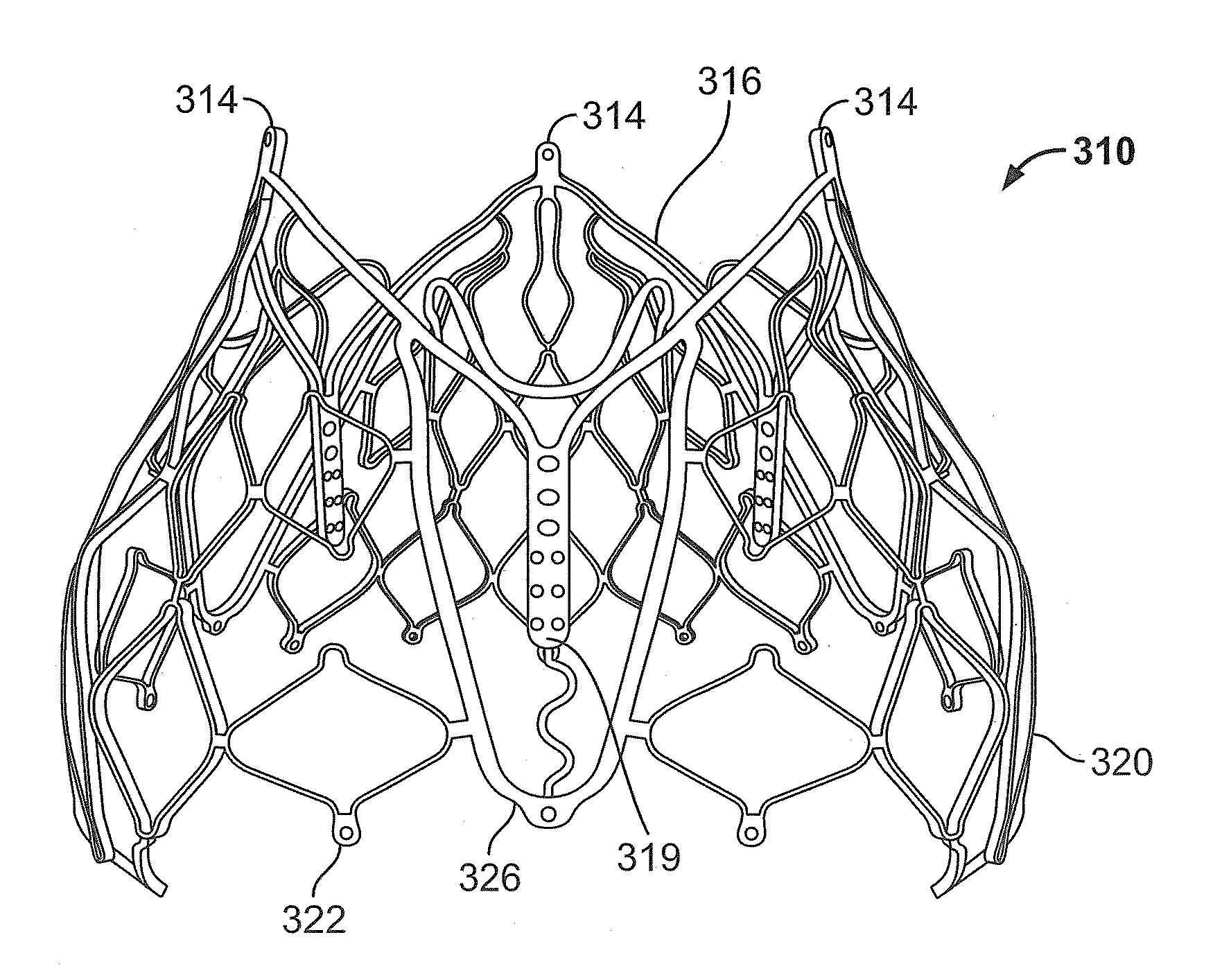

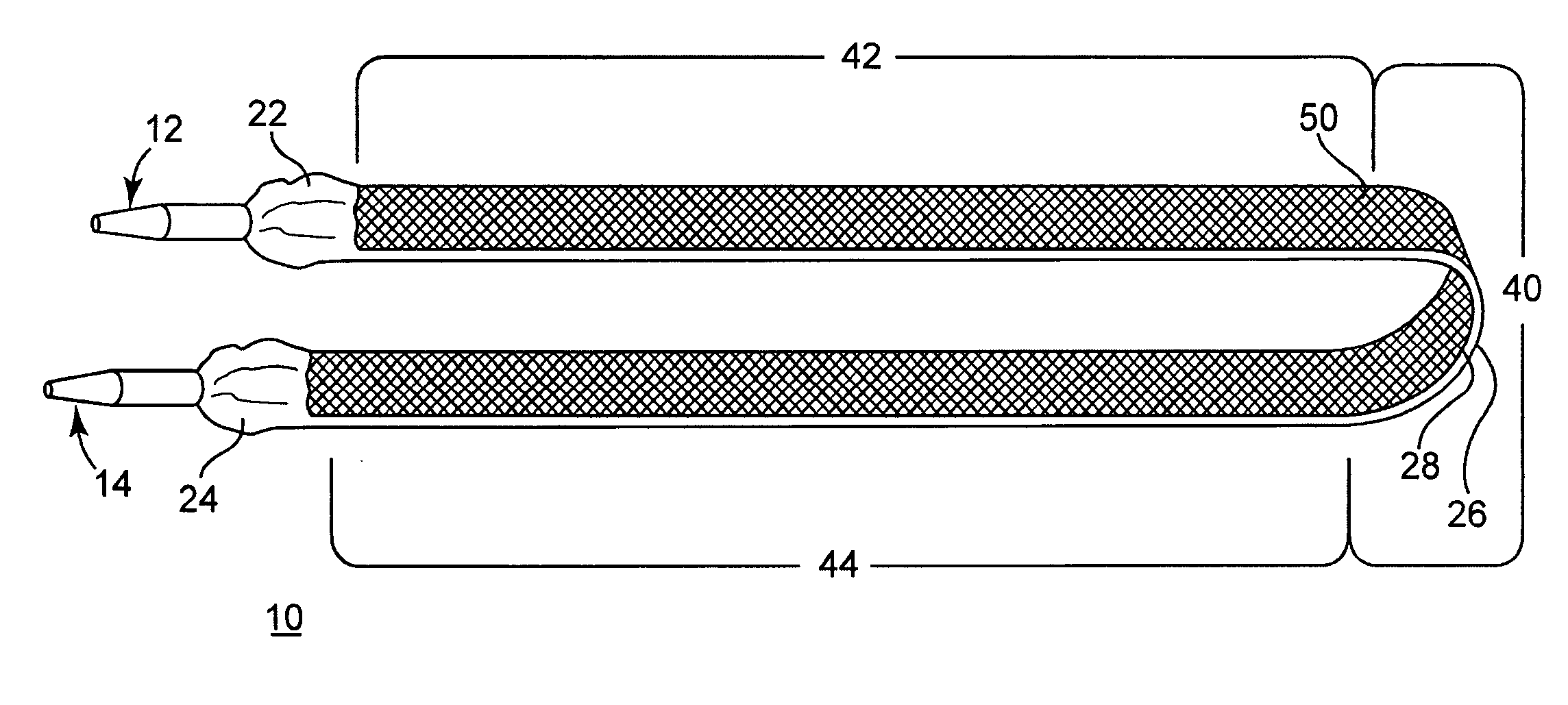

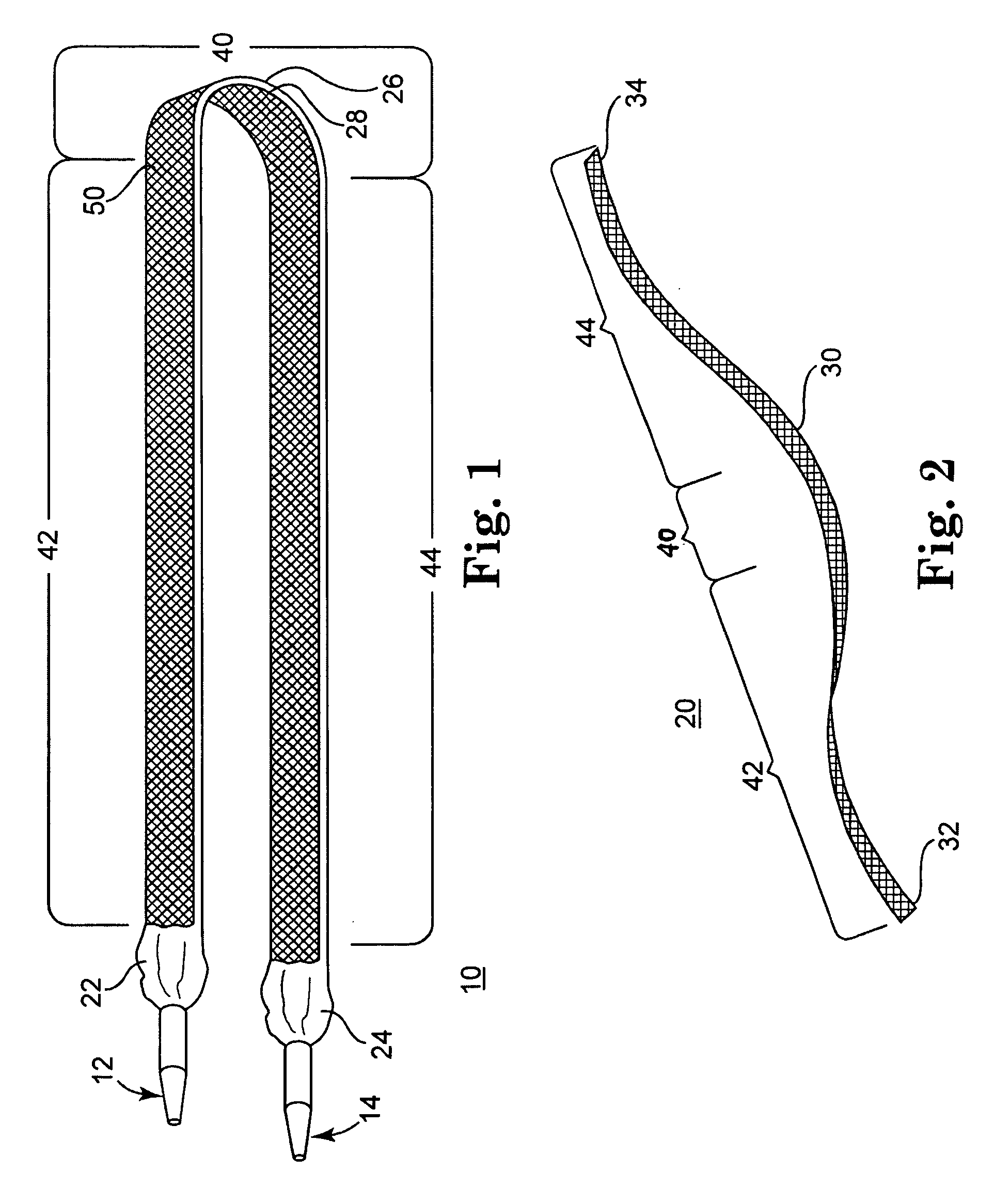

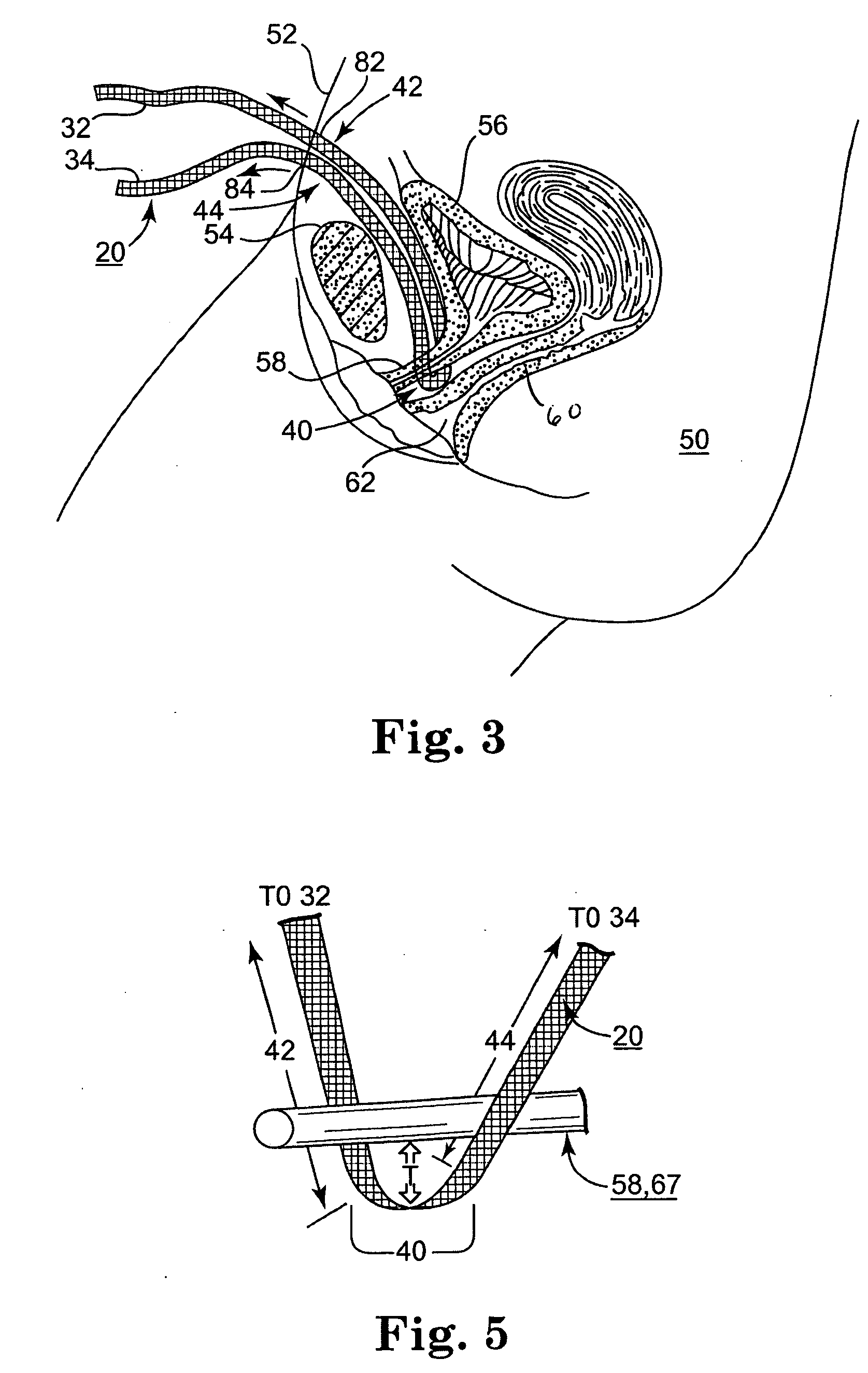

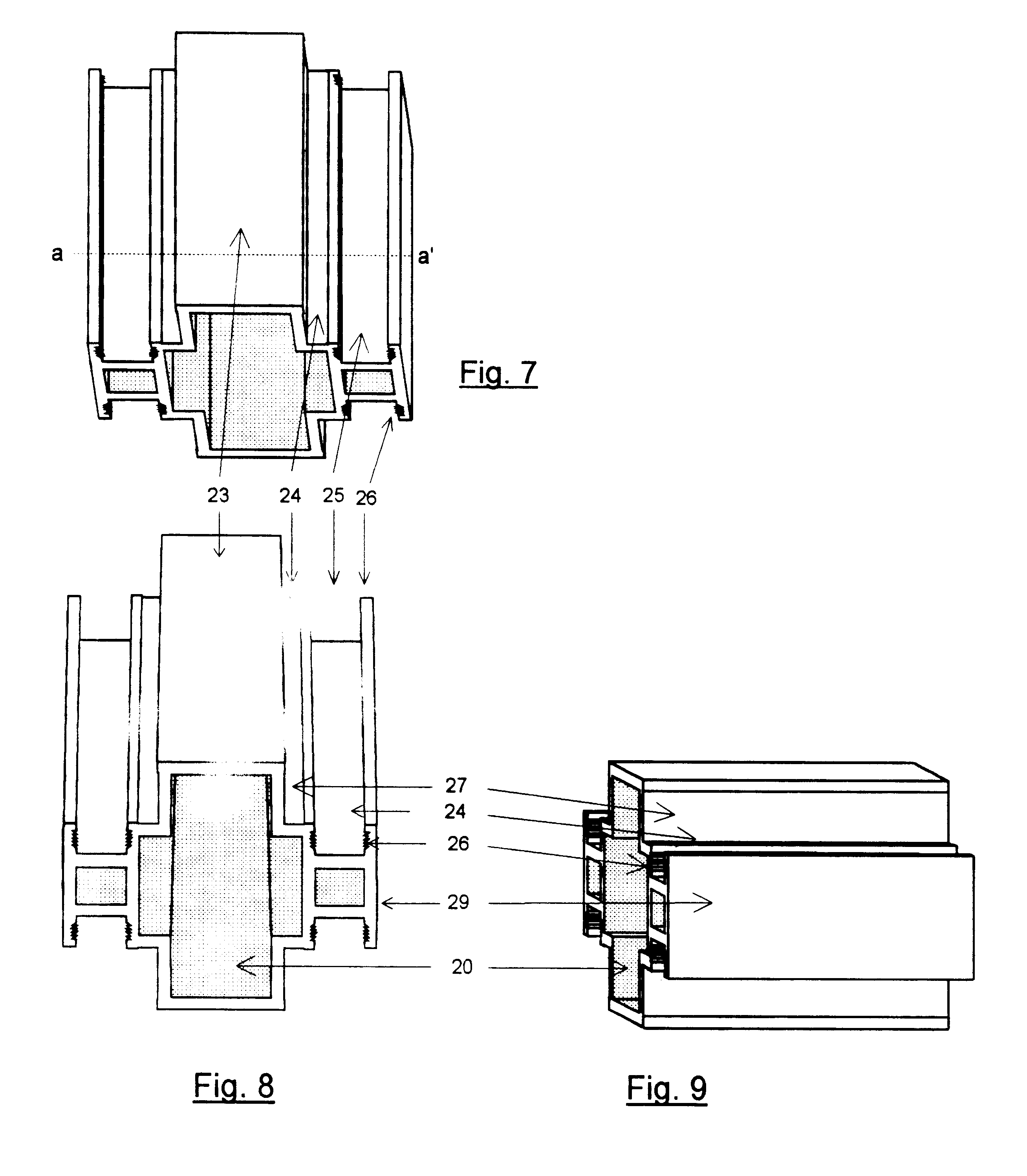

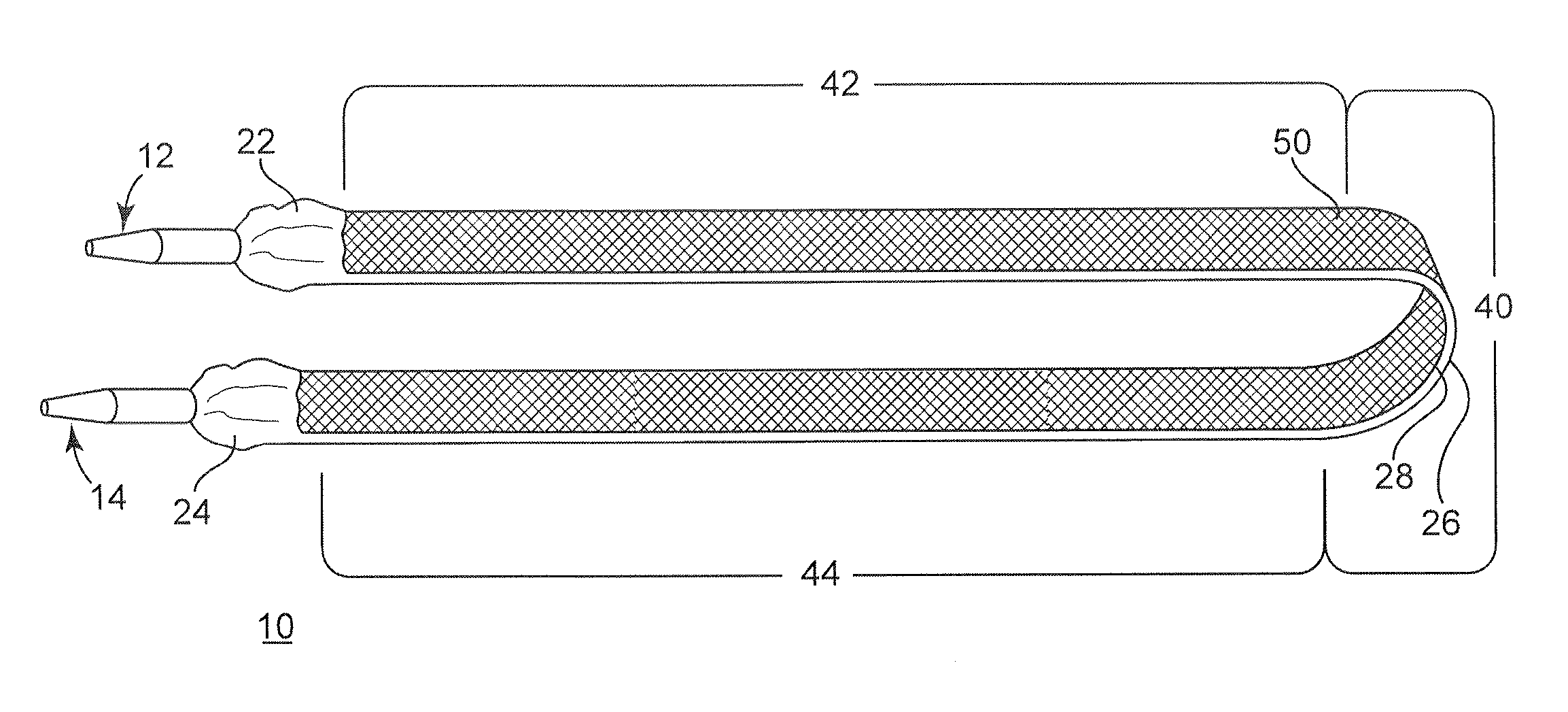

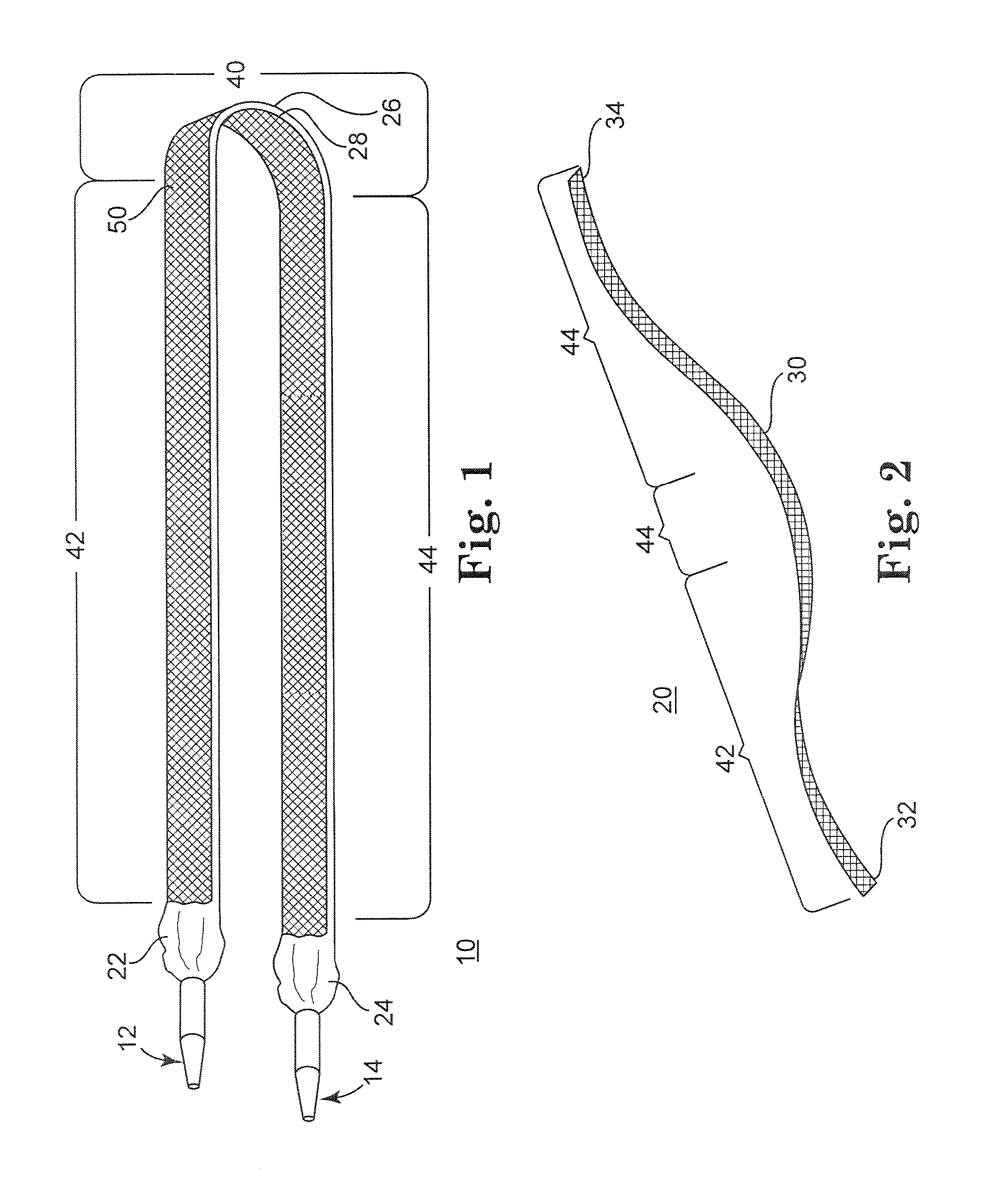

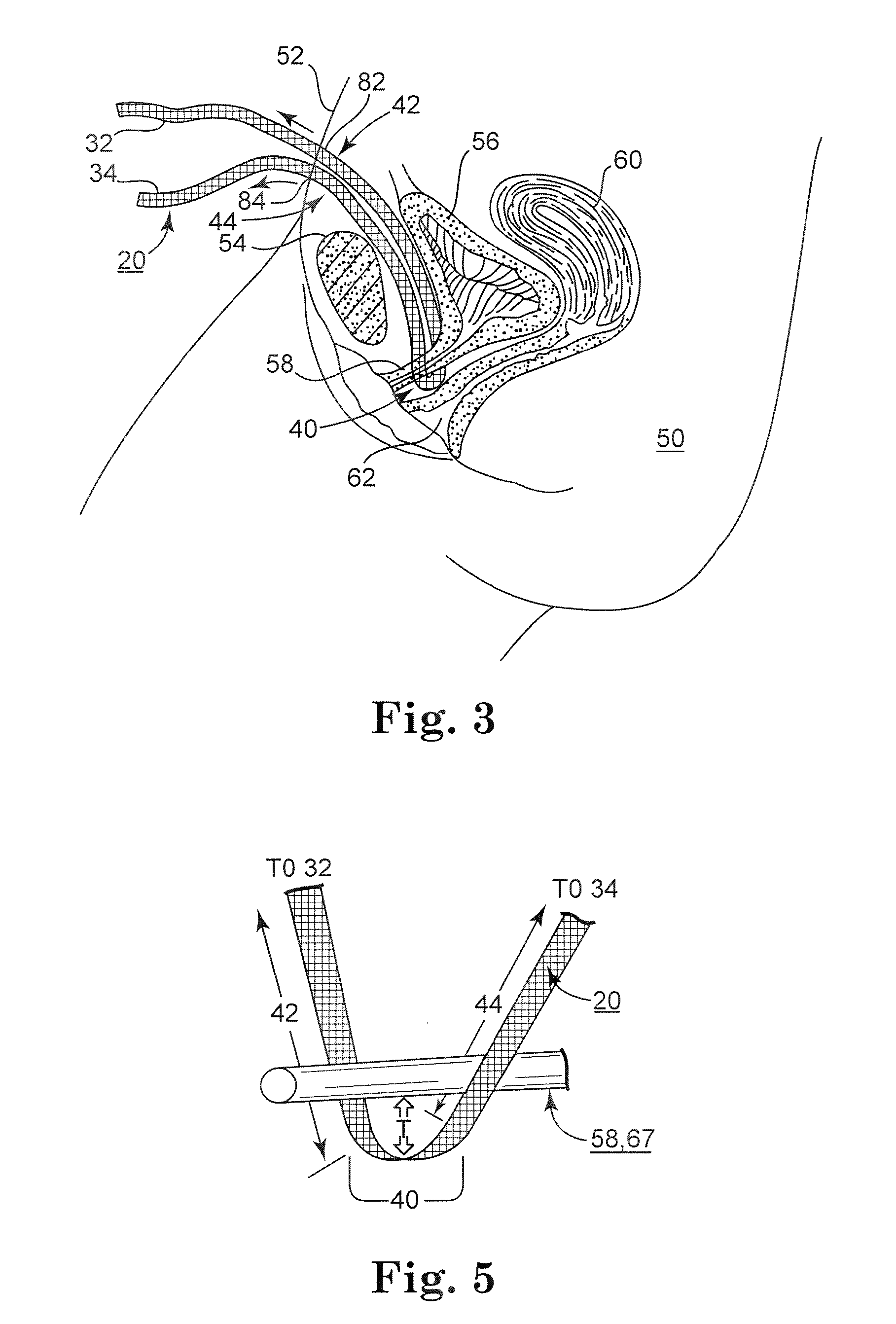

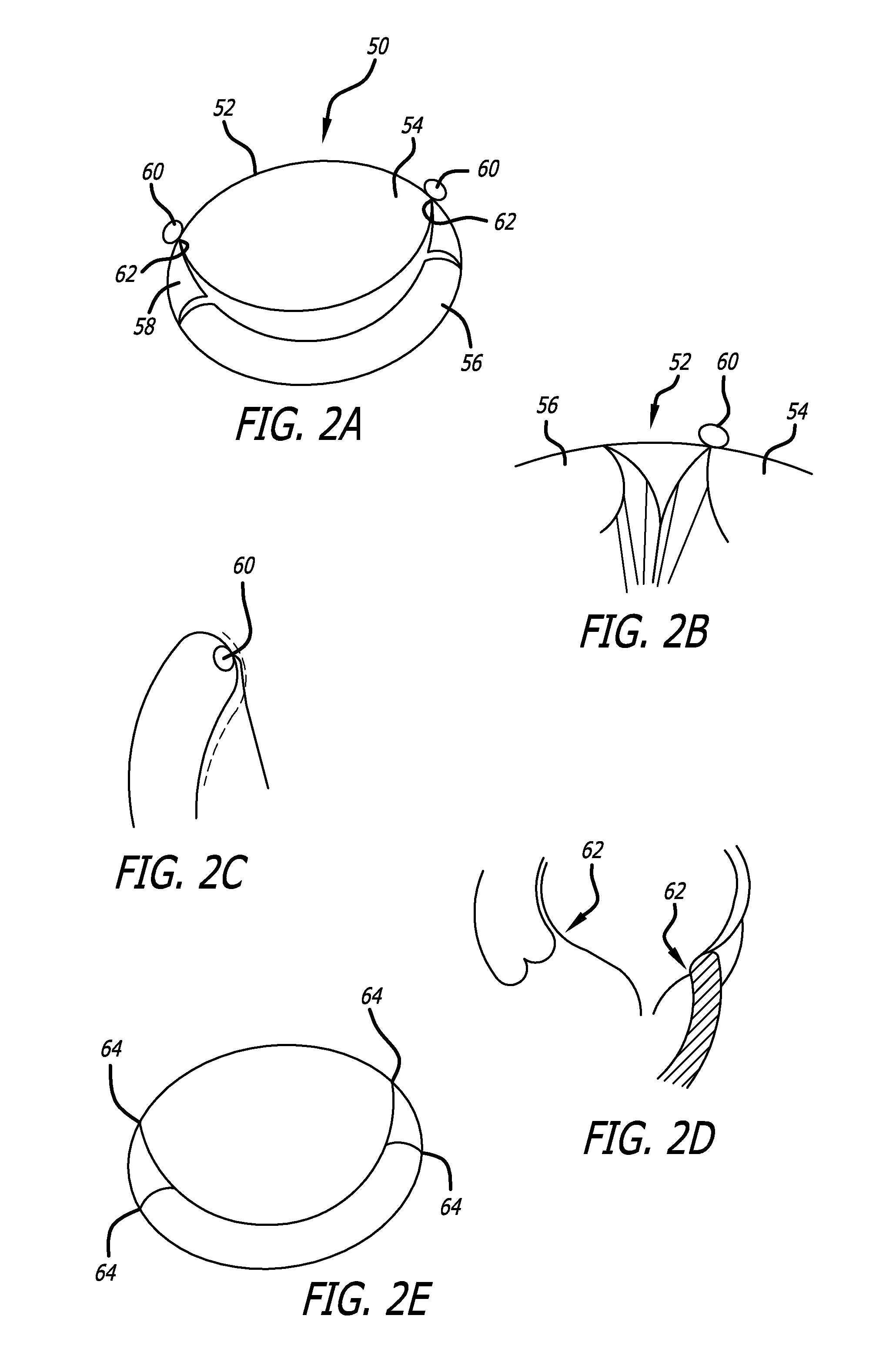

Adjustable tension incontinence sling assemblies

InactiveUS20110124954A1Easy tension adjustmentGood curative effectAnti-incontinence devicesSurgeryUrethraBody tissue

Systems for providing support to body tissue to alleviate incontinence are disclosed that comprise an elongated incontinence sling (20) having a central support portion (40) adapted to be positioned to support any one of the urethra or anus (58, 67) and first and second sling end portions (42, 44) extending from the central support portion through body tissue and a tension adjustment mechanism acting on or within one or both of the sling end portions. The sling tension adjustment mechanism comprises one or more of a sling tensioning suture (312, 314) or band, and a tensioning device (310) coupled to a suture or band free end.

Owner:BOSTON SCI SCIMED INC

Secure fiber optic network keyed connector assembly

InactiveUS7390203B2Prevent rotationAvoid damageLive contact access preventionOptical light guidesFiberEngineering

Owner:ORTRONICS INC +1

Orthopaedic implant and screw assembly

Systems, devices and methods are disclosed for treating fractures. The systems, devices and methods may include one or both of an implant, such as an intramedullary nail, and a fastening assembly, such as a lag screw and compression screw assembly. The implant in some embodiments has a proximal section with a transverse aperture and a cross-section that may be shaped to more accurately conform to the anatomical shape of cortical bone and to provide additional strength and robustness in its lateral portions, preferably without requiring significant additional material. The fastening assembly may be received to slide, in a controlled way, in the transverse aperture of the implant. In some embodiments, the engaging member and the compression device are configured so that the compression device interacts with a portion of the implant and a portion of the engaging member to enable controlled movement between the first and second bone fragments. This configuration is useful for, among other things, compressing a fracture.

Owner:SMITH & NEPHEW INC

Cigarette and wrapping materials therefor

ActiveUS7234471B2Easy transferConsistent flowNon-fibrous pulp additionNatural cellulose pulp/paperBobbinPulp and paper industry

Owner:R J REYNOLDS TOBACCO COMPANY

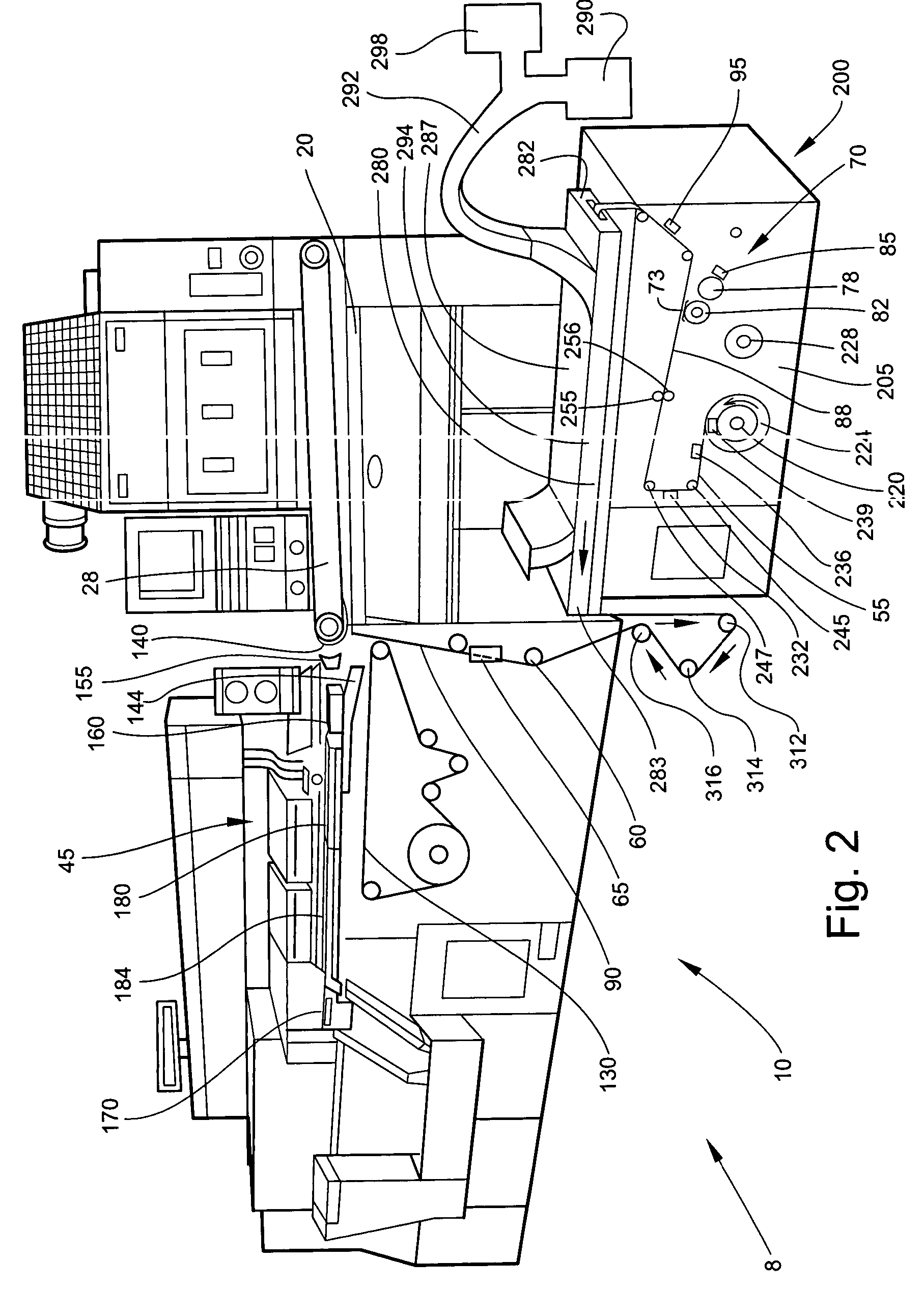

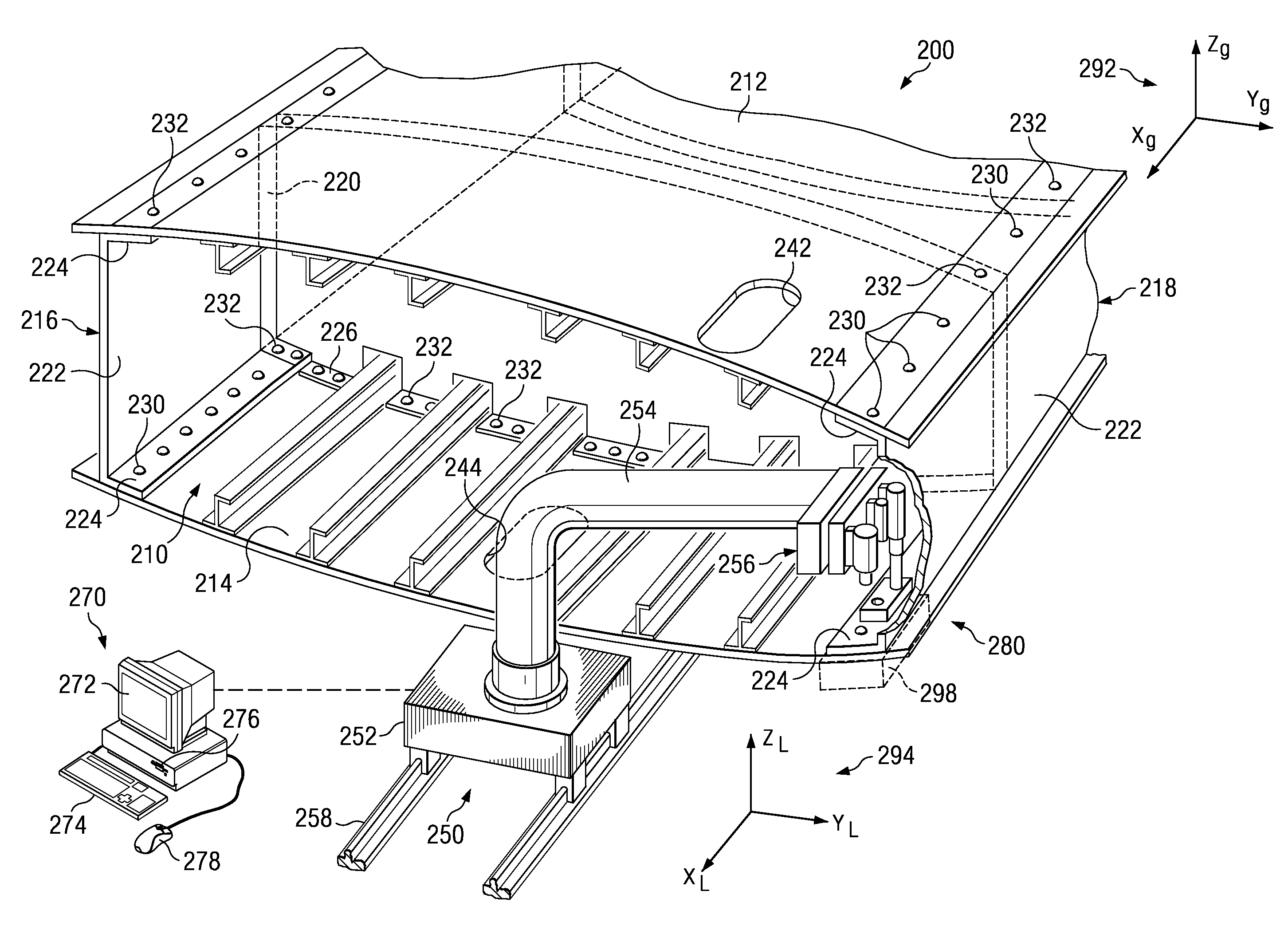

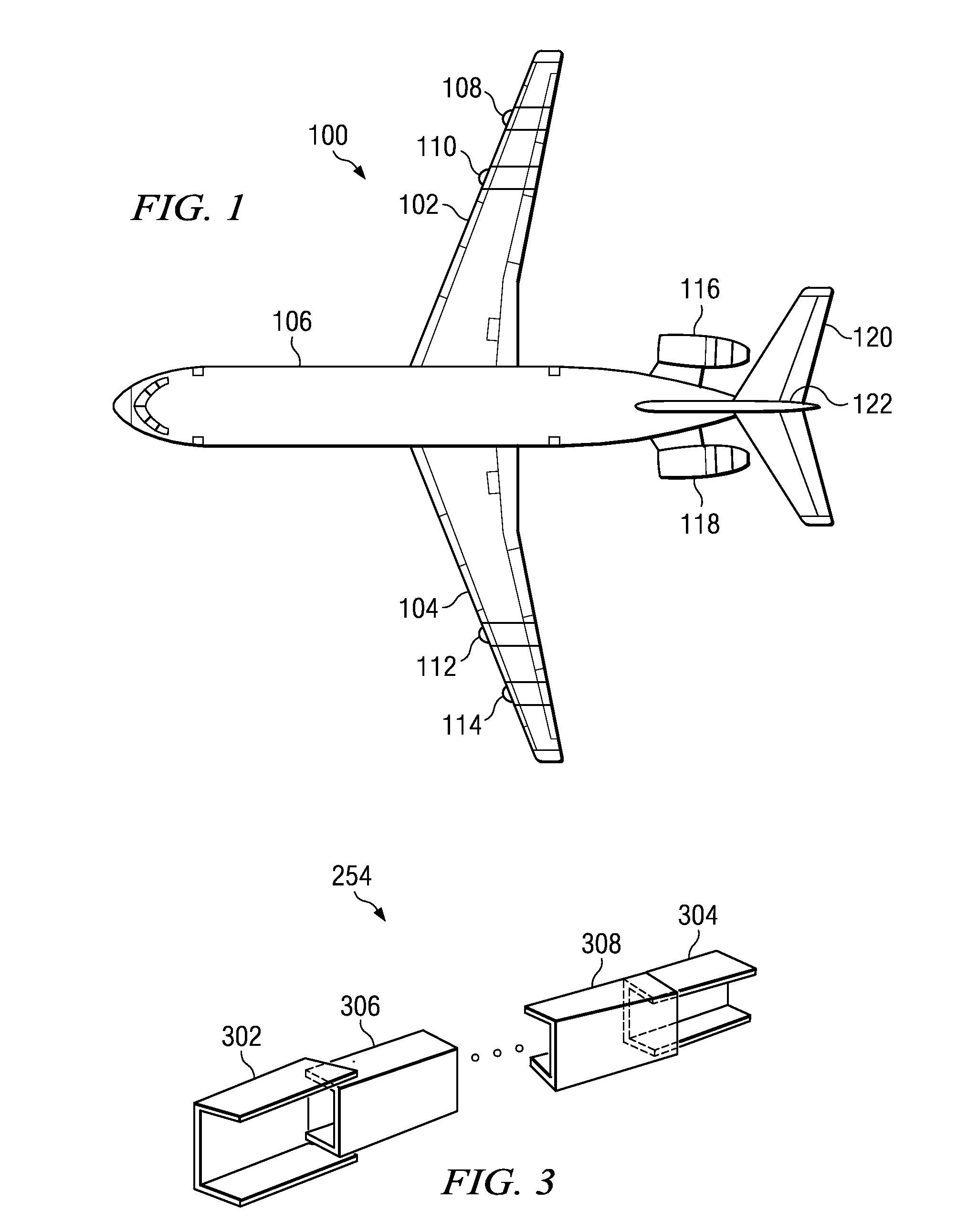

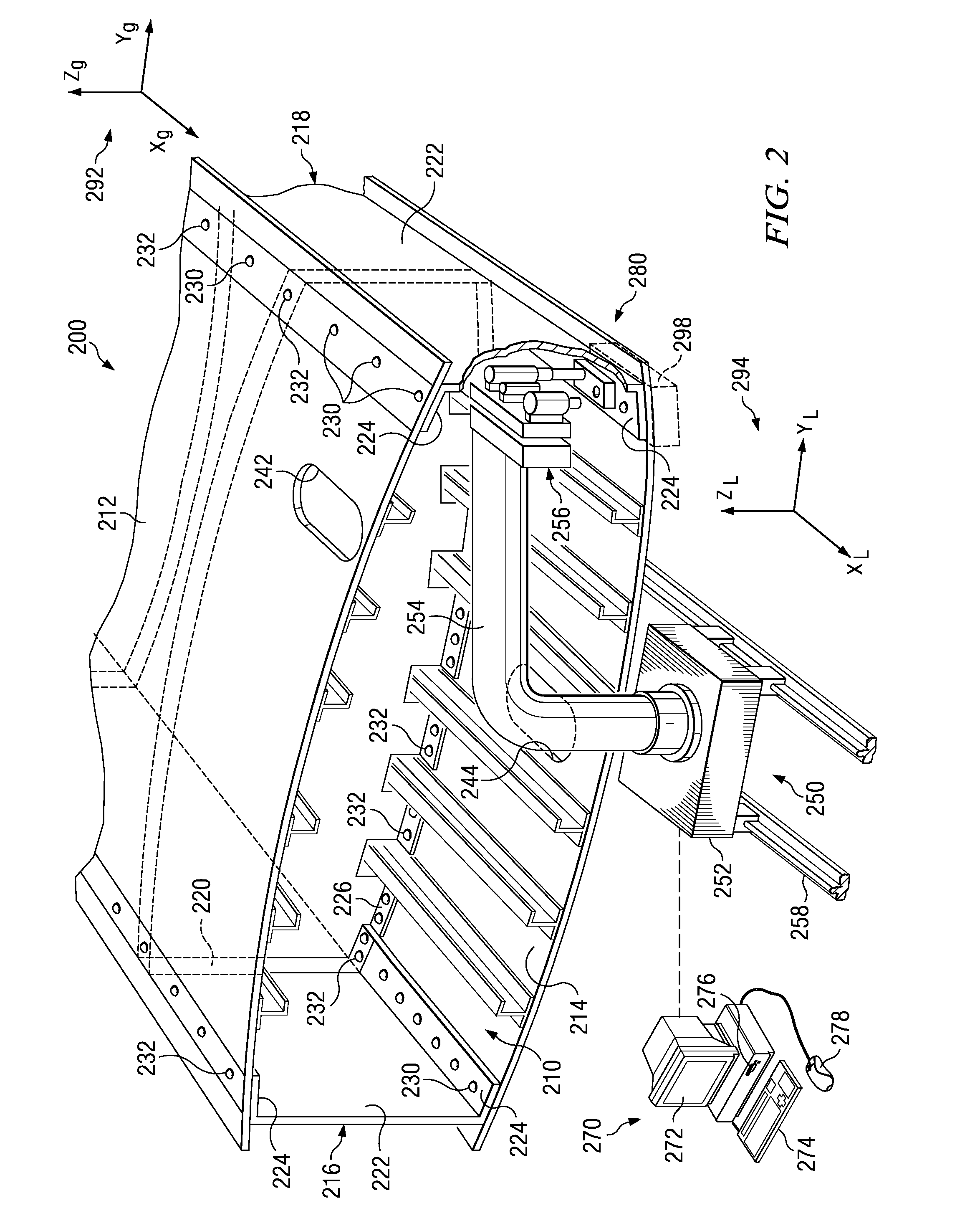

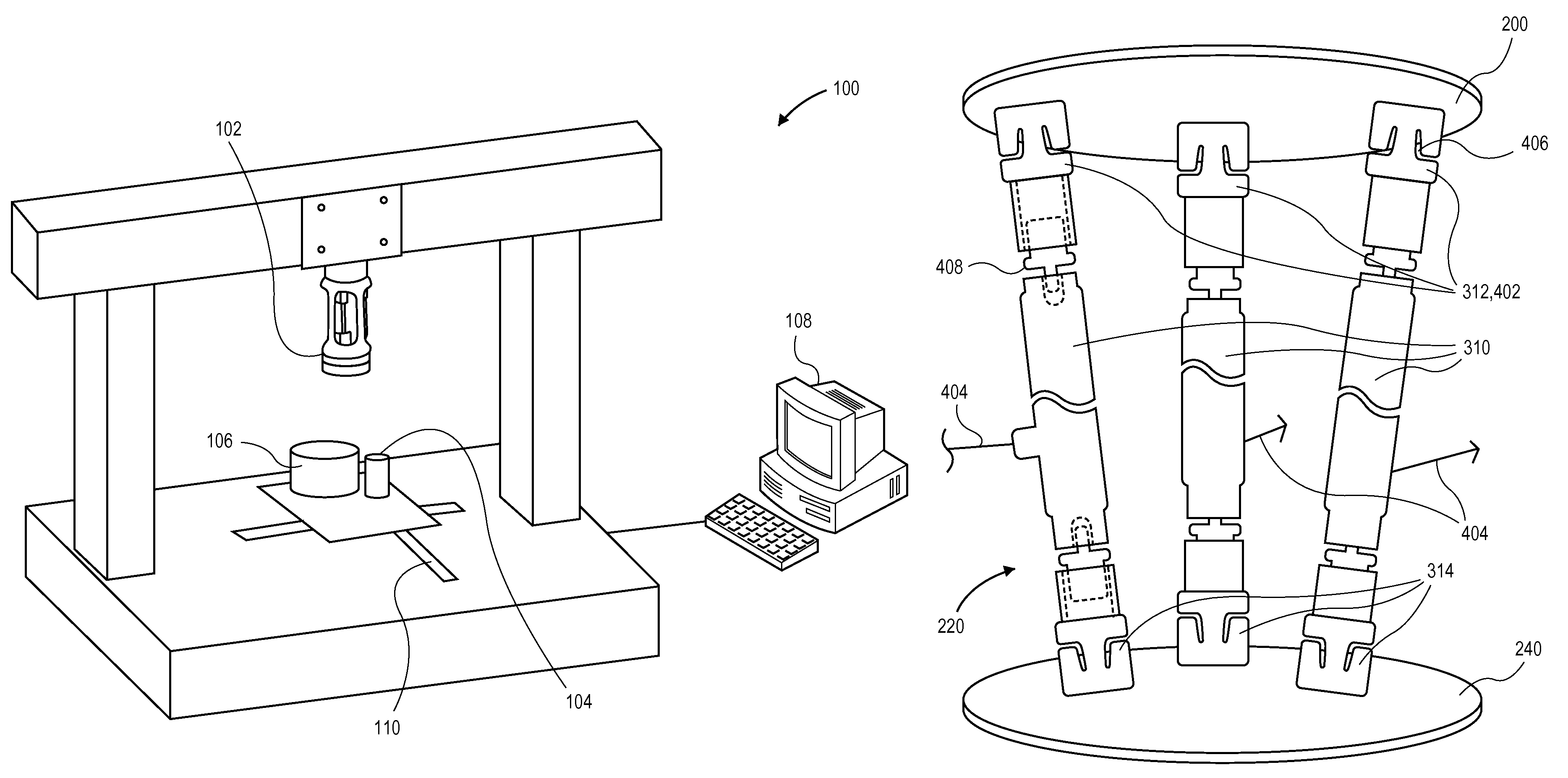

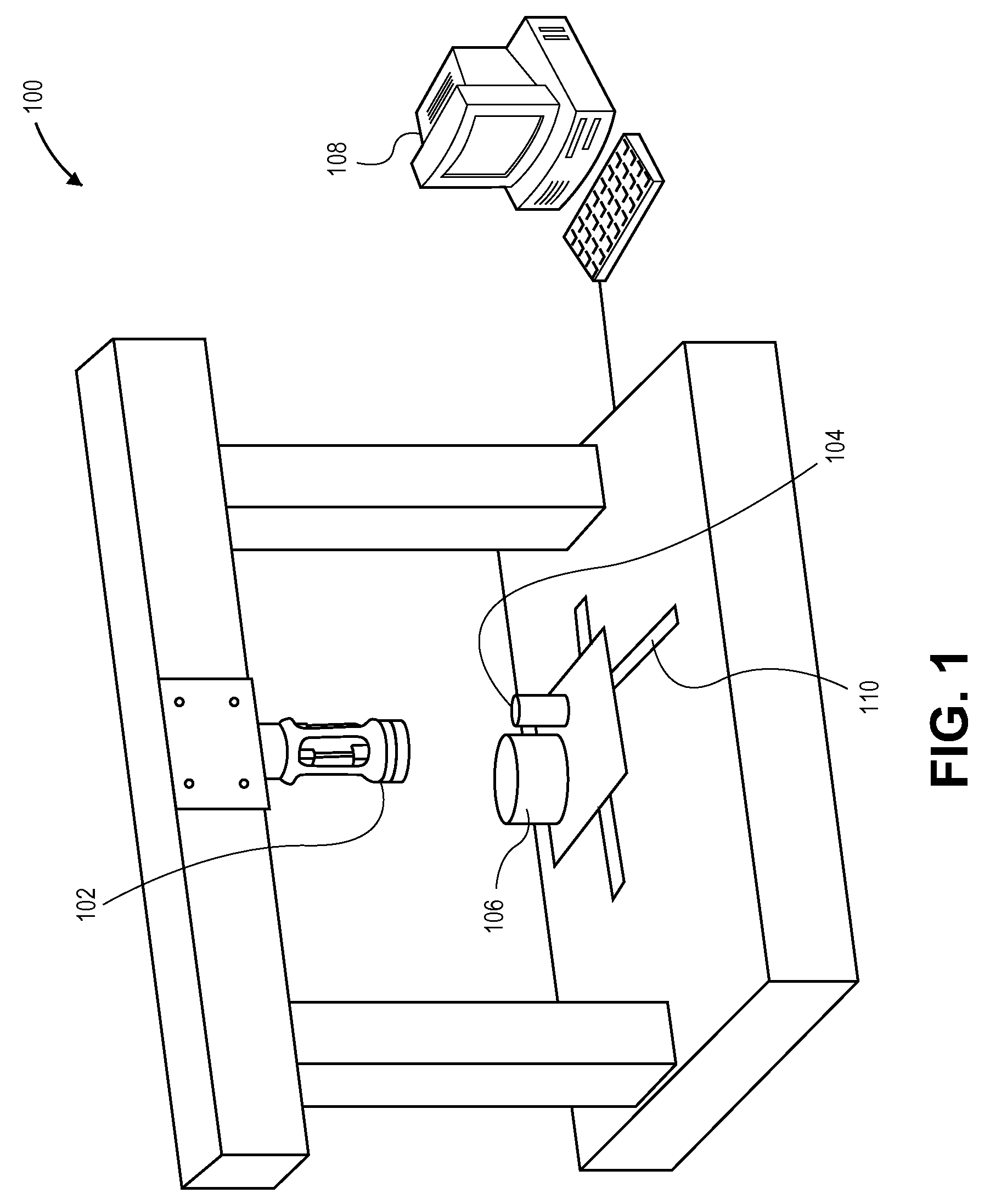

Robot-deployed assembly tool and method for installing fasteners in aircraft structures

ActiveUS20080155807A1Eliminate gapsAircraft componentsAutomatic control devicesFlight vehicleEngineering

An assembly system and method for assembling an aircraft wing box or other structure that may define an interior area accessible through at least one access opening are provided. The method includes inserting a robot having an assembly tool mounted thereto into the interior area through the at least one access opening. The assembly tool may be positioned at a fastener location, and may be clamped to the structure. A hole may be made through the structure, and a fastener may be installed in the hole.

Owner:THE BOEING CO

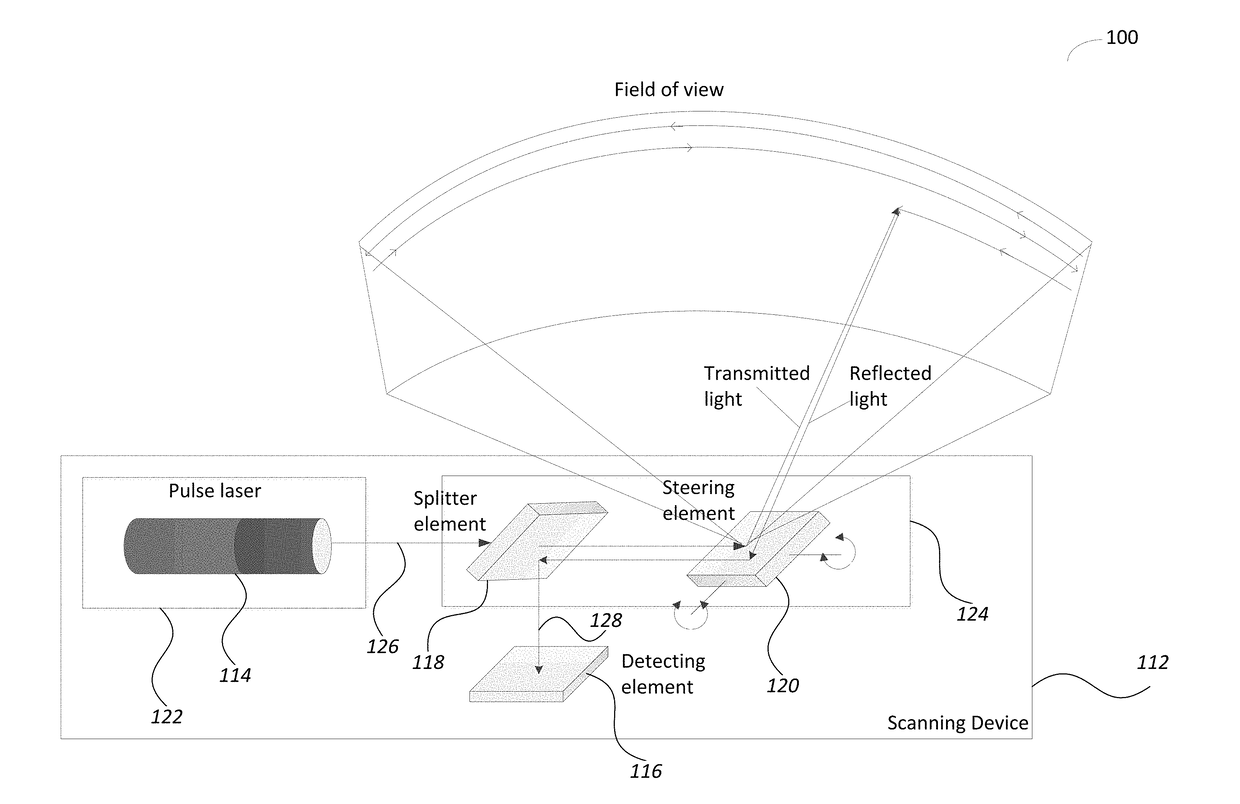

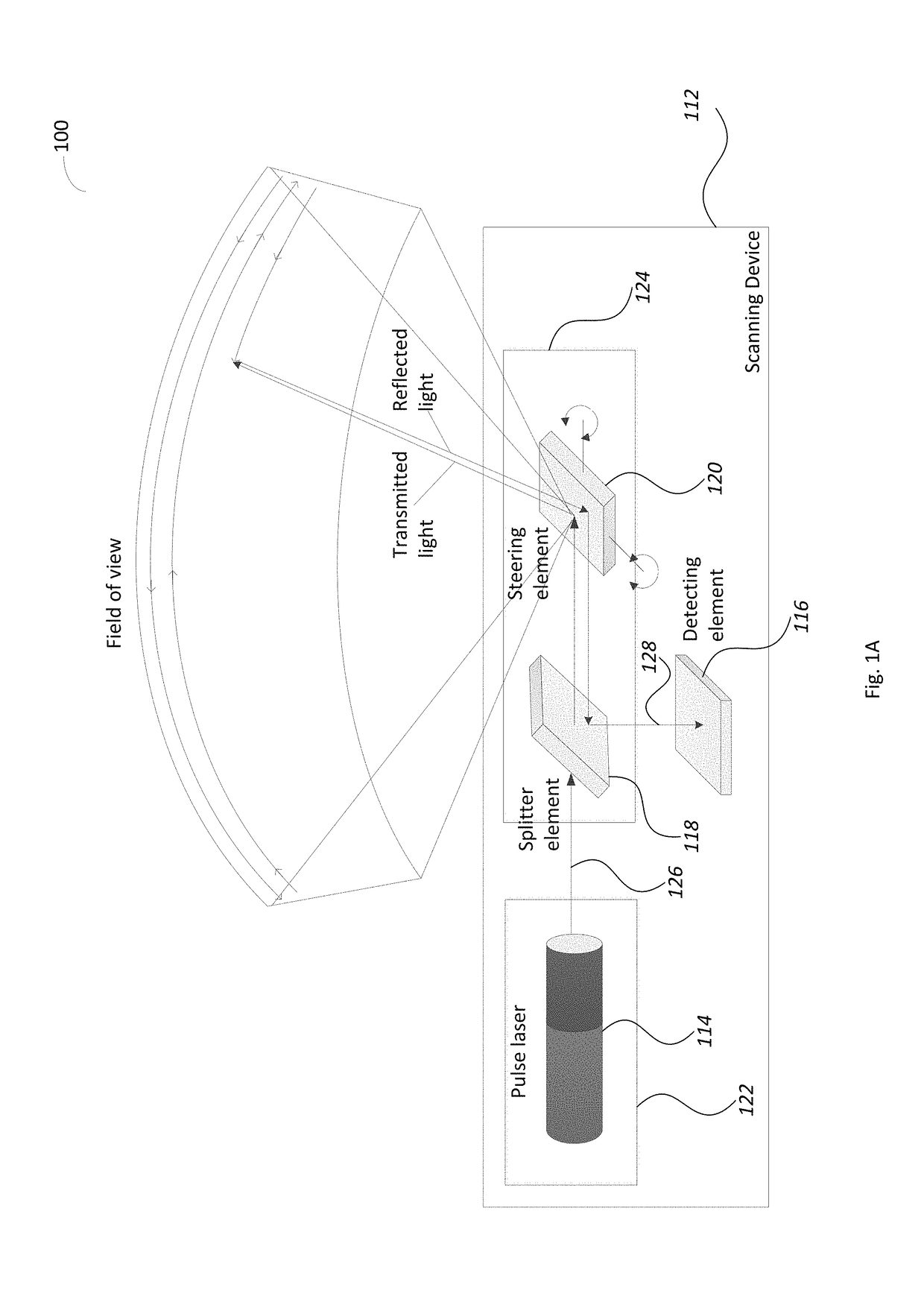

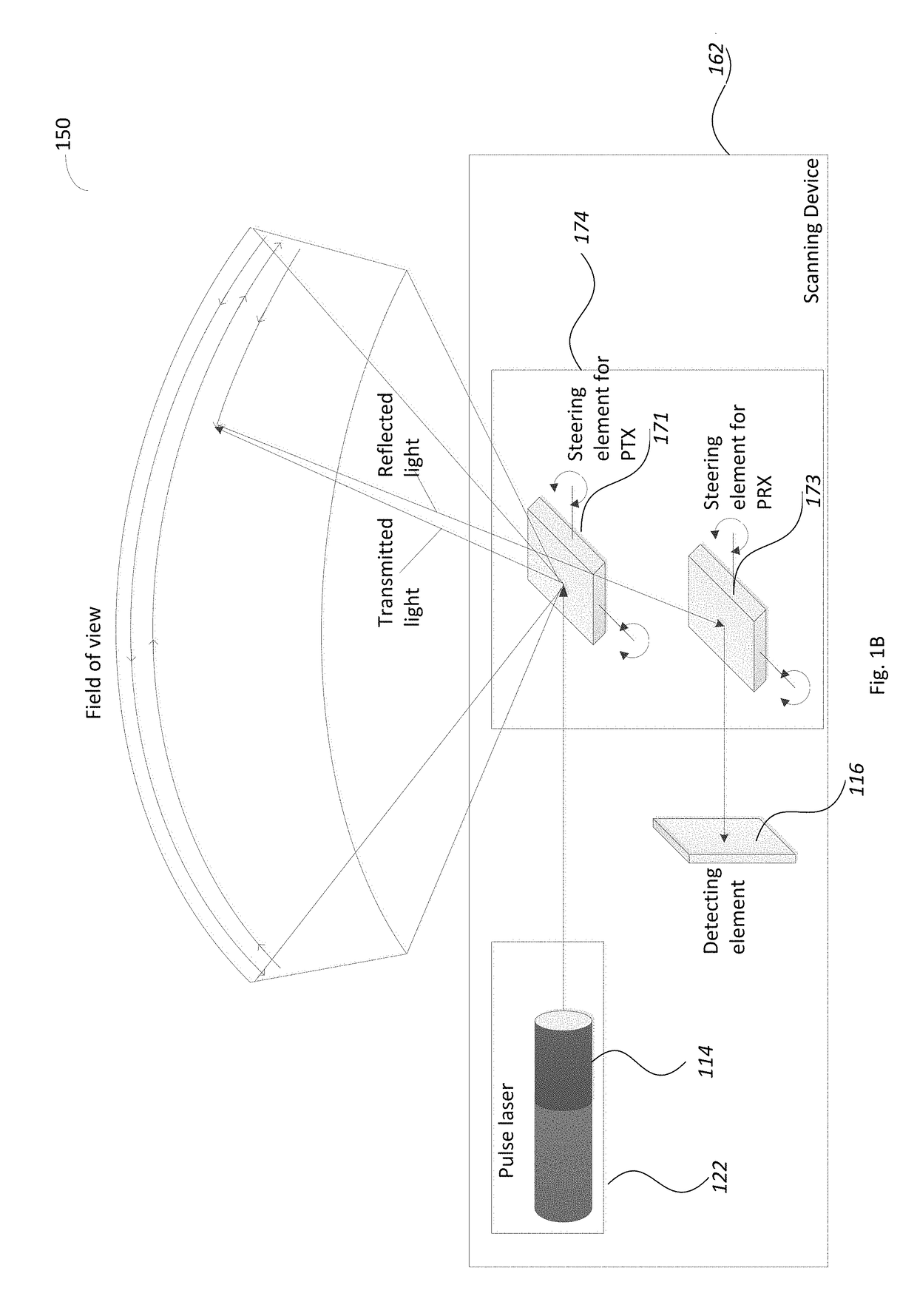

Methods Circuits Devices Assemblies Systems and Functionally Associated Machine Executable Code for Active Optical Scanning of a Scene

InactiveUS20180113216A1Particular environment based servicesVehicle wireless communication serviceWork planPulse parameter

Disclosed is a scanning device including: a photonic emitter assembly (PTX) to emit at least one pulse of inspection photons in accordance with at least one adjustable pulse parameter, a photonic reception and detection assembly (PRX) to receive reflected photons reflected back from an object, the PRX including a detector to detect in accordance with at least one adjustable detection parameter the reflected photons and produce a detected scene signal, and a closed loop controller to: (a) control the PTX and PRX, (b) receive the detected scene signal from the detector and (c) update said at least one pulse parameter and at least one detection parameter at least partially based on a work plan derived at least partially from the detected scene signal.

Owner:INNOVIZ TECH LTD

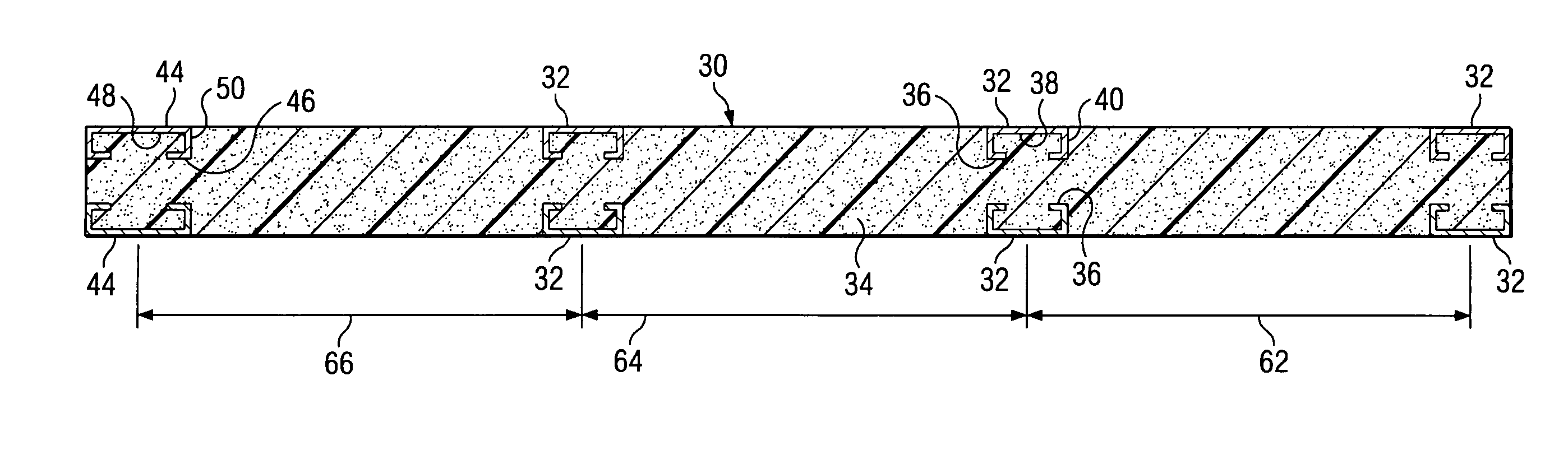

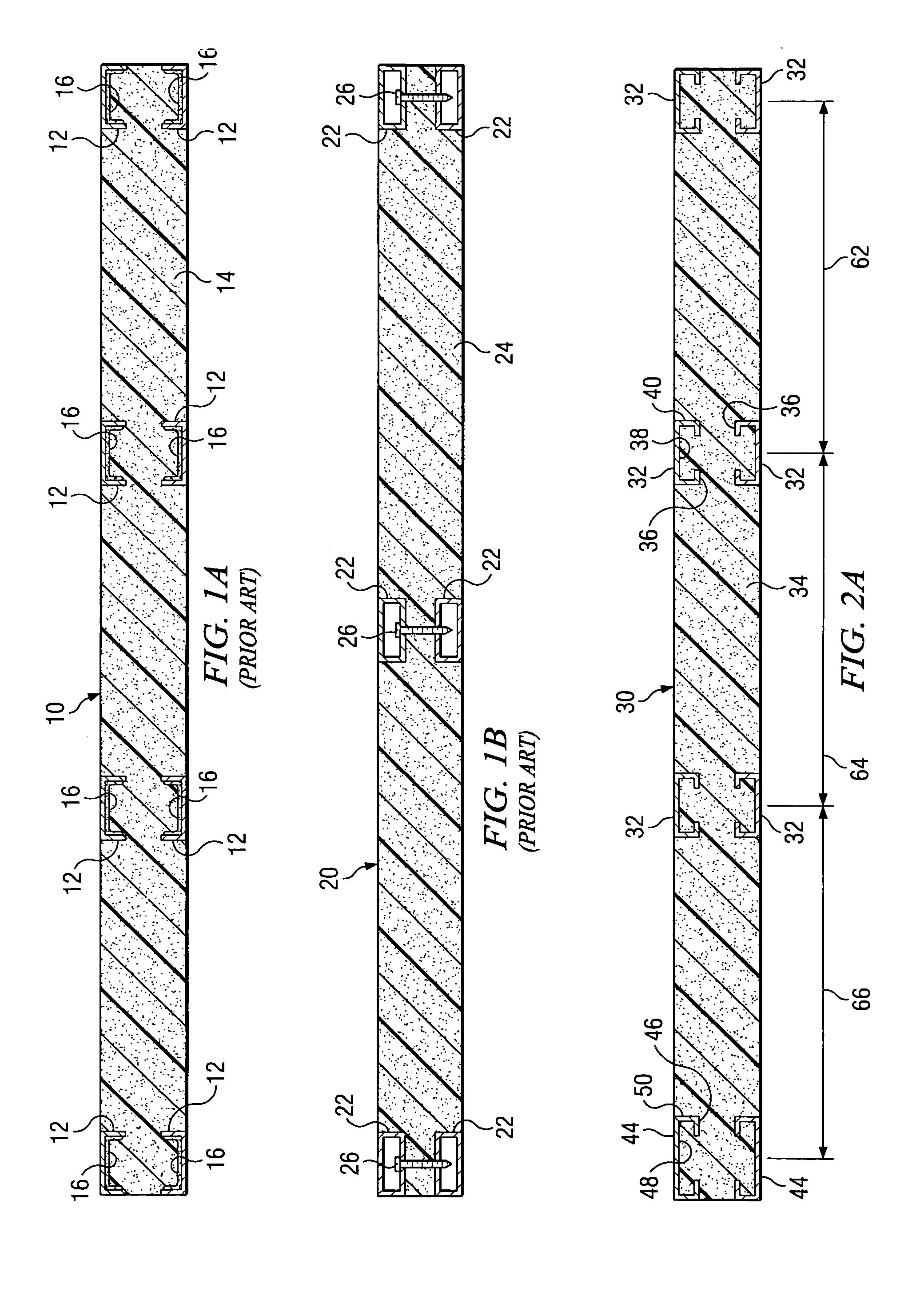

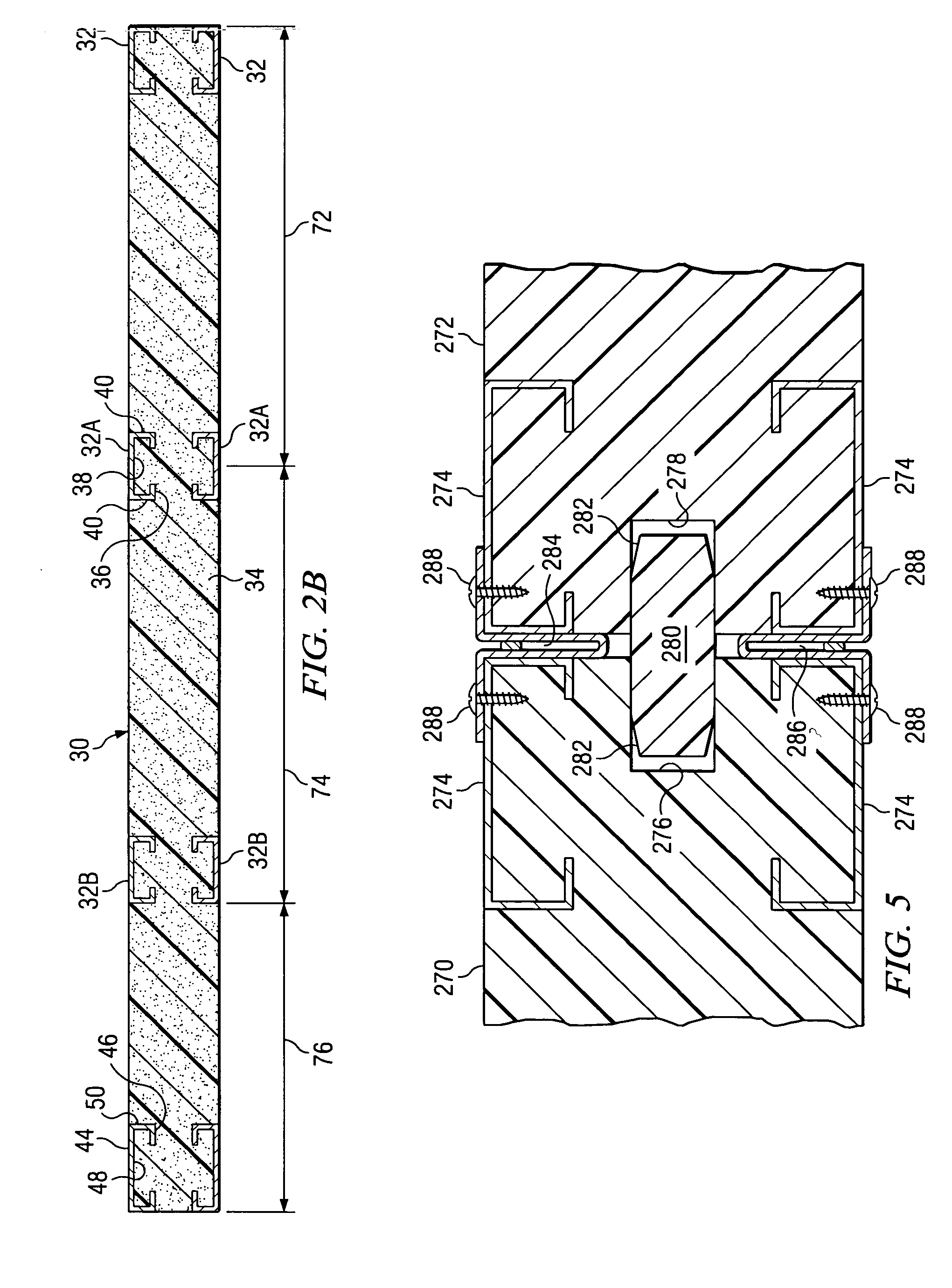

Insulated structural building panel and assembly system

An insulated structural building panel and header system, comprising a rectangular panel body molded of a rigid foam material and a plurality of elongated, channel-shaped framing members oriented parallel to each other and embedded during molding in each first and second face of the panel body. Each framing member is retained in place in the panel body by return lips formed into first and second edges of an open side of the framing members without the use of adhesive or mechanical fasteners. The panels may include utility recesses formed in one face of the panel and mortised edges for keying the panels securely together. The panels may be formed with alternate framing member spacings. Auxiliary framing members are disclosed having T and L shaped cross sections for joining panels together or reinforcing the panels to support greater loads.

Owner:RUE JERRY RANDALL

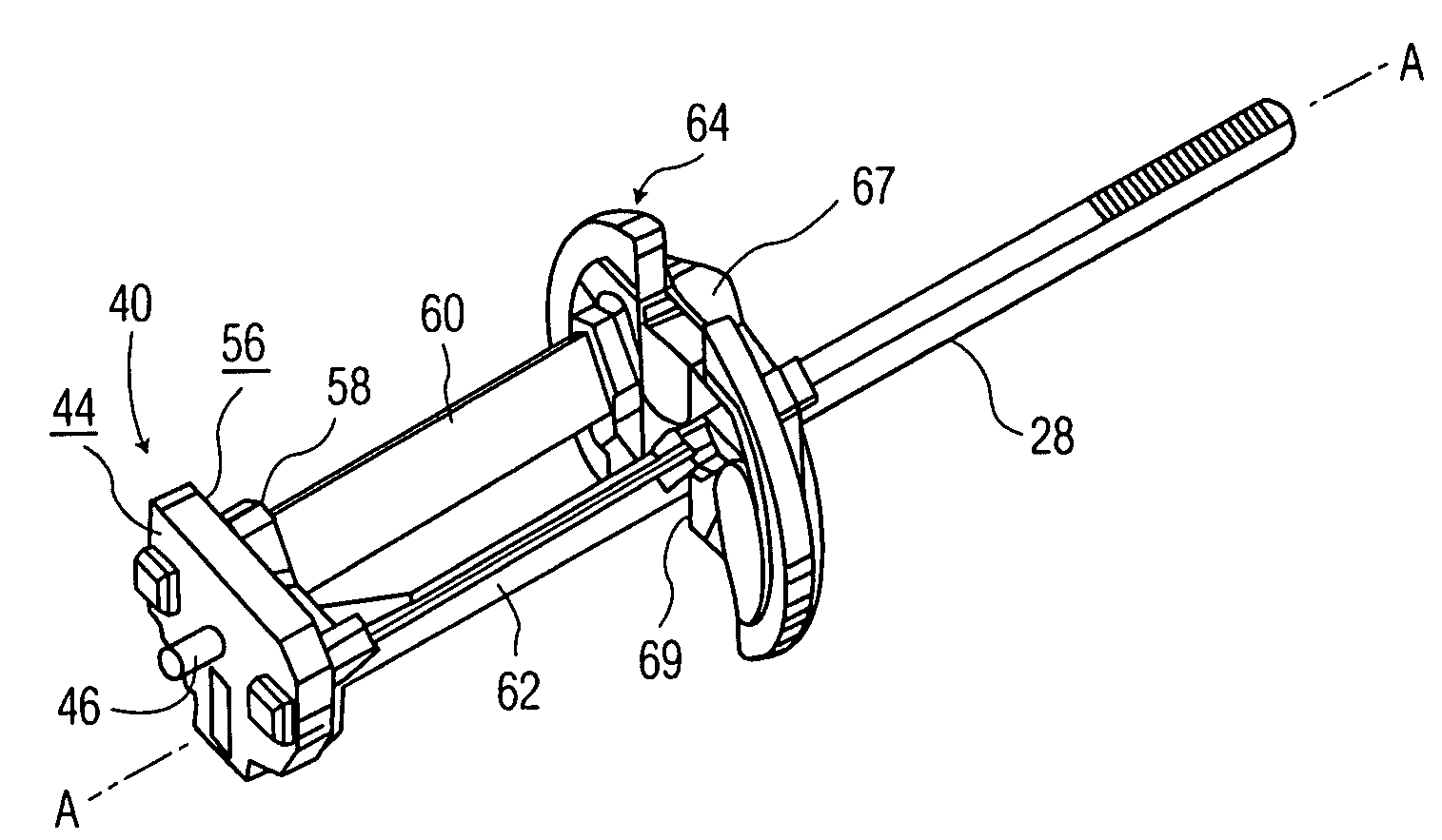

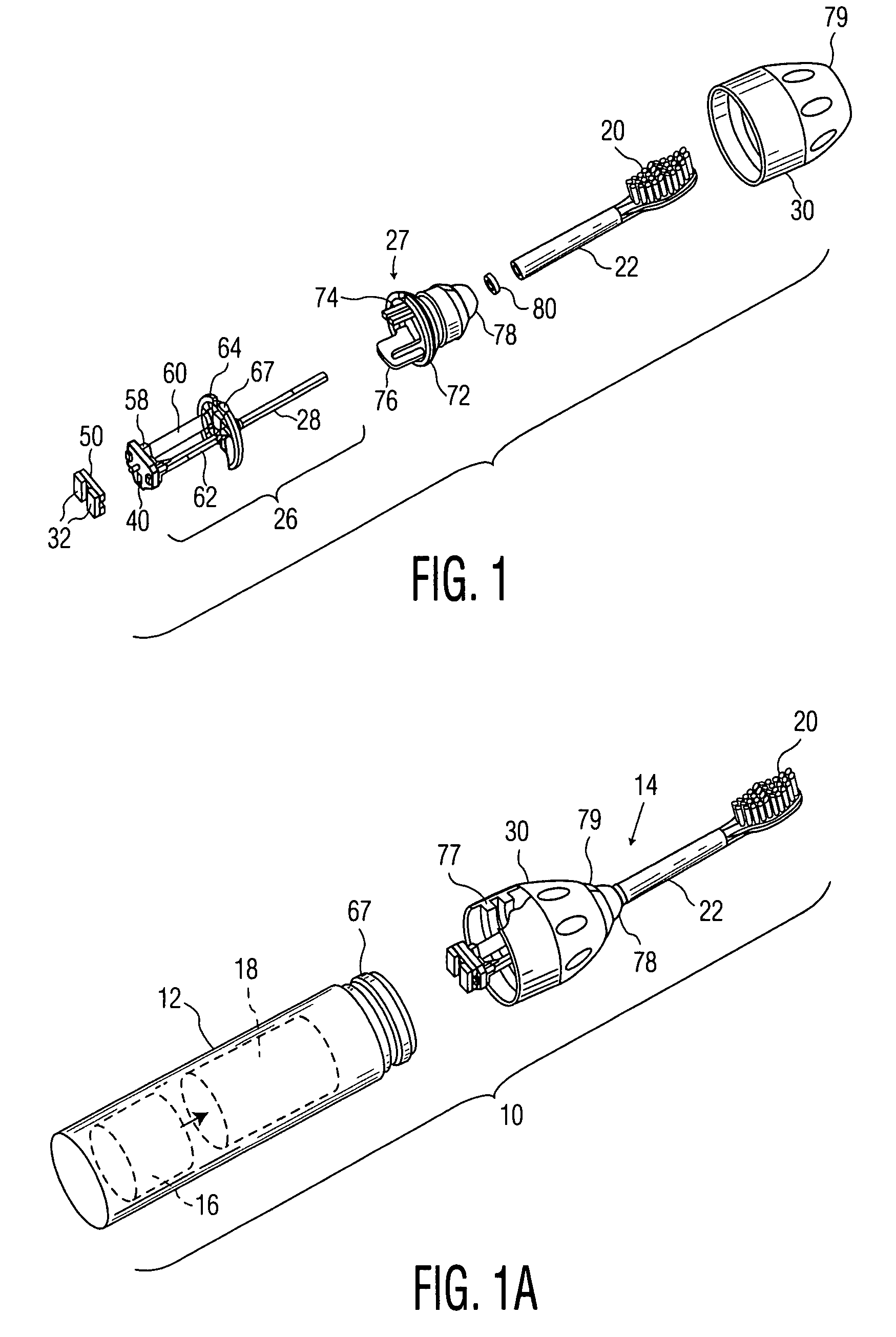

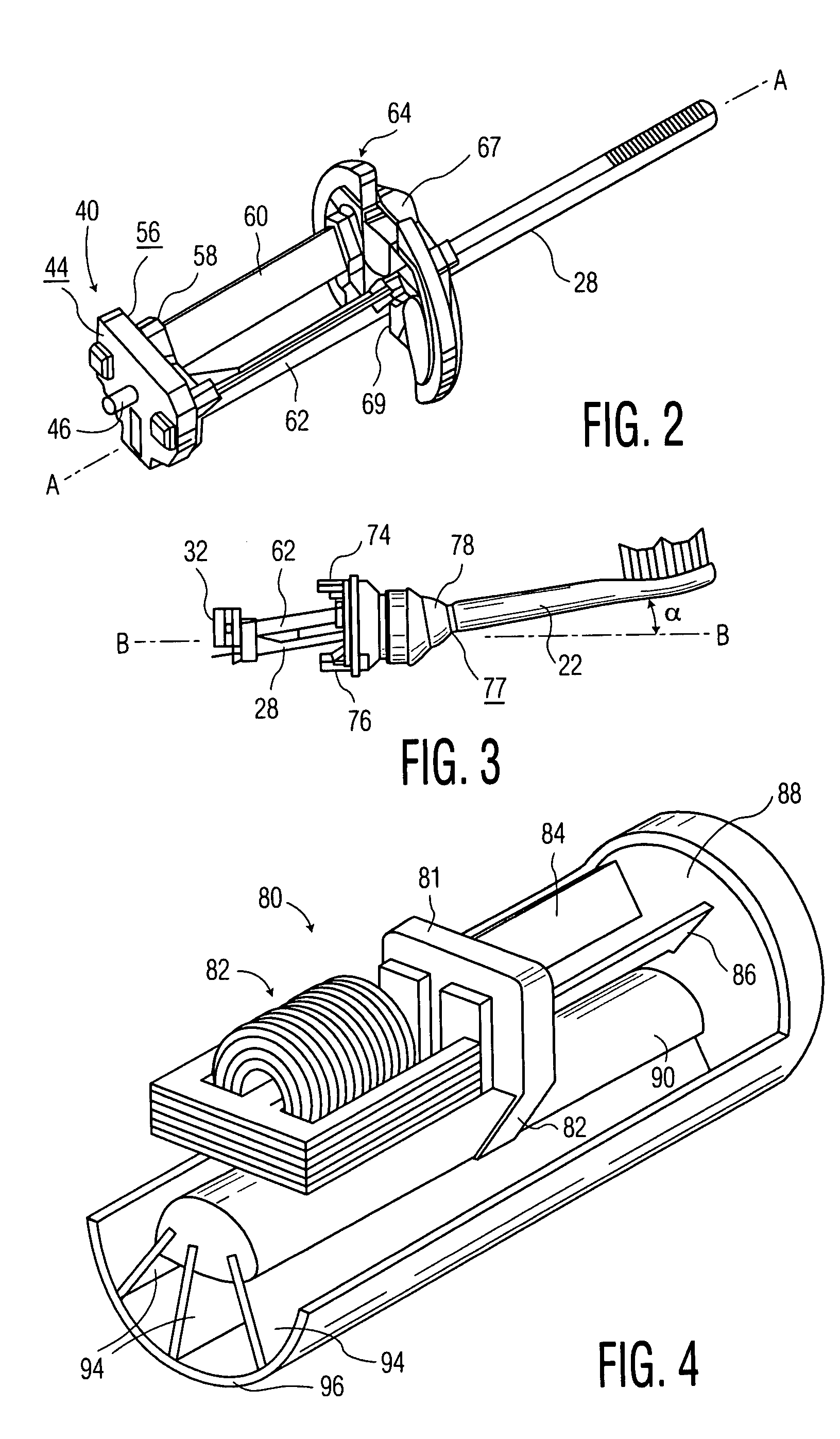

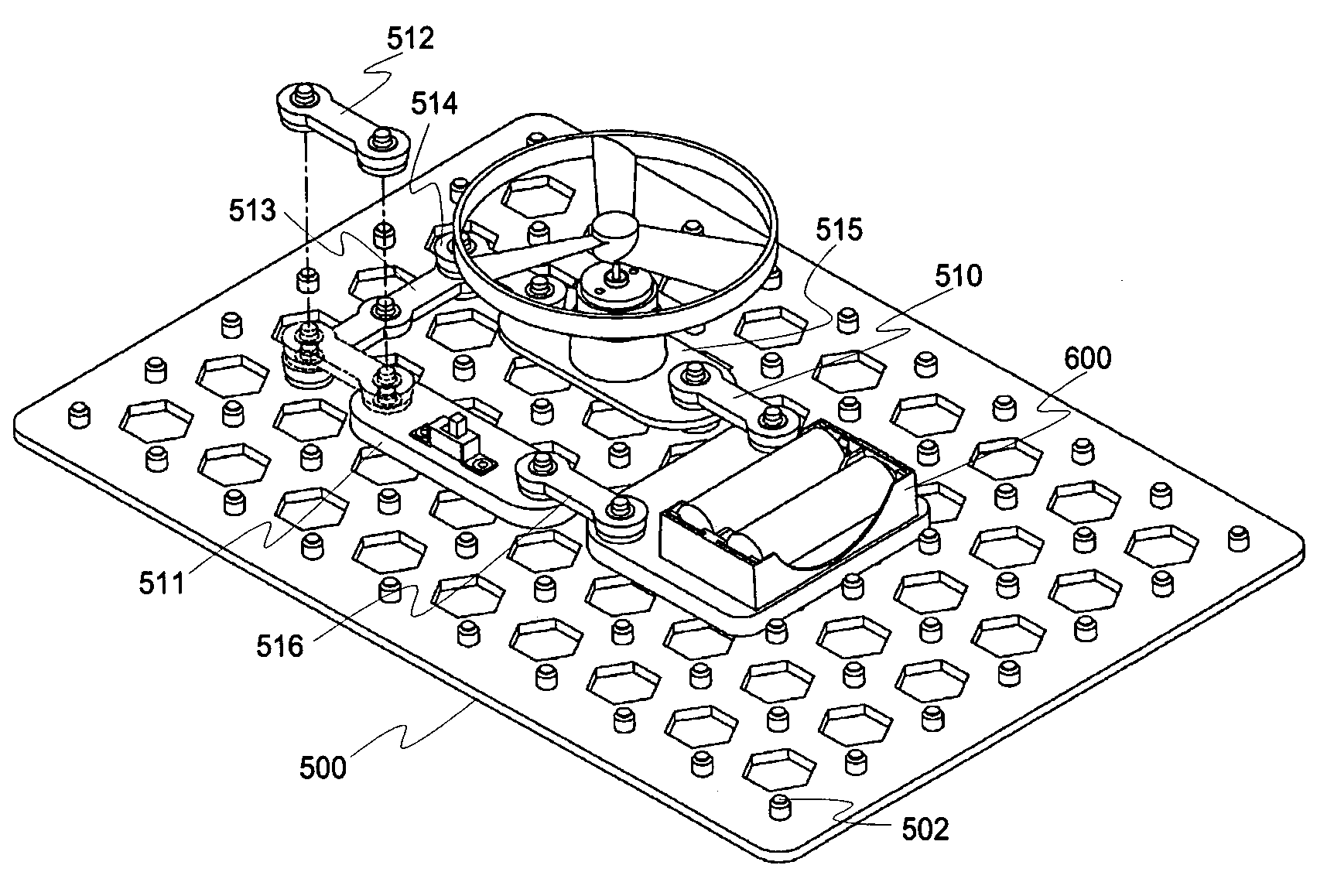

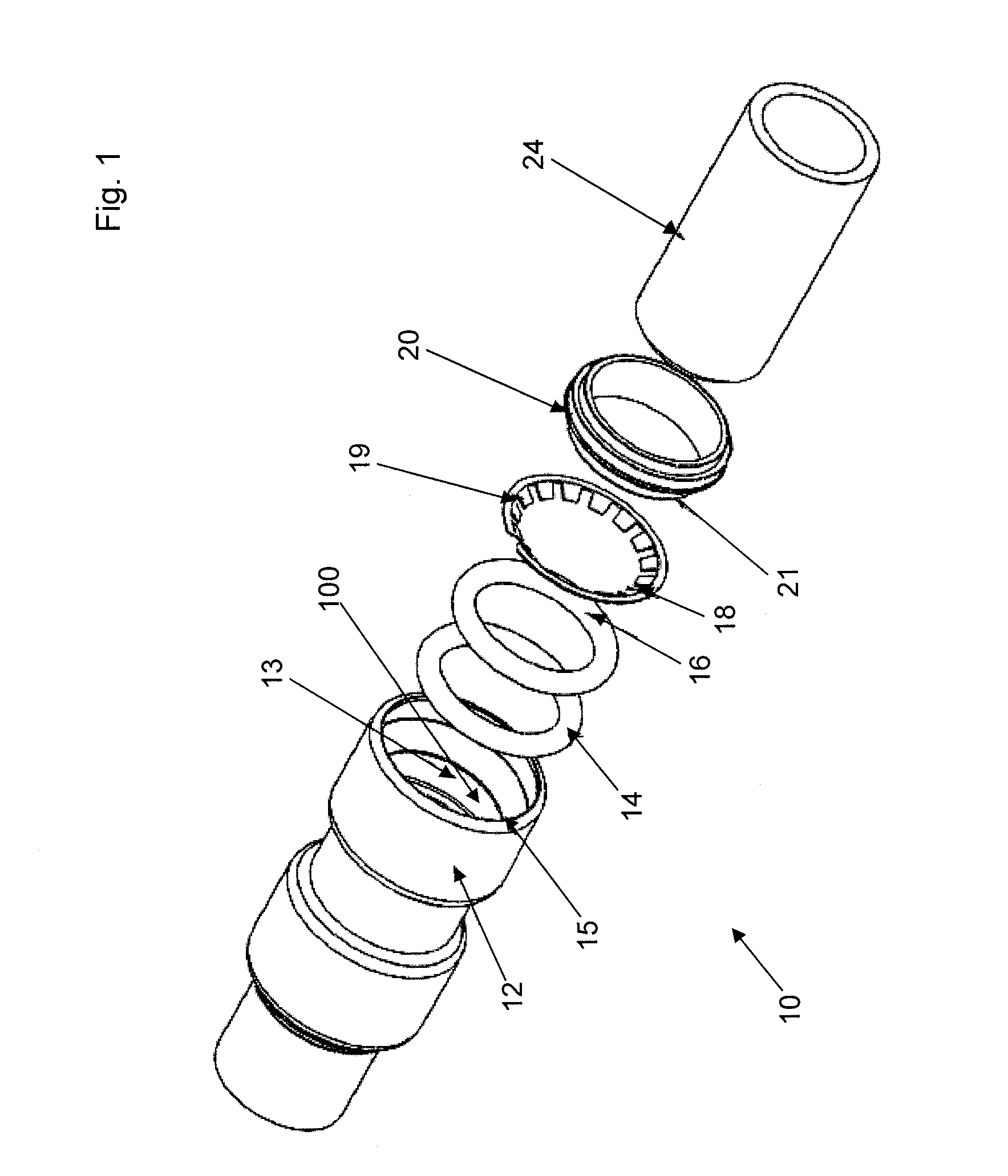

Apparatus for converting side-to-side driving motion to rotational motion with a spring assembly and system for tuning the spring assembly

The apparatus for converting side-to-side to rotational motion for a workpiece includes a spring assembly with a movable base mounting element which is driven in a slightly arcuate reciprocal side-to-side motion and a fixed mounting element spaced apart from the base element and mounted in the appliance so that it does not rotate or move in operation of the apparatus. A spring member, such as two planar leaf springs positioned at an angle to each other, is mounted between the movable base element and the fixed mounting element. A drive shaft member extends from the movable base element through the fixed mounting element and beyond. A workpiece such as a brushhead is mounted on the distal end of the drive shaft. The spring member is configured so that it is substantially less resistant to twisting action than bending action, such that the side-to-side motion of the base element results in rotation of the workpiece.A method for tuning resonant spring assembly systems used in appliances such as power toothbrushes, particularly leaf spring systems, includes the step of measuring the frequency-dependent amplitude of the appliance workpiece, and then removing a portion of the spring member so as to decrease its spring rate sufficiently that the resonant frequency of the spring member closely approximates the drive frequency of the appliance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

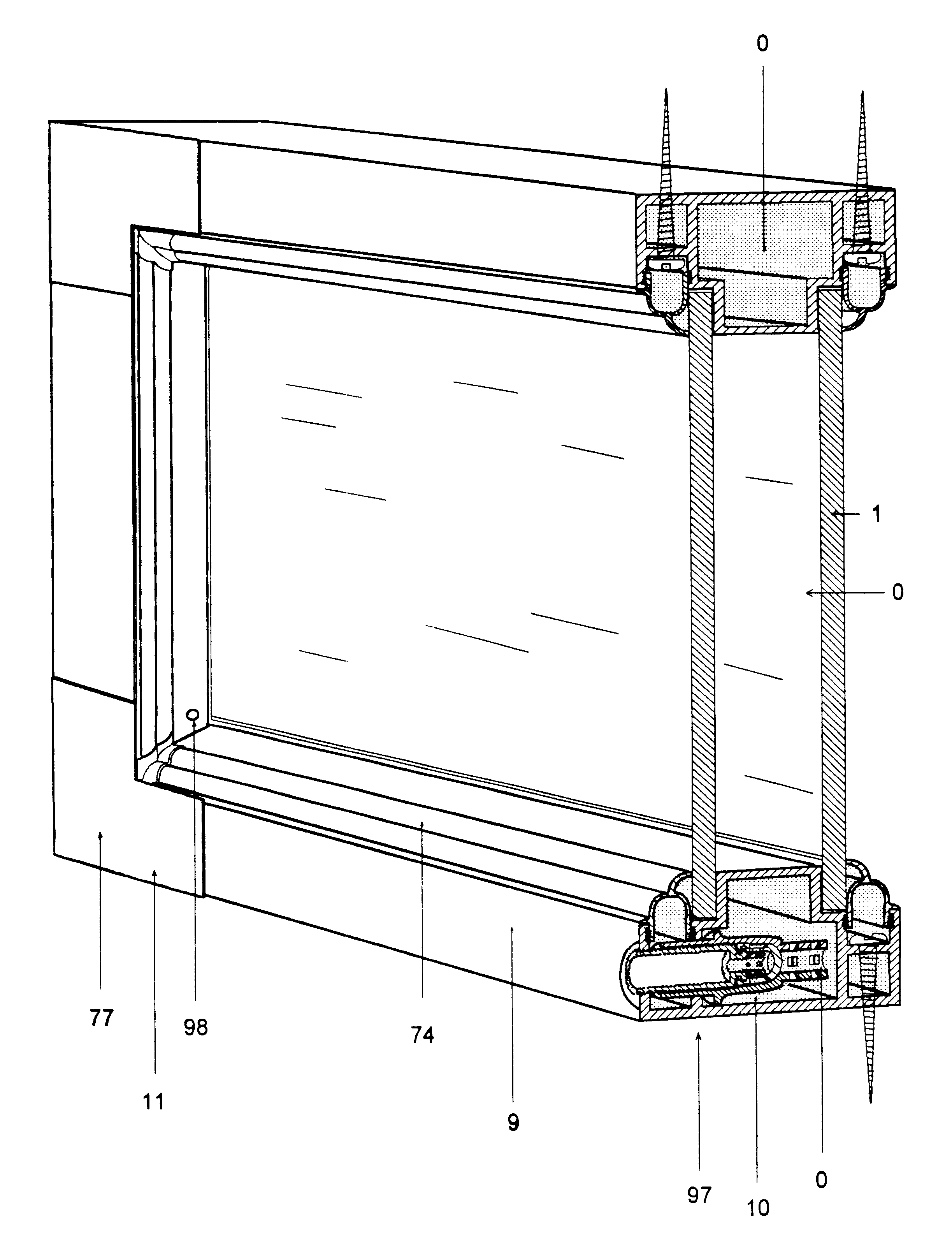

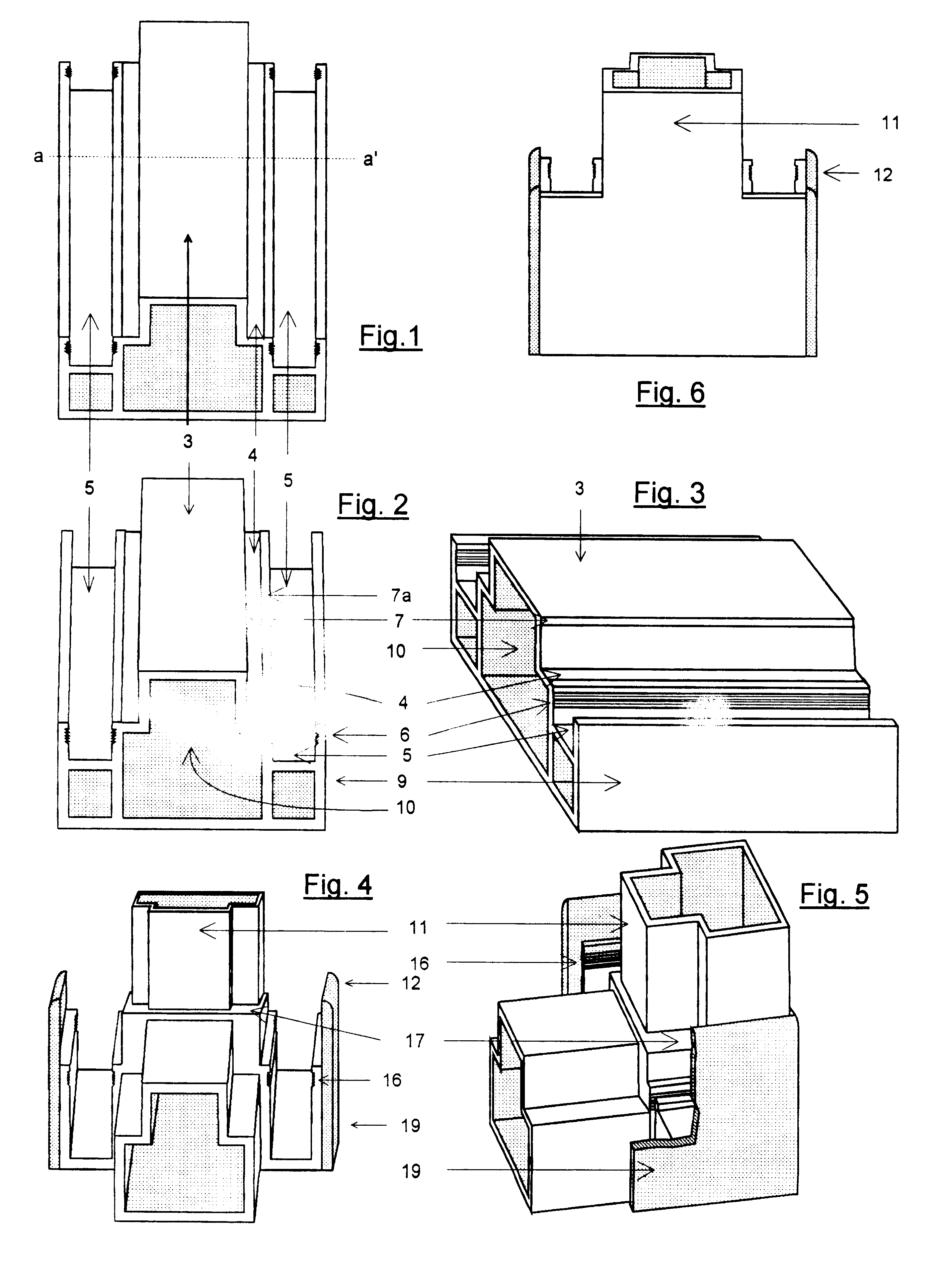

Assembly system for thermoacoustic windows

An assembly system used to build two pane thermoacoustic windows for houses and buildings is provided. The assembly system uses a set of profiles and joints and a permanently installed valve to assemble the window frame without a fusion welding machine. The system creates an airtight chamber directly on the frame. The valve allows the assembler to evacuate the air in the airtight chamber to make a vacuum, or to inflow a gas. The system improves the insulating thermal and acoustic capacity of the window, and allows a supplier to sell the components to build the window, which is then assembled by snapping together profiles and joints. The system can also be applied to assembly one pane window and for other purposes.

Owner:VALDERRAMA MARIO

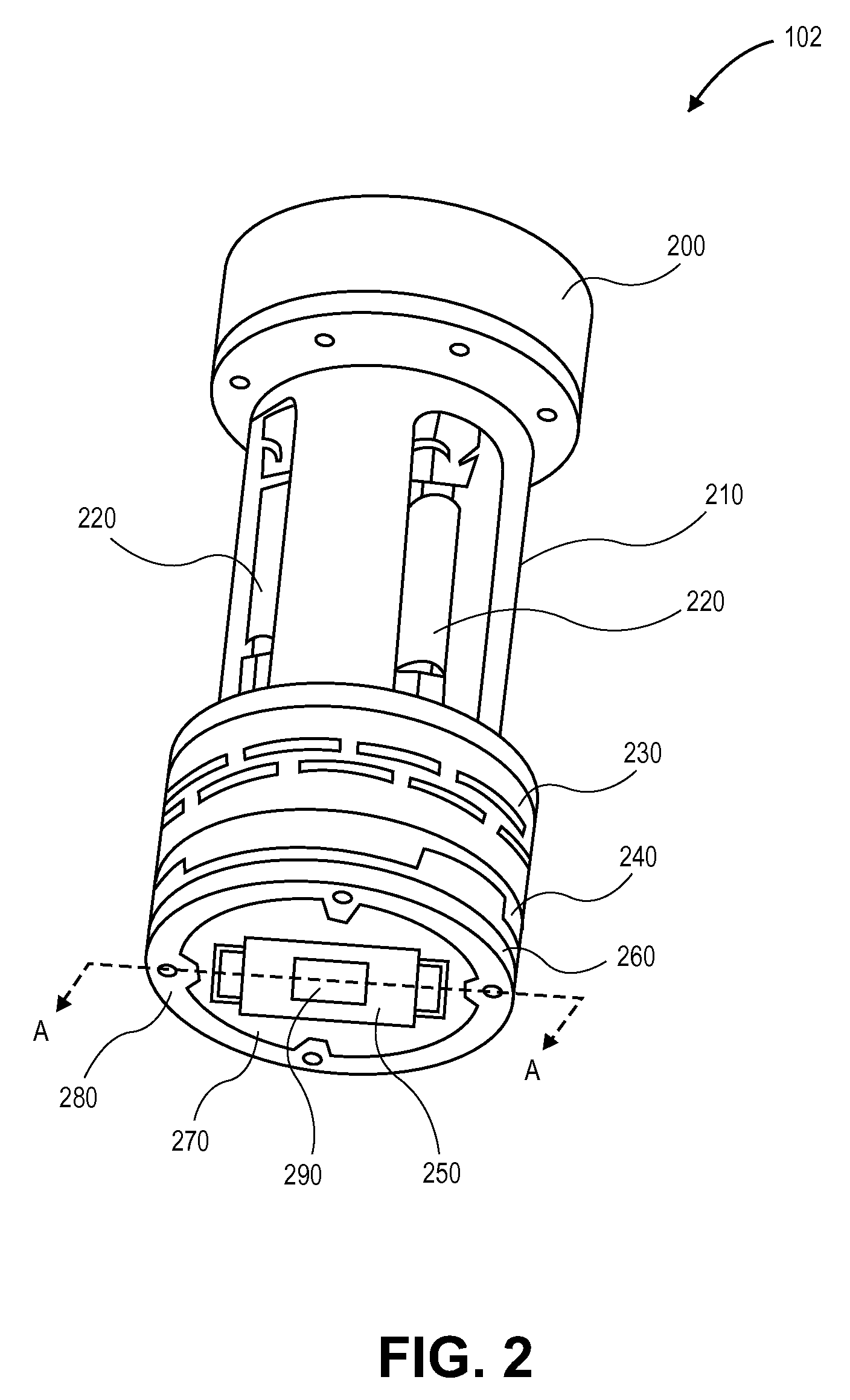

Mass transfer tool manipulator assembly

Systems and methods for transferring a micro device from a carrier substrate are disclosed. In an embodiment, a mass transfer tool manipulator assembly allows active alignment between an array of electrostatic transfer heads on a micro pick up array and an array of micro devices on a carrier substrate. Displacement of a compliant element of the mass transfer tool manipulator assembly may be sensed to control alignment between the array of electrostatic transfer heads and the array of micro devices.

Owner:APPLE INC

Adjustable Tension Incontinence Sling Assemblies

ActiveUS20100261950A1Increase and decrease adjustment spacingReduce tensionAnti-incontinence devicesSurgeryUrethraBody tissue

Systems for providing support to body tissue to alleviate incontinence are disclosed that comprise an elongated incontinence sling having a central support portion adapted to be positioned to support any one of the urethra or anus and first and second sling end portions extending from the central support portion through body tissue and a tension adjustment mechanism acting on or within one or both of the sling end portions. The sling tension adjustment mechanism is attached to and extends through an adjustment spacing between sling intermediate ends within at least one sling end portion. The adjustment spacing is lengthened to decrease sling tension and shortened to increase sling tension

Owner:BOSTON SCI SCIMED INC

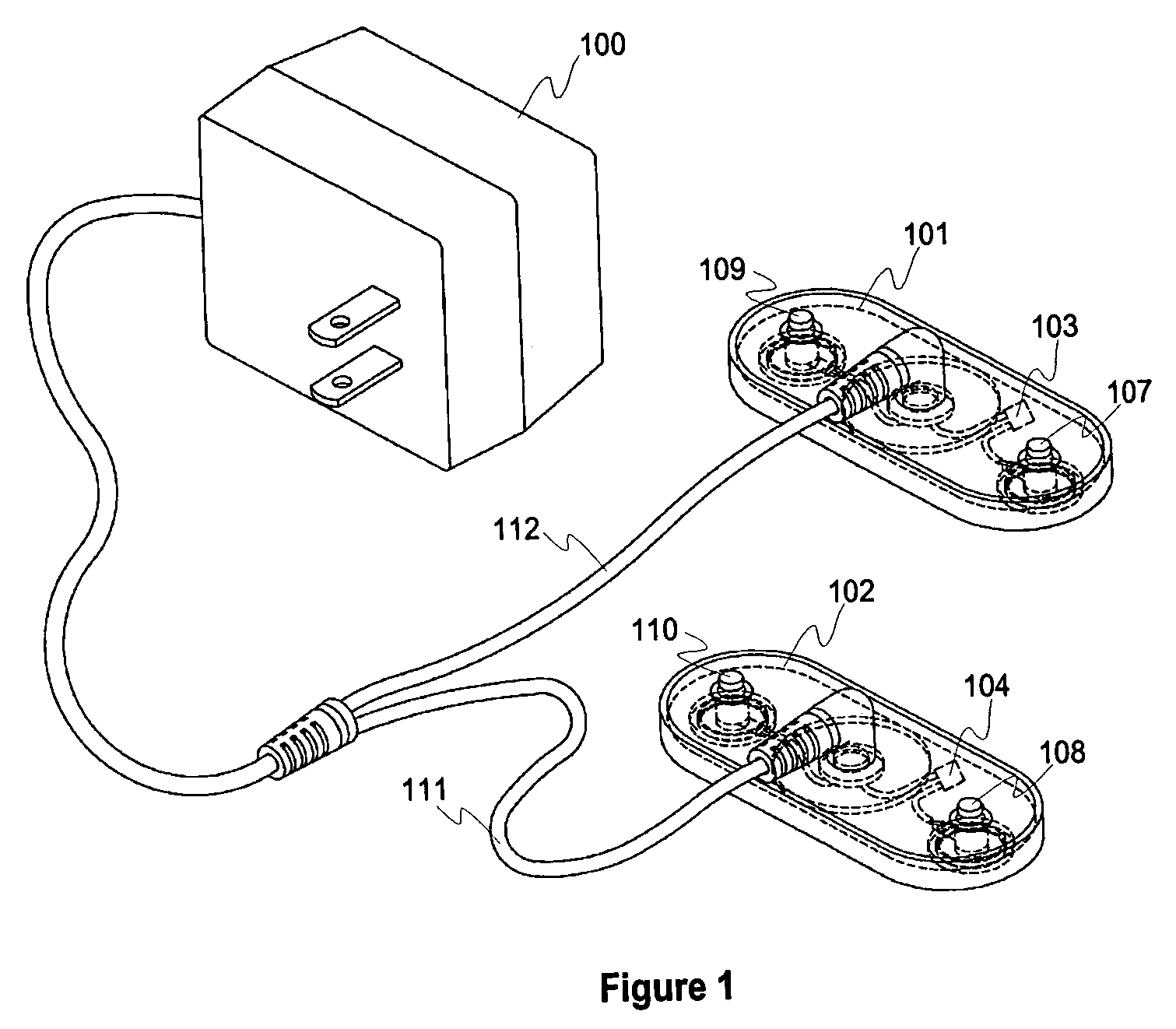

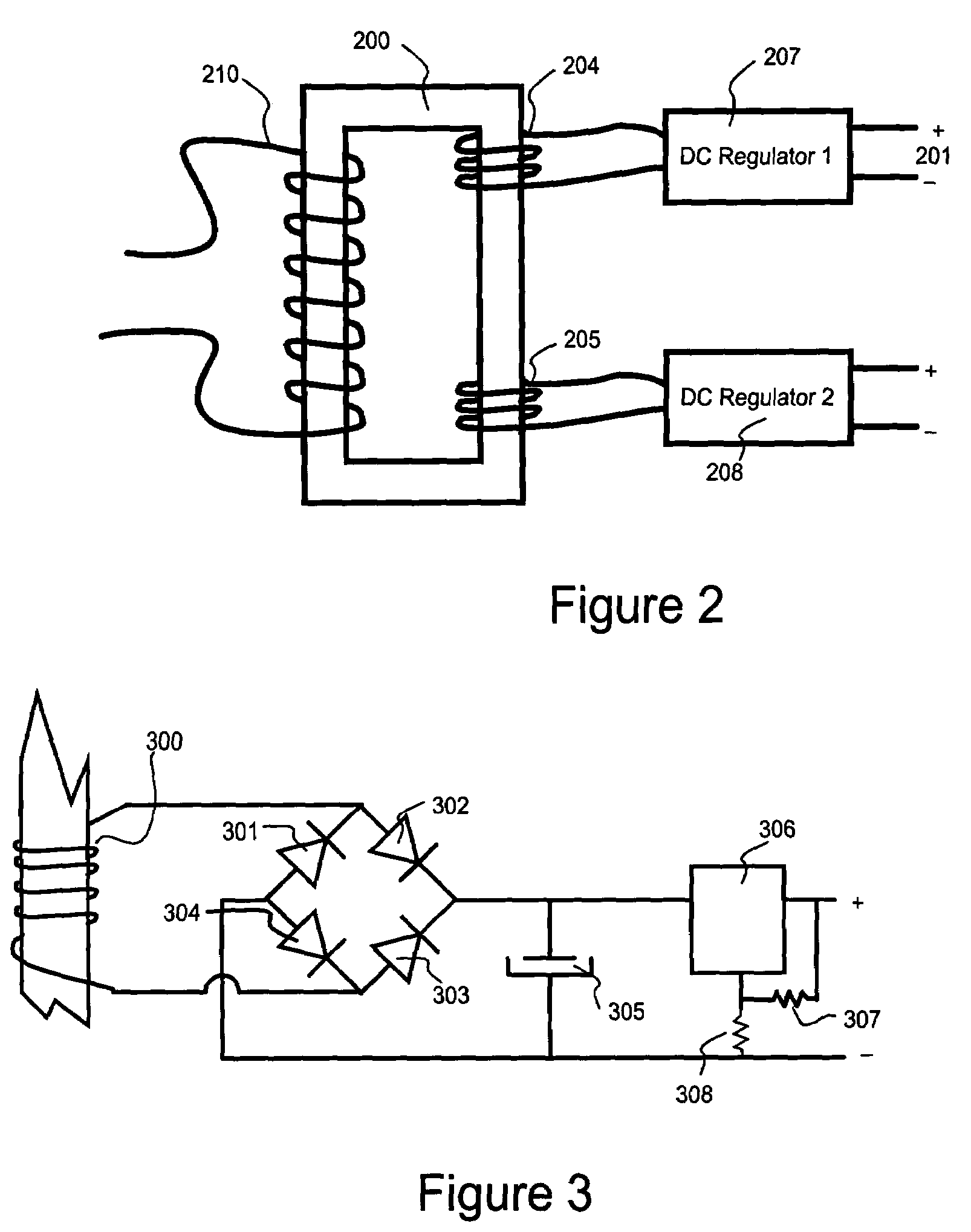

Electronic toy and teaching aid safety devices

ActiveUS7144255B2Limited amountAvoid damageSubstation/switching arrangement detailsCoupling device detailsElectronic componentPositive temperature

A battery holder containing positive temperature coefficient (PTC) resetable fuse to electronically limit the maximum current that can be drawn from circuits built using reusable electronic component housings. A power supply with similar housing to reusable battery holders, also designed to limit maximum current and perform electrically equivalent to two or more battery holders. A reusable electronic housing with means for attaching any two leaded electronic component for insertion into quick connect assembly system. This housing also contains a positive temperature coefficient (PTC) resetable fuse to electroniclly limit the maximum current that can be sent through the attached two leaded component.

Owner:ELENCO ELECTRONICS LLC

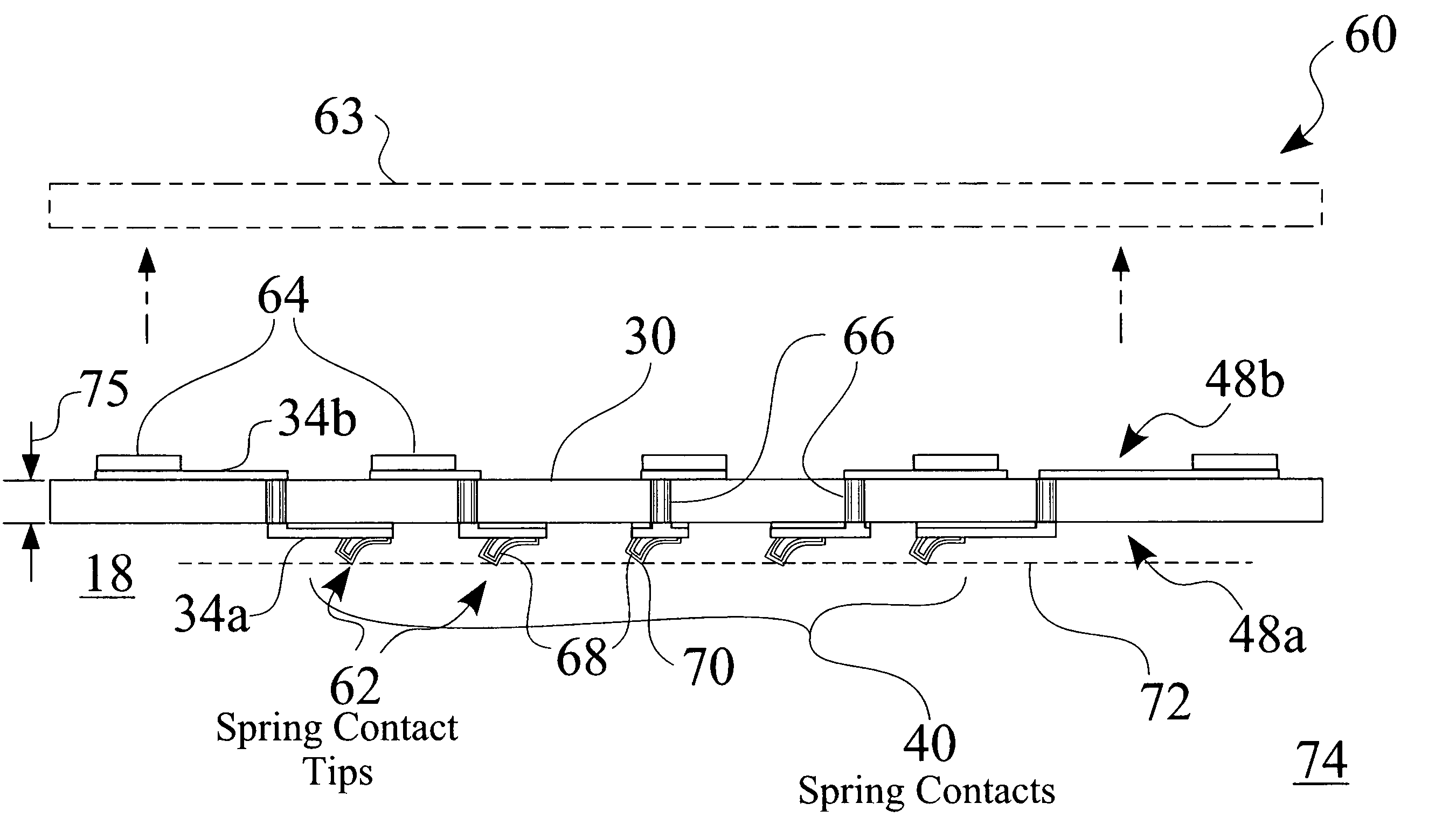

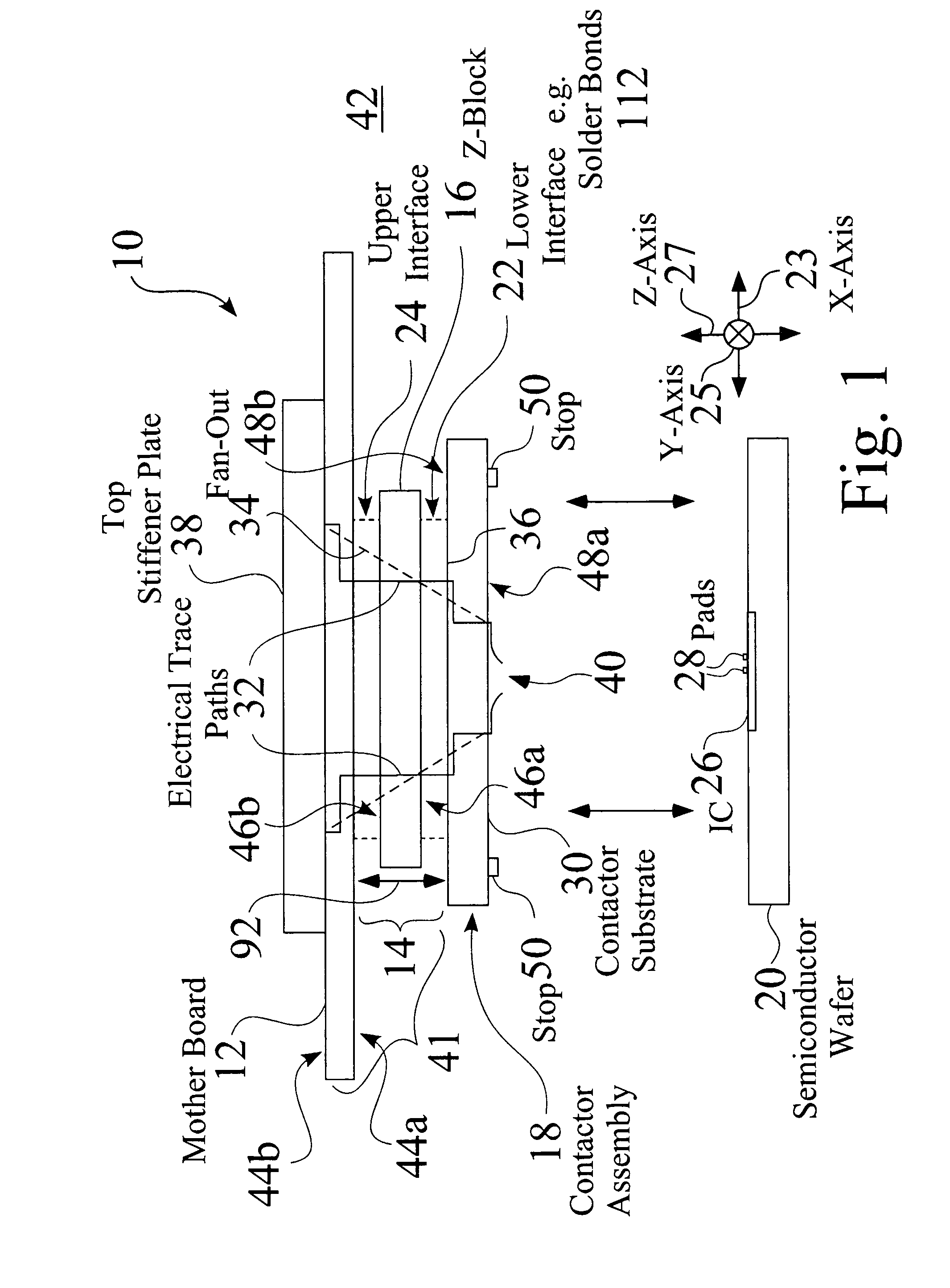

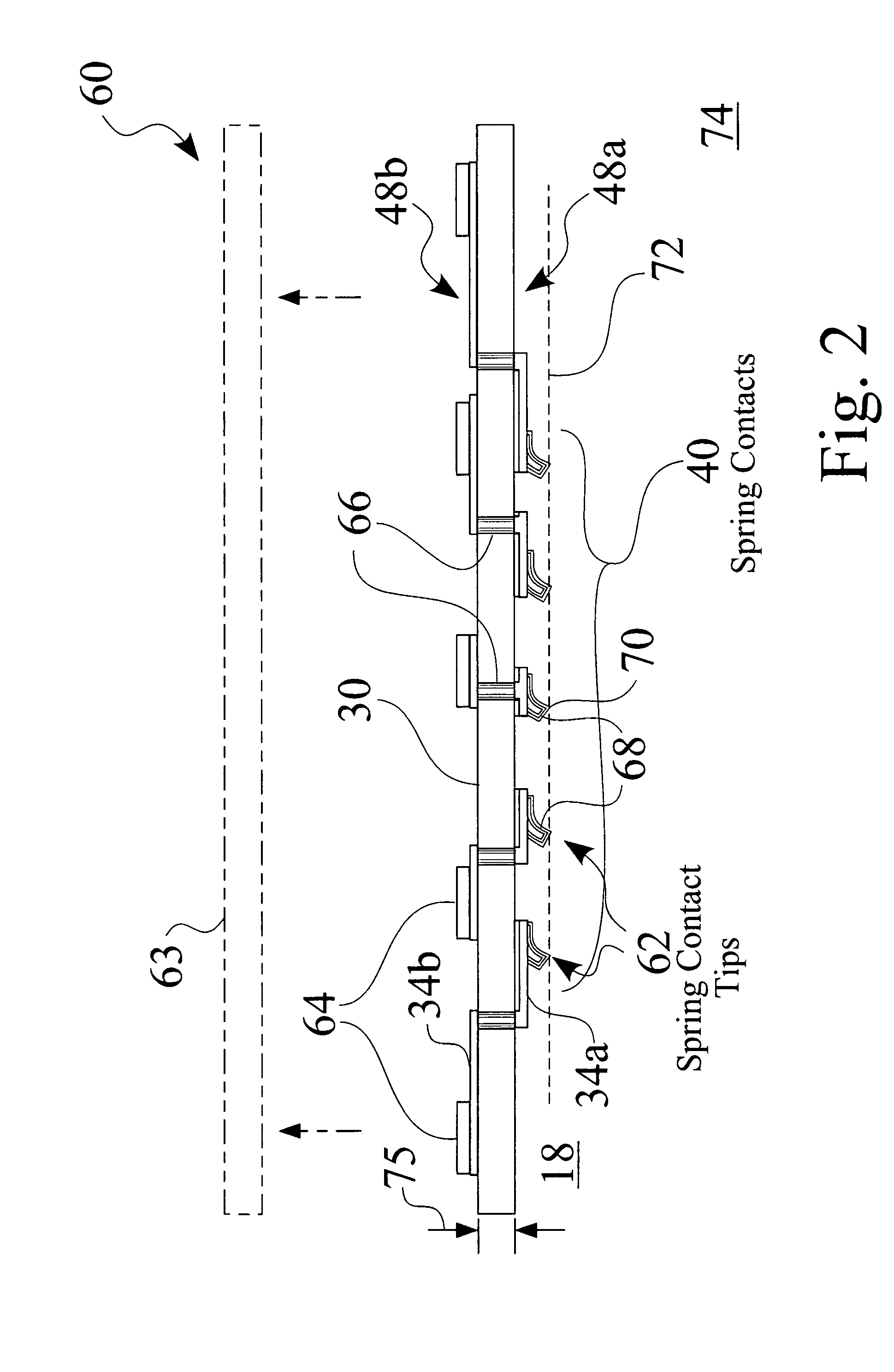

High density interconnect system for IC packages and interconnect assemblies

InactiveUS20060186906A1Electrical measurement instrument detailsManufacture of electrical instrumentsProbe cardHigh density

An improved interconnection system is described, such as for electrical contactors and connectors, electronic device or module package assemblies, socket assemblies, and / or probe card assembly systems. An exemplary connector comprises a first connector structure comprising a contactor substrate having a contact surface and a bonding surface, and one or more electrically conductive micro-fabricated spring contacts extending from the probe surface, a second connector structure comprising at least one substrate and having a set of at least one electrically conductive contact pad located on a connector surface and corresponding to the set of spring contacts, and means for movably positioning and aligning the first connector structure and the second connector structure between at least a first position and a second position, such that in at least one position, at least one electrically conductive micro-fabricated spring contact is electrically connected to at least one electrically conductive contact pad.

Owner:ADVANTEST SINGAPORE PTE LTD

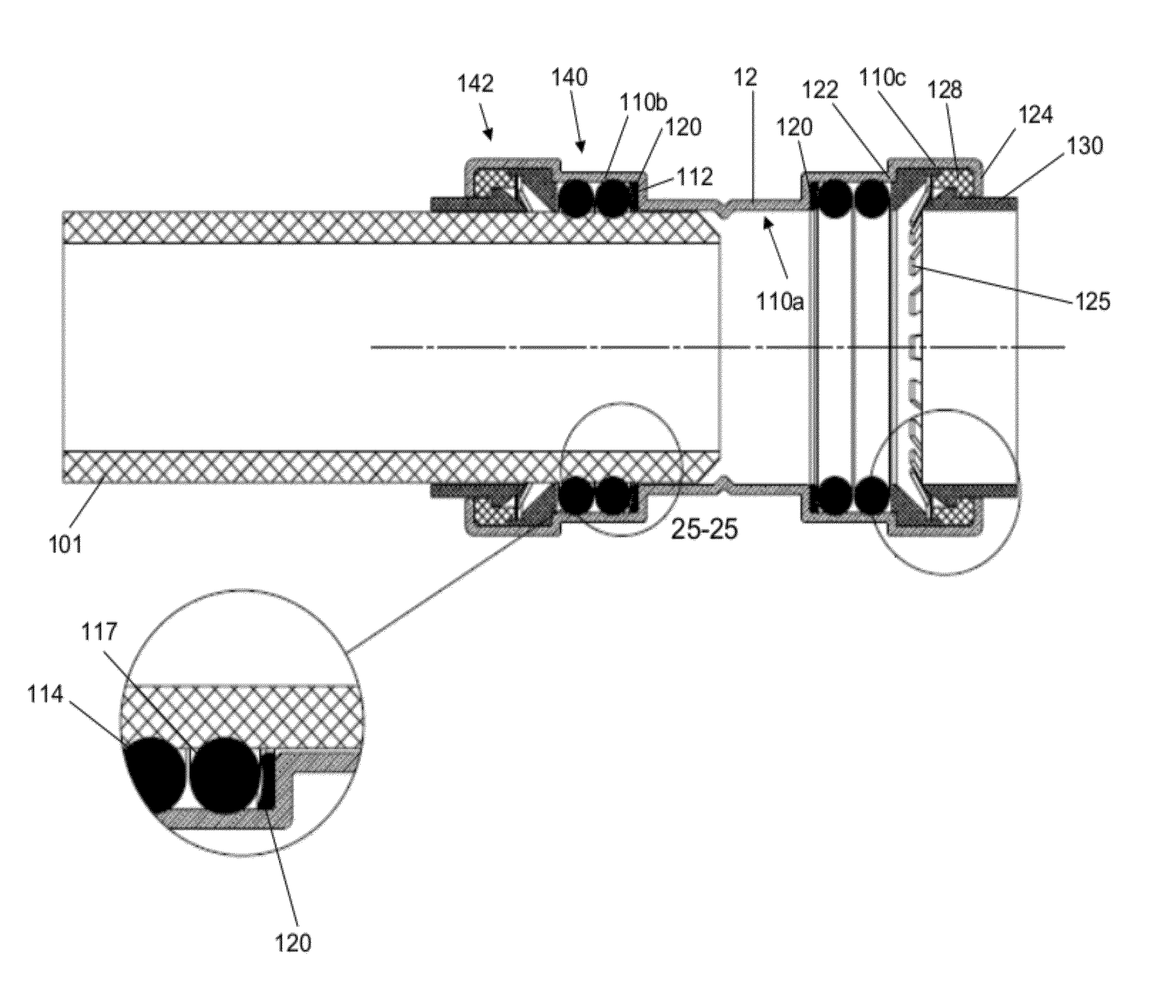

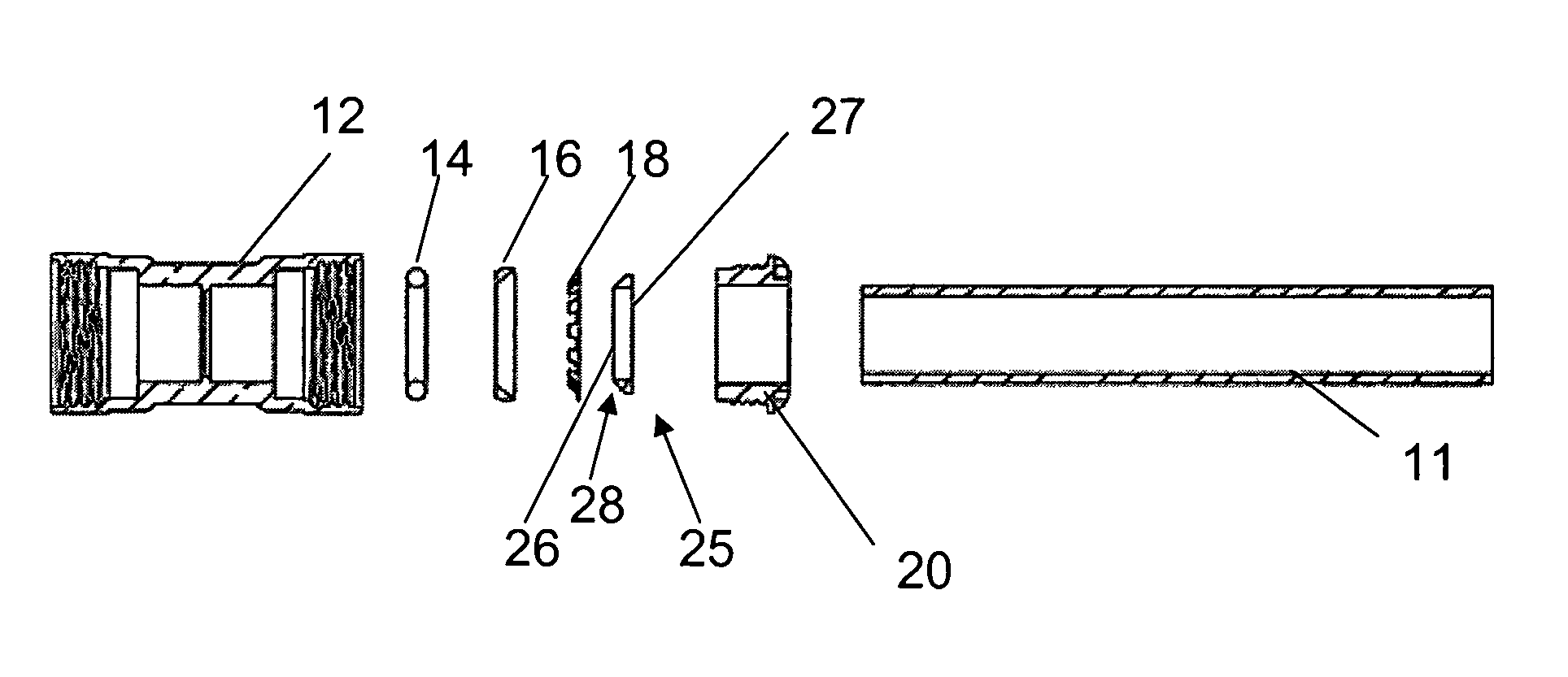

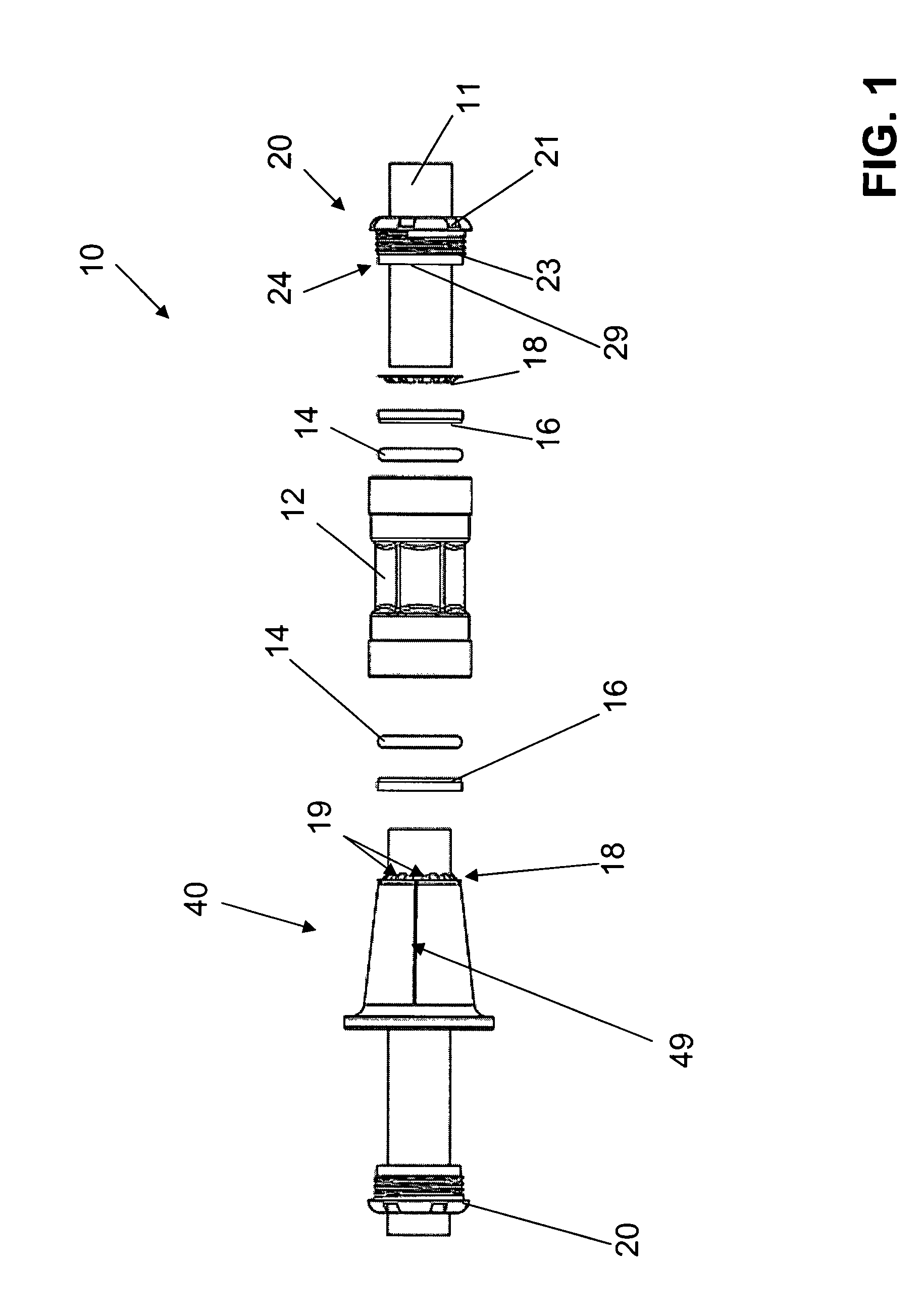

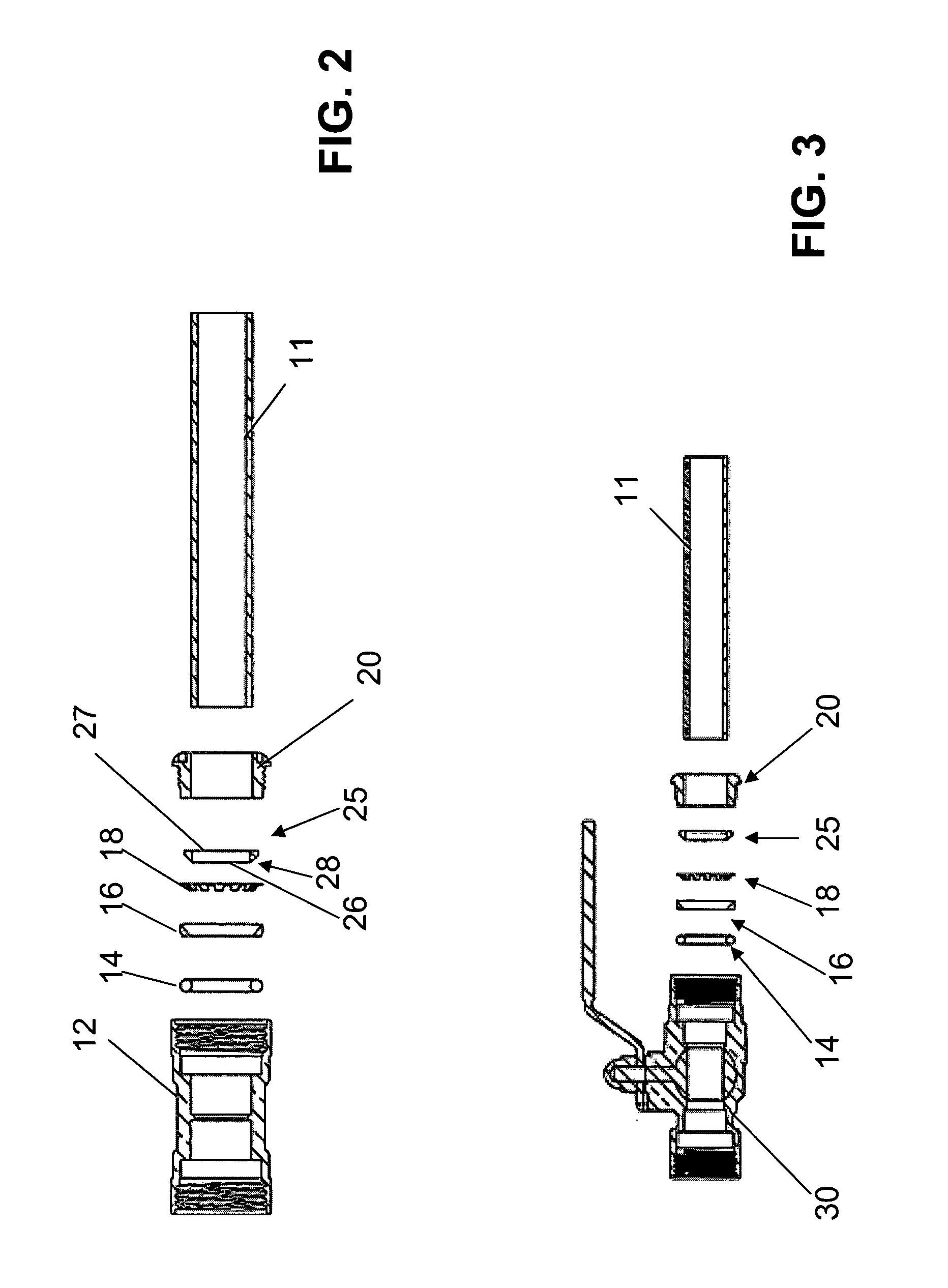

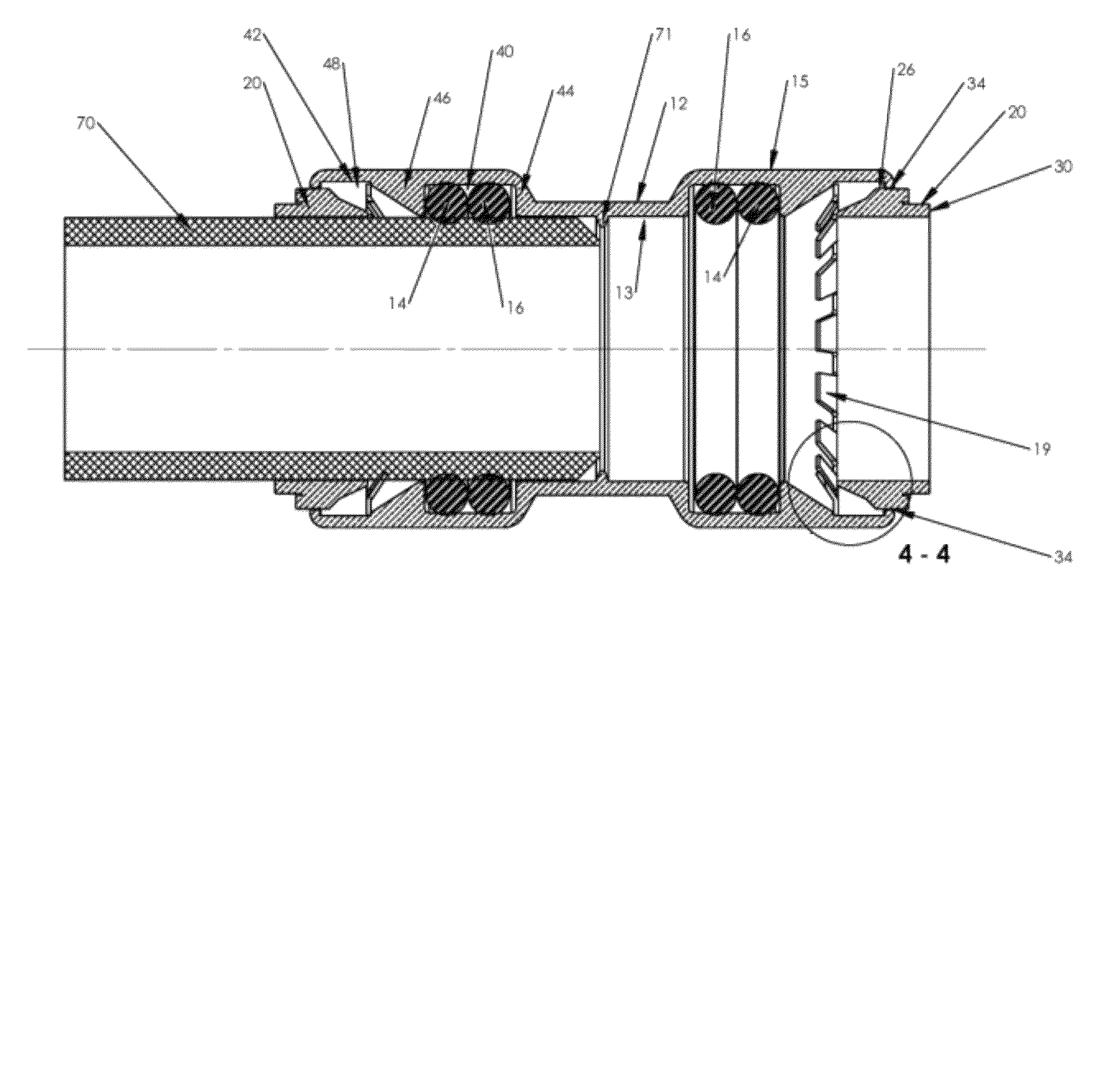

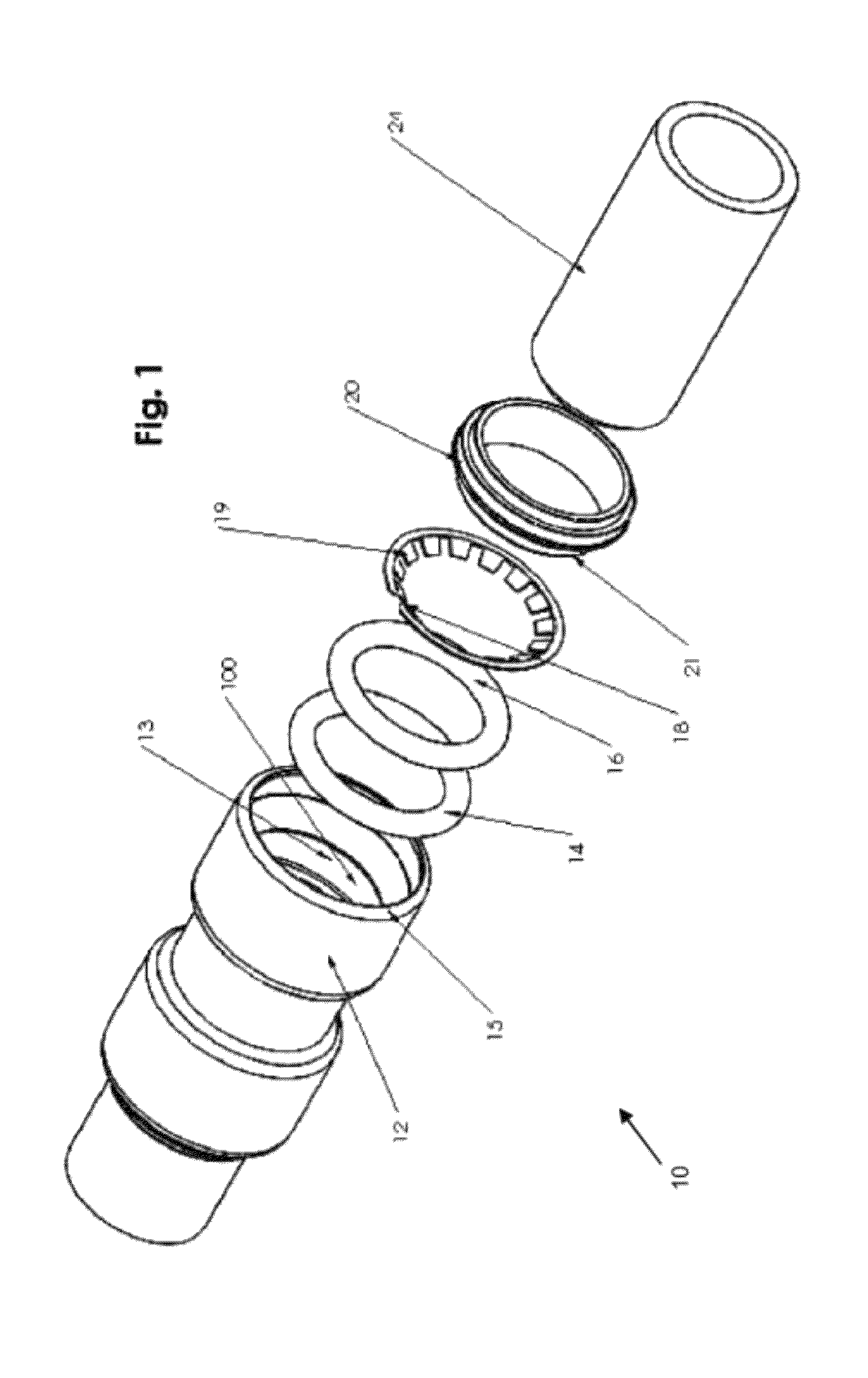

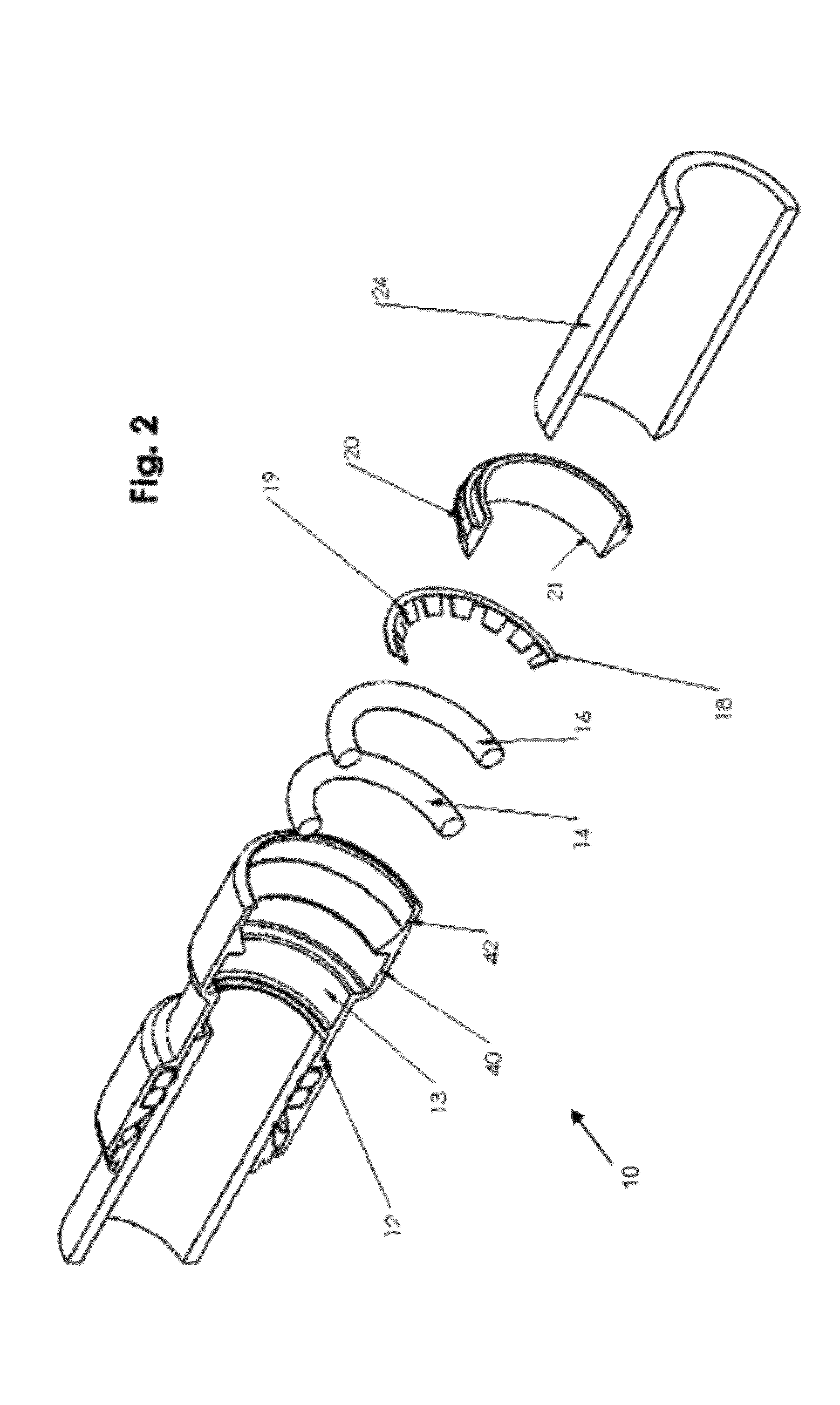

Piping joint assembly system and method with sealing ring stabilizer

ActiveUS8480134B2Facilitated releaseSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe fitting and associated piping joint assembly package allow re-use and repair of push-fit, formed piping elements without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment, the present invention includes a pipe fitting having first and second radial housing elements for receiving one or more sealing members and a fastening ring, respectively. In one embodiment, the present invention further includes a sealing member stabilizer element, a housing divider element and a snap ring support member cooperatively engageable so as to facilitate the secure retention and optional removal of an inserted piping element.

Owner:QUICK FITTING

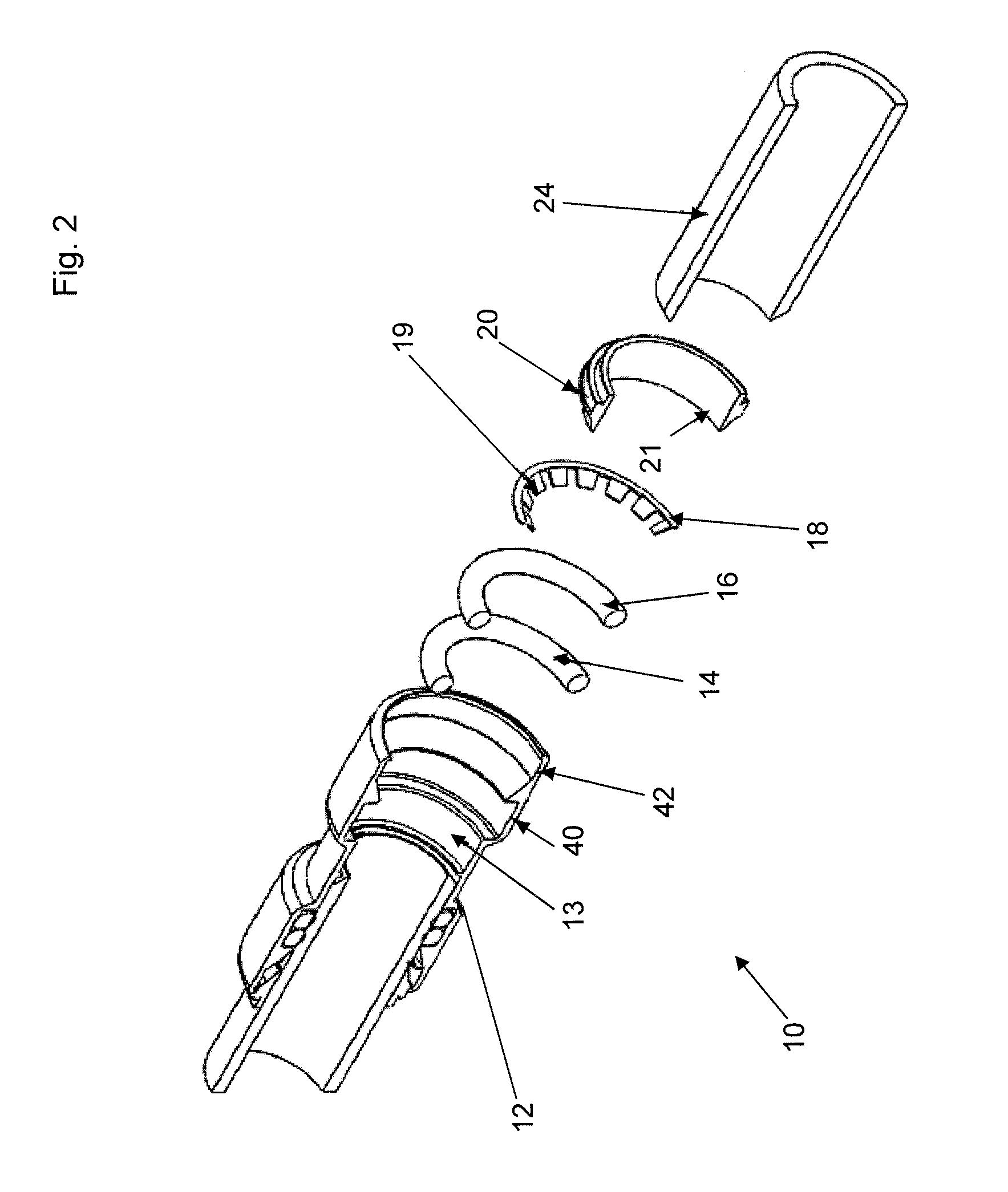

Delivery devices with coolable energy emitting assemblies

ActiveUS20120016364A1Conveniently passedAvoid and limit destructionUltrasound therapyBronchoscopesNervous systemTarget tissue

Owner:HOLAIRA INC

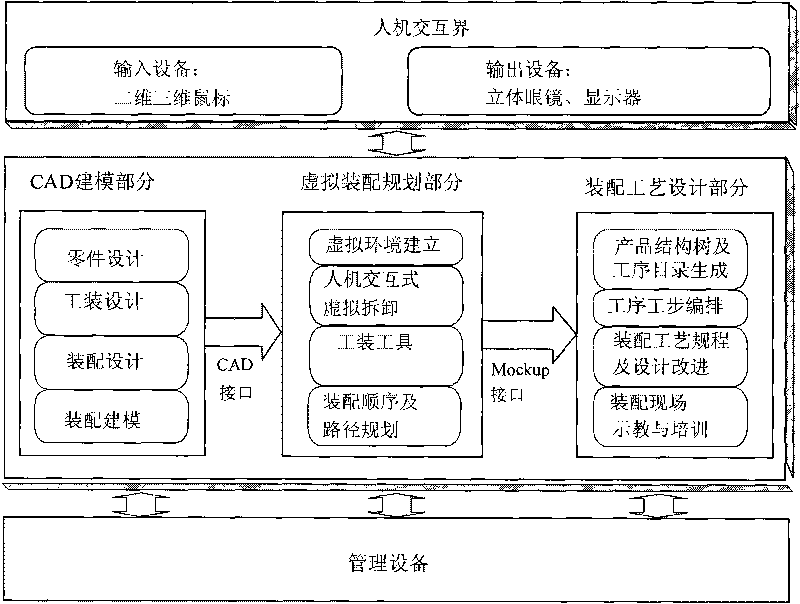

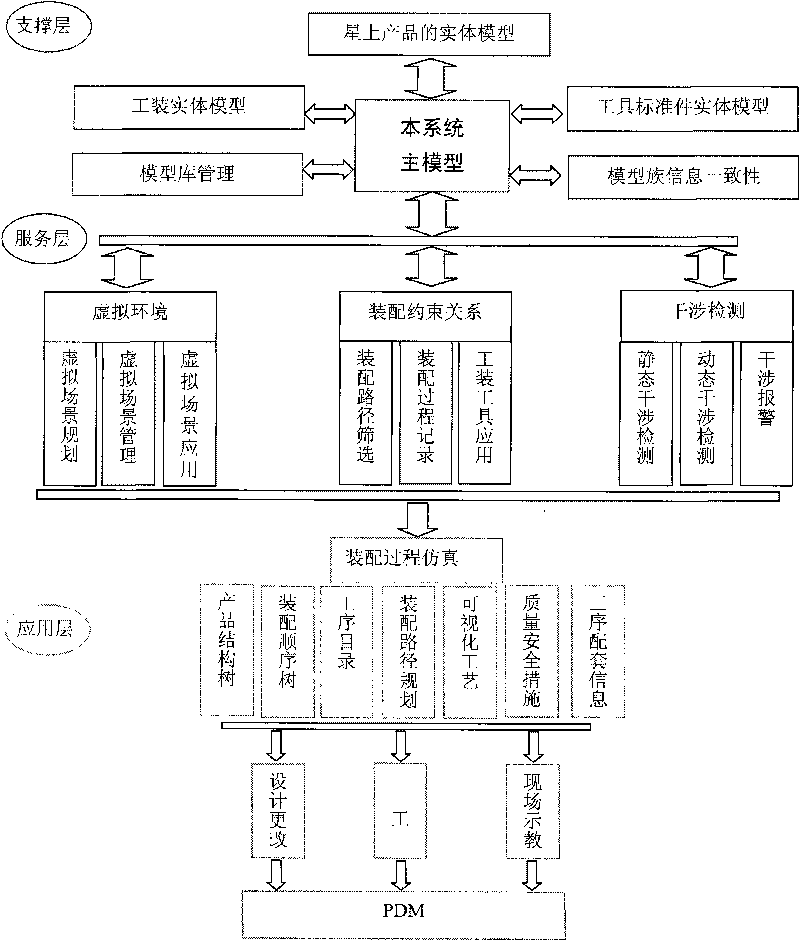

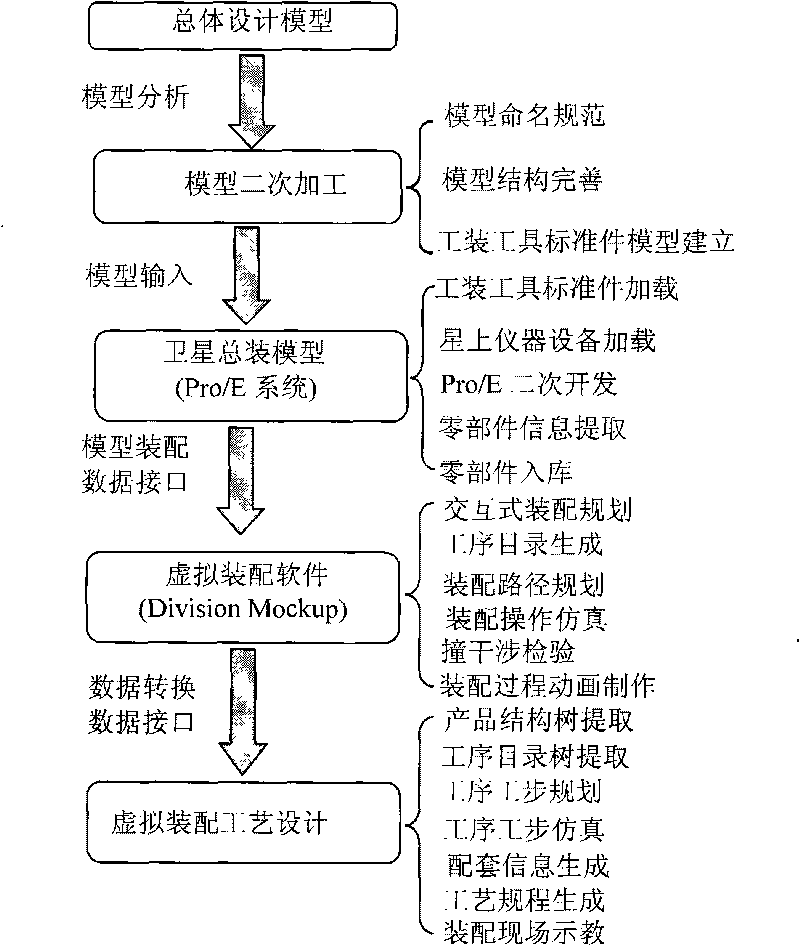

Spacecraft assembly simulation technique-based virtual assembly system and virtual assembly method

The invention relates to a spacecraft assembly simulation technique-based virtual assembly system. The virtual assembly system comprises a CAD modeling module, a virtual assembly planning module and an assembly process design module, wherein the CAD modeling module is used for designing components and tooling tools, and assembling the components together by defining a series of matching constraint relations so as to obtain an assembling model of products; the virtual assembly planning module is used for establishing a geometrical constraint-based virtual environment, planning an optimized assembly sequence according to disassembly directions, disassembly tools and precedence constraint information recorded in the virtual environment for execution, verifying the optimized assembly sequence, and performing simulation evaluation in the virtual environment; and the assembly process design module is used for designing a product structure tree and a process step catalog, editing process steps and assembling a technological process. The CAD modeling module is connected with the virtual assembly planning module through a CAD modeling interface so that models generated in the CAD modeling module are guided into the virtual assembly planning module; and the process planning result in the virtual assembly planning module is guided into the assembly process design module through a Mockup interface.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Piping joint assembly system and method

A pipe fitting assembly package and fastening ring removal tool allow re-use and repair of push-fit piping fittings and valves without damage to the fitting or valve elements or the pipe. The quick connection pipe fitting assembly package of the present invention employs a threaded retaining cap that when removed, exposes the clamping, sealing and fastening mechanism of the fitting or valve. In one embodiment, the present invention further includes a removable packing gland mounted on a body about an axis of an orifice. The fastening ring removal device provided as part of the present invention is manually pushed onto the cylindrical object and is capable of expanding to traverse over the installed fastening ring. The fastening ring removal device includes a parallel angular surface to lift the fastening ring off of the pipe member. In one embodiment of the present invention, the removal device has a plurality of cut areas or slits extending axially along its surface to allow for the expansion of the upper rim portion of the fastener removal tool as it slides over a remaining fastening ring. The present invention facilitates re-use of existing fittings and valves by allowing the internal components to be removed, repaired and / or replaced.

Owner:QUICK FITTING HOLDING COMPANY LLC

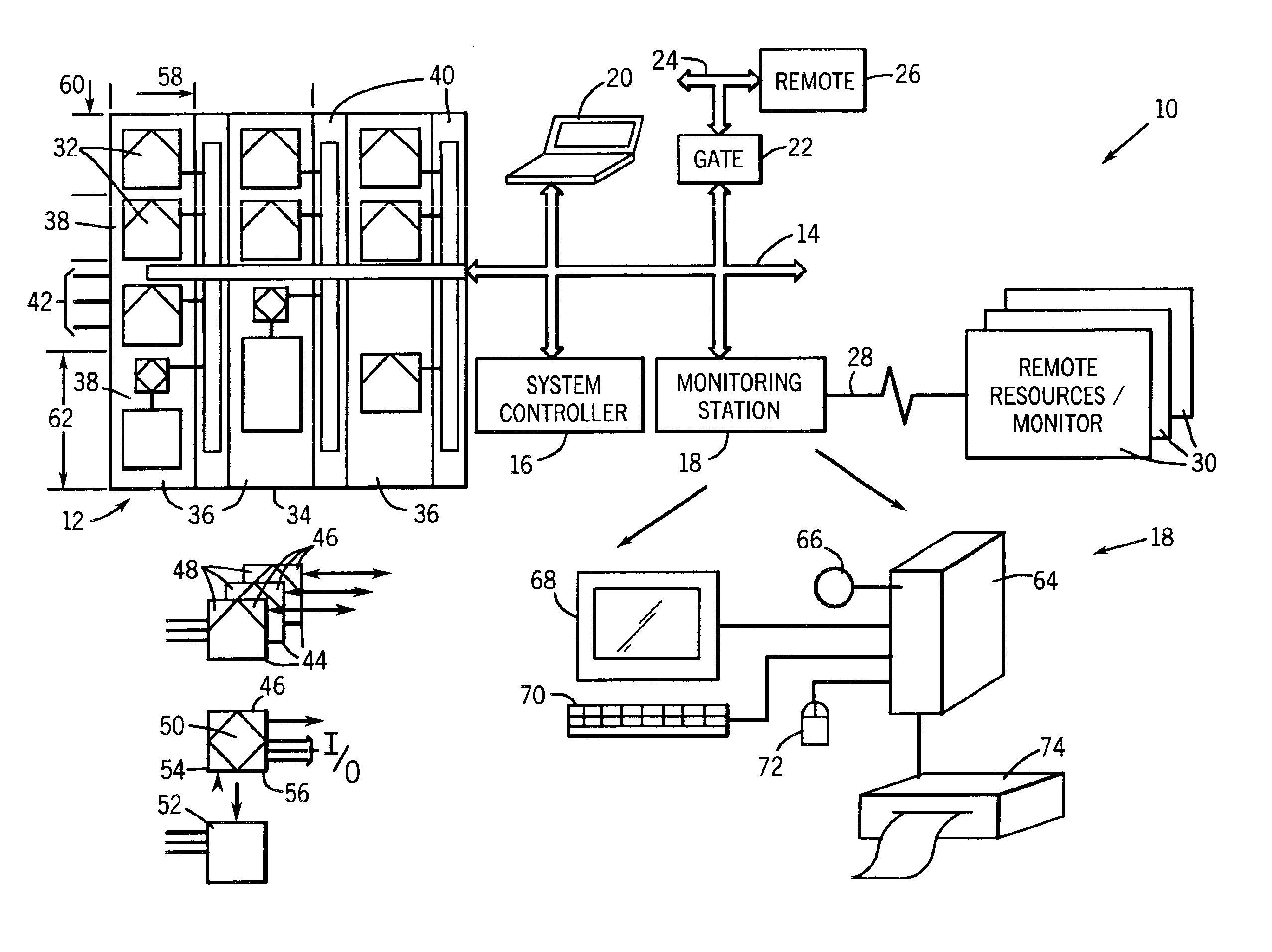

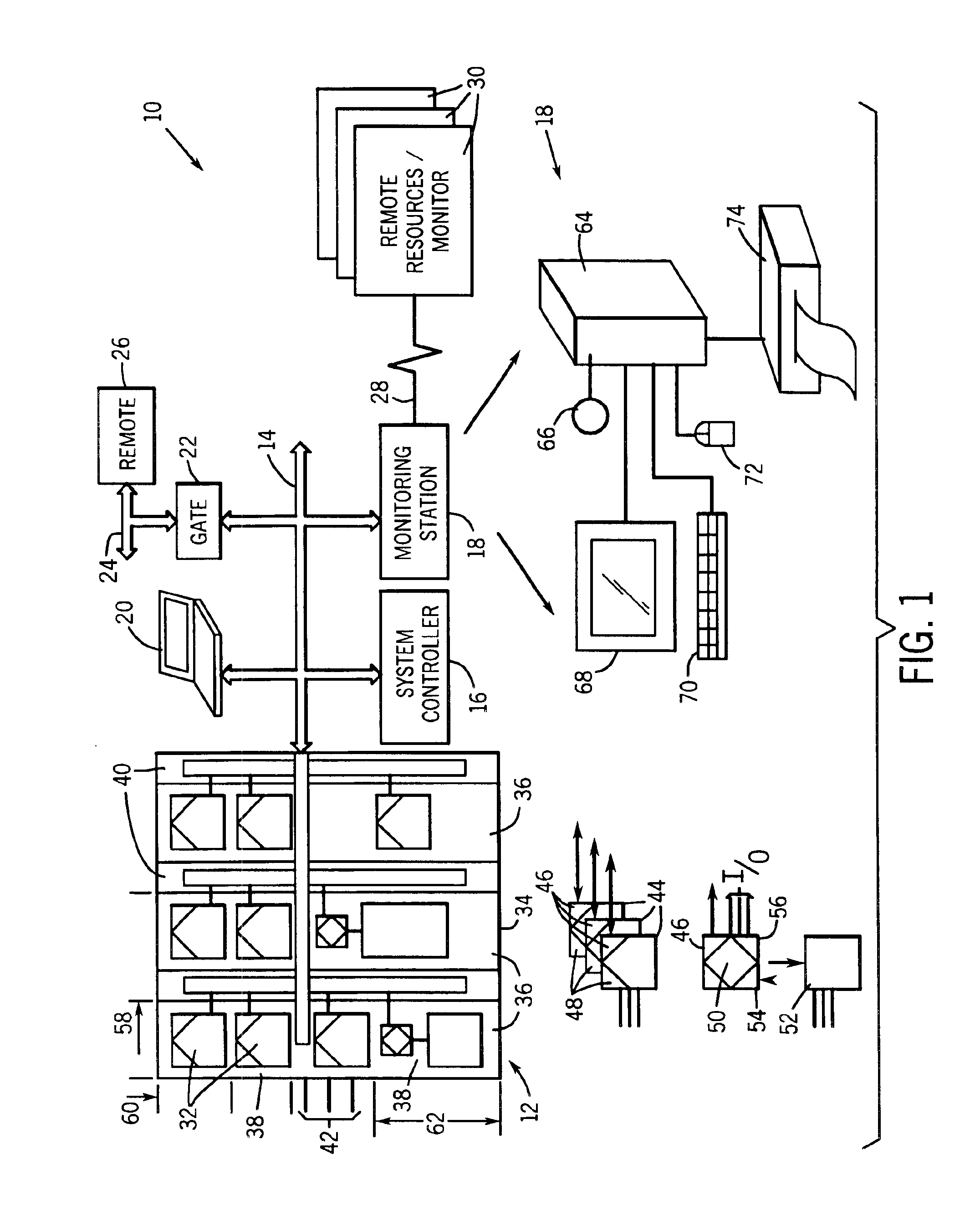

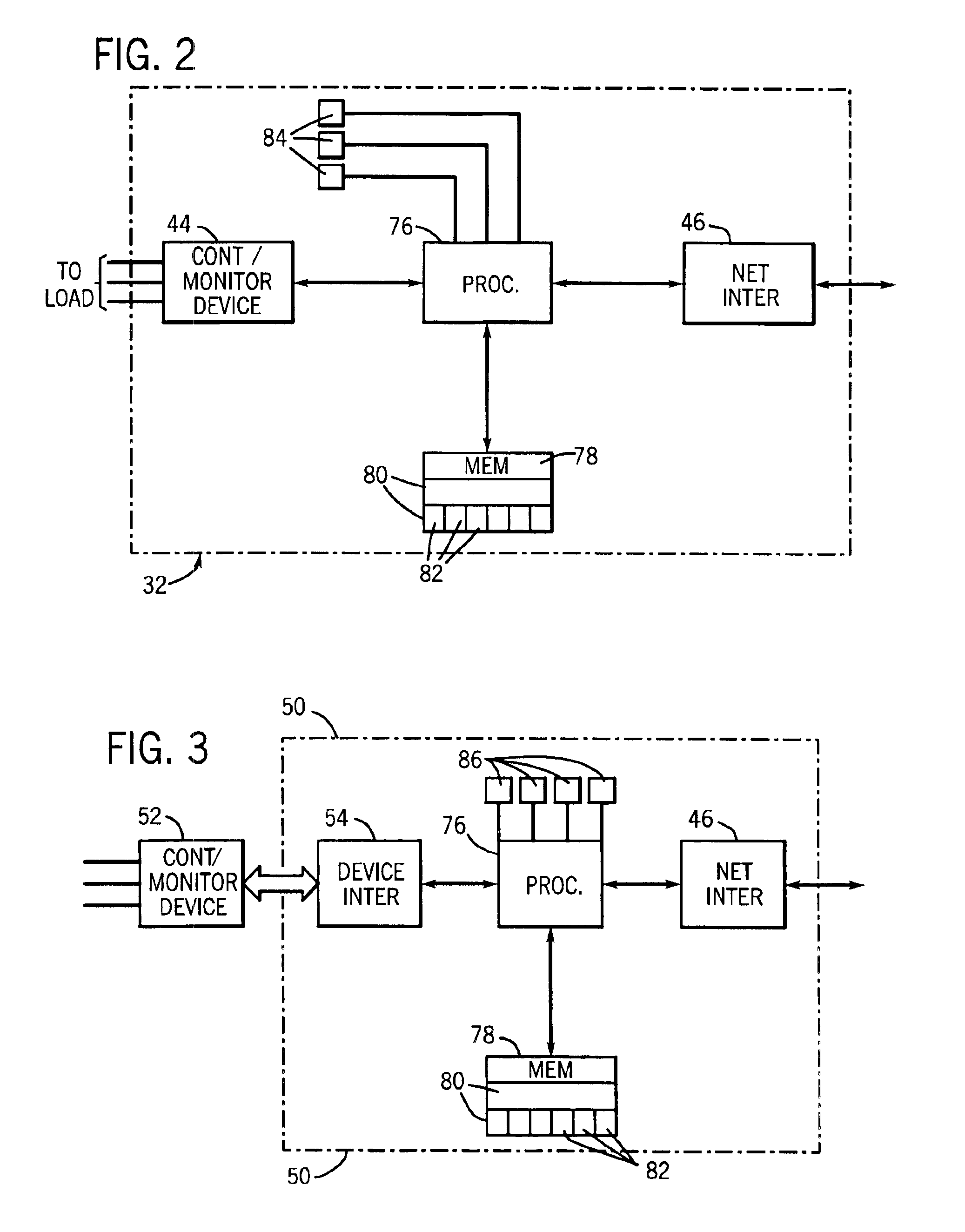

Electrical control system configuration method and apparatus

A technique for configuring programmable, networked electrical components of a system includes downloading data into each component from a configurator, based upon a database for the system. The components include memory objects which are designed to store data descriptive of the system, the component, the component location in the system, and the component configuration. The configurator may load the information prior to, during or following assembly of the components in the system. The configurator may also modify system and component configurations following installation of the system by modifying the data downloaded into the individual components.

Owner:ROCKWELL TECH

Piping joint assembly system and method

ActiveUS8205915B1Facilitated releaseSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe fitting and associated piping joint assembly package allow re-use and repair of push-fit piping fittings and valves without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment, the present invention includes a pipe fitting having first and second radial housing elements for receiving one or more sealing members and a fastening ring, respectively. The fastening ring can be a split fastening ring. The split fastening ring and the sealing members provided as part of the present invention are capable of being removed and / or replaced.

Owner:QUICK FITTING

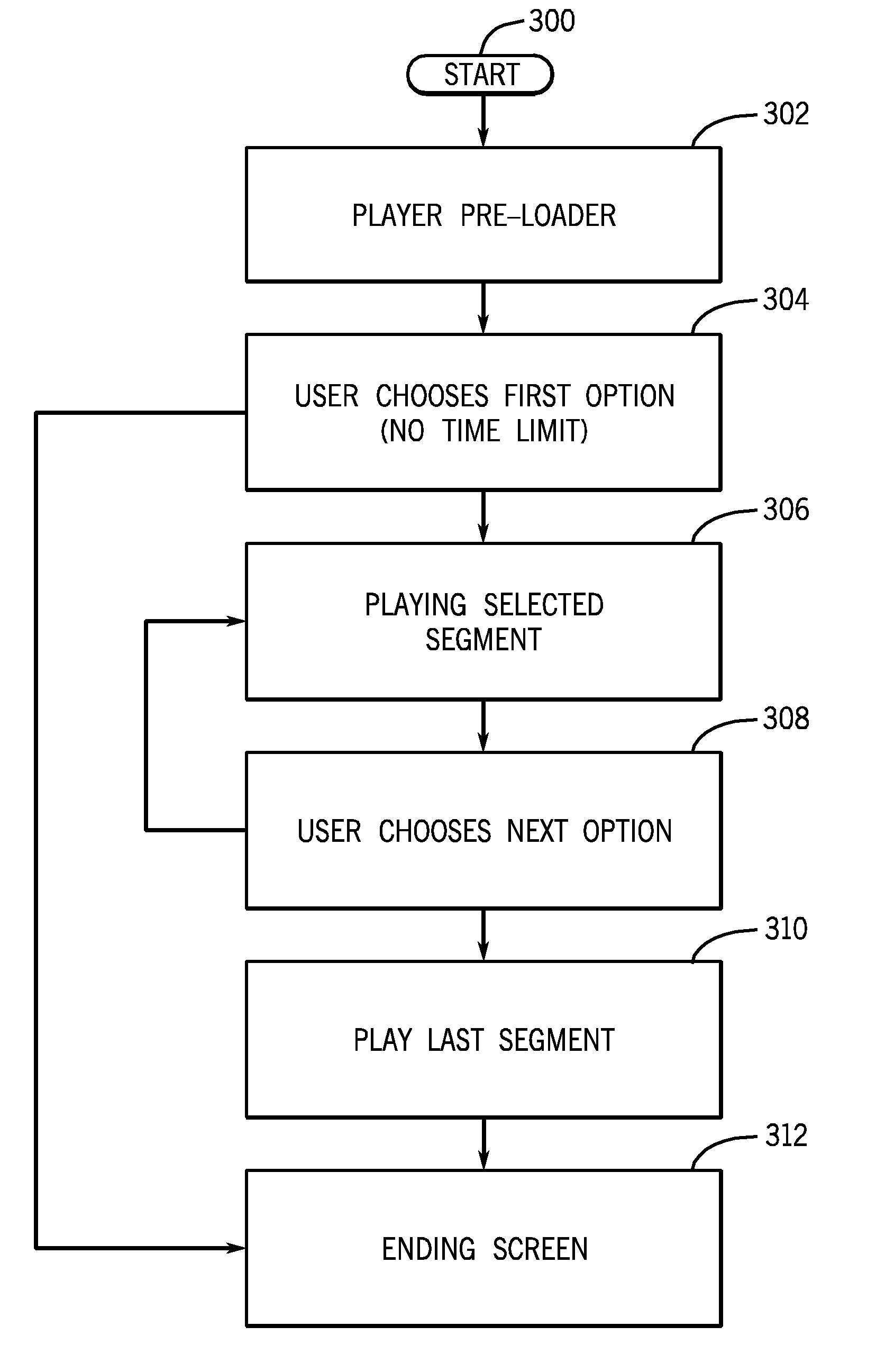

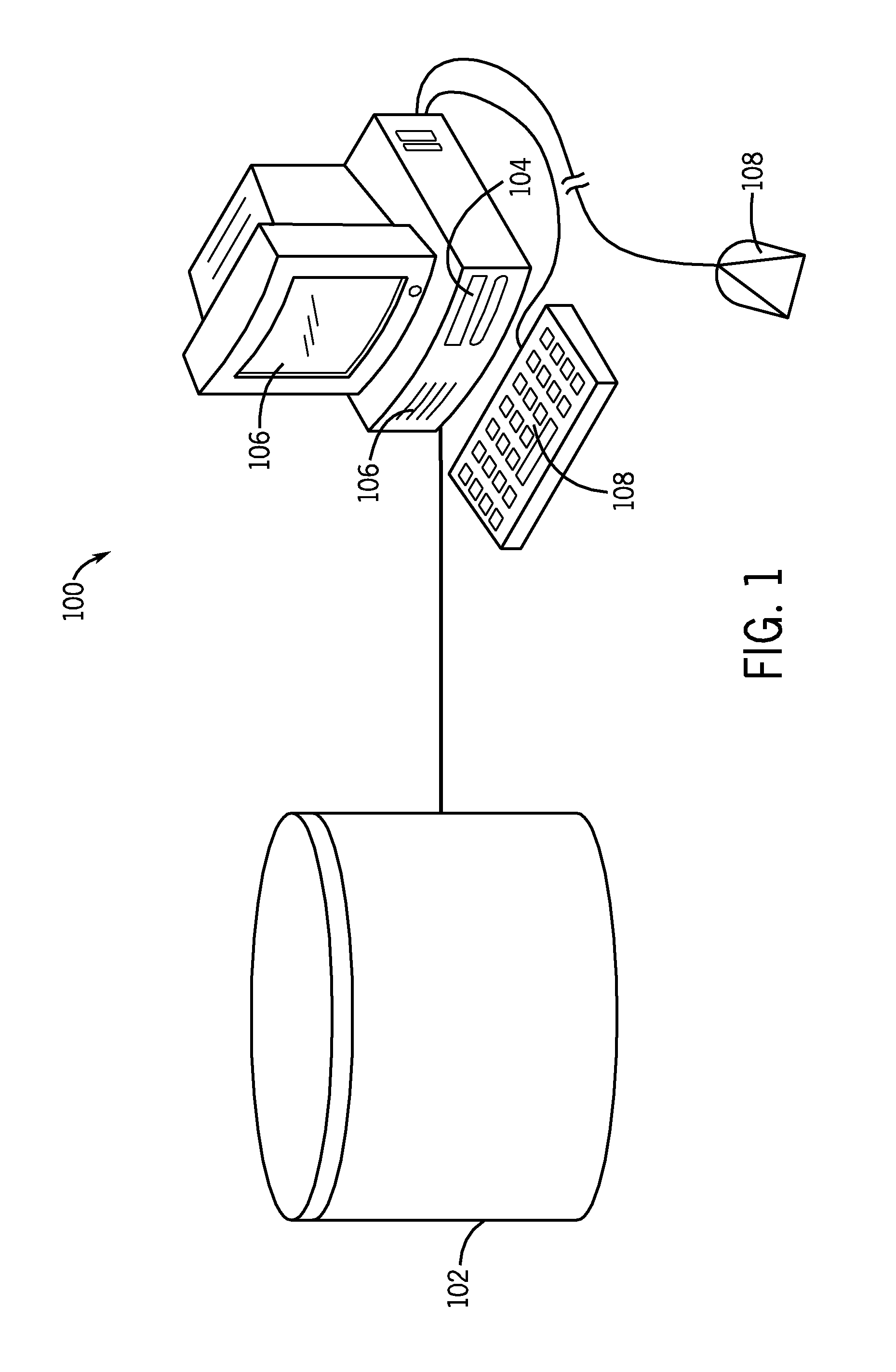

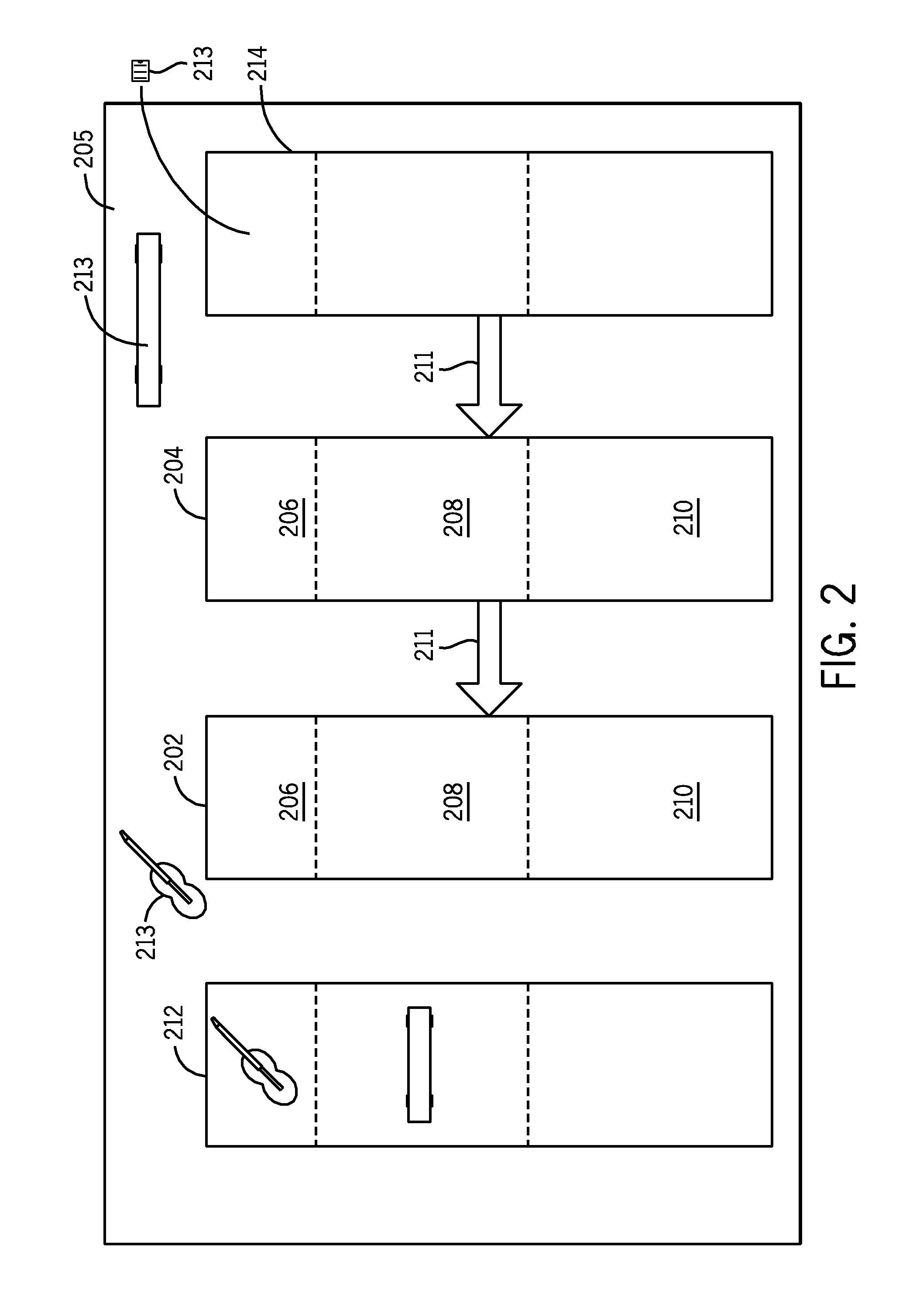

System and method for seamless multimedia assembly

ActiveUS20110200116A1Electrophonic musical instrumentsPicture reproducers using cathode ray tubesTransition pointAudio frequency

Systems and methods are provided for seamless assembly of video / audio segments. To achieve such seamless assembly during streaming / online progressive download of media, a second segment is downloaded to a client during the presentation of a first segment. The first segment is then attached to the beginning of the second segment, where no jitter or gap results with the transition point either in the video or audio portion of the segments. Hence, the merged segments are presented as a seamless assembly of video / audio segments, where the user is “unaware” that the merged segments are the result of two separate or different segments. To effectuate such gapless assembly of segments, a gapless media file is created for encoding the video and audio segments using a gapless audio encoding scheme, such as Ogg Vorbis, where synchronized, gapless audio tags are interleaved in the video segments.

Owner:JBF INTERLUDE 2009

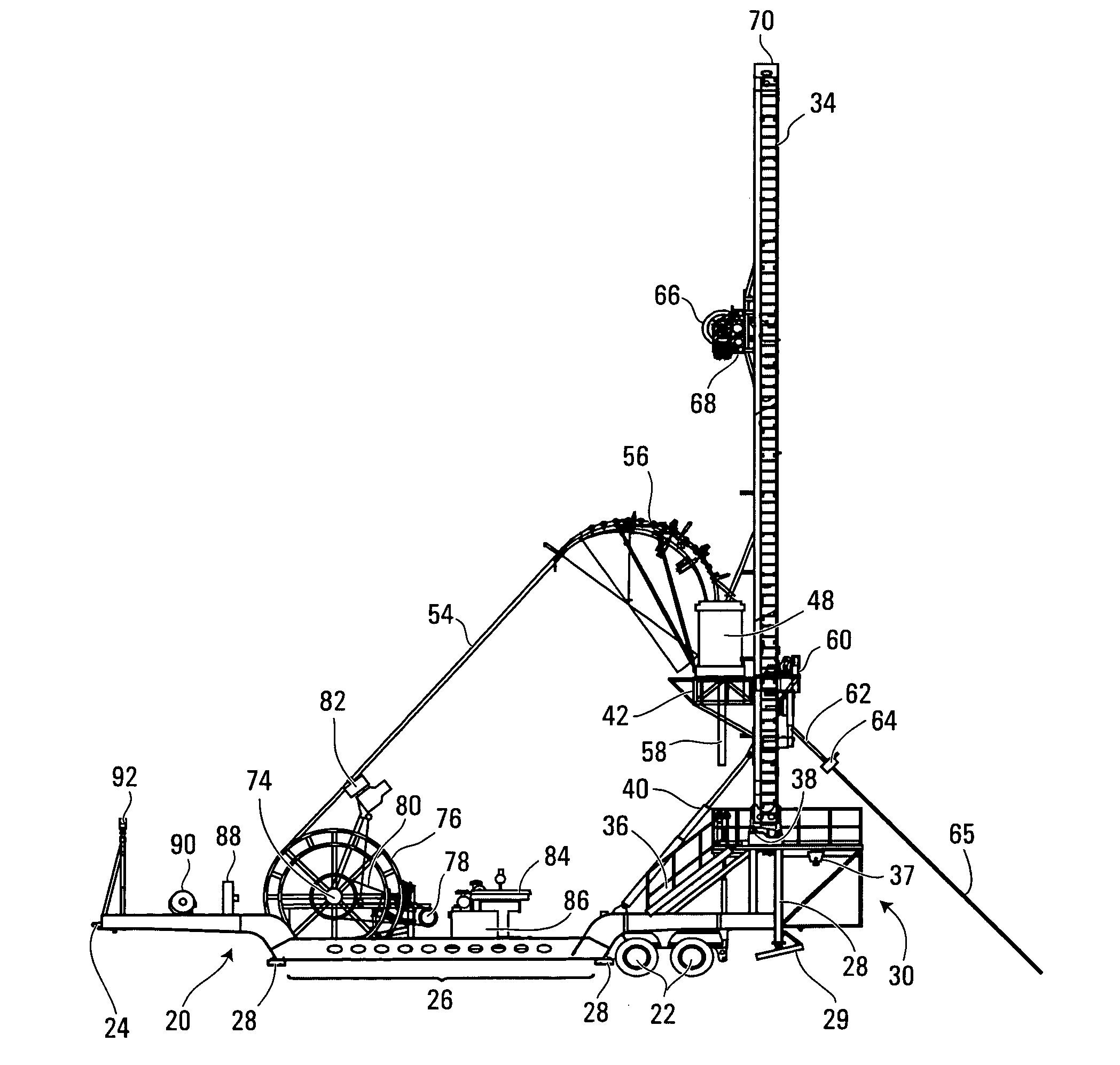

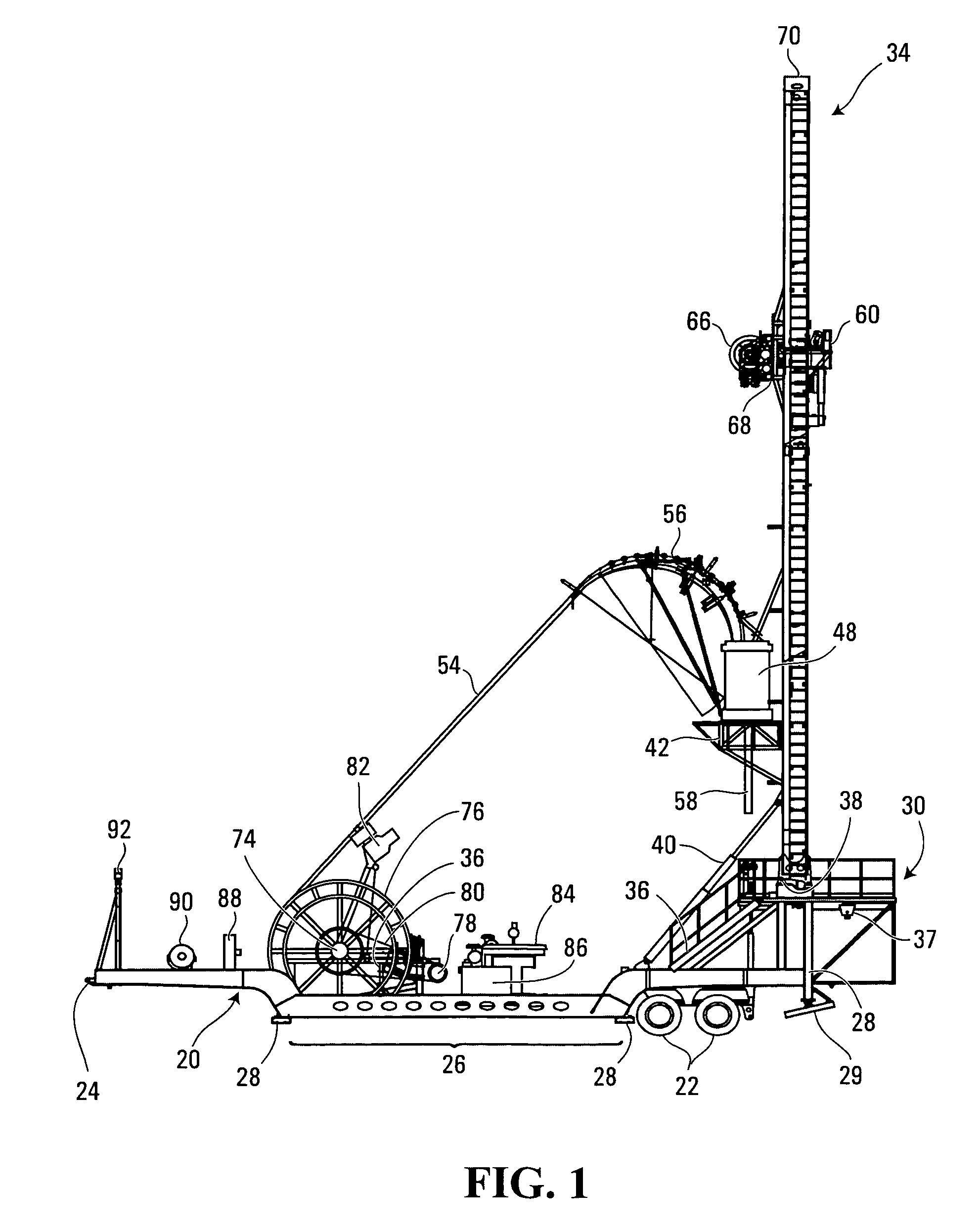

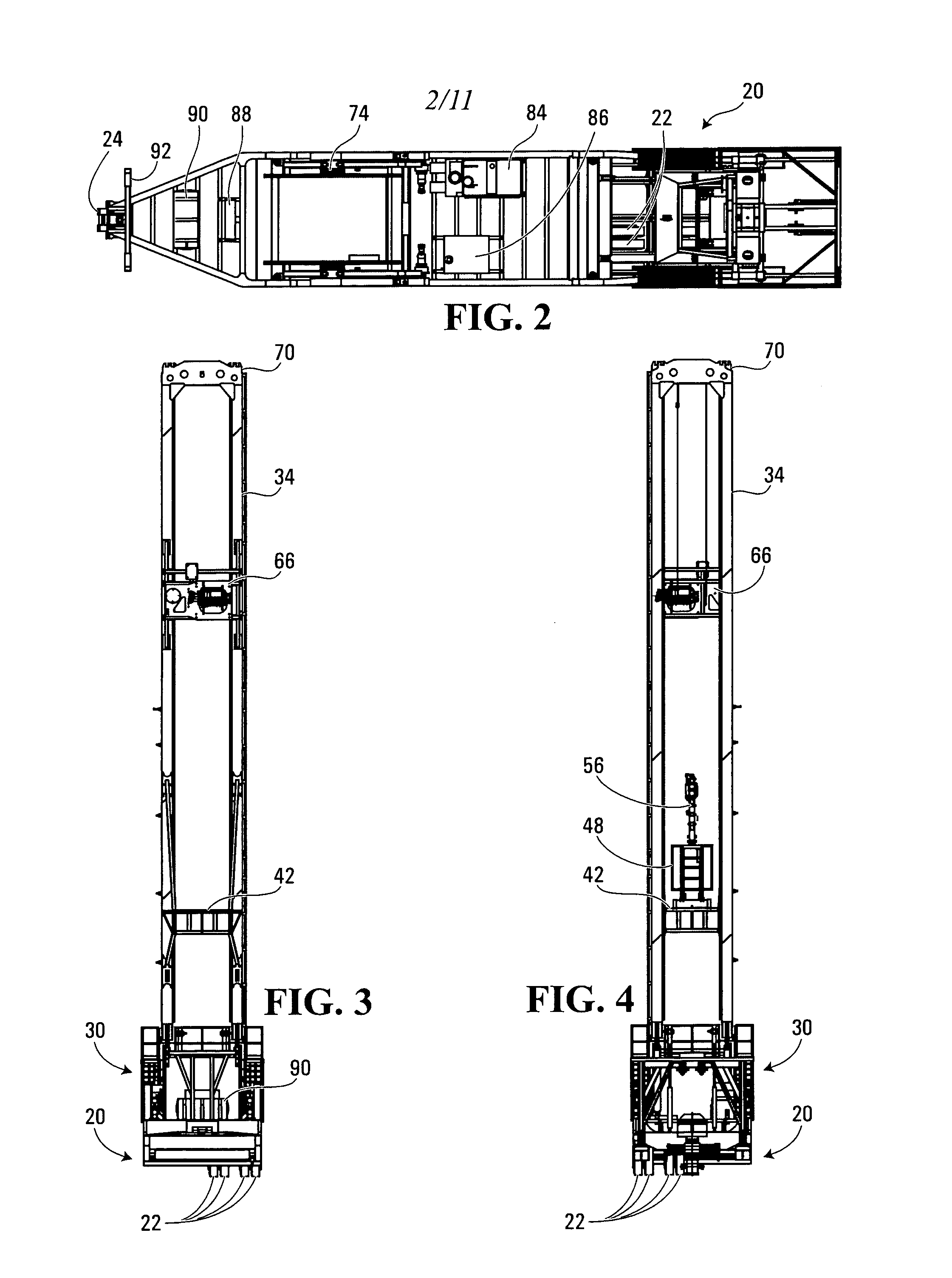

Drilling rig apparatus and downhole tool assembly system and method

A drilling rig is provided which is adapted to selectively drill using coiled tubing and jointed-pipe. The rig includes a base, a mast, a top drive slidably mounted to said mast for performing jointed-pipe operations, and a tubing injector for performing coiled tubing operations, mounted on said mast for selective movement from a first position in which the injector is in line with the mast and a second position in which the injector is out of line with the mast to permit jointed-pipe operations by the top drive. The rig is uniquely suited to easily and quickly assemble bottom hole assemblies (BHA's), and to connect such BHA's to coiled tubing.

Owner:SAVANNA ENERGY SERVICES

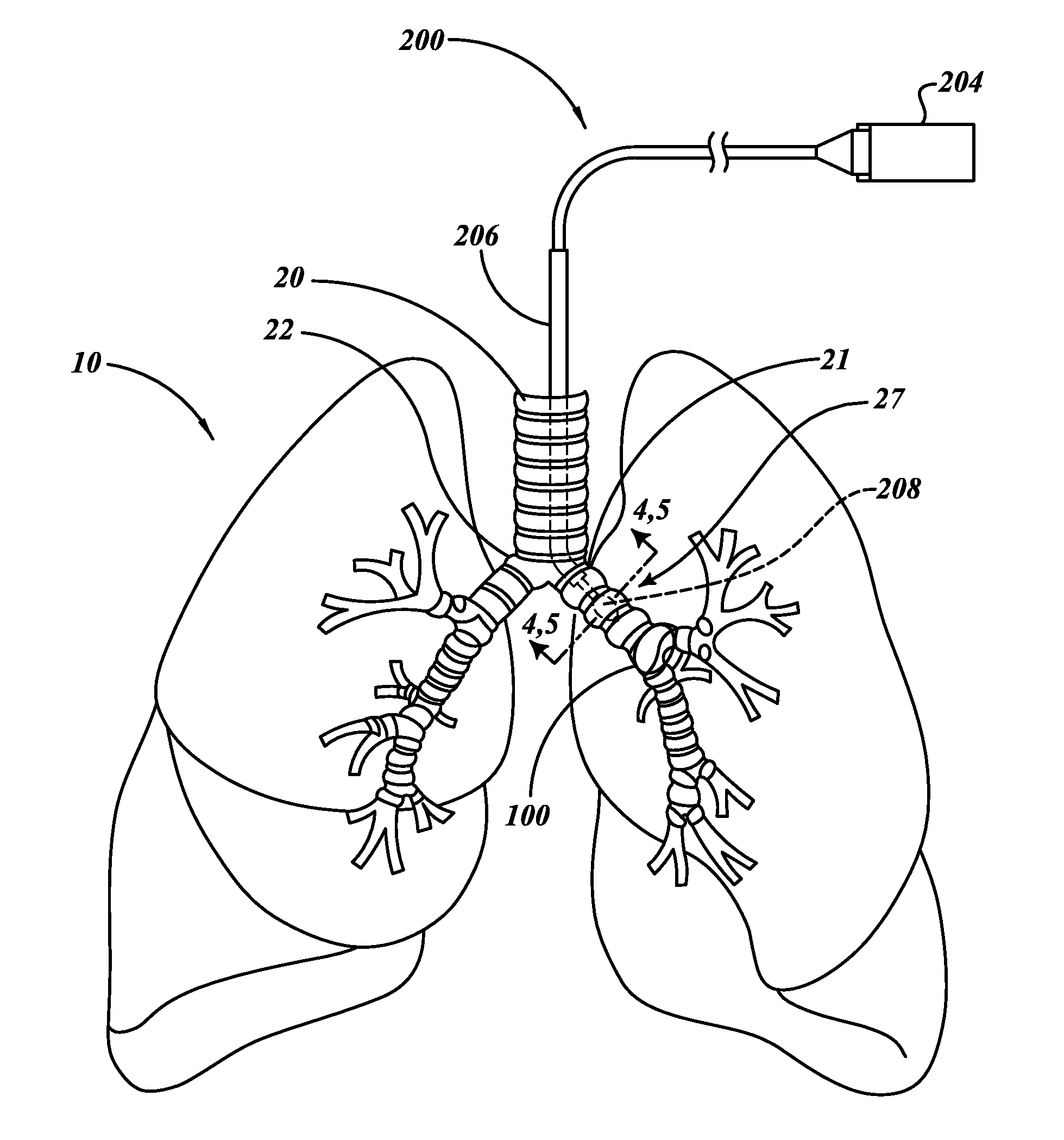

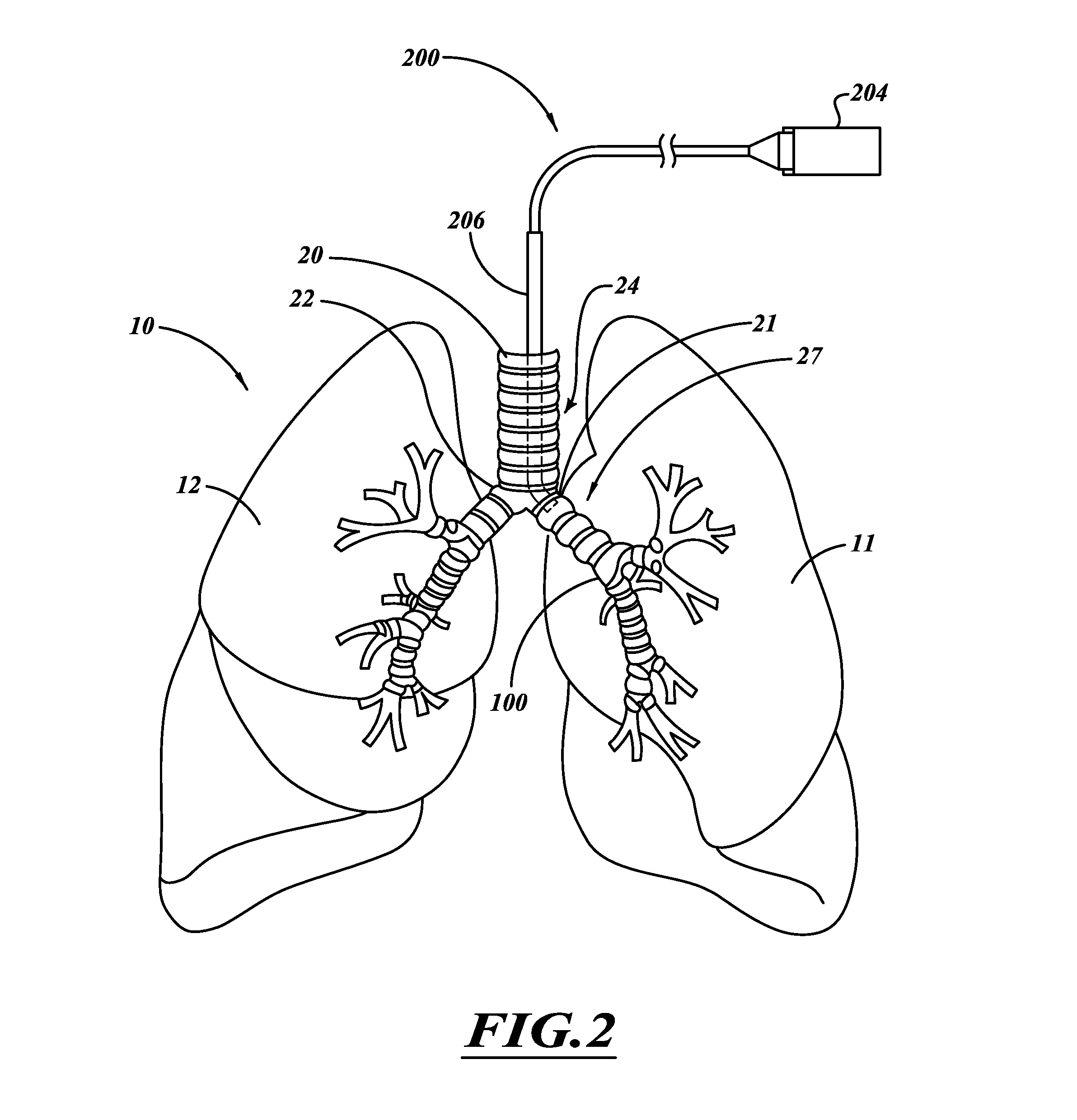

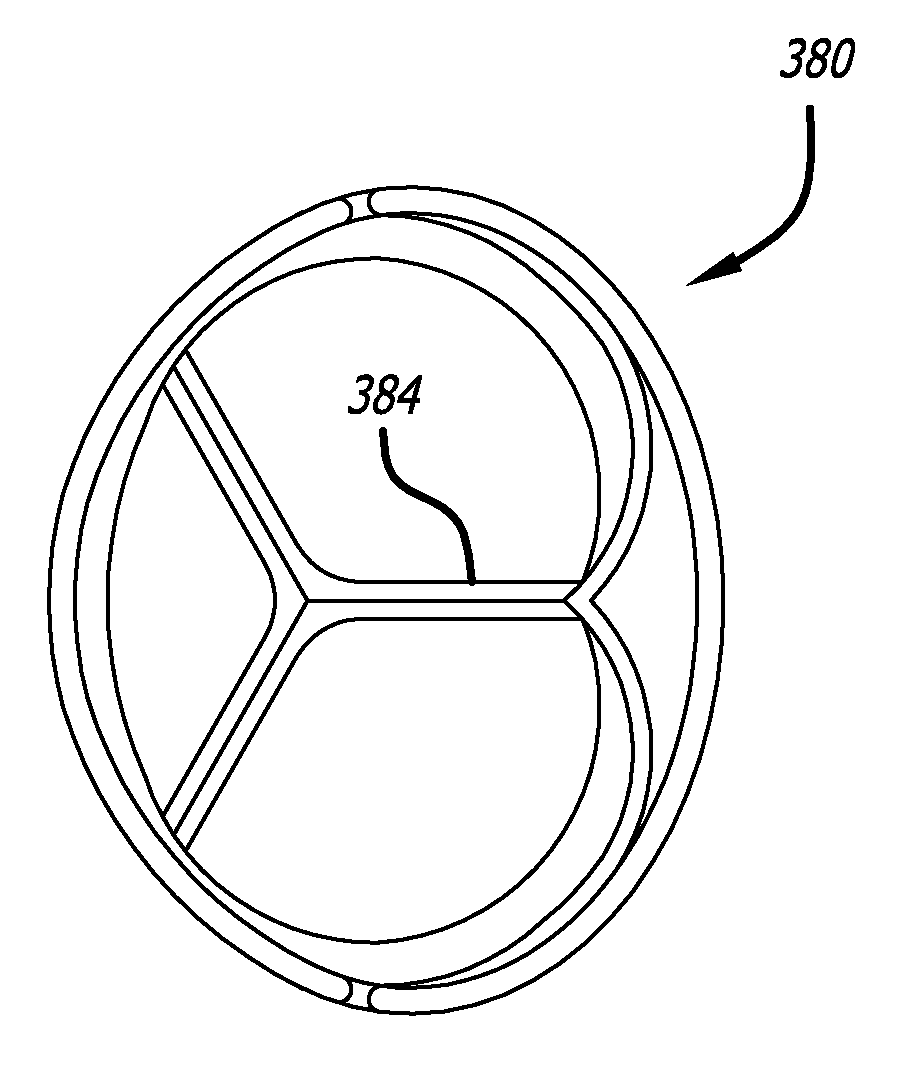

Heart valve assembly systems and methods

ActiveUS20130282114A1Optimal valve performanceSignificant design flexibilityAnnuloplasty ringsMachines/enginesMedical treatmentAssembly systems

Heart valve assembly systems and methods configured for medical interventional procedures. In one aspect, the methods and systems involve a modular approach to treatment.

Owner:CAISSON INT LLC

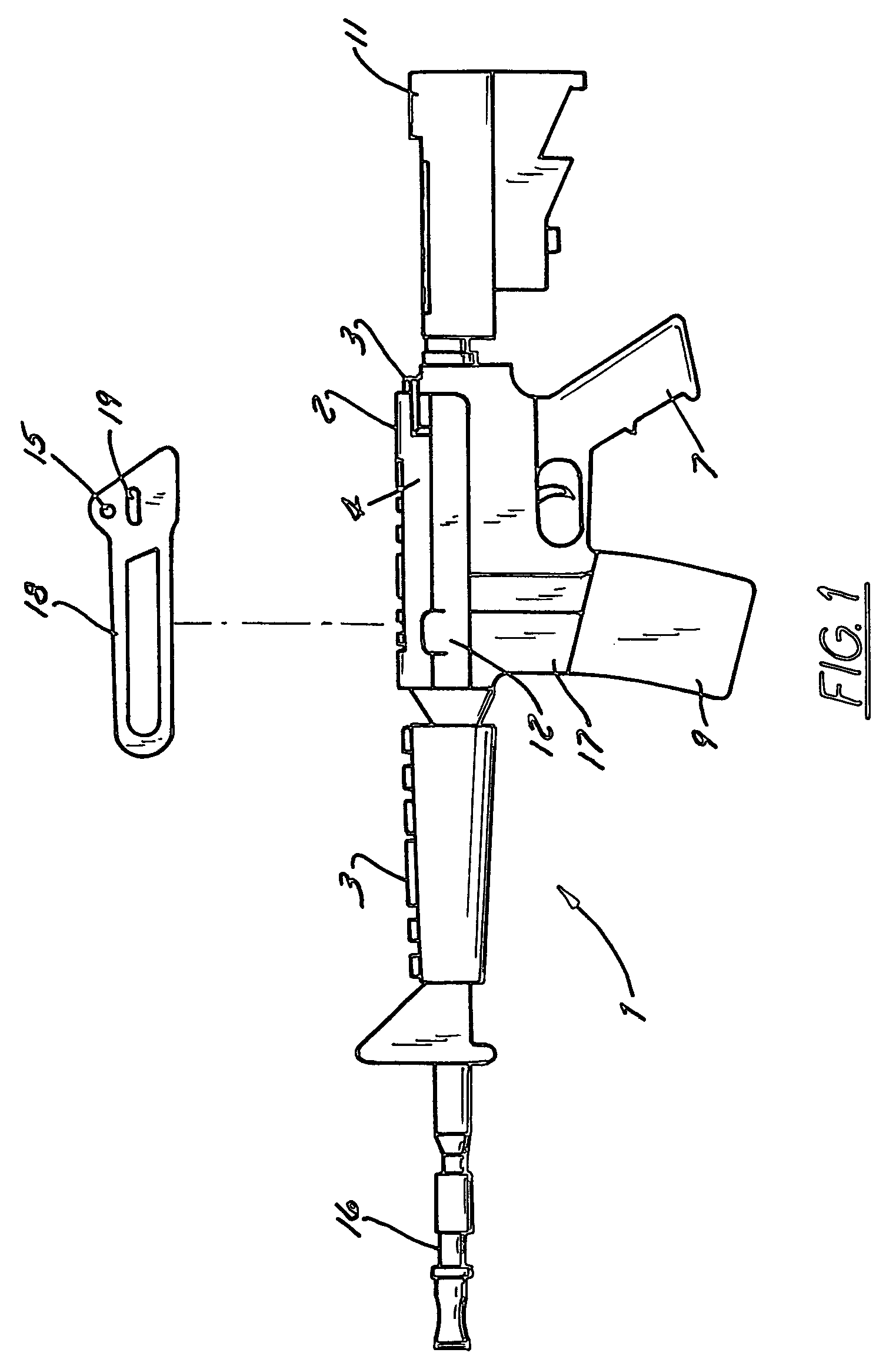

Locking quick release clamp assembly

ActiveUS8578647B2Easy to processEasy to assembleSighting devicesCouplings for rigid shaftsMechanical engineeringAssembly systems

Owner:AMERICAN DEFENSE MFG

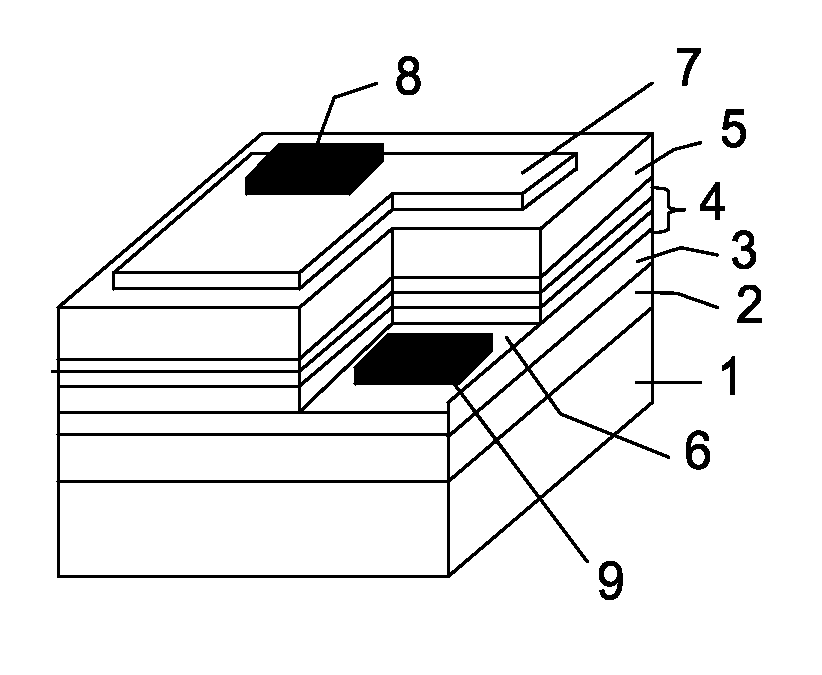

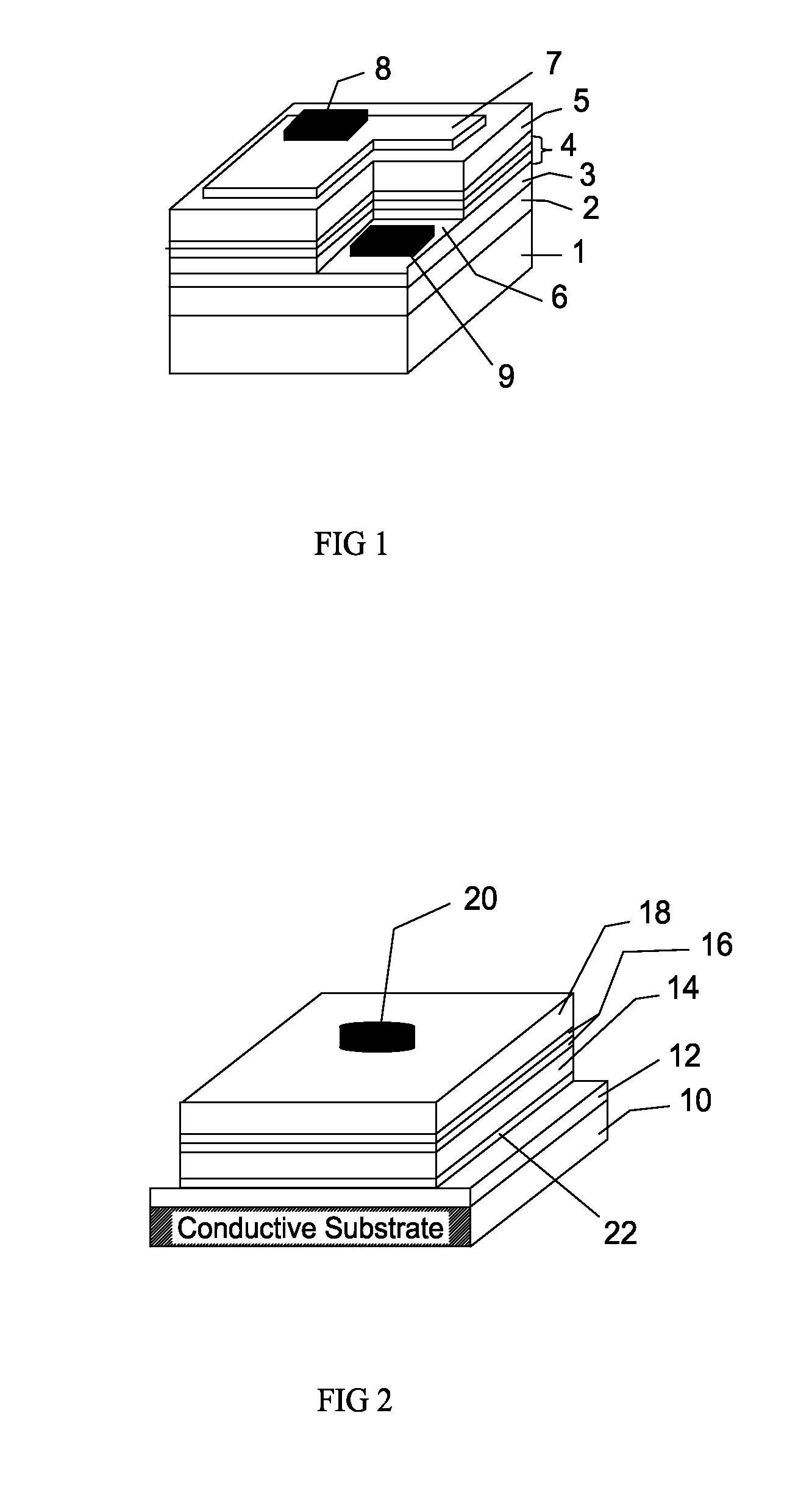

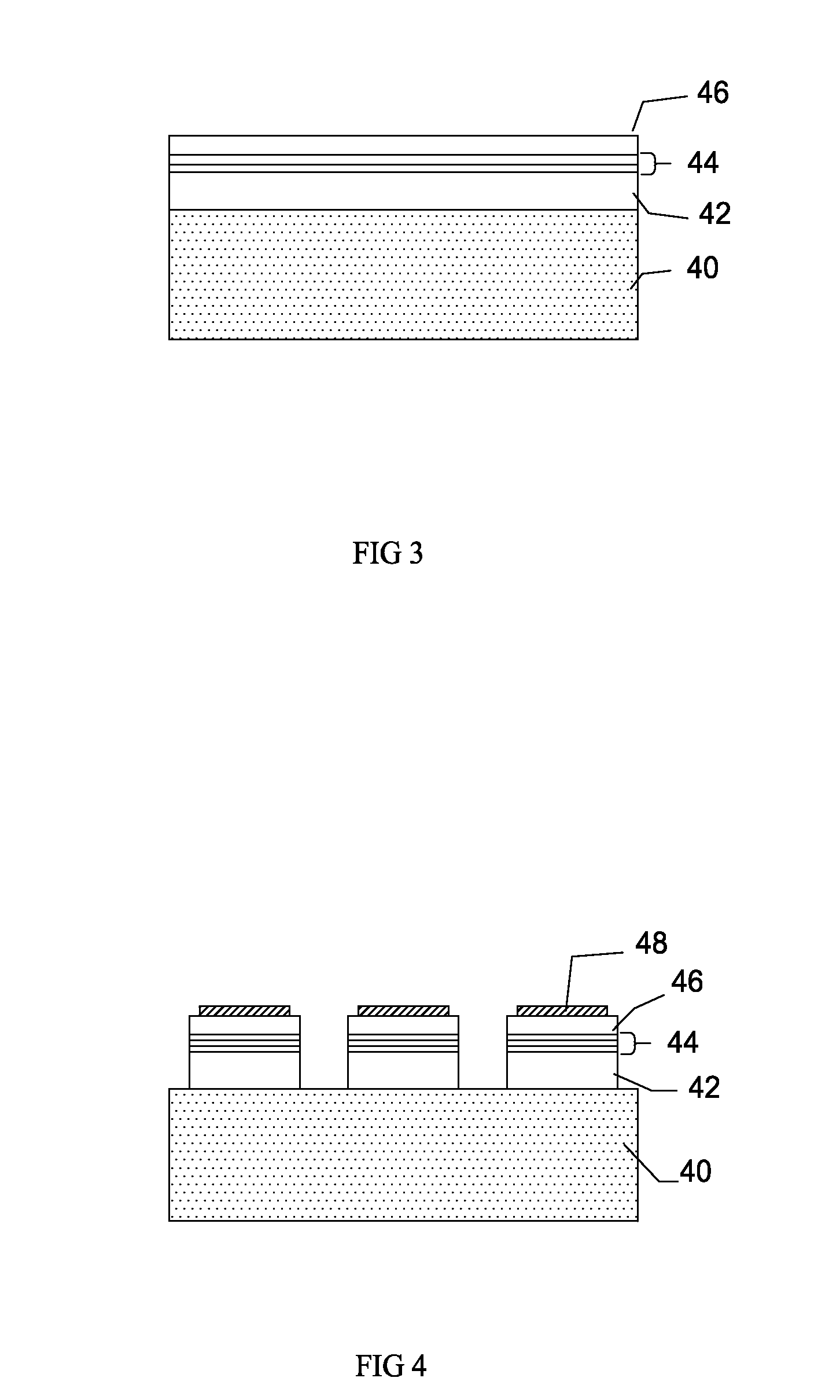

Method for handling a semiconductor wafer assembly

ActiveUS20070231963A1Avoid excessive lightDissipate more heatSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLight-emitting diode

Systems and methods for fabricating a light emitting diode include forming a multilayer epitaxial structure above a carrier substrate; depositing at least one metal layer above the multilayer epitaxial structure; removing the carrier substrate.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

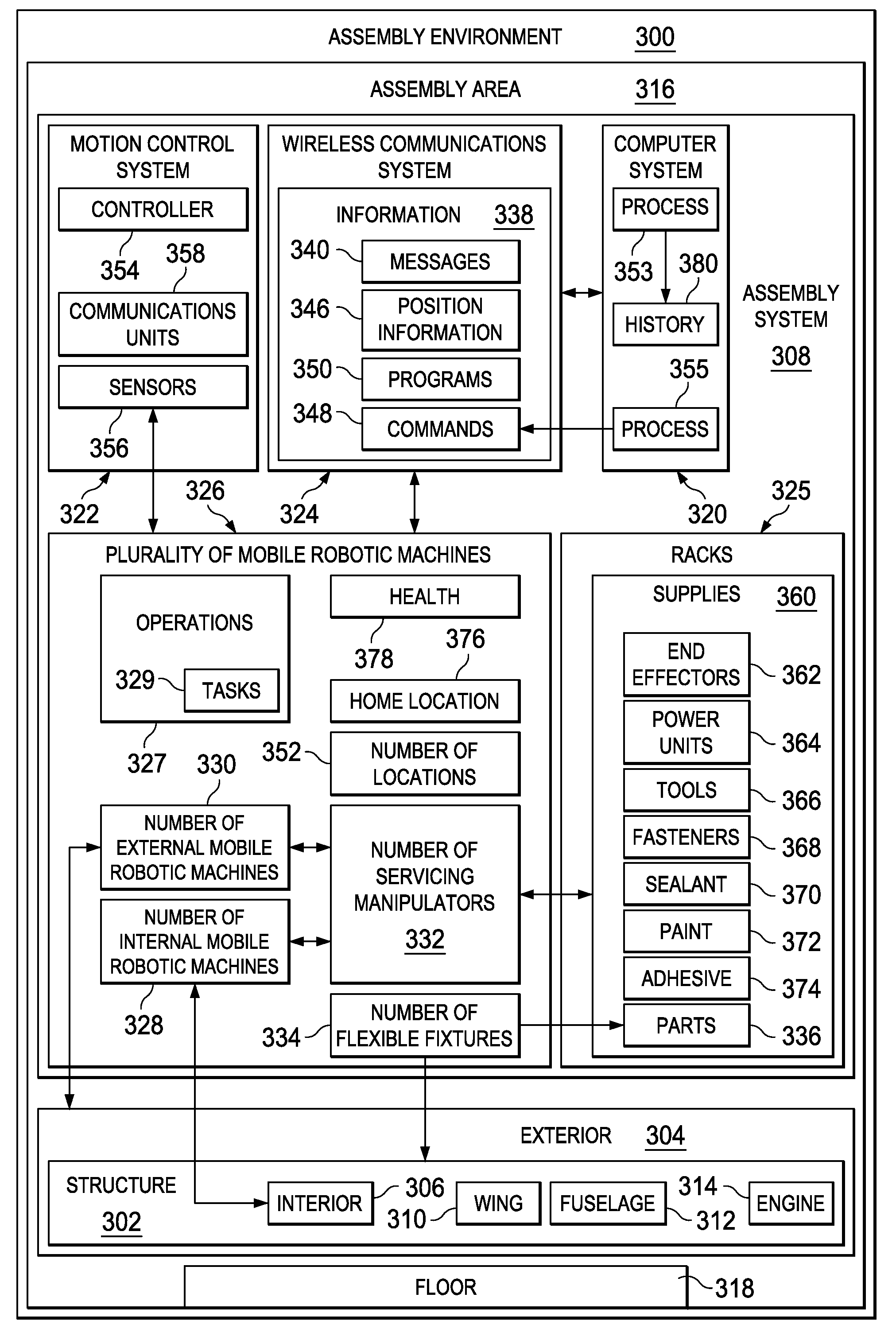

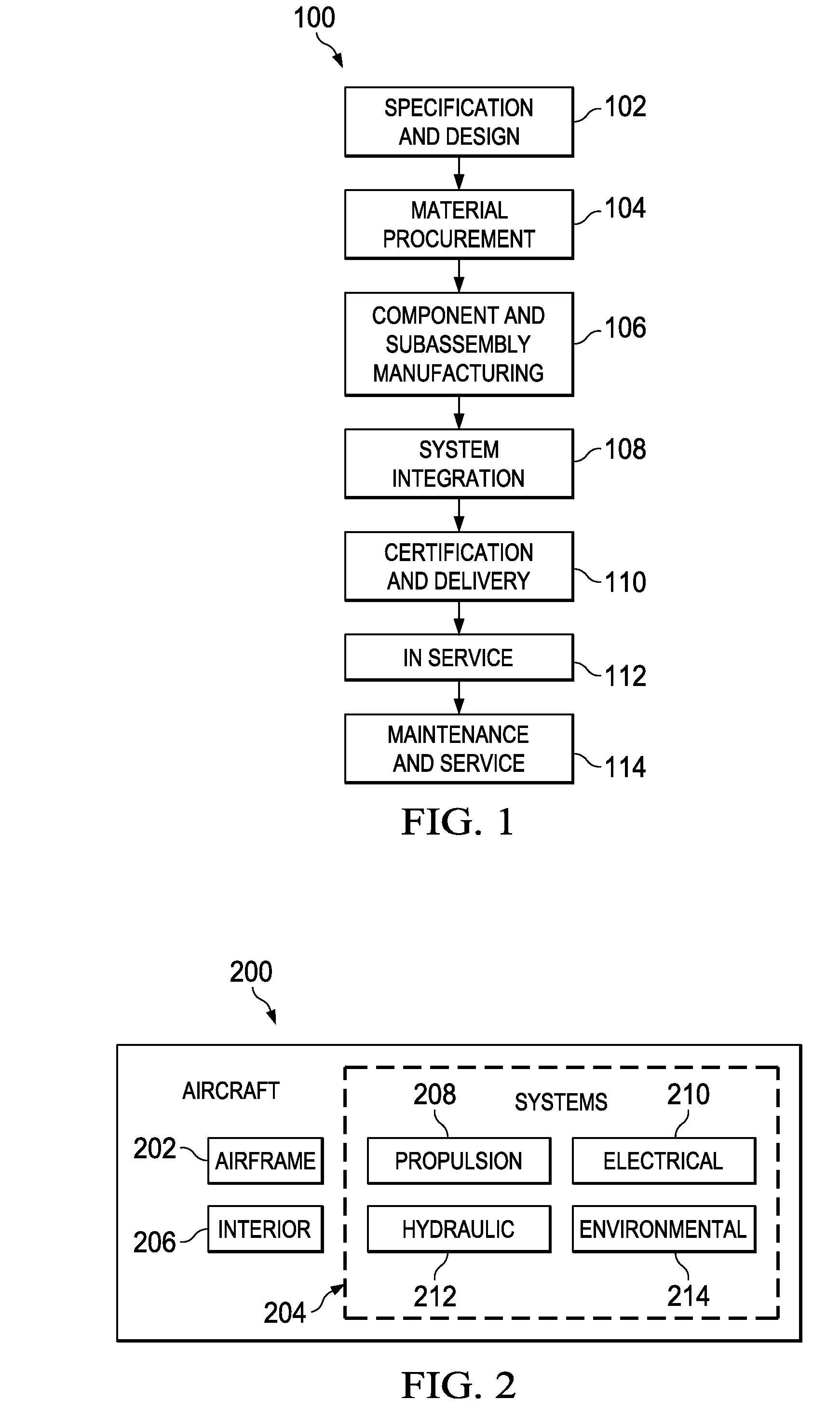

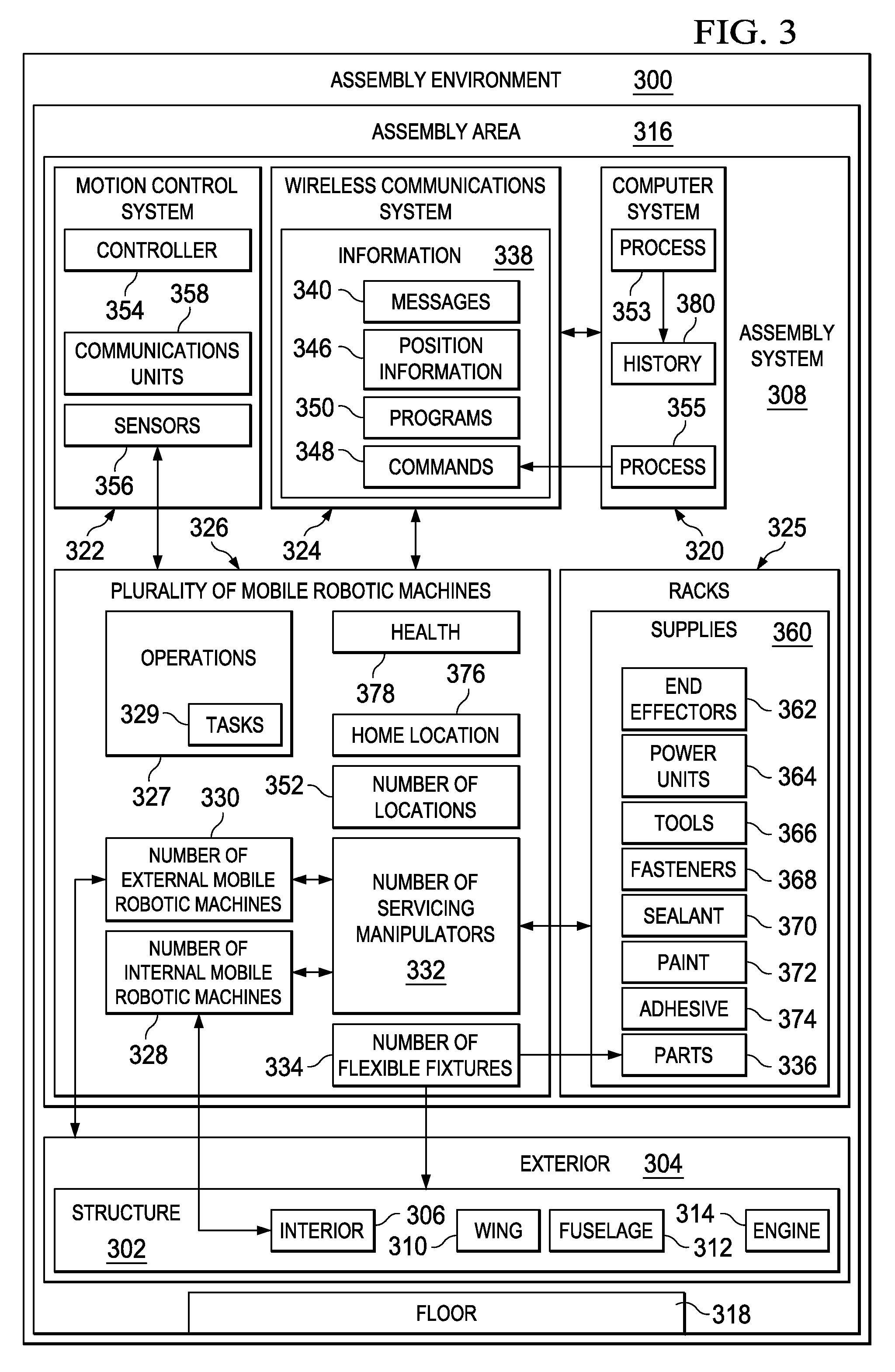

Autonomous robotic assembly system

InactiveUS20100217437A1Programme-controlled manipulatorComputer controlRoboticsCommunications system

An apparatus comprises a plurality of mobile robotic machines, a wireless communications system, and a motion control system. The plurality of mobile robotic machines may be capable of moving to a number of locations in an assembly area and performing operations to assemble a structure in the assembly area. The wireless communications system may be capable of providing communications with the plurality of mobile robotic machines within the assembly area. The motion control system may be capable of generating position information for the plurality of mobile robotic machines in the assembly area and communicating the position.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com