Patents

Literature

3223results about "Fluid pressure sealed joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

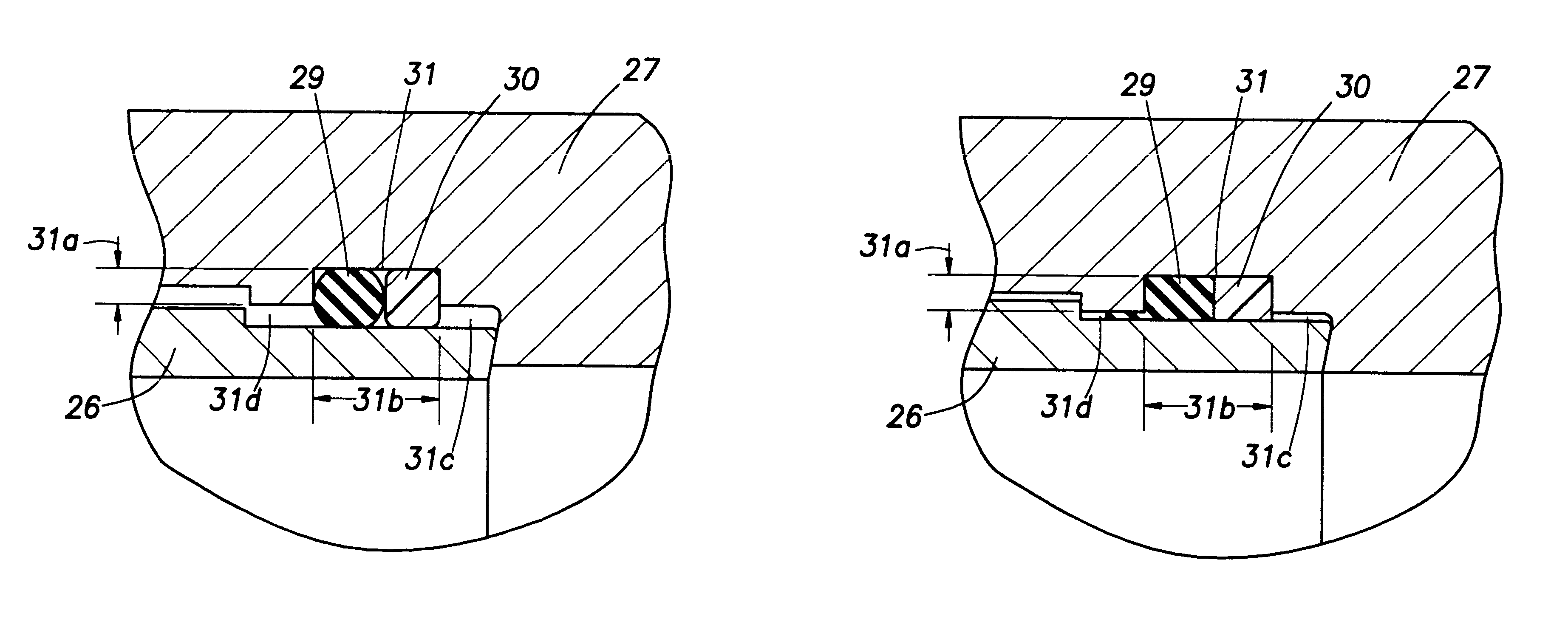

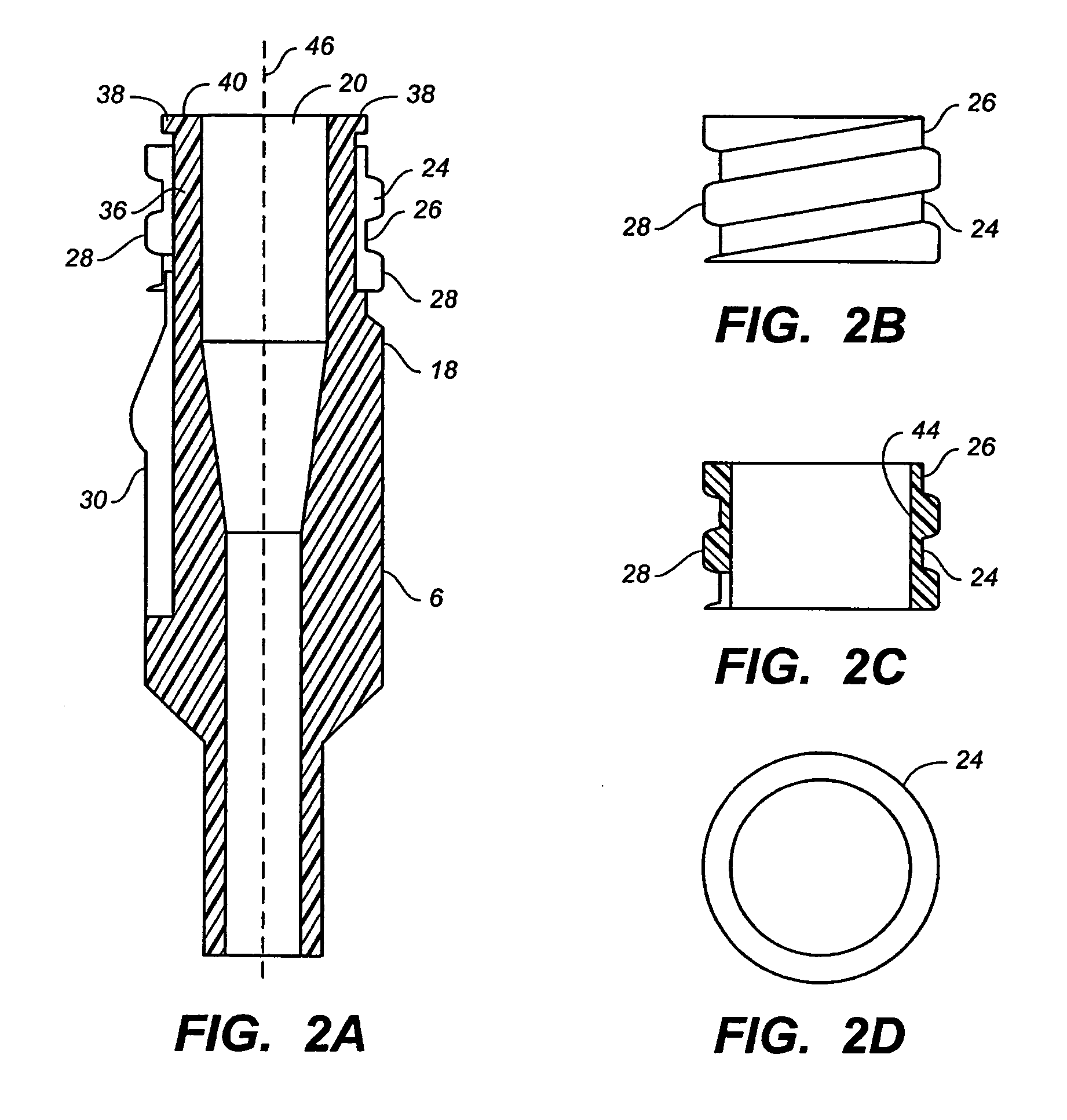

Ferrule with relief to reduce galling

InactiveUS7100949B2Reduce stress concentrationSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh torque

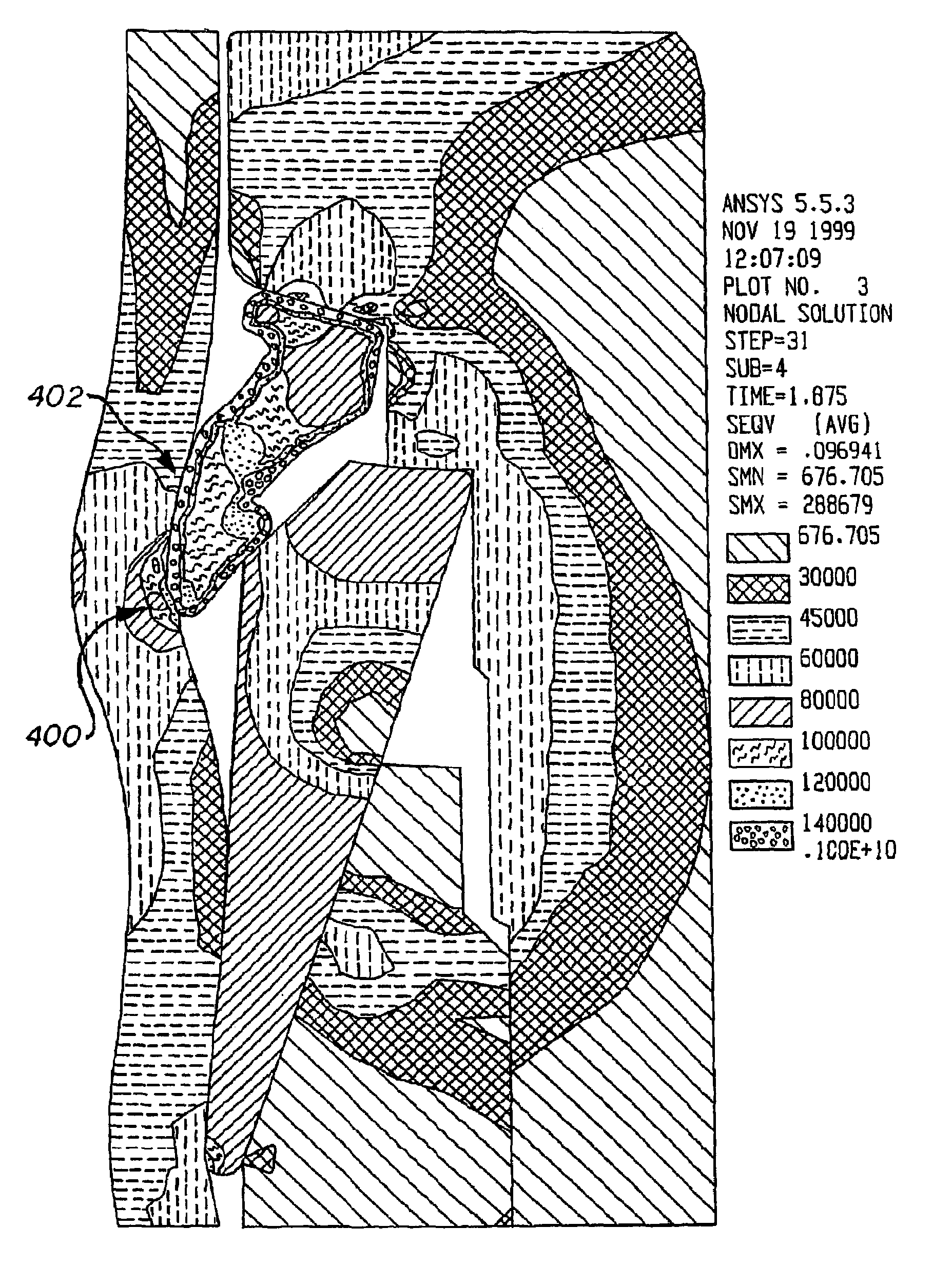

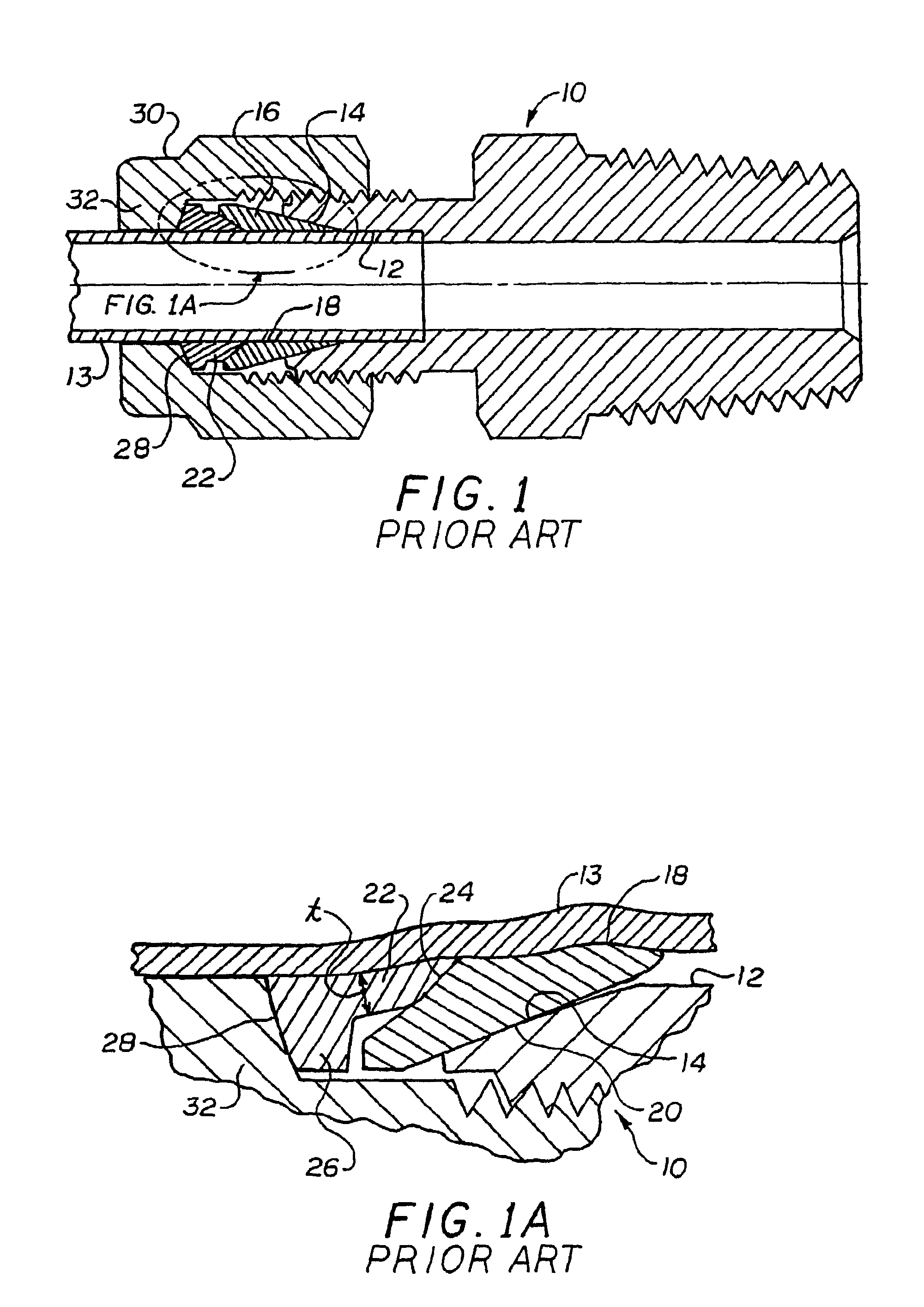

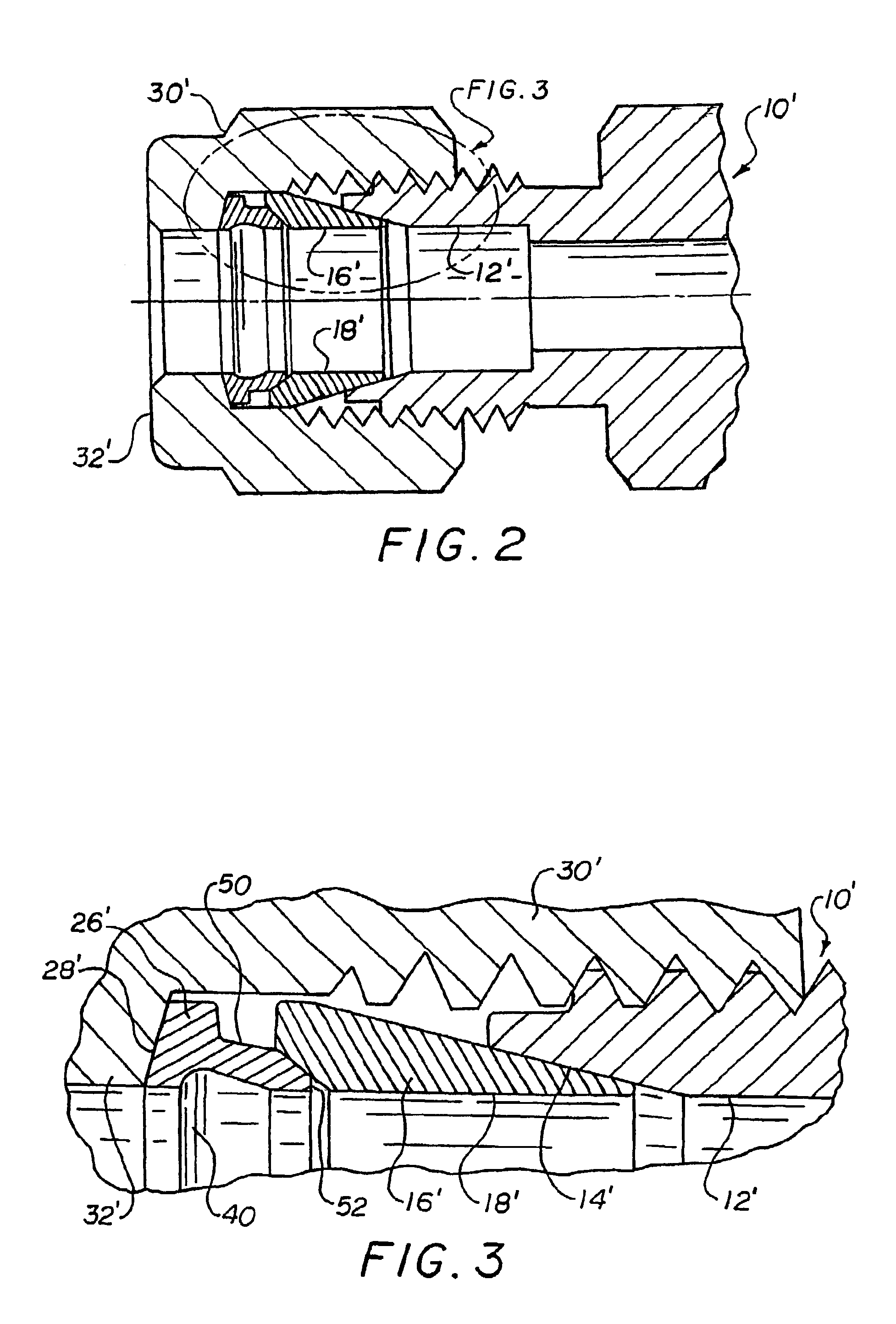

High localized loading, galling, and high torque forces have been generally eliminated or greatly reduced in a two ferrule tube fitting assembly through suitable modification of the rear ferrule so as to redirect the reaction forces acting between the front ferrule and the drive nut. The rear ferrule has a cylindrical interior wall that closely surrounds the tube end and is provided on the interior cylindrical wall with a circumferentially continuous radial recess that is located between the nose and rear wall of the rear ferrule. The rear ferrule also has a radially external wall that is substantially conical and additionally shaped to extend radially outward toward the enlarged diameter portion or flange of the rear ferrule. The rear ferrule further includes a contoured face on the rear driven surface of the ferrule that engages the drive surface of the drive nut.

Owner:SWAGELOK CO

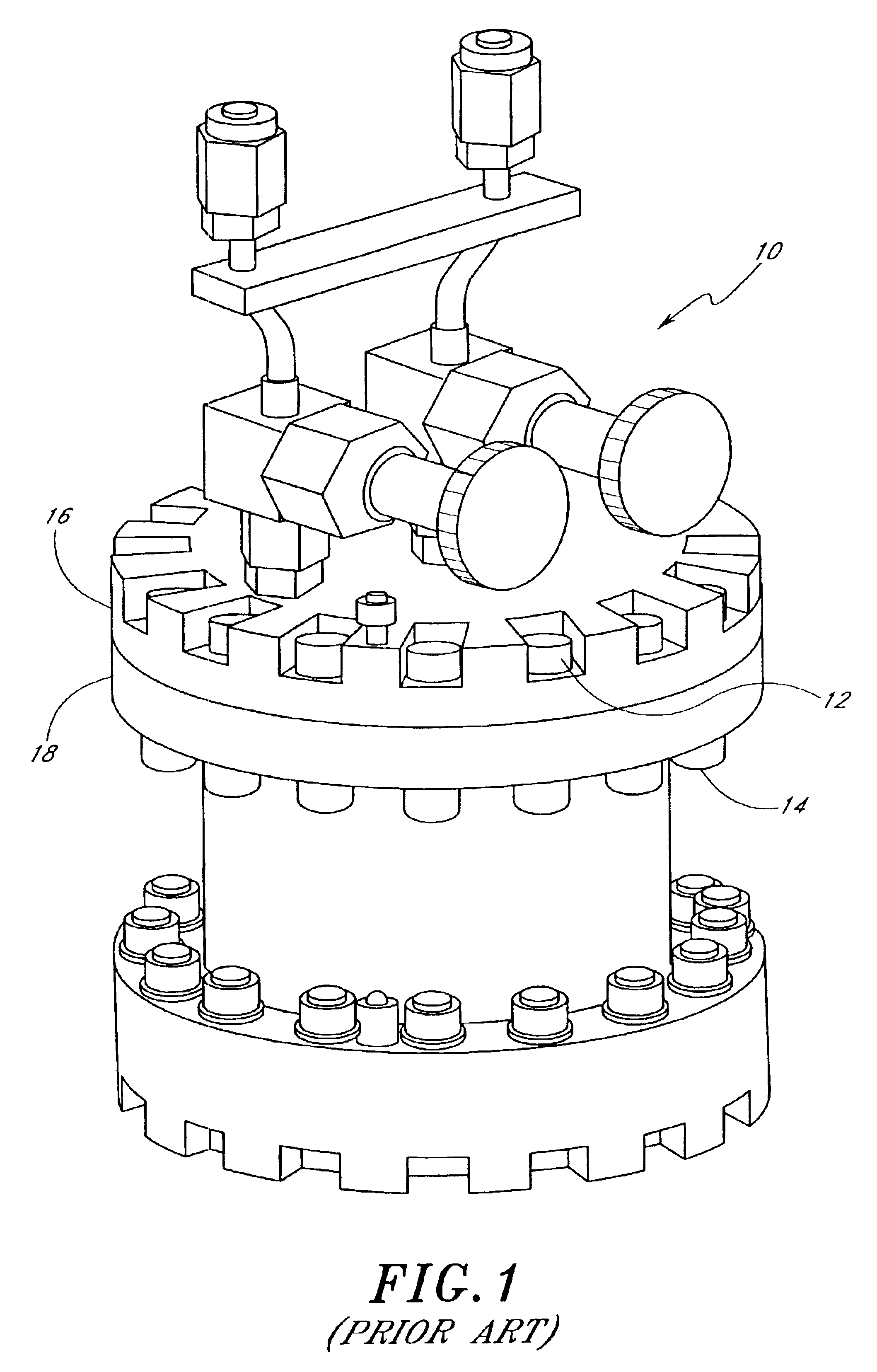

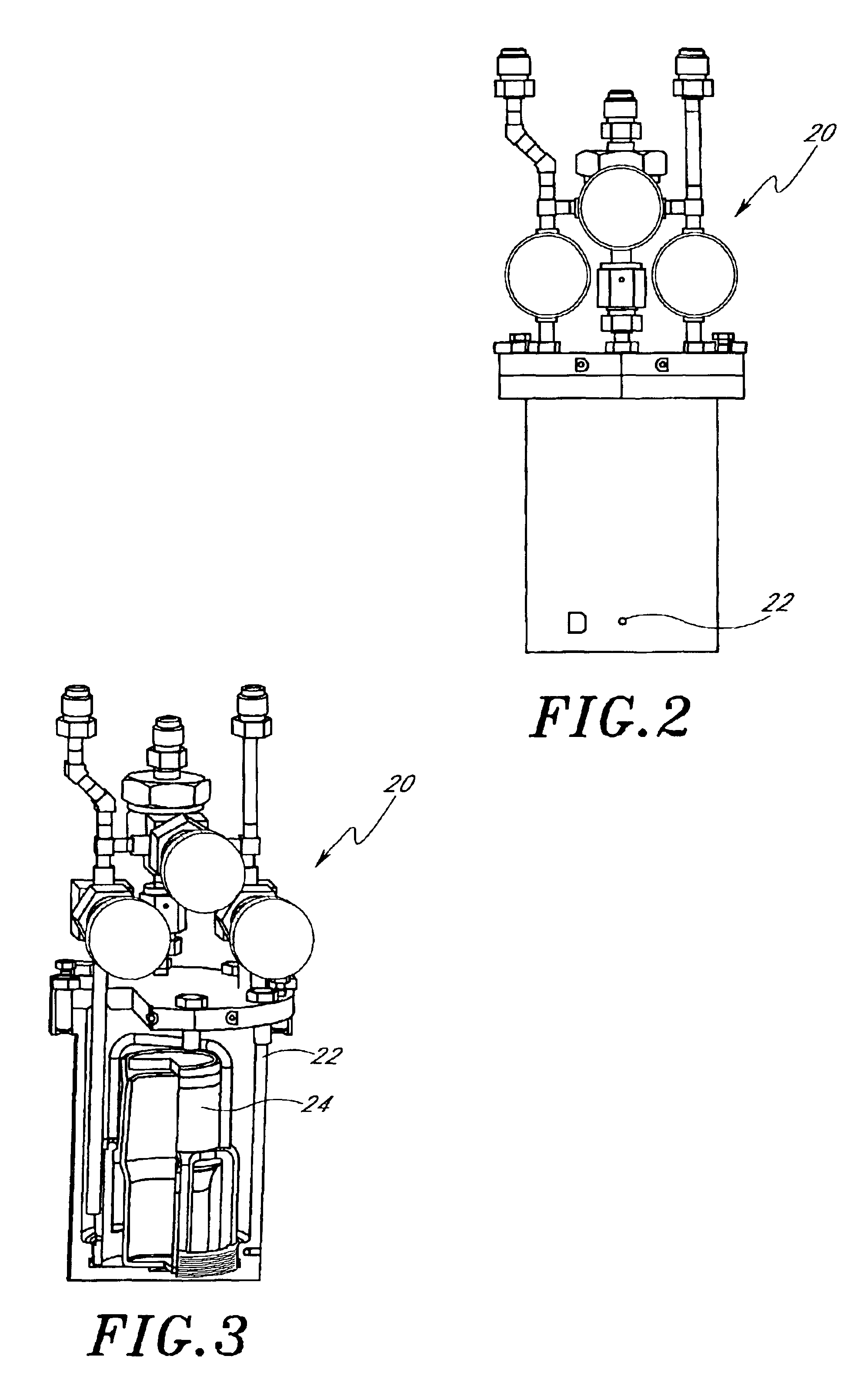

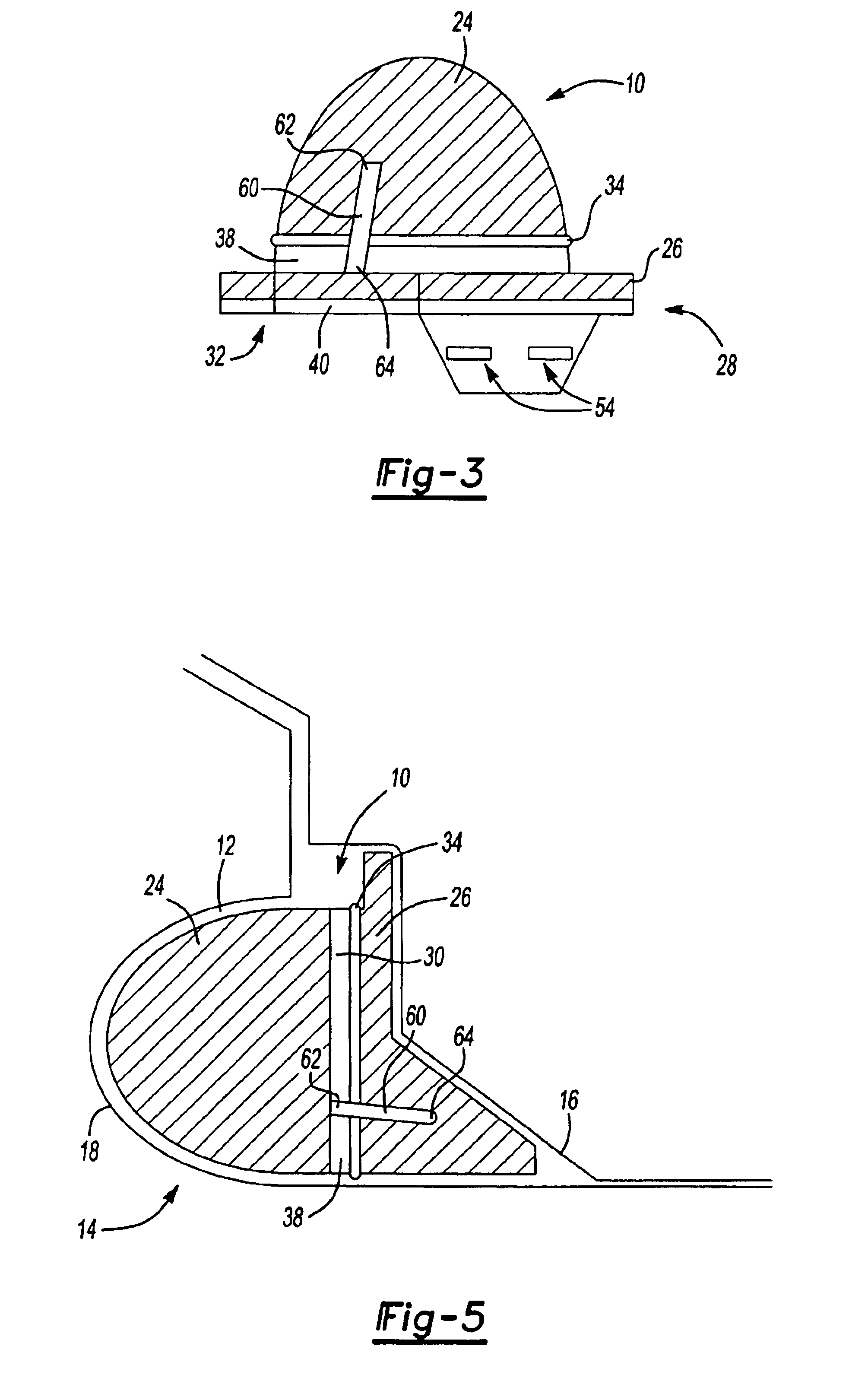

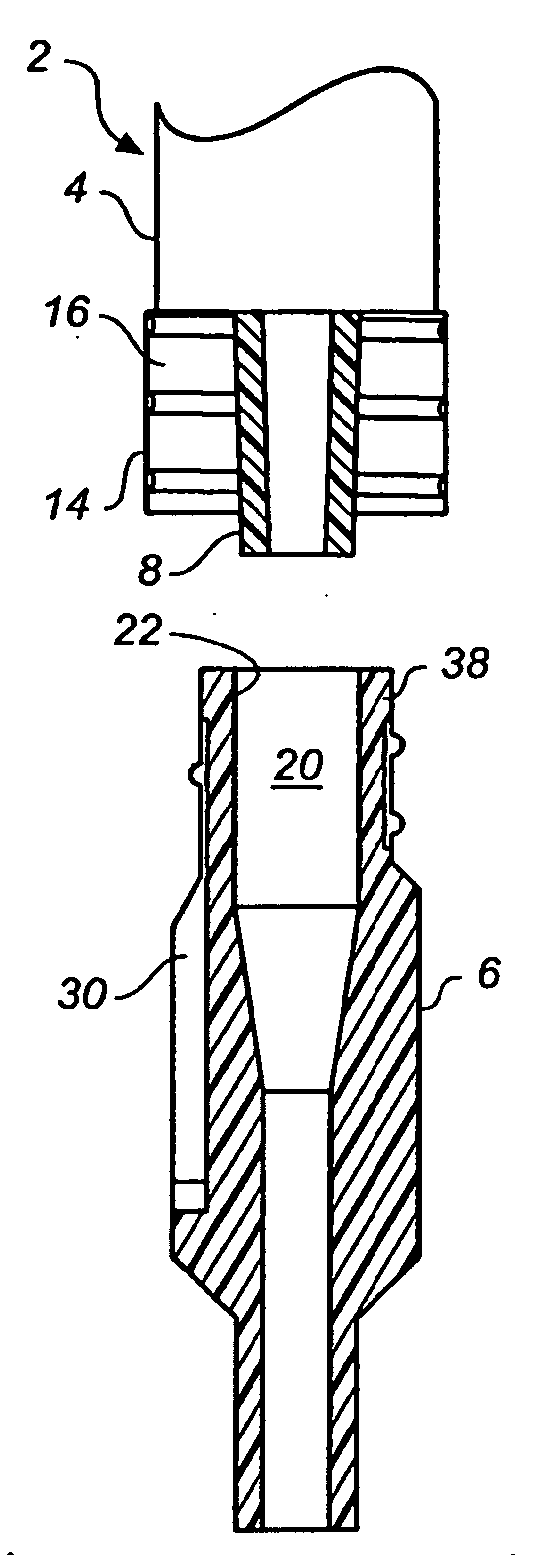

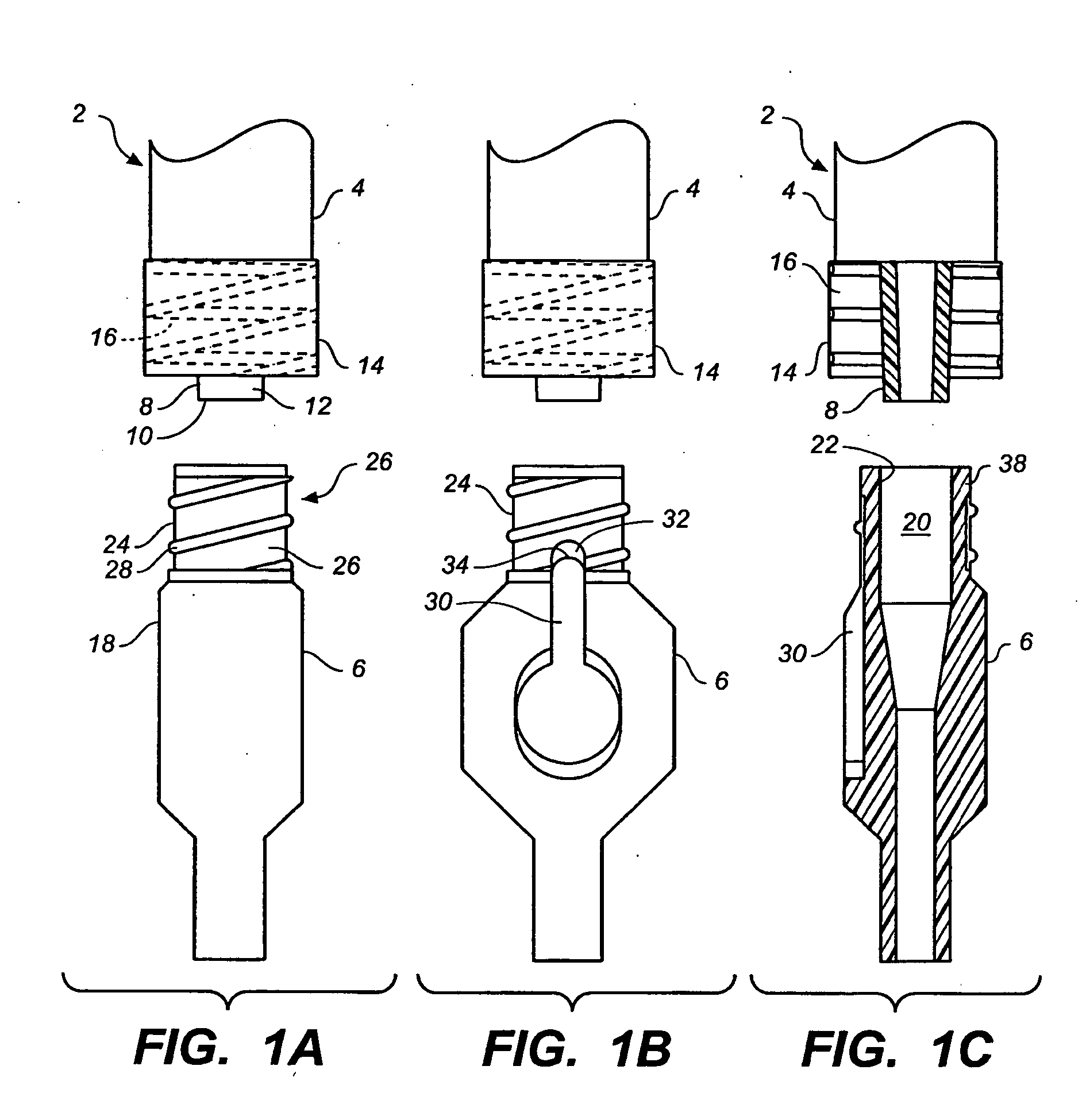

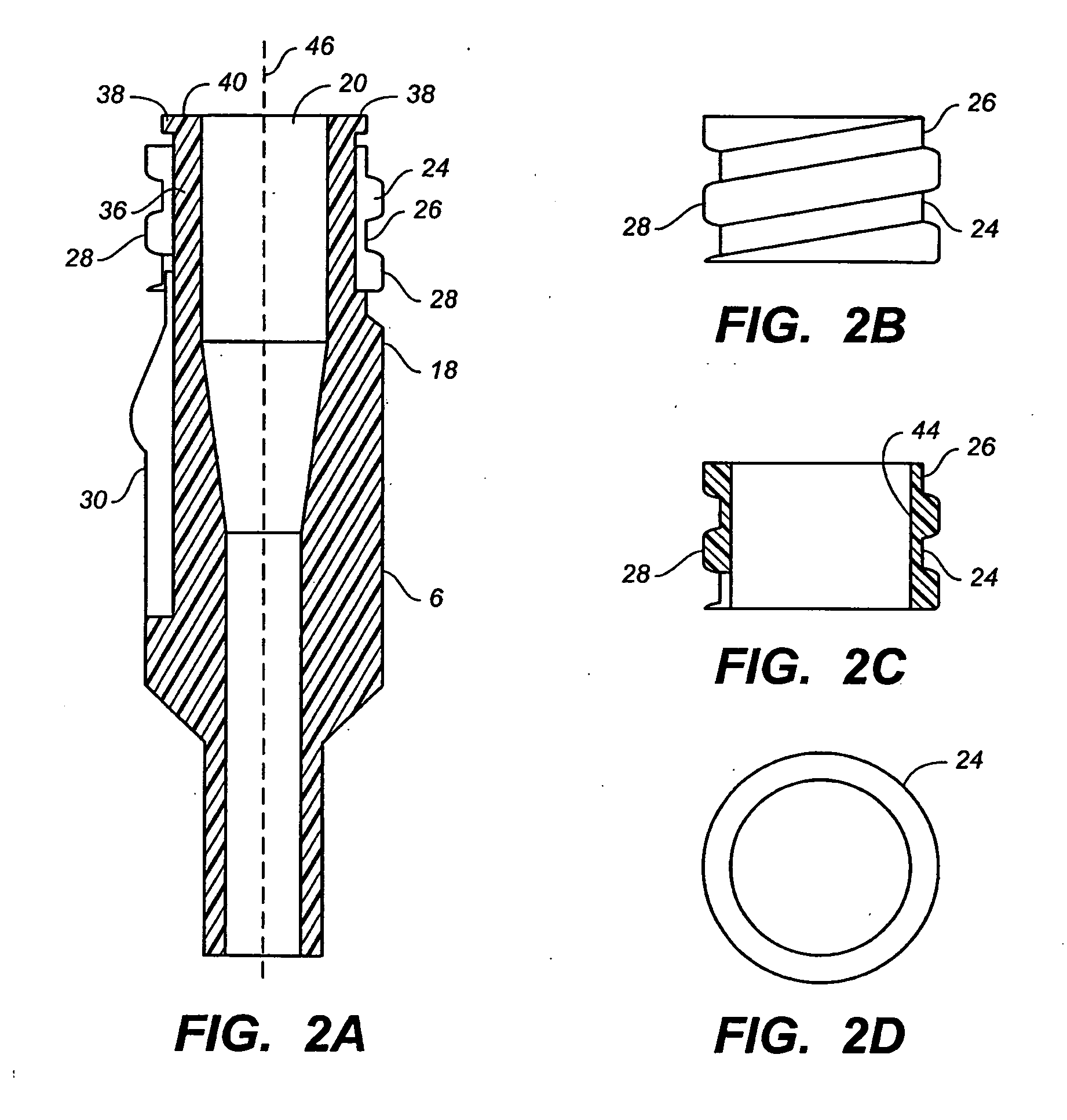

Source chemical container assembly

InactiveUS6889864B2Improve sealingHigh compression forceSleeve/socket jointsFlanged jointsVacuum chamberMechanical engineering

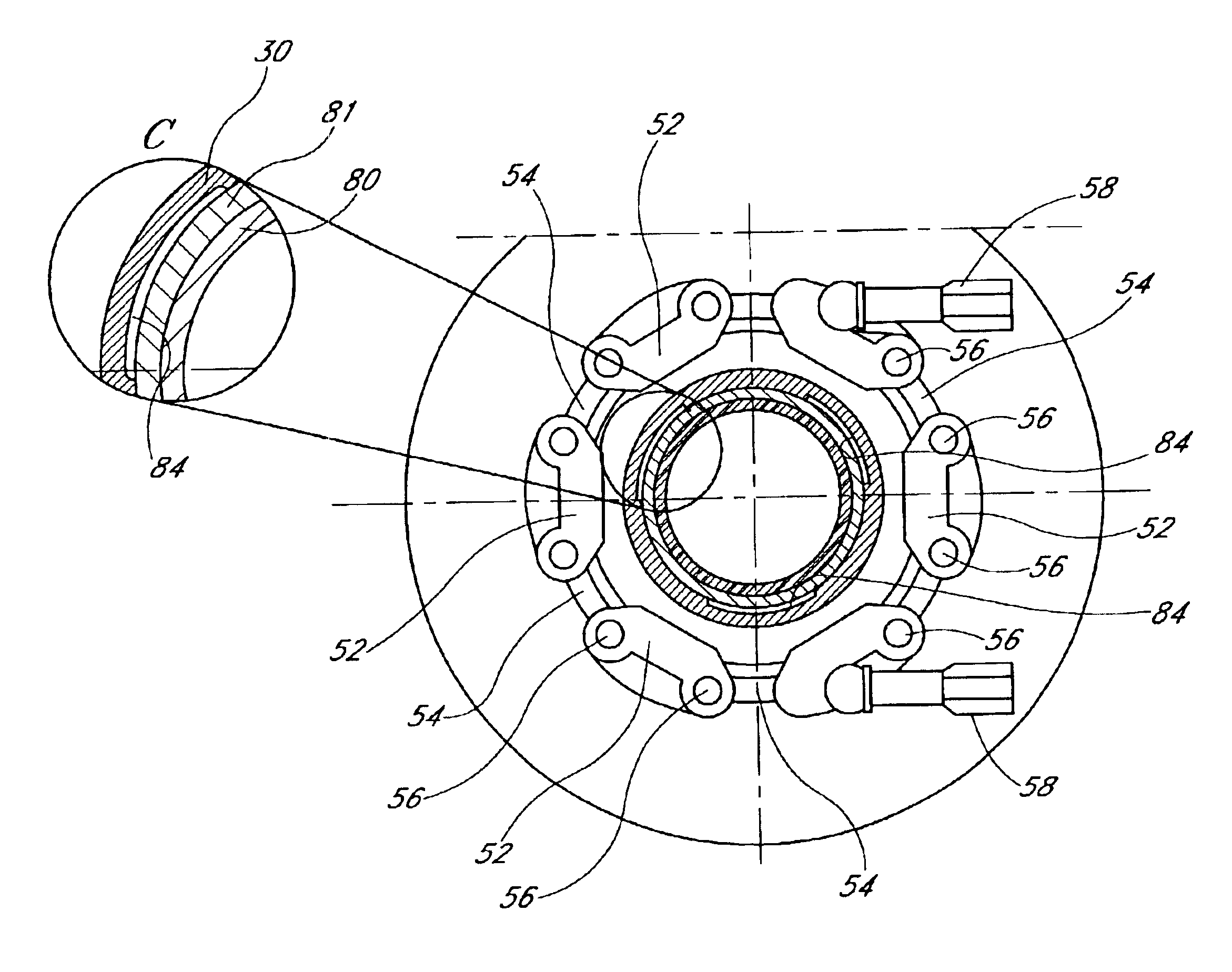

The invention relates to a source chemical container assembly, comprising a metal container functioning as a vacuum chamber and provided with a removable closure, which removable closure seals against the metal container with a metal seal. In order to facilitate easy recharging of the container assembly, compressive force is applied to the metal seal through a tension chain. In a preferred embodiment of the invention the metal seal and the tension chain are provided along a circumference of said metal container. The assembly can comprise an inner container in which the source chemical is contained.

Owner:ASM INTERNATIONAL

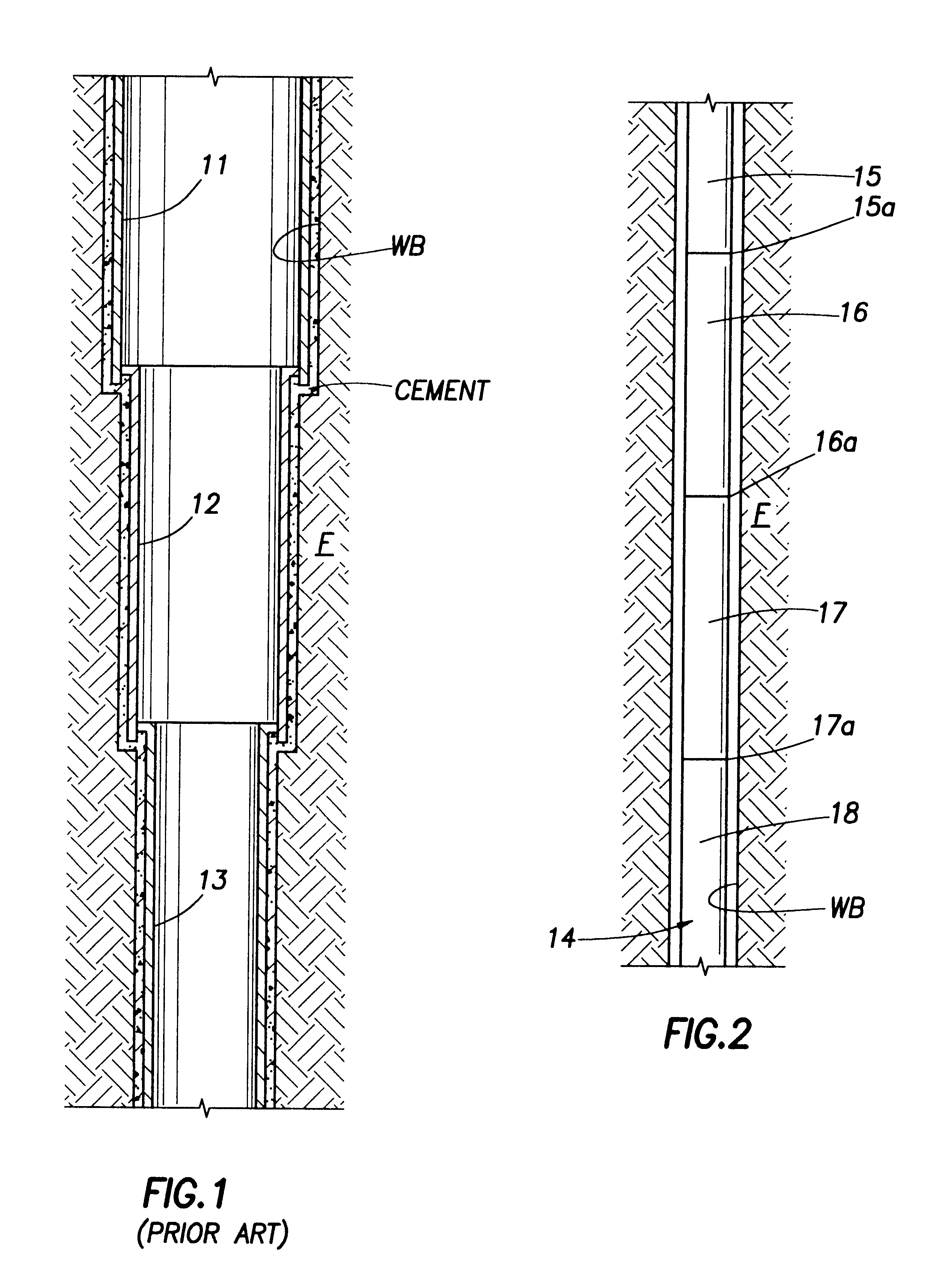

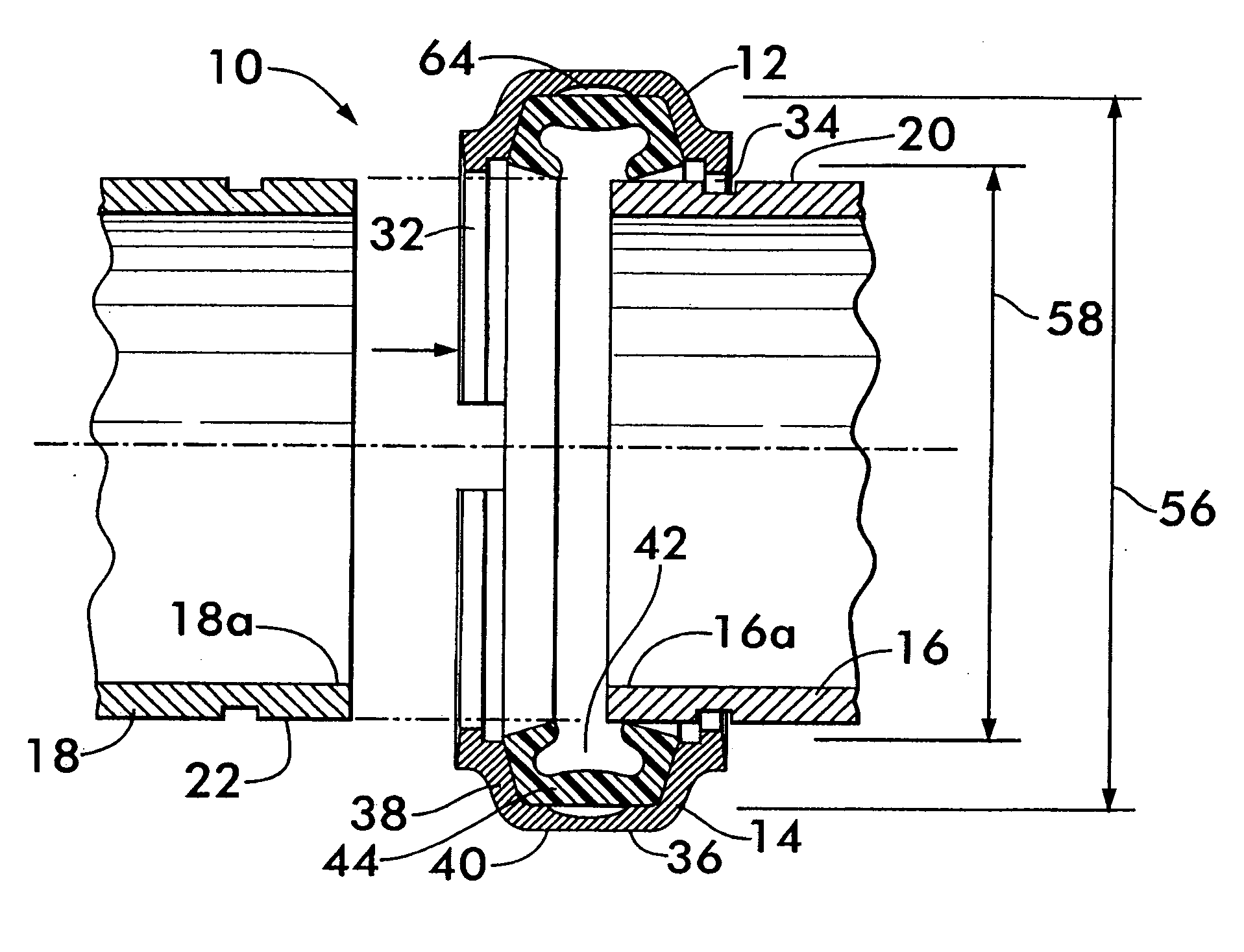

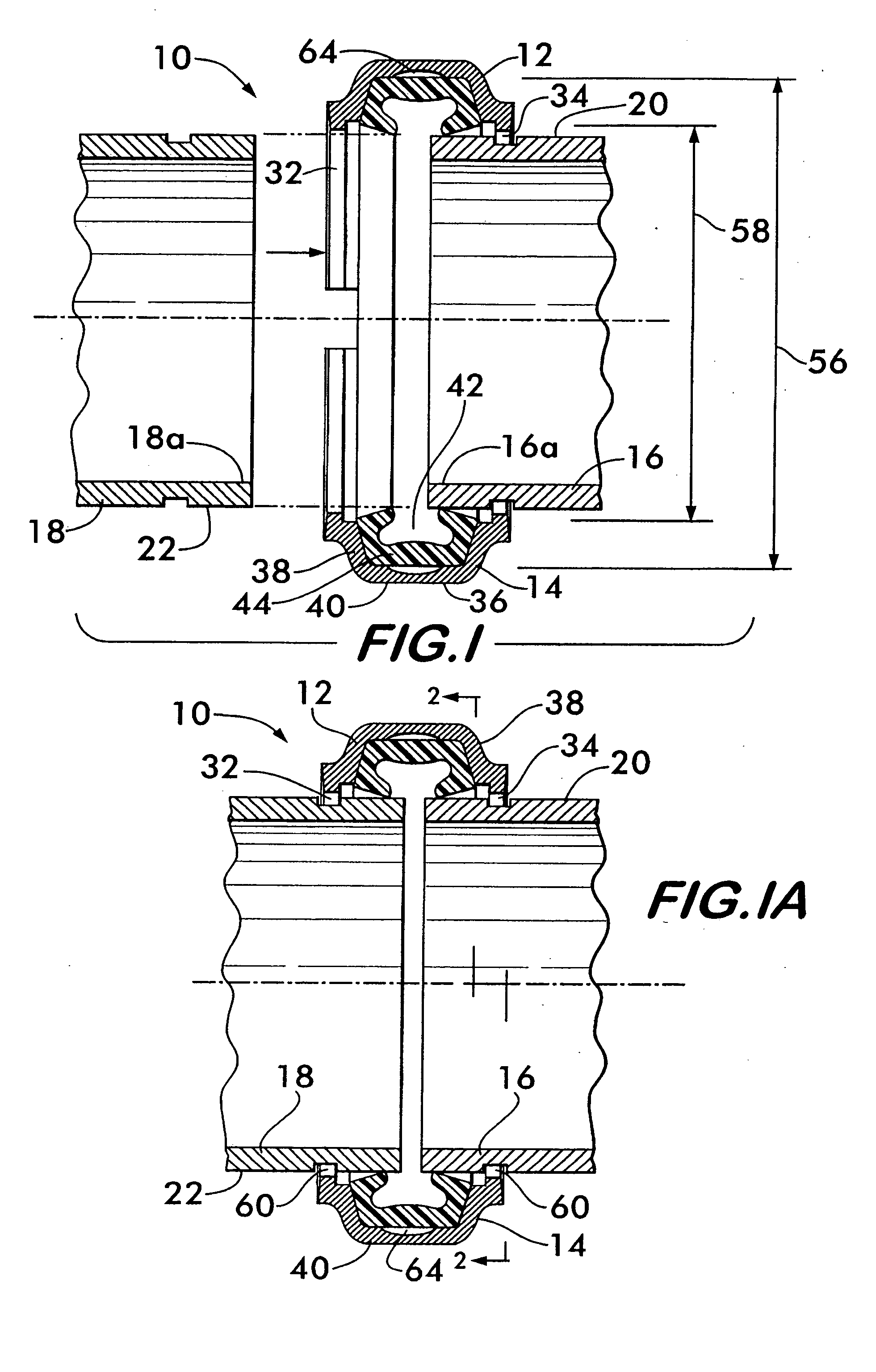

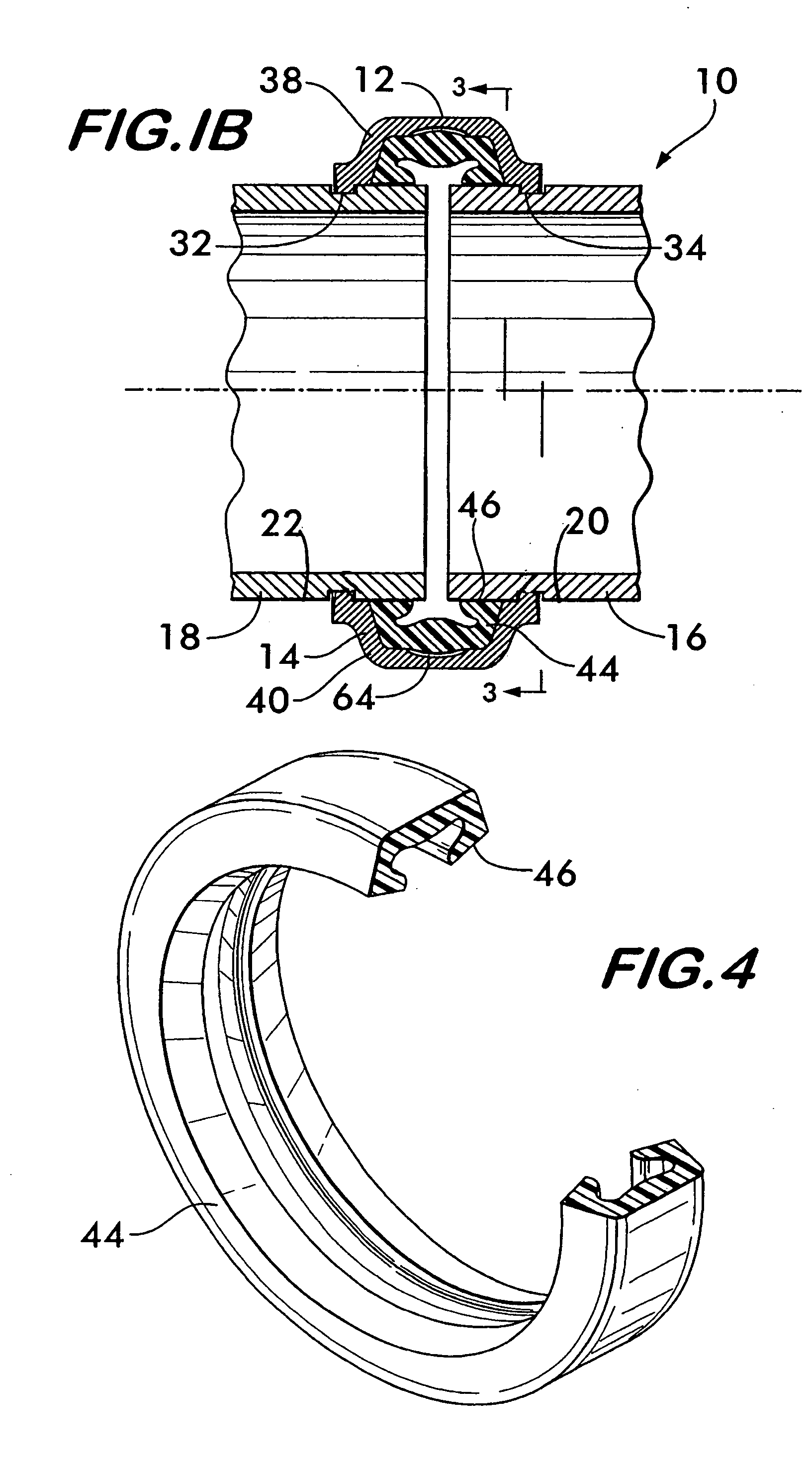

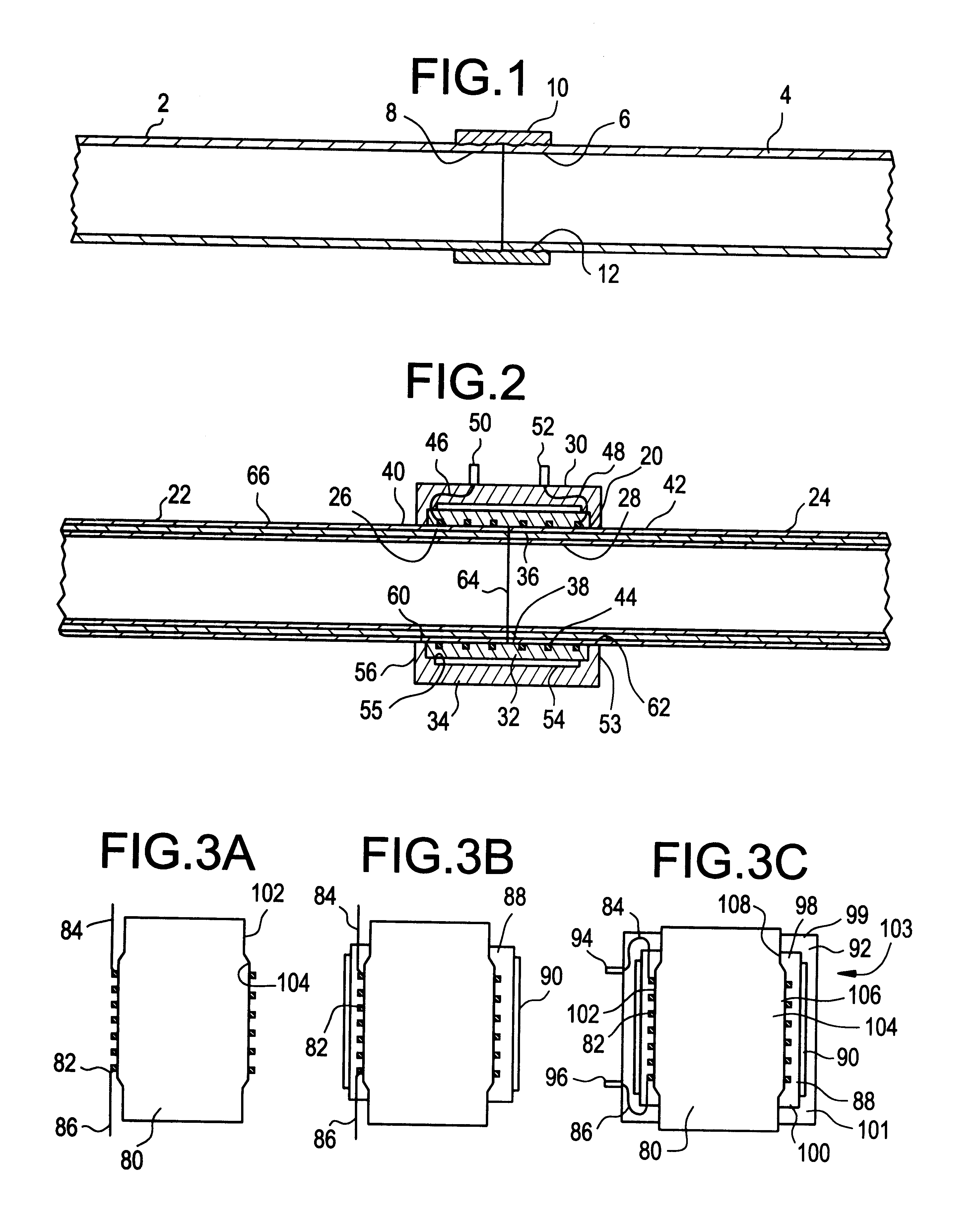

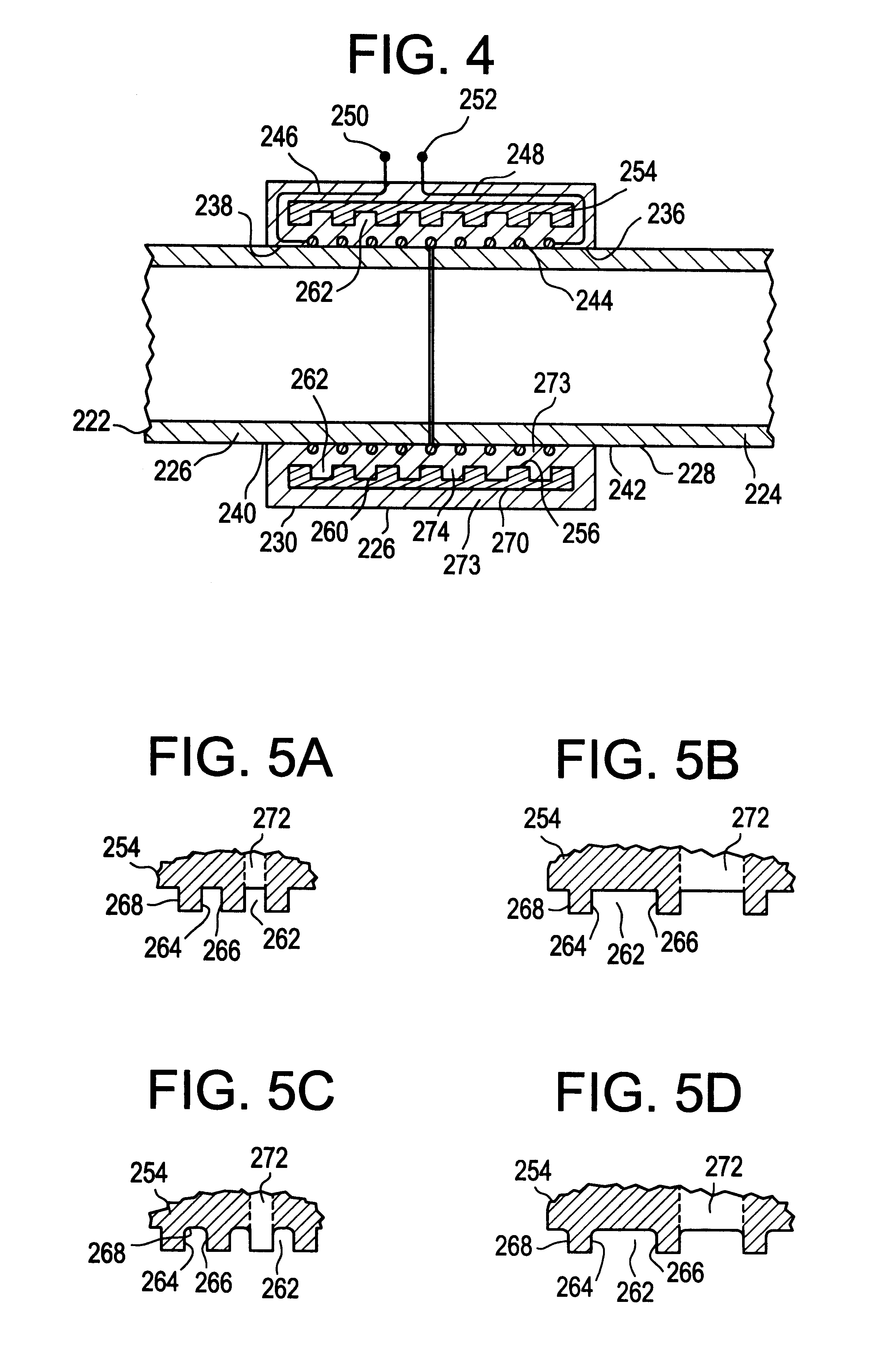

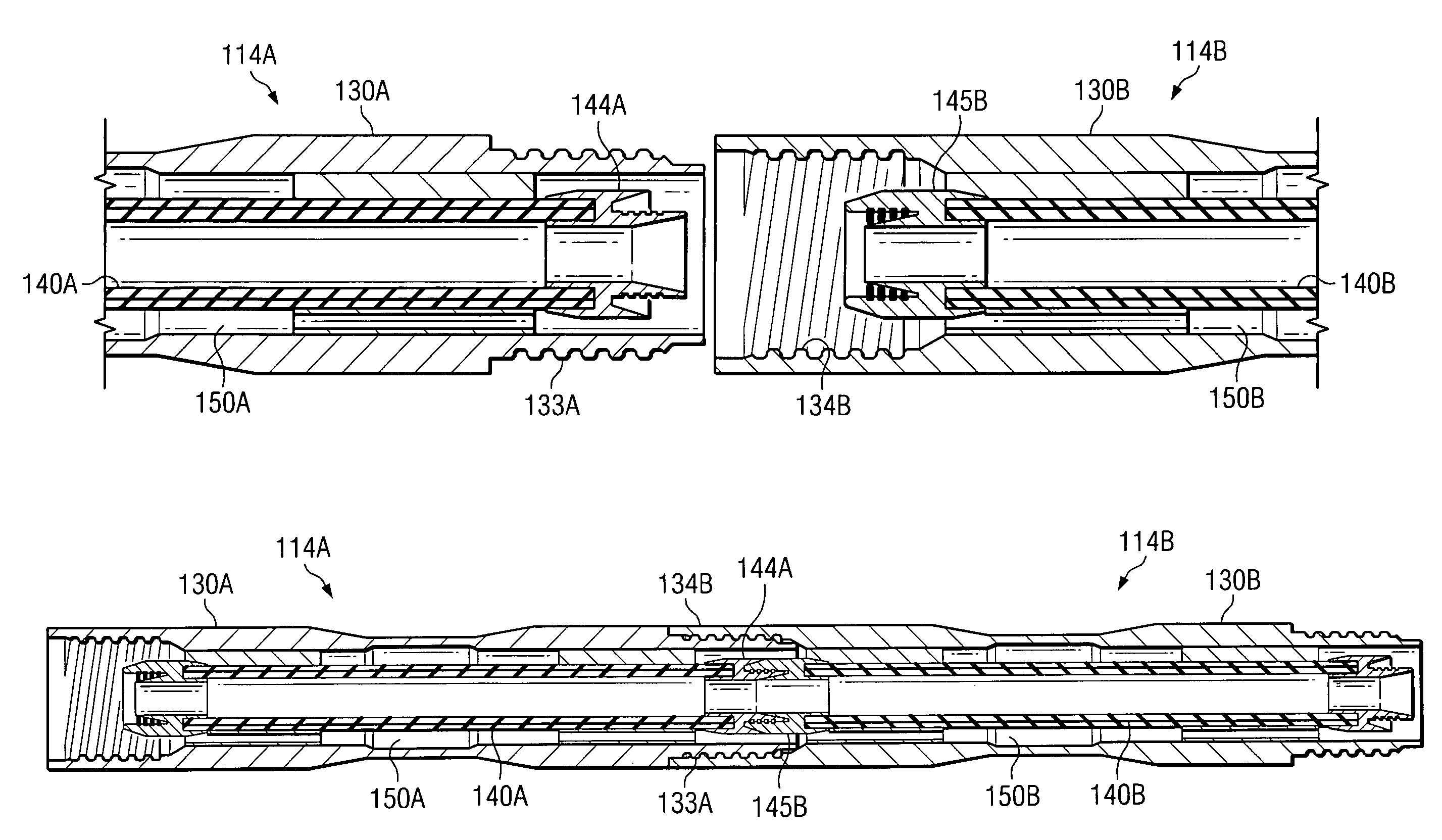

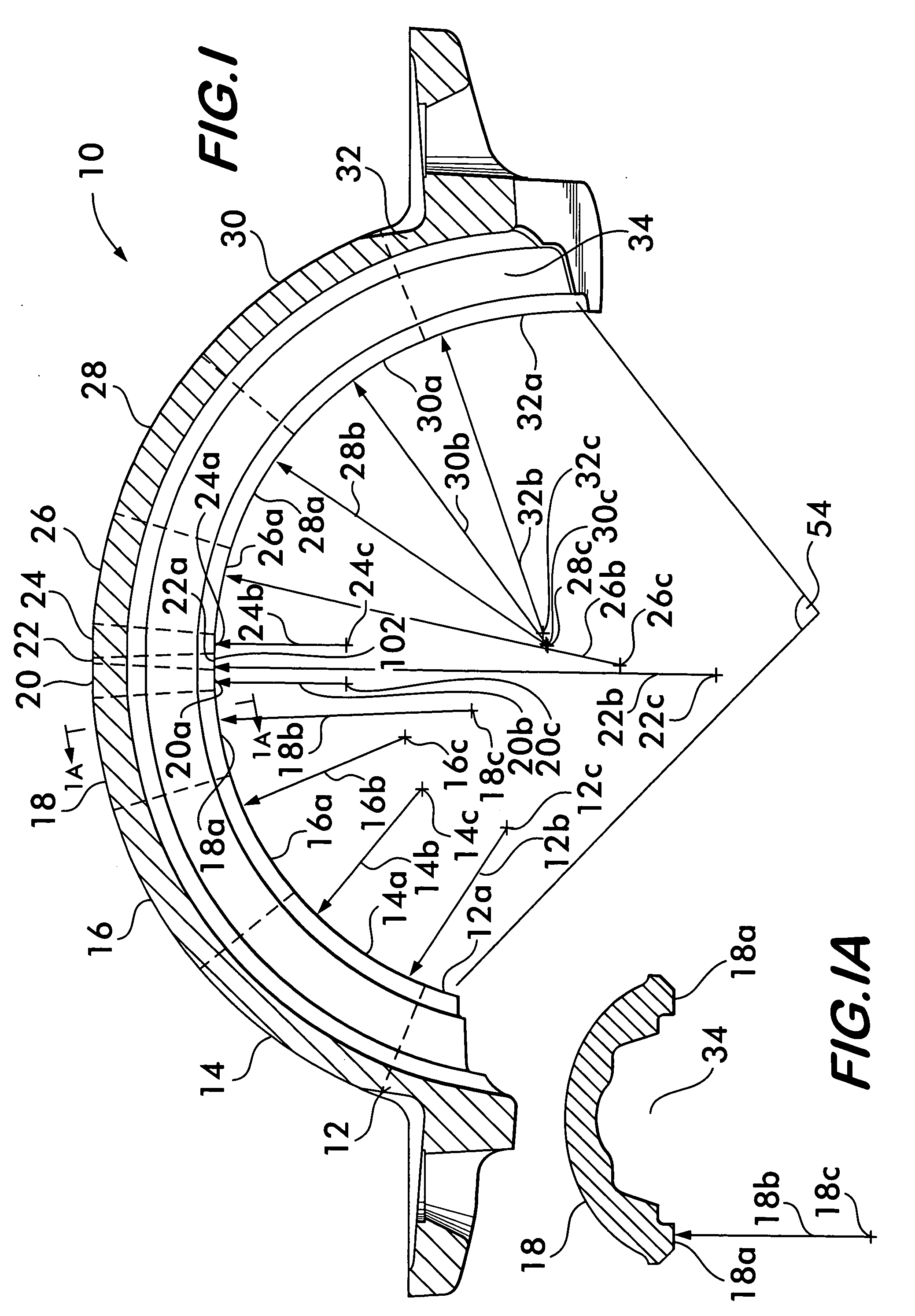

Expandable joint connector

InactiveUS6409175B1Lessen and eliminate radial engagementRadial expansionDrilling rodsCable inlet sealing meansEngineeringScrew thread

Methods and apparatus are provided for obtaining a secure mechanical connection and a pressure-tight seal in the overlapping area of two telescoping tubular bodies. The two bodies, including the overlapping area, are radially expanded to increase the inside diameter of the bodies. The expansion forces an annular seal in the overlapping area into a pressure-sealing engagement between the bodies. A string of pipe assembled from joints secured to each other by telescoping, threadedly engaged expanded pin and box connections may be radially expanded into a surrounding well bore to provide a cased well having an internal diameter greater than the original internal diameter of the pipe string. The seal in the connection comprises an annular elastomeric seal ring and an annular Teflon spacer ring carried in a specially dimensioned groove formed in either the box or the pin, or both members of the connection. Radial expansion of the connection causes axial contraction of the groove, which acts with the spacer ring to expand the seal ring radially to seal the annular space created between the expanded pin and box.

Owner:ENVENTURE GLOBAL TECH LLC

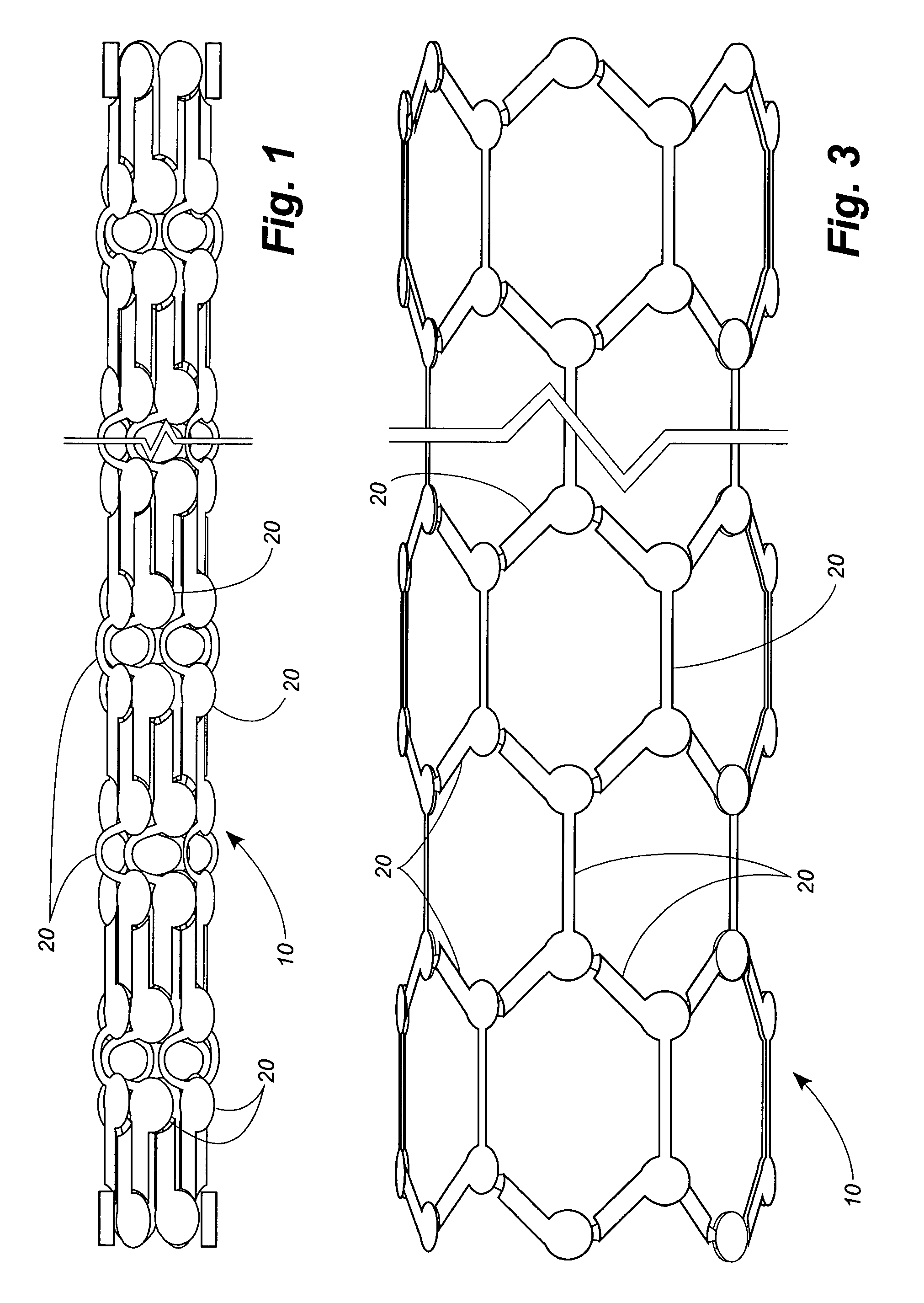

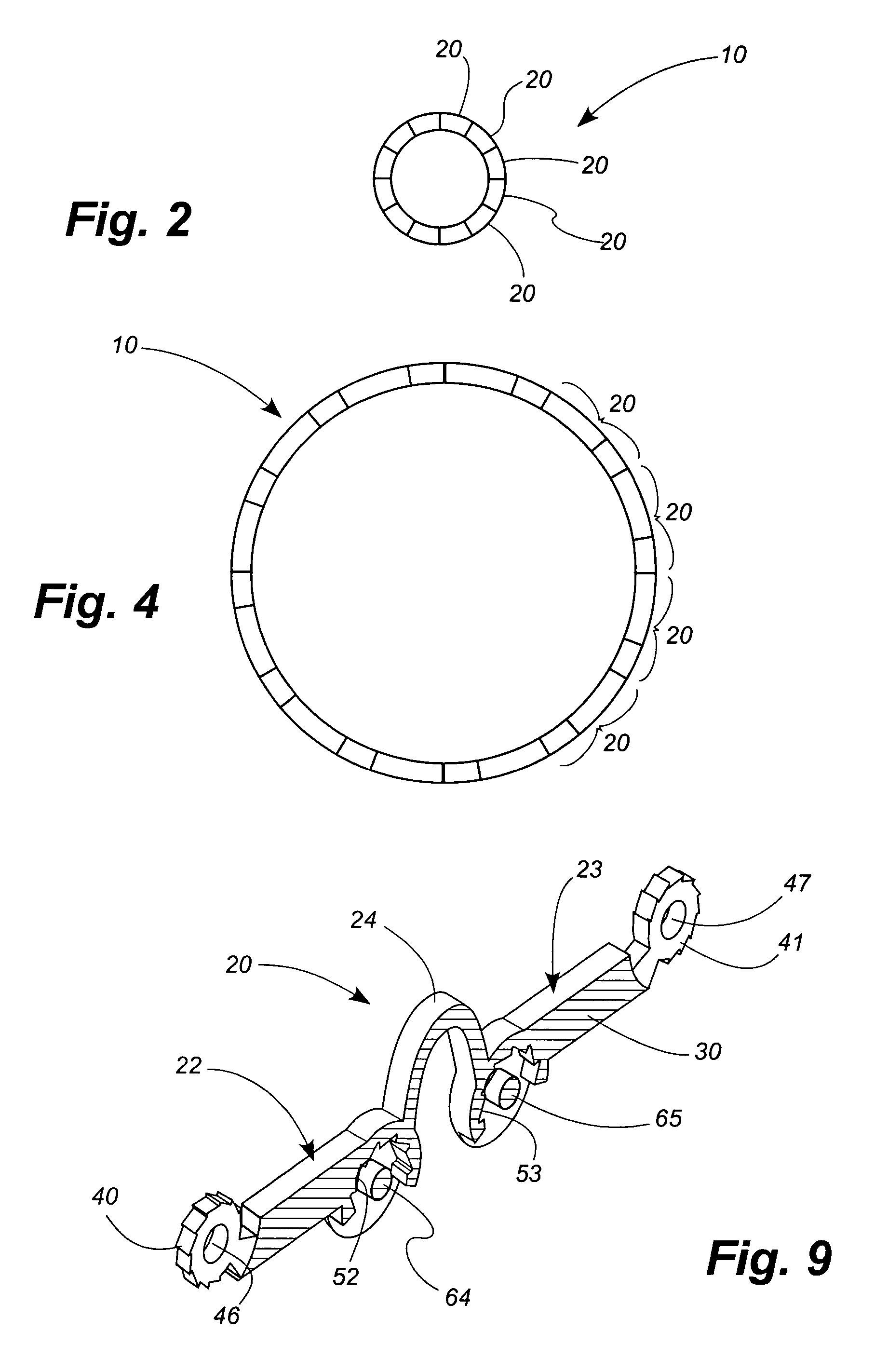

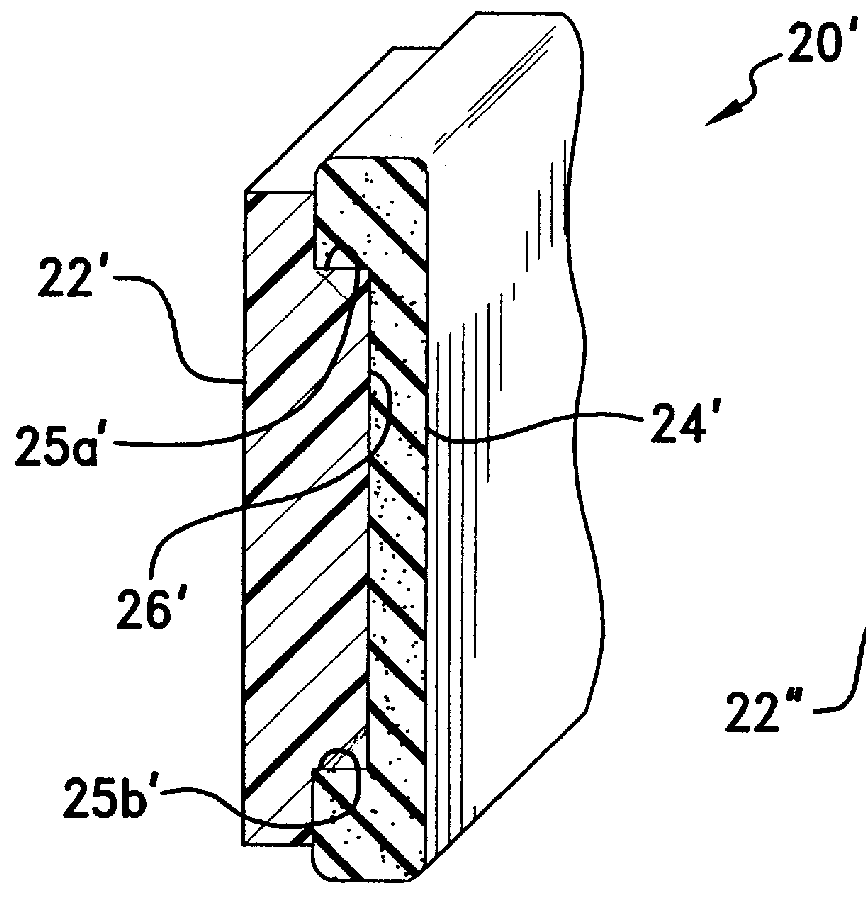

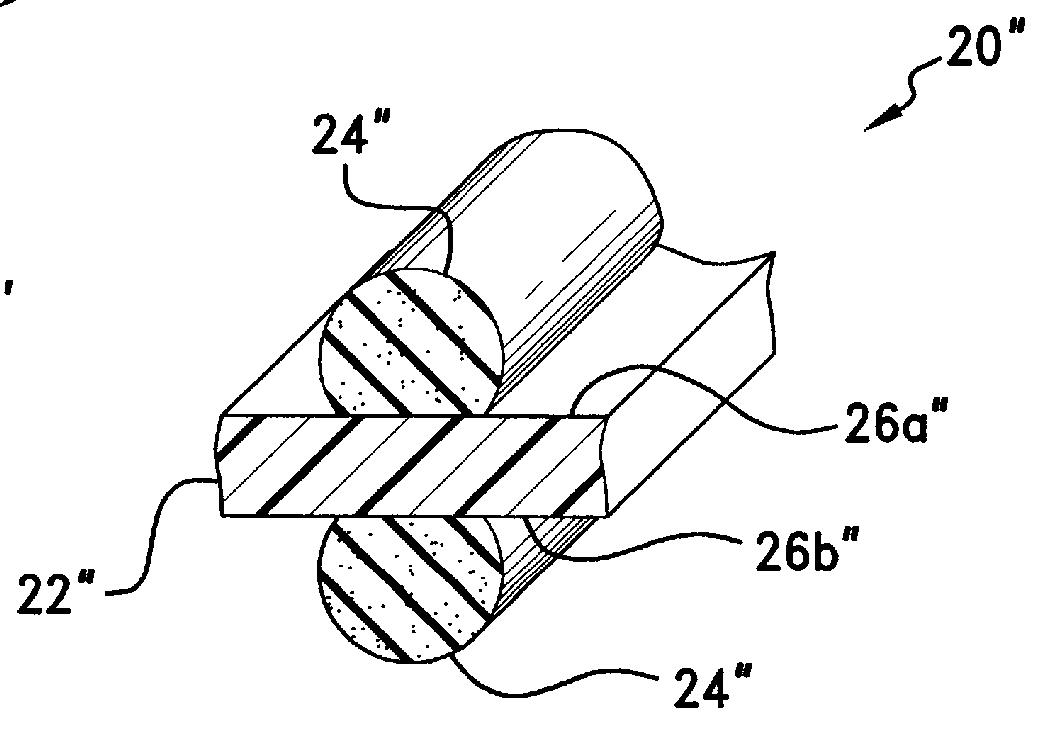

Stent with micro-latching hinge joints

A stent is constructed using interconnected links having micro-mechanical latching mechanisms. The micro-mechanical latching elements allow relative rotational movement of interconnected links in one rotational direction but restrict relative rotational movement of the two links in the opposite direction. The micro-mechanical latch surface features are formed using microelectronic mechanical systems (MEMS) manufacturing methods. The male surface of the latching components contains an array of ridges or protrusions, and the receiving surface contains a matching array of recesses. The array of ridges or protrusions and the corresponding recesses have uniformly dissimilar slopes that result in a substantially greater frictional force in one direction than in the opposite direction. The separation distance between the two surfaces is such that the male latch surface is engaged with the receiving surface recesses in the low stress “locked” state, preventing motion in the undesired direction. Each male ridge or protrusion can be underlined by a void that promotes elastic deflection when sliding in the desired direction and recovery into the ‘locked’ state when aligned with the recesses.

Owner:MIRUS LLC

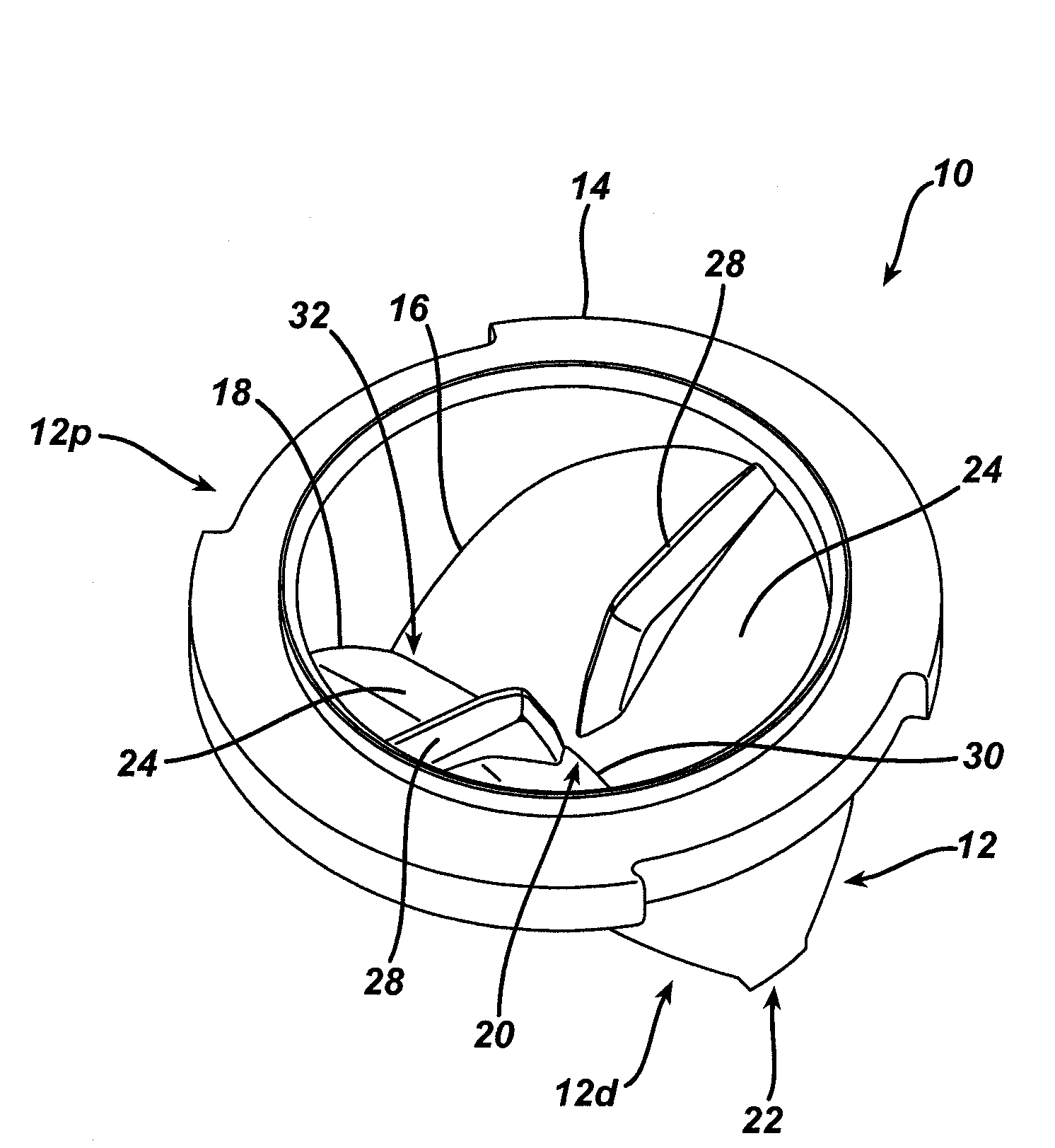

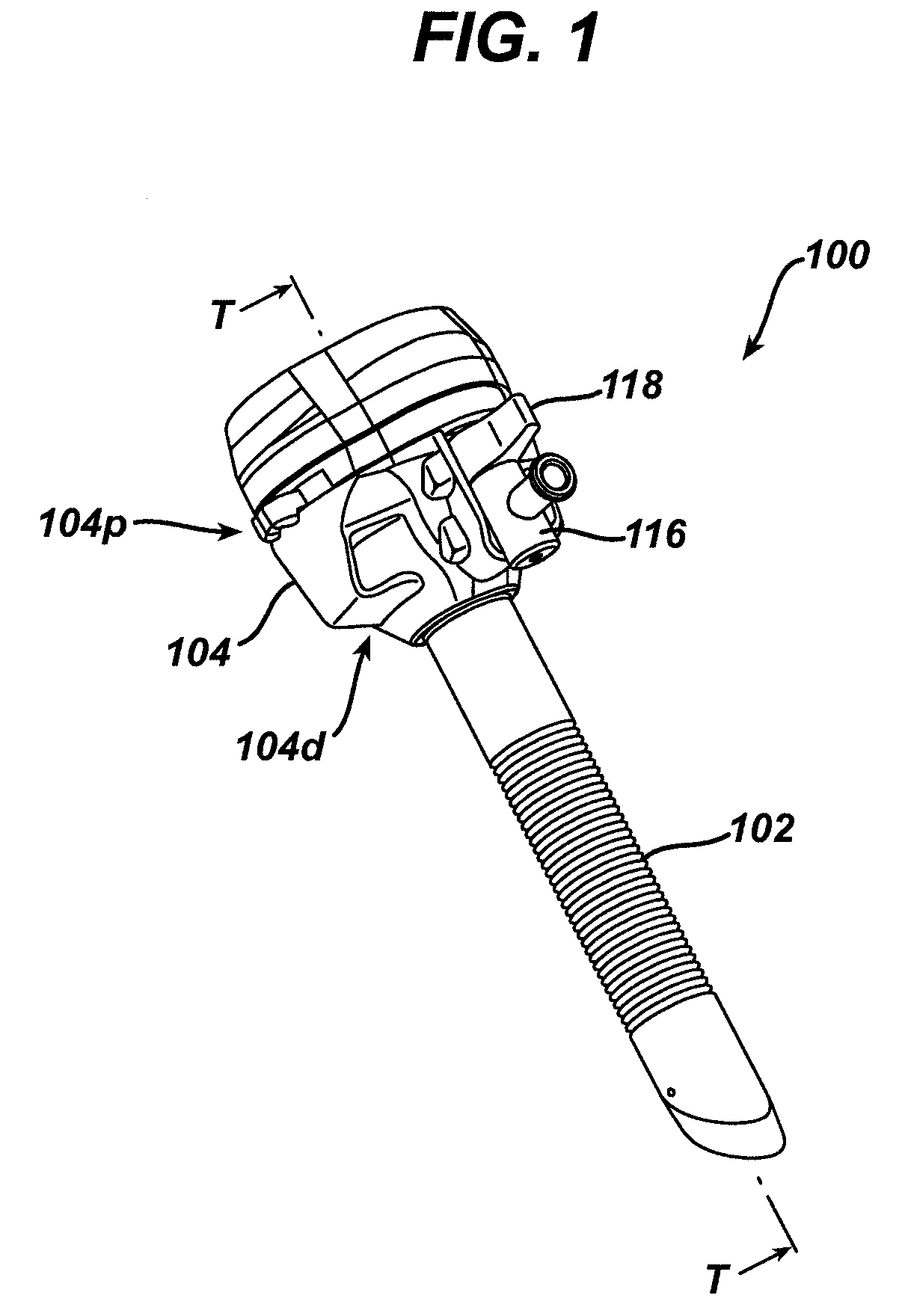

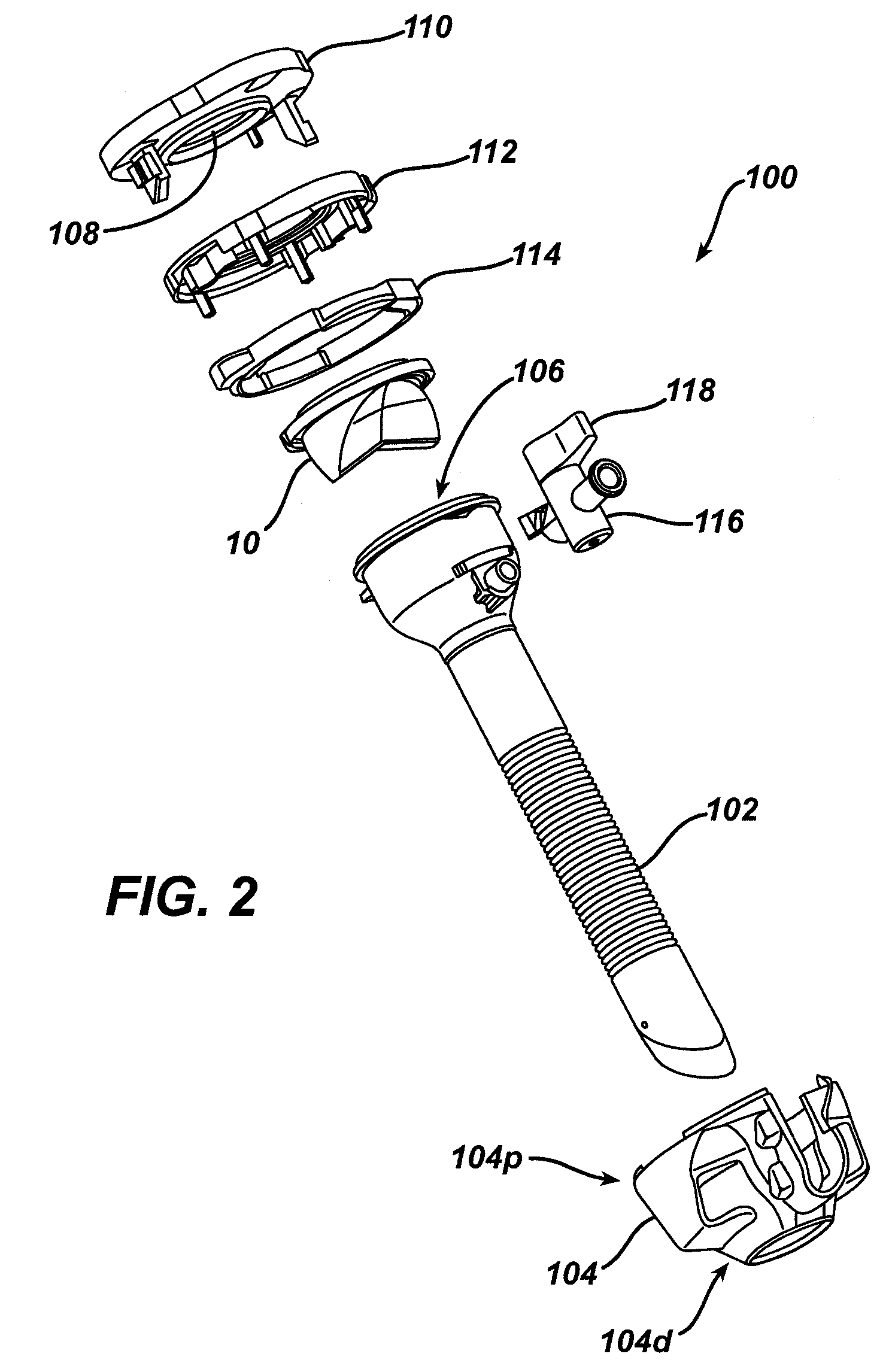

Duckbill seal with fluid drainage feature

ActiveUS20090005799A1Improve fluid flowPromote sportsFluid pressure sealed jointsCannulasEngineeringMechanical engineering

Seal assemblies, generally for use in trocar assemblies, are provided for selectively promoting movement of fluid away from a central portion of the seal assemblies. In one exemplary embodiment, an inner surface of a seal body of the seal assembly is configured to selectively promote such movement of fluid away from the central portion of the seal body toward a peripheral portion of the seal body. While various configurations, geometries, and dimensions are discussed, one example of such a configuration includes locating a central portion of the seal body at a more proximal position than a peripheral portion of the seal body.

Owner:CILAG GMBH INT

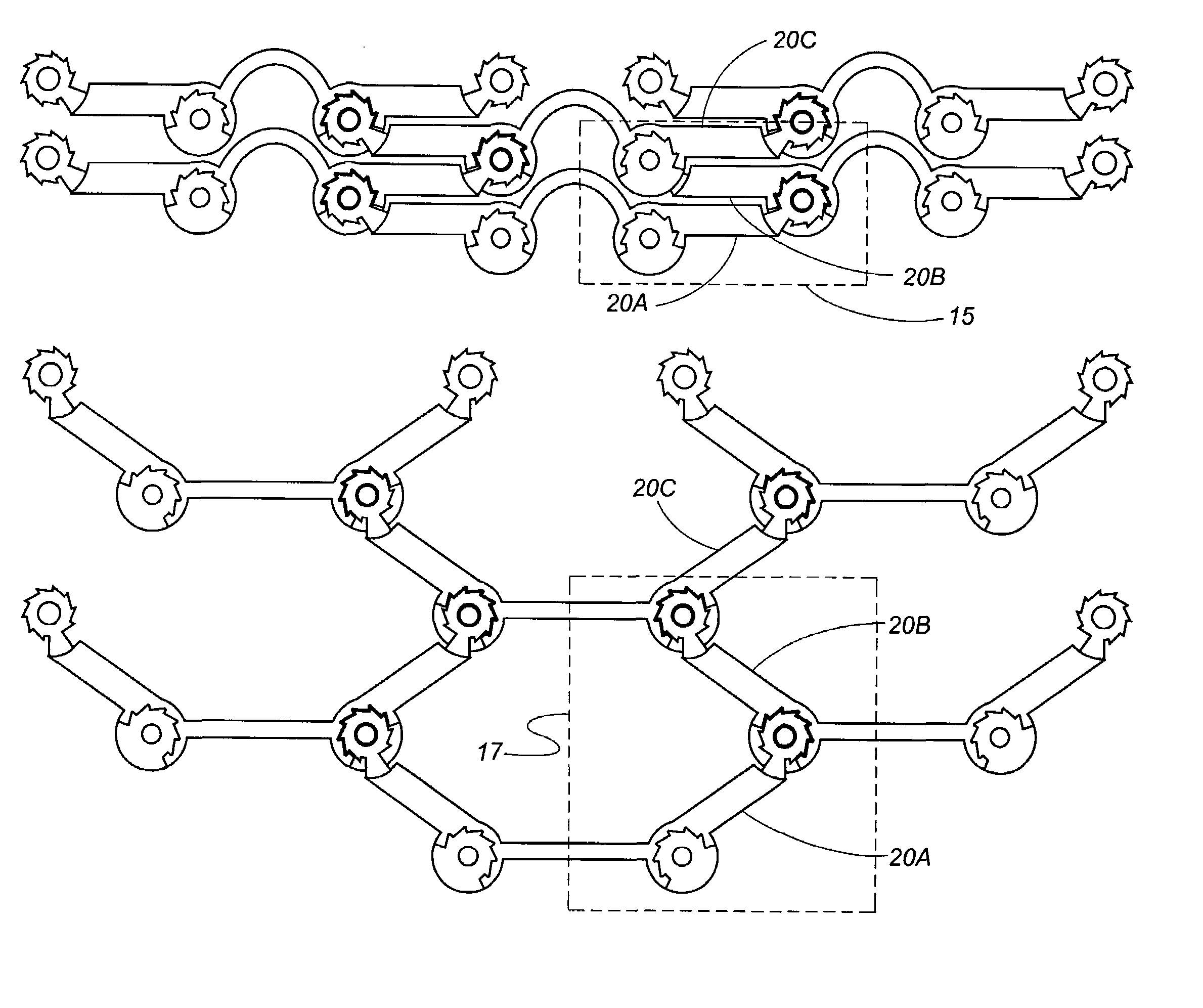

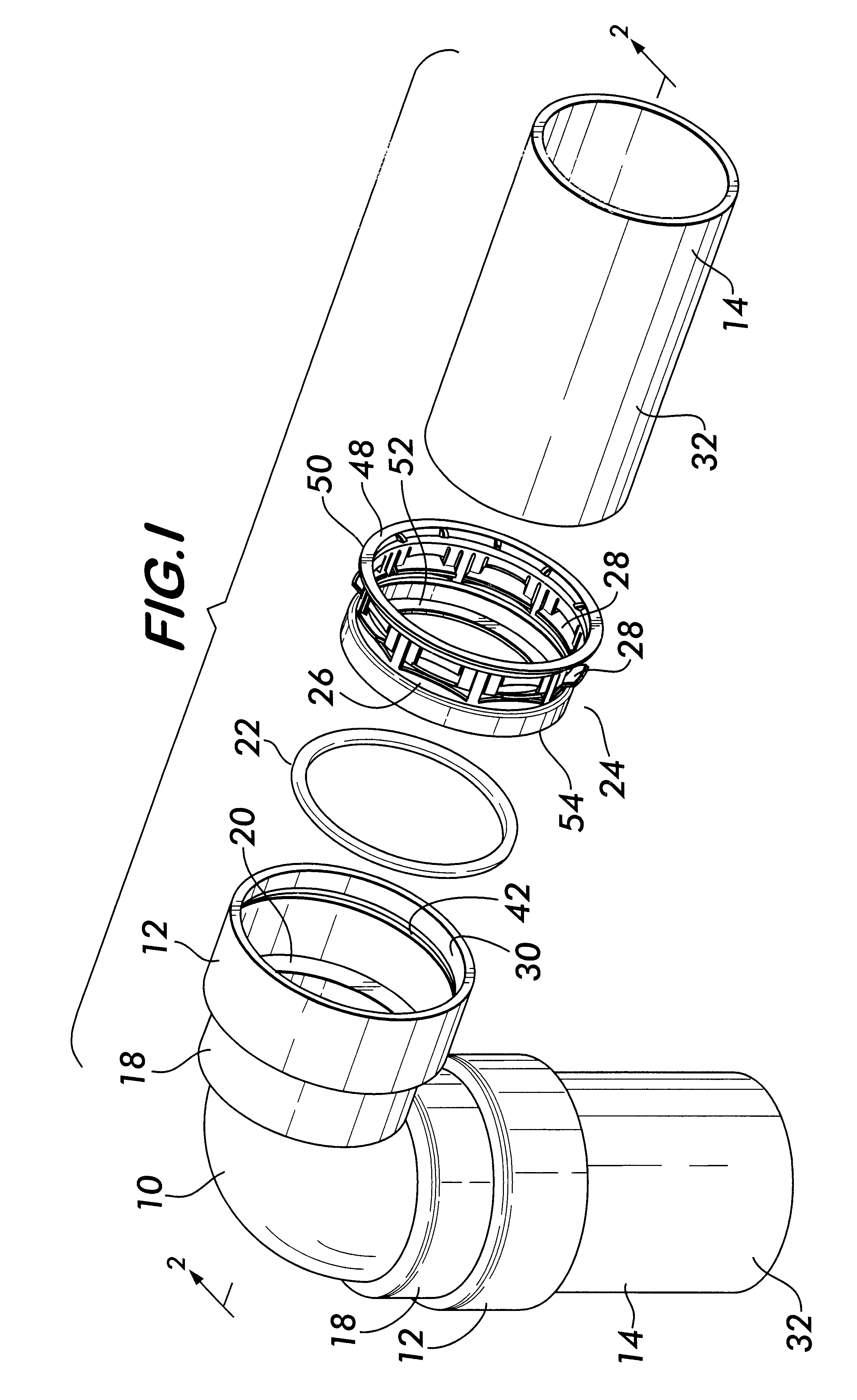

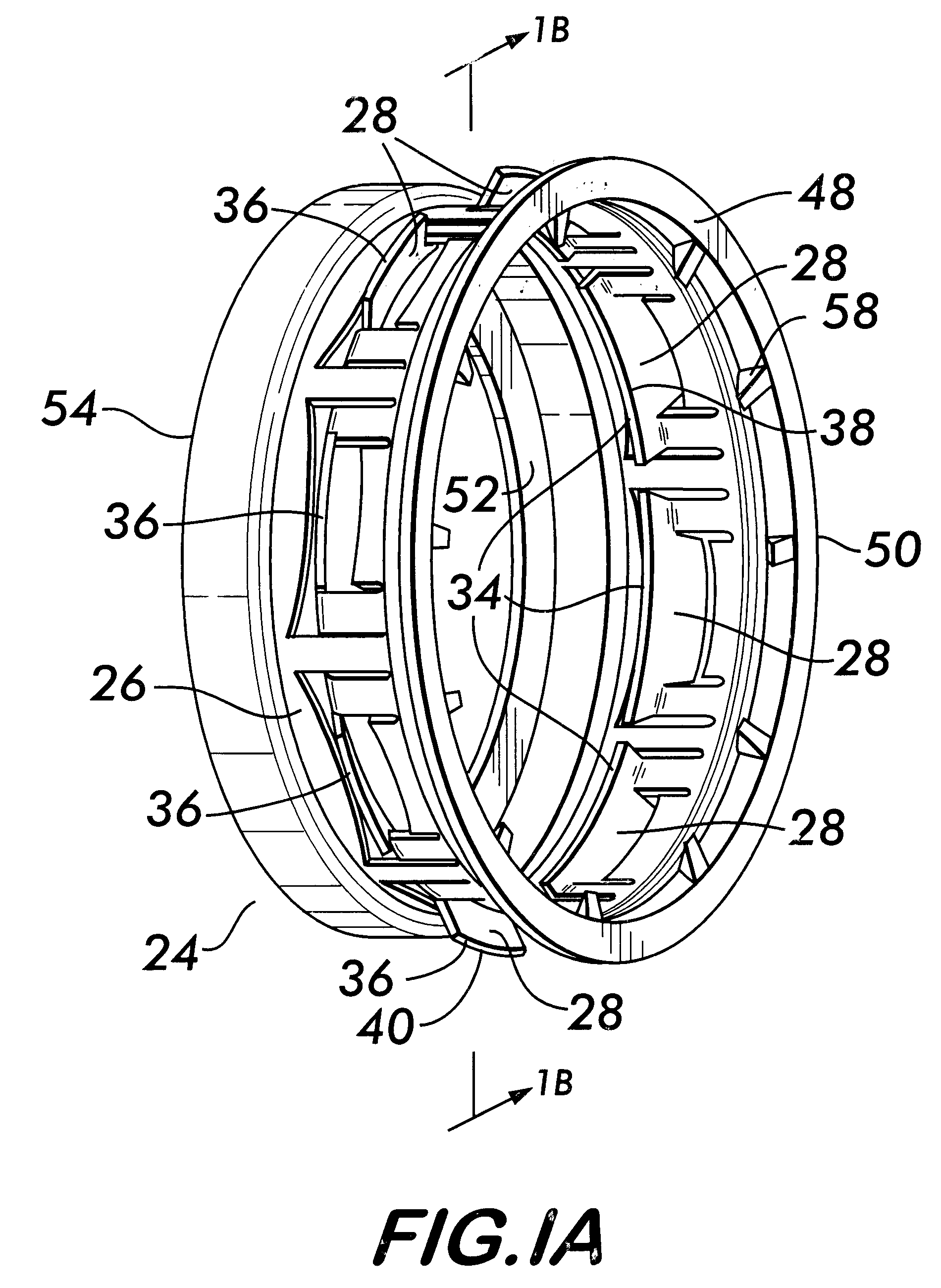

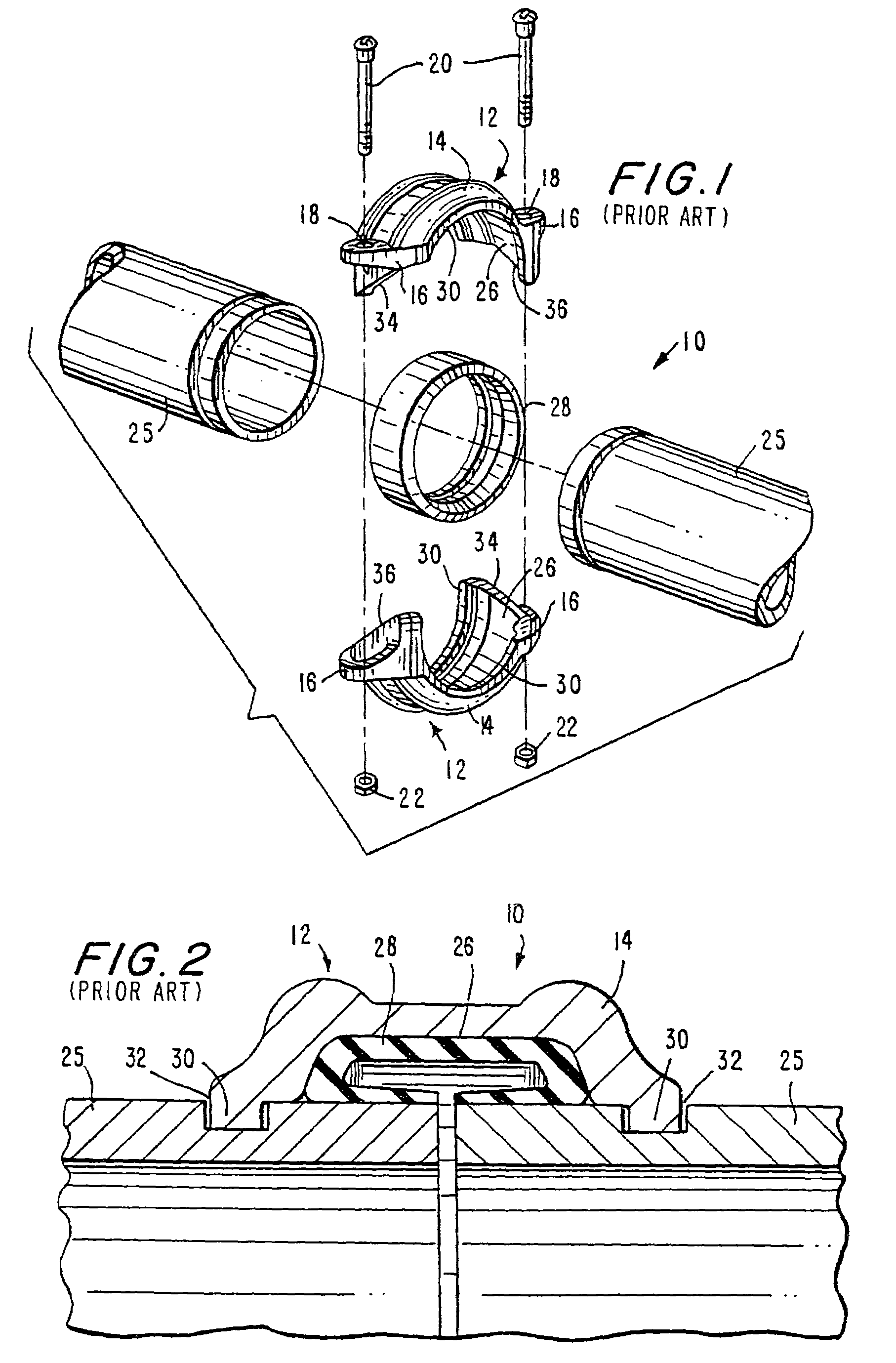

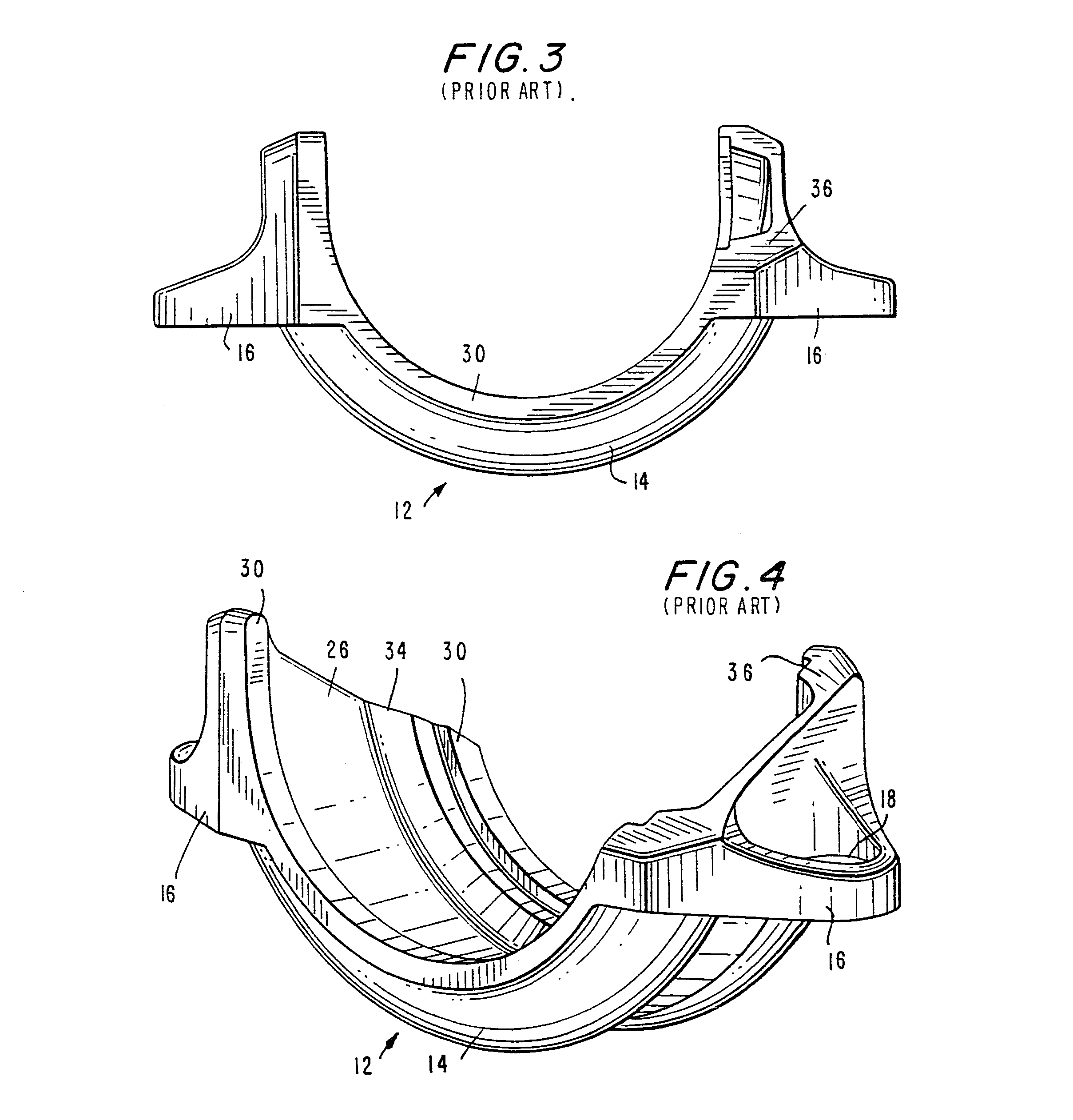

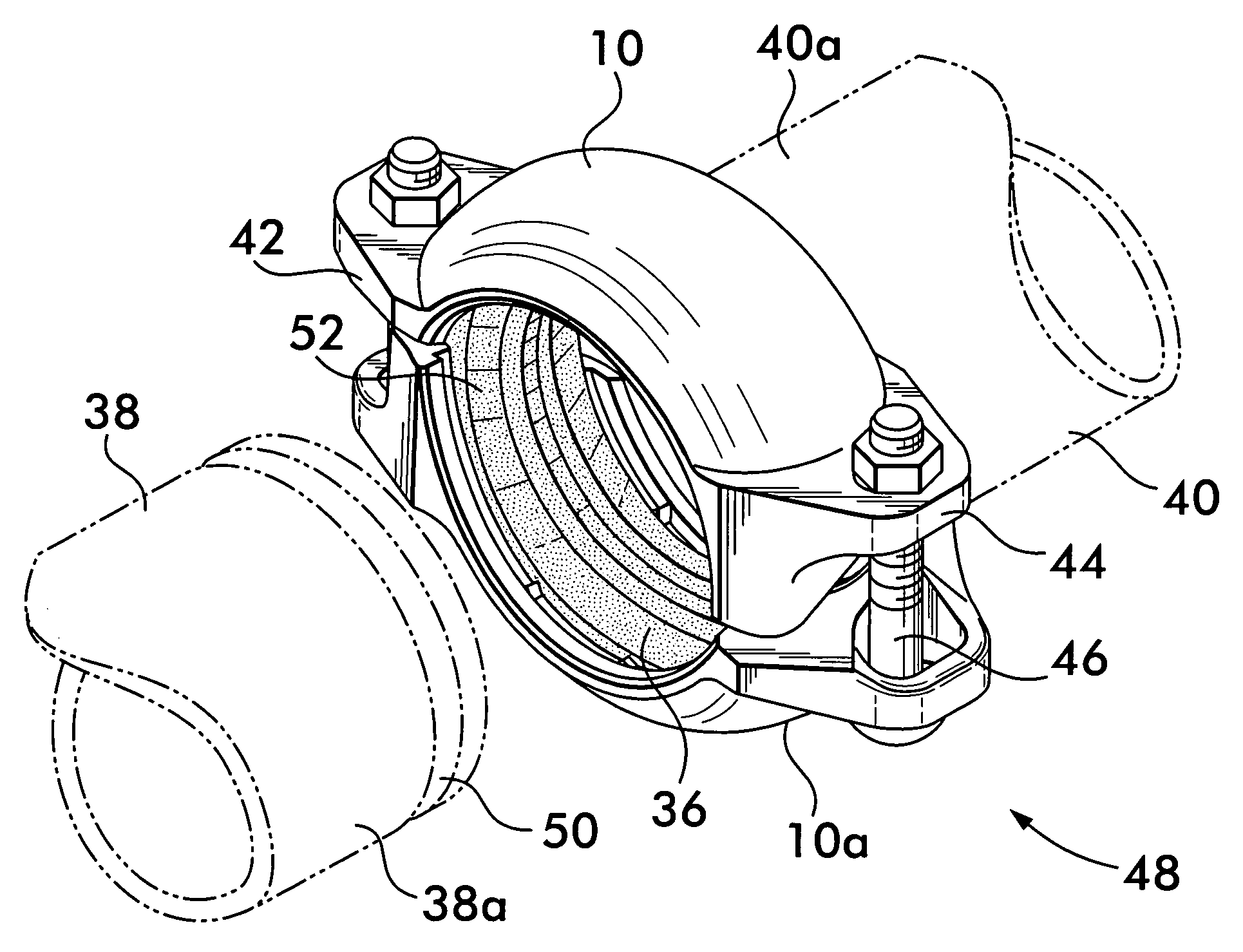

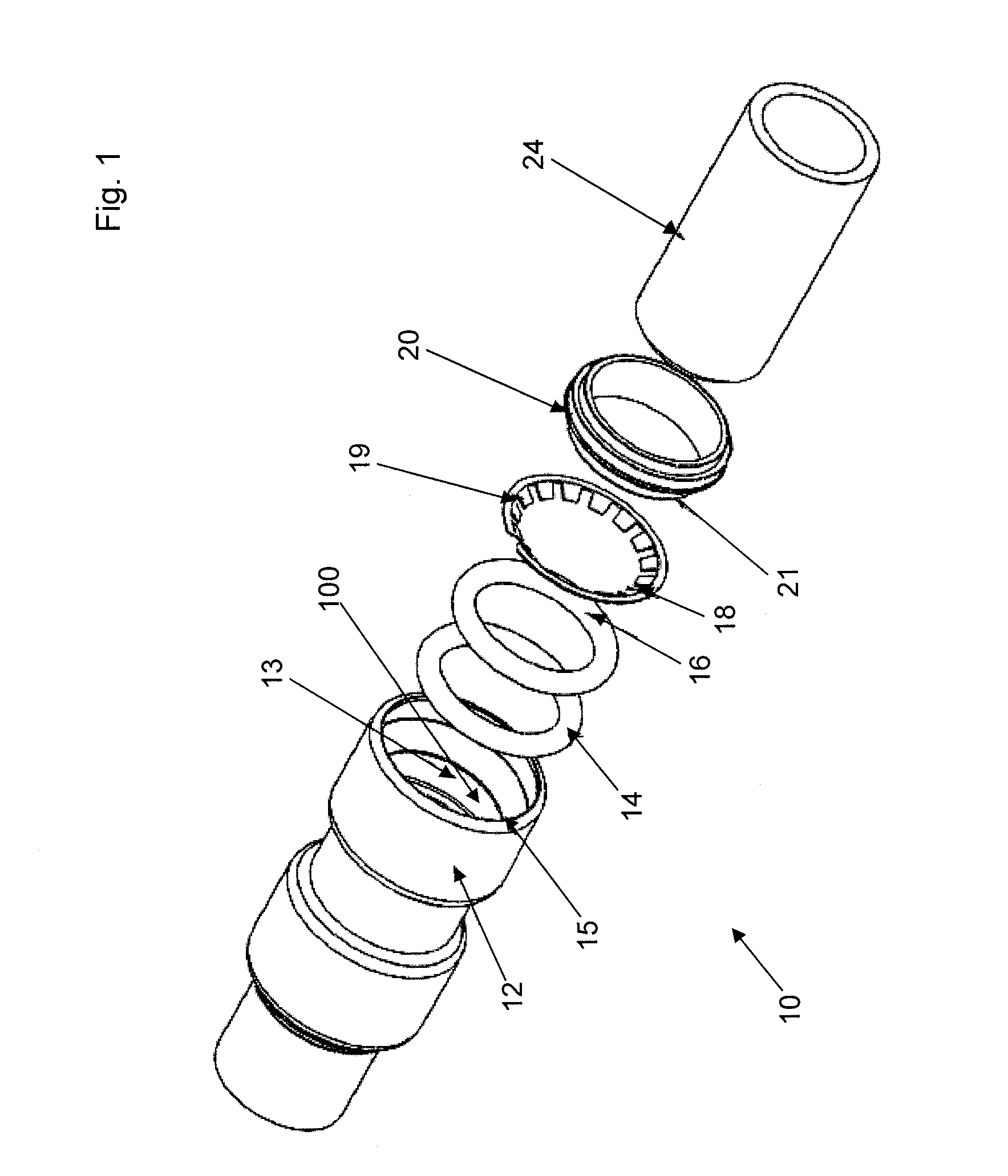

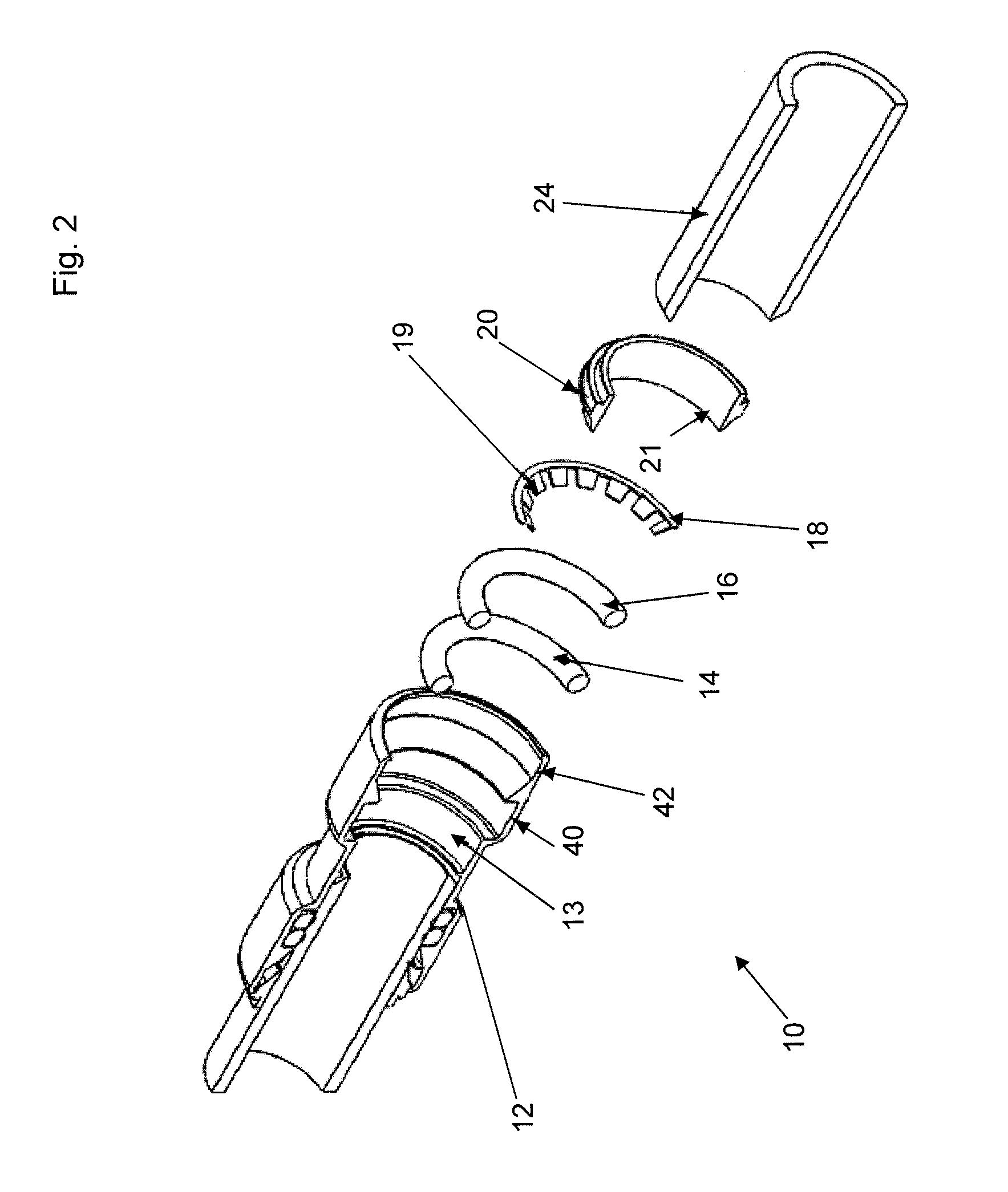

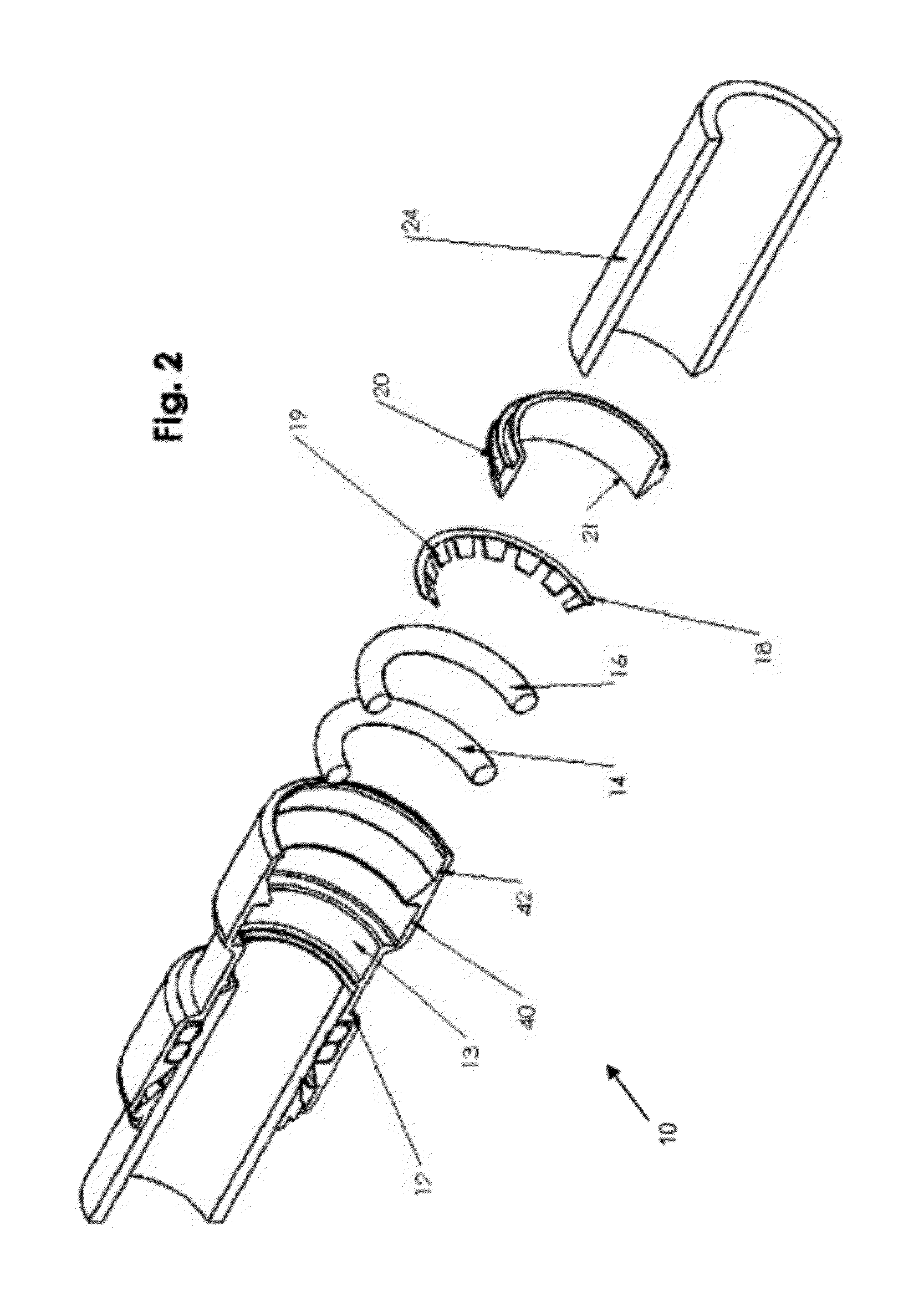

Mechanical pipe coupling with toothed retainer

InactiveUS6499771B1Reduce energy lossPositive engagementSleeve/socket jointsFluid pressure sealed jointsPipe fitting

An open end of a standard pipe fitting is enlarged in diameter to coaxially receive an O-ring and a retainer having a cylindrical surface. A plurality of locking teeth project from the cylindrical surface and are engageable with both the inner surface of the fitting and an outer surface of a pipe end inserted coaxially into the fitting open end. Each of the locking teeth have oppositely disposed edges facing obliquely inwardly and outwardly to engage both the pipe end and the fitting and resisting motion of the pipe end relatively to the fitting. In an alternate embodiment, a first plurality of teeth each have an edge facing obliquely inwardly of the fitting to engage the pipe end and resist motion tending to withdraw the pipe end from the fitting. A second plurality of teeth each have an edge facing obliquely outwardly of the fitting and resist motion tending to withdraw the retainer from the fitting.

Owner:VICTAULIC

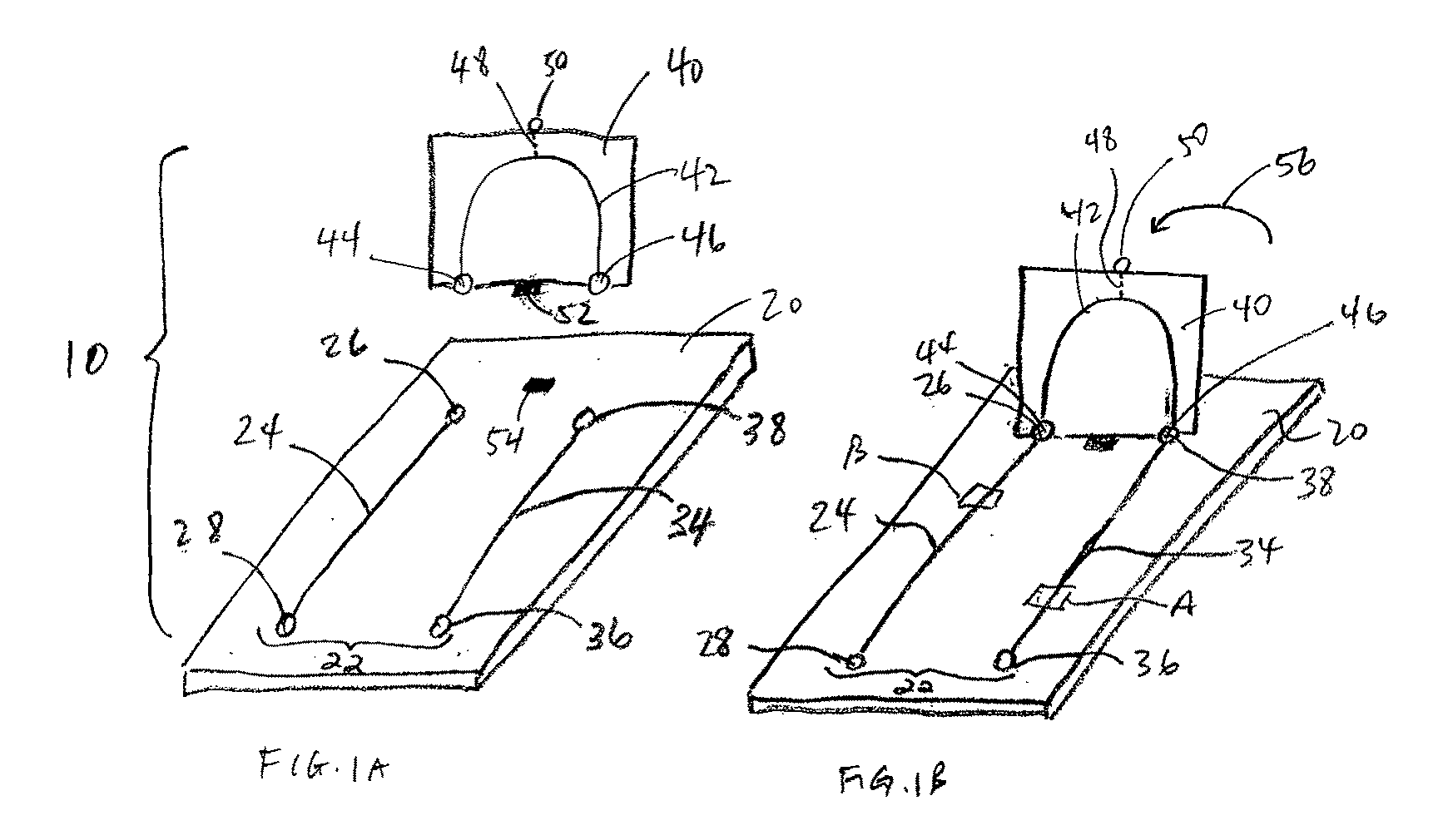

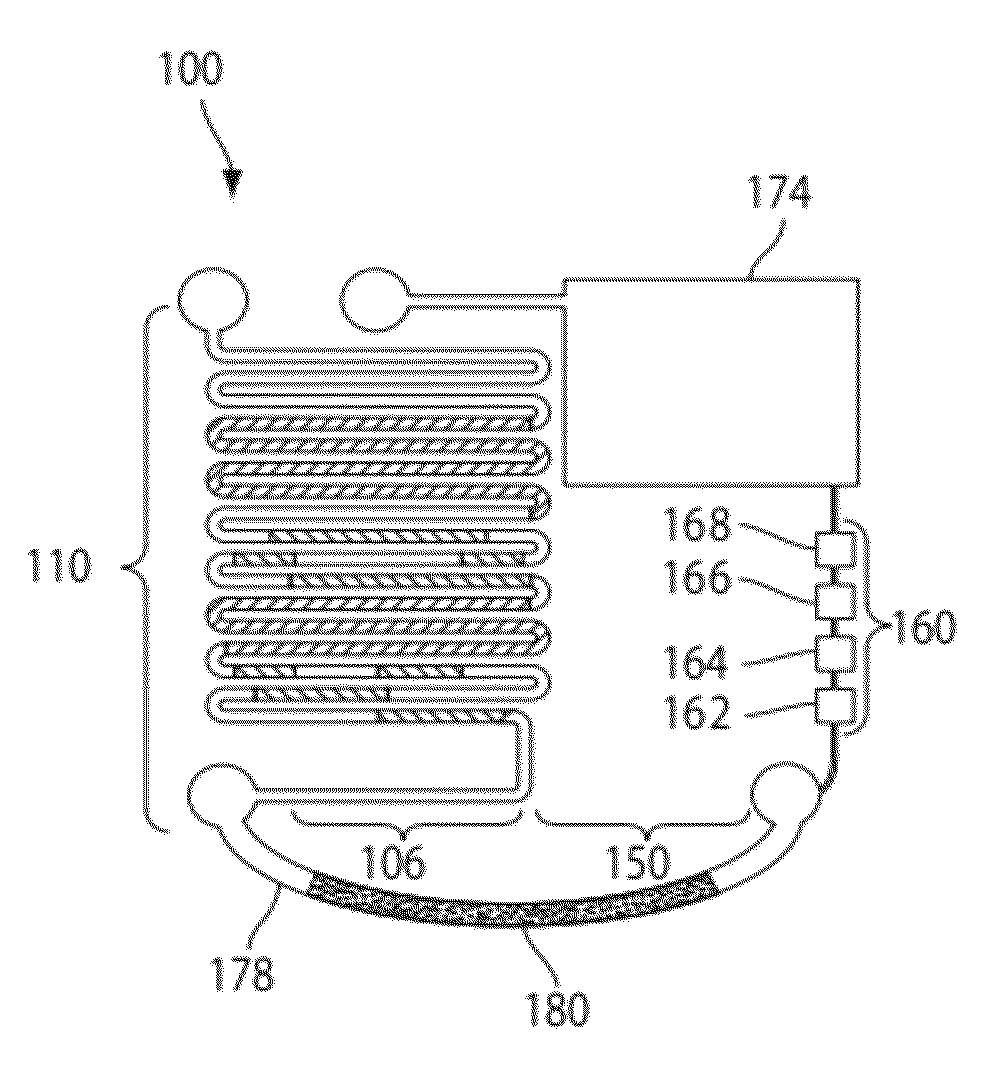

Dynamic self-adjusting assembly for sealing, baffling or structural reinforcement

There is disclosed a reinforced structural assembly and a method of using the assembly for sealing, baffling and / or reinforcing components of an automotive vehicle. The assembly generally includes at least a first mass of expandable material. Preferably, the first mass is movably (e.g., rotatably) connected to a second mass of material and / or another member. According to the method, the assembly is placed in a cavity of an automotive vehicle and the at least one mass is activated to expand. Preferably, upon activation, the first mass self adjusts by moving (e.g., rotating) relative to the second mass and / or the other member.

Owner:ZEPHYROS INC

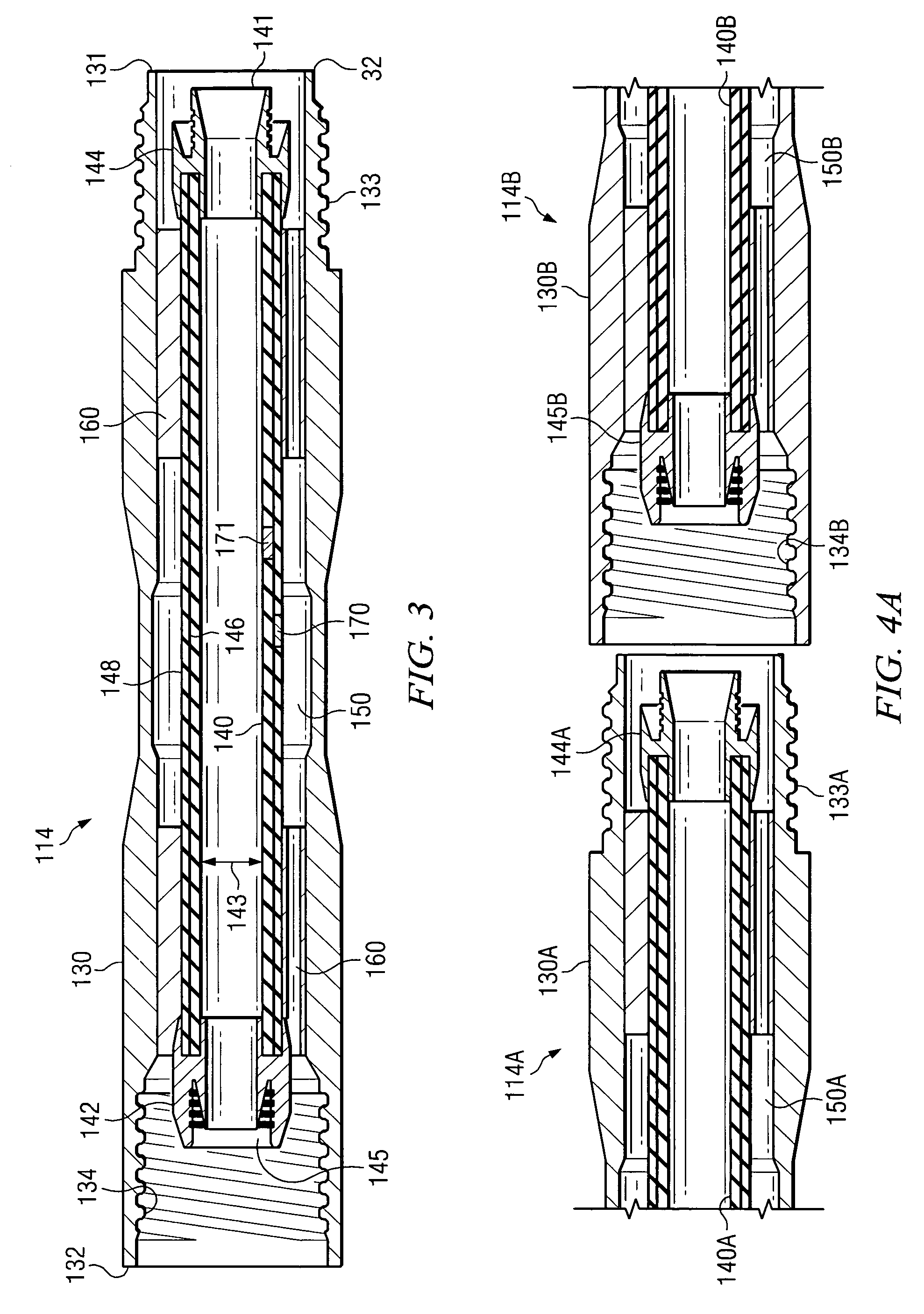

Deformable mechanical pipe coupling

A deformable mechanical pipe coupling is disclosed. The coupling has a plurality of interconnectable segments that straddle the ends of pipe elements to be joined. The segments have arcuate surfaces that engage outer surfaces of the pipe elements. The outer surfaces subtend an angle of less than 180° and have radii of curvature greater than the radii of curvature of the pipe element outer surfaces. The segments have adjustably tightenable connection members for connecting the segments to one another. When the connection members are tightened, the arcuate surfaces deform and conform to the radius of curvature of the outer surface of the pipe elements.

Owner:VICTAULIC

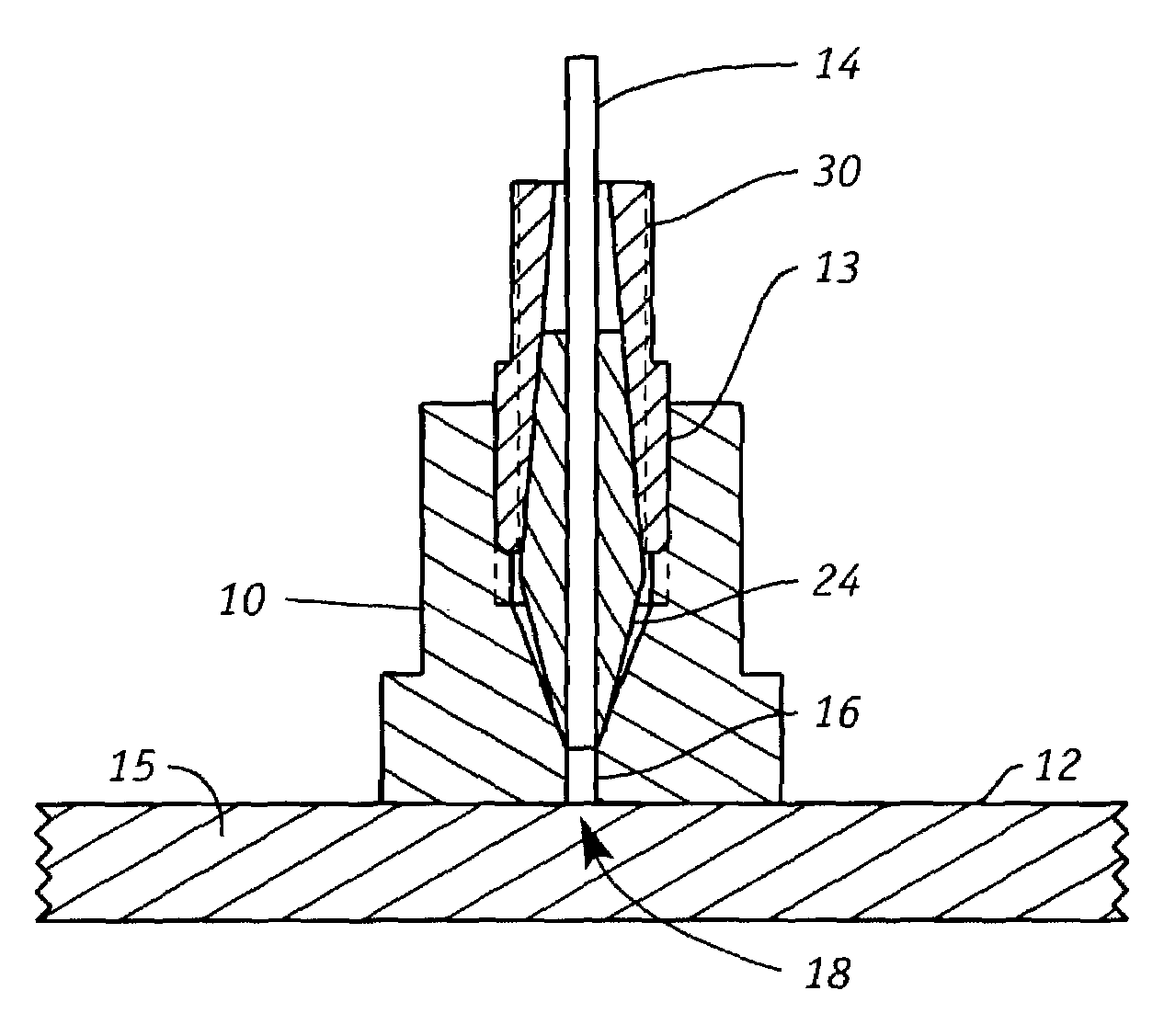

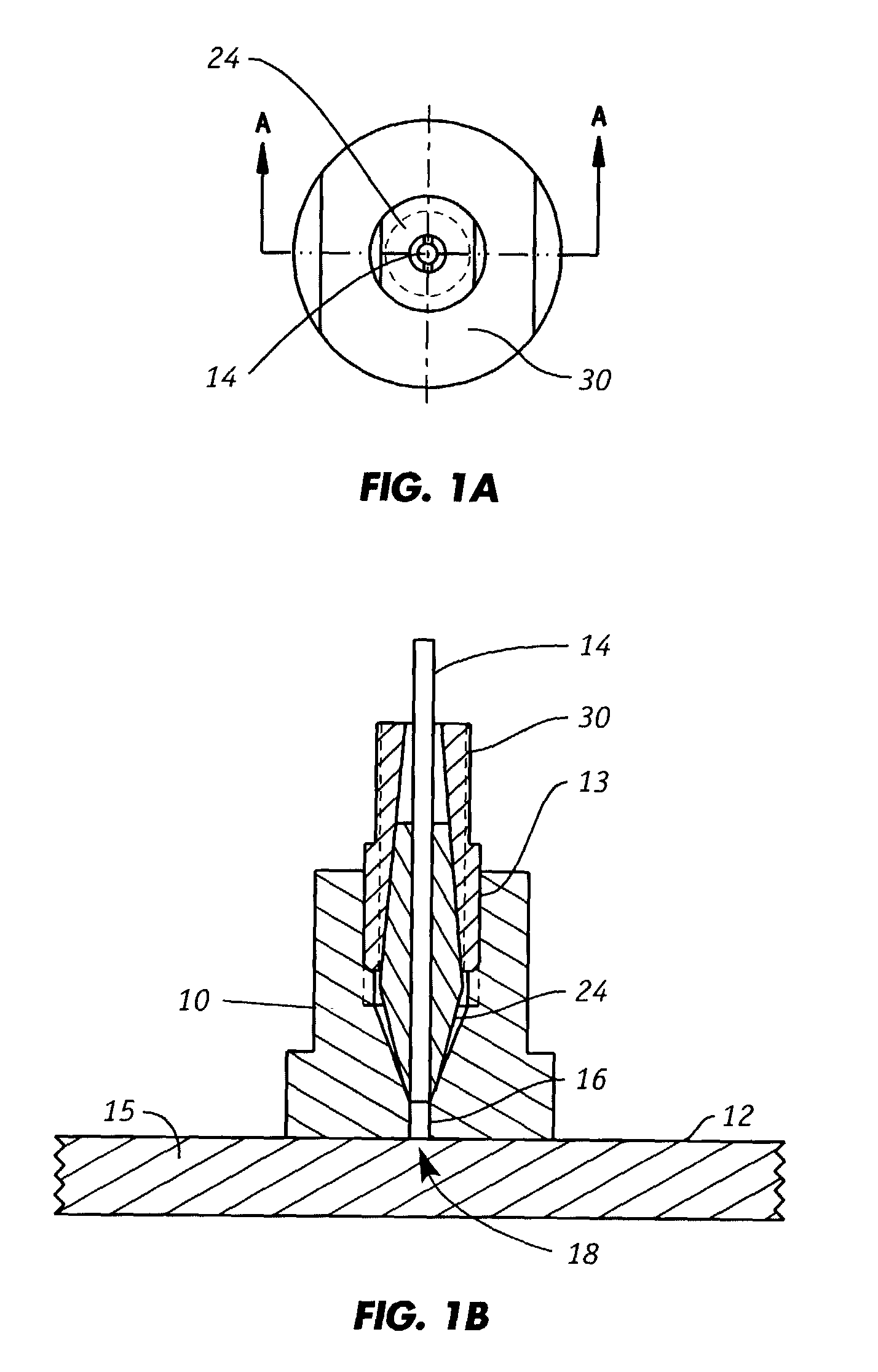

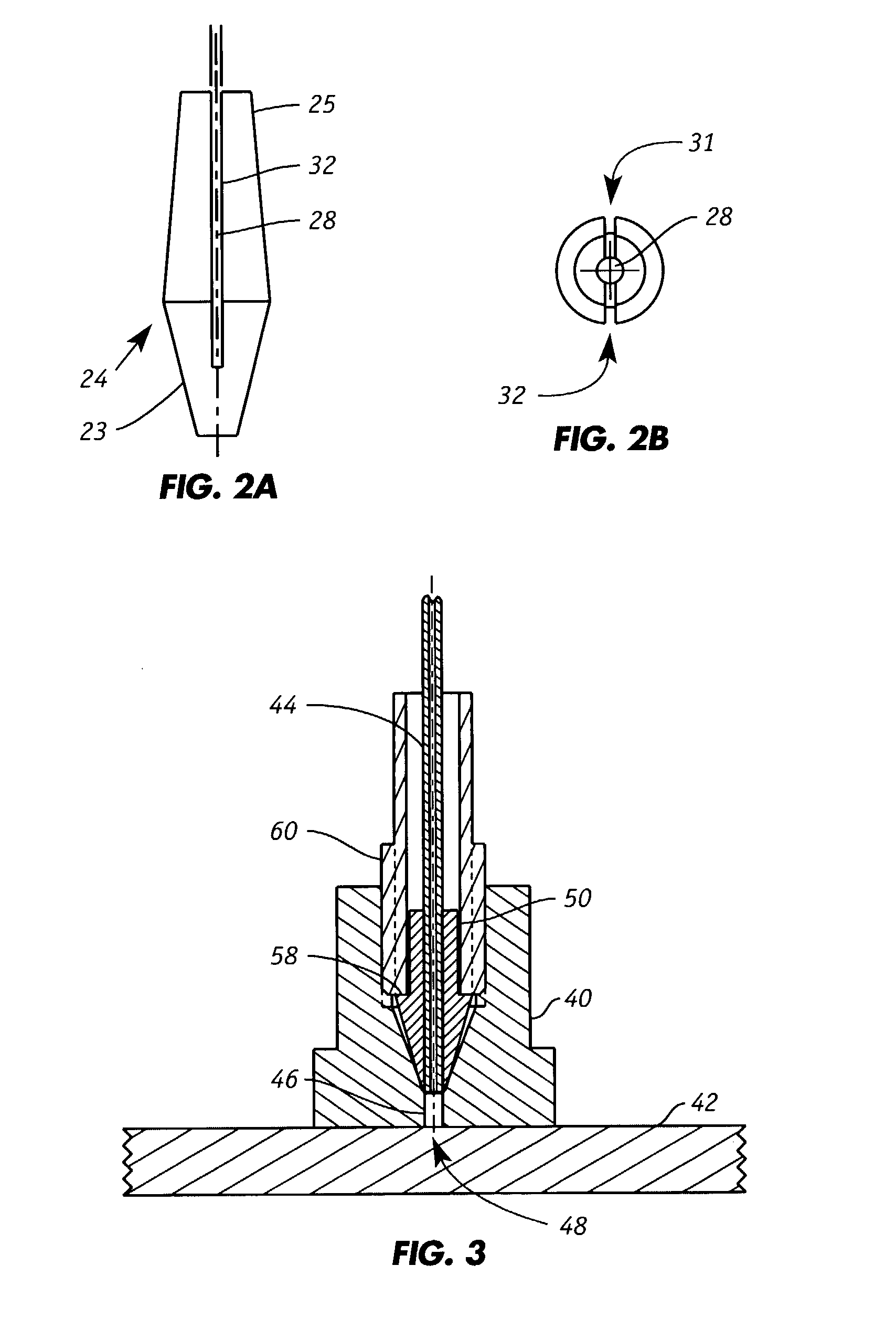

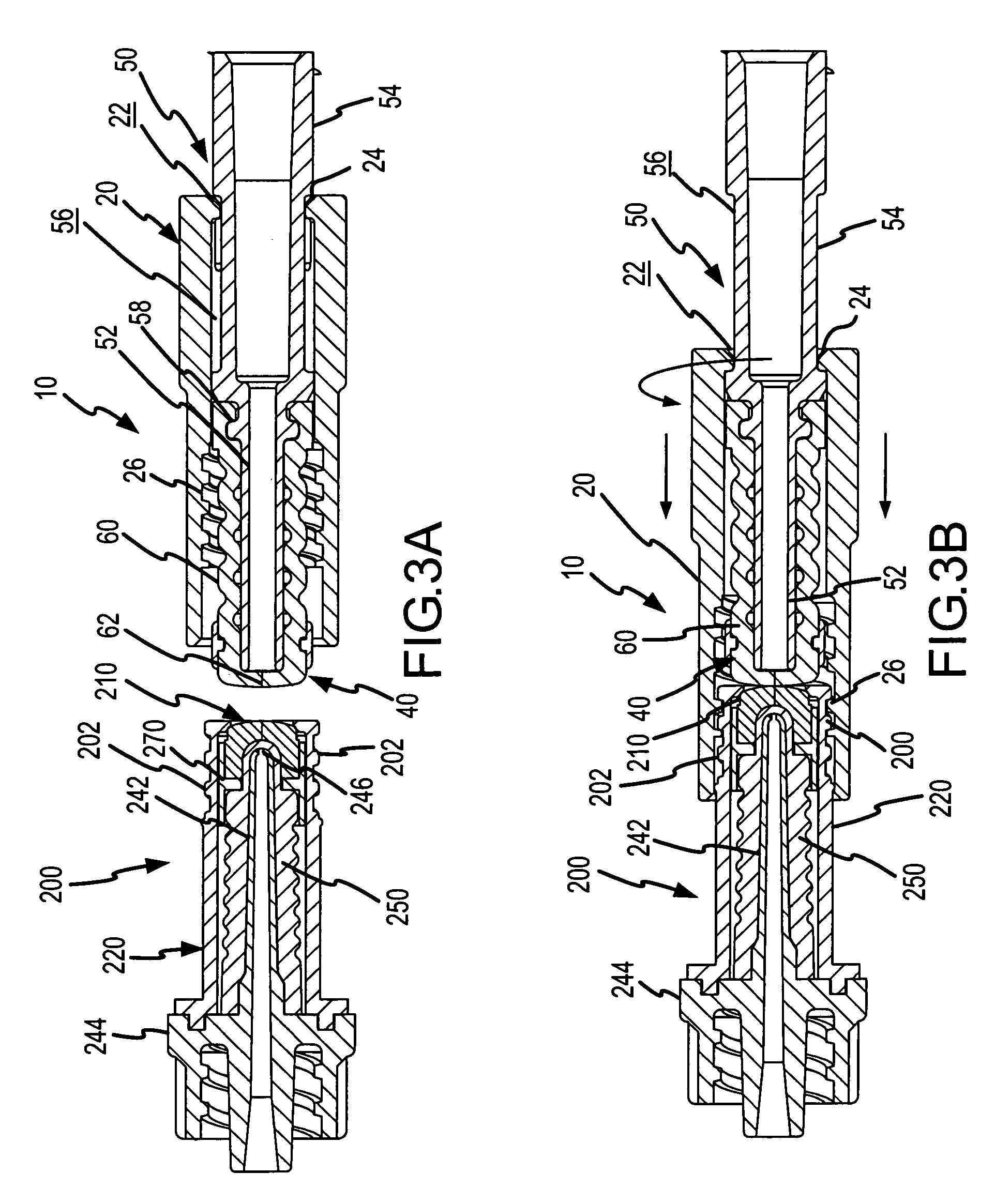

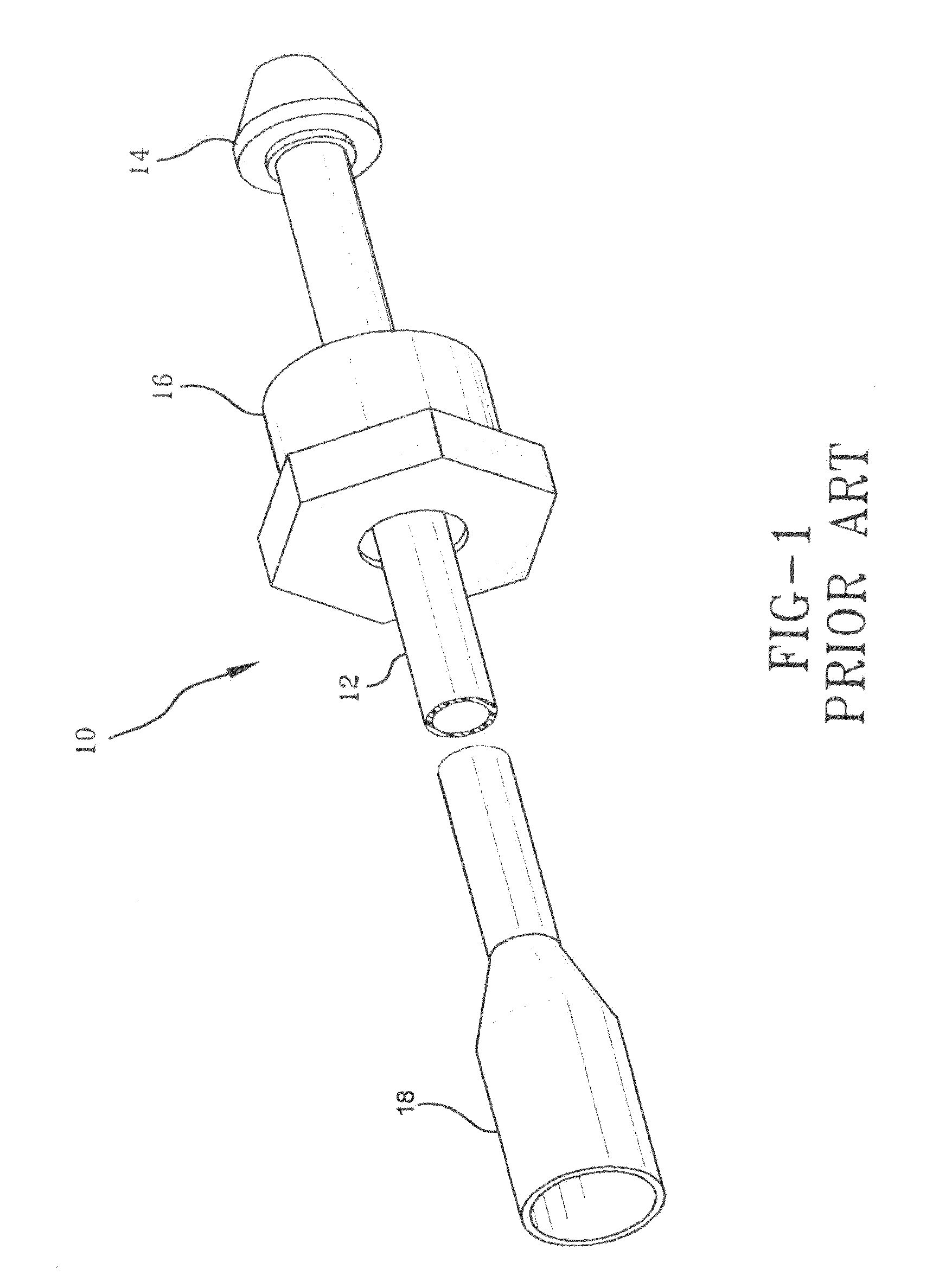

High pressure capillary connector

InactiveUS6926313B1Small sizeHigh strengthSleeve/socket jointsPositive displacement pump componentsCatheterHigh pressure

A high pressure connector capable of operating at pressures of 40,000 psi or higher is provided. This connector can be employed to position a first fluid-bearing conduit that has a proximal end and a distal end to a second fluid-bearing conduit thereby providing fluid communication between the first and second fluid-bearing conduits. The connector includes (a) an internal fitting assembly having a body cavity with (i) a lower segment that defines a lower segment aperture and (ii) an interiorly threaded upper segment, (b) a first member having a first member aperture that traverses its length wherein the first member aperture is configured to accommodate the first fluid-bearing conduit and wherein the first member is positioned in the lower segment of the internal fitting assembly, and (c) a second member having a second member aperture that traverses its length wherein the second member is positioned in the upper segment of the fitting assembly and wherein a lower surface of the second member is in contact with an upper surface of the first member to assert a compressive force onto the first member and wherein the first member aperture and the second member aperture are coaxial.

Owner:SANDIA NAT LAB

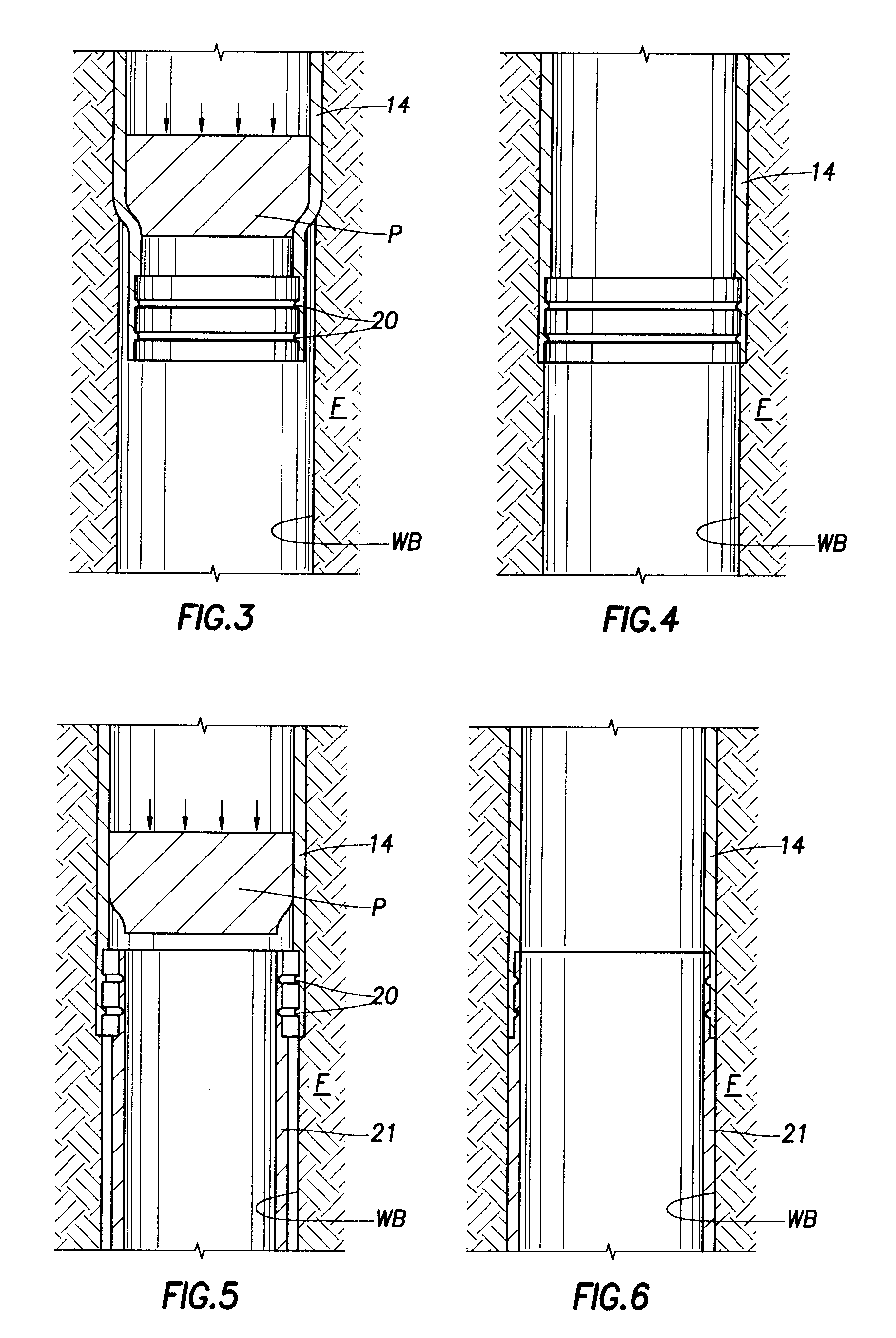

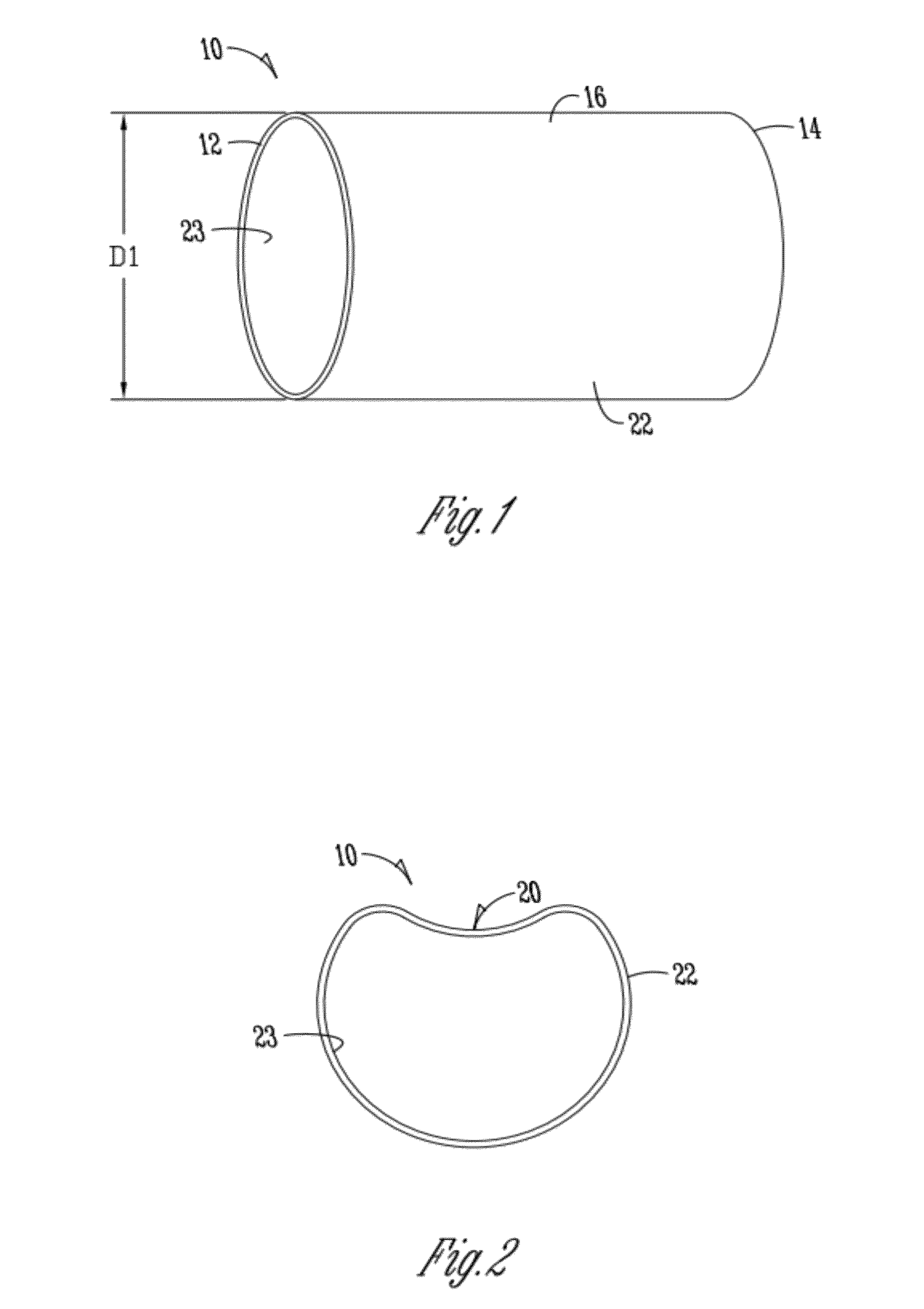

Apparatus and method for sealing pipes and underground structures

ActiveUS20120267863A1Prevent water infiltrationReduce manufacturing costSleeve/socket jointsEngine sealsCompressible materialEngineering

An apparatus and method for sealing pipes or underground structures is provided. In one embodiment, the end of a pipe is sealed by the use of a pipe liner and a sealing member. The sealing member may be a hydrophilic material, a hydrophobic material, a compressible material, or a paste. The sealing member is held in place by a mechanical fastener and a liner is installed adjacent the sealing member and against the wall of the pipe or other structure to be sealed. In another embodiment, a manhole is sealed by the use of a sealing member, a mechanical fastener, and a manhole liner.

Owner:LMK TECH LLC

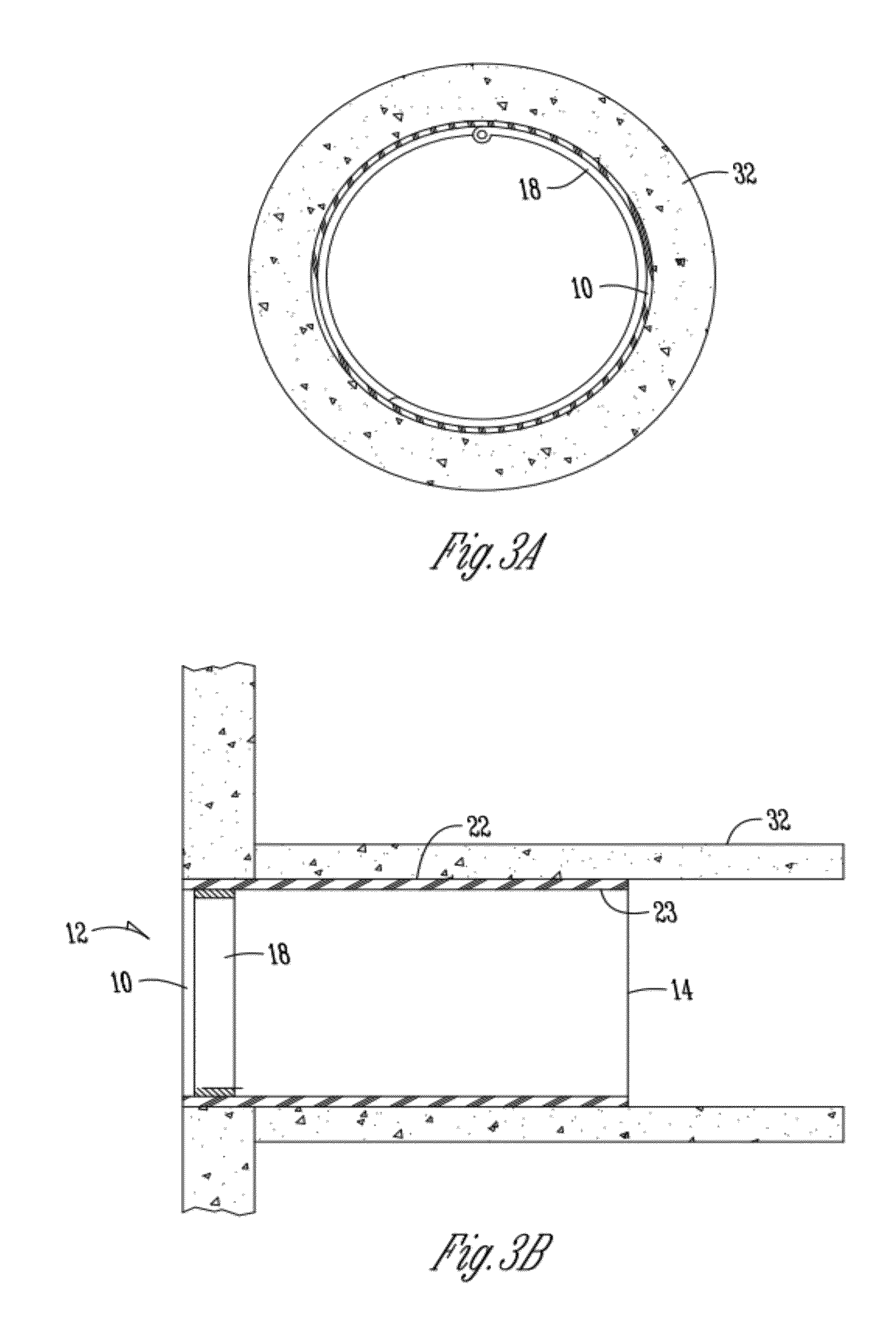

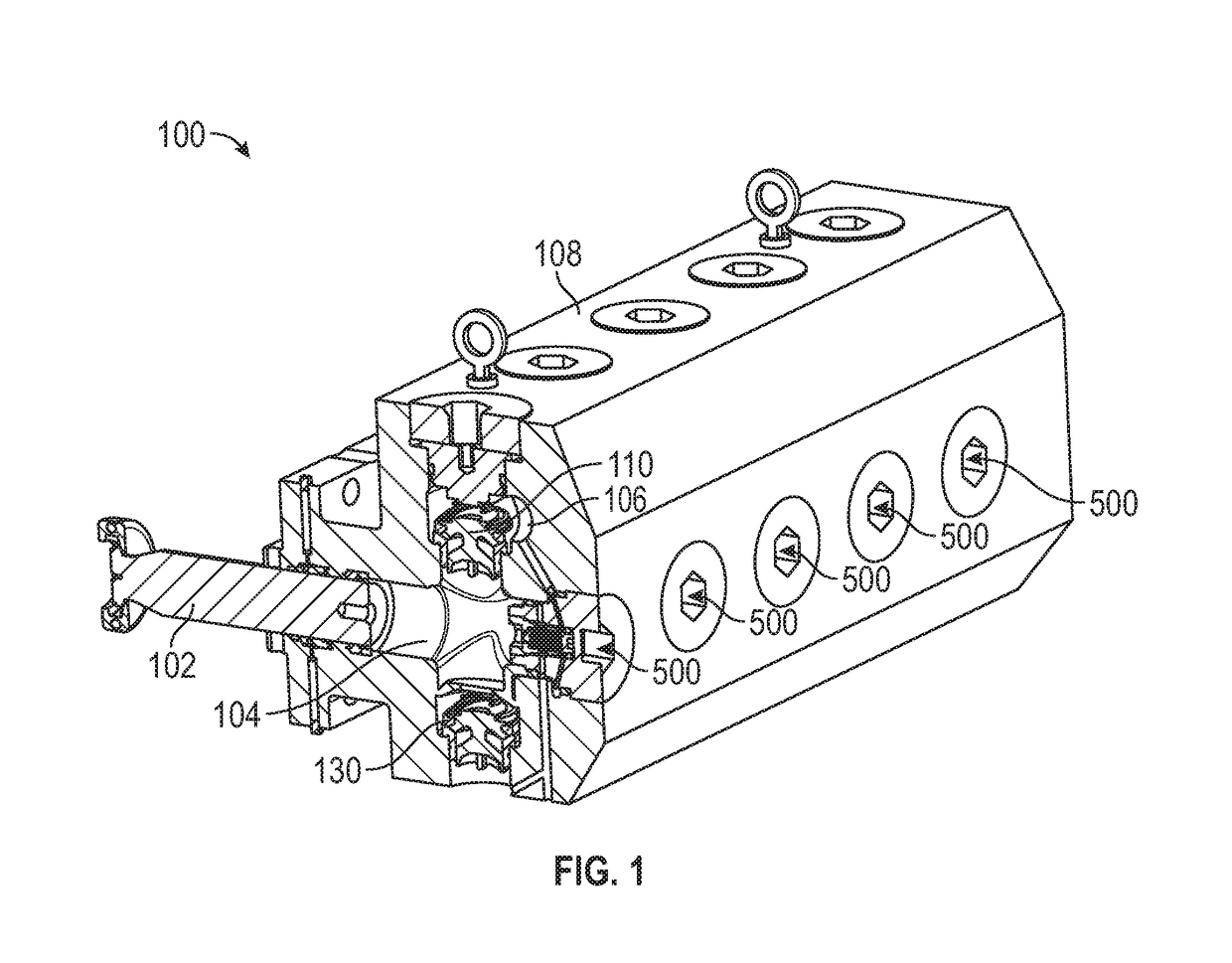

Over pressure relief system for fluid ends

ActiveUS10082137B2Fluid pressure sealed jointsPositive displacement pump componentsInlet pressurePiston

A relief valve assembly includes a housing assembly defining a chamber therein. The relief valve assembly includes a piston. The piston may be at least partially disposed within the chamber. The relief valve assembly includes a pilot inlet. The pilot inlet may be configured to provide a pilot pressure proximate a second end of the chamber. The relief valve assembly includes an overpressure inlet sealed from a first end of the chamber by the piston. The overpressure inlet may be configured to provide an inlet pressure which may actuate the piston when the inlet pressure exceeds the pilot pressure.

Owner:CATERPILLAR INC

Pipe fittings

A pipe fitting for coupling together opposed ends of two plastics pipes by fusion welding, the pipe fitting comprising an annular body having an inner cylindrical surface of plastics material surrounding a cylindrical cavity for receiving opposed ends of two plastics pipes to be coupled together, an electrically conductive coil provided in said inner cylindrical surface and surrounding the cylindrical cavity, the coil having opposed ends, a pair of terminals each connected to a respective end of the coil and provided on the body for connection to a source of controlled electrical power, and an annular reinforcing member disposed in the body and surrounding the coil, the annular reinforcing member having a grooved surface which interfaces the annular body, the grooved surface defining a plurality of axially facing surfaces.

Owner:FINA RES SA

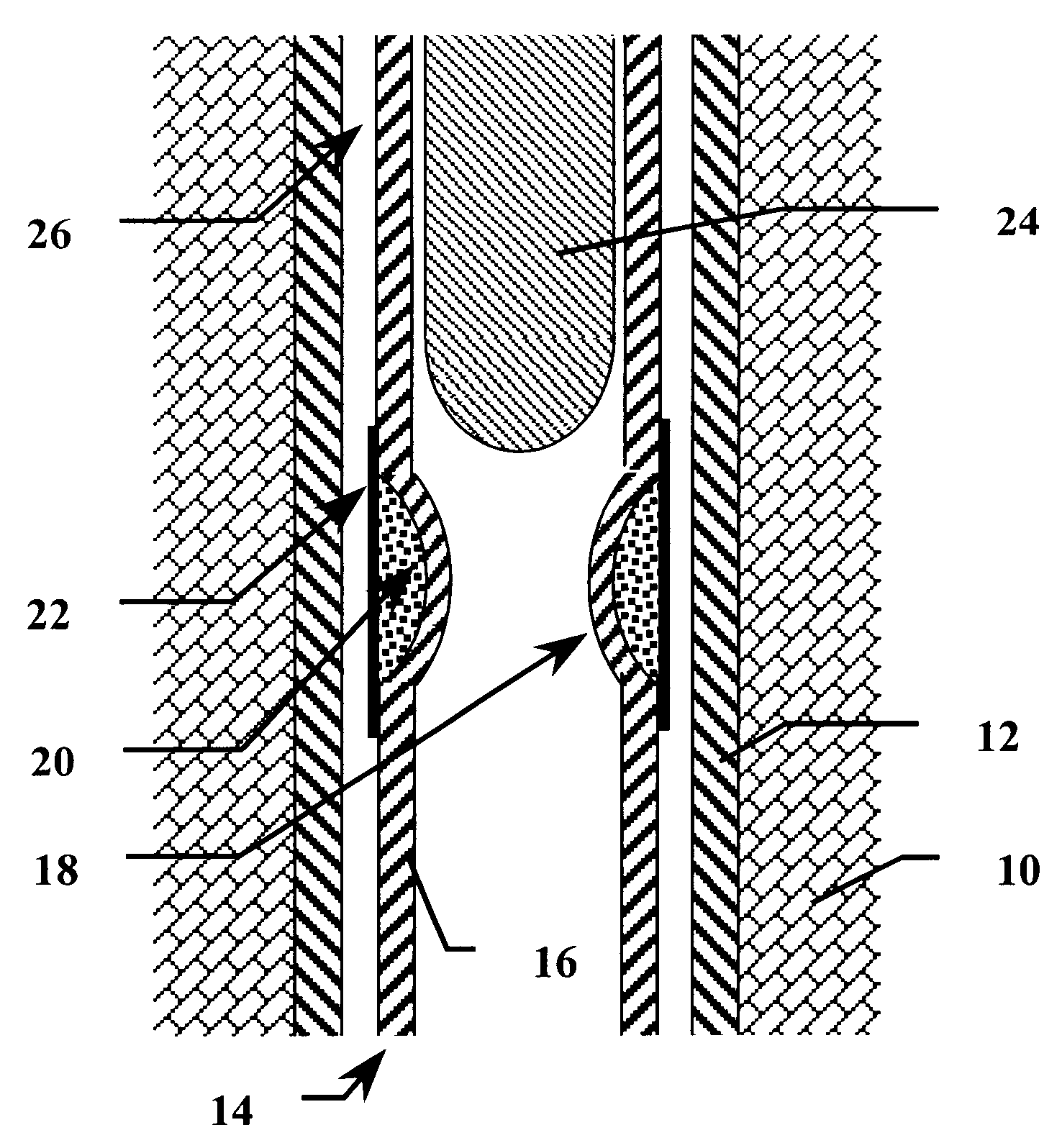

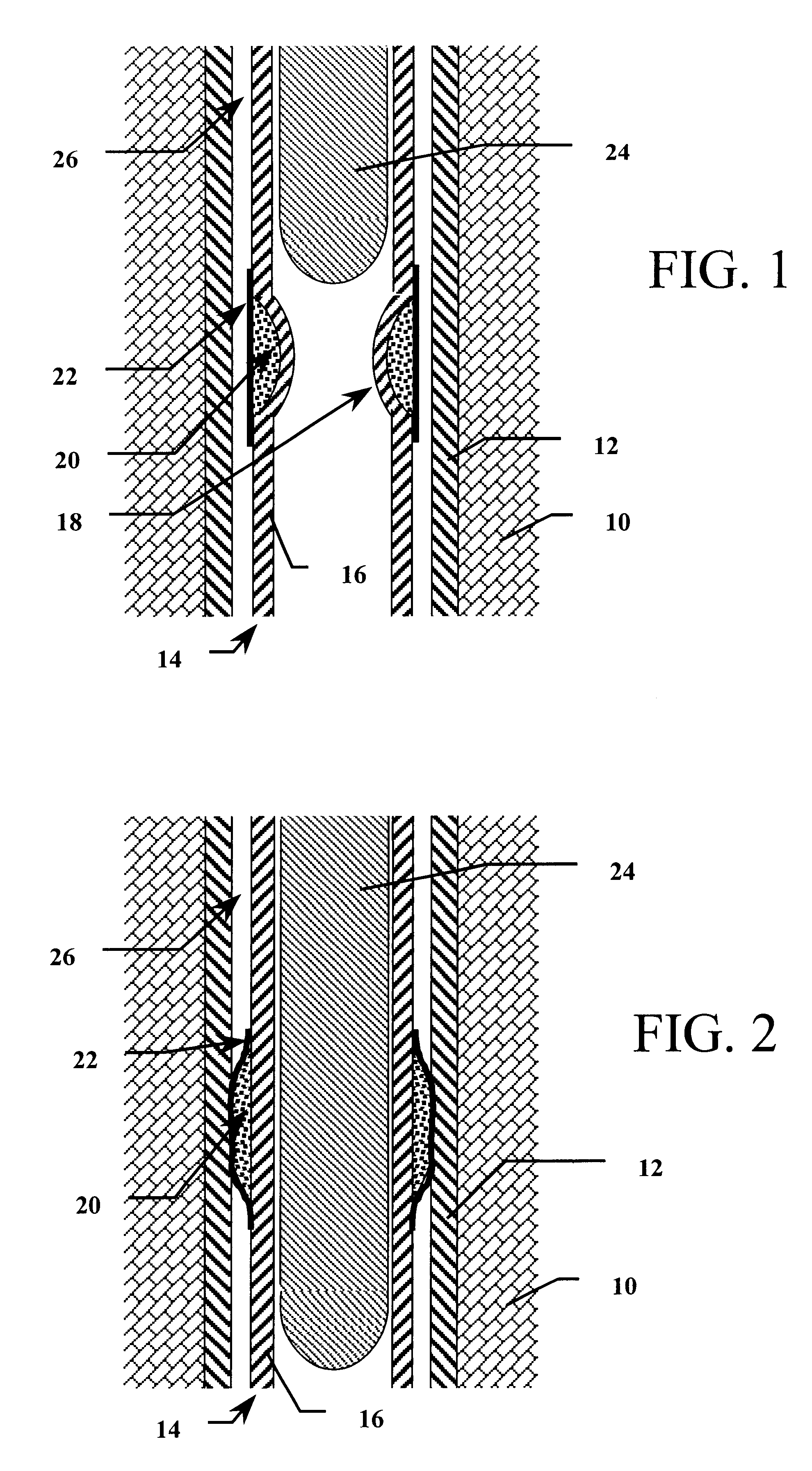

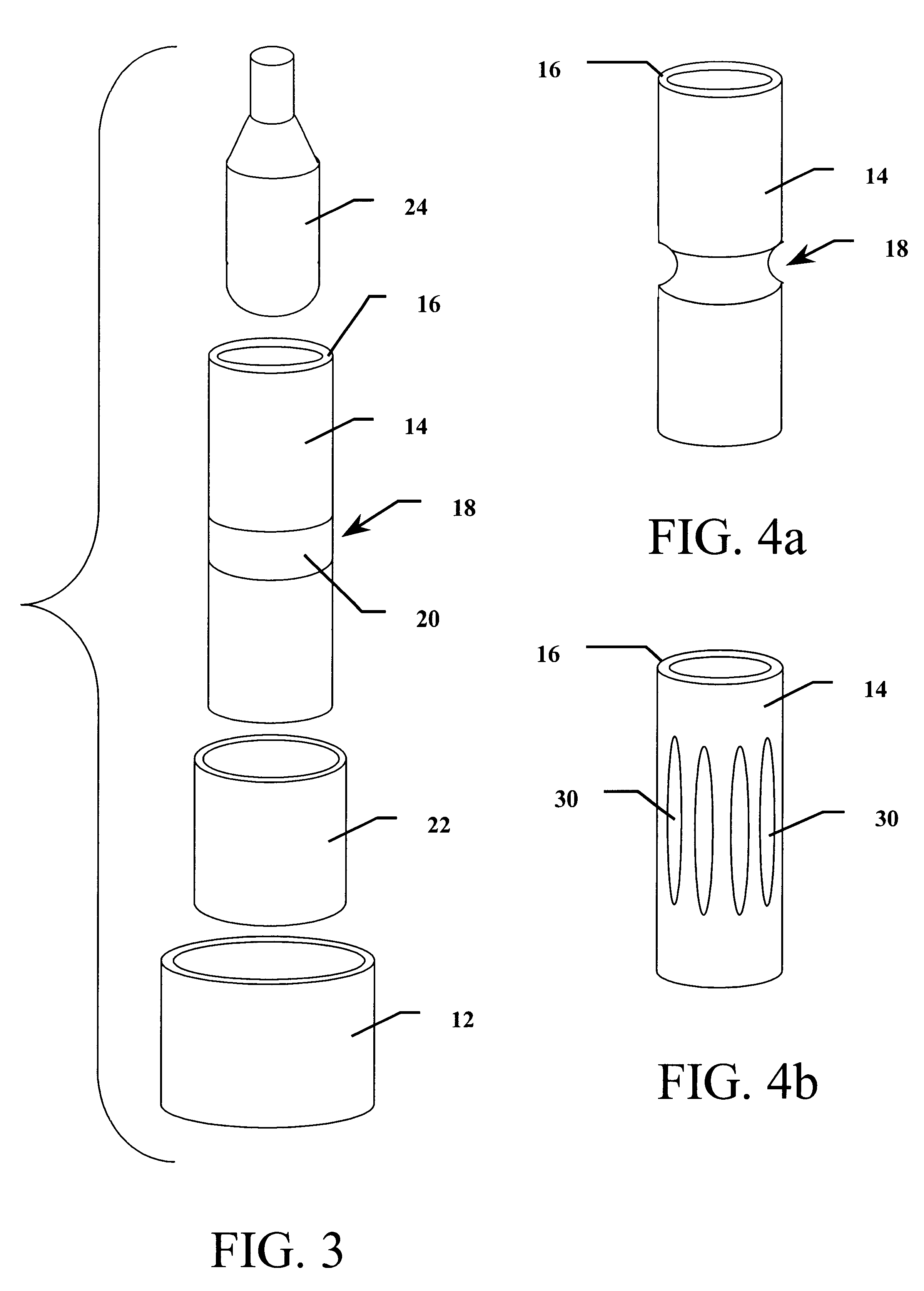

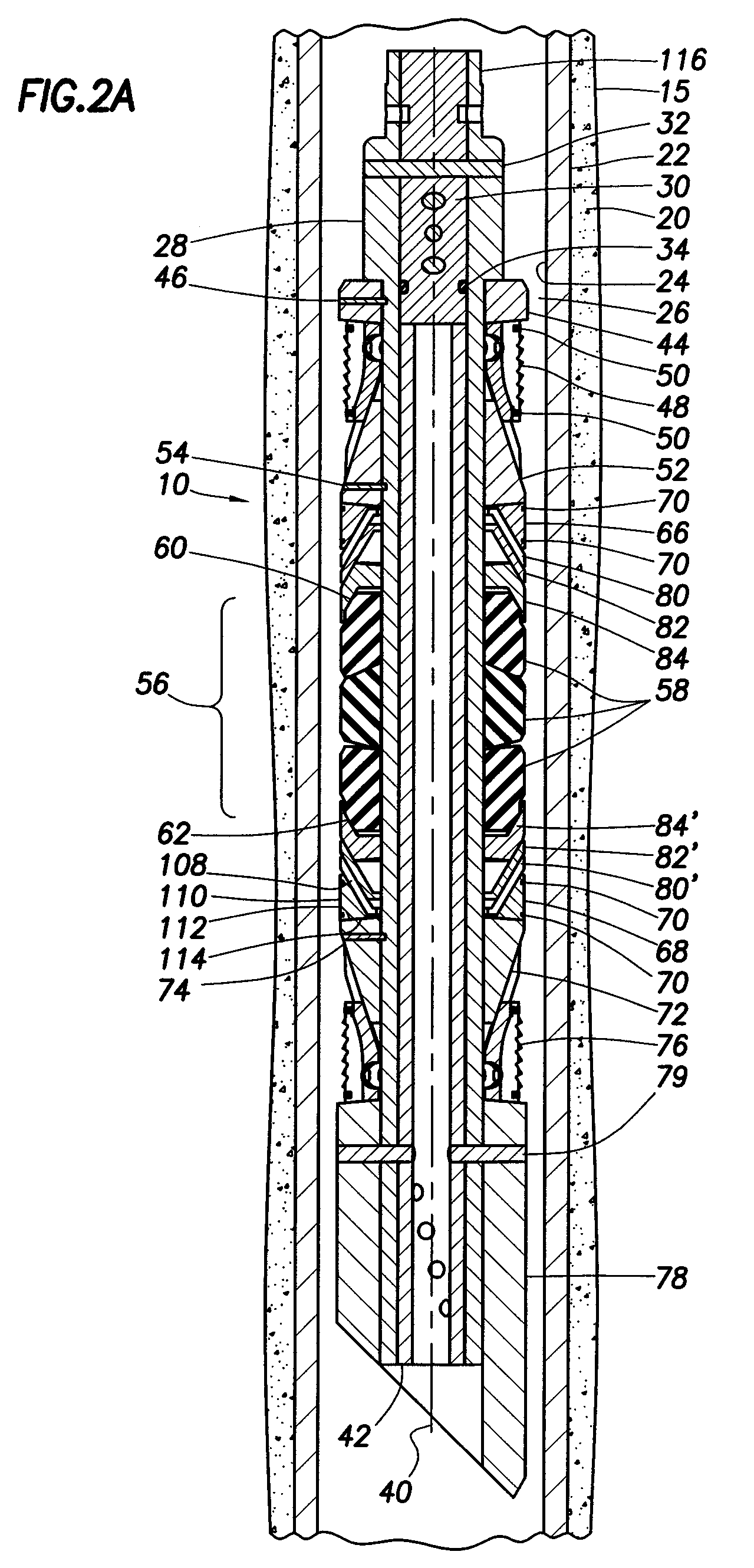

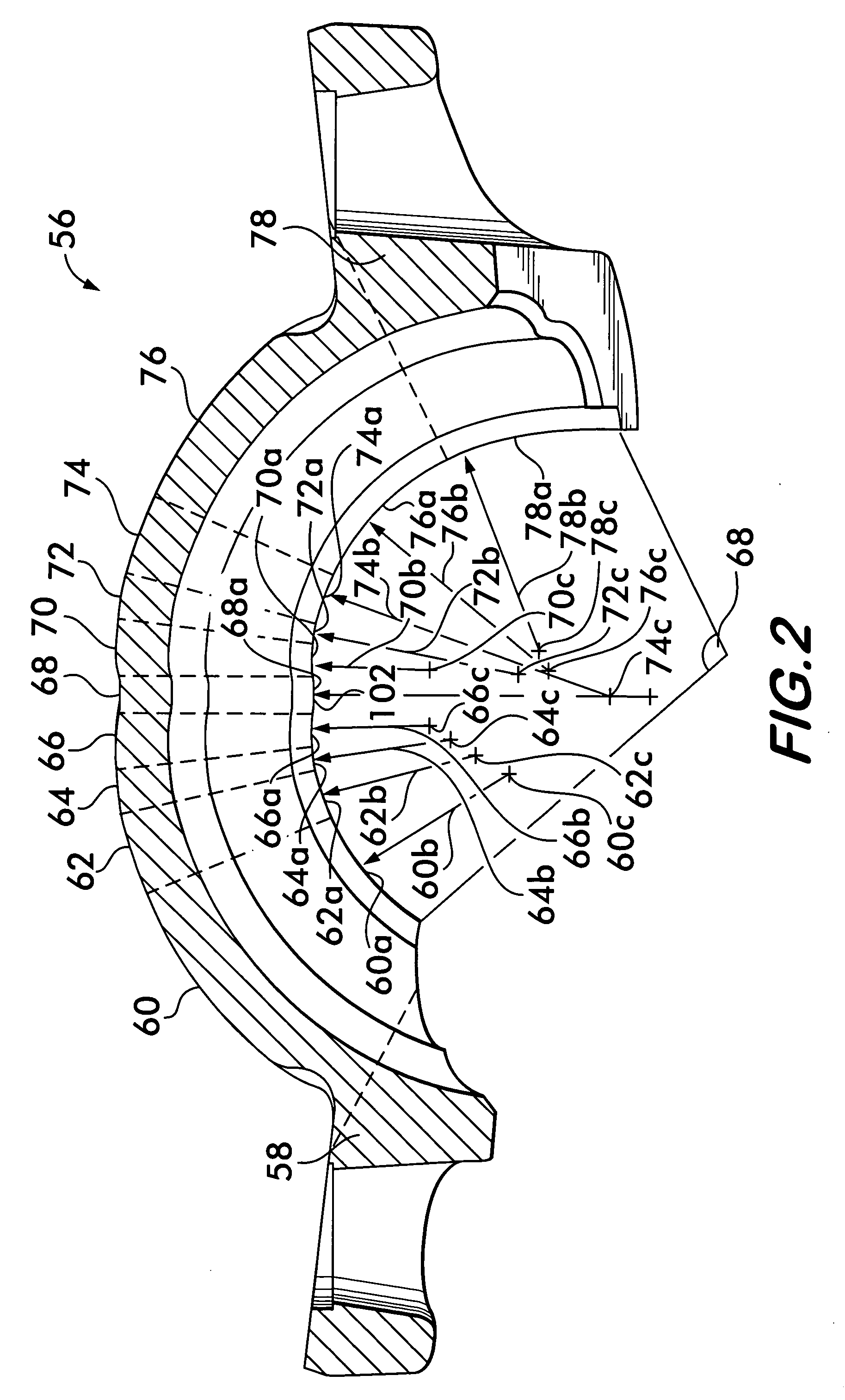

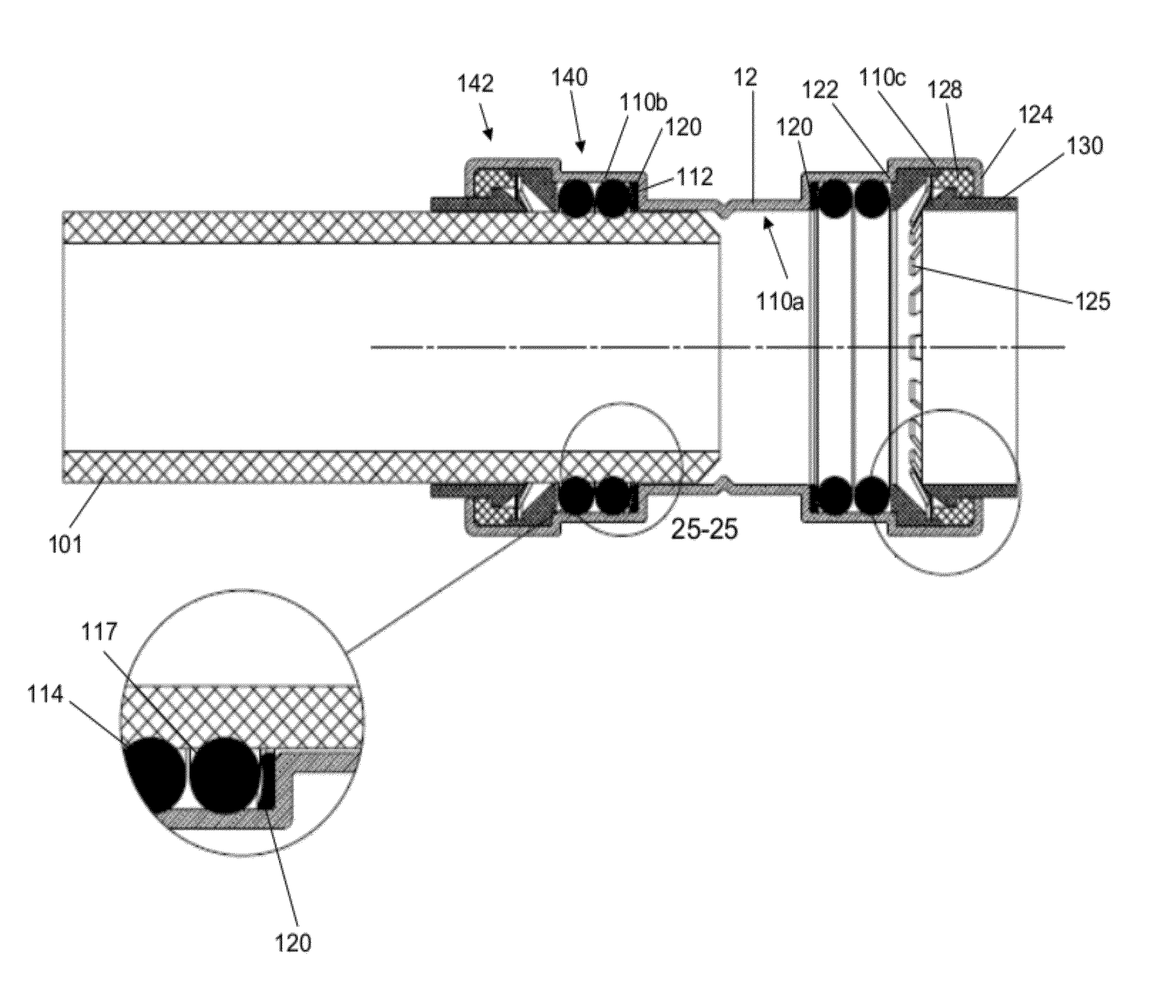

Method and apparatus for expansion sealing concentric tubular structures

InactiveUS6530574B1Resistance to degradationReduce the possibilitySleeve/socket jointsEngine sealsEngineeringSealant

A device and method for sealing a first cylinder in a fixed position inside a second concentric cylinder. The inner cylinder has an annular depression in its wall at the point of sealant placement, which causes the wall of the inner cylinder to intrude inwardly. The depression is filled with a partially compressible fluid and is covered over by a malleable / ductile sleeve. The inner cylinder is placed within the outer cylinder with the covered annular depression positioned at the desired sealing point. A cylindrical displacement device is directed through the inside of the inner cylinder where it encounters the intrusion of the annular depression. The displacement device is forced past the annular intrusion and pushes the wall outward. The partially compressible fluid is forced to expand outward under the malleable / ductile cover in a manner that intrudes into the annular space between the inner cylinder and the outer cylinder and into contact with the outer cylinder. The partially compressible fluid has a residual energy sufficient to maintain the sealing element in contact with the outer cylinder.

Owner:BAILEY GARY L +1

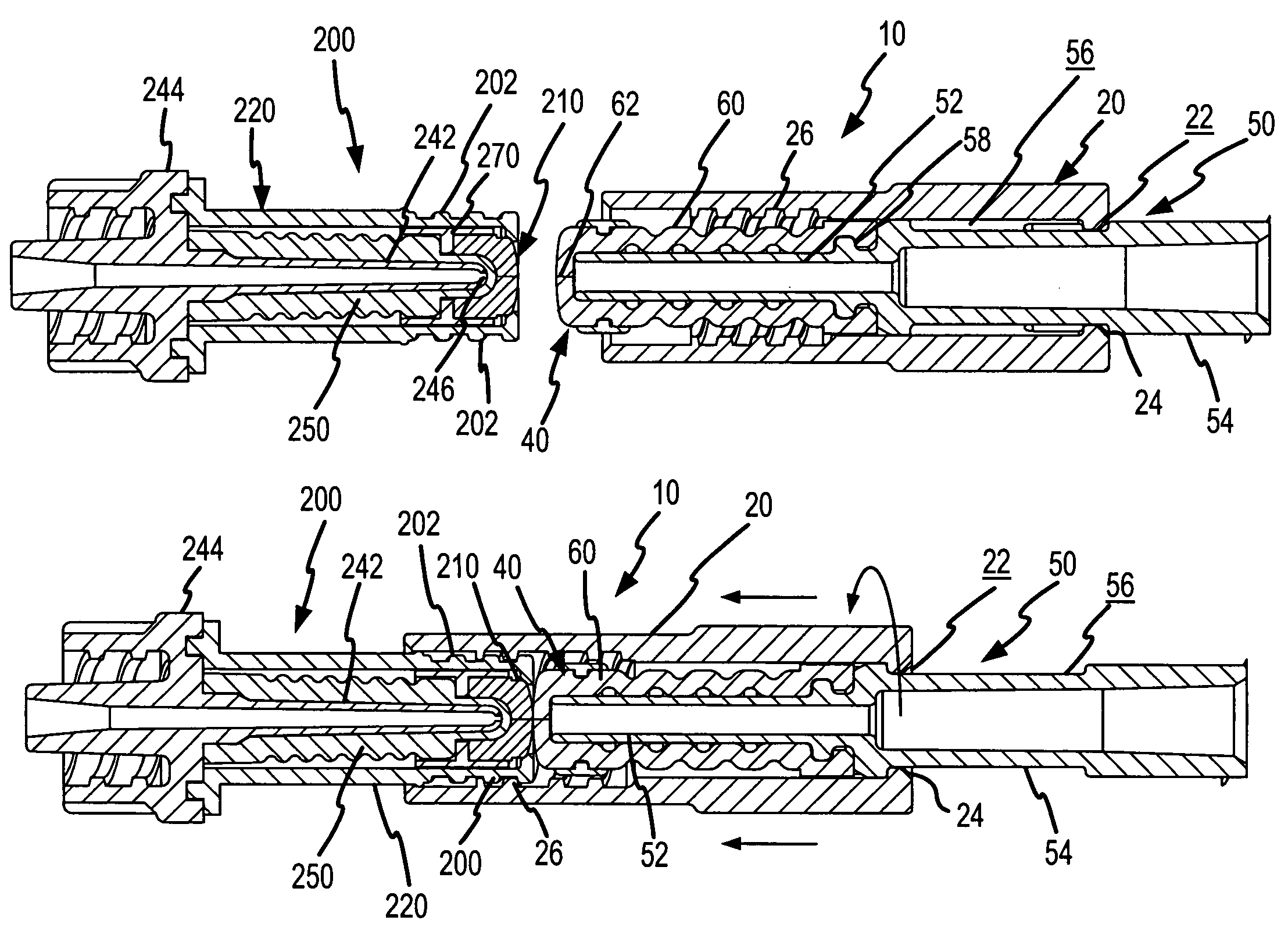

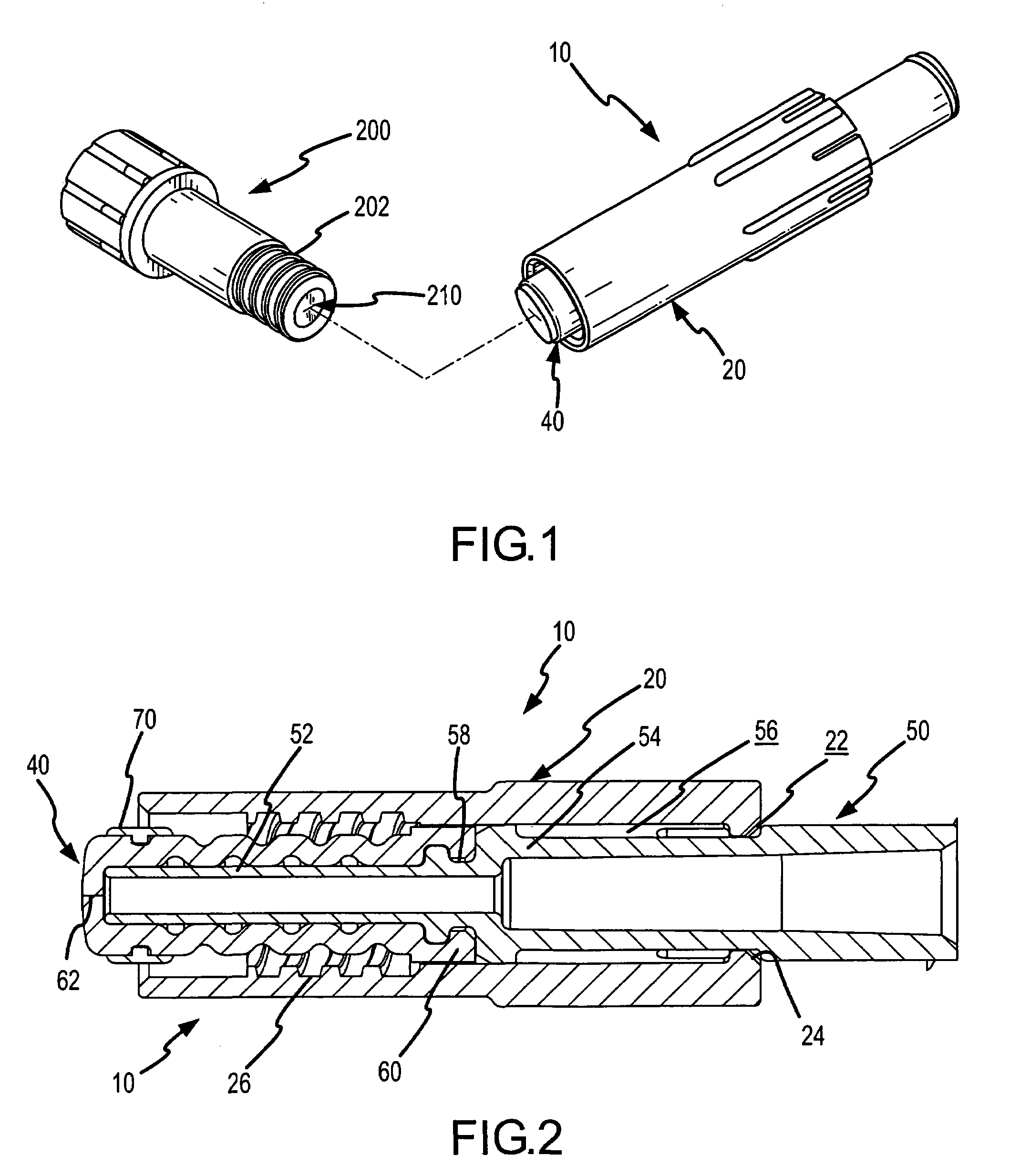

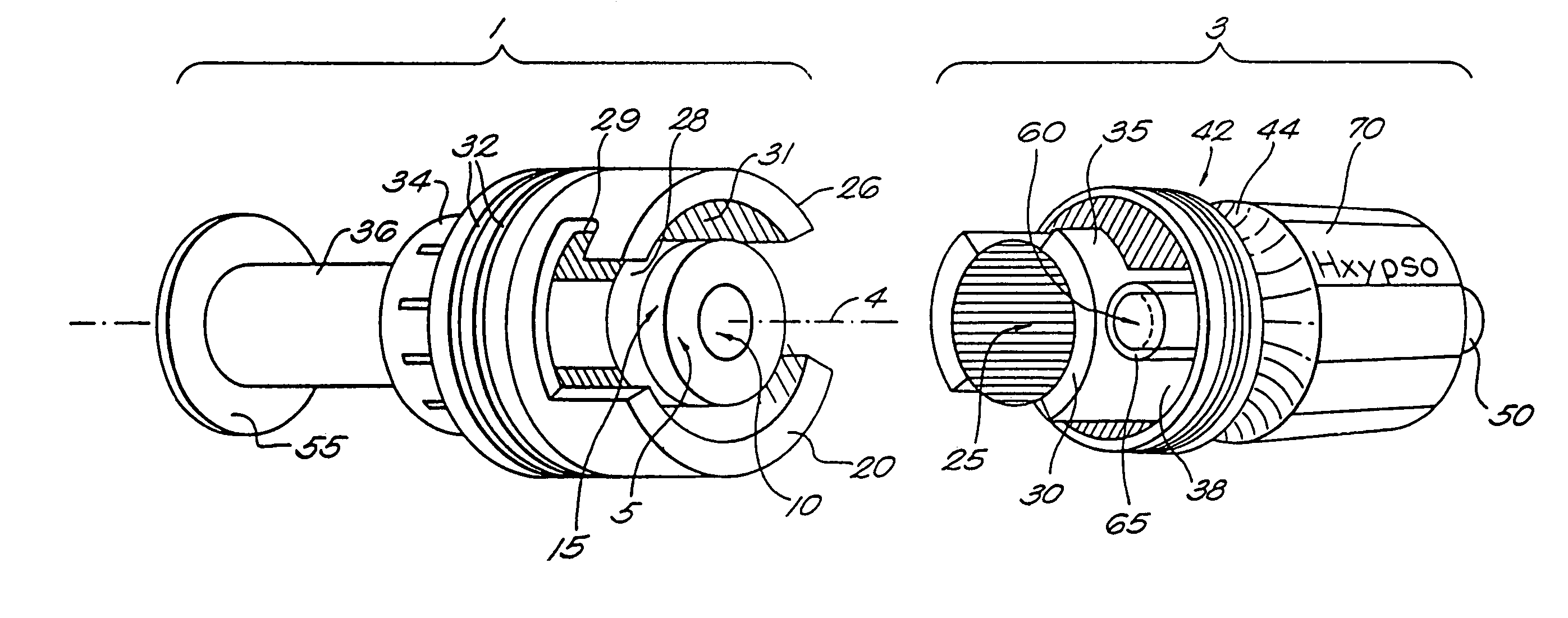

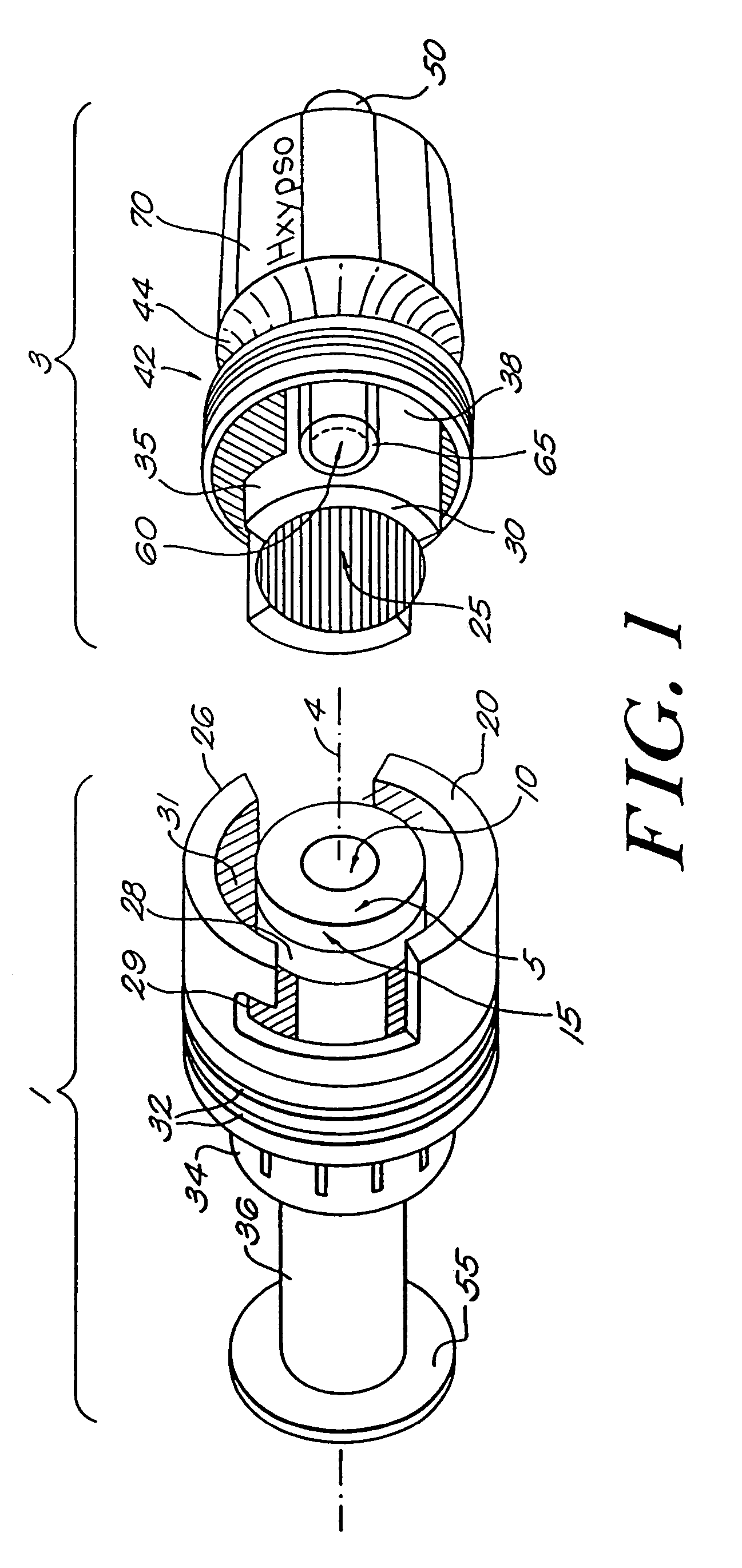

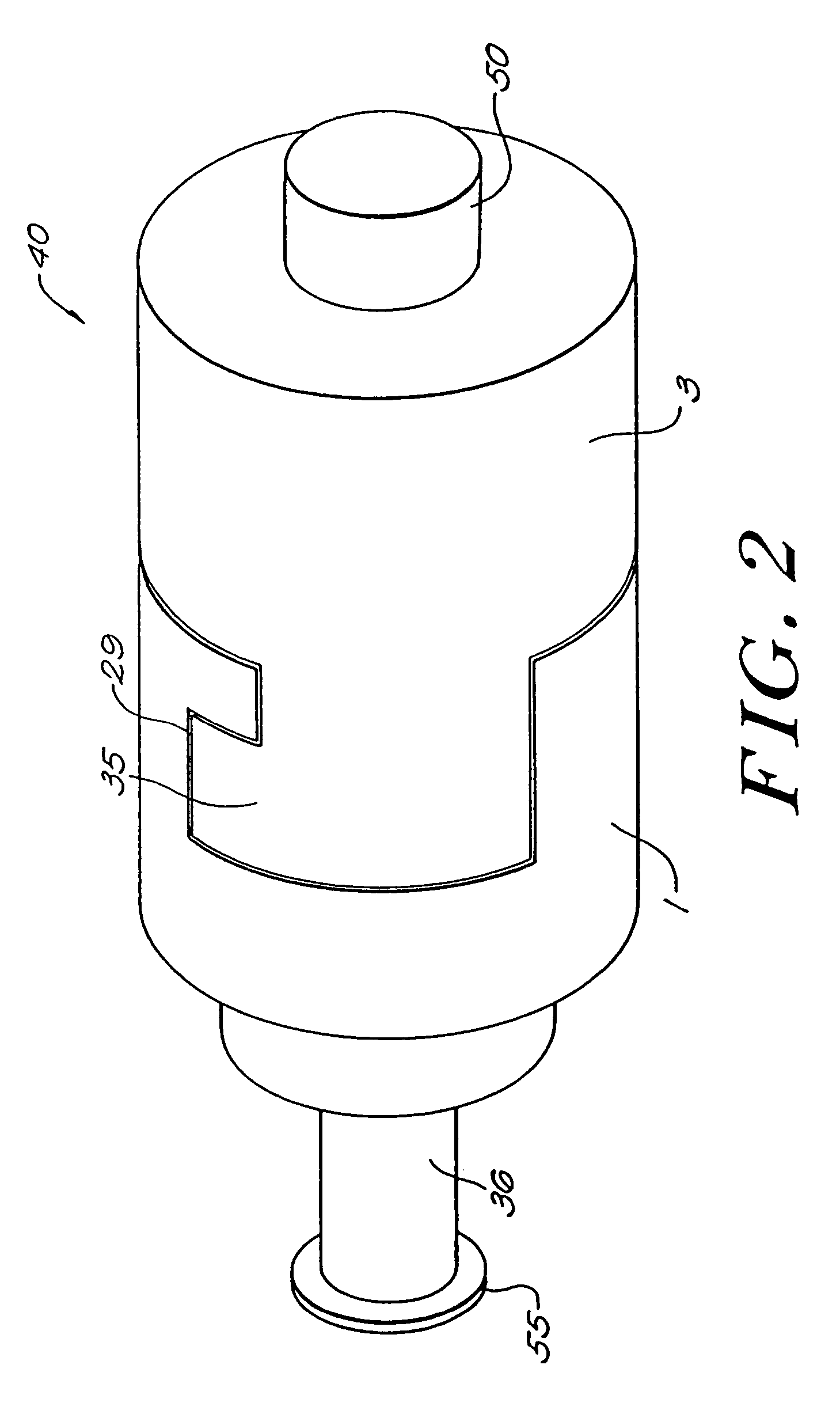

Swabable fluid connectors and fluid connector pairs

InactiveUS7396051B2Easy to cleanReduce the possibilityFluid pressure sealed jointsJoints with sealing surfacesDistal portionInterconnection

A first fluid connector is provided for selective interconnection to and fluid transfer with a second fluid connector. The first connector comprises a fluid passageway, an internal member and an outer collar supportably disposed about the internal member for selective advancement and retraction relative thereto. At least a portion of the fluid passageway may extend through the internal member. The outer collar may be selectively retracted to facilitate cleaning of the internal member. In some embodiments, the outer collar and internal member may be disposed so that a distal portion of the internal member is substantially flush with or a distal portion of internal member projects beyond a distal end of the outer collar when the outer collar is in a retracted position relative thereto. To facilitate cleaning, a distal end or distal portion of the internal member may be substantially closed when the first and second connectors are disconnected. The second connector may be adapted to facilitate fluid interconnection with the first connector, and may also present a cleanable distal end when disconnected.

Owner:BAXTER ENGLEWOOD

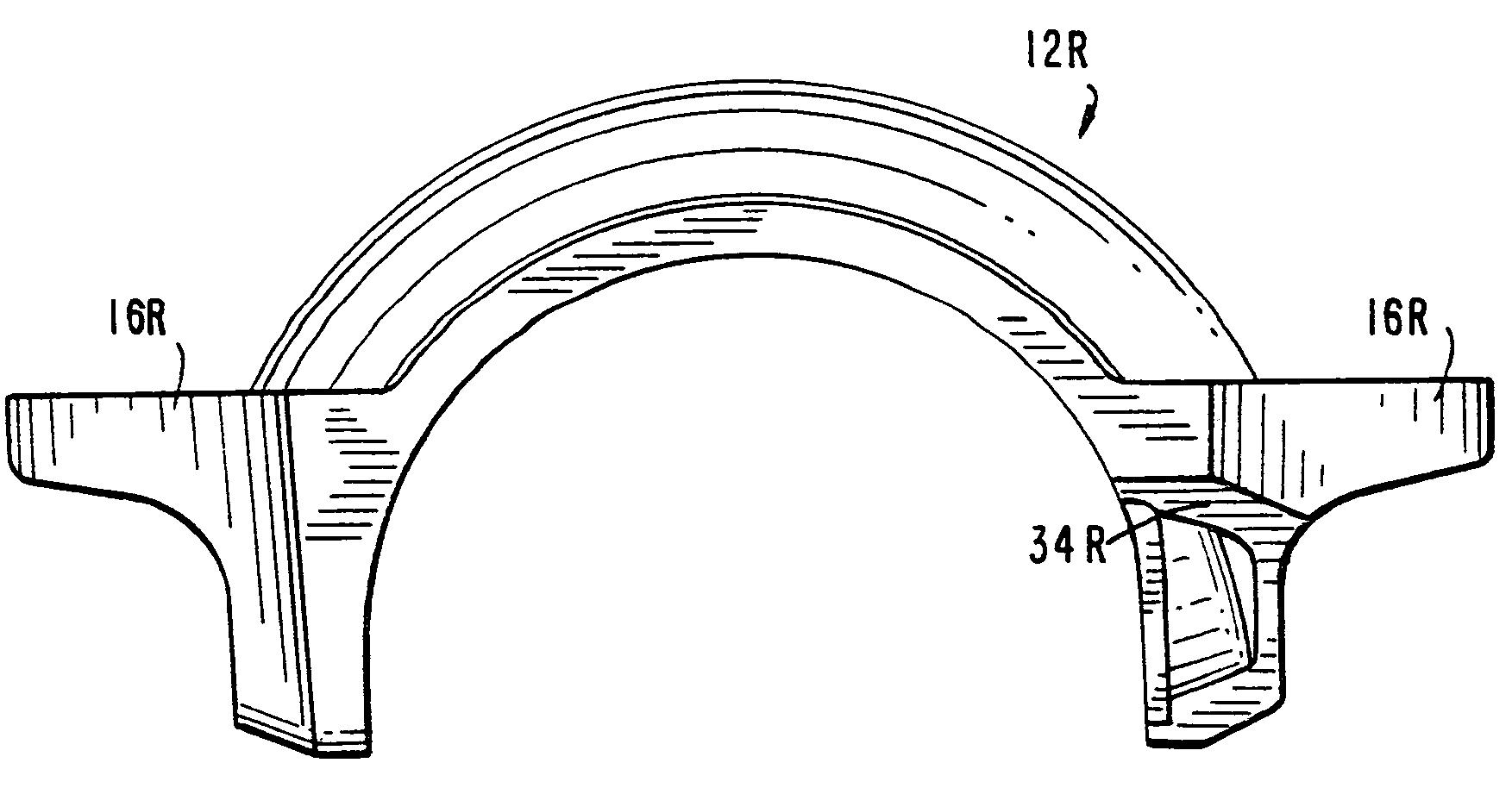

Anti-mismatch of near-sized coupling segments

A series of successively sized segmented arcuate pipe couplings in which anti-mismatch members are provided to prevent the inadvertent connection of two different, but closely sized coupling segments together. The anti-mismatch features are provided on the ends of the arcuate coupling segments which (a) will nest when the proper coupling segments are brought together, but (b) will be in an interference non-nested relationship when a mismatch is attempted. This will prevent the fully bolt tightened connection of the size mismatched coupling segments, as well as a visual indication to a user that a size mismatch is being attempted.

Owner:VICTAULIC

Fastening mechanism for medical connectors

InactiveUS7137654B2Eliminate and prevent and reduce occurrenceEasy to useSleeve/socket jointsFluid pressure sealed jointsLocking mechanismGuide tube

A medical connector adapted for placement between a catheter and a medical infusion or injection source includes a pair of interlocking half medical connector portions, one side of which attaches to the infusion source and the other side of which is coupled to the catheter connected to the patient and a locking mechanism for locking a medical connector portion to a medical fitting. The connection to the catheter and the infusion source can be via standard medical luer taper fittings, with or without specially designed locking mechanisms that prevent inadvertent disconnection. The medical connector itself is uniquely shaped and includes a raised surface feature and a recessed surface feature formed on the medical connector portions.

Owner:QD ENTERPRISES LLC

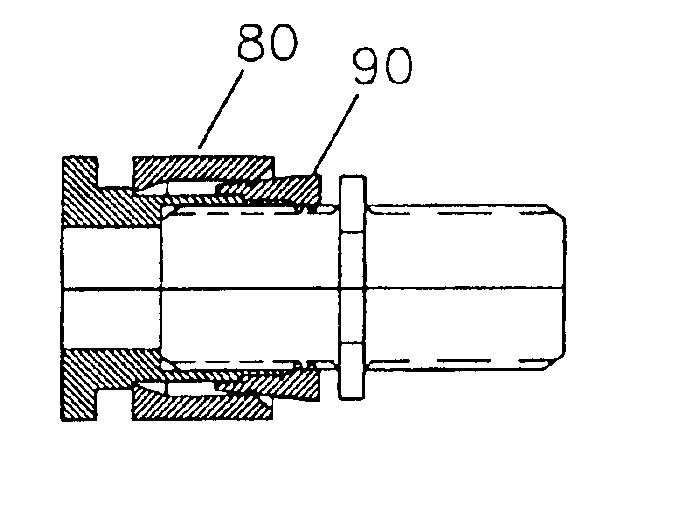

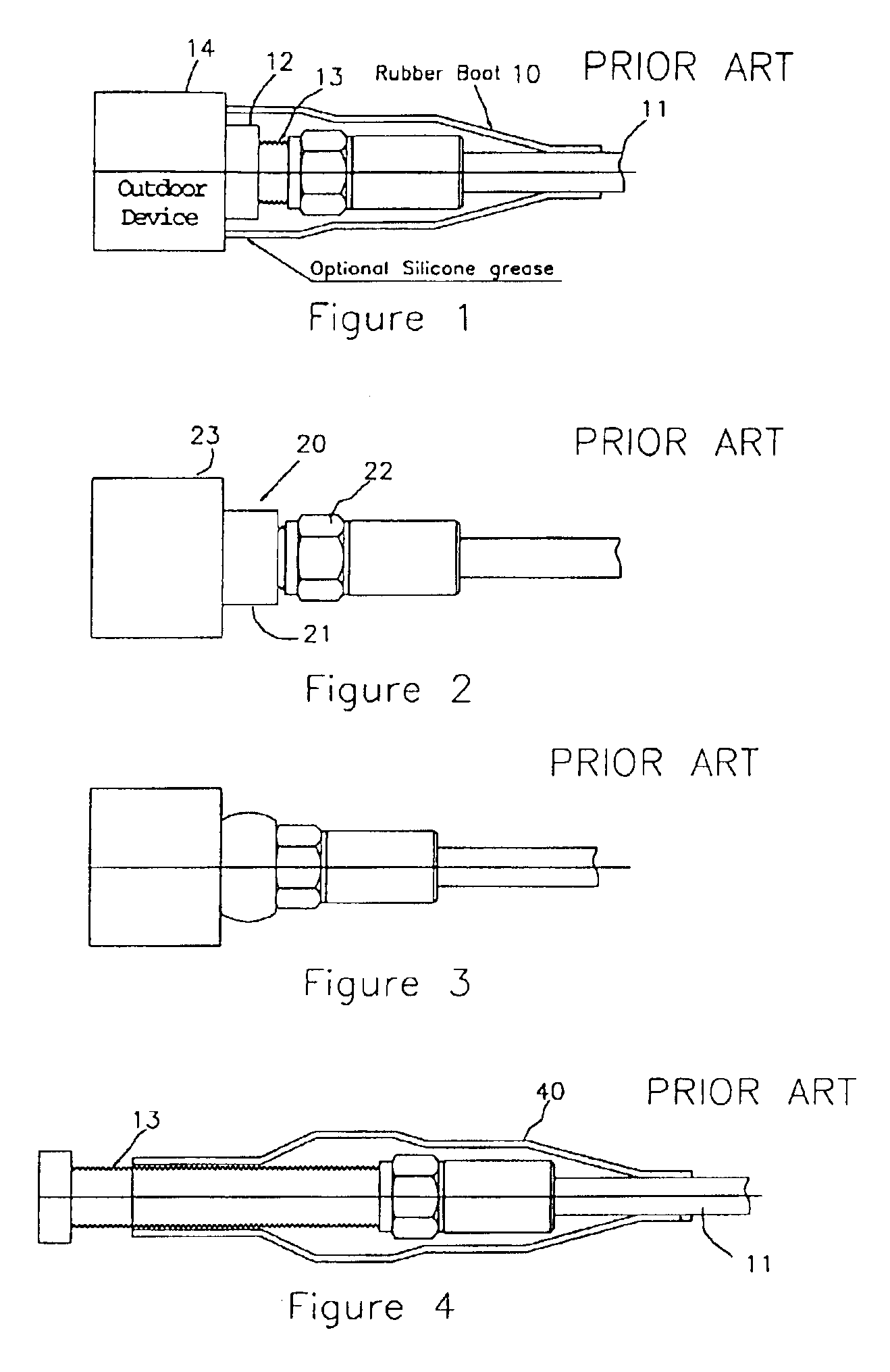

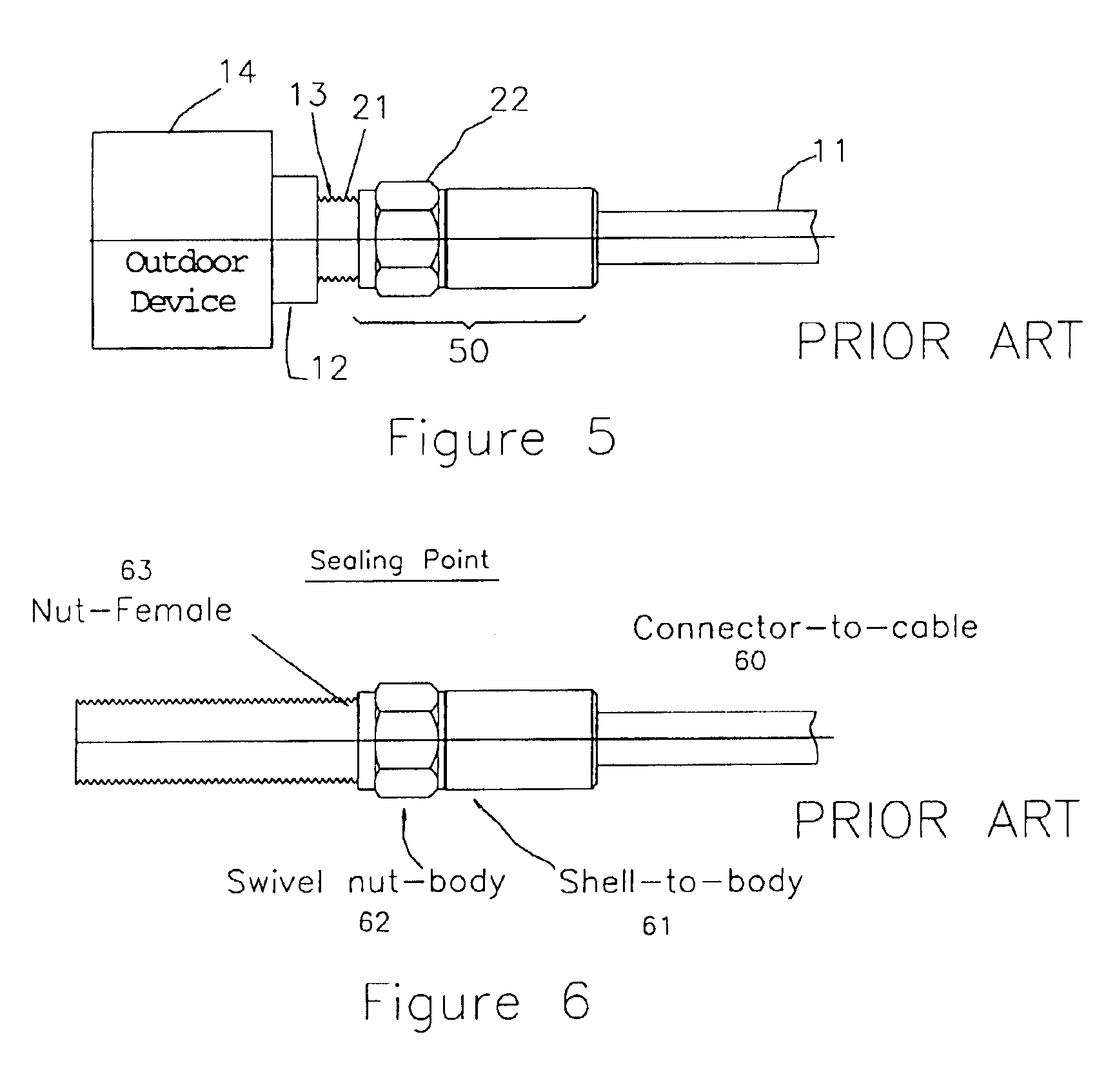

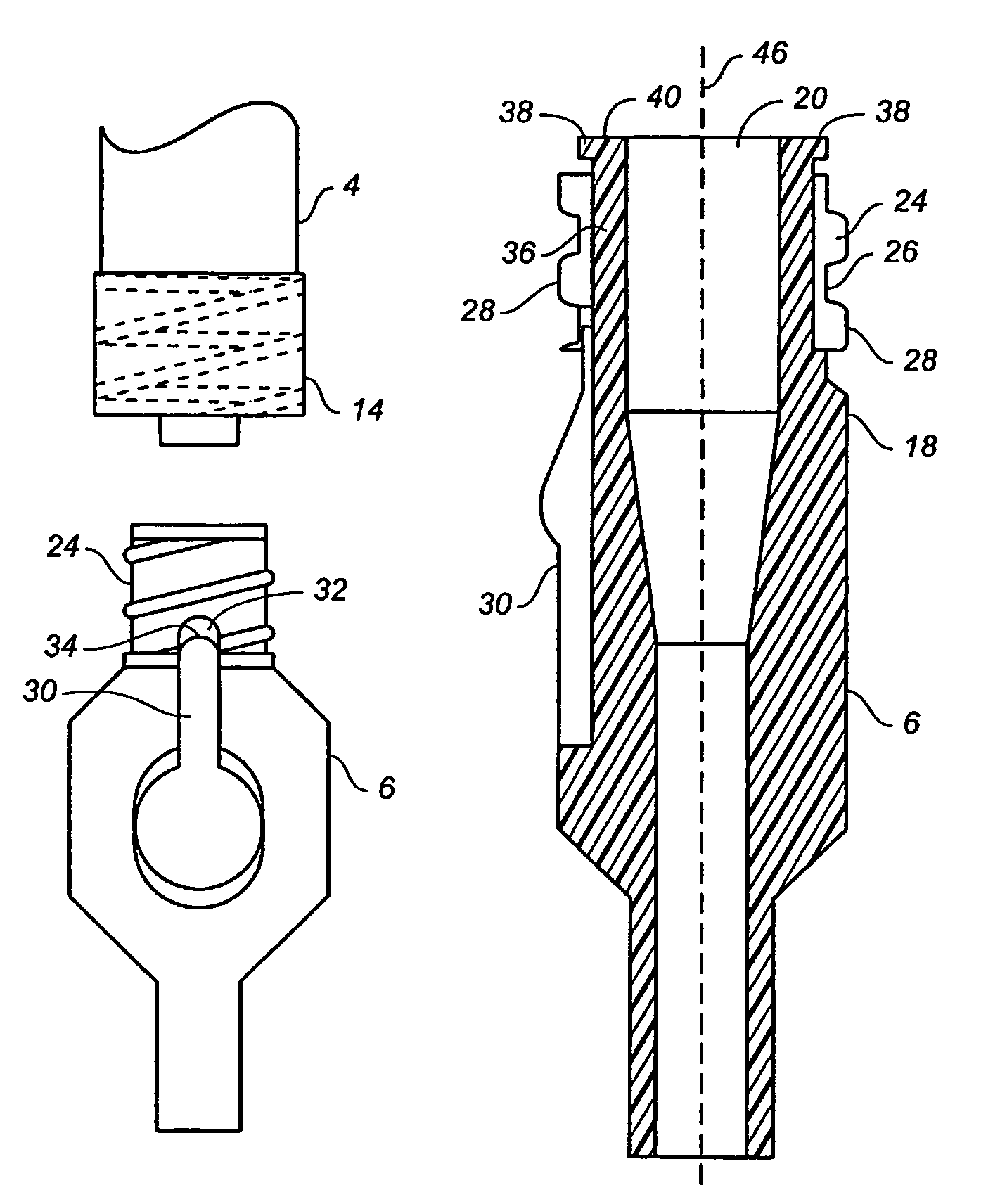

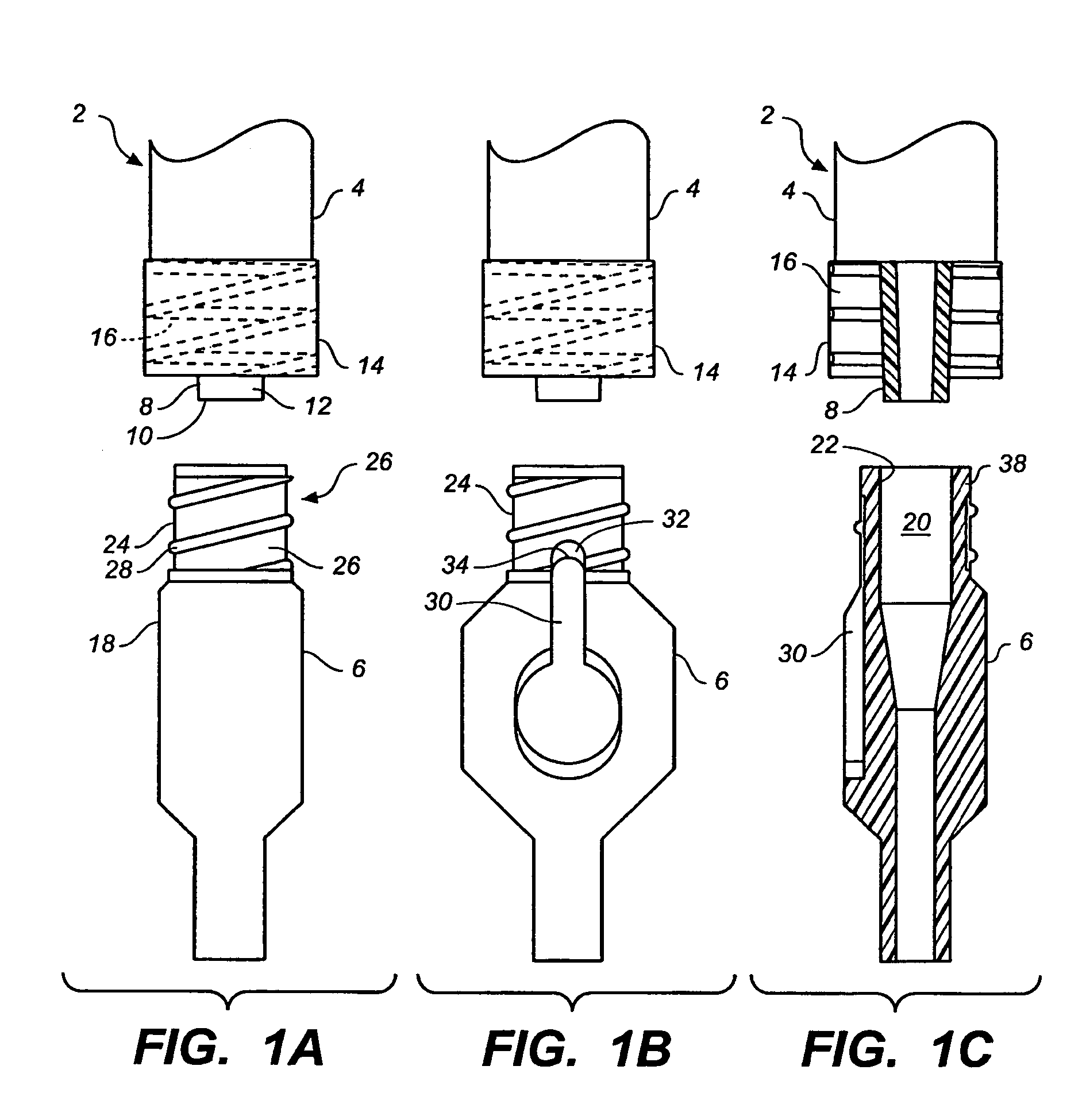

Moisture seal for an F-Type connector

The invention provides a method for moisture sealing the interface between a nut on the leading end of a male F-Type connector and the threaded tubular shaft of the female F connector. The male connector is attached to a coaxial cable and the female is mounted to an outdoor device such as a cable TV splitter, grounding device, satellite dish, or distribution device, amplifier or group. The sealing device includes a compressible portion comprising an elastically compressible member having a cylindrical bore and a conical outer surface. An annular compression ring overlies a portion of the conical outer surface of the compressible portion. The compressible portion is compressed radially inwardly against the shaft of the female F-Type connector as the leading edge of the male F nut is screwed onto the female threaded shaft of the female F-Type connector, providing a pressurized moisture ingress barrier. The compressible portion may have internal 3 / 8-32 threads to mate with threads on the shaft for a more secure seal.

Owner:HOLLAND ELECTRONICS

Locking luer fitting

InactiveUS7347458B2Avoid disconnectionPrevent rotationEngine sealsFluid pressure sealed jointsEngineeringCam

A locking luer fitting for connecting fluid lines. In one variation the connection interface includes a male luer connector and a corresponding female luer connector. The female luer connector includes a rotatable collar which engages the male luer connector. In another variation the female luer connector includes a cam configured to prevent inadvertent disconnection of the male luer connector. The locking luer fittings described herein may be implemented in various medical and industrial applications where secured fluid line connection interfaces are desirable.

Owner:CR BARD INC

Quick connect fastener and connection

A connecting fastener is provided. The fastener includes a cylindrical base that includes a first end and a second end and a wall. A central bore is defined in the base and an aperture is defined in the wall. At least one projection extends from an inner surface of the wall into the central bore proximate the first end of the base. A cylindrical collar has a first end disposed proximate the second end of the base, defines a central bore and includes a wall that defines a gap in the wall and a central bore. A shoulder is connected to and extends between the second end of the base and the first end of the collar along at least a portion of the respective circumferences of the base and the collar. A method of connecting tubing is also provided.

Owner:MERCURY PLASTICS LLC

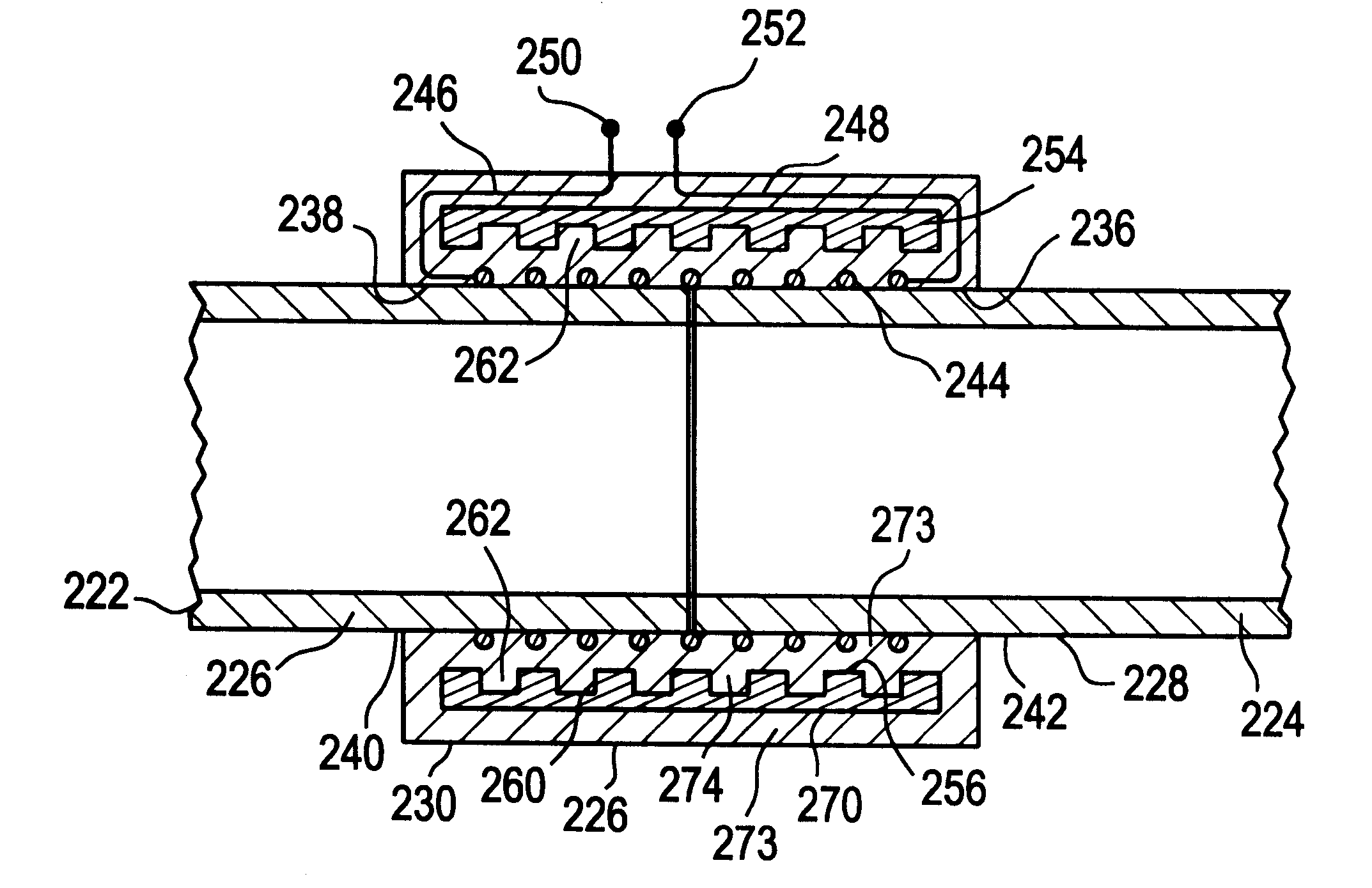

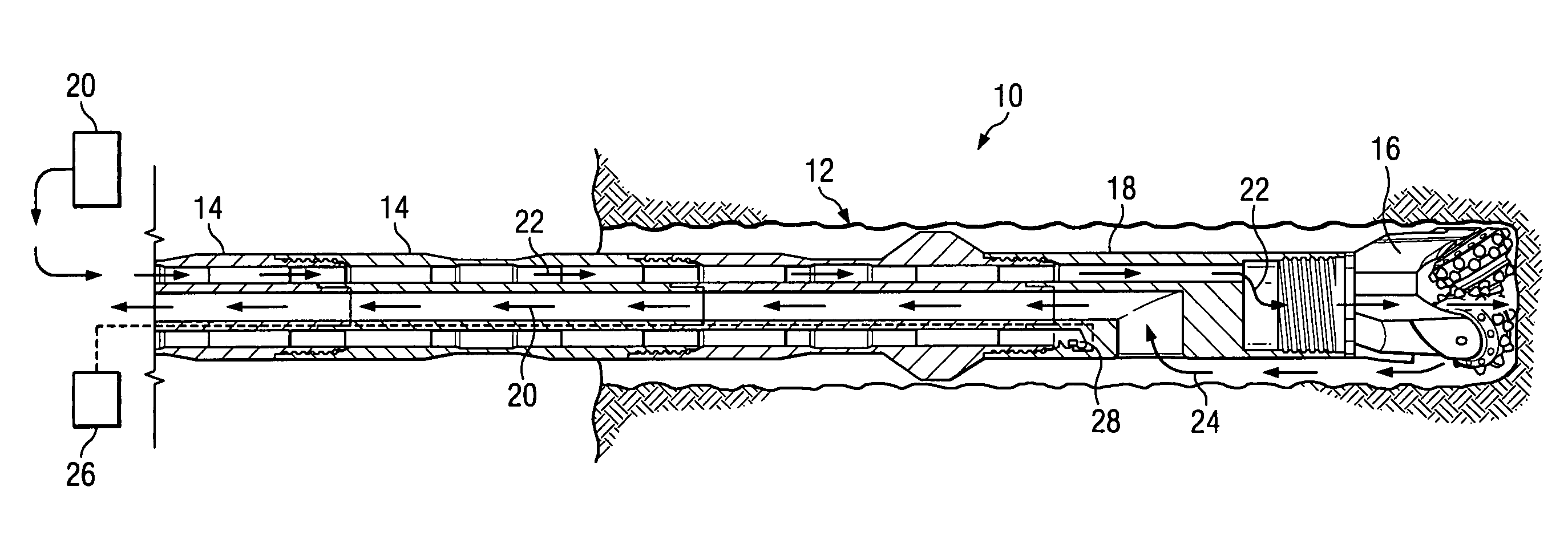

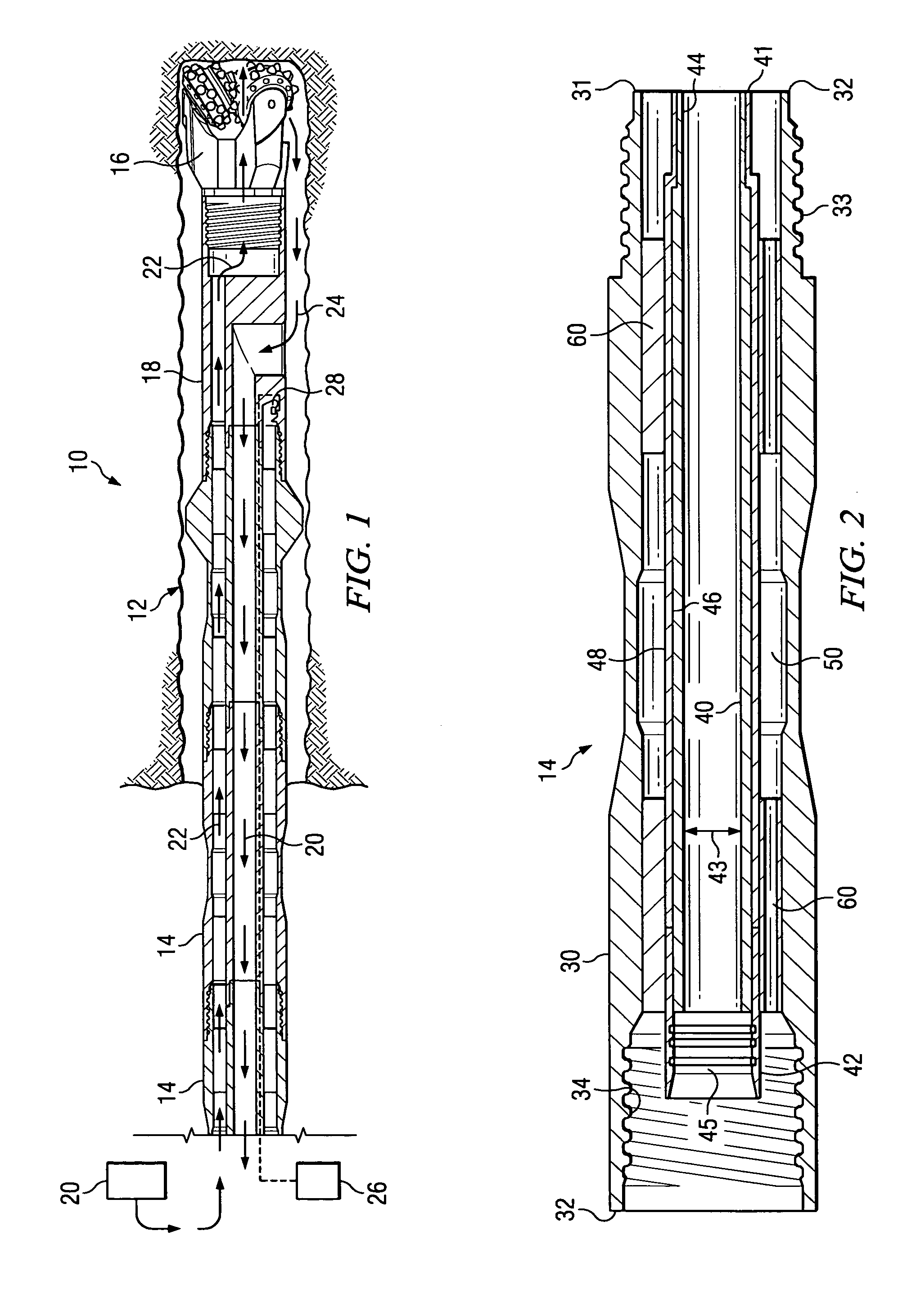

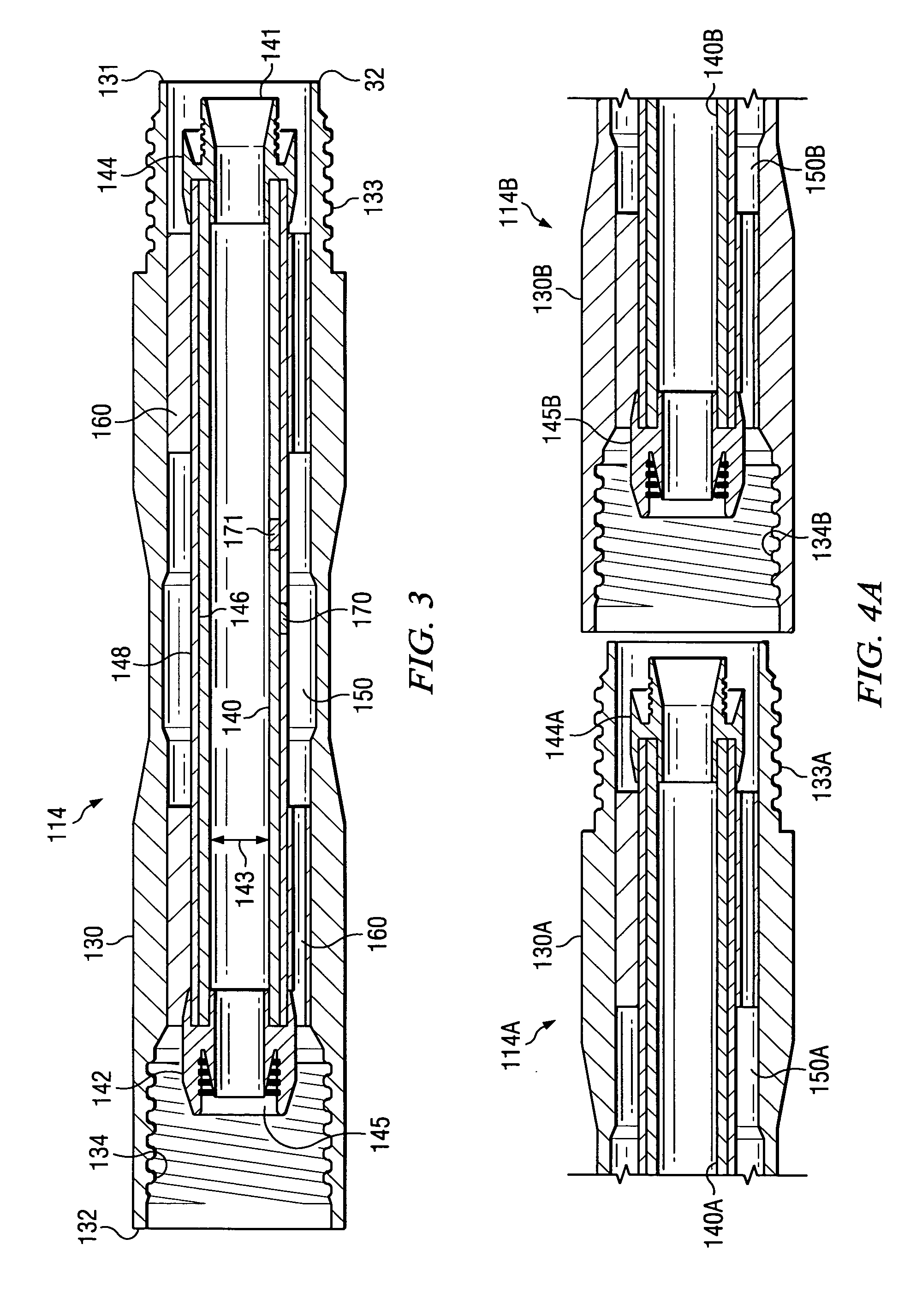

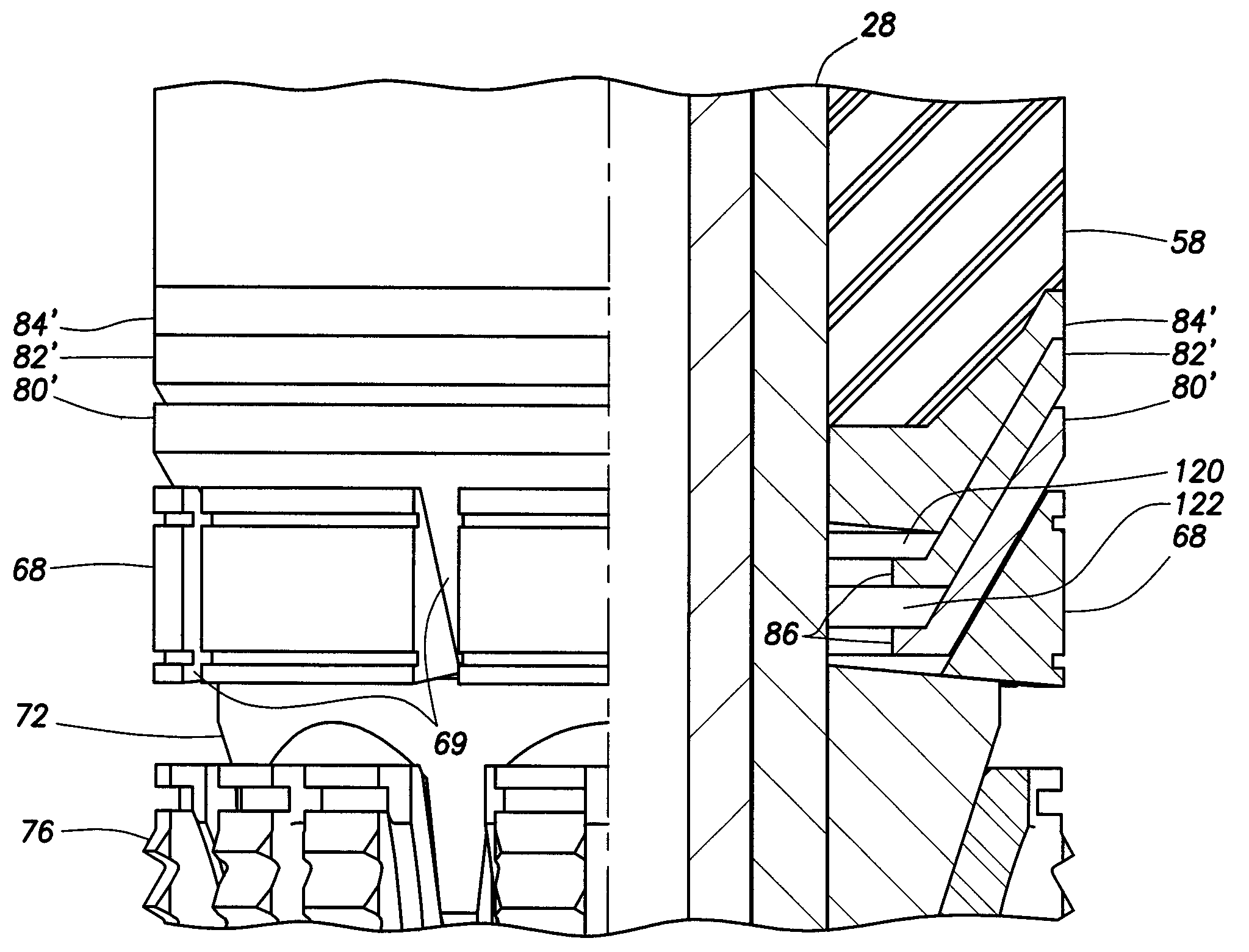

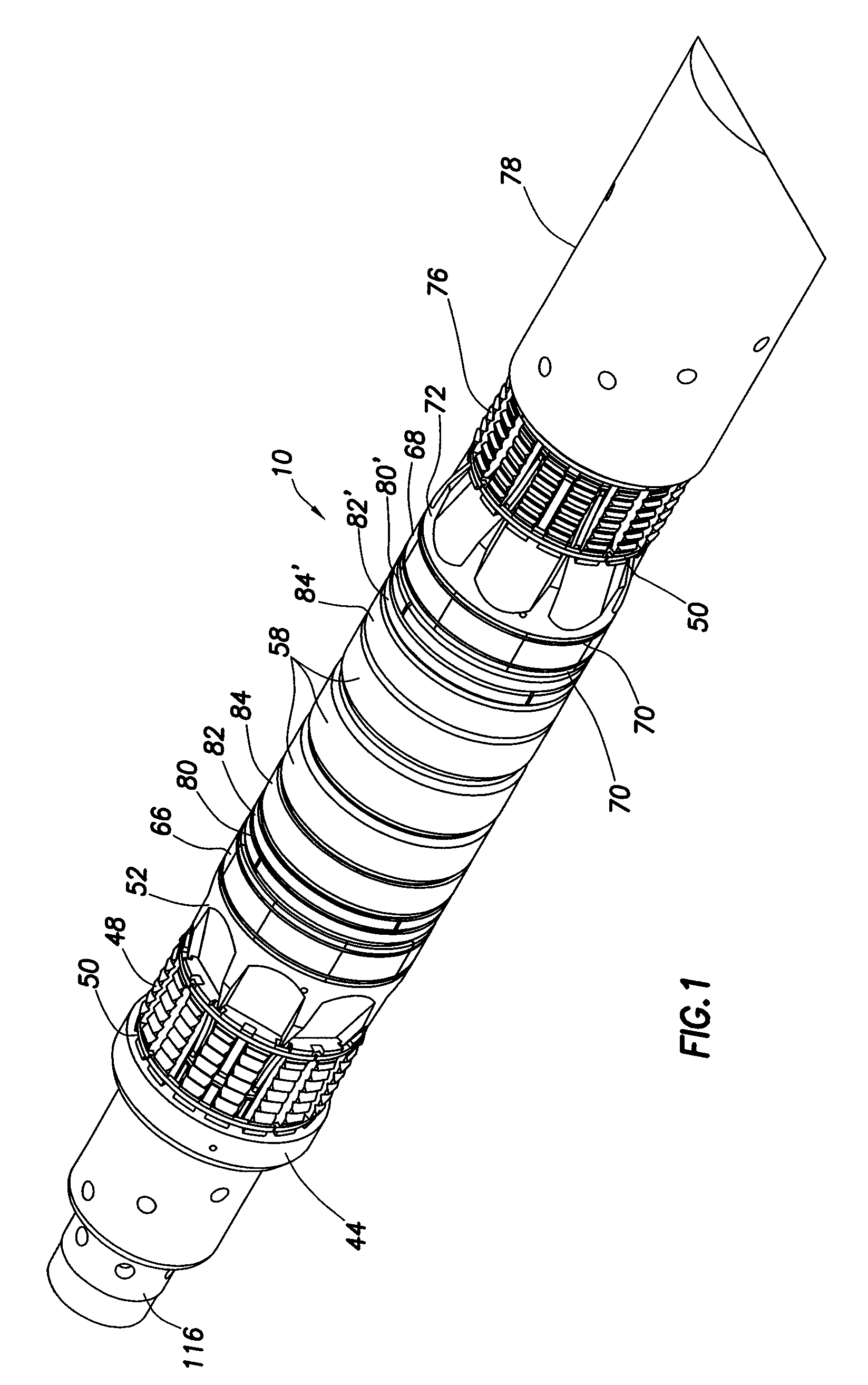

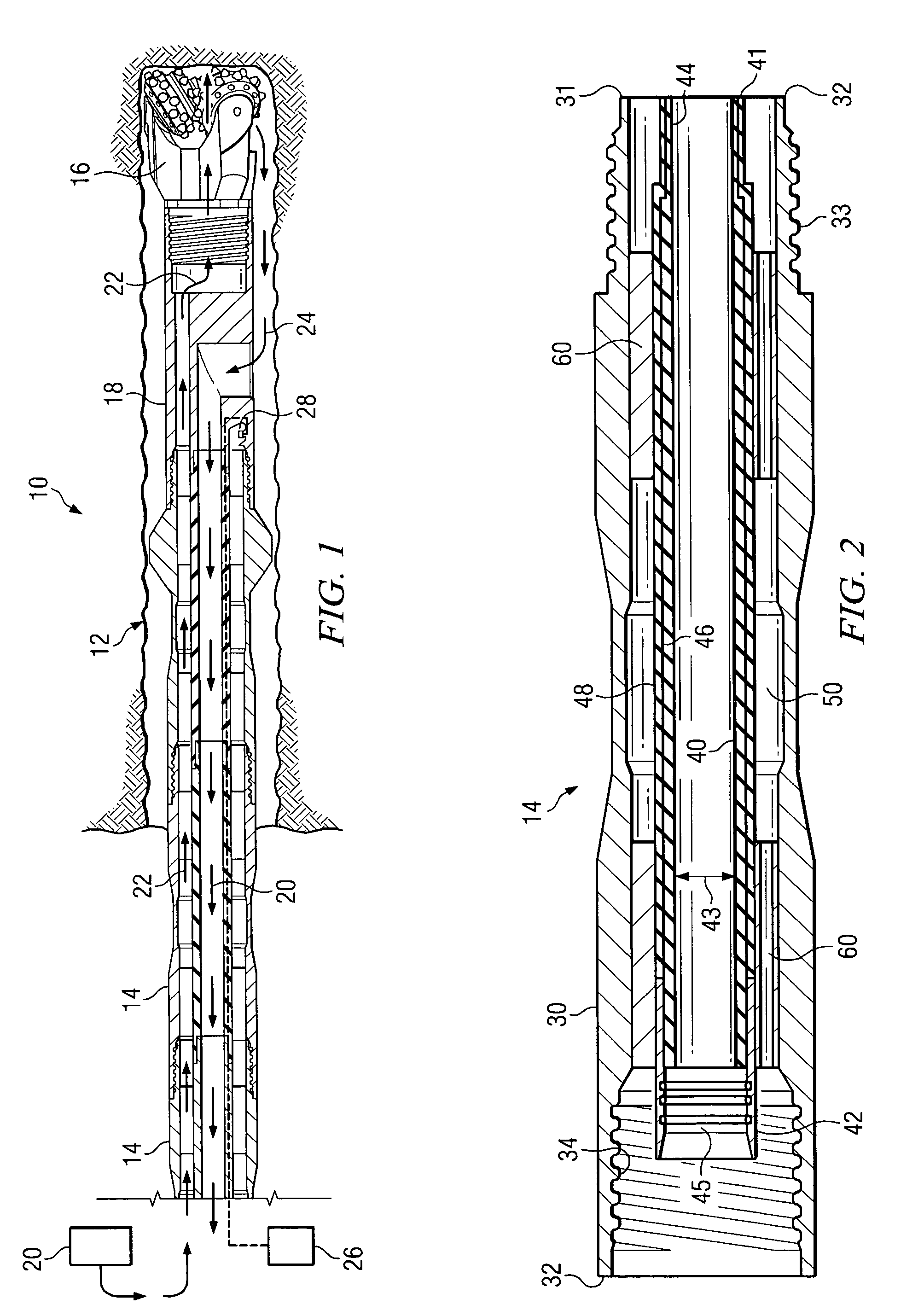

Dual wall drill string assembly

ActiveUS20050103527A1Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingEngineering

A coil tubing or jointed dual wall drill string assembly for subsurface drilling. The drill string assembly includes a metallic outer tube having an outer tube first end and an outer tube second end opposite the outer tube first end. The assembly also includes a flexible, substantially non-metallic inner tube that is substantially enclosed within and generally coaxially aligned with the outer tube. The flexible, substantially non-metallic inner tube has an inner tube first end, an inner tube second end opposite the inner tube first end, and an inner tube inner diameter. The inner tube and the outer tube define an annular channel therebetween. The drill string assembly also includes a means for conveying fluid through the annular channel toward the inner tube first end. The annular channel is adapted to convey drilling fluid under pressure toward the inner tube first end and the inner tube is adapted to convey cuttings toward the inner tube second end.

Owner:AMERICAN AUGERS +1

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

Packer element retaining system

A bridge plug having a segmented backup shoe, and at least one split cone extrusion limiter, the extrusion limiter comprising a two part conical retainer positioned between packer elements and the segmented backup shoe to block packer element extrusion though spaces between backup shoe segments. In one embodiment, two split cone extrusion limiters are used together and positioned so that each split cone extrusion limiter covers gaps in the other extrusion limiter and together the two split cone extrusion limiters block packer element extrusion though gaps between backup shoe segments regardless of their orientation relative to the segmented backup shoe. In one embodiment, a solid retaining ring is positioned between a split retaining cone extrusion limiter and a packer element and resists extrusion of packer elements into spaces in the split cone extrusion limiter or limiters.

Owner:HALLIBURTON ENERGY SERVICES INC

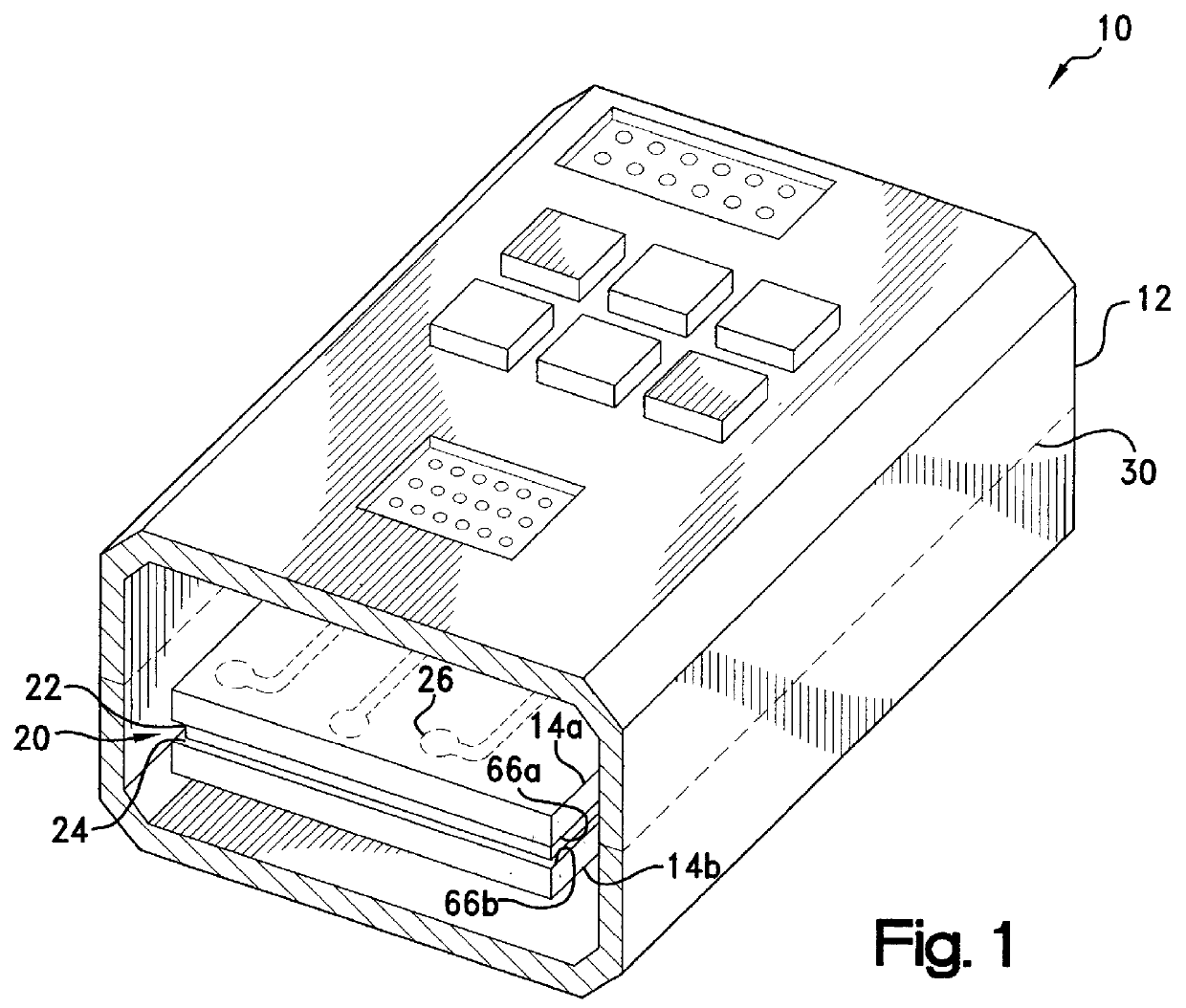

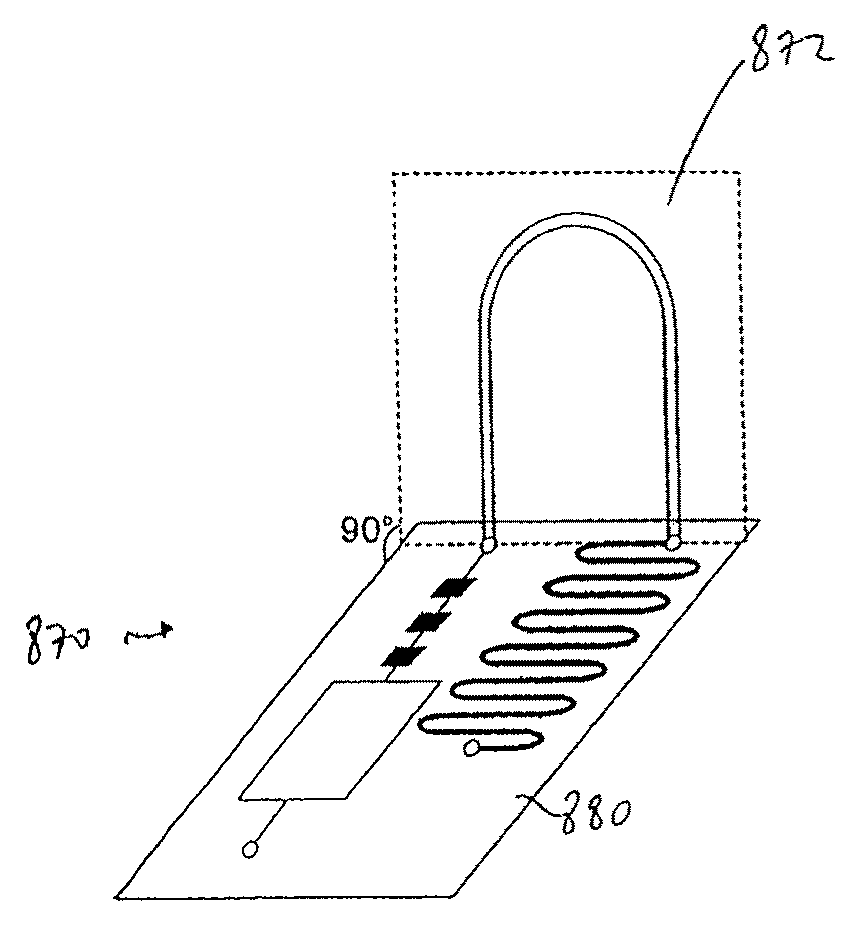

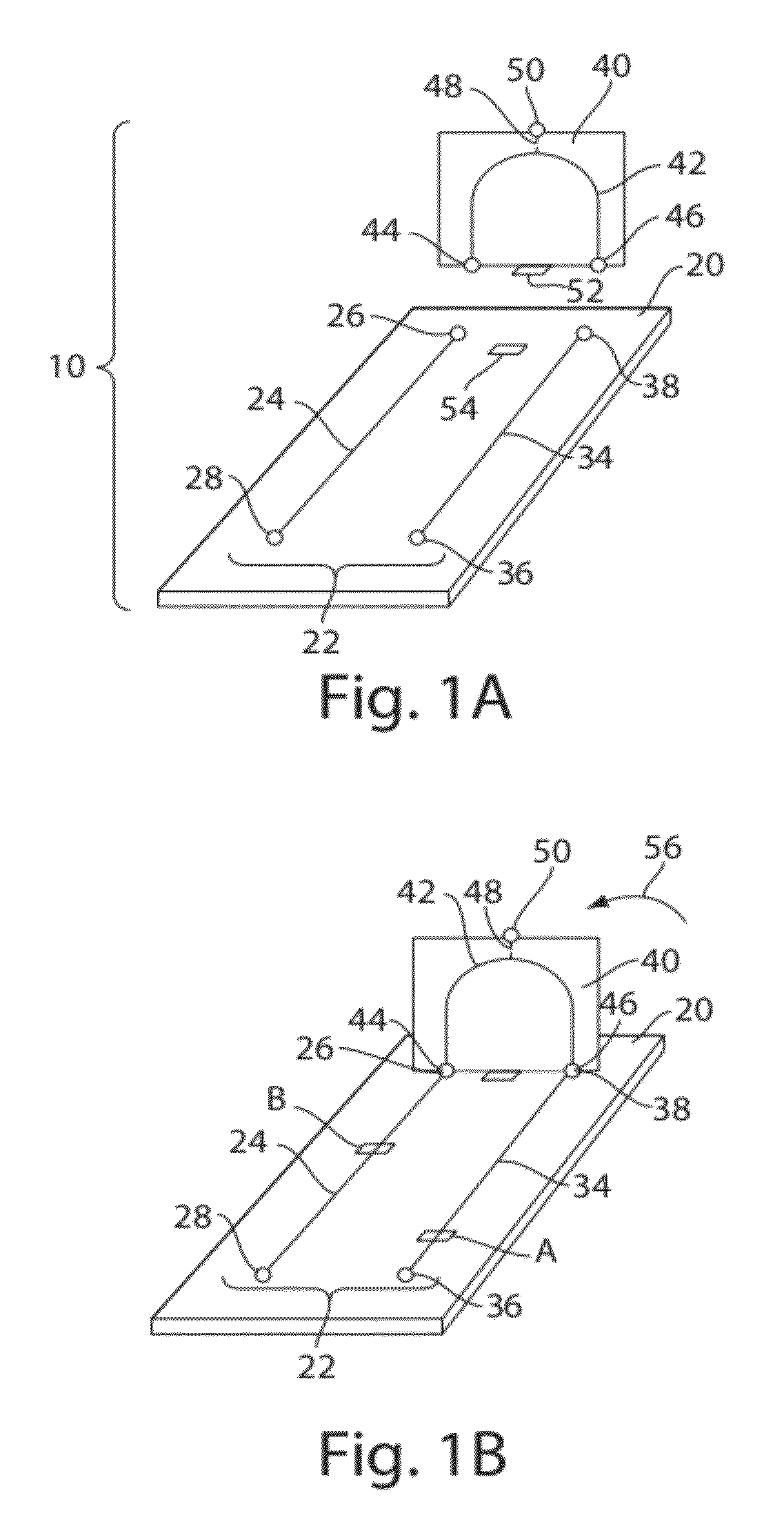

Fluidic connectors and microfluidic systems

Fluidic connectors, methods, and devices for performing analyses (e.g., immunoassays) in microfluidic systems are provided. In some embodiments, a fluidic connector having a fluid path is used to connect two independent channels formed in a substrate so as to allow fluid communication between the two independent channels. One or both of the independent channels may be pre-filled with reagents (e.g., antibody solutions, washing buffers and amplification reagents), which can be used to perform the analysis. These reagents may be stored in the channels of the substrate for long periods amounts of time (e.g., 1 year) prior to use. Prior to connection of the fluid connector and the substrate, the fluid path may be filled with a sample (e.g., blood). The sample may be obtained, for example, by pricking a finger of a user until blood is drawn from the finger into the fluid path (e.g., by capillary forces). Upon connection of the fluidic connector and the channels of the substrate, the sample can pass through a reaction area within the first channel of the substrate. This process can allow components of the sample to interact with components disposed in the reaction area. Afterwards, reagents from the second channel can flow to the reaction area via the fluid path, allowing components in the reaction area to be processed (e.g., amplified to produce detectable signal). Components in the reaction area can then be determined using various methods of detection.

Owner:OPKO DIAGNOSTICS

Locking luer fitting

InactiveUS20060157984A1Avoid disconnectionAvoid accidental disconnectionEngine sealsFluid pressure sealed jointsEngineeringCam

A locking luer fitting for connecting fluid lines. In one variation the connection interface includes a male luer connector and a corresponding female luer connector. The female luer connector includes a rotatable collar which engages the male luer connector. In another variation the female luer connector includes a cam configured to prevent inadvertent disconnection of the male luer connector. The locking luer fittings described herein may be implemented in various medical and industrial applications where secured fluid line connection interfaces are desirable.

Owner:CR BARD INC

Dual wall drill string assembly

InactiveUS7152700B2Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingDrilling fluid

Owner:AMERICAN AUGERS +1

Deformable pipe coupling having multiple radii of curvature

A pipe coupling for joining pipe elements end-to-end is disclosed. The pipe coupling is formed of segments attached to one another circumferentially straddling the pipe elements. The segments are formed from sub-sections connected to one another end-to-end. Each sub-section has a surface region disposed to engage the outer surfaces of the pipe elements. Each surface region has a different radius of curvature from a surface region on a neighboring sub-section. The radii are selected so that when the coupling segments are deformed around the pipe elements, portions of surface regions of selected sub-sections contact the pipe elements, while portions of surface regions of those sub-sections between the selected portions remain in spaced relation away from the pipe elements. A constant and minimal torque is required to bolt the segments together as a result.

Owner:VICTAULIC

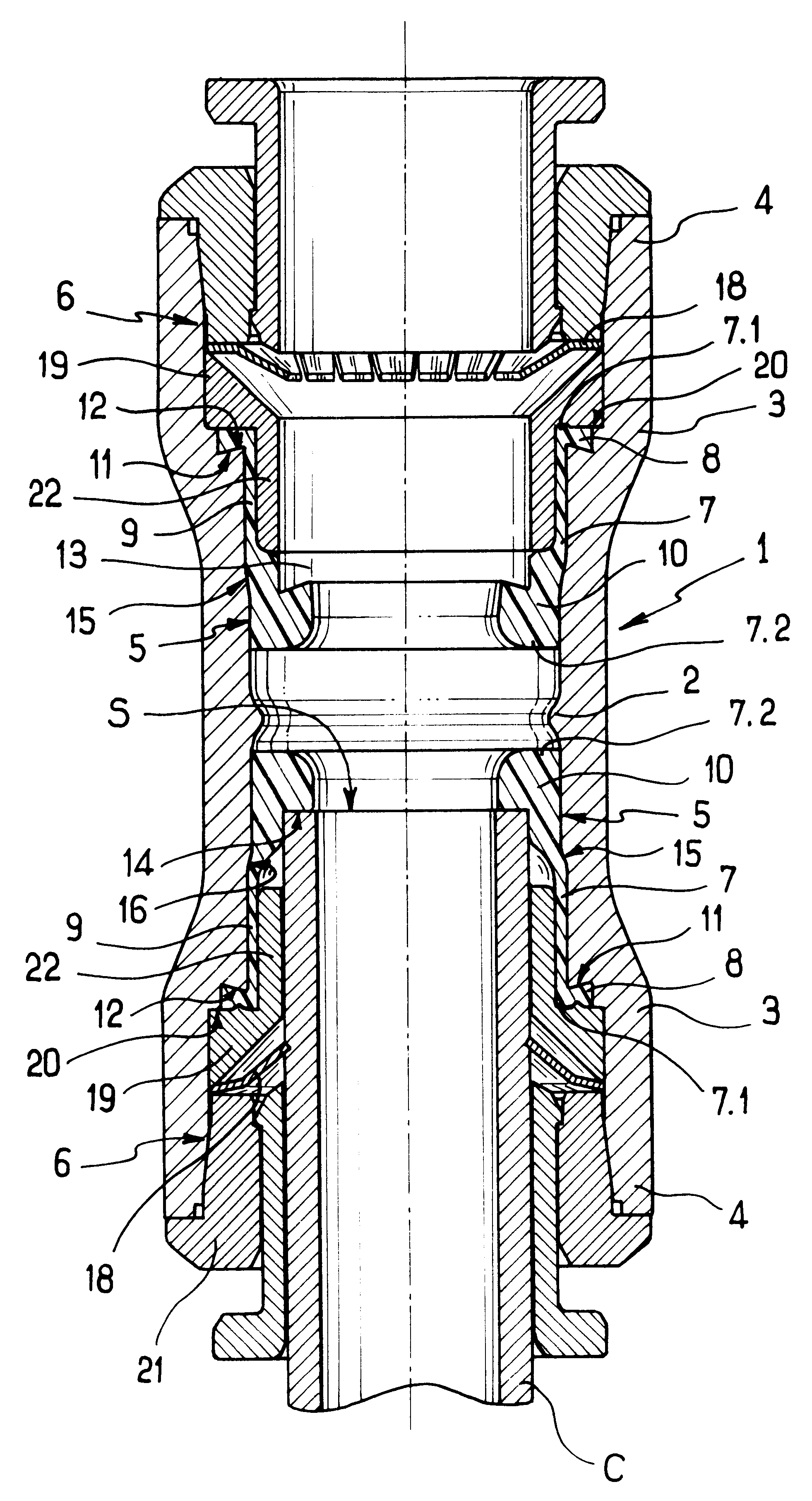

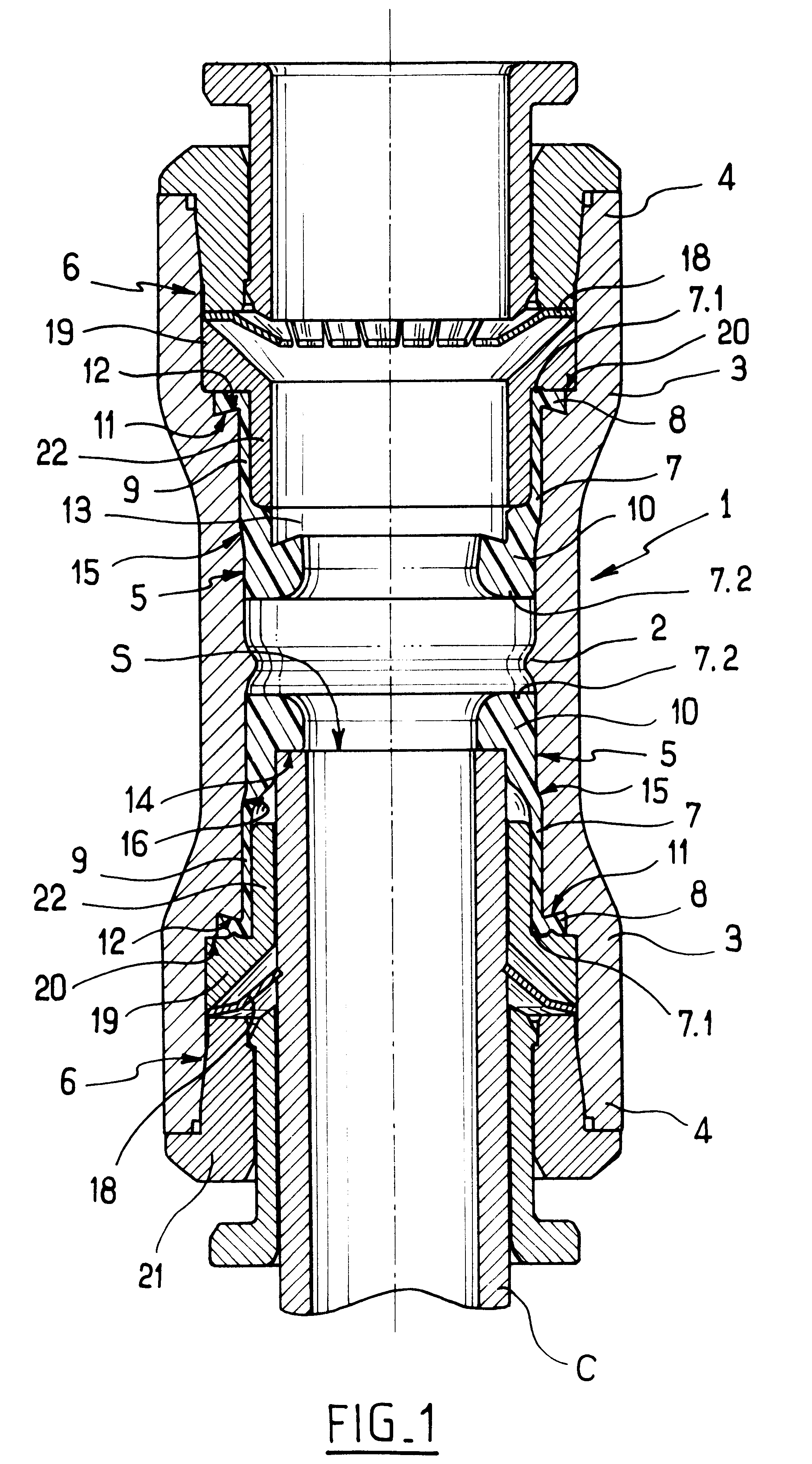

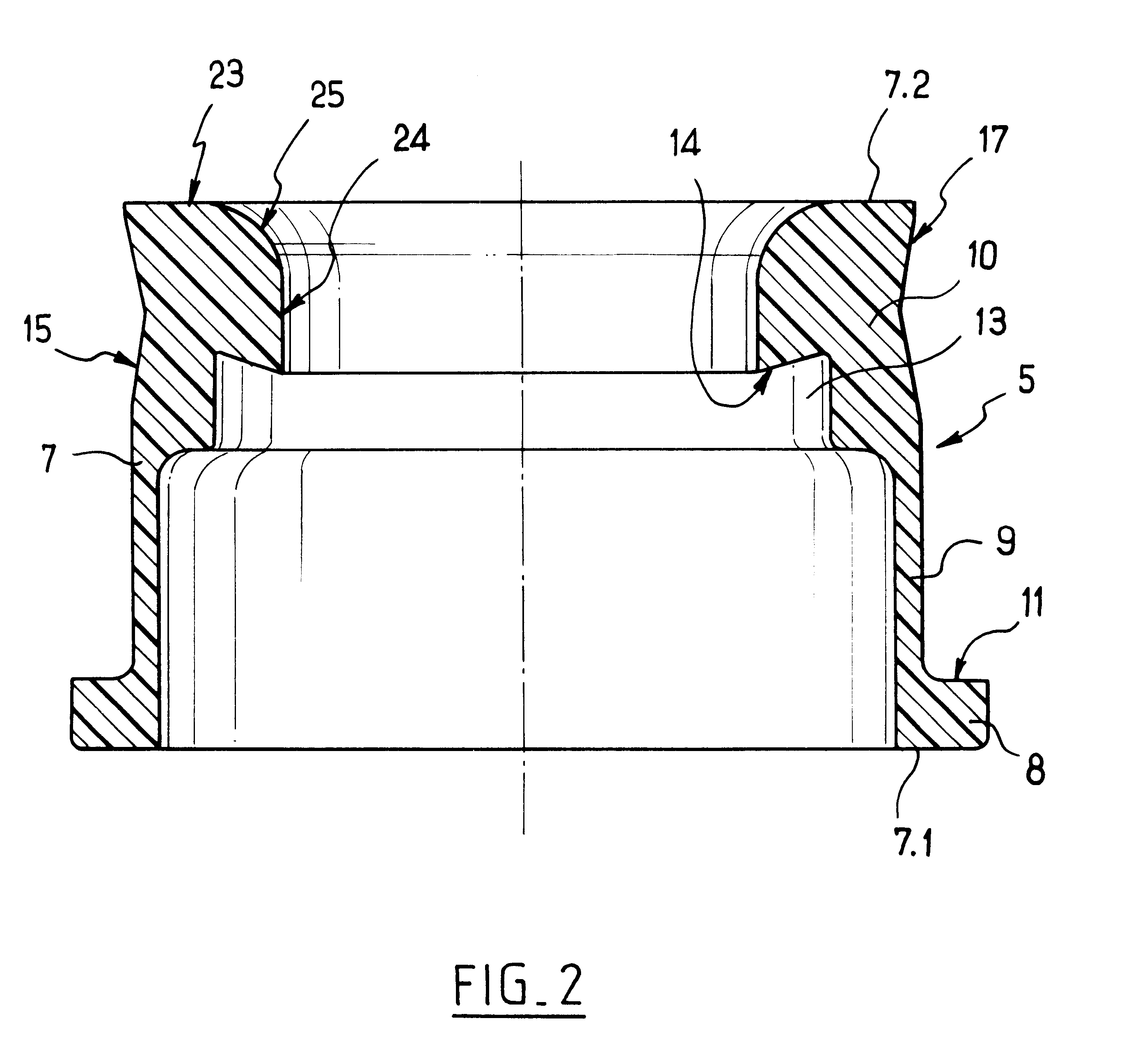

Device for connecting a pipe end to a member

InactiveUS6517124B1Simple structureReduce the number of partsSleeve/socket jointsFluid pressure sealed jointsAbutmentEngineering

A device for connecting a pipe end to a member. The device has a tubular endpiece with a first end secured to the member and a second end through which the pipe end can be engaged in the endpiece. The endpiece is provided internally with an abutment against engagement of the pipe end and a way for securing the pipe end in leakproof manner inside the endpiece, and a sleeve that is elastically deformable at least in an axial direction. The sleeve is fixable axially in the endpiece and, towards the first end of the endpiece, has an end provided with an annular internal shoulder for coming into abutment against an end face of the pipe end so as to form the abutment against engagement of the pipe end.

Owner:LEGRIS

Fluidic connectors and microfluidic systems

Fluidic connectors, methods, and devices for performing analyses (e.g., immunoassays) in microfluidic systems are provided. In some embodiments, a fluidic connector having a fluid path is used to connect two independent channels formed in a substrate so as to allow fluid communication between the two independent channels. One or both of the independent channels may be pre-filled with reagents (e.g., antibody solutions, washing buffers and amplification reagents), which can be used to perform the analysis. These reagents may be stored in the channels of the substrate for long periods amounts of time (e.g., 1 year) prior to use. Prior to connection of the fluid connector and the substrate, the fluid path may be filled with a sample (e.g., blood). The sample may be obtained, for example, by pricking a finger of a user until blood is drawn from the finger into the fluid path (e.g., by capillary forces). Upon connection of the fluidic connector and the channels of the substrate, the sample can pass through a reaction area within the first channel of the substrate. This process can allow components of the sample to interact with components disposed in the reaction area. Afterwards, reagents from the second channel can flow to the reaction area via the fluid path, allowing components in the reaction area to be processed (e.g., amplified to produce detectable signal). Components in the reaction area can then be determined using various methods of detection.

Owner:OPKO DIAGNOSTICS

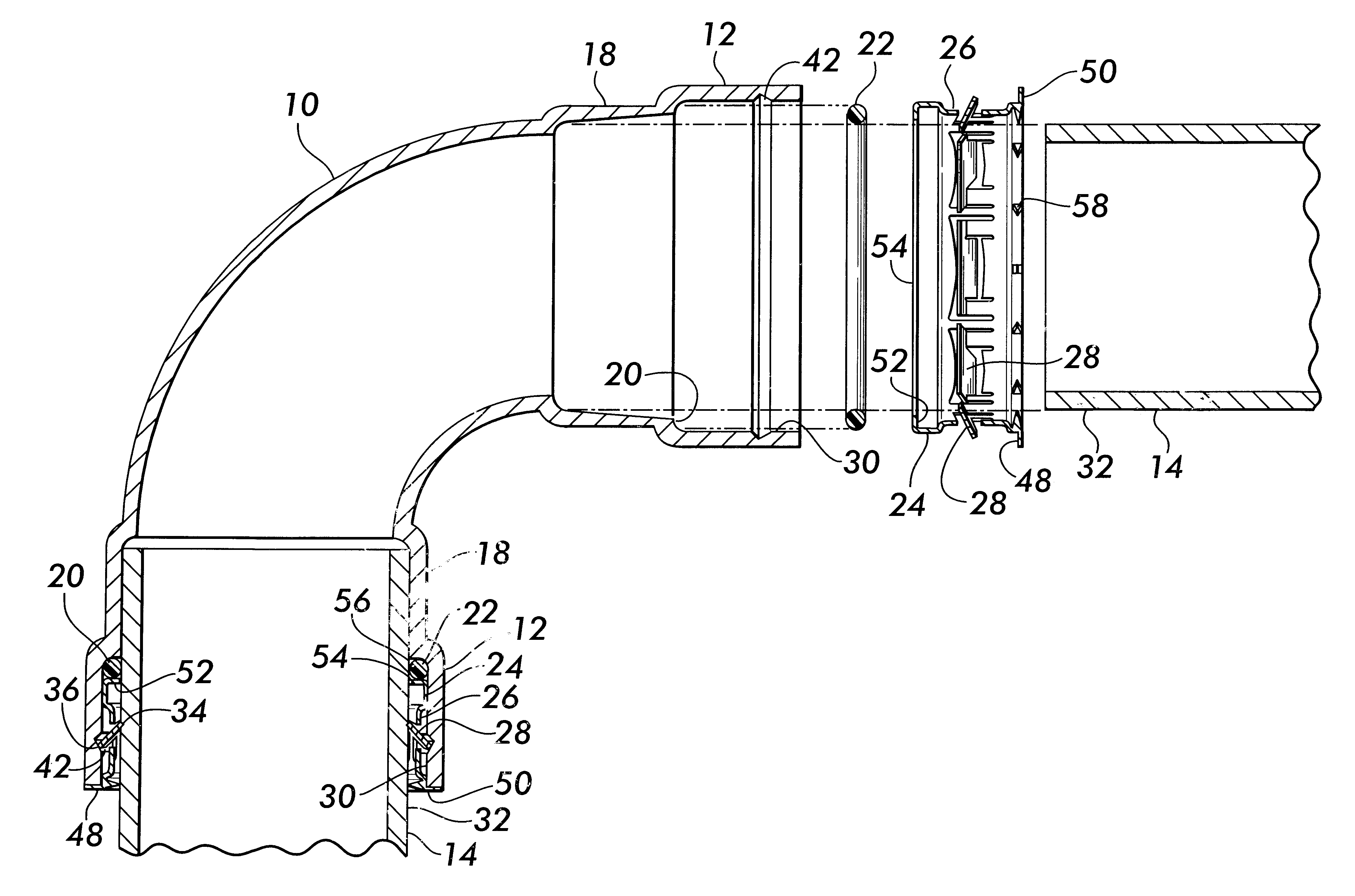

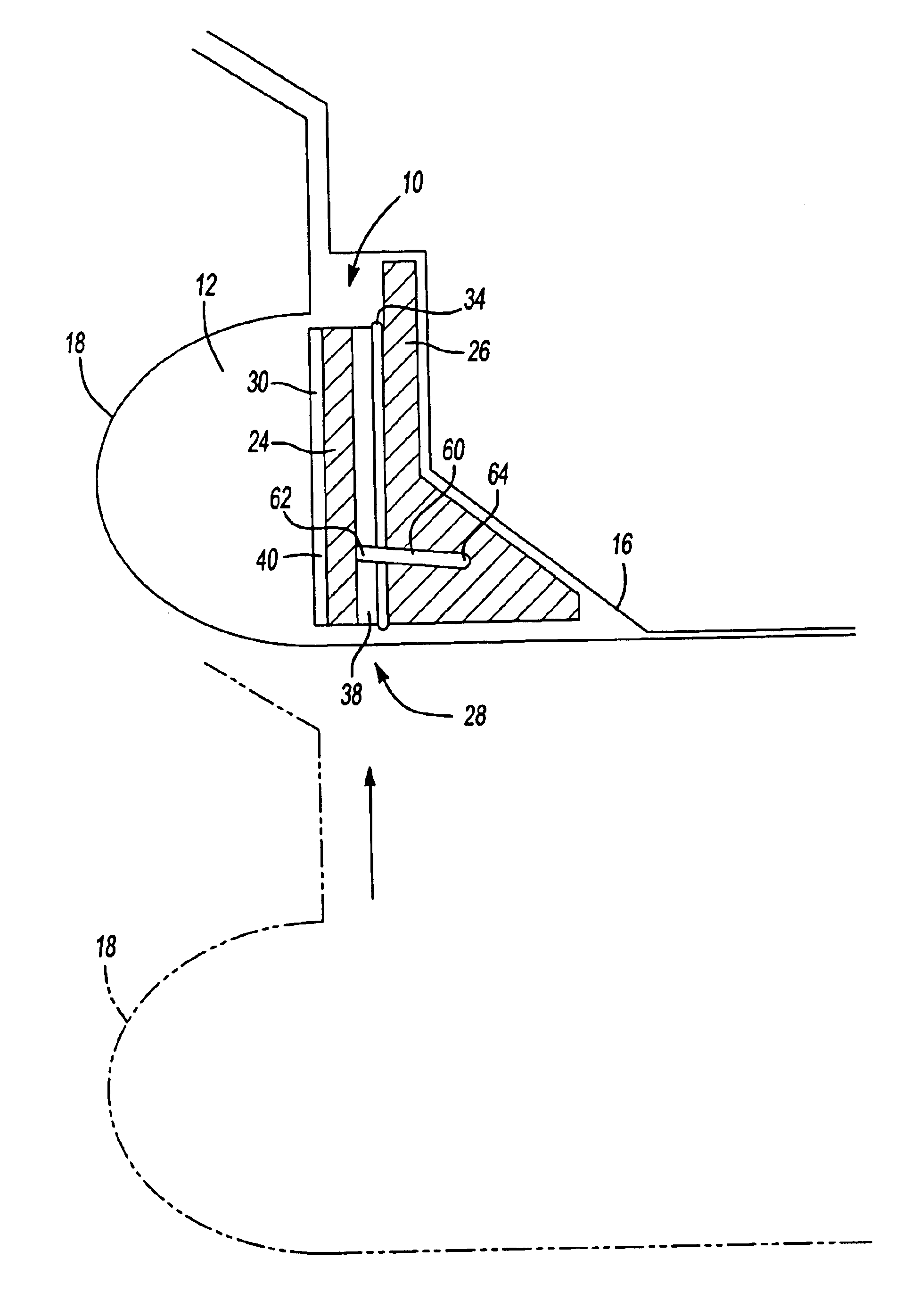

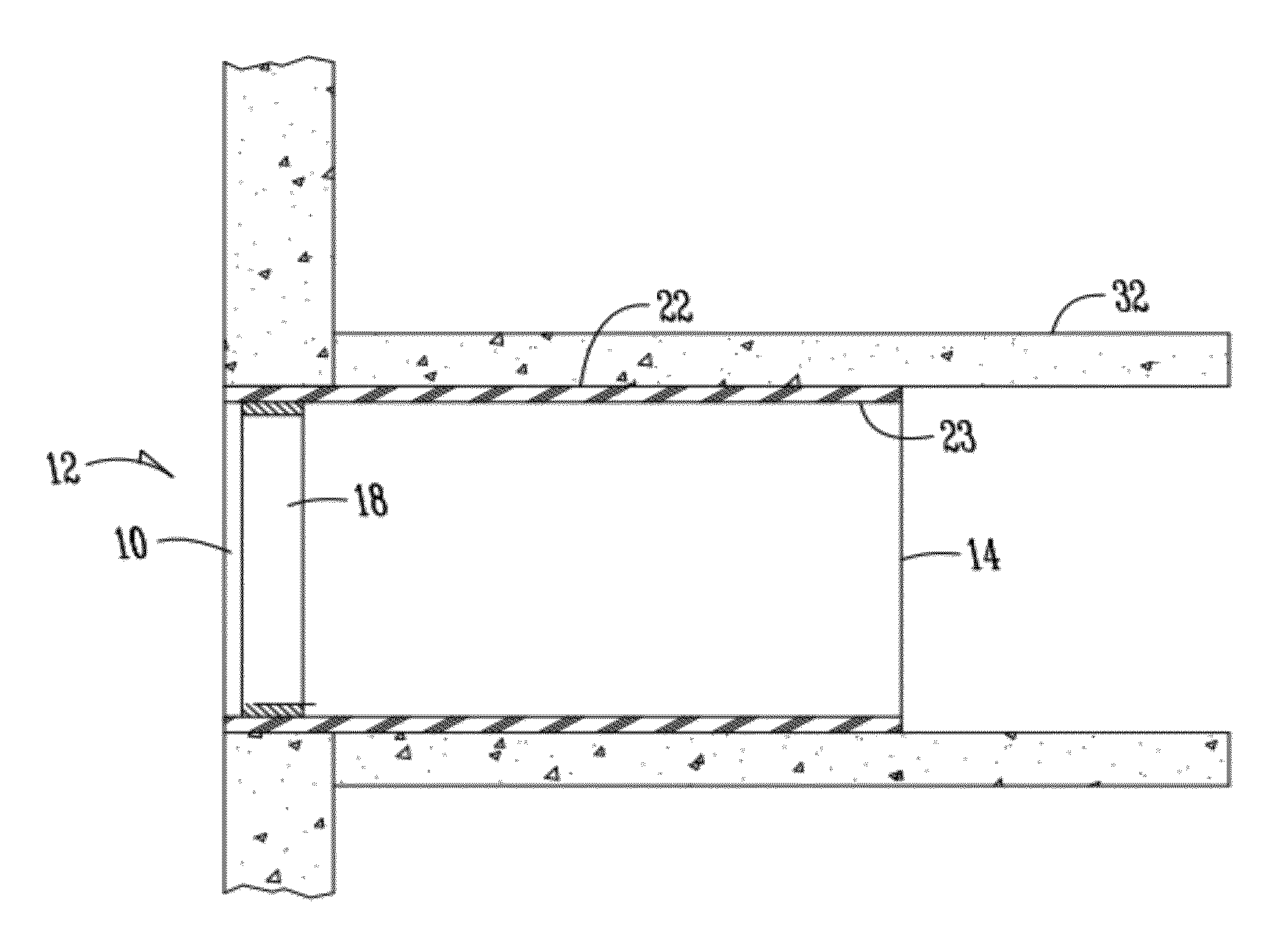

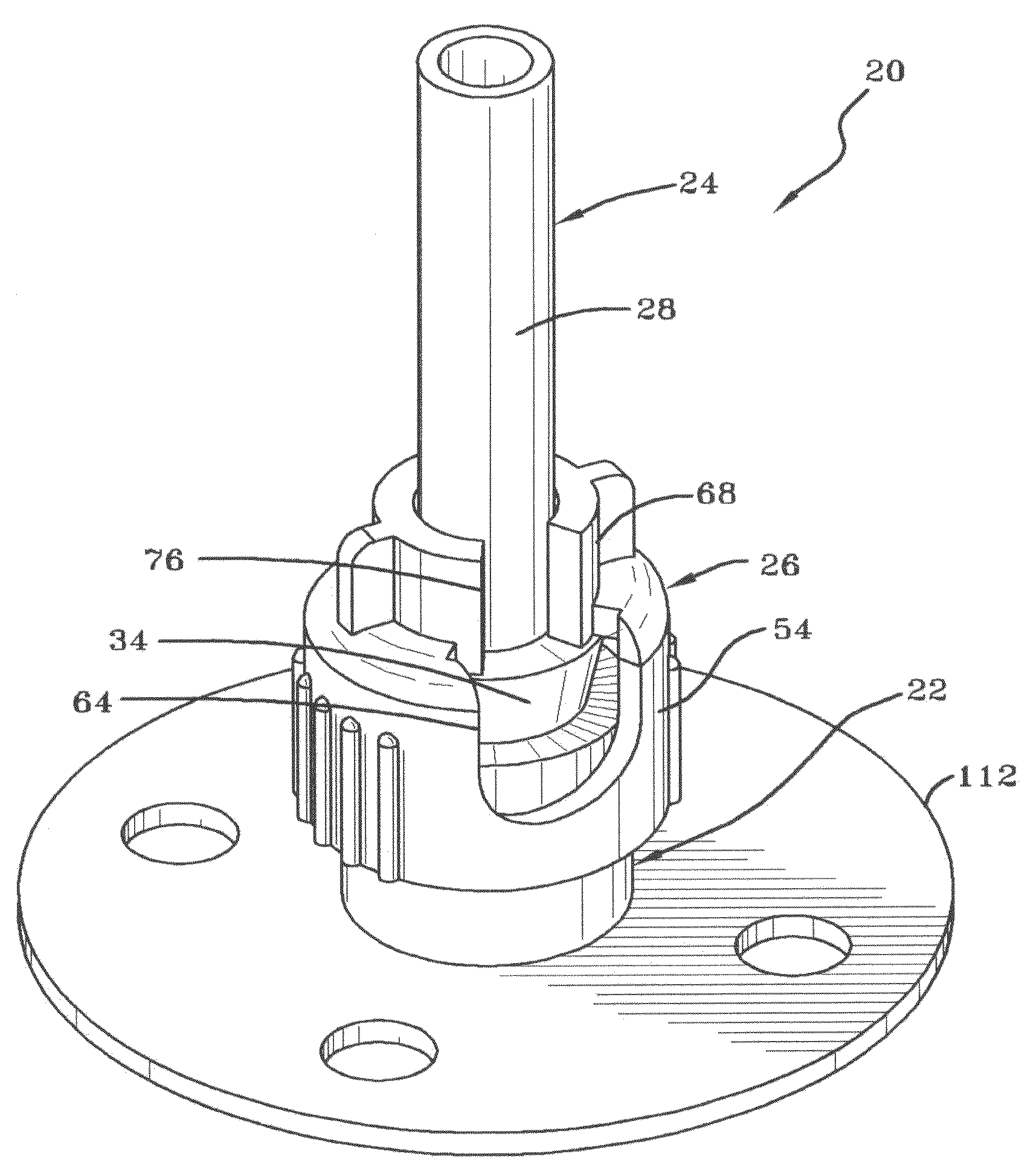

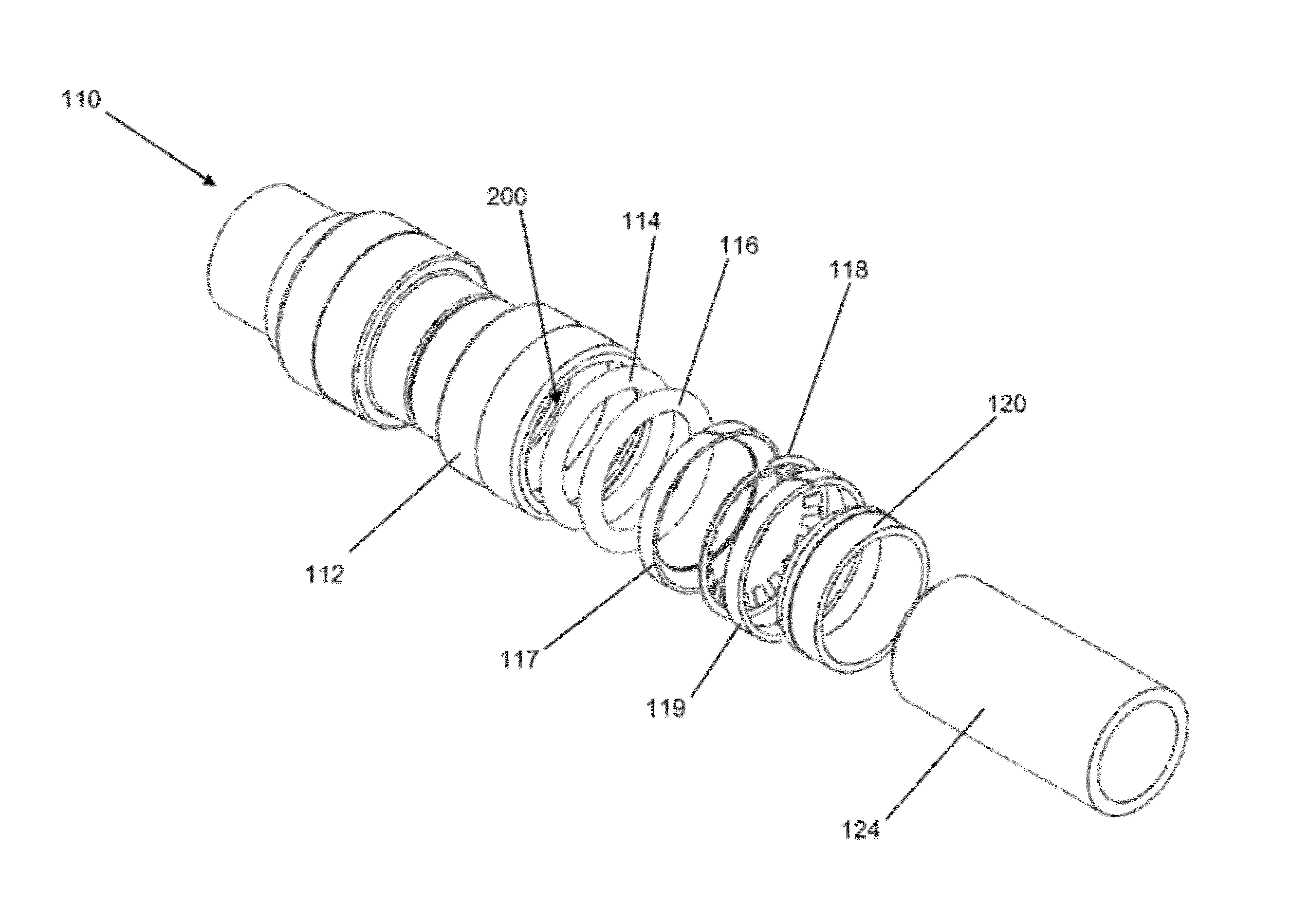

Piping joint assembly system and method with sealing ring stabilizer

ActiveUS8480134B2Facilitated releaseSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A pipe fitting and associated piping joint assembly package allow re-use and repair of push-fit, formed piping elements without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment, the present invention includes a pipe fitting having first and second radial housing elements for receiving one or more sealing members and a fastening ring, respectively. In one embodiment, the present invention further includes a sealing member stabilizer element, a housing divider element and a snap ring support member cooperatively engageable so as to facilitate the secure retention and optional removal of an inserted piping element.

Owner:QUICK FITTING

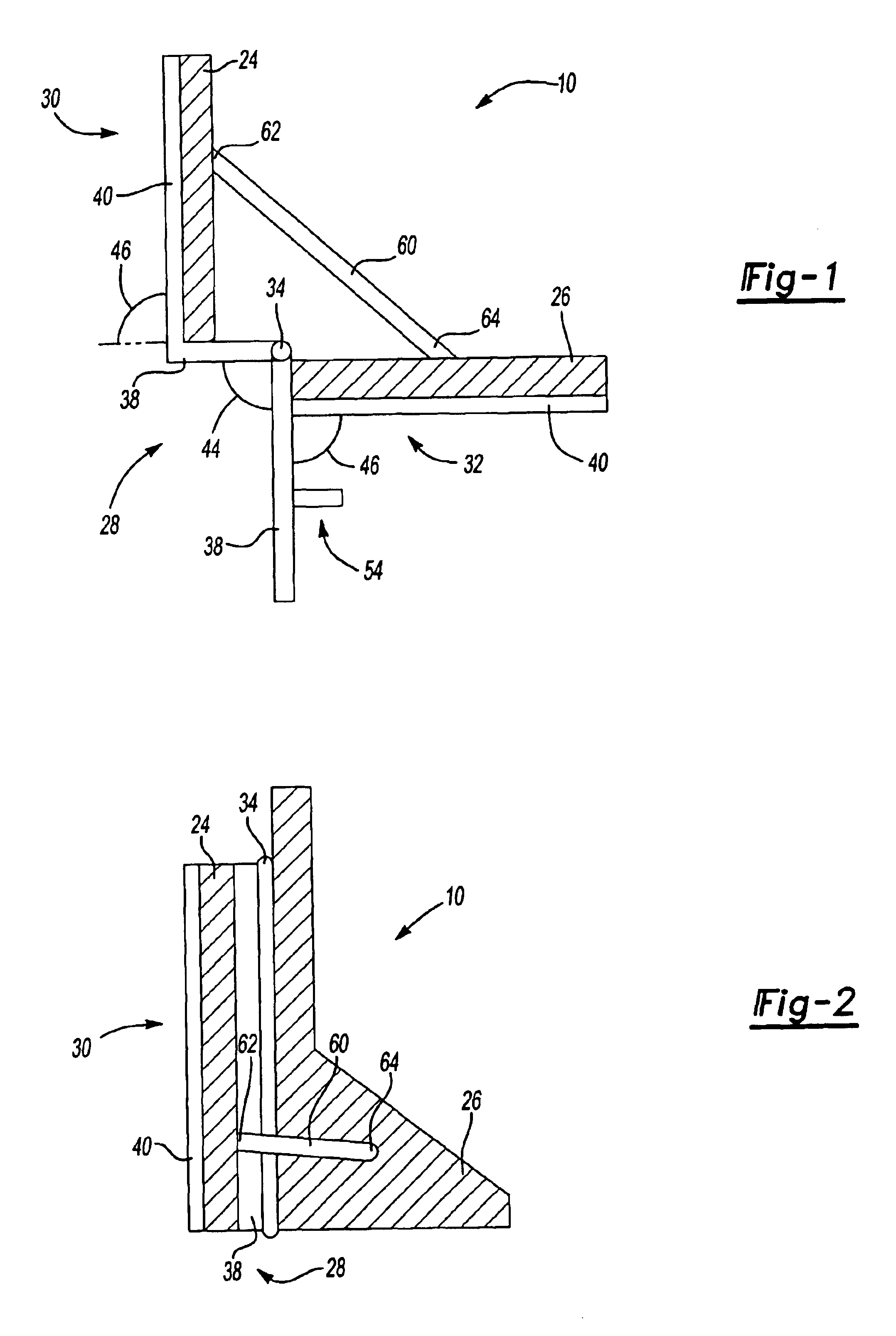

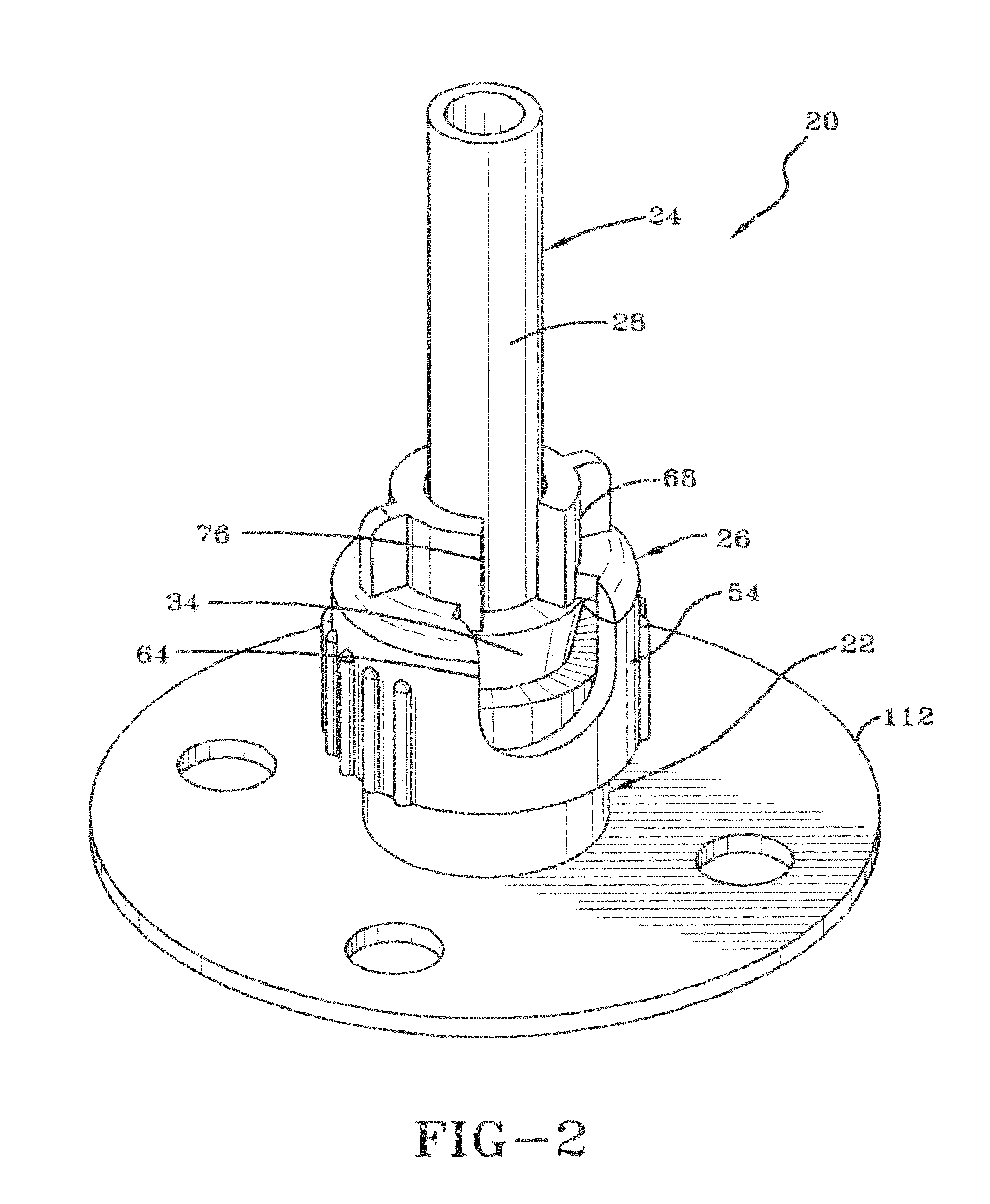

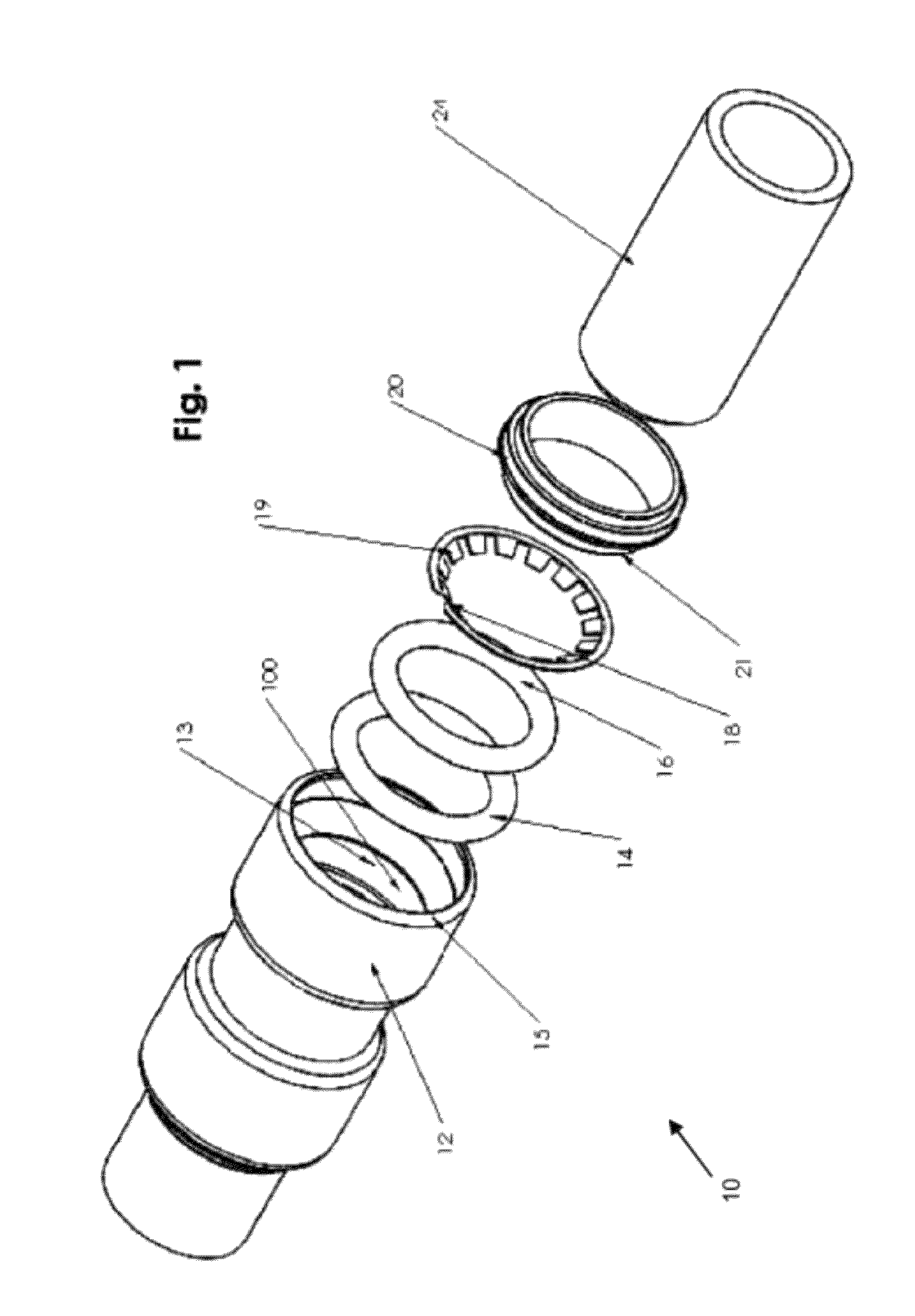

Push connect joint assembly, system and method

ActiveUS8398122B2Easy to useFacilitated releaseSleeve/socket jointsFluid pressure sealed jointsEngineeringScrew thread

A push fitting joint packaging arrangement allows the re-use and repair of push-to-connect fittings and valves without damage to the fitting or valve elements or the pipe, and without coining, gluing or threaded engagement of parts. In one embodiment of the present invention, the arrangement comprises a split fastening ring and a split O-ring support member.

Owner:QUICK FITTING HOLDING COMPANY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com