Patents

Literature

2977 results about "Inlet pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet pressure describes the pressure available where the suction pipe meets the booster pump. The inlet pressure derives from the pressure of the water supplier or the water pressure created if the booster draws from a break tank.

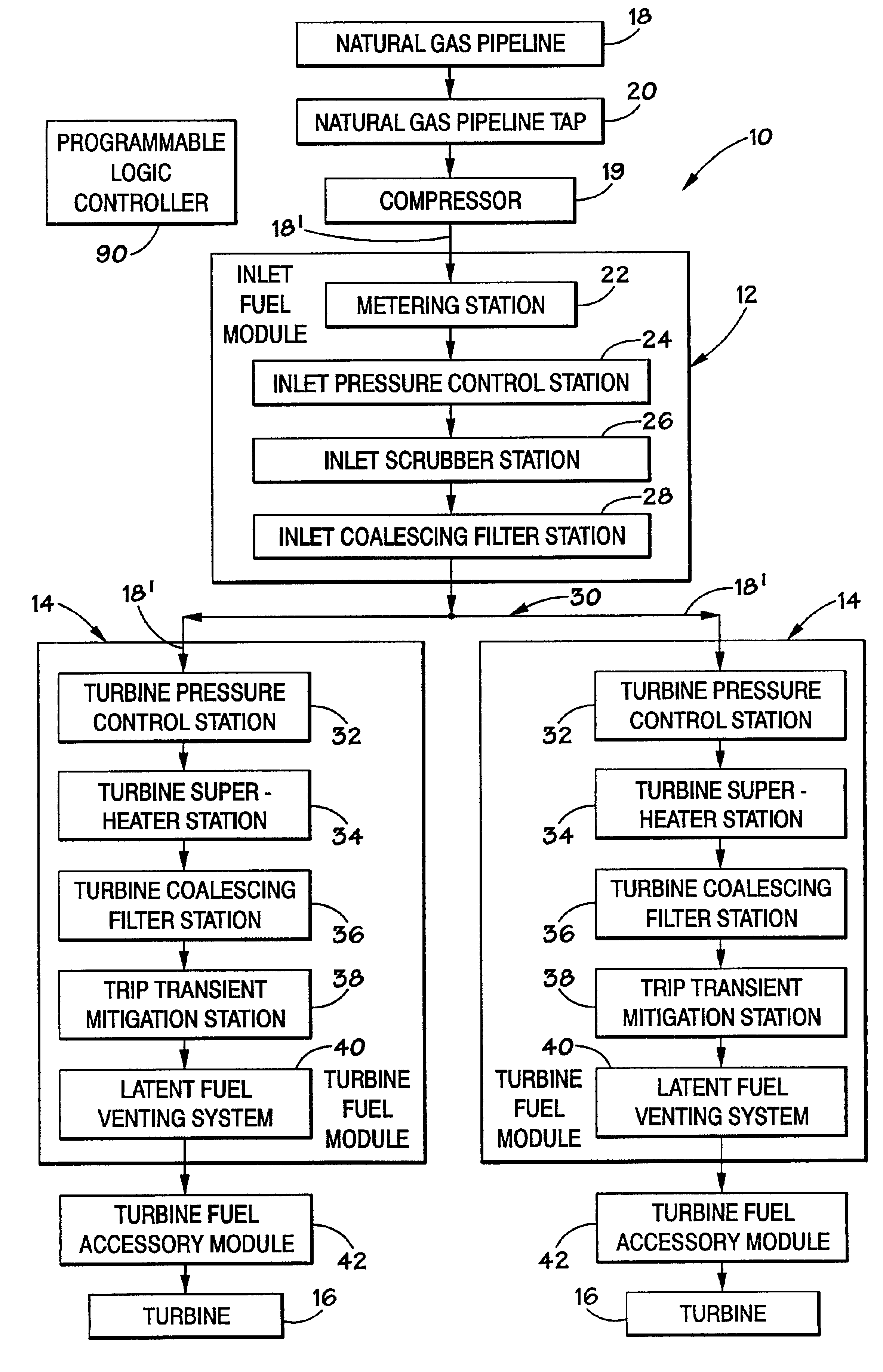

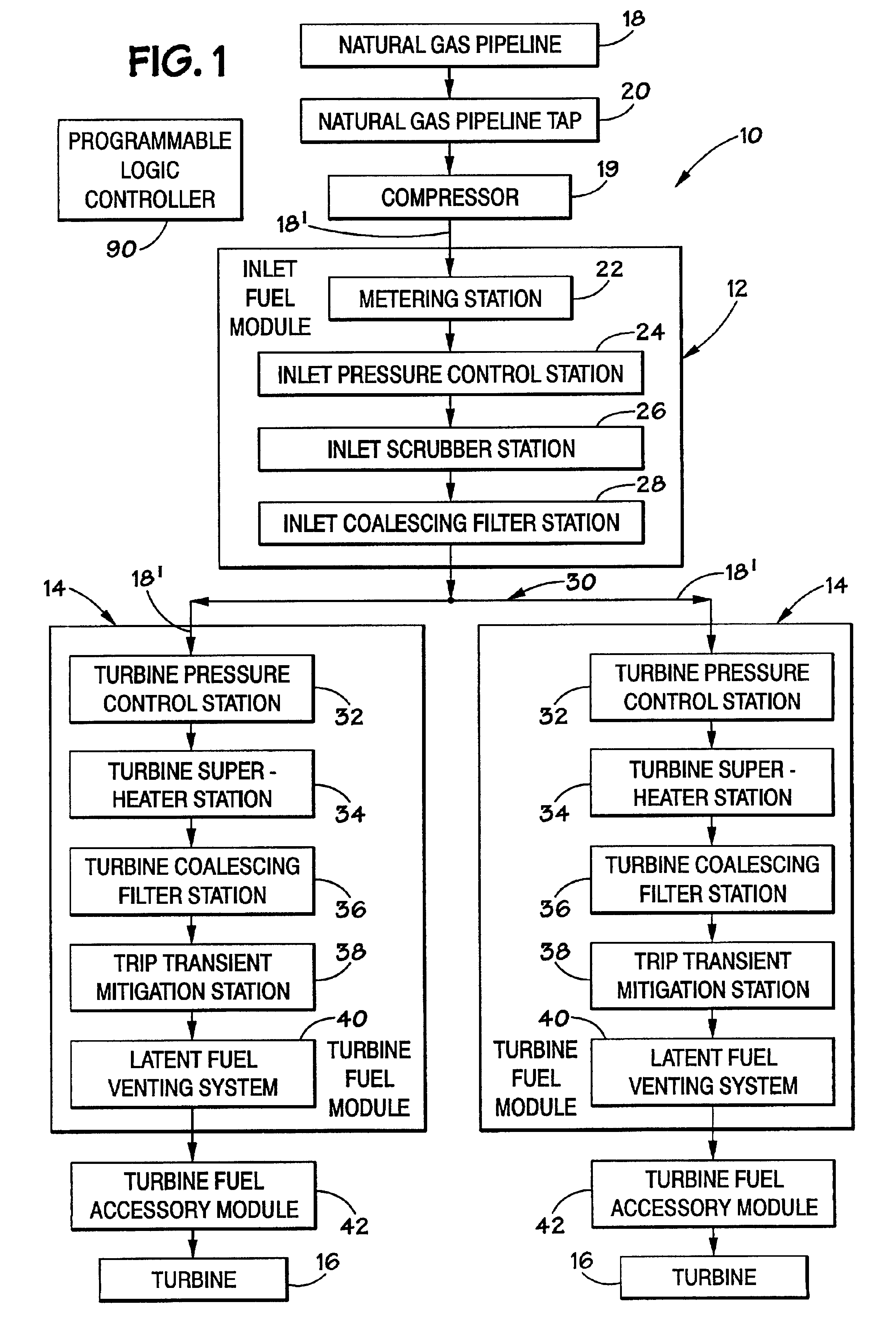

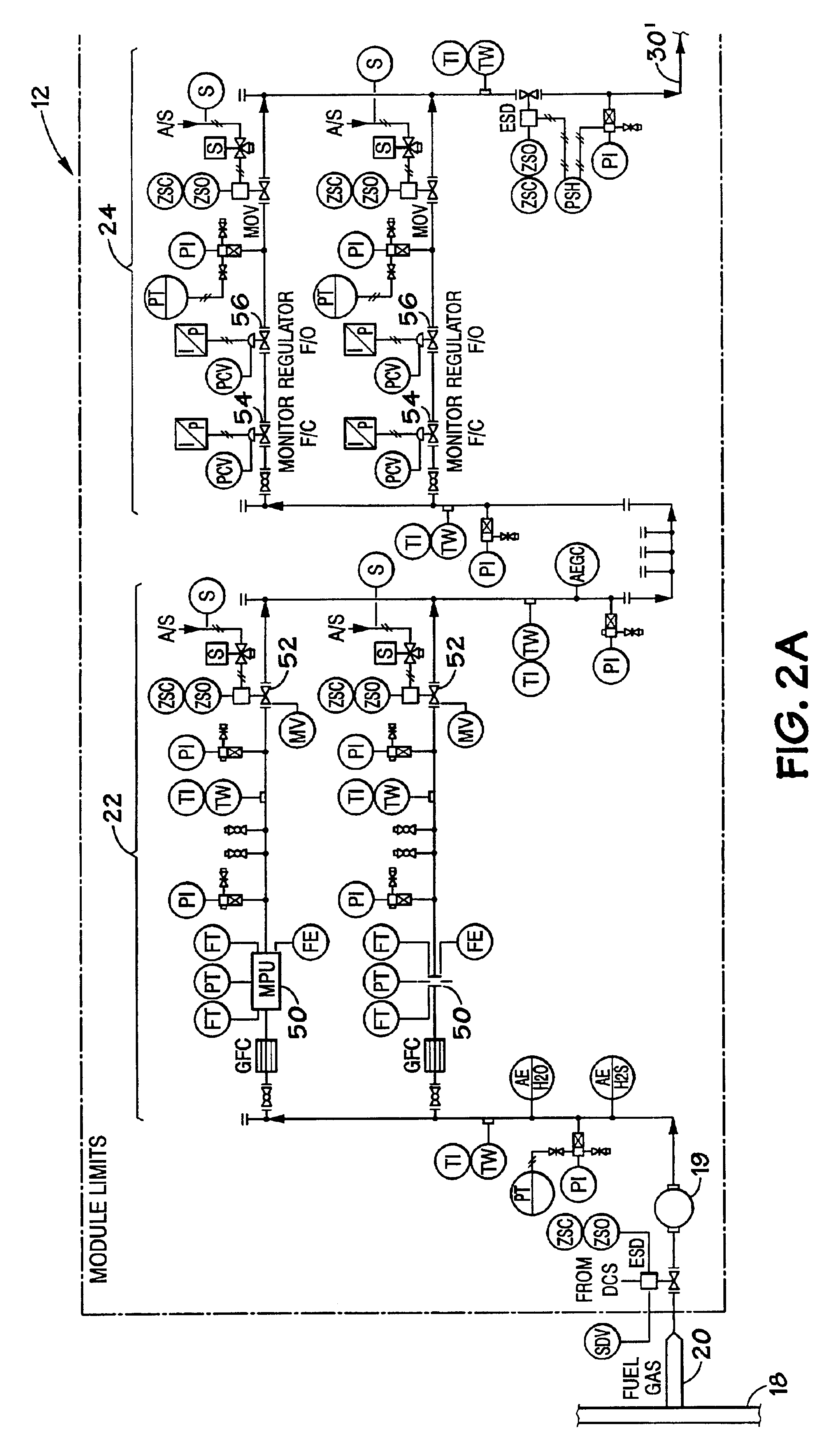

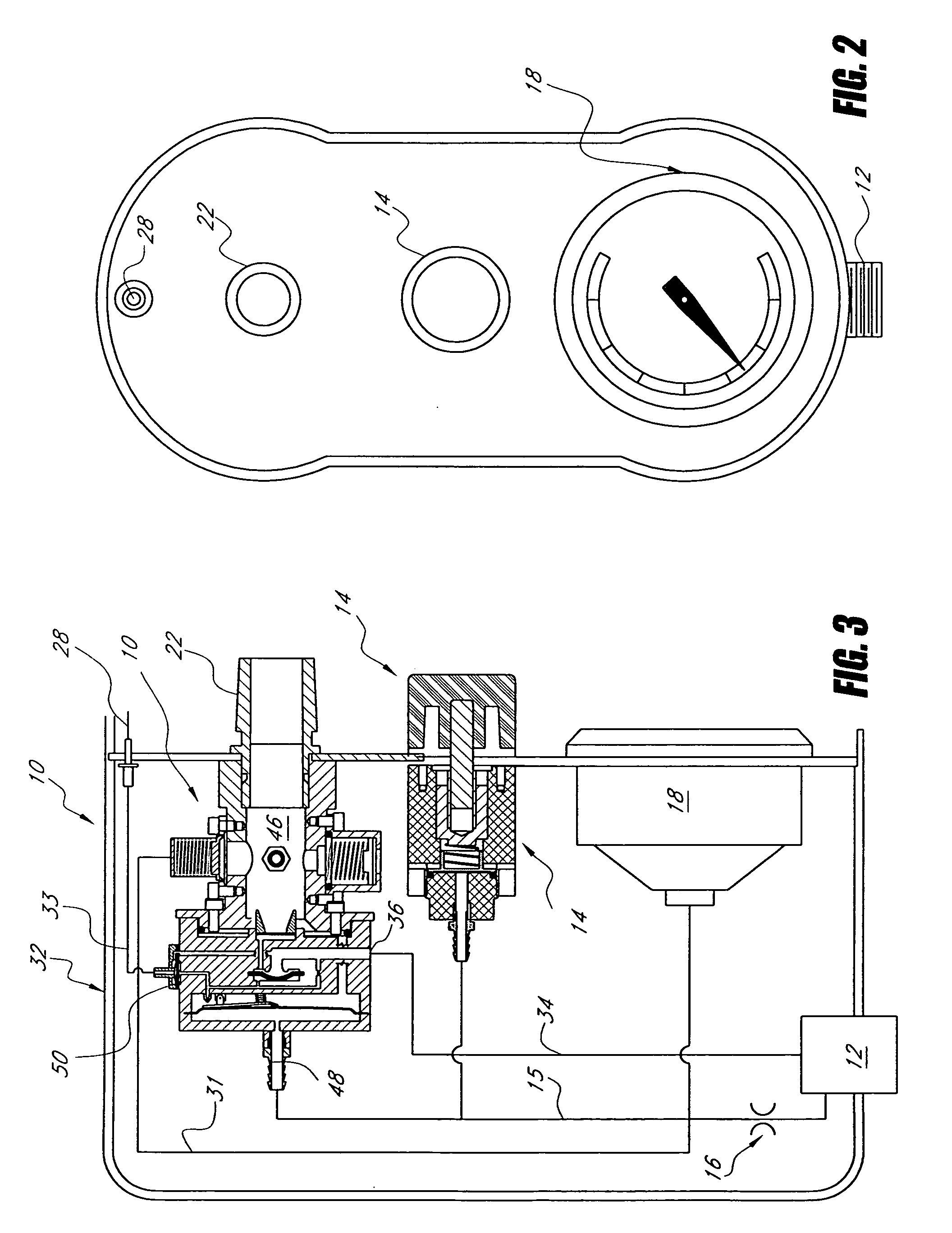

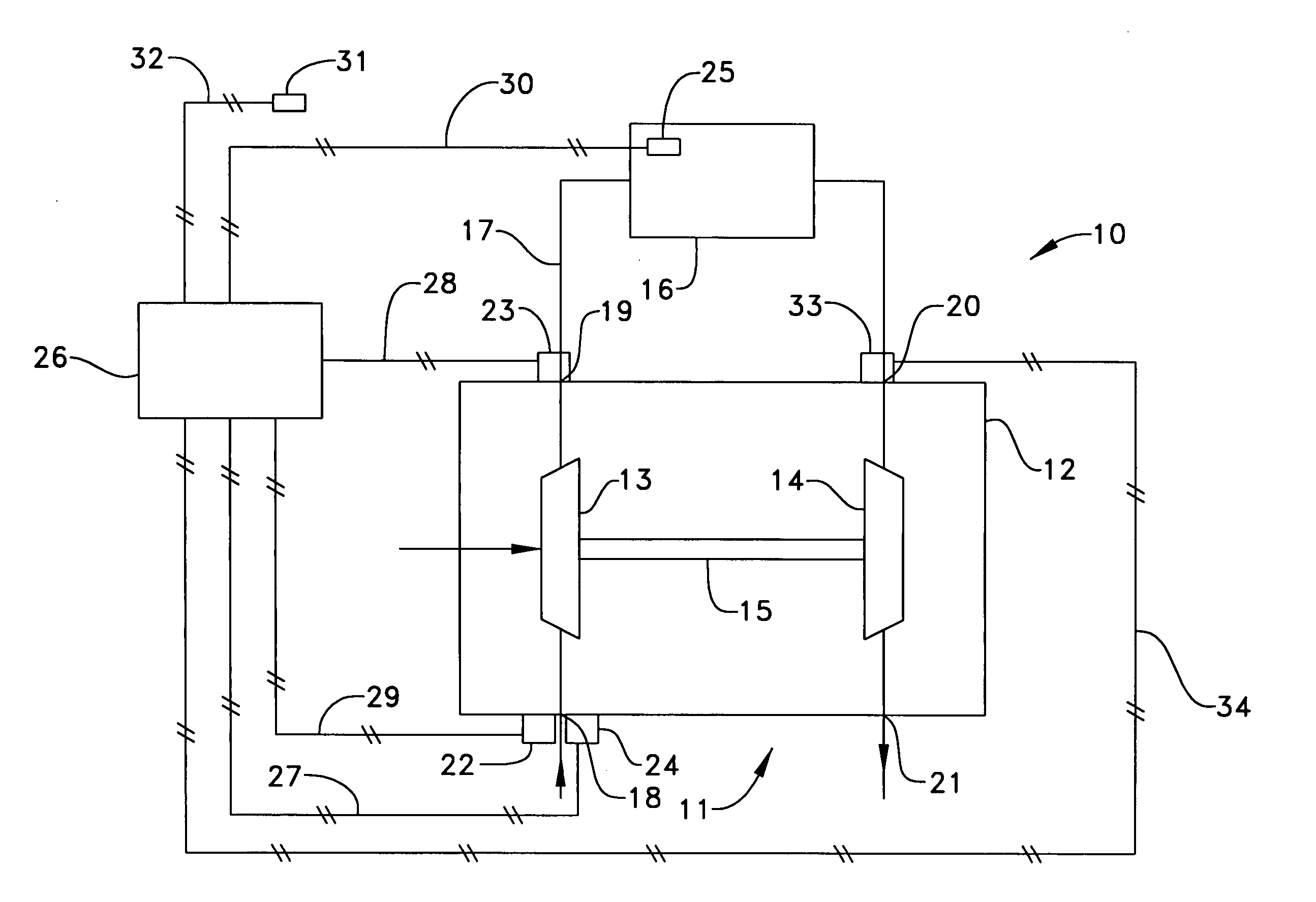

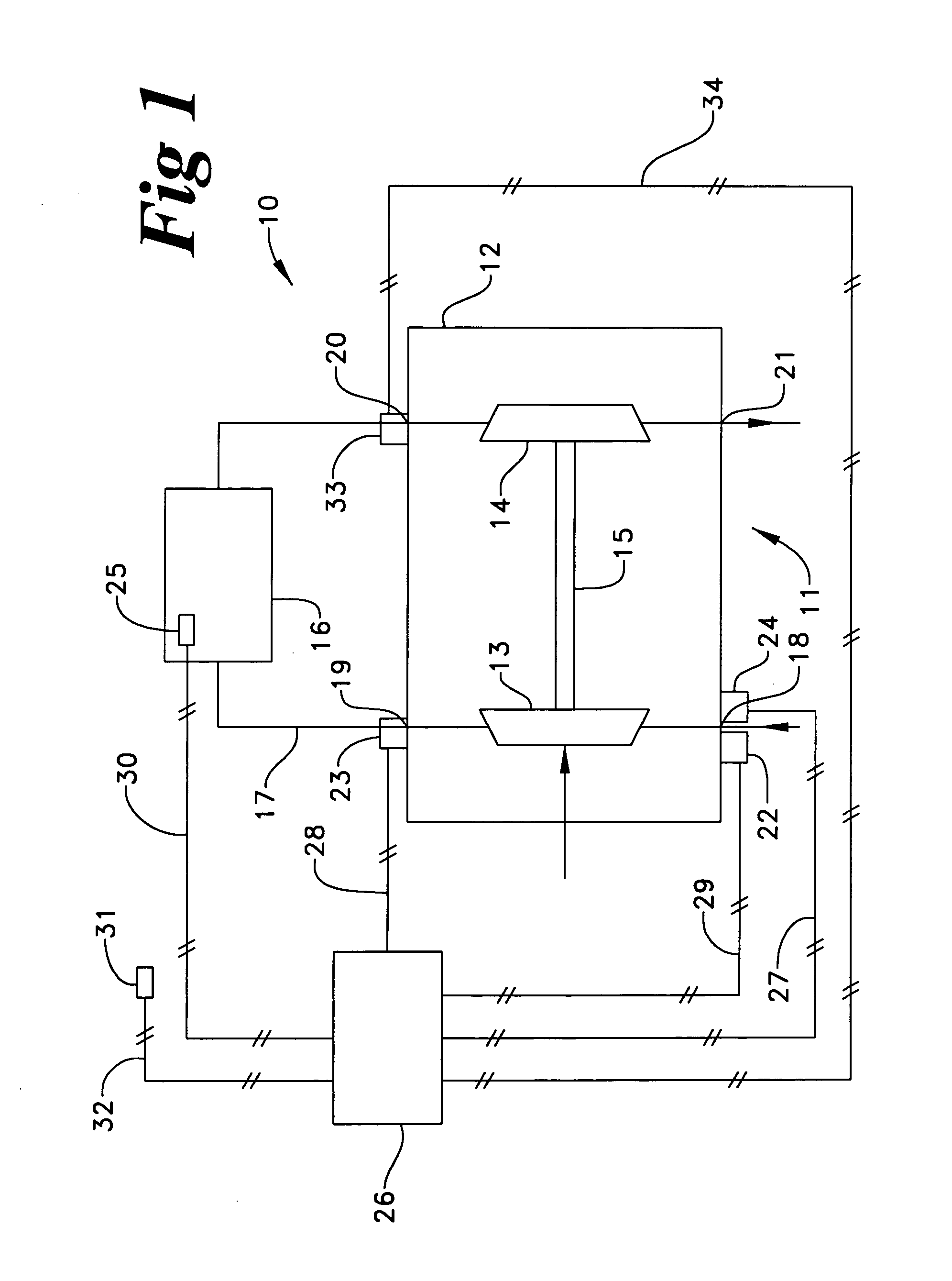

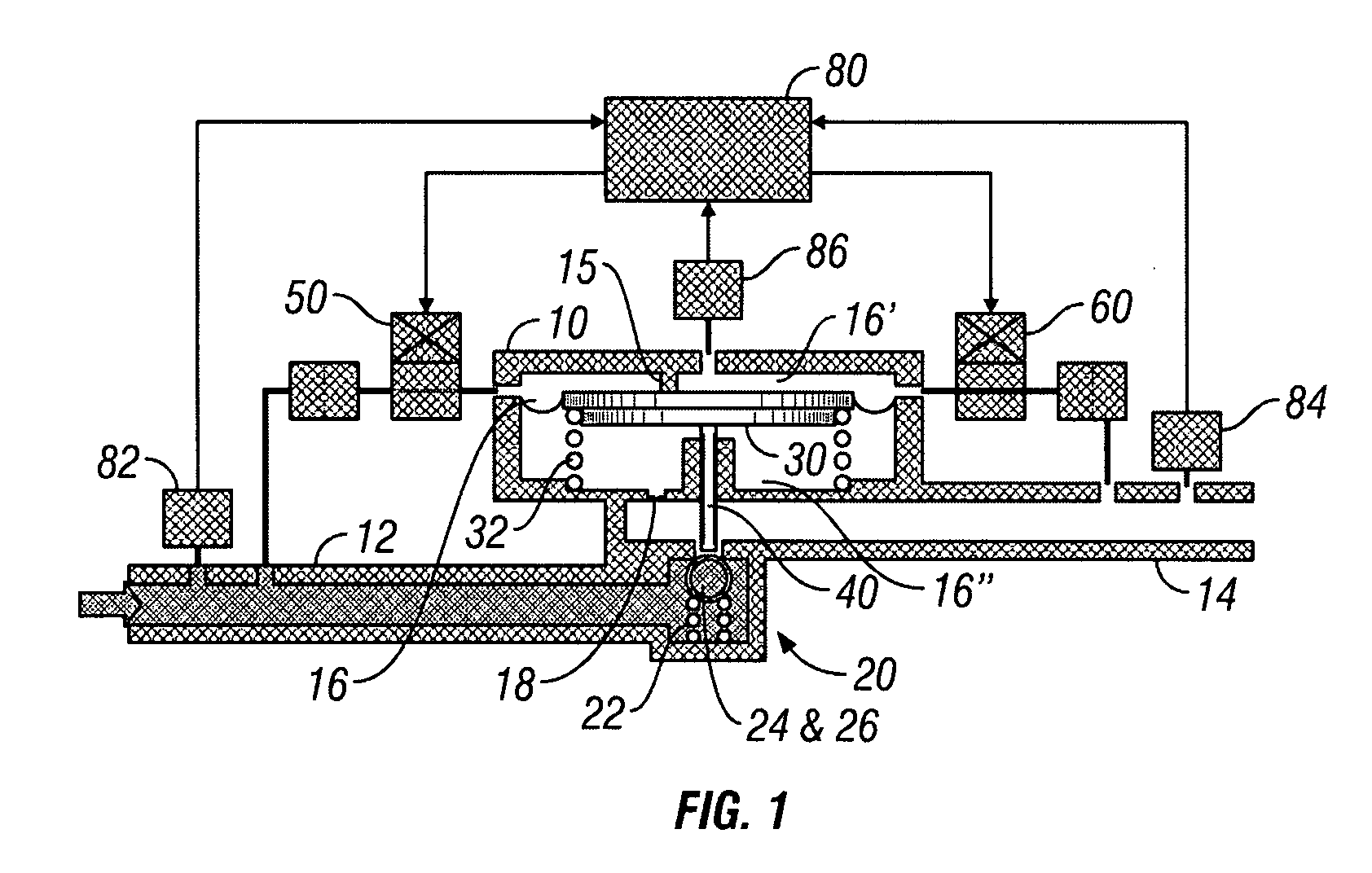

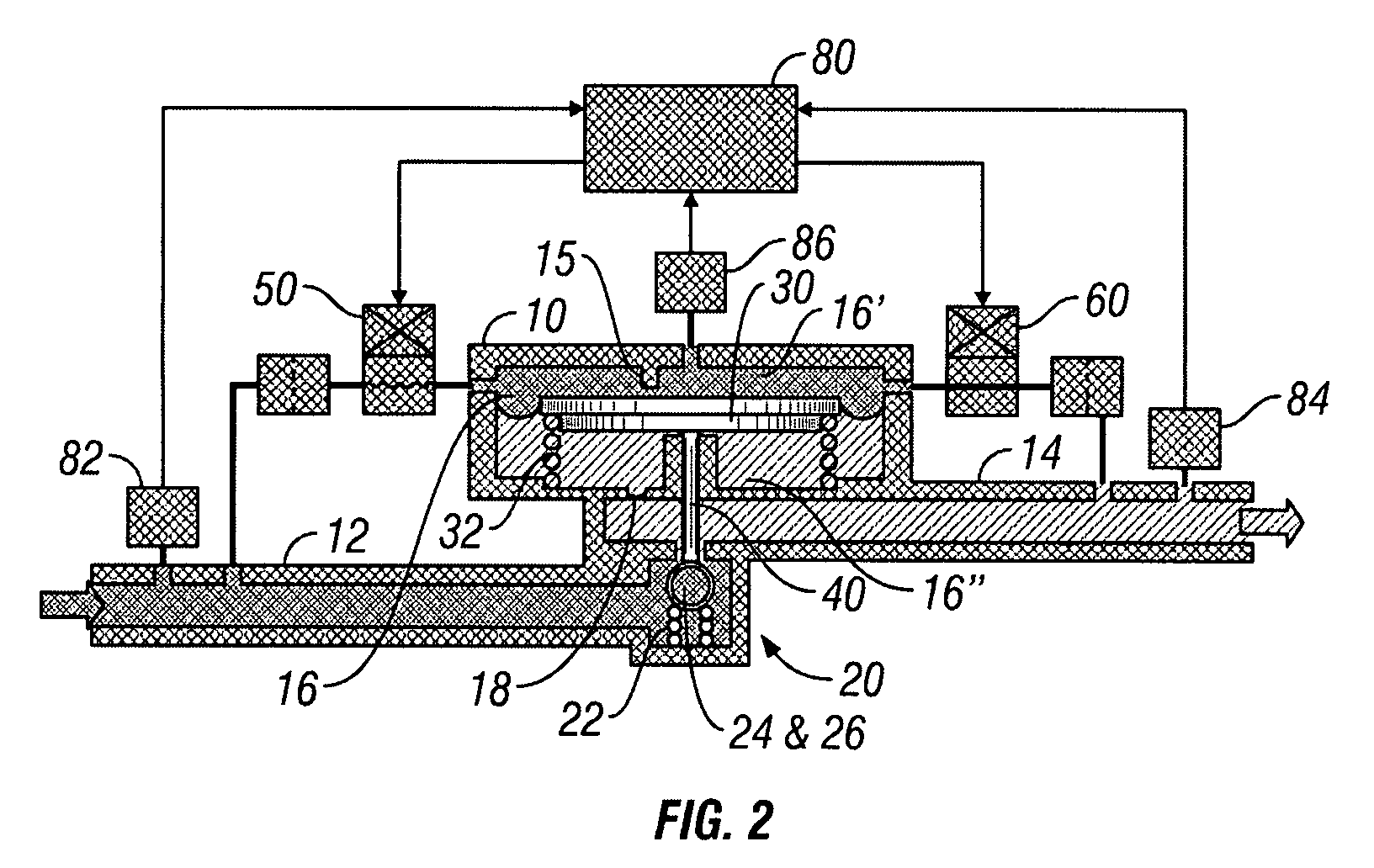

Modular fuel conditioning system

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

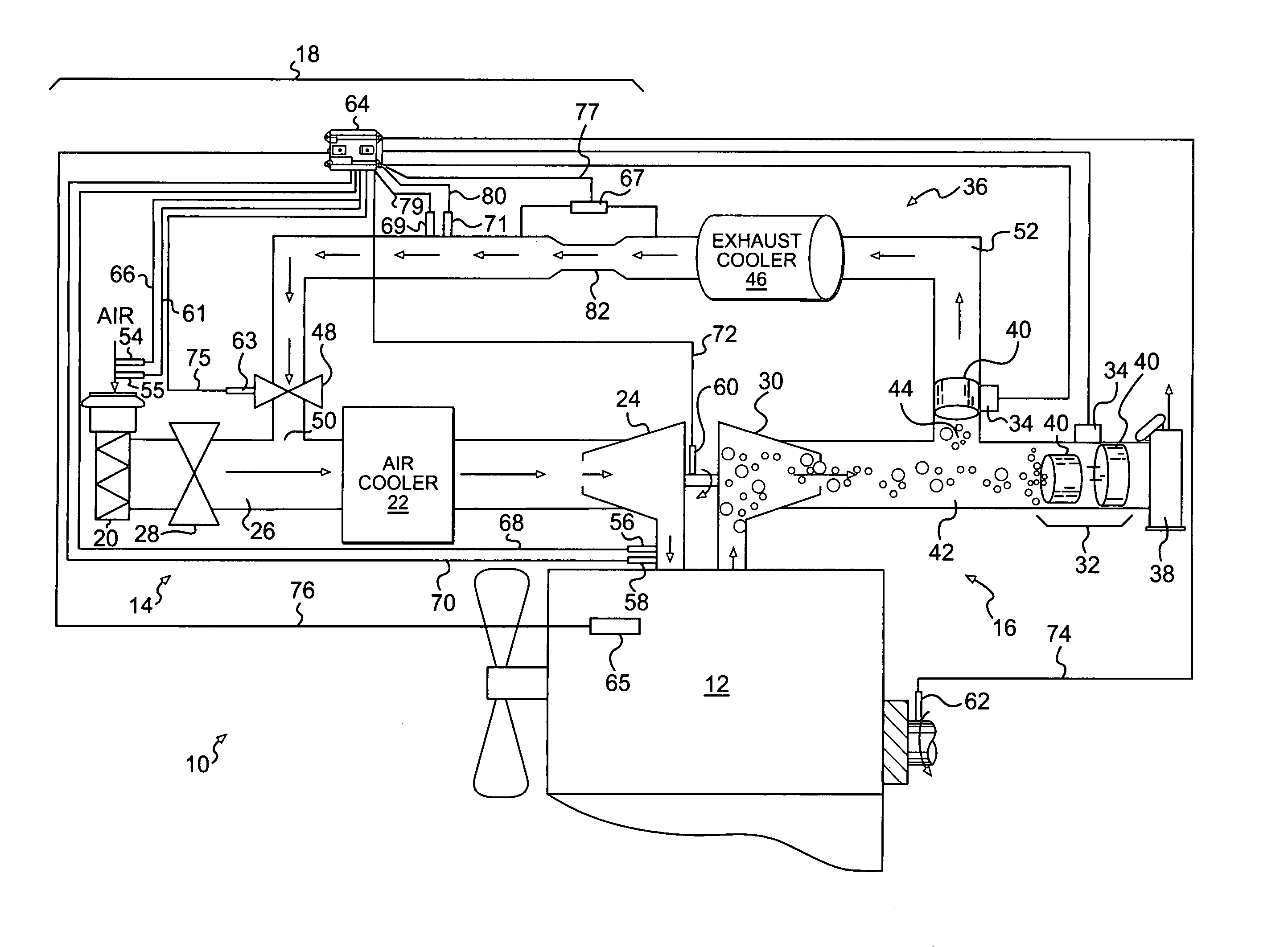

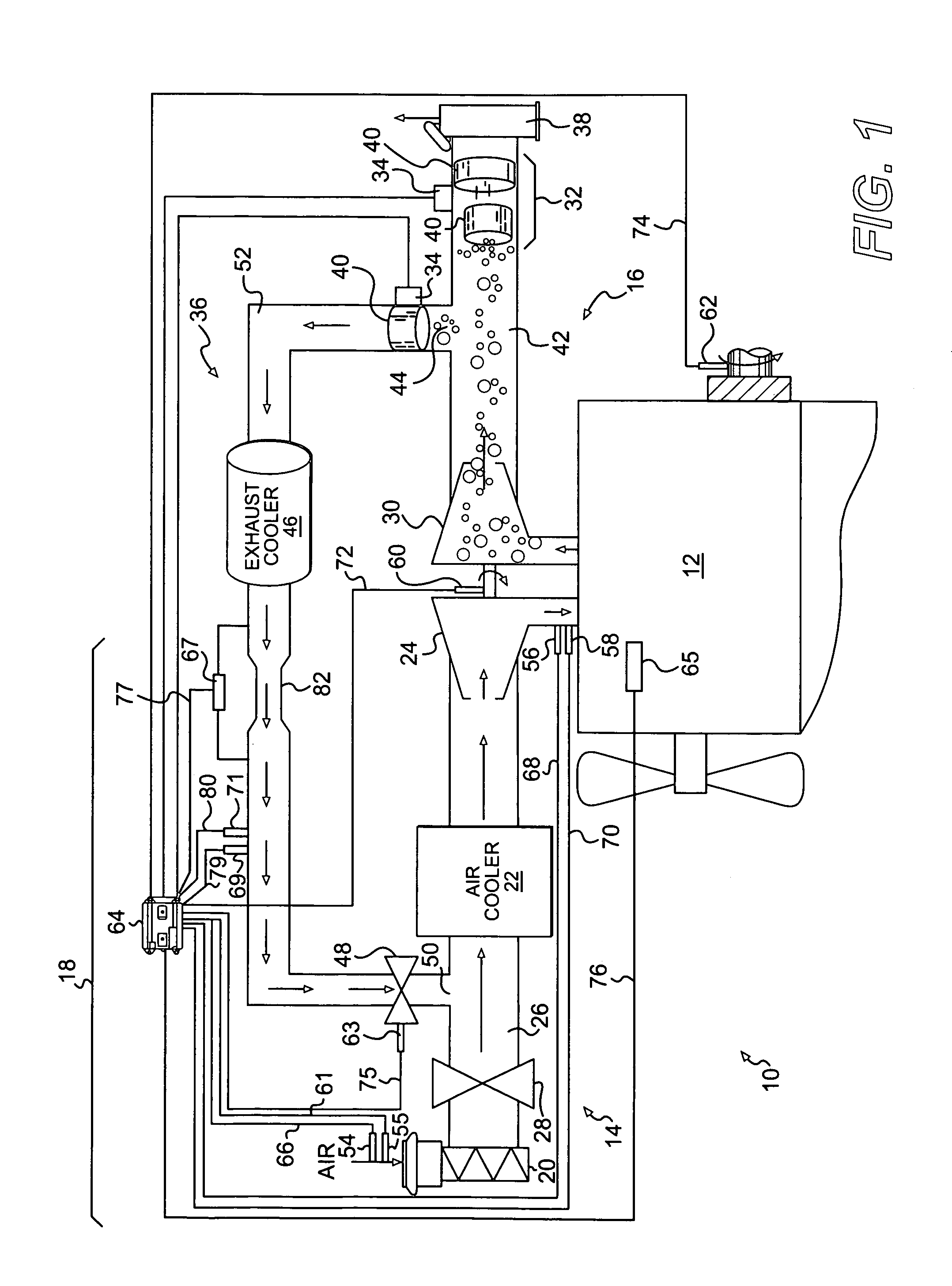

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

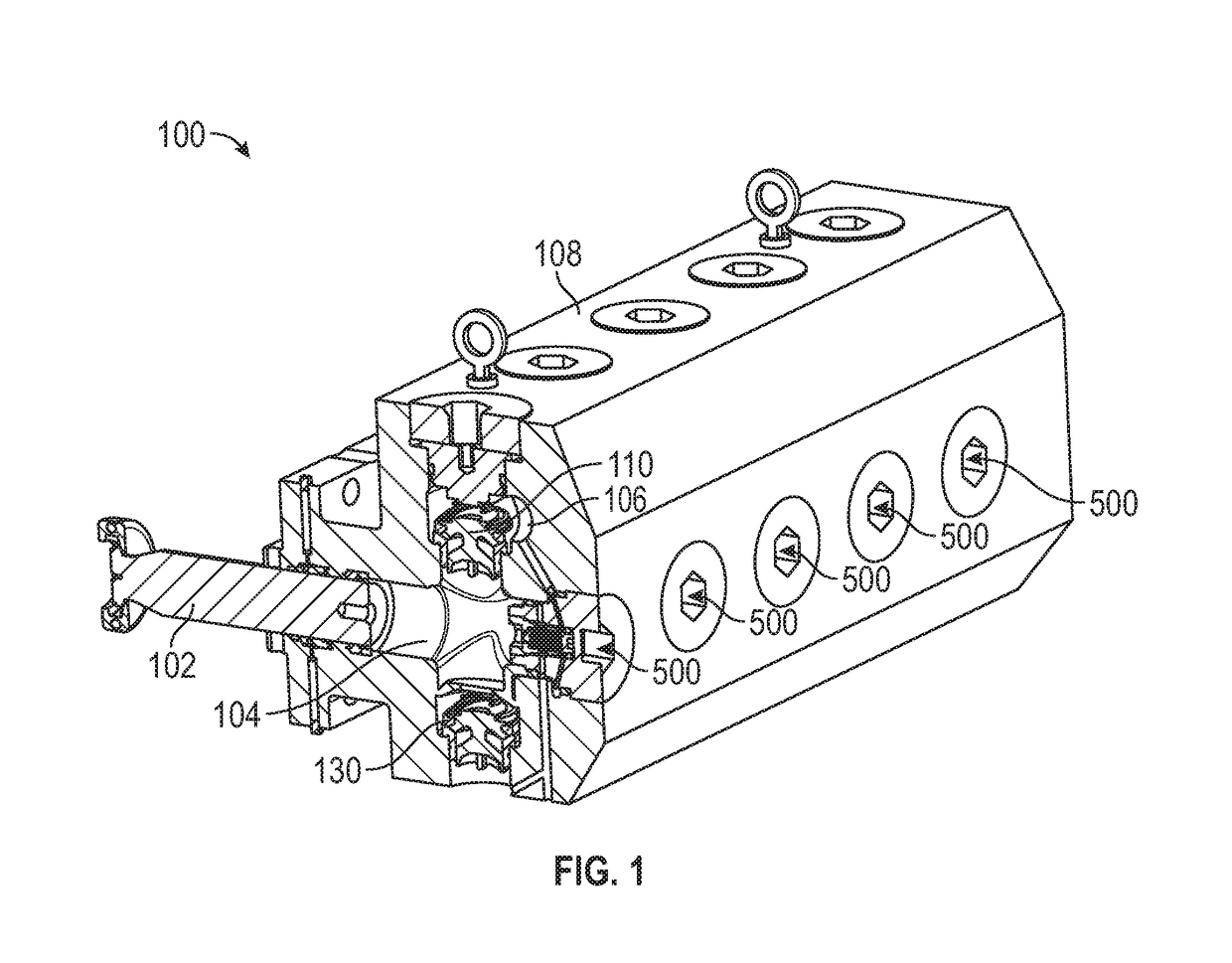

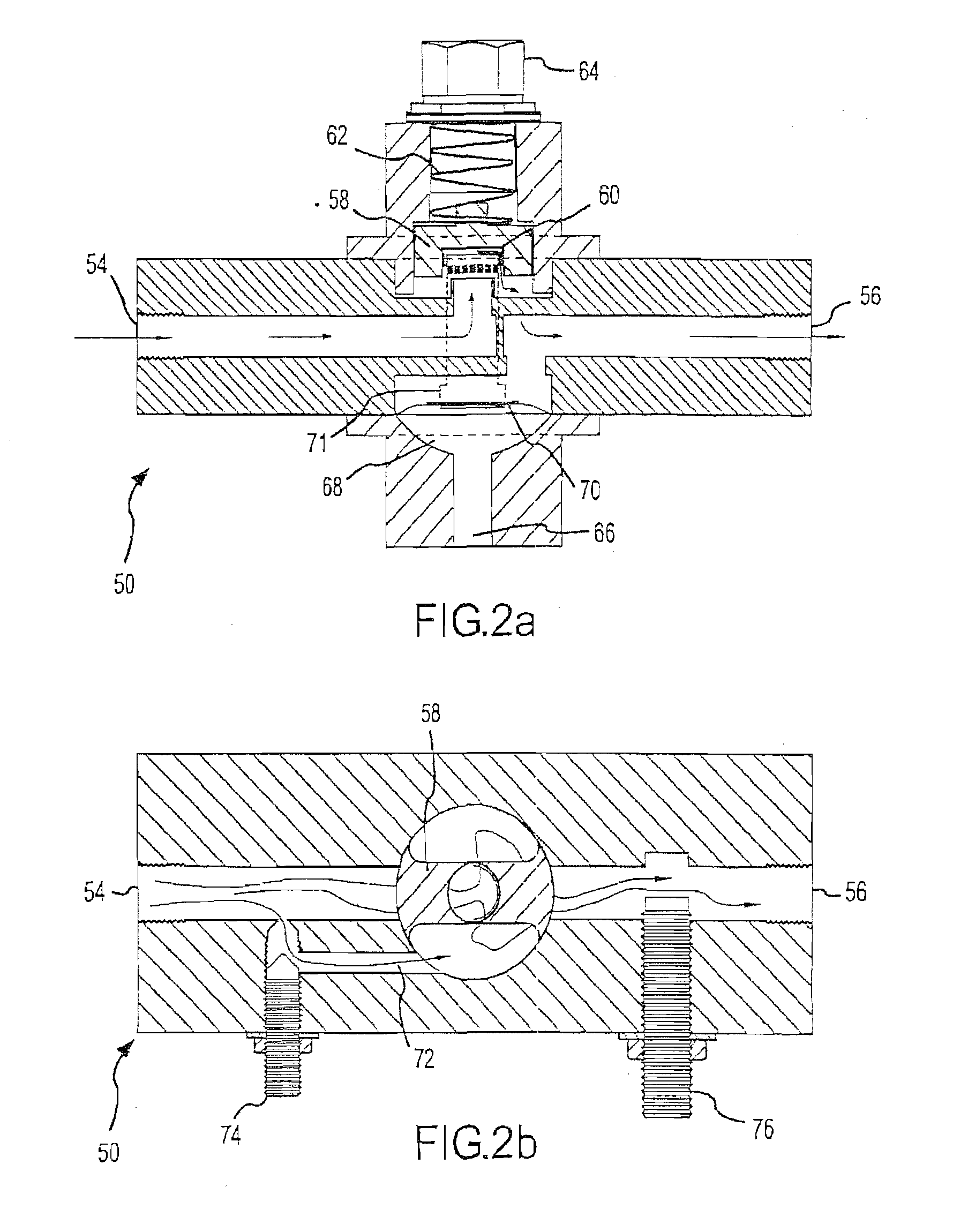

Over pressure relief system for fluid ends

ActiveUS10082137B2Fluid pressure sealed jointsPositive displacement pump componentsInlet pressurePiston

A relief valve assembly includes a housing assembly defining a chamber therein. The relief valve assembly includes a piston. The piston may be at least partially disposed within the chamber. The relief valve assembly includes a pilot inlet. The pilot inlet may be configured to provide a pilot pressure proximate a second end of the chamber. The relief valve assembly includes an overpressure inlet sealed from a first end of the chamber by the piston. The overpressure inlet may be configured to provide an inlet pressure which may actuate the piston when the inlet pressure exceeds the pilot pressure.

Owner:CATERPILLAR INC

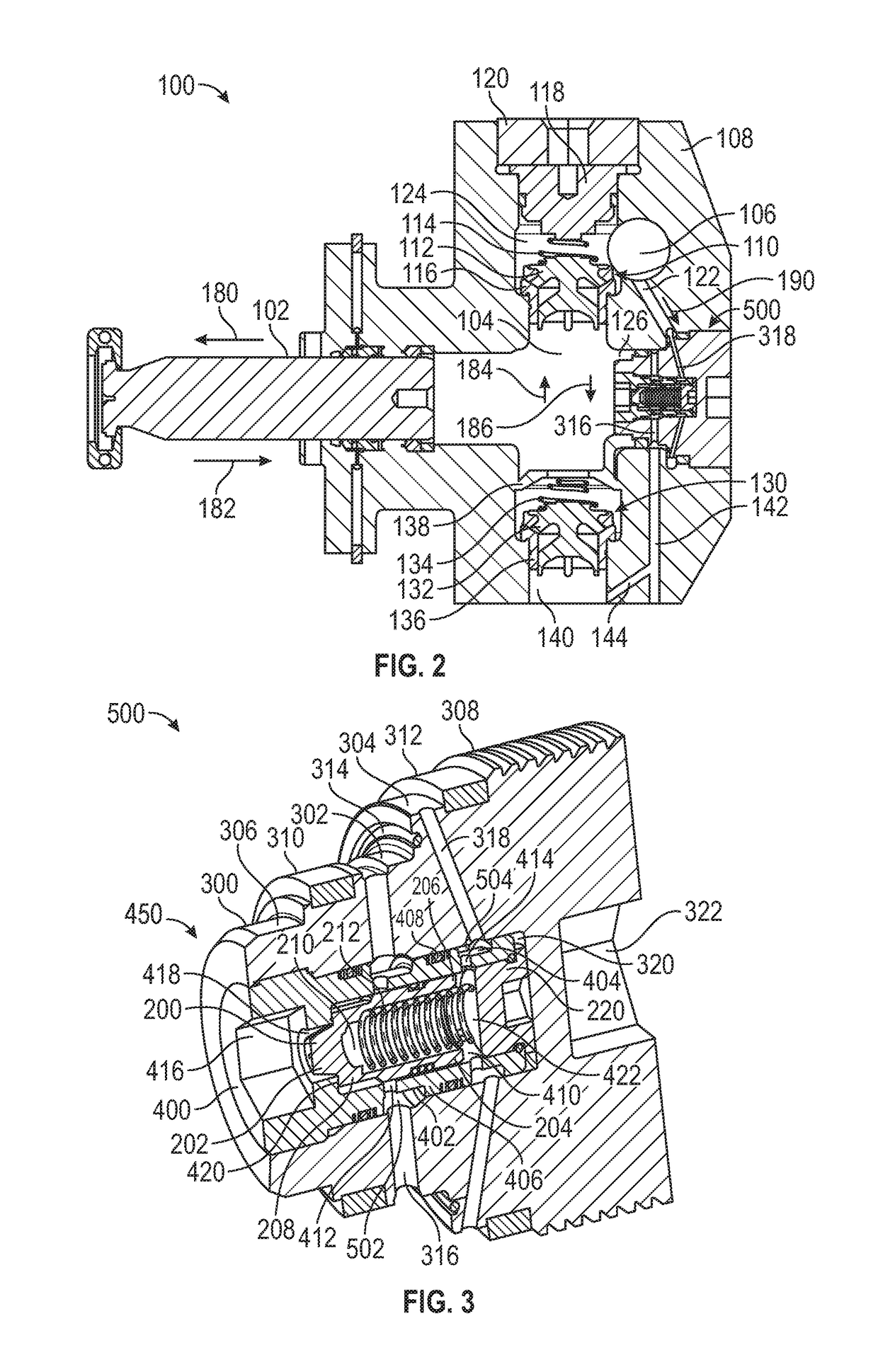

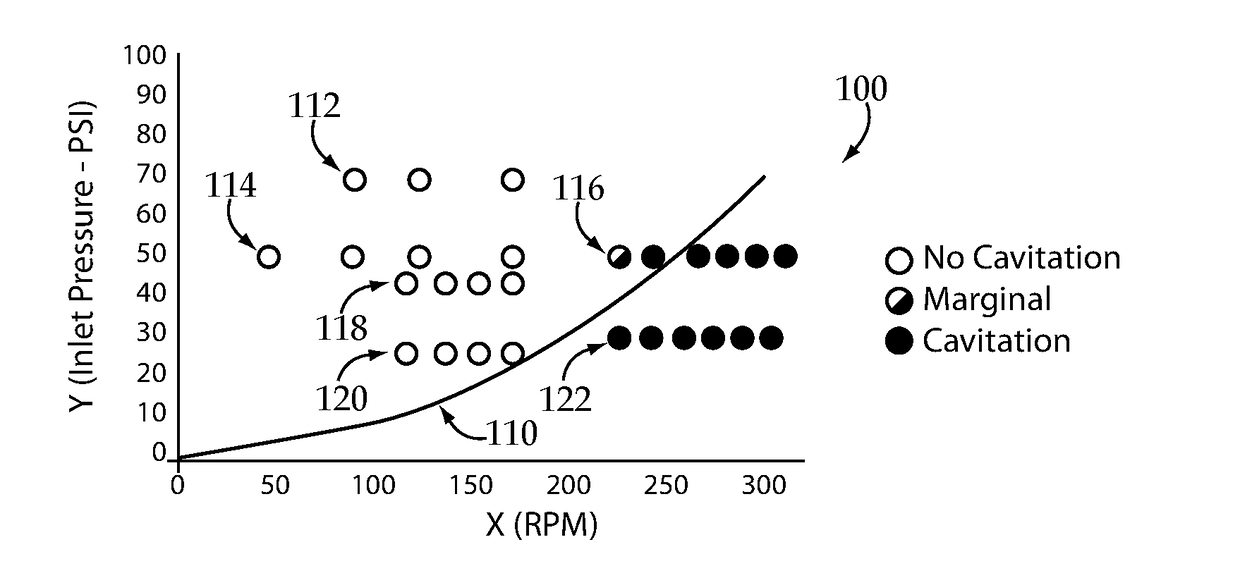

Cavitation limiting strategies for pumping system

Operating a pumping system includes moving a pumping element to transition liquid through the pump, and determining a value based at least in part upon inlet pressure and pumping speed that is indicative of a pressure of the liquid within a bore susceptible to cavitation. Pumping speed and / or inlet pressure can be varied responsive to the determined value to limit cavitation.

Owner:CATERPILLAR INC

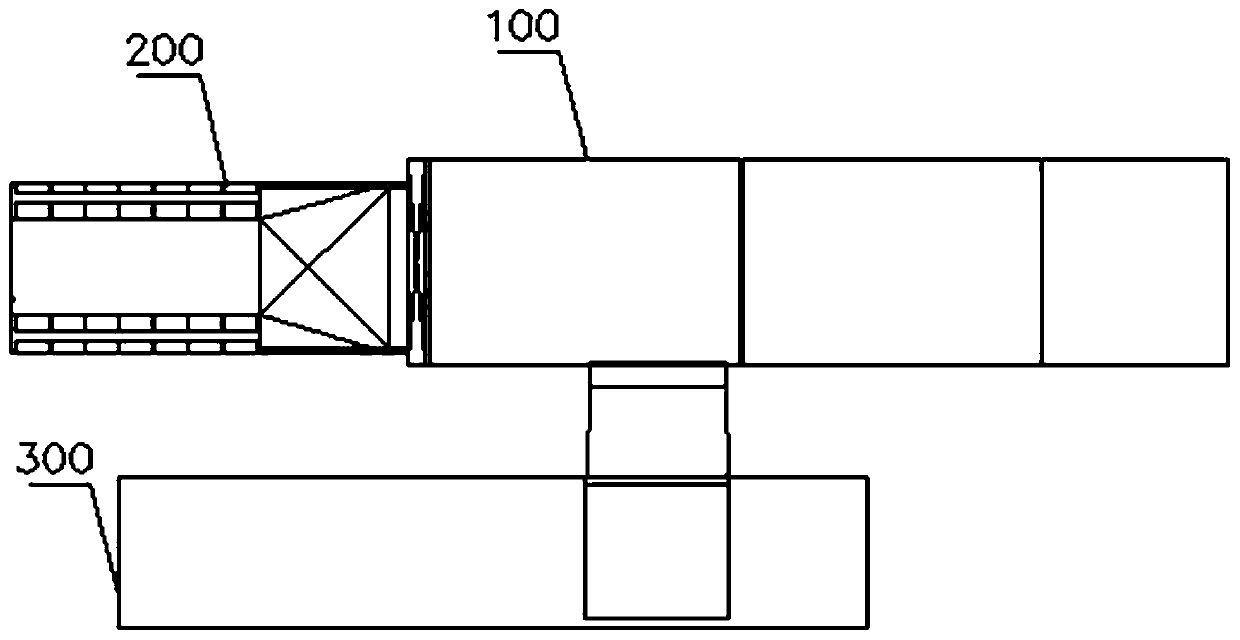

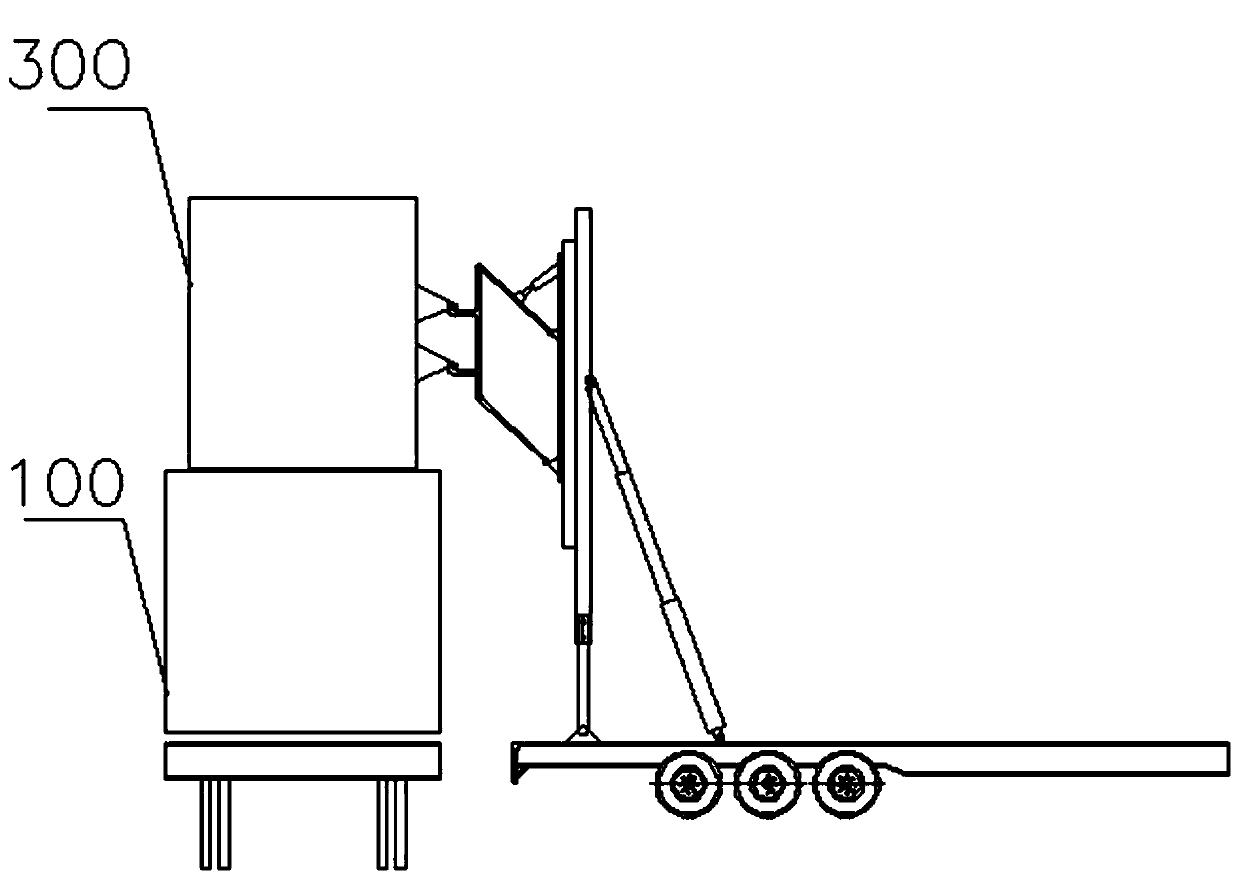

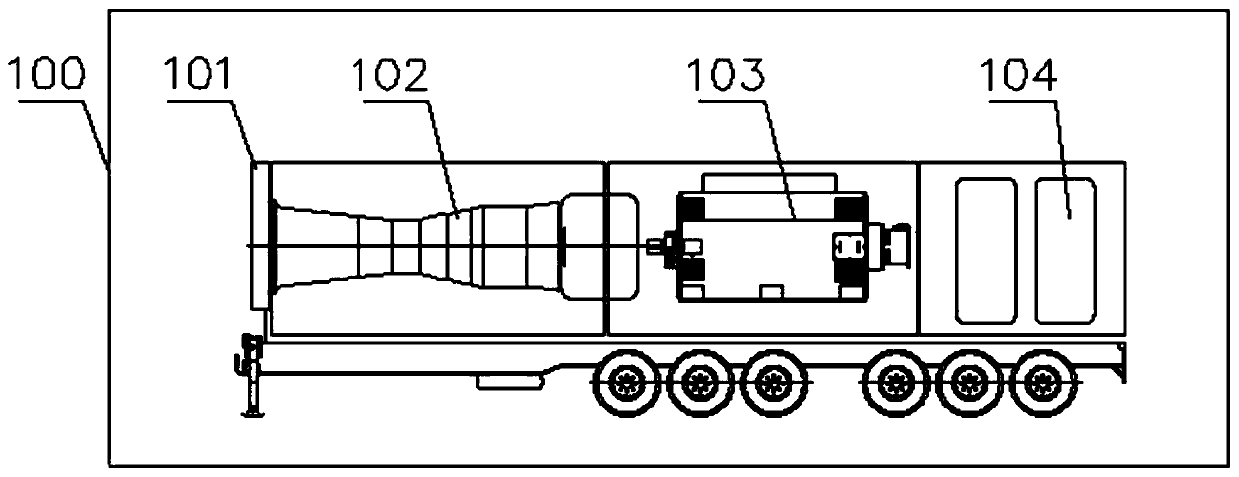

System for providing mobile electric power

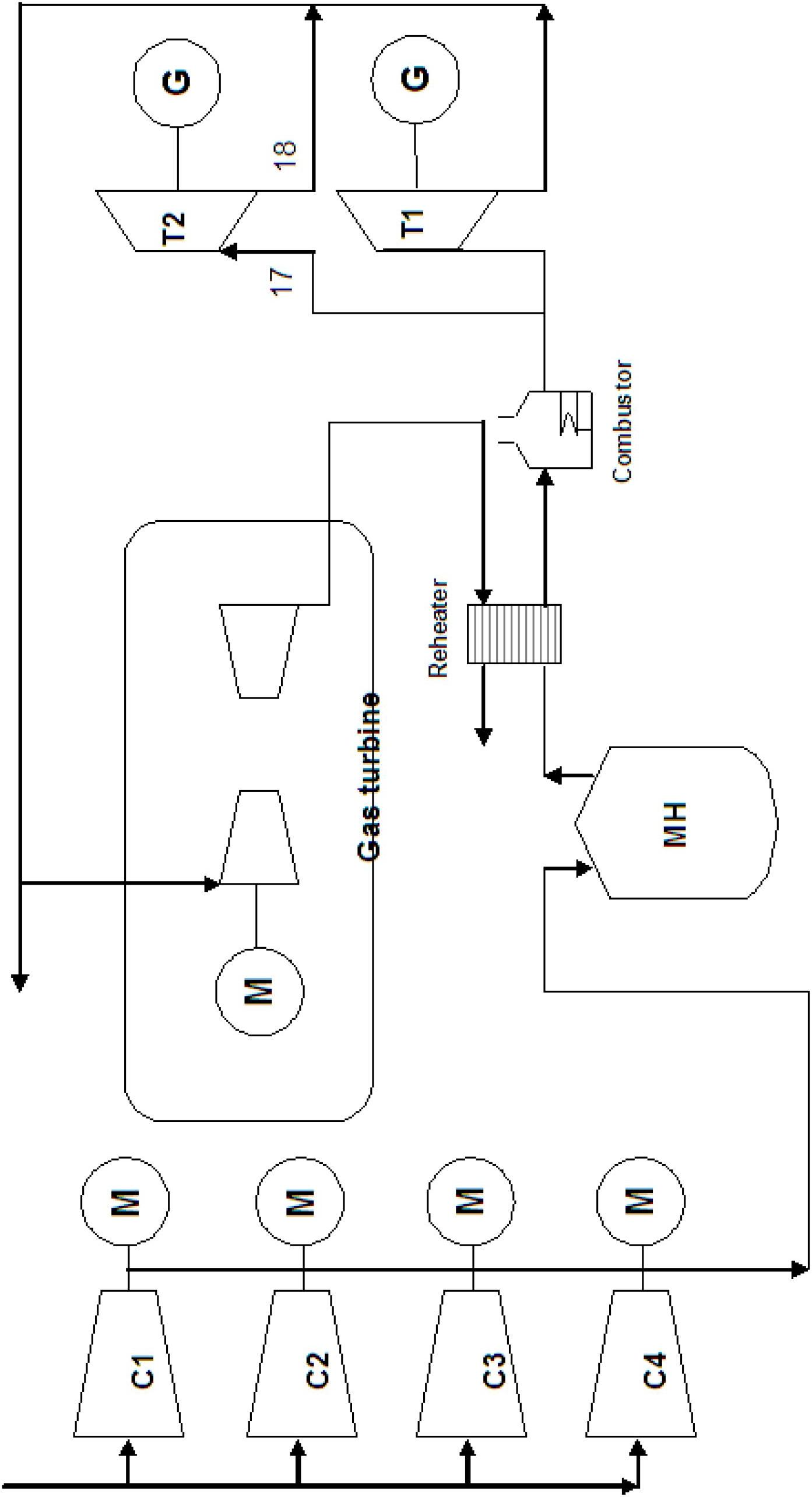

PendingCN110848028AReduce in quantityLow costEngine fuctionsGas turbine plantsInlet pressureControl theory

The invention discloses a system for providing mobile electric power. Equipment needed by mobile electric power is integrated on three transportation tools, so that one overall transportation can be combined, the connecting time needed by field operation is greatly shortened, and combination flexibility and high adaptability are achieved. An exhaust system can perform side connection and also canperform top connection, so the connection mode is flexible; and a gas inlet system is axially connected with a gas turbine engine and an electric generator, so that unnecessary bends are avoided, theloss of gas inlet pressure is small and the flowing direction is stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

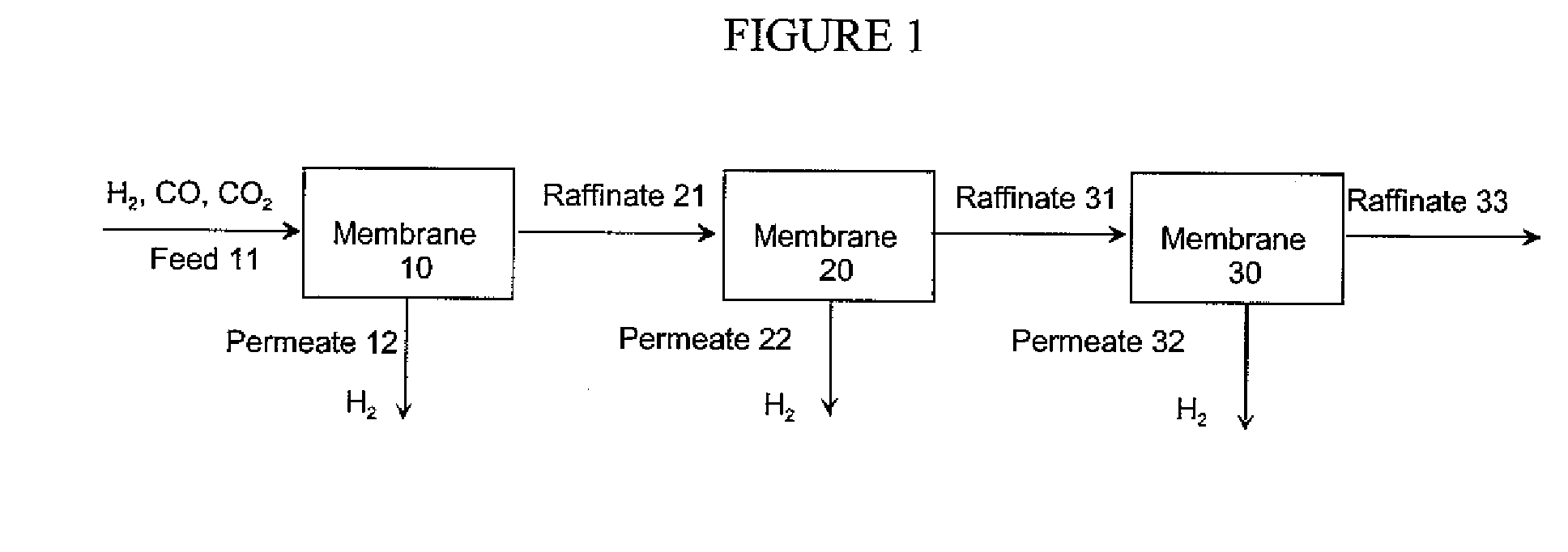

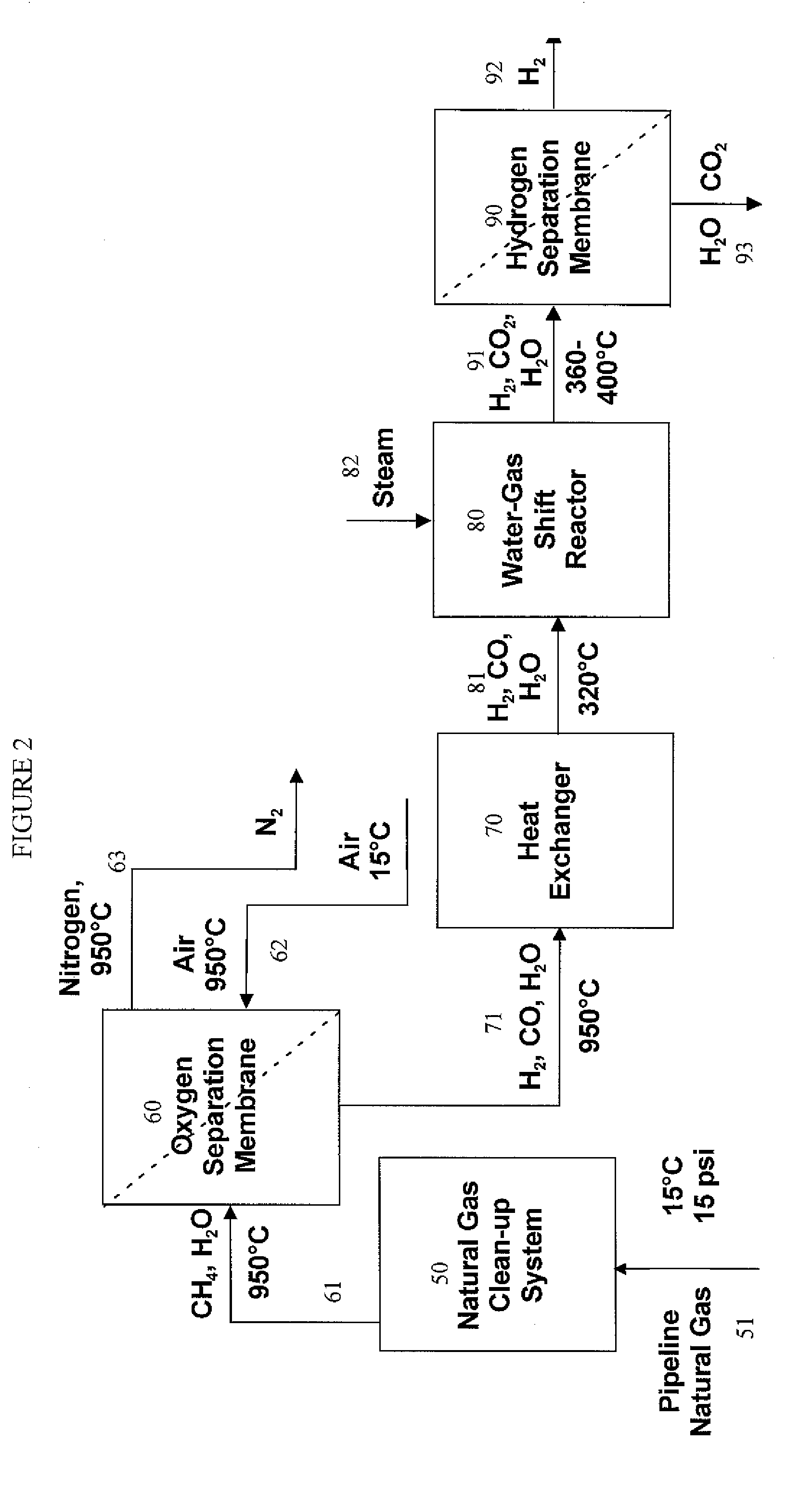

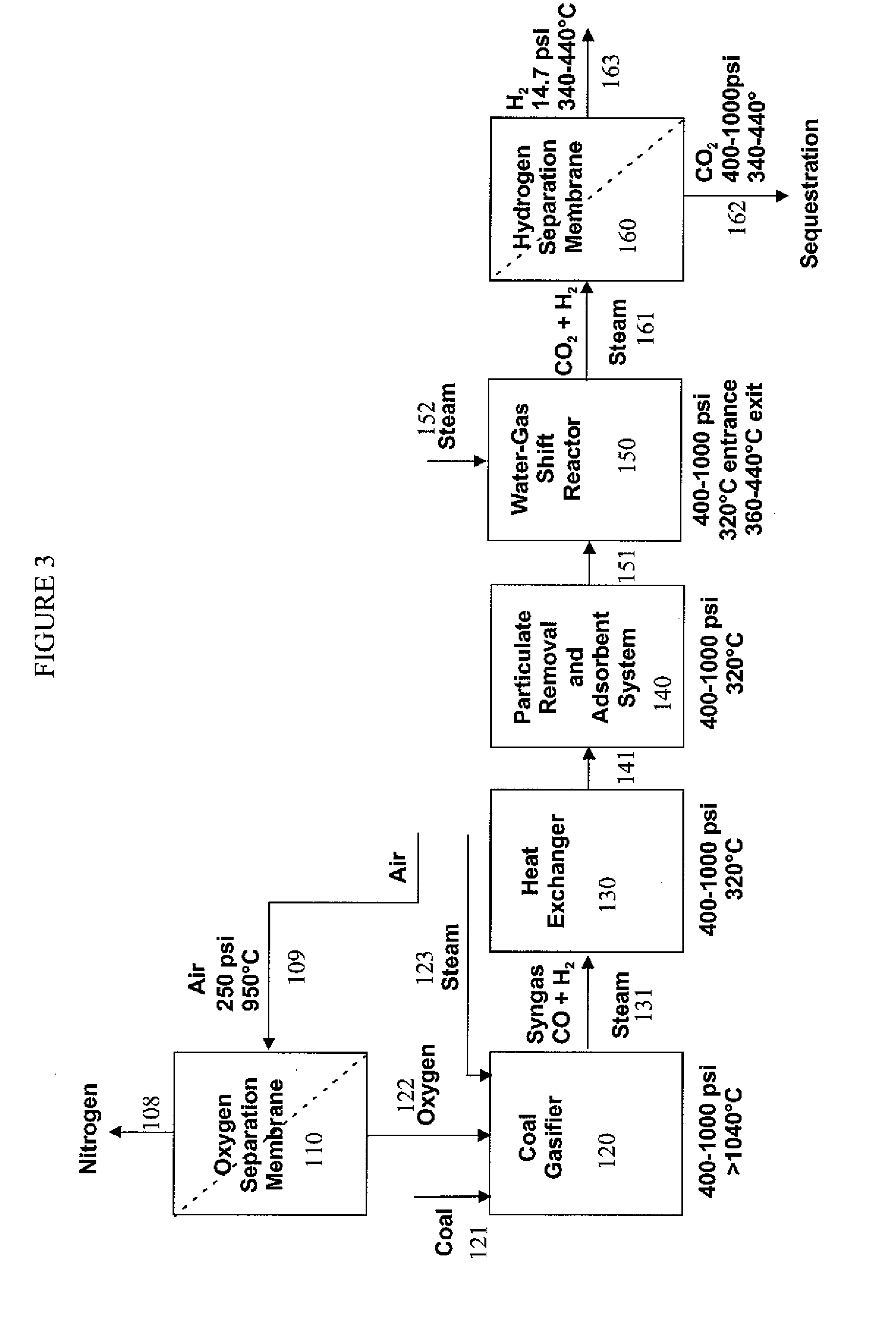

Hydrogen separation process

InactiveUS20080000350A1Isotope separationLoose filtering material filtersAmbient pressureInlet pressure

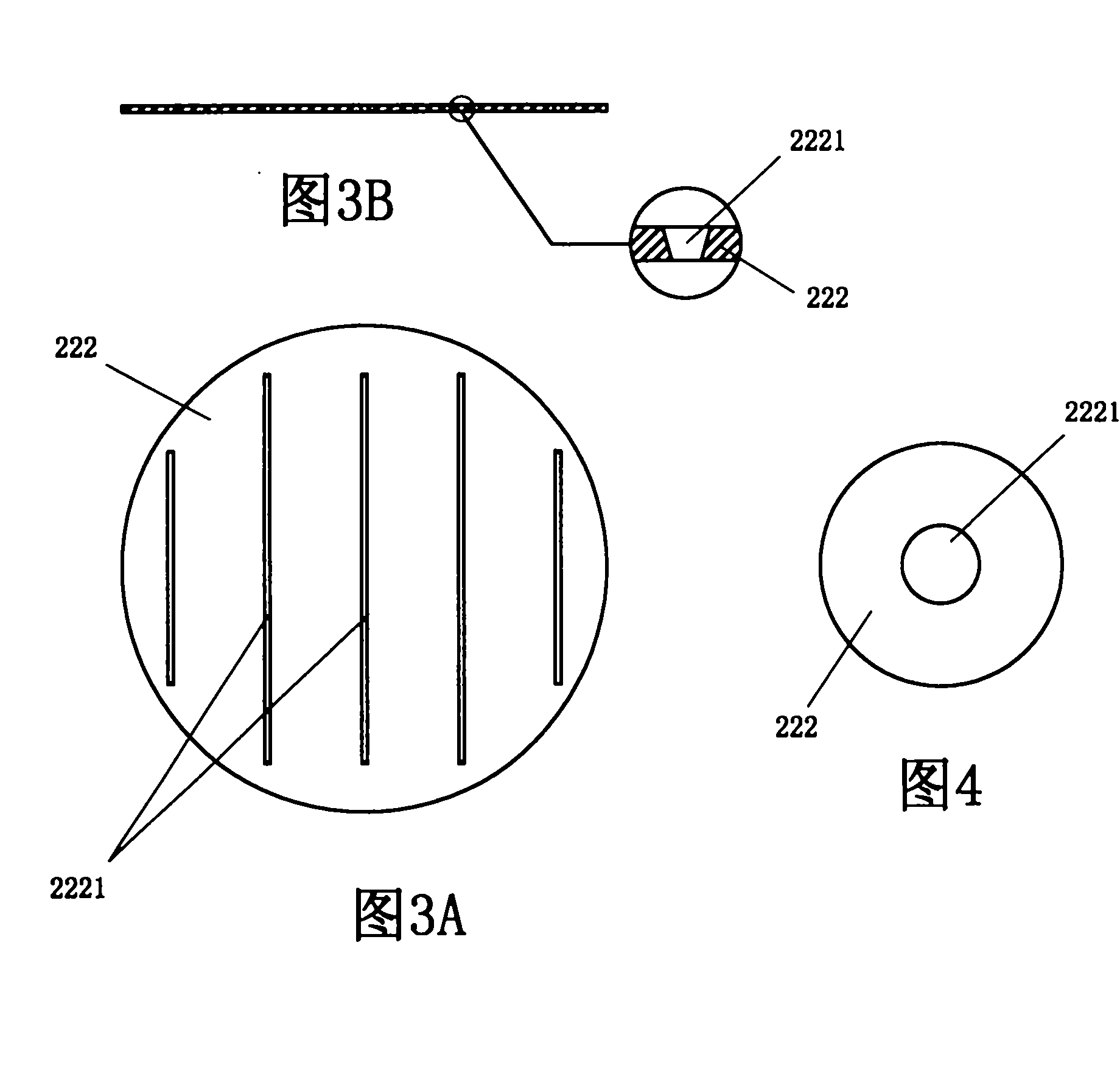

A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to a hydrogen separation membrane system comprising a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for separating a hydrogen-rich product stream from a feed stream comprising hydrogen and at least one carbon-containing gas, comprising feeding the feed stream, at an inlet pressure greater than atmospheric pressure and a temperature greater than 200° C., to an integrated water gas shift / hydrogen separation membrane system wherein the hydrogen separation membrane system comprises a membrane that is selectively permeable to hydrogen, and producing a hydrogen-rich permeate product stream on the permeate side of the membrane and a carbon dioxide-rich product raffinate stream on the raffinate side of the membrane. A method for pretreating a membrane, comprising: heating the membrane to a desired operating temperature and desired feed pressure in a flow of inert gas for a sufficient time to cause the membrane to mechanically deform; decreasing the feed pressure to approximately ambient pressure; and optionally, flowing an oxidizing agent across the membrane before, during, or after deformation of the membrane. A method of supporting a hydrogen separation membrane system comprising selecting a hydrogen separation membrane system comprising one or more catalyst outer layers deposited on a hydrogen transport membrane layer and sealing the hydrogen separation membrane system to a porous support.

Owner:ELTRON RES

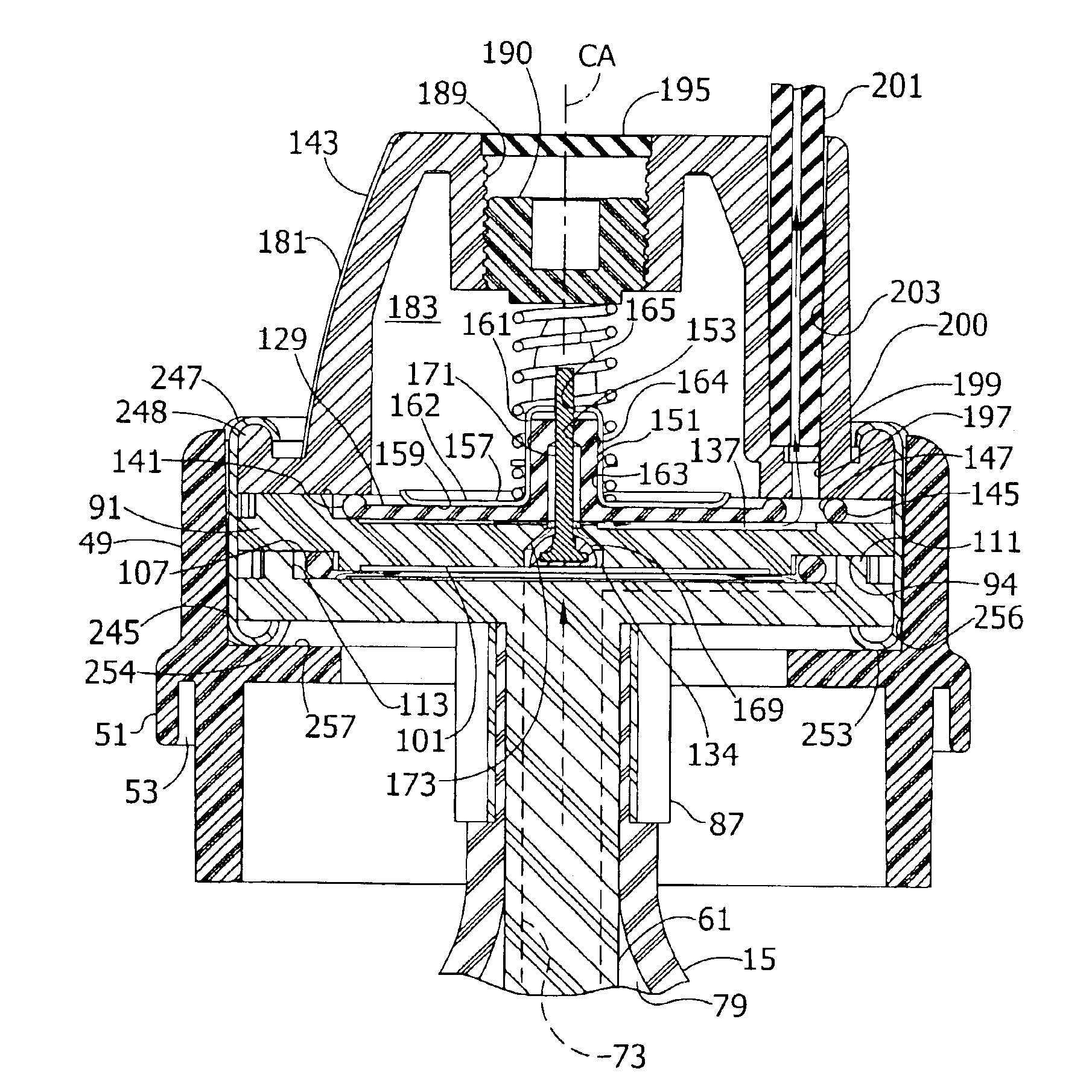

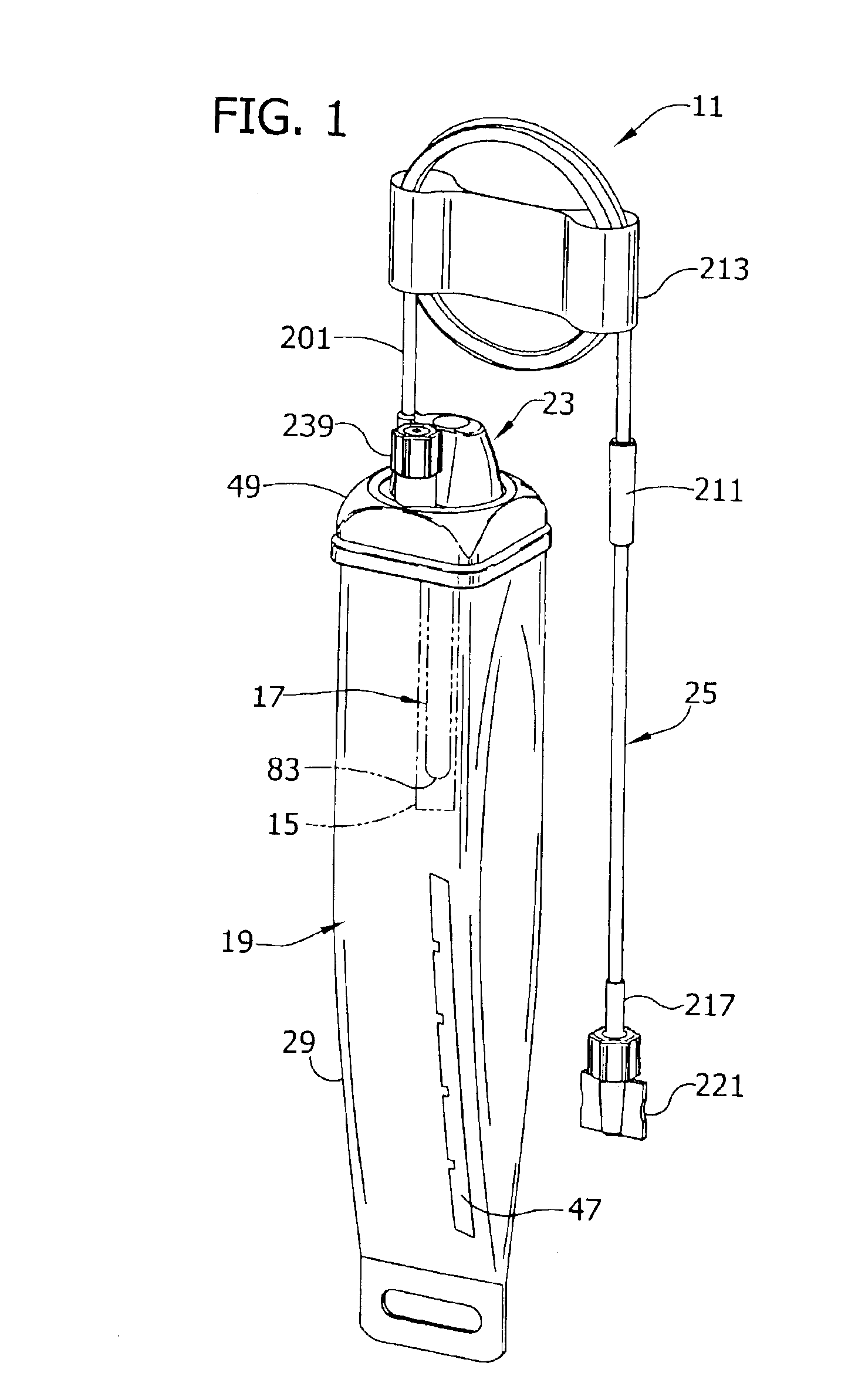

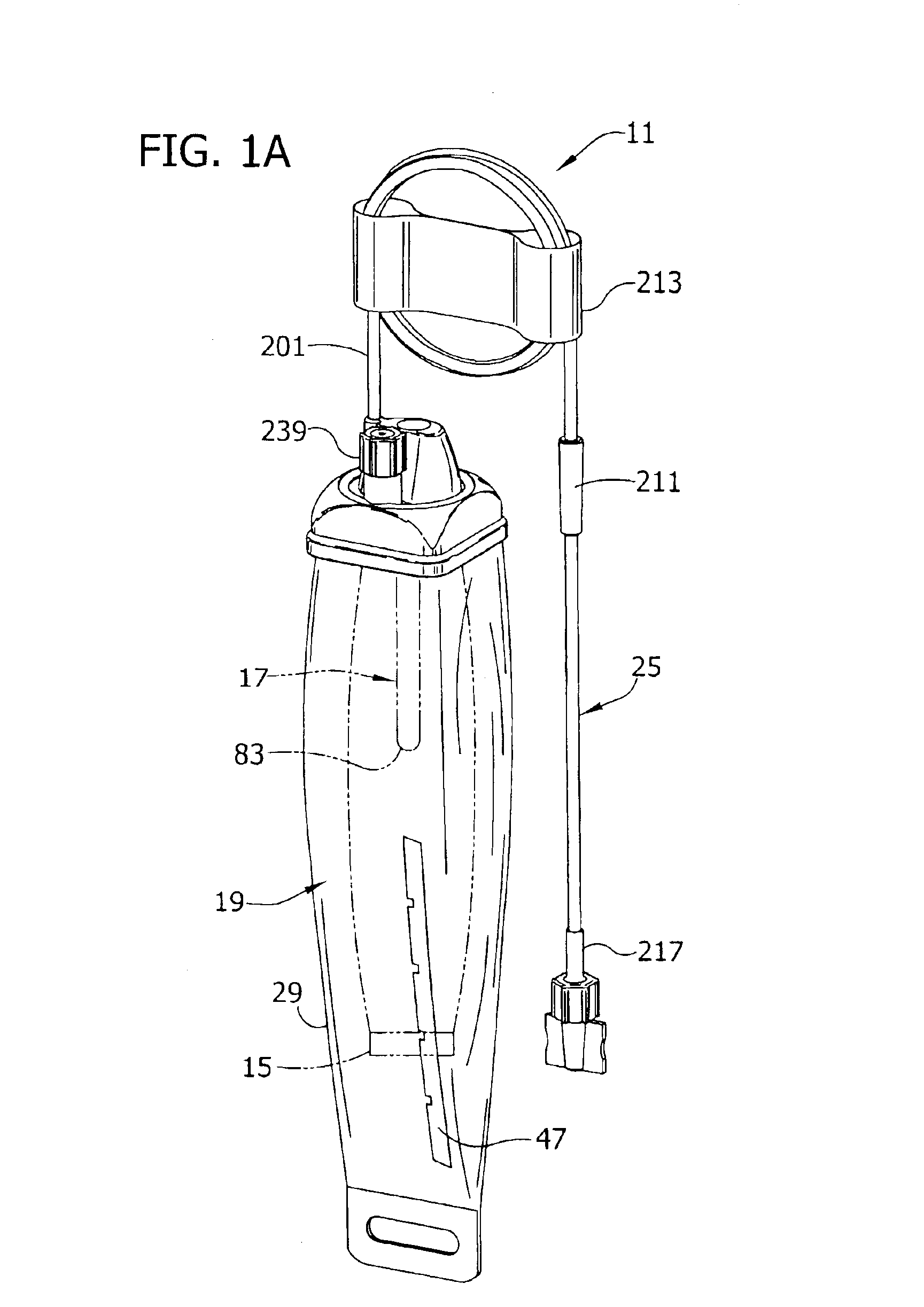

Pressure regulator for infusor

InactiveUS6892755B2Operating means/releasing devices for valvesMedical devicesInfusion setInlet pressure

An improved ambulatory infusion device for dispensing a fluid into a patient includes a flexible bladder enclosure having a first open end a closed second end. The closed second end of the sheath is free to conform to the body of the patient so that the device is comfortable when worn. In other aspects, a pressure regulator of the device is adapted to maintain the outlet pressure within a predetermined range of pressures so that the fluid flow rate is substantially constant during fluid flow. A flow restrictor of the device is formed of flexible tubing.An ambulatory infusion device for dispensing a fluid at a predetermined fluid flow rate includes an elastic bladder having an interior volume for storing the fluid under pressure and an opening for dispensing the fluid. A pressure regulator is in fluid communication with the opening of the bladder and includes an inlet for receiving fluid from the bladder at an inlet pressure and an outlet for discharging the fluid at a predetermined outlet pressure. A valve at the inlet has a hemispheric-shaped head adapted to cooperate with a frustoconic-shaped seat to promote uniform fluid flow therebetween. A movable diaphragm is connected to the valve, and a valve plate opposite a surface of the diaphragm has channels or texture therein. The diaphragm and the valve are movable in response to the fluid pressure acting on the diaphragm surface.

Owner:BAXTER INT INC

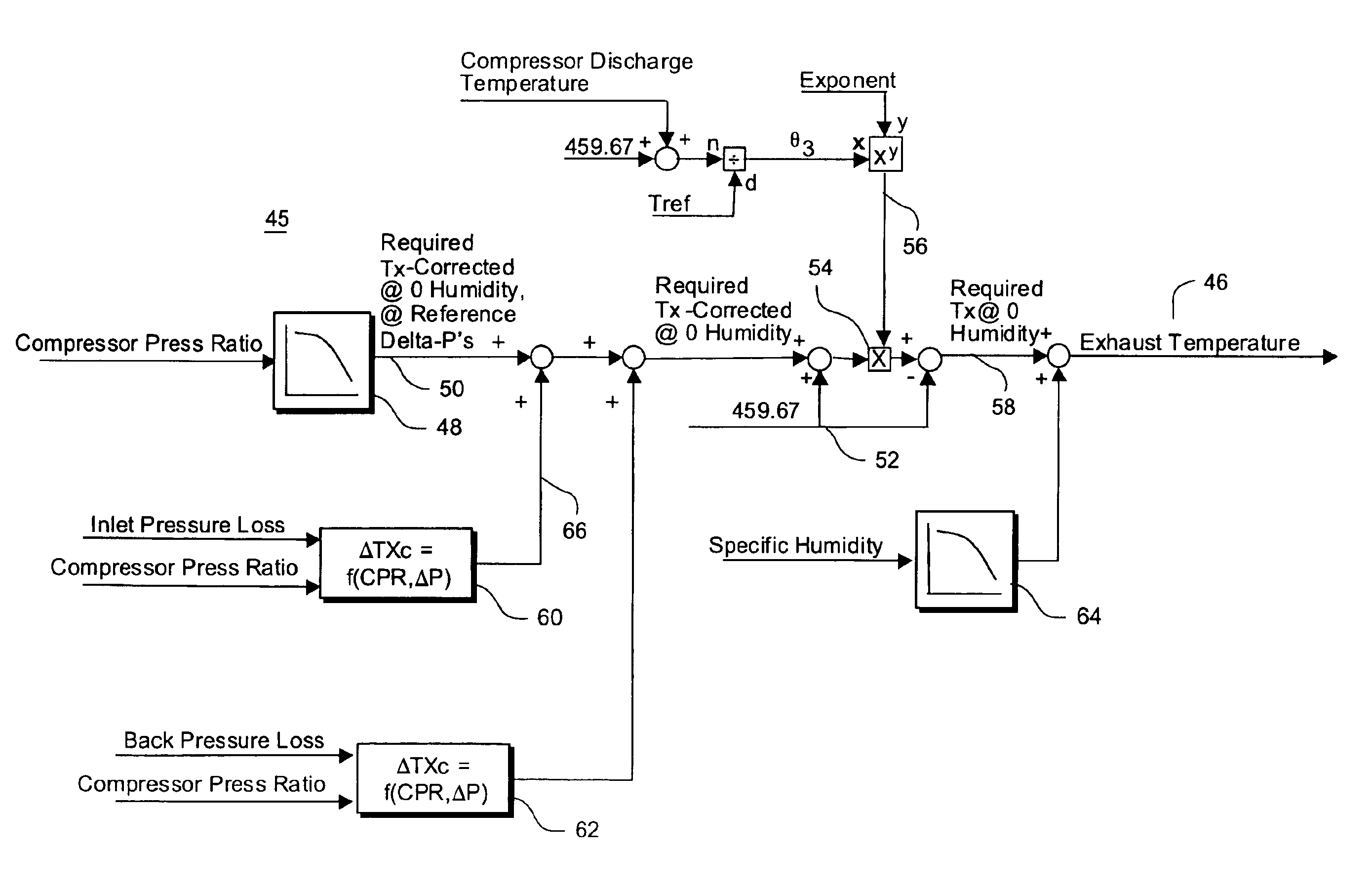

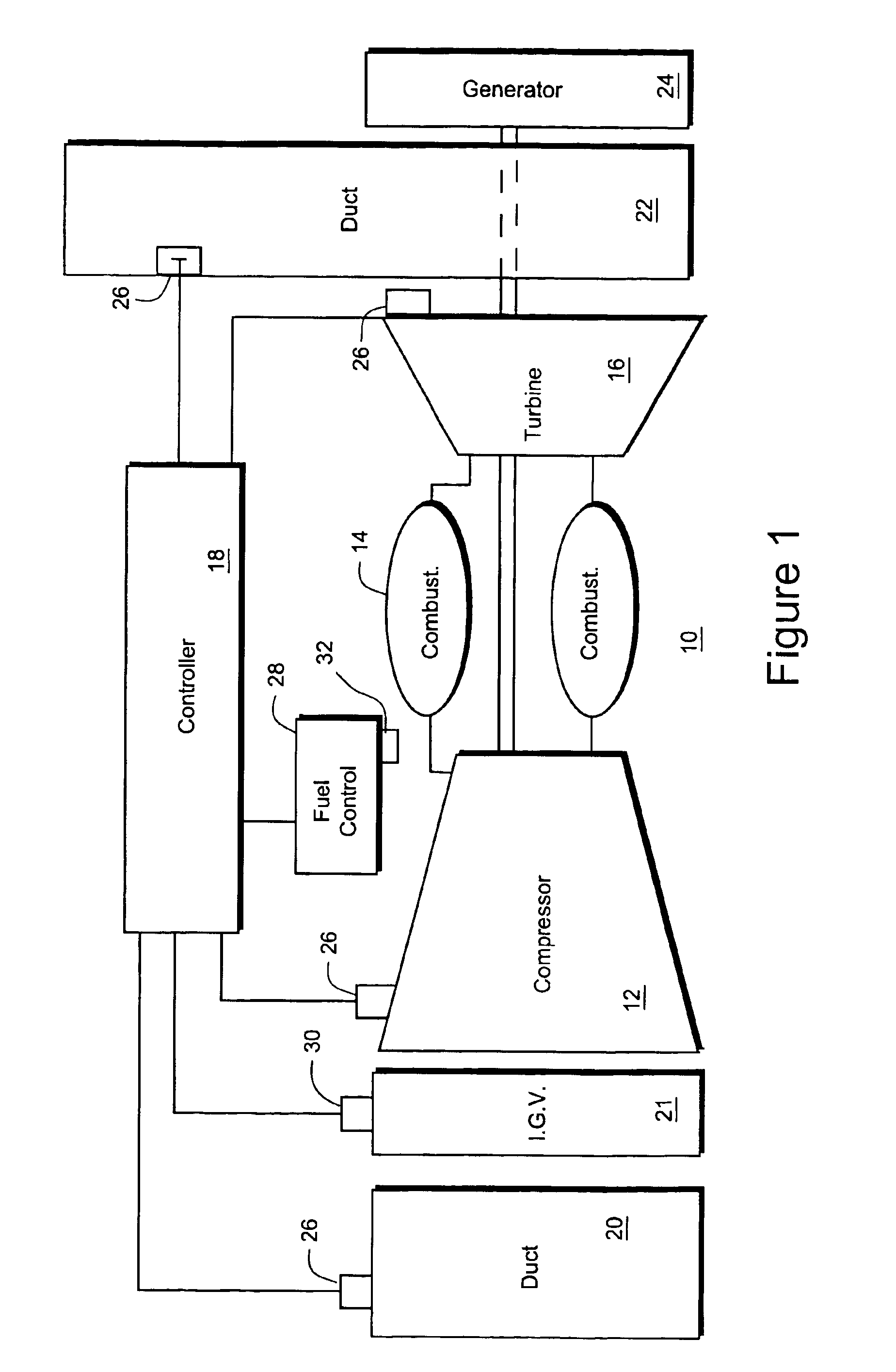

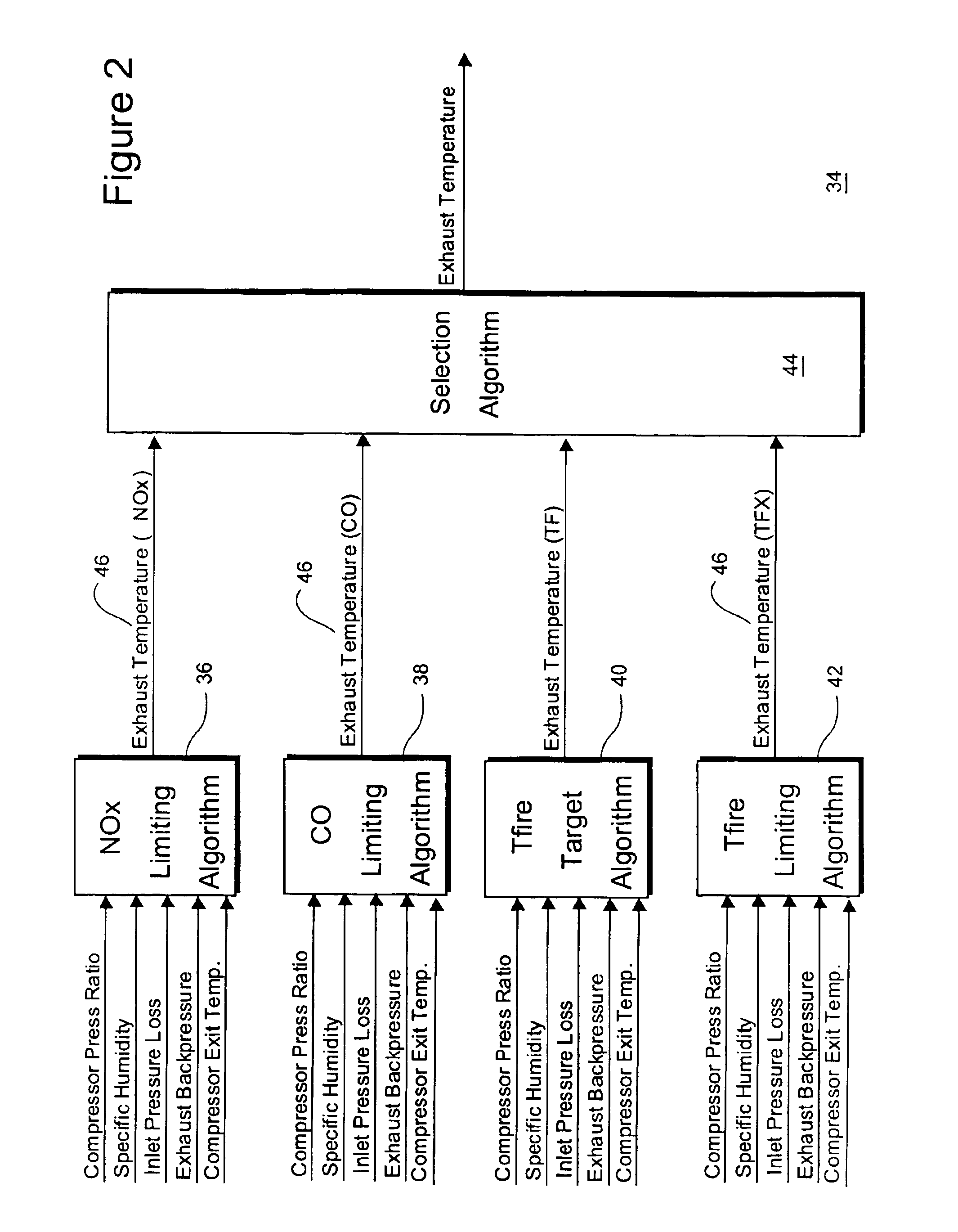

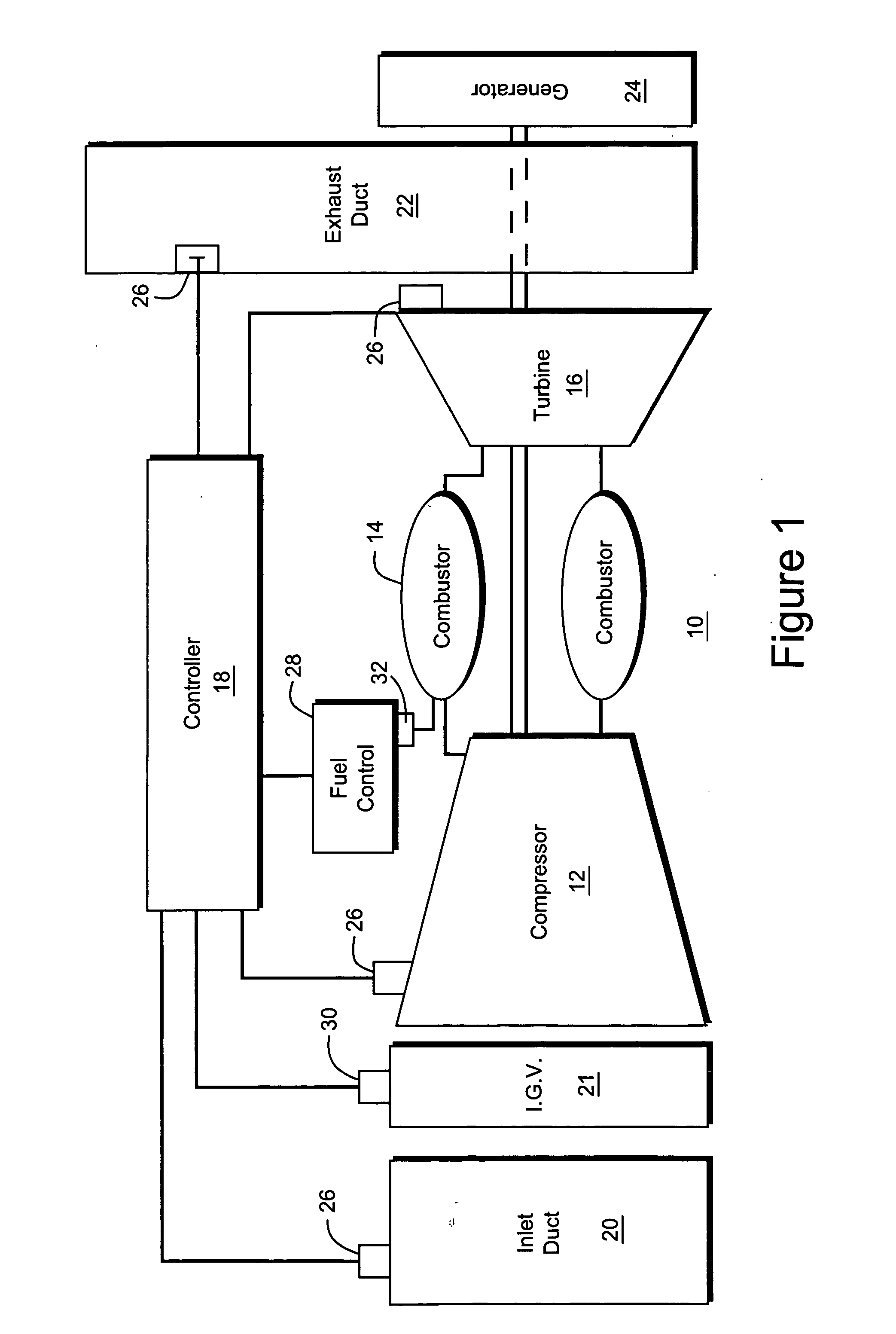

Method and system for controlling gas turbine by adjusting target exhaust temperature

A method for determining a target exhaust temperature for a gas turbine including: determining a target exhaust temperature based on a compressor pressure condition; determining a temperature adjustment to the target exhaust temperature based on at least one parameter of a group of parameters consisting of specific humidity, compressor inlet pressure loss and turbine exhaust back pressure; and adjusting the target exhaust temperature by applying the temperature adjustment.

Owner:GENERAL ELECTRIC CO

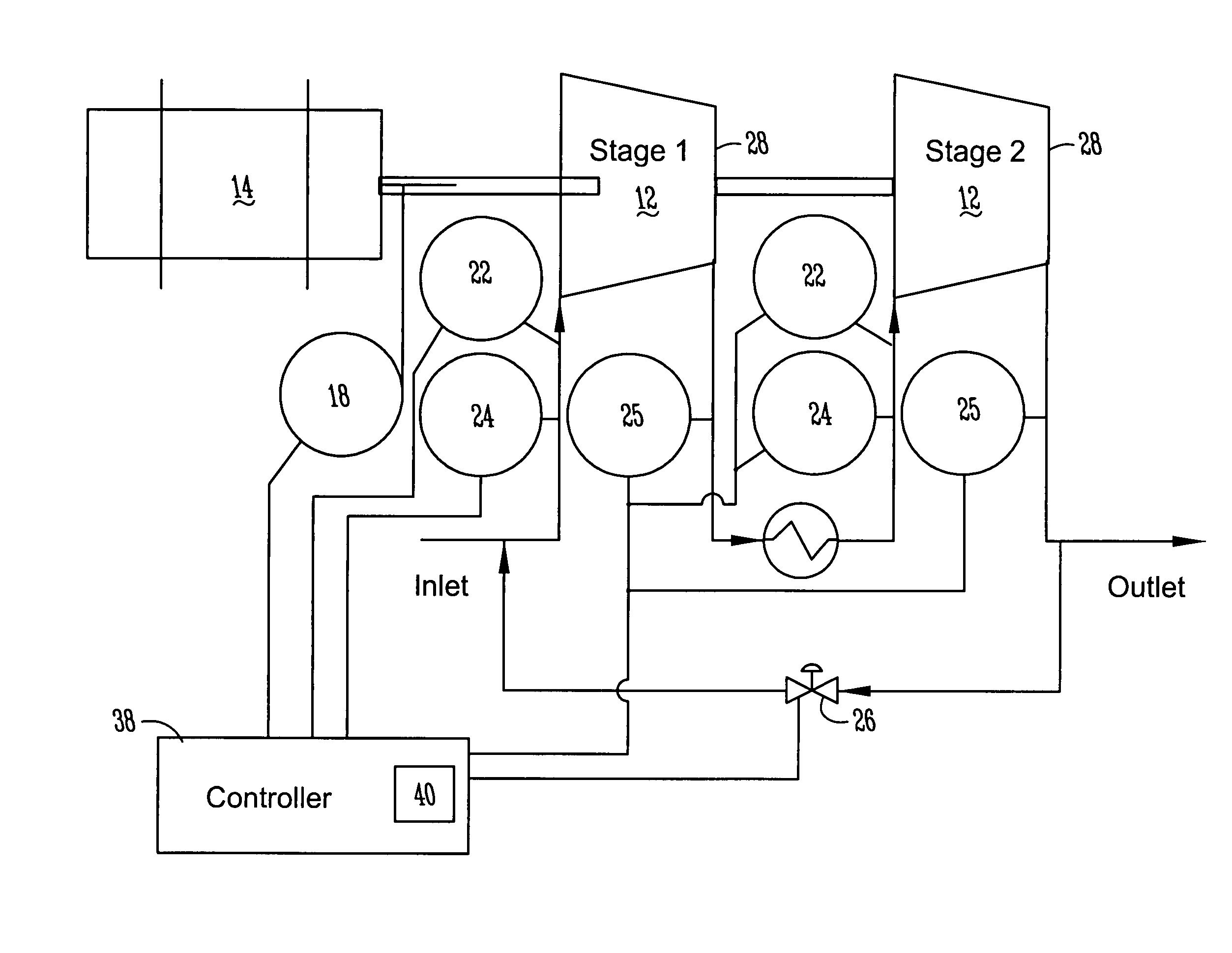

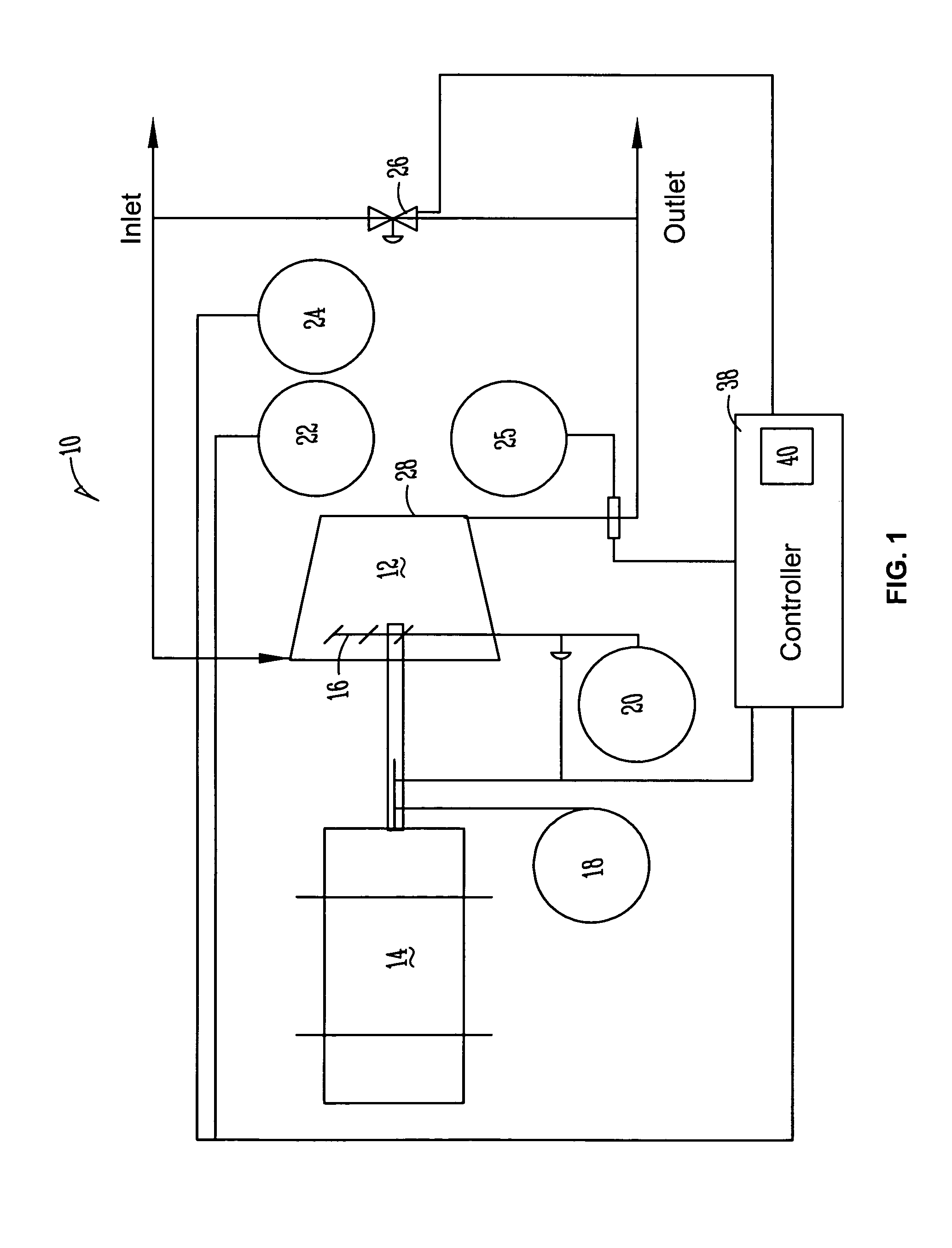

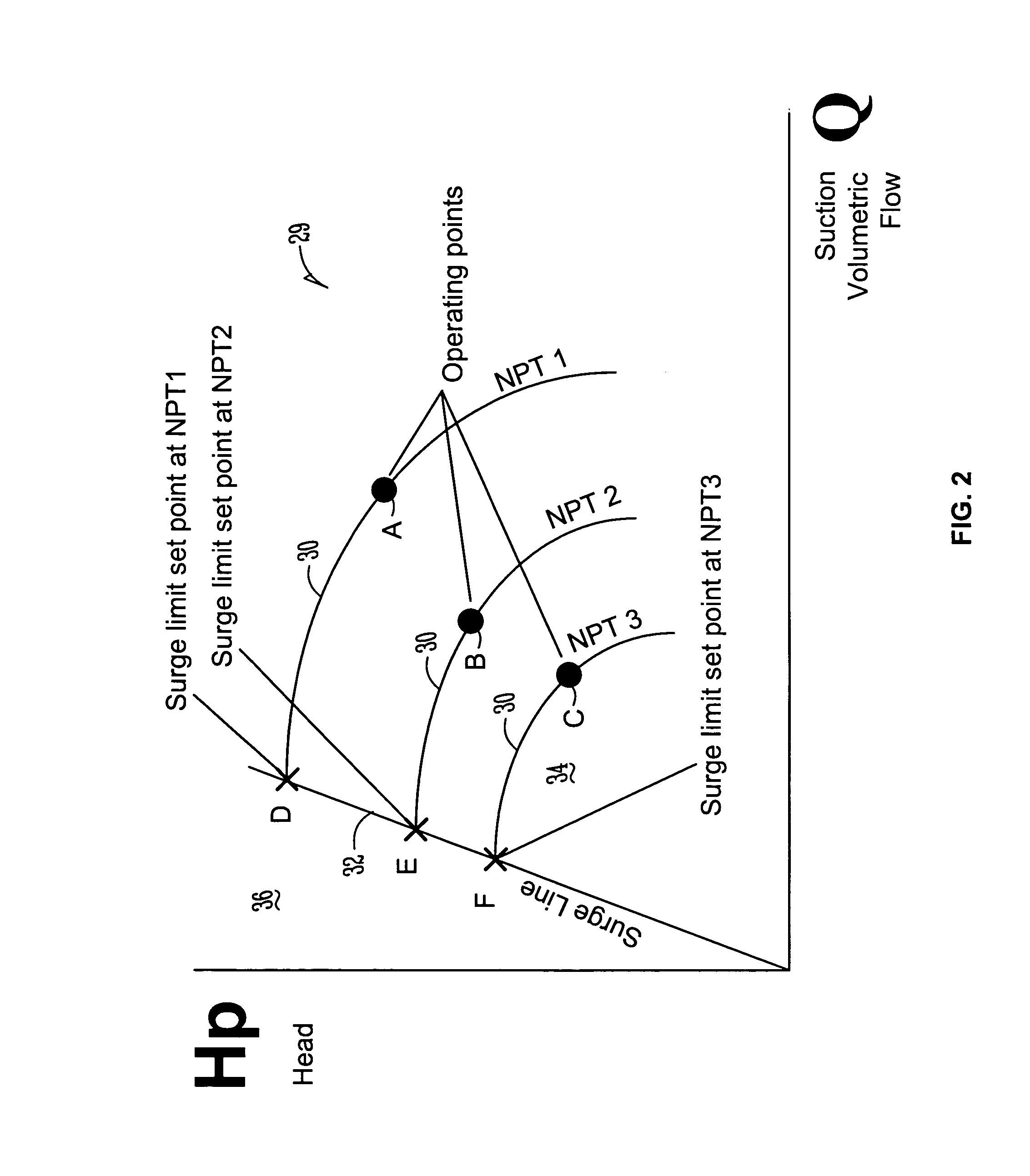

System and method of surge limit control for turbo compressors

A system and method of surge limit control for turbo compressors including a turbo compressor having an inlet and an outlet, an anti-surge valve, a variable speed drive to operate the compressor, a rotational speed transmitter, an inlet temperature transmitter, an inlet pressure transmitter, an outlet pressure transmitter and / or guide vanes, and a controller, the controller including a PID control module wherein the computer uses information from the transmitters to continuously calculate a pressure ratio of the compressor at the compressor's current operational speed and compare it to the compressor's calculated pressure ratio at surge limit conditions. A computer generates a control signal for determining when to open the anti-surge valve if the pressure ratio of the compressor at the compressor's current operational speed guide vanes are within a user defined safety margin to the calculated pressure ratio at surge limit conditions.

Owner:CONTINUOUS CONTROL SOLUTIONS

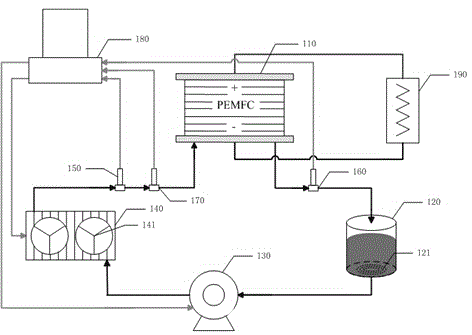

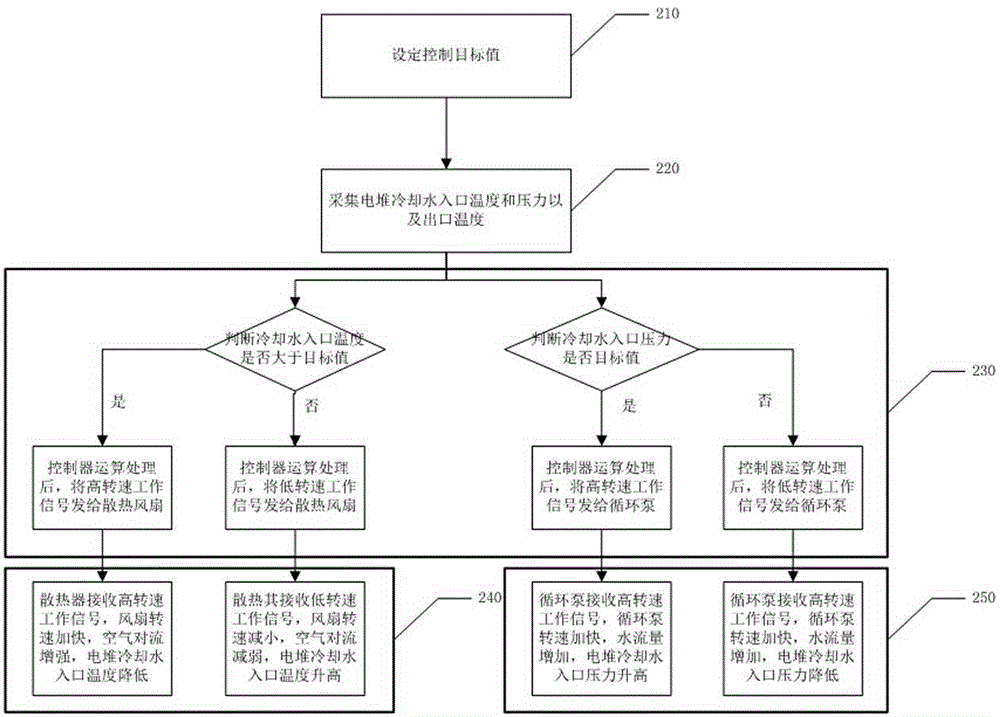

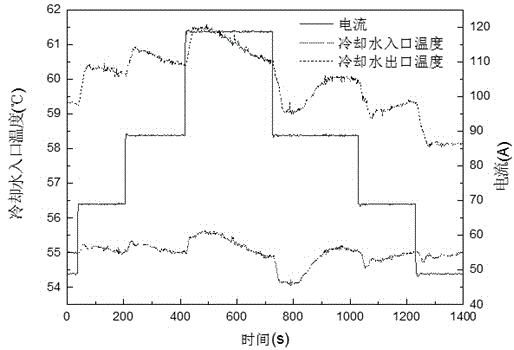

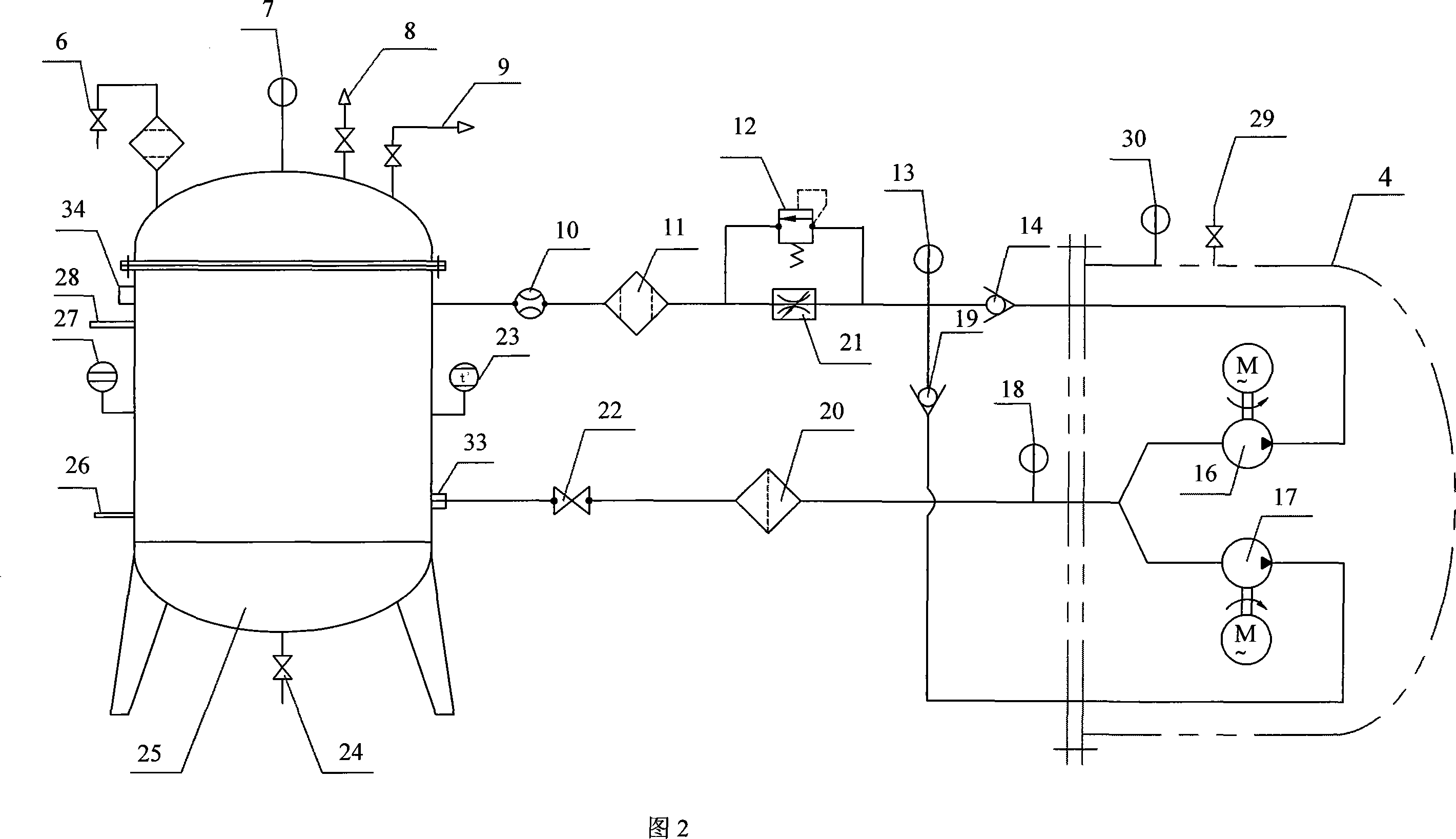

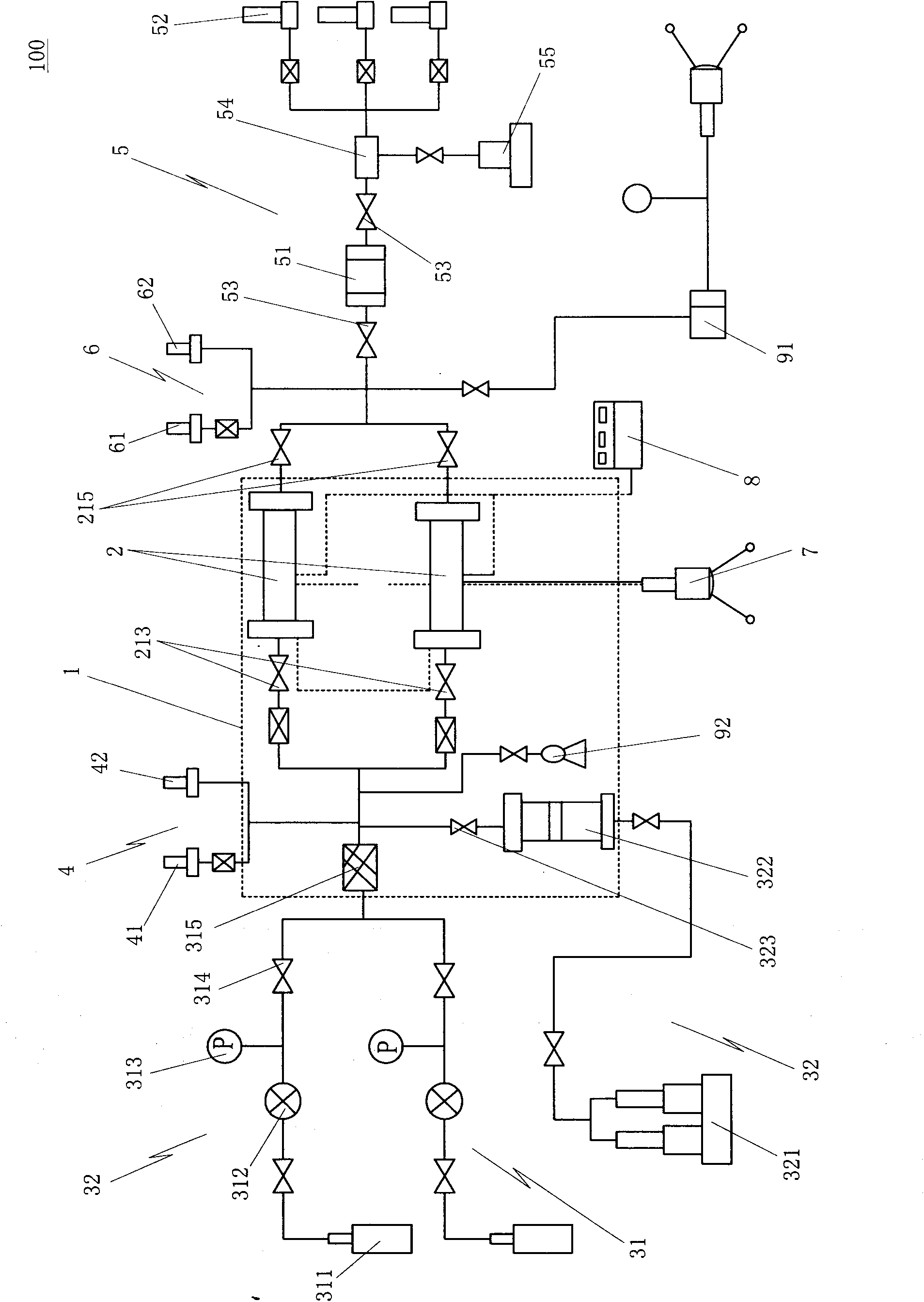

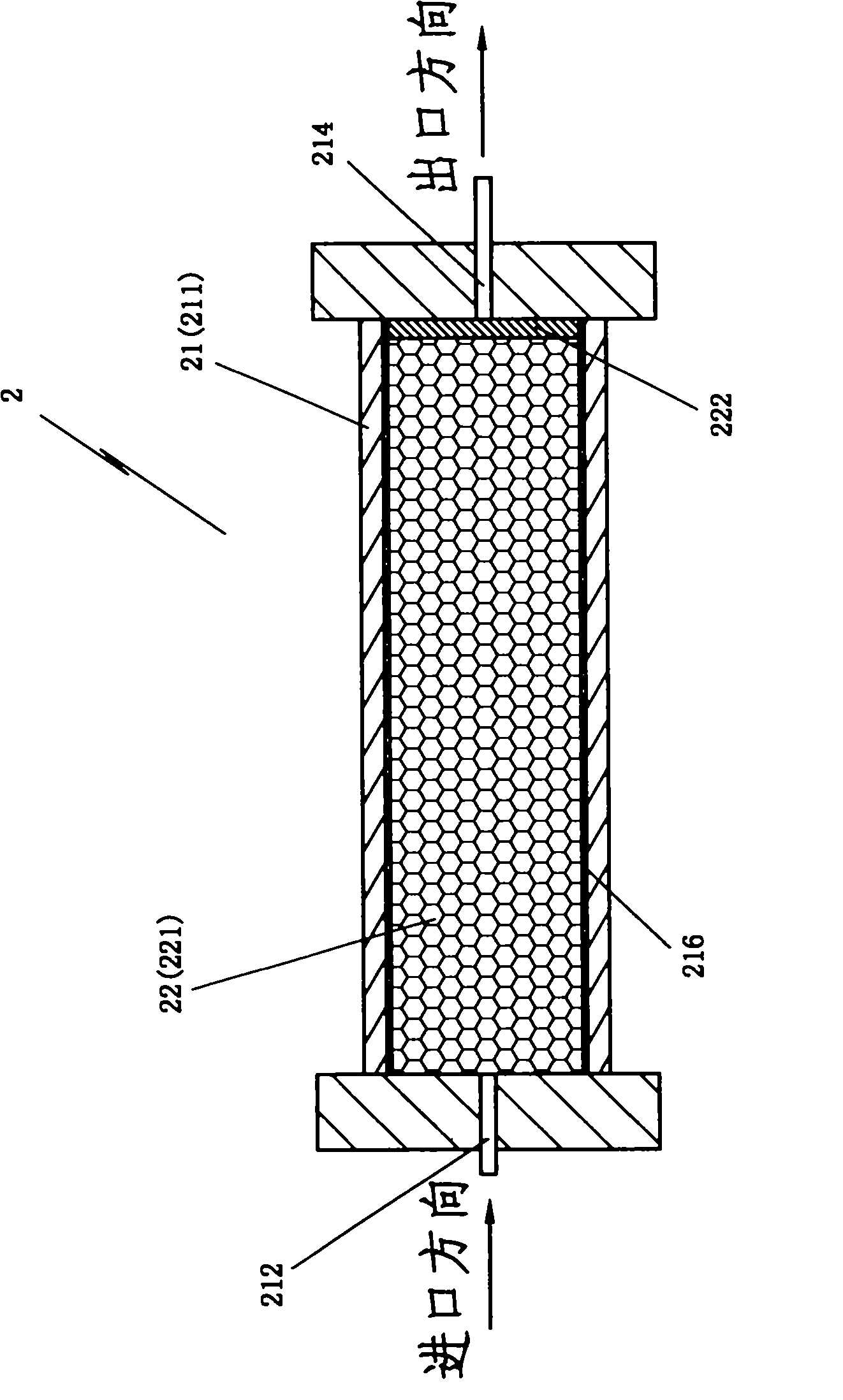

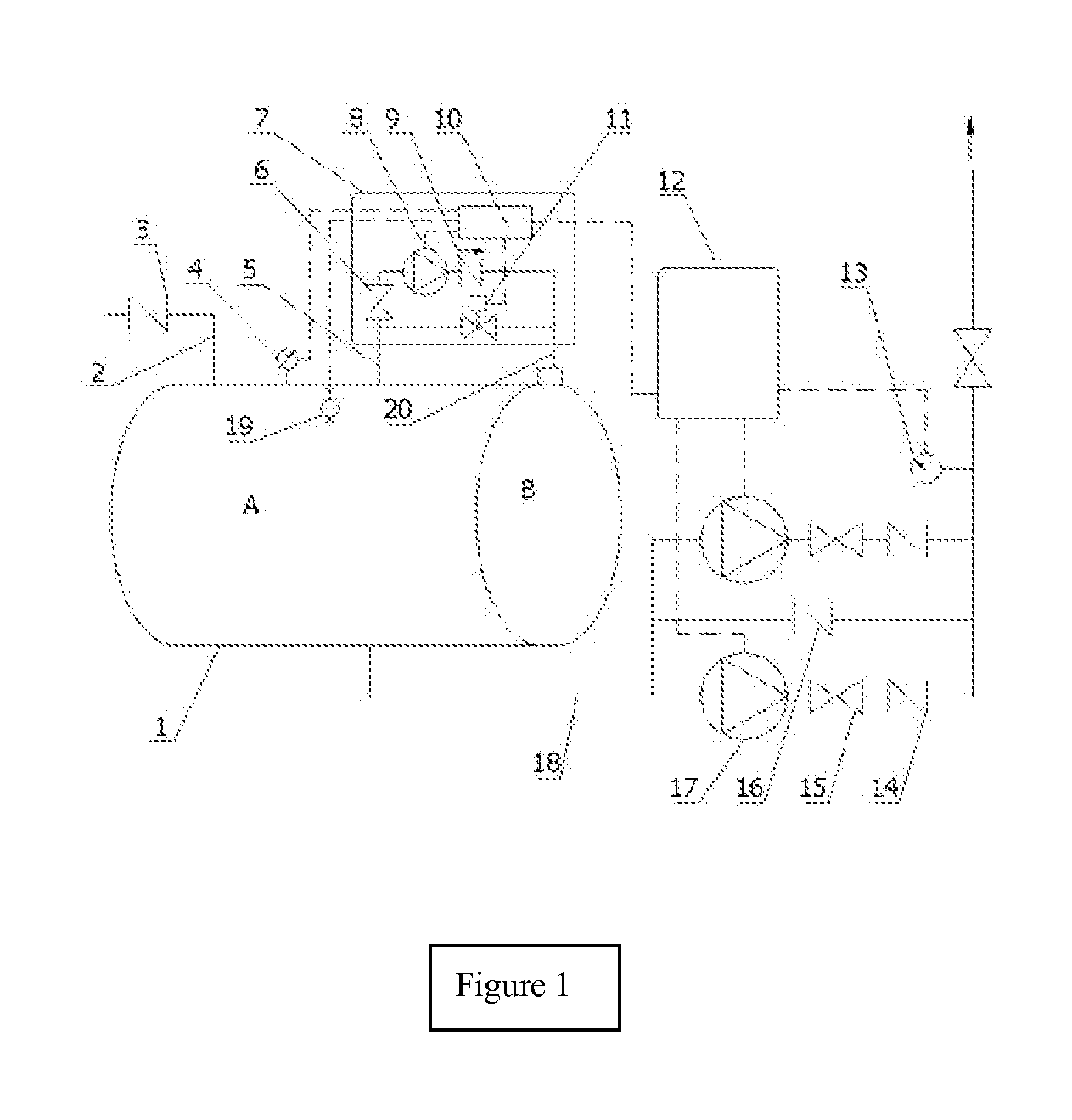

Thermal management system of water-cooling proton exchange membrane fuel cell and control method of thermal management system

ActiveCN104934619AReduce poisonEasy temperature controlFuel cell auxillariesThermal management systemEngineering

The invention provides a simple and effective thermal management system of a water-cooling proton exchange membrane fuel cell and a control method of the thermal management system. The thermal management system mainly comprises an electric pile, a water tank provided with a heating device, a cooling water circulating pump, a radiator, a cooling water pile inlet temperature sensor, a cooling water pile outlet temperature sensor, a cooling water pile inlet pressure sensor and a controller of the thermal management system. The control method following pressure change is provided to overcome the defects of lag, great overshooting, system coupling and the like caused by temperature change tracking in the traditional control strategy. The radiator is mainly used for controlling the cooling water inlet temperature of the pile and mainly controls the rotating speed of a radiator fan according to the cooling water inlet temperature of the pile of the fuel cell; and the cooling water circulating pump is mainly used for controlling the cooling water flow in the whole thermal management system and mainly controls the rotating speed of the circulating pump according to the cooling water inlet pressure of the pile of the fuel cell.

Owner:SOUTHWEST JIAOTONG UNIV

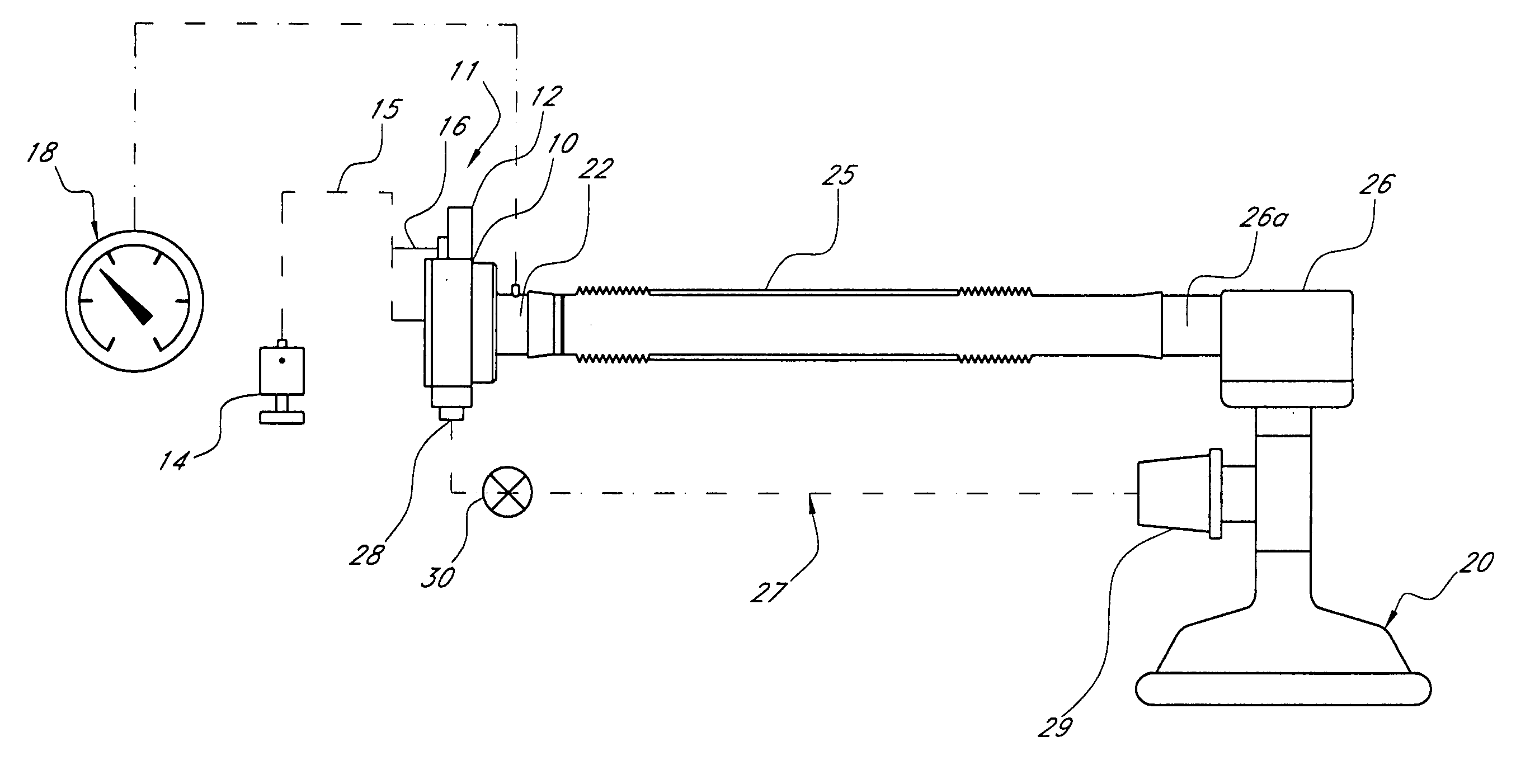

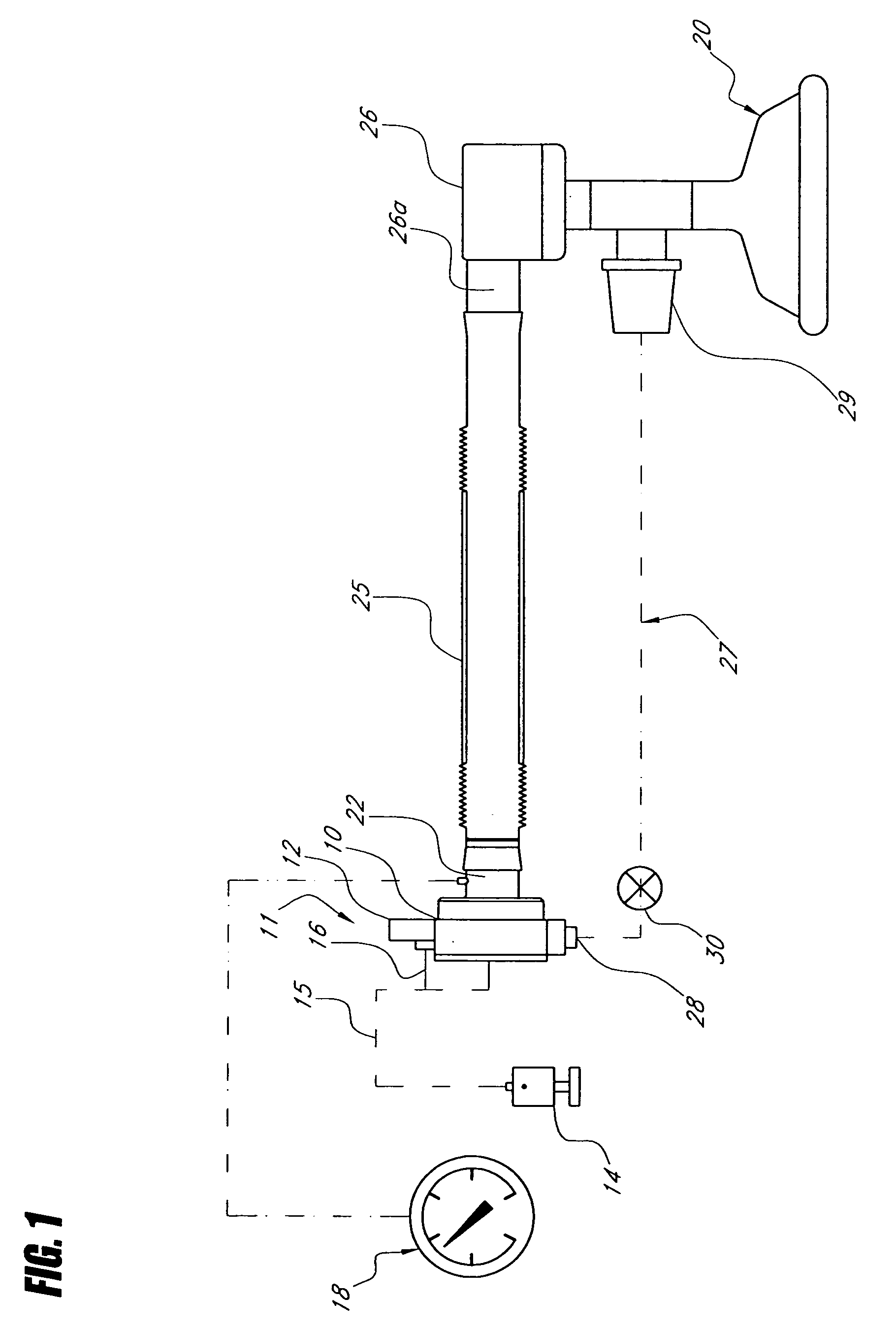

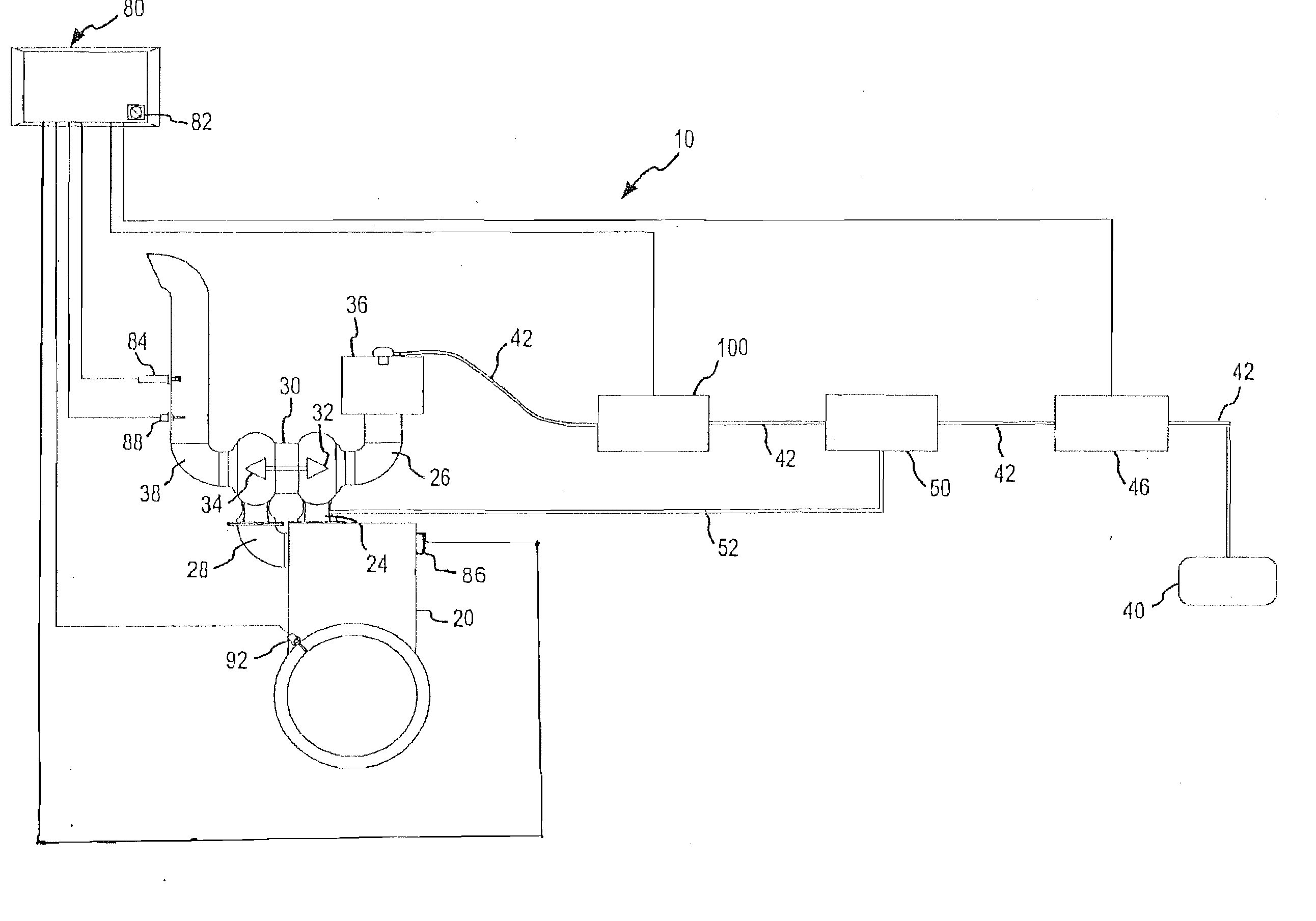

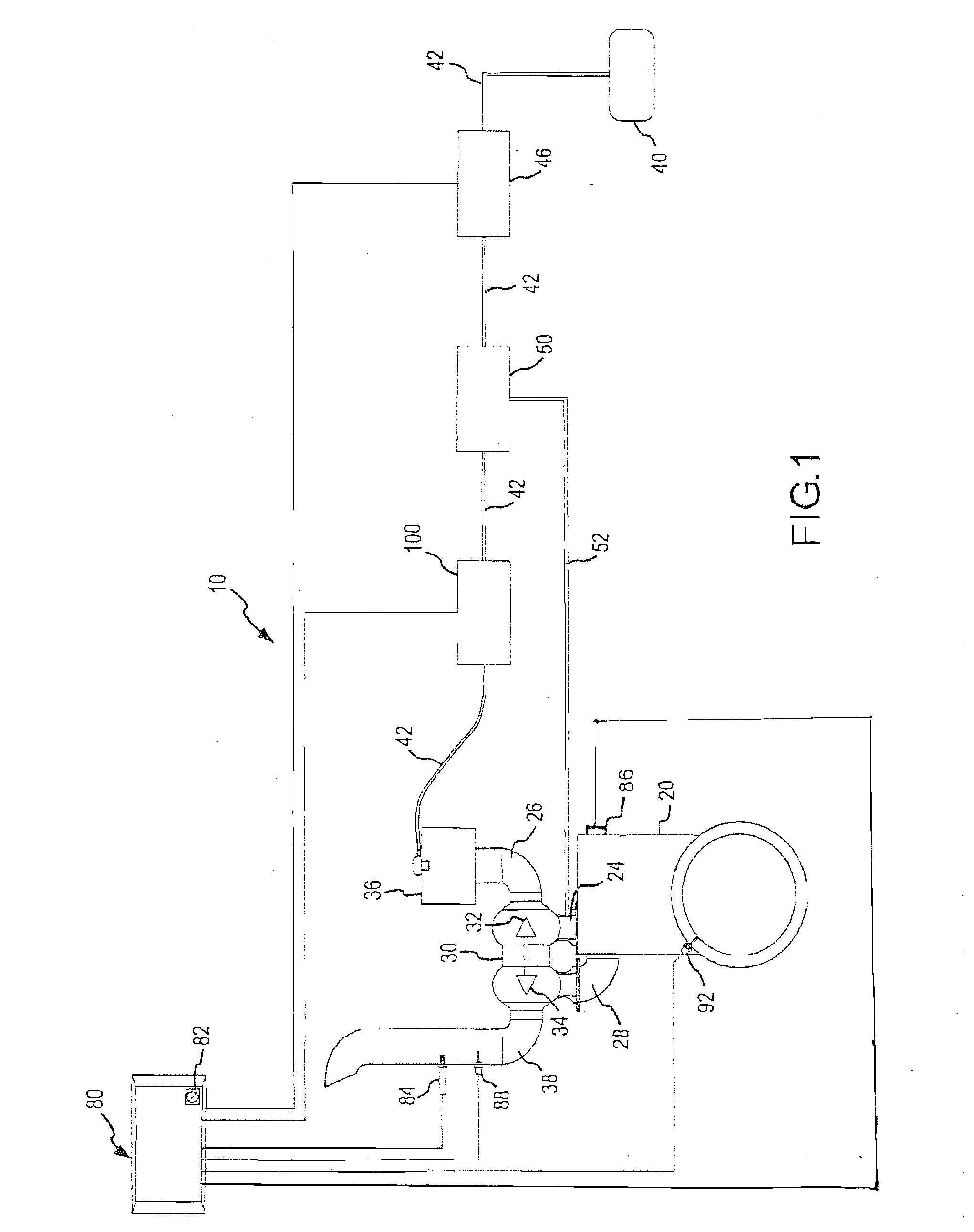

Portable gas powered positive pressure breathing apparatus and method

ActiveUS20060243278A1Keep the pressureRespiratorsOperating means/releasing devices for valvesPositive pressurePositive-Pressure Respiration

A portable positive pressure breathing apparatus includes a demand valve with a supply inlet port adapted to be connected to a pressurized source of oxygen and an outlet port adapted to be connected to the inlet of a patient's breathing appliance. The demand valve further includes a reference chamber and a valve assembly responsive to the reference chamber / appliance inlet pressure differential for connecting / disconnecting the inlet port to and from the outlet port. At least one manually adjustable back pressure regulator is connected to the pressure source and the reference chamber for setting the pressure in the reference chamber (and inlet to the breathing appliance) at a selected level above atmospheric pressure.

Owner:NEXT LIFE MEDICAL CORP

Process for use with dual-fuel systems

InactiveUS20070157912A1Avoid power outagesHigh outputElectrical controlInternal combustion piston enginesStream flowInlet pressure

A system and method is provided for use with a duel-fuel fumigation system. The system injects a gaseous-fuel flow into the air intake stream of a diesel engine. As presented, the system is operative to meter the gaseous-fuel flow into the diesel engine based on one or more engine parameters such as, for example, exhaust gas temperature, exhaust oxygen levels, engine speed, engine load and / or engine inlet pressure. Monitoring one or more engine parameters allows fine-tuning the flow of gaseous fuel into the engine and thereby prevents loss of engine power at high-end loads while maintaining favorable emission outputs over substantially the entire operating range of the engine.

Owner:TGI

Method and system of determining life of turbocharger

In order to accurately determine a life of a turbocharger, the specific use, herein referred to as a “duty cycle” of the turbocharger, should be monitored. However, in order to directly monitor the duty cycle of the turbocharger, there are additional costs of assembly and installation of a turbocharger rotational speed sensor. The present invention determines a life of a turbocharger by indirectly monitoring the duty cycle of the turbocharger through sensors that generally serve a pre-existing purpose within a vehicle or machine. A compressor inlet pressure sensor and compressor outlet pressure sensor are in communication with an electronic control module that includes a life determining algorithm. The life determining algorithm determines the life of the turbocharger based on a relationship between a sensed compressor inlet pressure and a sensed compressor outlet pressure. By monitoring the relationship between the sensed compressor inlet pressure and the sensed compressor outlet temperature, the fatigue and the creep of at least one component of the turbocharger is monitored.

Owner:CATEPILLAR INC PATENT DEPT

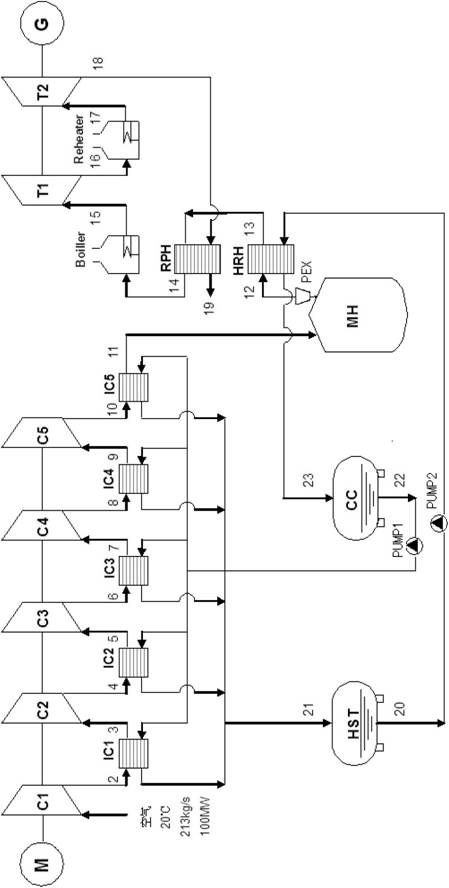

Compressed air energy storage system

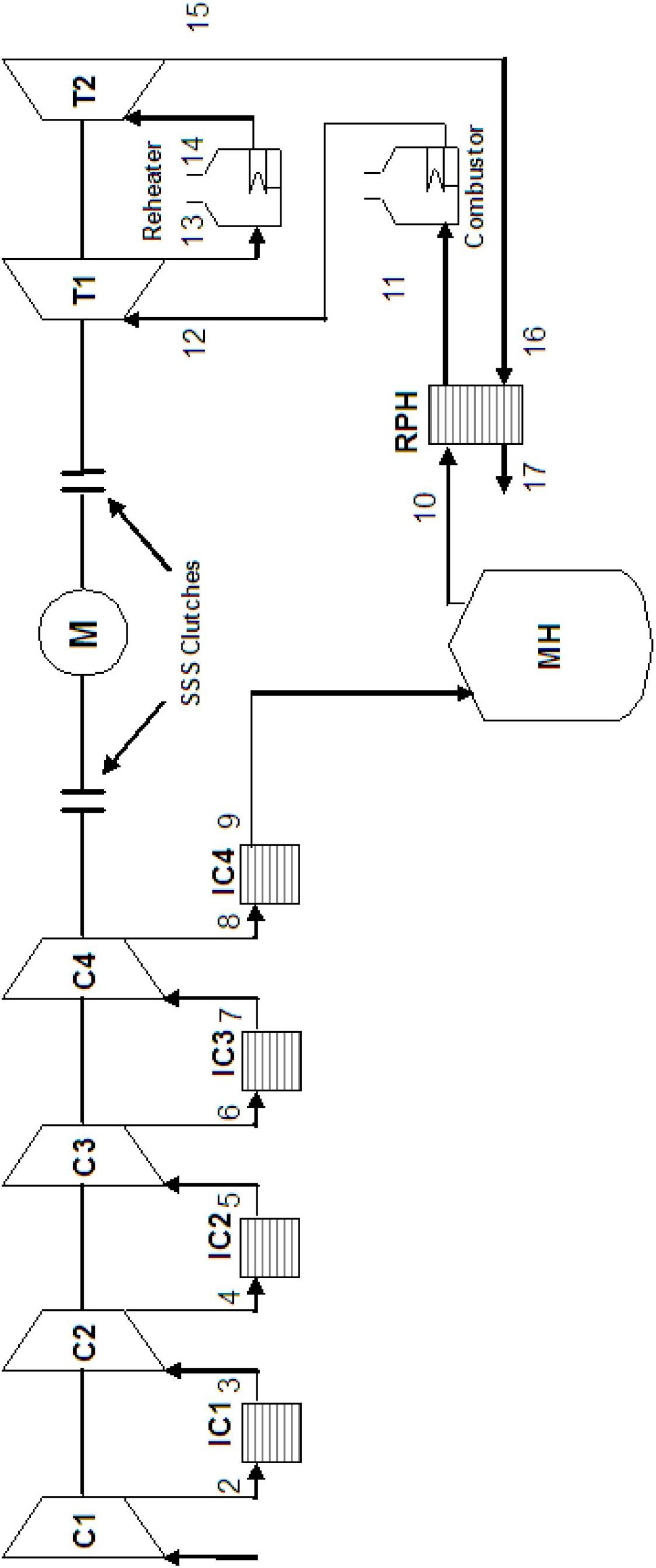

InactiveCN102661175ATake advantage ofImprove energy conversion efficiencyPump componentsEngine componentsPre expansionThermal energy storage

The invention discloses a compressed air energy storage system, which comprises a compressor unit, a pre-expansion device, a turbine expansion machine, an intermediate cooler, an electric motor, a power generator, a hot water storage tank and a cold water storage tank, wherein the system utilizes electric energy which is not used up in the user electricity consumption valley period or wind power station power generation peak period for driving the compressor unit to work, the air at the normal pressure is compressed to high pressure, in addition, the part of air with rich pressure energy is stored into a high-pressure-resistance hole, in addition, the stored high-pressure air is released in the user electric consumption peak period or the wind power field generation valley period, an expansion unit is pushed to apply work, and the electric energy is output. The air pre-expansion device is additionally arranged at an outlet of an air storage chamber, so the air inlet pressure of the air turbine expansion machine is stable, the work stability of a power generation system is enhanced, low-temperature air at an outlet of the pre-expansion device is utilized for cooling hot water from the hot water storage tank, the temperature of the low-temperature air is raised through absorption of heat from the hot water, and the cooled water enters the cold water storage tank. The compressed air energy storage system is provided with the hot water storage tank and the cold water storage tank, the water is cyclically utilized in a closed loop, the water is not consumed, in addition, the heat discharged by the compressor is fully utilized and conveyed back to the high-pressure air at the outlet of the pre-expansion device. The high-pressure air at the outlet of the pre-expansion device is recovered through a heat recovering device (HRH).

Owner:XI AN JIAOTONG UNIV

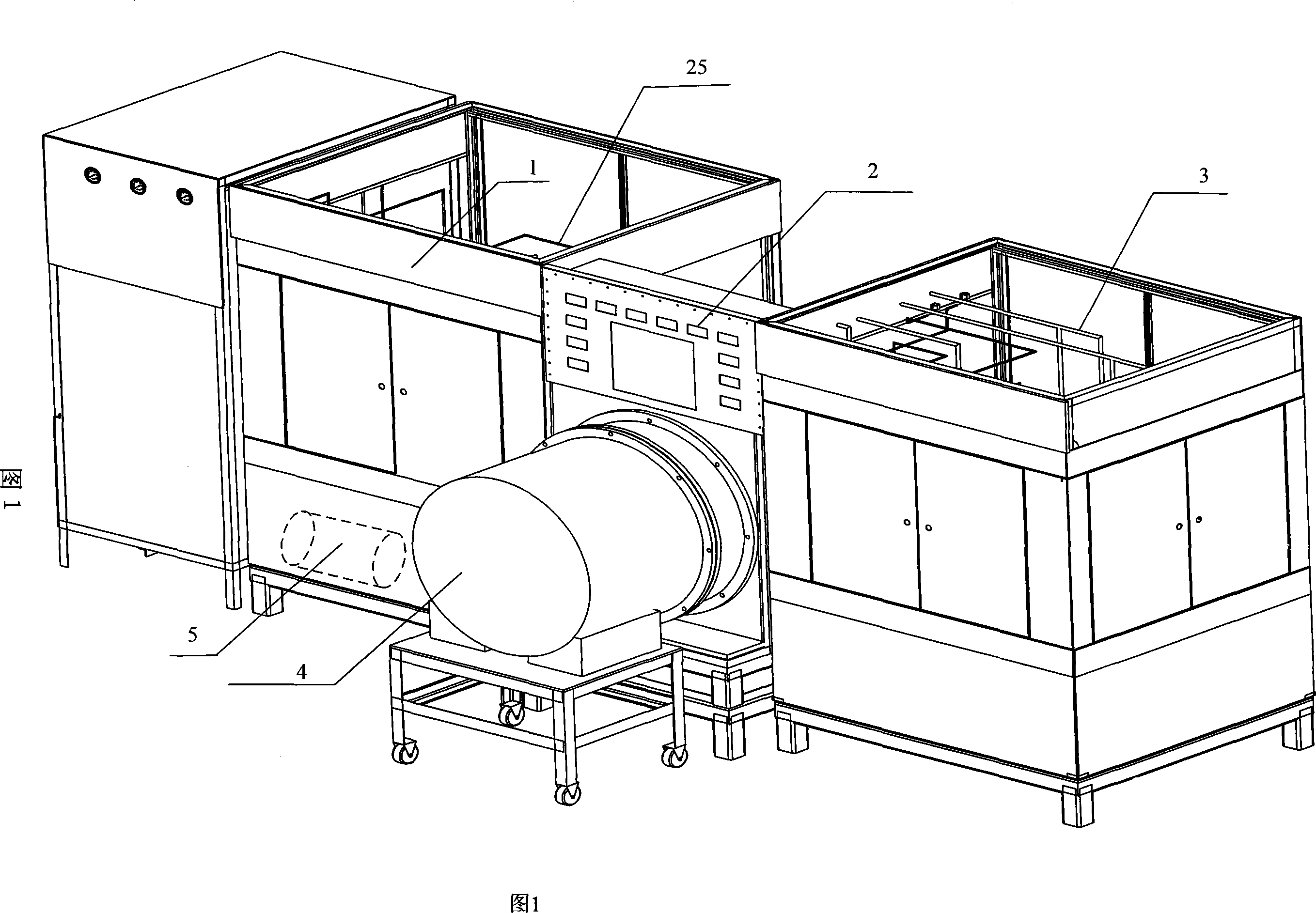

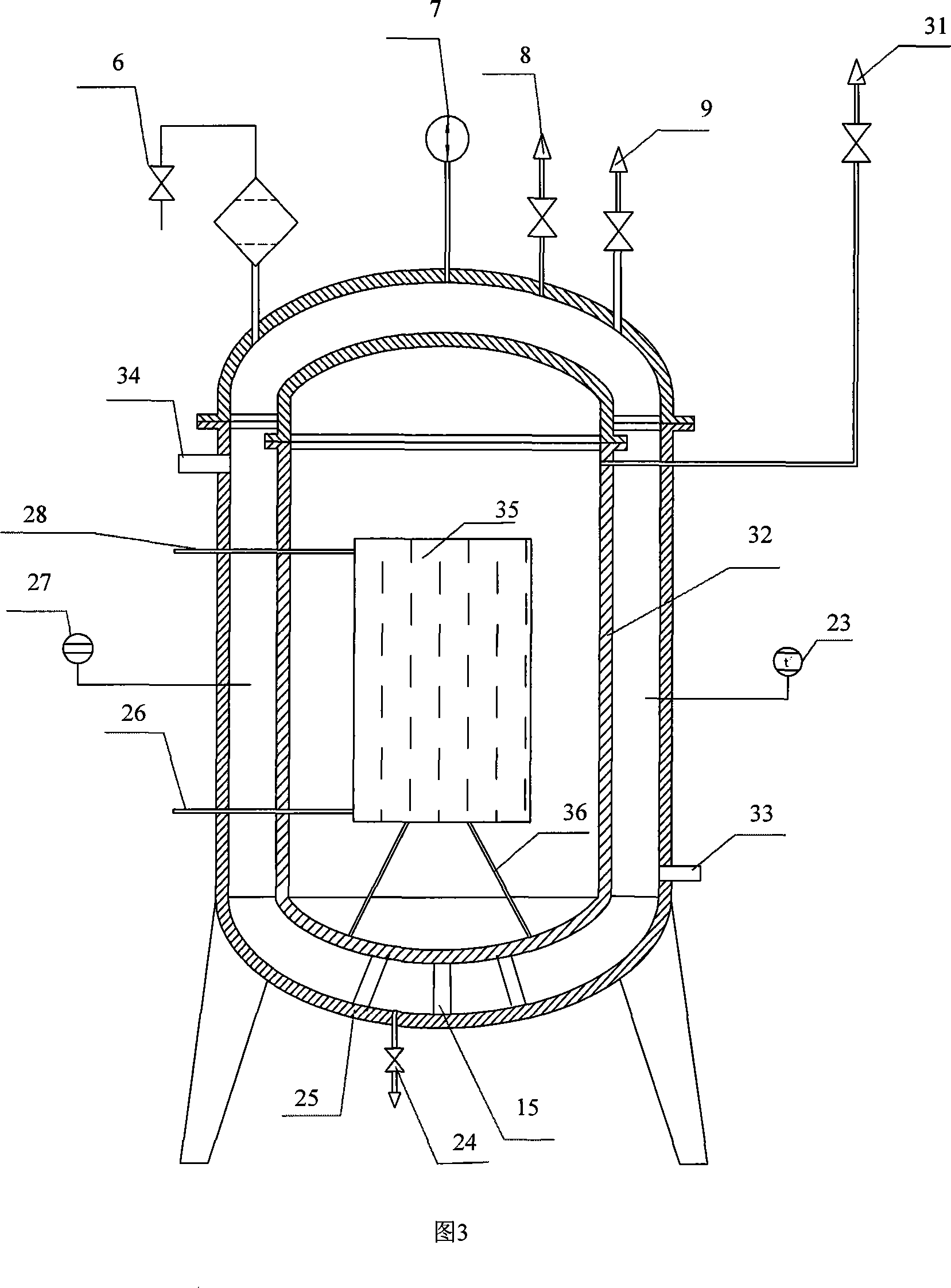

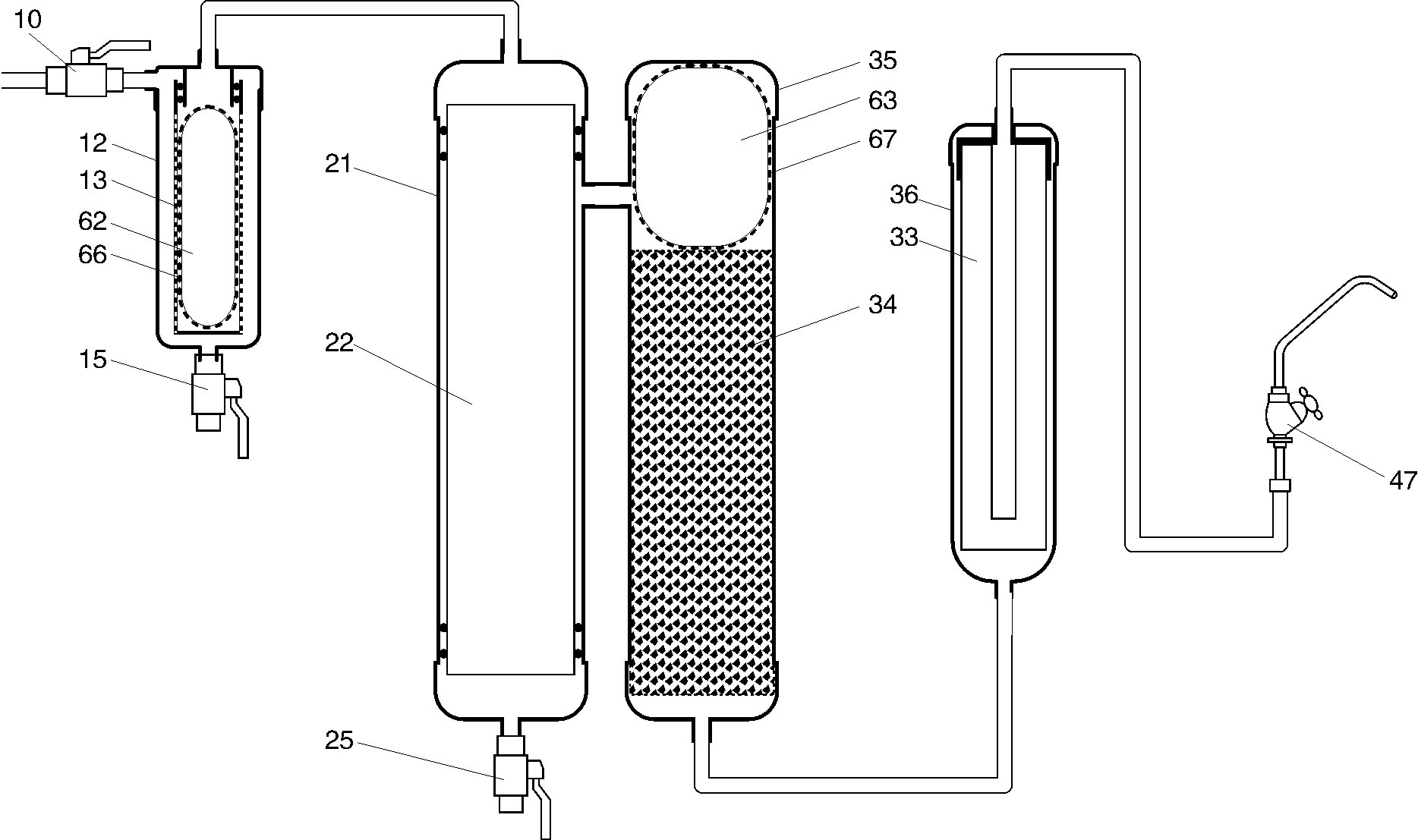

Device and method for testing upper air performance of aircraft engine fuel oil system

InactiveCN101231215AImplement performance testingAccurate control of fuel temperatureInternal-combustion engine testingAviationFuel tank

The invention discloses an aeroengine fuel system altitude performance testing unit and a test method thereof. The testing unit comprises an equipment cabinet, a control computer, a display instrument, a high altitude box, a fuel tank, an oil pipeline, a vacuum pump package and various valves, wherein, the inner part of the high altitude box is provided with a testing oil fuel pump which is connected with the fuel tank through the oil pipeline inside the equipment cabinet, the fuel tank has a structure with low temperature resistance and atmospheric depression resistance, can simulate the high altitude working environment of the fuel system of the aeroengine. The test method utilizes the fuel tank capable of simulating the atmospheric depression and the low temperature of the high altitude and a high altitude box capable of simulating the atmospheric depression, adopts the pipeline and the valves to adjust the oil inlet pressure and the oil return pressure, and uses a flowmeter, a thermometer and a pressure gauge to read the parameter values. The test of altitude simulations of an oil supply system of an electronic oil fuel pump of an aircraft piston engine can be performed by the method.

Owner:BEIHANG UNIV

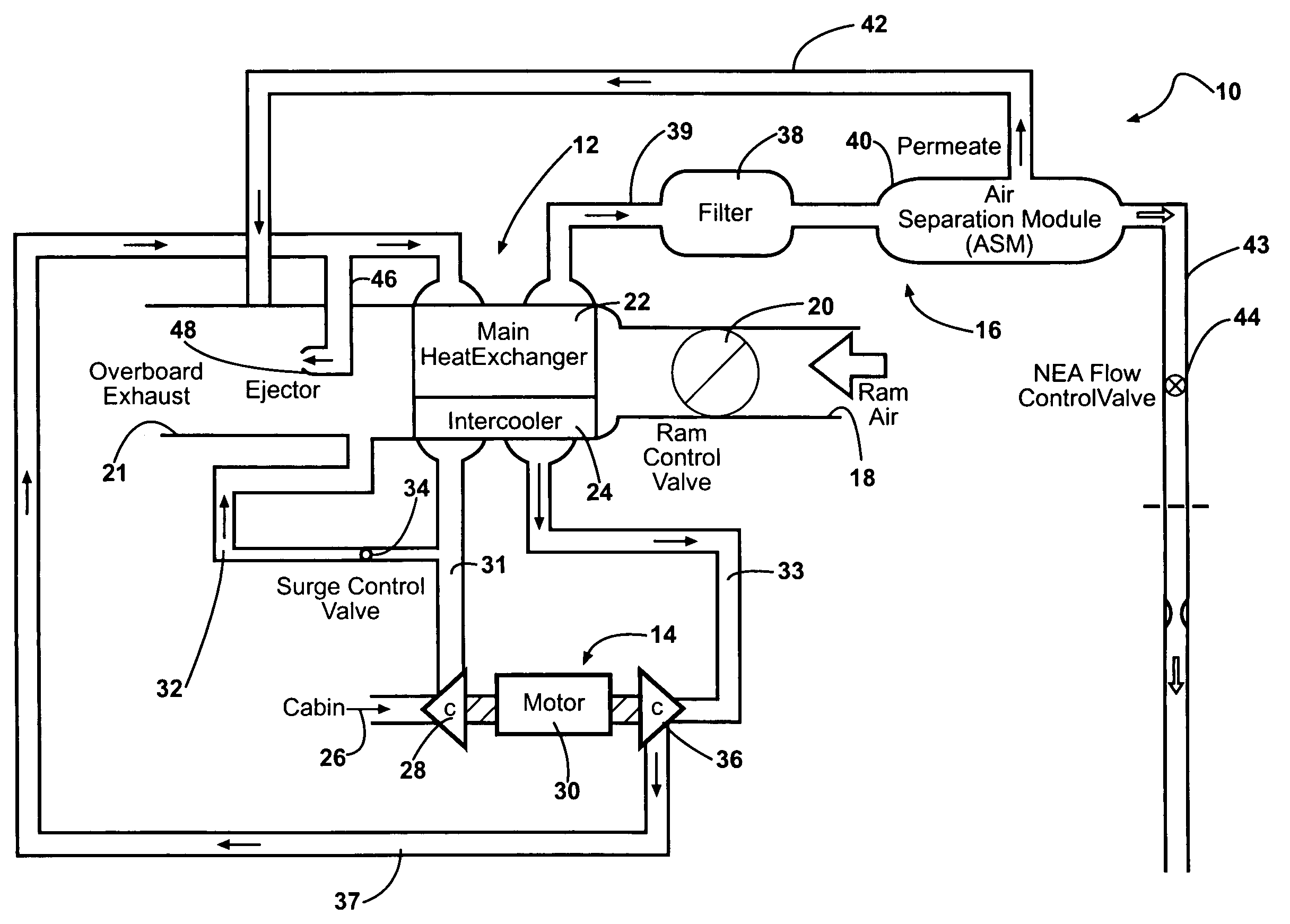

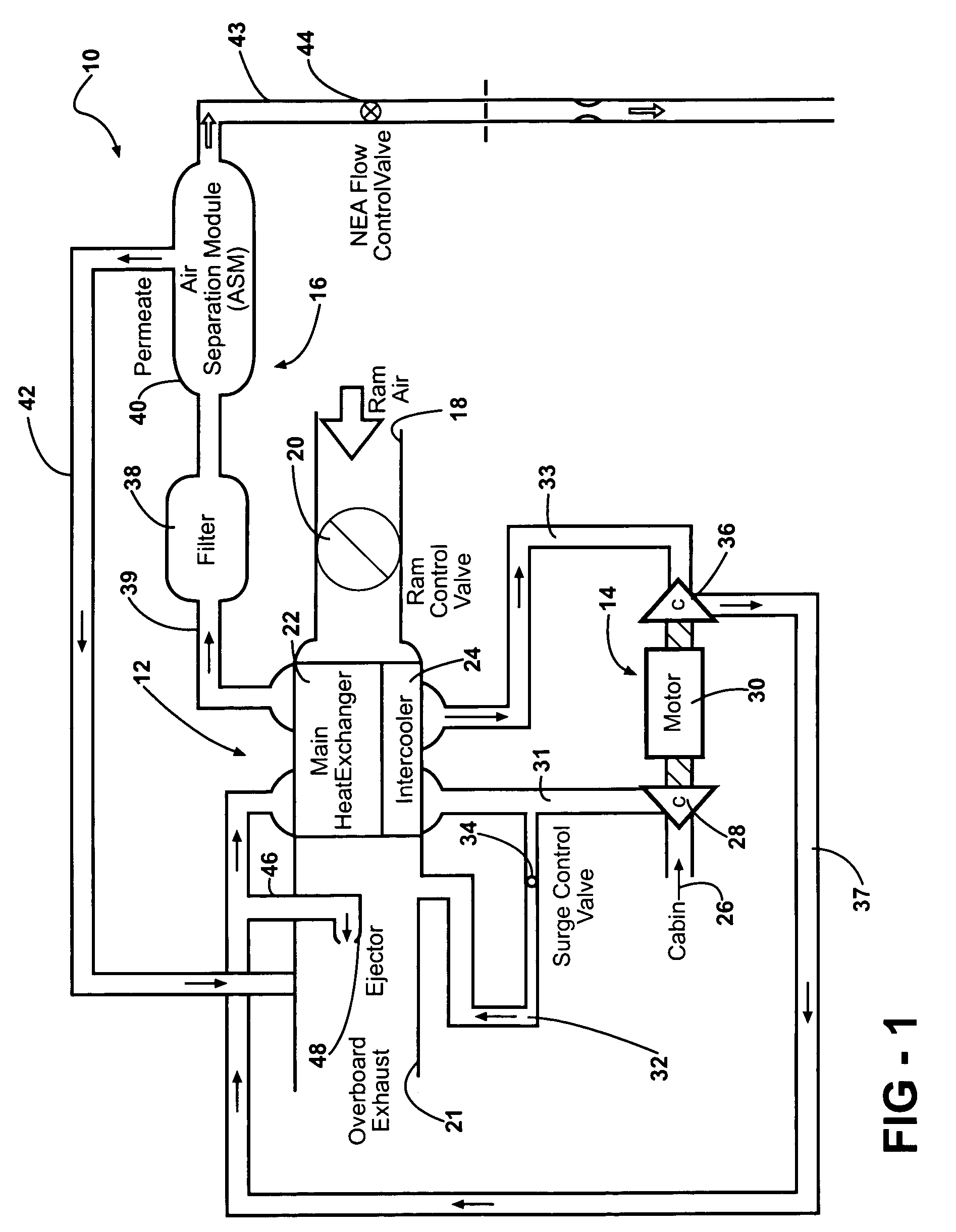

On-board inert gas generation system

ActiveUS7273507B2Increase inlet pressureIncrease airflowCombination devicesAuxillary pretreatmentOn boardInlet pressure

An on-board inert gas generation system provides first and second compressors in fluid communication with one another. The second compressor includes an inlet and an outlet. The inlet is in fluid communication with the first compressor. The second compressor is the final compressor stage of the system. An air separation module is fluidly connected to the outlet of the second compressor by a passageway. A vent passage is arranged between the outlet and the air separation module for venting fluid between the outlet and air separation module. The vent passage enables the flow from the second compressor to be increased thereby increasing compressor efficiency and increasing the inlet pressure to the air separation module, which enables use of a smaller air separation module.

Owner:HAMILTON SUNDSTRAND CORP

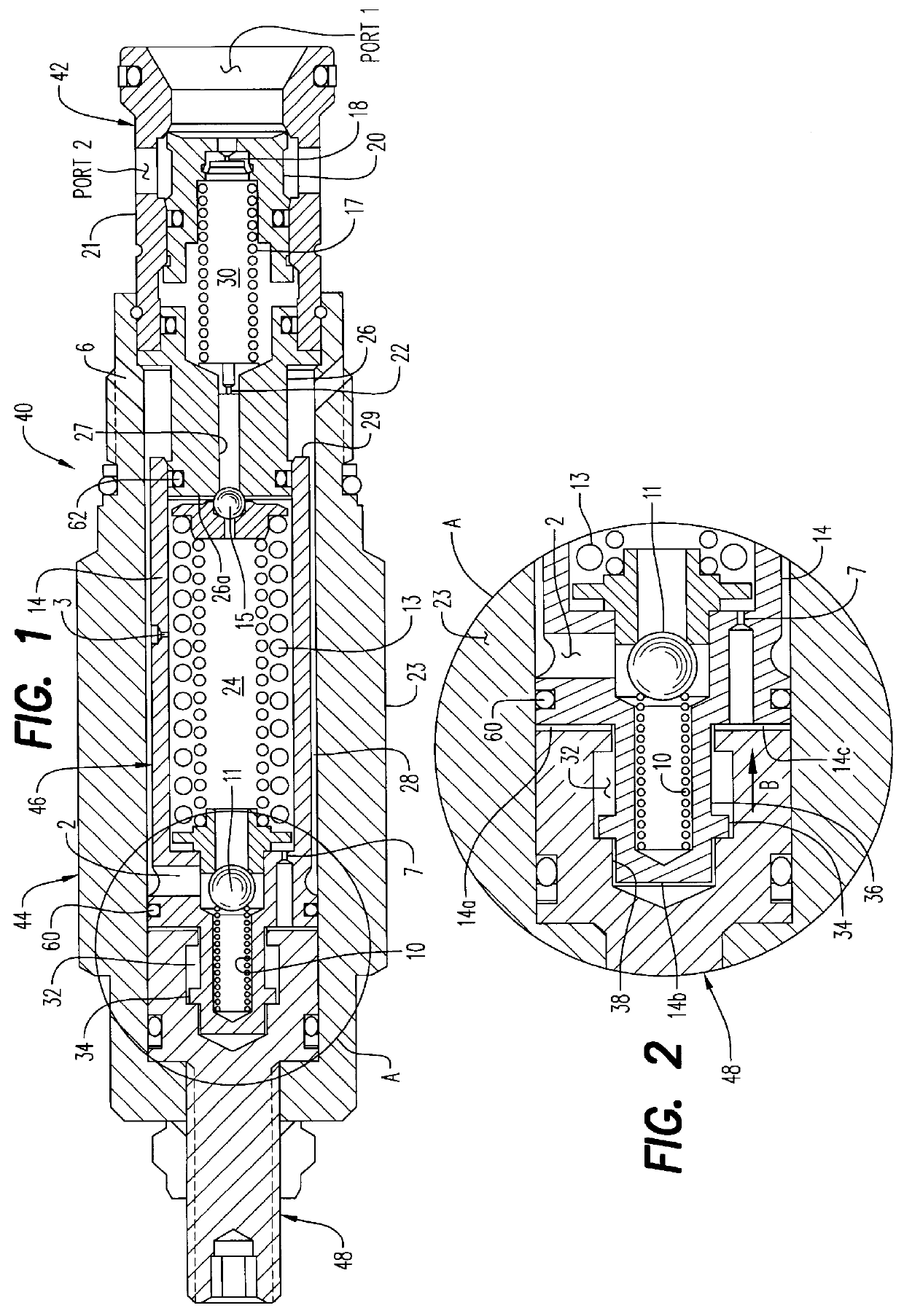

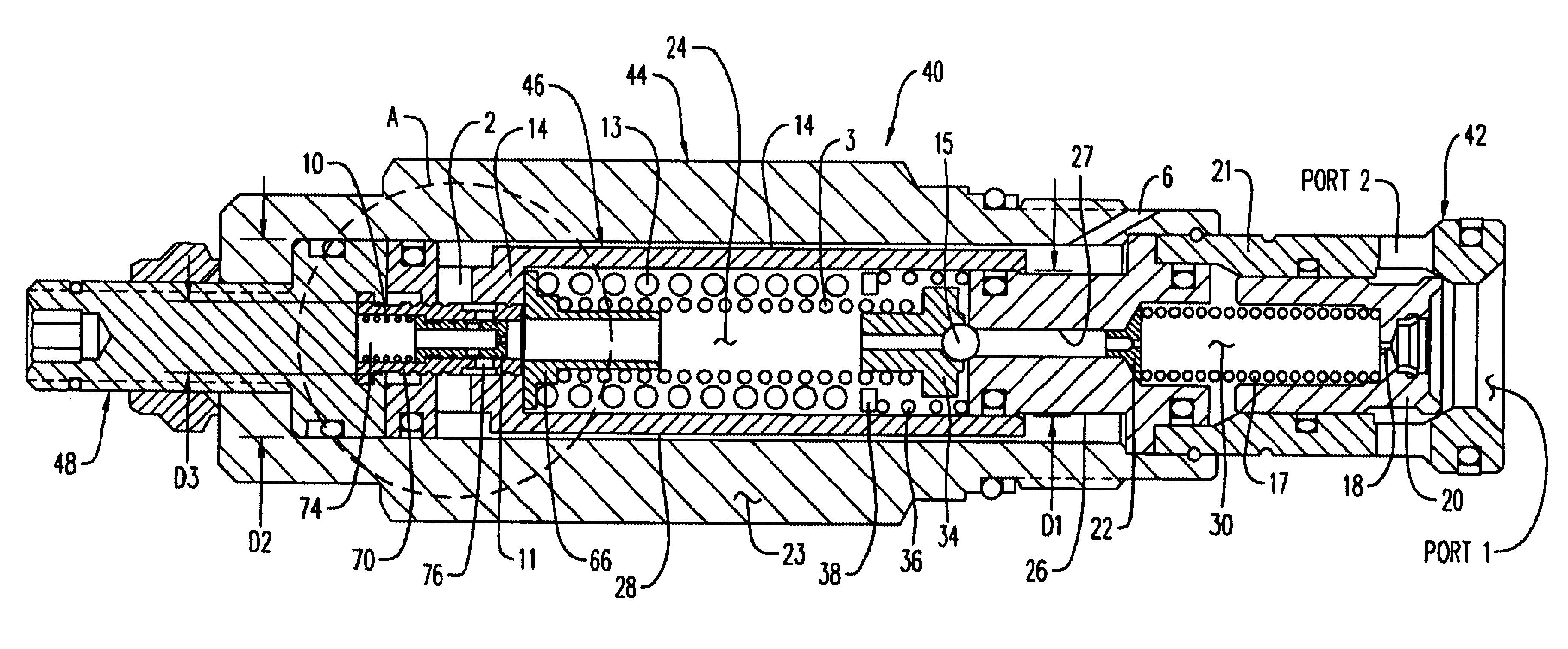

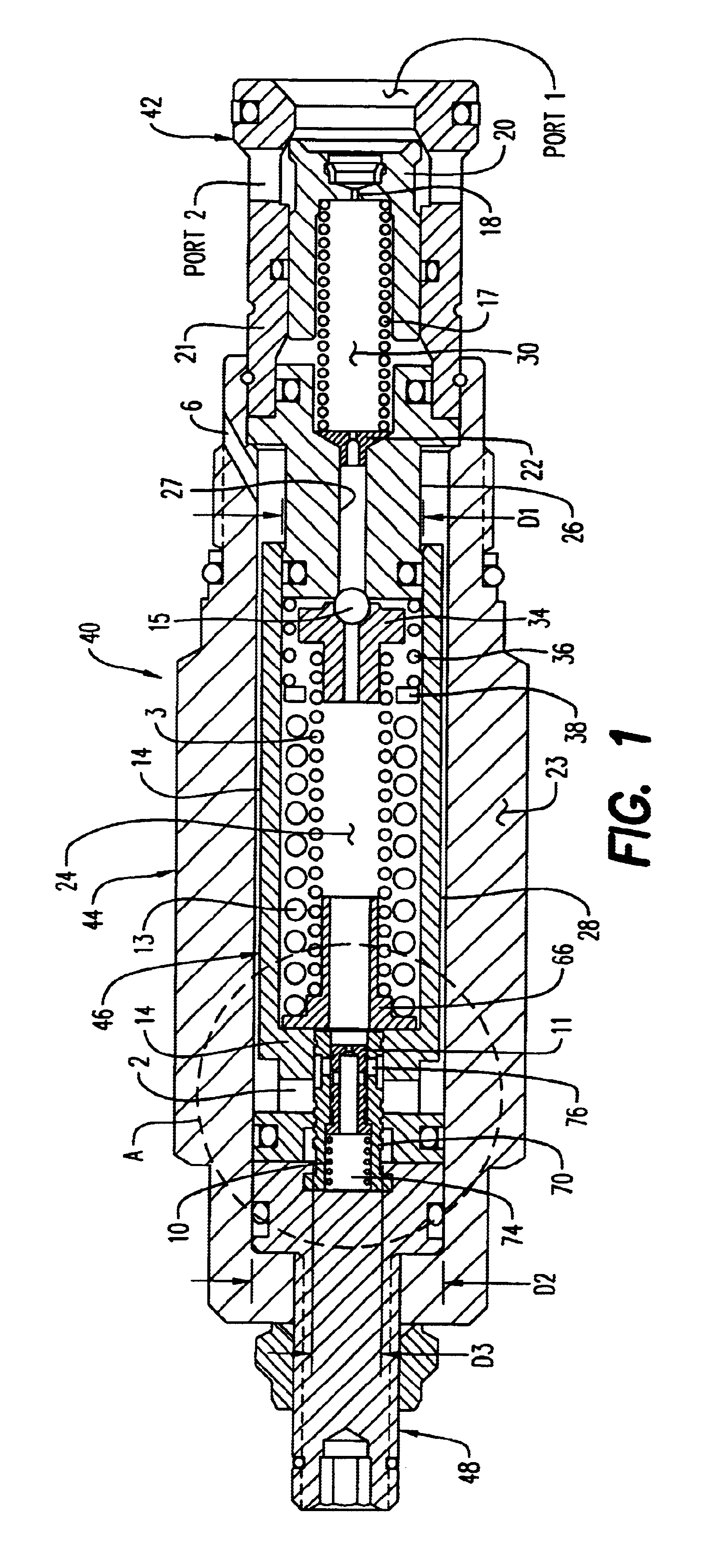

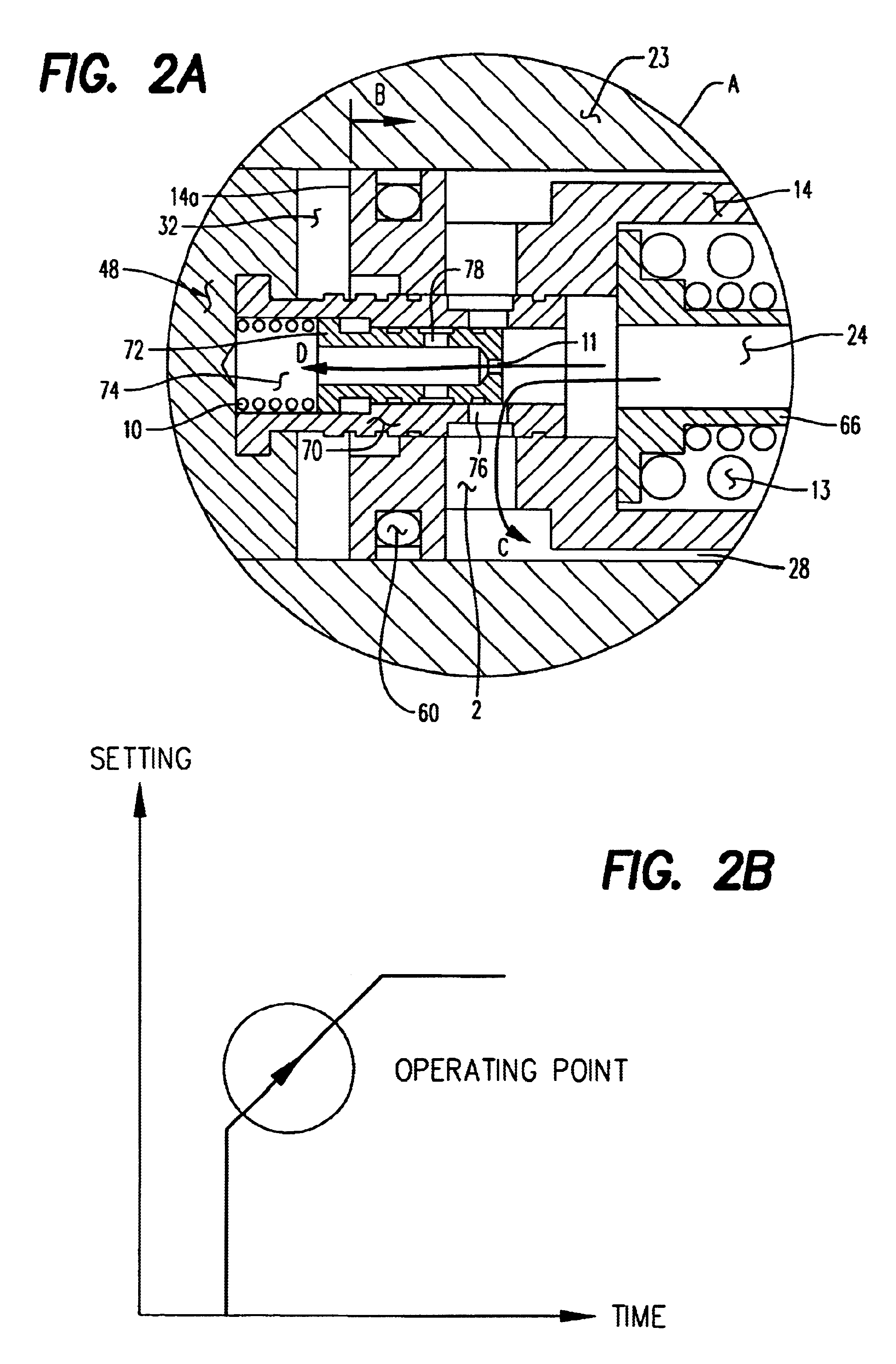

Pilot operated pressure valve

InactiveUS6039070AControl pressureOperating means/releasing devices for valvesEqualizing valvesSystem pressureInlet pressure

A pilot operated pressure valve which limits the rate of pressure rise and substantially eliminates excessive system pressure spikes, the valve including an inlet, a hollow cylindrical main body sealingly connected at one end thereof to the inlet, a pilot chamber having a sleeve slidably mounted within the main body and an operating pressure adjustment connected to another end of the main body adjacent another end of the pilot chamber for varying the operating pressure of the valve. A main chamber receives pressurized fluid metered through a main orifice and discharges pressurized fluid through a damping orifice when the main chamber is filled and fluid inlet pressure exceeds a preselected inlet pressure level sufficient to open a spring biased pilot ball downstream of the damping orifice. The inlet will open an exit port upstream of the main orifice for discharging pressurized fluid from the valve back to a supply tank when inlet pressure exceeds the operating pressure. Pressurized fluid is also metered from the pilot chamber through a control orifice into a loading chamber to automatically further vary the operating pressure of the valve by including a relief valve for discharging pressurized fluid from said pilot chamber when fluid pressure exceeds the operating pressure.

Owner:SUN HYDRAULICS LLC

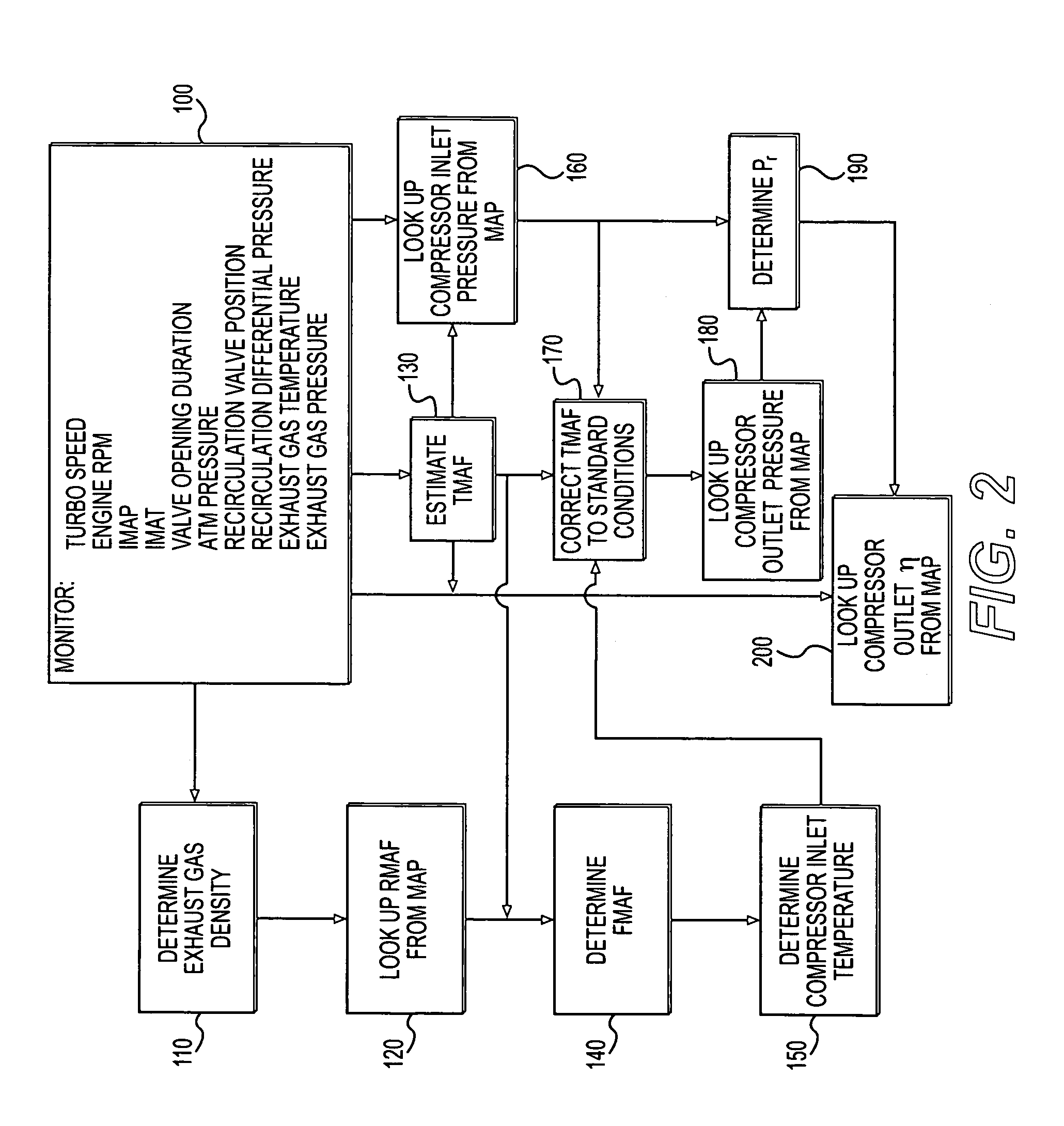

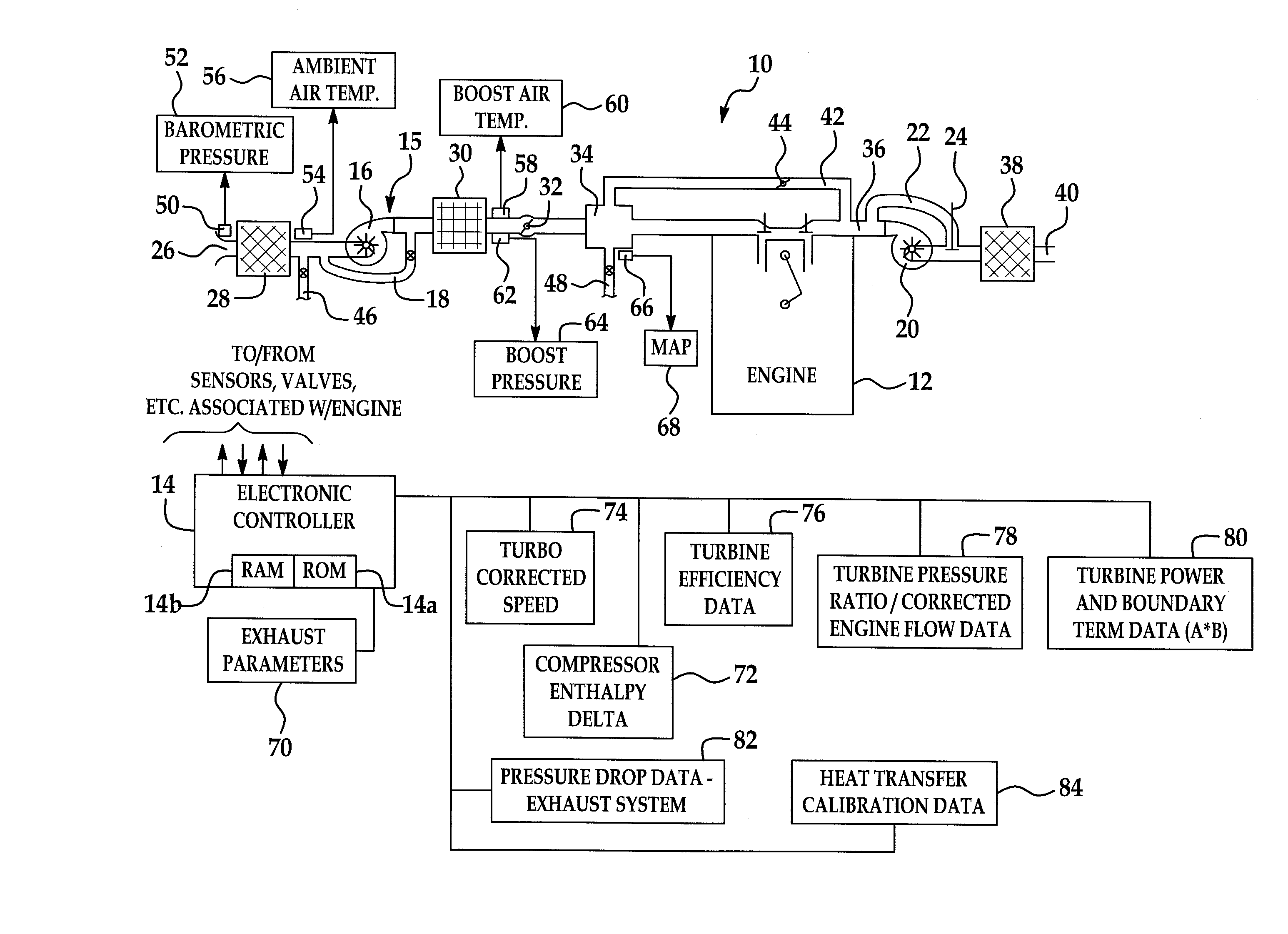

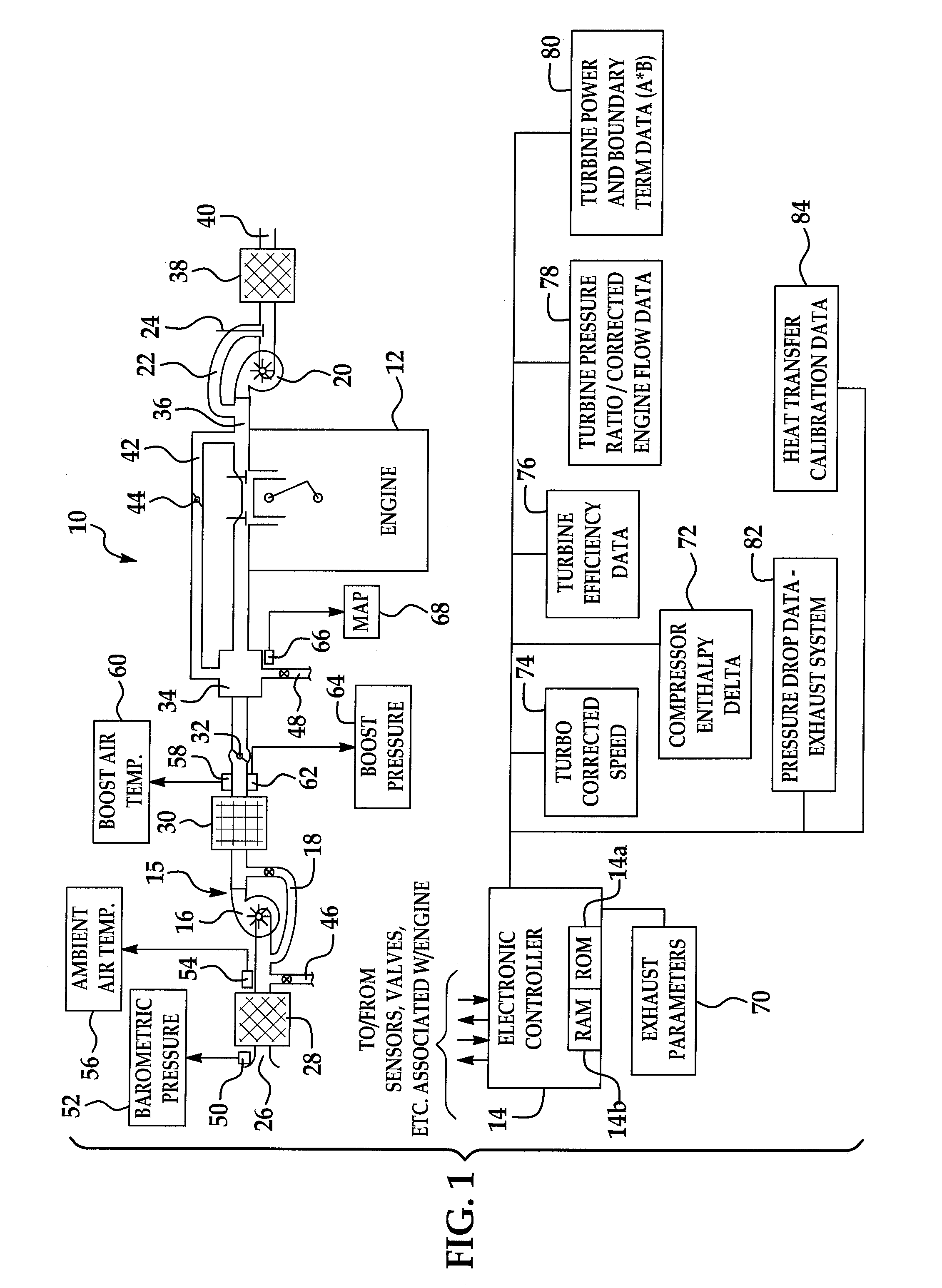

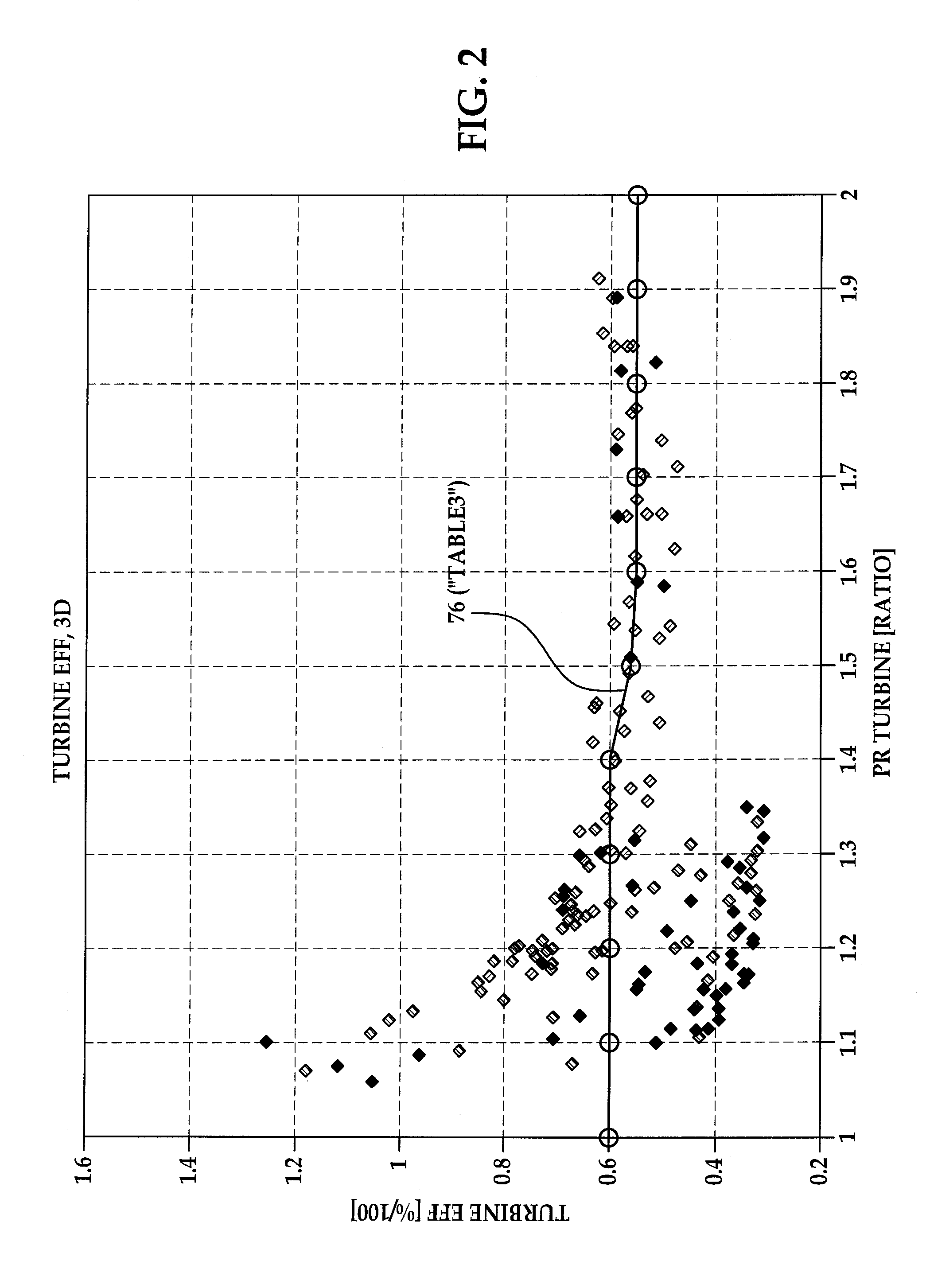

Control system and method for estimating turbocharger performance

A control system for estimating the performance of a compressor is disclosed. The control system has a compressor fluidly connected to an inlet manifold of a power source. The control system also has a power source speed sensor to provide an indication of a rotational speed of the power source, an inlet pressure sensor to provide an indication of a pressure of a fluid within the inlet manifold, an inlet temperature sensor to provide an indication of a temperature of the fluid within the inlet manifold, an atmospheric pressure sensor to provide an indication of an atmospheric pressure, and a control module in communication with each of the sensors. The control module is configured to monitor an engine valve opening duration and an exhaust gas recirculation valve position, and estimate a compressor inlet pressure based on the provided indications, the monitored duration, and the monitored position.

Owner:CATERPILLAR INC

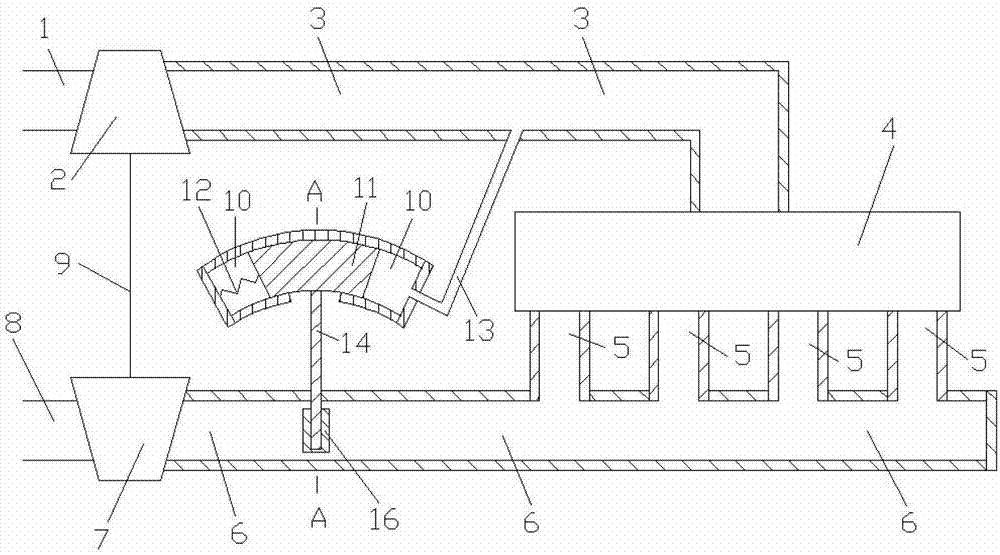

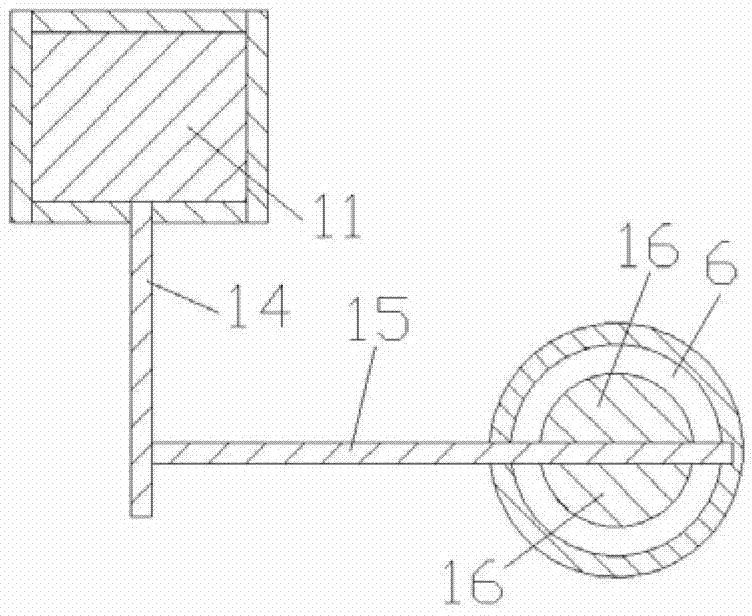

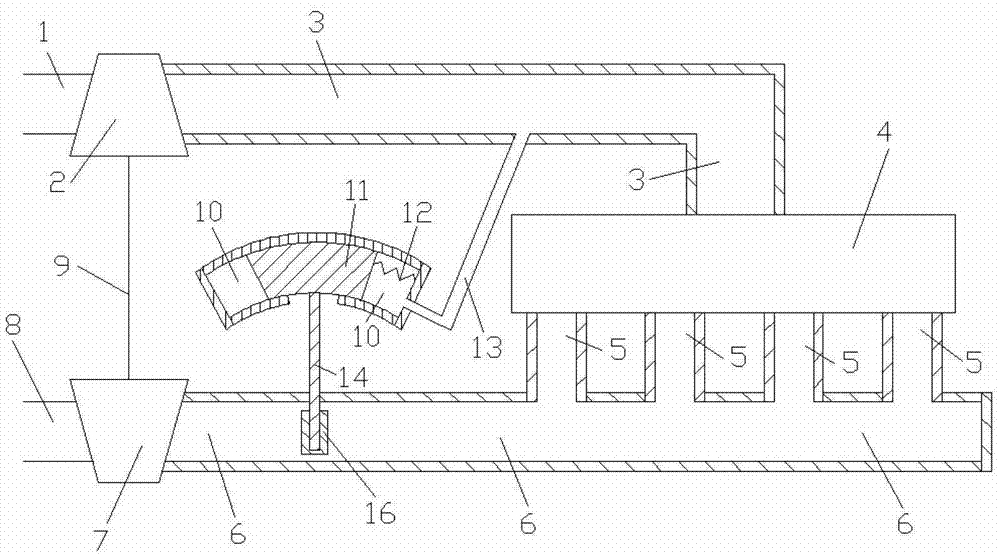

Variable air exhaust through flow area air inlet pressure control type adjusting device for turbocharged engine

InactiveCN103089409AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air inlet pressure control type adjusting device for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and an air inlet pipe of the engine. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air inlet pressure control type adjusting device for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

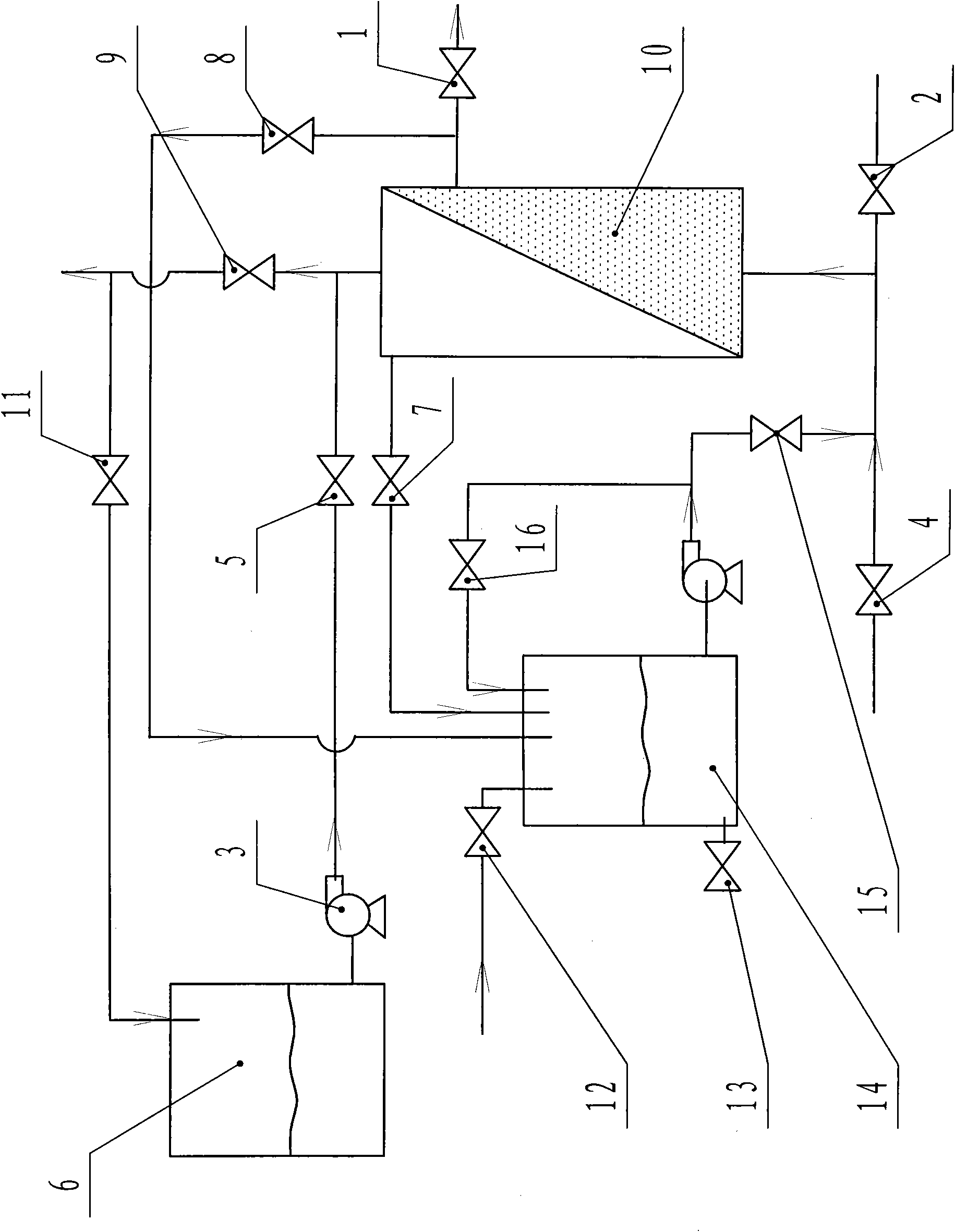

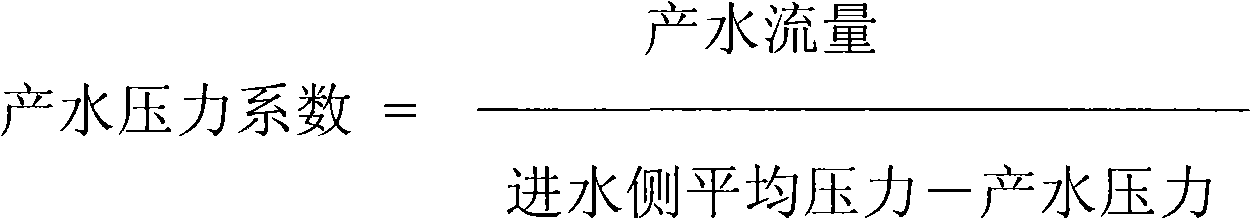

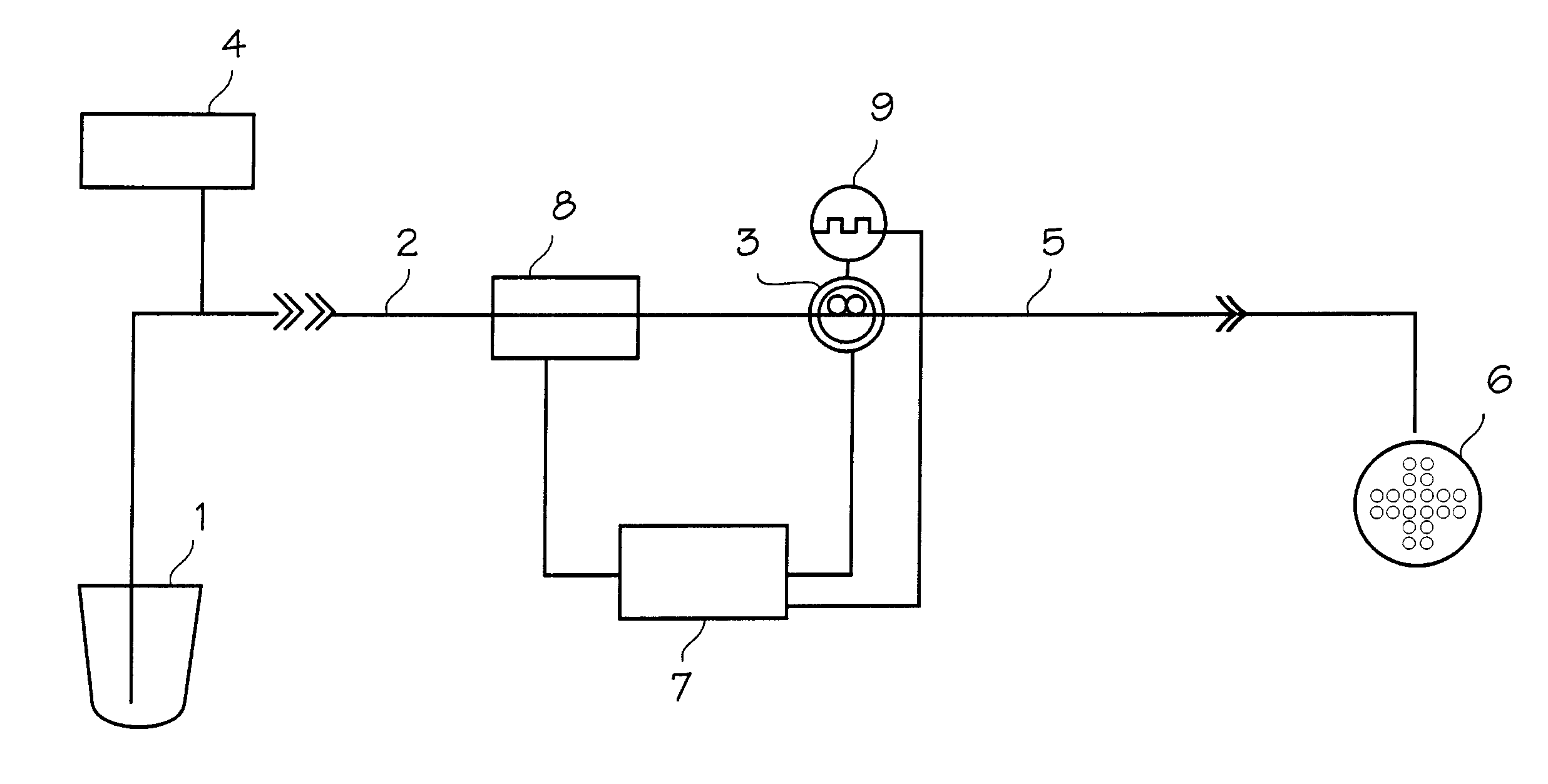

Method for cleaning ultrafiltration membrane

ActiveCN102397752AEliminate pollutionRestore performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisInlet pressureSewage

The invention provides a method for cleaning an ultrafiltration membrane, which comprises a physical cleaning method and a chemical cleaning method. The physical cleaning method comprises a process of air scrubbing of ultrafiltration membrane components and a process of backwashing of the ultrafiltration membrane components. The process of air scrubbing of the ultrafiltration membrane comprises the following steps: ultrafiltration membrane components discharges concentrated water when compressed air is introduced, wherein the air inlet pressure of the ultrafiltration membrane components is less than 2.5 bar and more than 1.5 bar, compressed air is introduced for 1 minute, sewage in the ultrafiltration membrane components is exhausted after air scrubbing is completed, backwashing for once is carried out according to the backwashing process of the ultrafiltration membrane components. The chemical cleaning method comprises the following steps: carrying out forward cleaning circulation ofthe ultrafiltration membrane components; preparing an alkaline cleaner, carrying out forward cleaning circulation of the ultrafiltration membrane components; immersing the ultrafiltration membrane components. The method for cleaning the ultrafiltration membrane is capable of eliminating the pollution of the ultrafiltration membrane components, recovering the performance of the ultrafiltration membrane components, ensuring the normal operation of the ultrafiltration membrane components and prolonging the usage life of the ultrafiltration membrane components as long as possible.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Multi-functional regulator

InactiveUS20080023662A1Reduce number and sizeReduce complexityOperating means/releasing devices for valvesCheck valvesDifferential pressureInlet pressure

A multifunctional regulator provides a housing having an inlet passage joined with an outlet passage through a poppet valve. The housing has a control diaphragm separating the control chamber into a first volume and a second volume and depending on the differential pressure between the two volumes, the diaphragm will push open the poppet valve. Pressurizing and depressurizing valves join the first volume with the inlet and outlet passages, whereby, with an inlet pressure level within the inlet passage greater than an outlet pressure level within the outlet passage, and with the pressurizing valve admitting the inlet pressure level to the first volume, the diaphragm is displaced into the second volume thereby forcing the poppet valve to open and thereby raising the outlet pressure toward the inlet pressure with fluid flow from the inlet to outlet passages.

Owner:STANDFORD MU

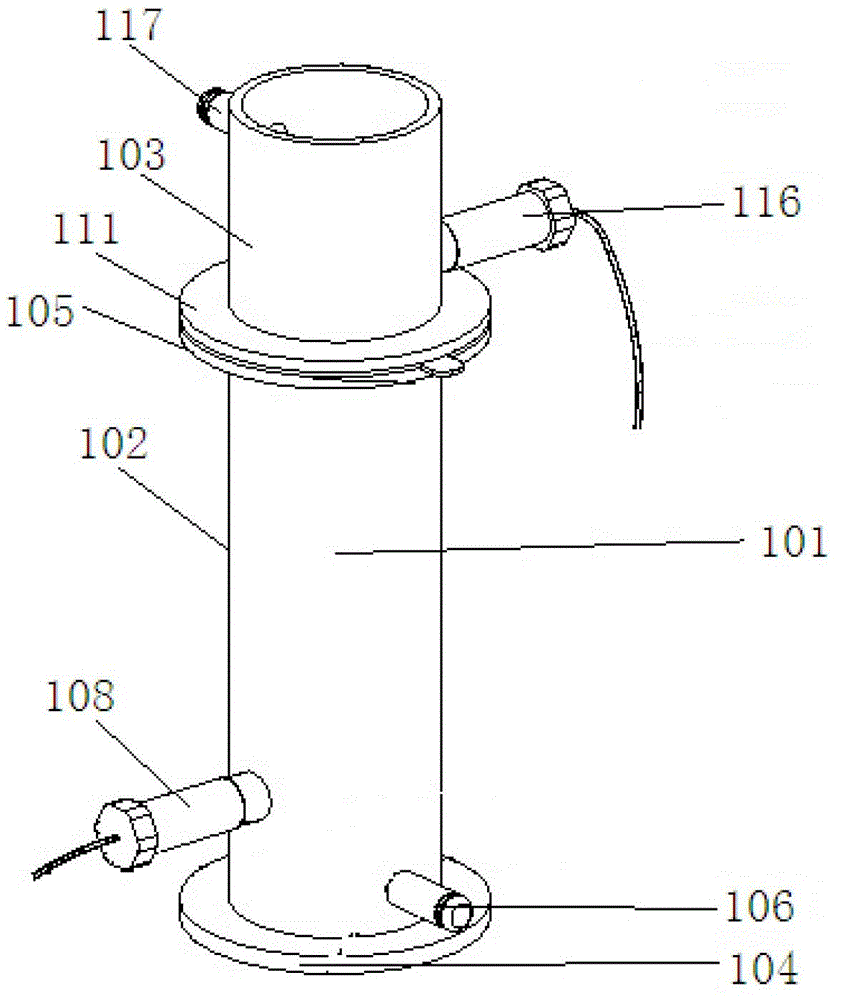

Test device for evaluating well completion manner of coal bed methane

The invention relates to a test device for evaluating a well completion manner of coal bed methane. The test device comprises a well completion manner simulation model system which is arranged in a constant-temperature box; the well completion manner simulation model system consists of a core holder and a well completion model which is arranged in the core holder; the core holder comprises a metal cylinder with both sealed ends; a gas-liquid inlet is arranged at one sealed end of the metal cylinder, and a gas-liquid outlet is arranged at the other sealed end of the metal cylinder; a cylindrical rubber sleeve with both opened ends is sleeved in the metal cylinder; the well completion model comprises a cylindrical raw coal core which is arranged in the cylindrical rubber sleeve; a well completion simulation sheet provided with a through cutting seam or a through hole is adhered to the end face opposite to the gas-liquid outlet of the raw coal core; a gas-liquid pressurized injection system and an inlet pressure sensor are connected with the gas-liquid inlet of the core holder; the gas-liquid outlet is connected with a coal powder collecting and metering system and an outlet pressuresensor; and the core holder is connected with a loading device which is used for loading a confining pressure to the well completion model inside the metal cylinder.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

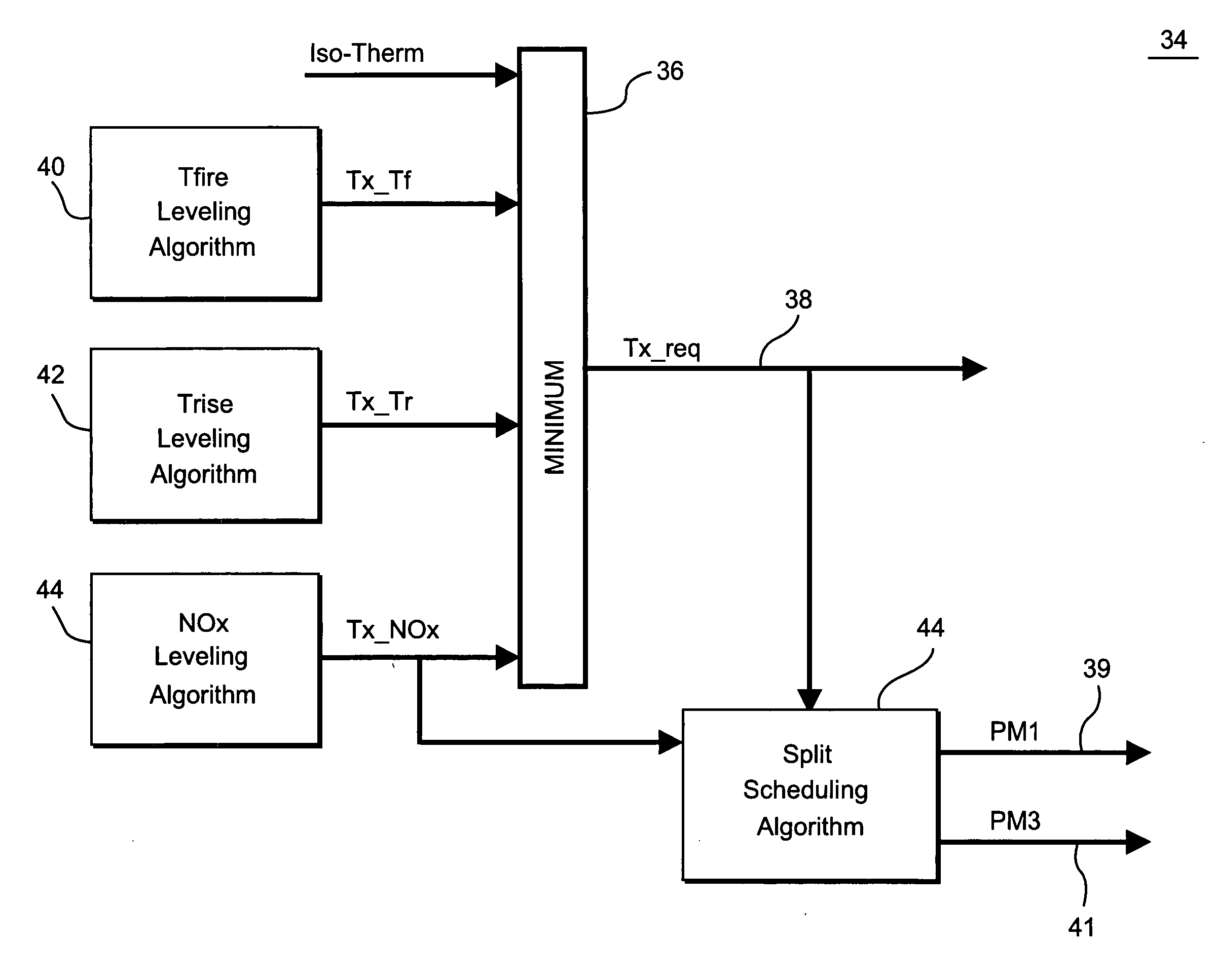

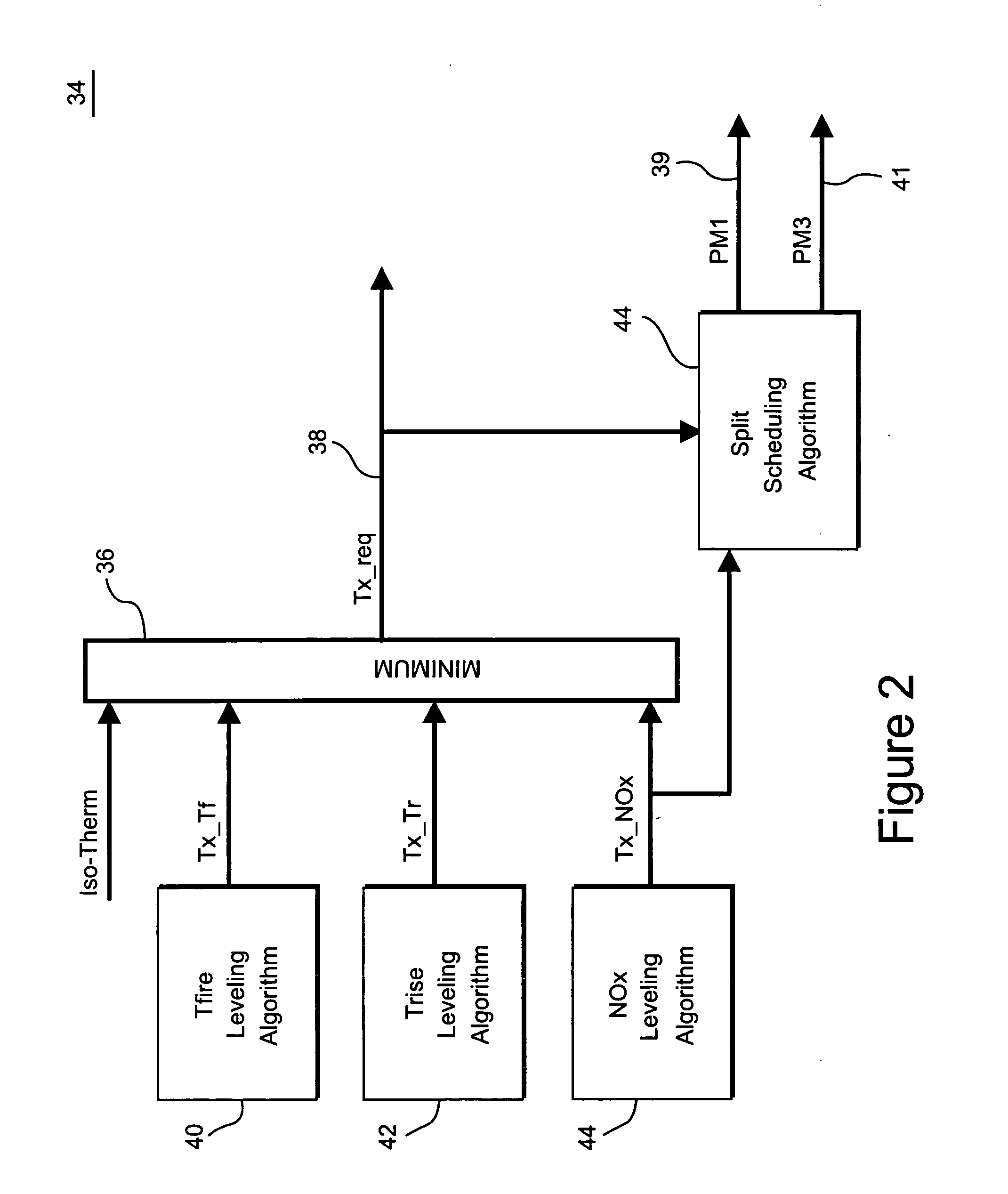

Method for controlling fuel splits to gas turbine combustor

A method for determining a target exhaust temperature for a gas turbine including: determining a target exhaust temperature based on a compressor pressure condition; determining a temperature adjustment to the target exhaust temperature based on at least one parameter of a group of parameters consisting of specific humidity, compressor inlet pressure loss and turbine exhaust back pressure; and adjusting the target exhaust temperature by applying the temperature adjustment.

Owner:GENERAL ELECTRIC CO

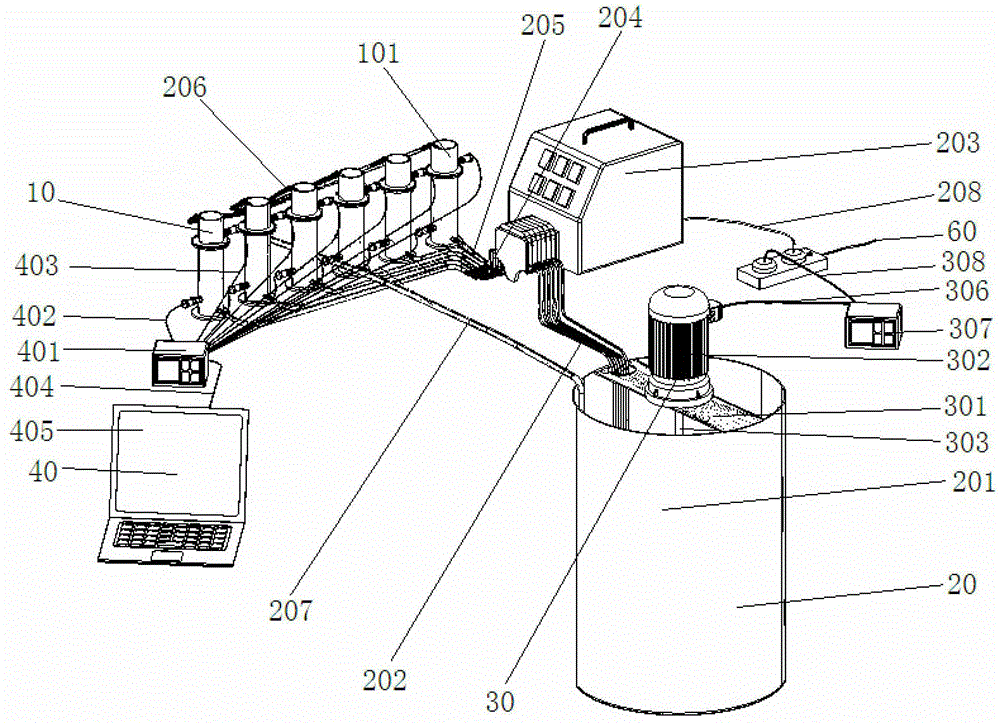

Porous medium biological clogging simulation test device and simulation test evaluation method

InactiveCN102866093AClogged true reflectionSatisfy automatic hydrodynamic conditionsPermeability/surface area analysisPeristaltic pumpPorous medium

The invention relates to a porous medium biological clogging simulation test device and a simulation test evaluation method. The porous medium biological clogging simulation test device is characterized by comprising a plurality of biological clogging simulation single bodies, wherein each biological clogging simulation single body comprises a first column body and a second column body; the first column body is provided with a water inlet and a water inlet pressure sensor; a first permeable plate is arranged inside the first column body; the junction of the first column body and the second column body is provided with a second permeable plate, and the second column body is provided with a water outlet pressure sensor and a water outlet; a circulating water supply device comprises a water storage tank, the inside of the water storage tank is connected with a peristaltic pump through a pipeline, and the peristaltic pump is connected with a water inlet on each first column body through a pipeline; a water outlet of each second column body is connected into the water storage tank through a pipeline; a stirring device comprises a motor which is arranged on the top of the water storage tank, the output end of the motor is connected with a stirring shaft which is plugged inside the water storage tank, and the stirring shaft is provided with a stirring blade; and a pressure collecting device comprises a pressure collection controller, the input end of the pressure collection controller is connected with each water inlet pressure sensor and each water outlet pressure sensor, and the output end of the pressure collection controller is connected with a computer.

Owner:CHINA AGRI UNIV

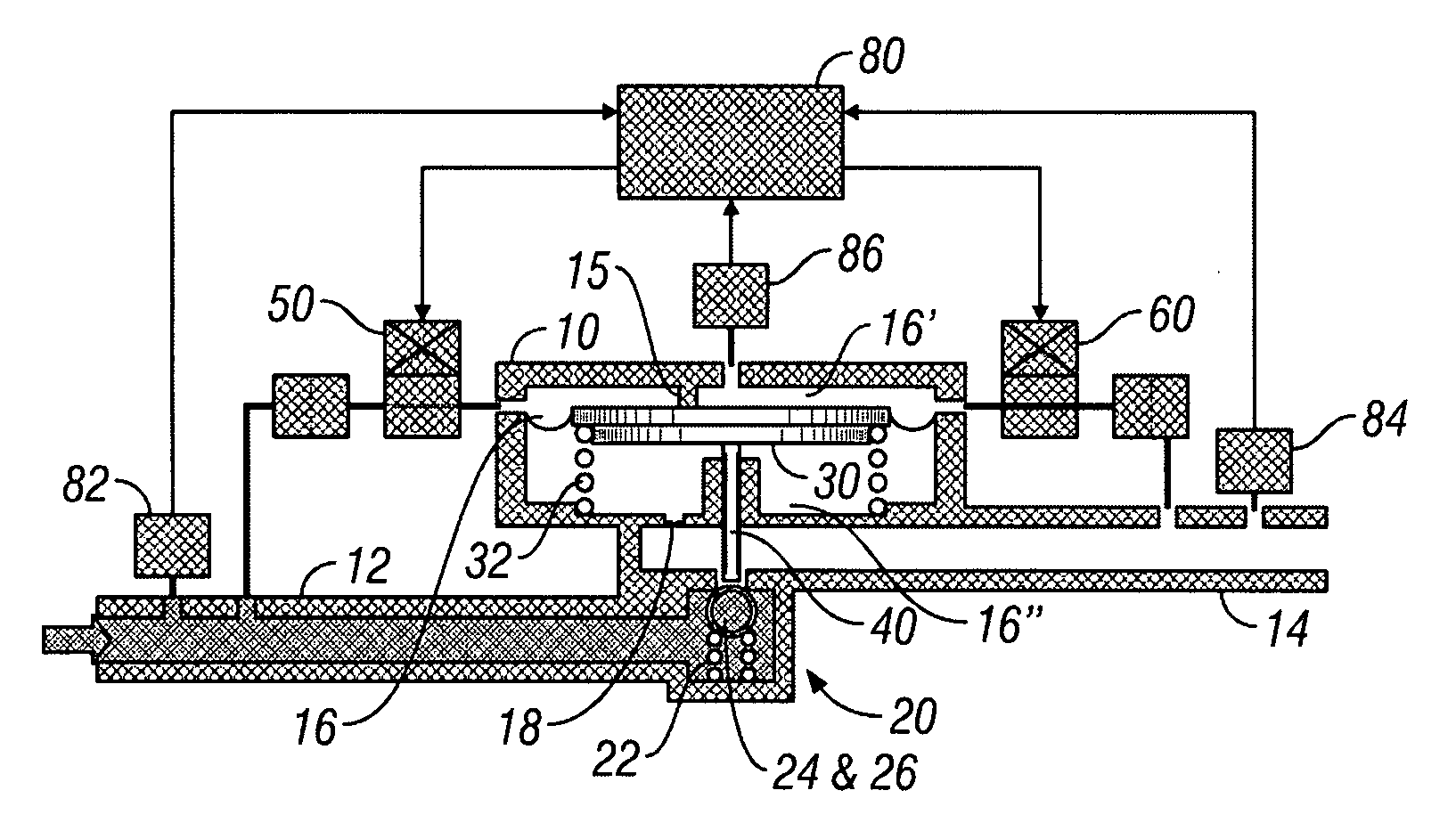

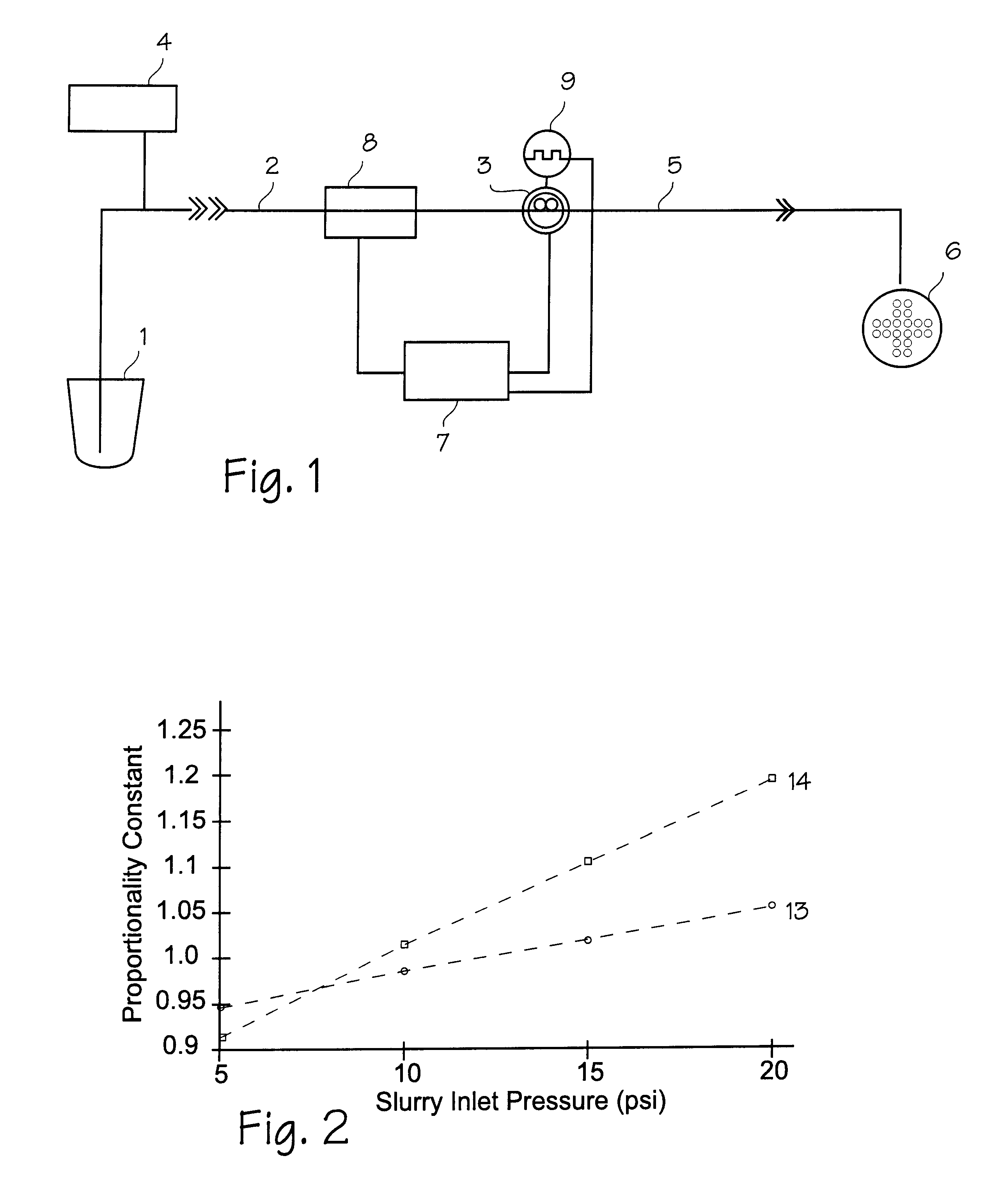

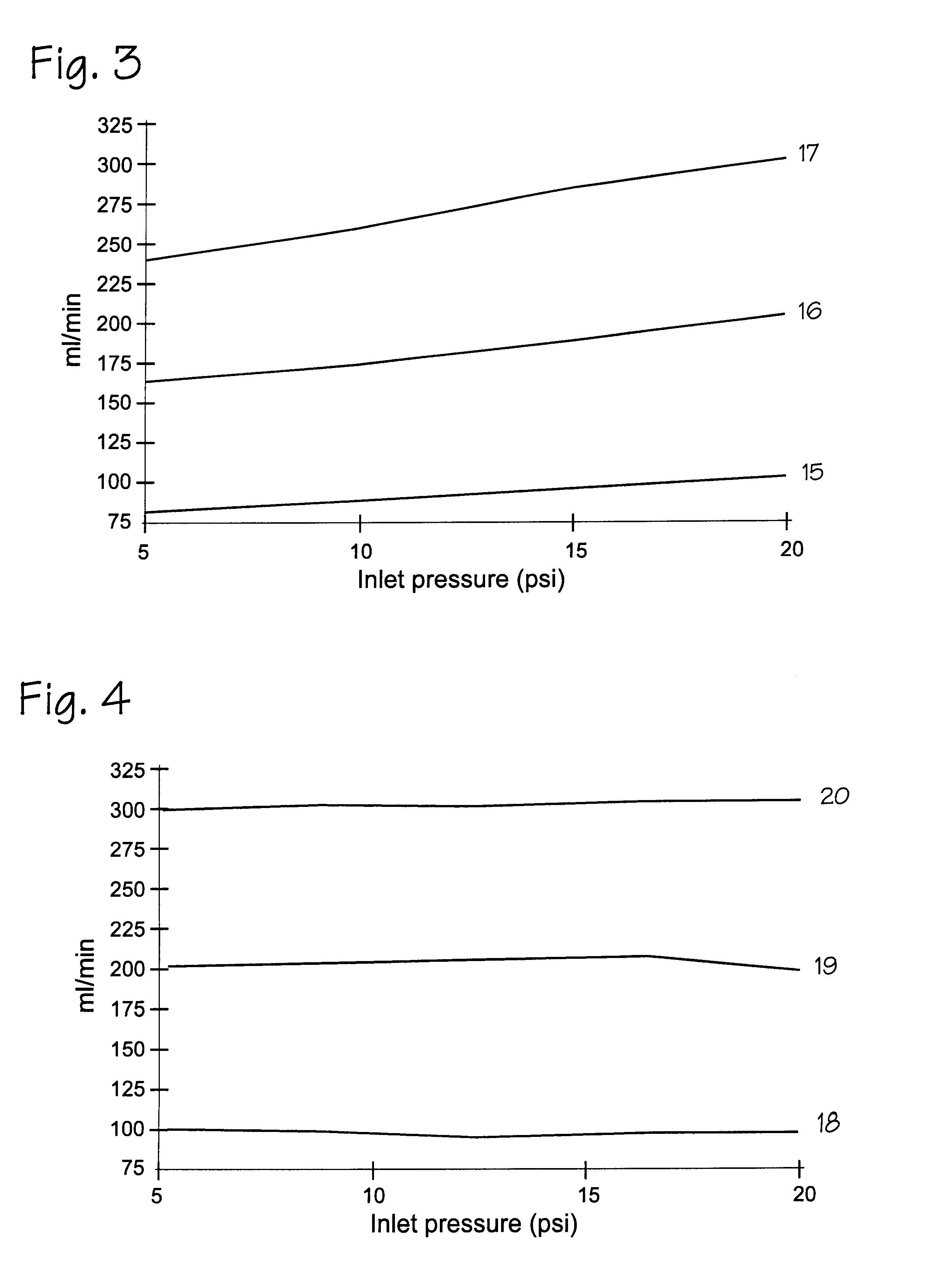

Slurry pump control system

A CMP slurry pumping system which uses the slurry pump inlet pressure as input to the pump controller, and adjusts pump speed to account for variations in inlet pressure.

Owner:REVASUM INC +1

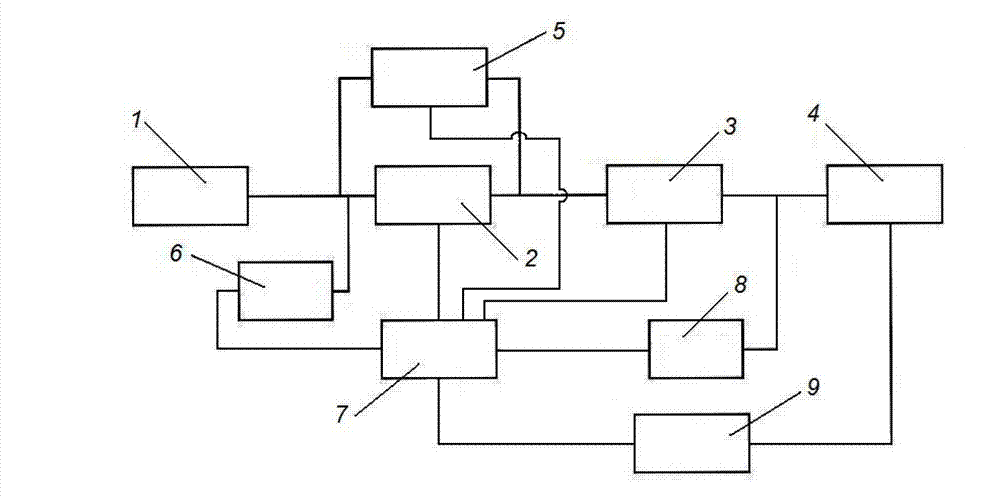

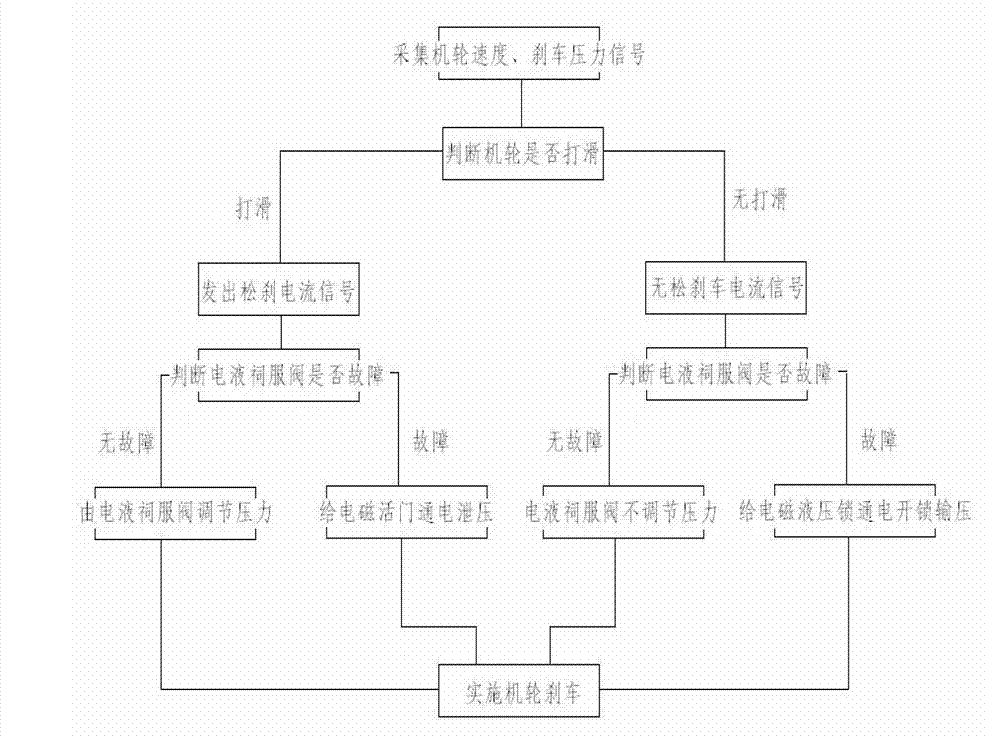

Mixed airplane brake system and control method

InactiveCN103158868AReduce workloadEasy to troubleshoot and overhaulBrake regulatorsDriver/operatorFuel tank

The invention relates to a mixed airplane brake system and a control method. A brake valve of the mixed airplane brake system is connected to a airplane pressure supply system, an electro hydraulic servo valve oil inlet and an oil returning tank through a pipeline; the electro hydraulic servo valve is connected to a brake nozzle of the brake valve, an oil inlet of the electromagnetic valve and an airplane oil return tube through the pipeline; and an electromagnetic hydraulic lock and the electro hydraulic servo valve are parallel channels on a hydraulic line. An oil inlet pressure transducer is arranged on the pipeline between the brake valve and the electro hydraulic servo valve; a brake port pressure transducer is arranged on the pipeline between the electromagnetic valve and a brake machine wheel. Under the failure of the electro hydraulic servo valve, an airplane antiskid brake control system can automatically convert a current normal brake mode to a standby brake mode and then enables reliable operation, driver intervention is not required, so that the work load of the driver is reduced. The mixed airplane brake system enables mode record on a fault state of the electro hydraulic servo valve, and is convenient for troubleshooting and maintenance by maintainer after flight.

Owner:XIAN AVIATION BRAKE TECH

System and method for modeling of turbo-charged engines and indirect measurement of turbine and waste-gate flow and turbine efficiency

A real-time system for modeling a turbo-charged engine includes a model configured to estimate various exhaust states such as turbine inlet pressure, turbine outlet pressure, turbine outlet temperature, turbine mass flow rate and waste-gate valve mass flow rate. The model is dependent only on the availability of normal operating values available in a conventionally-configured automotive controller and one or more measured intake side parameters such as ambient pressure, boost pressure, ambient temperature and compressor mass flow rate. The model is constructed to reflect a high-level application of energy conservation between the turbine (generated power) and compressor (absorbed power). A method for the indirect measurement of turbine and waste-gate flow uses turbine inlet and outlet pressure, inlet temperature and engine mass air flow rate measurements. A method for the indirect measurement of turbine efficiency avoids the need for manufacturer's turbine data.

Owner:DELPHI TECH INC

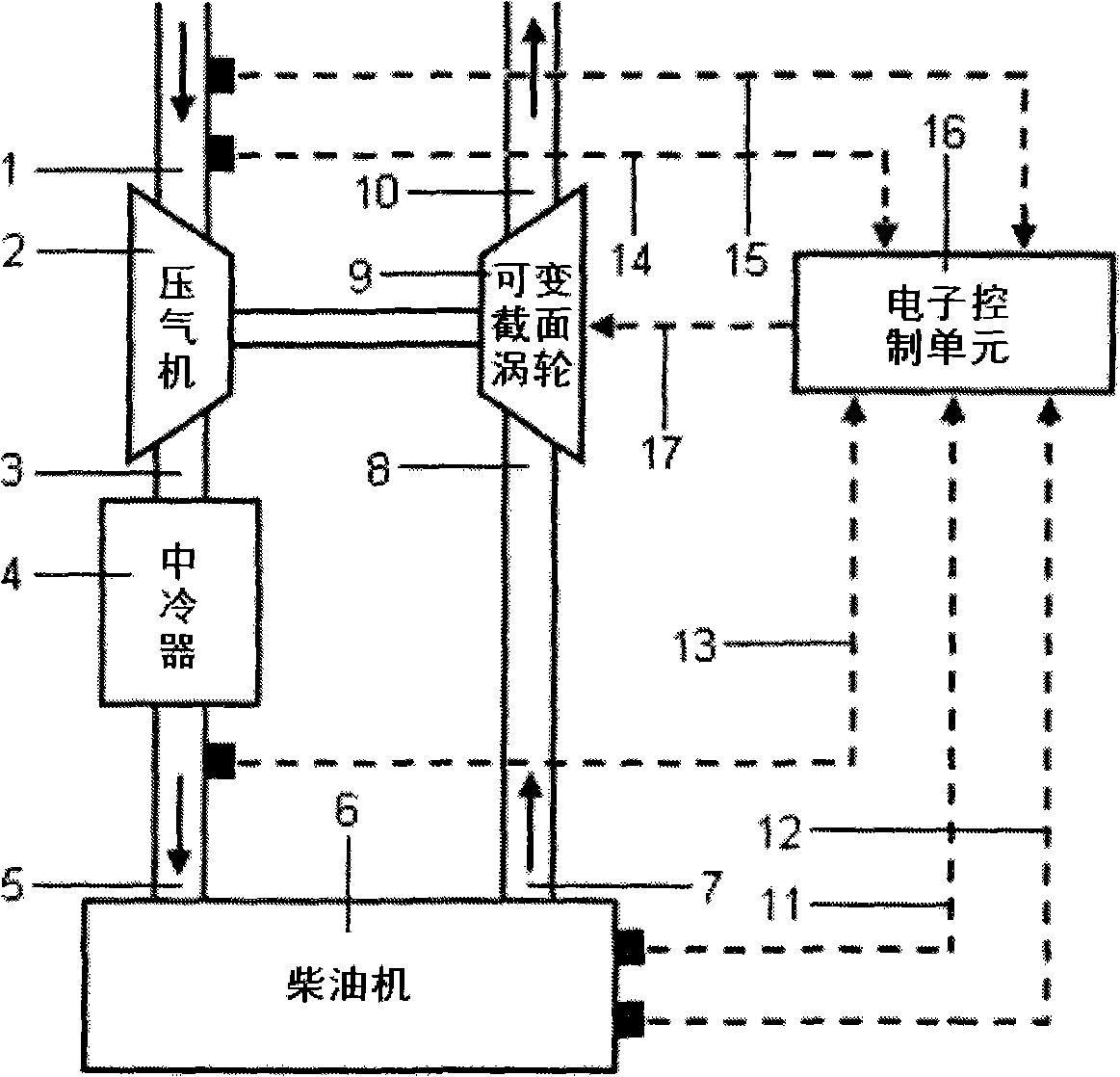

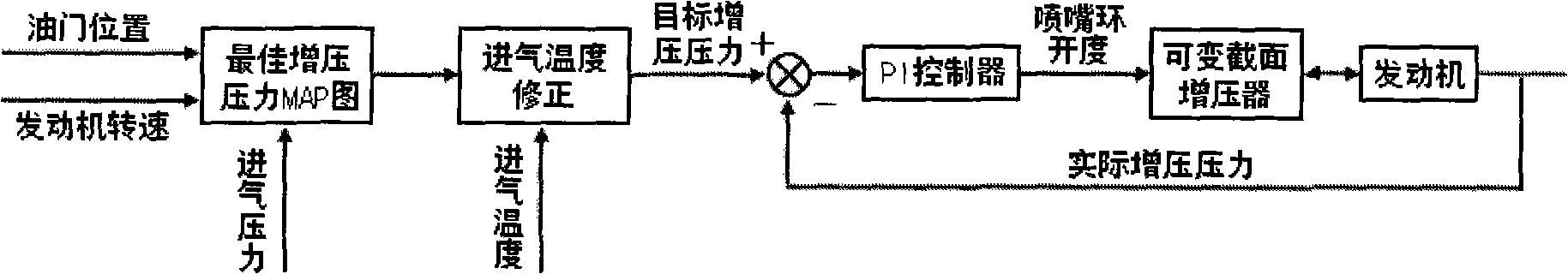

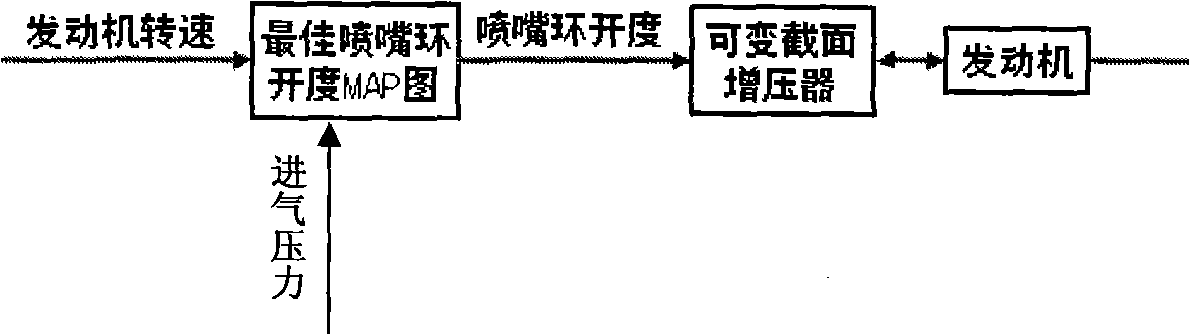

Diesel altitude-variable self-adapting supercharging control method and system

InactiveCN101328831AOptimum flow cross sectionPrevent speedingInternal combustion piston enginesIntercoolerInlet pressure

The invention discloses a method and a system for controlling a variable-altitude self-adapting supercharging for a diesel engine, relating to the technical field of supercharging control for a diesel engine, which is characterized in that an optimal supercharging pressure MAP is inquired to obtain the optimal supercharging pressure under the working condition of a stable state according to an inlet pressure signal of an air compressor, a rotating speed signal of an engine and a position signal of a gasoline throttle, the opening of a nozzle ring of a turbine is controlled by using a PI controller according to the difference value between the optimal supercharging pressure and the actual supercharging pressure to obtain an optimal circulating section; an optimal opening MAP of the nozzle ring is inquired to obtain the optimal opening of the nozzle ring under the working condition of a transient state according to the rotating speed signal of the engine and the inlet pressure signal of the air compressor so as to control the optimal circulating section. The system comprises a diesel engine, an intercooler, a variable-section supercharger consisting of an air compressor and a variable-section turbine, an electronic control unit, a pressure sensor and a temperature sensor etc. The method and system can adapt to the altitude variation and adjust the circulating section of the variable-section turbine so that the diesel engine has optimal dynamic property and fuel economy at each altitude.

Owner:TSINGHUA UNIV

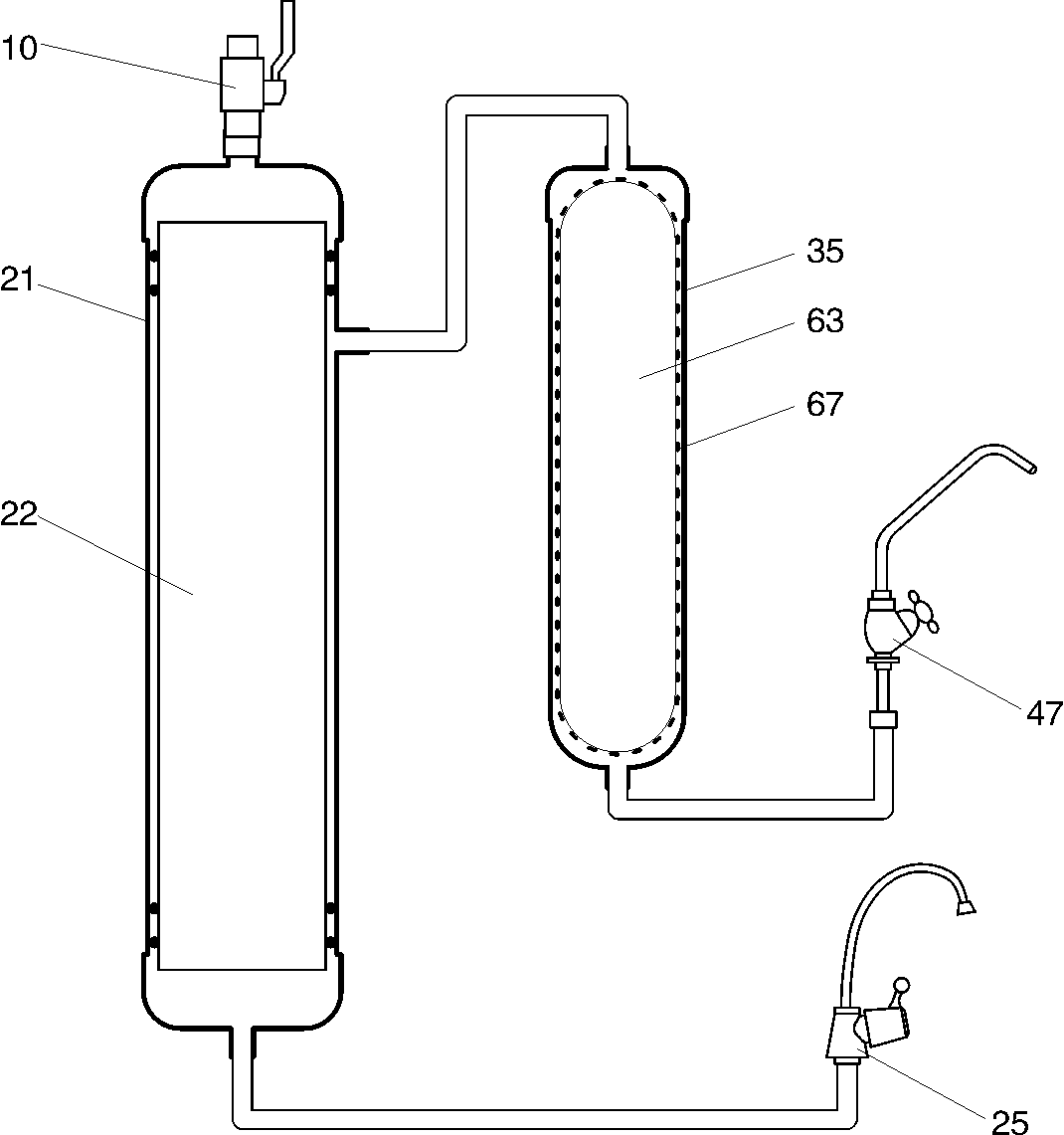

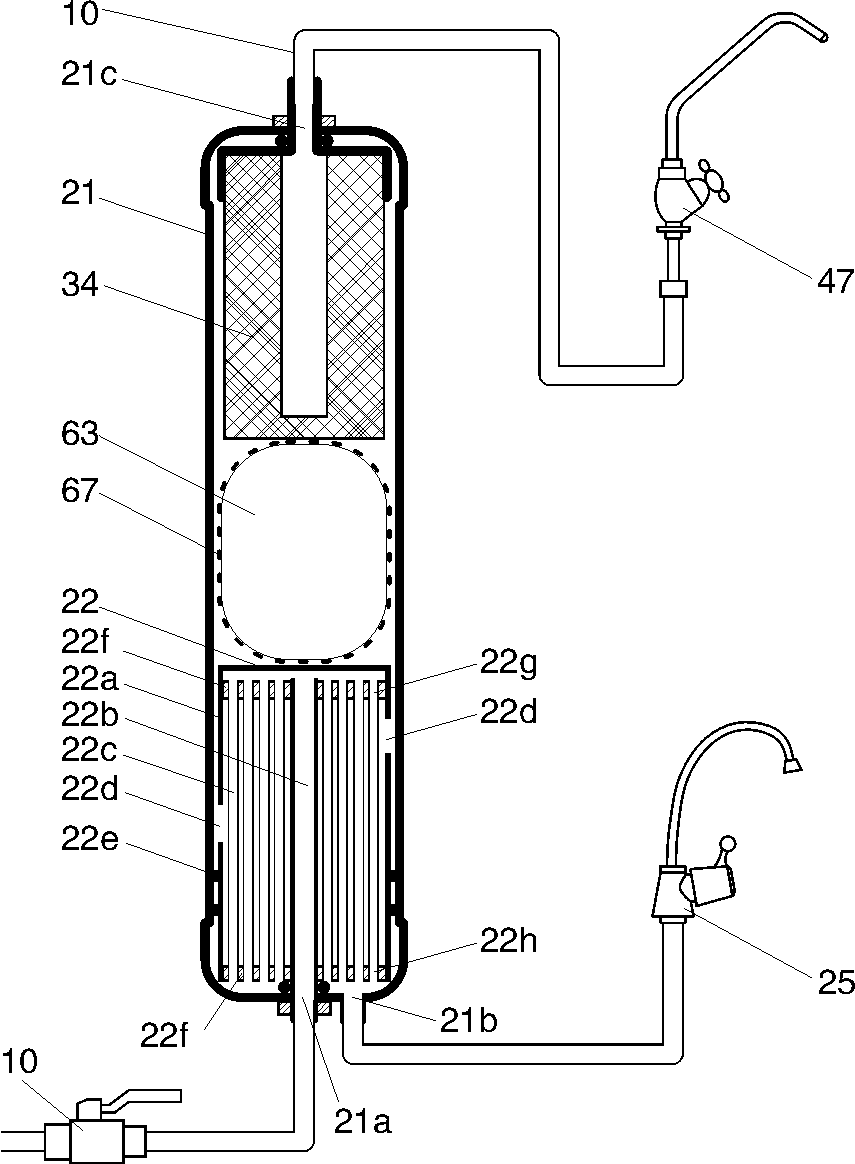

Pre-pressurized self-balanced negative-pressure-free water-supply apparatus

A water supply apparatus with self-balanced inlet pressure without negative pressure is described, which includes a tank, an air pump, a water pump, a micro-processor based automatic control unit, pressure sensors, level sensors, unidirectional valve. Features of this new design include dual cavity storage tank and air activated pressure stabilizer. In the tank a pre-pressed gas is contained. The pressure is maintained using a self-balanced pressure stabilizer. There is no need to add environmental air. Subsequently, environmental air related pollution is avoided.

Owner:WANG RUIBO

Pilot operated pressure valve

InactiveUS6640830B2Eliminates excessive system pressure spikesControl rateOperating means/releasing devices for valvesEqualizing valvesPressure riseSystem pressure

A pilot operated pressure valve which limits the rate of start-up pressure rise ("soft start-up") and substantially eliminates excessive system pressure spikes. The valve includes an inlet, a hollow cylindrical main body sealingly connected at one end thereof to the inlet, a pilot chamber having a sleeve slidably mounted within the main body and an operating pressure adjustment connected to another end of the main body adjacent another end of the pilot chamber for varying the threshold operating pressure of the valve. A main chamber receives pressurized fluid metered through a main orifice and discharges pressurized fluid through a damping orifice when the main chamber is filled and fluid inlet pressure exceeds the inlet threshold pressure which is just sufficient to open a spring biased pilot ball downstream of the damping orifice. An exit port upstream of the main orifice will open for discharging pressurized fluid from the valve back to a supply tank when inlet pressure exceeds the maximum operating pressure setting of the valve. Pressurized fluid is also metered from the pilot chamber into a pressure compensated priority flow control valve arrangement including an adjust chamber to automatically vary the operating pressure of the valve in "soft start-up" fashion by selectively discharging pressurized fluid from the pilot chamber and / or the adjust chamber in modulated fashion when fluid pressure reaches the threshold operating pressure.

Owner:SUN HYDRAULICS

Air bag used for water treatment, and water purification device with same

ActiveCN102910752ALow gas escape rateHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh resistanceWater flow

The invention belongs to the technical field of water treatment, relates to a water flow buffer and pure water back-wash technology, and particularly relates to an air bag used for water treatment and a water purification device with the air bag. According to the air bag used for water treatment, and the water purification device with the air bag, the air bag is formed by a high-resistance plastic film and is used for caching water flow and buffering pressure in a water treatment device. With the adoption of the water purification device with the air bag, the air bag is arranged in a filter shell space which is communicated with a filter core pure water port; pure water is cached by the compression of the air bag and discharged by expansion of the air bag, so that the purpose of the invention of back-flowing pure water and back-washing the filter core is achieved. With the adoption of the water purification device with the air bag, the air bag is arranged in the filter shell space which is communicated with a pressure switch in a reverse osmosis water purification device, the problems of frequency opening of the water inlet valve and the frequency starting of a booster pump are solved by caching the pure water and the pressure by the air bag. According to the water purification device with the air bag, the air bag is arranged in a water inlet pipeline of the filter core, so that the purpose of the invention of clearing up water hammer and buffering water inlet pressure is achieved.

Owner:段成同

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com