Patents

Literature

334results about How to "Restore performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

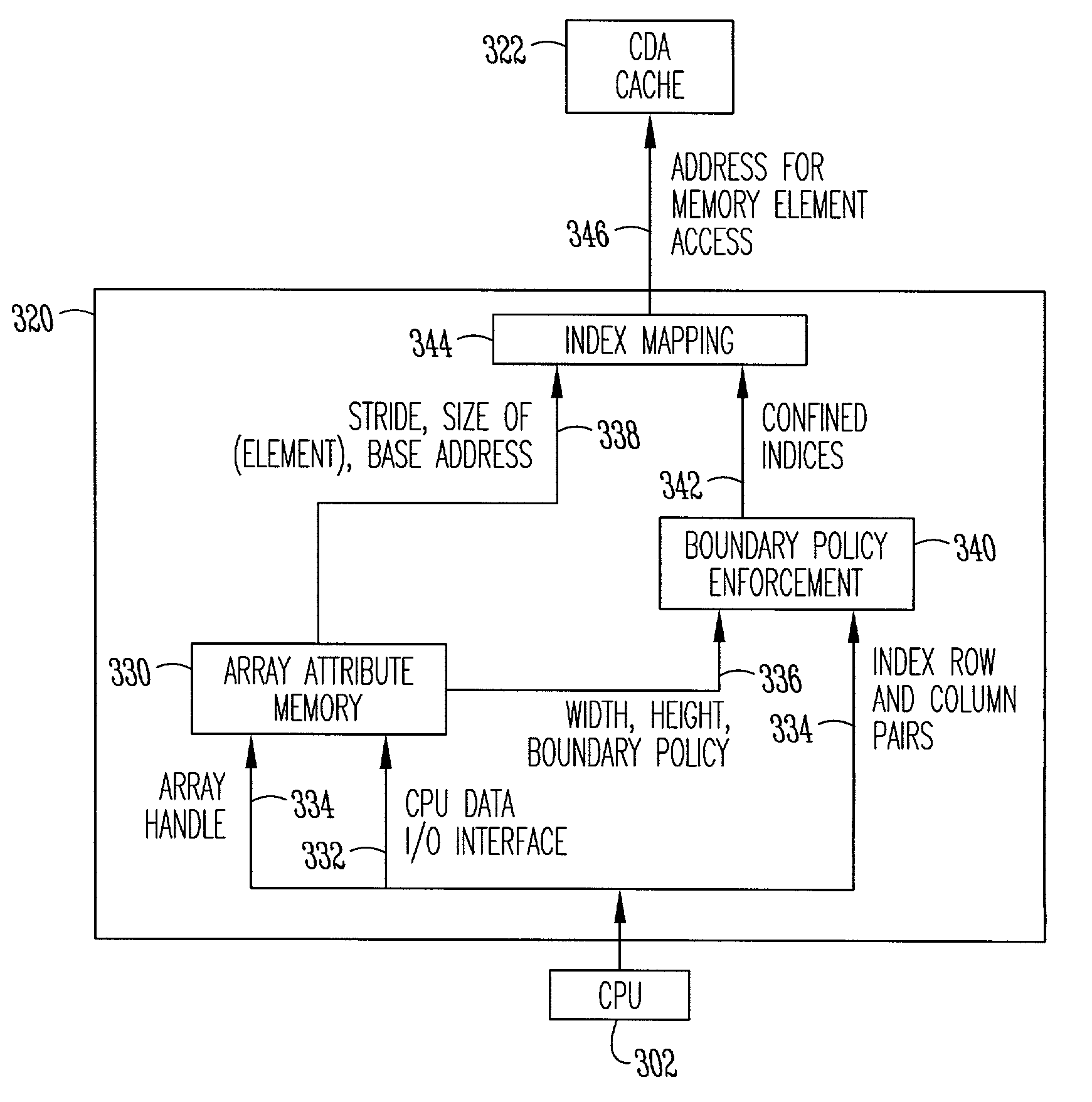

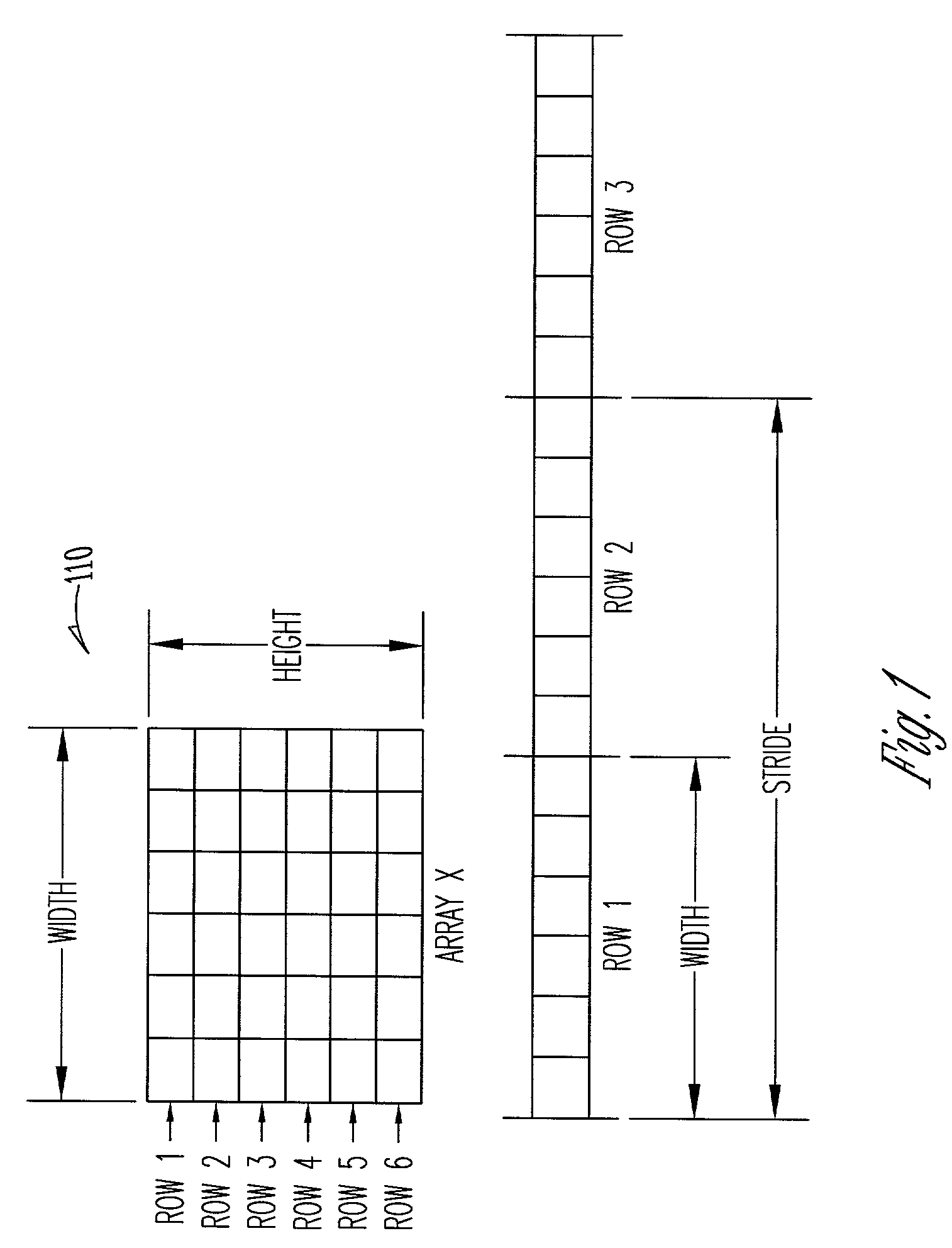

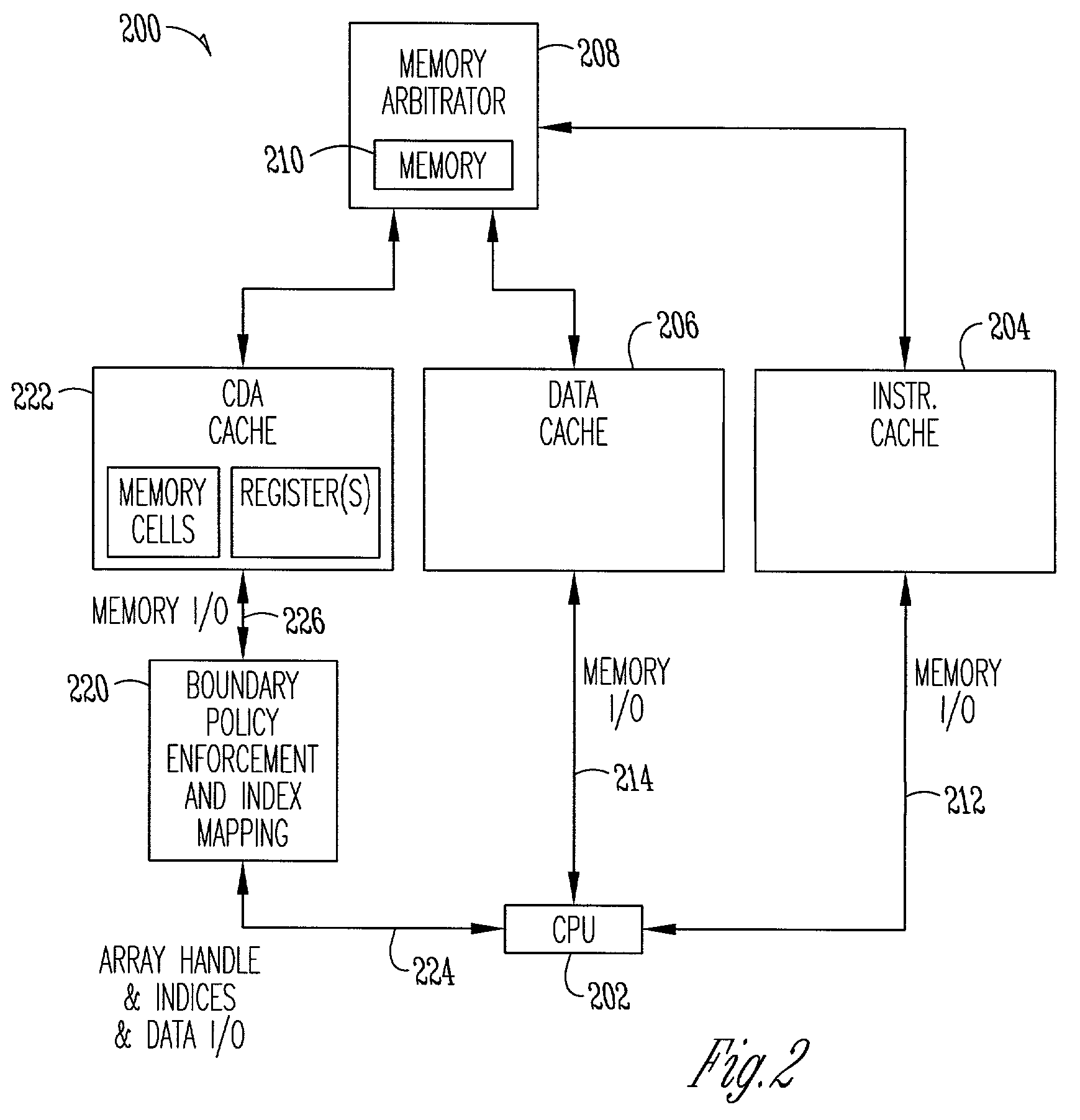

Dynamic arrays and overlays with bounds policies

InactiveUS7062761B2Simplify the codeEfficient accessResource allocationProgramming languages/paradigmsArray data structureOperating system

Systems and methods are provided for writing code to access data arrays. One aspect provides a method of accessing a memory array. Data is provided within a one-dimensional array of allocated memory. A dimensional dynamic overlay is declared from within a block of statements, and the declaration initializes various attributes within an array attribute storage object. The data is accessed from within the block of statements as a dimensional indexed array using the array attribute storage object. Another aspect provides a method of creating and accessing a dimensional dynamic array. A dimensional dynamic array is declared from within a block of statements, and memory storage for the array is dynamically allocated. A dynamic overlay storage object is also provided and its attributes are initialized from the dynamic array declaration. The data is accessed as a dimensional indexed array from within the block of statements using the array attribute storage object.

Owner:MICRON TECH INC

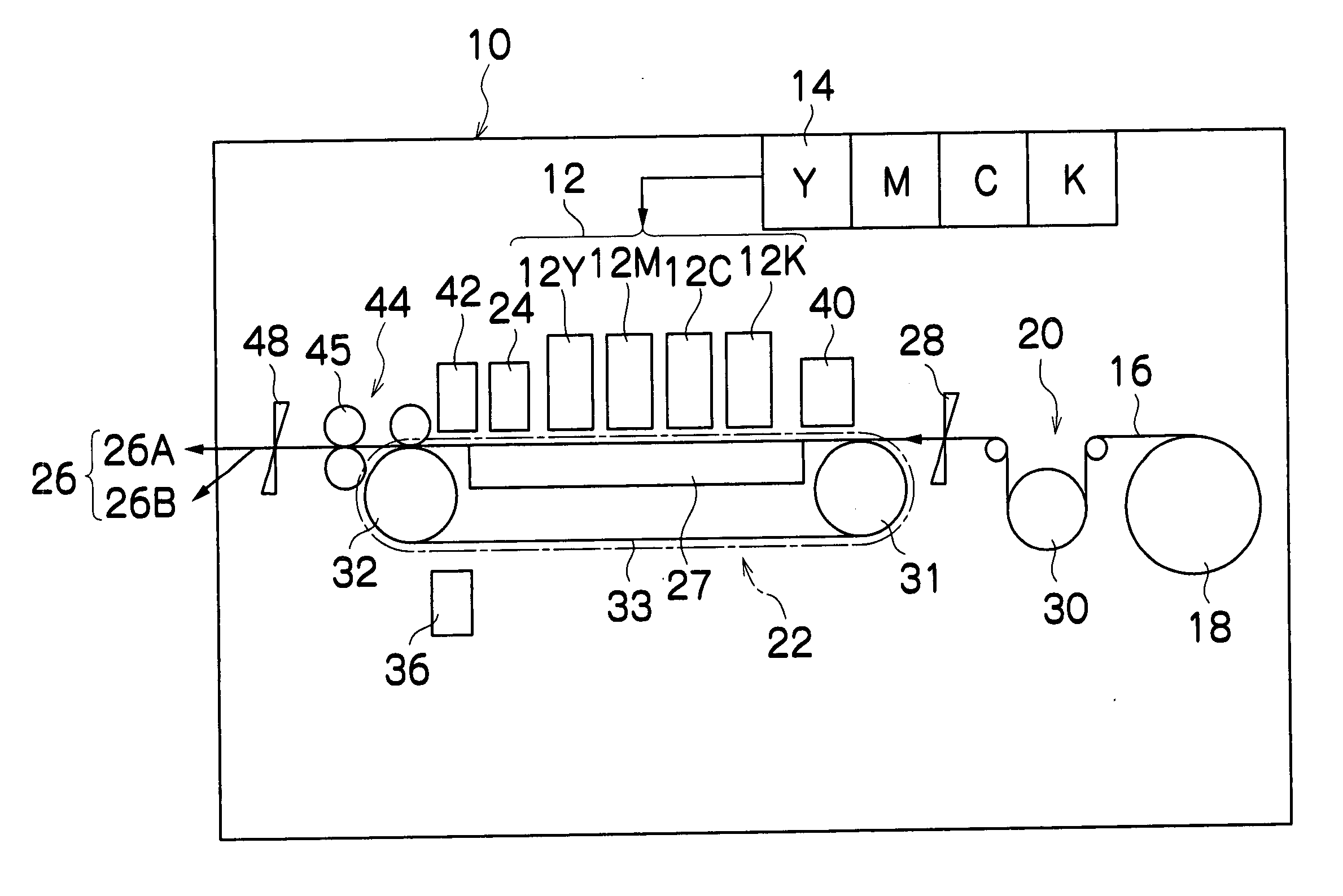

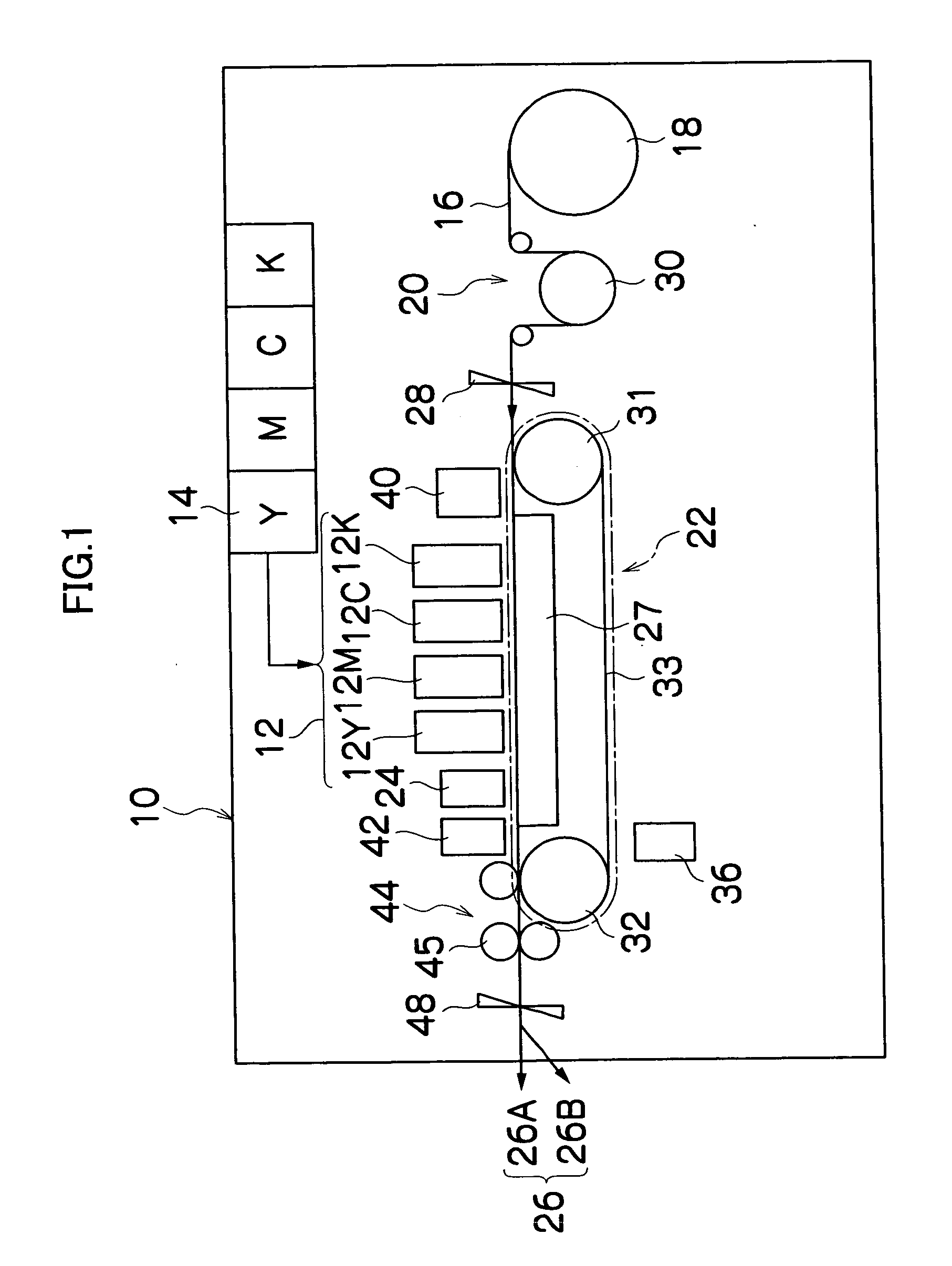

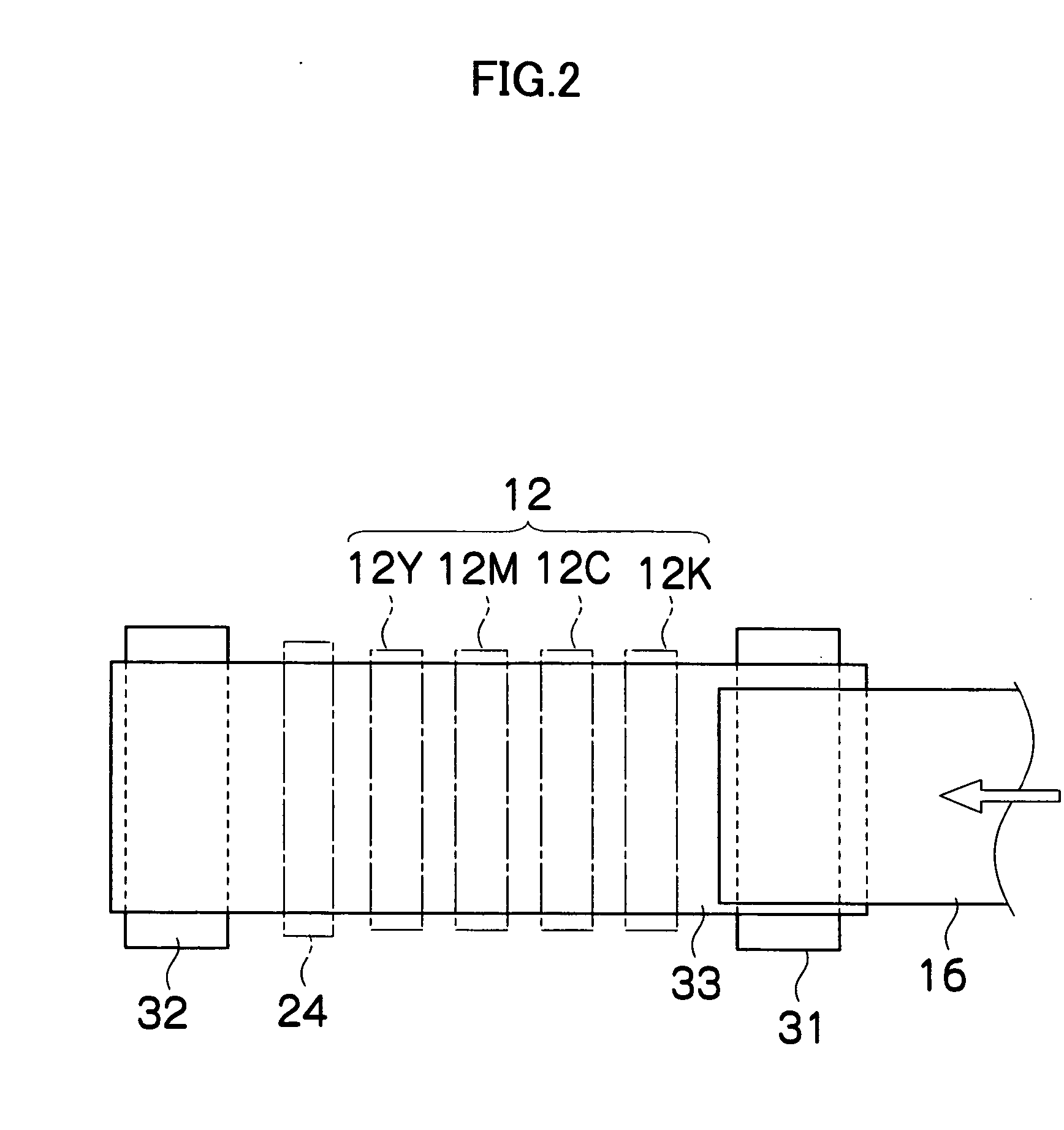

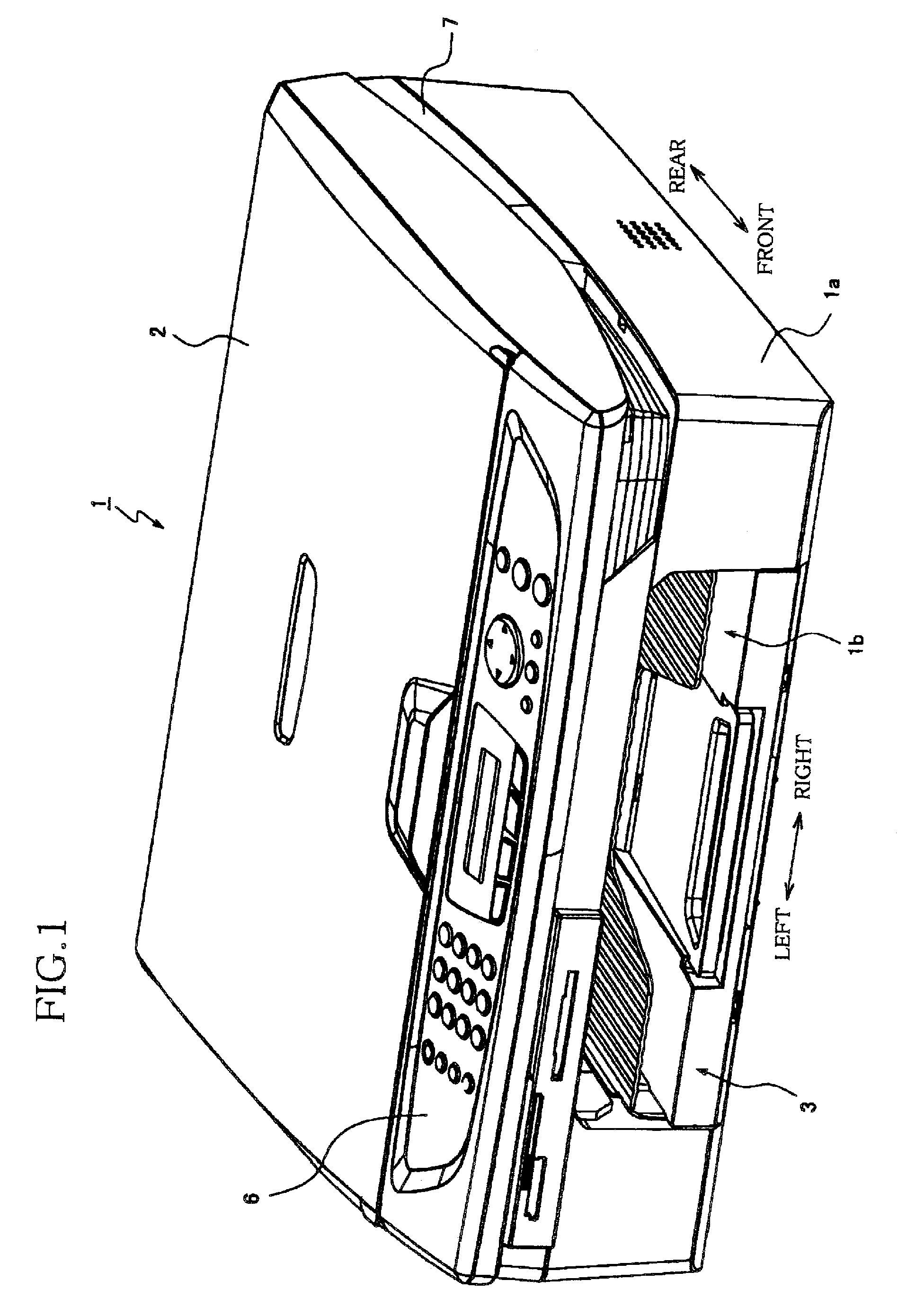

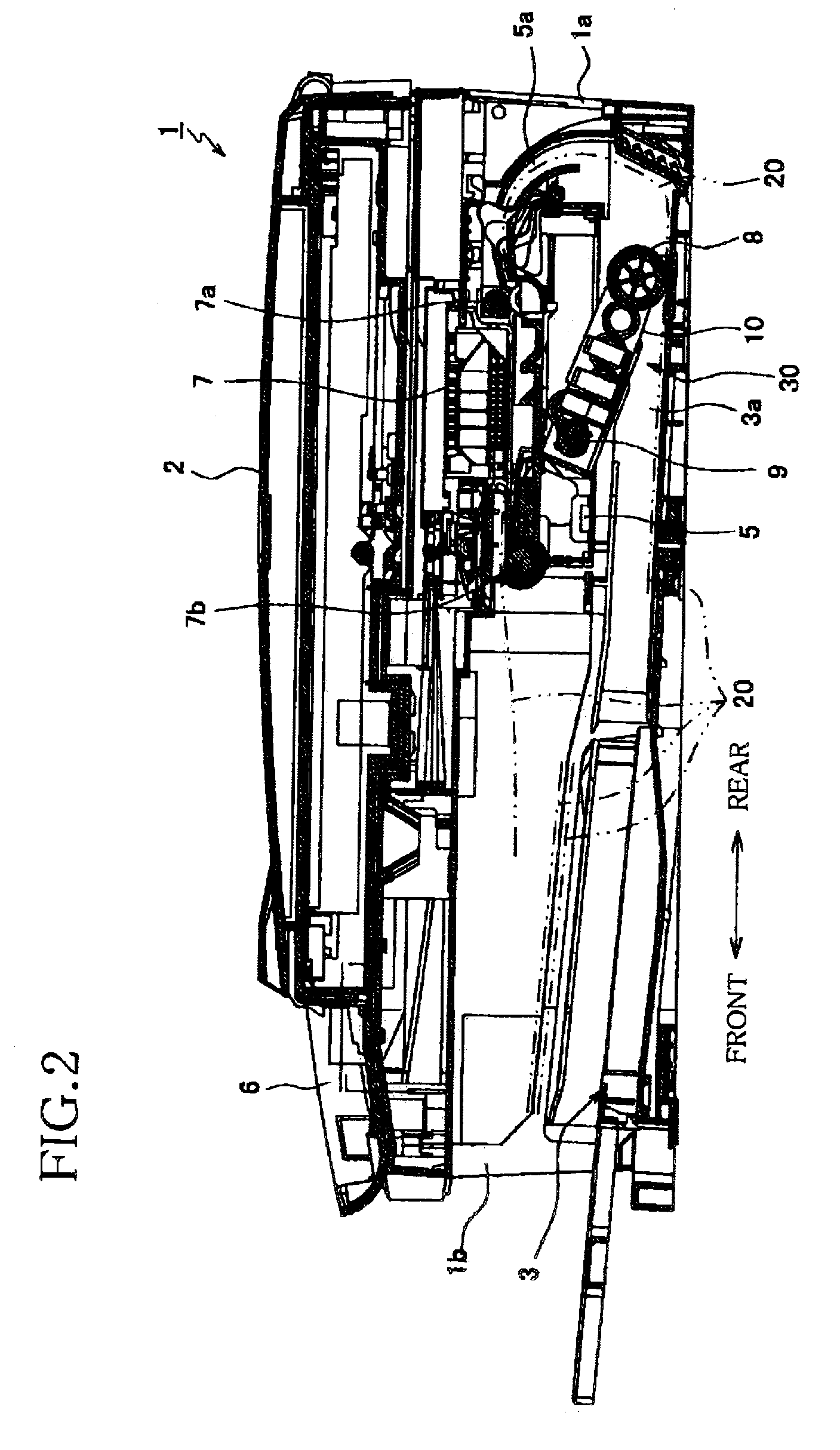

Liquid ejection apparatus and image forming apparatus

InactiveUS20060066665A1Maintain prescribed cleaning performanceSuitable for operationPrintingRestoration deviceEngineering

The liquid ejection apparatus comprises: a liquid ejection head having an ejection port surface on which ejection ports for ejecting liquid are formed; a wiping device having a blade member which wipes and cleans the ejection port surface; a sliding device which causes the blade member to slide relatively with respect to the ejection port surface; a cleaning capability identification device which identifies a cleaning capability of the wiping device; and a cleaning capability restoration device which restores the cleaning capability of the wiping device in accordance with the cleaning capability identified by the cleaning capability identification device.

Owner:FUJIFILM CORP

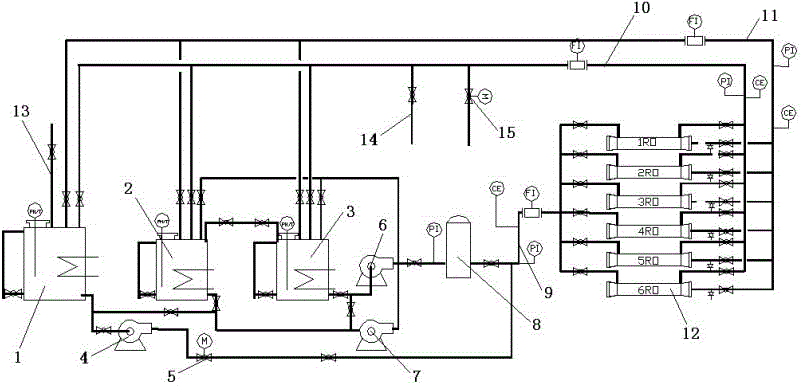

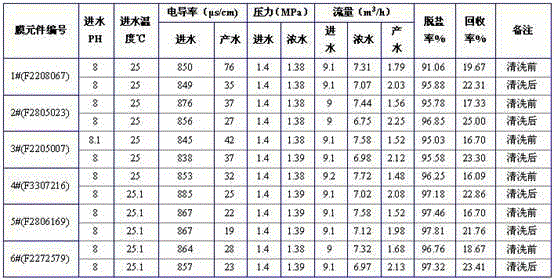

Offline cleaning and evaluating device of reverse osmosis membrane element and application method of device

ActiveCN103331102ARestore performanceEnsure cleaning flowSemi-permeable membranesReverse osmosisEngineering

The invention discloses an offline cleaning and evaluating device of a reverse osmosis membrane element and an application method of the device, belonging to the technical field of water treatment. The method can be used for evaluating the performance of the reverse osmosis membrane element, typically selecting cleaning agents according to the pollutant ingredients and contents and cleaning a single reverse osmosis membrane element in off-line multi-angle and multilevel manner by means of such operations as washing by a large amount of water, reverse washing, positive washing and soaking, and in the cleaning process, the method can be used for monitoring the performance of the reverse osmosis membrane element and controlling such factors as cleaning flow rate, pressure, cleaning time and temperature, so as to improve a cleaning effect. The offline cleaning and evaluating device disclosed by the invention can be also used for evaluating and testing the performance of the agents and the reverse osmosis membrane by simulating the onsite operation conditions.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

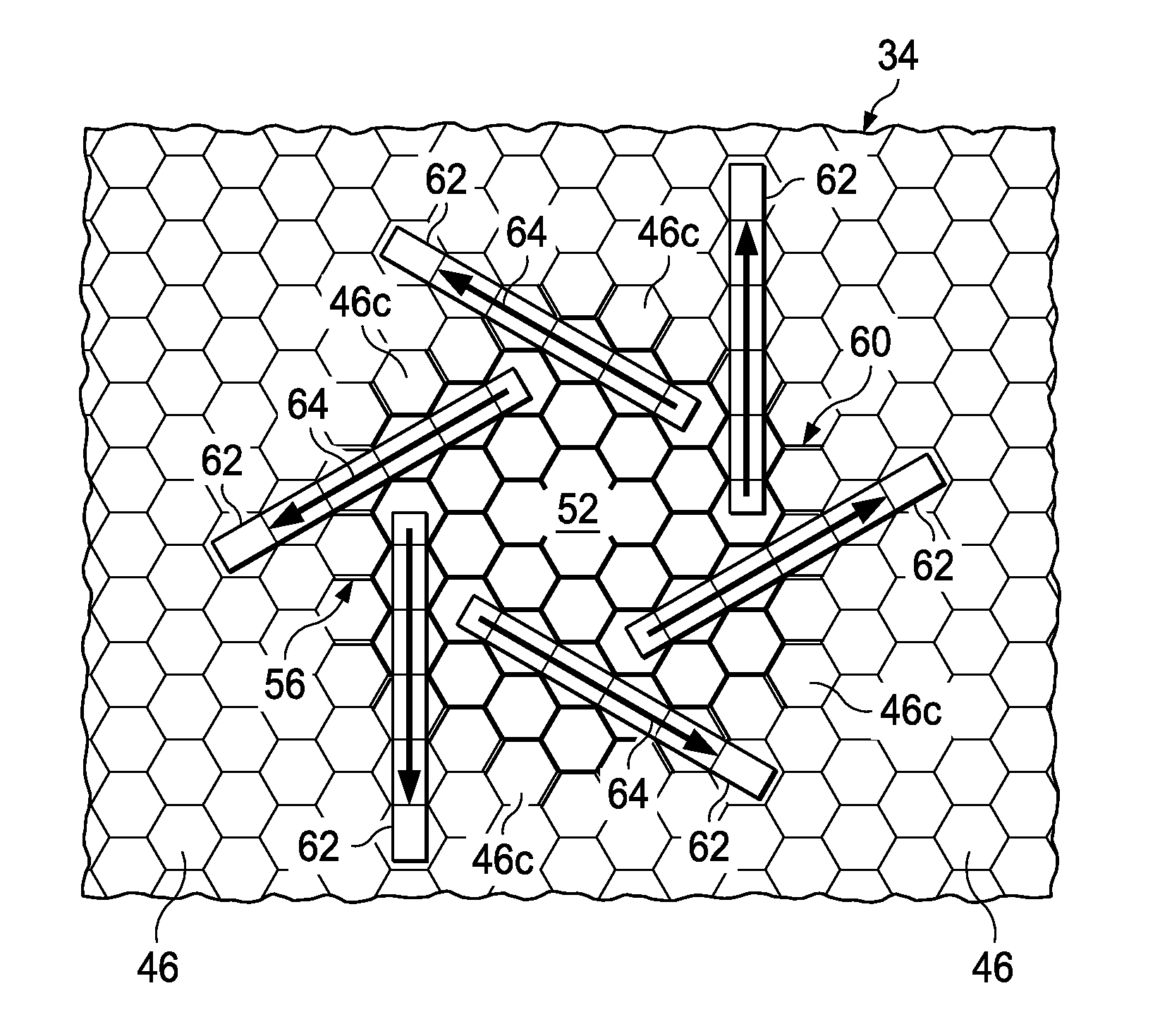

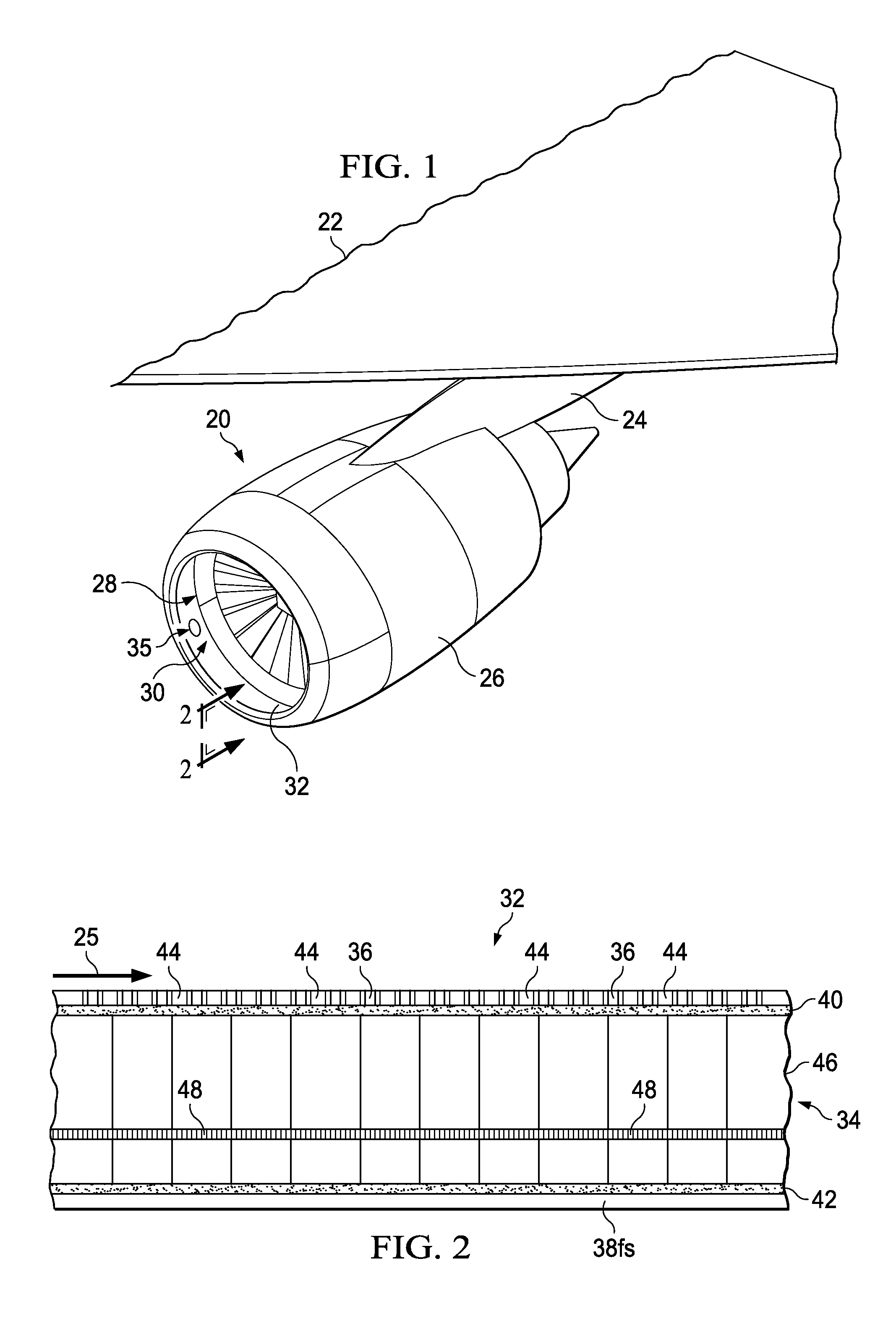

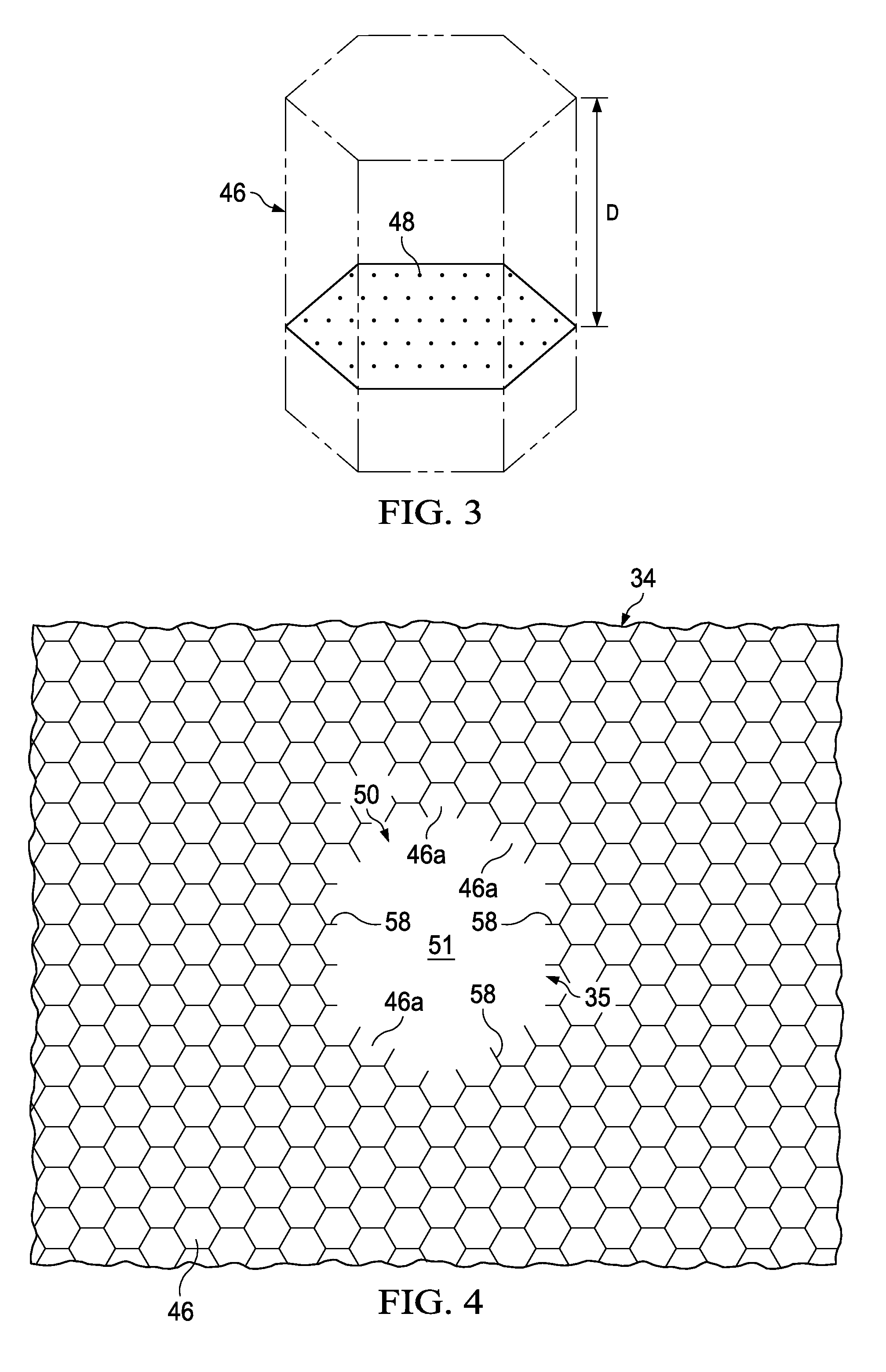

Repair of acoustically treated structures

InactiveUS8696843B1Restores acoustic and structural performance of structureMinimum of aircraft downtimeElectrical transducersRecord carriersHoneycombMaterials science

A method of repairing an acoustically treated area of a composite honeycomb sandwich structure restores the acoustic performance of the structure. An impaired section of the honeycomb core is removed and replaced with a honeycomb repair plug. Cell walls of the repair plug are bonded to cell walls of the core.

Owner:THE BOEING CO

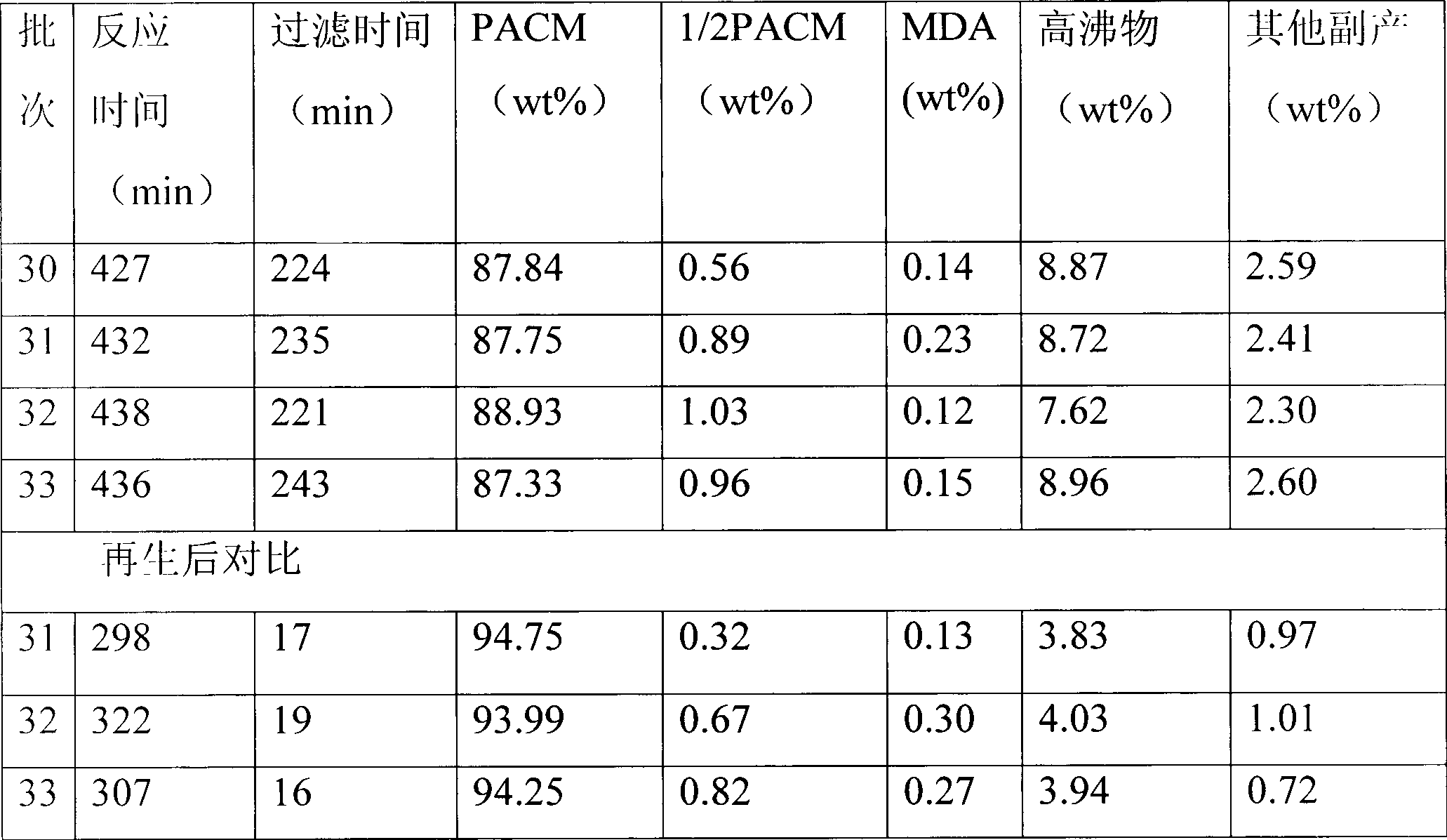

Method for regenerating ruthenium hydrogenation catalyst

ActiveCN103816923ARestore activityExtended service lifeMetal/metal-oxides/metal-hydroxide catalystsActive componentRuthenium

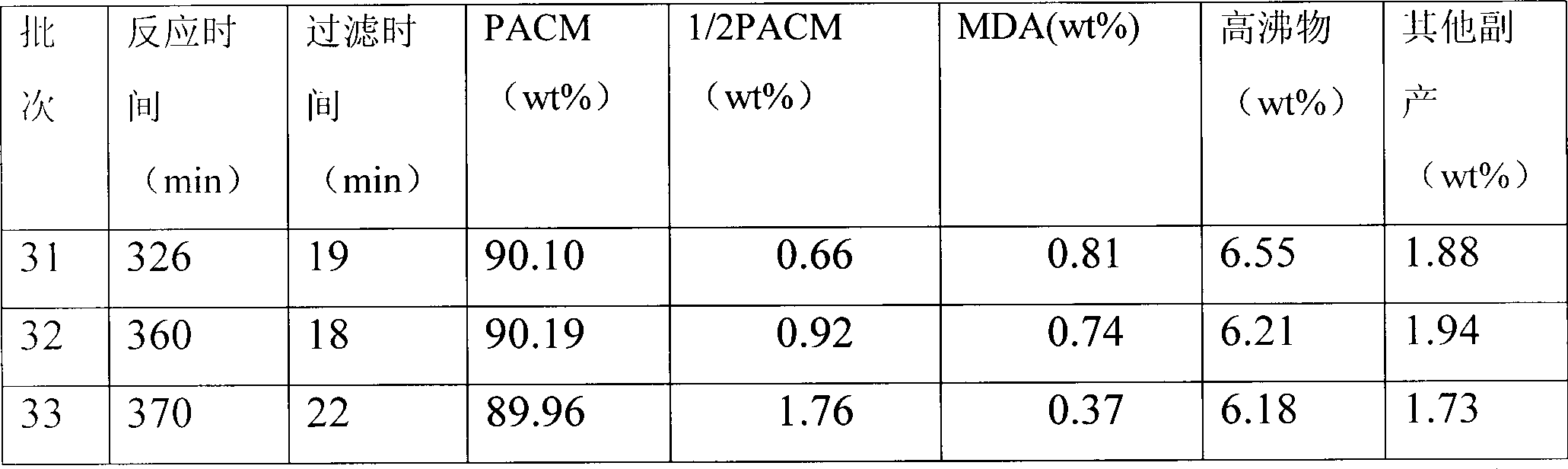

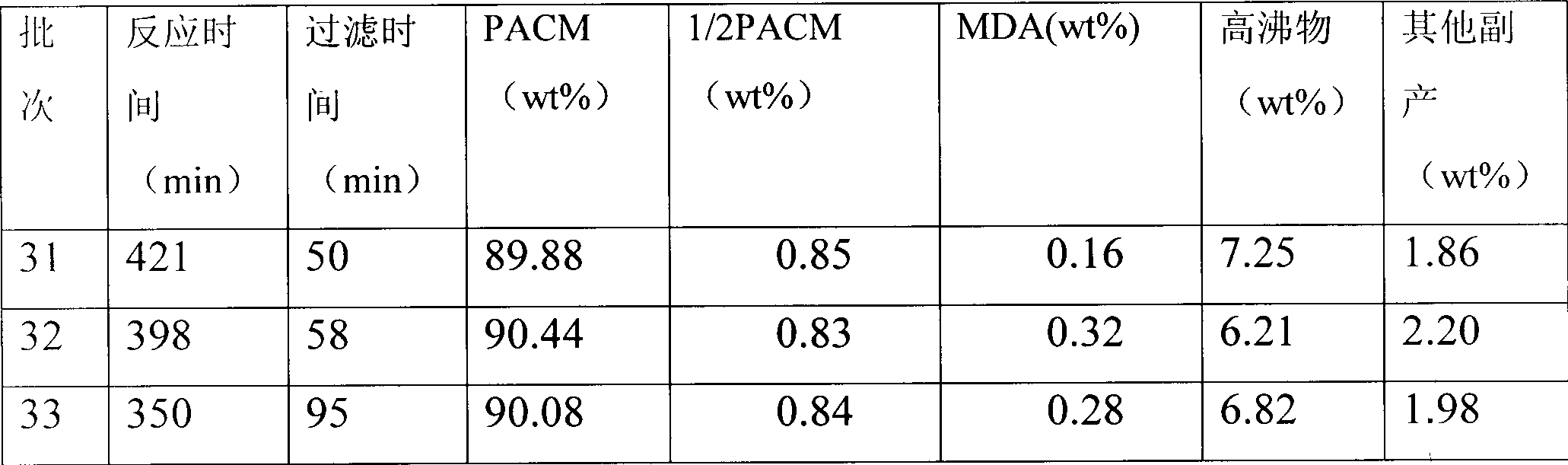

The invention discloses a method for regenerating a ruthenium hydrogenation catalyst. The method comprises the following steps: (a) inactivated load ruthenium hydrogenation catalyst is ultrasonically cleaned in ultrasonic equipment under the protection of inert gas in presence of a solvent; (b) the catalyst treated in the step (a) is oxidized and regenerated in liquid phase in presence of an oxidant; (c) the catalyst treated in the step (b) is dried and reduced. The method for regenerating the ruthenium hydrogenation catalyst can effectively remove high-boiling organic matters attached on the surface of the catalyst, can supplement load active components lost in the catalyst, can effectively recover the activity and selectivity of the catalyst, can prolong the service life of the catalyst, and can reduce the production cost.

Owner:WANHUA CHEM GRP CO LTD +1

Charge loss correction

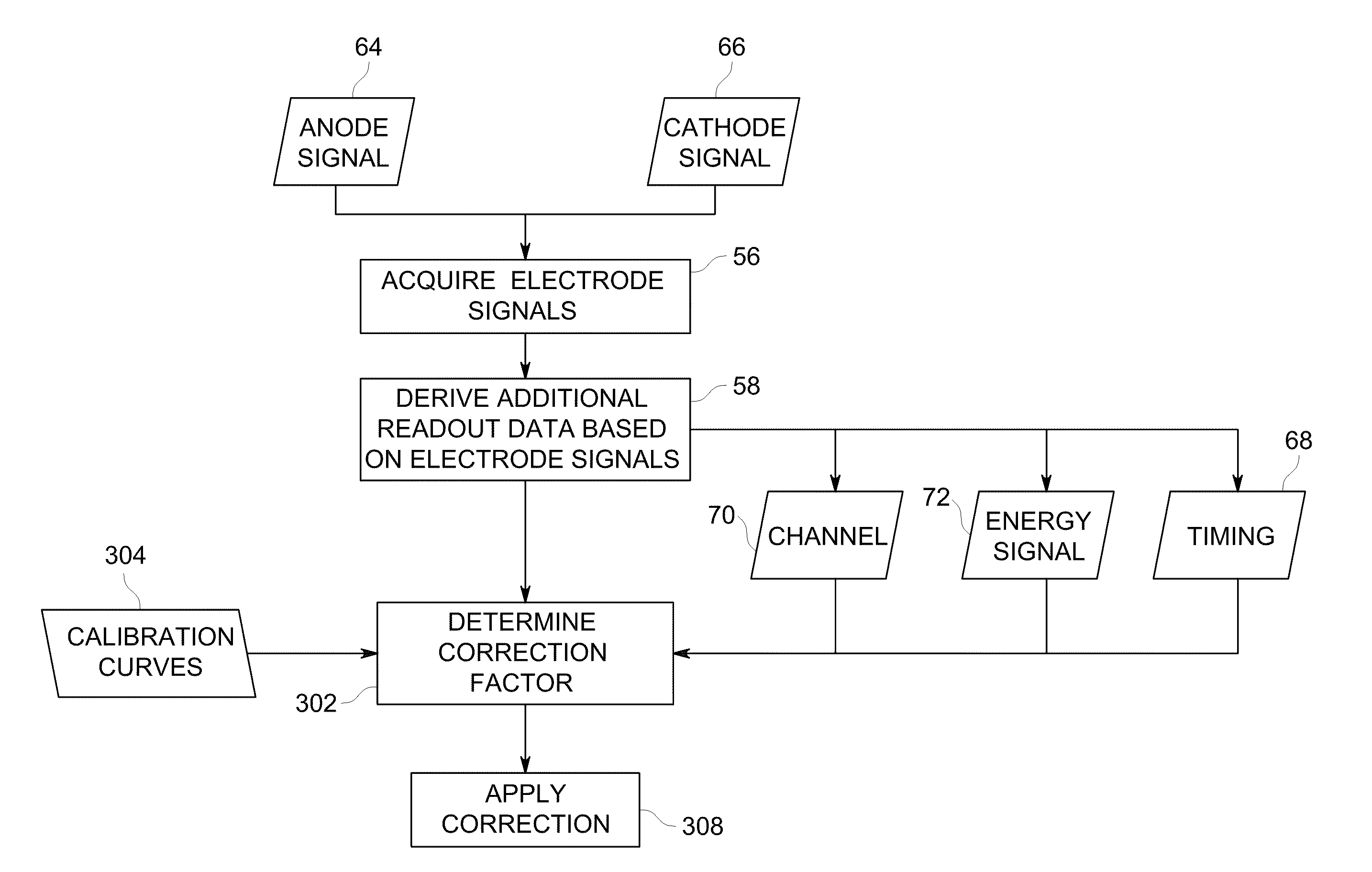

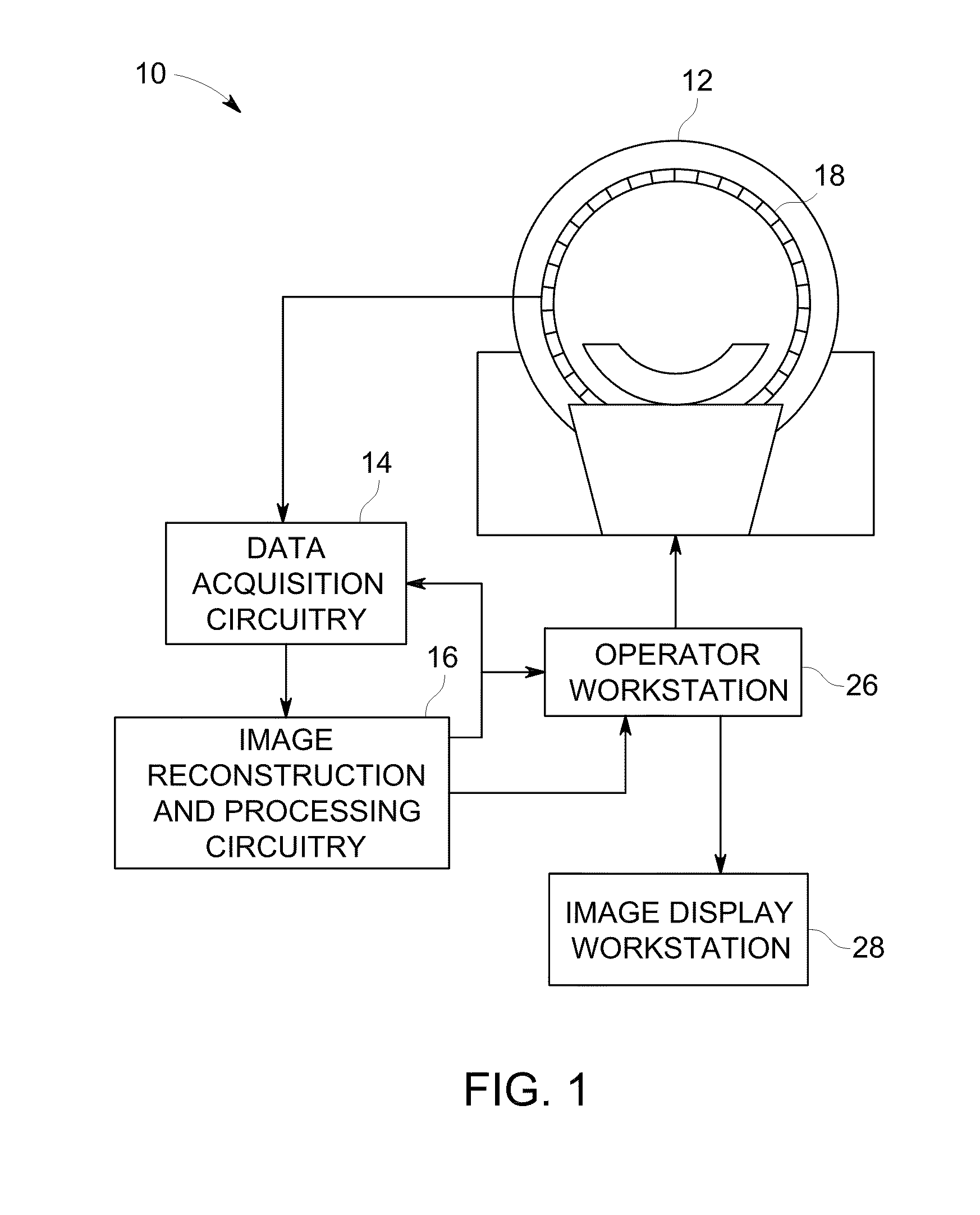

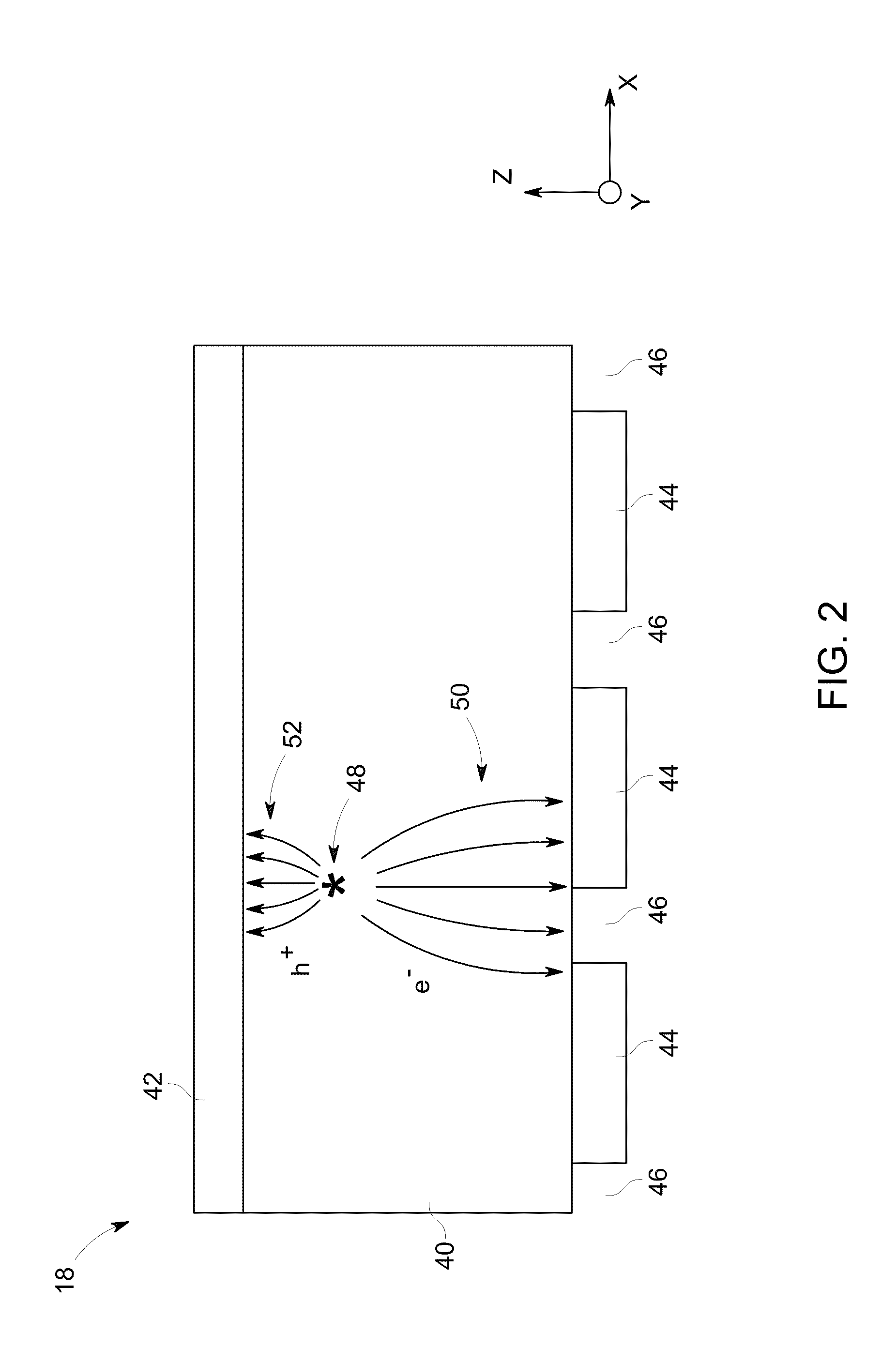

ActiveUS20110297838A1Restore performanceImprove efficiencySolid-state devicesMaterial analysis by optical meansRadiationCharge loss

The present disclosure relates to the correction of charge loss in a radiation detector. In one embodiment, correction factors for charge loss may be determined based on depth of interaction and lateral position within a radiation detector of a charge creating event. The correction factors may be applied to subsequently measured signals to correct for the occurrence of charge loss in the measured signals.

Owner:GENERAL ELECTRIC CO

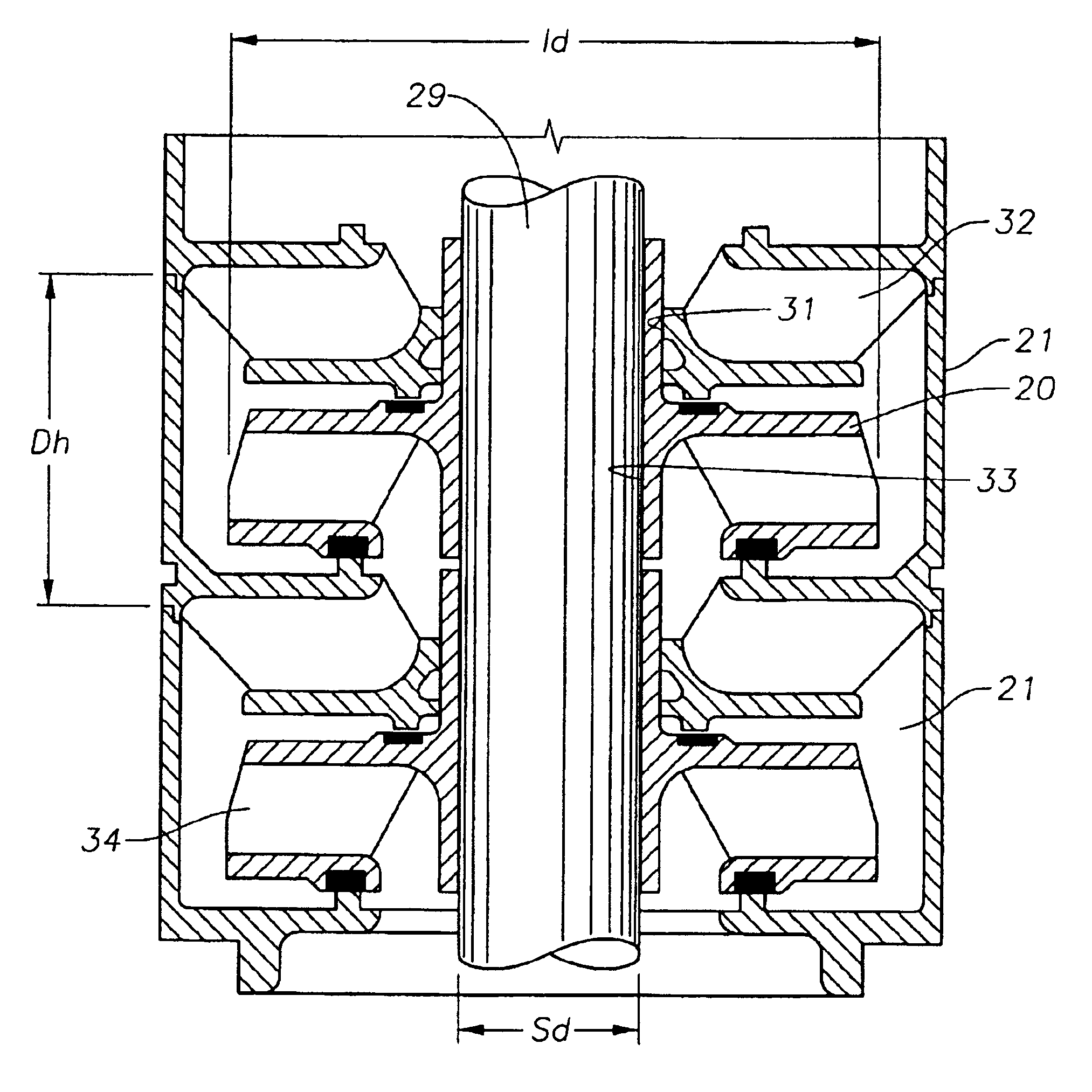

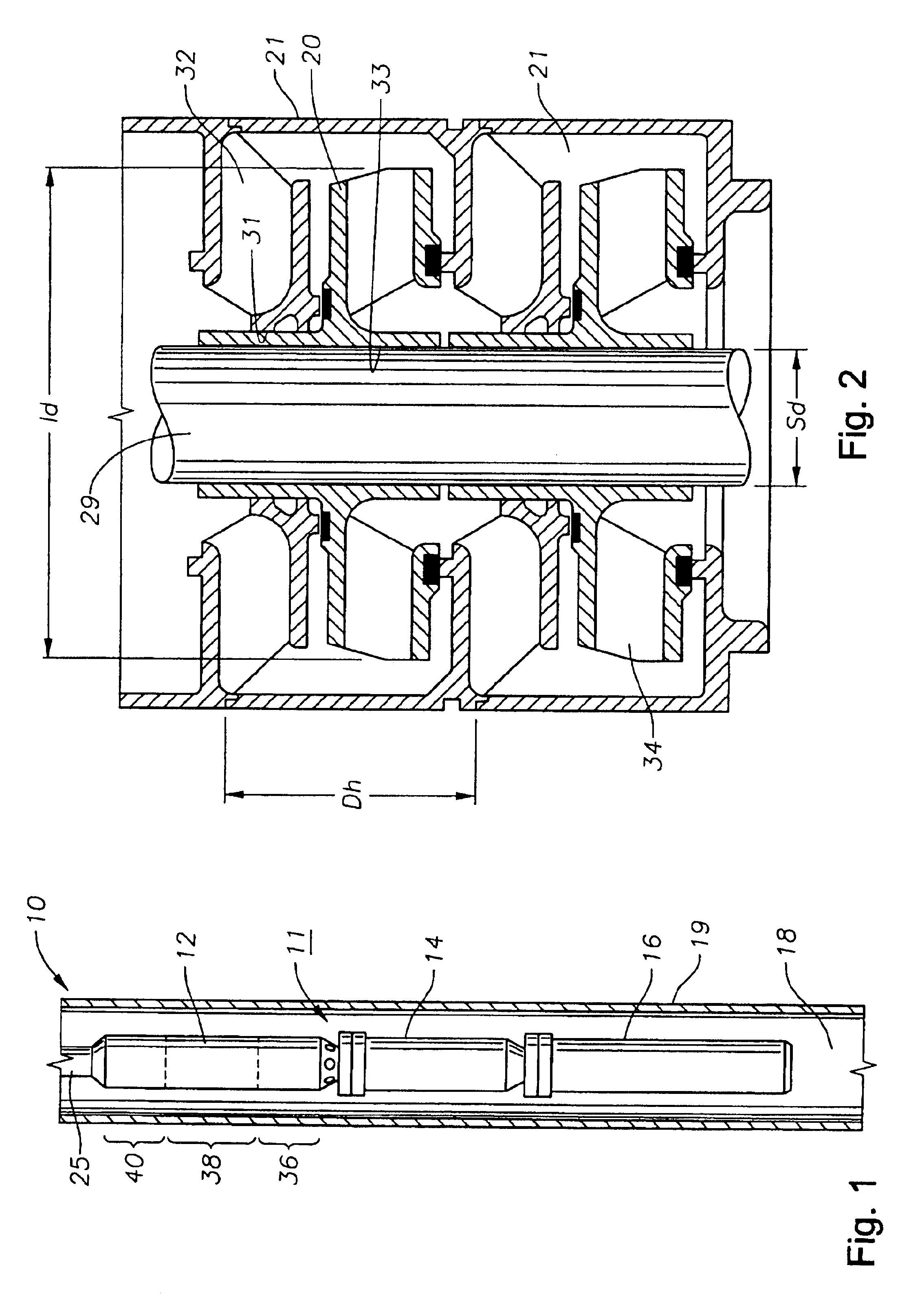

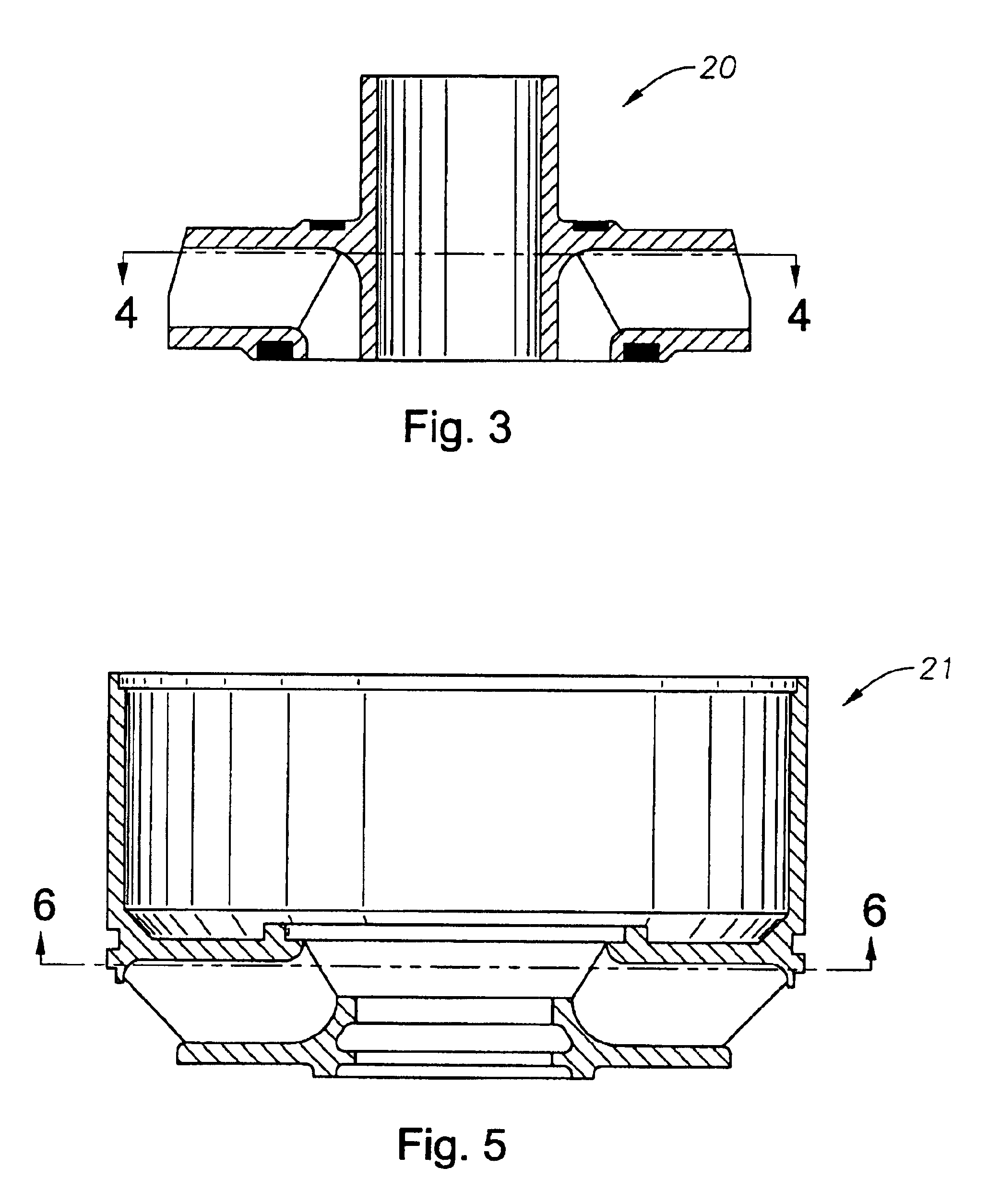

Electric submersible pump with specialized geometry for pumping viscous crude oil

InactiveUS6854517B2Impart energyMinimizes vane lengthFlexible member pumpsFluid removalExit angleEngineering

A centrifugal pump has impellers for pumping low flow, high viscous materials. The impellers have high exit angles greater than 30 degrees and preferably greater than 50 degrees. The impellers and diffusers have specific geometry that varies with viscosity. The pump has zones of impellers and diffusers with the exit angles and geometry in the zones differing from the other zones. The exit angles decrease and geometry varies in a downstream direction to account for a lower viscosity occurring due to heat being generated in the pump. One design employs small diameter impellers and high rotational speeds.

Owner:BAKER HUGHES INC

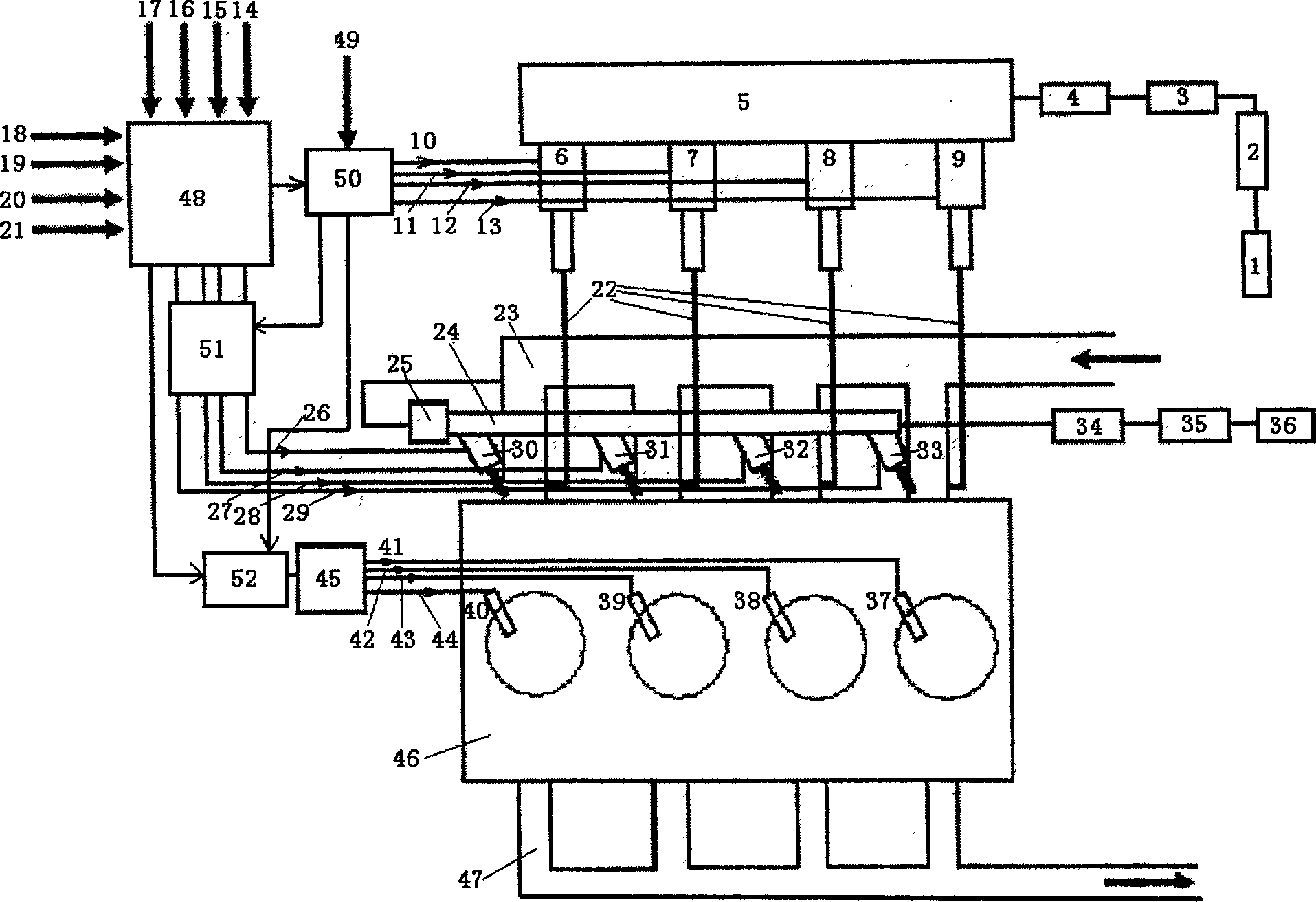

Hydrogen gasoline mixed fuel engine and its control method

ActiveCN1904329AReduce emissionsEasy to startElectrical controlMachines/enginesMixed fuelElectronic control unit

The invention relates to a hydrogen-gasoline mixed fuel engine and its control method, which mainly includes an electric control gasoline injection and ignition system and an electric control hydrogen injection and ignition system. The electric control hydrogen injection and ignition system includes a hydrogen injection and ignition control unit, a fuel injection pulse width control module and an ignition angular advance control module. The fuel injection pulse width control module is disposed between the electronic control unit and the fuel nozzle controlled by the hydrogen injection and ignition control unit. The ignition angular advance control module is disposed between the electronic control unit and the ignition module controlled by the hydrogen injection and ignition control unit.

Owner:BEIJING UNIV OF TECH

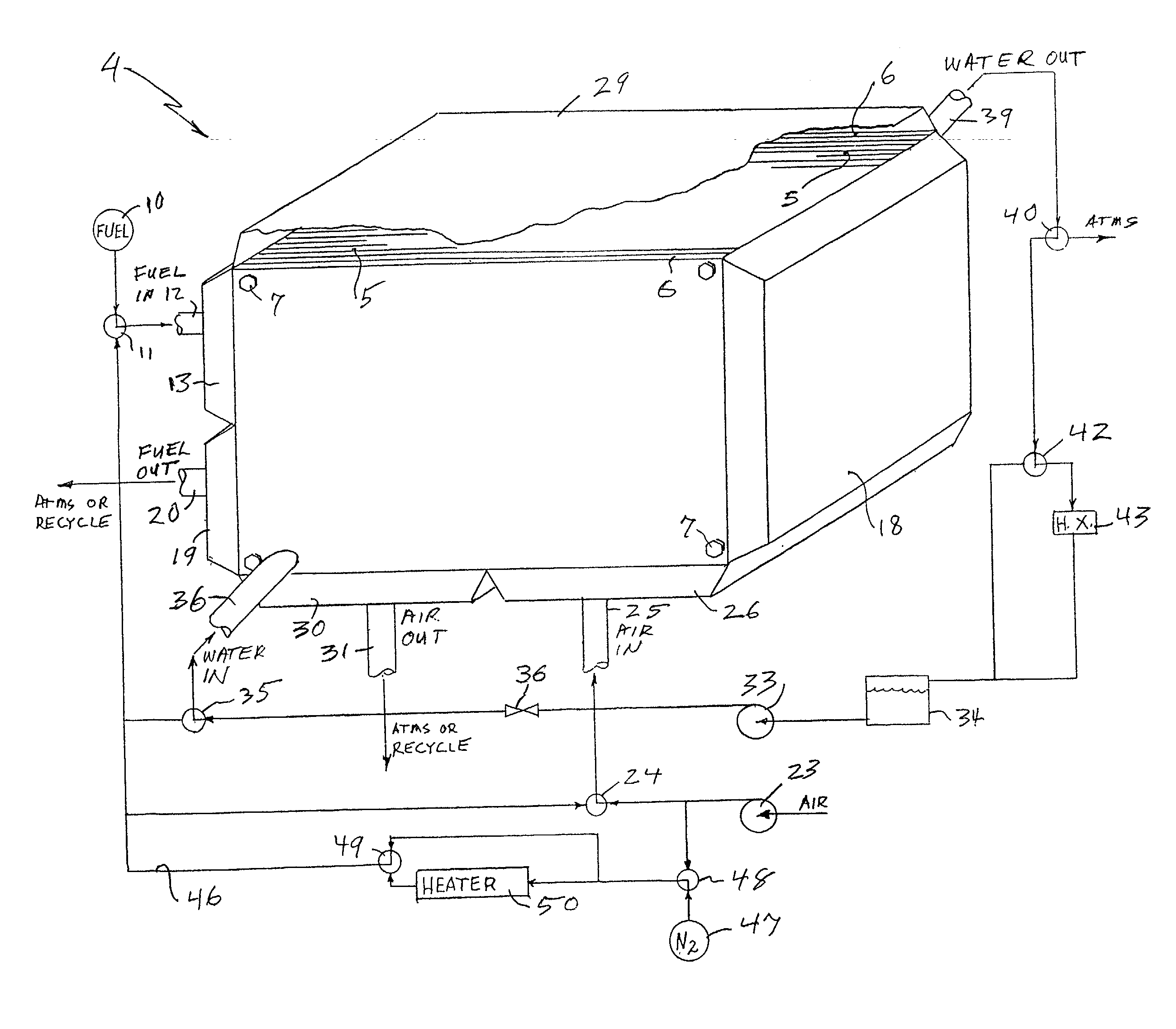

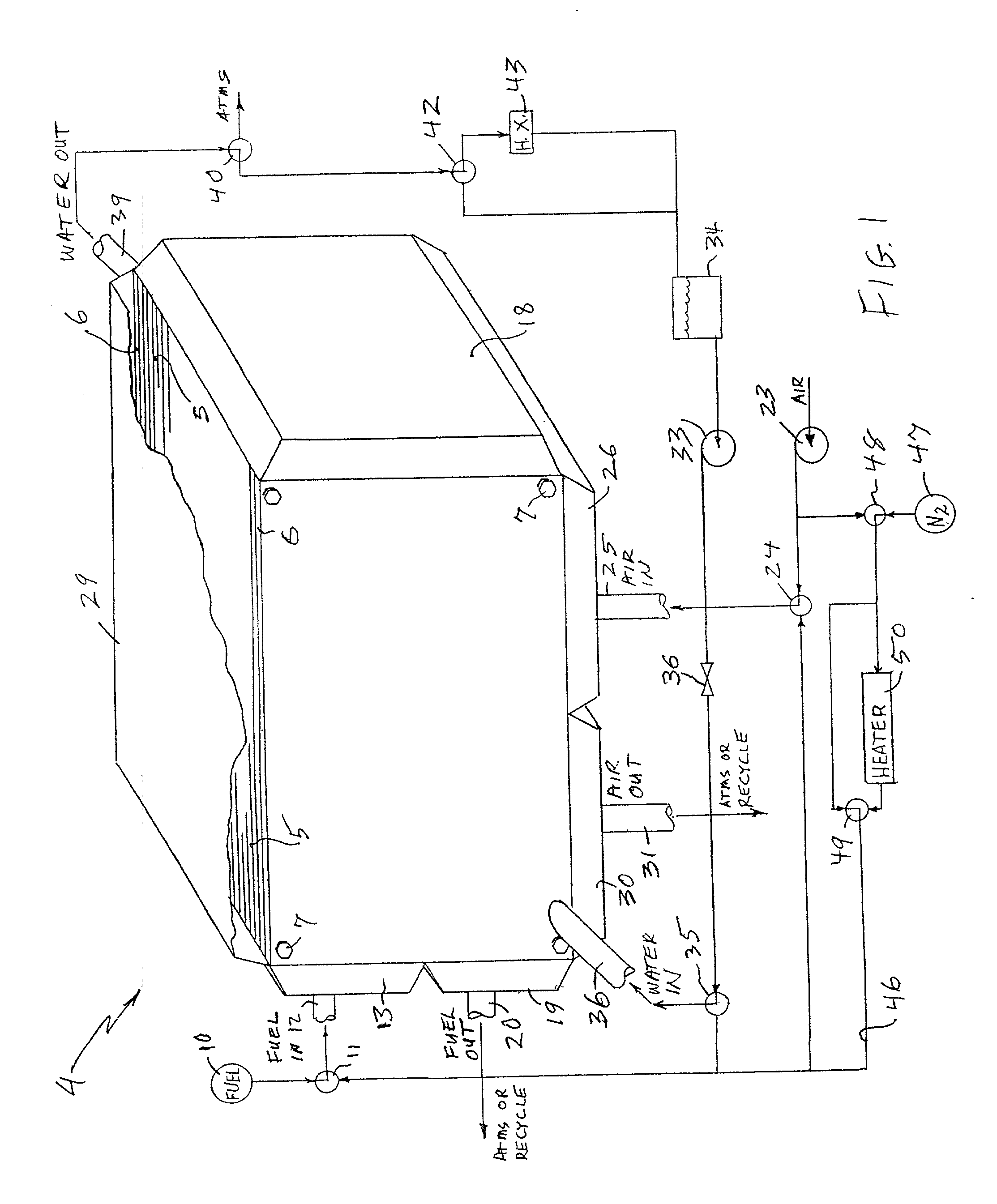

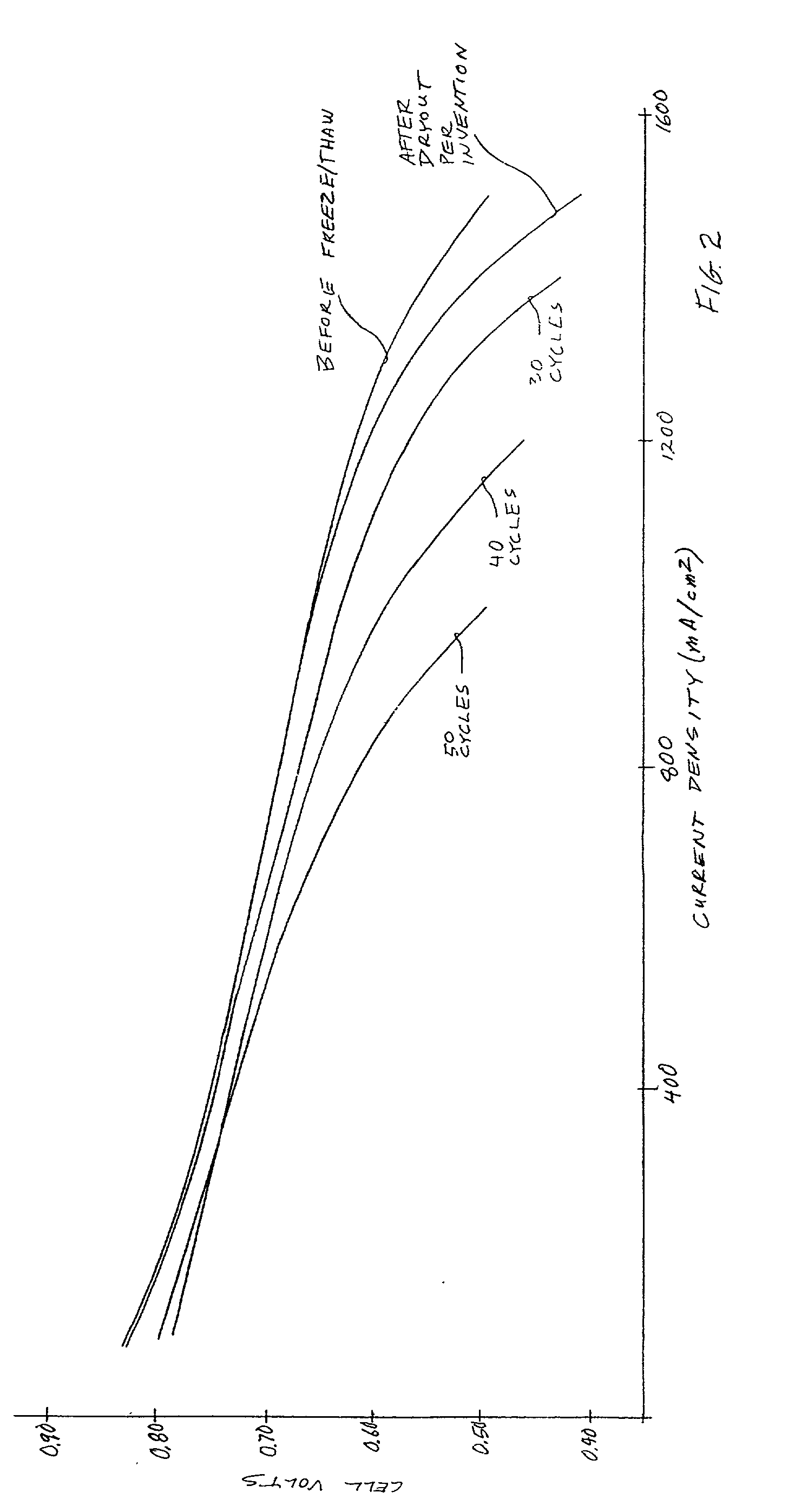

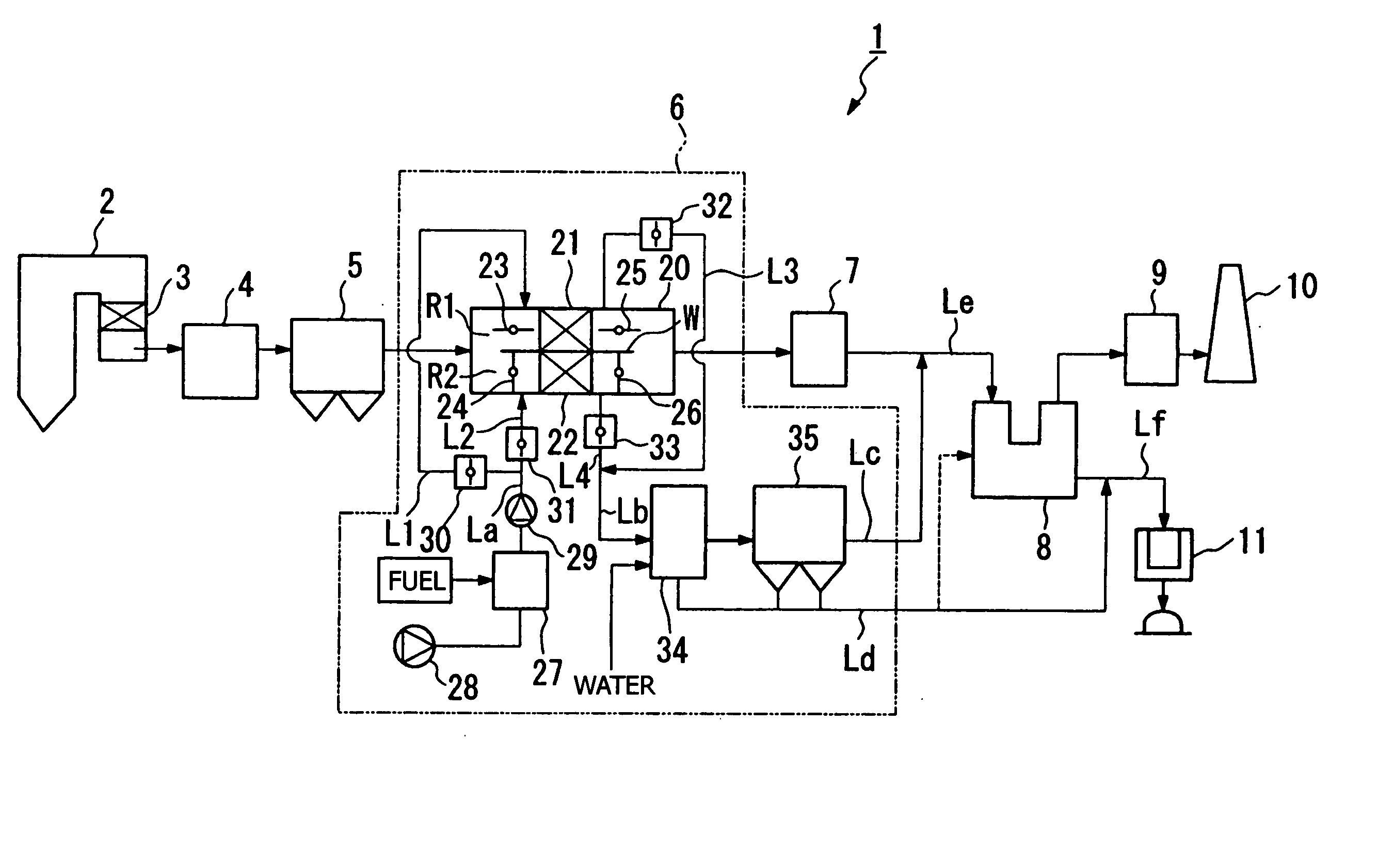

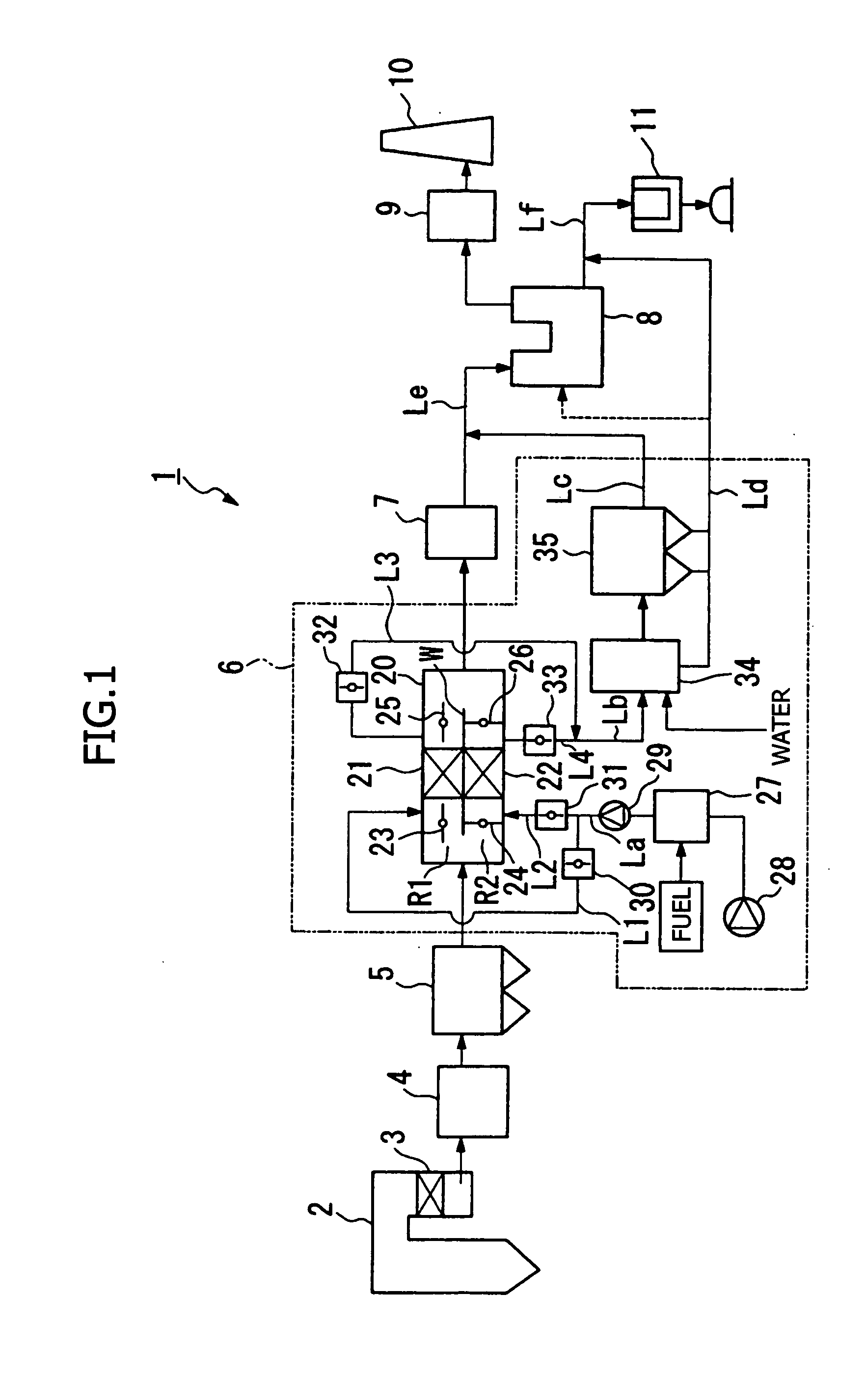

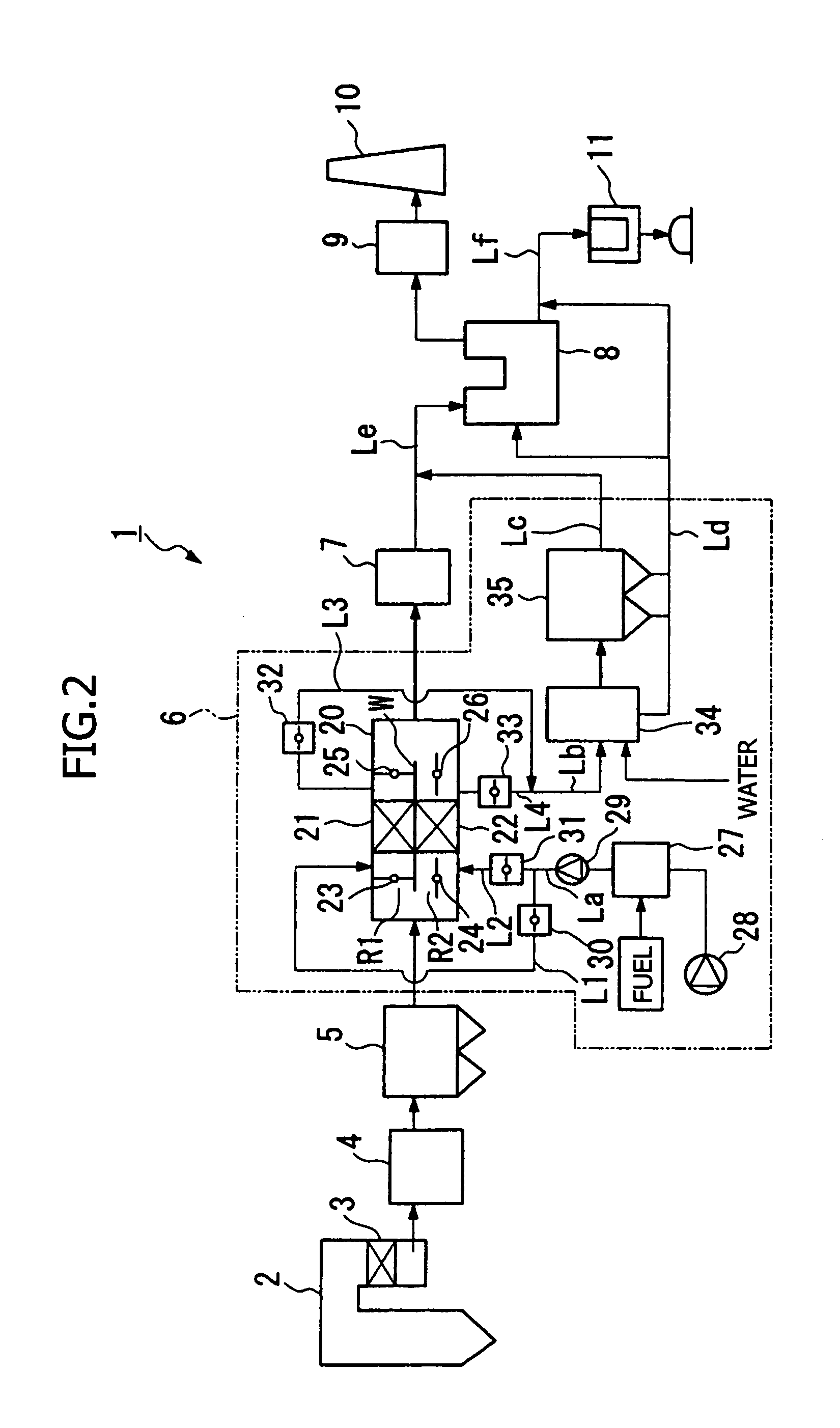

Performance recovery process for PEM fuel cells

InactiveUS20030180586A1Restore performanceMonitor effectivenessFuel cell auxillariesSolid electrolyte fuel cellsThermodynamicsFuel cells

Recovery of PEM fuel cell performance is achieved by evacuating (61, 62) or by flowing water absorbing gas (46) through, or both, the fuel flow field (12, 13, 19, 20), the air flow field (25, 26, 30, 31), and the water flow field (36, 39), while resistance of the individual cells, or of the fuel cell stack, is measured; the dry out process is continued until the resistance of the cells (or the resistance per cell, measured across the fuel cell stack as a whole), has increased by at least 5 to 1 (preferably 10 to 1) over the normal resistance of the cells. The water absorbing gas may be air (23) or nitrogen (47); it may be at ambient temperature or heated (50).

Owner:AUDI AG

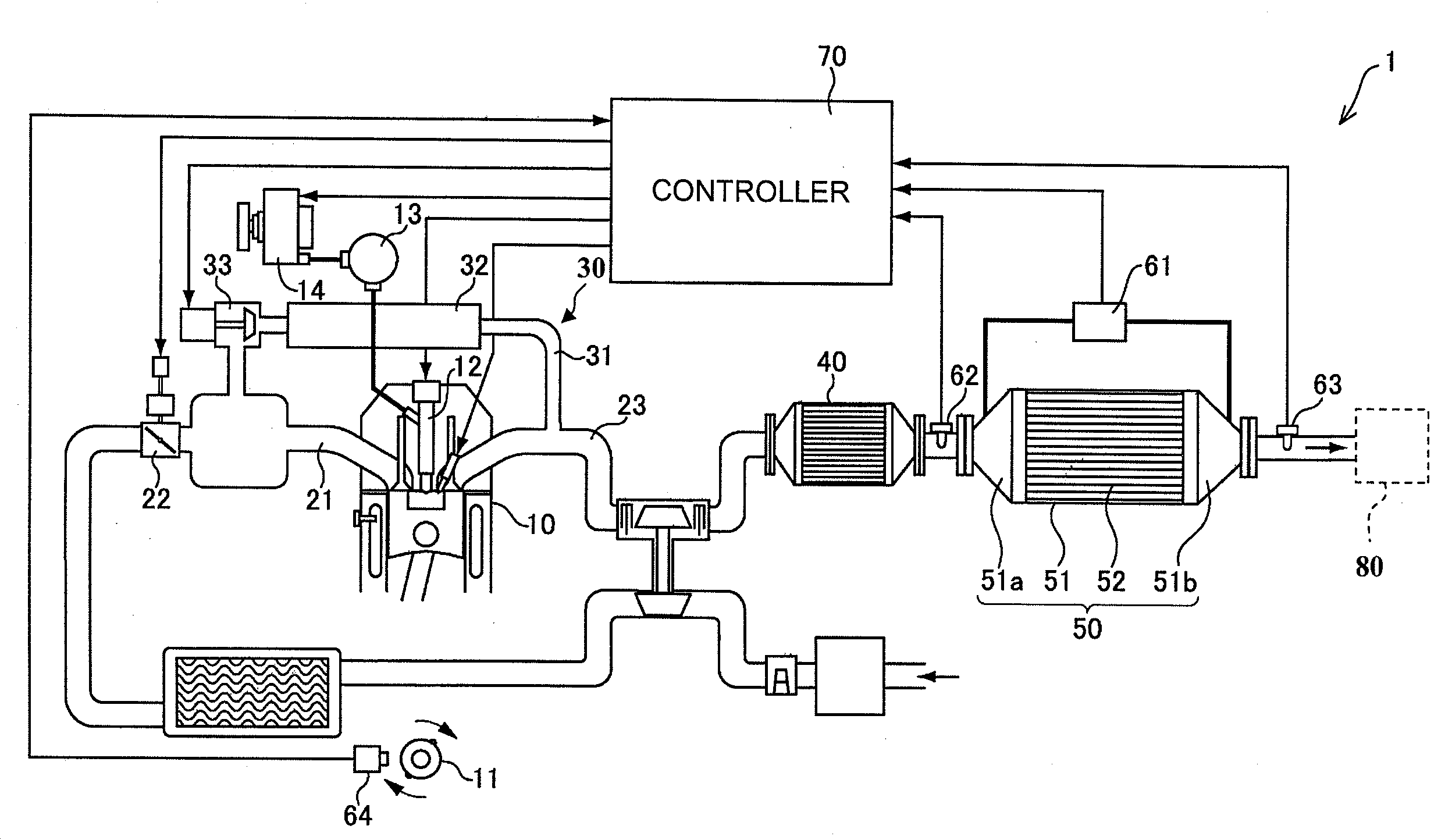

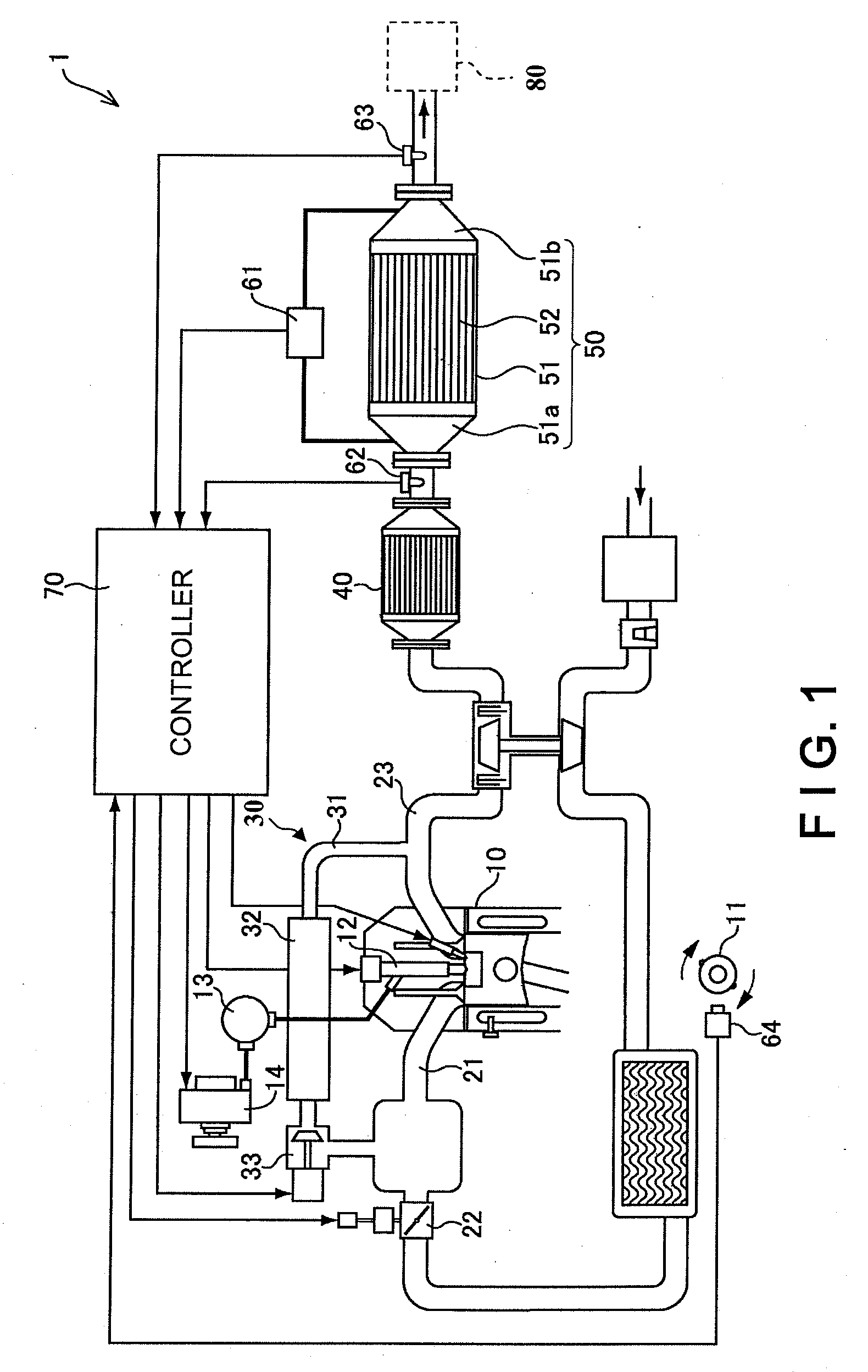

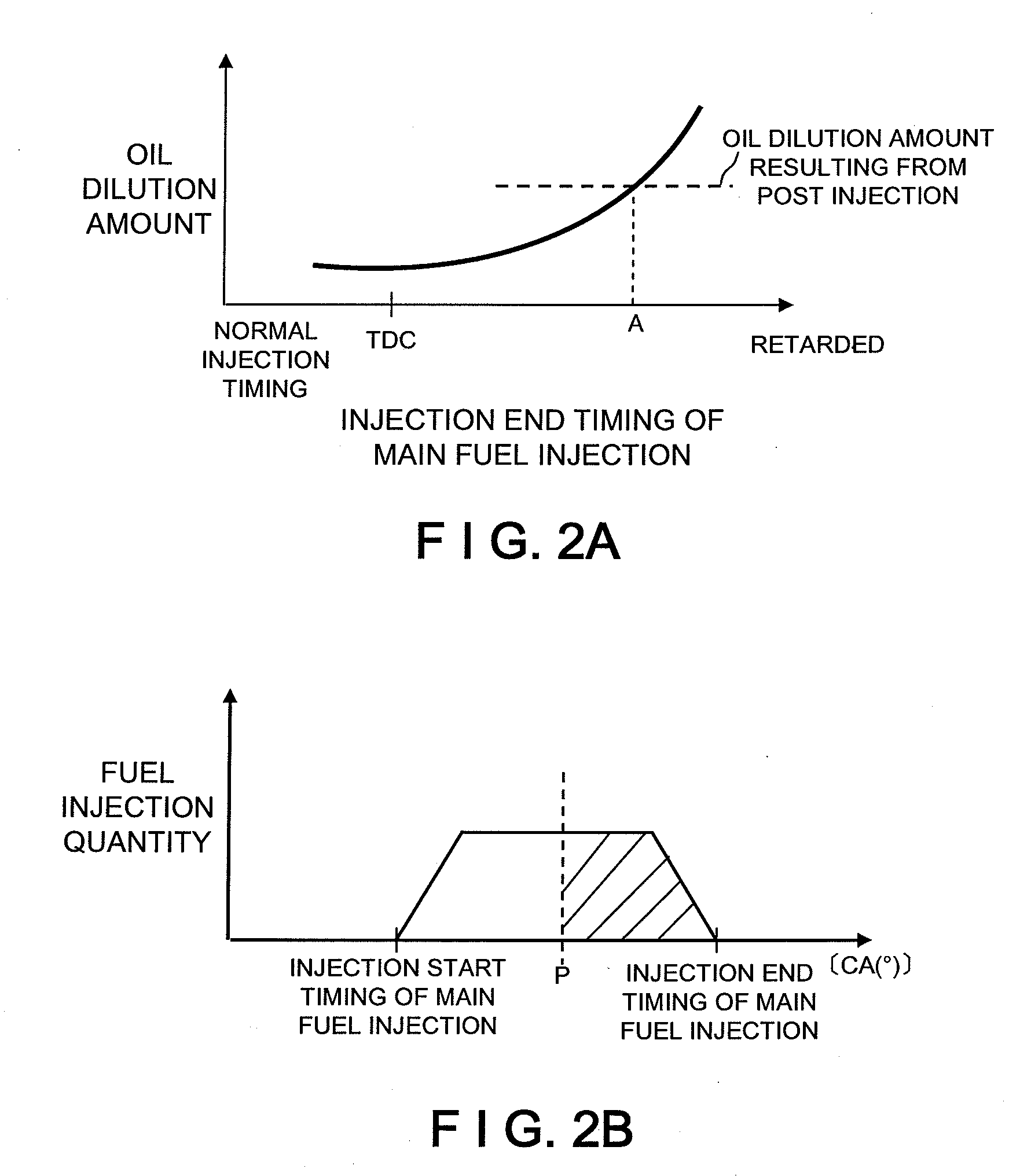

Exhaust gas temperature control method, exhaust gas temperature control apparatus, and internal combustion engine system

InactiveUS20080078169A1Restore performance of exhaust gas purificationIncrease temperatureElectrical controlInternal combustion piston enginesTemperature controlExternal combustion engine

The exhaust gas temperature control method includes executing an exhaust gas temperature control to raise an exhaust gas temperature upon determining that a purificatory performance of an exhaust gas purification device of an engine has declined. The step of executing of the exhaust gas temperature control includes performing a first fuel injection control in which a timing of a main fuel injection is retarded and a post fuel injection is executed after the main fuel injection when the internal combustion engine is operating in the first operating region, and performing a second fuel injection control in which the timing of the main fuel injection is retarded and an execution of the post fuel injection after the main fuel injection is prohibited when the internal combustion engine is operating in the second operating region.

Owner:NISSAN MOTOR CO LTD

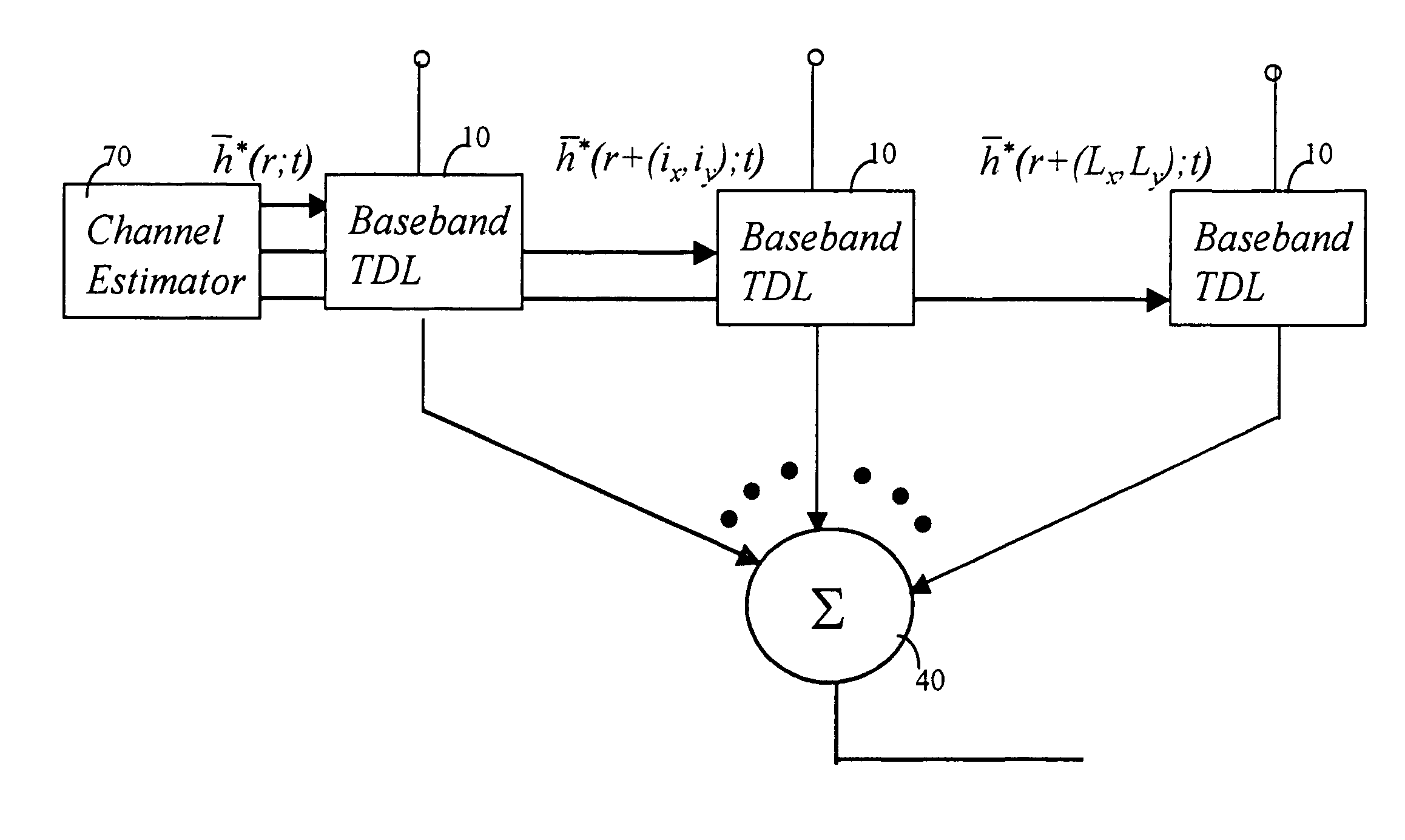

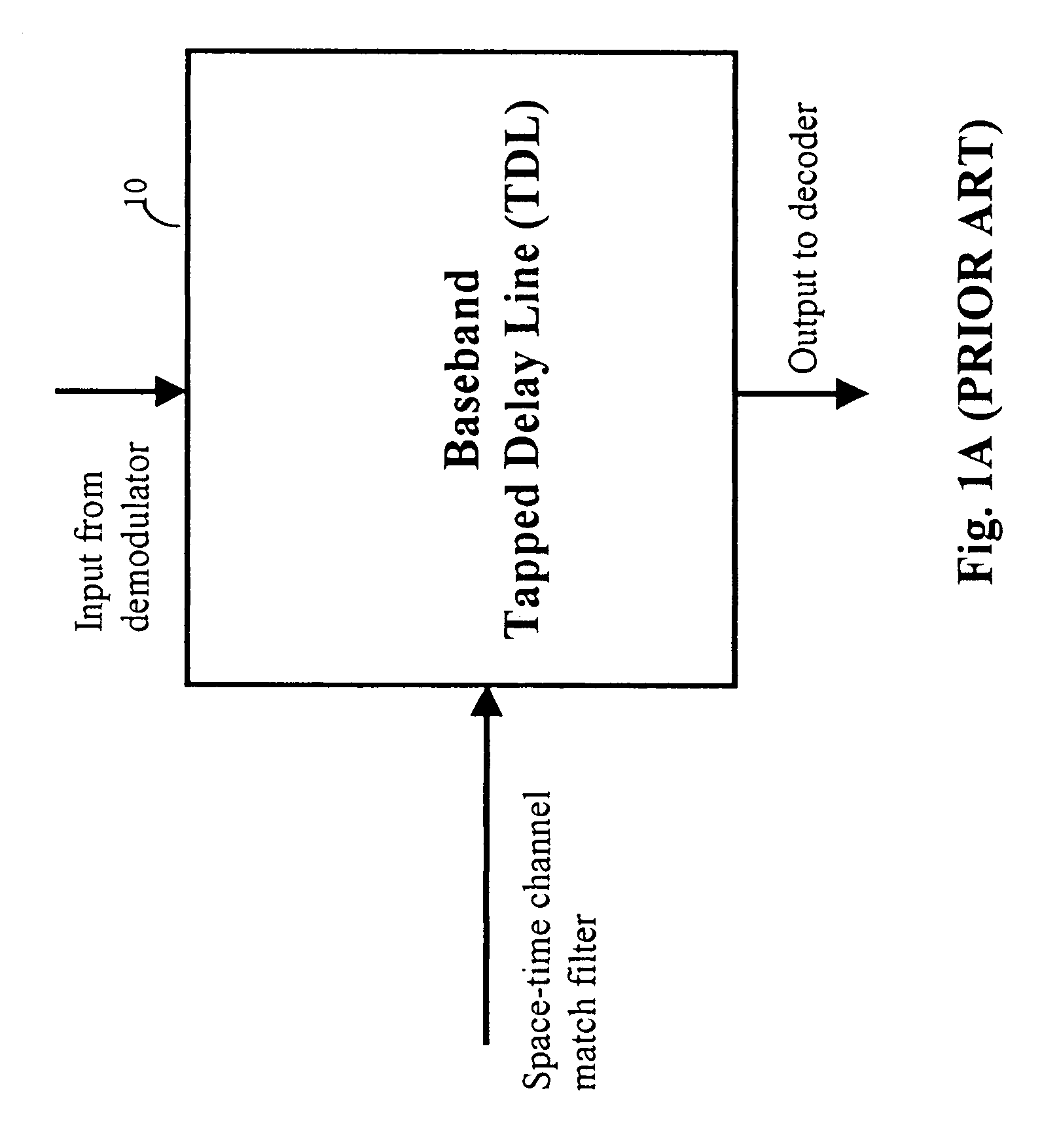

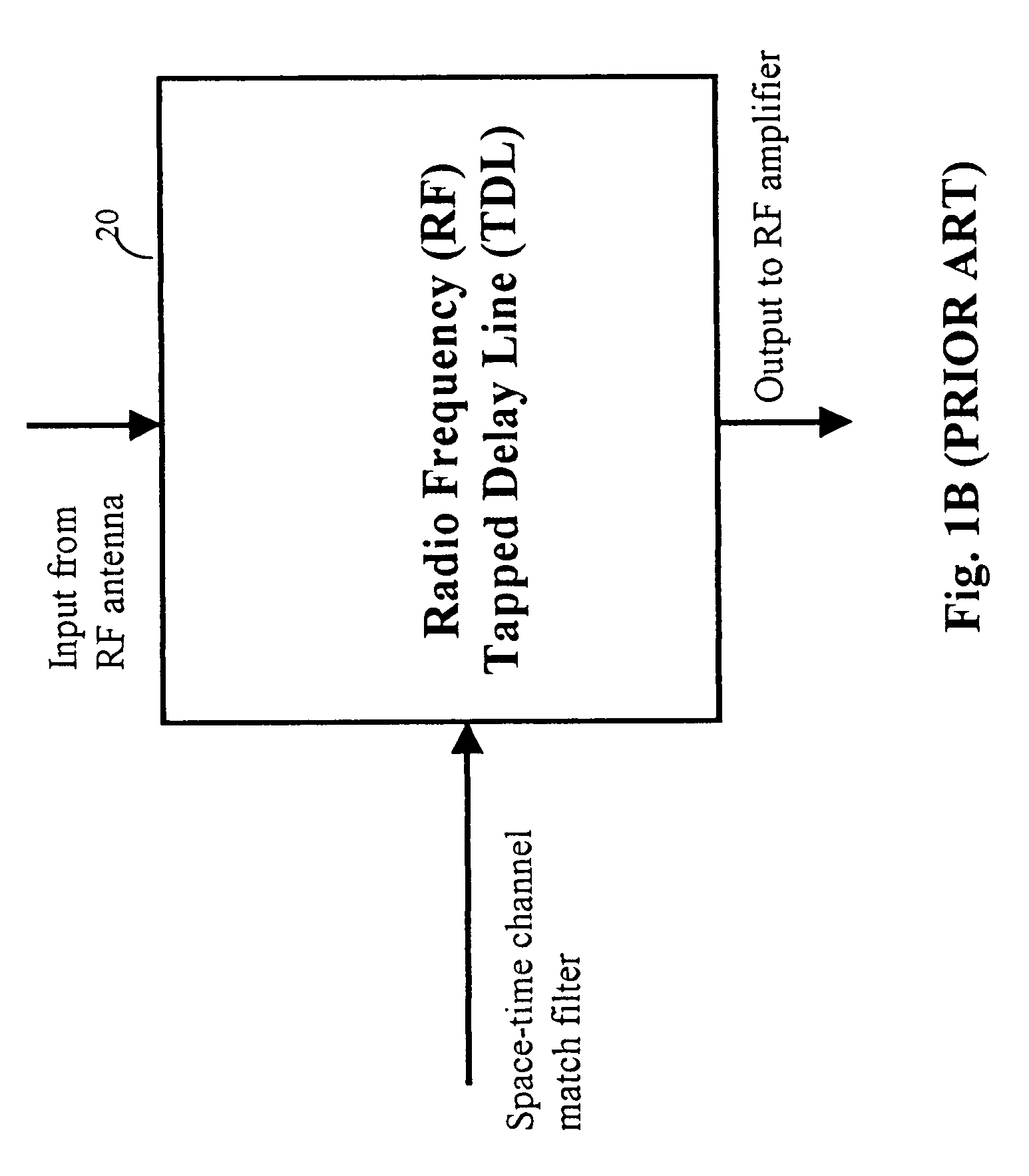

System and method of space-time equalization to mitigate effects of fading and scintillation for wireless communication

InactiveUS7319822B2Restores system performanceSpread signal powerPolarisation multiplex systemsChannel estimationOptical wirelessCommunication link

A system and method is disclosed for mitigating the scintillation and fading effects of baseband wireless, radio frequency wireless, optical wireless and satellite communication links. The system uses a space-time channel model to derive an optimal processing architecture for signal recovery through a scintillation channel. The signal power is collected by space-time sampling within the four dimensional volume of the spatial and temporal spread. Consequently, the space-time equalizer can effectively recover the lost signal power induced by the spreading effects of atmospheric scintillating medium. The advantages of this invention include a decrease in link outages resulting in higher link availability and more reliable data network services.

Owner:LO VICTOR YEEMAN

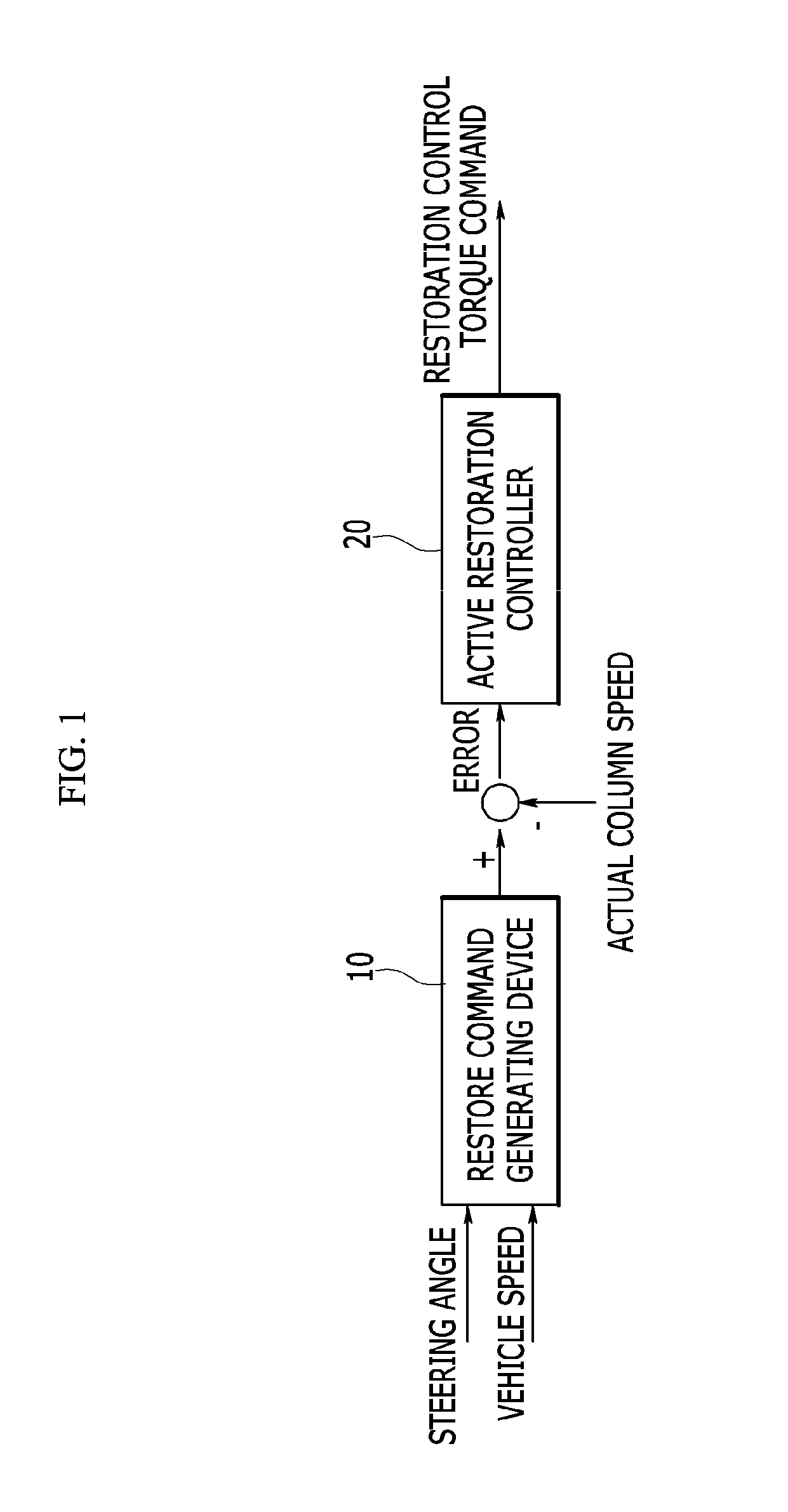

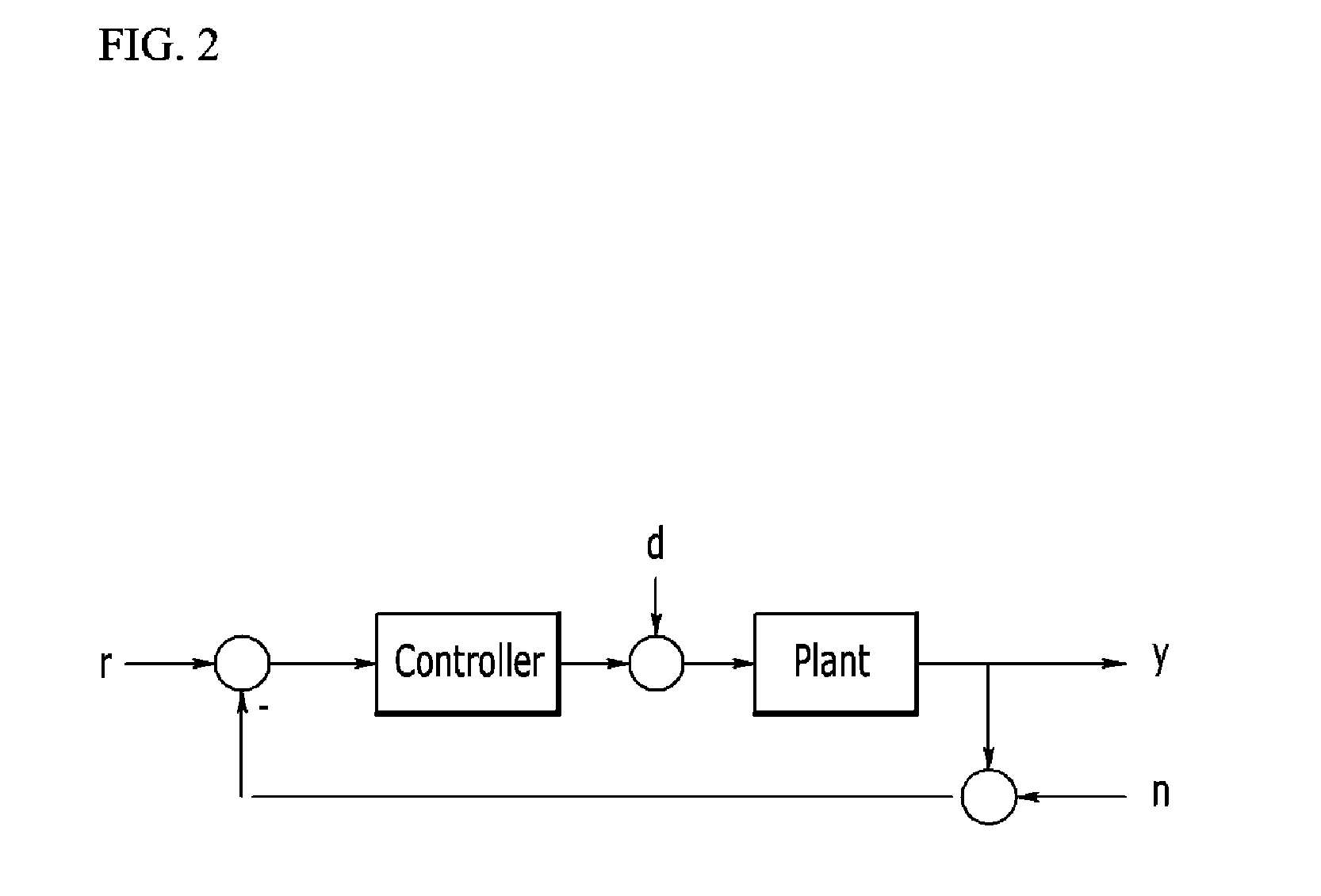

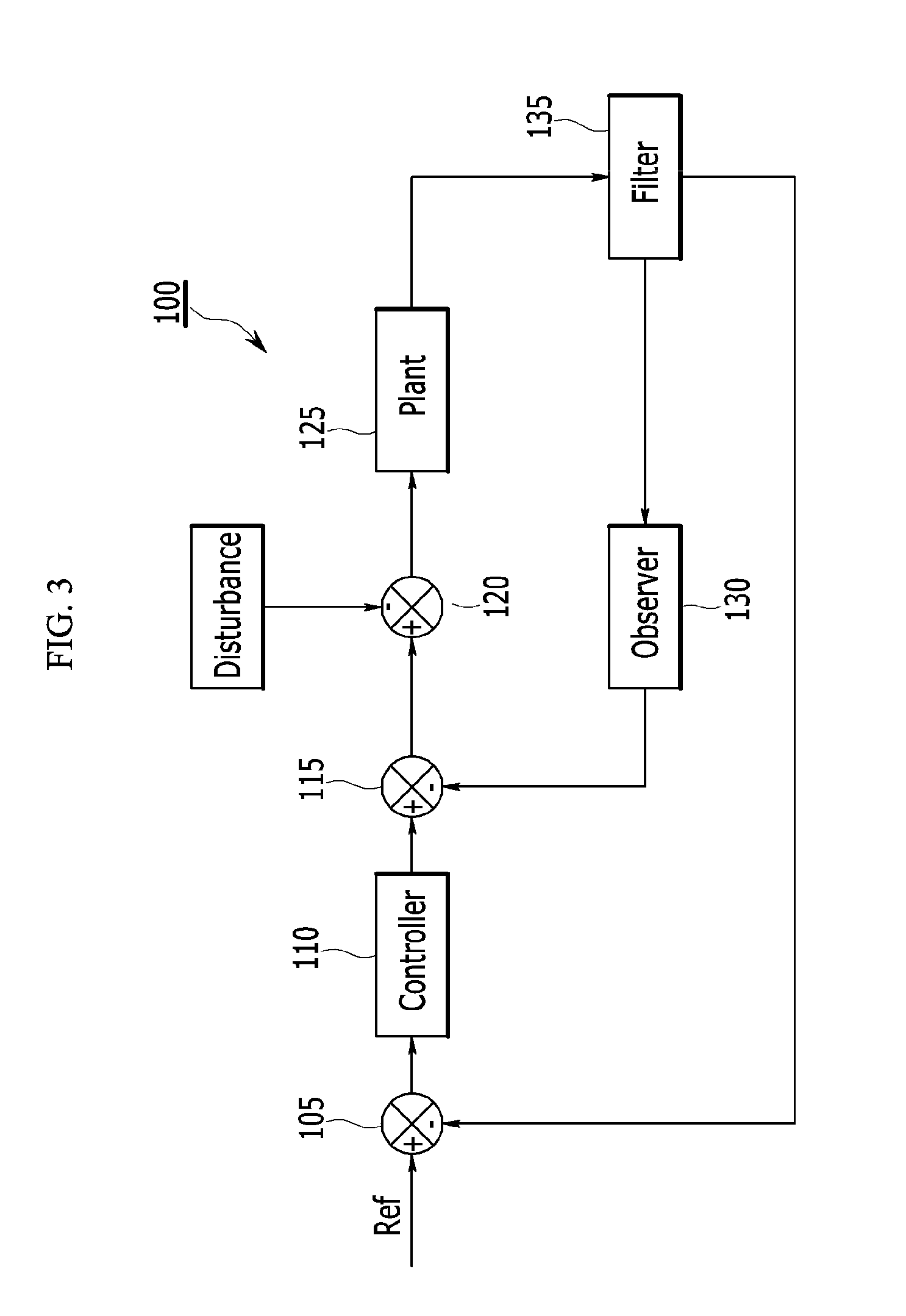

Device for controlling restoration of mdps system

ActiveUS20160318546A1Improve recovery effectEliminate dissatisfactionElectrical steeringSteering columnEngineering

A device for controlling restoration of a motor driven power steering (MDPS) system may include a controller configured to control an MDPS system model to output a target steering column speed command corresponding to a restoration control torque command based on a received error between a target steering column speed and an actual steering column speed, and a disturbance observer configured to compensate for a disturbance included in an output of the MDPS system model to provide the disturbance to an output of the controller, in which the output of the MDPS system model may be fed back to an input of the controller.

Owner:HYUNDAI MOTOR CO LTD

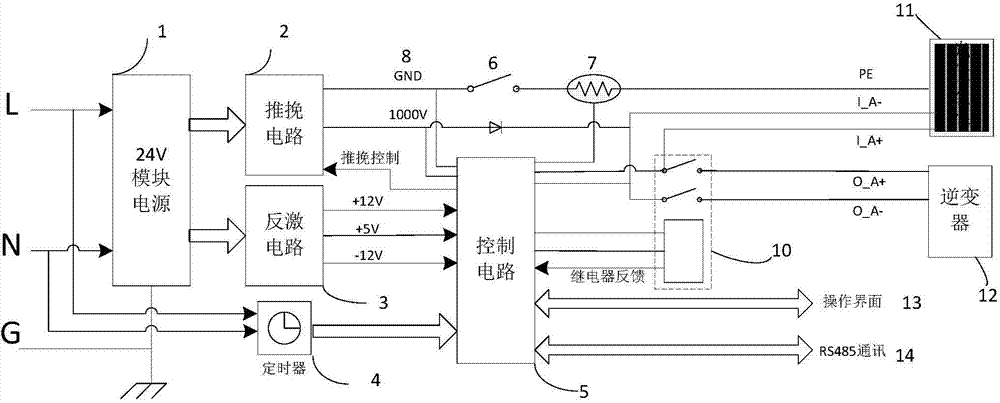

PID resistant device for solar photovoltaic component using non-isolated inverter

InactiveCN104506130ARecovery inhibitionRestore performancePhotovoltaicsPhotovoltaic energy generationEngineeringPerformance recovery

The present invention discloses a PID resistant device for a solar photovoltaic component using a non-isolated inverter. The device comprises a direct current power supply, a grounding switch, a diode, a timer and a control circuit. The PID resistant device of the present invention is able to automatically apply a positive to-earth direct current close to an open-circuit output voltage value of the solar photovoltaic component between the cathode at the voltage output of the solar photovoltaic component when the solar photovoltaic component is at a night inactive state, thereby counteracting the influence caused by the fact that the cathode at the voltage output of the solar photovoltaic component is at a negative voltage in the daytime, and realizing the suppression of PID phenomenon and performance recovery for the solar photovoltaic component and achieving the restoration of polarization effect generated in the daytime; furthermore, when the solar photovoltaic component is at an electricity generation state at the day time, the grounding switch 6 is automatically opened so as to effectively prevent the PID resistant device of the present invention from influencing the normal operation of the solar photovoltaic component.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

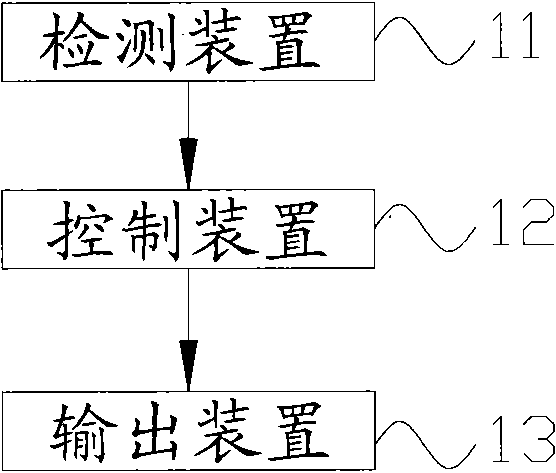

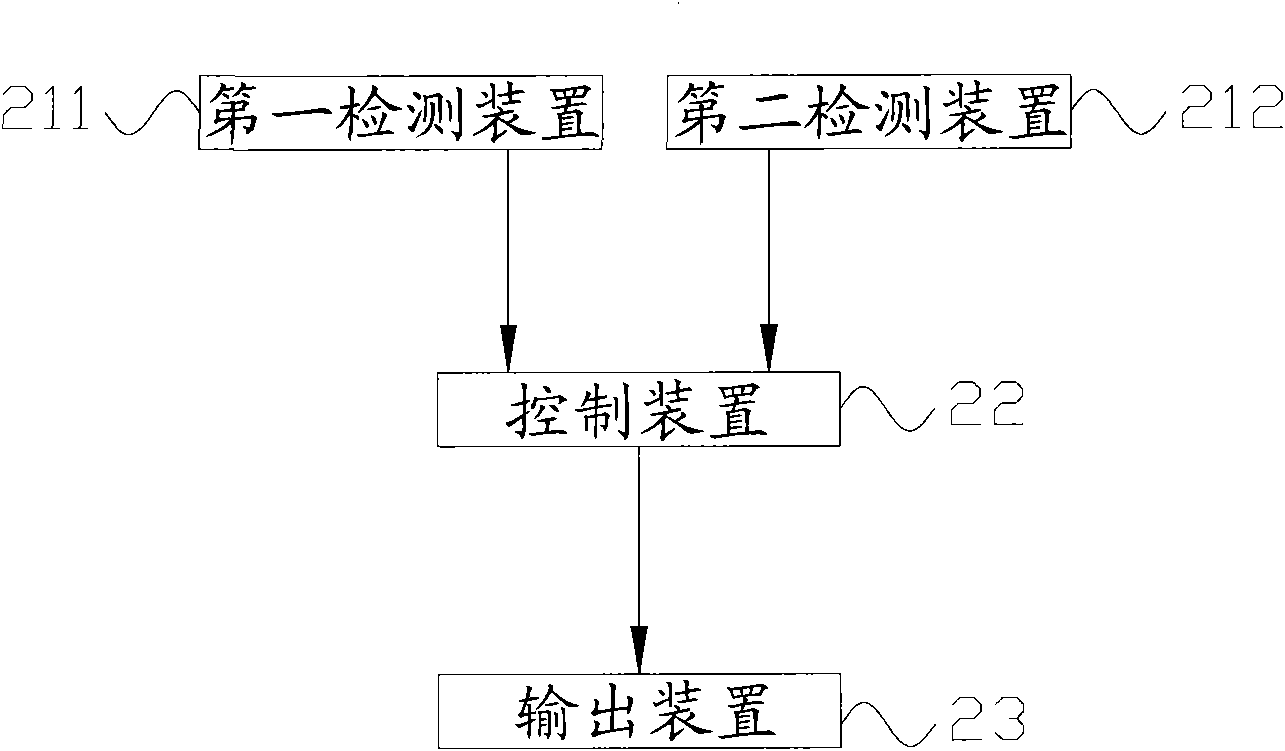

Wind generator set and fatigue load monitoring system thereof

InactiveCN101839806AImprove monitoring accuracyRepair in timeWind motor controlEngine testingFatigue loadingMonitoring system

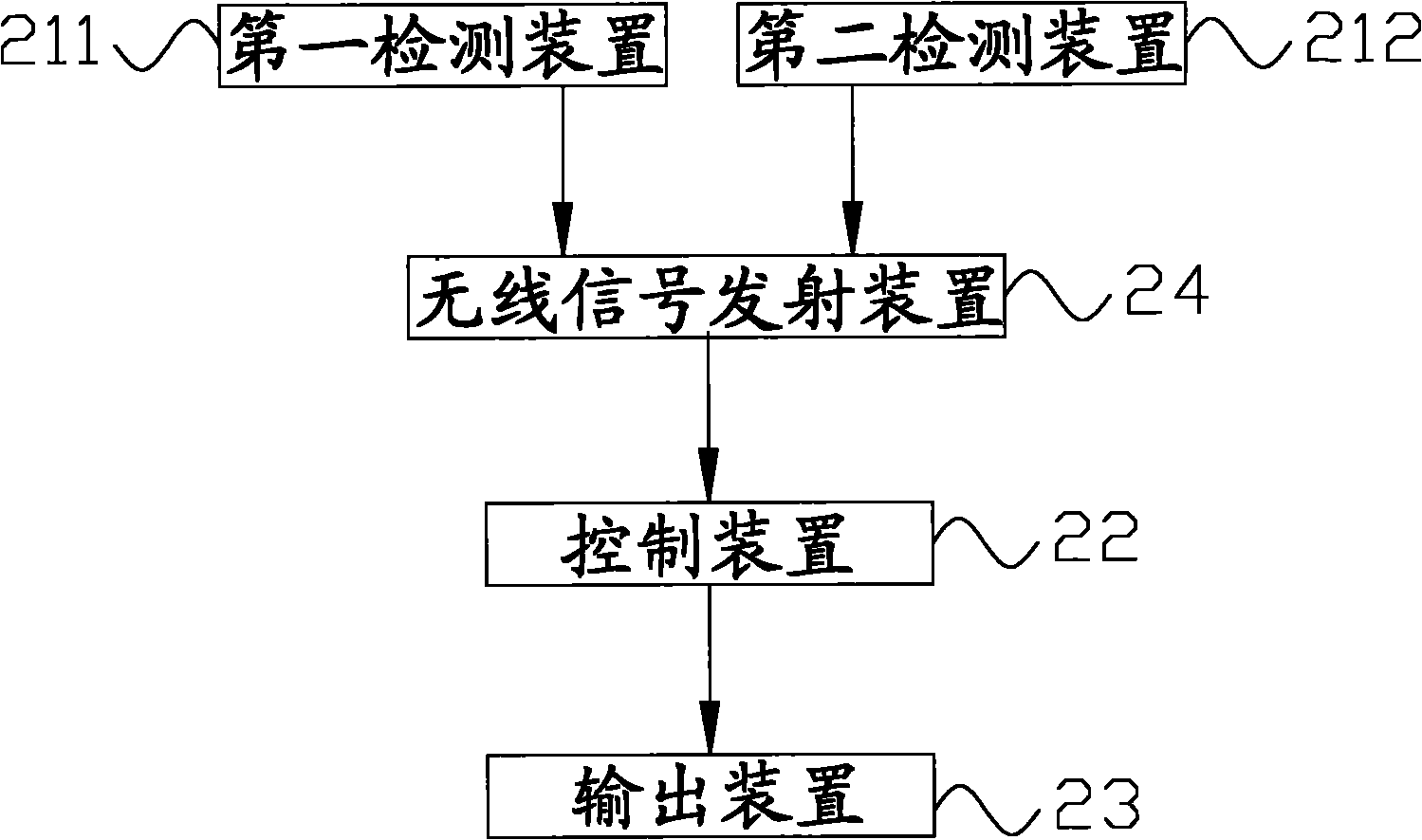

The invention discloses a fatigue load monitoring system for a wind generator set, comprising a first detecting device (211), a second detecting device (212), a control device (22) and an output device (23). The first detecting device (211) is used for detecting the fatigue state of the root of a tower barrel to obtain a first detection signal; the second detecting device (212) is used for detecting the fatigue state of at least one position outside the root of the tower barrel to obtain a second detection signal; the control device (22) is used for receiving the first detection signal and the second detection signal, processing the first detection signal and the second detection signal according to a preset strategy to obtain an actual damage value, and then comparing the actual damage value and the preset damage value to judge the damage state of the monitored position of the wind generator set; and the output device (23) is used for outputting the actual damage value of the monitored positioned. The fatigue load monitoring system has higher monitoring precision so as to maintain each member of the wind generator set in time and prolong the service life of each member. The invention also discloses the wind generator set comprising the fatigue load monitoring system.

Owner:SANY ELECTRIC CO LTD

Double-side polishing device and method capable of controlling rigidity of polishing pad through cluster dynamic magnetic field

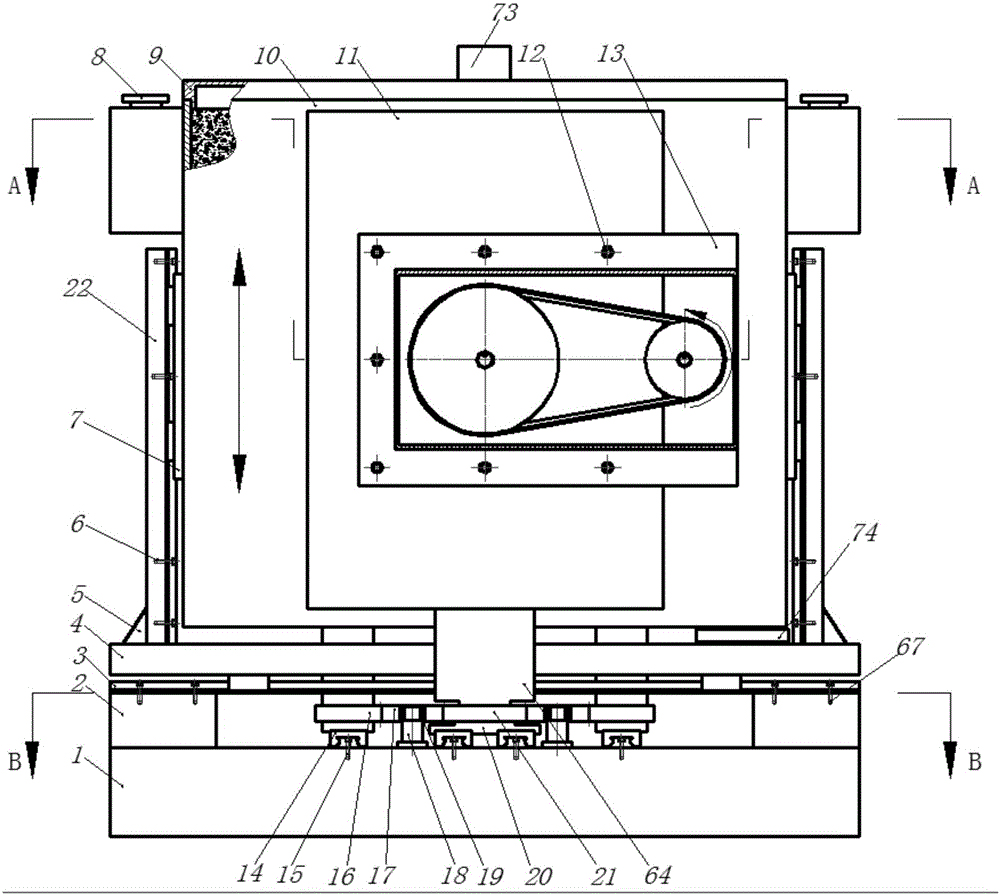

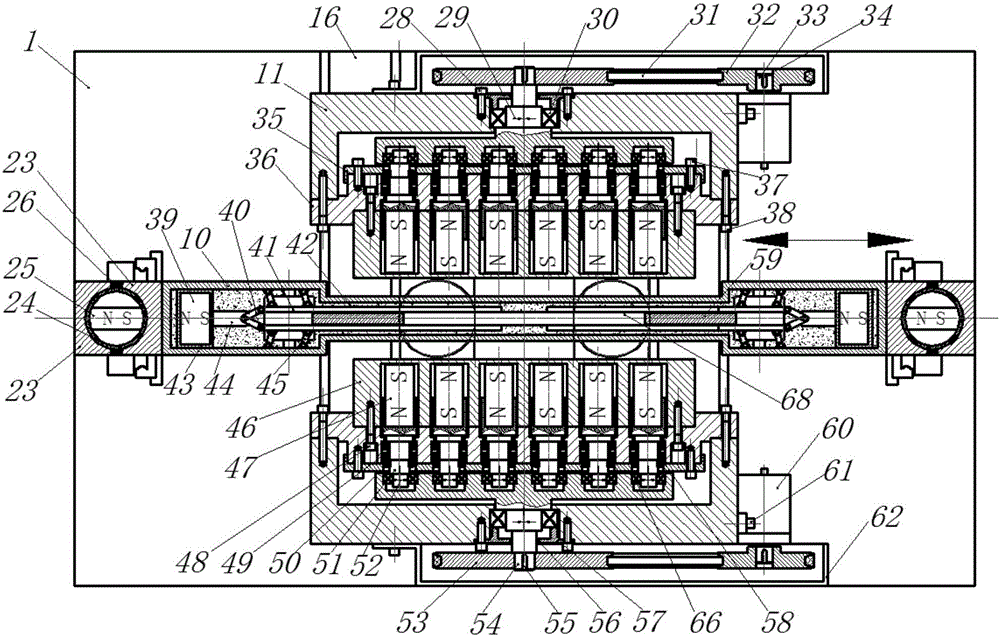

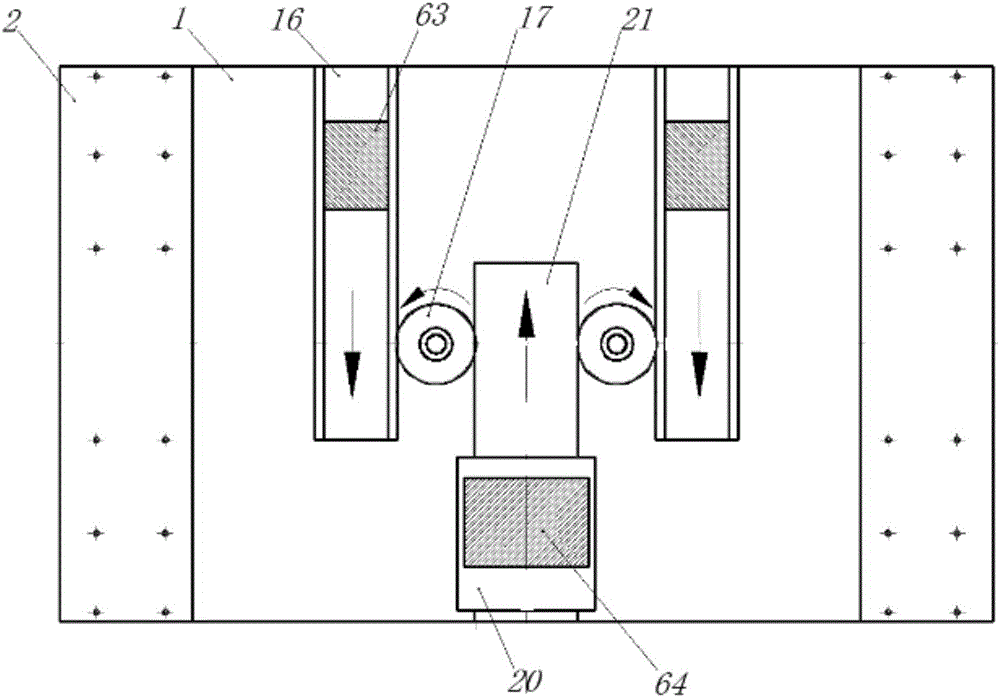

ActiveCN105904333AAvoid the important problem of uneven processingLow costEdge grinding machinesGrinding carriagesEngineeringLinear motor

The embodiment of the invention discloses a double-side polishing device and method capable of controlling the rigidity of a polishing pad through a cluster dynamic magnetic field. The whole process from rough polishing to fine polishing of both sides of a workpiece is achieved by adjusting the rigidity of the flexible polishing pad, and the problem that in the traditional machining process, machining of the workpiece is nonuniform due to the fact that the relative speed between different positions of the workpiece and the polishing pad is inconsistent is solved. The double-side polishing device capable of controlling the rigidity of the polishing pad through the cluster dynamic magnetic field comprises a variable-rigidity cluster magnetic-control polishing pad generating mechanism, a workpiece fast clamping mechanism and a workpiece movement driving mechanism, wherein the variable-rigidity cluster magnetic-control polishing pad generating mechanism comprises a first magnetic field generating block and a second magnetic field generating block which are arranged symmetrically; the first magnetic field generating block and the second magnetic field generating block each comprise a shell, a deflection spindle, an eccentric camshaft, a magnetic mounting seat, permanent magnets and a motor; the workpiece fast clamping mechanism comprises a working slot, a clamping plate, a connecting rod, a hinge plate, a fixed hinge, a square magnet, an electrical soft iron block, annular cast iron and a strip-shaped permanent magnet; and the workpiece movement driving mechanism comprises a supporting block, a crossbeam, a horizontal linear motor, a vertical beam and a vertical linear motor.

Owner:GUANGDONG UNIV OF TECH

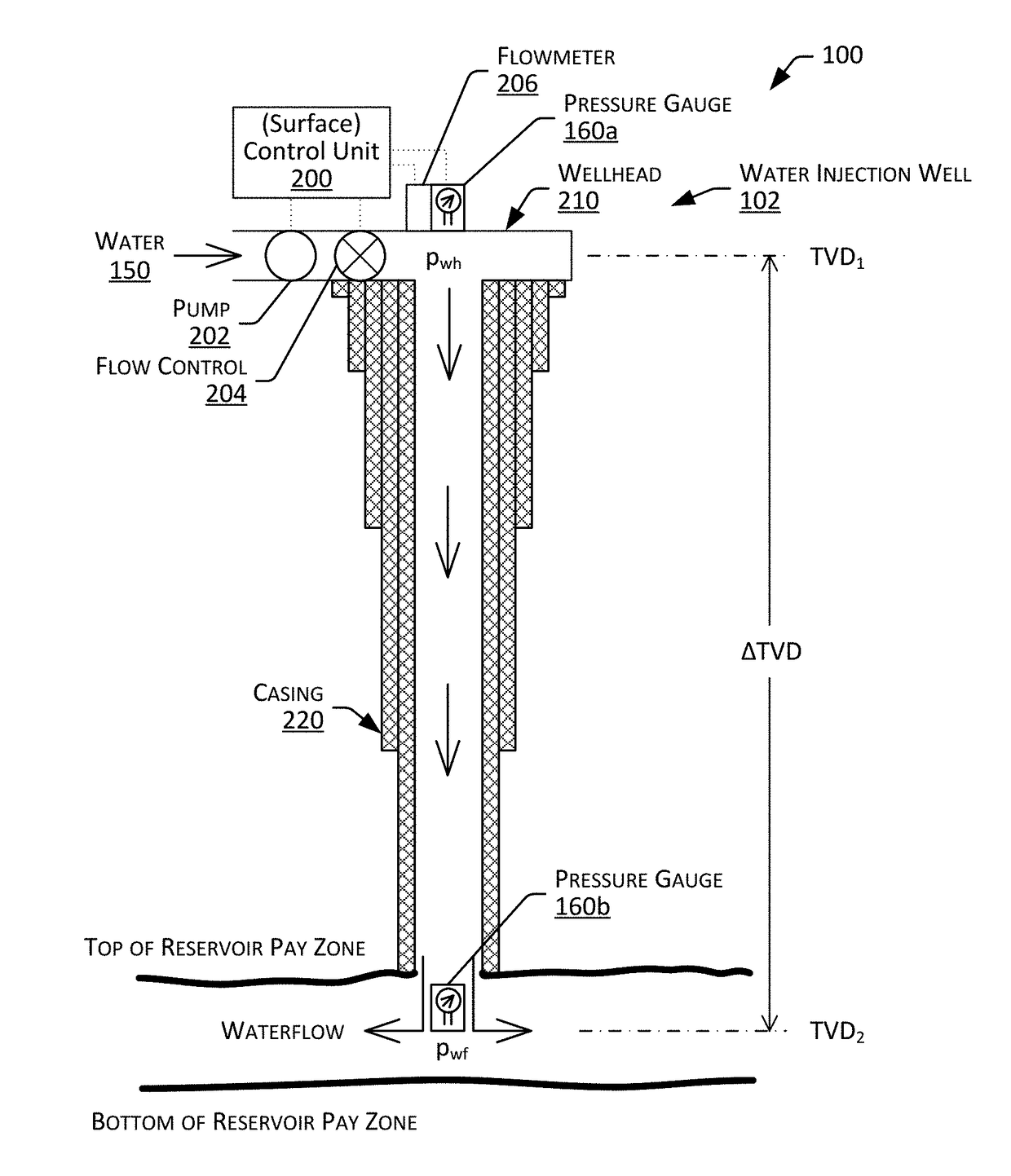

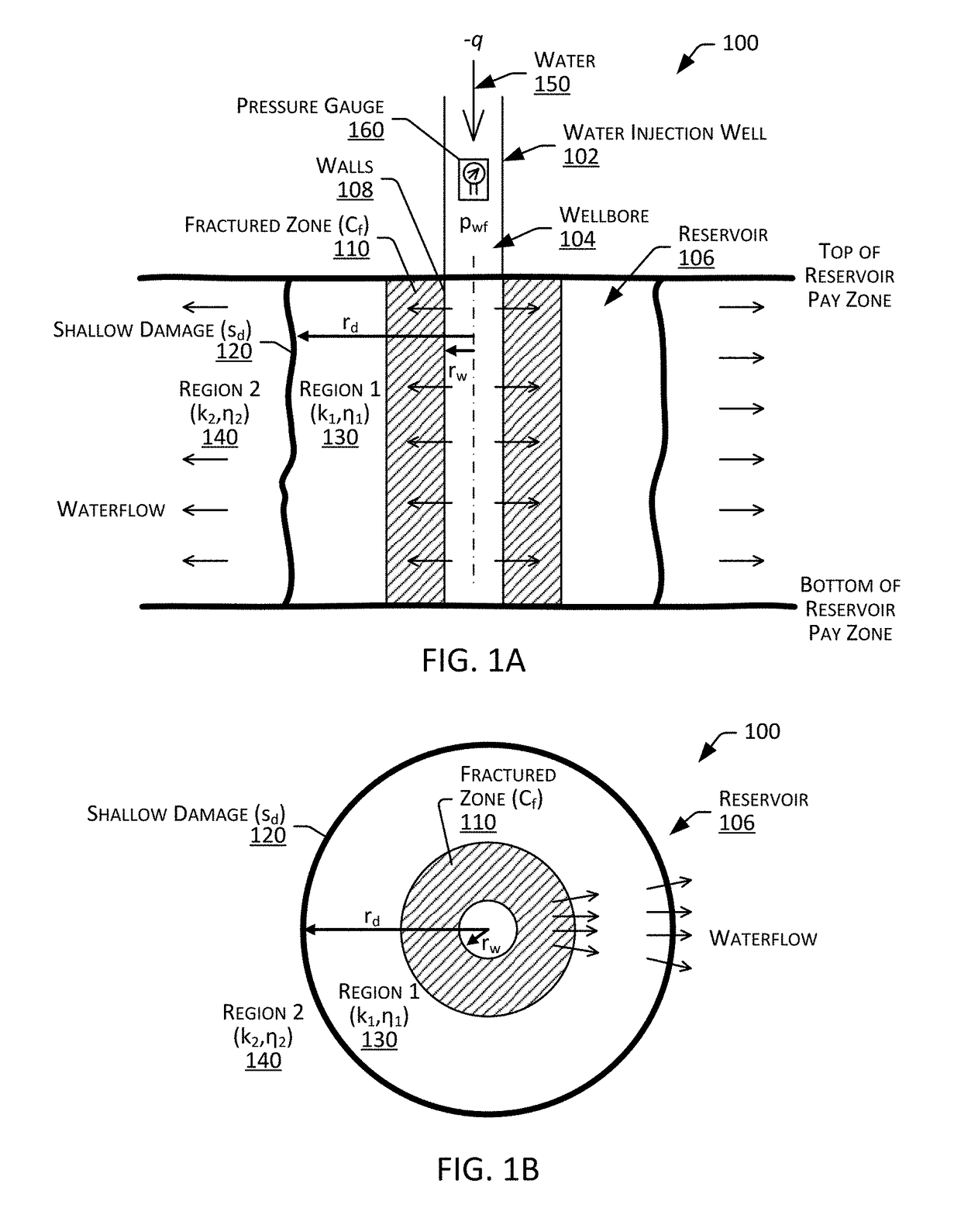

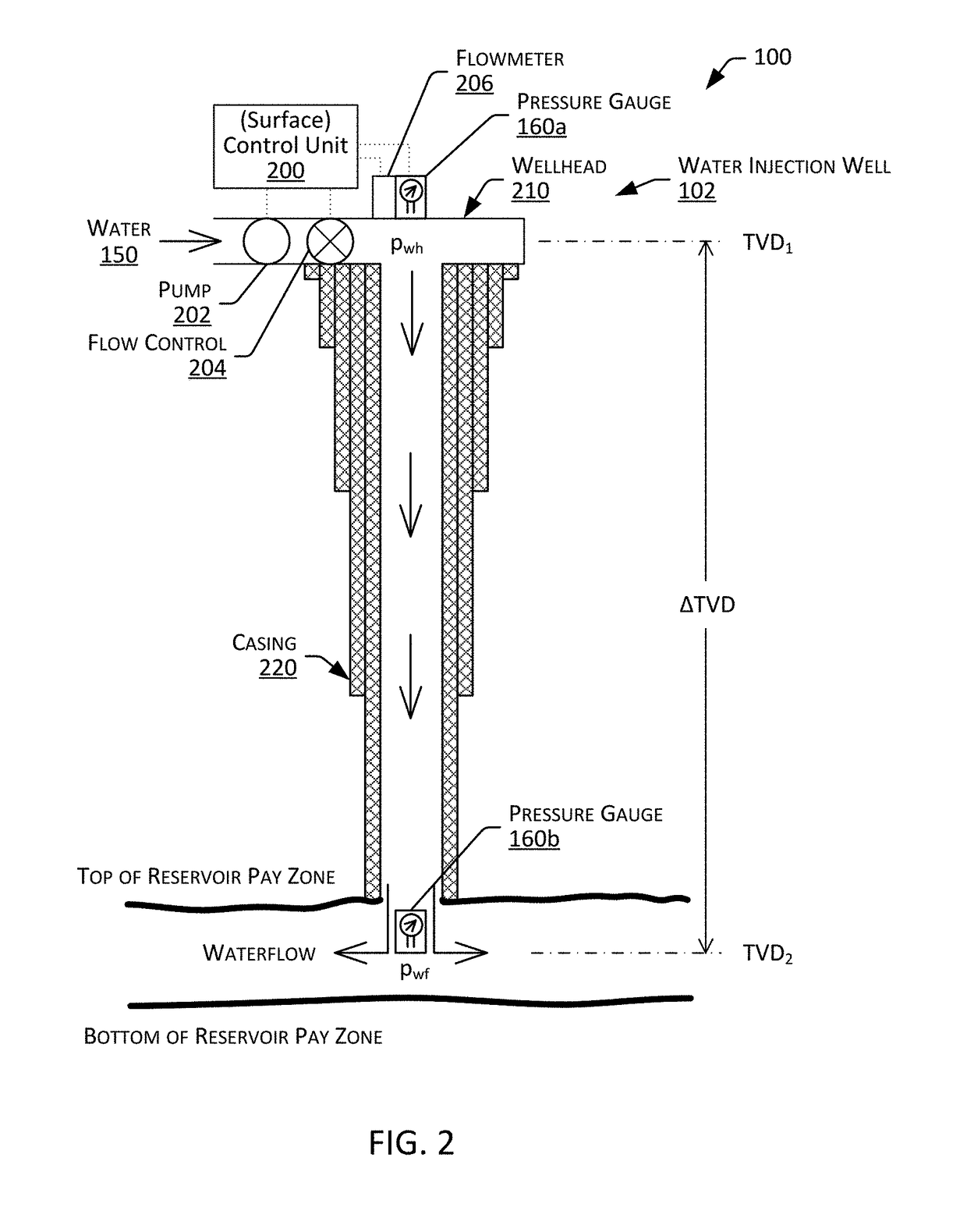

Systems and methods for transient-pressure testing of water injection wells to determine reservoir damages

ActiveUS20170234121A1Restore injection performanceMinimized volumeSurveyFluid removalReservoir waterInjection rate

Provided in some embodiments are systems and methods for transient-pressure test of an oil reservoir water injection well system. Embodiments provide for determining a fracturing injection rate for the well, setting a test injection rate preferably below the fracturing injection rate, conducting a stabilized injection of water into a wellbore of the well at the test injection rate for a prescribed period, and conducting a fall-off test including shutting-in the well for a prescribed fall-off period, and acquiring test data indicative of fluid pressure in the wellbore of the well during the injection and the fall-off periods. Embodiments also provide for generating a model prediction, comparing the model to the test data to determine whether it is a match for the well, and associating the parameter values with the well, including the severity and the location of the shallow damage, if the reservoir model is a match.

Owner:SAUDI ARABIAN OIL CO

Catalyst for ammonia selective reduction of nitrogen oxide and preparation method of catalyst

InactiveCN104492425ARestore performanceLower operating temperatureInternal combustion piston enginesDispersed particle separationNitrogen oxidesPtru catalyst

The invention relates to a compound oxide catalyst for ammonia selective reduction of nitrogen oxide and a preparation method of the compound oxide catalyst. The catalyst is mainly applied to purification of nitrogen oxide in flue gas of factories and tail gas of motor vehicles. The catalyst is mainly prepared from manganese oxide and rare-earth oxides with different contents, and is characterized by good low-temperature activity, strong water resistance and strong sulfur poisoning resistance for the reaction of ammonia selective reduction of nitrogen oxide, and over 80 percent of conversion rate of nitrogen oxide in a temperature range of 50-300 DEG C. The catalyst can be regenerated to completely recover the activity by means of simply rinsing after sulfur poisoning. The catalyst has a simple preparation method, low cost and good low-temperature activity, and has a good application prospect in purification of nitrogen oxide in flue gas of factories and tail gas of motor vehicles.

Owner:EAST CHINA UNIV OF SCI & TECH

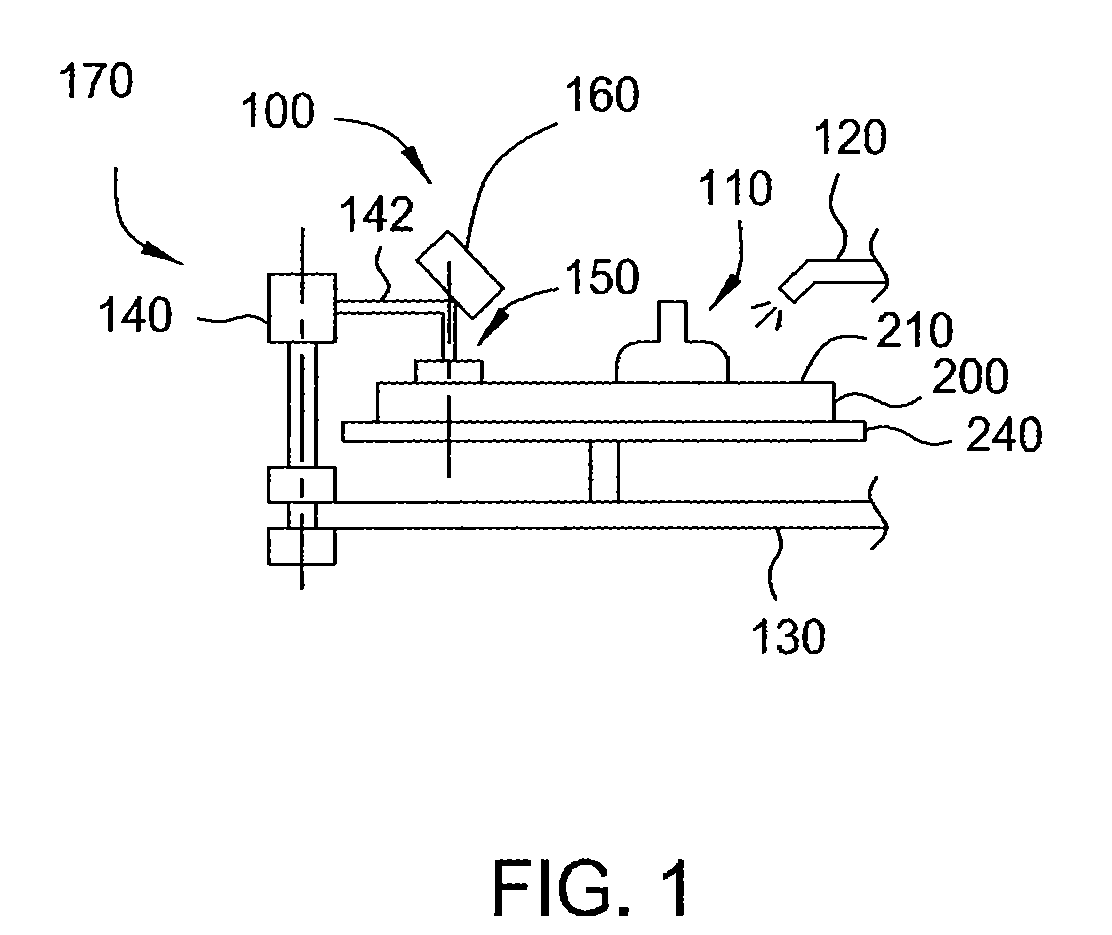

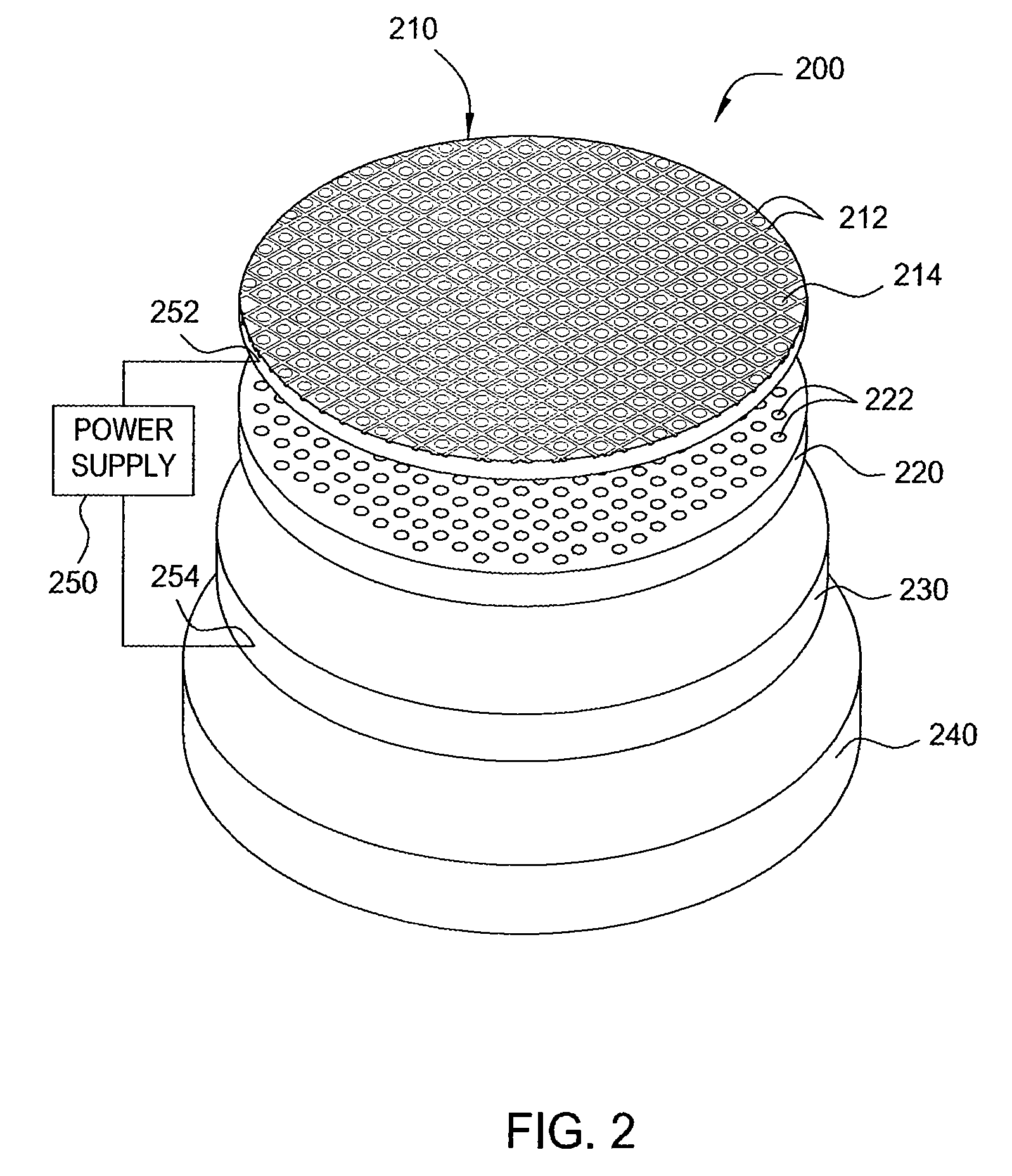

Cmp pad thickness and profile monitoring system

ActiveUS20090280580A1Restore performanceRestoring polishing performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMonitoring systemEngineering

In one embodiment a method is provided for maintaining a substrate processing surface. The method generally includes performing a set of measurements on the substrate processing surface, wherein the set of measurements are taken using a displacement sensor coupled to a processing surface conditioning arm, determining a processing surface profile based on the set of measurements, comparing the processing surface profile to a minimum profile threshold, and communicating a result of the profile comparison.

Owner:APPLIED MATERIALS INC

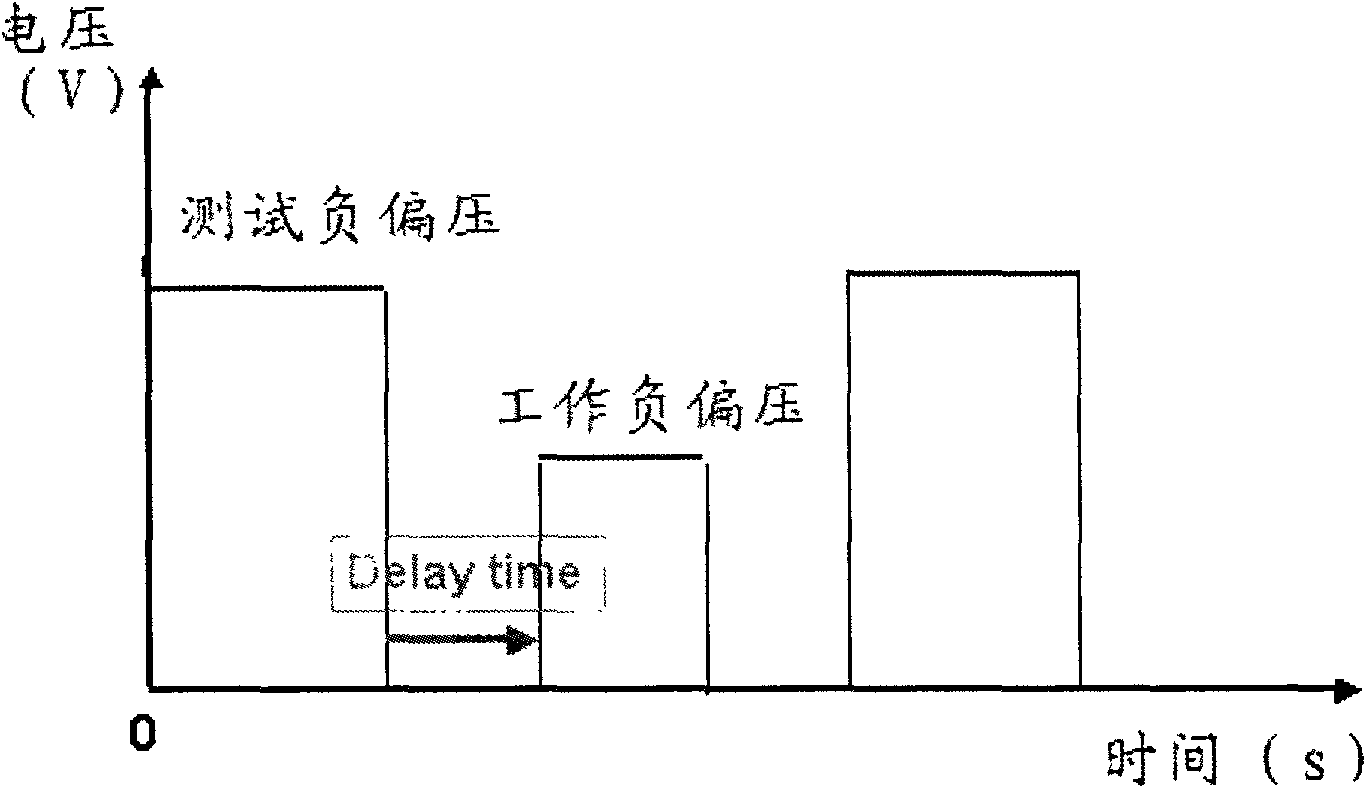

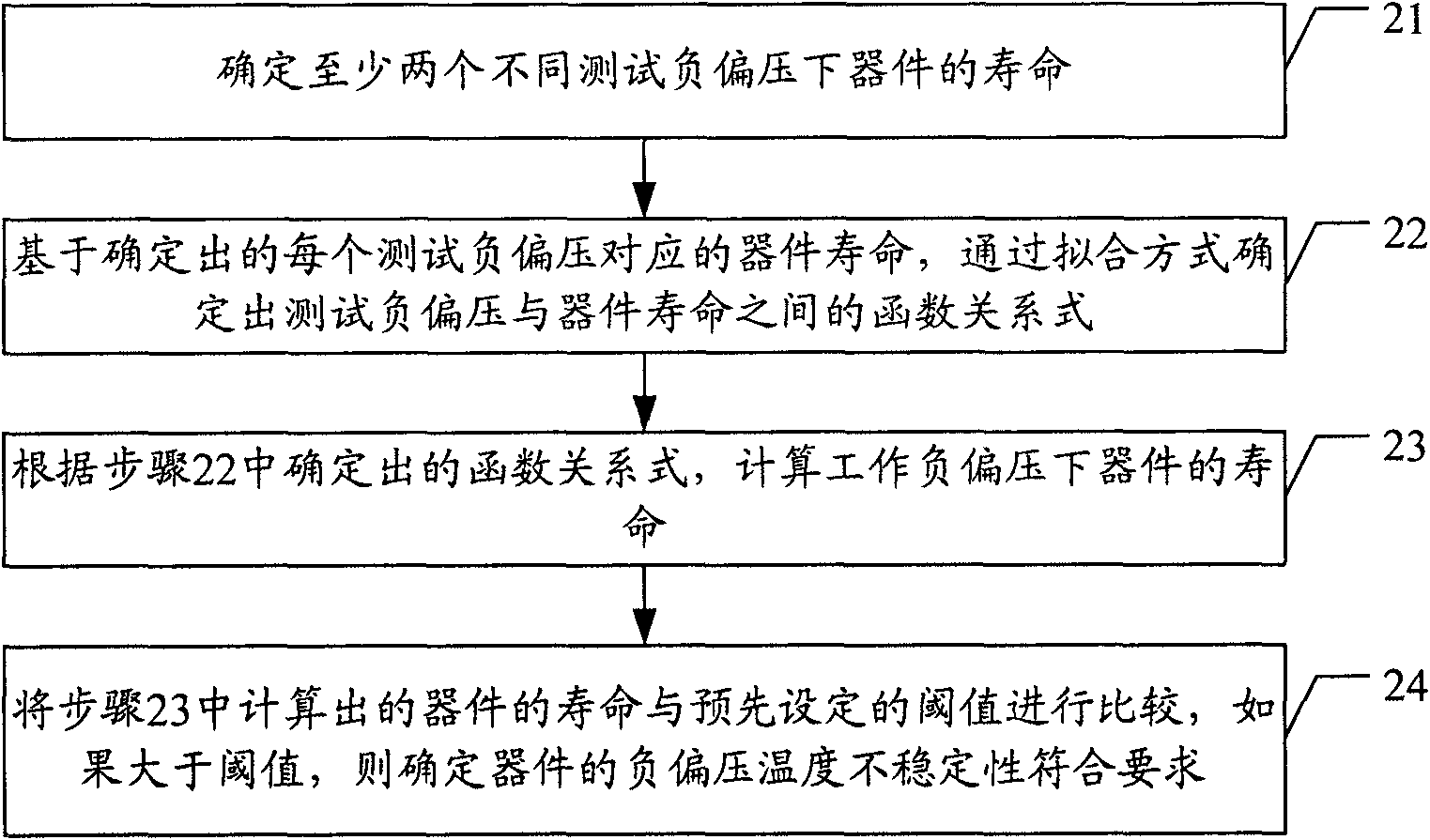

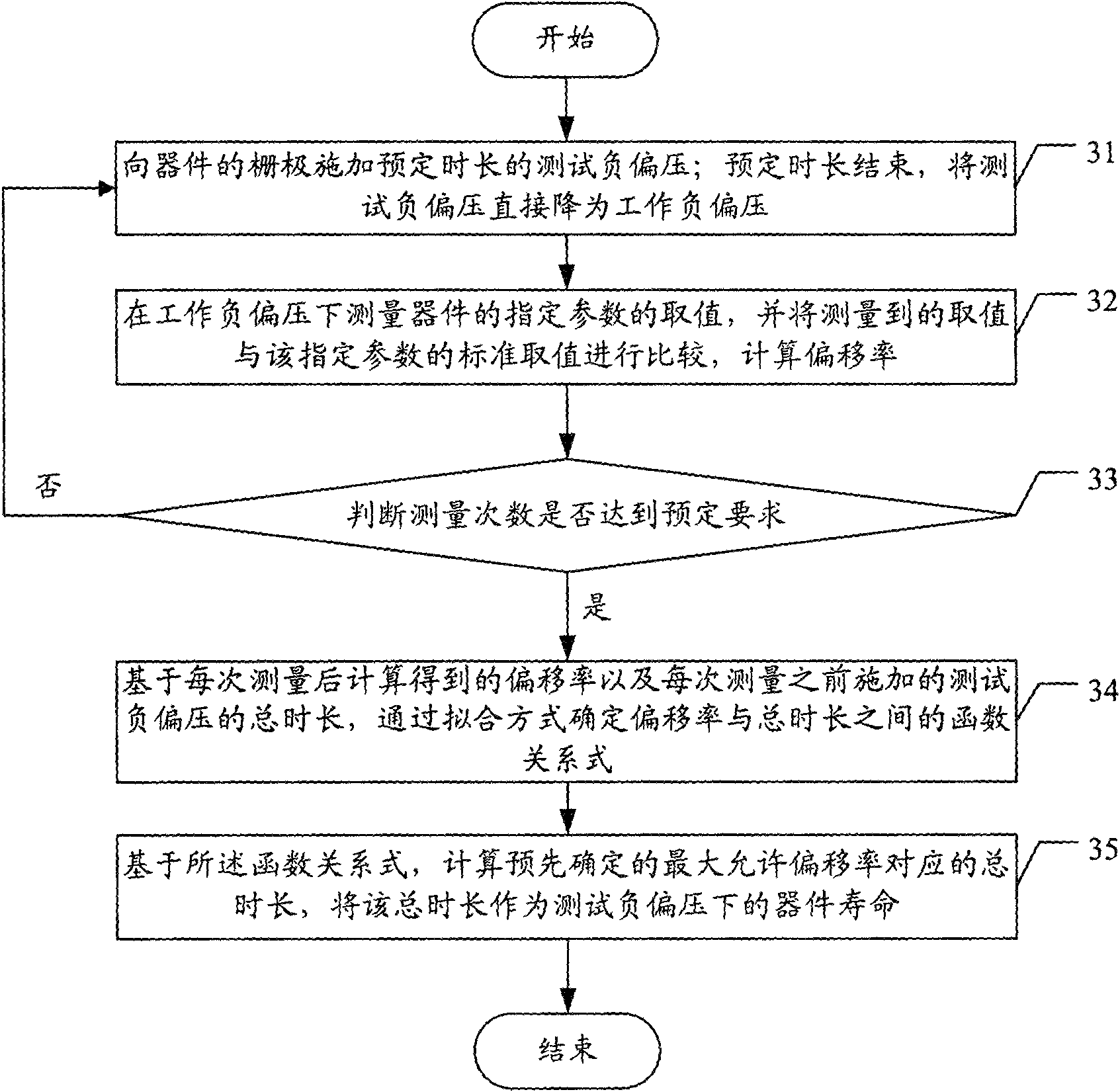

Method for testing instability of a negative bias temperature

InactiveCN102004216ARestore performanceGuaranteed accuracySemiconductor/solid-state device testing/measurementIndividual semiconductor device testingInstabilityEngineering

The invention discloses a method for testing instability of a negative bias temperature. The method comprises the following steps: determining the service life of a device under at least two different test negative biases, and determining a functional relationship between the test negative bias and the service life of the device in a fitting manner; calculating the service life of the device in a normal working state under a working negative bias according to the determined functional relationship; and comparing the calculated service life of the device with a pre-set threshold, wherein if the calculated service life is longer than the threshold, the test is passed. In the process of testing the service life of the device under different test negative biases, the test negative bias is reduced to the working negative bias before measuring a designated parameter of the device each time so as to avoid recovery of the device performance, ensure the accuracy of the measurement result and the accuracy of the entire test process and increase the processing speed of the entire test process; and moreover, compared with the prior art, only one important parameter of the device is tested in the scheme of the invention, and thus the test speed is further increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

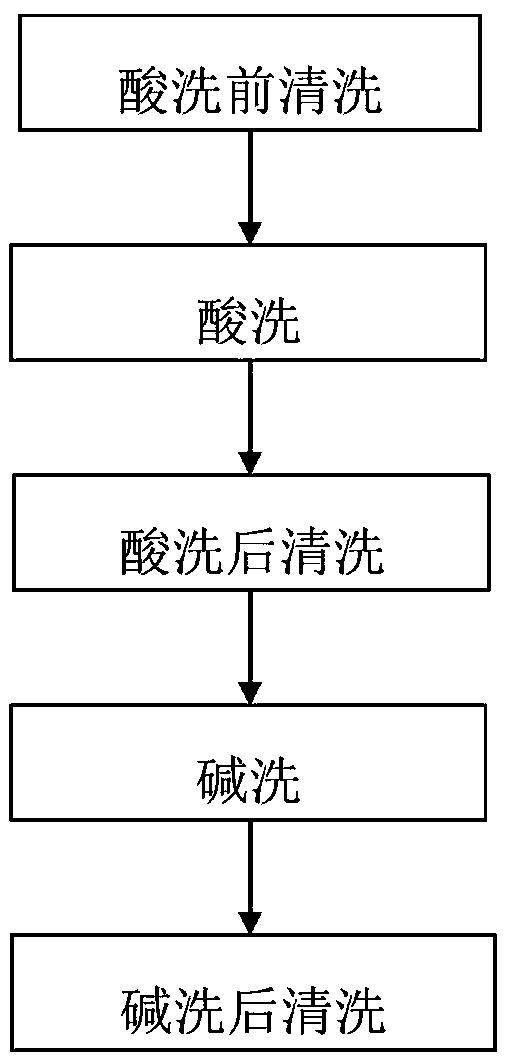

Chemical cleaning method for nanofiltration or reverse osmosis membranes

InactiveCN109224870AExtended service lifeImprove clear liquid handling capacitySemi-permeable membranesReverse osmosisNanofiltration

The invention discloses a chemical cleaning method for nanofiltration or reverse osmosis membranes. The chemical cleaning method includes the following steps: (1) pickling the nanofiltration or reverse osmosis membranes by acidic solutions; (2) cleaning the nanofiltration or reverse osmosis membranes by product water after pickling; (3) performing alkali washing on the nanofiltration or reverse osmosis membranes by alkaline cleaning solutions; (4) cleaning the nanofiltration or reverse osmosis membranes by the product water after alkali washing to complete cleaning of the nanofiltration or reverse osmosis membranes. The chemical cleaning method has the advantages that various pollutants on the nanofiltration or reverse osmosis membranes can be efficiently removed, the operating pressure ofthe nanofiltration or reverse osmosis membranes can be reduced, the yield of clear liquid of the nanofiltration or reverse osmosis membranes can be increased, the service life of the nanofiltration or reverse osmosis membranes can be prolonged, the power consumption of the clear liquid can be lowered, and stable operation of landfill leachate treatment plants can be guaranteed; the chemical cleaning method has the advantages of simple process, convenience in operation, low cleaning cost, high cleaning efficiency, good cleaning effect, high application value, good application prospect and thelike.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

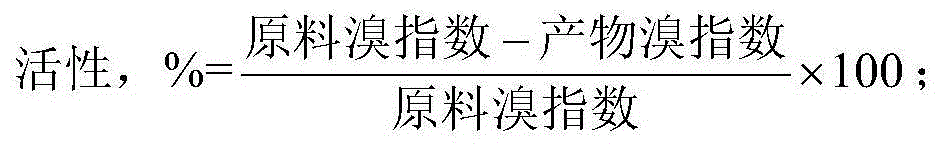

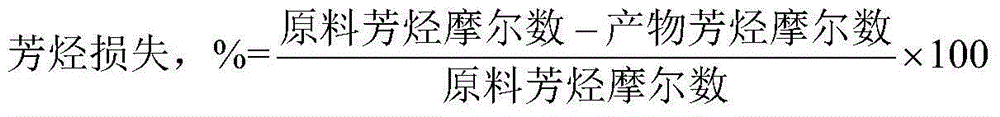

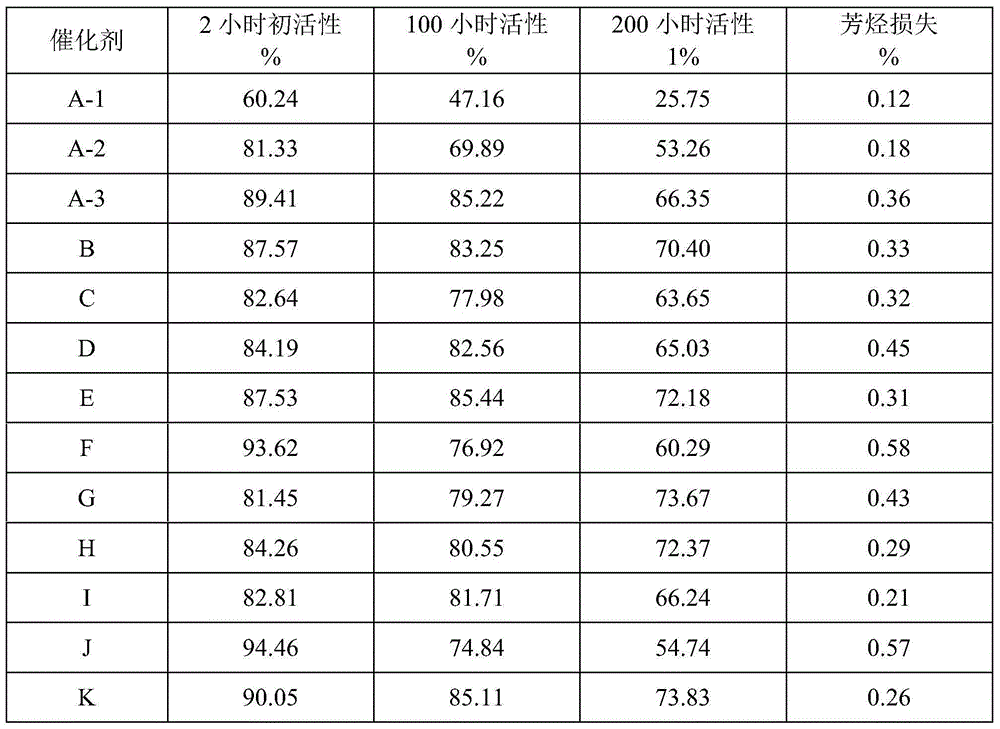

Aromatic olefin-reducing catalyst and use thereof

InactiveCN105080592AImproves carbon build-up resistanceReduce carbon deposition rateMolecular sieve catalystsRefining with metal saltsPore diameterOxide

The present invention relates to an aromatic olefin-reducing catalyst mainly solving the problems of short carclazyte life, frequent replacement, large labor intensity, and serious environmental pollution when the carclazyte is used for removing trace olefins in an aromatic material in current industry. The aromatic olefin-reducing catalyst is used, the average pore diameter of the aromatic olefin-reducing catalyst is 5-30nm, the aromatic olefin-reducing catalyst comprises the following components by weight: 0 to 15% of lanthanide elements or a mixture thereof; 0 to 20% of oxides of one or more elements selected from Ca, Zn , Mg and Ti; and 30 to 90% of a molecular sieve, the molecular sieve is at least one selected from mordenite, Y zeolite, ZSM-5 molecular sieve, MCM-22 molecular sieve, MCM-56 molecular sieve, and beta-molecular sieve; and a carrier is one substance selected from alumina and silica or a mixture thereof, and by the technical scheme, the problem is preferably solved, and the method can be used for aromatic olefin-reducing industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

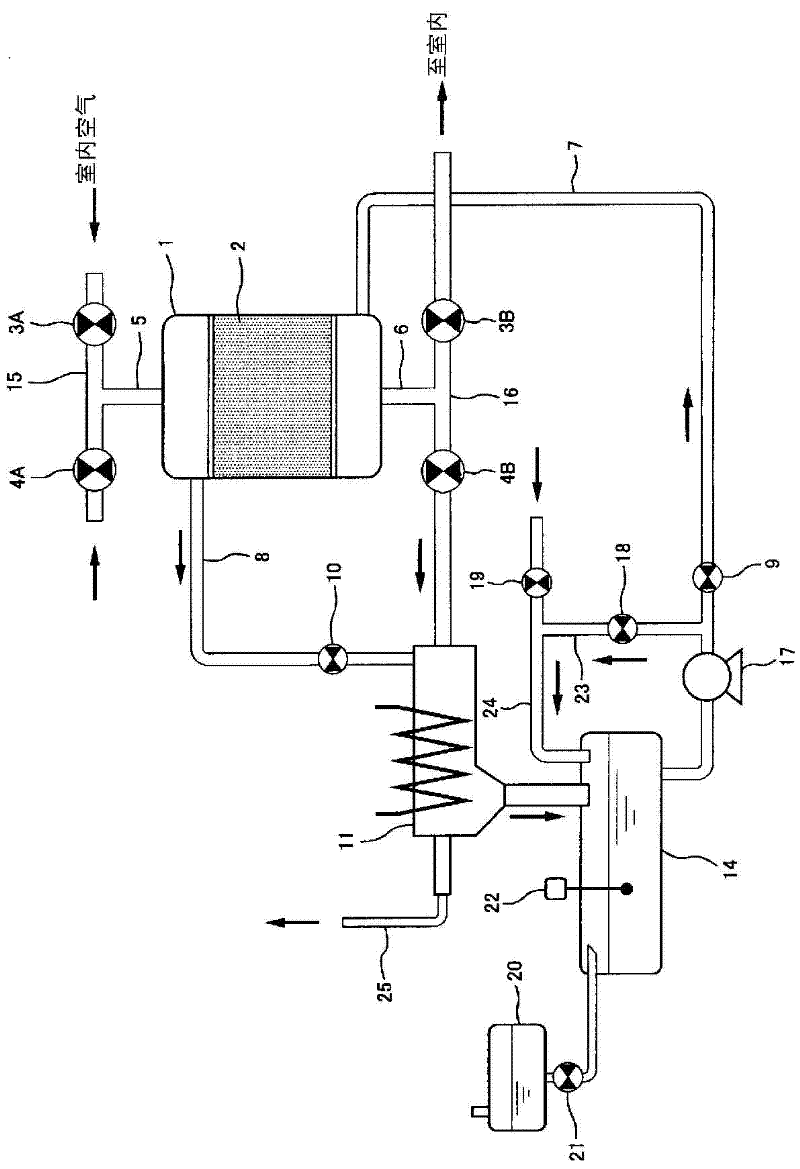

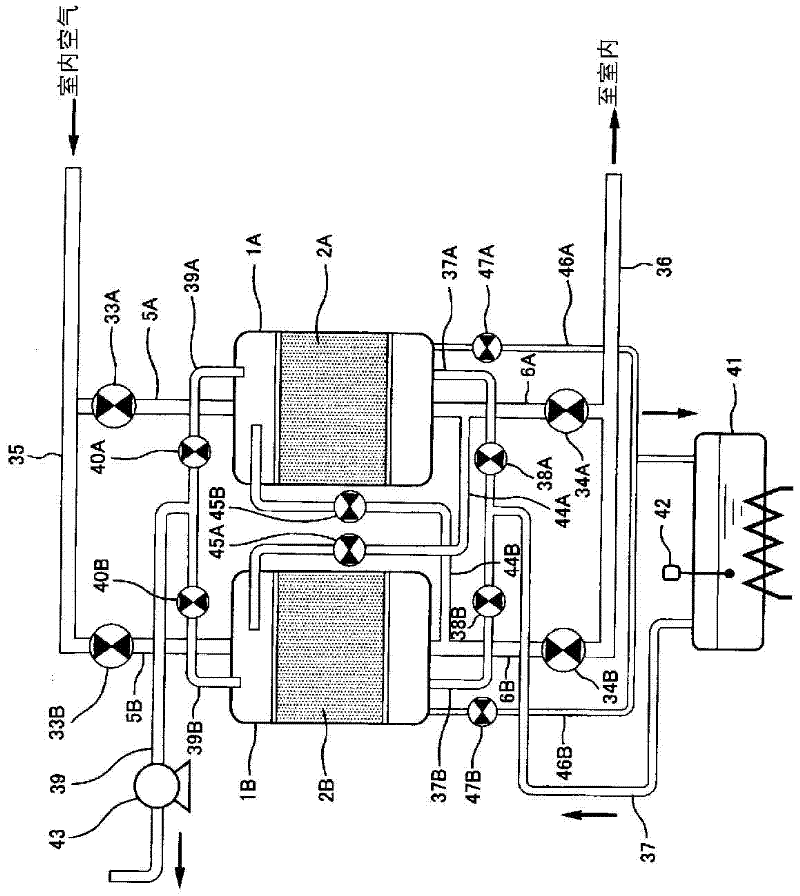

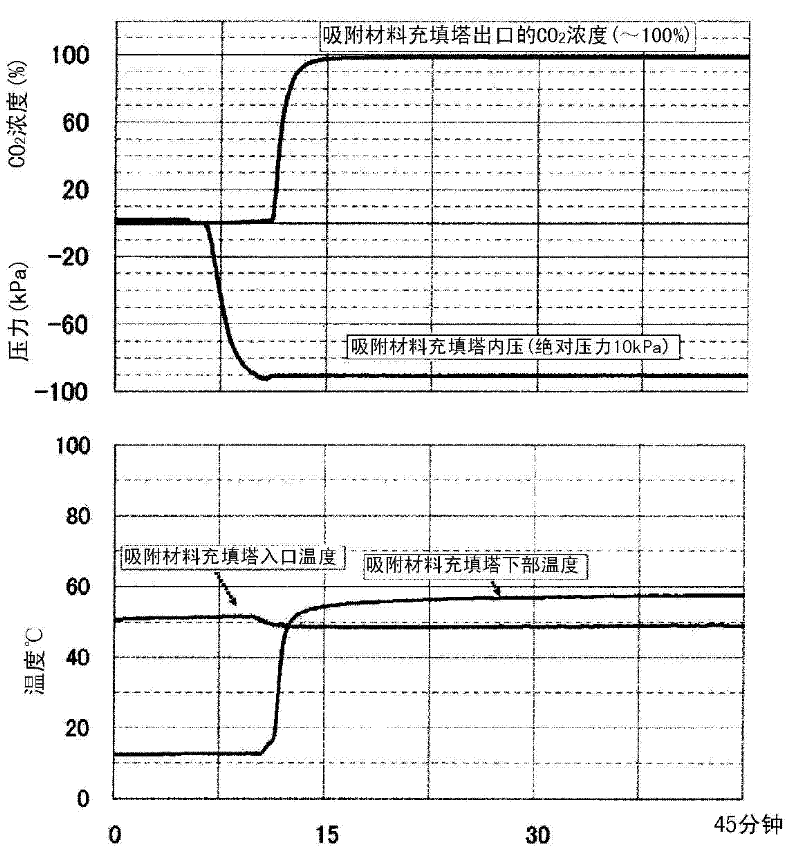

Method and device for separating carbon dioxide

ActiveCN102470314ANo reduction in adsorption capacityGuaranteed adsorption effectGas treatmentOther chemical processesAqueous solutionCo2 adsorption

Disclosed is a method and device for separating carbon dioxide, wherein carbon dioxide adsorption ability can be maintained over the long term by means of recovering and re-supporting on a carbon dioxide adsorption material amine compounds that vaporize during operation. An amine recovery device (11) and an aqueous amine solution preparation device (14) are connected to an adsorption-material-filled tank (1), which has been filled with the carbon dioxide adsorption material (2), amine compounds vaporized from the carbon dioxide adsorption material (2) during operation are recovered to the aqueous amine solution preparation device (14) by means of the amine recovery device (11), and recovered amine compounds are re-supported on the carbon dioxide adsorption material (2) via a supply line (7).

Owner:KAWASAKI HEAVY IND LTD

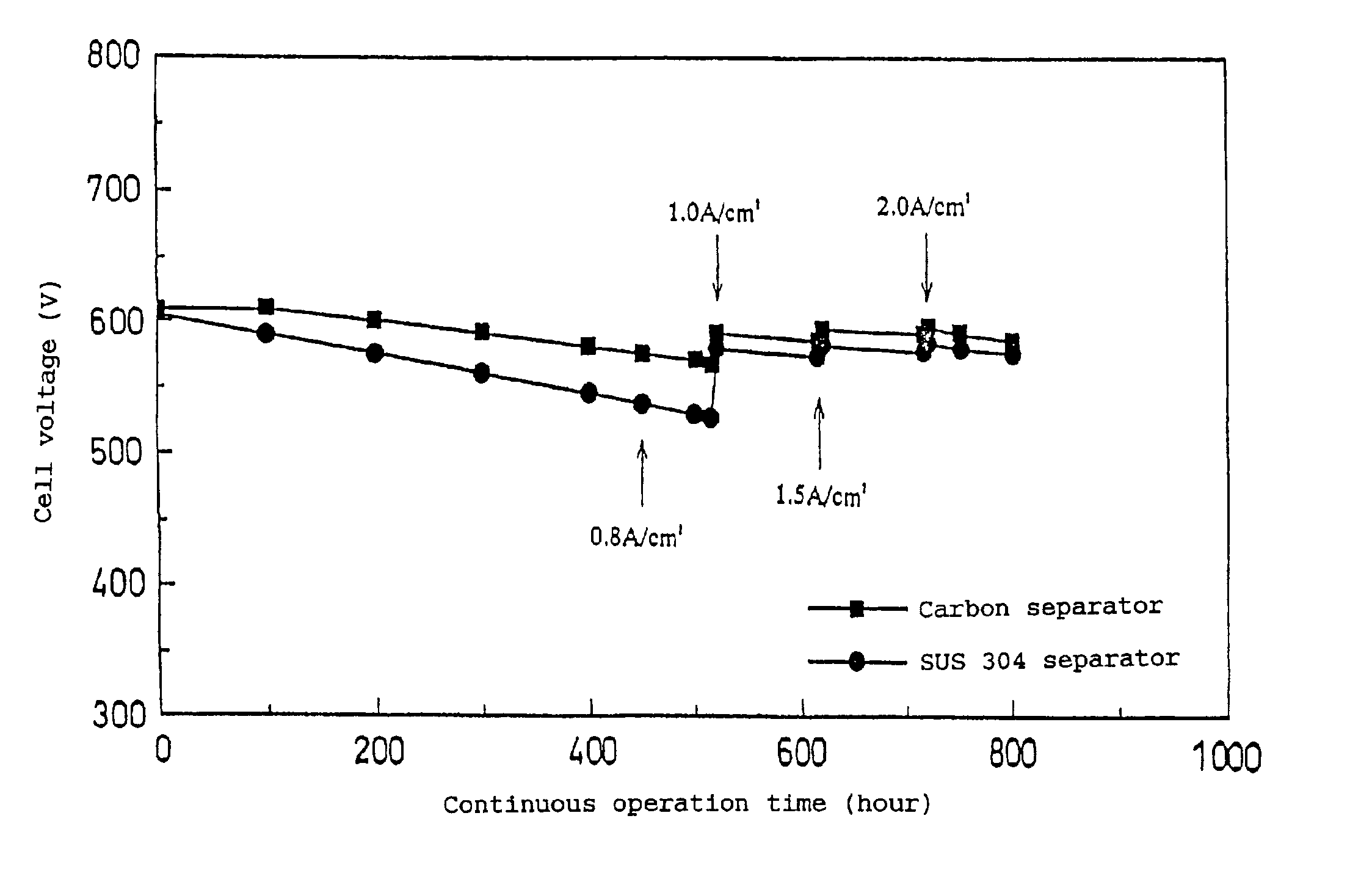

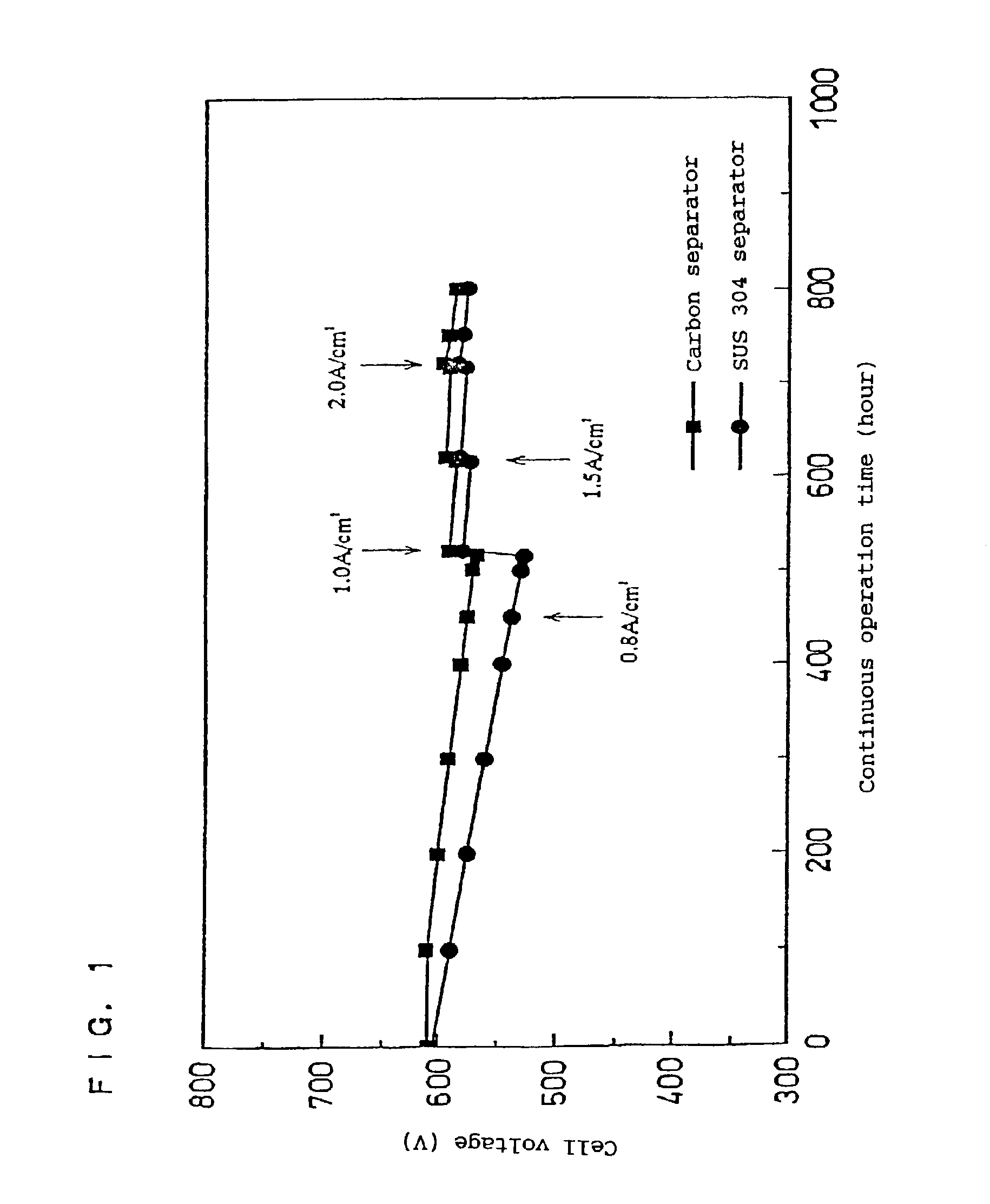

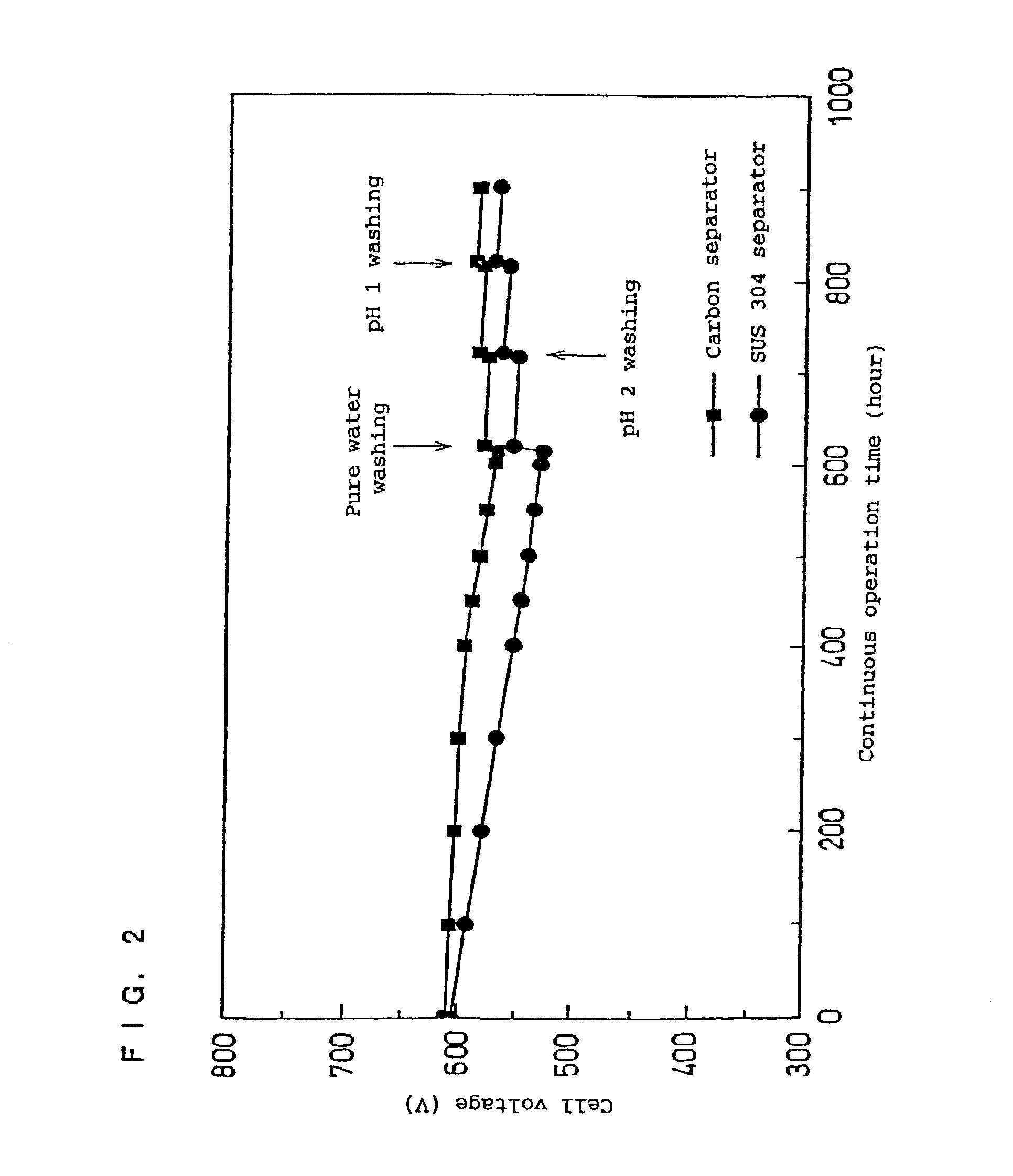

Method for resorting characteristics of polymer electrolyte fuel cell

InactiveUS6881510B1Restore performanceSolid electrolytesFuel cells groupingFuel cellsElectrical polarity

The present invention restores the performance of a fuel cell by: operating the cell in a loaded current mode different from that of a normal operation for a predetermined time; supplying an oxidant gas and a fuel gas to an anode and a cathode respectively and outputting a current from a cell body with the polarity being inverted; supplying a pressurized gas to at least one of the cathode and anode in an amount not less than 1.5 times as much as that in the normal operation or supplying oxygen to the cathode; or injecting a cleaning solution into the cathode and anode through a gas flow path. Consequently, it is possible to effectively restore a degraded performance of a polymer electrolyte fuel cell caused by a long operation.

Owner:PANASONIC CORP

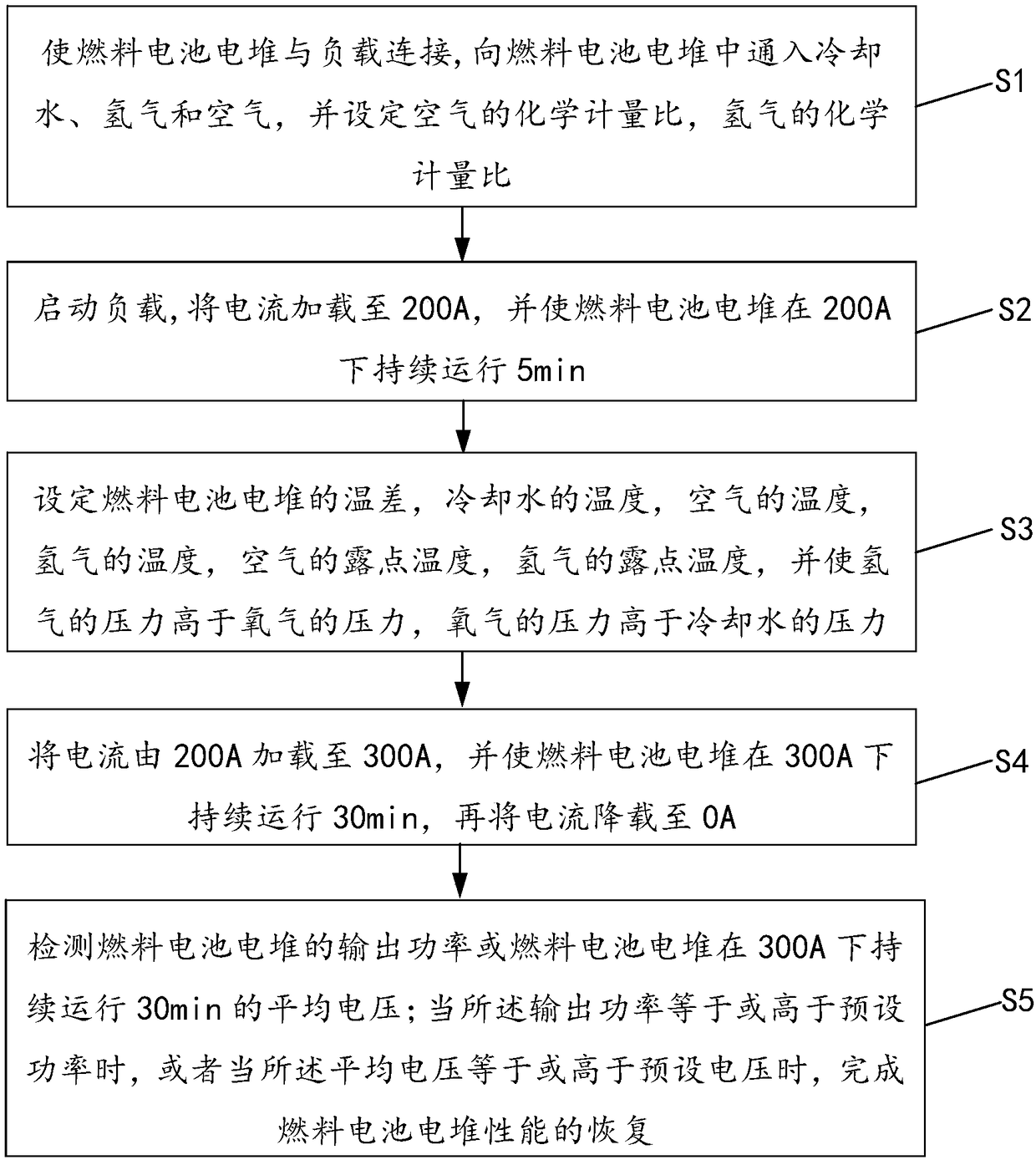

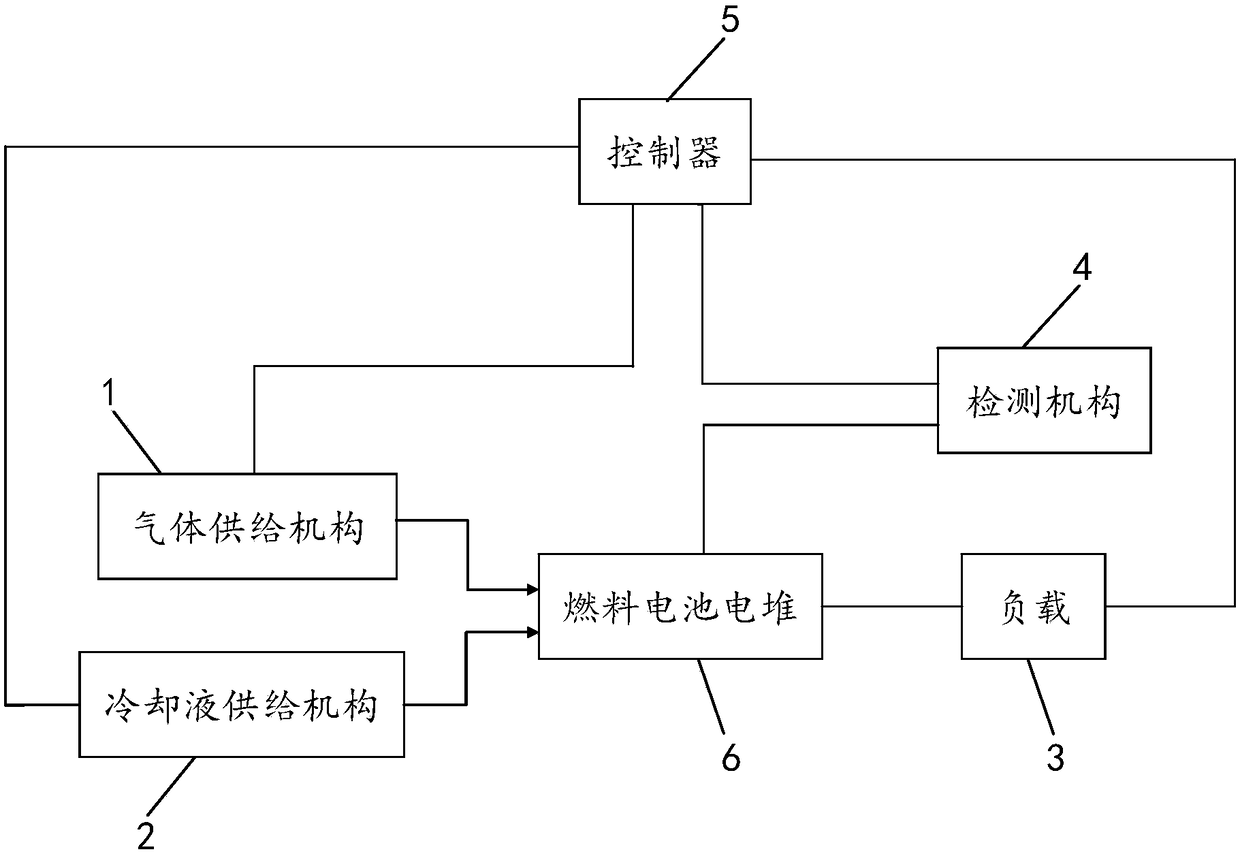

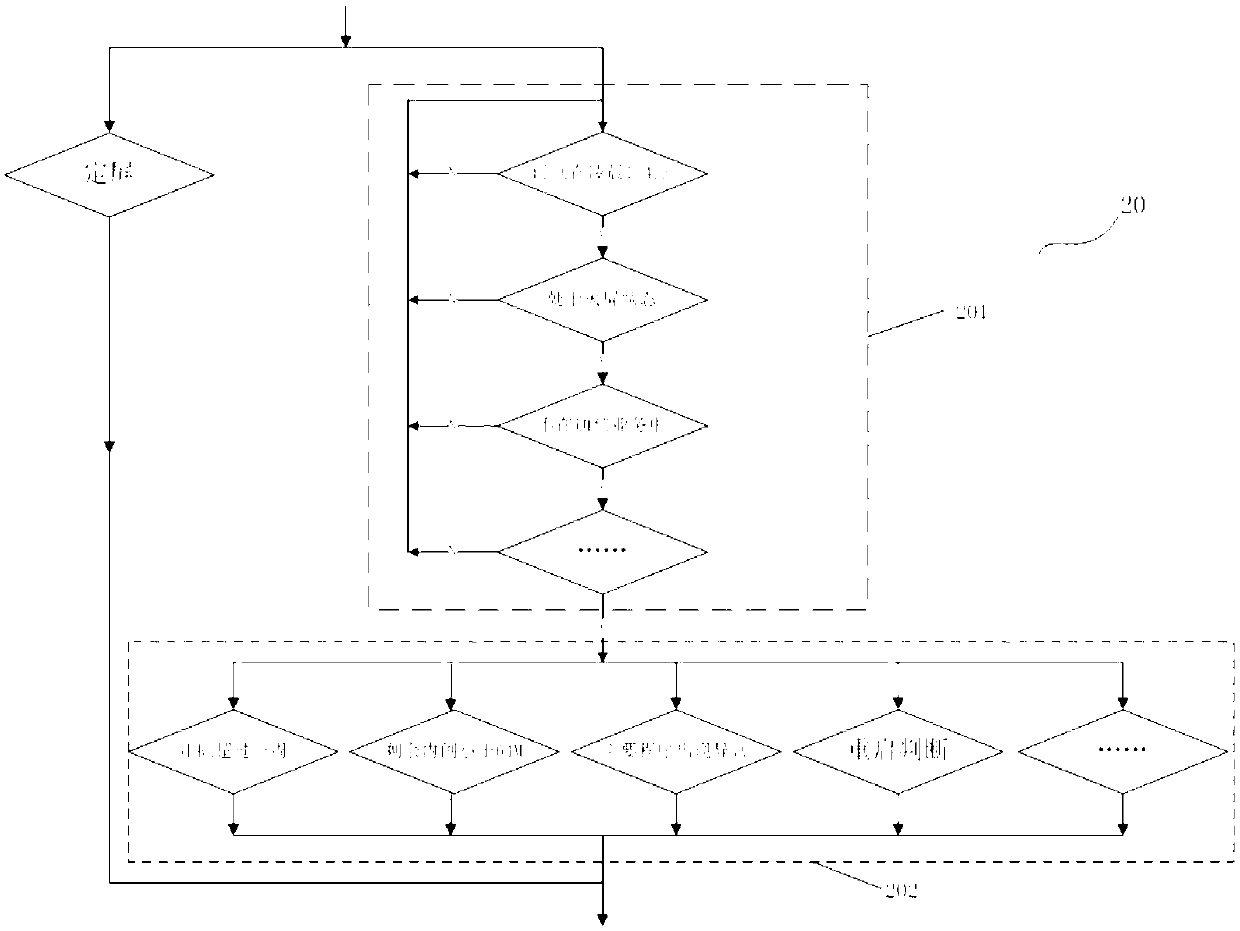

Method and device for recovering fuel battery electric pile performance

The invention relates to the technical field of a fuel battery, and discloses a method and device for recovering the fuel battery electric pile performance. The method for recovering the fuel batteryelectric pile performance comprises the following steps of starting a load; loading the current to 200A; enabling the fuel battery electric pile to continuously operate for 5min at 200A; setting the temperature difference of the fuel battery electric pile, the temperature of cooling water, the temperature of the air, the temperature of hydrogen gas, the dew point temperature of the air and the dewpoint temperature of the hydrogen gas; enabling the pressure of the hydrogen gas to be higher than the pressure of the oxygen; loading the current from 200 A to 300 A; continuously operating the fuelbattery electric pile for 30min at 300A; if the output power of the of the fuel battery electric pile equals to or is higher than the preset power, or the average voltage equals to or is higher thanthe preset voltage, the fuel battery electric pile performance recovery is completed. The method for recovering the fuel battery electric pile performance of the embodiment is simple and convenient; the realization is easy; the performance of the fuel battery electric pile in a non-operation state for a long time can be fast recovered, so that the performance recovery efficiency of the fuel battery electric pile is improved.

Owner:北京国鸿氢能科技有限公司 +1

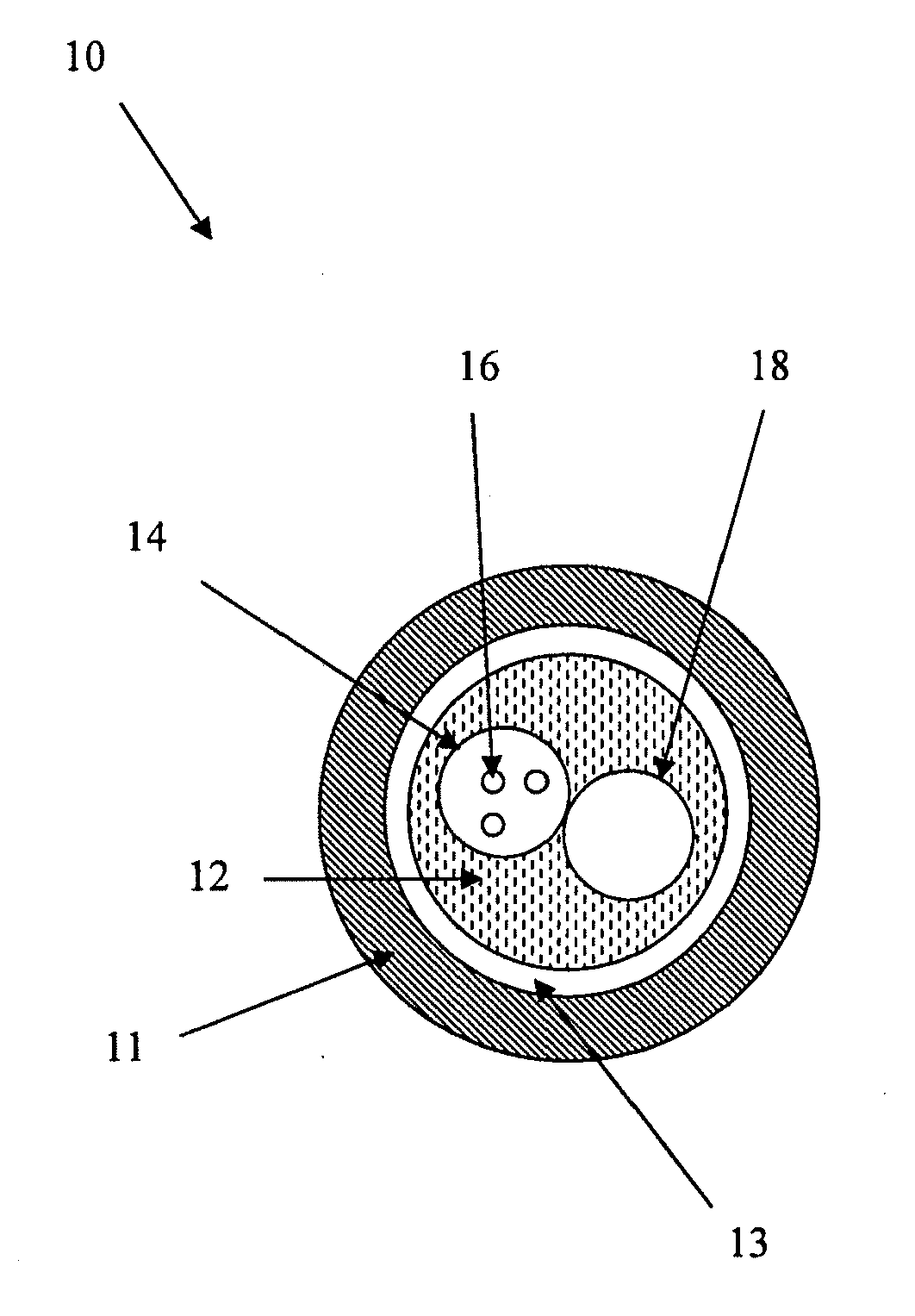

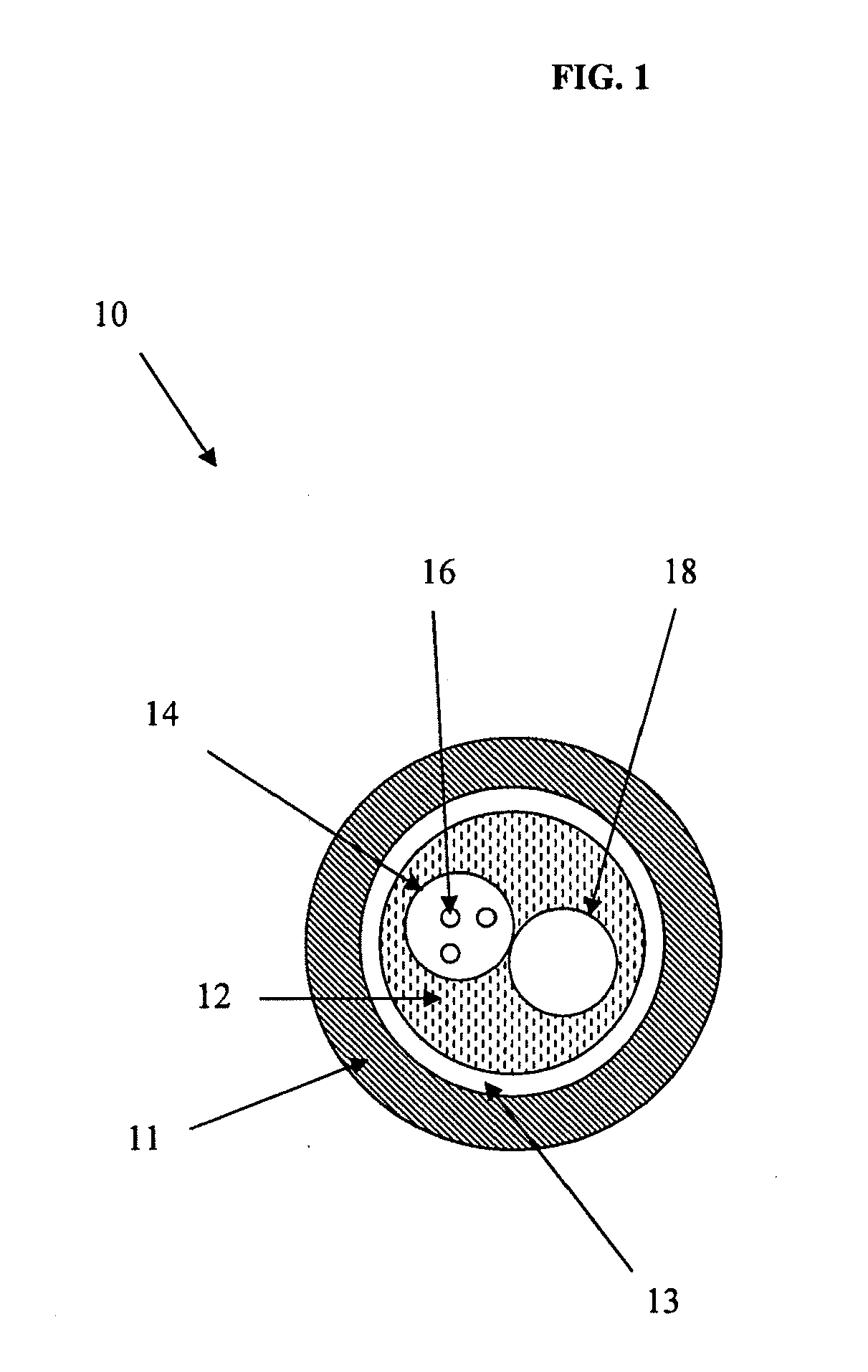

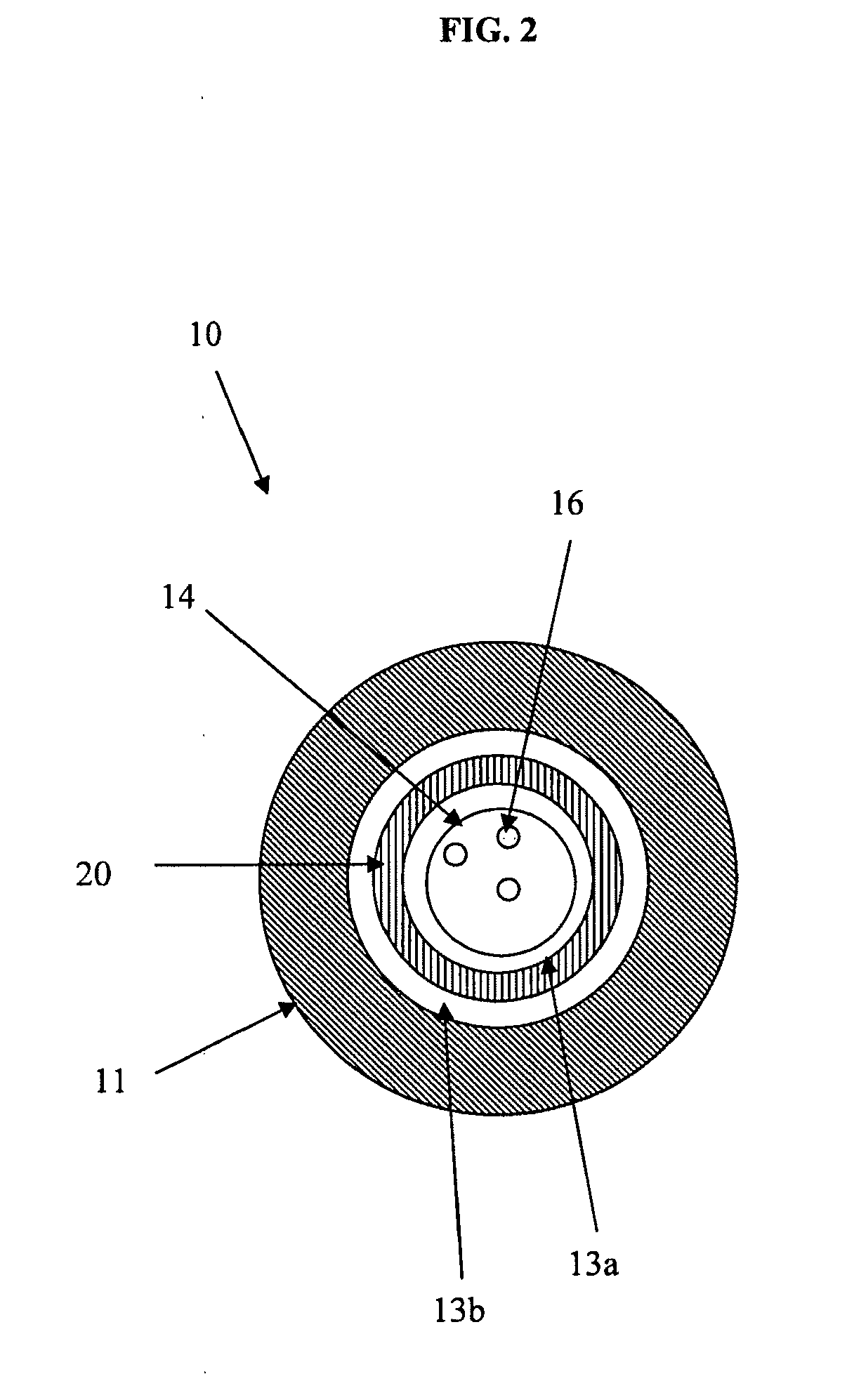

Breathable downhole fiber optic cable and a method of restoring performance

ActiveUS20100008632A1Reduce hydrogen partial pressureRestore performanceFibre mechanical structuresGas analyser construction detailsFiberHydrogen

A breathable downhole fiber optic cable is provided having an outer protective tube; a fiber optic tube having a plurality of optical fibers contained therein; at least one annulus disposed between the outer protective tube and the fiber optic tube; and at least one path, extending through the length of the fiber optic cable, which provides a channel for a purge gas to flow for removing a second gas, such as hydrogen, from the fiber optic cable.

Owner:AFL COMM LLC

Exhaust gas treatment method, exhaust gas treatment system, and catalytic oxidation apparatus

ActiveUS20050112042A1Inhibit deteriorationRestore performanceUsing liquid separation agentCombustible gas catalytic treatmentCombustionCatalytic oxidation

The present invention provides an exhaust gas treatment method including oxidation treatment for converting metallic mercury contained in combustion exhaust gas into mercury chloride; and mercury removal treatment for removing mercury from the combustion exhaust gas by dissolving the mercury chloride in water, wherein a plurality of oxidation catalysts for performing the oxidation treatment are provided, and during the time when the oxidation treatment is performed, at least one of the oxidation catalysts performs catalyst performance restoration treatment without performing oxidation treatment. According to the present invention, the deterioration in mercury removal performance can be restrained even in continuous operation on condition that mercury is oxidized in a low temperature region not higher than 300° C.

Owner:MITSUBISHI HEAVY IND LTD

Asphalt pavement net-shaped crack treatment regeneration sealing layer material and preparation method thereof

The invention relates to an asphalt pavement net-shaped crack treatment regeneration sealing layer material and a preparation method thereof. The asphalt pavement net-shaped crack treatment regeneration sealing layer material is characterized by being composed of the raw materials in parts by weight: 70-100 parts of a composite emulsion and 200-400 parts of a fine aggregate; the composite emulsion is prepared by mixing the raw materials in pars by weight: 20-50 parts of an inorganic solution and 200-600 parts of an organic emulsion; the inorganic solution is an acidic silicon solution or a neutral silicon solution, the silica content is 10-30% (mass), the pH value is 3-7, the sodium oxide content is less than 0.5% (mass), and the average particle size is 10-20 nm; the organic emulsion comprises the raw materials by weight: 100 parts of a regeneration agent emulsion and 100-500 parts of modified emulsified asphalt. The asphalt pavement net-shaped crack treatment regeneration sealing layer material has strong permeability, plays good seam-sealing and waterproof roles in cracks, and has remarkable regeneration and reduction improvement effects on aged asphalt.

Owner:上海乐辛新材料科技有限公司

Bituminous cold reclaiming agent and application of bituminous cold reclaiming agent in cold reclaiming of bituminous concrete

InactiveCN102924936ARestore performanceStrong penetrating powerIn situ pavingsBuilding insulationsVoid ratioSurface layer

The invention relates to a bituminous cold reclaiming agent and application of the bituminous cold reclaiming agent in cold reclaiming of bituminous concrete. The bituminous cold reclaiming agent comprises an impregnating compound and a desiccating agent. The bituminous cold reclaiming agent is strong in permeation and infiltration force and enables aging bitumen in reclaimed asphalt pavement (RAP) to be activated and recover performance of the bitumen, and then the desiccating agent is added to volatilize diluents in an infiltration material to solidify the infiltration material to form strength. Finally, the void ratio of reclaimed asphalt mixture is lower than 6%, strength performance, water stabilizing performance, high-temperature performance and low-temperature performance achieve performance indexes of hot-mix asphalt mixture, and operating requirements of upper and middle surface layers of asphalt roads in each level are met. According to the invention, the method is simple and easy to operate and energy-saving, the used bituminous concrete for each structure layer of asphalt concrete pavements in each level can be completely used and reused under the condition that composite cost is not greatly increased, and wide popularization and application values are achieved.

Owner:重庆市智翔铺道技术工程有限公司

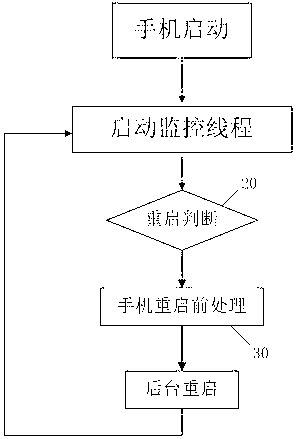

Intelligent mobile phone and performance optimization method for same

InactiveCN103345401ARestore performanceImprove user experienceProgram loading/initiatingEmbedded systemMobile phone

The invention discloses an intelligent mobile phone and a performance optimization method for the same, which relate to the field of intelligent terminal design. According to the intelligent mobile phone and the performance optimization method for the same, real-time monitoring for the mobile phone is realized, and background restart is performed on the mobile phone after certain preset conditions are achieved, so as to realize recovery for the performance of the mobile phone, and improve the use experience of a user; the design is simple in principle and easy to realize; the performance constancy of the mobile phone is ensured.

Owner:禹芙蓉

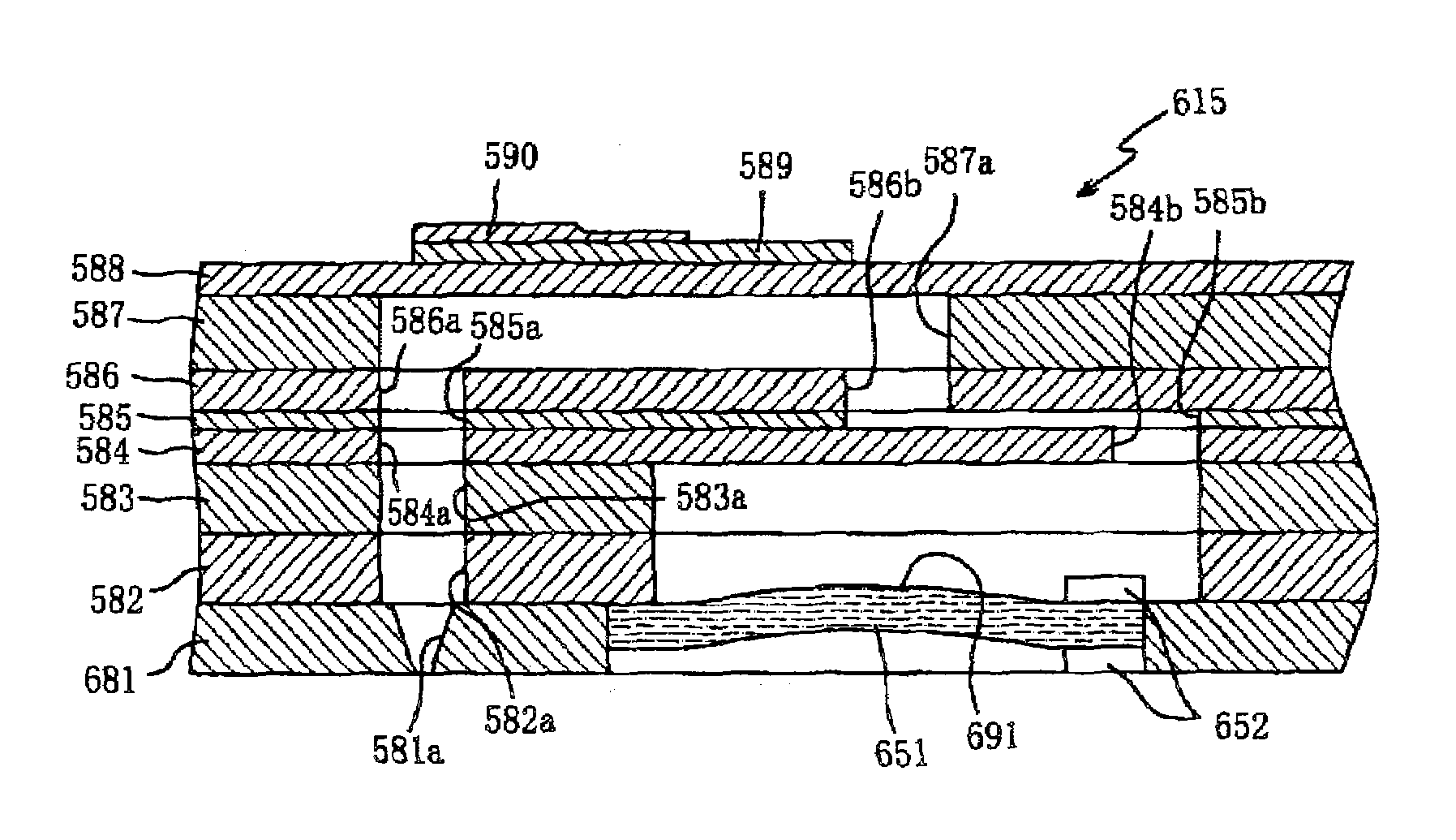

Liquid droplet ejecting apparatus

There is disclosed a liquid droplet ejecting apparatus including: a tank storing a liquid; a nozzle from which the liquid is ejected in the form of a droplet; a first pressure-feed portion which is disposed between the tank and the nozzle, and pressure-feeds the liquid as supplied from the tank, to eject the liquid droplet from the nozzle; a second pressure-feed portion which has an inner volume larger than that of the first pressure-feed portion, and is disposed between the tank and the first pressure-feed portion, the second pressure-feed portion pressure-feeding the liquid as supplied from the tank to the nozzle via the first pressure-feed portion, to eject the liquid from the nozzle in an amount larger than an amount of the liquid ejected by the first pressure-feed portion as the liquid droplet; and the second pressure-feed portion including: a pressure chamber; a pressurizing member that pressurizes the liquid in the pressure chamber by decreasing an inner volume of the pressure chamber; and a liquid communication passage which holds the tank and the nozzle in communication with each other via the pressure chamber, and which includes a flow resistance generator which is disposed in at least one of a portion of the liquid communication passage between the tank and the pressure chamber, and a portion of the liquid communication passage between the pressure chamber and the nozzle, the flow resistance generator giving a flow resistance to the liquid as flowing in the at least one of the two portions of the liquid communication passage.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com