Patents

Literature

281results about How to "Add cleaning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

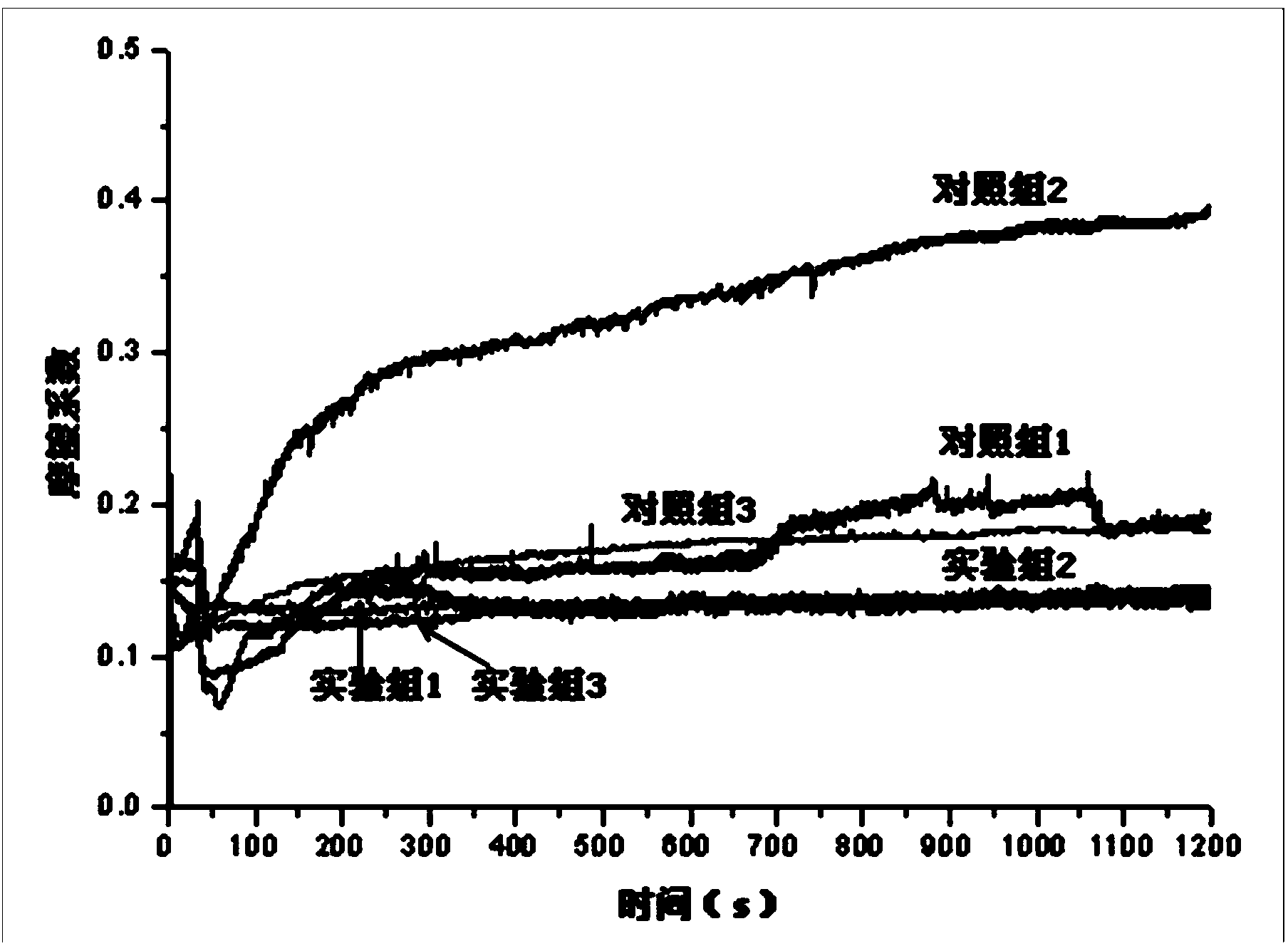

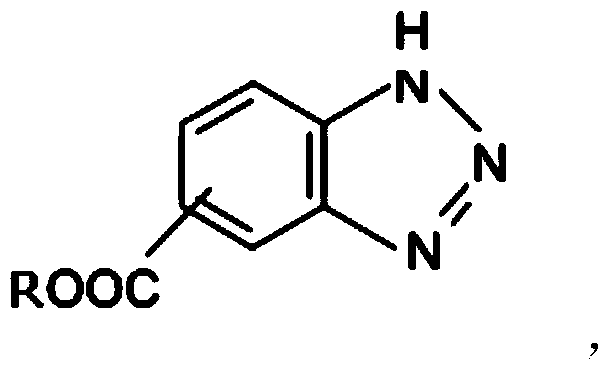

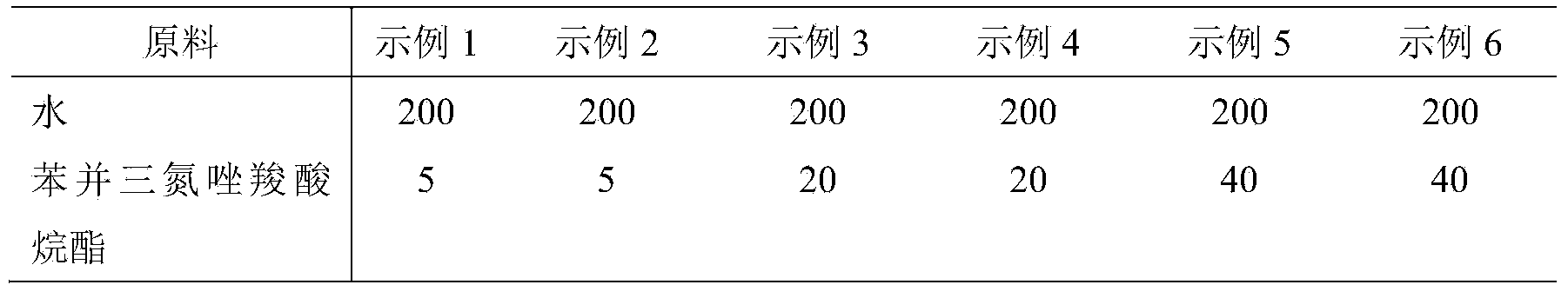

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

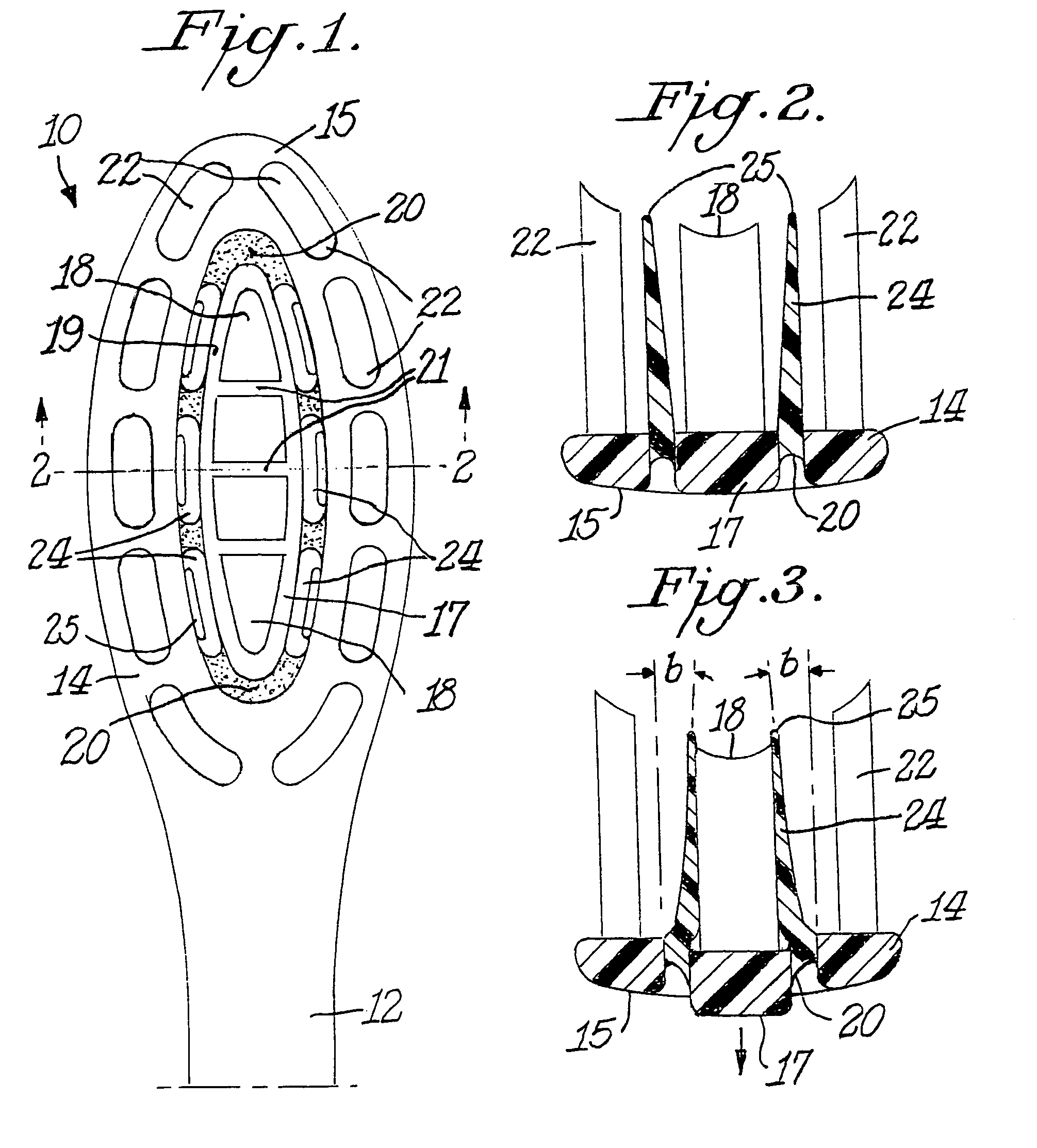

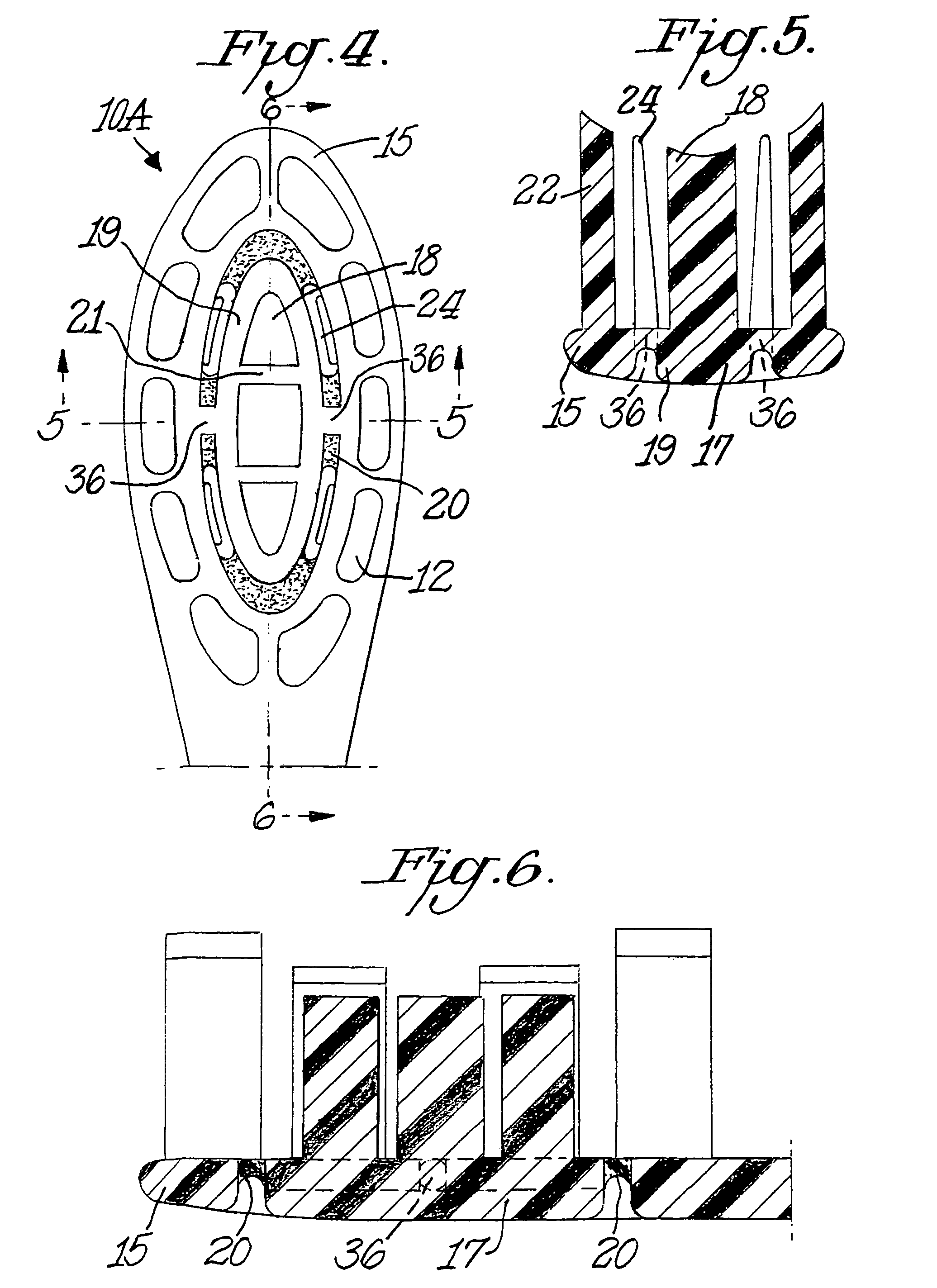

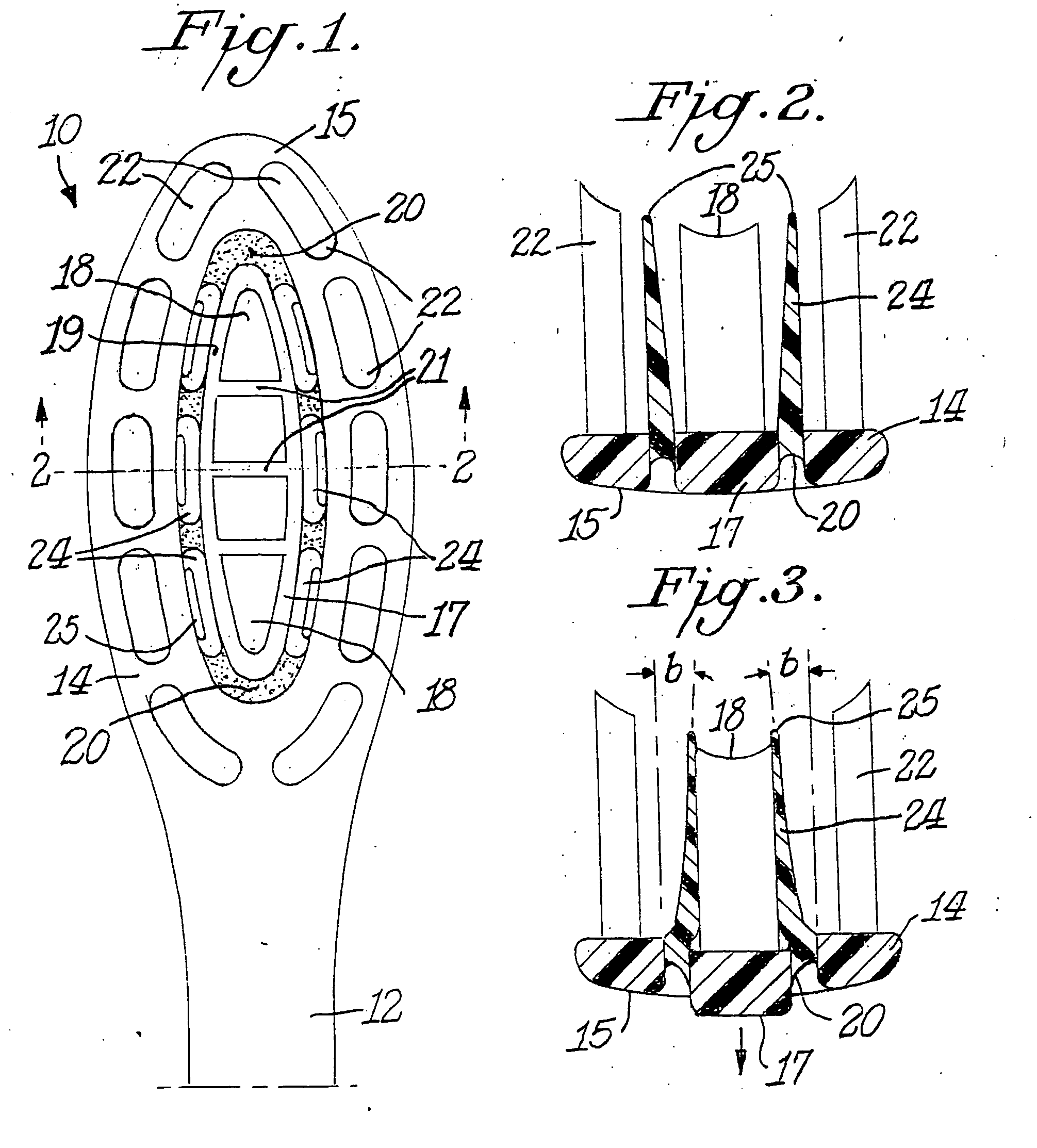

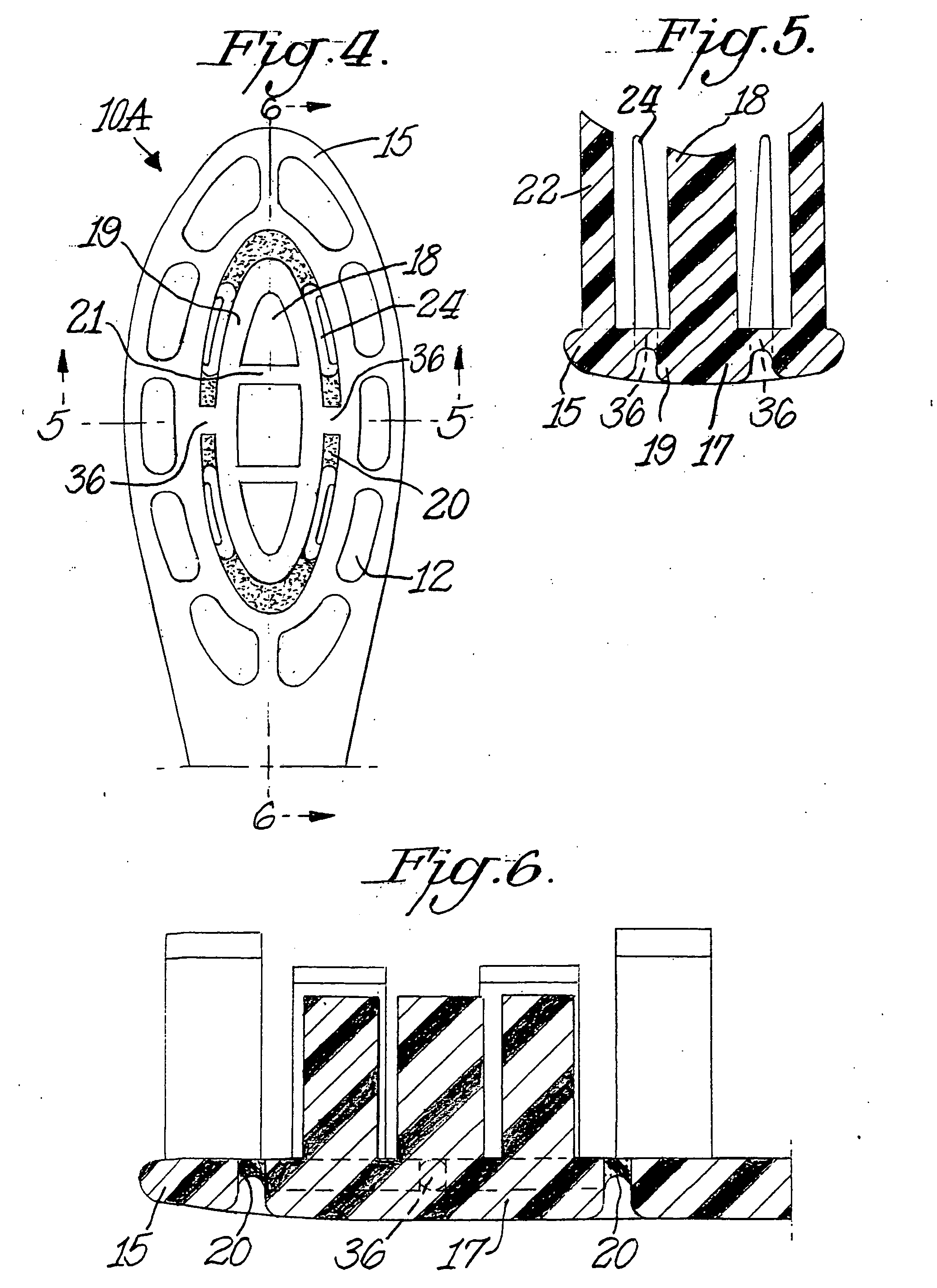

Toothbrush

InactiveUS7020928B2Flexible positioningGood flexibilityCarpet cleanersBrush bodiesMechanical engineeringToothbrush

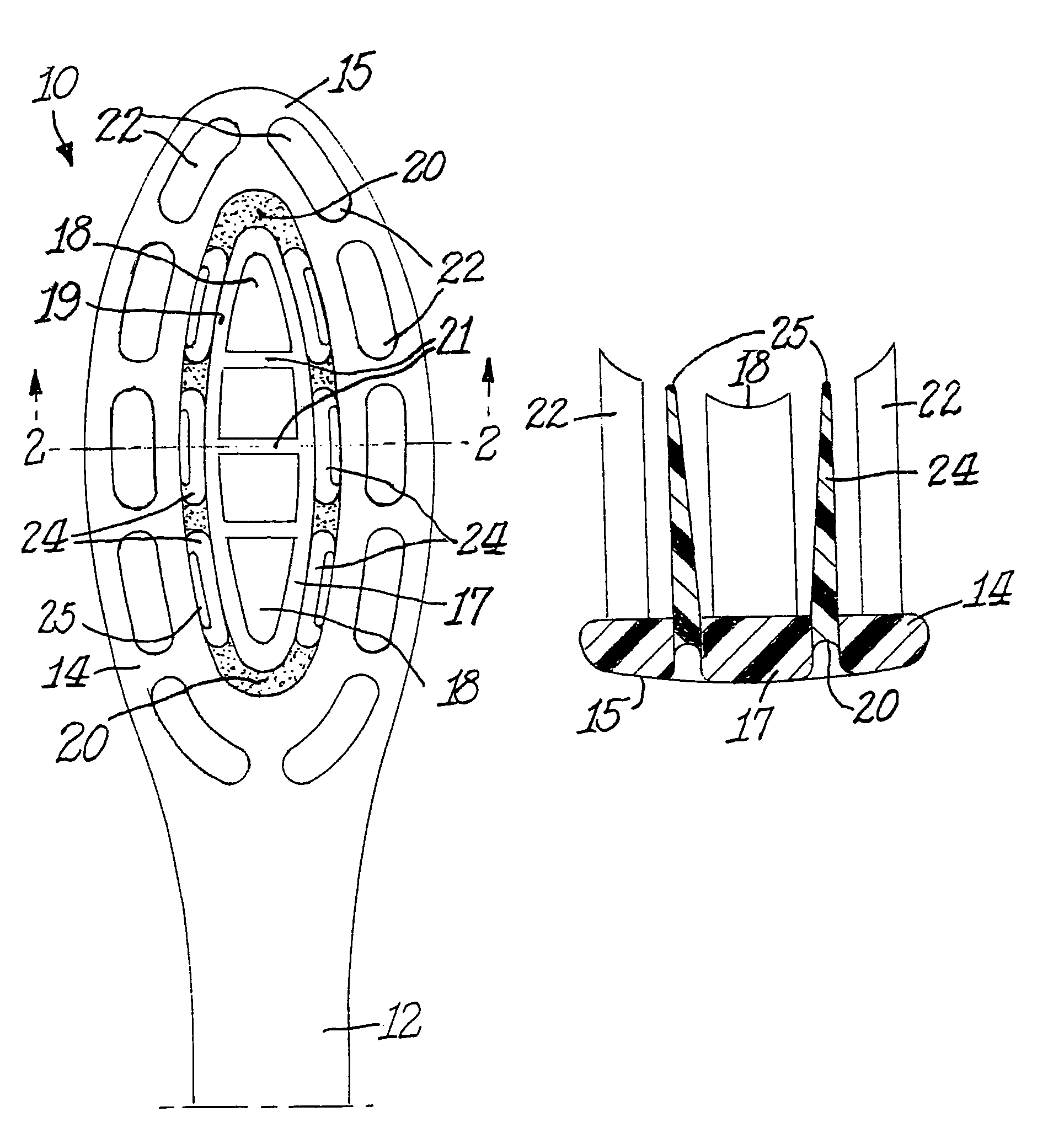

A toothbrush includes a head having multiple cleaning elements. One group of the cleaning elements is mounted on a movable portion of the head and another group may be fixedly mounted on the head. The movable portion of the head is attached by a flexible membrane to the fixed portion of the head so that the membrane is capable of flexing to alter its original orientation during use of the toothbrush and then recover to the original orientation randomly during use.

Owner:COLGATE PALMOLIVE CO

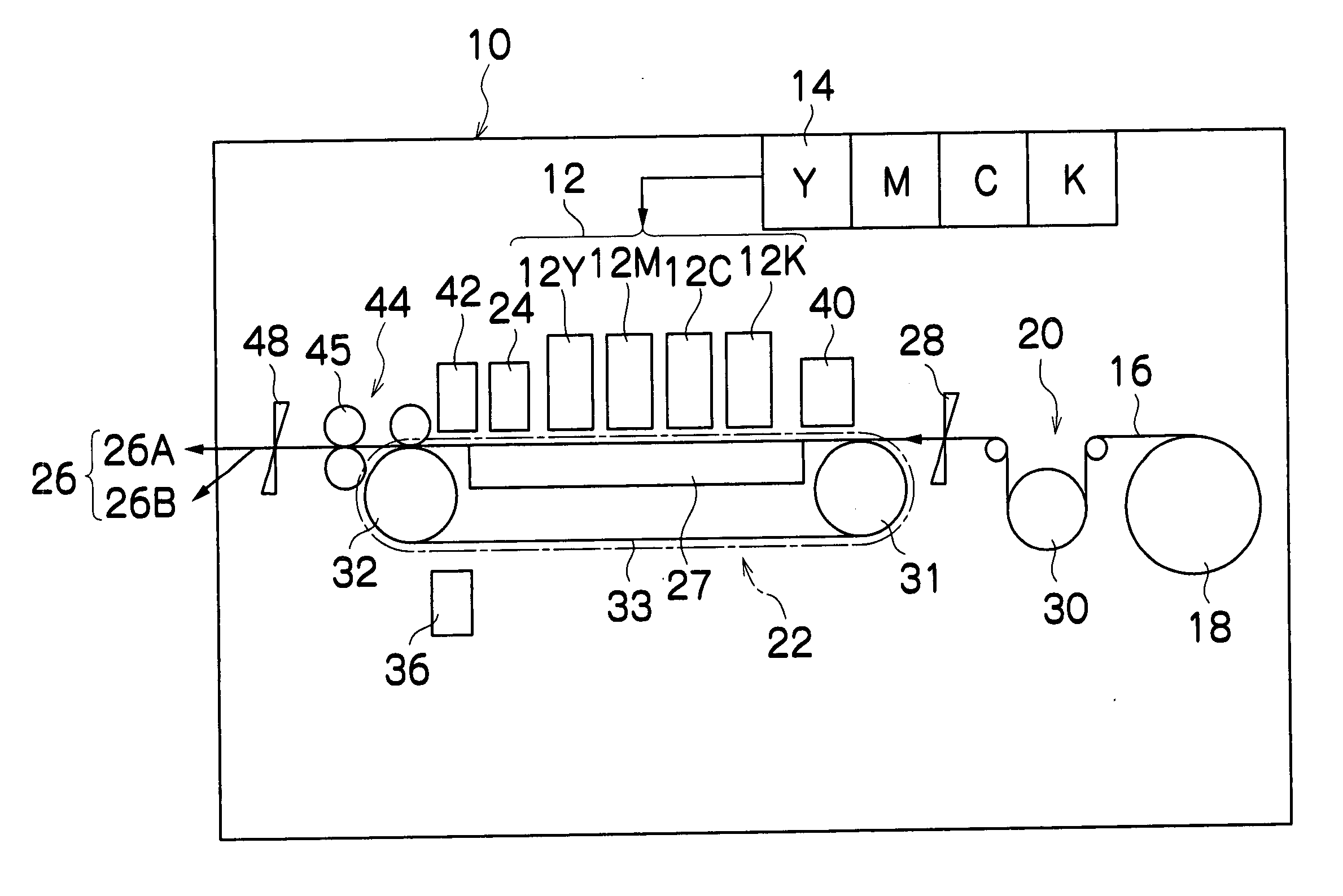

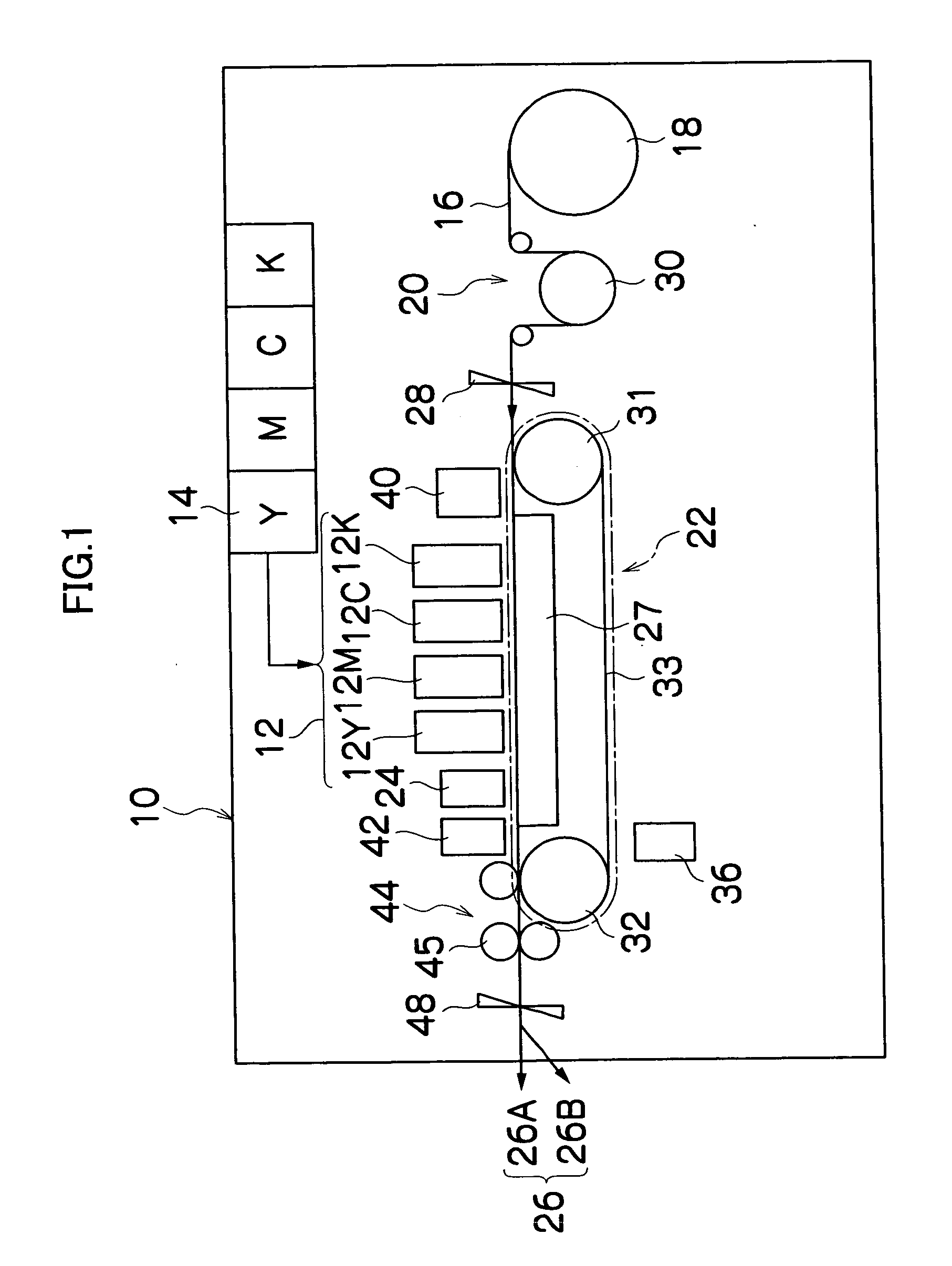

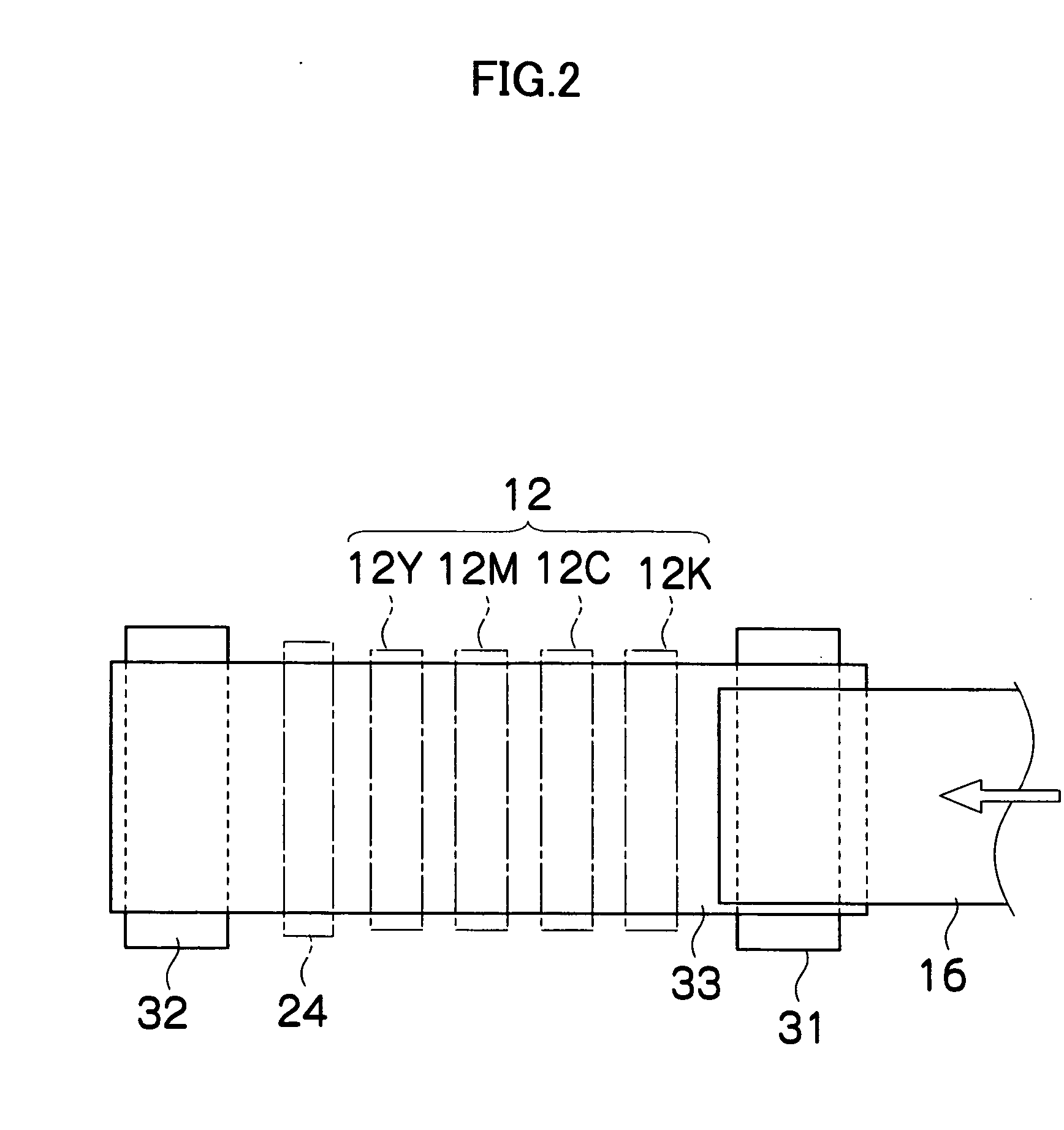

Liquid ejection apparatus and image forming apparatus

InactiveUS20060066665A1Maintain prescribed cleaning performanceSuitable for operationPrintingRestoration deviceEngineering

The liquid ejection apparatus comprises: a liquid ejection head having an ejection port surface on which ejection ports for ejecting liquid are formed; a wiping device having a blade member which wipes and cleans the ejection port surface; a sliding device which causes the blade member to slide relatively with respect to the ejection port surface; a cleaning capability identification device which identifies a cleaning capability of the wiping device; and a cleaning capability restoration device which restores the cleaning capability of the wiping device in accordance with the cleaning capability identified by the cleaning capability identification device.

Owner:FUJIFILM CORP

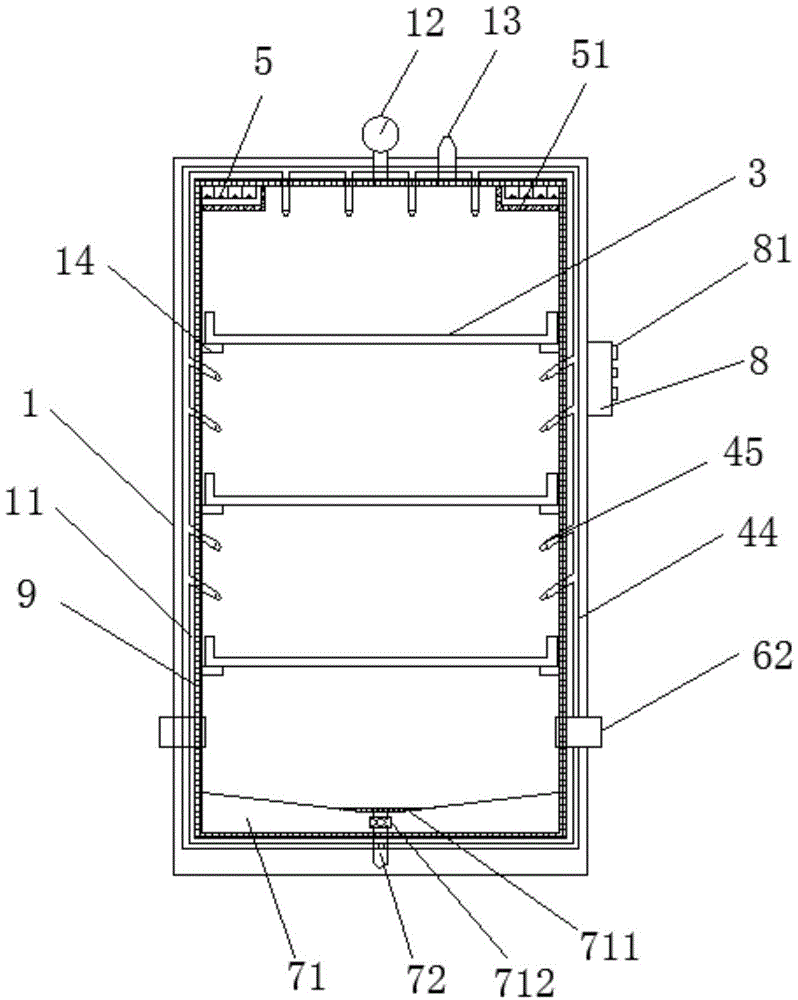

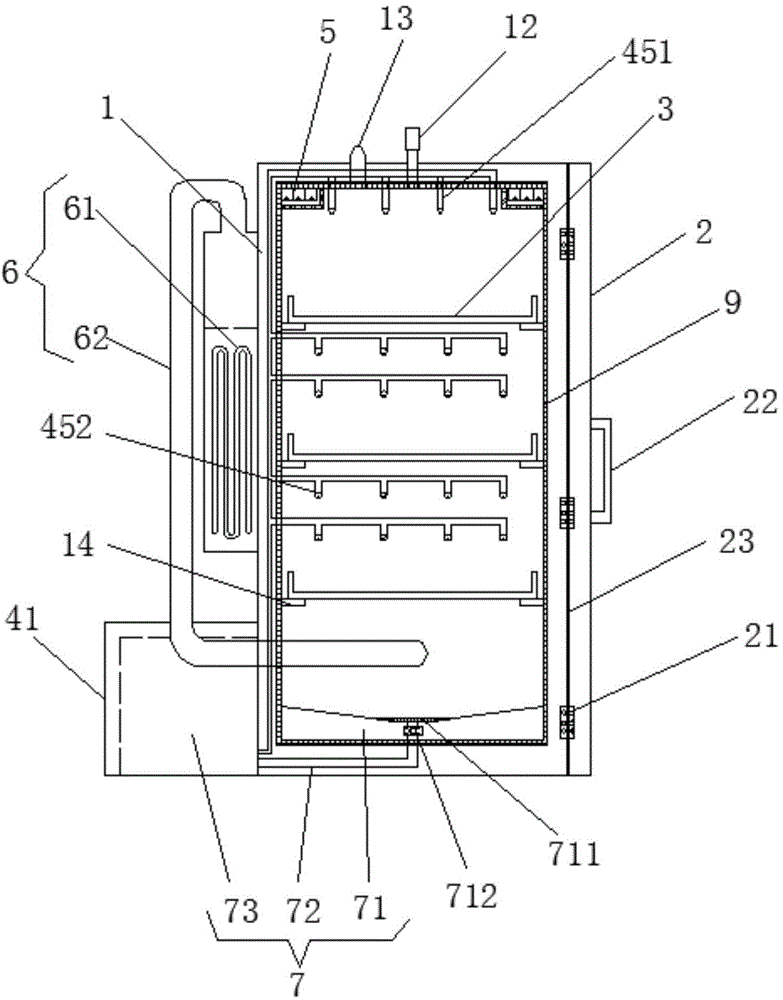

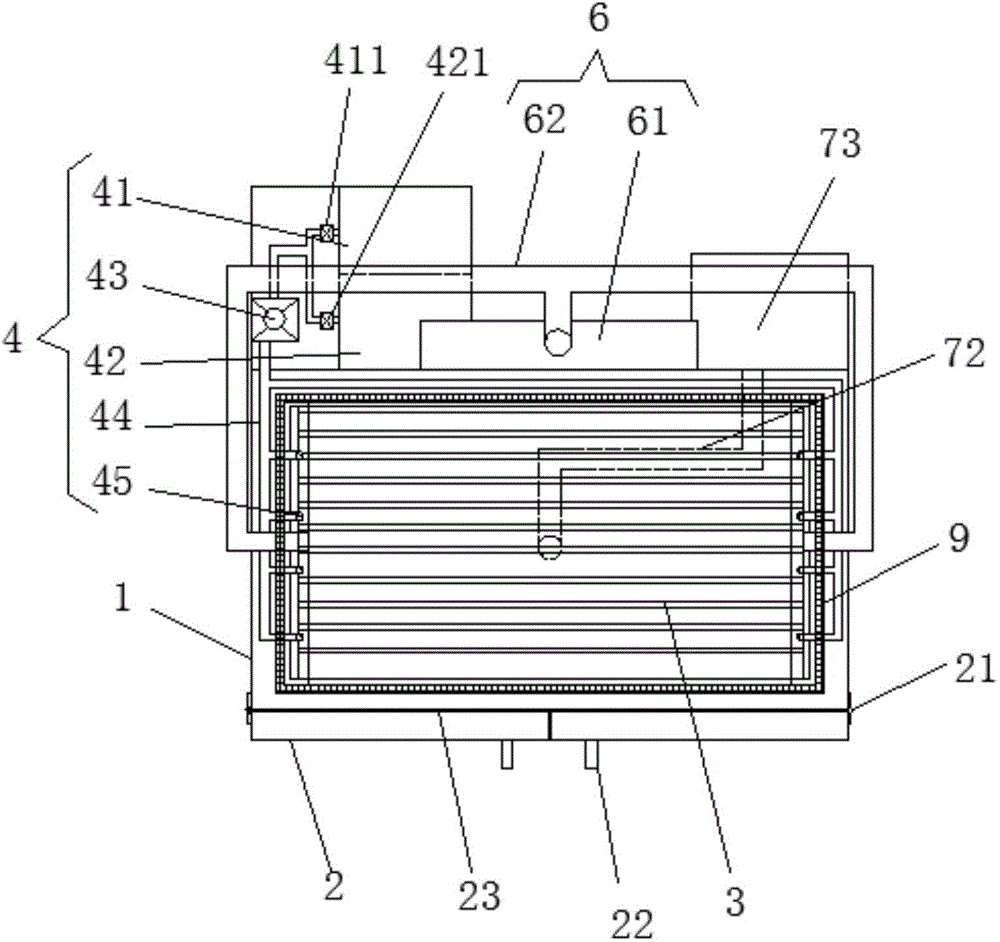

Medical washing and disinfecting machine

InactiveCN104826144AReduce usageImprove efficiencyCleaning using liquidsHeatThermal insulationWater pipe

The invention discloses a medical washing and disinfecting machine. The medical washing and disinfecting machine comprises a cabinet body, a cabinet door, placing supports, a cleaning system, ultraviolet ray sterilization light sources, an electric steam generator, a waste discharge system, and a controller; the cabinet body is divided into an inner layer and an outer layer, and a cavity is formed between the inner layer and the outer layer; a thermal insulation layer is arranged in the cavity close to the inner layer of the cabinet body; the inner side frame of the cabinet door is provided with a sealing rubber ring; the cleaning system comprises a sterile water tank, a cleaning fluid tank, a water pump, a water pipe, and nozzles; the ultraviolet ray sterilization light sources are arranged on the top part of the inner part of the cabinet body; and the electric steam generator comprises an electric steam generator main body and a steam delivery pipe. The medical washing and disinfecting machine can be used for one time cleaning of medical apparatus, avoiding artificial cleaning of medical apparatus, and reducing labor force; and ultraviolet disinfection and sterilization, and high pressure steam disinfection and sterilization are adopted, so that efficiency is high.

Owner:广州涞泊锐科技股份有限公司

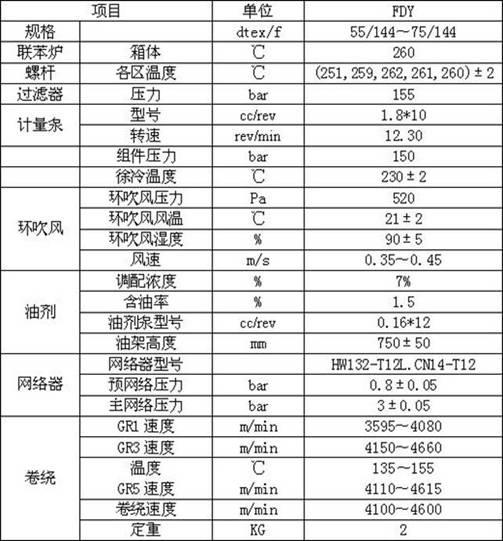

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

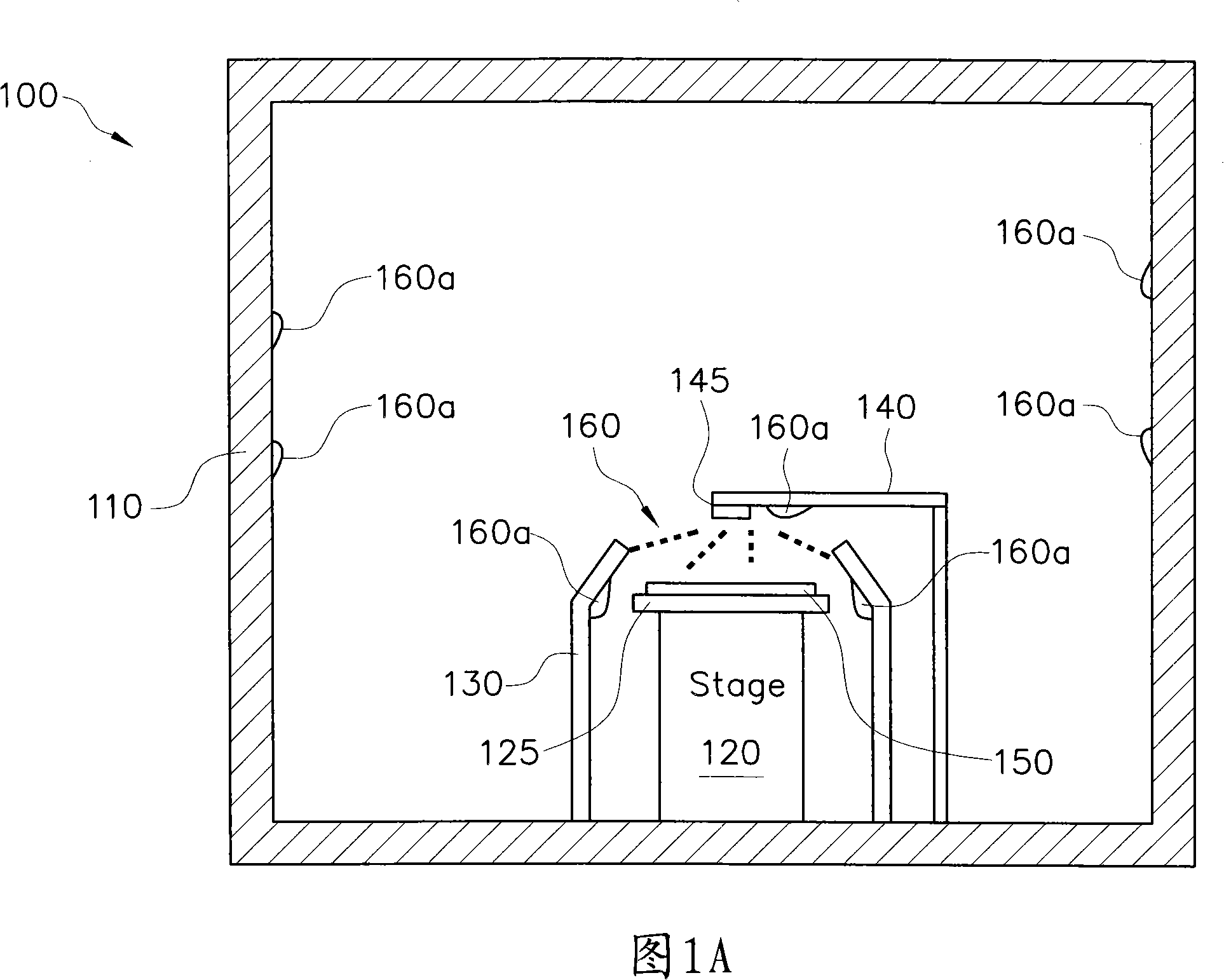

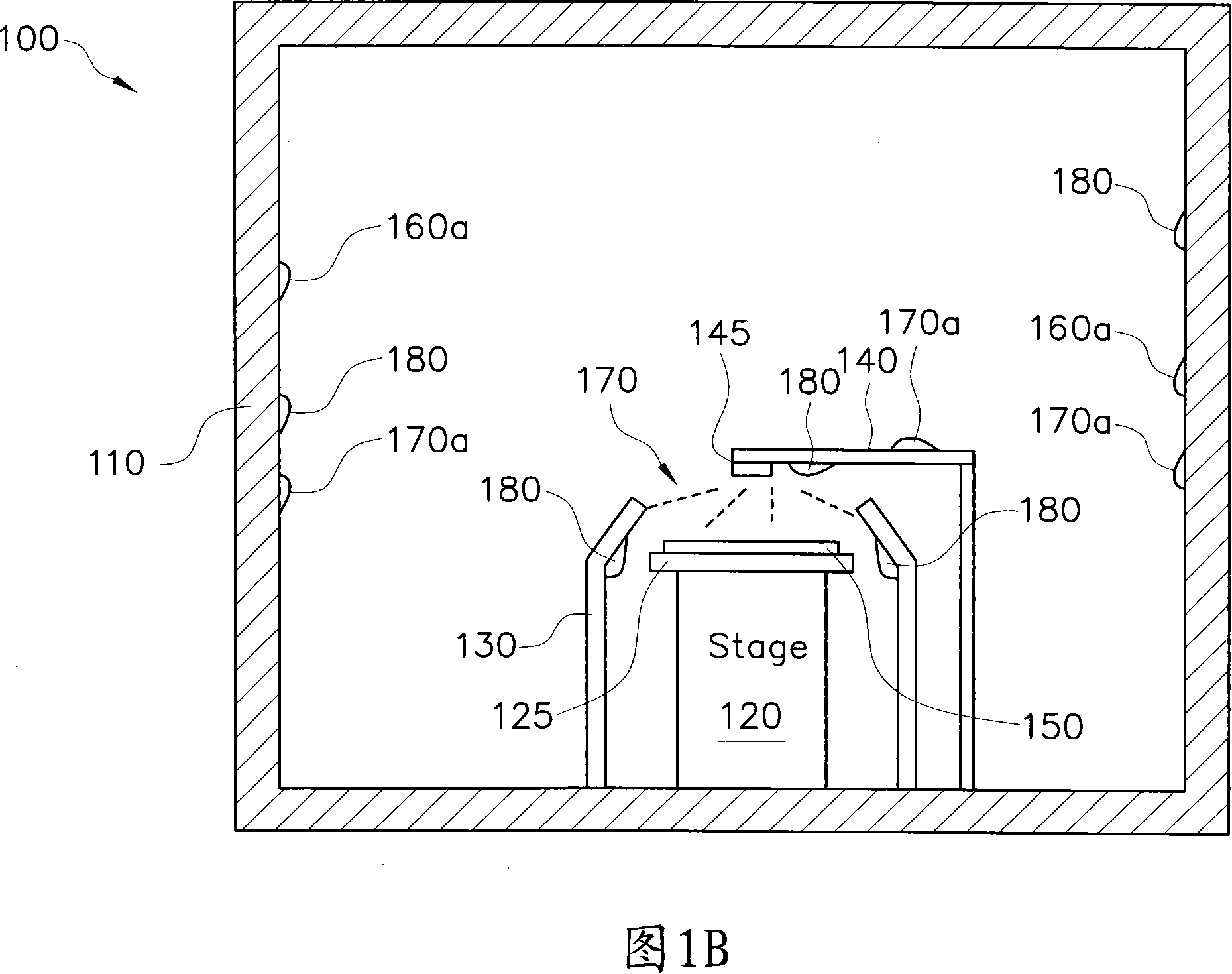

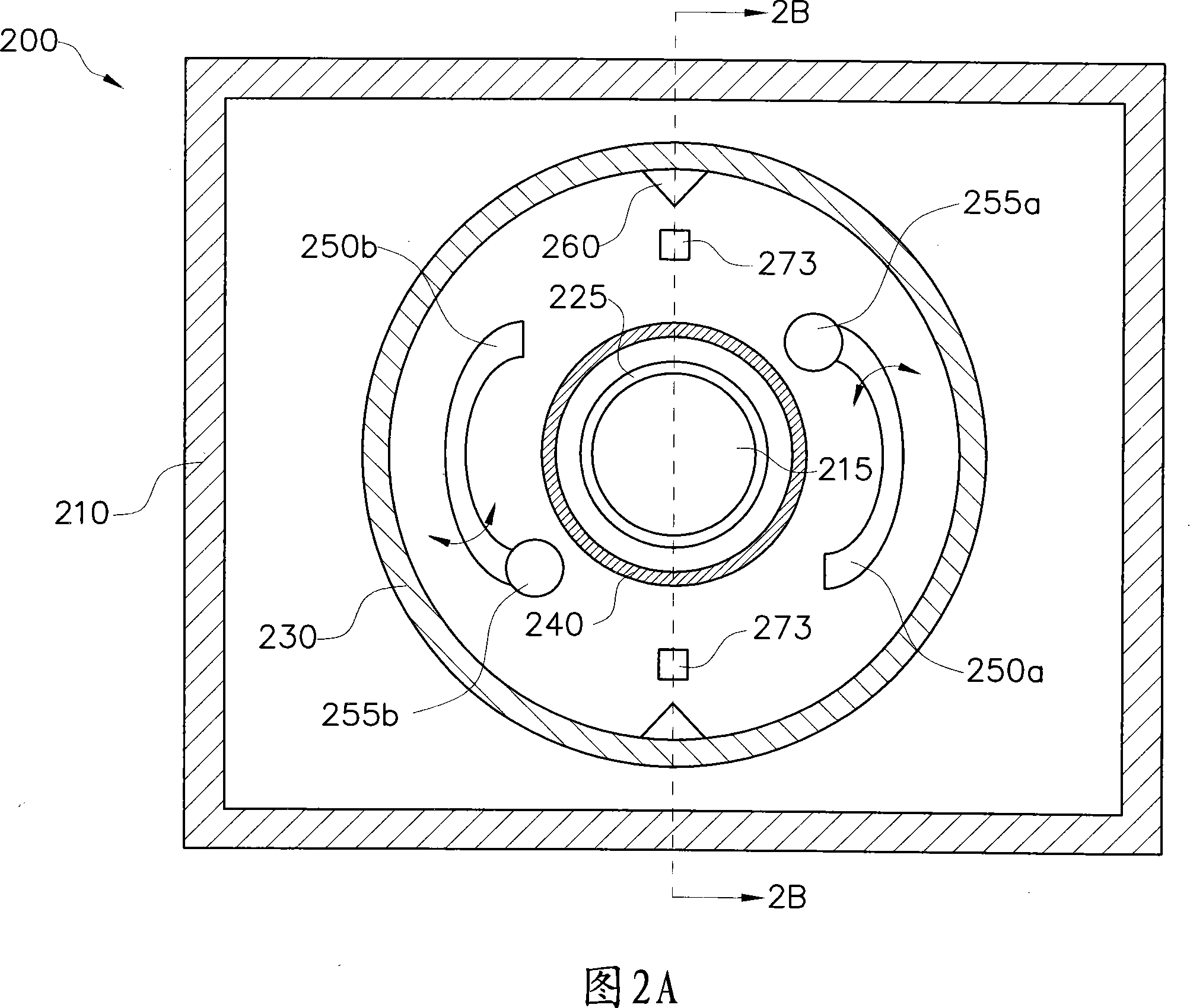

Apparatus and methods of cleaning substrates

ActiveCN101131925APrevent residual crystallizationEasy to cleanSemiconductor/solid-state device manufacturingCleaning using liquidsChemical reactionEngineering

The invention relates to a wafer cleaning method and an apparatus used in said method. The apparatus comprises an enclosure; a stage within the enclosure; at least one first wall around the stage within the enclosure; a plate within the enclosure and above the stage, operable to enclose a first region between the stage and the first wall; and an exhauster part coupled to the first region between the stage and the first wall. The method for cleaning a wafer includes: putting the stage with a wafer into a closed vessel which is arranged in the enclosure; spraying a first chemical onto the surface of a substrate with a first nozzle; spraying a second chemical onto the surface of the substrate with a second nozzle to avoid the products generated by chemical reaction between the first and the second chemical in the first and the second nozzle. The invention is suitable for practicality since an airtight space therein is arranged between a cleaning enclosure and a cleaning stage to avoid short circuit or opening of the integrated circuit on the wafer by means of preventing liquid ammonium sulfate residue from crystallizing when cleaning the wafer.

Owner:TAIWAN SEMICON MFG CO LTD

Multifunction antiseptic sterilizing cleaning agent composition and its preparation method

InactiveCN1786134ABroad-spectrum antimicrobial activityImprove the bactericidal effectNon-ionic surface-active compoundsOrganic detergent compounding agentsCleansing AgentsFatty alcohol

The invention relates to a multifunction disinfection sterilization detergent combination and the making method. It adopts quaternary ammonium salt, biguanide species, chelating agent, chlorine-hydroxyl diphenyl ether, fatty alcohol compound, organic acid compound, and nonionic reaction compound to make disinfection sterilization detergent. It is non-toxic and without side effect. So it can be widely used in various industries.

Owner:雷金丰 +2

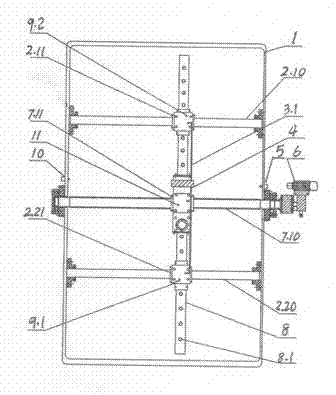

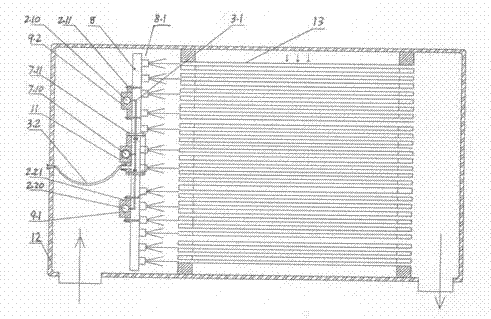

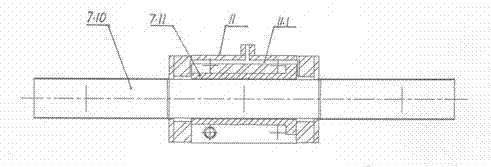

Online cleaning device for heat exchange tube of condenser

ActiveCN102401609AReduce internal drive jointsReduce the chance of failureFlush cleaningHigh pressure waterHigh pressure

The invention belongs to the field of cleaning, and provides an online cleaning device for a heat exchange tube of a condenser. The online cleaning device is mainly characterized in that: a conventional online cleaning mode is improved; a cleaning mechanism adopts a row of nozzles; the middle part of the row of nozzles is connected with a driving nut floating cavity body, and the end parts of therow of nozzles are connected with guide sleeve floating cavities; and a chemical cleaning agent gallipot is connected in series with a high-pressure water pipeline. The online cleaning device has theremarkable advantages of simple structure, running reliability, convenience for mounting and maintenance, high cleaning speed and good effects; moreover, the online cleaning device can be used for replacing rubber ball cleaning, also can be used together with the rubber ball cleaning and can realize all-round cleaning and the chemical cleaning of important parts.

Owner:深圳悦诚节能科技有限公司

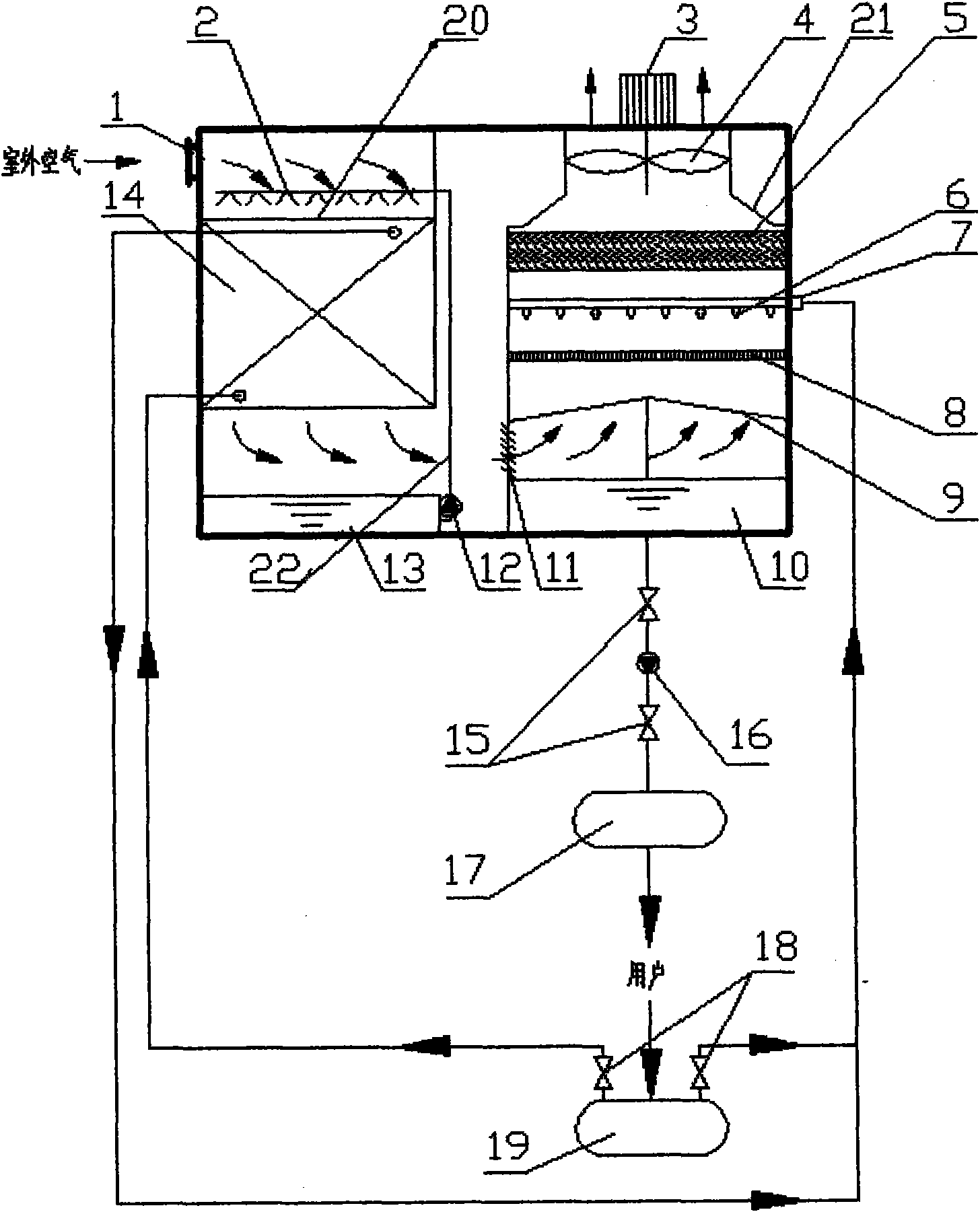

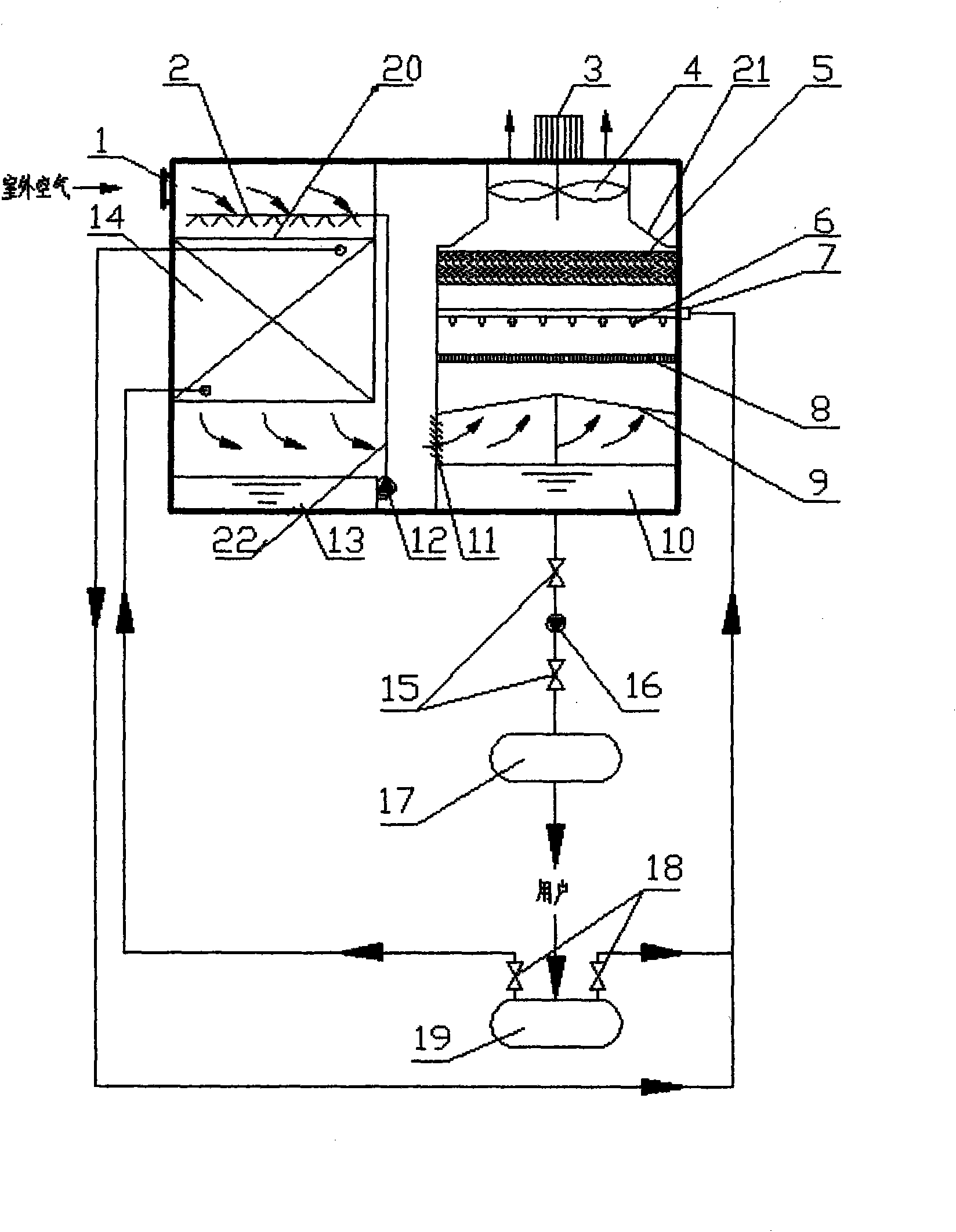

Spray air cooler and packless spray cooling tower combined high temperature water chiller

InactiveCN101788173AImprove cooling efficiencyExpand the range of air treatmentLighting and heating apparatusAir conditioning systemsCooling towerNetwork connection

The invention discloses a spray air cooler and packless spray cooling tower combined high temperature water chiller, which is formed by combining a spray air cooler and a counterflow packless spray cooling tower through pipe network connection. The spray air cooler consists of a high temperature cold water air cooler and a circulating water spraying device; and the upper part of the high temperature cold water air cooler is provided with an air inlet a, and exhaust air of the spray air cooler is taken as inlet air of the counterflow packless spray cooling tower. When the combined high temperature water chiller works in summer and outdoor air passes through the high temperature cold water air cooler, the outdoor air, the sprayed circulating water and the high temperature cold water in the high temperature cold water air cooler undergo sensible heat exchange and latent heat exchange, so on one hand, the heat exchange capacity of the air cooler is greatly improved and the outdoor air is effectively precooled; on the other hand, the air cooler is cleaned and the outdoor air is purified.

Owner:XI'AN POLYTECHNIC UNIVERSITY

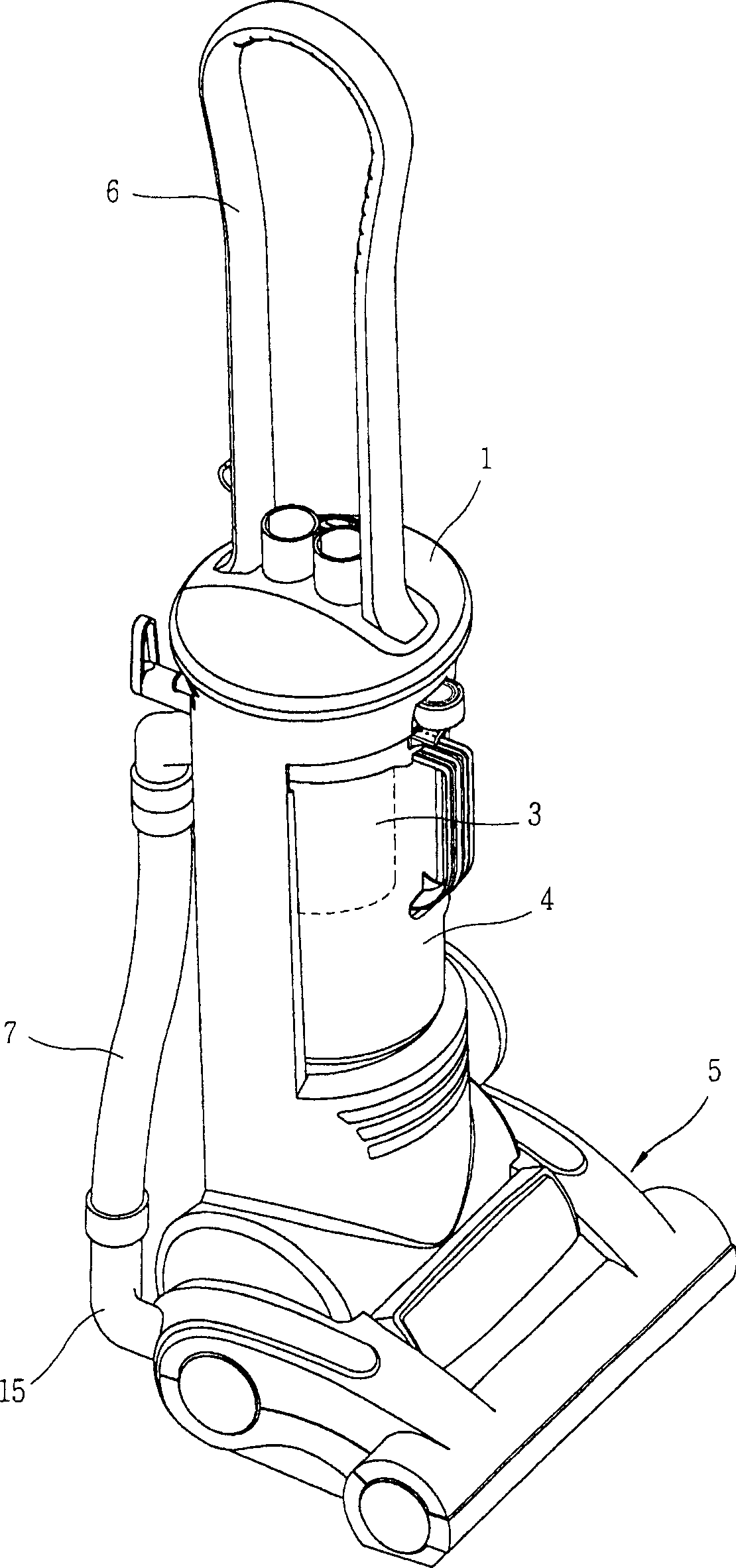

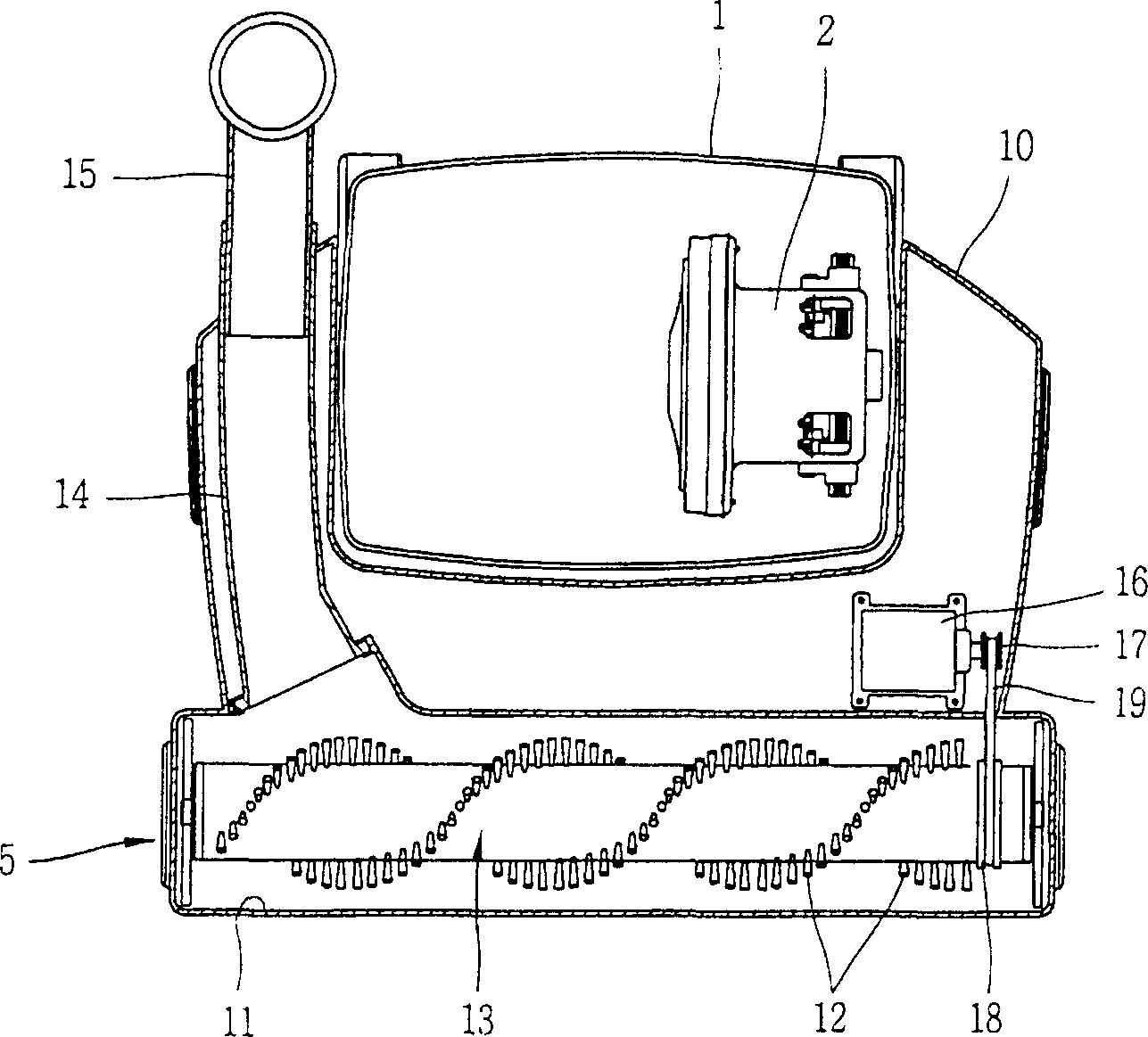

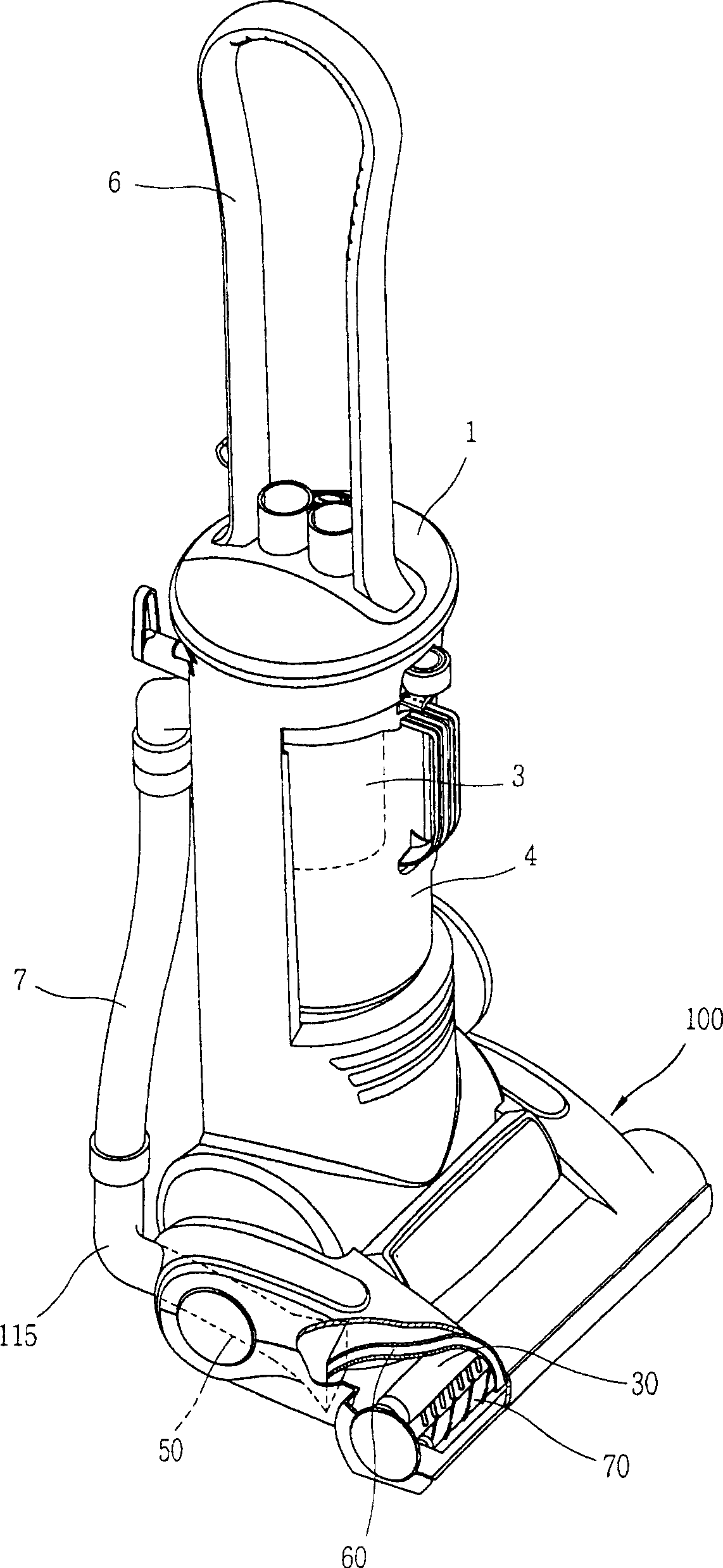

Suction head of vacuum cleaner

A suction head of a vacuum cleaner, which includes: a casing with a suction port through which dust on the floor is sucked through the suction port by the operation of a fan motor; a main brush rotatably installed at the suction port, and A plurality of bristles are arranged in a direction; a main brush driving device for reciprocatingly rotating the main brush within a predetermined angle range; and an auxiliary brush rotatably installed on one side of the main brush and arranged in a longitudinal direction thereof Brush, used to supplement the operation of the main brush by rotation. Accordingly, the entire area occupied by the suction head can be evenly brushed, and the brushed dust can be smoothly sucked in.

Owner:LG ELECTRONICS INC

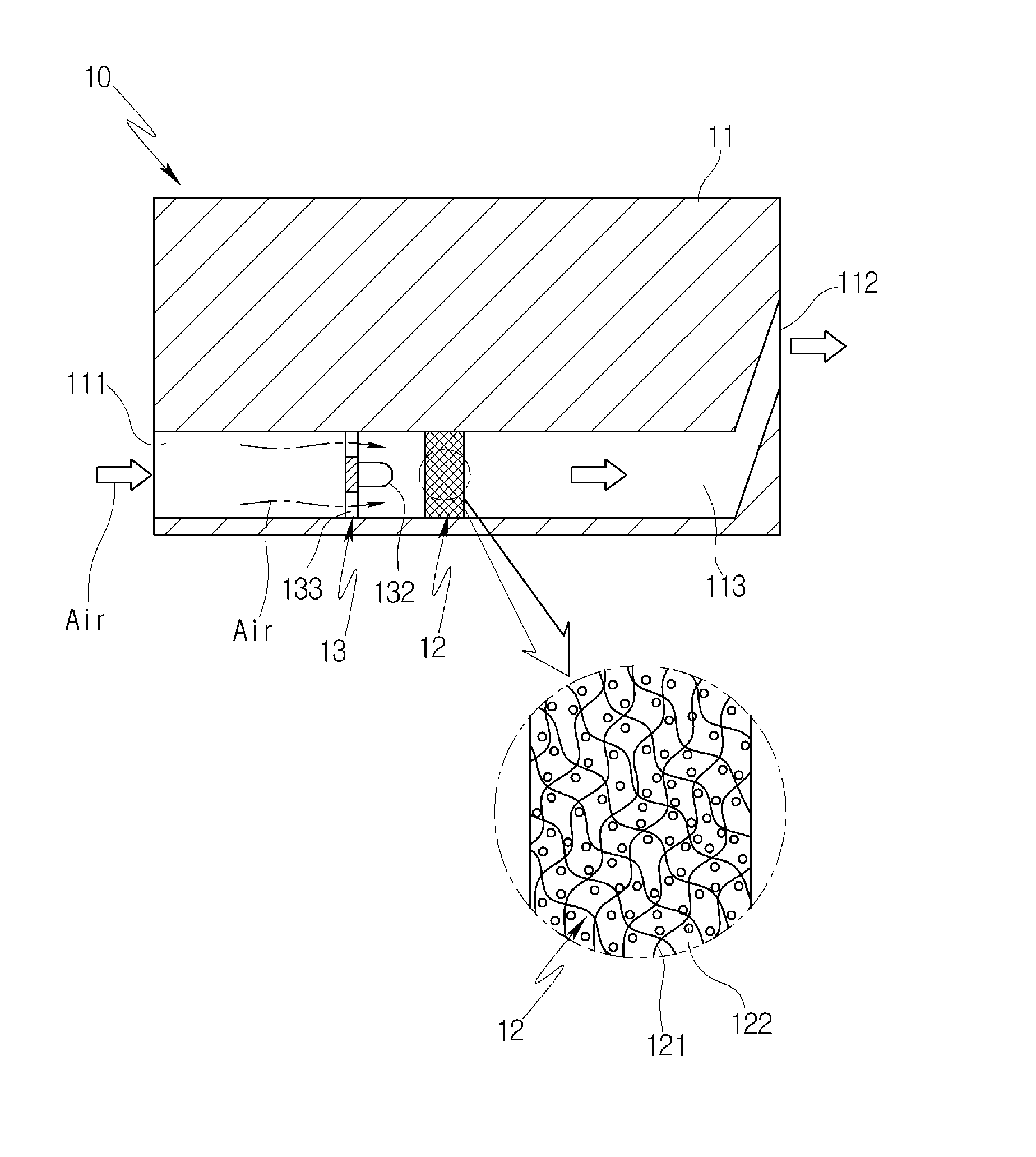

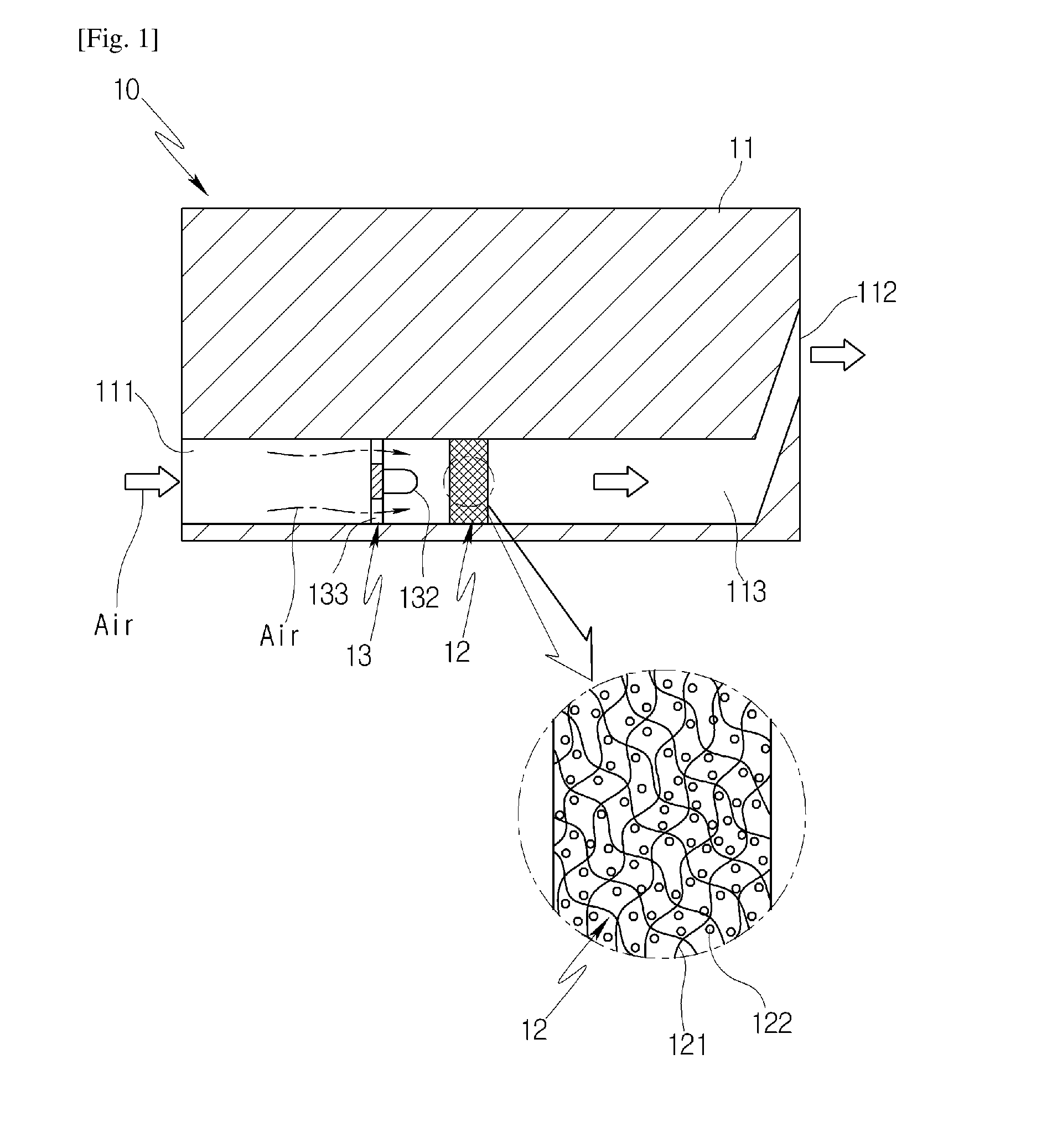

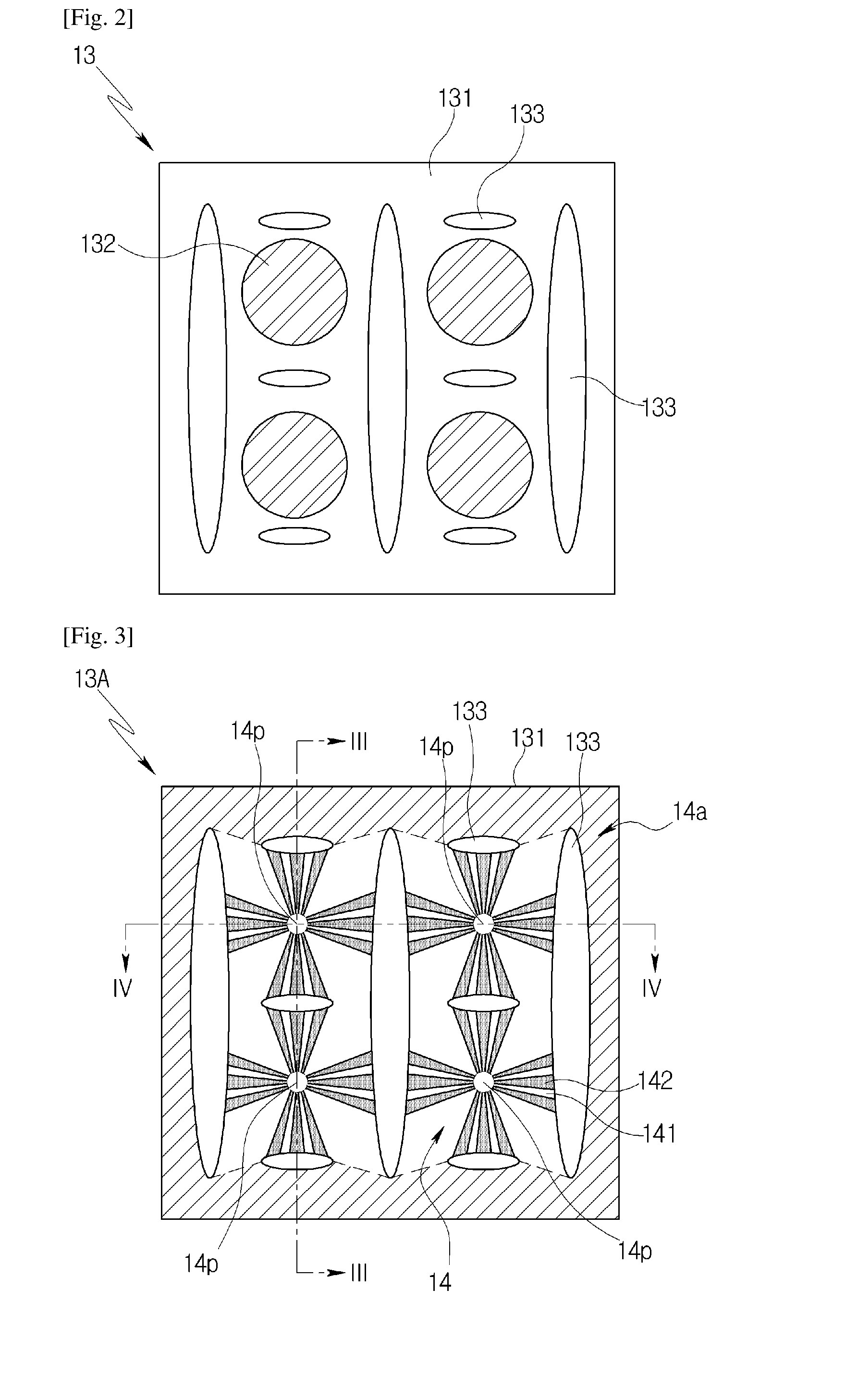

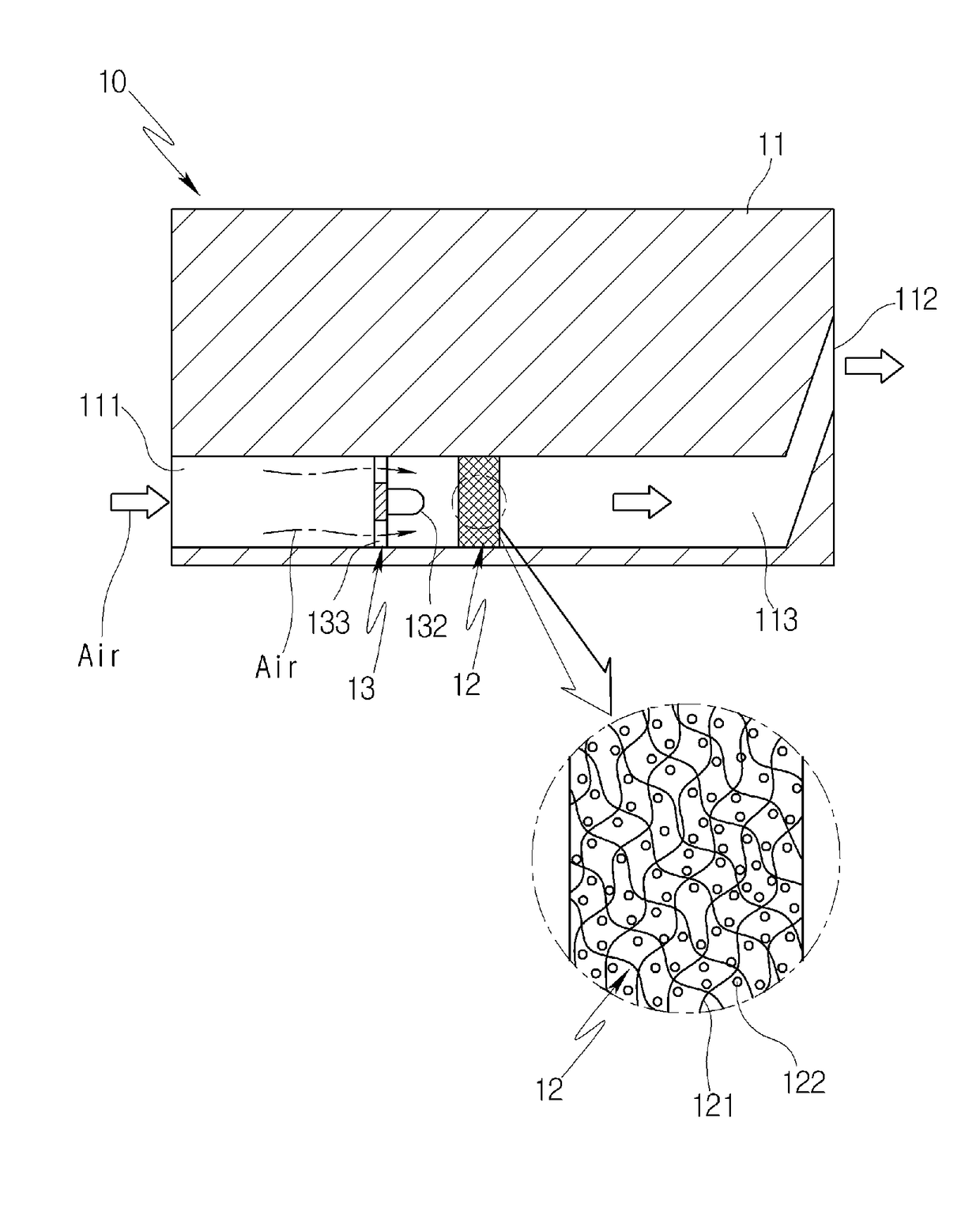

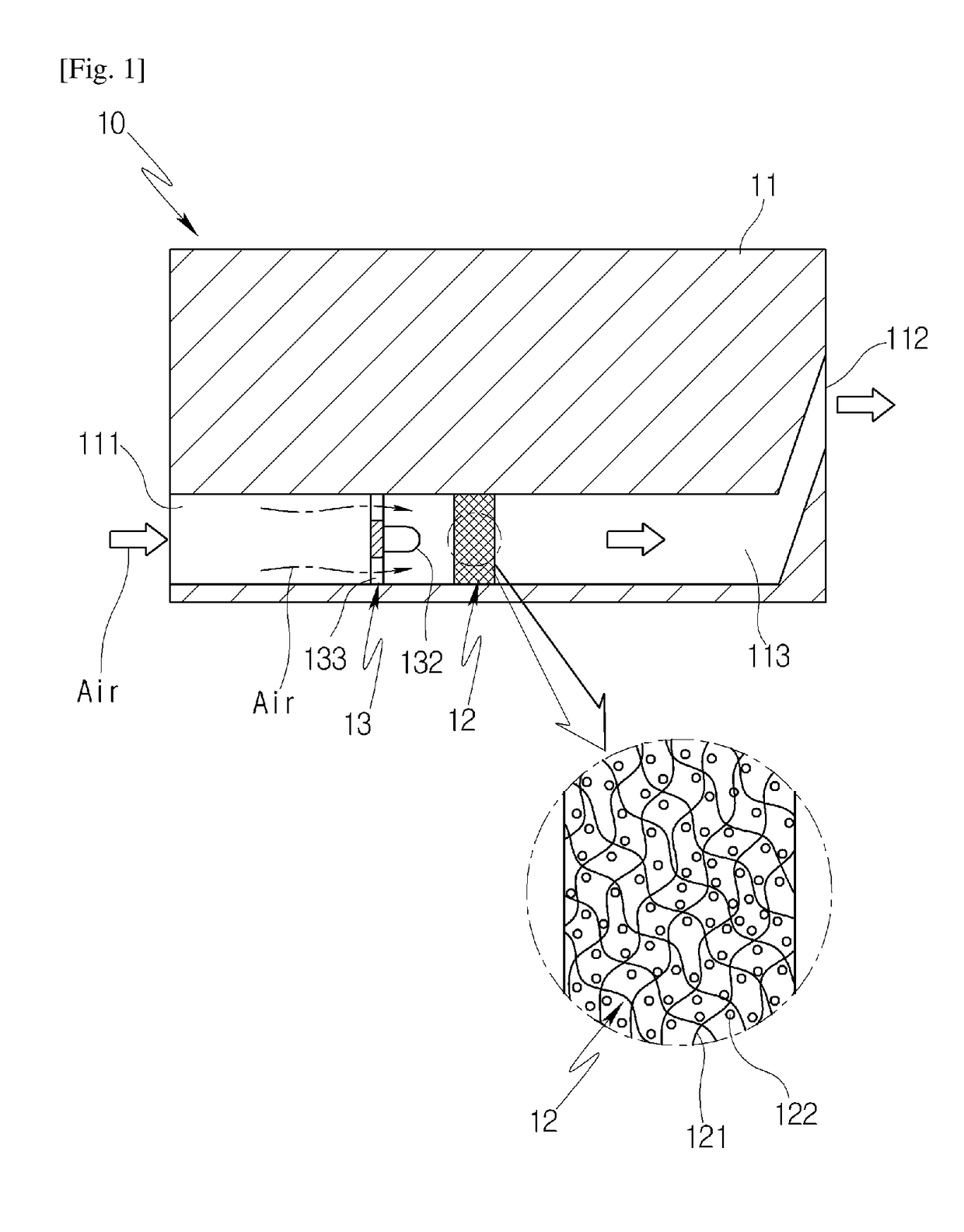

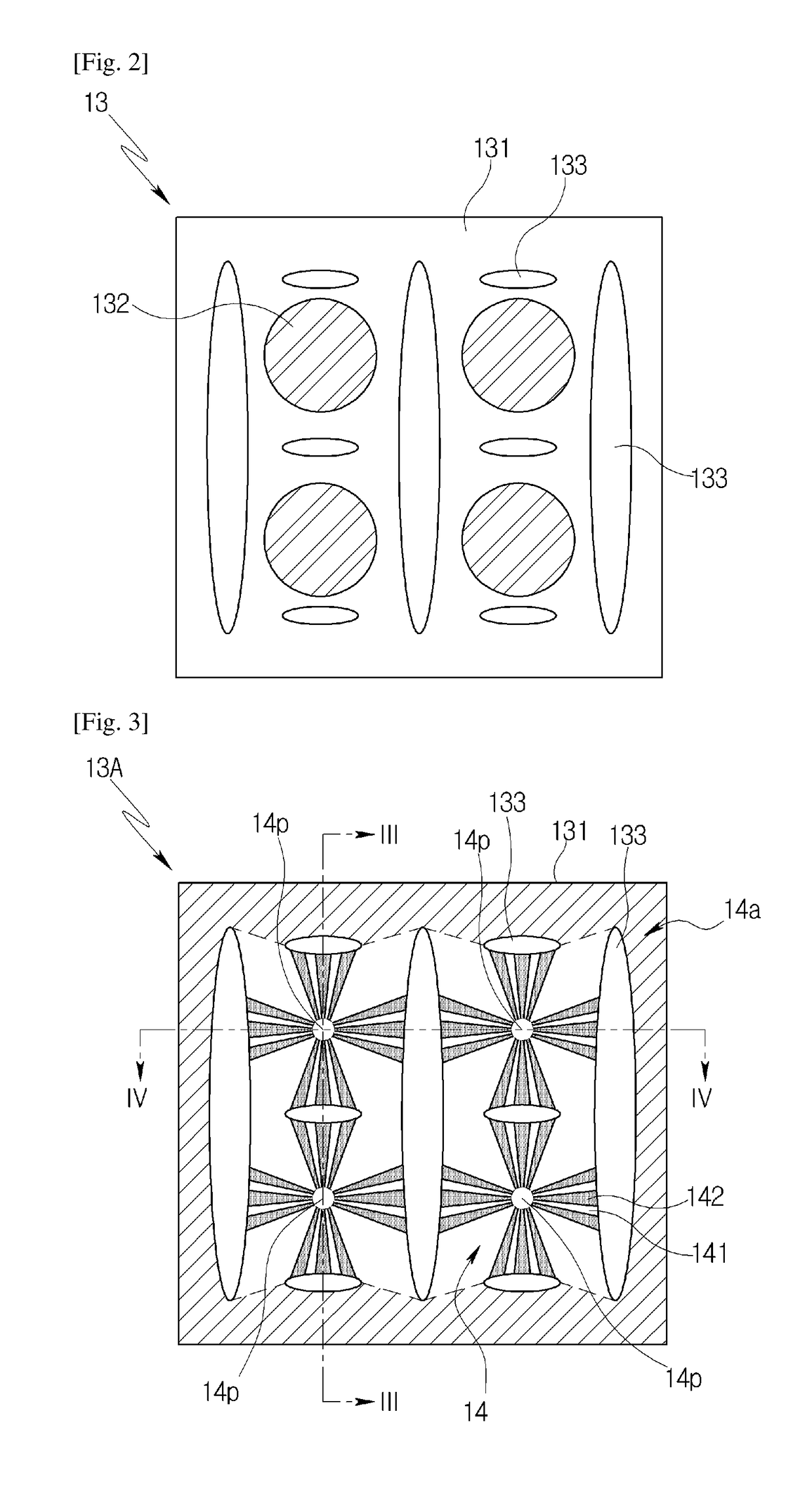

Air purifying apparatus using ultra violet light emitting diode

ActiveUS20150359922A1Easy to cleanIncreased air retention timeFire rescueDeodrantsHazardous substanceAir cleaning

The present invention relates to an air cleaning apparatus comprising a UVLED, which can efficiently clean air flowing in tubes by an effective combination of the UVLED and a photocatalyst and can effectively clean air flowing in a duct by enhancing the cleaning function or increasing the number of cleaning steps when the concentration of harmful substances increases. The air cleaning apparatus includes: a case comprising an inlet configured to introduce air, an outlet configured to discharge air, and a duct disposed between the air inlet and the air outlet; a photocatalyst unit disposed in the duct; and a UVLED module disposed in the duct and including a plurality of first UVLEDs arranged to irradiate UV light from the side of the inlet to the side of the outlet.

Owner:SEOUL VIOSYS CO LTD

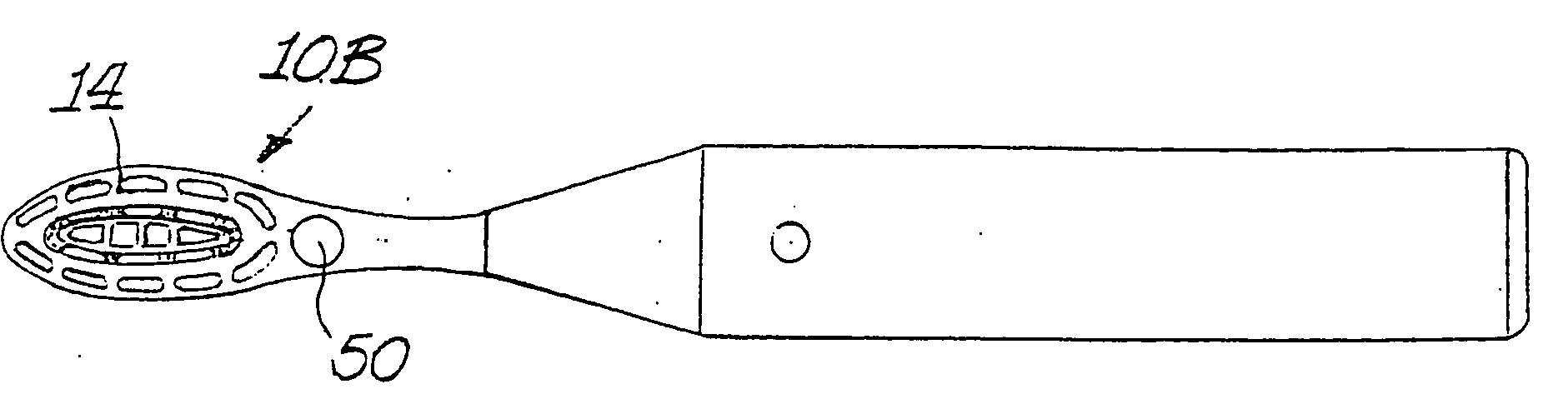

Toothbrush

InactiveUS20050144748A1Flexible positioningGood flexibilityCarpet cleanersBrush bodiesEngineeringMechanical engineering

A toothbrush includes a head having multiple cleaning elements. One group of the cleaning elements is mounted on a movable portion of the head and another group may be fixedly mounted on the head. The movable portion of the head is attached by a flexible membrane to the fixed portion of the head so that the membrane is capable of flexing to alter its original orientation during use of the toothbrush and then recover to the original orientation randomly during use.

Owner:COLGATE PALMOLIVE CO

Nonwoven Fabric Sheet Having Cleaning Function

InactiveUS20090011188A1Improve water retentionAdd cleaning functionCarpet cleanersLayered productsCelluloseInorganic salts

A nonwoven fabric sheet having a cleaning function having a total basis weight of 40 to 1,500 g / m2 in which a web layer (ii) having a basis weight of 10 to 400 g / m2 produced by an air-laid process, which comprises 20 to 100% by weight of heat-adhesive fibers (a) having a fineness of 1 to 4.4 dtex and 80 to 0% by weight of cellulosic pulp (b) (with the proviso that (a)+(b)=100% by weight) as main components, is laminated on a web layer (i) having a basis weight of 10 to 250 g / m2 produced by an air-laid process, which comprises heat-adhesive fibers having a fineness of 1.5 to 50 dtex as a main component; the same web layer (iii) as the above web layer (i) is further laminated on the web layer (ii) as needed to form an integrated sheet as a whole by thermal bonding of these heat-adhesive fibers; and an additive (c) comprising an alkaline inorganic salt powder (c1) having a cleaning function or a hydroxyl group-containing powdery organic acid (c2) having a melting point of 70° C. or higher is contained in an amount of 5 to 300 g / m2 to at least one portion of between the layer (i) and the layer (ii), inside of the layer (ii), and between the layer (ii) and the layer (iii).

Owner:KINSEI SEISHI

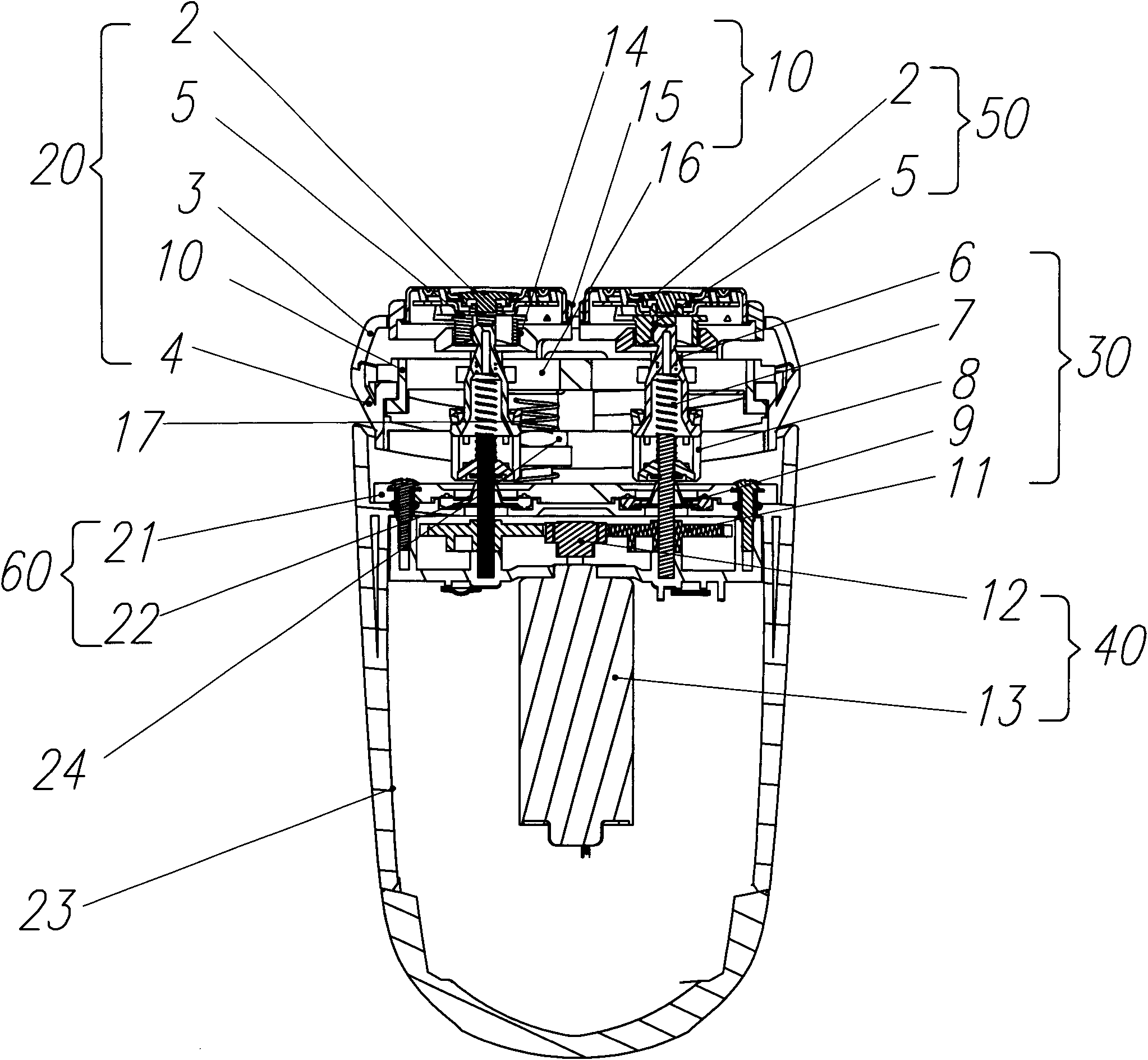

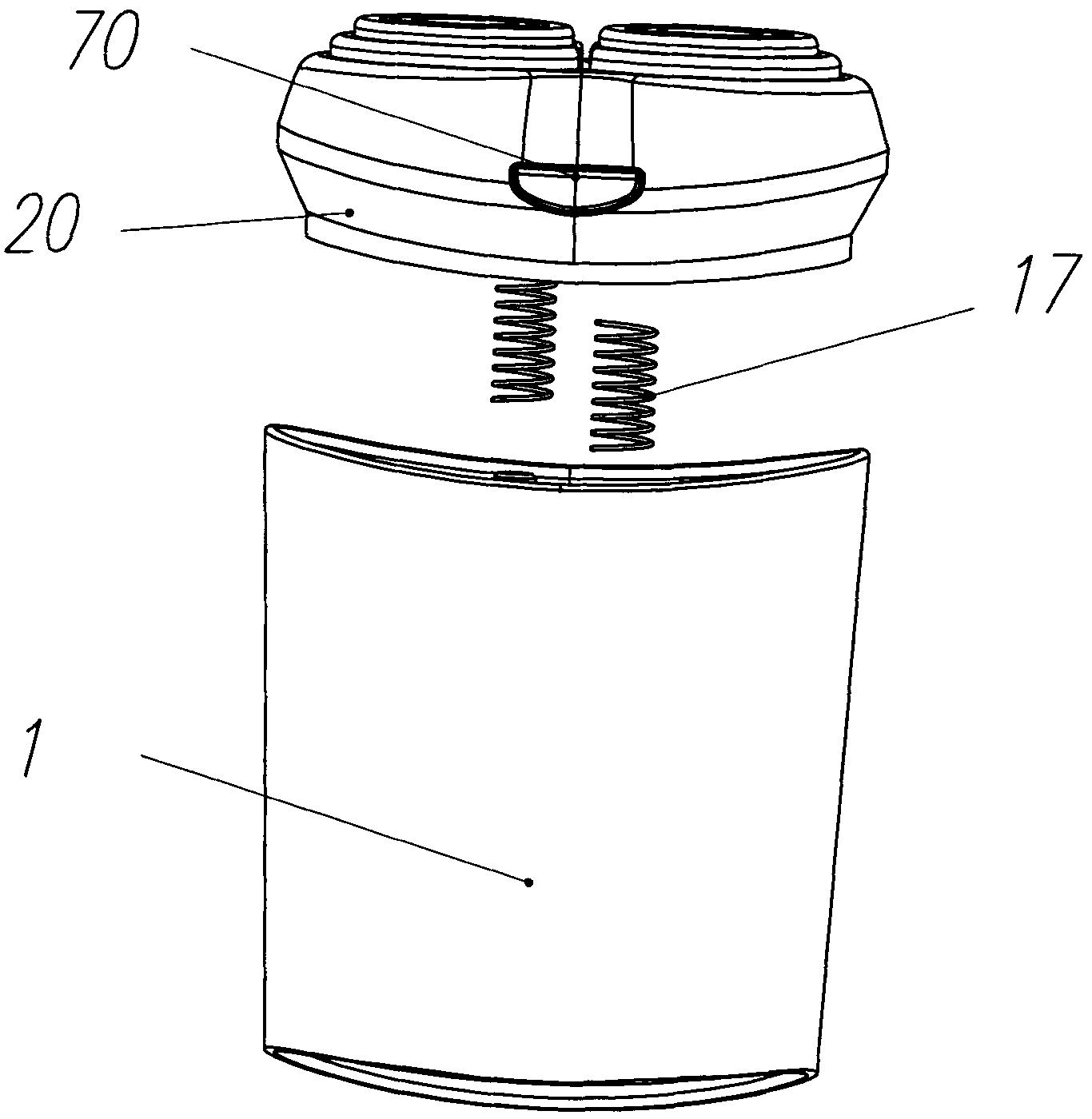

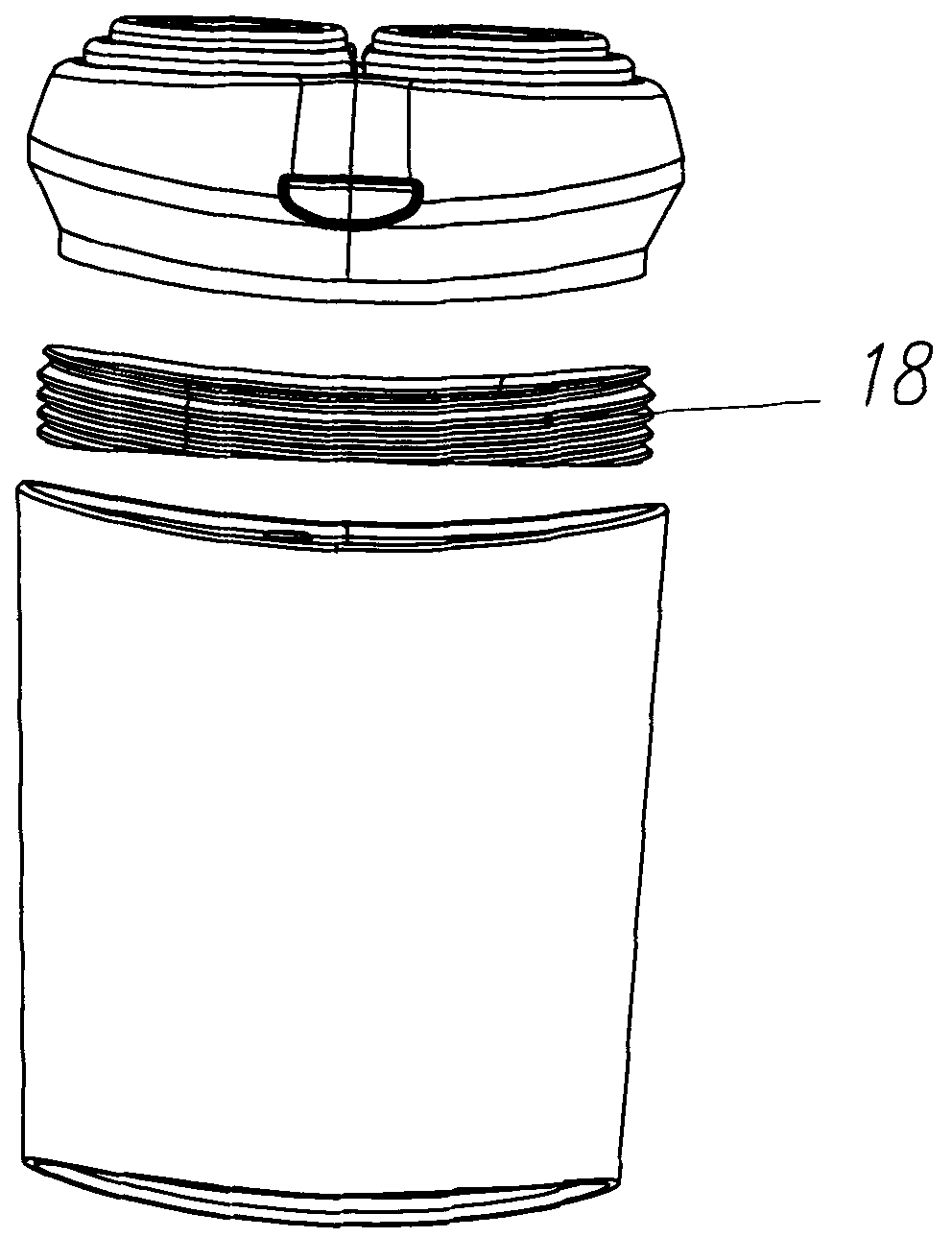

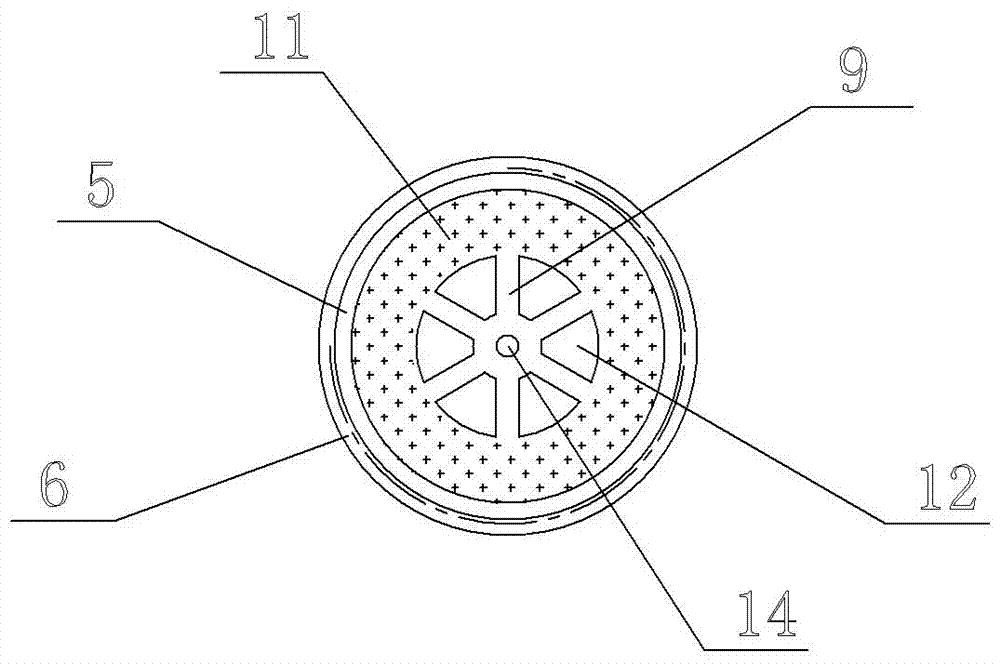

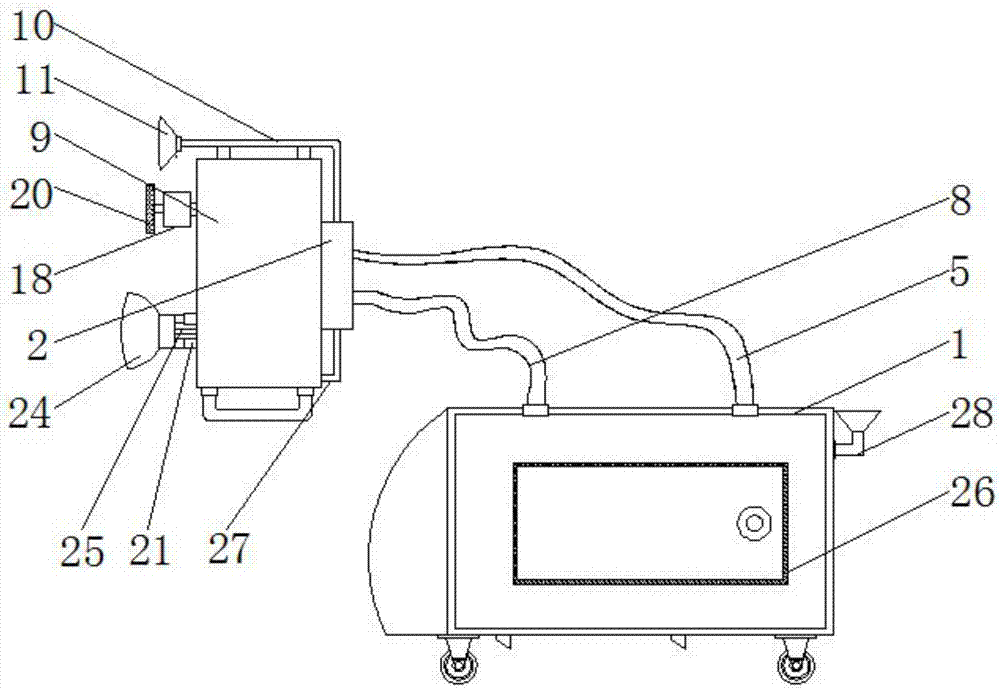

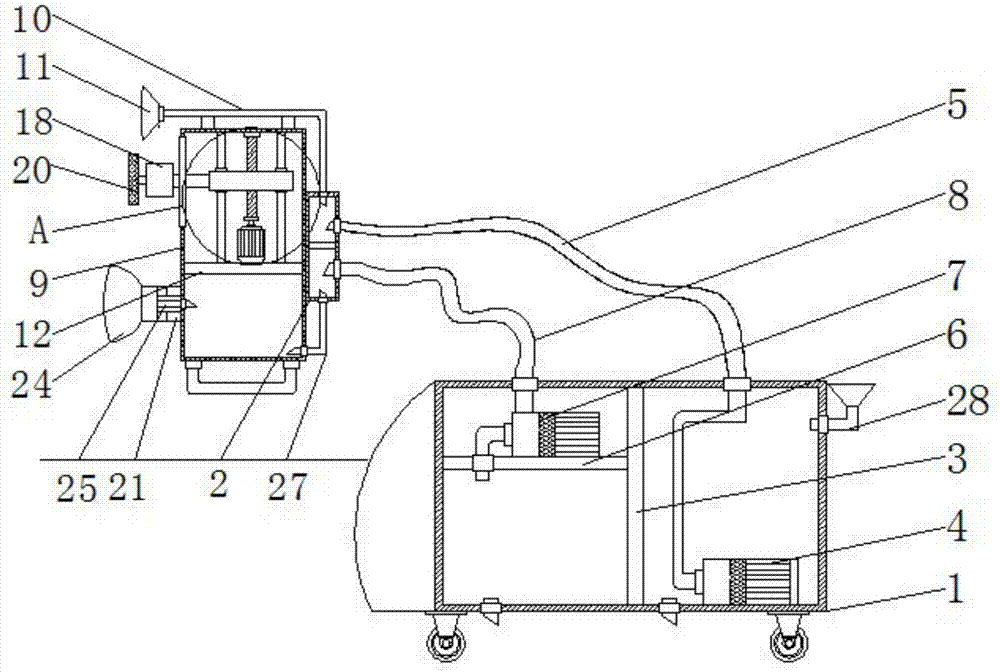

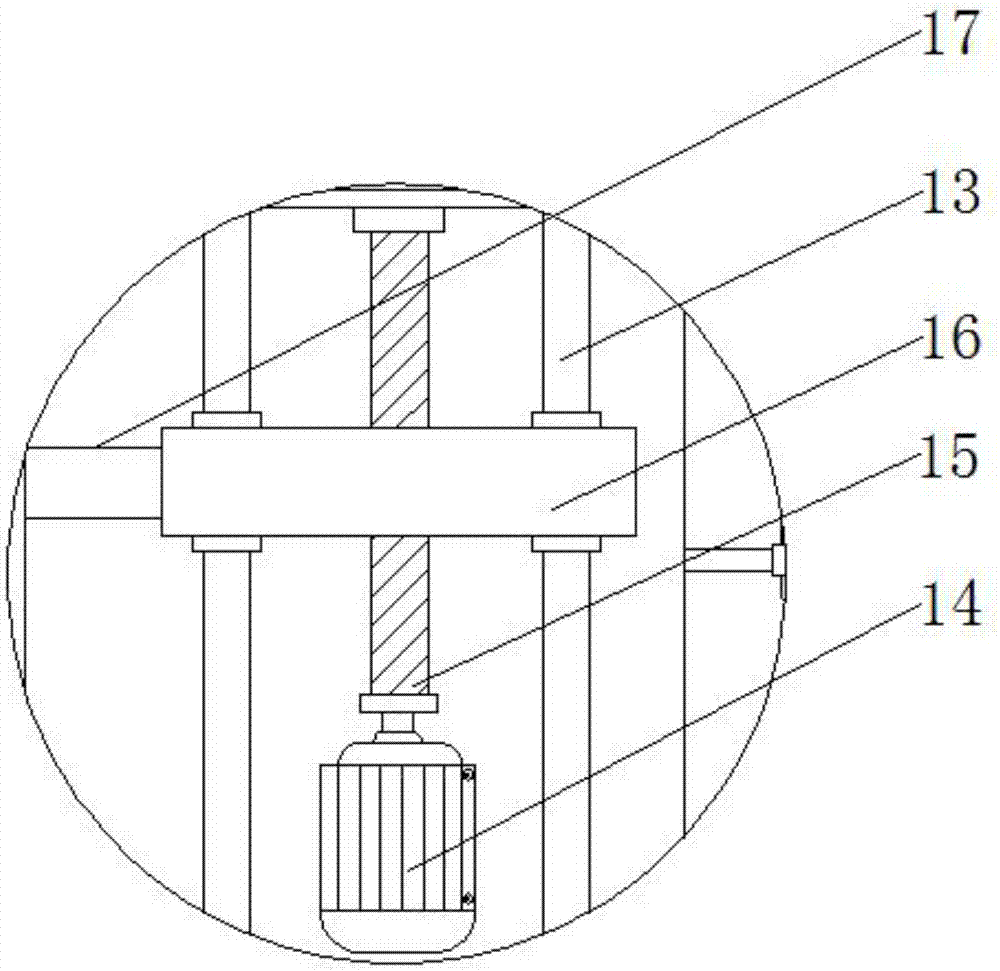

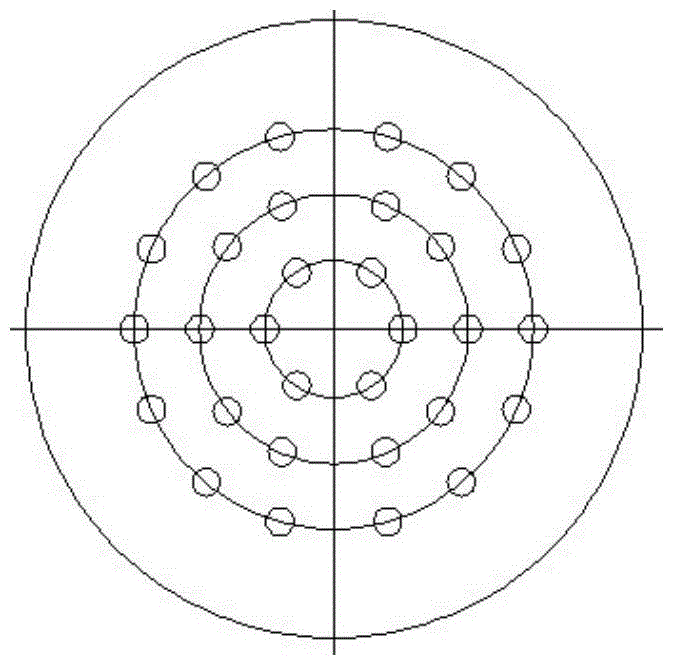

Omni-directionally-floated rotary type shaver

InactiveCN101890730AImprove comfortReduce burning painMetal working apparatusUnit structureMotor power

The invention provides an omni-directionally-floated rotary type shaver, which comprises a head part and a main body, wherein the head part comprises a shaver bracket, a shaver seat, at least one of shaving and cutting units and a cutting unit floating system which corresponds to the shaving and cutting units; the main body comprises a shell body and a motor power transmission system linked with the shaving and cutting units; the head part is separated from the main body, and the head part is connected with the main body through an elastic unit structure; one end of the elastic unit structure is directly or indirectly and fixedly connected with the shaver seat, and the other end thereof is directly or indirectly and fixedly connected with the main body, so that the head part can omni-directionally float along the X axis, the Y axis and the Z axis; and the main body is further provided with a waterproof system for sealing the inner part of the main body. The head part can omni-directionally float relative to the main body, and the head part is provided with a cutting unit floating system, so that a double-floating shaver is formed, which can freely shave with the movement at the different outlines of the face, thereby having good whole harmony, agility and comfortableness.

Owner:MIDEA GRP CO LTD

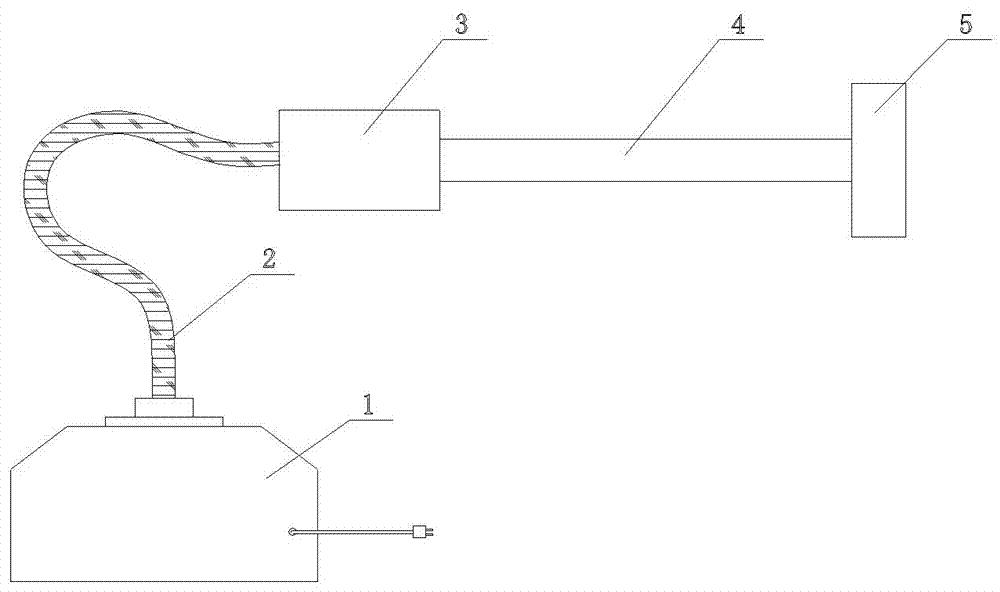

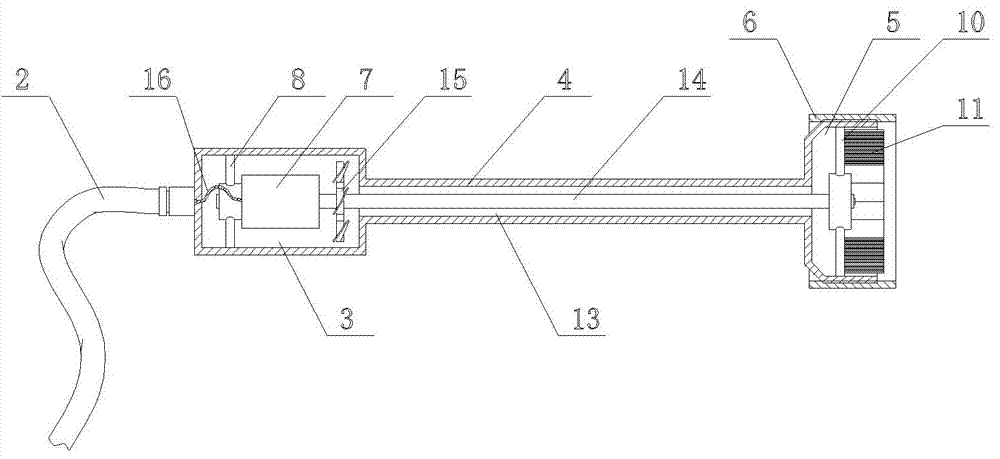

Handheld dust sucking brush

PendingCN106964582AInvisible absorptionAdd cleaning functionCleaning using toolsCleaning using gasesElectric machineDust control

The invention discloses a handheld dust sucking brush. The handheld dust sucking brush comprises a collecting device, a connecting hose, a handheld device, a dust sucking pipe and a brush head which are connected in sequence, and further comprises a switch and a power supply wire; a motor is mounted in the handheld device; after a rotating shaft of the motor penetrates through the dust sucking pipe, the tail end of the rotating shaft is mounted in a center hole of a spoke in the brush head; fan blades for exhausting are mounted at one section, positioned on the inner side of the handheld device, of the rotating shaft of the motor; and a brush disc is arranged on the edge of the spoke, and is provided with a brush. Compared with a traditional dust sucker, the handheld dust sucking brush is smaller, adds a cleaning function, and is more convenient to remove dust during working. The handheld dust sucking brush is simple in structure and convenient to manufacture. The brush head adopts a wheel structure, can achieve a cleaning effect, and cannot influence suction of the dust by the device. A transmission device adopts an extension form to achieve adjustment.

Owner:STATE GRID CORP OF CHINA +2

Efficient wall cleaning device for domestic use

InactiveCN107260077AImprove cleanliness and sanitationExtended service lifeCarpet cleanersFloor cleanersEngineeringPollution

The invention discloses an efficient wall cleaning device for domestic use. The efficient wall cleaning device comprises a box body and a communicating box, wherein a partition board is connected between the top and the bottom of an inner cavity of the box body, and at one side of the partition board, a water pump is fixedly connected to the bottom of the inner cavity of the box body; a first connecting soft hose communicates a water outlet of the water pump; and the end, away from the water pump, of the first connecting soft hose runs through the box body and extends to the top of the box body. The invention relates to the technical field of cleaning devices. With the application of the efficient wall cleaning device for domestic use, stains can be cleaned well, so that clean and sanitary status of a wall is enhanced and service life of the wall is prolonged, and the device has a good wall cleaning function; the efficient wall cleaning device is convenient for a user, good in cleaning effect and free from secondary pollution; the device is excellent in water stain cleaning function; the device is long in service life, safe and reliable and is convenient to move; and the device is excellent in maintenance function and convenience.

Owner:合肥潜望镜机械科技有限公司

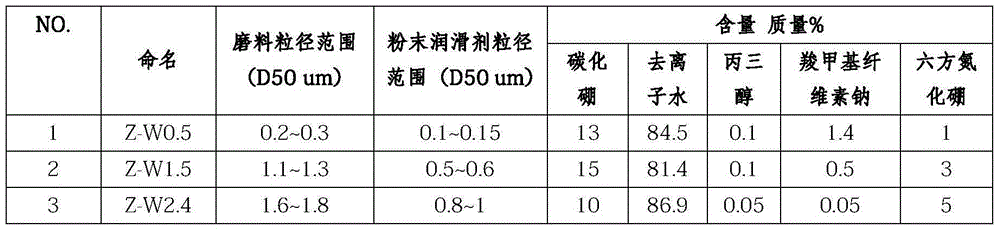

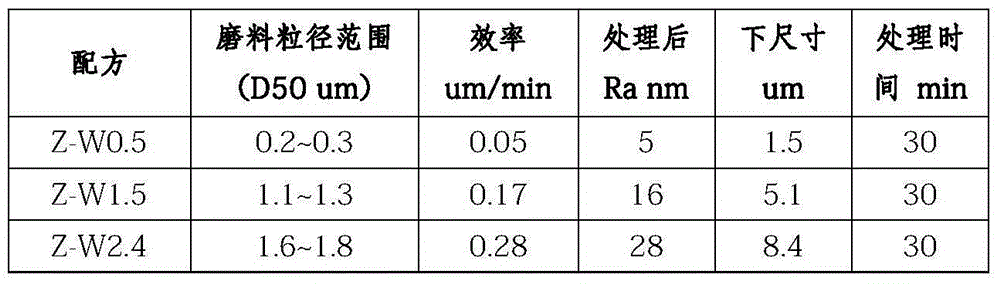

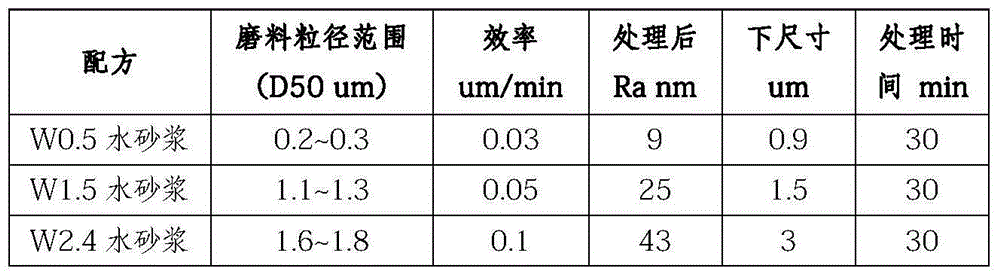

Effective sapphire fine grinding method and fine grinding solution

ActiveCN105038607AImprove liquidityEasy transferLapping machinesPolishing compositions with abrasivesHexagonal boron nitrideHardness

The invention relates to the technical field of sapphire grinding and polishing, in particular to a fine grinding solution for sapphire grinding. The fine grinding solution comprises the following components in percentage by weight: 10-15% of superfine high-hardness micro powder, 0.1-1.5% of a dispersing agent, 1-5% of a powder lubricant and the balance of deionized water, wherein the powder lubricant is graphite or hexagonal boron nitride. Through the adoption of the dispersing agent, micro powder can form a stable suspension system, so that flowing and transmission of the micro powder are facilitated, and a sol system has excellent permeation and cleaning functions to take fines generated in the grinding process away in a fluidal manner; aiming at the problem of the short service life, the powder lubricant is added in the fine grinding solution, so that a grinding contact surface has a sliding buffering effect, the powder can roll under the high pressure to prevent the superfine high-hardness micro powder from being in contact with a sapphire crystal surface and damaging a grinding material, and the service life of the fine grinding solution is prolonged; the invention further provides an efficient sapphire fine grinding method.

Owner:东莞市中微力合半导体科技有限公司

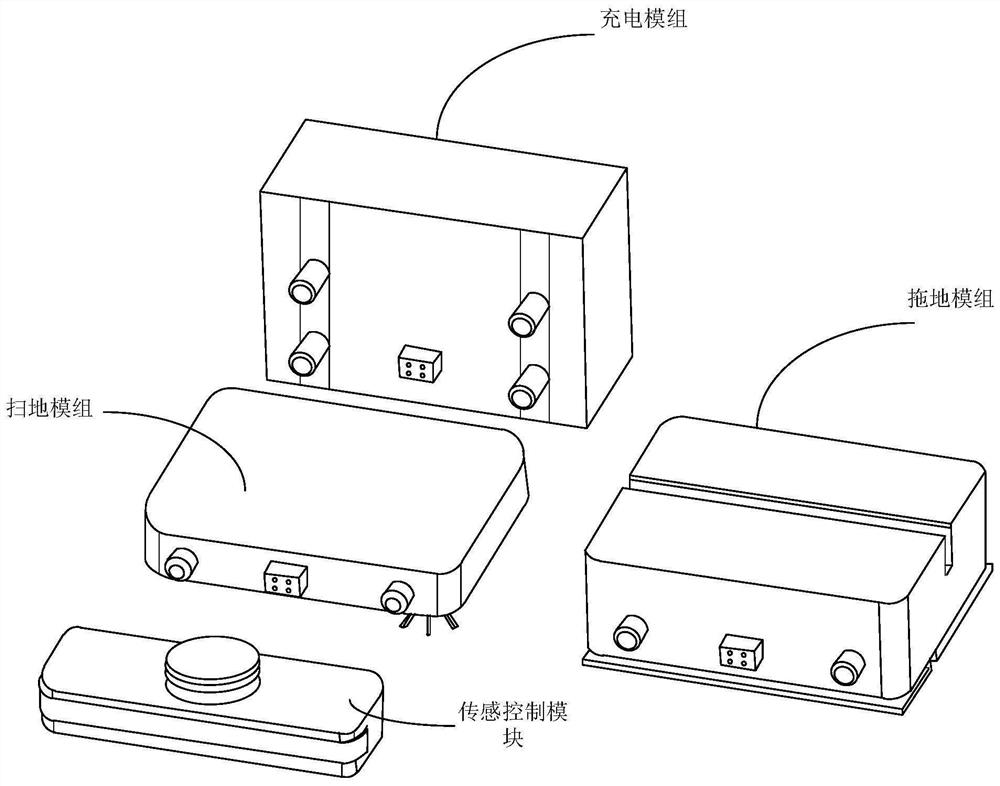

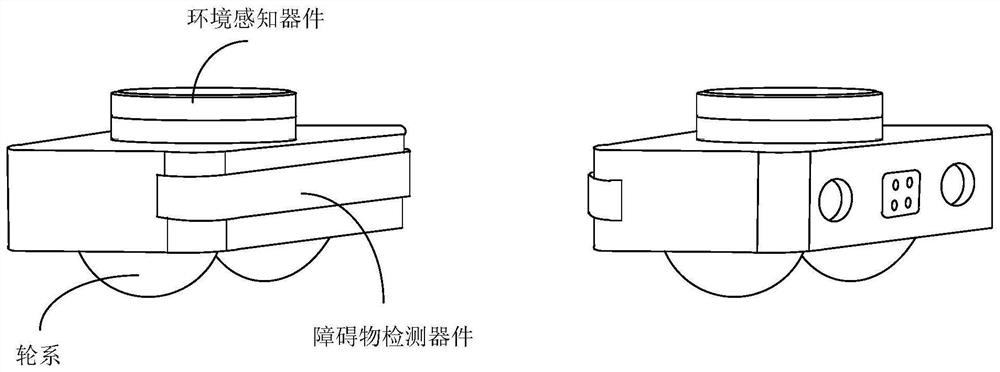

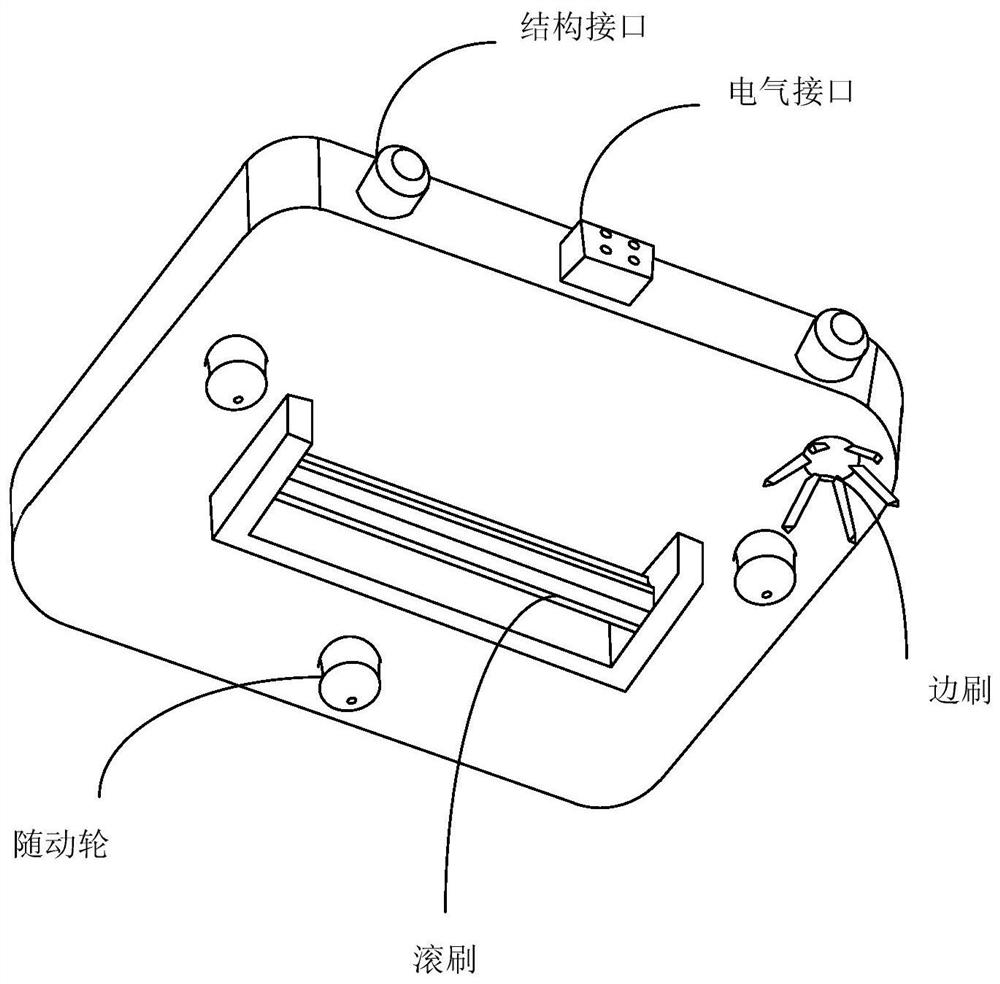

Cleaning robot and control method thereof

ActiveCN112336267AAchieve sharingLow costCarpet cleanersFloor cleanersControl engineeringModular design

The invention discloses a cleaning robot, which comprises a sensing control module and a cleaning function module, and the sensing control module acquires a cleaning task and determines a target docking cleaning function module according to the cleaning task; based on a cleaning area map in a cleaning task, a cleaning path is planned according to the combination form of the perception control module body and the target butt joint cleaning function module body; and the sensing control module body is connected with a target butting cleaning function module body, and the cleaning task is executed. For main cleaning functions, hardware sharing is achieved, hardware cost is saved, the size of each functional module is not limited by the cleaning robot body, and robot function extension is facilitated; on the basis of modular design, the cleaning path is planned based on the combined form, and the cleaning efficiency and effect are improved.

Owner:HANGZHOU EZVIZ SOFTWARE CO LTD

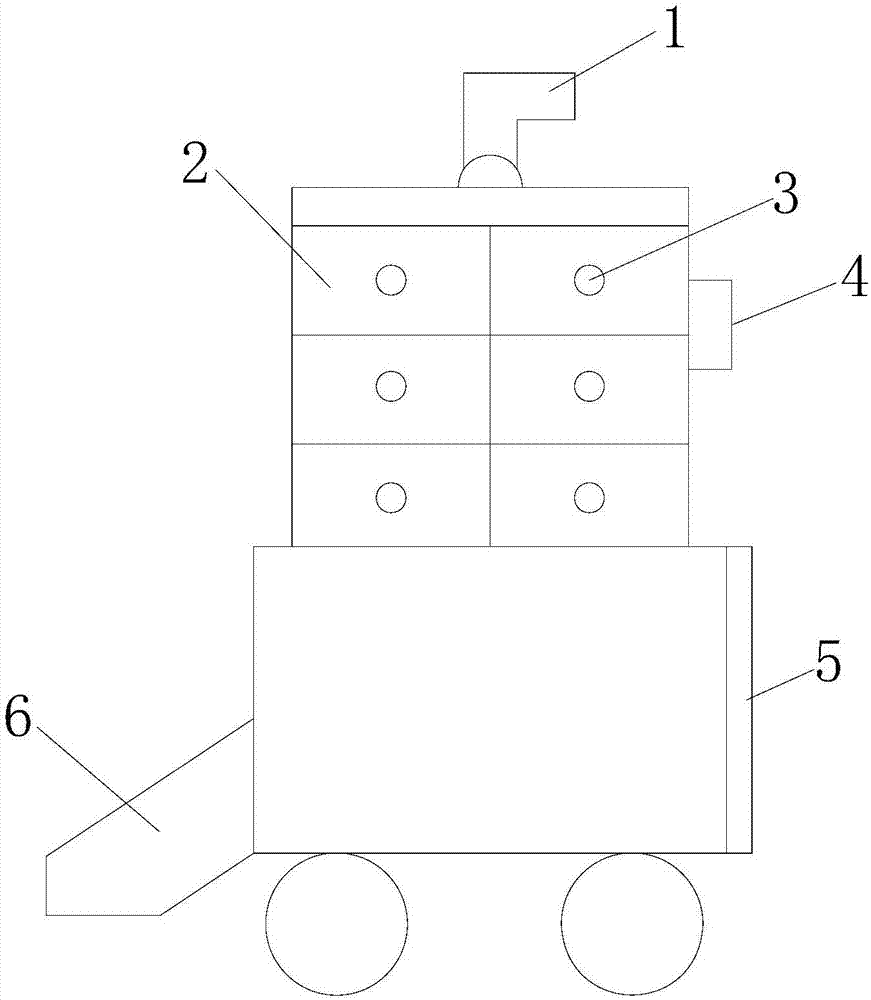

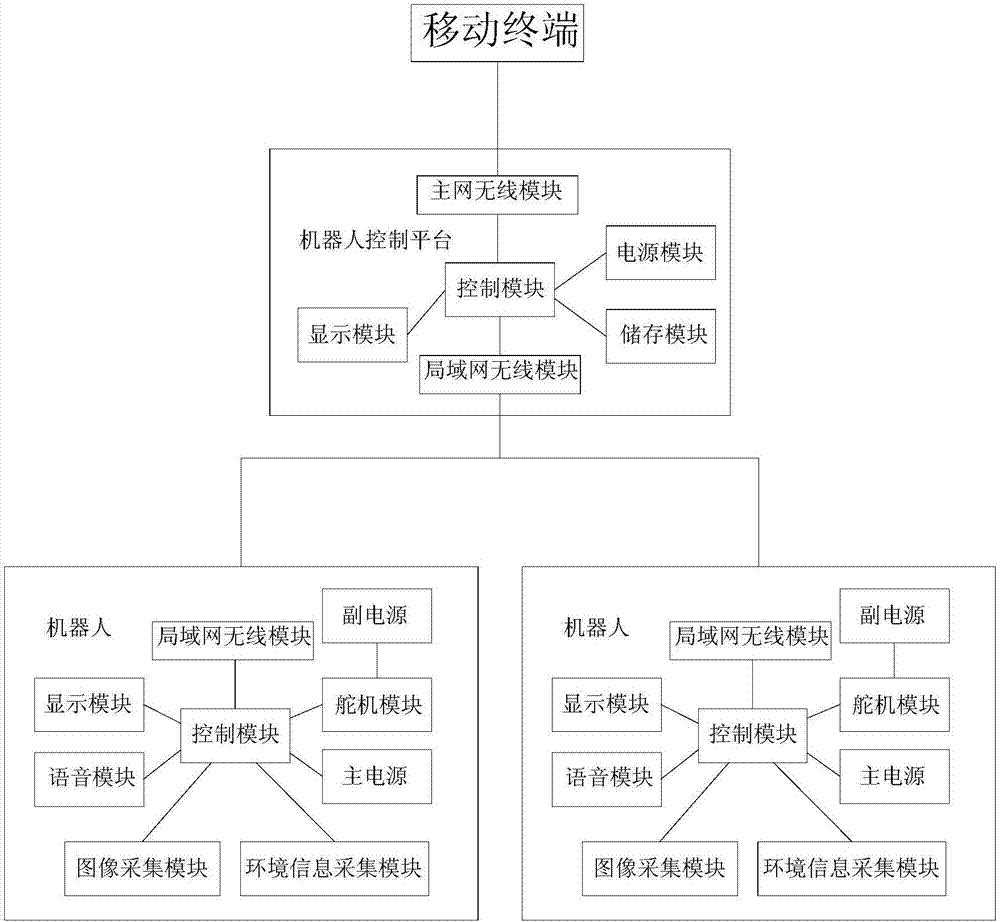

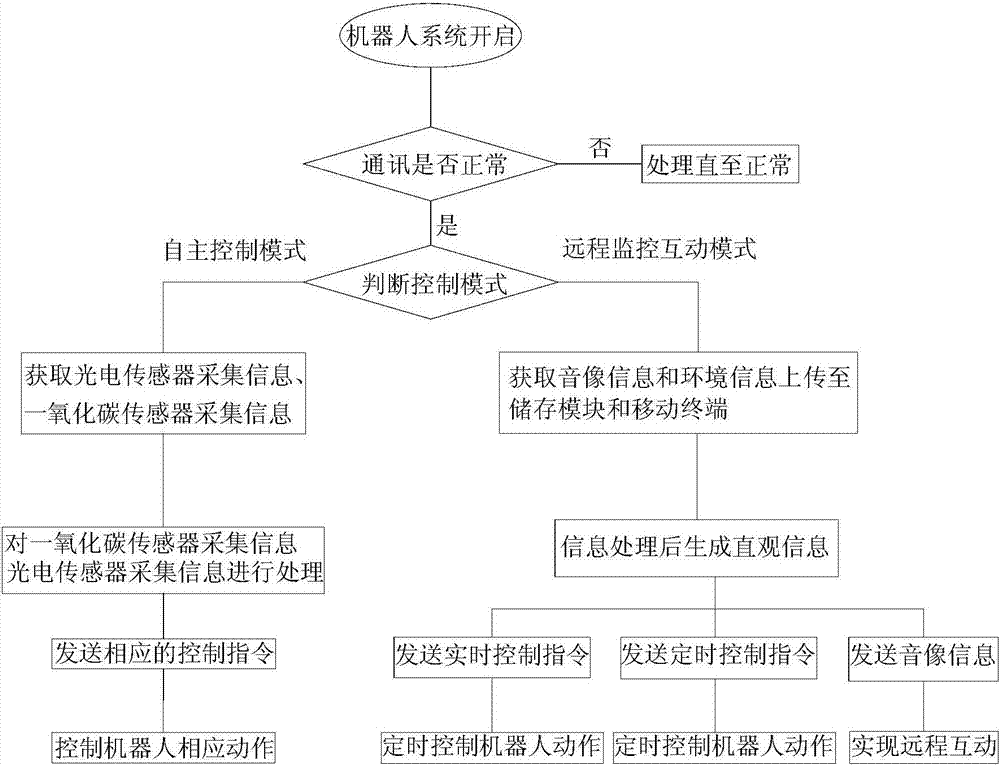

Household-robot control system and control method thereof

InactiveCN107186718ASmooth transmissionLess power consumptionProgramme-controlled manipulatorEngineeringRobot control system

The invention discloses a household-robot control system and a control method thereof, and belongs to the field of robots. The household-robot control system comprises a plurality of robots, a robot control platform and a mobile terminal. Each robot comprises a robot body, a robot control module, an image collecting module, a robot display module, an environmental information collecting module, a robot local-area-network wireless module, a voice module, a steering engine module and a robot power module. The robot bodies, the image collecting modules, the robot display modules, the environmental information collecting modules, the robot local-area-network wireless modules, the voice modules, the steering engine modules and the robot power modules are connected with the robot control modules. The robot bodies comprise upper robot bodies and lower robot bodies, each upper robot body is provided with a plurality of drawers, and indicator lights are arranged outside the drawers correspondingly. According to the household-robot control system and the control method thereof, remote monitoring and protecting can be conducted on the aged and children.

Owner:HECHI UNIV

Processing technology of canned multi-flavor bamboo shoots

InactiveCN104472659AAdd cleaning functionEnhance immune functionFruit and vegetables preservationBiotechnologyDisease

The invention discloses a processing technology of canned multi-flavor bamboo shoots, and belongs to the field of food processing. The processing technology is characterized by comprising the following technological process: selecting raw materials; treating the raw materials; precooking; canning; exhausting and sealing; sterilizing; cooling; and forming finished products. The processing technology has the beneficial effects that the canned multi-flavor bamboo shoots are moderate in hardness, tender and crisp in tissue, full in juice, rich in a plurality of nutrient substances such as protein and plant fibers, and easy to absorb by a human body, have a unique faint scent of bamboo shoots, and a very good intestinal cleansing function, are conducive to enhancement of an immune function of the organism and improvement of the disease resistance, have the efficacies of whetting the appetite, tonifying spleen, relieving chest stuffiness, disinhibiting diaphragms, dredging intestines, defecating, losing weight and slimming, are low-sugar and low-fat healthcare food, are convenient to eat, and are suitable for people of all ages.

Owner:洪寒俊

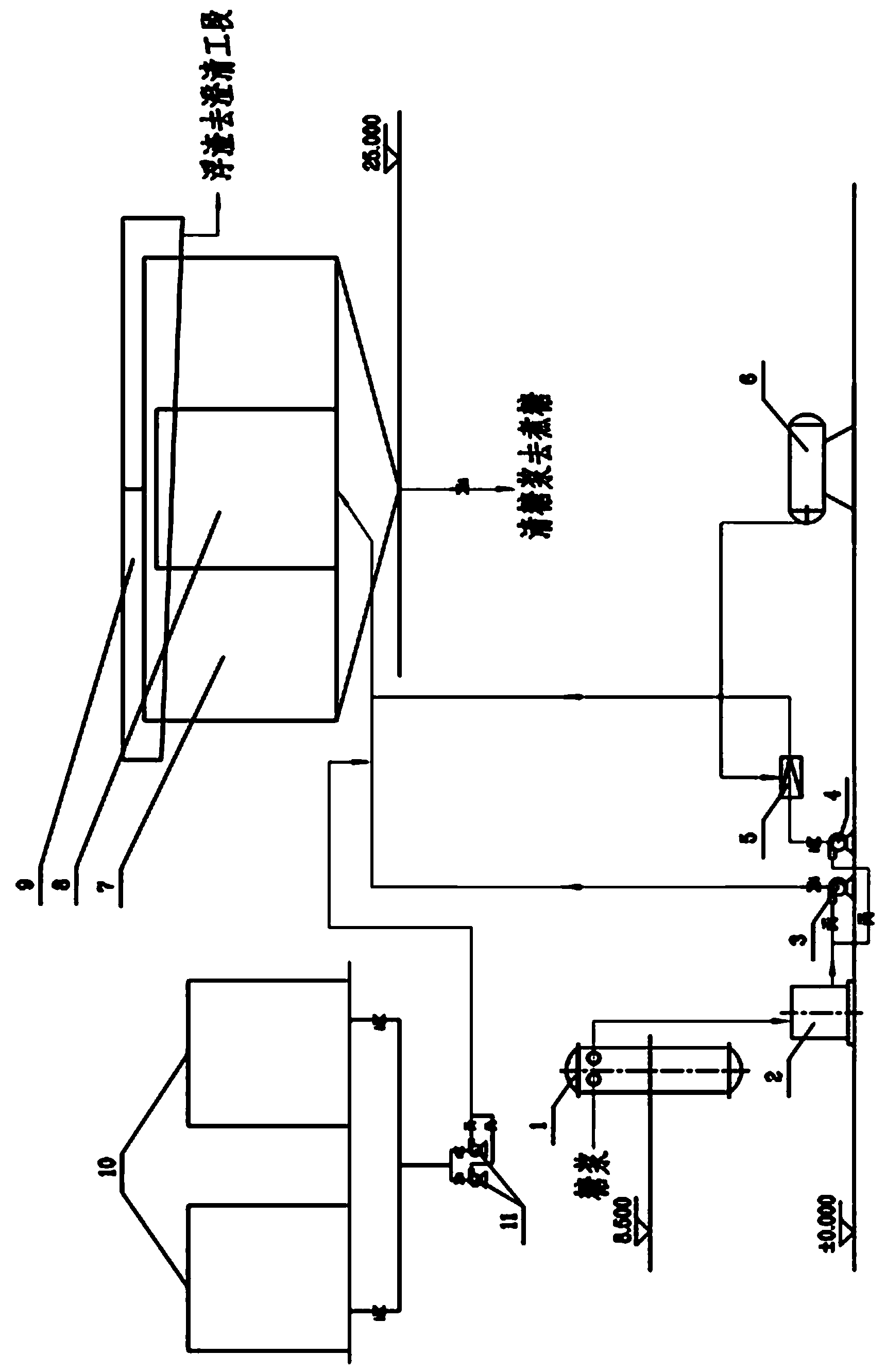

Method for automatically clearing syrup in conveying and storing processes

InactiveCN104313193AAdd cleaning functionReduce sulfur dioxide contentPurification using chemicalsThermodynamicsEconomic benefits

The invention provides a method for automatically clearing syrup in conveying and storing processes. After syrup is discharged from the former procedure, the syrup is firstly heated to a temperature of 80-85 DEG C and then discharged into a syrup box on +_0.000 layer. Then, the syrup is conveyed into a syrup storage box at the top layer of a sugar boiling building through a main and auxiliary pipeline, and a high-molecular flocculant is added before the syrup enters the syrup storage box. On the +_0.000 layer, gas is absorbed and dissolved through an online pipeline air breather and pressure formed by liquid level height difference. After the syrup enters the syrup storage box at the top layer of the sugar boiling building, impurities and air bubbles in the syrup rise to the top of the syrup storage box and are discharged out, and pure syrup is discharged from the bottom of the syrup storage box. The function of automatically clearing the syrup is increased under the condition of storing the syrup by the syrup storage box. The impurities are effectively removed from the syrup, the syrup purity is improved, the syrup conversion losses are reduced, the quality of a white granulated sugar product is effectively improved, and the economical benefit of a sugar making industry is improved.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

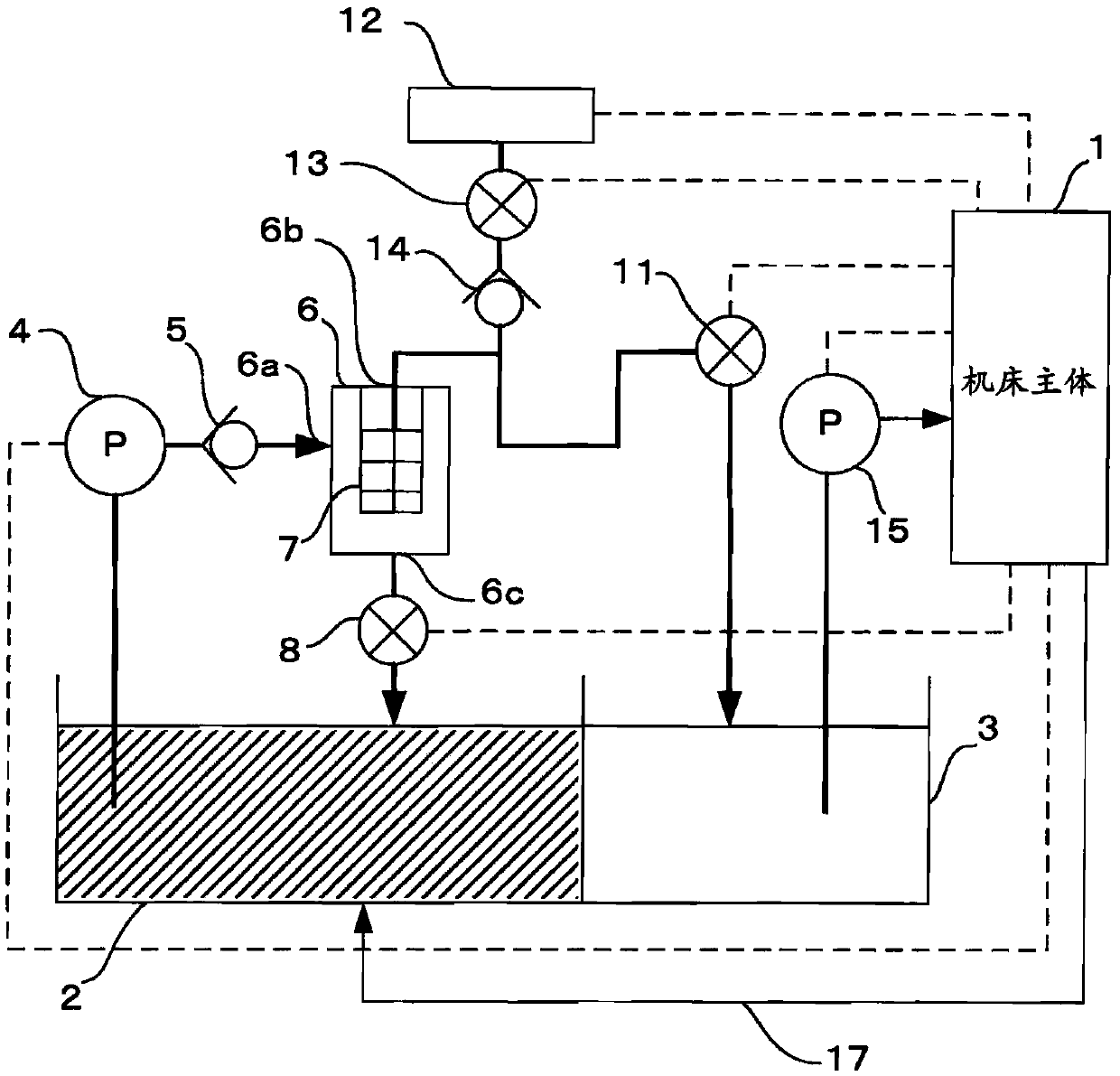

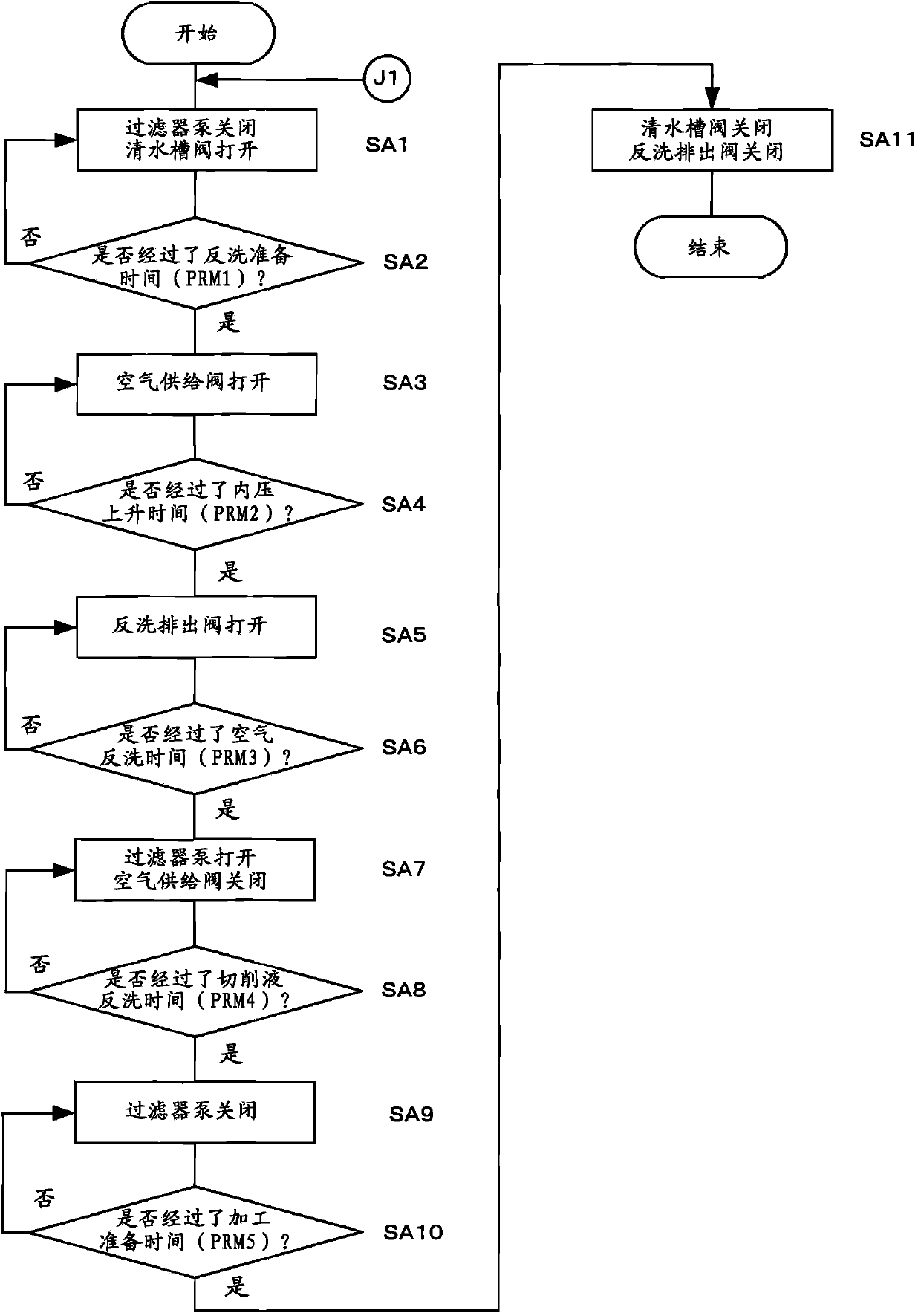

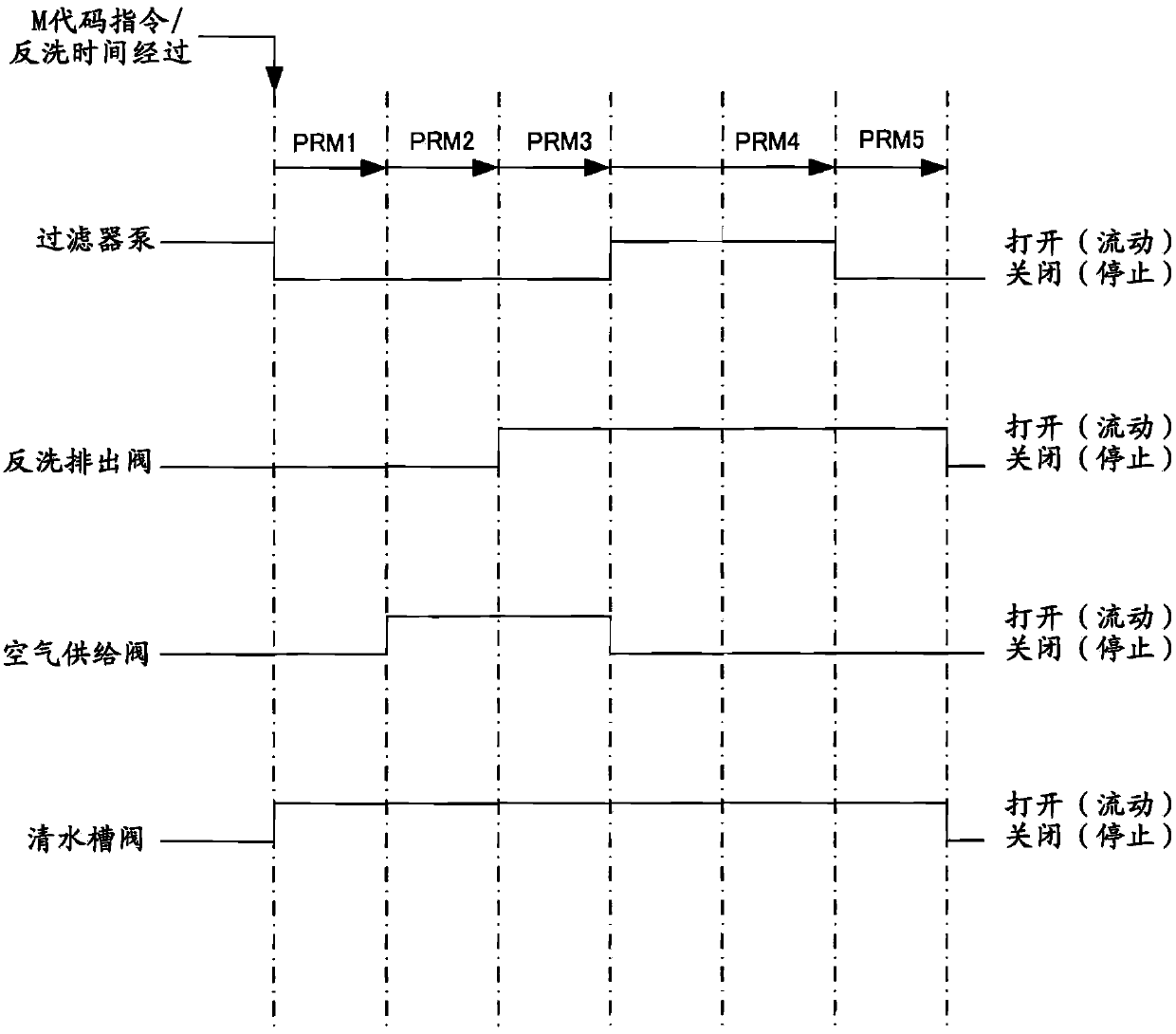

Machine tool equipped with cutting fluid filtering device

InactiveCN103722446AAdd cleaning functionImprove backwashing effectMaintainance and safety accessoriesStationary filtering element filtersInternal pressureSludge

A filter which is used to remove chips and sludge produced by the processing using a machine tool is backwashed. At this time, a valve provided in an outlet of a filter container is opened based on an elapse time from the start of the supply of compressed air or a cutting fluid to the filter container or a detection value of a pressure inside the filter container. In this way, the supply pressure of the cutting fluid or the compressed air is sufficiently applied to the filter, so that chips adhering to a surface of the filter are sufficiently removed.

Owner:FANUC LTD

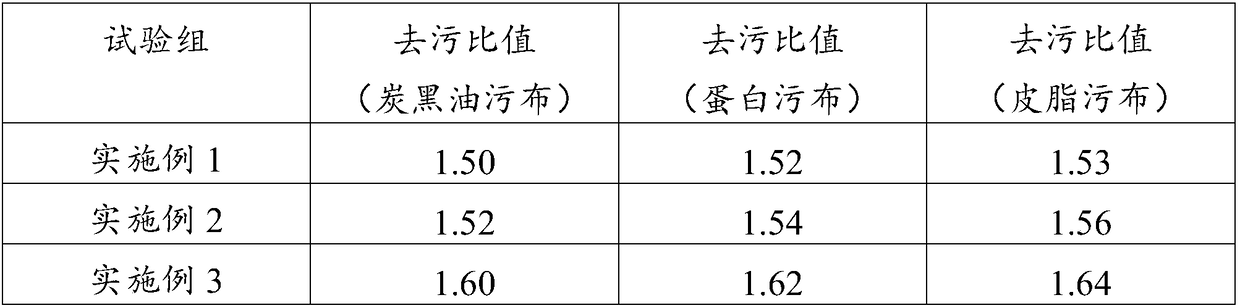

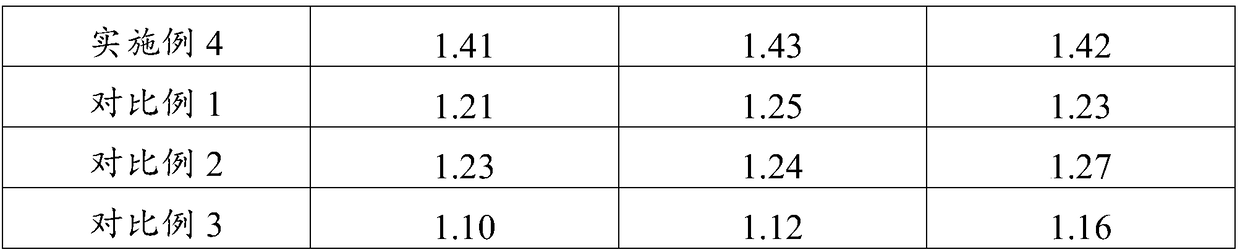

Laundry detergent

InactiveCN108300606AAdd cleaning functionPlay an inhibitory roleInorganic/elemental detergent compounding agentsCationic surface-active compoundsSolventCross infections

The invention discloses a laundry detergent, which is prepared from the following ingredients in parts by weight: 5 to 10 parts of anionic surfactants, 10 to 20 parts of nonionic surfactants, 0.5 to 2.0 parts of cellulase, 0.5 to 2.0 parts of protease, 0.01 to 1.5 parts of enzyme stabilizers, 0.1 to 1.0 part of organosilicon quaternary ammonium salt, 0.1 to 1.0 part of chitosan, 2.0 to 5.0 parts of cosolvents and 30 to 70 parts of deionized water. The provided laundry detergent using the technical scheme has a good clean washing function, and can also achieve the inhibition effect on bacteriaon the clothes, so that cross infection caused by various bacteria on the clothes during machine washing can be avoided.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

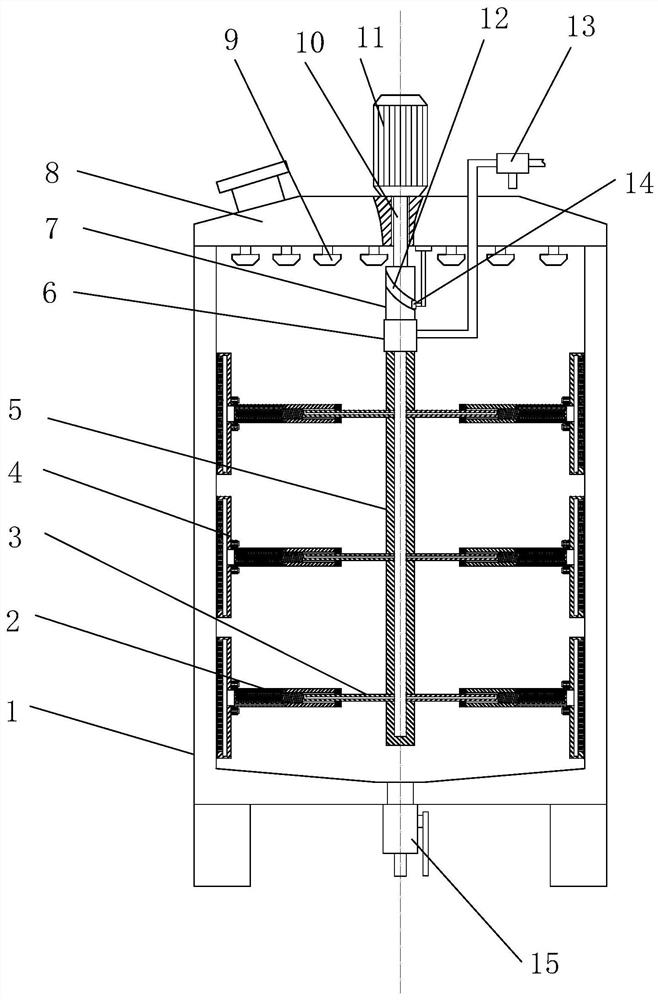

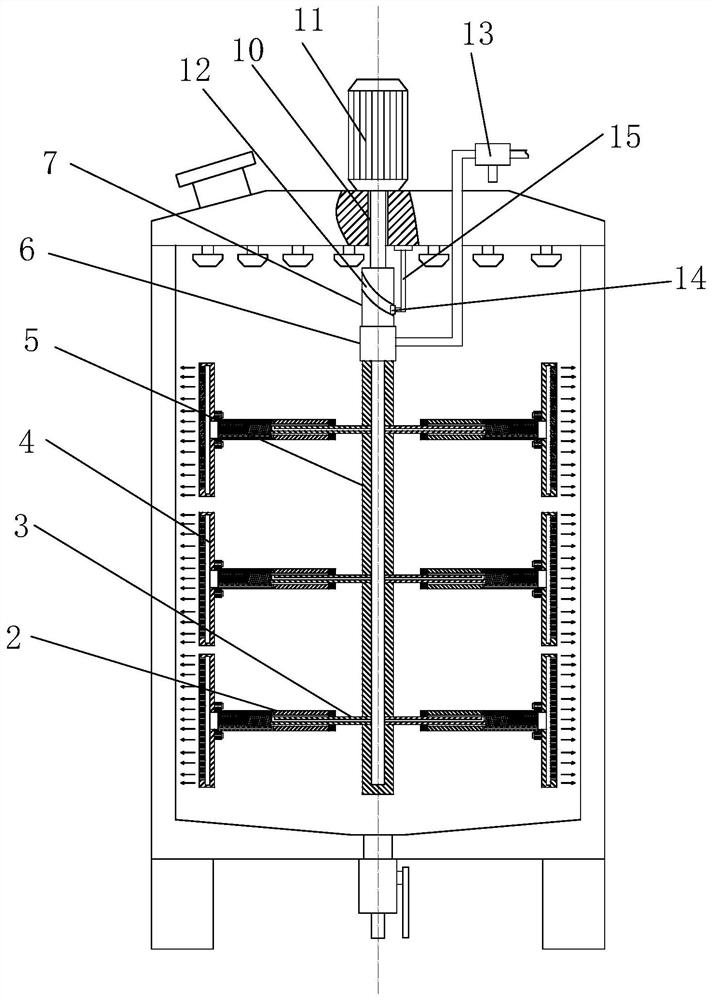

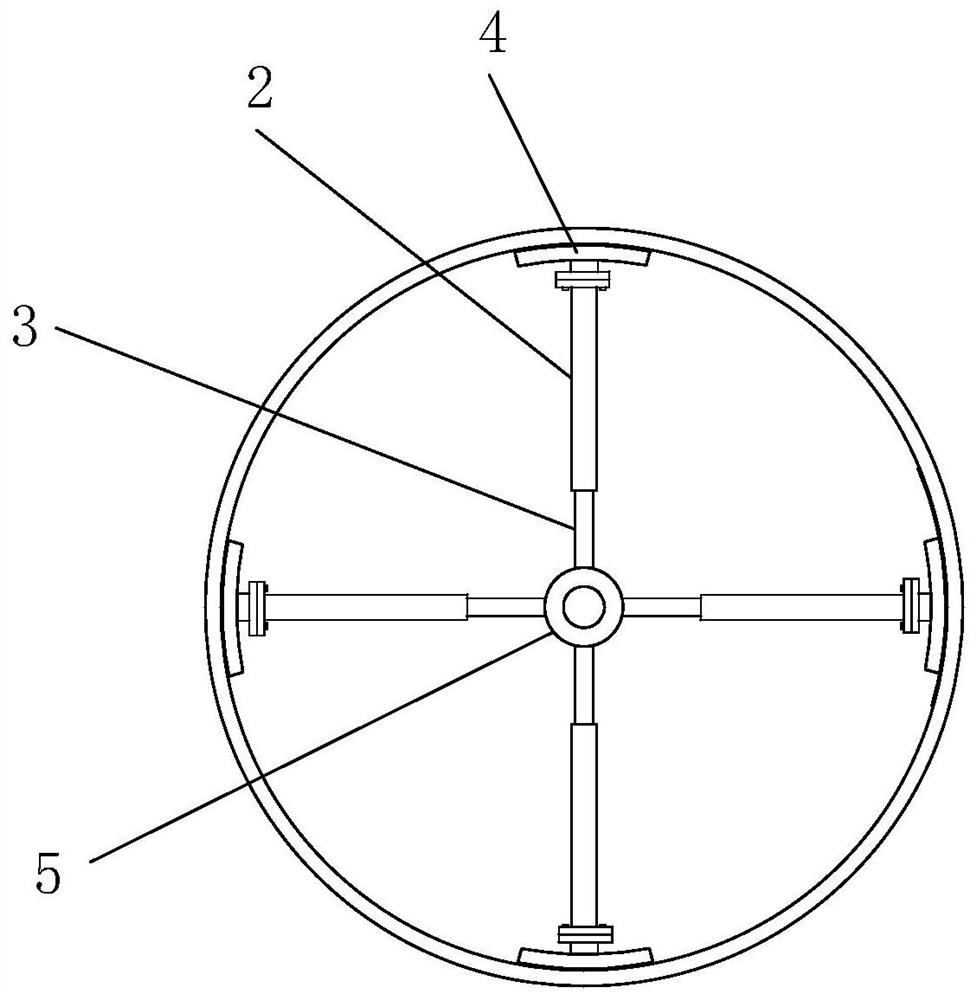

Liquid milk fermentation system

PendingCN111700111AGood cleaning effectThe overall structure design is simple and reasonableMilk preparationRotary stirring mixersFluid milkEngineering

The invention provides a liquid milk fermentation system. The system comprises a fermentation tank, a stirring device is arranged in the fermentation tank and is connected with a motor arranged at theouter top of the fermentation tank, a plurality of cleaning nozzles are arranged at the inner top of the fermentation tank, and the stirring device comprises a main shaft, fixed cross rods, movable loop bars and stirring blades, wherein the fixed cross rods are connected with the main shaft, the movable loop bars are sleeved with the fixed cross rods in a sliding mode, the stirring blades are connected with the movable loop bars, corresponding runners are formed among the main shaft, the fixed cross rods, the movable loop bars and the stirring blades, and switching of a stirring station and acleaning station of each stirring blade is achieved through high-pressure water flow in the runners. On one hand, the fermentation effect of liquid milk can be improved, and on the other hand, the cleaning effect of the fermentation tank can be improved, and practicability is high.

Owner:威海嘉盛乳业有限公司

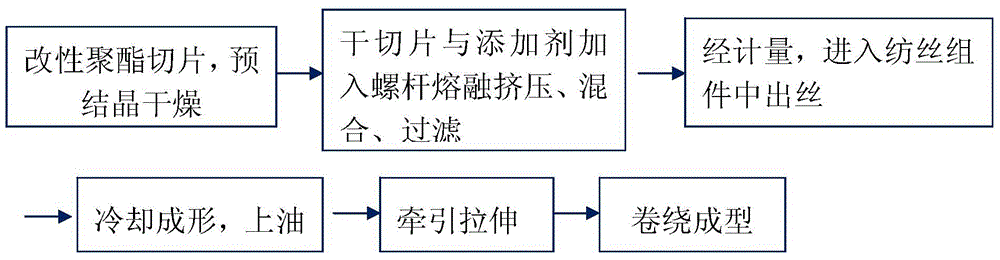

Production process of high-elasticity-feature terylene pre-oriented fibers

InactiveCN104480555AImprove water absorptionImprove sexual functionSpinnerette packsNew-spun product collectionFiberPolyester

The invention provides a production process of high-elasticity-feature terylene pre-oriented fibers. The production process is characterized by comprising the steps of 1) slicing a raw material, namely, modified polyester, conveying the material to a wet material bin to enable pre-crystallizing, and then ventilating and drying to obtain dry slices; 2) feeding the dry slices and an additive into a screw extrusion machine together under a melting condition, filtering and then transferring into a spinning box to obtain a melt; 3) metering the melt through a metering pump, and feeding into a spinning assembly to yield silks; 4) performing slow cooling and side blowing for the silks obtained in step 3) to cool and shape, and then applying oil; 5) pulling, stretching, and thermally shaping; 6) coiling through a coiling head to obtain the high-elasticity-feature terylene pre-oriented fibers. The high-elasticity-feature terylene pre-oriented fibers prepared by the production process have the advantages that the specification is up to 180dtex / 36f, the breaking strength is not less than 1.80cN / dtex, the elongation at break is 200+ / 30; the softness, sense of touch and rebound elasticity are superior to those of the general fibers, and moreover, the water absorbing performance, the oil absorbing performance and the cleaning function are high.

Owner:ZHONGRUN SCI & TECH

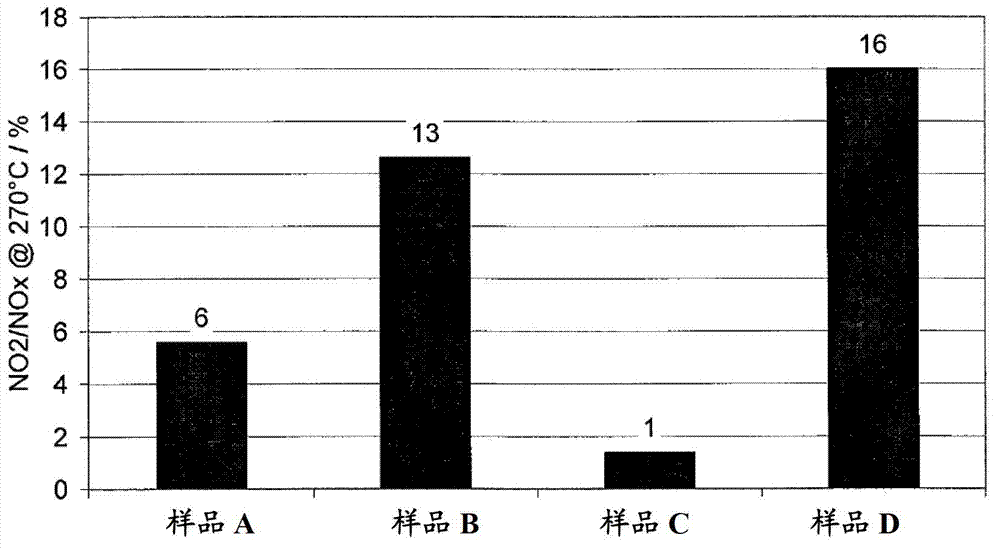

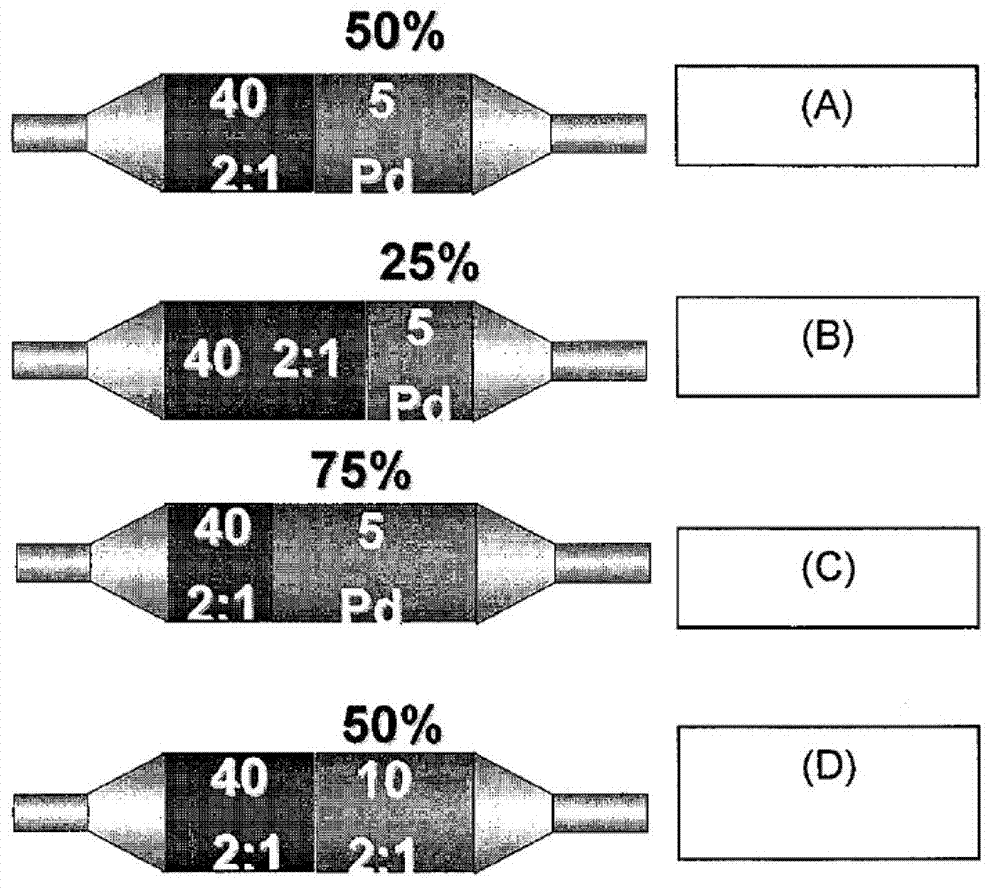

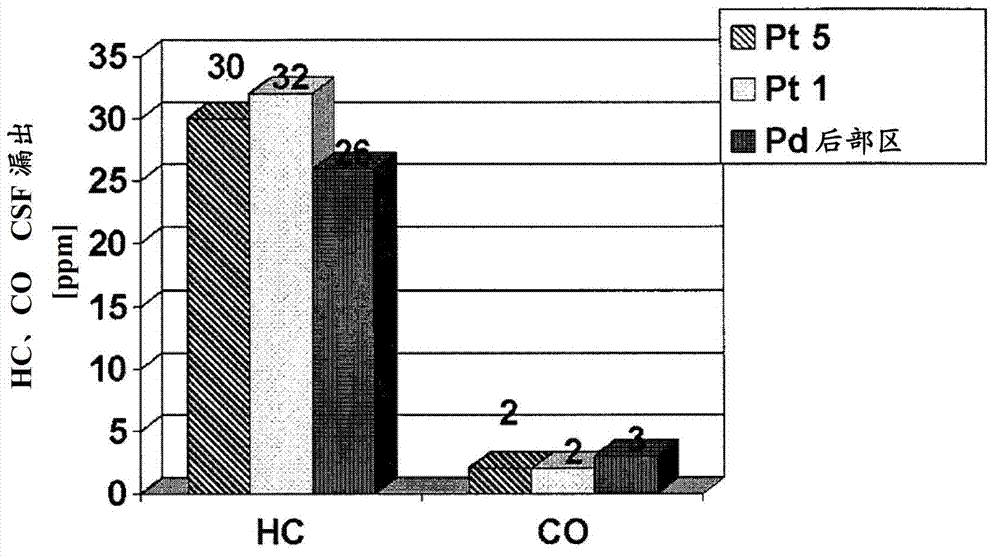

Improved catalyzed soot filter

A catalyzed soot filter is provided wherein its inlet coating comprises an oxidation catalyst comprising platinum (Pt) and optionally palladium (Pd), and its outlet coating comprises an oxidation catalyst comprising Pd and optionally Pt. The Pt concentration in the outlet coating is lower than that in the inlet coating. The weight ratio of Pt:Pd in the outlet coating is in the range of 0:1-2:1. The inlet coating and the outlet coating are present on the wall flow substrate at a coating loading ratio in the range of 0.5-1.5, calculated as ratio of the loading of the inlet coating (in g / inch3(g / (2.54cm)3)):loading of the outlet coating (in g / inch3(g / (2.54cm)3)).

Owner:BASF AG +1

Air purifying apparatus using ultra violet light emitting diode

ActiveUS9974881B2Easy to cleanExtended retention timeLavatory sanitoryDeodrantsHazardous substanceAir cleaning

The present invention relates to an air cleaning apparatus comprising a UVLED, which can efficiently clean air flowing in tubes by an effective combination of the UVLED and a photocatalyst and can effectively clean air flowing in a duct by enhancing the cleaning function or increasing the number of cleaning steps when the concentration of harmful substances increases. The air cleaning apparatus includes: a case comprising an inlet configured to introduce air, an outlet configured to discharge air, and a duct disposed between the air inlet and the air outlet; a photocatalyst unit disposed in the duct; and a UVLED module disposed in the duct and including a plurality of first UVLEDs arranged to irradiate UV light from the side of the inlet to the side of the outlet.

Owner:SEOUL VIOSYS CO LTD

High-efficiency sterilization detergent combination

The invention relates to a high-efficiency disinfecting detergent composition, which is an online disinfectant product for equipment and apparatuses of a food and drink production line. The composition comprises the following components: a sodium dichloro isocyanurate disinfectant, a carbonate detergent, a chelating agent, an organic acid buffering agent and an excipient. A composition powder stock reagent is prepared by uniformly mixing, and is a disinfecting detergent which has the double functions of disinfecting and cleaning, wherein the weight ratio of the powder stock reagent to water is 1:100. When the sodium dichloro isocyanurate disinfectant in the powder stock reagent is progressively increased within the range of between 17 and 70 percent, the effective chloride content is correspondingly increased within the range of between 10 and 40 percent. A disinfecting detergent water solution is prepared according to the weight ratio of the powder stock reagent to the water of 1:100, the pH value of the disinfecting detergent water solution is approximately neutral, and the corrosivity is low; moreover, the disinfecting detergent water solution is easy to be washed to be clean with the water without residue left, has high-efficiency, quick and broad-spectrum disinfecting and cleaning efficacies when used at normal temperature, is safe, has no toxic and side effect, and is widely suitable for disinfecting and cleaning online equipment and apparatuses of the food and drink production line, household table ware and fruits and vegetables.

Owner:WUHAN PONKONG SCI&TECH

Multifunctional wiping robot

InactiveCN106214056AAdd cleaning functionAutomatic obstacle detectionTravelling automatic controlStopped workDrive wheel

The invention discloses a multifunctional wiping robot capable of crossing gaps. The multifunctional wiping robot comprises a body shell, a vacuum generation device, an air pressure sensor, a moving collider, a wireless signal obstacle detection system, left and right driving wheel assemblies, a control system, a power supply system and wiping cloth. The vacuum generation device, the air pressure sensor, the moving collider, the wireless signal obstacle detection system, the left and right driving wheel assemblies, the control system and the power supply system are arranged in the body shell, and the wiping cloth is arranged at the bottom of the body shell. When the robot works on an inclined interface, the wiping cloth, the vacuum generation device and a base of the body shell form a negative-pressure cavity, the air pressure detector detects pressure variation value conditions of the negative-pressure cavity to feed back to the control system, whether the multifunctional wiping robot passes through a gap or is in a suspended state is judged, and then subsequent action commands are sent out. When the robot works on a flat interface, the vacuum generation device and the air pressure sensor both stop working, and obstacles and suspension are judged by the moving collider and the wireless signal obstacle detection system. The multifunctional wiping robot has advantages that crossing of gaps of connected interfaces is realized, and a cleaning function of the robot is expanded to a range including all inclined hard smooth interfaces requiring adsorption and free of retaining side connection and flat operation interfaces free of adsorption.

Owner:深圳市宇辰智能科技有限公司

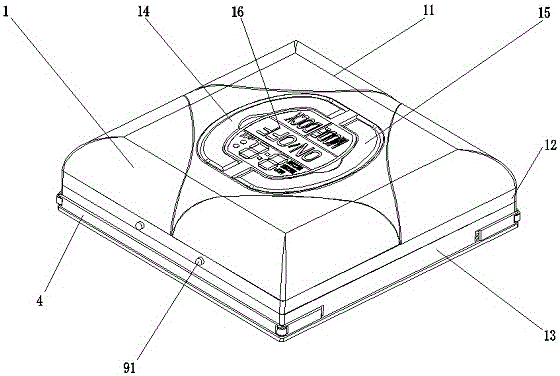

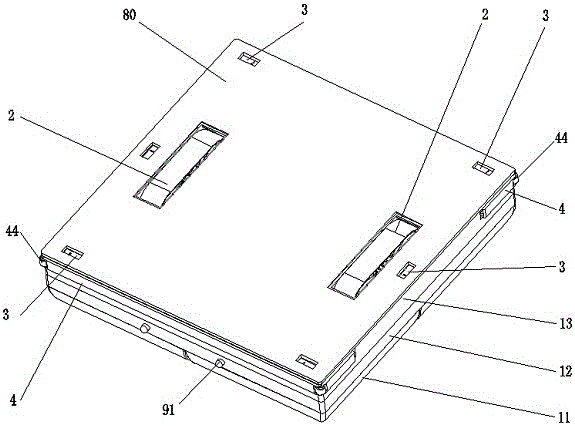

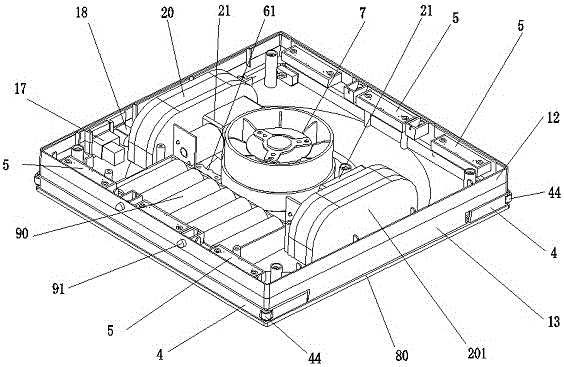

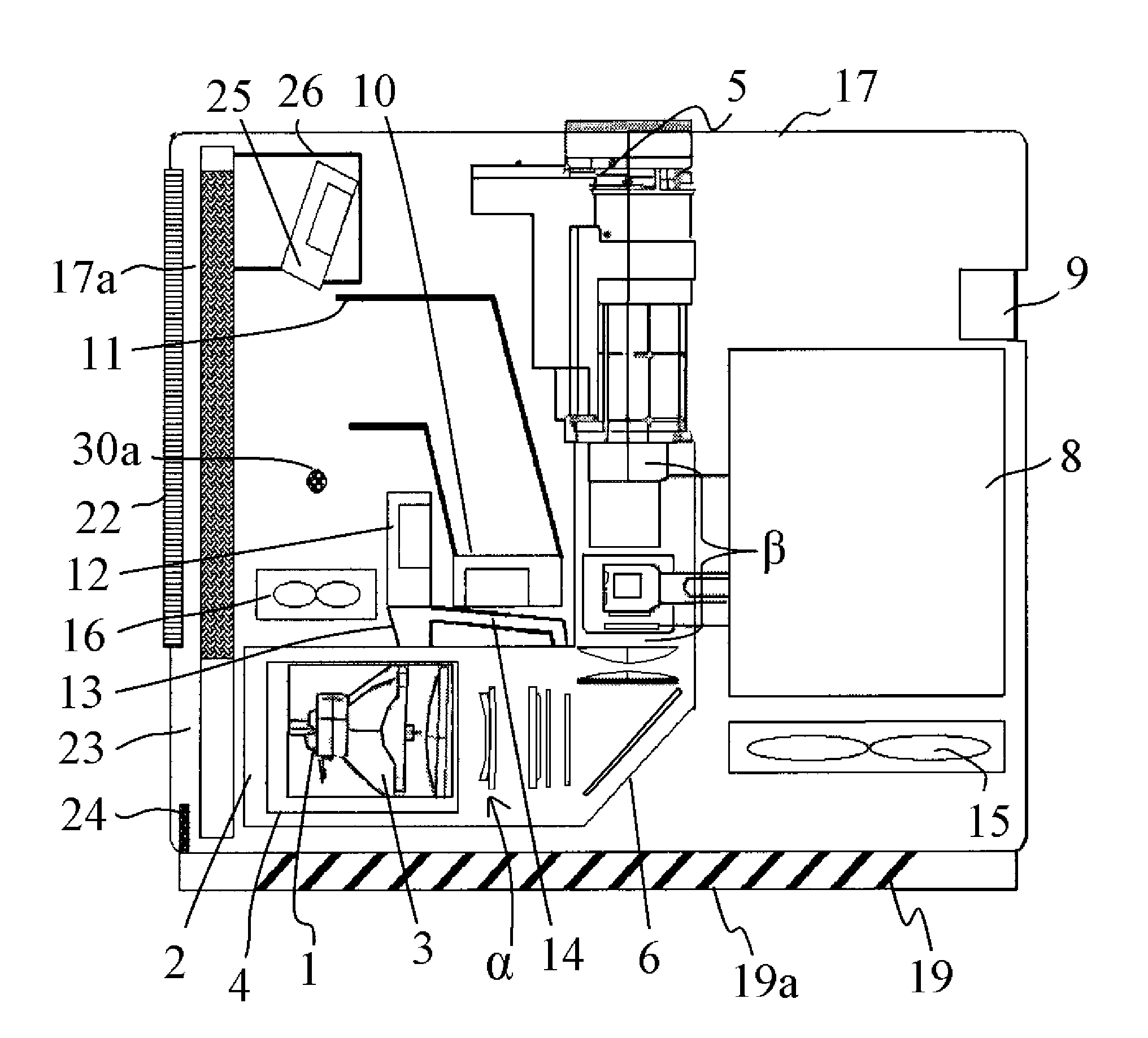

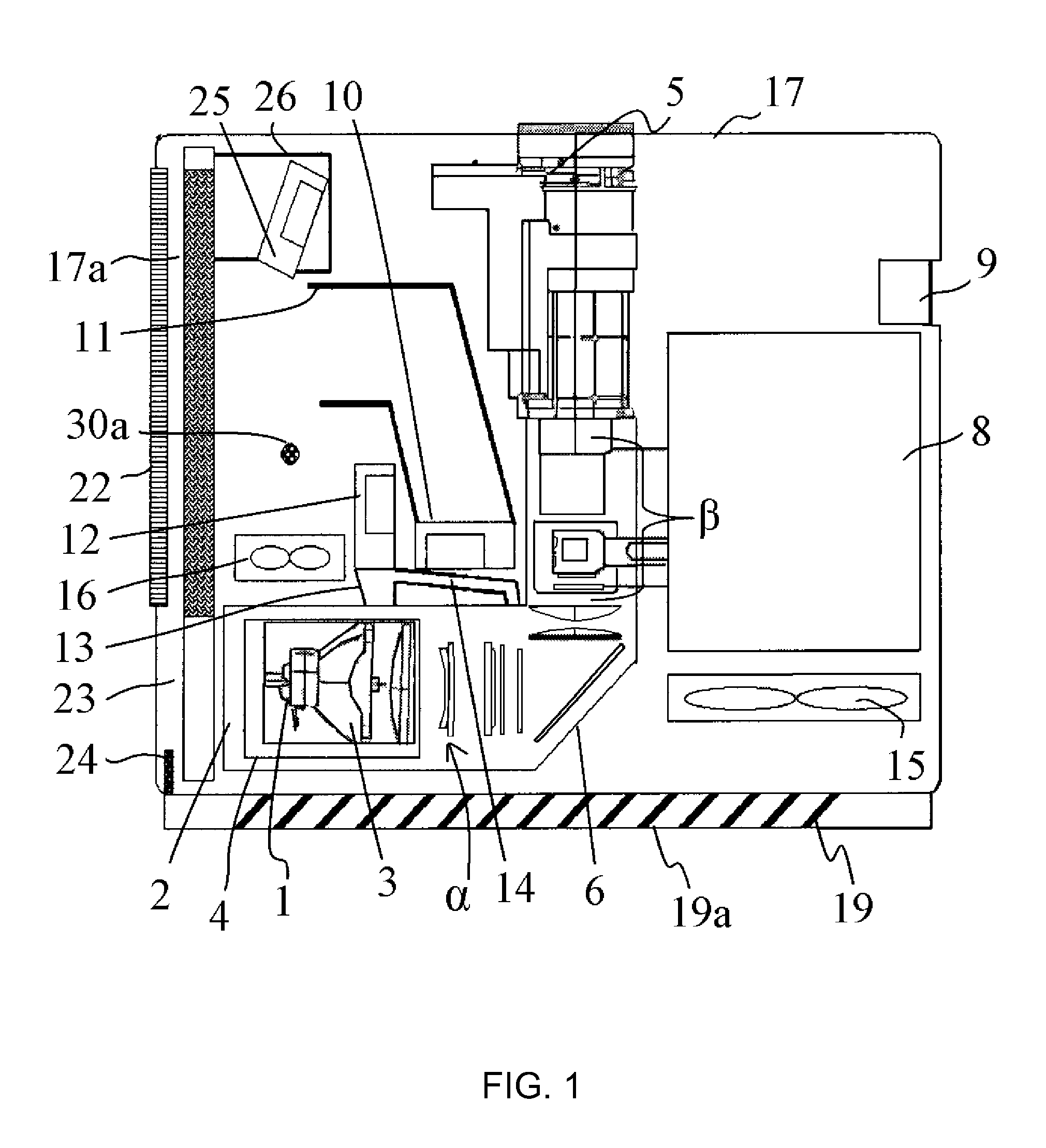

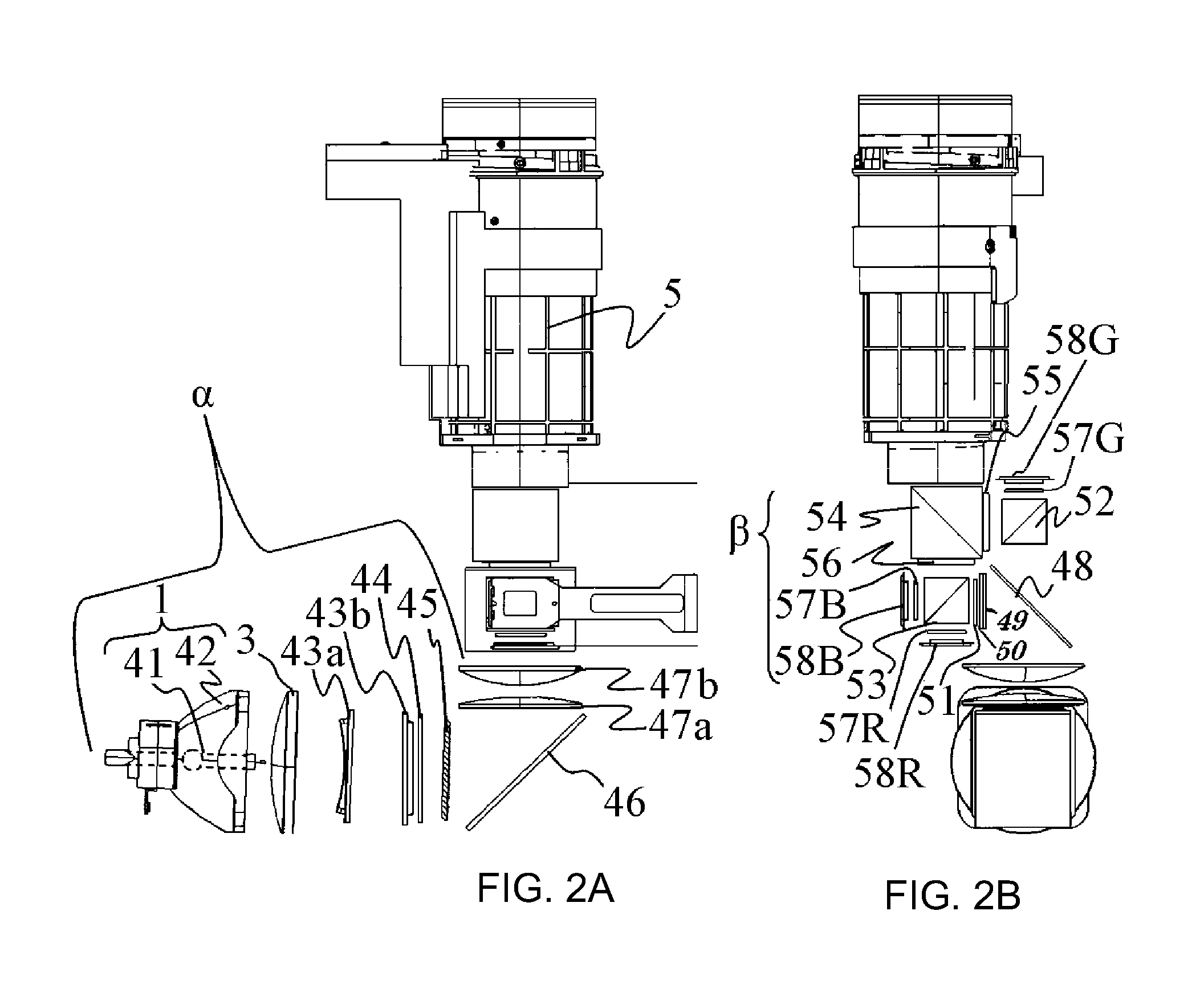

Image projection apparatus having cleaning function of air filter

An image projection apparatus includes cooling fans 10, 12, and 16 provided inside a chassis 17 and configured to take in cooling air from a cooling inlet port 17a formed in the chassis, an air filter 22 that covers the cooling inlet port, an exhaust port 19a formed in the chassis and configured to exhaust the cooling air from an inside to an outside of the chassis, and a cleaning fan 25 provided inside the chassis and configured to take in cleaning air from a cleaning inlet port 17b formed in the chassis separately from the exhaust port. The image projection apparatus exhausts the cleaning air discharged from the cleaning fan, from the inside to the outside of the chassis via the cooling inlet port and the air filter.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com