Online cleaning device for heat exchange tube of condenser

A technology for cleaning devices and heat exchange tubes, applied in the directions of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of difficult positioning of heat exchange tubes, increasing the probability of device failure, and complex device structure, so as to improve long-term cleaning. Operational efficiency, saving investment and maintenance costs, expanding the effect of cleaning functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific structure and working principle of the present invention will be further described in conjunction with the accompanying drawings and embodiments, and its features and advantages will be clearer.

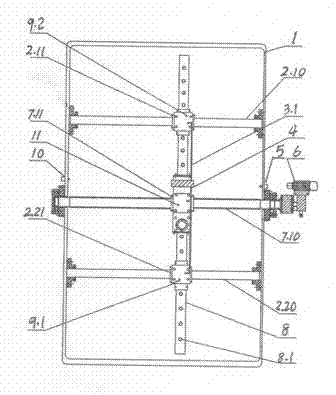

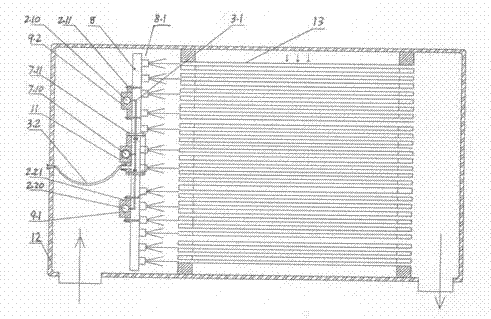

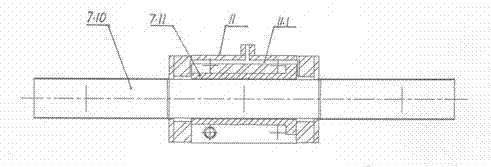

[0025] The present invention creates an embodiment of an online cleaning device for condenser heat exchange tubes, see figure 1 , figure 2 , image 3 , its structure includes: frame 1, servo motor and reducer 6 of power mechanism, transmission lead screw 7.10 connected to the output shaft of reducer, drive nut 7.11, guide rod of guide mechanism arranged symmetrically and parallel to drive lead screw 7.10 2.10, 2.20, the guide bearing sleeve combined with the guide rod 2.11, 2.21, the high-pressure cooling water inlet hose 3.2 of the cleaning mechanism is connected to the nozzle row 8, each nozzle 8.1 corresponds to a row of heat exchange tubes 13, and the nozzle row 8 The middle part is fixed with the casing of the floating chamber 11 of the drive nut, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com