Patents

Literature

45182 results about "Sludge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. For example, it can be produced as a settled suspension obtained from conventional drinking water treatment, as sewage sludge from wastewater treatment processes or as fecal sludge from pit latrines and septic tanks. The term is also sometimes used as a generic term for solids separated from suspension in a liquid; this 'soupy' material usually contains significant quantities of 'interstitial' water (between the solid particles). Sludge can consist of a variety of particles, such as animal manure.

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

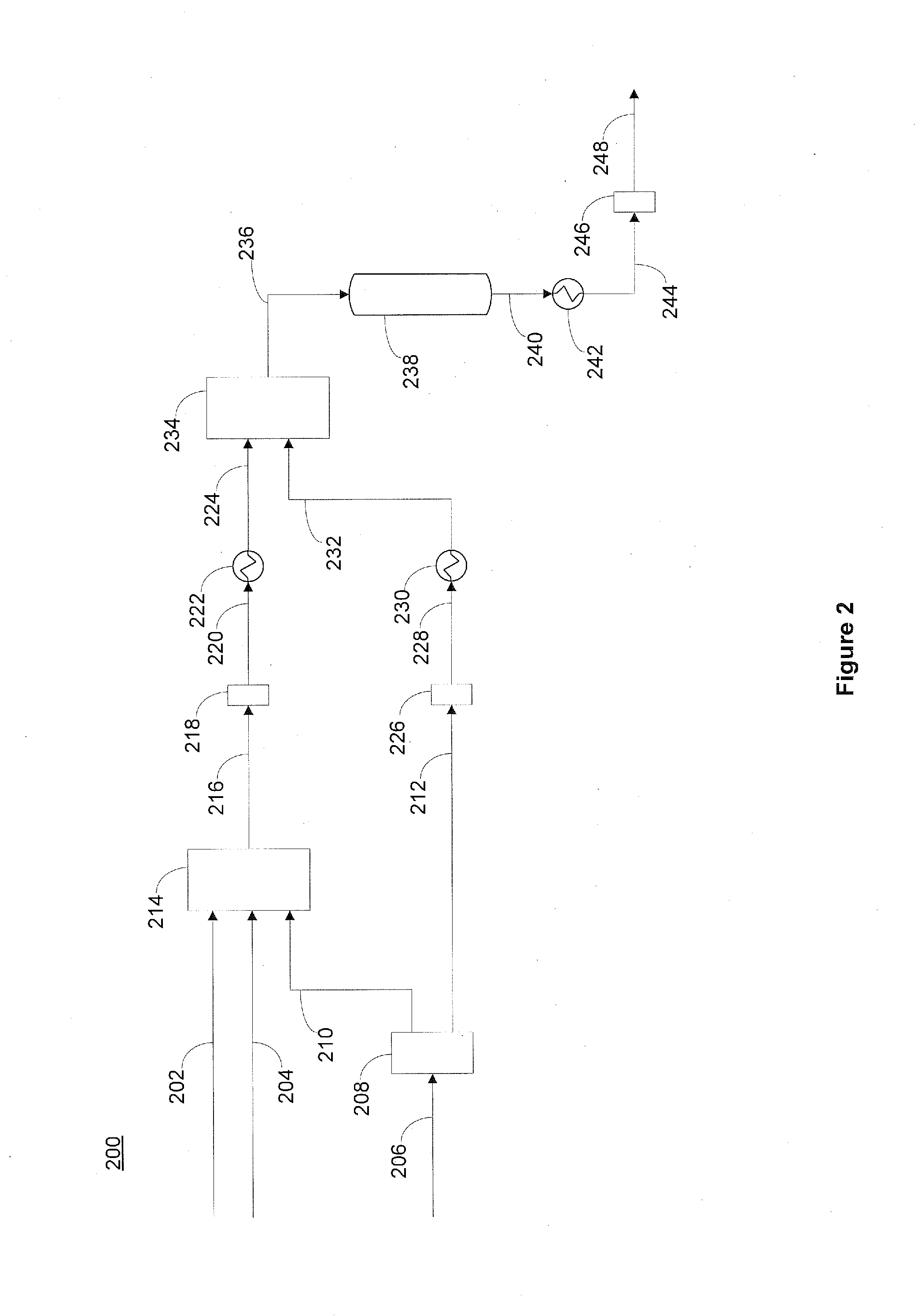

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

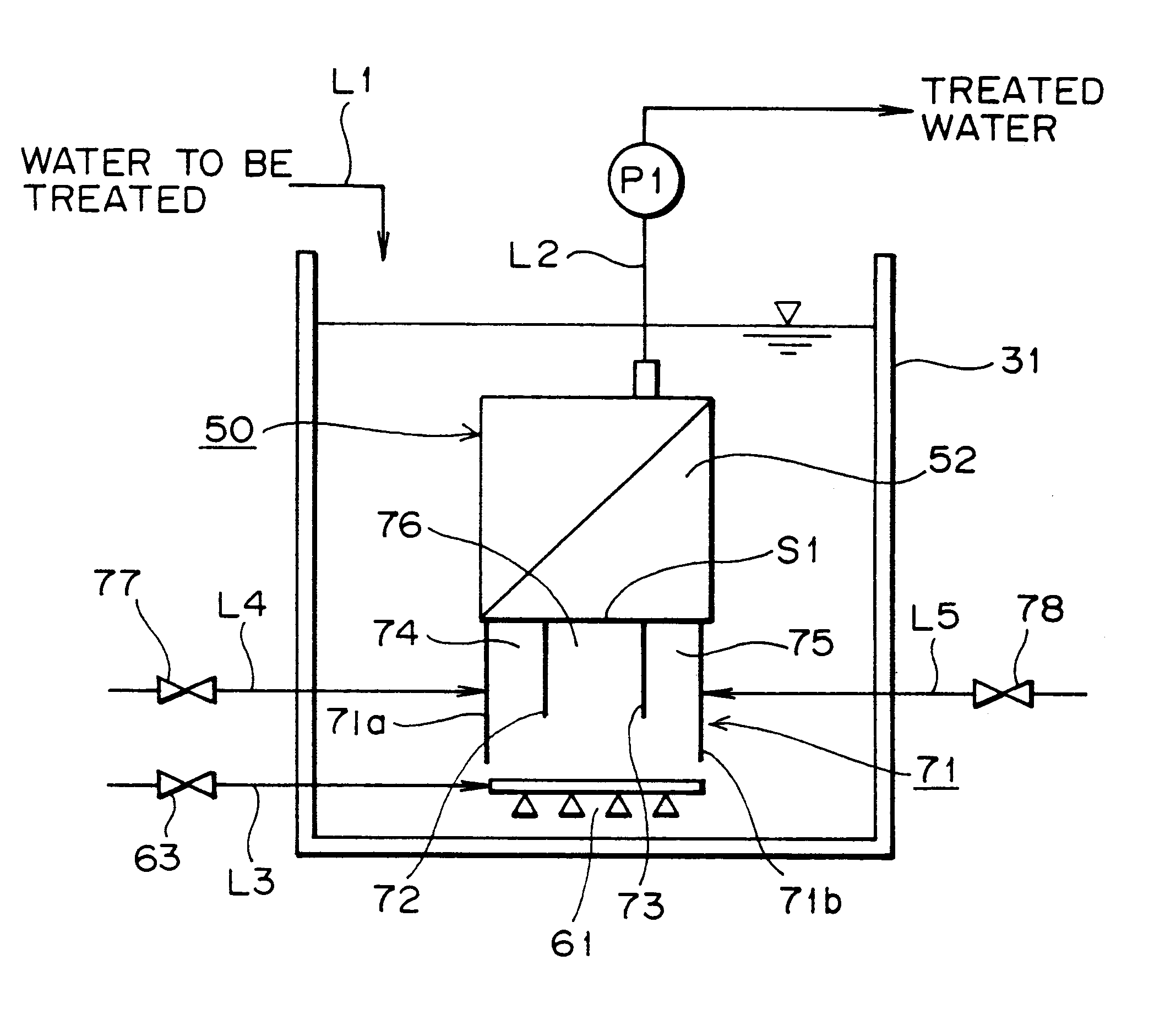

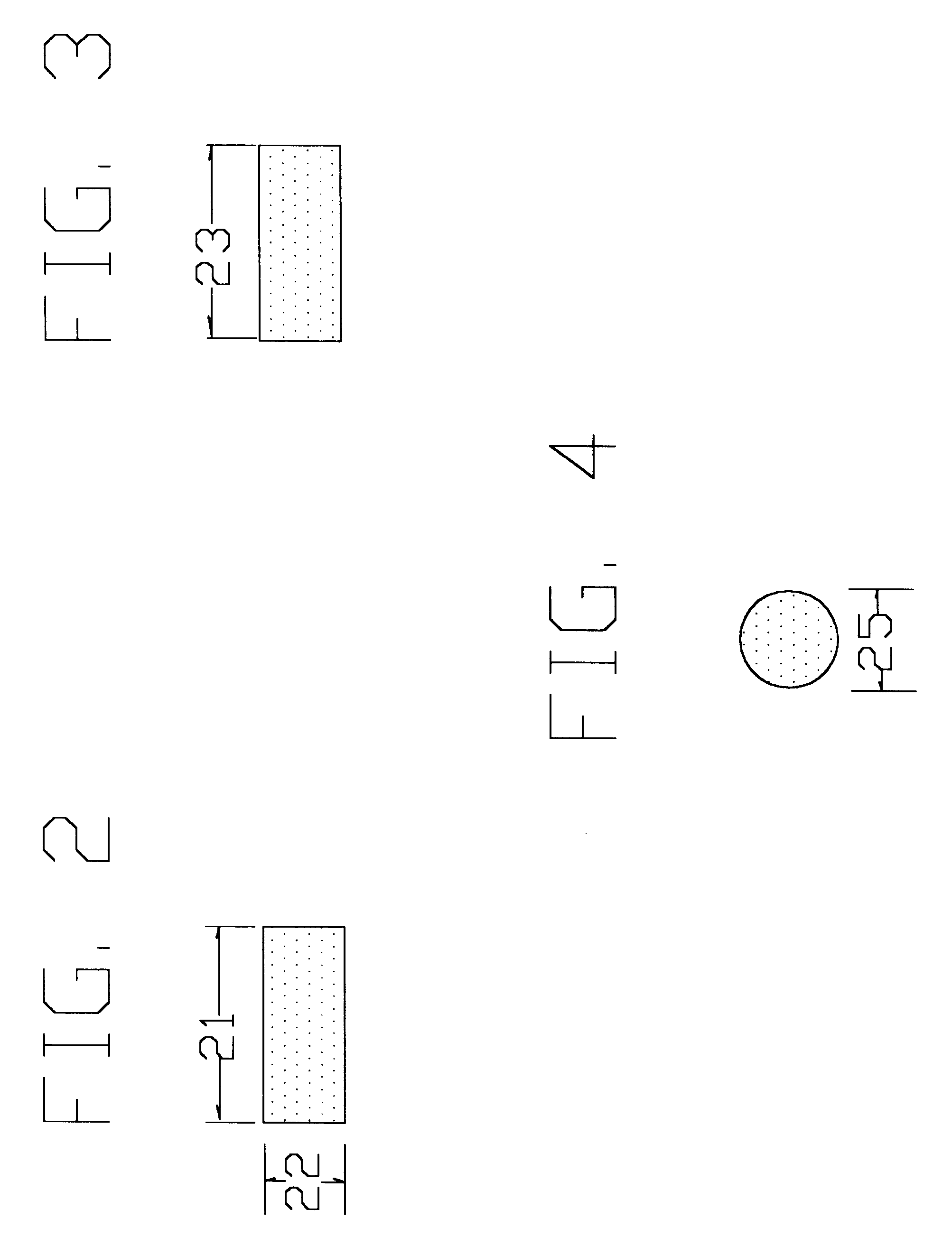

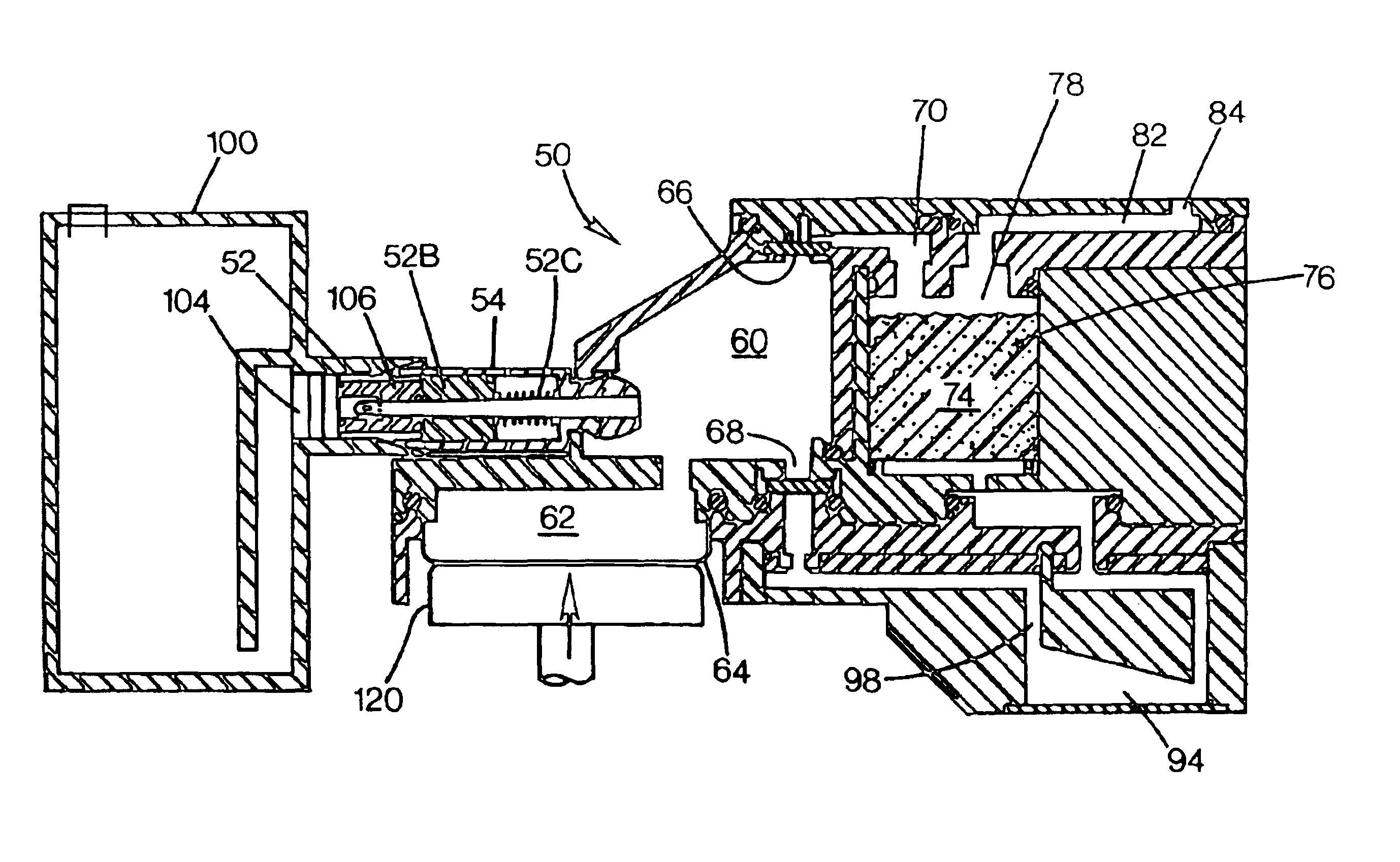

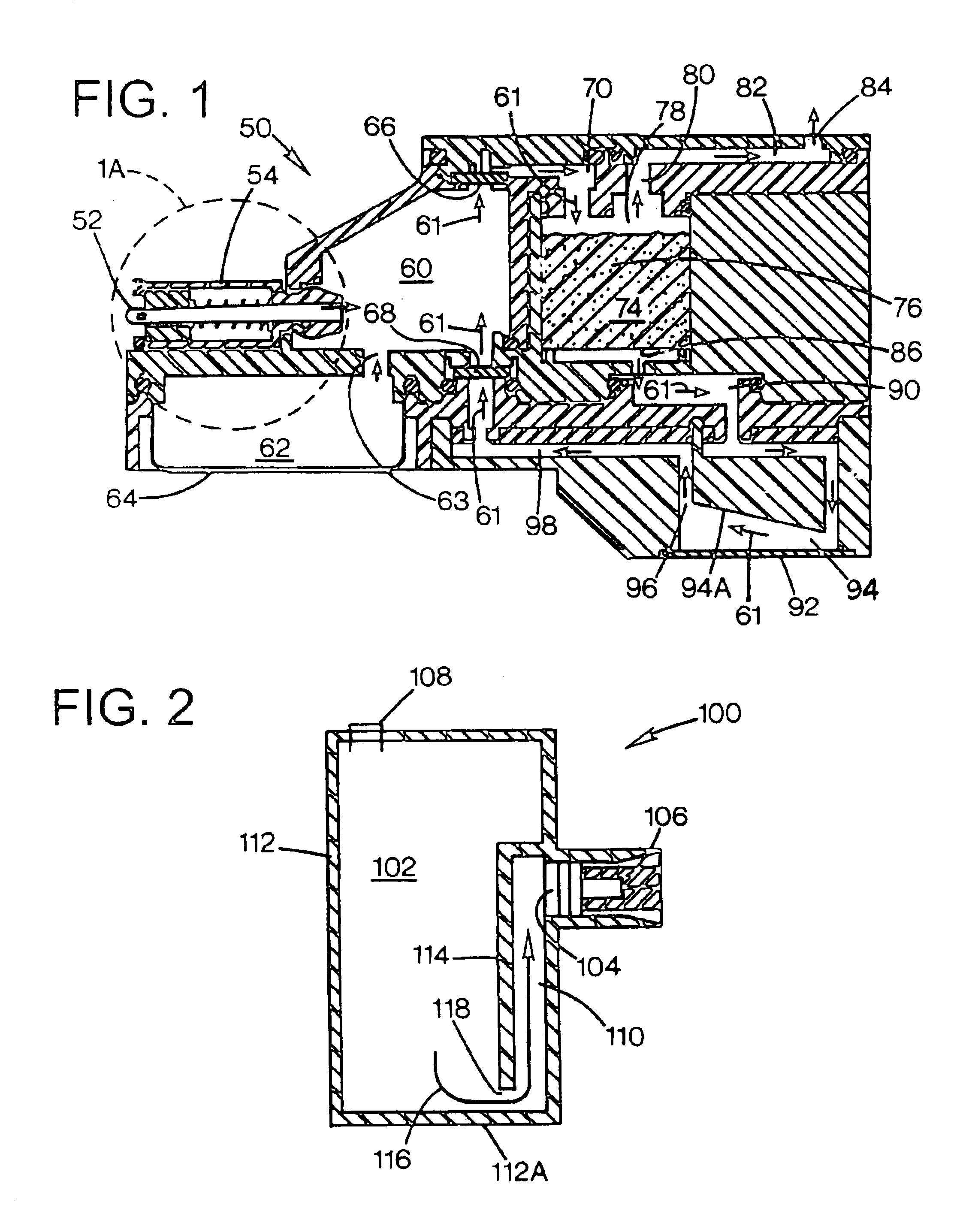

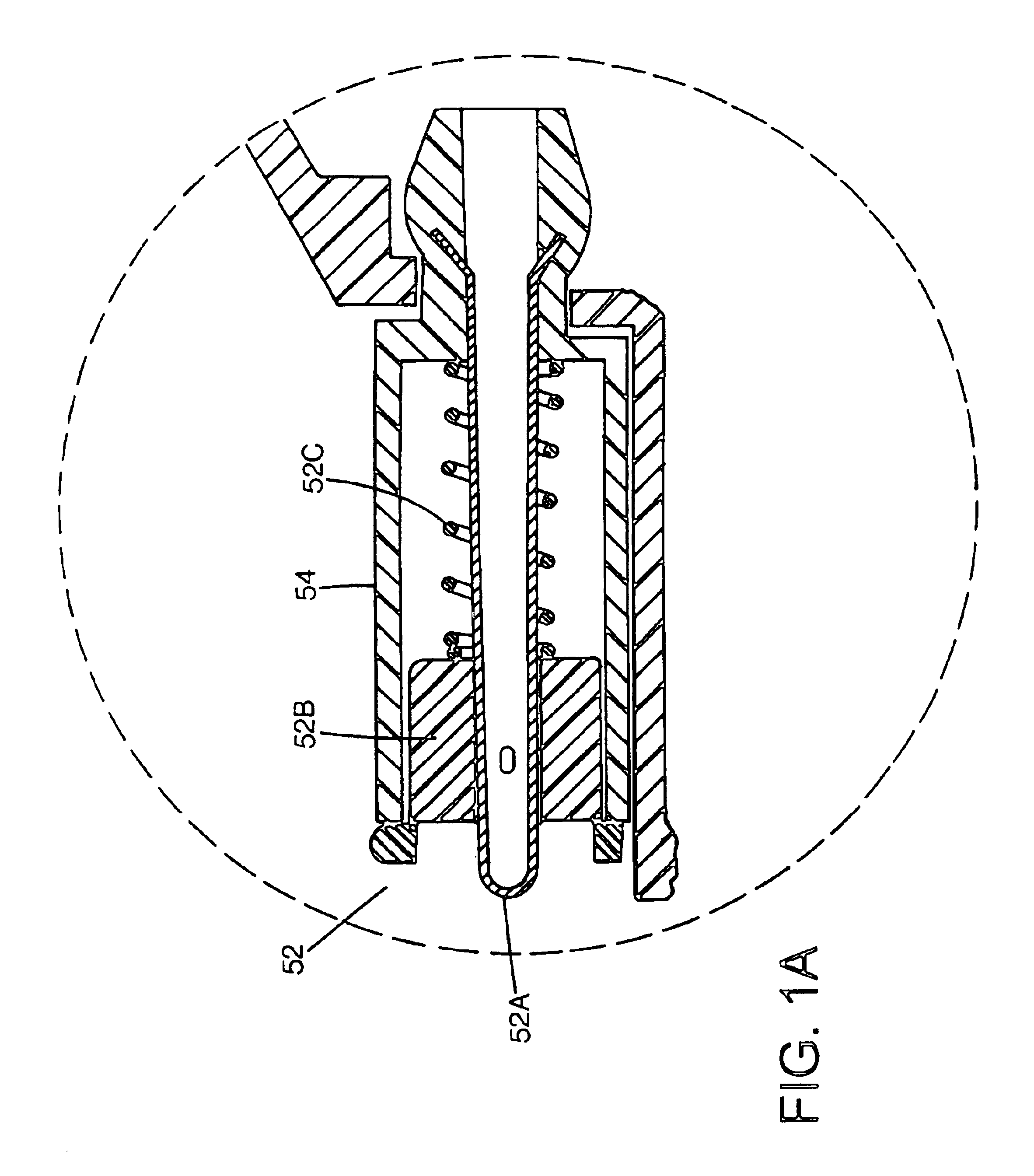

Membrane filter apparatus with gas discharge cleaning means

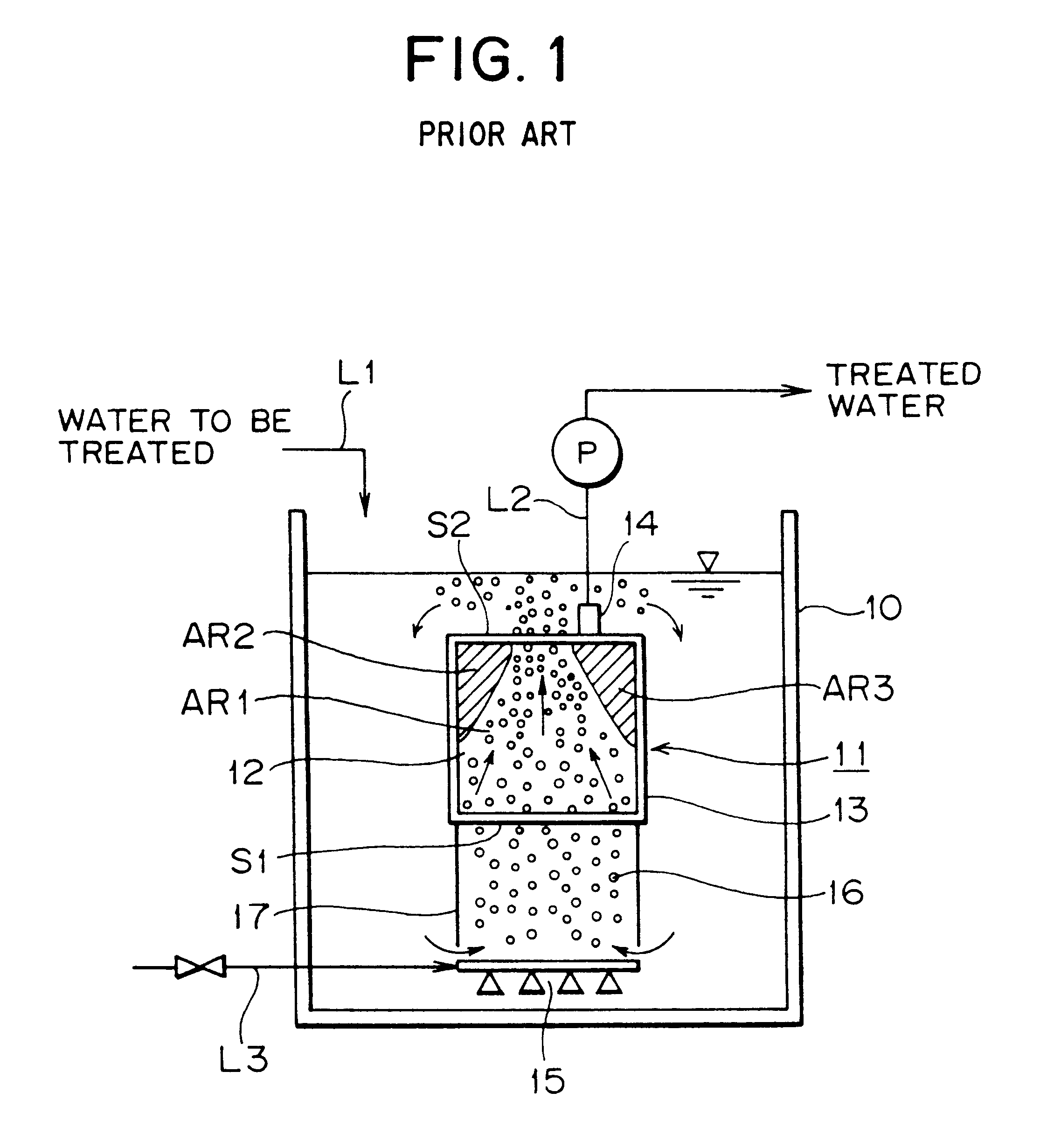

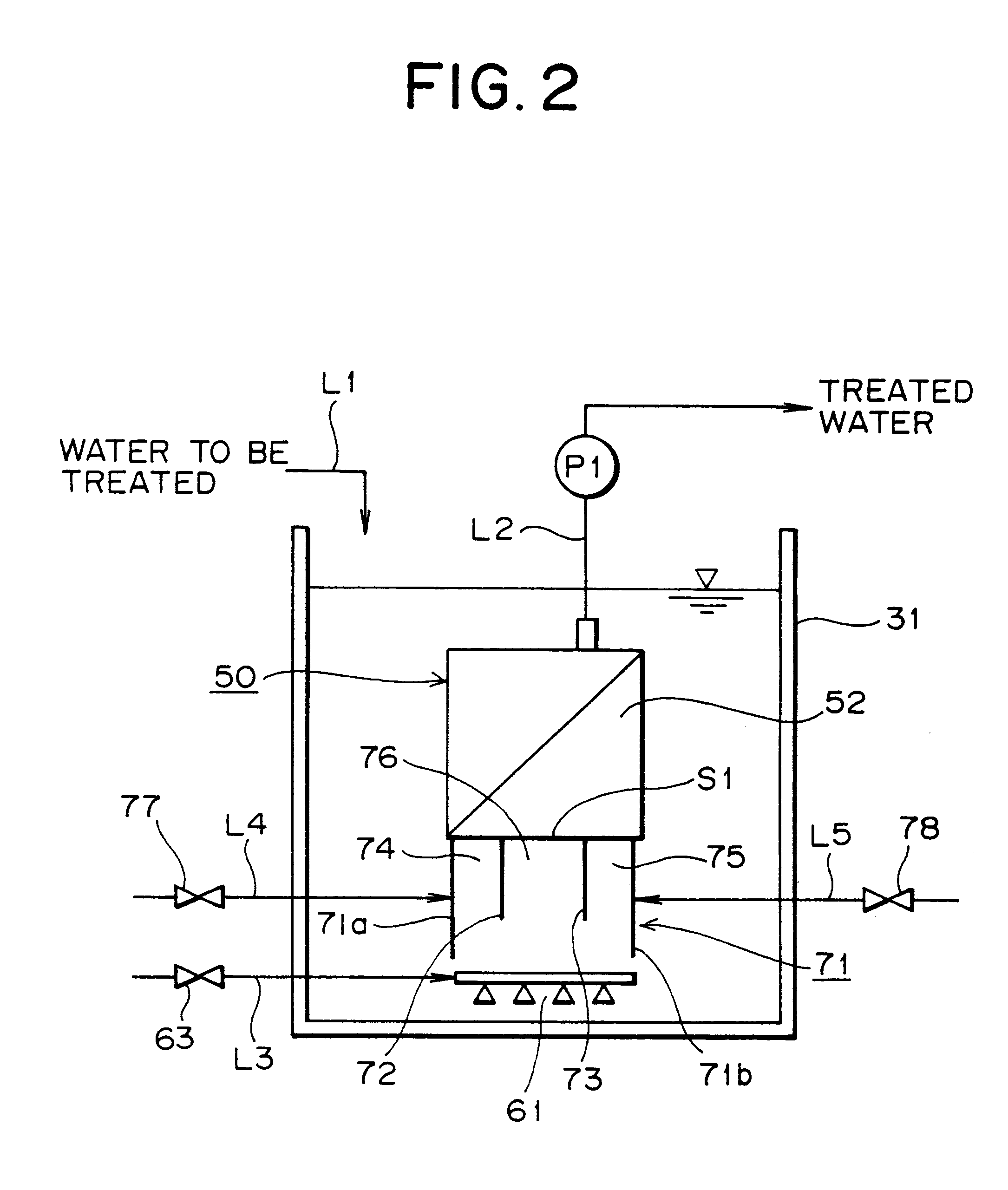

A membrane filter apparatus includes a membrane unit 50 composed of an array of membrane elements 51 disposed within a treatment tank 31. A skirt element 71 is disposed at a bottom portion of the membrane unit and an aerator 61 is disposed under the skirt. A partition is also disposed at the bottom of the membrane unit forming compartments within the skirt element. The gas bubbles discharged from the aerator increase their rising force upon entry into gaps between the membranes. Because of the arrangement of the partition within the skirt element the flow rate of bubbles along the opposite side edge portions of the membrane unit can be increased having the advantage of cleaning the entire surface of each membrane, thereby preventing clogging by sludge, SS, colloid, etc. within the gaps between the membranes. Therefore, filtration can be maintained over a longer period of time and the power required for filtration can be reduced, as well as, the frequency of manual periodic cleaning, chemical cleaning, etc.

Owner:SUMITOMO HEAVY IND LTD

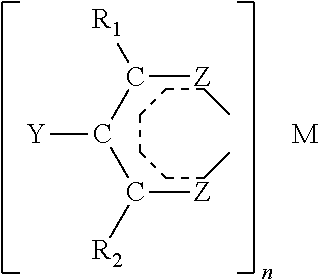

Catalytic antioxidants

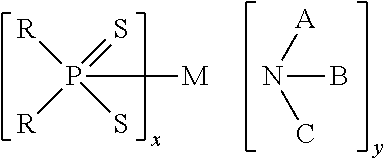

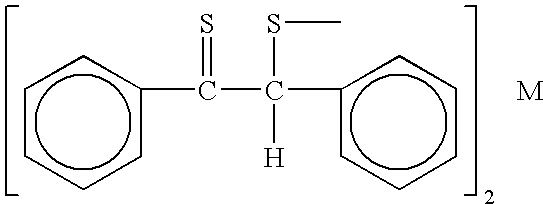

The present invention is directed to lubricating oils exhibiting improved resistance to oxidation and deposit / sludge formation comprising a lubricant base oil and catalytic antioxidants comprising an effective amount of a) one or more polymetal organometallic compound; and, b) effective amounts of one or more substituted N,N′-diaryl-o-phenylenediamine compounds or c) one or more hindered phenol compounds or both, to a method for improving the antioxidancy and the resistance to deposit / sludge formation of formulated lubricating oil compositions by the addition thereto of an effective amount of the aforementioned catalytic antioxidants, and to an additive concentrate containing the aforementioned catalytic antioxidants.

Owner:EXXON RES & ENG CO

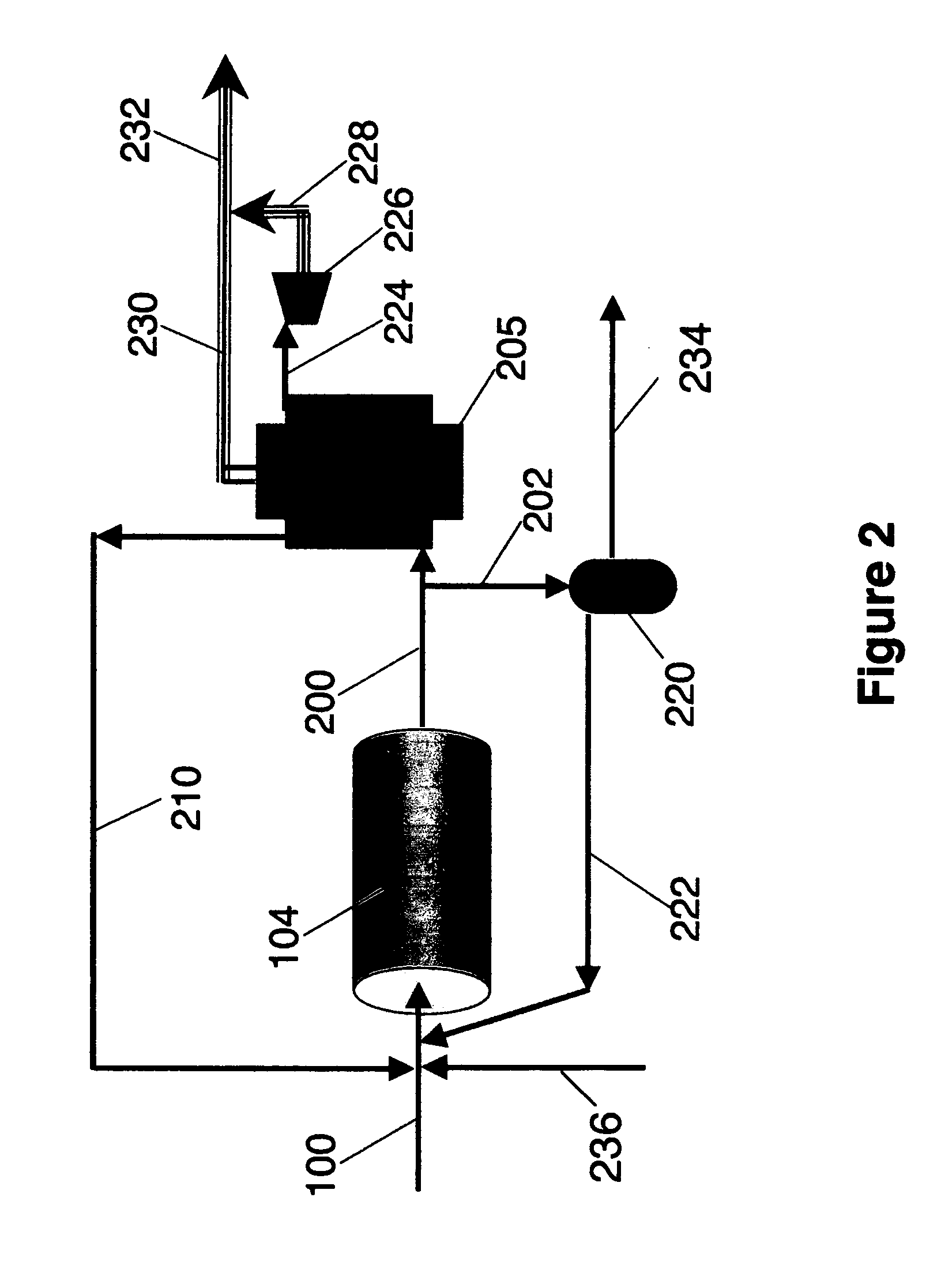

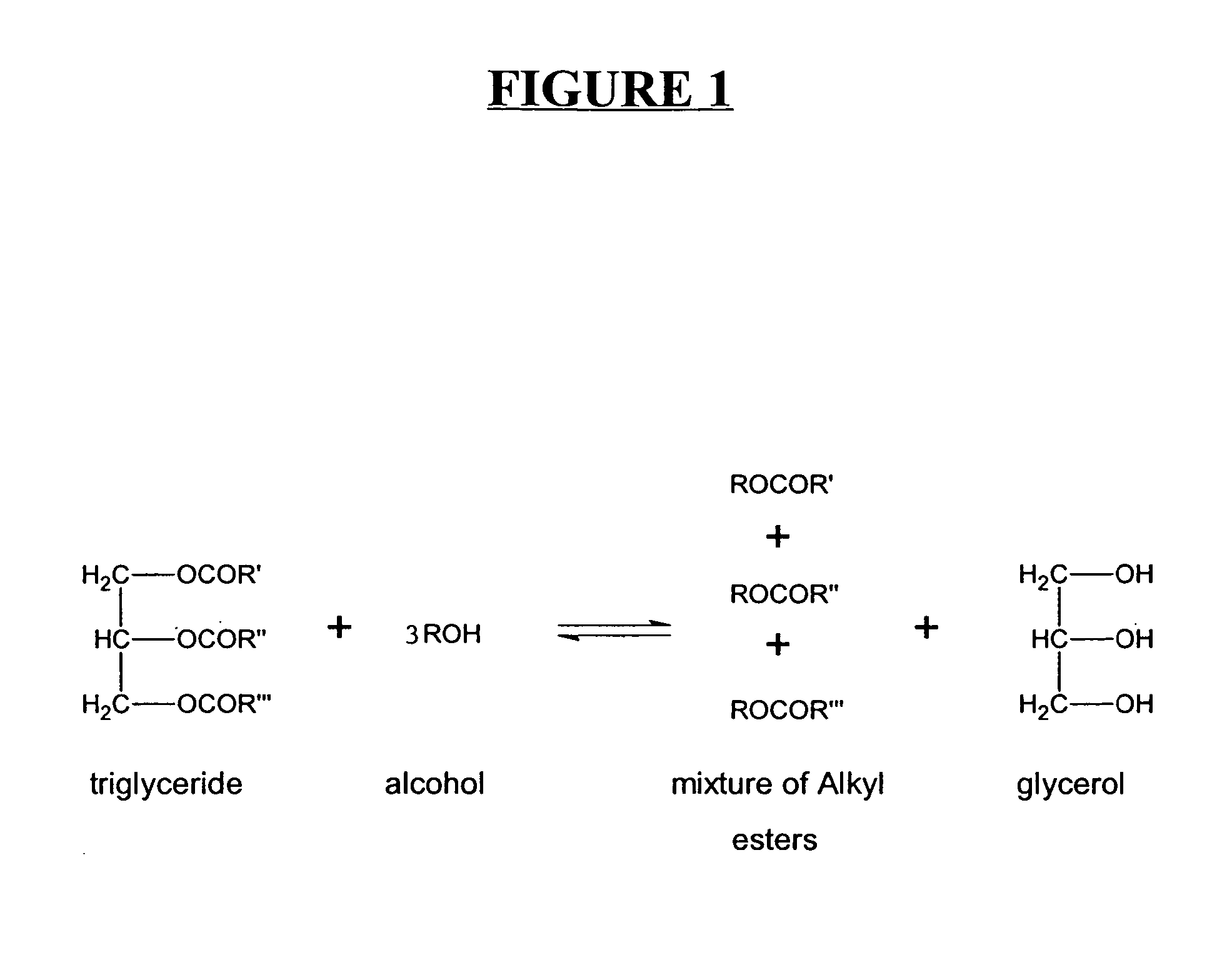

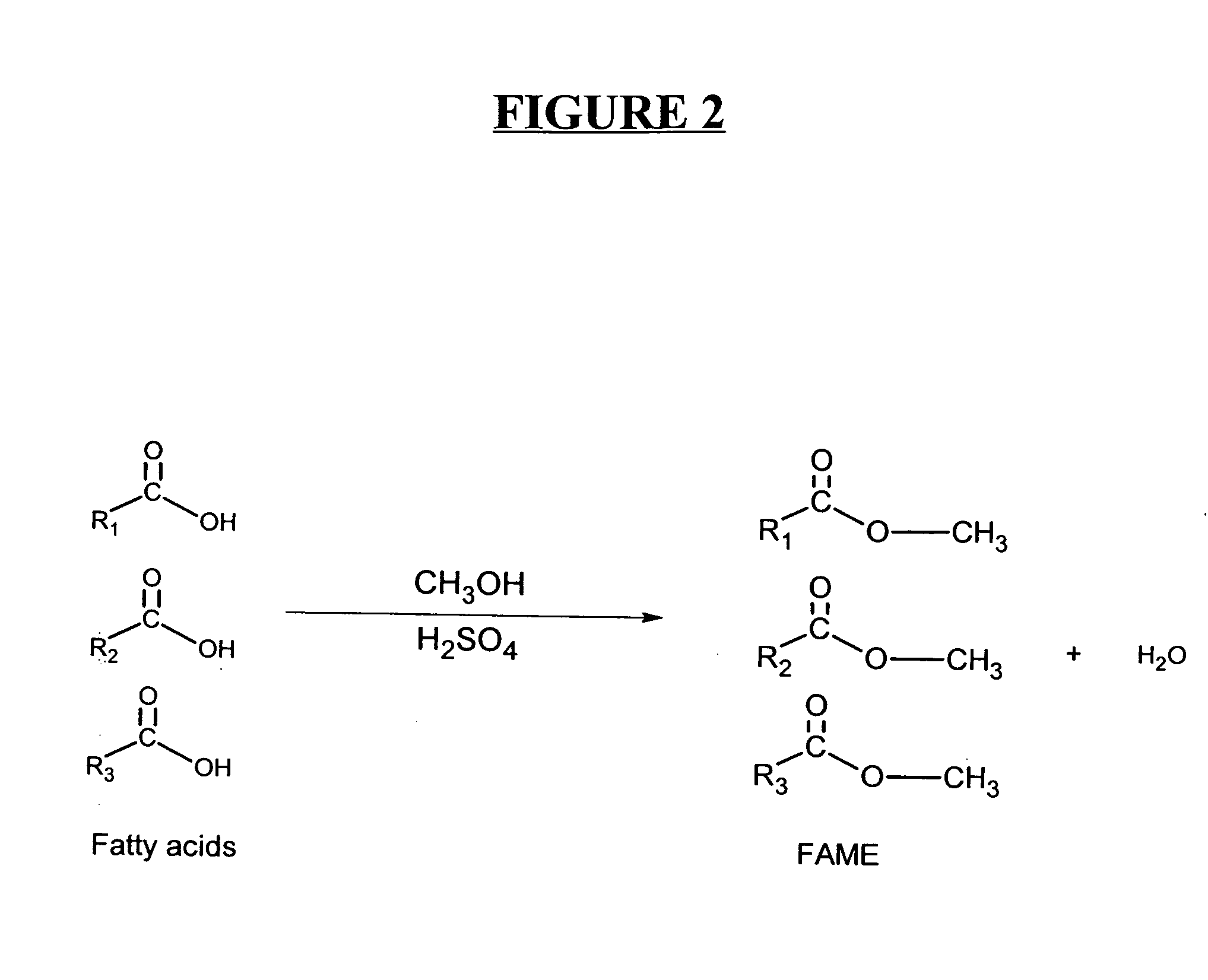

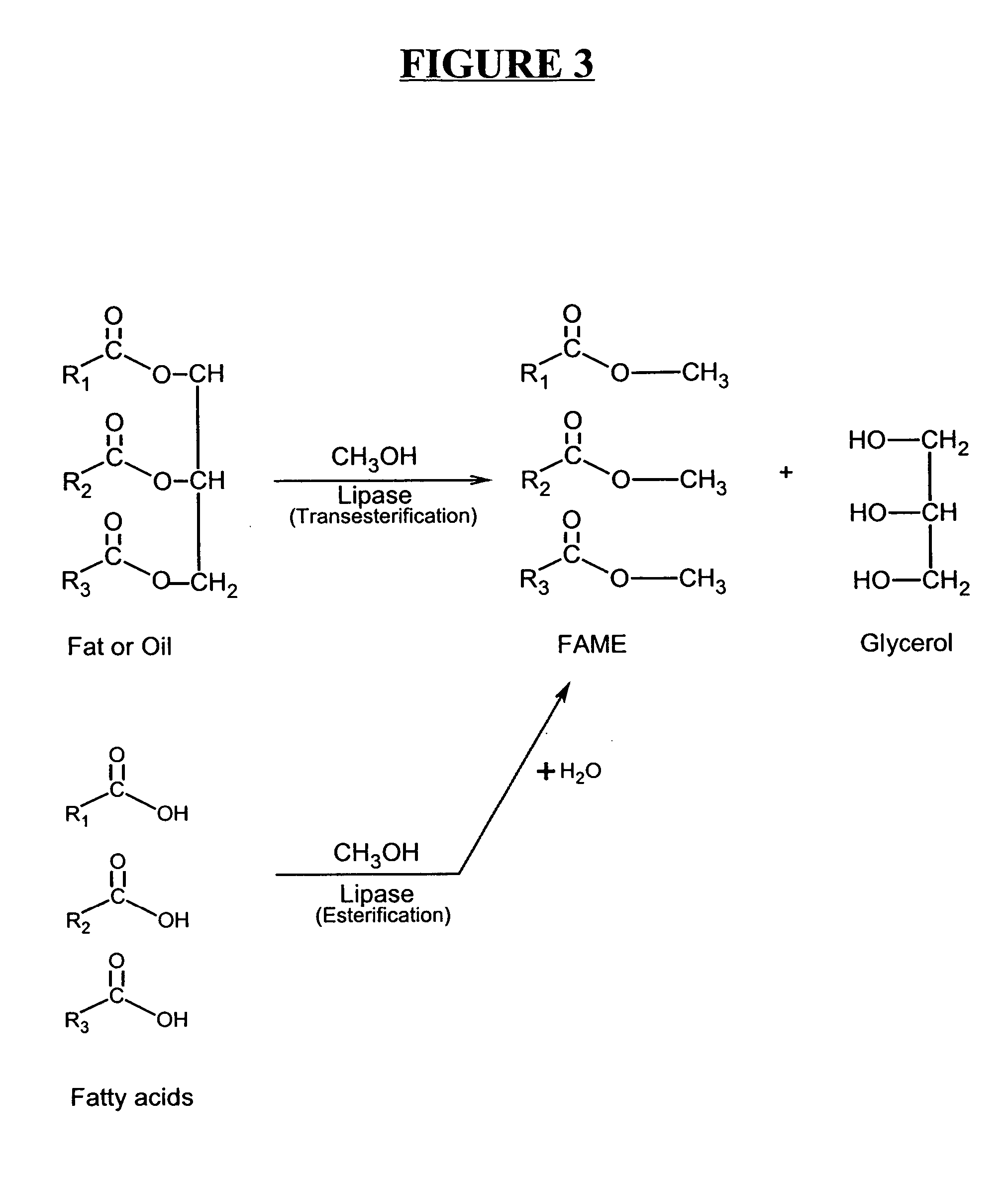

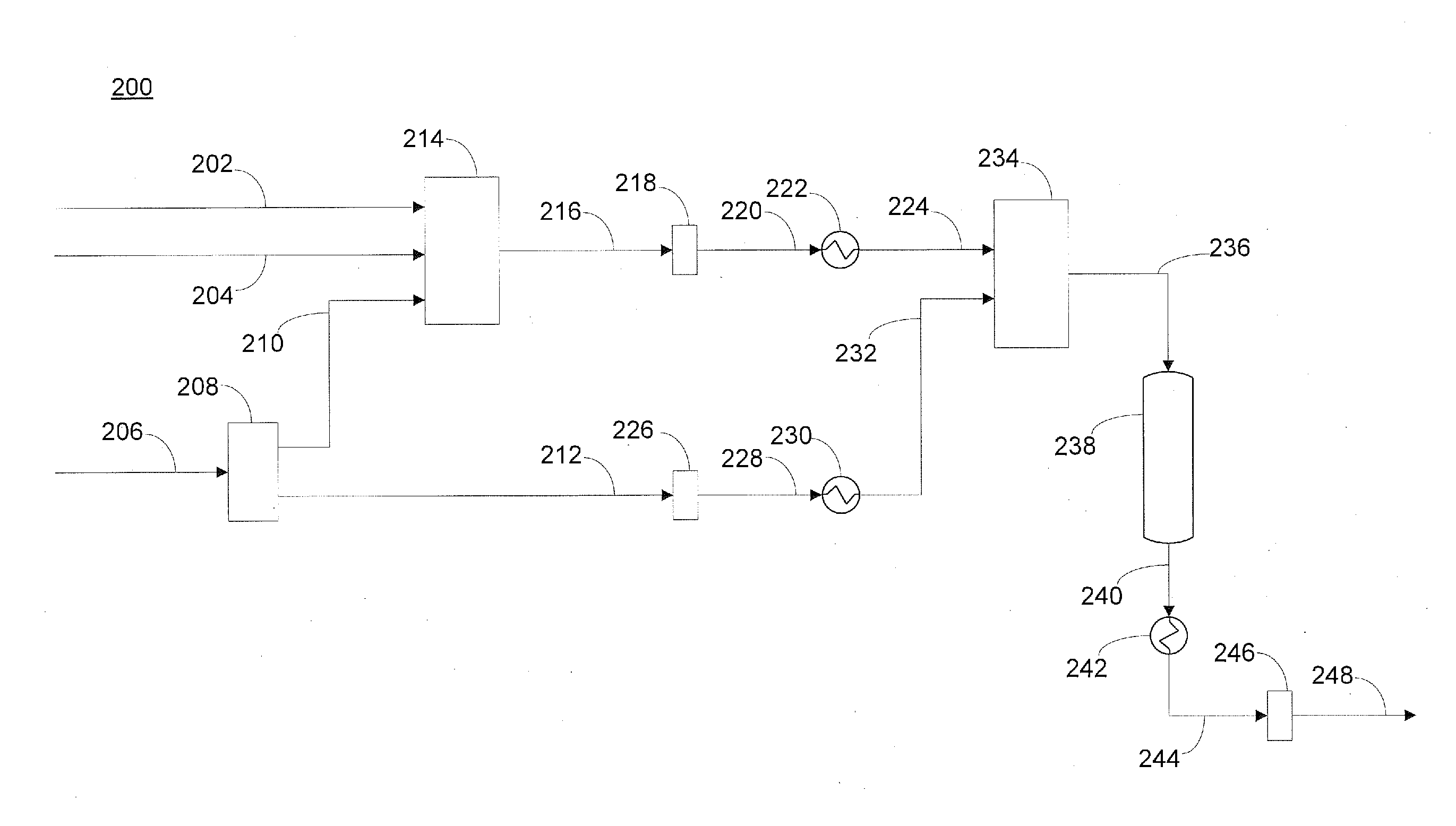

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

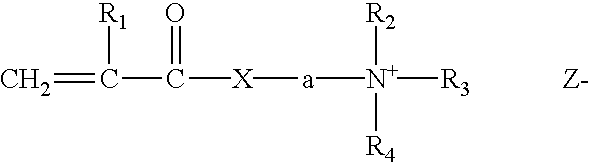

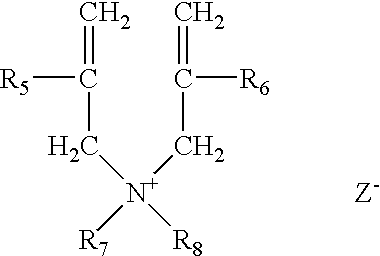

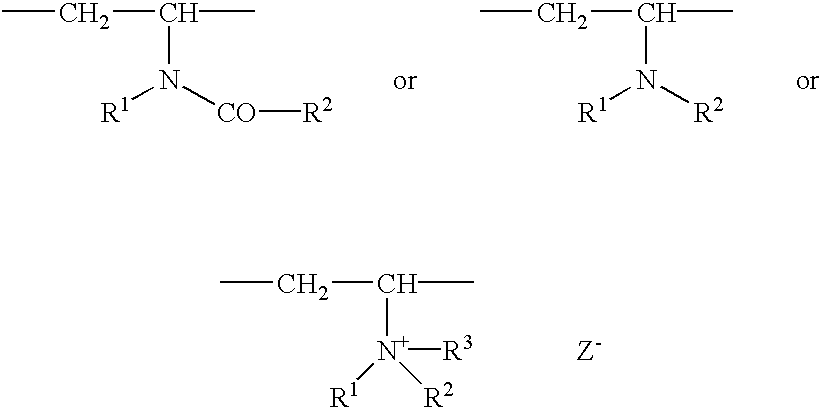

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

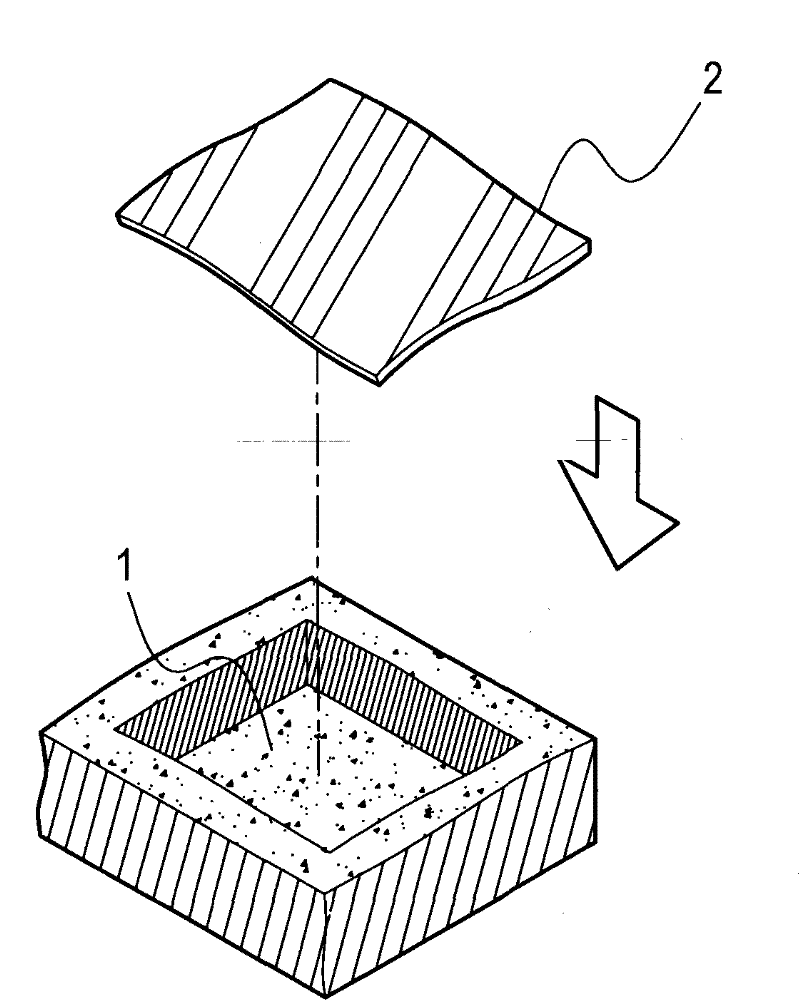

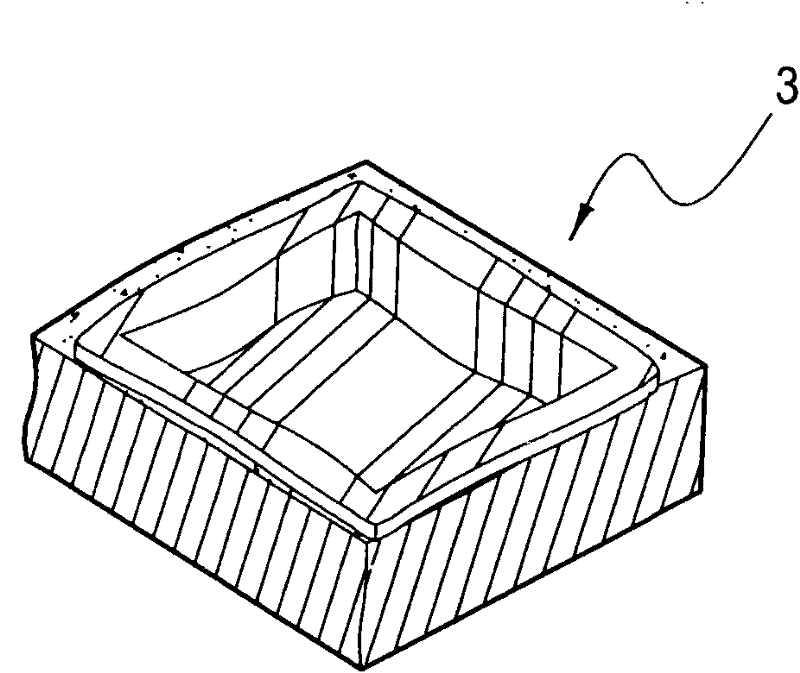

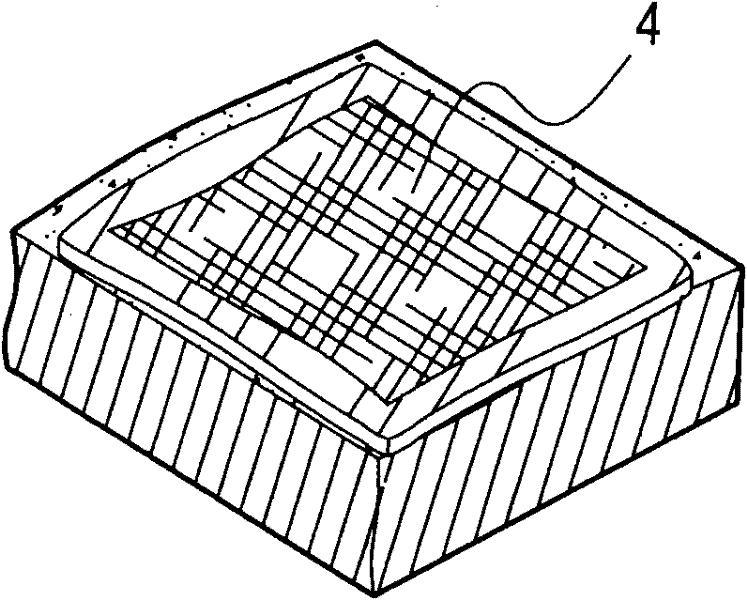

Organic cultivation medium and application method thereof

InactiveCN102217469ARefined grain structurePromote proliferationPlant cultivationCultivating equipmentsRoot growthSludge

The invention discloses an organic cultivation medium and an application method thereof. The organic cultivation medium is formed by fermenting a mixture comprising organic wastes (comprising straws, animal manures and organic garbage), sludge soil (urban sludge and substrate sludge of rivers and lakes) and composite soil microorganism preparations. The organic cultivation medium can be applied to plant and crop planting, and can be mixed with microelements, water-retaining agents and root-growth accelerants according to proportions in accordance with the nutrition requirement characteristics of plants and crops to form organic soil with common soil, and then the organic soil can be arranged in a manual anti-leakage cultivation slot or a specific container cultivation system to cultivate crops, vegetables and fruits, flowers or Chinese herbal medicine plants, etc.

Owner:陆振冈 +1

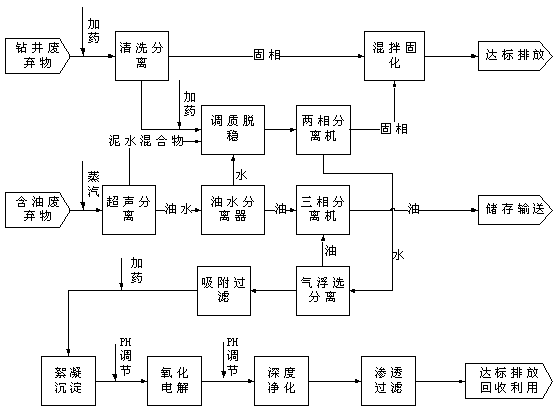

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

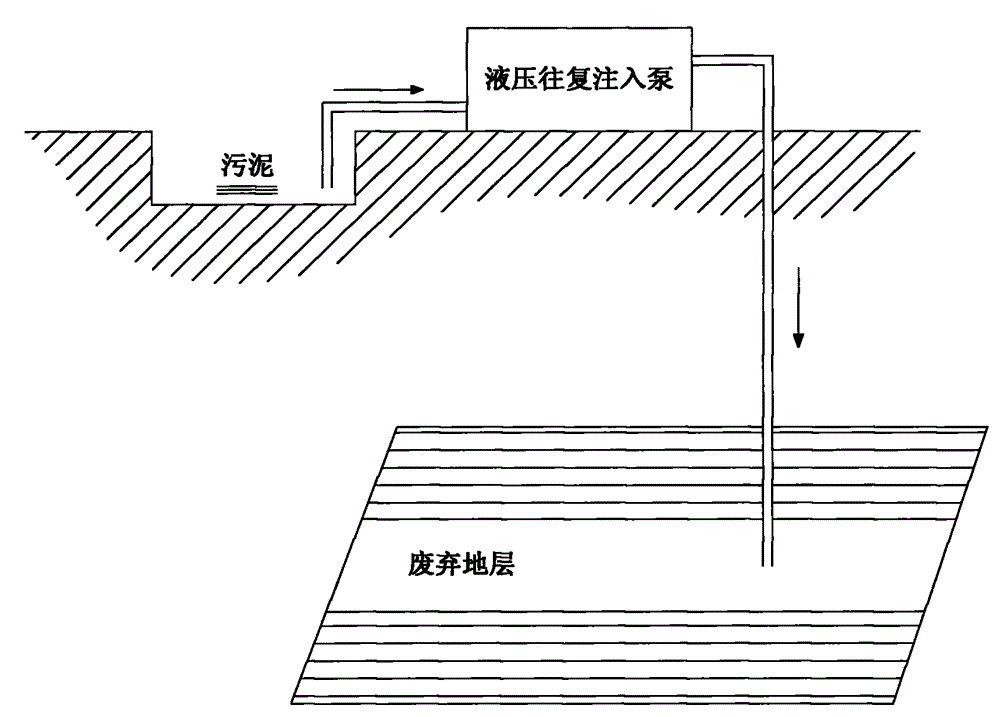

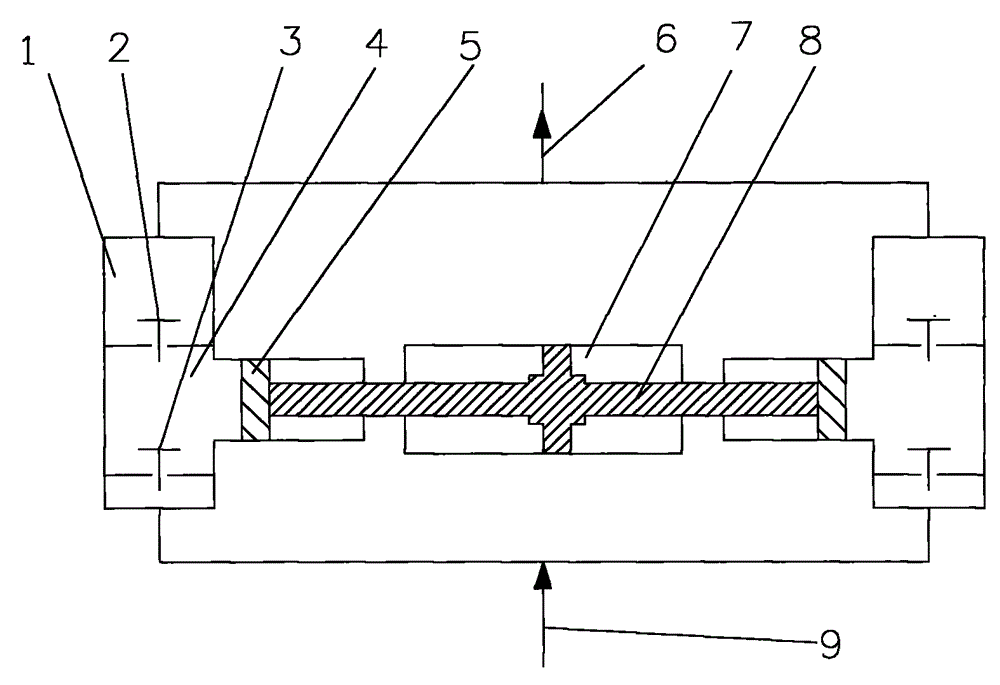

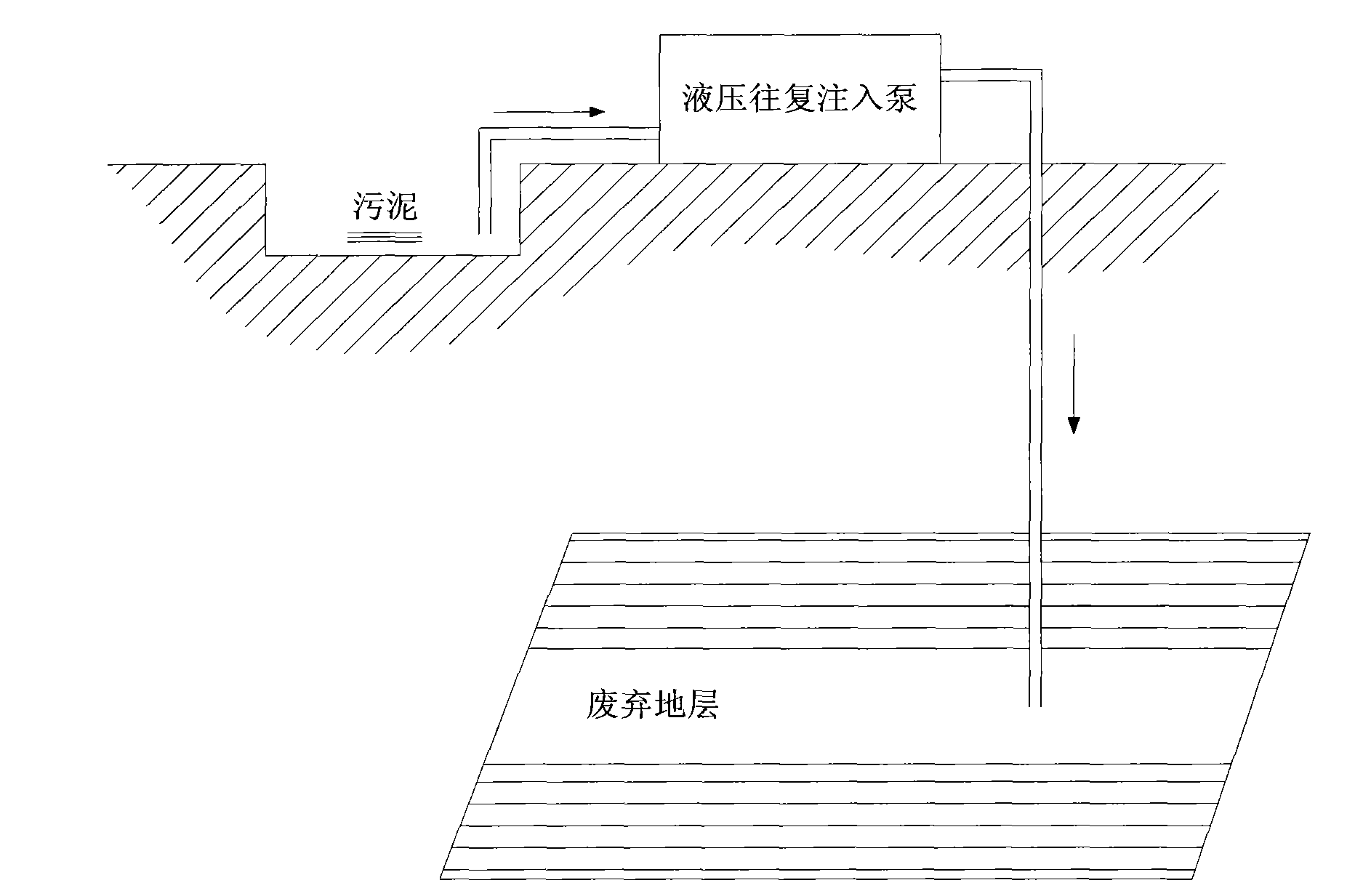

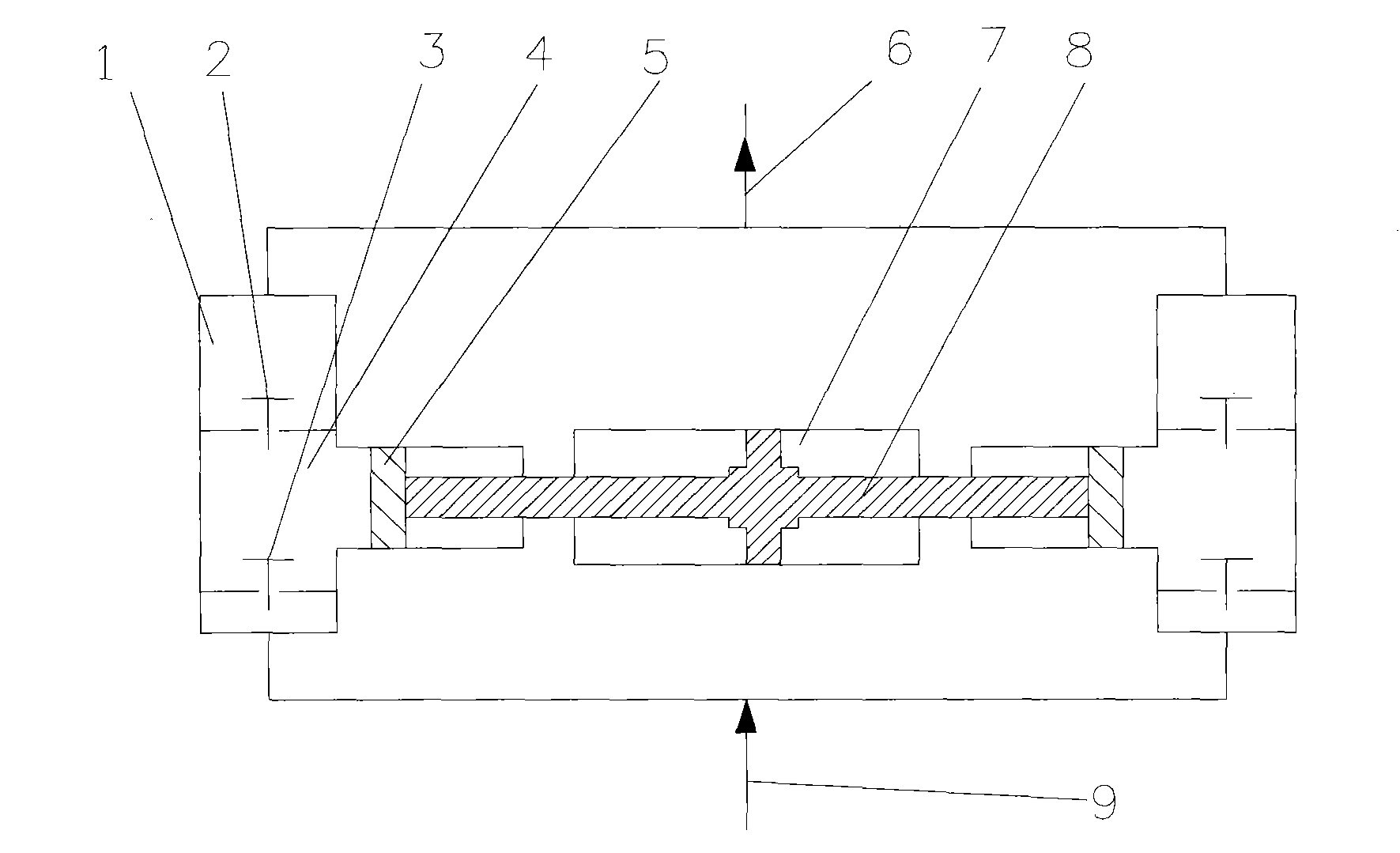

Harmless treatment method for reinjection of oil mining sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Harmless reinjection treatment method for petroleum exploitation sludge

Relating to the technical field of harmless treatment of petroleum exploitation sludge, the invention provides a harmless reinjection treatment method for petroleum exploitation sludge. By means of a pump station composed of several hydraulic injection pumps in parallel connection, the sludge generated in petroleum exploitation is sent to an abandoned layer of an oil field. The method provided in the invention employs the hydraulic injection pumps with long stroke, low stroke frequency and high pressure to inject the sludge into the abandoned layer of the oil field, therefore, the treatment problem of oilfield exploitation sludge is solved, and simultaneously the sludge is returned to underground, thus realizing recycling of petroleum resources in the sludge, enhancing the petroleum recovery rate of the oil field, and changing the waste petroleum exploitation sludge into things of value.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

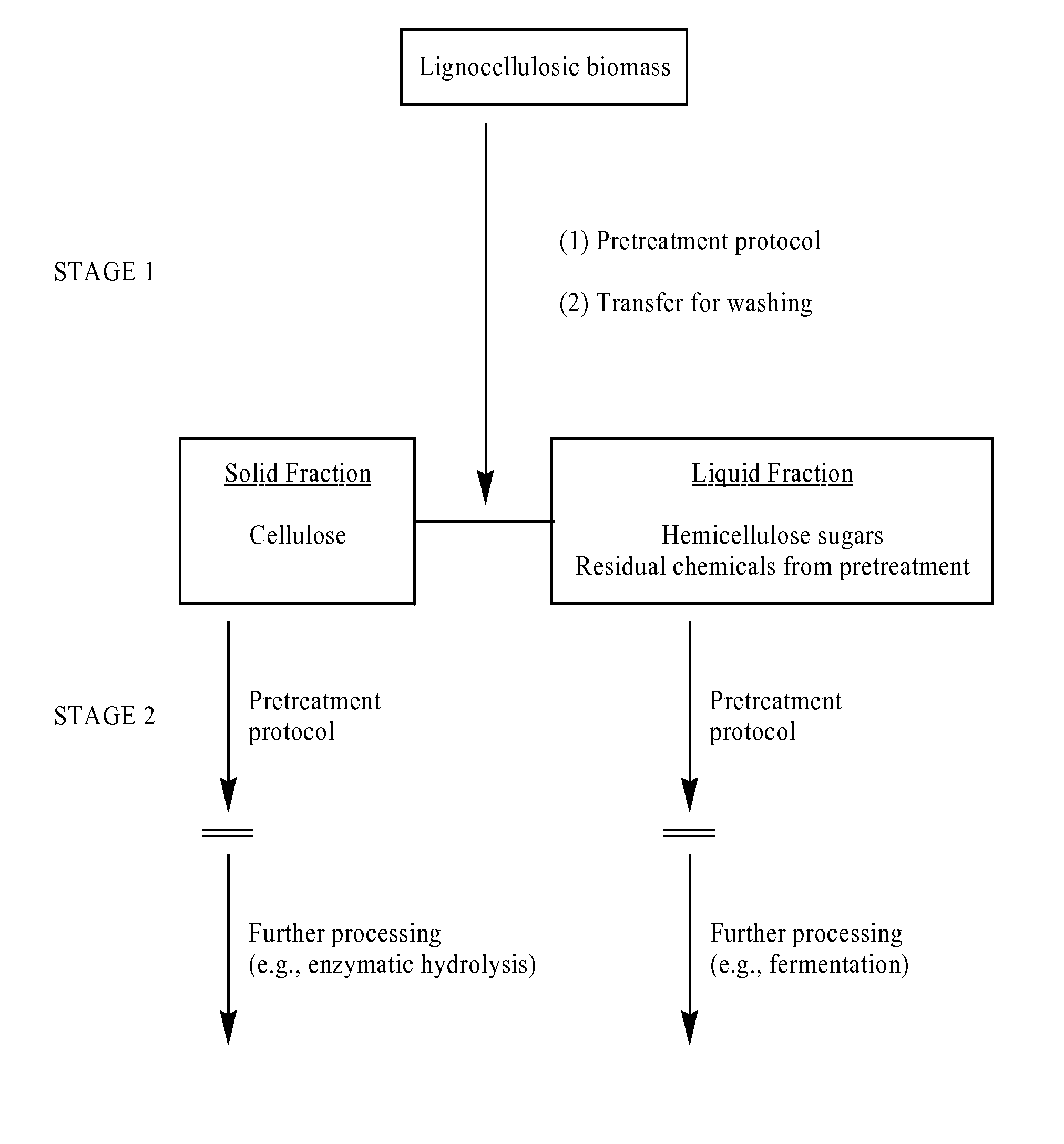

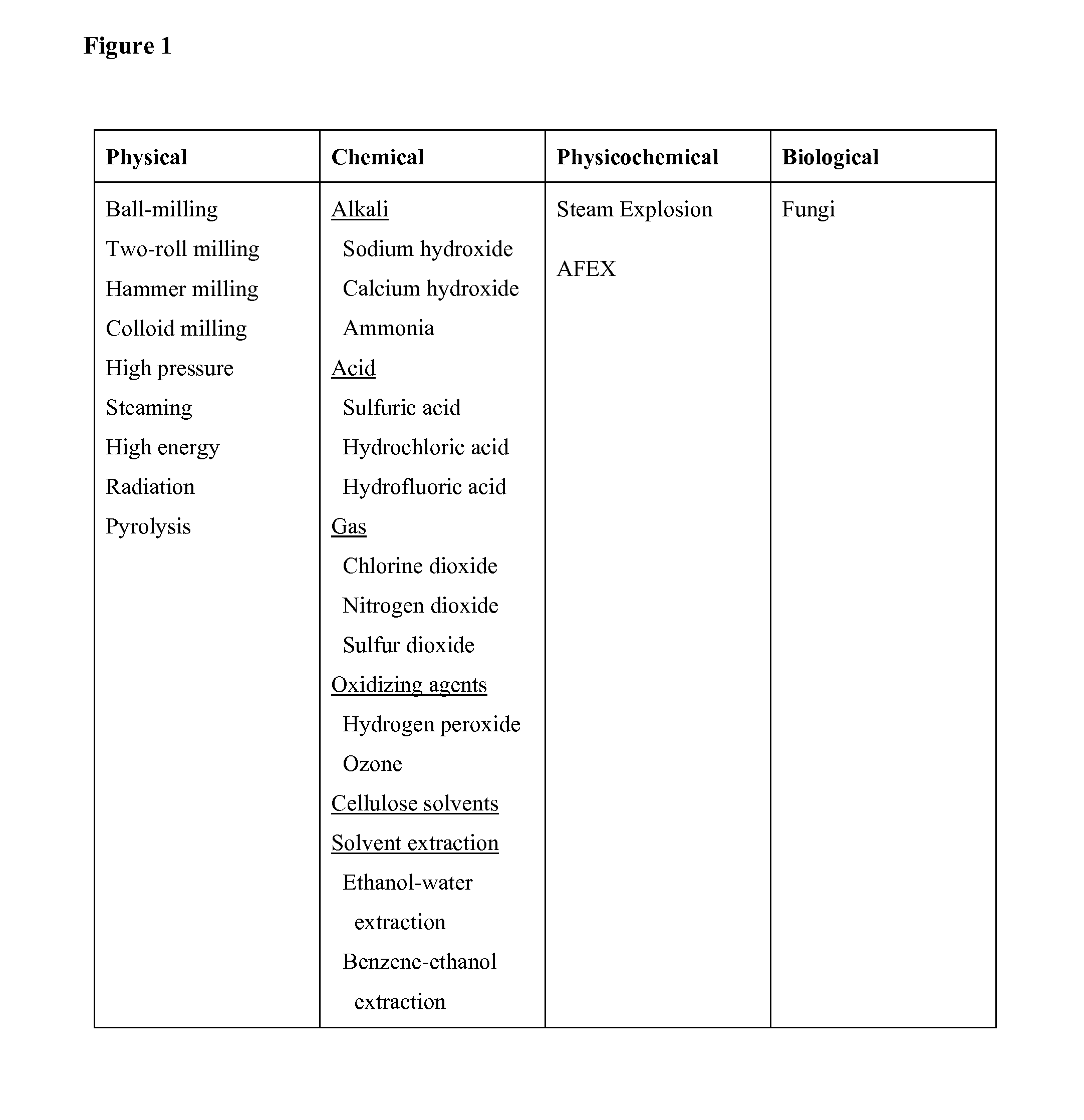

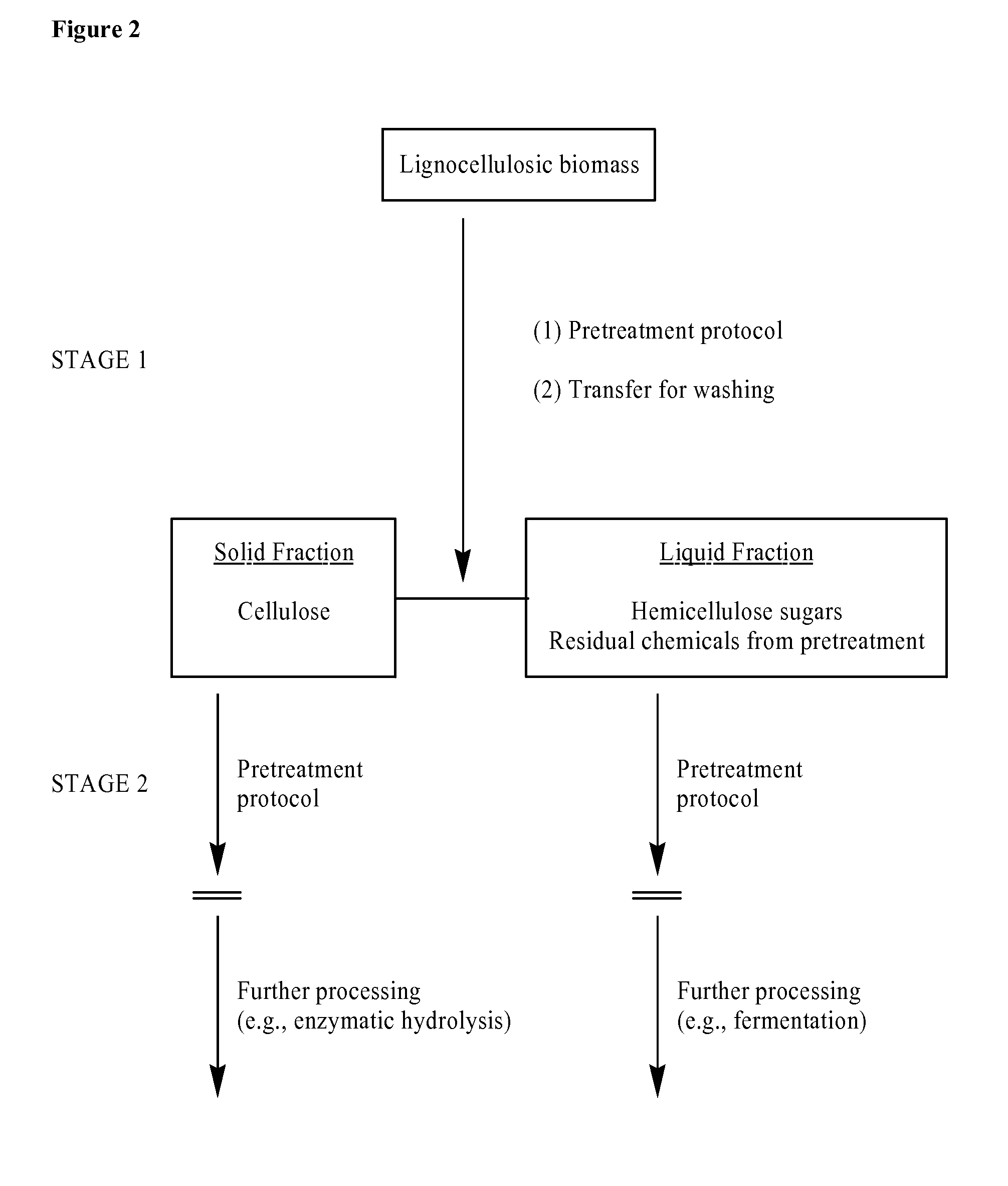

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

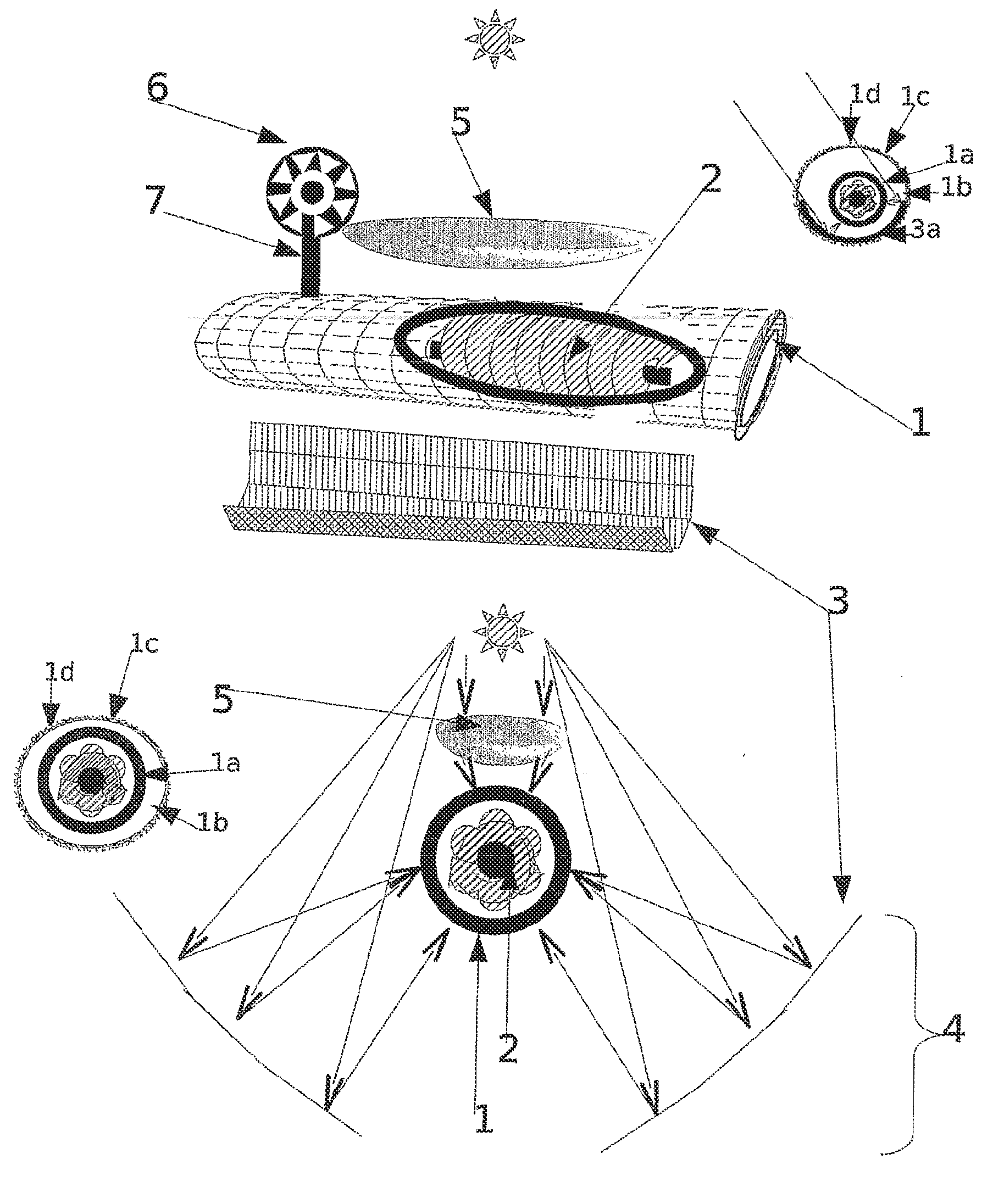

Method using solar energy, microwaves and plasmas to produce a liquid fuel and hydrogen from biomass or fossil coal

ActiveUS20100258429A1Promote gasificationImproving thermal inertiaElectrical coke oven heatingSolar heating energySludgeFractionating column

A system uses thermal solar energy coupled with microwaves and plasma for producing carbon monoxide (CO) and dihydrogen (H2) from carbonated compounds (biomass, domestic waste, sludge from waste water, fossil coal), wherein the obtained gaseous mixture yields, amongst others, hydrocarbon fuels (olefins, paraffin), esters, and alcohols via a Fischer-Tropsch synthesis. In a first step the carbonated compounds are roasted and pyrolized to produce char and dry coal, and a mixture of superheated gases containing CO2, steam, tars and non-condensable volatile materials. The method includes in a second step, and from the pyrolyis products (char or coal, gas mixture), generating a syngas substantially containing a mixture of carbon monoxide and dihydrogen, the mixture being used in Fischer-Tropsch synthesis units. After the Fischer-Tropsch step, the synthesis products are separated in a distillation column after heating in solar furnaces of mixed furnaces (solar / microwave).

Owner:UGOLIN NICOLAS

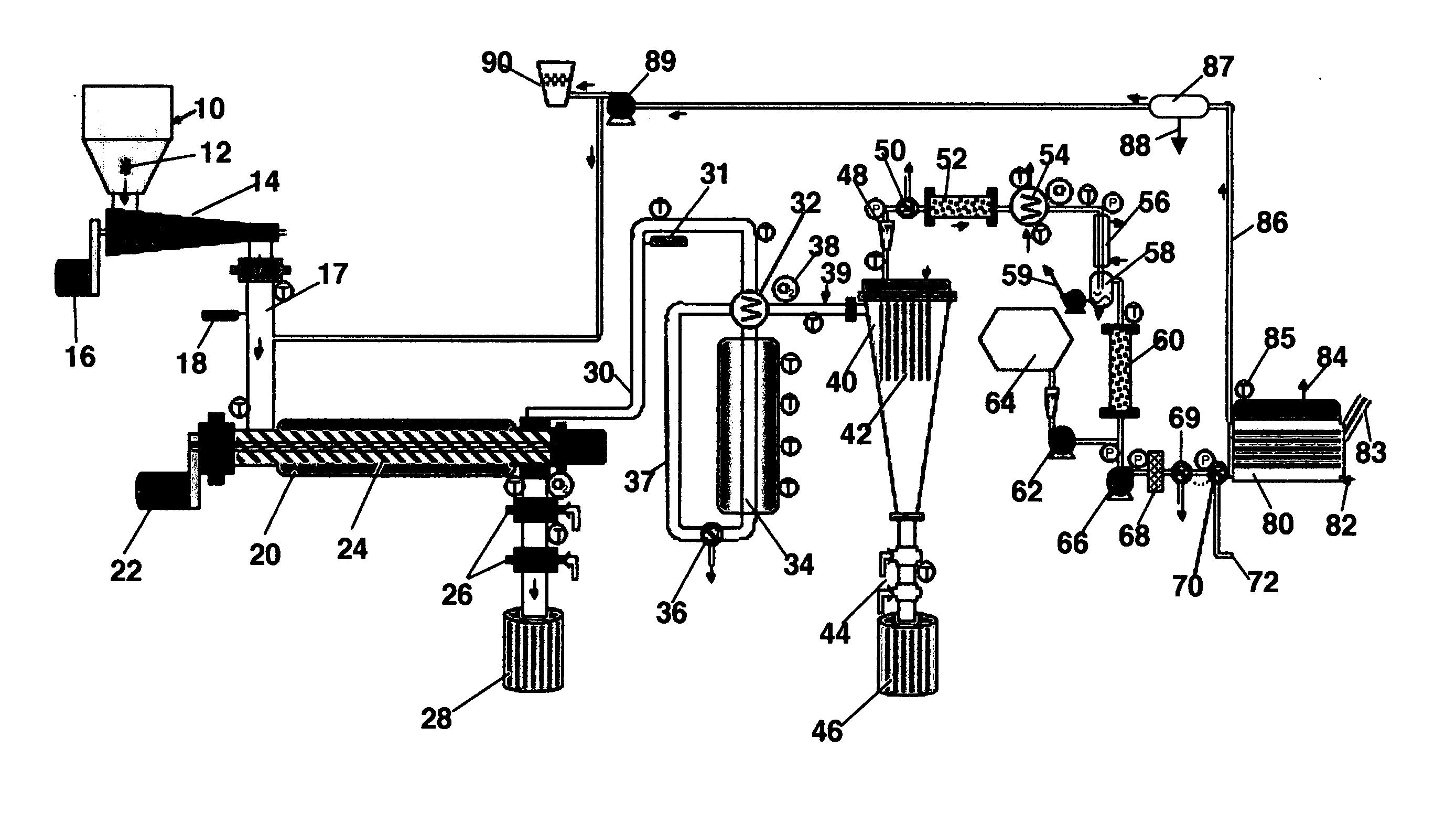

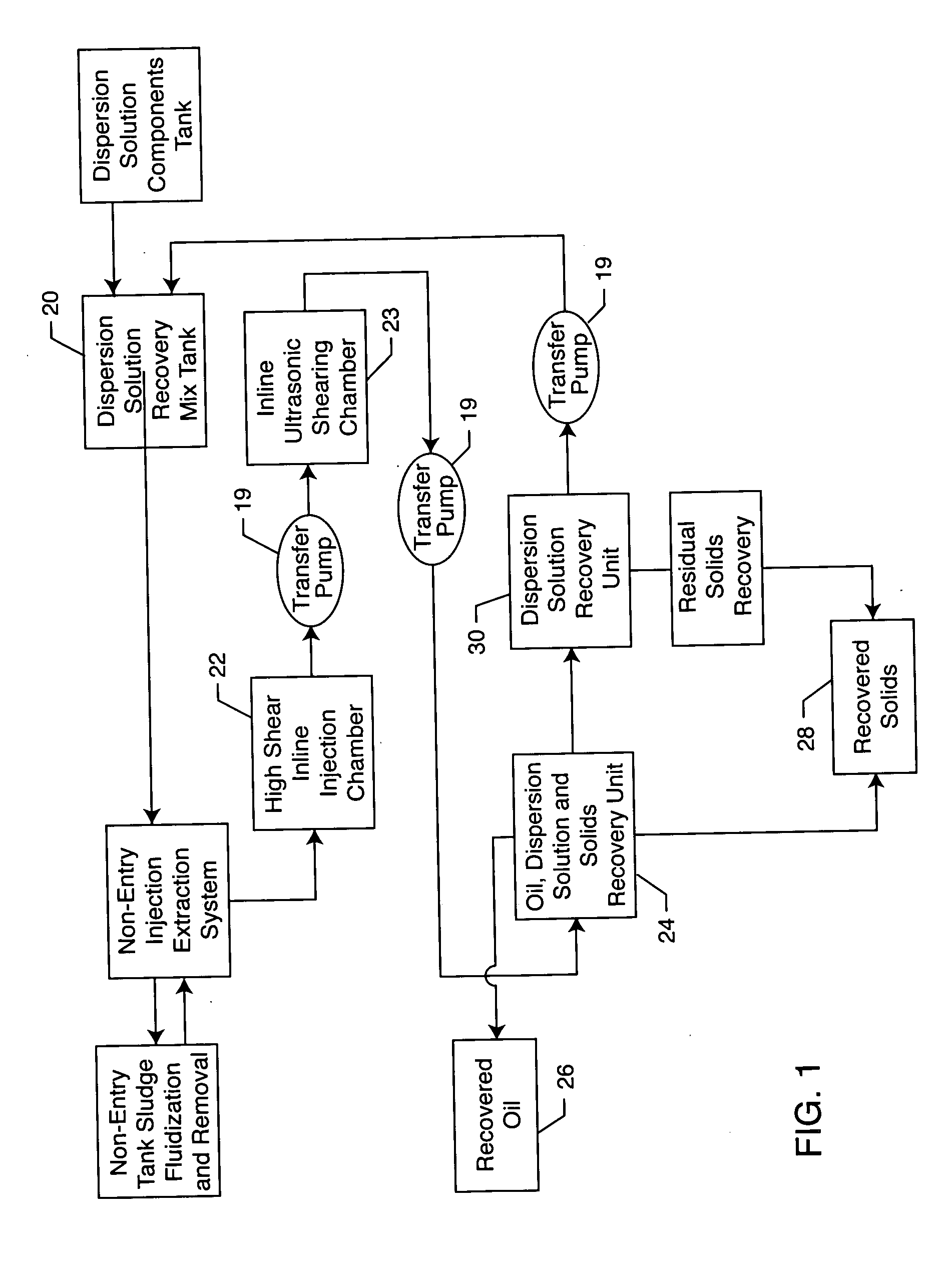

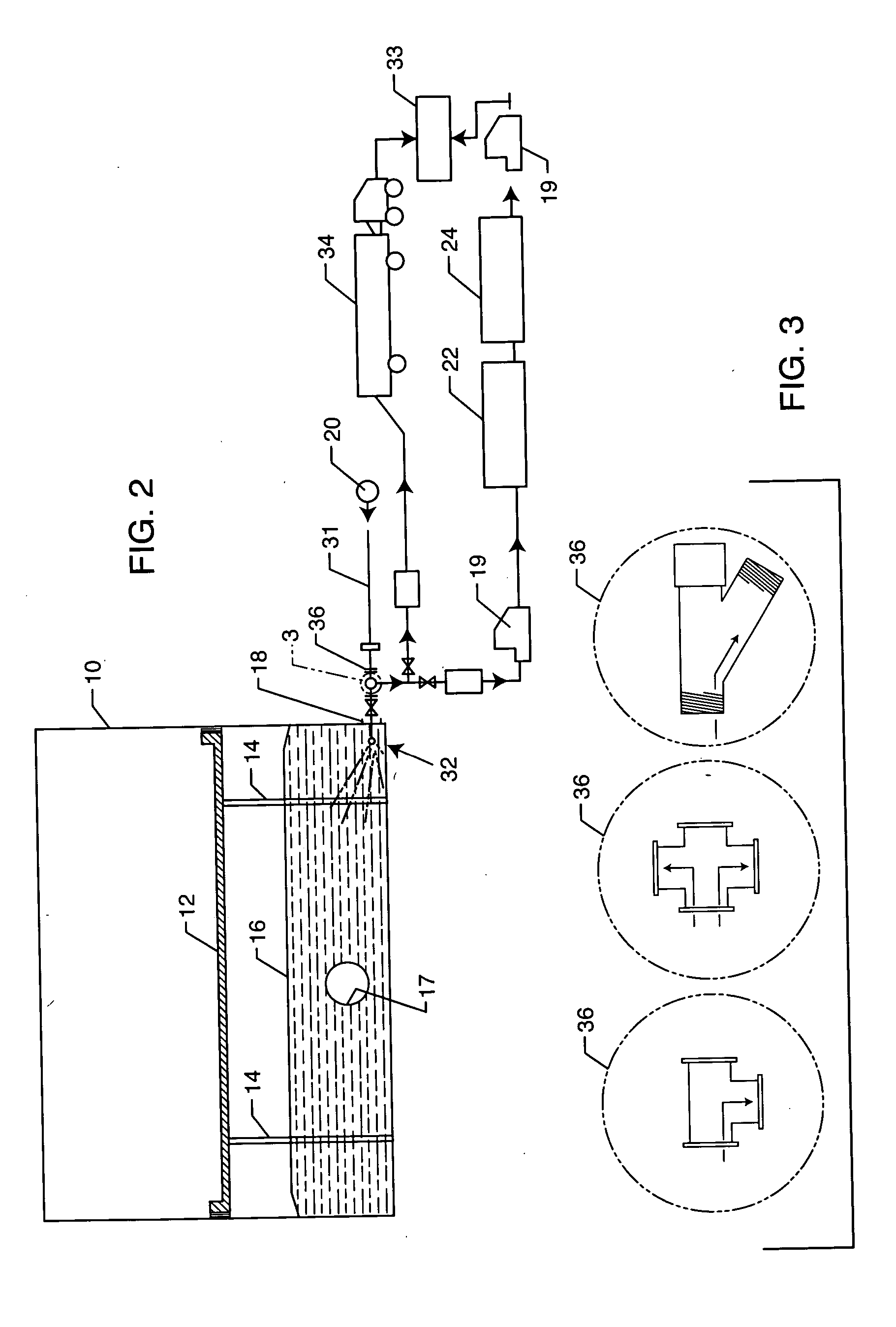

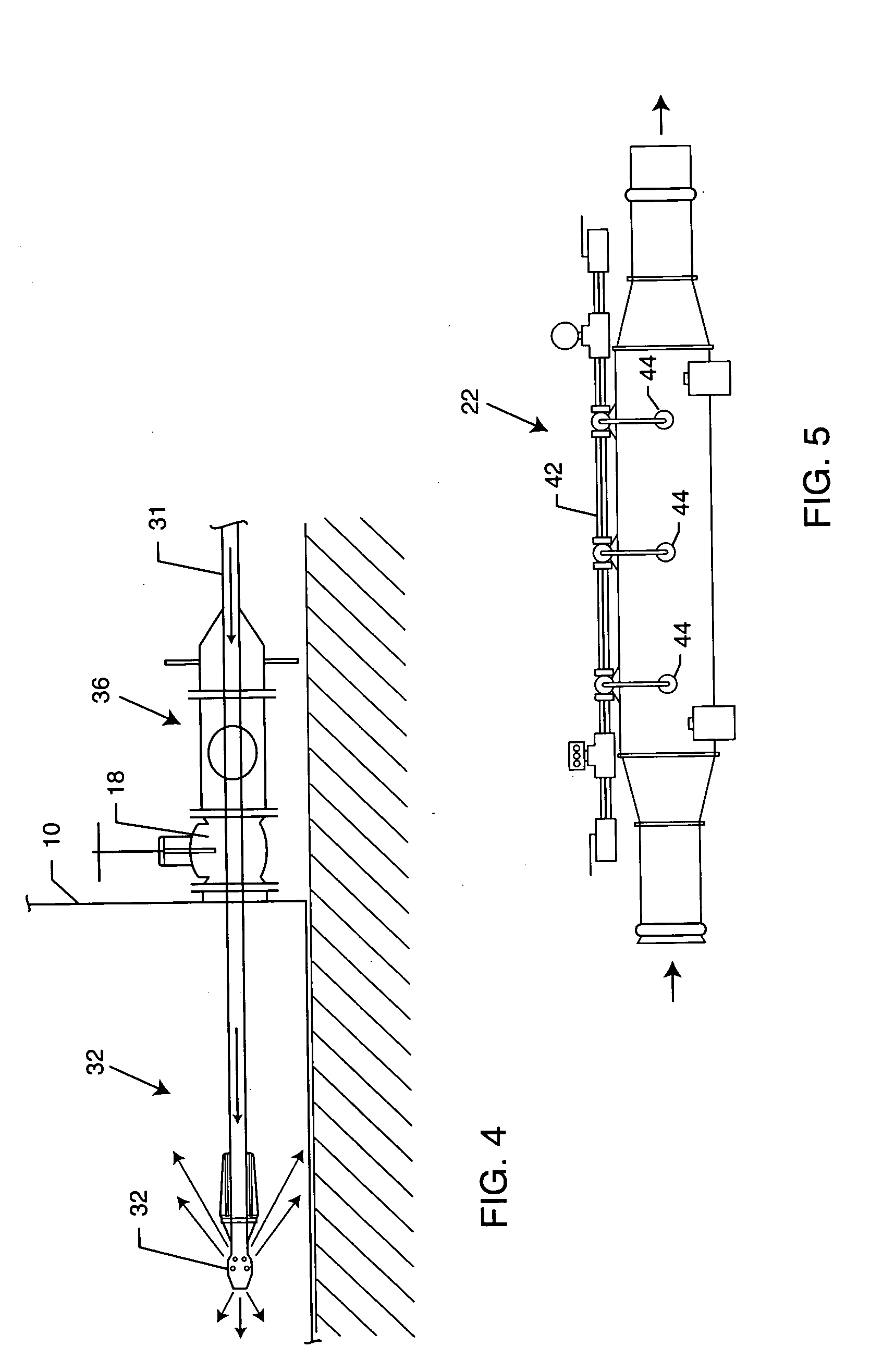

Petroleum recovery and cleaning system and process

InactiveUS20050161372A1Enhancing petroleum recoveryIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

Owner:AQUA TECH LLC

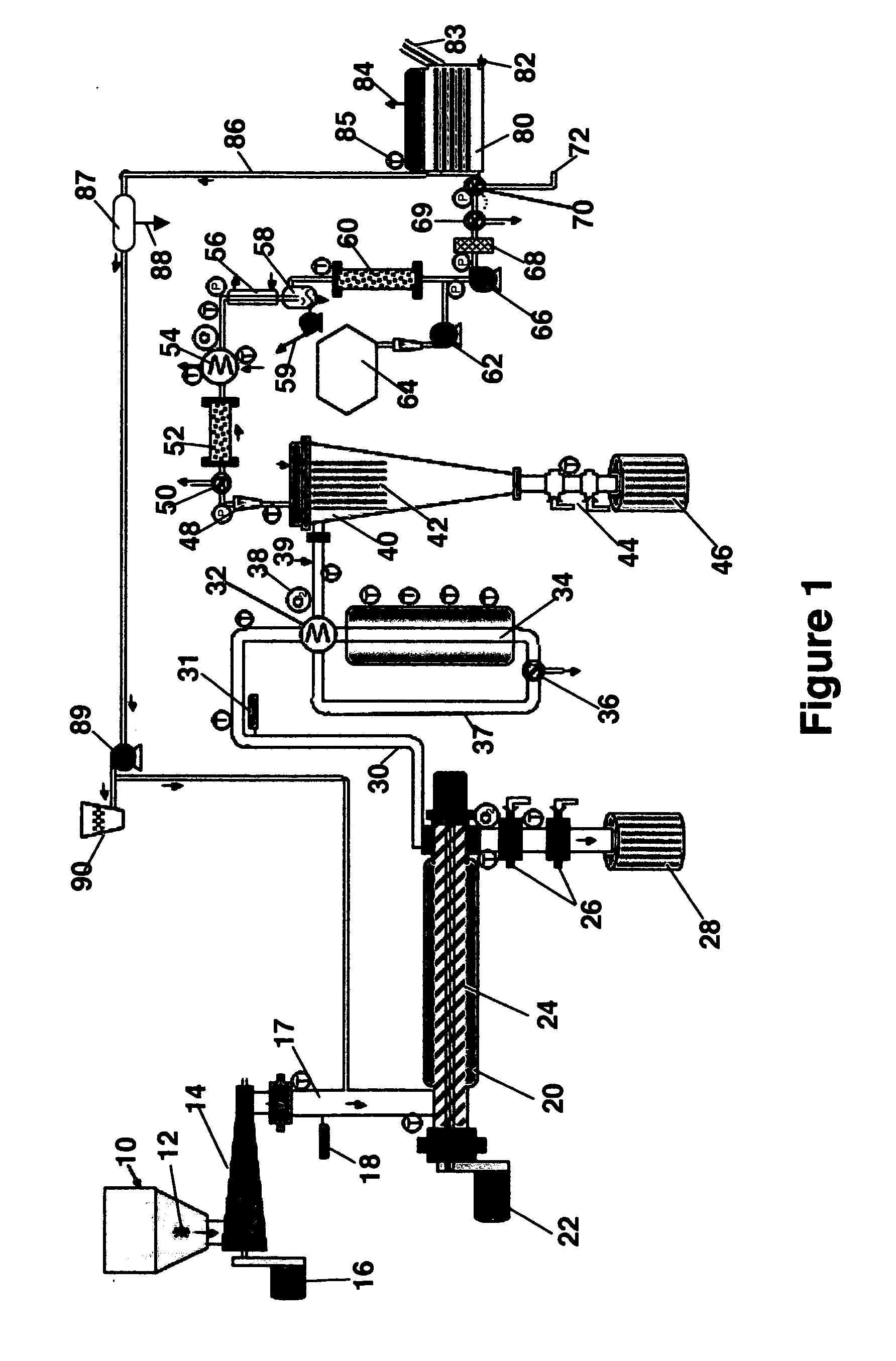

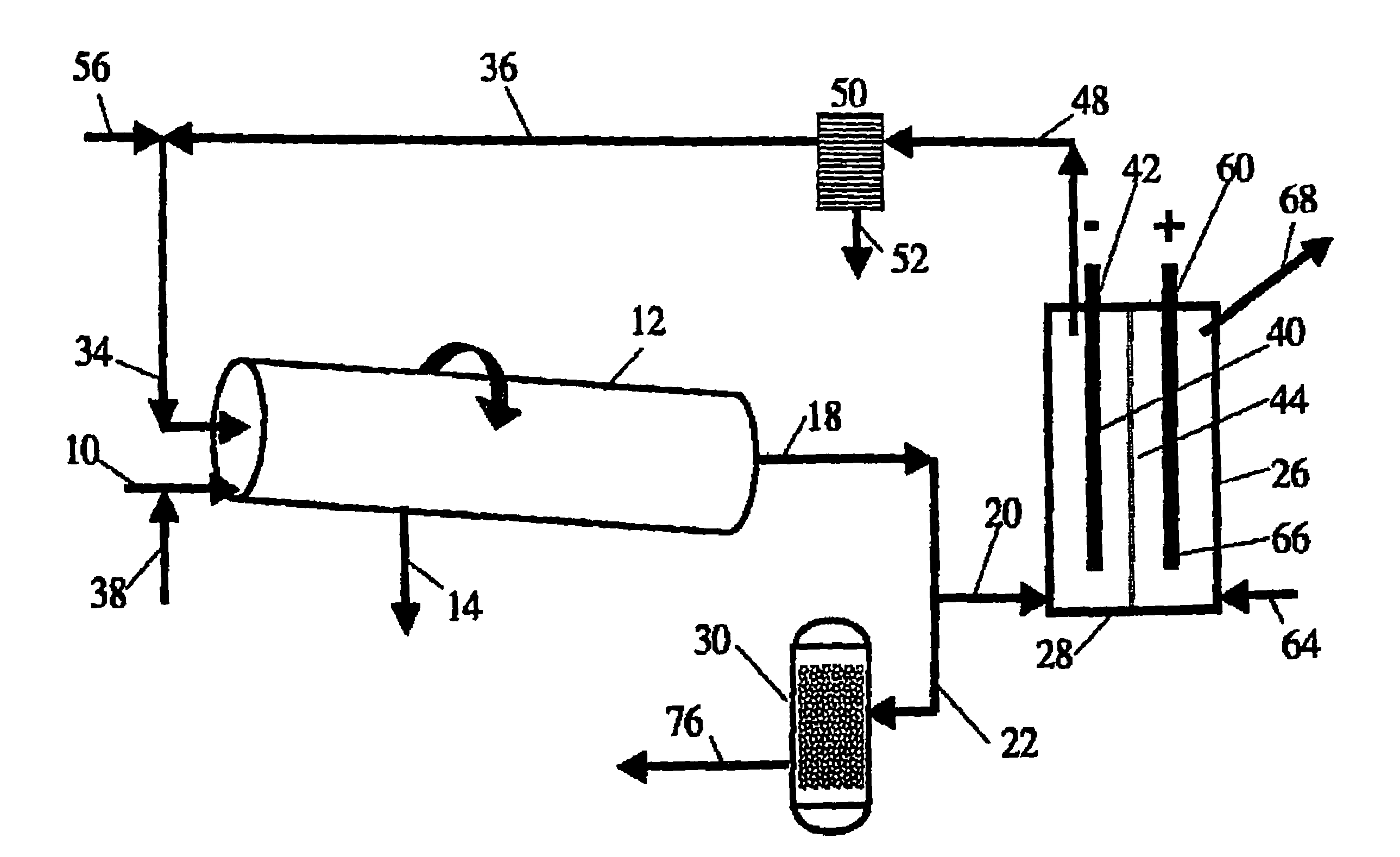

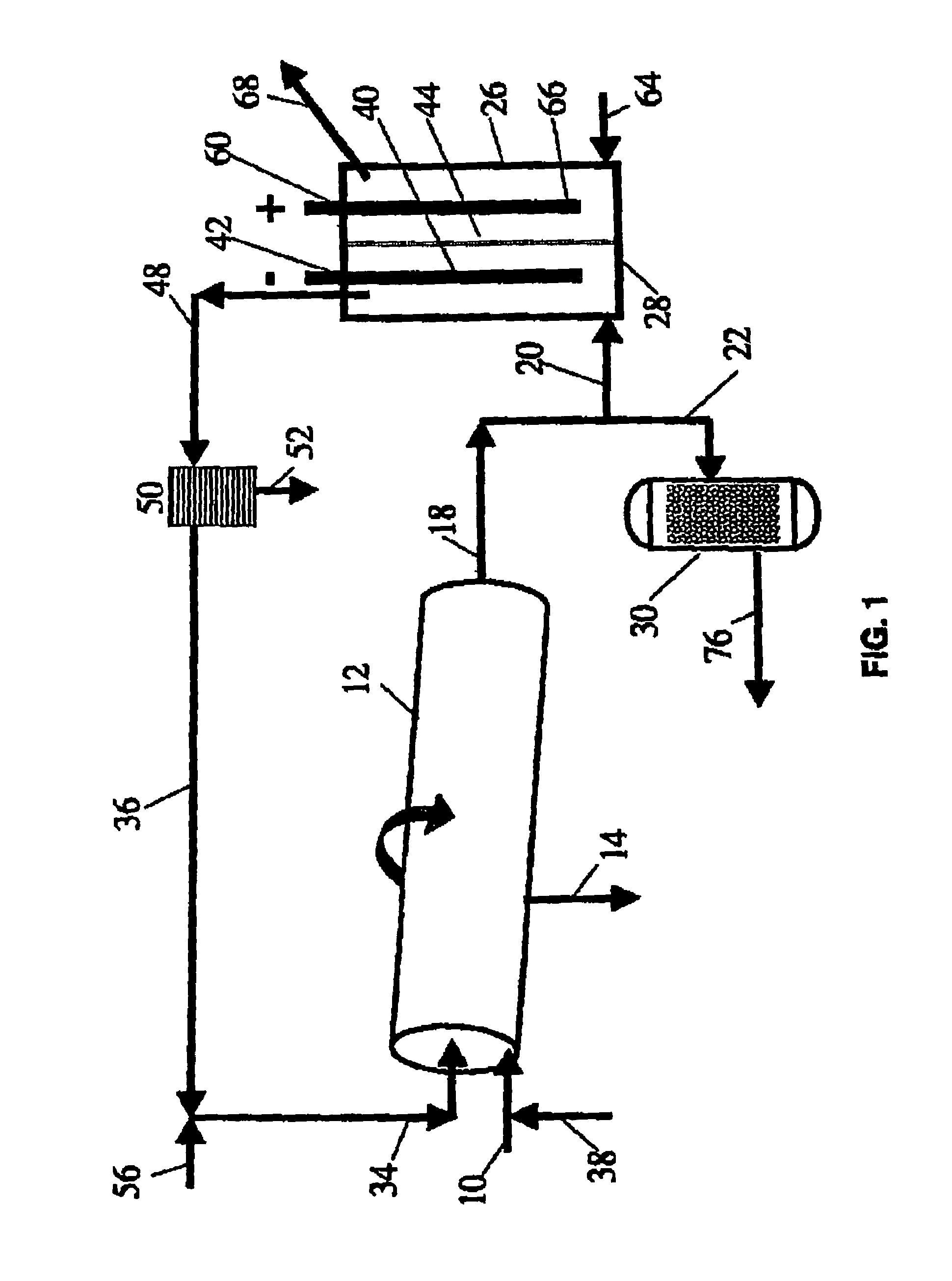

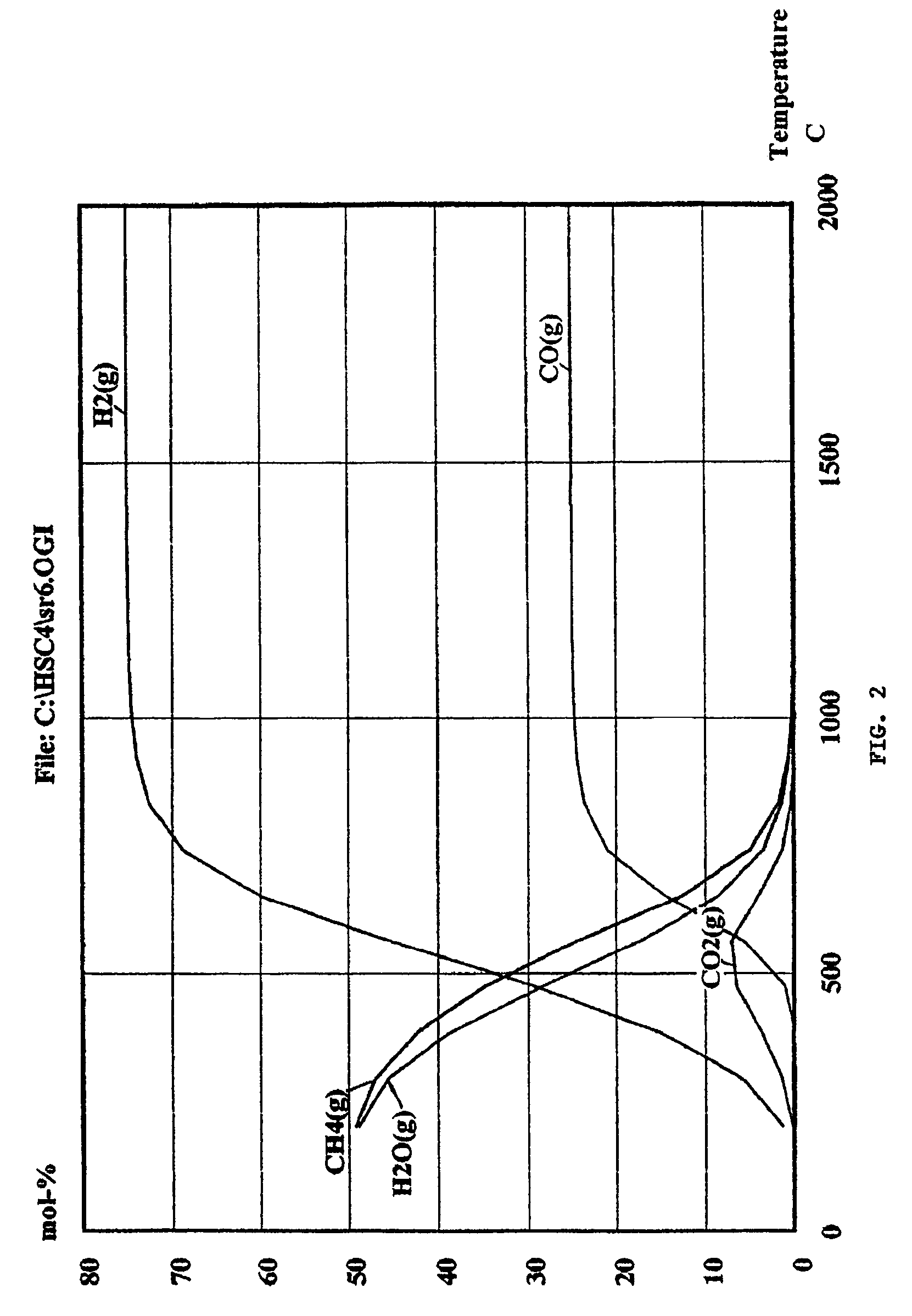

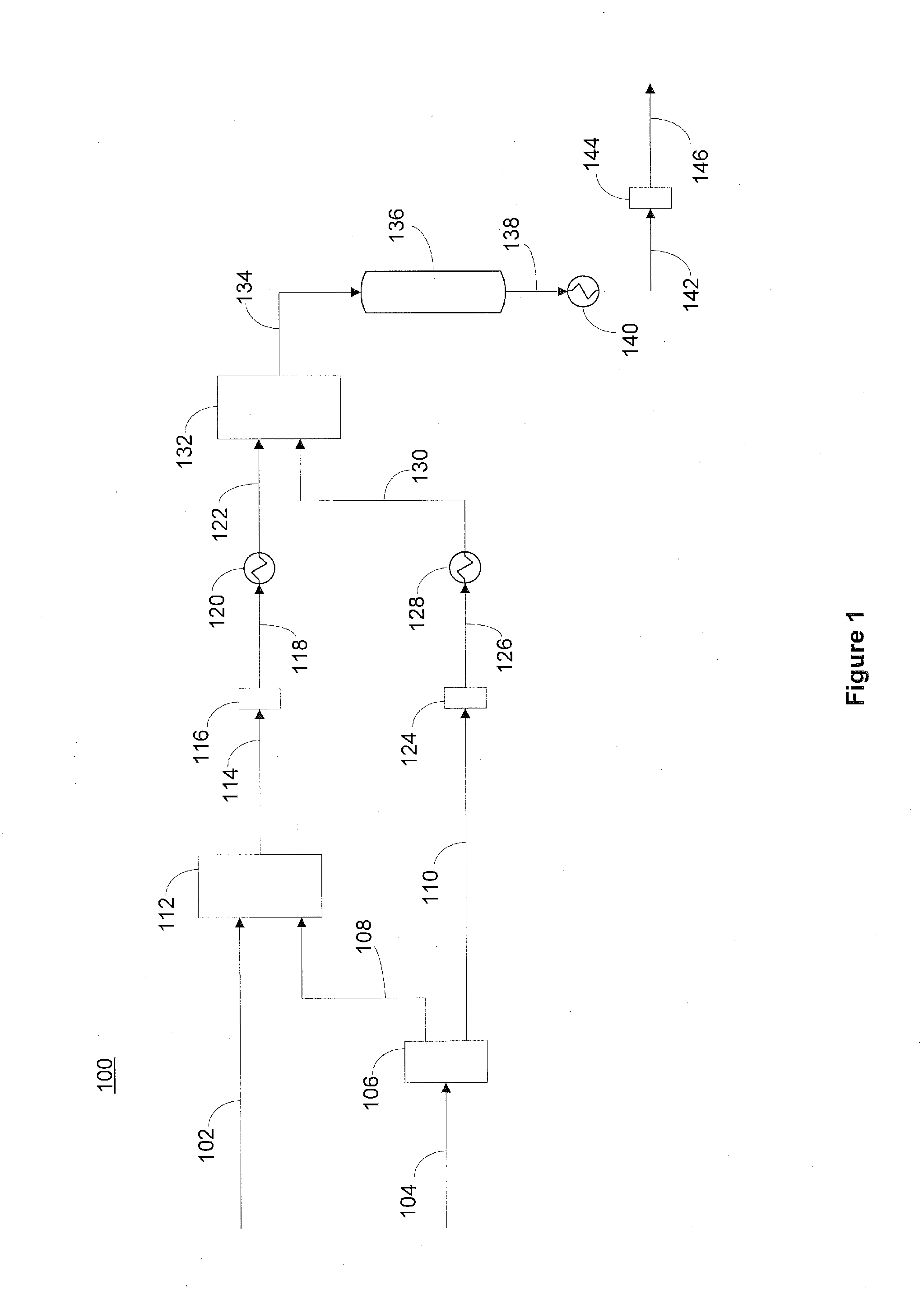

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

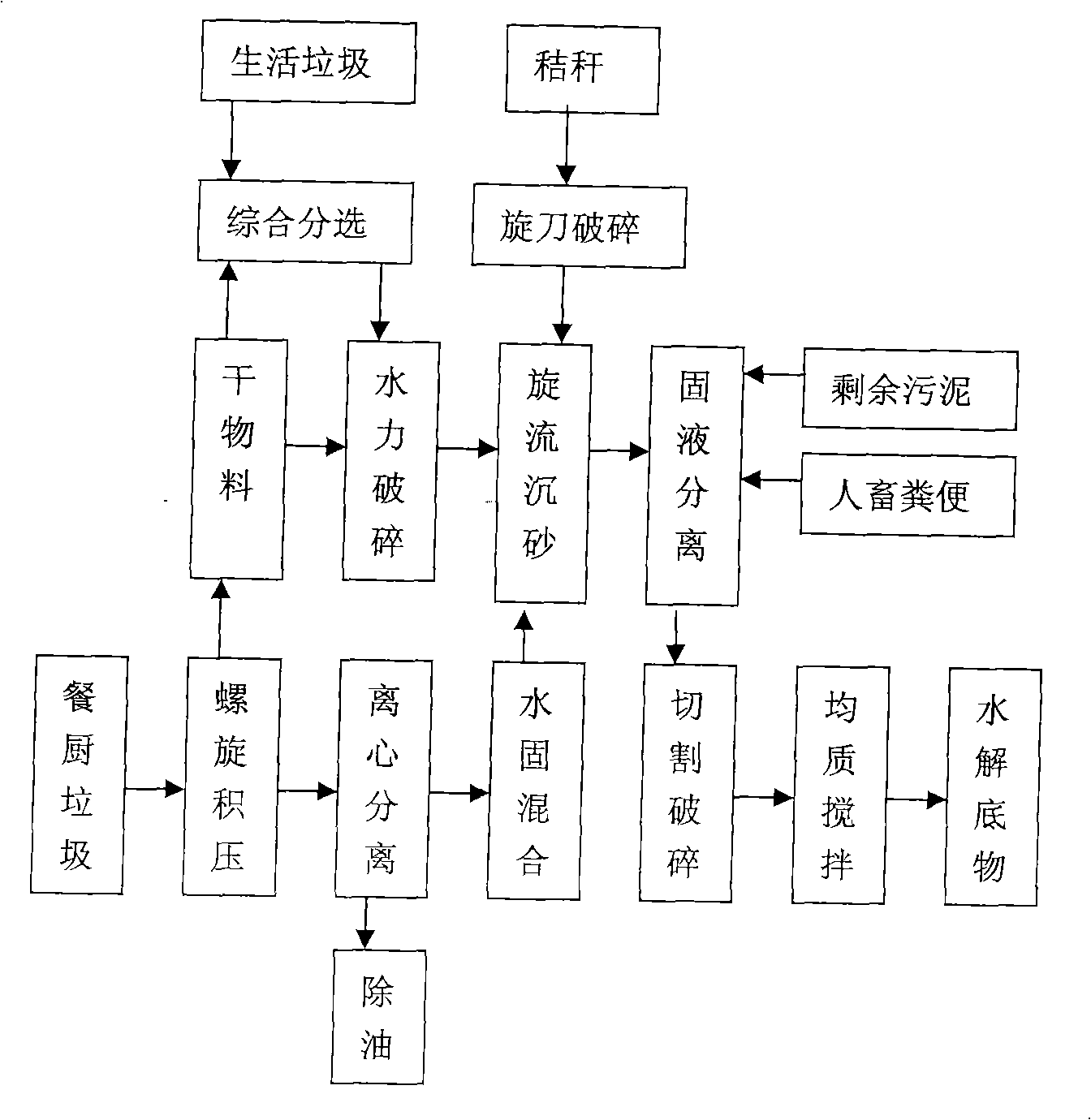

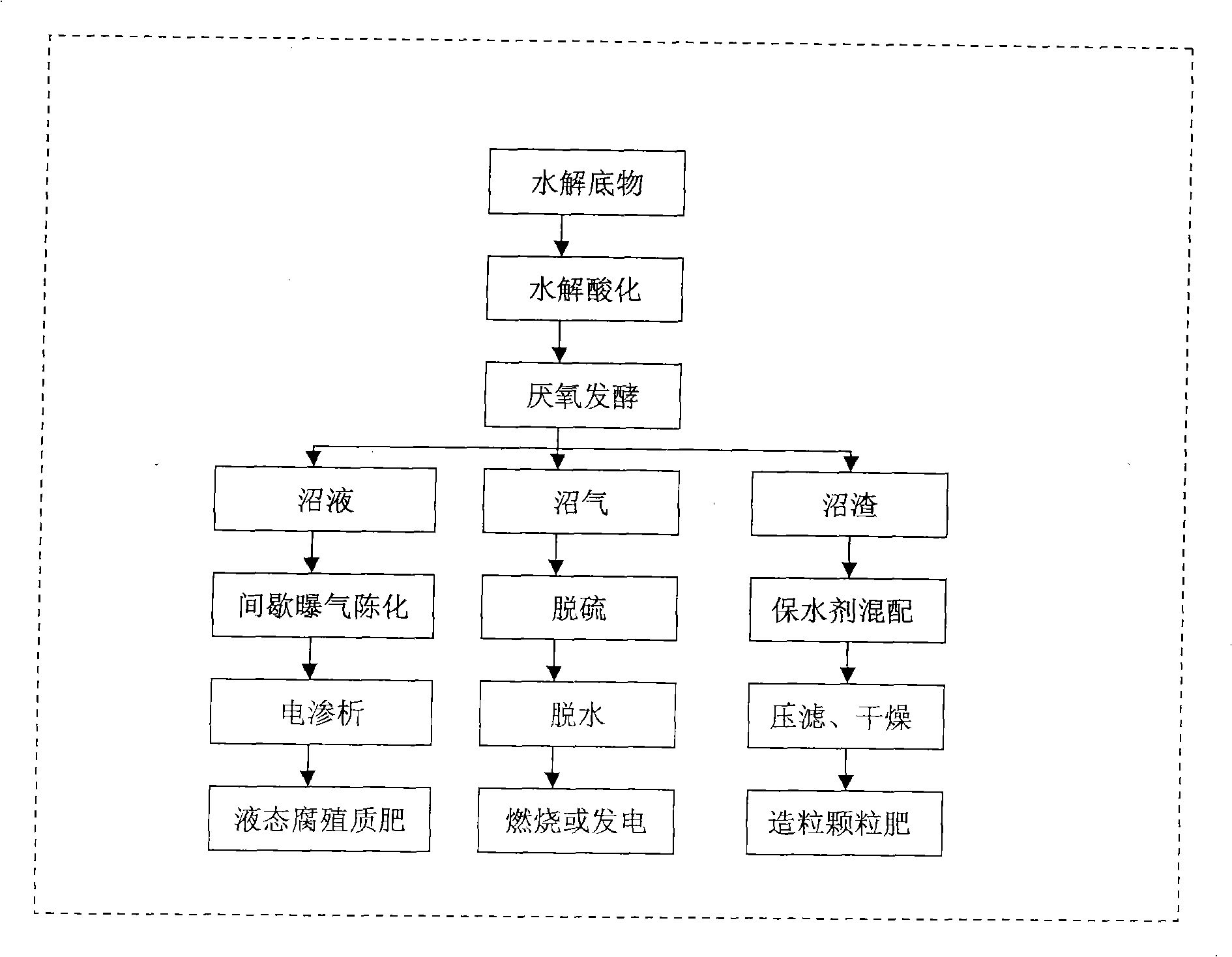

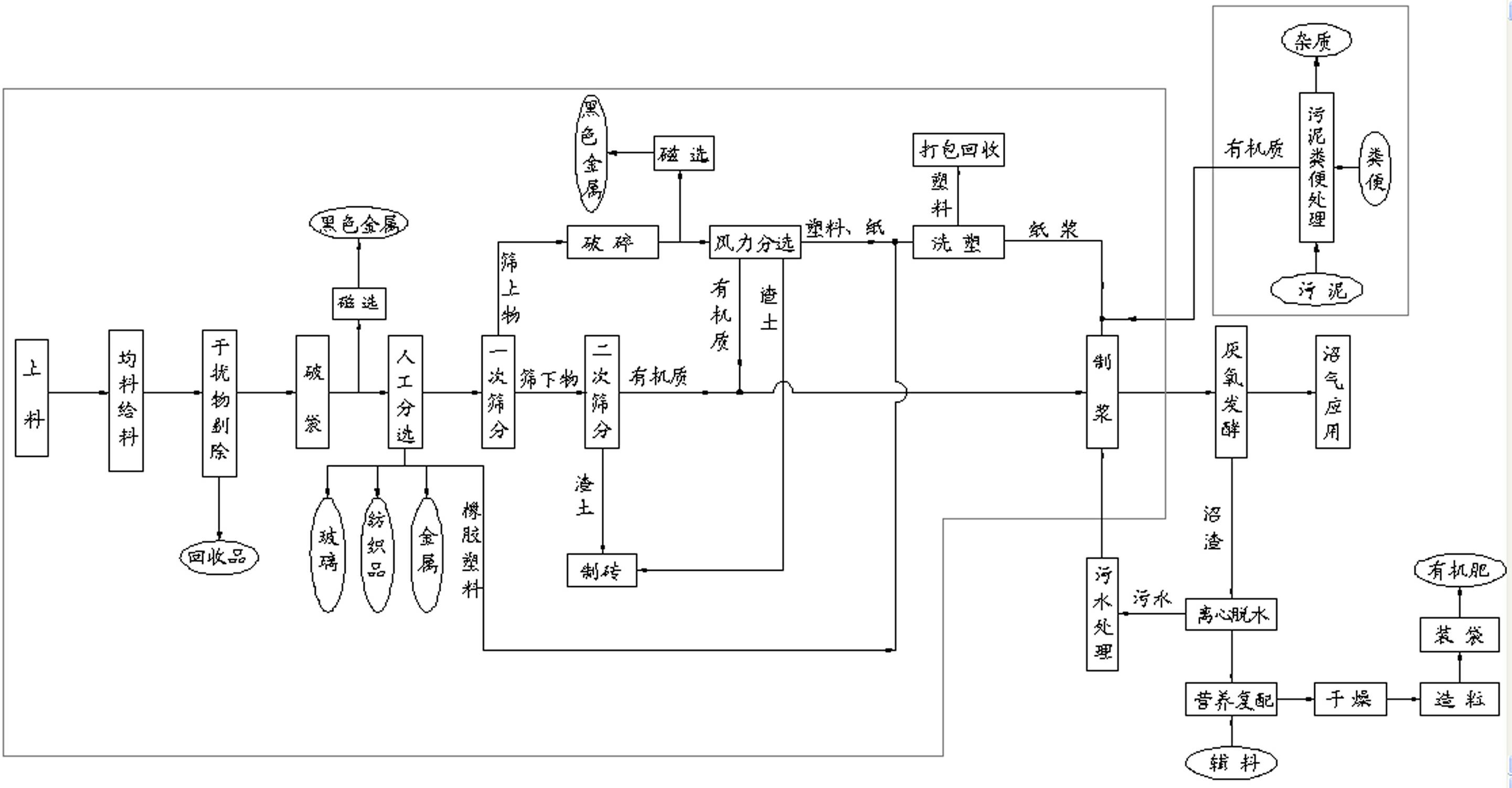

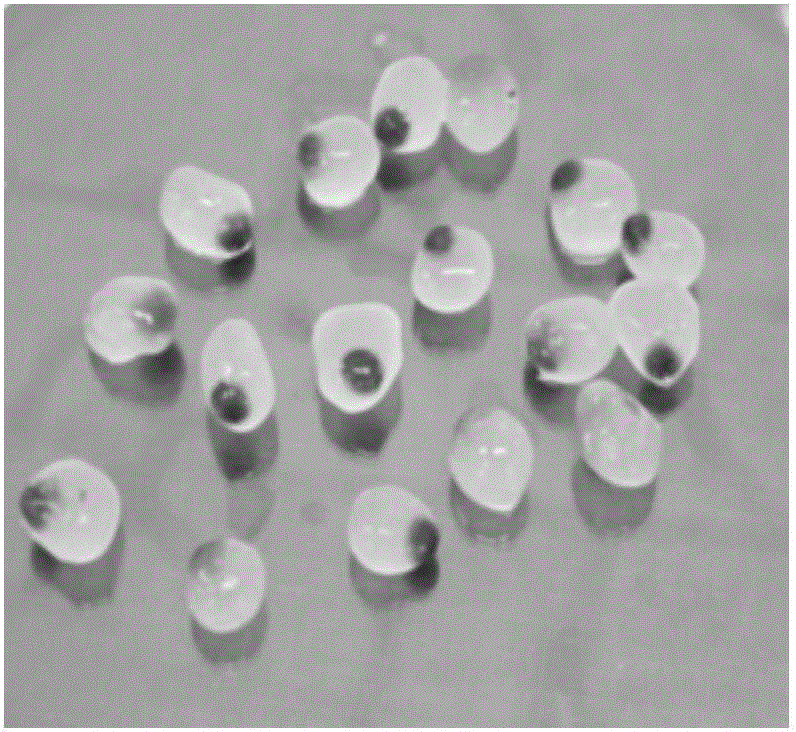

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

Process for extracting bitumen

Bitumen extraction done using a process comprising: (a) preparing a bitumen froth comprising particulate mineral solids and hydrocarbons dispersed in aqueous lamella in the form of an emulsion; (b) adding a sufficient amount of a paraffinic solvent to the froth to induce inversion of the emulsion and precipitate asphaltenes from the resultant hydrocarbon phase; (c) mixing the froth and the solvent for a sufficient time to dissolve the solvent into the hydrocarbon phase to precipitate asphaltenes; and (d) subjecting the mixture to gravity or centrifugal separation for a sufficient period to separate substantially all of the water and solids and a substantial portion of the asphaltenes from the bitumen; wherein a separation enhancing additive is present in the process. The separation enhancing additive is a polymeric surfactant that has multiple lipophilic and hydrophilic moieties, which can effect easier handling of asphaltene sludges and less foaming during solvent recovery.

Owner:MARATHON OIL SANDS +2

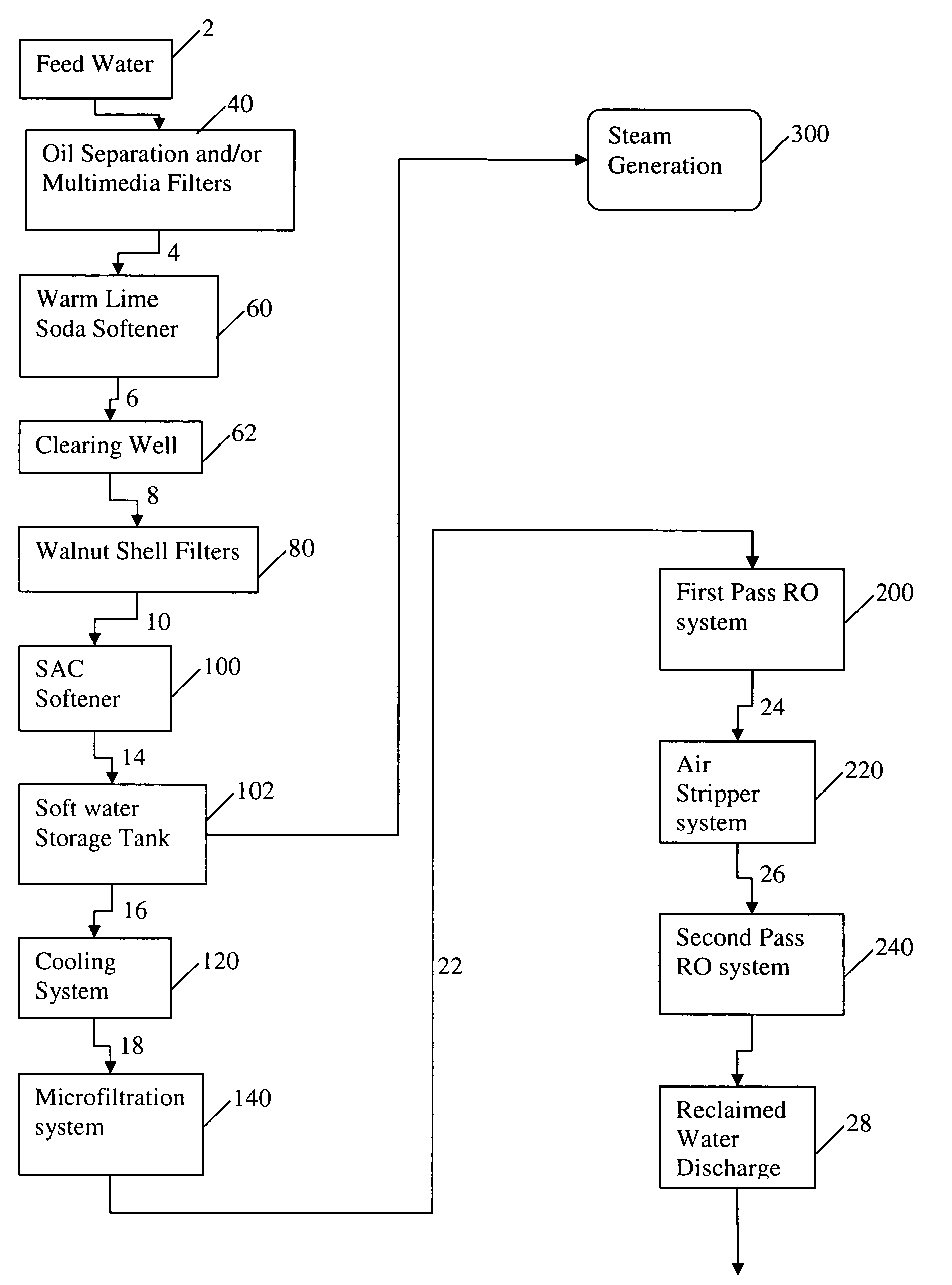

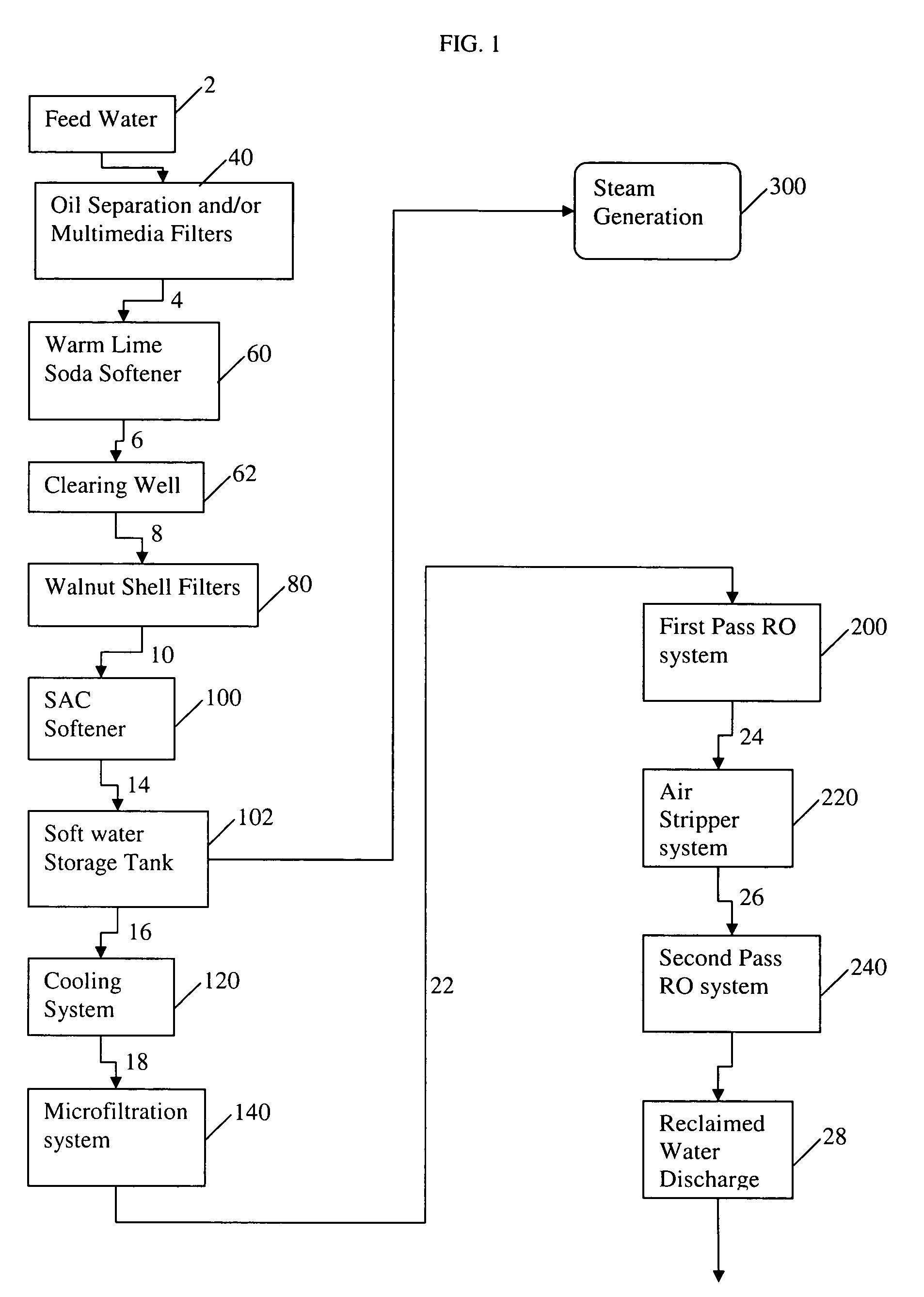

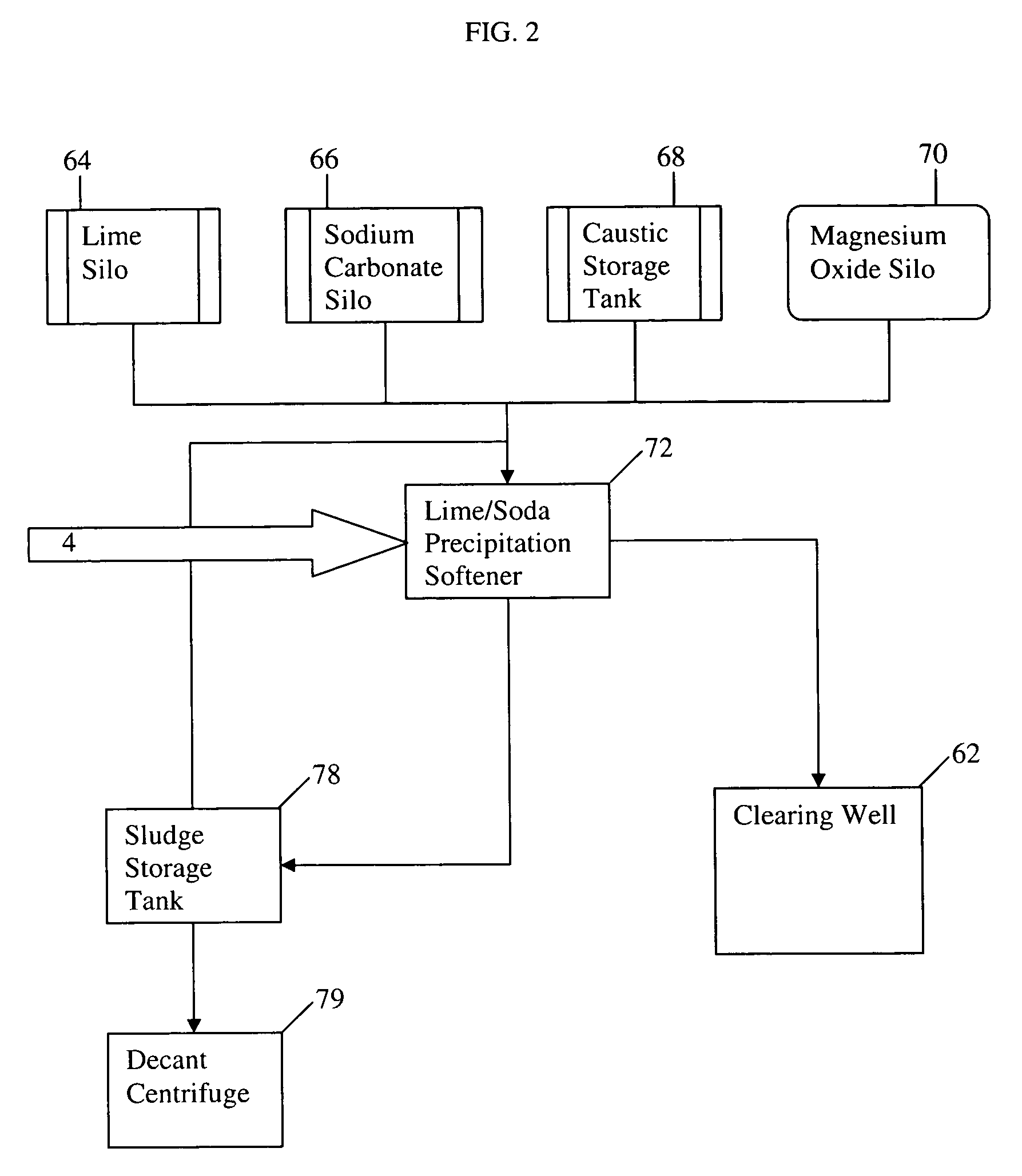

Water treatment process for oilfield produced water

ActiveUS7520993B1Minimize continued precipitationLiquid separation auxillary apparatusUsing liquid separation agentSludgeTreatments water

The invention relates to a method and system for treating an aqueous liquid containing dissolved minerals and dissolved hydrocarbons. Method steps and apparatus for treating a waste water feed stream are disclosed which utilize a warm lime softening system in fluid communication with the waste water feed stream, wherein sludge from the warm lime softening system is recycled to improve lime utilization and enhance silica and boron removal without the addition of an external source of magnesium. In addition, a microfiltration system and / or an air stripper system may be used in fluid communication with at least one reverse osmosis system to produce a treatment water that meets state and federal guidelines for surface discharge.

Owner:WATER & POWER TECH

Active alumina/active carbon composite material and preparation method thereof

InactiveCN102319557ASolve the strength problemSolve the problem of longevityCatalyst carriersOther chemical processesActivated carbonSludge

The invention discloses an active alumina / active carbon composite material and a preparation method thereof. The composite material comprises the following ingredients: 70-90 weight portions of sludge, 10-30 weight portions of active carbon, and 15-35 weight portions of binder, and is prepared by uniformly mixing, pelleting, aging, molding, drying in the air, sintering, rinsing and drying. Using sludge as raw material has an important meaning to environmental protection and recycling of waste. The invention has the advantages of simple preparation method, easy obtainment of raw material, and low cost, and can be widely applied in the fields of industry, agriculture, environmental protection, air cleaning, water treatment and the like.

Owner:FUZHOU UNIV

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

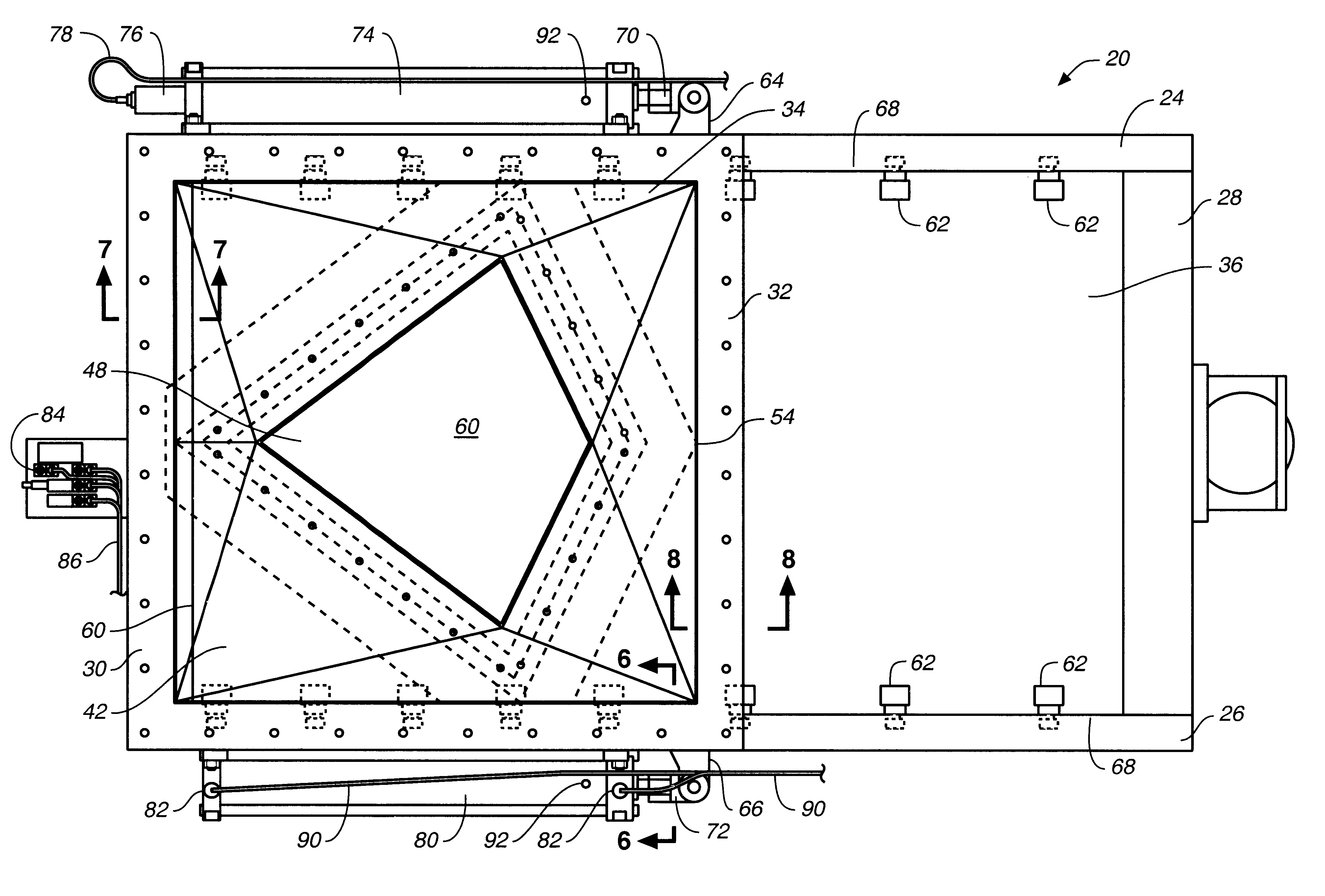

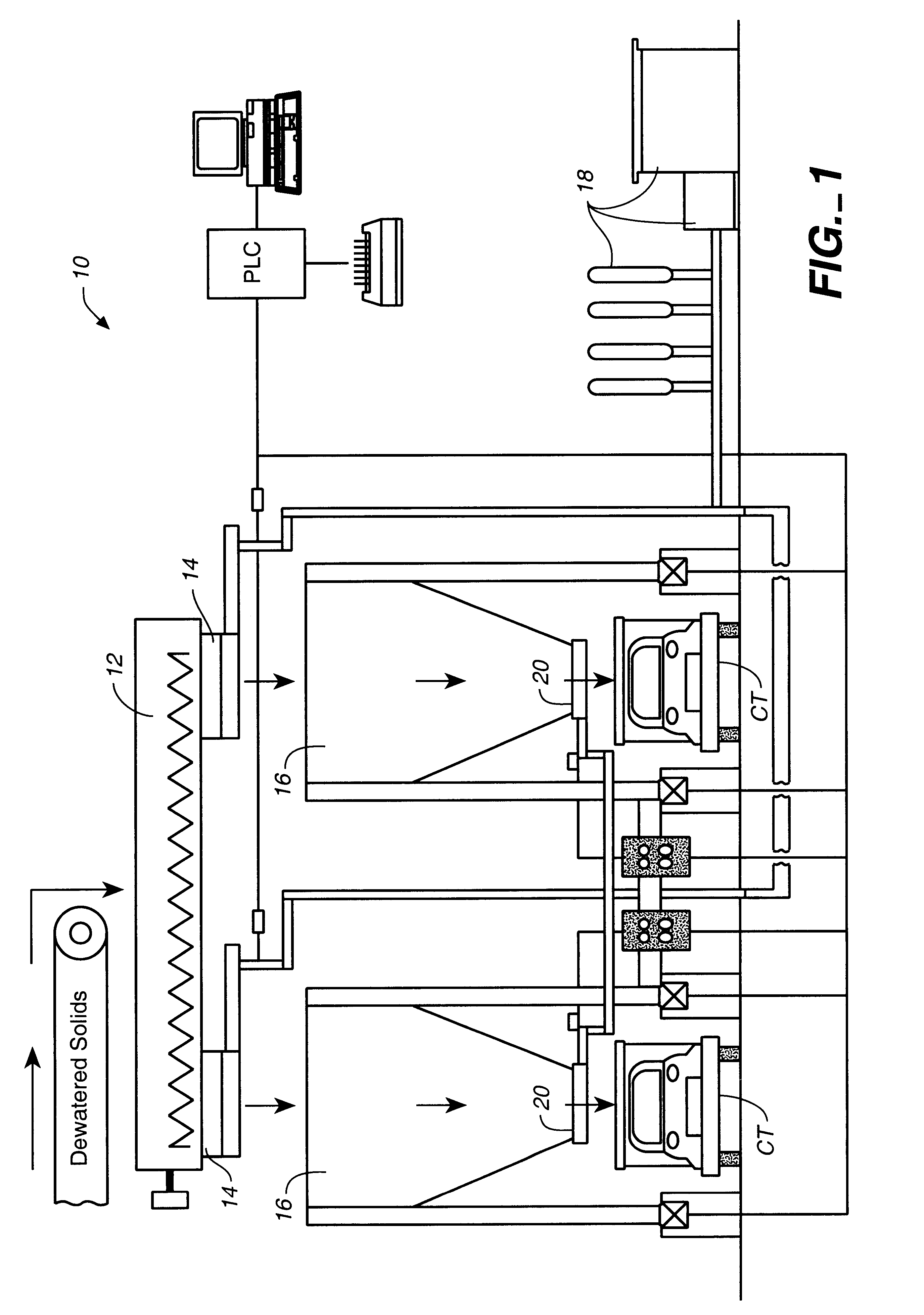

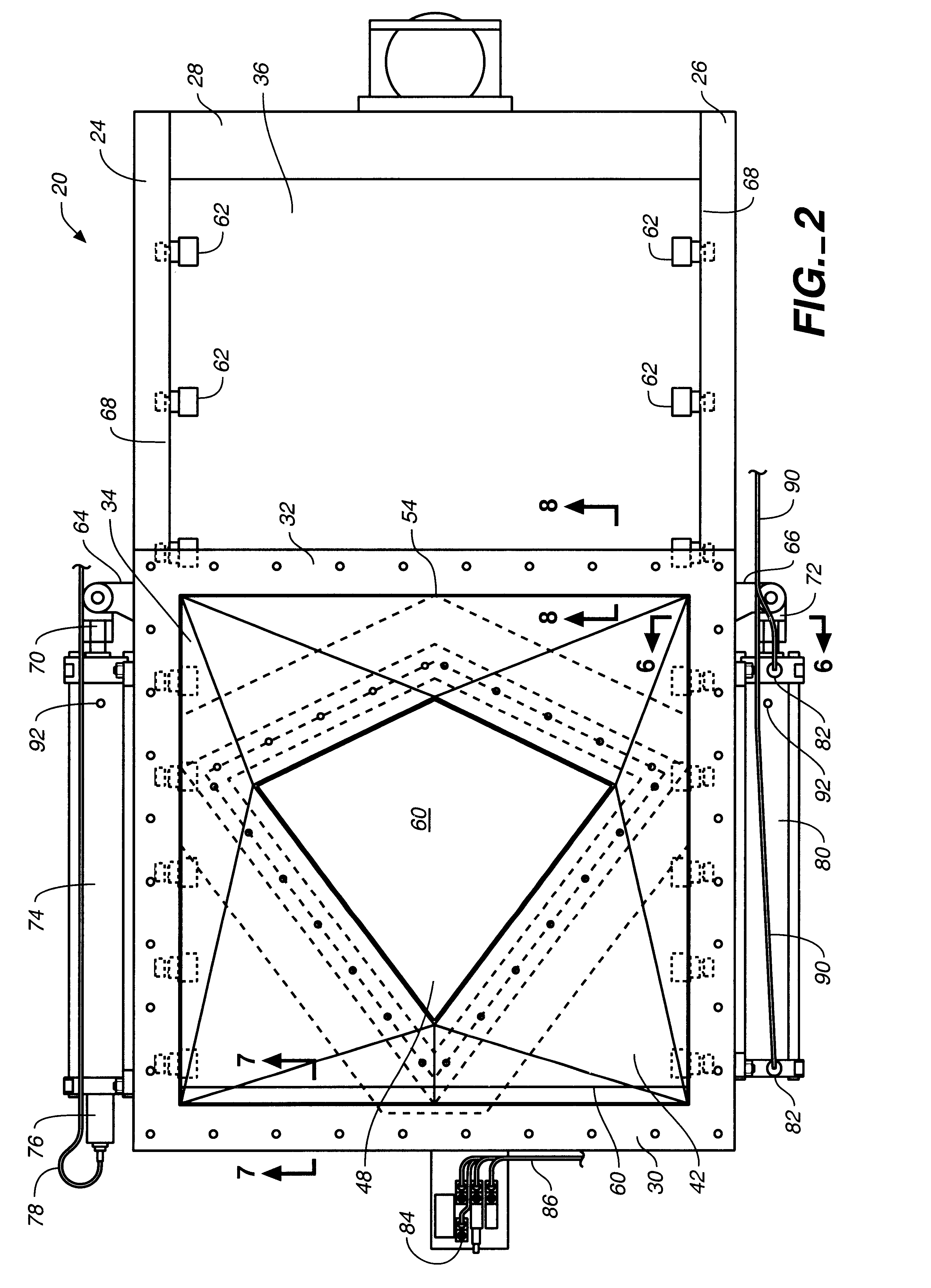

Gravity flow sludge load-out metering gate

InactiveUS6508387B1Easy to controlReduction in splashing and splatteringClosuresLiquid flow controllersSludgeEngineering

A gravity flow sludge load-out metering gate comprising a frame having longitudinal and horizontal frame rails and a transverse rail member which defines a gate front portion and a smaller gate rear portion. A sludge inlet funnel is positioned above the front portion for insertion into the interior of a hopper discharge outlet. In the preferred embodiment, the sludge inlet funnel is substantially square and has four triangular, tapering interior sides, which, when viewed from above define an asymmetrical four-pointed star, the interior configuration of which further defines an asymmetrical diamond-shaped sludge discharge orifice. Interior to the metering gate frame is a metering gate blade, slidingly positioned between a plurality of support rollers and a bulb seal, the gate operatively connected to electric, hydraulic, or pneumatic power.

Owner:RDP TECH

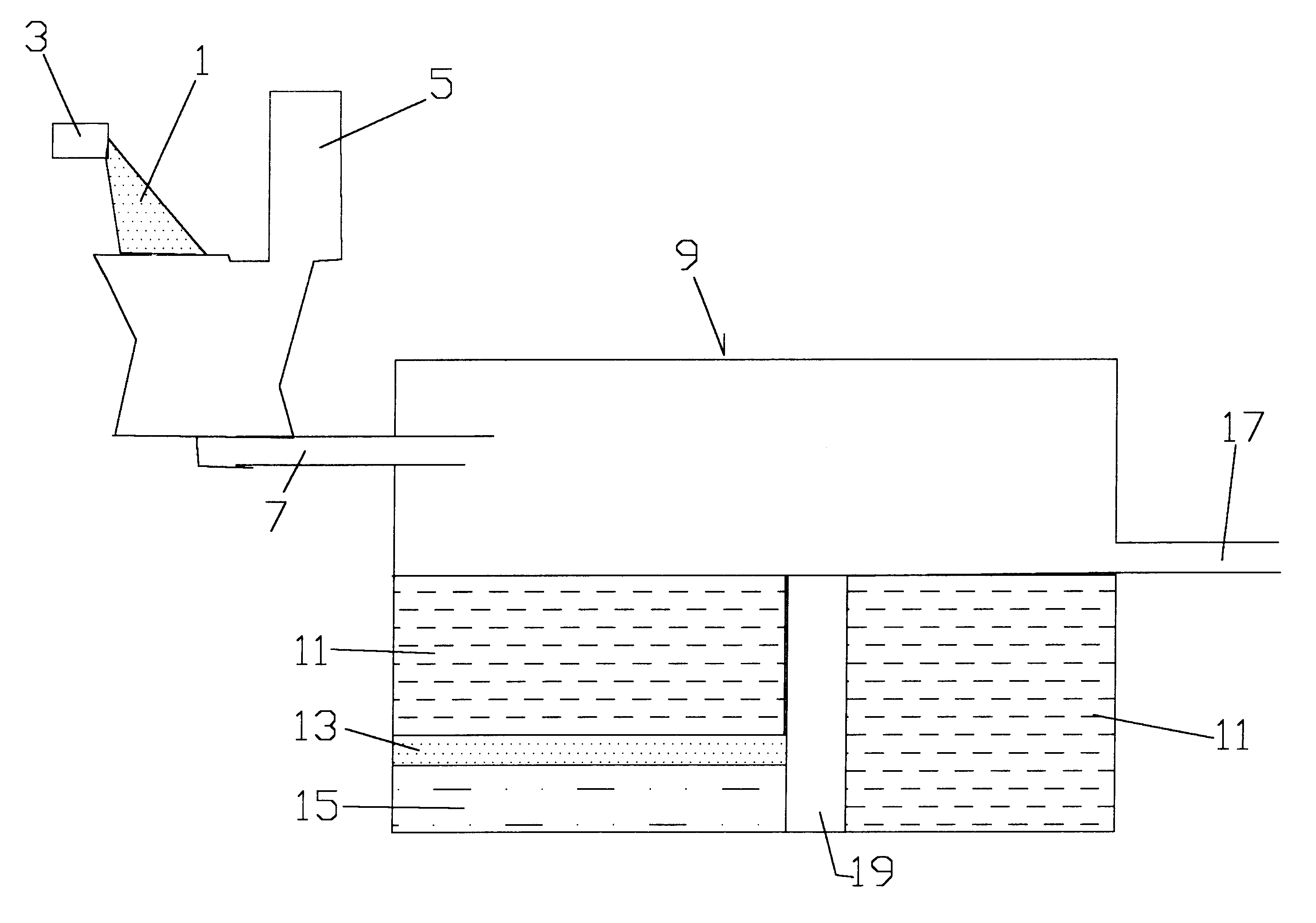

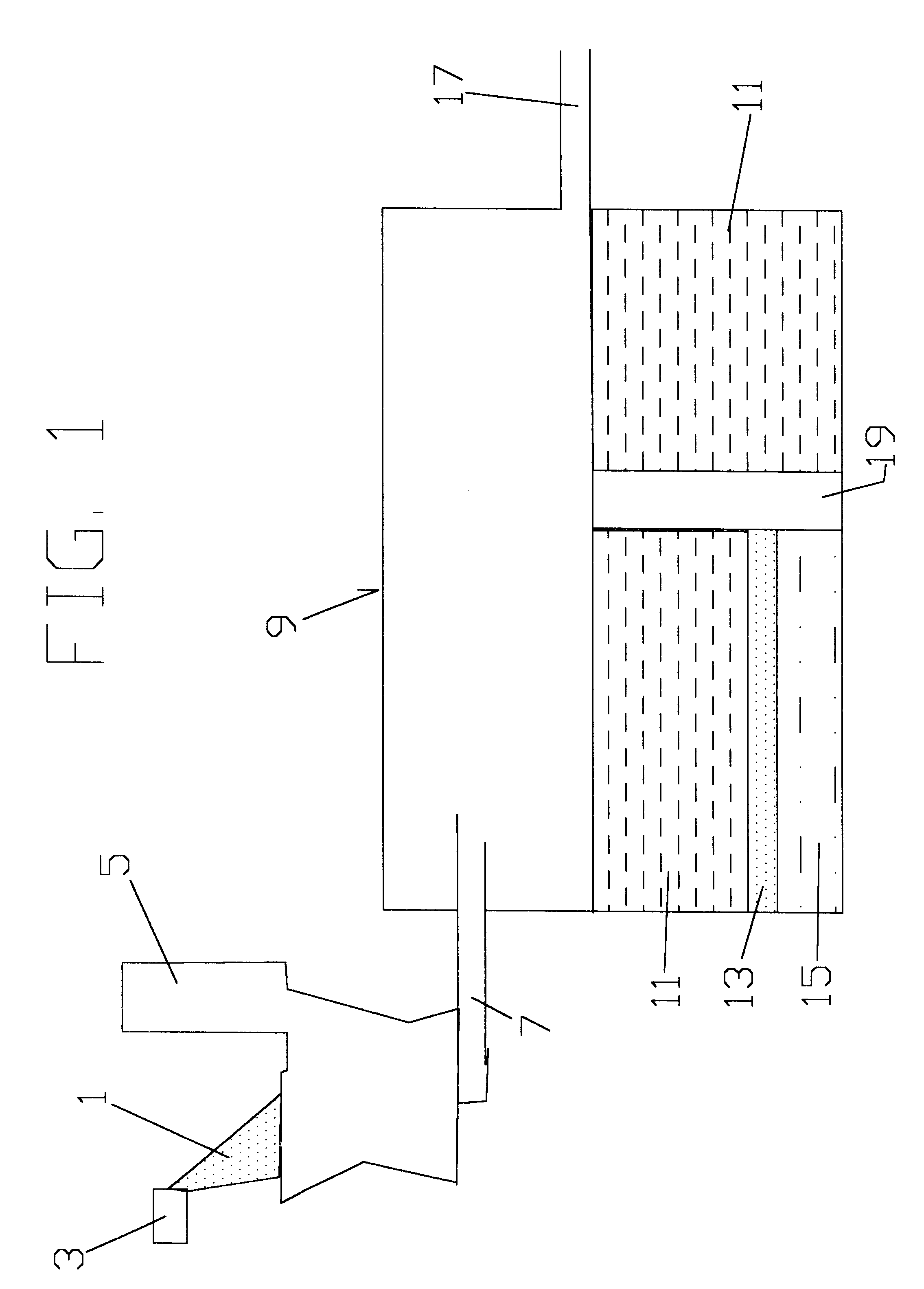

Enzyme and bacterial combination in a slowly dissolvable matrix for septic tanks, grease traps and waste treatment

Sewage waste digestive bacteria and enzymes are incorporated into a slow release material and delivered to the site of the waste to digest the solid waste. The slow release material is made heavy so the enzymes and bacteria will be delivered to the sludge in the bottom of a sewage digester chamber and made fat soluble so that the enzymes and bacteria will be delivered to the grease in the waste system to be digested. This selective delivery system prevents the enzymes and bacteria from being diluted in grey water rendering them less effective and discharged from the sewage system without digesting waste.

Owner:NOVOZYMES AS

Fluid delivery techniques with improved reliability

InactiveUS6752493B2Improve reliabilityImprove printing reliabilityInking apparatusOther printing apparatusHeat managementSludge

Techniques for improving reliability of print cartridges that employ a fluid recirculation path within the cartridges. One reliability feature is provided by active heat management, wherein the recirculation path is employed to provide printhead cooling. Another feature is an in-printer printhead and standpipe priming technique. Idle time tolerance can also be improved, with the ability to re-circulate ink and purge air, to provide a mode of operation that can improve the reliability of the print cartridge during idle times. A "cleaning fluid" can be introduced that could break-up the sludge as it circulates through the print cartridge. Improved particle filtering is provided, through fluid recirculating through the system, passing through the standpipe or plenum area and across the backside of the printhead. As the fluid moves through this region, particles trapped in the standpipe get swept out of the area and eventually through a filter before reaching the printhead again.

Owner:HEWLETT PACKARD DEV CO LP

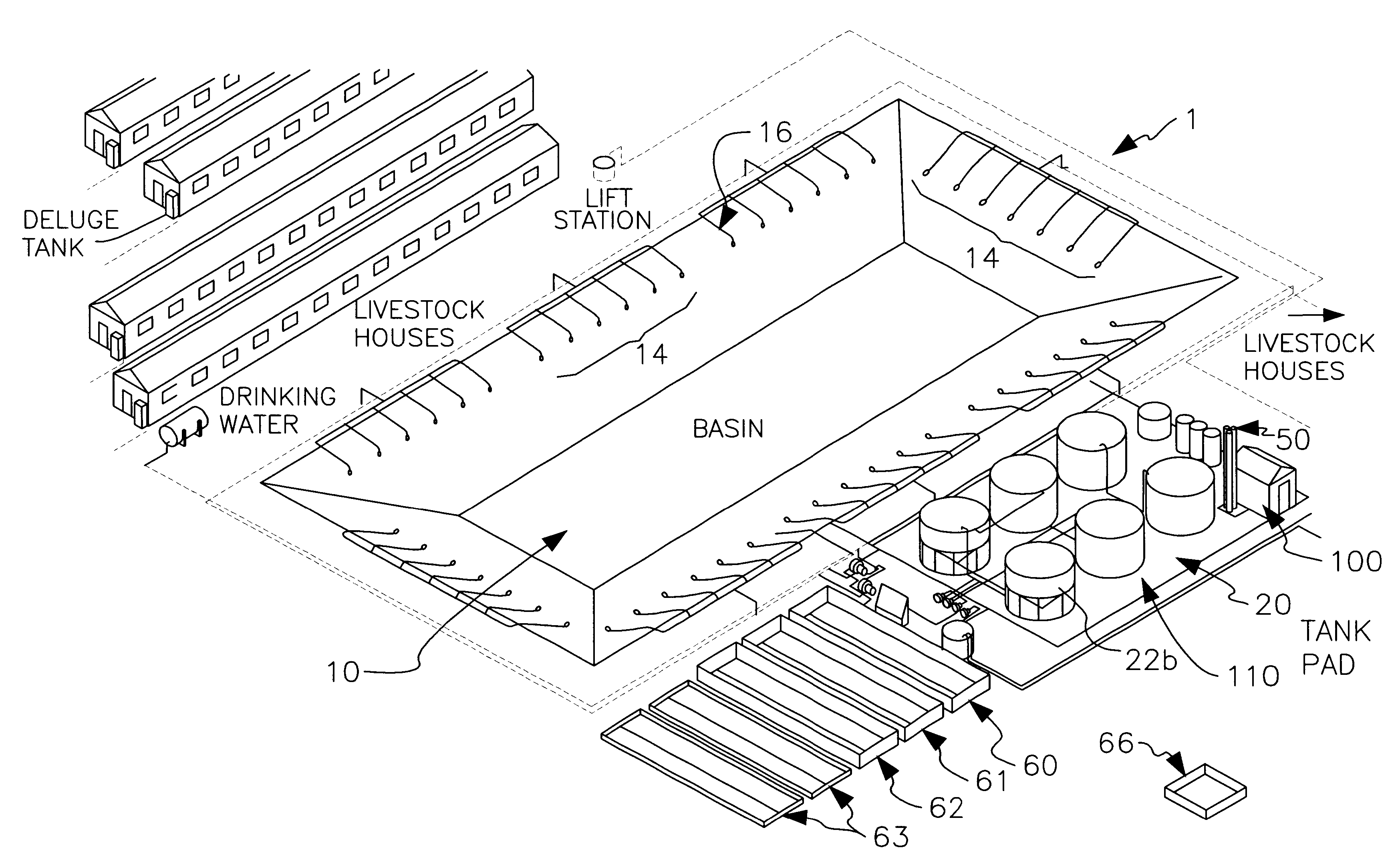

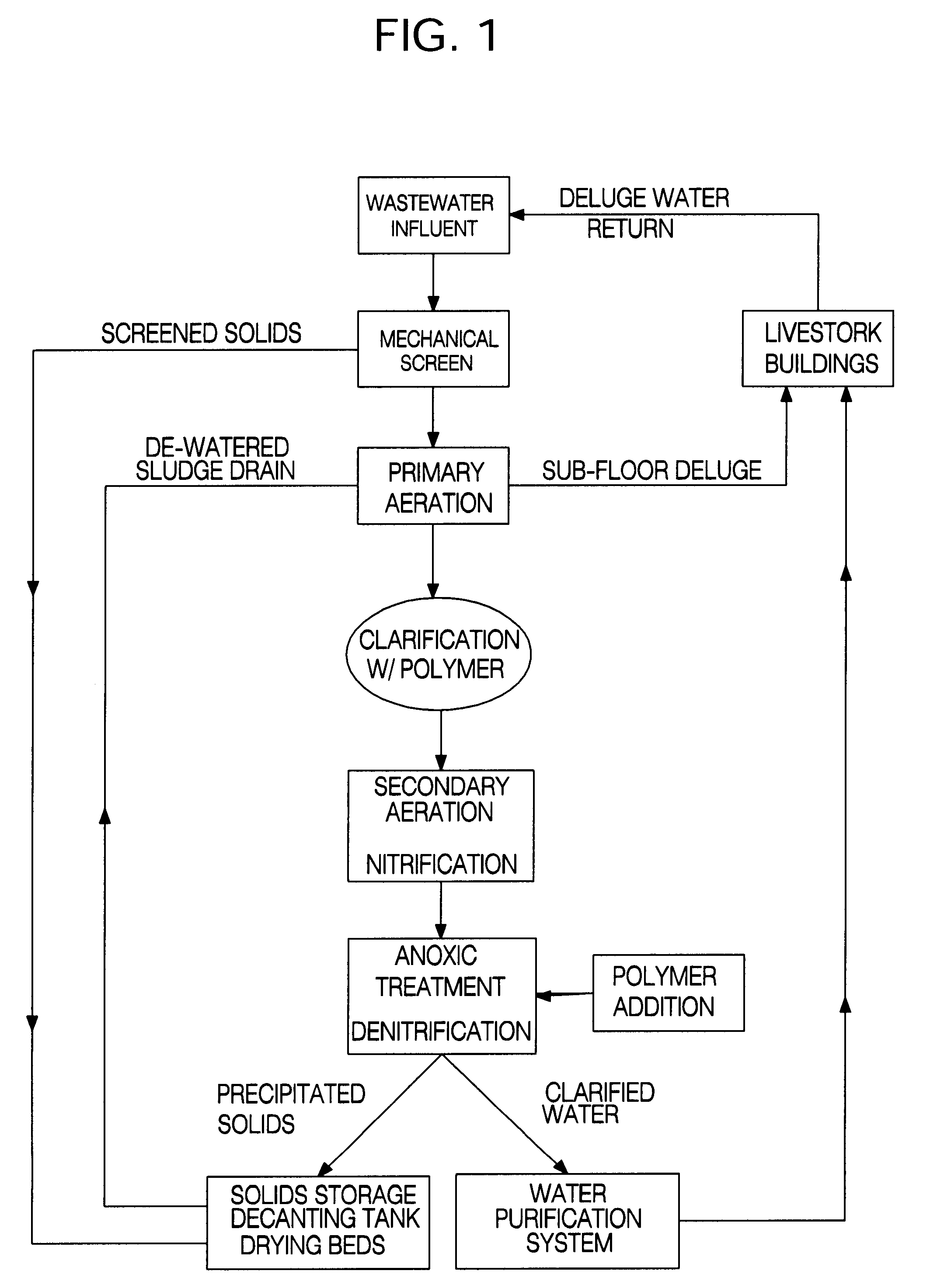

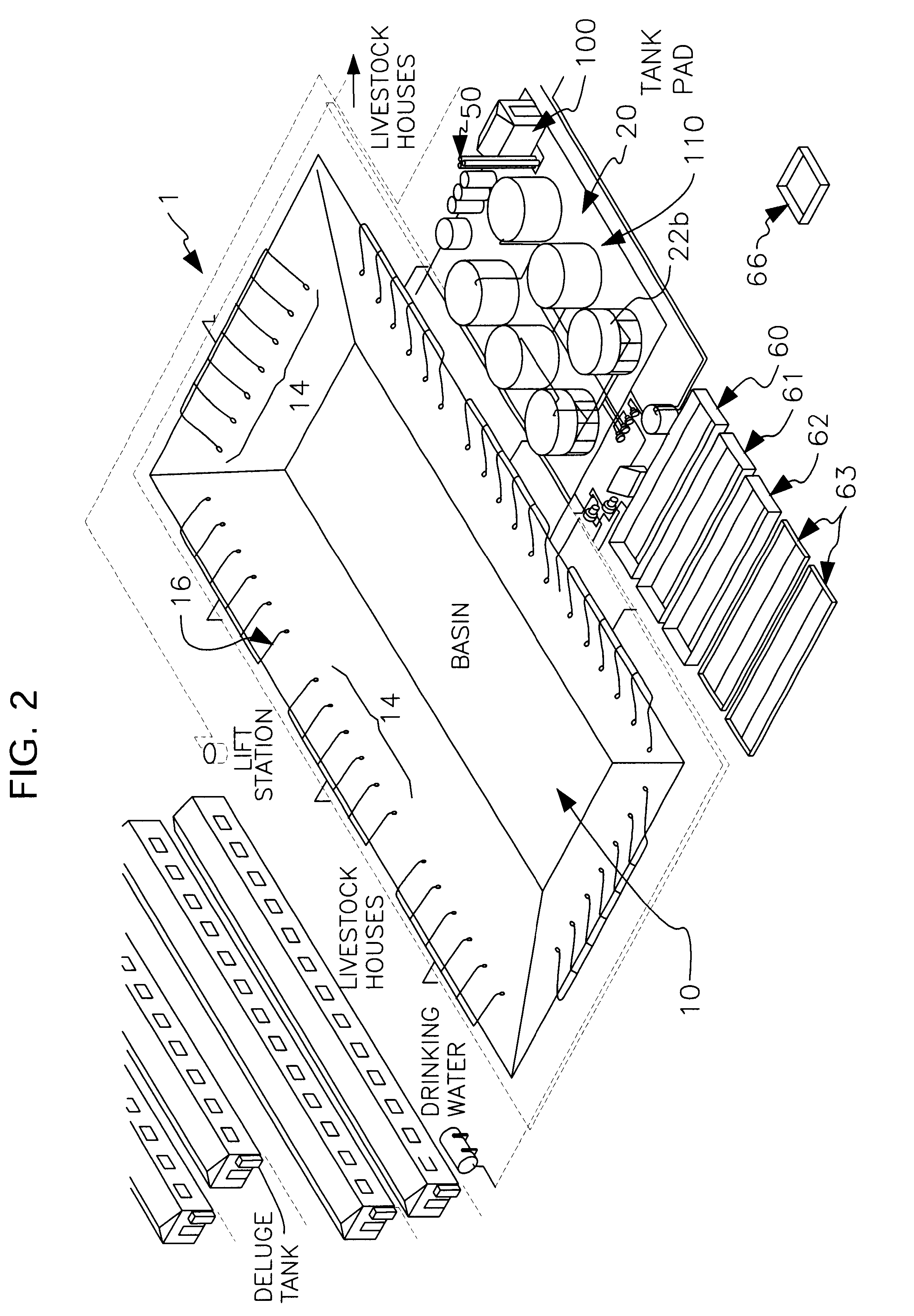

Aerobic treatment of liquids to remove nutrients and control odors

InactiveUS6398959B1Effective treatment of wastewaterReduce nutrientsTreatment using aerobic processesWaste water treatment from animal husbandrySludgeWastewater

The present invention is drawn to a unique apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention may be readily-sized and configured depending upon the amount and constituent(s) of the wastewater to be treated. In a first embodiment, the apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or land applied. In use, the apparatus and method of the first embodiment may actually require addition of make-up water during periods of low rainfall to make up water losses due to evaporation and drift. It is contemplated that the only byproduct of the apparatus and method of the first embodiment may be a beneficial sludge if a sufficient number of installations are operated. In a second embodiment, the apparatus and method of the present invention provides a treatment system capable of reducing the nutrient loading in a step-wise fashion so that the wastewater can be used from different steps of treatment in order to apply the varying nutrient loads required by crops on a seasonal basis.

Owner:AGRIMOND USA CORP

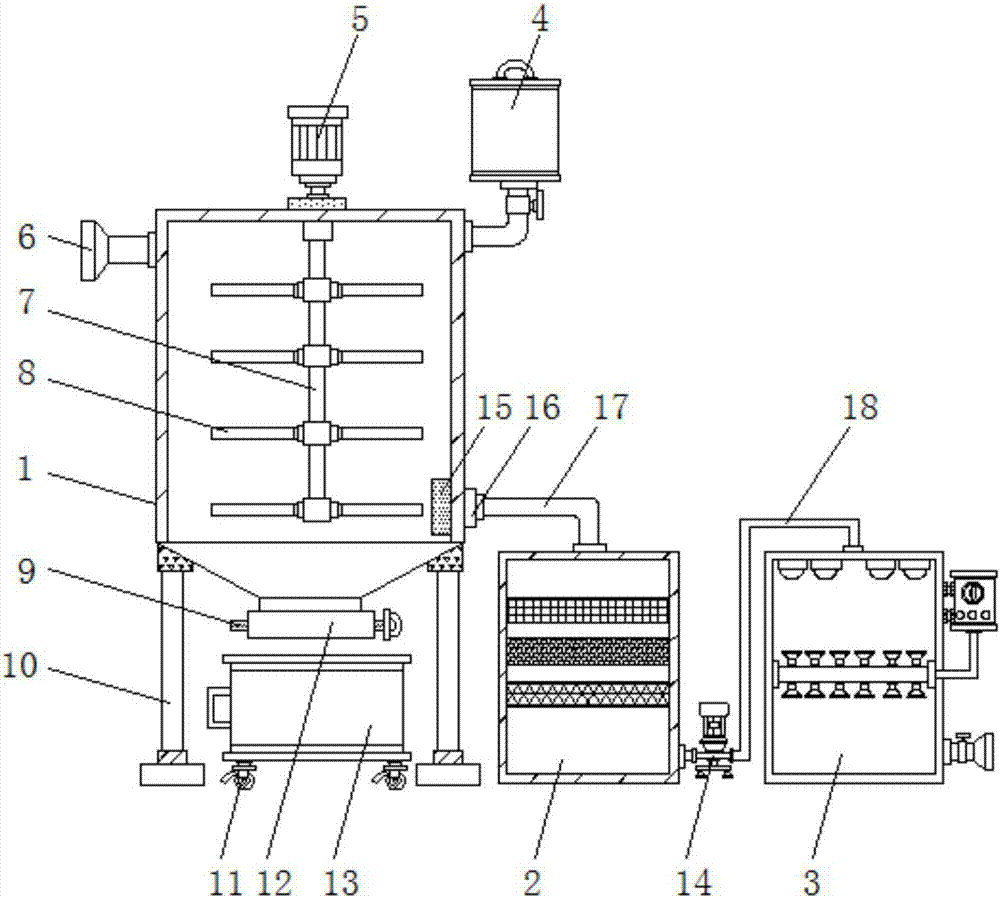

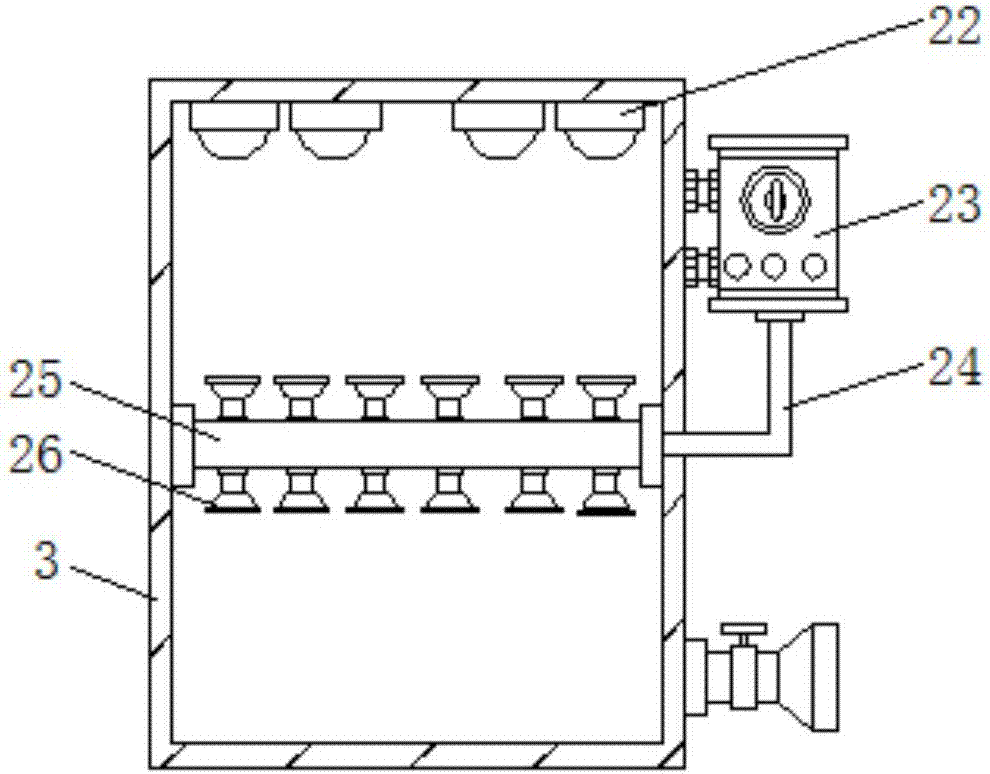

Sewage treatment unit with good practicality

InactiveCN107010792AEasy to handleRemove fullyWater/sewage treatment by irradiationSpecific water treatment objectivesSludgeActivated carbon filtration

The invention discloses a sewage treatment unit with good practicality. The sewage treatment unit comprises a settling box, a purifying box and a disinfection box, wherein the top end of one side of the settling box is provided with a chemical reagent tank; the top of the settling box is provided with a stirring motor; a sludge discharge outlet is formed in the bottom end of the settling box; the interior of the purifying box is provided with, from top to bottom, a magnet adsorption screen, a biomembrane filter screen and an active carbon filter screen; the sidewall of the disinfection box is provided with an ozone generator; and gas-distributing pipes are arranged in the disinfection box. The sewage treatment unit provided by the invention can effectively eliminate heavy metals, microbes, organic harmful substances, particulate matters and other impurities in water, is capable of removing pigments and peculiar smell in water, and has improved sewage treatment effect; and since the ozone generator is mounted on the sidewall of the disinfection box, ozone generated by the ozone generator can be used for sterilization and disinfection of purified clear water after purification of sewage, so sewage is allowed to reach discharge standard.

Owner:盐城百利豪环保机械制造有限公司

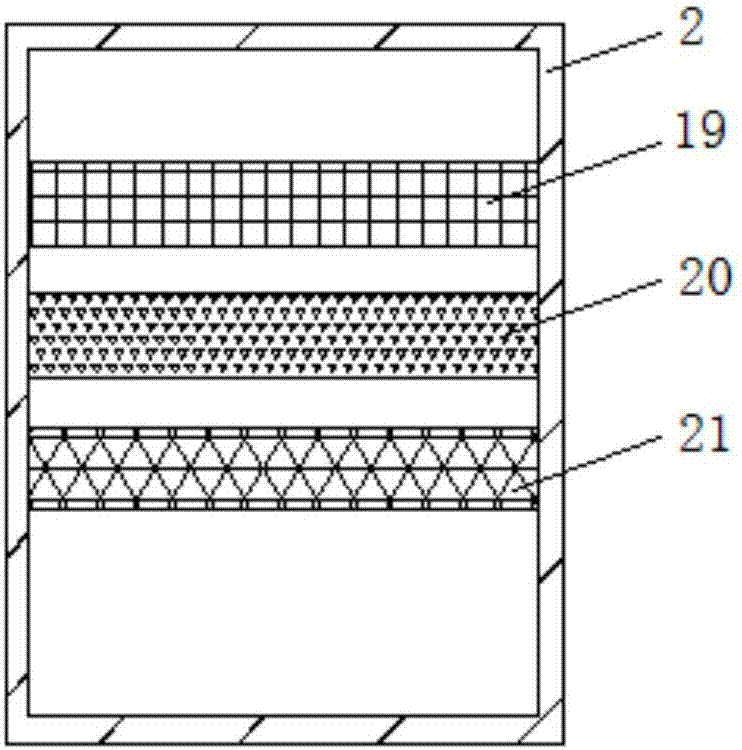

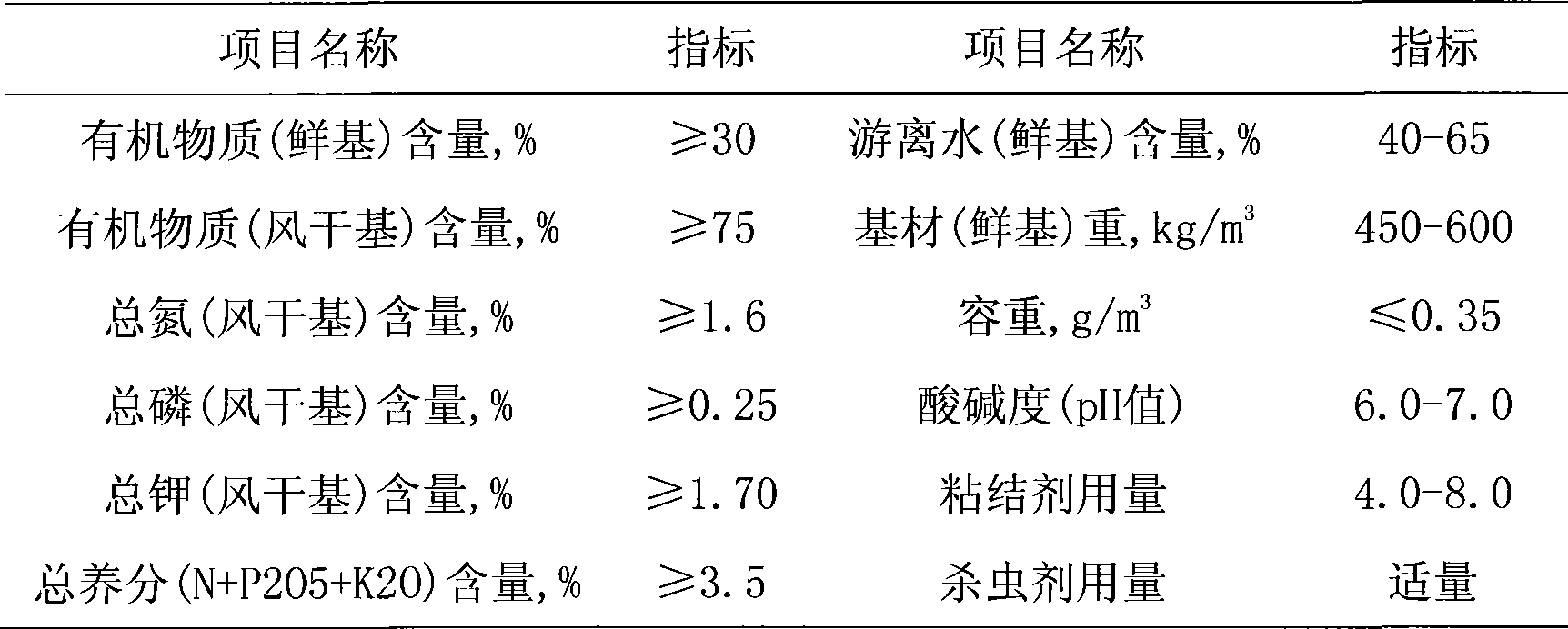

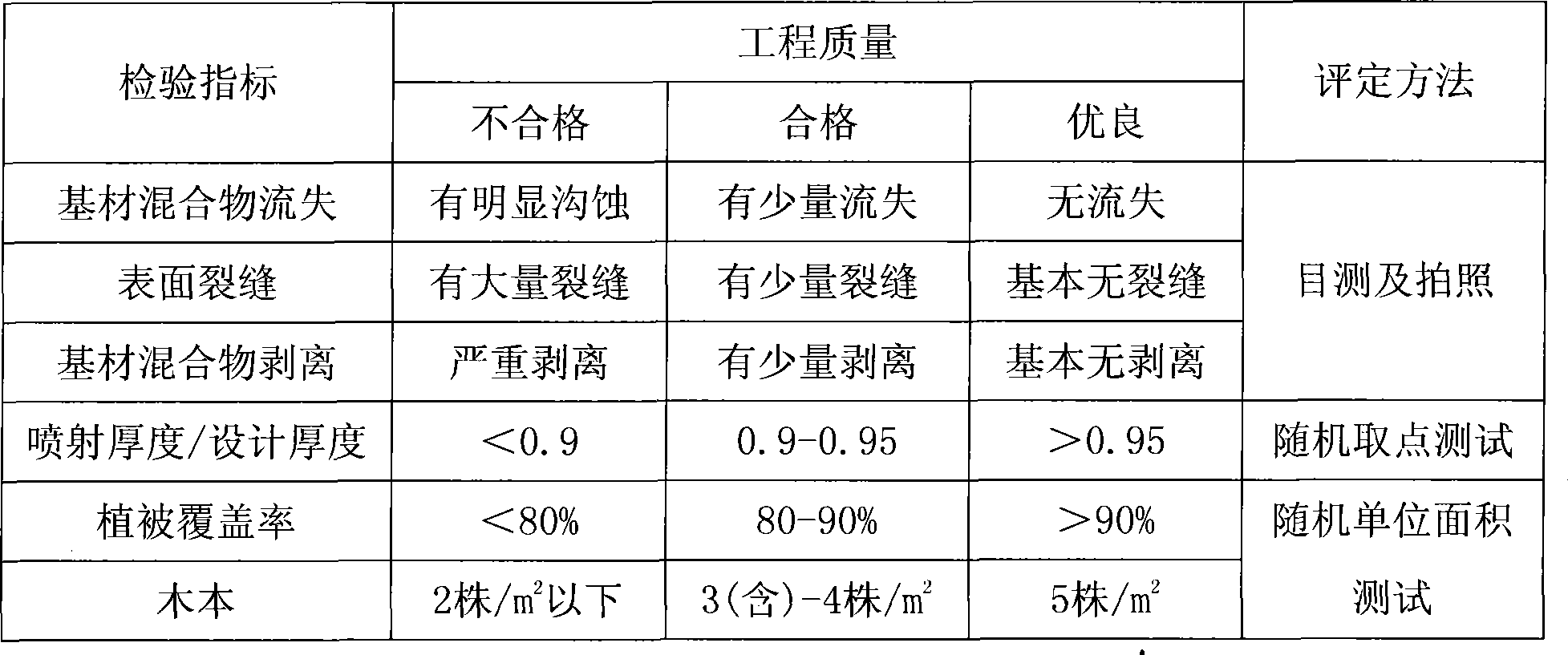

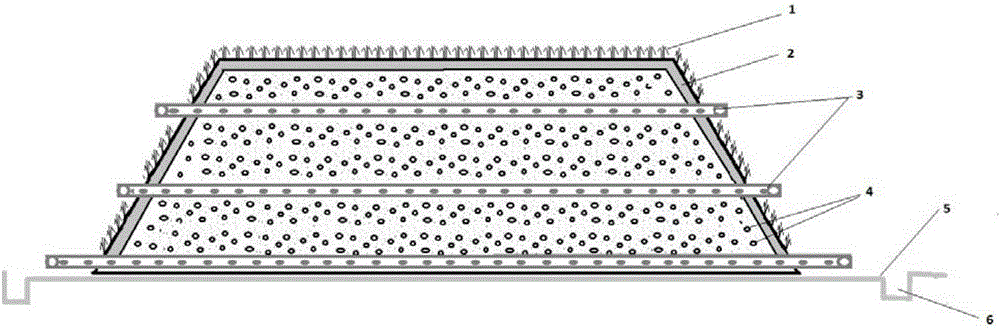

Ecological protection greening substrate for rock slope

InactiveCN101485282AQuick closurePrevent weathering and peelingCultivating equipmentsSoilless cultivationFiberSludge

The invention discloses a rock slope ecological protection afforestation substrate. The substrate is prepared by evenly mixing a mixture of mixed and fermented straw, cattle manure, edible fungus refuse (the waste after the edible fungus production), sludge and organic matter fibers, compound fertilizer, a soil moisture holding agent, a binding agent, attapulgite powder and a pH regulator. The rock slope ecological protection afforestation substrate is used to carry out the spray seeding and greening on the exposed rock slope, the discarded mine and the mountain gap, and can maximally restore the vegetation ecology in a shorter period, thereby reaching the aims of afforestation and slope protection. The substrate can supply a reasonable physical structure and nutrient contents needed by the growth of the vegetation, and ensure the sufficient cohesion force between the substrate mixture on the slope surface and the rock slope so as to ensure that the vegetation on the slope surface can take root and grow well on the rock slope. The substrate can ensure the stability of the substrate mixture on the slope surface so as to resist the rain erosion. The substrate can rapidly seal the slope surface and prevent the slope surface from flaking off due to efflorescence together with the vegetation.

Owner:ANHUI AGRICULTURAL UNIVERSITY

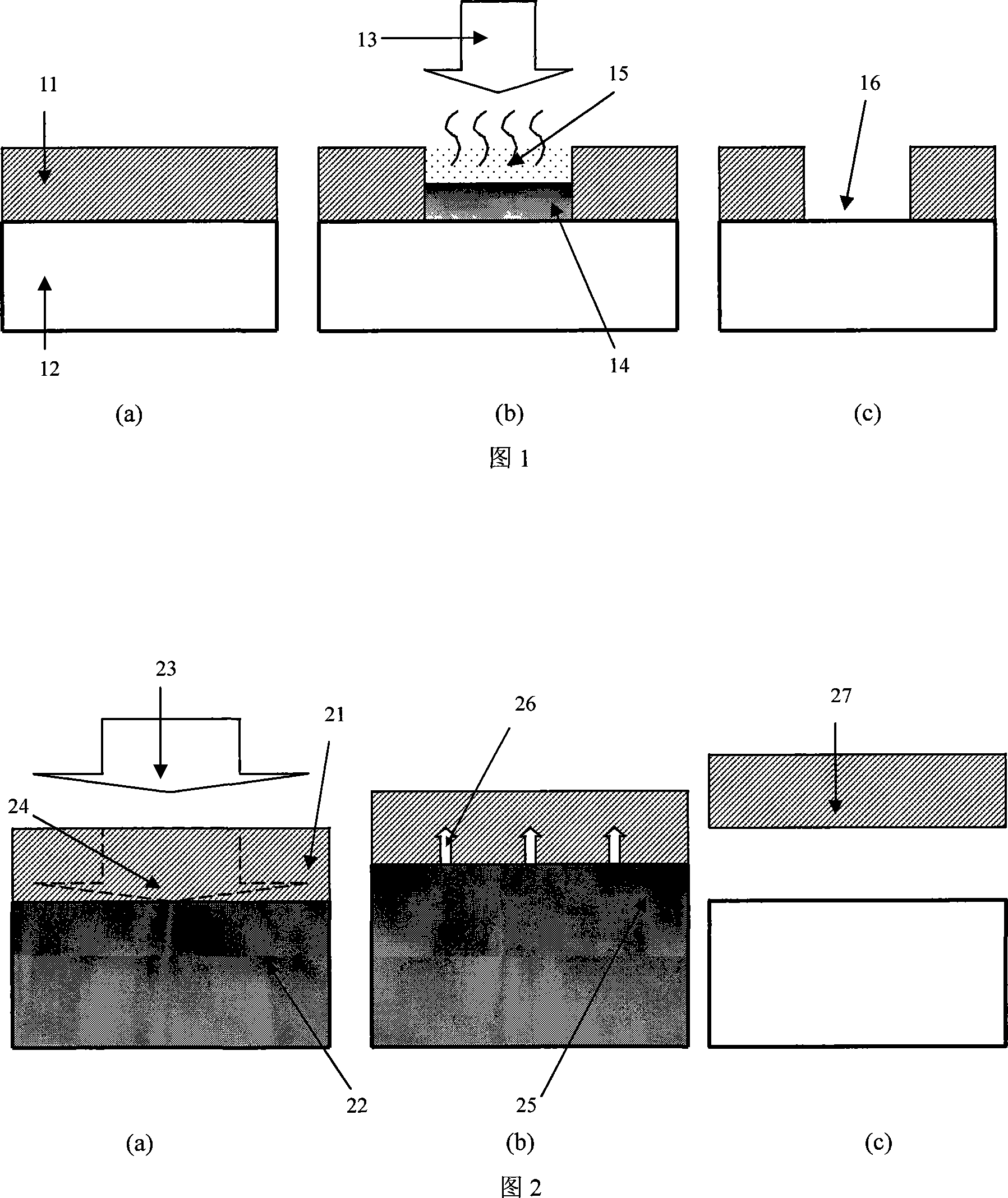

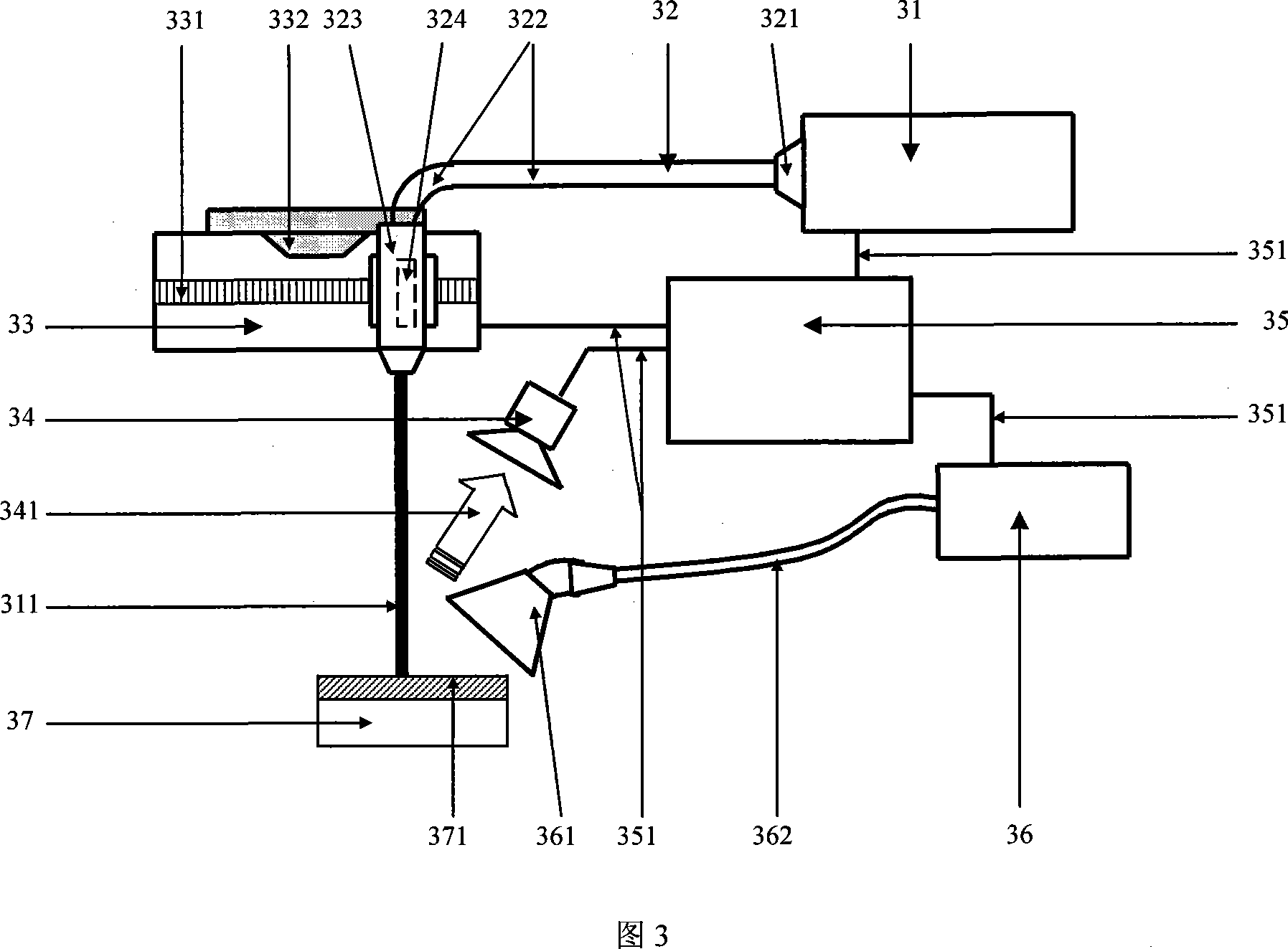

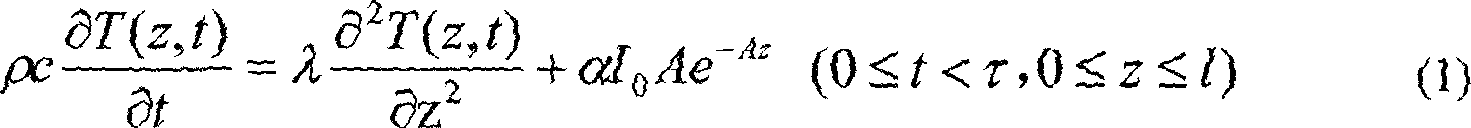

Ultrasonic detection narrow pulsewidth laser sludge remover and its sludge removing method

InactiveCN101143364AWon't happenGood decontamination effectAnalysing solids using sonic/ultrasonic/infrasonic wavesDirt cleaningShock waveAutomatic control

An ultrasonic detection narrow pulse wide laser cleaner includes a narrow pulse wide laser device (1), a beam adjustment transmission device (2), a moving platform device (3), an ultrasonic detection device (4), an automatic control device (5), a dust absorption recovery device (6) and an ultrasonic detection narrow pulse wide laser filth clearing method. A cleaned object surface is irradiated with narrow pulse wide lasers. And a strong vibration shock wave is produced in short time to remove filths from the medium surface. At the same time, an instrument device is used to monitor and analyze ultrasonic waves caused by the vibration during the cleaning process to ensure the good medium surface and realize the automatic cleaning process. The cleaner is used to remove various filths of oxides, corrosion matters, paint, grease marks, residues, etc. of the media surfaces of metals, semiconductors, buildings, etc. The cleaner has the advantages of good effect, non-damages, high efficiency, automation, etc.

Owner:NANKAI UNIV

Alkali soil modification fertility intensifying amendment and preparation method thereof

The invention discloses a fertilizing and conditioning agent for improving the saline alkali soil, and the fertilizing and conditioning agent includes an organic material, an inorganic material and a regulator for the plant growth, wherein, the weight proportion between the organic material and the inorganic material is 3:2 to 1:1. The organic material is fermented and maturated by one or a plurality of such organic matters as town living sludge, excrements of livestock and poultry, and furfural slag; and the inorganic material is formed by one or a plurality of such industrial waste and materials as desulfurized gypsum, phosphogypsum, and ammonium sulphate. Moreover, appropriate growth regulator for plant which is added according to the growing requirements can not only improve the saline alkali soil and fertilize the soil, but also can improve the plant growth and promote the plant to grow well as well as providing an effective path for promoting the recycling of the waste resources and reducing the secondary pollution to the town and the country.

Owner:天津市北方绿业生态科技有限公司

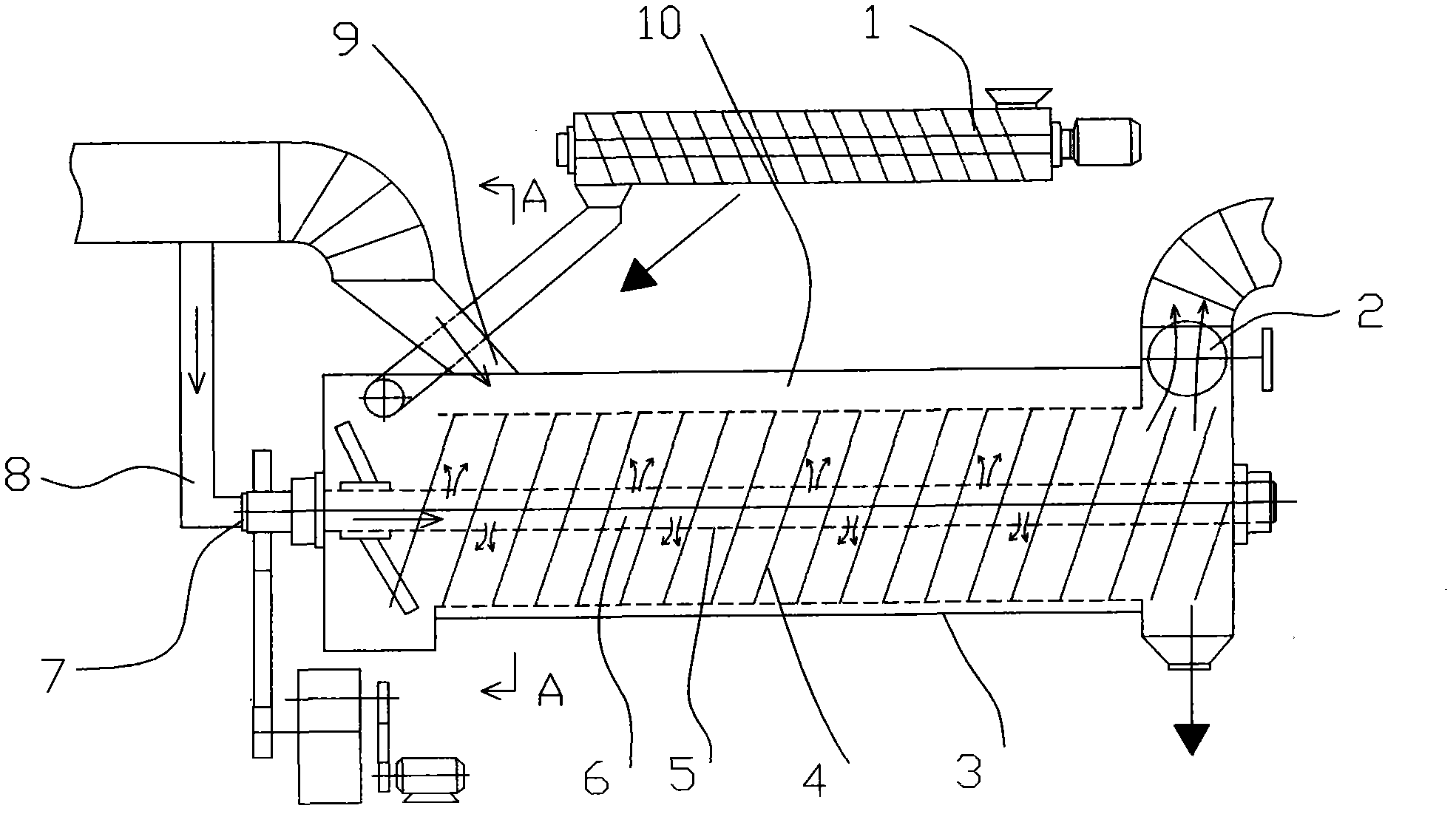

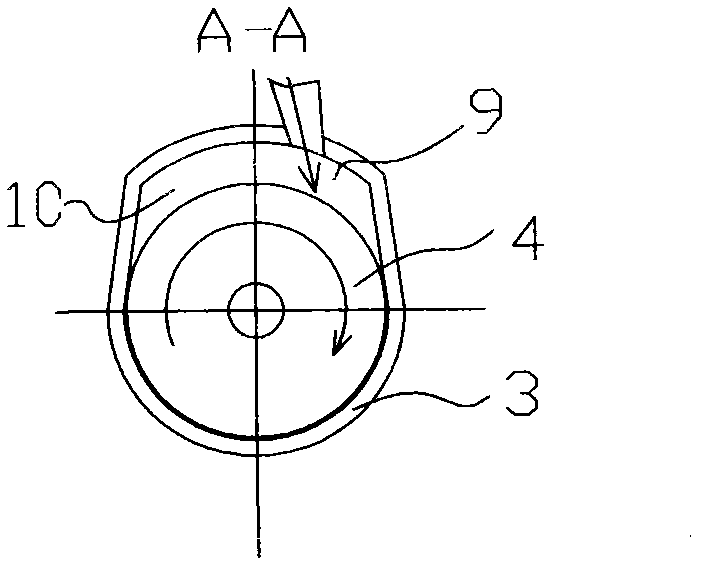

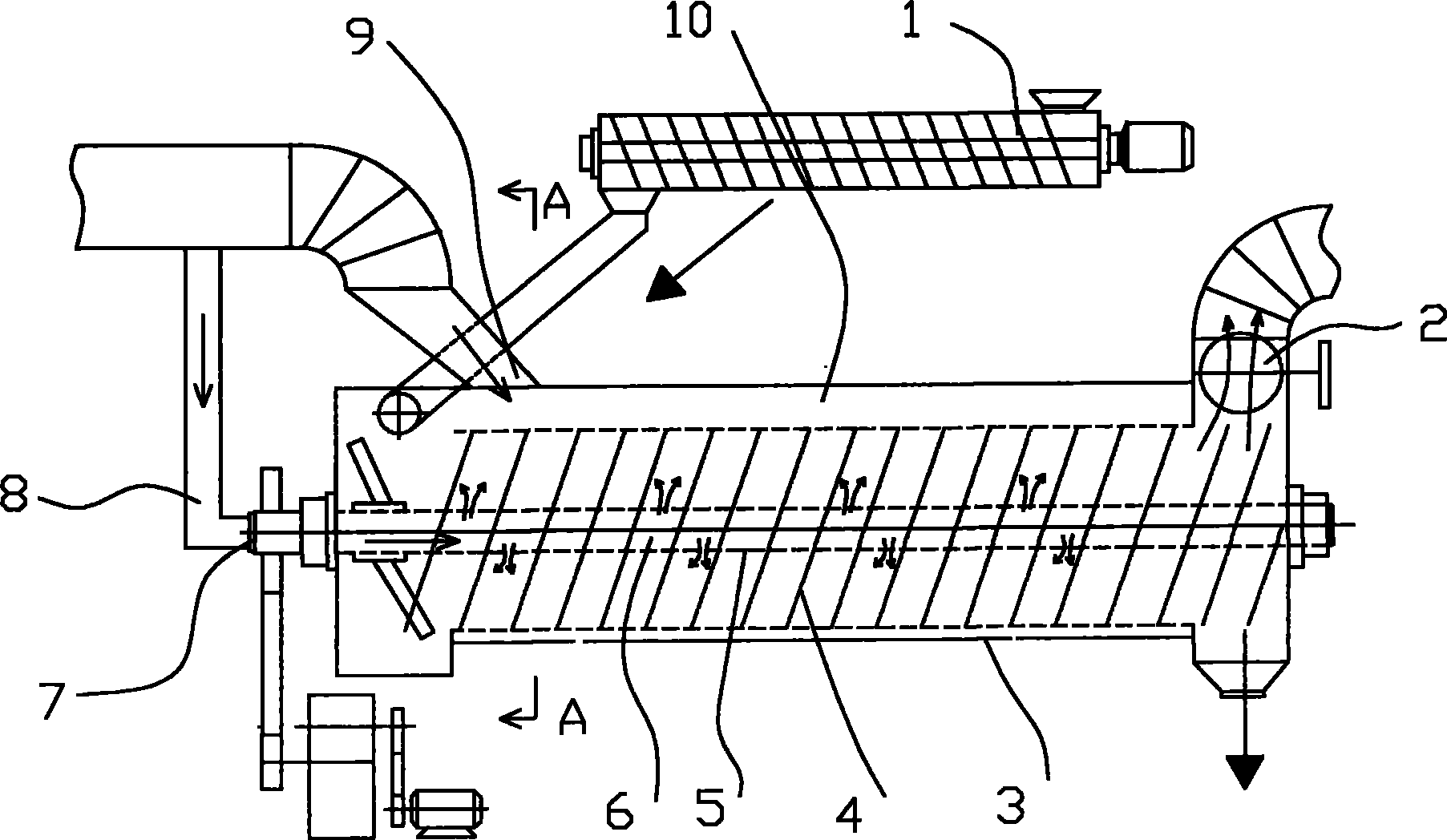

Drying device for drying sludge by using flue gas

InactiveCN102464441AAvoid stickingPrevent liquidity lossSludge treatment by de-watering/drying/thickeningSludgeFlue gas

The invention provides a drying device for drying sludge by using flue gas. The invention relates to an environment-friendly treatment device, in particular to a drying device for dynamically drying wet sludge by using high-temperature (120-200 DEG C) flue gas. The drying device comprises a flue gas conveying pipeline and a sludge conveying device. The drying device is characterized by comprising a cylinder body, a hollow shaft, a material conveying spiral and a gas inlet duct communicated with the flue gas conveying pipeline. Aiming at the problems, the invention provides the drying device for online drying wet sludge by using flue gas so as to greatly improve treatment efficiency and reduce environmental pollution.

Owner:JIANGDU SUNENG ELECTRICAL EQUIP

Supercritical water process to upgrade petroleum

ActiveUS20130140214A1Proceed efficientlyThermal non-catalytic crackingCatalytic crackingSludgePetroleum

Provided is a process for the supercritical upgrading of petroleum feedstock, wherein the process includes the use of a start-up agent, wherein the use of the start-up agent facilitates mixing of the petroleum feedstock and water, thereby reducing or eliminating the production of coke, coke precursor, and sludge.

Owner:SAUDI ARABIAN OIL CO

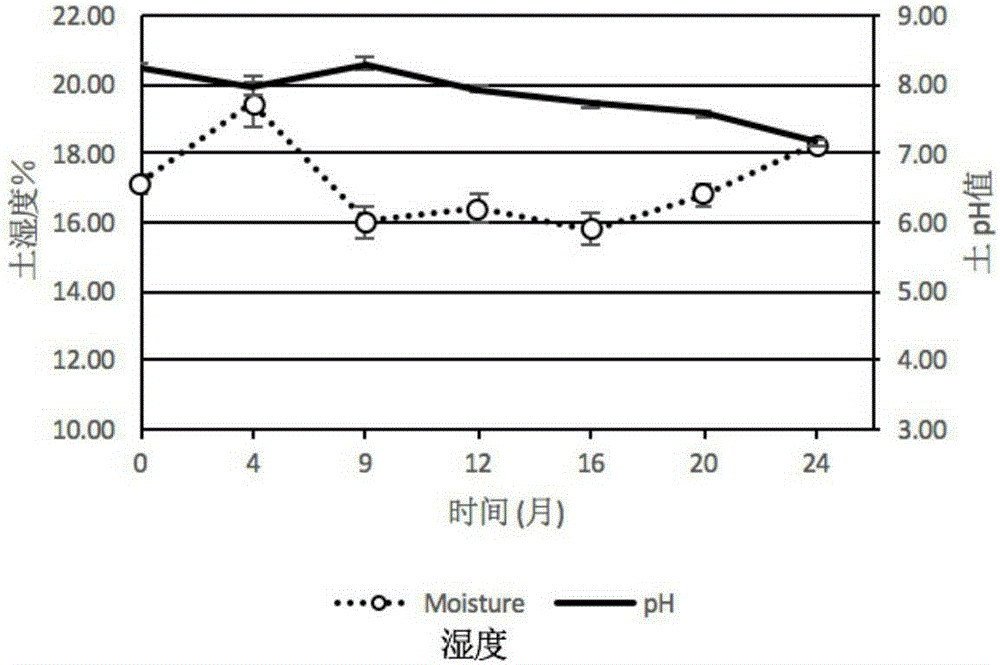

A method for the remediation of harmful organics and/or heavy metal contaminated matrix

ActiveCN105344709APlay a role in loosening and ventilatingRestoration concepts for green sustainabilityContaminated soil reclamationBiostimulationMicrobial agent

The present invention provides a method for the remediation of harmful organics and / or heavy metal contaminated matrix in order to remediate harmful organics and / or heavy metal contaminated soil, sediment and / or sludge. The method involves the processes of biostimulation, bioaugmentation, rhizoremediation, phytoremediation and a passive biopile. The method comprises steps of: a) designing a microbial agent comprising pollutant degrading bacteria, plant promoting bacteria and / or biosurfactant producing bacteria; b) preprocessing the matrix; c) constructing a passive biopile; and d) capping the biopile with plants for phytoremediation. The method achieves internationally-dominant green and persistent remediation while achieving bioremediation / phytoremediation degrading the organics and removing heavy metal.

Owner:山东迈科珍生物科技有限公司

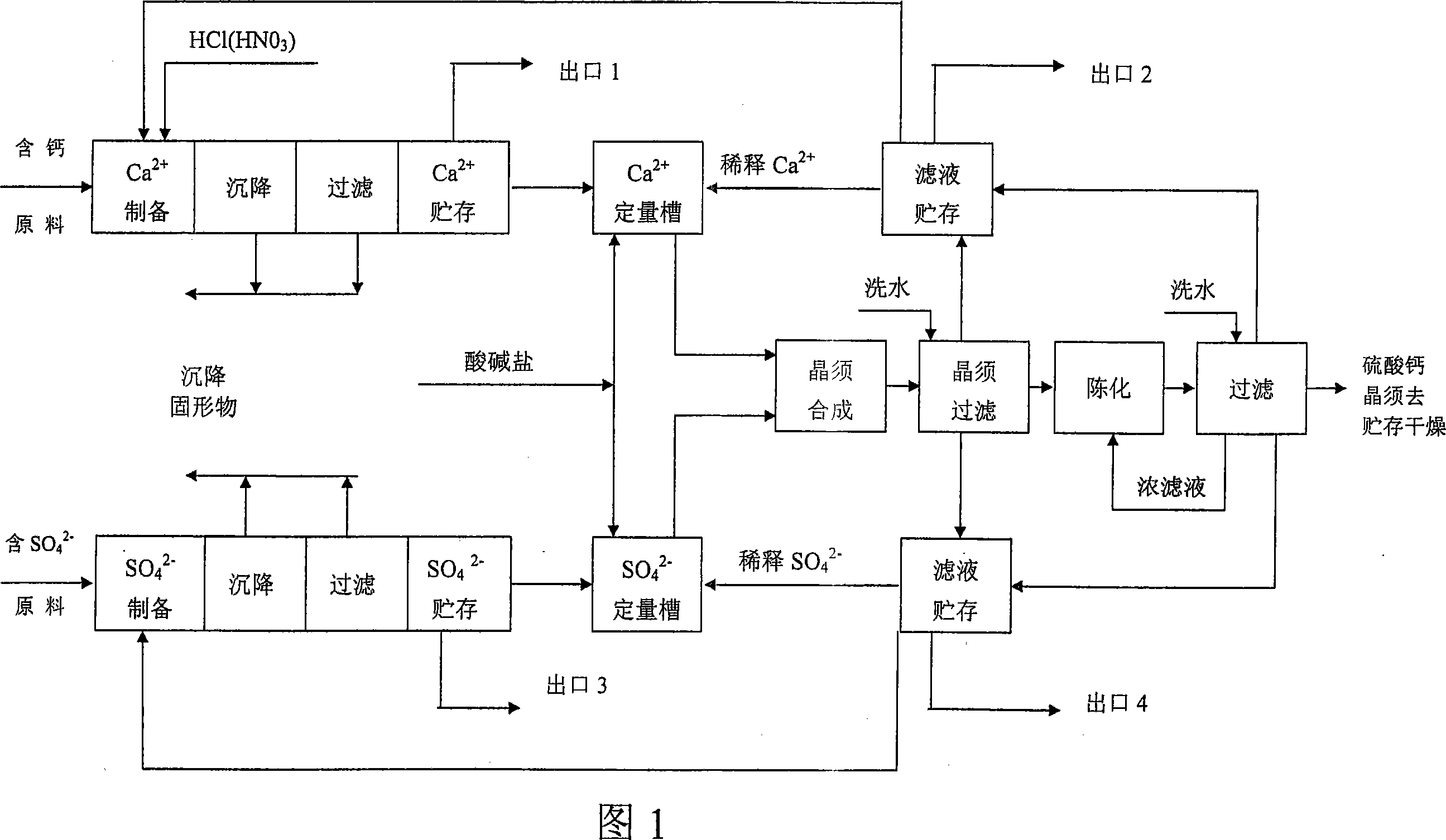

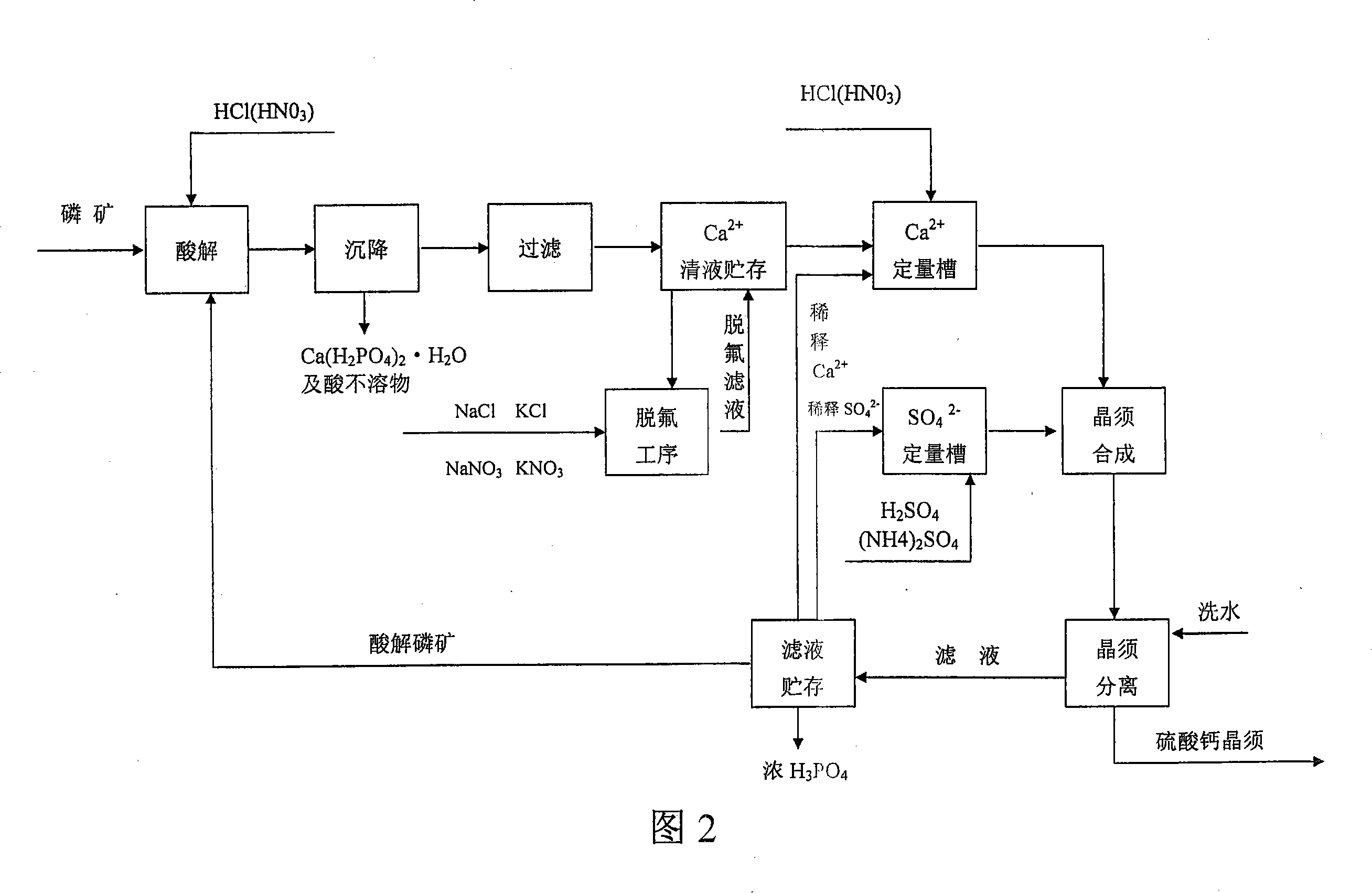

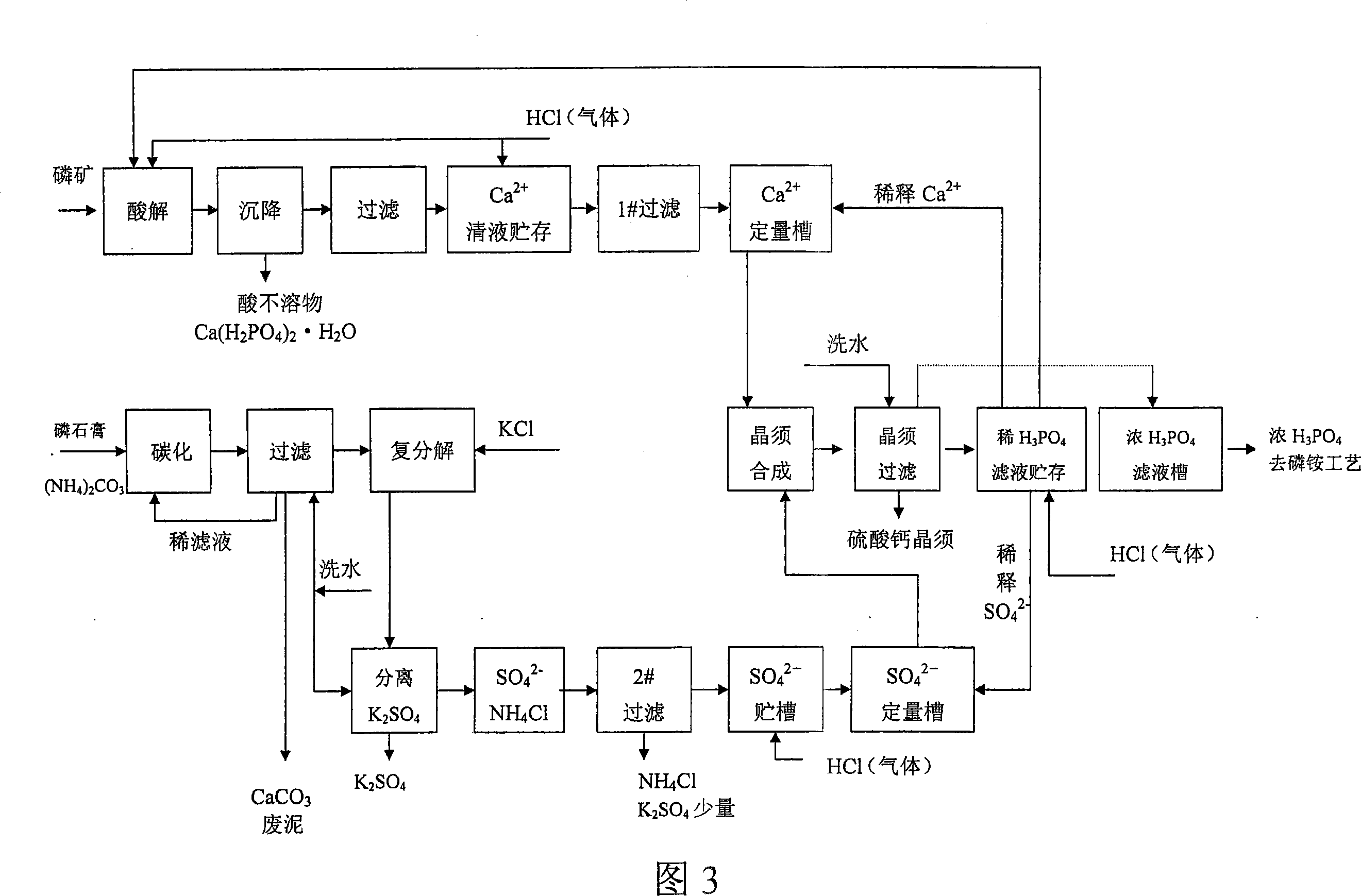

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com