Patents

Literature

822 results about "Lime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lime is a calcium-containing inorganic mineral composed primarily of oxides, and hydroxide, usually calcium oxide and/ or calcium hydroxide. It is also the name for calcium oxide which occurs as a product of coal seam fires and in altered limestone xenoliths in volcanic ejecta. The word lime originates with its earliest use as building mortar and has the sense of sticking or adhering.

Cement-base dual-liquid slip-casting material

The invention relates to a kind of pair-slurry affusing material prepared with cement as basic raw material. It is comprised of two kinds of dry powdery mixed materials A and B of affusing slurry pair-liquid formed after adding water. Their weight percents are respectively: mixed material A: sulfur aluminate cement 30% - 98.1%, retarder citric acid 0.1% - 0.5%, flocculant polyacrylamide 0% - 0.8%, water-reducing agent FDN 0.6% - 1.5% and inorganic padding pulverized coal ash 0% - 69.1%; mixed material B: Portland cement 20% - 88%, land plaster 6% - 15%, flocculant UWN 0% - 0.7%, accelerator lithium carbonate 0.4% - 1.0%, water-reducing agent FDN 0.5% - 1.3%, calcareousness 2.0% - 5.0% and inorganic padding pulverized coal ash 0% - 70.8%.

Owner:张振秋

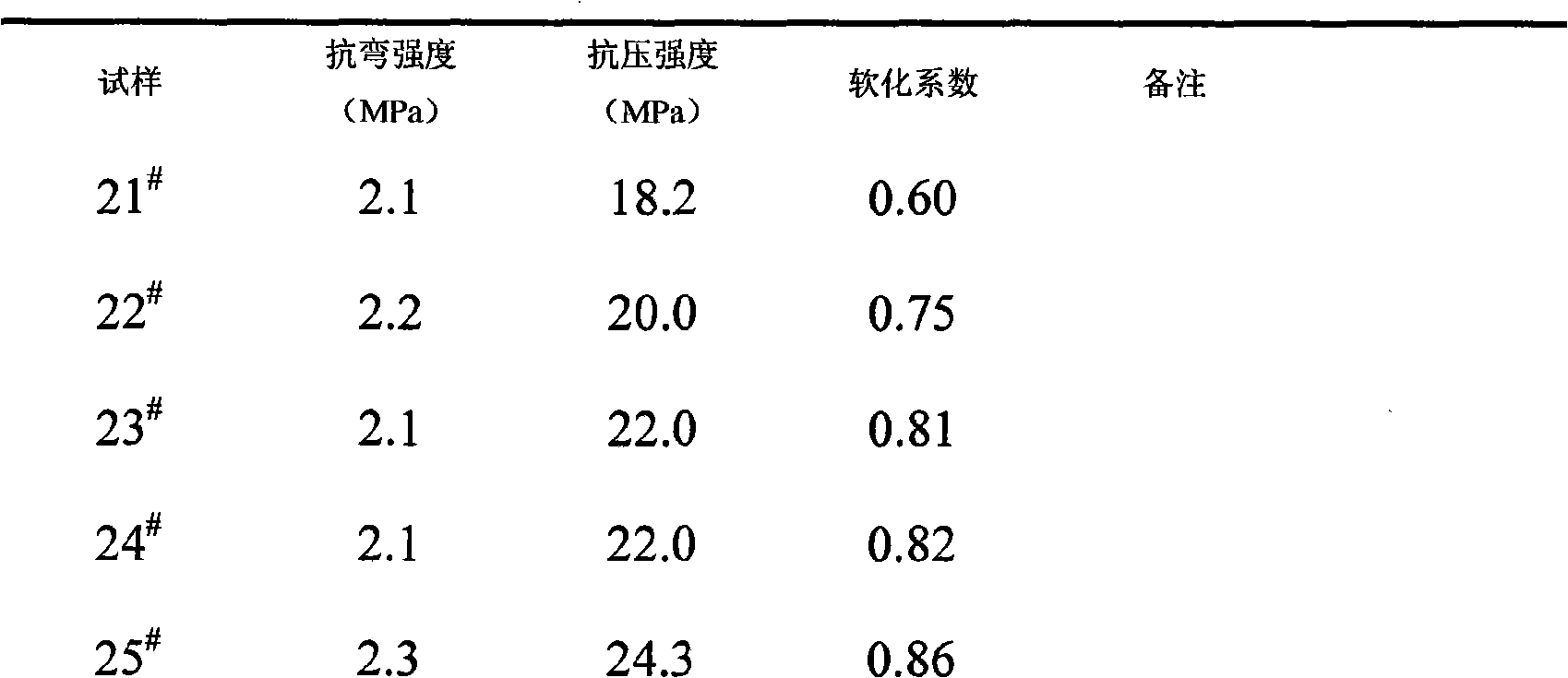

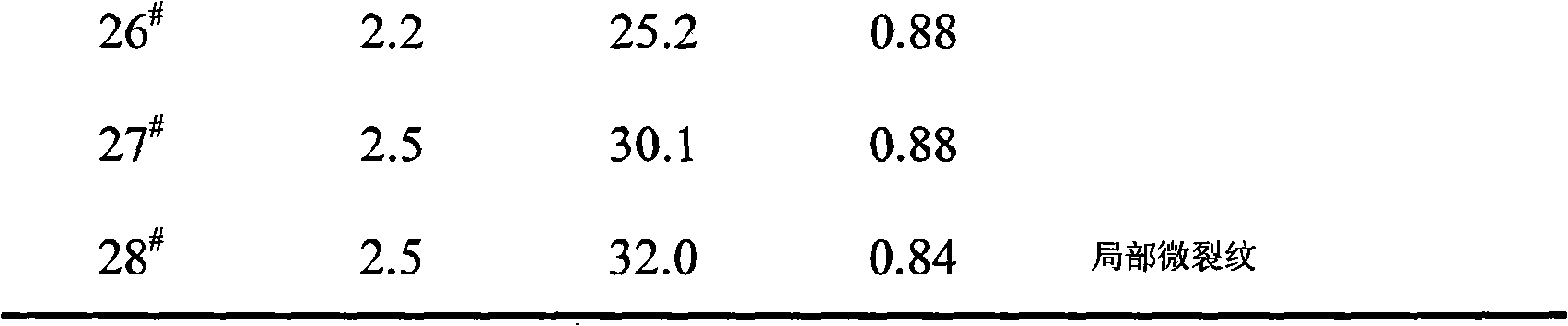

Water-resisting high-strength gypsum-base concrete brick or building block, and producing method thereof

The invention relates to a waterproof high-strength gypsum-based concrete brick or building block and a production method thereof. The waterproof high-strength gypsum-based concrete brick or building block mainly contains gypsum-based composite binding agent, coagulation accelerator and filler. The weight proportions of the components are as follows: 10-100% of gypsum-based composite binding agent, 0-6% of coagulation accelerator, 0-90% of filler, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-6% of lime and 0-15% of gypsum hemihydrate. 80% of the raw materials of the high-strength gypsum-based concrete brick or building block are industrial byproducts, so that the invention reduces the production cost, realizes energy conservation and discharge reduction, avoids the land occupancy and water pollution caused by chemical gypsum, ore slag, coal ash, furnace slag, alkali waste and carbide slag, and protects the environment.

Owner:长沙归一新材料科技股份有限公司

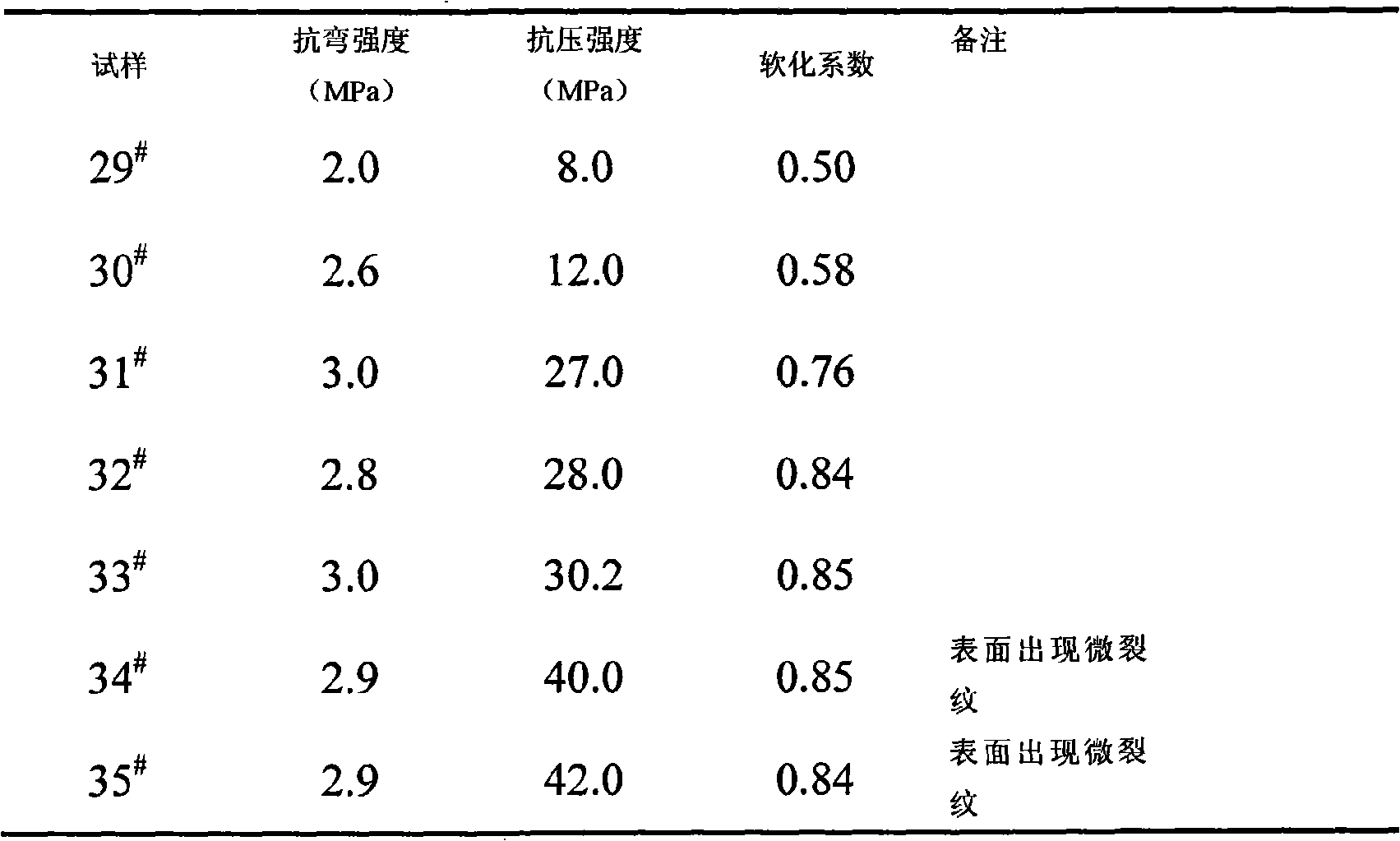

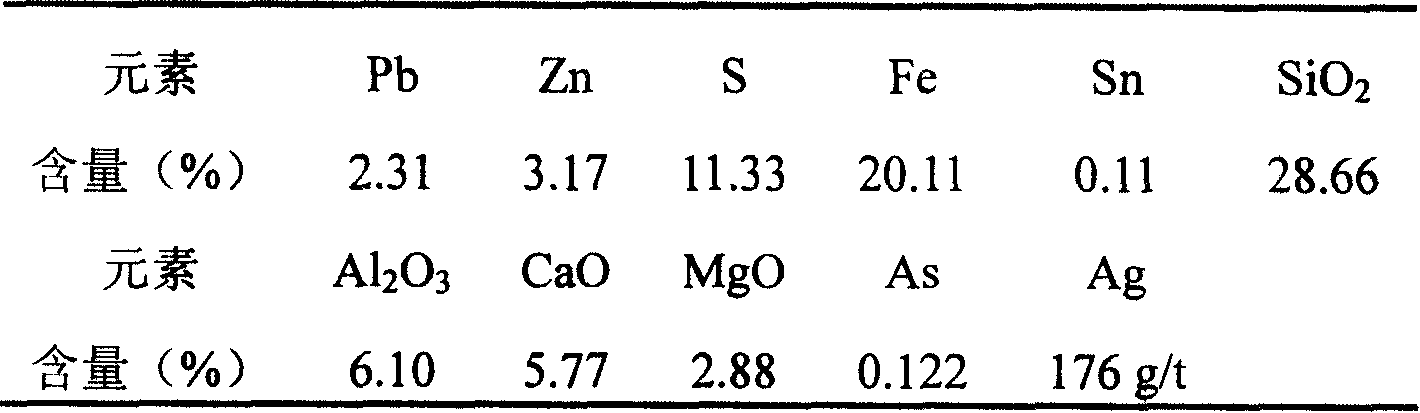

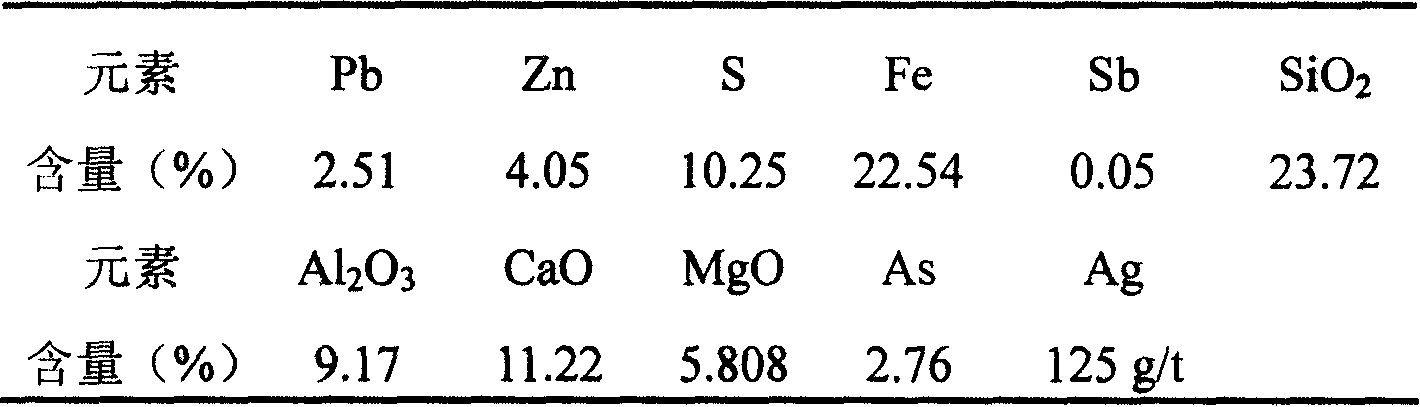

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

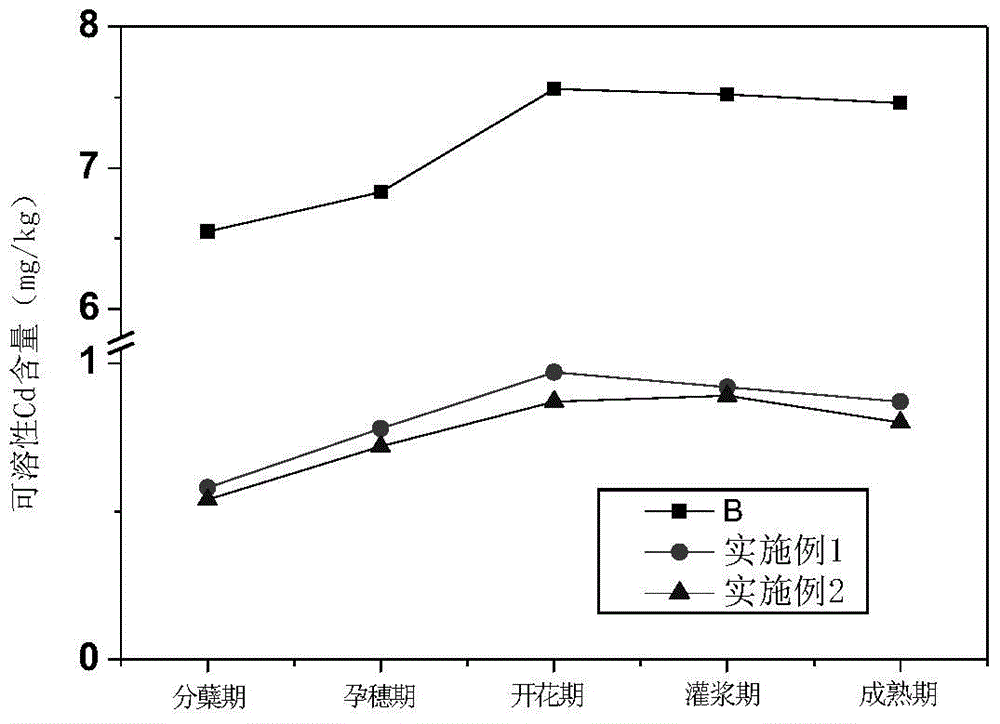

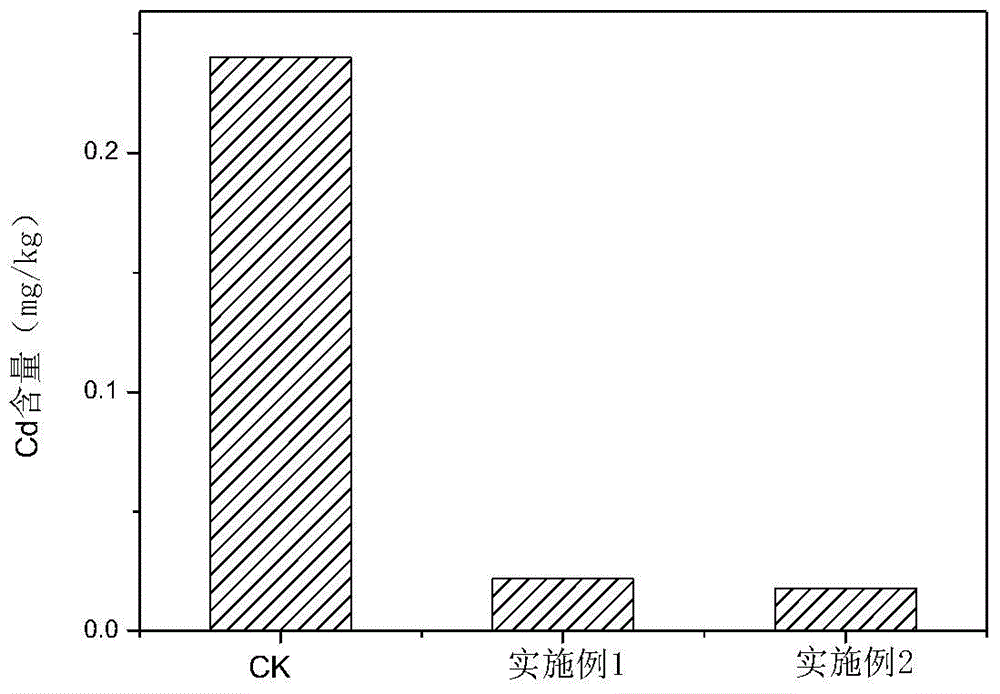

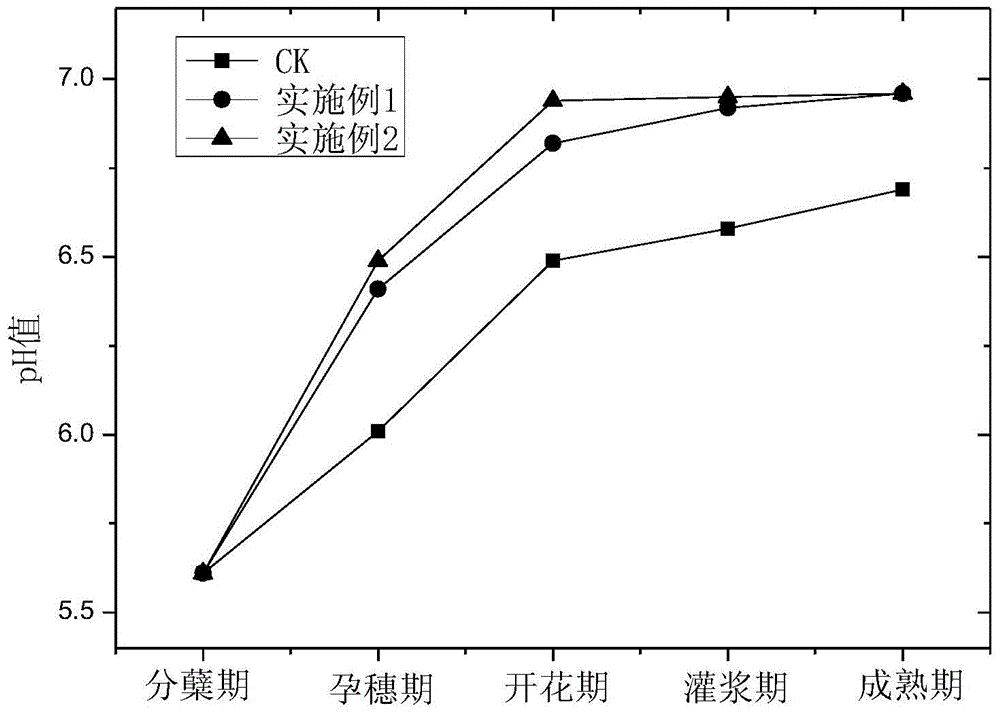

Composite soil conditioner for treating Cd pollution, and preparation and use methods thereof

InactiveCN105670640ARaise the pHReduce soluble Cd contentOther chemical processesContaminated soil reclamationClay mineralsMicrobial agent

The invention discloses a composite soil conditioner for treating heavy metal Cd pollution, and preparation and use methods thereof. The composite soil conditioner comprises the composition and content: 20-30% of clay minerals, 10-20% of peat, 10-20% of biochar, 25-35% of slaked lime, 5-15% of an oxide of iron, and 5-10% of a microbial agent. The preparation of the composite soil conditioner comprises the following steps: adding the clay minerals, the peat, the biochar, the slaked lime and the oxide of iron in proportion, then fully stirring until the raw materials are evenly mixed; adding the microbial agent with the amount of 5-10%, to prepare an inorganic and organic composite conditioner, wherein the microbial agent contains at least one of iron-reducing bacteria, photosynthetic bacteria and bacillus. The composite soil conditioner prepared by the method is directly added to crop field soil polluted by heavy metals in proportion, and then ploughed fallowing is performed. Compared with the prior art, the product has the advantages of ingenious and reasonable formula design, excellent in-situ passivation effect, simple preparation method, low production cost, simple application method and the like.

Owner:HUNAN MEIXINLONG ECOLOGICAL ENVIRONMENTAL PROTECTION TECH

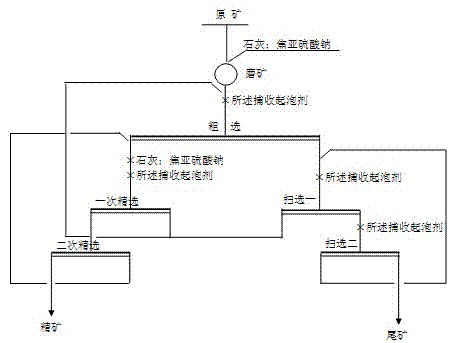

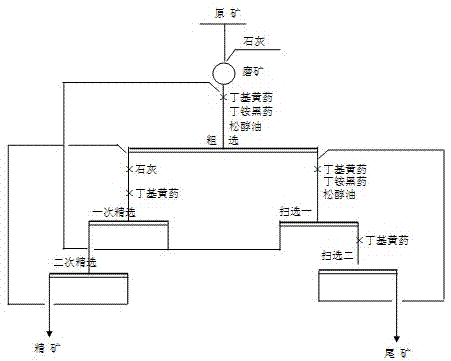

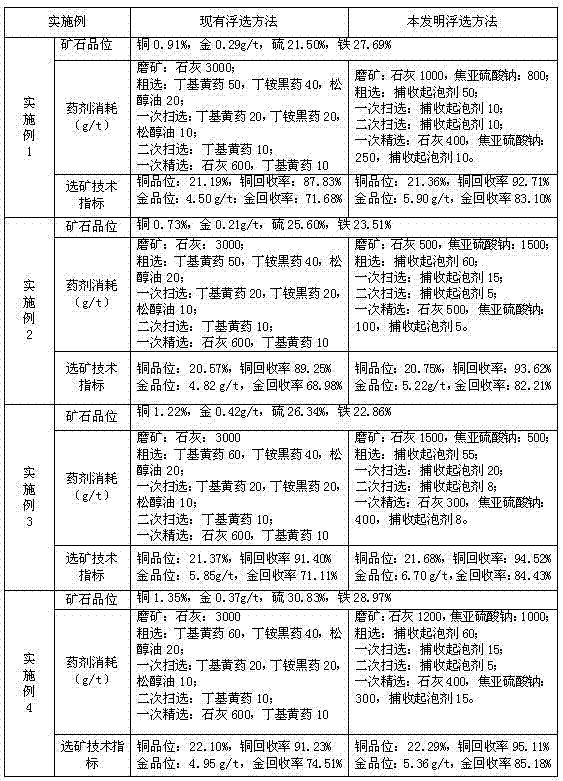

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

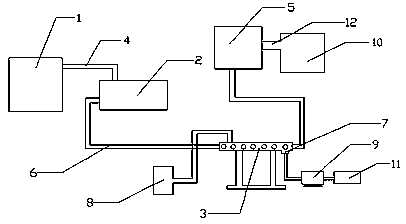

Sludge curing agent and sludge curing process employing sludge curing agent

ActiveCN104016626AImprove delivery efficiencyHigh degree of automationSludge treatment by de-watering/drying/thickeningSolid waste managementSludgePolyacrylamide

The invention relates to a sludge curing agent and an application thereof in sludge curing treatment, and belongs to the field of sludge treatment. In order to overcome the technical defect of poor curing effect of the existing sludge curing agent in the prior art, the sludge curing agent which is low in cost and good in curing effect is provided by the invention. The sludge curing agent comprises the following components in parts by weight: 25 to 45 parts of coal ash, 20 to 30 parts of swollen resin, 15 to 20 parts of cement, 7 to 9 parts of water glass, 10 to 12 parts of kieselguhr, 10 to 12 parts of quick lime, 6 to 9 parts of sodium hydroxide, 3 to 8 parts of aluminum sulfate, 8 to 10 parts of polyacrylamide, 6 to 8 parts of magnesium perchlorate and 5 to 15 parts of quartz sand. The sludge curing agent has the advantages of high curing efficiency and large hardness when being applied to the sludge curing treatment. Thus, the sludge curing agent is very suitable for the sludge curing treatment for water conservancy.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Sludge curing agent and sludge curing method using same

The invention discloses a sludge curing agent and a sludge curing method using the same, relating to the field of sludge treatment. The sludge curing agent is prepared by the following method: firstly mixing seven components including expansible graphite, cement, coal ash, carbon black, silicon powder, porcelain clay and quick lime, leading the expansible graphite to expand under the condition without being lower than the expansion temperature of the expansible graphite, stirring mixture and obtaining a semifinished product; adding two components including expansion resin and water glass, stirring together, mixing fully and preparing the curing agent. The sludge curing agent disclosed by the invention is added into sludge, so that the water content of the sludge can be reduced, and the problem of weak acidity of the sludge is solved.

Owner:广州珞珈环境技术有限公司

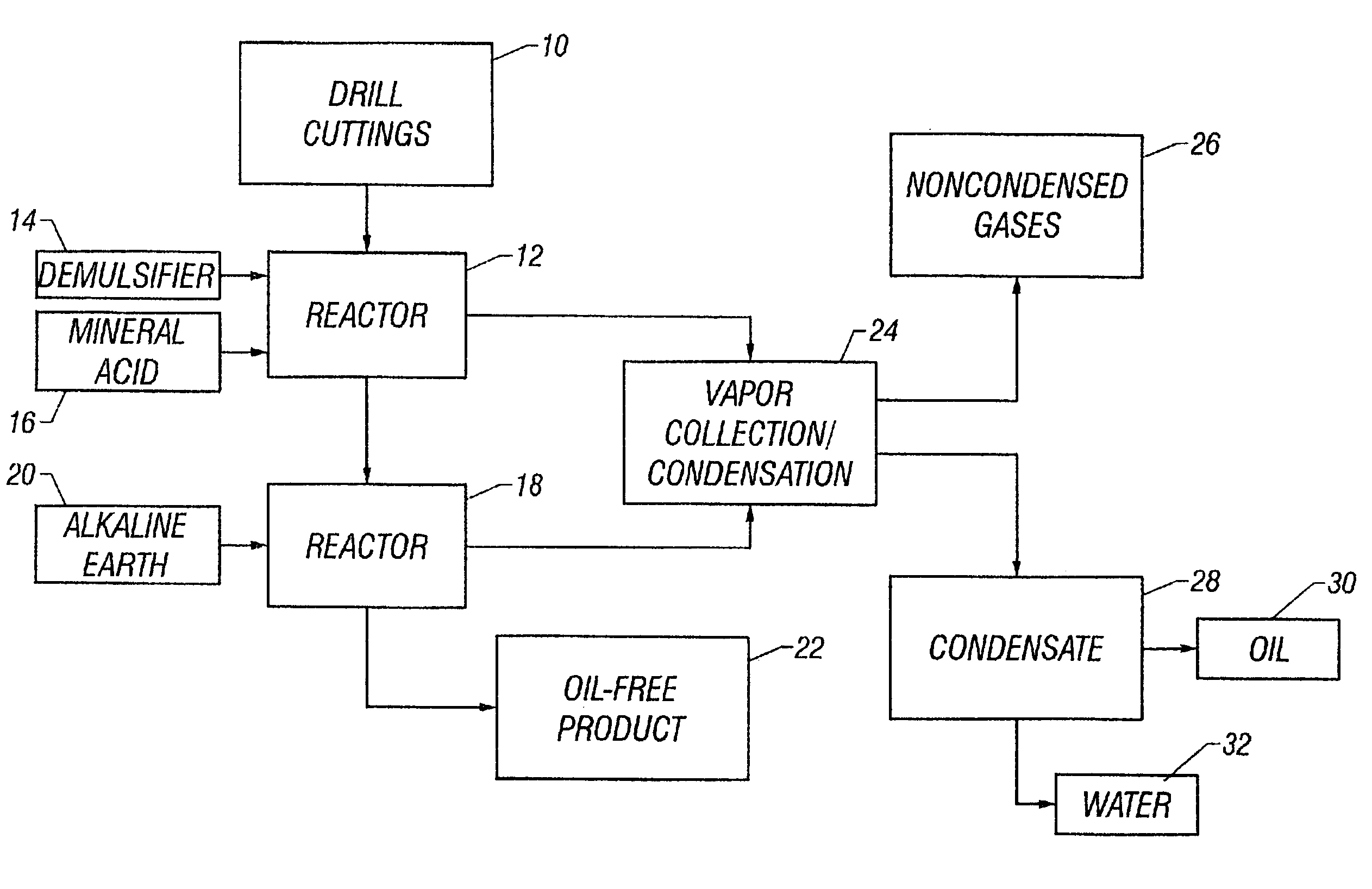

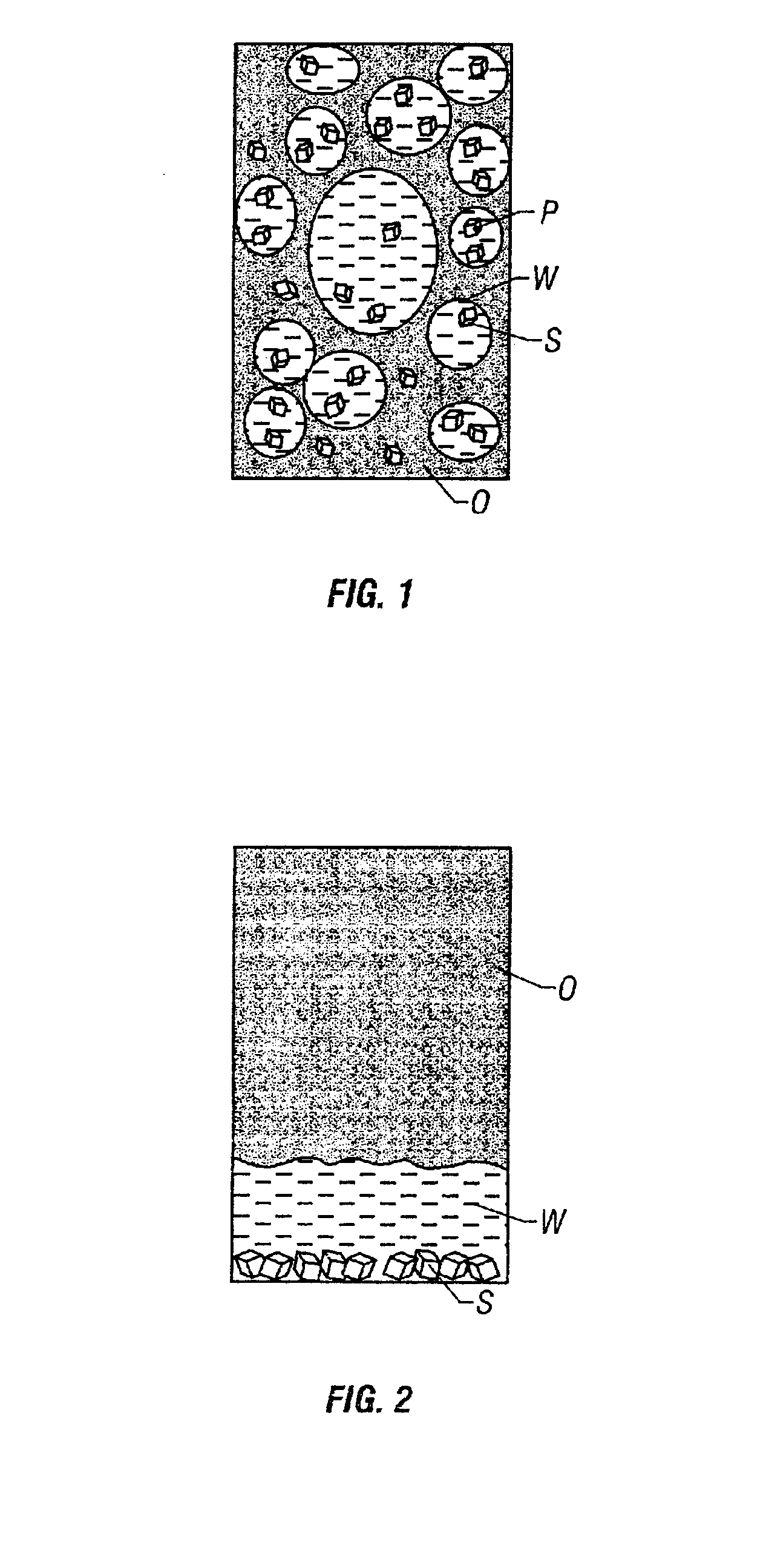

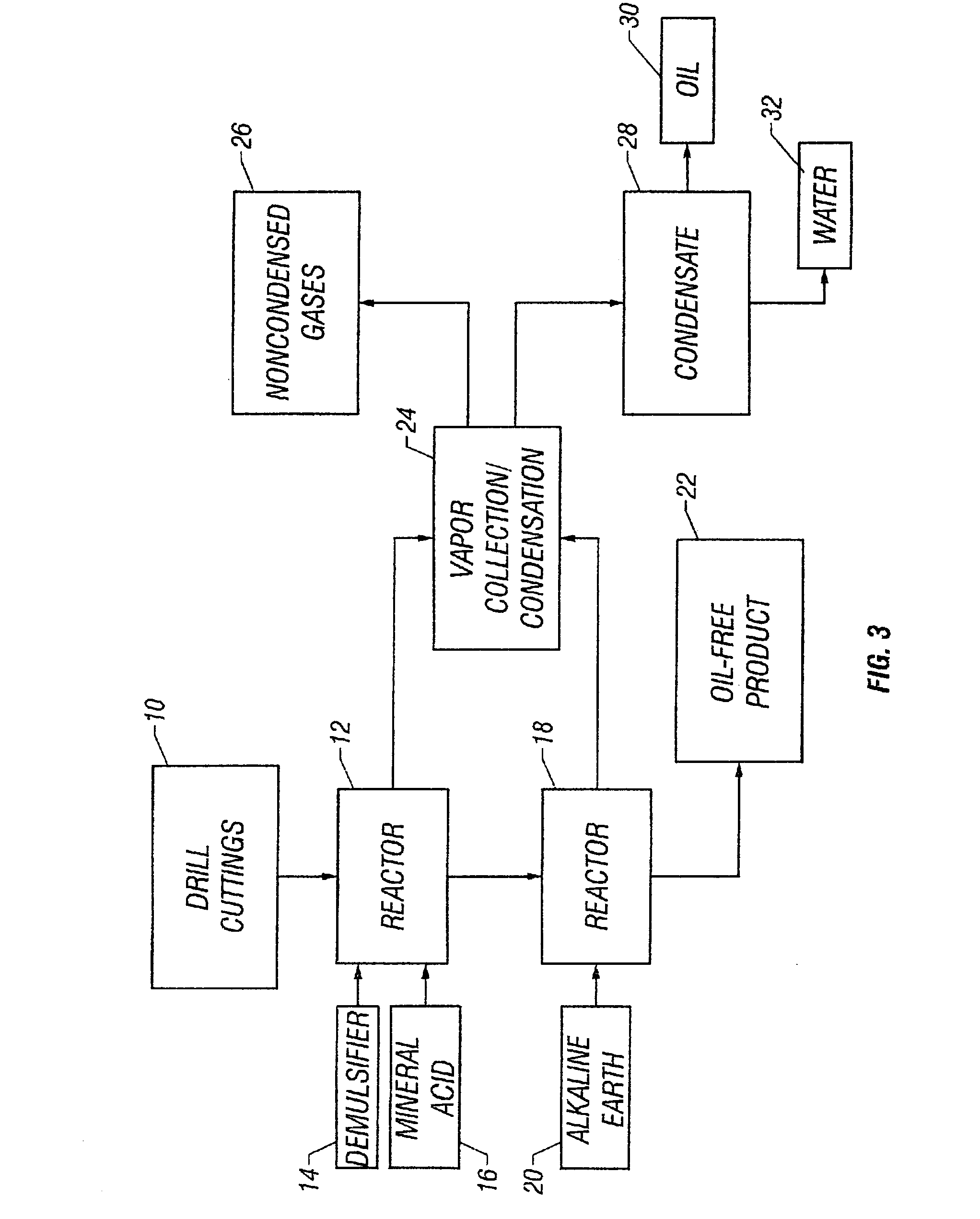

Drill cutting treatment method

InactiveUS6668947B2Easy to removeRapid and extensive and costsLighting and heating apparatusTransportation and packagingOrganic acidEmulsion

A method and apparatus for treating for disposal oil-contaminated clay substrates such as drill cuttings from drilling with an oil-based mud. If necessary, the substrate is pretreated with an aqueous emulsion breaker such as alkylbenzenesulfonic acid. The substrate is mixed under high shear conditions with a mineral acid such as sulfuric acid. This can be done in an agitated reactor with sequential addition of the organic and inorganic acids. The substrate is then mixed with alkaline earth such as lime in a second agitated reactor. The reactions between the acid(s), alkaline earth and substrate are exothermic and provide heat to vaporize the oil, reaction products and water. Recoverable constituents in the vapor can be condensed in a vapor collection system. The treated substrate is essentially free of oil and has a controlled water content.

Owner:RACIONAL ENERGY & ENVIRONMENT

Copper mine waste oxidized ore hillock ecological restoration method

InactiveCN105724016AReduce migration conversionHarm reductionHops/wine cultivationContaminated soil reclamationEnvironmental resource managementEnvironmental engineering

The invention discloses a copper mine waste oxidized ore hillock ecological restoration method. The method comprises the first step of land preparation, the second step of first layer grating laying, the third step of ecological bag slope protection, the fourth step of lime layer spraying, the fifth step of physical isolation layer laying, the sixth step of ecological bar erecting, the seventh step of second layer grating laying, the eighth step of soil matrix improvement layer spraying, the ninth step of seed layer spray-sowing, the tenth step of straw curtain covering and fixing and the eleventh step of water intercepting and drainage facility arranging. By means of the ecological restoration method, acid can be effectively isolated and controlled, and the effect of heavy metal and other pollutants on the surroundings can be controlled from a source.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +2

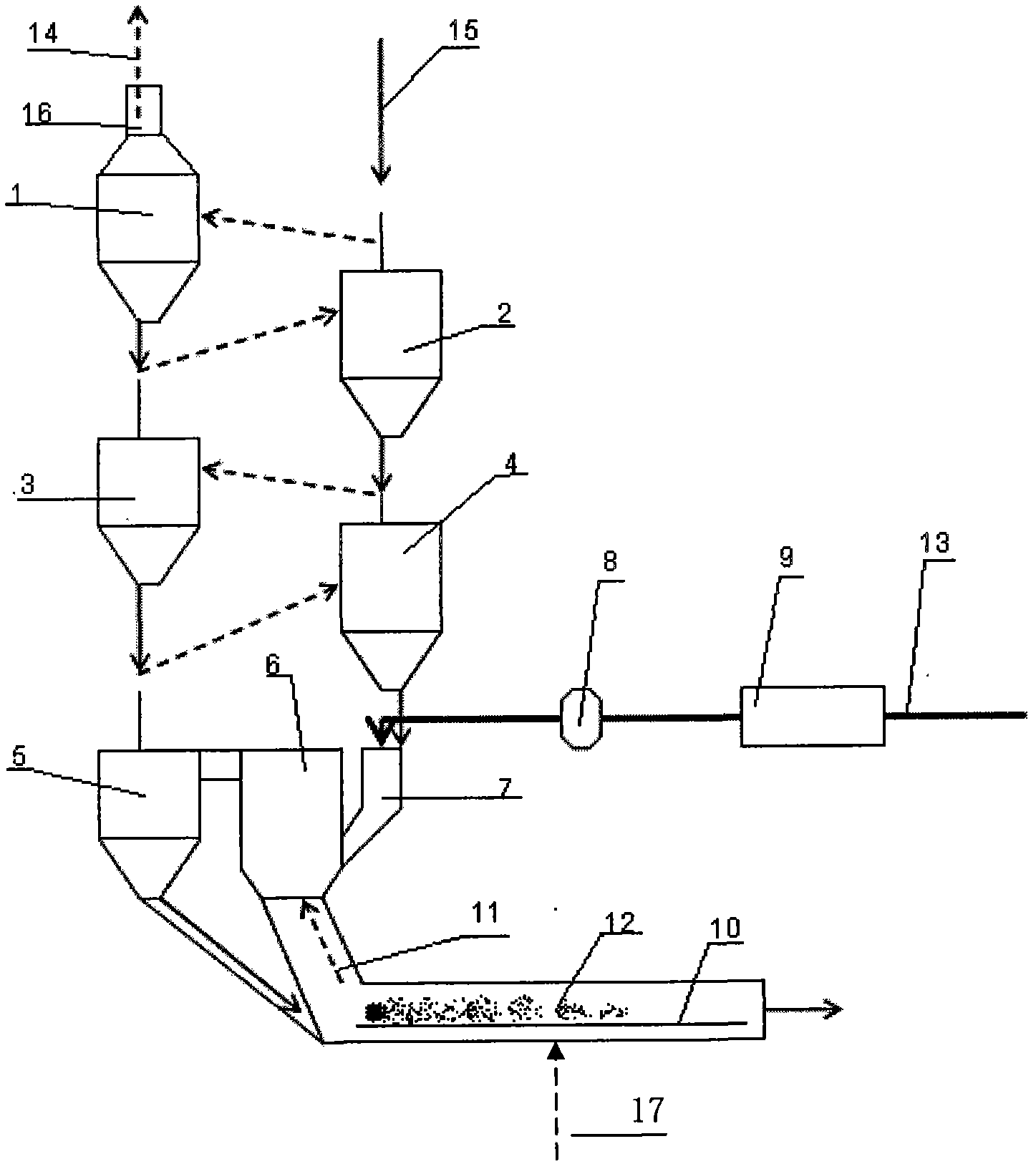

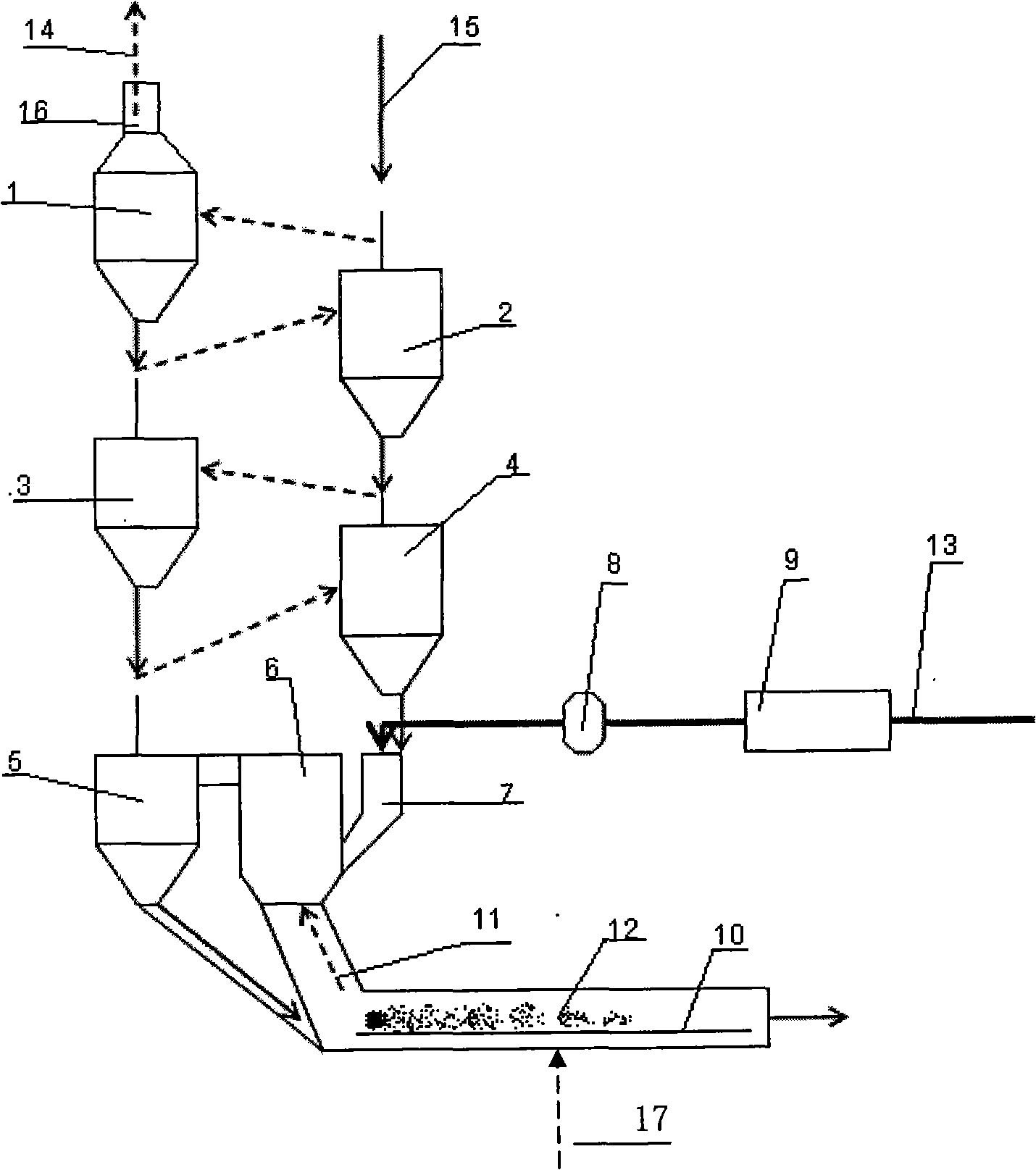

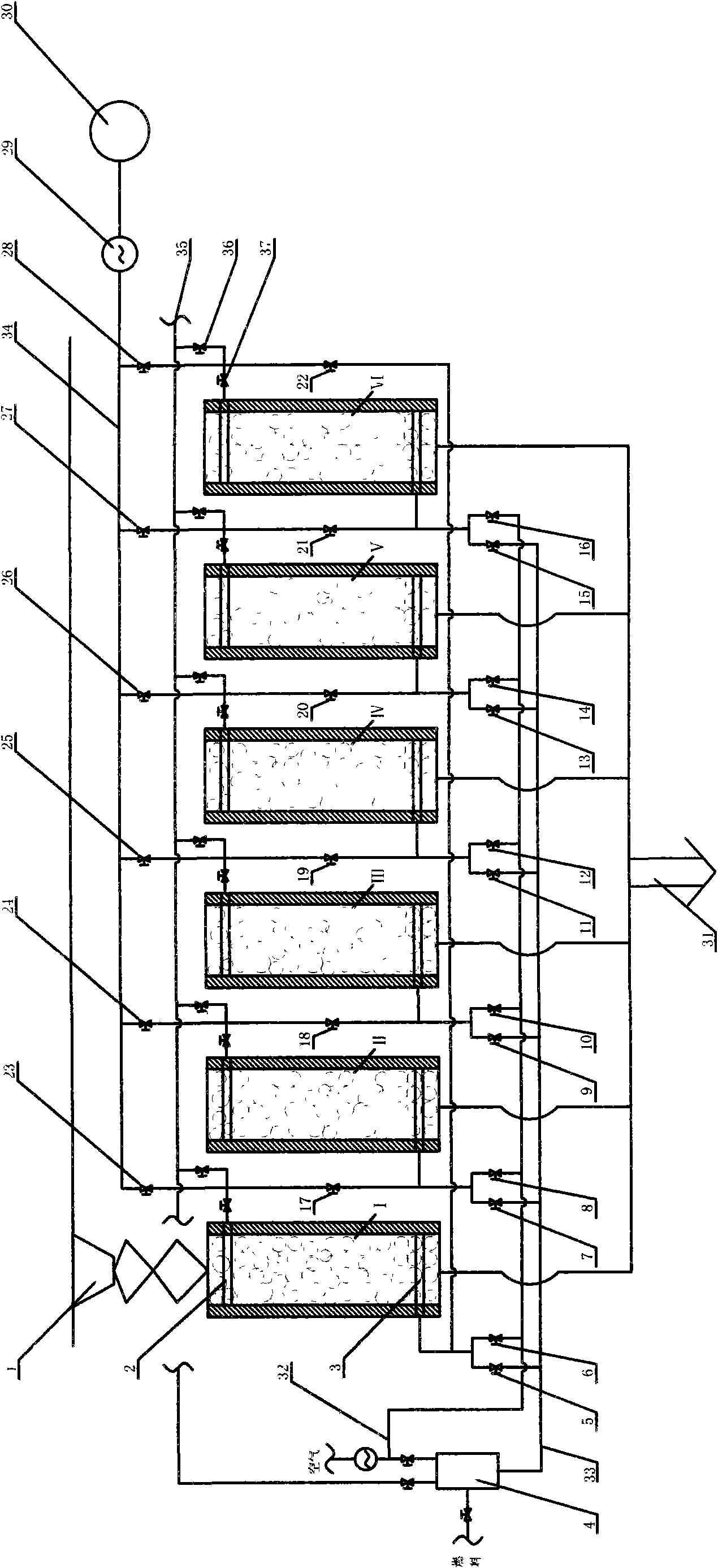

Method for producing active pulverized lime by utilizing coal gas to calcine limestone through suspended state pre-heating decomposing furnace

The invention relates to a method for producing active pulverized lime by utilizing coal gas to calcine limestone through a suspended state pre-heating decomposing furnace, which belongs to the field of environment protection production of building materials. The method comprises the voltage stabilizing and conveying process of coal gas, the combustion heating process of the coal gas in a decomposing furnace for sufficiently combusting the coal gas in the suspended state pre-heating decomposing furnace to obtain the active quicklime powder as staflux in the lime calcining production, and the process for cooling the lime by a grate type cooler. Coke-oven coal gas, blast furnace coal gas, converter coal gas and mixed coal gas in the metallurgy production process are respectively adopted as fuel for replacing the coal powder in the traditional process for calcining and decomposing the lime powder. The method solves the problem of environment pollution caused by coal firing, improves the utilization rate of the excessive coal gas generated during steel making, reduces the outwards discharge of the coal gas, simultaneously improves the production efficiency and the heat efficiency of the lime calcination, and improves the activity of the lime.

Owner:SHANDONG IRON & STEEL CO LTD

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

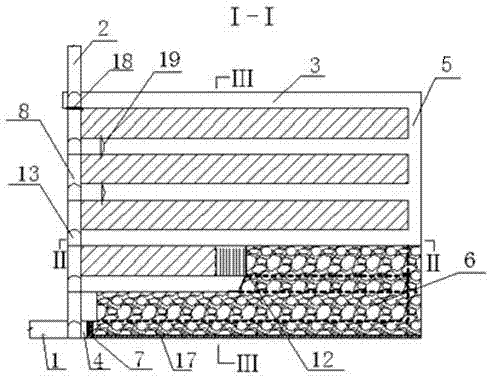

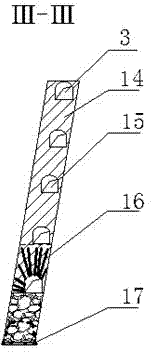

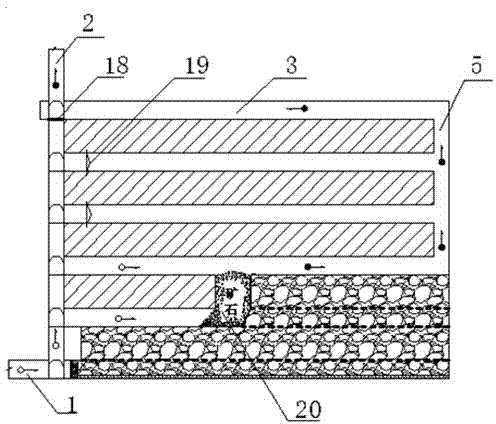

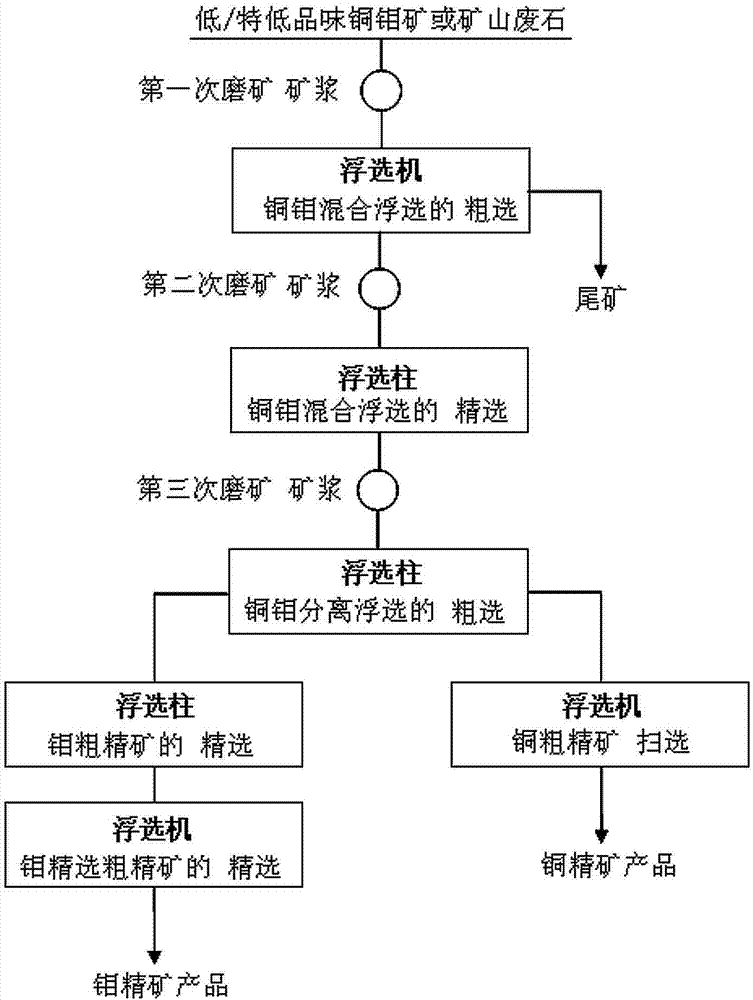

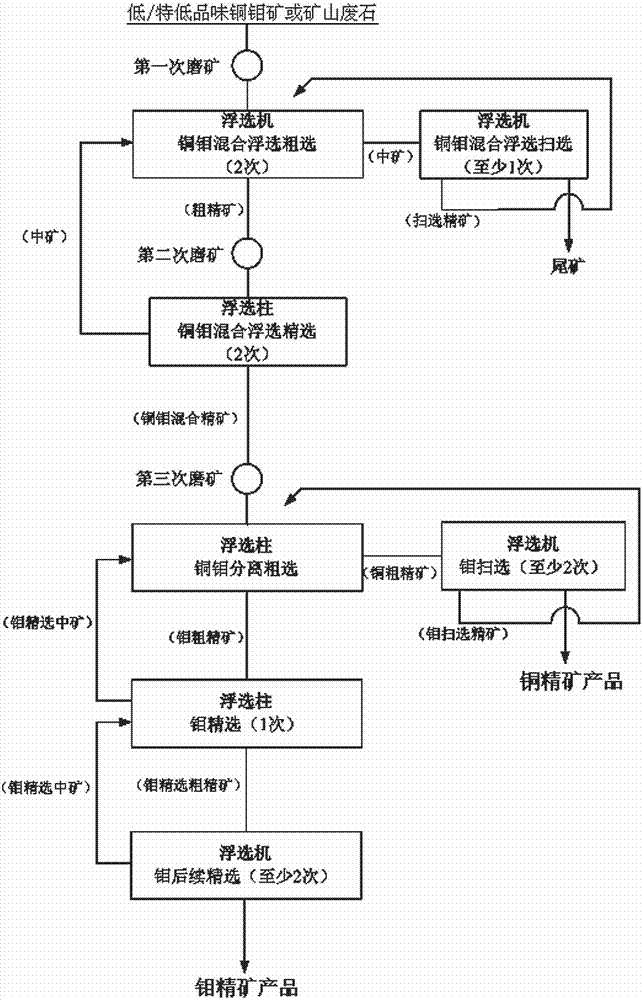

Flotation separation method of low / extra-low grade copper-molybdenum ore or chat

InactiveCN104722409AReduce production energy consumptionEasy to operate and controlFlotationCopperMaterials science

The invention discloses a flotation separation method of low / extra-low grade copper-molybdenum ores or chats. The raw material is smashed until the fineness of the raw material is 0.074 mm, the occupying rate ranges from 50% to 80%, the raw material is prepared into ore pulp with the weight ranging from 25% to 40%, the PH value of lime is adjusted and ranges from 7 to 9, and then copper-molybdenum bulk flotation and rougher flotation are conducted by a flotation machine, so that copper-molybdenum bulk flotation rough concentrate is acquired; the copper-molybdenum bulk flotation rough concentrate is smashed until the fineness of the copper-molybdenum bulk flotation rough concentrate is 0.043 mm, the occupying rate ranges from 50% to 80%, and the copper-molybdenum bulk flotation rough concentrate is prepared into ore pulp with the weight ranging from 20% to 35%; a flotation column is adopted to conduct the detailed flotation of the copper-molybdenum bulk flotation, and copper-molybdenum bulk concentrate is acquired, the copper-molybdenum bulk concentrate is re-smashed until the until the fineness of the copper-molybdenum bulk concentrate is 0.038 mm, the occupying rate ranges from 70% to 90%, and the copper-molybdenum bulk concentrate is prepared into ore pulp with the weight ranging from 15% to 30%; the flotation column is used for conducting the rougher flotation of copper-molybdenum, one or more times of flotation on the occupied copper rough concentrate and molybdenum rough concentrate are conducted by the flotation machine / flotation column, and the final copper concentrate and molybdenum concentrate are acquired. The flotation separation method can deal with extra-low hard-flotation copper-molybdenum ores or chats with the copper grade lower than 0.2% and the molybdenum grade lower than 0.01%, and the copper concentrate with the copper grade higher than 23% and the molybdenum concentrate with the molybdenum grade higher than 43% are acquired.

Owner:四川省冶金地质勘查院 +1

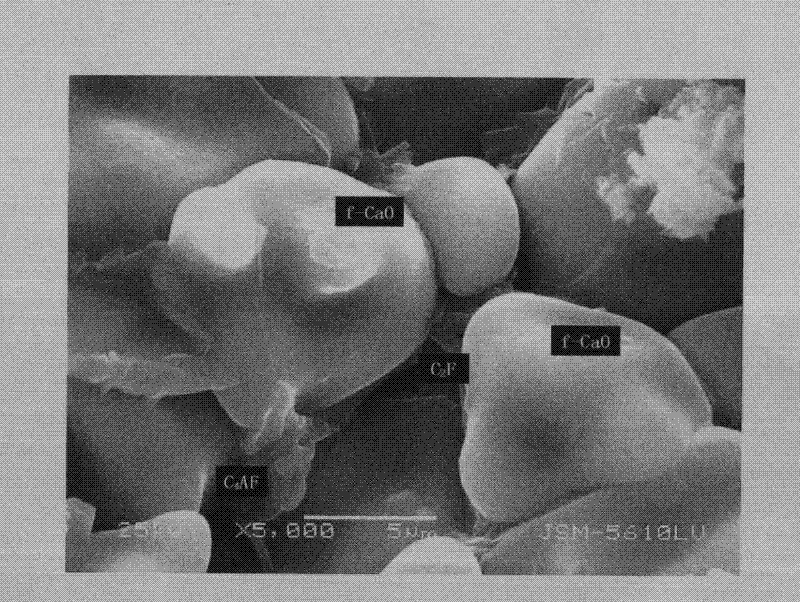

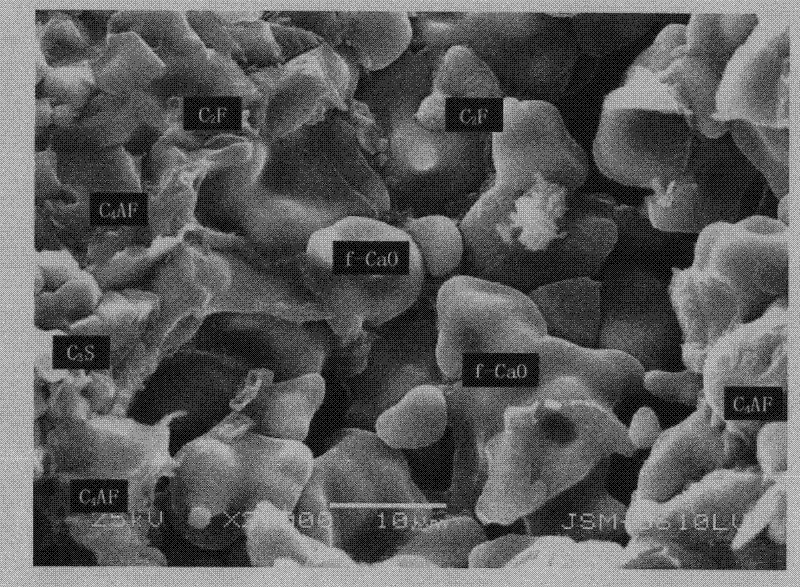

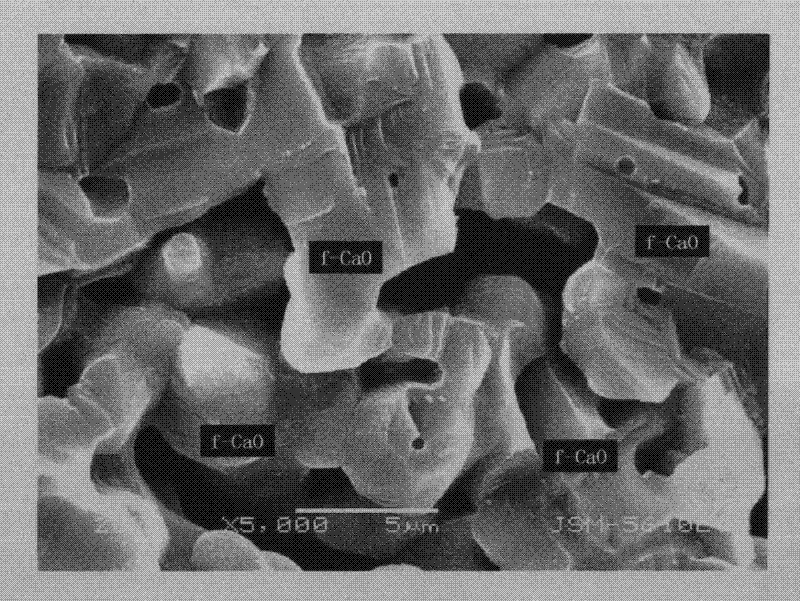

Expanding clinker, expanding agent, concrete and preparation method of expanding clinker

The invention relates to expanding clinker. The expanding clinker is formed by mixing and calcining raw materials of lime stone and iron powder, wherein in the raw materials, the calcium carbonate content based on the calcium oxide (CaO) content is 48 to 53 weight percent; the ferric oxide (Fe2O3) content is 1 to 5 weight percent; and the weight percentage is based on the total weight of the lime stone and the iron powder. The invention also relates to an expanding agent containing the expanding clinker and a preparation method of the expanding clinker. The invention further relates to an expanding agent containing the expanding clinker or the expanding agent provided by the invention.

Owner:武汉三源特种建材有限责任公司

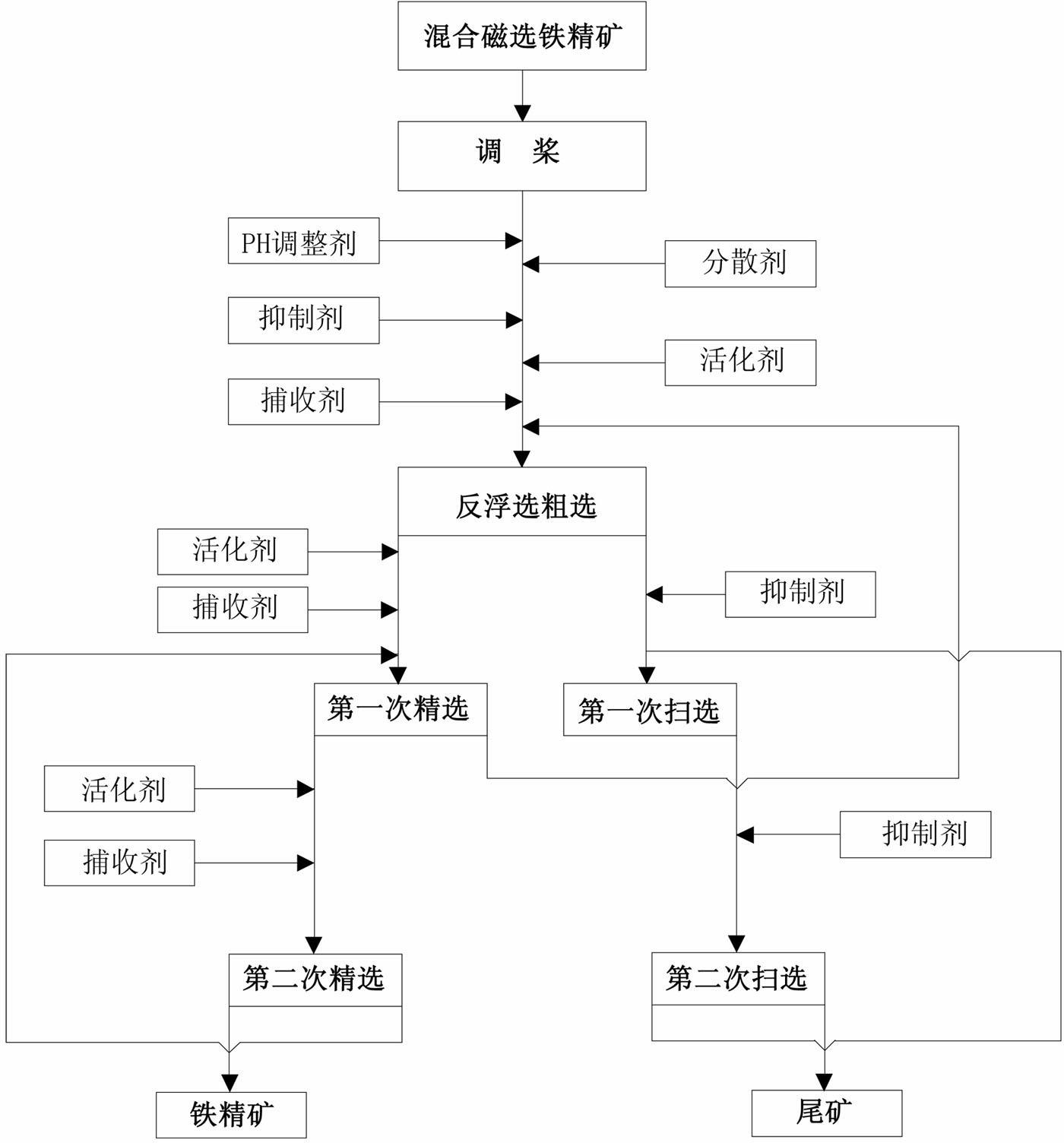

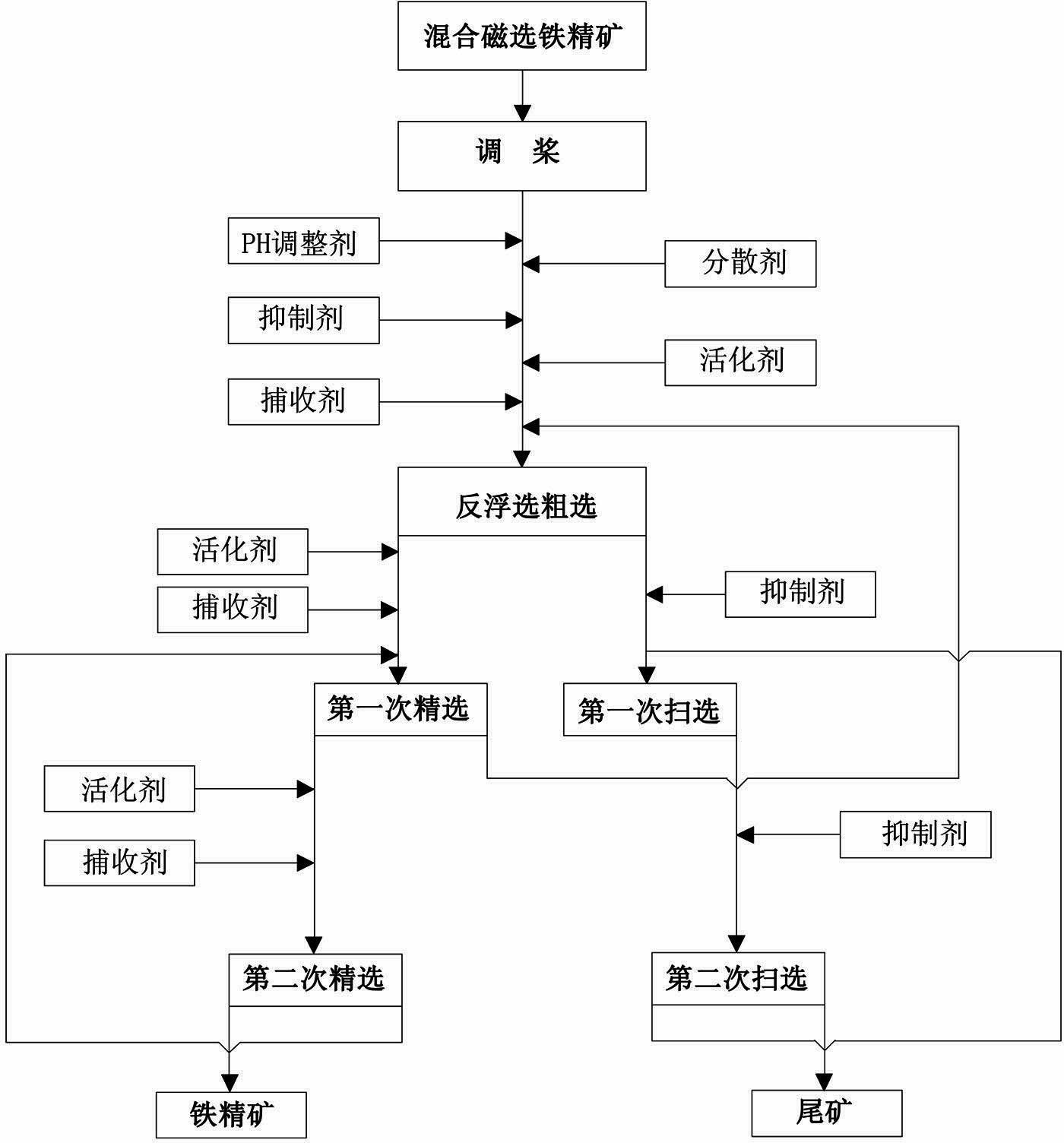

Dispersed flotation separation method for carbonate-containing iron ore

InactiveCN102688806AEliminate or reduce cap phenomenonEliminate or reduce the effects of flotationFlotationIronstoneMining engineering

The invention relates to a dispersed flotation separation method for carbonate-containing iron ore. The reverse flotation is directly carried out on carbonate-containing mixed magnetic separation iron ore concentrate, i.e. the rough concentration, the scavenging and the selection separation. Particularly, a roughing separation method comprises the following steps of: adjusting the mixed magnetic separation iron ore concentrate into ore pulp with the weight concentration of 20-40%, adding 200-1000g / t of dispersing agent-salinized water glass, adding 1200-2400g / t of inhibitor-starch, adding 400-1000g / t of activating agent-lime, and adding 600-1400g / t of collecting agent-KS-III. As the dispersing agent is added, the covering phenomenon among minerals can be eliminated or weakened, so that the ore pulp is under the stable dispersing status, the influence of the iron carbonate to the flotation can be weakened or reduced, and the iron ore concentrate of which the Fe grade is larger than 66% and the recovery rate is 65%-75% can be finally obtained. The method is simple in technological process and lower in cost.

Owner:ANSTEEL GRP MINING CO LTD

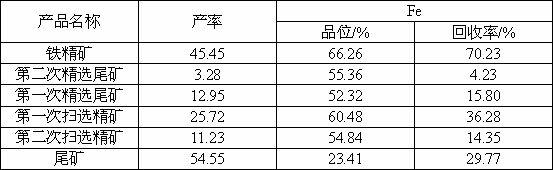

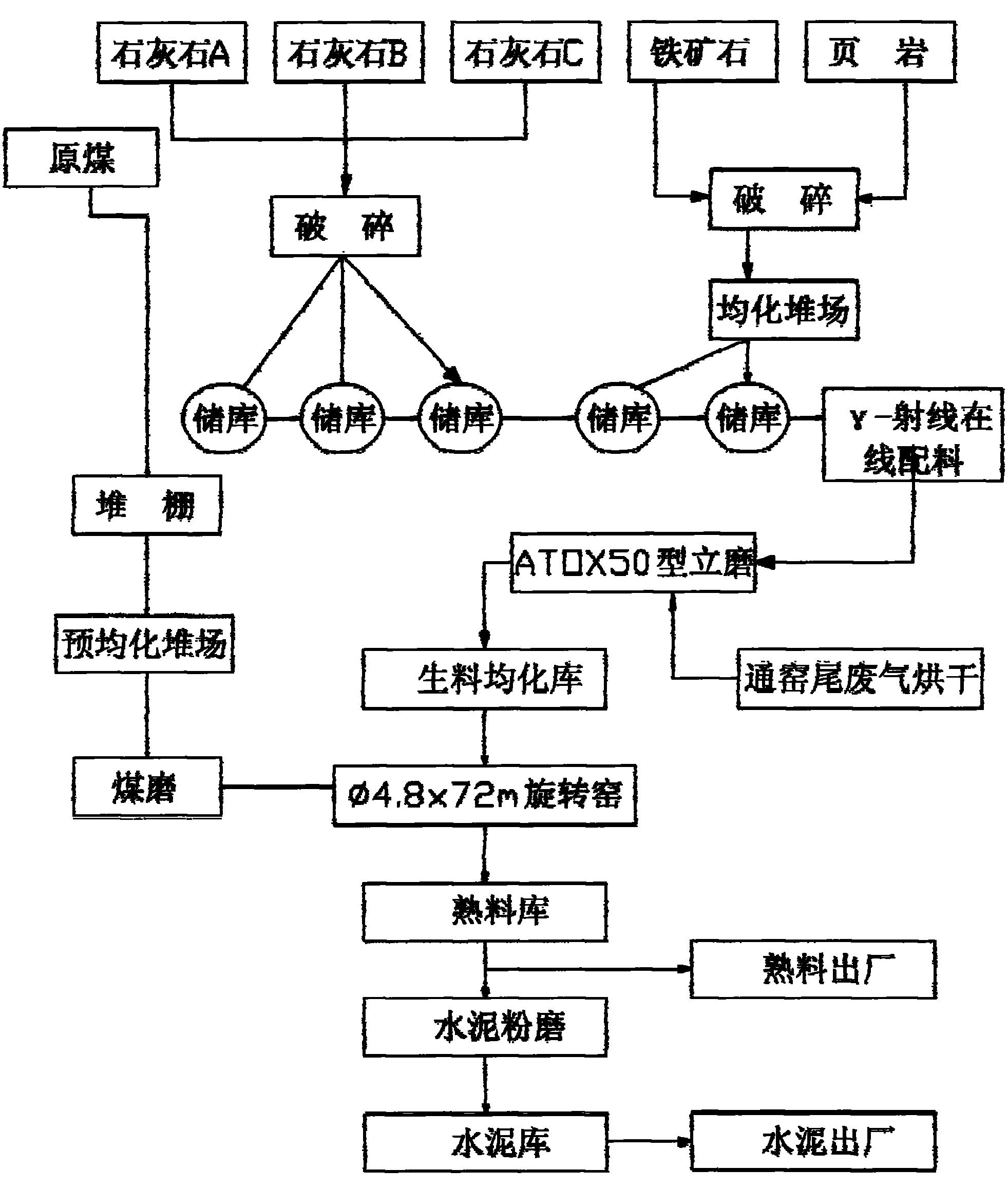

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

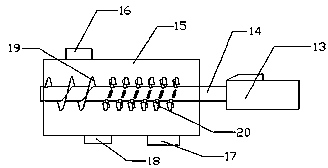

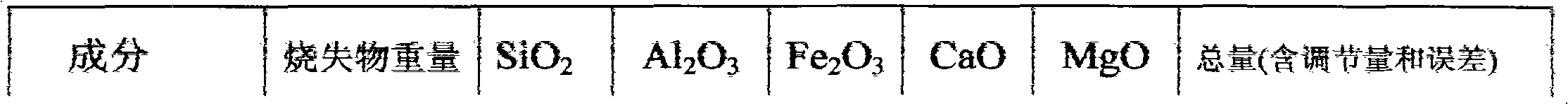

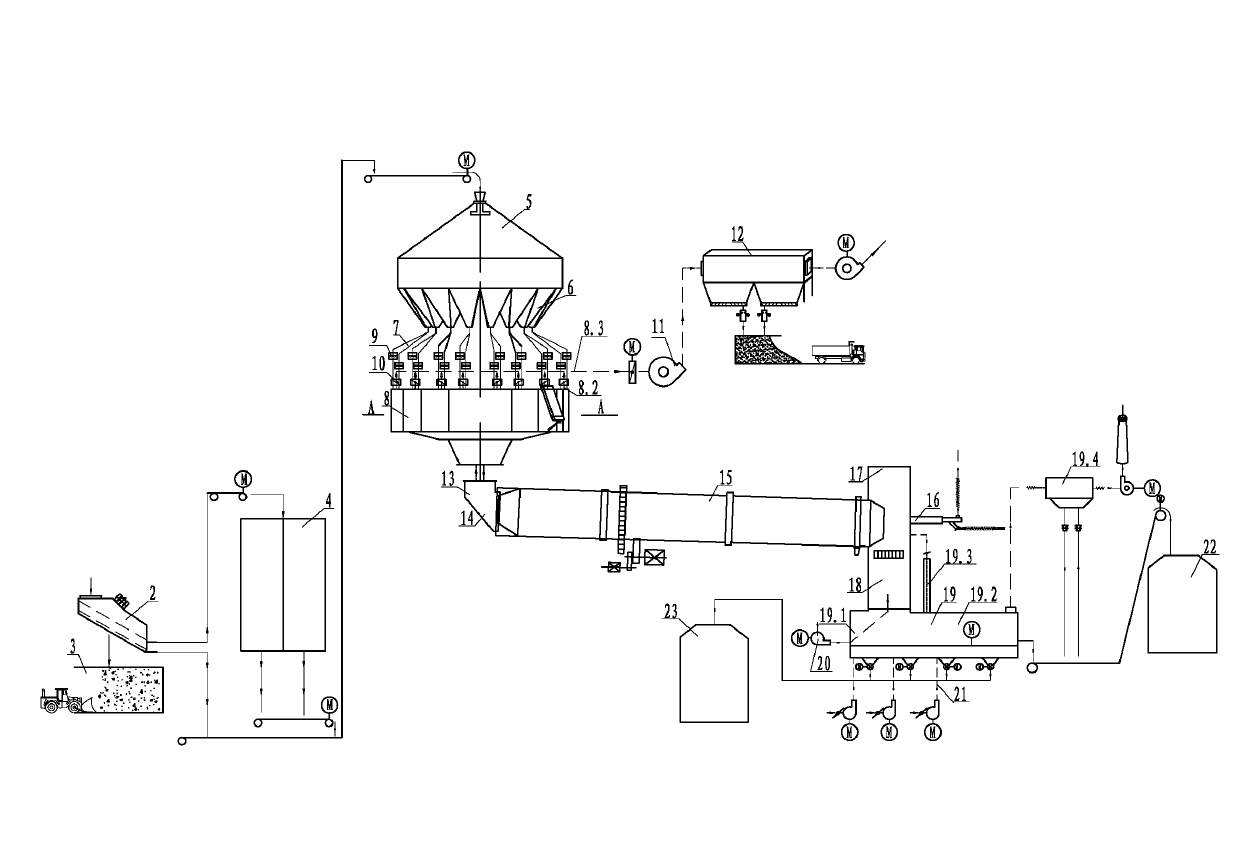

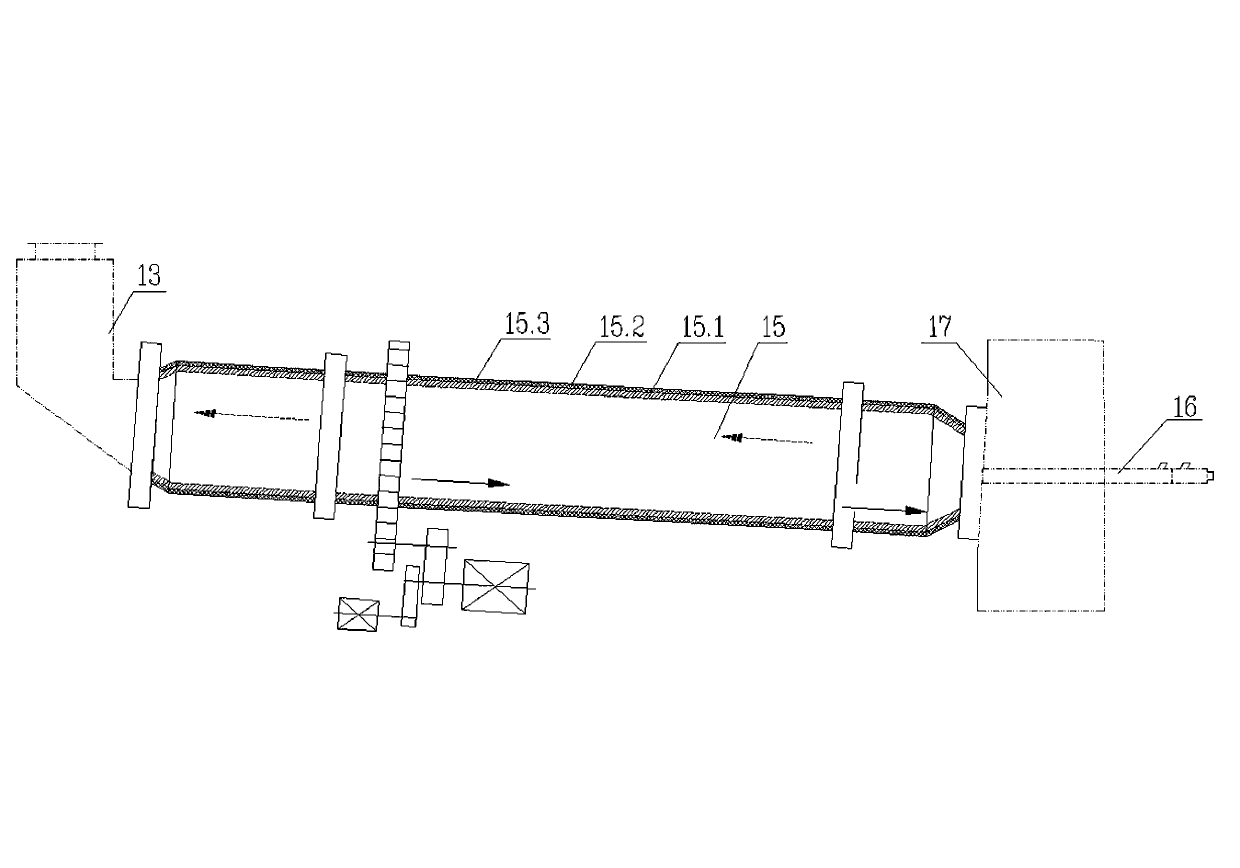

Energy-conservation and emission-reduction type active lime calcination method and apparatus

ActiveCN103304157AGranularity Requirements RelaxedImprove resource utilizationLime productionExhaust gas emissionsExhaust fumes

The invention provides a burning method for preparing an energy-conservation and emission-reduction type active lime. The method comprises the following steps: subjecting the raw material (1) limestone to size grading; respectively and evenly distributing the limestone of different grades into each preheating chamber (8.1) of a novel vertical preheater (8), preheating and partially decomposing the limestone with high temperature exhaust gas and introducing the limestone into a rotary kiln (15); calcining and decomposing the limestone under the action of a temperature field to allow CO2 to be produced and the limestone to become lime; and allowing the lime to enter into a shaft well device (18) for annealing and heat exchange, then introducing the lime into a cooling machine (19) for cooling and carrying out screening to separate blocky lime from powdery lime, thereby obtaining finished products, i.e., blocky lime and powdery lime. The invention further provides an apparatus composed of a size grading device (2), a distributor (5), a distribution warehouse (6), the novel vertical preheater (8), the rotary kiln (15), a kiln hood (17), a combustor (16), the shaft well device (18) and the cooling machine (19) for the method. The method and the apparatus provided by the invention has the characteristics of an expandable range of the size of the raw material limestone, low heat consumption, high production efficiency, a high activity degree of the products, low discharge of SO2 and exhaust gas, low cost, simple and convenient operation and capacity of meeting needs of larger-scale industrial production.

Owner:泰安中意重型工业设备有限公司

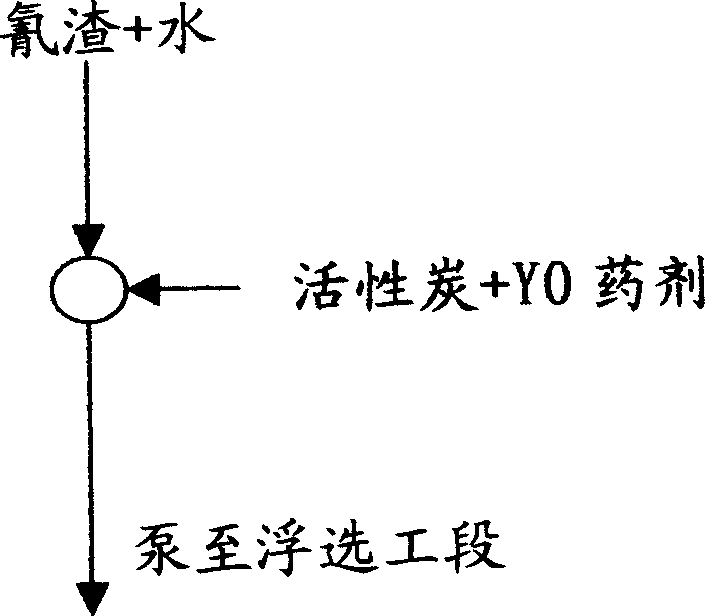

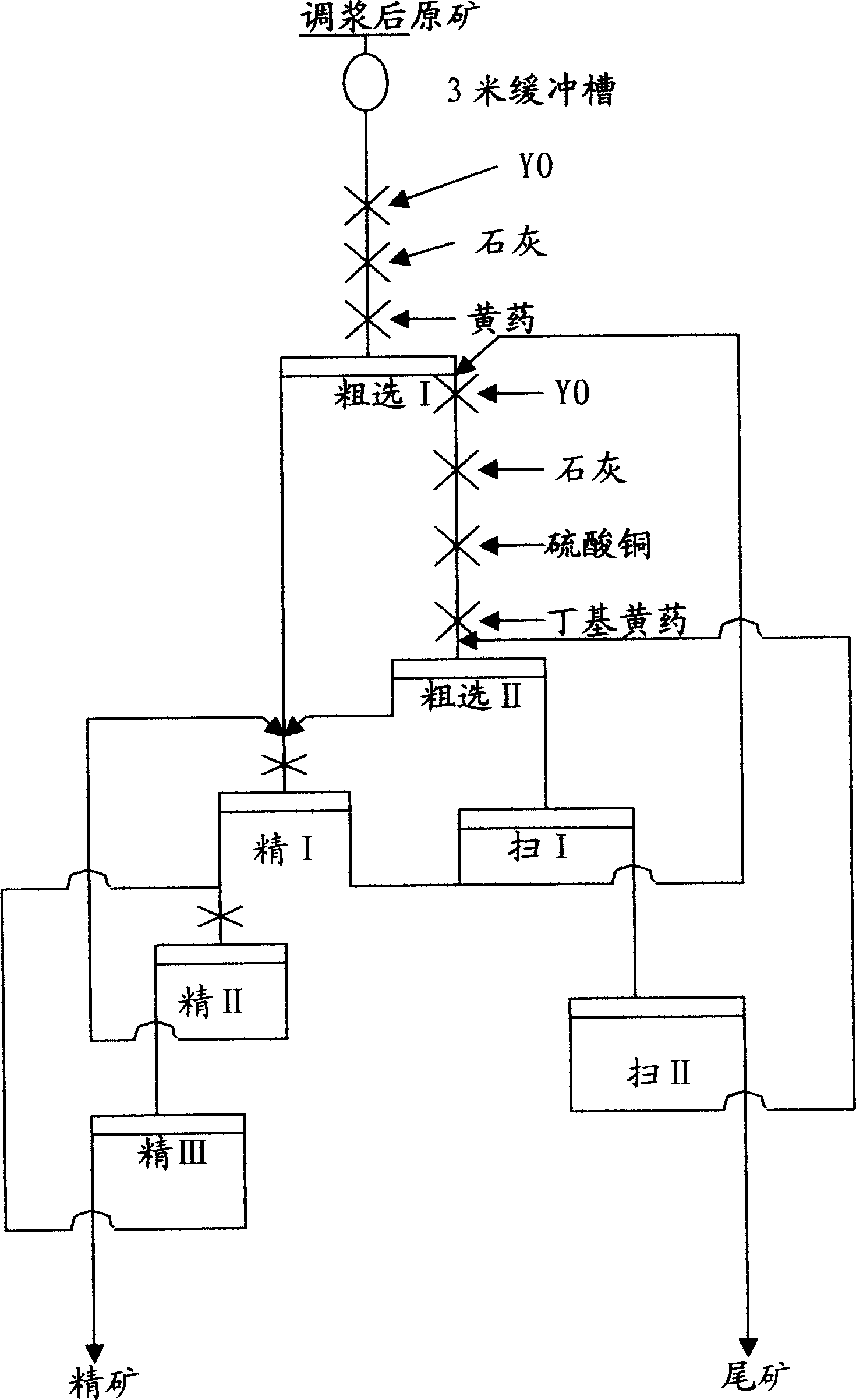

Method for floatation and recovery of lead zinc mixed concentrate from gold mine cyaniding slag tails

InactiveCN1865461AHigh recovery rateNo emissionsFlotationProcess efficiency improvementChlorinated limeSlag

The invention discloses a lead-zinc floating recycling method from gold ore cyanation tailings, which comprises the following steps: (1) predisposing: adding water in the cyanation tailings; stirring to form ore paste; adding active carbon, Y0 agent, FeSO4+ammonium persulphate in the ore paste; (2) asynchronous mixing-selecting: sending the predisposed ore paste to the floater group I to proceed first roughing separation; adding Y0 agent, limestone, butyl airpotato yam to float galena; sending the tailings in the first roughing separation to floater group II; adding Y0 agent, limestone, cupric sulfate, butyl airpotato yam to float zincblende; (3) recycling and purifying tailing water: adding chlorinated lime in the tailing water to decompose CN- less than 0.5 mg per L; recycling the tailing water.

Owner:青岛黄金铅锌开发有限公司

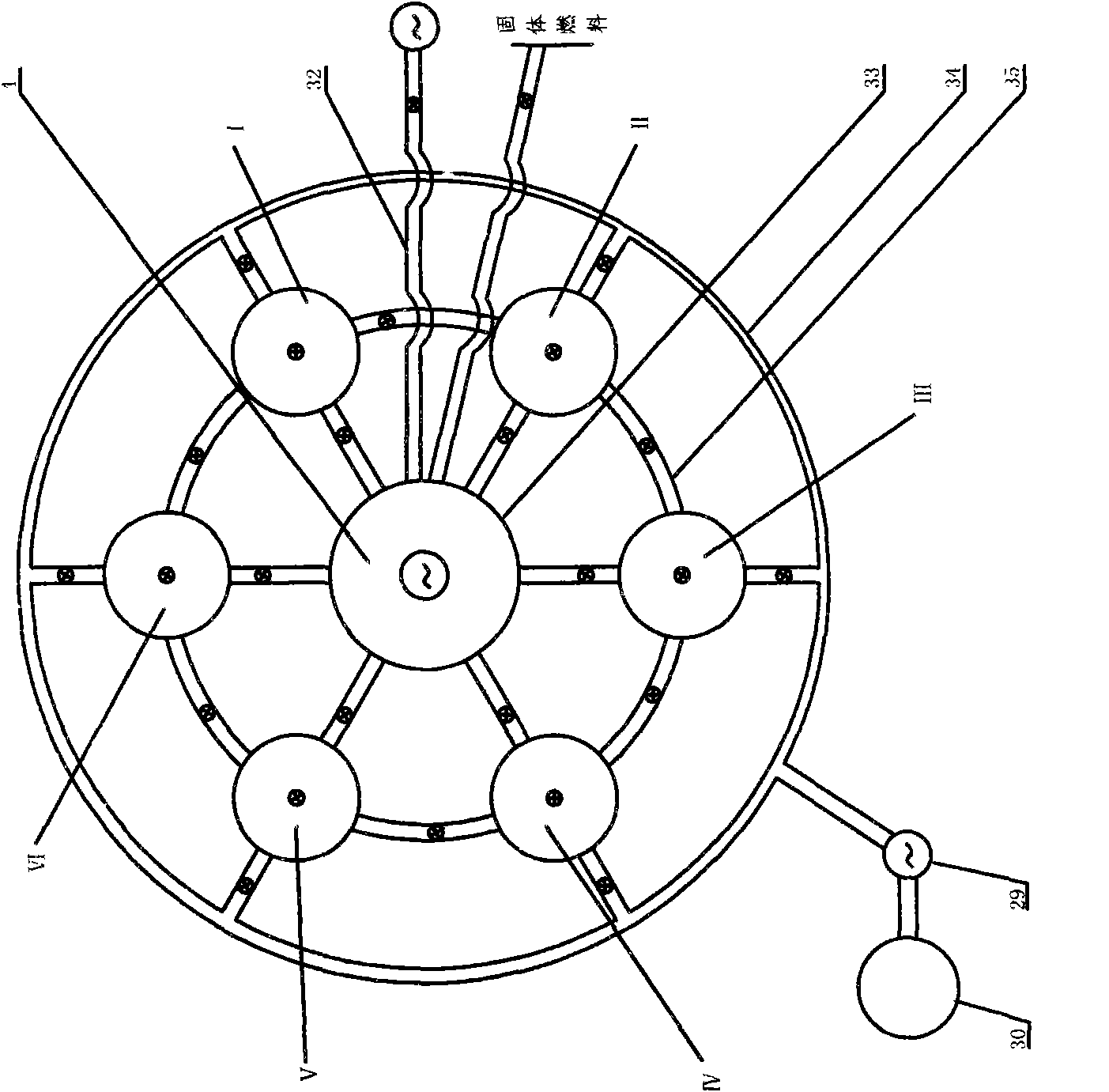

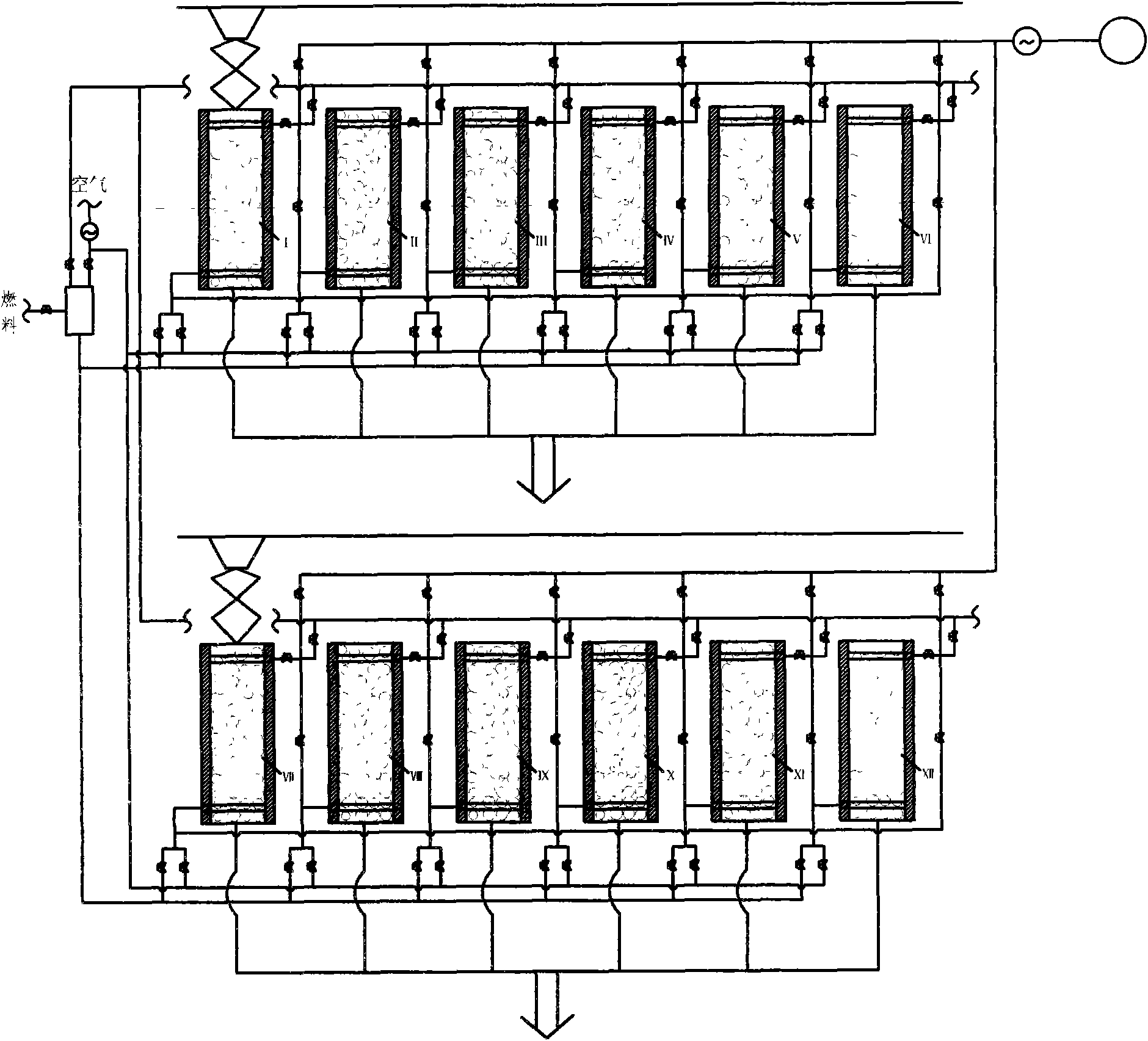

Method and device for sintering lime

The invention relates to a method and a device for sintering lime. The device comprises a plurality of kilns which are distributed in a ring or matrix or other shapes. Solid fuel such as coal powder, and the like, or gas fuel or liquid fuel, or mixed fuels of solid, gas and liquid combusts in the kilns or a separately arranged combustion chamber, and generated high-temperature smoke sinters limestone in the kilns and preheats the limestone in other kilns. Each kiln is internally provided with an air inlet girder and an up-sucking girder. The top of each kiln is provided with a movable feeding device capable of feeding for each kiln in a system. The bottom of each kiln is provided with a movable discharging device connected with a discharging channel and gathering dust generated by each kiln. By using the method and the device for sintering lime, the limestone can be sintered more sufficiently and evenly and has good quality and high activity degree; and meanwhile, the invention can sufficiently utilize afterheat, save the energy source, improve the thermal efficiency of the system, lower the production cost and realize large-scale continuous production.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method for treating inorganic solid waste and application

InactiveCN1480264AImprove performanceQuality improvementSolid waste disposalEnvironmental engineeringMagnetic separation

A process for reclaiming the inorganic solid waste (waste silicon, waste concrete blocks, coal gangue, and slags) includes crushing to less than 400 mm for granularity, removing impurities, breaking to less than 80 mm for granularity to obtain the reclaimed aggregate, classifying, magnetic dressing, flushing dressing, and floatation. Said reclained aggregate can be used for road bed or concrete.

Owner:王剑

Preparation method of high-performance gas-filling building block composite material

The invention discloses a preparation method of a high-performance gas-filling building block composite material, belonging to the technical field of building materials. According to the invention, the coal ash, tailings, slag, yellow sand and the like are used as major raw materials, the cement, carbide slag and lime are used as excitants, the aluminum powder paste and hydrogen peroxide are used as gas production agents, the phosphoric acid and water glass are used as foam stabilizers, the ardealite and titanium gypsum are used as retarders, and the calcium lignosulphonate and hydroxylmethylcellulose are used as dispersing agents. The preparation method is characterized in that the coal ash, the tailings, the slag, the yellow sand and the like are subjected to the technologies of PLC system grinding, mixing, pouring, precuring, cutting, steaming and pressing, building block separation, packing and the like; and the technology for preparing the silicate composite material for a building is adopted. Through the invention, the produced building block has the characteristics of stable chemical property, excellent physical performance and the like. The preparation method has a simple technology and high efficiency, can consume a great quantity of solid wastes, prevents the emission of three wastes and the environmental pollution, reduces the environmental pollution caused by other wastes, and creates obvious economic and social benefits.

Owner:安徽建鑫新型墙材科技有限公司

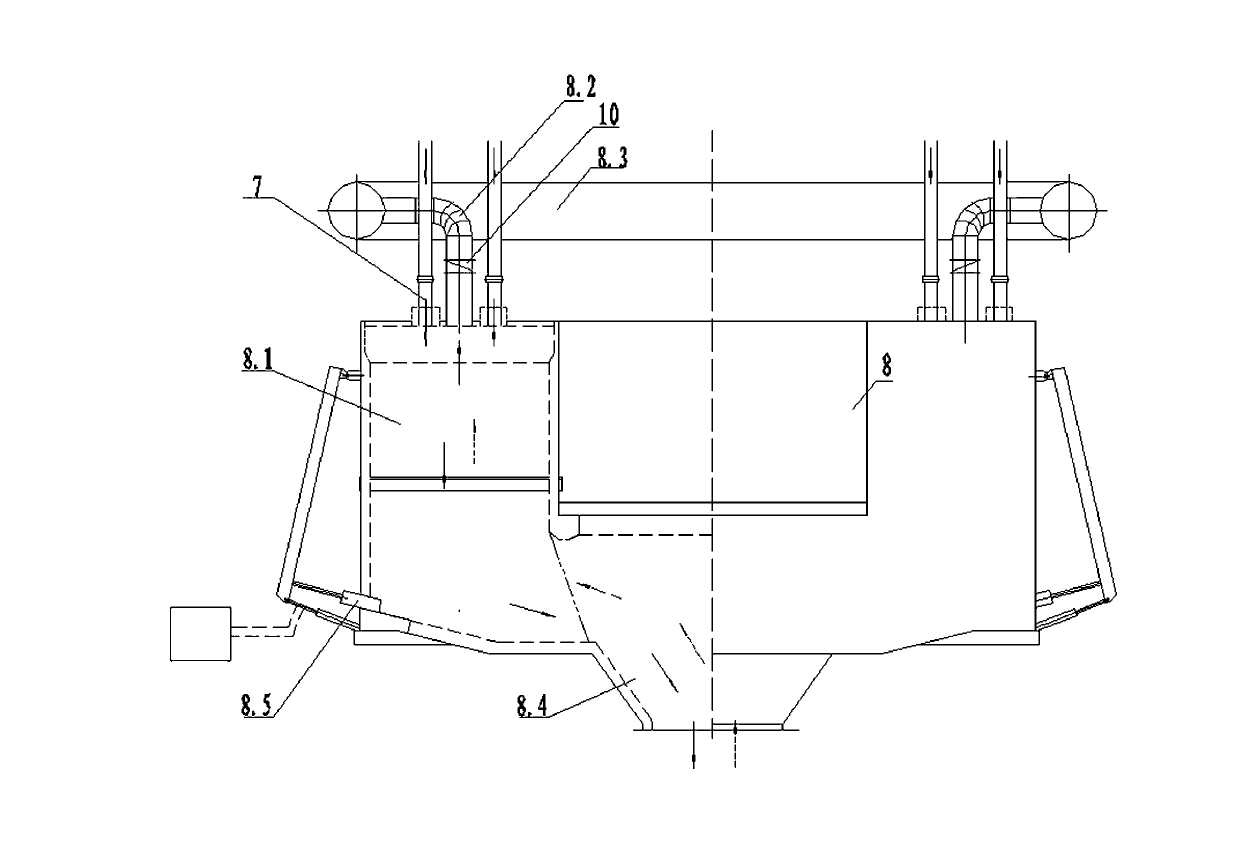

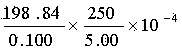

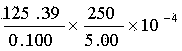

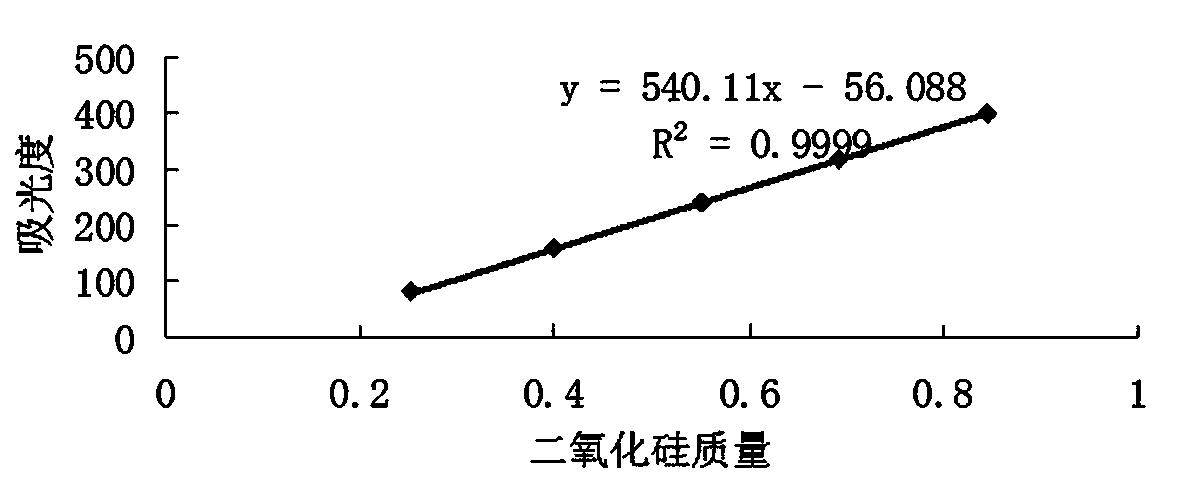

Fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite

ActiveCN103728261AConducive to complete dissolutionImprove stabilityColor/spectral properties measurementsOXALIC ACID DIHYDRATEAscorbic acid + ferrous sulphate

The invention discloses a fast and accurate detection method for silicon dioxide content in limestone, kalk and dolomite. The detection method comprises the following steps: crushing samples, and drying for 1.5-2.5 h under thea temperature of 105-110 DEG C; mixing 0.1000 g samples and 3.0-4.0 g mixed fluxing agent of sodium carbonate and boric acid evenly, liquating for 18-20 min under athe temperature of 890-910 DEG C, dissolving frits by a 45-55 ml hydrochloric acid and 25-35 ml water, and placing the test solution in a 250-ml volumetric flask; taking and adding 5.00 ml test solution in a 100-ml volumetric flask, adding 18-22 ml ammonium molybdate and still standing for 18-22 min, and adding 45-55 ml mixed acid of oxalic acid and sulfuric acid, 4.80-5.20 ml ascorbic acid-ammonium ferrous sulfate mixed solution; measuring the absorbency of a color development solution at the wavelength of 680 nm through a spectrophotometer, and using blank as a reference; preparing a silicon dioxide standard sample with the concentration of 40 ug / ml, moving and taking 0.00 ml, 2.00 ml, 4.00ml, 6.00 ml, 8.00 ml and 10.00 ml silicon dioxide standard samples, and placing the standard samples in 100-ml volumetric flasks respectively, adding 5.00 ml blank test solution in the volumetric flasks respectively, after color-developing, measuring the absorbency at the same conditions, and then drawing a working curve. The silicon dioxide content in the samples is calculated according to the following formula (shown in the specification). The detection method is fast and efficient, excellent in accuracy, reproducibility and stability, and particularly suitable for detection of samples with silicon dioxide content equal to or higher than 4 %.

Owner:WUKUN STEEL

300 stage pulverized coal ash heat preservation fireproof aerated concrete building block and method of production

InactiveCN1482099ALight weightImprove seismic performanceSolid waste managementCeramic shaping apparatusMethods of productionCoal

The materials for the aerated concrete block include flyash, lime, cement clicker or cement, gypsum, gas former aluminum powder paste, bubble stabilizer active matter or wash powder, and regulator water glass. The block is light and firm, has excellent heat insulating performance, and utilizing flyash as waste can save energy source. Its production process is also provided.

Owner:陈德余

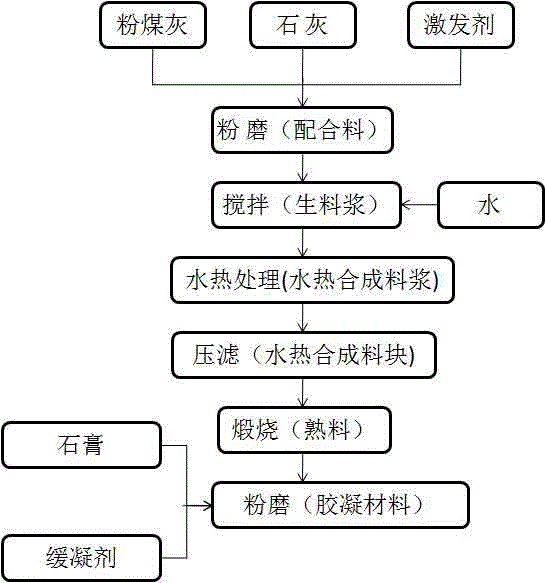

Cementing material prepared from fly ash and preparation method thereof

The invention discloses a cementing material prepared from fly ash and a preparation method thereof. The preparation method of the cementing material comprises the following steps: milling 62-78 parts by mass of fly ash, 22-38 parts by mass of lime and 0.5-2 parts by mass of excitant to obtain an admixture of which the 80 mu m screen residue is less than 5%, adding 150-250 parts by mass of water, stirring to obtain a uniform raw slurry, carrying out hydrothermal treatment on the raw slurry at 90-98 DEG C for 8-16 hours, dewatering in a filter press to obtain a hydrothermal synthesis block, calcining at 750-950 DEG C for 30-120 minutes, and cooling with air to obtain clinker; and milling 92-95 parts by mass of clinker, 5-8 parts by mass of gypsum and 0.2-1.5 parts by mass of retarder until the 80 mu m screen residue is less than 4%. The cementing material can utilize low-grade fly ash, and has the advantages of high utilization ratio of fly ash, low calcination temperature and low heat loss. The product has the characteristics of quick setting and hardening, high long-term strength and high sulfate attack resistance. The cementing material is especially suitable for tunnel, underwater, alkaline land and coastal area engineering.

Owner:HOHAI UNIV

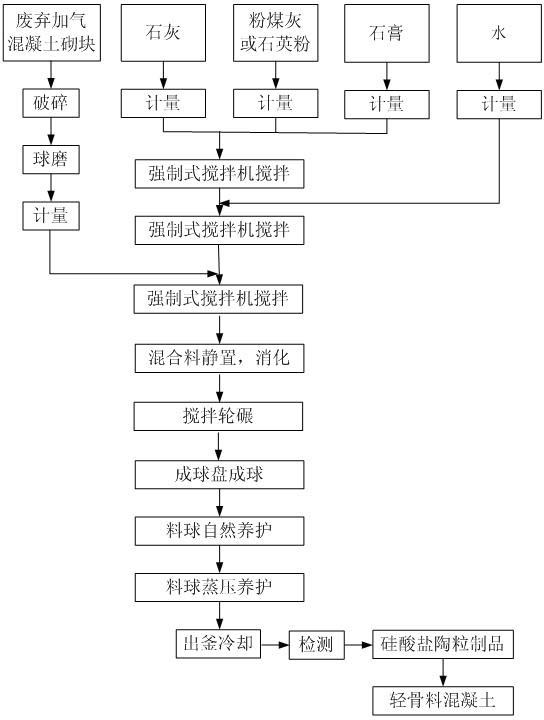

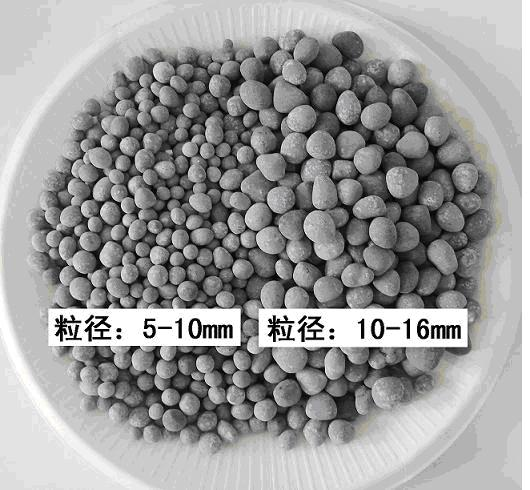

Method for preparing silicate ceramic pellets by using waste aeroconcrete building blocks

ActiveCN102424599ASmall sizeFull utilizationSolid waste disposalCeramicwareWaste productSilicon dioxide

The invention discloses a method for preparing silicate ceramic pellets by using waste aeroconcrete building blocks, comprising the following steps: crushing the waste aeroconcrete building blocks, then grinding the crushed waste aeroconcrete building blocks into powder in a ball mill; determining the content of effective calcium oxide in lime, the content of silica in fly ash or quartz powder, and the content of unreacted silica in the waste aeroconcrete; blending lime, fly ash or quartz powder, gypsum powder, aeroconcrete powder, and water for stirring, and stirring, standing, and rolling, putting the rolled mixture in a balling disc for preparing into pellets, placing the prepared balls at room temperature and moisturizing for maintenance, putting the maintained ceramic pellets in an autoclave for autoclaving to obtain the silicate ceramic pellets. The invention effectively solves the problem of recycling waste aeroconcrete with high utilization rate. According to the invention, toaeroconcrete factories, the problem of waste stockpiling is solved, and the benefits of additional products are increased.

Owner:浙江中劲环保科技有限公司

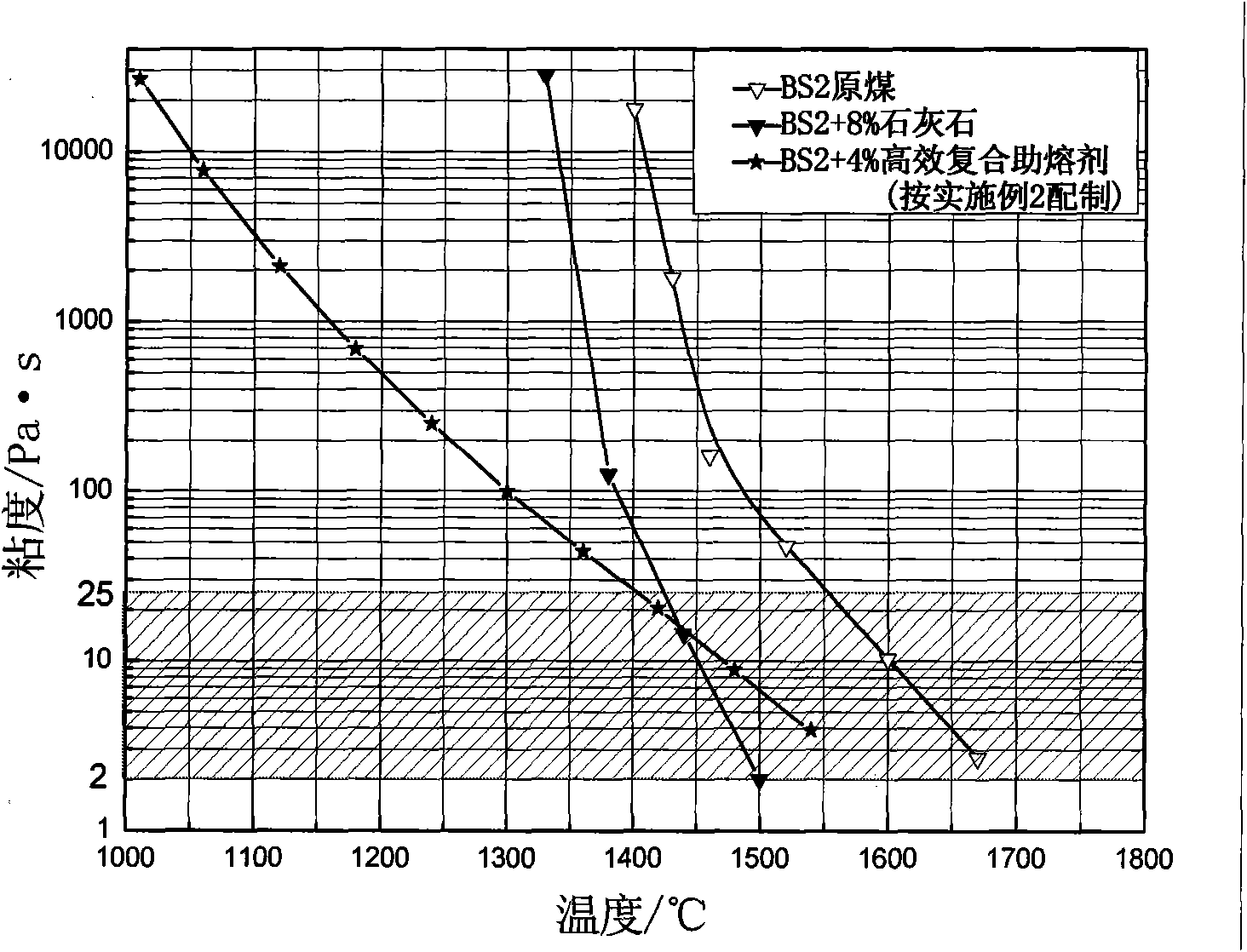

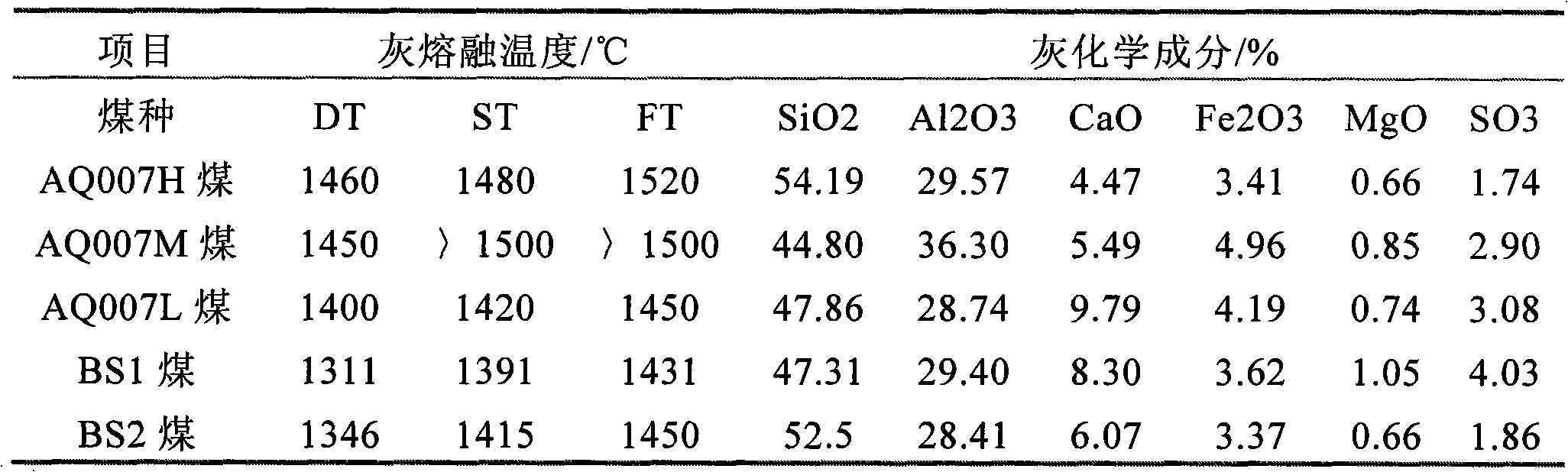

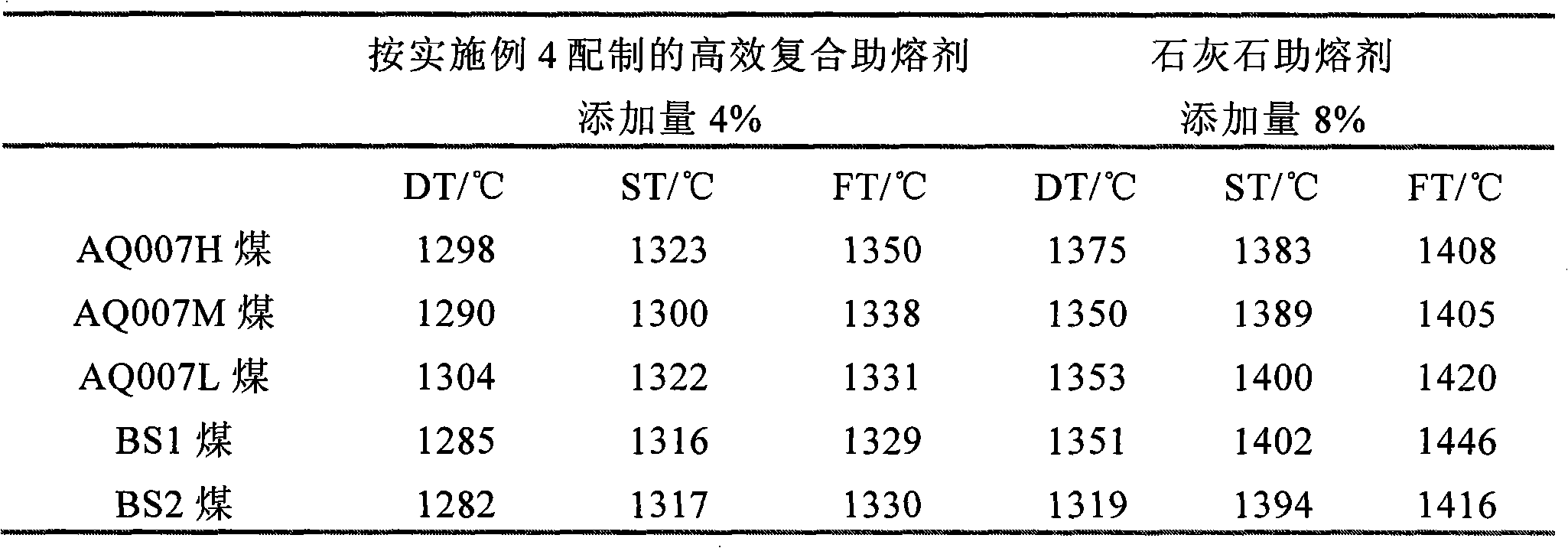

Efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag

The invention provides an efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag. The efficient composite fluxing agent is compounded by two or more ore powders containing basic oxides. The efficient composite fluxing agent comprises the components by weight percentage of 12-30% of MgO and 3-30% of CaO. As for the coals at the mine field in the northern Anhui province, when the addition amount is 2-6%, the melting temperature of the pulverized coal can be reduced from 1500 DEG C to below 1400 DEG C, the viscosity of the pulverized coal can be ranged from 2 to 25 Pa*s, thus effectively improving the melting characteristic of the coals in the mine field in the northern Anhui province. The fluxing agent can be used for replacing lime stone fluxing agent and the addition amount is only half of that of the lime stone.

Owner:CHINA PETROLEUM & CHEM CORP +1

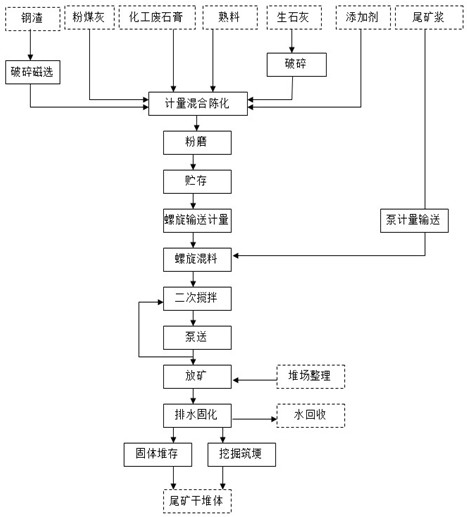

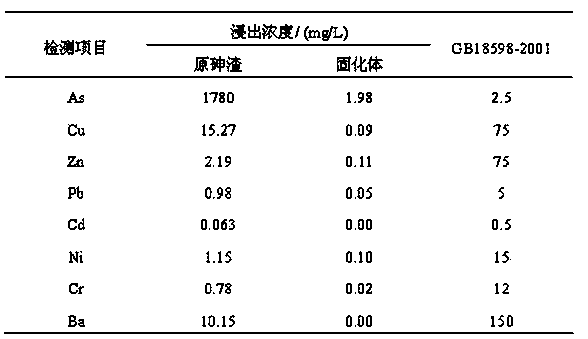

Curing and dry-piling method of iron tailings

The invention relates to a curing and dry-piling method of iron tailings, belonging to the technical field of mine safety. The curing and dry-piling method comprises the following steps of: adding a curing agent and a chemical additive produced by adopting steel slag, chemical waste gypsum, clinker, coal ash and quick lime in tailing pulp, and synchronously realizing precipitation, water drainage and curing and pile-up by secondary mixing and stirring. Compared with the prior art, the curing and dry-piling method has the advantages of simple technical process, low cost, small occupied area and high safety, and is a new method for safe pile-up of the iron tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

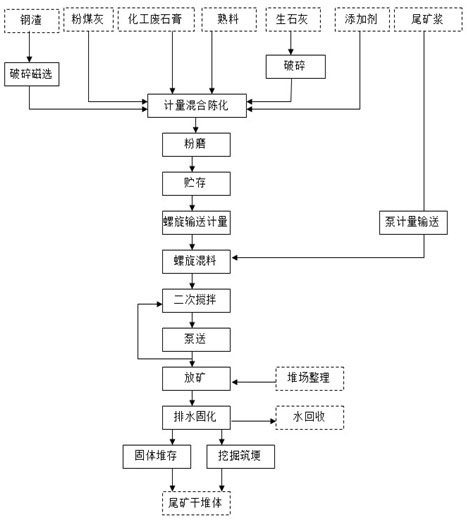

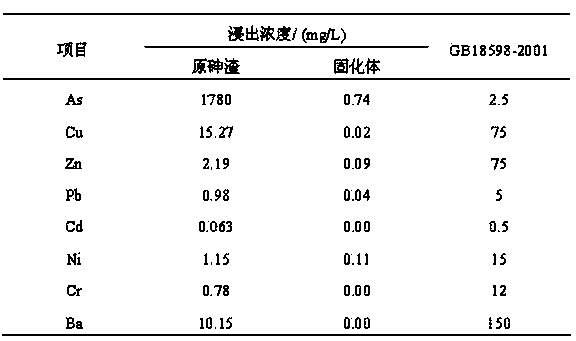

Stable curing method of strongly acidic arsenic sulfide waste residues

ActiveCN104174634AReduce leachingReduce contentSolid waste disposalTransportation and packagingCalcium hydroxideSludge

The invention discloses a stable curing method of strongly acidic arsenic sulfide waste residues. The stable curing method comprises the following steps: (1) adding heavy-metal sludge to to-be-treated strongly acidic arsenic sulfide residues, and stirring, so as to obtain muddy materials; (2) adding calcium hydroxide powder to the muddy materials obtained in the step (1) in the state of stirring, and continuing to stir until all yellow substances in the muddy materials disappear; (3) adding yellow sand and cement to the materials obtained after stirring in the step (2); (4) cooling the stirred materials obtained in the step (3) to room temperature, transferring to a forming die, taking out from the die after forming, and curing at room temperature, so as to obtain solidified bodies which conforms to the landfill standard. According to the stable curing method, the heavy-metal sludge is used as an arsenic stabilizer, so as to control waste by waste; sources of the materials such as the heavy-metal sludge, the lime, the cement and the yellow sand required for treating the strongly acidic arsenic sulfide waste residues are wide, and additionally, other drugs do not need to be added; compared with other methods, the stable curing method has the advantage of low treatment cost.

Owner:扬州杰嘉工业固废处置有限公司

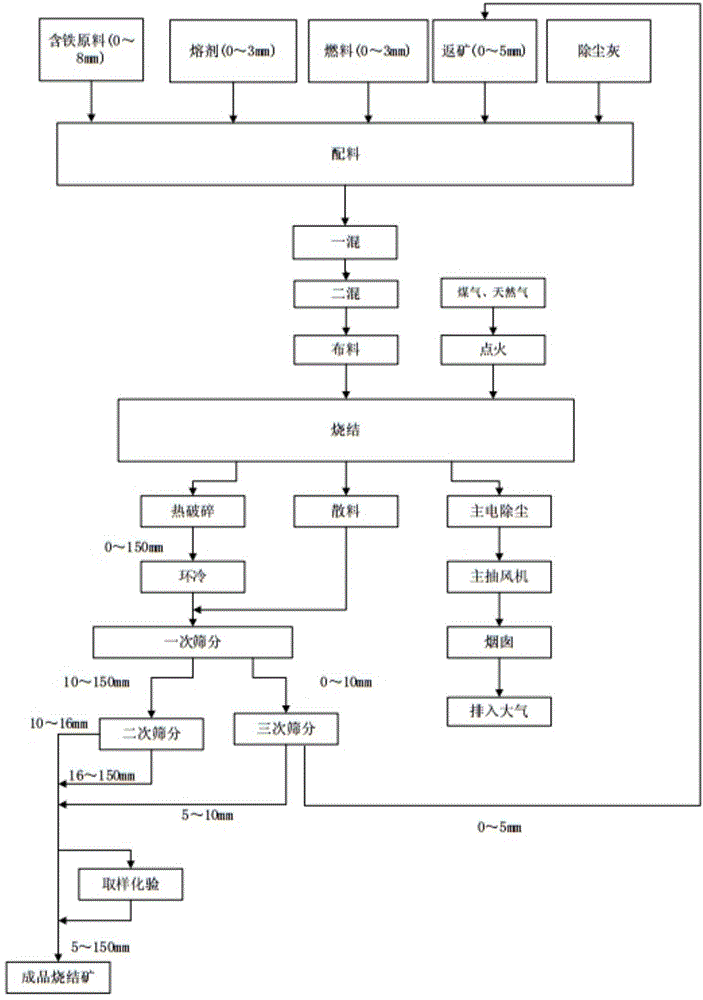

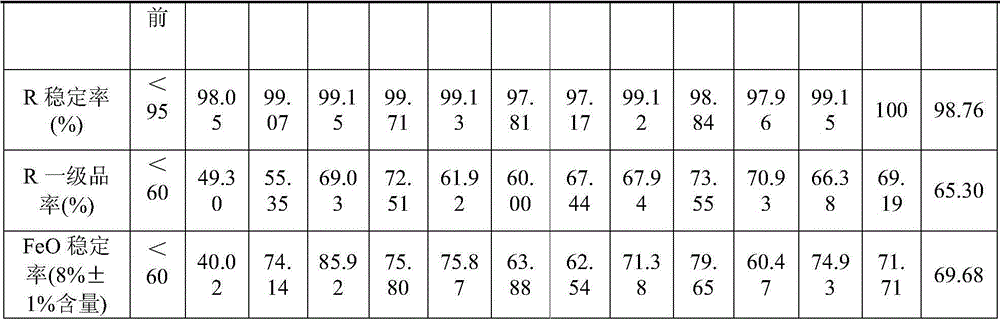

Sintered ore quality control method in sintering process

The invention discloses a sintered ore quality control method in a sintering process. The method comprises the following steps: regulating a fluxing agent ratio before sintering and in the sintering process, regulating the alkalinity of fly ash by using a fluxing agent, so that the alkalinity of the fly ash is the same as alkalinity of a target product sintered ore, controlling the amount of digestion water according to color and particle size of quick lime, and setting the cycle time of sintered internal return and blast furnace return ore; and periodically sampling and checking the alkalinity and content of SiO2 and CaO, calculating the fluxing agent ratio of subsequent ingredients needing to be increased or decreased, and adjusting the fluxing agent amount in the ingredients according to the ratio. According to the method, the influence of various ores on the sintered ore quality is greatly reduced, and the quality stability of the sintered ore is improved. Quantitative adjustment is performed through check and calculation of the components of the sintered ore, the anticipation ability of an operator is improved, the quality fluctuation tendency and amplitude are mastered, and the retardation time is greatly shortened and adjusted. Moreover, complex and troublesome ingredient calculation is simplified, and the method is easily mastered and operated by the operator.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Composition of materials for production of acid resistant cement and concrete and methods thereof

InactiveUS20030136305A1Reduce amountImprove acid resistanceSolid waste managementAlkali metal silicate coatingsSlagPortland cement

A cement composition for use in acidic environment containing liquid alkali silicate, vitreous silicate setting agent, lime containing material and inert filler and building materials made therefrom as well as the method of making such building materials. The liquid alkali silicate may include sodium silicate or potassium silicate. The vitreous silicate setting agent may include soda-lime glass powder or coal fly ash. The lime containing material refers to the materials containing more than 20% lime and may include quicklime, hydrated lime, Portland cement, blast furnace slag or steel slag. The inert fillers include ground quartz, ground ceramic, and / or clay.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com